Patents

Literature

36results about How to "Does not consume water resources" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

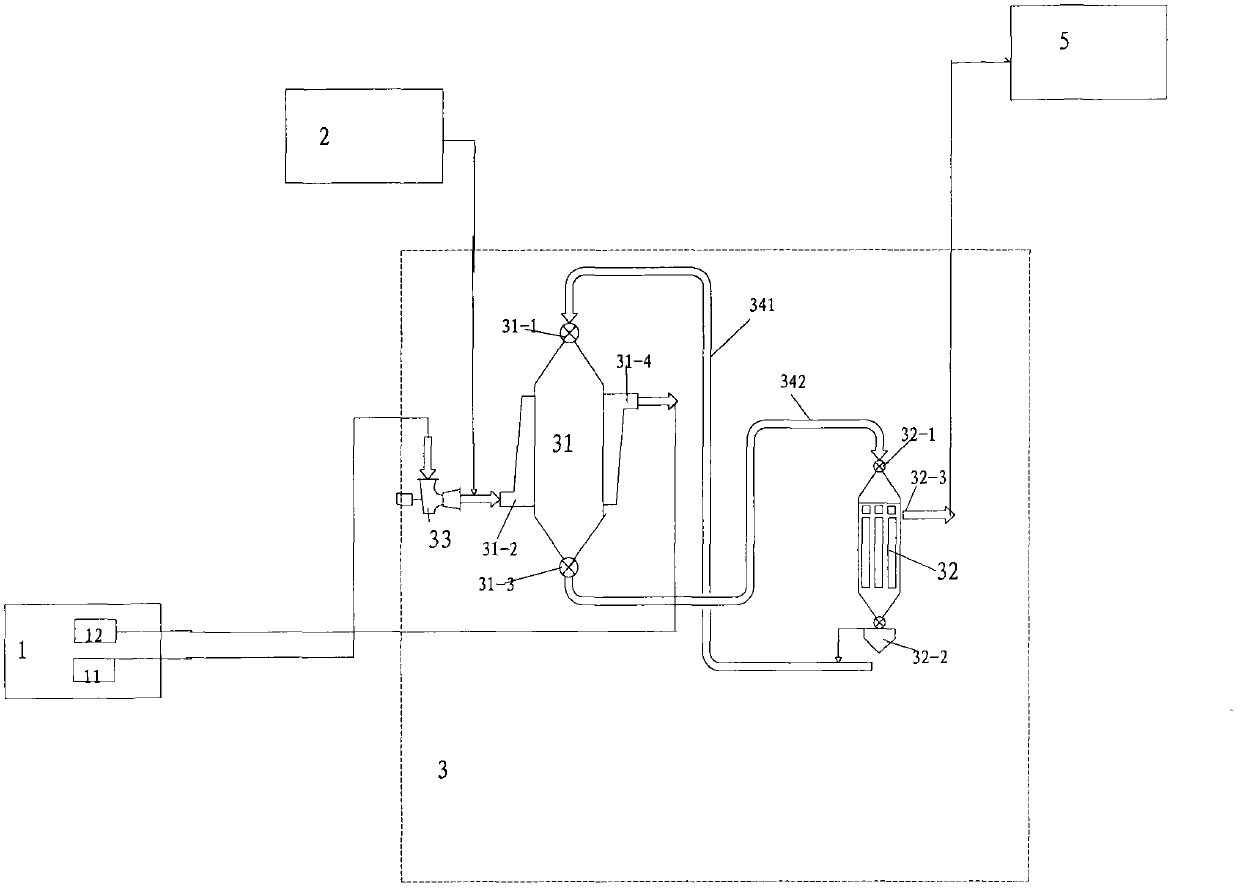

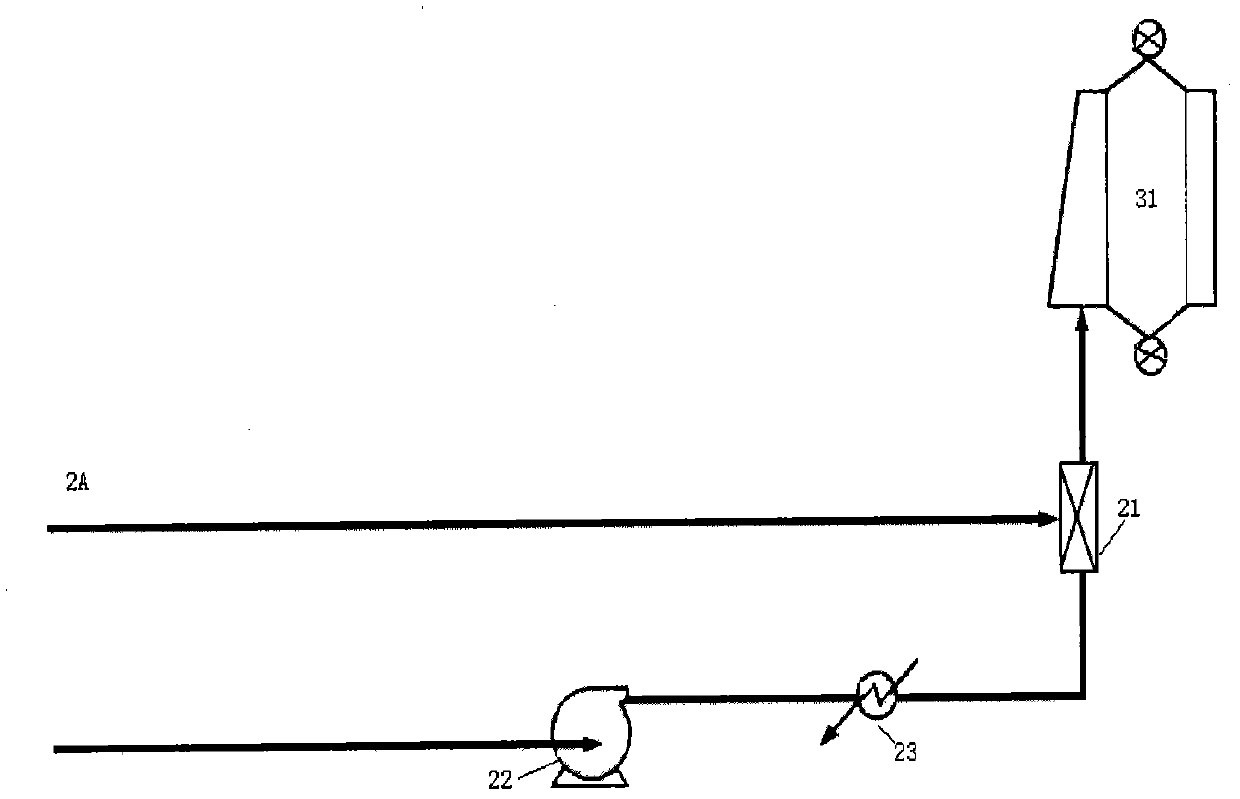

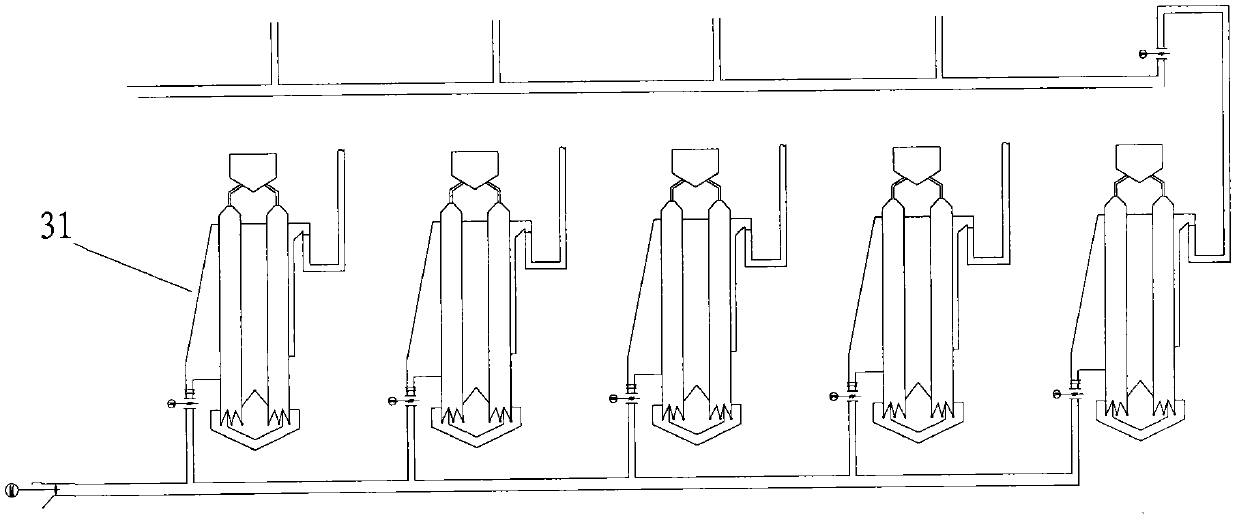

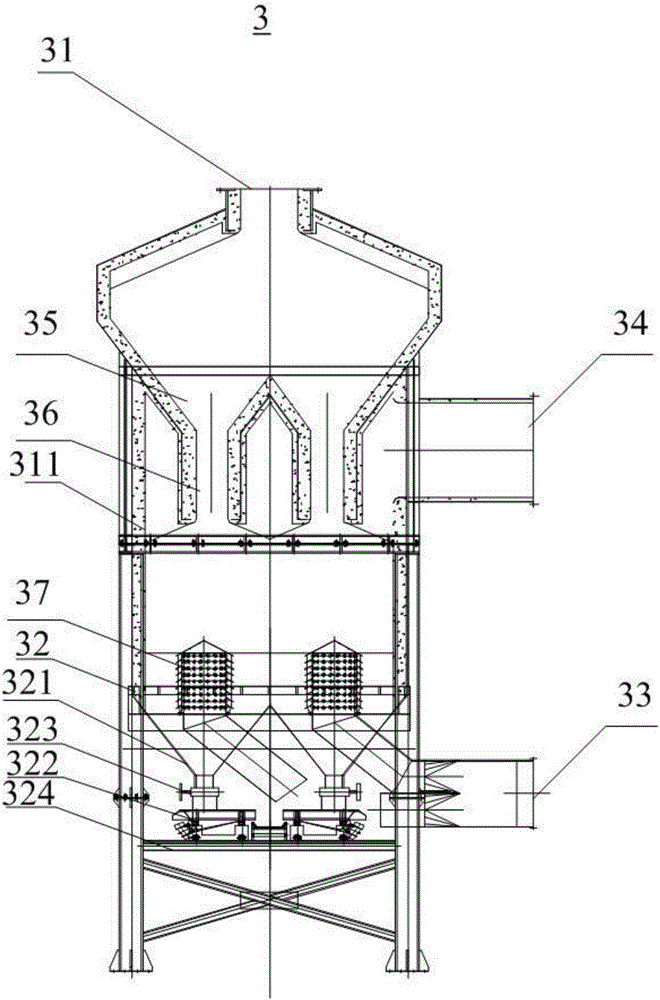

Sintering smoke treatment system and sintering smoke treatment method

InactiveCN102580455AComprehensive management benefit maximizationHigh adsorptionDispersed particle separationMetallurgyMaterials science

The invention provides a sintering smoke treatment system and a sintering smoke treatment mode, which are used in synchronized desulfuration, denitration, purification and acid making. The sintering smoke treatment system comprises a smoke system (1), an ammonia filling system (2), a smoke treatment system (3) and an acid making system (5), wherein the smoke system (1) comprises a main exhaust fan (11) and a chimney (12), the smoke treatment system (3) comprises an adsorption tower (31) and an analyzing tower (32), and the adsorption tower (31) and the analyzing tower (32) are connected with each other. The main exhaust fan (11) of the smoke system (1) and the chimney (12) are respectively connected with the adsorption tower (31), the analysis tower (32) of the smoke treatment system (3) is connected with the acid making system (5), and the adsorption tower (31) of the smoke treatment system (3) is connected with the chimney (12) of the smoke system (1).

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

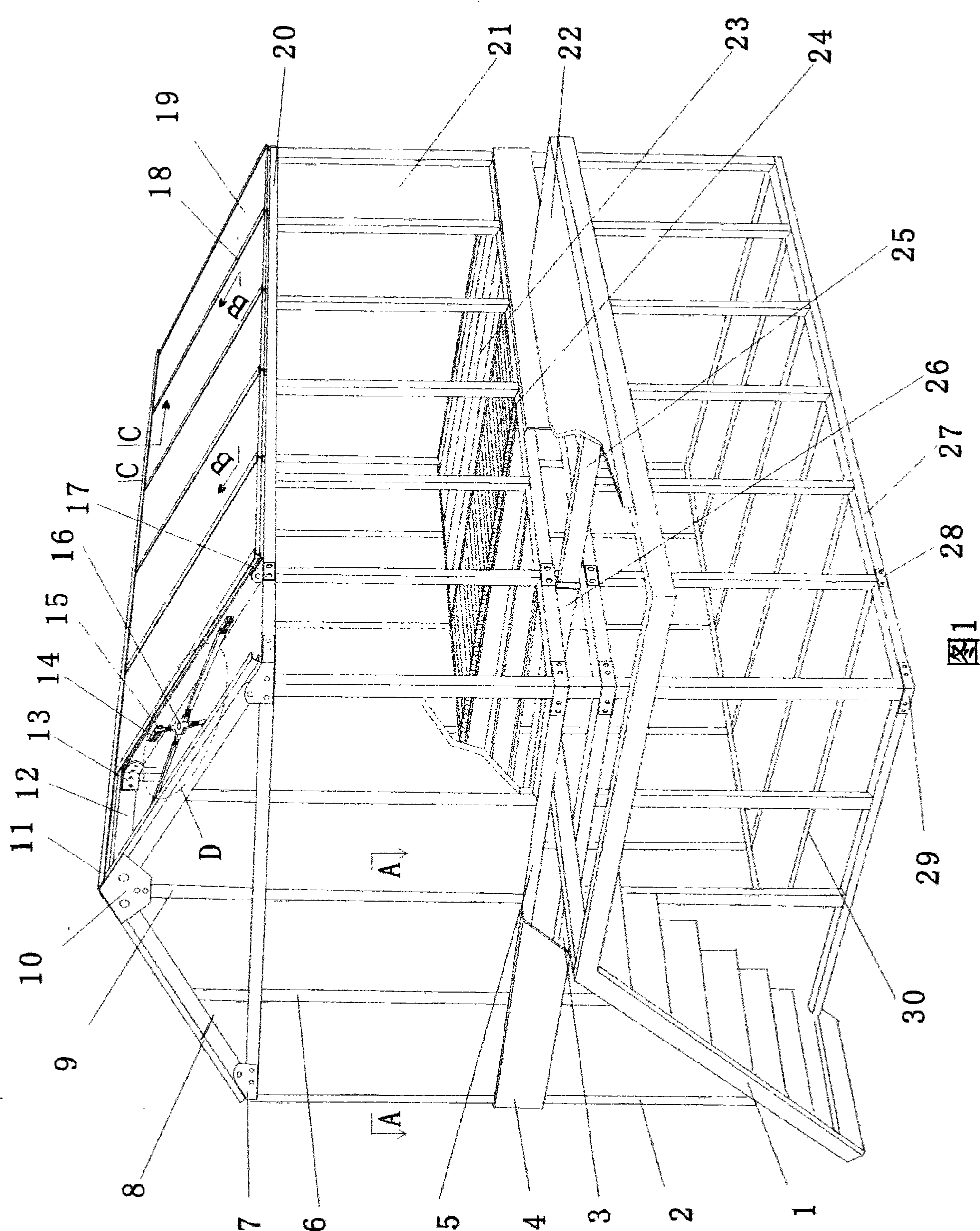

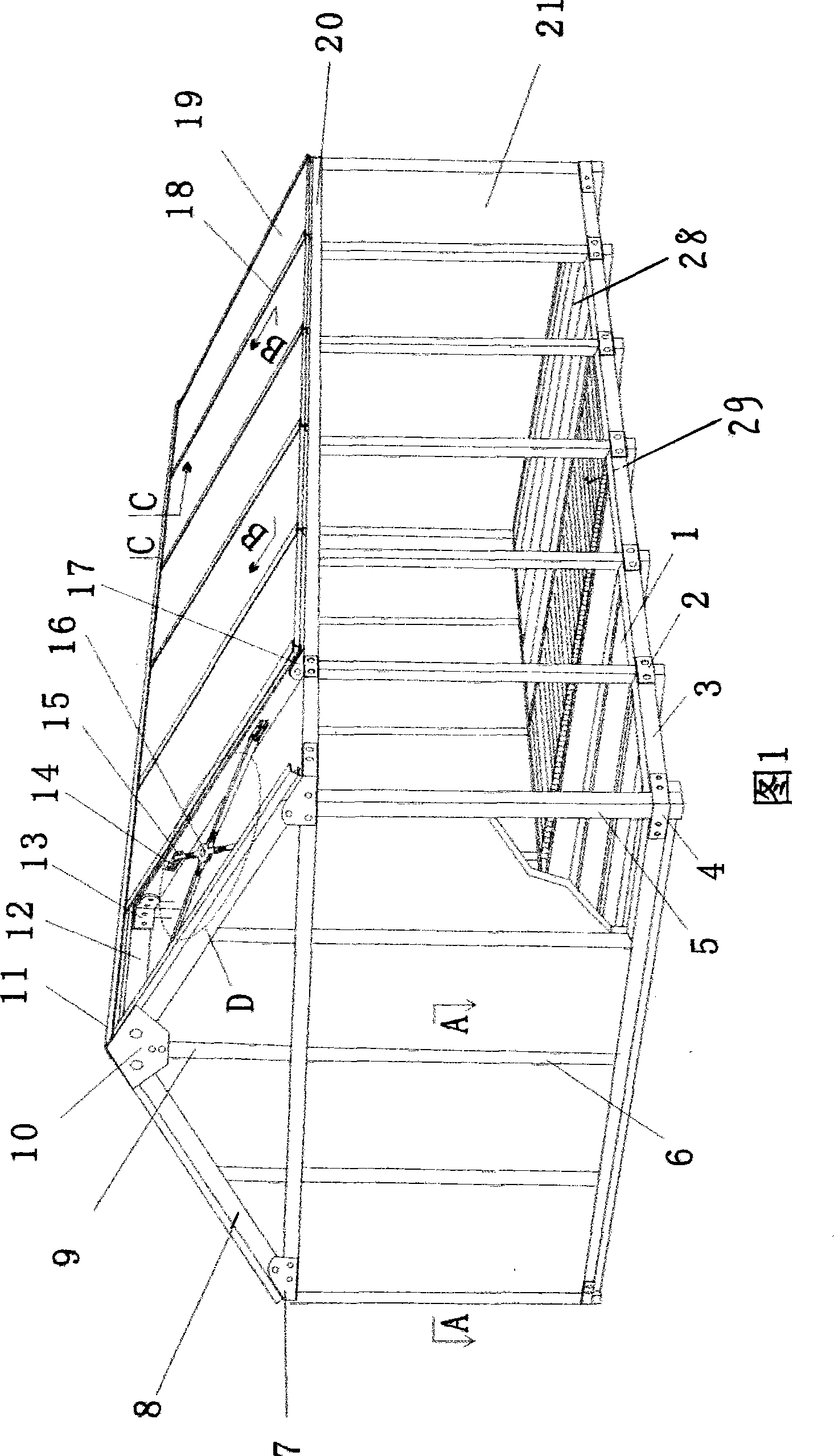

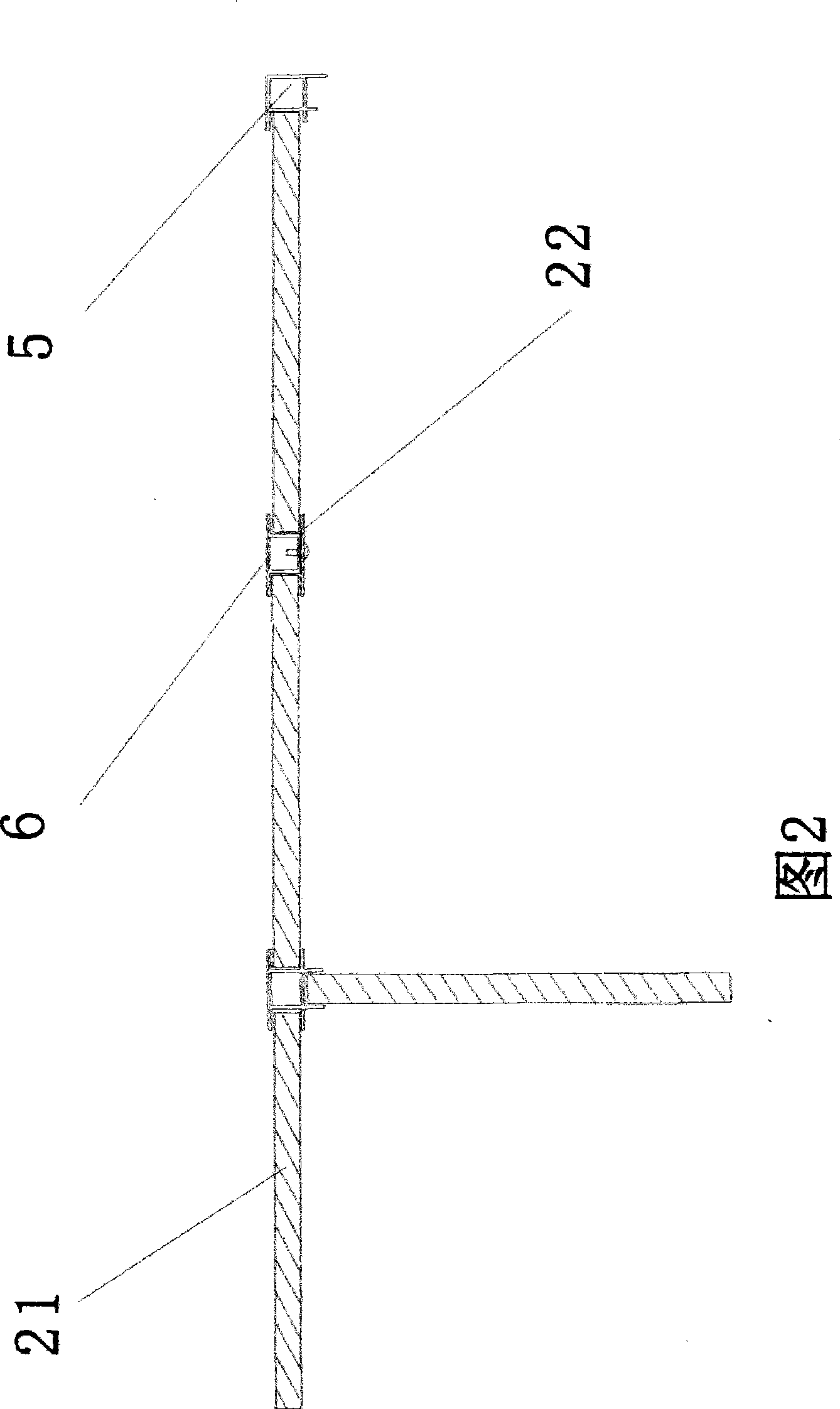

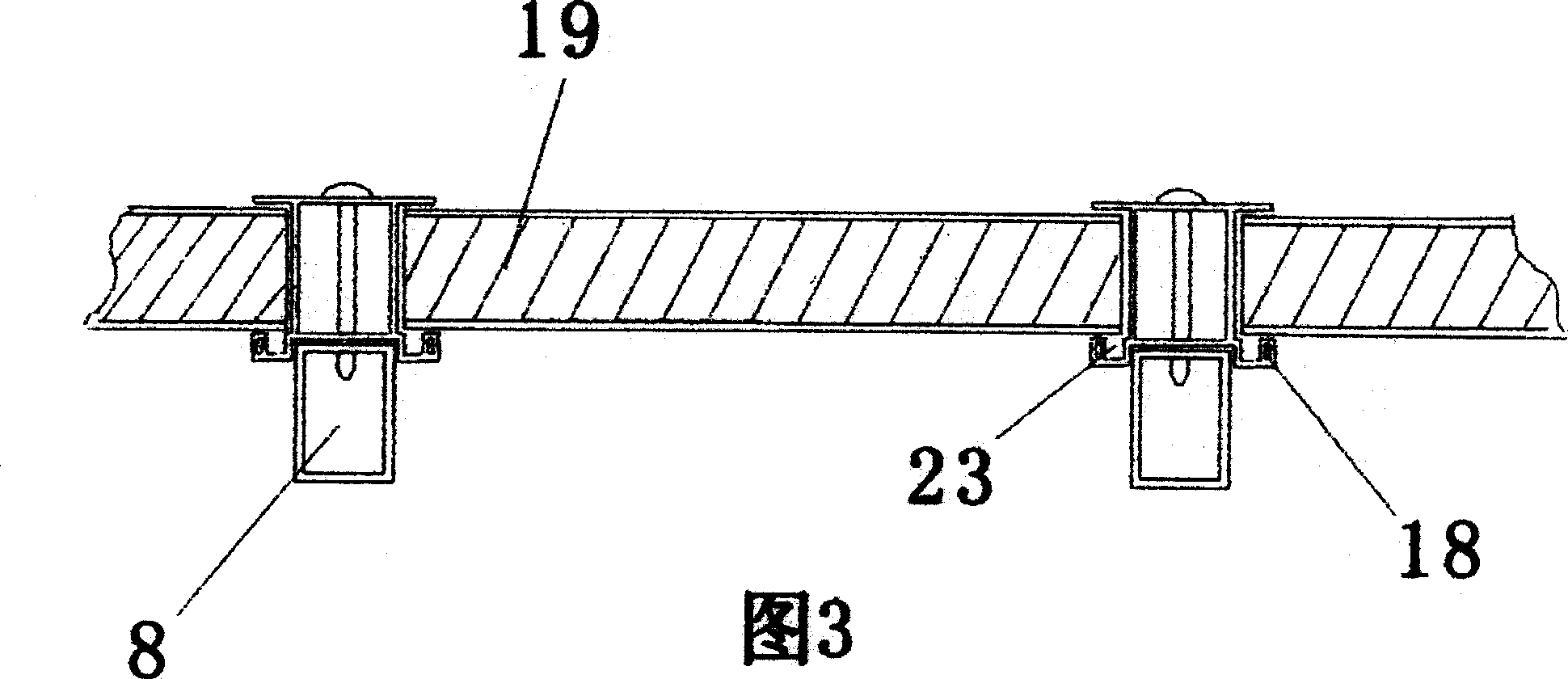

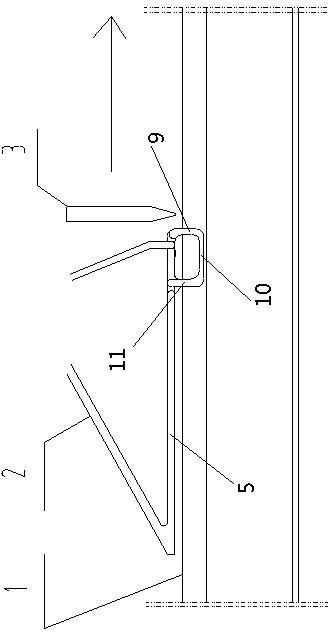

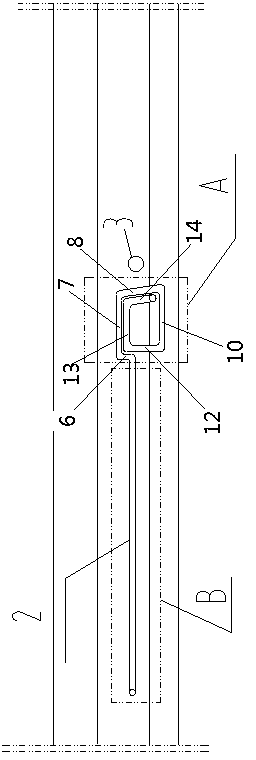

Combined light steel structure house and mounting method thereof

InactiveCN101418592AHigh degree of factoryReduce the ratio of output value to energy consumptionBuilding constructionsFloor slabSandwich panel

The invention relates to a combined lightweight steel structure building and an assembling method thereof. The combined lightweight steel structure building comprises ground beams, angular upright posts, upright posts, ring beams, sandwich panels, a roof, staircases, doors and windows. The key technical points of the combined lightweight steel structure building are as follows: a plurality of floor bottom girders in parallel are arranged on the ground; four ground beams are arranged on the circumference of each floor bottom girder in turn; bolt fastening sheets which are connected with the ground beams and the ring beams are arranged on joints of upper ends and lower ends of each angular upright post and each upright post respectively; limit baffle plates of wall panels are arranged on angular upright posts and upright posts near the outside of the building; bolt fastening limit treadle bars of the wall panels are arranged on upright posts near the inside of the building; the wall panels comprise wall panels provided with door bodies or wall panels provided with window bodies; metal section supporting layers which are suitable to be connected with balcony bottom girders or / and corridor bottom girders are uniformly distributed between two adjacent floors; metal floor slabs are laid on the metal section supporting layers; and the roof is as follows: a waterproof ridge section is arranged on the upper part of a ridge main girder; the edge of a roof slab is embedded into the ridge section; and a roof slab slot section provided with a drainage channel is arranged on the upper part of a ramp beam of the roof.

Owner:官木喜

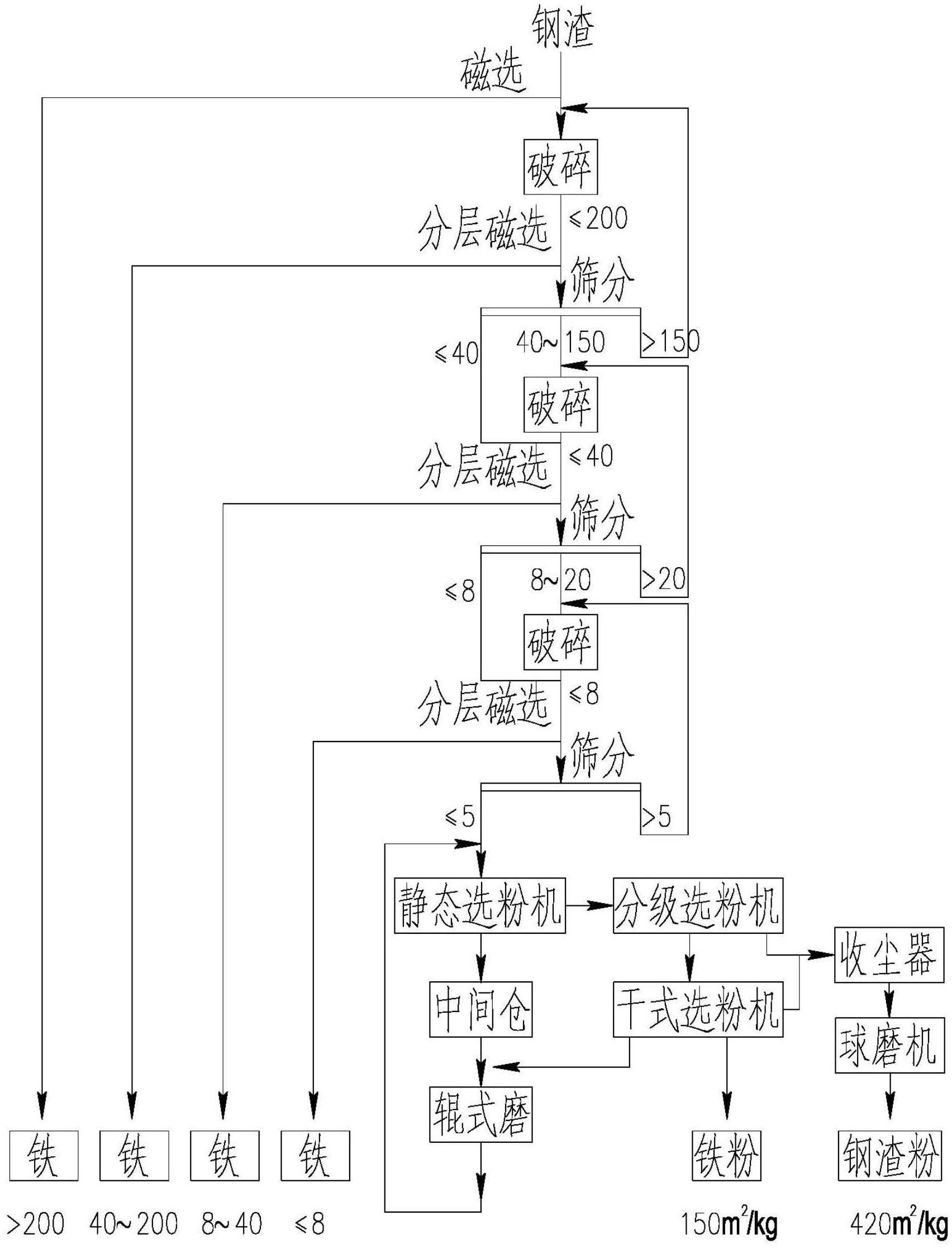

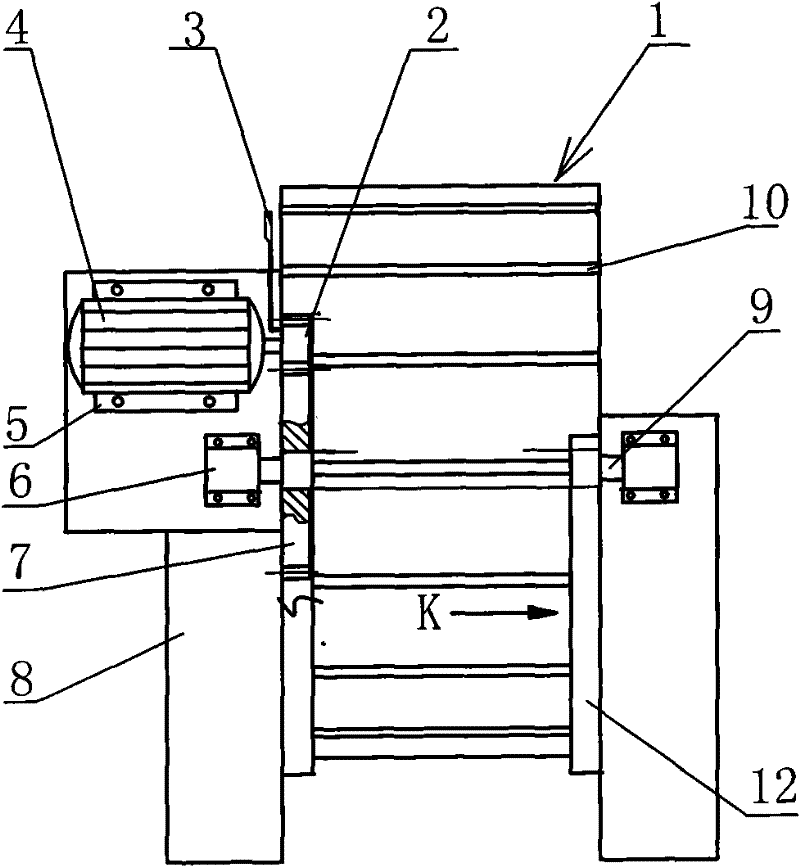

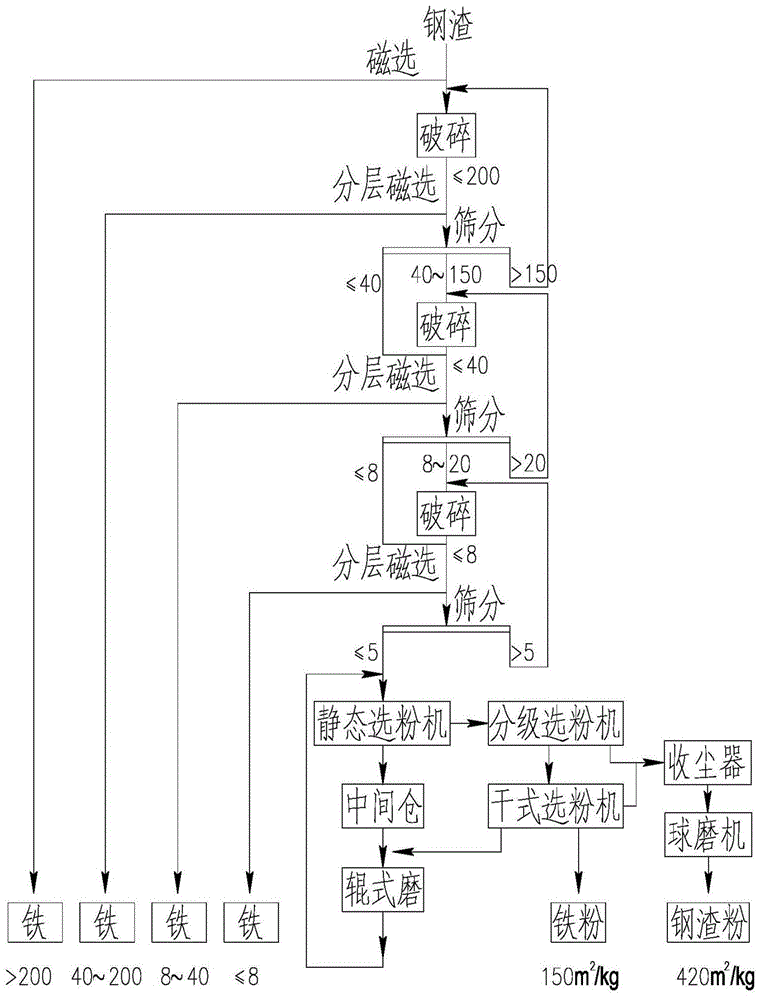

Method for efficiently recovering and reselecting steel slag

ActiveCN102688880AEffectively electedIncrease cycle loadSolid waste disposalRecycling and recovery technologiesEcological environmentSlag

The invention discloses a method for efficiently recovering and reselecting steel slag, comprising the following steps of: A, smashing and magnetically selecting: selecting iron in steel slag in a stock dump by a lifting electromagnet, directly charging the steel slag into a smasher to be smashed, and magnetically selecting the smashed steel slag by a rubber belt conveyor and a permanent magnetic iron remover in a layering way; B, smashing and magnetically selecting again: magnetically selecting the treated steel slag by the rubber belt conveyor of a head wheel belt permanent magnetic tumbling cylinder and the permanent magnetic iron remover in a layering way; C, extruding and smashing the steel slag into fine powder by a roller type grinding circulating system; D, selecting the iron powder with refine grain diameter by a dry type powder selector; and E, grinding the fine powder steel slag which is separated by the roller type grinding circulating system and a steel slag selecting and recovering system by a ball grinder system. The method is simple and easy, and convenient to operate, so that when the iron is selected, the steel slag low-heat concrete which accords with the national standard requirement can be produced by the steel slag. The production cost and the energy consumption can be reduced, the land occupancy can be reduced, the ecological environment can be protected, and the good economic benefit, social benefit and environmental benefit can be obtained.

Owner:武汉市天沭科技发展有限公司

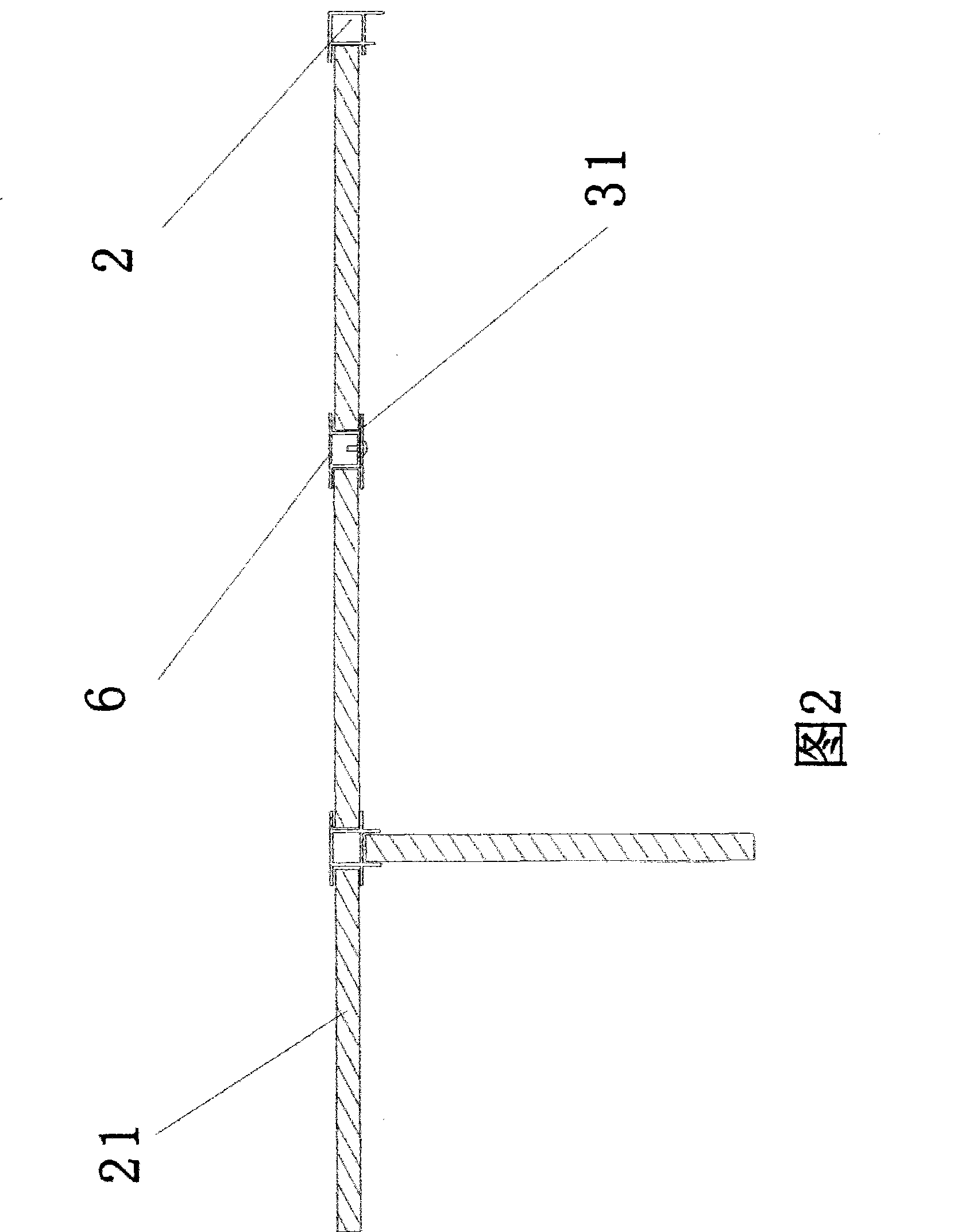

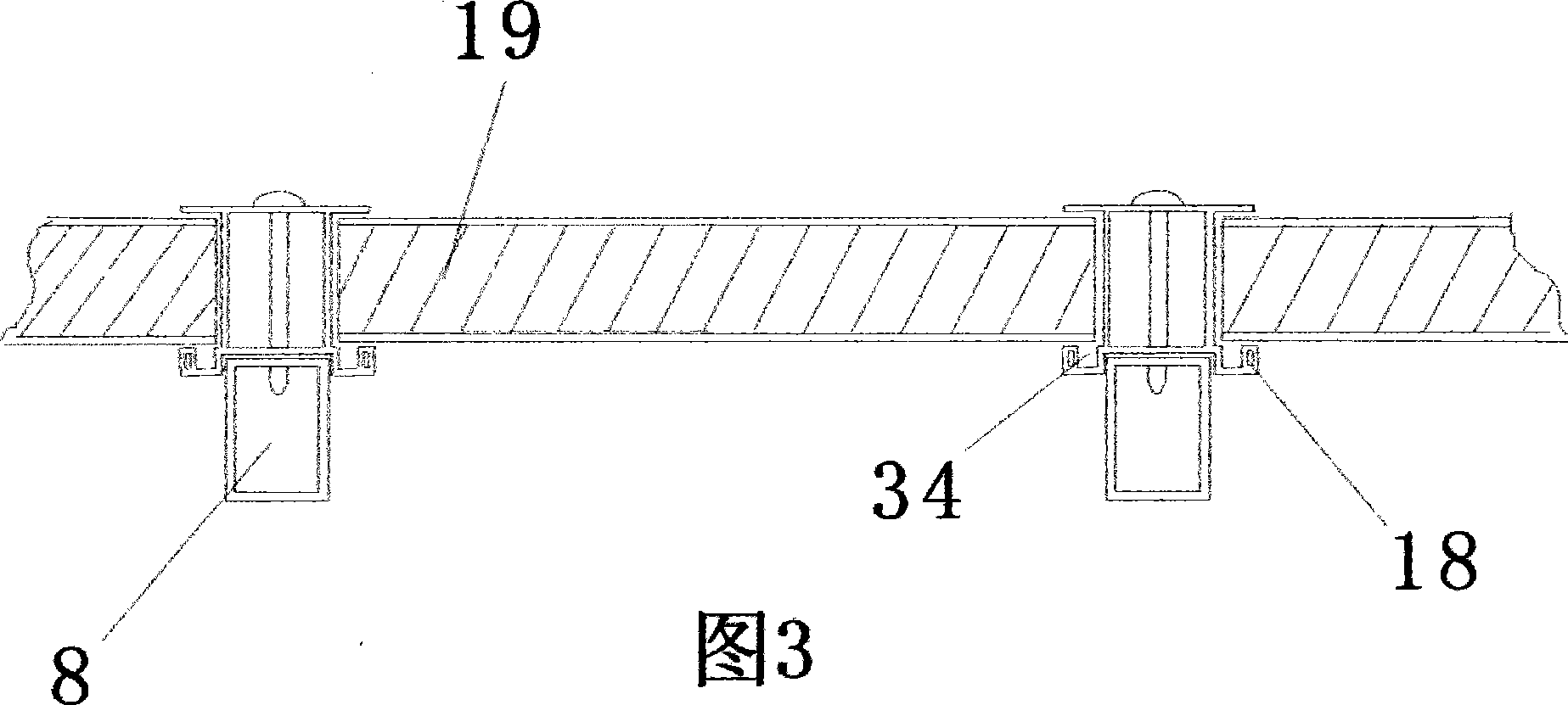

One layer combined type light steel structure house and installation method thereof

InactiveCN101440635ASatisfy the needs of clientsHigh degree of factoryBuilding constructionsSandwich panelBolt connection

The invention relates to a one-story combined type lightweight steel structure house and a mounting method thereof. The house comprises ground beams, corner upright posts, upright posts, ring beams, a sandwich panel, a roof, a door and windows. The house comprises the following technical points: a plurality of parallel floor mudsills are arranged on the ground; the periphery of the floor mudsills are sequentially provided with four ground beams; the connecting parts between the upper ends and the lower ends of each corner upright post and each upright post are provided with a bolt connecting sheet connected with the ground beam and the ring beam respectively; the positions of the corner upright post and the upright post close to the outer side of the house are provided with a limiting baffle plate of a wallboard; the position of the upright post close to the inner side of the house is provided with a bolt connecting and limiting treadle bar of the wallboard; the wallboard comprises the wallboard with a door body or window bodies; and the roof comprises: the upper part of a main girder of a roof ridge is provided with a water retaining roof ridge section; a roof board is embedded into the roof ridge section; and the upper part of an oblique beam of the roof is provided with a roof board slot section with a drainage channel. The method standardizes and generalizes members of the building structure, totally adopts bolt connection without needing welding in mounting and is suitable for the requirement of a routine lightweight structure house.

Owner:官木喜

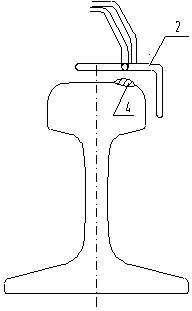

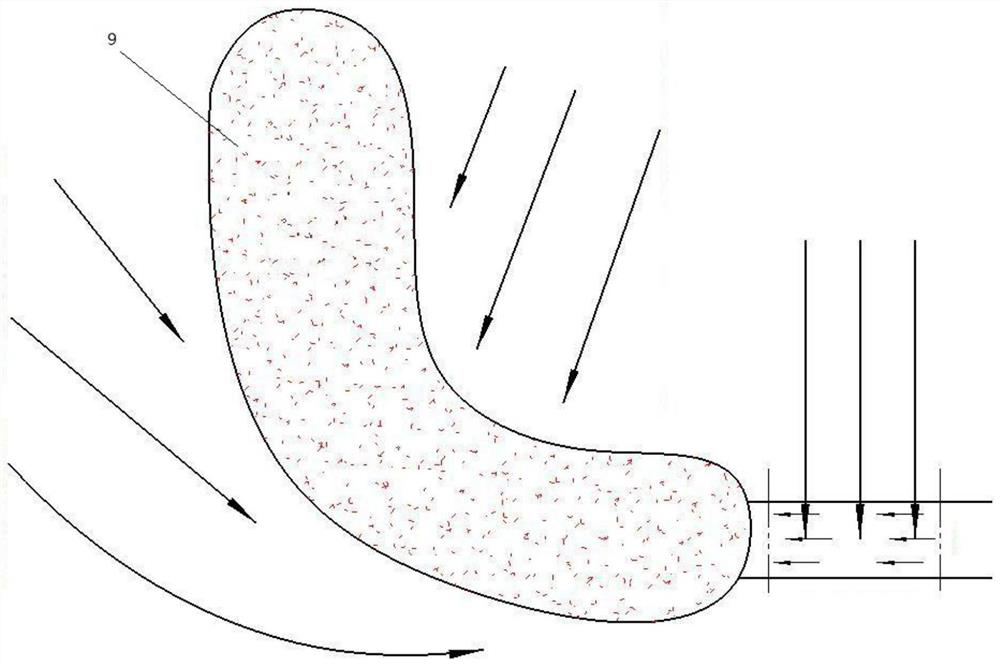

Induction heater and method for realizing non-preheating cladding of alloy on steel rail by using same

InactiveCN103132008ASave energyExtended heating rangeMolten spray coatingHeat transmissionMiniaturization

The invention discloses an induction heater which comprises a heating zone 1 and a heating zone 2, wherein the heating zone 1 is divided into two heating surfaces; a first heating surface is shaped like a trapezoid without the bottom; a second heating surface is a U-shaped one; the two lateral sides of the trapezoid-shaped heating surface are connected with the U-shaped heating surface; and an included angle is formed between the first heating surface and the second heating surface. When the induction heater is used to perform alloy cladding on a steel rail, preheating does not need to be performed in advance, so that on the premise of the same steel rail cladding speed, heat energy required by the method is only one third or less of the prior art; and meanwhile, the method lays a foundation for miniaturization of a generator or even construction without the aid of a rail car. By performing detailed analysis on structure phase change and heat transmission of a steel rail in the cladding process, the invention breaks through the theory that the steel rail must be preheated prior to welding for the first time, and presents that the steel rail can be directly subjected to alloy cladding without being preheated while generation of martensite can be avoided. The technology disclosed by the invention is put forward for the first time at home and abroad.

Owner:CHENGDU ZHONGGUI TECH CO LTD

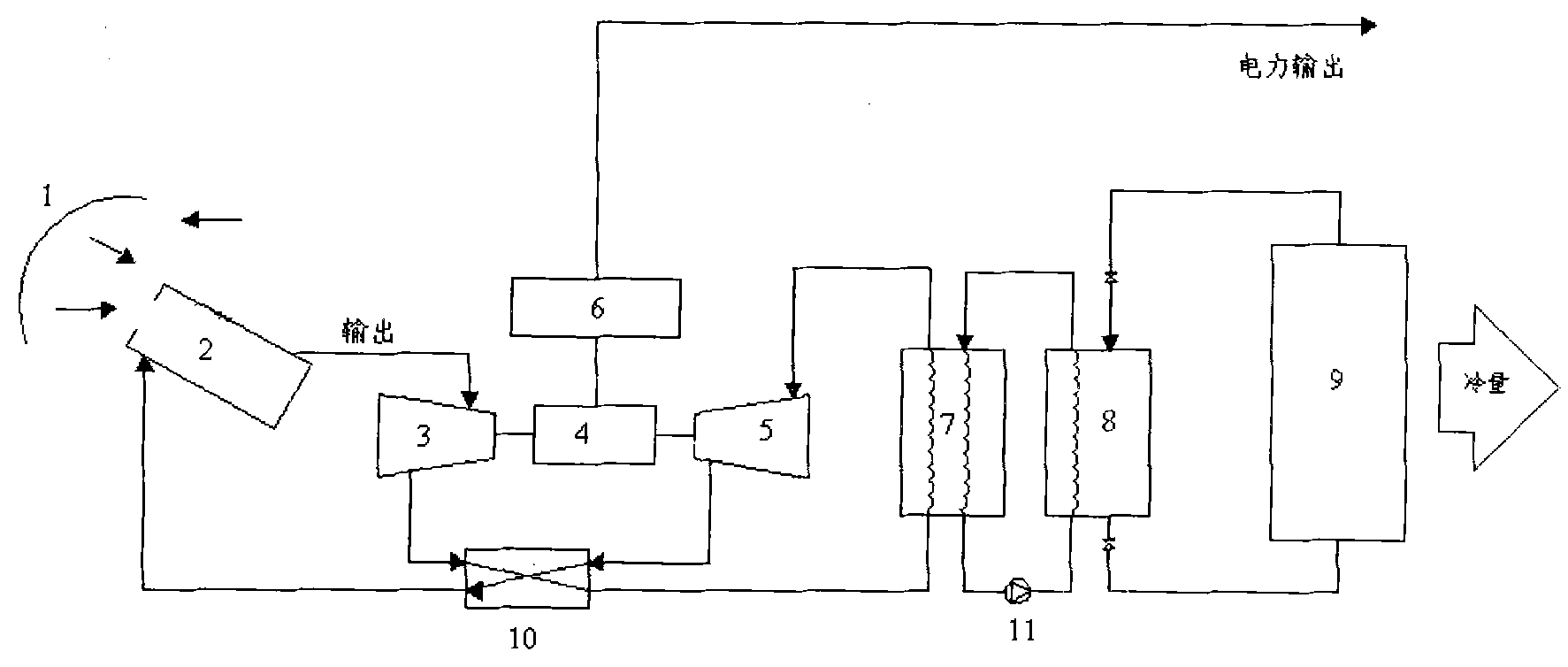

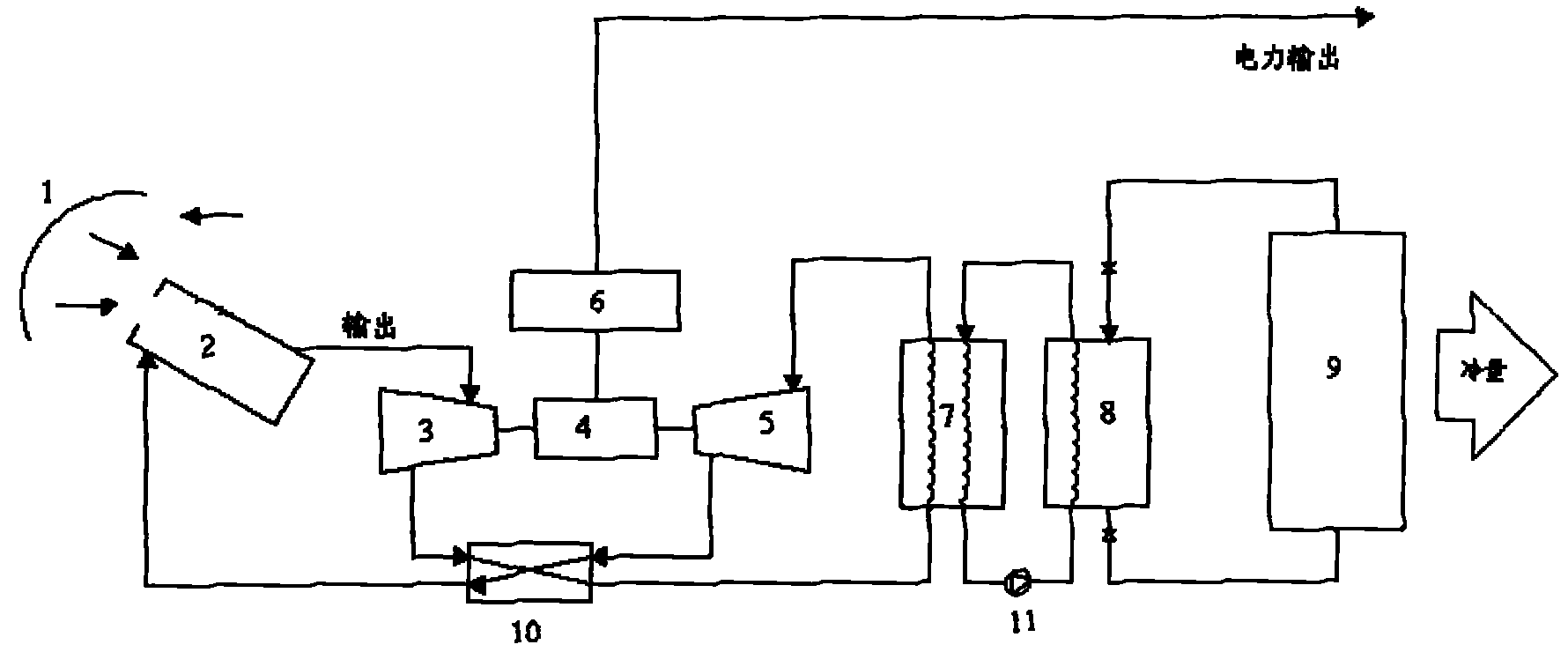

Distributed solar energy combined heating/cooling-power system

InactiveCN101929445AImprove utilization efficiencyAdjustable powerFrom solar energyMachines/enginesLithium bromideEngineering

The invention relates to a distributed solar energy combined heating / cooling-power system, comprising a concentrator, a heat absorber on the focus of the concentrator, a heat exchanger and a heat storage water tank, wherein the heat exchanger and the heat storage water tank are circularly connected and a circulating water pump is arranged between the heat exchanger and the heat storage water tank; and the heat storage water tank is also circularly connected with a waste heat refrigerating device. The system also comprises a generating system, electric conversion equipment and a heat regenerator, wherein through closed Brayton circulation generation, the generating system comprises a turbomachine, a generator and a compressor which are connected in sequence; the generator is connected with the electric conversion equipment; and the gas in the heat absorber passes through the turbomachine, the heat regenerator, the heat exchanger and the compressor in sequence and finally returns to the heat absorber via the heat regenerator, thus forming a circulation loop. The system utilizes the solar energy and through closed Brayton circulation generation, uses the circulating waste heat for direct heating or refrigerating by way of refrigerating with lithium bromide waste heat, thus realizing combined heating / cooling-power and improving the utilization efficiency of the solar energy.

Owner:DONGHUA UNIV

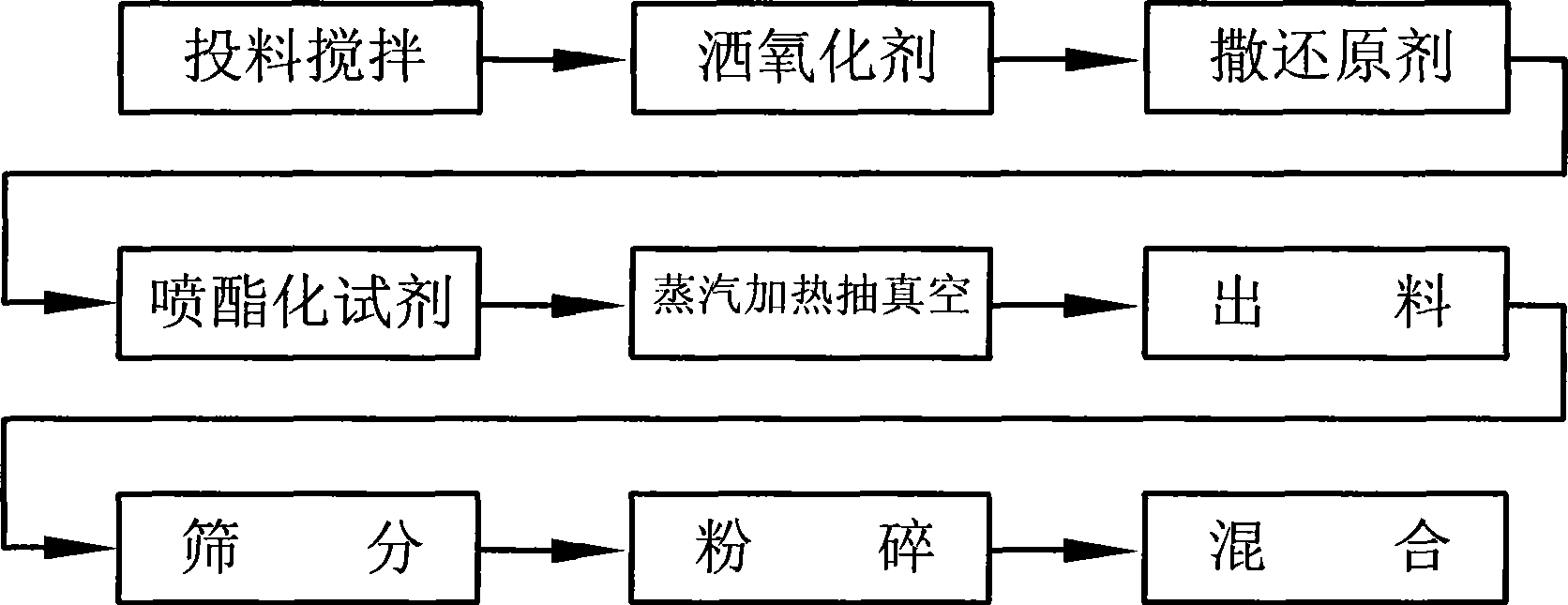

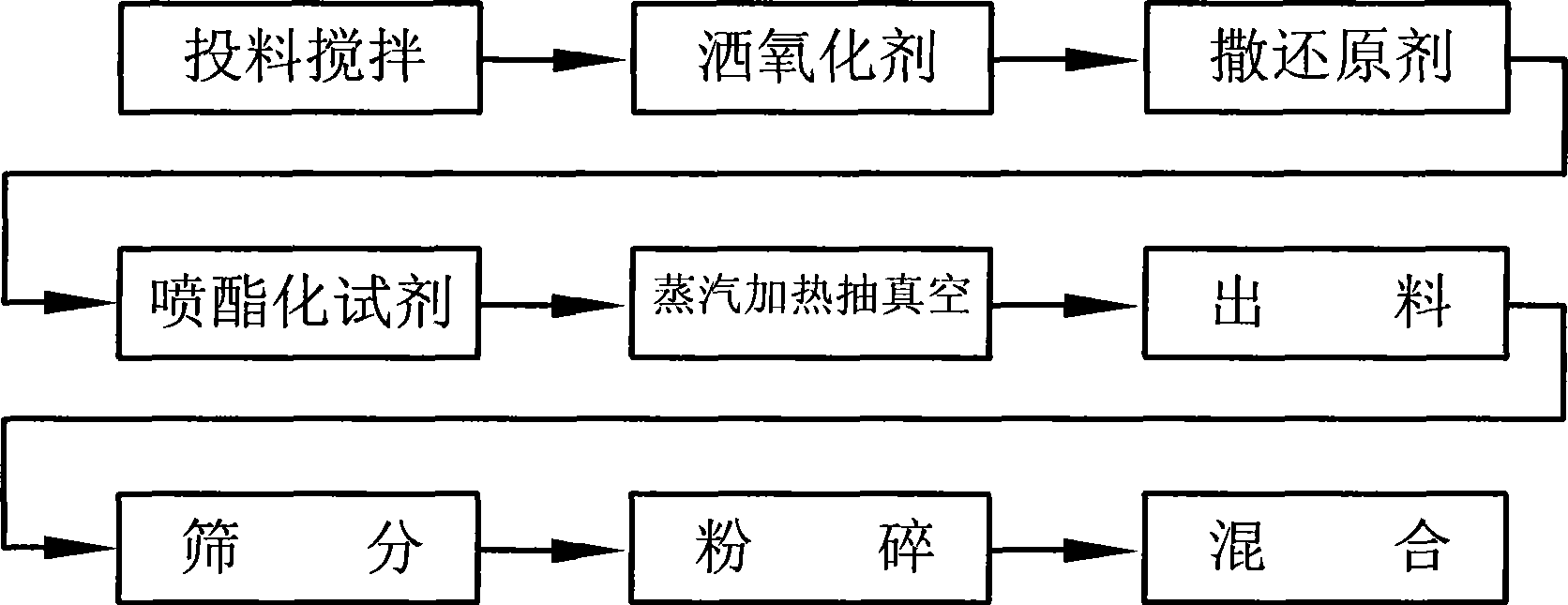

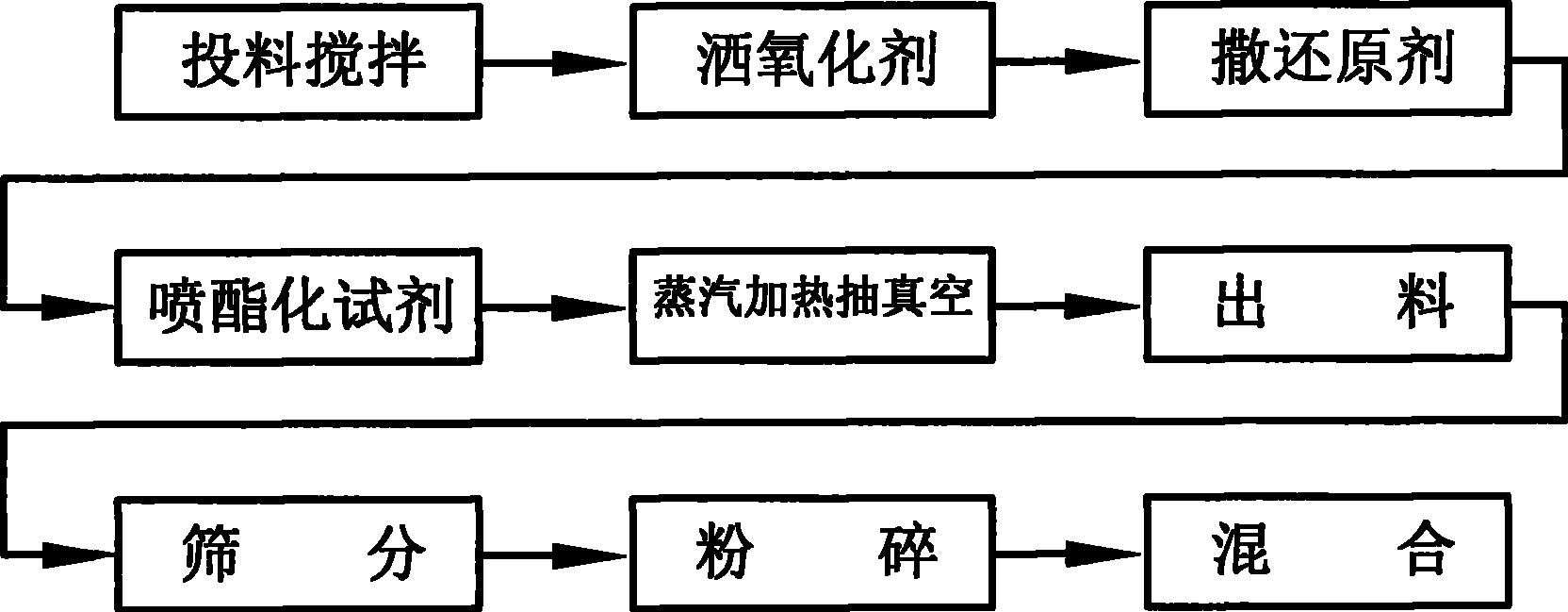

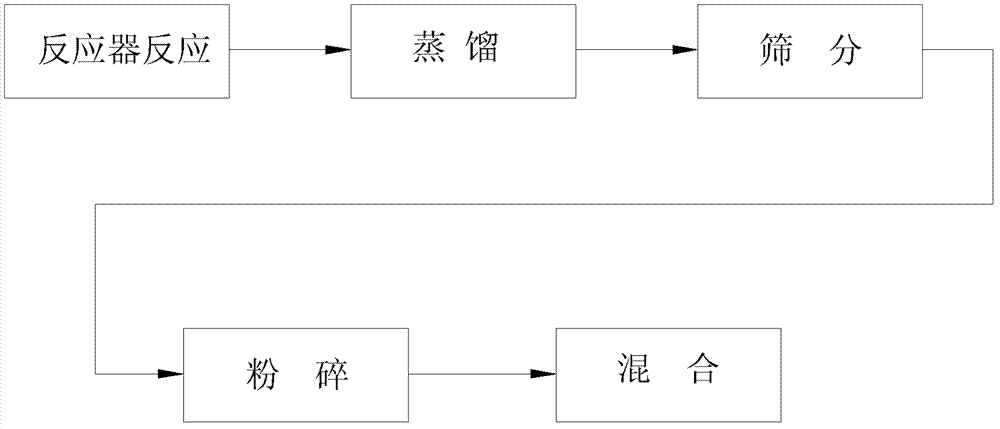

Formula of acetate starch and preparation technique thereof

ActiveCN101376678AImprove quality and levelExcellent serous film performanceFibre treatmentSolventChemistry

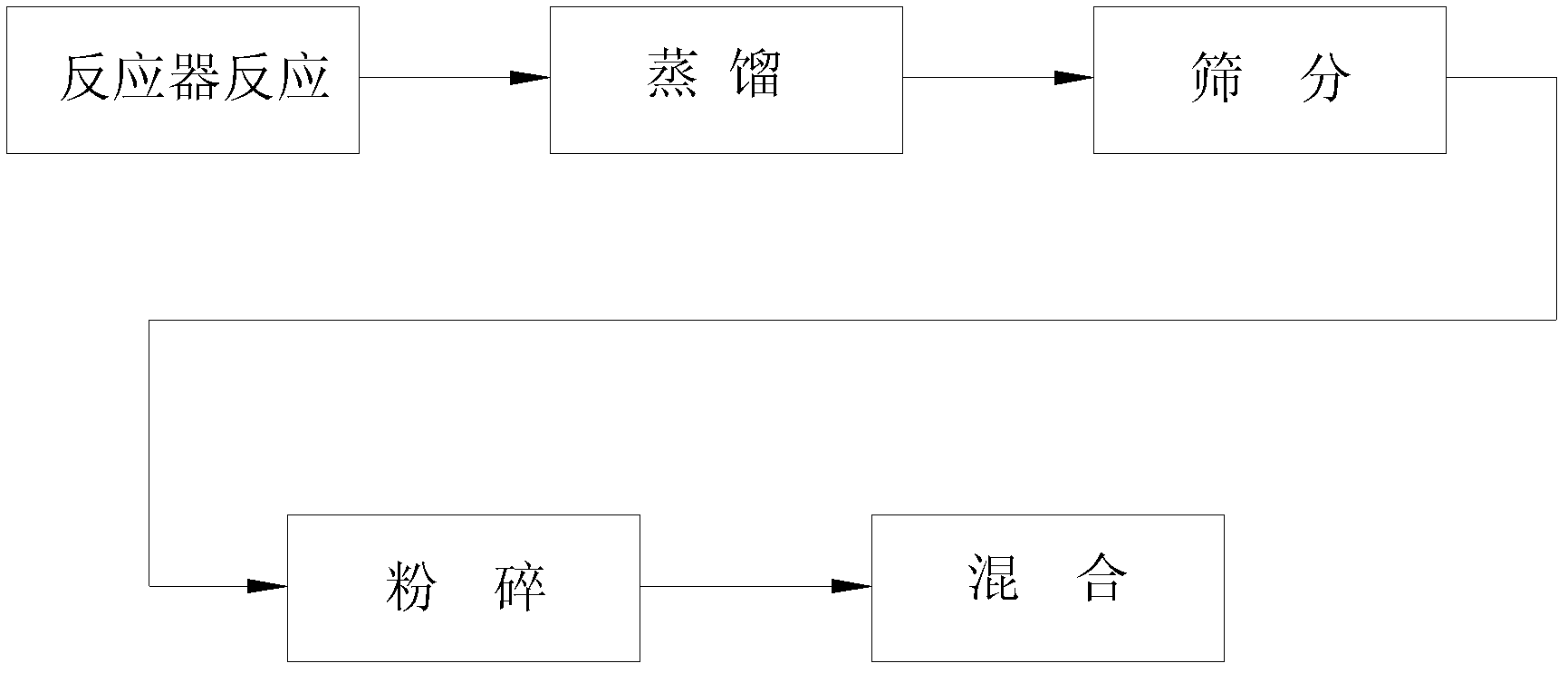

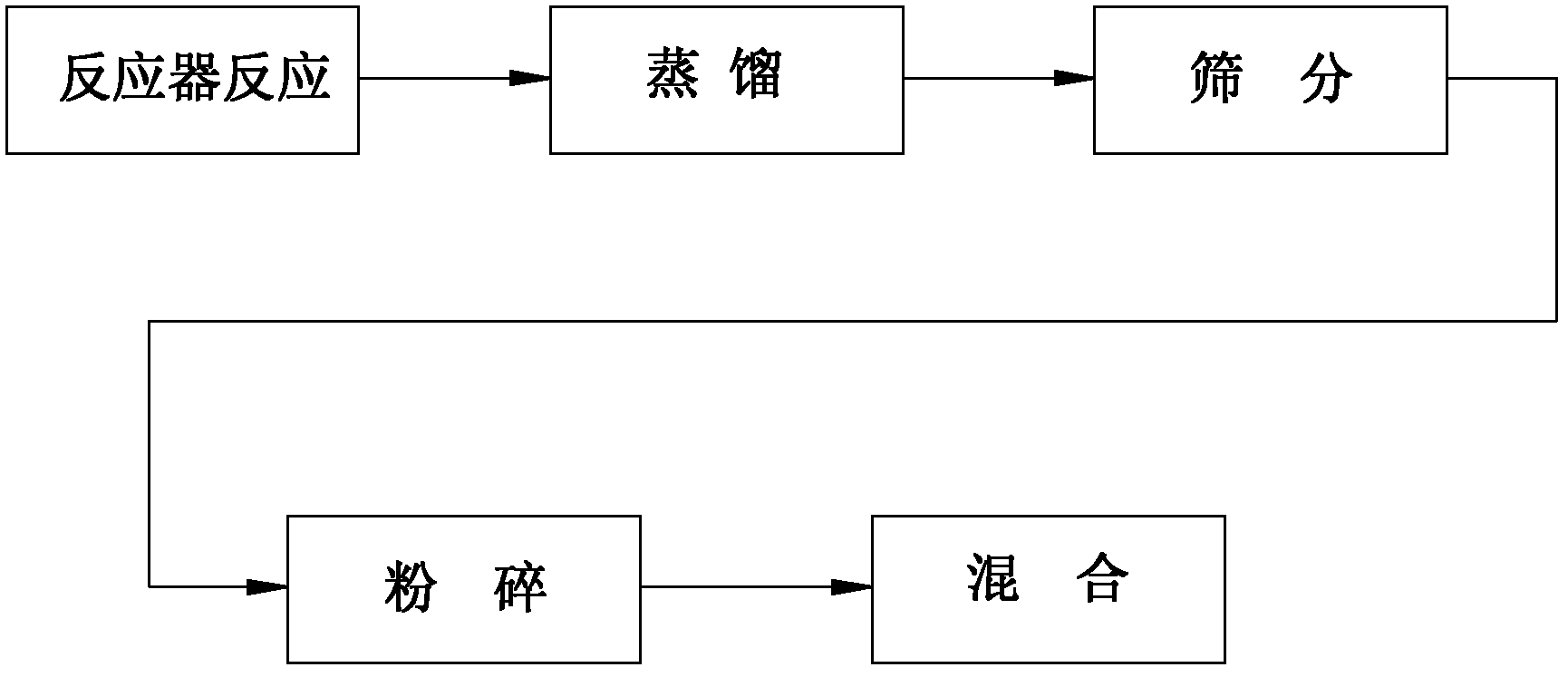

The invention relates to an acetate starch formulation for textile sizing material, and a preparation method thereof. The acetate starch formulation comprises corn starch, caustic soda, oxidizer, reducer, and esterifying reagent, and is characterized in that the acetate starch formulation also comprises alcohol. The preparation method comprises the following steps: adding the corn starch, caustic soda and alcohol into a feed box, and stirring; sprinkling liquid oxidizer, sprinkling powdery reducer in dispersed manner, spraying with liquid esterifying reagent, heating with steam, evacuating, heating with steam to 65 DEG C, and persistently evacuating until the alcohol in the feed box is completely volatilized, distilled and recovered; and discharging, sieving, pulverizing and mixing. The alcohol solvent phase is employed to prepare acetate starch to reduce the production cost. The acetate starch replaces PVA in textile pulp application to acquire good effect, higher substitution degree, and excellent size film performance, and improve the sizing quality and level of subsequent textile sizing. The alcohol solvent phase production does not require water resource to have no waste water treatment.

Owner:西达(无锡)生物科技有限公司

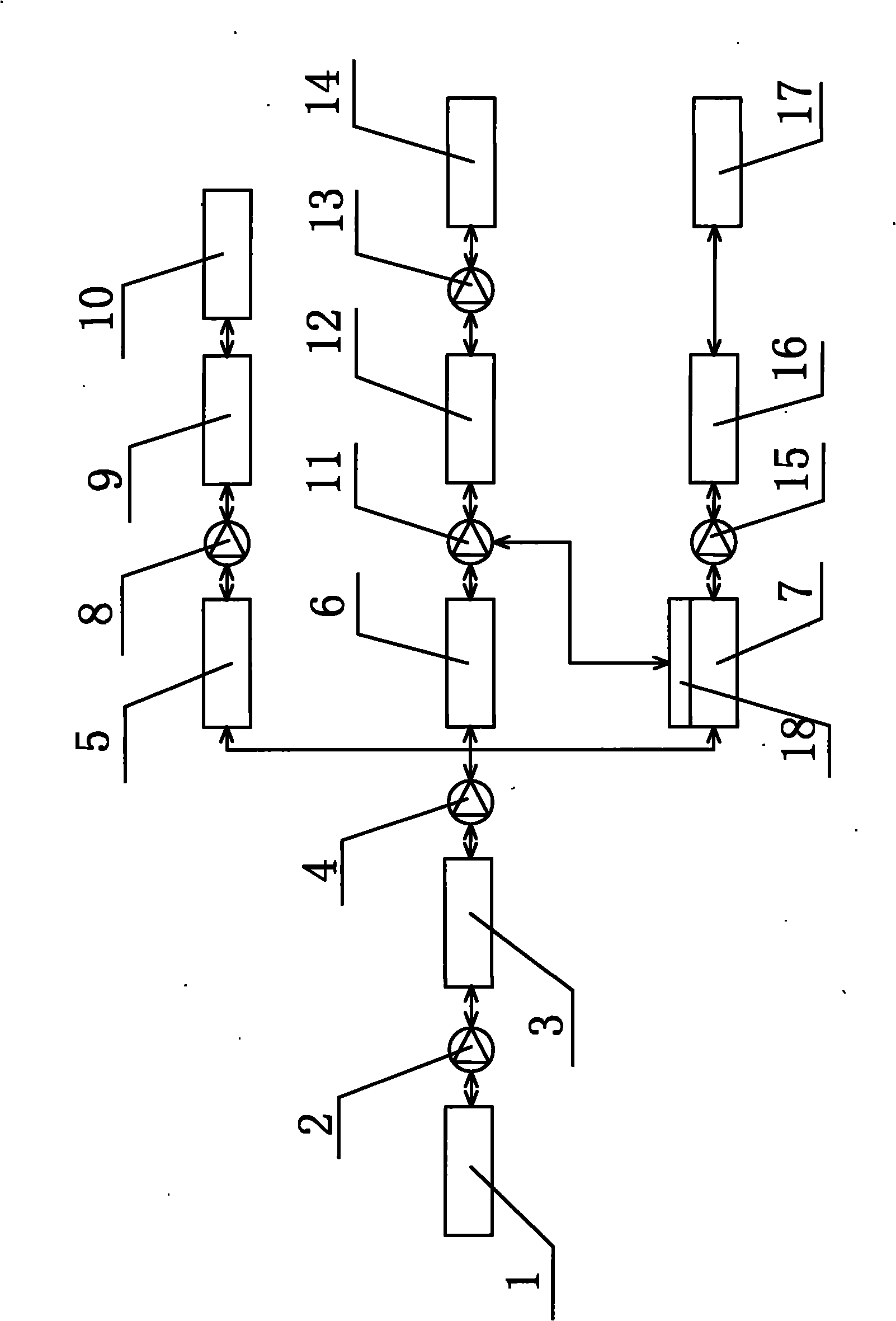

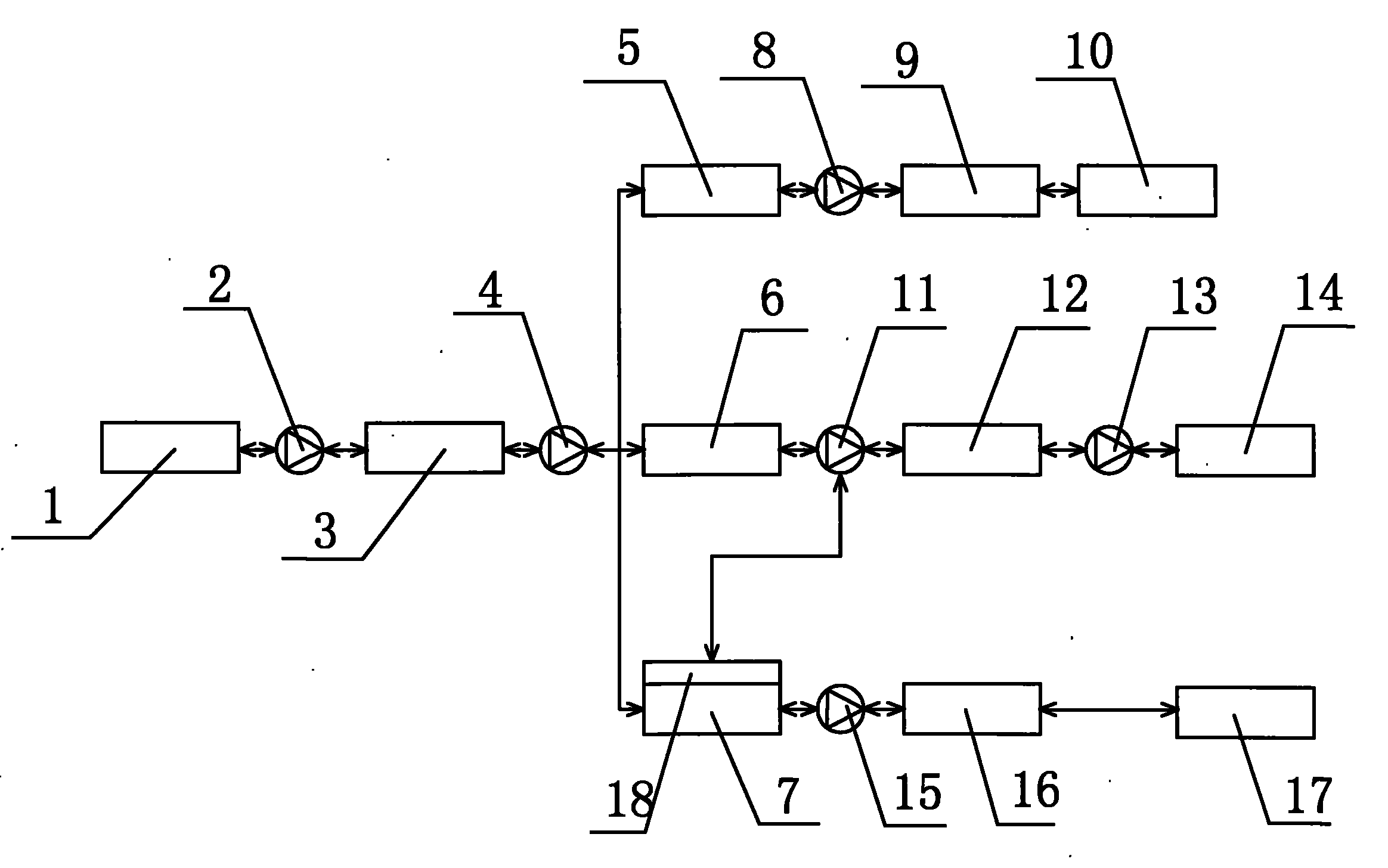

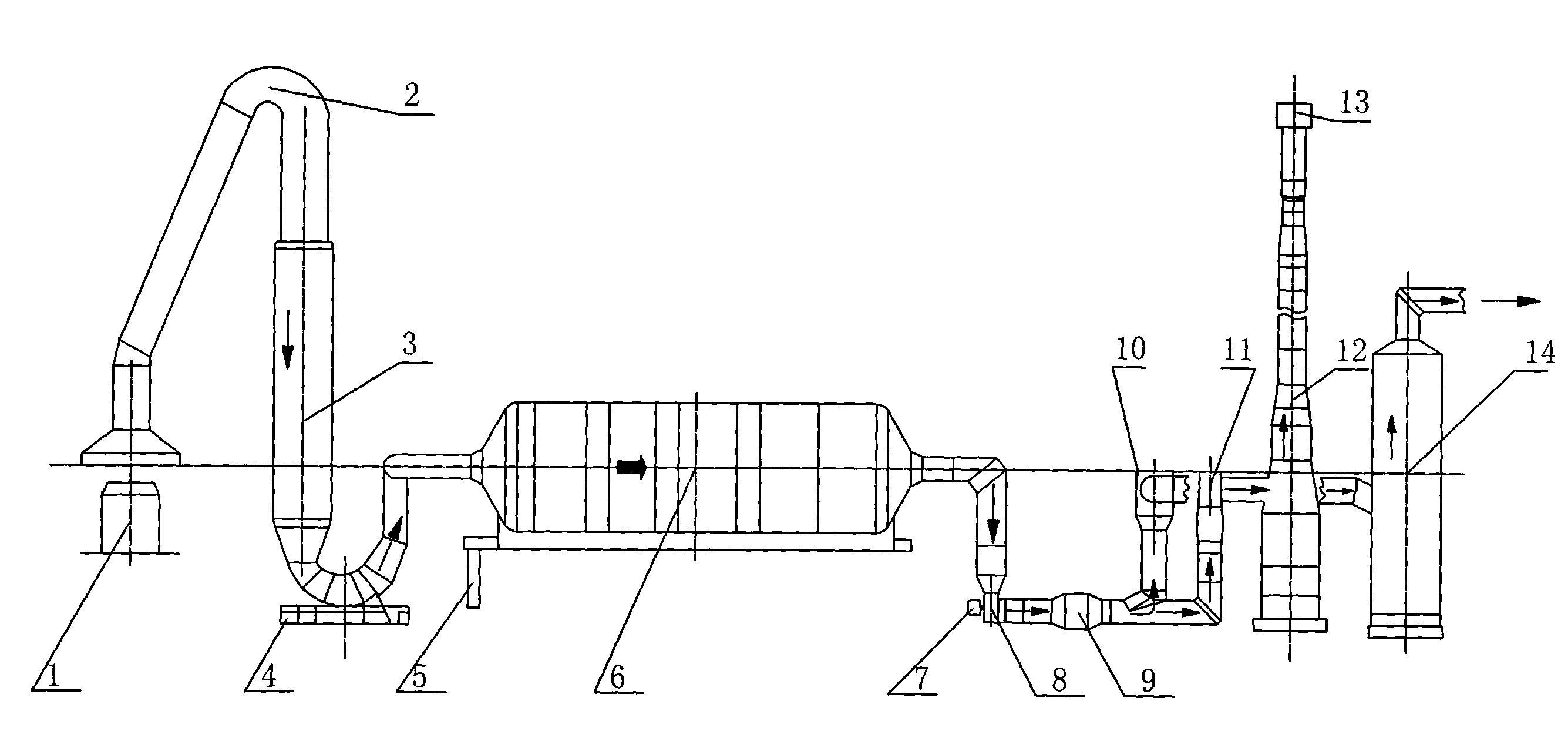

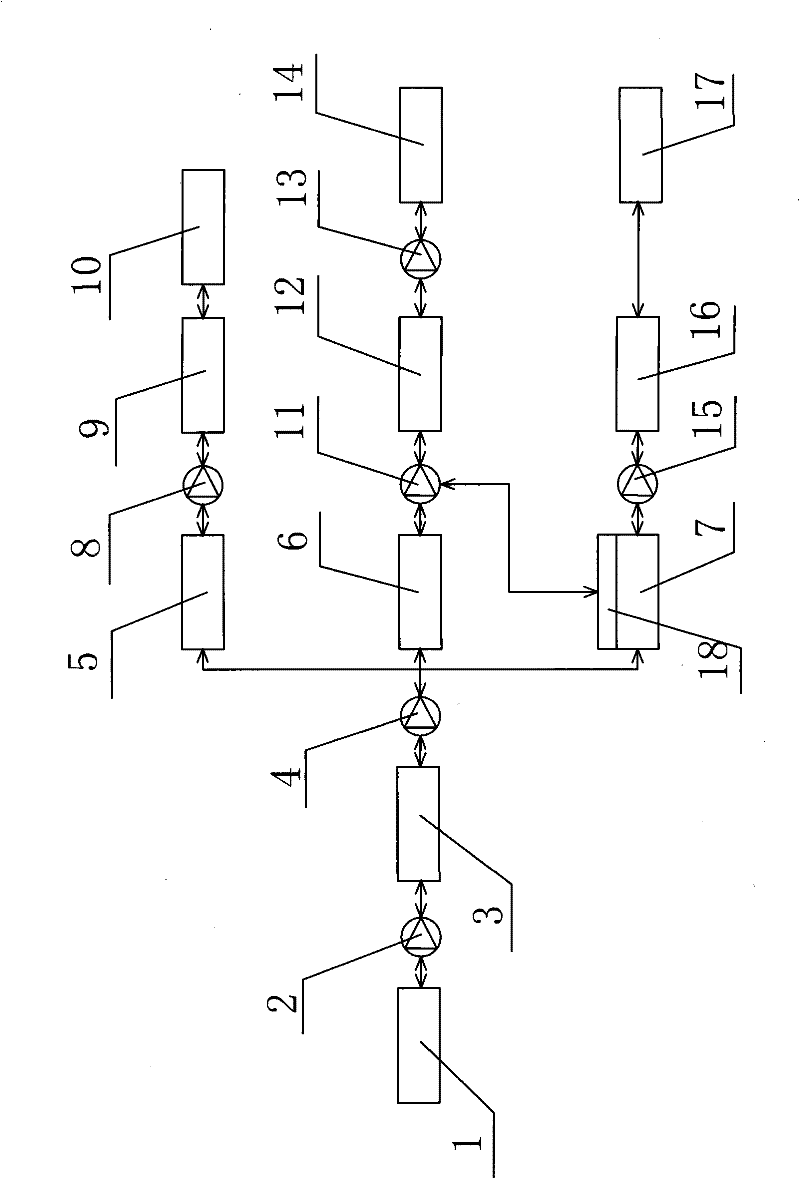

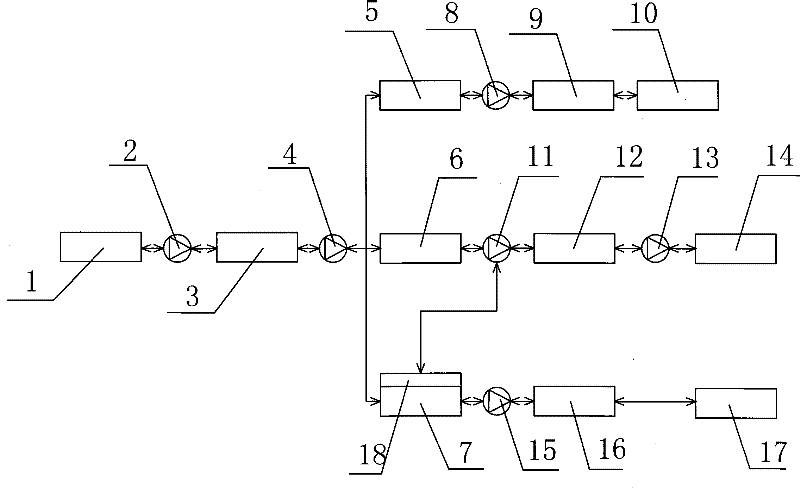

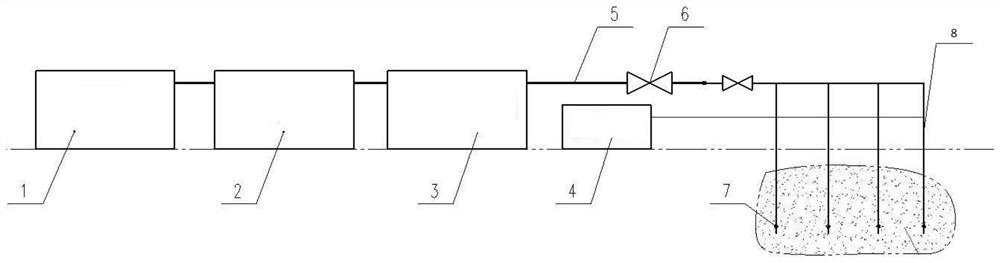

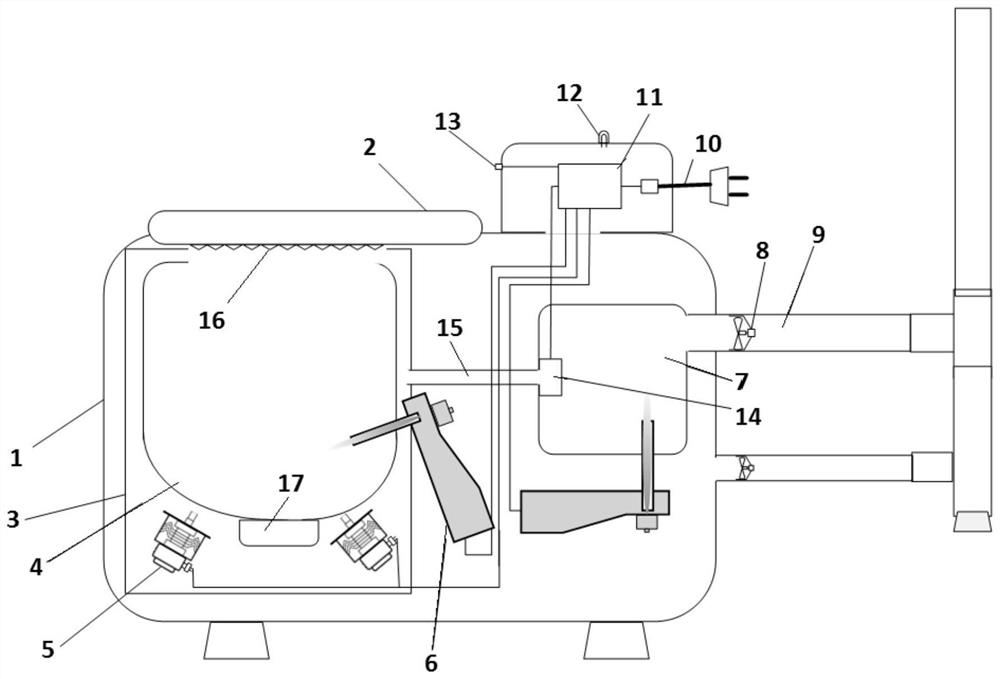

Heating and cooling system using swallet waste heat by industrial and mining enterprises

InactiveCN101893348ADoes not consume water resourcesChange energy structureHeat recovery systemsInsulationWater sourceResource utilization

The invention discloses a heating and cooling system using swallet waste heat by industrial and mining enterprises, relating to the field of residual heat waste heat resource utilization. The heating and cooling system comprises a well-head freeze protection water source heat pump unit (5), a worker bath water source heat pump unit (6), an industrial heating and cooling water source heat pump unit (7), a mine water recycle pump (2), a primary water recycle pump (4), three secondary water recycle pumps, a bath water heating recycle pump (13), two plate-type heat exchangers and a sub-water catcher (17). In the invention, a water source heat pump technology is used and reclaimed water waste heat in a mine water treatment plant is comprehensively utilized for worker bath, industrial heating in winter, well-head freeze protection and cooling of office buildings and apartment blocks in summer; a coal-fired boiler system is thoroughly replaced; a water source heat pump system only extracts the heat of the reclaimed water of the treated mine water and domestic sewage, and additional water resources are not consumed; and the heating and cooling system has the advantages of remarkable energy saving effect, obvious economic benefit, outstanding environmental benefit and the like.

Owner:SHANDONG TONGFANG ENERGY ENG TECH

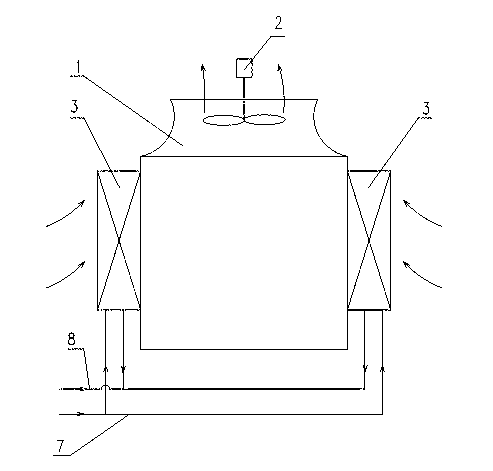

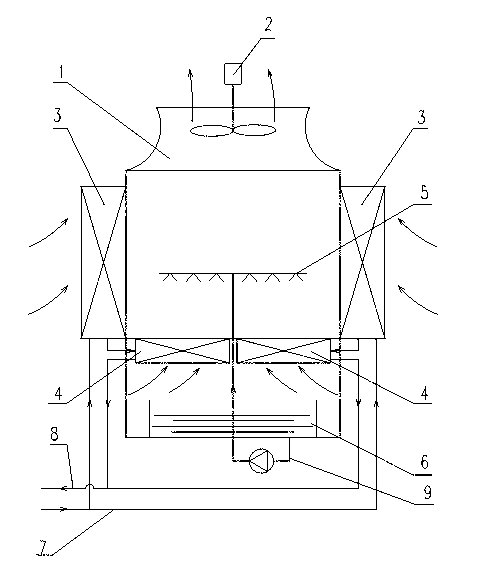

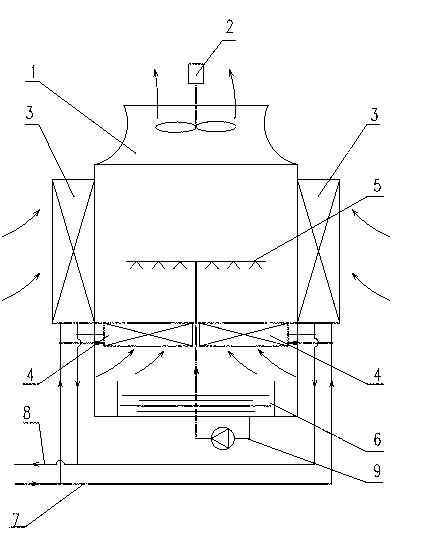

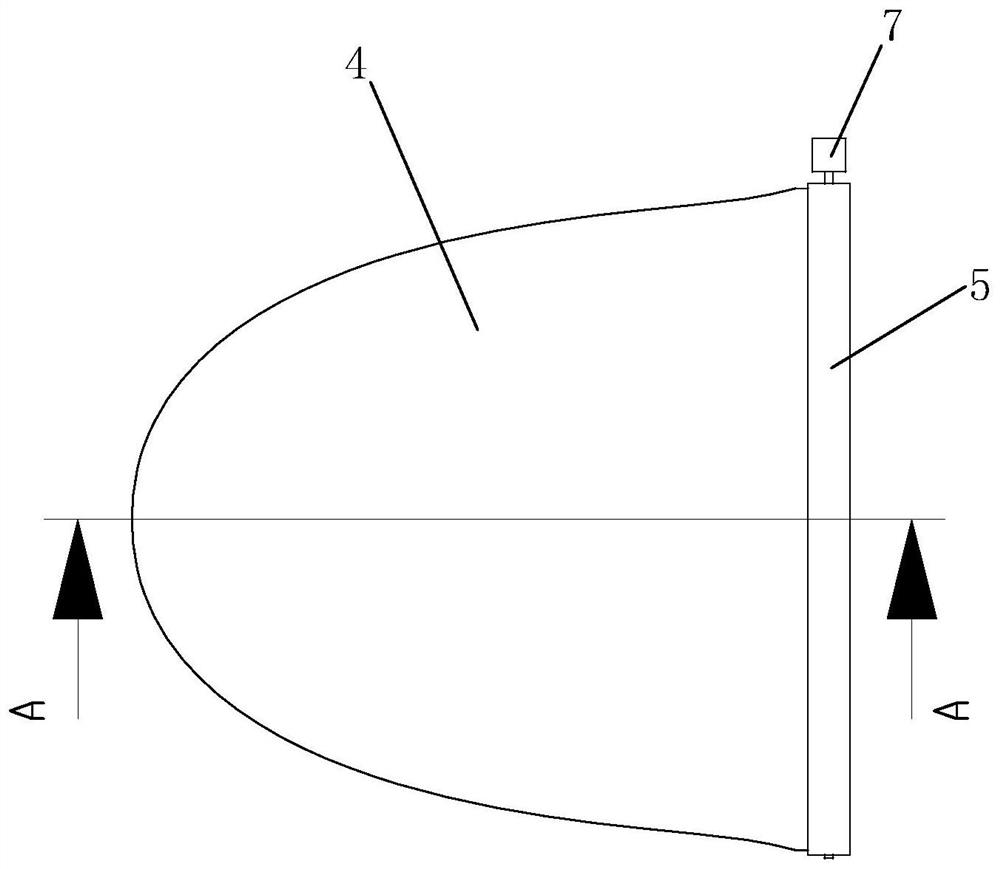

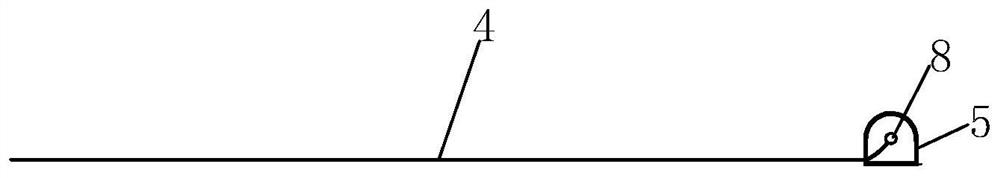

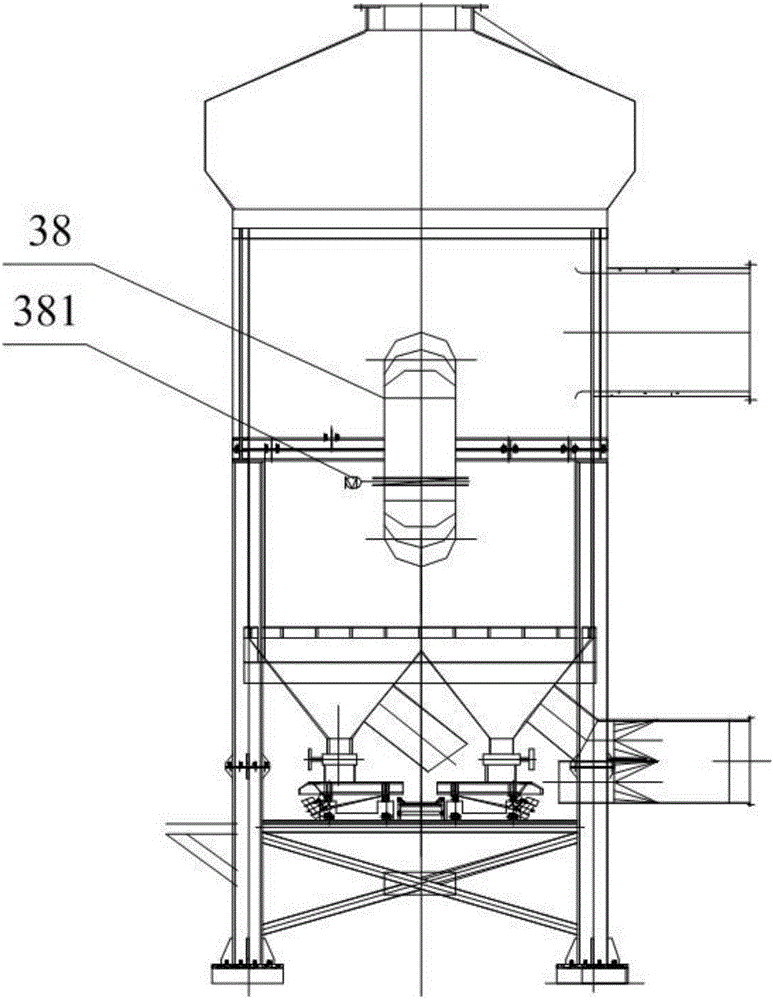

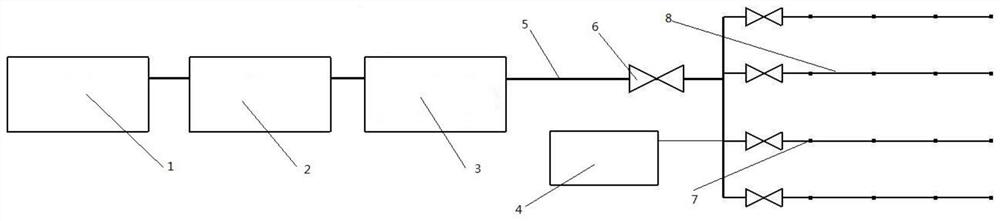

Mechanical ventilation air cooling tower

InactiveCN103123228AImprove heat transfer capacityDoes not consume water resourcesStationary conduit assembliesChemical industrySpray nozzle

The invention relates to a mechanical ventilation air cooling tower which is mainly used in an industrial circulating water cooling process of the chemical industry, the metallurgy industry, the electric power industry and other industries. The mechanical ventilation air cooling tower comprises a tower body (1), a draught fan (2), a dry type air cooling radiator (3), a water inlet pipeline (7) and a water outlet pipeline (8), wherein the dry type air cooling radiator (3) is perpendicularly arranged on the periphery of the tower body (1), a wet type air cooling radiator (4) and a spray nozzle (5) are arranged inside the tower body (1), the wet type air cooling radiator (4) is horizontally arranged, the spray nozzle (5) is arranged above the wet type air cooling radiator (4), and a water collecting tank (6) is arranged below the wet type air cooling radiator (4) and connected with the spray nozzle (5) through a water spraying device (9). The mechanical ventilation air cooling tower has the advantage that when the environment temperature is quite high in summer, the water outlet temperature of circulating water can be lowered.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

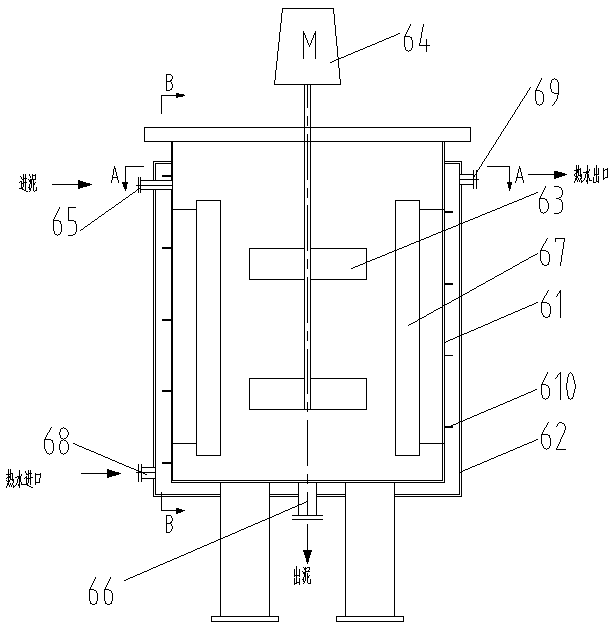

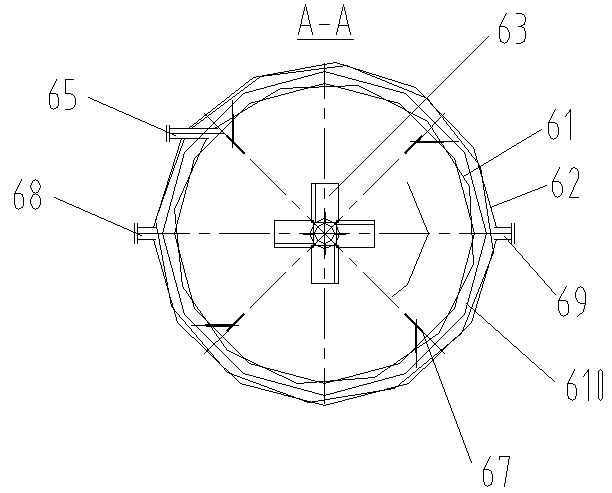

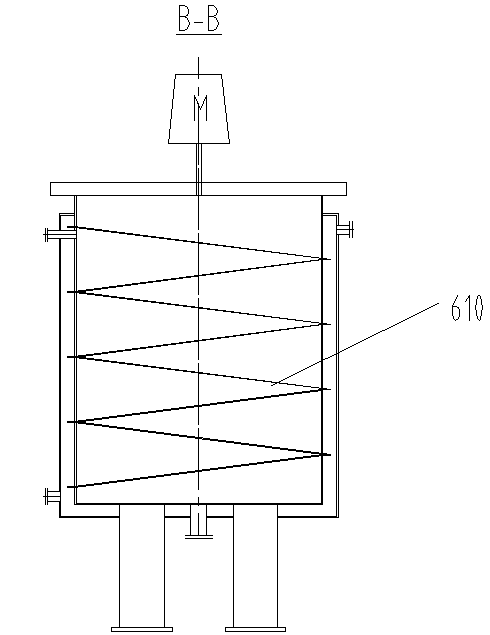

Sludge hydrolysis acidification system

ActiveCN102849912AMaximize Acid Production EfficiencyAchieve reductionSludge processingBiological sludge treatmentSludgeWater source

The invention relates to a sludge hydrolysis acidification system and relates to the technical field of sludge hydrolysis acidification. According to the sludge hydrolysis acidification system, existing 12 DEG C secondary sedimentation tank effluent in the sewage treatment process is used for providing heat sources for a plate-type heat exchange device, cold water entering the plate-type heat exchange device from a cold water tank exchanges heat with the secondary sedimentation tank effluent to obtain warming cold water, and the warming cold water enters a heat pump device. Under the condition that electric energy is input, a heat pump system extracts heat from a water source used for the secondary sedimentation tank effluent to exchange heat, and the heat is transmitted to a water source entering a hot water tank by working and then exchanges heat with sludge in a muddy water heat exchanger so that the sludge is preliminarily warmed; and simultaneously, the heat source enters a jacket outside an internal cylinder so that the sludge entering the internal cylinder is warmed again until the temperature required for hydrolyzing is reached.

Owner:JIANGDU COUNTY ENVIRONMNT PROTECTION EQUIPS FACTORY

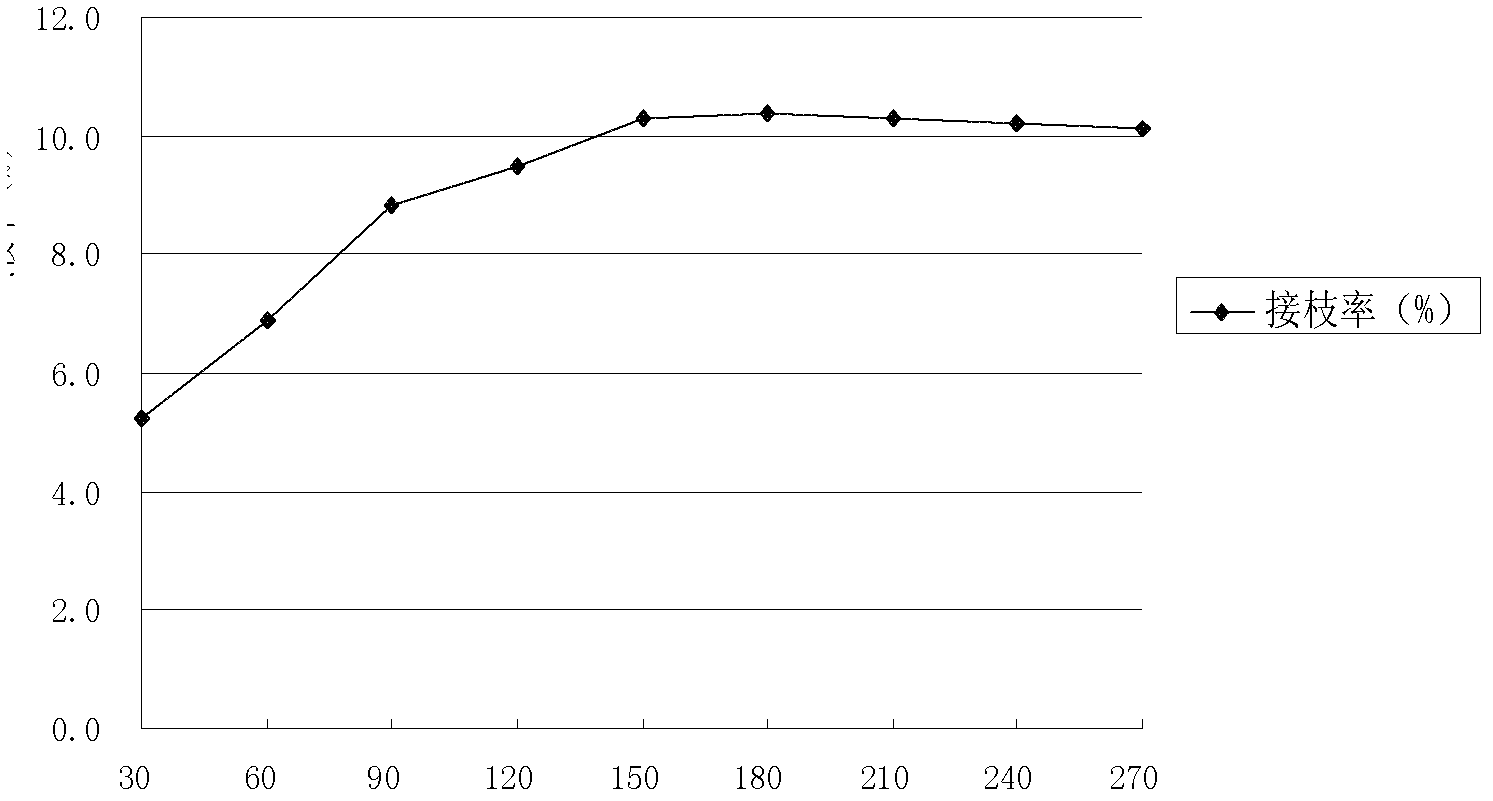

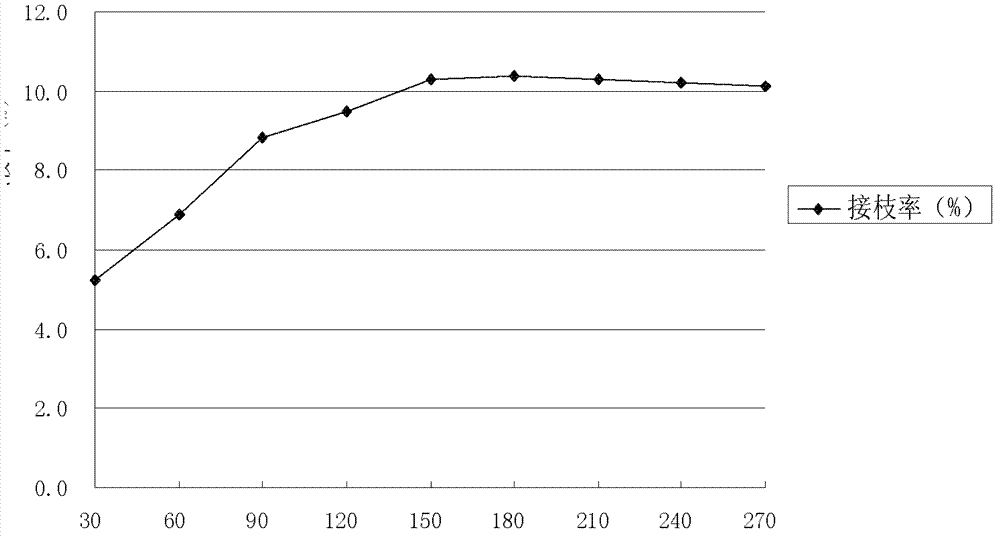

Composite modified graft starch for textile slurry and preparation method thereof

The invention discloses a proportioning and preparing method for producing graft starch and particularly relates to composite modified graft starch for textile slurry. The composite modified graft starch for the textile slurry comprises the following raw materials in parts by weight according to proportion: 900 parts of acetate starch, 80-100 parts of alcohol, 40 parts of acrylamide, 10 parts of acrylic acid, 40 parts of vinyl acetate, 5 parts of caustic soda flakes, and 0.2-0.5 part of composite catalyst; and the requirements on the viscosity of the acetate starch is that L (Low Viscosity) is 4.0-0.0mPa.S, M (Middle Viscosity) is 8.1-12.0mPa.S, H (High Viscosity) is 12.1-16.0mPa.S, and the degree of substitution is 0.10+ / -10%. According to the invention, a small amount of alcohol is adopted for production for the first time in China, and two problems to be solved on no utilization of water resources and no wastewater emission and treatment are solved. Ternary mixed monomers are grafted onto starch macromolecules under the condition of the alcohol solvent. Therefore, the serous coat performance of starch slurry is greatly improved, the requirements of textile manufactures on the starching of high-count polyester / cotton varieties, and the composite modified graft starch can replace PVA (Polyvinyl Acetate) to perform environment-friendly starching.

Owner:西达(无锡)生物科技有限公司

Water power regeneration generator set

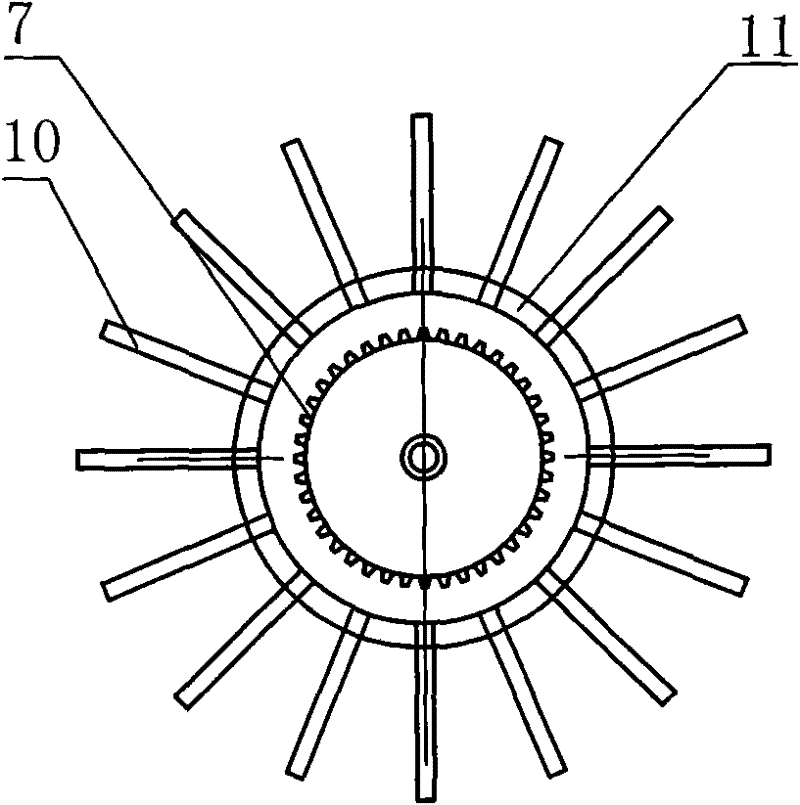

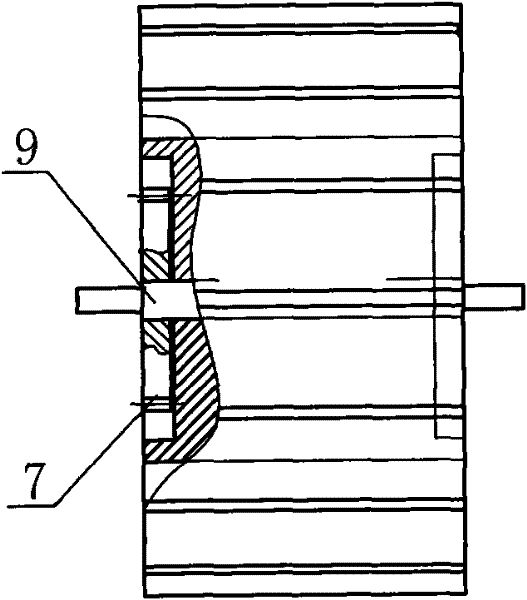

InactiveCN102128123ALess investmentQuick resultsMachines/enginesEngine componentsWater wheelUnit generator

The invention relates to a water power regeneration generator set which comprises a generator, water turbines and water turbine supports, wherein each water turbine is composed of two water wheel positioning rings, a plurality of water wheel paddle boards, water wheel outer gear rings and water wheel shafts, wherein the water wheel positioning rings are fixed on the water wheel shafts; the plurality of water wheel paddle boards are uniformly distributed between the two water wheel positioning rings; the water wheel outer gear rings are fixed on the water wheel positioning rings; the water turbines are respectively installed in the semicircular water wheel positioning convex-edged grooves of two water turbine supports by virtue of the water wheel positioning rings at two sides; the water turbines are supported on the two water turbine supports by virtue of bearing seats and bearings at two ends; the generator is fixed on one of the water turbine supports; the input shaft of the generator is provided with a generator driving gear; the generator driving gear is meshed with the water wheel outer gear rings, thus a unit generator set is formed; and a plurality of unit generator sets are arranged along a river, thus the water power regeneration generator set can be formed. The water power regeneration generator set provided by the invention has the advantages of less investment, rapid effectiveness, changeable size of scale, no water resource consumption, no pollution, low cost and good economic effect; the transverse power of water flow can be fully utilized, the natural power of water flow can be regenerated multiple times, and can be expanded limitlessly downstream and constructed by stages.

Owner:李发中

Formula of acetate starch and preparation technique thereof

The invention relates to an acetate starch formulation for textile sizing material, and a preparation method thereof. The acetate starch formulation comprises corn starch, caustic soda, oxidizer, reducer, and esterifying reagent, and is characterized in that the acetate starch formulation also comprises alcohol. The preparation method comprises the following steps: adding the corn starch, causticsoda and alcohol into a feed box, and stirring; sprinkling liquid oxidizer, sprinkling powdery reducer in dispersed manner, spraying with liquid esterifying reagent, heating with steam, evacuating, heating with steam to 65 DEG C, and persistently evacuating until the alcohol in the feed box is completely volatilized, distilled and recovered; and discharging, sieving, pulverizing and mixing. The alcohol solvent phase is employed to prepare acetate starch to reduce the production cost. The acetate starch replaces PVA in textile pulp application to acquire good effect, higher substitution degree, and excellent size film performance, and improve the sizing quality and level of subsequent textile sizing. The alcohol solvent phase production does not require water resource to have no waste water treatment.

Owner:鑫西达(上海)生物科技有限公司

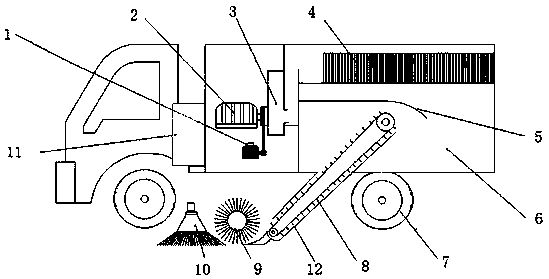

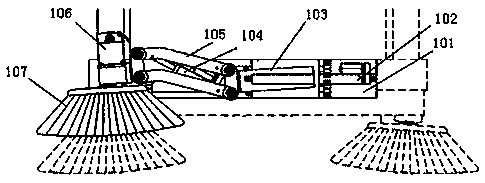

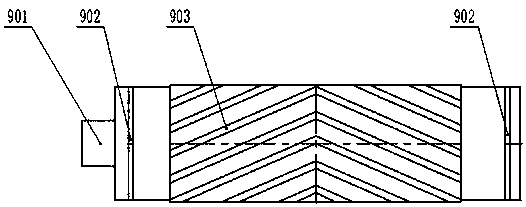

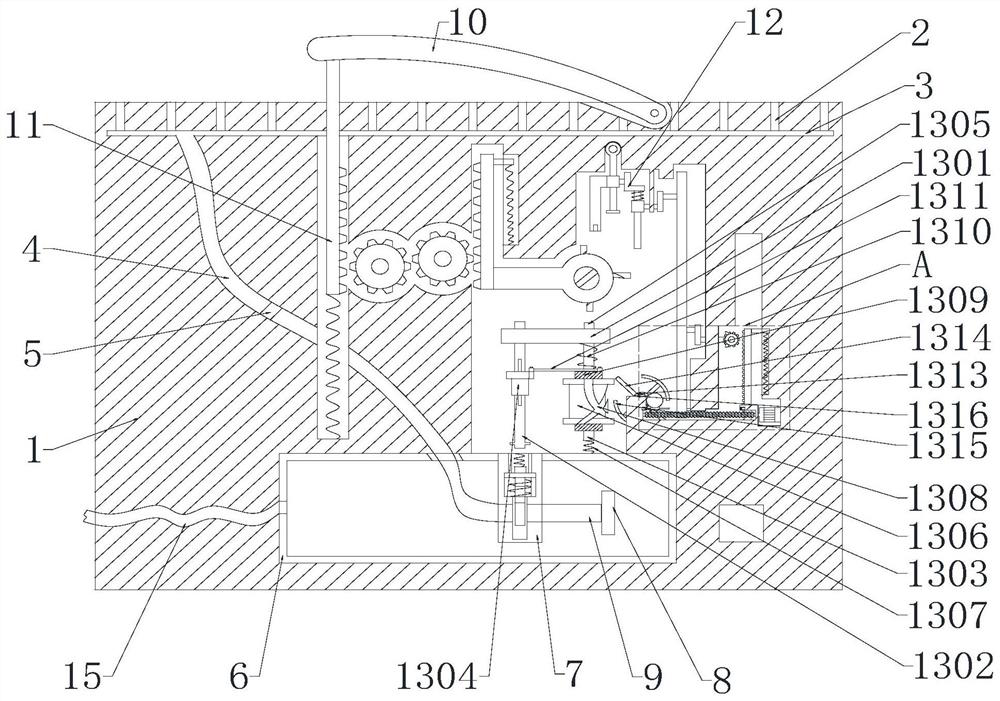

Electric dry sweeper

PendingCN107938561ASave powerReduce pollutionRoad cleaningProcess efficiency improvementCollection systemEngineering

The invention provides an electric dry sweeper which is good in sweeping effect, high in operation efficiency, sanitary and environment-friendly. The electric dry sweeper comprises a power system, a walking system, a sweeping system, a garbage conveying and collecting system and a dust removal system. The power system comprises an engine, an electric generator connected with the engine and a battery pack. The electric dry sweeper is characterized in that the sweeping system comprises vertical brush components located on the two sides of a car body and rolling brush components located behind the vertical brush components, the garbage conveying and collecting system comprises a conveyor belt obliquely arranged on the car body and a dustbin located on the car body, one end of the conveyor belt is located behind the rolling brush components, the other end of the conveyor belt is arranged in the dustbin, the dust removal system comprises a draught fan arranged in the dustbin and a pipelineconnected with the draught fan, the draught fan is connected with the engine, and the pipeline is arranged on the periphery of the portion, located outside the dustbin, of the conveyor belt.

Owner:康洁科技集团有限公司

Composite modified graft starch for textile slurry and preparation method thereof

The invention discloses a proportioning and preparing method for producing graft starch and particularly relates to composite modified graft starch for textile slurry. The composite modified graft starch for the textile slurry comprises the following raw materials in parts by weight according to proportion: 900 parts of acetate starch, 80-100 parts of alcohol, 40 parts of acrylamide, 10 parts of acrylic acid, 40 parts of vinyl acetate, 5 parts of caustic soda flakes, and 0.2-0.5 part of composite catalyst; and the requirements on the viscosity of the acetate starch is that L (Low Viscosity) is 4.0-0.0mPa.S, M (Middle Viscosity) is 8.1-12.0mPa.S, H (High Viscosity) is 12.1-16.0mPa.S, and the degree of substitution is 0.10+ / -10%. According to the invention, a small amount of alcohol is adopted for production for the first time in China, and two problems to be solved on no utilization of water resources and no wastewater emission and treatment are solved. Ternary mixed monomers are grafted onto starch macromolecules under the condition of the alcohol solvent. Therefore, the serous coat performance of starch slurry is greatly improved, the requirements of textile manufactures on the starching of high-count polyester / cotton varieties, and the composite modified graft starch can replace PVA (Polyvinyl Acetate) to perform environment-friendly starching.

Owner:鑫西达(上海)生物科技有限公司

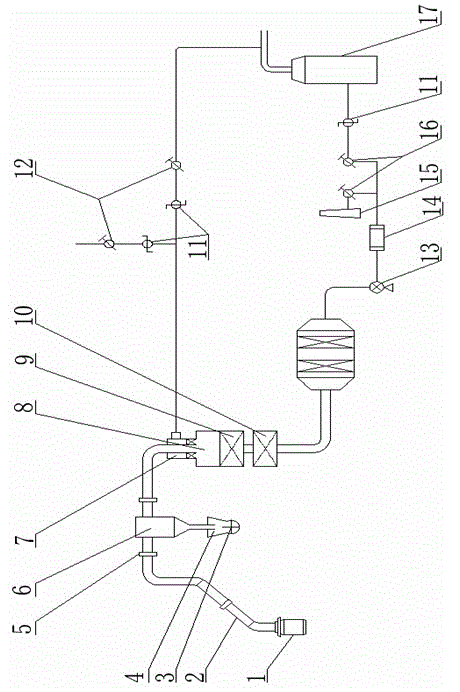

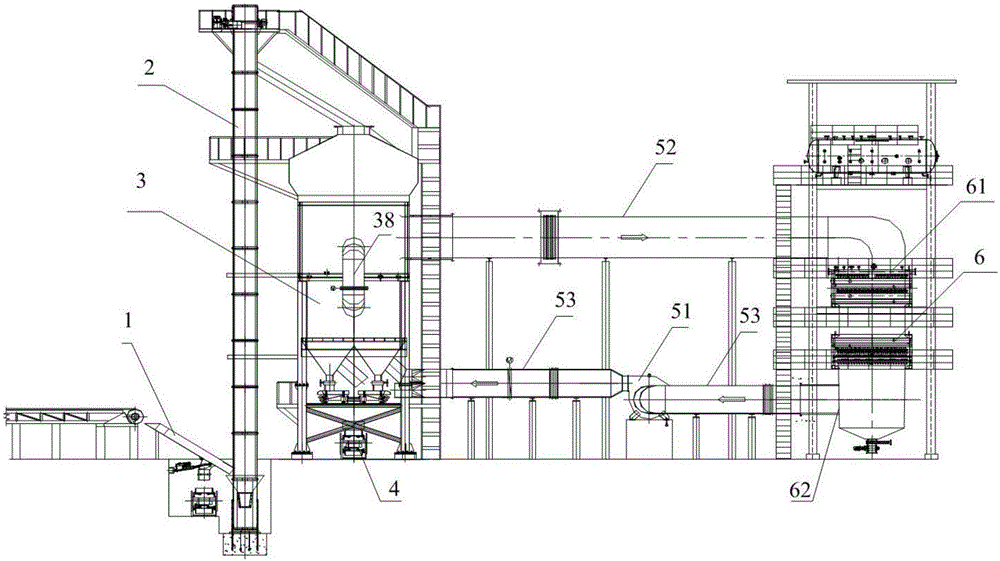

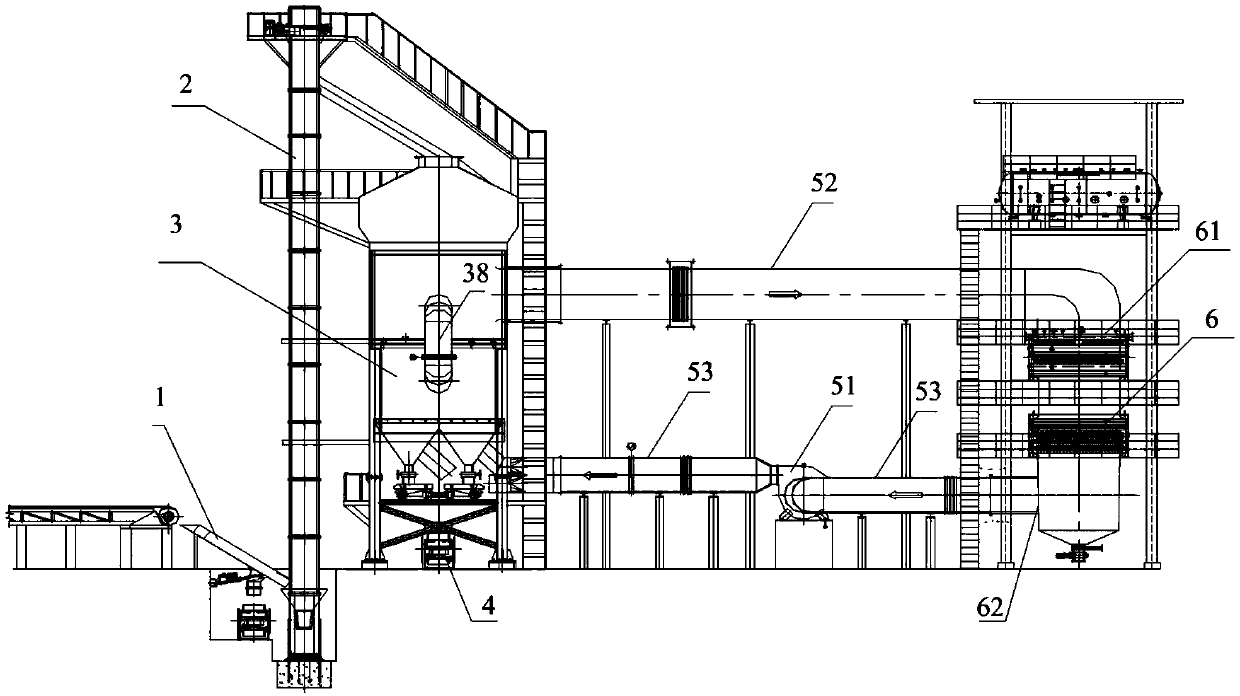

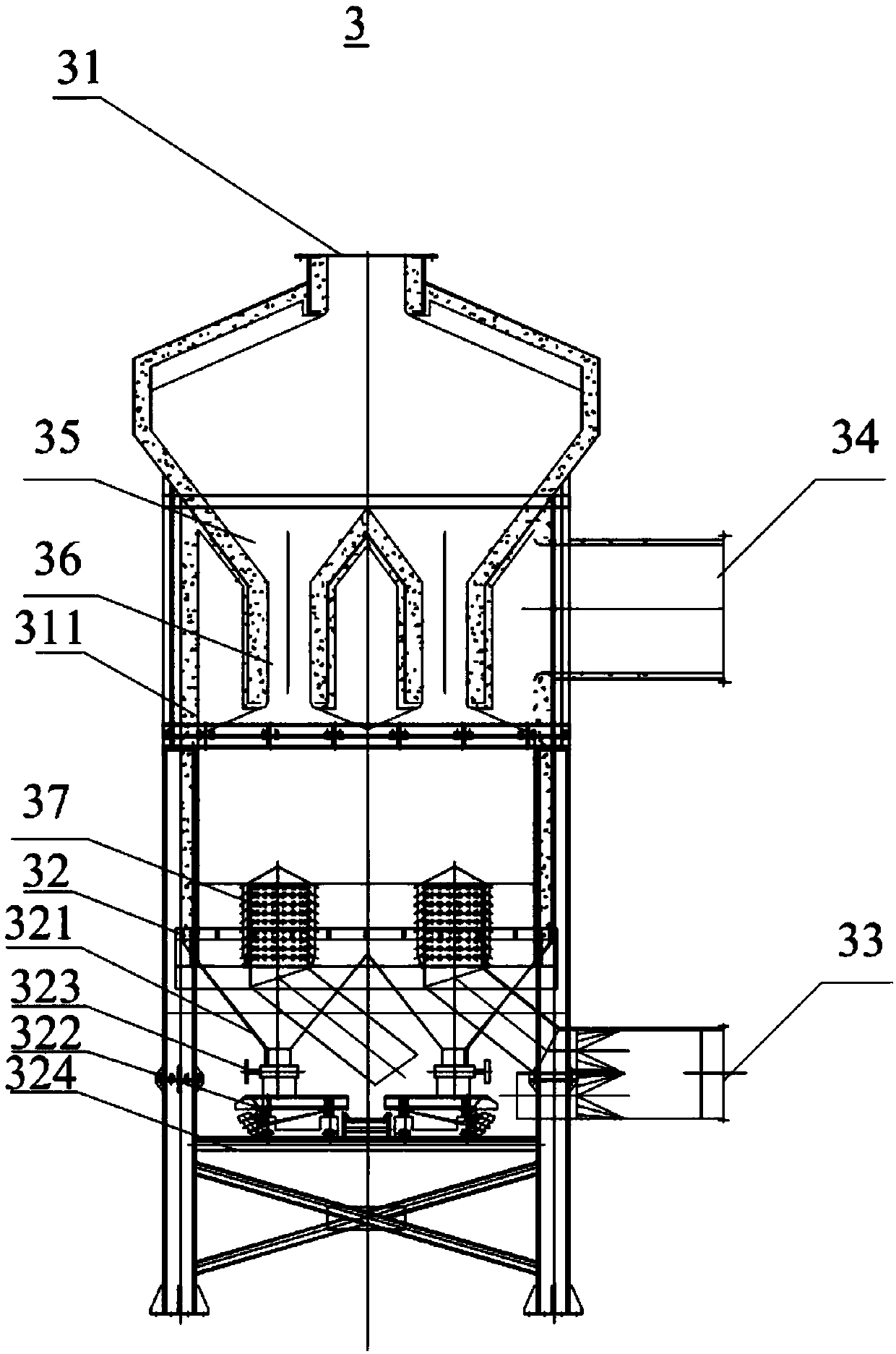

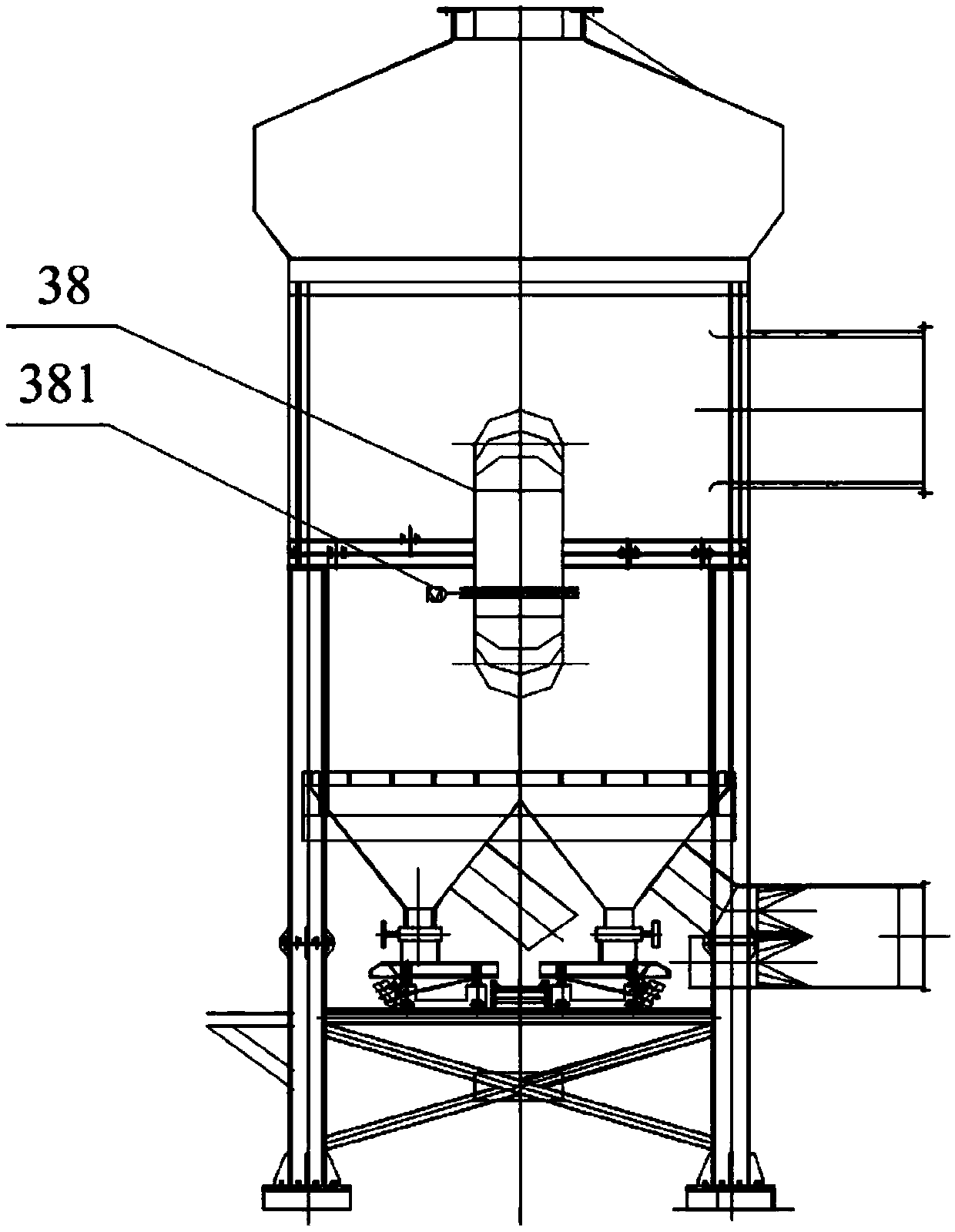

All-dry method converter gas purification recovery technology

InactiveCN105132615AReduce steelmaking costsLow costManufacturing convertersIncreasing energy efficiencySteelmakingEvaporative cooler

The invention relates to an all-dry method converter gas purification recovery technology. By means of the cold and clean gas dilution effect, converter gas with the temperature of 900-1000 DEG C and cold and clean converter gas from a gasometer are rapidly mixed and cooled to reach the temperature of 600 DEG C, and mixed gas with the temperature of 600 DEG C is formed; then, a heat pipe exchanger is utilized for recycling intermediate and low temperature exhaust heat in the converter gas, the mixed gas is cooled to reach the temperature of 200-250 DEG C, and dust removal is performed to obtain clean gas. The converter gas waste heat can be recycled to the largest extent, the steel melting cost is lowered, no water resources are consumed, and the sewage disposal cost is saved; the accidents that a steam cooler accumulates dust seriously, the service life of a spraying gun of the steam cooler is short, wet dust is likely to be accumulated on an electrostatic dust collector and polar lines are bound are fundamentally eradicated; nitrogen atomization cooling water is not needed, the nitrogen content in the converter gas is lowered, and the CO content is improved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

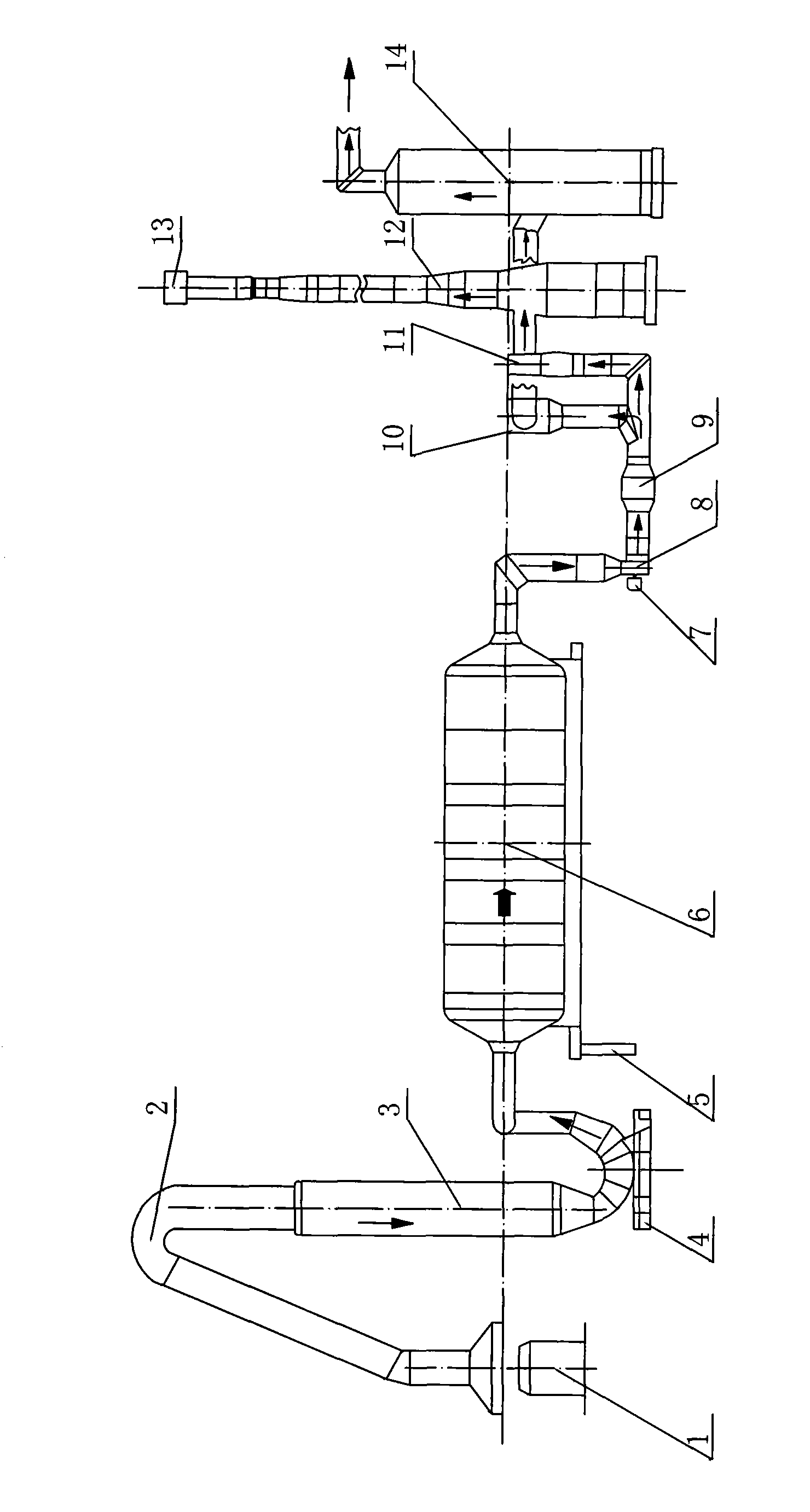

Oxygen top-blown converter flue gas purification and waste heat recovery system device

InactiveCN102337374ASimple processReduce resistanceManufacturing convertersWaste heat treatmentOxygenWaste heat recovery unit

An oxygen top-blown converter flue gas purification and waste heat recovery system device belongs to a boiler energy saving and purifying technology. The flue gas recovery and purification system has advantages of simple flow, less equipment investment, low flue dust resistance and low blower fan energy consumption. By the adoption of an exhaust-heat boiler, flue gas temperature can be reduced from around 1400 DEG C to 200 DEG C, a lot of damp-heat can be recovered; a large amount of saturated vapor is generated, and the saturated vapor is sent to a steam turbine for power generation after voltage stabilization by a heat accumulator, thus greatly minimizing electric furnace energy consumption. By waste heat energy of the exhaust-heat boiler and flue dust purification, ash in ash exhausting system is dry and returns to the converter for steel-making after passing through hot briquetted iron, thus raising the converter output by 1-2%. Water resource is essentially not consumed in the whole system, steam generated passes through the heat accumulator for voltage stabilization and is then sent to the steam turbine for power generation, and after power generation, condensate water is processed and returns to a boiler room for recycle and reuse. By the use of a purifying deduster, coal gas and exhaust flue gas and dust are less than 10mg / Nm<3>, thus achieving the purpose of energy saving and emission reduction and benefiting the nation and the people.

Owner:JIANGSU DONGJIU HEAVY IND

Method for efficiently recovering and reselecting steel slag

ActiveCN102688880BEffectively electedIncrease cycle loadSolid waste disposalRecycling and recovery technologiesEcological environmentSlag

The invention discloses a method for efficiently recovering and reselecting steel slag, comprising the following steps of: A, smashing and magnetically selecting: selecting iron in steel slag in a stock dump by a lifting electromagnet, directly charging the steel slag into a smasher to be smashed, and magnetically selecting the smashed steel slag by a rubber belt conveyor and a permanent magnetic iron remover in a layering way; B, smashing and magnetically selecting again: magnetically selecting the treated steel slag by the rubber belt conveyor of a head wheel belt permanent magnetic tumbling cylinder and the permanent magnetic iron remover in a layering way; C, extruding and smashing the steel slag into fine powder by a roller type grinding circulating system; D, selecting the iron powder with refine grain diameter by a dry type powder selector; and E, grinding the fine powder steel slag which is separated by the roller type grinding circulating system and a steel slag selecting and recovering system by a ball grinder system. The method is simple and easy, and convenient to operate, so that when the iron is selected, the steel slag low-heat concrete which accords with the national standard requirement can be produced by the steel slag. The production cost and the energy consumption can be reduced, the land occupancy can be reduced, the ecological environment can be protected, and the good economic benefit, social benefit and environmental benefit can be obtained.

Owner:武汉市天沭科技发展有限公司

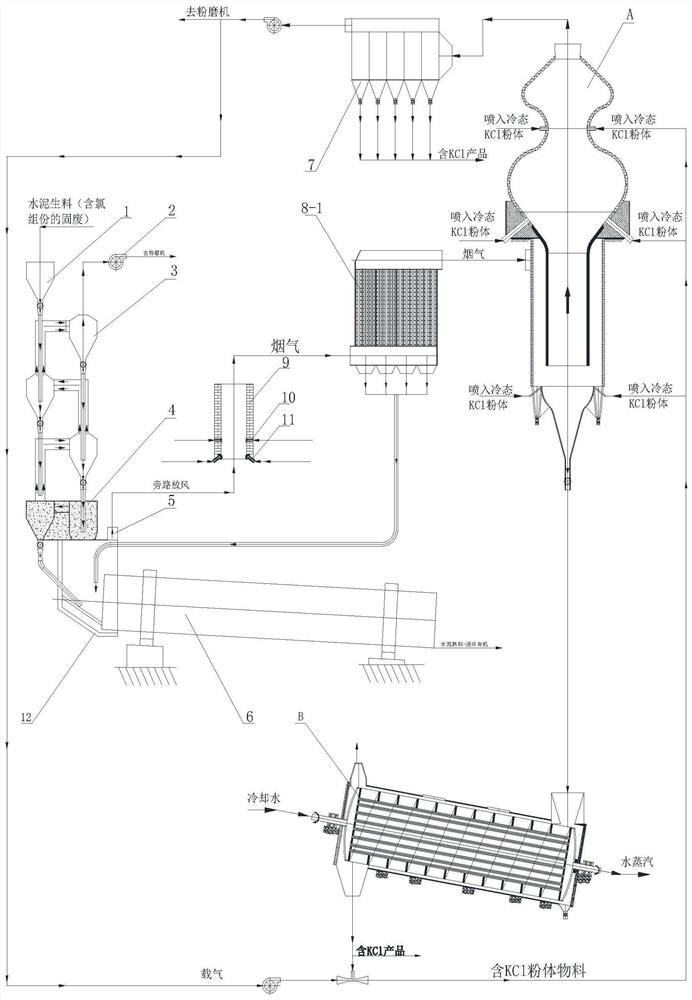

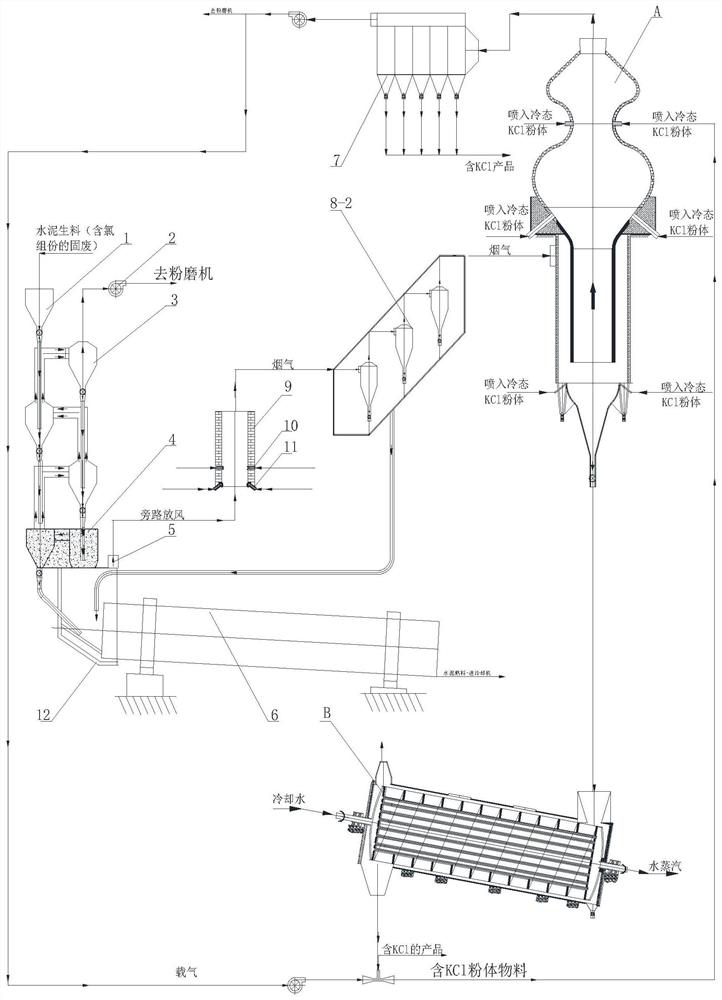

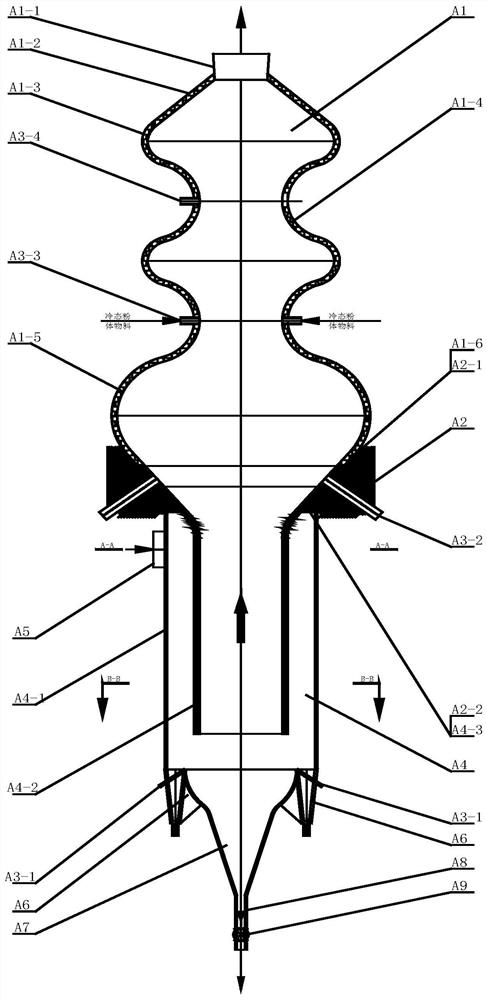

Chlorine component dry recovery process for co-processing chlorine-containing solid waste based on cement kiln

ActiveCN113975919AHigh recovery rateImprove qualityCombination devicesCement productionCooling towerFlue gas

The invention discloses a chlorine component dry recovery process for co-processing chlorine-containing solid waste based on a cement kiln, and solves the problems of long flow, high energy consumption, high equipment investment and operation cost and environmental pollution in the traditional wet processing of chlorine-containing components. According to the technical scheme, solid waste containing chlorine components enters a cement production line, under the high-temperature environment in a rotary kiln, the chlorine-containing components are gasified and enter flue gas, part of the flue gas is led out from a kiln head flue gas cover of the rotary kiln, and the led-out part of the flue gas is fed into a cooling tower after being subjected to dry dust removal and directly exchanges heat with potassium chloride powder materials for cooling; chlorine-containing components in the flue gas are condensed and enter the potassium chloride powder material, the flue gas after heat exchange is discharged from the top of the cooling tower, and the potassium chloride powder material after heat exchange is discharged from the bottom of the cooling tower. The method is simple in process, low in investment cost and operation cost, environment-friendly, energy-saving and consumption-reducing, and capable of effectively recovering the potassium chloride product.

Owner:WUHAN WUTUO TECH

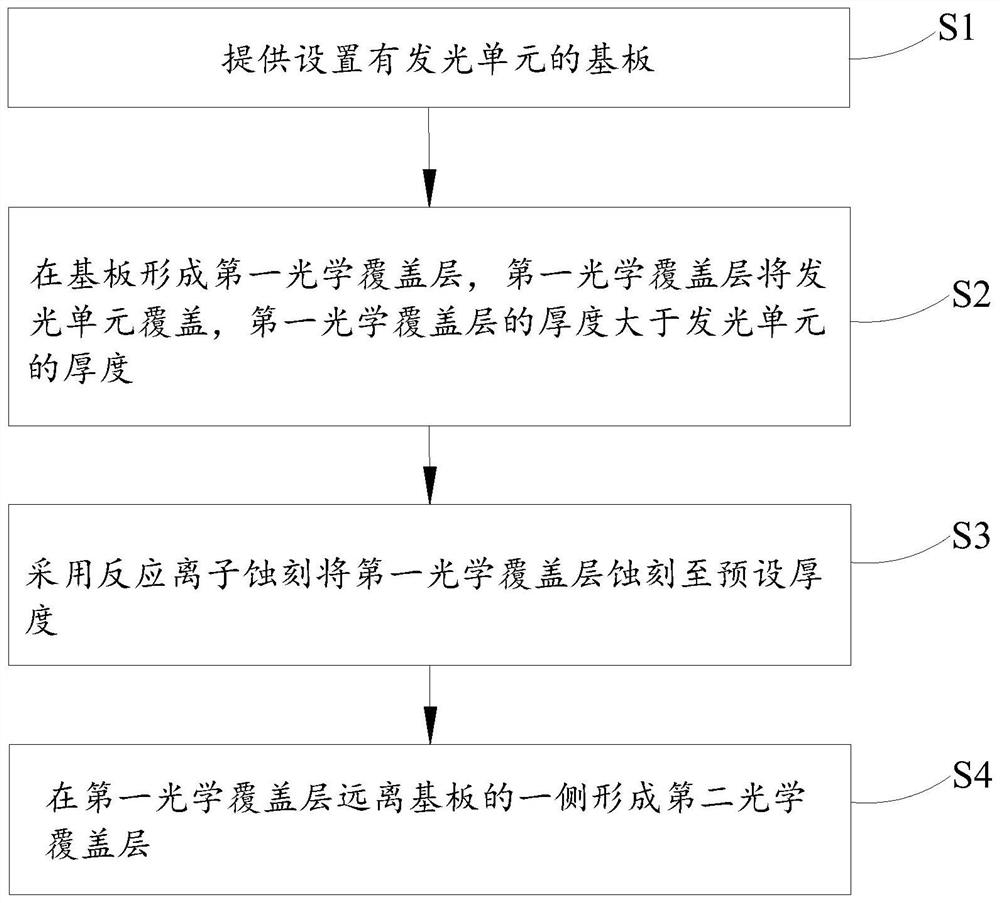

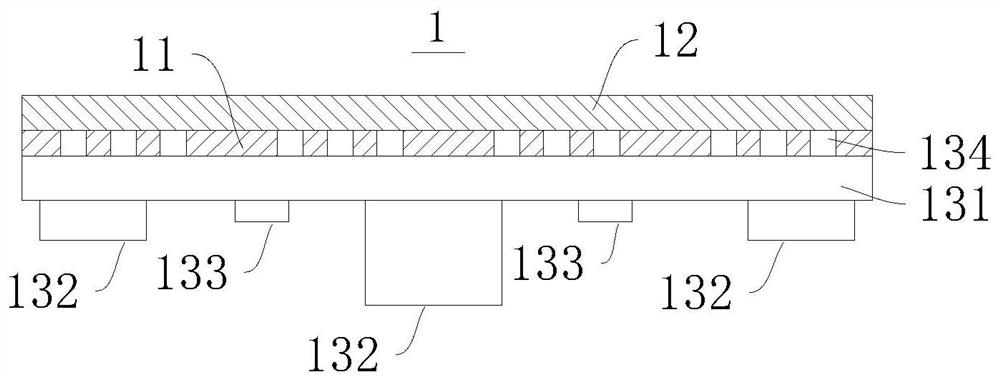

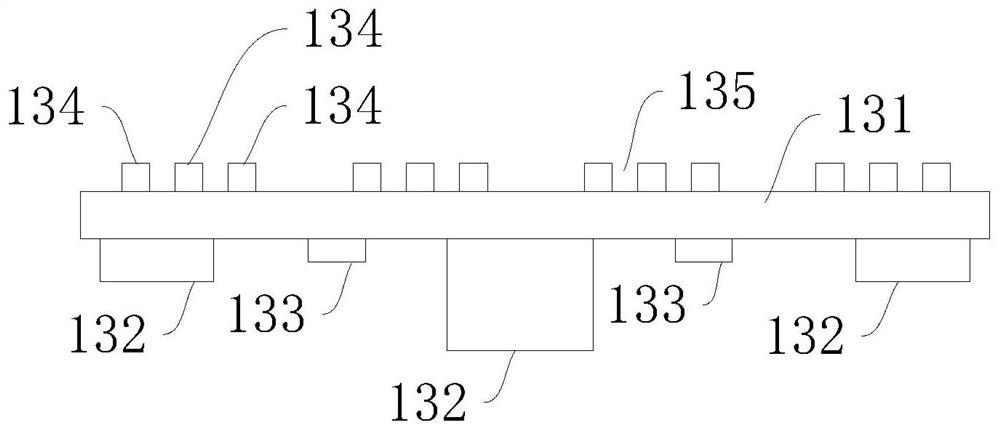

Preparation method of display module and display module

ActiveCN113130462AGuaranteed flatnessGuaranteed uniformitySolid-state devicesIdentification meansEngineeringReactive-ion etching

The invention belongs to the field of display components and relates to a preparation method of a display module and a display module.The preparation method comprises the steps that: a substrate provided with a light-emitting unit is provided; a first optical covering layer is formed on the substrate, the first optical covering layer covers the light-emitting unit, and the thickness of the first optical covering layer is larger than that of the light-emitting unit; the first optical covering layer is etched to a preset thickness by adopting reactive ion etching; and a second optical covering layer is formed on one side, far away from the substrate, of the first optical covering layer. The flatness and uniformity of an etched surface can be guaranteed, and the product quality and the light emitting effect are improved. The display module is prepared through the preparation method, and the light emitting effect of the display module is good.

Owner:广州市鸿利显示电子有限公司

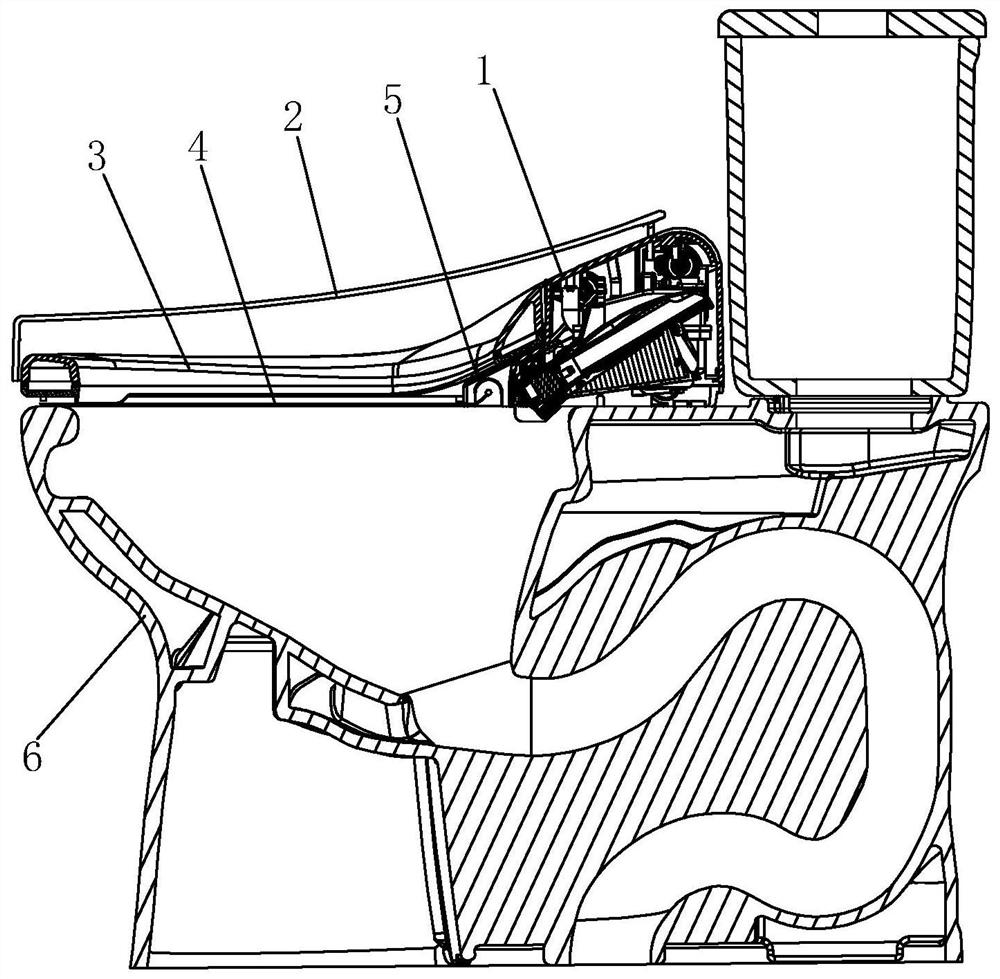

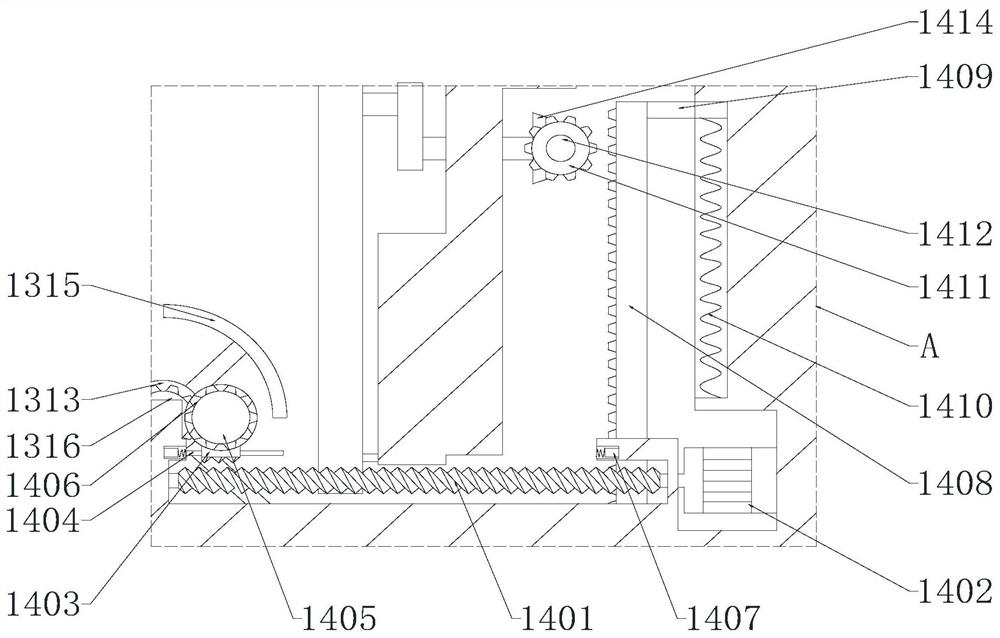

Electronic toilet seat cover, intelligent toilet seat and environment pollution prevention method thereof

ActiveCN113455947AFor the purpose of isolation and protectionEasy to cleanFlushing devicesBathroom coversPollution preventionPower unit

The invention discloses an electronic toilet seat cover, an intelligent toilet seat and an environment pollution prevention method thereof. The electronic toilet seat cover comprises a machine body, an upper cover and a seat ring, wherein the upper cover and the seat ring are arranged on the machine body; an isolation mechanism is arranged on the machine body, the isolation mechanism comprises a power unit and an isolation part, the isolation part is driven by the power unit to achieve switching between an unfolding state and a folding state, and the isolation part is located between the seat ring and the toilet seat body below the seat ring in the unfolding state and covers a urinal opening of the toilet seat body. The isolation mechanism does not consume water resources in the using process, and the concept of energy conservation and environmental protection is met. The isolation part is located between the seat ring and the toilet seat body below the seat ring in the unfolded state, the seat ring can be isolated and protected, the seat ring is prevented from being polluted by excrement droplets and excrement aerosol, and therefore the excrement droplets and the excrement aerosol are prevented from being spread to other people through the seat ring; and the seat ring is easier and more convenient to clean.

Owner:JOMOO KITCHEN & BATHROOM

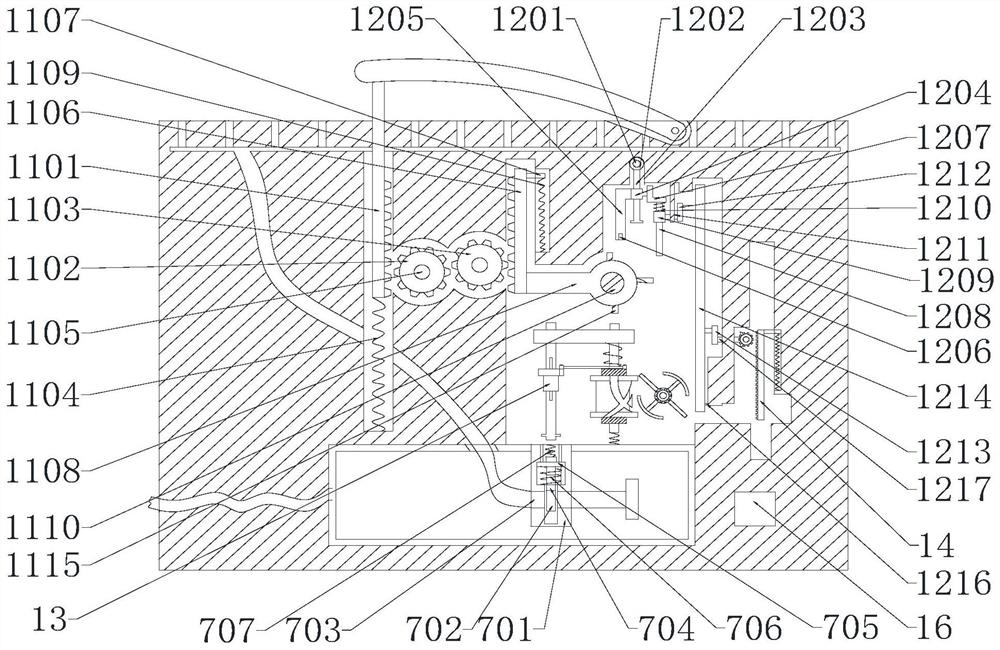

High-temperature pellet sensible heat recycling device and method

ActiveCN106766950ADoes not consume water resourcesSensible heat is sufficientIncreasing energy efficiencyControl devices for furnacesRecovery methodMaterials science

Owner:北京天朗致达节能环保股份有限公司

Green composition taking stevioside as matrix and preparation method thereof

InactiveCN103349196AImprove stabilityImprove bitternessFood preparationChemical synthesisBeta-Carotene

The invention relates to a green composition taking stevioside as a matrix. The green composition comprises the following components in parts by weight: 65-80 parts of stevioside, 20-25 parts of sugarcane powder and 10-20 parts of cyclodextrin. The stevioside in the composition disclosed by the invention contains a variety of amino acids, VB (vitamin B), beta-carotene and other nutritional ingredients, and the sugarcane powder contains three ingredients, namely sucrose, fructose and glucose, as well as a variety of essential amino acids for human bodies, and can be compounded with the stevioside to obtain excellent taste; in addition, the cyclodextrin is added, so that and the unfavorable bitter aftertaste of the stevioside can be relieved, and the stability of the composition can be obviously enhanced; and the green composition has the advantages of low calorie, abundant amino acids and strong stability, can be used for substituting sugar, saccharin and other various chemically synthesized sweeteners, meets the diet requirements of modern people, and can be widely applied in foods, drinks, pickled products, pharmaceutical preparations and other industries.

Owner:TIANJIN UNIV OF SCI & TECH

Automatic wheel cleaning device

PendingCN113928271ADoes not consume time resourcesDoes not consume water resourcesCleaning apparatus for vehicle exteriorsCleaning using liquidsWater storage tankWater resources

The invention belongs to the technical field of wheel cleaning devices and particularly relates to an automatic wheel cleaning device. The device comprises a cleaning seat, wherein a plurality of cleaning holes are evenly formed in the top of the cleaning seat, the cleaning holes are connected through a cleaning cavity, two first cleaning pipes are arranged at a bottom end of the cleaning cavity, and electromagnetic valves are arranged on the first cleaning pipes; an end, away from the cleaning cavity, of the first cleaning pipe is connected through a water storage tank, a water inlet pipe is arranged on one side of the water storage tank, an end, away from the water storage tank, of the water inlet pipe extends to the outer side of the cleaning seat, and two one-way assemblies are arranged at the top of an inner cavity of the water storage tank; and an end, away from the cleaning cavity, of the first cleaning pipe is connected with the one-way assembly. According to the device, a cleaning mode of the wheels is updated, water can be automatically sprayed to the wheels by driving the vehicle to pass through the arc-shaped plate, the wheels are cleaned in a self-service mode, and therefore the cleaning mode does not consume a large amount of manpower, time and water resources.

Owner:田继鹏

Heating and cooling system using swallet waste heat by industrial and mining enterprises

InactiveCN101893348BDoes not consume water resourcesChange energy structureHeat recovery systemsInsulationWater sourceResource utilization

The invention discloses a heating and cooling system using swallet waste heat by industrial and mining enterprises, relating to the field of residual heat waste heat resource utilization. The heating and cooling system comprises a well-head freeze protection water source heat pump unit (5), a worker bath water source heat pump unit (6), an industrial heating and cooling water source heat pump unit (7), a mine water recycle pump (2), a primary water recycle pump (4), three secondary water recycle pumps, a bath water heating recycle pump (13), two plate-type heat exchangers and a sub-water catcher (17). In the invention, a water source heat pump technology is used and reclaimed water waste heat in a mine water treatment plant is comprehensively utilized for worker bath, industrial heating in winter, well-head freeze protection and cooling of office buildings and apartment blocks in summer; a coal-fired boiler system is thoroughly replaced; a water source heat pump system only extracts the heat of the reclaimed water of the treated mine water and domestic sewage, and additional water resources are not consumed; and the heating and cooling system has the advantages of remarkable energy saving effect, obvious economic benefit, outstanding environmental benefit and the like.

Owner:SHANDONG TONGFANG ENERGY ENG TECH

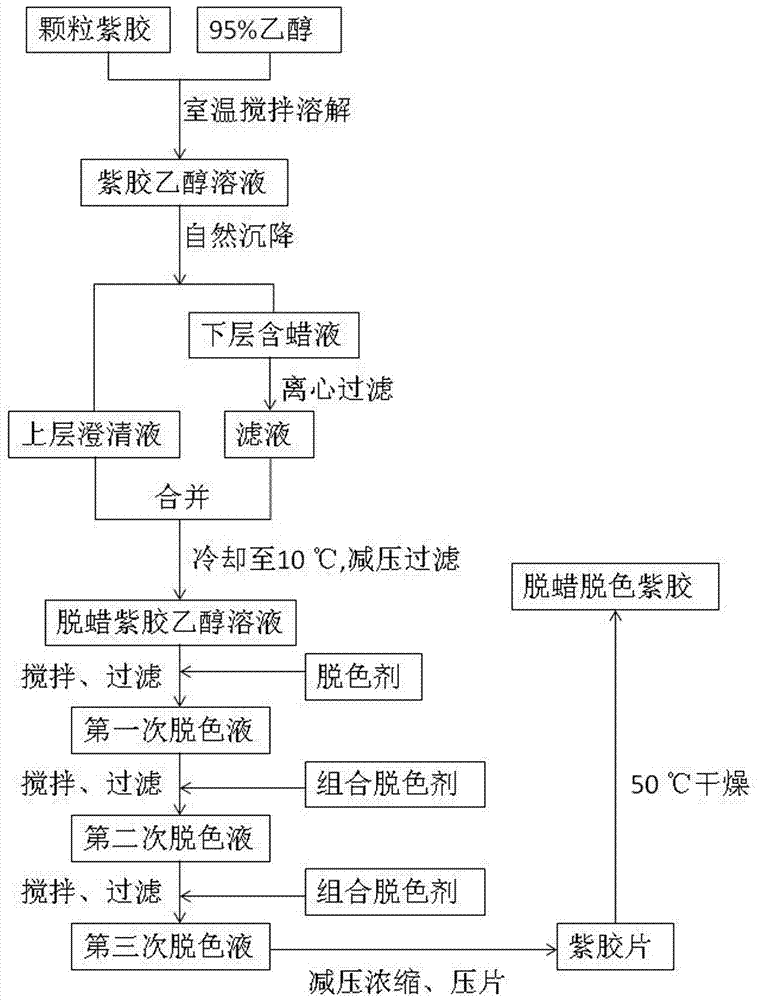

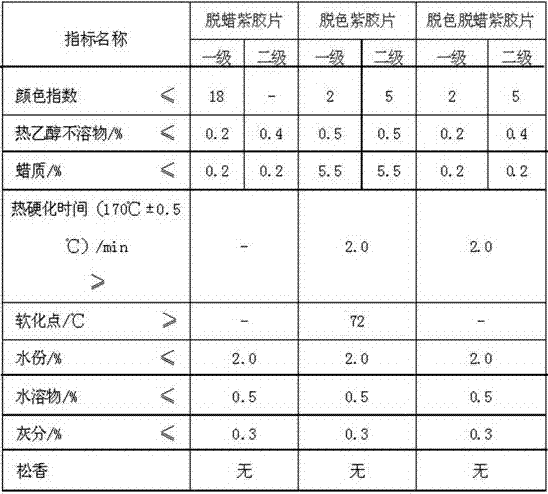

A kind of preparation method of dewaxing and decolorizing lac

The invention relates to a production method of natural resin, in particular to a preparation method of dewaxed decolorized shellac. The present invention is raw material with granule shellac, adds 95% ethanol solvent, obtains shellac ethanol solution; Allow shellac wax and impurity in the shellac ethanol solution to fully precipitate, will account for 2 / 3 of the total volume of the solution, wax in shellac The content of < 0.5% of the upper clarified liquid is separated, and the lower layer, which accounts for 1 / 3 of the total volume of the solution, is centrifugally filtered, and the filtered clear liquid is combined with the above clarified liquid. Cool the combined ethanol solution of shellac to 10°C, filter under reduced pressure to obtain dewaxed ethanol solution of shellac with a wax content of <0.2% in shellac, and perform three decolorization treatments on the ethanol solution of dewaxed shellac respectively: to obtain dewaxed lac ethanol solution Decolorized lac sheets. The method of the invention has the advantages of simple operation, mild decolorization condition and good product quality, and can be used for large-scale production of dewaxed and decolorized lac.

Owner:MOJIANG SENYUAN TECH

A high-temperature pellet sensible heat recovery device and recovery method

ActiveCN106766950BDoes not consume water resourcesSensible heat is sufficientIncreasing energy efficiencyControl devices for furnacesRecovery methodWater source

The invention discloses a high-temperature pellet sensible heat recycling device and method. Sensible heat recycling of high-temperature pellets is conducted in an airtight device through gas, water sources are not consumed, dust and harmful gas are not generated either, sufficient recycling of sensible heat can be achieved, and the beneficial effects of energy conservation and consumption reducing are achieved.

Owner:北京天朗致达节能环保股份有限公司

Fire prevention and extinguishing system and fire extinguishing method thereof

InactiveCN112156397AGood fire extinguishing effectCompletely extinguish the fireFire rescueNitrogen generatorEnvironmental resource management

The invention discloses a fire prevention and extinguishing system and a fire extinguishing method thereof, and belongs to the field of fire prevention and extinguishing. The fire prevention and extinguishing system comprises an air compressor, a nitrogen making machine and a nitrogen cooling device, wherein an outlet of the air compressor is connected with an inlet of the nitrogen making machinethrough a pipeline; an outlet of the nitrogen making machine is connected with an inlet of the nitrogen cooling device through a pipeline; and the inlet of the nitrogen cooling device is connected toa fire prevention area through a pipeline. The temperature of an underground coal seam or a goaf is monitored by a temperature sensor buried in the underground coal seam or the goaf, when the temperature reaches an alarm temperature, the temperature sensor sends out an alarm signal, at the moment, field personnel or a dispatching center immediately make a response to transfer fire extinguishing equipment and open fire prevention and extinguishing equipment and pipeline valves (including the air compressor, the nitrogen making machine, the nitrogen cooling device and a district pipeline valve),low-temperature nitrogen is injected into a pipe network, and the fire prevention and extinguishing effect is rapidly achieved.

Owner:FUXIN JINHAO AIR COMPRESSOR

Waterless environment-friendly electric control toilet and electric control method thereof

PendingCN112336236AEfficient and stable processingEliminate engineering and materialsMeasurement devicesBathroom accessoriesPlasma torchPlasma technology

The invention discloses a waterless environment-friendly electric control toilet and an electric control method thereof. The toilet comprises a toilet body, a microwave heating unit, a plasma torch, an exhaust unit and an electric control unit, wherein the toilet body comprises a toilet shell and a cover body for covering the toilet shell and an opening of a metal shielding shell; the microwave heating unit comprises a metal shielding shell in the toilet shell, a drying chamber which is arranged in the metal shielding shell and is provided with an opening, and a microwave heating module whichis arranged in the metal shielding shell and is used for heating the drying chamber; the plasma torch is arranged in the toilet shell, and a discharge tube extends into the drying chamber; the exhaustunit is used for exhausting gas in the metal shielding shell; the electric control unit is installed on the toilet shell and electrically connected with the microwave heating module, the plasma torchand / or the exhaust unit. By utilizing microwave and plasma technologies, excrement is efficiently and stably treated under the condition that water and a sewer pipe network are not needed, and no pollution is caused to the environment.

Owner:TSINGHUA UNIV

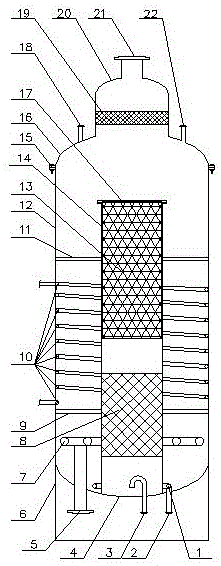

Gas deoiling purifier

ActiveCN104998490BGood for healthCompact structureUsing liquid separation agentPhysical healthSolid particle

The invention provides a gas de-oiling purifier which is characterized in that the bottom and the upper end of a cylindrical housing are provided with a lower seal head and an upper seal head; the upper seal head is provided with a gas collecting bag of an exhaust port; an inner cylinder is installed inside the cylindrical housing; the inner cylinder is positioned on the lower seal head; a removable adsorption bed and an oil-water separation bed are arranged inside the inner cylinder; the top of the inner cylinder is equipped with a screen; the lower seal head is provided with a water outlet, a water inlet and a gas inlet; the water inlet and a water inlet coil inside the cylindrical housing are connected; the gas inlet and a gas inlet coil inside the cylindrical housing are connected; upper and lower current equalizers are arranged between the inner cylinder and the cylindrical housing above the gas inlet coil; a refrigerating coil connected with a refrigerating machine is arranged between the upper and lower current equalizers; and the refrigerating coil is fixed on the cylindrical housing. By the gas de-oiling purifier, oils, solid particles and part of harmful gases in the air in an enclosed space can be removed, and purified gases are discharged. Thus, physical health of people in those enclosed spaces is guaranteed.

Owner:QINGDAO KELIYUAN ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com