All-dry method converter gas purification recovery technology

A converter gas, all-dry technology, applied in the direction of improving process efficiency, manufacturing converters, improving energy efficiency, etc., can solve the problems of spray gun bursting, high nitrogen consumption, high nitrogen consumption, and reduce steelmaking costs and waste heat. High recovery rate and the effect of preventing serious fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the examples, but the present examples do not constitute any limitation to the present invention.

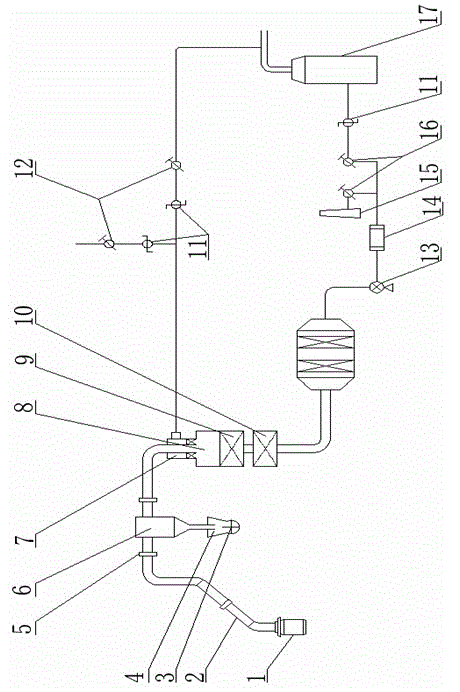

[0024] see figure 1 , the full-dry converter gas purification recovery process that the present embodiment provides, its technological process is as follows:

[0025] (1) The molten iron is blown in the converter 1, and the converter gas first passes through the vaporization cooling flue 2 to cool down to between 900°C and 1000°C, and then enters the high-temperature cyclone separator 6 for dust removal to separate most of the 50% of the converter gas. particles larger than microns.

[0026] The inner layer of high-temperature cyclone separator 6 is made of high-temperature-resistant and wear-resistant refractory material, the middle is heat-insulating material, and the outermost layer is a tightly welded iron plate shell. The gap between high-temperature cyclone separator 6 and vaporization coolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com