Oil sleeve steel ball and manufacturing process thereof

A technology for oil casing and steel grades, which is applied in manufacturing tools, metal processing equipment, metal rolling, etc., and can solve the problems of high cost, increased burden on billet management, and large market demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Taking the production of 177.80mm*9.19mm casing as an example

[0027] The oil casing steel grade described in this embodiment is composed of the following components in terms of weight percentage: C: 0.28%, Si: 0.17%, Mn: 1.10%, P: 0.016 %, S: 0.008%, Cu: 0.06%, Ni: 0.10%, Cr: 0.11%, Mo: 0.002%, V: 0.005%, Al: 0.008%, other elements: 0.11%, and the balance is Fe.

[0028] For one of the oil and casing steel types mentioned above, the weight percentages of other elements are: As: 0.009%, Sn: 0.007%, Pb: 0.0008%, Sb: 0.0005%, Bi: 0.0008%, As+Sn+Pb+Sb+Bi: 0.0181%.

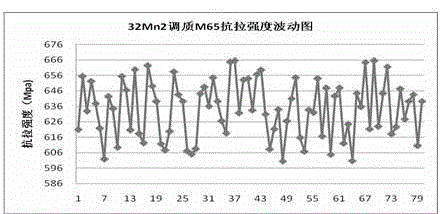

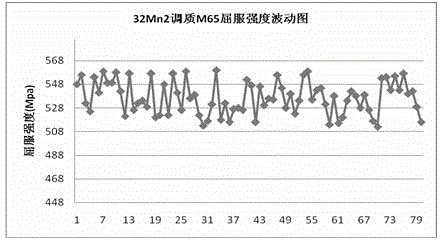

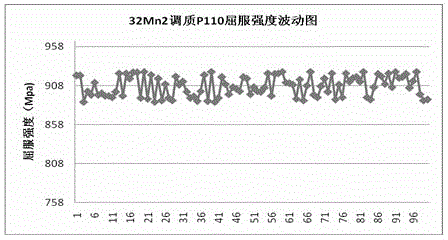

[0029] The composition of the 32Mn2 steel described in this example fully meets the composition requirements of J55, M65, N80Q, L80-1, R95, and P110 steel grades in the API 5CT 9th standard. These steel grades have a large strength range and need to meet better requirements. toughness.

[0030] The processing technology of oil casing steel is characterized in that it includes the following techno...

Embodiment 2

[0045] Example 2: Taking the production of 177.80mm*9.19mm casing as an example

[0046] The oil casing steel grade described in this embodiment is composed of the following components in terms of weight percentage: C: 0.36%, Si: 0.32%, Mn: 1.60%, P: 0.017 %, S: 0.014%, Cu: 0.10%, Ni: 0.06%, Cr: 0.13%, Mo: 0.007%, V: 0.005%, Al: 0.029%, other elements: 0.10%, and the balance is Fe.

[0047] For one of the oil and casing steel types mentioned above, the weight percentages of other elements are: As: 0.010%, Sn: 0.001%, Pb: 0.0008%, Sb: 0.001%, Bi: 0.0003%, As+Sn+Pb+Sb+Bi: 0.0131%.

[0048] The processing technology of an oil casing steel grade described in this embodiment is the same as that in Embodiment 1. The temperature of the heating section in the ring furnace heating described in the tube billet rolling process is 1300°C, and the temperature of the soaking section is 1270°C .

[0049] In the quenching and tempering process described in the heat treatment process, both ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quenching hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com