Patents

Literature

279results about How to "Reduce steelmaking costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Metallurgical V-N microalloying and compound deoxidation cored wire

A metallurgical V-N microalloying and compound deoxidation cored wire contains a core wire and a cladding steel belt. The technical key point of the cored wire is as follows: the core wire of the cored wire consists of a vanadium-increasing agent, a nitrogen-increasing agent and a deoxidizing nitrogen-fixing agent of which particle sizes are less than 6mm, wherein the vanadium-increasing agent is ferrovanadium, nitrided ferrovanadium or vanadium pentoxide; the nitrogen-increasing agent is ferrosilicon nitride, silicomanganese nitride, ferromanganese nitride, ferrochromium nitride, silicon nitride, aluminum nitride or calcium cyanamide; and the deoxidizing nitrogen-fixing agent contains one or more of aluminum, calcium, magnesium and barium, and can also contain one or more of titanium, zirconium, niobium, manganese, chromium, silicon, carbon and iron. By adopting the cored wire, the V / N ratio of steel can get closer to the optimal proportion, the enhancing function of vanadium can be utilized furthest, vanadium resources can be saved, the recovery rate of nitrogen is high, the nitrogen content is stable, the compound deoxidation function can also be realized, the V-N microalloying cost can be reduced and the quality of steel can be increased.

Owner:侯巍 +2

High-strength weather resisting steel with Cu2-xS dispersed precipitates and manufacturing method thereof

ActiveCN101928894AReduce steelmaking costsInhibition of segregationTemperature control deviceManufacturing convertersChemical compositionHigh intensity

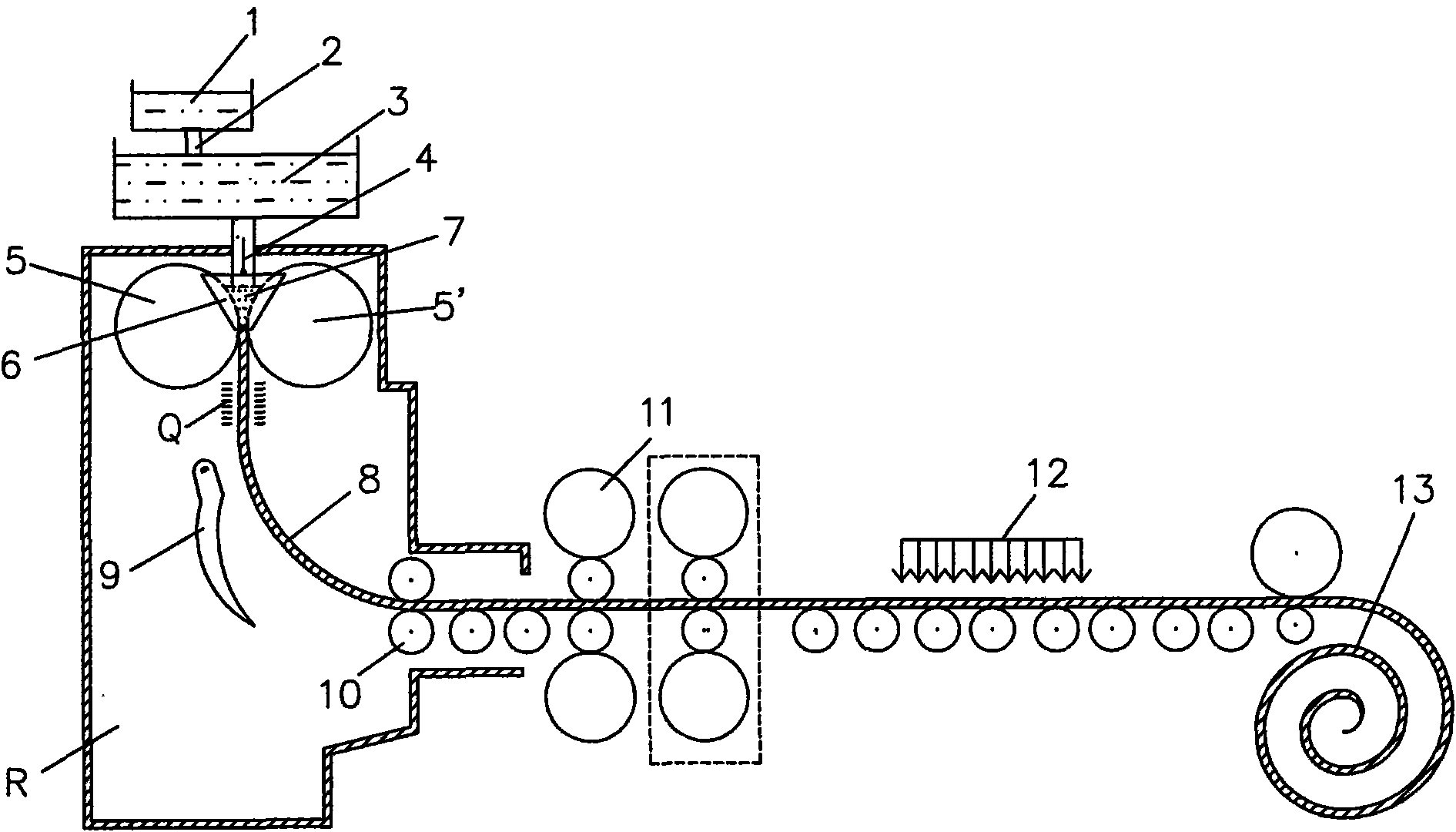

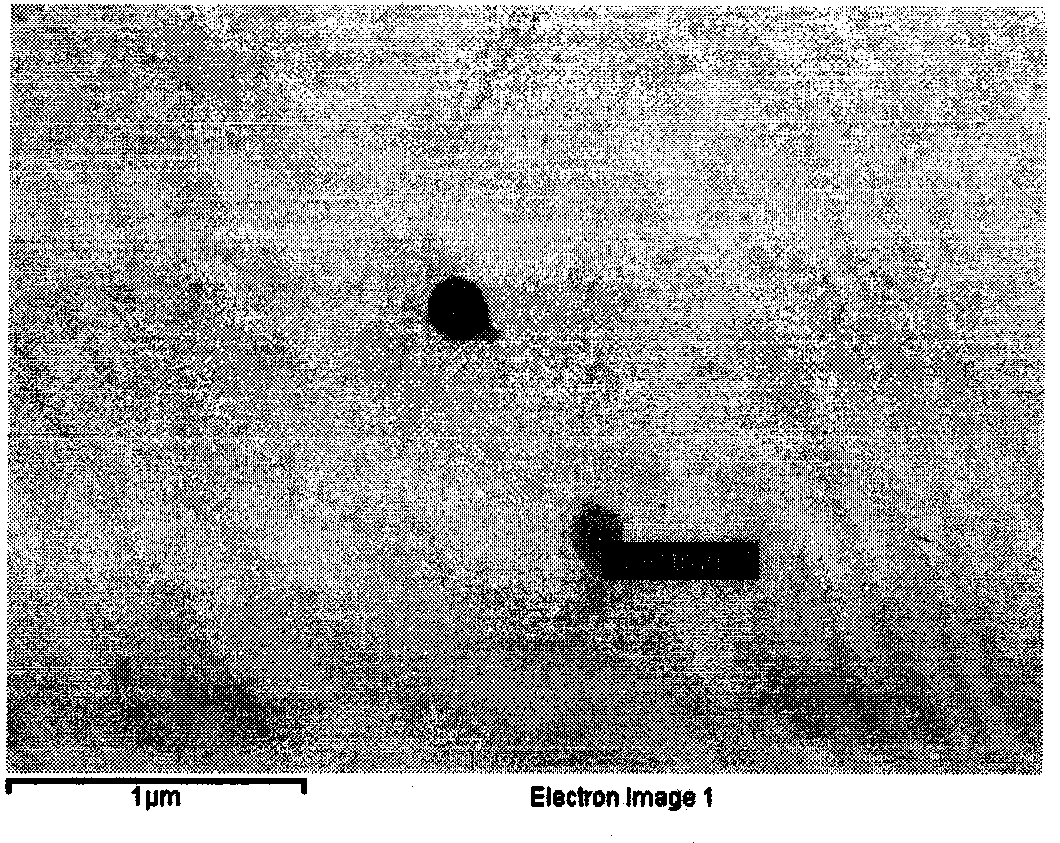

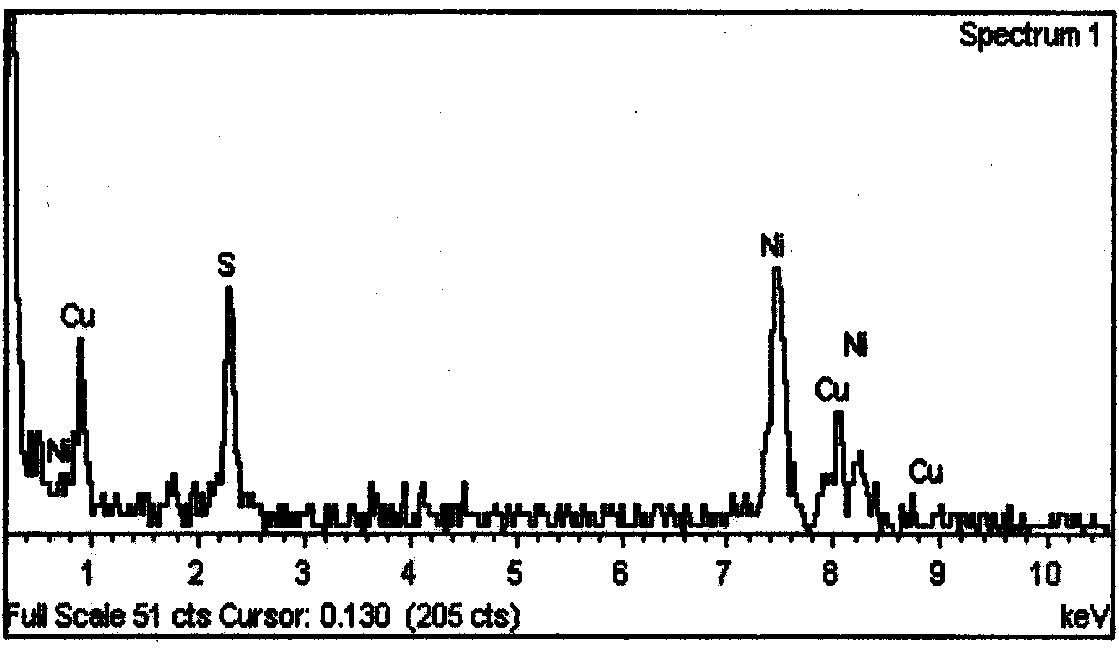

The invention relates to high-strength weather resisting steel with Cu2-xS dispersed precipitates, which comprises the following chemical components in percentage by weight: 0.04-0.08% of C, 0.20-0.40% of Si, 0.4-1.0% of Mn, 0.03-0.12% of P, not more than 0.2% of S, 0.01-0.06% of Al, 0.20-0.80% of Cu, 0.40-0.6% of Cr, 0.12-0.40% of Ni, 0.001-0.006% of Ca and the balance of Fe and inevitable impurities. The welding cold crack sensitivity coefficient Pcm is not more than 0.18%. A manufacturing method comprises the following steps of: acceleratedly cooling both sides of a cast belt formed by continuous casting by using a gas and adopting a thin belt continuous casting production technology, wherein the cooling rate is 150-200 DEG C / s; performing the entire double-roller continuous casting process in a closed chamber filled with protective atmosphere; and arranging one to two stands for online hot rolling, wherein the thickness of a finished steel belt reaches 0.6-2 mm. The desulfurization procedure in steel making process can be omitted, and the steel making cost is reduced. The segregation of copper elements is inhibited, meanwhile, a large quantity of dispersed Cu2-xS precipitates can be formed to achieve the effect of dispersion strengthening.

Owner:BAOSHAN IRON & STEEL CO LTD

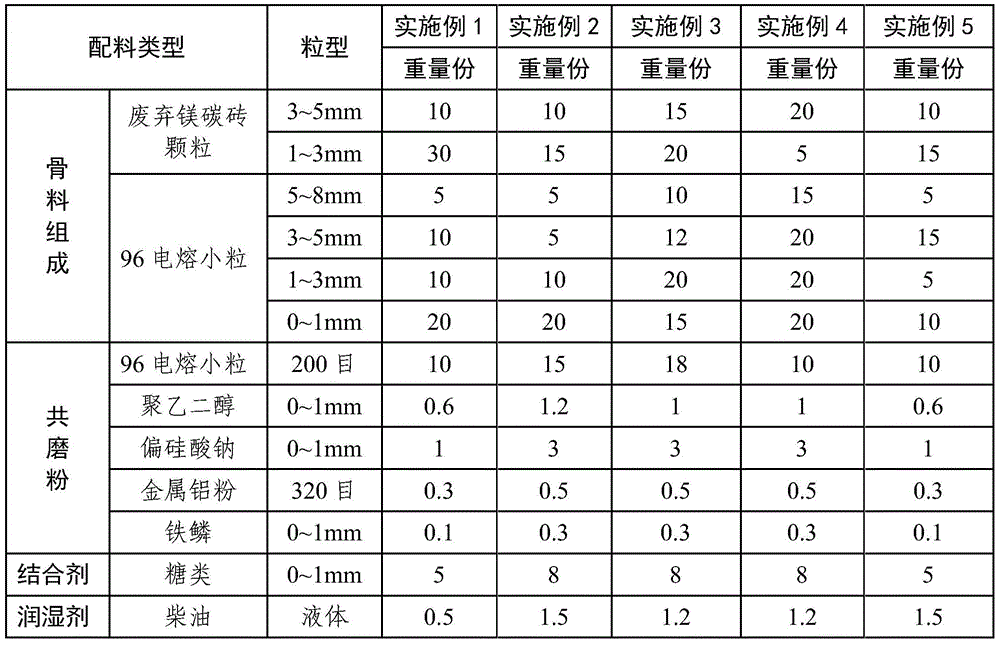

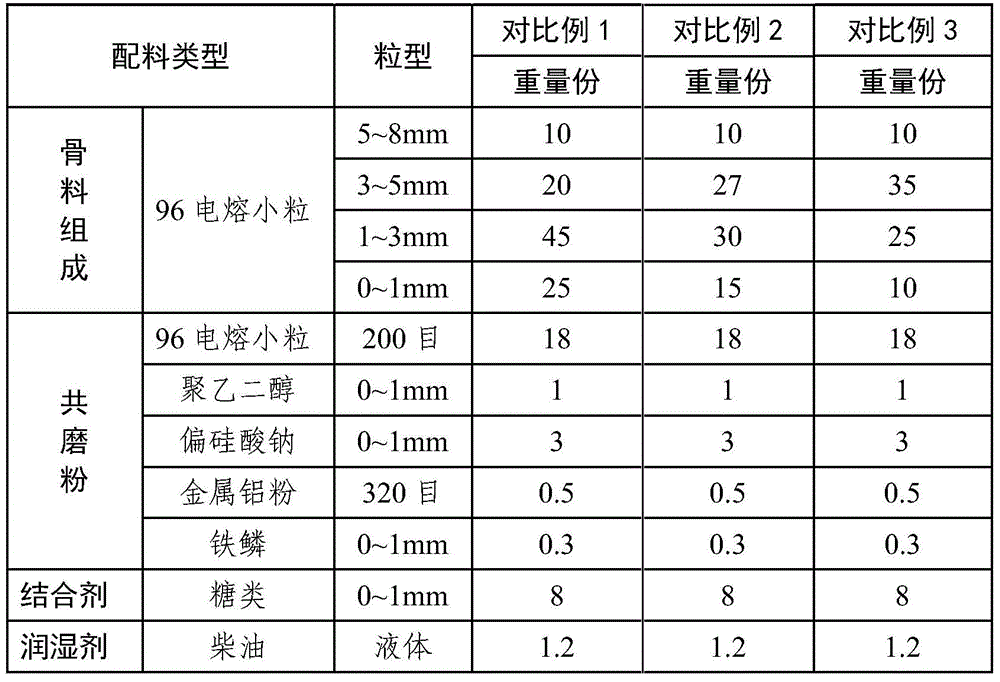

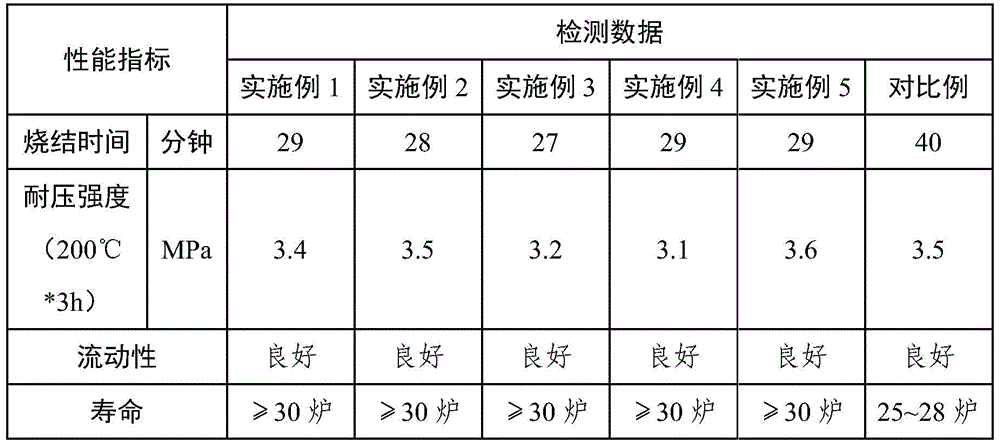

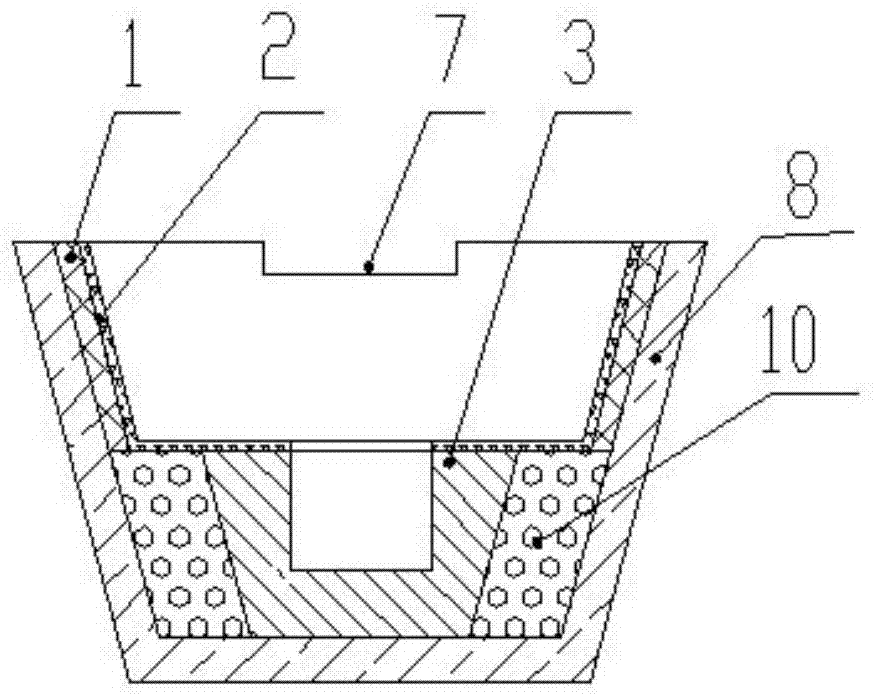

Tundish dry type vibration material taking waste magnesia carbon bricks as raw materials and preparation method thereof

The invention relates to a tundish dry type vibration material taking waste magnesia carbon bricks as raw materials and a preparation method thereof. The technical scheme is as follows: mixing 50-80wt% of the waste magnesia carbon bricks, 10-40wt% of fused magnesia or sintered magnesia fine powder, 3-8wt% of binding agent and 0.5-5wt% of additive, evenly stirring, carrying out vibration moulding, baking under the temperature of 200-400 DEG C, and demoulding to obtain the tundish dry type vibration material, wherein the MgO content in the waste magnesia carbon bricks are no less than 70wt%. The invention has the characteristics of simple process, low cost and energy conservation, is environmental friendly, and is convenient in construction. As for the tundish dry type vibration material, the main chemical components are MgO and C, the main crystalline phases are periclase and graphite, the continuous casting rate is high, the metallurgical effect is favorable, and the disassembly is easy after use. The tundish dry type vibration material is mainly applicable to continuous casting of tundish linings. The invention provides a new way for recycling the waste magnesia carbon bricks of a steel mill, and has important significances on energy conservation, consumption reduction and environment protection.

Owner:WUHAN UNIV OF SCI & TECH

Manufacture method for preventing edge crack generated during low-carbon cold rolling of paper-thin strip steel

InactiveCN101811134AThe chemical composition is simple and easy to controlSimple designTemperature control deviceMetal rolling arrangementsAcid washingStrip steel

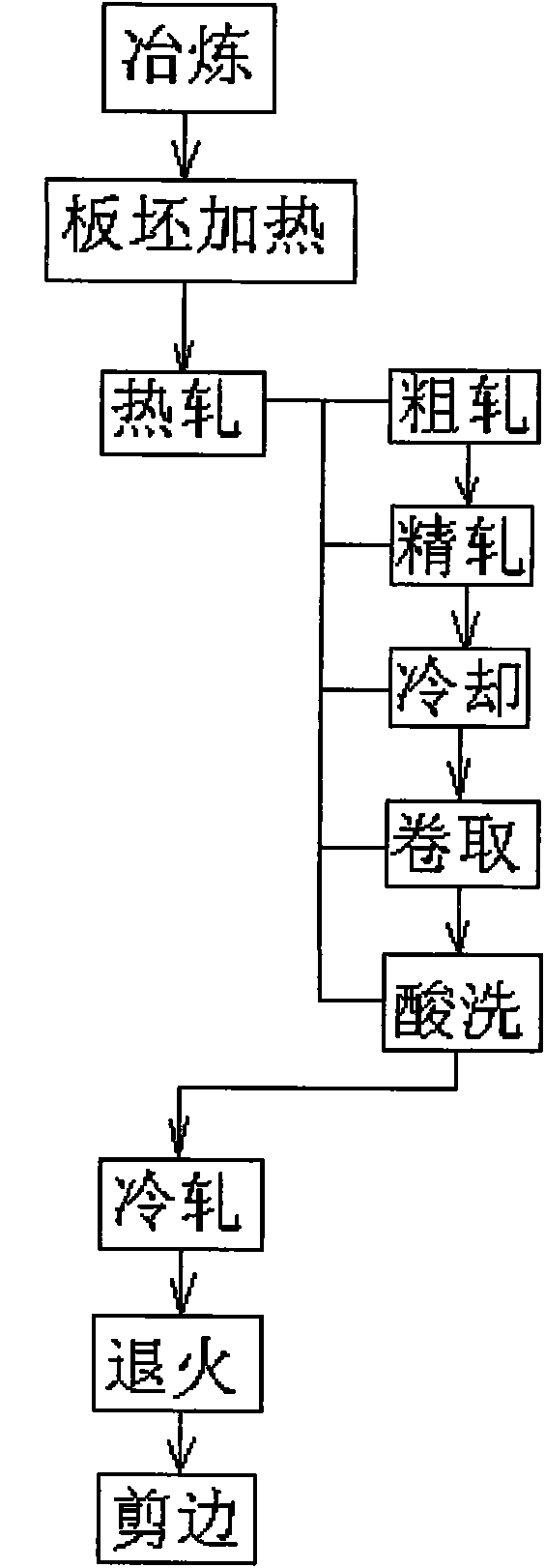

The invention relates to a manufacture method for preventing edge crack generated during low-carbon cold rolling of paper-thin strip steel, which sequentially comprises the steps: melting, plate blank heating, coarse milling, fine milling, cooling, coiling, acid washing, cold rolling, annealing and finishing and edge cutting, wherein the edge is not cut during steel coil acid washing, and the circular arc-shaped edge is maintained when the steel enters the cold rolling work procedure after the acid washing. The same plate temperature different in the plate blanking heating is lower than or equal to 40 DEG C, and the side pressure amount of the coarse milling is smaller than or equal to 50 mm. The final rolling temperature of the fine rolling is between 880 and 920 DEG C, an auxiliary vertical roller F1E of a machine frame F1 has the side pressure amount of 3 to 10 mm. The cooling is the laminar cooling of fast front section cooling with the cooling speed between 15 and 30 DEG C / s. The coiling temperature is between 650 and 710 DEG C. The single-edge cutting amount during the edge cutting is controlled between 5 and 7 mm, and the double-edge cutting amount is controlled between 10 and 14 mm. The thickness of cold rolling finished products of strip steel is between 0.15 and 0.45 mm, and the pressing rate is between 87.1 and 95 percent. The invention can solve the problem of edge crack of the paper-thin strip steel in the prior art.

Owner:NINGBO IRON & STEEL

Slag adjusting and furnace protecting method for controlling rising of converter bottom and furnace wall slag deposition

InactiveCN102127612AIncrease the content of MgOImprove furnace protection effectManufacturing convertersSteelmakingSludge

The invention belongs to the technical field of steelmaking and provides a slag adjusting and slag splashing furnace protecting method for controlling rising of a converter bottom and furnace wall slag deposition, solving the problems that the effective volume is reduced and the center of gravity of a furnace body shifts as slag stacked at the converter bottom rises and slag deposits at the lining of the furnace wall when the traditional slag splashing furnace protecting process is adopted. The method provided by the invention is characterized by adopting a two-step slag adjusting method, primary slag adjusting is carried out before molten steel is tapped, a boric sludge-magnesia slag adjusting agent is added into a furnace to reduce the viscosity of the slag, slag deposition at the lining of the unilateral furnace wall and slagging at the converter bottom in the tapping process can be prevented, the slag remaining and no steel remaining operation is adopted in the follow-up tapping process; and secondary slag adjusting is carried out after tapping, namely a magnesia carbon slag adjusting agent (coke powder and material containing magnesium oxide) is added into the slag remained in the furnace, and then the slag splashing slag protecting process is carried out. By adopting the method provided by the invention, the rising of the converter bottom and thickening of slag depositedon the furnace wall can be controlled, the thickness uniformity of the furnace wall can be guaranteed, and the slag splashing furnace protecting effect is obviously improved, thus the service life ofthe lining of a converter can be greatly prolonged.

Owner:JIANGSU UNIV

Aluminum industrial red mud-based dephosphorizing agent for converter steelmaking and preparation method thereof

InactiveCN103725825AMeet general requirementsReduce phosphorus contentManufacturing convertersSteelmakingRed mud

The invention discloses an aluminum industrial red mud-based dephosphorizing agent for converter steelmaking and a preparation method thereof, belonging to the field of converter steelmaking. The dephosphorizing agent is mainly prepared from the following raw materials by mass percent: 50-70% of dried red mud, 5-15% of lime, 15-30% of iron ore concentrate or iron sheet ball, 2-10% of light roasting dolomite, and 0.5% of binding agent. The dephosphorizing agent is prepared by the following steps of crushing the raw materials, mixing uniformly, pressing into chunks, roasting for 2-4 hours at 300-500 DEG C, cooling down, and then crushing into the dephosphorizing agent with grain size of 15-30mm. The dephosphorizing agent is added in dephosphorizing step in steelmaking by the converter, can be used for processing molten iron with middle or low content of phosphorus, and can remove more than 90% of phosphorus. By utilizing large amount of CaO and Fe2O3 in the red mud, the dephosphorizing agent not only has good dephosphorizing effect, but also solves the problem of red mud pollution, thus recycling the red mud and lowering the cost for steelmaking.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

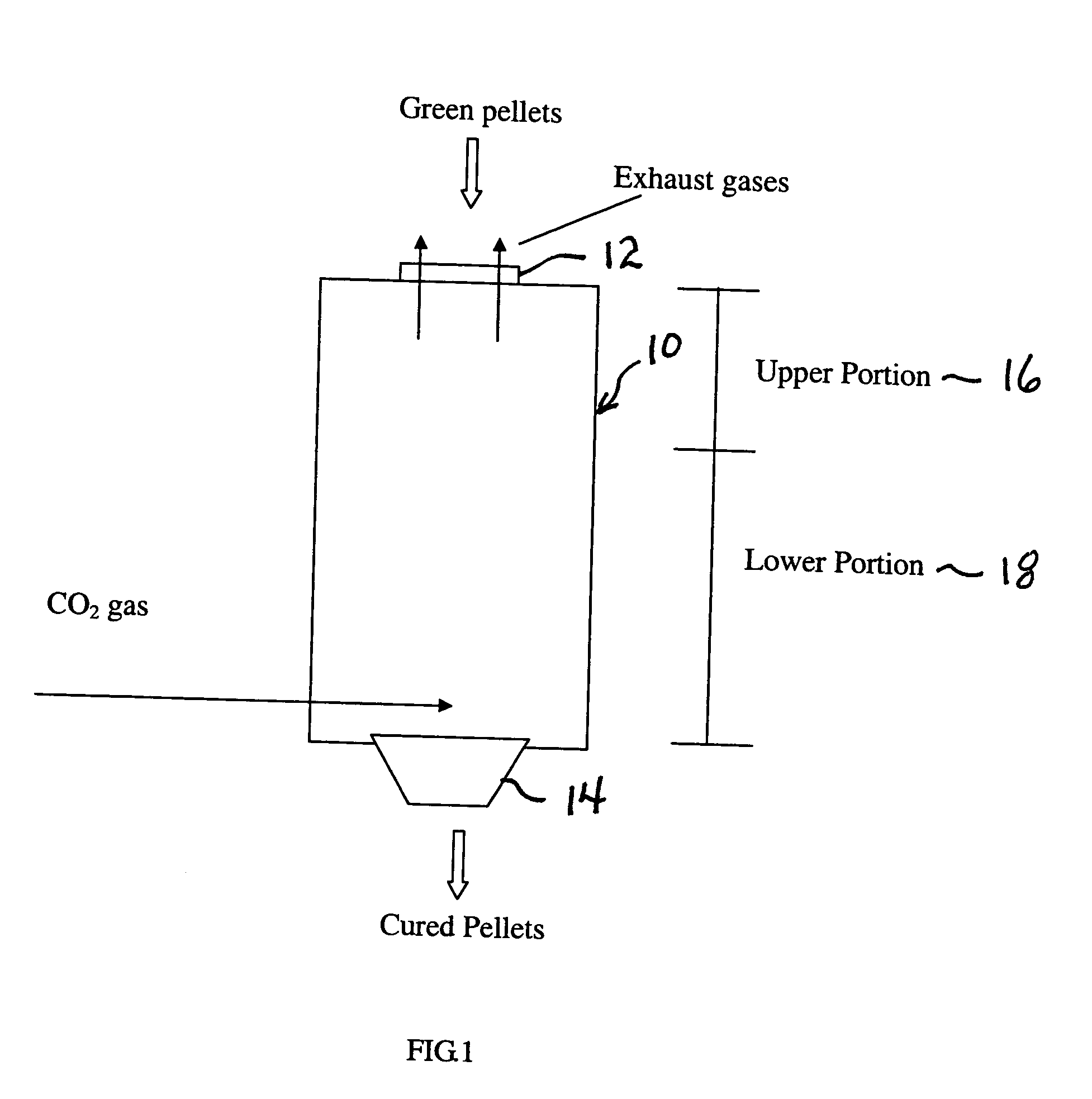

Self-reducing, cold-bonded pellets

ActiveUS20050061207A1Lower production costHigh flexibilityCeramic shaping apparatusCarbon dioxidePortland cement

Self-reducing, cold-bonded pellets and a method for their production for smelting a great variety of steels, including blast furnace iron-making, non-blast furnace iron-making, and all sorts of steelmaking in steel smelting furnaces, etc. The self-reducing, cold-bonded pellets comprise iron ore concentrate, carbonaceous reducing agent, and finely divided Portland cement clinker with special requirements as binder. The components are combined together to form a mixture. Pellets are produced when the mixture is placed into a balling disc or rotating drum and water is added. Pellets with predetermined size normally ranging from about 8-16 mm are obtained by using roller screens. The pellets are then continuously placed into a curing device. Inside the curing device, the pellets will then be hydrated and carbonated by using hot gases containing carbon dioxide with a temperature range of about 100-300° C. Thereafter, after drying, the dried pellets are discharged from the curing device and will be ready for use.

Owner:HANQING LIU

Composite deoxidizing agent aluminum-calcium-iron alloy for smelting steel

The invention provides steel-smelting complex deoxidizing agent- calcium-aluminium- ferrum alloy. It is to solve problems of great loss of aluminium during deoxidation process, low effective component content, bad utilization rate and large consumption, easy secondary oxidation and Al2O3 generation. The alloy comprises aluminium 20- 70%, calcium 1- 10% and left is ferrum and inevitable foreign substance. The manganese 1- 20%, silicon 1- 20% and titanium 1- 5% can be added into said alloy to prevent alloy efflorescence and increase steel alloy element. The invention is characterized by high deoxidation efficiency, lowered foreign substance content in steel, smooth steel smelting process, improved steel quality and reduced cost.

Owner:谢应凯

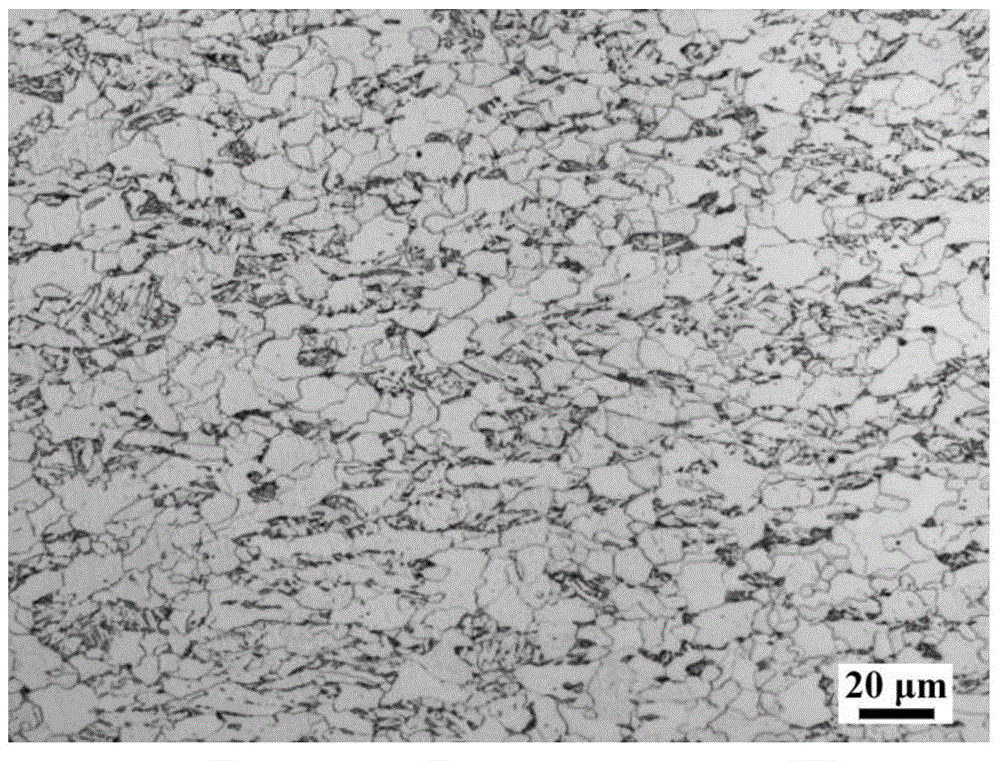

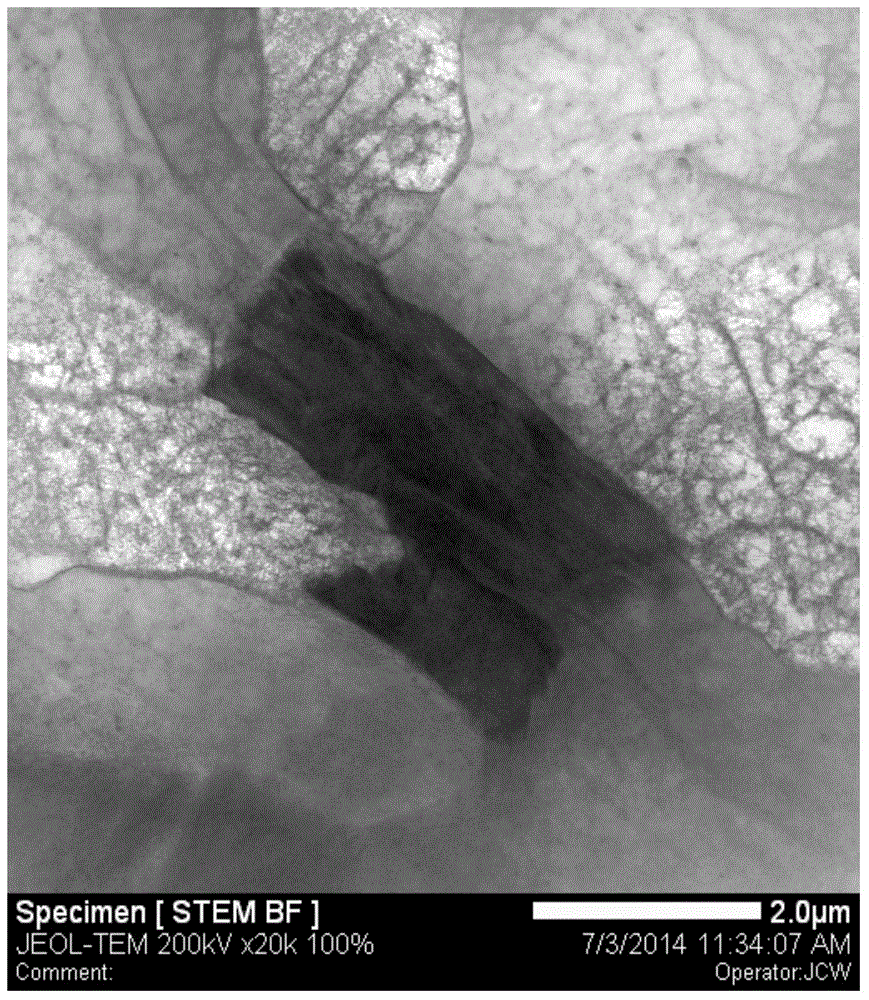

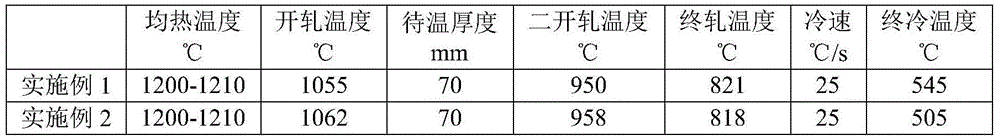

Pipeline steel, wide and thick plate, resistant to H2S corrosion, and production method thereof

The invention relates to a pipeline steel, wide and thick plate, resistant to H2S corrosion, and a production method thereof. The pipeline steel, wide and thick plate comprises, by weight, 0.018% to 0.068% of C, 0.12% to 0.42% of Si, 0.33% to 0.68% of Mn, not greater than 0.0098% of P, not greater than 0.0098% of S, 0.022% to 0.062% of Nb, 0.009% to 0.021% of Ti, 0.28% to 0.67% of Cr, not greater than 0.32% of Ni, not greater than 0.47% of Cu, 0.013% to 0.057% of Alt, 0.001% to 0.05% of Sn, 0.001% to 0.05% of Sb, one or both of 0.001% to 0.05% of Sn and 0.001% to 0.05% of Sb, and the balance of iron and avoidable foreign. The production method includes the steps of smelting by a blast furnace, pretreatment of molten iron, processing by a converter, refining, vacuum degassing, continuous casting, slab heating, descaling, controlled rolling, controlled cooling and air cooling; heating for hot rolling is at 1150 to 1210 DEG C, final rolling temperature is 800 to 850 DEG C, and final cooling temperature is 450 to 600 DEG C. The low-Mn component design is adopted, Sn or / and Sb are added, no noble metals such as Mo are added, and smelting cost and alloy cost are lowered; by component design and process control, the produced pipeline steel, wide and thick plate, resistant to H2S corrosion, has good comprehensive performances.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

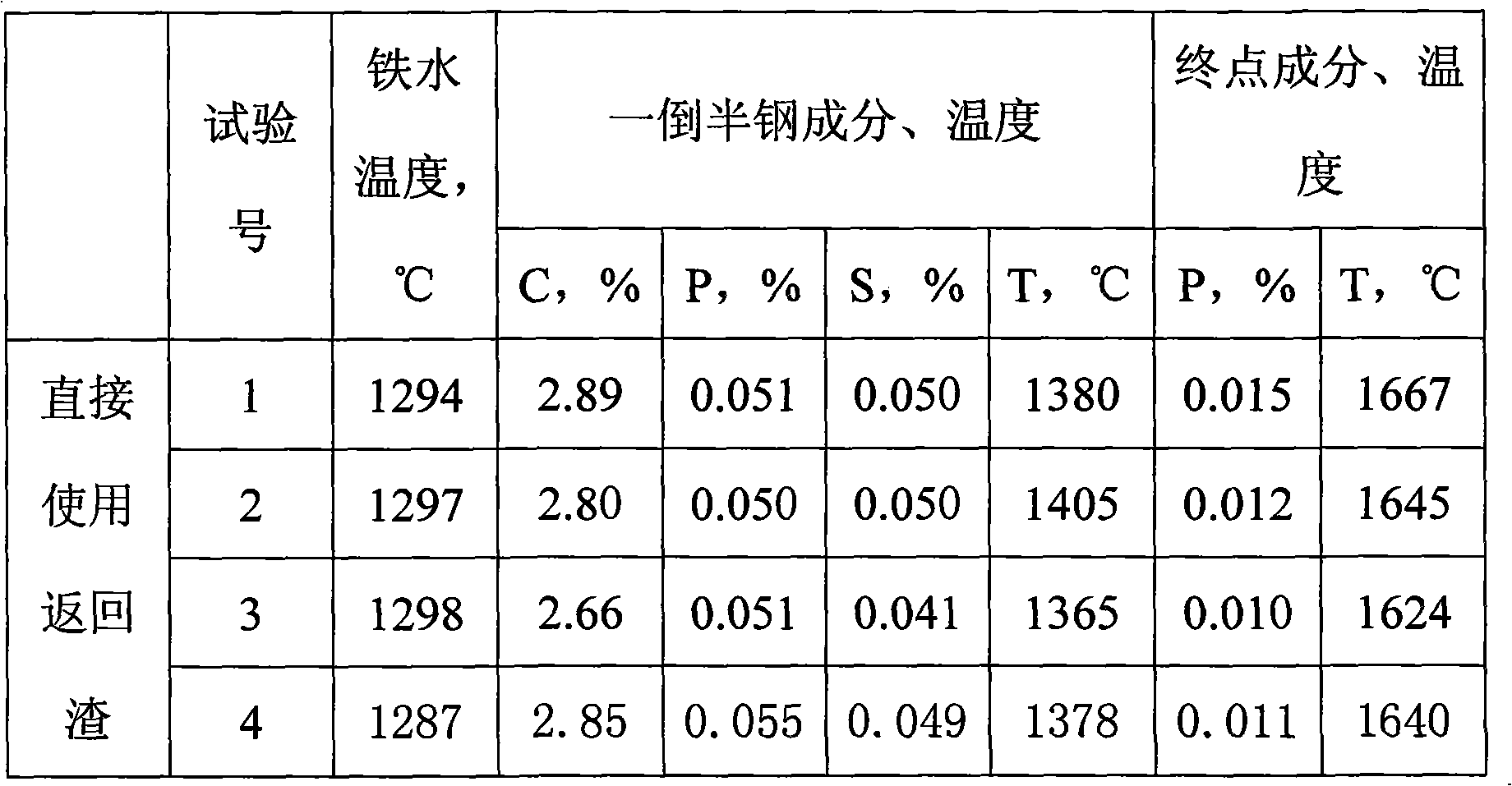

Compound dephosphorization agent with converter slag as raw material and preparing method thereof

The invention discloses a molten iron pretreatment compound dephosphorization agent with converter slag as the raw material, and the compound dephosphorization agent contains the following raw materials by weight: 45 to 55 percent of converter slag, 3 to 5 percent of quartz sand, 22 to 34 percent of steel-rolling iron sheet, 3 to 6 percent of bauxite, 10 to 14 percent of soda and 0 to 5 percent of fluorite; the raw materials meeting the ingredient demands are evenly mixed according to the proportions after being crushed, and then the product with the diameter being 20 to 50mm is produced after ball-milling, screen separation, palletizing and drying. The compound dephosphorization agent realizes cyclic utilization of the converter slag which accounts for 45 to 55 percent, thus reducing the produced slag amount in the steel-making process and the environmental load; the converter slag contains plenty of CaO and FeO, which can reduce consumption of lime to a certain degree, thus increasing the metal yield rate and reducing the steel-making cost; the compound dephosphorization agent has low melting point, slag can be formed fast, the liquidity is good, thus shortening the treatment time, the dephosphorizing efficiency is high, and the dephosphorized final slag has low alkalinity and low melting point.

Owner:CHONGQING UNIV

Efficient utilization process of aluminum ash in electrolytic aluminum plant

ActiveCN107245549AAvoid pollutionReduce steelmaking costsProcess efficiency improvementSlagAluminium

The invention discloses an efficient utilization process of aluminum ash in an electrolytic aluminum plant. Limestone powder and graphite carbon are added into white aluminum ash in the electrolytic aluminum plant and pressed to form spheres for the LF refining process; the weight percentage contents of three components are respectively aluminum ash of 60%, limestone powder of 30% and graphite carbon of 10%; limestone and graphite are crushed, are finely grinded in a Raymond mill to reach the particle size below 1 mm, are mixed with the aluminum ash for uniform mixing, and are added in a high-pressure ball press to be pressed to form slag balls; the slag balls are transferred to a converter tapping station for future use; a deoxidizing agent is replaced during LF smelting; 0.8-3 kg of slag balls are added in each ton of steel; and a traditional steel refining process is operated.

Owner:王强

Process method for producing steel shots by ladle-casting slag pelletization

ActiveCN102605115AImprove use valueReduce churnGranulation by liquid drop formationProcess efficiency improvementSlagSteel casting

The invention discloses a process method for producing steel shots by ladle-casting slag pelletization. The process method comprises the following steps that: a) a ladle nozzle is closed after the steel casting is finished, a ladle is lifted to be above a temperature-rising liquefying device, the ladle is tilted after alignment, and the lade slag is poured into the temperature-rising liquefying device; b) a power supply of the temperature-rising liquefying device is switched-on to heat and increase the temperature, and after the ladle slag is completely molten and the temperature is increased, the temperature-rising liquefying device is tilted to enable the ladle slag to flow out slowly; c) the ladle slag forms stream through a middle flow chute and falls off freely from the front part of a pneumatic pelletizer, the pneumatic pelletizer sprays out high-speed gas flow to crush the ladle slag stream into fine liquid drops, the liquid drops fly along with the gas flow, and simultaneously, a controlled-cooling atomizer distributed below the pneumatic pelletizer sprays out gas-water mixed flow to push liquid drops of the ladle slag to fly continuously and carries out enhanced cooling on the liquid drops of the ladle slag, so that the fine liquid drops are cooled and solidified into steel shots and small slag balls in the flying process, and are prevented from being melted and bonded together after falling to the ground. The method effectively improves the utilization value of the ladle slag.

Owner:MAGANG (GROUP) HOLDING CO LTD

Treatment method for slag adjustment before slag splashing protection of converters

InactiveCN102392097AImprove fire and corrosion resistanceGuaranteed lifeManufacturing convertersSteelmakingConverters

The invention belongs to the technical field of steel making and provides a treatment method for slag adjustment before slag splashing protection of converters, which is used for solving the existing problems of bad slag hanging effect in high iron oxide type slag splashing protection after high-temperature steel tapping and short lining life. The method provided by the invention is characterized in that: coke powder, magnesite and titanium white are used as slag adjustment agents; the coke powder is capable of decreasing the ferric oxide in residual slag and reacting with the titanium white to generated titanium carbide with high melting point; and the titanium carbide acts synergistically with the magnesite to increase the viscosity and the melting temperature of the slag. Therefore, by using the invention, the adherence stability and high temperature and slag steel erosion resistance of the slag on furnace walls can be markedly improved, the slag splashing protection effect can be improved and the lining life of the converters can be greatly prolonged.

Owner:JIANGSU UNIV

Steel making nitriding silicon-manganese alloy and preparation method thereof

The invention relates to a steel making nitriding silicon-manganese alloy and a preparation method thereof, belonging to the alloy technical field; the steel making nitriding silicon-manganese alloy comprises the following compositions by weight percent: 25-75% of Mn, 10-60% of Si, 10-38% of N and the balance Fe and other trace elements. The preparation method comprises the following steps: (1) using ordinary silicomanganese and ferrosilicon or ordinary silicomanganese and manganese as raw materials to grind, sieving with a 60 meshes of sieve, mixing the materials evenly, adding 7-9wt% of polyving alcohol water solution used as binder of which the weight percent of polyving alcohol is 8% and then preparing 10-40mm of spheres by wet mixing; (2) placing the spheres in a crucible, sending the crucible into a pusher kiln, injecting high purity nitrogen, keeping 10-70Pa of positive pressure in the kiln to reaction sintering at 1000-1250 DEG C for 5-7h; (3) gradually cooling to under 100 DEG C and finally discharging to obtain the high-nitrogen silicon-manganese alloy.

Owner:郸城财鑫特种金属有限责任公司

Converter repairing mass and preparation method thereof

The invention relates to the technical field of unshaped refractory materials in converter steelmaking and particularly relates to a converter repairing mass and a preparation method thereof. The converter repairing mass is prepared from the following raw materials in parts by weight: 70-110 parts of mixture of fused magnesite and waste magnesia carbon brick particles, 10-30 parts of fused magnesite fine powder, 5-8 parts of bonding agent and 2-5 parts of filler, wherein the mixture of fused magnesite and waste magnesia carbon brick particles at least comprises 10-30 parts of fused magnesite fine powder. The preparation method of the converter repairing mass comprises the following steps of: adding 0.5-1.5 weight parts of wetting agent into the raw materials of the converter repairing mass, and mixing and stirring to obtain loose, dry and uniform aggregate. According to the converter repairing mass and preparation method thereof, the waste magnesia carbon brick serves as a raw material, and the converter lining built by the magnesia carbon bricks realizes a better protection effect; the converter repairing mass has the advantages of good high-temperature fluidity, short sintering time, high sintering strength, long service life, environmental protection and the like.

Owner:北京利尔高温材料股份有限公司

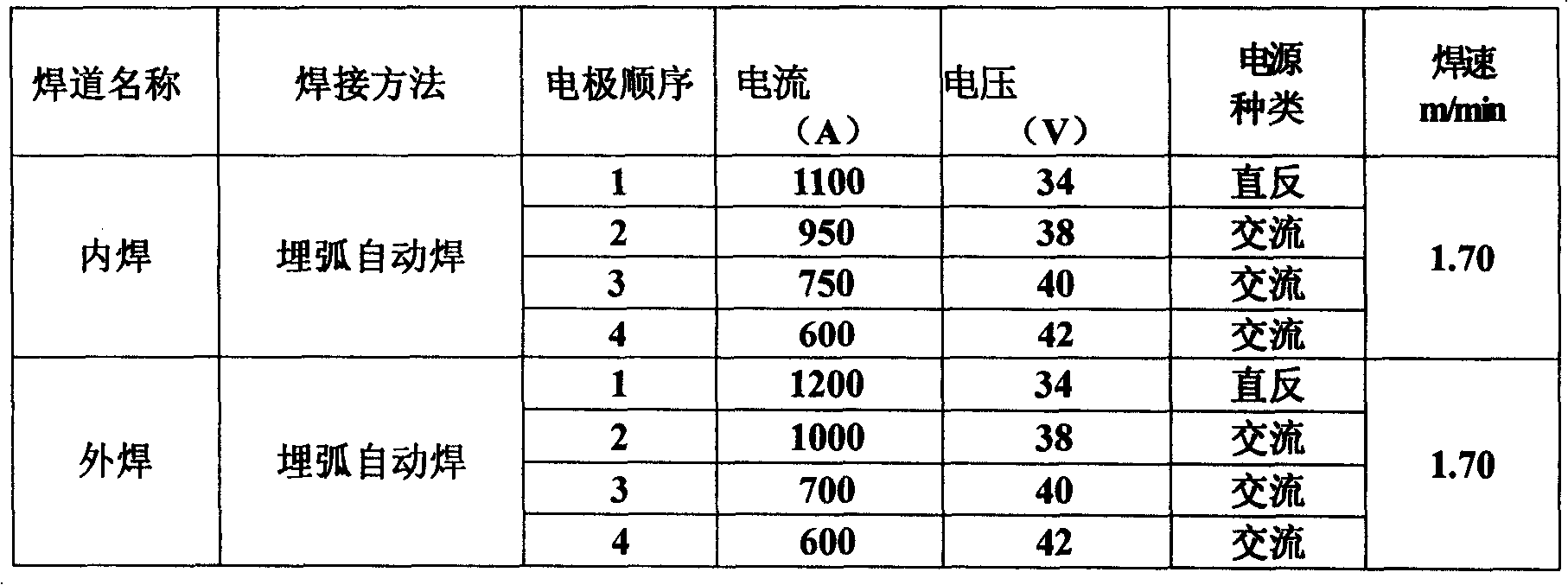

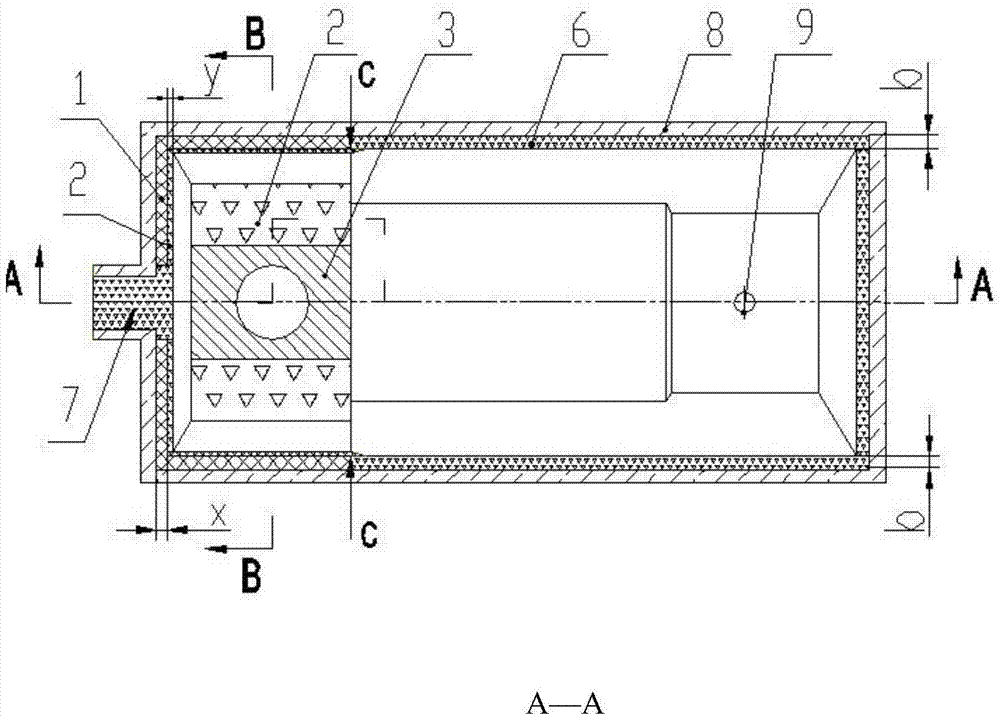

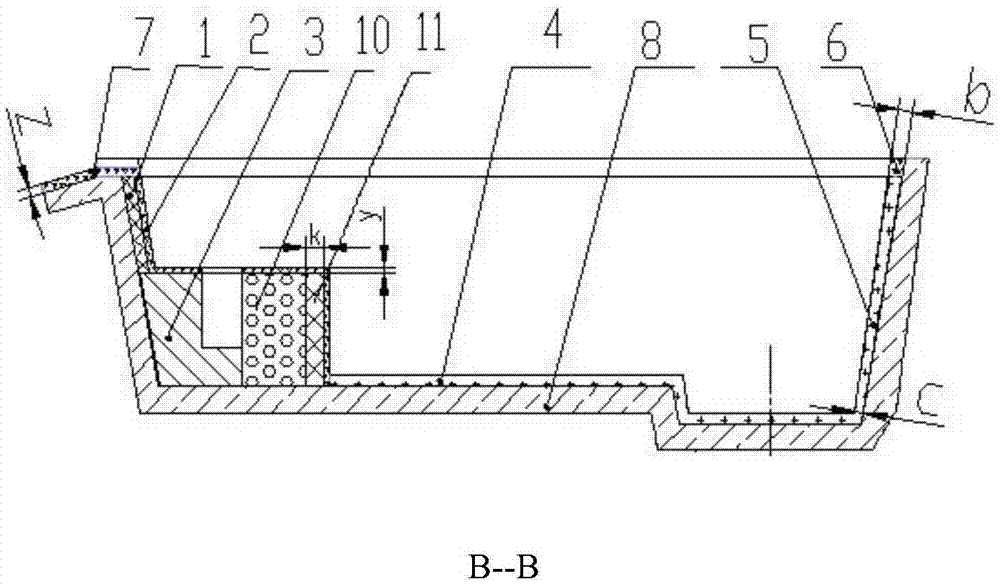

X80 pipeline steel submerged arc welding wire

InactiveCN101254575AReduce plasticityReduce intensityArc welding apparatusWelding/cutting media/materialsWeld seamHigh intensity

The invention discloses a steel welding wire of submerged arc welding for X80 pipeline, which is used for submerged arc welding for welding steel with high strength and high toughness for X80 pipeline for transporting petroleum and gas. The welding wire contains following chemical components (by weight percentage): C 0.06 to 0.10%, Mn 1.5 to 1.8%, Si 0.25 to 0.35%, P less than or equal to 0.016%, S less than or equal to 0.005%, Mo 0.3 to 0.4%, Cu less than or equal to 0.08%, Ti 0.1 to 0.2%, B 0.004 to 0.008%, N less than or equal to 0.006%, H less than or equal to 0.003%, and O less than or equal to 0.003%. The welding wire can be used for welding X80 submerged arc welded pipes with high strength and high toughness, and the quality of the welding seam and a heat affected zone can meet the technical requirements of welded steel pipes for petroleum and gas transportation such as high strength, high roughness and low rigidity, and particularly can meet the technical standard requirement for submerged arc welded pipes for two gas pipelines of the worldwide-focused engineering for transporting natural gas from west to east.

Owner:CNPC BOHAI EQUIP MFG +3

Reworked material working lining of continuous casting tundish and preparation method for reworked material working lining

ActiveCN105436492ASolve the problem of bulging cracks and even material collapseEasy to useMelt-holding vesselsBrickRefractory

The invention relates to a reworked material working lining of a continuous casting tundish and a preparation method for the reworked material working lining. The reworked material working lining is divided into an impact zone working lining and a non-impact zone working lining, which are internally attached to a permanent lining; the non-impact zone working lining sequentially comprises a ladle edge working lining, a ladle wall working lining and a ladle bottom working lining from top to bottom; the impact zone working lining is built by adopting waste magnesia-carbon bricks and regenerated coating material mud through a wet process; the ladle wall working lining and the ladle bottom working lining are built by adopting a regenerated dry material; an overflow port working lining and the lade edge working lining are built by adopting the regenerated coating material; a space between the two sides of a turbulent flow controller and the ladle wall permanent lining is filled by waste; and a regenerated coating material layer coats the outer surfaces of the waste magnesia-carbon bricks, the outer surface of the waste and the upper surface of the turbulent flow controller. By applying the reworked material working lining, the service life of a shaped blank continuous casting tundish reaches 33-38 hours, and refractory material cost of the regenerated material working lining is reduced by more than 60% year on year.

Owner:SHANDONG IRON & STEEL CO LTD

Stainless steel smelting method

ActiveCN101476016AShorten heating timeReduce restore timeElectric furnaceProcess efficiency improvementElectric arc furnaceIntermediate frequency

The invention belonging to the field of smelting relates to a stainless steel smelting method.The invention is characterized in that the method comprises the following steps: 1) electric furnace smelting; 2) a intermediate frequency furnace melting alloy; 3) LF furnace heating; 4) VOD vacuum decarburizing; 5) VOD vacuum reducing and adding aluminum as the reductive in the vacuum state; 6) argon protecting and teeming.According to the invention, by adopting an electric furnace added with a intermediate frequency furnace and adopting a method of adding reductive under a vacuum state, the LF heating and reducing time is shortened, stay time of molten steel in ladle is reduced, steel-making cost is reduced and the manufacture security is improved. The technology has a remarkable economic benefit by producing stainless steel with a high alloy content. The reducing time is shortened from 7 hours primarily to 3-4 hours currently, therefore, the production efficiency is improved greatly, the forgeable pieces producing capability is extended and the economic benefit is remarkable.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

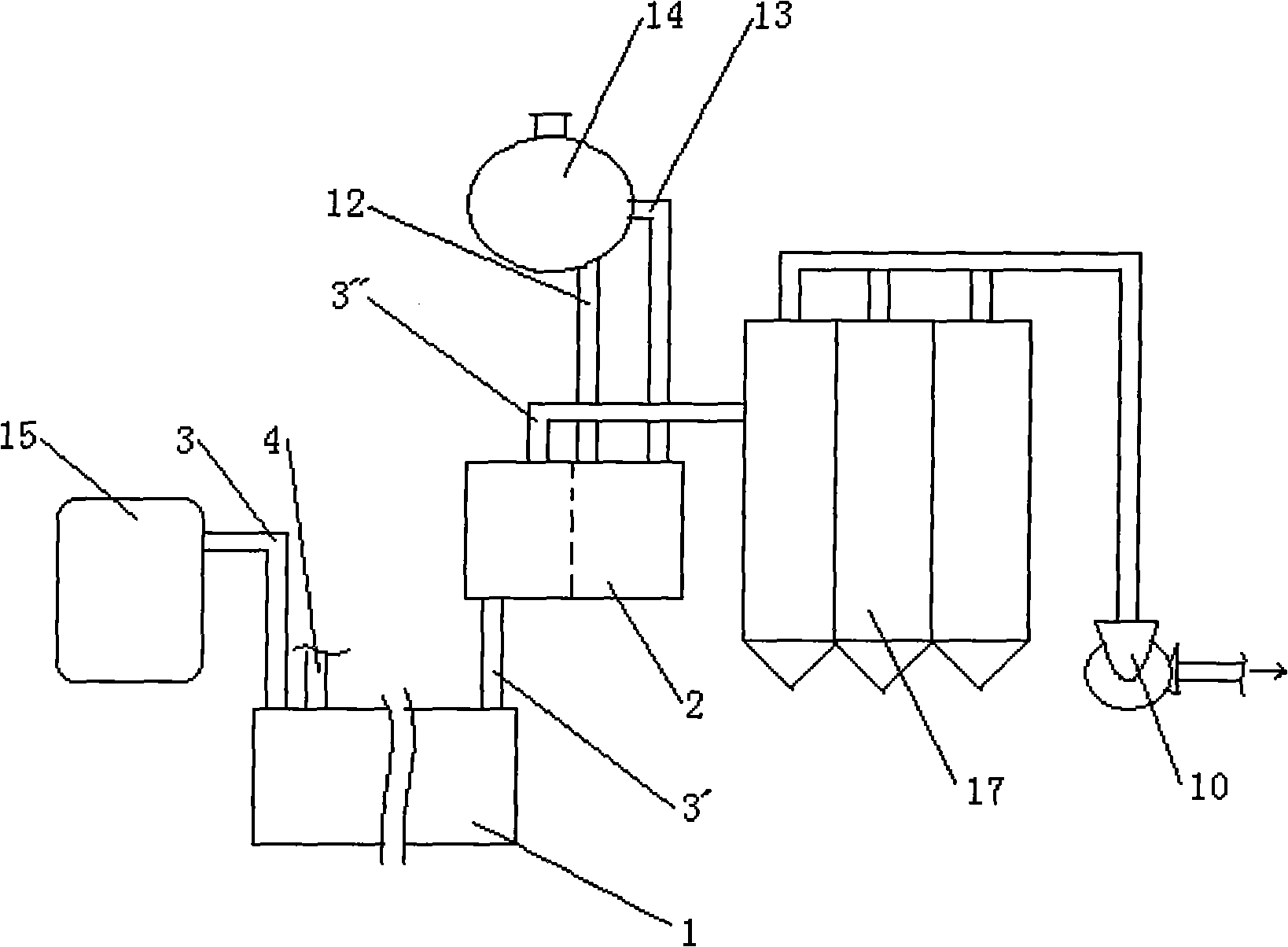

Device for reducing dioxins discharge during steel smelting in electric furnace and method thereof

InactiveCN101274212ABurn fullyDecomposition maximizationDispersed particle separationProcess efficiency improvementSteelmakingElectric arc furnace

The invention discloses a device and a method used for reducing the exhaust of electric furnace steelmaking dioxin, comprising a bag-typed deduster which is communicated with the electric furnace by a flue gas pipeline and a loading device. The invention is characterized in that the pipeline between the electric furnace and the bag-typed deduster is sequentially communicated with a combustion settlement chamber and a temperature reduction device. The method comprises the steps as follows: the electric furnace adopts the molten iron hot charging technique; the steelmaking flue gas enters the combustion settlement chamber for sufficient combustion, then enters the temperature reduction device, with the temperature reduced from 800 to 1000 DEG C at the inlet to below 200 DEG C at the outlet within 1 to 3 seconds, and is finally exhausted after being disposed by the bag-typed deduster; wherein, the content of the dioxin is not more than 0.2ngTEQ / m<3>. The device and the method of the invention reduce the content of the dioxin, generate a plurality of saturated steam at the same time and have the advantages of saving energy and reducing the steelmaking cost.

Owner:JIANGSU SHAGANG GROUP HUAIGANG SPECIAL STEEL CO LTD

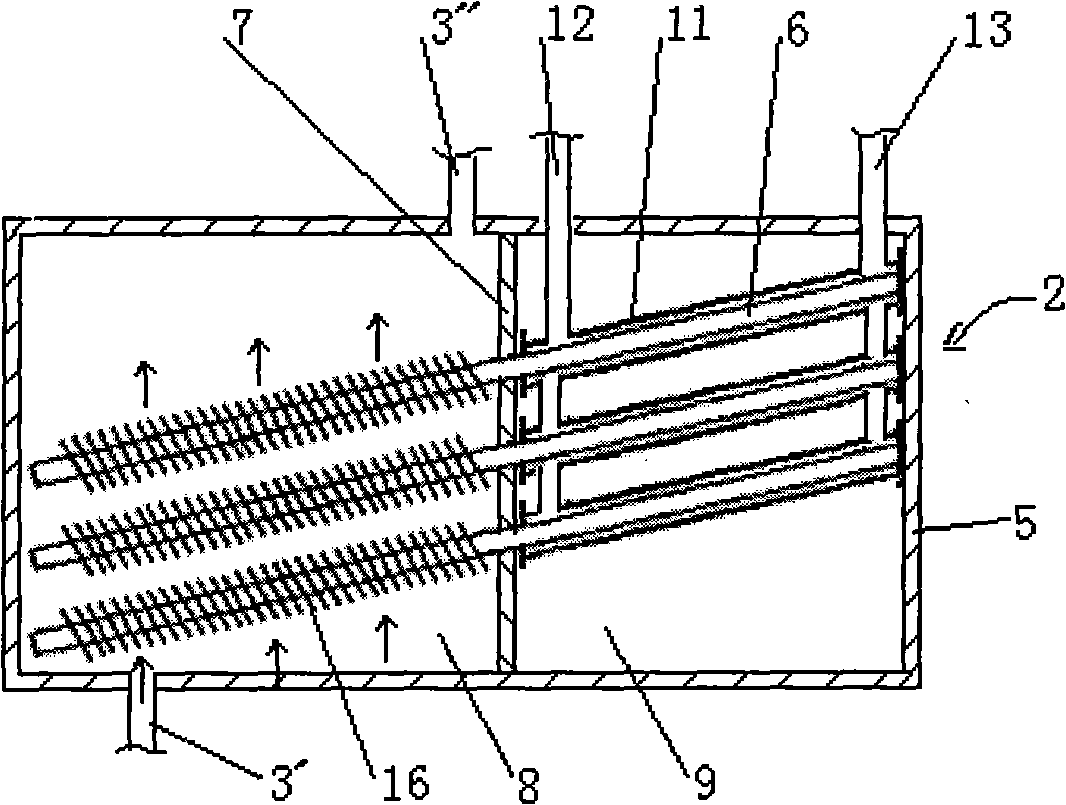

Pure aluminium iron compound deoxidant and its production process

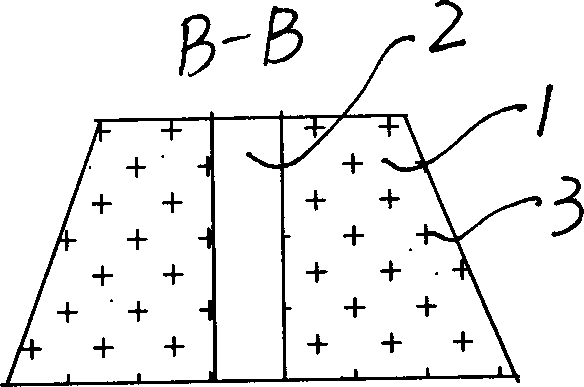

The present invention relates to a pure aluminium iron composite deoxidant and its production process. It includes 30-70% of aluminium and 70-30% of iron, and its production process includes the following steps: (1). adopting aluminium-melting furnace to melt high-purity aluminium; (2) pouring the molten aluminium into the mould with frustum form, trapezoidal tower form or triangular tower form and forming, continuously heating the mould and making the molten aluminium be in liquid state; (3). quick adding preheated pure iron granules or iron chipings; and (4) lightly and slowly vibrating mould and making the iron granules or iron chipings uniformly dispersed in molten aluminium, solidifying to form aluminium-iron composition whose specific weight can be up to 2.8 g / cu.cm-6.8 g / cu.cm.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

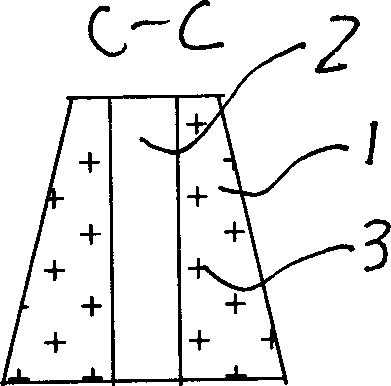

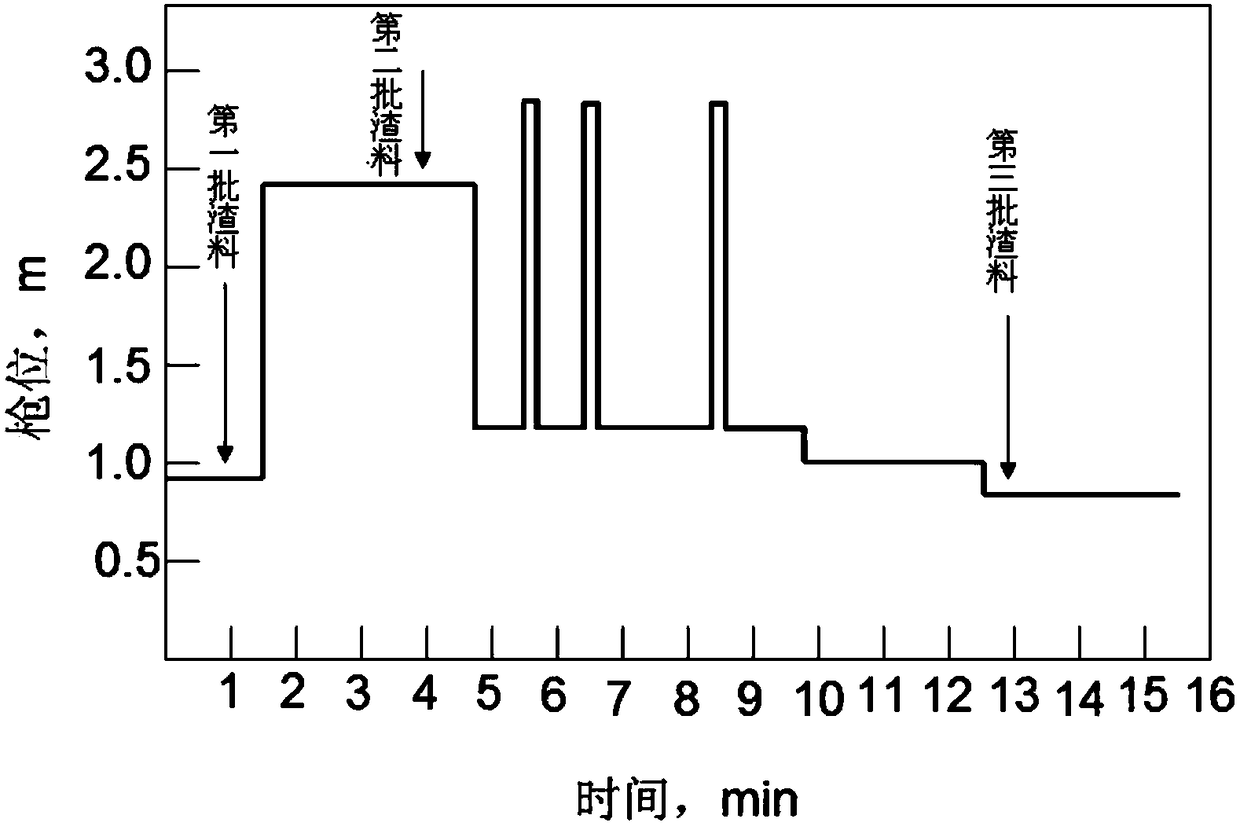

Method for increasing residual manganese content in molten steel at end point of converter

InactiveCN108396093AIncrease the residual manganese contentReduce the amount addedManufacturing convertersProcess efficiency improvementSteelmakingManganese

The invention provides a method for increasing the residual manganese content in molten steel at the end point of a converter. According to the method, the waste steel loading amount of the converteris controlled according to the waste steel ratio of not more than 15%; at the early stage of the smelting, the iron-carbon ball slag is added while the white ash slag is added into the converter, theadding amount of the first batch of the slagging material is 50-70% of the total adding amount, the blowing starting position of the oxygen gun is 0.8-1.2 m, and the gun position is increased to 2.2-2.6 m after blowing is performed for 1-2 min; 25-40% of the remaining slag is added after blowing is performed for 3-6 min; at the middle stage of the smelting, the oxygen gun is lifted to 2.5-3.0 m, blowing is performed for 10-30 s, and then the oxygen gun is lowered to the basic gun position; and at the late stage of the smelting, the gun position is controlled at 1.0-1.2 m, and the remaining slag is added to the converter at 2-5 min before the tapping. According to the present invention, with the method, the residual manganese content in the end point molten steel can be increased, the alloyaddition amount during alloying can be reduced, the steelmaking cost can be reduced, the FeO content in the final slag can be reduced, the converter blow loss can be reduced, and the rephosphorization and the tapping slag discharge can be effectively prevented.

Owner:ANGANG STEEL CO LTD

Aluminum-magnesium-iron alloy deoxidant

An AlMgFe alloy deoxidant contains Al (40-95 wt.%), Mg (5-20) and Fe (rest). Its advantages are direct application in molten steel, high desulfurizing power and low cost.

Owner:本溪冶炼厂

Production process of aluminium slag adjusting agent for LF refining furnace

The invention provides a production process of an aluminium slag adjusting agent for an LF refining furnace. Waste refractory materials are taken and cooled to be at an indoor temperature, the waste refractory materials are crushed into 5-50mm particles, then the particles are added into a Raymond mill to be processed into powder with the particle size being smaller than 3mm, the powder and limestone powder with the particle size being smaller than 1mm are mixed according to the mass percent of 1:9, the mixed powder is placed in a coercive stirring mixer to be stirred and mixed and then is discharged evenly, the mixed powder is then added into a steel slag powder ball press machine or a refractory material ball press machine to be pressed into ball bodies of 20+ / -5mm, and the ball bodies are dried under the temperature of 20-50 DEG C and then used. In the process of LF smelting, 50-150kg of the aluminium slag adjusting agent needs to be added when every 100-300kg lime is added.

Owner:XINJIANG ZHONGHE DAZHENG COMMERCE & TRADE

Special steel ladle draining sand for stainless steel and production process thereof

ActiveCN102001854AContinuous casting processReduce steelmaking costsMelt-holding vesselsOxygenMolten steel

The invention discloses a special steel ladle draining sand for stainless steel and a production process thereof. The product and the process can effectively improve the self-opening rate of a steel ladle, greatly relieve the labor intensity of workers, reduce oxygen-blast draining times, improve the quality of molten steel and ensure the progressive execution of a continuous casting process. When the stainless steel is produced by using the steel ladle draining sand, the self-opening rate of the steel ladle can reach above 98% so that the purposes of fewer oxygen-blast draining times, high quality of molten steel and progressive execution of the continuous casting process are achieved, and simultaneously, the total steel-making cost of a steel mill is also reduced.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Methodof smelting Ti-IF steel withiron melt containing vanadium titanium

ActiveCN109022664ASolve the problem of excessive P contentShorten smelting IF processManufacturing convertersProcess efficiency improvementSteelmakingNitrogen

The invention provides a method of smelting Ti-IF steel with iron melt containing vanadium titanium. Iron melt containing vanadium titanium is used as a raw material, and Ti-IF steel is obtained afterprocedures of pre-dephosphorization, de-vanadium, and desilication of a vanadium extraction converter, compound injection desulphurization, decarburization and dephosphorization of a steelmaking converter, and RH refining. The method solves the problems that, on the one hand, P content in the iron melt containing vanadium titanium is high, dephosphorizing by single converter smelting is difficult, and phosphorus content at the end point of the iron melt is high; and on the other hand, heat in the iron melt containing vanadium titanium is insufficient, the LF heating procedure is omitted by adopting the method of heat compensation, and nitrogen content in steel rising and procedure energy consumption in the LF heating process can be avoided. The quality of Ti-IF steel is improved, contentof T[O] in the steel is controlled to be reduced below 0.0020%, technology procedure is shortened, production efficiency is improved, and production procedure energy consumption is reduced.

Owner:HEBEI IRON AND STEEL

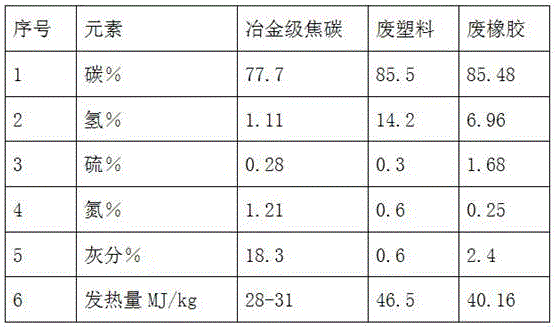

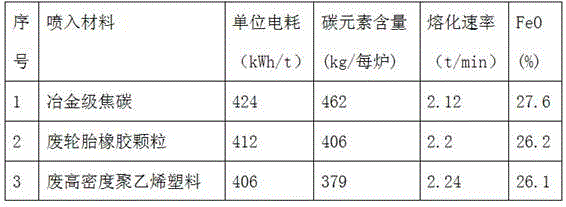

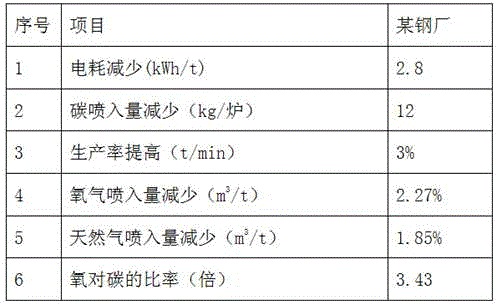

Method for making foaming slag for electric arc furnace steelmaking using waste plastic and waste rubber

ActiveCN106350635ASolve pollutionReduce pollutionElectric furnaceProcess efficiency improvementSteelmakingElectric arc furnace

The invention discloses a method for making foaming slag for electric arc furnace steelmaking using waste plastic and waste rubber, wherein the steps are as follows: The waste plastic and the waste rubber are to be crushed. When the temperature of the slag reaches 1600-1650oC and the limestone is completely dissolved, the pulverized waste plastic and waste rubber and metallurgical grade coke are injected into the slag. At this time, there is a large amount of FeO in the slag layer, and then FeO is reduced by waste plastics and waste rubber and C in metallurgical grade coke to produce Fe and CO gas, and CO gas is trapped by slag to form foam slag. In order to produce a large amount of foaming slag, oxygen-enriched operation is carried out for feeding oxygen. When the O2 content in the slag exceeds the CO equilibrium curve, excessive CO gas is generated. After the CO gas is captured by the slag, a large amount of foam slag is formed. By mixing the waste plastics, waste rubber and metallurgical grade coke, the foaming slag is characterized by improvement of the electric arc furnace steelmaking efficiency, cost reduction of electric arc furnace steel and less environmental pollution.

Owner:HENAN TAIHANG QUANLI HEAVY IND

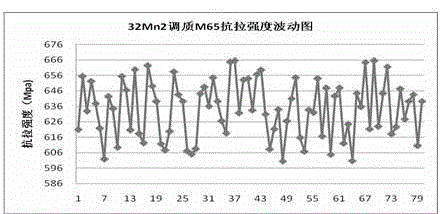

Oil sleeve steel ball and manufacturing process thereof

ActiveCN103556084AComply with steel requirementsReduce steelmaking costsMetal rolling arrangementsIn process controlSmelting

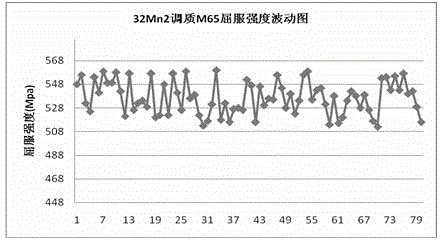

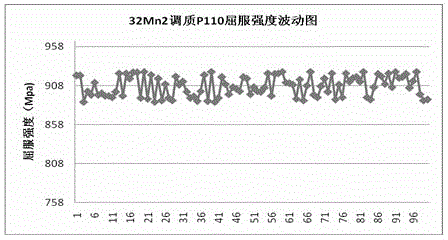

The invention discloses an oil sleeve steel ball. The oil sleeve steel ball consists of the following components by weight percent: 0.28-0.36% of C, 0.17-0.32% of Si, 1.10-1.60% of Mn, less than or equal to 0.02% of P, less than or equal to 0.2% of S, less than or equal to 0.2% of Cu, less than or equal to 0.2% of Ni, less than or equal to 0.25% of Cr, less than or equal to 0.1% of Mo, less than or equal to 0.08% of V, 0.008-0.03% of Al, less than or equal to 0.15% of other elements and the balance of Fe. The manufacturing process comprises the steps of converter smelting, external refining, continuous casting of a round billet, hot rolling of seamless pipes and heat treatment of an oil sleeve pipe. 0.008-0.030% of Al is specially added in the oil sleeve steel ball for refining grains, the toughness of steel pipes is improved, and the requirement that the steel for oil sleeves by API5CT is fine-grain killed steel. The steel ball is low in steel-making cost and easy in process control, and multi-steel-grade oil sleeves of J55, M65, N80Q, L80-1, R95 and P110 with wide intensity range can be produced by a proper process, so that the marks of steel for oil sleeves can be reduced, so that the oil sleeve steel ball is economical and practical, on one hand, the management of blanks and production are facilitated, on the other hand, stocks are reduced, and overstocked funds are lowered.

Owner:JIANGSU VALIN XIGANG SPECIAL STEEL

Calcium carbide ferro-aluminium alloy used for smelting steel, and preparation method thereof

InactiveCN102827997AQuality is not affectedGuarantee the quality of steelmakingImpurityCalcium carbide

The invention relates to a calcium carbide ferro-aluminium alloy used for smelting steel, and a preparation method thereof. The calcium carbide ferro-aluminium alloy employs calcium carbide, aluminium, ferrum and the like as raw materials, is produced by a remelting perrin process, and is used for deoxidation and desulphurization of smelting the steel. The calcium carbide ferro-aluminium alloy comprises the following components of, by mass, 20-60% of aluminium, 5-40% of calcium, 1-15% of carbon, and the balance being ferrum and inevitable impurities. The calcium carbide ferro-aluminium alloy has good effects of deoxidation and desulphurization, and can reduce cost for smelting the steel while guaranteeing the quality of the steel.

Owner:谢应旭

Method for smelting medium-high alloy low-phosphorous steel through electric furnace with high molten iron proportion

ActiveCN106544467AReduce steelmaking costsEfficient dephosphorizationProcess efficiency improvementElectric furnaceScrapElectric furnaces

The invention discloses a method for smelting medium-high alloy low-phosphorous steel through an electric furnace with a high molten iron proportion. Through strictly control over oxygen blowing, power transmission and feeding processes during smelting of the electric furnace, the purposes of efficient smelting, energy saving and consumption reducing are achieved. The method includes the detailed steps that the proportion of molten iron entering the furnace is controlled to be 60-80%, steel scraps are added into the furnace at a time through a basket, the molten iron enters from a door of the furnace through a molten iron adding trolley during power transmission, the flow of a multifunctional bundling oxygen lance is reasonably adjusted, power supply time is dynamically controlled, lime is supplemented into the furnace in batches in combination with an automatic feeding system, and therefore molten steel rapidly meets the requirements for components and temperature needed by a steel grade. Compared with a common electric furnace technology, the time consumed for adding the molten iron is shortened, and the smelting efficiency of the electric furnace is improved; the power supply time of the electric furnace is quite short, and therefore the energy consumption of steel smelting is lowered; during smelting of the electric furnace, efficient dephosphorizing and decarbonizing are achieved.

Owner:SHANDONG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com