Pipeline steel, wide and thick plate, resistant to H2S corrosion, and production method thereof

A production method and technology of wide and thick plates, applied in the field of pipeline steel wide and thick plates and its production technology, can solve the problems of increasing steelmaking cost and difficulty, high difficulty and cost of steelmaking, high content of precious metals, etc., so as to reduce the difficulty of steelmaking and save Alloy cost, effect of improving hydrogen sulfide corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with embodiment further illustrate the present invention.

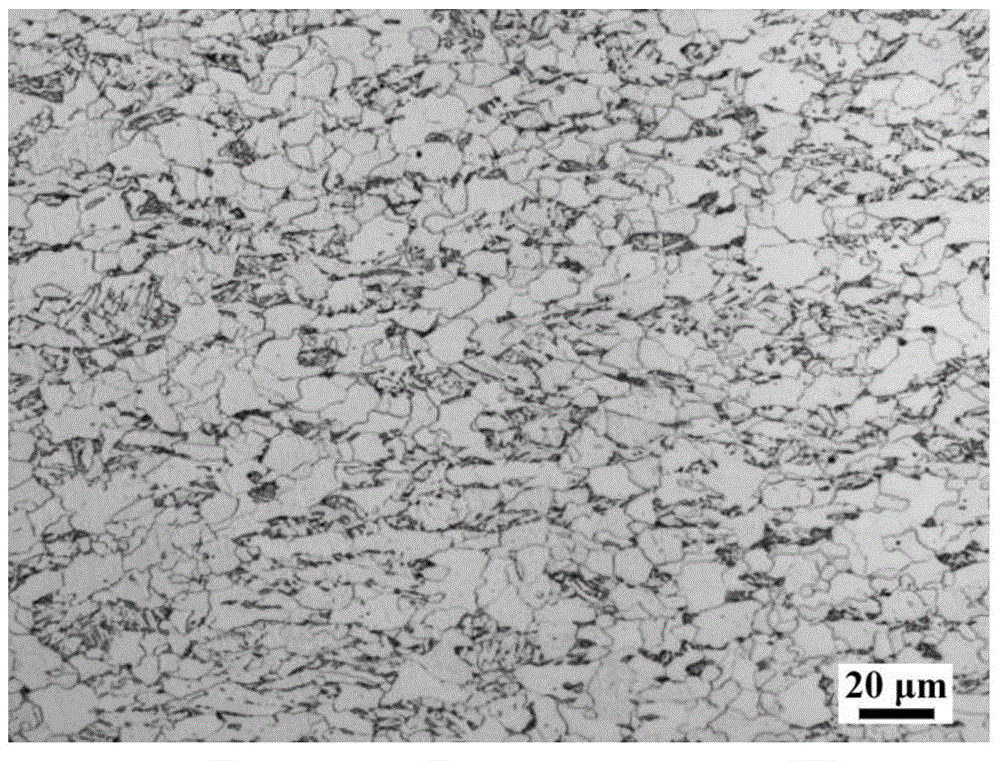

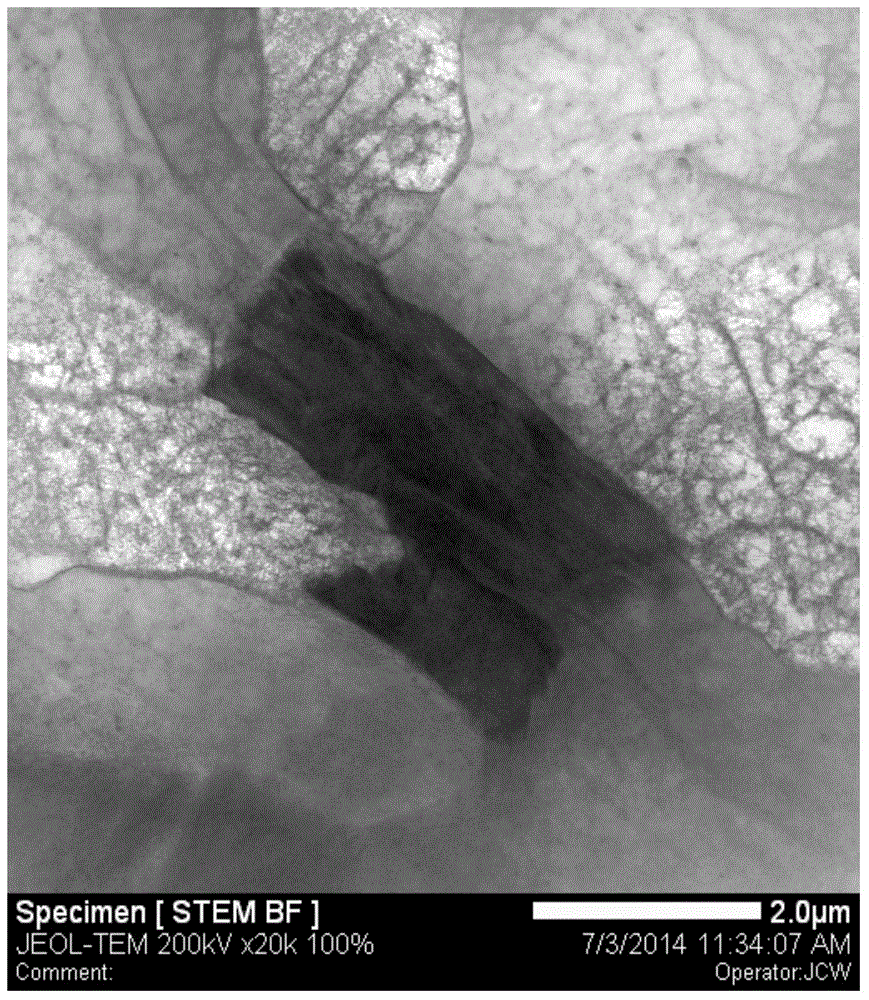

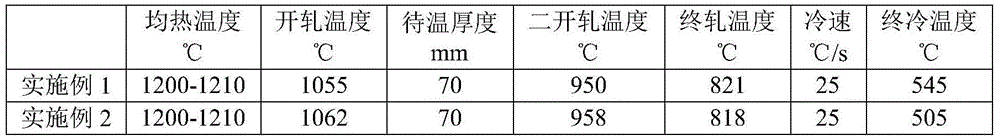

[0034]Blast furnace ironmaking → molten iron pretreatment → converter steelmaking → refining → vacuum degassing → continuous casting X65, X70 pipeline steel continuous casting slabs, after heating → descaling → controlled rolling → controlled cooling → air cooling, the main process parameters See Table 1, make wide and thick plates with a thickness of 15.9mm, the specific components of the obtained 5 numbered experimental steels and conventional X65 pipeline steel are shown in Table 2, the final structure of the embodiment is polygonal ferrite+granular bainite, as figure 1 As shown, the morphology of granular bainite was observed under the transmission electron microscope, and it was found that it was in the form of short rods, such as figure 2 The mechanical properties are shown in Table 3.

[0035] The main rolling process parameter of table 1 embodiment of the present invention and com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield ratio | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com