Patents

Literature

328 results about "In process control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In-Process Control (IPC): In-Process Control are commonly understood as checks being performed during a Production process for the purpose of monitoring and if necessary, to adjust the process to assure that the Product conforms to its specifications.

Dynamic process control

InactiveUS6907741B2Promote localizationImprove isolationFrozen sweetsConfectioneryAdditive ingredientEngineering

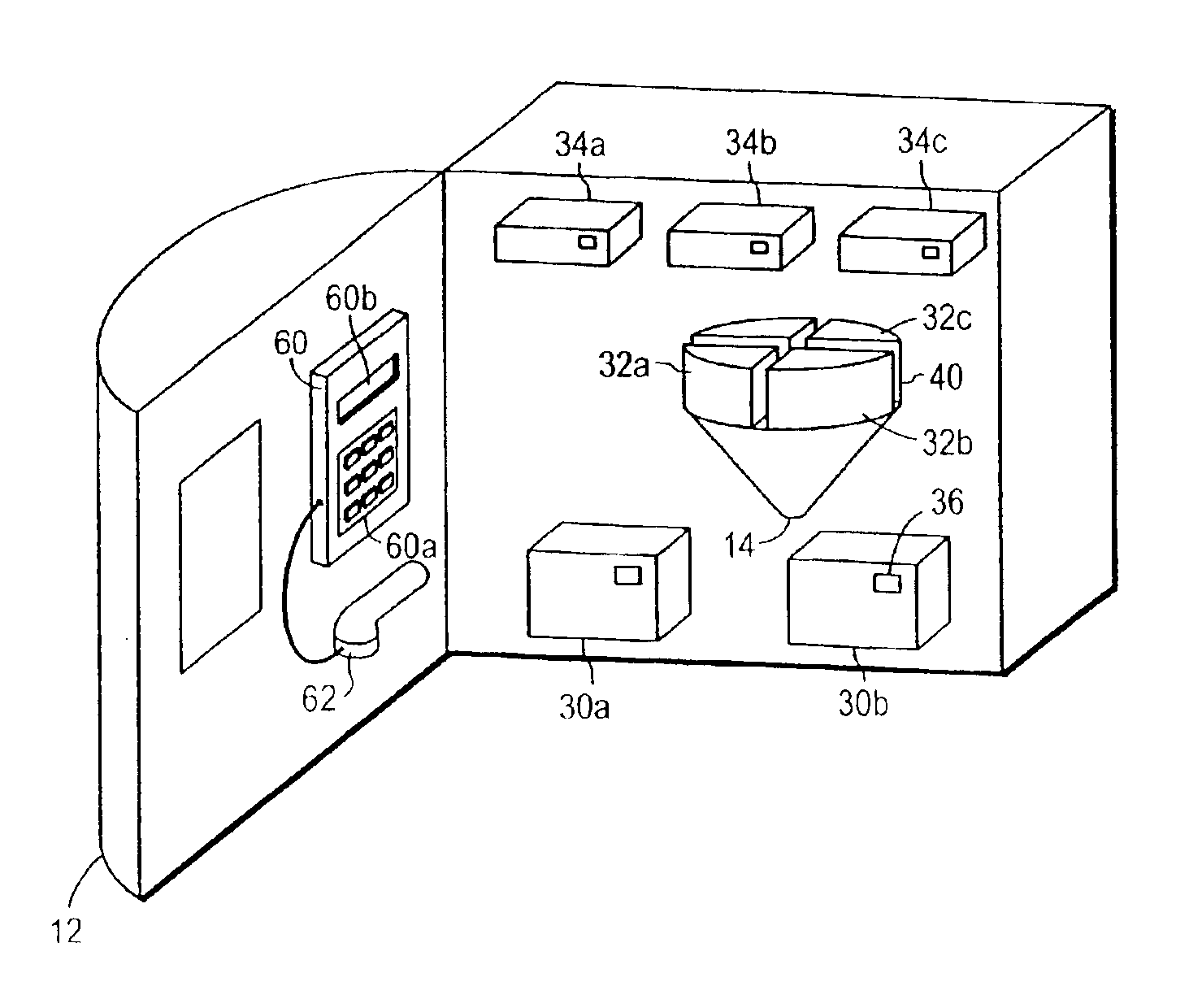

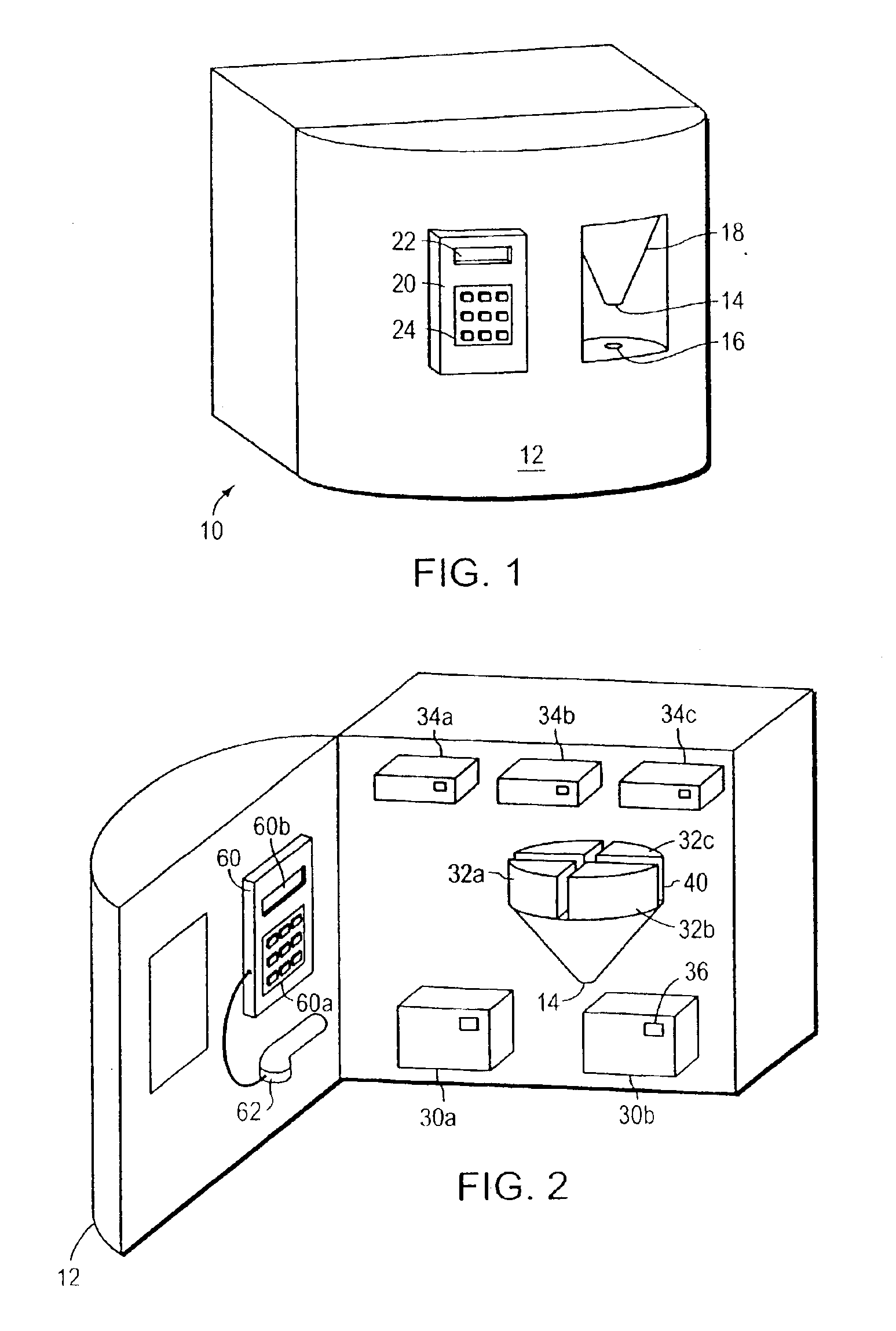

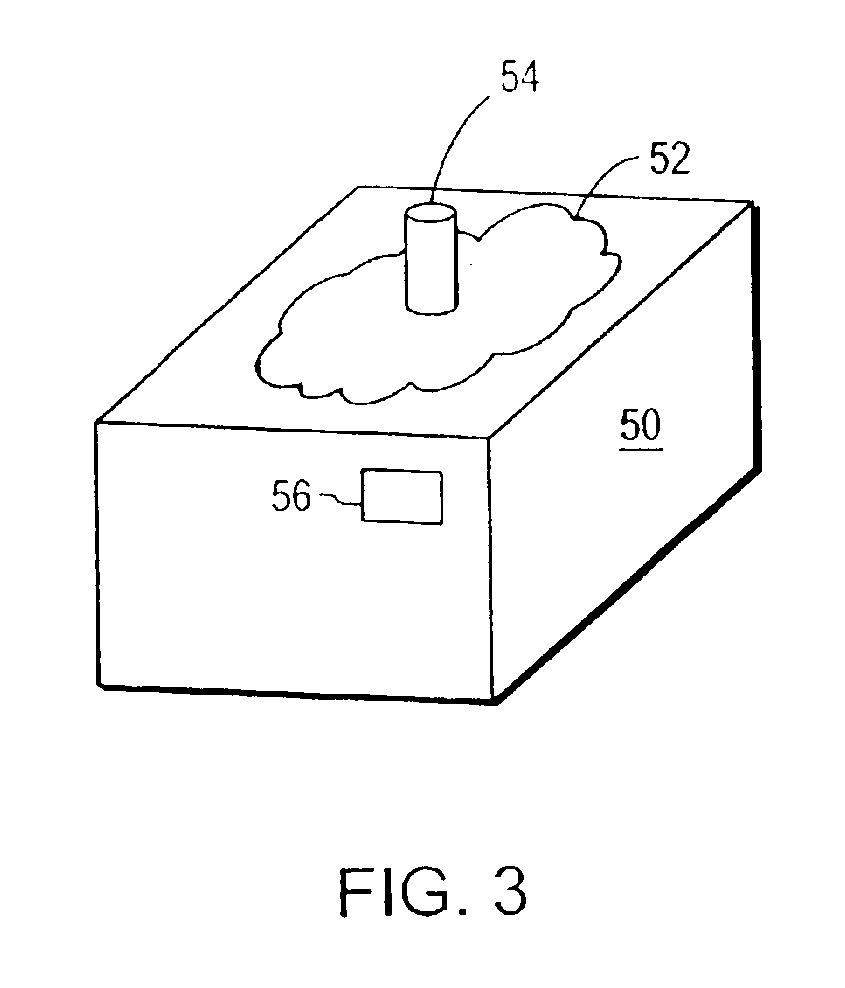

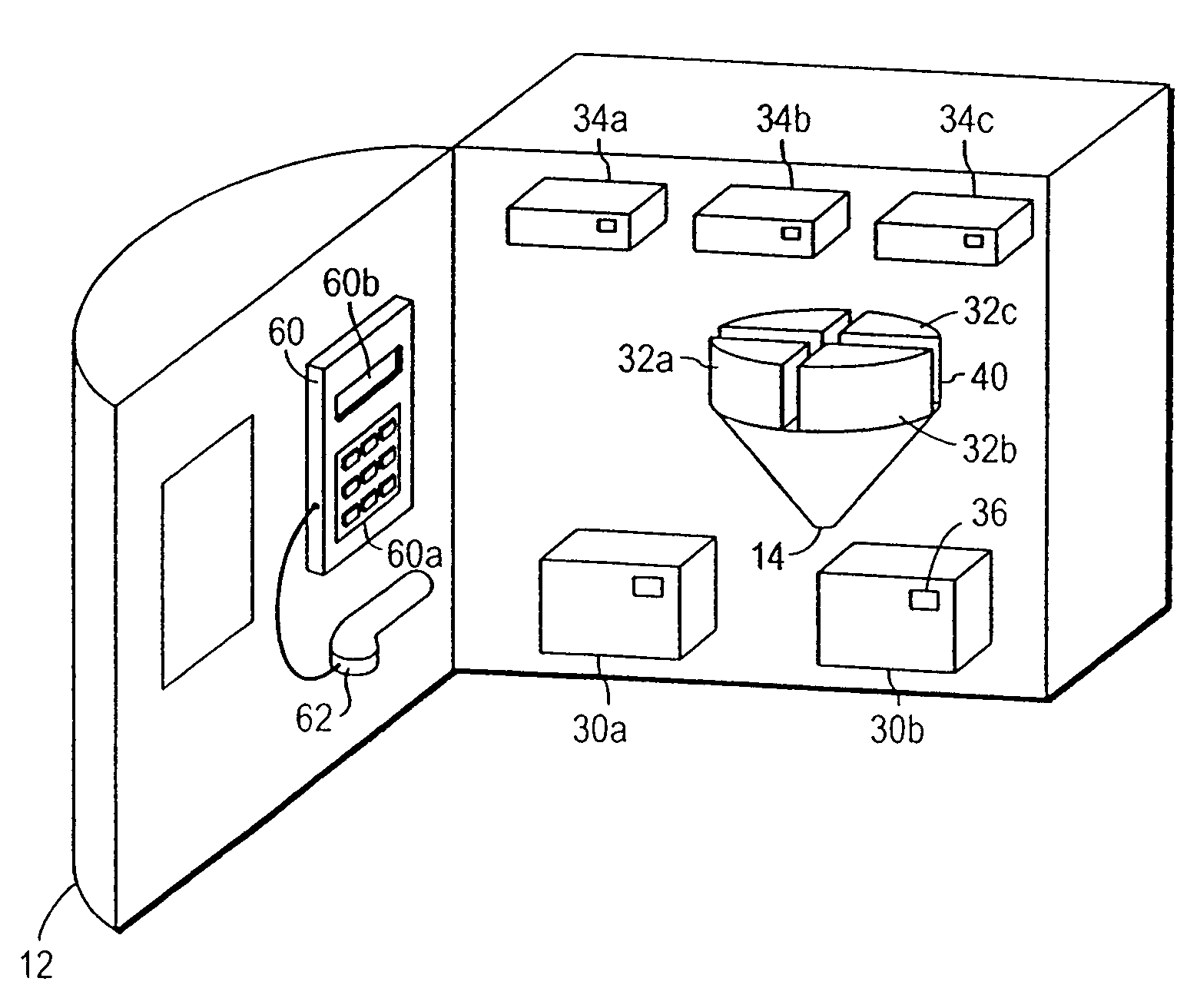

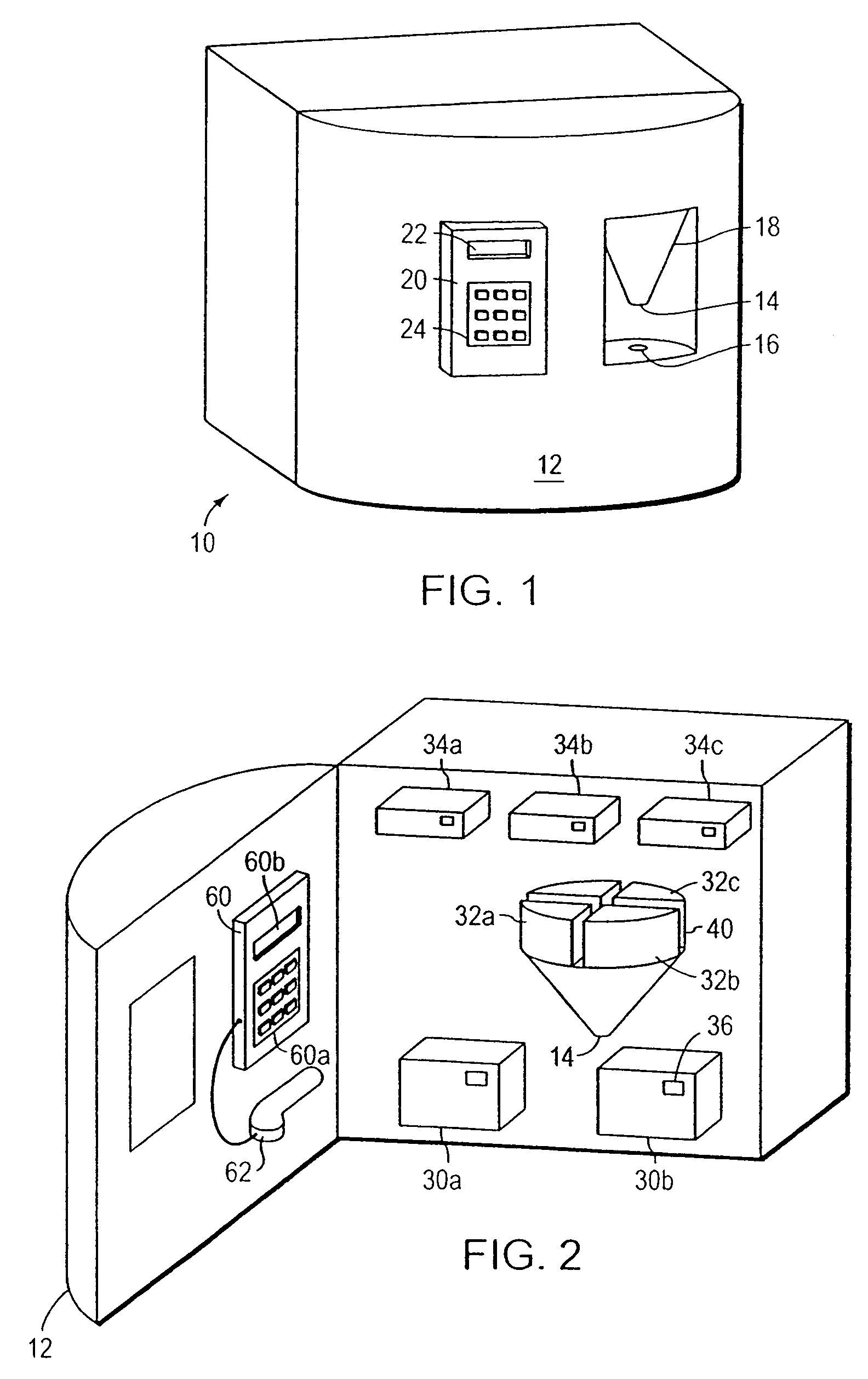

A method and apparatus for defining the processing of an ingredient of a manufactured product, particularly one that is manufactured “one-the-spot” to a consumer's specification, such as ice cream, among other products. A tag encoded on a container for the product carries indicia that, directly or indirectly, define one or more formulations for the product. Apparatus into which the ingredient is loaded sets the processing of ingredients in accordance with the formulations so specified. By connecting the apparatus which is to process the ingredients to a control station, the formulations may be changed at will.

Owner:MOOBELLA ACQUISITION +1

Method, apparatus, and article to facilitate evaluation of objects using electromagnetic energy

ActiveUS20090112101A1Low costPermit useRadiation pyrometryInertial sensorsQuality controlFinancial transaction

Spectral information may be employed in process control and / or quality control of goods and articles. Spectral information may be employed in process control and / or quality control of media, for example financial instruments, identity documents, legal documents, medical documents, financial transaction cards, and / or other media, fluids for example lubricants, fuels, coolants, or other materials that flow, and in machinery, for example vehicles, motors, generators, compressors, presses, drills and / or supply systems. Spectral information may be employed in identifying biological tissue and / or facilitating diagnosis based on biological tissue.

Owner:VISUALANT

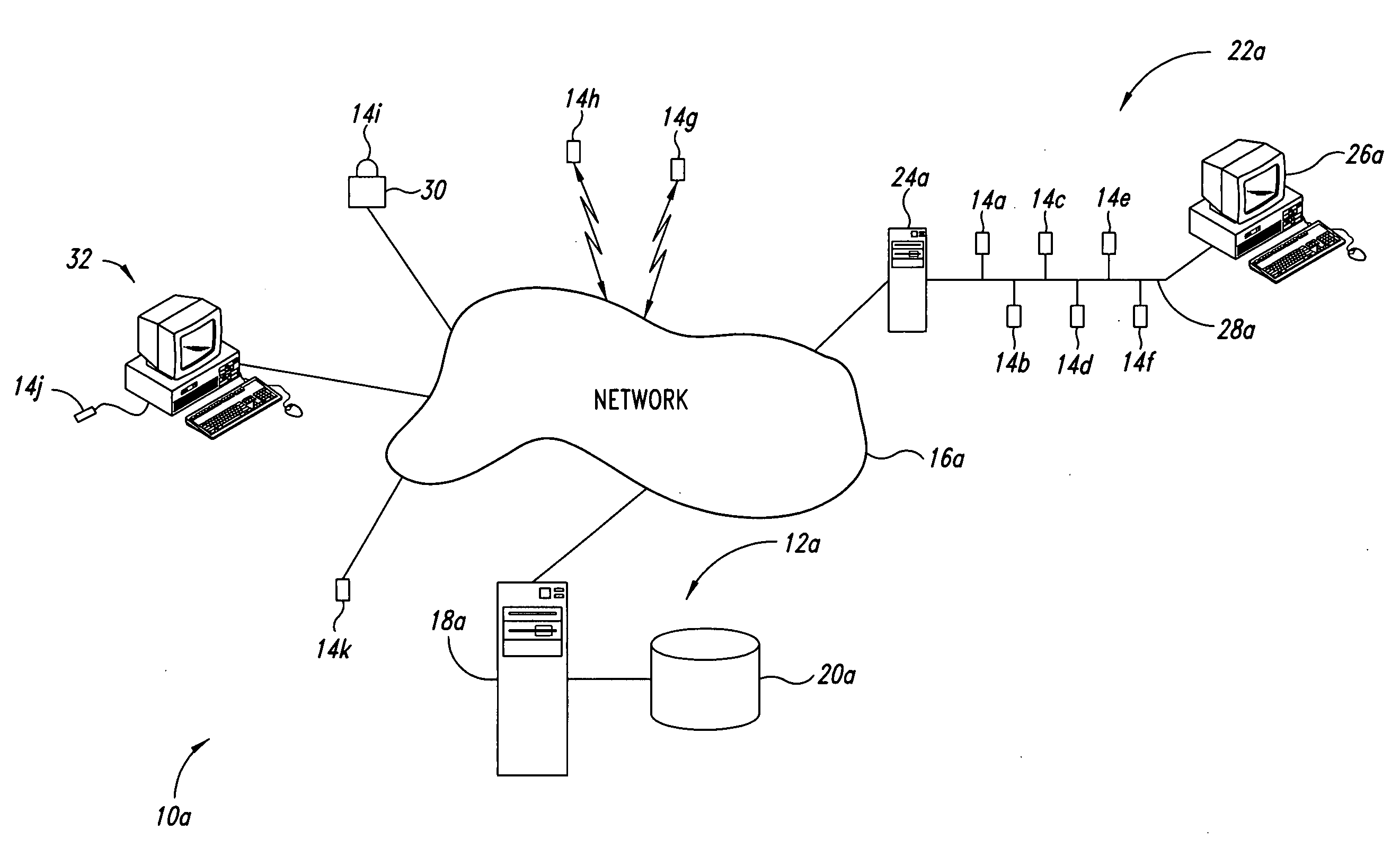

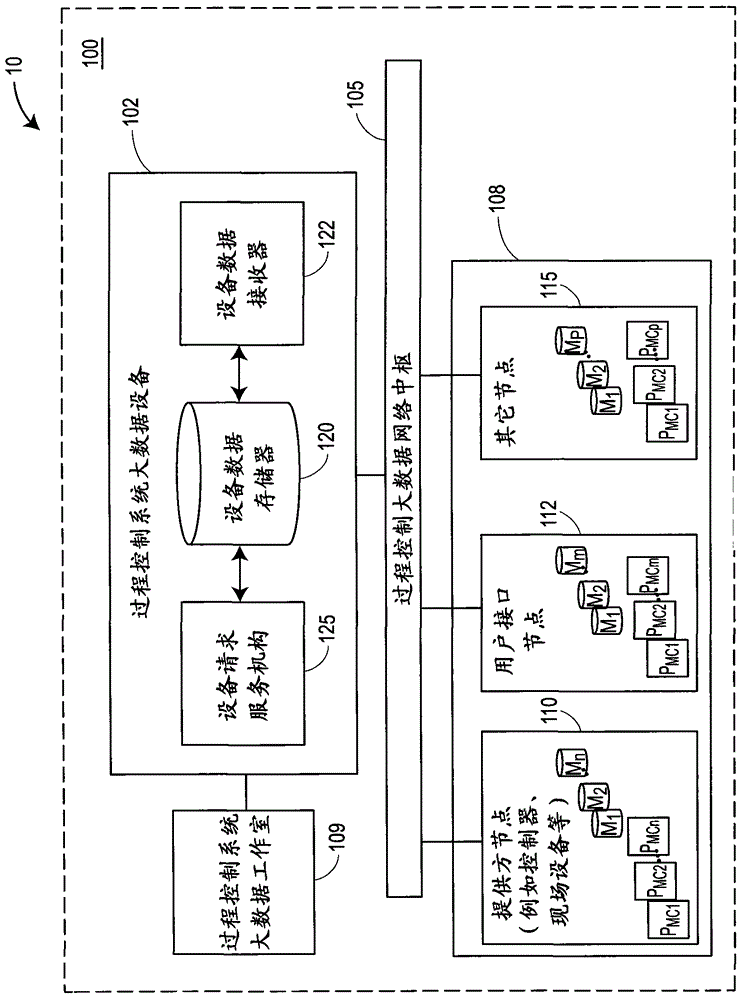

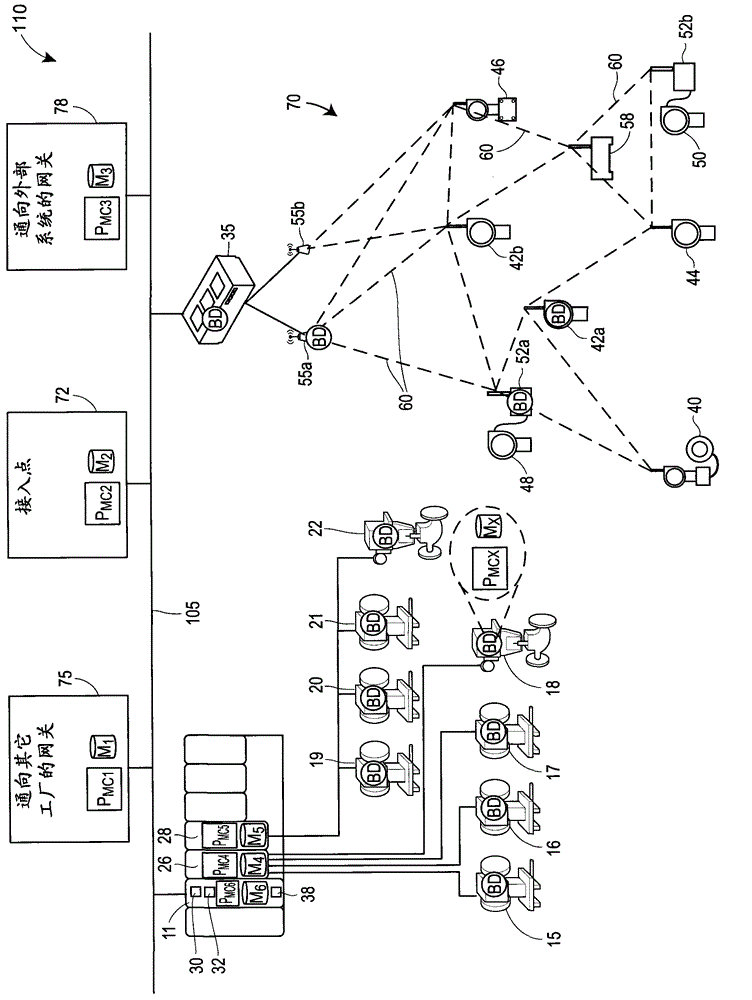

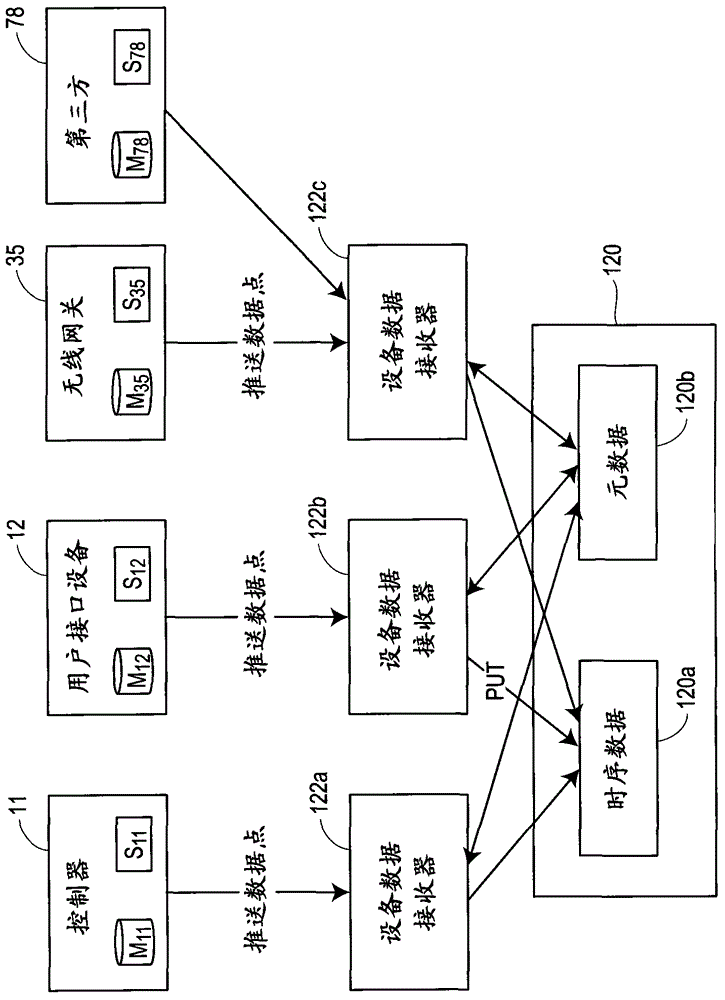

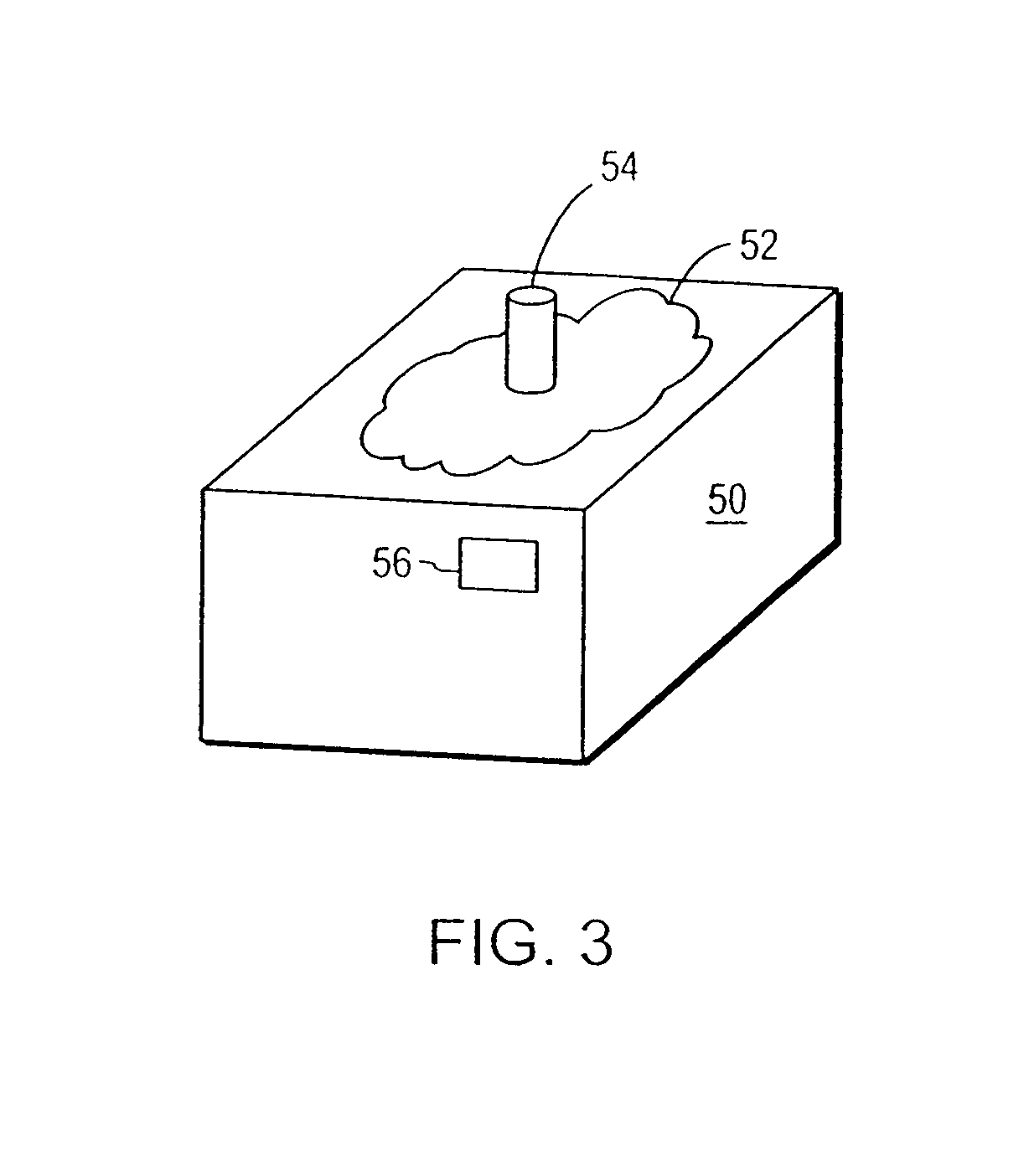

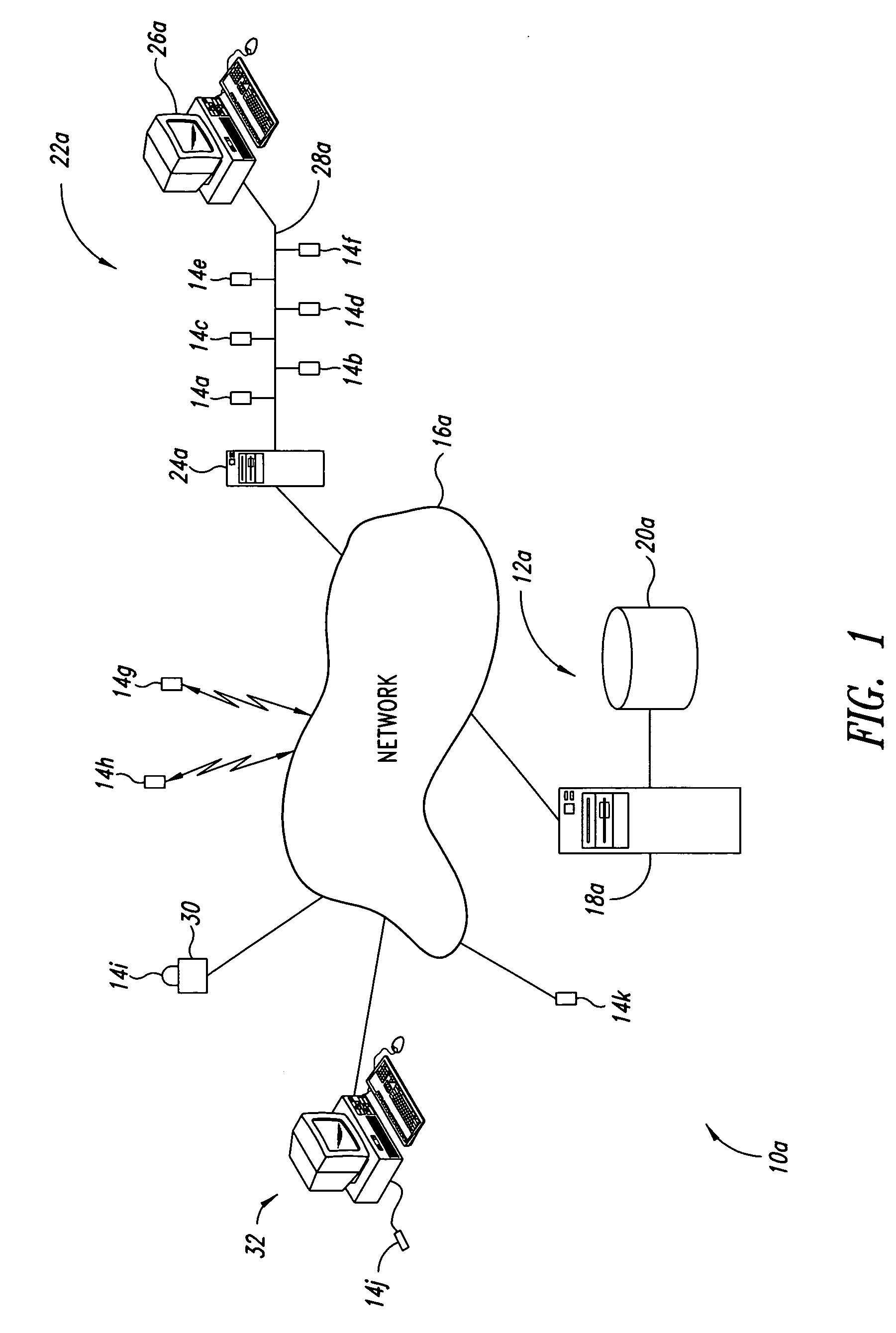

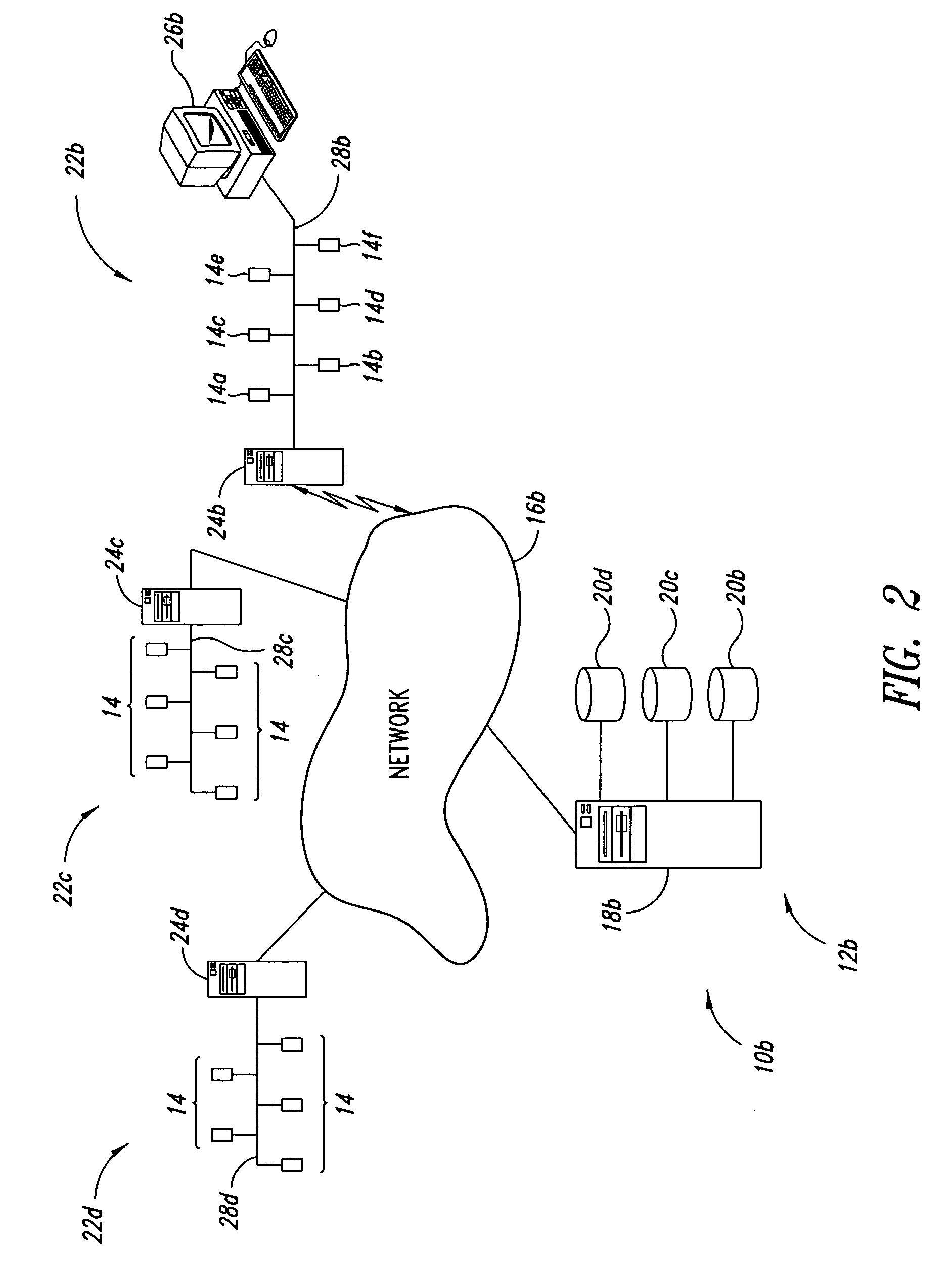

Big data in process control systems

A big data network for a process control system or plant includes a big data apparatus including a data storage area configured to store, using a common data schema, multiple types of process data and / or plant data such as configuration and real-time data. Data receiver computing devices receive the data from multiple nodes or devices. The data may be cached and time-stamped at the nodes and streamed to the big data apparatus for storage. The process control system big data system provides services and / or data analyses to automatically or manually discover prescriptive and / or predictive knowledge, and to determine, based on the discovered knowledge, changes and / or additions to the process control system and to the set of services and / or analyses to optimize the process control system or plant.

Owner:FISHER-ROSEMOUNT SYST INC

Dynamic process control

A method and apparatus for defining the processing of an ingredient of a manufactured product, particularly one that is manufactured “one-the-spot” to a consumer's specification, such as ice cream, among other products. A tag encoded on a container for the product carries indicia that, directly or indirectly, define one or more formulations for the product. Apparatus into which the ingredient is loaded sets the processing of ingredients in accordance with the formulations so specified. By connecting the apparatus which is to process the ingredients to a control station, the formulations may be changed at will.

Owner:MOOBELLA ACQUISITION +1

Information processing device, process control method, and computer program

InactiveUS20050278719A1Avoid it happening againAvoid processing overheadProgram initiation/switchingSoftware simulation/interpretation/emulationInformation processingOperational system

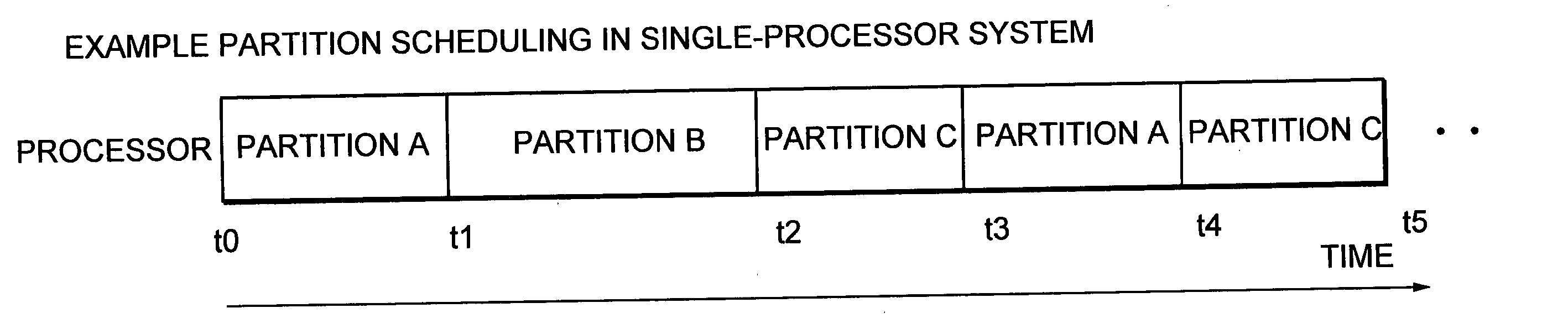

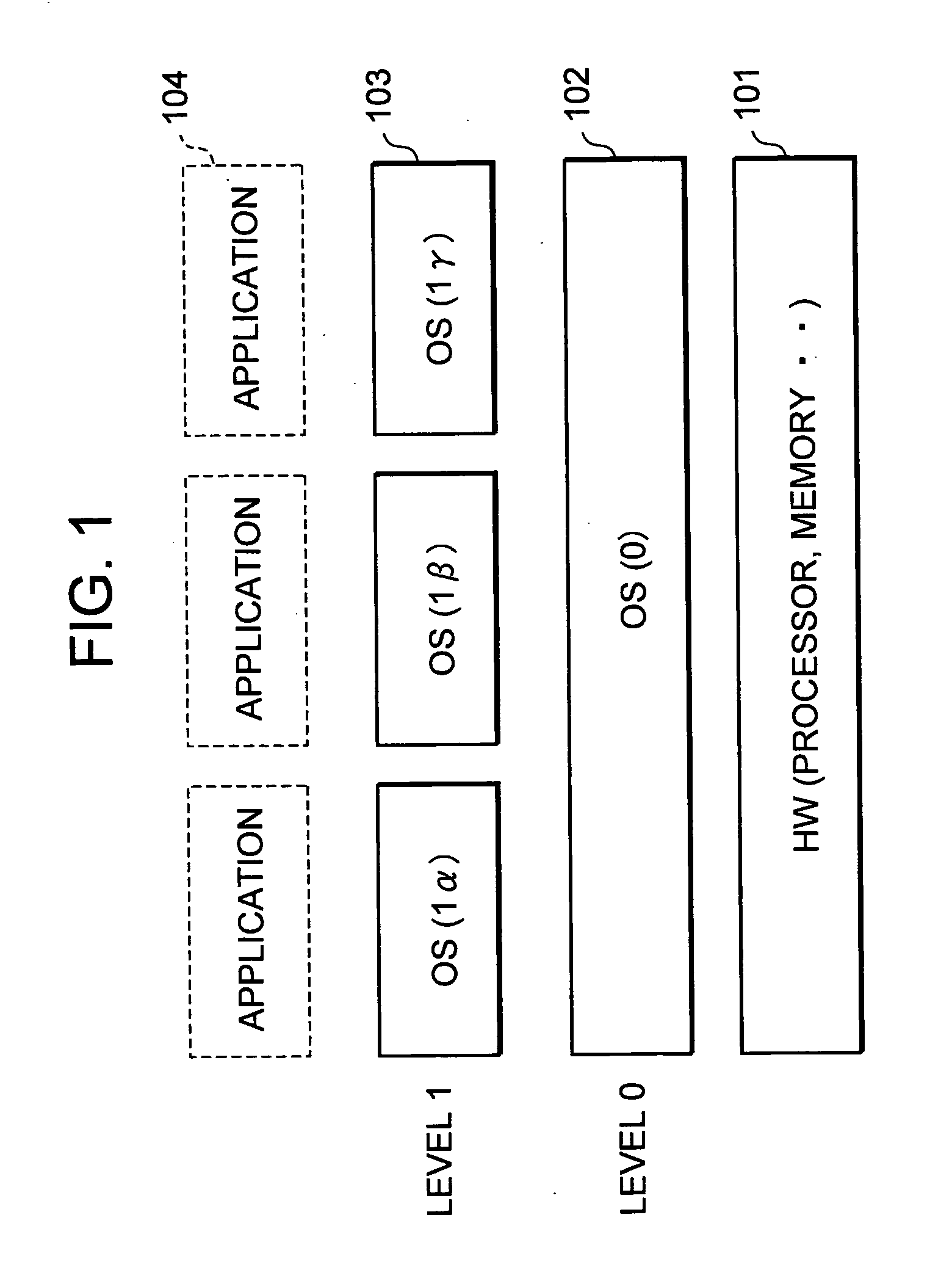

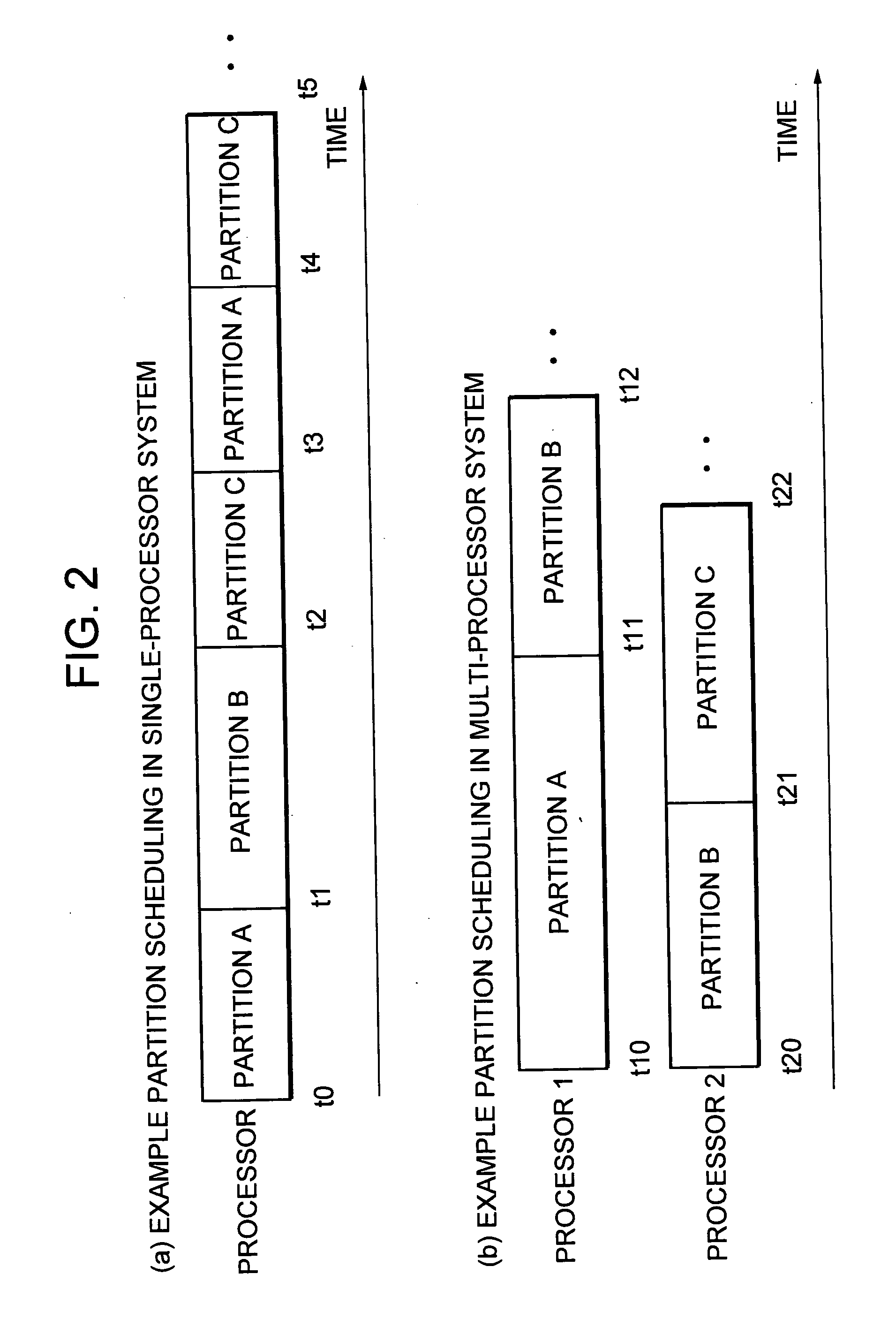

In process control based on partition setting which is a process corresponding to a plurality of operating systems (OSs), a configuration is implemented in which an interrupt request can be processed efficiently. In process control for switching processes which are based on the plurality of OSs, it is configured to set an interrupt processing partition as an interrupt processing execution period corresponding to an interrupt processing request so as to coincide with a pre-set partition switching timing. Further, a processing schedule is set, taking a maximum allowable delay time, a minimum allowable delay time into account. As a result of the present configuration, an increment in the number of partition switching processes can be kept to 1, and thus efficient data processing becomes possible.

Owner:SONY CORP

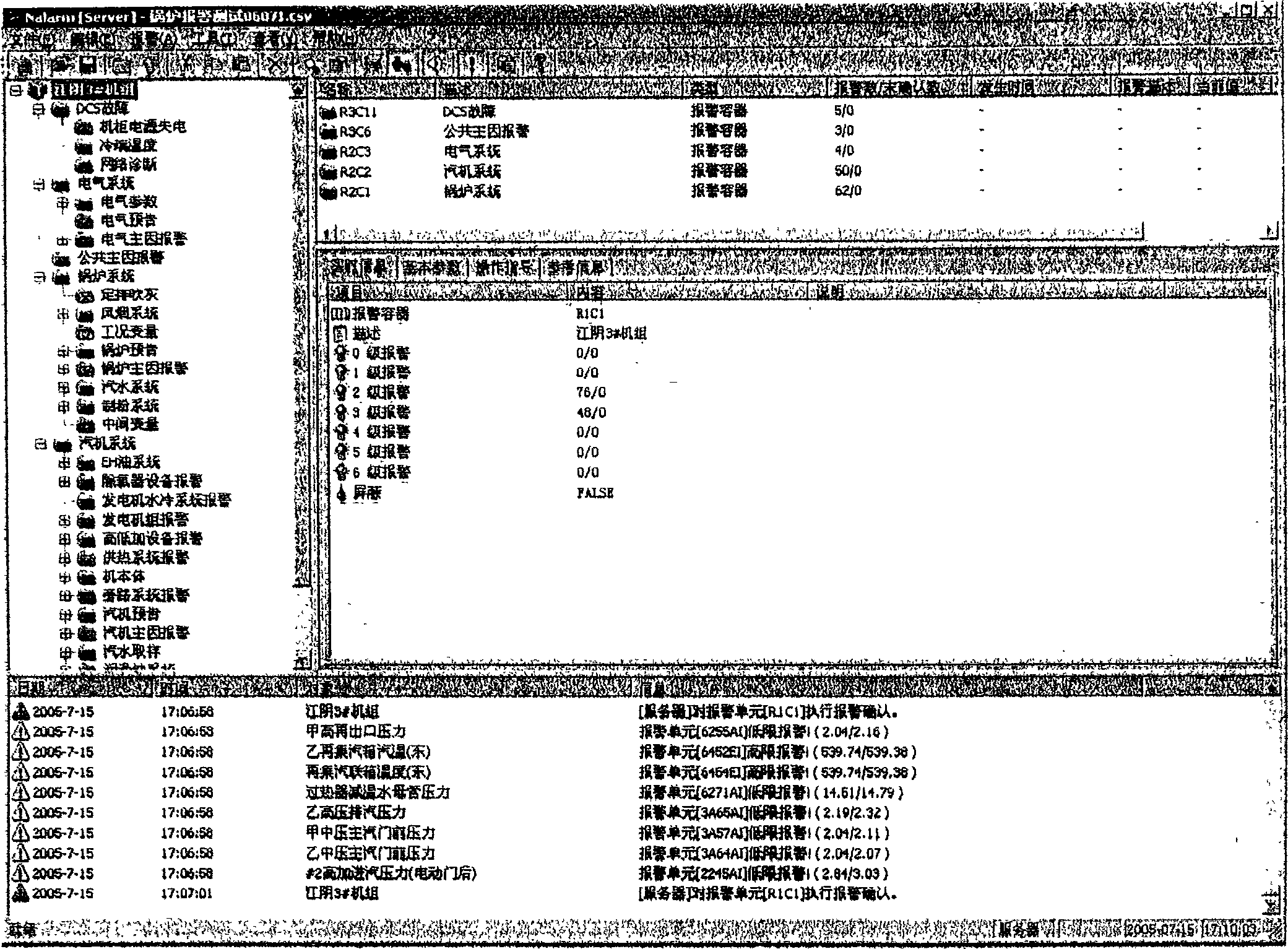

Setting method for fault diagnosis and accident prediction

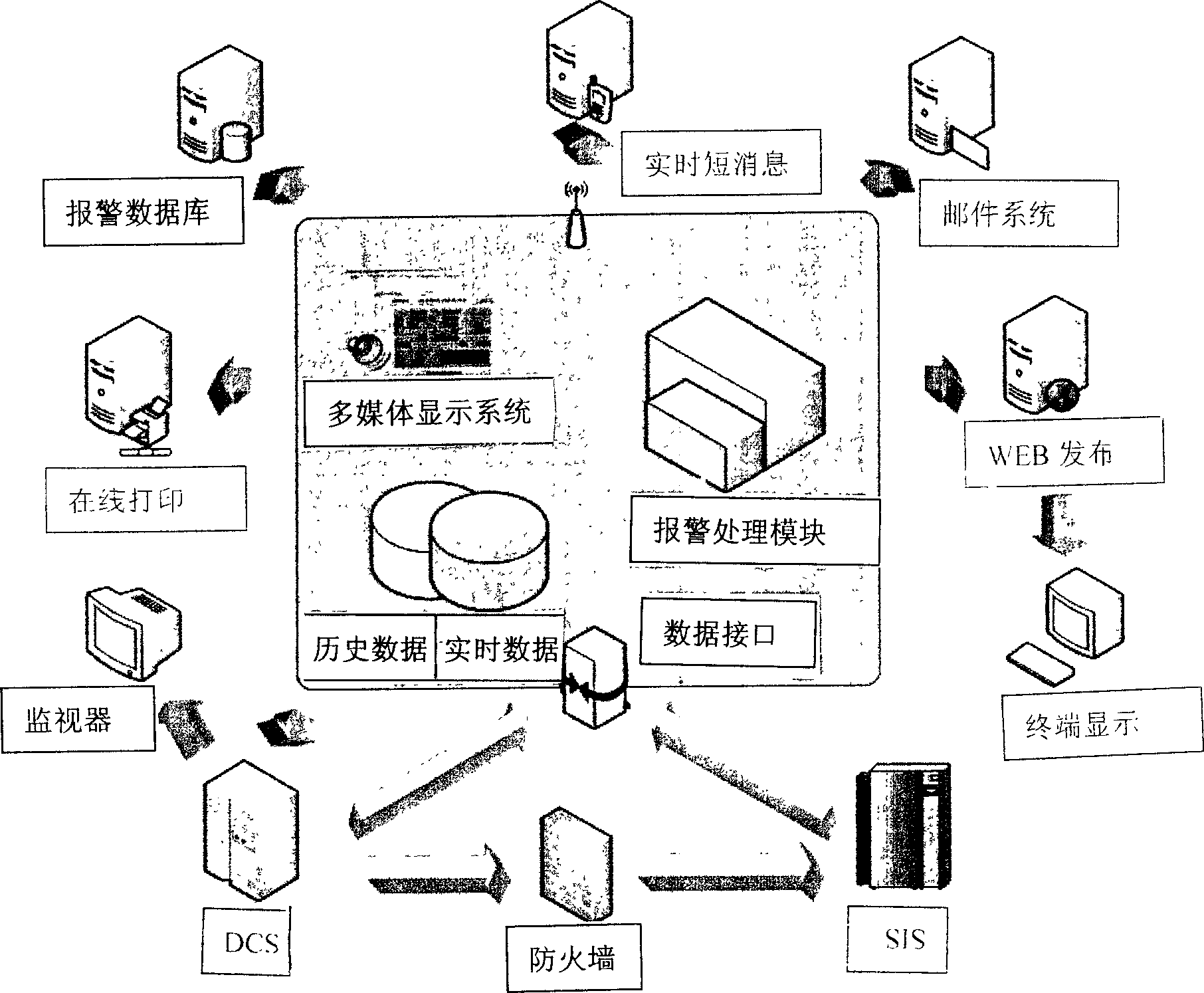

ActiveCN1845029AIncrease trustRelieve pressureTesting/monitoring control systemsReal-time dataControl system

The invention relates to a method for setting accidence diagnose and accidence prediction, which comprises a real-time data interface and a processing module. It provides many kinds of data interfaces to collect and treat data. Wherein, the accidence diagnose and accident prediction module can real-time detect the state of device, and diagnose accidence to alarm and give treating advice; the process detecting, accidence diagnose, accidence analysis and prediction are based on real-time data, that used in process control system; it uses the real-time and history database system modules to provide to the data service of alarm processing module, and provide the quick search of real-time and history data via function type; the alarm unit comprises an alarm operation function treating unit, an alarm container and an alarm manage unit. The invention can integrate the process detection, accidence diagnose, accidence analysis prediction and on-line operation instruction.

Owner:南京科远智慧能源投资有限公司

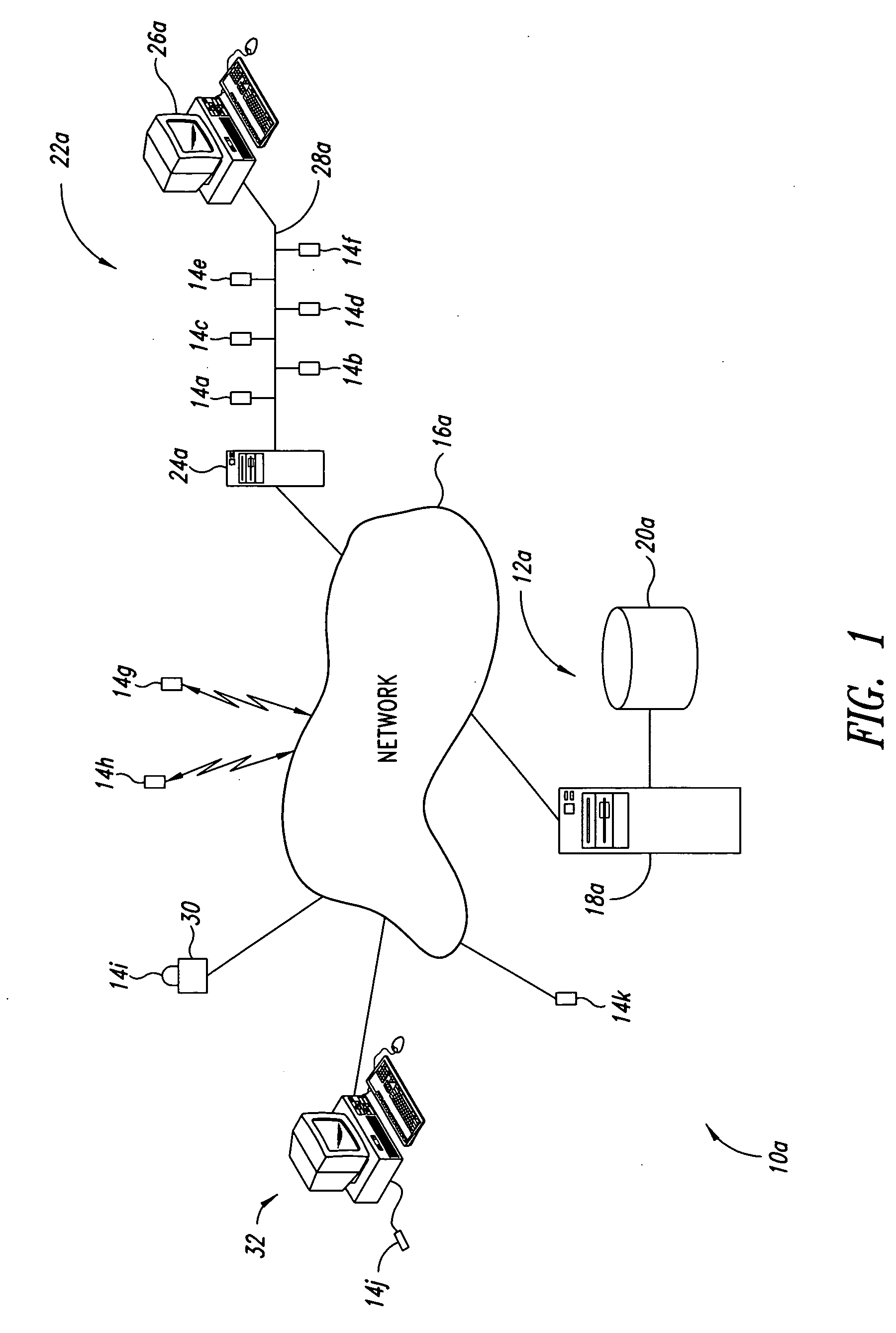

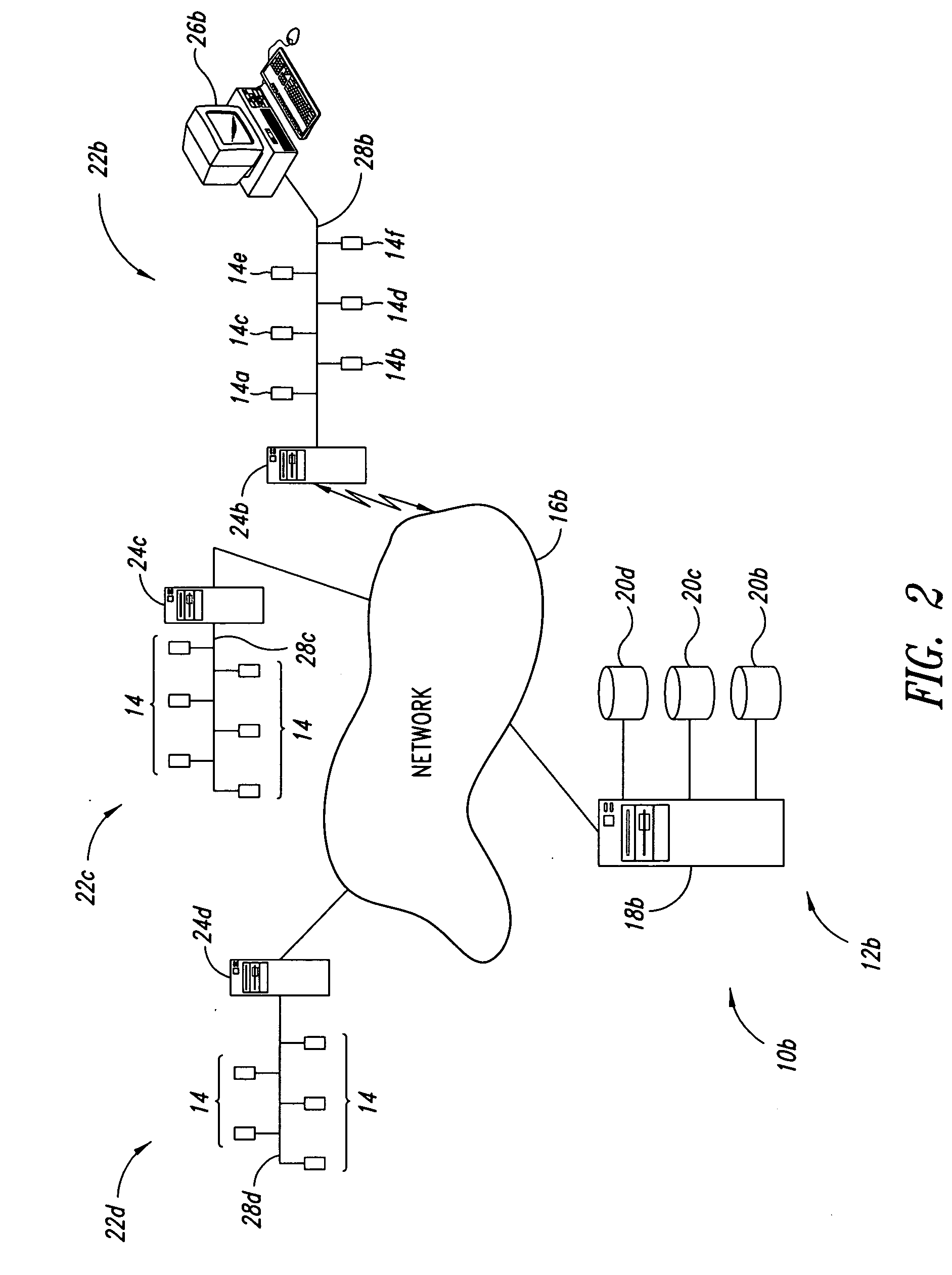

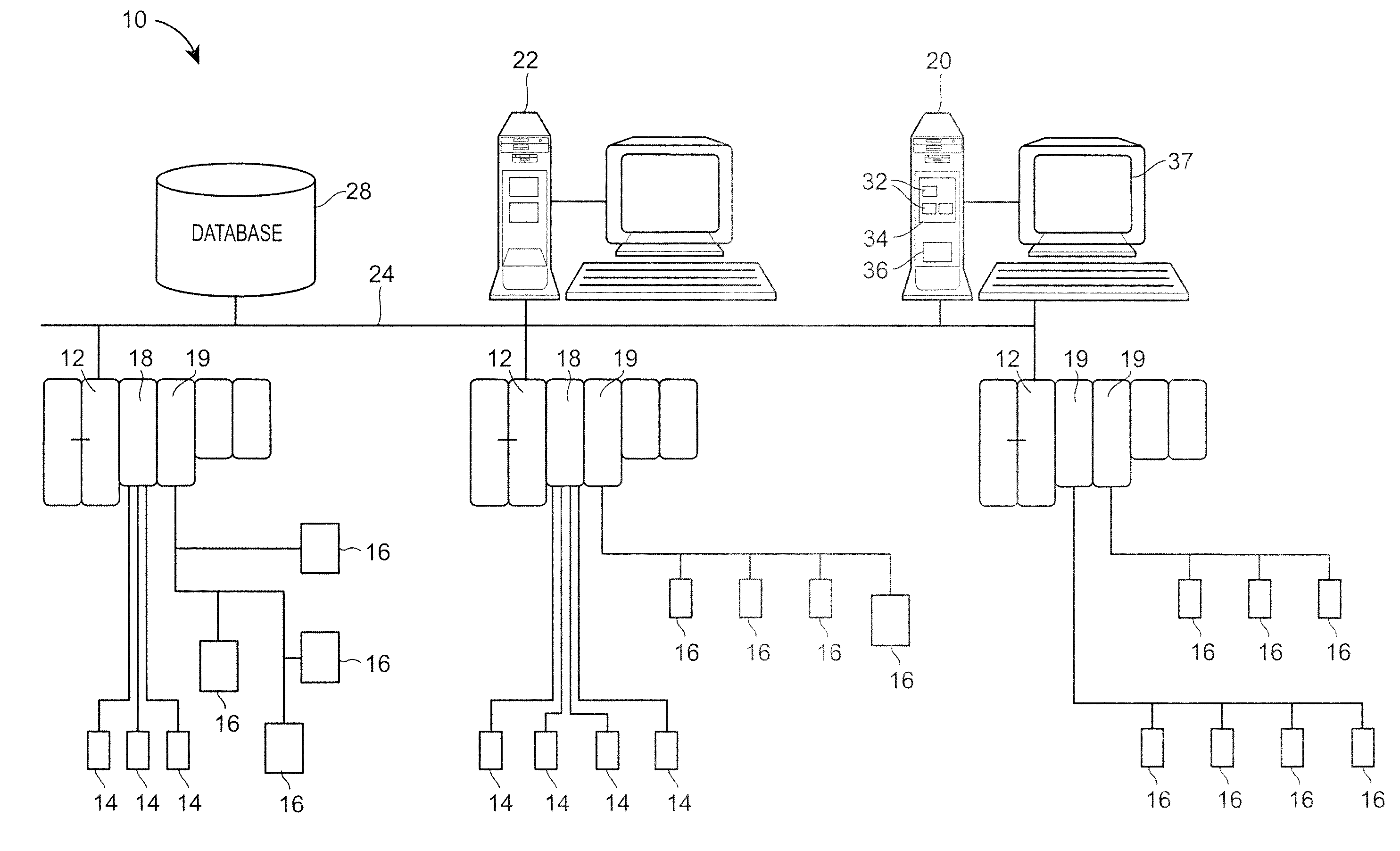

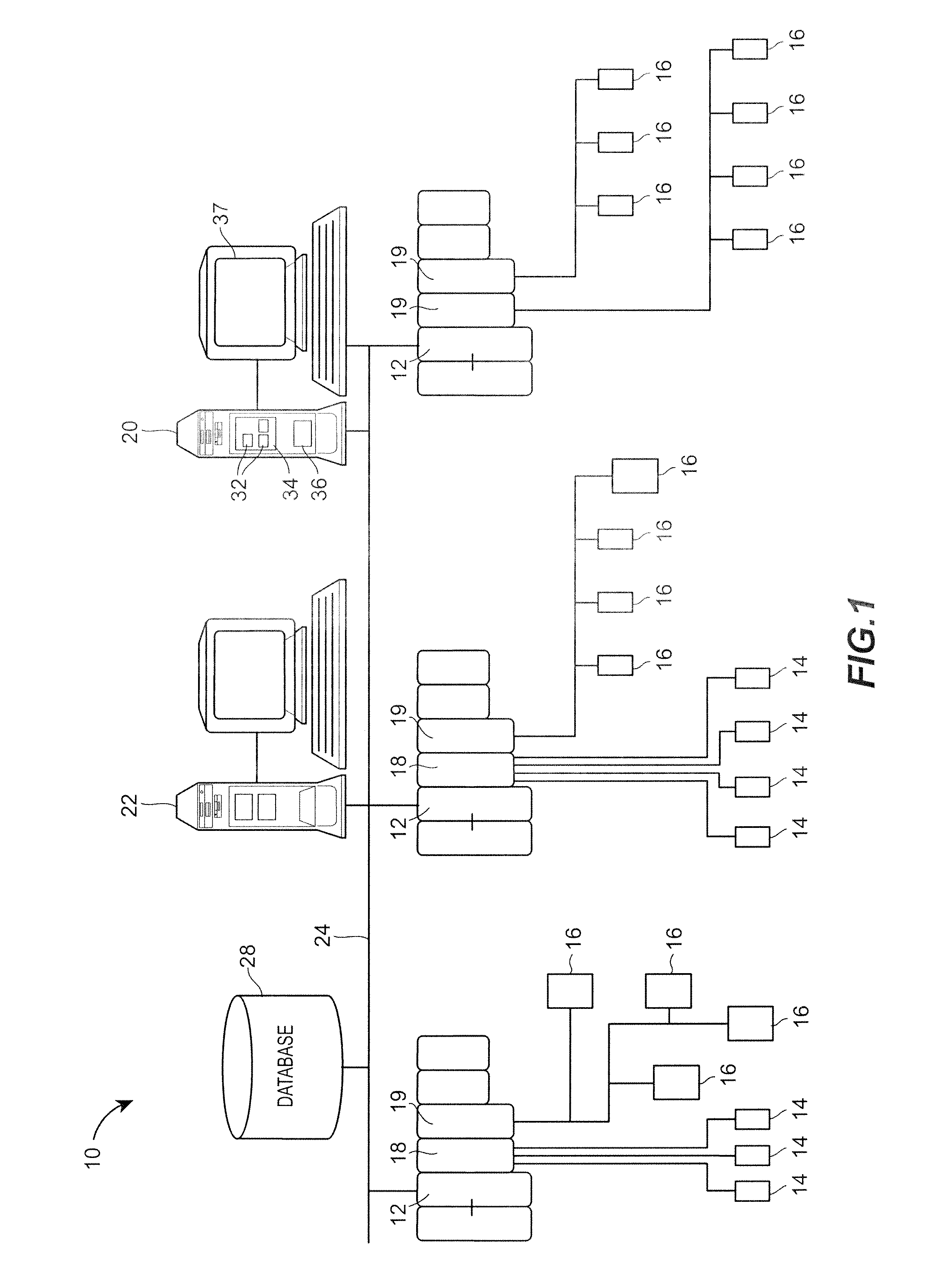

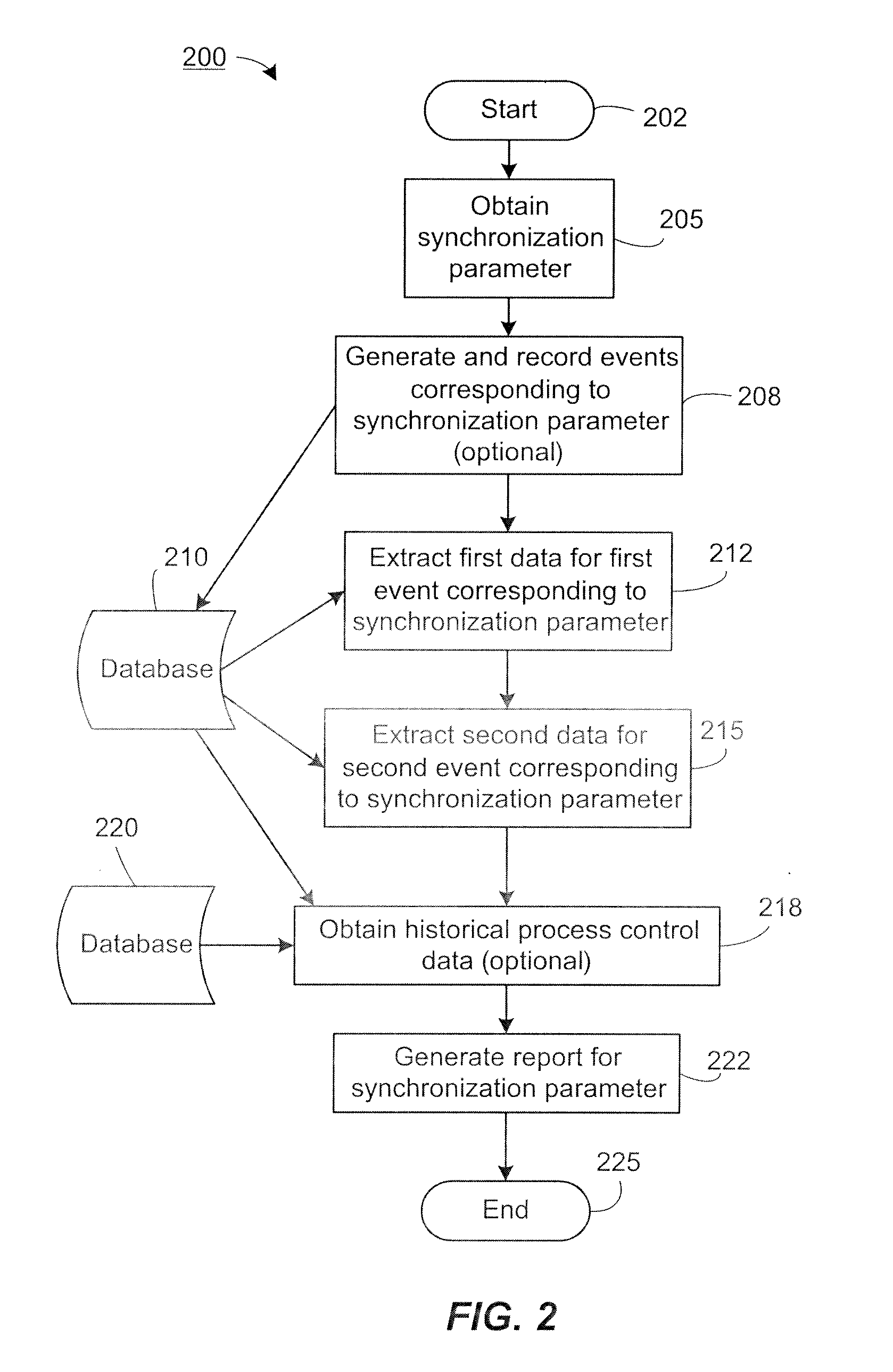

Event Synchronized Reporting in Process Control Systems

InactiveUS20100082396A1Complete banking machinesRegistering/indicating time of eventsEvent synchronizationControl system

Methods, systems, and computer-executable instructions for event synchronized reporting in an process control system are disclosed. Events may be synchronized by a synchronization parameter, whose instances of occurrence may be non-contiguous in time. Examples of synchronization parameters may include a work shift, a work group, an individual's on-duty time, a logged-on period of an individual, the execution times of a process control entity, a batch run type, and a procedure or sub-unit of a batch run. Instances of occurrence of the synchronization parameter may be recorded into a process control event database. Event synchronized reports may contain at least one synchronization value based on both the instances of occurrence of the synchronization parameter as well as historical process control data. Data from various historian databases may be accessed from process control system tools and integrated into a single report.

Owner:FISHER-ROSEMOUNT SYST INC

Production method of core-shell hierarchical structure porous carbon

The invention belongs to the technical field of carbon material production and relates to a production method of core-shell hierarchical structure porous carbon. The production method based on a metal organic frame is characterized in that polymer monomer containing nitrogen polymerizes on the surface of the hollow metal organic frame to form a core-shell structure, calcination is controlled to obtain the core-shell hierarchical porous carbon, the core is nanoscale hollow hierarchical porous carbon, and the shell is nitrogen-doped carbon. The core-shell hierarchical structure porous carbon has a hierarchical duct structure, nanoscale particle size and high conductivity. The method is simple, easy in process control, widely applicable to electrochemical fields such as super-capacitors, capacitive desalting and lithium ion battery.

Owner:SHANGHAI UNIV

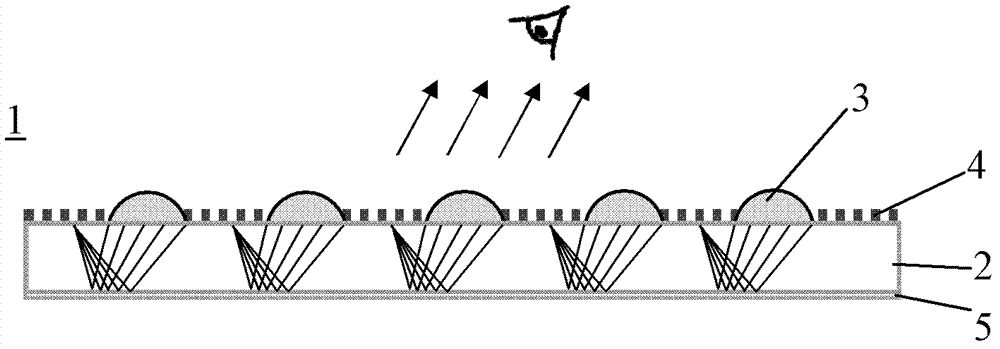

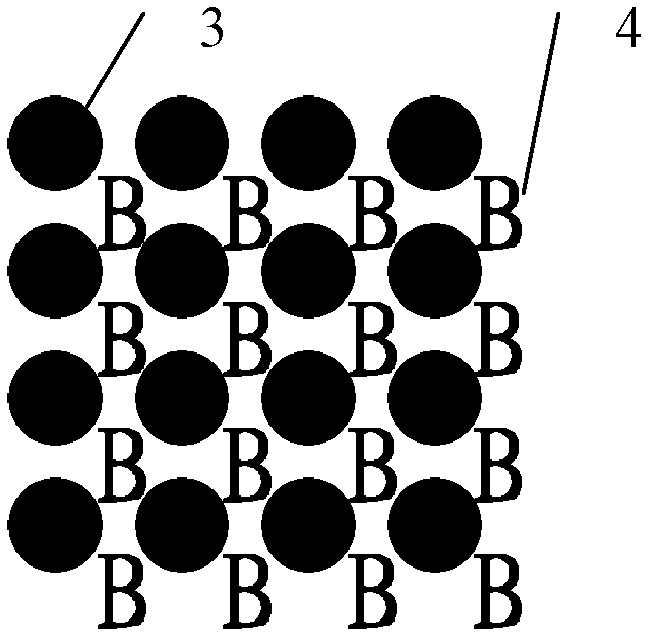

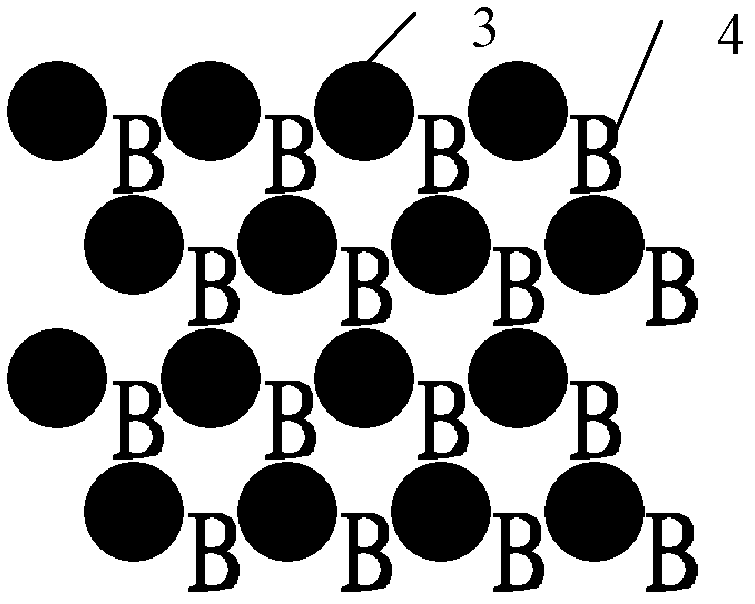

Optical anti-fake element and products utilizing same

ActiveCN103358808AStrict Alignment GuaranteeStrong process controllabilityLight effect designsLensState of artGraphics

The invention aims to overcome defects that in prior art, the optical anti-counterfeiting element is difficult in production, complicated in process and low in process control and strict alignment of the micro graphics array and the micro lens array can't be guaranteed during the production, and provides an optical anti-counterfeiting element and products utilizing the same. The optical anti-fake element comprises base material, a micro relief structure which is arranged on a first surface of the base material and at least partially covers the first surface of the base material, and a reflecting layer which is arranged on a second surface of the base material and at least partially covers the second surface of the base material. The micro relief structure comprises a micro lens array and a micro graphics array which is embedded in the micro lens array and is in the same plane with the micro lens array but is not overlapped with the micro lens array. The micro lens array is capable of sampling and synthesizing the micro graphics array through the reflecting layer so as to produce represented images.

Owner:ZHONGCHAO SPECIAL SECURITY TECH +1

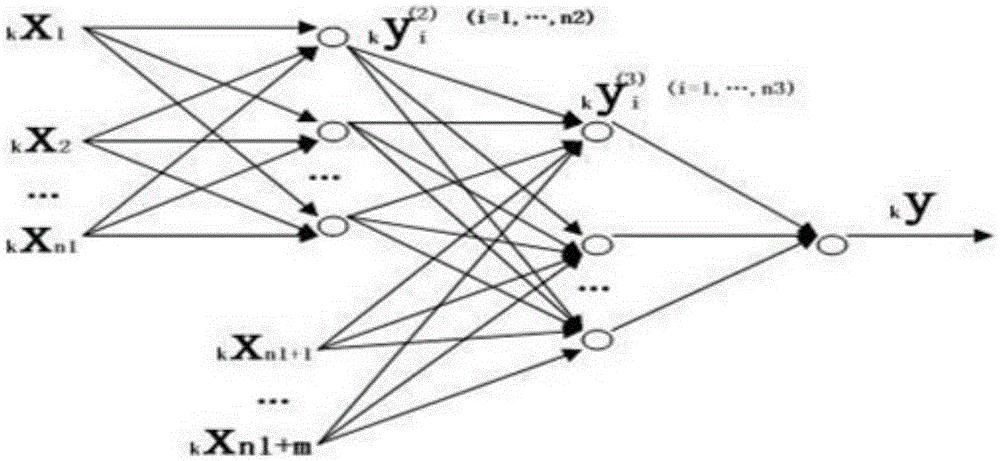

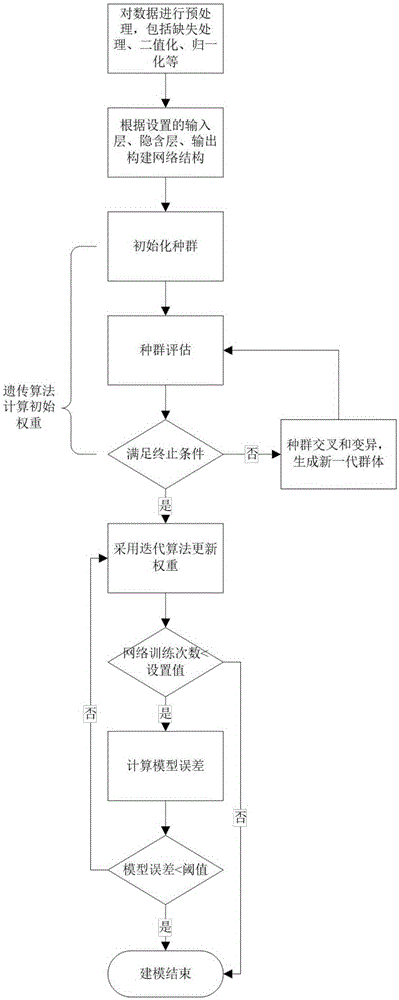

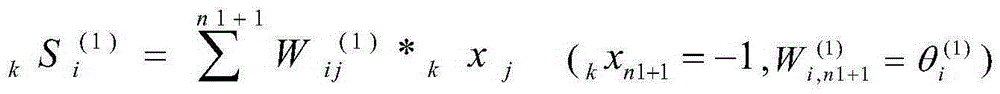

Multi-stage nerve network model training method based on genetic algorithm

The invention relates to a multi-stage nerve network model training method based on a genetic algorithm. The multi-stage nerve network model training method is technologically characterized by comprising the steps of preprocessing data for eliminating the physical dimension effect of a field; constructing a multi-input-layer network structure according to the number of nodes in an input layer, the number of nodes in a hidden layer and the number of nodes in an output layer; training an initial weight and a threshold by means of the genetic algorithm; updating the weight by means of an iterative algorithm; determining whether a model termination condition is satisfied according to the number of iteration times and a model error, terminating the model if the model termination condition is satisfied, and otherwise updating the weight again. According to the multi-stage nerve network model training method, a multi-stage nerve network structure is constructed for aiming at a problem that parameters in process control are periodical and deteriorate output. According to a fact that the genetic algorithm has a global searching characteristic, the multi-stage nerve network model training method is used for selecting a group of relatively reasonable initial weight for the network structure, thereby preventing local minimum point in network training, and settling a problem that the nerve network structure with only one input layer cannot settle a problem of product processing speed reduction caused by incapability of settling the parameters in a time sequence in engineering control.

Owner:NAT COMP NETWORK & INFORMATION SECURITY MANAGEMENT CENT +1

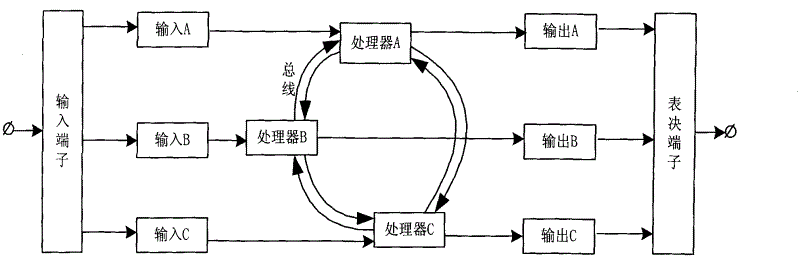

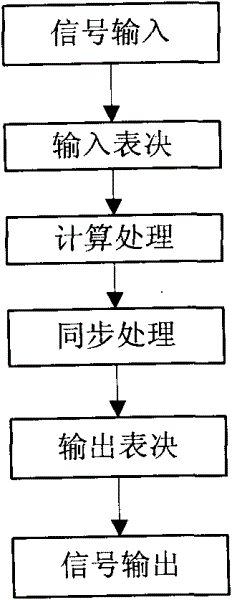

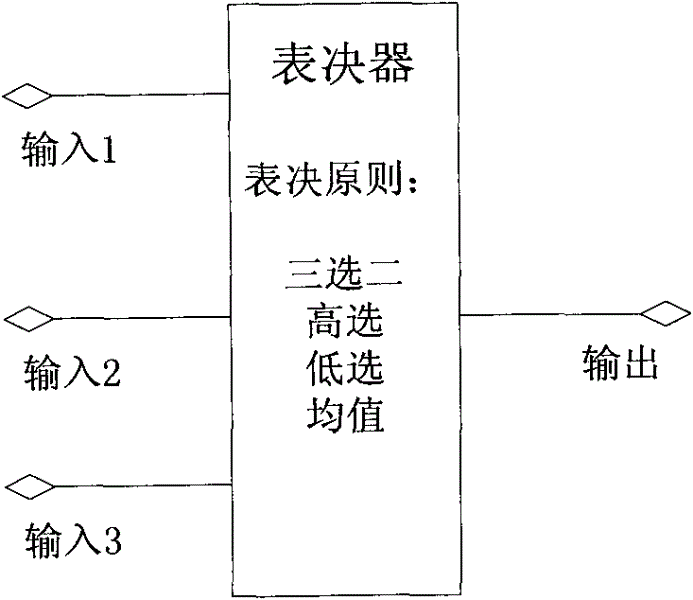

Triple redundancy control system in process control and method thereof

InactiveCN102621938AWork reliablyEnsure safetyTotal factory controlProgramme total factory controlControl systemComputer module

The invention discloses a triple redundancy control system in process control and a method thereof. The system comprises three independent processors. The processors are connected with each other through a bus. The control system also comprises one output vote terminal which is connected with the three processors and is used to vote three processor output taken as voting input. Each processor comprises: one input voting module, which is used for the each processor to carry out input voting on the obtained three path input respectively; one calculation processing module, which is used for the each processor to carry out calculation according to a preset control logic respectively after the input voting, and adding 1 to respective cycle count after the calculation; one synchronous processing module, which is used for carrying out comparison taking a master processor as a reference, and sending the synchronization information to a slave processor after the main processor completes calculation. In the invention, by using a synchronization mechanism, a voting mechanism and a master-slave switching mechanism, high reliability and high security of the system can be guaranteed.

Owner:SHANGHAI XINHUA CONTROL TECH GROUP

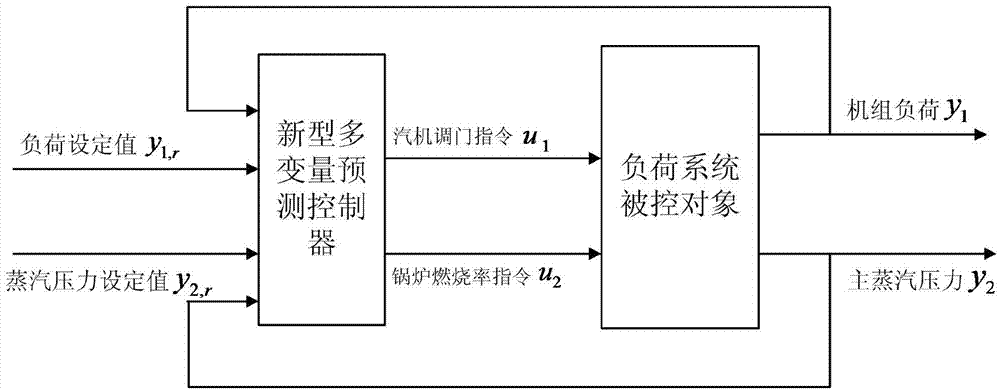

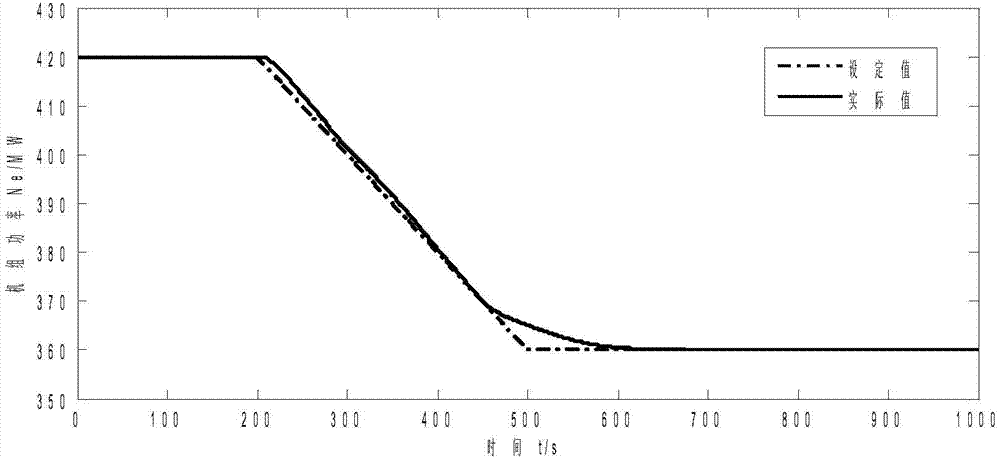

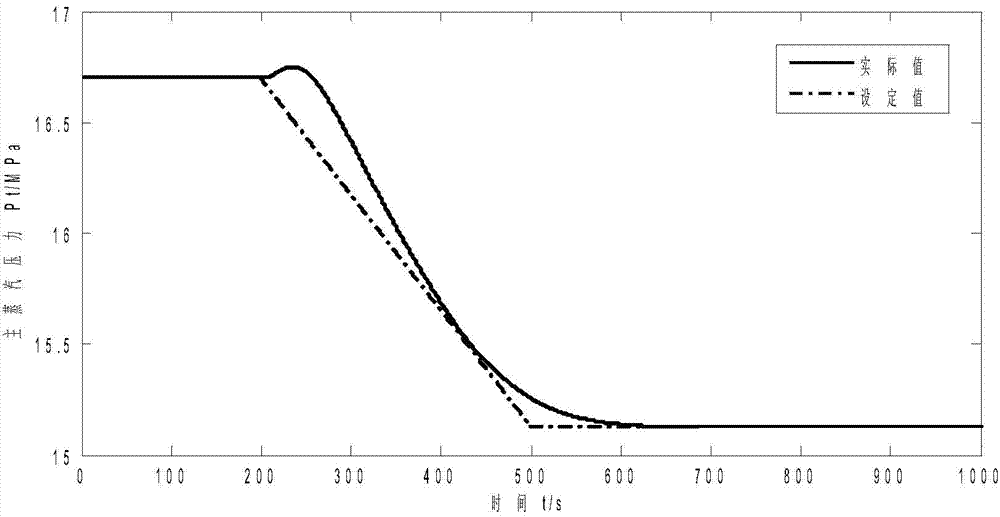

Novel thermal power generating unit load multivariable predictive control method

InactiveCN104122797AStable economic operationMeet real-time requirementsAdaptive controlSteam pressureControl system

The invention discloses a novel thermal power generating unit load multivariable predictive control method. According to the method, novel performance indexes are provided by being specific to characteristics of great inertia of a boiler, slow process response and the like, and a multivariable predictive control method of a unit load control system is designed according to the indexes. The performance indexes of the method are designed on the basis of the relation among unit output power, single-step predicted deviations of main steam pressure and deviation change rate. During process controlling, when demands of outside loads are changed, the valve opening degree of a turbine is adjusted to change inlet steam quantity of the turbine, the main steam pressure is changed to release stored heat of the boiler so that a unit can rapidly respond to the outside load demands, meanwhile, the boiler burning ratio is rapidly adjusted to meet the outside load demands and meanwhile, prevent the deviation between the main steam pressure and a set value from exceeding a limit, the set value can be tracked, stable operation of the unit can be maintained, and the stability of the load control system and the operating efficiency of the unit can be improved.

Owner:SOUTHEAST UNIV

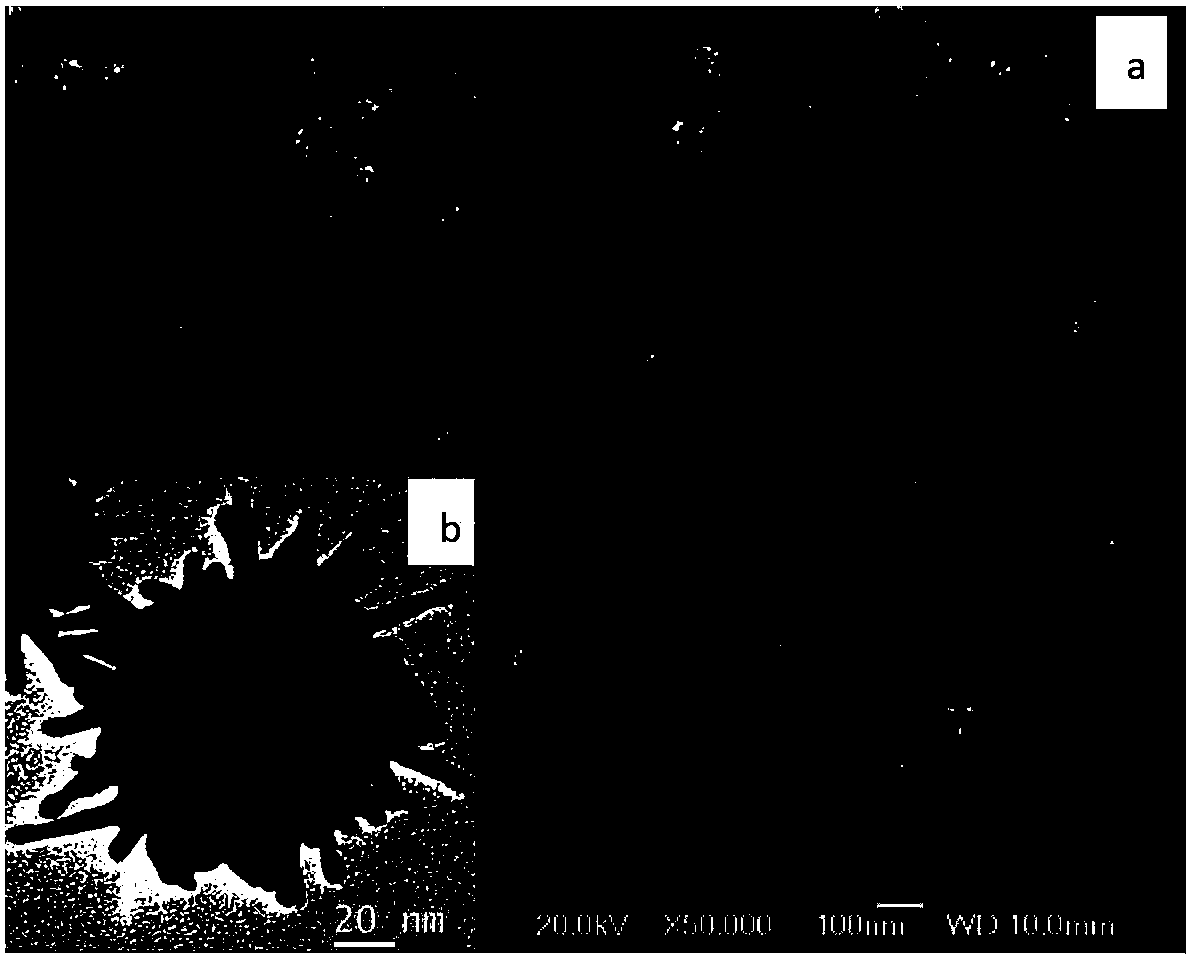

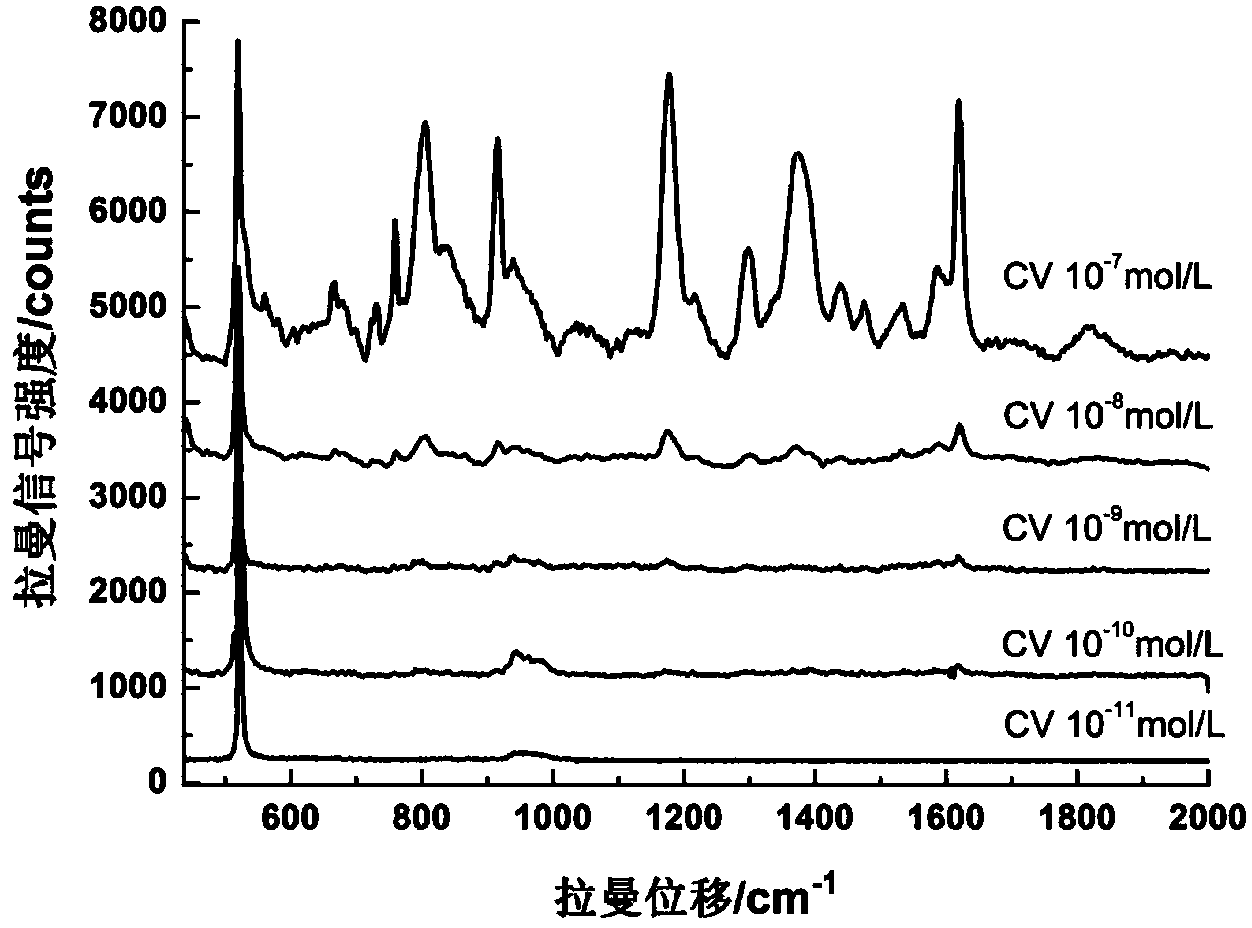

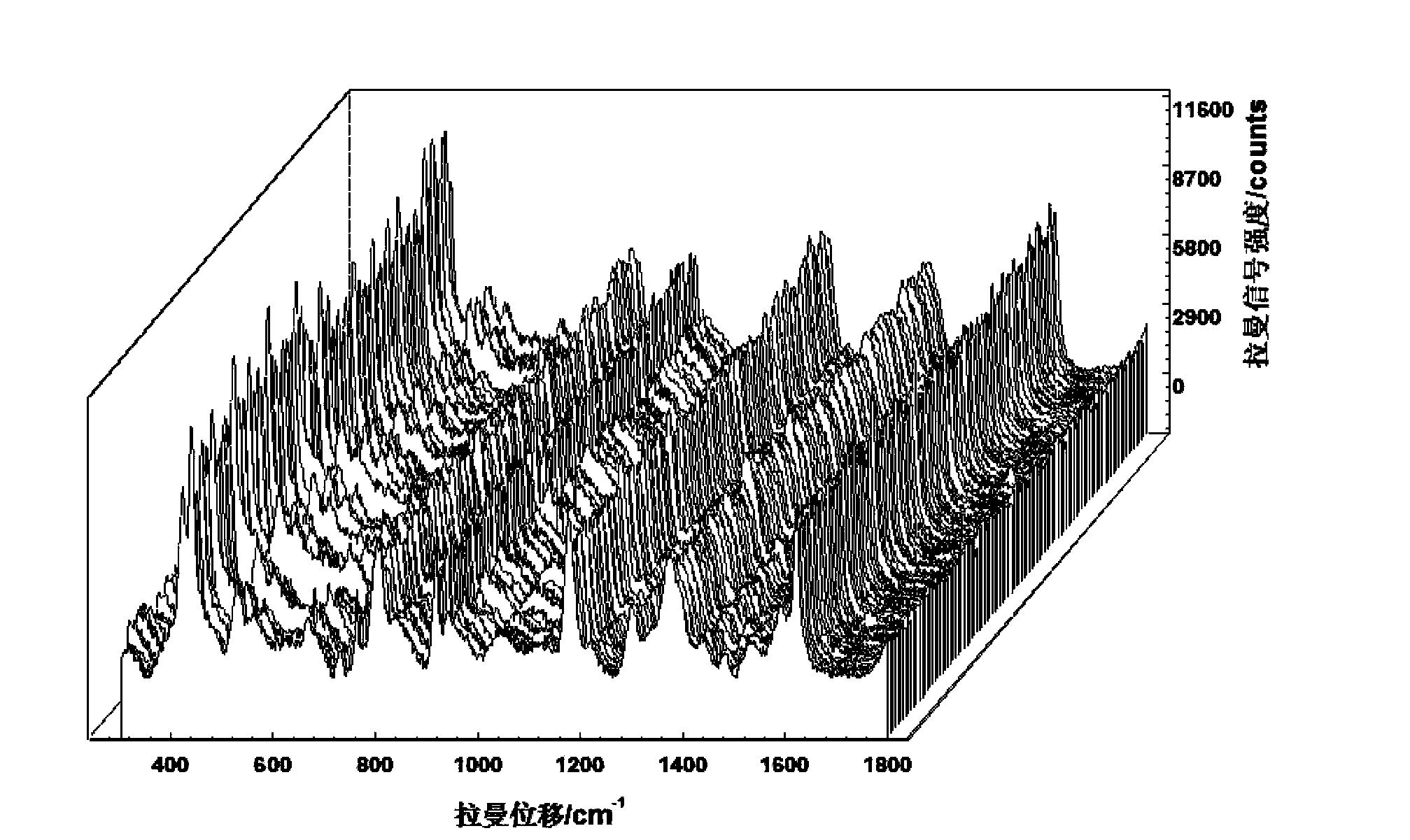

Sea urchin-shaped hollow gold and silver alloy nano particle and preparation method and application thereof

InactiveCN103357887AEvenly distributedUniform shapeEnergy modified materialsRaman scatteringNanoparticleSilver colloid

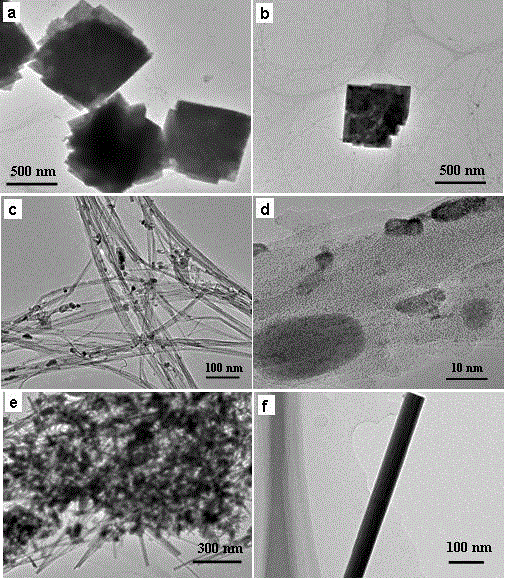

The invention discloses a sea urchin-shaped hollow gold and silver alloy nano particle and a preparation method and application thereof. The method comprises the following steps: dissolving silver nitrate into water; heating the mixture of the silver nitrate and the water till boiling; adding trisodium citrate aqueous solution in the mixture and keeping boiling for 3-30 minutes to obtain a silver colloid; mixing chloroauric acid aqueous solution and the water; adding the silver colloid under the condition of agitation at the temperature of 15 DEG C; adding hemoporphyrin metalporphyrin aqueous solution and obtaining a reaction solution after 5 min reaction; performing centrifugalization of the reaction solution, washing deposit obtained via centrifugalization, and obtaining the sea urchin-shaped hollow gold and silver alloy nano particle. The diameter of the nano particle is 80 nm-300 nm, the hollow size is 20 nm-50 nm, the length of a stab is 10 nm-30 nm, the diameter of the stab is 10 nm. The preparation method is simple, low in cost, gentle in condition, short in time, easy in process control, and large in production capacity. The obtained nano particle can be well applied to organic molecule detection, earlier detection of tumour and photothermal treatment.

Owner:XI AN JIAOTONG UNIV

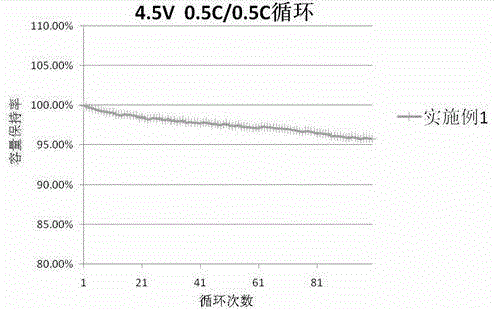

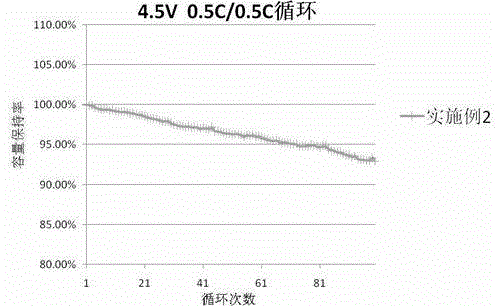

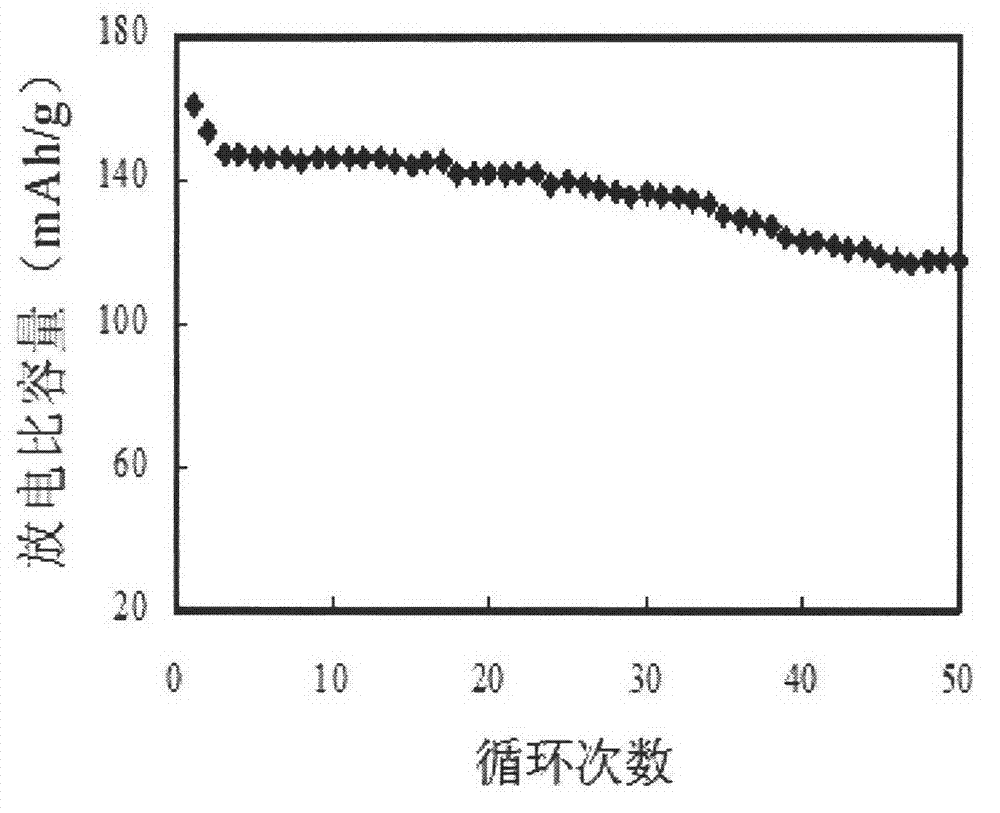

Cathode material for boracic lithium ion battery and preparation method thereof

InactiveCN105244492AGood electrochemical performance of the batteryGood capacity retentionCell electrodesComposite cathodeLithium iron phosphate

The invention discloses a cathode material for a boracic lithium ion battery and a preparation method thereof. The cathode material for the lithium ion battery disclosed by the invention comprises two parts including a composite oxide core and a coating layer. The core is single or is doped with ternary materials such as modified lithium cobalt oxide, nickel cobalt manganese or nickel cobalt aluminum, lithium manganese oxide, lithium iron phosphate, lithium-rich manganese and the like, and the coating layer is a high-molecular polymer containing boron-oxygen bonds. The preparation method of the composite cathode material for the lithium ion battery disclosed by the invention is simple in technology, easy in process control and convenient for industrial production.

Owner:BEIJING EASPRING MATERIAL TECH CO LTD

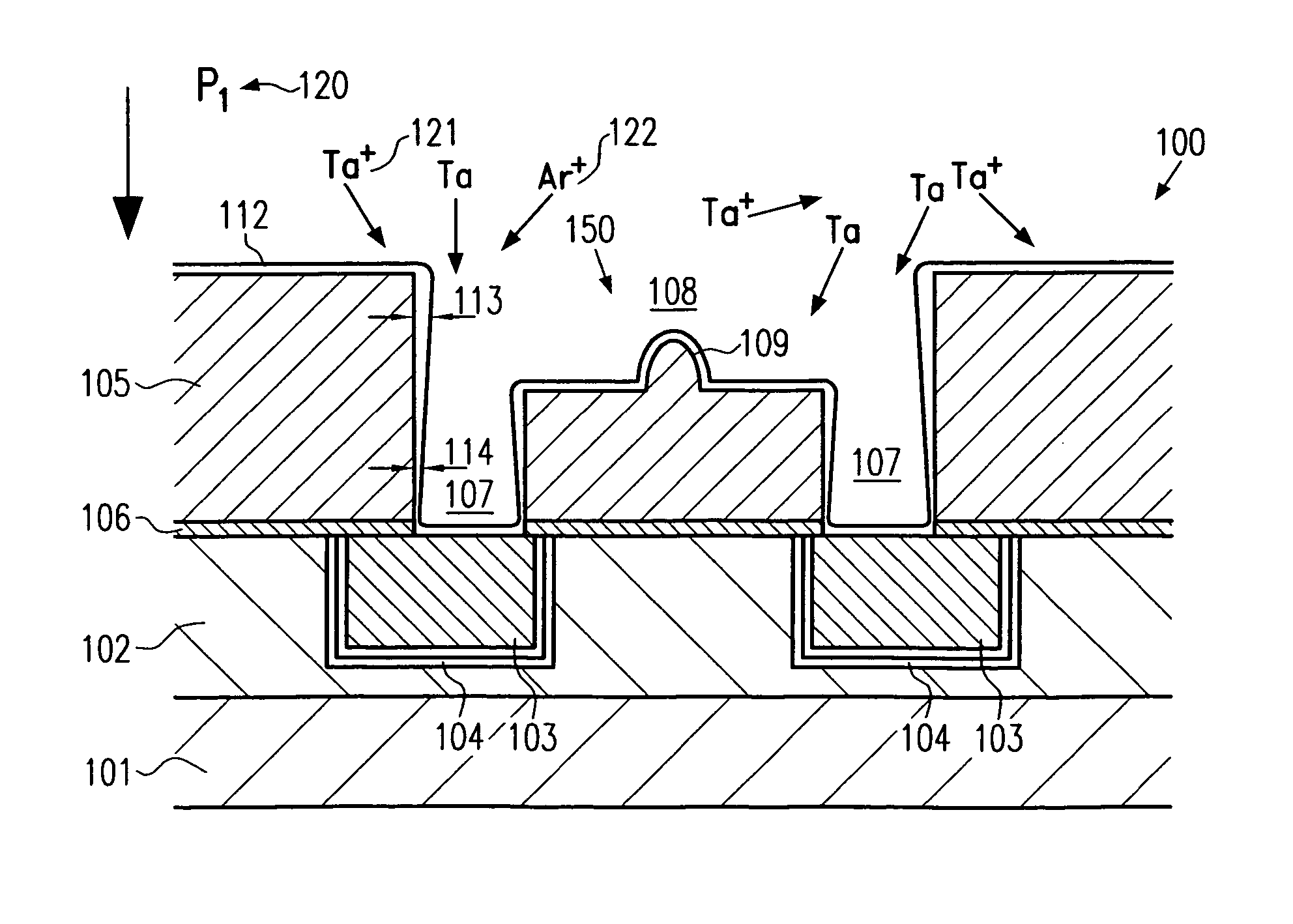

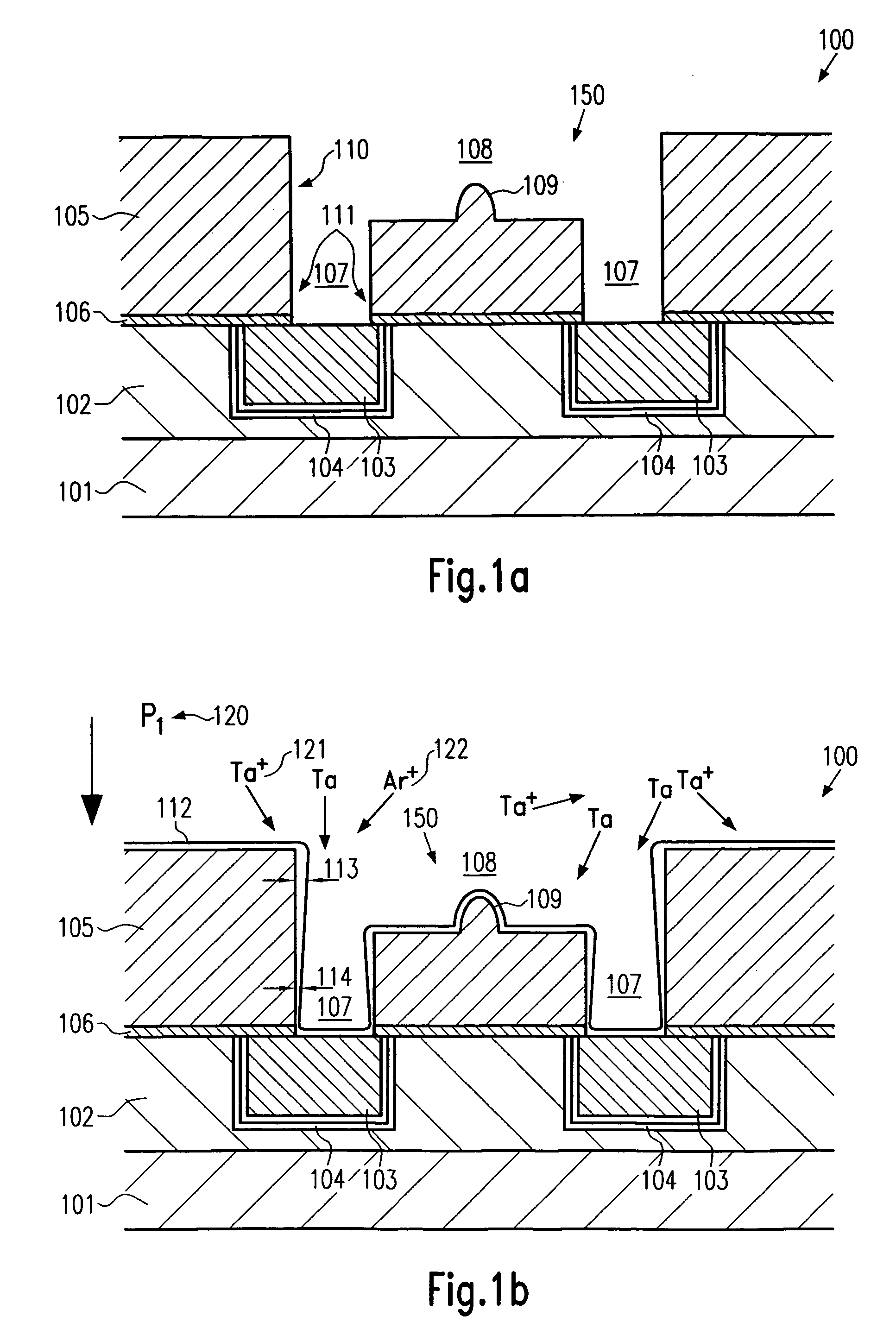

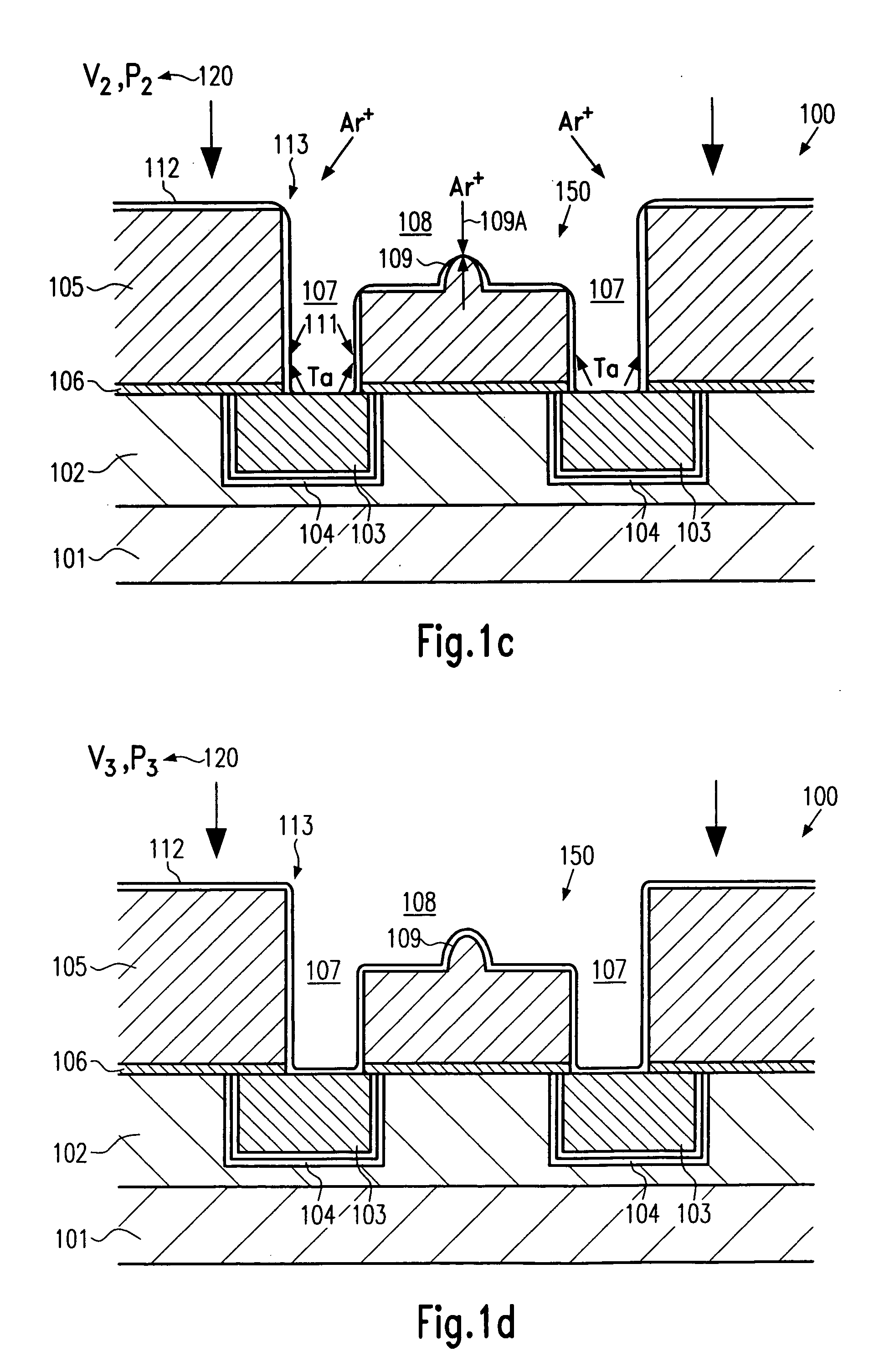

Method of forming a conductive barrier layer within critical openings by a final deposition step after a re-sputter deposition

InactiveUS20050233582A1Well formedSemiconductor/solid-state device manufacturingEngineeringSputter deposition

In forming a thin conductive layer in an interconnect structure by sputter deposition including a re-sputtering step, a flash deposition step is performed after the re-sputtering step to provide a sufficient layer thickness at critical locations, such as at positions of structure irregularities. The flash deposition step may be performed for a fixed process time so that less effort in process control is required while, at the same time, an increased reliability may be obtained compared to conventional approaches without a flash deposition.

Owner:GLOBALFOUNDRIES INC

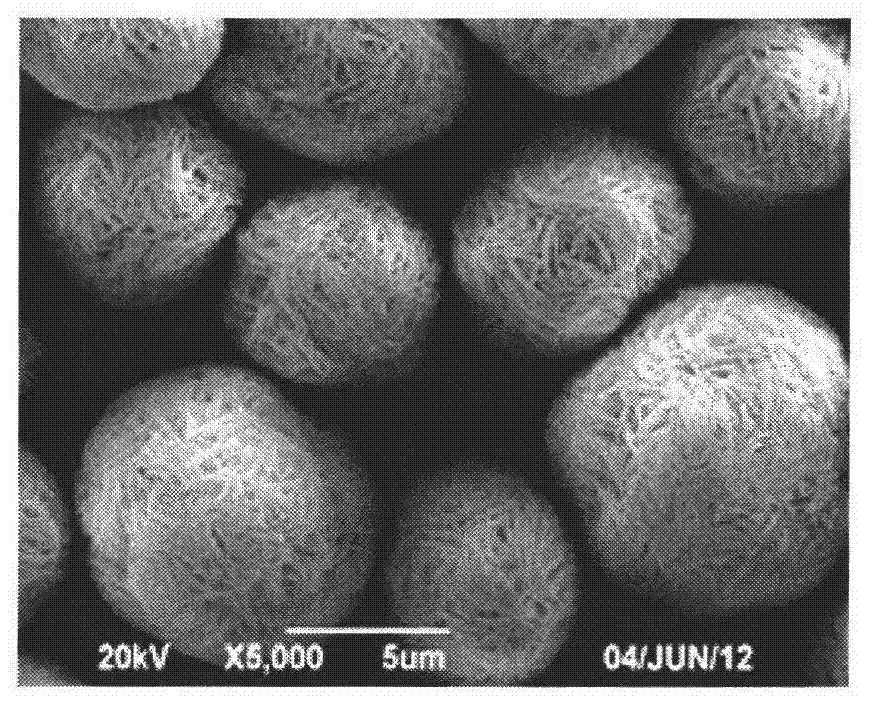

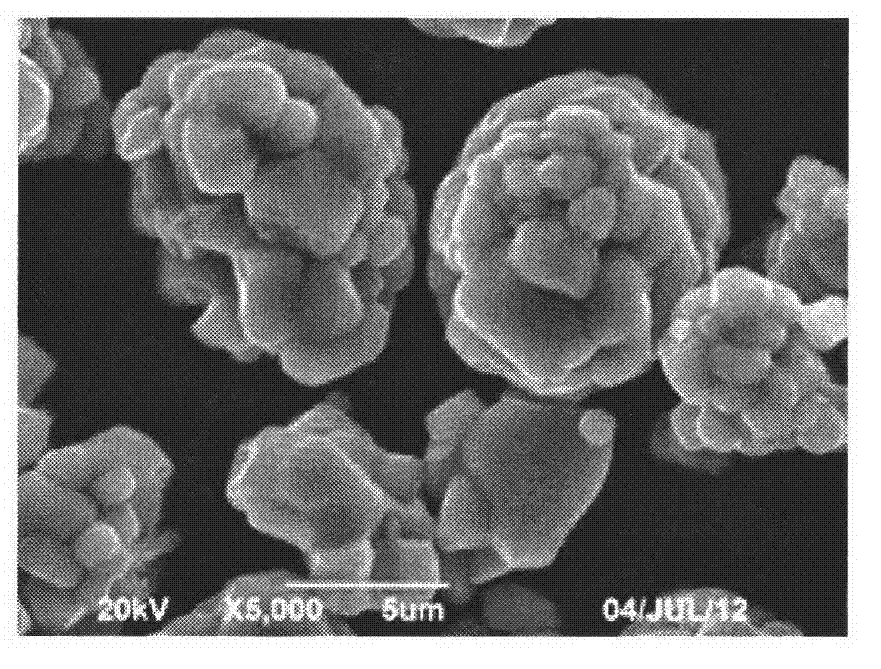

Lithium ion battery nickel-cobalt-manganese ternary composite anode material and method for preparing precursor thereof

The invention relates to the field of lithium ion batteries, in particular to a lithium ion battery nickel-cobalt-manganese ternary composite anode material LiNi1 / 3Co1 / 3Mn1 / 3O2 and a method for preparing a precursor Ni1 / 3Co1 / 3Mn1 / 3OOH of the lithium ion battery nickel-cobalt-manganese ternary composite anode material. The method includes: subjecting nickel-cobalt-manganese ion mixed liquid and precipitant to precipitation reaction, obtaining a hydroxyl hydroxide precursor by procedures of pre-oxidation, washing, leaching and drying, mixing the precursor and a lithium source compound by means of ball milling proportionally, and calcining the mixture to obtain the lithium ion battery nickel-cobalt-manganese ternary composite anode material. The synthetic method is simple, easy in process control, high in efficiency, low in cost and suitable for industrial production, overhigh temperature calcinations is avoided, and the prepared lithium ion battery anode material is fine in sphericility, uniform in particle distribution and high in tap density and has fine electrochemical performance.

Owner:ANHUI ALAND NEW ENERGY MATERIALS

Treatment method for cobalt-nickel waste water

ActiveCN105384277AEasy to removeReduce dosageWater contaminantsWater/sewage treatment by ion-exchangeIn process controlCobalt

The invention relates to a treatment method for cobalt-nickel waste water, and belongs to the field of sewage treatment. The treatment method includes the steps of pretreating, wherein suspended solids and oil of the cobalt-nickel waste water are pretreated; ammonia nitrogen steam stripping and air stripping, wherein treatment is completed through ammonia nitrogen steam stripping and air stripping; deep oil removing through oxidization, wherein the oil is decomposed in an oxidization aeration mode; heavy metal ion precipitating, wherein heavy metal ions are precipitated by adding alkali; deep impurity removing, wherein activated carbon and ion exchange resin are used for deep impurity removing. The treatment method for the cobalt-nickel waste water is simple in process, low in cost and simple in process control, and the treated waste water can be discharged in an up-to-standard mode.

Owner:RIZHAO HENGTONG WATER TREATMENT EQUIP

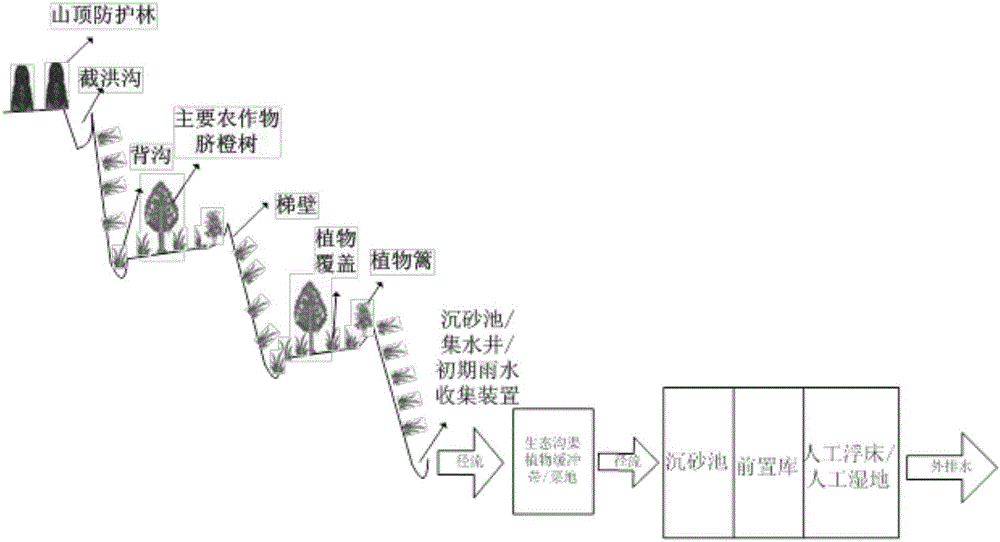

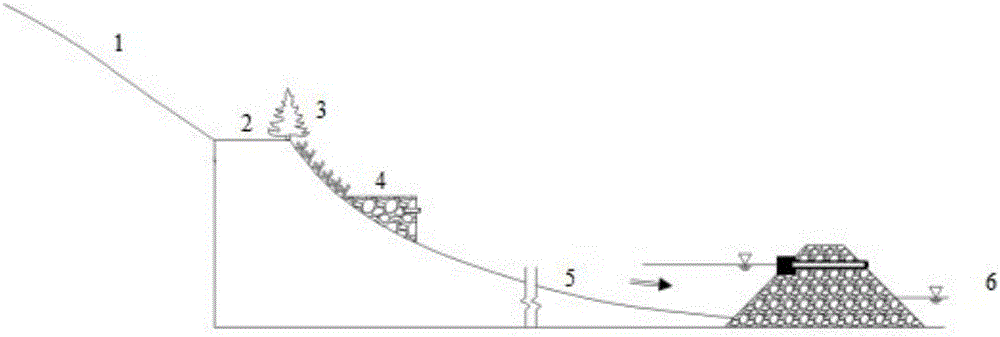

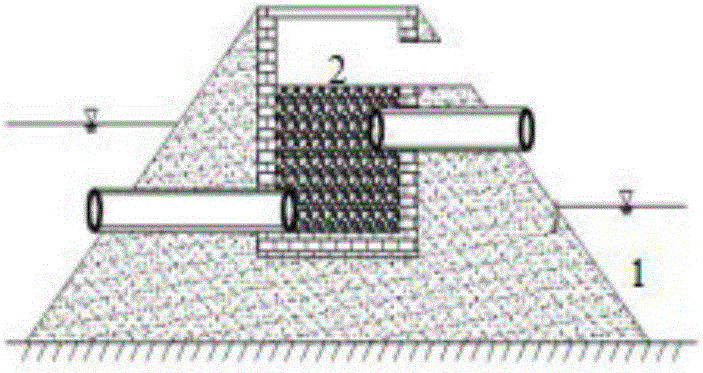

Method for treating agricultural non-point source pollution in hilly areas

The invention provides a systematic method for treating agricultural non-point source pollution in hilly areas. According to the systematic method, hilly uplands are reclaimed as counter-slope terrace lands, terrace lands per line are kept at equal height, and different lines of terrace lands are parallel mutually and are perpendicular to the inclination direction of upslope lands. The systematic method includes source reduction, runoff interception, process control and nutrient utilization, wherein source reduction refers to substitution for and reduction of chemical pesticides and chemical fertilizers; runoff interception is implemented by planting hedgerow on the external slope surfaces of the counter-slope terrace lands and planting land cover plants on the slope surfaces, dorsal furrows and terrace ridges; in process control, flood intercepting trenches, longitudinal drainage ditches and the dorsal furrows are formed and grit chambers, water-collecting wells and primary rainwater collecting devices are arranged to form a network; nutrient utilization is implemented by a pretreatment unit and a main treatment unit. The systematic method for treating the agricultural non-point source pollution in the hilly areas has the advantages that onsite terrain conditions are fully utilized, and corresponding ecological control and treatment methods are adopted in different forming phases of runoff and pollution, so that runoff nutrient cycling utilization efficiency is improved and production and discharge of the non-point source pollution are reduced.

Owner:JIANGXI ACADEMY OF ENVIRONMENTAL PROTECTION SCI

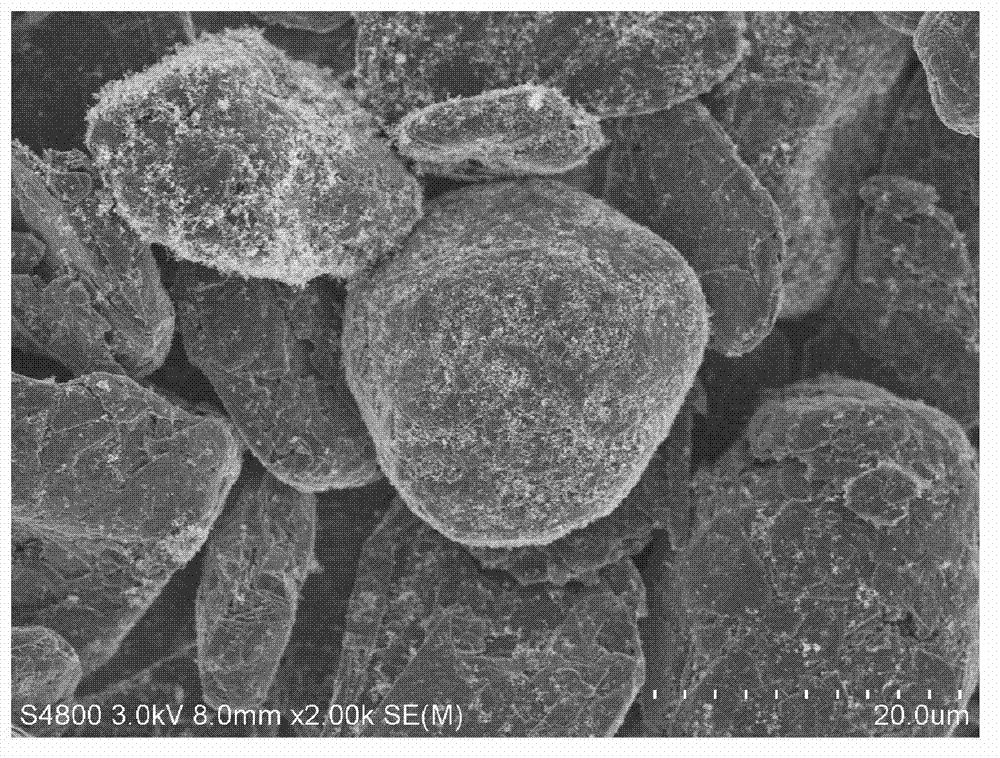

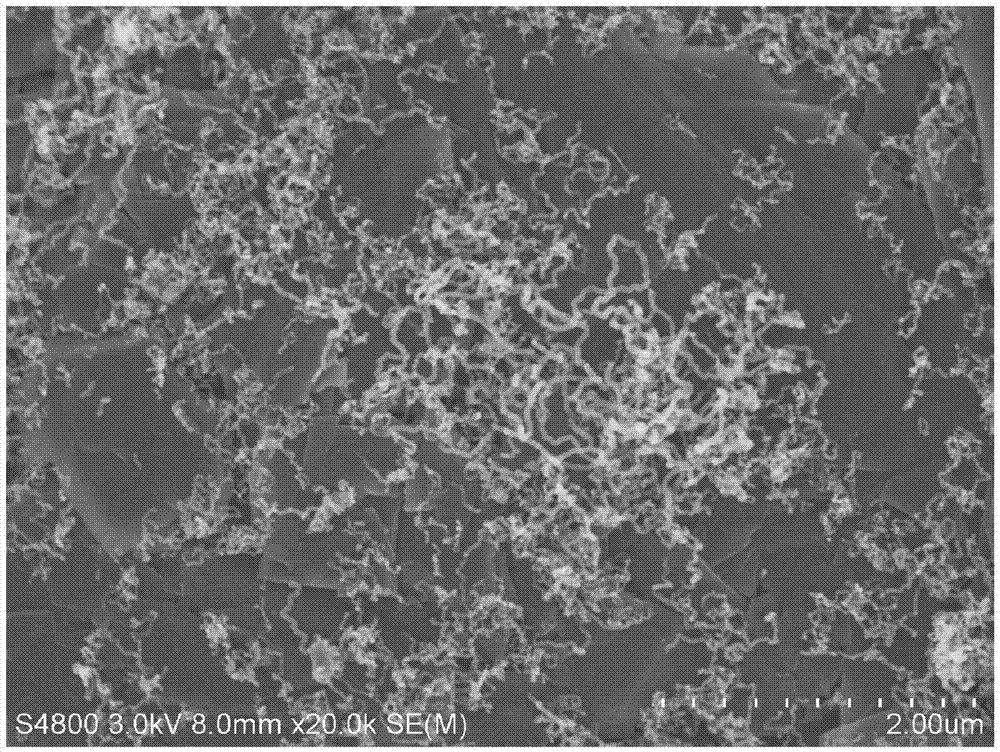

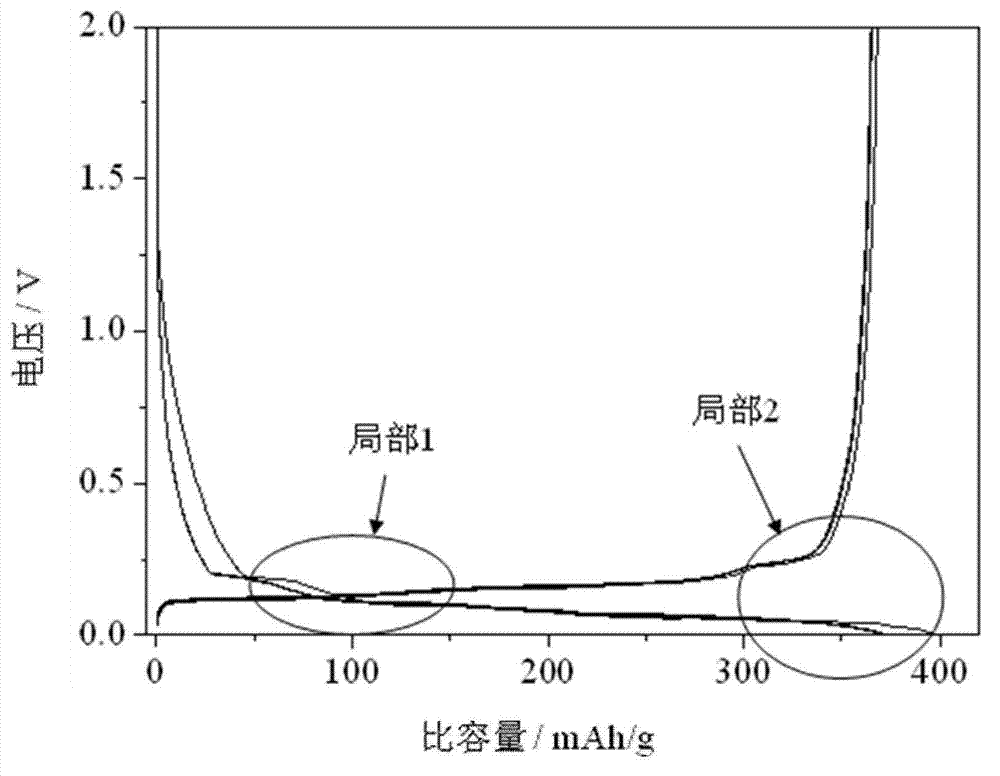

Graphite composite negative electrode material for lithium ion battery, preparation method of material, and lithium ion battery

ActiveCN103247802AImprove conductivityImprove liquid retention capacityCell electrodesSecondary cellsLithium electrodeIn process control

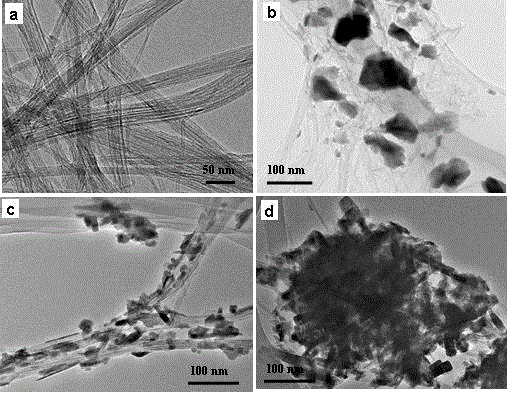

The invention discloses a graphite composite negative electrode material for a lithium ion battery, a preparation method of the material, and the lithium ion battery. The graphite composite negative electrode material for the lithium ion battery has a core-shell structure, wherein graphite is used as an inner core; carbon nano tubes and / or carbon nanofibers which are uniformly distributed on the surface of the graphite and are in in-situ growth are used as the shell; the growth root points of the carbon nano tubes and / or the carbon nanofibers are in tight contact with the surface of the graphite; and the other ends of the carbon nano tubes and / or the carbon nanofibers are distributed on the surface of the graphite randomly. The preparation method comprises the following steps of: fully soaking the graphite as a raw material by a catalyst-containing solution, and drying to obtain a graphite composite material precursor; performing chemical vapor deposition to generate the carbon nano tubes and / or the carbon nanofibers; and finally performing the purification and annealing treatment. The graphite composite negative electrode material has high height ratio, conductivity, and rate capability, and excellent solution absorption performance and cycle performance; and the method is simple in production flow, accurate in process control, low in cost, free from severe conditions, and easy to realize the industrialization.

Owner:BTR NEW MATERIAL GRP CO LTD

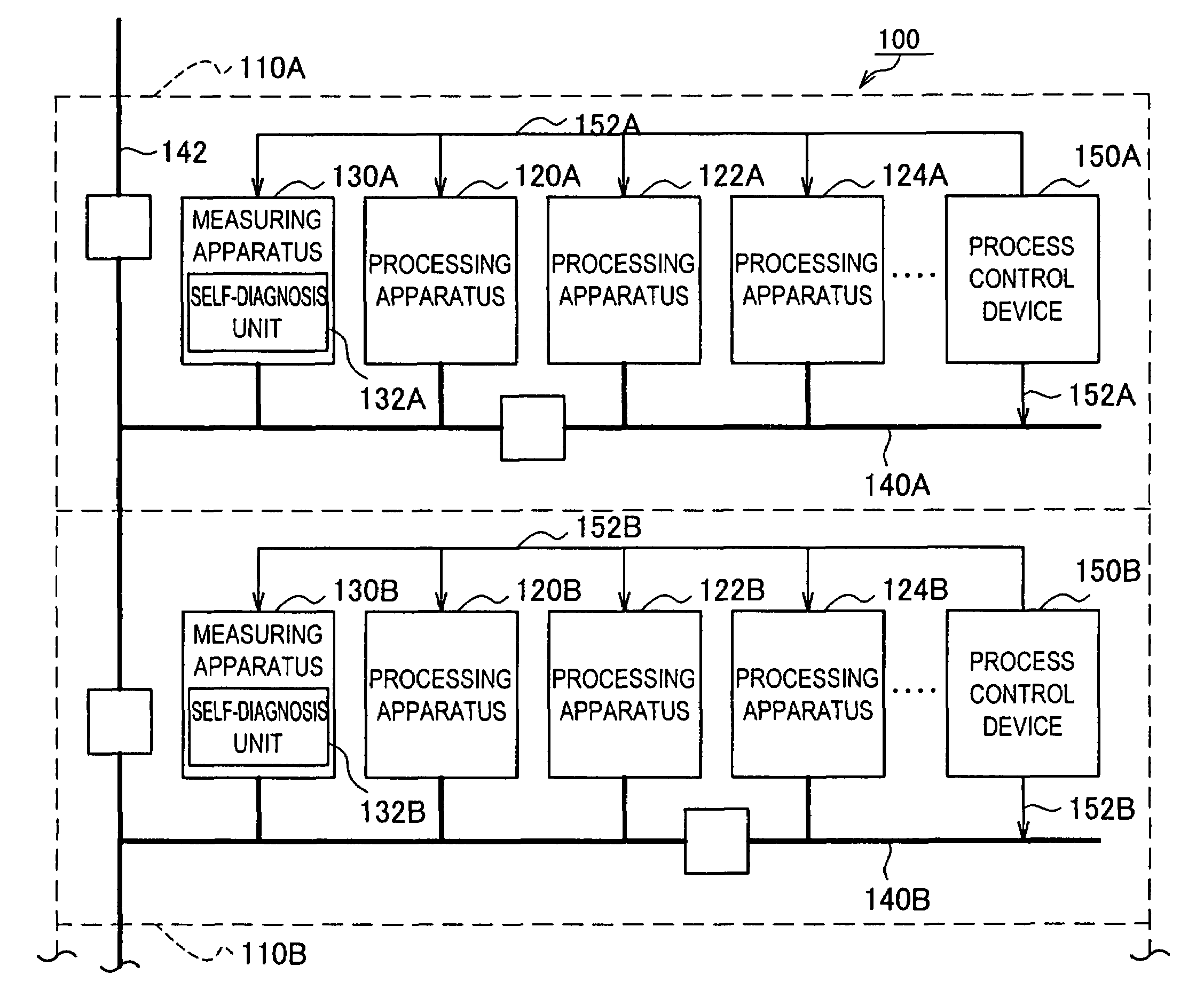

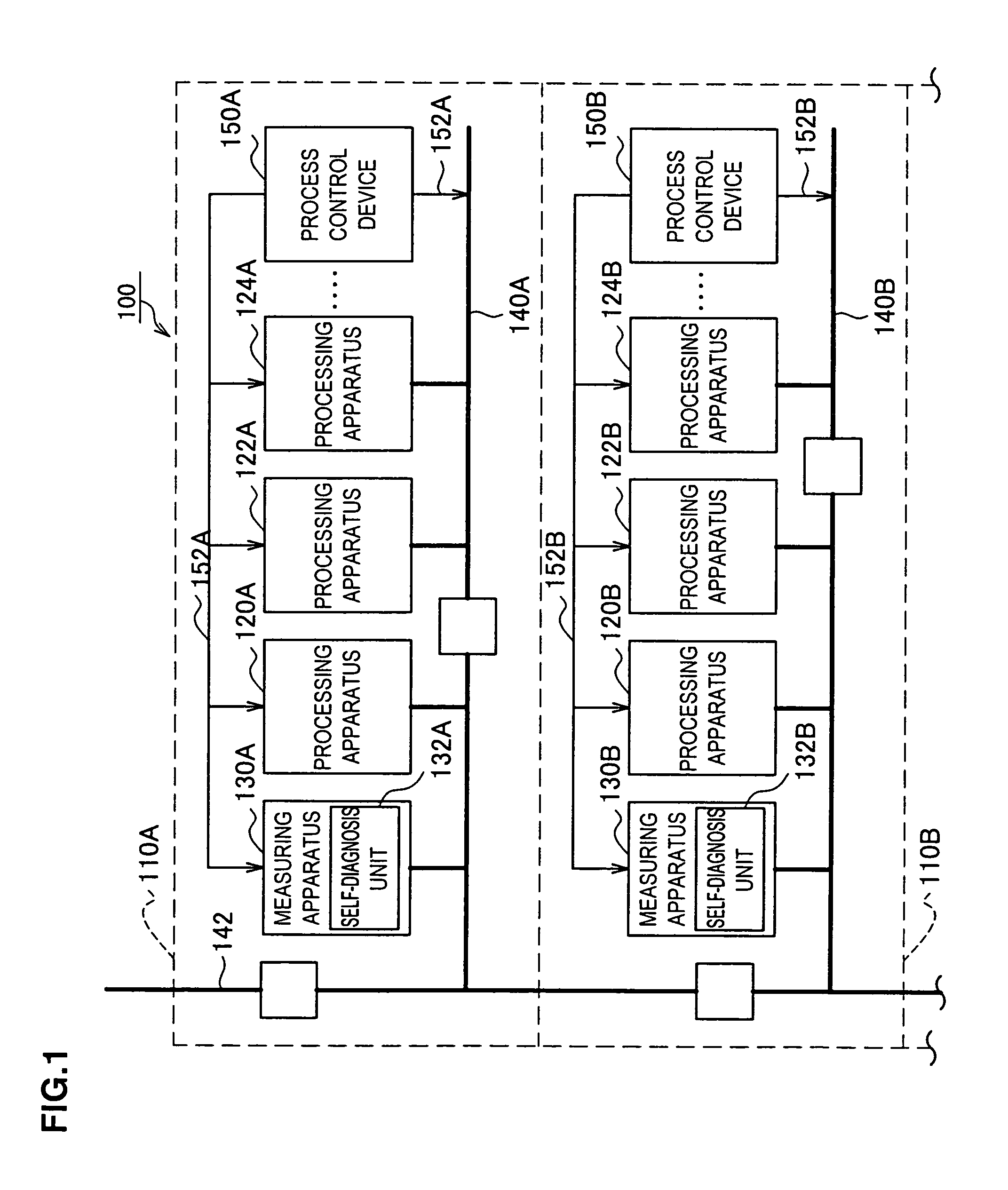

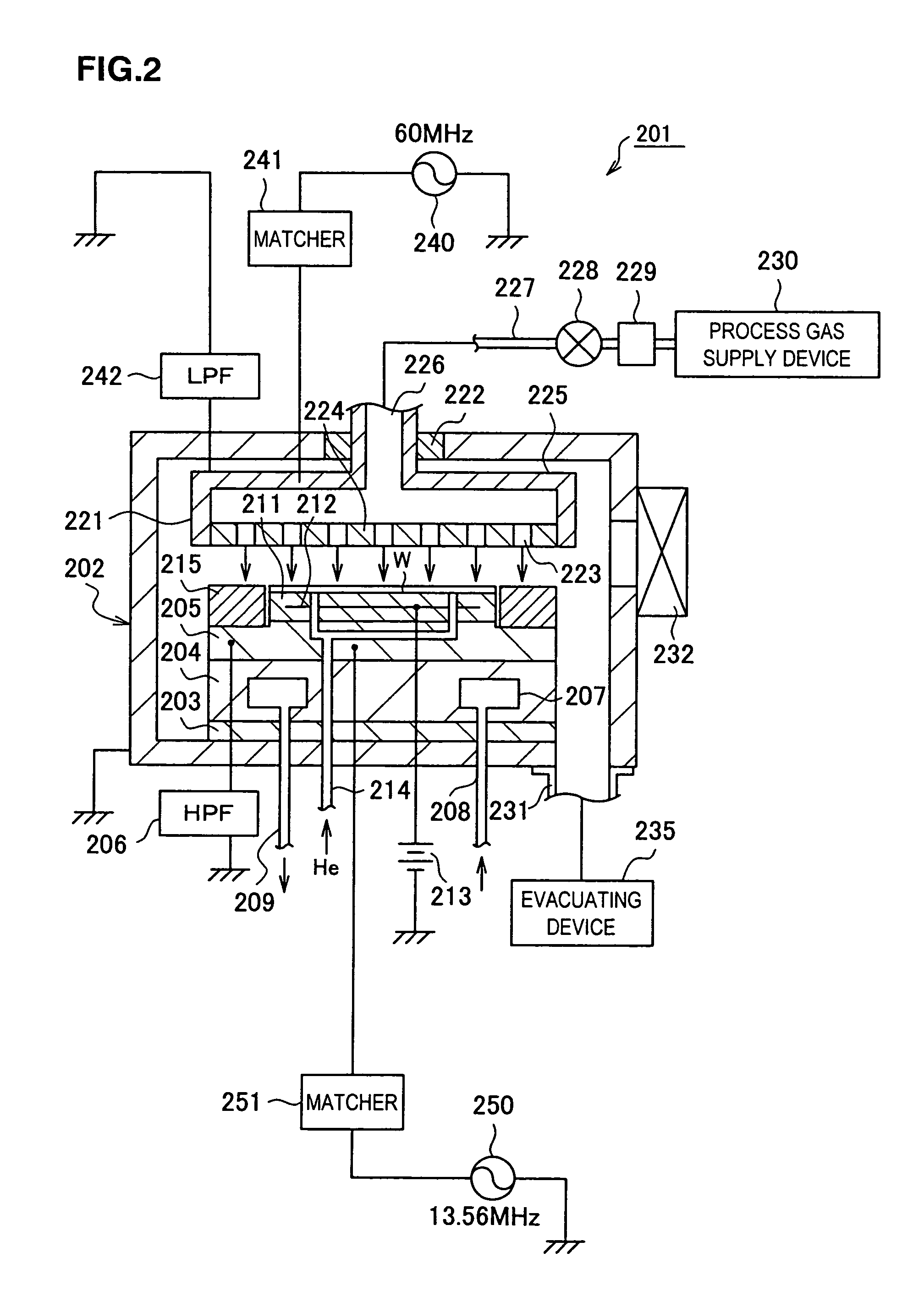

Process control system and process control method

ActiveUS7047095B2Reduce decreaseMaximizes operating rateDigital computer detailsNuclear monitoringControl systemProcess engineering

A process control system that controls processing executed on semiconductor wafers by processing apparatuses 120, 122, 124 installed in each bay (area) 110 inside a factory the processing results of which are predictable, having installed in the corresponding bay, at least one measuring apparatus 130 that executes a measuring operation on workpieces undergoing the processing in the bay, a transfer path 140 of a transfer apparatus, through which the workpieces are transferred among various apparatuses installed within the bay including the individual processing apparatuses and the measuring apparatus and a process control device 150 that controls the processing apparatuses, the measuring apparatus and the transfer apparatus in the bay. This structure reduces the length of time (cycle time) to elapse from the processing through the inspection operation and also improves the operating rate of each processing apparatus.

Owner:TOKYO ELECTRON LTD

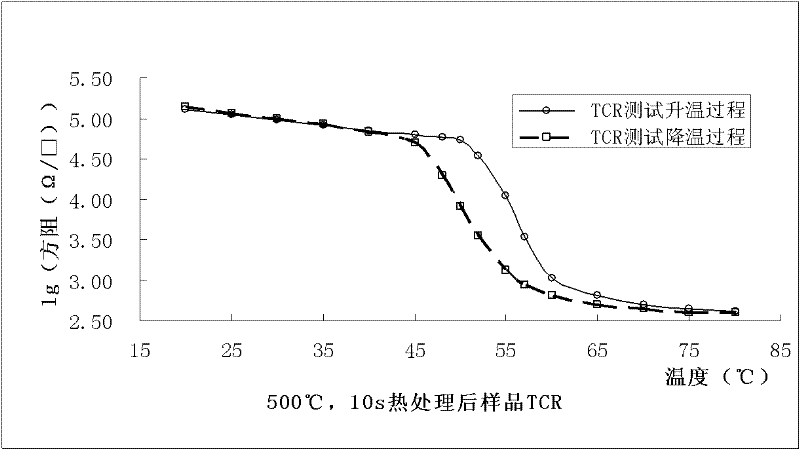

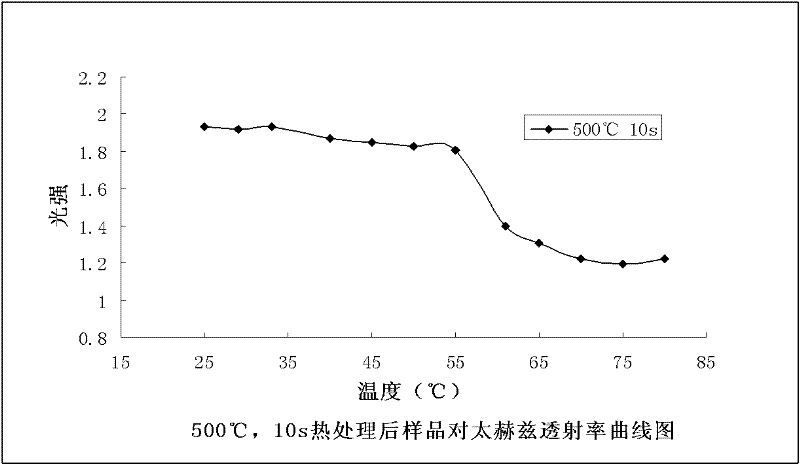

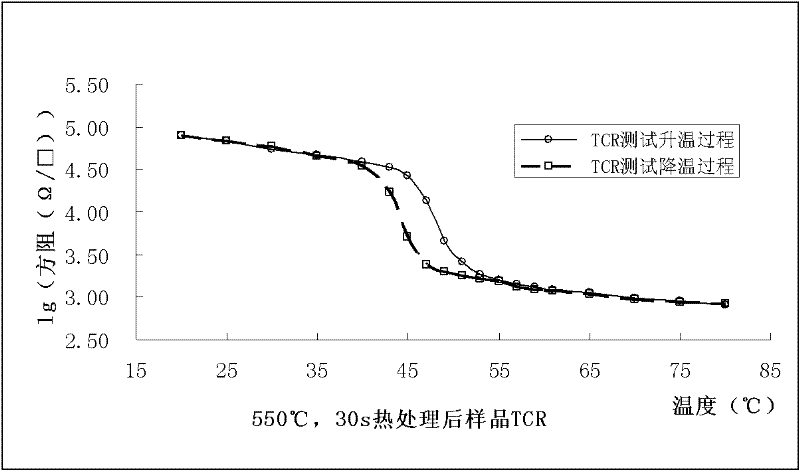

Quick thermal treatment method for preparing vanadium dioxide film

InactiveCN102212782ARapid heat treatment methodExcellent ElectricalVacuum evaporation coatingSputtering coatingVanadium dioxideShielding gas

The invention discloses a quick thermal treatment method for preparing a vanadium dioxide film. The method comprises the following steps of: (1) cutting a silicon chip to form a substrate, and cleaning and drying the silicon substrate; (2) placing the silicon substrate of the step (1) in a vacuum chamber, and depositing a vanadium dioxide film on the silicon substrate by adopting a target magnetron sputtering method, wherein the target is 99.99 percent metallic vanadium, argon is used as a working gas and oxygen is used as a reaction gas; (3) putting the vanadium dioxide film product sputtered in the step (2) into a quick annealing furnace to prepare a vanadium dioxide film, wherein the annealing temperature is 500 to 550 DEG C, the heating rate is 50 DEG C per second, the heat preservation time is 10 to 30 seconds, cooling is performed within 3 minutes, and the protective gas is nitrogen; and (4) measuring. By the method, the thermal treatment time is shortened, and obvious phase change property can be obtained after the vanadium dioxide film product is quickly and thermally treated for 10 to 30 seconds; the method is simple in process control, high in repeatability and suitable for large-area production; and electric and optical properties of the vanadium dioxide film are optimized. The method is widely applied in the fields of infrared detectors, memories, optical communications and the like.

Owner:TIANJIN UNIV

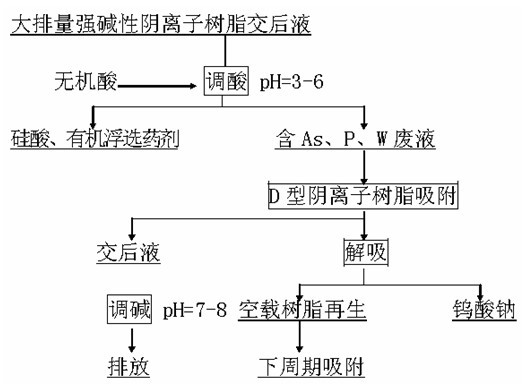

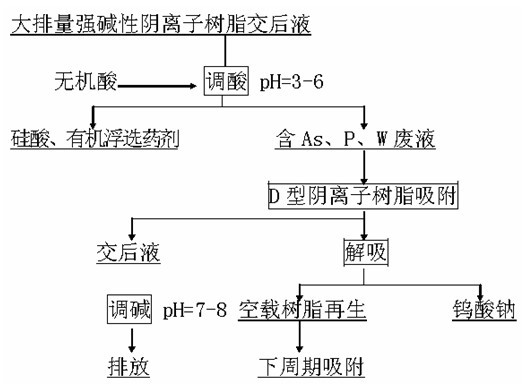

Method for removing arsenic and recycling tungsten from tungsten smelting wastewater

InactiveCN101985692AAvoid pollutionWater contaminantsWaste water treatment from metallurgical processLiquid wasteSlag

The invention discloses a method for removing arsenic and recycling tungsten from tungsten smelting wastewater, which comprises the following steps of: 1, adding inorganic acid into waste liquor after sodium tungstate solution is subjected to strongly basic anion resin exchange to adjust the waste liquor to be faintly acid, namely pH=3-6, and simultaneously adding a trace amount of flocculating agent; 2, injecting the faintly acid wastewater from which suspended matters are filtered out into an exchange column filled with D313 or D314 type anion resin, and adsorbing all arsenic and phosphorus in the wastewater by using the D type anion resin; and 3, desorbing the resin by using caustic soda solution, making 90 percent of tungsten crystallized and separated out in a form of Na2WO4.2H2O, reacting most harmful elements with an additive, and removing a slag phase. The method has the advantages that: the resin can thoroughly adsorb the tungsten and arsenic, so that the harmful element arsenic in the discharged production wastewater is reduced to less than 0.05mg / L from 1.5mg / L; the metal recovery rate is improved to 96-97 percent from 93-94 percent; and the tungsten detection in the in-process control process is saved, so the operation is simplified, the product quality is ensured, and the consumption of a NH4Cl strippant and water can be reduced.

Owner:江西修水湘赣有色金属有限公司

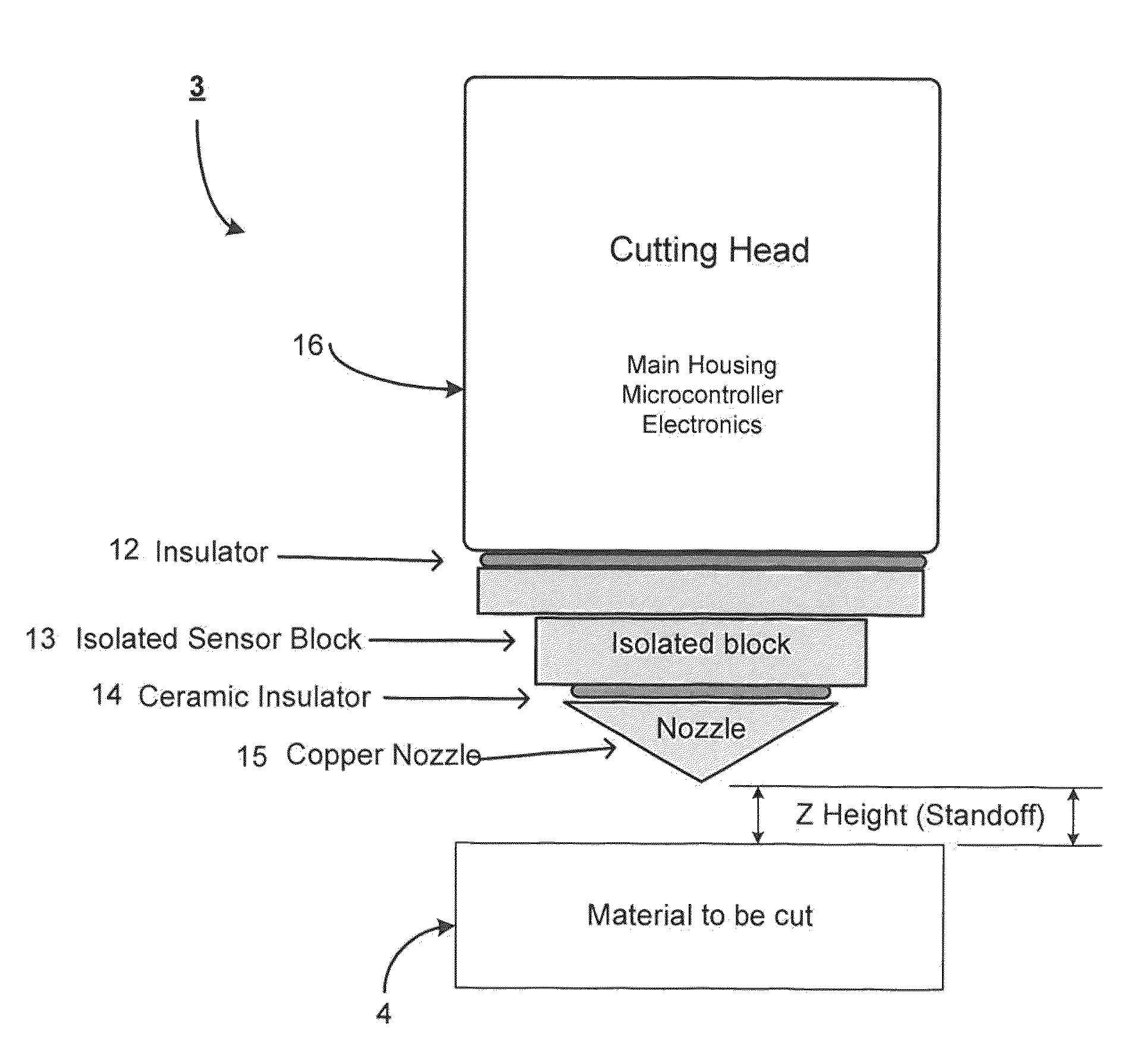

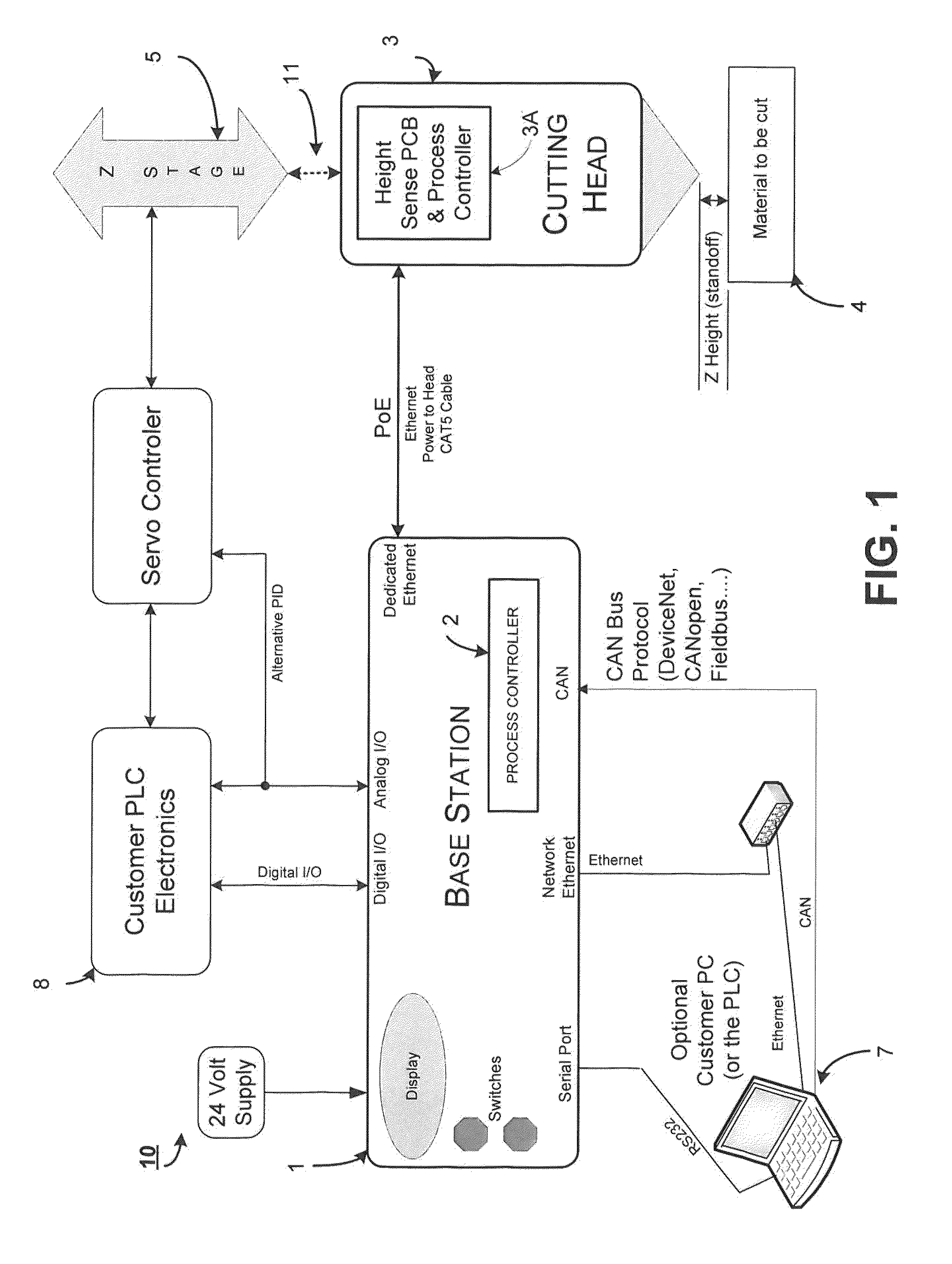

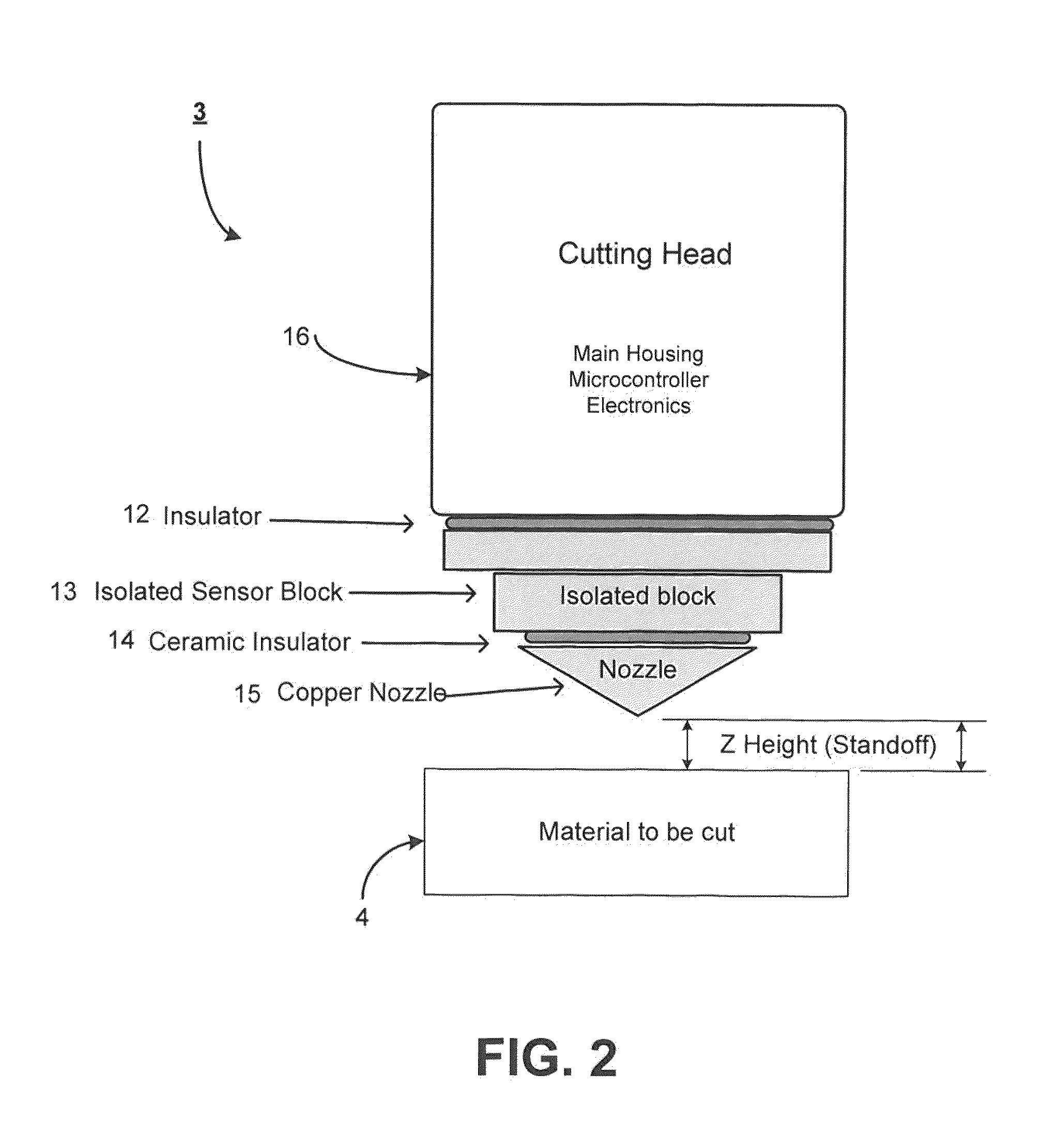

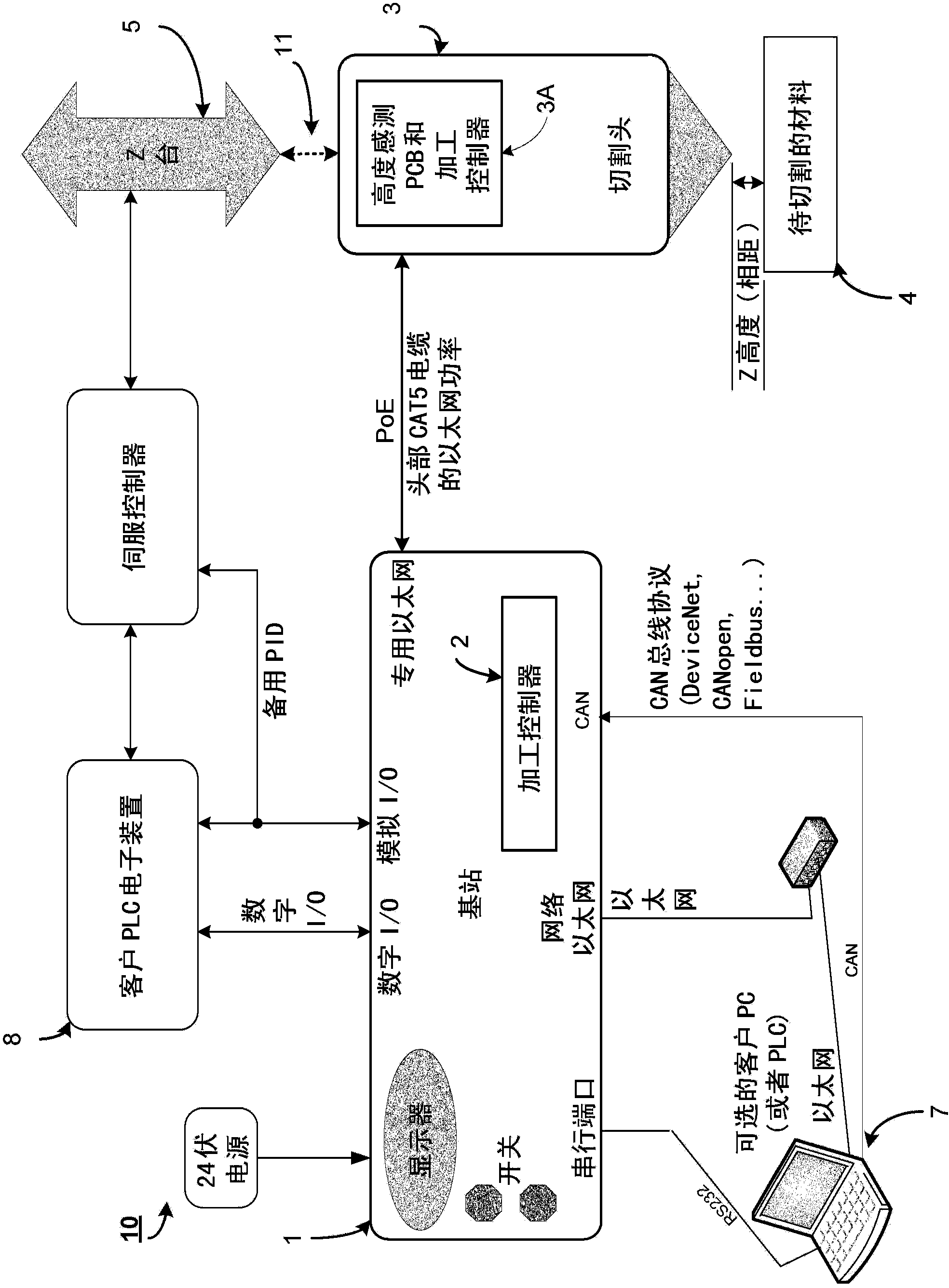

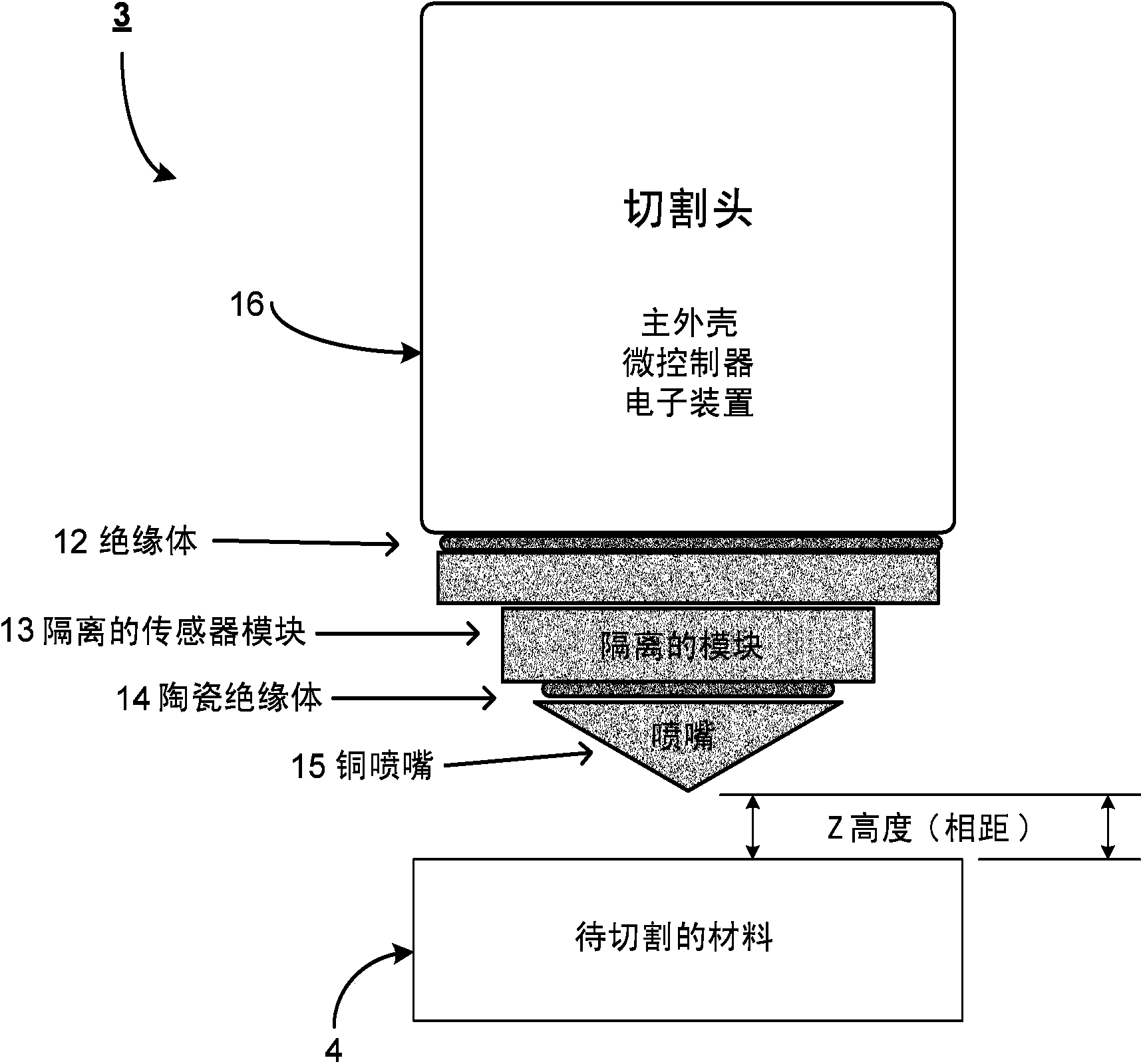

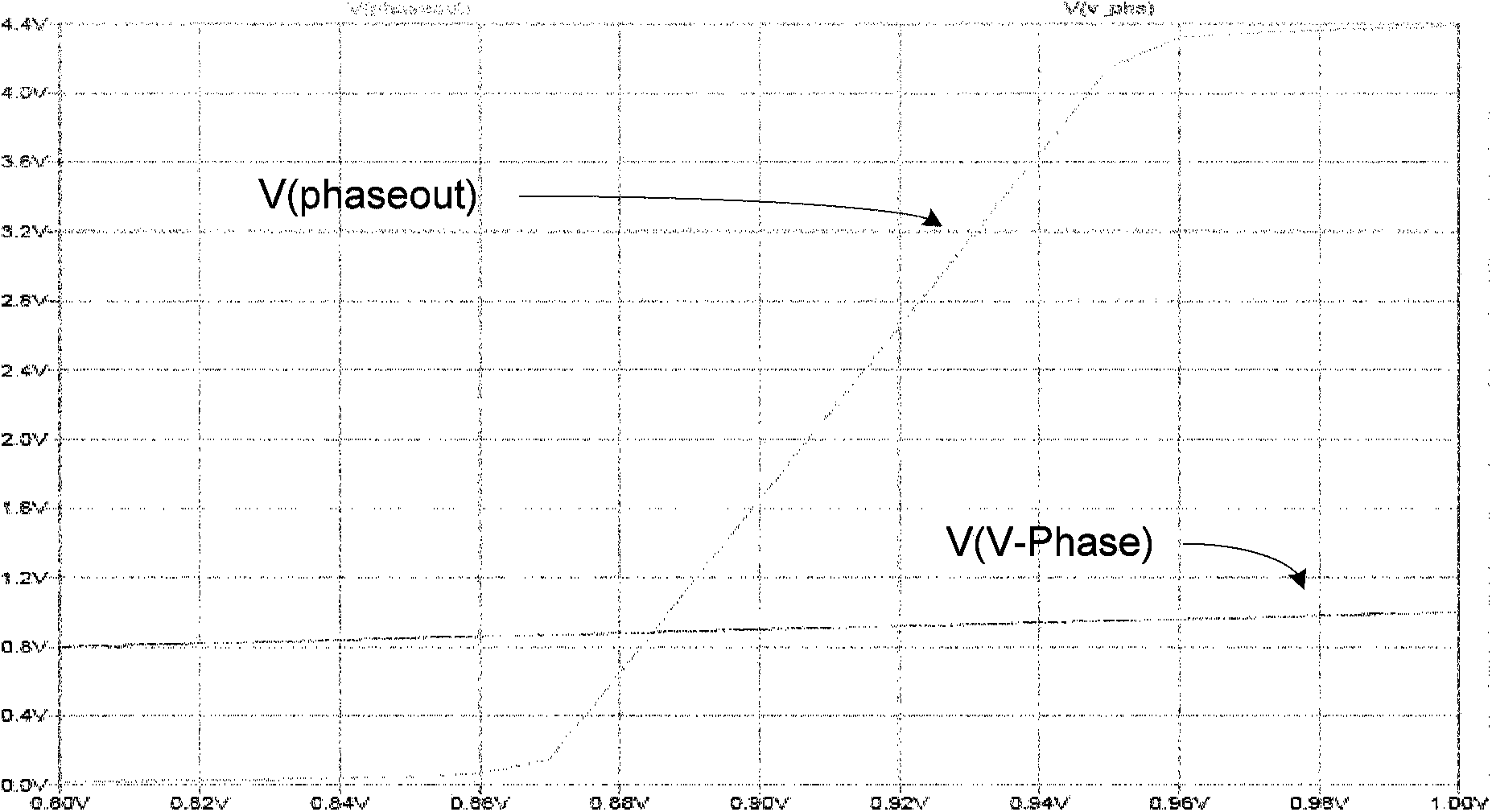

Dynamic Height Adjusting System and Method for Head Assembly of Laser Processing System

InactiveUS20140312018A1Easy to controlEasy to integrateResistance/reactance/impedenceUsing electrical meansCapacitanceLaser processing

The present invention relates to a dynamic height adjusting system and method that uses capacitance for a head assembly of a laser processing system throughout a process cycle. The proposed system and method involves use of a single frequency in which a change in phase is measured and processed to determine changes in height and distance between a work piece with an increased reliability. The system further enables operative computerized processor control and substantial improvements in process control signal and feedback distribution throughout an integrated system and optional remote interfaces.

Owner:IPG PHOTONICS CORP

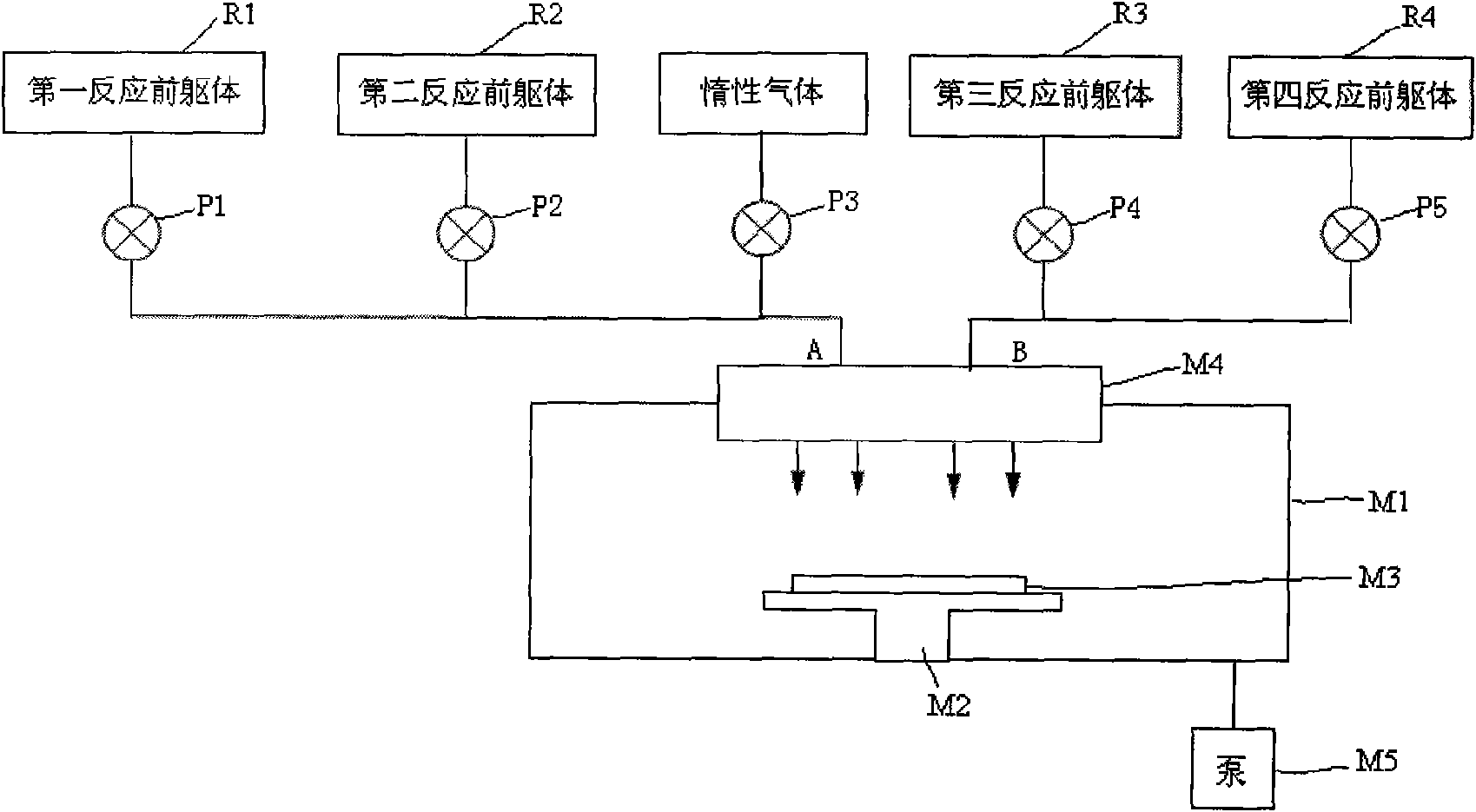

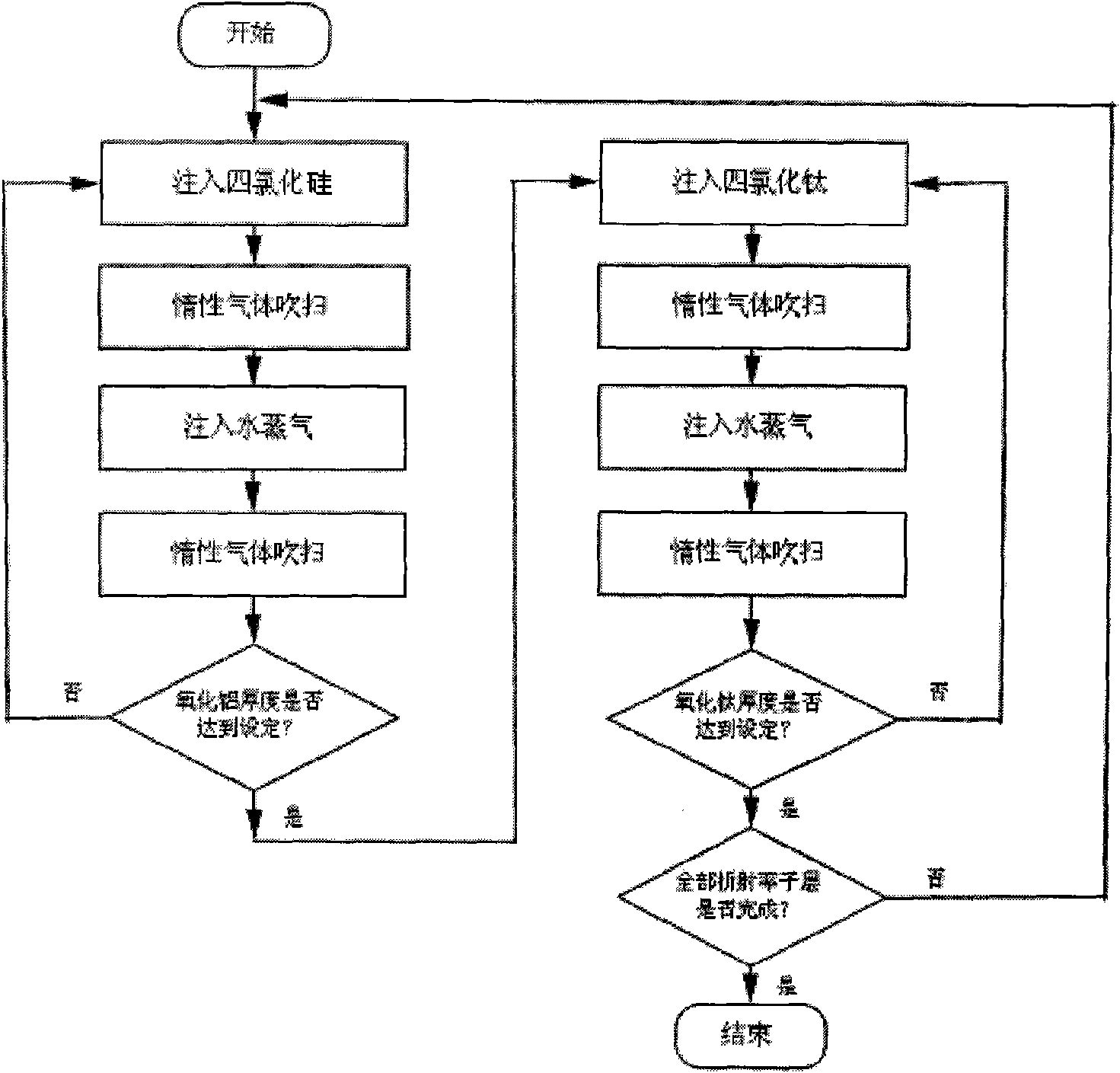

Method for preparing gradient-index film

InactiveCN101560653ASimple process controlLow index of refractionChemical vapor deposition coatingVacuum pumpingDeposition temperature

The invention discloses a method for preparing a gradient-index film. The method comprises the following steps: 1) putting a high-refractive-index material precursor and a low-refractive-index material precursor into a precursor reaction vessel respectively; 2) heating a substrate, performing vacuum pumping and turning on a coating machine; 3) depositing a low-refractive-index film; 4) depositing a high-refractive-index film; and 5) performing alternate deposition to form the gradient-index film. Compared with the prior art, the method has the following advantages that: 1) the method adopts an atomic-layer deposition technique and realizes sub-films different in refractive index by controlling the parameters of two material deposition processes; 2) the method adopts an alternate deposition mode, controls the number of cycles, and is simple in process control; 3) two film materials are a high-refractive-index film material and a low-refractive-index film material close in deposition temperature; 4) the refractive index of the deposited sub-films can be any value between a high refractive index and a low refractive index; and 5) the refractive-index sub-films are mixed films, and the refractive index can be controlled by controlling the deposition proportion of the two film materials alternately deposited.

Owner:ZHEJIANG UNIV

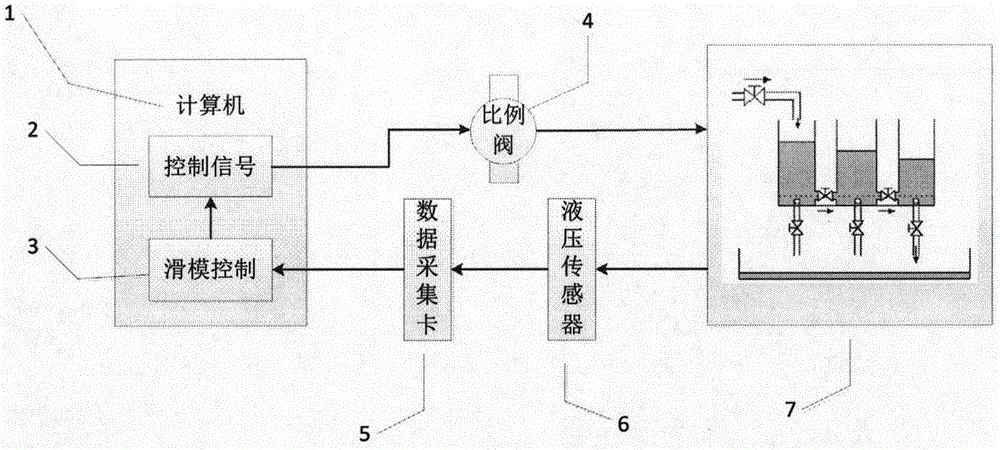

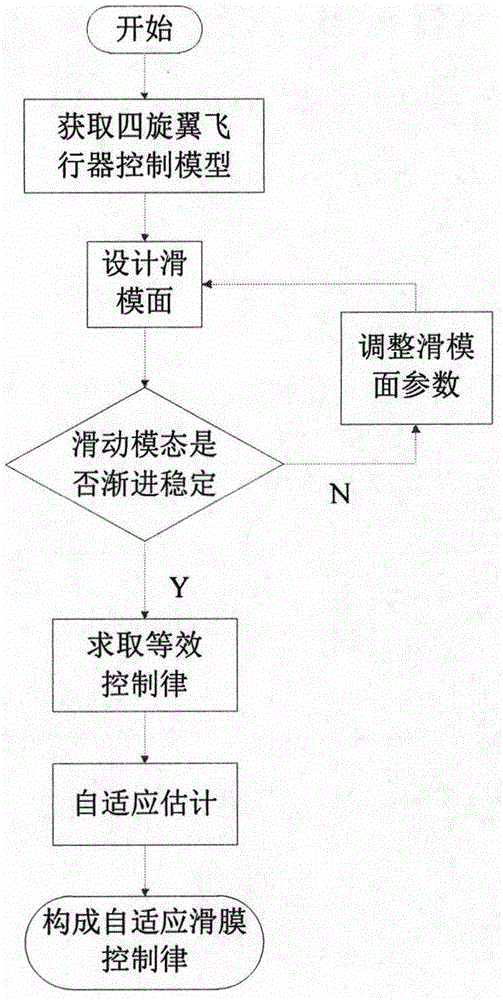

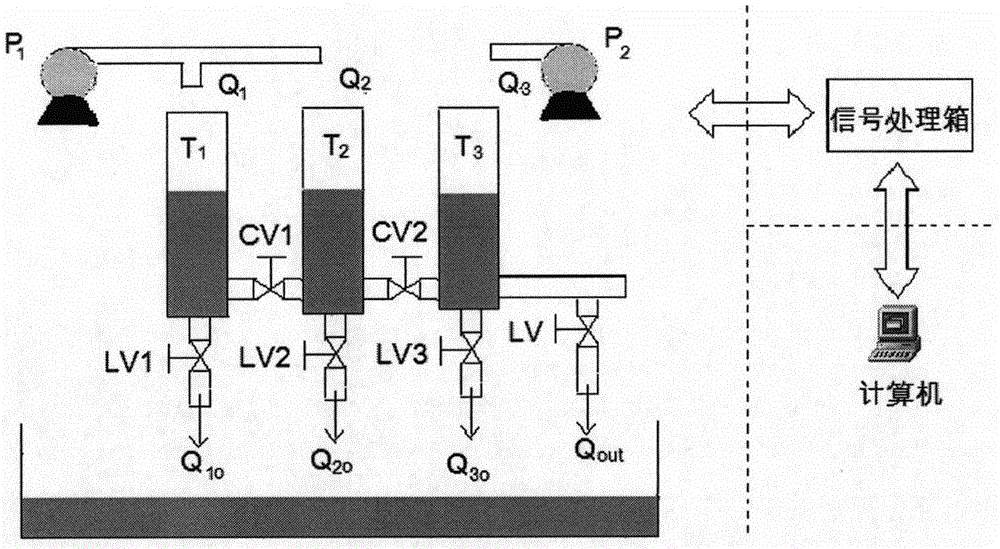

Self-adaptive sliding-mode control method for liquid level control system based on Delta operator

InactiveCN105388758AImprove practicalityReduce conservatismLevel controlAdaptive controlTime delaysDesign control

The present invention discloses a self-adaptive sliding-mode control method for a liquid level control system based on a Delta operator. In process control systems such as liquid control, uncertainty and time delay existing in the control systems may influence stability of the system, thus a sliding-mode control method based on a delta operator in combination with self-adaptive control is provided. A non-linear sliding mode surface is designed, a sufficient condition for asymptotic stability of a time-delay uncertain system is given in the form of linear matrix inequality, input disturbance is taken in consideration, and an upper bound is estimated through a self-adaptive boundary estimation method, so that a complete self-adaptive sliding-mode controller is formed. According to the self-adaptive sliding-mode control method of the present invention, a special non-linear sliding mode surface is designed, thus motion quality of the system is improved; by combining the advantages of self-adaptive control with the advantages of sliding-mode control, the designed control law can have a good control effect when the system has time delay and uncertainty. The self-adaptive sliding-mode control method is used for a liquid level control system with time-varying delay and system modeling uncertainty.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Dynamic height adjusting system and method for head assembly of laser processing system

ActiveCN104080570AAchieve correctionEliminate Signal ErrorsUsing electrical meansLaser beam welding apparatusCapacitanceLaser processing

The present invention relates to a dynamic height adjusting system and method that uses capacitance for a head assembly of a laser processing system throughout a process cycle. The proposed system and method involves use of a single frequency in which a change in phase is measured and processed to determine changes in height and distance between a work piece with an increased reliability. The system further enables operative computerized processor control and substantial improvements in process control signal and feedback distribution throughout an integrated system and optional remote interfaces.

Owner:IPG PHOTONICS CORP

Method for adjusting morphology and size of tungsten oxide by using carbon nanotube

ActiveCN105600825AIncrease profitControl shapeMaterial nanotechnologyTungsten oxides/hydroxidesCarbon nanotubeIn process control

The invention discloses a method for adjusting the morphology and the size of a tungsten oxide by using carbon nanotubes, and belongs to the technical field of tungsten-based nano materials. The method comprises the following steps: by taking the carbon nanotubes as a template and a morphology adjusting agent, ethylene glycol as a dispersing agent and a tungsten metal salt as a tungsten source, adding an acid solution into a reaction system, enabling a tungstic acid to nucleate and grow up on the surface of a carbon nanotube bundle, so as to form a carbon nanotube / tungstic acid compound; putting the compound into a high-temperature reaction area, and performing thermal treatment in the presence of an inert atmosphere. The method is simple in preparation process, concise in process control and wide in application prospect, the raw materials are easy to obtain, and the morphology and the size of the prepared tungsten oxide can be regulated and controlled.

Owner:JIANGXI UNIV OF SCI & TECH

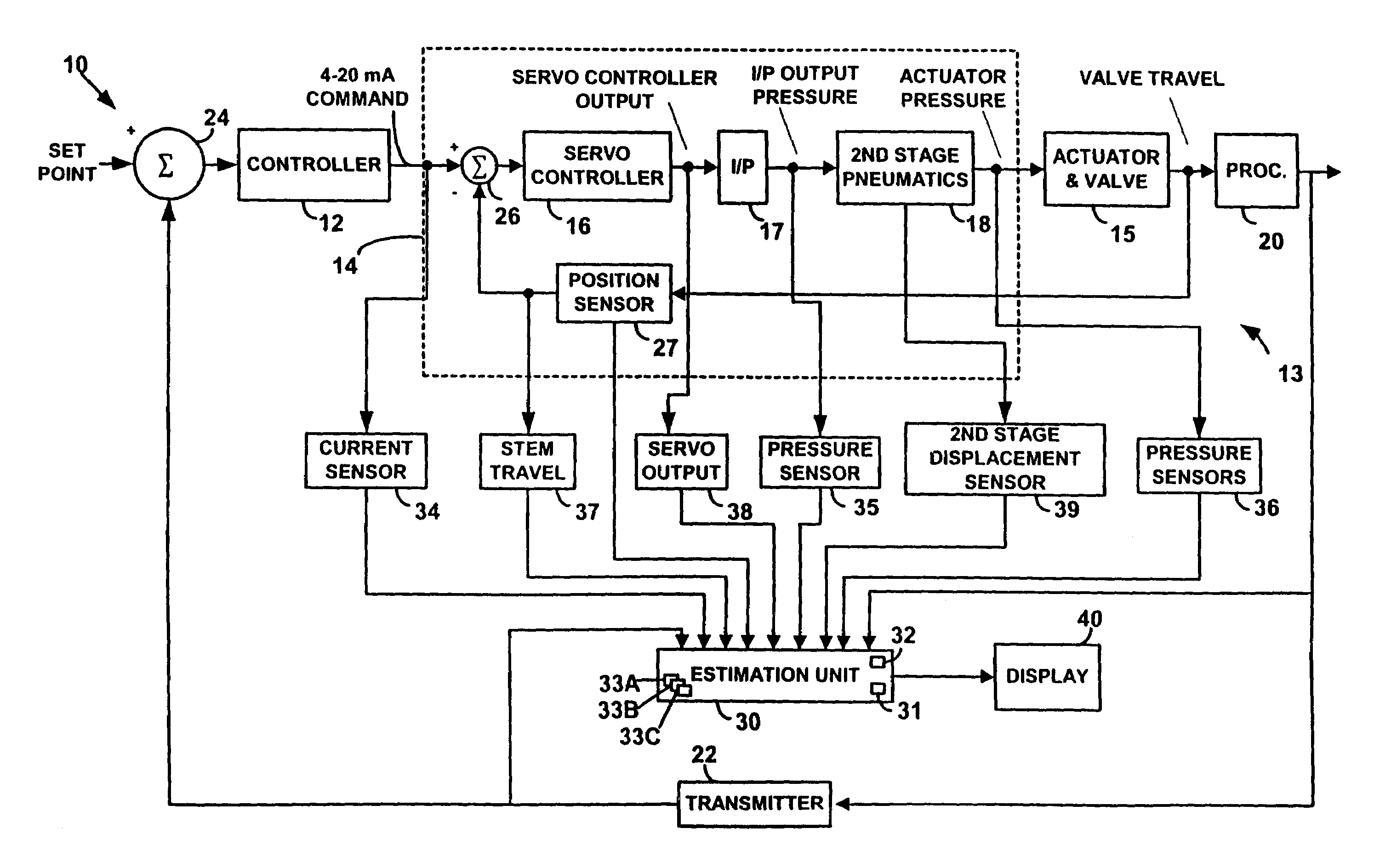

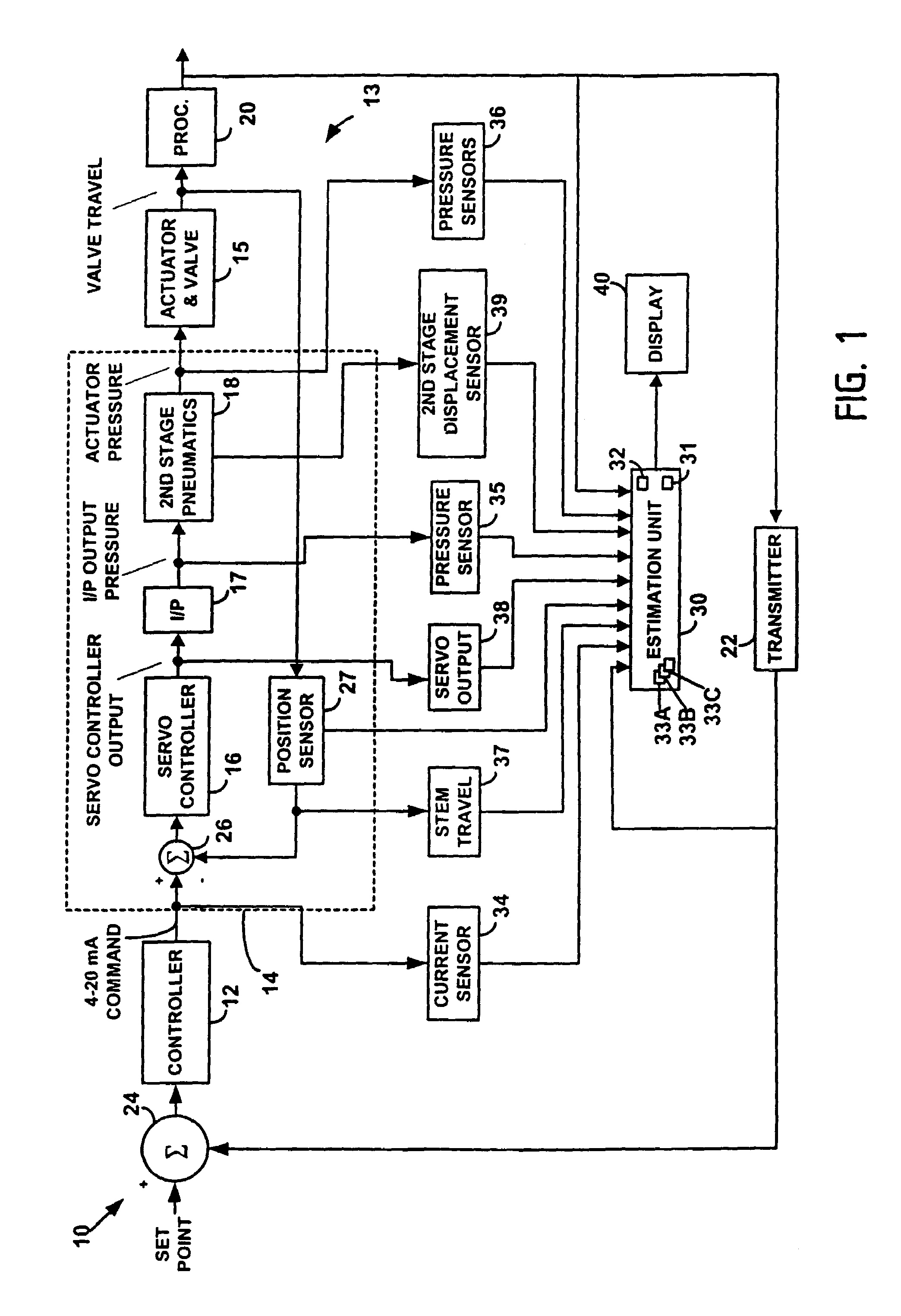

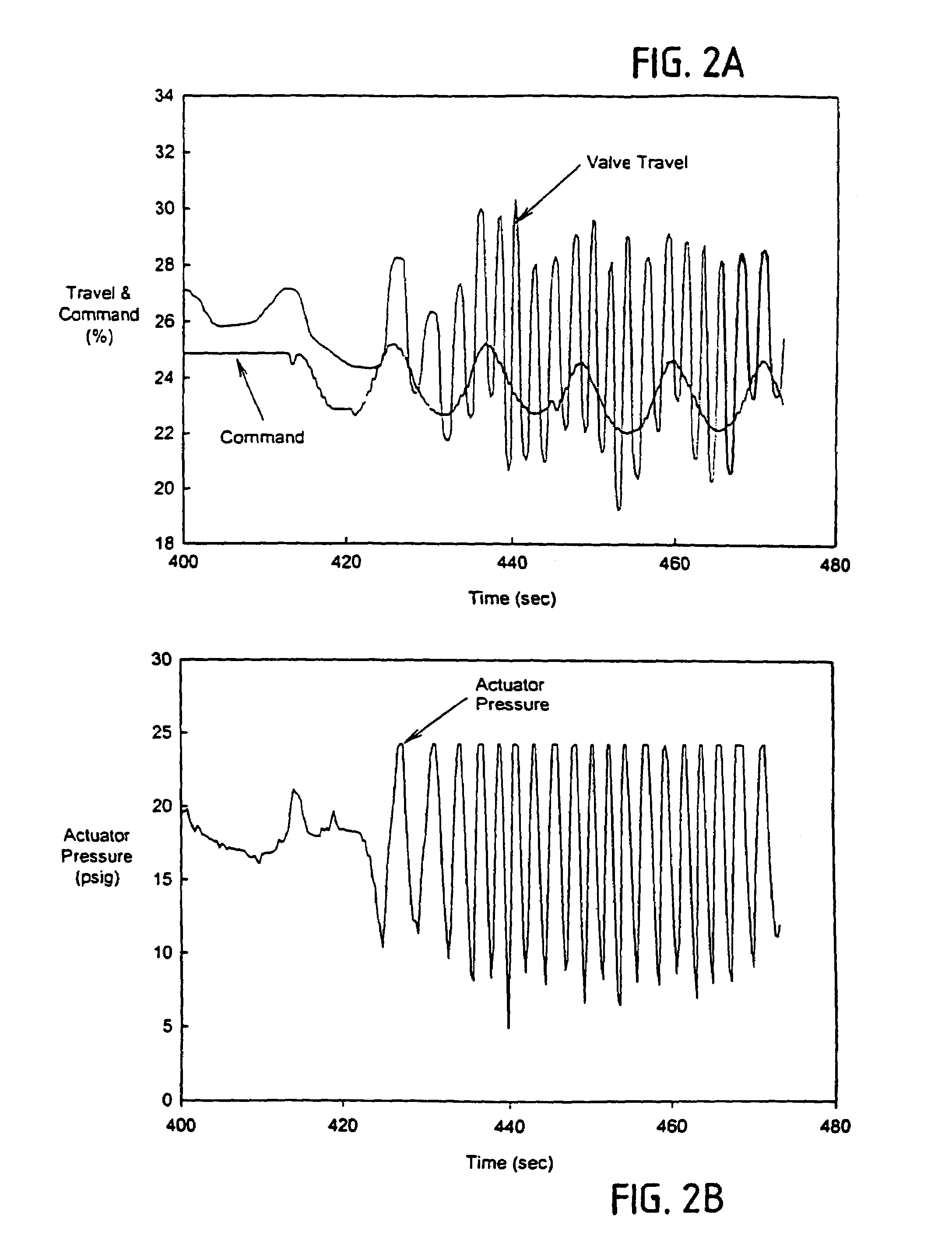

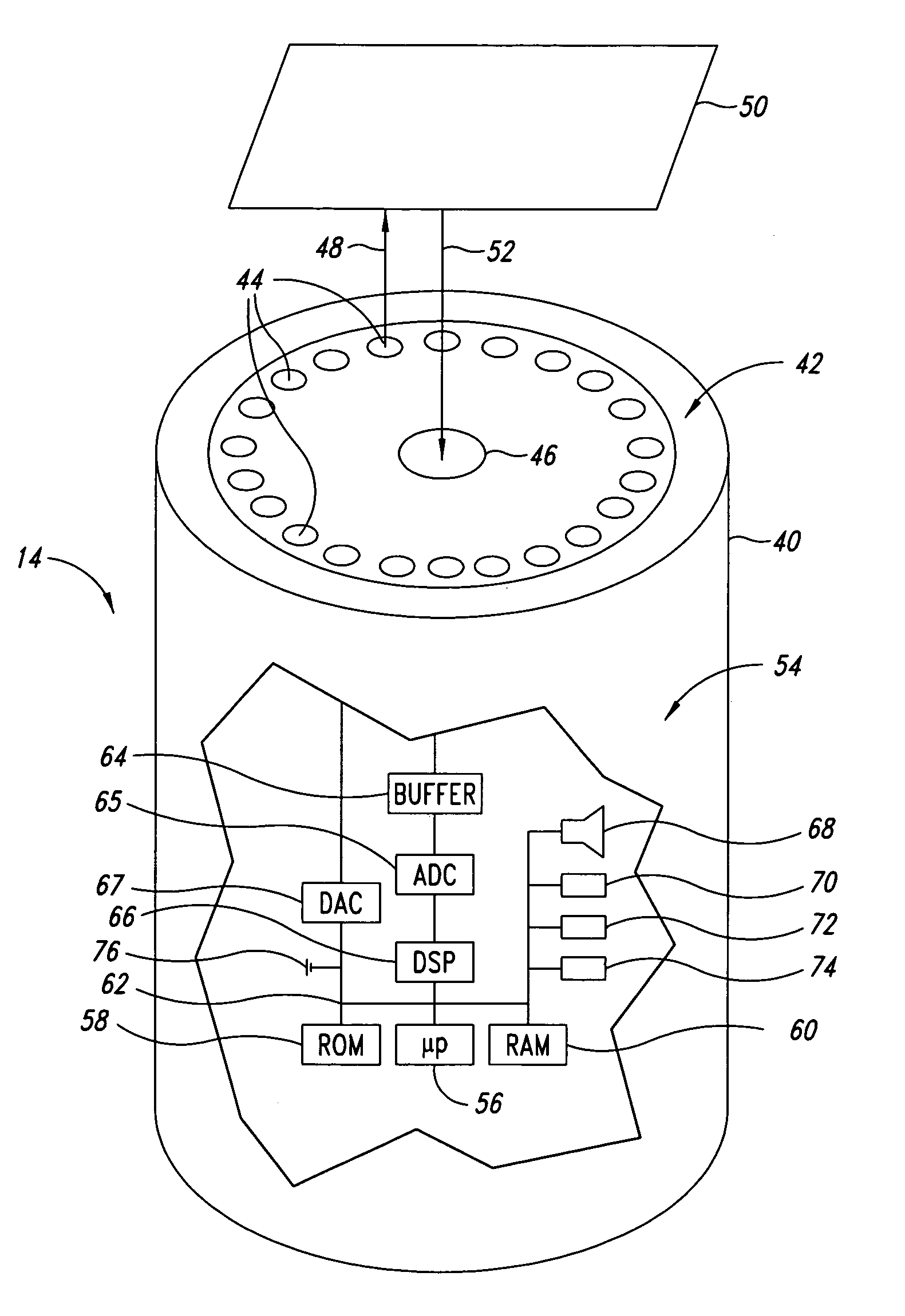

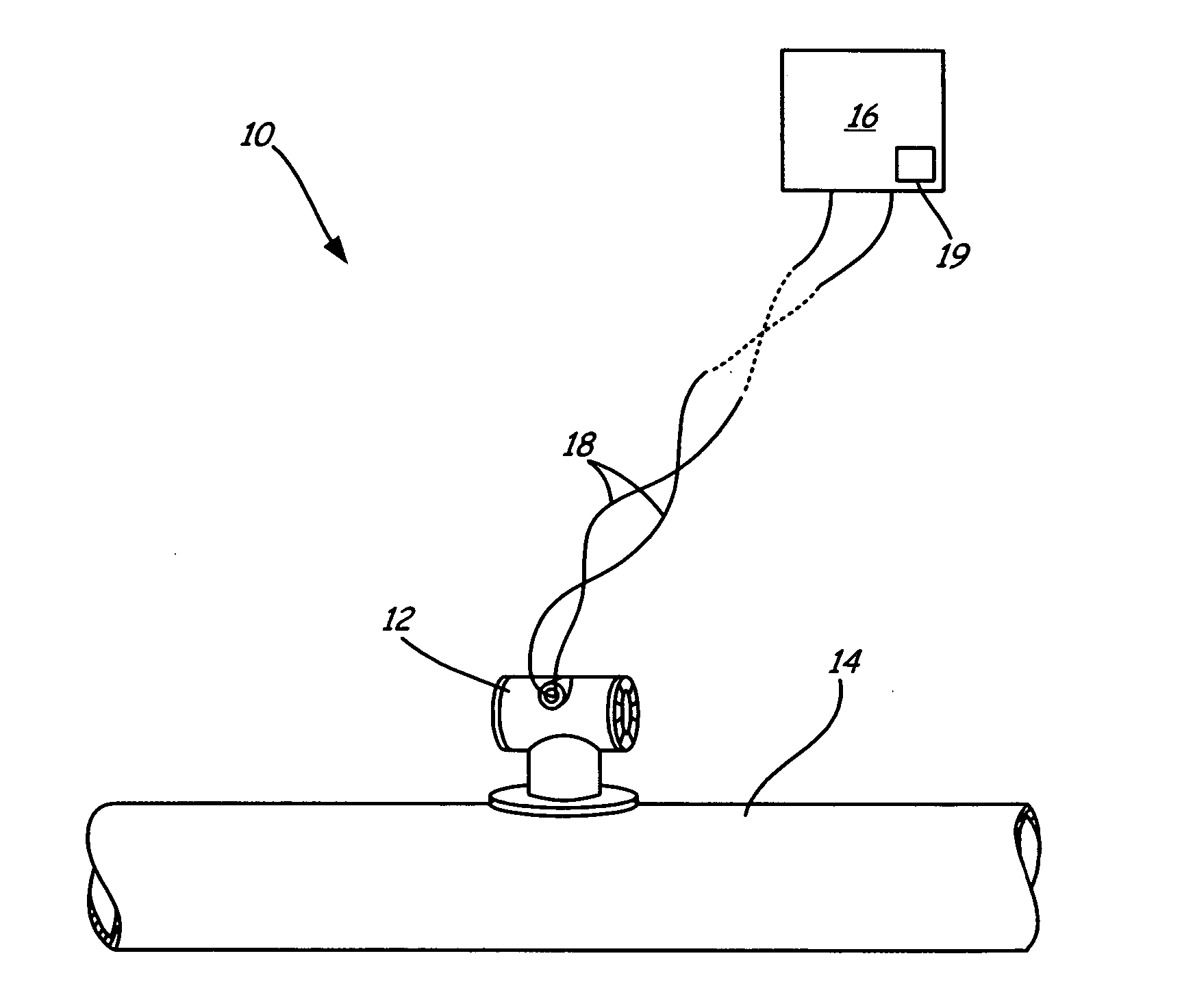

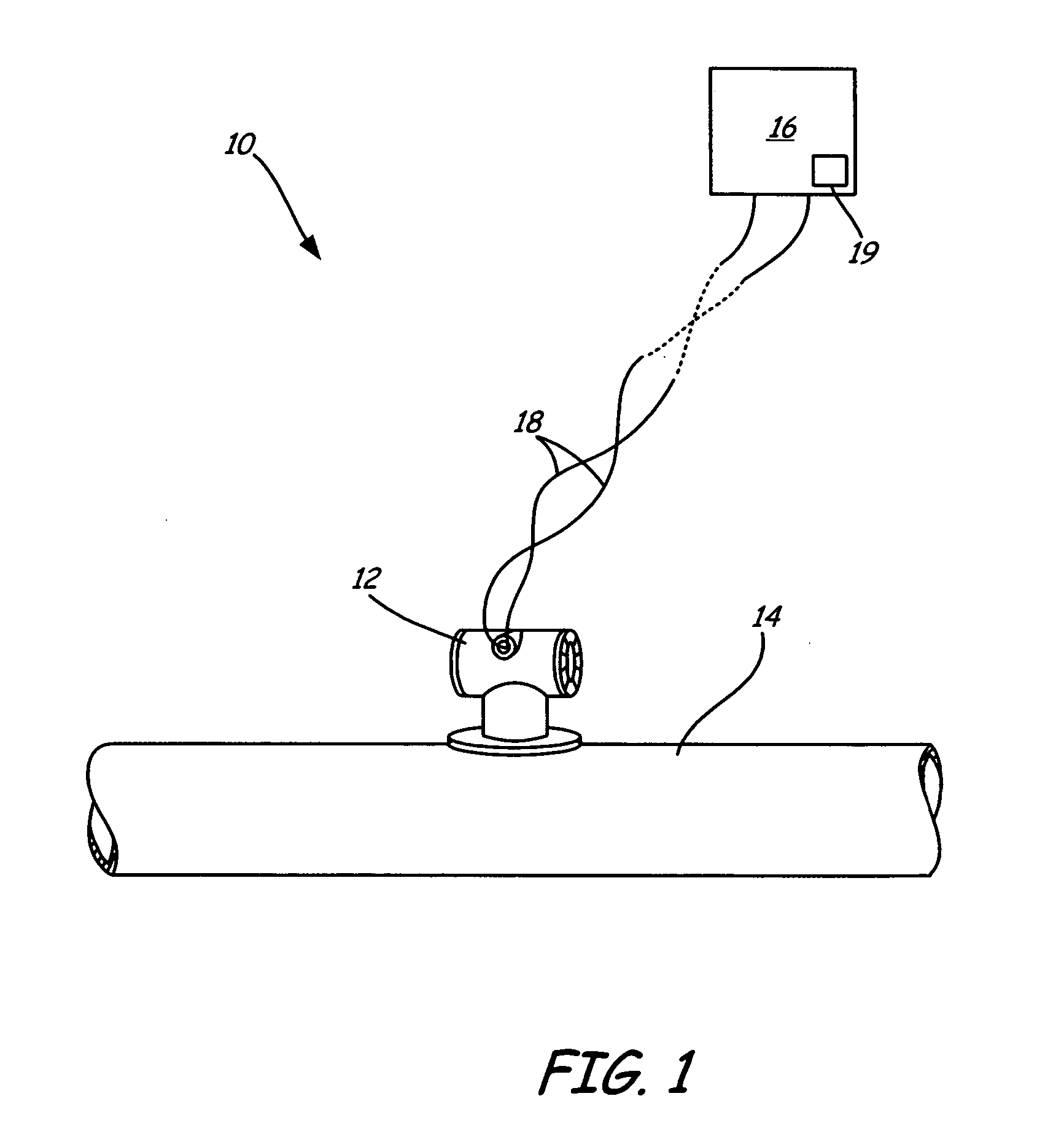

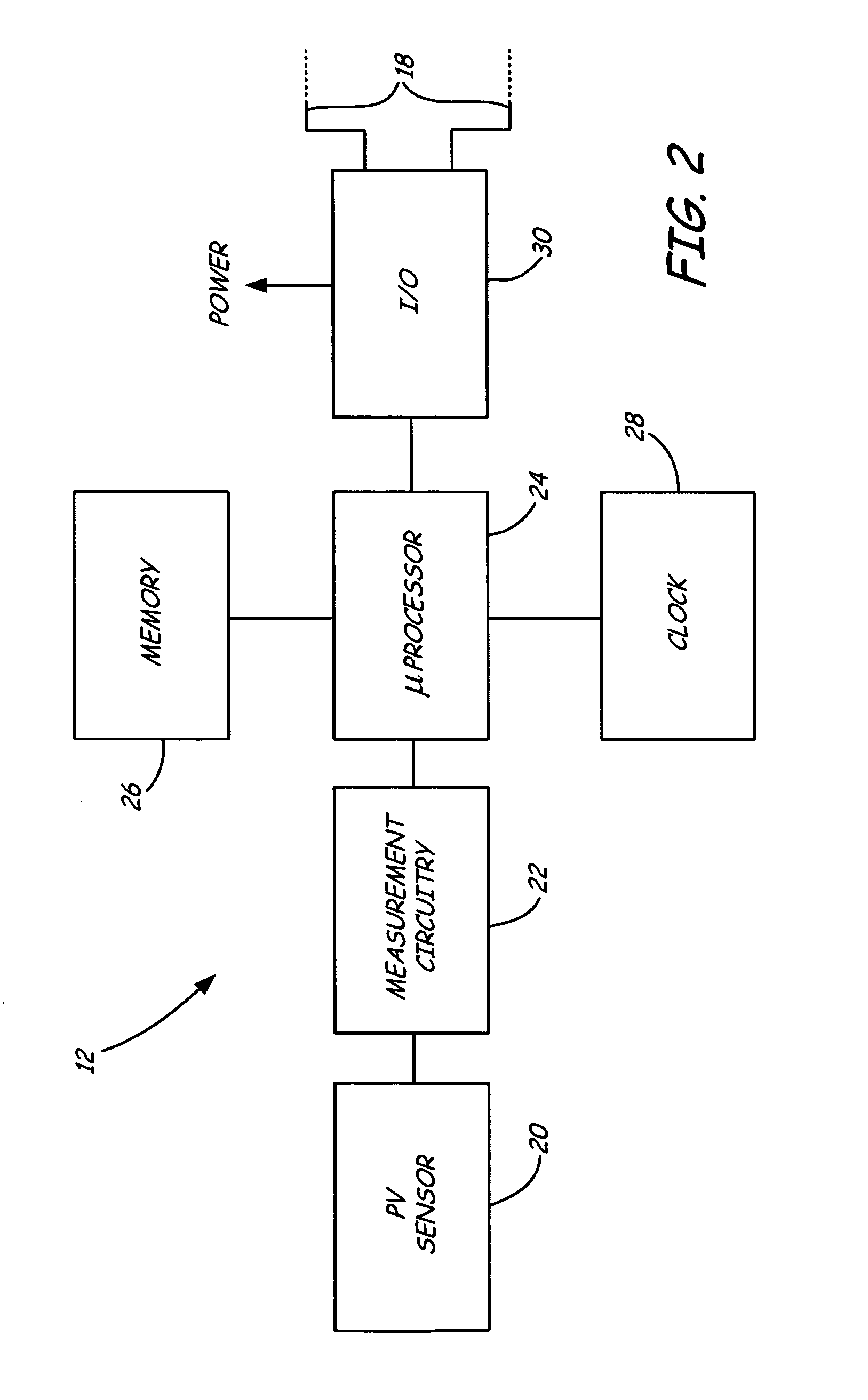

Detection and discrimination of instabilities in process control loops

InactiveUS7039537B2Spectral/fourier analysisDigital computer detailsMechanical AbnormalityStatistical analysis

Owner:FISHER CONTROLS INT LLC

Method, apparatus, and article to facilitate evaluation of objects using electromagnetic energy

ActiveUS8081304B2Low costPermit useRadiation pyrometryInertial sensorsQuality controlElectromagnetic shielding

Spectral information may be employed in process control and / or quality control of goods and articles. Spectral information may be employed in process control and / or quality control of media, for example financial instruments, identity documents, legal documents, medical documents, financial transaction cards, and / or other media, fluids for example lubricants, fuels, coolants, or other materials that flow, and in machinery, for example vehicles, motors, generators, compressors, presses, drills and / or supply systems. Spectral information may be employed in identifying biological tissue and / or facilitating diagnosis based on biological tissue.

Owner:VISUALANT

Diagnostics in process control and monitoring systems

ActiveUS20070270982A1Time indicationSynchronous motors for clocksTemporal informationMonitoring system

A condition of an industrial process is diagnosed based upon process variable information related to a value of a measured process variable. Histogram information is calculated based upon the determined process variable information and time information related to a duration of time the measured process variable has the value. Condition of the industrial process is diagnosed based upon the calculated histogram information.

Owner:MICRO MOTION INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com