Graphite composite negative electrode material for lithium ion battery, preparation method of material, and lithium ion battery

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of difficulty in controlling the uniformity and thickness of the coating layer, affecting the electrical conductivity of raw materials, and reducing the wettability of electrolytes. Improve liquid retention performance, increase specific surface area, and improve the effect of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

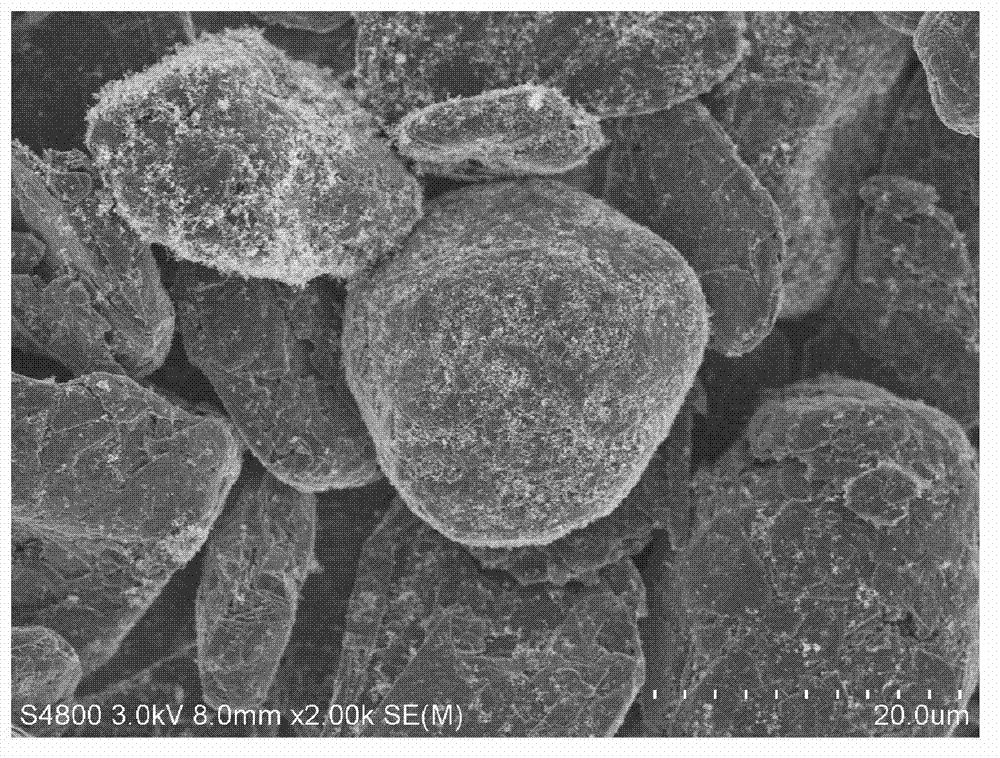

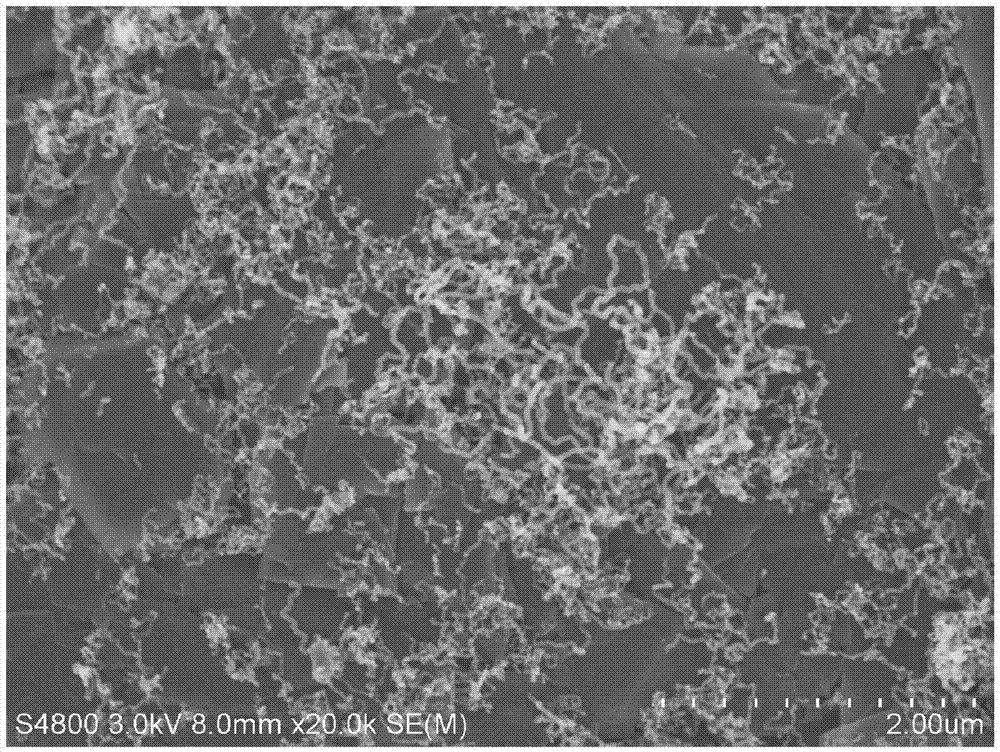

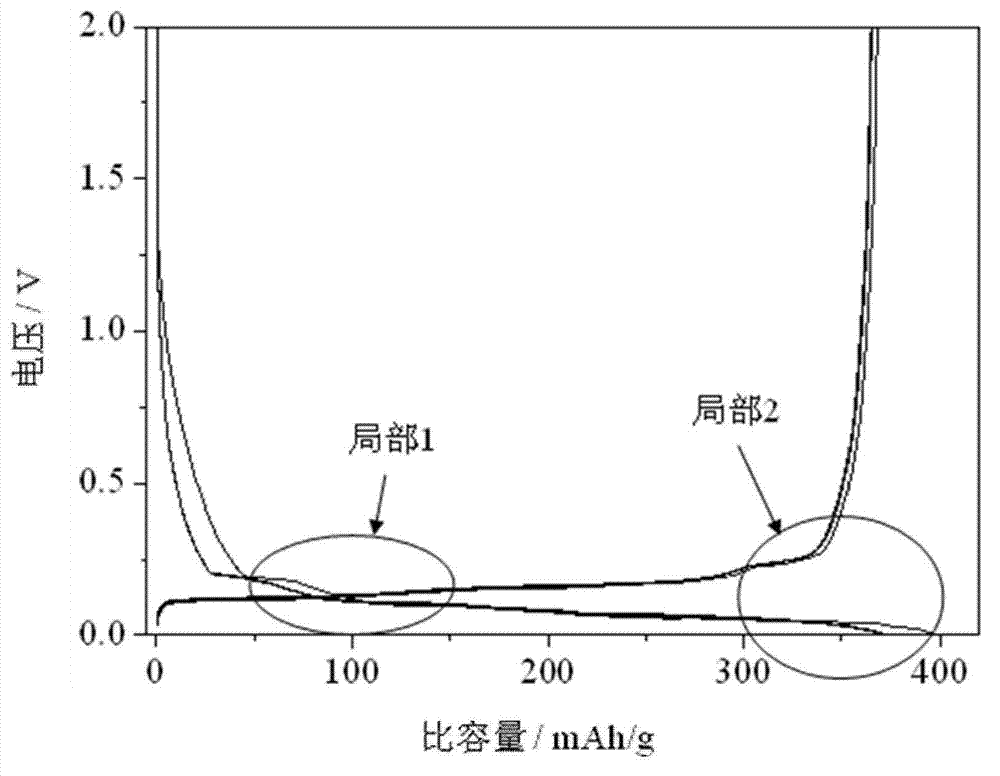

Embodiment 1

[0050] Fully dissolve ferric nitrate in water to prepare a solution with iron ion concentration of 0.001mol / L, then add 99.90% pure flake graphite and stir well, soak for 24h, filter out the solution, and then dry at 99℃ to obtain graphite Composite material precursor: Put the above graphite composite material precursor into a rotary kiln, in a helium atmosphere with a flow rate of 0.1L / min and at 400°C, acetylene is introduced at a flow rate of 10L / min for chemical vapor deposition, and the reaction lasts for 0.1 h, to generate carbon nanotubes and / or carbon nanofibers; calcining the product obtained by the above chemical vapor deposition in a vacuum and 2000 ℃ for 10h; placing the product obtained by the above calcination in a box-type resistance furnace, in an oxygen atmosphere and 300 It was calcined at a constant temperature for 5 hours at ℃ and then naturally cooled to room temperature to obtain a graphite composite anode material.

Embodiment 2

[0052] Fully dissolve nickel chloride in water to make a solution with a nickel ion concentration of 0.01 mol / L, then add microcrystalline graphite with a purity of 95.00% and stir well, soak for 15 hours, filter out the solution, and then dry at 90°C. The graphite composite material precursor is obtained; the above graphite composite material precursor is put into a tube furnace, and methane is fed into the tube furnace at a flow rate of 0.5L / min in a neon atmosphere and at a flow rate of 5L / min for chemical vapor deposition. The reaction lasts for 1 hour to generate carbon nanotubes and / or carbon nanofibers; the product obtained by chemical vapor deposition is immersed in a strong mixed acid of nitric acid, hydrochloric acid and sulfuric acid for 0.5 hours, then washed with water, dehydrated, and dried; The purified product is placed in a tubular sintering furnace, calcined at a constant temperature of 400° C. for 1 h in an air atmosphere, and then naturally cooled to room tem...

Embodiment 3

[0054] Fully dissolve cobalt sulfate in water to prepare a solution with a cobalt ion concentration of 0.1 mol / L, then add a needle coke graphitized product with a purity of 99.00% and stir well, soak for 10 hours, filter out the solution, and then bake at 80°C Dry to obtain a graphite composite material precursor; put the above graphite composite material precursor into a box furnace, and pass ethylene at a flow rate of 1L / min under an argon atmosphere at a flow rate of 1L / min and at 800°C for chemical vapor deposition , The reaction lasts for 2 hours to generate carbon nanotubes and / or carbon nanofibers; the product obtained by chemical vapor deposition is calcined under nitrogen and 2500°C for 5 hours; the product obtained by the above calcination is placed in a high-temperature microwave ashing furnace, It was calcined in an oxygen atmosphere at a constant temperature of 500° C. for 0.5 h, and then naturally cooled to room temperature to obtain a graphite composite anode mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com