Patents

Literature

202results about How to "High rate characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrolyte for lithium secondary battery and lithium secondary battery using the same

ActiveUS20150064578A1Excellent characteristicsImprove life characteristicsCell electrodesOrganic electrolyte cellsOrganic solventElectrical battery

An electrolyte for a lithium secondary battery, the electrolyte including: a lithium salt; a non-aqueous organic solvent; and a piperazine derivative represented by Formula 1 having an oxidation potential lower than an oxidation potential of the non-aqueous organic solvent by about 2 V to about 4 V:wherein, in Formula 1, X, Y, and R1 to R4 are defined in the specification.

Owner:SAMSUNG ELECTRONICS CO LTD

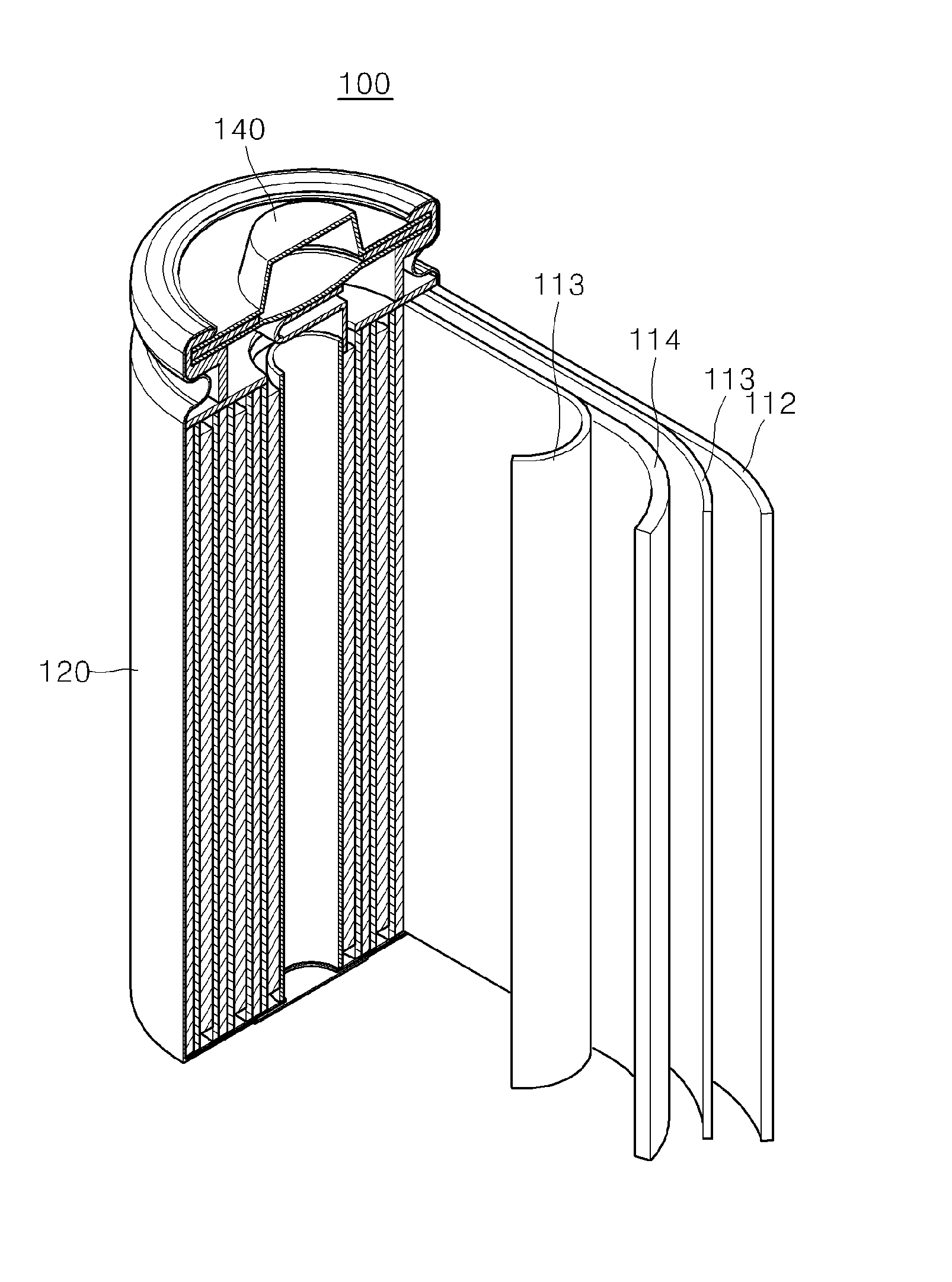

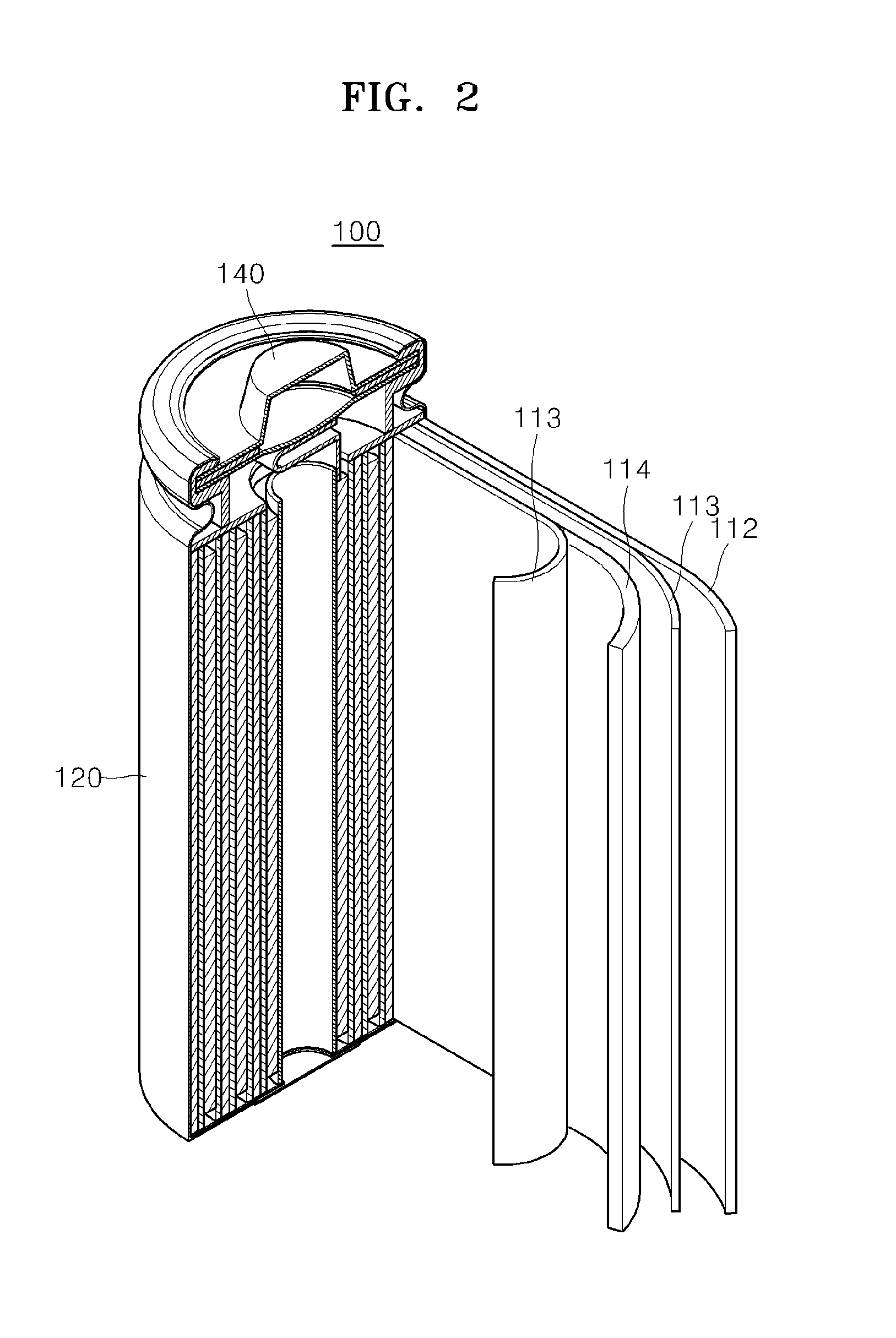

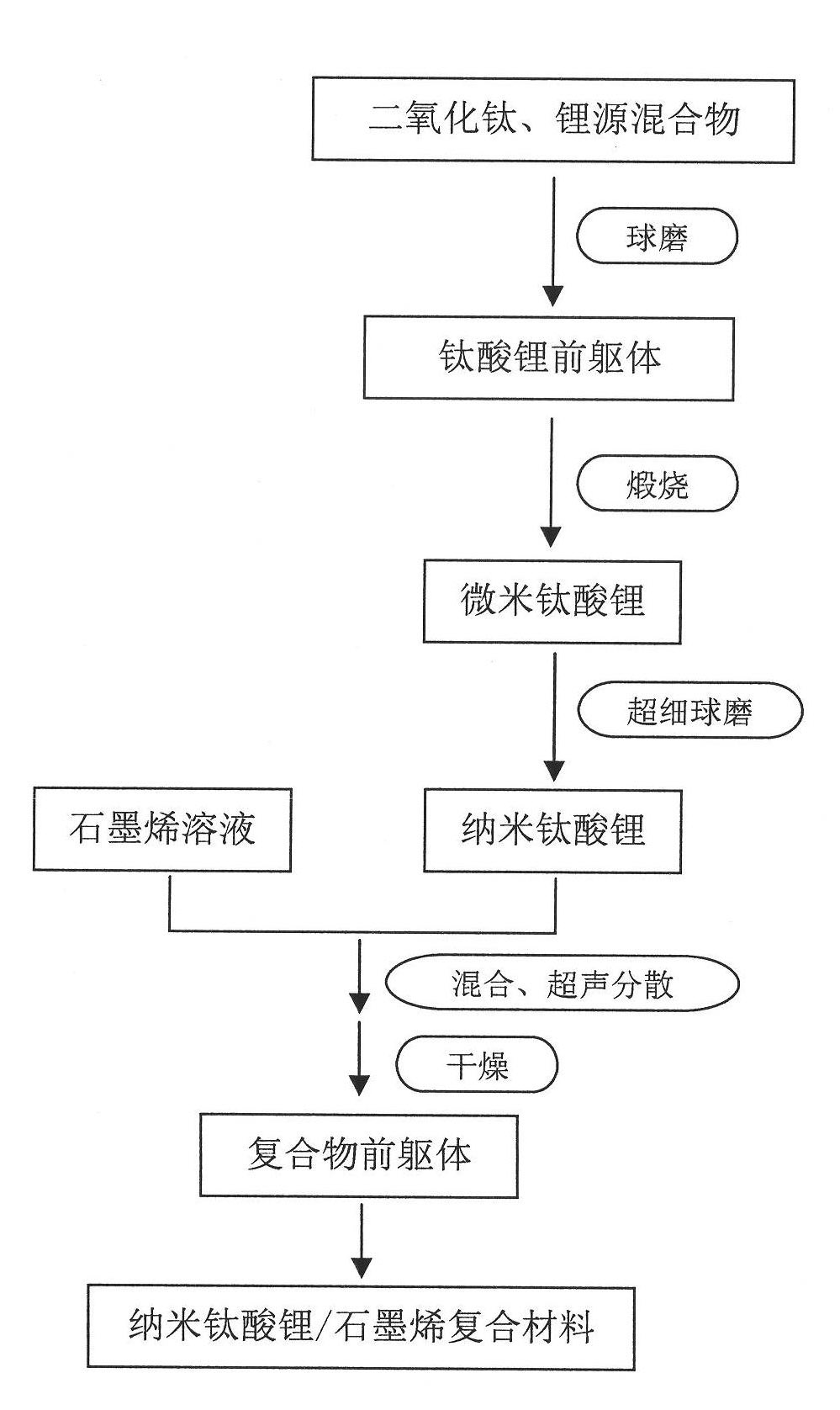

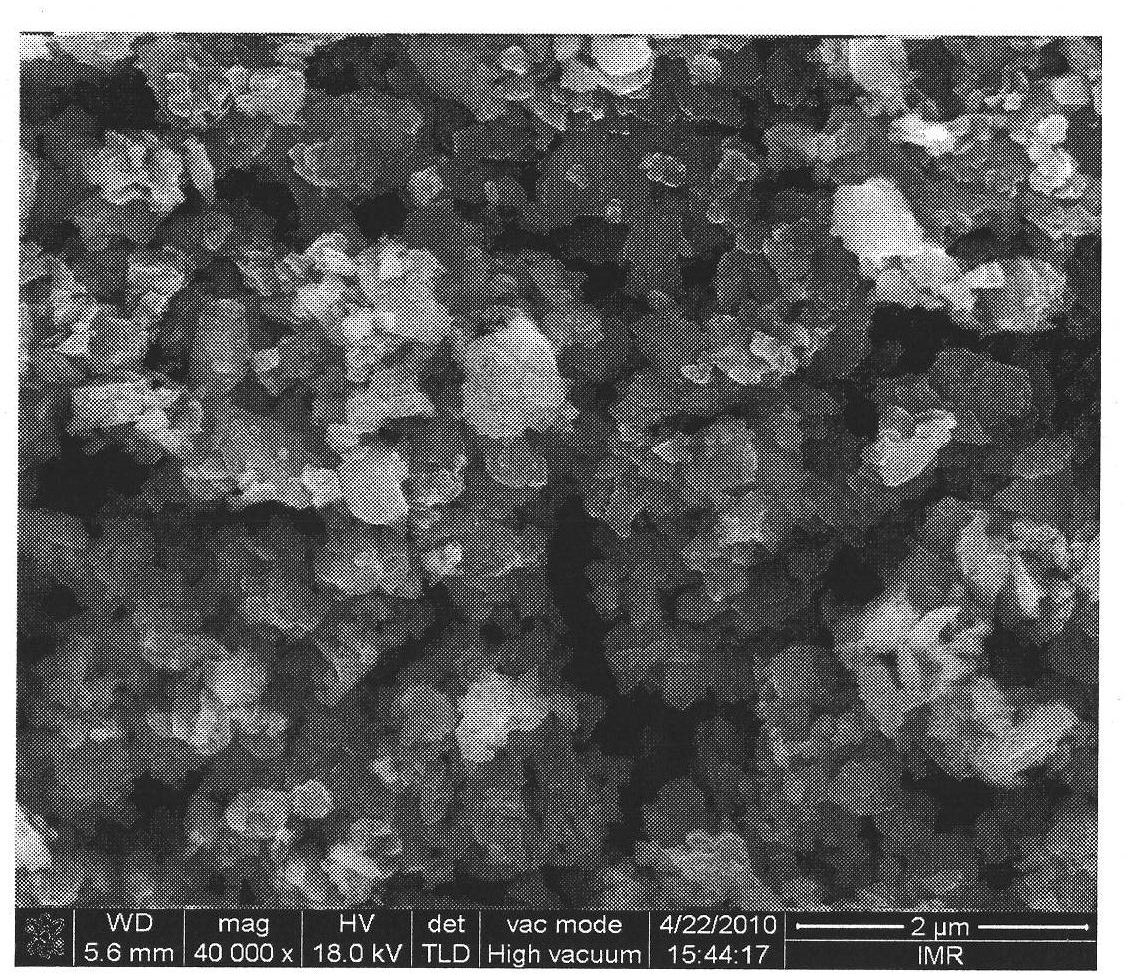

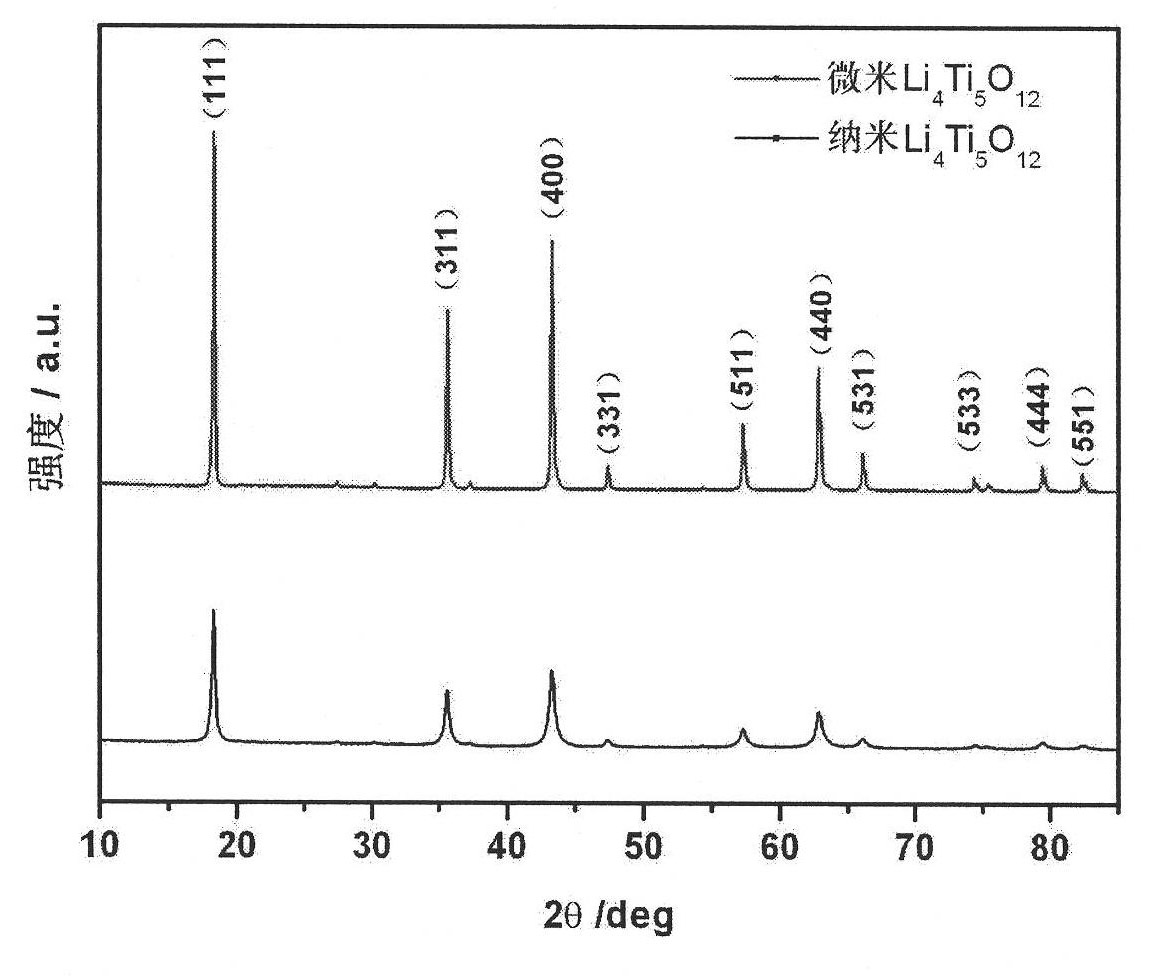

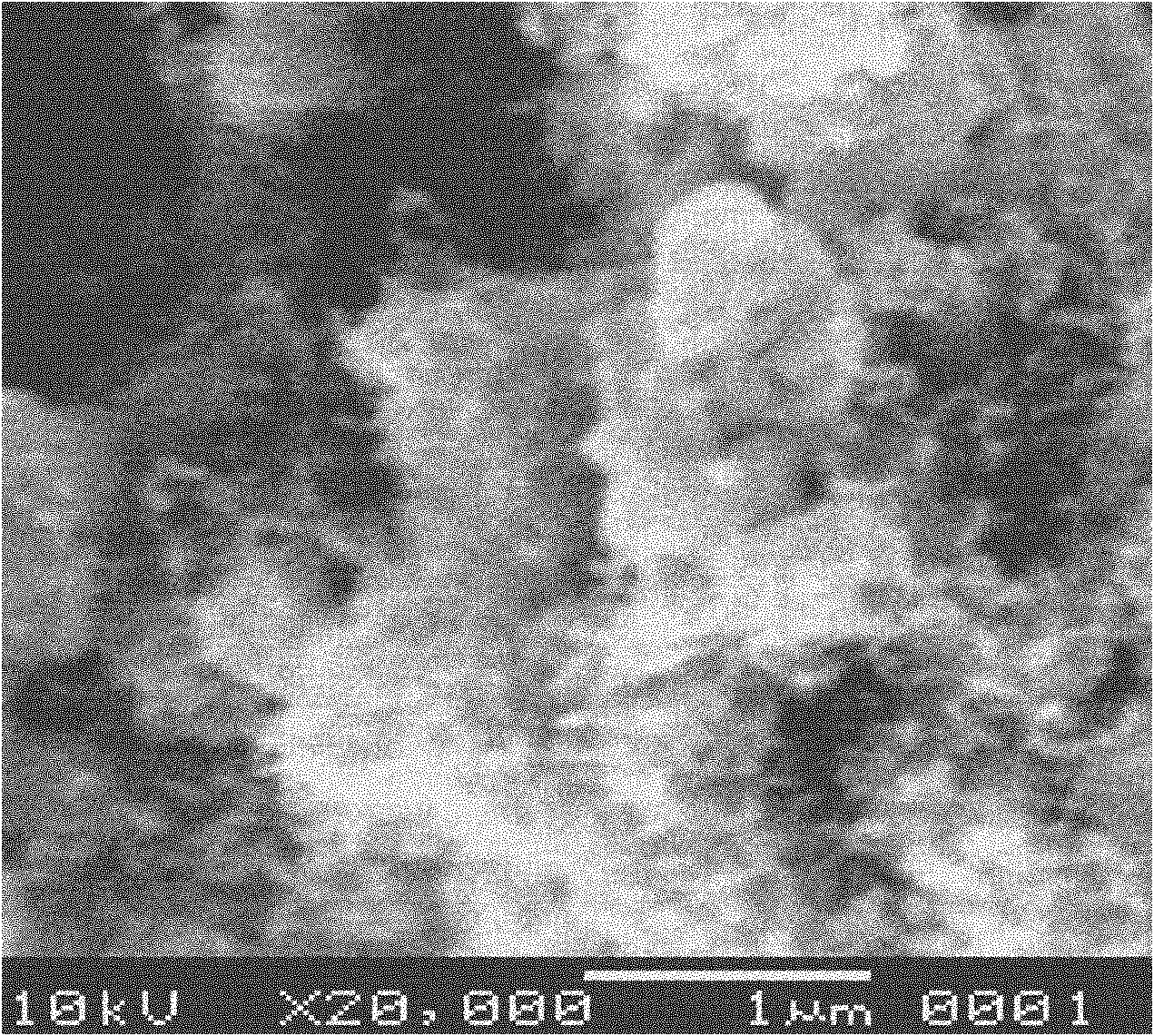

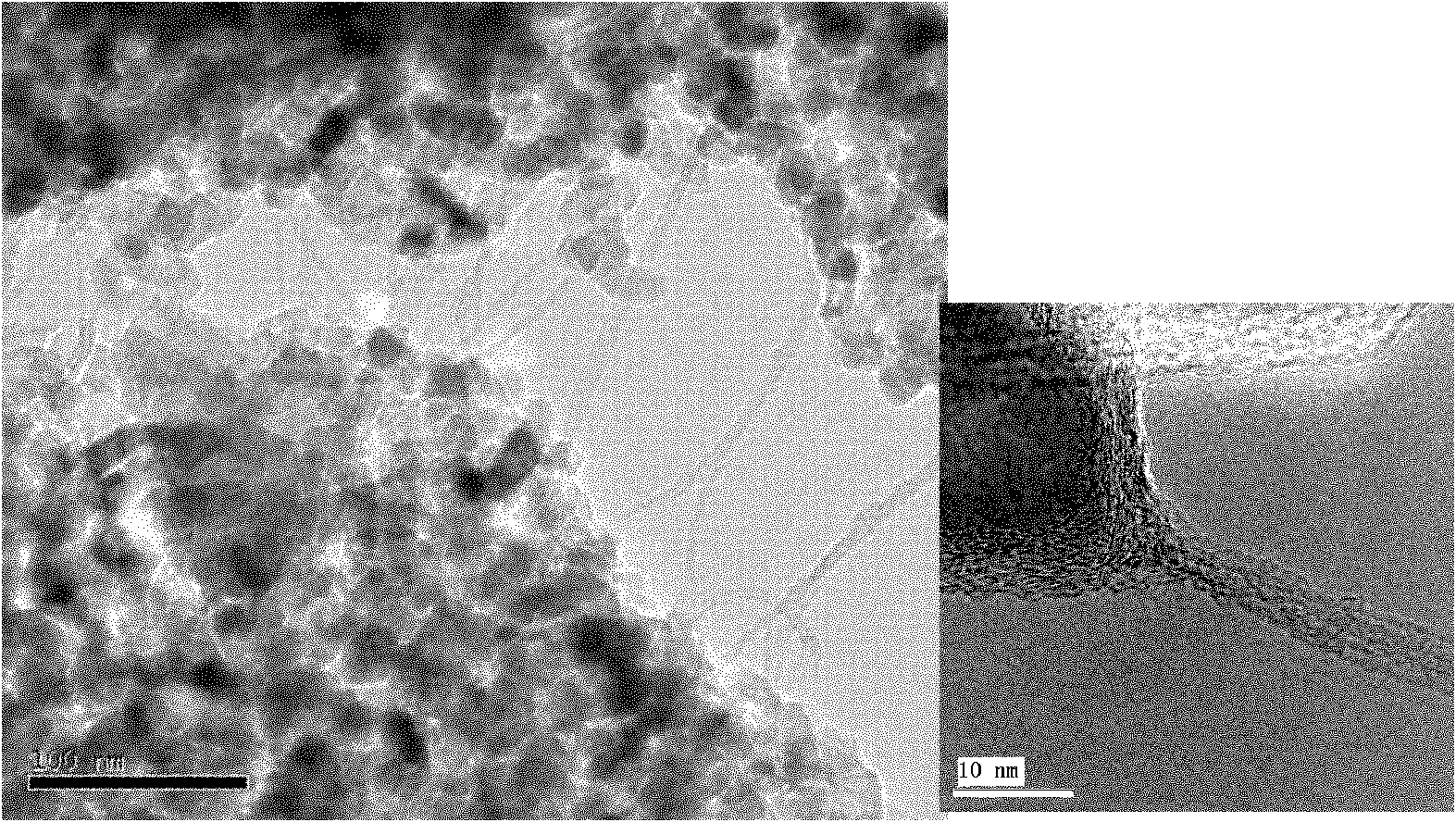

Nanometer lithium titanate/graphene composite negative electrode material and preparation process thereof

InactiveCN102376937AImprove electrochemical performanceAvoid defectsNon-aqueous electrolyte accumulator electrodesGrain treatmentsSodium-ion batteryCvd graphene

The invention relates to the field of negative electrode materials of lithium ion batteries, and specifically to a nanometer lithium titanate / graphene composite negative electrode material and a preparation process thereof. According to the invention, micron-sized lithium titanate prepared by the solid phase method is subjected to ultrafine ball milling to obtain nanometer powder, and the nanometer lithium titanate powder and graphene are uniformly compounded and subjected to heat treatment so as to obtain a high performance lithium ion battery negative electrode material; the invention is characterized in that uniform distribution of graphene in the nanometer lithium titanate powder is realized through in situ compounding; the weight of graphene in the composite negative electrode material accounts for 0.5 to 20%, and the weight of lithium titanate accounts for 80 to 99.5%. The lithium ion battery negative electrode material has good electrochemical performance, 1C capacity greater than 165 mAh / g, 30C capacity greater than 120 mAh / g and 50C capacity greater than 90 mAh / g. Nanometer lithium titanate in the lithium ion battery negative electrode material prepared in the invention has high phase purity; the preparation process of the material is simple and is easy for industrial production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

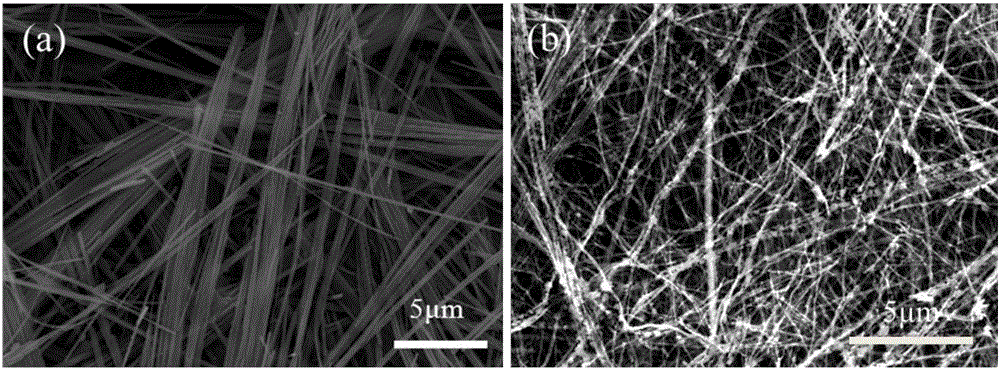

Lithium iron phosphate-carbon nanotube composite material, preparation method, and application thereof

ActiveCN102427130AThe phase is pure and the crystal form is goodLow resistivityCell electrodesLithium iron phosphateCarbon nanotube

The present invention discloses a lithium iron phosphate-carbon nanotube (LiFePO4-CNTs) composite material. The composite material comprises LiFePO4 particles, a nano-carbon layer and CNTs, wherein the nano-carbon layer is positioned outside the LiFePO4 particles, and the CNTs grow in the nano-carbon layer in an in situ growth manner by a chemical vapor deposition (CVD) process. In addition, the present invention further discloses a preparation method for the composite material. The method comprises: uniformly mixing and coating the prepared LiFePO4 precursor powder, a catalyst and liquid carbon source to prepare into the slurry; adopting a spraying feeding device to convey the slurry to a high-temperature reaction furnace to form a floating CVD process; carrying out heat insulation calcination for the resulting mixture so as to complete the treatments of granulation of the LiFePO4 precursor, in situ growth and coating of the CNTs and synthesis sintering of the LiFePO4 in one step, such that the uniform nano-carbon layer and the CNTs are formed on the surfaces of the LiFePO4 particles. In addition, the present invention further discloses an application of the composite material in battery preparation. According to the composite material of the present invention, the nano-carbon layer and the CNTs have good crystallization, the total carbon content is low, the electrical conductivity and the specific capacity are high so as to substantially increase the rate performance.

Owner:HUBEI RT ADVANCED MATERIALS CO LTD

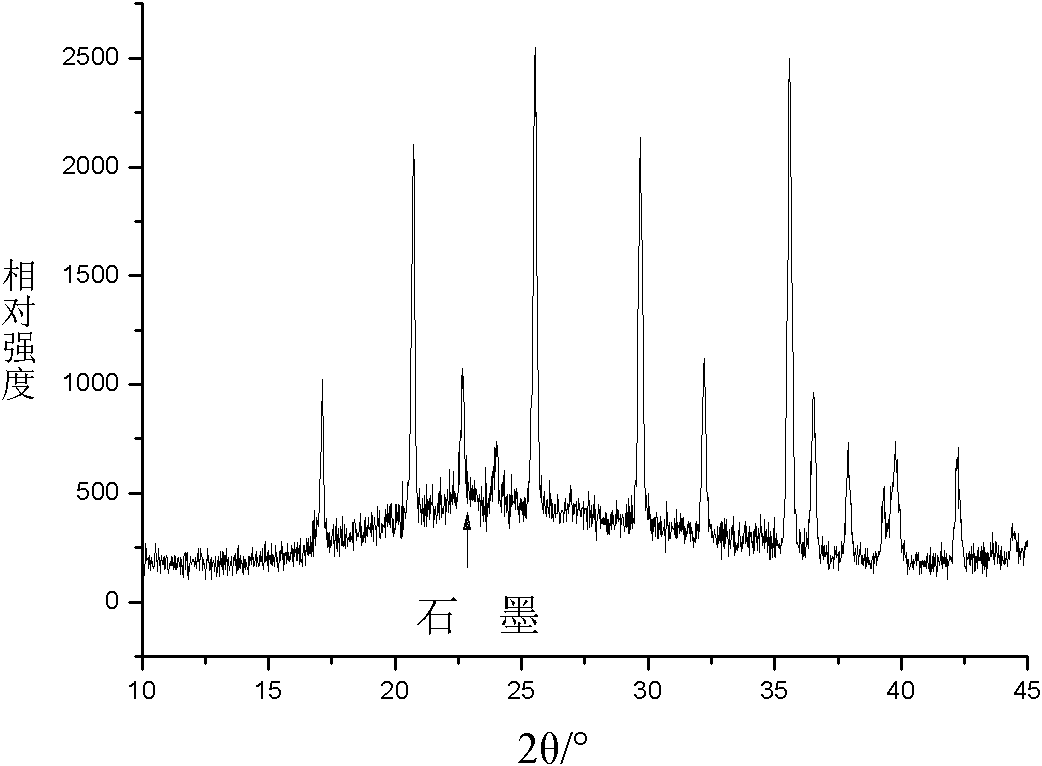

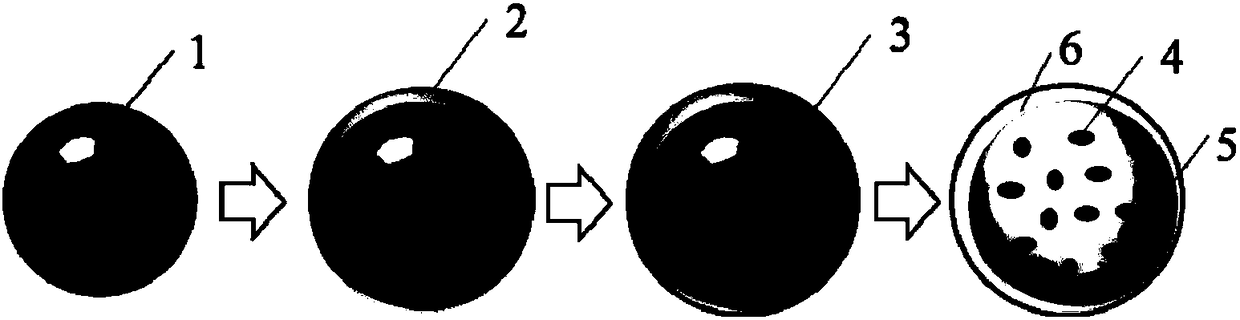

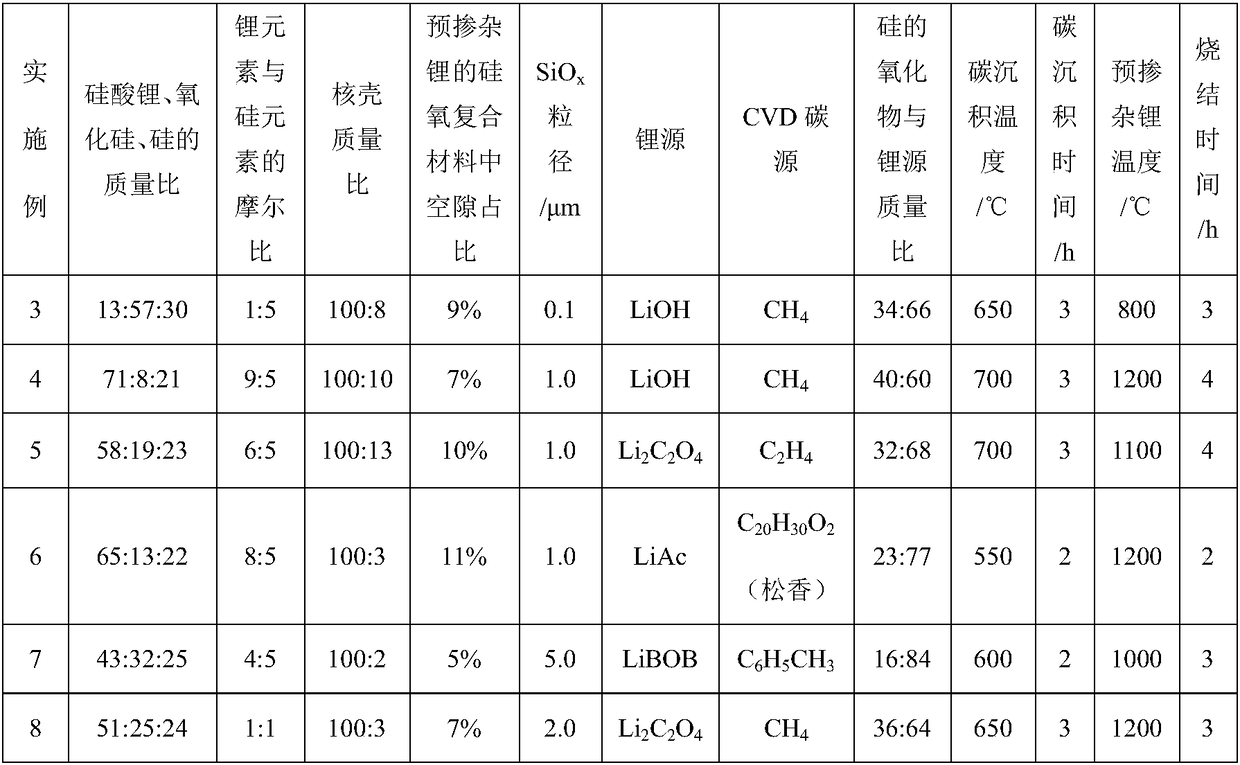

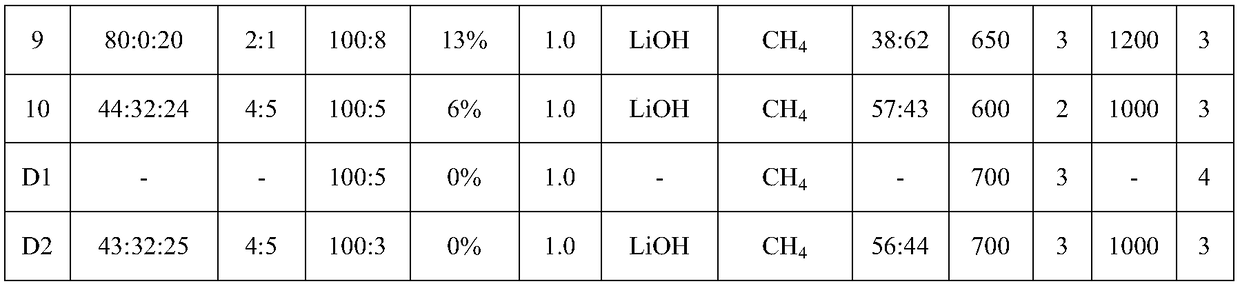

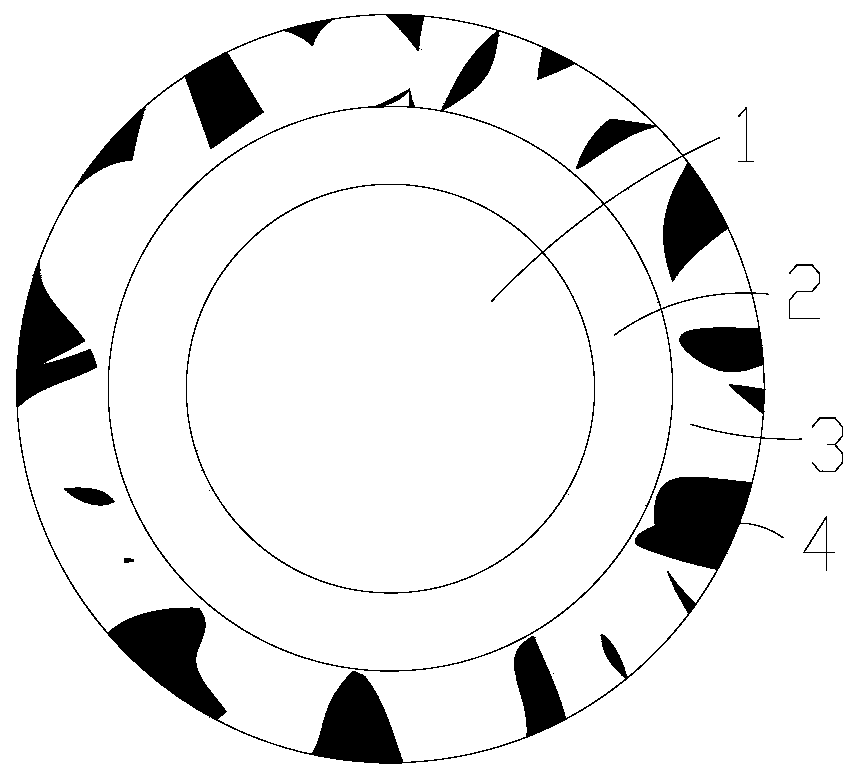

Space buffer lithium-doped silicon oxide composite material, preparation method of composite material and lithium ion battery

ActiveCN108232145AImprove charge and discharge efficiencyImproved cycle stability and rate characteristicsNegative electrodesSecondary cellsLithium electrodeSilicon oxide

The invention relates to a space buffer lithium-doped silicon oxide composite material, a preparation method of the composite material and a lithium ion battery, and belongs to the technical field ofthe lithium ion battery. The material is of a core shell structure; the core is a lithium predoped silicon oxide composite material; the shell is a coated with carbon layer. For the doped lithium, silicon oxide in the silicon oxide composite material is converted into lithium silicate through solid phase reaction in the preparation process. The preparation method of the space buffer lithium-dopedsilicon oxide composite material comprises the steps that after a lithium source is covered on the silicon oxide particle surface, a coating carbon layer is formed at the obtained particle surface through chemical vapor carbon deposition; the obtained coated material is sintered in vacuum or inert atmosphere; a surface coated lithium source reacts with silicon oxide; on one hand, the lithium doping of the silicon oxide material is realized; on the other hand, the building of a cavity structure is realized. The space buffer lithium-doped silicon oxide composite material has the characteristicsof high specific capacity, high first-time charging and discharging efficiency and long service life.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

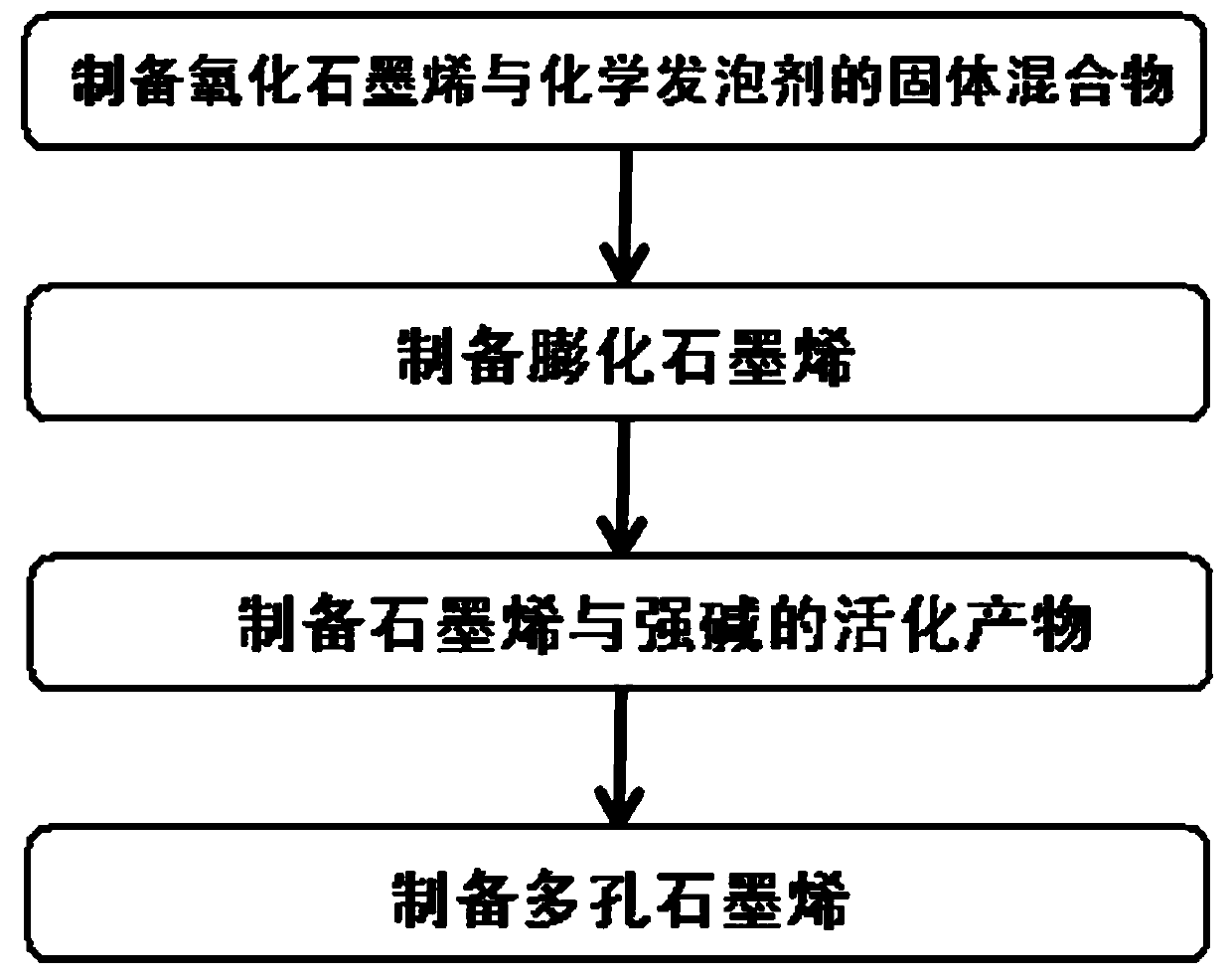

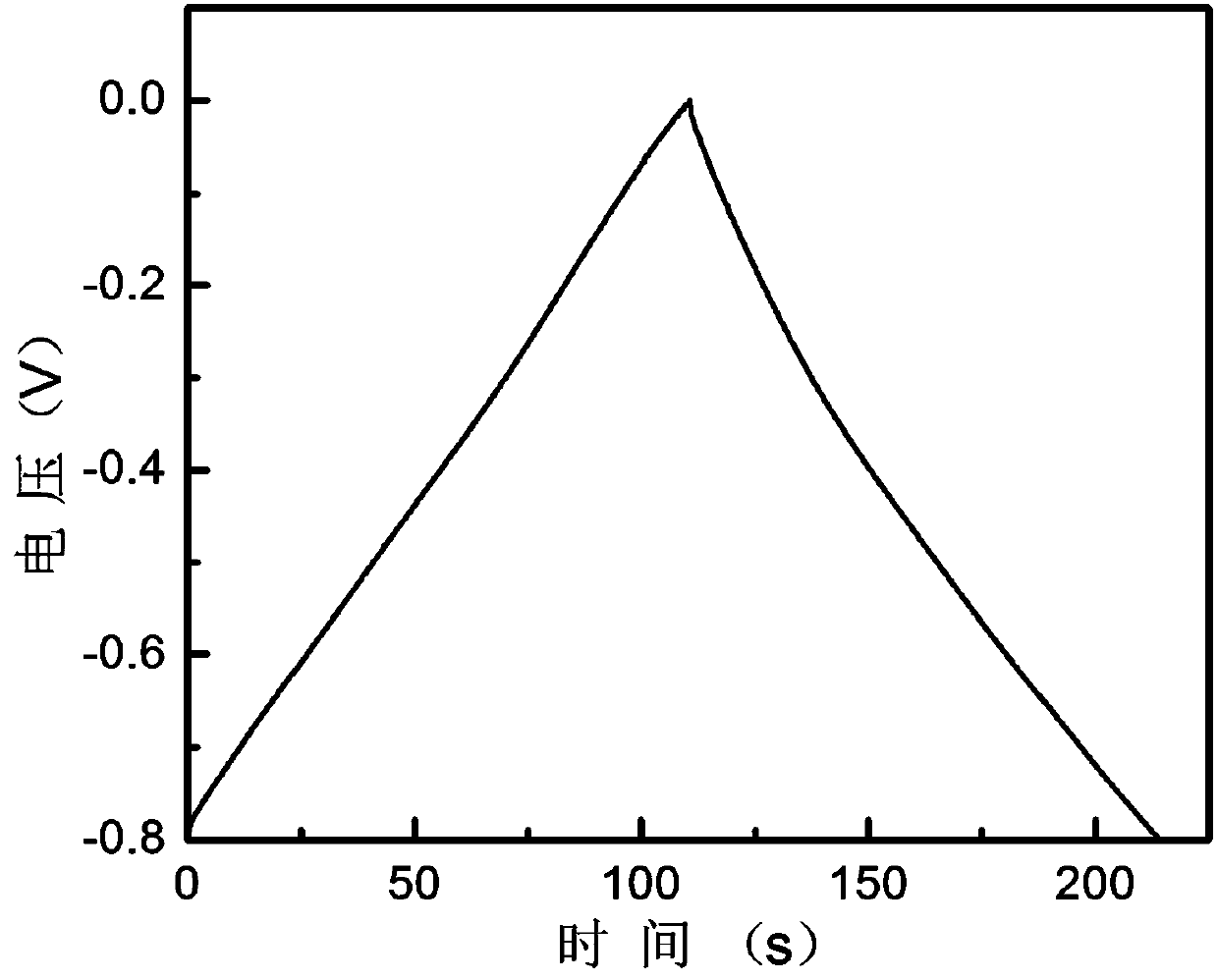

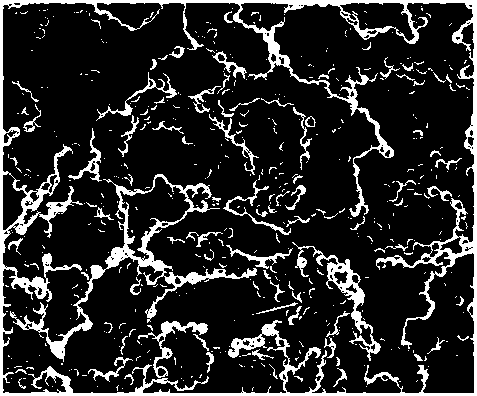

Preparation method of porous graphene

InactiveCN103466604AInhibit high temperature agglomeration effectHigh degree of peelingCarbon compoundsPorous grapheneCapacitance

The invention discloses a preparation method of porous graphene. The method comprises the steps of: (1) stripping graphite oxide in a water / ethanol mixed solution with pH of 9-10, adding a chemical foaming agent and mixing them uniformly, carrying out filtering and drying to obtain a solid mixture; (2) placing the mixture in a reducing atmosphere, and performing heating expansion reduction to obtain expanded graphene; (3) blending the expanded graphene with strong base, and conducting high temperature activation; and (4) washing the product with hydrochloric acid and deionized water, and performing drying so as to obtain porous grapheme. The porous graphene prepared by the method involved in the invention has a specific surface area up to 2075m<2> / g, a pore volume up to 1.8cm<3> / g, and an average pore size of 1-7nm. As a supercapacitor electrode material, the specific capacitance can reach 155F / g under a current density of 1Ag<-1>. As a porous graphene electrode, the specific capacitance can reach 84.4% along with the increase of current density from 0.2Ag<-1> to 20Ag<-1>. The porous graphene has high specific capacitance and cycle stability. The preparation method disclosed in the invention has the advantages of simple process, low cost, and easy scale production.

Owner:EAST CHINA UNIV OF SCI & TECH

Foam metal matrix oxide electrode used in lithium-ion battery cathode and preparation method thereof

ActiveCN102013470AExtended service lifeIncrease capacityElectrode carriers/collectorsOxide compositeAlloy

The invention relates to a preparation method of a foam metal matrix oxide electrode used in the lithium-ion battery cathode, relating to a metal electrode used in the lithium-ion battery cathode and a preparation method thereof. The invention aims to solve the problems of the existing lithium-ion battery anode material that the specific capacity is low, the cycle performance is poor and the preparation method is complicated. The foam metal matrix oxide electrode uses one or two of foam metals comprising Cu, Ni and Fe as the matrix. The preparation method of the foam metal matrix oxide electrode comprises the following steps: 1) cleaning with acid solution; 2) soaking with alkaline solution; and 3) generating one or two of the corresponding transition metal oxides, namely CuO, Cu2O, NiO, Ni2O, Fe2O3 and Fe3O4 on the foam metal in situ through low-temperature roasting and other steps to obtain the foam metal / transition metal oxide composite electrode. The preparation method is simple, the electrode has high specific capacity, long cycle life and excellent rate performance; and the electrode is suitable for the lithium-ion battery system of an electric vehicle.

Owner:HARBIN INST OF TECH

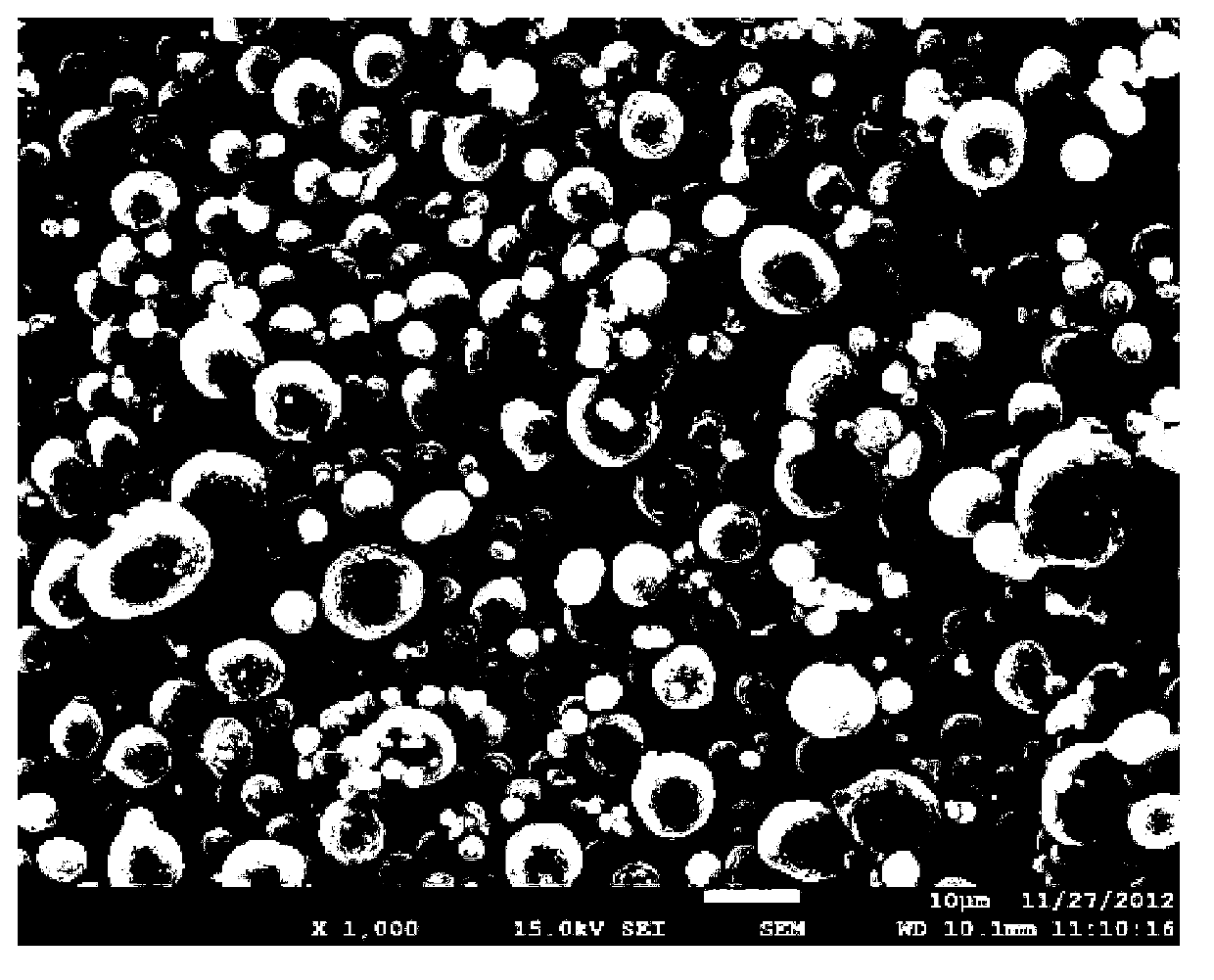

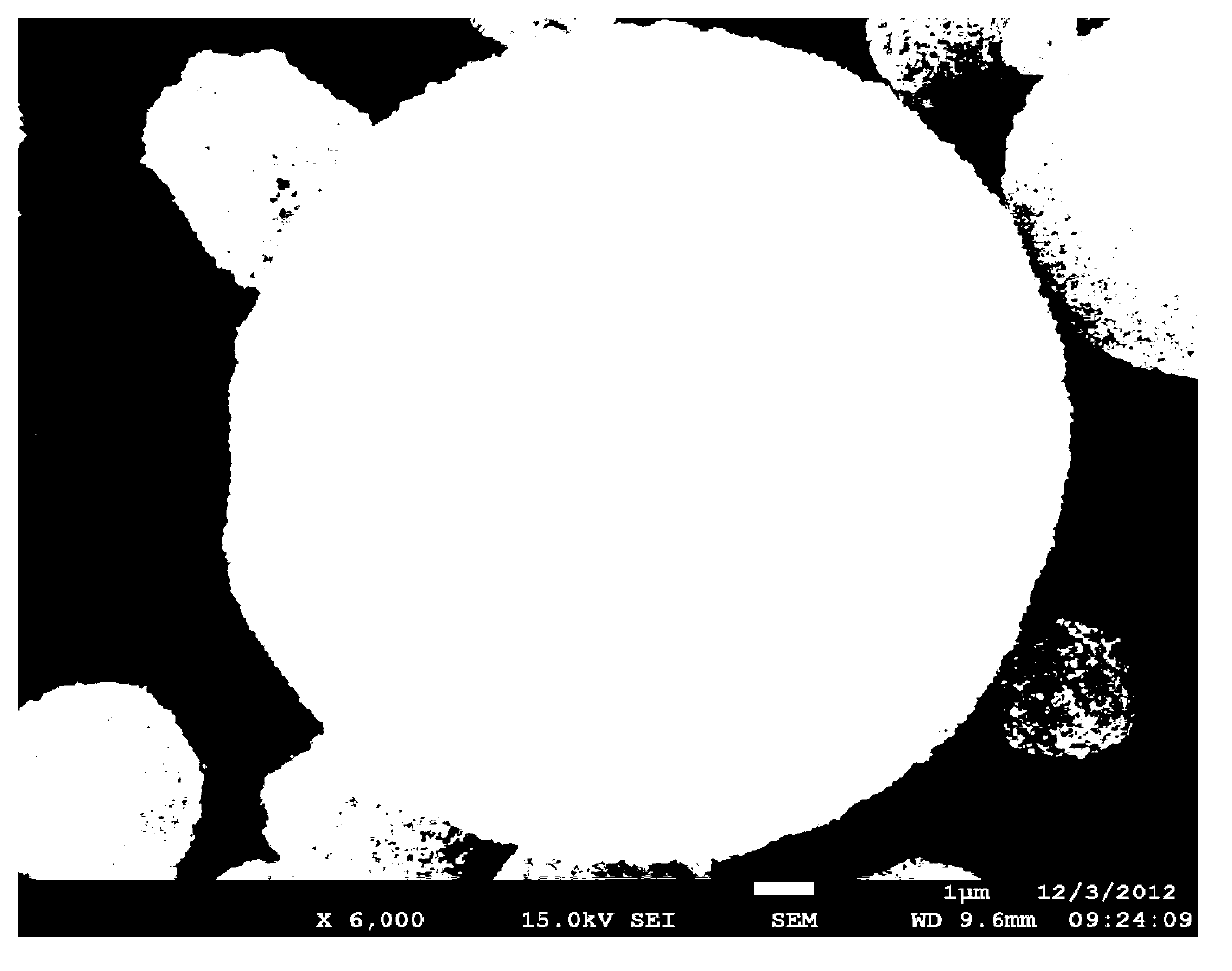

Lithium ion battery carbon microsphere negative electrode material and preparation method thereof

ActiveCN103107319AHigh rate characteristicsLow costCell electrodesSecondary cellsSolventCarbon black

The invention relates to a preparation method of a lithium ion battery carbon microsphere negative electrode material. The method comprises: mixing carbon black, a binder and a solvent to prepare a slurry, conducting spray drying for molding, and then carrying out a high temperature treatment so as to obtain the lithium ion battery carbon microsphere negative electrode material. The lithium ion battery carbon microsphere negative electrode material provided in the invention has a high degree of sphericity and a controllable particle size, so that close packing of the negative electrode material is realized, the volume energy density of electrodes is enhanced. Meanwhile, lithium ions can be embedded from all directions, and the structural stability, the rate capability and the first coulombic efficiency of the material are improved. The carbon microspheres internally have size-controllable gaps, which make up a plurality of ion transport channels, thus being conducive to improving the charge-discharge capacity and cyclic capacity retention rate of the material. Also, the main preparation raw material is carbon black, which has wide sources, no need for breaking, and a low price. And the preparation method has the advantages of simple process, environmental friendliness, low energy consumption and cost, and is easy for large scale production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

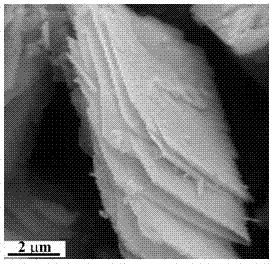

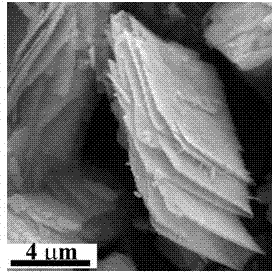

Co3O4 nano lamellar material and preparation method and application thereof

InactiveCN102412397AGood water solubilityPromote nucleationCell electrodesNanotechnologyCobalt saltLithium-ion battery

The invention discloses a Co3O4 nano lamellar material and a preparation method and application thereof. The preparation method comprises the following steps of: mixing cobalt salt, a surfactant, a precipitator and deioned water in stoichiometric ratio; transferring the mixed solution into a reaction kettle and carrying out hydro-thermal reaction for 17.5-18.5 hours at 115-125 DEG C; and then washing and drying to obtain a powdery mixed precursor; and carrying out heat treatment on the powdery mixed precursor in air to finally obtain the Co3O4 nano lamellar material. The prepared Co3O4 material is of a regular nano lamellar structure, and can be applied to the negative electrode of a chargeable lithium ion battery so as to improve the storage capacity of lithium.

Owner:SHANGHAI INST OF TECH

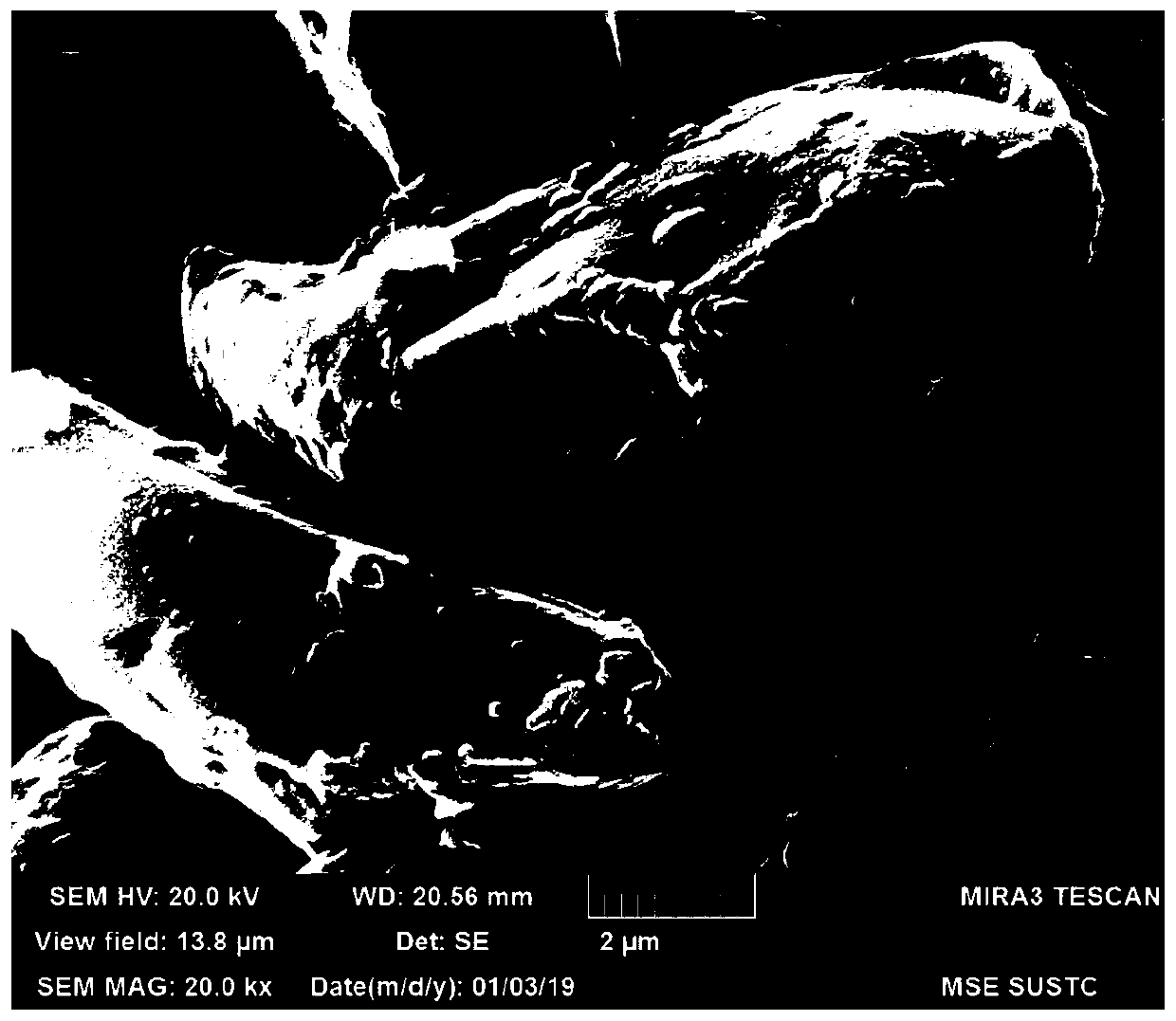

Silicon-based composite material, preparation method thereof, and lithium-ion battery

InactiveCN110010861AImprove conductivityImprove structural stabilityCell electrodesSecondary cellsCarbon layerIn situ polymerization

The invention provides a silicon-based composite material, a preparation method thereof and a lithium-ion battery. The preparation method comprises a step of mixing SiOx and a carbon source to obtaina SiOx@carbon source mixture, a step of curing and carbonizing the SiOx@carbon source mixture under an inert atmosphere to obtain SiOx@carbon, a step of dispersing the SiOx@carbon in a solution with oxidant, simultaneously adding a conductive polymer monomer and a conductive carbon material, uniformly dispersing, and polymerizing in situ to obtain the silicon-based composite material. The silicon-based composite material is a double-shell core-shell structure material, an outer shell layer is a conductive polymer layer, an inner shell layer is a carbon layer, and the conductive carbon materialis embedded into the conductive polymer monomer. The silicon-based composite material obtained by the method can effectively improve the electrochemical performance of the lithium-ion battery when the silicon-based composite material is used as a negative electrode material of the lithium-ion battery.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

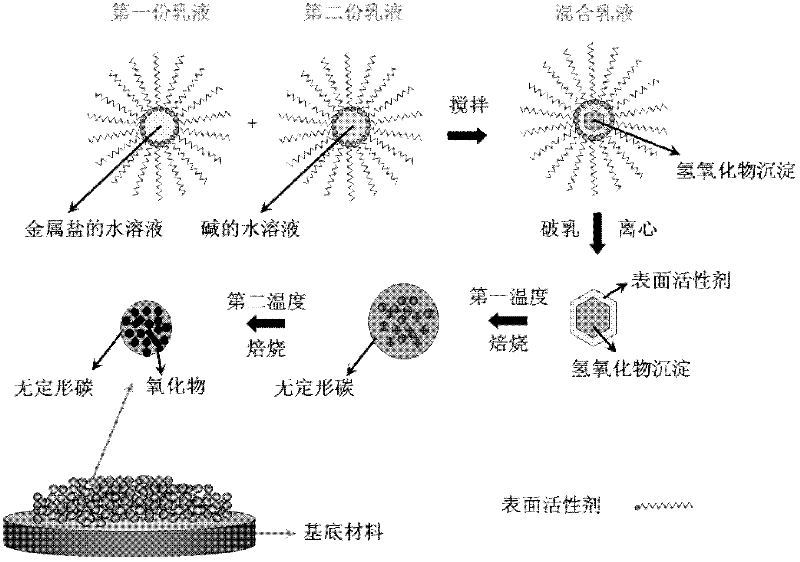

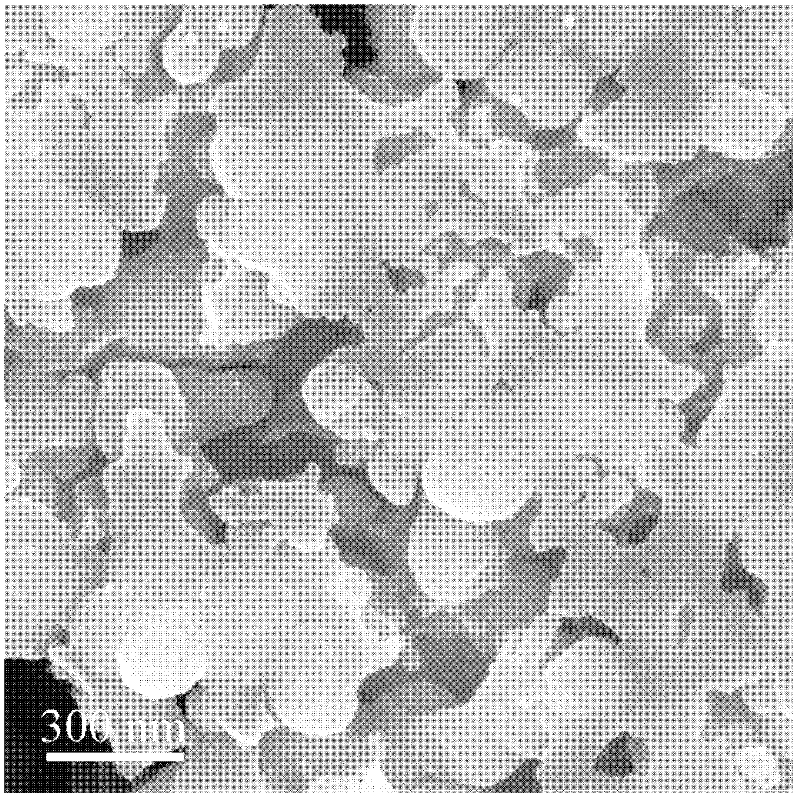

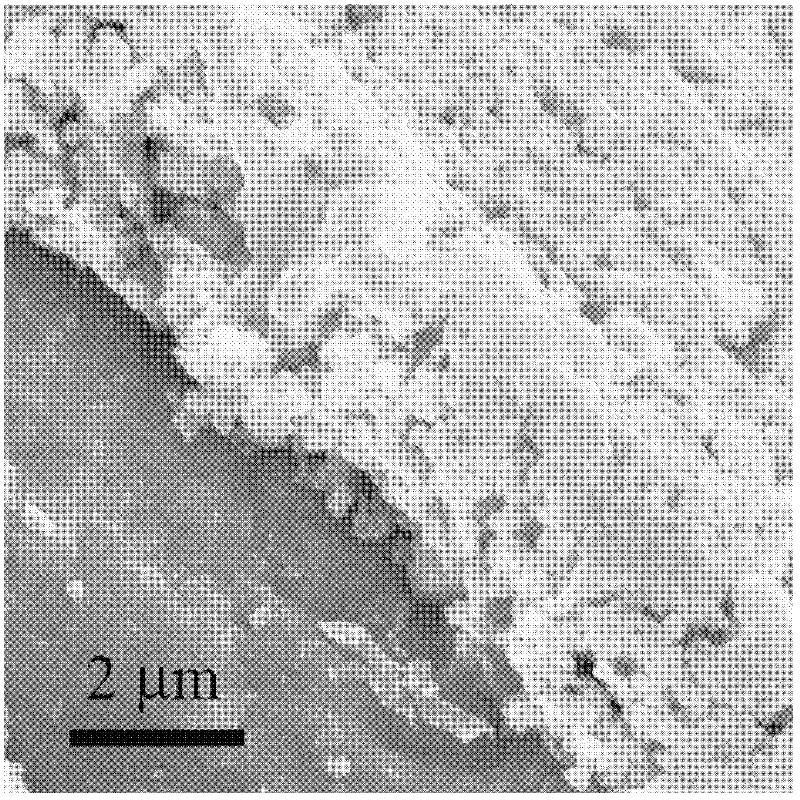

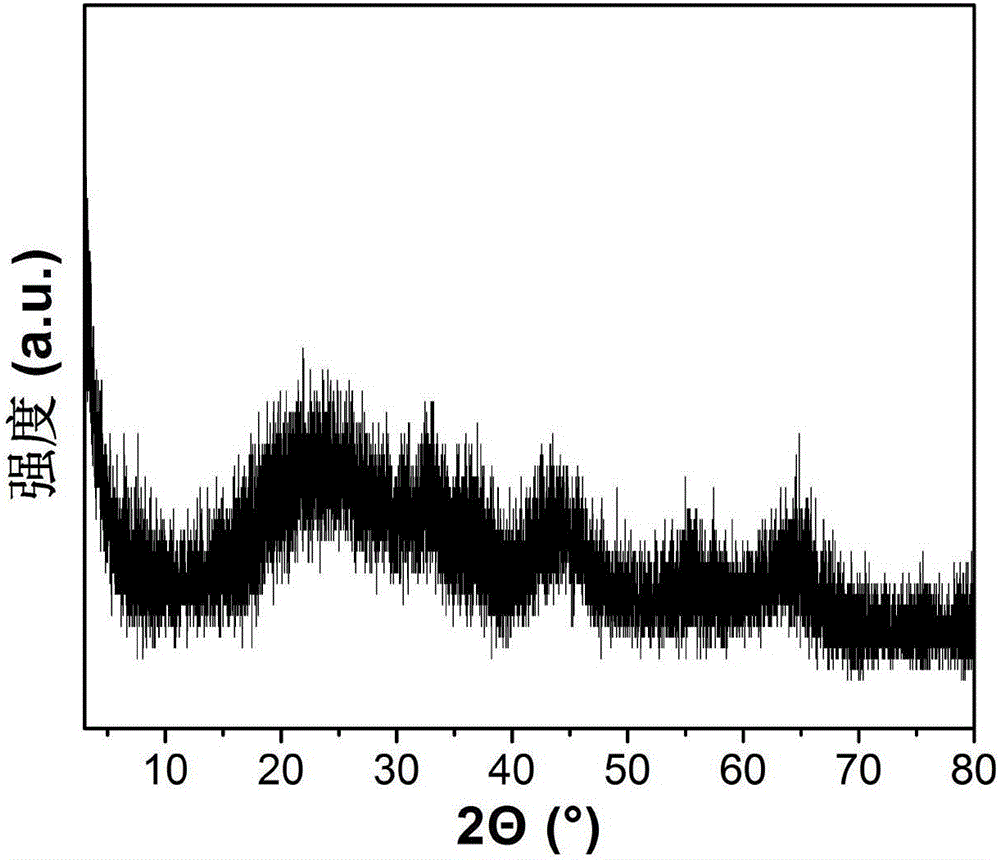

Porous metal oxide-carbon composite thin film electrode and preparation method thereof

InactiveCN102509786AImprove cycle performanceShorten the migration path of lithium ionsCell electrodesEmulsionCopper foil

The invention relates to a porous metal oxide-carbon composite thin-film electrode and a preparation method of the porous metal oxide-carbon composite thin-film, which belong to the technical field of lithium ion battery. The porous metal oxide-carbon composite thin film electrode free of other additional conductive agents and adhesives consists of a copper foil collector, and a porous metal oxide-carbon composite thin film on the surface of the copper foil collector. The preparation method of the porous metal oxide-carbon composite thin-film electrode comprises the following steps: blending a metal salt emulsion with an alkaline emulsion for reaction; demulsifying and centrifuging to obtain a precipitate; applying the precipitate on the surface of the copper foil collector; and calcining the copper foil collector twice to obtain the final product. The porous metal oxide-carbon composite thin-film electrode has the advantages of high specific capacity and high rate capability when used as the negative electrode of a lithium ion battery.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing metallic compound/porous carbon nanorod of hierarchy structure

InactiveCN106410145ASimple processAvoid the detemplating processMaterial nanotechnologyCell electrodesIonOrganic acid

The invention discloses a method for preparing a metallic compound / porous carbon nanorod of a hierarchy structure, and belongs to the technical field of new energy. The method comprises the following steps: firstly, mixing inorganic transition metal salt, 1,4-naphthalic acid and water so as to obtain a turbid solution of an organic acid complex of metal ions; secondly, under a high-temperature hydrothermal condition, performing reaction for a certain period of time so as to generate a precursor of a metal organic frame; and finally, in the protection of an inert gas, performing high-temperature thermal treatment control, thereby obtaining the metallic compound / porous carbon nanorod. As a sodium-ion battery negative material, the metallic compound / porous carbon nanorod shows excellent multiplying power characteristic and cycling stability. The method has the advantages of being simple in preparation process, low in equipment requirement, rich in raw material resource, low in production cost, short in synthesis cycle, gentle in reaction condition, high in yield, free of template removal, good in material property and the like, industrial production can be easily achieved, and a product can be used in the field of electrochemical energy storage.

Owner:NANKAI UNIV

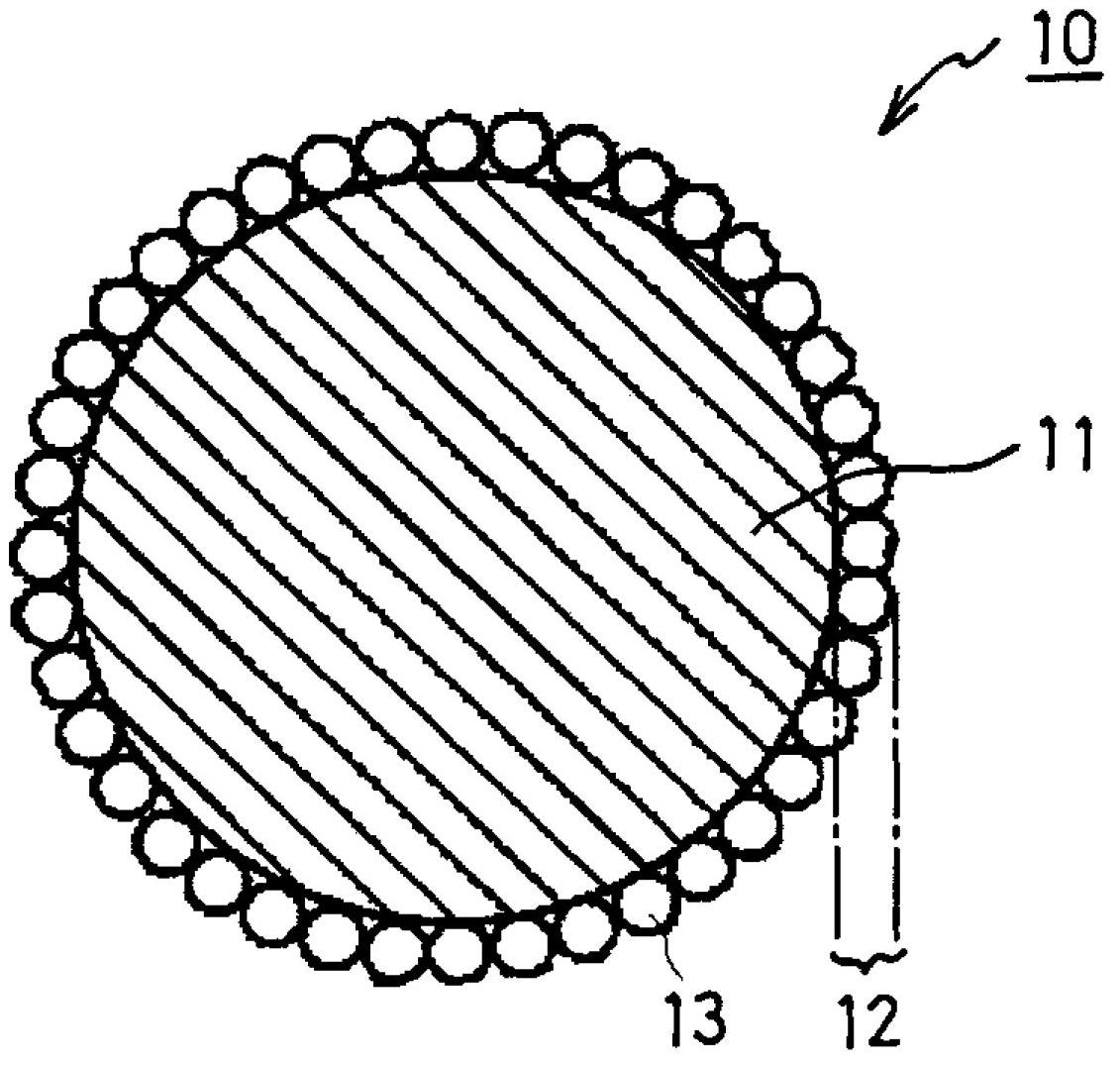

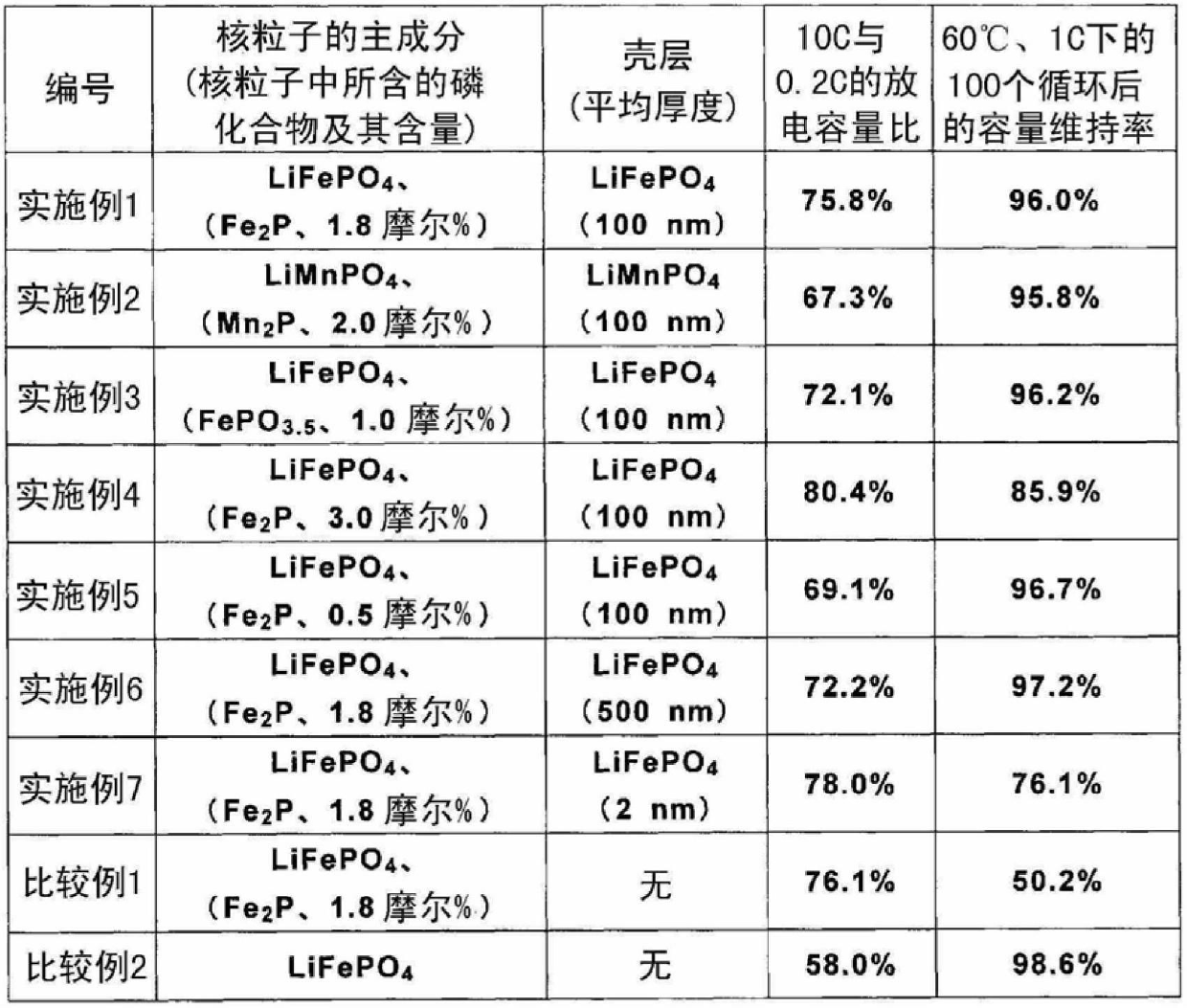

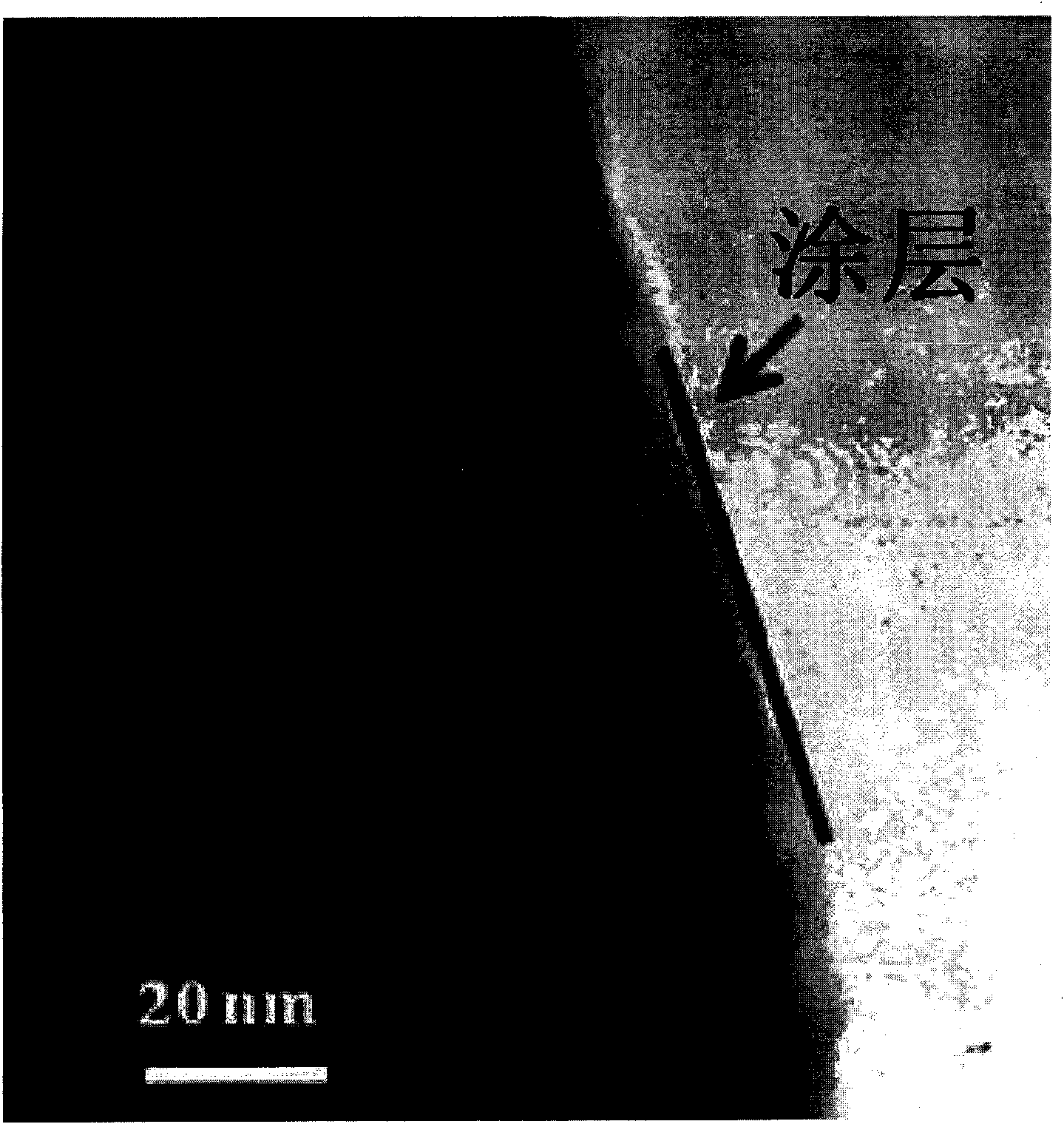

Positive electrode active material particles for lithium ion secondary battery, positive electrode using said positive electrode active material particles, and lithium ion secondary battery

ActiveCN102640332AHigh rate characteristicsExcellent cycle characteristicsMaterial nanotechnologyCell electrodesLithiumPhosphate

The purpose of the present invention is to improve rate characteristics and to improve cycle characteristics even at high temperatures in a lithium ion secondary battery using an olivine active material for a positive electrode active material. These positive electrode active material particles for a lithium ion secondary battery contain a core particle and a sealing layer adhering to the surface thereof. The core particle contains a first lithium-containing olivine phosphate compound that contains Fe and / or Mn with Li, and the sealing layer contains a second lithium-containing olivine phosphate compound that contains Fe and / or Mn with Li. The core particle contains at least a phosphorous compound of formula (1): MemPnOp (1) (wherein, Me is Fe and / or Mn; 0 < m <= 3; 0 < n <= 3; and 0 <= p <= 5). Proportion (C1) of the phosphorous compound content to the total number of moles of the first lithium-containing olivine phosphate compound in the core particle is 0.5 - 3 mol%, and when the sealing layer contains a phosphate compound represented by formula (1) the proportion (C2) of the phosphate compound content to the total number of moles of the second lithium-containing olivine phosphate compound in the sealing layer is less than (C1).

Owner:PANASONIC CORP

Method for preparing carbon nano tube doped lithium titanate composite electrode material

The invention discloses a method for preparing a carbon nano tube doped lithium titanate composite electrode material. The composite material is prepared from lithium titanate and carbon nano tubes, wherein the mass ratio of lithium titanate to carbon nano tubes is 88-95:5-12. The method is characterized by taking lithium acetate or lithium carbonate, titanium dioxide and carbon nano tubes as rawmaterials and preparing the lithium titanate / carbon nano tube composite electrode material through ball mill and a microwave method. The lithium titanate composite electrode material has the characteristics of simple process, uniform material, small grain size, high specific capacity, high rate and the like.

Owner:GUANGDONG UNIV OF TECH

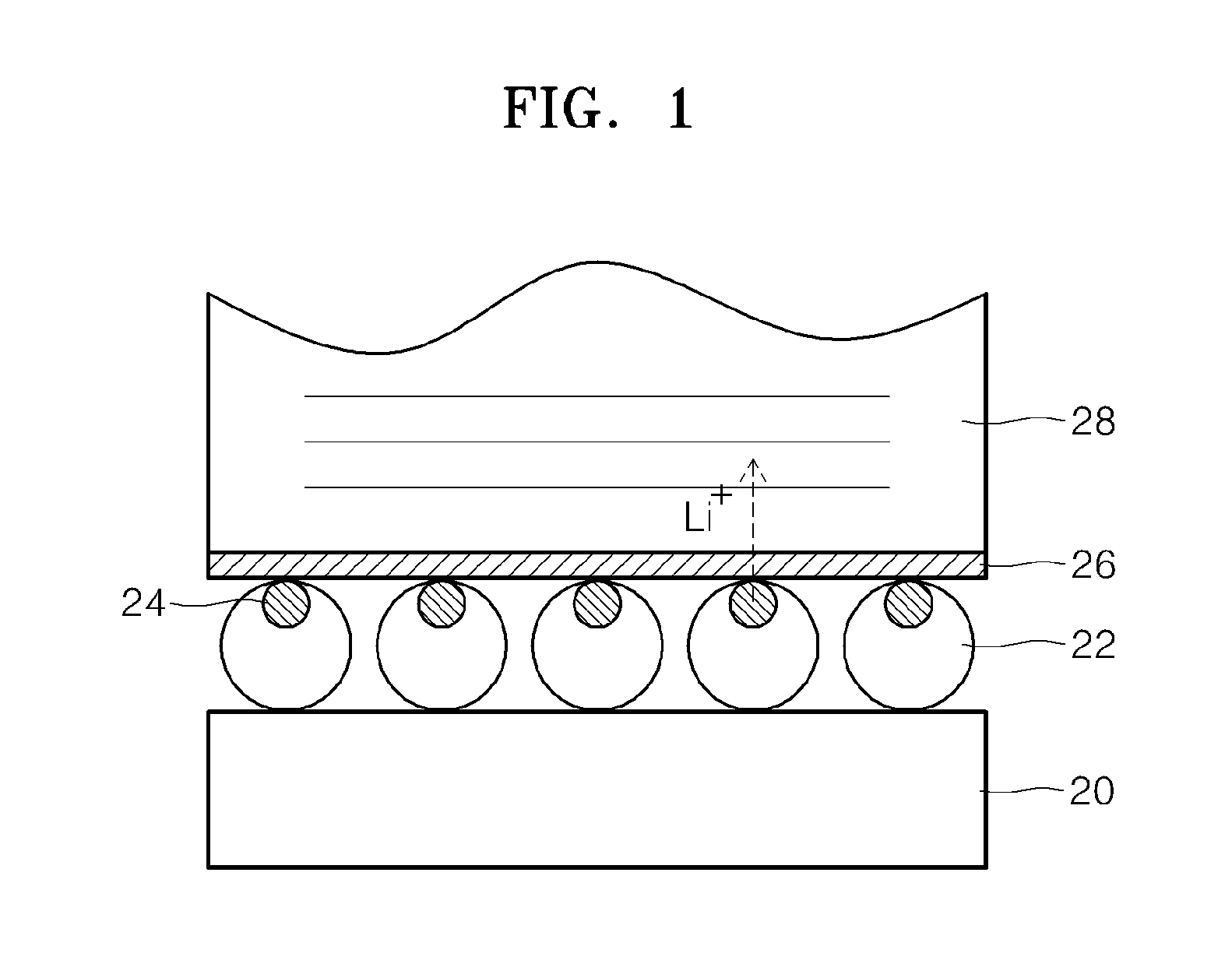

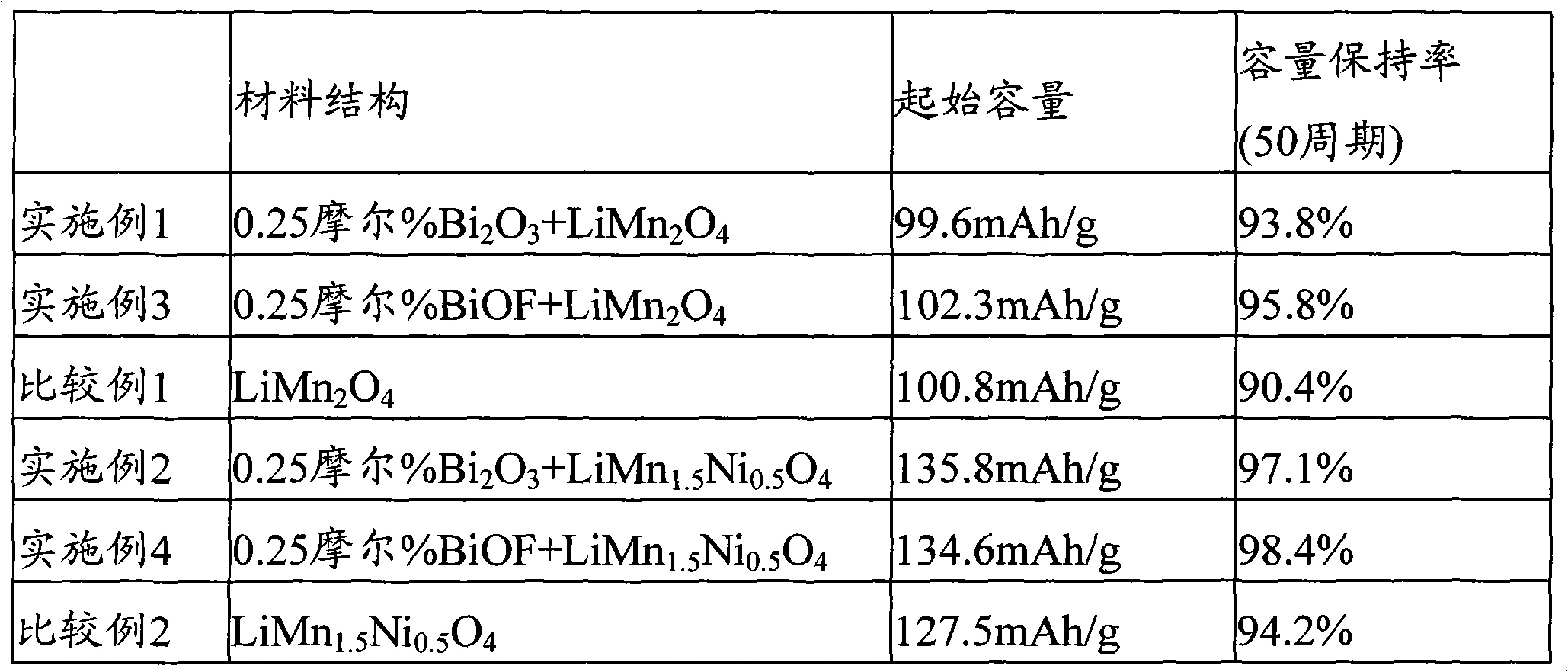

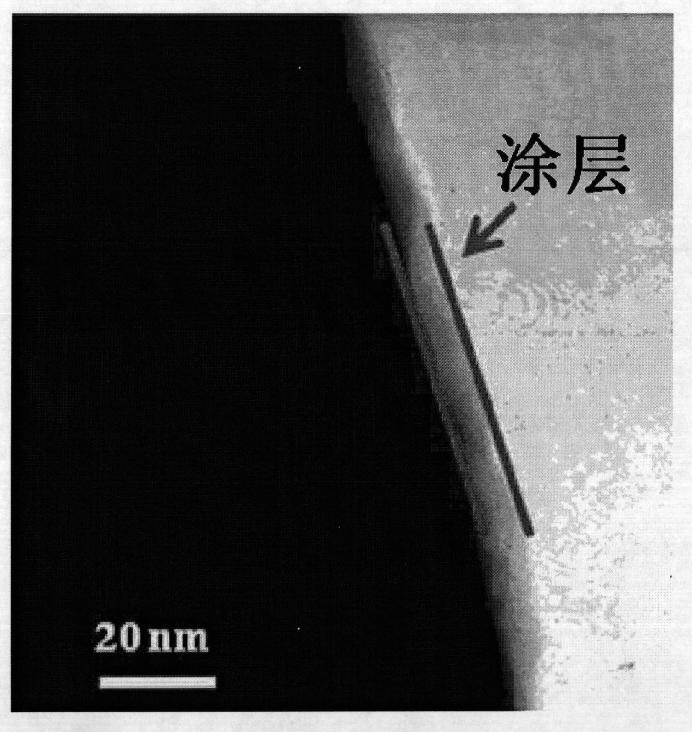

Anode active material and secondary lithium battery

InactiveCN101931072AInhibition of dissolutionImprove featuresMolybdeum compoundsZirconium compoundsHigh temperature storageBismuth compound

The invention relates to an anode active material for a secondary lithium battery and a secondary lithium battery containing the anode active material. The anode active material contains an active compound which can be embedded with and separated from a lithium ion and a bismuth (Bi) compound on the surface of the active compound. The bismuth compound on the surface of the active compound can suppress possibly generated structural change of the anode active material and solve the reaction problem between the anode active material and electrolyte due to impedence reduction of acid generated near the anode active material, so as to prevent a transition metal which is composed of the anode active material from being dissolved. Therefore, the anode active material can improve the high-temperature storage characteristic and high-temperature cycle life characteristic of the secondary lithium battery, improve the lithium ion mobility in the electrolyte, bring an improved effect on a discharge potential and also enhance the charging and discharging characteristics, service life characteristic and multiplying power characteristic of the secondary lithium battery.

Owner:ENERCERAMIC

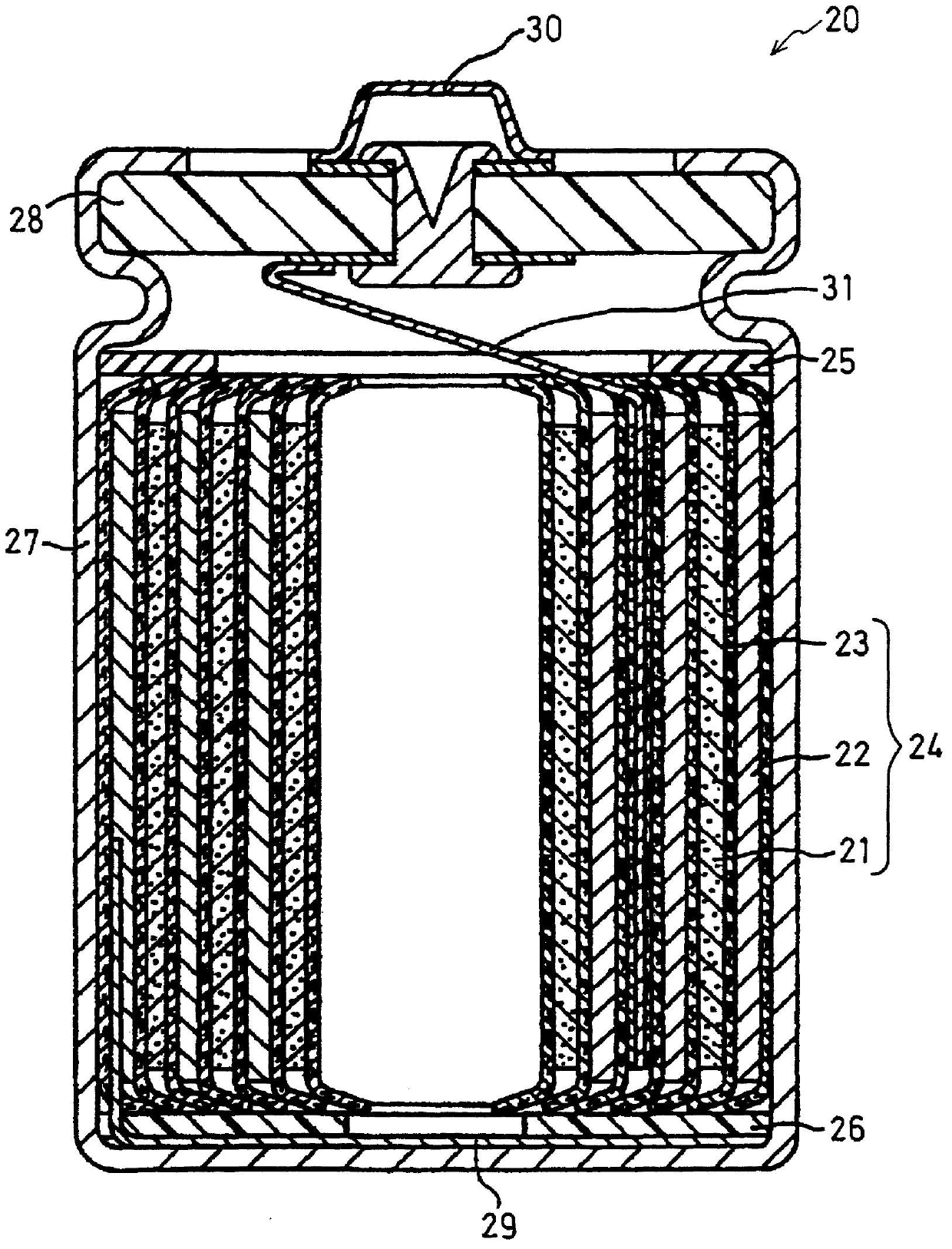

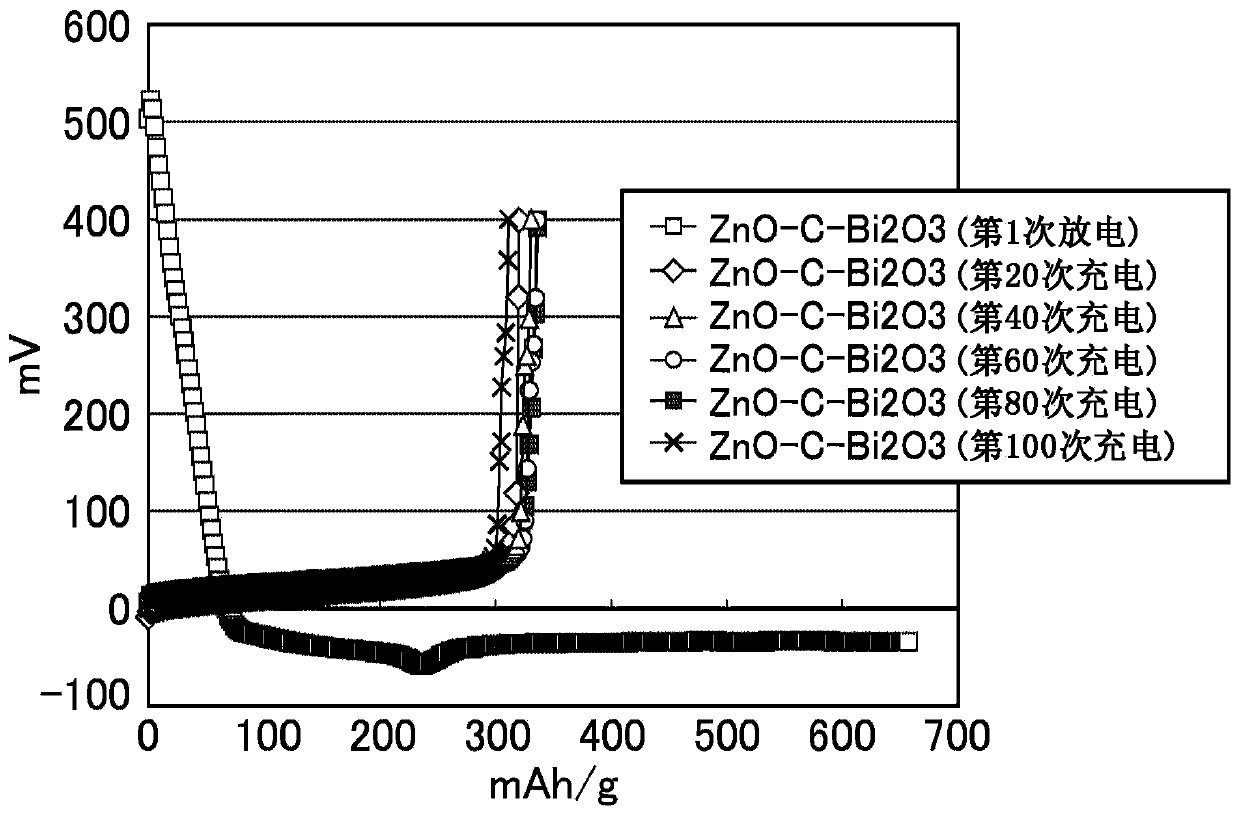

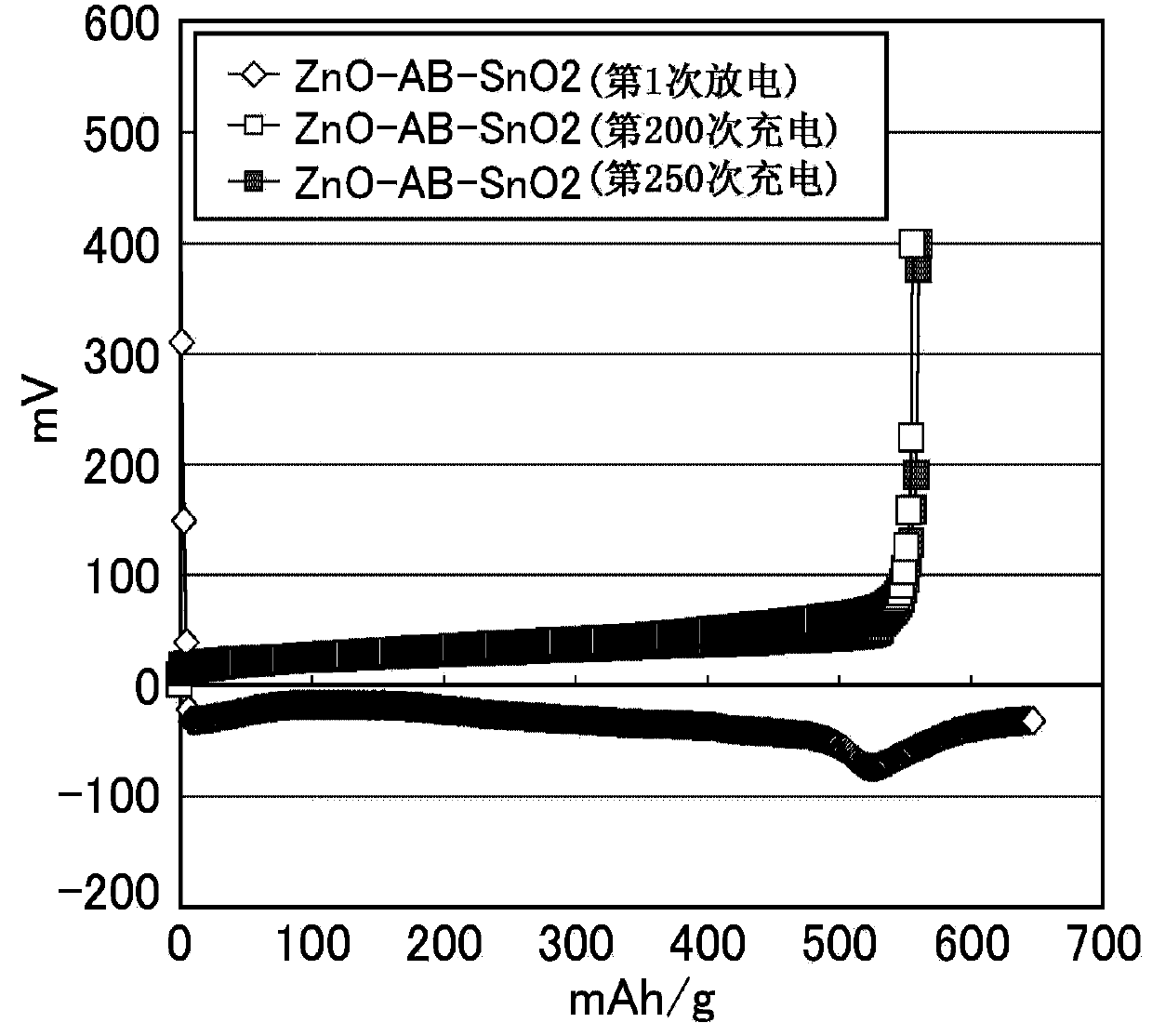

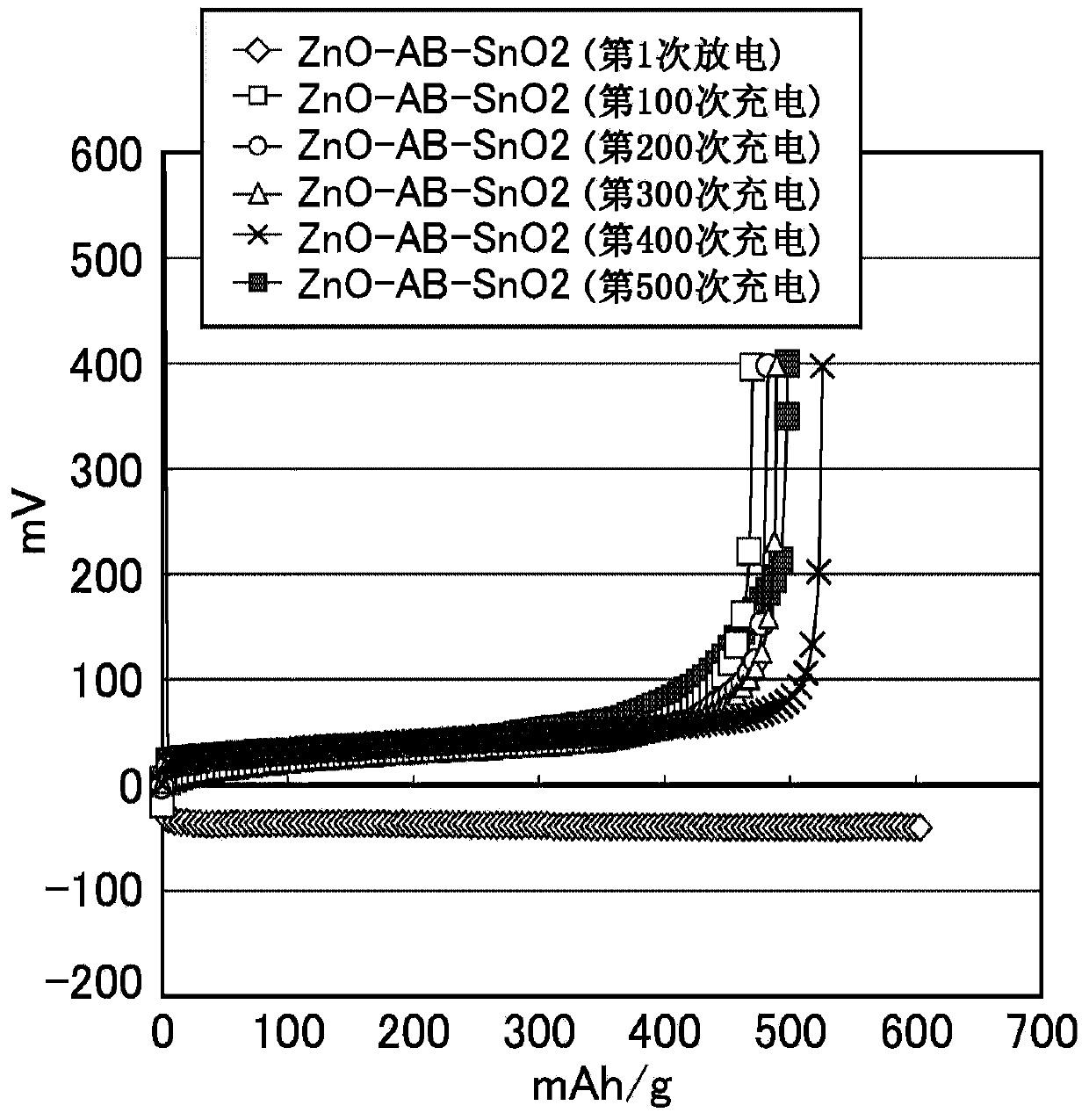

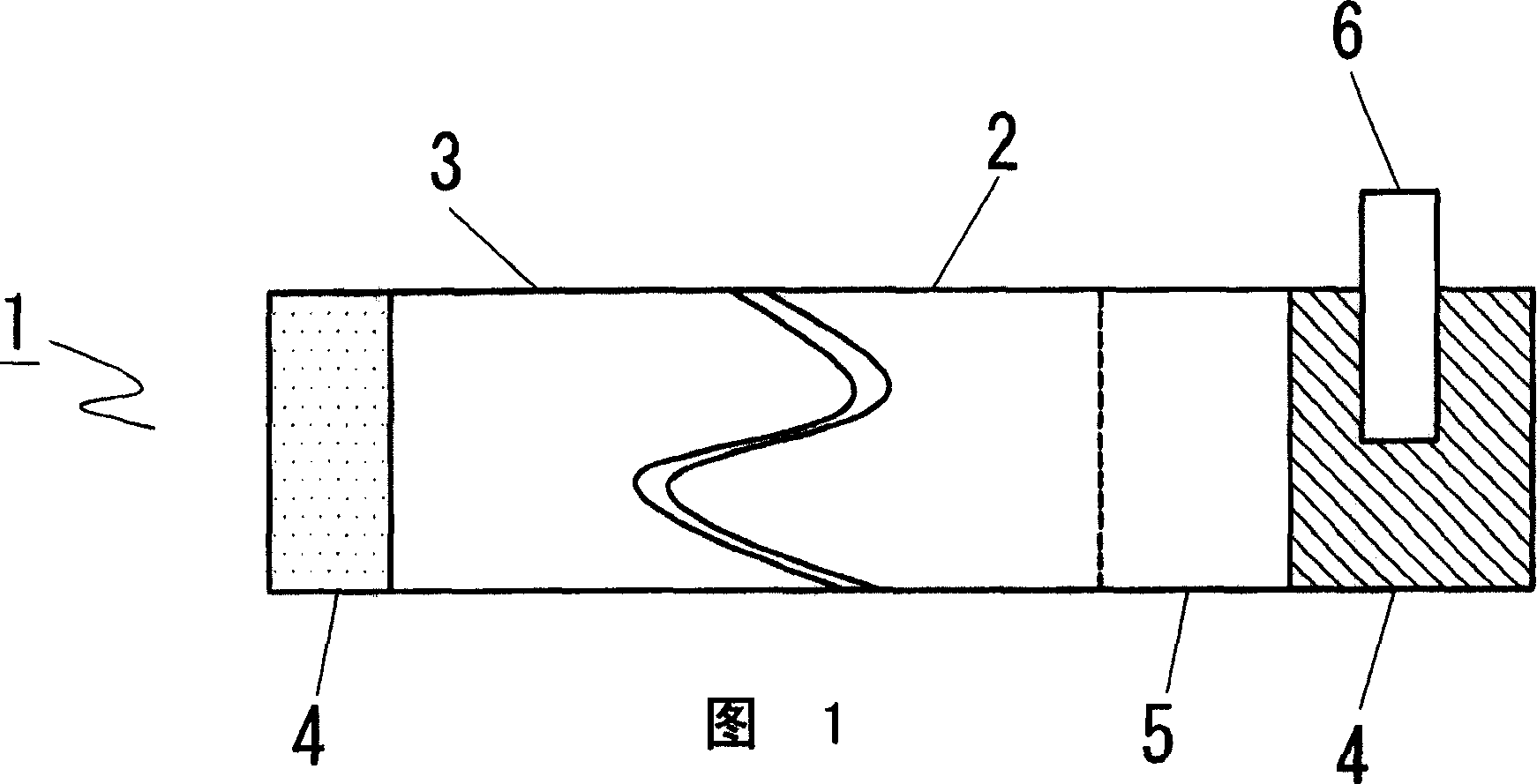

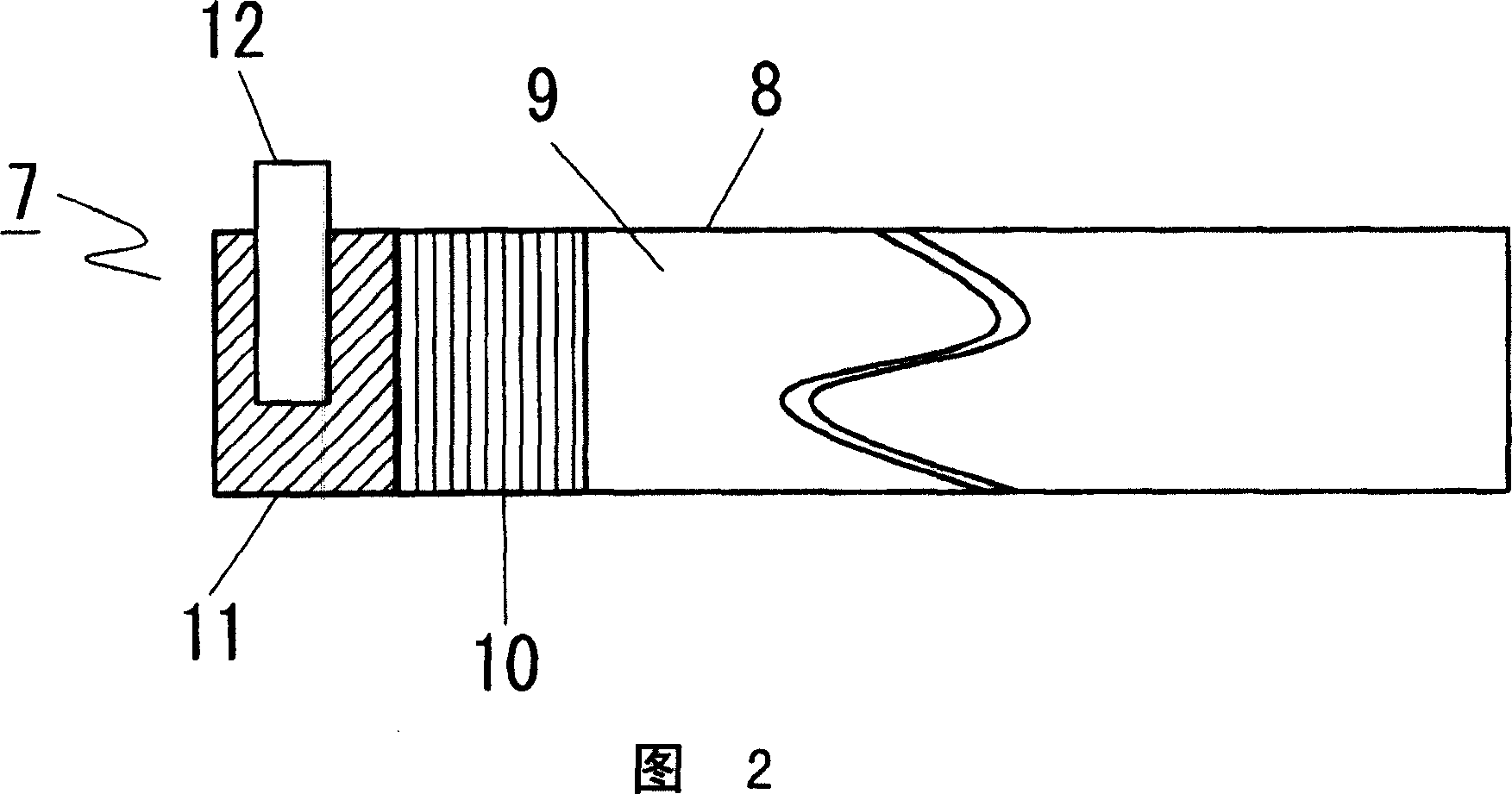

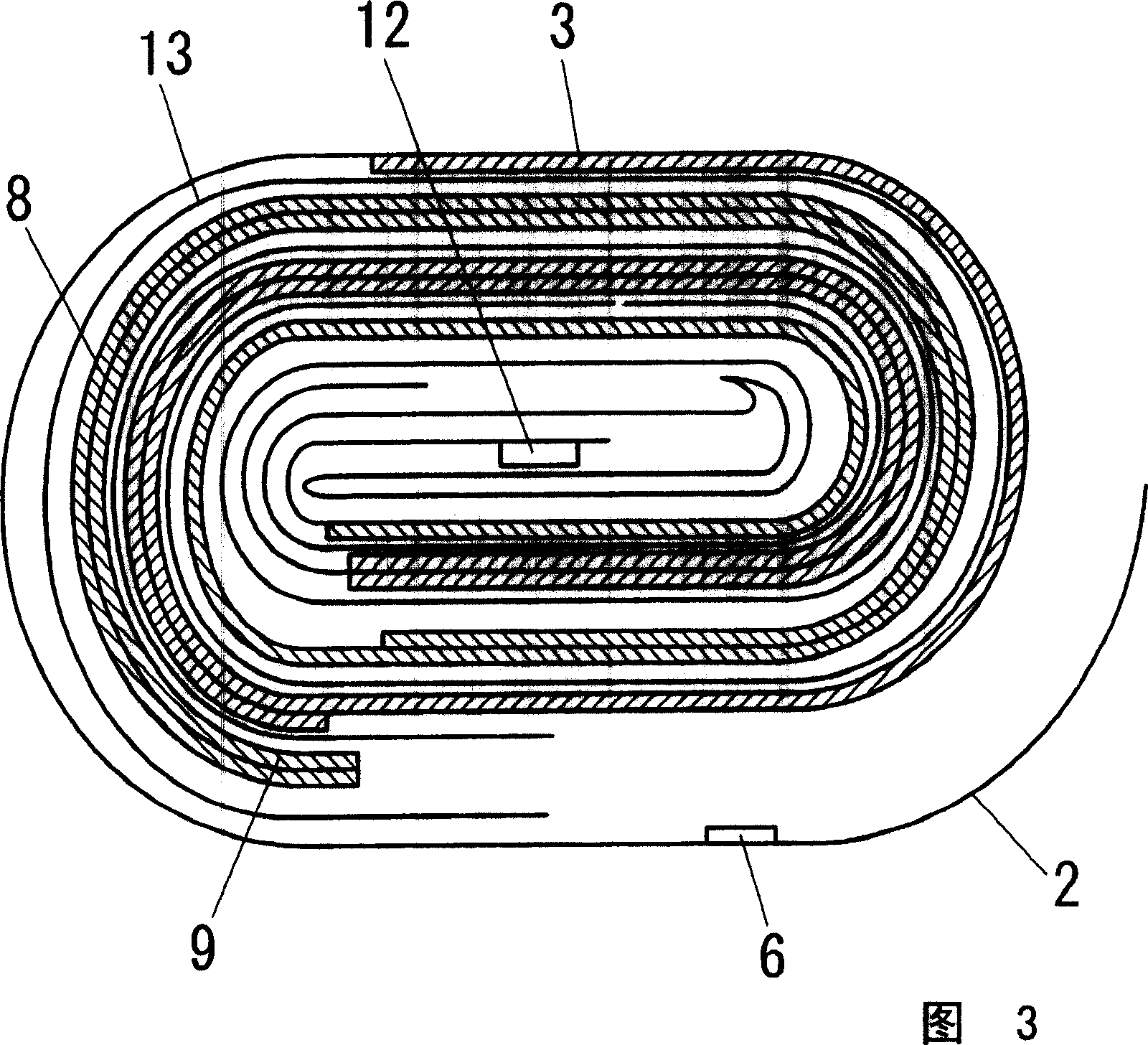

Negative electrode mixture or gel electrolyte, and battery using said negative electrode mixture or said gel electrolyte

ActiveCN103748710AExcellent cycle characteristicsHigh rate characteristicsFuel and primary cellsFuel and secondary cellsCross-linkShape change

The purpose of the present invention is to provide a zinc negative electrode mixture for forming the negative electrode for a safe and economic battery exhibiting excellent battery performance, and a gel electrolyte or a negative electrode mixture which can be suitably used for forming a storage battery exhibiting excellent battery performances such as a high cycle characteristics, rate characteristics, and coulombic efficiency while inhibiting passivation and morphology of an electrode active material such as dendrite and shape change in the electrode active material. Another purpose of the present invention is to provide a battery using the zinc negative electrode mixture or the gel electrolyte. A zinc negative electrode mixture (1) containing a zinc-containing compound and a conductive auxiliary agent, wherein the zinc-containing compound and / or the conductive auxiliary agent contain particles having an average particle size of 1000 [mu]m or less and / or particles having an aspect ratio (vertical / lateral) of 1.1 or more. A gel electrolyte (2) used in a battery, the gel electrolyte being characterized by having a cross-linking structure formed by a multivalent ion and / or an inorganic compound. A negative electrode mixture (3) used in a battery, the negative electrode mixture being characterized by containing a negative electrode active material and a polymer.

Owner:NIPPON SHOKUBAI CO LTD

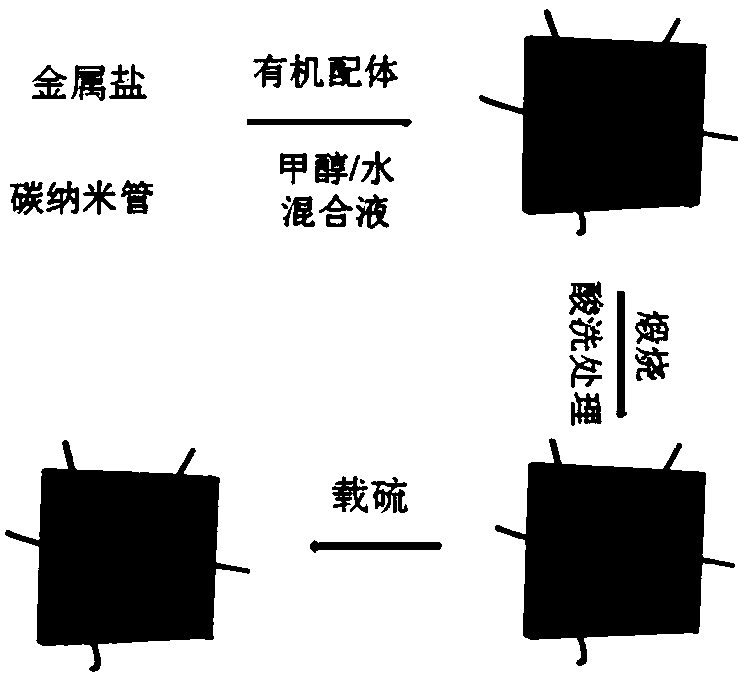

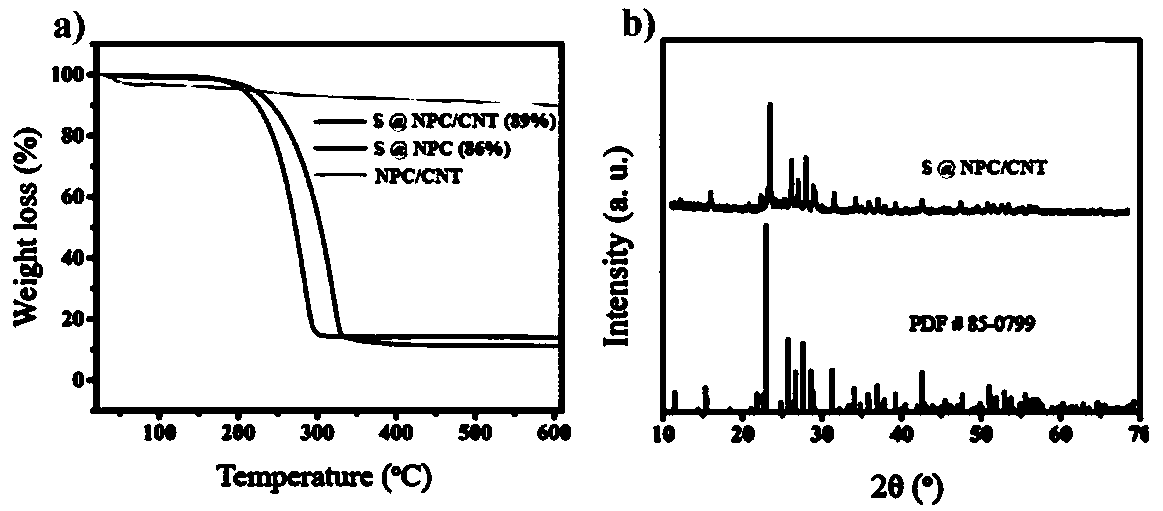

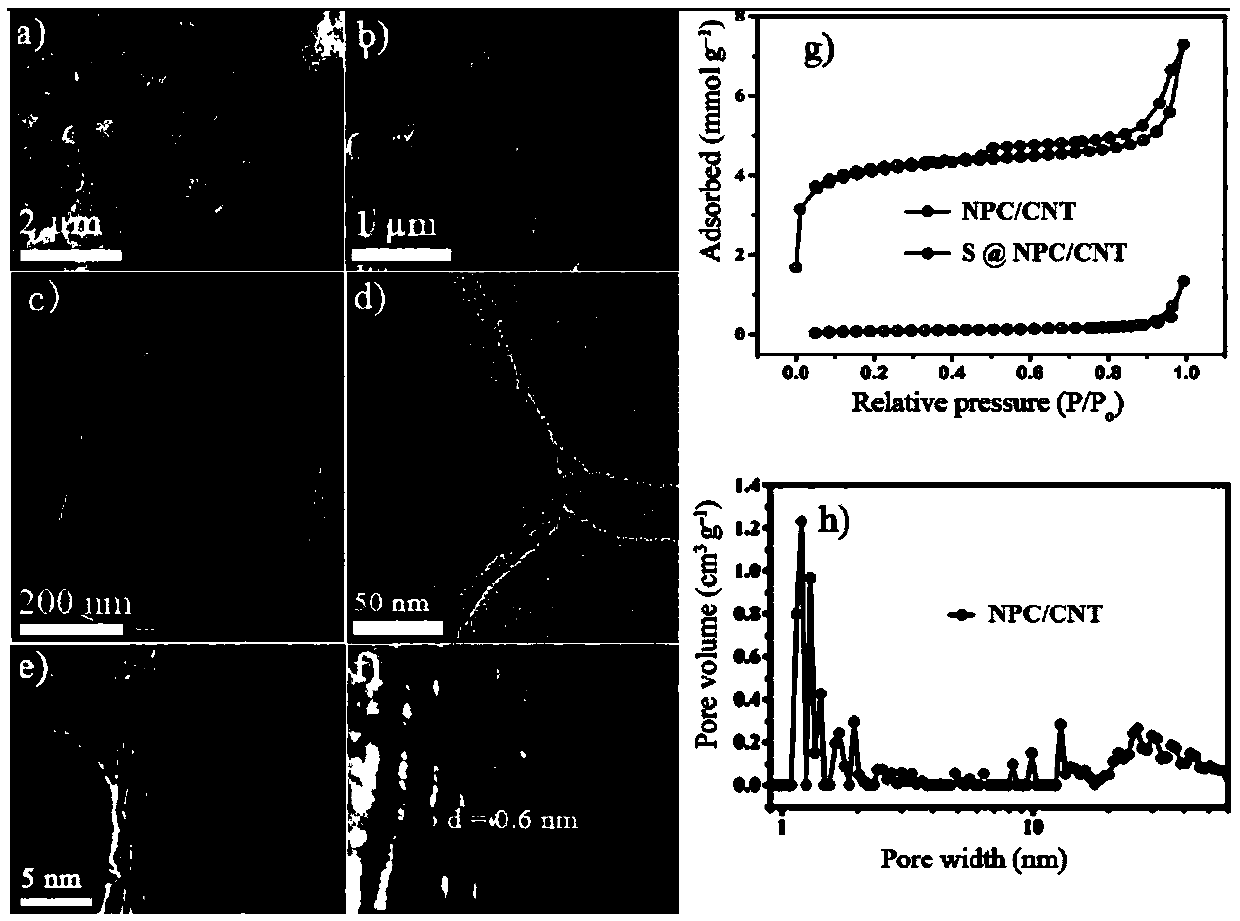

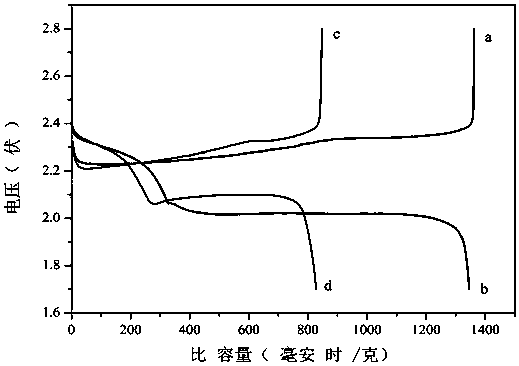

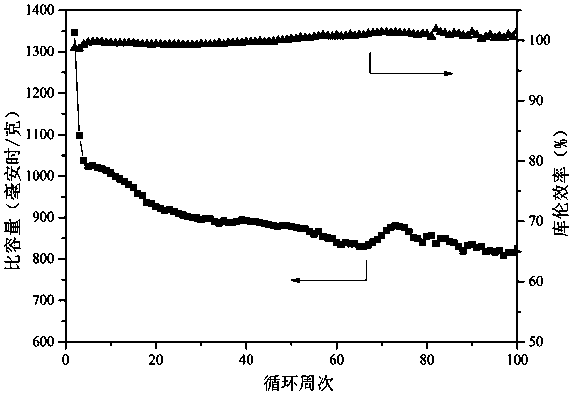

S@NPC/CNT composite material and preparation method and application thereof

InactiveCN109686951AInhibition of dissolutionStop the spreadCell electrodesDiffusion methodsPorous carbon

The invention discloses an S@NPC / CNT composite material and a preparation method and application thereof. The S@NPC / CNT composite material is obtained from an NPC / CNT composite material by sulfur loading. The NPC / CNT composite material is composed of nitrogen doped porous carbon and carbon nanotubes in the interweaving mode. The nitrogen doped porous carbon is a carbon material derived from a Zn / Co-bimetallic organic framework. The nitrogen doped carbon material is obtained by stirring, drying, calcining and acid treatment of a methyl alcohol and water mixed solution containing zinc and / or cobalt transition metal salt, organic ligand and a carbon material, and finally the high sulfur loaded S@NPC / CNT composite material is prepared by a melt diffusion method. The material exhibits extremelyhigh sulfur content. In addition, the invention also discloses the application of the high sulfur loaded nitrogen doped carbon material prepared by the method in a lithium sulfur battery. The composite material is used for an anode material of the lithium sulfur battery. The obtained battery has high area capacity and good electrochemical performance. The efficient method for preparing the nitrogen doped carbon material with high performance and high sulfur content is provided.

Owner:CENT SOUTH UNIV

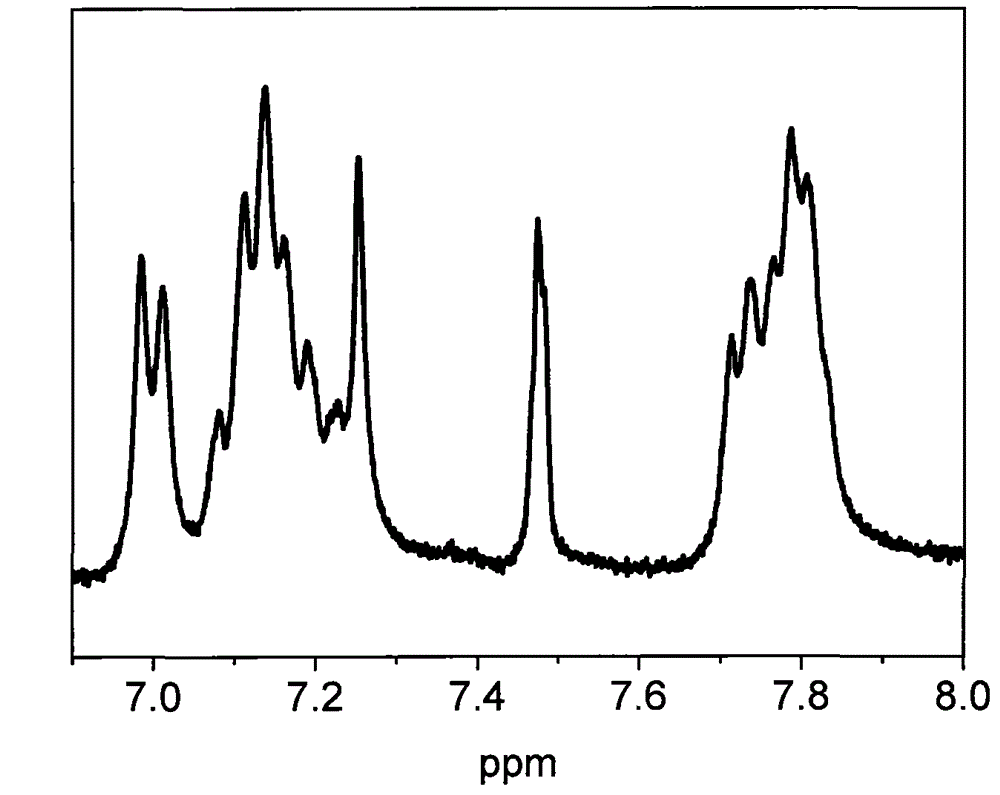

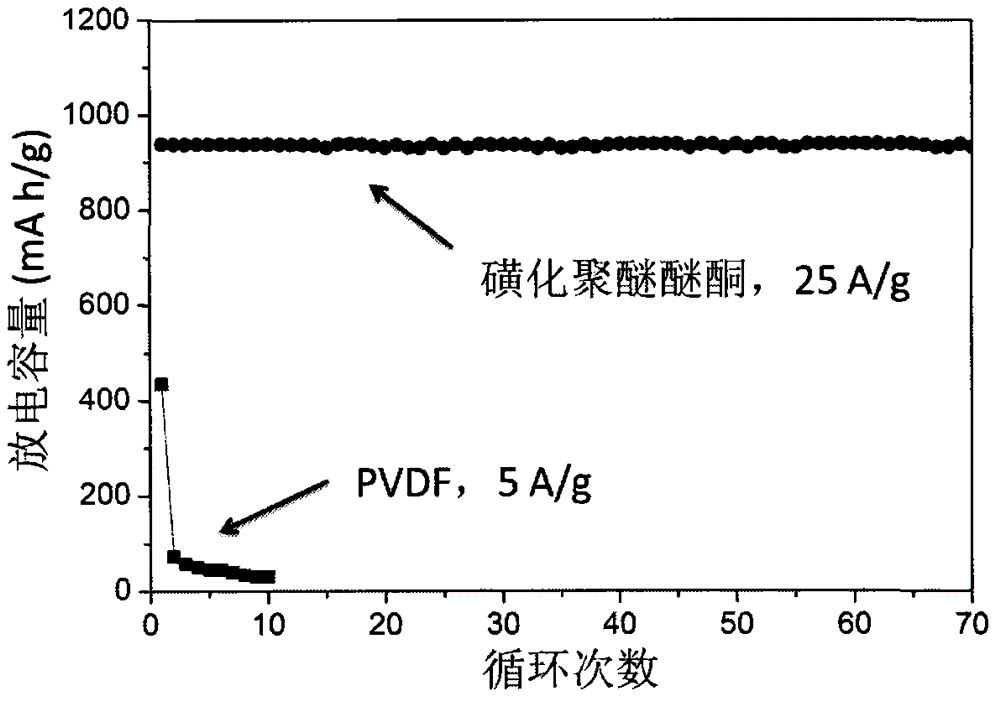

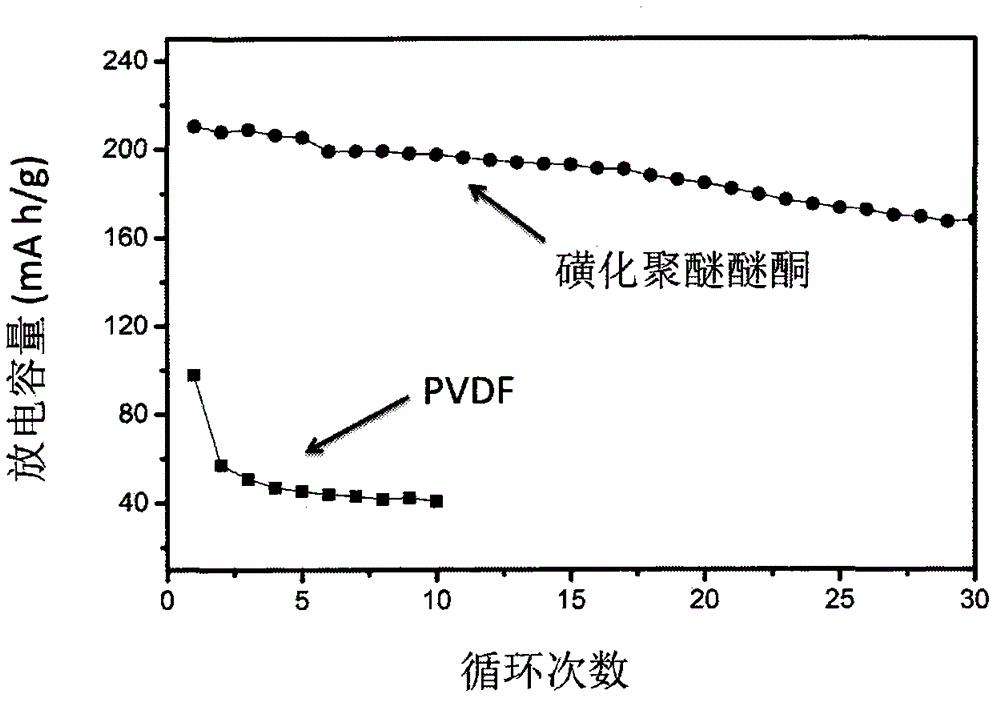

Sulfonated polymer applied to lithium battery electrode as binder

ActiveCN104466112AHigh performance featuresHigh rate characteristicsSecondary cellsNon-aqueous electrolyte accumulator electrodesHigh current densitySulfonated polymer

The invention relates to a sulfonated polymer applied to a lithium battery electrode as a binder as well as a method for preparing the lithium battery electrode. The sulfonated polymer is used as the binder in electrode slurry of the lithium battery electrode, the obtained lithium battery electrode is used for assembling a lithium battery, and the lithium battery is relatively long in charging-discharge cycle life and stable in work under a relatively high current density. The sulfonated polymer with a sulfonic acid group has excellent capacity of transferring lithium ions, so that the lithium ions can be rapidly transmitted back and forth between an electrode active material and an electrolyte, and the lithium battery which is stable to run under the rapid charging-discharging condition can be obtained. The sulfonated polymer which is used as the binder is sufficient in cohesion force and binding strength, and the electrode active material and a conductive medium are stuck onto a current collector by the sulfonated polymer and are unlikely to fracture and dust, so that the lithium battery has sufficient capacity and cycle performance as well as excellent rate capacity.

Owner:BEIJING NATURE STONE SCI TECH DEVP

Polymer gel electrolyte and polymer secondary battery using the same

A polymer gel electrolyte, comprising a polymer gel including an aprotic organic solvent, a carrier salt and a sulfur-containing organic compound having at least one -O-SO2- in its chemical structure, for instance, a straight-chain sulfonic acid ester or a cyclic sulfonic acid ester, and a lithium polymer secondary battery using the polymer gel electrolyte and having improved rate performance and cycle performance.

Owner:NEC ENERGY DEVICES LTD

Preparation method for nano titanium dioxide lithium ion battery cathode material

ActiveCN102627320AEffect of particle sizeUniform particle sizeMaterial nanotechnologyCell electrodesOxalateAcetic acid

The invention provides a preparation method for a nano titanium dioxide lithium ion battery cathode material. The preparation method comprises the following steps of: (a) dissolving a titanium source compound into a mixed solution of acetic acid and ethanol to obtain a first reaction solution; (b) dissolving oxalic acid mixed solution into ethanol to obtain a second reaction solution; (c) mixing the first reaction solution with the second reaction solution and reacting the oxalic acid with the titanium source compound to generate precipitation; and (d) roasting the precipitation obtained in the step (c) to obtain the lithium ion battery cathode material. The preparation method provided by the invention is short in preparation time and is simple and convenient in operation; and the prepared cathode material is uniform in particle size, high in capacity and high in multiplying power characteristic.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

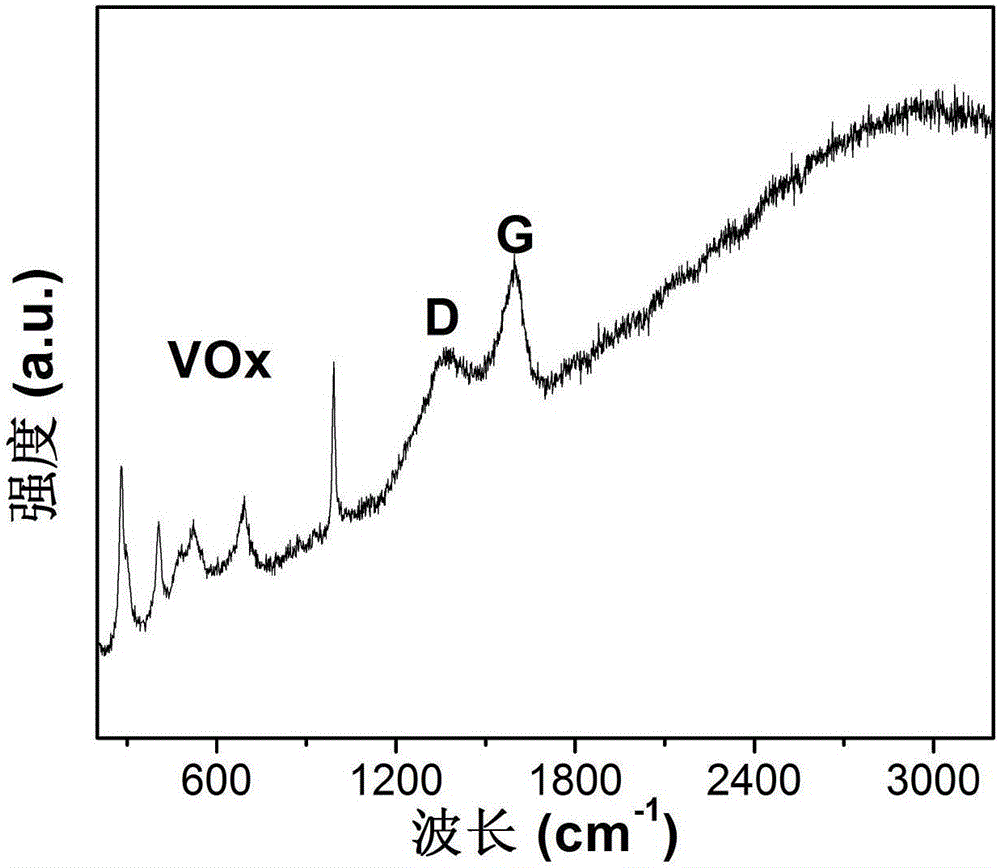

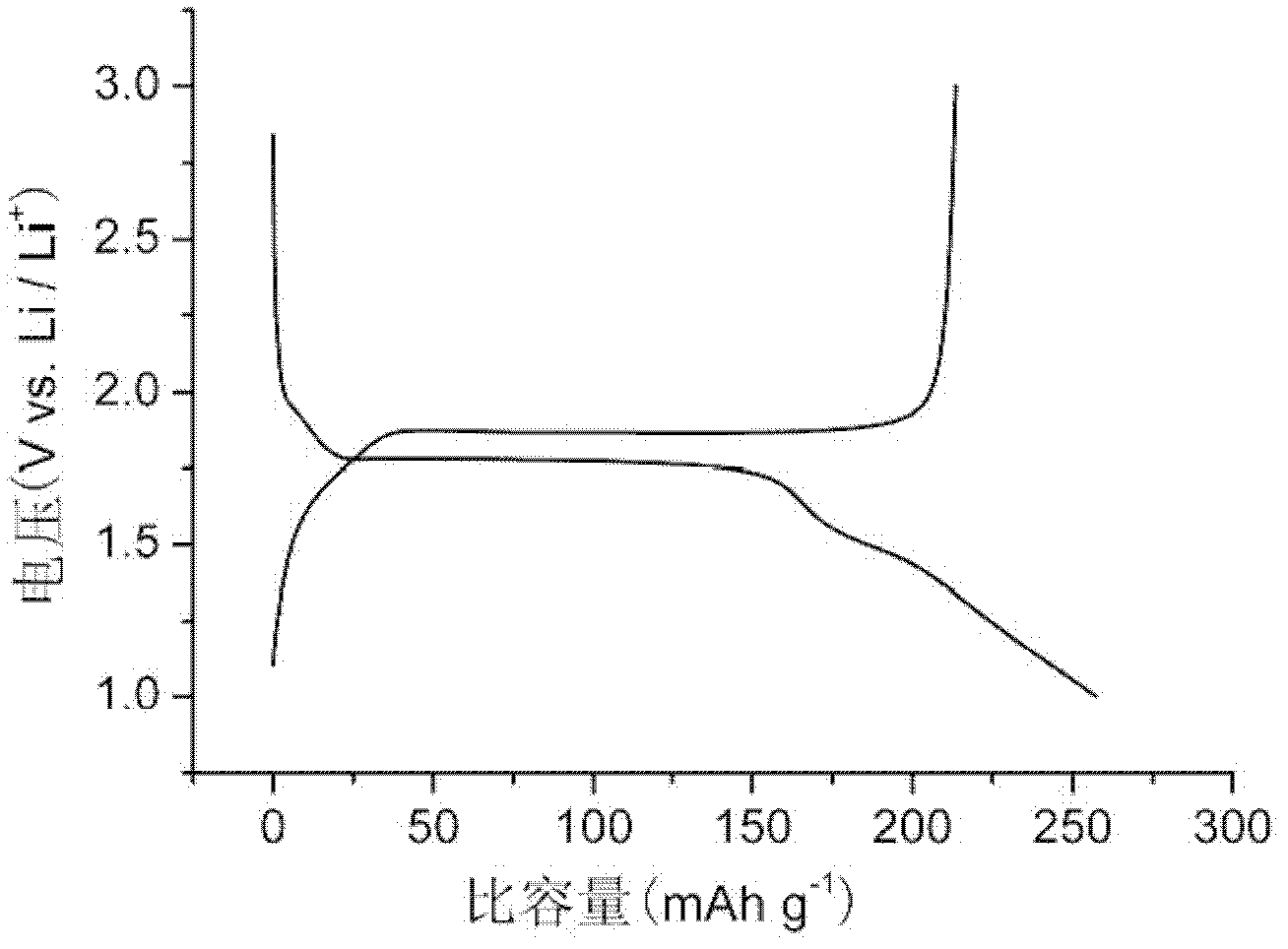

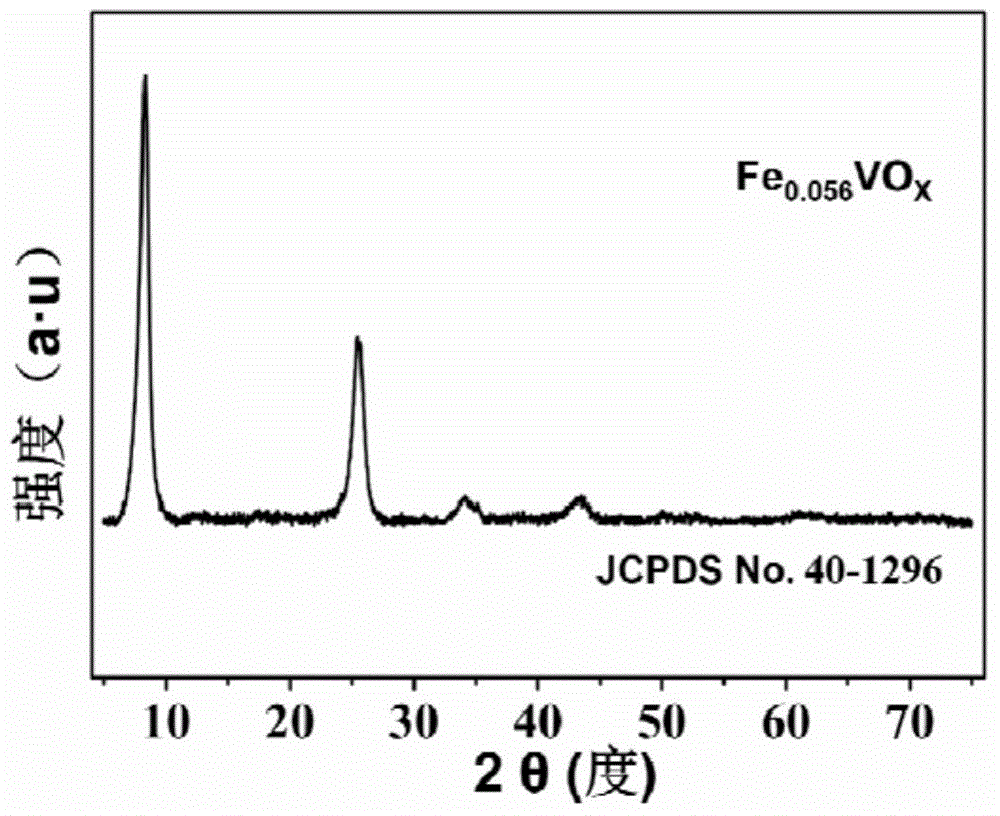

Vanadium oxide ultra-thin nanobelt with embedded ions and preparation method and application thereof

ActiveCN105006561APromote circulationHigh rate characteristicsMaterial nanotechnologyCell electrodesHigh rateFreeze-drying

The invention relates to a vanadium oxide ultra-thin nanobelt with embedded ions and a preparation method thereof. The vanadium oxide ultra-thin nanobelt can be used as positive electrode active materials, with good rate capability, of a sodium-ion battery, metal ions are embedded into crystal layer-shaped structural layers of vanadium oxide, the interlayer spacing is controlled to range from 9.6 angstroms to 10.9 angstroms, the length of the vanadium oxide ultra-thin nanobelt ranges from 10 microns to 100 microns, the width of the vanadium oxide ultra-thin nanobelt ranges from 0.5 micron to 3 microns, and the thickness of the vanadium oxide ultra-thin nanobelt ranges from 5 nanometers to 20 nanometers. The vanadium oxide ultra-thin nanobelt with the embedded ions and the preparation method thereof have the advantages that based on the synergistic effect between the ultra-thin nanobelt structure and the metal ions embedded into the crystal structural layers, the vanadium oxide ultra-thin nanobelt material with the embedded ions is synthesized through the hydrothermal process and the freeze drying and vacuum drying processes; when the vanadium oxide ultra-thin nanobelt with the embedded ions is used as the positive electrode active materials of the sodium-ion battery, the excellent cycling property and high-rate capability of the nano material are achieved, and the vanadium oxide ultra-thin nanobelt with the embedded ions is a high-performance potential application material for the sodium-ion battery; the technology is simple, the requirements of green chemistry are met, and the requirement for equipment is low.

Owner:WUHAN UNIV OF TECH

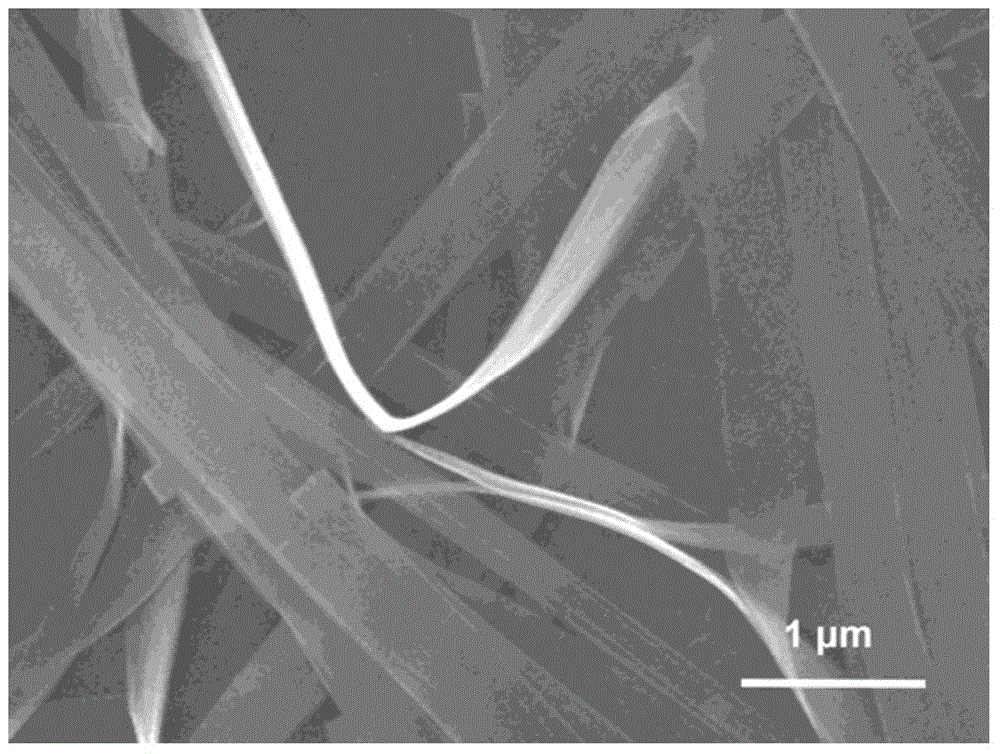

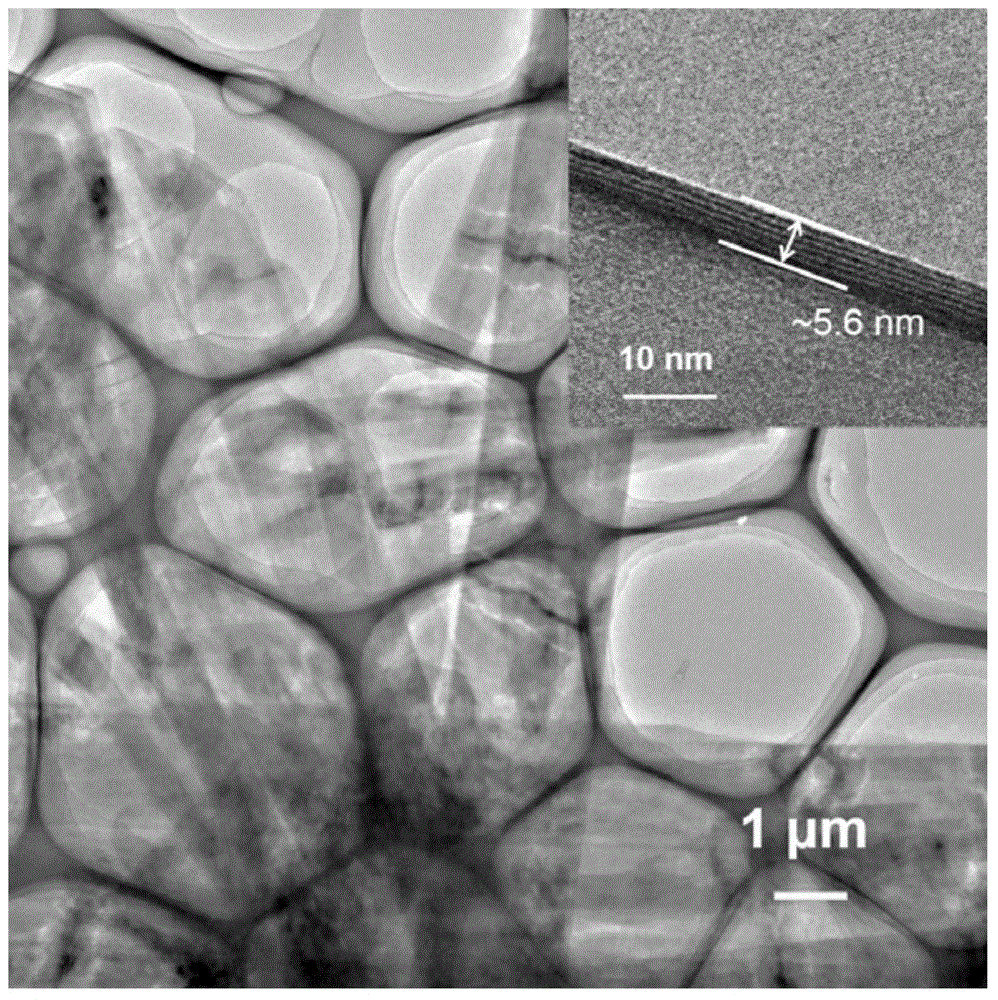

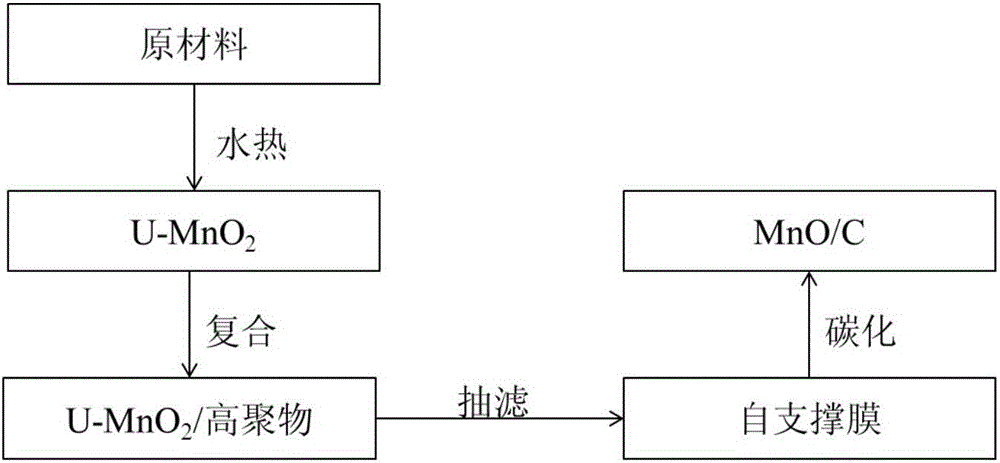

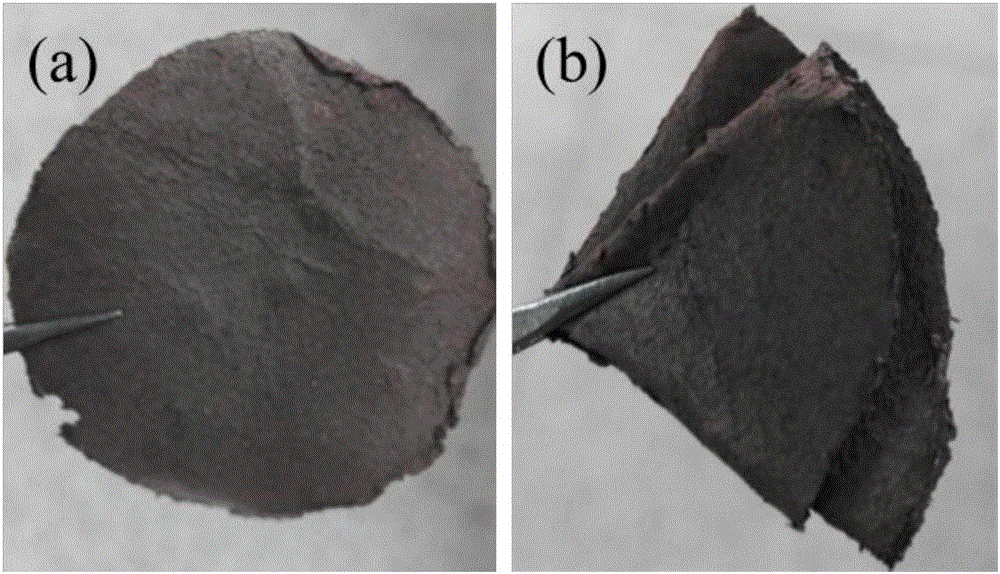

Preparation method of self-support lithium ion battery cathode material

InactiveCN104993143ASimple preparation processImprove structural stabilityCell electrodesSecondary cellsNanowireFiltration

The invention relates to a preparation method of a self-support lithium ion battery cathode material. The method includes: making a manganese salt, an oxidant and a solvent into an ultralong one-dimensional manganese dioxide (U-MnO2) nanowire by a hydrothermal technique, dispersing the U-MnO2 in an acidic solution and adding a proper amount of an organic monomer to obtain a U-MnO2@high polymer compound, carrying out cleaning, pumping filtration and drying to obtain a self-support membrane, and carrying out high temperature heat treatment to obtain the self-support carbon coated MnO(MnO@C) electrode material. The MnO@C prepared by the method can be directly used as the cathode material of a lithium ion battery without additional current collector, conductive additive and binder. The material has the characteristics of simple preparation process, high structure stability, self-current collection, excellent electrochemical performance and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

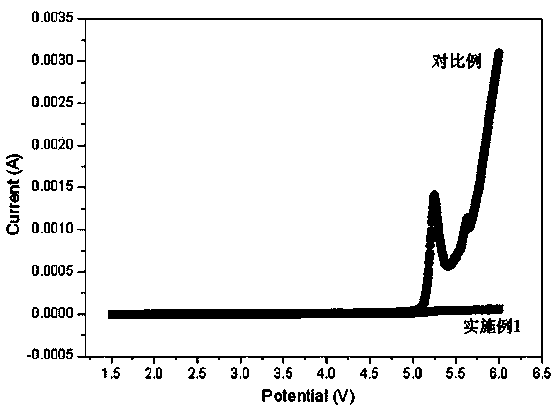

High voltage electrolyte for lithium ion batteries

ActiveCN104282939AImprove solubilityAvoid structural changesSecondary cellsSolubilityHydrofluoroether

The invention discloses a high voltage electrolyte for lithium ion batteries, the high voltage electrolyte is composed of an organic solvent, electrolyte lithium salt and a cathode film-forming additive, wherein the organic solvent is a mixed solvent of fluorinated ethylene carbonate, trifluorinated propylene carbonate and hydrofluoroether, the electrolyte lithium salt mixed is lithium salt of lithium hexafluorophosphate and lithium bis(oxalate)borate. The high voltage electrolyte effectively solves the problems that fluorinated solvents are high in viscosity and the electrolyte lithium salt is poor in solubility in fluorinated organic solvents, so that the fluorinated organic solvents can be directly used as the organic solvents in lithium ion battery electrolyte, the high voltage electrolyte has wide electrochemical window and good oxidation resistance and high voltage resistant characteristics, has high electric conductivity, can guarantee the high magnification and power characteristics of a power battery, is high in safety, and can greatly improve the safety performance of the power battery.

Owner:WANXIANG 123 CO LTD

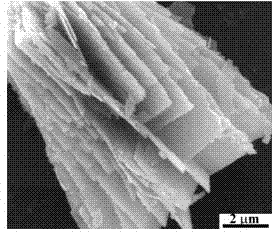

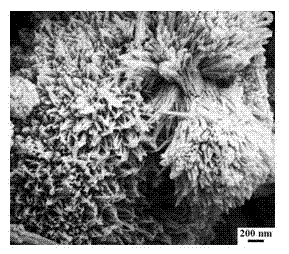

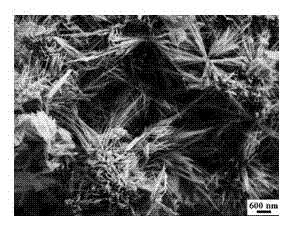

Chrysanthemum-shaped cobaltosic oxide (Co3O4) material and preparation method and application thereof

InactiveCN102332576AIncreased specific surface area of the structureShorten the conduction pathCell electrodesActive agentSurface-active agents

The invention discloses a chrysanthemum-shaped cobaltosic oxide (Co3O4) material and a preparation method and application thereof. The preparation method comprises the following steps of: mixing cobalt salt, a surface active agent, a precipitating agent and a solvent in a stoichiometric ratio; putting a mixed solution into a reaction kettle and performing hydro-thermal reaction at the temperature of 95 to 105 DEG C for 7.5 to 8.5 h; washing and drying, and thus obtaining a powdery mixed precursor; and performing heat treatment on the powdery mixed precursor in air, and thus obtaining the chrysanthemum-shaped Co3O4 material. The obtained chrysanthemum-shaped Co3O4 material has better electrochemical performance and is applicable to a cathode of a rechargeable lithium ion battery.

Owner:SHANGHAI INST OF TECH

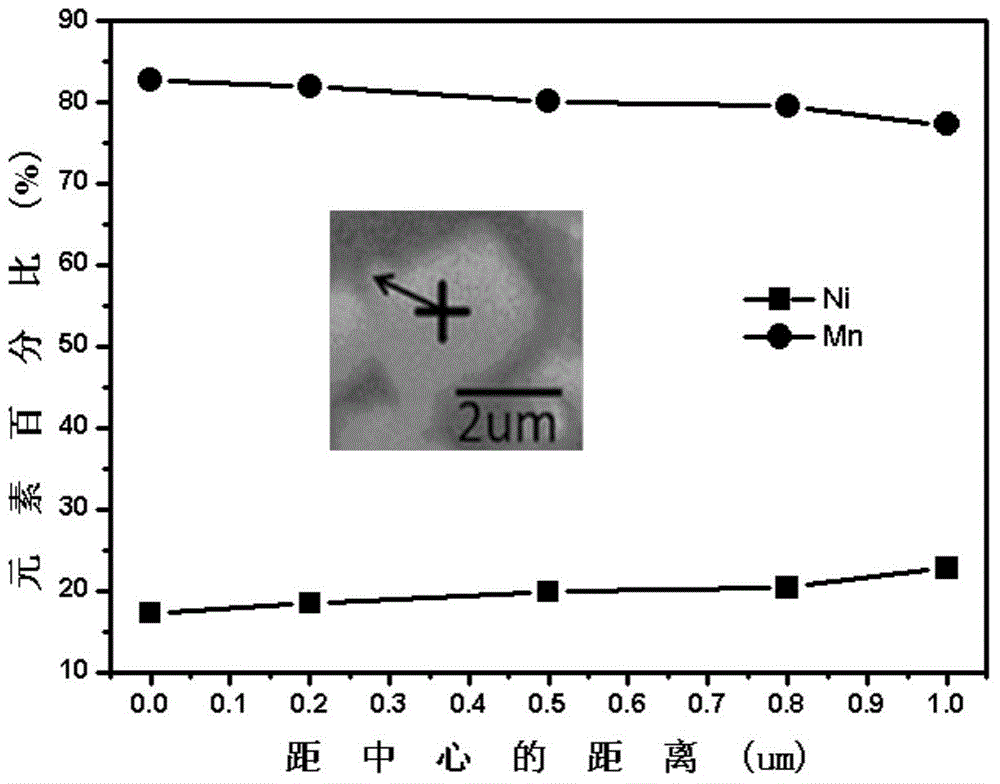

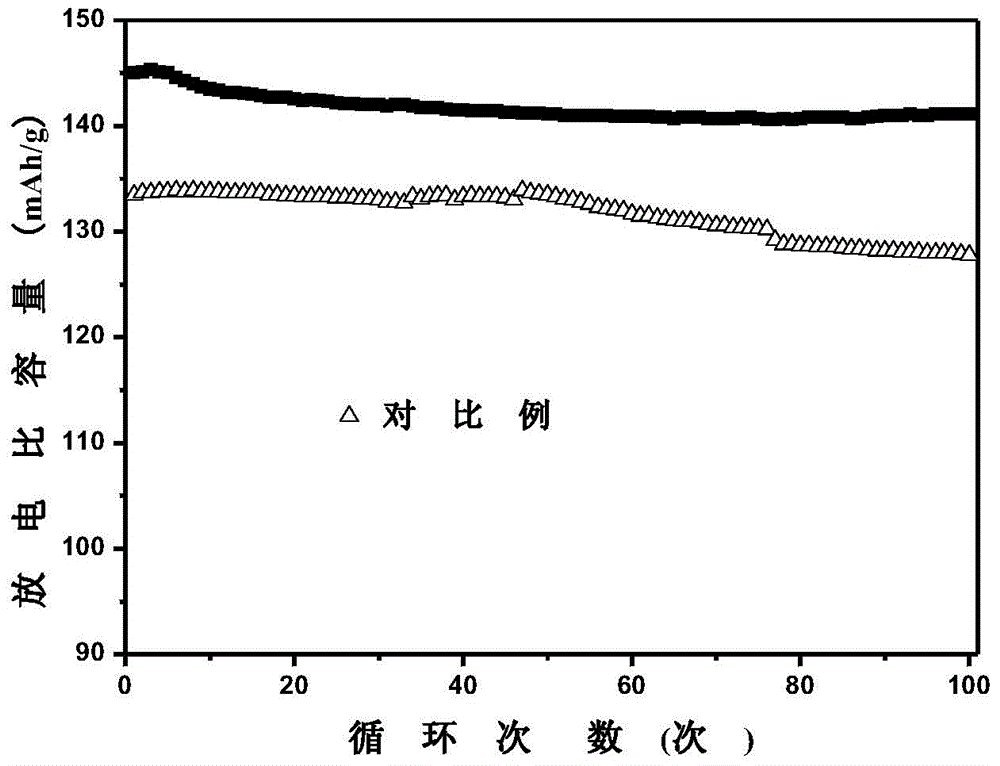

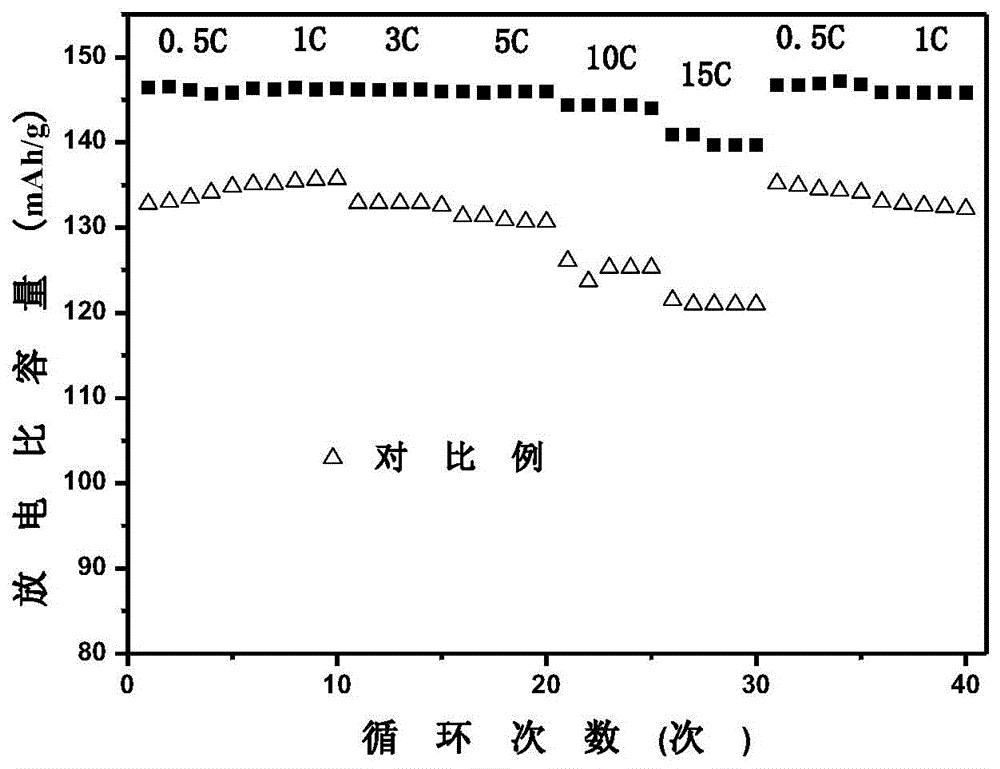

Lithium manganese nickel oxide cathode material having nickel manganese concentration gradient and preparation method thereof

ActiveCN105226270AHigh chemical stabilityEliminate Volume Change MismatchesCell electrodesSecondary cellsChemical compositionRoasting

The invention discloses a lithium manganese nickel oxide cathode material having nickel manganese concentration gradient and a preparation method thereof. The average chemical composition of the lithium manganese nickel oxide cathode material can be shown as a molecular formula of LiNi<0.5-x>Mn<1.5+x>O<4>, wherein x is more than or equal to 0.1 and less than or equal to 0.35, the concentration of Ni is gradually reduced in a gradient distribution manner from the particle center to the particle surface of the lithium manganese nickel oxide cathode material, and the concentration of Mn is gradually reduced in a gradient distribution manner from the particle center to the particle surface of the lithium manganese nickel oxide cathode material. The preparation method comprises the following steps of firstly, synthesizing a spherical-like particle having a core-shell structure by a co-precipitation process; and finally, preparing the lithium manganese nickel oxide cathode material with change on the nickel and manganese concentration by element diffusion during the high-temperature roasting process. The cathode material disclosed by the invention has excellent high-temperature cycle stability and rate performance, high reversible capacity, high chemical stability, long cycle life, and excellent comprehensive electrochemical performance.

Owner:UNIV OF SCI & TECH BEIJING

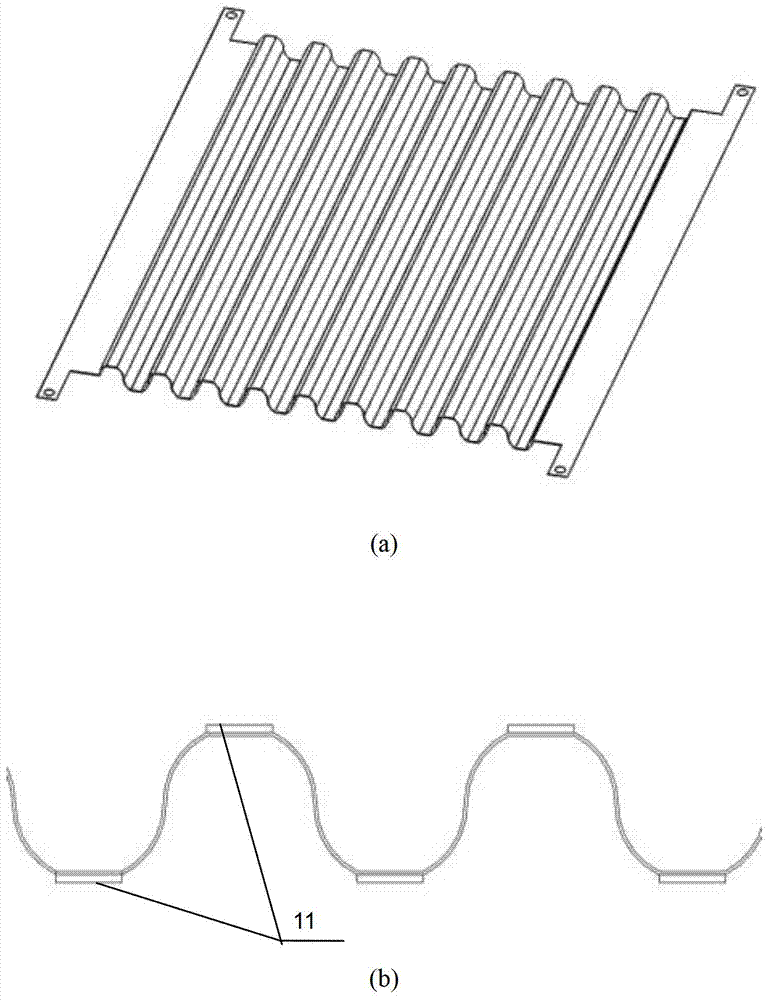

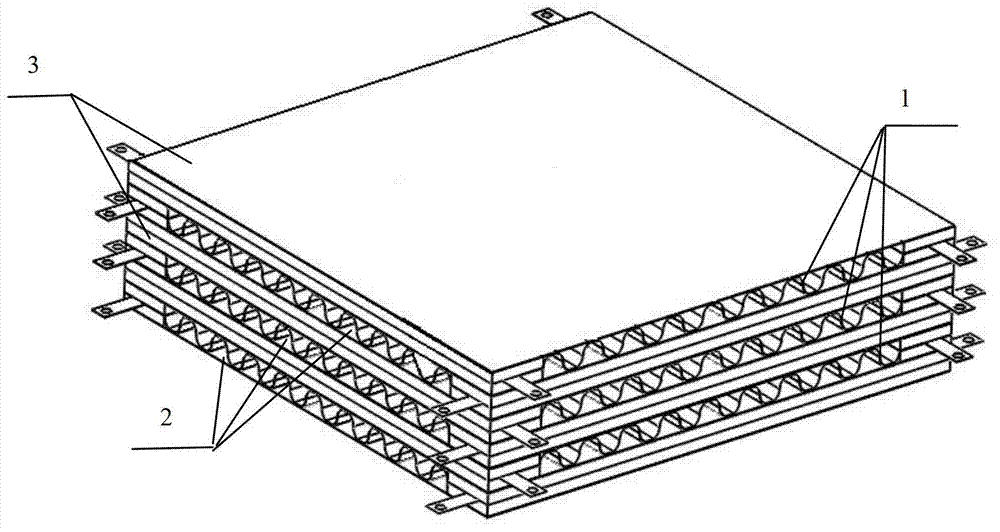

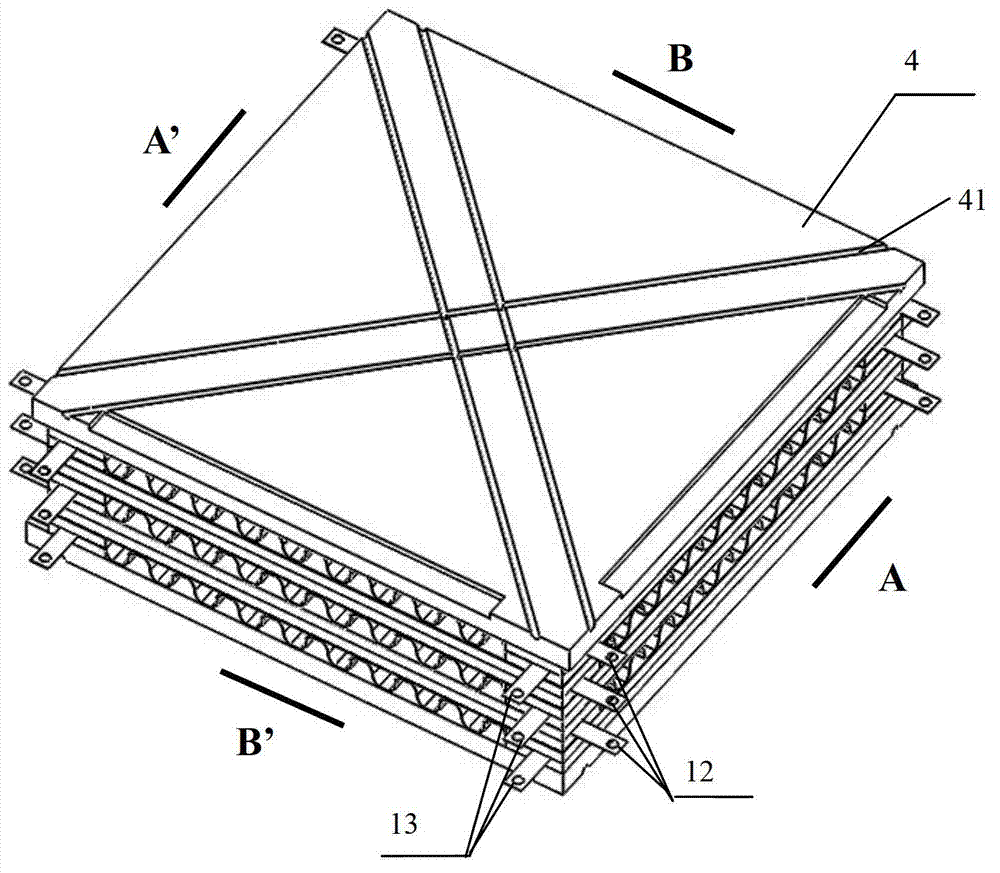

Lithium-ion flow battery reactor

ActiveCN102931427AImprove liquidityHigh rate characteristicsRegenerative fuel cellsCell component detailsWater vaporGas passing

The invention discloses a lithium-ion flow battery reactor. A collecting plate is a corrugated plate, electrode suspension liquid can flow into cavities evenly, the collecting area is increased, and the multiplying power performance of a battery can be improved effectively; steering coves are arranged on sides of two adjacent battery modules, so that the electrode suspension liquid flows every battery module sequentially, an S-shaped flowing field is formed, the flowing speed of the electrode suspension liquid is accelerated, the effective volume of the battery reaction is increased, the energy density of the battery can be improved greatly, and at the same time, the electrode suspension liquid in battery modules flows evenly; a liquid inlet diversion chamber and a liquid outlet diversion chamber with a main flowing channel and a branch flowing channel can reduce effects on battery uniformity, which are due to a turbulent flow phenomenon caused by liquid inlet and liquid outlet; inert gases enter a battery reactor through gas flow channels of a gas protective chamber and a cooling plate, the gas tightness and the radiating performance of the whole battery reactor are guaranteed, and at the same time, water vapor and oxygen in the air are prevented from being in contact with the electrode suspension liquid.

Owner:BEIJING HAWAGA POWER STORAGE TECH +1

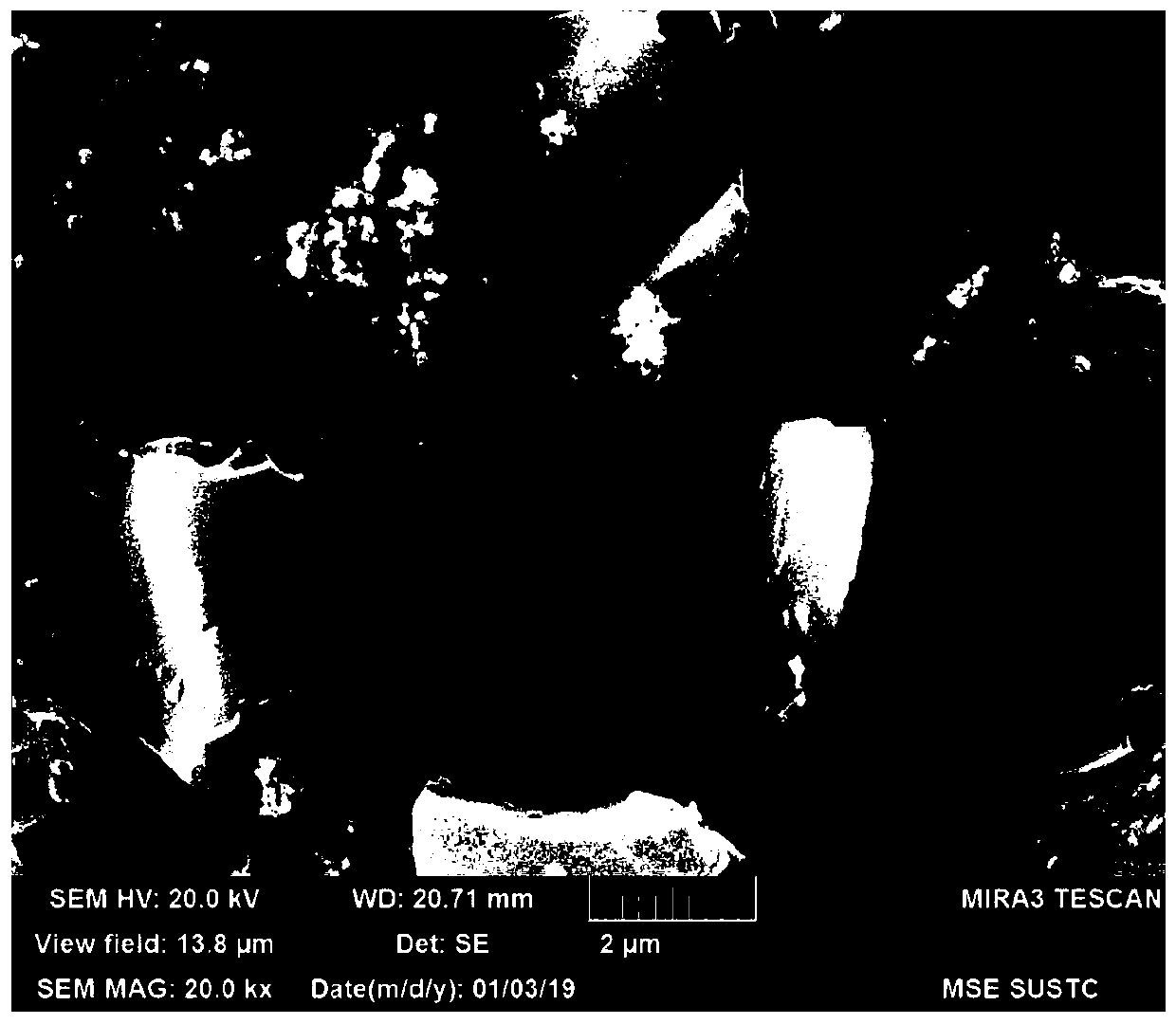

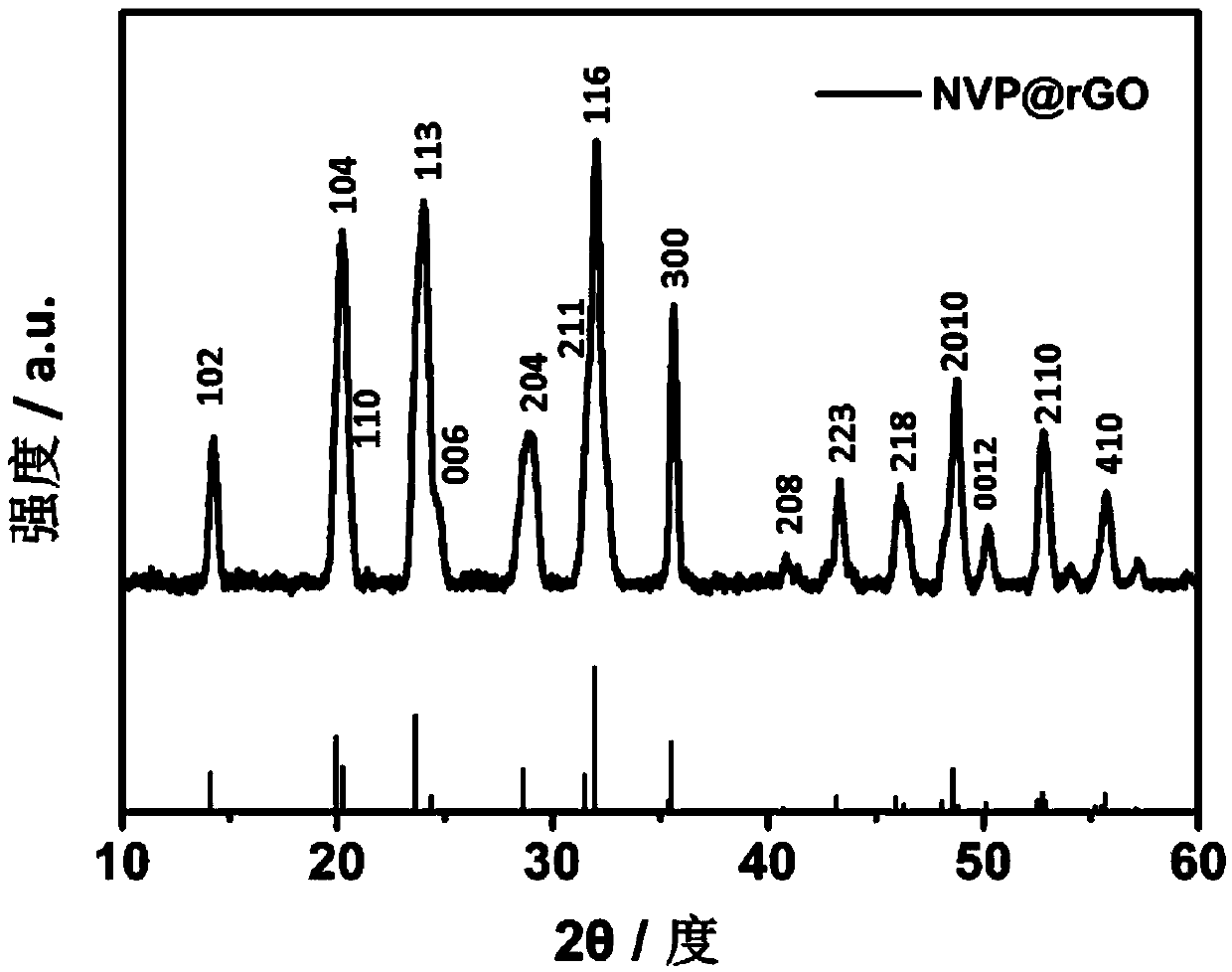

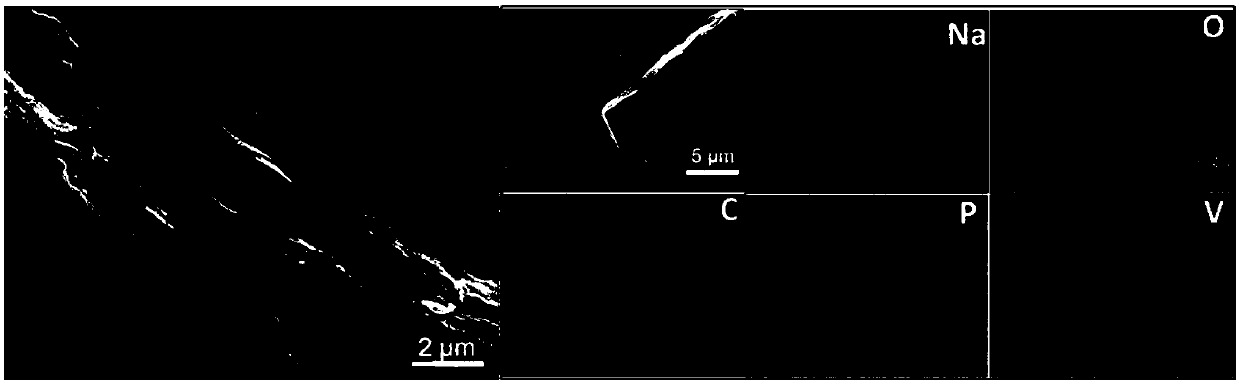

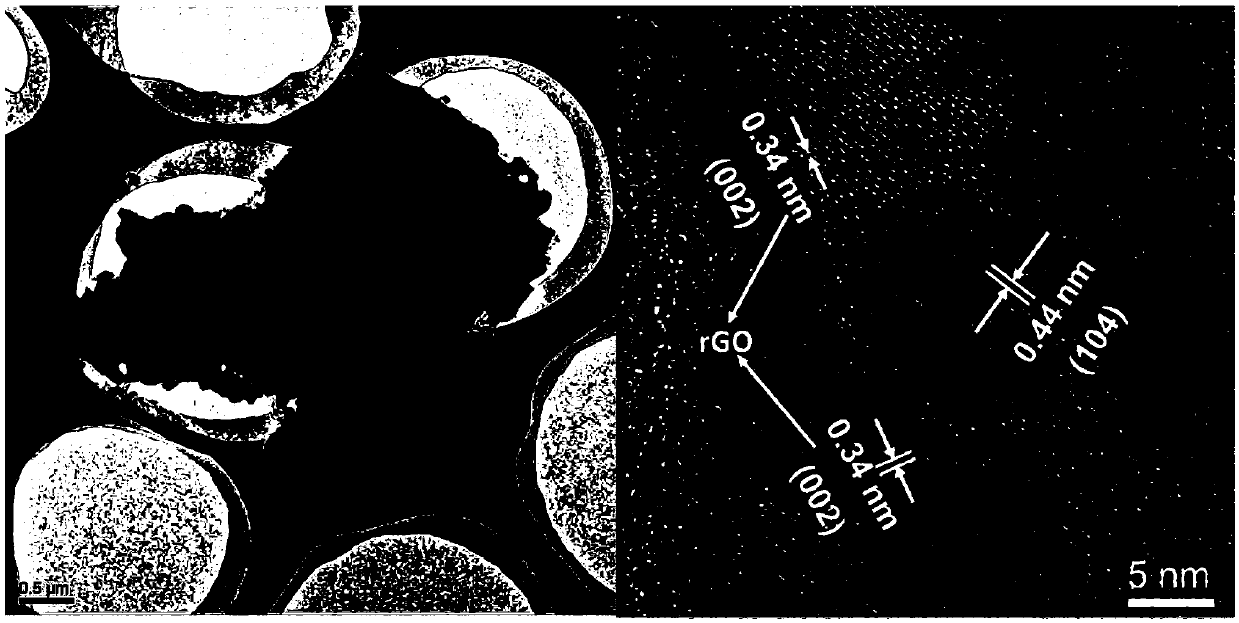

Laminated Na3V2(PO4)3@rGo nanocomposite and preparation method and application therefor

ActiveCN105375008AImprove conductivityImprove electrochemical performanceMaterial nanotechnologyCell electrodesHigh rateSodium-ion battery

The invention relates to a laminated Na3V2(PO4)3@rGo nanocomposite and an preparation method and an application therefor. The nanocomposite can be used as a sodium ion battery positive electrode active material with high rate capability and long service life; and the nanocomposite is formed by a sheet structure and rGO nano-sheets in a layer-to-layer overlapping manner, wherein the sheet structure is formed by nanoscale sub-unit Na3V2(PO4)3 particles. When the laminated Na3V2(PO4)3@rGo nanocomposite is used as the sodium ion battery positive electrode active material, the material is excellent in cycling stability and high in rate capability, so that the laminated Na3V2(PO4)3@rGo nanocomposite is the potential application material for the sodium ion batteries with high rate capability and long service life; and in addition, the preparation method is simple in process, capable of meeting the green chemistry demand, low in equipment requirement and good for the marketization promotion.

Owner:WUHAN UNIV OF TECH

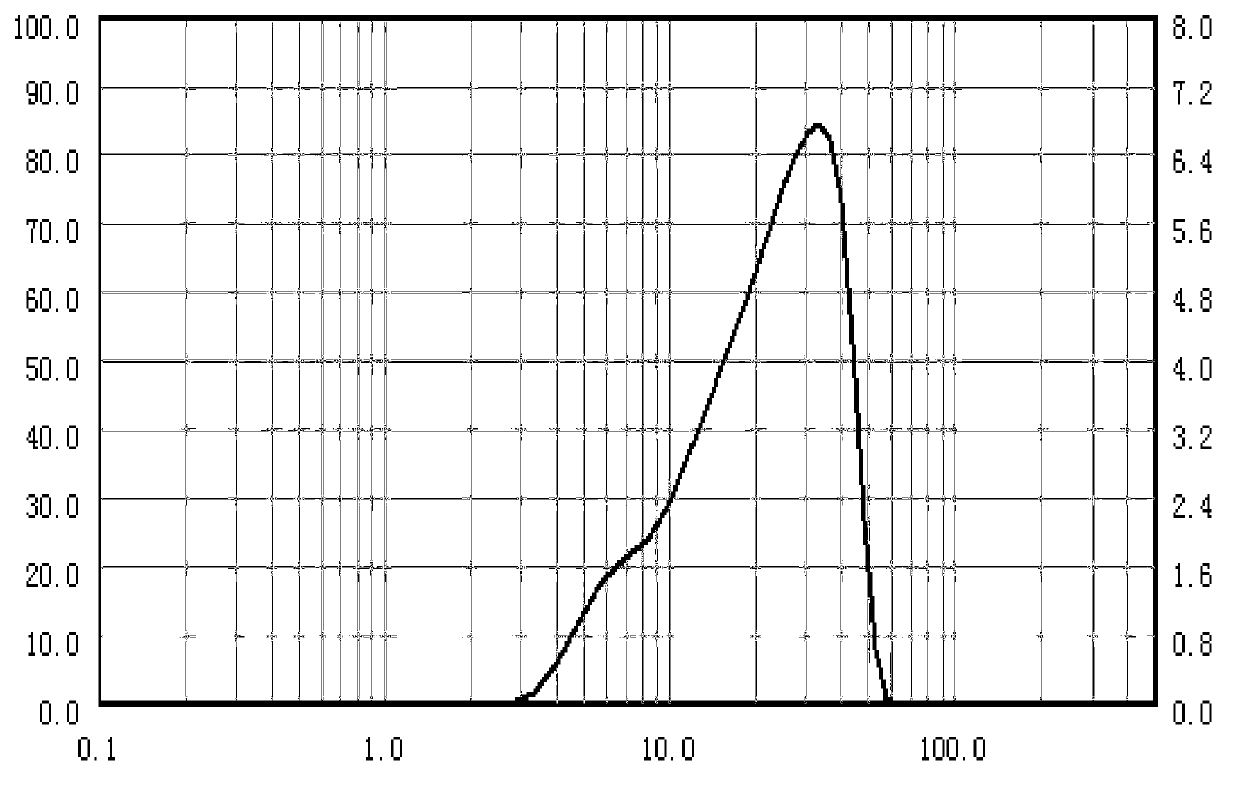

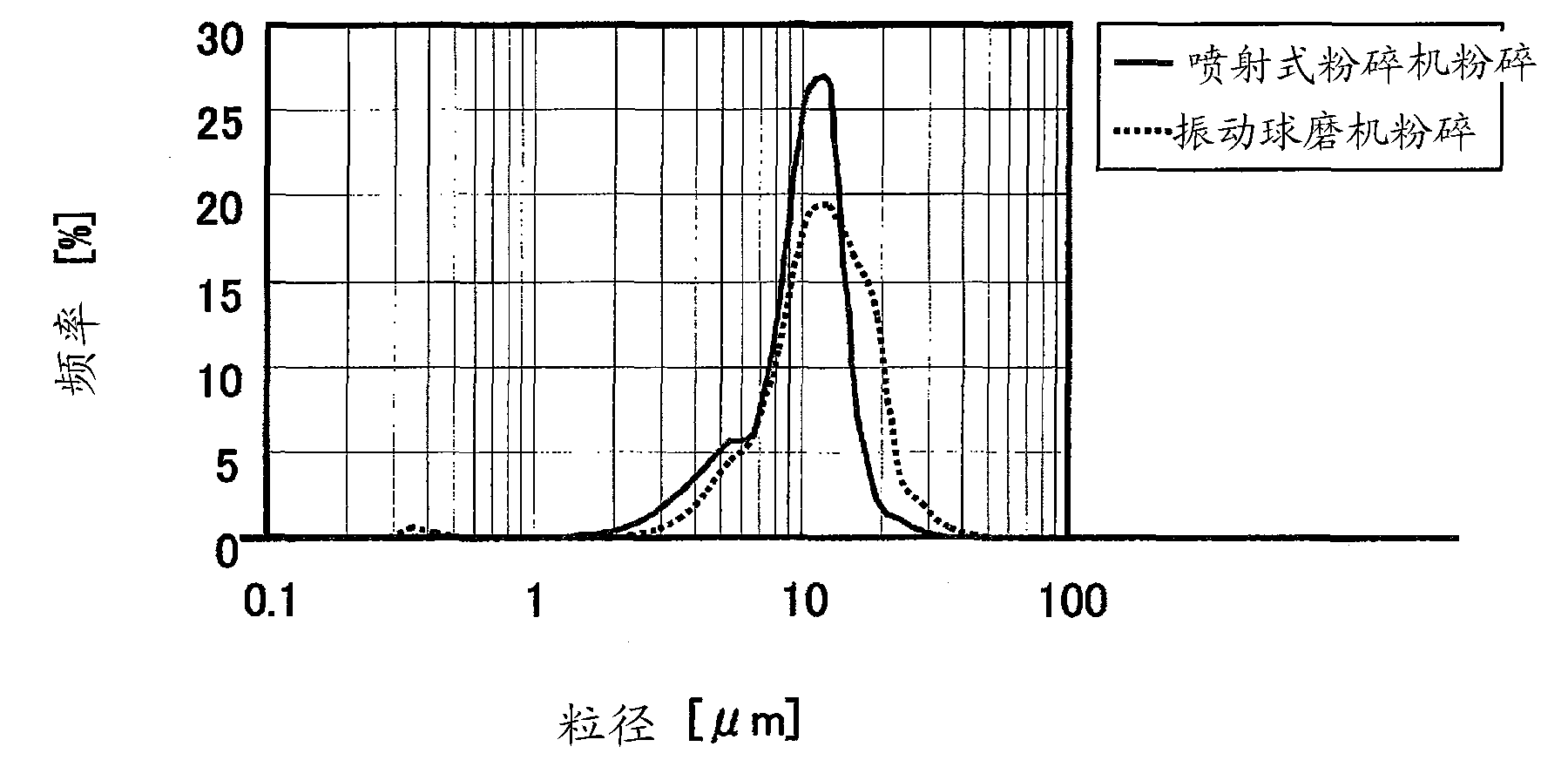

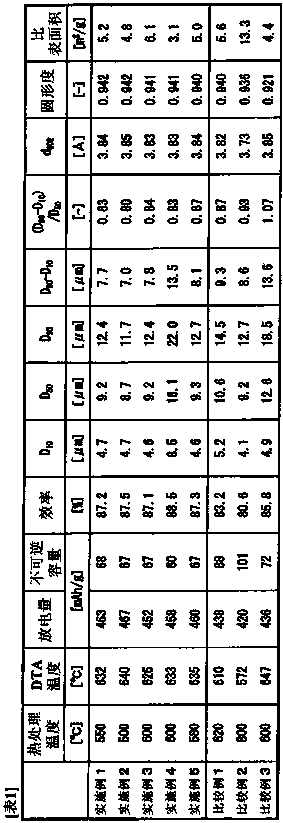

Carbonaceous material for non-aqueous electrolyte secondary battery negative electrode

InactiveCN103415948AImprove charge and discharge efficiencyReduce thicknessCell electrodesCarbon preparation/purificationAir atmosphereMicrometer

The purpose of the present invention is to provide a carbonaceous material for a non-aqueous electrolyte secondary battery negative electrode, which has large charge-discharge capacity, high charge-discharge efficiency and excellent charge-discharge cycle properties. The purpose is achieved by a carbonaceous material for a non-aqueous electrolyte secondary battery negative electrode, characterized in that the average interlayer spacing on face (002) is 0.365-0.40 nm as measured by an X-ray diffraction method, no exothermic peak appears in a temperature region of 620 DEG C or lower as measured by a differential thermal analysis under an air atmosphere, the BET specific surface area is 1-7 m2 / g, the average particle diameter (D50) is 5-25 micrometer, and the (D90-D10) / D50 ratio is 1.05 or less.

Owner:KUREHA KAGAKU KOGYO KK

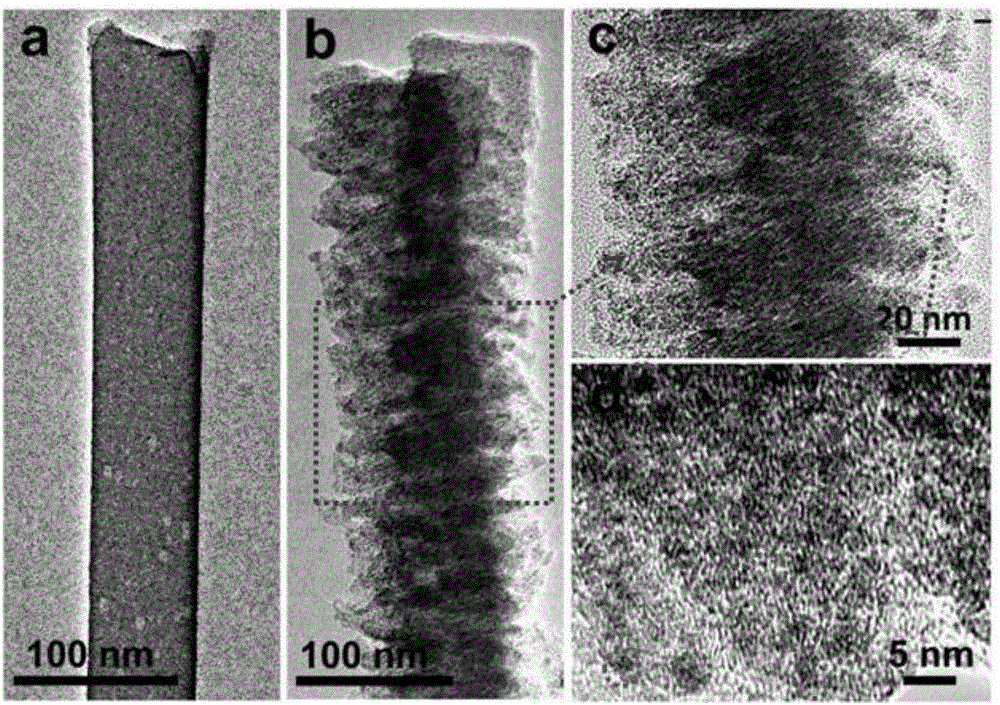

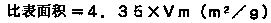

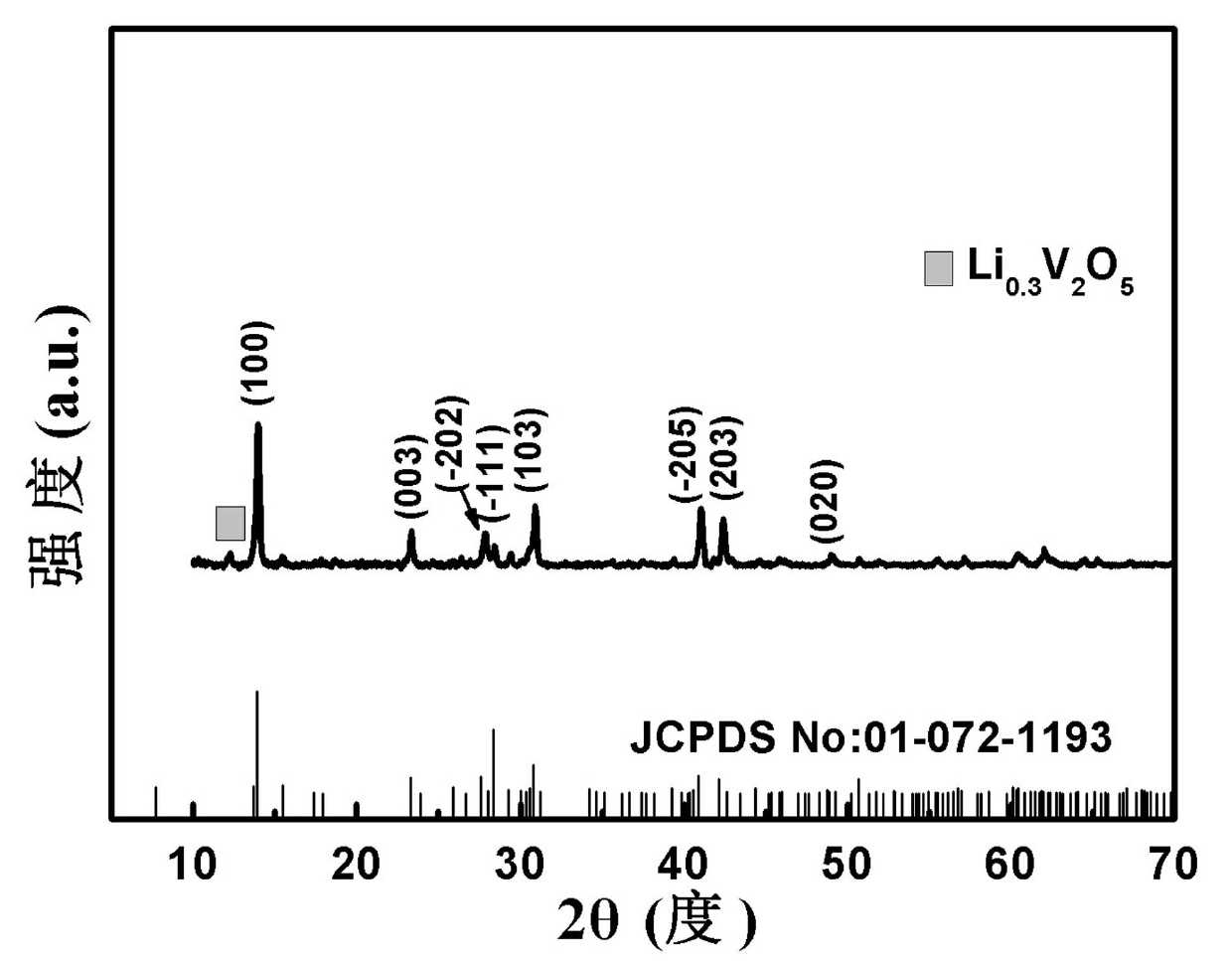

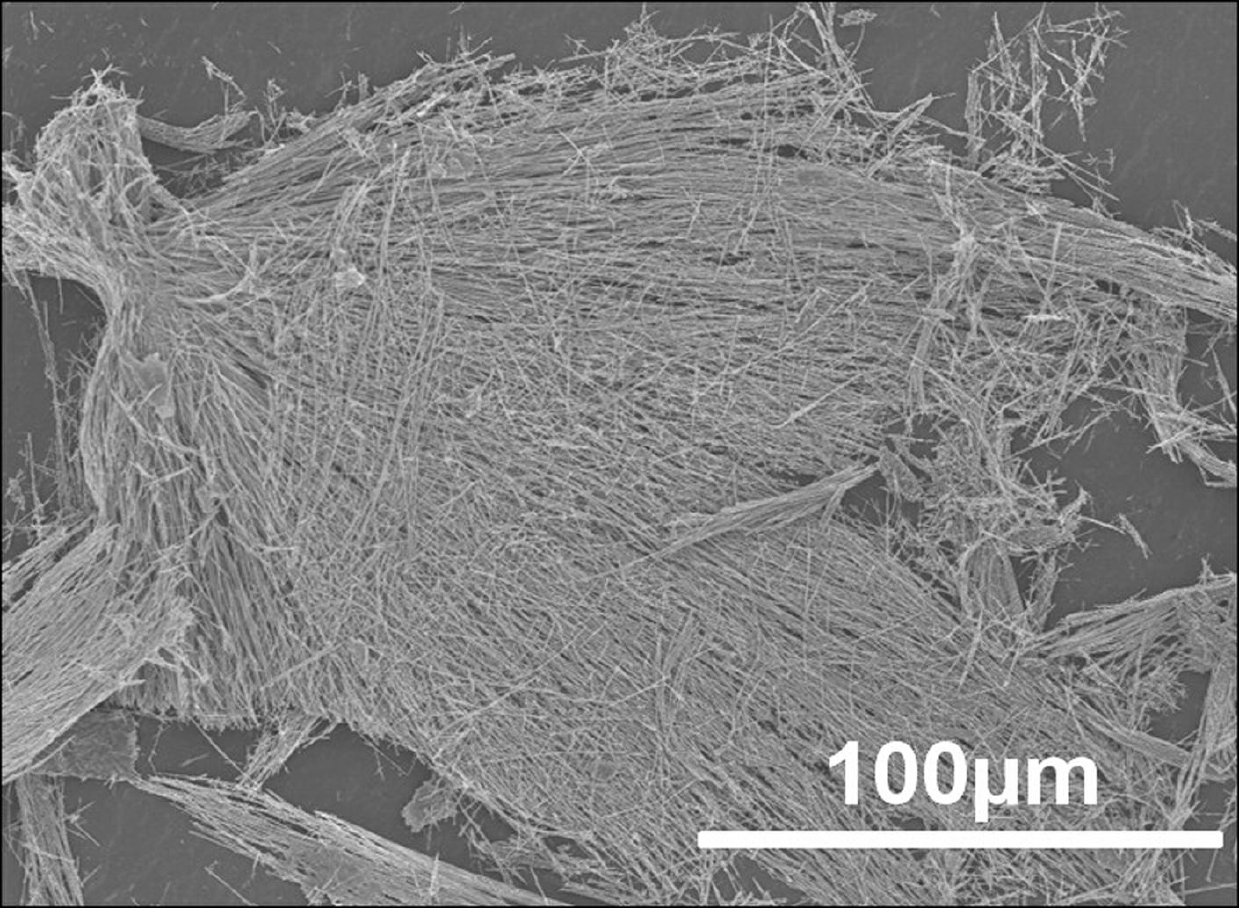

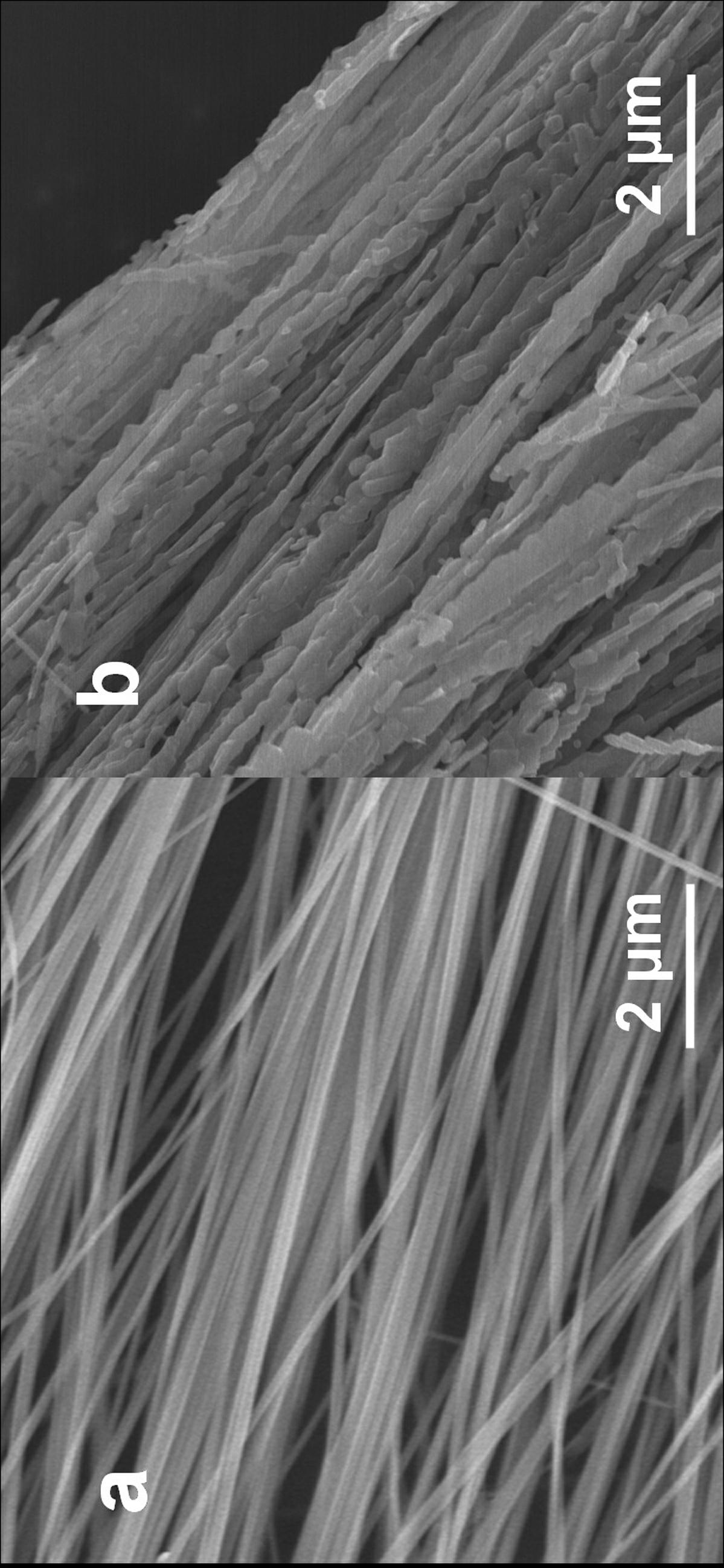

Lithium-vanadium oxide over-long nano wire and preparation method and application thereof

ActiveCN102683665AIncrease powerHigh rate characteristicsMaterial nanotechnologyCell electrodesPower flowReaction temperature

The invention relates to a lithium-vanadium oxide over-long nano wire and a preparation method thereof. The lithium-vanadium oxide over-long nano wire can be taken as an anode active material for a high-power long-service-life lithium ion battery, is 200-300 microns in length, and is 100-200 nanometers in diameter. The lithium-vanadium oxide over-long nano wire is obtained in a simple calcining way. When the lithium-vanadium oxide over-long nano wire is taken as an anode active material for the lithium ion battery, the discharge capacity can still be up to 120mAh / g after circulating at the current density of 2,000mA / g for 600 times, and the capacity attenuation ratio per time is only 0.022 percent. As proved by a result, the lithium-vanadium oxide over-long nano wire has excellent high magnification characteristic, and is a potential application material for the high-power long-service-life lithium ion battery. In a simple hydro-thermal method adopted for preparing a precursor H2V3O8 over-long nano wire, the shape and size of a material can be controlled by changing the reactant concentration, reaction temperature and time, and the prepared material has high purity and high dispersivity.

Owner:WUHAN UNIV OF TECH

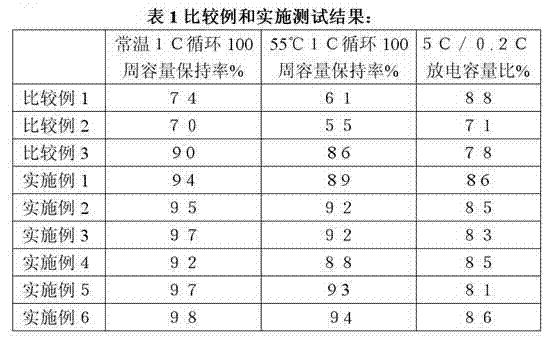

Modified spinel lithium manganate for secondary lithium ion battery and preparation method thereof

InactiveCN102412395AHigh rate characteristicsGood rate characteristicsCell electrodesCarbon coatingCarbon film

The invention is modification of spinel lithium manganate for secondary lithium ion batteries and its preparation method, and is characterized in that the spinel lithium manganate is orderly coated with a silica film and an outer carbon film, which forms a composite material with a spinel lithium manganate-silica-carbon three-layer core-shell structure. The coating is performed by a sol-gel method and a solid phase coating method respectively. The composite material with the three-layer core-shell structure has excellent rate capability, and has a 5C / 0.2C discharge capacity ratio of up to 86%. The normal-temperature and high-temperature cycle performance are greatly improved; the capacity retention rate for 100 cycles of normal-temperature 1C is up to 98%; the capacity retention rate for 100 cycles of 55 DEG C 1C is up to 94%, such as a modified spinel lithium manganate material coated with Li1.04Al0.05Mn1.95O4 body-5 wt% silica coating-5 wt% carbon coating. The problems of unstable cycle performance and poor rate capability of the spinel lithium manganate for secondary lithium ion batteries are effectively solved. The preparation method of the invention is simple and practical, low in cost, and is applicable to large-scale production.

Owner:WUXI LITAI ENERGY TECH

Polymerization emulsion, preparation method thereof, aqueous adhesive, and preparation method and application of aqueous adhesive

ActiveCN107652390AMolecular weight controllableUniform particle size distributionCell electrodesLi-accumulatorsCross-linkPolymer science

The invention discloses a polymerization emulsion, a preparation method thereof, an aqueous adhesive, and a preparation method and an application of the aqueous adhesive. The preparation method of thepolymerization emulsion comprises the following steps: adding water, a chain transfer agent and a sulfonic acid type reactive emulsifier, performing mixing, dropwise adding an acrylic monomer, performing pre-emulsifying, introducing an inert gas to remove O2, adding a cross-linking agent and an initiator, and performing RAFT polymerization to obtain the polymerization emulsion. The aqueous adhesive is prepared through compounding a water-soluble polymer compound, the polymerization emulsion and water, or is prepared through the RAFT polymerization of the water-soluble polymer compound, raw materials for preparing the polymerization emulsion and water. The invention also discloses the preparation method of the aqueous adhesive. The aqueous adhesive is applied to the production of a lithium-sulfur battery positive plate. The polymerization emulsion has the advantages of wide range of suitable monomers, easiness in control and uniform particle size distribution; the aqueous adhesive hasthe advantages of low solid content and wide viscosity range, and a positive electrode made by using the aqueous adhesive has excellent electrochemical performances; and the preparation methods have the advantages of simplicity, low cost, greenness and environmental protection.

Owner:GUIZHOU INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com