Patents

Literature

2367results about How to "Promote crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

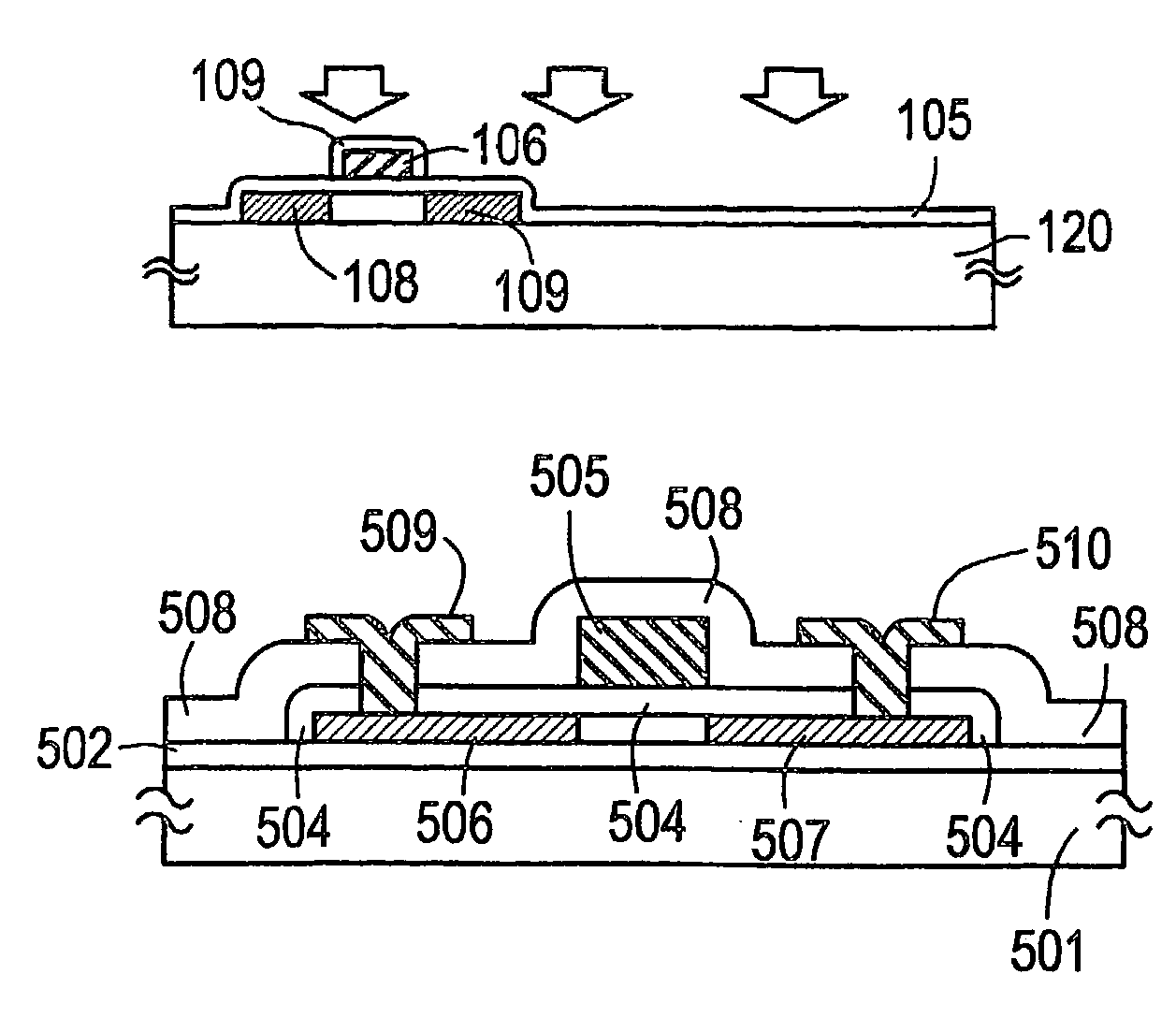

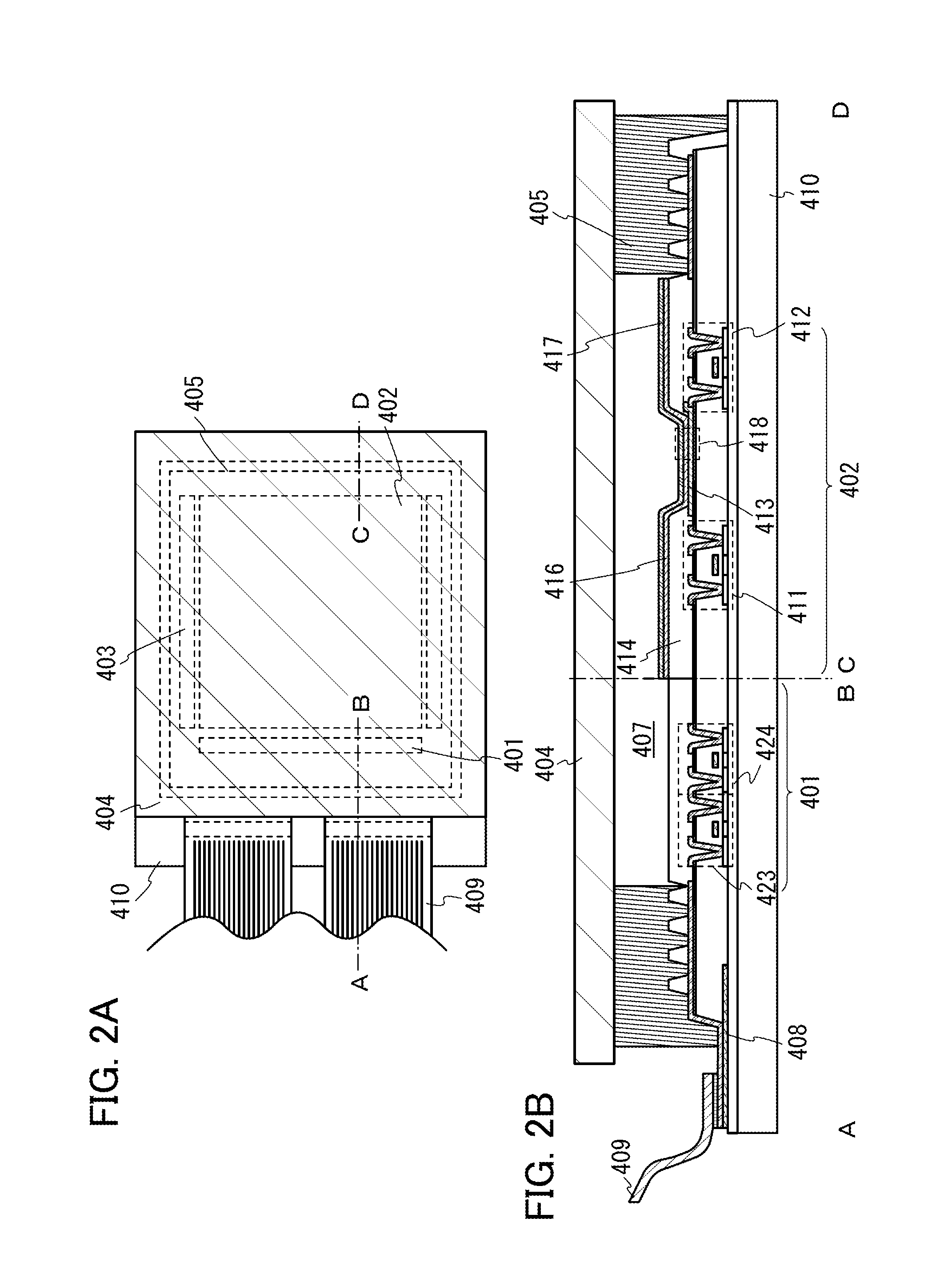

Semiconductor thin film forming method, production methods for semiconductor device and electrooptical device, devices used for these methods, and semiconductor device and electrooptical device

InactiveUS7183229B2Promote crystallizationTransistorDrying solid materials with heatSingle crystalCrystallinity

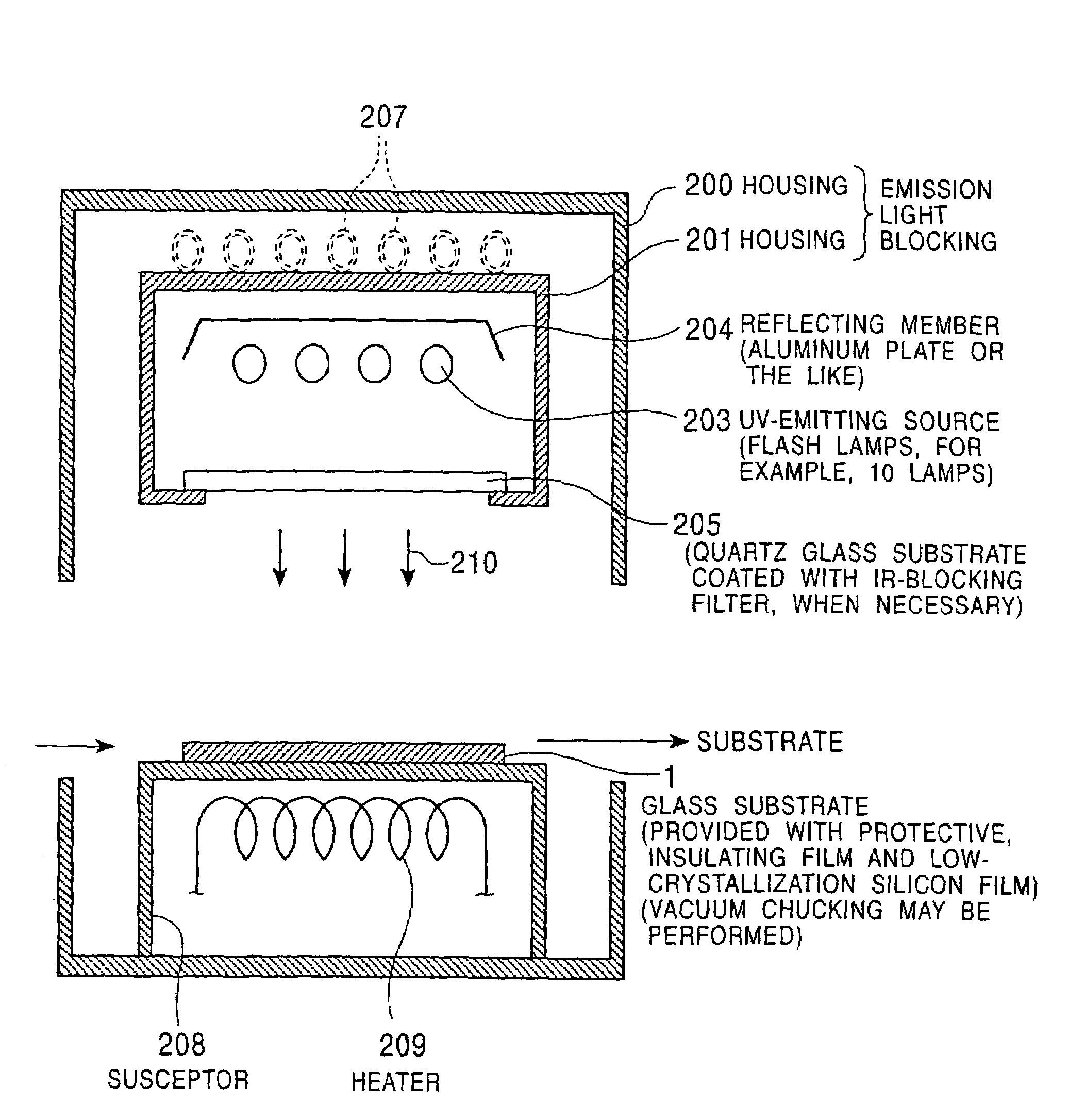

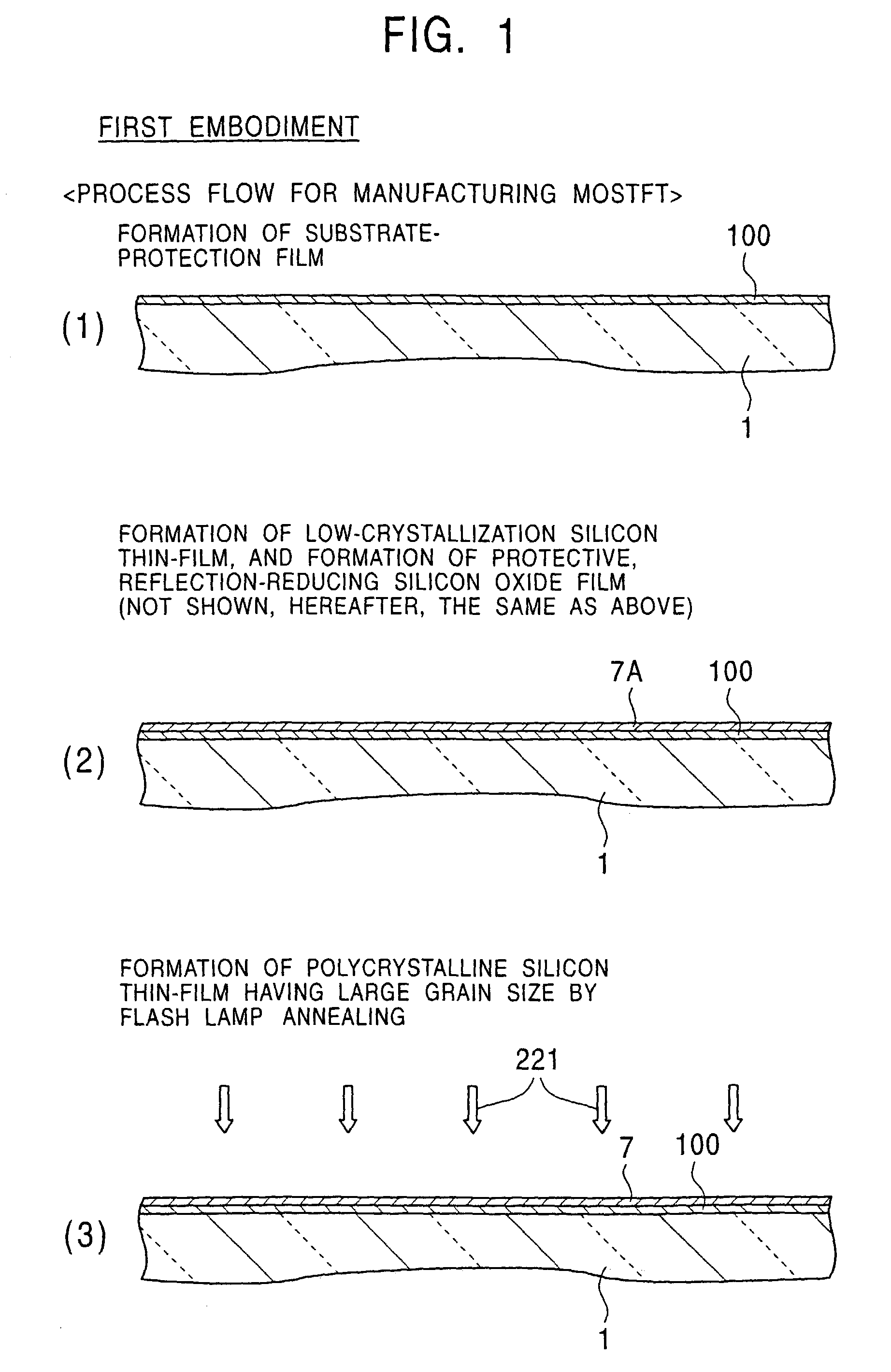

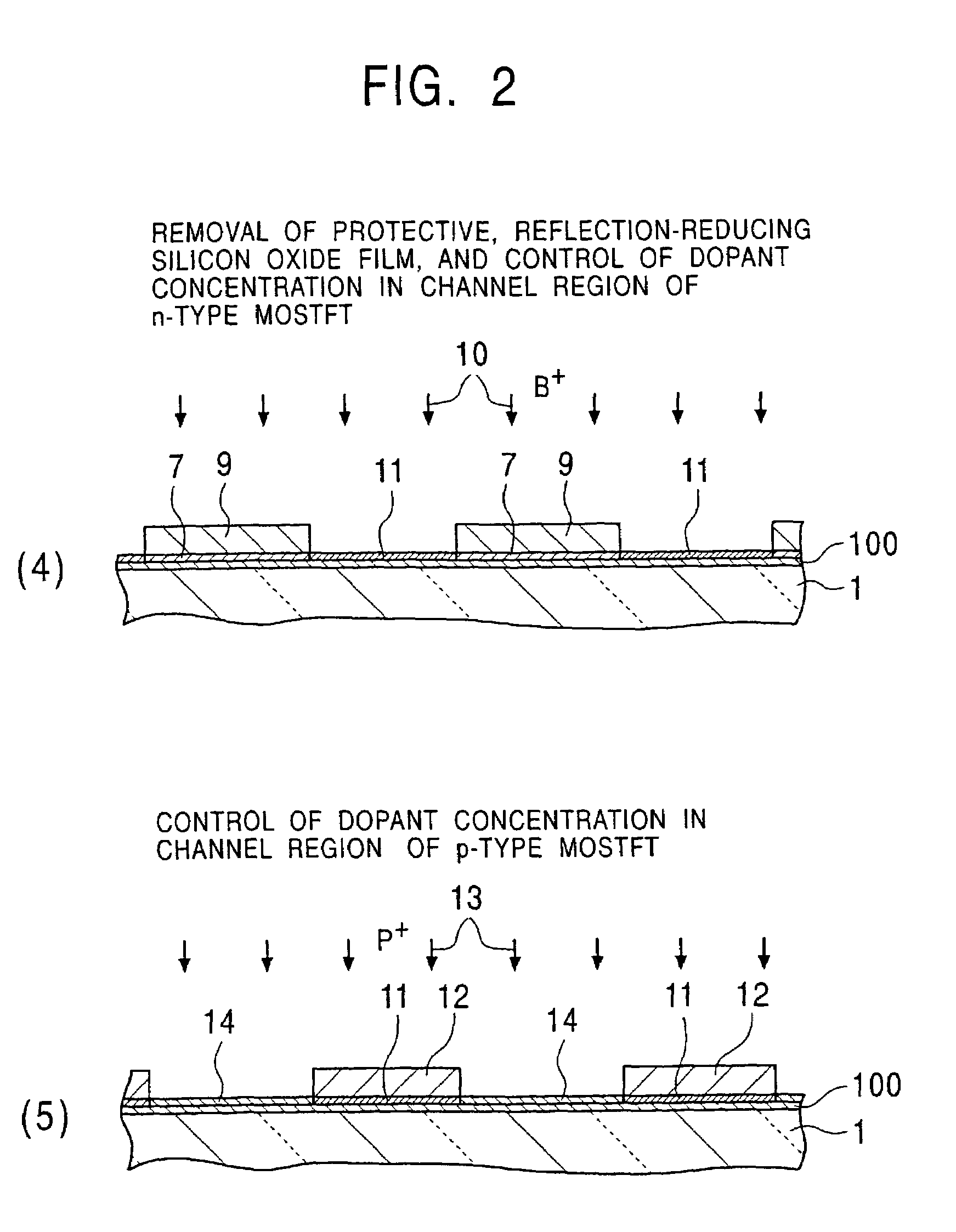

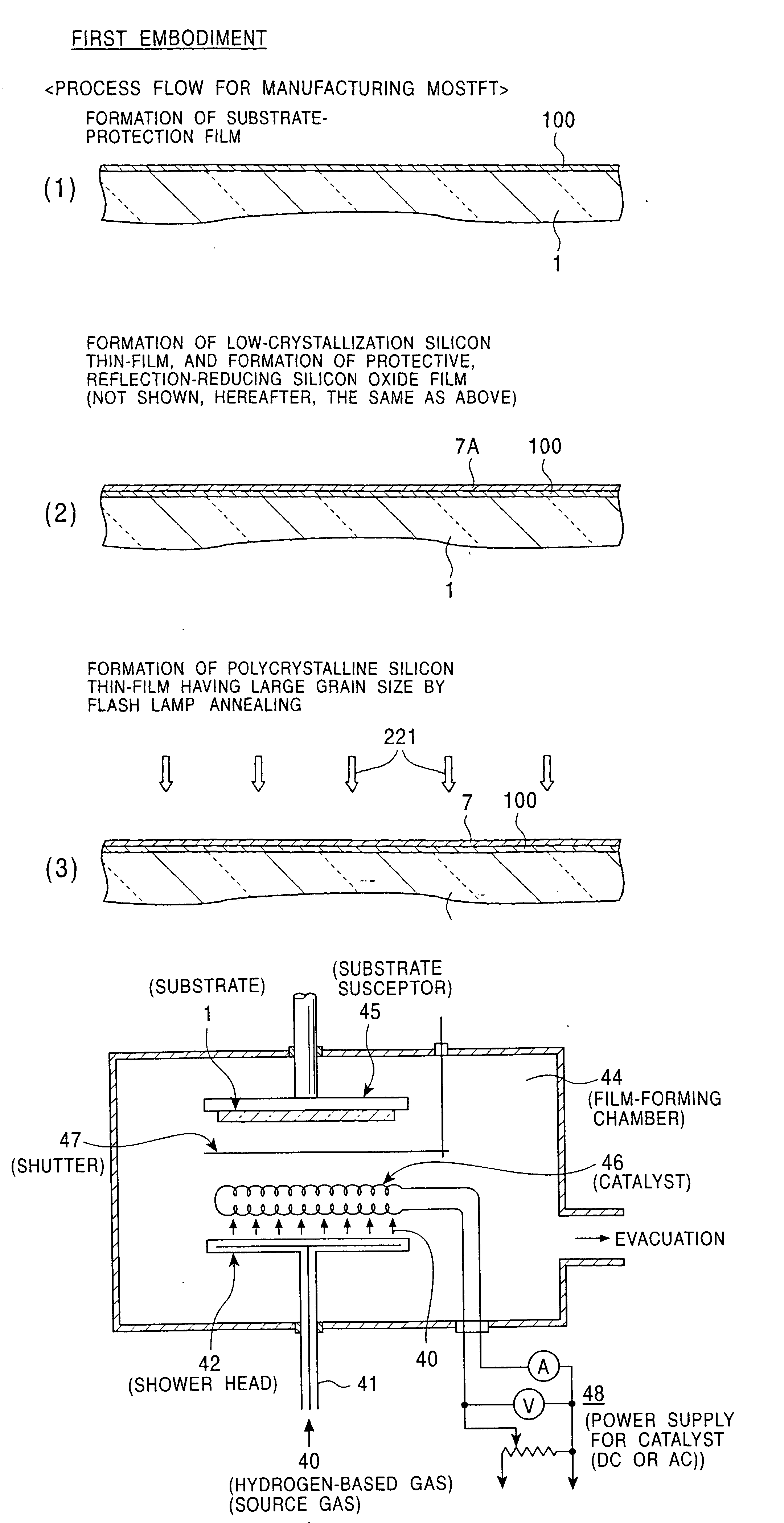

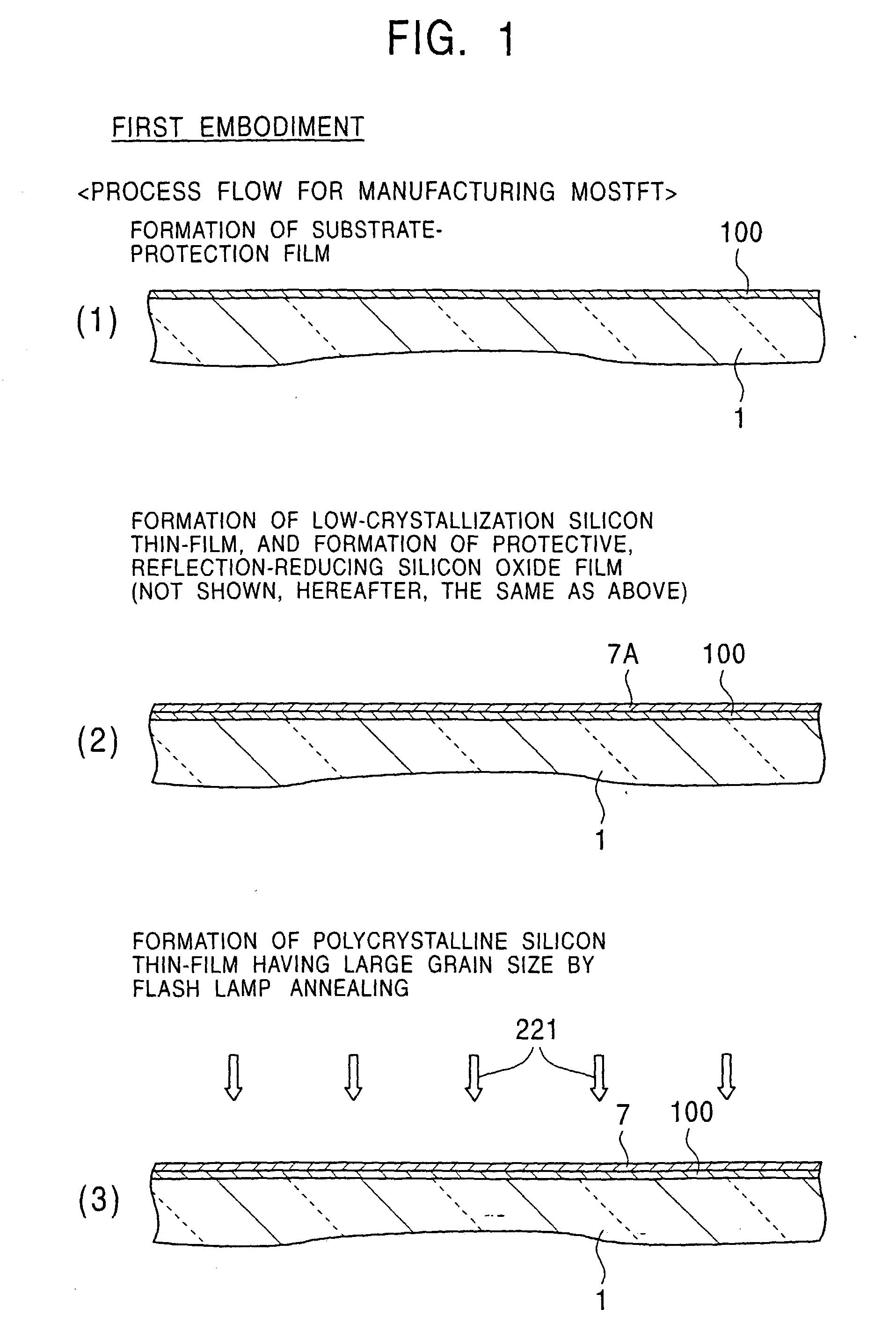

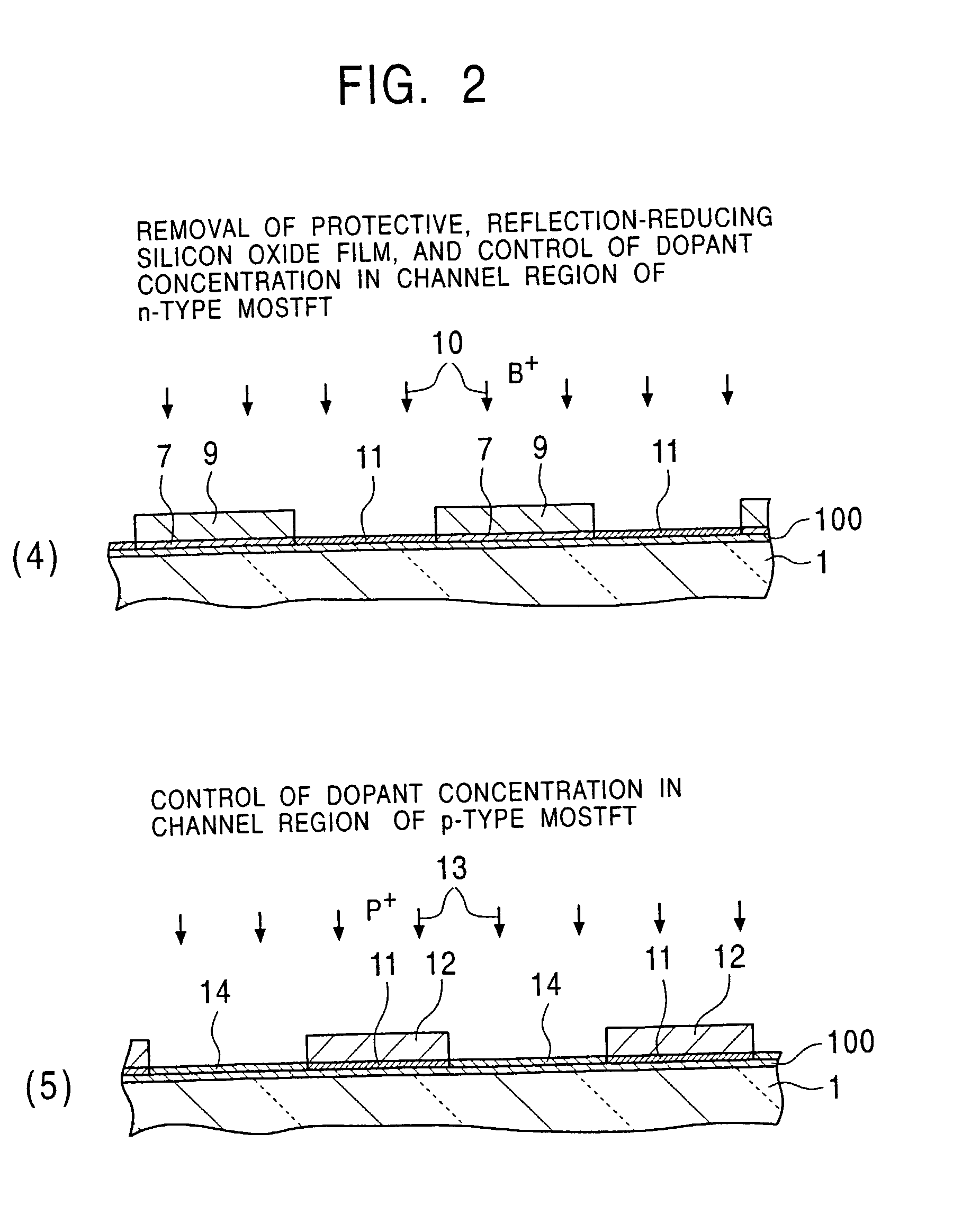

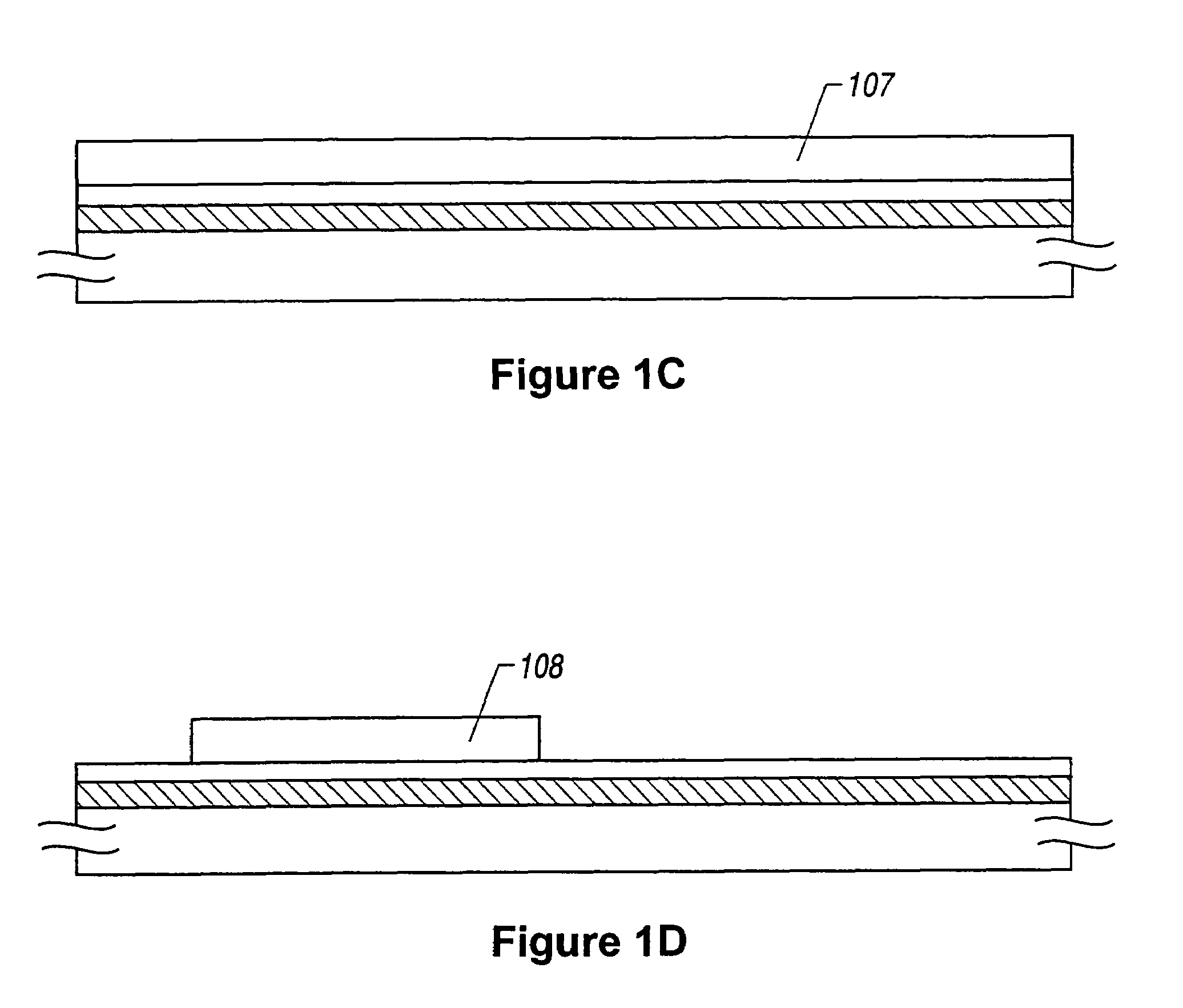

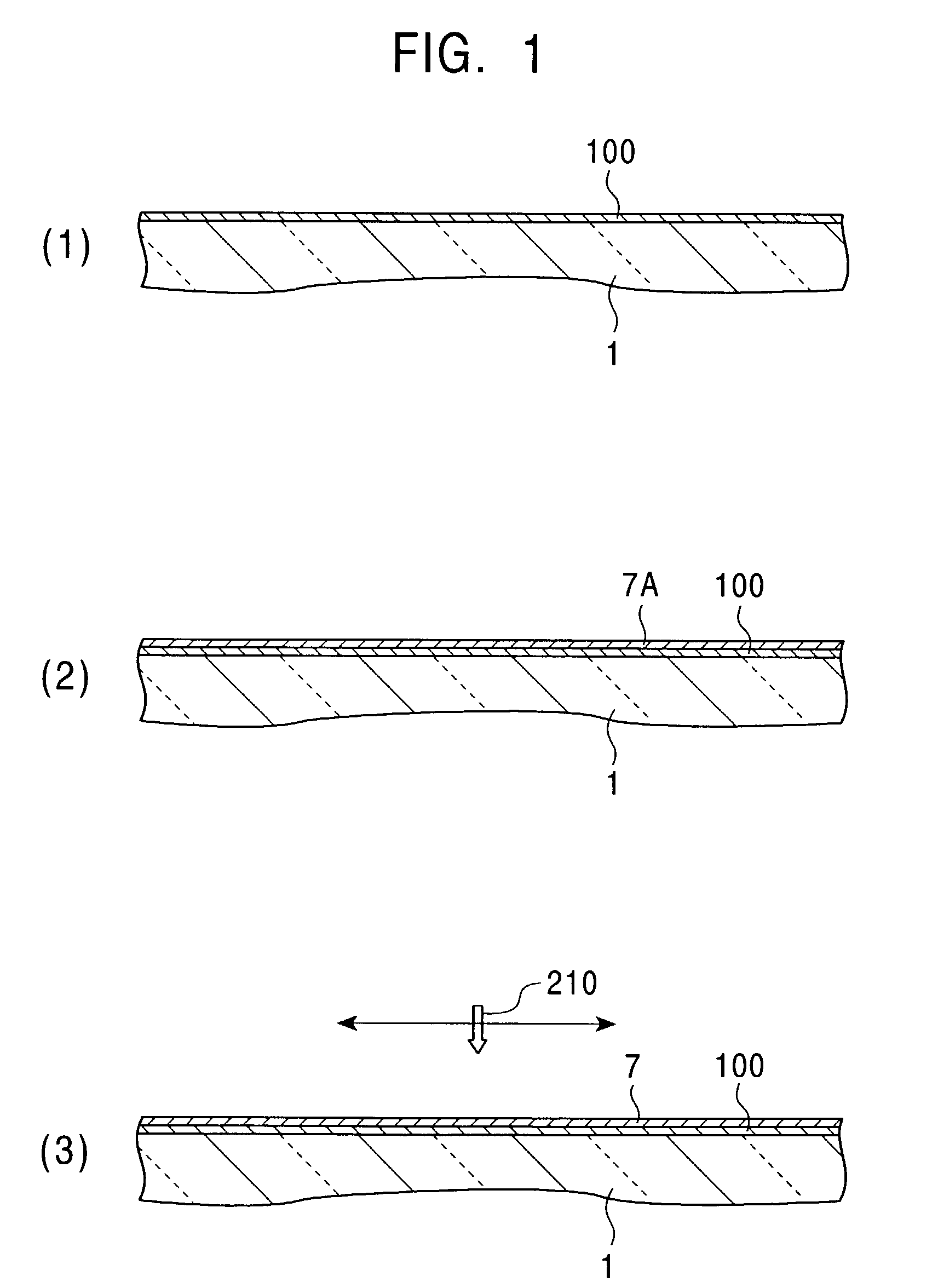

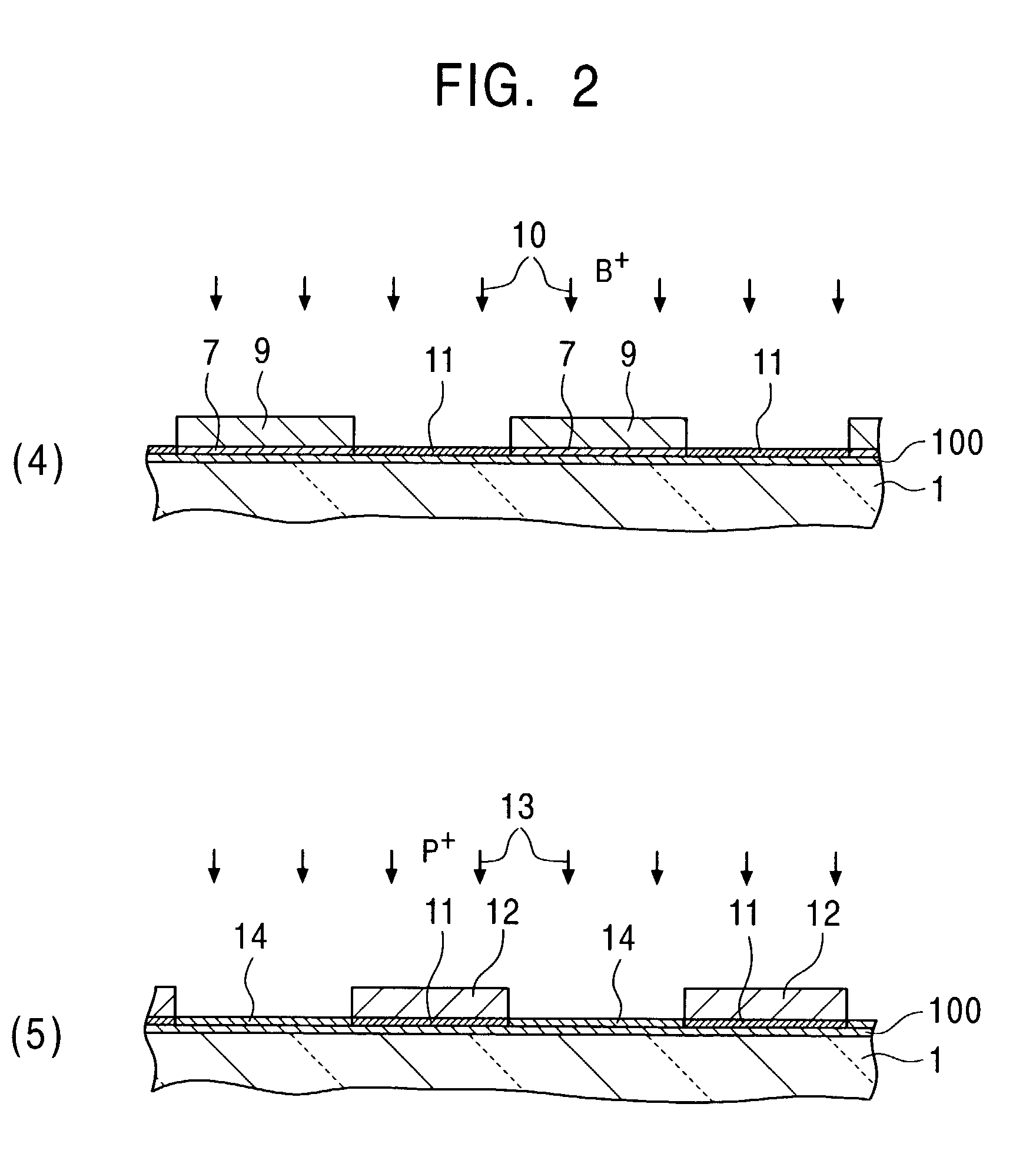

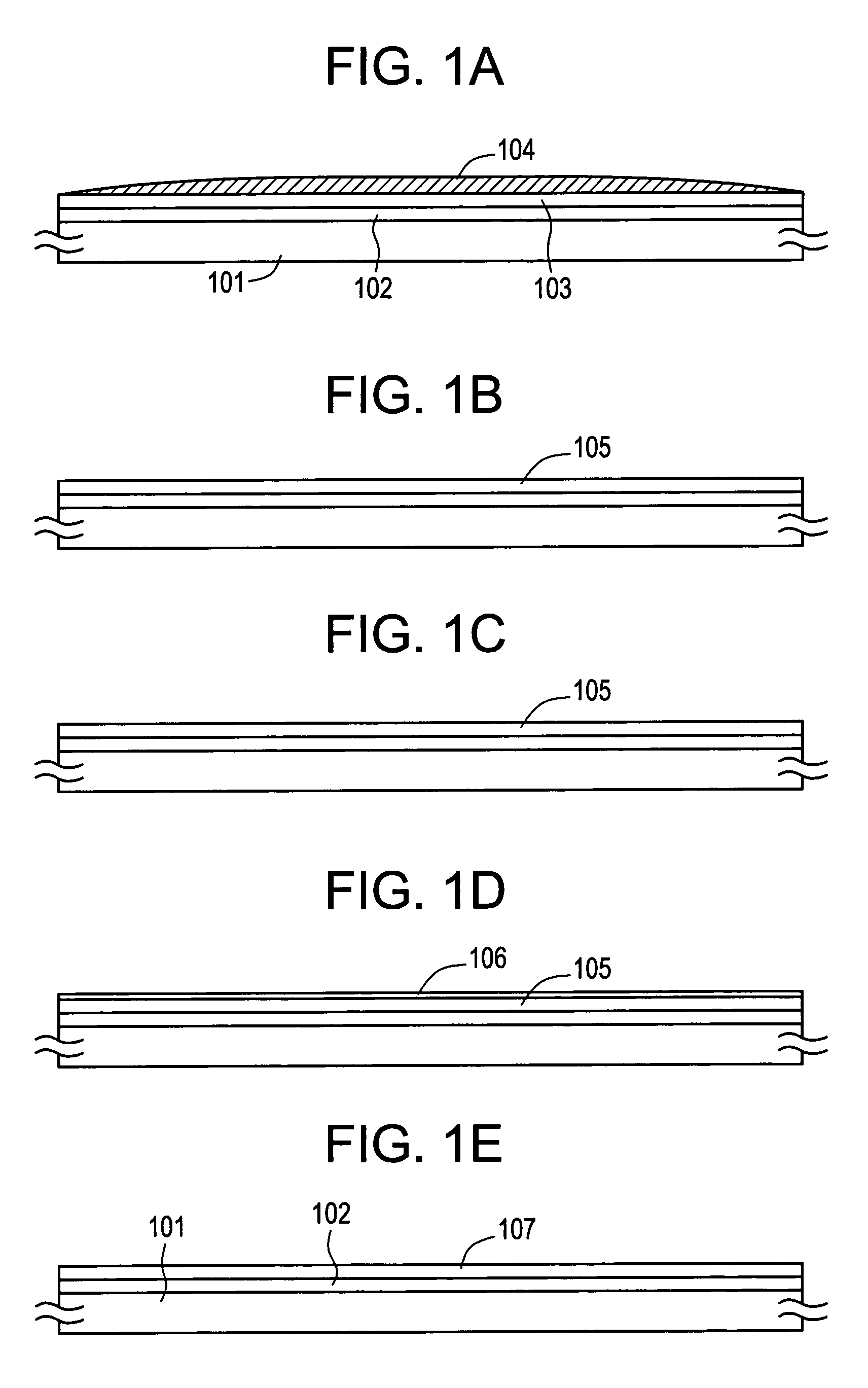

An object of the present invention is to provide a method for easily forming a polycrystalline semiconductor thin-film, such as polycrystalline silicon having high crystallinity and high quality, or a single crystalline semiconductor thin-film at inexpensive cost, the crystalline semiconductor thin-film having a large area, and to provide an apparatus for processing the method described above. In forming a polycrystalline (or single crystalline) semiconductor thin-film (7), such as a polycrystalline silicon thin-film, having high crystallinity and a large grain size on a substrate (1), or in forming a semiconductor device having the polycrystalline (or single crystalline) semiconductor thin-film (7) on the substrate (1), a method comprises forming a low-crystallization semiconductor thin-film (7A) on the substrate (1), and subsequently heating and cooling this low-crystallization semiconductor thin-film (7A) to a fusion, a semi-fusion, or a non-fusion state by flash lamp annealing to facilitate the crystallization of the low-crystallization semiconductor thin-film, whereby a polycrystalline (single crystalline) semiconductor thin-film (7) is obtained. A method for forming the semiconductor device and an apparatus for processing the methods are also disclosed.

Owner:SONY CORP

Semiconductor thin film forming method, production methods for semiconductor device and electrooptical device, devices used for these methods, and semiconductor device and electrooptical device

InactiveUS20030013280A1Promote crystallizationTransistorPolycrystalline material growthSingle crystalCrystallinity

An object of the present invention is to provide a method for easily forming a polycrystalline semiconductor thin-film, such as polycrystalline silicon having high crystallinity and high quality, or a single crystalline semiconductor thin-film at inexpensive cost, the crystalline semiconductor thin-film having a large area, and to provide an apparatus for processing the method described above. In forming a polycrystalline (or single crystalline) semiconductor thin-film (7), such as a polycrystalline silicon thin-film, having high crystallinity and a large grain size on a substrate (1), or in forming a semiconductor device having the polycrystalline (or single crystalline) semiconductor thin-film (7) on the substrate (1), a method comprises forming a low-crystallization semiconductor thin-film (7A) on the substrate (1), and subsequently heating and cooling this low-crystallization semiconductor thin-film (7A) to a fusion, a semi-fusion, or a non-fusion state by flash lamp annealing to facilitate the crystallization of the low-crystallization semiconductor thin-film, whereby a polycrystalline (single crystalline) semiconductor thin-film (7) is obtained. A method for forming the semiconductor device and an apparatus for processing the methods are also disclosed.

Owner:SONY CORP

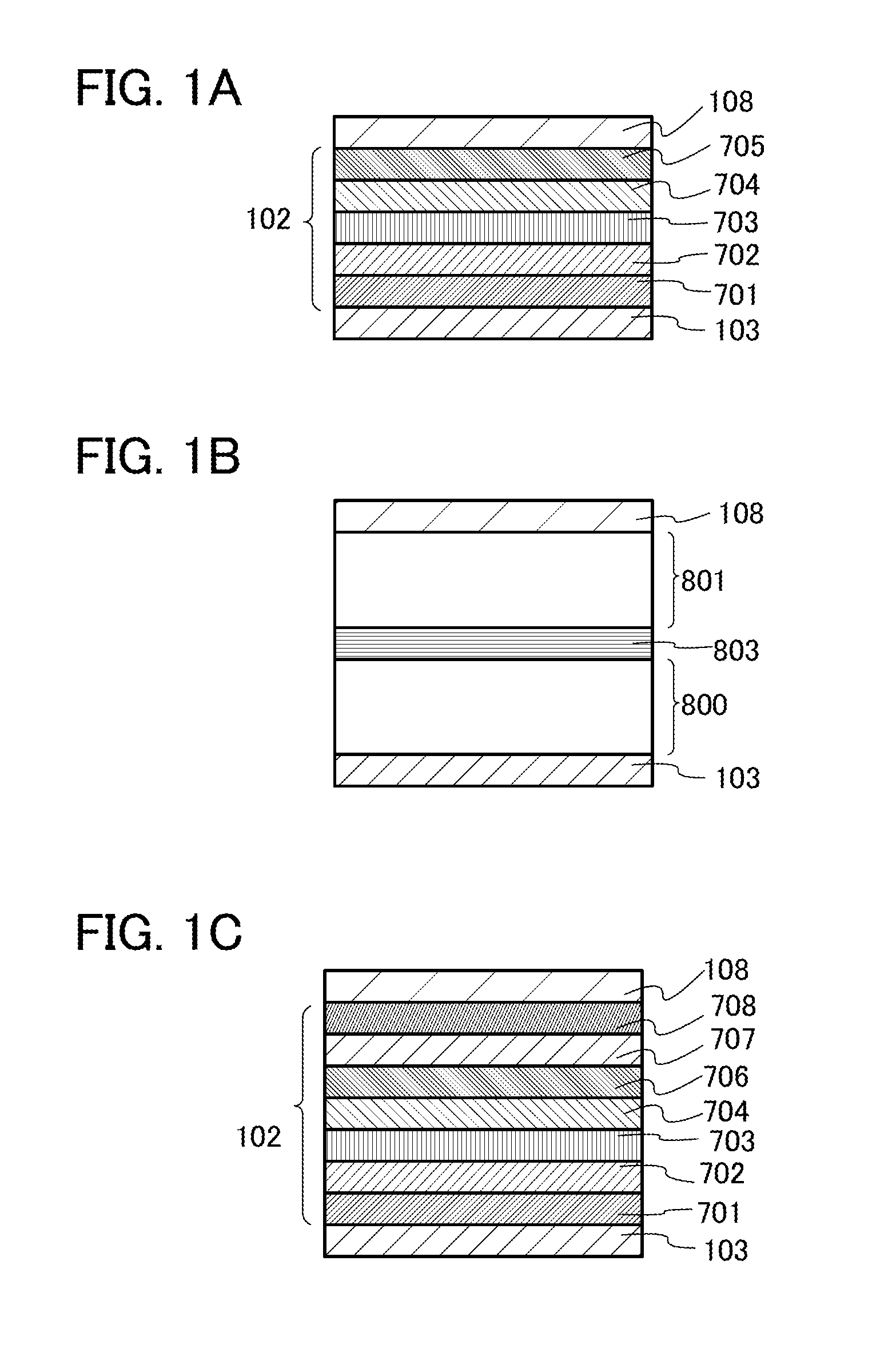

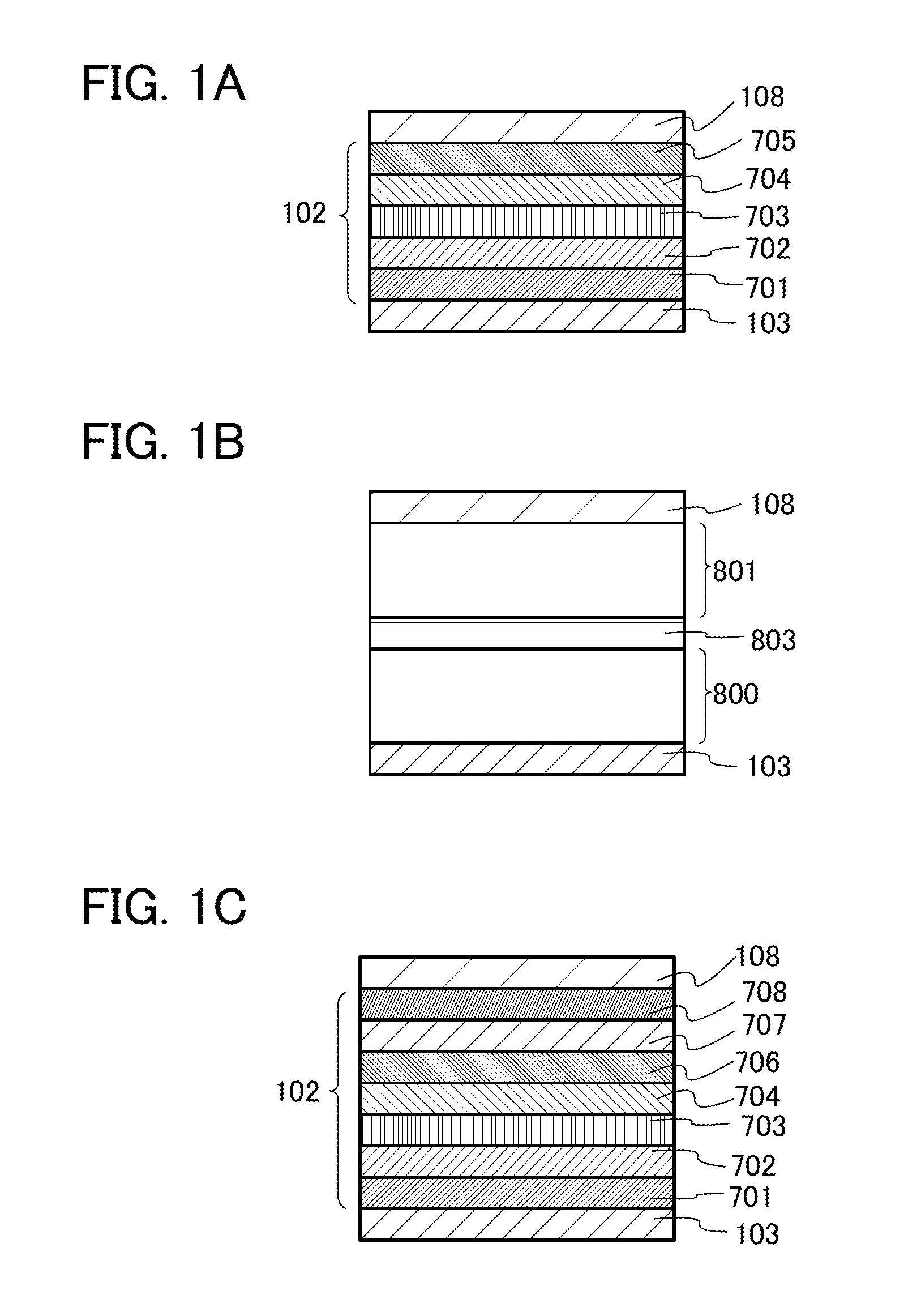

Heterocyclic compound, light-emitting element, light-emitting device, electronic device, and lighting device

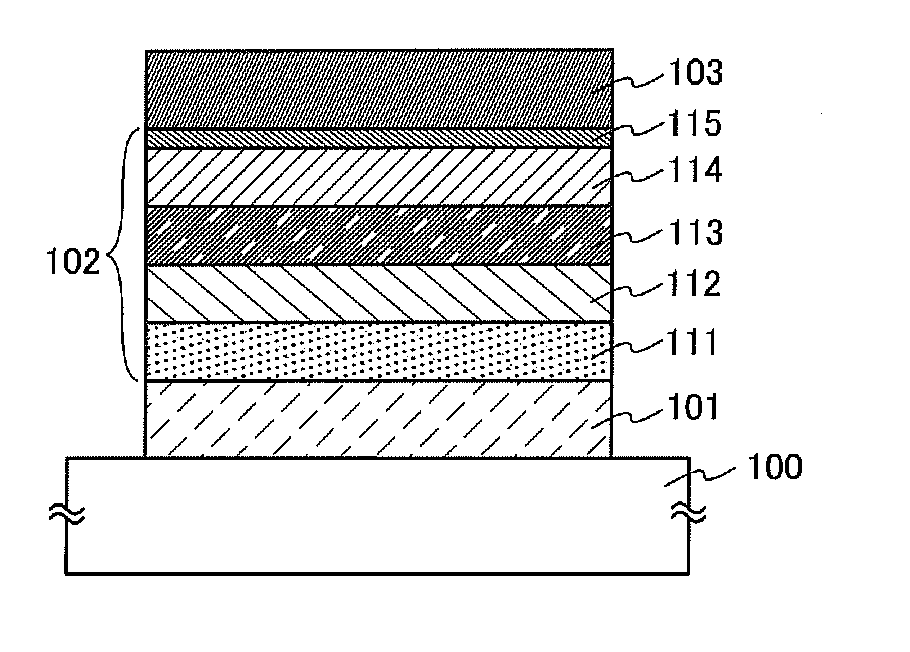

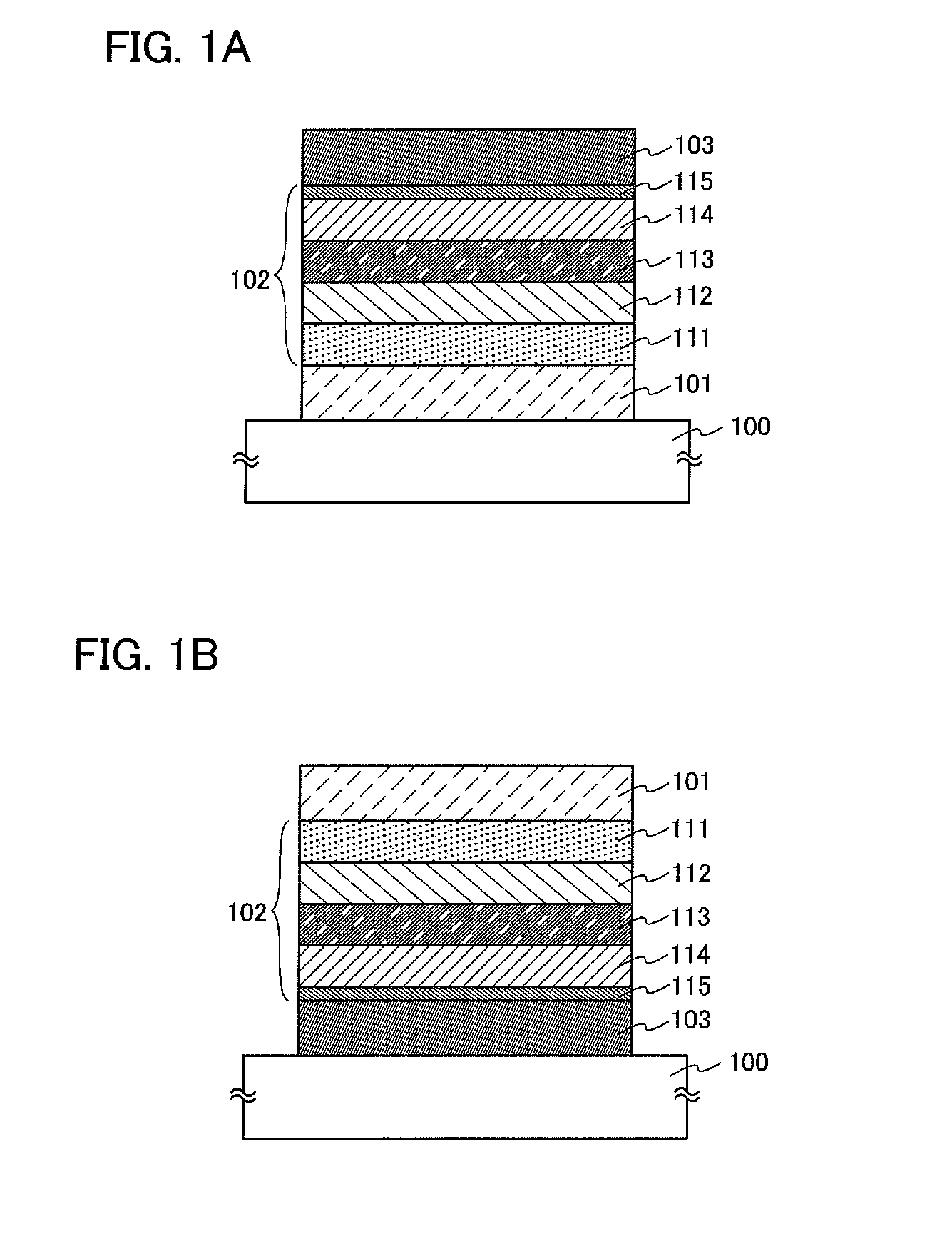

ActiveUS20110210316A1Reduce the driving voltageImprove current efficiencyOrganic chemistryElectroluminescent light sourcesHost materialEngineering

An object is to provide a novel heterocyclic compound which can be used for a light-emitting element, as a host material of a light-emitting layer in which a light-emitting substance is dispersed. Other objects are to provide a light-emitting element having low driving voltage, a light-emitting element having high current efficiency, and a light-emitting element having a long lifetime. Provided are a light-emitting element including a compound in which a dibenzo[f,h]quinoxaline ring and a hole-transport skeleton are bonded through an arylene group, and a light-emitting device, an electronic device, and a lighting device each using this light-emitting element. The heterocyclic compound represented by General Formula (G1) below is provided.

Owner:SEMICON ENERGY LAB CO LTD

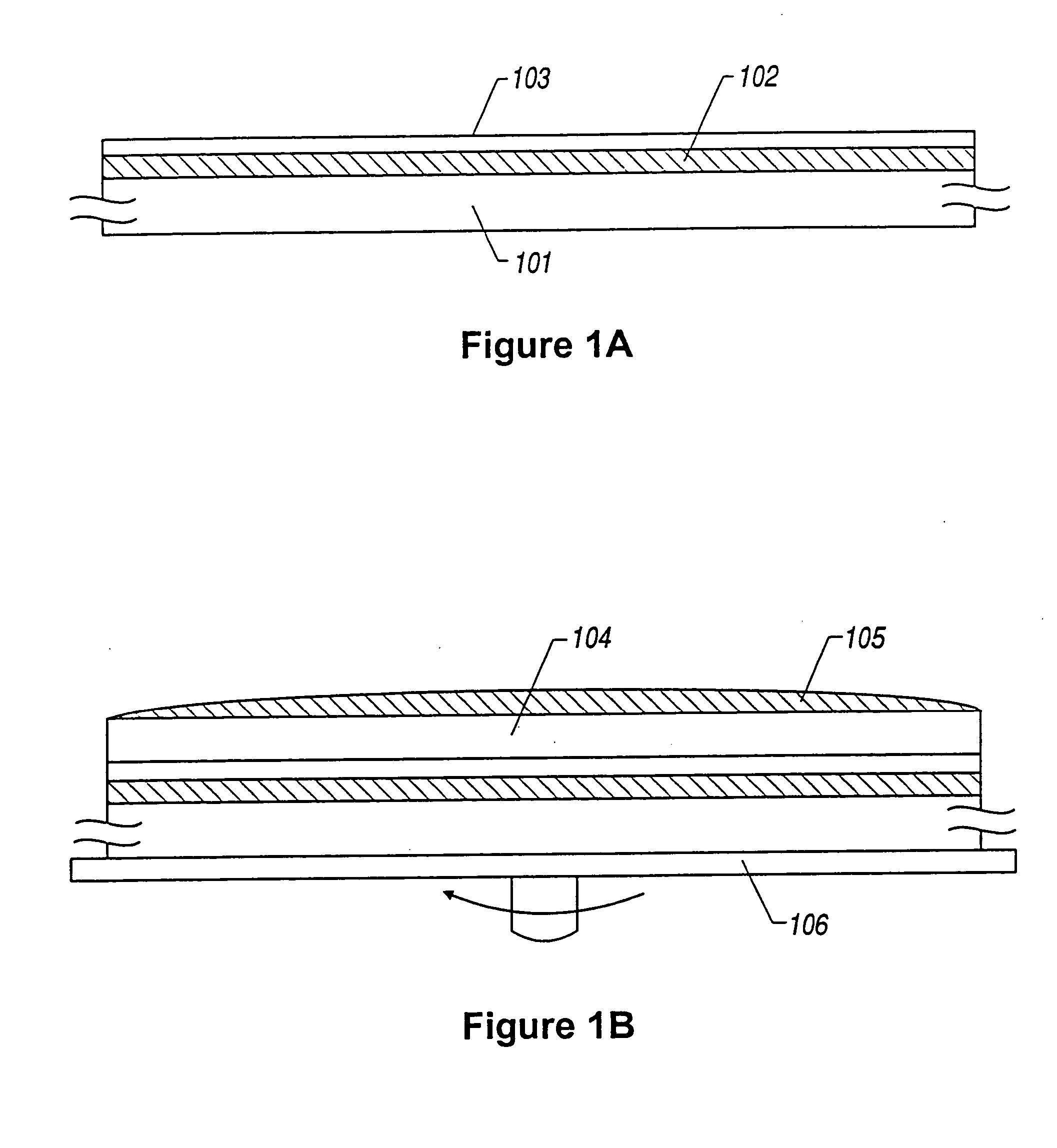

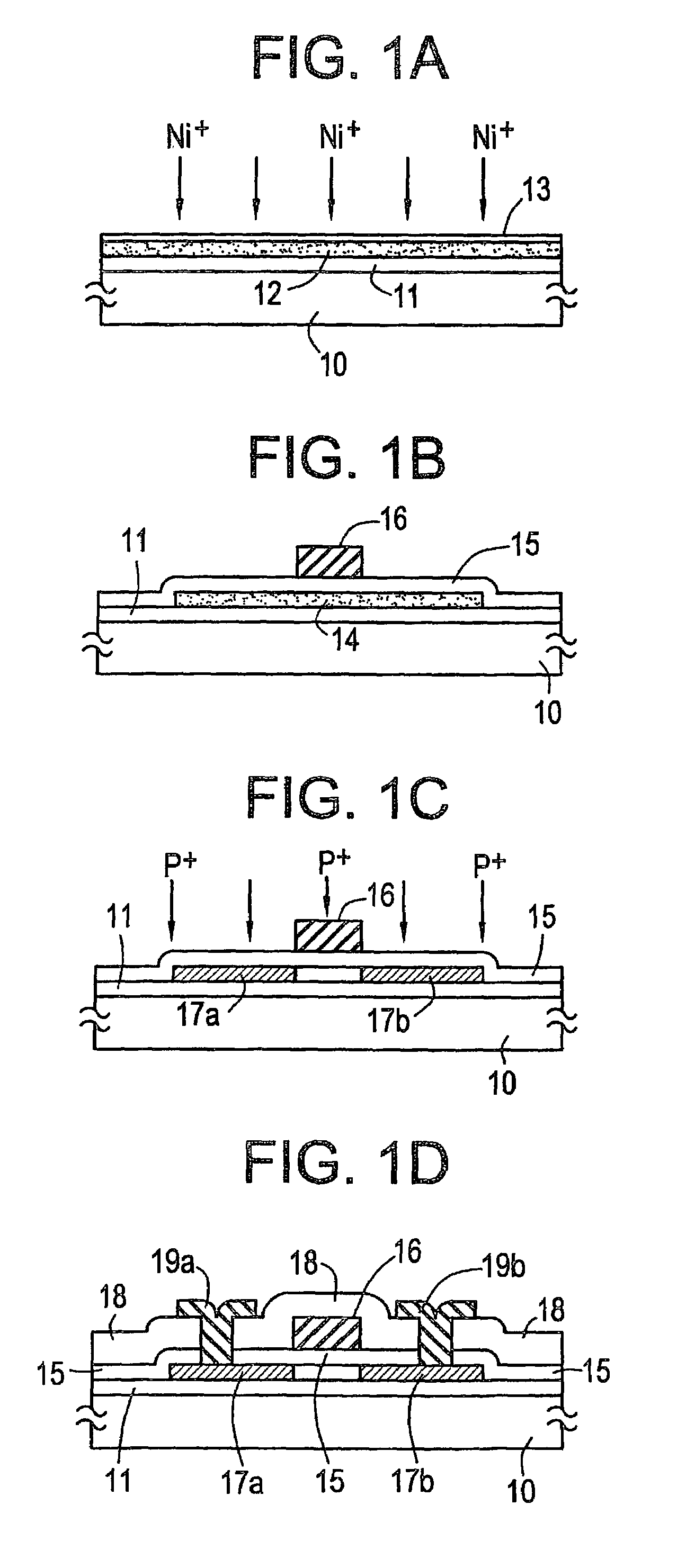

Semiconductor device and method for fabricating the same

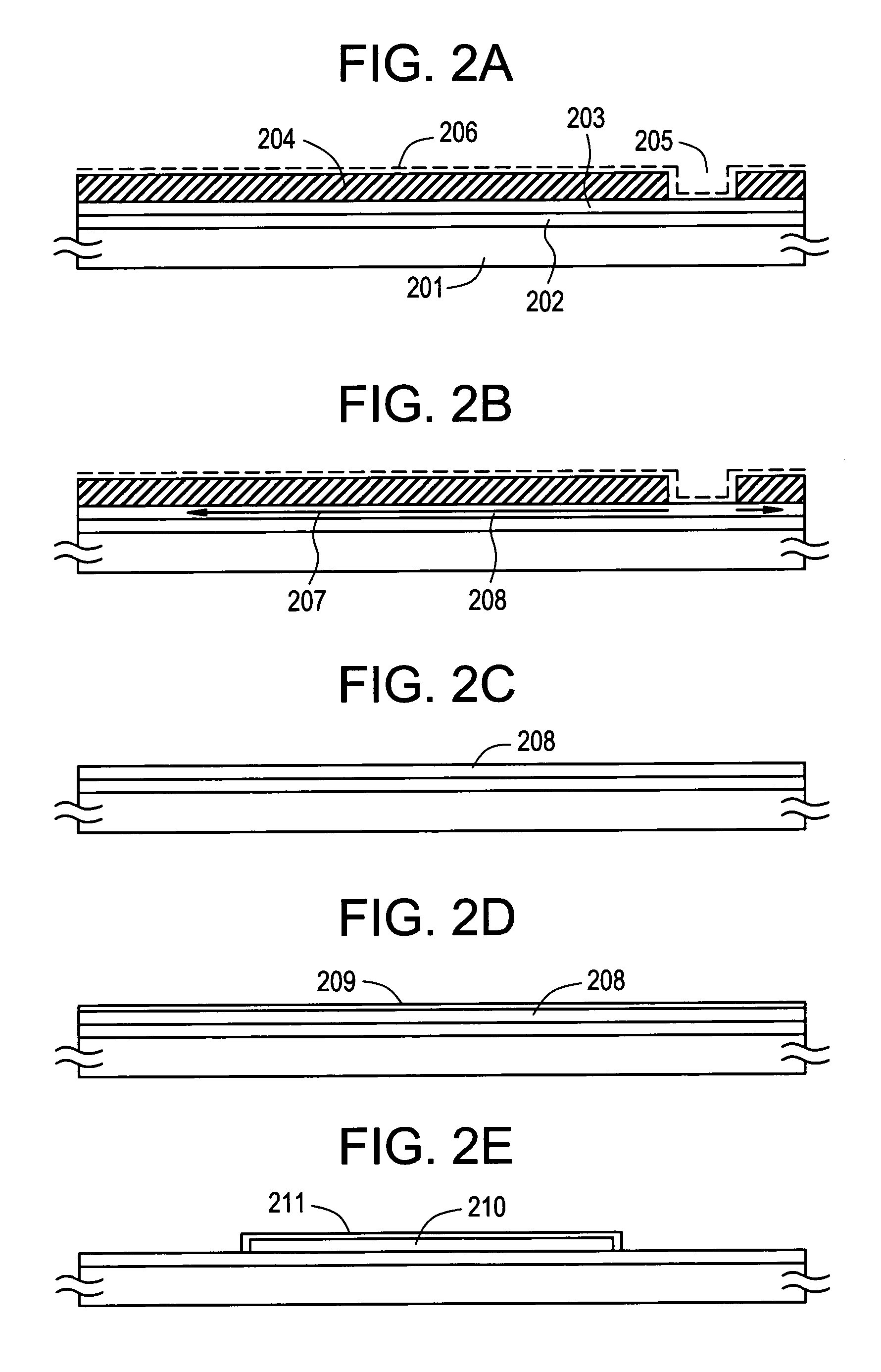

InactiveUS6077731AImprove featuresPromote crystallizationTransistorSolid-state devicesCrystalline siliconSemiconductor

A novel and very useful method for forming a crystal silicon film by introducing a metal element which promotes crystallization of silicon to an amorphous silicon film and for eliminating or reducing the metal element existing within the crystal silicon film thus obtained is provided. The method for fabricating a semiconductor device comprises steps of intentionally introducing the metal element which promotes crystallization of silicon to the amorphous silicon film and crystallizing the amorphous silicon film by a first heat treatment to obtain the crystal silicon film; eliminating or reducing the metal element existing within the crystal silicon film by implementing a second heat treatment within an oxidizing atmosphere; eliminating a thermal oxide film formed in the previous step; and forming another thermal oxide film on the surface of the region from which the thermal oxide film has been eliminated by implementing another thermal oxidation.

Owner:SEMICON ENERGY LAB CO LTD

Biodegradable resin compositions

InactiveUS6669771B2Increase resistanceHigh strengthCosmetic preparationsAntifouling/underwater paintsBiodegradable productDigestion

Owner:NAT INST OF ADVANCED IND SCI & TECH +2

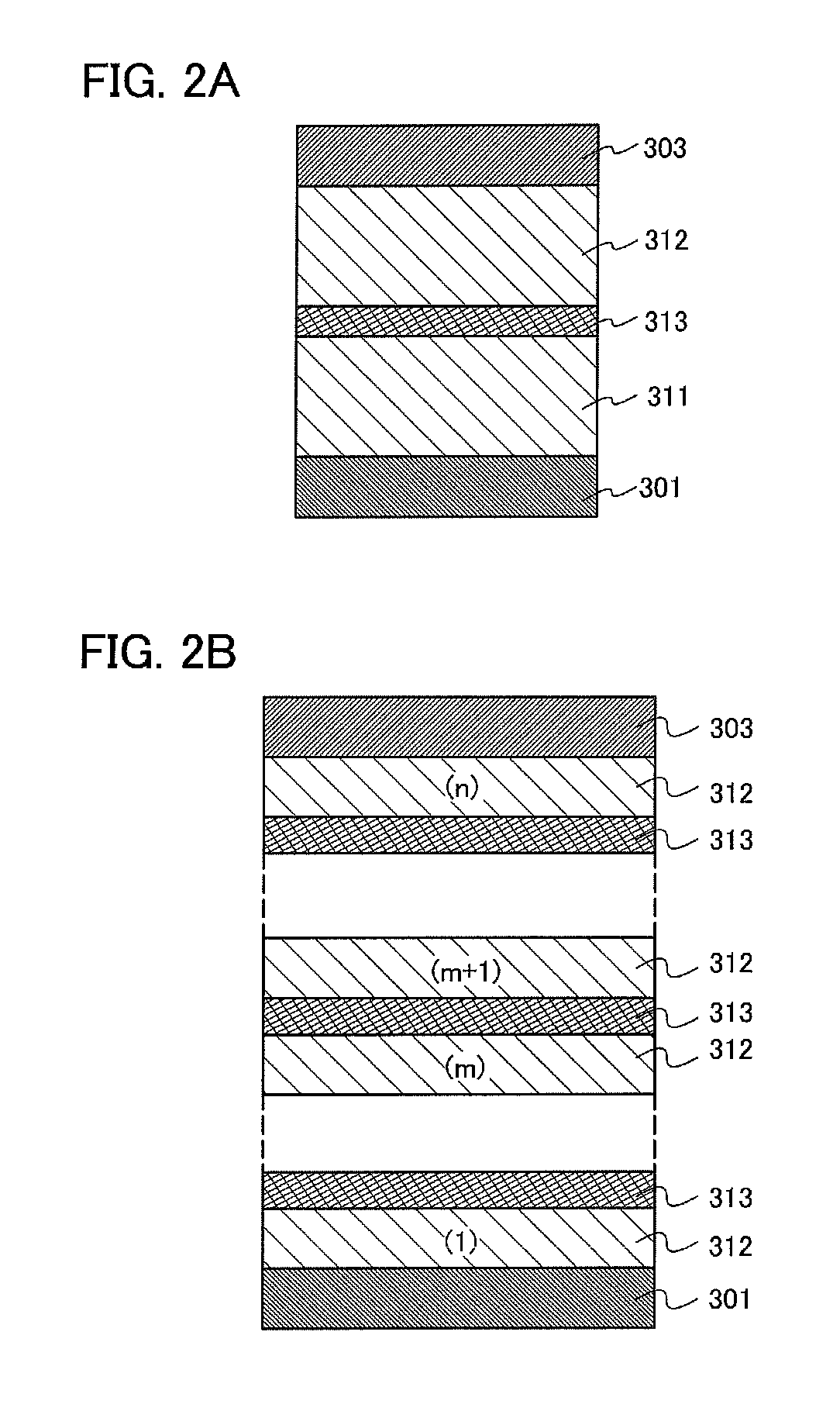

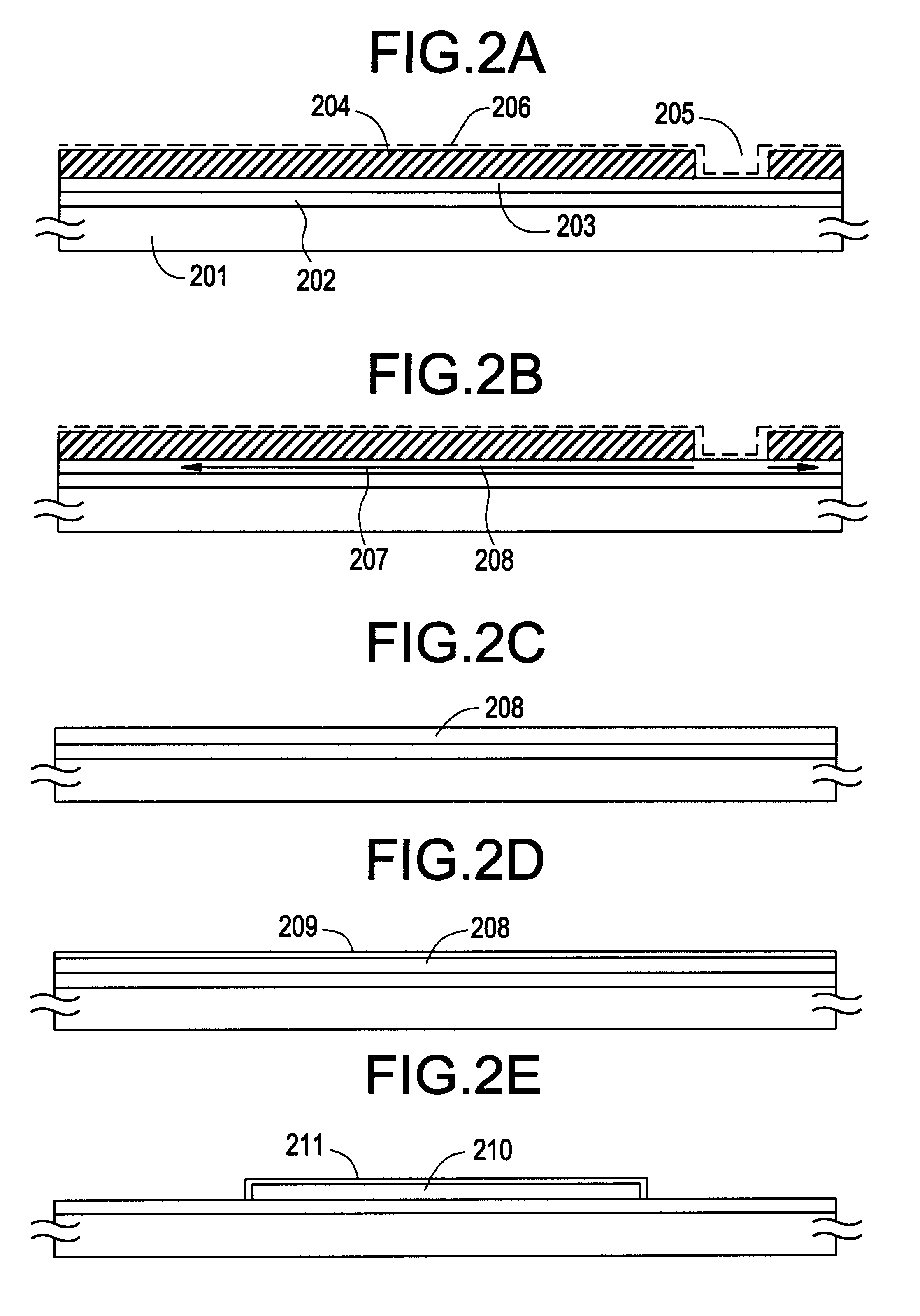

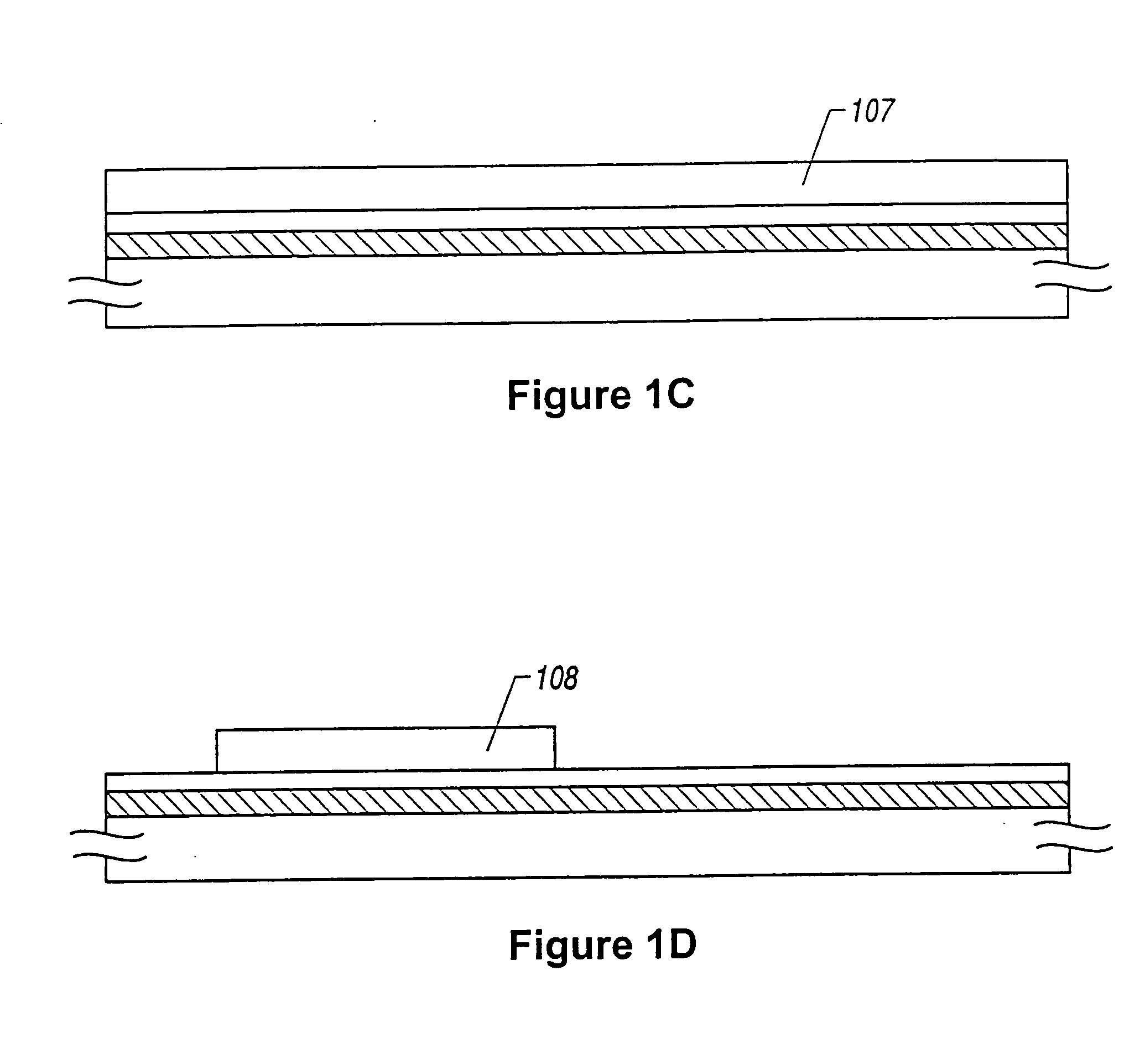

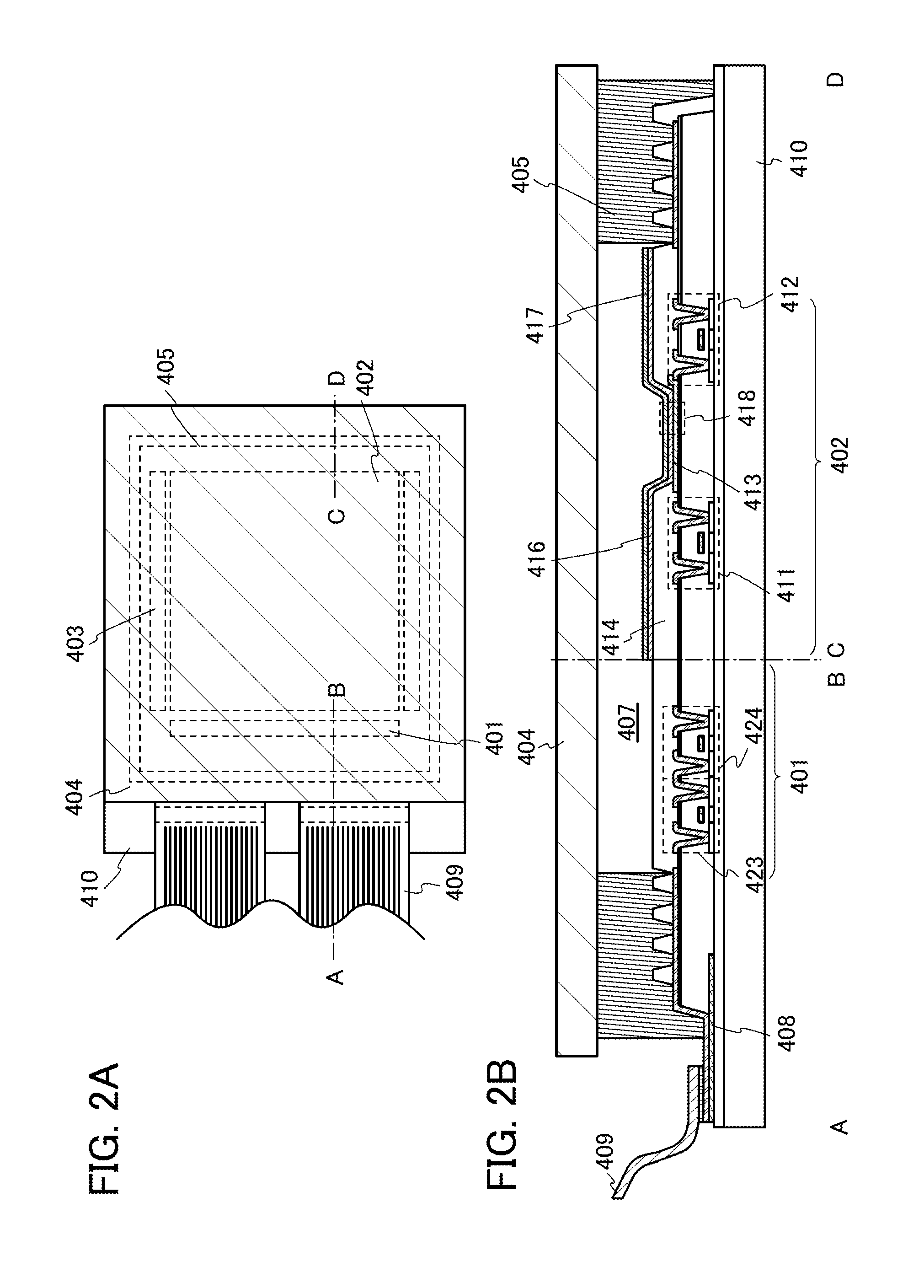

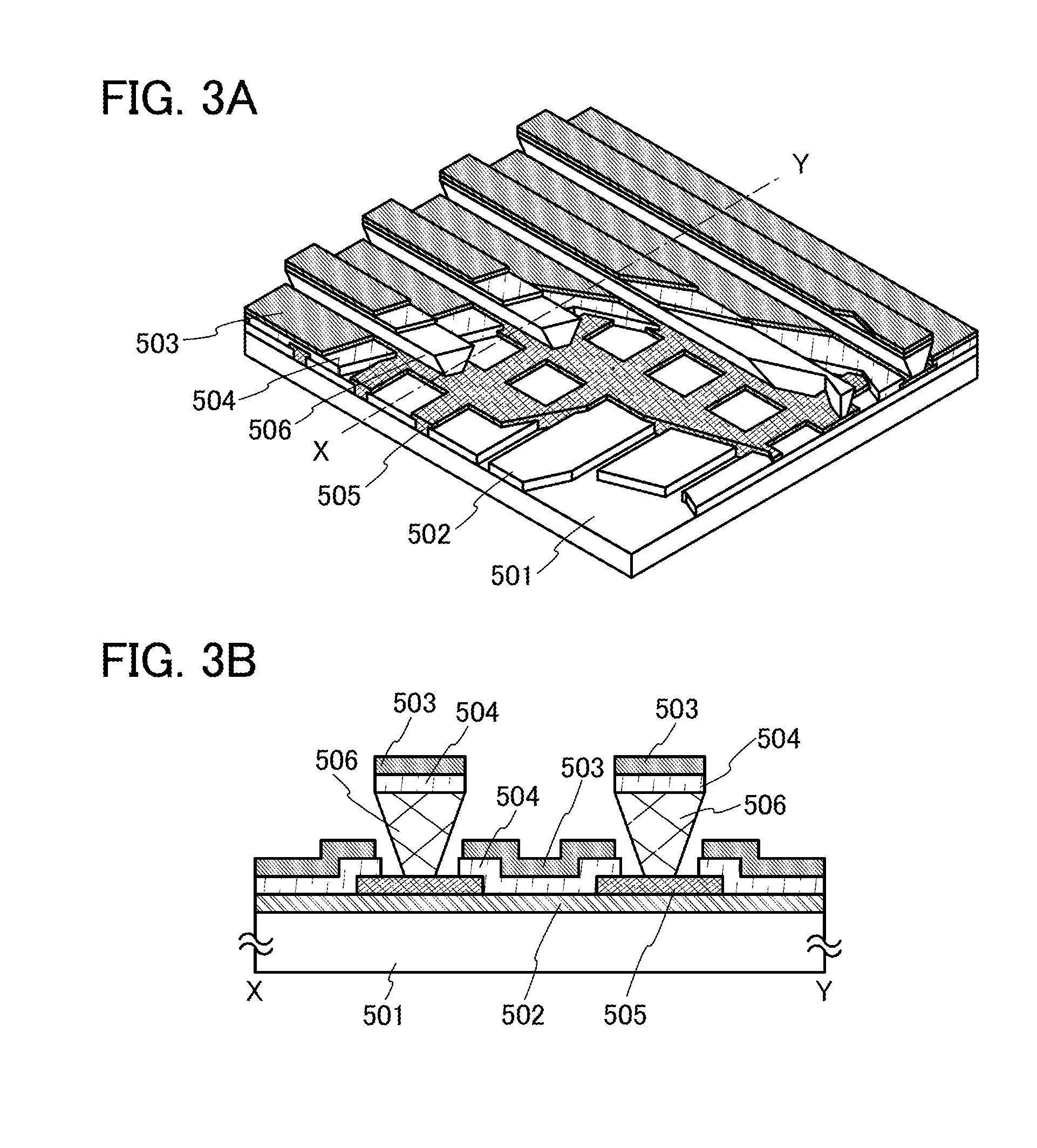

Method of manufacturing a semiconductor device

InactiveUS6998282B1Promote crystallizationHigh effectTransistorSolid-state devicesAmorphous siliconCrystalline silicon

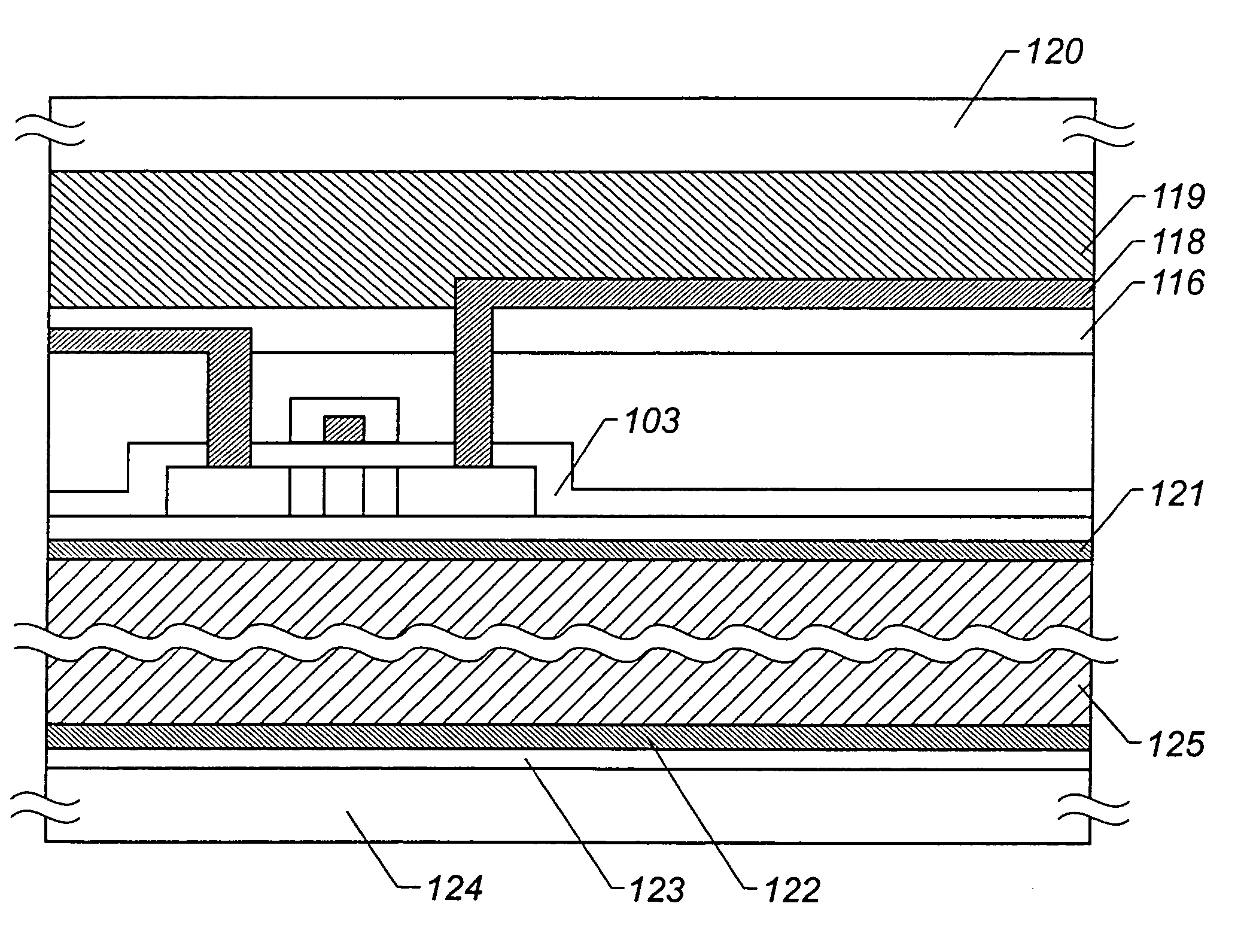

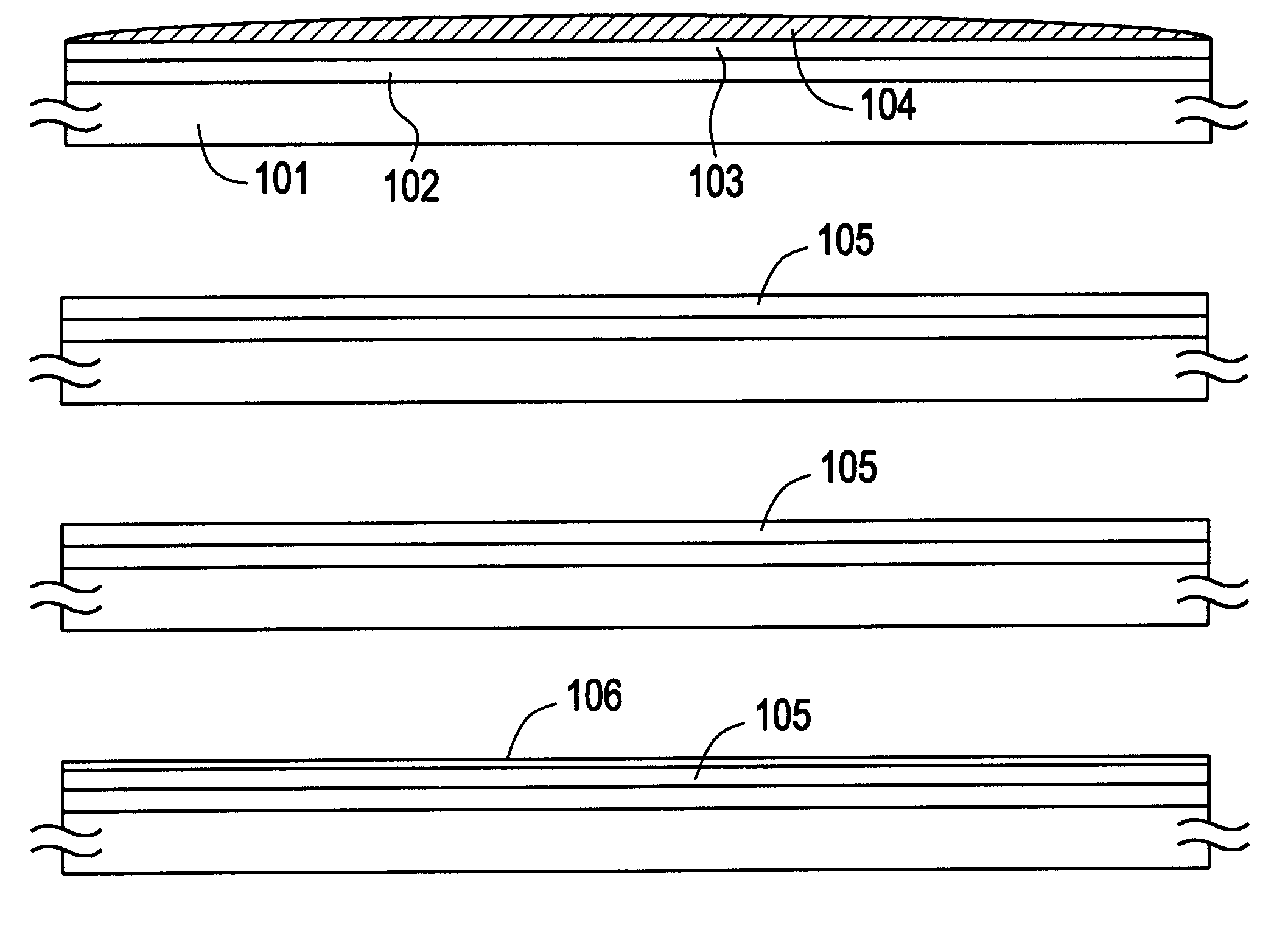

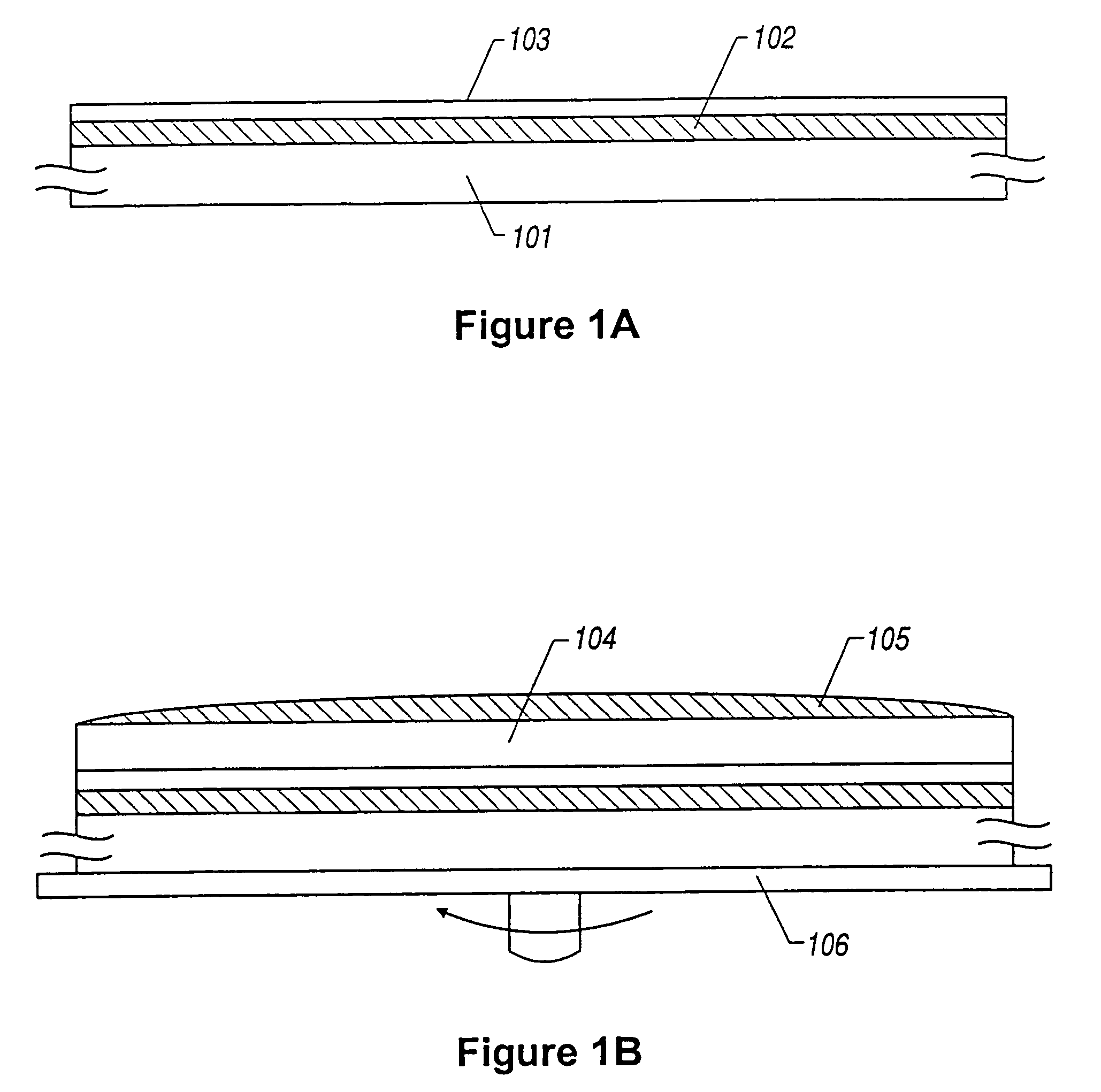

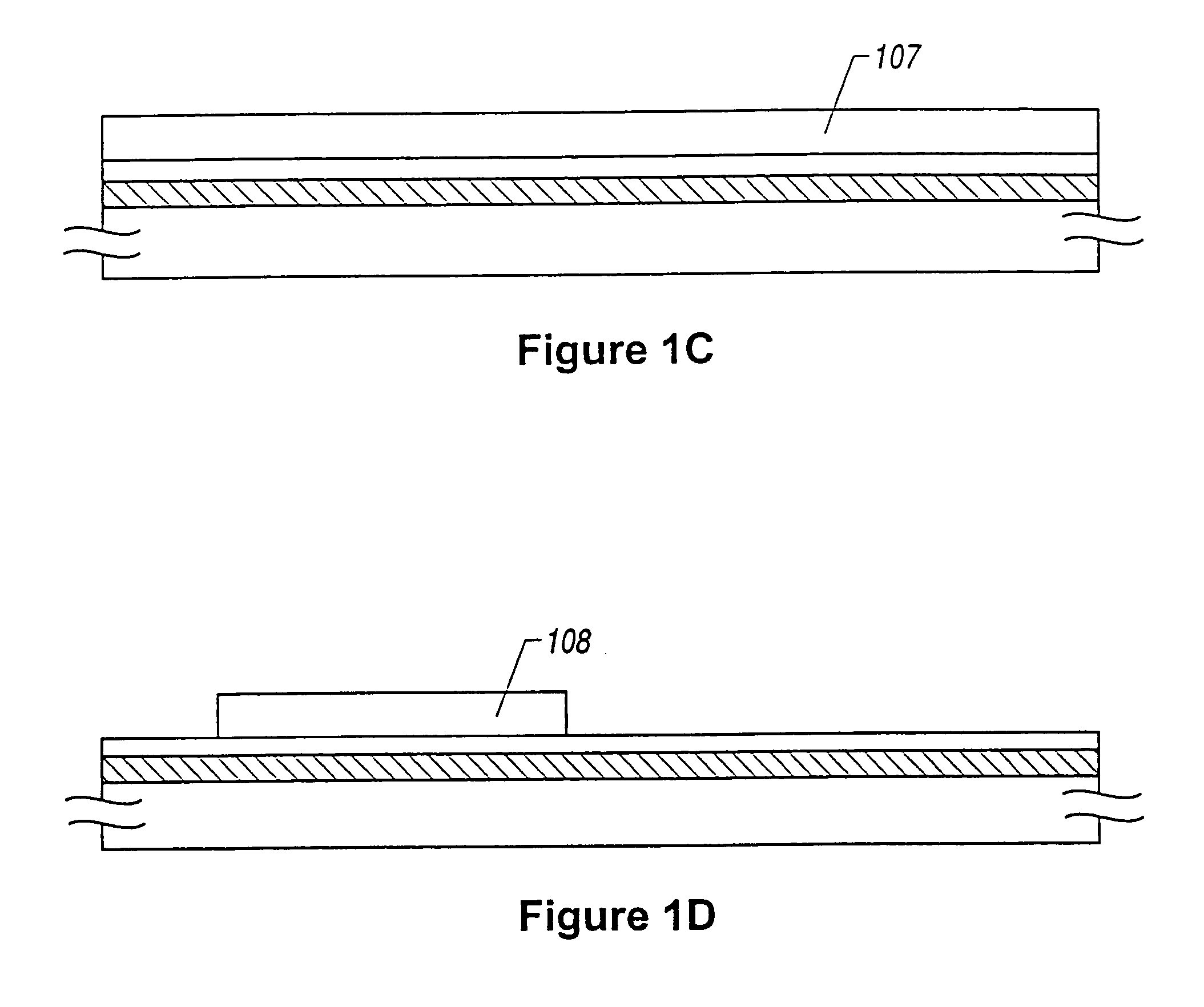

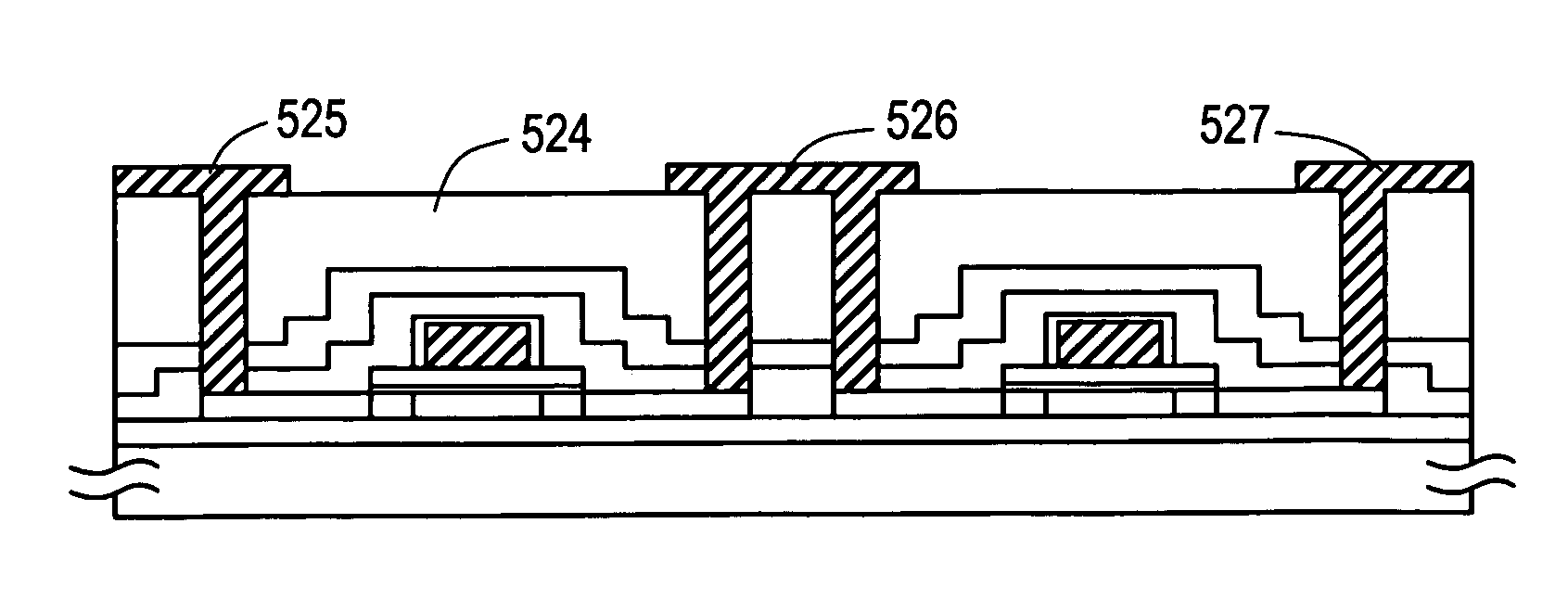

A method of manufacturing a semiconductor device, comprises the steps of: forming a first insulating film on a first substrate; forming a second insulating film on the first insulating film; forming an amorphous silicon film on the second insulating film; holding a metal element that promotes the crystallization of silicon in contact with a surface of the amorphous silicon film; crystallizing the amorphous silicon film through a heat treatment to obtain a crystalline silicon film; forming a thin-film transistor using the crystalline silicon film; forming a sealing layer that seals the thin-film transistor; bonding a second substrate having a translucent property to the sealing layer; and removing the first insulating film to peel off the first substrate.

Owner:SEMICON ENERGY LAB CO LTD

Method for forming thin semiconductor film, method for fabricating semiconductor device, system for executing these methods and electrooptic device

InactiveUS20030148565A1Promote crystallizationEasily realizedTransistorSolid-state devicesMolten stateUltraviolet

The present invention provides a method capable of easily forming a polycrystalline or monocrystalline semiconductor thin film of polycrystalline silicon with a high degree of crystallization and high quality at low cost, and an apparatus for carrying out the method. In a method of forming a polycrystalline (or monocrystalline) semiconductor thin film, a method of manufacturing a semiconductor device and an apparatus for carrying out these methods, in order to form a large-grain polycrystalline (or monocrystalline) semiconductor thin film (7) such as a polycrystalline silicon film with a high degree of crystallization on a substrate (1) or manufacturing a semiconductor device having the polycrystalline (or monocrystalline) semiconductor thin film (7), a low-crystalline semiconductor thin film (7A) is formed on the substrate (1), and then heated in a molten, semi-molten or non-molten state by laser annealing with ultraviolet rays (UV) or / and deep ultraviolet rays (DUV) and cooled to promote crystallization of the low-crystalline semiconductor thin film (7A), obtaining the polycrystalline (or monocrystalline) semiconductor thin film (7).

Owner:SONY CORP

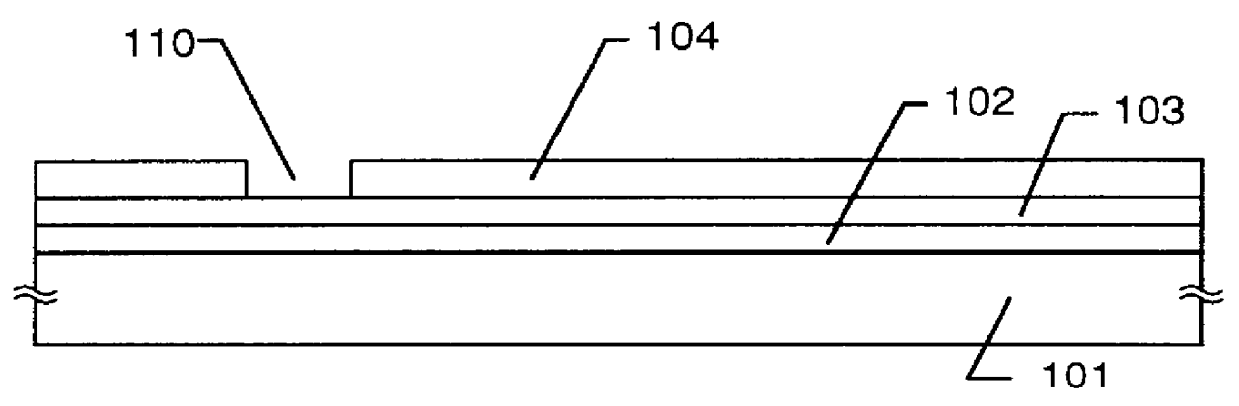

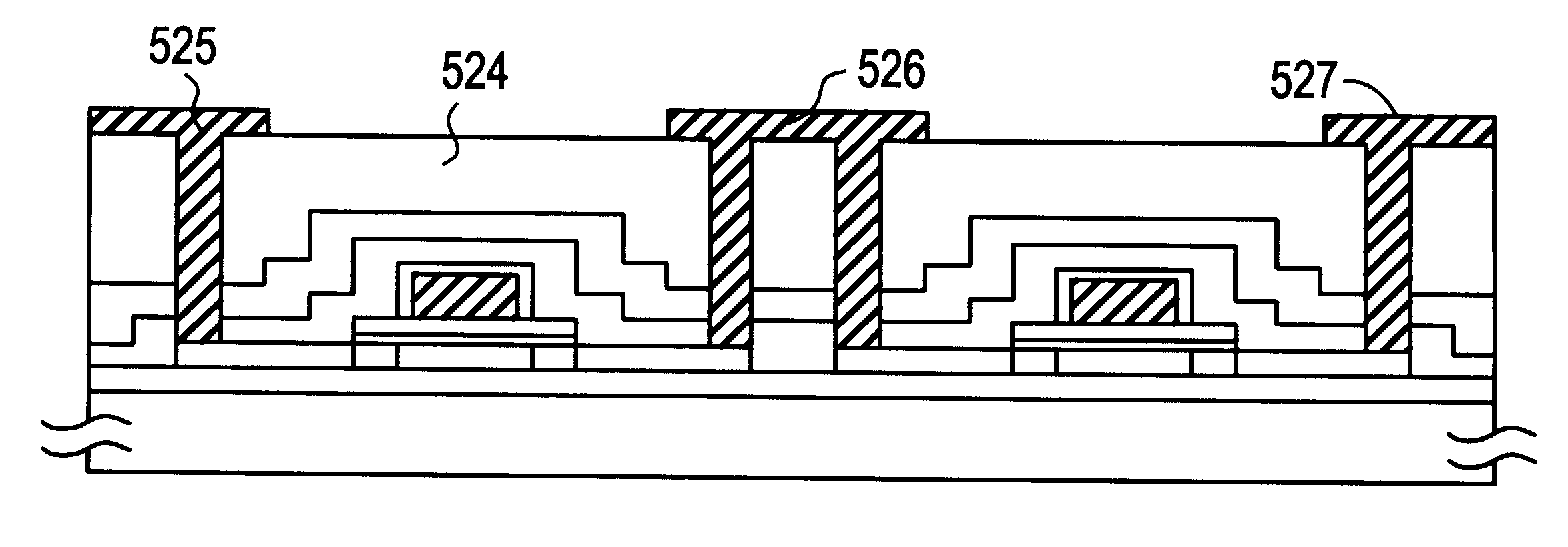

Method for fabricating a semiconductor device

InactiveUS6180439B1Promote crystallizationReduce concentrationTransistorSolid-state devicesAtmospheric airLaser light

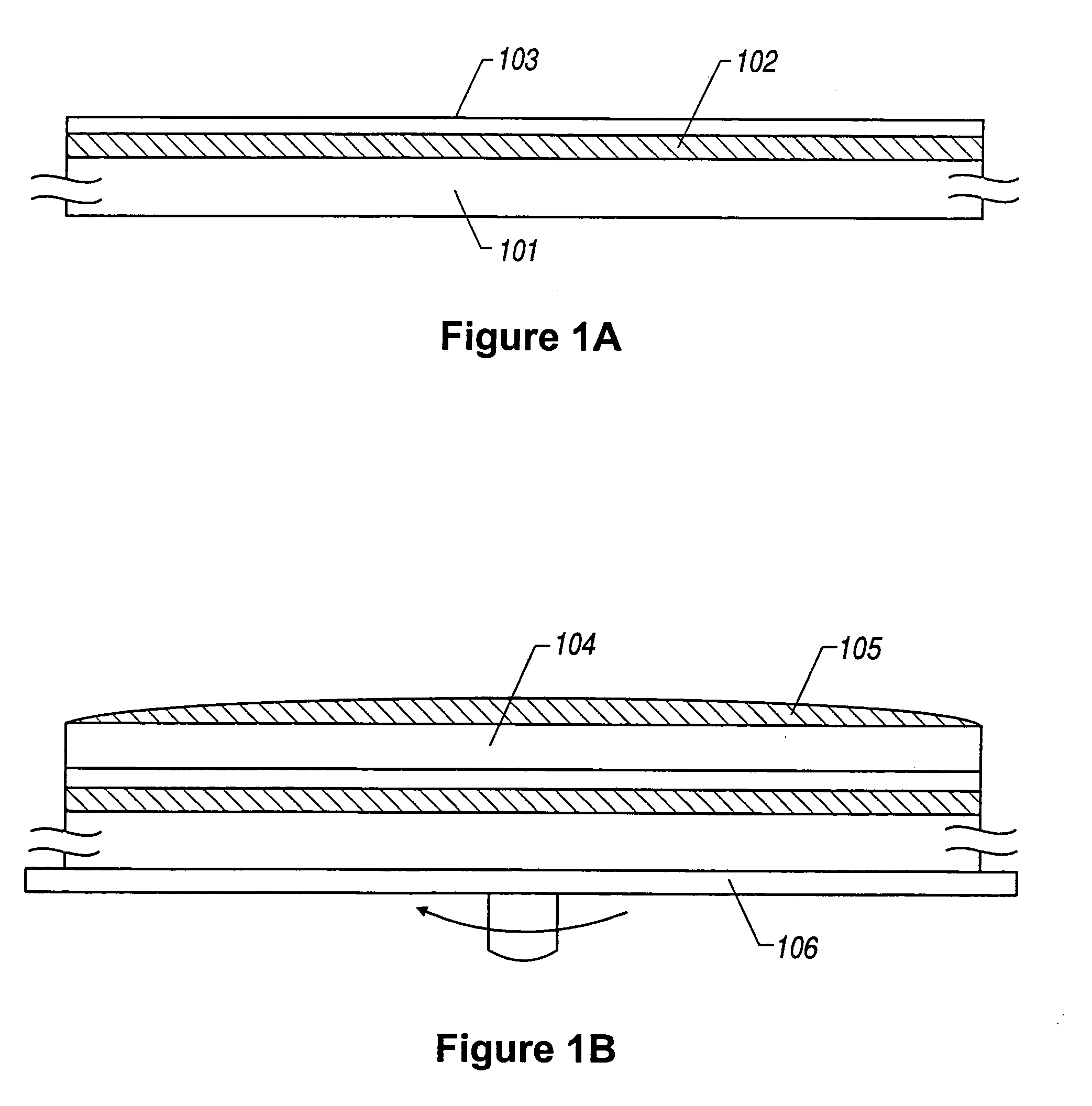

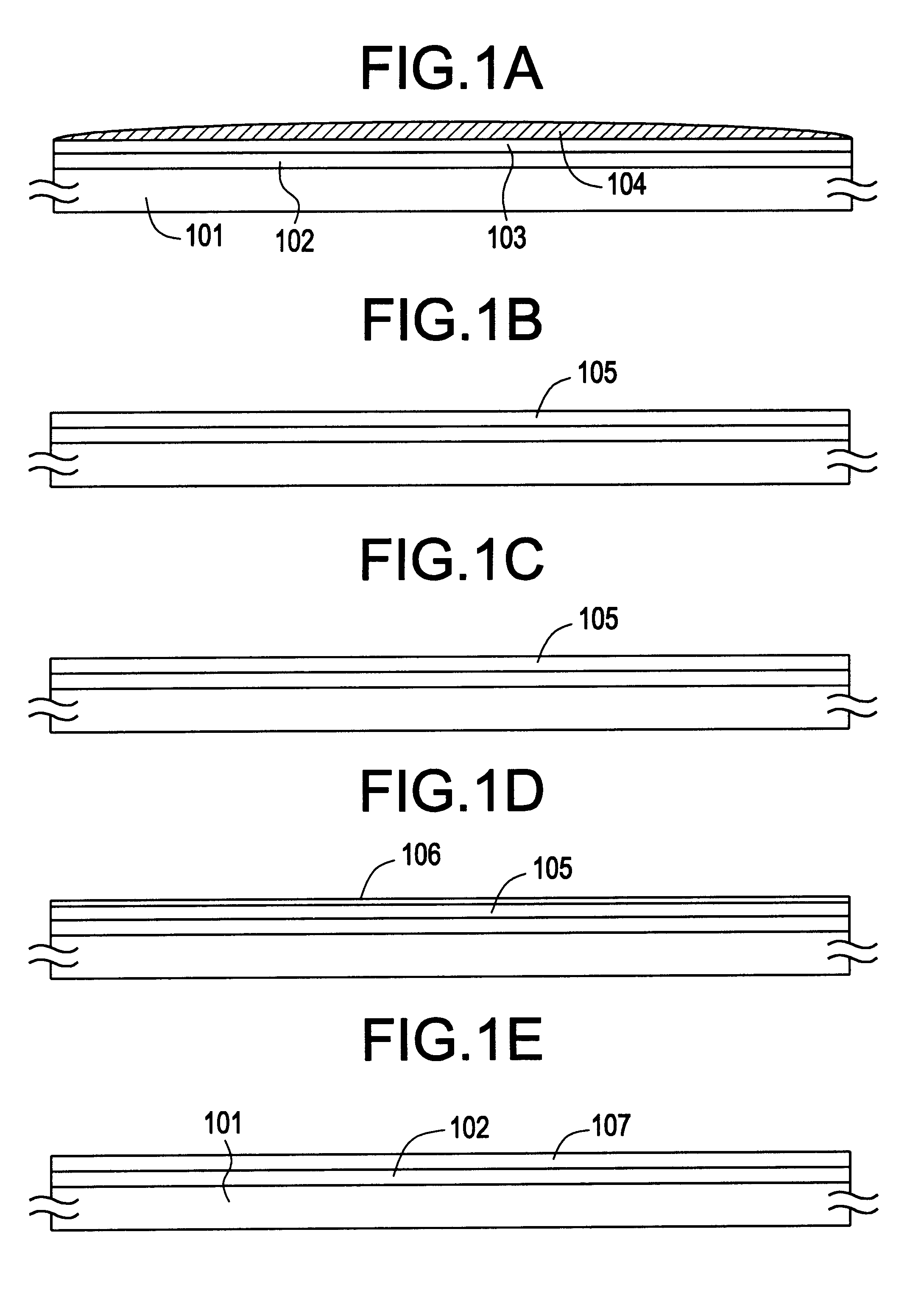

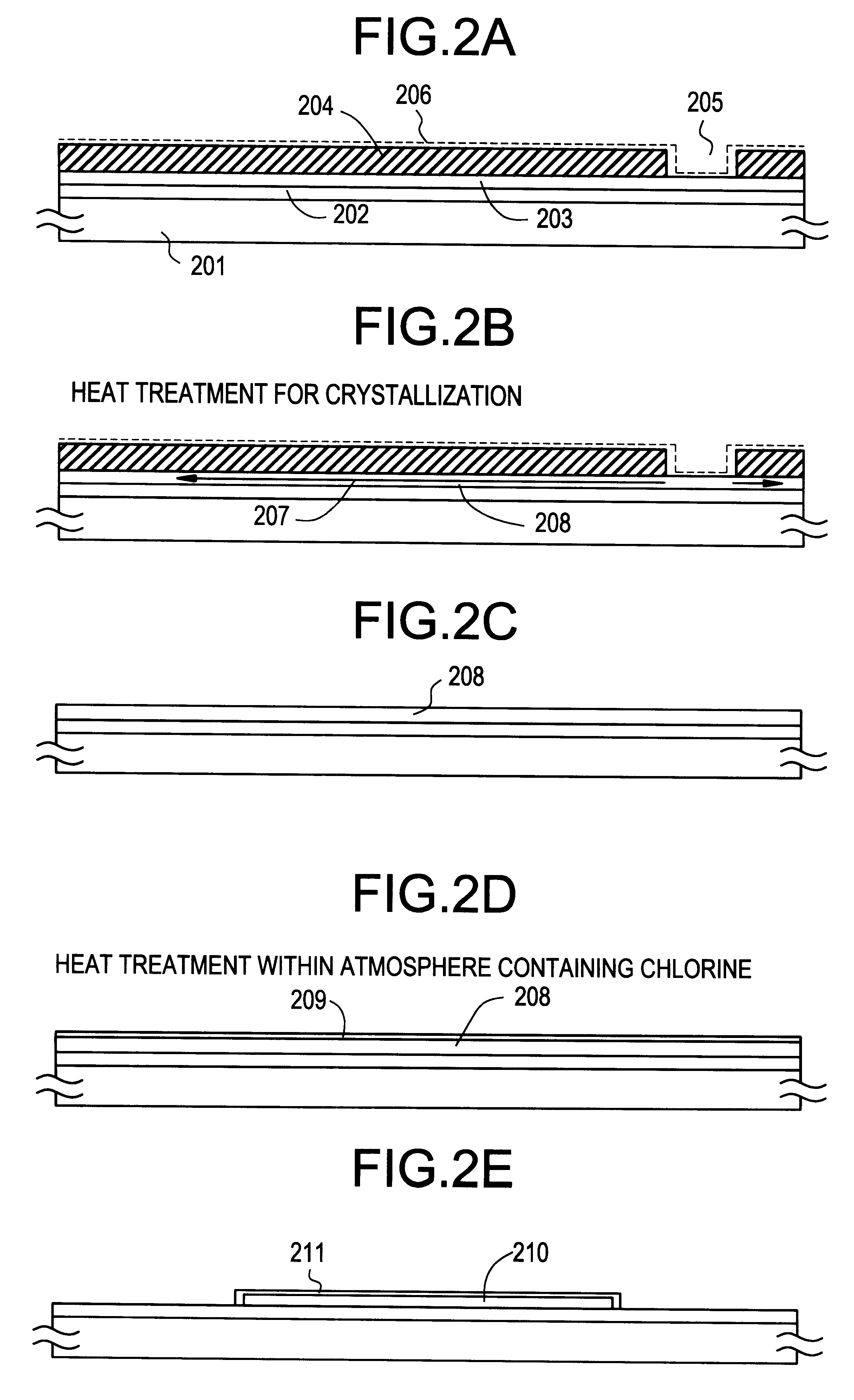

Concentration of metal element which promotes crystallization of silicon and which exists within a crystalline silicon film obtained by utilizing the metal element is reduced. A first heat treatment for crystallization is performed after introducing nickel to an amorphous silicon film 103. Then, laser light is irradiated to diffuse nickel element which is concentrated locally. After that, another heat treatment is performed within an oxidizing atmosphere at a temperature higher than that of the previous heat treatment. At this time, HCl or the like is added to the atmosphere. A thermal oxide film 106 is formed in this step. At this time, gettering of the nickel element into the thermal oxide film 106 takes place. Then, the thermal oxide film 106 is removed. Thereby, a crystalline silicon film 107 having low concentration of the metal element and a high crystallinity can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

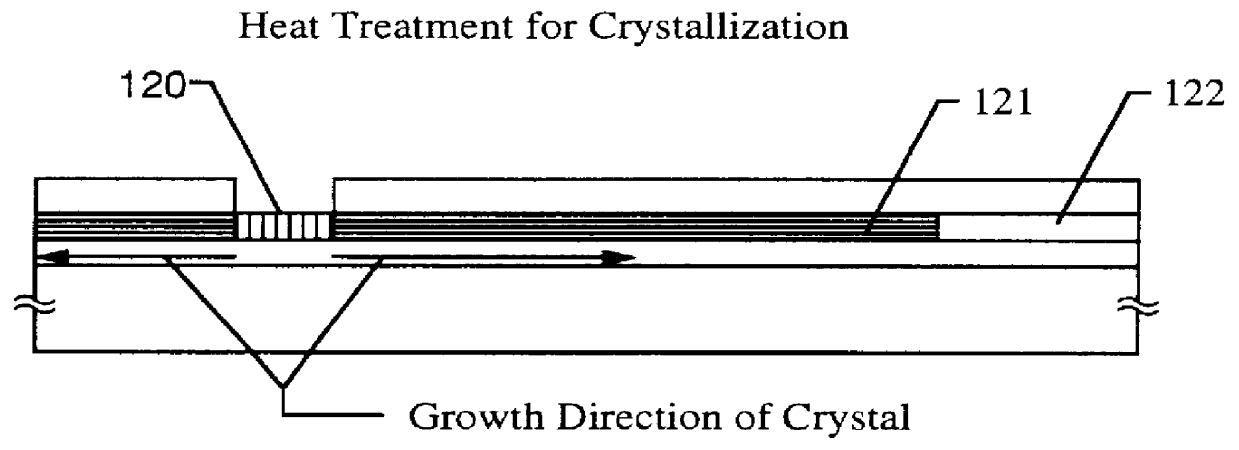

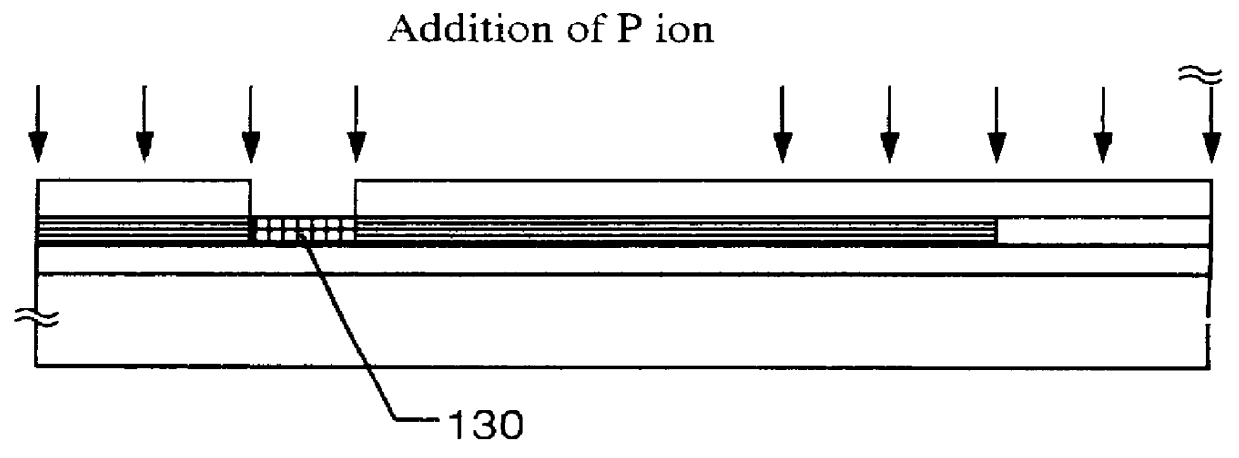

Method of manufacturing semiconductor devices using a crystallization promoting material

InactiveUS6066518AReduce concentrationPromote crystallizationTransistorSolid-state devicesCrystallinityThermal treatment

In a method of manufacturing a semiconductor device, an insulating film having an opening is formed on an amorphous film 103 containing silicon therein. After catalytic elements are introduced from the opening, the amorphous film 103 is crystallized. Thereafter elements (phosphorus) selected from Group XV are introduced from the opening, and then a heat treatment is conducted to obtain a film having crystallinity. Thereafter, a portion of the film containing silicon into which the catalytic elements and phosphorus is introduced are removed.

Owner:SEMICON ENERGY LAB CO LTD

Method of manufacturing a semiconductor device

InactiveUS7361519B2Promote crystallizationHigh effectTransistorSolid-state devicesAmorphous siliconCrystalline silicon

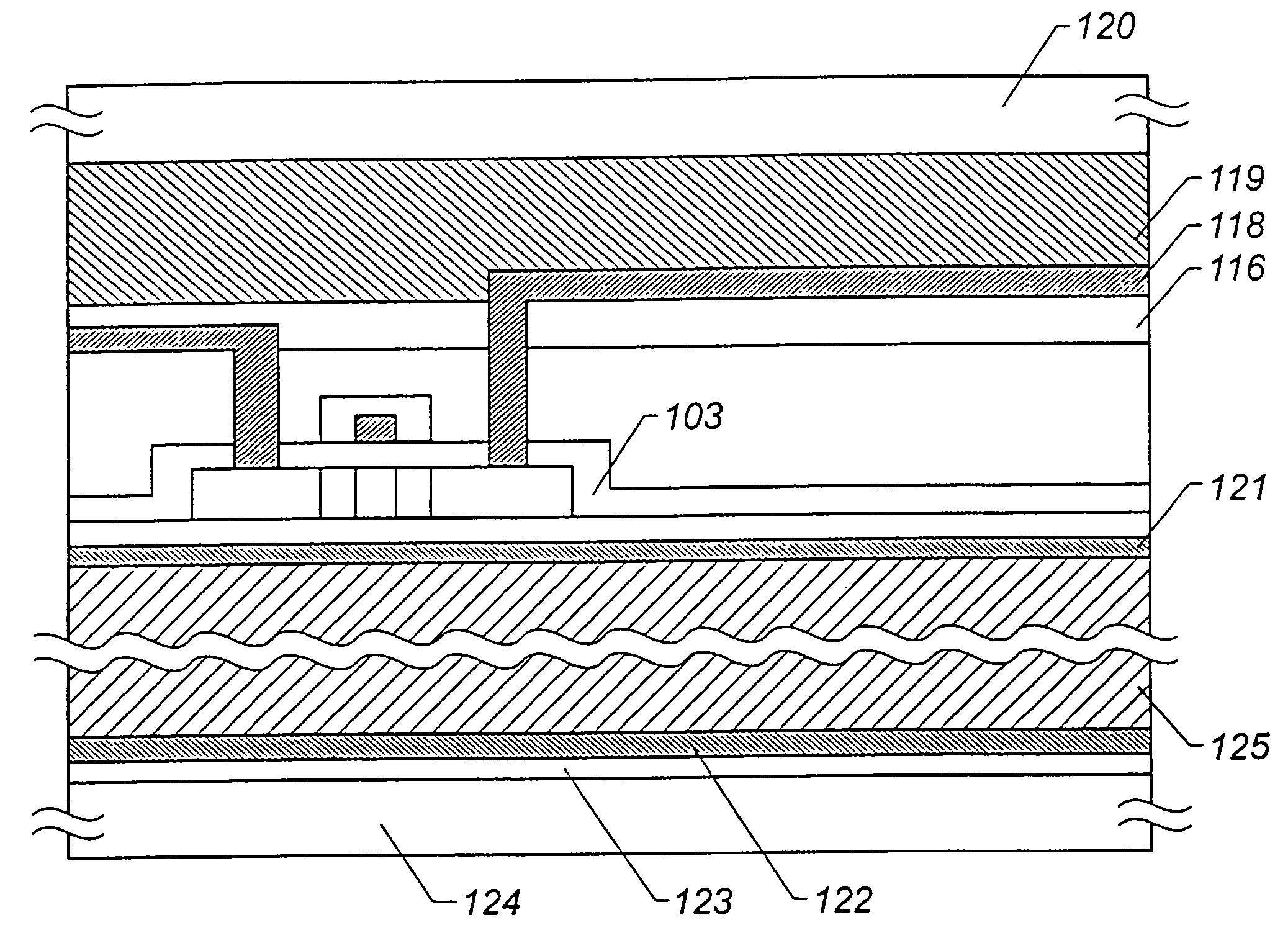

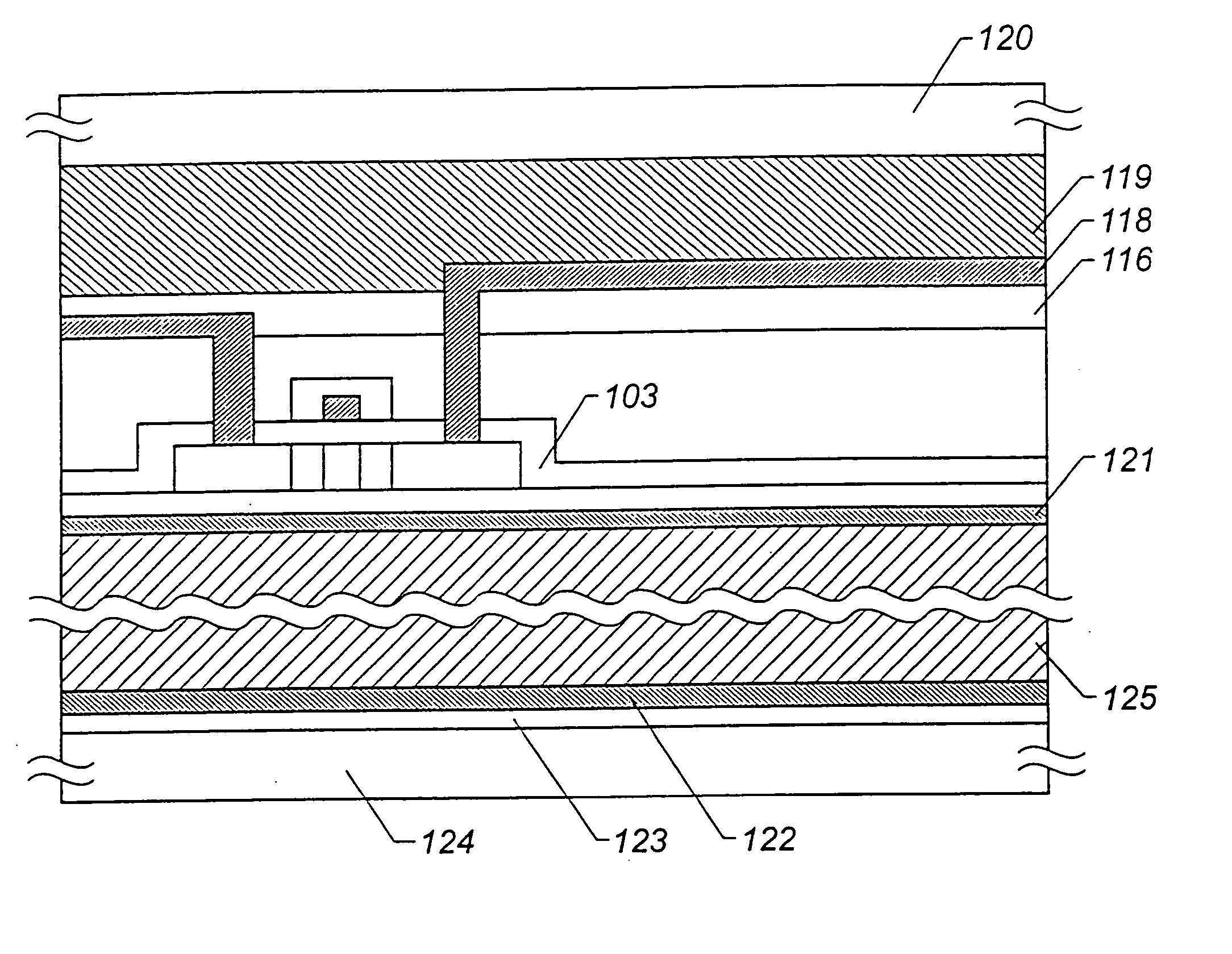

A method of manufacturing a semiconductor device, comprises the steps of: forming a first insulating film on a first substrate; forming a second insulating film on the first insulating film; forming an amorphous silicon film on the second insulating film; holding a metal element that promotes the crystallization of silicon in contact with a surface of the amorphous silicon film; crystallizing the amorphous silicon film through a heat treatment to obtain a crystalline silicon film; forming a thin-film transistor using the crystalline silicon film; forming a sealing layer that seals the thin-film transistor; bonding a second substrate having a translucent property to the sealing layer; and removing the first insulating film to peel off the first substrate.

Owner:SEMICON ENERGY LAB CO LTD

Method of manufacturing a semiconductor device

InactiveUS20050162578A1Promote crystallizationHigh effectTransistorSolid-state devicesCrystalline siliconSemiconductor

A method of manufacturing a semiconductor device, comprises the steps of: forming a first insulating film on a first substrate; forming a second insulating film on the first insulating film; forming an amorphous silicon film on the second insulating film; holding a metal element that promotes the crystallization of silicon in contact with a surface of the amorphous silicon film; crystallizing the amorphous silicon film through a heat treatment to obtain a crystalline silicon film; forming a thin-film transistor using the crystalline silicon film; forming a sealing layer that seals the thin-film transistor; bonding a second substrate having a translucent property to the sealing layer; and removing the first insulating film to peel off the first substrate.

Owner:SEMICON ENERGY LAB CO LTD

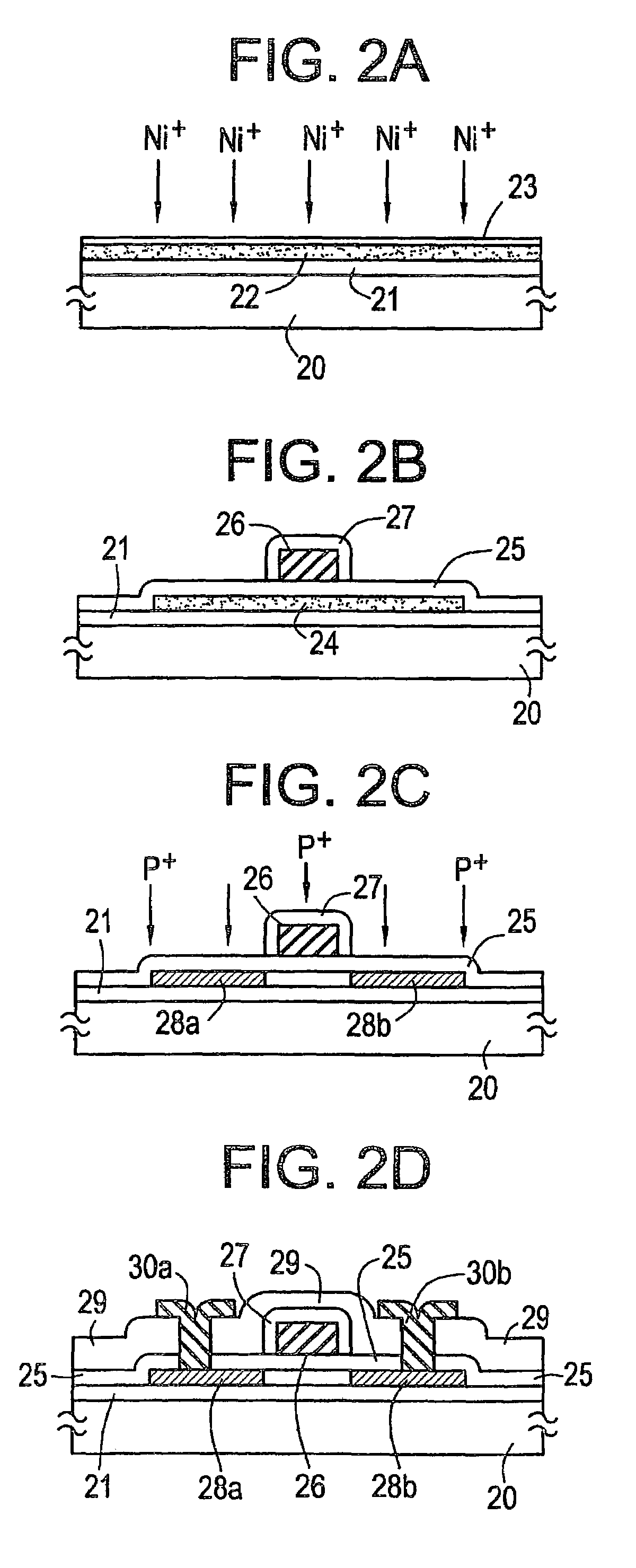

Display switch with double layered gate insulation and resinous interlayer dielectric

InactiveUS6316810B1Reduce concentrationPromote crystallizationTransistorSolid-state devicesDielectricAtmospheric air

Concentration of metal element which promotes crystallization of silicon and which exists within a crystal silicon film obtained by utilizing the metal element is reduced. A first heat treatment for crystallization is implemented after introducing nickel element to an amorphous silicon film 103. Then, after obtaining the crystal silicon film, another heat treatment is implemented within an oxidizing atmosphere at a temperature higher than that of the previous heat treatment. At this time, HCl or the like is added to the atmosphere. A thermal oxide film 106 is formed in this step. At this time, gettering of the nickel element into the thermal oxide film 106 takes place. Next, the thermal oxide film 106 is removed. Thereby, a crystal silicon film 107 having low concentration of the metal element and a high crystalinity can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

Fabrication method of semiconductor device

InactiveUS7056381B1Metal concentration be relatively lowerHigh crystallinityPolycrystalline material growthSolid-state devicesLaser lightCrystallinity

Concentration of metal element which promotes crystallization of silicon and which exists within a crystal silicon film obtained by utilizing the metal element is reduced. A first heat treatment for crystallization is implemented after introducing nickel to an amorphous silicon film 103. Then, laser light is irradiated to diffuse the nickel element concentrated locally. After that, another heat treatment is implemented within an oxidizing atmosphere at a temperature higher than that of the previous heat treatment. A thermal oxide film 106 is formed in this step. At this time, the nickel element is gettered to the thermal oxide film 106. Then, the thermal oxide film 106 is removed. Thereby, a crystal silicon film 107 having low concentration of the metal element and a high crystallinity can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

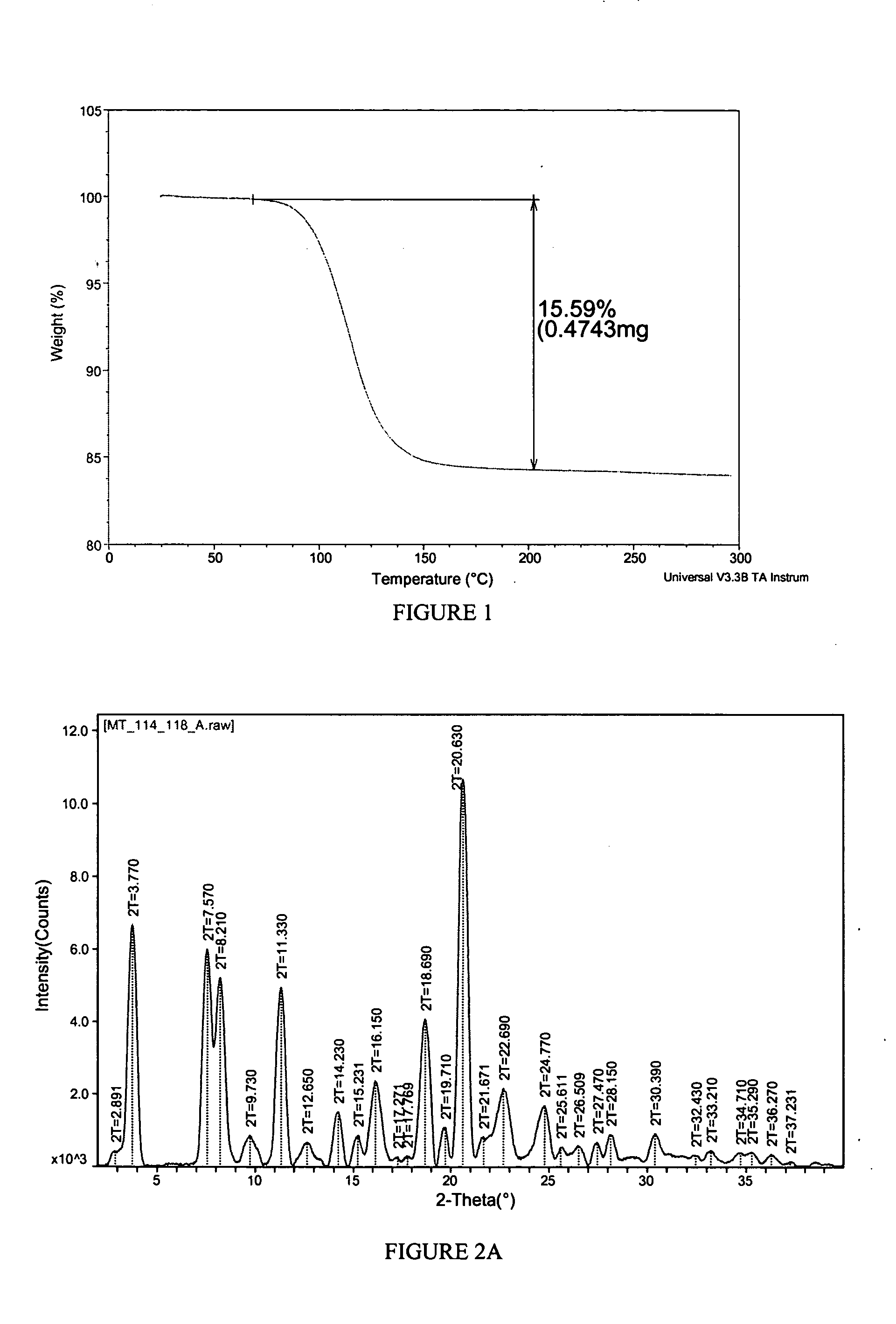

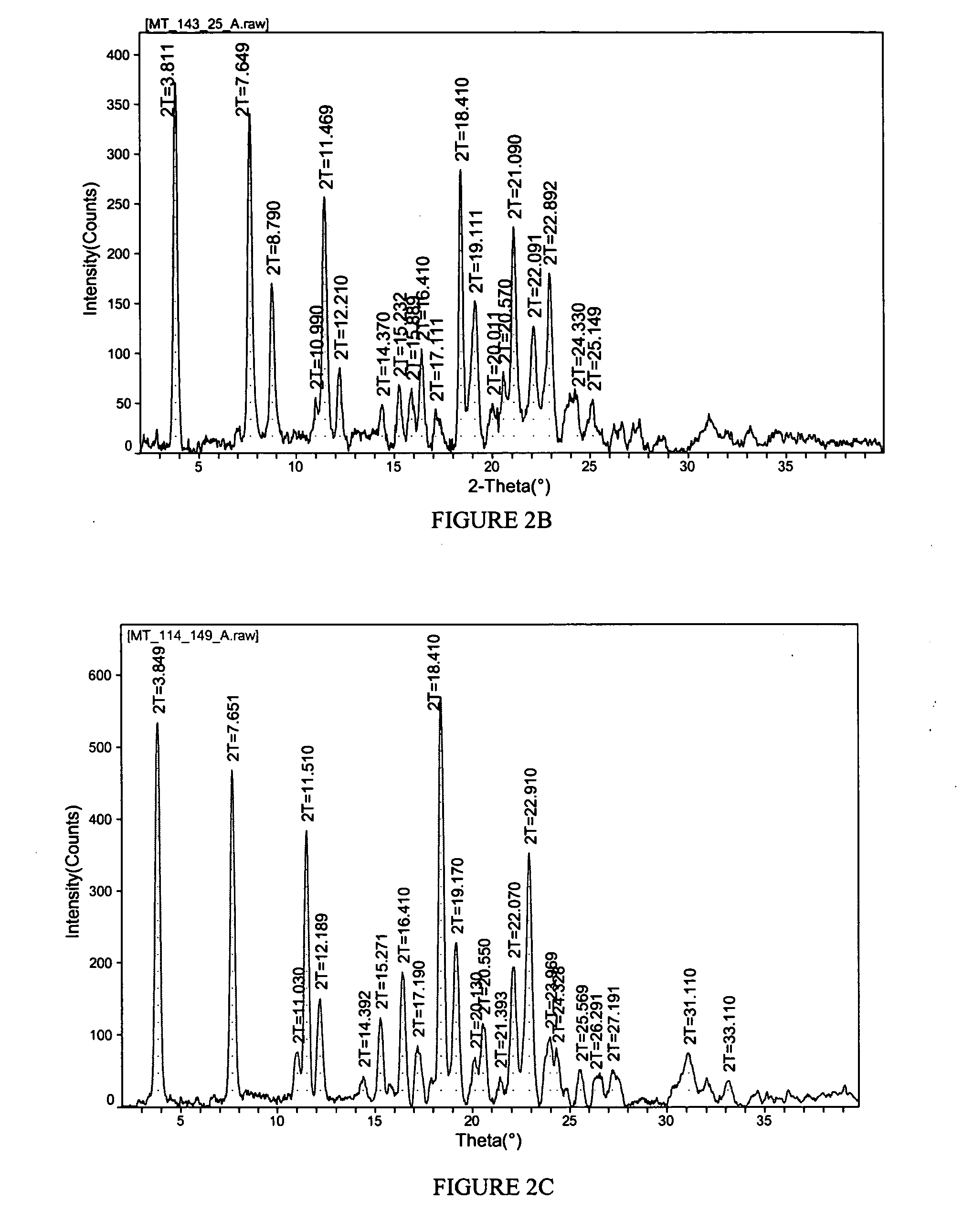

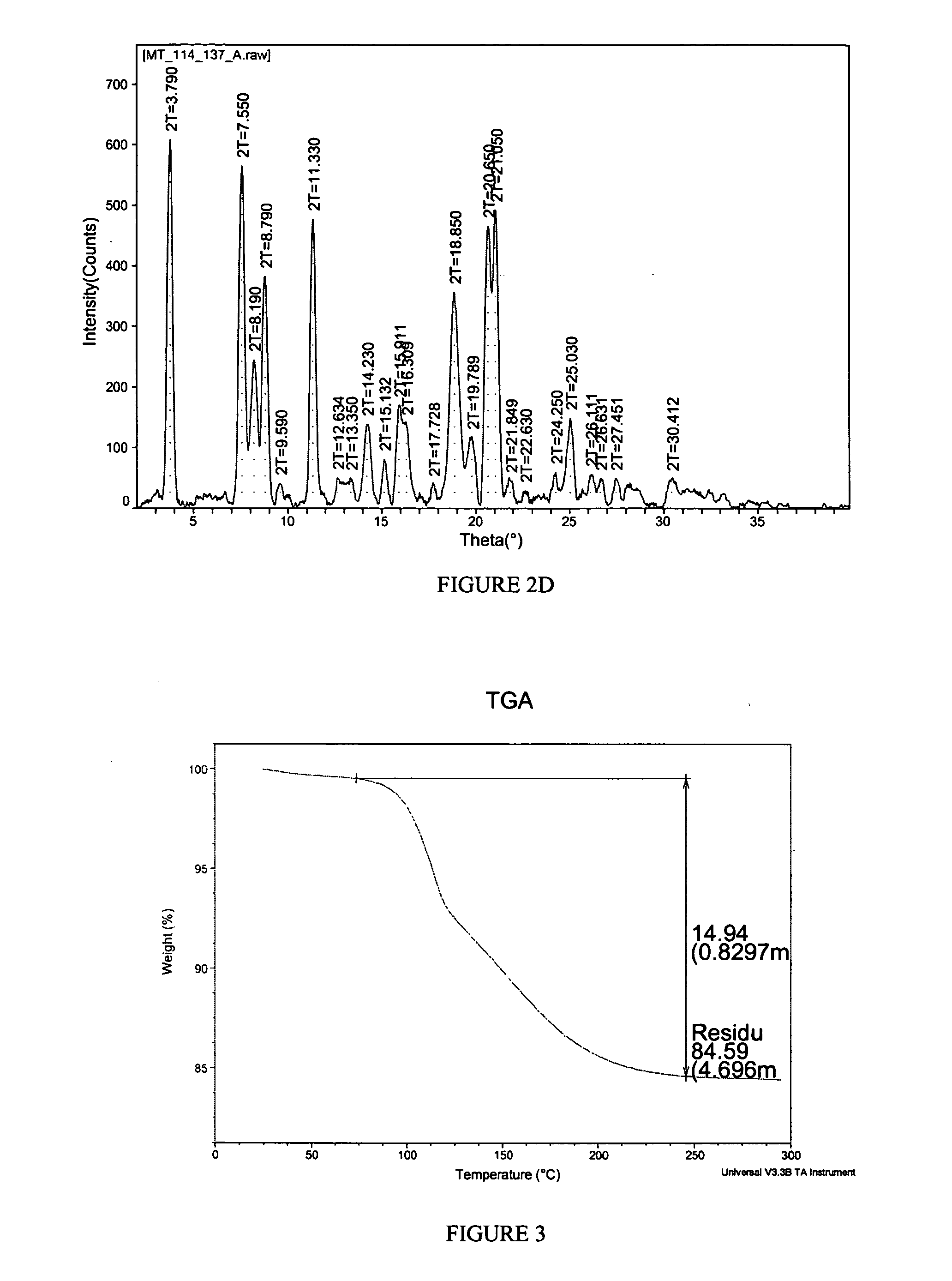

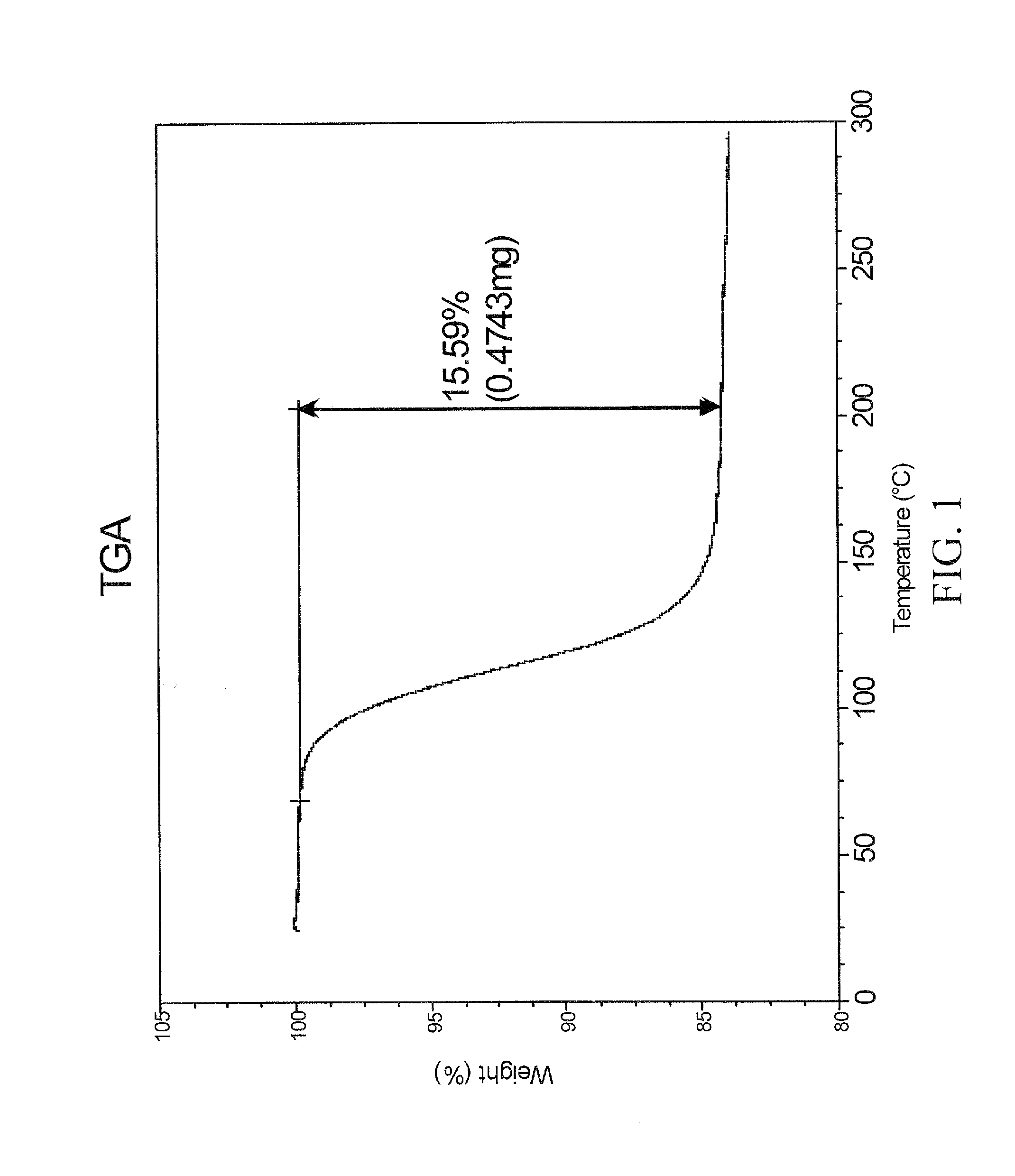

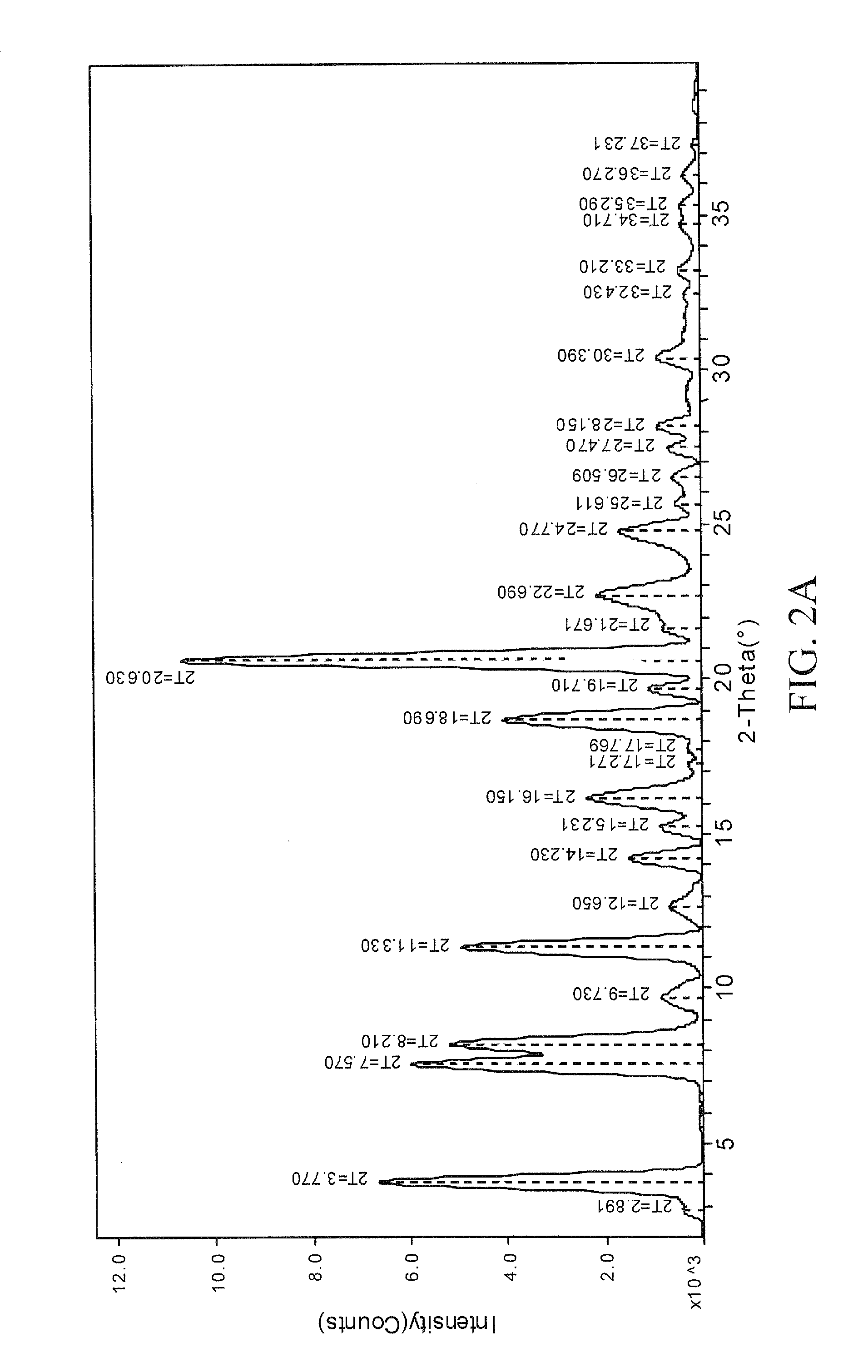

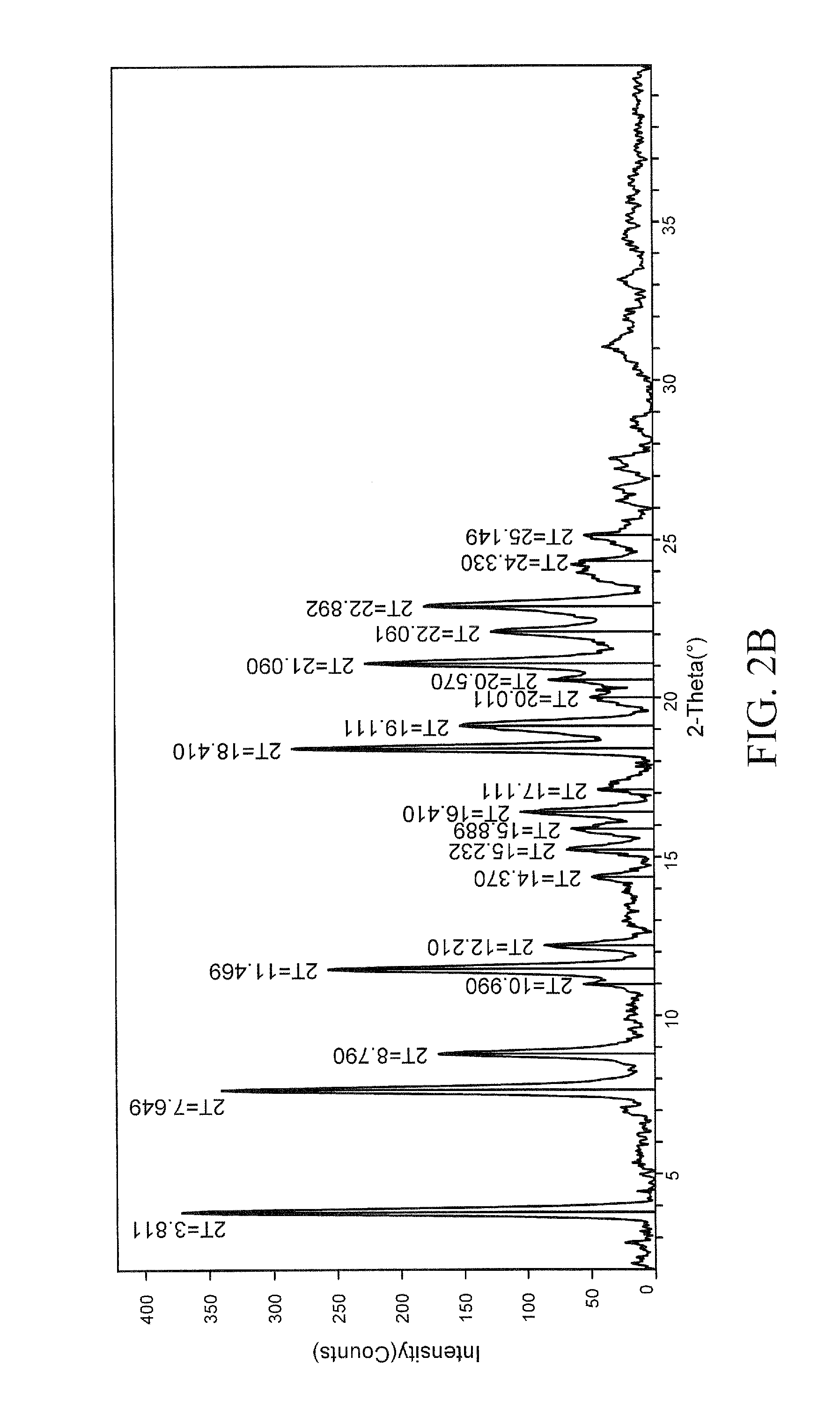

Pharmaceutical propylene glycol solvate compositions

InactiveUS20070015841A1Less hygroscopicMore solubleBiocideOrganic chemistryIsopropylene glycolChemistry

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

Semiconductor device structure

InactiveUS6987283B2Shorten crystallization timeReduce the temperatureTransistorStatic indicating devicesDevice materialCrystallinity

In thin film transistors (TFTs) having an active layer of crystalline silicon adapted for mass production, a catalytic element is introduced into doped regions of an amorphous silicon film by ion implantation or other means. This film is crystallized at a temperature below the strain point of the glass substrate. Further, a gate insulating film and a gate electrode are formed. Impurities are introduced by a self-aligning process. Then, the laminate is annealed below the strain point of the substrate to activate the dopant impurities. On the other hand, Neckel or other element is also used as a catalytic element for promoting crystallization of an amorphous silicon film. First, this catalytic element is applied in contact with the surface of the amorphous silicon film. The film is heated at 450 to 650° C. to create crystal nuclei. The film is further heated at a higher temperature to grow the crystal grains. In this way, a crystalline silicon film having improved crystallinity is formed.

Owner:SEMICON ENERGY LAB CO LTD

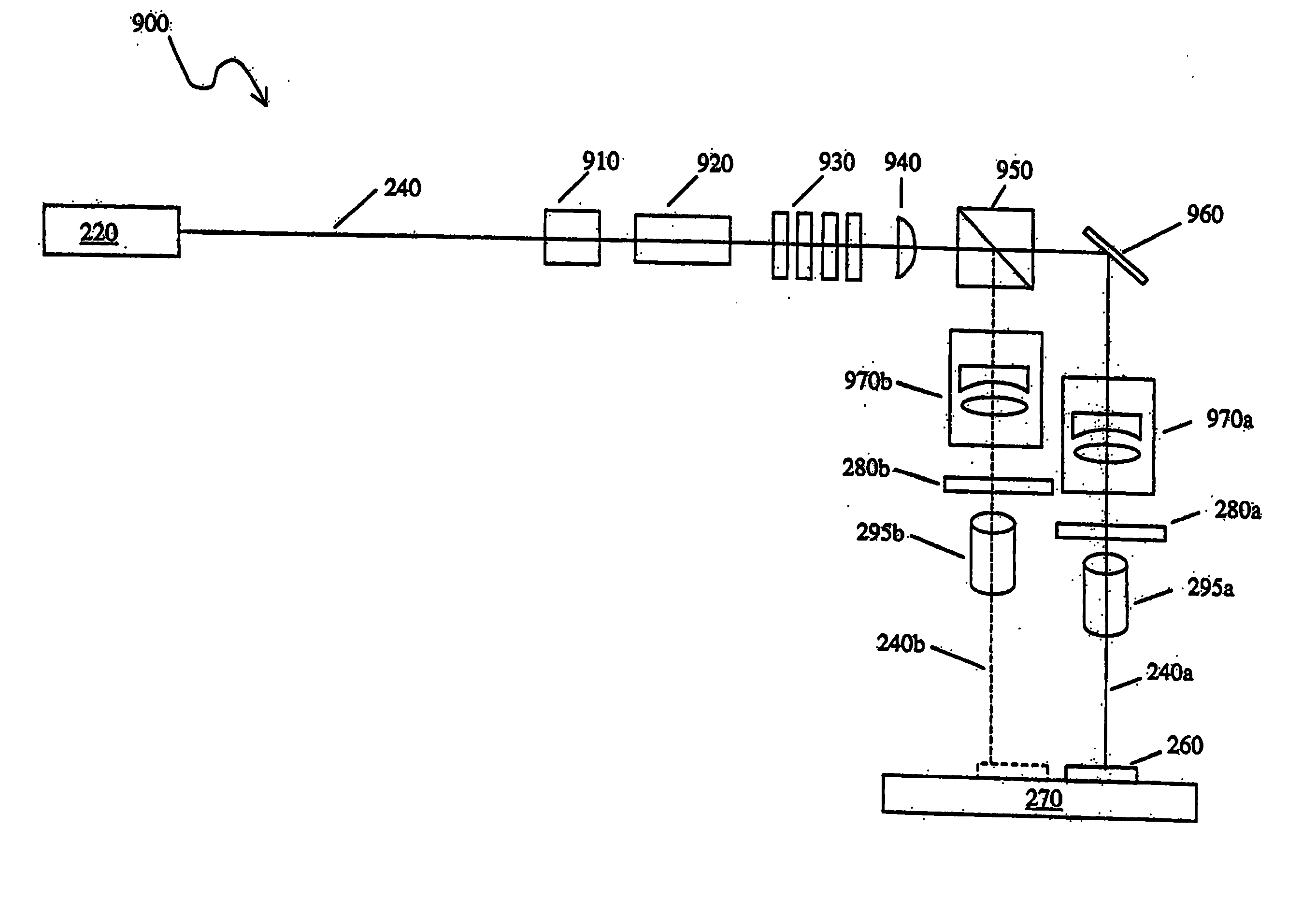

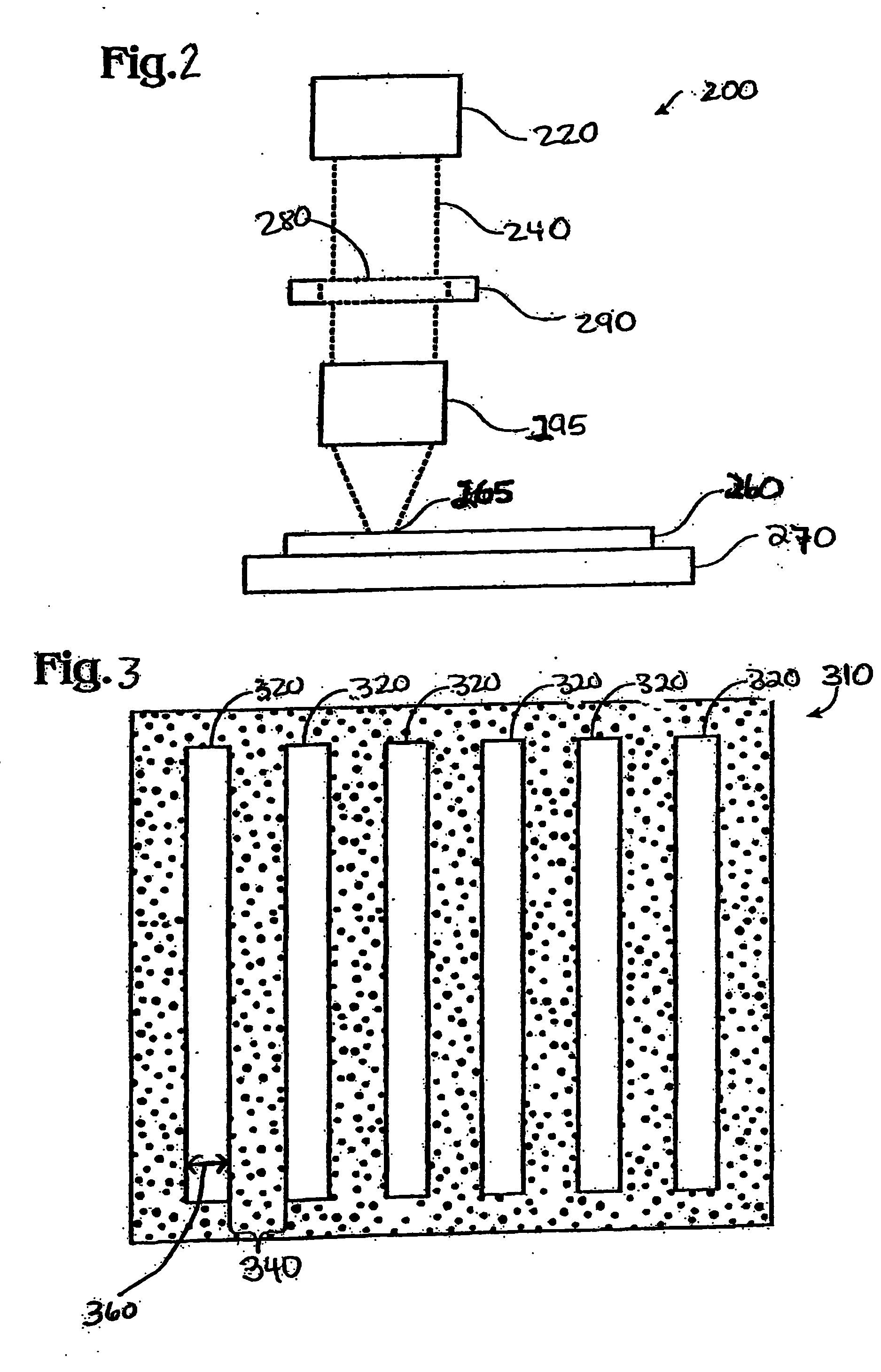

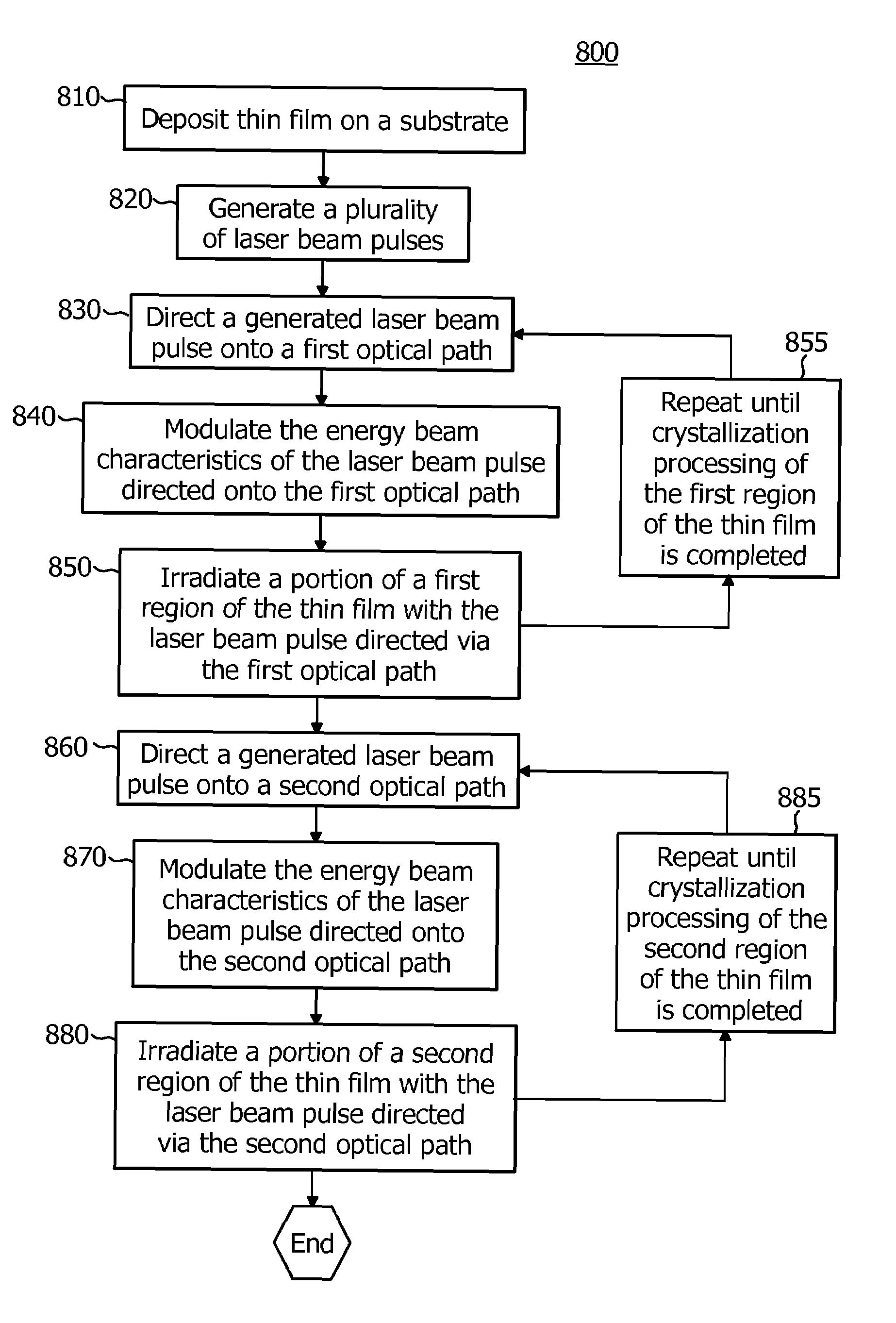

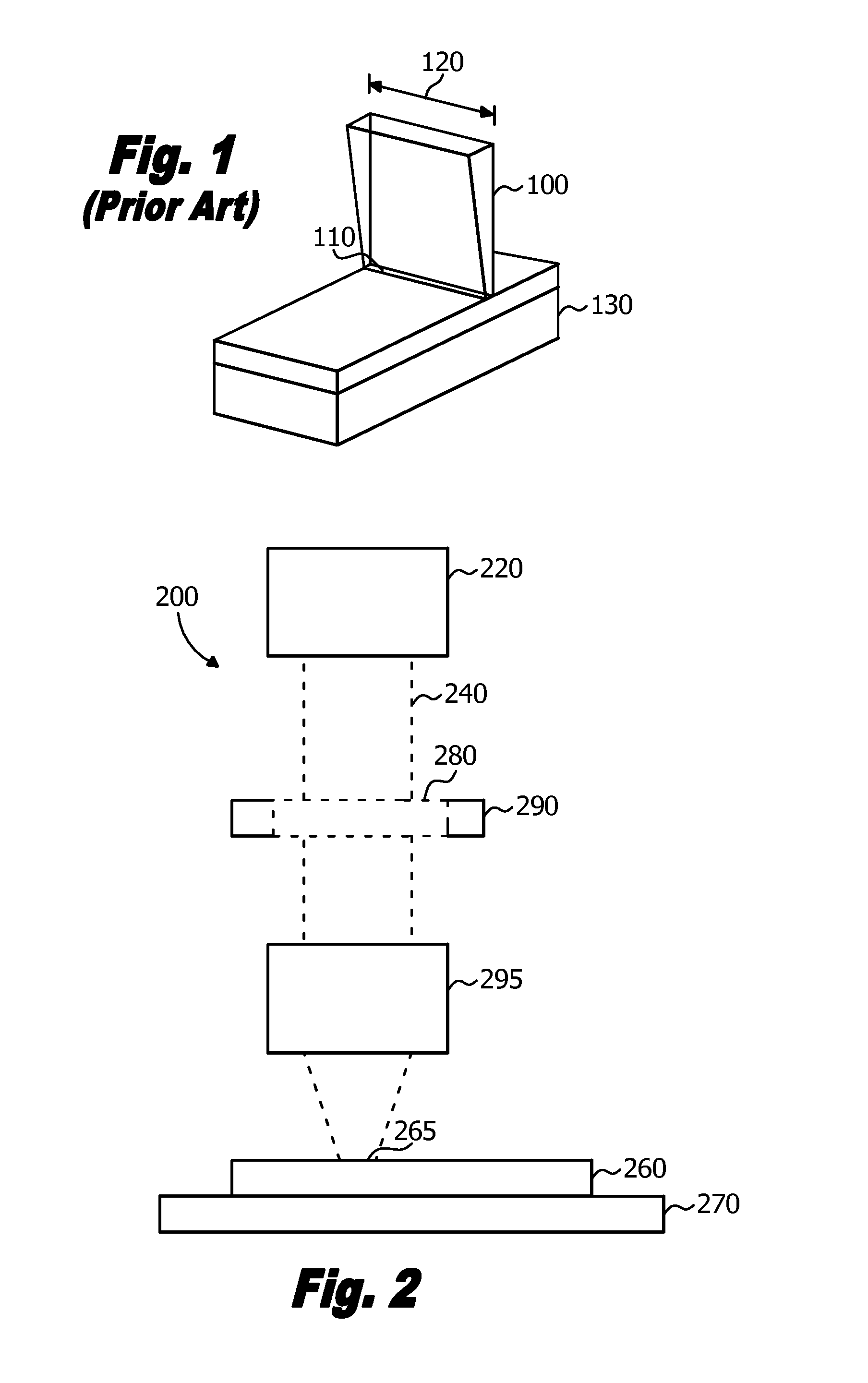

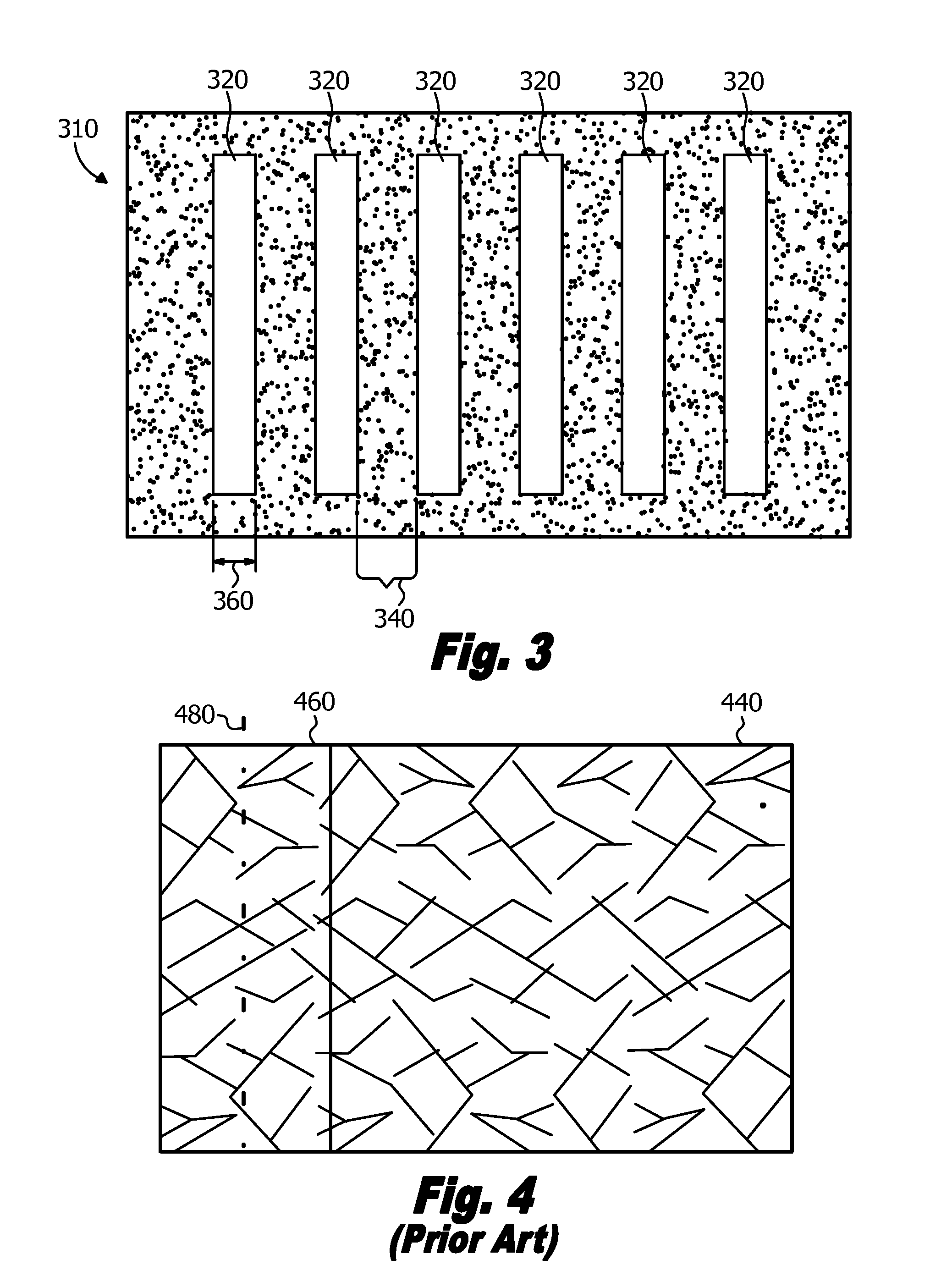

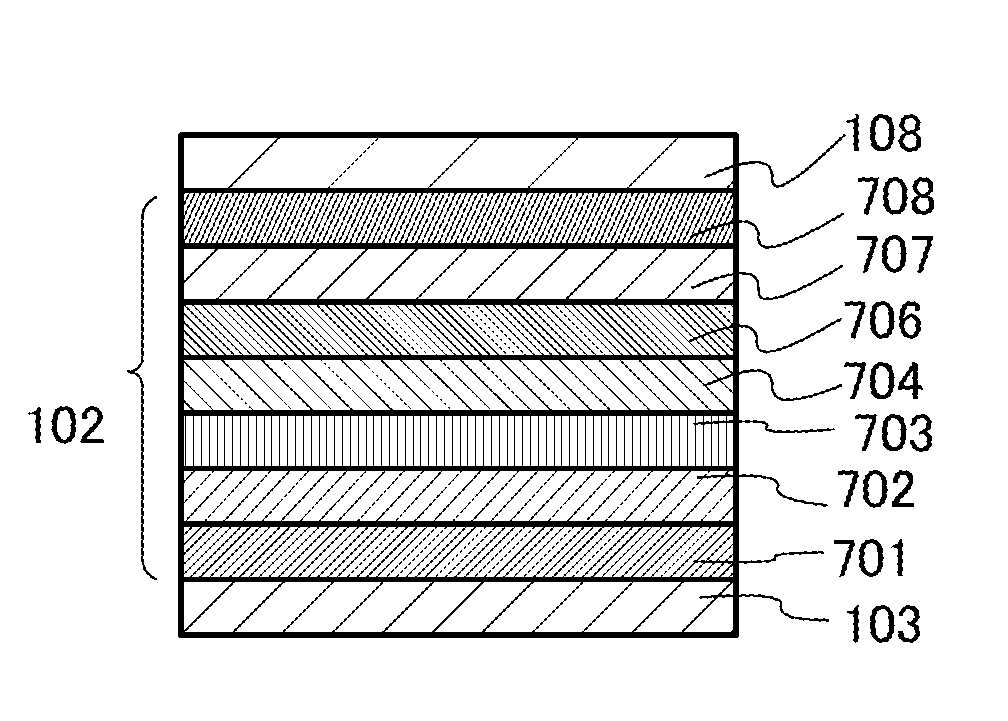

Systems and methods for inducing crystallization of thin films using multiple optical paths

InactiveUS20050059224A1Promote crystallizationReduce the amount of energyFrom solid stateSemiconductor/solid-state device manufacturingLight beamBeam steering

The present invention is directed to systems and methods for irradiating regions of a thin film sample(s) with laser beam pulses having different energy beam characteristics that are generated and delivered via different optical paths. Exemplary methods include the steps of generating a plurality of laser beam pulses having energy beam characteristics, directing a generated laser beam pulse onto a first optical path, modulating the energy beam characteristics of the first optical path-directed laser beam pulse, irradiating at least a portion of a first region of the thin film with the first optical path-directed laser beam pulse to induce crystallization of the portion of the first region, directing a generated laser beam pulse onto a second optical path, modulating the energy beam characteristics of the second optical path-directed laser beam pulse, wherein the energy beam characteristics of the second optical path-directed laser beam pulse is different from the energy beam characteristics of the first optical path-directed laser beam pulse, and irradiating at least a portion of a second region of the thin film with the second optical path-directed laser beam pulse to induce crystallization of the portion of the second region. An exemplary system includes a first optical path, a second optical path, a beam steering element for directing laser beam pulses onto the first optical path and the second optical path; and a handling stage for controlling the position of a thin film relative to the laser beam pulses being directed via the first and second optical paths.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

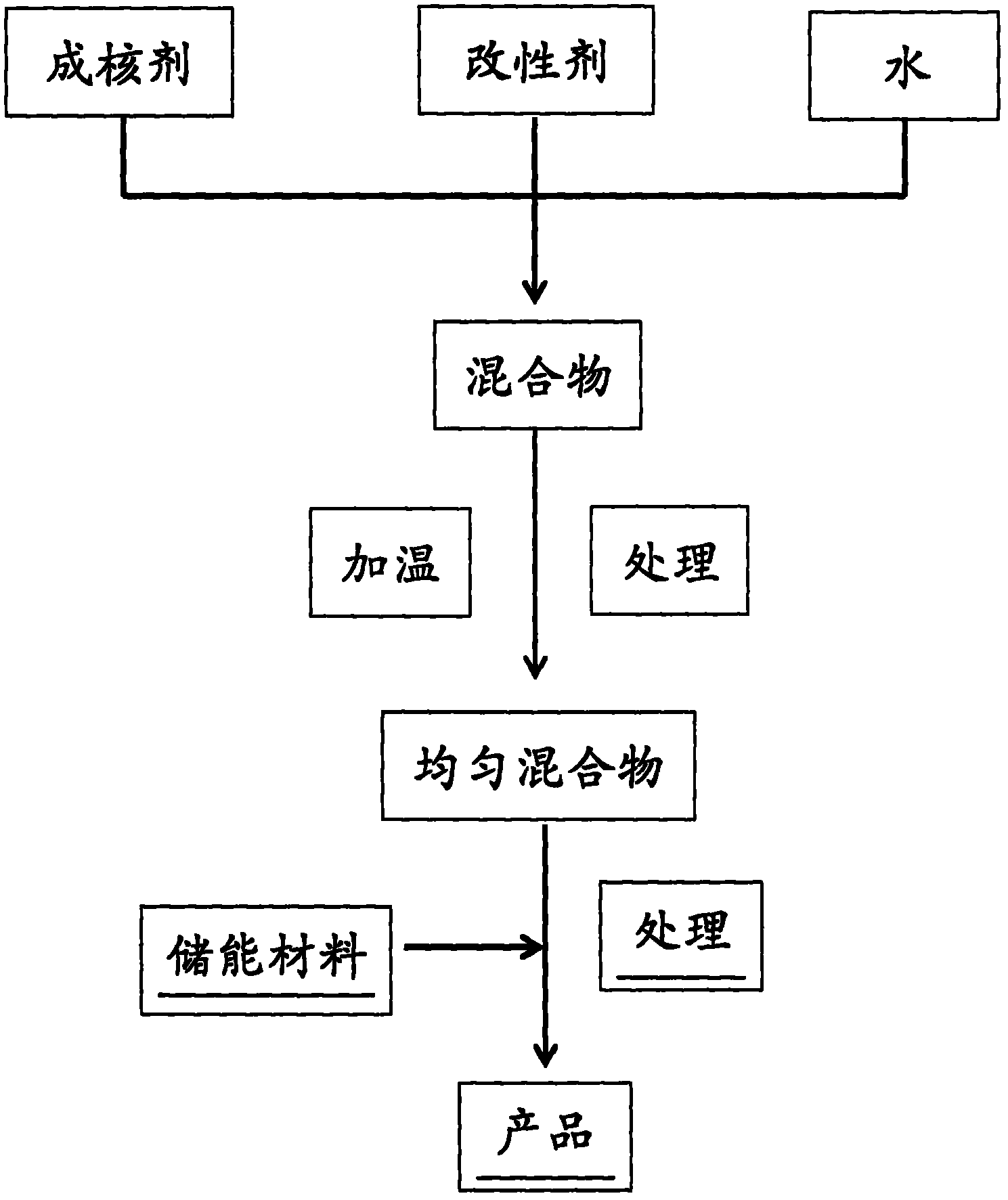

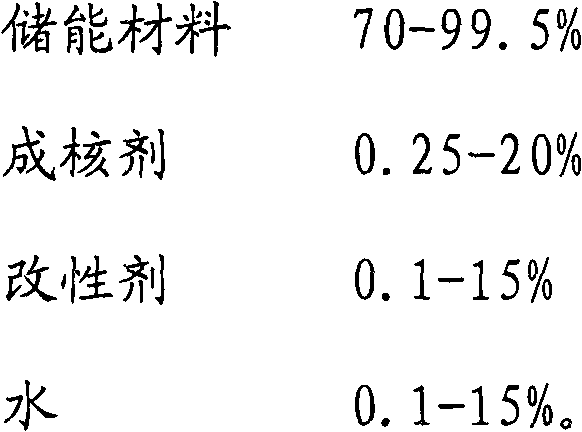

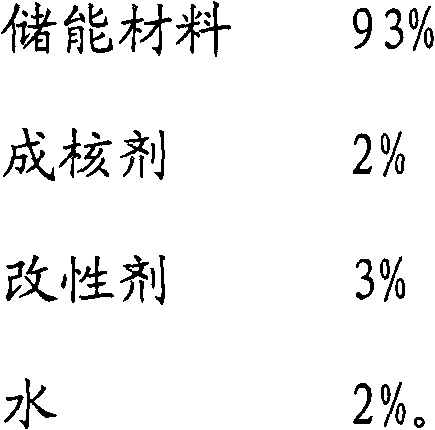

Inorganic phase change energy storage material

InactiveCN102604599AImprove liquidityPrevent Mutual AggregationHeat-exchange elementsPhase changeEnergy storage

The invention relates to the technical field of energy storage material, in particular to inorganic phase change energy storage material. The material comprises the following components by mass: 70 to 99.5 % of energy storage material, 0.25-20 % of nucleating agent, 0.1-15 % of modifying agent and 0.1-15 % of water. The bases hydrate or crystalline hydrous salt, especially the bases hydrate is adopted as energy storage material; the nucleating agent adopts carbonate; and the modifying agent is dispersant. According to the inorganic phase change energy storage material, by selecting proper nucleating agent and the ration of the nucleating agent, material phase separation can be effectively solved, especially the phase change energy storage material prepared by adding the dispersant into a system has good cycling stability, and simultaneously the potential heat value does not change after circulation for thousands of times.

Owner:SHANGHAI XUNENG NEW ENERGY TECH

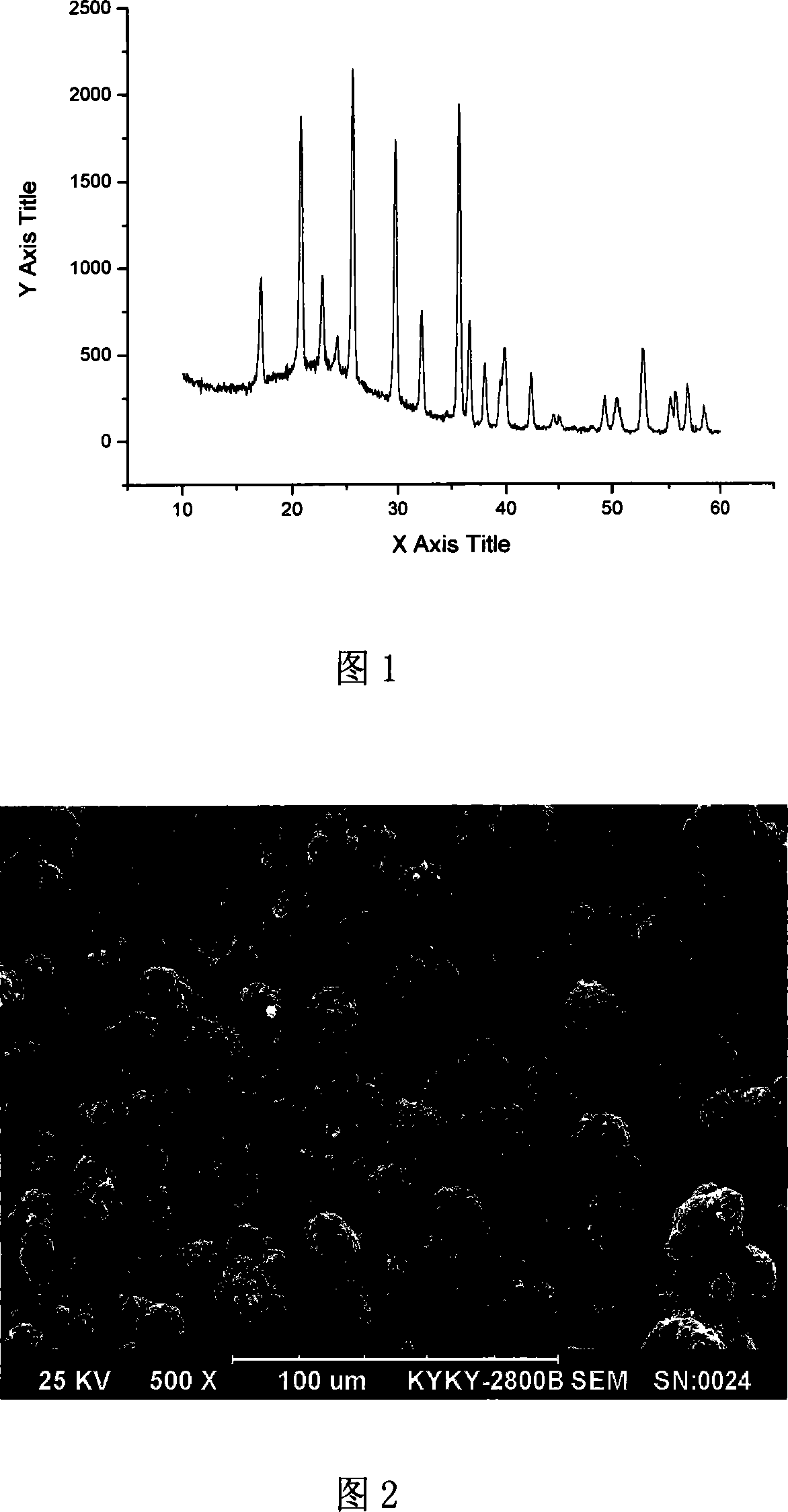

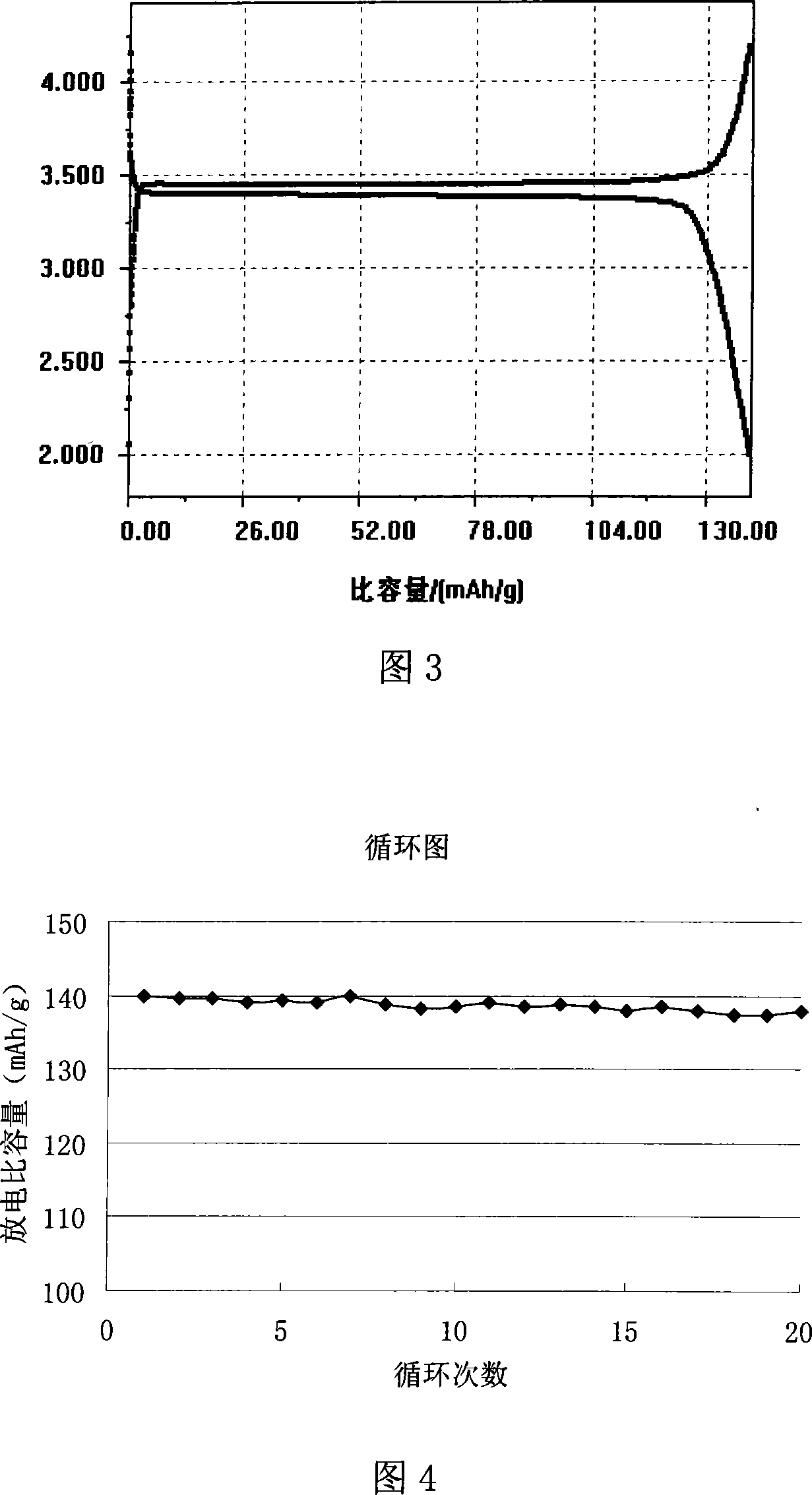

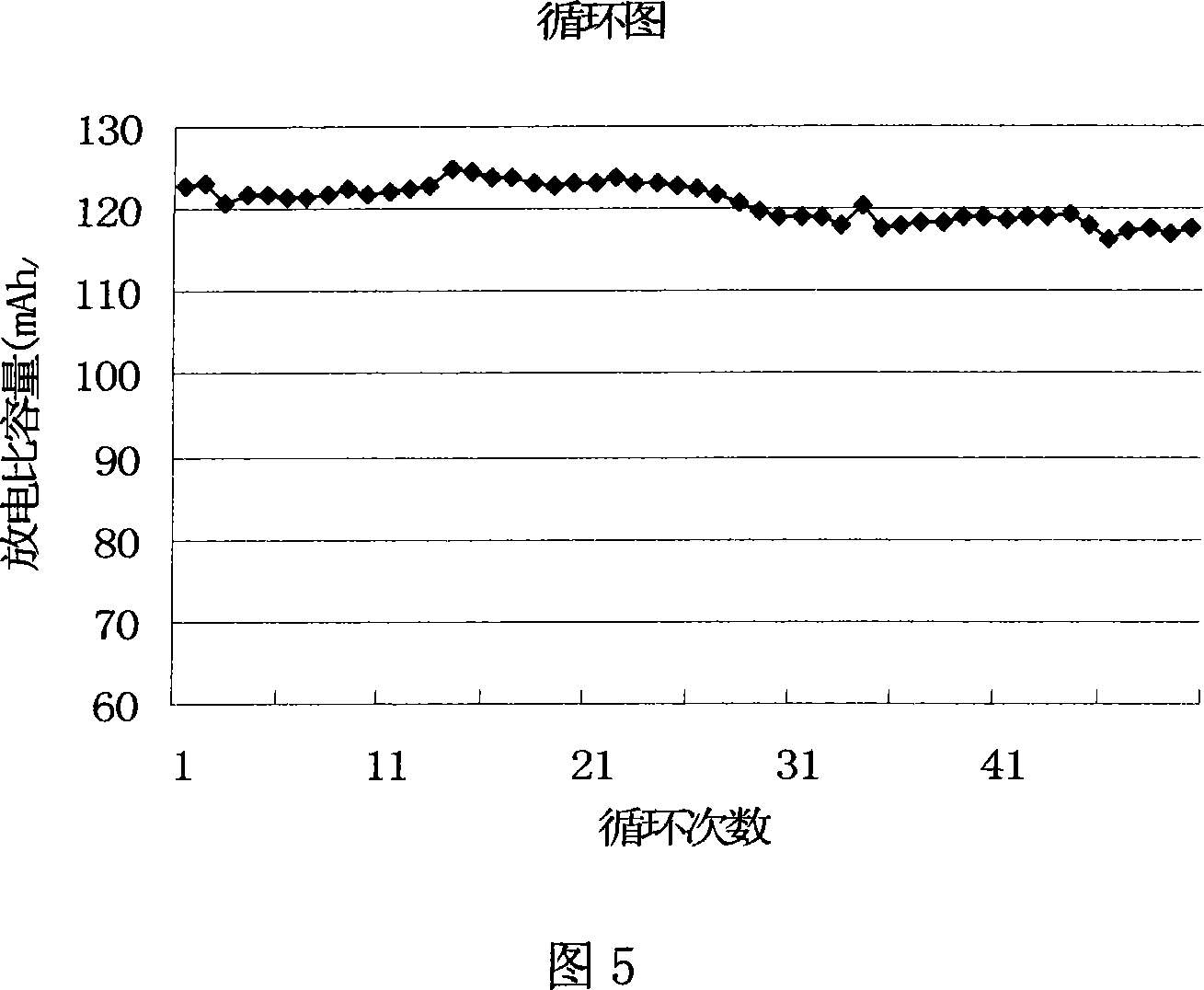

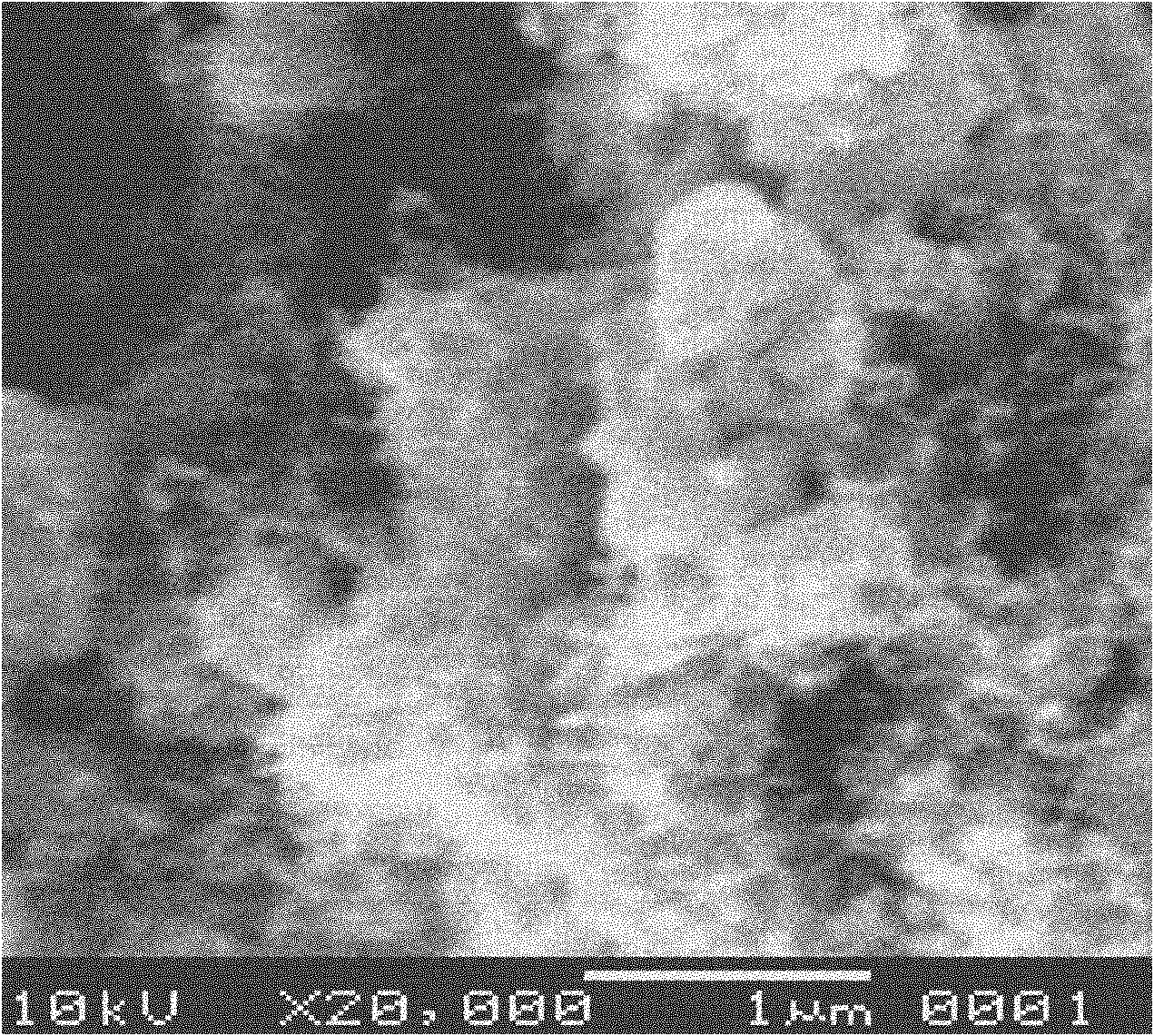

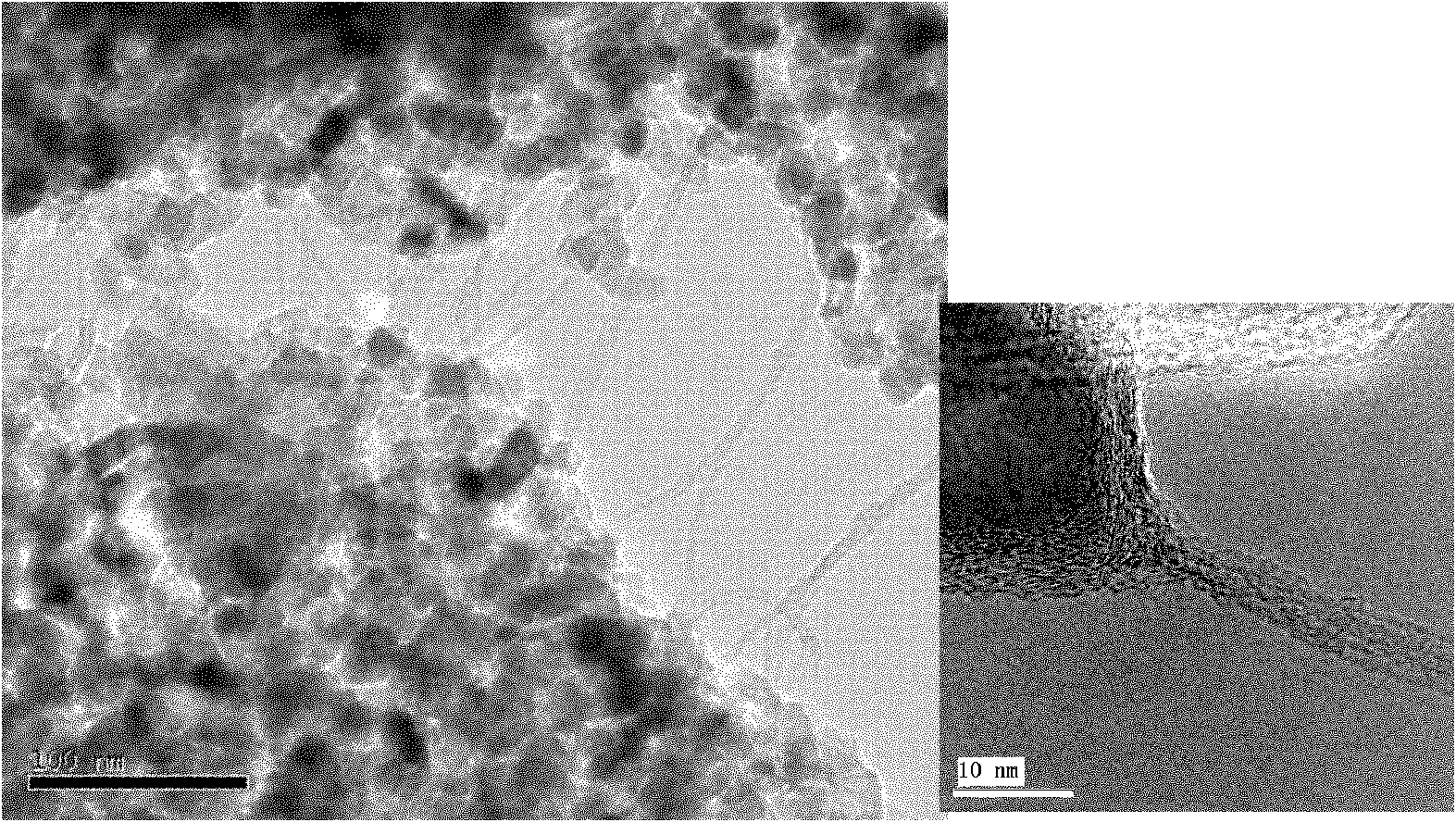

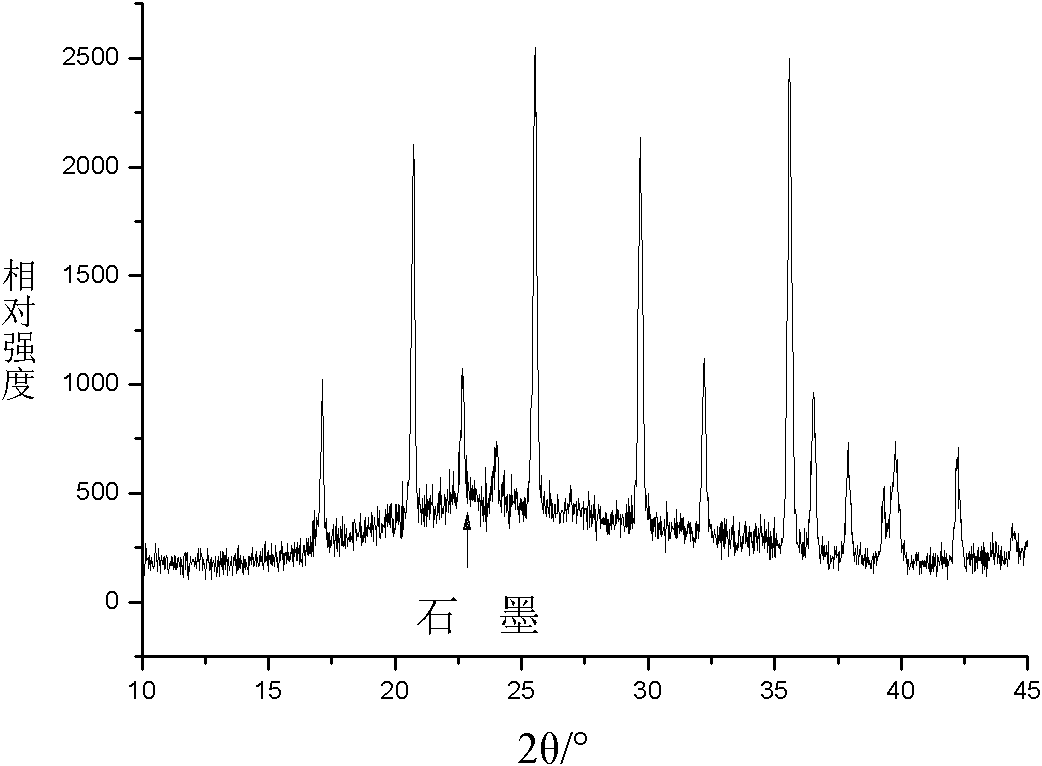

Ferric phosphate lithium material for lithium ion powder cell and preparation method thereof

ActiveCN101081696APromote crystallizationSingle structureElectrode manufacturing processesLithium compoundsCarbon layerLithium iron phosphate

The present invention discloses lithium iron phosphate material for lithium ion power cell and its preparation process, and dissolves the technological problem of raising the discharge power and safety performance. The lithium iron phosphate material is spherical or spheroid composite particle with one base body of lithium iron phosphate and doping and modifying agent and one coating carbon layer. Its preparation process includes wet ball milling the mixture comprising lithium salt, ferric salt, phosphoric acid, doping and modifying agent and dispersant, spraying to pelletize, heating for pre-treatment, maintaining temperature, cooling, pulverizing and shaping. Compared with available technology, the present invention has the features of high crystallization, single structure, average composite particle size of 5-60 microns, specific surface area of 8.0-15.0 sq m / g, bulk density of 1.4-1.7 g / cu cm, high specific capacity, high safety, etc.

Owner:BTR (TIANJIN) NANO MATERIAL MFG CO LTD

Systems and methods for inducing crystallization of thin films using multiple optical paths

InactiveUS7318866B2Promote crystallizationReduce the amount requiredAfter-treatment apparatusFrom gel stateLight beamBeam steering

The present invention is directed to systems and methods for irradiating regions of a thin film sample(s) with laser beam pulses having different energy beam characteristics that are generated and delivered via different optical paths. Exemplary methods include the steps of generating a plurality of laser beam pulses having energy beam characteristics, directing a generated laser beam pulse onto a first optical path, modulating the energy beam characteristics of the first optical path-directed laser beam pulse, irradiating at least a portion of a first region of the thin film with the first optical path-directed laser beam pulse to induce crystallization of the portion of the first region, directing a generated laser beam pulse onto a second optical path, modulating the energy beam characteristics of the second optical path-directed laser beam pulse, wherein the energy beam characteristics of the second optical path-directed laser beam pulse is different from the energy beam characteristics of the first optical path-directed laser beam pulse, and irradiating at least a portion of a second region of the thin film with the second optical path-directed laser beam pulse to induce crystallization of the portion of the second region. An exemplary system includes a first optical path, a second optical path, a beam steering element for directing laser beam pulses onto the first optical path and the second optical path; and a handling stage for controlling the position of a thin film relative to the laser beam pulses being directed via the first and second optical paths.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Heterocyclic compound

ActiveUS20120197020A1Reduce the driving voltageImprove current efficiencyOrganic chemistrySolid-state devicesCarbazoleDibenzofuran

Provided is a novel heterocyclic compound which can be used for a light-emitting element, as a host material of a light-emitting layer in which a light-emitting substance is dispersed. A heterocyclic compound represented by a general formula (G1) is provided. In the formula, A represents any of a substituted or unsubstituted dibenzothiophenyl group, a substituted or unsubstituted dibenzofuranyl group, and a substituted or unsubstituted carbazolyl group, R11 to R19 separately represent any of hydrogen, an alkyl group having 1 to 4 carbon atoms, and a substituted or unsubstituted aryl group having 6 to 14 carbon atoms, and Ar represents a substituted or unsubstituted arylene group having 6 to 13 carbon atoms.

Owner:SEMICON ENERGY LAB CO LTD

Synthetic method of visible light catalyst Bi2MoO6

InactiveCN101254463AEvenly dispersedSmall particle sizeMetal/metal-oxides/metal-hydroxide catalystsMolybdateSynthesis methods

A synthetic method of a novel visible light photocatalyst Bi2MoO6 (bismuth molybdate) is provided. The method includes the following steps: weighing Bi(NO3)3*5H2O and (NH4)6Mo7O24*4H2O solids at the theoretical ratio by mass of 14:1, dispersing the weighed solids into an appropriate amount of deionized water, stirring to obtain white curdy precipitates, placing the precipitates in a magnetic stirrer and stirring at normal temperature for 30 minutes, subjecting to ultrasonic treatment with a ultrasonic generator for 30 minutes to allow intensively mixing, allowing reactions of the treated white precipitates at 150-200 DEG C under sealed conditions, filtering the reaction product to collect flavescent precipitates, washing, drying, and grinding to obtain Bi2MoO6 (bismuth molybdate) photocatalyst. The photocatalyst has good photodegradation effect on target pollutants; and when the temperature of hydrothermal synthesis is 160 DEG C, the removal rate of target pollutant 4BS after photodegradation for 90 minutes reaches 99.5%. The inventive synthetic method has the advantages of simple process and low requirement for equipment, and is suitable for the synthesis of highly-active visible light photocatalyst Bi2MoO6 (bismuth molybdate).

Owner:NANJING UNIV

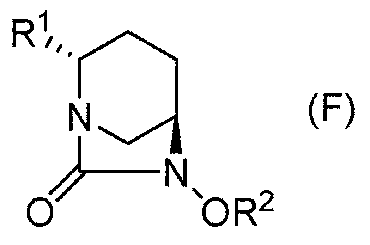

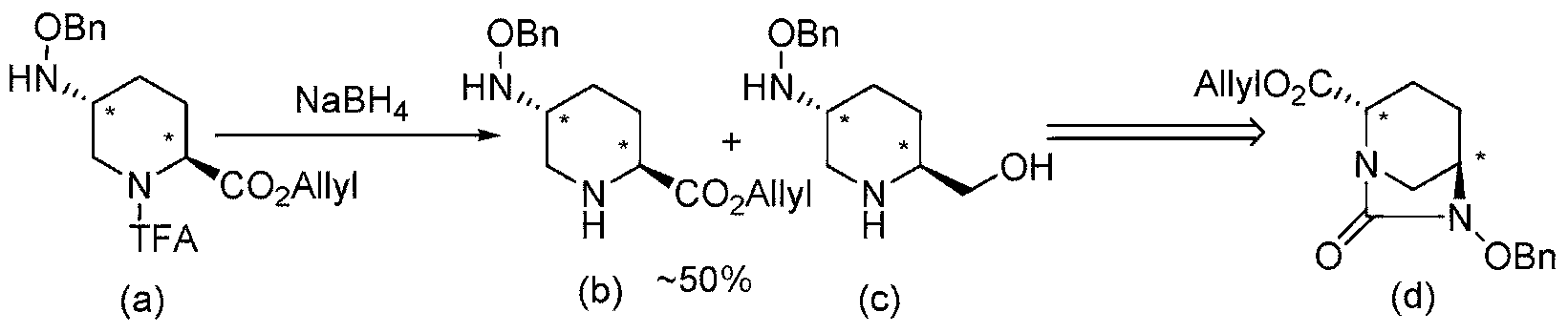

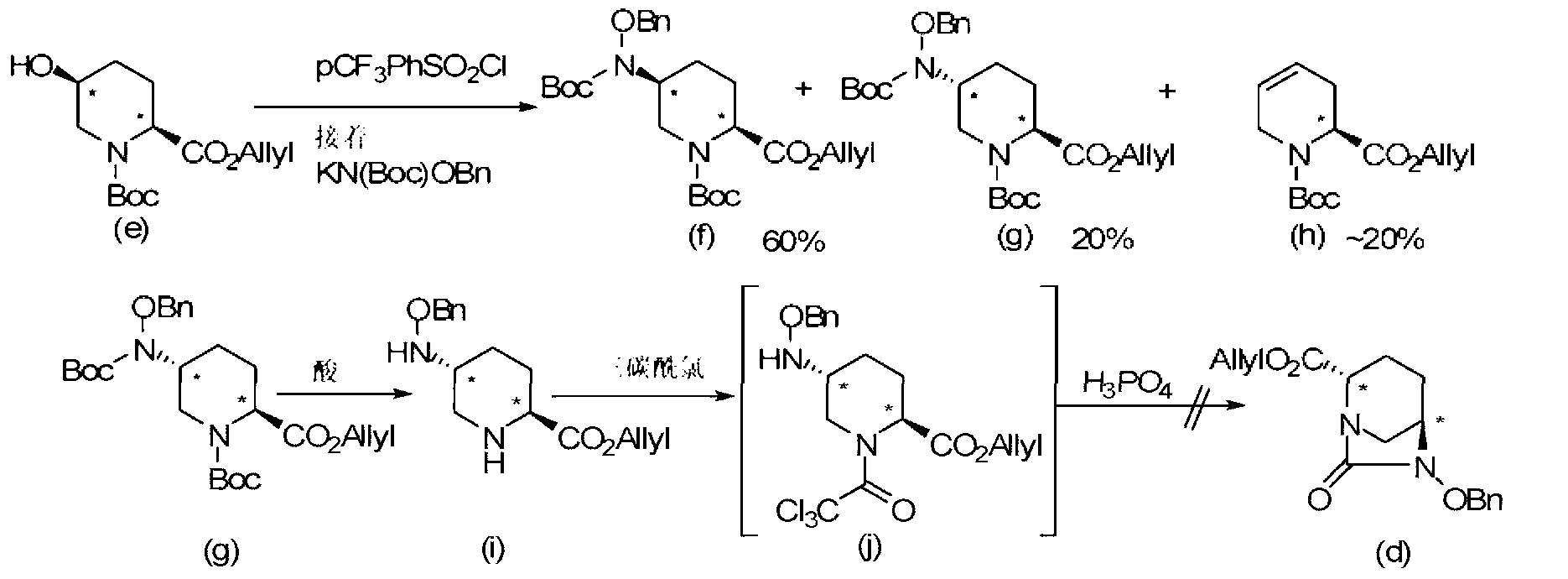

Optically-active diazabicyclooctane derivative and method for manufacturing same

ActiveCN103328476APromote crystallizationImprove effectivenessAntibacterial agentsOrganic active ingredientsHydrogen atomBenzyl group

Provided are an optically-active diazabicyclooctane derivative represented by a formula (F) that is useful as a medicinal intermediate of a ss-lactamase inhibitor, and a method for manufacturing the same. In the formula (F), R1 represents CO2R, CO2M, or CONH2; R represents a methyl group, a tert-butyl group, an allyl group, a benzyl group, or a 2,5-dioxopyrrolidine-1-yl group; M represents a hydrogen atom, an inorganic cation, or an organic cation; and R2 represents a benzyl group or an allyl group.

Owner:MEIJI SEIKA KAISHA LTD

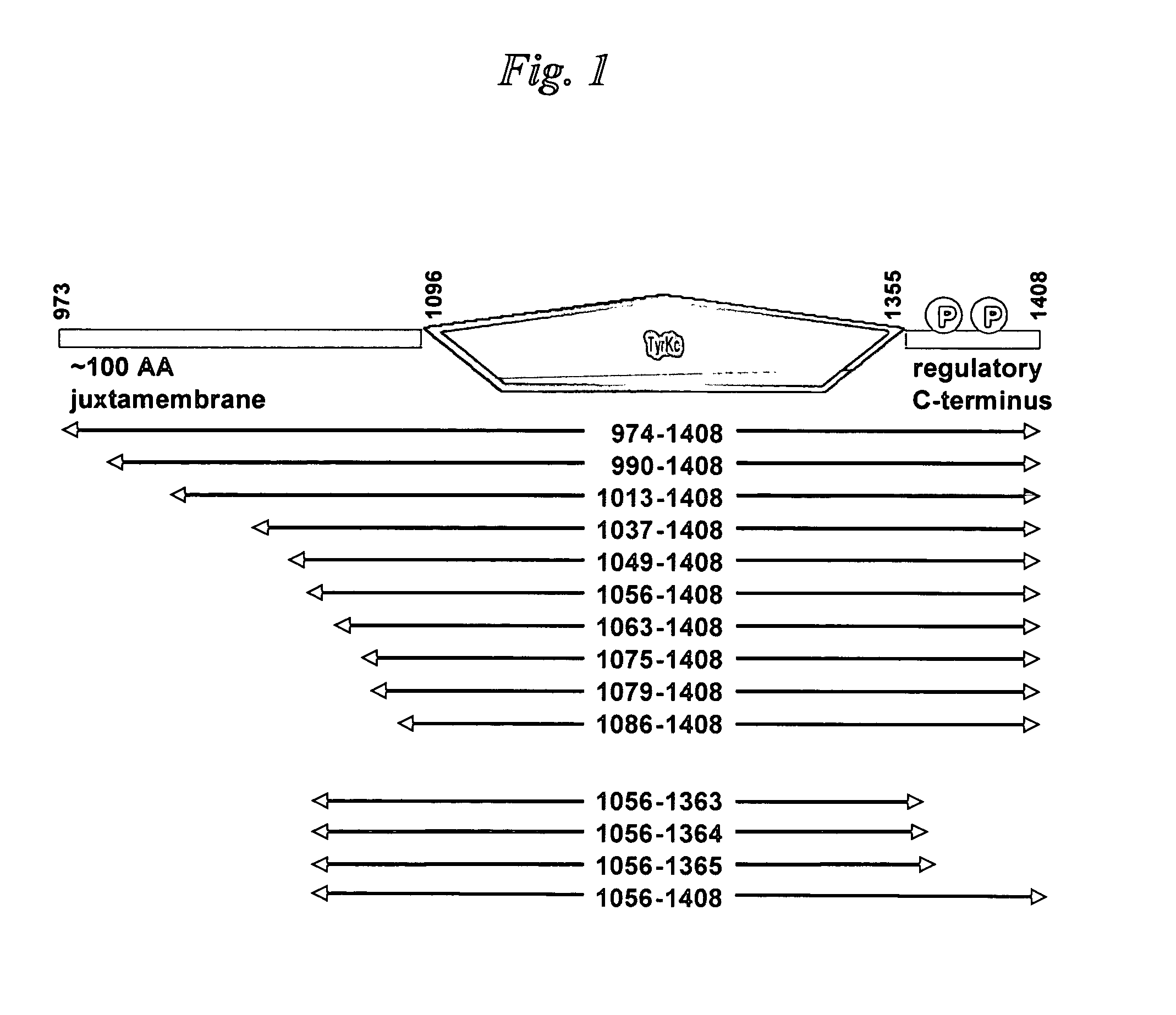

Nucleic acids encoding kinase and phosphatase enzymes, expression vectors and cells containing same

InactiveUS7517970B2Good quality crystalImprove crystallizationSugar derivativesHydrolasesActive enzymeSystematic variation

Methods for expressing active enzymes are described that involve co-expressing a first enzyme with a second enzyme that has an enzymatic activity that reverses a modification on the first enzyme and / or for identification of soluble and / or active catalytic domains by systematic variation of fragment lengths around catalytic domain boundaries.

Owner:PLEXXIKON INC

Pharmaceutical propylene glycol solvate compositions

InactiveUS7790905B2More stableLow hygroscopicityBiocideOrganic active ingredientsPropylene glycolPharmacology

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

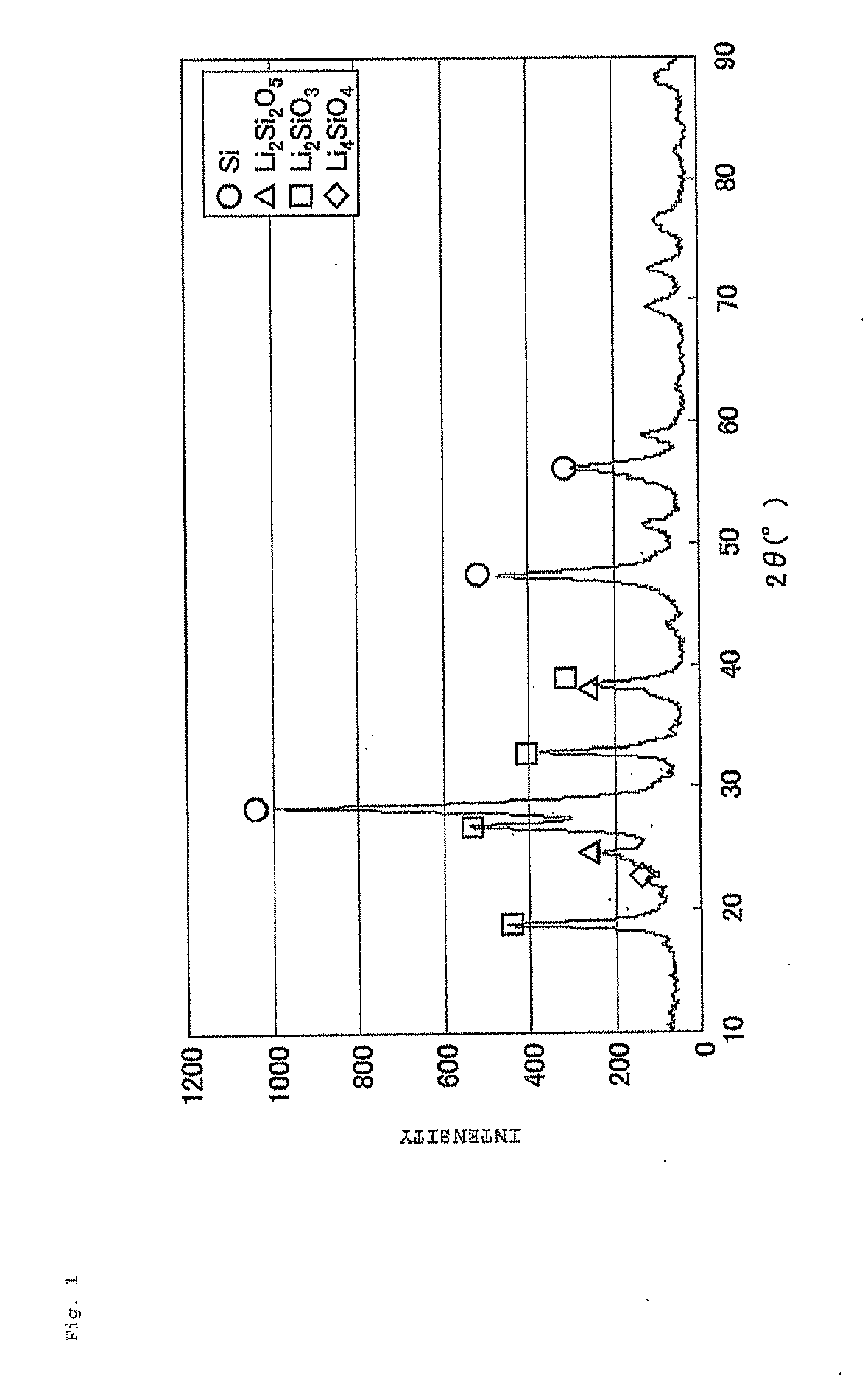

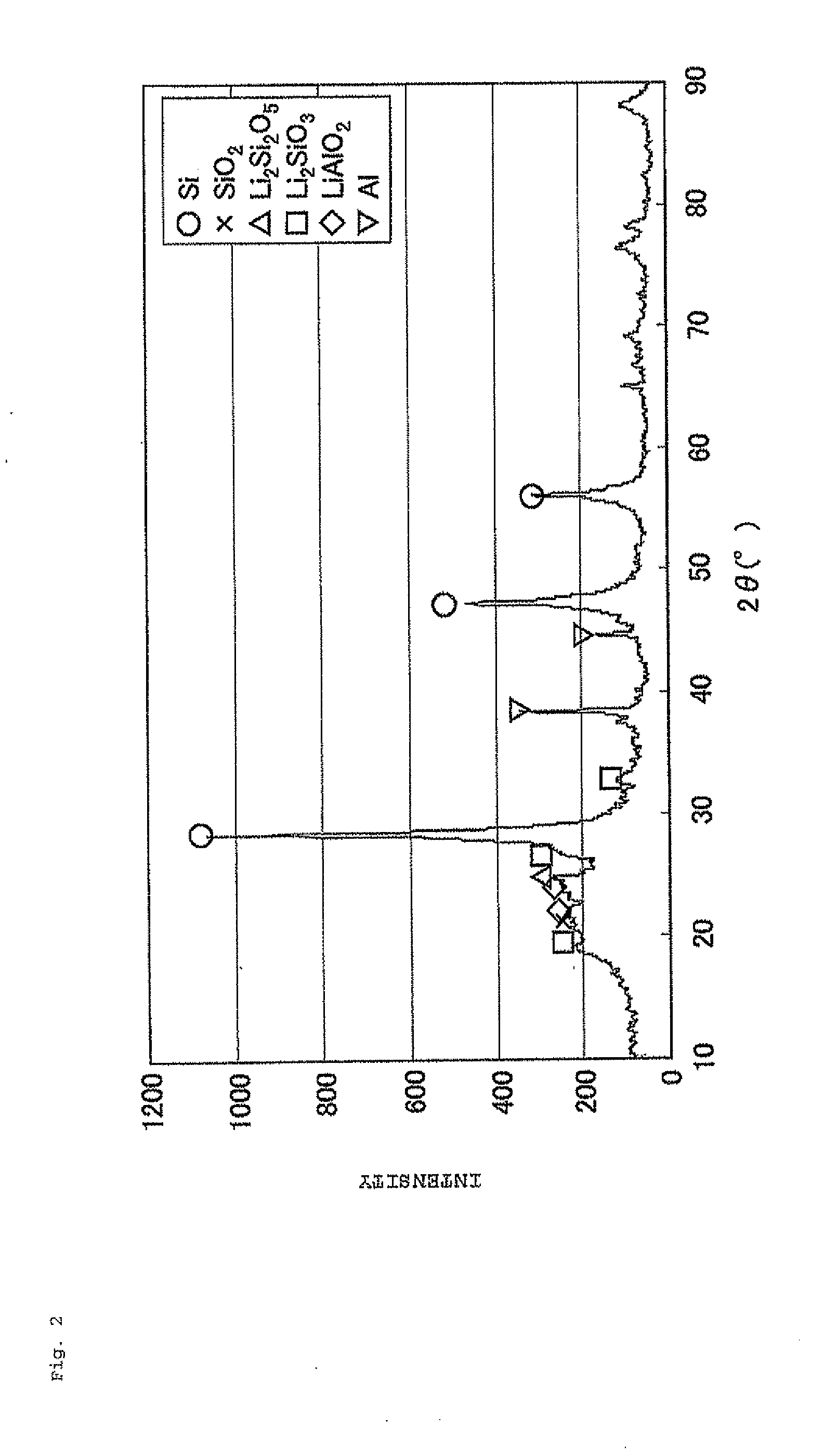

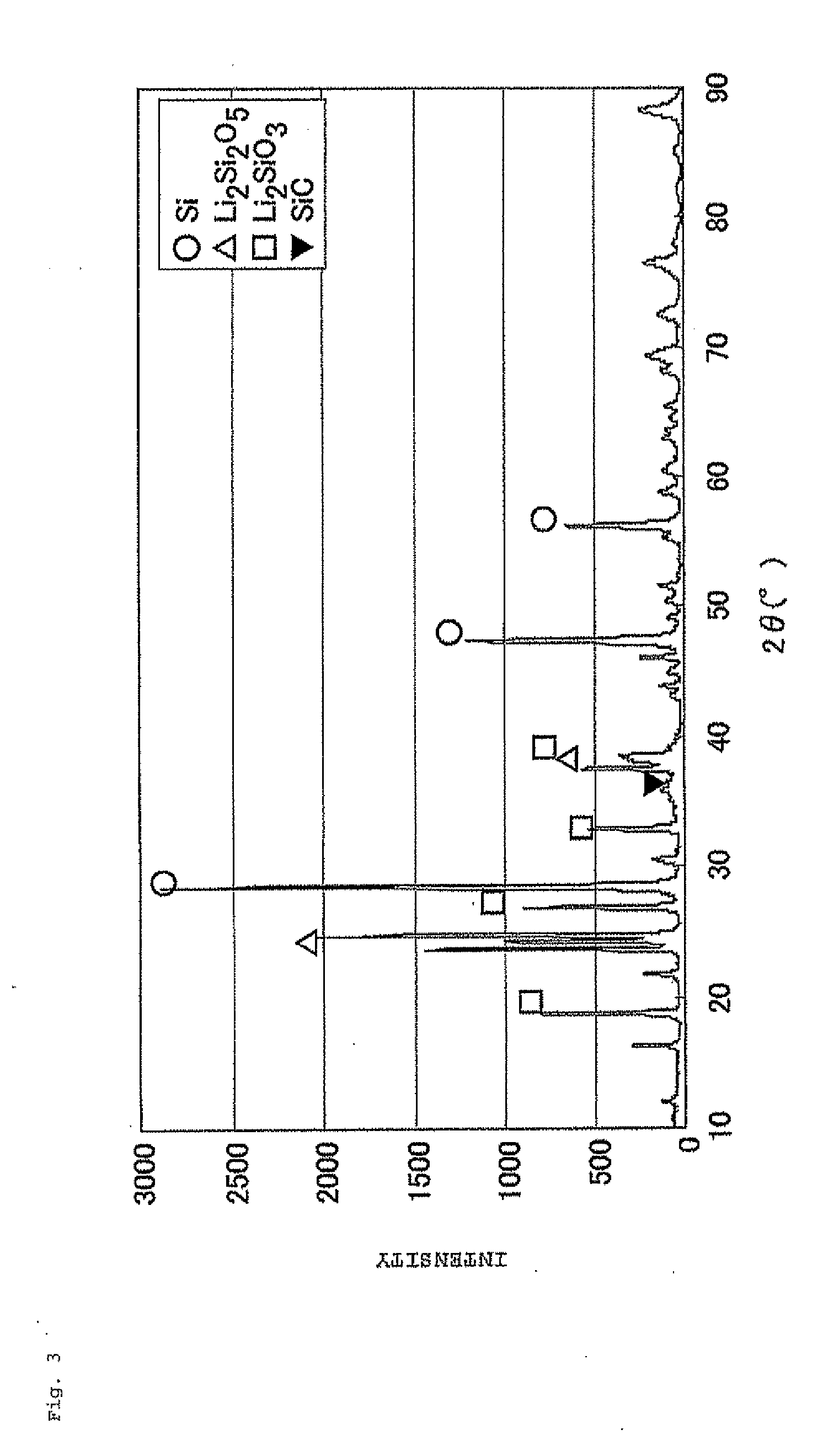

Negative electrode material for secondary battery with non-aqueous electrolyte, method for manufacturing negative electrode material for secondary battery with non-aqueous electrolyte, and lithium ion secondary battery

ActiveUS20110244334A1Large capacityHigh cycle durabilityFinal product manufactureLi-accumulatorsCarbon coatingX-ray

The present invention is a negative electrode material for a secondary battery with a non-aqueous electrolyte comprising at least a silicon-silicon oxide composite and a carbon coating formed on a surface of the silicon-silicon oxide composite, wherein at least the silicon-silicon oxide composite is doped with lithium, and a ratio I(SiC) / I(Si) of a peak intensity I(SiC) attributable to SiC of 2θ=35.8±0.2° to a peak intensity I(Si) attributable to Si of 2θ=28.4±0.2° satisfies a relation of I(SiC) / I(Si)≦0.03, when x-ray diffraction using Cu—Kα ray. As a result, there is provided a negative electrode material for a secondary battery with a non-aqueous electrolyte that is superior in first efficiency and cycle durability to a conventional negative electrode material.

Owner:SHIN ETSU CHEM IND CO LTD

Heterocyclic compound

InactiveUS20120193613A1Reduce the driving voltageImprove current efficiencyOrganic chemistryElectroluminescent light sourcesHydrogenDibenzofuran

Provided is a novel heterocyclic compound which can be used for a light-emitting element, as a host material of a light-emitting layer in which a light-emitting substance is dispersed. A heterocyclic compound represented by a general formula (G1) is provided. In the formula, A represents any of a substituted or unsubstituted dibenzothiophenyl group, a substituted or unsubstituted dibenzofuranyl group, and a substituted or unsubstituted carbazolyl group, R11 to R19 separately represent any of hydrogen, an alkyl group having 1 to 4 carbon atoms, and a substituted or unsubstituted aryl group having 6 to 13 carbon atoms, and Ar represents a substituted or unsubstituted arylene group having 6 to 13 carbon atoms.

Owner:SEMICON ENERGY LAB CO LTD

Microwave curing process for ceramic material gel casting

The invention relates to a microwave curing process for ceramic material gel casting, which comprises the following steps: firstly, dissolving organic monomer and crosslinker in sequence in the solvent, adding a dispersant and obtaining pre-prepared liquid; adjusting the pH value of the pre-prepared liquid to be 7-11, adding ceramic powder to the pre-prepared liquid, stirring the mixture stronglyand mechanically for 1h and obtaining even slurry; adding an initiating agent and a catalytic agent to the slurry and mixing evenly; soon afterward, removing the gas in the slurry by vacuum; casting the slurry into a module; placing the module packed with the slurry in a microwave oven for a curing process, and obtaining a gel casting ceramic body; and drying the ceramic body, and then sintering at the temperature of 1200 DEG C-2200 DEG C for 1-6h, and finally obtaining a ceramic product. Compared with the conventional gel casting curing method, the microwave curing process has the advantagesthat the process has fast heating speed and uniform temperature field, reduces the activation energy of reaction, accelerates the reaction rate, causes the polymerization reaction to be finished rapidly and achieves the purpose of high speed and high quality moulding of materials.

Owner:OCEAN UNIV OF CHINA

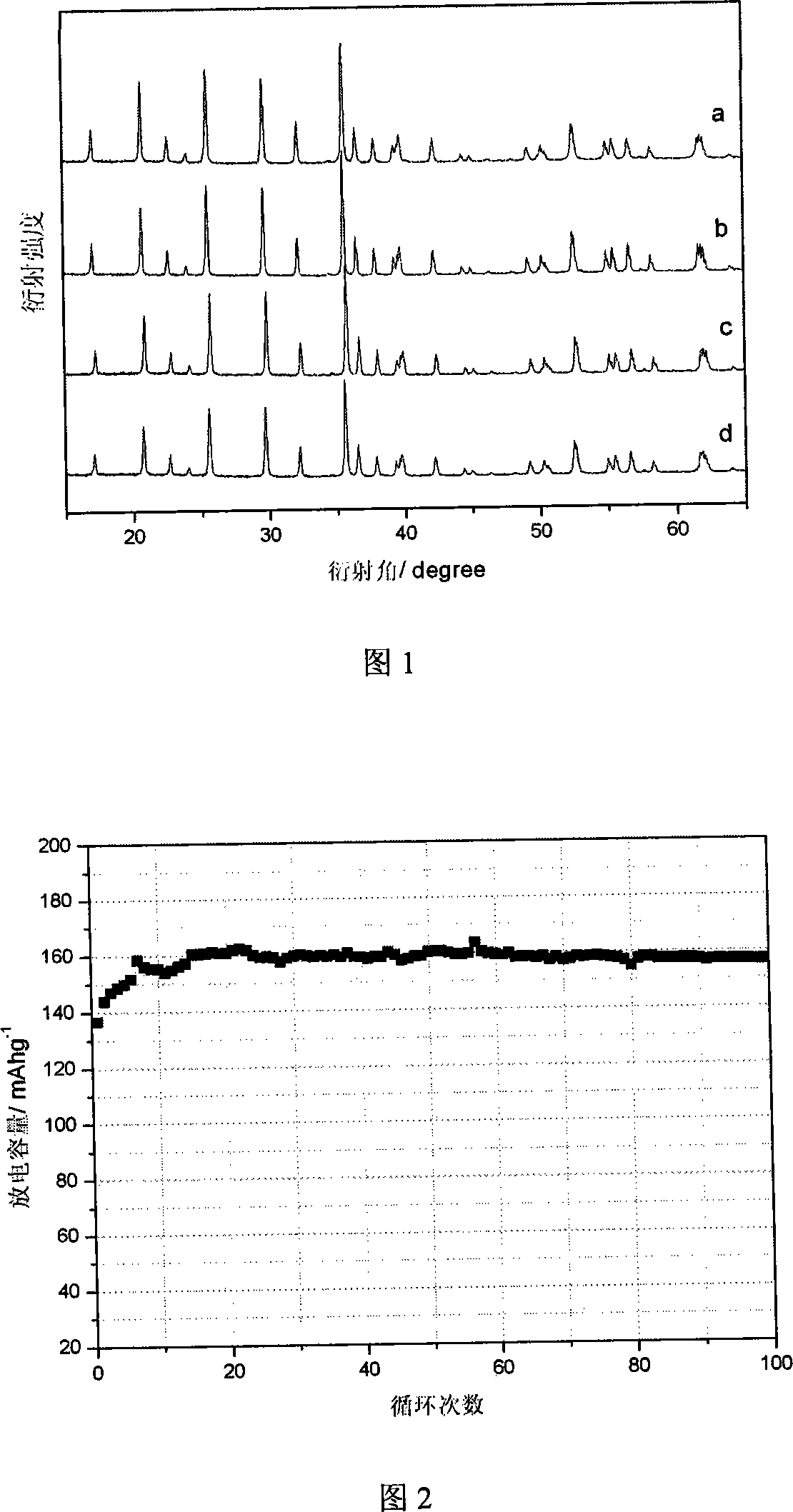

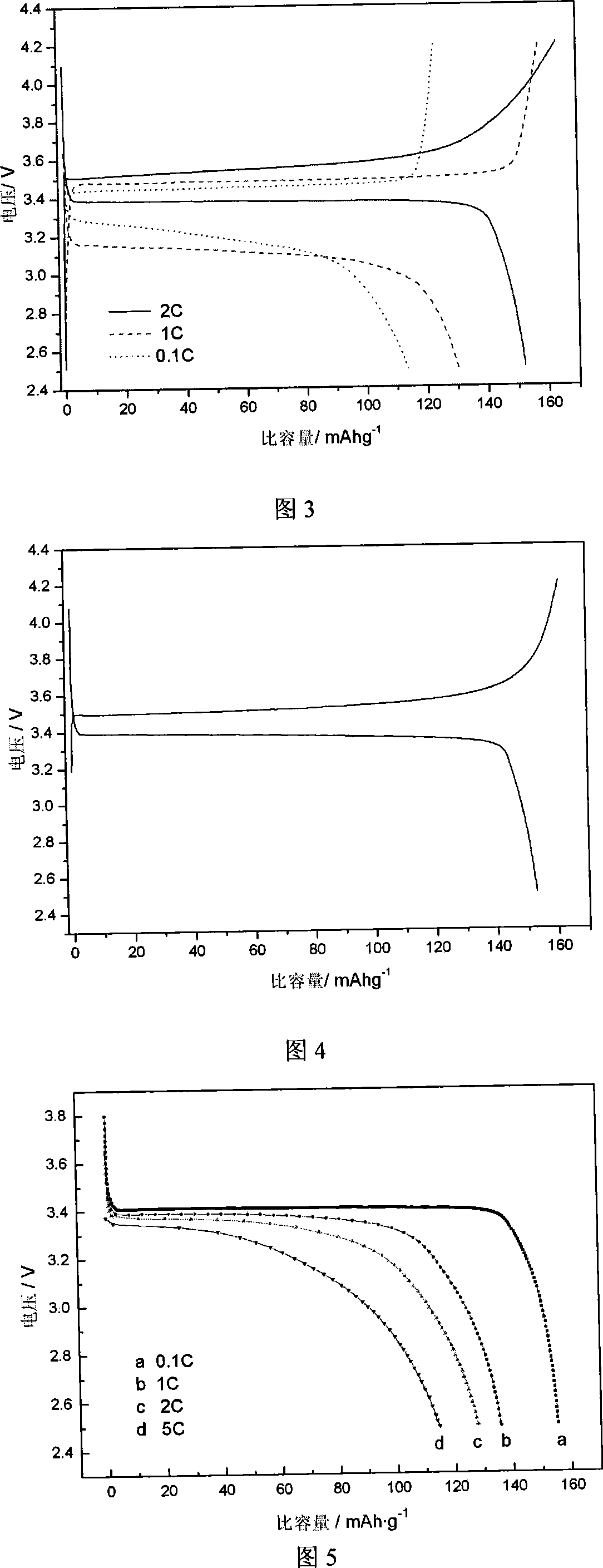

Lithium iron phosphate-carbon nanotube composite material, preparation method, and application thereof

ActiveCN102427130AThe phase is pure and the crystal form is goodLow resistivityCell electrodesLithium iron phosphateCarbon nanotube

The present invention discloses a lithium iron phosphate-carbon nanotube (LiFePO4-CNTs) composite material. The composite material comprises LiFePO4 particles, a nano-carbon layer and CNTs, wherein the nano-carbon layer is positioned outside the LiFePO4 particles, and the CNTs grow in the nano-carbon layer in an in situ growth manner by a chemical vapor deposition (CVD) process. In addition, the present invention further discloses a preparation method for the composite material. The method comprises: uniformly mixing and coating the prepared LiFePO4 precursor powder, a catalyst and liquid carbon source to prepare into the slurry; adopting a spraying feeding device to convey the slurry to a high-temperature reaction furnace to form a floating CVD process; carrying out heat insulation calcination for the resulting mixture so as to complete the treatments of granulation of the LiFePO4 precursor, in situ growth and coating of the CNTs and synthesis sintering of the LiFePO4 in one step, such that the uniform nano-carbon layer and the CNTs are formed on the surfaces of the LiFePO4 particles. In addition, the present invention further discloses an application of the composite material in battery preparation. According to the composite material of the present invention, the nano-carbon layer and the CNTs have good crystallization, the total carbon content is low, the electrical conductivity and the specific capacity are high so as to substantially increase the rate performance.

Owner:HUBEI RT ADVANCED MATERIALS CO LTD

Method for synthesizing LiFePO4/C material based on chemical gas phase sediment auxiliary solid phase method

InactiveCN101237039AControl chemical compositionSmall particle sizeElectrode manufacturing processesChemical vapor deposition coatingGas phasePhosphate

The invention relates to a method for synthesizing LiFePO4 / C material by chemical vapor deposition supporting the solid phase reaction method, namely, the method for preparing carbon coating lithium iron battery anode material, belonging to the Li-ion battery material preparation art technical field. The characteristics of the method for synthesizing LiFePO4 / C materials by solid phase and auxiliary chemical vapor deposition are that auxiliary chemical vapor deposition supporting the solid phase reaction method is adopted to synthesize the carbon coating phosphate lithium iron, namely, the LiFePO4 / C material. In the method for synthesizing LiFePO4 / C material by chemical vapor deposition supporting the solid phase reaction method, a precursor comprising raw materials of lithium, iron and phosphor is adopted to prepare the carbon coating phosphate lithium iron after being blended, grinded by a globe mill, treated by preheating and calcined as well as vapor deposition. The method for synthesizing LiFePO4 / C material by chemical vapor deposition supporting the solid phase reaction method has the advantages that the chemical composition, carbon contents and grain size of LiFePO4 can be controlled effectively; the Li-ion battery anode material prepared has sound conductive performance and can improve the charge-discharge rate and cycling performance of the material.

Owner:SHANGHAI CHIYUAN NEW MATERIAL TECH

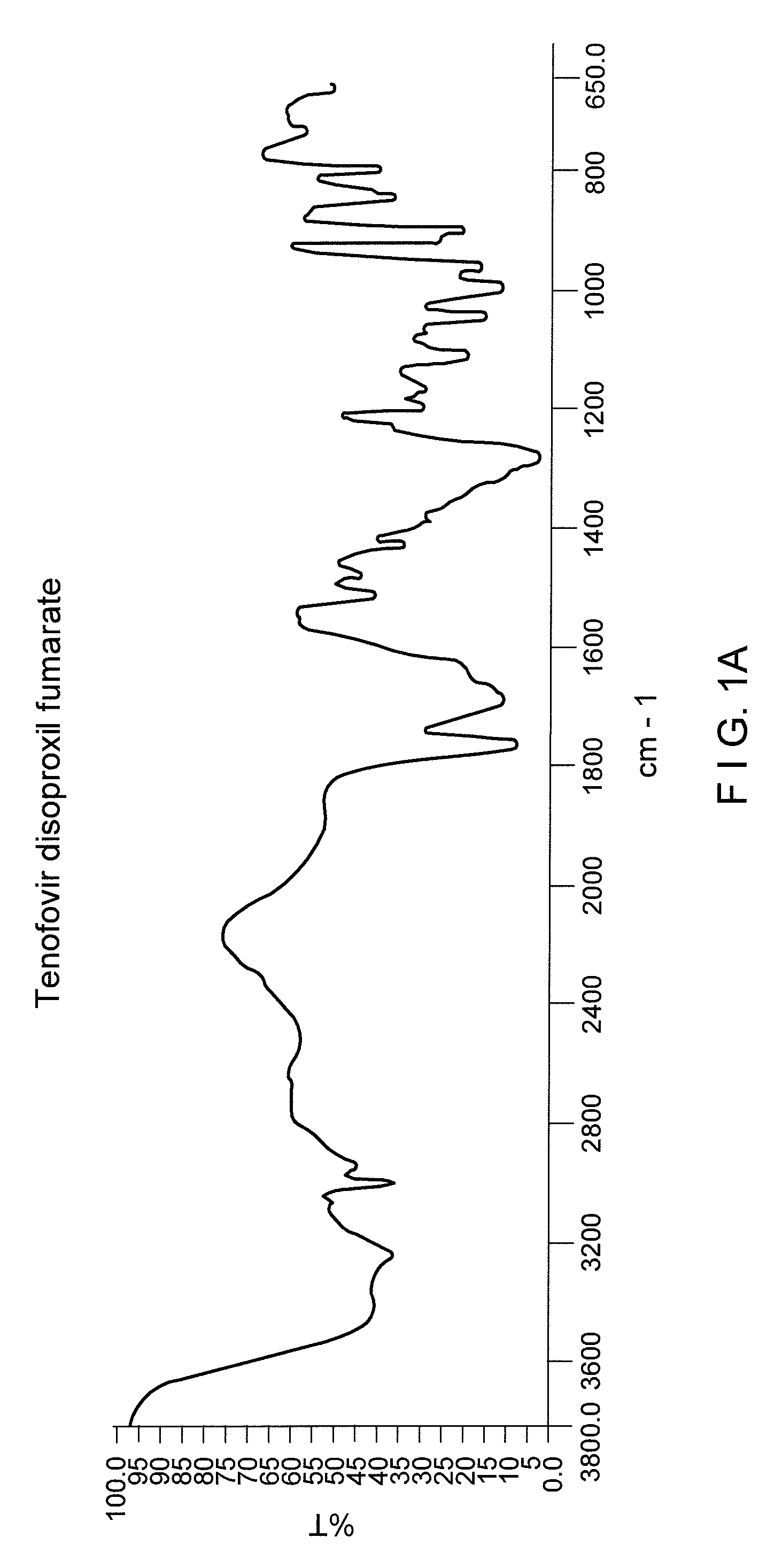

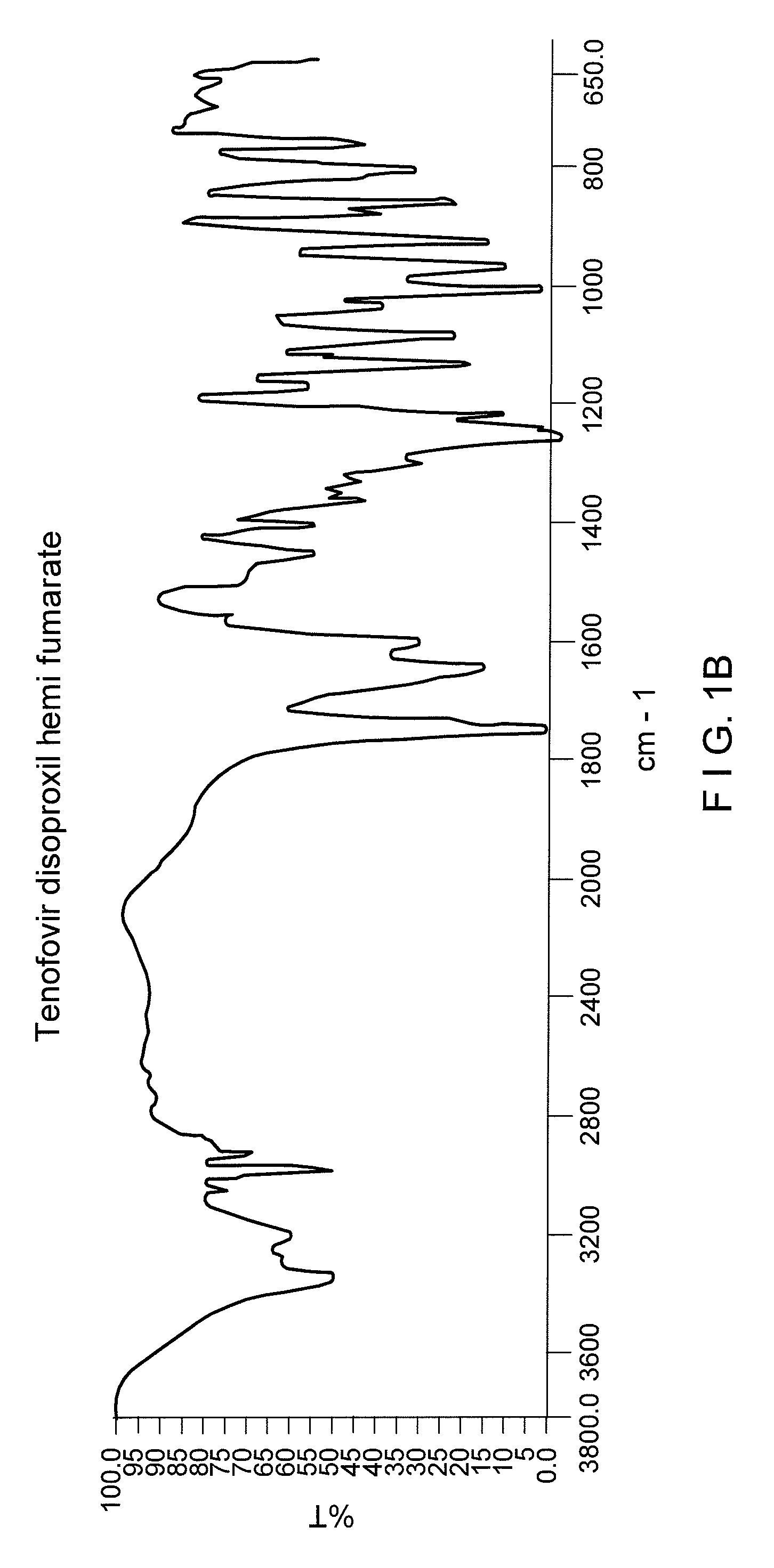

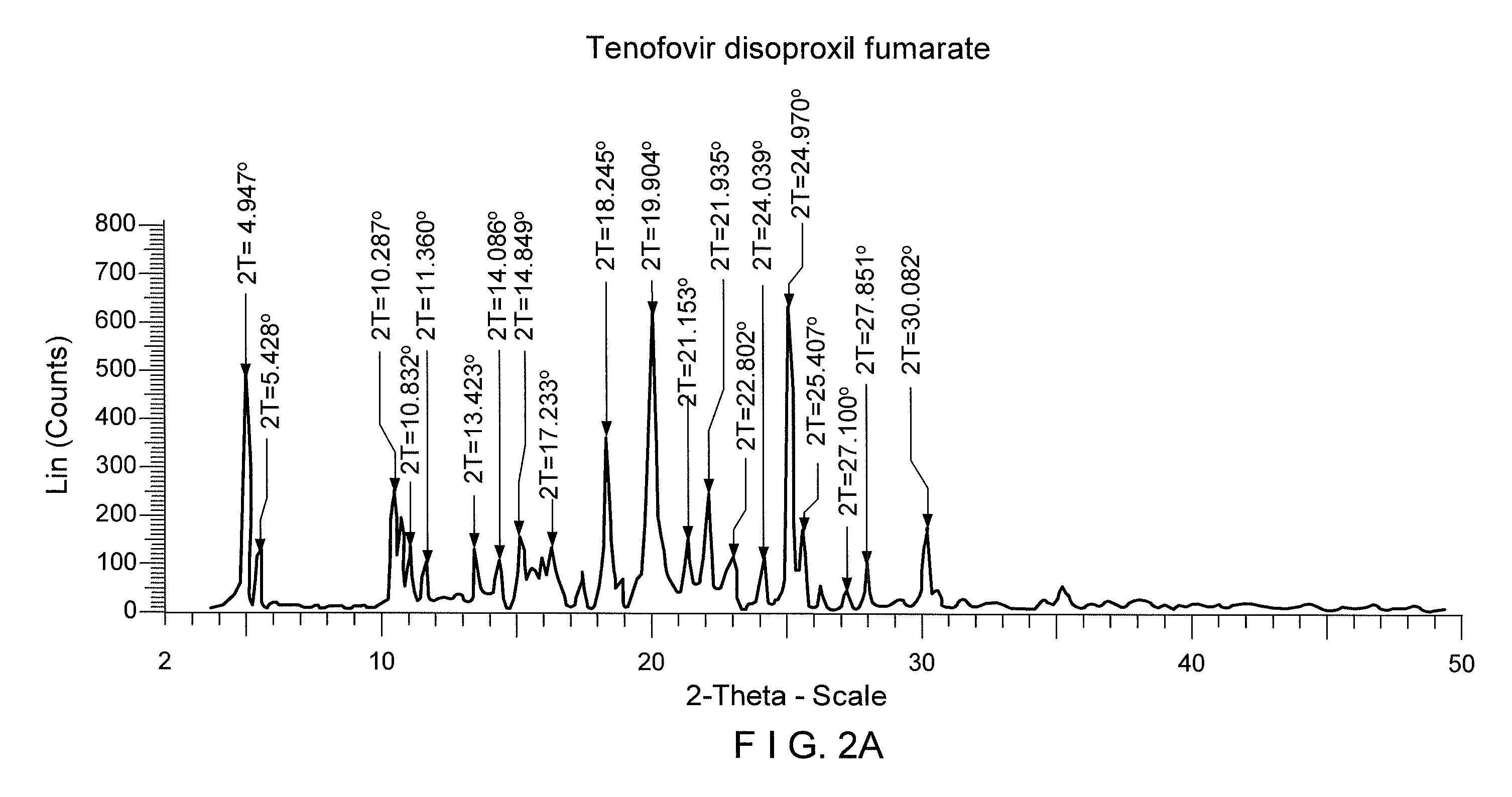

Process for the prepartion of tenofovir

ActiveUS20090286981A1Improved yieldIncrease productionPhosphorus organic compoundsTenofovirMedicinal chemistry

The present invention relates to novel Tenofovir disoproxil hemifumarate salt, which is prepared by dealkylation of Phosphonate esters by using mineral acids followed by esterification and crystallization to give crystalline Tenofovir disoproxil. The Tenofovir disoproxil is further converted to fumarate salts with improved yield.

Owner:MYLAN LAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com