Patents

Literature

1896 results about "Carbon coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

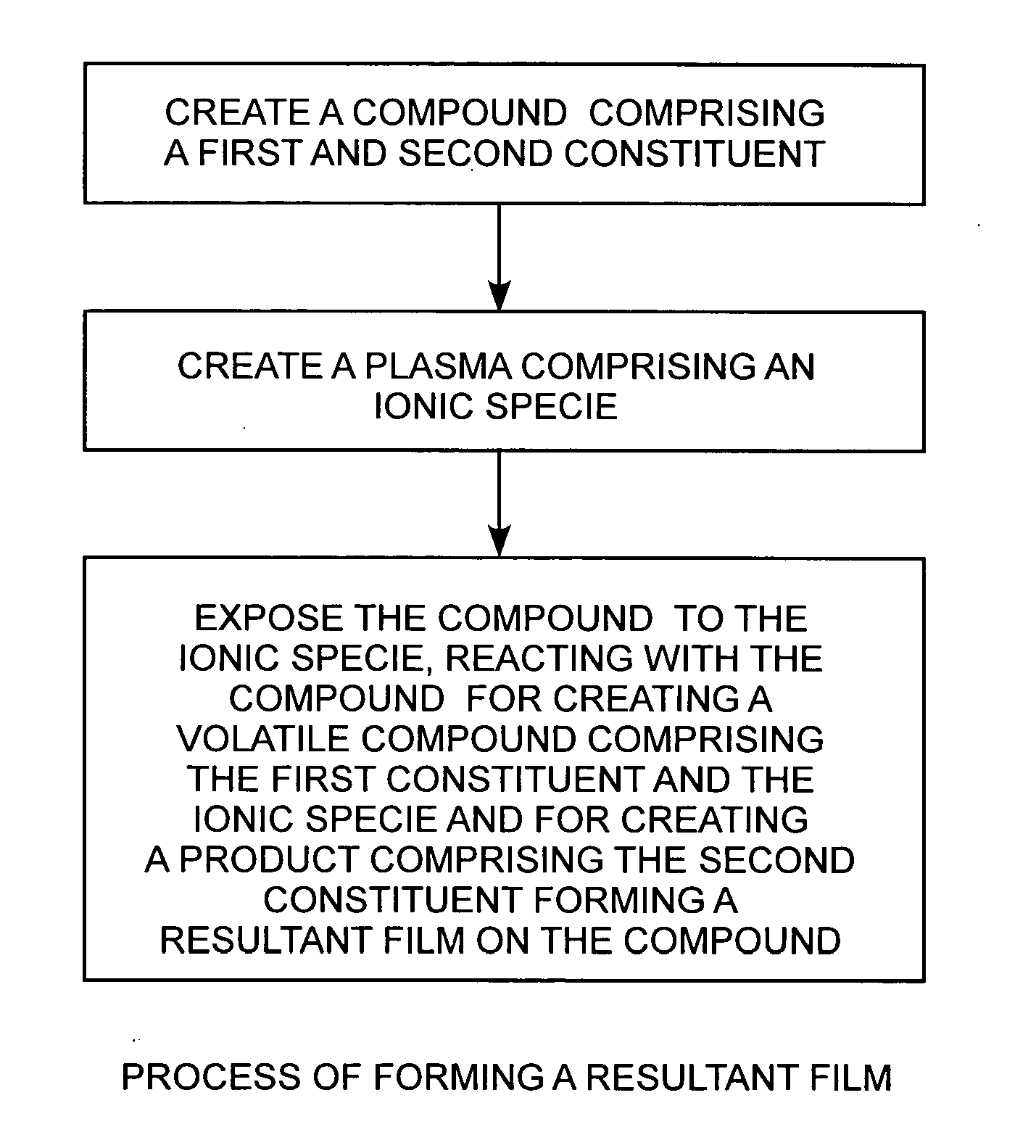

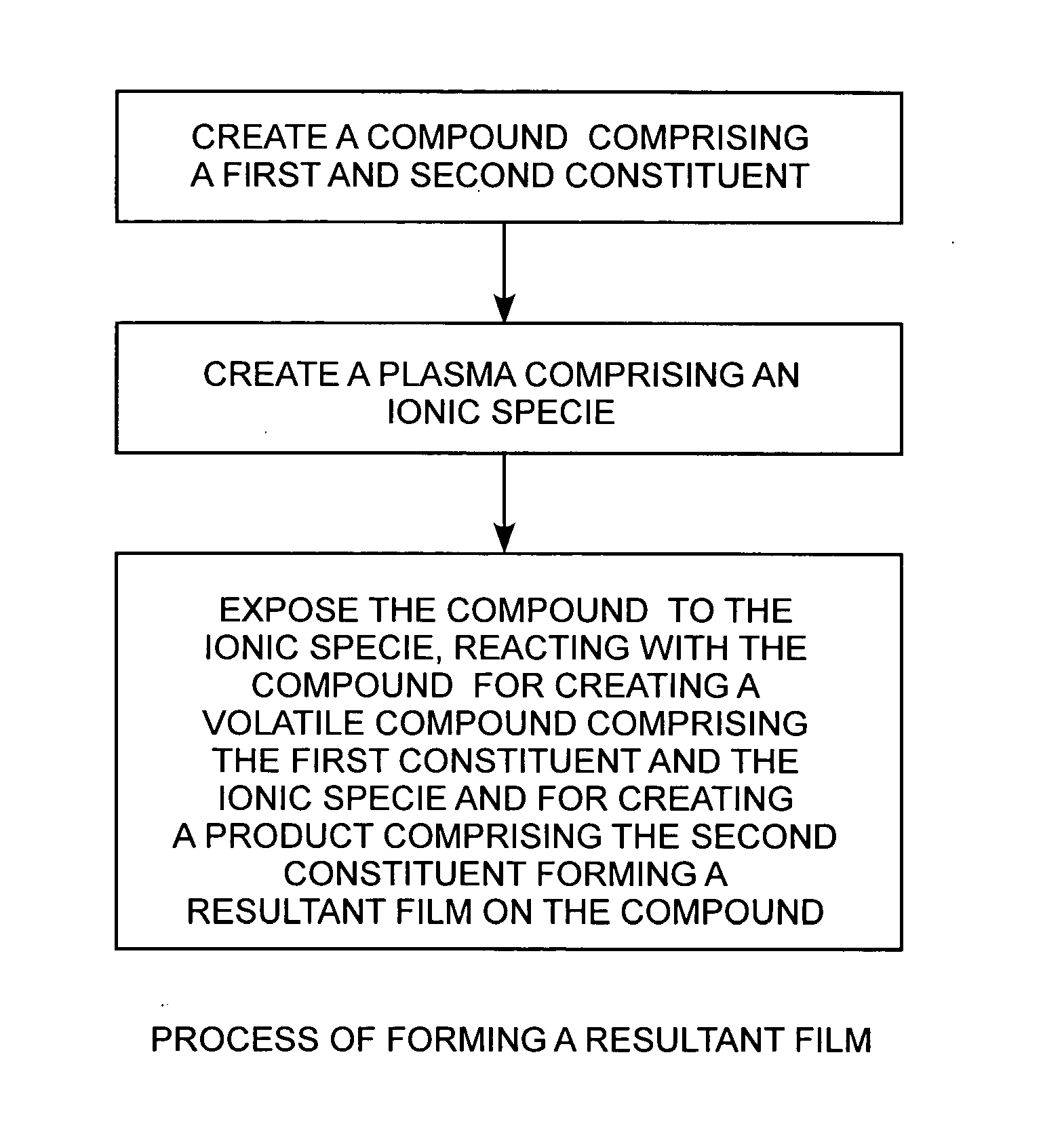

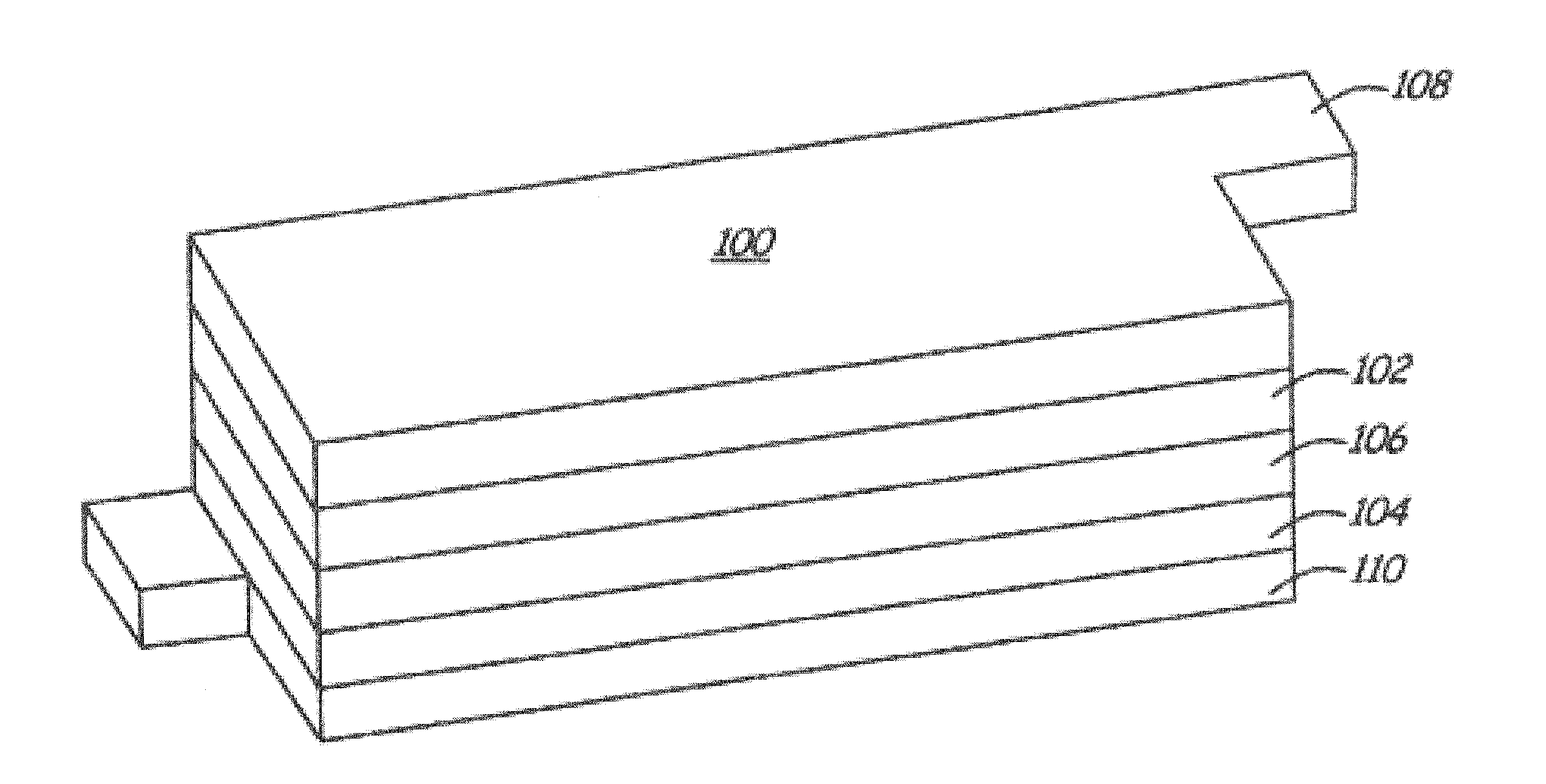

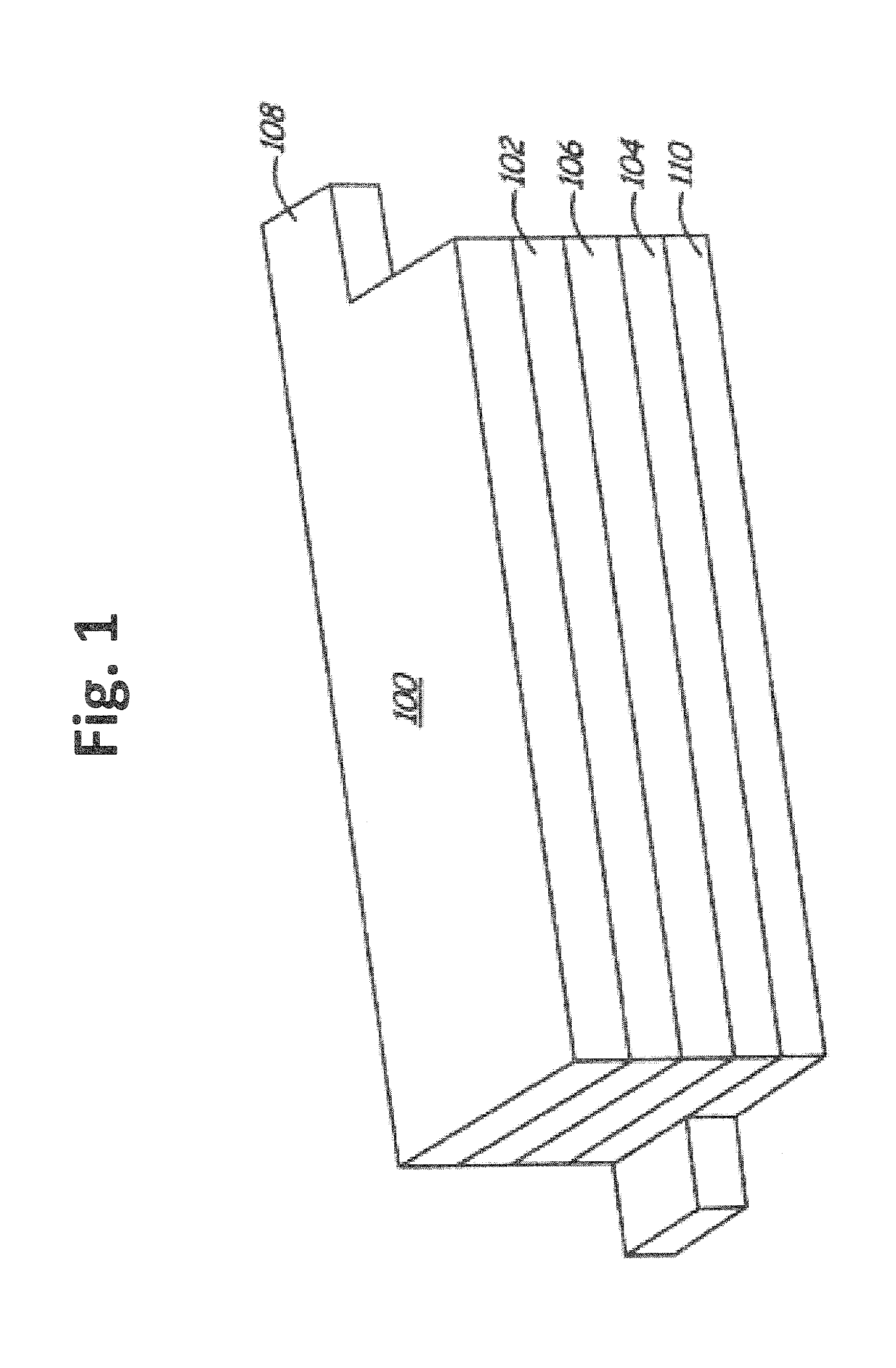

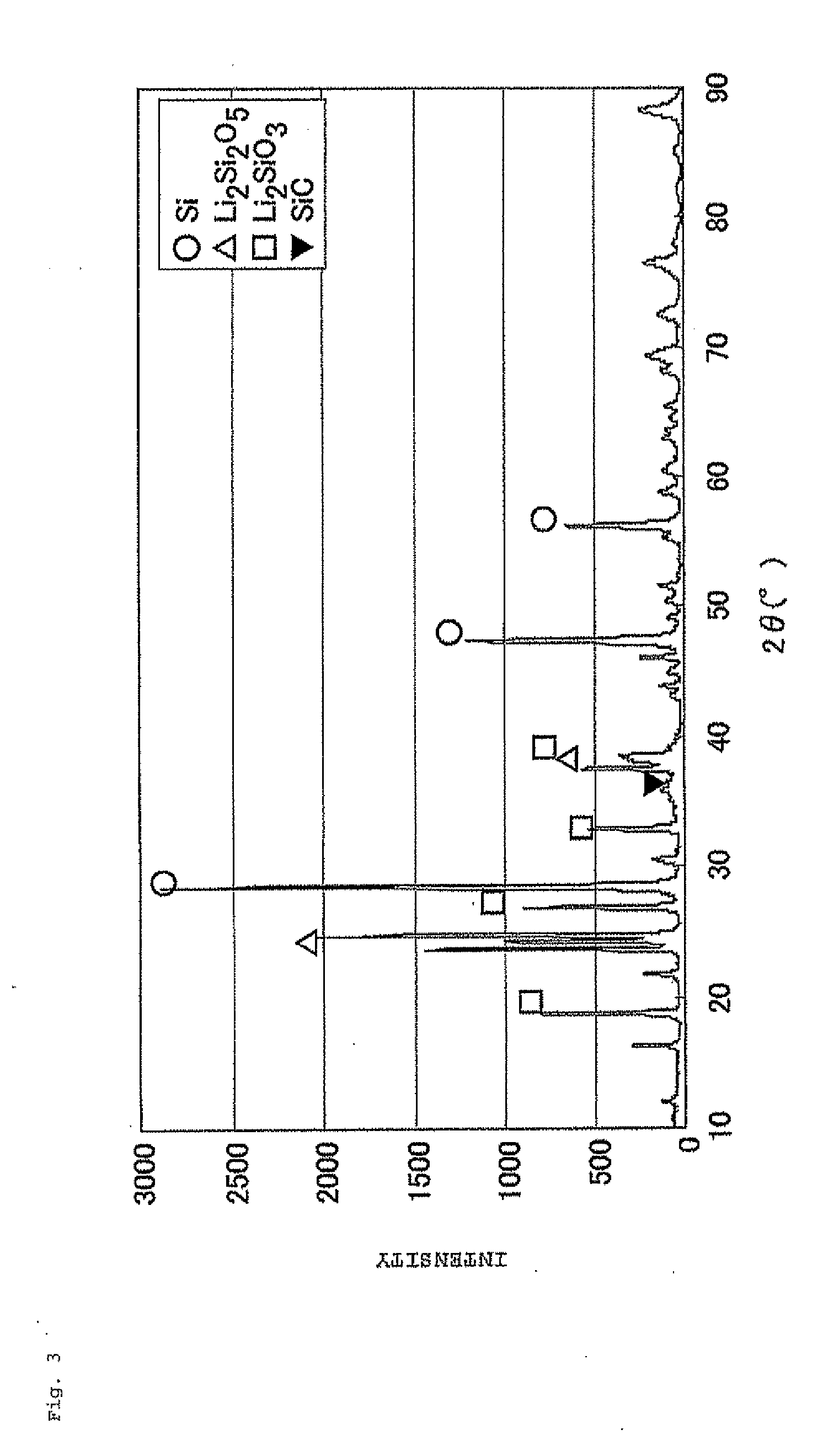

Method for producing carbon surface films by plasma exposure of a carbide compound

InactiveUS20060068125A1Reduce frictionEasy to controlChemical vapor deposition coatingFlexible microstructural devicesCarbon filmCarbon coating

Reactive halogen-ion plasmas, having for example, generating chloride ions, generated from low-pressure halogen gases using a radio-frequency plasma are employed for producing low-friction carbon coatings, such as a pure carbon film, at or near room temperature on a bulk or thin film of a compound, such as titanium carbide.

Owner:THE AEROSPACE CORPORATION

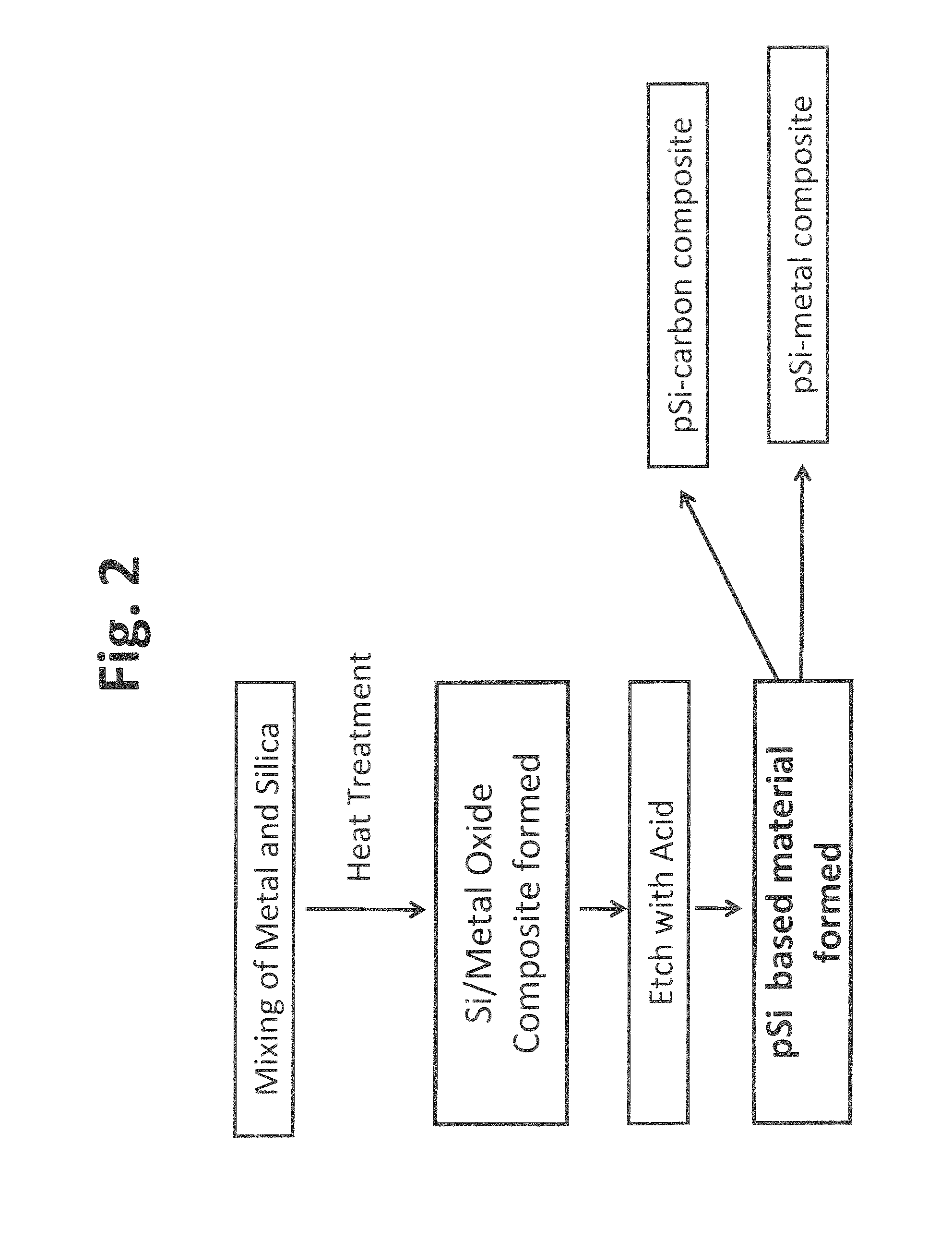

Porous silicon based anode material formed using metal reduction

A porous silicon based material comprising porous crystalline elemental silicon formed by reducing silicon dioxide with a reducing metal in a heating process followed by acid etching is used to construct negative electrode used in lithium ion batteries. Gradual temperature heating ramp(s) with optional temperature steps can be used to perform the heating process. The porous silicon formed has a high surface area from about 10 m2 / g to about 200 m2 / g and is substantially free of carbon. The negative electrode formed can have a discharge specific capacity of at least 1800 mAh / g at rate of C / 3 discharged from 1.5V to 0.005V against lithium with in some embodiments loading levels ranging from about 1.4 mg / cm2 to about 3.5 mg / cm2. In some embodiments, the porous silicon can be coated with a carbon coating or blended with carbon nanofibers or other conductive carbon material.

Owner:IONBLOX INC

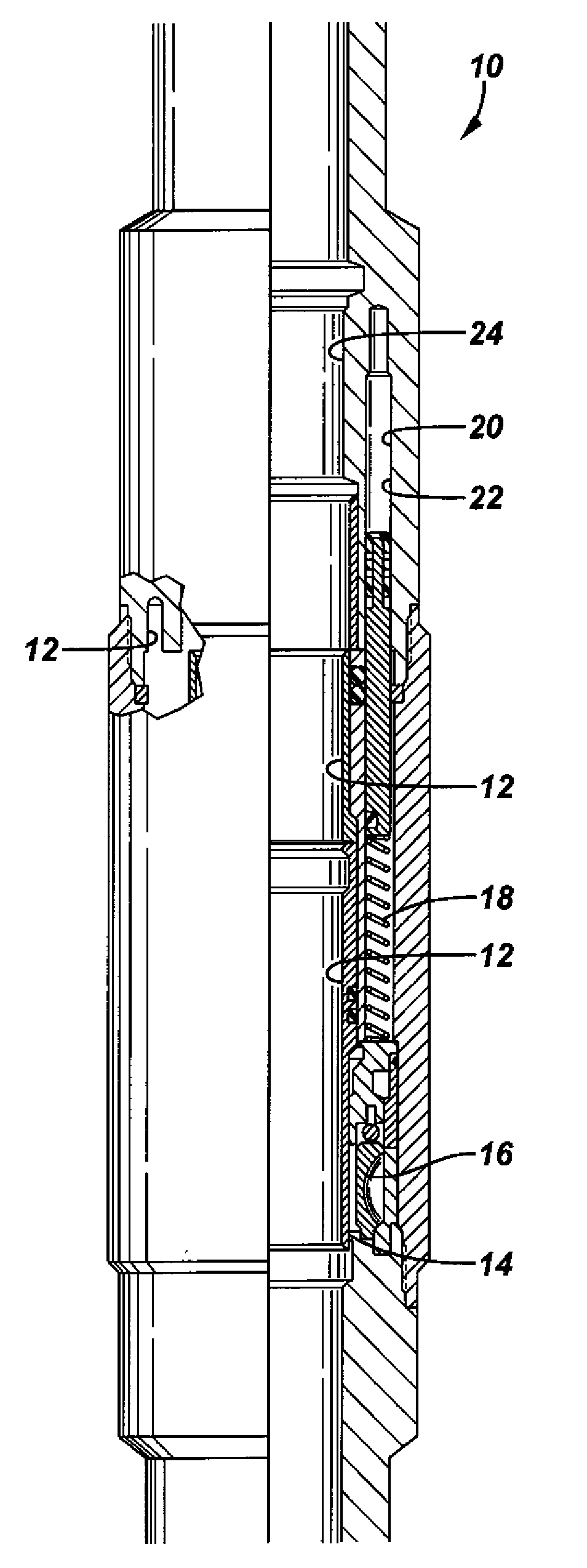

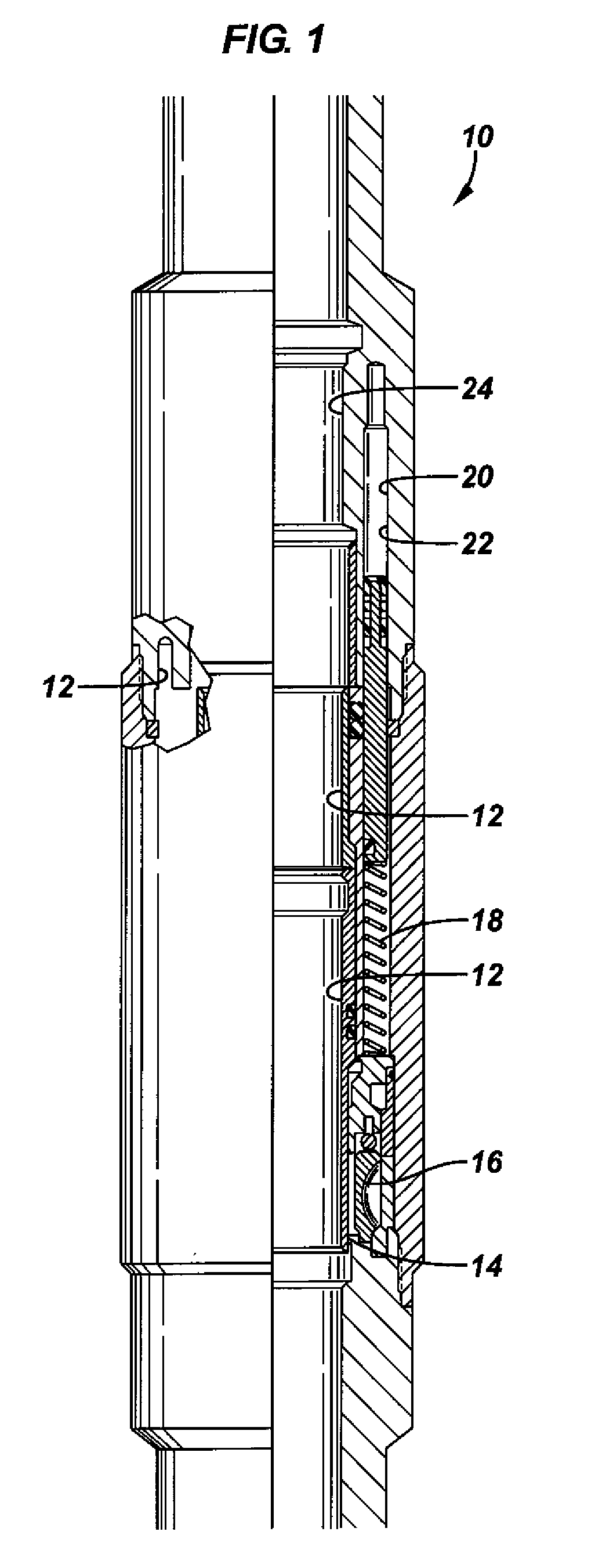

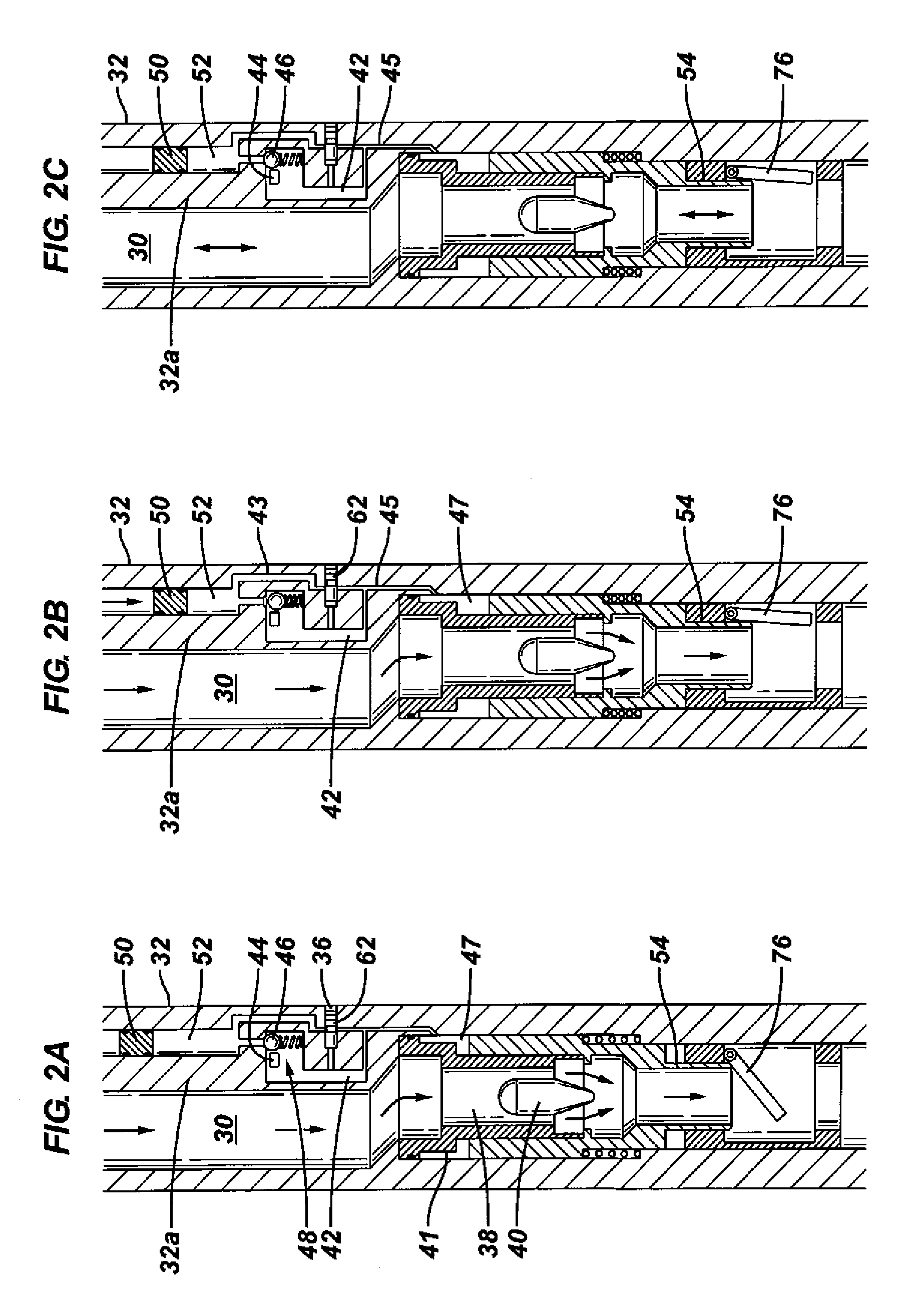

Downhole oilfield apparatus comprising a diamond-like carbon coating and methods of use

Downhole apparatus and methods of using the apparatus are described, the apparatus comprising at least one metallic component having a DLC coating thereon, the coating present at least on one or more internal passageways of the base metal or alloy to be exposed to downhole environments. Methods of using an apparatus in downhole oilfield operations are also described. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims.

Owner:SCHLUMBERGER TECH CORP

Method of depositing silicon on carbon nanomaterials

InactiveUS20120264020A1Increase surface areaHigh pore volumeMaterial nanotechnologyLiquid surface applicatorsCarbon coatingGas phase

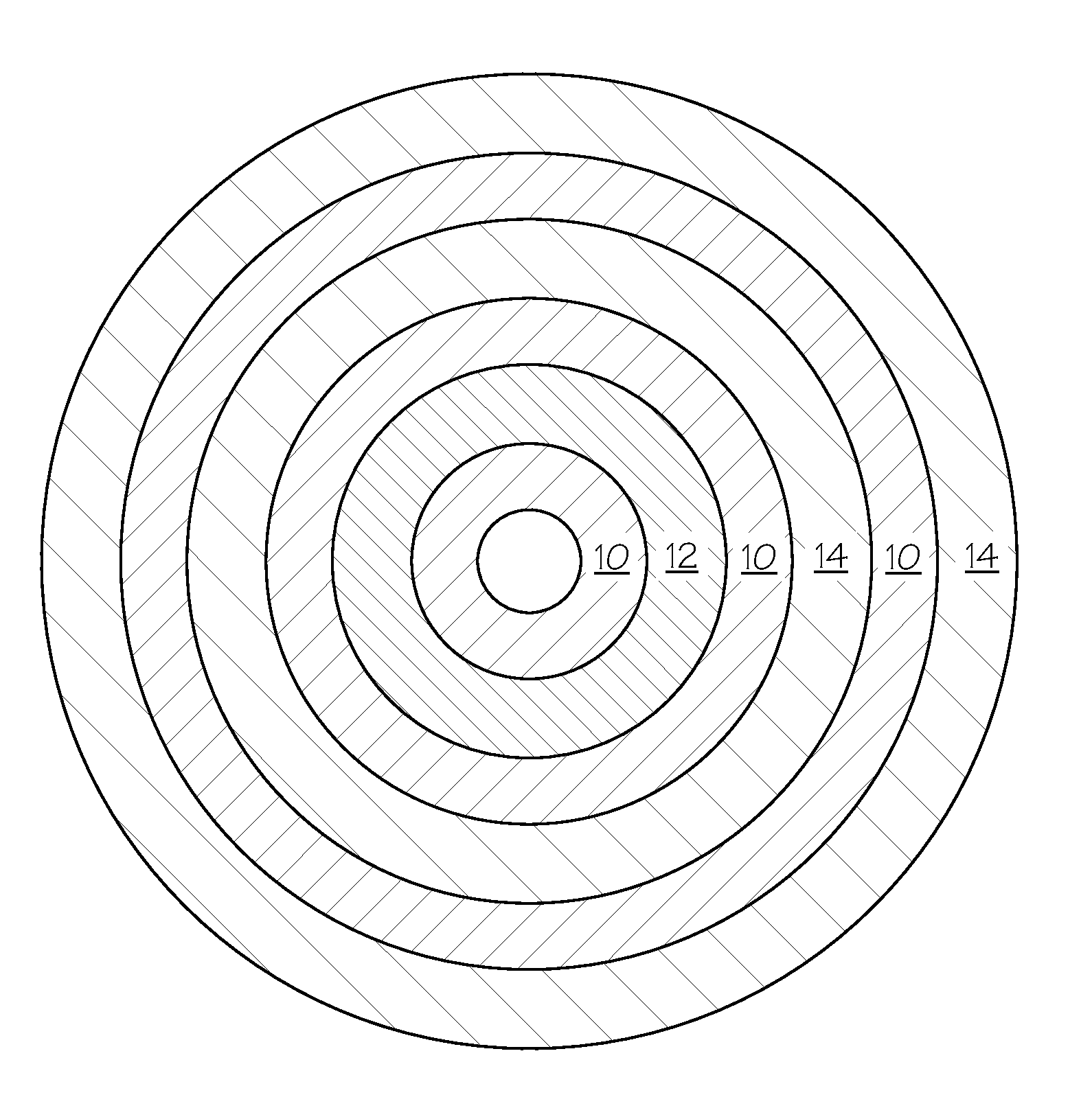

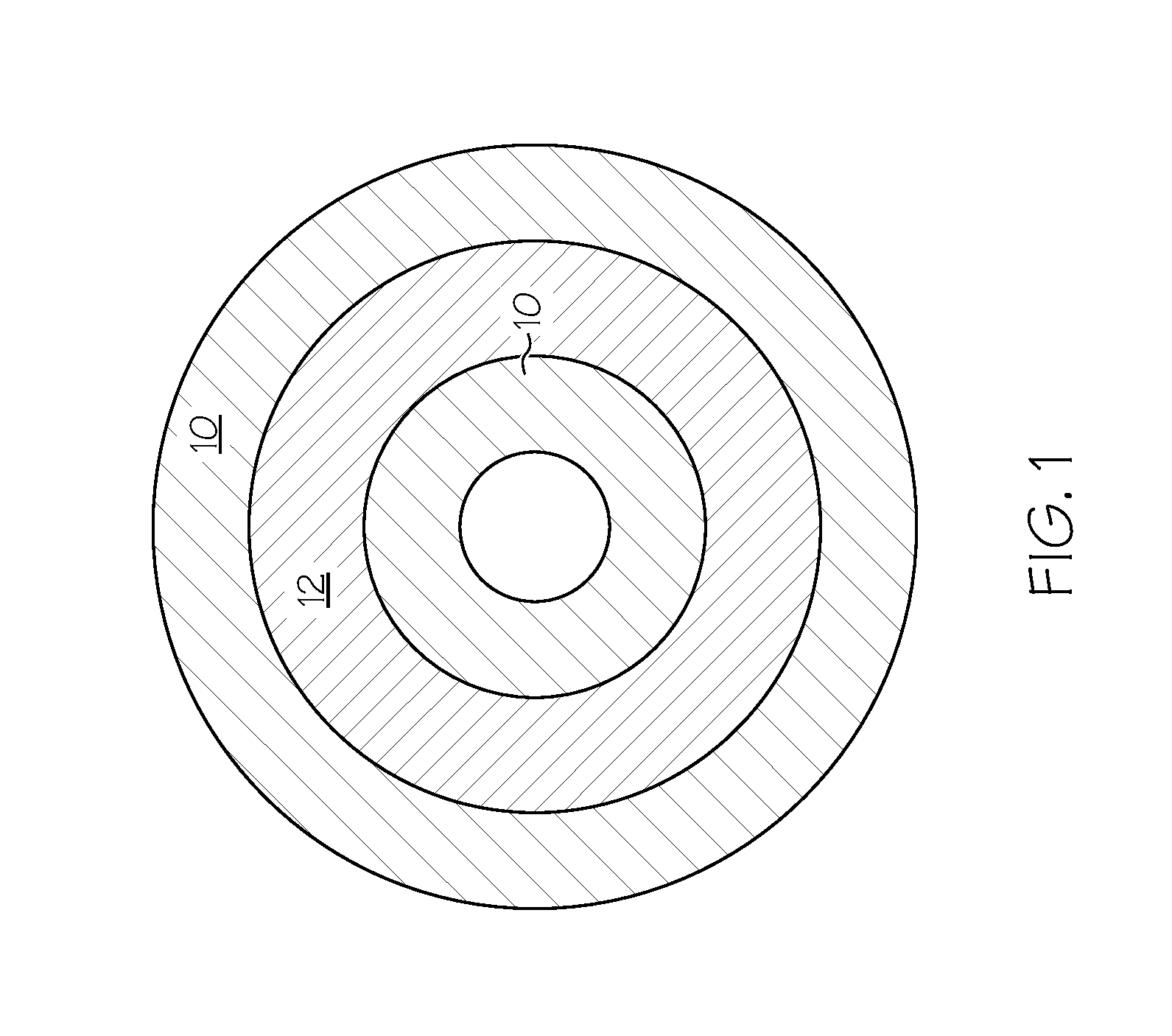

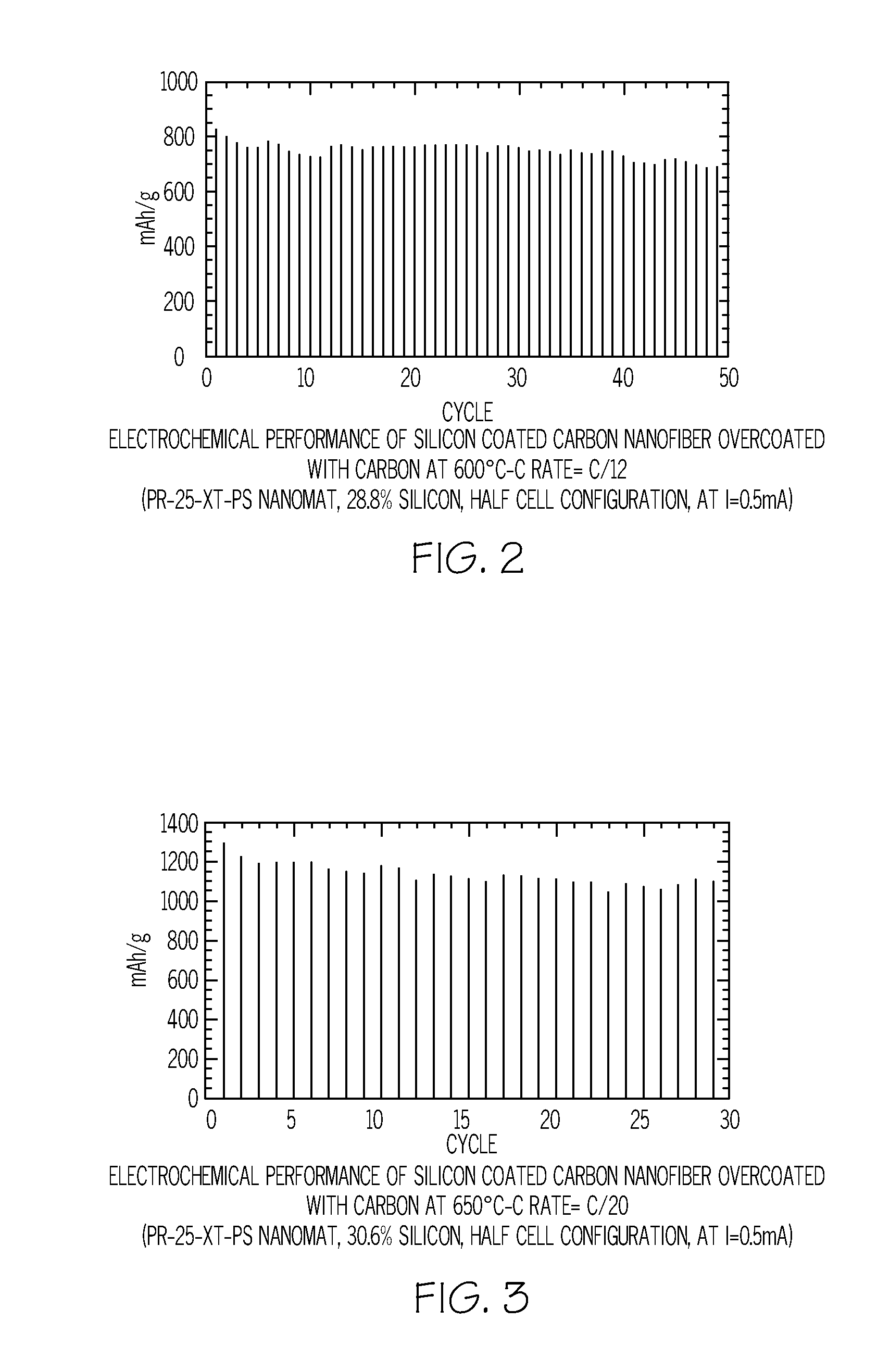

A method of depositing silicon on carbon nanomaterials such as vapor grown carbon nanofibers, nanomats, or nanofiber powder is provided. The method includes flowing a silicon-containing precursor gas in contact with the carbon nanomaterial such that silicon is deposited on the exterior surface and within the hollow core of the carbon nanomaterials. A protective carbon coating may be deposited on the silicon-coated nanomaterials. The resulting nanocomposite materials may be used as anodes in lithium ion batteries.

Owner:APPLIED SCI

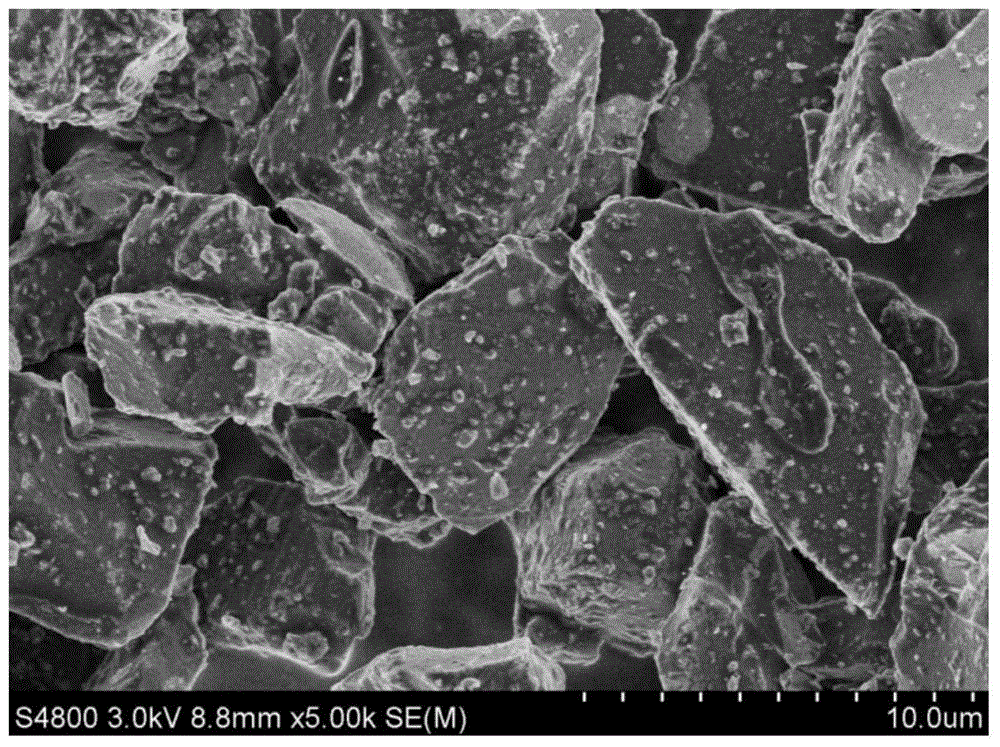

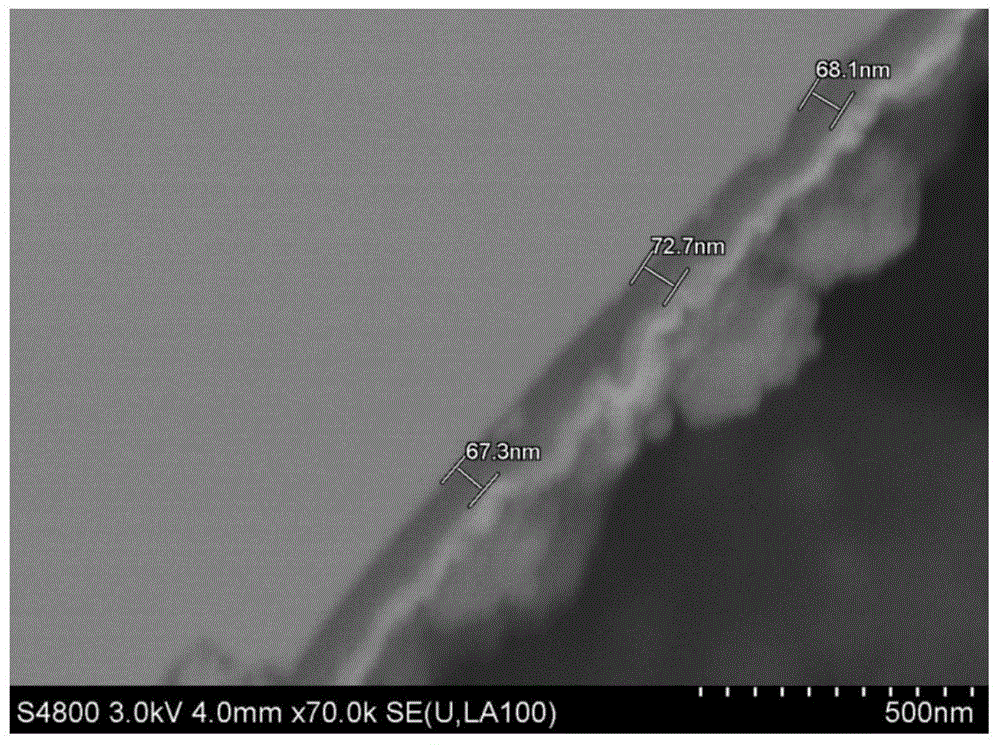

Silicon-carbon composite negative electrode material for lithium ion battery and preparation method thereof

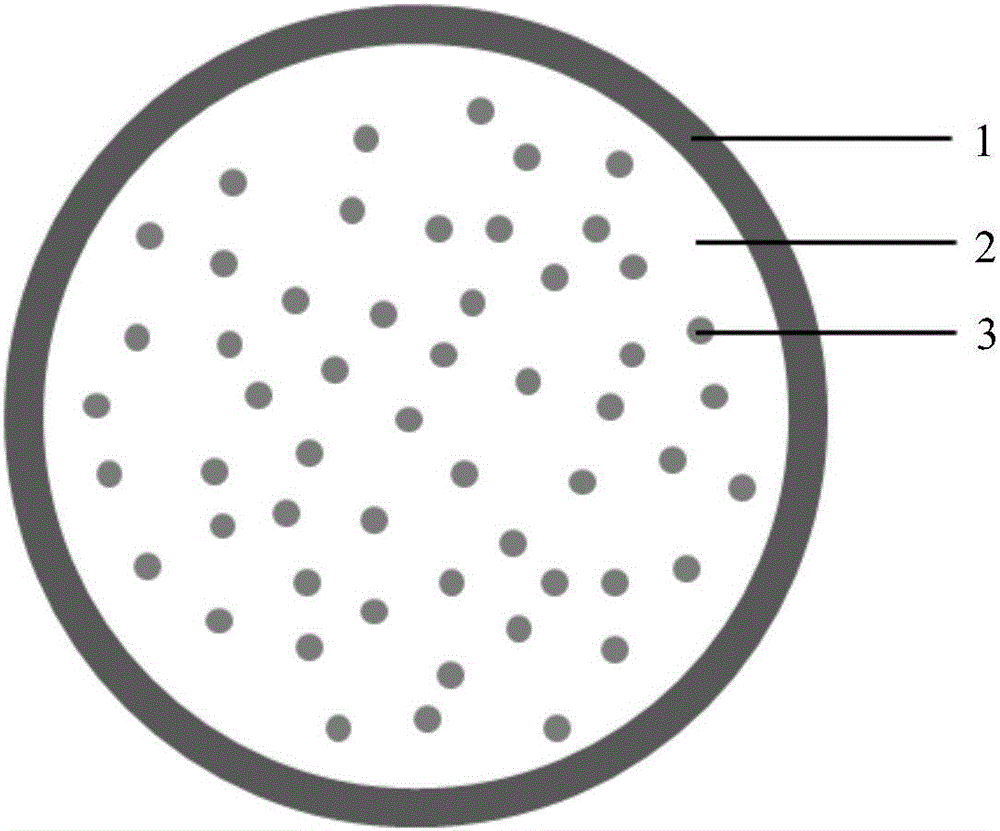

ActiveCN103474667AImprove cycle performanceHigh charge and discharge capacityMaterial nanotechnologyCell electrodesCarbon compositesCarbon layer

The invention relates to a silicon-carbon composite negative electrode material and a preparation method thereof. The silicon-carbon composite negative electrode material successively comprises nano silicon / graphite particles, a first carbon coating layer and an organic cracking carbon layer from inside to outside. The nano silicon / graphite particles are globular or globular-like composite particles formed by employing graphite as an inner core of a volume expansion buffer substrate and coating a nano silicon particle layer; the first carbon coating layer comprises carbon nanotubes and / or amorphous carbon, the carbon nanotubes and / or amorphous carbon are interspersed in a gap network formed by gaps of the nano silicon particles and / or are coated outside the nano silicon particle layer, so that the nano silicon is tightly wrapped between the carbon nanotubes and / or between the carbon nanotubes and the graphite substrate, and besides, the material ion conductivity is effectively enhanced; the organic cracking carbon layer is an outermost coating layer of the silicon-carbon composite negative electrode material. The silicon-carbon composite negative electrode material has excellent cycle performance, excellent multiplying power charging and discharging performance and lower volume expansion effect.

Owner:BTR NEW MATERIAL GRP CO LTD

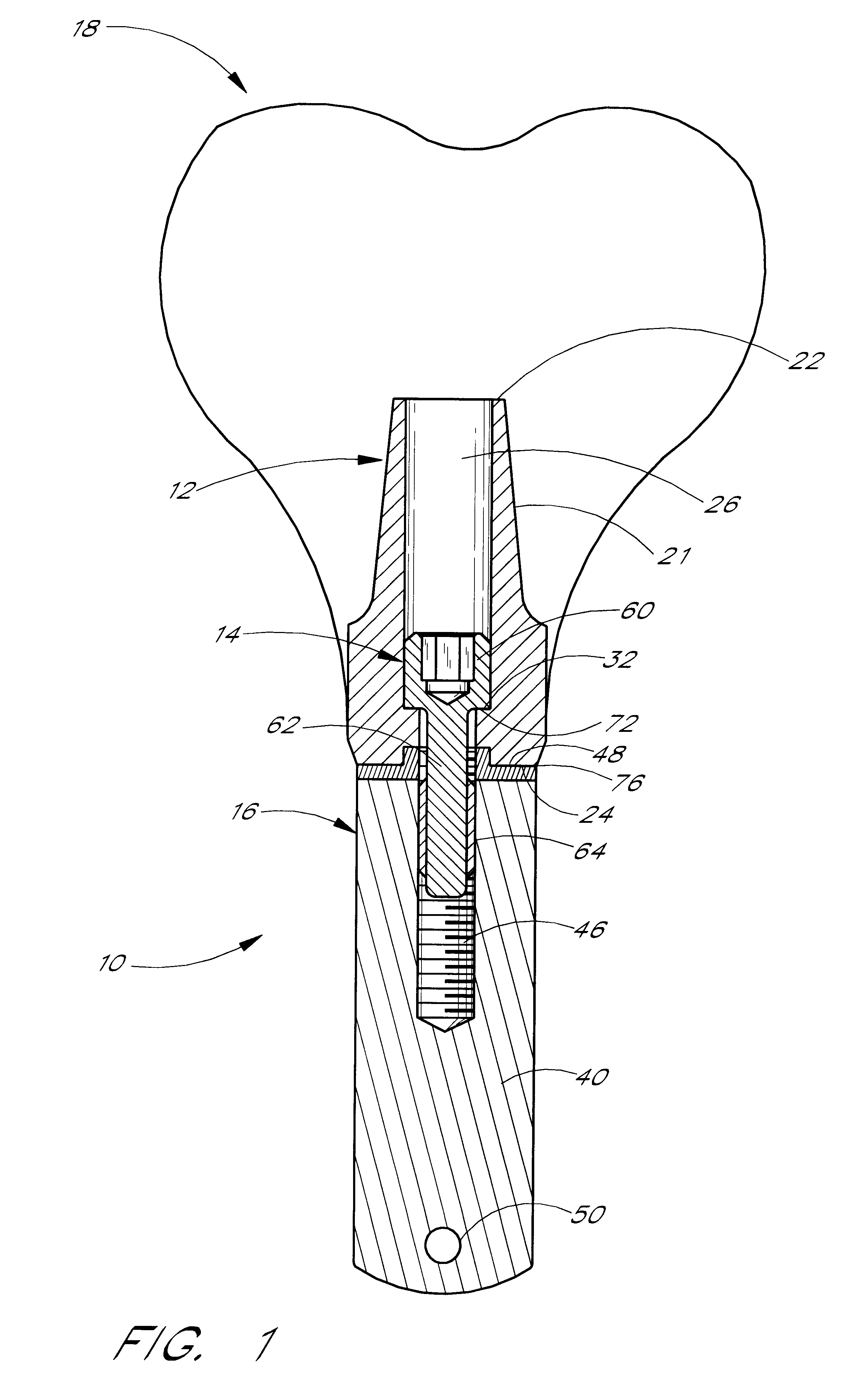

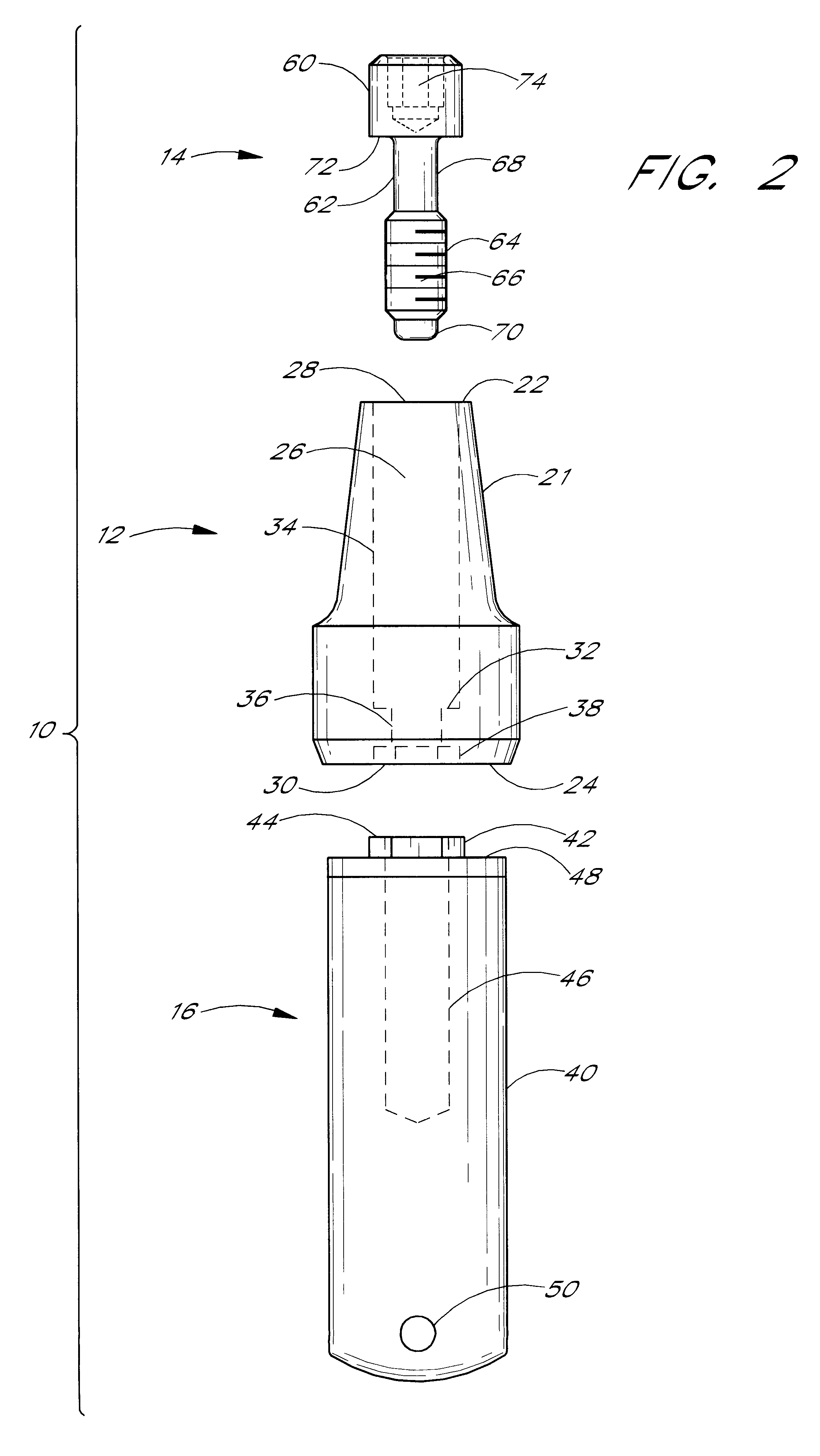

Diamond-like carbon coated dental retaining screws

The invention relates to a coated dental screw for retaining and securing components of a dental prosthetic implant stack. The screw is coated with a hard carbon coating / film to provide a low friction surface finish which advantageously results in improved preloading of the screw, and hence a high clamping force between the components of the dental prosthetic implant stack. The coating can comprise diamond-like carbon (DLC), amorphous diamond, crystalline diamond, or a combination thereof. The dental screw can include abutment retaining screws and prosthesis retaining screws. Other advantages provided by the hard carbon coating include high mechanical surface hardness, biocompatibilty, corrosion resistance, chemical inertness and low cost.

Owner:NOBEL BIOCARE SERVICES AG

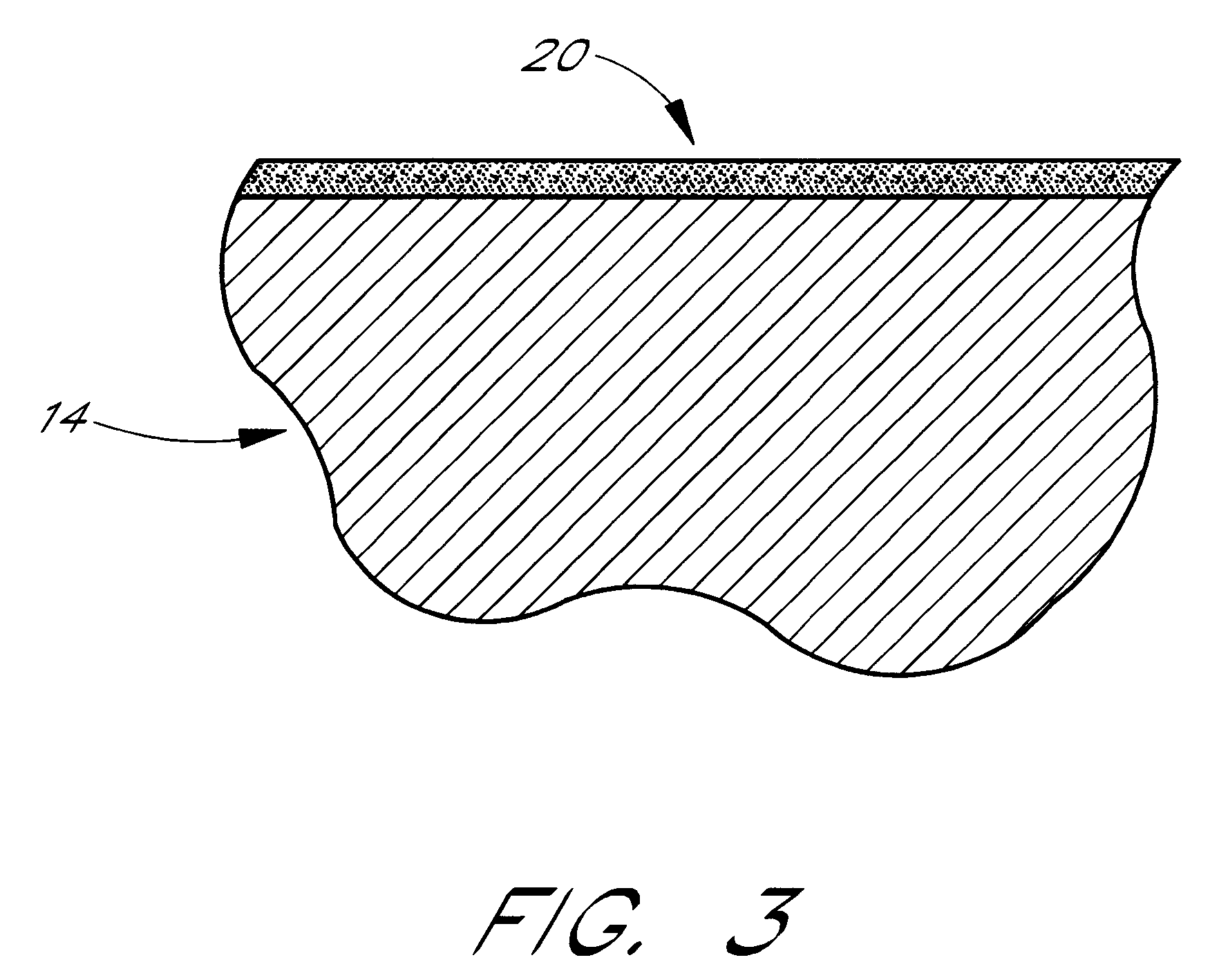

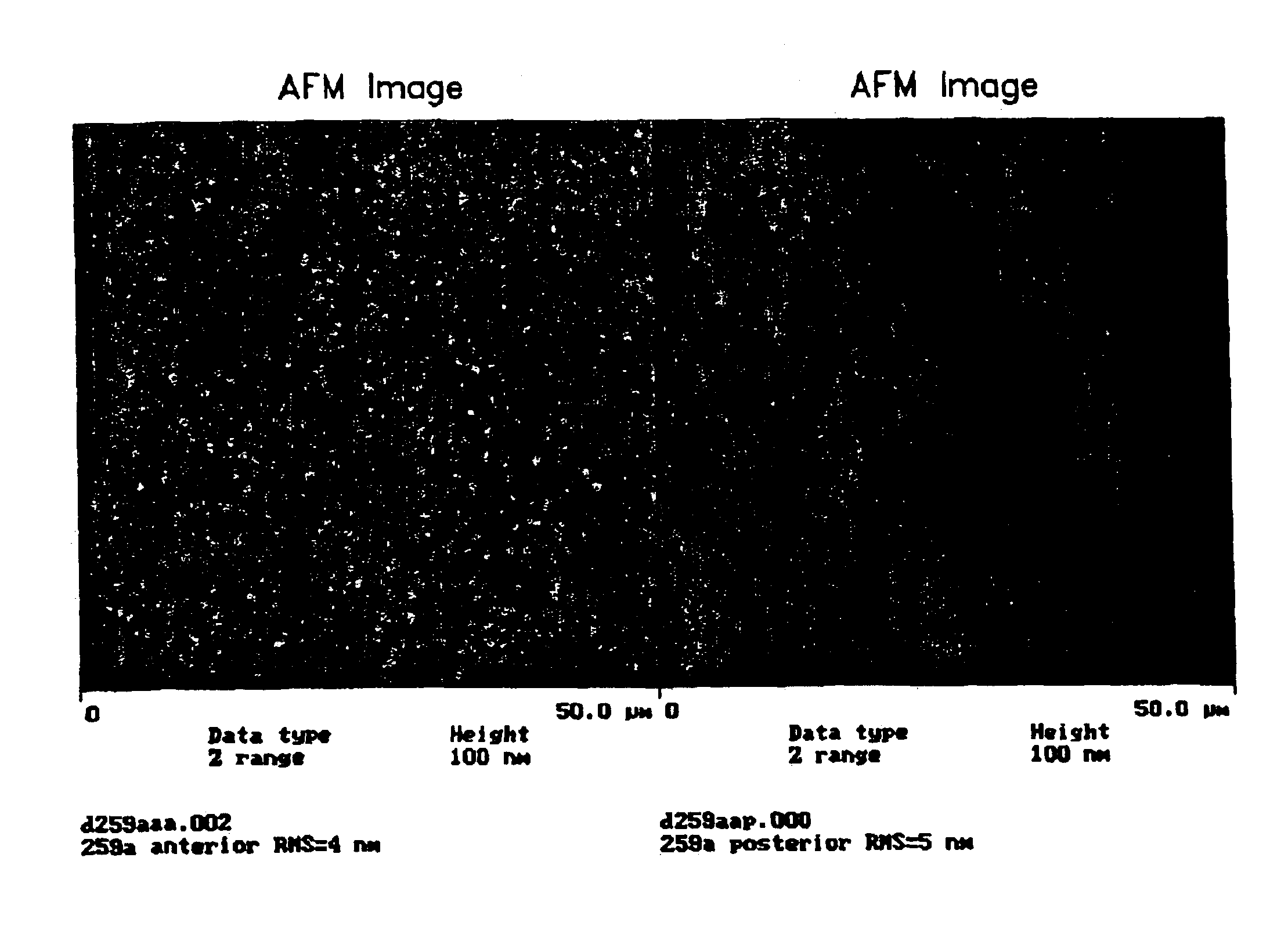

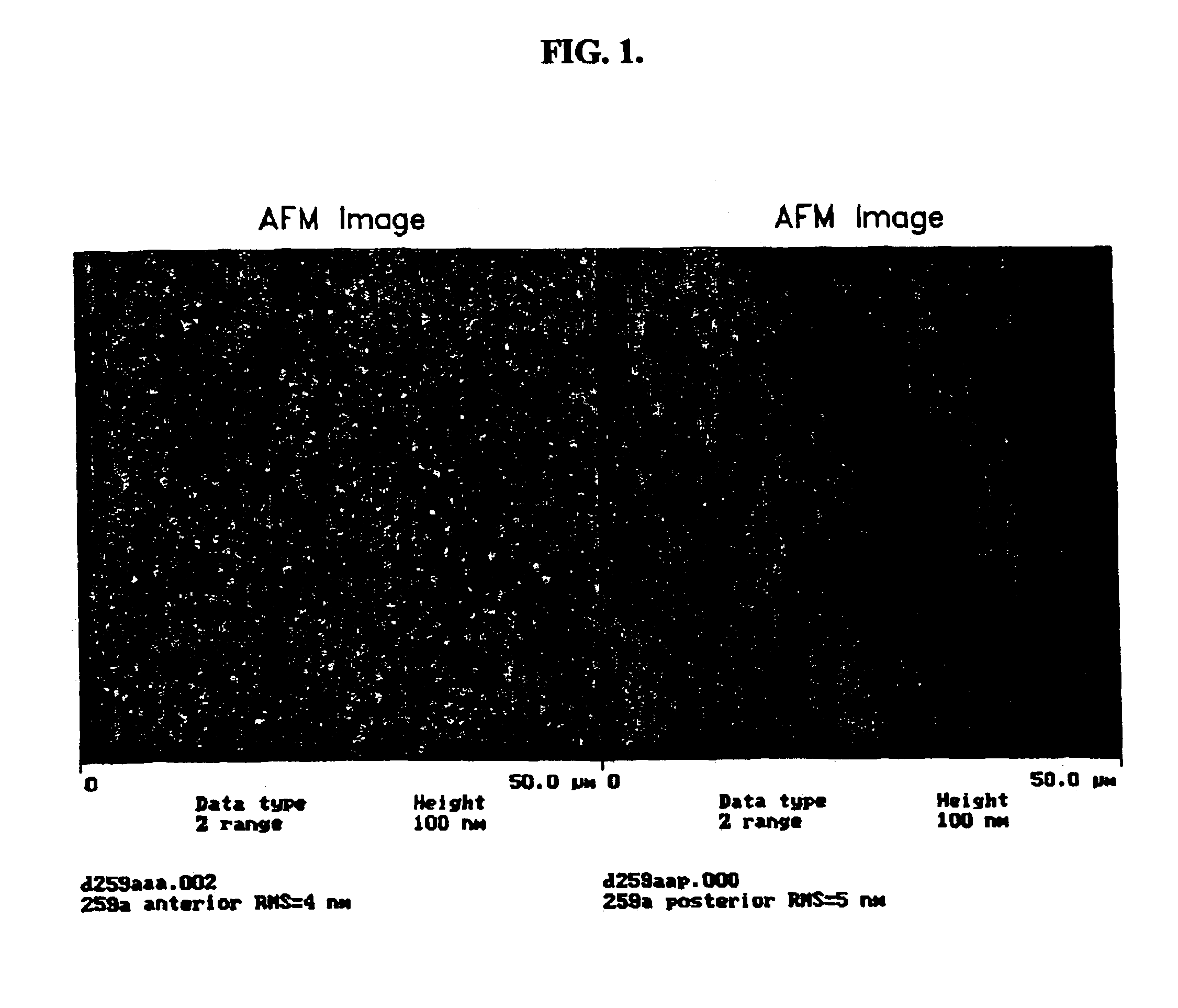

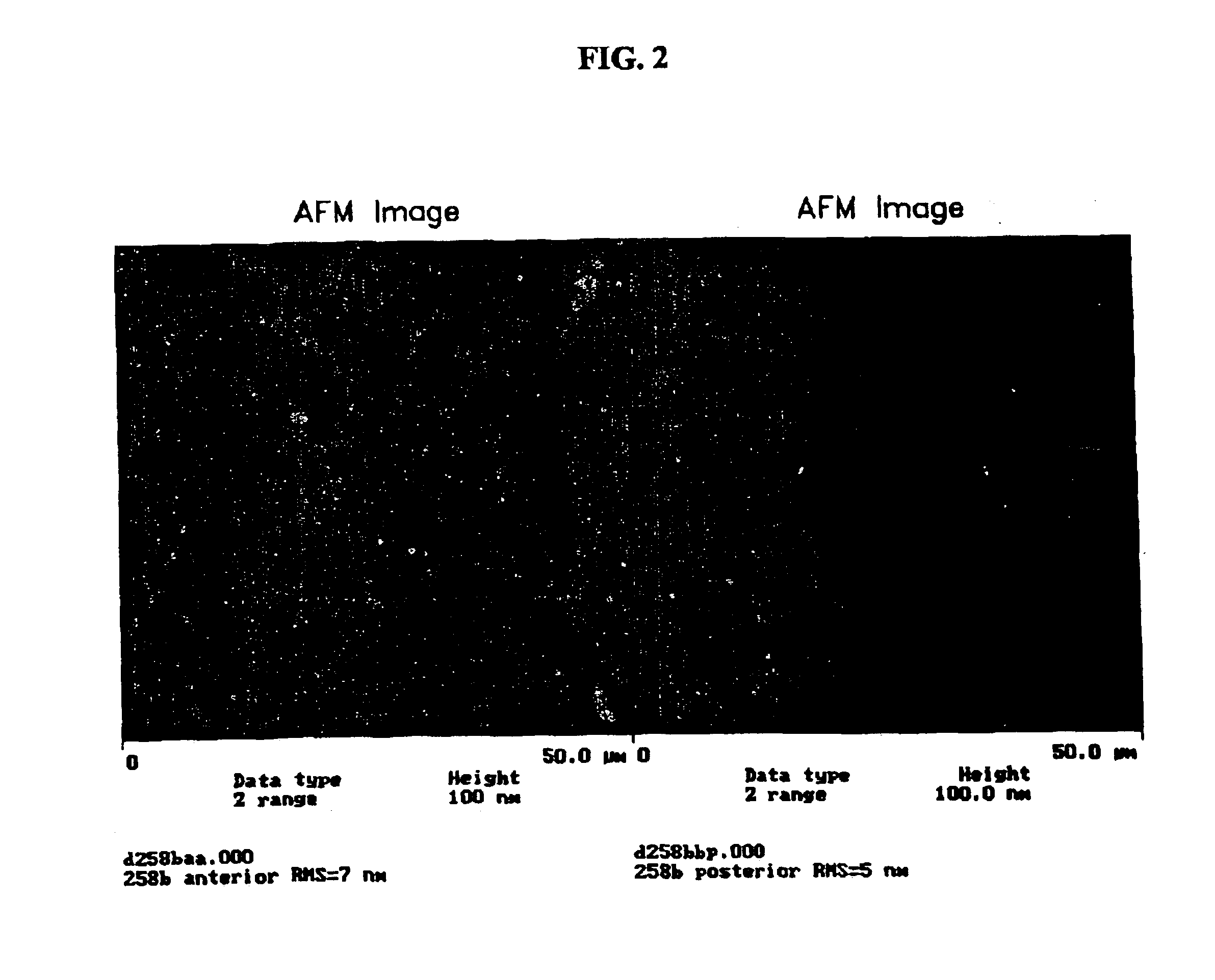

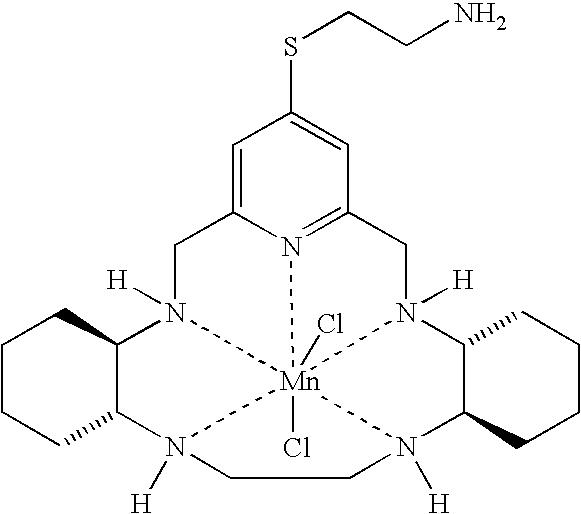

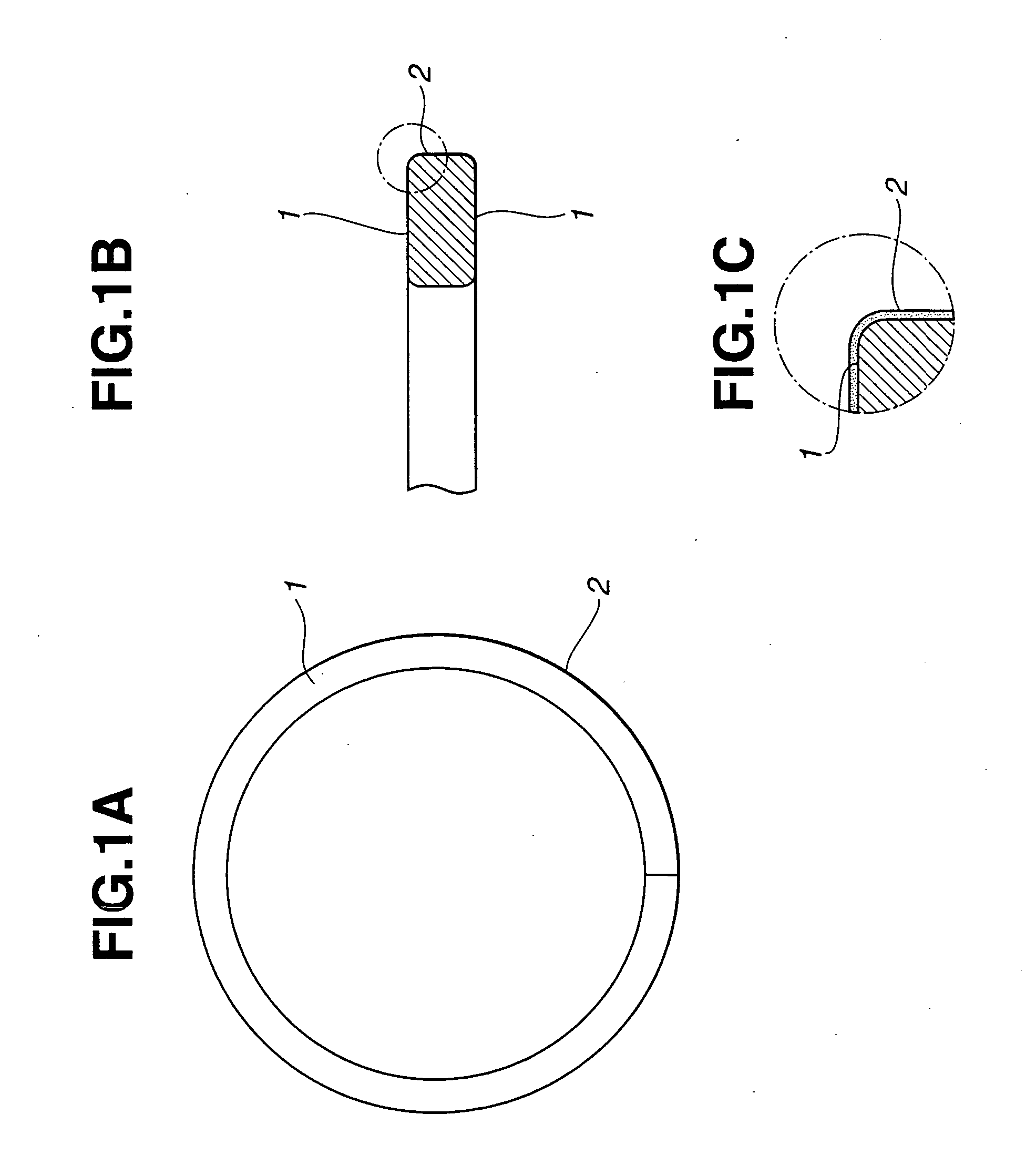

Surface treatment for silicone hydrogel contact lenses comprising hydrophilic polymer chains attached to an intermediate carbon coating

InactiveUS6902812B2Improve hydrophilicityImprove wettabilityOptical articlesPaper/cardboard layered productsCarbon coatingSurface finishing

The present invention provides an optically clear, hydrophilic coating upon the surface of a silicone medical device by sequentially subjecting the surface of the lens to plasma polymerization in a hydrocarbon-containing atmosphere and then covalently attaching a preformed hydrophilic polymer to the surface of the carbon coating. The invention is especially useful for forming a biocompatible coating on a silicone contact lens.

Owner:BAUSCH & LOMB INC

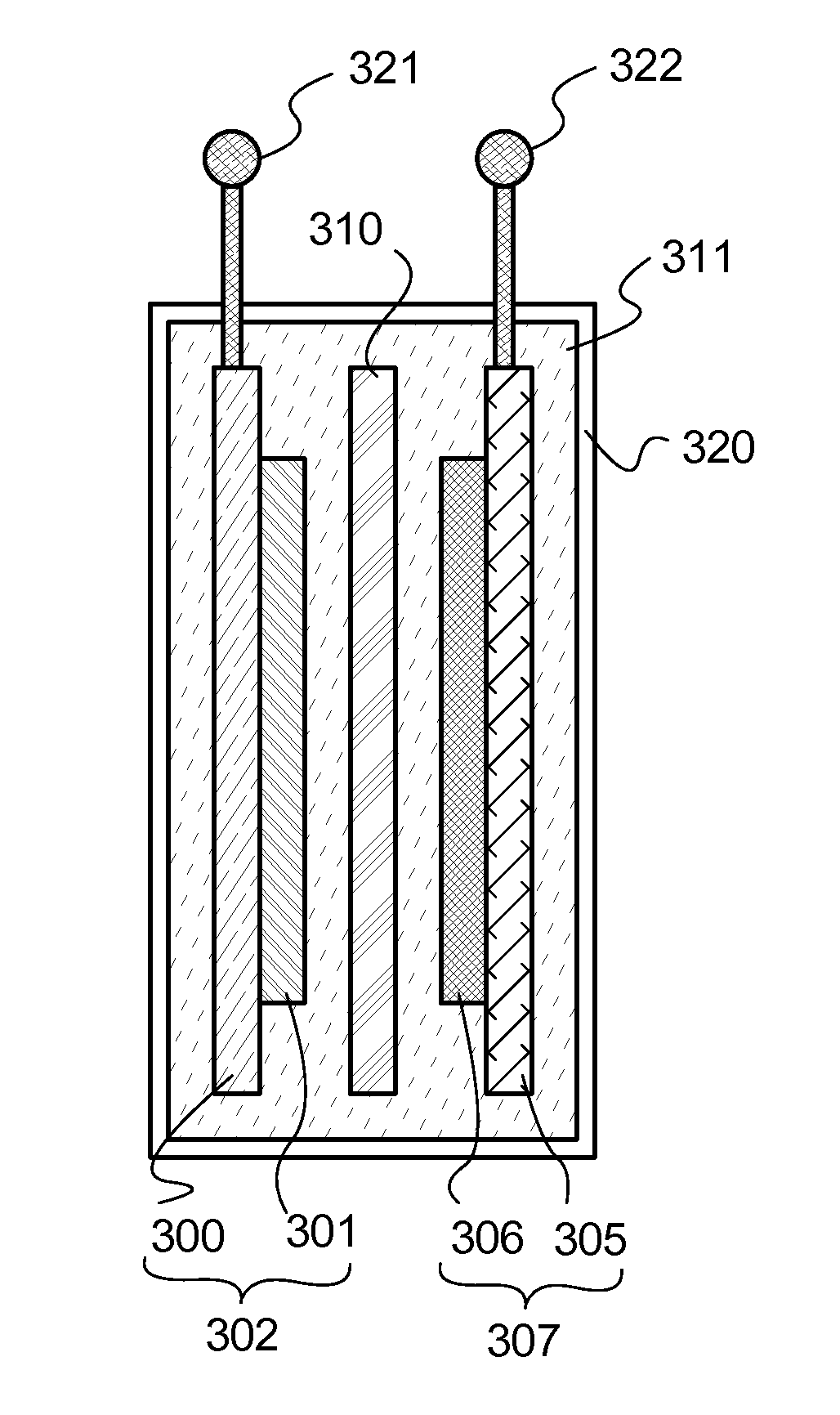

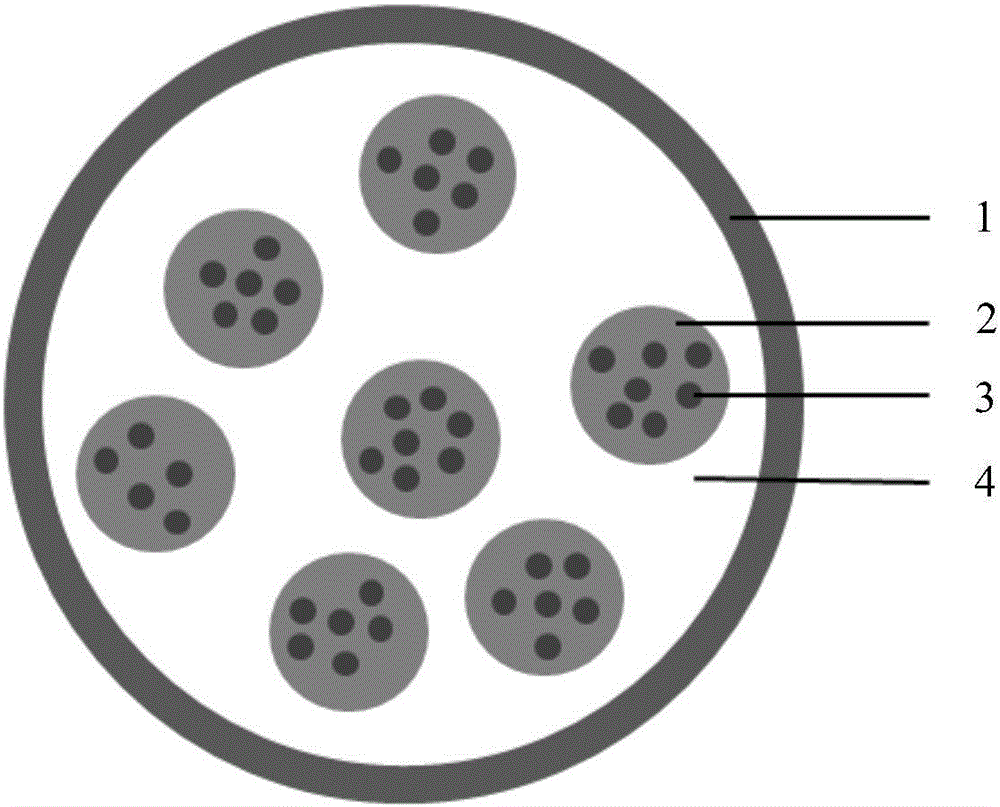

Lithium ion battery silicon-based composite anode material, preparation method thereof and battery

ActiveCN103682287AGood dispersionInhibit swellingCell electrodesSecondary cellsCarbon coatingRetention ratio

The invention relates to a lithium ion battery silicon-based composite anode material, a preparation method of the lithium ion battery silicon-based composite anode material, and a battery. The lithium ion battery silicon-based composite anode material adopts an embedded composite core-shell structure, a core has a structure formed by embedding nano silicon particles into a gap of an inner layer of hollowed graphite, and a shell is made from a non-graphite carbon material. According to the silicon-based composite anode material, mechanical grinding, mechanical fusing, isotropic compression processing and carbon coating technologies are combined, so that the nano silicon particles can be successfully embedded into the inner layer of the graphite and the surfaces of graphite particles are uniformly coated; the high-performance silicon-based composite anode material is obtained and is excellent in cycle performance (the 300-times cycle capacity retention ratio is more than 90%) and high in first efficiency (more than 90%); in addition, the silicon-based composite anode material is high in specific energy and compaction density, and can meet the requirements of a high-power density lithium ion battery; the preparation process is simple, the raw material cost is low, and the environment is protected.

Owner:BTR NEW MATERIAL GRP CO LTD

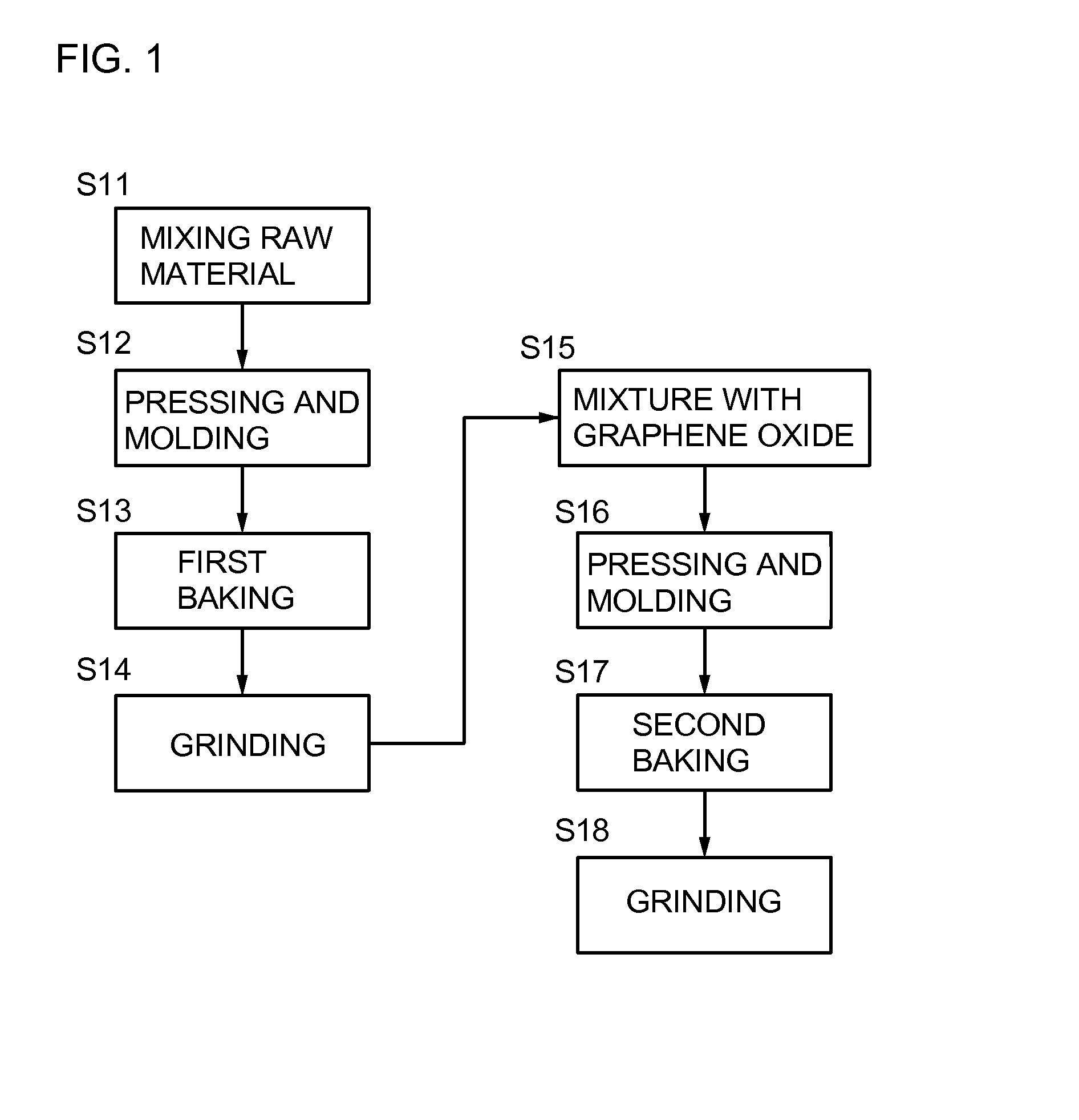

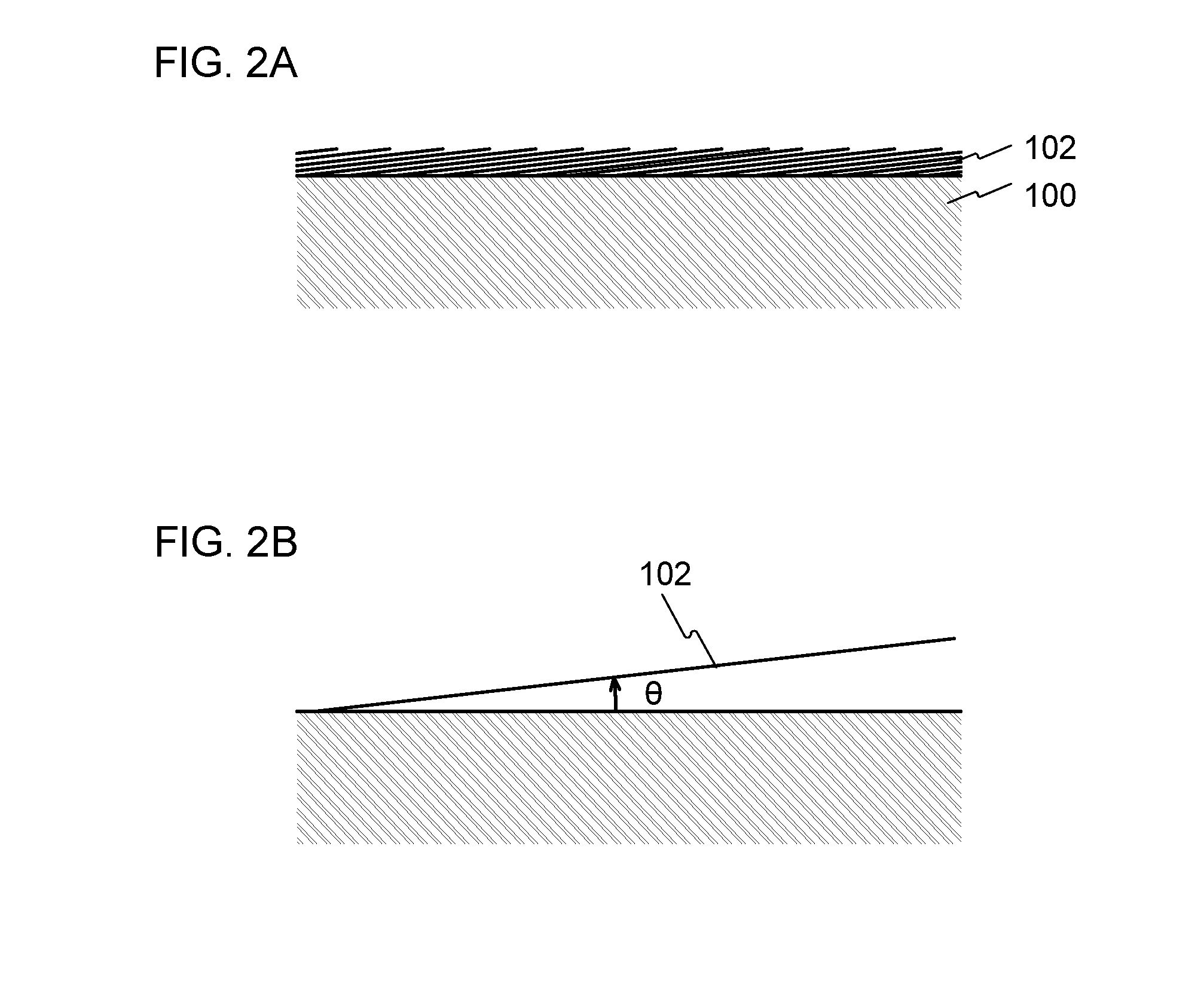

Method for manufacturing positive electrode active material for energy storage device and energy storage device

ActiveUS20120088156A1Reduce loadLow costNon-metal conductorsCarbon compoundsCarbon coatingConductive materials

An energy storage device having high capacity per weight or volume and a positive electrode active material for the energy storage device are manufactured. A surface of a main material included in the positive electrode active material for the energy storage device is coated with two-dimensional carbon. The main material included in the positive electrode active material is coated with a highly conductive material which has a structure expanding two-dimensionally and whose thickness is ignorable, whereby the amount of carbon coating can be reduced and an energy storage device having capacity close to theoretical capacity can be obtained even when a conduction auxiliary agent is not used or the amount of the conduction auxiliary agent is extremely small. Accordingly, the amount of carbon coating in a positive electrode and the volume of the conduction auxiliary agent can be reduced; consequently, the volume of the positive electrode can be reduced.

Owner:SEMICON ENERGY LAB CO LTD

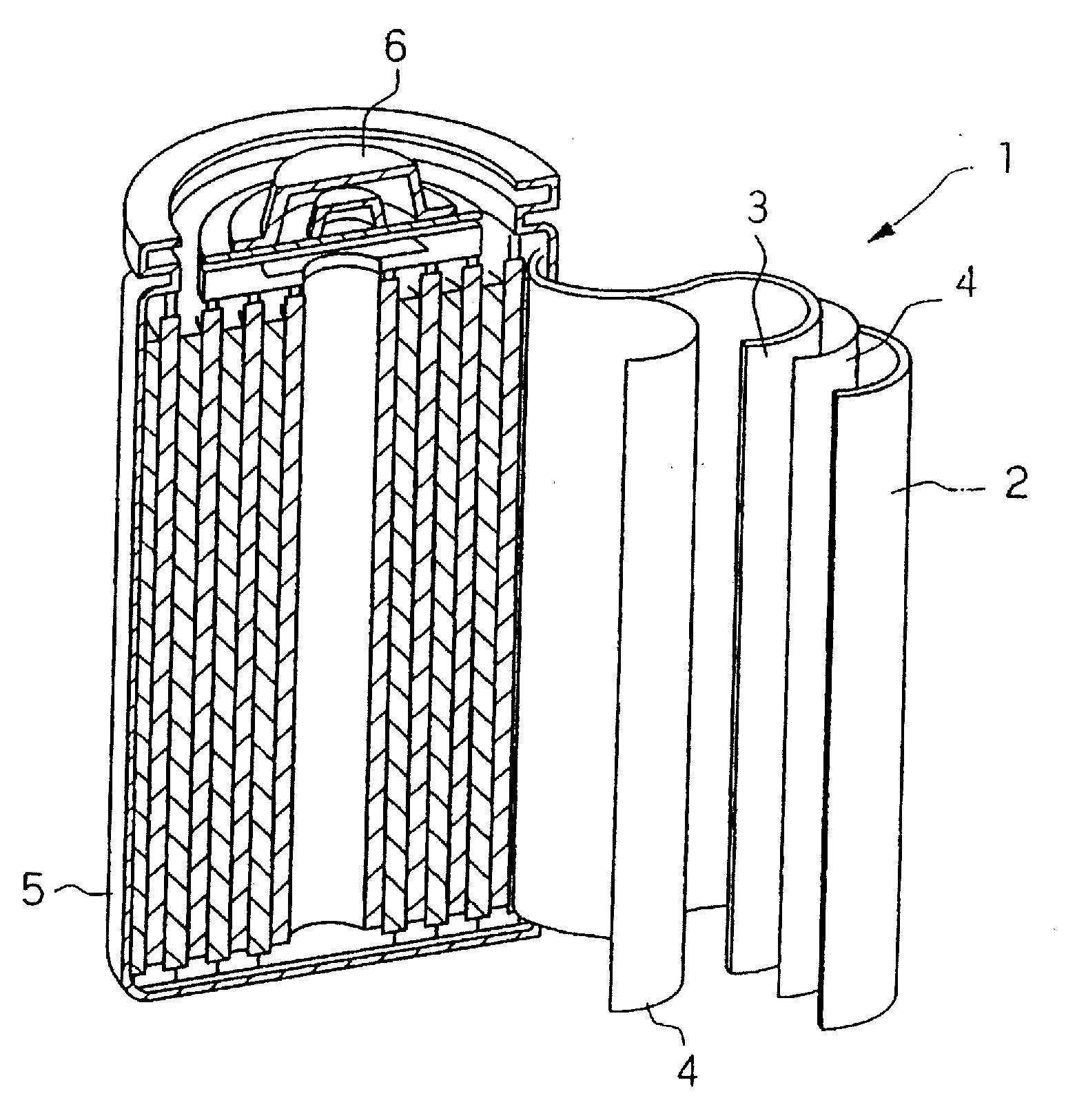

Silicon-carbon Composite Anode Material for Lithium Ion Batteries and A Preparation Method Thereof

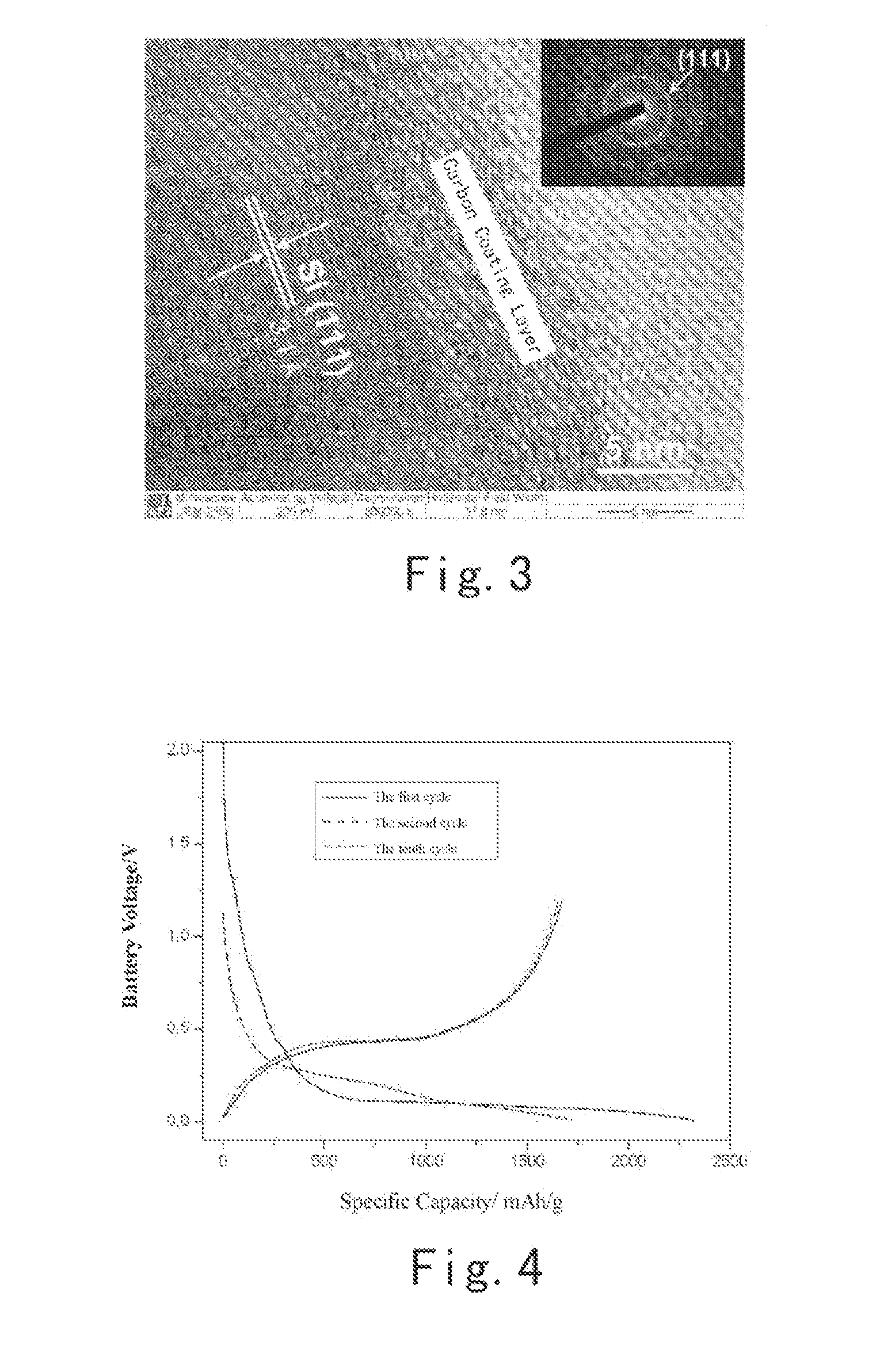

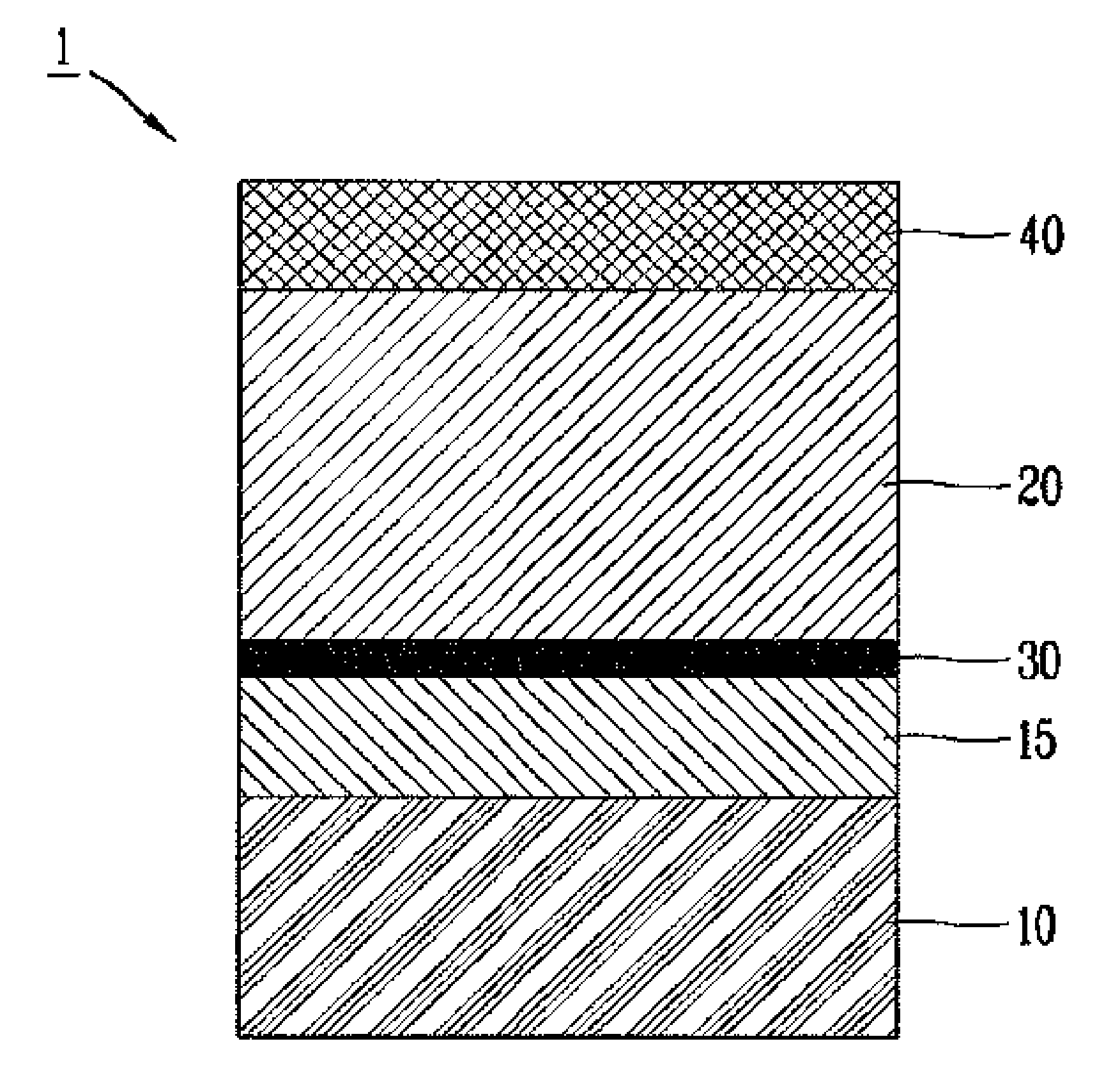

ActiveUS20140147751A1Large capacityImprove cycle stability performanceMechanical vibrations separationLiquid/solution decomposition chemical coatingCarbon compositesCarbon coating

Disclosed in the invention are a silicon-carbon composite anode material for lithium ion batteries and a preparation method thereof The material consists of a porous silicon substrate and a carbon coating layer. The preparation method of the material comprises preparing a porous silicon substrate and a carbon coating layer. The silicon-carbon composite anode material for lithium ion batteries has the advantages of high reversible capacity, good cycle performance and good rate performance. The material respectively shows reversible capacities of 1,556 mAh, 1,290 mAh, 877 mAh and 474 mAh / g at 0.2 C, 1 C, 4 C and 15 C rates; the specific capacity remains above 1,500 mAh after 40 cycles at the rate of 0.2 C and the reversible capacity retention rate is up to 90 percent.

Owner:BOSCH CHINA INVESTMENT

Silicon thin film anode for lithium secondary battery and preparation method thereof

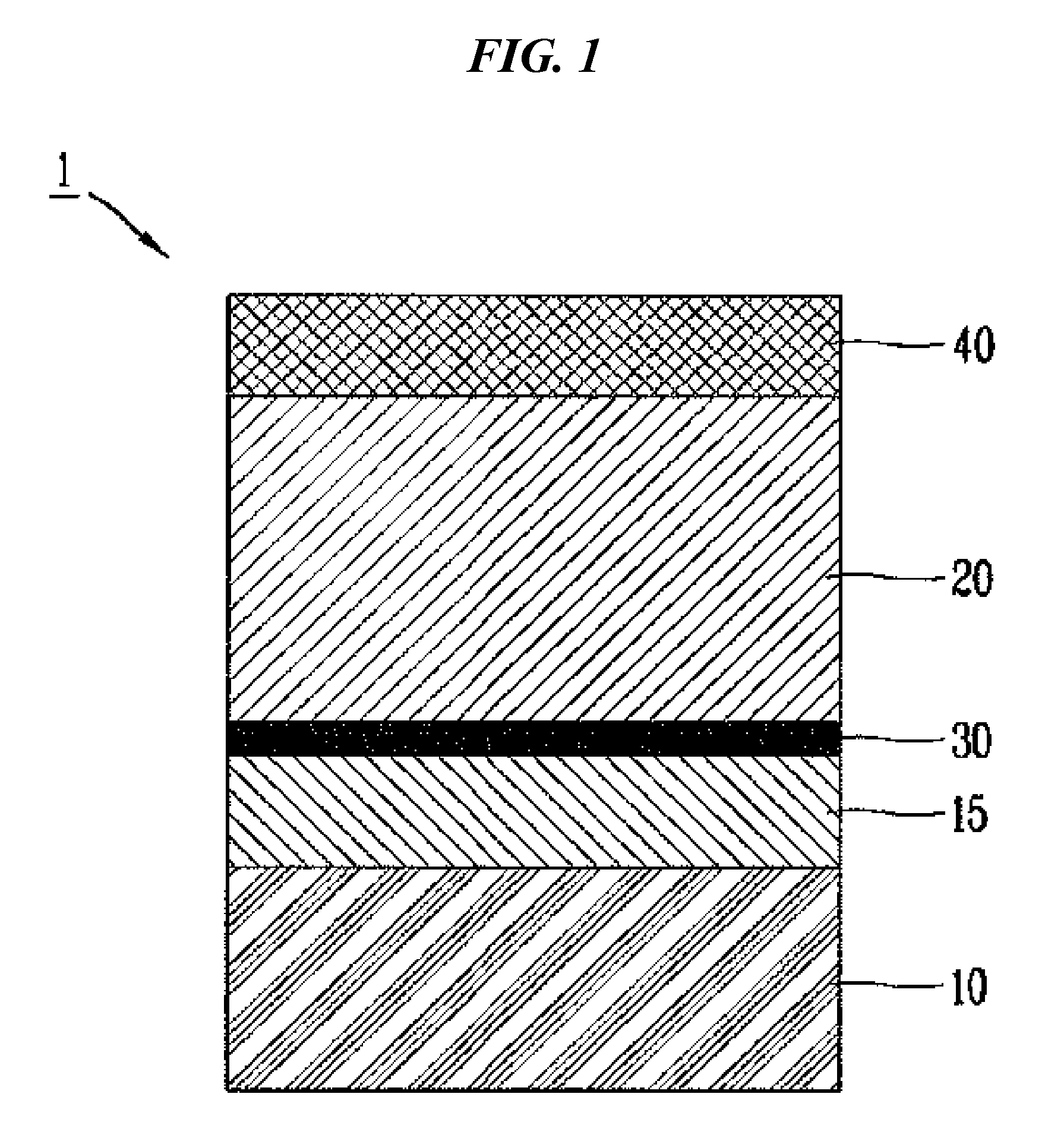

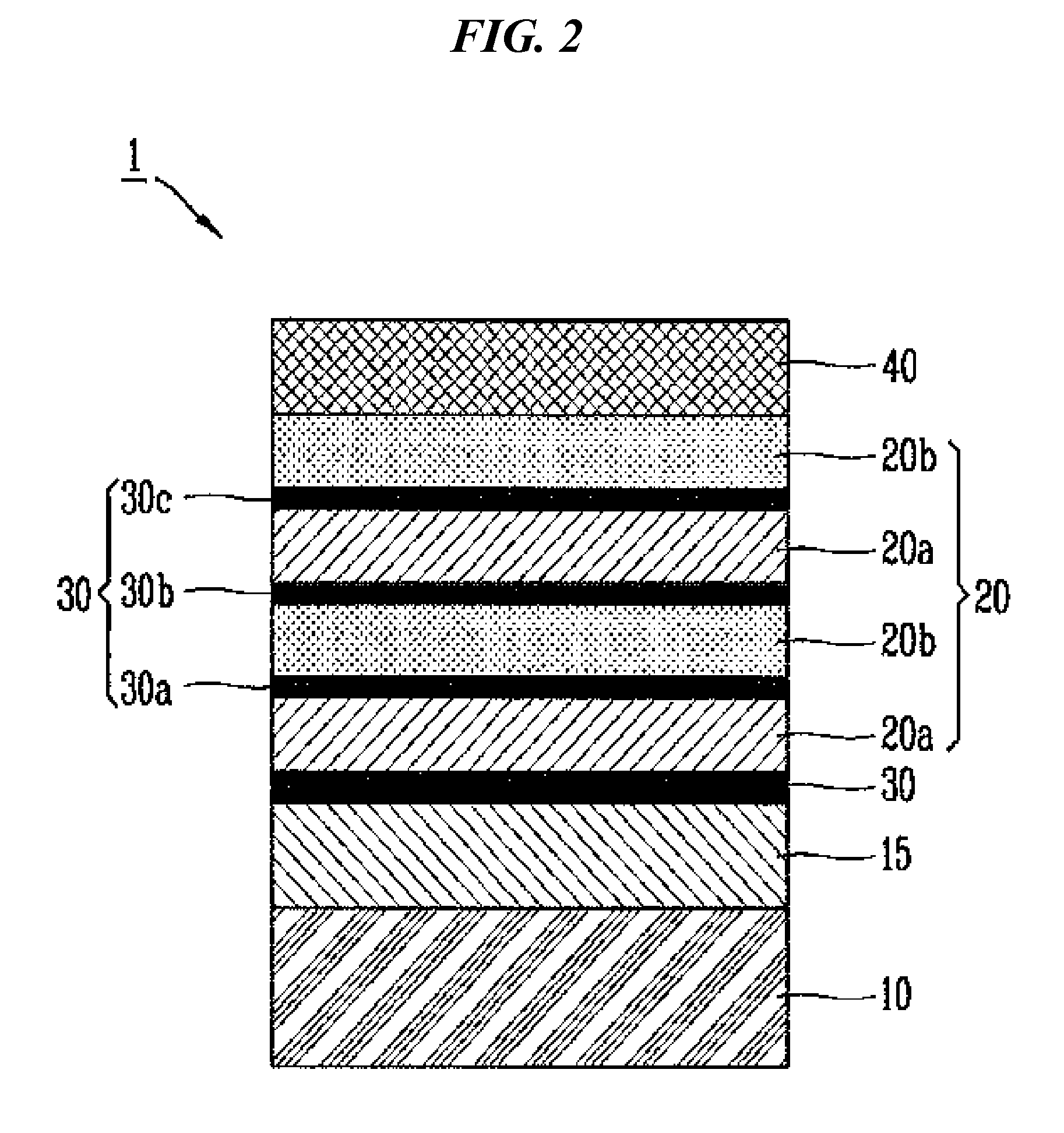

ActiveUS20090061319A1Increase capacityExcellent characteristicsElectrode carriers/collectorsVacuum evaporation coatingCarbon coatingReducing atmosphere

Disclosed are a silicon thin film anode for a lithium secondary battery having enhanced cycle characteristics and capacity and a preparation method thereof. A preparation method for a silicon thin film anode for a lithium secondary battery, comprises: preparing a collector including a metal; forming an anode active material layer including a silicon on the collector; forming one or more interface stabilizing layer, by annealing the collector and the anode active material layer under one of an inert atmosphere, a reduced atmosphere, and a vacuum atmosphere to react a metallic component of at least one of the collector and the anode active material layer with a silicon component of the anode active material layer at an interface therebetween; and forming a carbon coating layer on the anode active material layer by performing an annealing process in a hydrocarbon atmosphere.

Owner:KOREA INST OF SCI & TECH

Negative electrode material for nonaqueous electrolyte secondary battery, making method and lithium ion secondary battery

InactiveUS20100288970A1High charge-discharge efficiencyImprove cycle performanceHybrid capacitor electrodesSecondary cellsDischarge efficiencyCarbon coating

A negative electrode material for nonaqueous electrolyte secondary batteries comprises composite particles which are prepared by coating surfaces of particles having silicon nano-particles dispersed in silicon oxide with a carbon coating, and etching the coated particles in an acidic atmosphere. The silicon nano-particles have a size of 1-100 nm. The composite particles contain oxygen and silicon in a molar ratio: O<O / Si<1.0. Using the negative electrode material, a lithium ion secondary battery can be fabricated which features a high 1st cycle charge / discharge efficiency, a high capacity, and improved cycle performance.

Owner:SHIN ETSU CHEM IND CO LTD

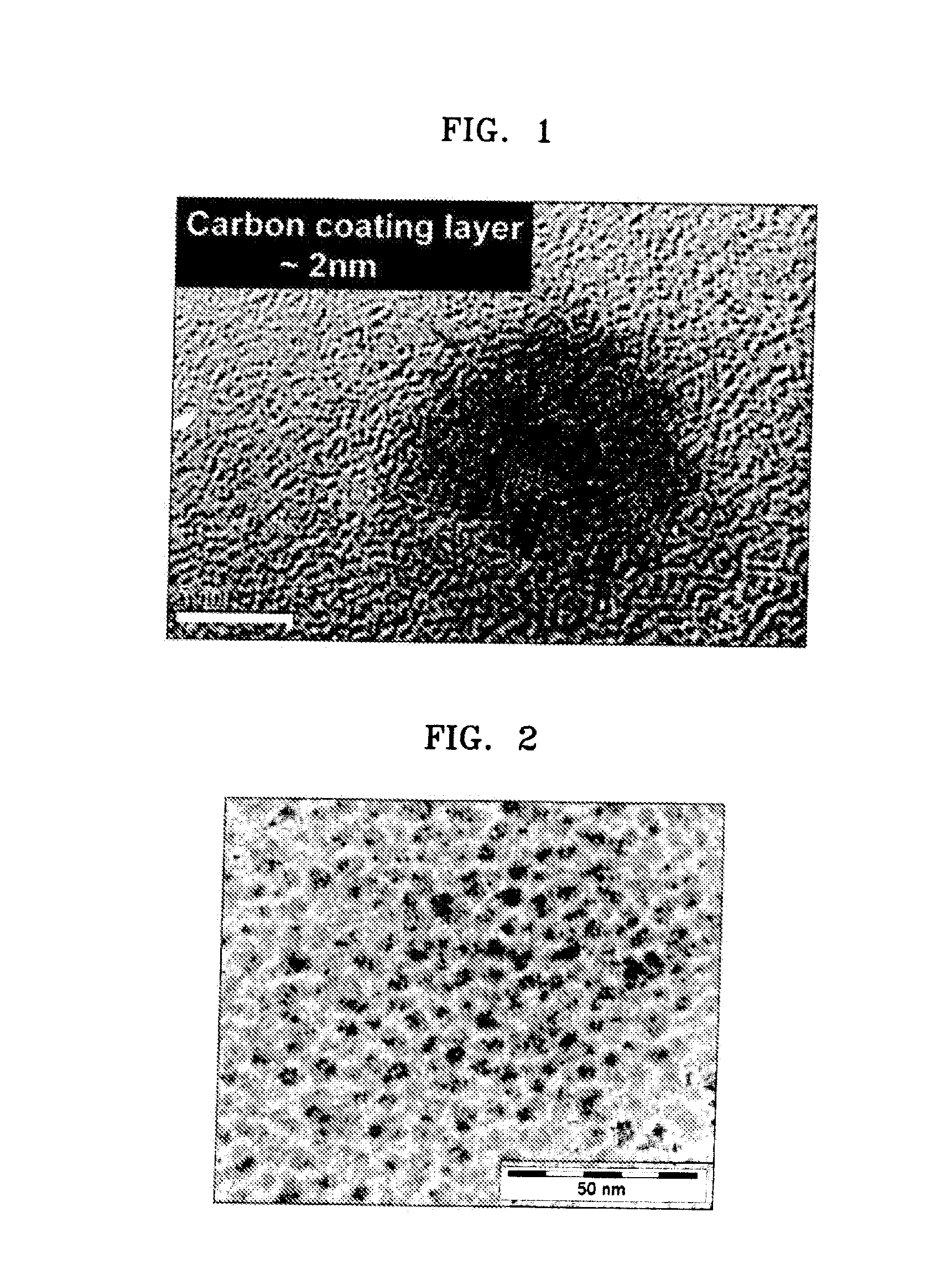

Negative active material including metal nanocrystal composite, method of preparing the same, and anode and lithium battery including the negative active material

InactiveUS20070264574A1Reduce formationHigh charge and discharge capacityMaterial nanotechnologyNon-aqueous electrolyte accumulator electrodesCarbon layerCarbon coating

Negative active materials including metal nanocrystal composites comprising metal nanocrystals having an average particle diameter of about 20 nm or less and a carbon coating layer are provided. The negative active material includes metal nanocrystals coated by a carbon layer, which decreases the absolute value of the change in volume during charge / discharge and decreases the formation of cracks in the negative active material resulting from a difference in the volume change rate during charge / discharge between metal and carbon. Therefore, high charge / discharge capacities and improved capacity retention capabilities can be obtained.

Owner:SAMSUNG SDI CO LTD

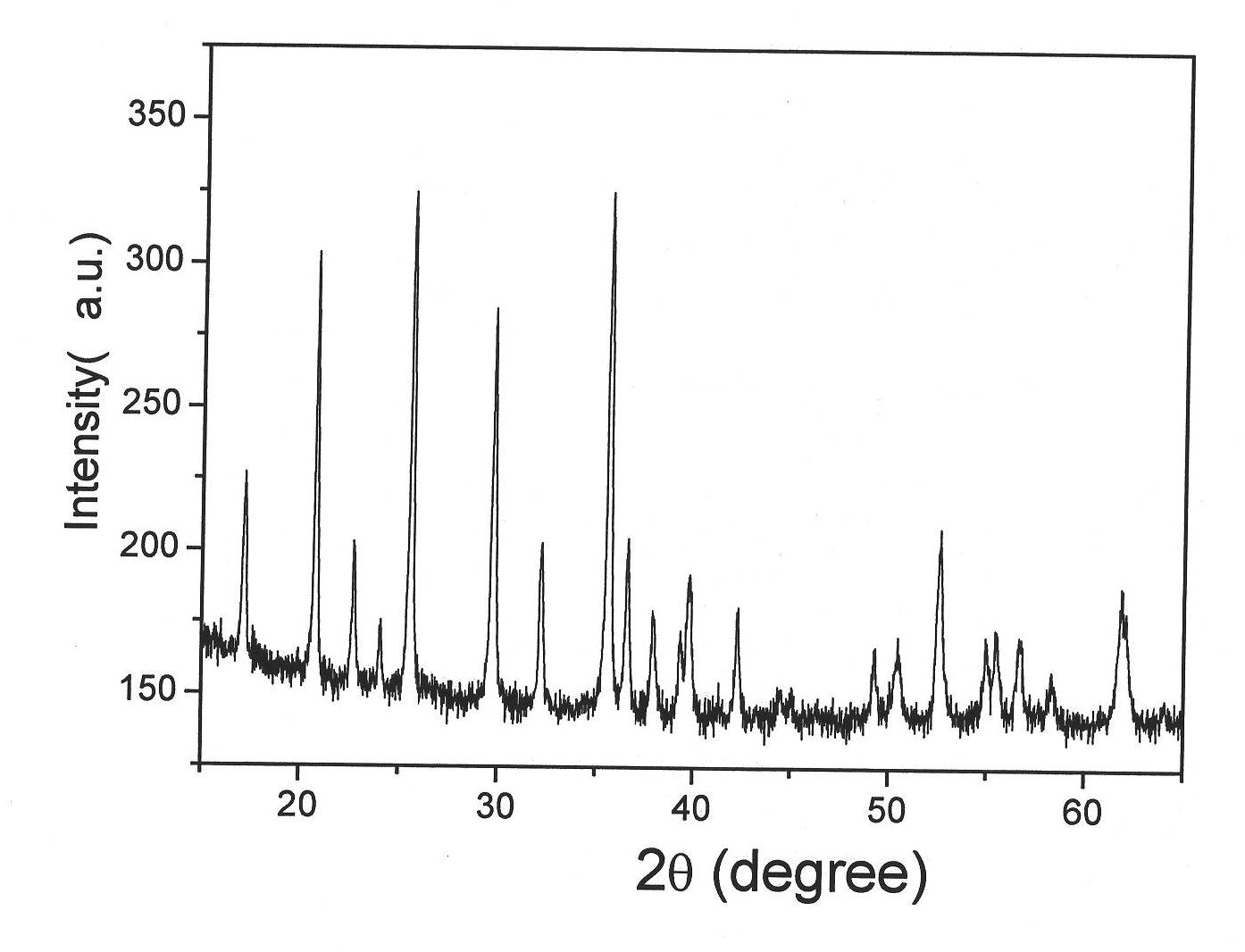

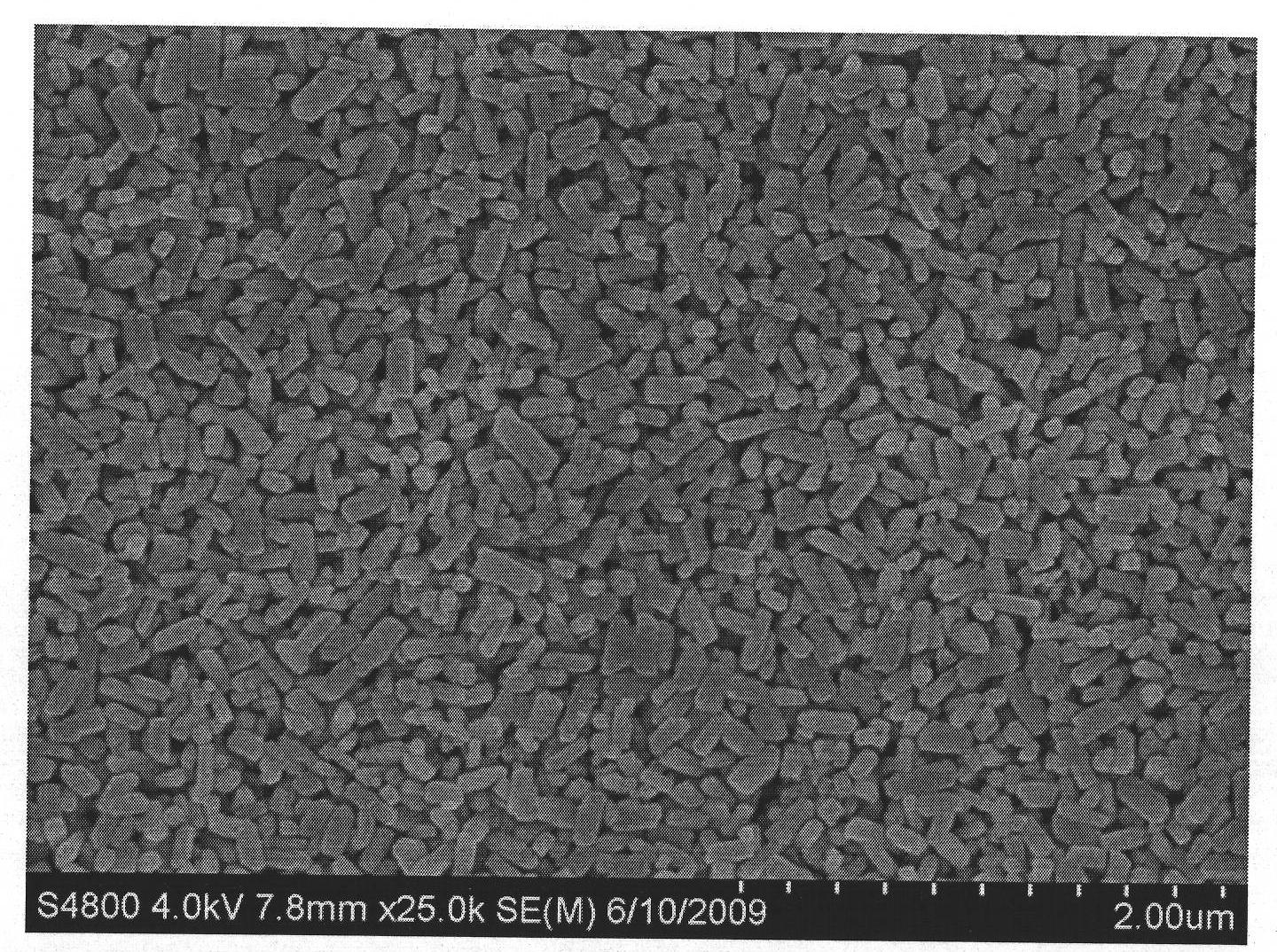

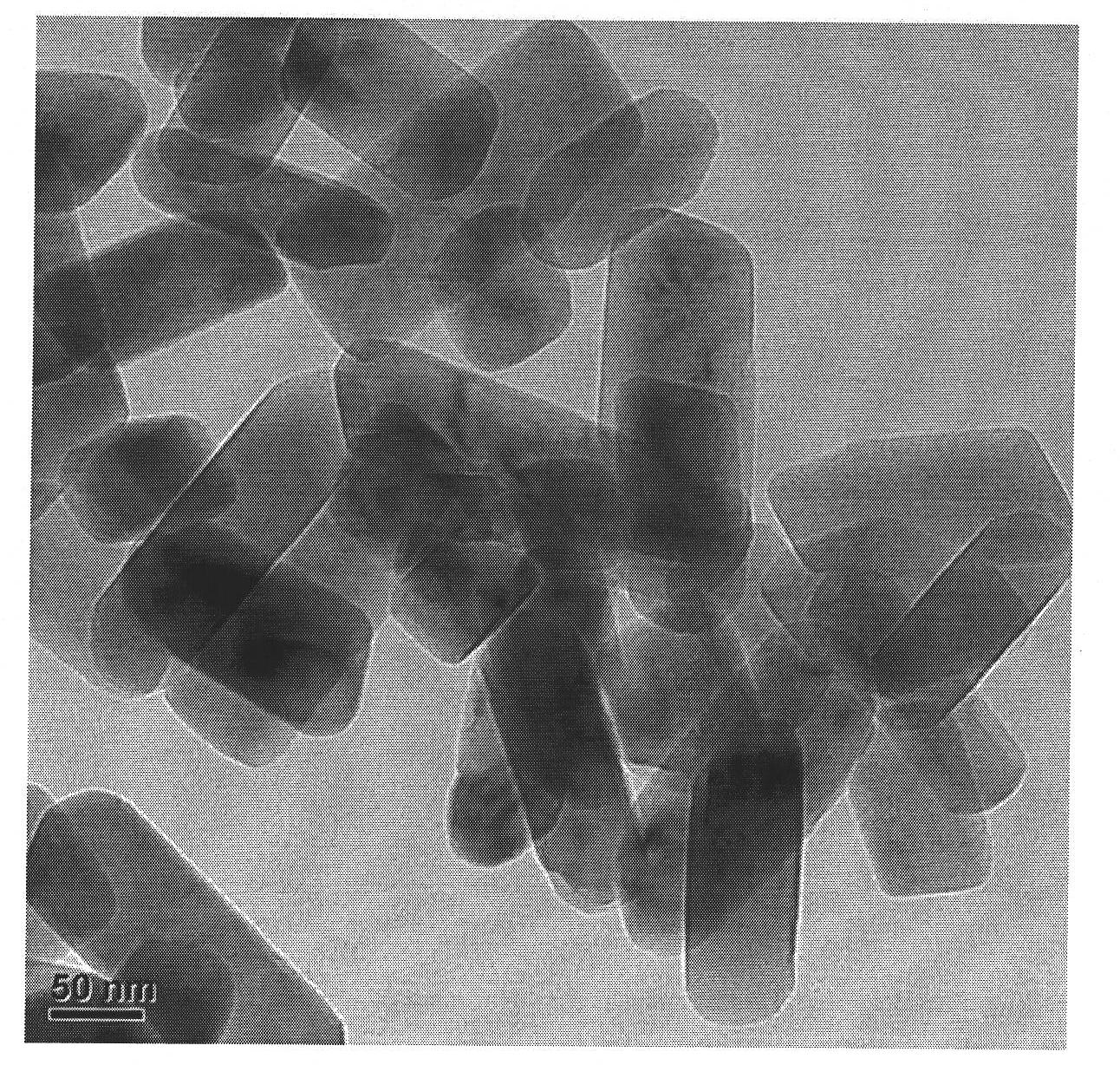

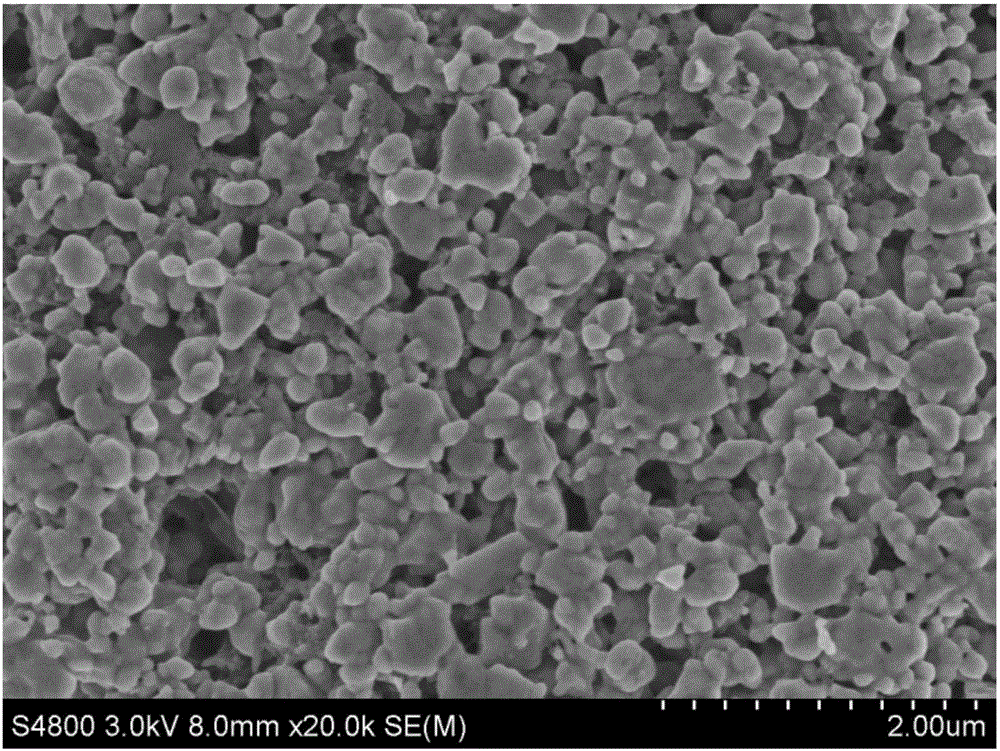

Preparation method of monodisperse lithium iron phosphate nanometer material and lithium-ion secondary battery

ActiveCN101777648AUniform shapeSmall sizeCell electrodesSecondary cellsCarbon coatingOrganic solvent

The invention relates to a preparation method of a monodisperse lithium iron phosphate nanometer material, which is characterized by comprising the following steps of: dissolving a soluble lithium source compound, a ferrous source compound, a phosphorus source compound, a dopping element compound, a carbon source compound, and the like into water or a mixed solvent of the water and an organic solvent; sequentially adding to the organic solvent for stirring and mixing according to specific material mole ratio and order, and keeping the volume ratio of the organic solvent to the water to be within a certain range; transferring a mixture to a high-pressure reaction still for heating treatment; and processing a product through a plurality of steps of washing, drying, carbon coating, ball-milling, mixing, annealing, and the like to obtain the lithium iron phosphate anode active material which has high multiplying power circulation and property. The invention also discloses a relevant lithium-ion secondary battery. By adopting a hydrothermal / solvothermal method and using soluble materials as reactants, the invention enables ions to be uniformly mixed in the synthesizing process, thereby obtaining better crystal forms and very pure phases and further enhancing the property of batteries.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

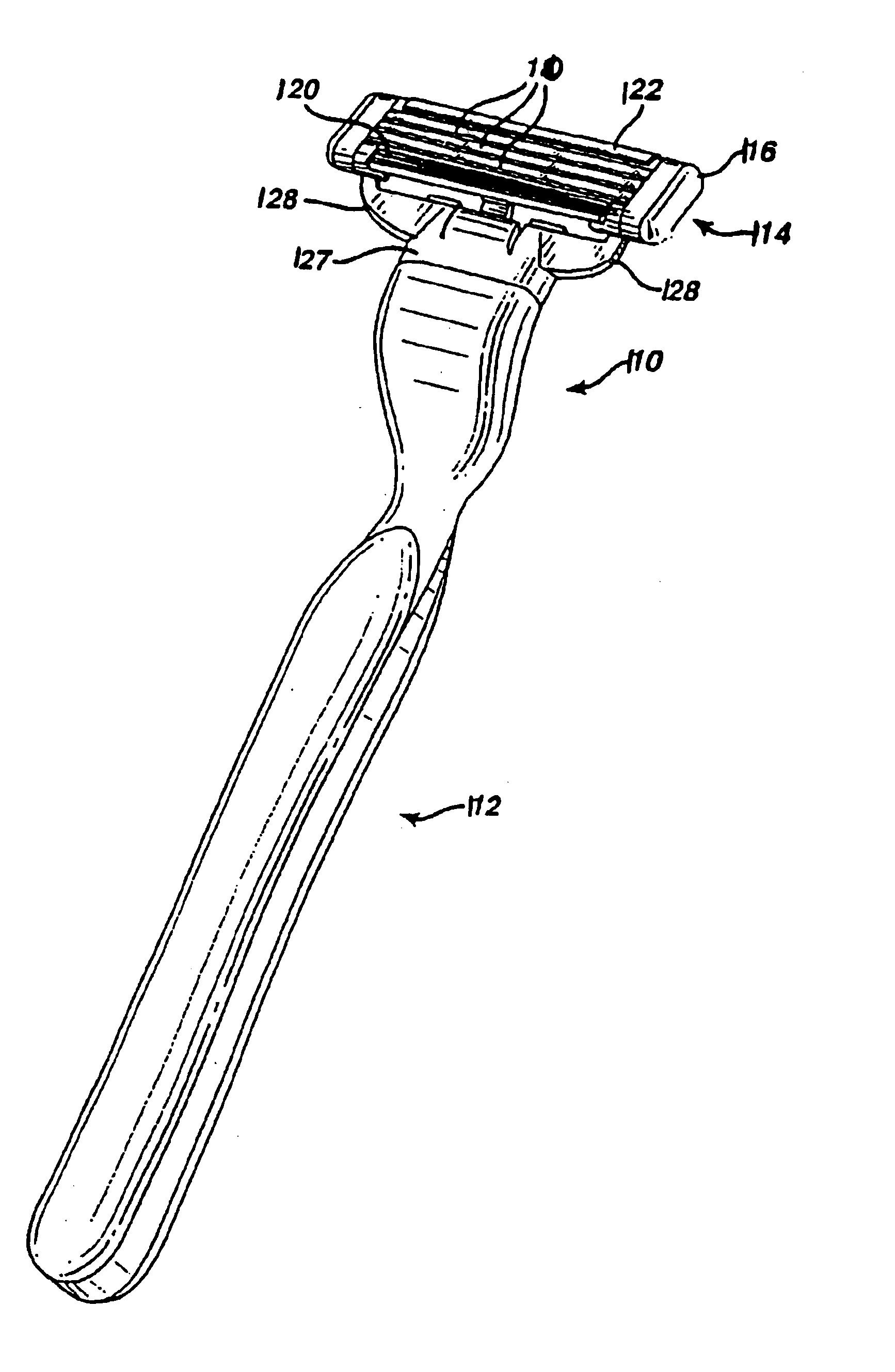

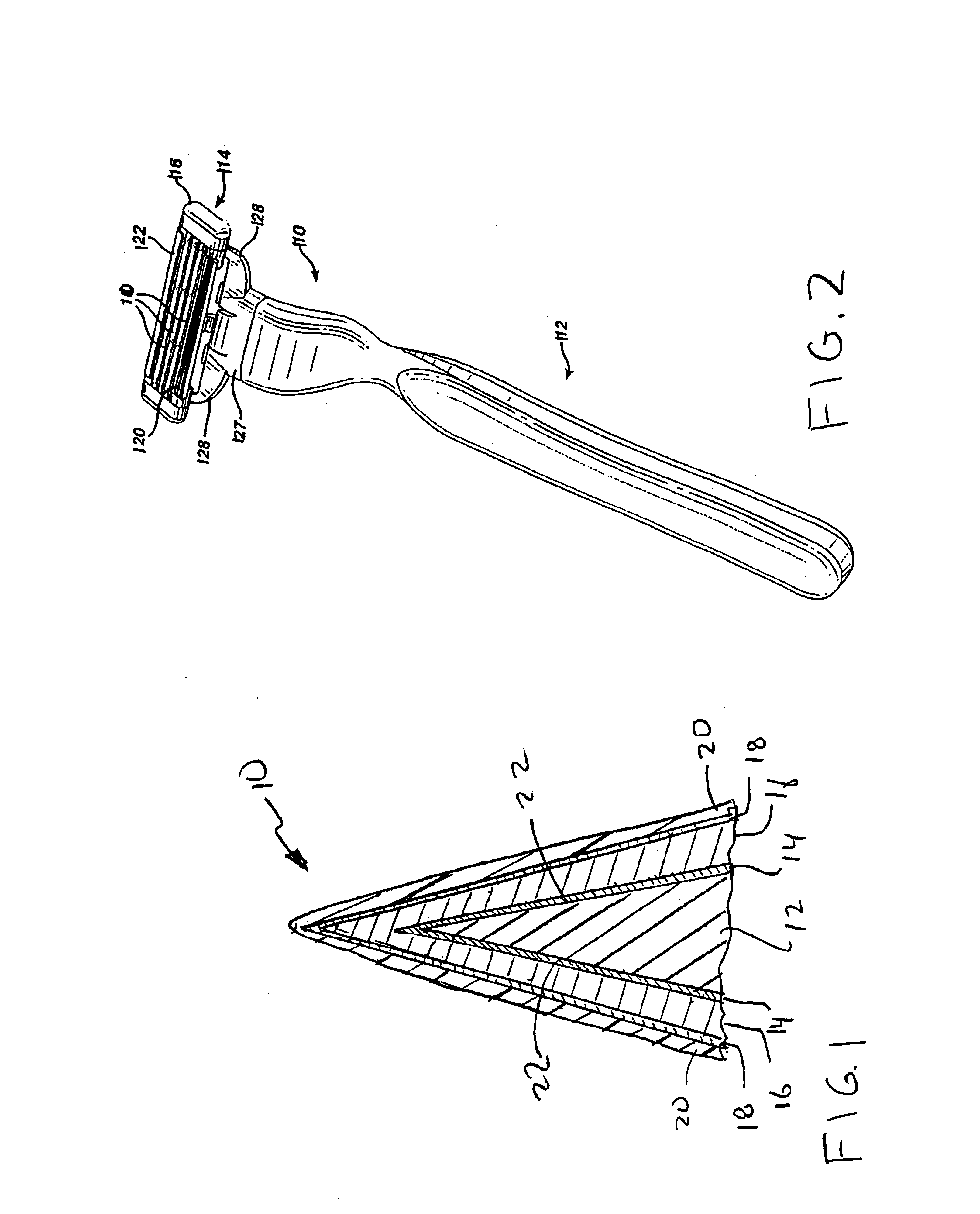

Razor blade technology

InactiveUS6866894B2Improve adhesionReduced tip roundingPretreated surfacesCoatingsCarbon coatingChromium

A razor blade including a substrate with a cutting edge defined by a sharpened tip and adjacent facets, a layer of hard coating on the cutting edge, an overcoat layer of a chromium containing material on the layer of hard carbon coating, and an outer layer of polytetrafluoroethylene coating over the overcoat layer. Also disclosed is a method of making a razor blade including providing a substrate with a cutting edge defined by a sharpened tip and adjacent facets, and applying an aqueous solution including polytetrafluoroethylene coating over the sharpened tip to result in an outer layer, the polytetrafluoroethylene having a molecular weight of about 45,000.

Owner:THE GILLETTE CO

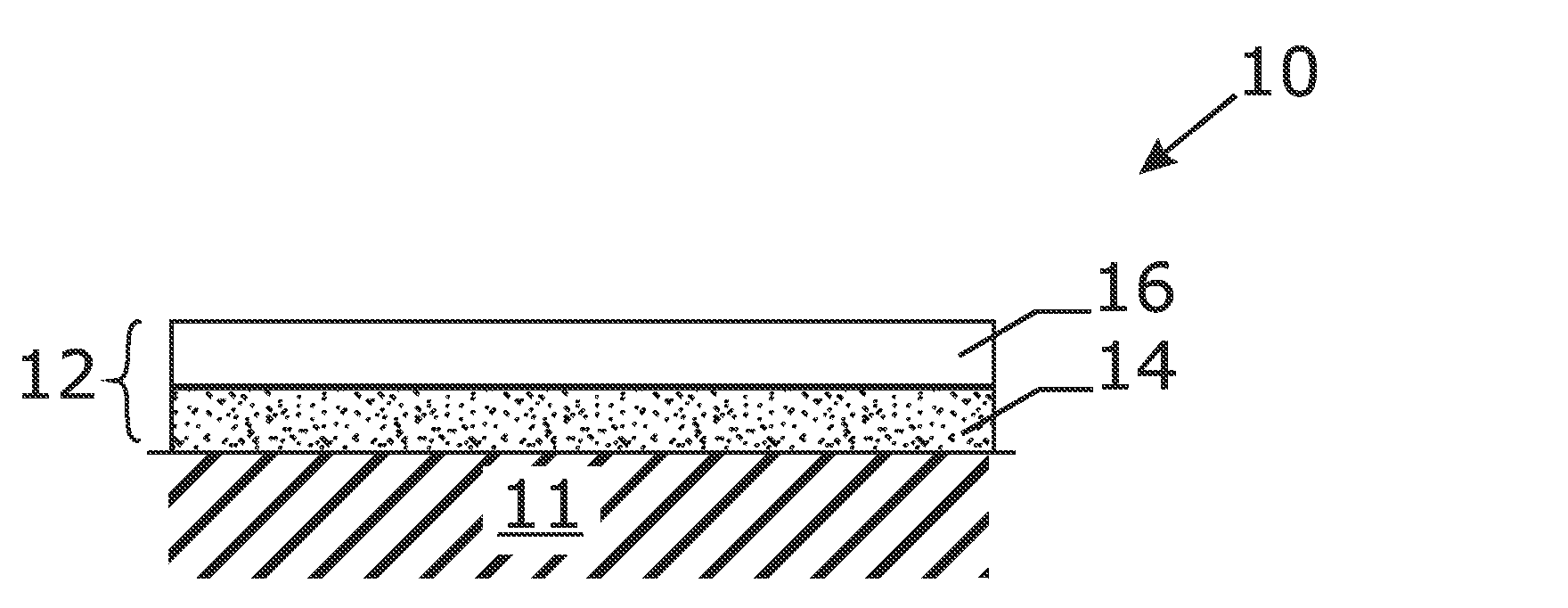

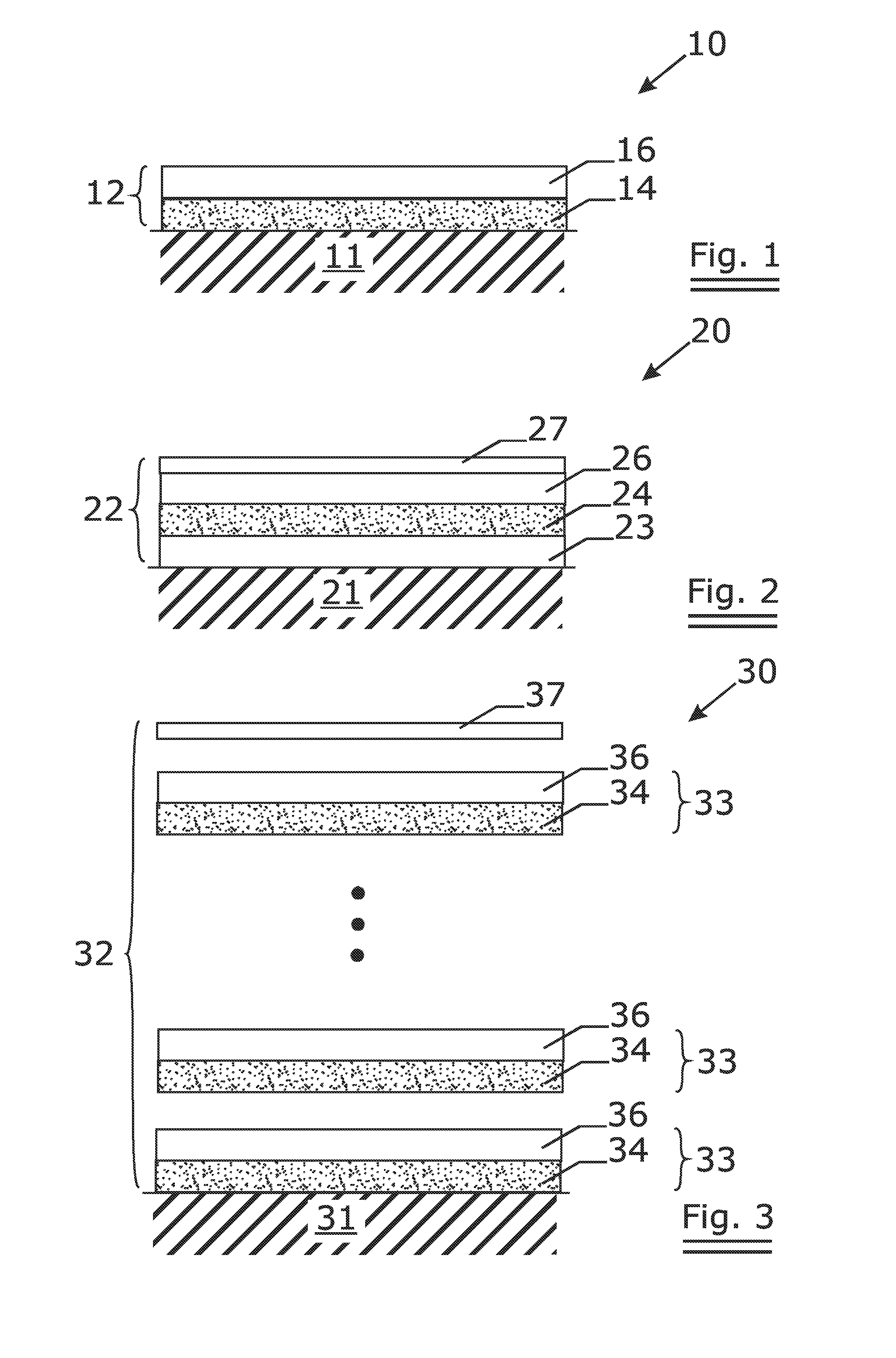

Substrate Coated with a Layered Structure Comprising a Tetrahedral Carbon Layer and a Softer Outer Layer

ActiveUS20080220257A1Easy to wearReduce wearNatural mineral layered productsChemical vapor deposition coatingCarbon coatingCarbon layer

The invention relates to a metal substrate coated at least partially with a layered structure. The layered structure comprises an intermediate layer deposited on the metal substrate and an amorphous carbon layer deposited on the intermediate layer. The amorphous carbon layer has a Young's modulus lower than 200 GPa. The intermediate layer comprises a tetrahedral carbon layer having a Young's modulus higher than 200 GPa. The invention further relates to a method to reduce the wear on a counterbody of a metal substrate coated with a tetrahedral carbon coating.

Owner:SULZER METAPLAS

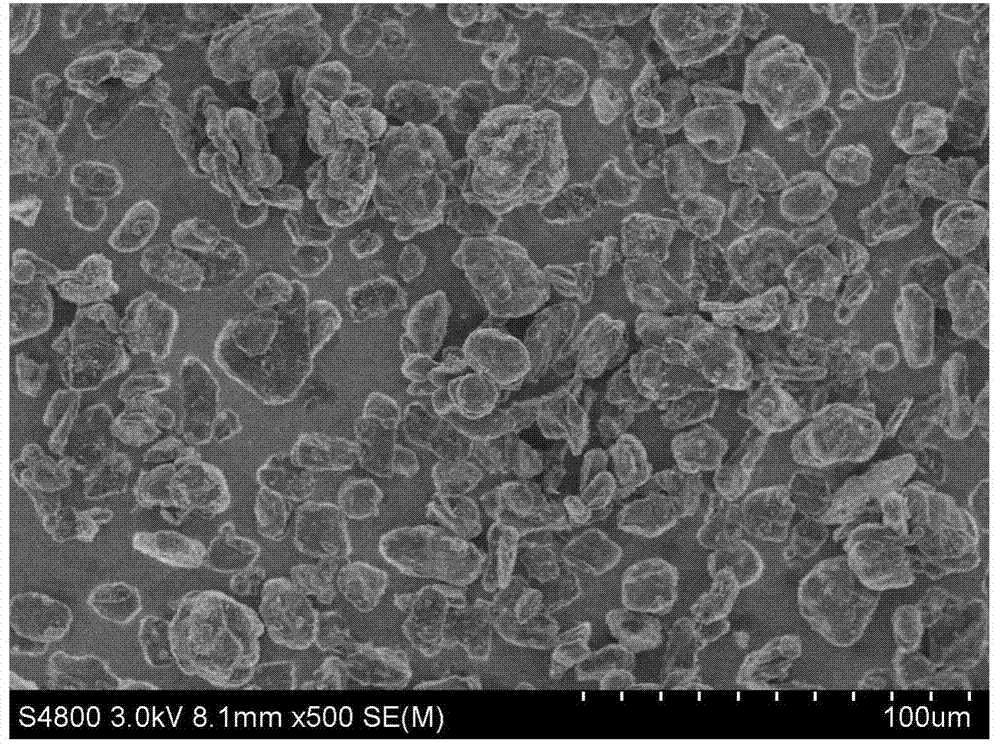

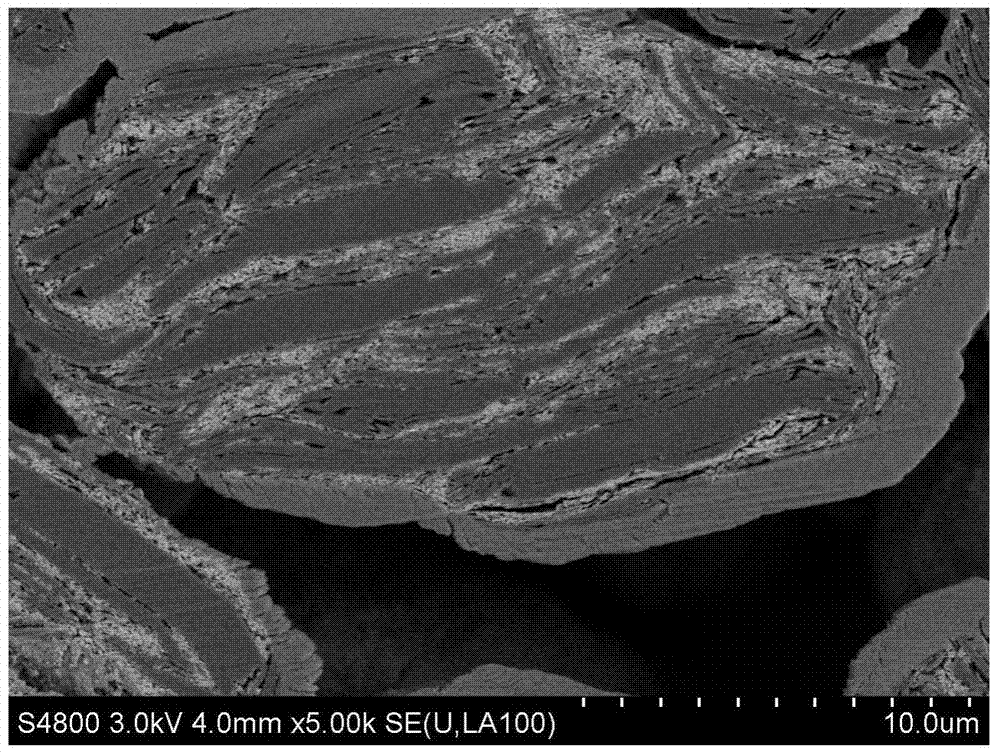

SiOx based composite negative electrode material, preparation method and battery

ActiveCN103647056AGood dispersionQuick blend effectCell electrodesLi-accumulatorsCarbon coatingSilicon oxide

The invention relates to a high-capacity SiOx based composite negative electrode material, a preparation method and a battery, wherein the negative electrode material comprises a silicon oxide material, a carbon material and an amorphous carbon coating layer; the silicon oxide material is silicon oxide or silicon oxide material modified in a carbon coating manner; surfaces of carbon material particles are coated with the silicon oxide material. A preparation method of the high-capacity SiOx based composite negative electrode material comprises the steps of performing physical processing or carbon coating modification on a silicon oxide raw material, thus obtaining a micron-sized silicon oxide material; and then mechanically fusing, coating with a solid phase and sintering at a high temperature to obtain the high-capacity negative electrode material. Through the high-capacity SiOx based composite negative electrode material, the effect of uniform dispersing and coating of the micron-sized silicon oxide particles on the surfaces of the carbon material particles can be achieved by virtue of the combination of mechanical fusion and solid-phase coating processes. The silicon oxide particles are well dispersed on the surface of the carbon material particle; the strength of bonding between the silicon oxide particles and the carbon material particles is high; the recycling performance of the material can be greatly improved; and meanwhile, the high-capacity SiOx based composite negative electrode material is high in first efficiency (breaking through the theoretical efficiency of SiOx), low in expansion rate, long in service life, environmental-friendly, pollution-free and low in cost.

Owner:BTR NEW MATERIAL GRP CO LTD

Composite, preparation method and application thereof in lithium ion secondary battery

ActiveCN106816594AImprove performanceRaw materials are easy to getMaterial nanotechnologySilicaCarbon coatingSilicon oxide

The invention discloses a composite. The composite comprises nanometer silicon, a lithium-containing compound and a carbon coating, or comprises nanometer silicon, a silicon oxide, a lithium-containing compound and a carbon coating. The method comprises the following steps: (1) mixing a carbon-coated silicon oxide and a lithium-source solid phase; and (2) thermally processing a prefabricated lithium precursor obtained in step (1) in a vacuum or non-oxidative atmosphere to obtain the composite. The method is simple, small in requirement on equipment, and low in cost; the obtained composite is stable in structure; the structure and property cannot be degraded after long-term storage; a battery prepared from a negative electrode material containing the composite is high in lithium taking-off capacity, high in first coulomb efficiency, and high in circulating performance; the charging capacity is equal to or above 1920mAh / g; the discharging capacity is equal to or above 1768mAh / g; and the first effect is equal to or more than 90.2%.

Owner:BTR NEW MATERIAL GRP CO LTD

Conductive silicon oxide powder, its mfg. method and negative electrode material of nonaqueous electrolyte secodary battery

InactiveCN1428880AIncrease capacityImprove cycle performancePigmenting treatmentSilicaCarbon coatingGas phase

A conductive silicon oxide powder in which particles of silicon oxide having the formula: SiOx wherein 1 ‰¤ x < 1.6 are covered on their surfaces with a conductive carbon coating by chemical vapor deposition treatment is useful as a negative electrode active material to construct a lithium ion secondary cell having a high capacity and improved cycle performance.

Owner:SHIN ETSU CHEM IND CO LTD

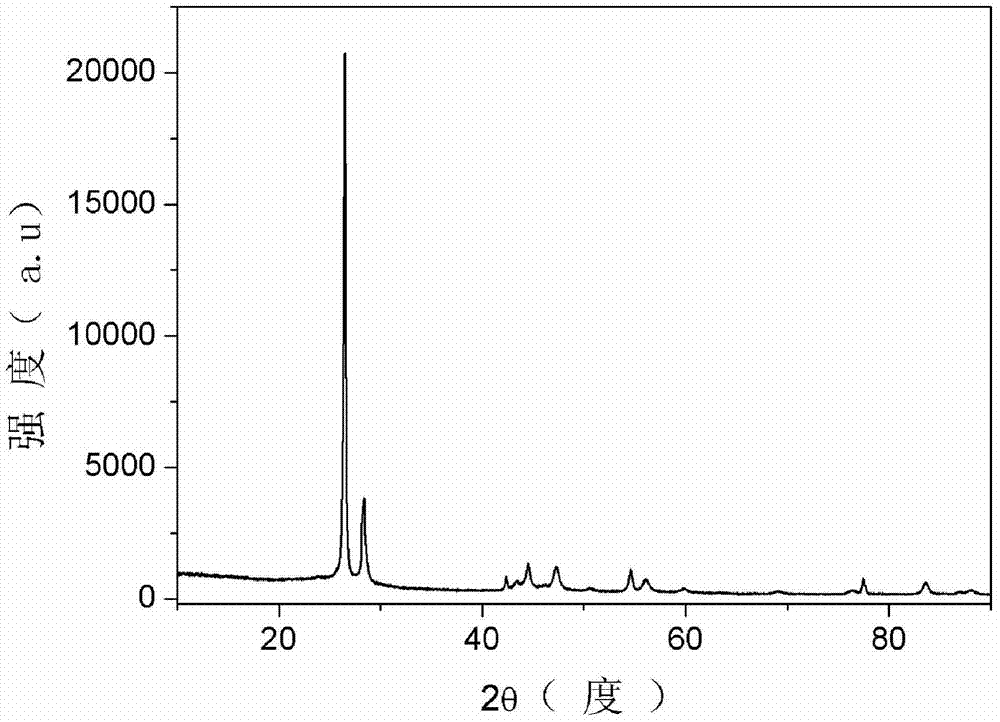

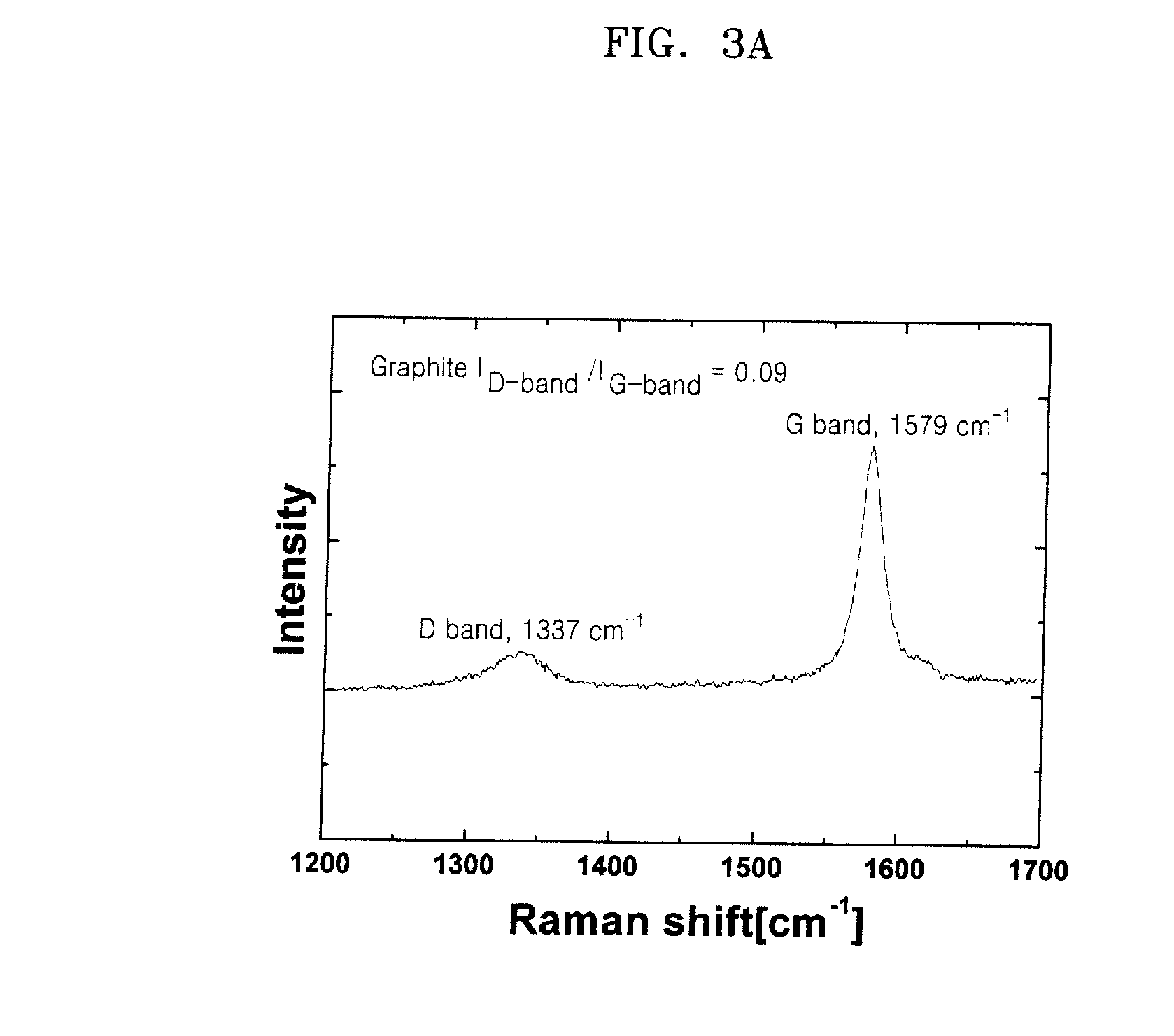

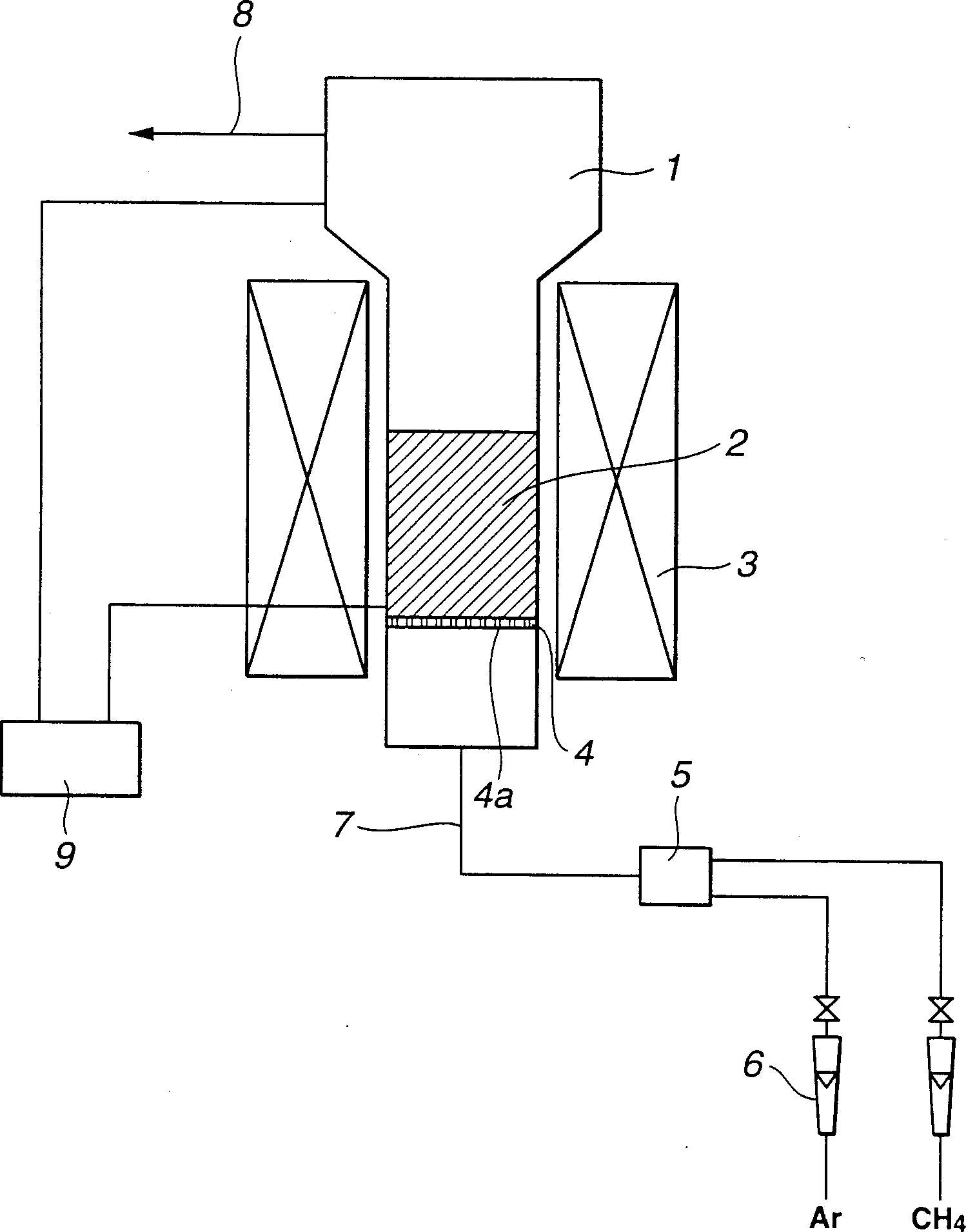

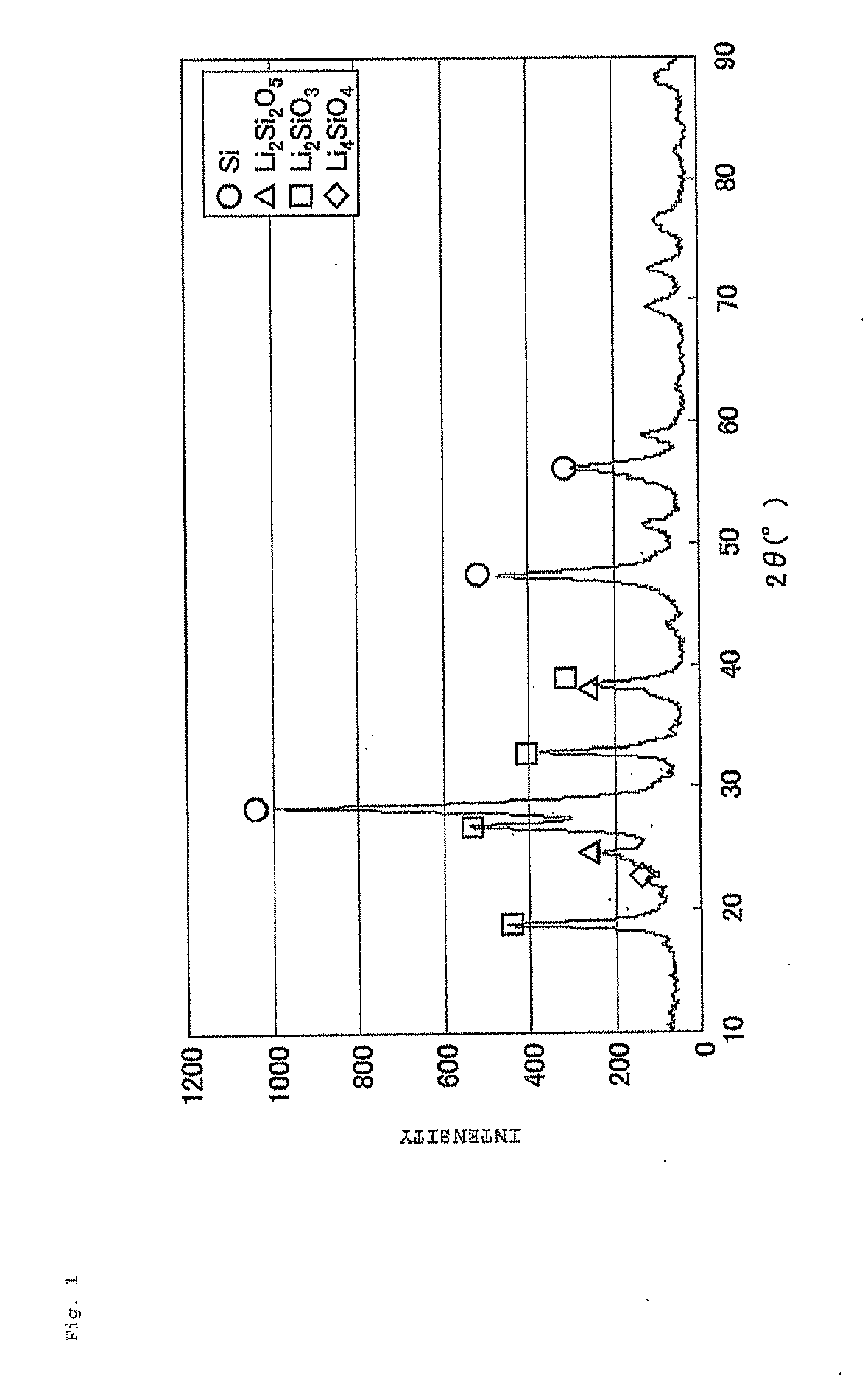

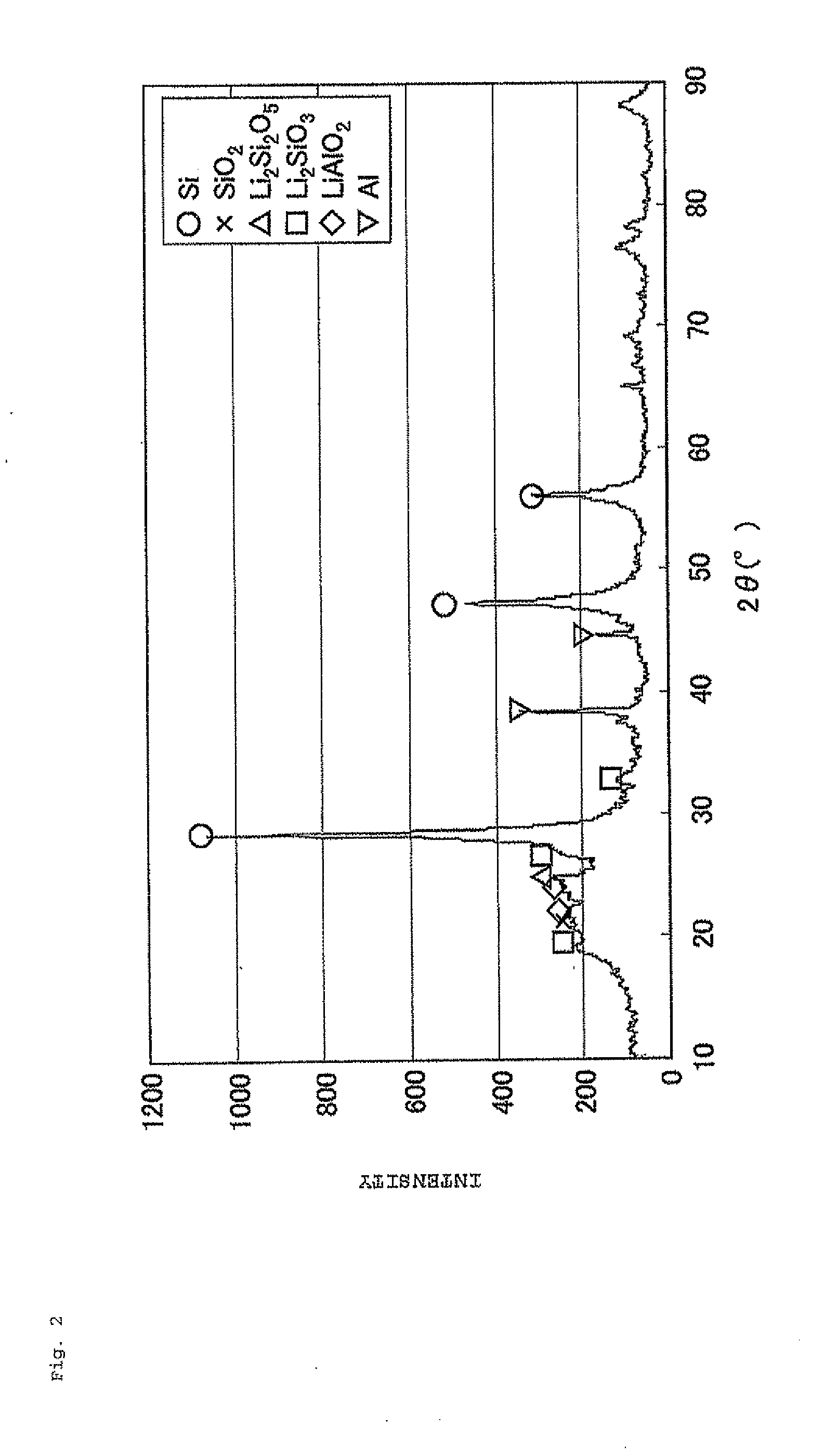

Negative electrode material for secondary battery with non-aqueous electrolyte, method for manufacturing negative electrode material for secondary battery with non-aqueous electrolyte, and lithium ion secondary battery

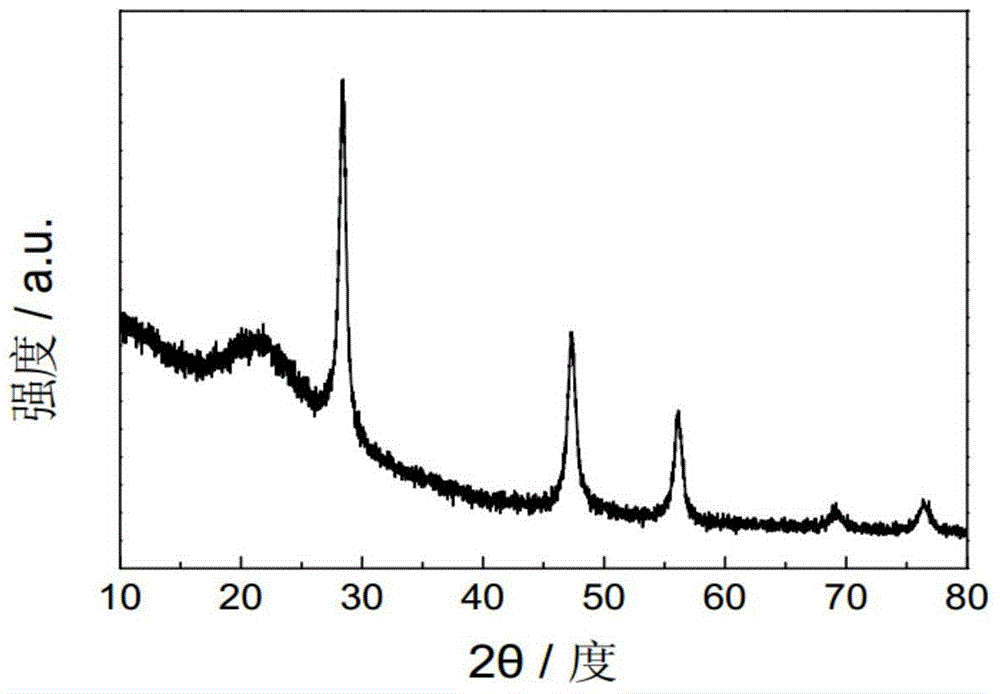

ActiveUS20110244334A1Large capacityHigh cycle durabilityFinal product manufactureLi-accumulatorsCarbon coatingX-ray

The present invention is a negative electrode material for a secondary battery with a non-aqueous electrolyte comprising at least a silicon-silicon oxide composite and a carbon coating formed on a surface of the silicon-silicon oxide composite, wherein at least the silicon-silicon oxide composite is doped with lithium, and a ratio I(SiC) / I(Si) of a peak intensity I(SiC) attributable to SiC of 2θ=35.8±0.2° to a peak intensity I(Si) attributable to Si of 2θ=28.4±0.2° satisfies a relation of I(SiC) / I(Si)≦0.03, when x-ray diffraction using Cu—Kα ray. As a result, there is provided a negative electrode material for a secondary battery with a non-aqueous electrolyte that is superior in first efficiency and cycle durability to a conventional negative electrode material.

Owner:SHIN ETSU CHEM IND CO LTD

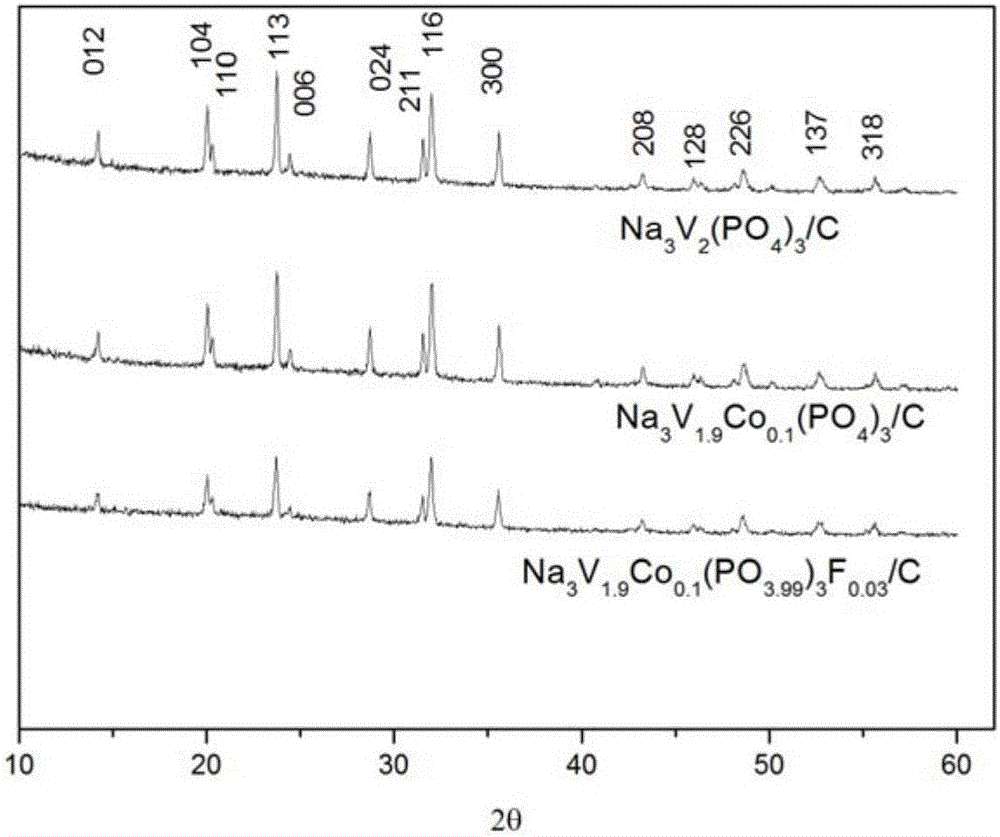

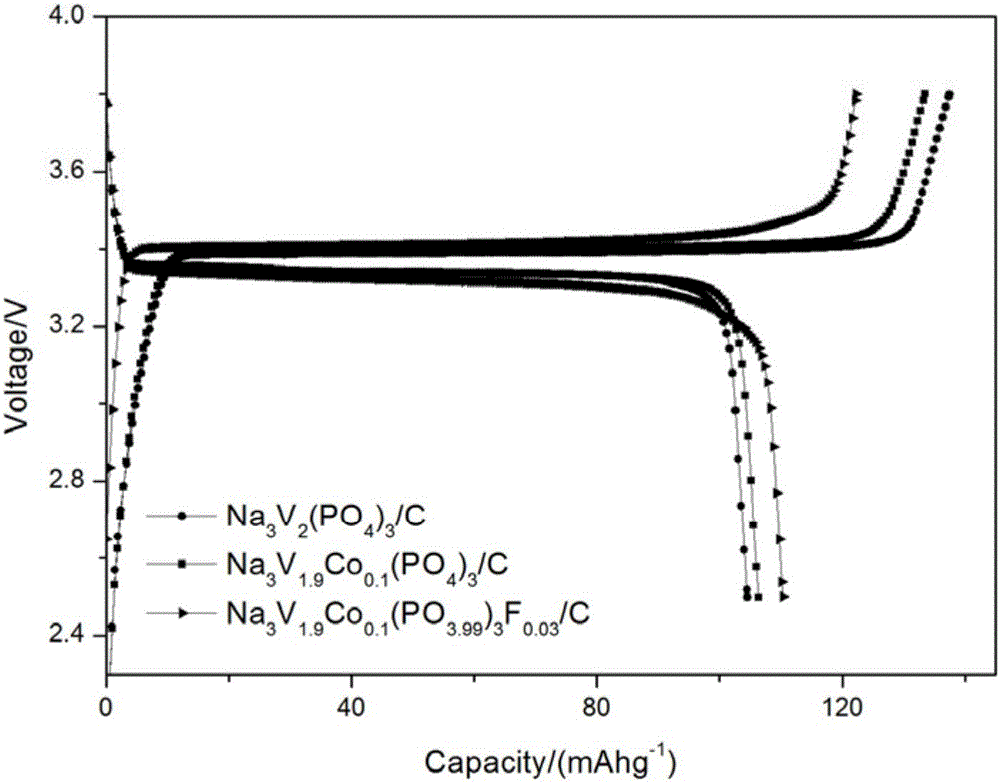

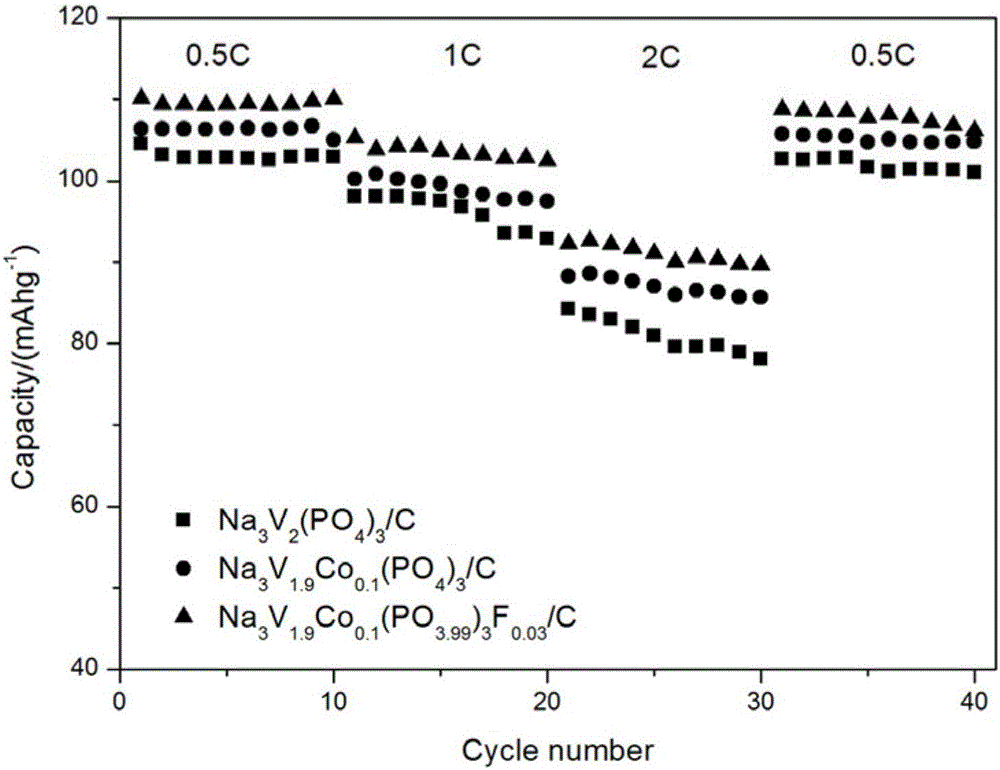

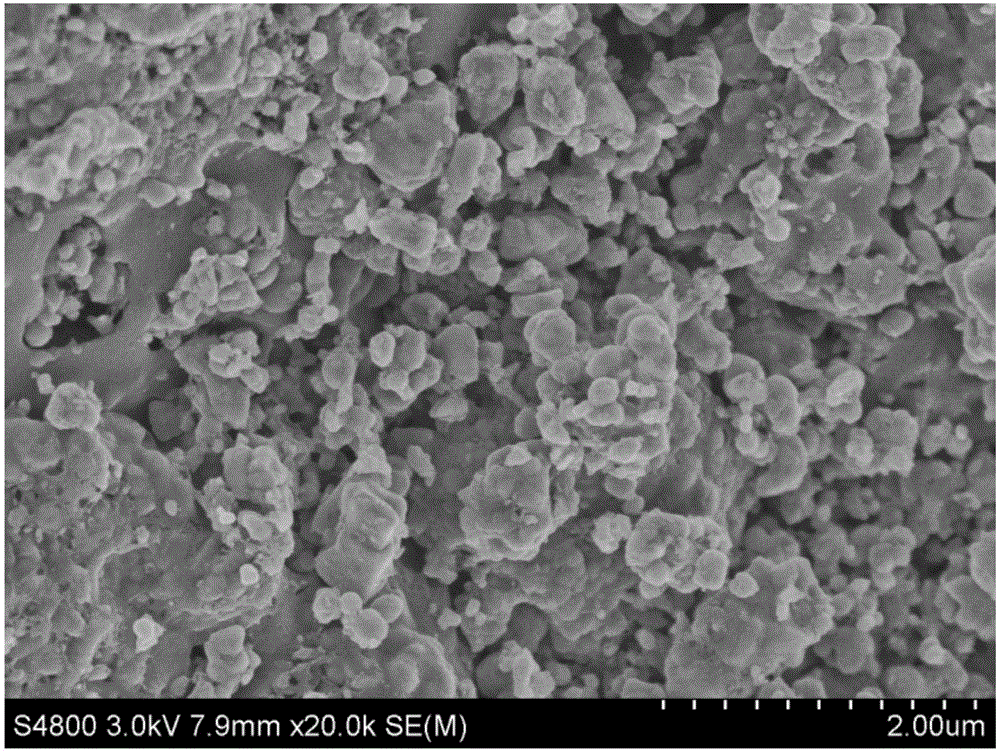

Material with mixture of ions with sodium vanadium phosphate cathode material coated by carbon and preparing method thereof

ActiveCN106328911AImprove electronic conductivityImprove electrochemical performanceCell electrodesSecondary cellsCarbon coatingPhysical chemistry

The invention discloses material with mixture of ions with sodium vanadium phosphate cathode material coated by carbon and a preparing method thereof, characterized in that the general formula of sodium vanadium phosphate cathode material is Na3V2-xMx(PO4-y)3Y3y / C, wherein 0<x<=0.2, 0><y<=0.05, M is Al, Fe, Cr, Ni, Co, Mg, Zn, La, Cu, Mn, Ti, Mo, Sn, Sr, Nb, Ce or Y, Y is For Cl. Through the carbon coating and the doping modification with ions for sodium vanadium phosphate cathode material, the electron conductivity of the material is improved and the electron-chemical property of material can be improved obviously.

Owner:HEFEI UNIV OF TECH

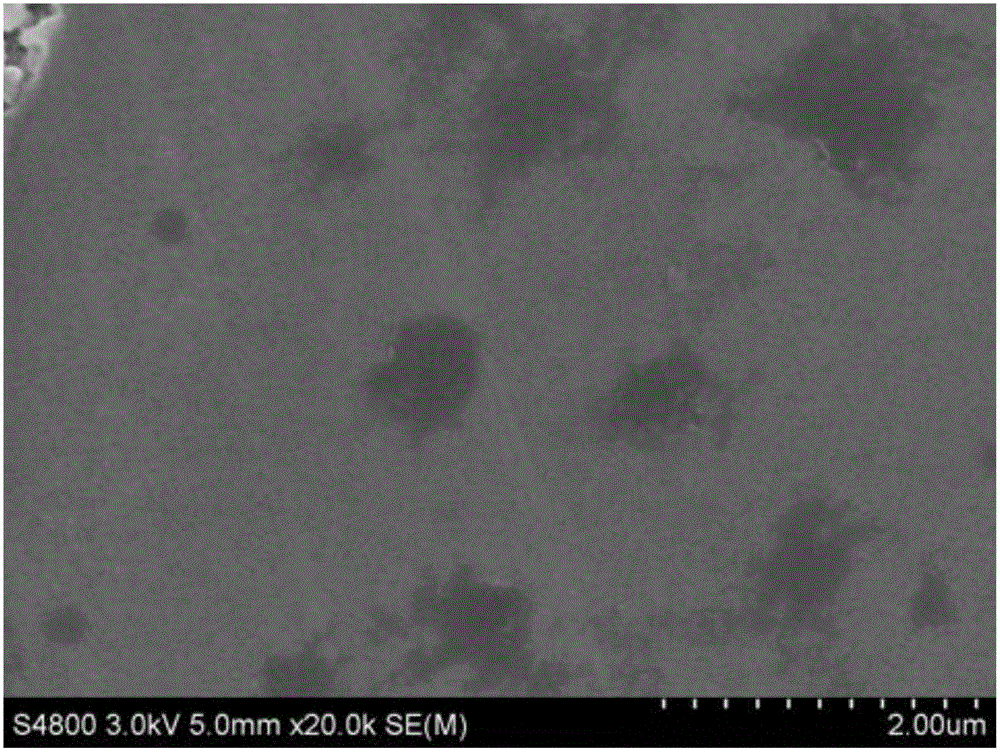

Method for performing carbon coating modification on nano-powder by adopting water-soluble polymer

InactiveCN103035899AInhibition of agglomerationHigh performance advantageCell electrodesCarbon coatingActive agent

The invention discloses a method for performing carbon coating modification on nano-powder by adopting a water-soluble polymer. The method comprises the following steps: weighing the water-soluble polymer (such as one or more of industrial modified starch, glucose and the like), surface active agent and the nano-powder according to the weight ratio of (0.1-10) : (0-5) : (80-100) as solid raw materials, preparing slurry with a dissolution and dispersion agent according to the solid-liquid ratio of (1-1000) g / 50mL, uniformly stirring and dispersing, then performing suction filtration (or centrifugation) and drying to get a precursor, and then annealing at the temperature of 300 DEG C-700 DEG C under a protective atmosphere to get the nano-powder with good carbon-coating property. According to the method disclosed by the invention, the surface uniform carbon coating can be effectively performed on nano-material, electron and ion migration ratio in the material can be accelerated, the agglomeration of the nano-material can be inhibited, the void ratio and the like of the material can be improved, and the performance advantages of the nano-material can be further enhanced.

Owner:山东天润丰新能源科技有限公司

High efficiency self-stripping high temperature oxidation-prevention/decarbonization coating material

The invention relates to a coating material for metal heat treatment process, especially a protective coating material for preventing oxidation / decarburization of steel workpieces during heat treatment heating. Composed of binder and its formula by weight percentage is: 10-20% glass powder, 33-30% quartz sand, 23-20% silica sand, 24-20% Al2O3, 2-10% C; this high-efficiency self-stripping High-temperature anti-oxidation / decarburization coating material, widely applicable to anti-oxidation / decarburization of various steels when heated at 800-1200°C / 4-10 hours, and can be naturally peeled off in the subsequent cooling process. The surface of the steel workpiece after heat treatment still has the original metallic luster, and the surface layer of the steel workpiece still maintains the original chemical composition; this coating material is easy to use, has excellent anti-oxidation / decarburization effects, strong natural peeling ability, and wide applicability .

Owner:CENT SOUTH UNIV

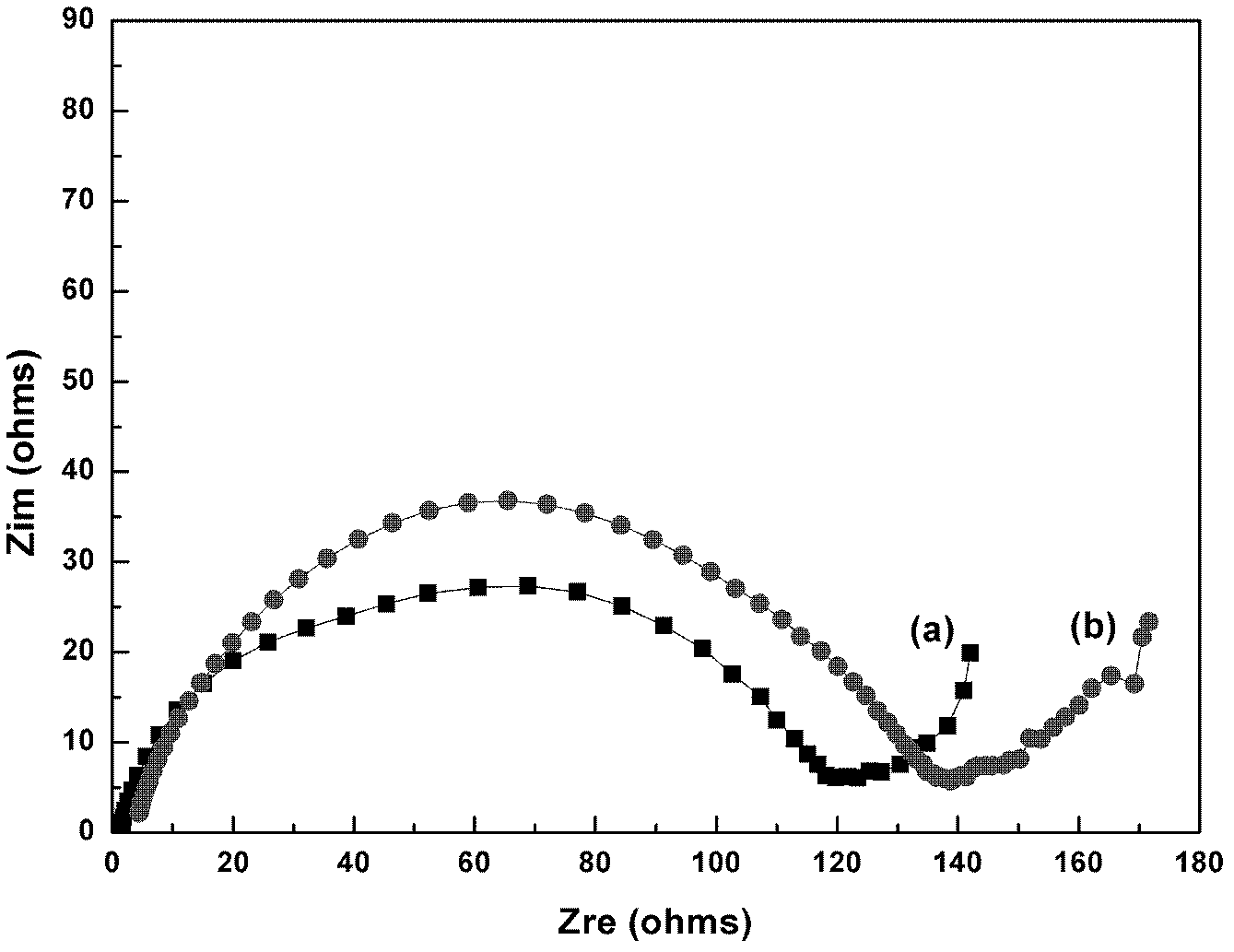

Positive electrode of lithium sulfur battery and preparation method thereof

ActiveCN102569816AImprove corrosion resistanceNot oxidizedNon-aqueous electrolyte accumulator electrodesCarbon coatingInternal resistance

The invention discloses a positive electrode of a lithium sulfur battery and a preparation method of the positive electrode of the lithium sulfur battery. The positive electrode of the lithium sulfur battery comprises two parts, namely a carbon coating layer with low-active substance content on a current collector and an active layer with high-active substance content. The carbon coating layer on the surface of the current collector can improve the corrosion resistance of the current collector and prevent the current collector from being oxidized or corroded chemically. The positive electrode with the structure reduces the interface impedance of the current collector and the active layer, the electric conduction of the positive electrode of the battery is enhanced, and the volume volatilization of active substance materials is facilitated. The positive electrode with the structure is applied to the lithium sulfur battery, beneficial to the reduction of the internal resistance of the battery, prolongs to the cycle life of the battery and improves the multiplying power property of the battery.

Owner:CENT SOUTH UNIV

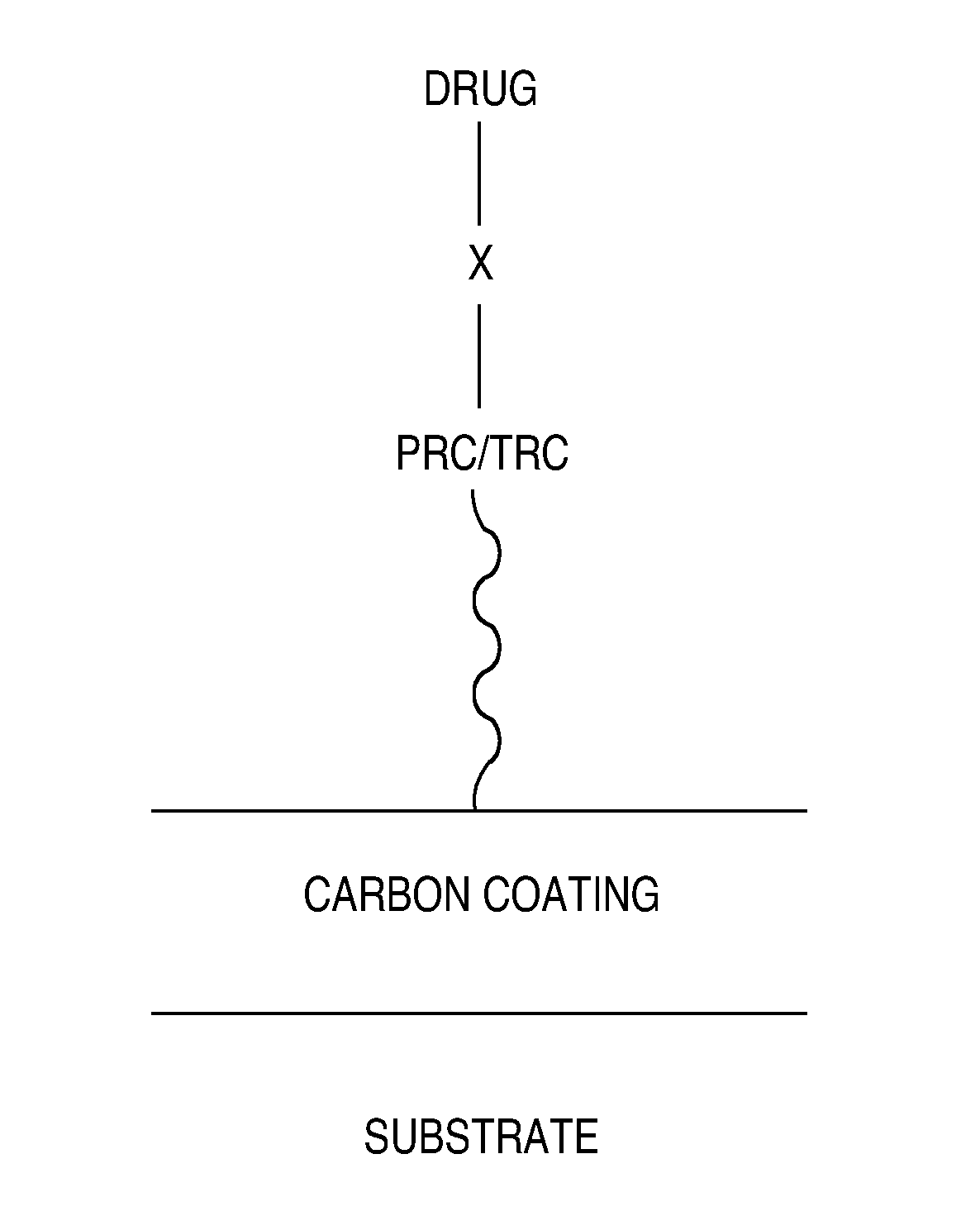

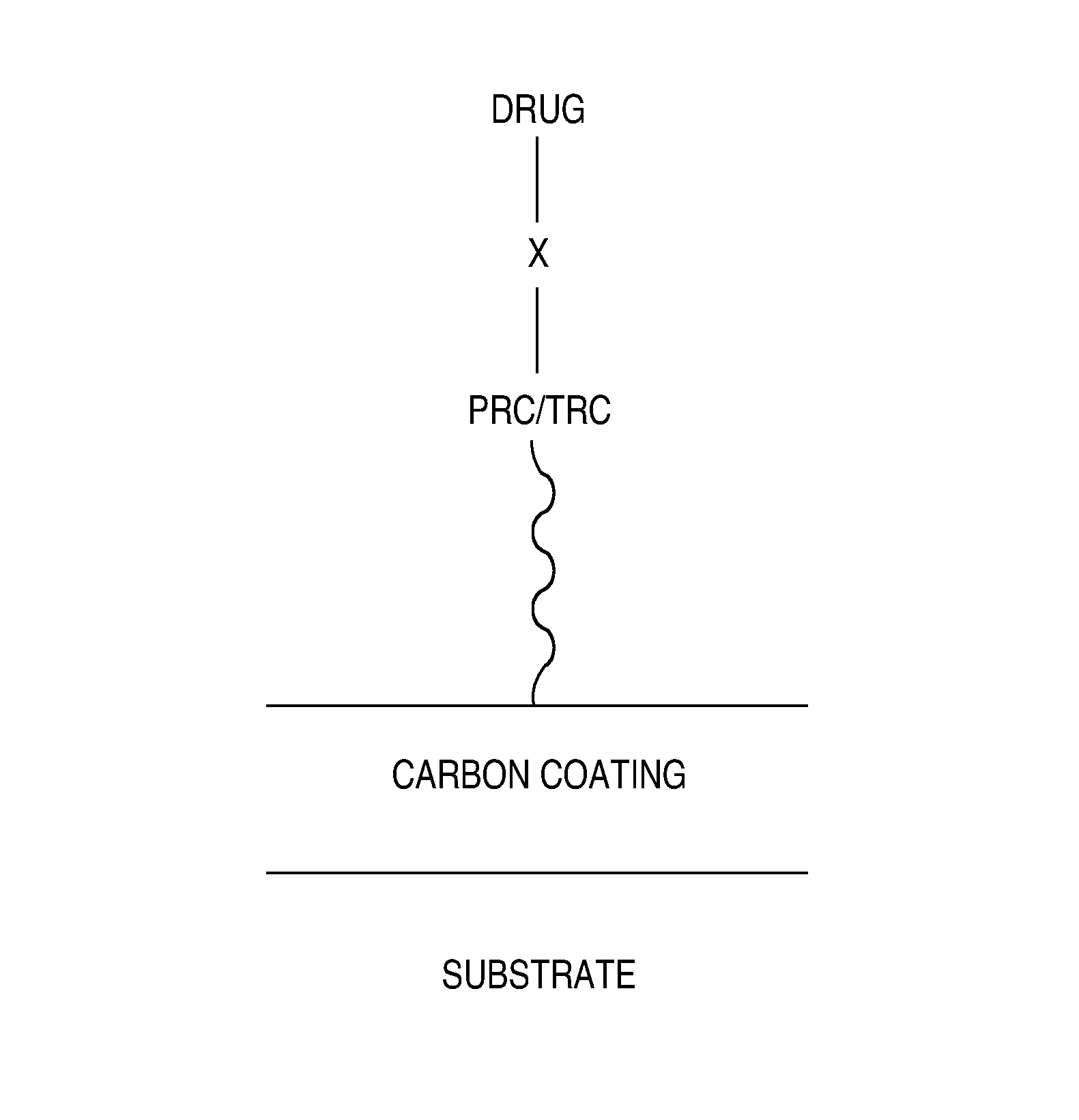

Carbon coating on an implantable device

InactiveUS8128688B2Reduce early or late thrombosisHigh degreeSurgeryPhotomechanical apparatusCarbon coatingActive agent

Owner:ABBOTT CARDIOVASCULAR

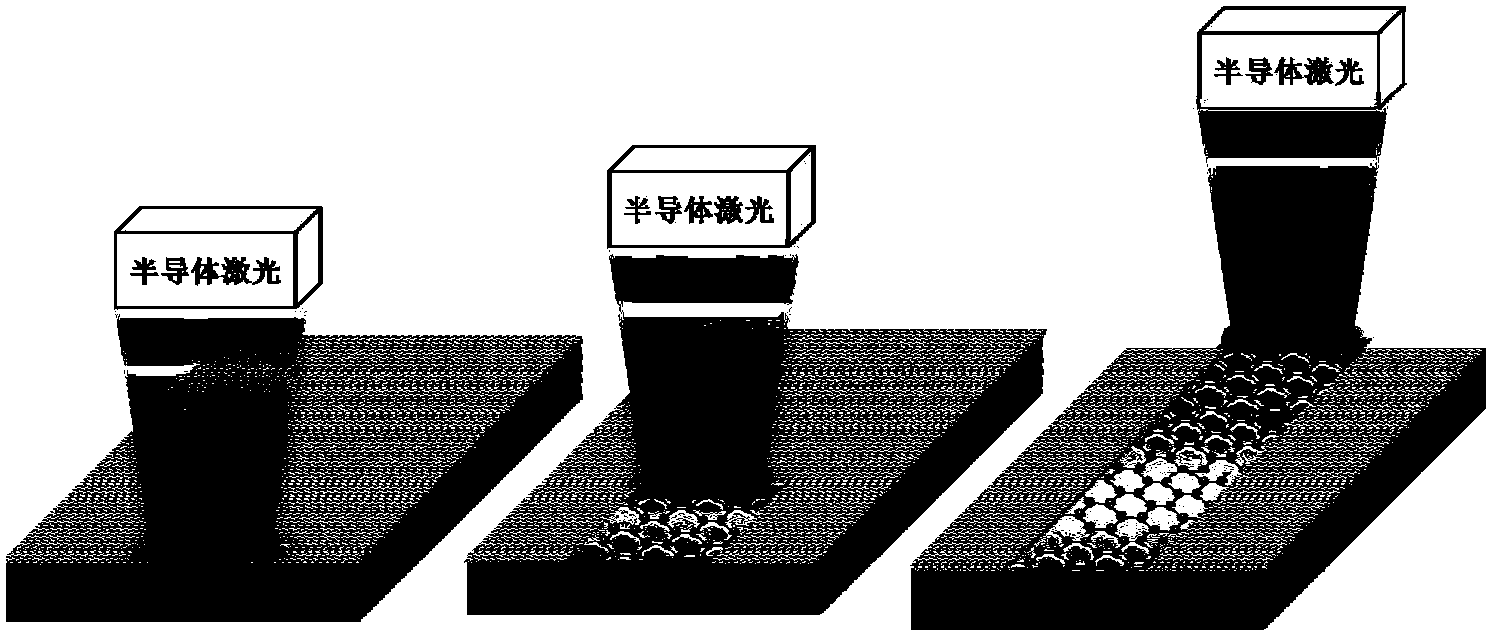

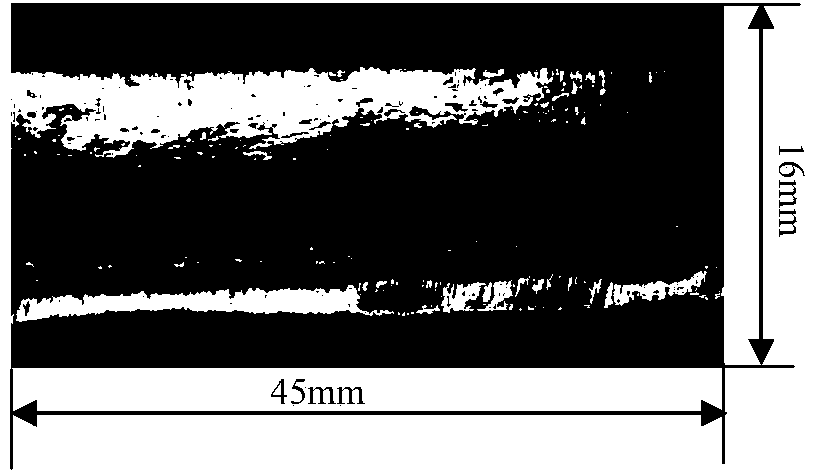

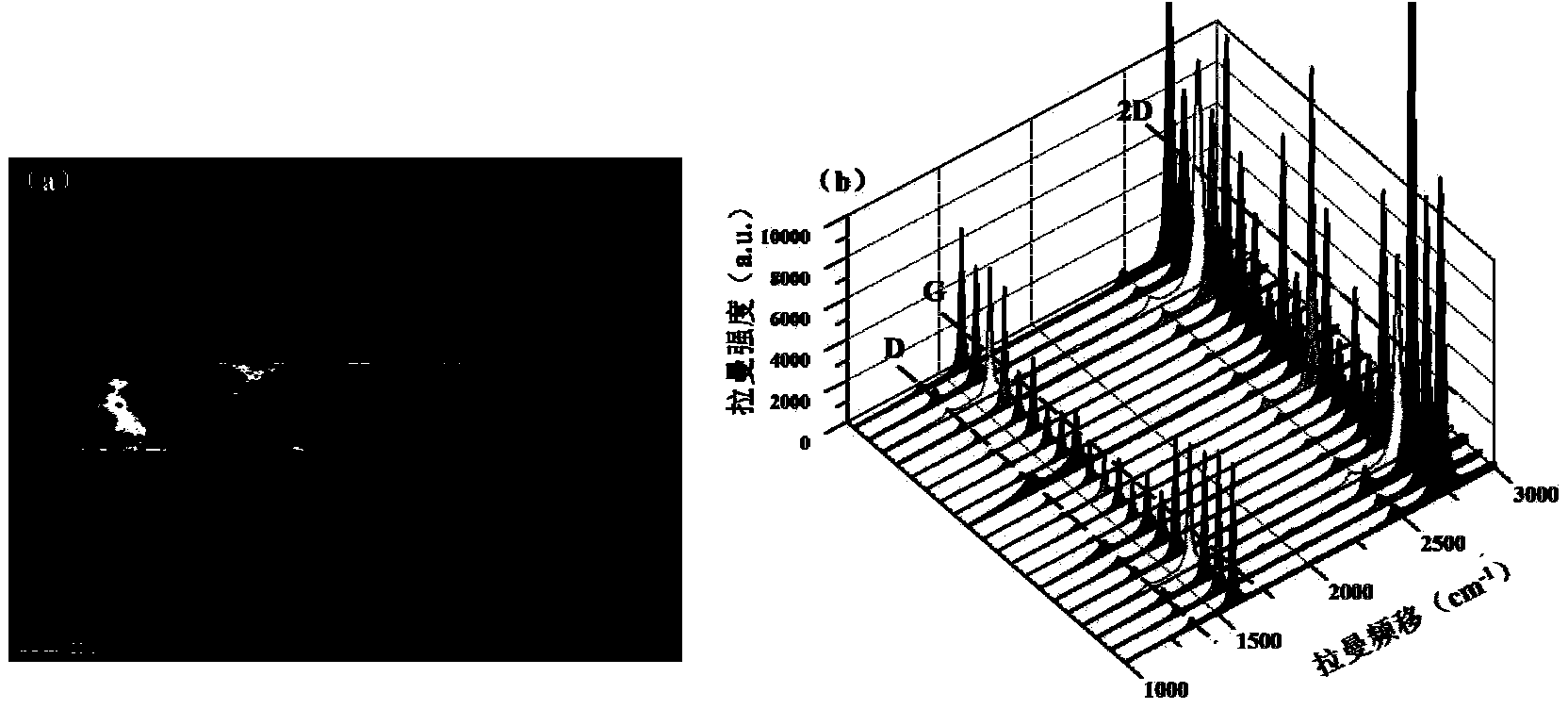

Laser preparation method for large-area patterned graphene

The invention discloses a laser preparation method for large-area patterned graphene. The preparation method comprises the following steps: (1) a solid carbon source is dispersed in an organic solvent to obtain a dispersion liquid, and the surface of a metal substrate is coated with the dispersion liquid in a spinning manner to obtain a uniform carbon coating; (2) under the condition of the protection of inert gas, a high power density laser beam is adopted to irradiate the carbon coating, and carbon atoms in the solid carbon source and metal atoms in the metal substrate are formed into a solid solution under function of irradiation; the high power density laser beam is moved away or the irradiation operation is stopped, when the metal substrate is cooled, the oversaturated solid solution is formed, and the carbon atoms are separated out of the oversaturated solid solution and formed on the surface of the substrate to form graphene. The invention provides a novel method which is convenient, fast, low in cost and high in efficiency and prepares the large-area patterned graphene. The product obtained through the method can be applied to the following fields: next generation microcomputers, flat-panel displays, super-capacitors, transparent conductive electrodes, sensors, solar batteries, micro-nano electronic devices, photoelectronic devices, self-spinning quantum devices, novel compound materials and so on.

Owner:TSINGHUA UNIV

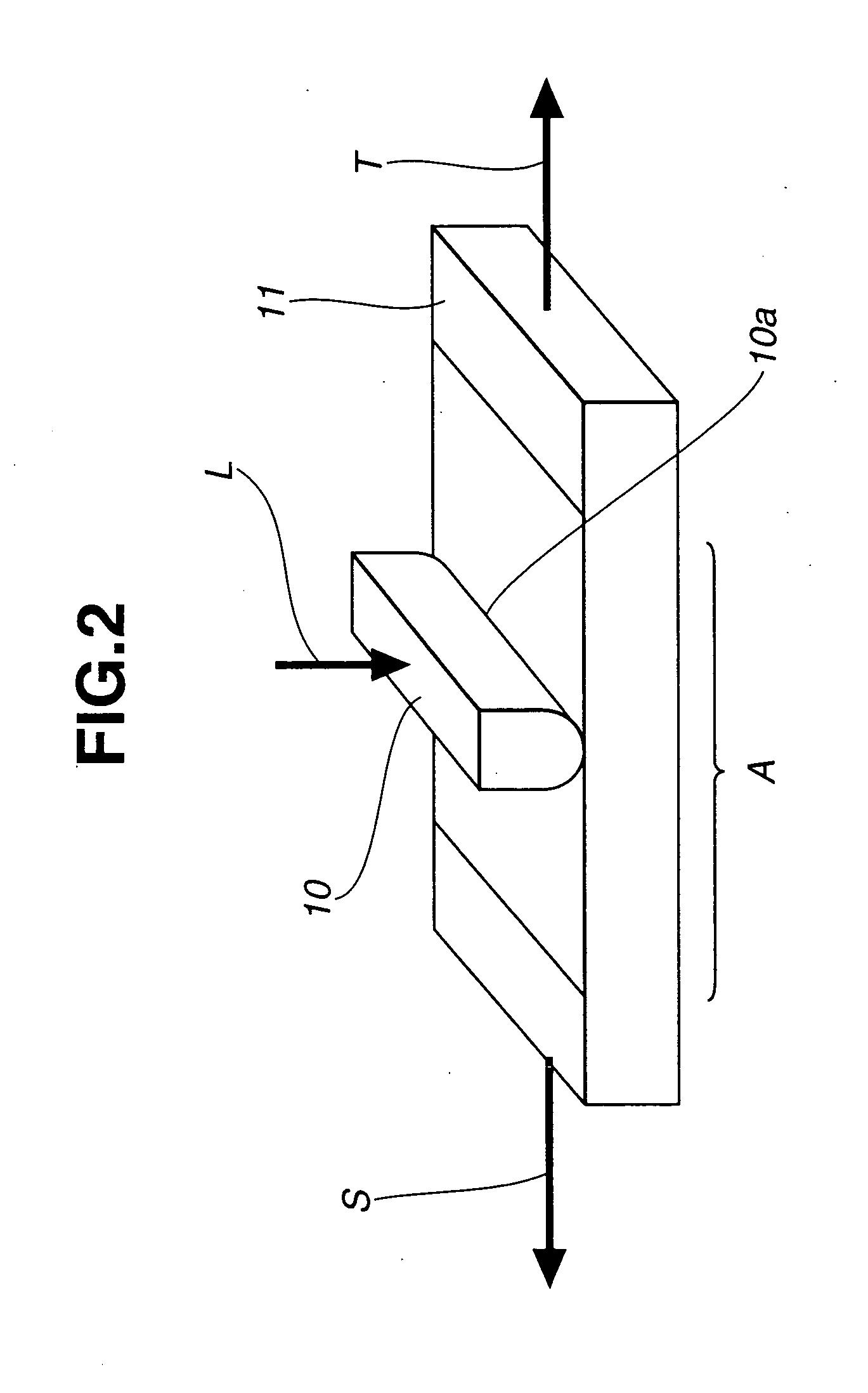

Sliding member and production process thereof

ActiveUS20050100701A1Excellent low-friction characteristicIncreased durabilityPiston ringsVacuum evaporation coatingCarbon coatingMetallurgy

There is provided a sliding member including a base body and a hard carbon coating formed on the base body to define a sliding surface for sliding contact with an opposing member under lubrication according to one embodiment of the present invention. The hard carbon coating has an outermost surface portion lower in hydrogen content than a remaining portion thereof, or an outermost coating layer lower in hydrogen content than at least one other coating layer.

Owner:NISSAN MOTOR CO LTD

Lithium ion battery SiO composite material as well as preparation method and application thereof

ActiveCN104638237AImprove the first Coulombic efficiencyImprove capacity playCell electrodesSecondary cellsCarbon coatingHigh rate

The invention relates to a lithium ion battery SiO composite material which comprises powder and a conductive carbon coating layer, wherein the chemical formula of the powder is SiOx; x is greater than 0.9 and less than 1.1; the volume of powder with particle diameters below 1.0mu m accounts for less than 15.0% of that of all the SiOx powder; D90 / D10 is greater than 3.0 and less than 15.0; D90 is less than 25.0mu m; Dmax is less than 50.0mu m; and the median particle diameterD50 of the SiOx changes within 0.5-2.0mu m before and after carbon coating. When the composite material charges and discharges at 0-1.5V as a lithium ion battery cathode material, the reversible specific capacity is high (over 1,650mAh / g), the initial coulomb efficiency is up to a theoretical value (over 79.0%), and meanwhile the composite material has excellent cycle performance, excellent conductive performance and low volume expansion, is suitable for high-rate charge and discharge, and can be applied to the power market.

Owner:BTR NEW MATERIAL GRP CO LTD

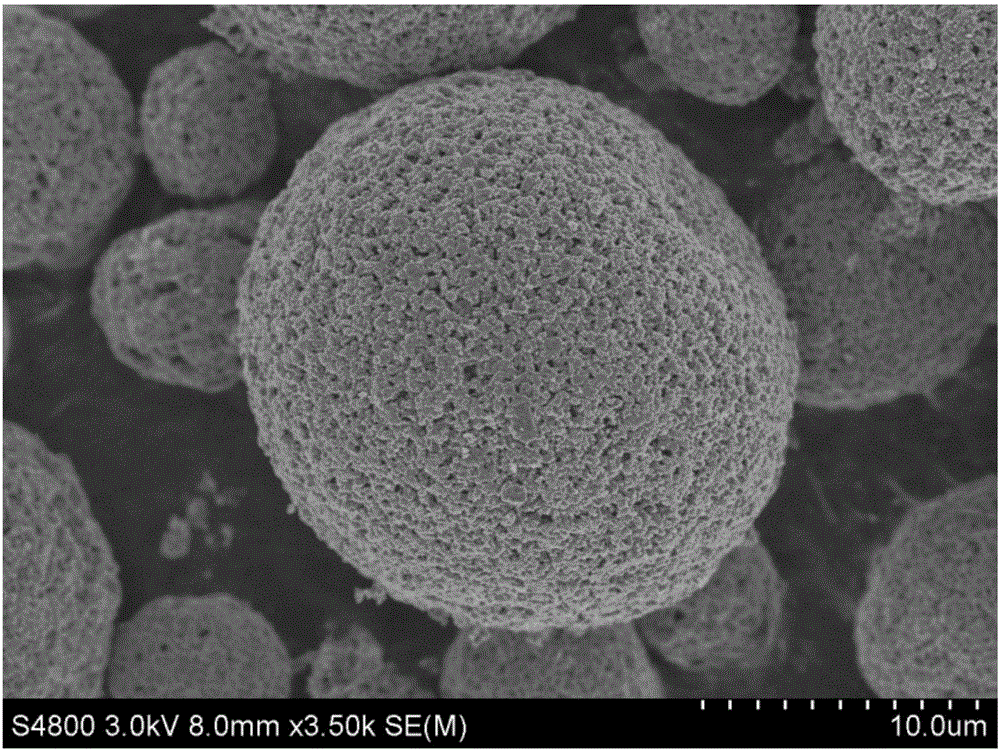

Sodium-titanium phosphate/carbon composite material and preparation method and use thereof

InactiveCN106784696AUneven solutionImprove uniformityCell electrodesSecondary cellsCarbon layerCarbon coating

The invention belongs to the field of electrode material synthesis, and relates to a sodium-titanium phosphate / carbon composite material and a preparation method and use thereof. The sodium-titanium phosphate / carbon composite material comprises secondary particles formed by clustering primary particles, the primary particles comprise sodium-titanium phosphate particles and carbon layers coated on the surfaces of the sodium-titanium phosphate particles, and the carbon layers are prepared through two times of carbon coating. According to the sodium-titanium phosphate / carbon composite material and the preparation method and use thereof, by means of preparing a precursor of the sodium-titanium phosphate and then adopting a spray drying method to carry out primary carbon coating and secondary carbon coating, the sodium-titanium phosphate / carbon composite material having a uniform and compact coating carbon layer is prepared, and the problem that the coating carbon layer obtained by the primary carbon coating is not uniform is solved. The composite material is good in stability, electrodes prepared from the sodium-titanium phosphate / carbon composite material and assembled batteries have excellent electrochemical properties, the discharge capacity is above 115mAh / g, and the capacity retention ratio is above 95% after 500 weeks of circulation.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

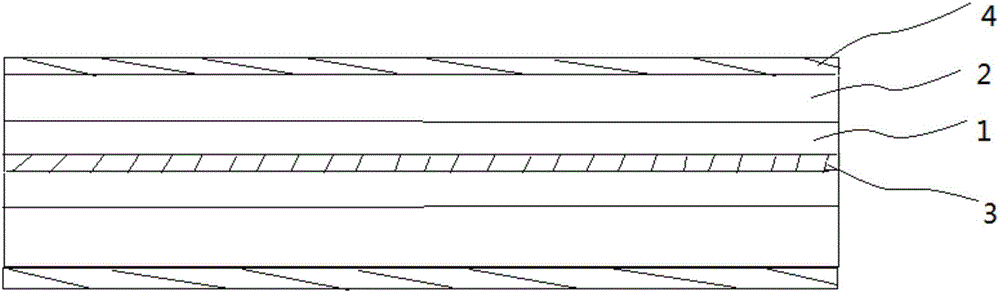

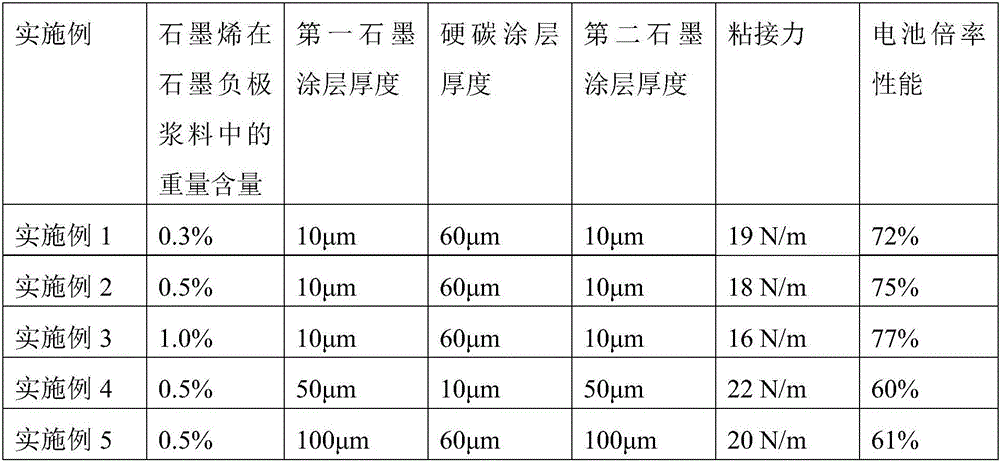

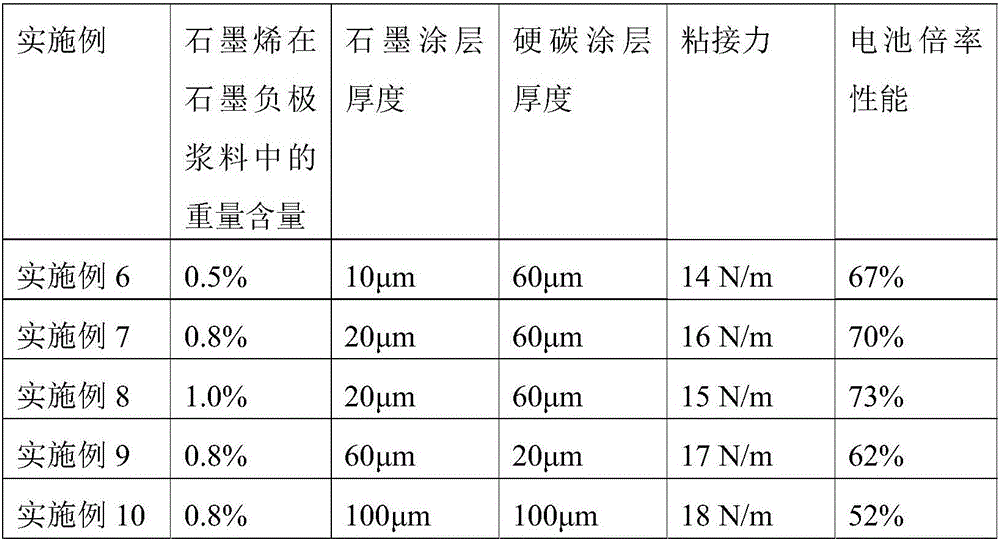

Pole piece of negative electrode and preparation method of pole piece as well as lithium-ion battery using negative electrode

InactiveCN106058154AIncrease compaction densityImprove dynamic performanceCell electrodesSecondary cellsCarbon coatingPole piece

The invention relates to the field of lithium-ion battery materials and in particular relates to a pole piece of a negative electrode and a lithium-ion battery using the negative electrode. The pole piece of the negative electrode, provided by the invention, comprises a negative electrode current collector, a graphite coating and a hard carbon coating; graphene is used as a conductive agent and is added into the graphite coating, so that on one hand, dynamics properties of the graphite coating can be improved; on the other hand, the lubrication effect of the graphene conductive agent is utilized, so that damage to materials by residual stress caused by cold pressing can be reduced, and the compaction density of the negative electrode is improved. A corresponding negative electrode preparation method is simple and feasible, and the materials do not need to be modified, so that the manufacturing cost of battery cells is reduced.

Owner:DONGGUAN AMPEREX TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com