Sodium-titanium phosphate/carbon composite material and preparation method and use thereof

A carbon composite material, sodium titanium phosphate technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems affecting sodium ion batteries, low capacity of sodium titanium phosphate, uneven carbon coating, etc. The layer is uniform and dense, the gram capacity is improved, and the uniformity is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Preparation of sodium titanium phosphate / carbon composite:

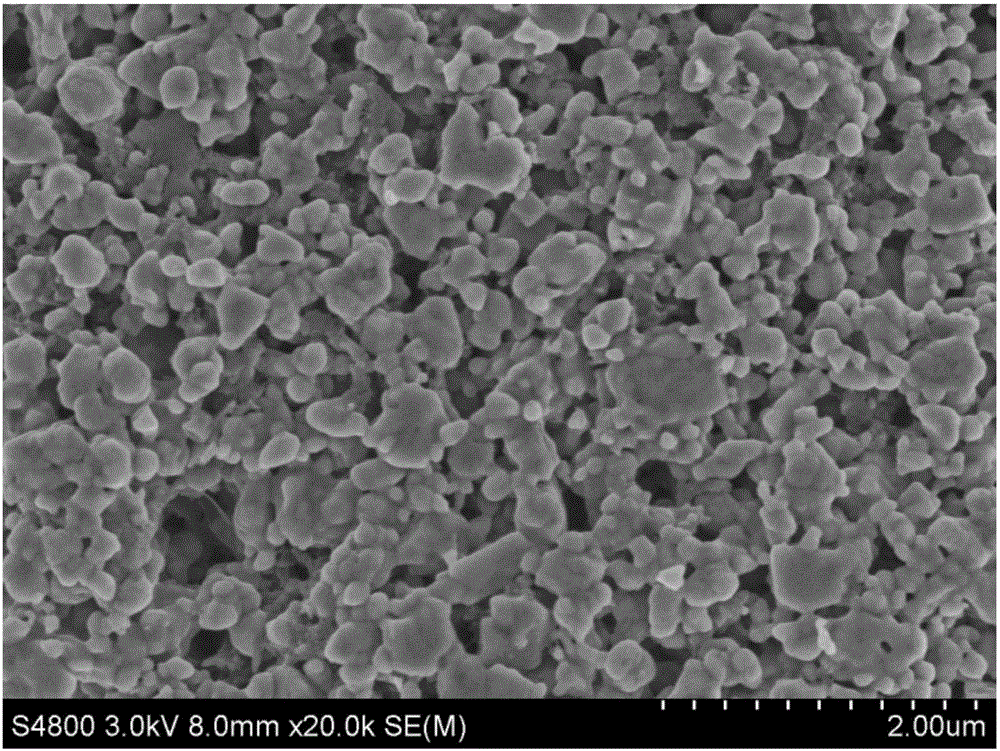

[0061] Mix sodium carbonate, titanium dioxide, and ammonium dihydrogen phosphate to obtain a precursor, make the molar ratio of Na:Ti:P in the precursor 1:2:3, add citric acid according to 10% of the total mass of the precursor, and then press the Add ethanol to 50% of the total mass of the body for ball milling, take out the slurry once after 5 hours, and dry it with a closed spray. Under the atmosphere, the temperature was raised to 300°C at 2°C / min, and the temperature was kept at 300°C for 6 hours to achieve primary carbon coating and obtain a primary carbon-coated product. Add super-p according to 1% of the total mass of the primary carbon-coated product, and then Add ethanol to 50% of the total mass of the primary carbon-coated product for ball milling, take out the secondary slurry after 5 hours, and dry it with a closed spray, set the air inlet temperature to 220°C, and the air outlet temperature to 75...

Embodiment 2

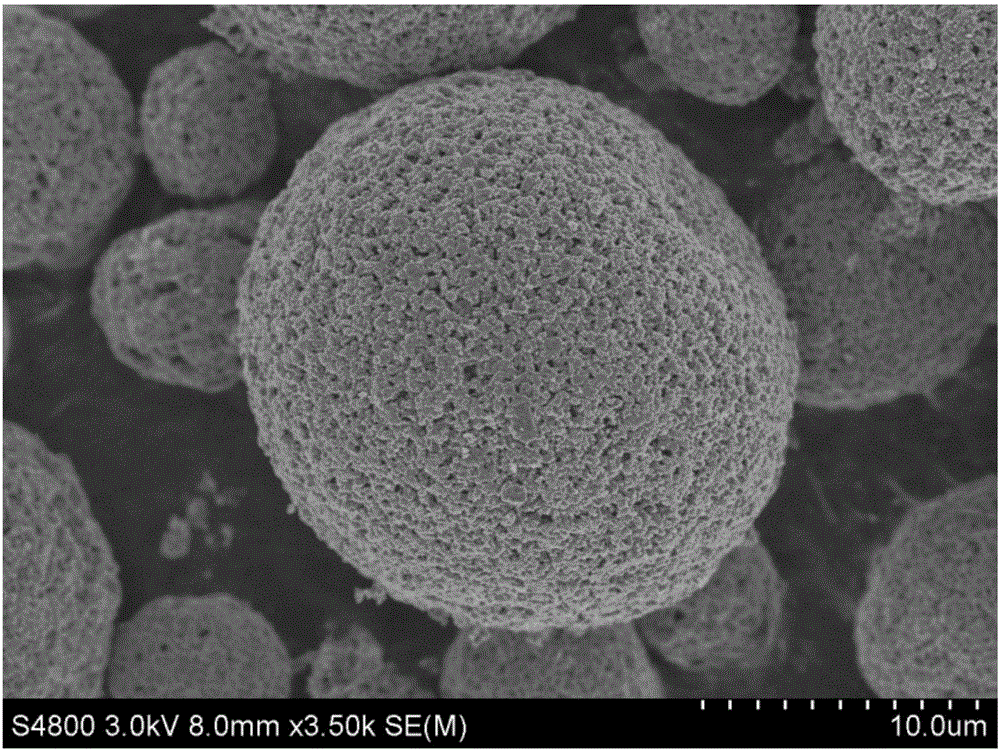

[0073] Mix sodium dihydrogen phosphate, titanium dioxide, ammonium phosphate, and magnesium acetate to obtain a precursor, so that the molar ratio of Na:Ti:P:Mg in the precursor is 1.03:1.9:3.15:0.05, according to 20% of the total mass of the precursor Add polyvinyl alcohol, then add water according to 30% of the total mass of the precursor for ball milling, take out the slurry once after 3 hours, and dry it with a closed spray, set the air inlet temperature to 250°C, and the air outlet temperature to 90°C, and then the obtained Material in N 2 Under the atmosphere, the temperature was raised to 500°C at 10°C / min, and the temperature was kept at 500°C for 10h to obtain a primary carbon-coated product. Glucose was added according to 10% of the total mass of the primary carbon-coated product, and then according to the primary carbon-coated product Add water to 30% of the total mass for ball milling, take out the secondary slurry after 5 hours, and dry it with a closed spray. 2 ...

Embodiment 3

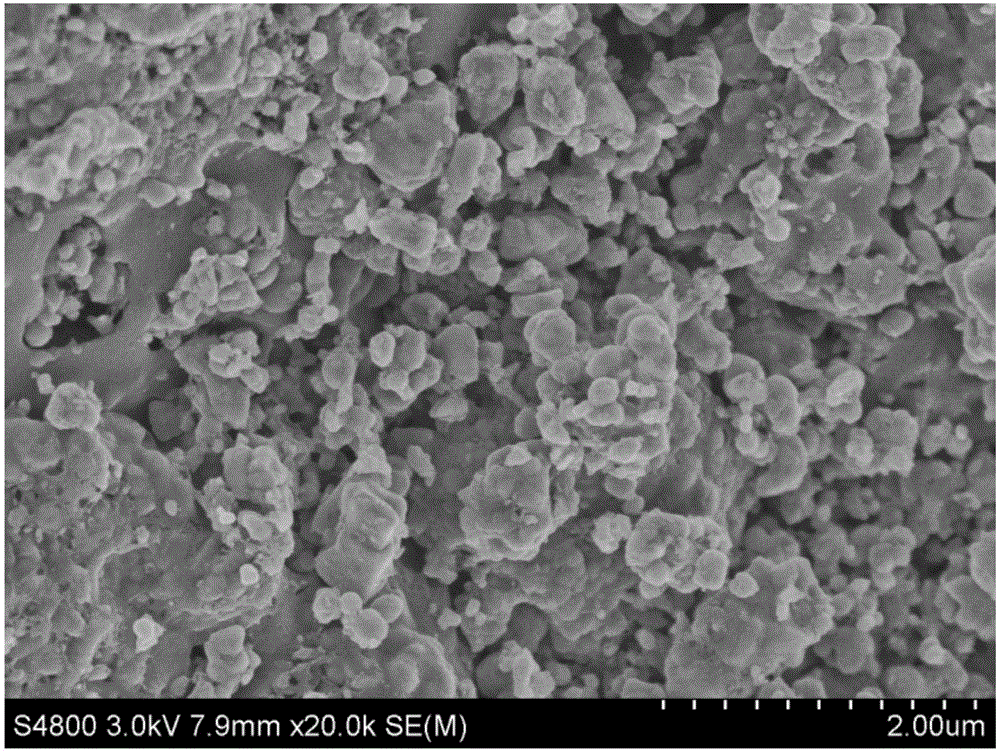

[0078] Mix disodium hydrogen phosphate, titanium hydroxide, ammonium dihydrogen phosphate, and niobium pentoxide to obtain a precursor, so that the molar ratio of Na:Ti:P:Nb in the precursor is 0.95:2.05:3:0.01, according to the precursor Add sucrose to 12% of the total mass of the precursor, then add acetone to 50% of the total mass of the precursor for ball milling, take out the slurry once after 5 hours, and dry it with a closed spray, set the air inlet temperature to 220°C, and the air outlet temperature to 75°C , and then spray-dry the material obtained in N 2The temperature was raised to 600°C at 20°C / min under the atmosphere, and the temperature was kept at 600°C for 15 hours to achieve primary carbon coating and obtain a primary carbon-coated product. Add cyclodextrin according to 5% of the total mass of the primary carbon-coated product, Then add water according to 30% of the total mass of the primary carbon-coated product for ball milling, take out the secondary slur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com