Patents

Literature

1967 results about "Material synthesis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material synthesis. Material synthesis was a development of the ancient Gree species and was a remarkable piece of technology. It allowed a reconfiguration of matter on a molecular level by changing its nuclear structure.

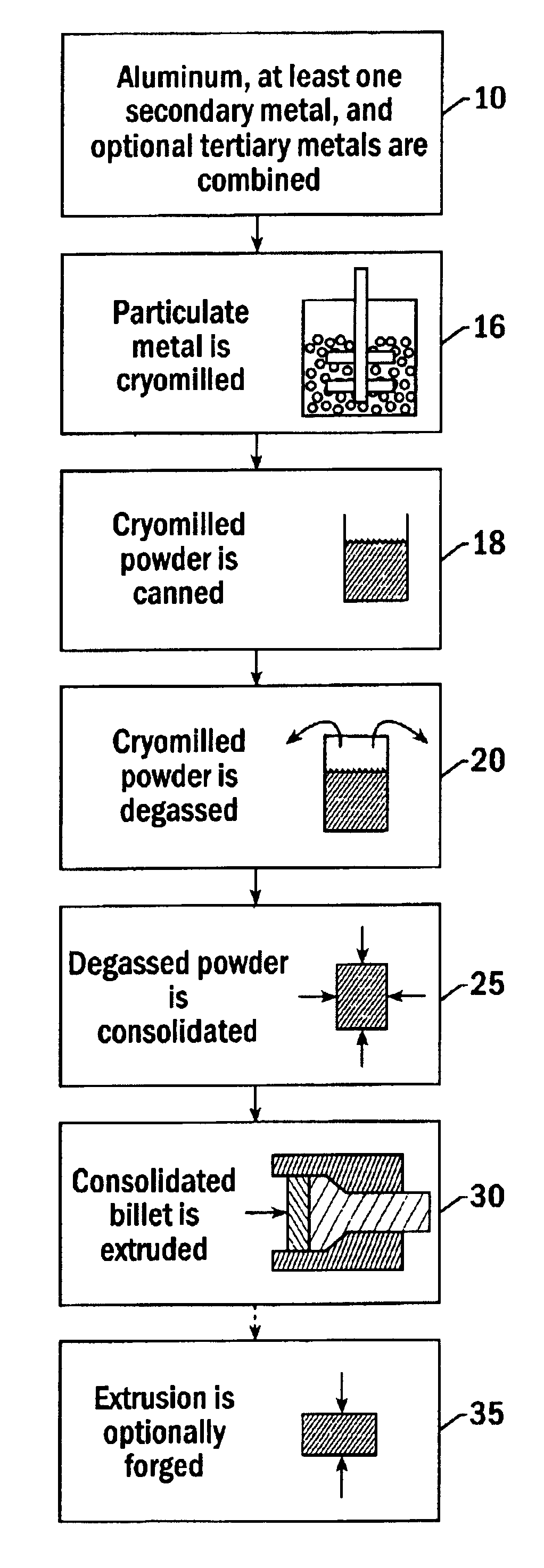

Method for preparing cryomilled aluminum alloys and components extruded and forged therefrom

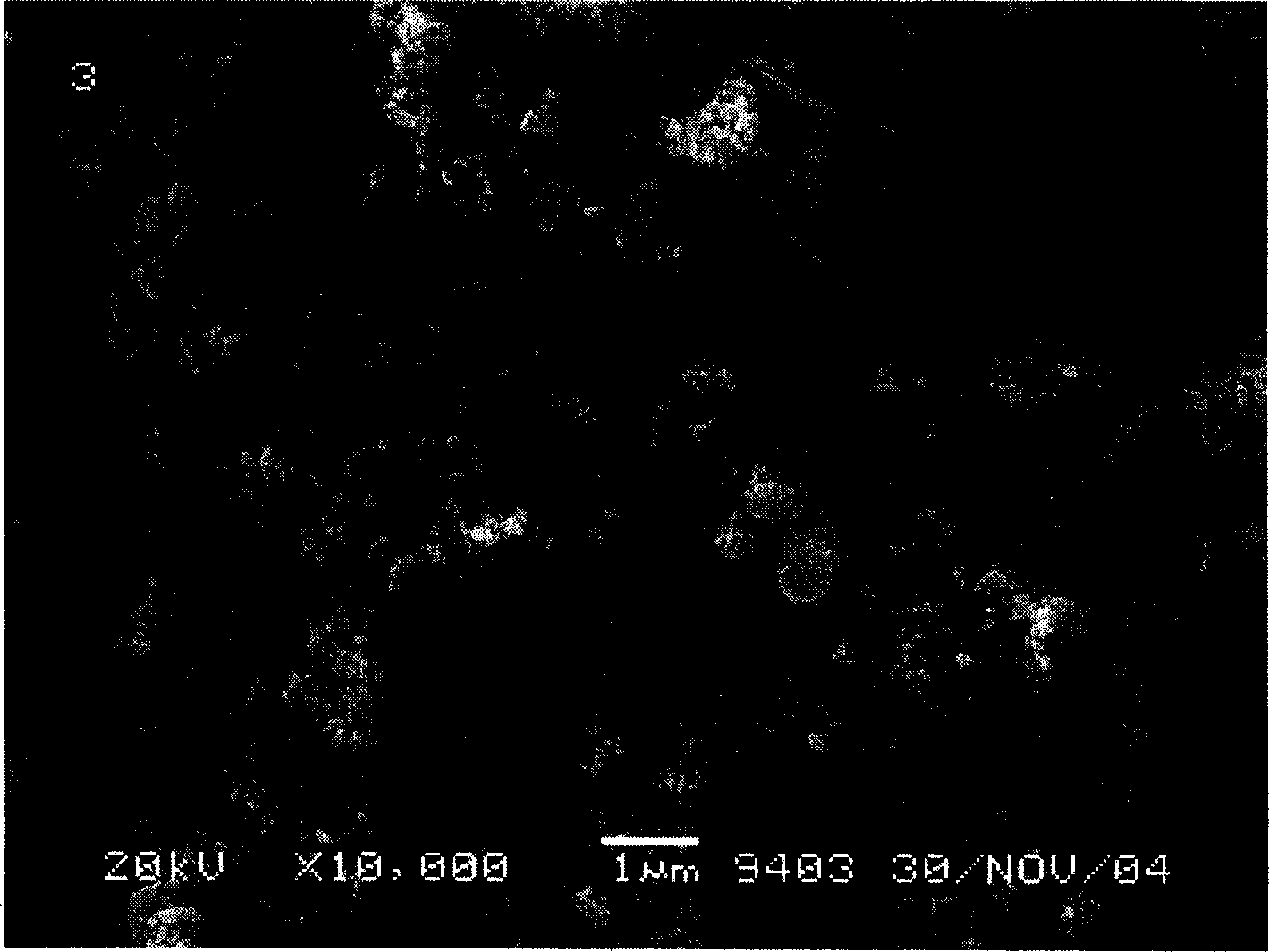

InactiveUS6902699B2Stable structureHigh strengthTransportation and packagingMetal-working apparatusNanostructureAluminium alloy

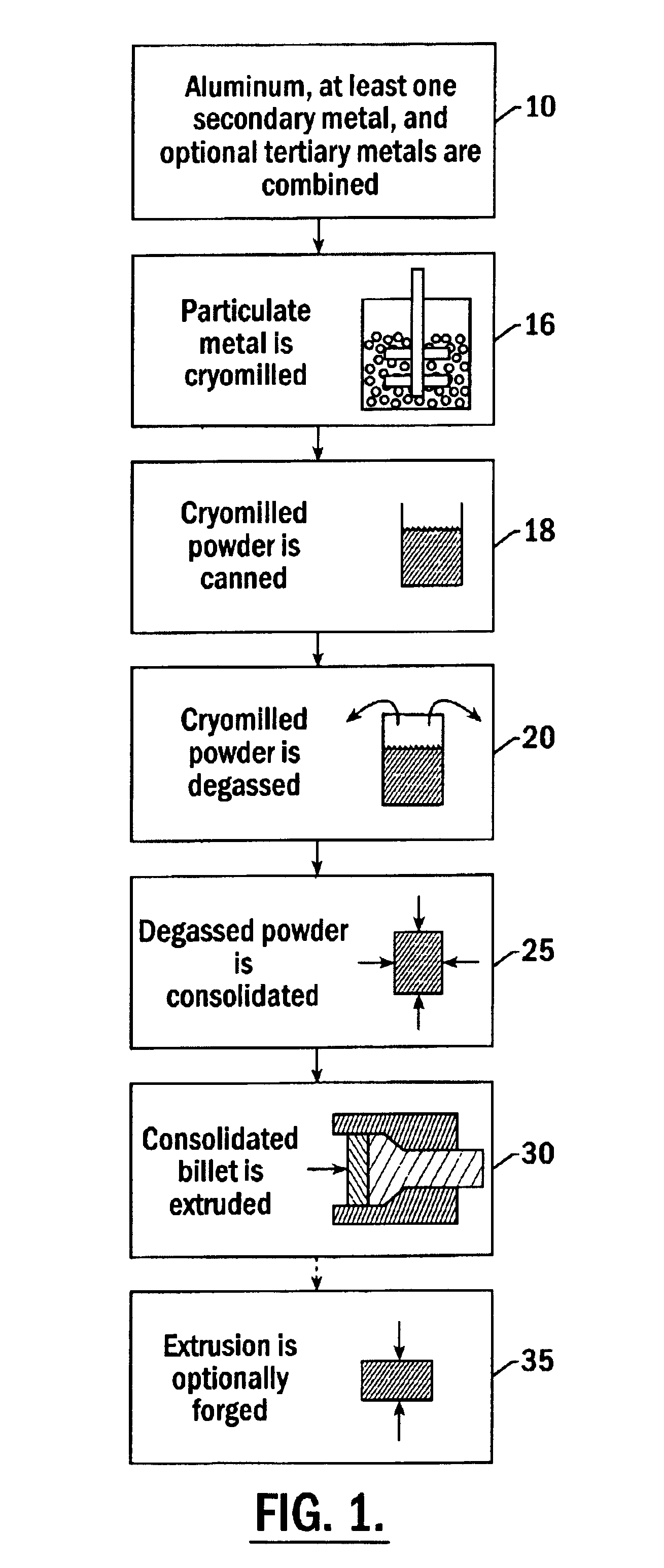

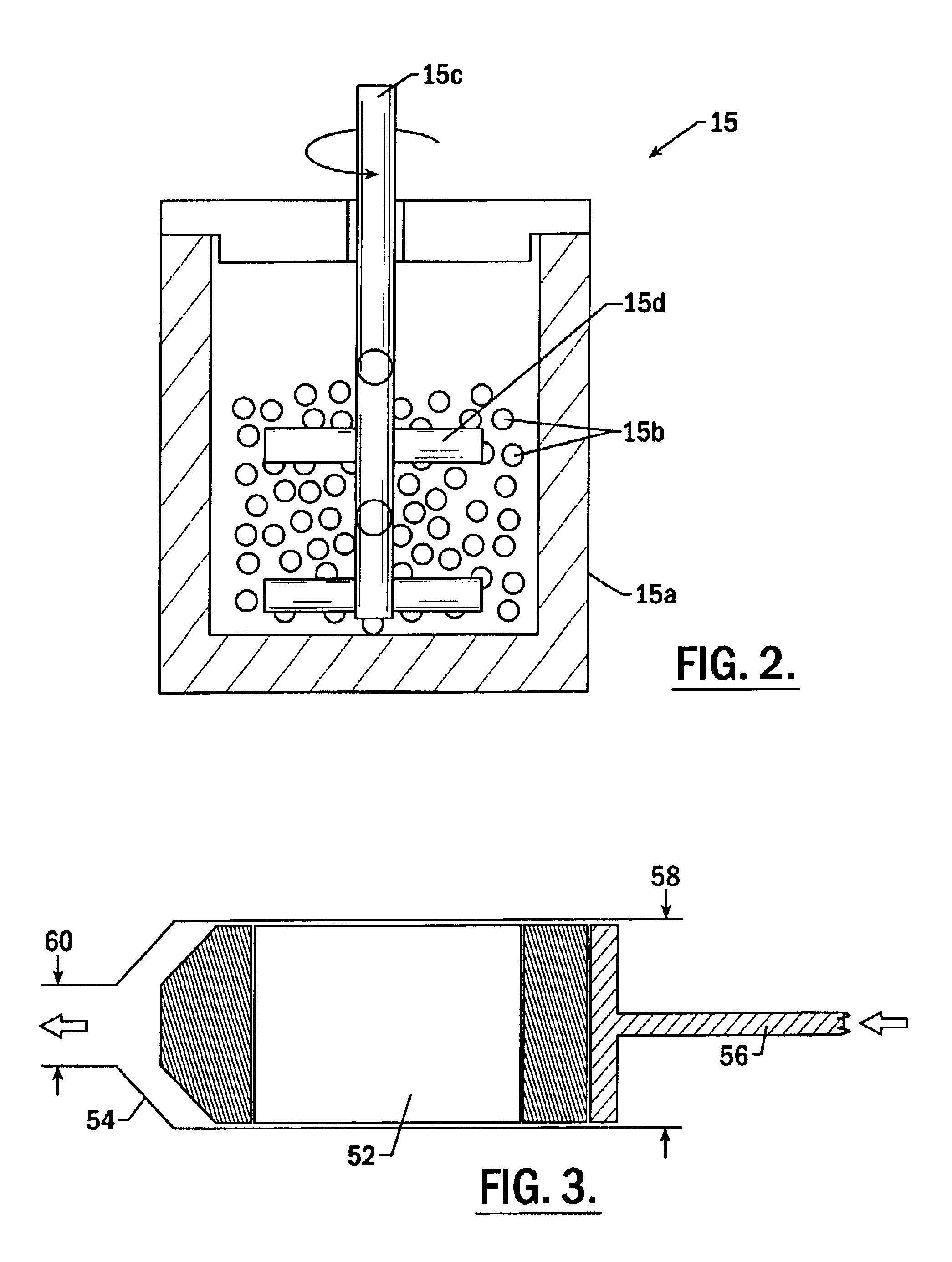

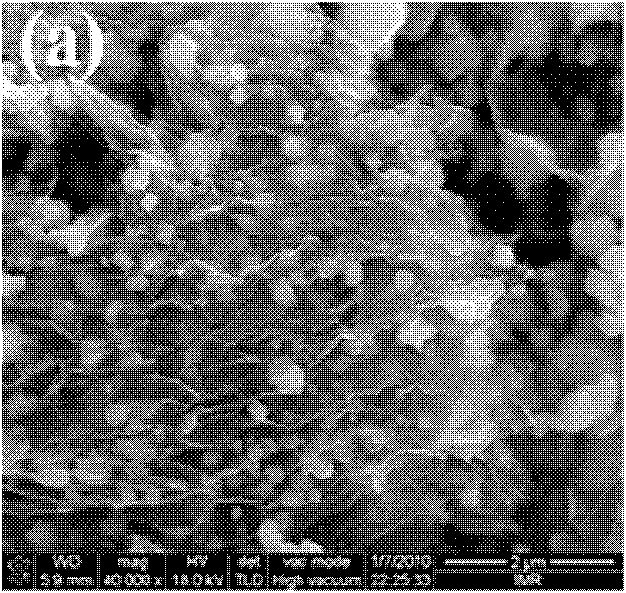

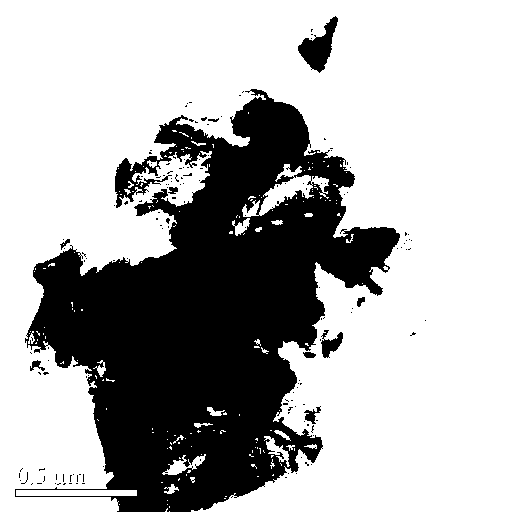

High strength aluminum alloy powders, extrusions, and forgings are provided in which the aluminum alloys exhibit high strength at atmospheric temperatures and maintain high strength and ductility at extremely low temperatures. The alloy is produced by blending about 89 atomic % to 99 atomic % aluminum, 1 atomic % to 11 atomic % of a secondary metal selected from the group consisting of magnesium, lithium, silicon, titanium, zirconium, and combinations thereof, and up to about 10 atomic % of a tertiary metal selected from the group consisting of Be, Ca, Sr, Ba, Ra, Sc, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Y, Nb, Mo, Tc, Ru, Rh, Pd, Ag, Cd, W, and combinations thereof. The alloy is produced by nanostructure material synthesis, such as cryomilling, in the absence of refractory dispersoids. The synthesized alloy is then canned, degassed, consolidated, extruded, and optionally forged into a solid metallic component. Grain size within the alloy is less than 0.5 μm, and alloys with grain size less than 0.1 μm may be produced.

Owner:THE BOEING CO

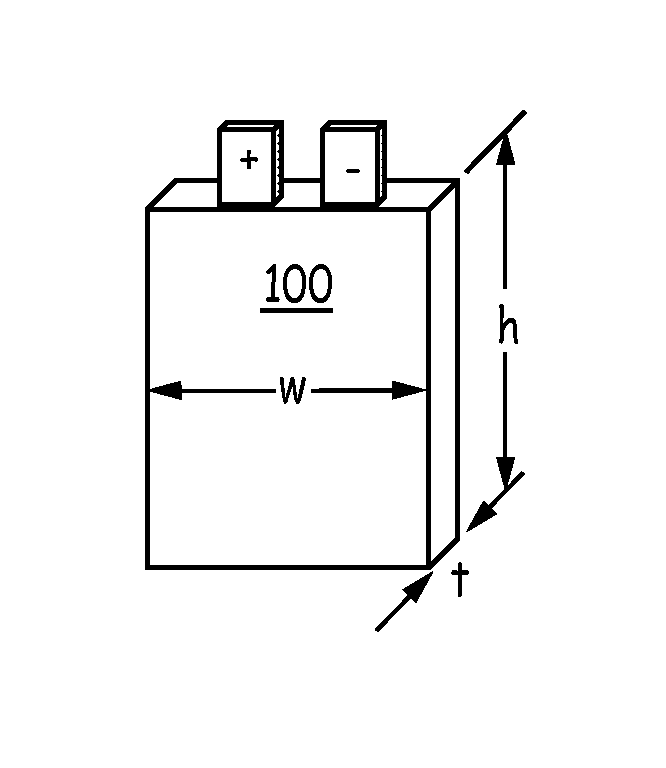

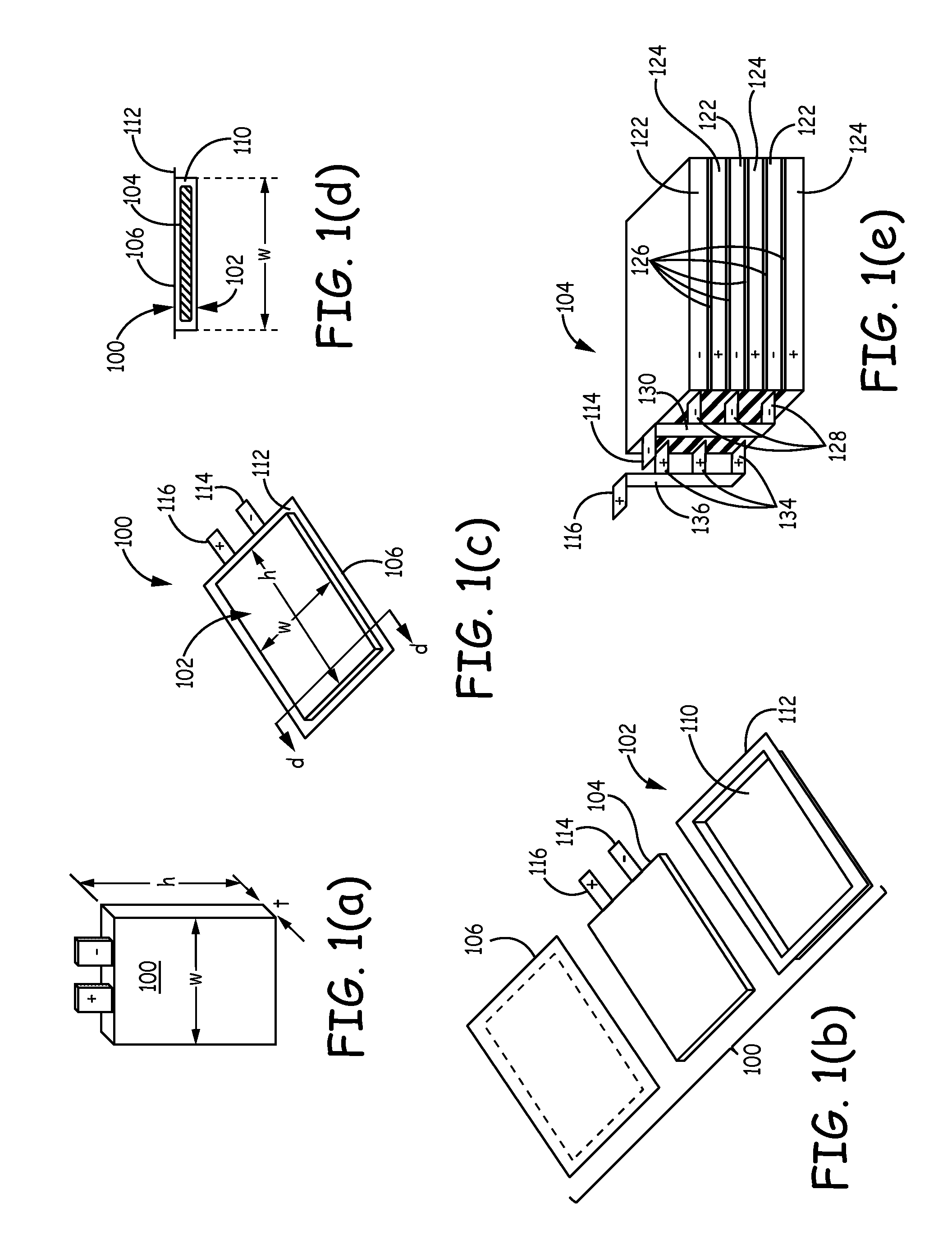

Graphene/metal oxide composite cathode material for lithium ion battery and preparation

InactiveCN102646817APromote circulationExcellent rate performanceCell electrodesHigh energyIn situ polymerization

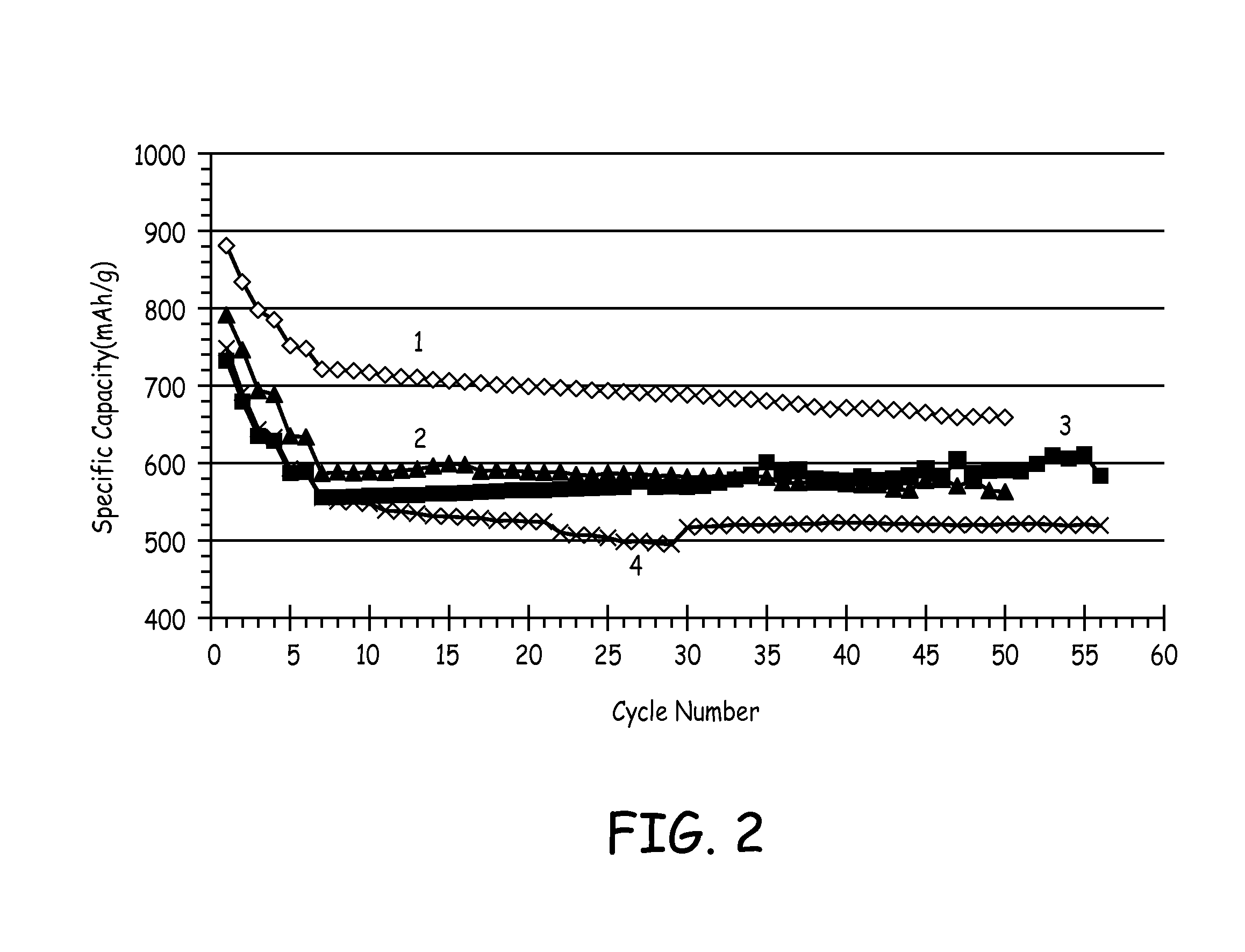

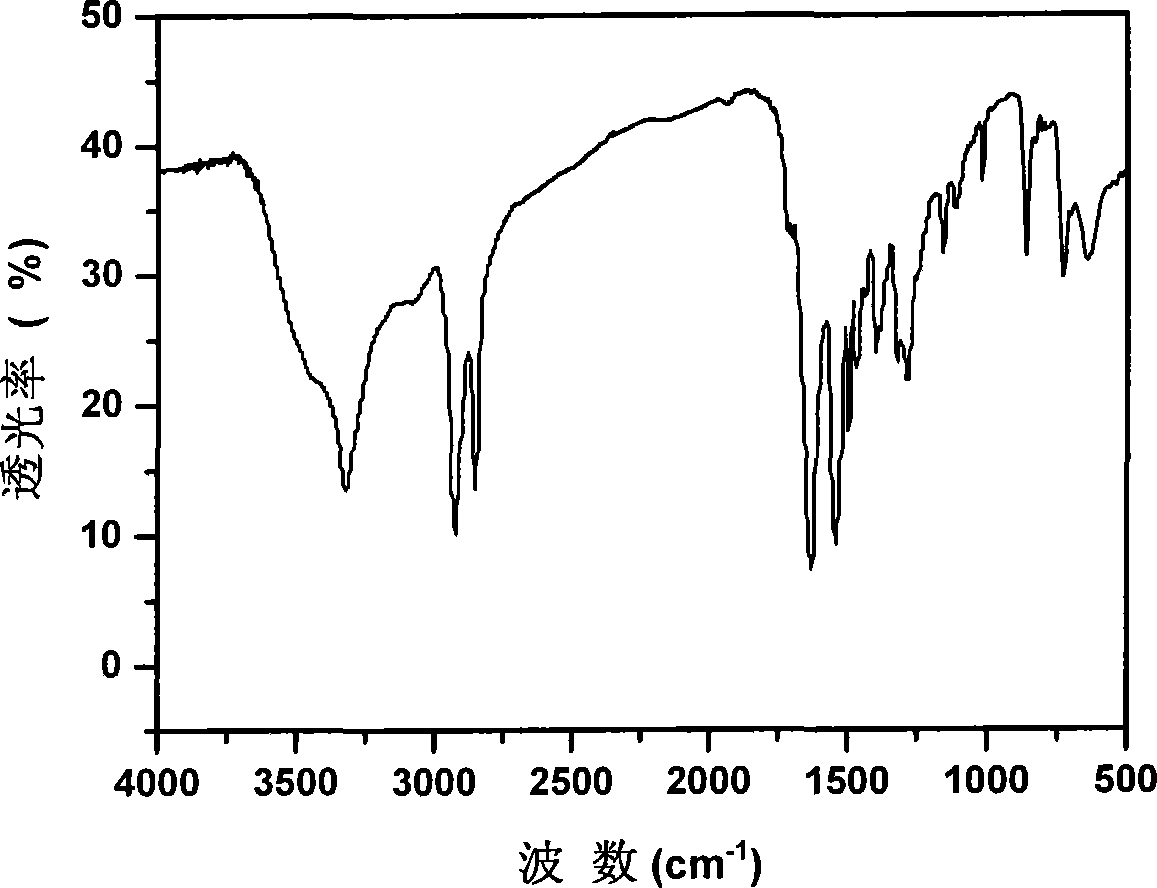

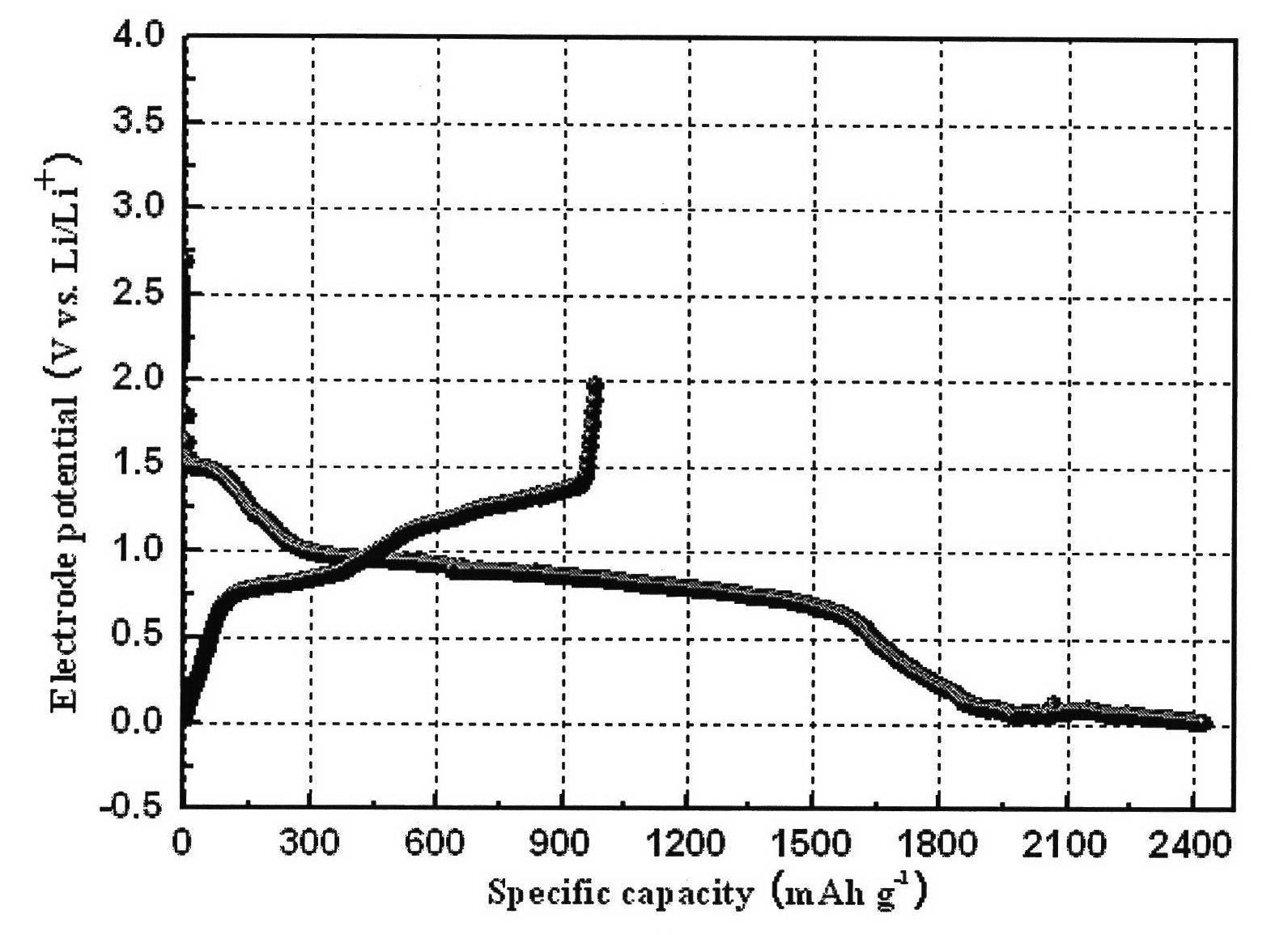

The invention belongs to the fields of material synthesis and energy technology, and especially relates to a graphene / metal oxide composite cathode material for lithium ion batteries and a preparation method thereof. Grapheme is dispersed into various metal oxide precursor salt solutions; a graphene / metal oxide compound is obtained directly by a hydrothermal method, or an graphene / metal oxide compound is obtained by a liquid in-situ polymerization method or a coprecipitation process; and the graphene / metal oxide compound is obtained by heat treatment or hydrothermal treatment. In the invention, the novel three-dimensional composite cathode material of graphene-coated metal oxide or graphene-anchored metal oxide is prepared by carrying metal oxide particles with graphene as a carrier. The obtained composite material can be used as a lithium ion battery cathode, which has a high specific capacity, excellent cycle stability and rate capability, and is expected to be used as a lithium ion battery cathode material with a high energy density and a high power density.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

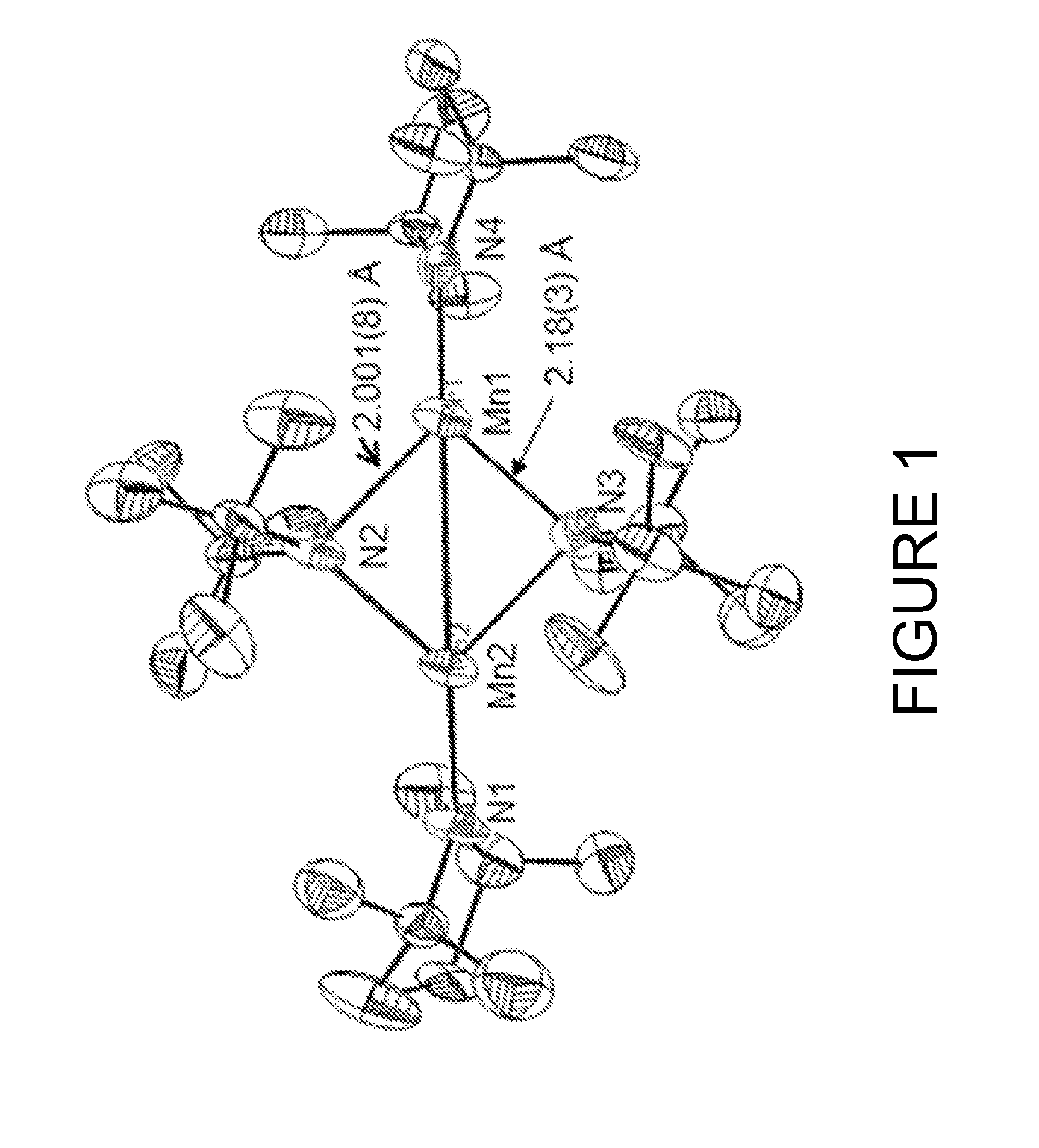

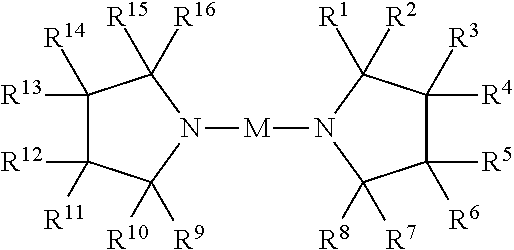

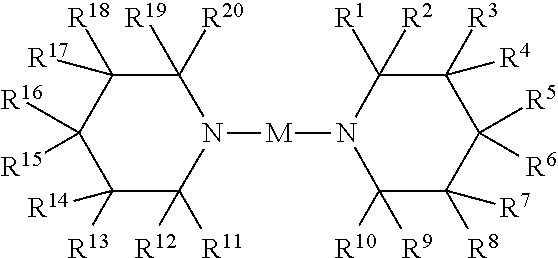

Metal amides of cyclic amines

ActiveUS20160152649A1Improve thermal stabilityImprove conductivityIron group organic compounds without C-metal linkagesNickel organic compoundsGermanideMetal silicide

Compounds, and oligomers of the compounds, are synthesized with cyclic amine ligands attached to a metal atom. These compounds are useful for the synthesis of materials containing metals. Examples include pure metals, metal alloys, metal oxides, metal nitrides, metal phosphides, metal sulfides, metal selenides, metal tellurides, metal borides, metal carbides, metal silicides and metal germanides. Techniques for materials synthesis include vapor deposition (chemical vapor deposition and atomic layer deposition), liquid solution methods (sol-gel and precipitation) and solid-state pyrolysis. Suitable applications include electrical interconnects in microelectronics and magnetoresistant layers in magnetic information storage devices. The films have very uniform thickness and high step coverage in narrow holes.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Silicon-based active materials for lithium ion batteries and synthesis with solution processing

Silicon based anode active materials are described for use in lithium ion batteries. The silicon based materials are generally composites of nanoscale elemental silicon with stabilizing components that can comprise, for example, silicon oxide-carbon matrix material, inert metal coatings or combinations thereof. High surface area morphology can further contribute to the material stability when cycled in a lithium based battery. In general, the material synthesis involves a significant solution based processing step that can be designed to yield desired material properties as well as providing convenient and scalable processing.

Owner:IONBLOX INC

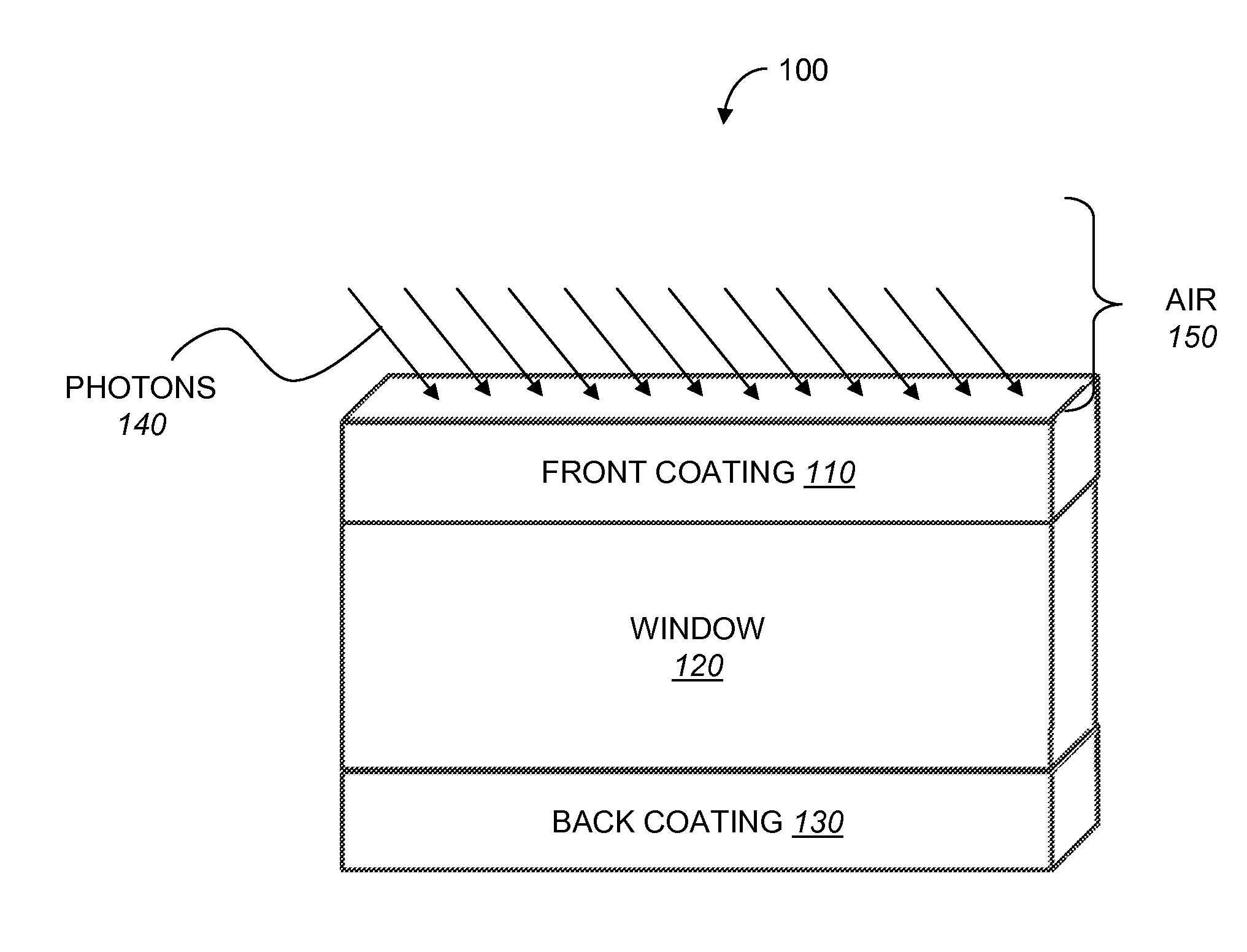

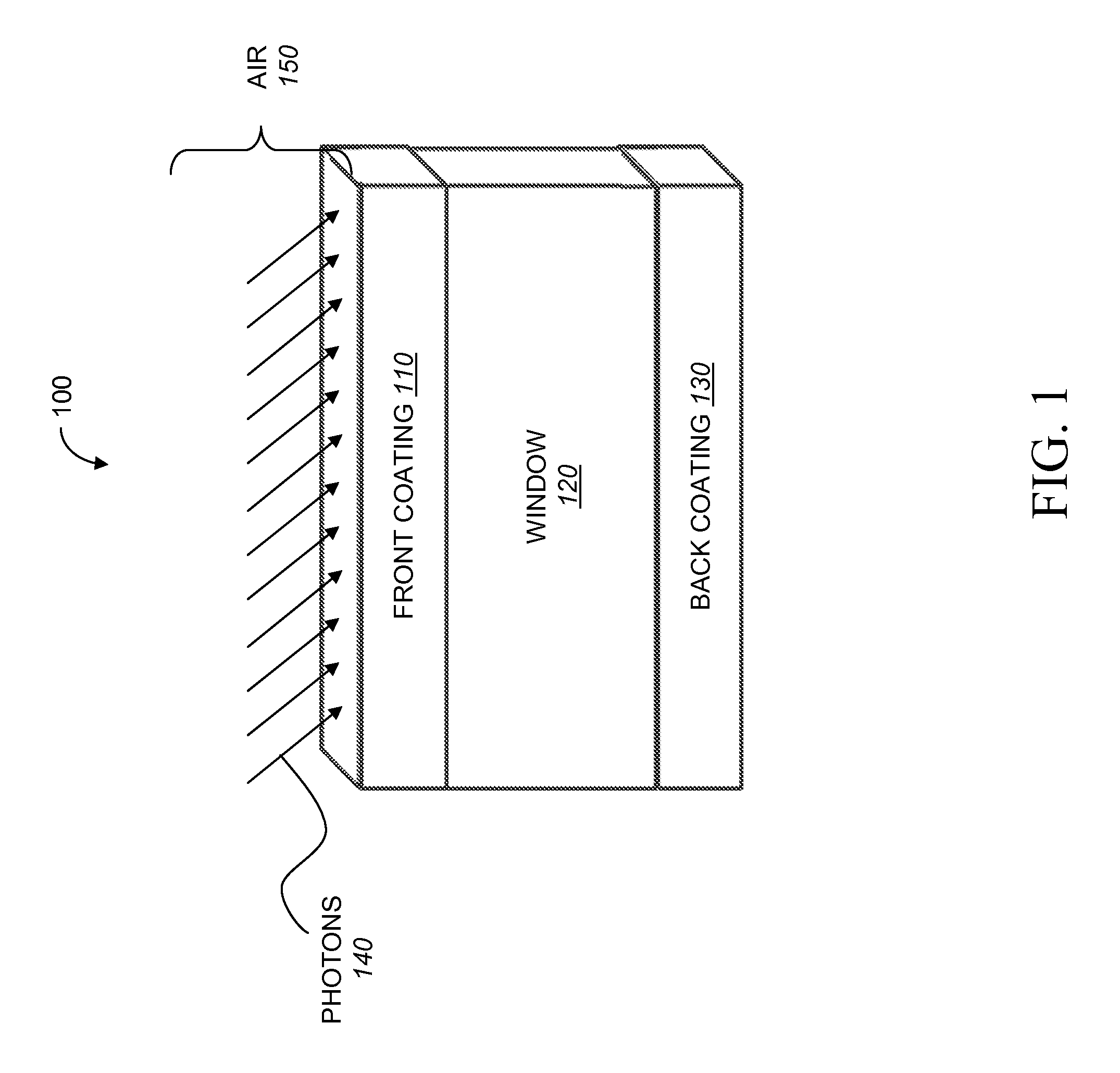

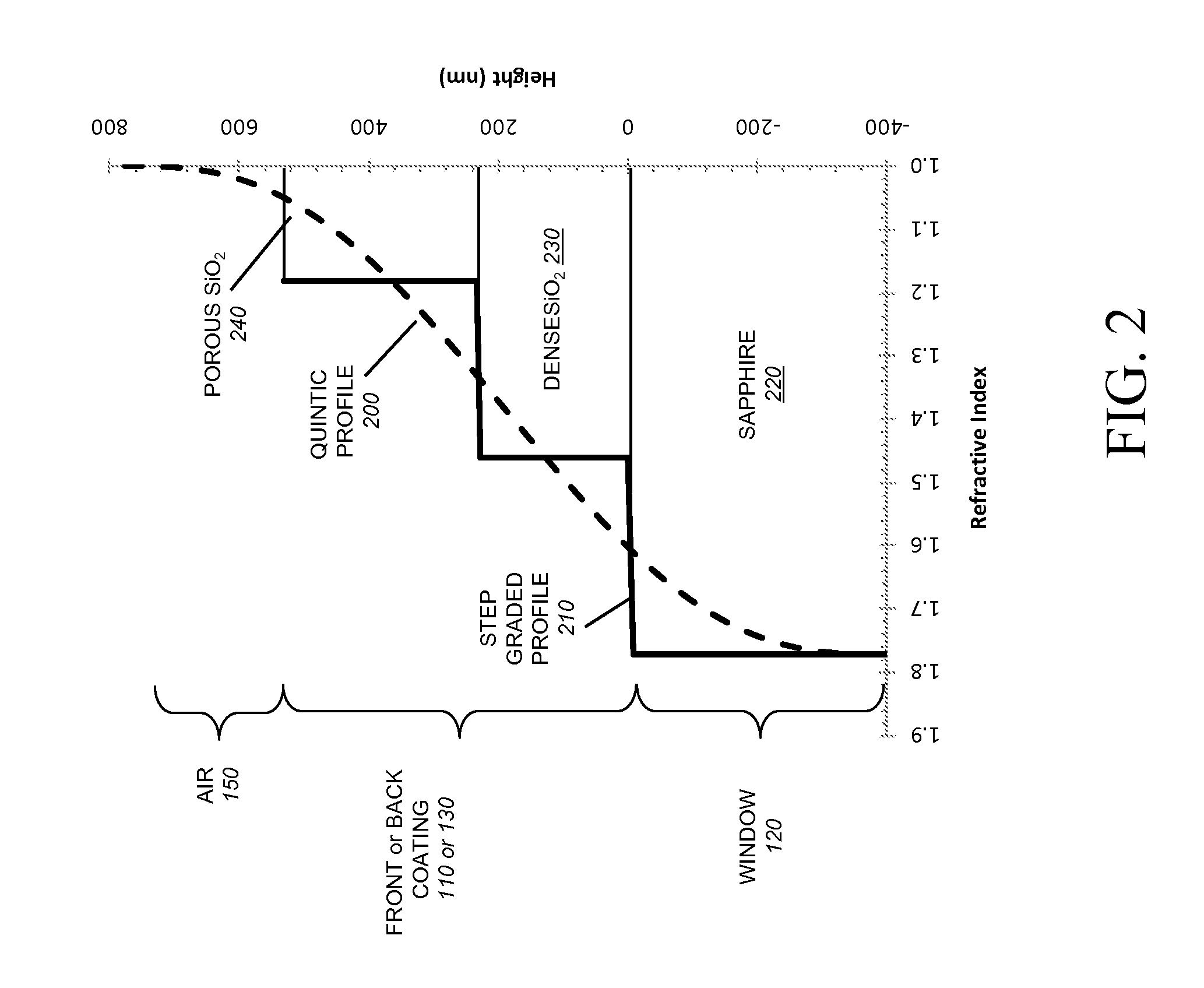

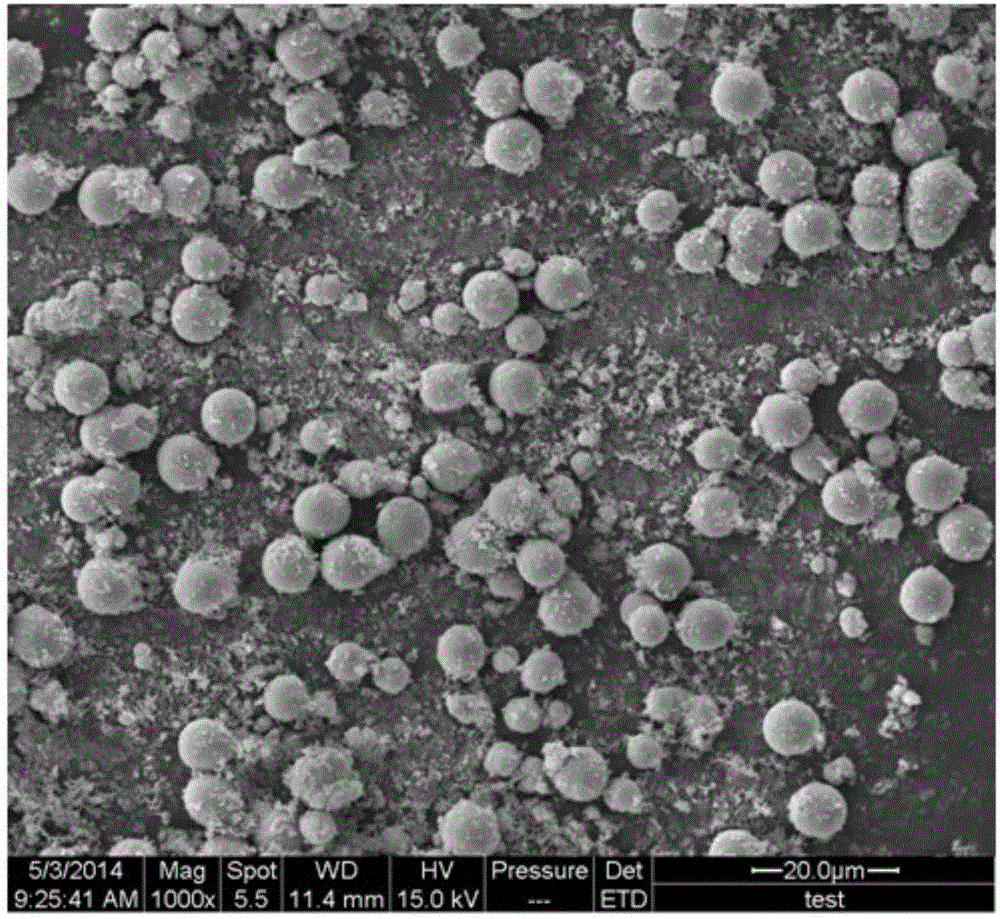

High transmittance optical windows and method of constructing the same

InactiveUS20110168261A1Avoid reflectionsHigh light transmittanceSemiconductor/solid-state device manufacturingPhotovoltaic energy generationOptical coatingMaterial synthesis

Designs for ultra-high, broadband transmittance through windows over a wide range of incident angles are disclosed. The improvements in transmittance result from coating the windows with a new class of materials consisting of porous nanorods. A high transmittance optical window comprises a transparent substrate coated on one or both sides with a multiple layer coating. Each multiple layer coating includes optical films with a refractive index intermediate between the refractive index of the transparent substrate and air. The optical coatings are applied using an oblique-angle deposition material synthesis technique. The coating can be performed by depositing porous SiO2 layers using oblique angle deposition. The high transmittance window coated with the multiple layer coating exhibits reduced reflectance and improved transmittance, as compared to an uncoated transparent substrate.

Owner:MAGNOLIA OPTICAL TECH +1

Spinel nickel manganese acid lithium and layered lithium-rich manganese-based composite cathode material with core-shell structure and preparation method thereof

ActiveCN104157831APromote circulationRaise the ratioCell electrodesSecondary cellsComposite cathodeMaterial synthesis

The invention relates to a spinel nickel manganese acid lithium and layered lithium-rich manganese-based composite cathode material with a core-shell structure and a preparation method thereof, which belongs to the technical field of material synthesis. The prepared lithium ion composite cathode material takes a layered lithium-rich manganese-based Li[Lia(NixCoyMnz)]O2 as a core material, takes spinel nickel manganese acid lithium LiNi0.5Mn1.5O4 as a shell material; a coprecipitation method is employed to obtain a core-shell precursor, the core-shell precursor and the lithium source are uniformly mixed and calcined to obtain the spinel nickel manganese acid lithium and layered lithium-rich manganese-based composite cathode material with the core-shell structure. According to the invention, the layered lithium-rich manganese-based is taken as the core material, and the spinel nickel manganese acid lithium is taken as the shell material; under the prerequisite that material gram capacity is kept, material structural stability is increased, material cycle, multiplying power and safety performances are improved, function composite and complementation of the core material and the shell layer material can be realized, and the problem that high capacity and high security can not be achieved simultaneously is solved. The composite cathode material has the advantages of simple process and obviously increased performance.

Owner:南京时拓能源科技有限公司

Production of Oligosaccharides By Microorganisms

InactiveUS20080145899A1Highly efficient and rapid and relatively low cost synthesisFermentationEnzymatic synthesisOligosaccharide

The present invention relates to the enzymatic synthesis of oligosaccharides, including sialylated product saccharides. In particular, it relates to the use of recombinant cells to take up low cost precursors such as glucose, pyruvate and N-actyl-glucosamine, and to synthesize activated sugar moieties that are used in oligosaccharide synthesis. The methods make possible the synthesis of many oligosaccharides using microorganisms and readily available, relatively inexpensive starting materials.

Owner:SENEB BIOSCI

High-temperature composite phase change heat storage material and preparation method thereof

ActiveCN102585775ANo preprocessing requiredSimple manufacturing methodHeat-exchange elementsElectricityHeat conducting

The invention relates to a preparation method of a high-temperature composite phase change heat storage material, and relates to a high-temperature composite phase change heat storage material and a preparation method thereof. The method can be used for preparing high-temperature composite phase change heat storage material with high heat conductivity, so that the heat conductivity of the heat storage material is greatly improved, and the heat storage / release rate is greatly improved; and the preparation method is easy to control and simple to operate. The heat storage material can be directly obtained by sintering, without need of any bonding agent or other protectants, so that the heat-conducting property of the heat storage material is greatly improved, and the utilization ratio of the heat storage material is improved; the preparation method is simple to operate; and the prepared product can also be used for other intermediate-temperature low-temperature composite heat storage materials, as well as light heat utilization, heat-cold-electricity combined use, composite material synthesis and other many fields.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

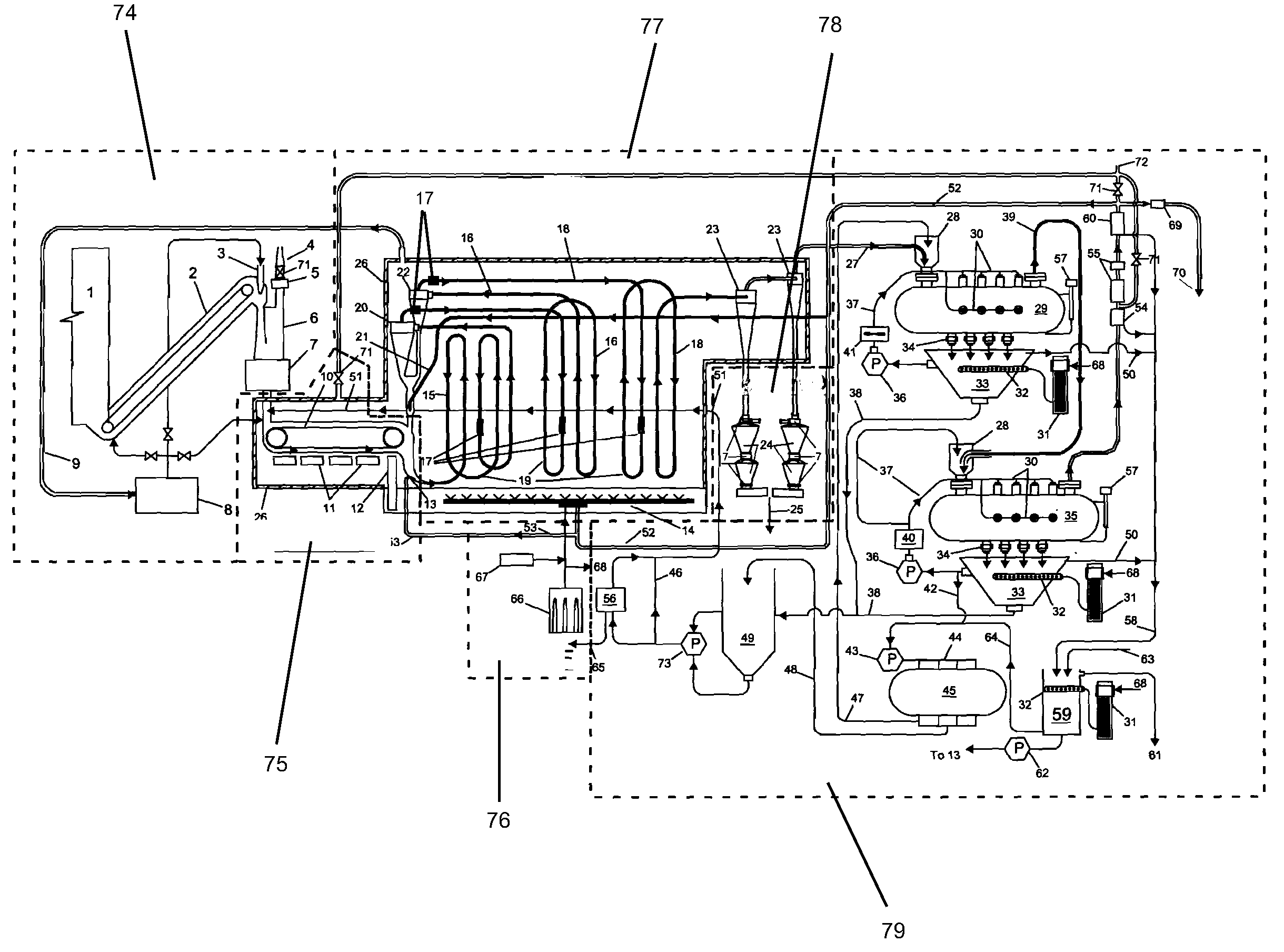

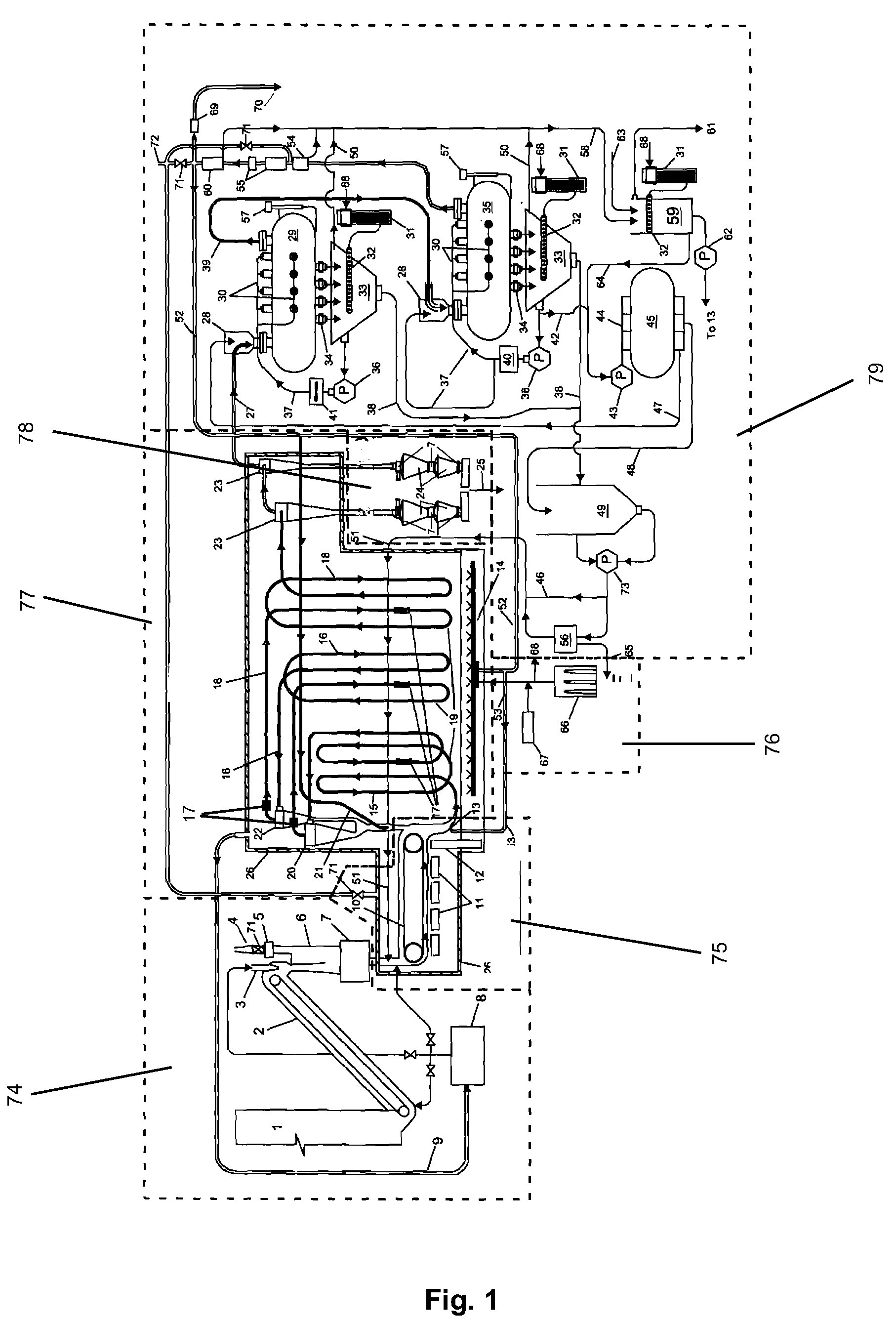

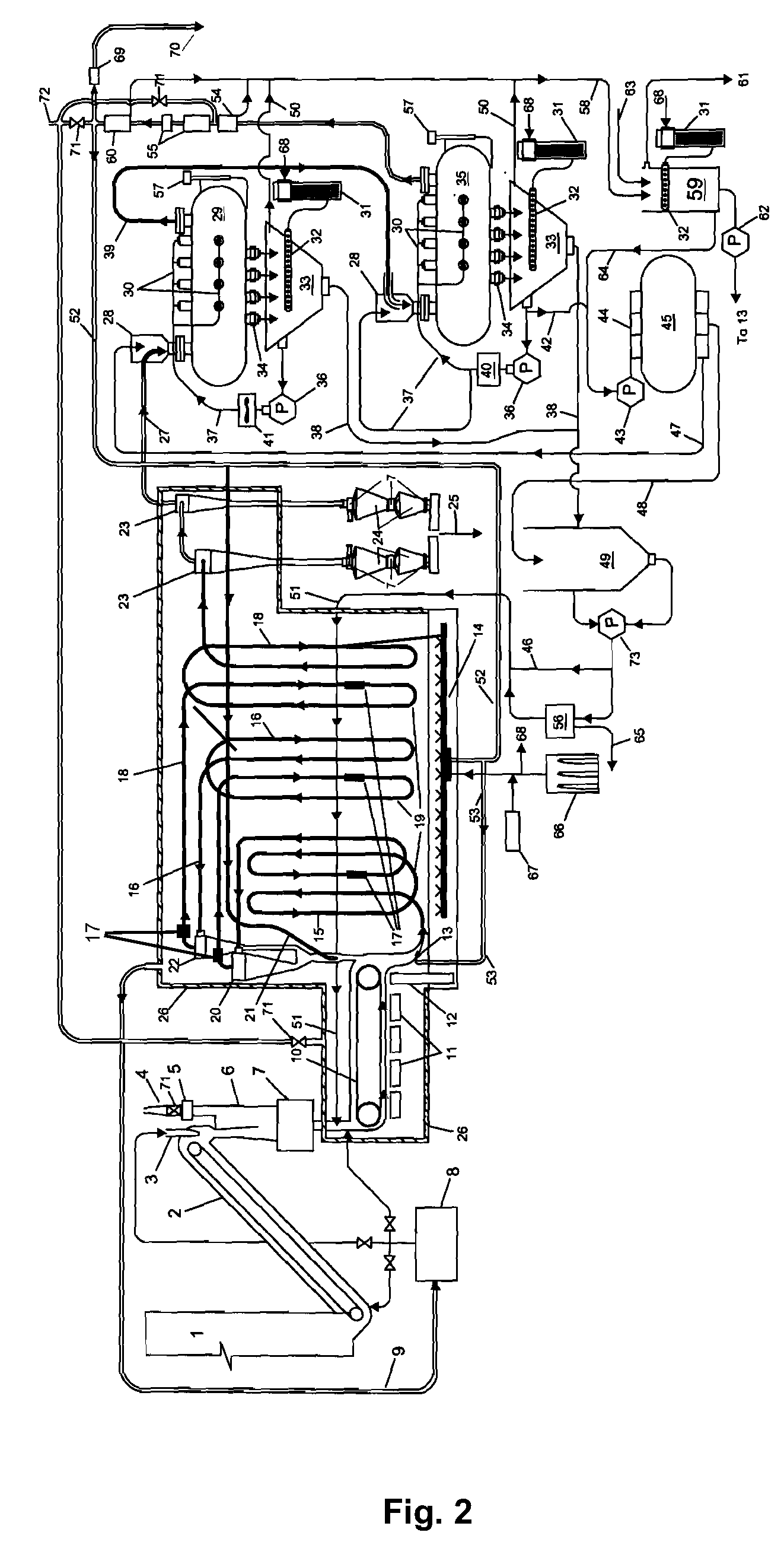

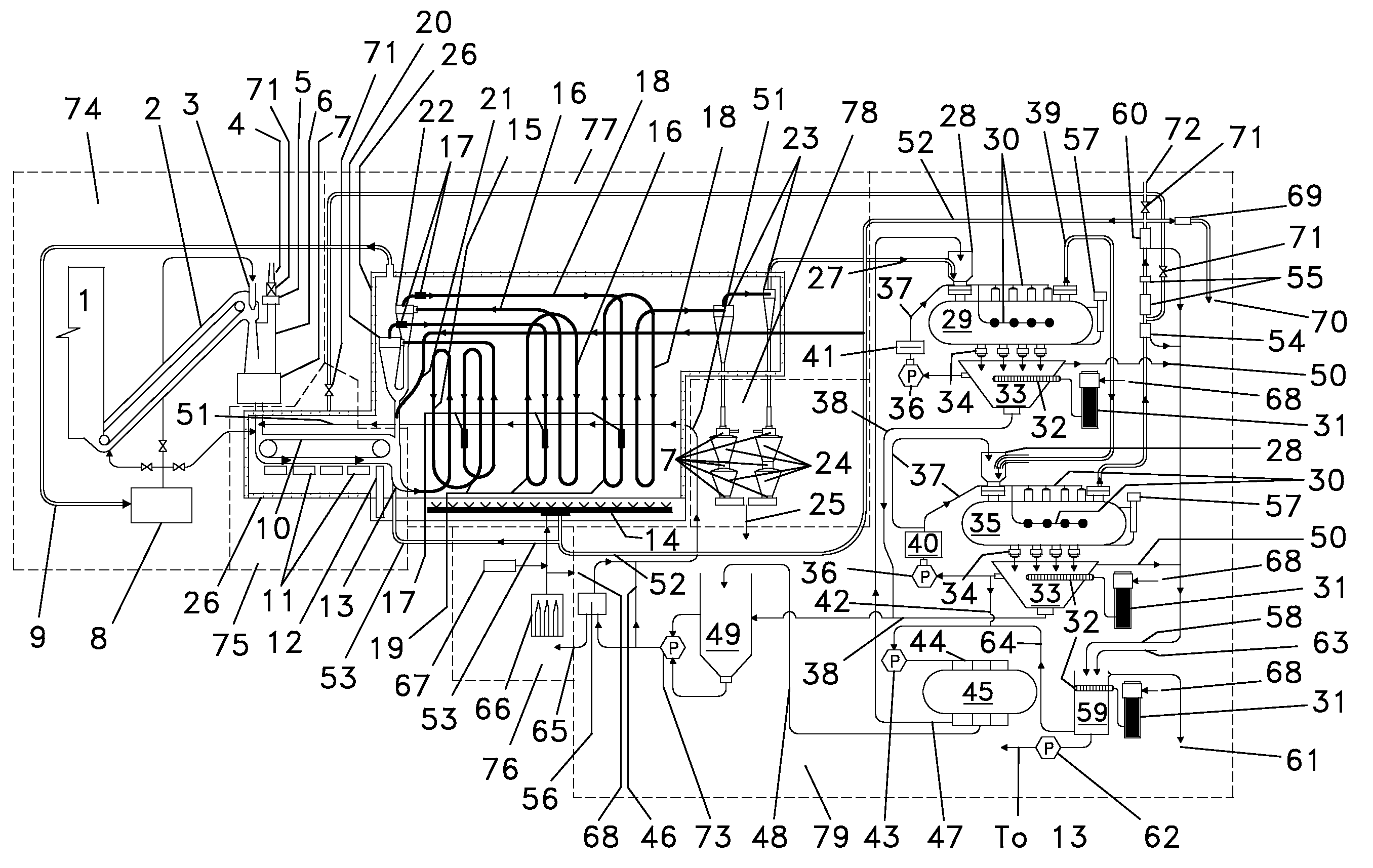

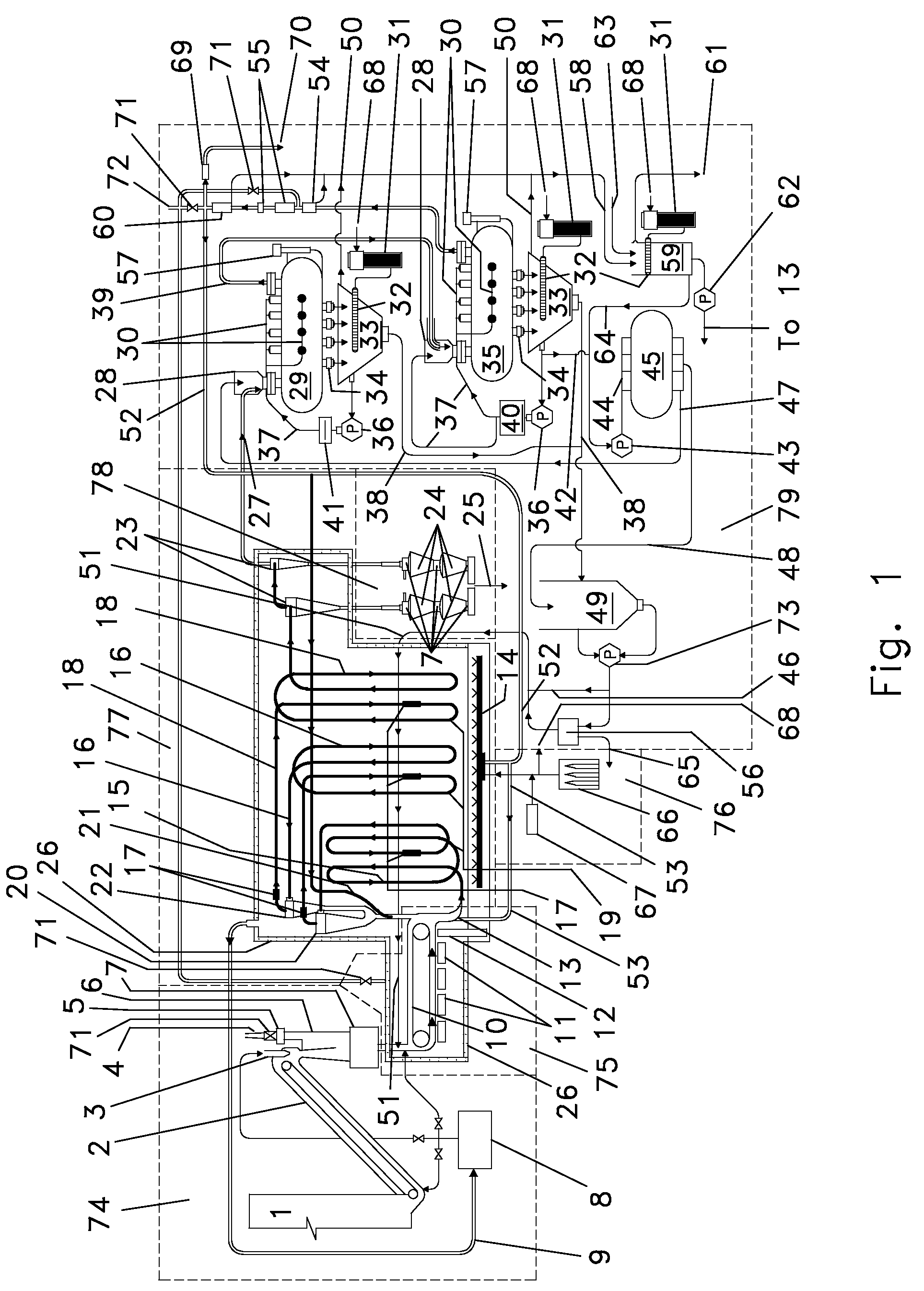

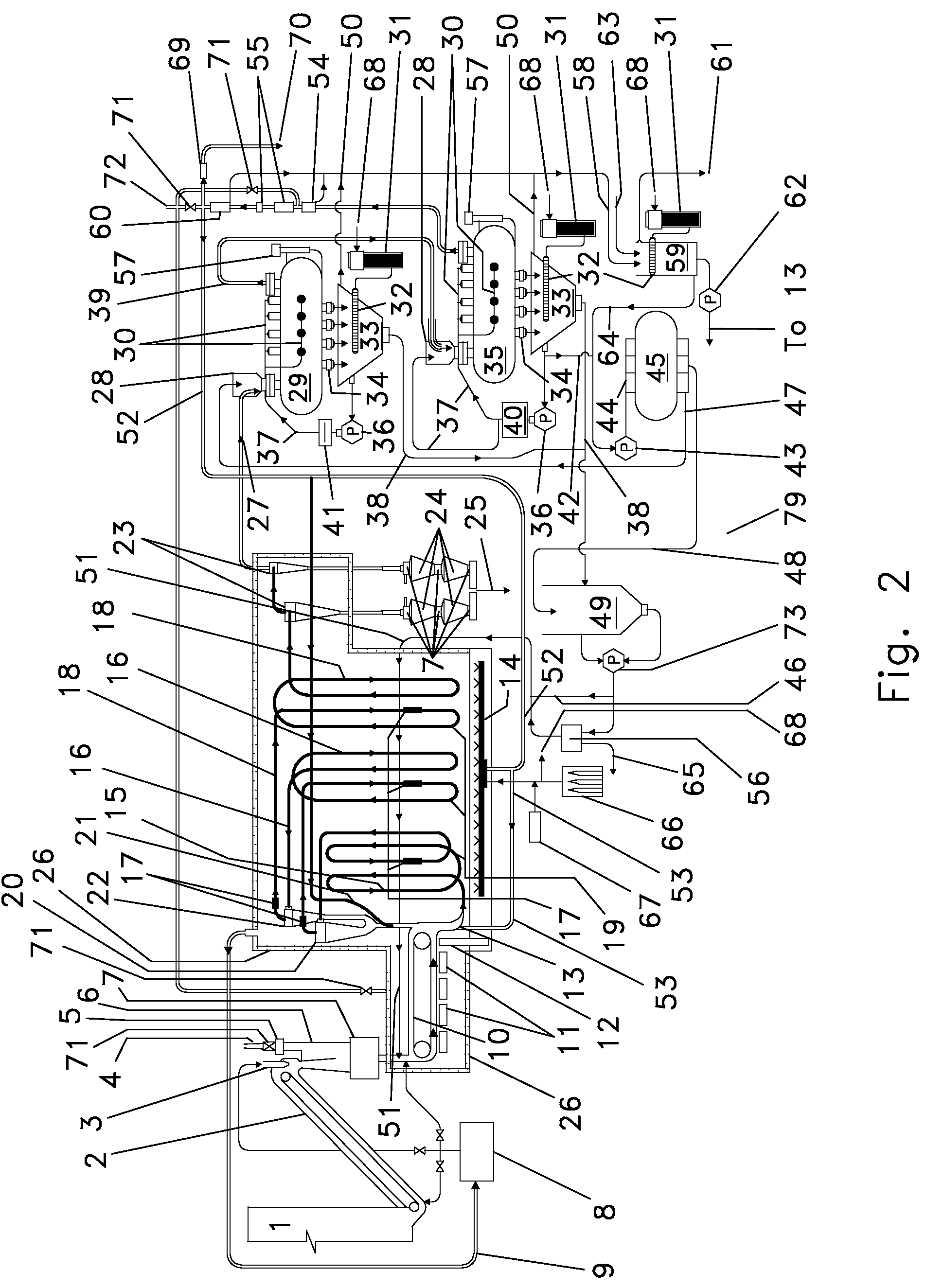

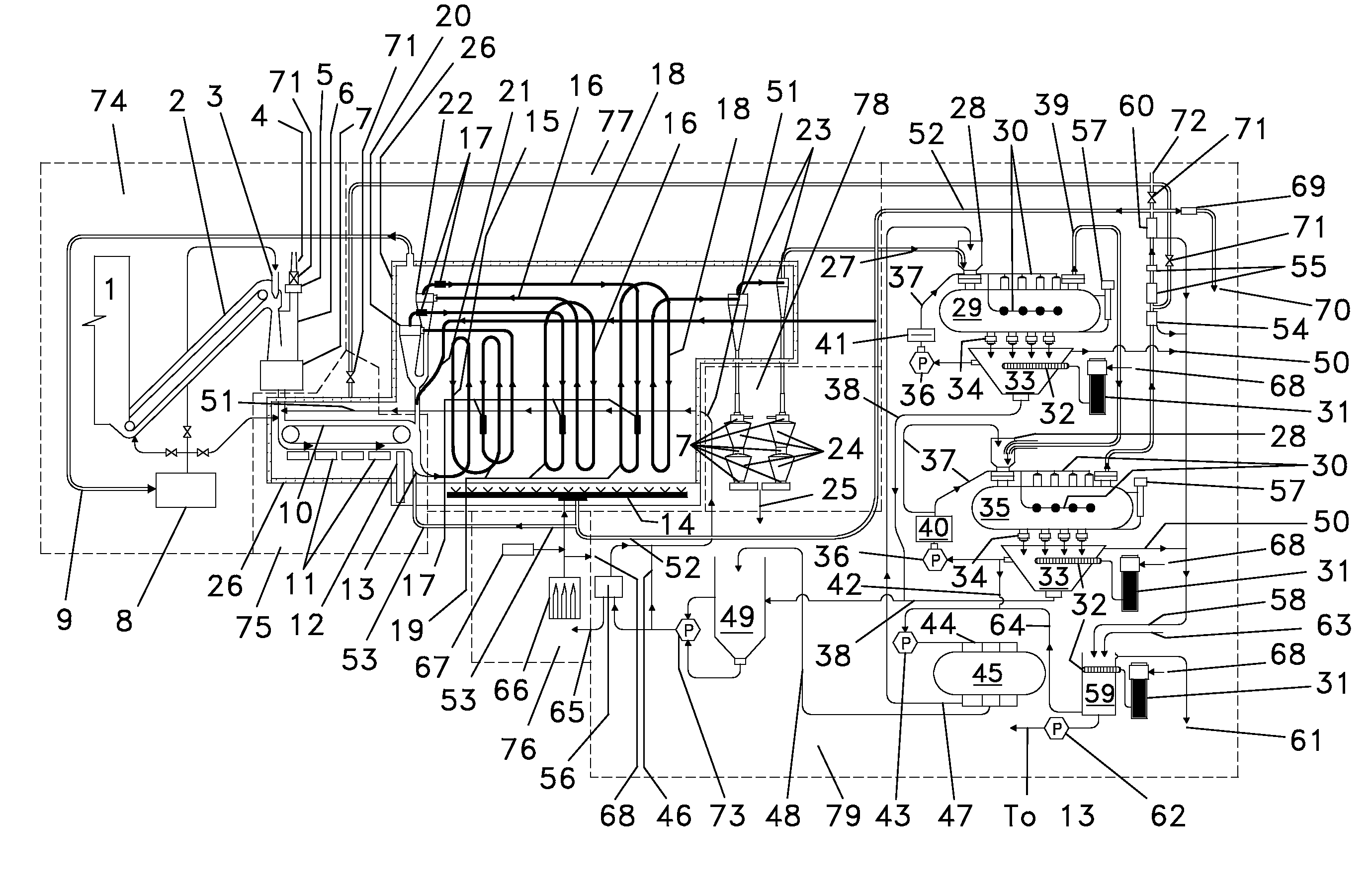

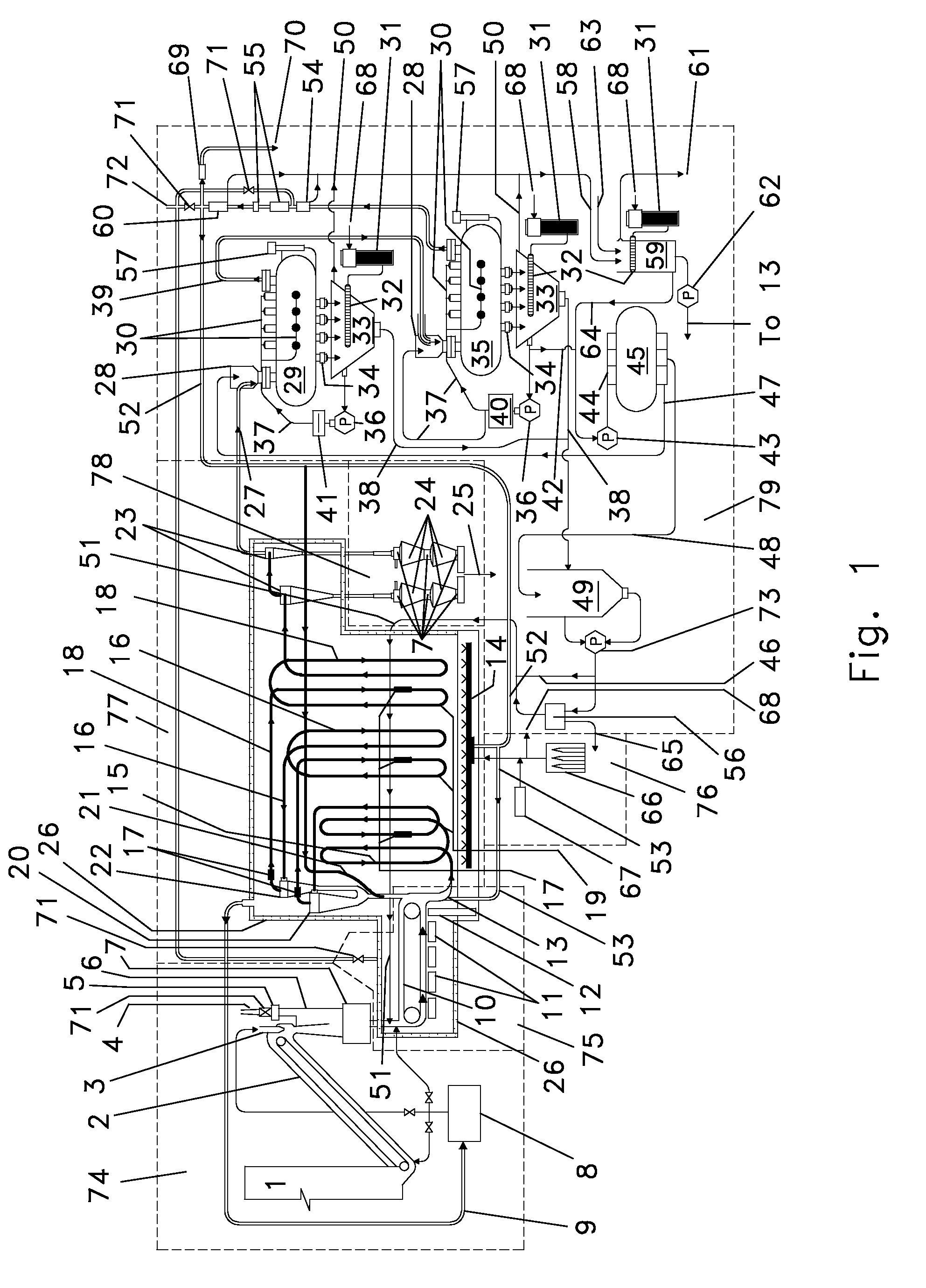

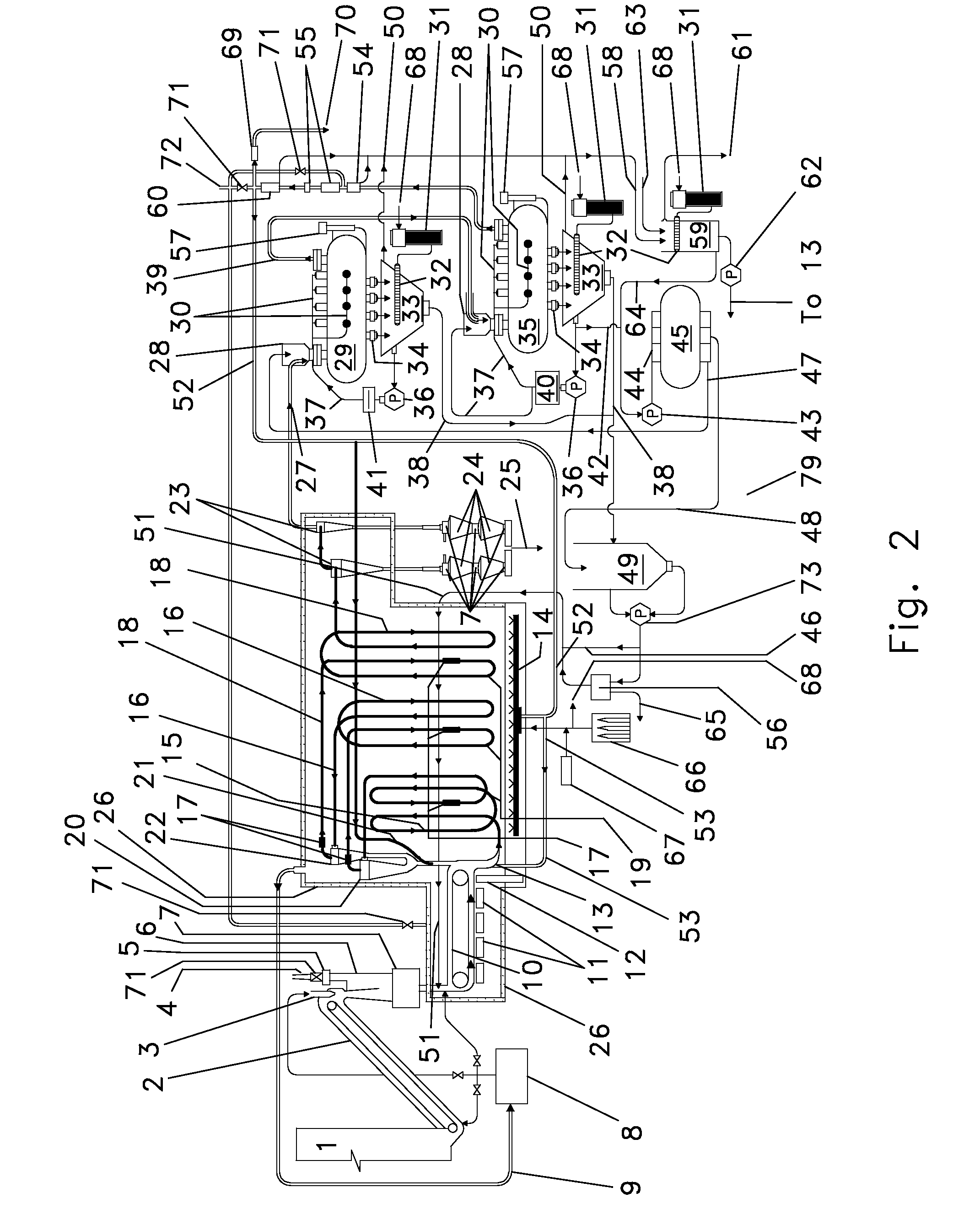

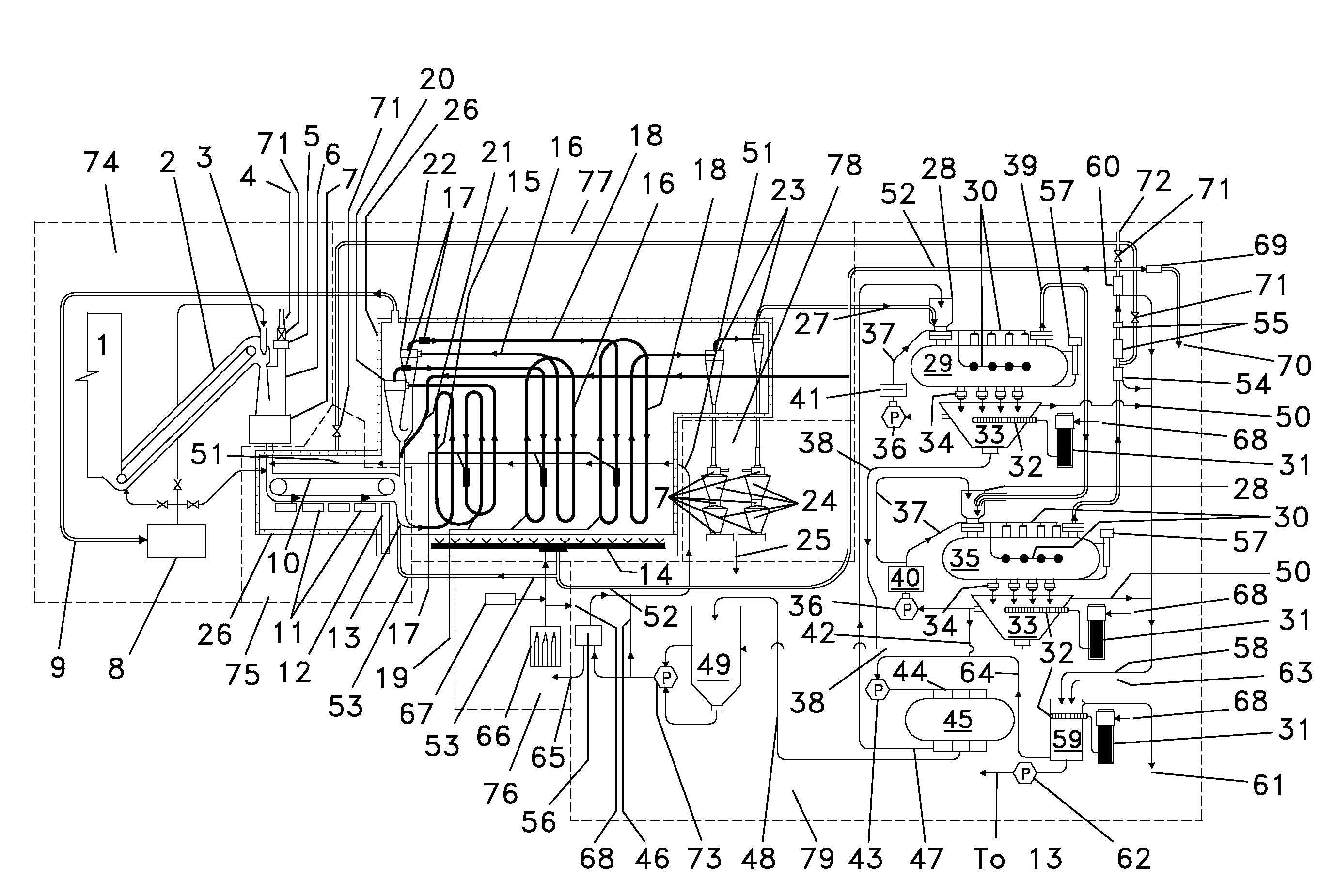

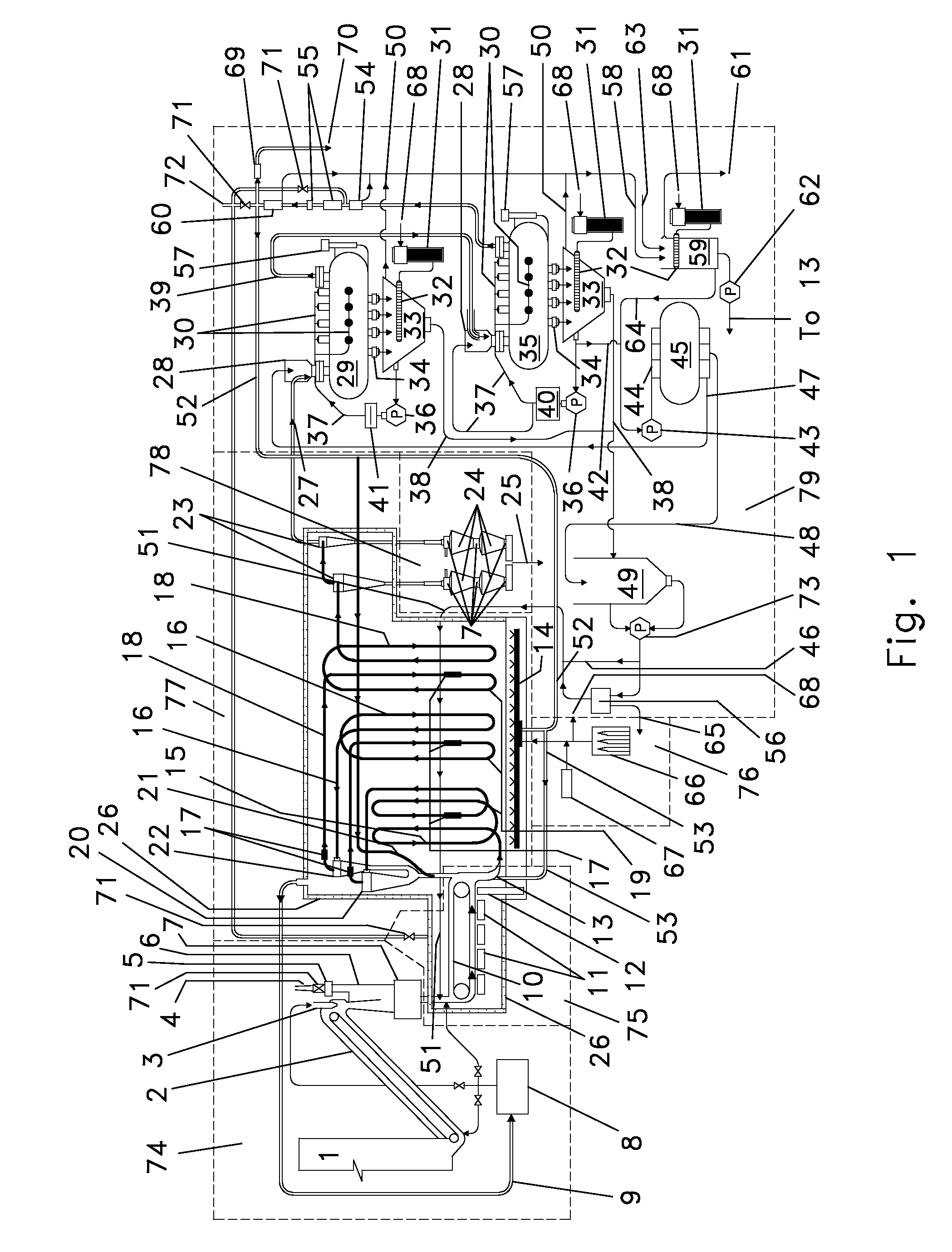

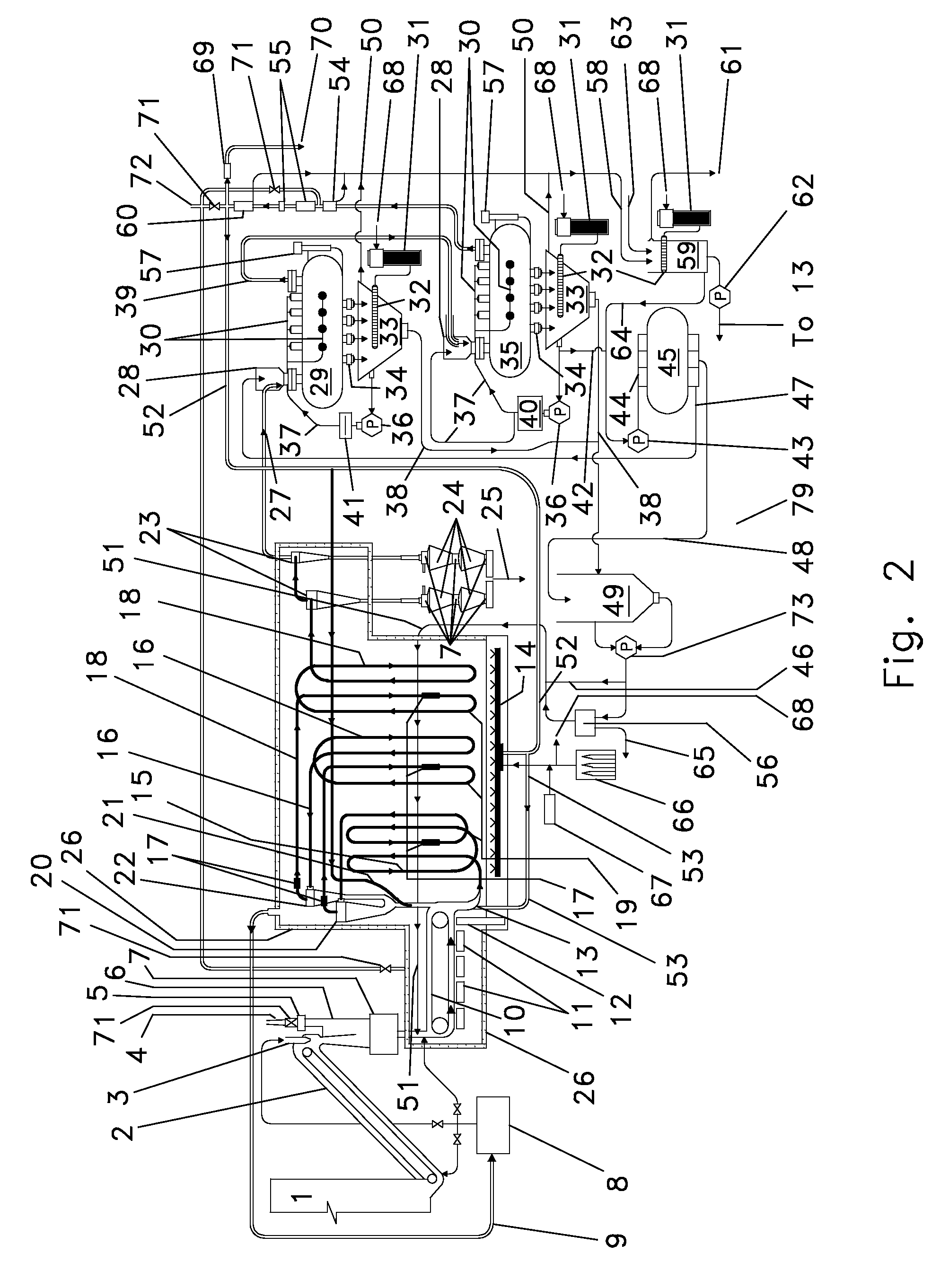

Methods and Apparatus for Solid Carbonaceous Materials Synthesis Gas Generation

Methods and apparatus may permit the generation of consistent output synthesis gas from highly variable input feedstock solids carbonaceous materials. A stoichiometric objectivistic chemic environment may be established to stoichiometrically control carbon content in a solid carbonaceous materials gasifier system. Processing of carbonaceous materials may include dominative pyrolytic decomposition and multiple coil carbonaceous reformation. Dynamically adjustable process determinative parameters may be utilized to refine processing, including process utilization of negatively electrostatically enhanced water species, process utilization of flue gas (9), and adjustment of process flow rate characteristics. Recycling may be employed for internal reuse of process materials, including recycled negatively electrostatically enhanced water species, recycled flue gas (9), and recycled contaminants. Synthesis gas generation may involve predetermining a desired synthesis gas for output and creating high yields of such a predetermined desired synthesis gas.

Owner:THERMOTEK

Method for preparing semi-aromatic nylon

The invention discloses a method for preparing semi-aromatic nylon and belongs to the technical field of macromolecular material synthesis. The method comprises the following steps: (1) uniformly mixing aliphatic diamine and water of which the weight is two to ten times that of the aliphatic diamine, heating the mixture to the temperature of between 50 and 90 DEG C, adding aromatic diacid into the mixture with stirring till a pH value of the solution reaches 7.0-7.7, continuously stirring for 1 to 5 hours, cooling the solution to room temperature, continuously stirring the solution for 1 to 5 hours again, and filtering and drying to obtain nylon salt for later use; and (2) adding the prepared nylon salt and a solvent to a polymerization kettle in a certain mixture ratio (0.5 to 3.0 g / mL), raising the temperature to between 190 and 230 DEG C under the protection of inert gas, keeping the pressure in the kettle between 2.0 and 3.0 MPa, discharging gas after 1 to 5 hours to make the pressure in the kettle reduced to normal pressure within 1 to 5 hours, raising the temperature to between 210 and 270 DEG C, and continuing to react for 1 to 5 hours, and discharging to obtain a powdery semi-aromatic nylon product. The method has mild reaction condition and low energy consumption; the product is easy to mold and machine; and the method solves the difficult problem of difficult discharging of the semi-aromatic nylon, and is applicable to industrialized production.

Owner:青岛智库生物技术有限公司

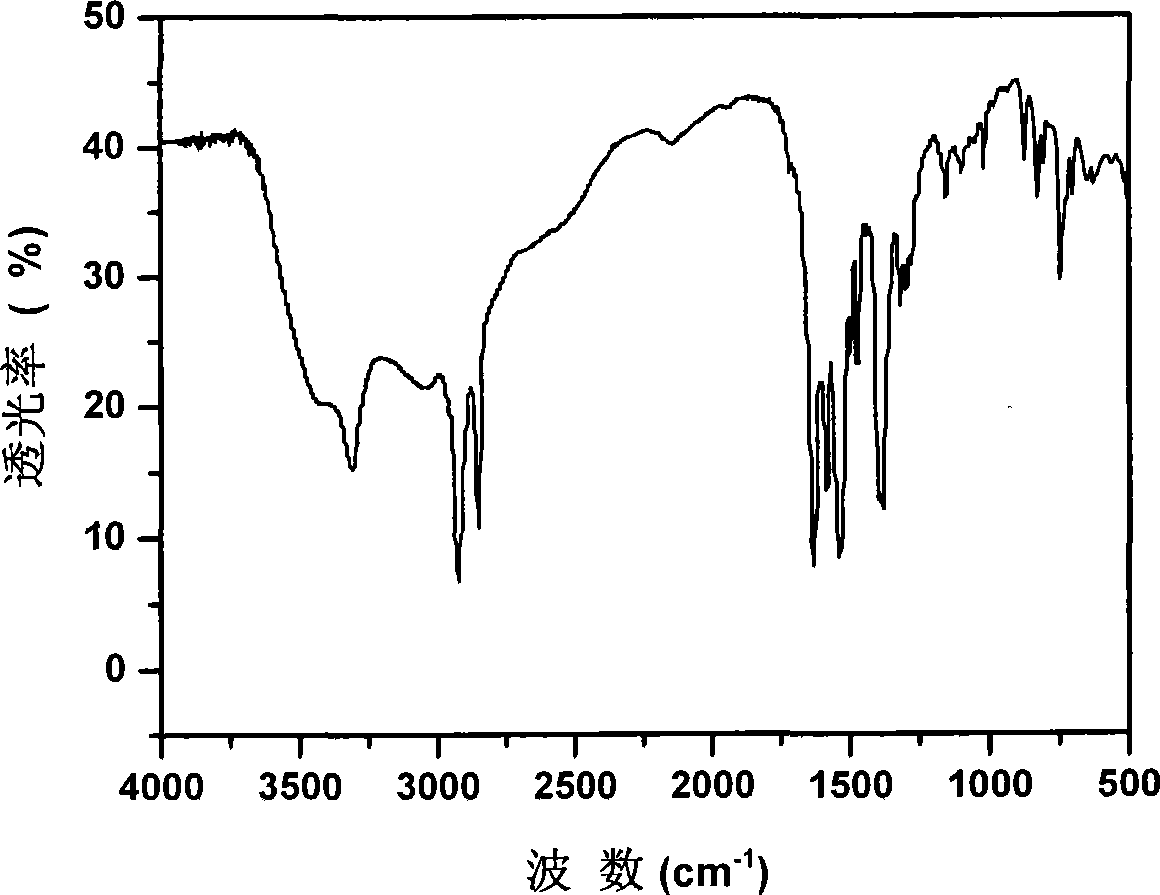

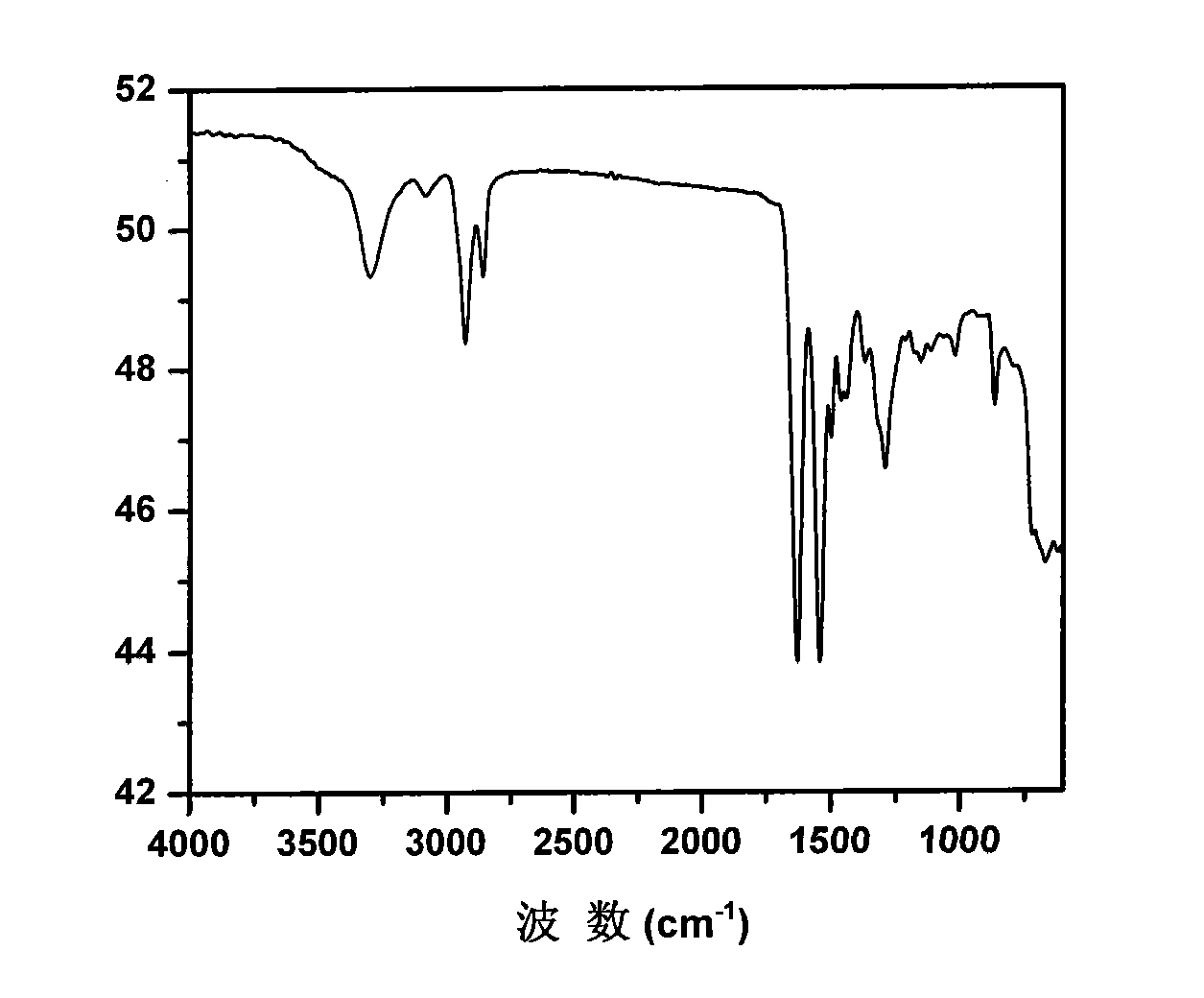

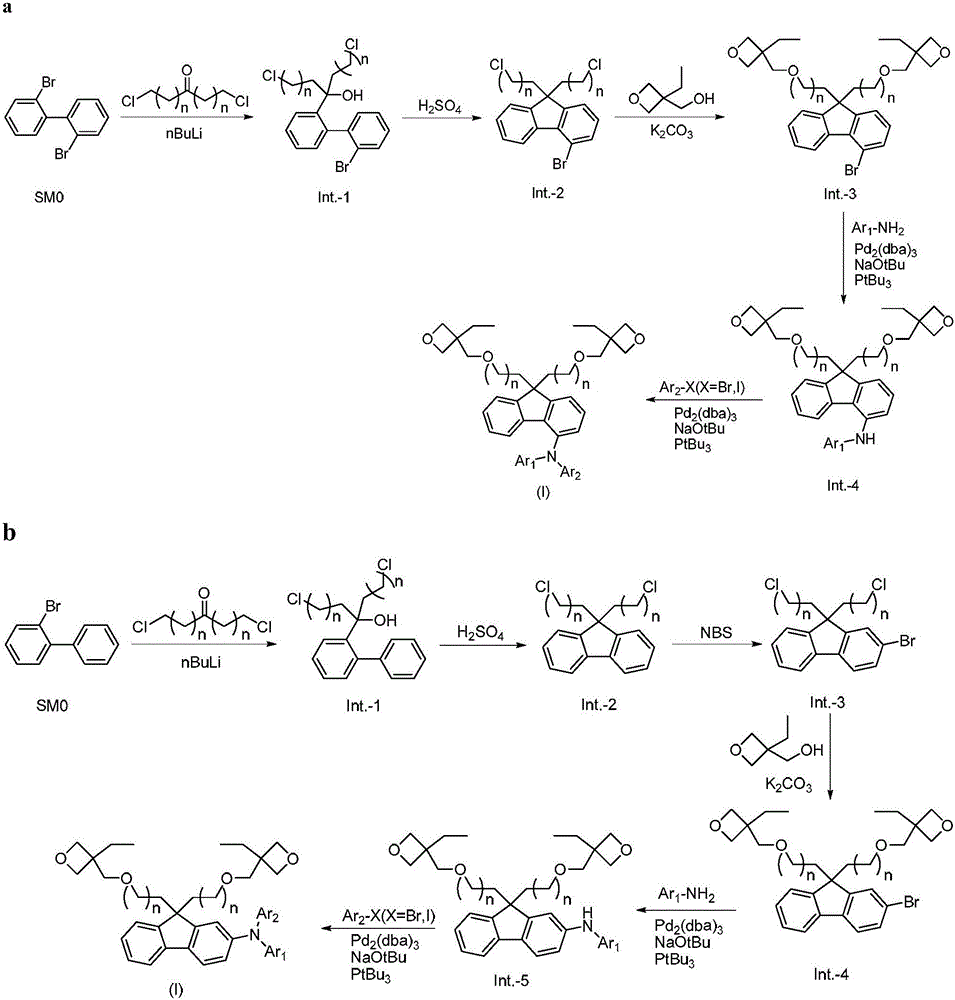

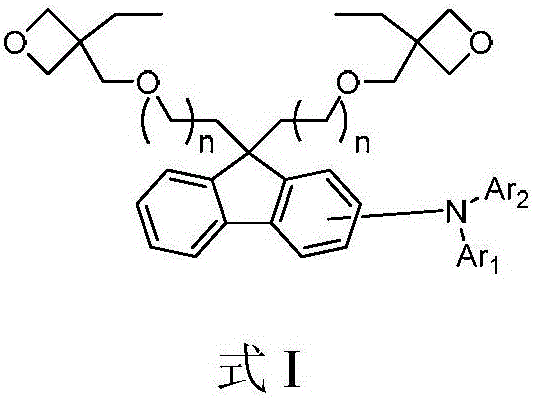

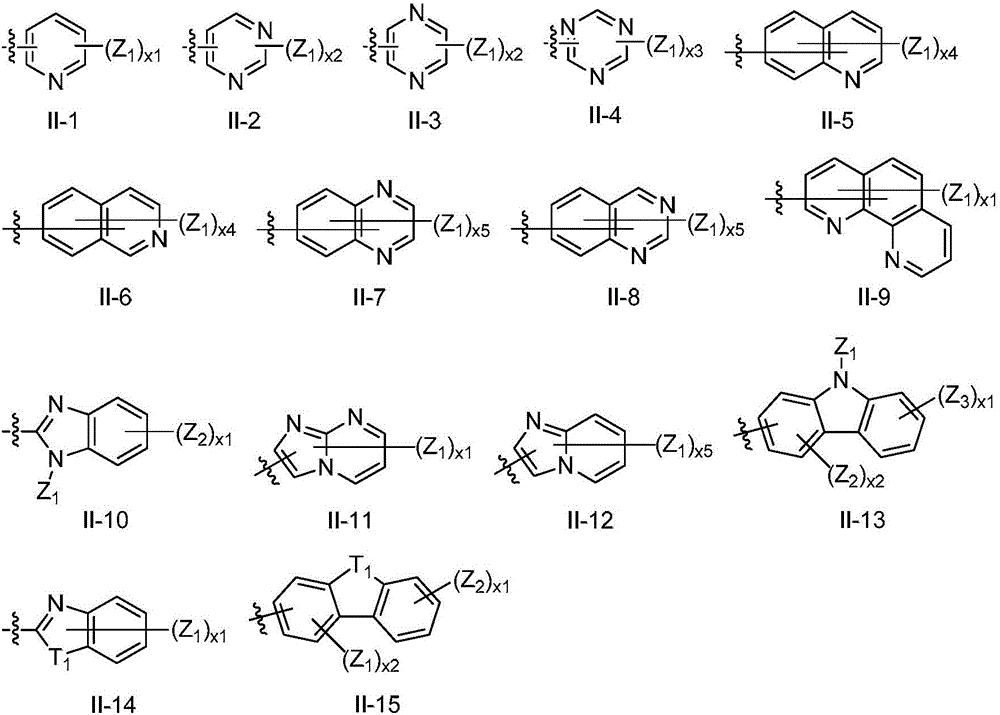

Luminescent material of a series of fluorene derivatives

ActiveCN105733562AHigh glass transition temperatureImprove thermal stabilityOrganic chemistrySolid-state devicesPurification methodsLight-emitting diode

The invention discloses a luminescent material of a series of fluorene derivatives. A structure of the material is as shown in formula I. The material as shown in formula I is easily dissolved in an organic solvent, is good in heat stability and can be used to prepare a luminescent device in a way of fluid manufacturing procedures such as printing, instilling, coating and printing. An organic electroluminescent device prepared by coating the material has the characteristics that the power efficiency is good, the material utilization rate is high, the manufacturing cost of an OLED device is greatly decreased, and the material synthesis and purification method is simply suitable for mass production, so that the luminescent material is an ideal choice of the organic electroluminescent device luminescent material. Utilizing the organic electroluminescent diode material as a main body material or a doping material in a luminescent layer or independently as a luminescent material or a hole transmission material or an electron transmission material also falls within a protection scope (see the specification).

Owner:SHIJIAZHUANG CHENGZHI YONGHUA DISPLAY MATERIALS CO LTD

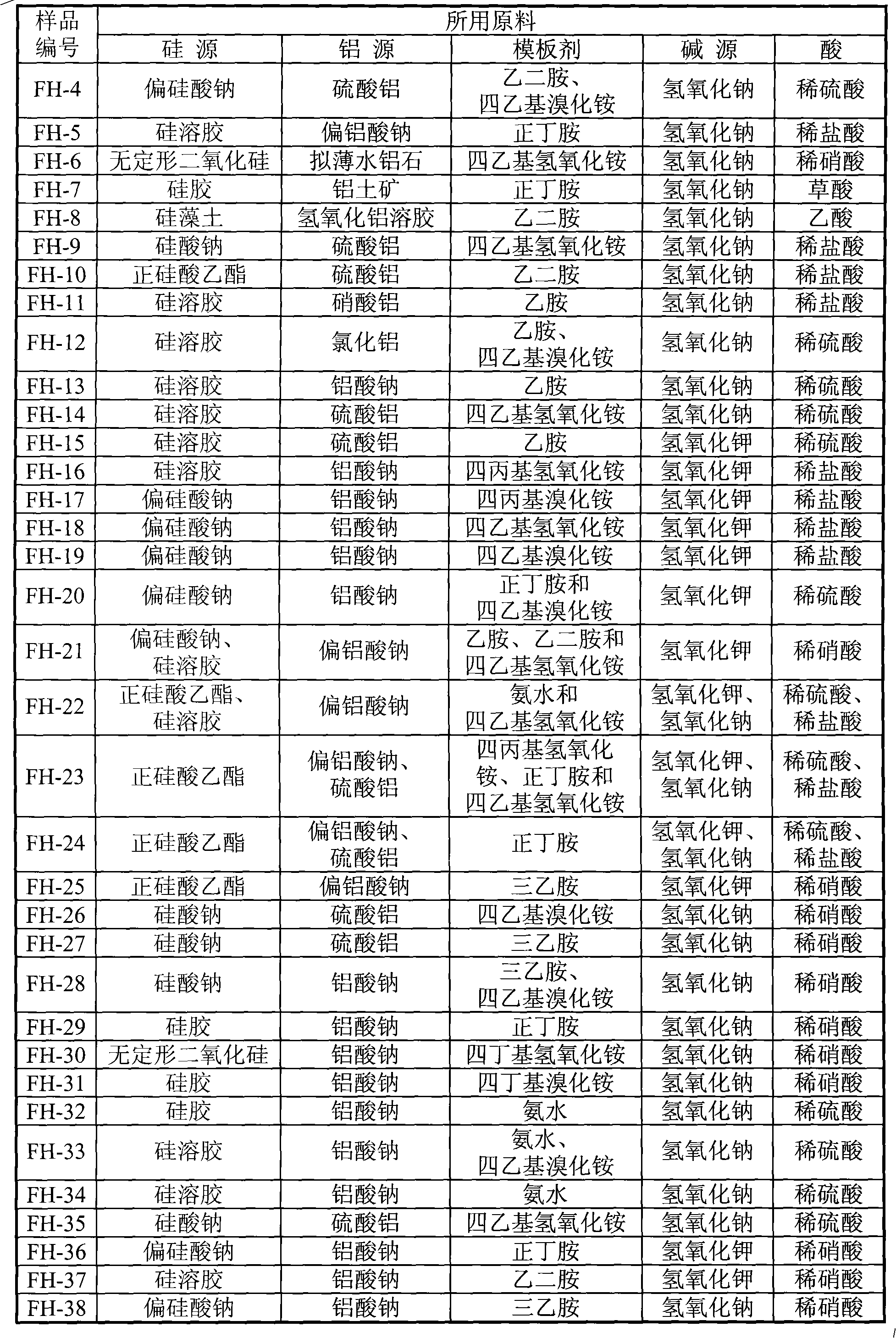

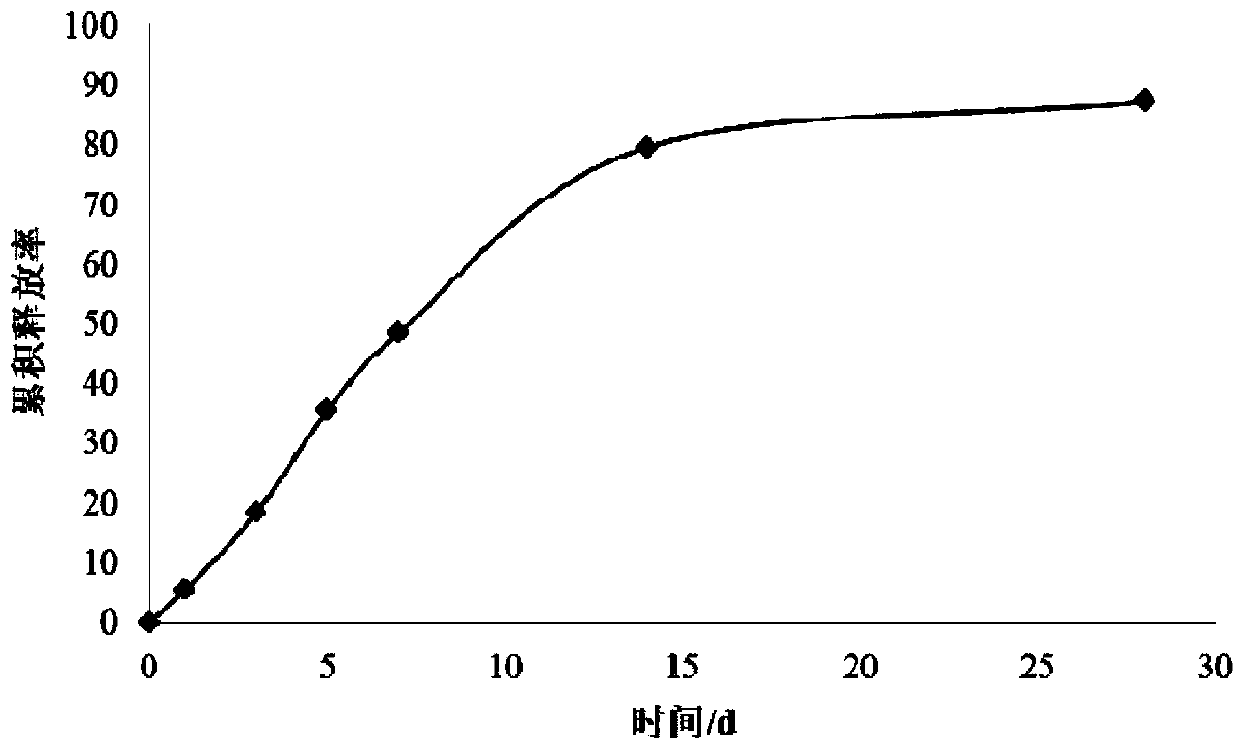

Film coated control release composite fertilizer special for regetables and its making method

InactiveCN100999427ASimple production processLow costFertilizer mixturesPolyvinyl alcoholReproductive life

This invention relates to a preparation method of coated controlled release fertilizer for the vegetable, which includes the liquid membrane material synthesis and fertilizer's parcel process. It select natural, environmental protecting and high polymer of polyvinyl alcohol and starch as the main material, by adding modifiers, surfactants, foam remove agent, water-retaining agent, inhibitors and carrier trace elements to made coated liquid material; in particular, simple conditions, add the inorganic mine powder wrapped fertilizer drops, made a environment-friendly, multi-purpose, capsule controlled and slow-release fertilizer that not only can control nutrients releasing, but also can improve soil physical and chemical nature. The efficiency up to 80 ~ 100 days, one crop fertilizer can meet the nutrient demand of entire reproductive life, and effectively improve the utilization of fertilizers, reducing pollution, saving energy.

Owner:SHENYANG AGRI UNIV

Methods and apparatus for solid carbonaceous materials synthesis gas generation

Methods and apparatus may permit the generation of consistent output synthesis gas from highly variable input feedstock solids carbonaceous materials. A stoichiometric objectivistic chemic environment may be established to stoichiometrically control carbon content in a solid carbonaceous materials gasifier system. Processing of carbonaceous materials may include dominative pyrolytic decomposition and multiple coil carbonaceous reformation. Dynamically adjustable process determinative parameters may be utilized to refine processing, including process utilization of negatively electrostatically enhanced water species, process utilization of flue gas (9), and adjustment of process flow rate characteristics. Recycling may be employed for internal reuse of process materials, including recycled negatively electrostatically enhanced water species, recycled flue gas (9), and recycled contaminants. Synthesis gas generation may involve predetermining a desired synthesis gas for output and creating high yields of such a predetermined desired synthesis gas.

Owner:THERMOTEK

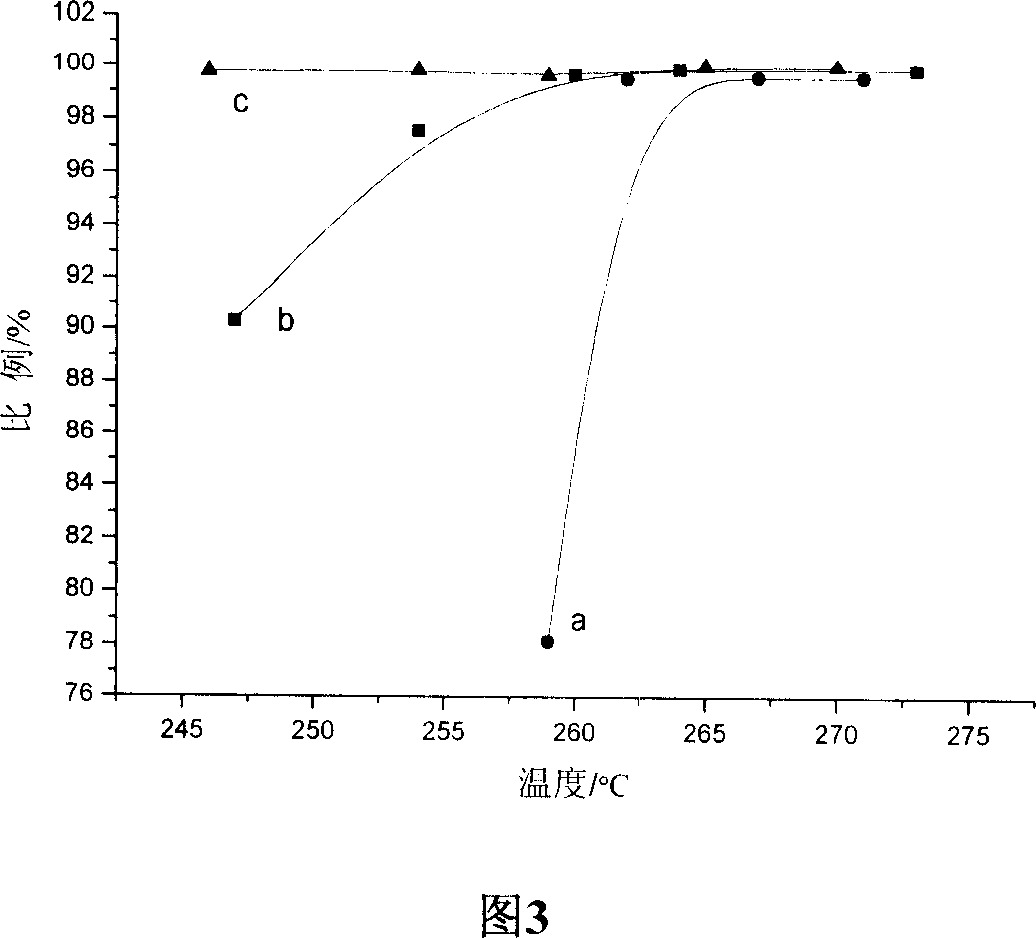

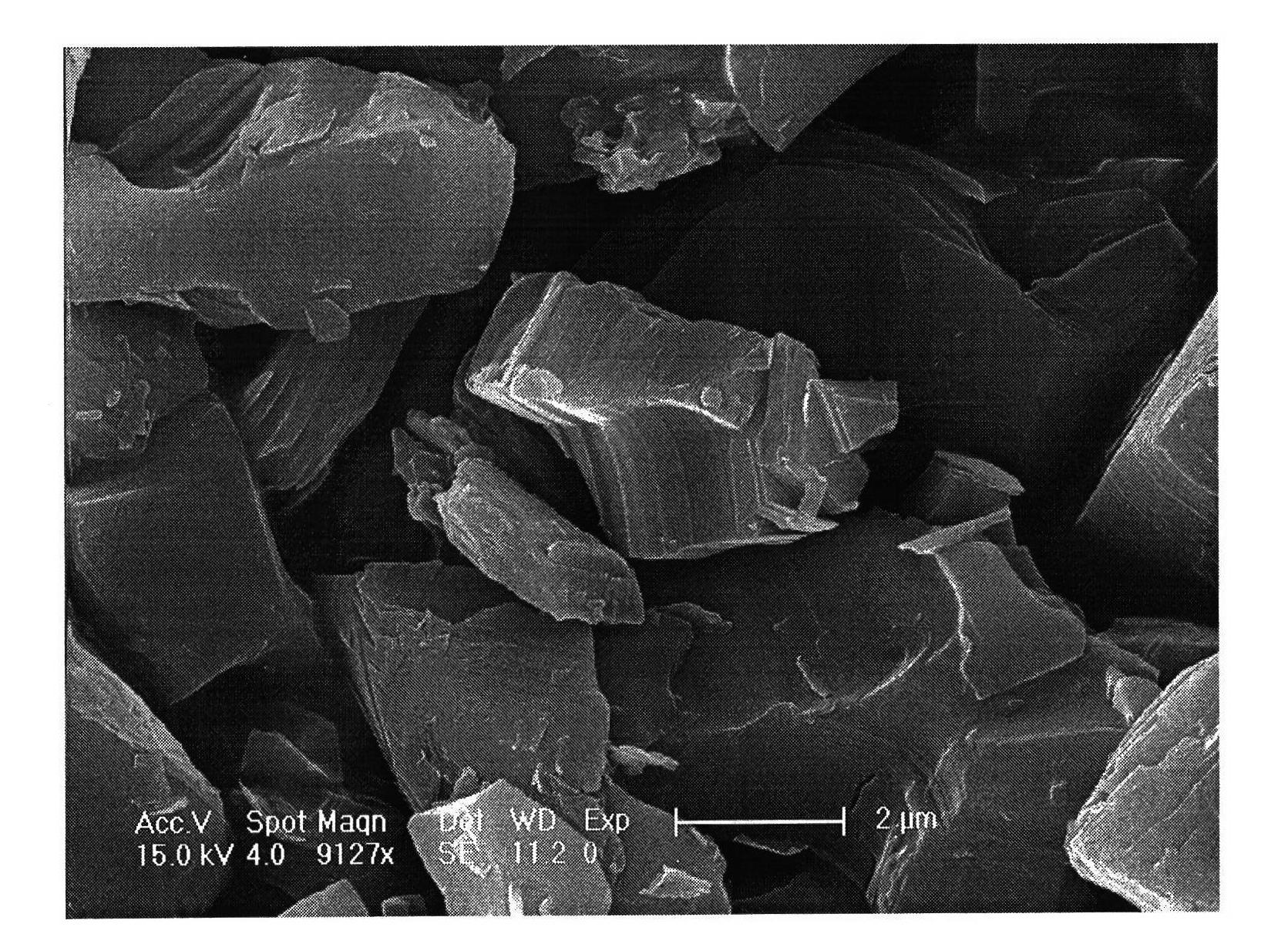

Modified no-adhesive ZSM-5 zeolite catalyst and its prepn process

InactiveCN1974007ASimple preparation processLow costMolecular sieve catalystsHydrocarbon from oxygen organic compoundsAlcoholWater vapor

The present invention belongs to the field of material synthesis technology, and is especially modified no-adhesive ZSM-5 zeolite catalyst and its preparation process and application in catalyzing the dewatering of dilute alcohol solution to prepare ethylene. The catalyst is prepared with no-adhesive ZSM-5 zeolite as basic material and through one modification process combining high temperature water vapor and acid treatment. The catalyst has high content of effective component ZSM-5 zeolite, high molecule diffusion, high crystallization degree, opened channels and great specific surface area. In catalyzing the dewatering of dilute alcohol solution to prepare ethylene, the catalyst has high catalytic activity, low reaction solution ethanol concentration, low reaction temperature, high ethanol converting rate, high ethylene selectivity and high space velocity.

Owner:FUDAN UNIV

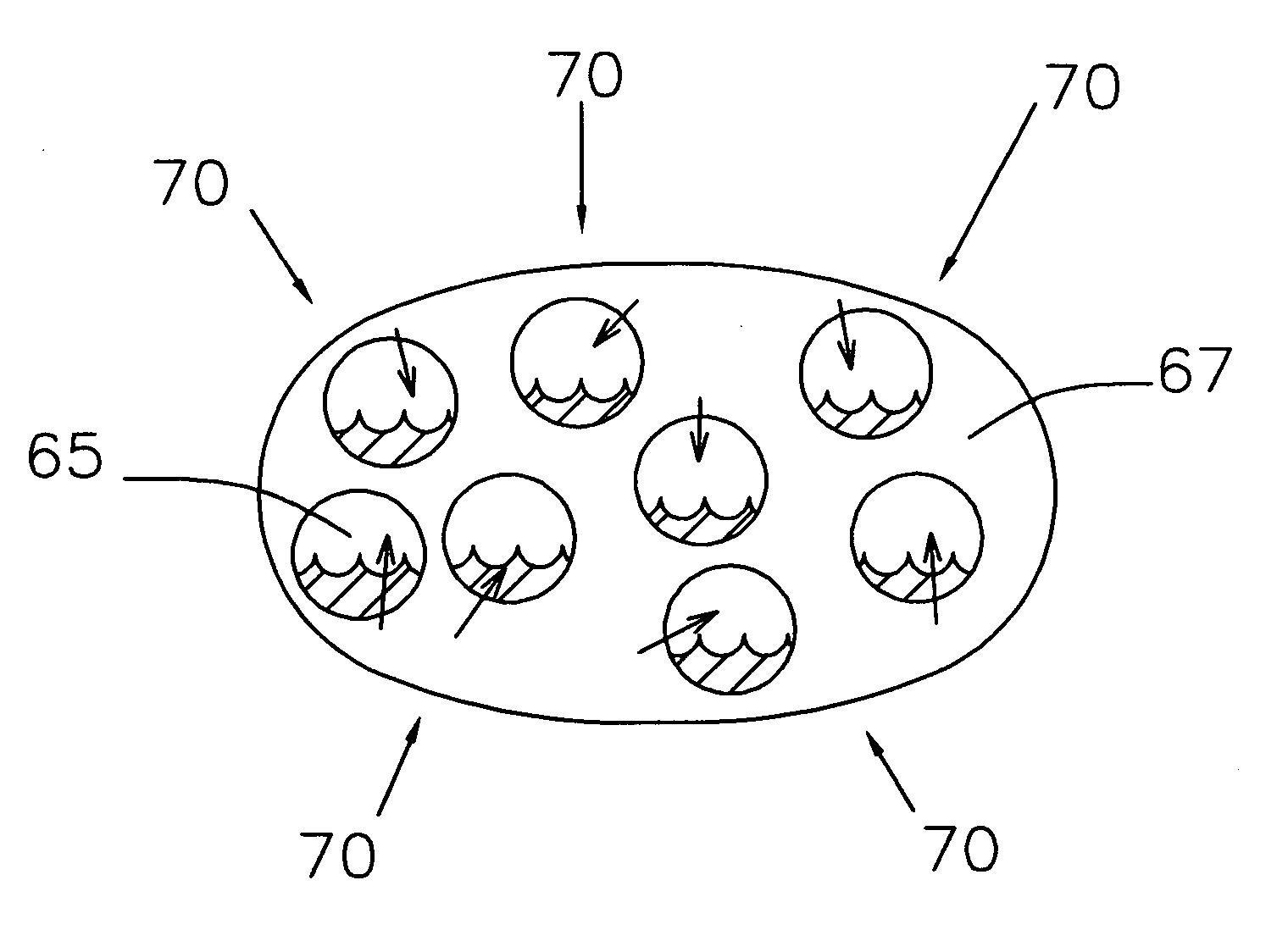

Closed system artificial intervertebral disc

Devices and methods for manufacturing devices for treating degenerated and / or traumatized intervertebral discs are disclosed. Artificial discs and components of discs may include an artificial nucleus and / or an artificial annulus and may be comprised of shape memory materials synthesized to achieve desired mechanical and physical properties. An artificial nucleus and / or annulus according to the invention may comprise a first and second reservoir and one or more fluids, wherein upon application of a load upon the artificial nucleus and / or disc, the one or more fluids enters said second reservoir from said first reservoir.

Owner:SYNECOR LLC

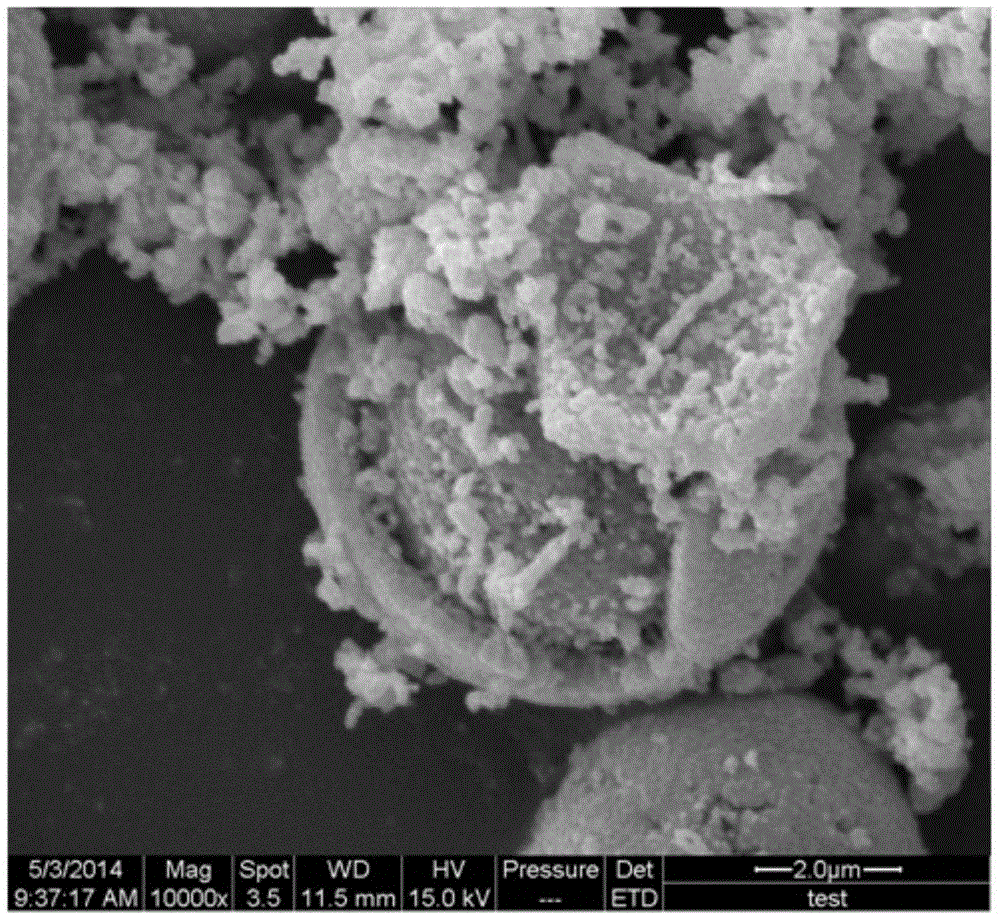

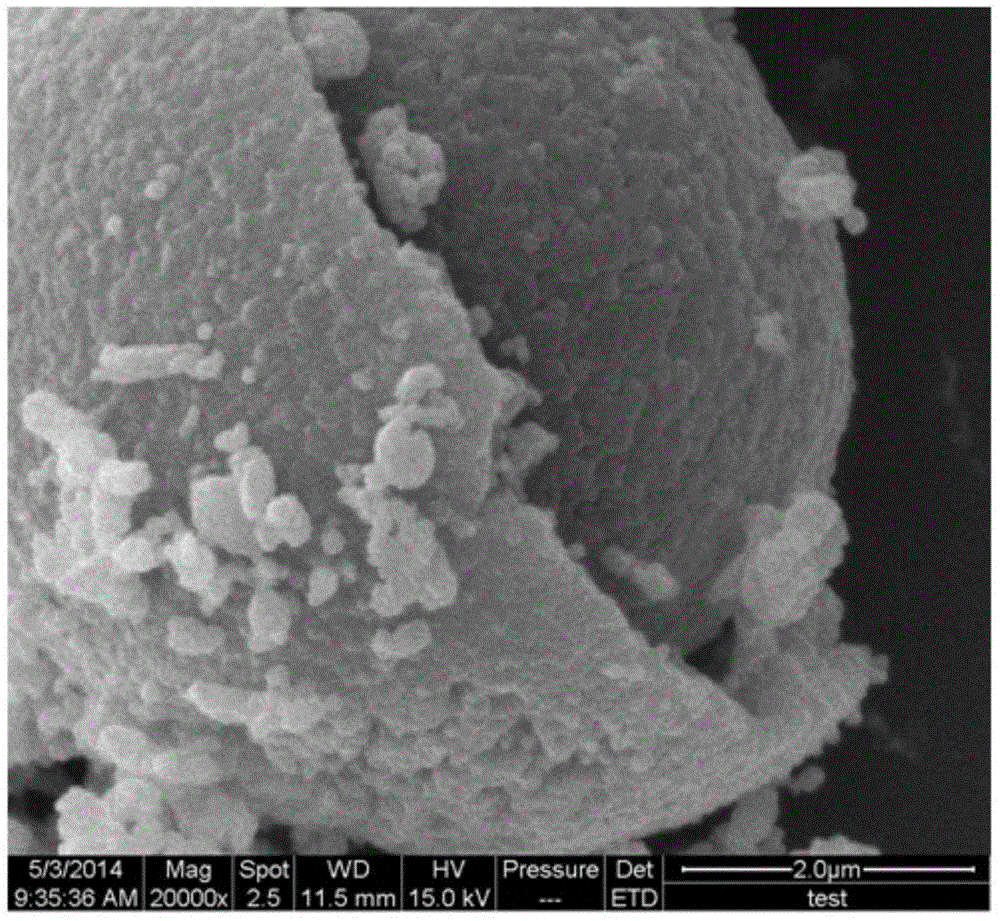

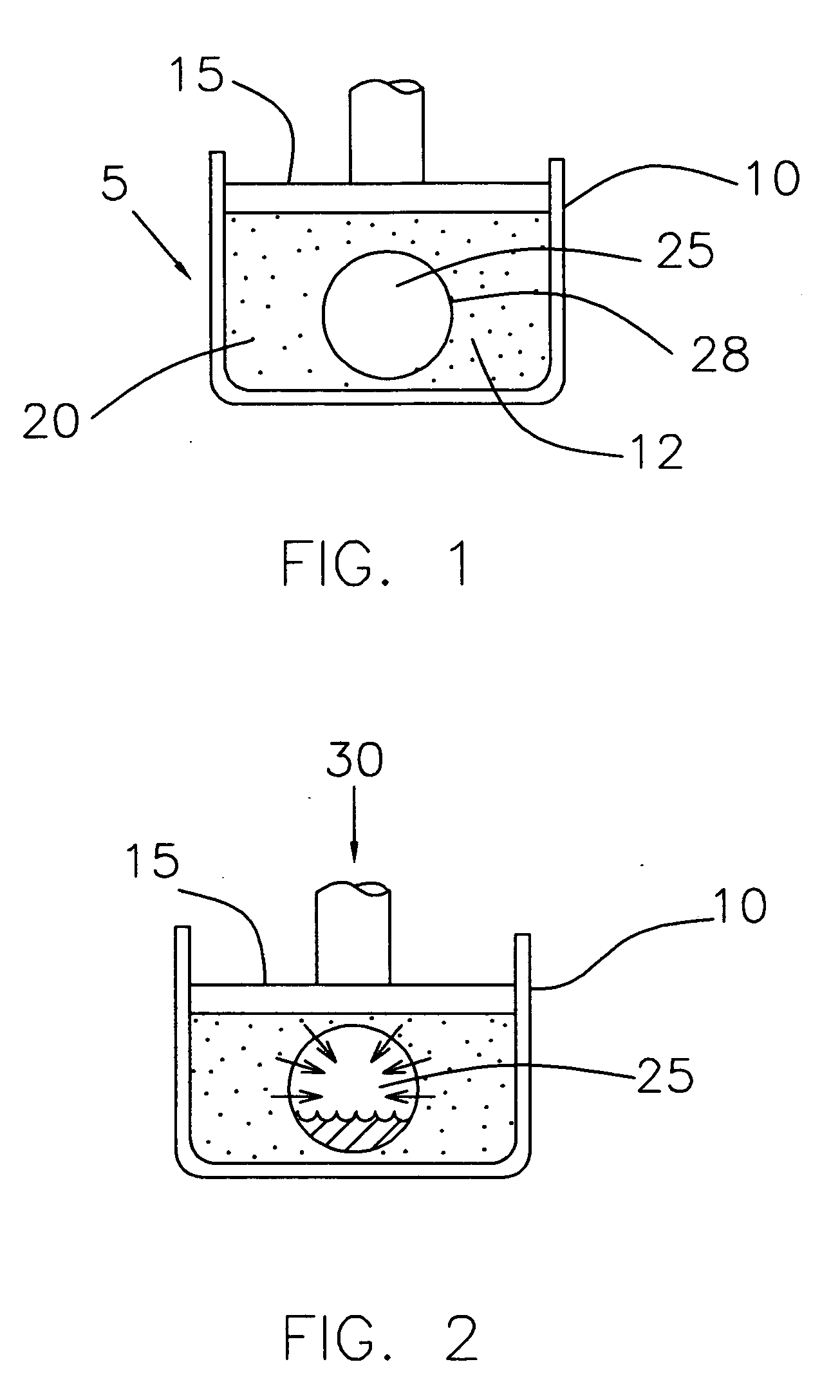

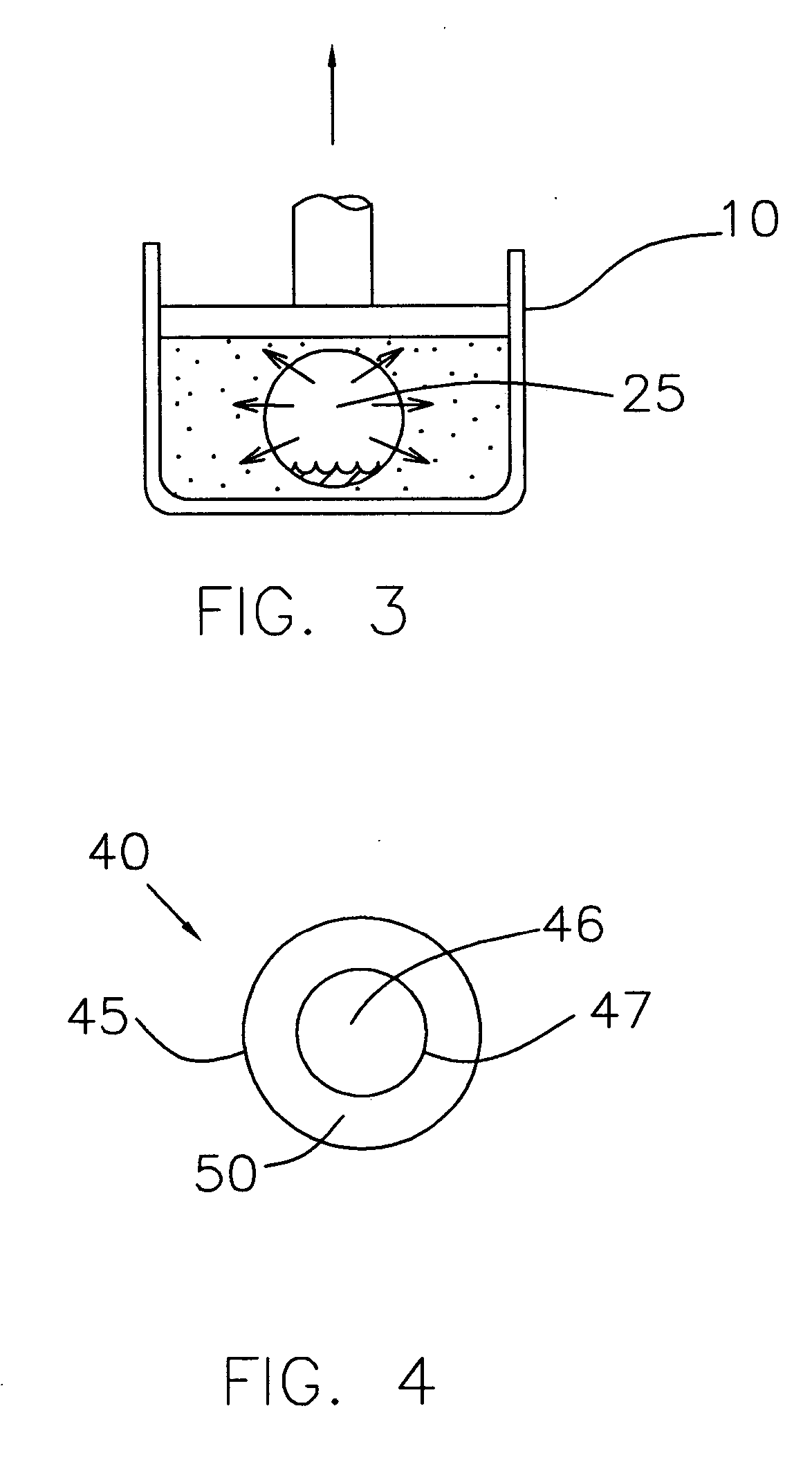

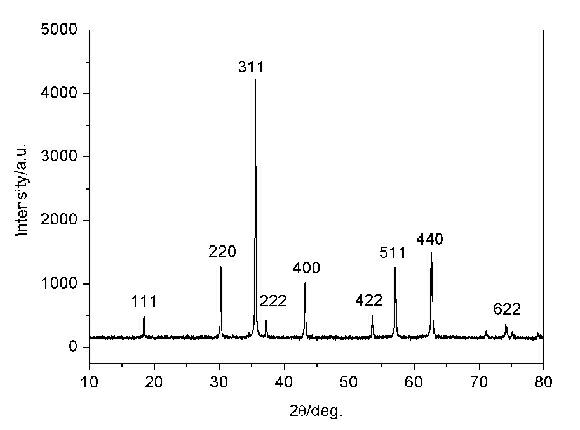

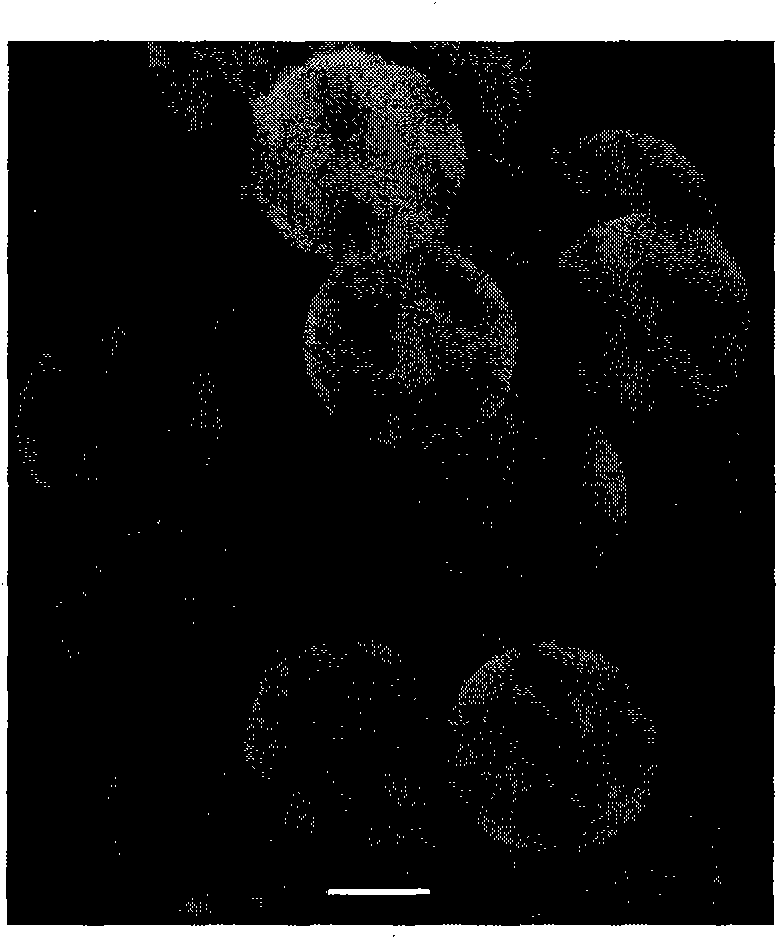

Method for synthesizing Fe3O4/C lithium ion battery cathode material with hollow sphere structure by one-step process

The invention discloses a preparation method of a lithium-stored composite material Fe3O4 / C with a hollow sphere structure and an application of the lithium-stored composite material Fe3O4 / C with a hollow sphere structure in a lithium ion battery, belonging to the technical fields of material synthesis and high-energy lithium-ion storage batteries. The preparation method is characterized in that a solvothermal method or hydrothermal method is utilized to prepare the Fe3O4 / C composite material with a hollow sphere and narrower particle size distribution, wherein the Fe3O4 / C composite material is high in purity; and the mean particle size of the Fe3O4 / C composite material is 750 nanometers and the wall thickness of the Fe3O4 / C composite material is 250 nanometers. An electrochemical test proves that the first discharging specific capacity of the Fe3O4 / C composite material prepared by the method can be 1157mAh / g, and the discharging specific capacity of the Fe3O4 / C composite material can be 900mAh / g after being circulated for 65 times, thus showing the perfect cyclical stability. The Fe3O4 / C composite material has good rate performance; and the charging specific capacity of the Fe3O4 / C composite material is 620mAh / g and 460mAh / g respectively under 2C and 5C charge-discharge rates, thus the rate performance is superior to that of an existing commonly-used carbon cathode material (theoretical specific capacity is 372mAh / g). The Fe3O4 / C lithium ion battery cathode material is low in cost, simple in process and easy to industrialize, and has wide application prospects in the high-energy lithium ion battery field.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

Star-shaped comb type butadiene/phenylethylene block copolymers and preparation method thereof

ActiveCN101456938AThe synthetic route is simpleAchieve high performanceMaterial synthesisMacromolecule

The invention belongs to the technical field of polymer material synthesis and preparation, relating to a star-shaped comb butadiene / styrene segmented copolymer, which is characterized in that the copolymer has the following structure: An-C, wherein A is the butadiene / styrene segmented copolymer, C is star-shaped seed tree coupler residue which is an epoxidation liquid star-shaped copolymer, n is branching degree which is larger or equal to 3, the number average molecular weight of the star-shaped comb segmented copolymer An-C is 5*10<4>-50*10<4>, the number average molecular weight of the segmented copolymer A is 1*10<4>-15*10<4>, the content of styrene is 55 percent to 85 percent (weight percent, same below), the content of butadiene is 15 percent to 45 percent, the content of 1, 2-structure is less than 30 percent (weight percent, which is counted by 100 percent of the total amount of monomer butadiene). The synthesis has the effect and benefit of simplifying the synthetic route of the star-shaped comb butadiene / styrene segmented copolymer, which can be widely applied to the preparation of the star-shaped comb butadiene / styrene segmented copolymer.

Owner:DALIAN UNIV OF TECH

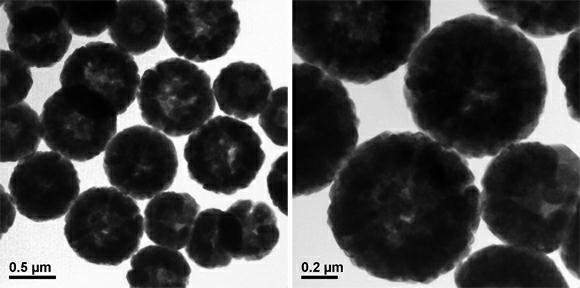

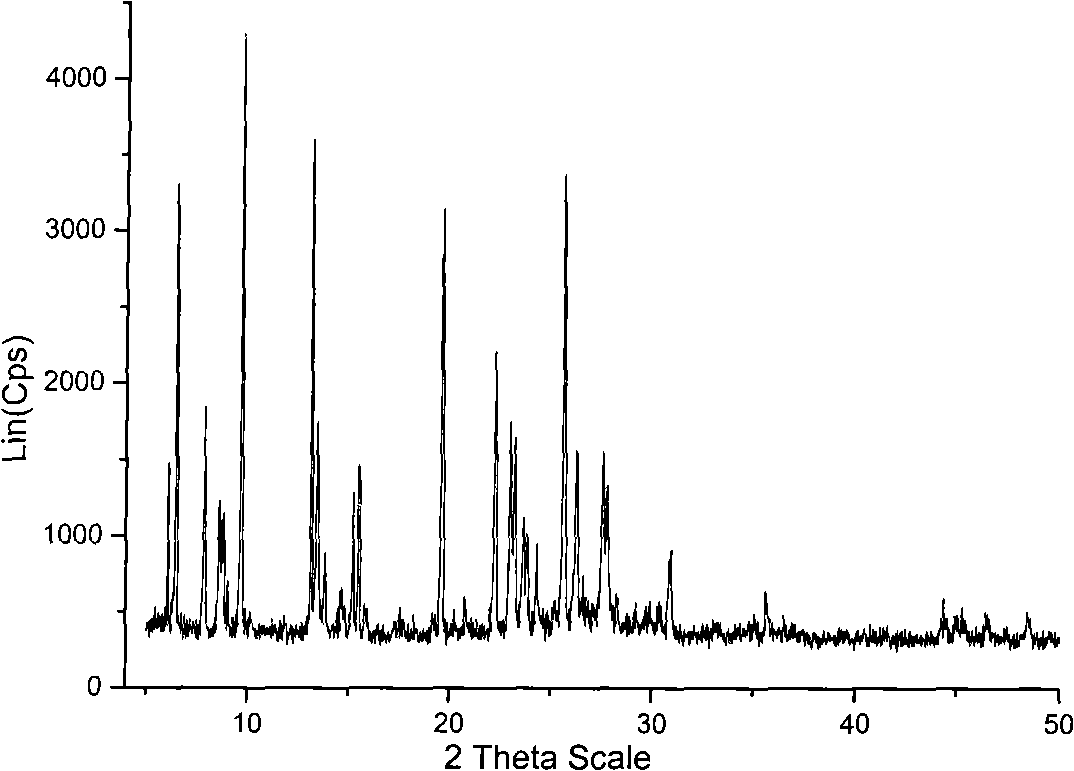

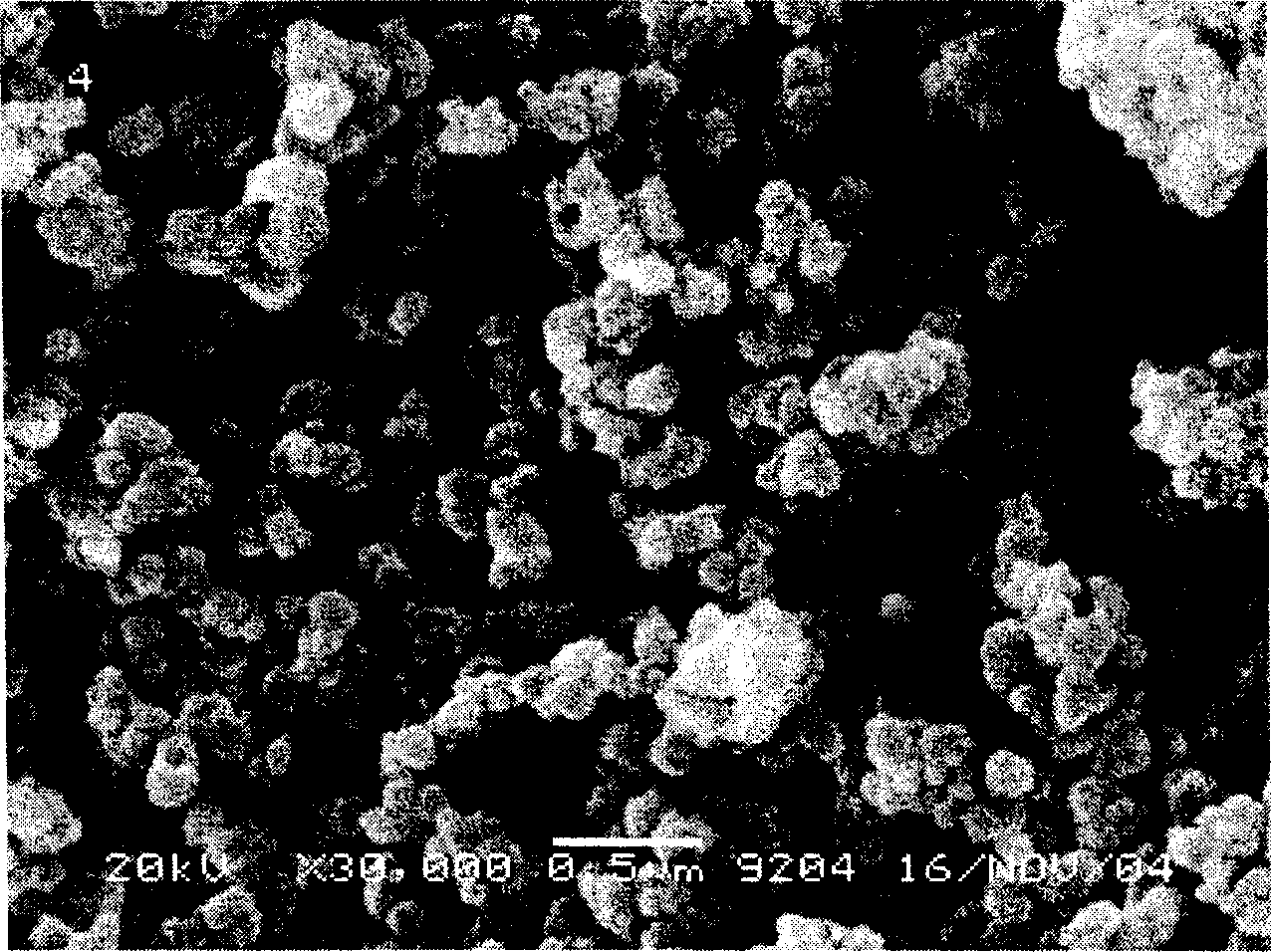

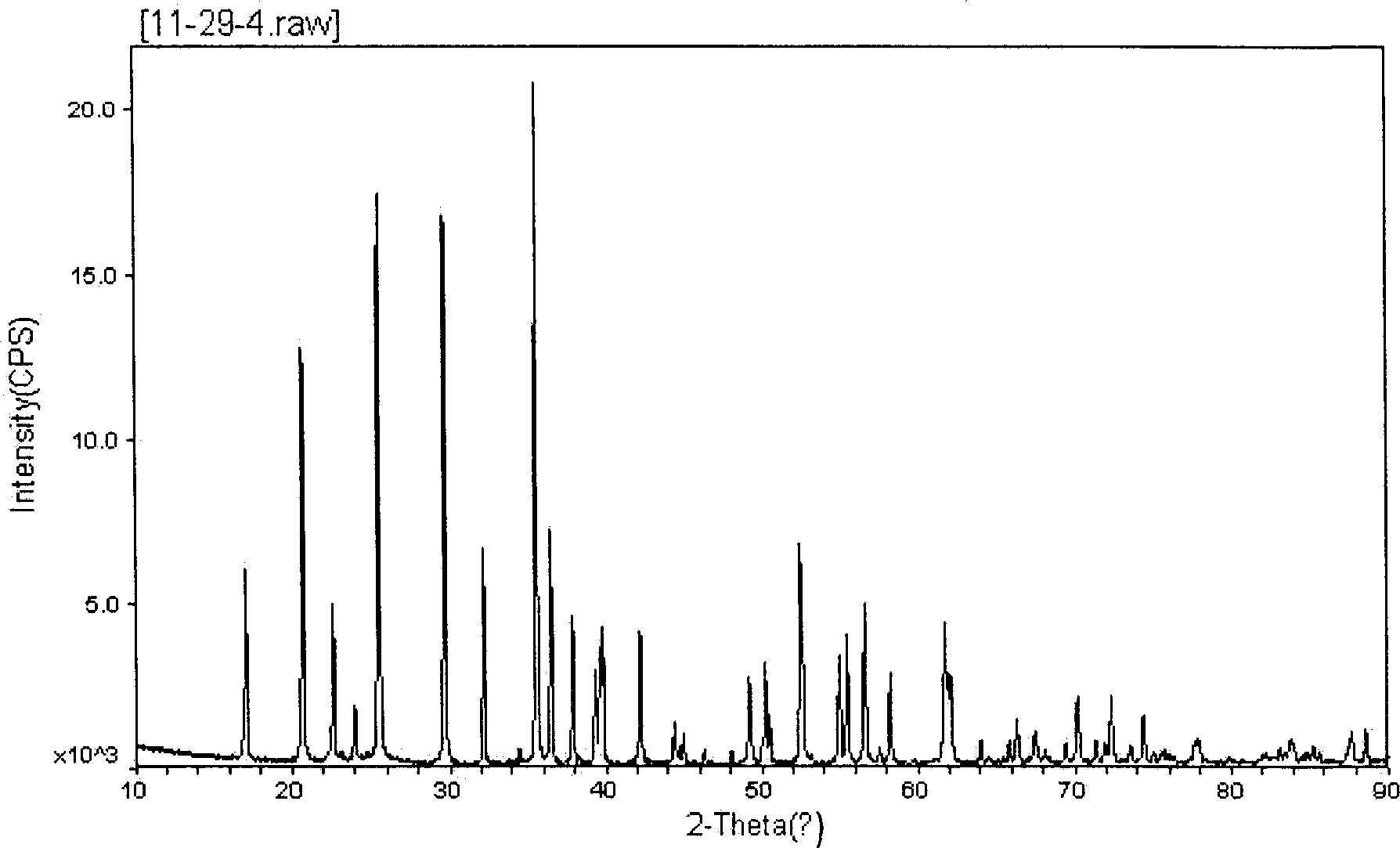

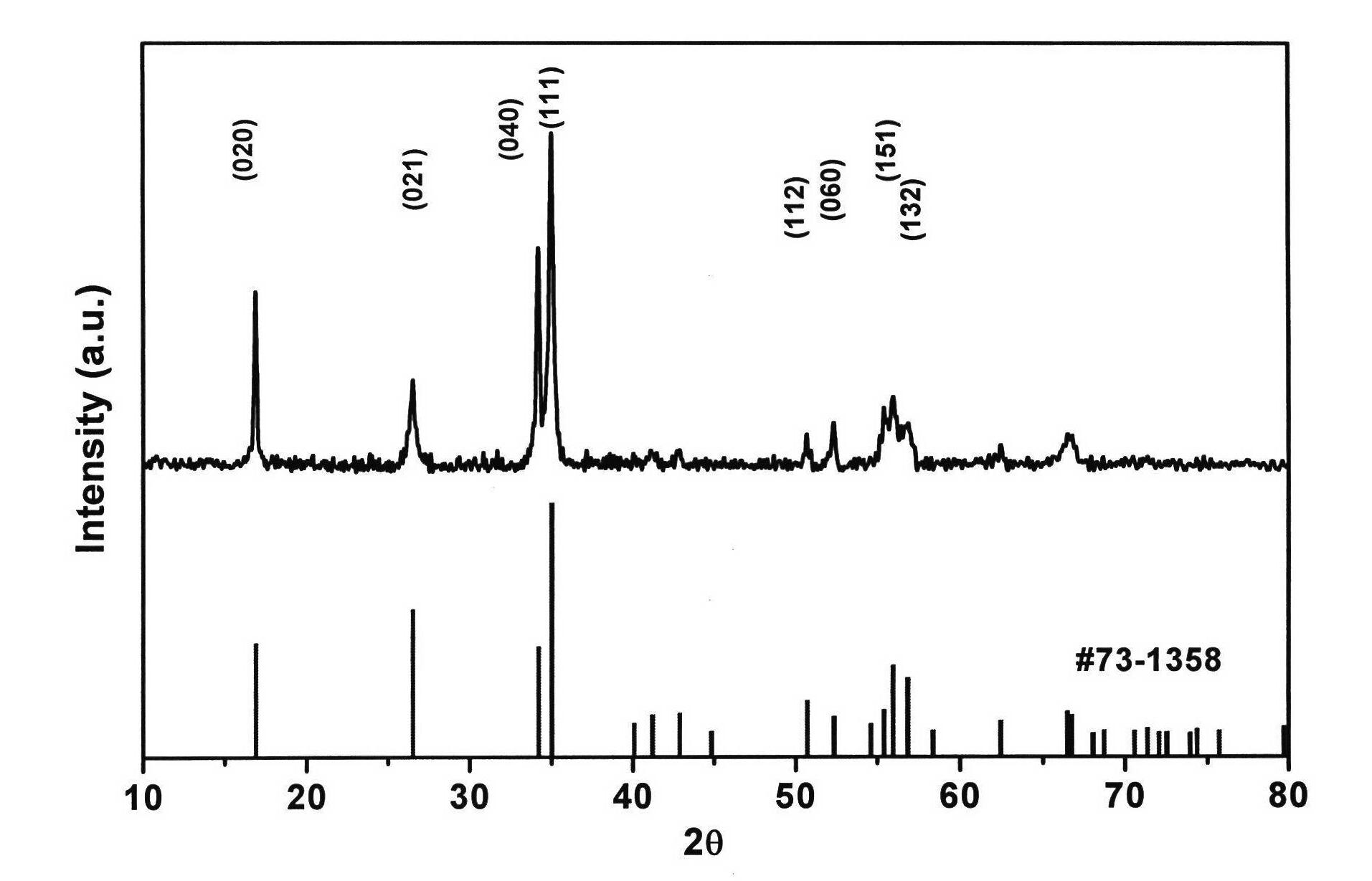

Mordenite/beta zeolite/Y zeolite coexisting material and method for synthesizing same

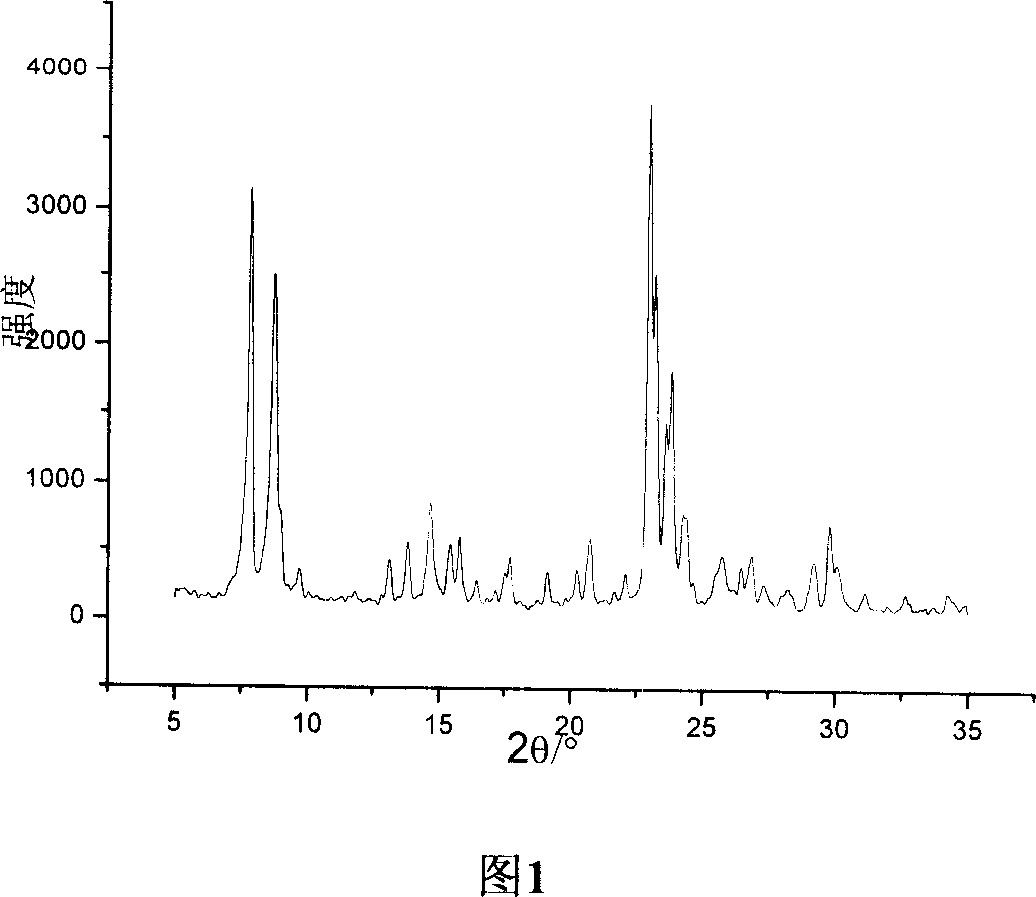

ActiveCN101514009AStrong acidImprove catalytic performanceFaujasite aluminosilicate zeoliteMordenite aluminosilicate zeoliteCatalytic pyrolysisNaphtha

The invention relates to a mordenite / beta zeolite / Y zeolite coexisting material and a method for synthesizing the same, and mainly solves the problems that a porous material synthesized by the prior art is single in pore-size, weak in acid and low in activity. The method prepares the mordenite / beta zeolite / Y zeolite coexisting material by adding a seed crystal containing a Y zeolite precursor during a synthesis process of mordenite / beta zeolite / Y zeolite coexisting material. A mole relation of the components of the synthesized mordenite / beta zeolite / Y zeolite coexisting material is nSiO2 :Al2O3, wherein n is between 4 and 400; the XRD diffraction pattern of the mordenite / beta zeolite / Y zeolite coexisting material comprises a technical proposal that a maximum value of a distance d is at positions between 14.52-0.1 and 14.52+0.1 A, 13.52-0.1 and 13.52+0.1 A,11.32-0.1 and 11.32+0.1 A, 8.96-0.1 and 8.96+0.1 A, 6.71-0.1 and 6.71+0.1 A, 5.71-0.1 and 5.71+0.1 A, 4.51-0.05 and 4.51+0.05 A, 4.15-0.05 and 4.15+0.05 A, 3.97-0.05 and 3.97+0.05 A, 3.78-0.05 and 3.78 +0.05 A, 3.51-0.05 and 3.51+0.05 A, 3.02-0.05 and 3.02+0.05 A, and 2.86-0.1 and 2.86+0.1 A; therefore, the problems are solved well. The mordenite / beta zeolite / Y zeolite coexisting material can be used in the industrial production of ethylene and propylene through the catalytic pyrolysis of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

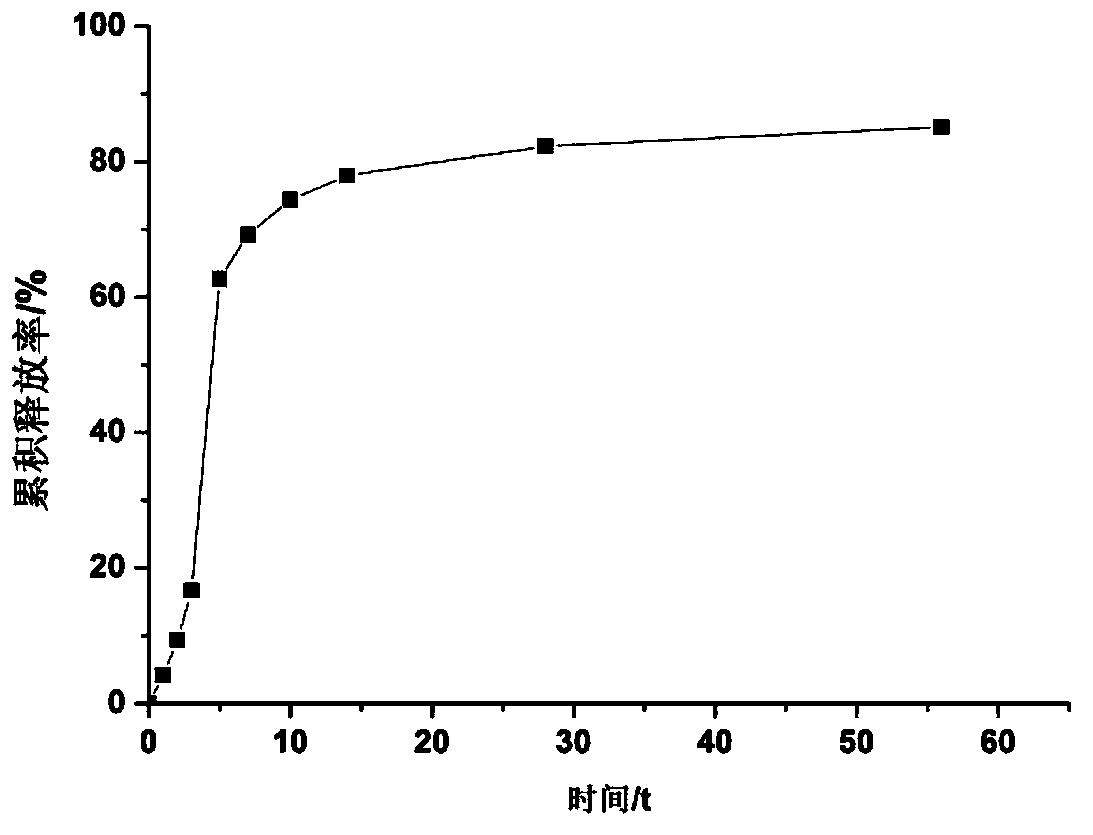

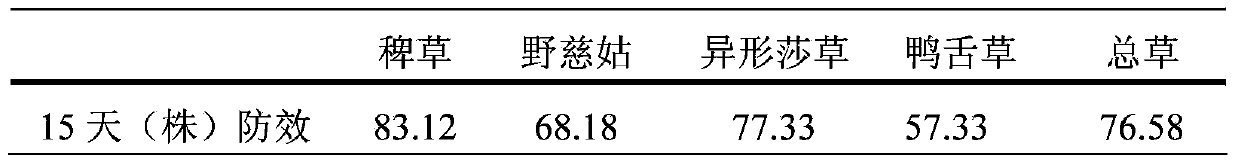

Polymer-coated controlled release pesticide granule and preparation method thereof

ActiveCN103387456AImprove water resistanceImprove targetingFertilizer mixturesWater basedPolyurethane membrane

The invention discloses a polymer-coated controlled release pesticide granule and a preparation method thereof. The polymer-coated controlled release pesticide granule comprises a pesticide granule and a polymer layer, wherein the pesticide granule is coated by the polymer layer; the pesticide granule contains one or more effective pesticide components; the polymer layer is a hydrophobic membrane layer and comprises a water-based polyacrylate membrane material or a polyurethane membrane material; the mass of the polymer layer accounts for 3%-15% of the weight of the polymer-coated controlled release pesticide granule. The effective pesticide components are acted on the peripheries of crop roots after the polymer-coated controlled release pesticide granule disclosed by the invention is applied along with a base fertilizer. The polymer-coated controlled release pesticide granule has good prevention and control effects on farmland weeds, soil insects and soil-borne diseases, and the coating material synthesis and preparation process is advanced and the polymer-coated controlled release pesticide granule has good controlled release property. The polymer-coated controlled release pesticide granule provided by the invention has the advantages of pesticide utilization ratio improvement, environment pollution reduction, sustainable development and wide application prospect.

Owner:BEIJING BOYICHENG SCI & TECH

Method for preparing olivine structure lithium iron phosphate

InactiveCN1800003ASolve easy oxidationSolve the problem of difficult to mix evenlyPhosphorus compoundsLithium iron phosphateMaterial synthesis

The invention discloses a making method of chrysolite-structured ferric lithium phosphate, which is characterized by the following: mixing the bivalent Fe source compound, P source compound and oxidant at LiFePO4 chemical gauge; controlling the pH value equal to 1-8; filtering; cleaning; drying; generating about 100 nm FePO4 pioneer body; putting the mixture of FePO4 pioneer body and Li source compound and reducer in the furnace; calcining the mixture in the non-oxidized atmosphere to make LiFePO4. The invention prevents the ferrous ion from oxygenizing and difficult blending of raw material, which improves the material synthesis and property to cover the residual carbon on the LiFePO4 particle.

Owner:CENT SOUTH UNIV

Methods and Apparatus for Solid Carbonaceous Materials Synthesis Gas Generation

Methods and apparatus may permit the generation of consistent output synthesis gas from highly variable input feedstock solids carbonaceous materials. A stoichiometric objectivistic chemic environment may be established to stoichiometrically control carbon content in a solid carbonaceous materials gasifier system. Processing of carbonaceous materials may include dominative pyrolytic decomposition and multiple coil carbonaceous reformation. Dynamically adjustable process determinative parameters may be utilized to refine processing, including process utilization of negatively electrostatically enhanced water species, process utilization of flue gas (9), and adjustment of process flow rate characteristics. Recycling may be employed for internal reuse of process materials, including recycled negatively electrostatically enhanced water species, recycled flue gas (9), and recycled contaminants. Synthesis gas generation may involve predetermining a desired synthesis gas for output and creating high yields of such a predetermined desired synthesis gas.

Owner:THERMOTEK

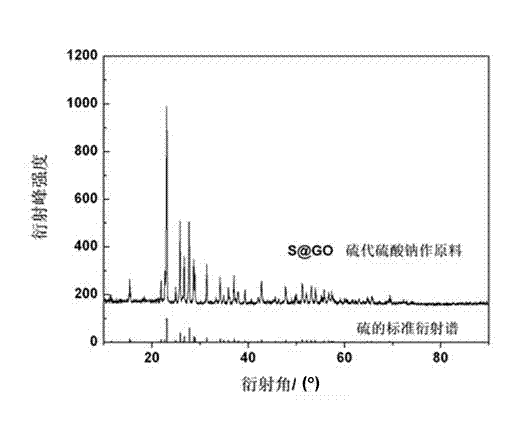

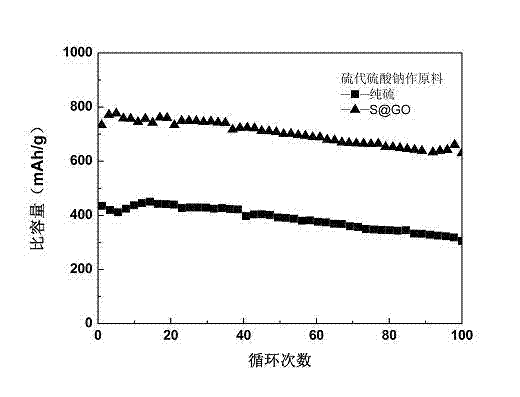

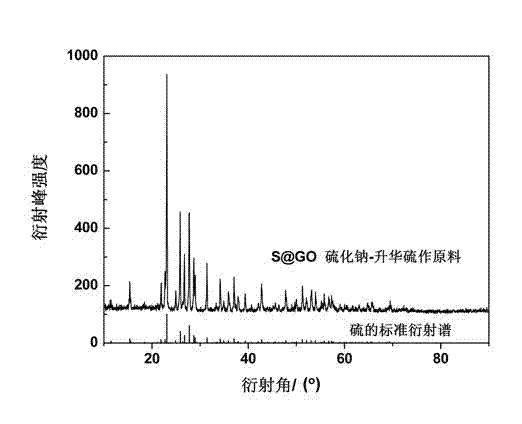

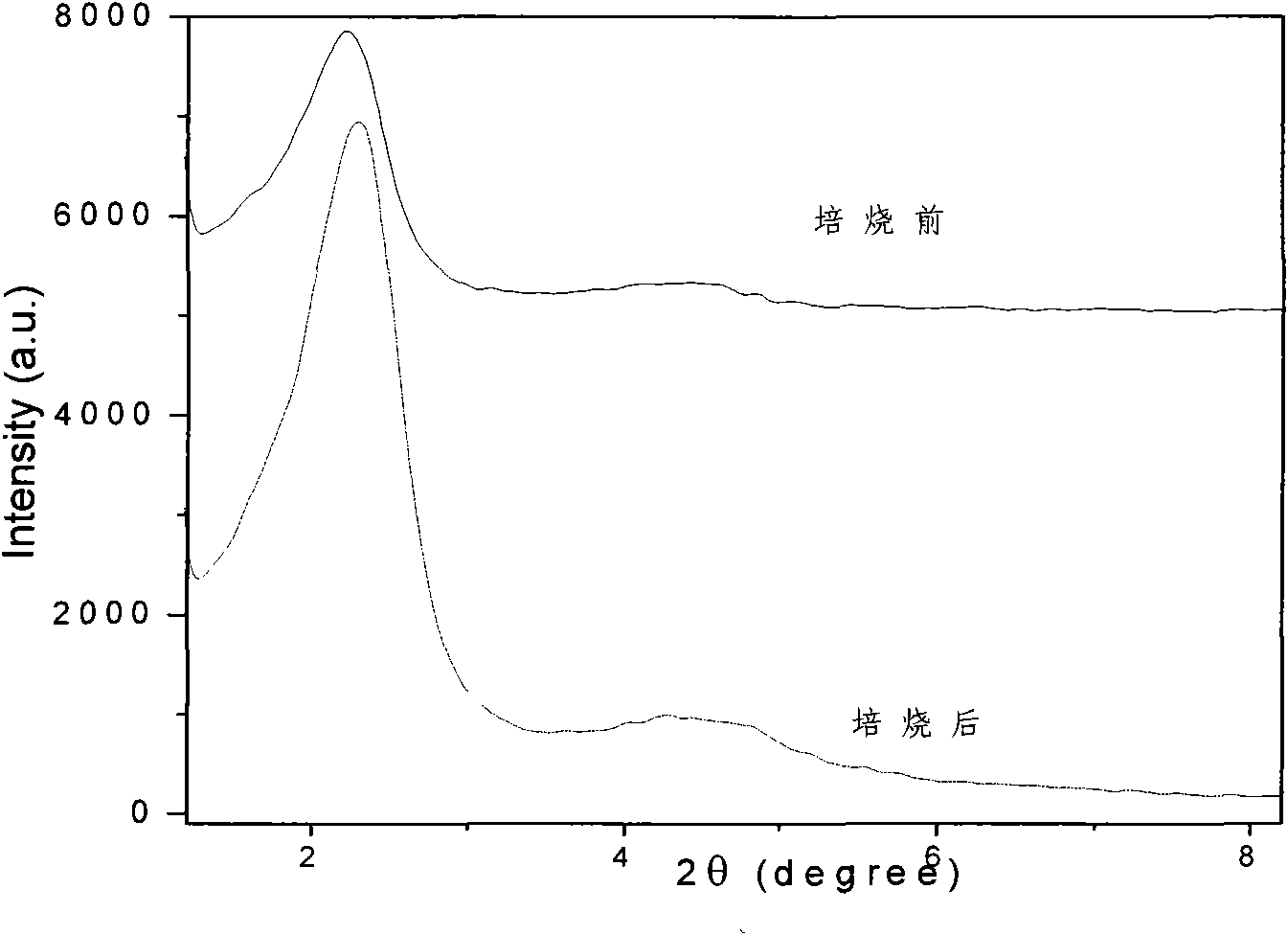

Method for preparing nano-sulfur / graphene oxide composite electrode material

The invention relates to a method for preparing a nano-sulfur / graphene oxide composite material with high specific capacity and belongs to the field of cross application of material synthesis and electrochemical power supplies. The nano-sulfur / graphene oxide composite material is applicable to an electrode material of a lithium sulfur secondary battery with the high specific capacity. The method is characterized by comprising the following steps of: synthesizing nano-sulfur particles by using a simple chemical method under the protection of a surfactant; and uniformly attracting graphene oxide and a carbon material to the surfaces of the nano-sulfur particles by interaction of the surfactant and the graphene oxide to form a core-shell type nano-sulfur / graphene oxide composite material. The graphene oxide and the carbon material coat a sulfur surface, so a sulfur electrode material is stable in structure, high in electric conductivity and high in cycle performance. Environmentally-harmful materials are not employed, and the method can be implemented at low temperature, and is low in energy consumption in the synthesis process and low in equipment requirement. The synthesized material is high in charging / discharging capacity, non-toxic and harmless to a human body, and sulfur is abundant in nature, so the material has a good industrial prospect and can be applied to large-scale industrial production.

Owner:SHANGHAI UNIV

Method for synthesizing composite material of organic - inorganic bentonite

InactiveCN101003374AOvercome the disadvantage of easy falling offStrong forceSilicon compoundsPorositySodium Bentonite

This invention discloses a method for synthesizing organic-inorganic bentonite composite. The method comprises: utilizing bentonite as the main material, performing inorganic modification through cation-exchange reaction by using hydroxyl aluminum aqueous solution, torrefying to obtain hydroxyl-containing aluminum-pillared bentonite with high porosity and high specific surface area, and reacting between the hydroxyls and silylation agent to graft silane groups onto aluminum-pillared bentonite and obtain organic-inorganic bentonite composite. The organic-inorganic bentonite composite has both the advantages of inorganic pillared bentonite such as high porosity and high specific surface area, and those of organic bentonite such as high organic carbon content and high hydrophobicity thus can be used to treat organic waste gases and wastewater with a good effect by surface adsorption as well as distribution.

Owner:ZHEJIANG UNIV

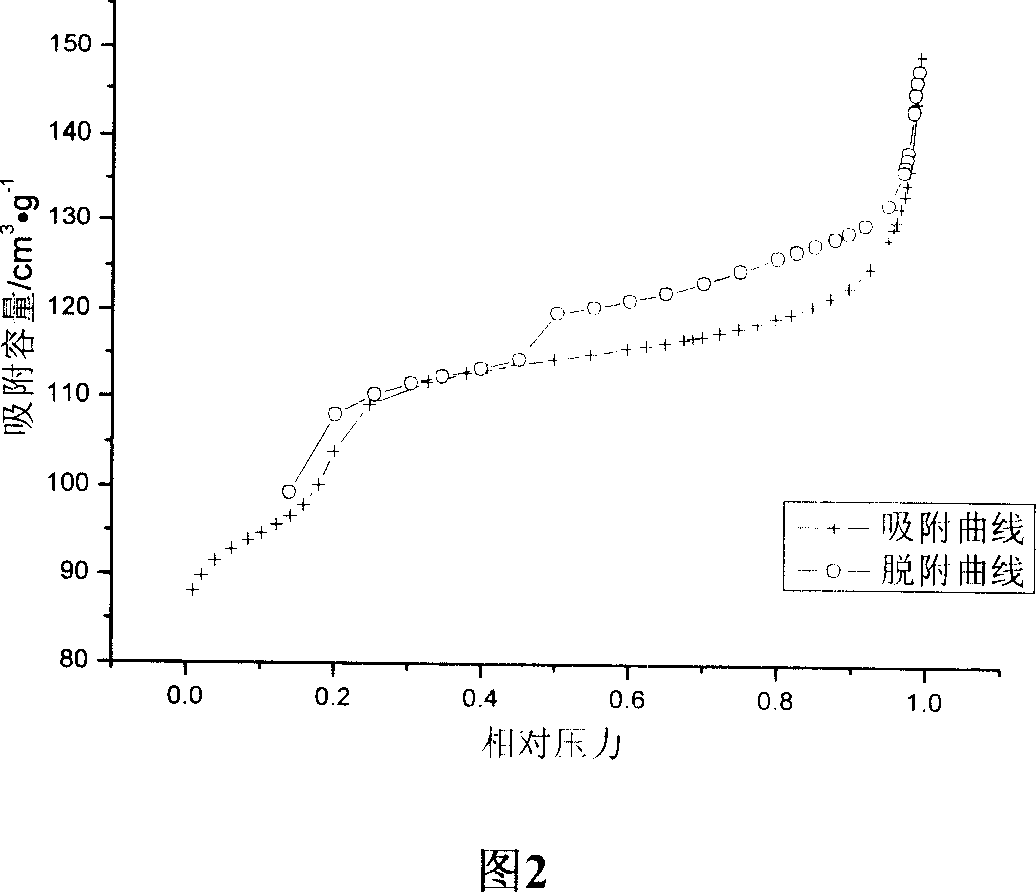

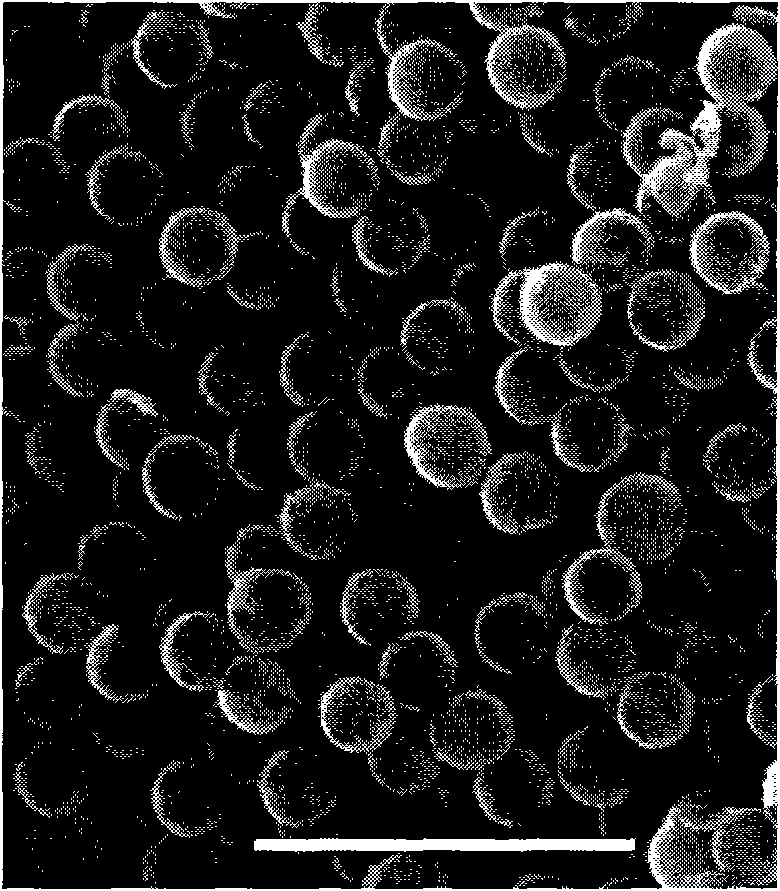

Method for preparing hollow mesoporous lamella spherical silica material

The invention relates to an inorganic porous material synthesis technology field, and concretely relates to a method for preparing hollow mesoporous lamella spherical silica material. In a mixed solvent of alcohol and water, under the catalytic action of ammonia, using a cationic surface active agent of cetyl trimethyl ammonium bromide as a mesoporous template, the inorganic silicon material self-assembles to be mesoporous uniform spheres on the polyphenylacetylene sphere surface, the surface active agent and the polyphenylacetylene sphere are deprived in high temperature environment, the hollow silica spheres with uniform size from micron to millimeter and mesoporous lamella are obtained. The specific surface area of the obtained hollow silica sphere is 800-2000m<2> / g, the bore diameter is 1.8-3.5nm, and the bore volume is 0.5-0.8 ml / g.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing black phosphorus of negative electrode materials of high-capacity lithium-ion battery

InactiveCN102491294AImprove electrochemical performanceGood compatibilityCell electrodesPhosphorus preparationWhite PhosphorusSynthesis methods

The invention belongs to the technical field of chemical material synthesis and electrochemistry and particularly relates to a method for preparing composite materials and black phosphorus of negative electrode materials of a high-capacity lithium-ion battery. According to the method, the black phosphorus of negative electrode materials of the high-capacity lithium-ion battery is synthesized by a high-pressure synthesis method. On one hand, a high-pressure synthesis device is adopted, white phosphorus and red phosphorus are respectively used as raw materials, and pure-phase black phosphorus is synthesized at different pressures and temperatures; on the other hand, the white phosphorus and the red phosphorus are used as raw materials, modified materials are doped, modified black phosphorus is synthesized, the raw materials account for 10 to 90 percent, and the modified materials account for 5 to 50 percent. The black phosphorus prepared by the method is used as the negative electrode materials of the lithium-ion battery, the specific capacity is 3 to 7 times of that of the industrialized graphite negative electrode, the tap density of the black phosphorus negative electrode materials reaches 1.7 to 2.4g / cm<3> and is 2 to 3 times of that of the graphite negative electrode, and the black phosphorus negative electrode has good compatibility with the existing electrolyte and is hopeful to become a new generation of negative electrode materials of the high-capacity lithium-ion battery.

Owner:NORTHEAST NORMAL UNIVERSITY

Material and method for preparing aluminum alloy structural member by using laser 3D (Three-Dimensional) printing technology

InactiveCN104759625AImprove performanceIncrease profitAdditive manufacturing apparatusComputer Aided DesignMaterial synthesis

The invention discloses a material and method for preparing an aluminum alloy structural member by using a laser 3D (Three-Dimensional) printing technology. Technologies such as a CAD (Computer Aided Design) three-dimensional entity model slicing technology, a digital programming technology and a laser quick forming technology and a material synthesis technology are combined integrally; under the condition that no any special mold or tool is used, multi-layer cladding accumulation is performed through quick melting and solidification of a laser beam on an aluminum alloy substrate by taking the powder of Al, Fe, Cu, Si, Ti, B, Mn, C and Ce according to the mass percentage of 80.0, 3.0, 2.0, 3.0, 4.0, 3.0, 1.5, 2.0 and 1.5 as a raw material; an aluminum alloy structural member with good comprehensive performance such as high performance, full compactness and high fatigue life is directly finished from a part digital model in one step. The method has the characteristics of low cost, short period and high material utilization rate, and is suitable for integrated quick forming manufacturing of large-sized and complex aluminum alloy structural members; the shapes and the sizes of the prepared parts are not limited, and the requirement on structural integration can be met.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Methods and Apparatus for Solid Carbonaceous Materials Synthesis Gas Generation

Methods and apparatus may permit the generation of consistent output synthesis gas from highly variable input feedstock solids carbonaceous materials. A stoichiometric objectivistic chemic environment may be established to stoichiometrically control carbon content in a solid carbonaceous materials gasifier system. Processing of carbonaceous materials may include dominative pyrolytic decomposition and multiple coil carbonaceous reformation. Dynamically adjustable process determinative parameters may be utilized to refine processing, including process utilization of negatively electrostatically enhanced water species, process utilization of flue gas (9), and adjustment of process flow rate characteristics. Recycling may be employed for internal reuse of process materials, including recycled negatively electrostatically enhanced water species, recycled flue gas (9), and recycled contaminants. Synthesis gas generation may involve predetermining a desired synthesis gas for output and creating high yields of such a predetermined desired synthesis gas.

Owner:THERMOTEK

Process for synthesizing LiFePO4 as positive electrode materials of lithium ion cell

InactiveCN1837033AEvenly distributedImprove charging capacityCell electrodesPhosphorus compoundsCompound aPhosphate ion

The invention discloses a Synthesis of lithium ferrous phosphate which is anode material of lithium ion battery. The material synthesis is as follows: geeting lithium salt, malysite and mammonium dihydrogen phosphate, according to the mole ratio of lithium ion: iron ion: phosphate radical ion is (0.8-1.2):(0.8-1.2):(0.8-1.2), getting compound A of equal proportion, joining some compound A in aqueous solution B which contains soluble salt and soluble organic species, putting it in high temperature furnace, then cooling naturely, compounding ferrous phosphate powder containing carbon and adulterating metal ion, milling the synthetical aqueous lithium solution powder, controllong the grain diameter between 1-50 mum. The synthetical material of this invention distribute equally, using this material as positive material can improve batteries' charging capacity effectively.

Owner:SHANDONG UNIV OF SCI & TECH

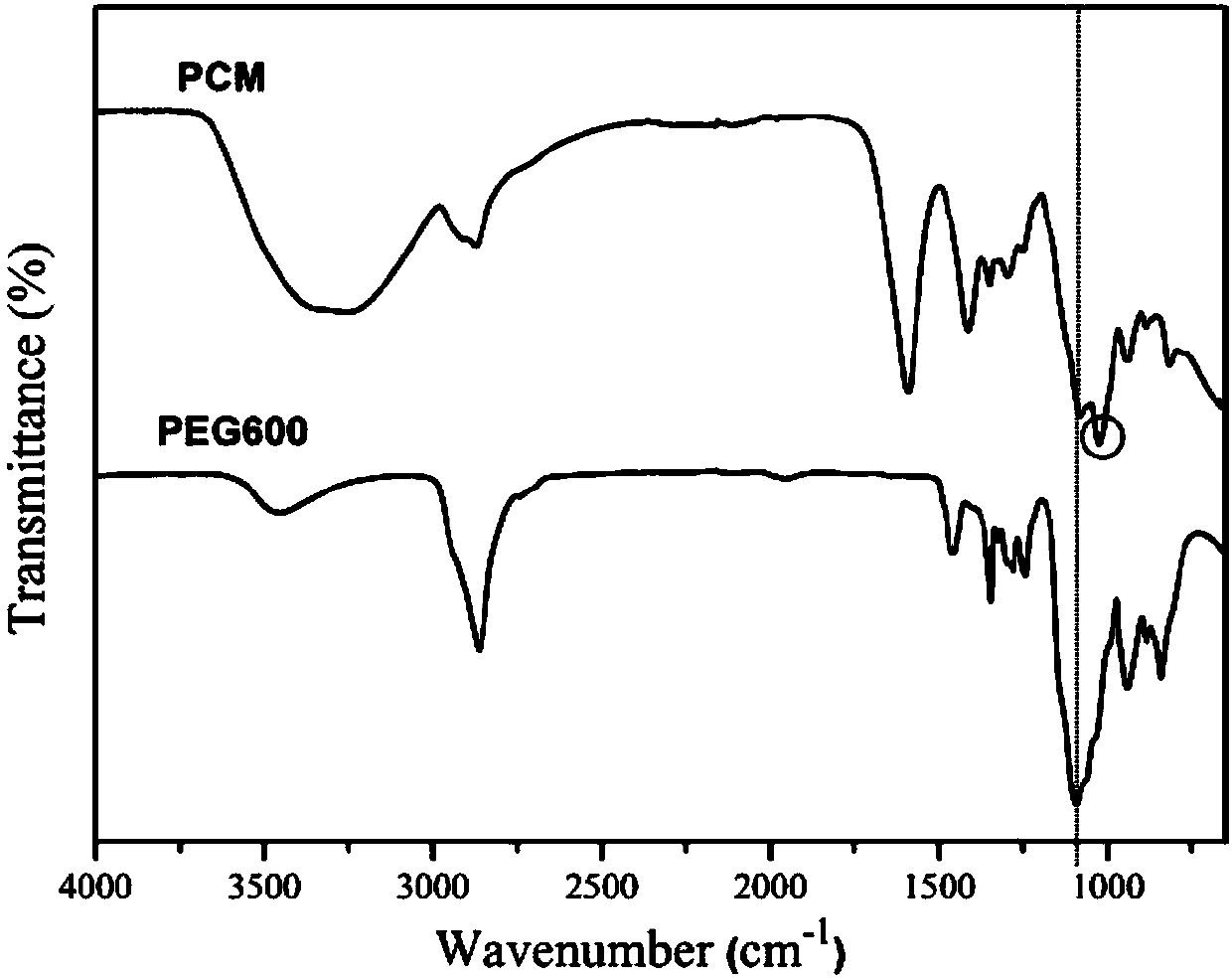

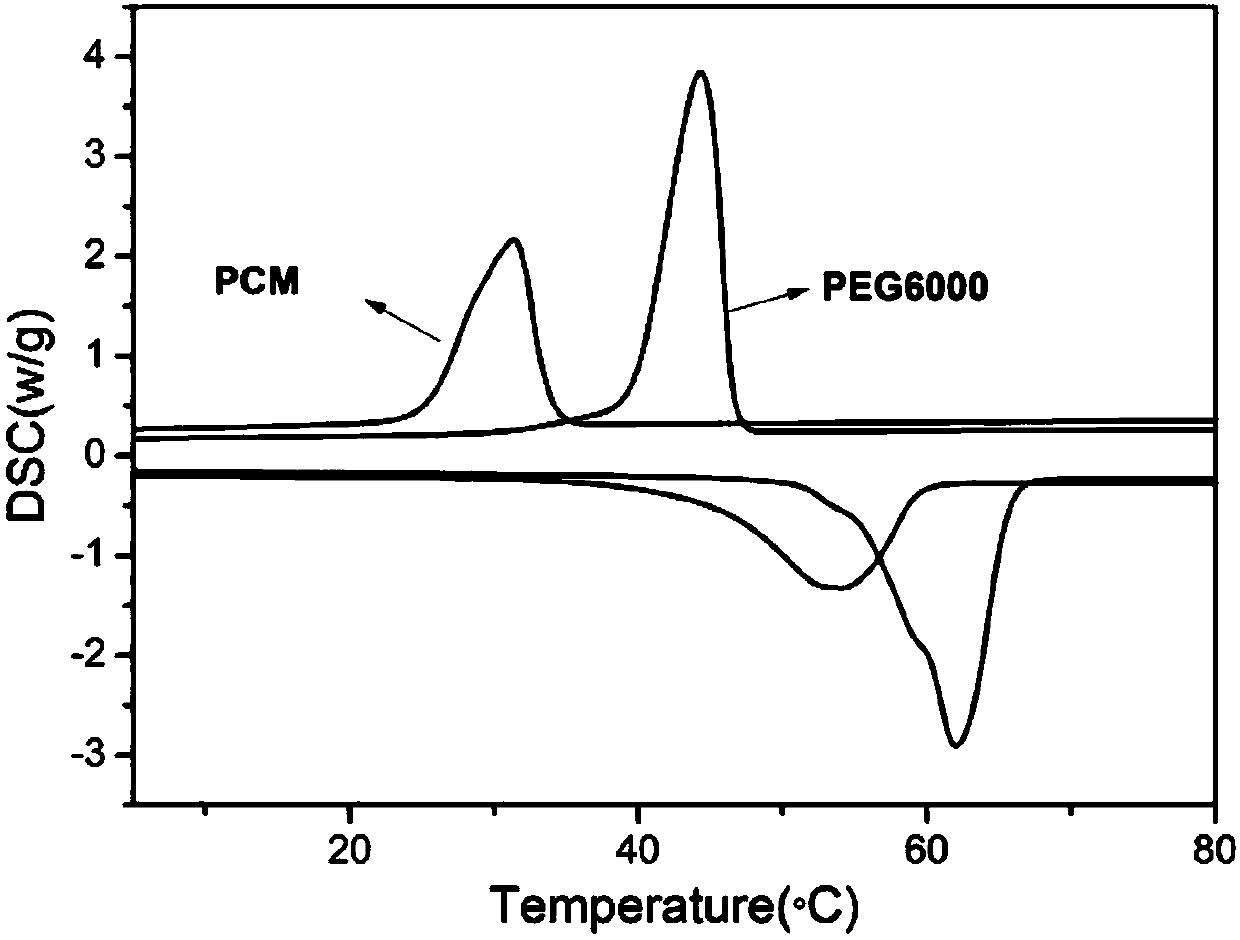

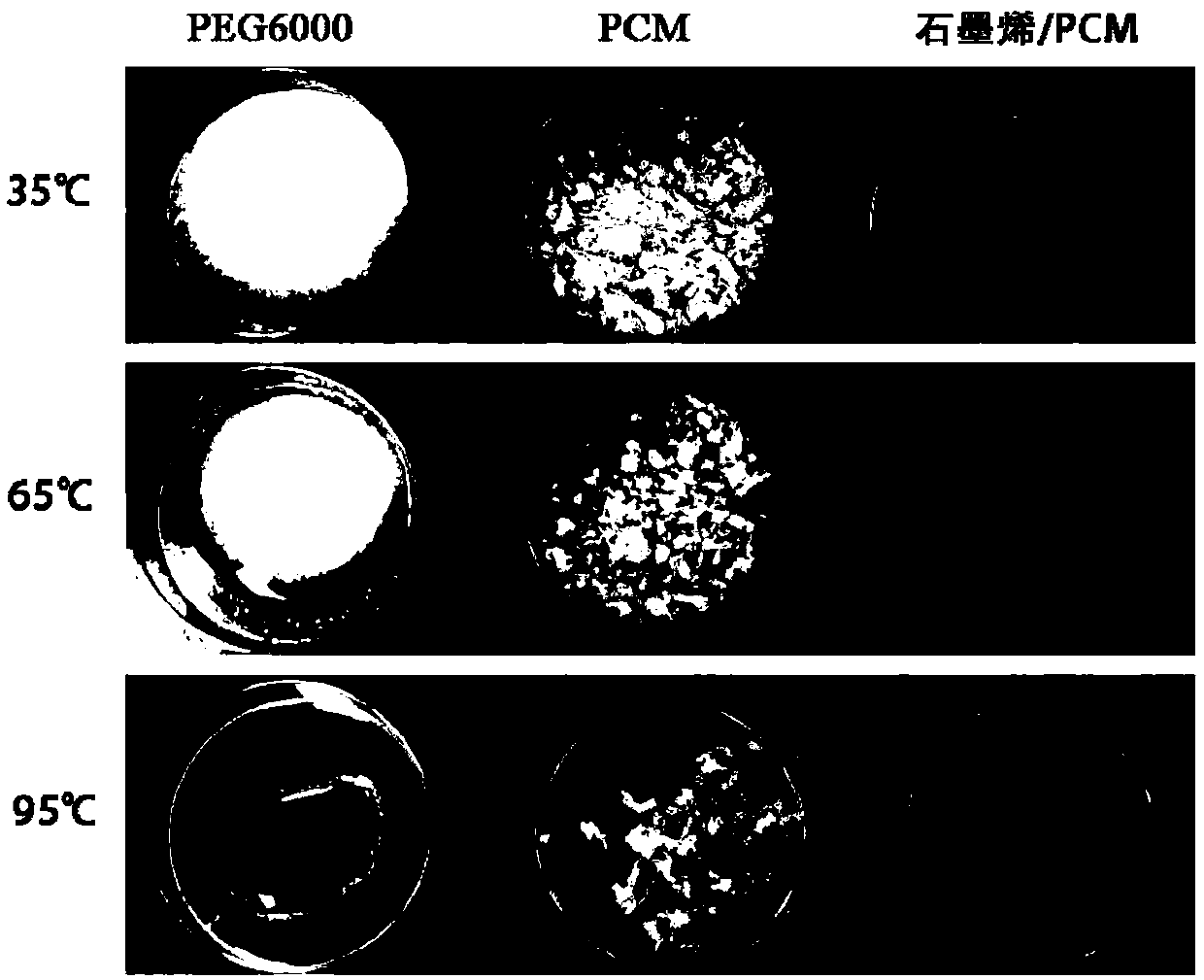

Thermal conductivity enhanced organic composite shaped phase change material and preparation method thereof

ActiveCN108048045AImprove thermal conductivityHigh phase change enthalpyHeat-exchange elementsThermal energyCross-link

The invention relates to a thermal conductivity enhanced organic composite shaped phase change material and a preparation method thereof, and belongs to the technical field of new materials. The thermal conductivity enhanced organic composite shaped phase change material is characterized in that the composite shaped phase change material is prepared from, by mass, 1-50% of coordination cross-linking network polymer, 40-98.9% of organic solid liquid phase change material and 0.1-10% of thermal conductivity enhancer, wherein the coordination cross-linking network polymer is prepared by coordination complexation of a polymer compound with metal ions. The material has a simple synthesis process, convenient application, a large phase change enthalpy value and an excellent shaping effect, and liquid leakage does not occur during operation. The material has a simple synthesis process, convenient application and broad application prospects in the field of thermal energy storage and management.

Owner:DALIAN UNIV OF TECH

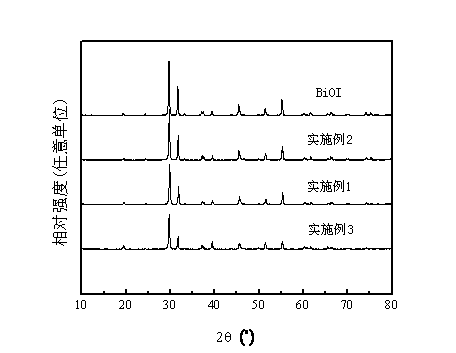

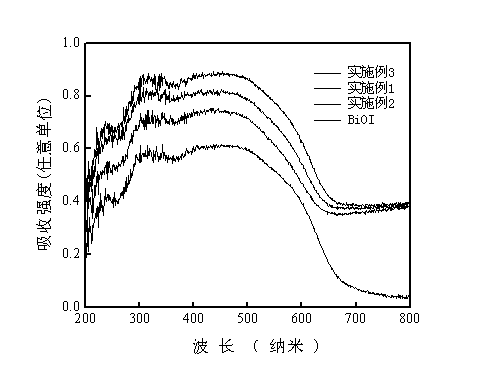

BiOI-graphene visible light catalyst and preparation method thereof

InactiveCN102698775ASimple preparation processThe preparation process is economical and environmentally friendlyPhysical/chemical process catalystsWater/sewage treatment by irradiationSolar photocatalysisPtru catalyst

The invention relates to a BiOI-graphene visible light catalyst and a preparation method thereof, belonging to the technical field of inorganic material synthesis and photocatalysis. BiOI and graphene are in the shape of a slice, and the graphene is 1.0%-3.0% by weight. The preparation method of the BiOI-graphene visible light catalyst comprises the following steps of: firstly ultrasonically dispersing graphite oxides into ethanol; then stirring, and adding a certain amount of sodium iodide or potassium iodide water solutions and bismuth nitrate glacial acetic acid solutions at the same time; transferring suspending liquid into a high-pressure reaction kettle with a polytetrafluoroethylene liner, and carrying out crystallization reaction at 120-150 DEG C for 6-12 hours; filtering, washing and drying obtain solid products so as to finally obtain the BiOI-graphene compound light catalyst. The preparation method has environment friendliness and simple process; and the prepared BiOI-graphene visible light catalyst has very high visible light catalytic activity and potential application value in a control technology decomposing organic pollutants by utilizing solar photocatalysis.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com