Patents

Literature

291results about How to "Solve easy oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

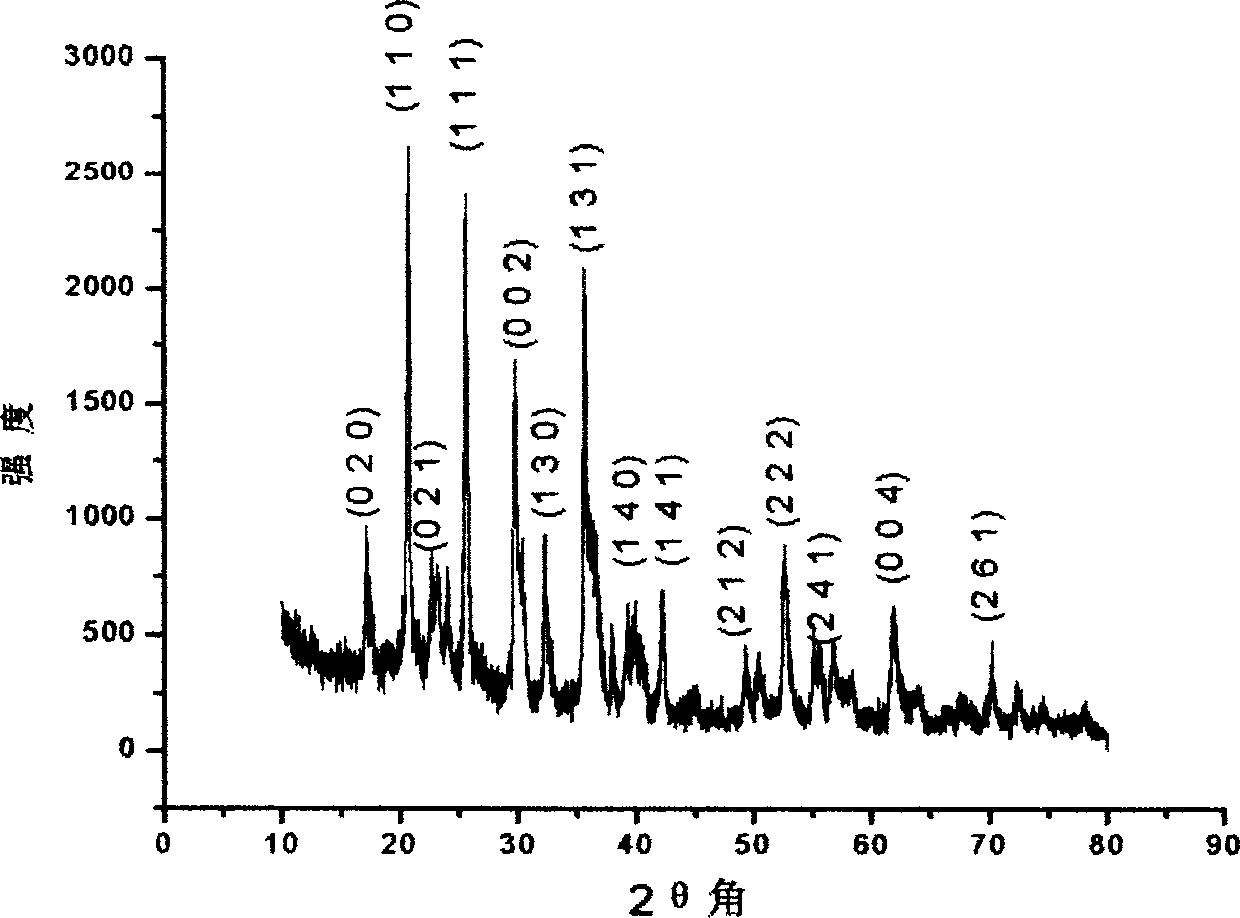

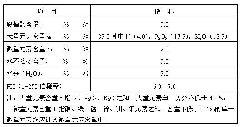

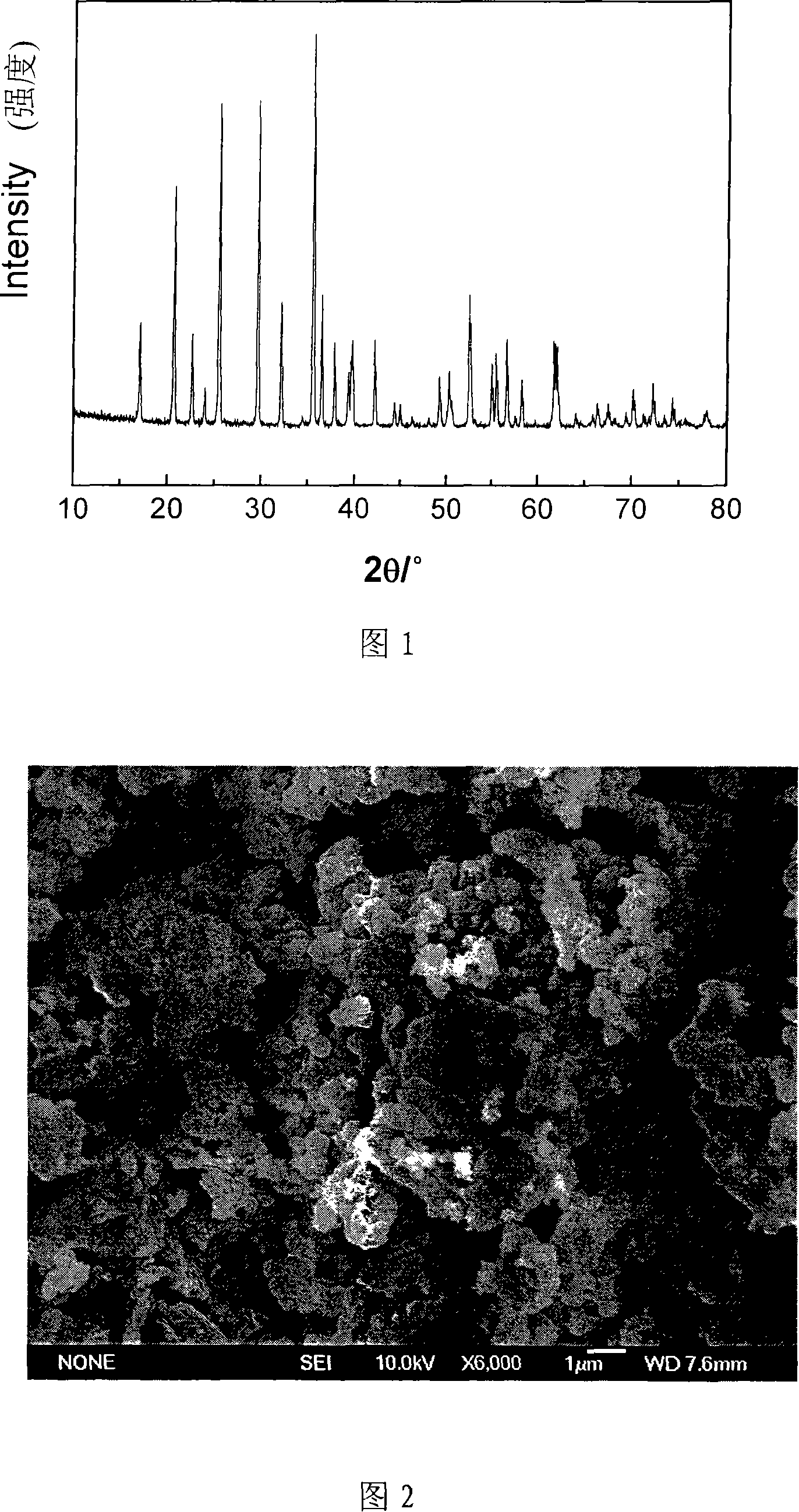

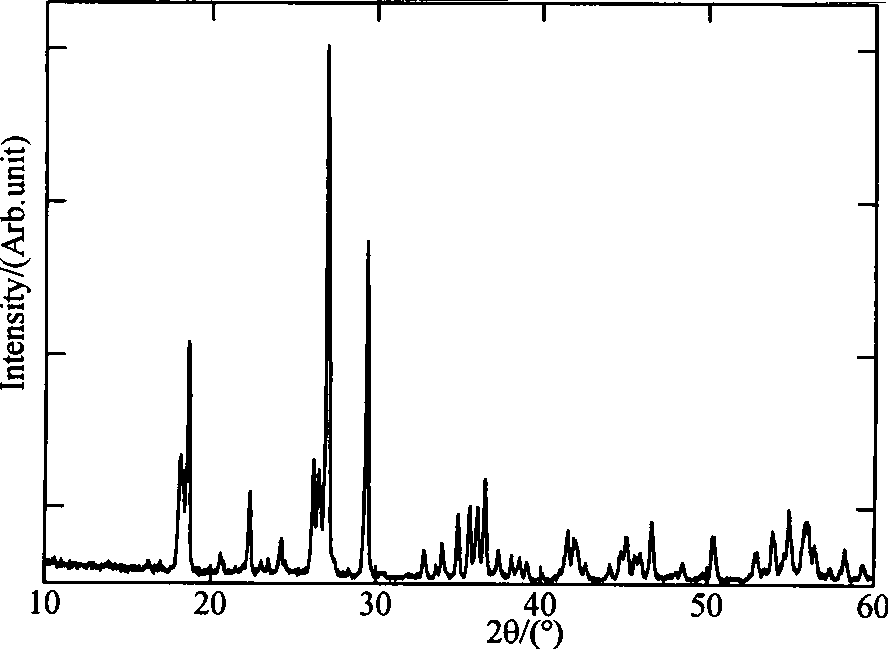

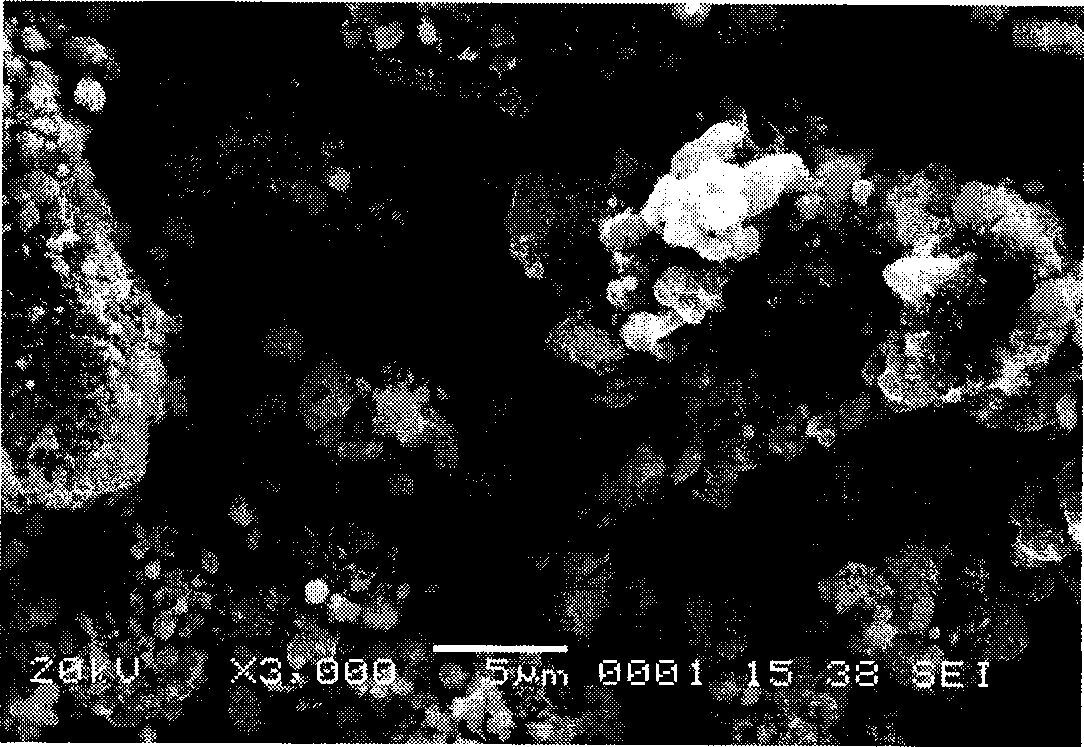

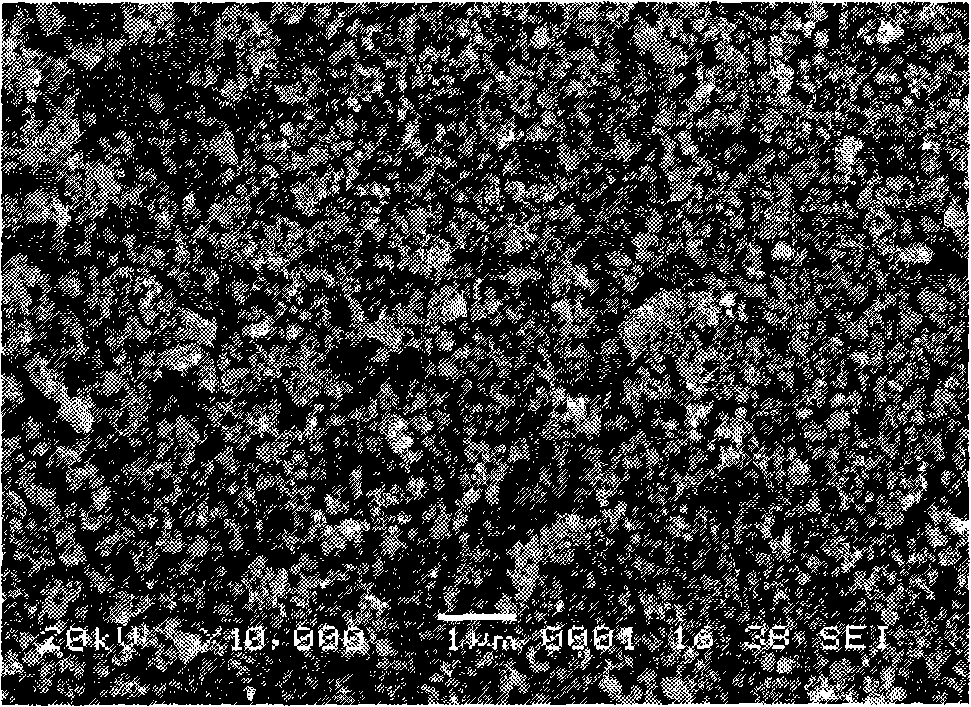

Preparation method of multicrystal LiFePO4 powder having olivine structure

InactiveCN1410349ASolve easy oxidationSolve precipitationCell electrodesRare earth metal compoundsOrganic acidGranularity

A polycrystalline LiFePO4 powder with olivine structure is prepared from Fe(Ac)2, FeSO4.7H2O, Ba(Ac)2 and organic acid by the sol-gel method. Its advantages are short period, low burning temp., low energy consumption, high purity and electric conductivity, and high granularity uniformity. It is suitable for making Li-ion battery.

Owner:TSINGHUA UNIV

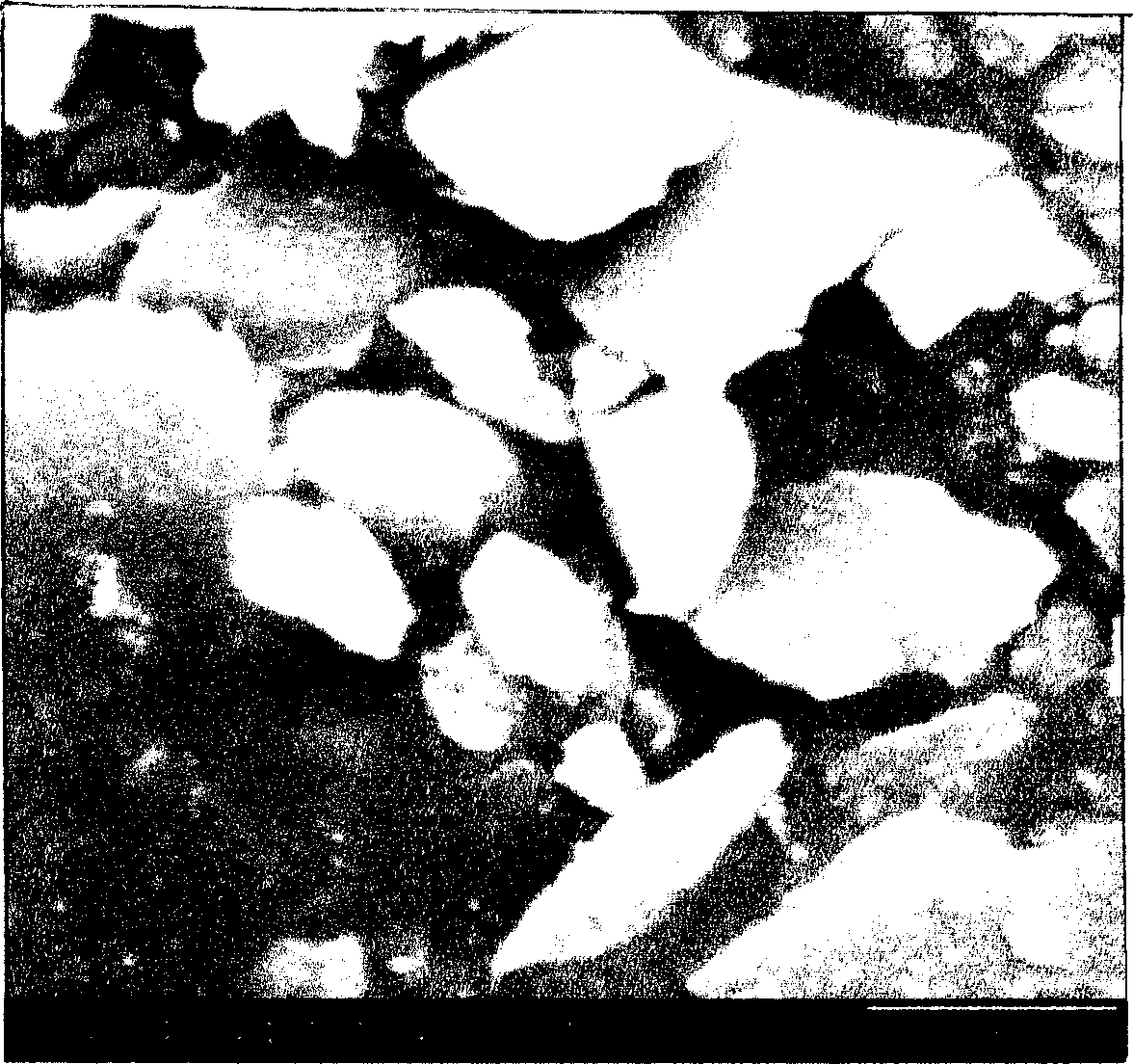

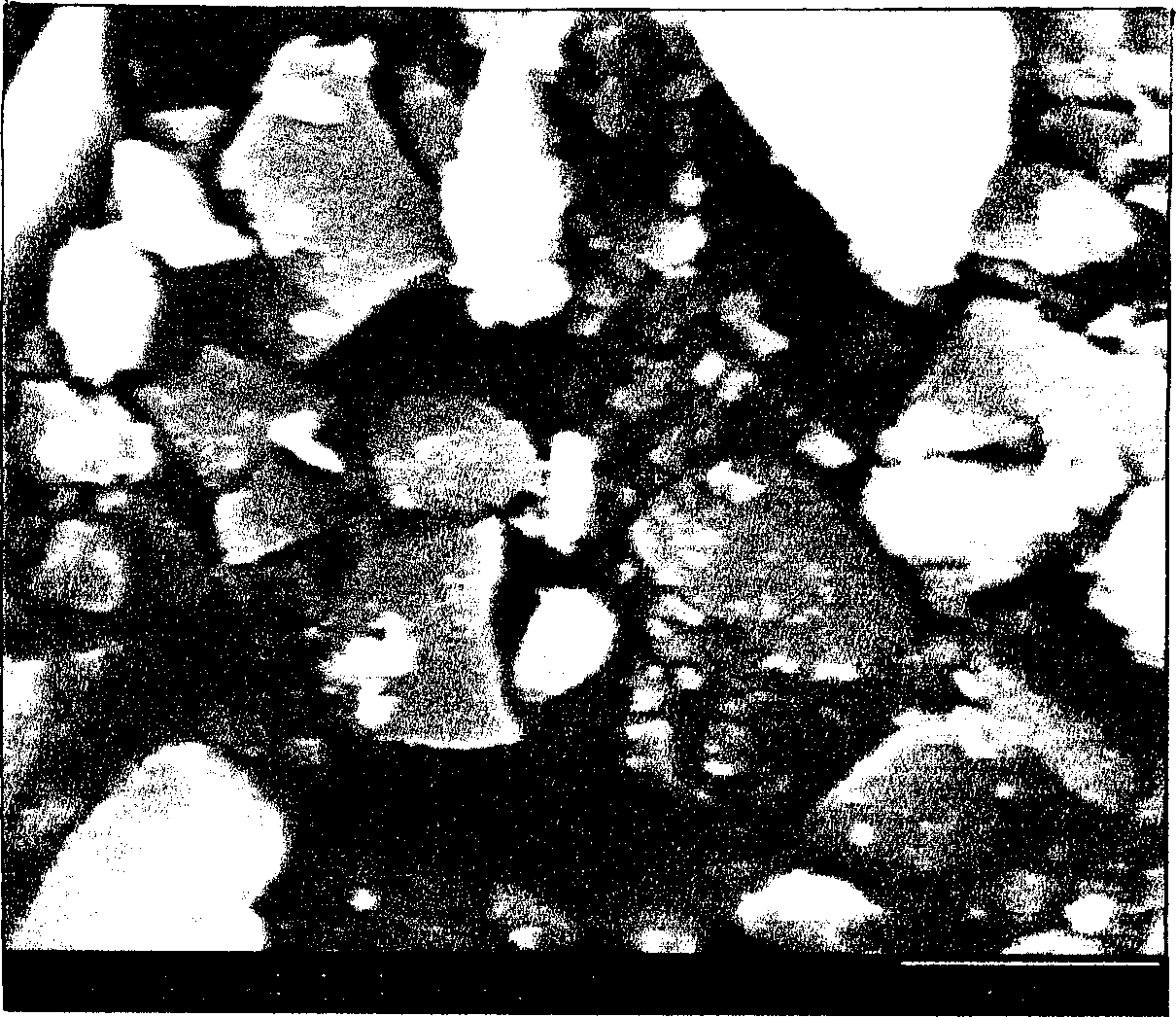

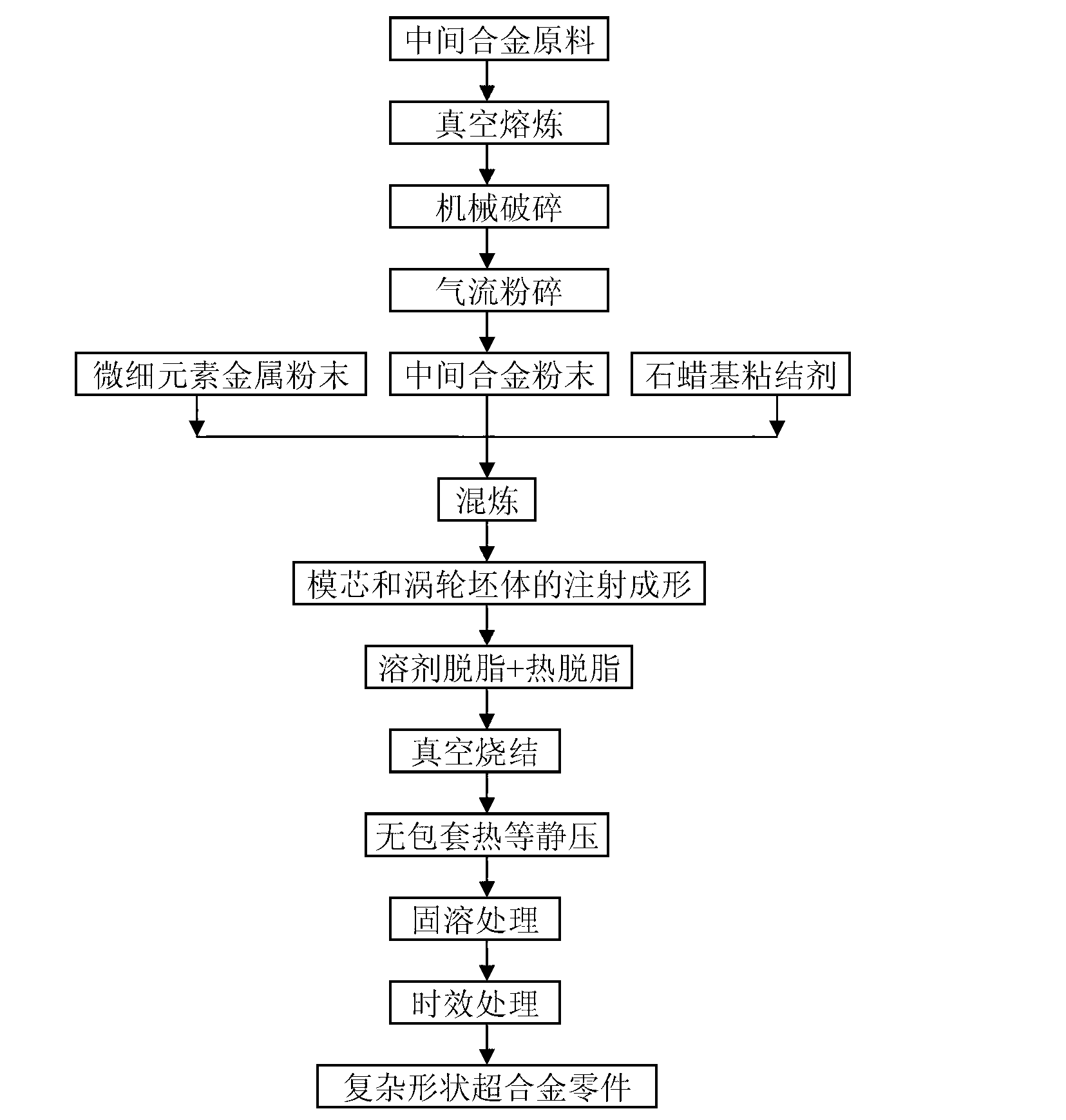

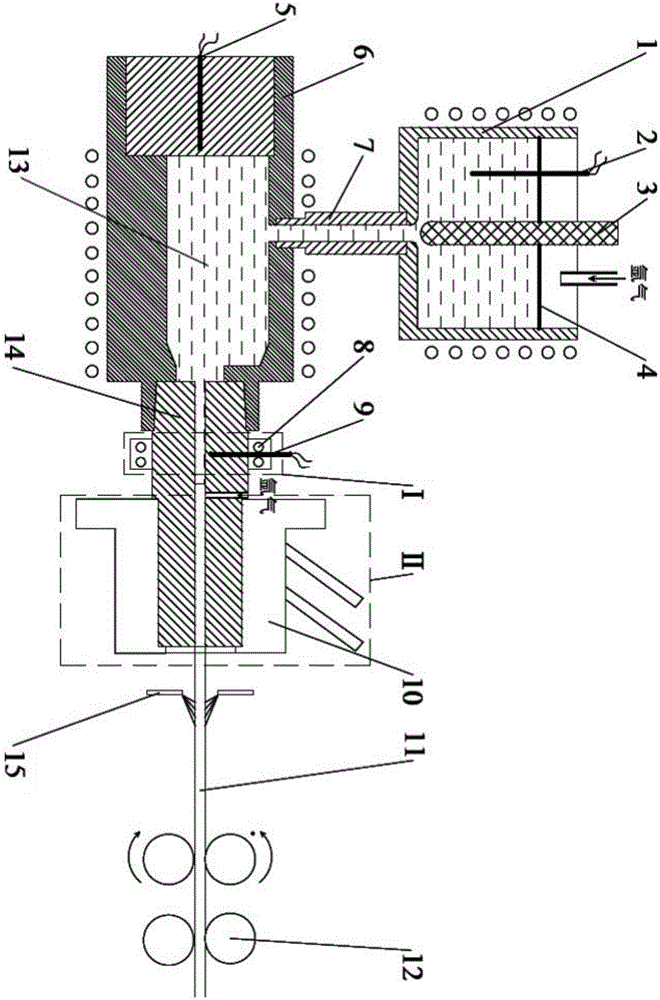

Method for preparing powder super-alloy by near net shape

Disclosed is a method for preparing powder super-alloy by a near net shape. Firstly, high-purity intermediate alloy powder is prepared by the aid of vacuum melting and air jet pulverization technology. Secondly, the intermediate alloy powder and fine particle diameter metal powder (such as carbonyl nickel powder, carbonyl iron powder, reduction tungsten powder and reduction molybdenum powder) are mixed in a high-energy ball mill with protective atmosphere to obtain mixed powder. The mixed powder and paraffin base binders are uniformly premixed, feedstock with a uniform rheological performance is obtained by mixing and is formed on an injection forming machine to obtain a blank in a complicated shape. The binders are removed from the blank in the complicated shape by the aid of solvent degreasing and hot degreasing technologies, the degreased blank is sintered in the vacuum atmosphere, the sintered blank is further compacted by the aid of unjacketed hot isostatic pressure, and finally, a super-alloy part in the complicated shape is obtained by the aid of solid solution and aging treatment. Raw material powder cost and technological energy consumption are remarkably reduced, and prepared super-alloy is almost fully compact, uniform in structure and excellent in comprehensive mechanical property.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of titanium-steel composite plate

InactiveCN101992344ASolve easy oxidationIncreased interfacial shear strengthLaminationLamination apparatusComposite plateVacuum chamber

The invention relates to a preparation method of a composite steel plate, in particular to a preparation method of a titanium-steel composite plate. The preparation method comprises the following steps of: firstly selecting titanium plates and steel plates which have equal width and length and removing rusty layers and oxide layers; then making surfaces of the titanium plates and the steel plates opposite, and completely coinciding to form a combined blank; then sealing up the periphery of the combined blank by taking four titanium plates as side seal plates, and clamping the side seal plates and the combined blank by using a clamp and then putting the side seal plates and the combined blank into a vacuum chamber together; tightly welding all contact seams of the combined blank and the side seal plates, then conveying the combined blank and the side seal plates into a heating furnace together and heating to 600-1200 DEG C, and carrying out heat preservation for 0.1-2h; and finally, conveying the heated combined blank into a rolling mill for rolling to obtain the titanium-steel composite plate with the interface bonding strength of 350MPa. The invention well solves the problem that the interface of the titanium-steel composite plate is oxidized and improves the interface bonding strength of the composite plate, and moreover, argon or brazing filler metal does not need to be added, thereby saving the cost and simplifying the flow of the production process.

Owner:沈阳科安捷材料技术有限公司

Method for preparing ganoderma spore oil

ActiveCN1883590AFunction increaseEnhance immune functionMetabolism disorderDigestive systemSporeCentrifugation

The invention relates to a process for preparing glossy ganoderma spore oil by using lucid ganoderma spore powder and glossy ganoderma as the raw material, which comprises enzyme method wall-breaking, wet method palletizing, supercritical CO2 extracting, finally carrying out centrifugation.

Owner:GUANGDONG YUEWEI EDIBLE FUNGI TECH +1

Water-soluble fertilizer by complexing humic acid with plurality of nutrient elements and preparation method thereof

ActiveCN101798246AAvoid fixationFacilitate the operation of transmissionFertilizer mixturesWater insolublePotassium

The invention belongs to the technical field of agriculture, in particular relates to a water-soluble fertilizer by complexing humic acid with a plurality of nutrient elements and a preparation method thereof. The water-soluble fertilizer is prepared by complexing the following raw materials by weight parts: 8 parts of potassium humic acid powder containing more than or equal to 50 percent of humic acid component, more than or equal to 10 percent of potassium oxide component and less than or equal to 2 percent of water-insoluble substances, 42-46 parts of water, 33-38 parts of major element compound, 10 parts of trace element compound, 1.3-1.5 parts of additives and 1.8-2.5 parts of plant growth regulator. The preparation method comprises six steps. The water-soluble fertilizer has the advantages of complete nutrient elements, higher crop absorption utilization rate and stronger directivity.

Owner:陕西赛恩农业科技股份有限公司

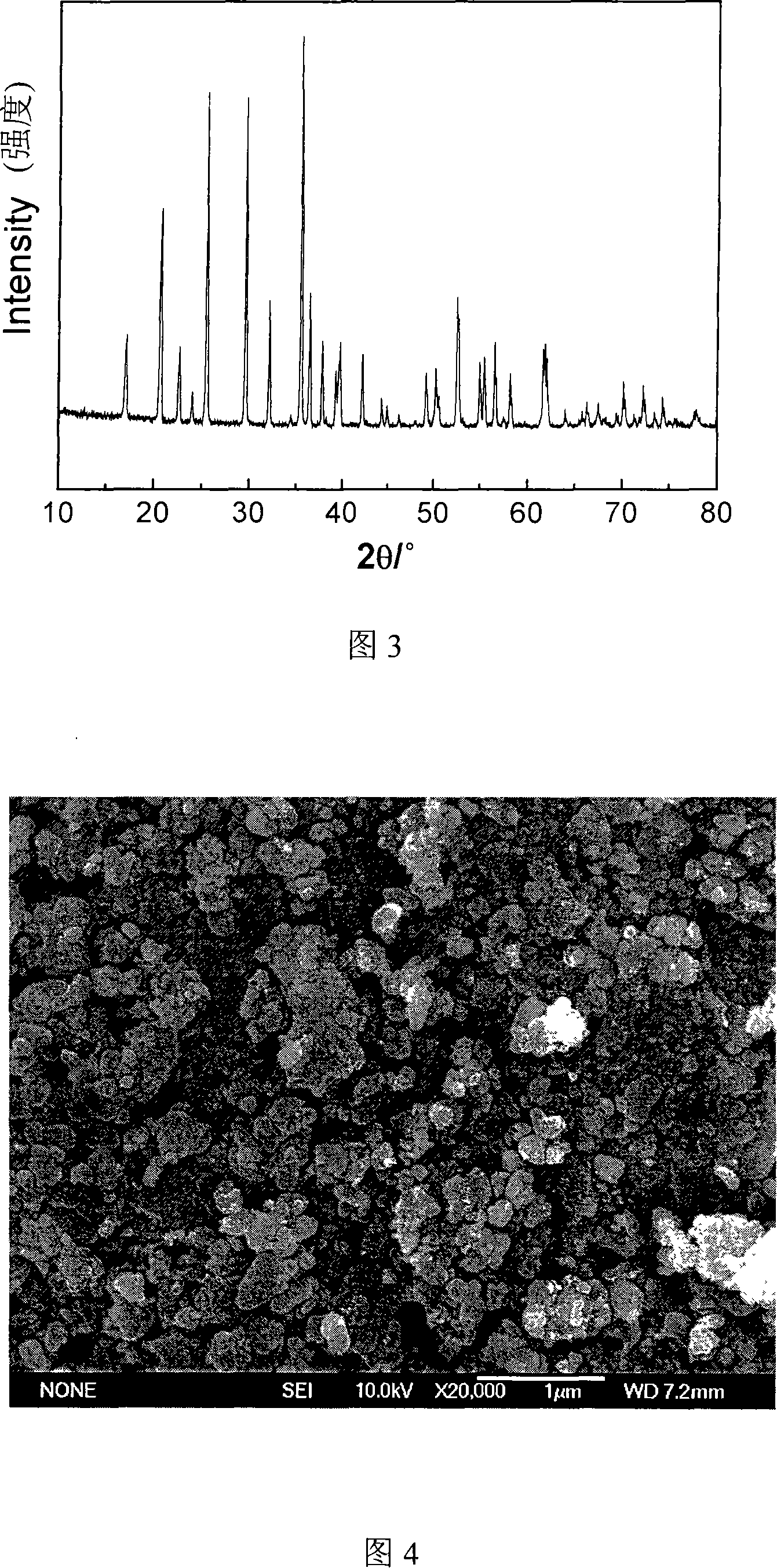

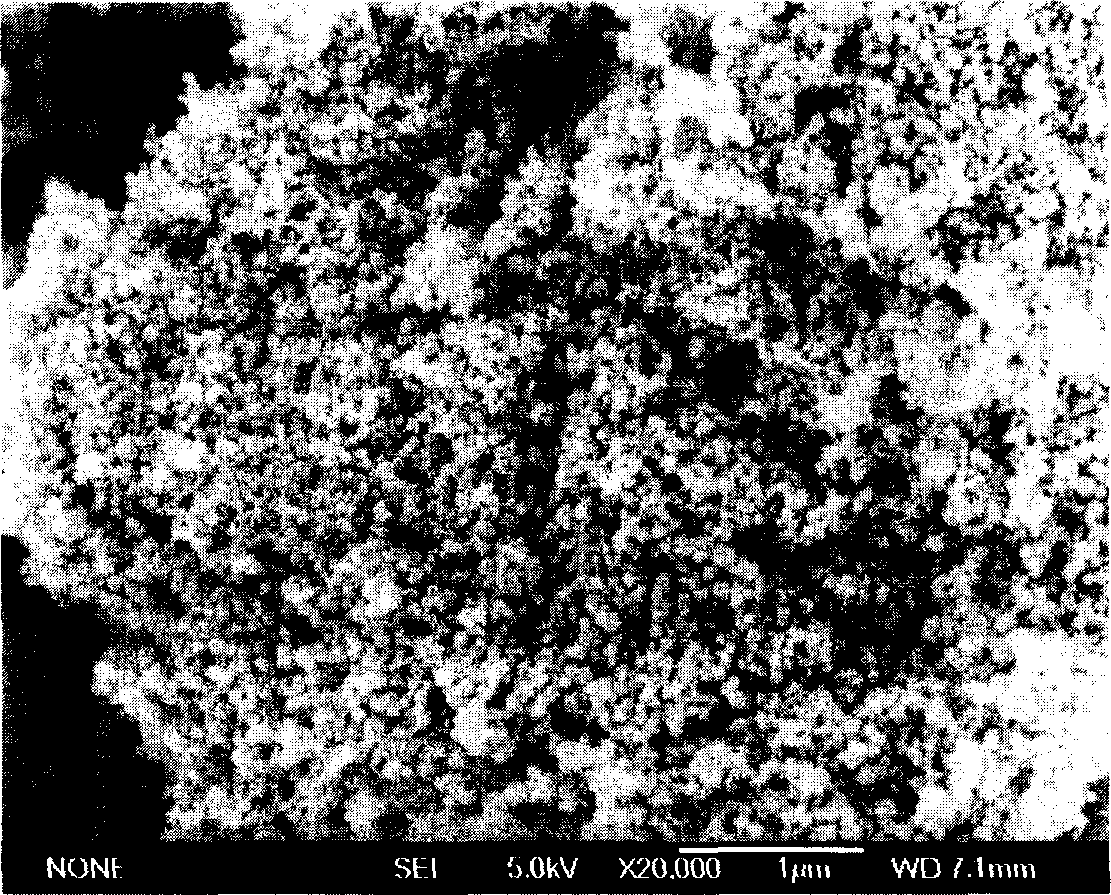

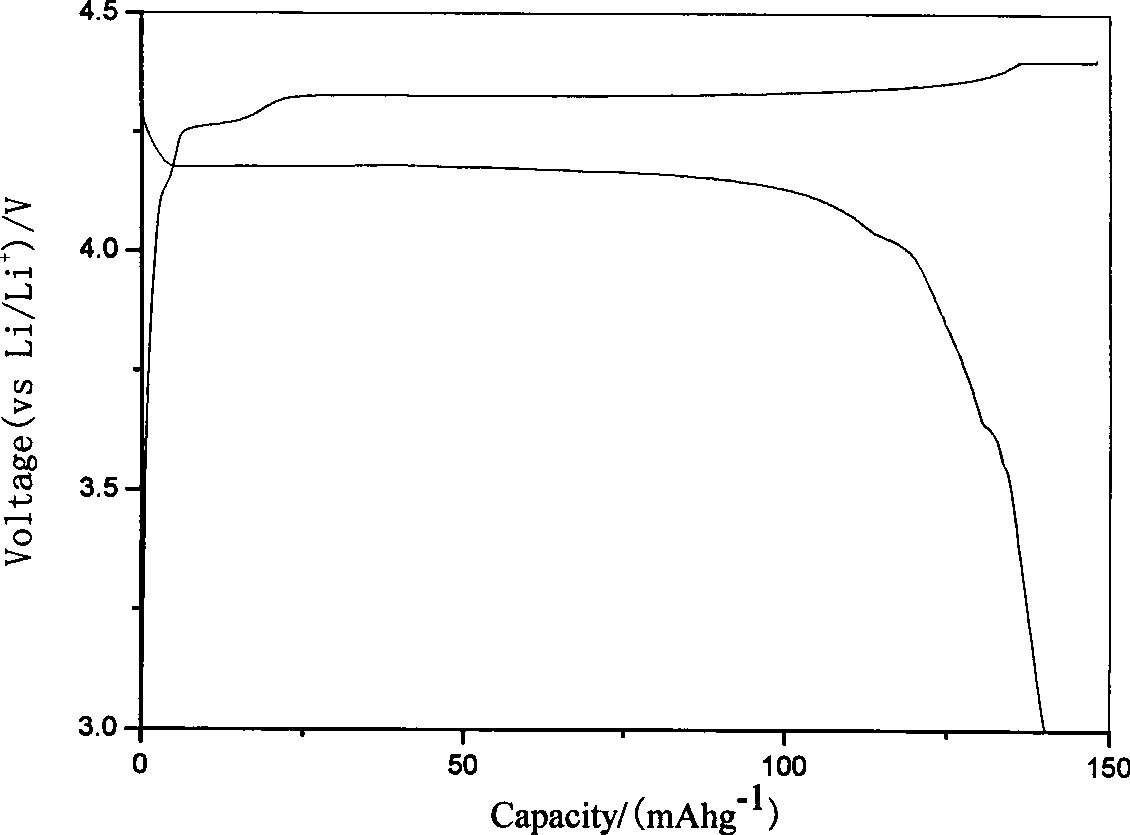

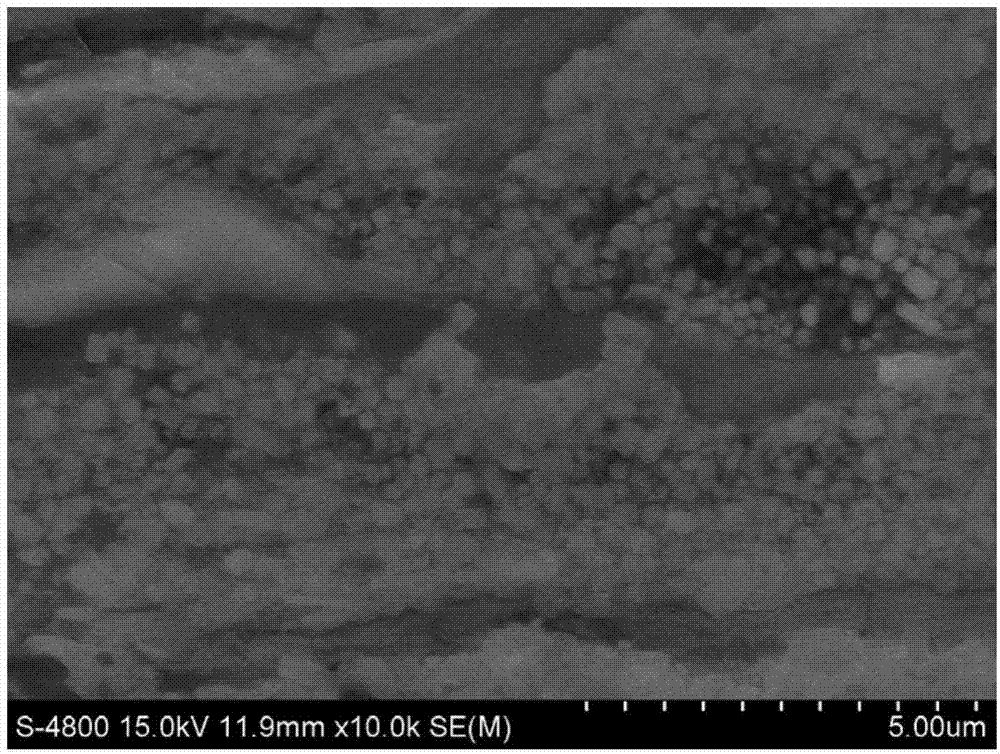

Anode material lanthanum or Ac adulterated LiFePO4 of lithium ion secondary battery and its making method

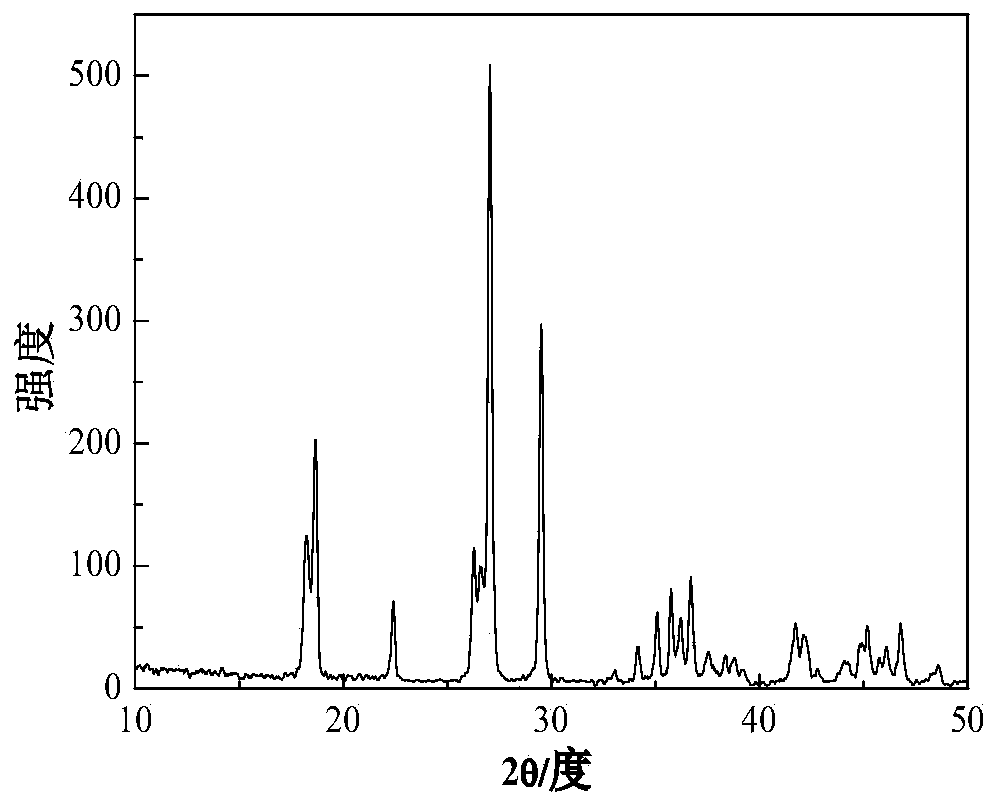

InactiveCN101150191AHigh charge and discharge capacityPromote crystallizationCell electrodesPhosphorus compoundsPhosphateVolumetric Mass Density

This invention relates to FeLiPO4 doped with La or Ac, positive material of Li ionic secondary cells and its preparation method characterizing that the formula is: LiMxFe1-xPO4 (M is La or Ac, 0.01<-x<-0.05) in the structure of olivine, the preparation includes the following steps: taking Li compound, Fe, phosphate, La or Ac as the raw materials to add them into a ball mill for wet mill then putting them into N2 and H2 mixed atmosphere for pre-calcining, then wet-grinding them and drying them and then ball-milling them, then putting them into N2 and H2 mixed atmosphere for secondary calcining to get the invented positive material. Advantages: fine crystalizatin, conduction performance of ions is good and discharge performance of heavy current is good, tap density is great and the problem of easy oxidation of Fe2+ is solved.

Owner:TIANJIN B&M SCI & TECH

Vitamin E microcapsule preparation method

InactiveCN101444495AReduce lossesPlay the packageOrganic active ingredientsAntinoxious agentsFood additiveWater content

A vitamin E microcapsule preparation method belongs to the technical field of preparation of controlled-release microcapsule for food additives and bioactive substances. The vitamin E microcapsule preparation method can improve the stability of vitamin E and amplify the application range. The method comprises the following steps: selecting chitosan and maltodextrin as wall material, selecting soybean lecithin (P powder) and Tween-80 as the composite emulsifying agent; and synthesizing vitamin E microcapsule by spray drying. The vitamin E microcapsule has embedding rate up to 92.45%, retention rate up to 91.73%, and water content lower than 3%, and has wide application prospect in the fields of bread or snack products, beverages, biscuits, health products and nutrient fortified food, etc. The method has the advantage of low cost and simple process, can meet the environmental protection and practical requirement.

Owner:JIANGNAN UNIV

Processing method of grain and nut nutrient composite paste food

ActiveCN103404771ASolve the problem of easy oxidationEasy to store for a long timeFood shapingFood preparationNutrientMicroencapsulations

The invention provides a processing method for grain and nut nutrient composite paste food. The mass ratio of the principle raw materials, namely oat to tartary buckwheat to corn to soybean to peanut to apricot kernel to walnut to Chinese chestnut, is (4-8) to (4-8) to (1-4) to (1-4) to (0.5-2) to (0.5-2) to (0.5-2) to (0.5-2). The preparation method comprises the following steps: smashing grains at low temperature; adding complex enzyme for enzymolysis, then puffing and smashing; performing microencapsulation by taking smashed zymolytic nuts as a core material and taking grains and cyclodextrin as embedding media; finally, drying and packaging in a sterile environment so as to prepare the paste food suitable for middle and old aged people. The paste food contains multiple types of grains and nuts, has rich nutrition, is easy to brew, has low probability of agglomerating and clustering, is fine and smooth in taste and easy to digest, and is more suitable for middle and old aged people.

Owner:ZHEJIANG YIPAI FOOD

Preparation of nano zinc powder by single groove ultrasonic electrolytic process

InactiveCN1912193ASolve easy oxidationComposition is stablePhotography auxillary processesNanometreSurface-active agents

The invention relates to a nanometer zinc dust single groove ultrasound electrolytic preparing method. Its features are that adding certain distilled water, zinc salt, and surface active agent into conductivity organic solution; cutting into titanium alloy ultrasound probe as cathode, zinc plate as anode; exerting pulse current; zinc ion will electrodeposit on the titanium alloy probe, and peel off from the cathode under the action of the ultrasound to form nanometer simple substance zinc powder. The whole electrolytic process is processed in one groove, and can be continuous by using zinc as the anode to complement the consumed zinc ion. The filtrate can be continuously used after zinc powder collecting. Thus this can realize no waste liquor producing in the whole preparation course which is controllable, and can satisfy the real production demand.

Owner:HUAZHONG NORMAL UNIV

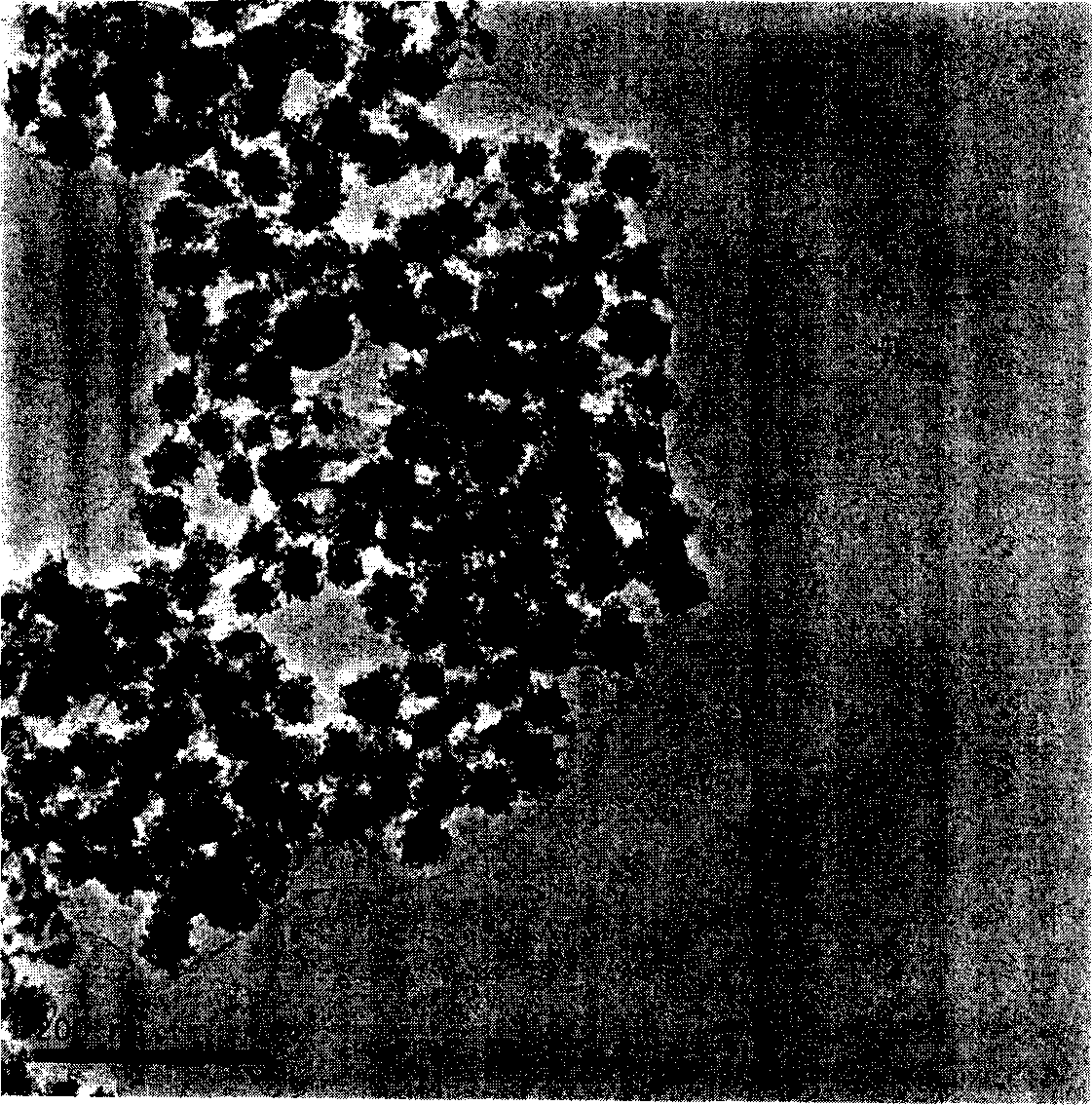

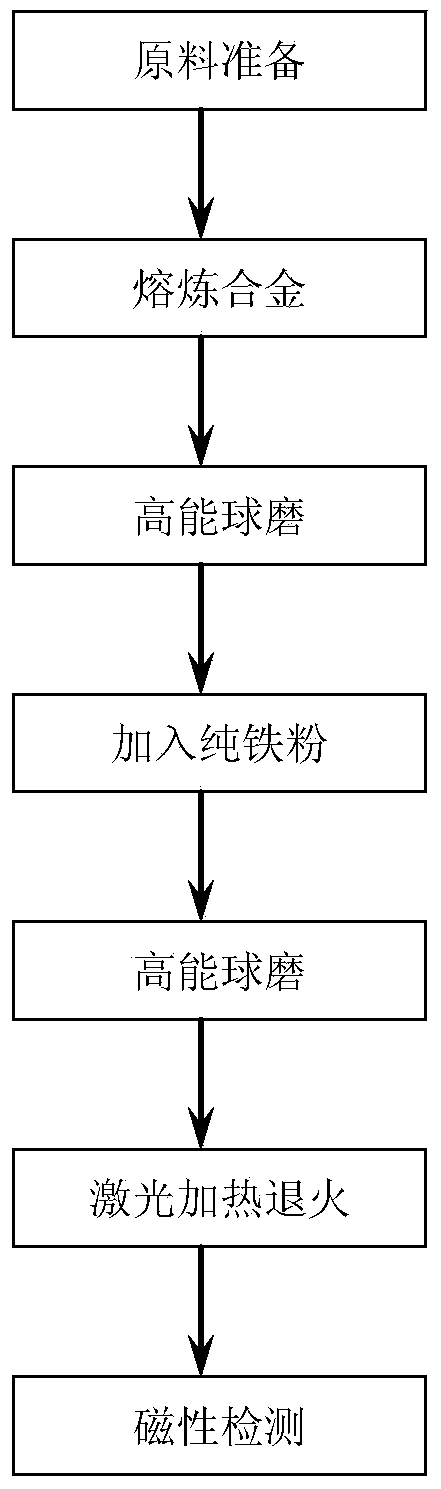

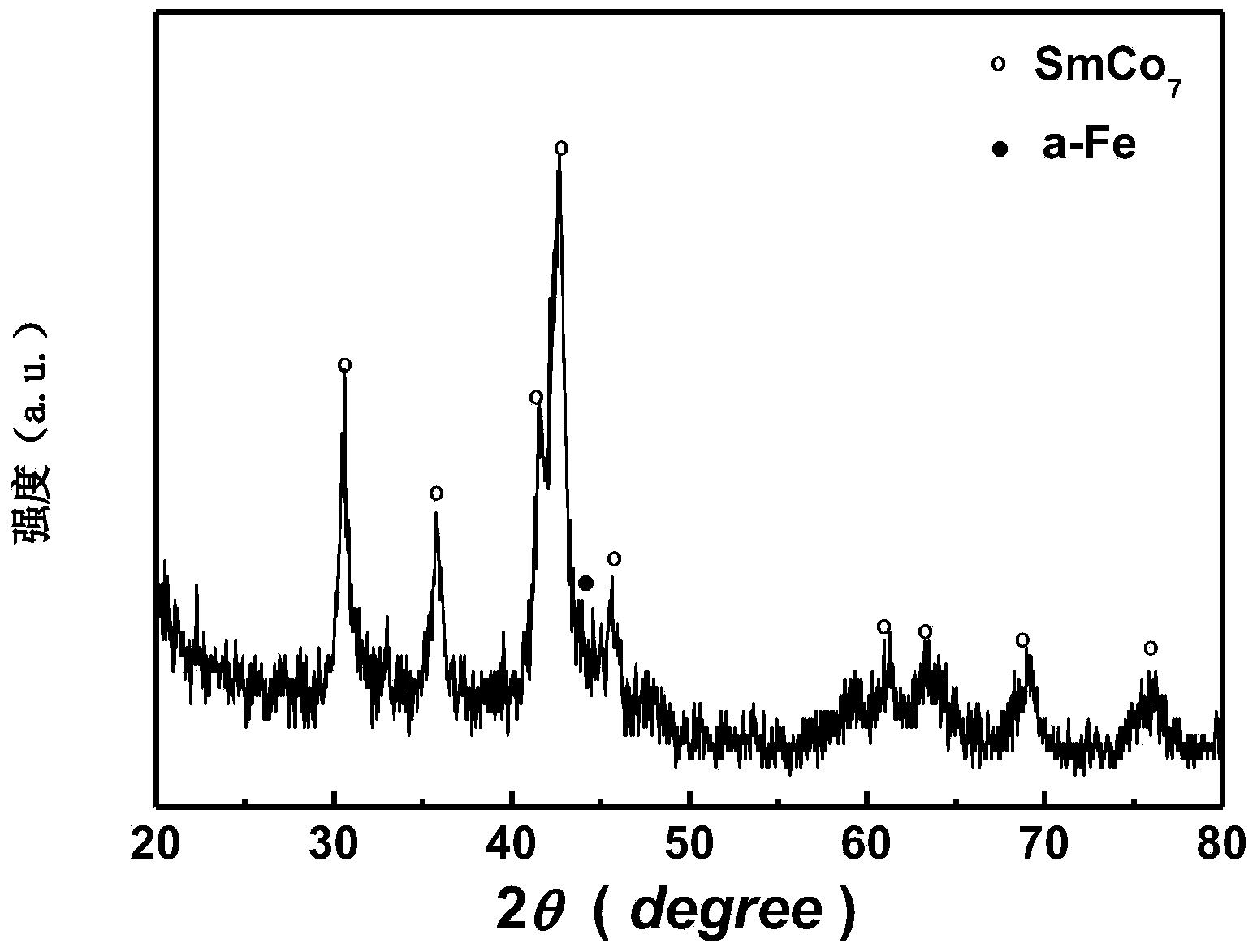

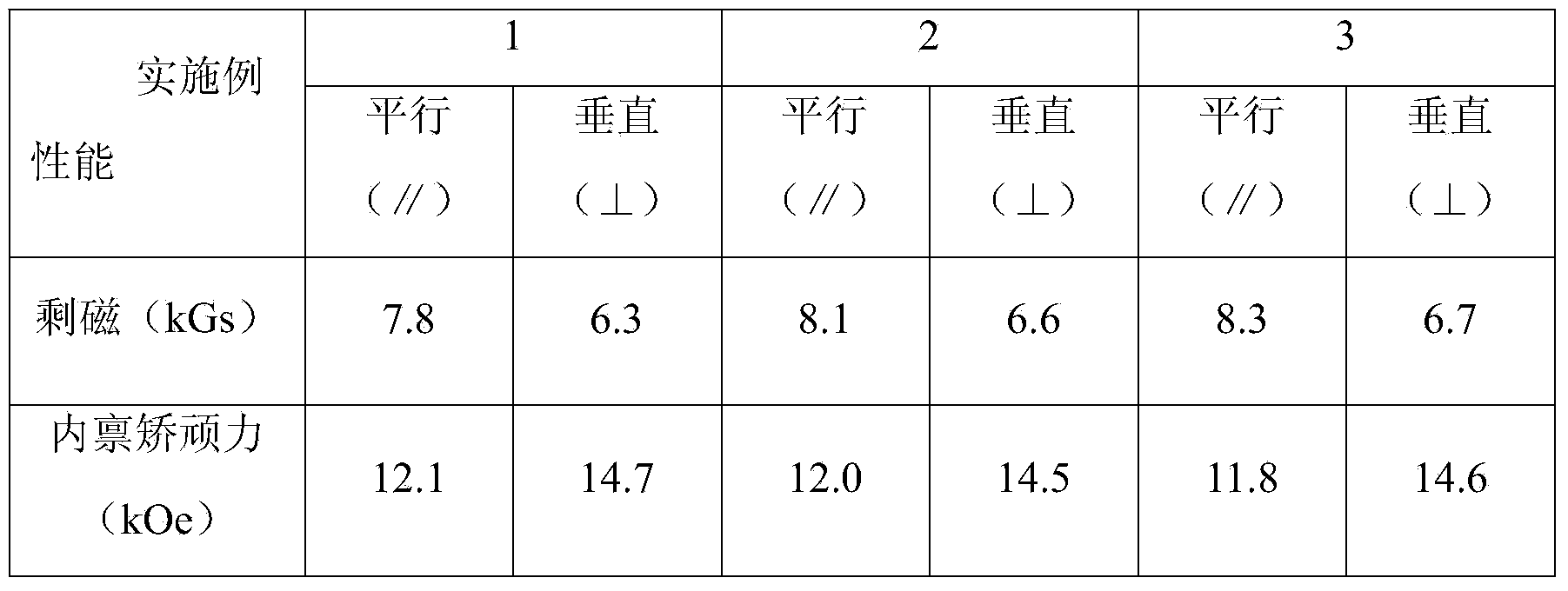

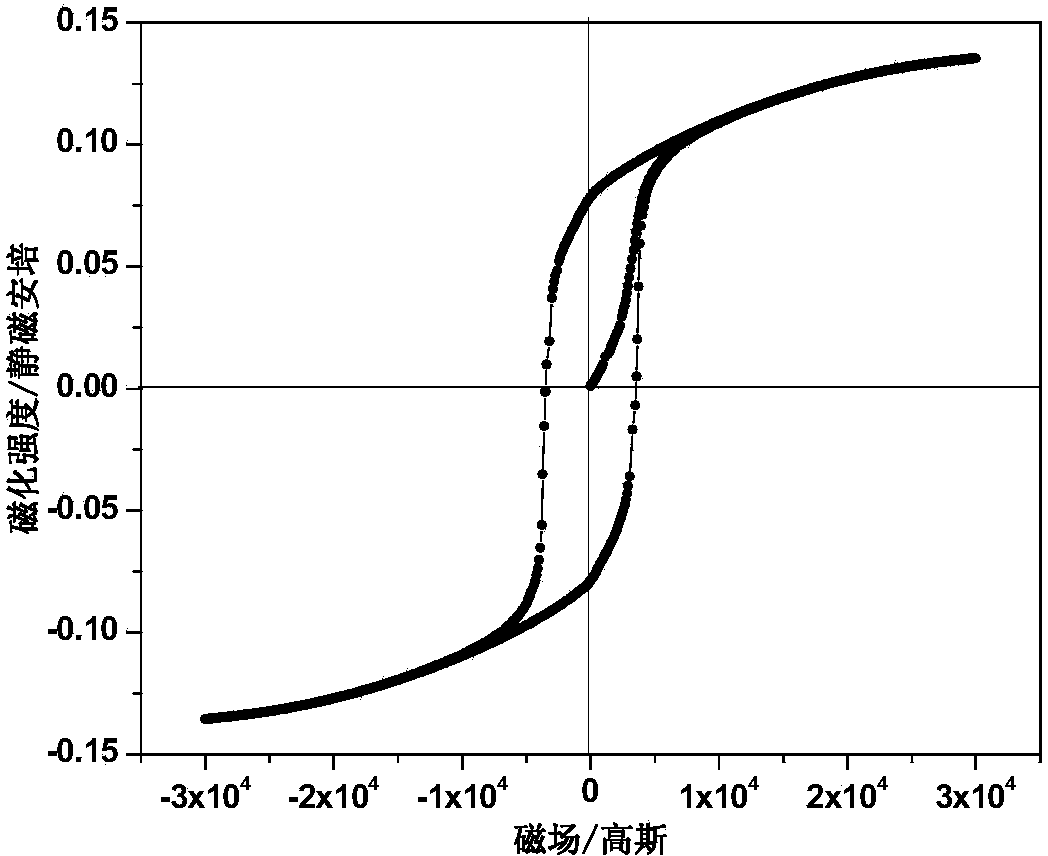

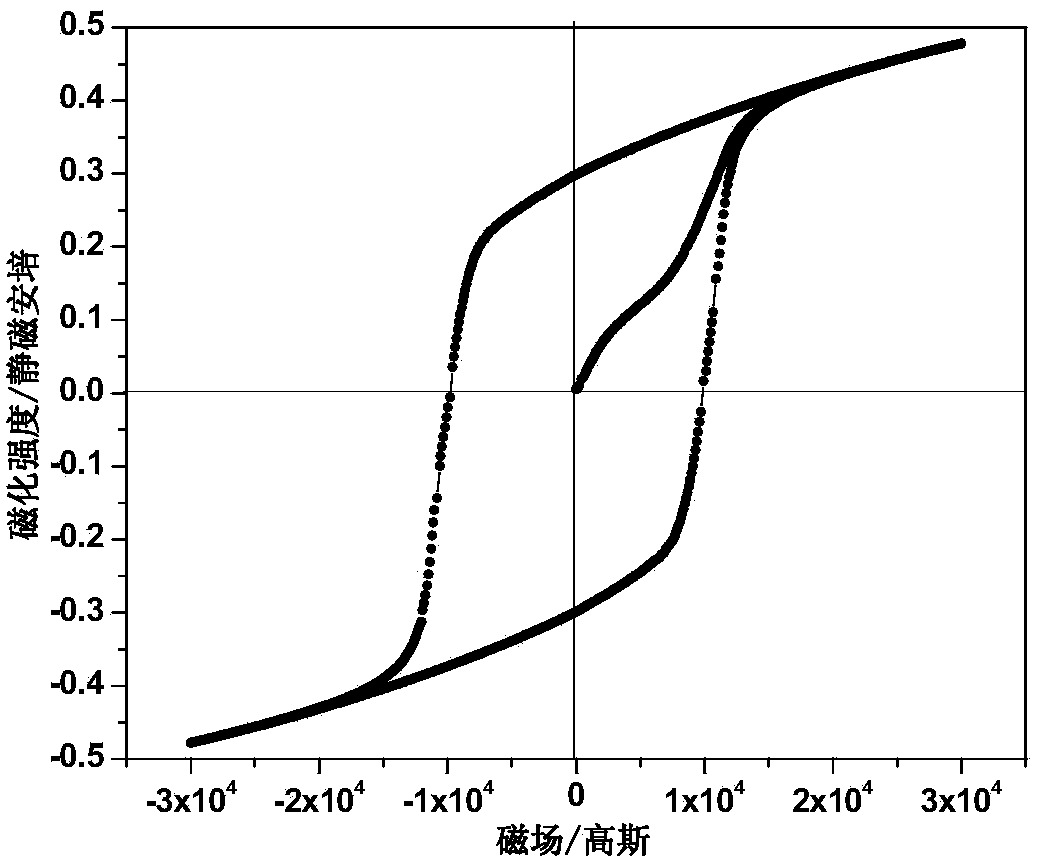

Samarium-cobalt-base nanocrystalline permanent magnet material and preparation method thereof

The invention relates to the metallurgy field and discloses novel samarium-cobalt-base nano-composite permanent magnetic material. The samarium cobalt base is (Sm, R)1(Co, Fe, Cu, Zr)7 in type and comprises a TbCu7 type structure, and Co is partially replaced by Fe, Cu and Zr; Re is any one of heavy rare earth Lu, Dy and Tb and partially replaces Sm. The preparation method includes steps that 1) mixing raw materials of the samarium cobalt base according to proportion, and smelting to obtain a 1: 7 type samarium cobalt base alloy ingot; 2) ball milling the alloy ingot through a high-energy ball milling technique, mixing with Fe powder according to proportion, and performing high-energy ball milling to obtain nanocrystalline composite magnetic powder; 3) carrying out annealing heat treatment on the nanocrystalline composite magnetic powder. According to the samarium-cobalt-base nanocrystalline permanent magnet material and the preparation method thereof, the soft / hard-magnetic phase composite magnetic powder is prepared through the high-energy ball milling, laser heat treatment and other techniques, a high magnetic energy product is obtained through exchange coupling between the nanocrystalline hard magnetic phase and nanocrystalline soft magnetic phase, and meanwhile, because rare-earth Fe phase is not used, the cost is lowered, and the operation technique is simplified.

Owner:嘉兴市鹏程磁钢有限公司 +1

Non-vacuum melting horizontal continuous casting production technology for high-strength high-conductivity Cu-Cr-Zr alloy rod

The invention provides a non-vacuum melting horizontal continuous casting production technology for a high-strength high-conductivity Cu-Cr-Zr alloy rod and belongs to the technical field of metallic material preparation and processing. According to the horizontal continuous casting production technology provided by the invention, the measures, such as, atmosphere protection and addition of a covering agent and a refining agent, are taken in a non-vacuum melting furnace, so that the problem of easy oxidization of molten Cu-Cr-Zr can be effectively solved and the problems of high equipment cost and limited melting capacity brought by a conventional vacuum furnace can be solved. Besides, the application of the horizontal continuous casting production technology provided by the invention for producing the Cu-Cr-Zr alloy rod is favorable for discharging impurities and solidified separated gas in the molten alloy into a liquid phase and promoting the rod tissue compactness; high-axial oriented columnar crystals can be acquired, and the subsequent cold processing performance of the alloy rod can be promoted; and the production technology can realize the high-quality continuous casting for the high-strength high-conductivity copper alloy rod characterized by heavy weight and long size and having easily oxidized and segregated elements.

Owner:UNIV OF SCI & TECH BEIJING

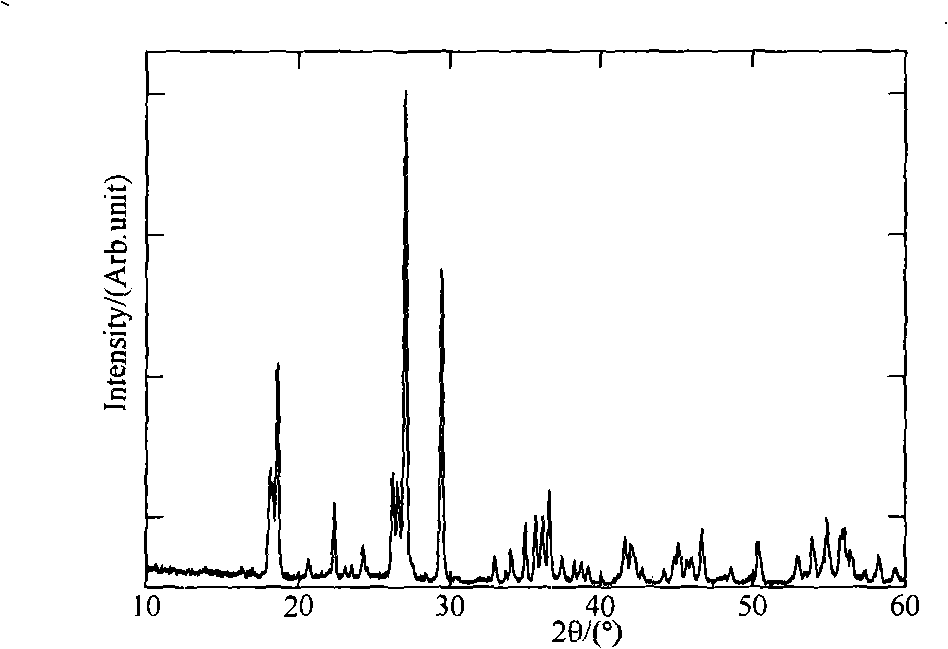

Method for preparing lithium ionic cell anode material lithium vanadium fluorophosphate by hydro-thermal synthesis reaction

InactiveCN101456550ASolve easy oxidationImprove charge and discharge performanceCell electrodesPhosphorus compoundsChemistryOrganic acid

The invention discloses a method for preparing a lithium ion battery anode material, namely vanadium lithium fluophosphate, through hydrothermal synthesis reaction, which comprises: dissolving ammonium metavanadate, phosphate, organic acid, lithium salt and villaumite into water according to the mol ratio of 1.9-2.1:1.9:2.1:0.95-1.1:1.9-2.1:1.9-2.1, making the mixture react for 1 to 4 days in a hydrothermal synthesis reaction kettle at a temperature of between 200 and 350 DEG C, and drying the mixture to obtain a finished product, namely LiVPO4F. The method is simple and convenient, is easy to control, has low cost, simplifies the synthesis technology, and improves the charge and discharge performance and the cycle performance of samples.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

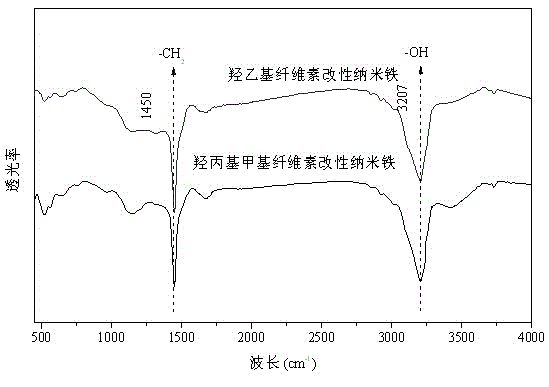

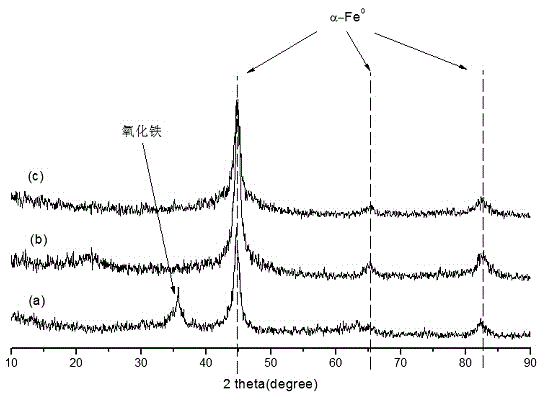

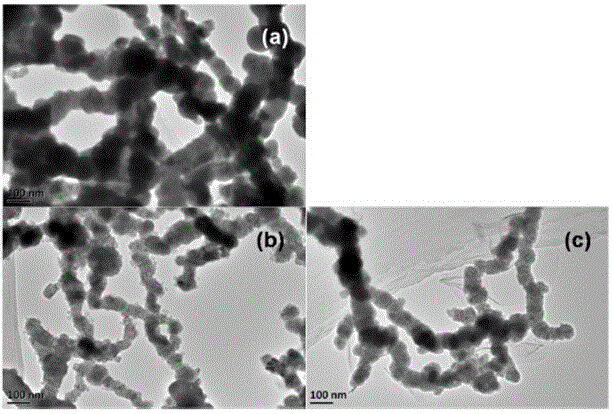

Preparation method for cellulose modification nano iron particles

ActiveCN104785793AFacilitate adaptation to in situ and heterotopic repairSimple processWater/sewage treatmentCelluloseNitrate salts

The invention discloses a preparation method for cellulose modification nano iron particles. According to the preparation method, two kinds of environment-friendly non-poisonous and innocuous cellulose are taken as dispersing agents to conduct surface modification on particles in the preparation process of the nano iron particles, and the cellulose dispersing agent modified nano iron particles are obtained. According to the preparation method for the cellulose modification nano iron particles, the process is simple and convenient, the operation is easy, the cost is low, the dispersity of the nano iron particles is good, the agglomeration of the particles in water can be reduced, and the removal efficiency of the particles to organic pollutants, dyestuff, pesticides, nitrate and heavy metal is improved.

Owner:KUNMING UNIV OF SCI & TECH

Amorphous reinforced metal matrix composite material preparing and forming method

ActiveCN109434118AHigh strengthImprove performanceAdditive manufacturing apparatusIncreasing energy efficiencyCorrosionMetal matrix composite

The invention belongs to the technical field of 3D printing, and discloses an amorphous reinforced metal matrix composite material preparing and forming method. The method comprises the following steps that (a), amorphous alloy powder and metal powder are selected as raw materials, the two kinds of powder are mixed and subjected to low energy ball milling to form mixed powder, wherein the amorphous alloy is dispersed in the metal powder as a wild phase and is used for improving strength, hardness, abrasion resistance and corrosion resistance of a product to be formed, low energy ball milling enables the amorphous alloy powder and the metal powder to be uniformly mixed and prevents the two kinds of powder from plastic deformation; and (b), according to the three-dimensional structure of theproduct to be formed, the obtained mixed powder is used for laser selective melting forming to obtain the product to be formed. The problems of poor wettability, cracking, holes and easy material oxidization of a traditional ceramic reinforcement phase can be solved. The amorphous reinforced metal matrix composite material with the excellent mechanical property and complex shape is obtained.

Owner:JIANGSU VILORY ADVANCED MATERIALS TECH CO LTD

Synthesizing lithium ion cell positive material fluorophosphoric vanadium-lithium by sol-gel method

InactiveCN101005134ASolve easy oxidationUniform particle size distributionElectrode manufacturing processesFluoride preparationPhosphateVacuum drying

The disclosed sol gel method includes steps: stirring, and mixing objects: water solutions of lithium salt, villiaumite, vandic salt in pentavalence, phosphate, and chelating agent according to mol ratio 2í†2í†1-2í†2í†4; controlling pH at 7-11, carrying out reaction in stirred reactor under 40-80 deg.C for 1-5 hours to form gel; drying the gel in vacuum drying oven for 5-15h under 80-150 deg.C, and cracking the dried gel for 1-4h; after being ground evenly, the dried gel is roasted at 400-800 deg.C under atmosphere of inert gases for 5-20h so as to obtain finished product. Using vandic salt in pentavalence as raw material, the invention solves issue that vanadium ion is to be oxidized. The invention reduces burning temperature; producing fine and grain size even distributed material so as to raise conductivity. Adjustable synthesis temperature can obtain material with different granularities. Advantages are: simple and convenient method, and shortened synthetic cycle.

Owner:CENT SOUTH UNIV

Ferro-cerium-based rapid quenching permanent magnet powder and preparation method of ferro-cerium-based rapid quenching permanent magnet powder

ActiveCN103714928ALower melting temperatureShorten smelting timeInorganic material magnetismCeriumEngineering production

The invention relates to ferro-cerium-based rapid quenching permanent magnet powder and a preparation method of the ferro-cerium-based rapid quenching permanent magnet powder. The alloy composition chemical formula of the ferro-cerium-based rapid quenching permanent magnet powder is [Ce100-x, Rex]aFe100-a-b-cBbTMc, wherein the x is the mass percent of the rare earth gross, the a, the b and the c show the mass percents of corresponding elements respectively, 0<=x<=50%, 27.5%<=a<=32%, 0.8%<=b<=1.5%, 0.5%<=c<=5%, the Re is one or more of Nd, Pr, Dy and Tb, and the TM is one or more of Ga, Co, Cu, Nb and Al. According to the preparation method, the ferro-cerium-based rapid quenching permanent magnet powder and Re'-Fe-B without Ce can be prepared with a water-cooling electromagnetic roller (a copper alloy roller or a molybdenum roller), and a ferro-cerium-based hot-pressing magnet with double hard magnetic principal phases or multiple hard magnetic principal phases can be prepared with the two kinds of magnetic powder. The ferro-cerium-based rapid quenching permanent magnet powder fills up blanks of middle-grade magnet powder and lower-grade magnet powder on the market at present, the product performance cost ratio is high, and the ferro-cerium-based rapid quenching permanent magnet powder and the preparation method are suitable for engineering production.

Owner:CENT IRON & STEEL RES INST

Manufacturing method of plastic sealed solar photovoltaic assembly

The invention discloses a manufacturing method of a plastic sealed solar photovoltaic assembly. The manufacturing method comprises the following steps: arranging a first EVA material layer on a glassy layer, arranging a cell layer on the first EVA material layer, arranging a second EVA material layer on the cell layer, and arranging a back plate material layer on the second EVA material layer, wherein all the parts are laminated and shaped into laminates by a laminating machine, and plastic frames with the plastic sealing function are arranged at the circumferences of the laminates and are subject to plastic sealing by ultrasonic hot melting. The invention thoroughly solves the problems that the conventional aluminum alloy frame is easy to oxidize and scratch, too much time is spent in waiting for the curing of silica gel and the like, raises the production efficiency, and lowers the cost.

Owner:HANWHA SOLARONE QIDONG

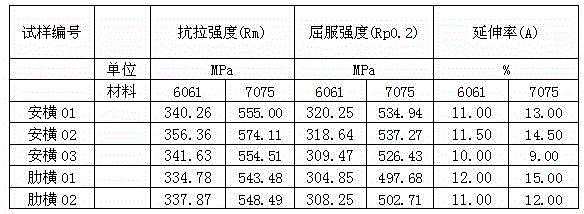

Aluminum alloy hub forging method

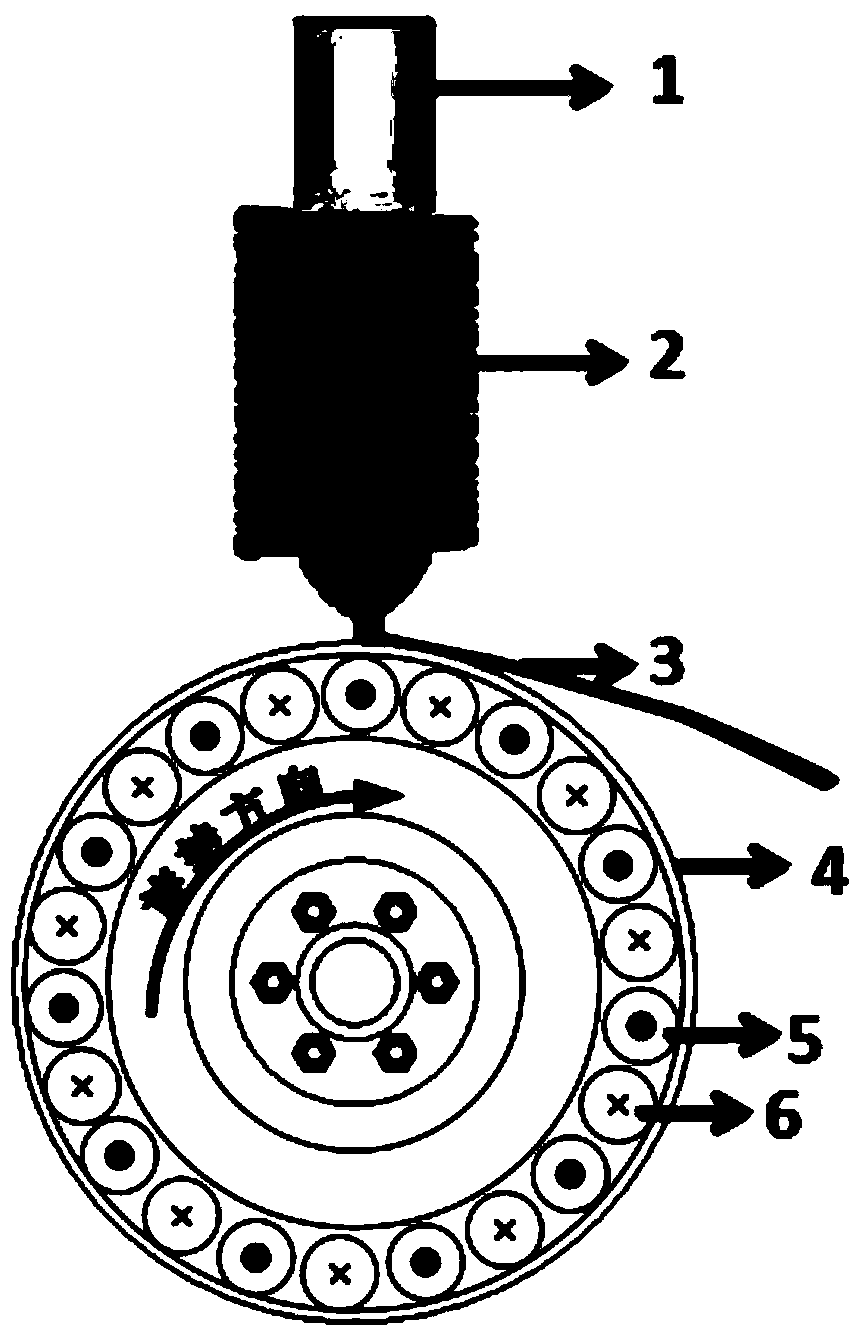

The invention discloses an aluminum alloy hub forging method. The aluminum alloy hub forging method comprises the following steps that (1) materials are prepared; (2) feeding is conducted; (3) a forged blank is obtained through forging, wherein the forged blank is in the form of a rim of a hub; (4) heat treatment is conducted; (5) a semi-finished hub is obtained through machining; (6) anti-oxidation treatment is conducted, so that a finished aluminum alloy hub is obtained. According to the mechanical properties of the aluminum alloy hub obtained by means of a special casting bar through forging and heat treatment, the tensile strength can reach 570MPa, the yield strength can reach 540MPa, and the ductility can reach 15%. Compared with a truck hub in the same specification, the weight can be reduced to 17.2 kg, and the weight of the hub is greatly reduced; due to the fact that the anti-oxidation treatment is conducted on the hub, the problem that an existing aluminum alloy hub is prone to oxidation can be effectively solved, and the requirements for hubs of existing trucks can be met.

Owner:JIANGSU POMLEAD CO LTD

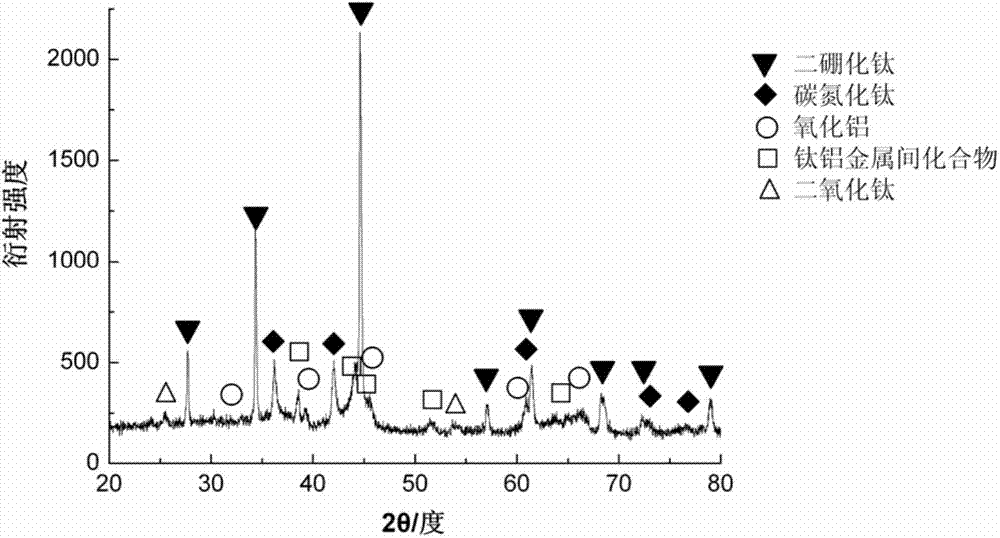

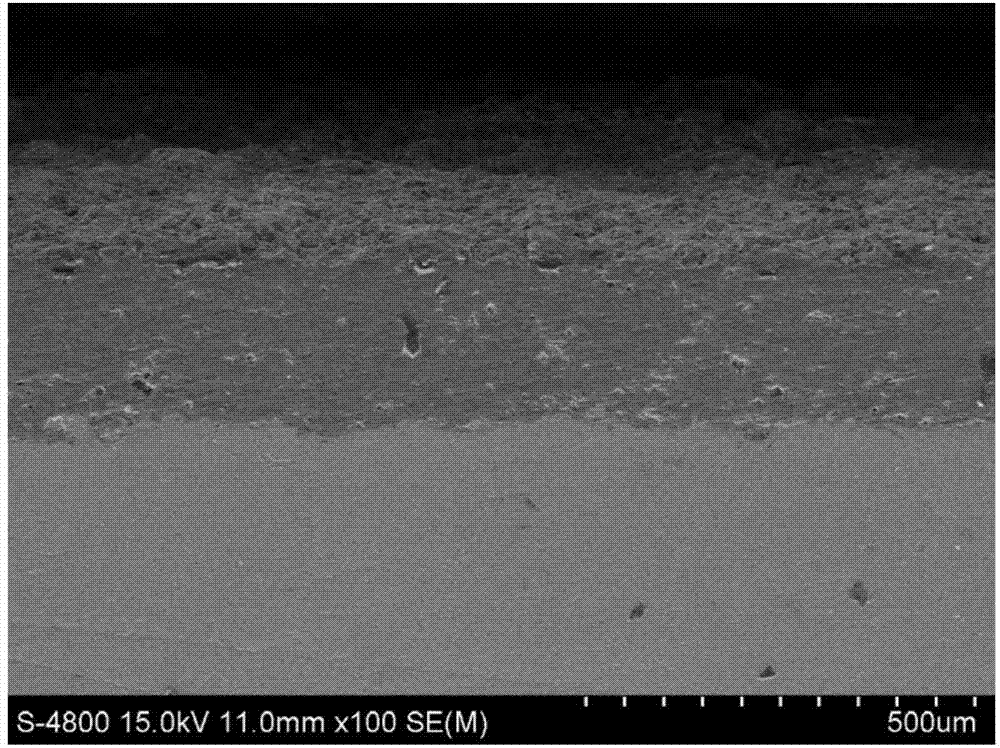

Preparation method of titanium boride based inorganic composite coating

Relating to plating of metal materials, the invention provides a preparation method of a titanium boride based inorganic composite coating. The mixed powder of micron-sized metal Al powder, micron-sized, submicron-sized or nano-sized TiO2 powder, and micron-sized, submicron-sized or nano-sized B4C powder is taken as a raw material, the mixed powder is sprayed on the alloy underlayer surface of a metal or alloy workpiece surface by thermal spraying. During thermal spraying, the Al, TiO2 and B4C in the mixed powder react with nitrogen in a powder feeding gas to synthesize the titanium boride based inorganic composite coating in situ. The method provided in the invention overcomes the defects of high raw material cost, complicated preparation process, high energy consumption, low efficiency, difficult control of coating processing precision, low coating density, poor coating uniformity, weak binding force between the coating and a substrate, low coating toughness, easy coating cracking, and unsuitability for application in large-scale industrial production existing in the prior art for preparation of titanium boride based composite coatings.

Owner:HEBEI UNIV OF TECH

Method for doping paraffin forming agent in cemented carbide mixture

The invention discloses a method for doping a paraffin forming agent in a cemented carbide mixture. The method comprises the following steps of: melting solid paraffin into fused mass; heating a cemented carbide wet-grinding mixture to be at a temperature higher than the melting point temperature of the paraffin; adding melted paraffin to the cemented carbide wet-grinding mixture; continuously heating and stirring the cemented carbide wet-grinding mixture; and screening and granulating the cemented carbide wet-grinding mixture according to a general method when the cemented carbide wet-grinding mixture reaches a drying requirement so as to obtain a qualified cemented carbide mixture. The method integrates and finishes the steps of drying the cemented carbide wet-grinding mixture and adding the paraffin and evenly stirring in a link and equipment by utilizing the characteristics that the cemented carbide mixture contains alcohol, and the paraffin is dissolved in the alcohol at a temperature higher than the melting point temperature, can dissolve the paraffin without adopting a gasoline or another solvent, avoid mixing impurities in the solvent and has the advantages of decreased production cost, simple process, small equipment investment, simple operation and high cemented carbide wet-grinding mixture quality.

Owner:ZHUZHOU KINGTAL CEMENTED CARBIDE

Method for preparing lithium ion battery anode material vanadium lithium fluophosphate by one-step solid phase reaction

InactiveCN101320808ASolve easy oxidationImprove charge and discharge performanceElectrode manufacturing processesChemical/physical/physico-chemical processesLithiumOrganic acid

The invention discloses a method for producing fluorophoshoric acid vanadium lithium of lithium iron battery positive pole material at low temperature by one-step solid phase reaction, comprising the step of: uniformly blending vanadic oxide powders, phosphate, organic acid, lithium salts with villaumite to sinter for 3 to 12 hours under the protection of inert gases, consequently the final product LiVPO4F is obtained after cooling; the invention is simple and convenient in usage, easy in control and low in cost, and simplifies the synthesis process and promotes the discharge and charge performance and circulation performance of samples.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Corundum-mullite composite brick for COREX furnace and preparation method thereof

The invention discloses a corundum-mullite composite brick for a COREX furnace and a preparation method thereof. The raw materials of the corundum-mullite composite brick are composed of a corundum-mullite homogenized material, white corundum, andalusite, a-Al2O3 powder and binding clay, as well as paper pulp liquid waste. The preparation method comprises the steps of firstly, preparing raw materials with various particle sizes according to the ratio; then, using raw materials with particle sizes of 1-3mm and particle sizes smaller than 1mm as aggregate to perform dry mixing, adding a paper pulp liquid waste mixture, finally adding the residual raw materials, and milling to obtain a pug; sequentially performing material trapping, press forming and drying on the obtained pug, and finally roasting to obtain a product. The corundum-mullite composite brick produced in the invention has very low porosity, high compression strength and excellent thermal shock resistance and corrosion resistance, can completely satisfy the harsh application environment of the COREX furnace, and can prolong the service life.

Owner:TONGDA REFRACTORY TECH CO LTD +1

Stable easy-separation nanoscale iron ball, preparation method thereof and application thereof

InactiveCN102600777AOvercoming easy oxidation and difficult separationImprove utilization efficiencyMicroballoon preparationMicrocapsule preparationZerovalent ironScrap

The invention discloses a stable easy-separation nanoscale iron ball, a preparation method thereof and application thereof. The stable easy-separation nanoscale iron ball comprises crosslinking precursor solution and nanoscale zero-valent iron dispersion solution by the volume ratio of 15:1-3:1. The crosslinking precursor solution comprises, in weight / volume percent, 0.1%-15% of chitosan-acetum solution, and the nanoscale zero-valent iron dispersion solution comprises 0.1%-15% of Tween20, 20%-55% of nanoscale zero-valent iron powder and 1%-10% of scrap iron. When the nanoscale iron ball prepared by the preparation method is used for treating contaminated sludge and water, the basic decontamination performance of the nanoscale zero-valent iron powder can be kept, and the shortcomings of easiness in oxidization, difficulty in separation and the like of the nanoscale zero-valent iron powder can be overcome, the oxidizing velocity of NZVI (nanoscale zero-valent iron) particles is adjusted, and the utilization efficiency of the NZVI particles is improved. Therefore, the functional nanoscale iron ball can be used for practical engineering of contaminated sludge and water treatment on a large scale.

Owner:TIANJIN NORMAL UNIVERSITY

Lead-free welding flux alloy suitable for dissimilar metals soldering flux of aluminum and copper

InactiveCN101007374APrevent oxidationSolve easy oxidationWelding/cutting media/materialsWelding/soldering/cutting articlesCopperMaterials science

A lead-free solder alloy suitable for copper-aluminum heterogenic metal soft braze welding. The weight percentage of its components is the following: Zn 0.1 ~ 3.0, Cu 0.2 ~ 3.5, Ce 0.001 ~ 0.6, P 0.001 ~ 0.14, Ge or / and Ga 0. 001 ~ 0.13 and the rest is Sn. The solder alloy in the invention has better spreading property on the connection of copper-aluminum heterogenic metal, and the extensibility of alloy is better than Sn-0.7Cu and Sn63Pb37 solder alloy, it applies to soft braze welding of copper-aluminum heterogenic metal.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

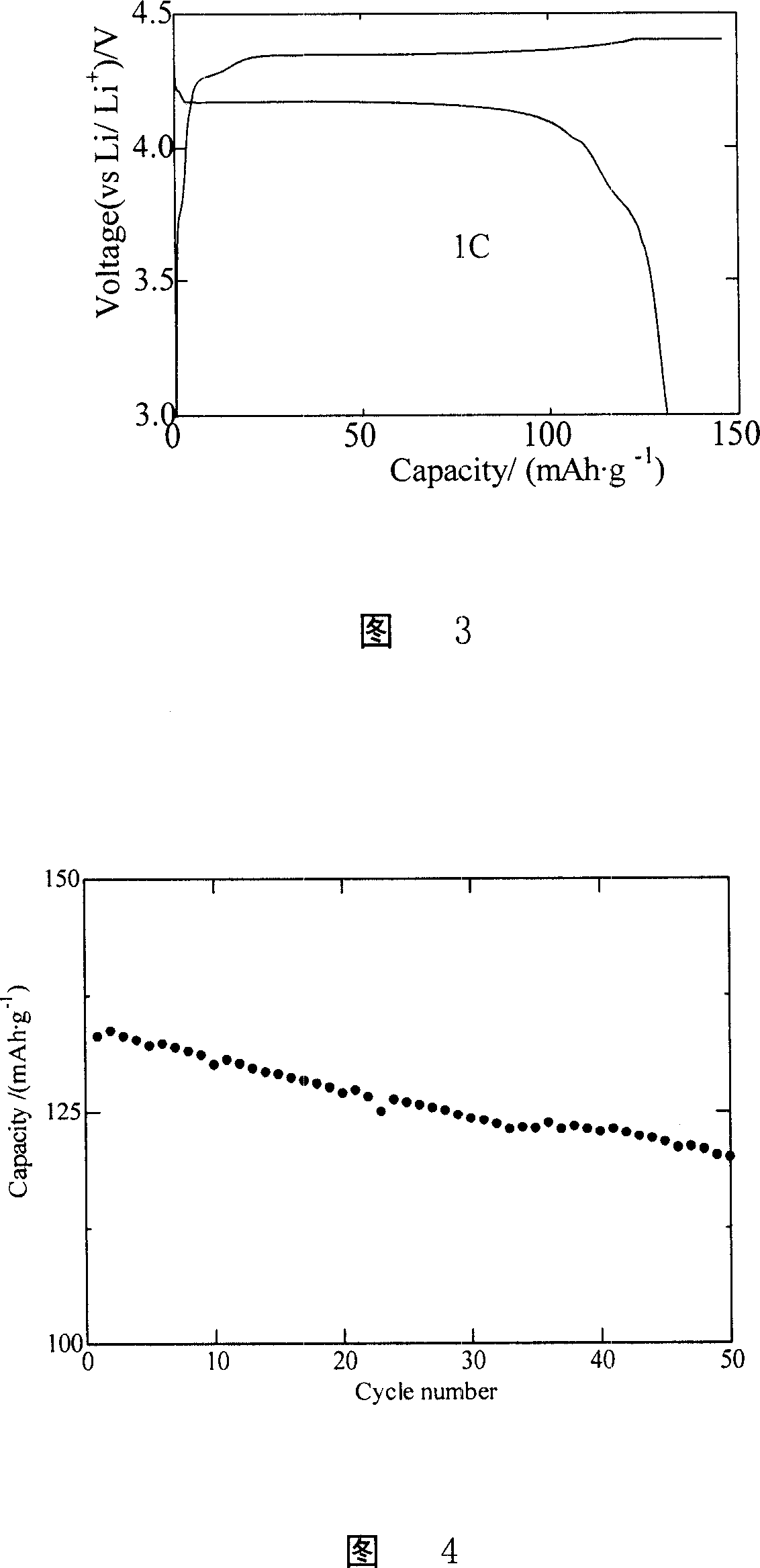

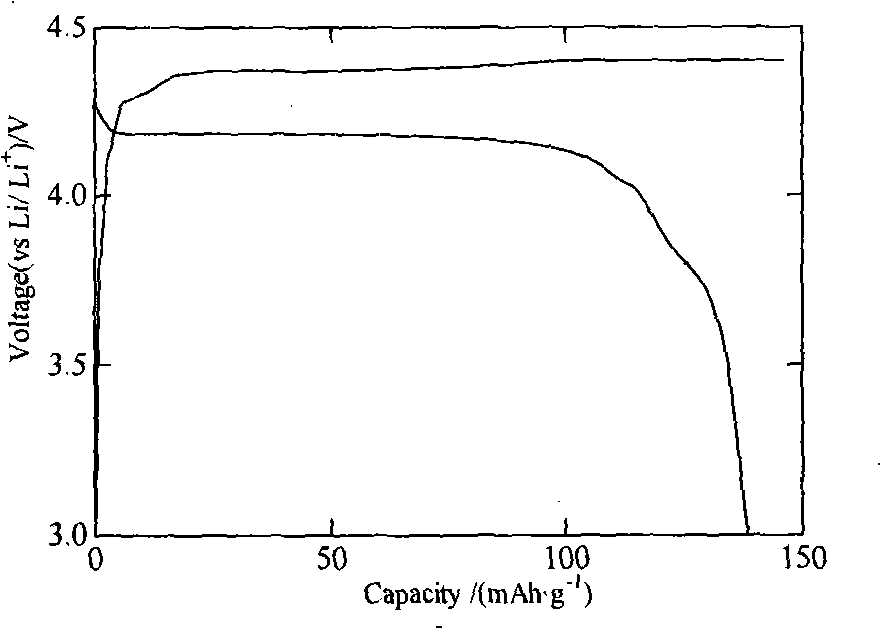

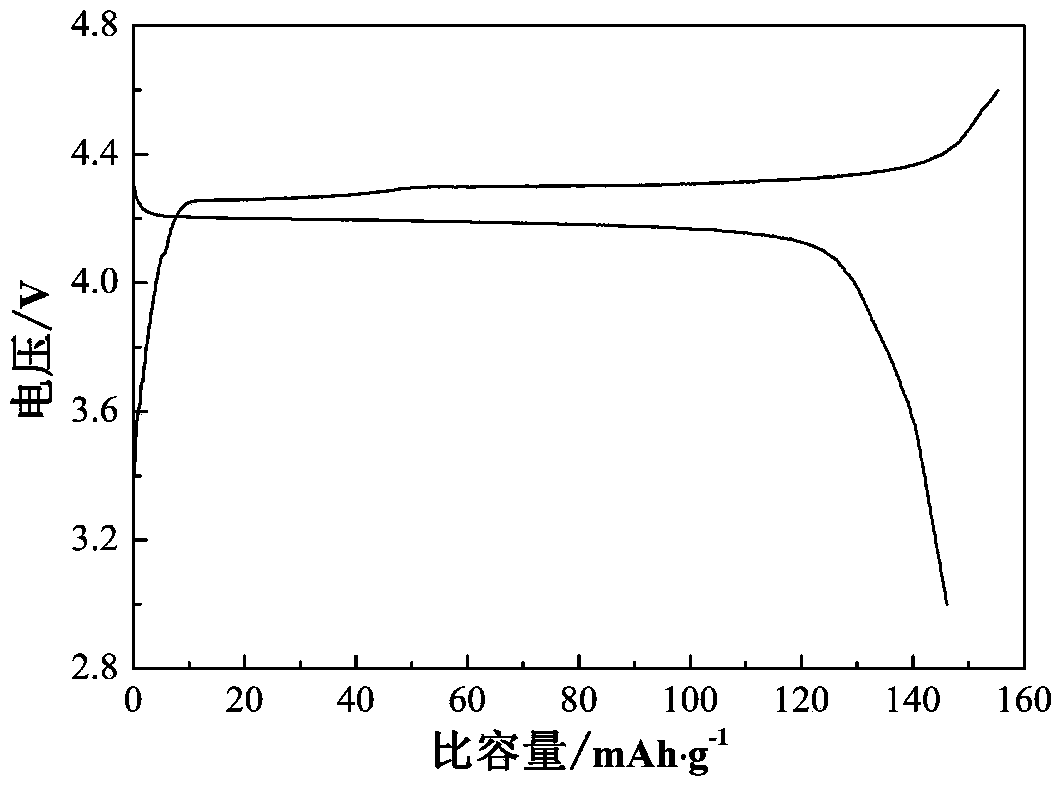

Method for preparing cathode material of lithium-ion battery, namely lithium vanadium fluorophosphates

InactiveCN103594715ASmall particlesUniform particle size distributionCell electrodesHigh energyBiological activation

The invention belongs to the technical field of lithium-ion batteries and relates to a method for preparing the cathode material of the lithium-ion battery, namely lithium vanadium fluorophosphates through mechanical activated auxiliary solid phase sintering. The preparation method comprises the following steps: weighing a hypervalent vanadium source compound, a phosphorus source compound and a reducing agent according to a certain stoichiometric ratio, putting in a high-energy ball mill container for mechanical activation treatment, and then carrying out calcining treatment in a non-oxidizing atmosphere to obtain a precursor; after ball-milling and uniformly mixing the precursor with a lithium source compound and fluoride, and putting in the non-oxidizing atmosphere for heating to 600-800 DEG C; after keeping the temperature for 0.2-5hours, rapidly cooling to the room temperature to obtain lithium vanadium fluorophosphates. The method has the advantages of simple process, easiness in control and low cost. The synthetized lithium vanadium fluorophosphates material has high purity, particles are similar to spherical and are uniform, and the synthetized lithium vanadium fluorophosphates material has a good electrochemical performance. The lithium-ion battery is charged and discharged in the range of voltage of 3.0-4.6V, the discharge specific capacity for the first time can achieve 146.2mAh / g under 0.1 C rate, and the cycling performance is good.

Owner:UNIV OF SCI & TECH BEIJING

Gold-silver-palladium alloy single-crystal bonding wire and manufacturing method thereof

InactiveCN103779308ALow priceReduce performanceSemiconductor/solid-state device detailsSolid-state devicesMinor metalsMetallic materials

Provided are a gold-silver-palladium alloy single-crystal bonding wire and a manufacturing method thereof. The main material of the gold-silver-palladium alloy single-crystal bonding wire is high-purity silver, and the gold-silver-palladium alloy single-crystal bonding wire further comprises gold, palladium, europium, lanthanum and other trace metal materials. The gold-silver-palladium alloy single-crystal bonding wire comprises, by weight, 98.713%-99.157% of the silver, 0.8%-1.2% of the gold, 0.04%-0.08% of the palladium, 0.002%-0.004% of the europium and 0.001%-0.003% of the lanthanum. The manufacturing method comprises the steps that the high-purity silver with the purity higher than 99.9999% is extracted and manufactured into silver alloy ingots, as-cast gold-silver-palladium alloy single-crystal main wires are manufactured, the single-crystal main wires are manufactured into single-crystal wires of around 1mm through a drawing mode, heat treatment is carried out on the single-crystal wires, and then gold-silver-palladium alloy single-crystal bonding wires of different specifications are manufactured through precise drawing, heat treatment and cleaning.

Owner:江西蓝微电子科技有限公司

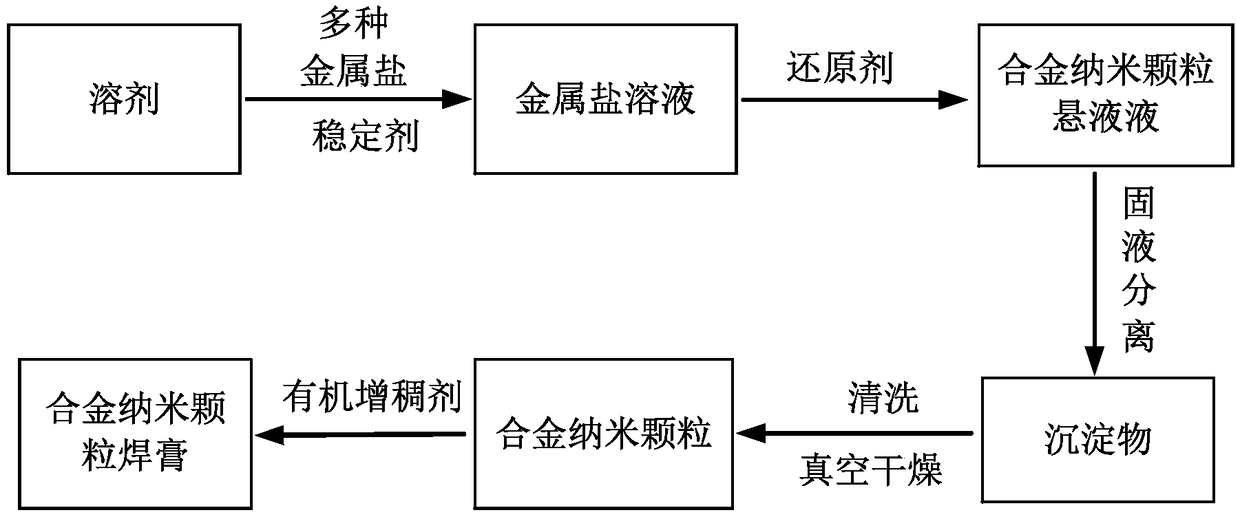

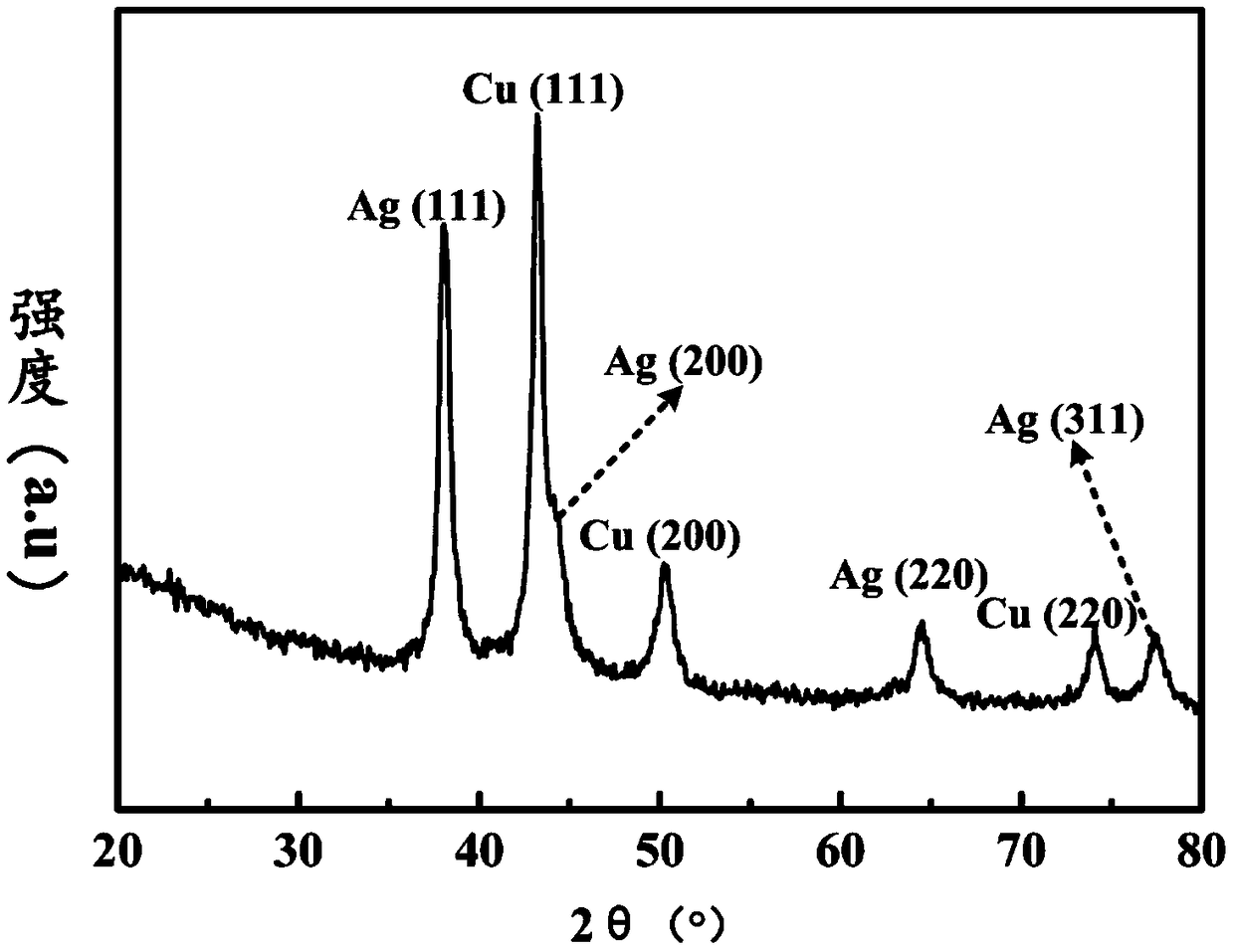

Alloy nanometer particle soldering paste and preparation method thereof

InactiveCN109352206ASimple processProcess parameters are easy to controlWelding/cutting media/materialsSoldering mediaAlloyCleansing Agents

The invention belongs to the field of nanometer technology and microelectronic packaging and discloses alloy nanometer particle soldering paste and a preparation method thereof. The method includes the specific steps that metal salt and a stabilizing agent are completely dissolved in a solvent to prepare a metal salt solution, a reducing agent is added in the metal salt solution and is stirred, and is enabled to perform a full reaction, and an alloy nanometer particle suspension is acquired; the alloy nanometer particle suspension is subjected to solid-liquid separation, precipitate is obtained, the precipitate is washed with a washing agent, and then drying is performed so that alloy nanometer particles can be obtained; and the alloy nanometer particles are added into an organic thickening agent, and after vacuum stirring and bubble removing treating, the alloy nanometer particle soldering paste is made. According to the alloy nanometer particle soldering paste and the preparation method thereof, the alloy nanometer particles are prepared by adopting a liquid phase reducing method, the process is simple, control is easy, and cost is low; and the stabilizing agent is added in whilethe metal salt solution is prepared, agglomeration and oxidization of the particles can be effectively avoided, and the oxidization resistance of the alloy nanometer particles is enhanced.

Owner:HUAZHONG UNIV OF SCI & TECH

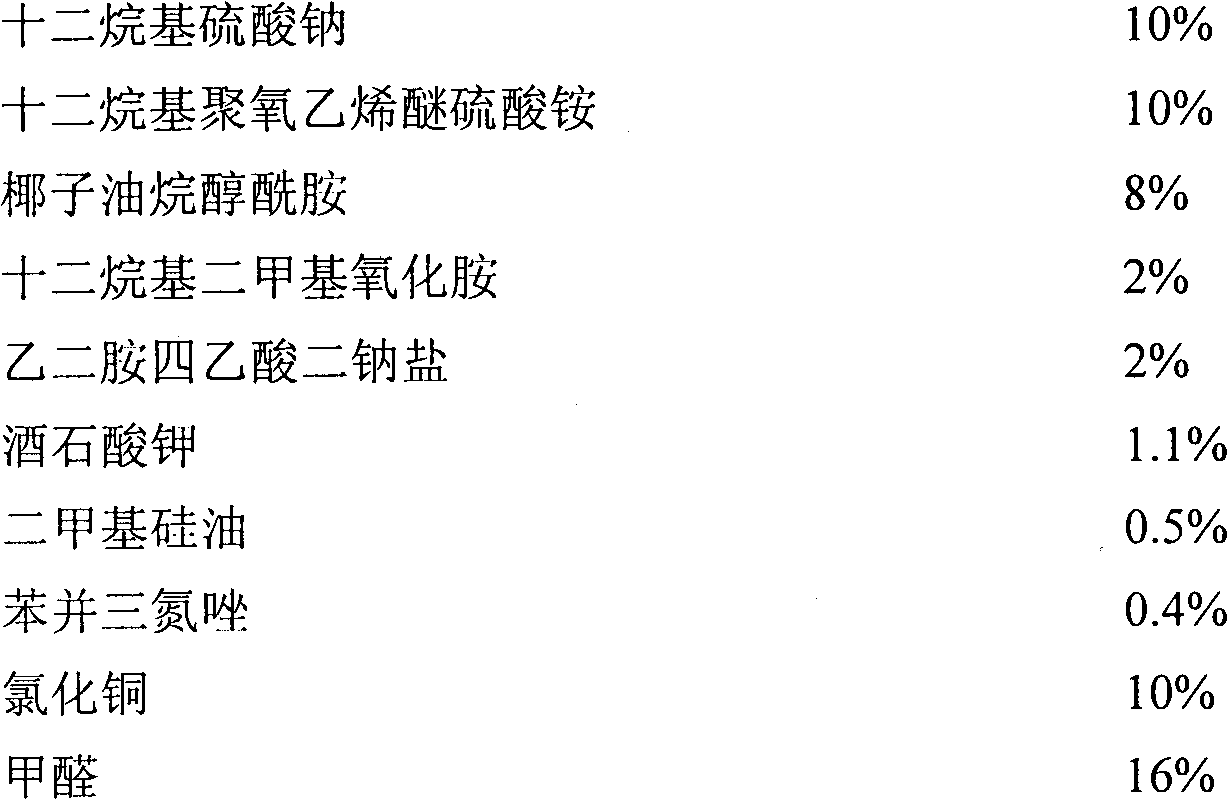

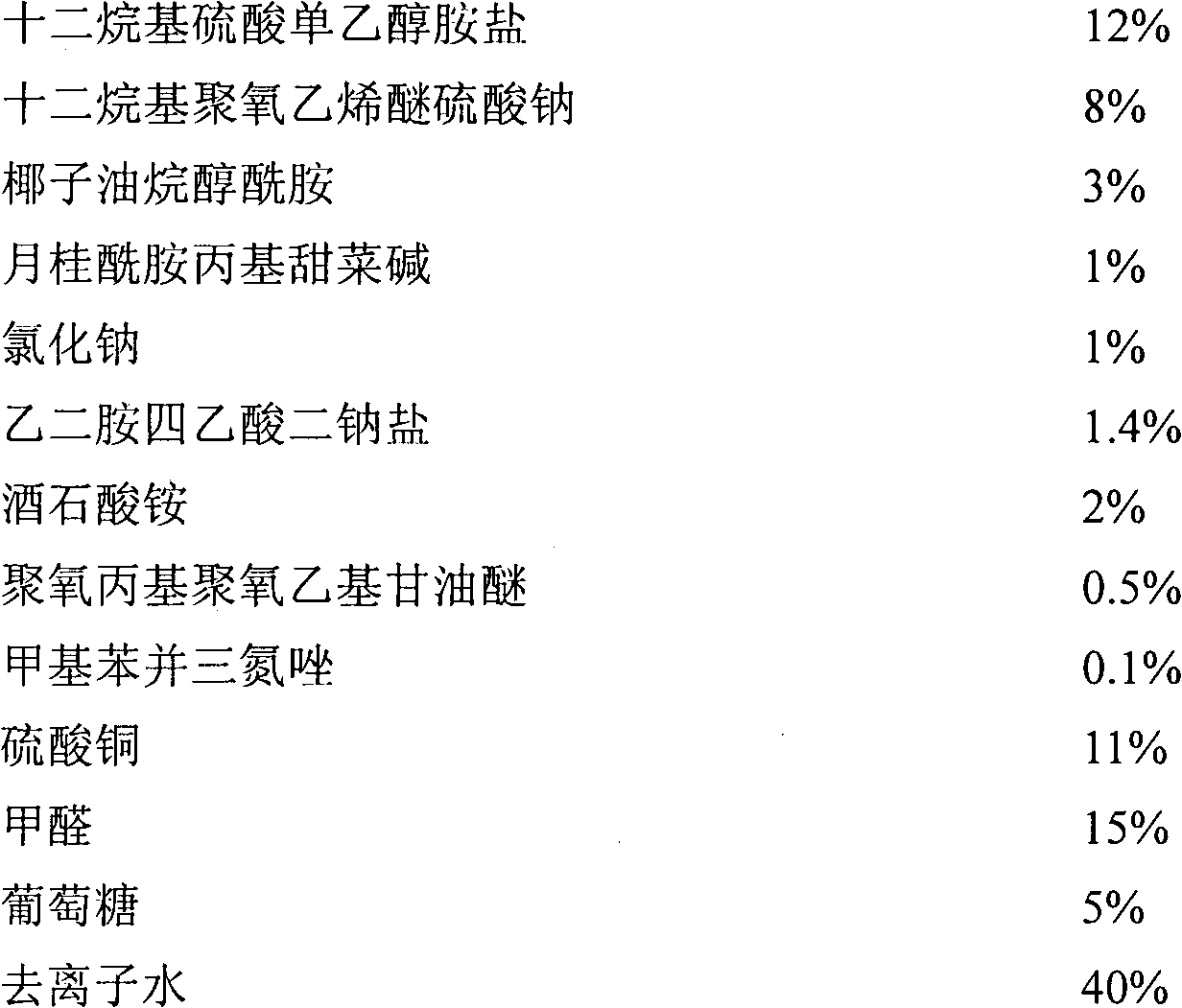

A method for preparing nanometer copper powder in a small molecule viscous medium

The invention discloses a method for preparing nano copper powder in a micromolecular viscous medium. The method comprises the steps of: by taking a surface active agent, salt, a complexing agent, an antifoaming agent, an antioxidant, cupric salt, a reducing agent and deionized water as raw materials and according to the proportion of (0.001-95 percent) : (0.001-95 percent) : (0.001-80 percent): (0.001-75 percent): (0.001-70 percent): (0.001-75 percent): (0.001-70 percent): (0.001-98 percent), preparing the micromolecular viscous medium by using the surface active agent, the salt, the complexing agent, the antifoaming agent, the antioxidant and the deionized water; adding the cupric salt and uniformly mixing; adding the reducing agent and mixing; adding the deionized water to dilute so asto reduce the degree of viscosity according to a mass ratio of 1:0.5-10 of the total quantity of all materials abovementioned to the deionized water after the reaction completes; and obtaining nano copper powder through filter-pressing, deionized water washing, acetone washing and vacuum drying. According to the method disclosed by the invention, the raw materials selected in the invention are easily available, the manufacturing technique is simple and short, the production efficiency is high, the production cost and the energy compunction are low, and powder has low possibility of agglomeration and has good dispersibility, therefore the method is suitable for large-scale production and solves the problems of easy oxidation and easy agglomeration of the nano copper powder existing in the traditional chemical preparation method.

Owner:NANJING FORESTRY UNIV

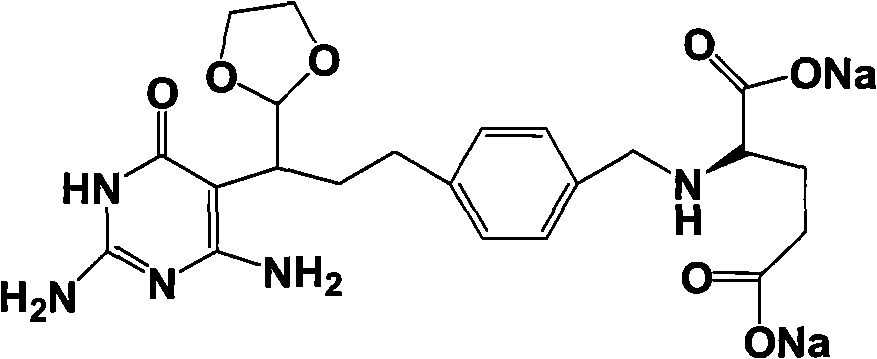

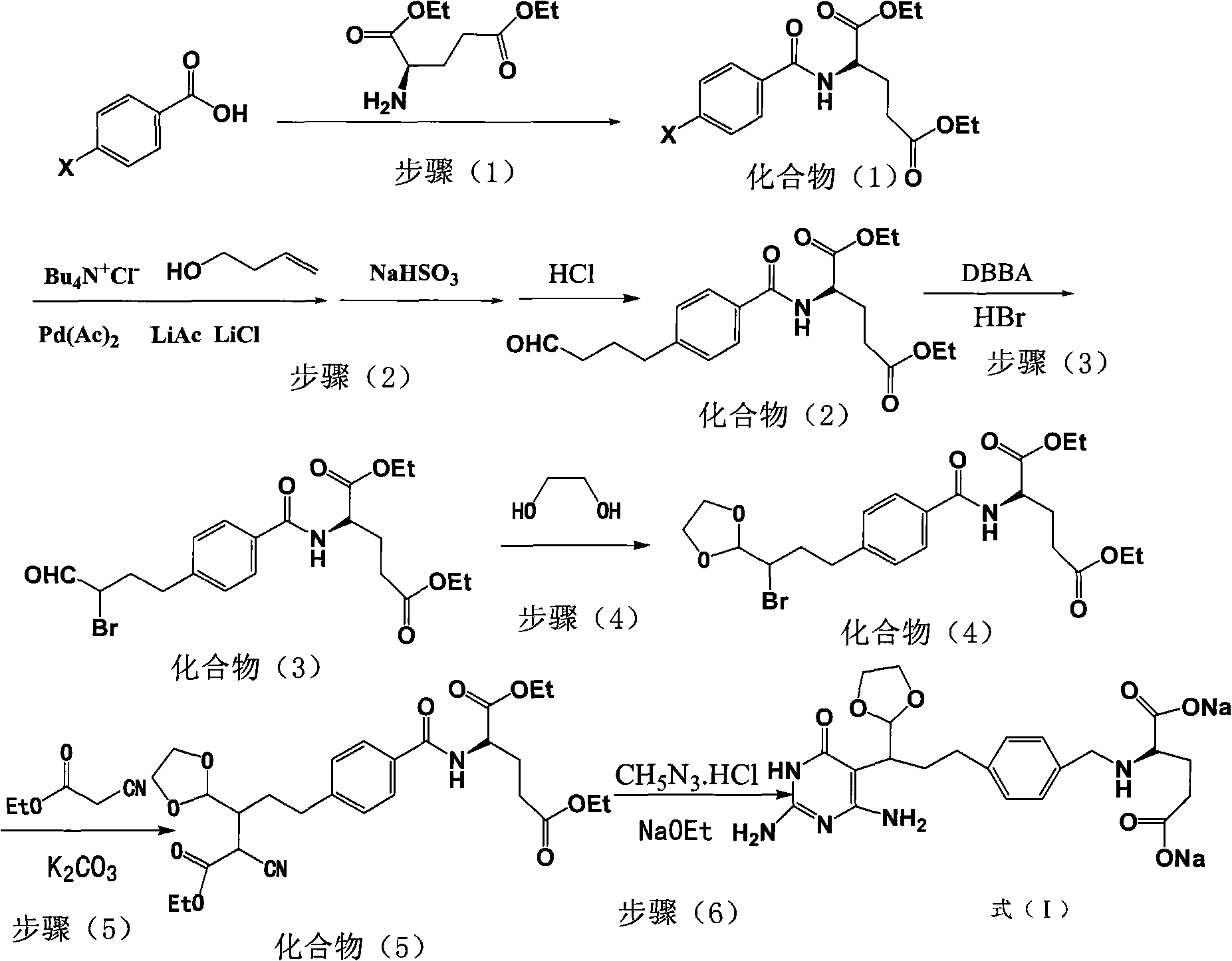

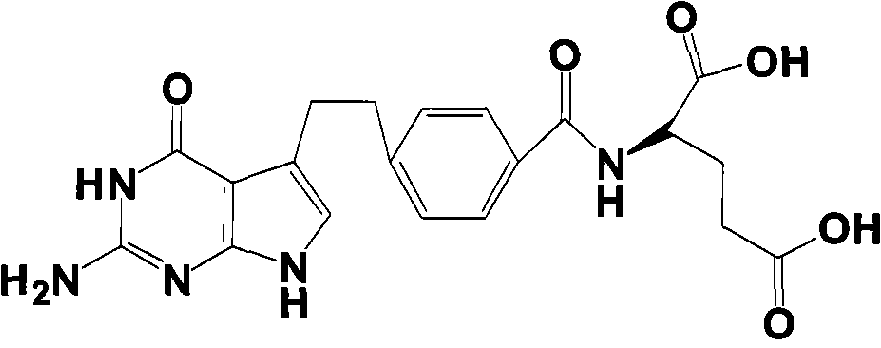

Intermediate of pemetrexed disodium, preparation method thereof and method for preparing pemetrexed disodium thereby

ActiveCN101560206AHigh yieldReduce manufacturing costOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsBenzoic acidGlutaric acid

The invention relates to an intermediate of pemetrexed disodium, a preparation method thereof and a method for preparing pemetrexed disodium thereby; and the intermediate is (2-(4-(3-(2,4-diamino-6-oxy-1,6-dihydro-pyridine-5-group)-3-(1,3)dioxolane-2-group-propyl) benzylamine)sodium glutaric acid. The synthesis of the intermediate comprises the following steps: firstly, condensation reaction is conducted on 4-bromobenzoic acid or 4-iodobenzoic acid and L-glutamate diethylester, then Hack reaction is conducted, 4-bromo is replaced and 4-butyraldehyde is formed, then selective bromo replacement is conducted and the 4-butyladehyde is converted into 2-bromobutyraldehyde, and then condensation reaction of aldehyde and ethylene glycol is utilized for protecting the aldehyde, and pyrimidine ring is further synthesized, and finally the intermediate is obtained. Acid hydrolysis ring-closing reaction and sodium hydroxide salification are respectively conducted for once on the intermediate so as to obtain the pemetrexed disodium. The method for preparing pemetrexed disodium in the invention has high yield, low cost and easy operation and is applicable to industrialized production.

Owner:山东立新制药有限公司

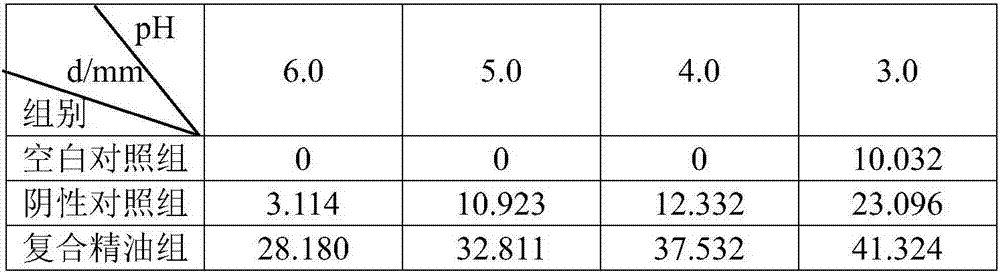

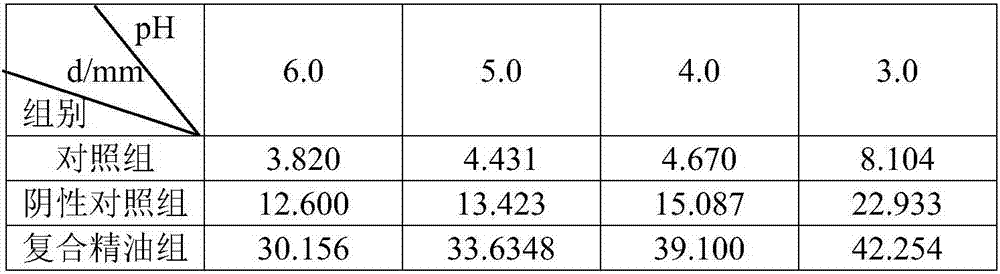

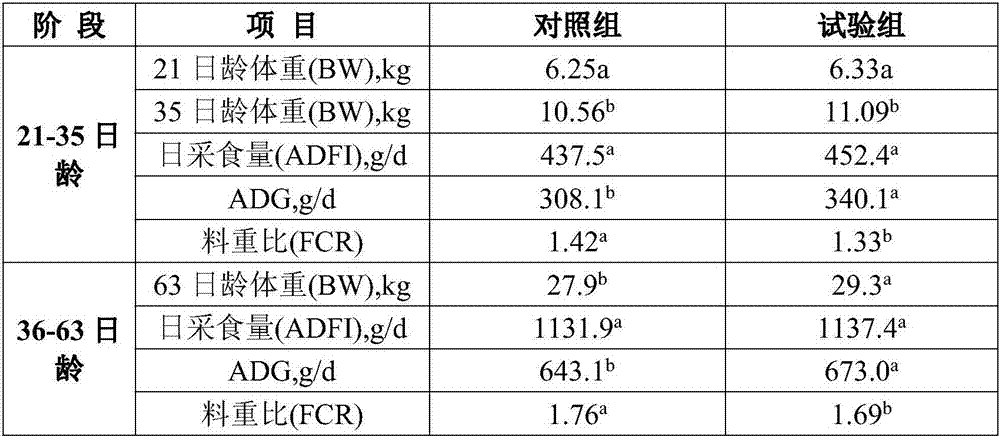

Acid and essential oil composite preparation and preparation method thereof

InactiveCN107156455AImprove stabilityGood antibacterial effectAccessory food factorsWorking-up animal fodderCelluloseMagnesium stearate

The invention discloses an acid and essential oil composite preparation and a preparation method thereof. The acid and essential oil composite preparation comprises organic acid raw materials, a plant essential oil raw material, an adsorbent, a bonding agent, a lubricant and a packing material, wherein the organic acid raw materials comprise 20-30% of sorbic acid, 10-15% of citric acid, 8-15% of malic acid and 5-10% of fumaric acid; the plant essential oil raw material comprises any one of cinnamyl aldehyde or vanillin or carvacrol and 5-8% of thymol, and the mass content of any one of the cinnamyl aldehyde or the vanillin or the carvacrol is 3-5%; the adsorbent is any one of silicon dioxide or white carbon black or vermiculite or sepiolite with the mass content of 3-6%; the bonding agent is any one or more of dextrin lactose or gelling starch or cellulose with the mass content percentage of 4-6%; the lubricant is any one of white carbon black or talcum powder or magnesium stearate with the mass percentage of 1-3%; and the packing material comprises 10-20% of hydrogenated fat. By the acid and essential oil composite preparation, stability of organic acids and essential oil can be protected; moreover, the acid and essential oil composite preparation can soak in gastric acid, and can be slowly released in the intestinal tract of an animal; the antibacterial effect of plant essential oil can be improved; and the actual using effect is excellent.

Owner:ZHEJIANG WANFANG BIO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com