Aluminum alloy hub forging method

A technology of aluminum alloy wheels and wheels, which is applied in the directions of wheels, wheels, transportation and packaging, etc., can solve the problems that the tensile strength, yield strength, elongation and weight cannot meet the requirements of the wheels, so as to reduce weight and solve the problem of easy oxidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

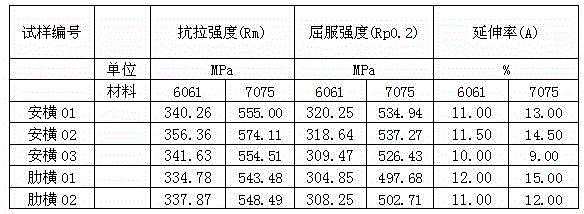

[0015] Embodiment 1, a method for forging an aluminum alloy wheel hub, including the following steps, (1) material preparation: using a cast rod whose main material is Al as the base material, and homogenizing the cast rod before blanking, the cast rod In addition to Al, it also contains the following mass percentages: 0.04-0.06% for Si, 2-2.3% for Mg, 1.3-1.5% for Cu, 0.1-0.25% for Fe, 0.03-0.05% for Mn, and 5.1% for Zn -5.4%, Ti 0.03-0.05%, Cr 0.15-0.25%; (2) Cutting: Saw the cast rod with a sawing machine into a bar with a weight of 35.8-36.2Kg, and put it in at a temperature of 460-490°C (3) Forging: Use a pressure forging machine to pre-forge the front of the cast rod to form a bowl shape, and then use a pressure forging machine to forge the reverse side of the cast rod once to form a barrel shape, and finally roll the cast rod through a spinning machine to obtain a forging billet, which is in the shape of a wheel hub; (4) heat treatment: the forging billet is solution tr...

Embodiment 2

[0016] Embodiment 2, in the aluminum alloy wheel hub forging method described in Embodiment 1: the diameter of the cast rod is 254mm.

Embodiment 3

[0017] Example 3, in the aluminum alloy wheel hub forging method described in Example 1 or 2: In addition to Al, the cast rod also contains the following substances in mass percentages: Si is 0.044%, Mg is 2.2%, and Cu is 1.4%. , Fe is 0.11%, Mn is 0.04%, Zn is 5.3%, Ti is 0.035%, Cr is 0.18%, and the balance is Al.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com