Patents

Literature

110249 results about "Machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Machining is any of various processes in which a piece of raw material is cut into a desired final shape and size by a controlled material-removal process. The processes that have this common theme, controlled material removal, are today collectively known as subtractive manufacturing, in distinction from processes of controlled material addition, which are known as additive manufacturing. Exactly what the "controlled" part of the definition implies can vary, but it almost always implies the use of machine tools (in addition to just power tools and hand tools).

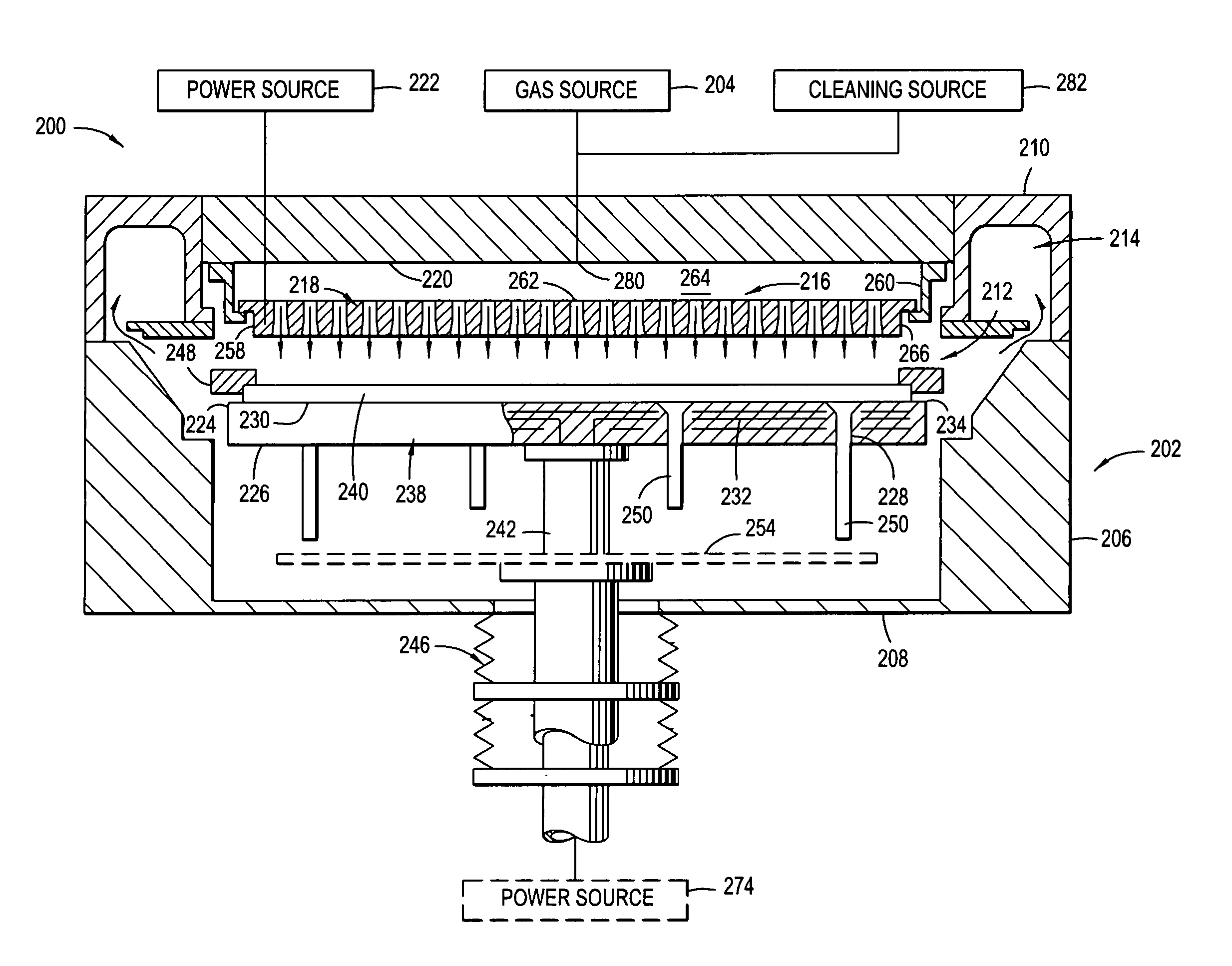

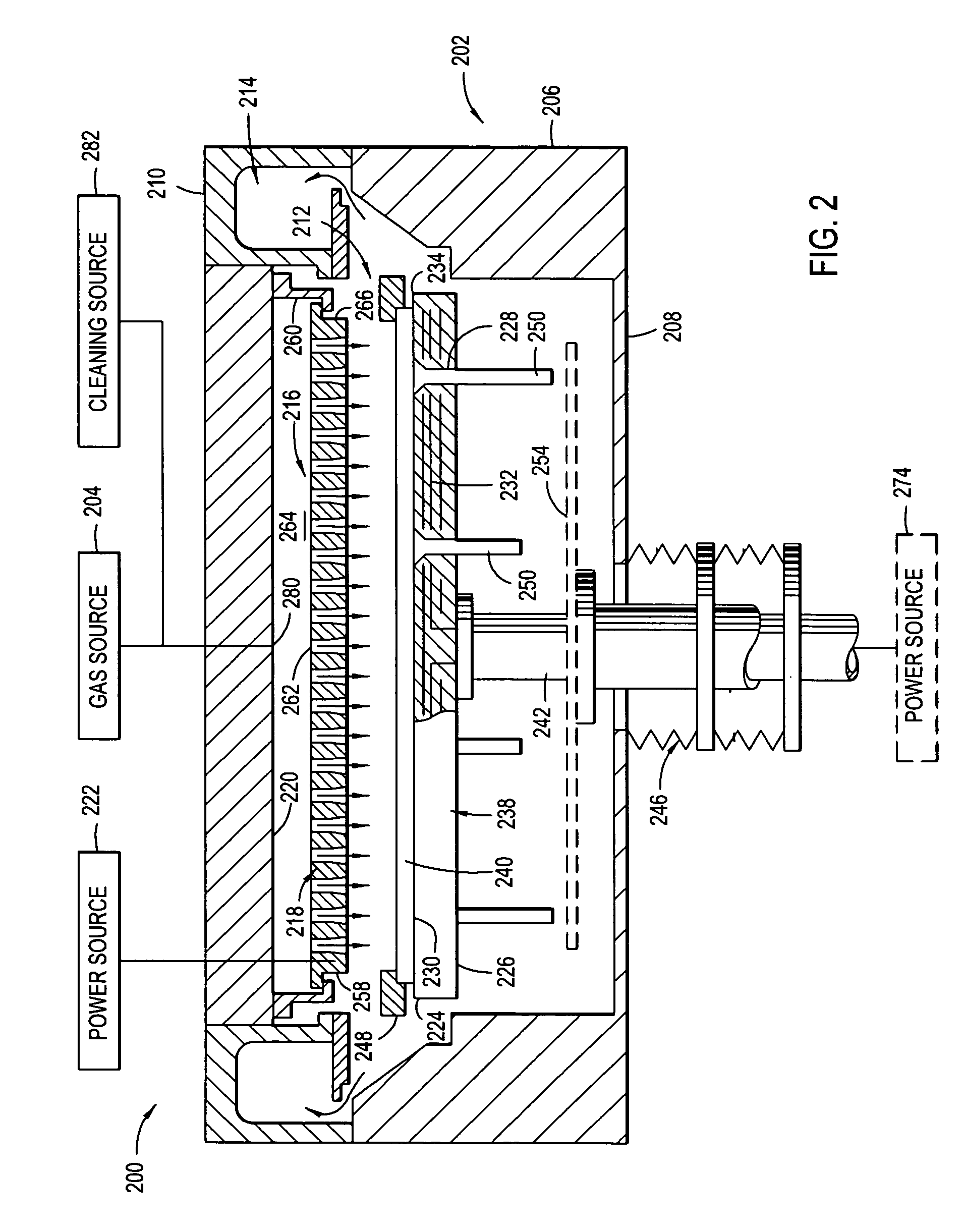

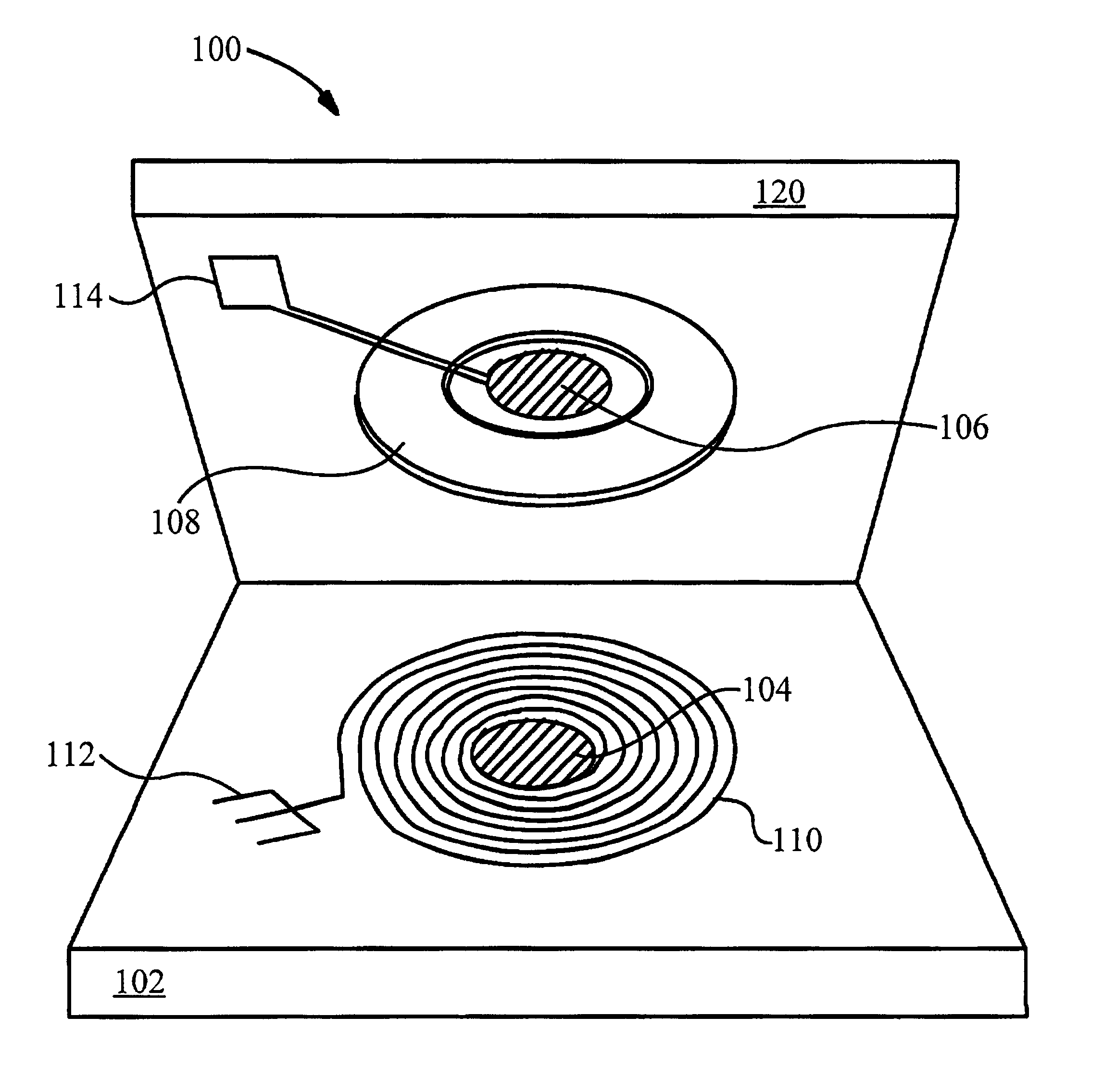

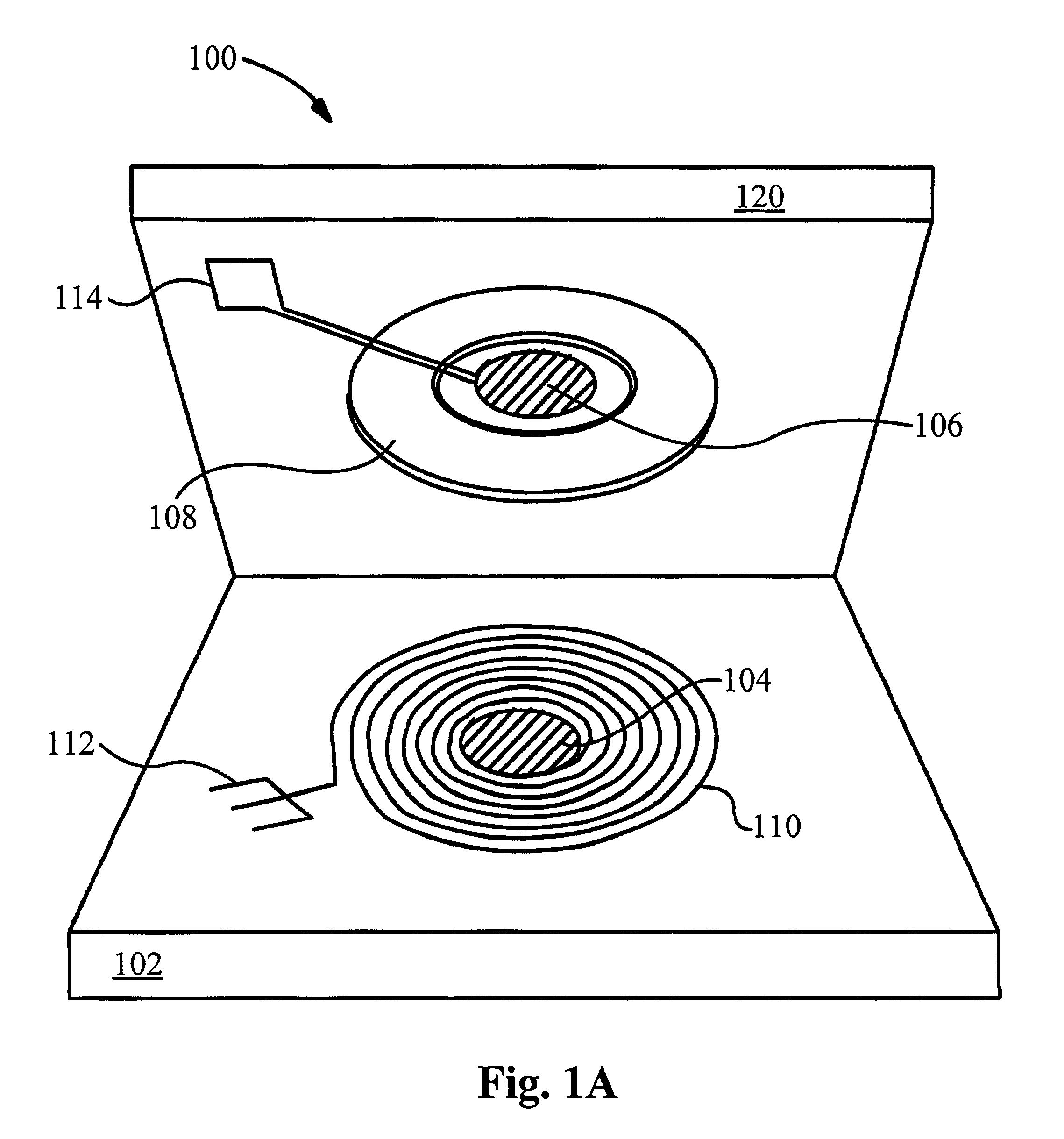

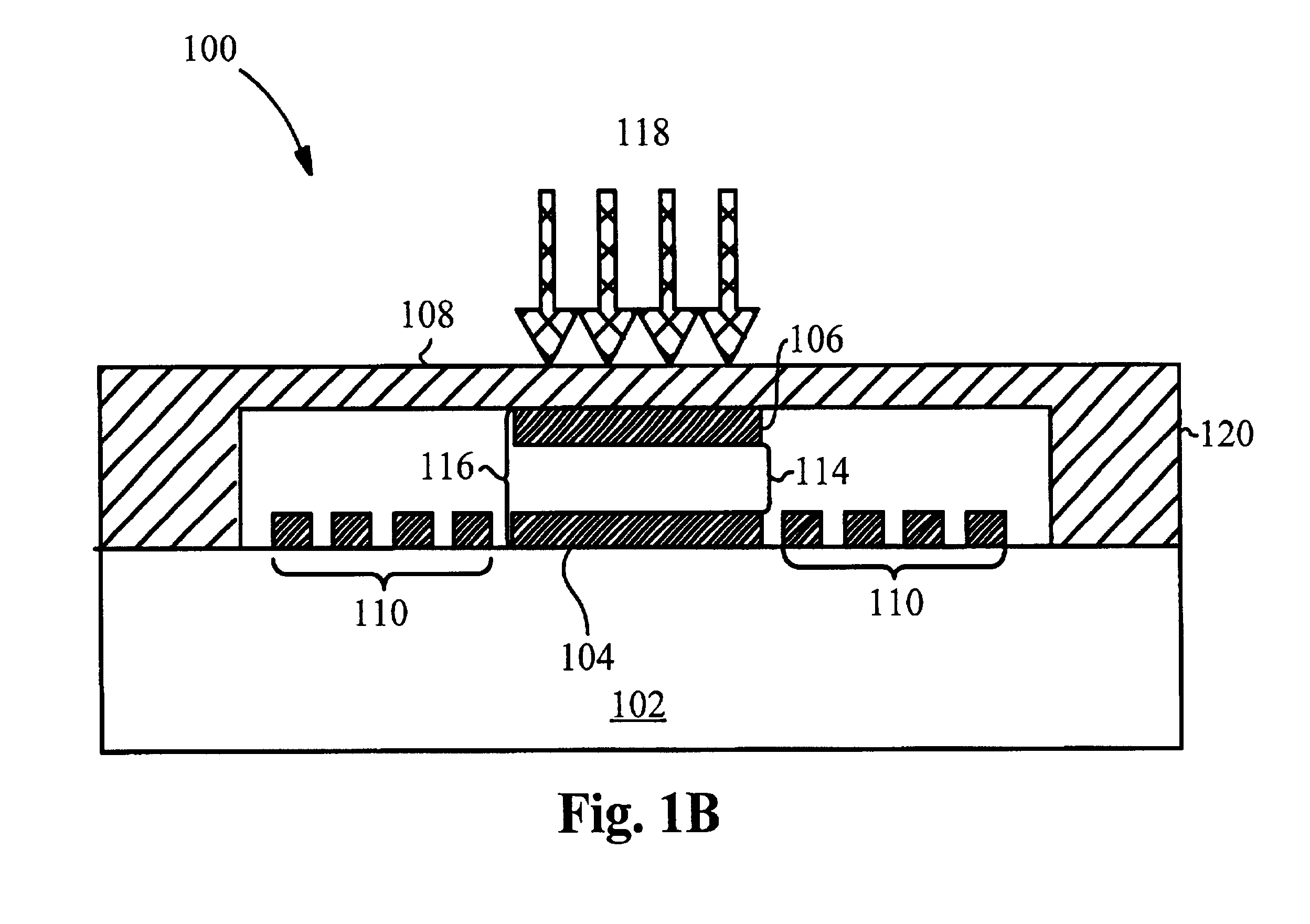

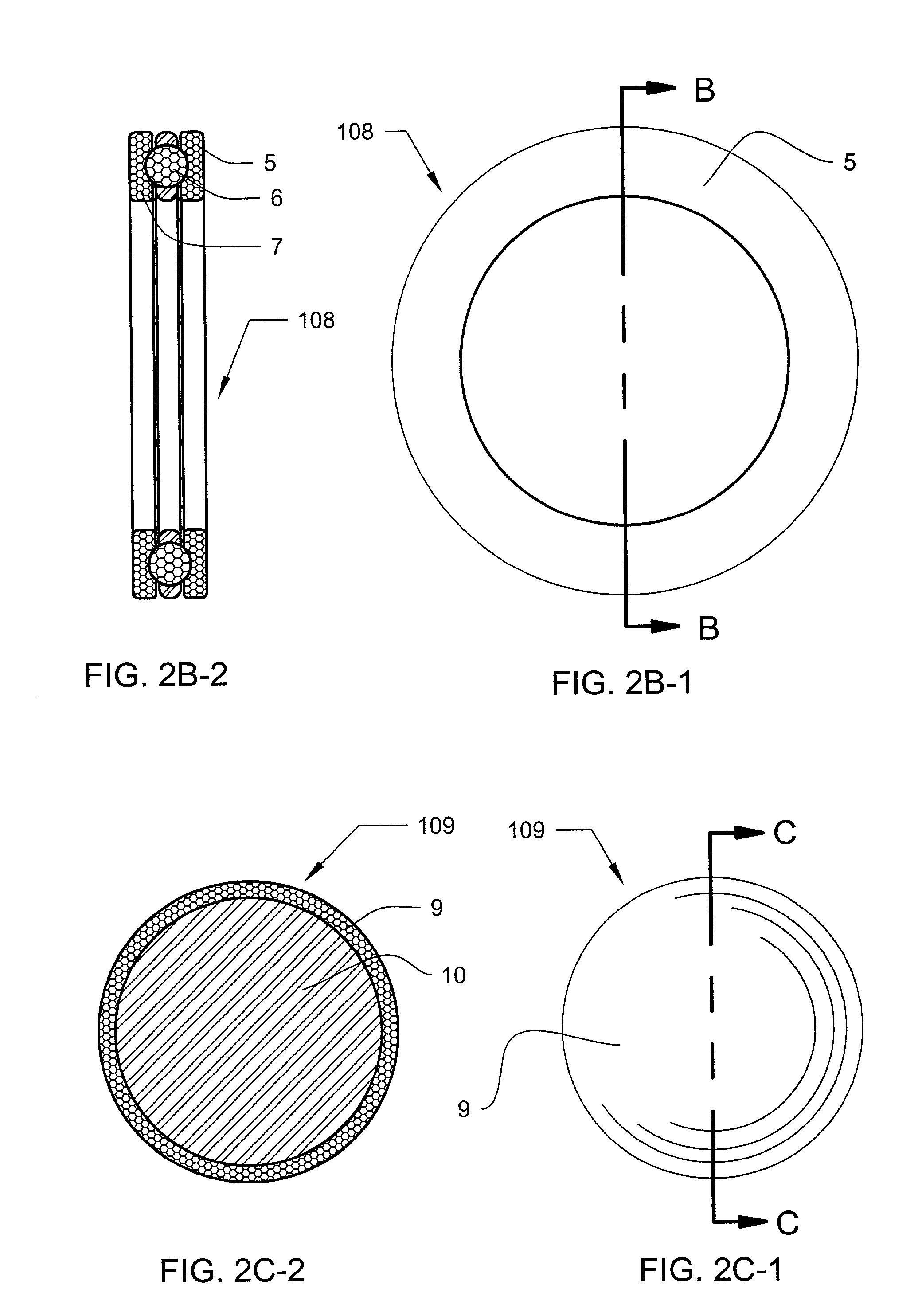

Plasma uniformity control by gas diffuser hole design

ActiveUS20050251990A1Electric discharge tubesSemiconductor/solid-state device manufacturingEngineeringVolumetric Mass Density

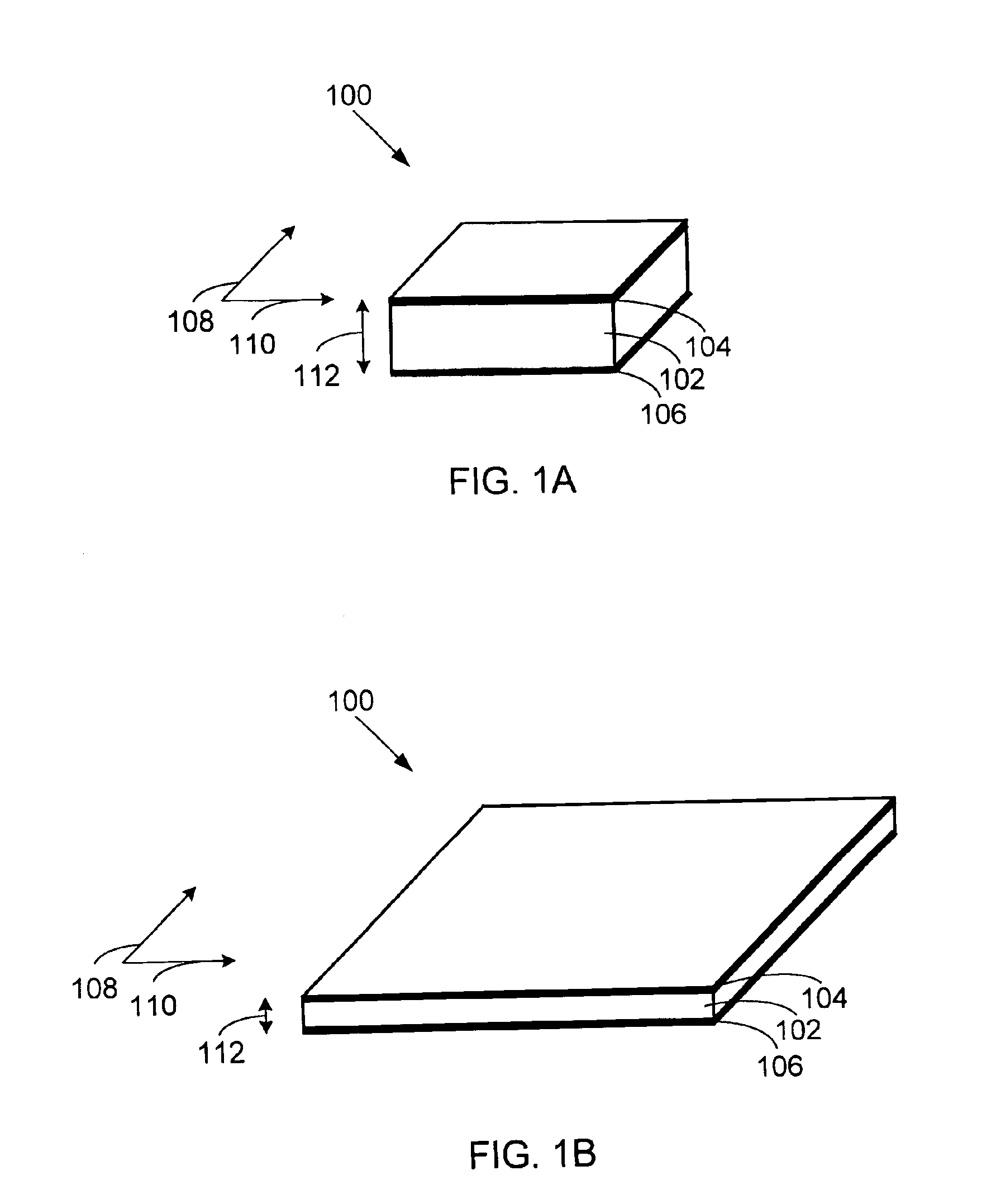

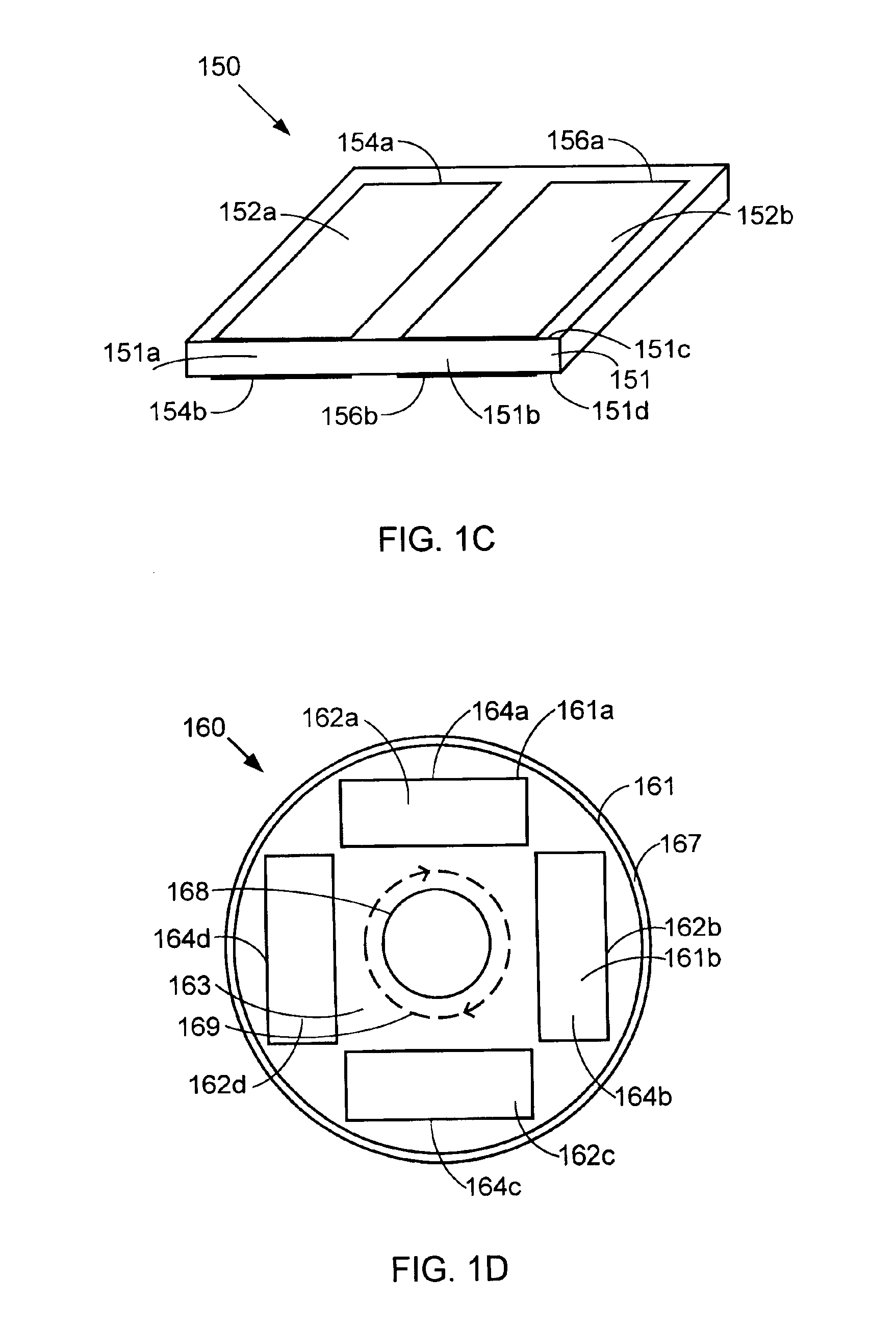

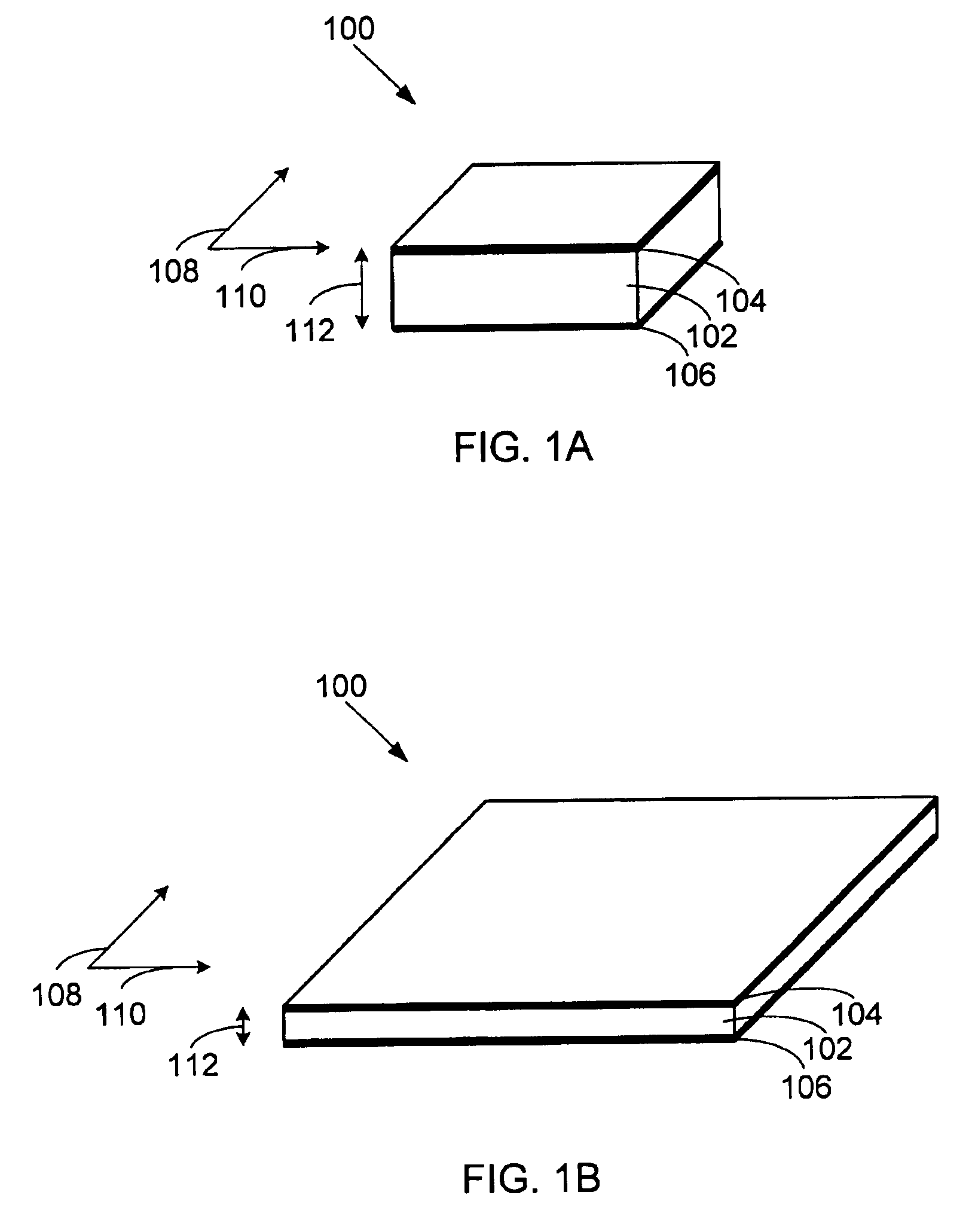

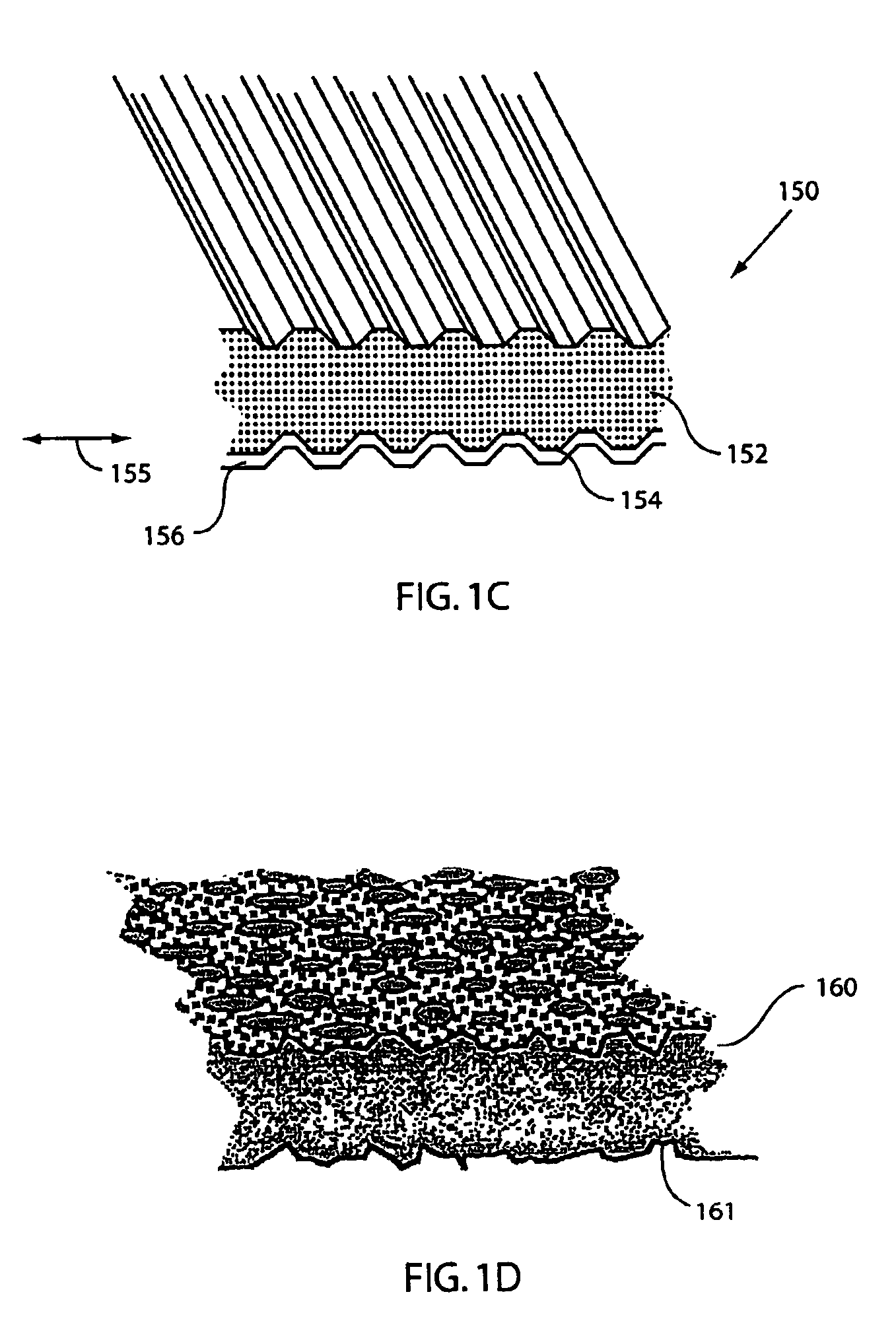

Embodiments of a gas diffuser plate for distributing gas in a processing chamber are provided. The gas distribution plate includes a diffuser plate having an upstream side and a downstream side, and a plurality of gas passages passing between the upstream and downstream sides of the diffuser plate. The gas passages include hollow cathode cavities at the downstream side to enhance plasma ionization. The depths, the diameters, the surface area and density of hollow cathode cavities of the gas passages that extend to the downstream end can be gradually increased from the center to the edge of the diffuser plate to improve the film thickness and property uniformity across the substrate. The increasing diameters, depths and surface areas from the center to the edge of the diffuser plate can be created by bending the diffuser plate toward downstream side, followed by machining out the convex downstream side. Bending the diffuser plate can be accomplished by a thermal process or a vacuum process. The increasing diameters, depths and surface areas from the center to the edge of the diffuser plate can also be created computer numerically controlled machining. Diffuser plates with gradually increasing diameters, depths and surface areas of the hollow cathode cavities from the center to the edge of the diffuser plate have been shown to produce improved uniformities of film thickness and film properties.

Owner:APPLIED MATERIALS INC

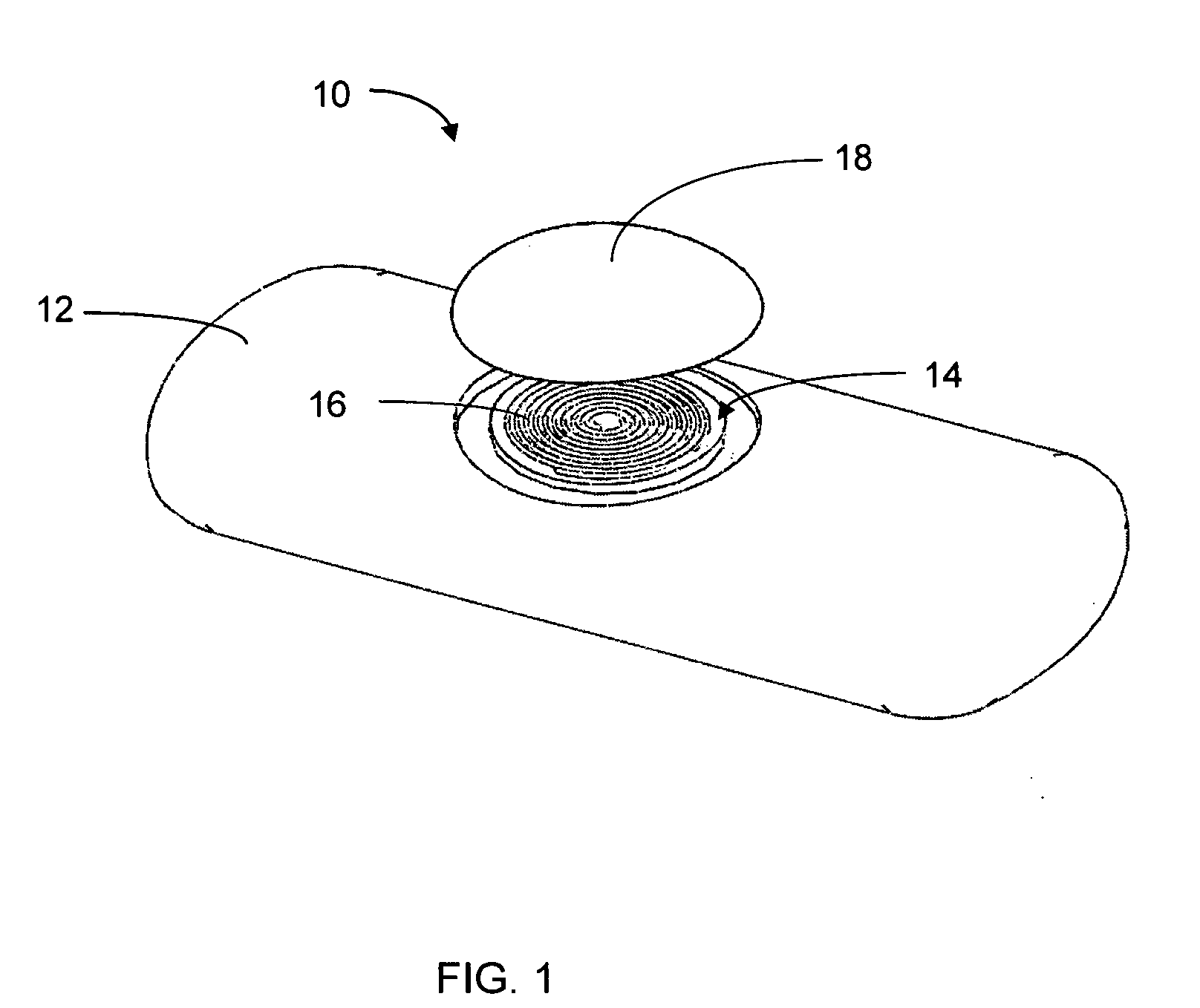

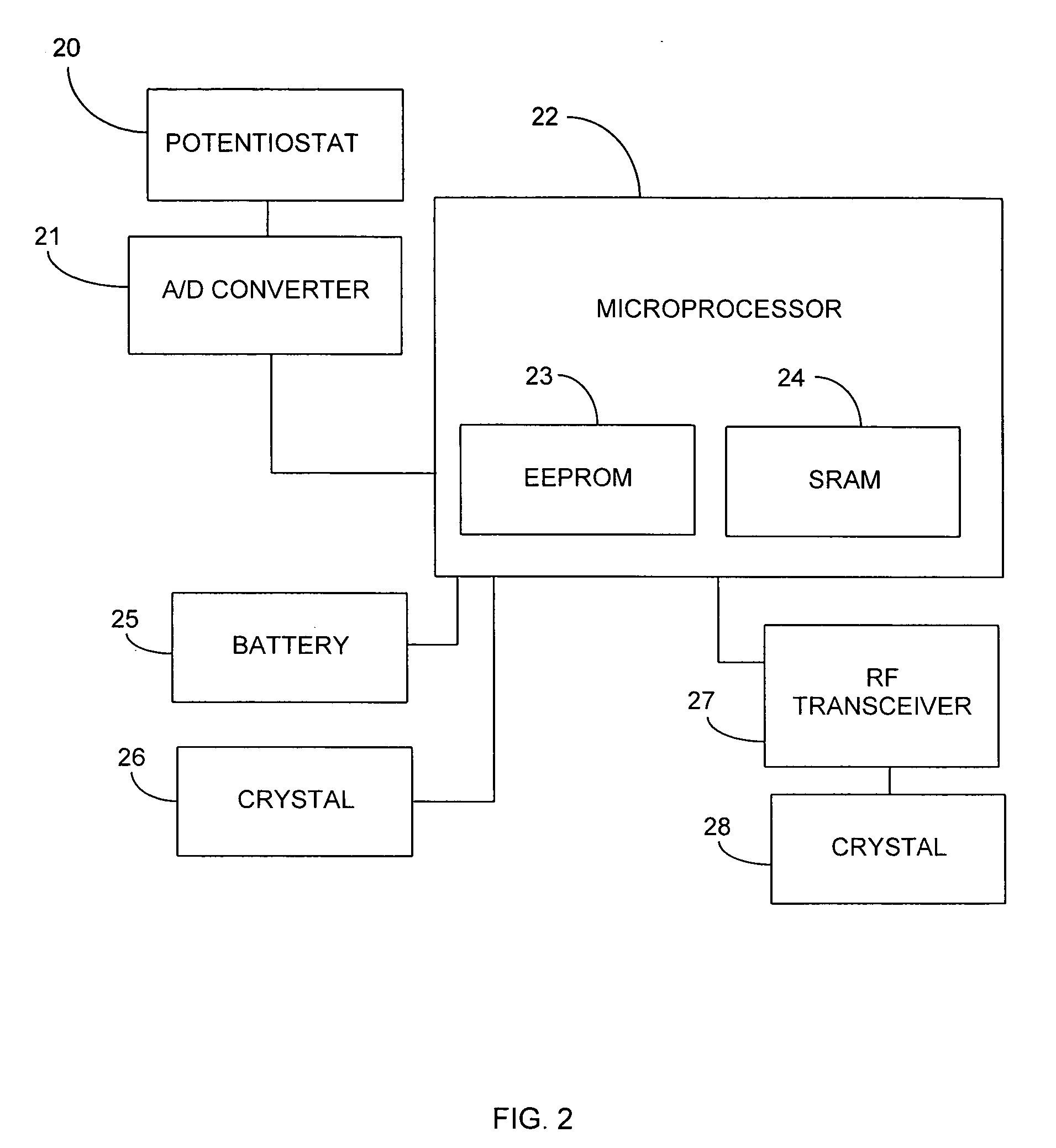

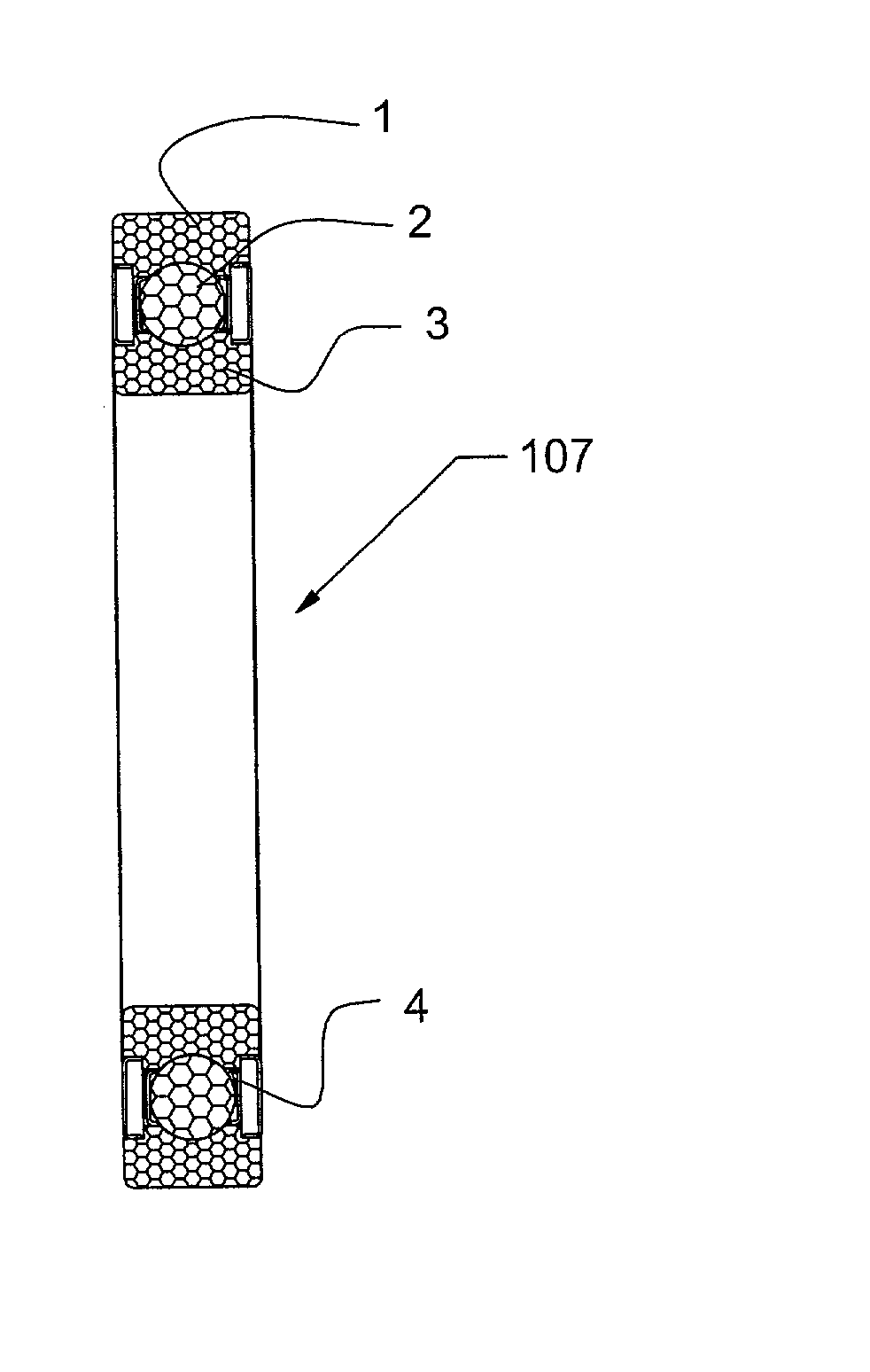

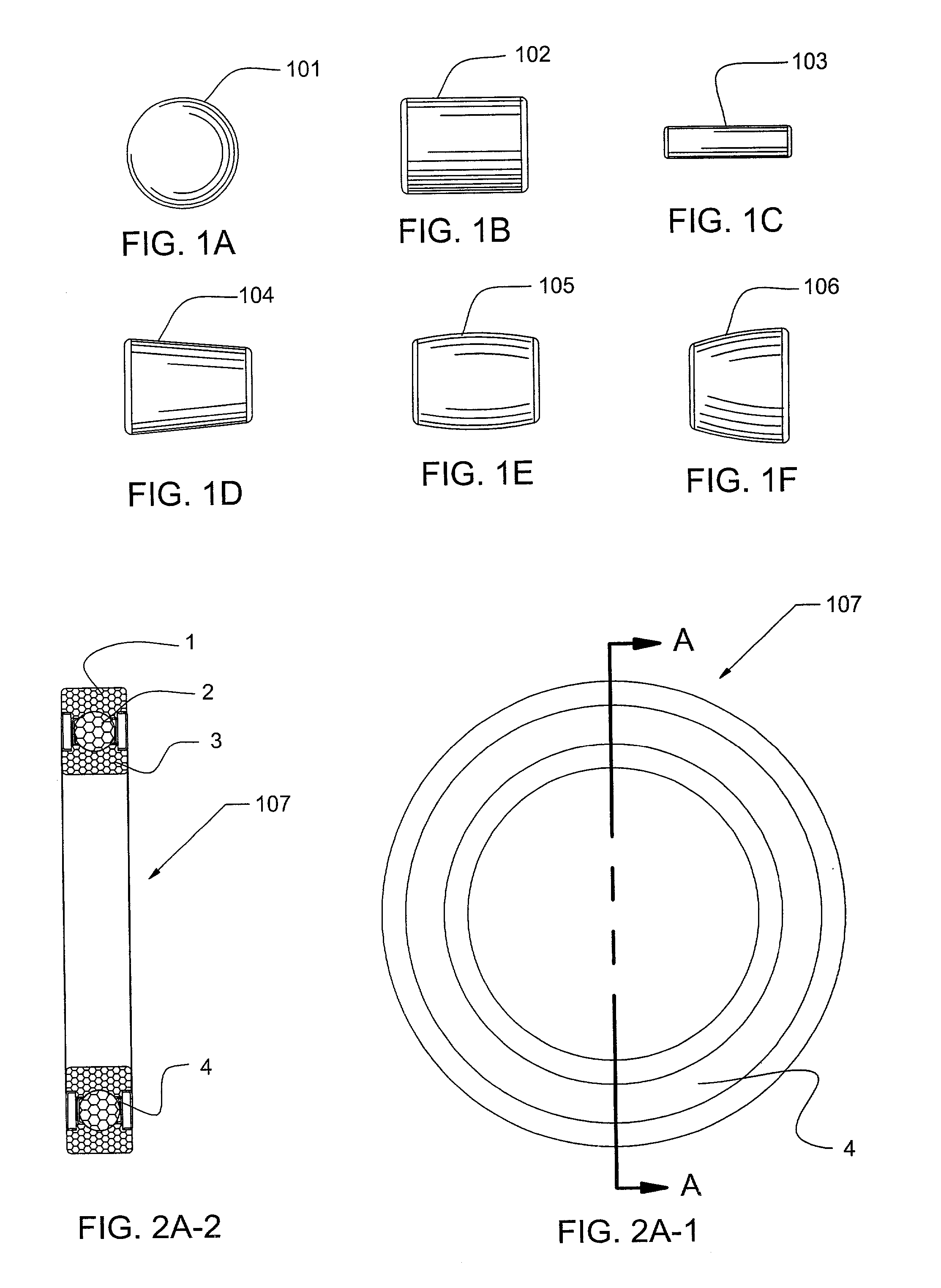

Rolled electrode array and its method for manufacture

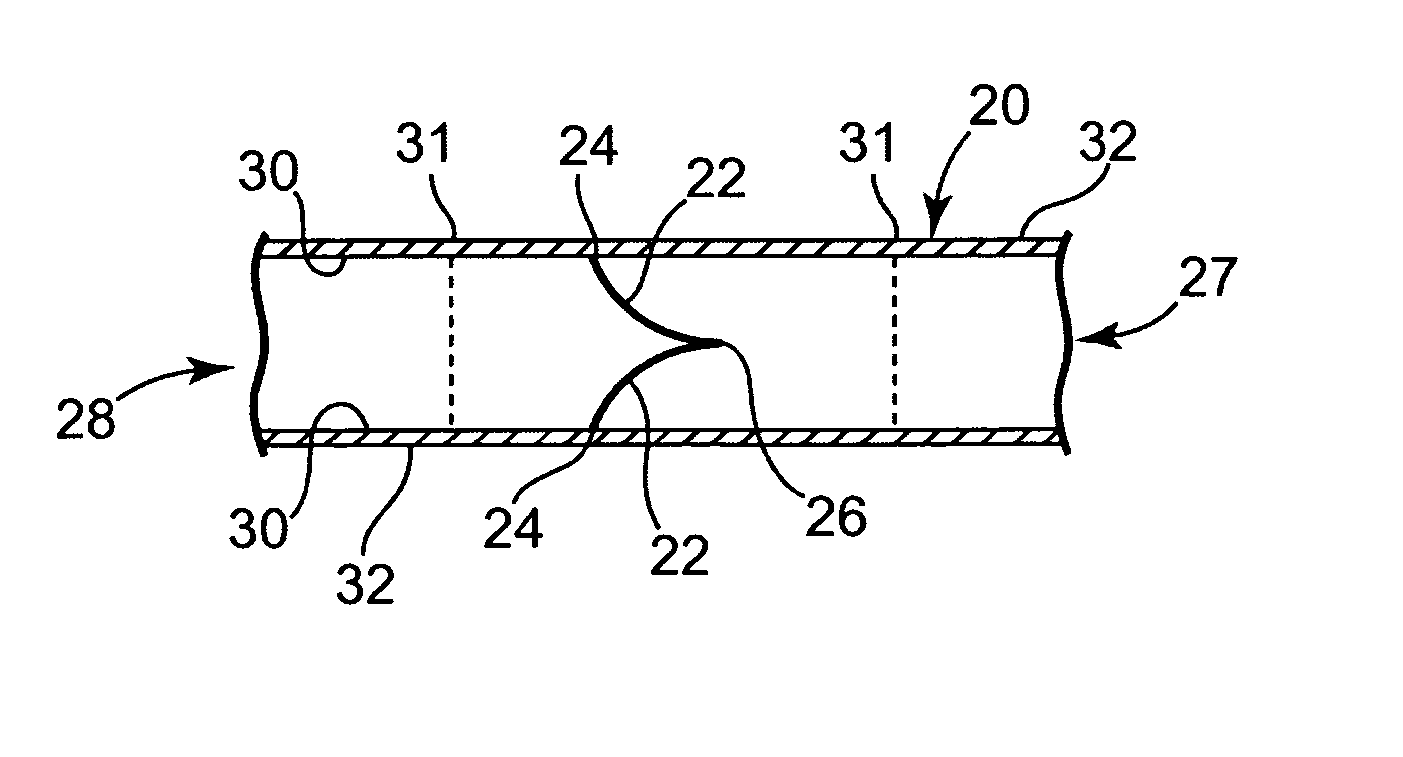

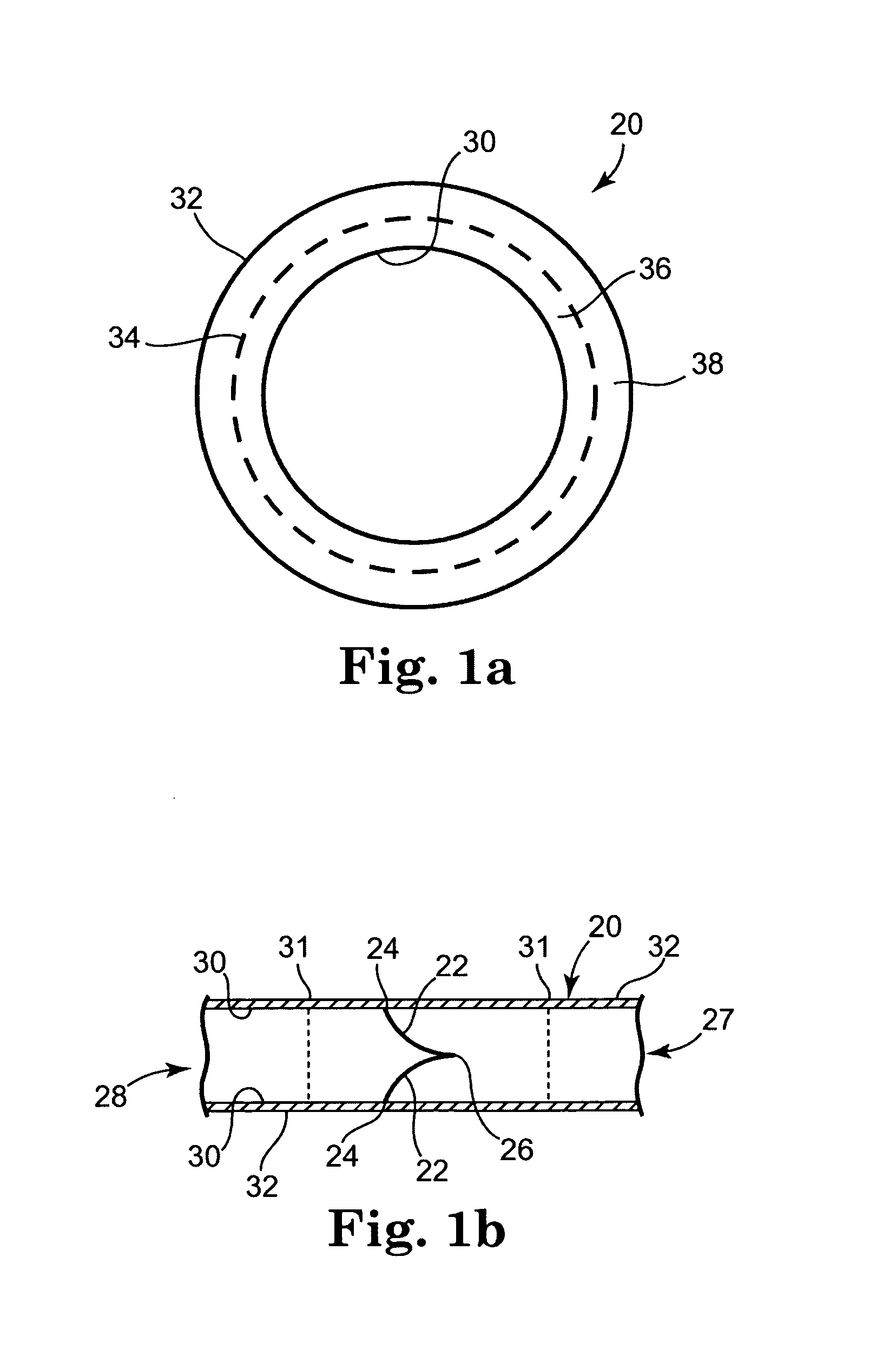

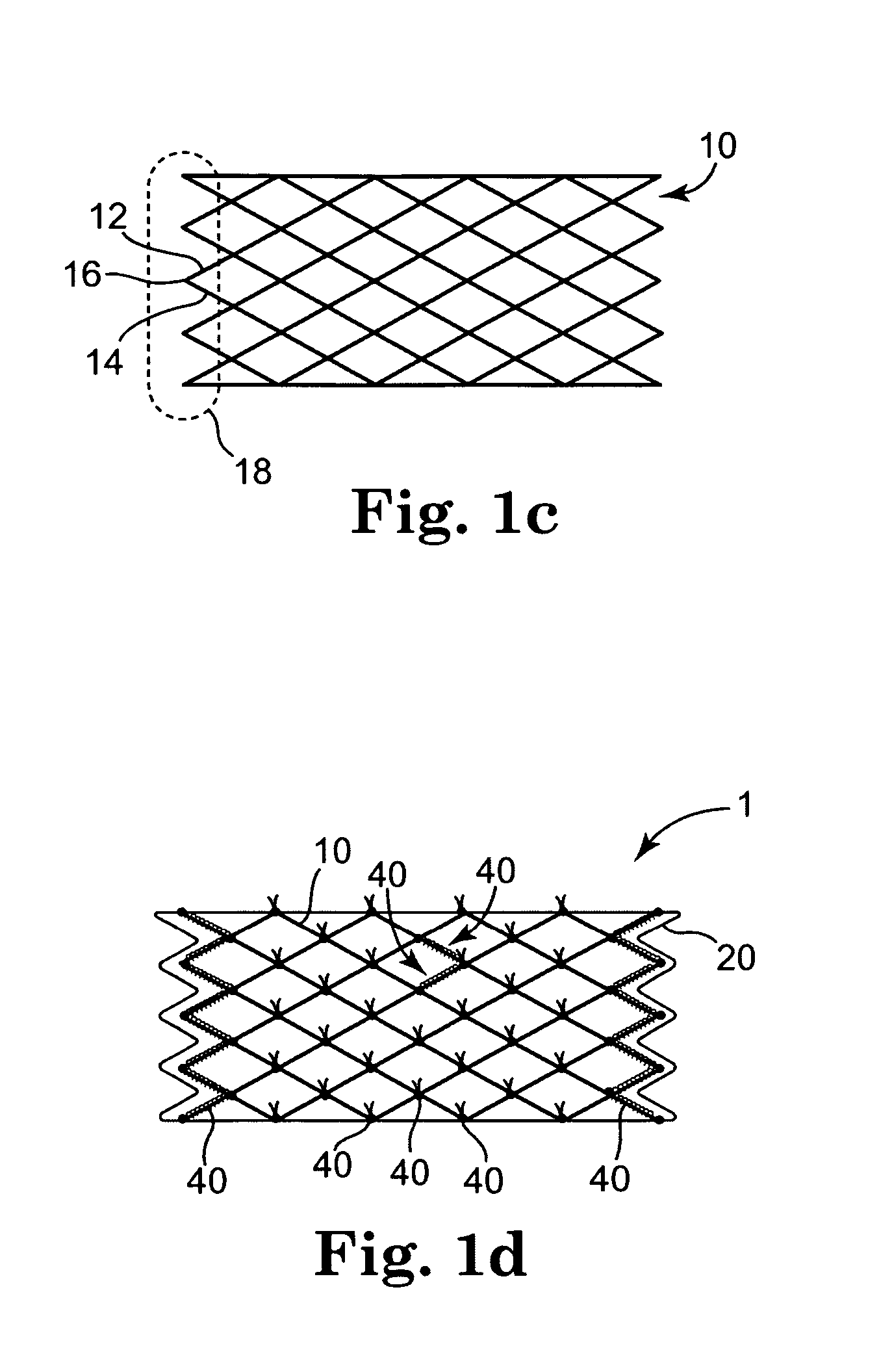

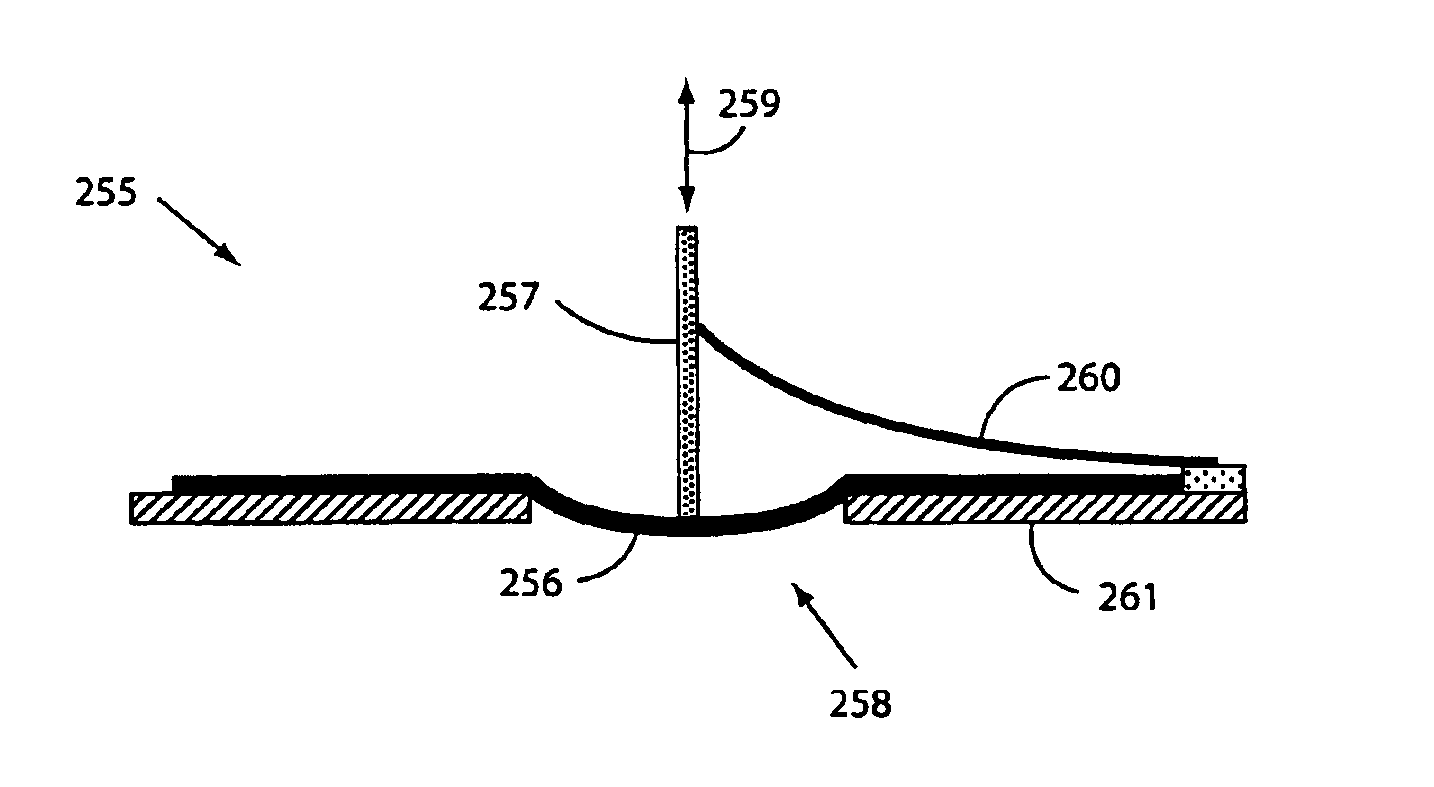

InactiveUS20050051427A1Long-term robustnessSemiconductor/solid-state device manufacturingEndoradiosondesOptoelectronicsElectrode array

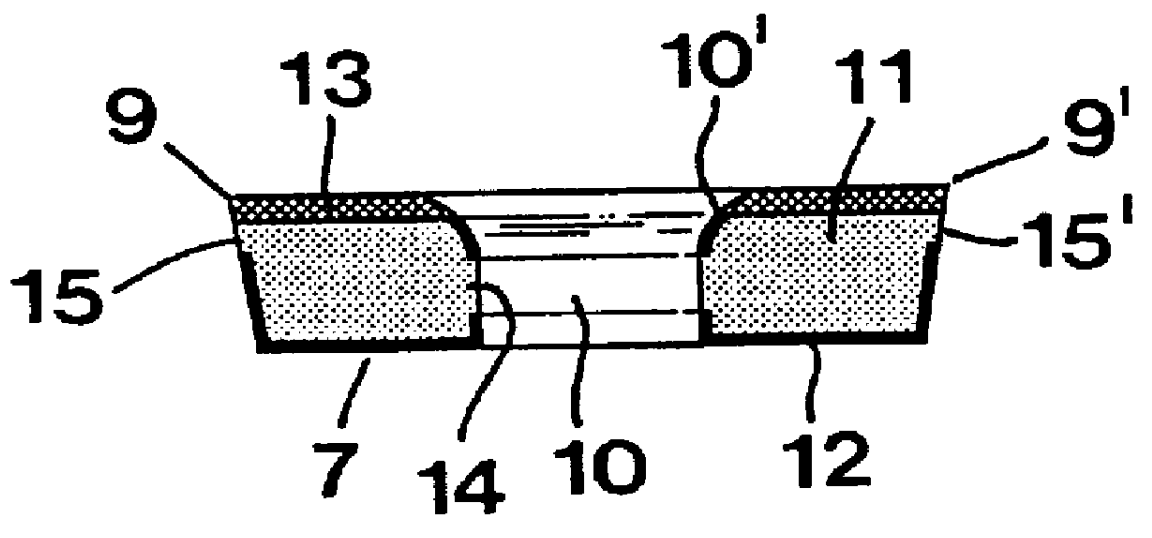

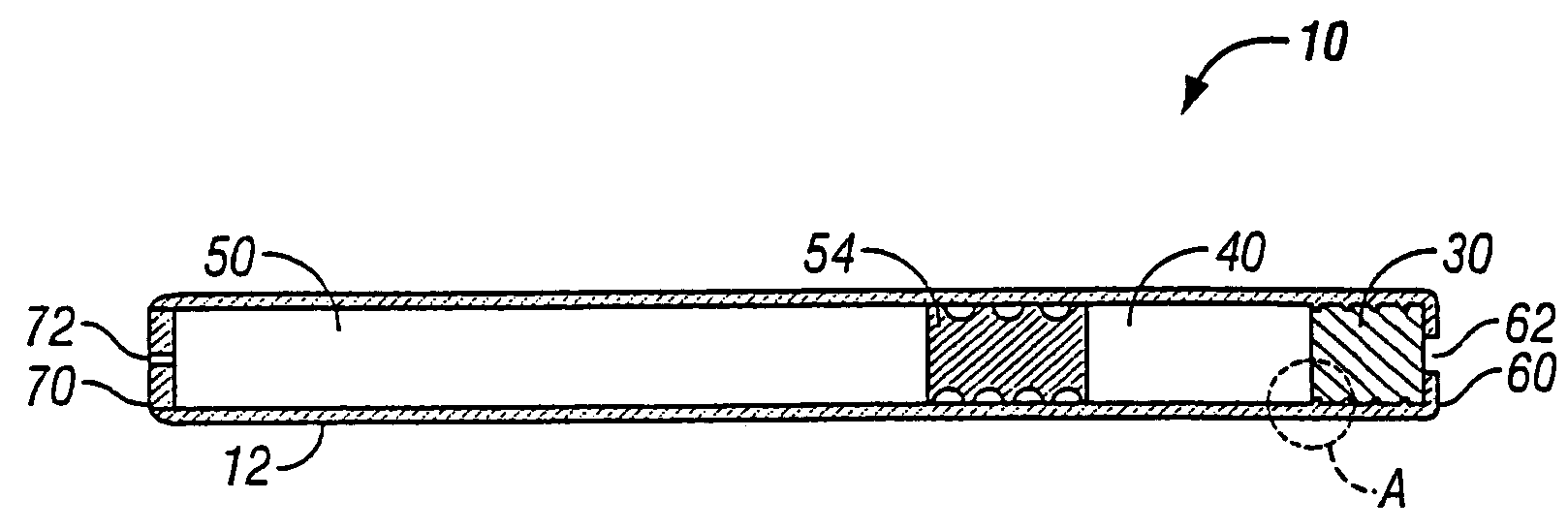

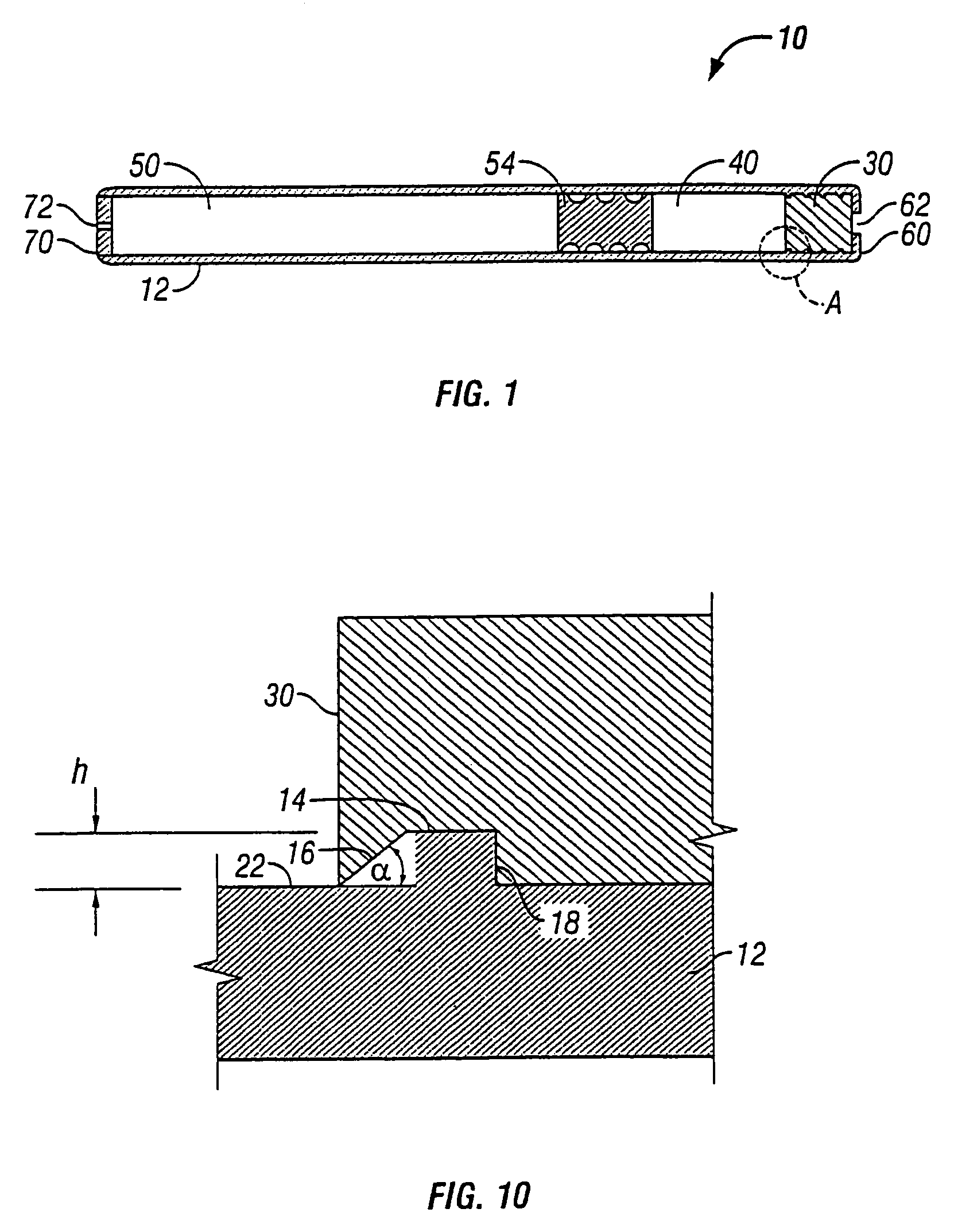

An electrode array for use in an electrochemical device is provided. The electrode array includes at least one electrode material and at least one insulating material arranged in a spiral configuration. The electrode array is manufactured by forming a composite stack of the at least one electrode material and the at least one insulating material, such that the insulating material(s) surrounds the electrode material(s) after which the stack is rolled into a spiral roll. The spiral roll can be cut, sliced, and / or dissected in numerous ways to form the electrode array of the preferred embodiments. Optionally, the sections can be further processed by machining, polishing, etching, or the like, to produce a curvature or stepped configuration.

Owner:DEXCOM

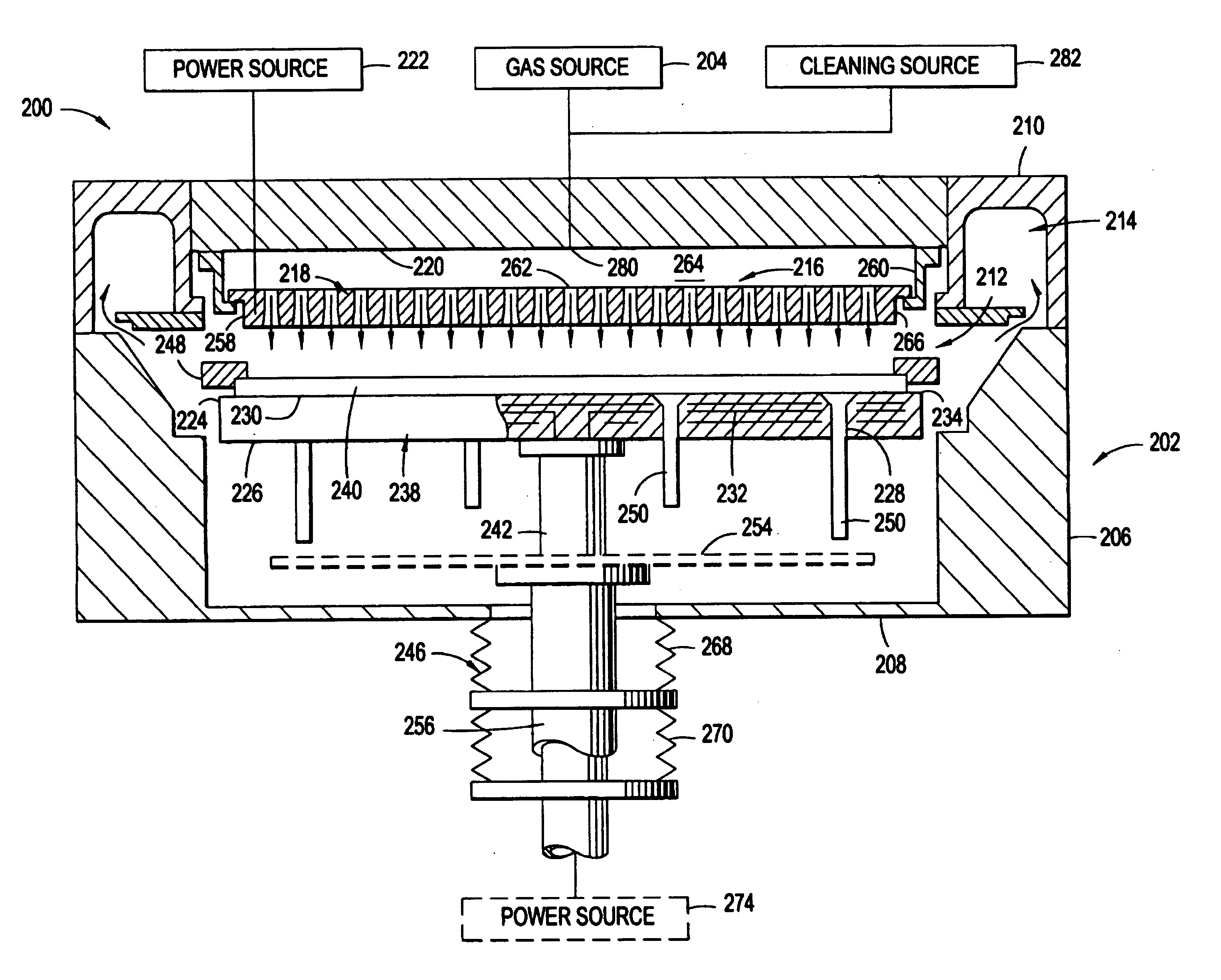

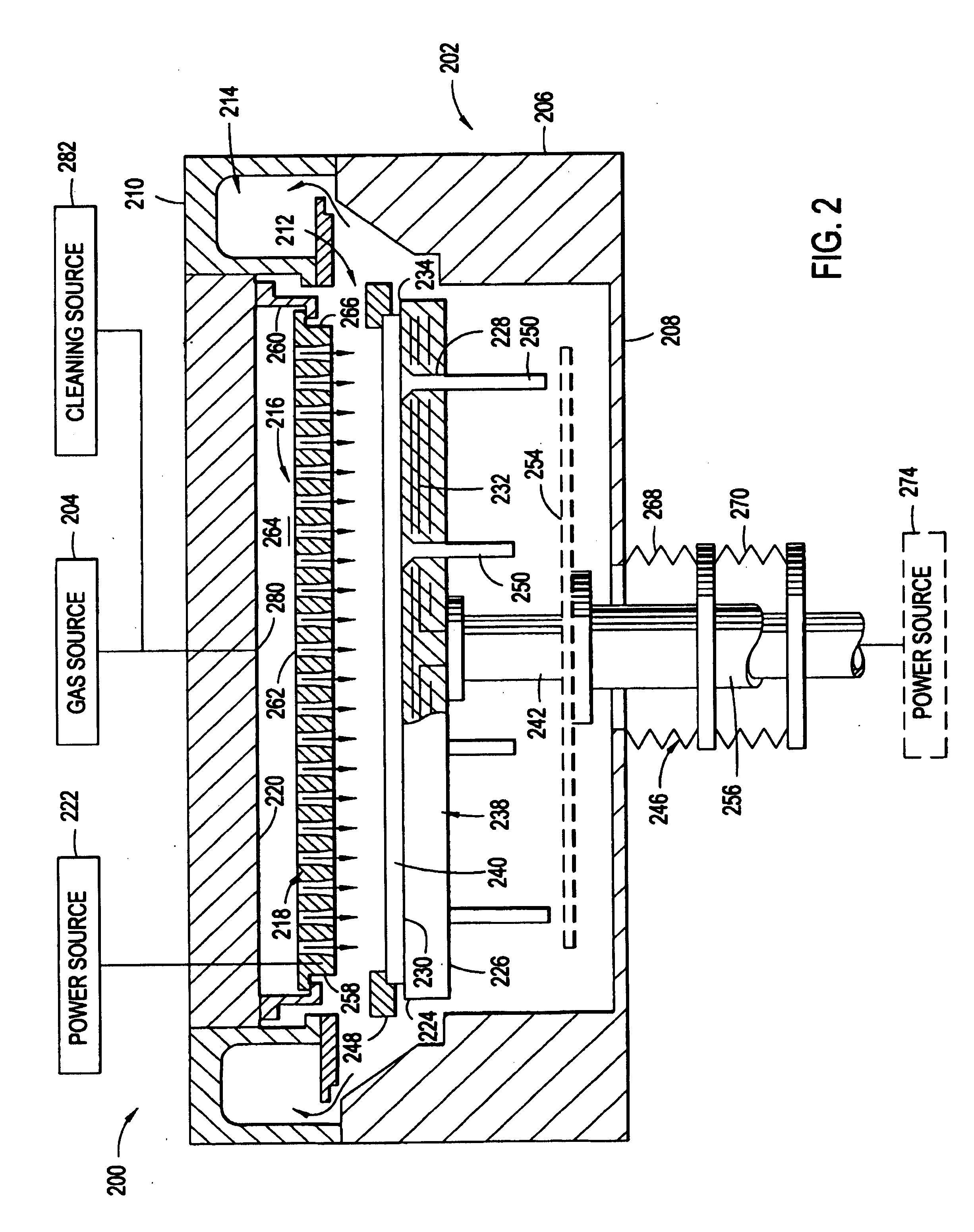

Plasma uniformity control by gas diffuser hole design

InactiveUS20060236934A1Electric discharge tubesSemiconductor/solid-state device manufacturingEngineeringVolumetric Mass Density

Embodiments of a gas diffuser plate for distributing gas in a processing chamber are provided. The gas distribution plate includes a diffuser plate having an upstream side and a downstream side, and a plurality of gas passages passing between the upstream and downstream sides of the diffuser plate. The gas passages include hollow cathode cavities at the downstream side to enhance plasma ionization. The depths, the diameters, the surface area and density of hollow cathode cavities of the gas passages that extend to the downstream end can be gradually increased from the center to the edge of the diffuser plate to improve the film thickness and property uniformity across the substrate. The increasing diameters, depths and surface areas from the center to the edge of the diffuser plate can be created by bending the diffuser plate toward downstream side, followed by machining out the convex downstream side. Bending the diffuser plate can be accomplished by a thermal process or a vacuum process. The increasing diameters, depths and surface areas from the center to the edge of the diffuser plate can also be created computer numerically controlled machining. Diffuser plates with gradually increasing diameters, depths and surface areas of the hollow cathode cavities from the center to the edge of the diffuser plate have been shown to produce improved uniformities of film thickness and film properties.

Owner:CHOI SOO YOUNG +9

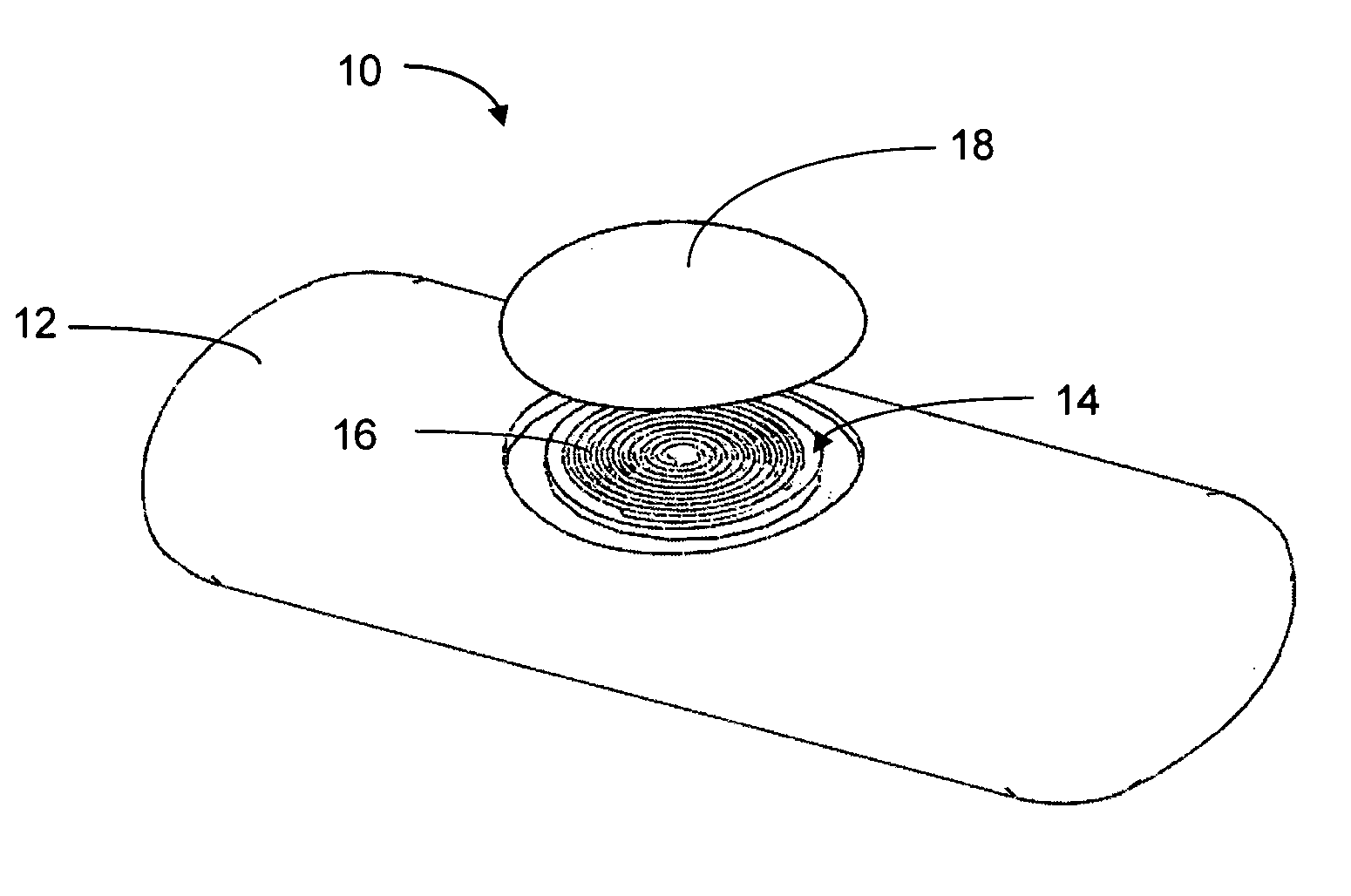

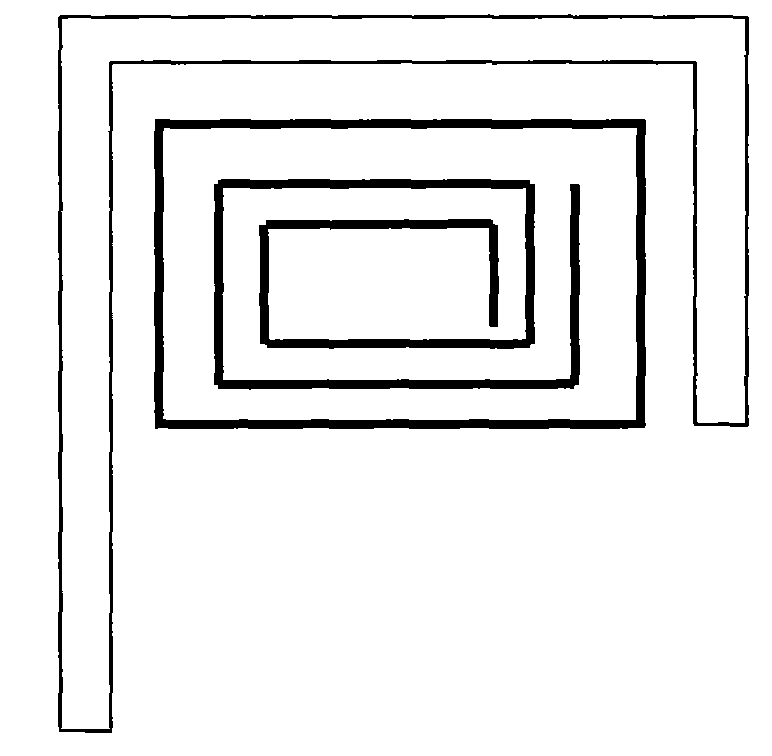

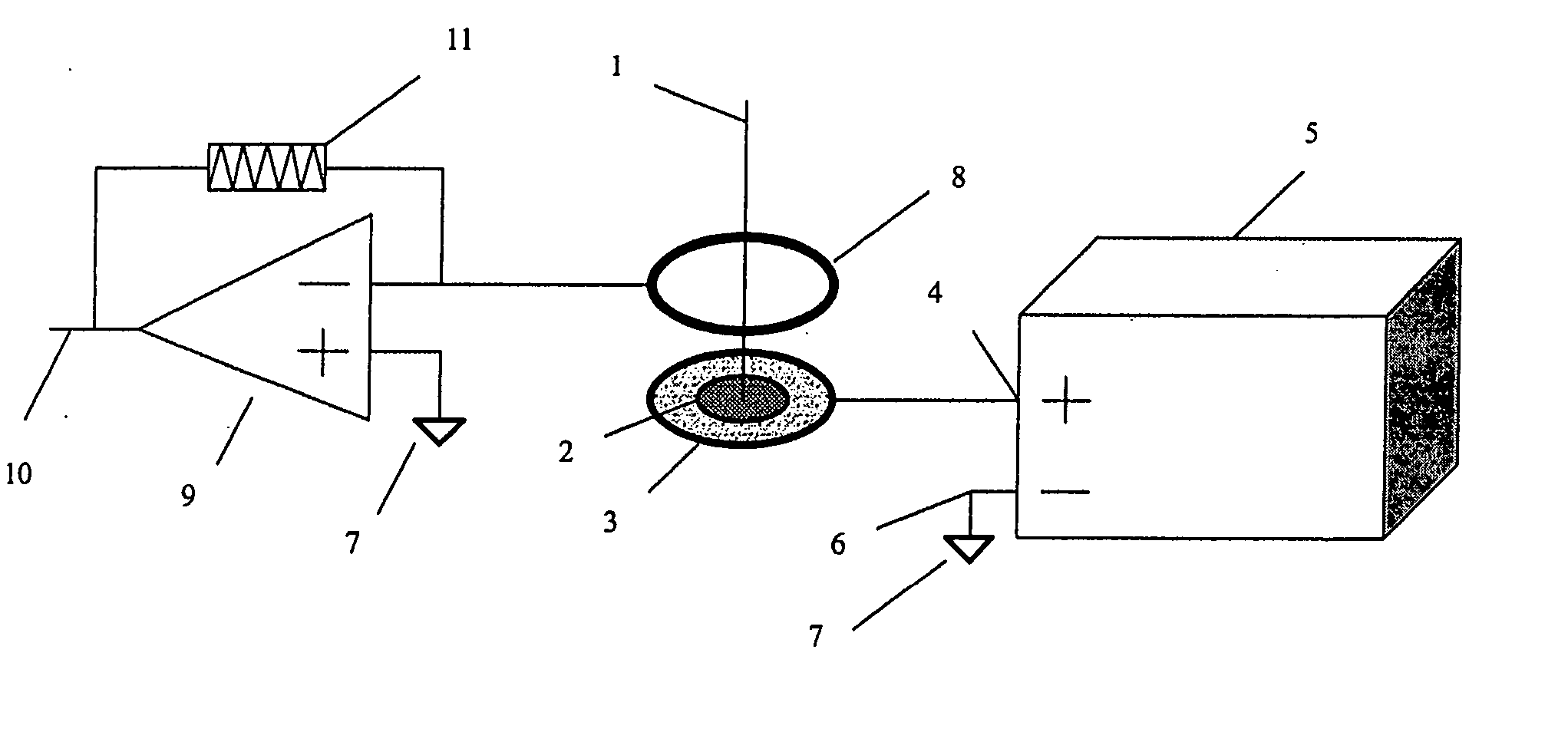

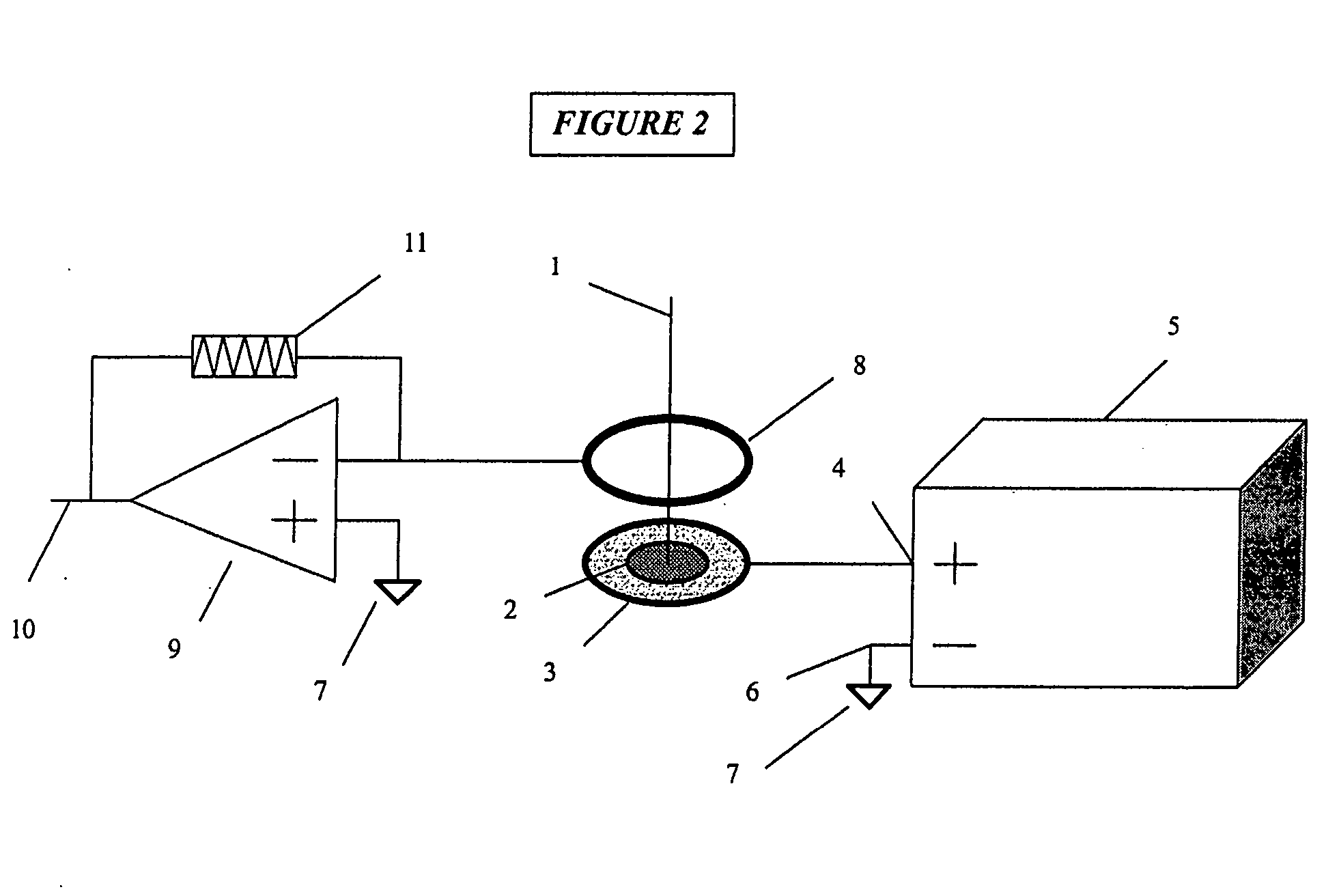

Implantable continuous intraocular pressure sensor

InactiveUS6939299B1Worn safely and comfortably and convenientlyPerson identificationTonometersIntraocular pressureSpiral inductor

An implantable miniaturized pressure sensor integrates a capacitor and an inductor in one small chip, forming a resonant LC circuit having a Q value of 10 or greater. The capacitor has an upper capacitor plate and a lower capacitor plate disposed proximate thereof. The upper and lower capacitor plates are connected to one or more spiral inductor coils. The sensor is micromachined from silicon to form a thin and robust membrane disposed on top of the upper capacitor plate. The sensor is hermetically sealed and the membrane is deflected relative to the upper capacitor plate by an external fluid, gas, or mechanical pressure. The resonant frequency of the sensor can be remotely monitored and continuously measured with an external detector pick up coil disposed proximate the sensor. The sensor can be smaller than 2×2×0.5 mm and is particularly useful for intraocular applications.

Owner:IOSENSOR

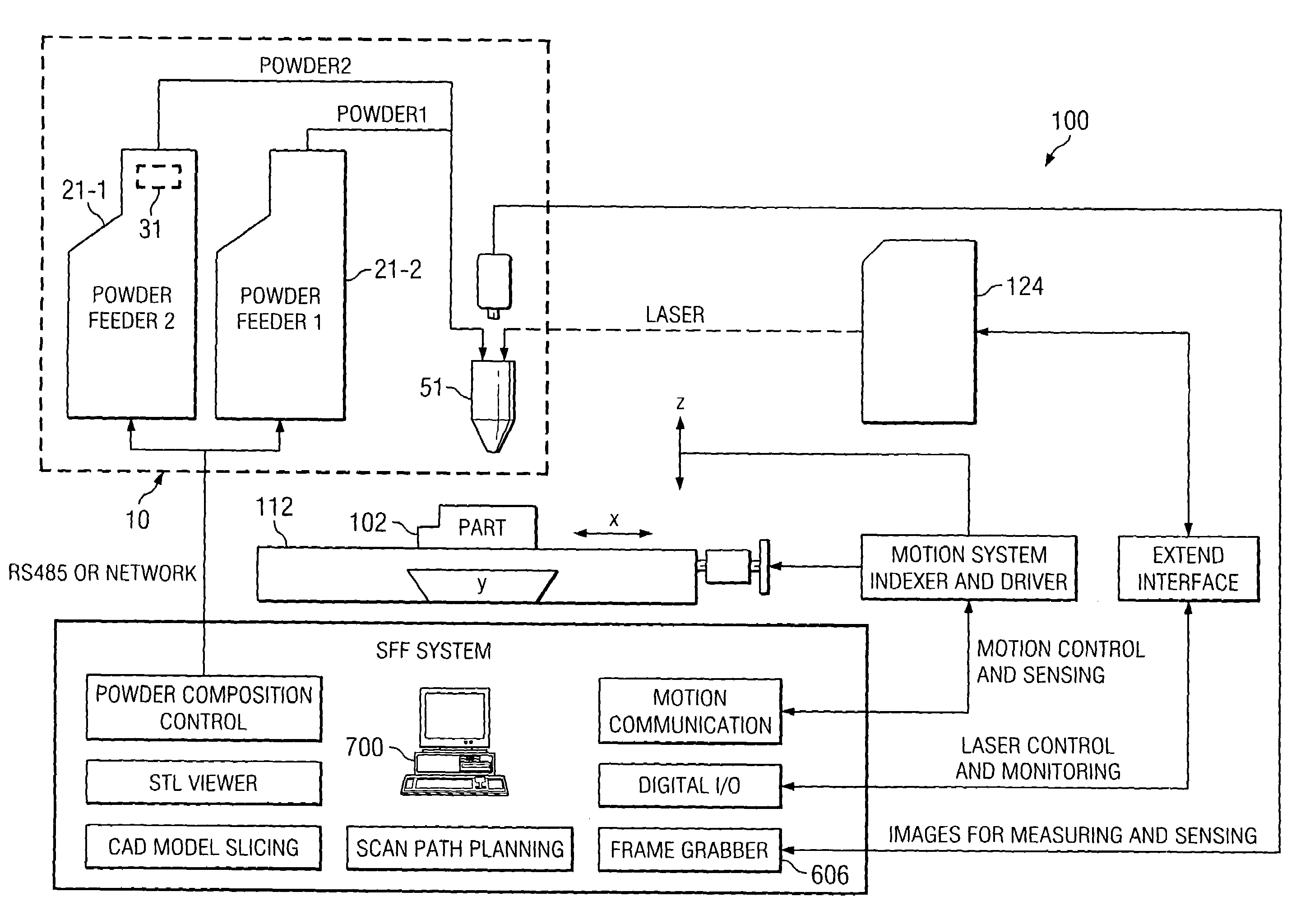

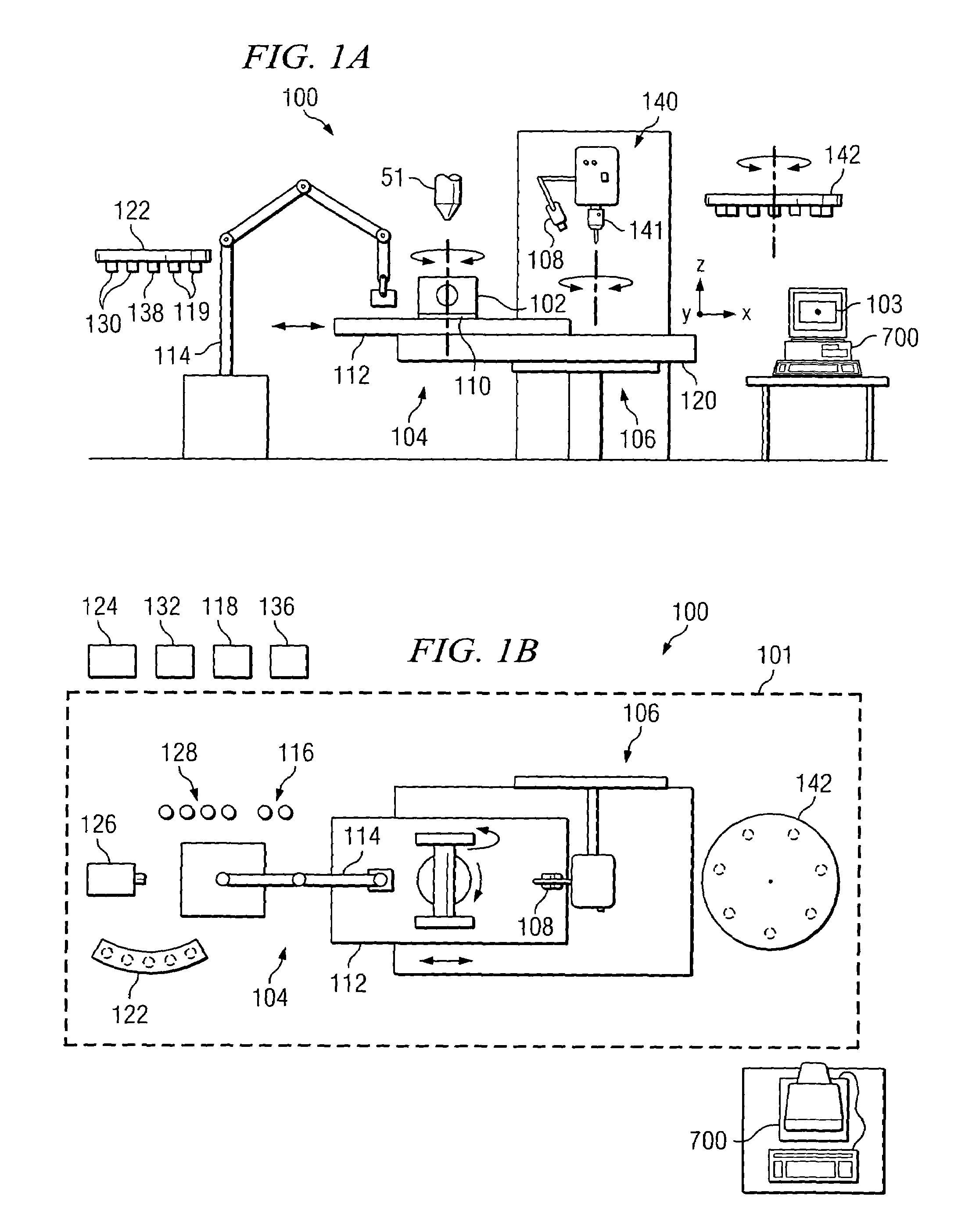

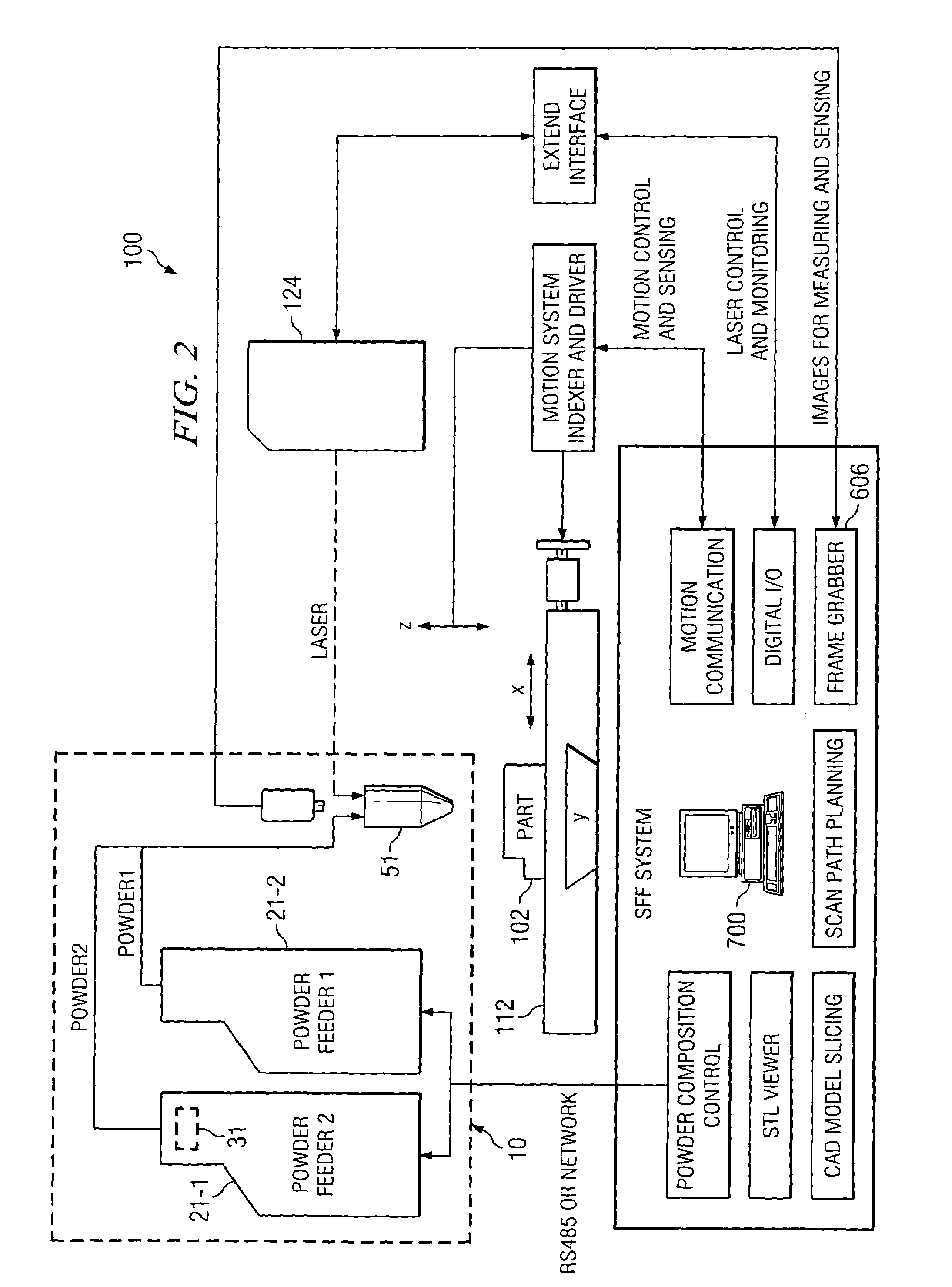

System and method for fabricating or repairing a part

InactiveUS7020539B1Improve accuracyHigh geometric accuracyAdditive manufacturing apparatusTool changing apparatusMulti axisMachining

According to one embodiment of the invention, a system for fabricating a part includes a computer operable to control the fabrication of a three-dimensional part using a solid CAD model, a deposition station operable to deposit successive two-dimensional layers of material to fabricate the three-dimensional part, and a machining station operable to remove at least a portion of one or more of the deposited two-dimensional layers of material. The deposition station includes a substrate on which to fabricate the three-dimensional part, a welding-based deposition system having a welding torch, a laser-based deposition system having a laser head, a plasma powder cladding system having a plasma torch, and a multi-axis robot operable to, when directed by the computer, utilize one of the welding-based deposition system, laser-based deposition system, and plasma powder cladding system to deposit any of the two-dimensional layers of material. The machining station includes a multi-axis milling machine and an automatic tool changer. The milling machine is operable to, when directed by the computer, select from a plurality of machining tools associated with the automatic tool changer for use in the milling machine.

Owner:SOUTHERN METHODIST UNIVERSITY

Energy efficient electroactive polymers and electroactive polymer devices

InactiveUS6911764B2Increase deflectionImprove energy conversion efficiencyTransducer detailsPiezoelectric/electrostriction/magnetostriction machinesActive polymerMechanical energy

Owner:SRI INTERNATIONAL

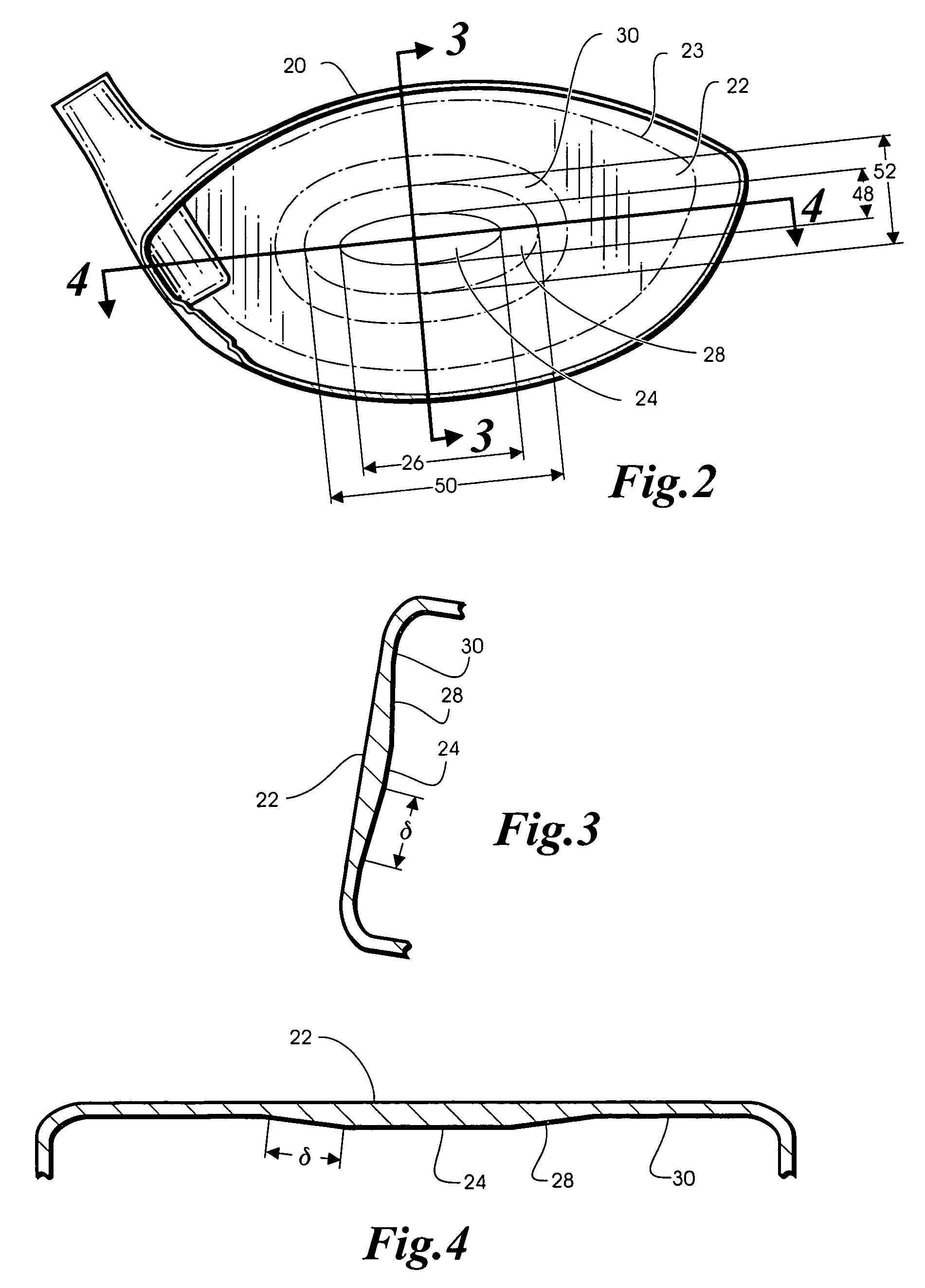

Method of manufacturing a face plate for a golf club head

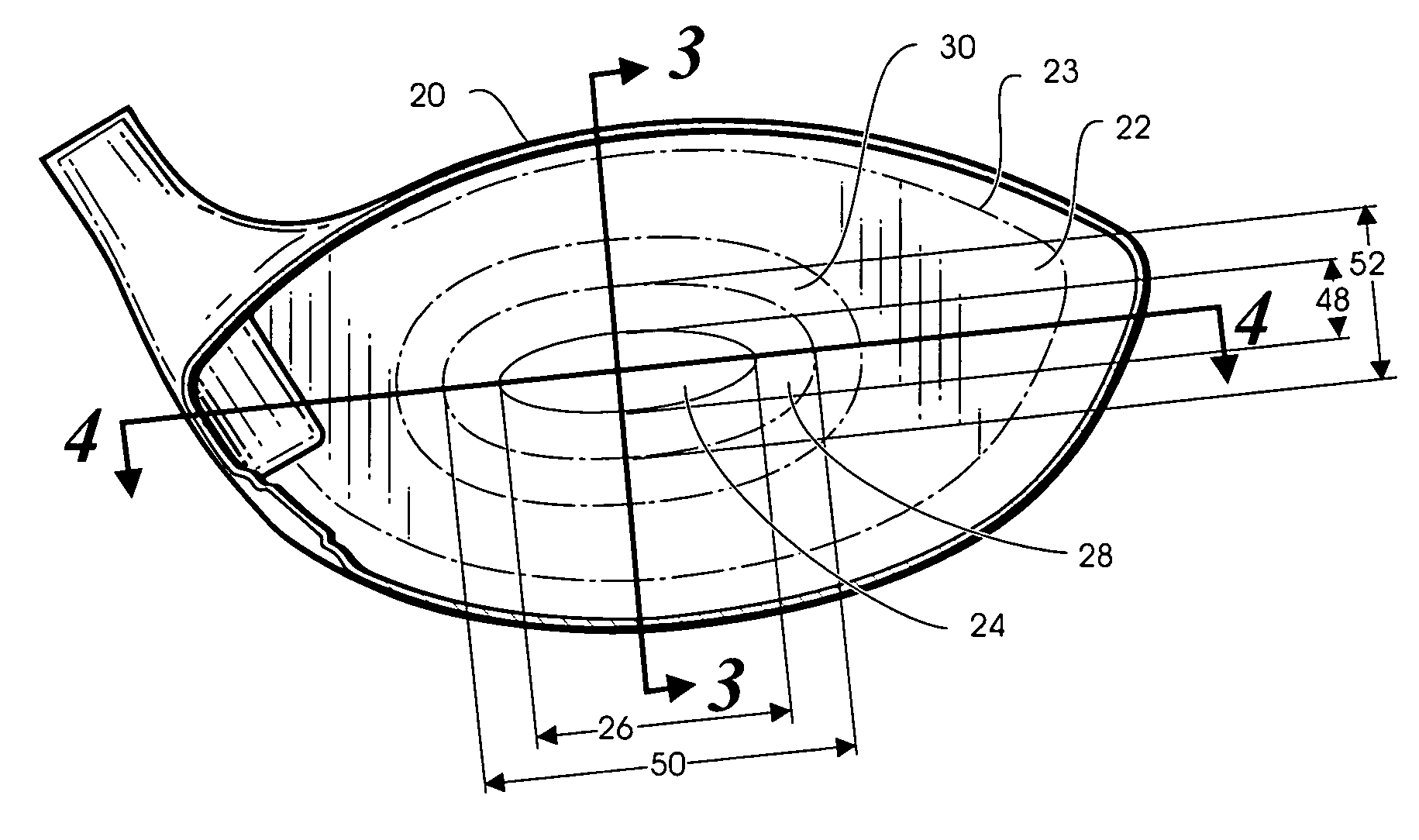

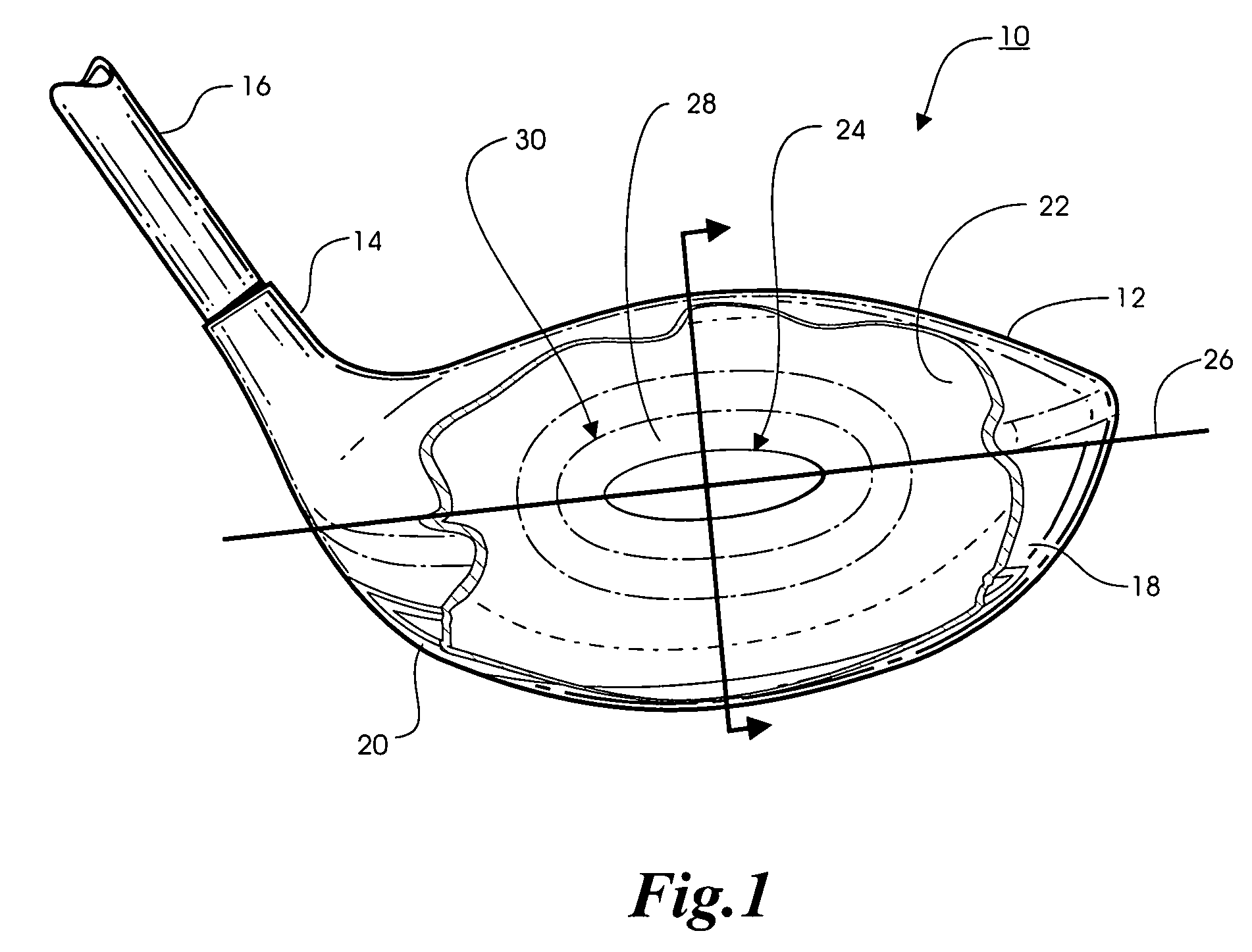

ActiveUS7347794B2Improve uniformitySignificant timeMilling equipment detailsShaping cuttersEngineeringGolf Ball

A golf club is manufactured by machining away a portion of the rear surface of a club face blank to form an elliptical central thickened region that tapers through a transition region to a thinner peripheral region. The elliptical central thickened region, transition region and the portion of the peripheral region surrounding the raised portion are formed in a single elliptical pass with a special cutting tool. The cutting tool, or “form cutter” has a conical lateral cutting surface, which forms the sloped transition region and the peripheral region surrounding it in a single operation.

Owner:KARSTEN MFG CORP

Composite heart valve apparatus manufactured using techniques involving laser machining of tissue

ActiveUS20070073392A1Modifies tissue much fasterLow scrap rateTubular organ implantsVenous valvesVeinLaser processing

Methodology for using laser machining techniques to modify a tissue for use in a medical device. In a representative mode of practice, relatively low energy laser machining is used to thin down at least a portion of a valved jugular vein. The thinned down vein may then be sutured to, or otherwise integrated with, a corresponding stent to make a percutaneous heart valve.

Owner:MEDTRONIC INC

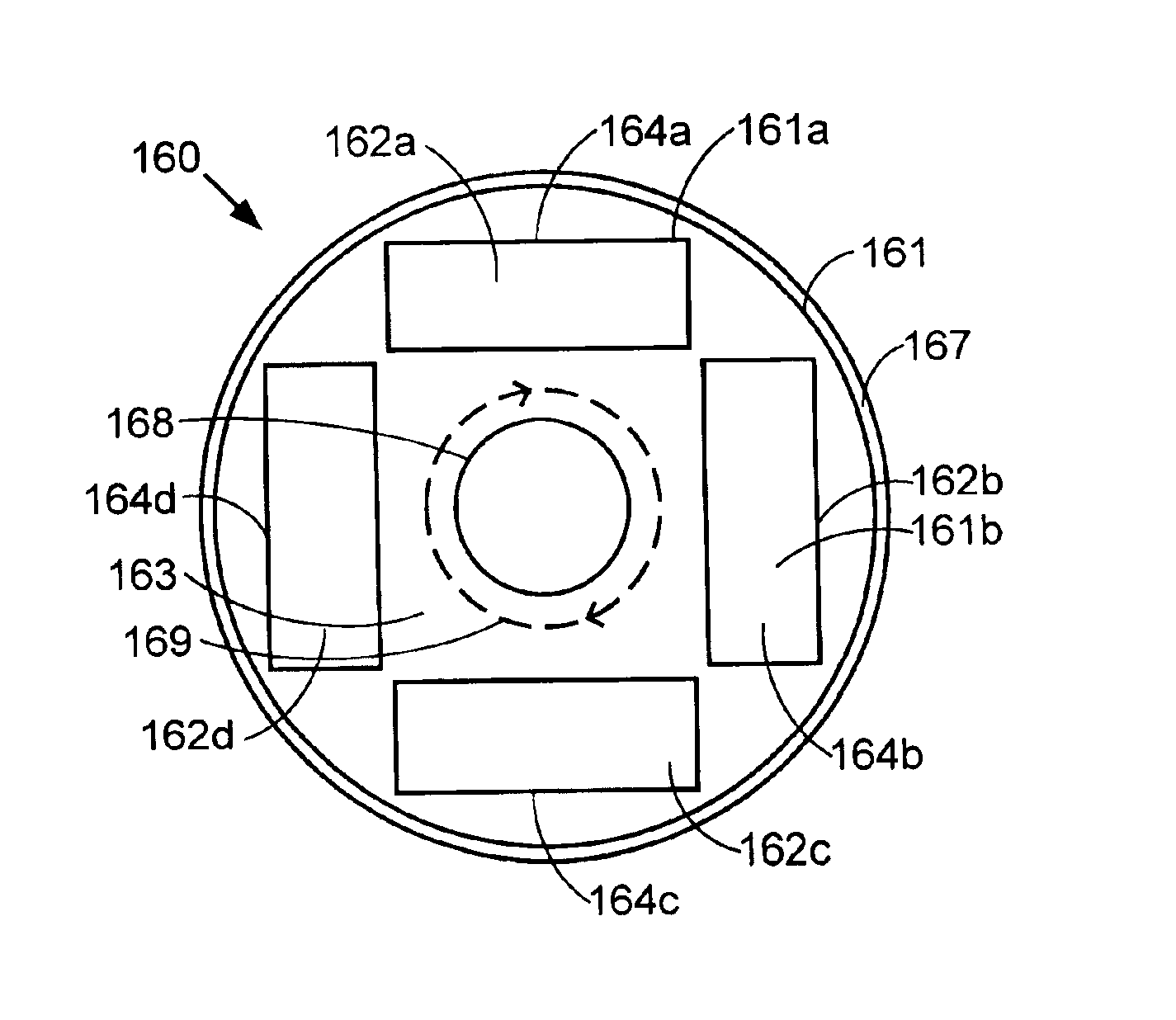

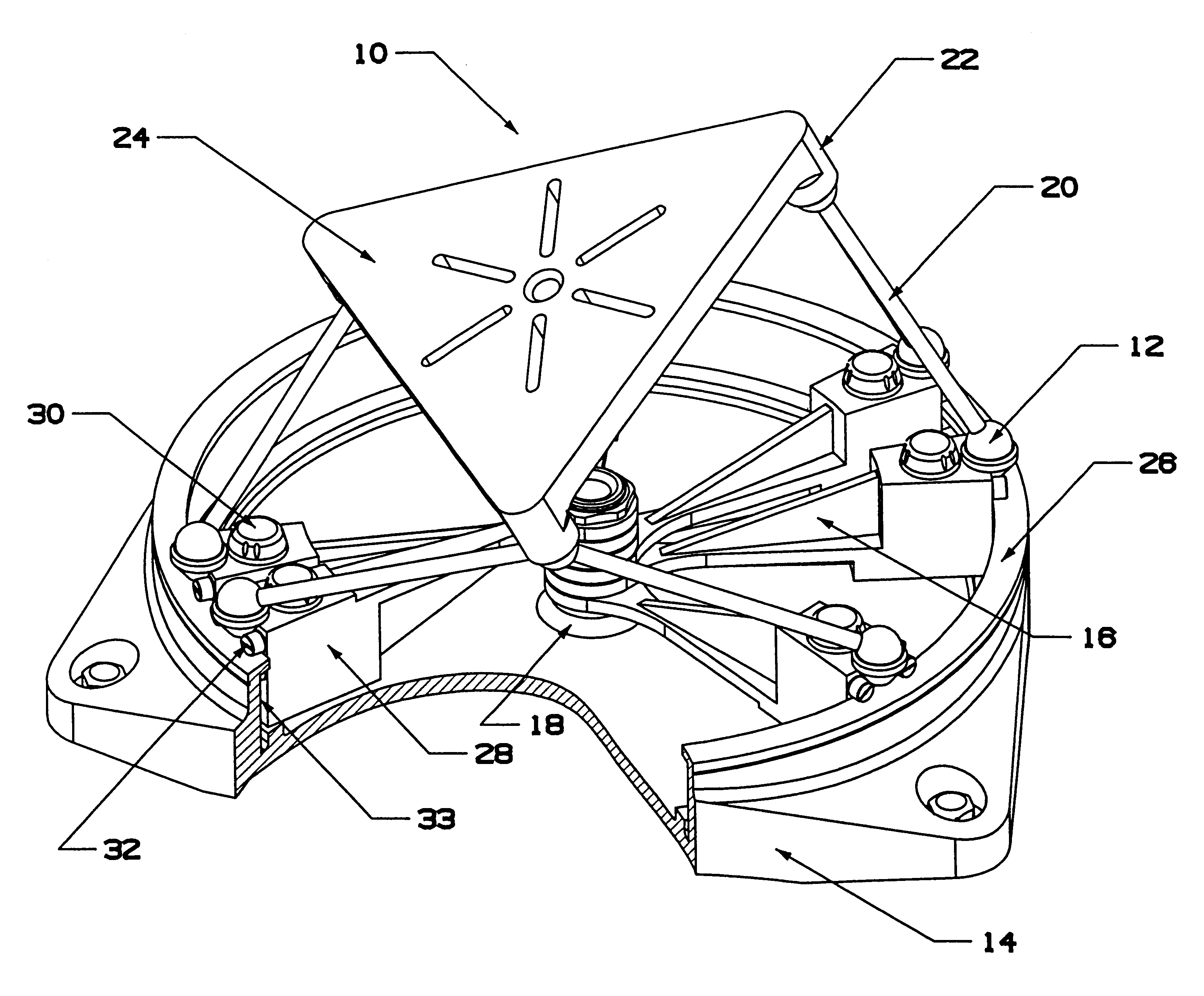

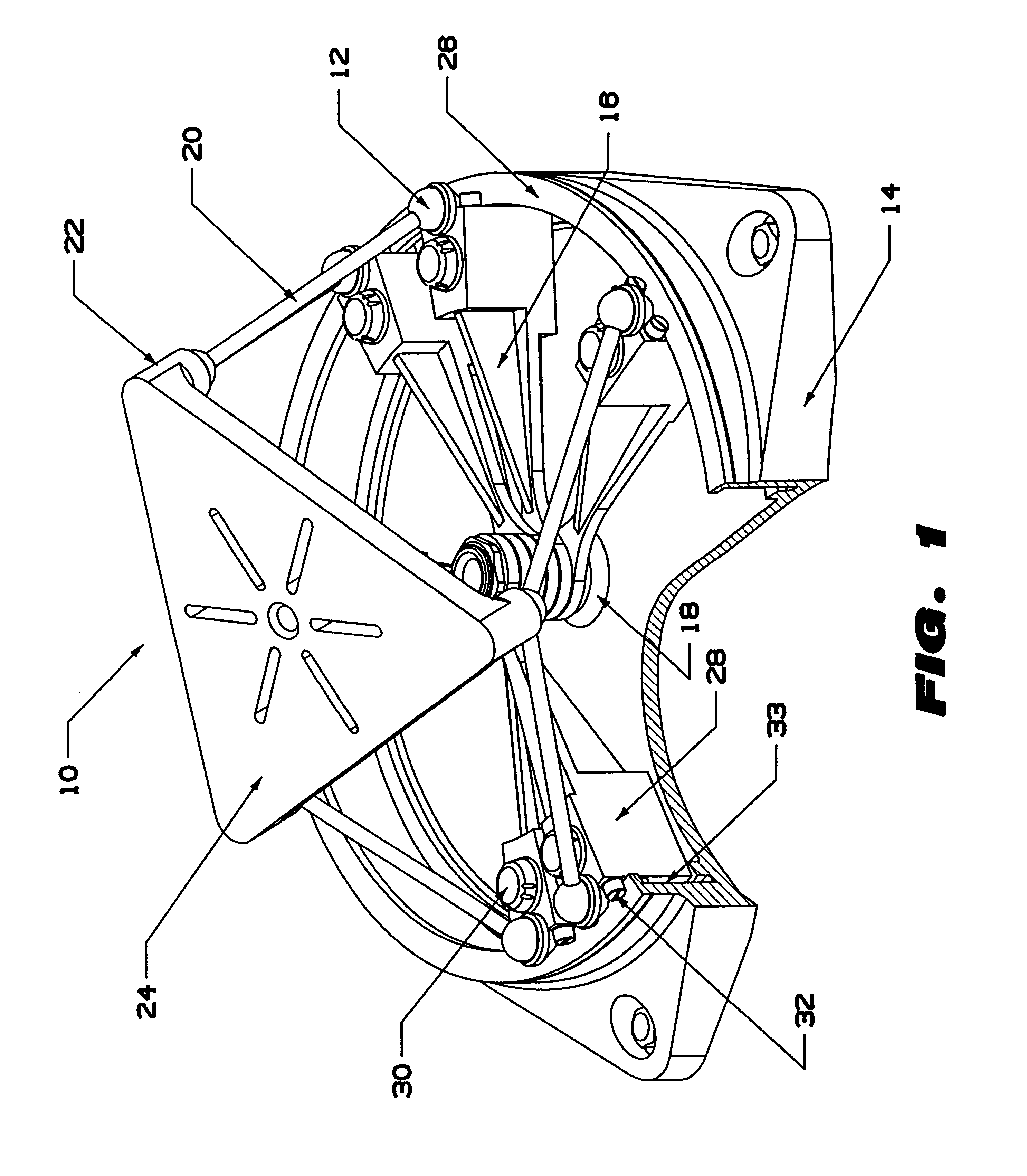

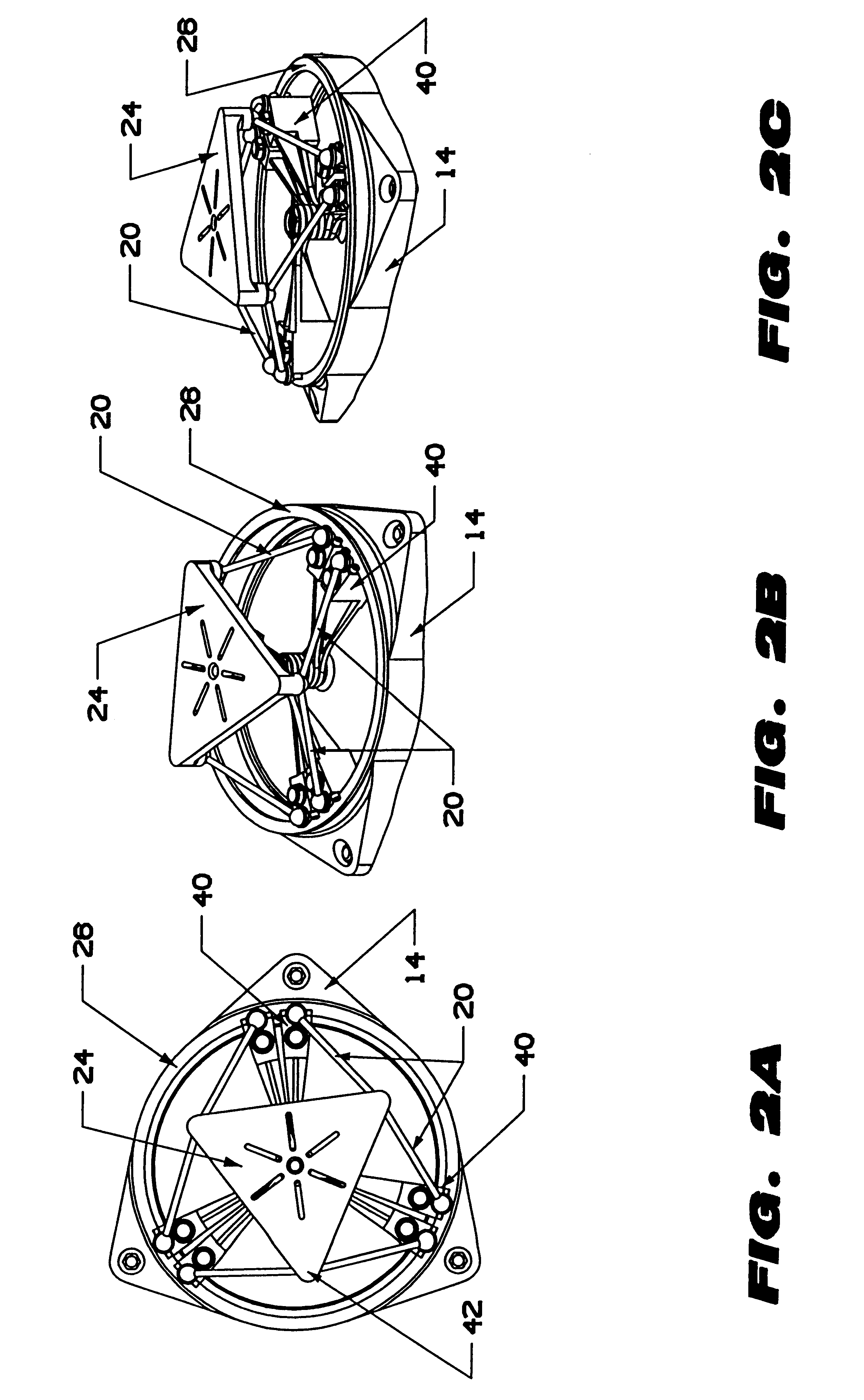

Systems and methods employing a rotary track for machining and manufacturing

InactiveUS6196081B1Low thermal expansionOptimization rangePortable framesJointsThree-dimensional spaceEngineering

The systems and methods described herein include hexapod systems, Stewart platform systems and other mechanical movement systems, in which a set of independently moveable trucks support legs that couple to a working surface capable of holding a machine tool or other end-effector, and preferably wherein the trucks travel across a reference surface, such as around the circumference of a circle or along some other pre-defined geometrical pattern or track. For example, as described herein, the systems include Stewart platform machines that have six supportive legs each of which connects to a truck that can travel independently along a track. By coordinating the movement of these six trucks, the working surface can be moved in three dimensional space and can be oriented about three axes, providing control of roll, pitch and yaw.

Owner:HEXEL CORP

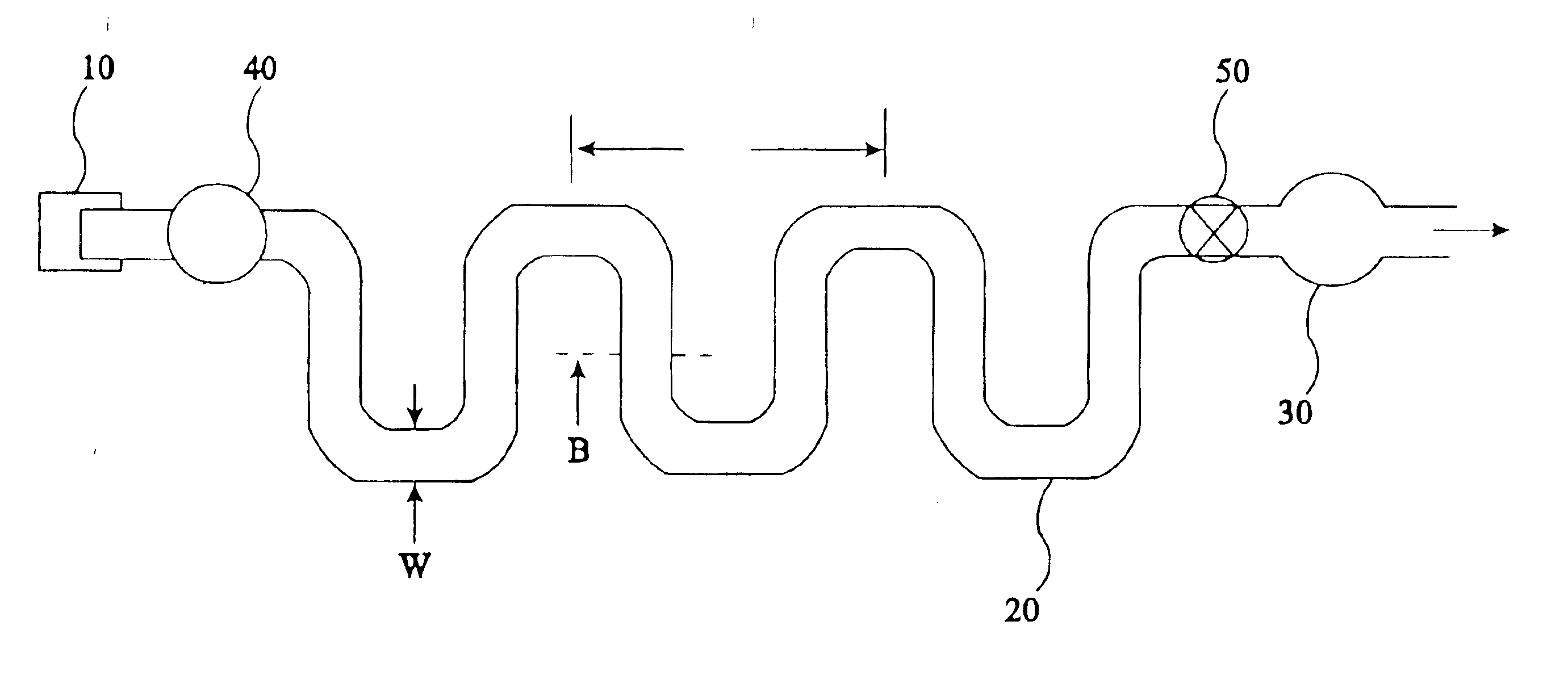

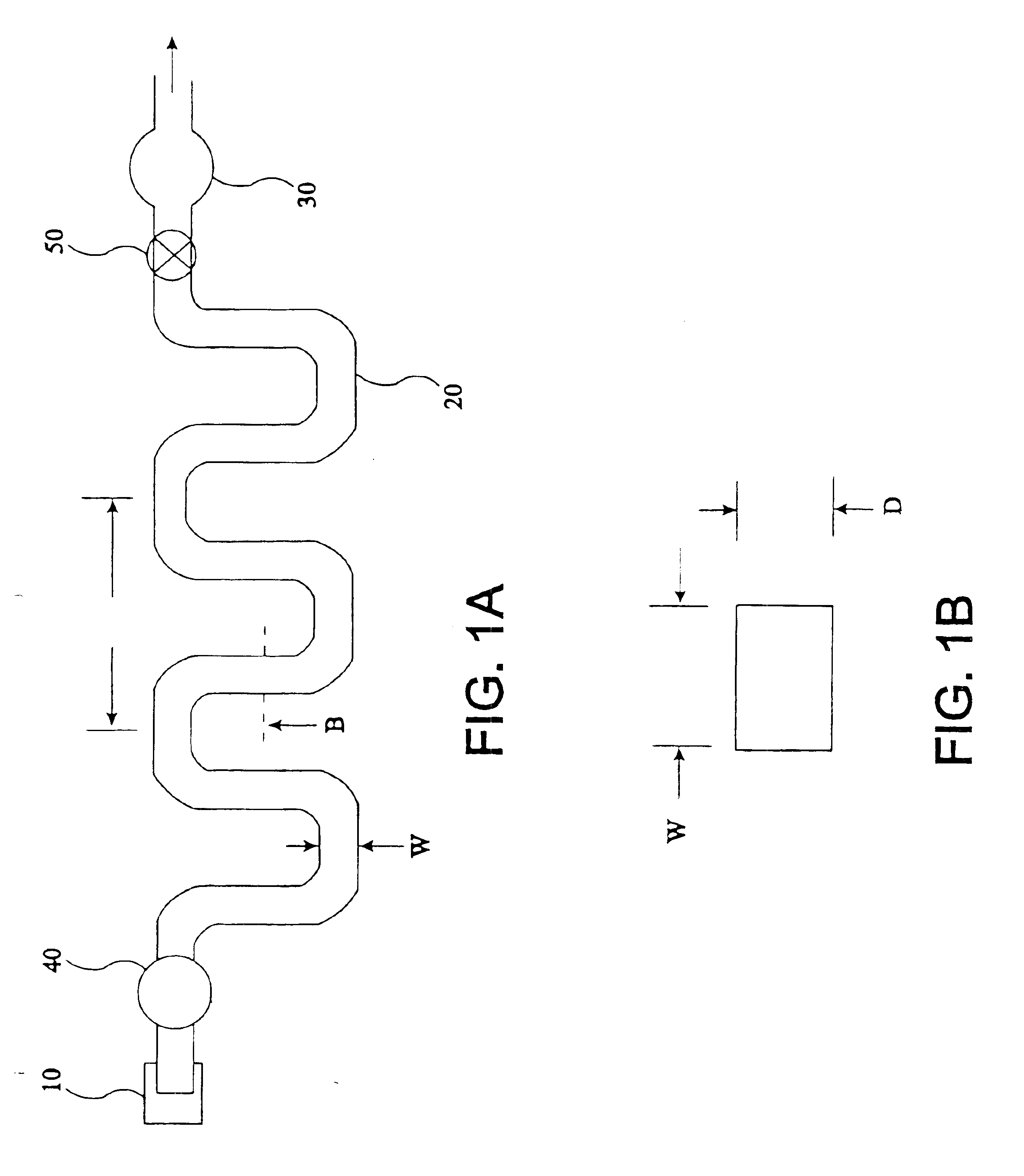

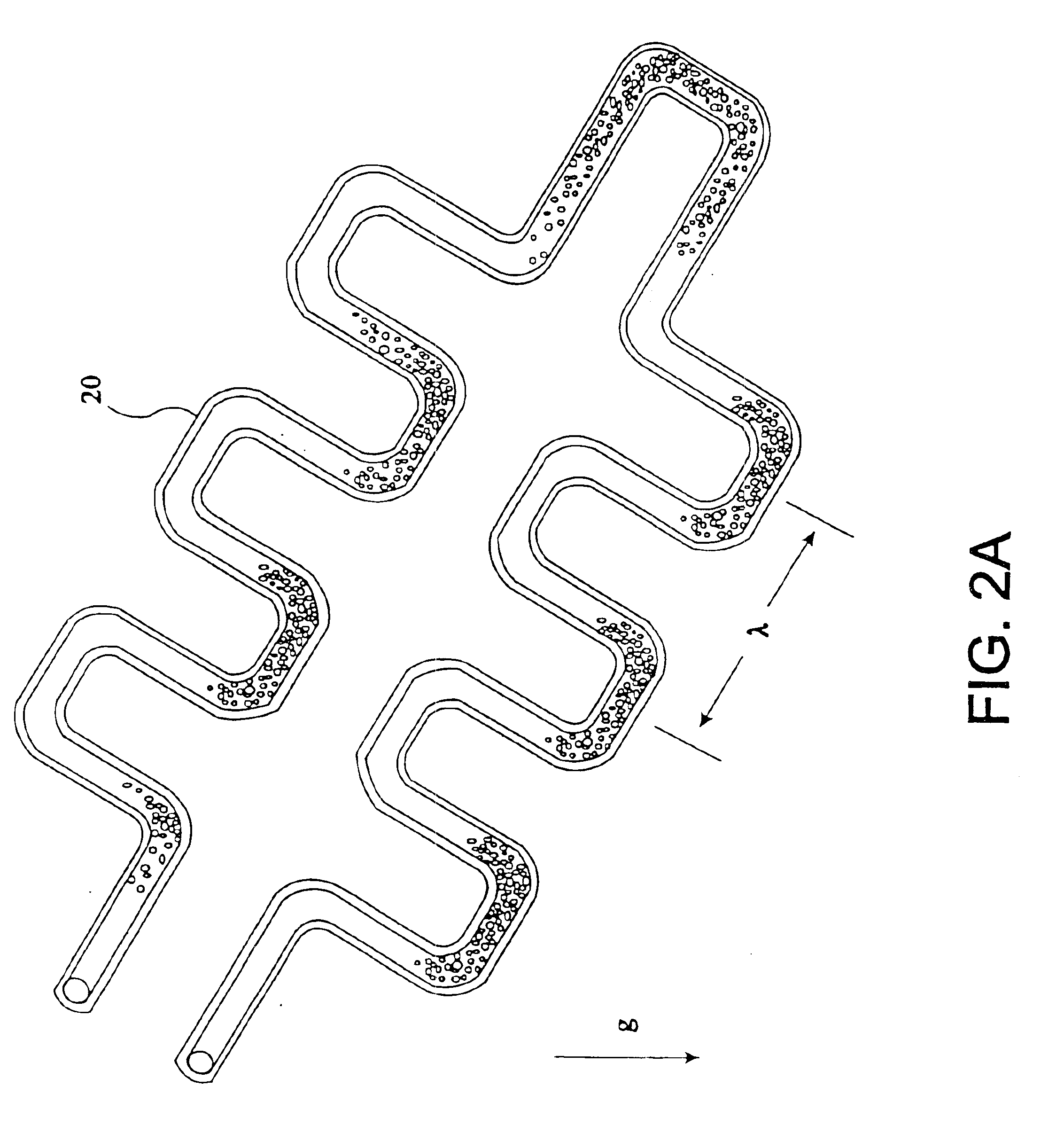

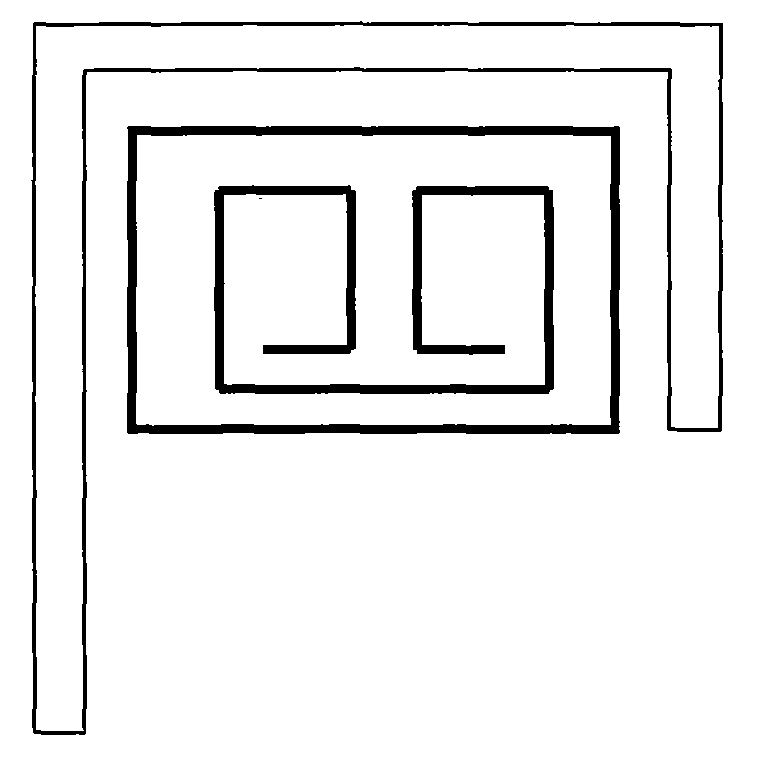

Liquid analysis cartridge

InactiveUS6852284B1Rapidly and effectively reconstituteEasy to reorganizeFlow mixersTransportation and packagingShell moldingDiluent

The present invention provides an apparatus and method for storing a particle-containing liquid. The storage apparatus comprises a microfluidic convoluted flow channel having a plurality of article capture regions. The storage channel is preferably an isotropic spatially periodic channel. Sedimented particles can be resuspended following storage. This invention further provides a microfluidic analysis cartridge having a convoluted storage channel therein. The sample analysis can use optical, electrical, pressure sensitive, or flow sensitive detection. A plurality of analysis channels can be included in a single cartridge. The analysis channels can be joined to reagent inlets for diluents, indicators or lysing agents. A mixing channel can be positioned between the reagent inlet and the analysis region to allow mixing and reaction of the reagent. The cartridge can include additional valves and pumps for flow management. The analysis cartridge can be a self-contained disposable cartridge having an integral waste storage container. This invention further provides a sheath flow assembly. The sheath flow assembly includes a sample channel and first and second sheath fluid channels positioned on either side of and converging with the sample channel. The assembly also includes upper and lower sheath fluid chambers positioned above and below and converging with the sample channel. The flow cartridges of this invention can be formed by molding, machining or etching. In a preferred embodiment they are laminated. This invention further provides a method of fabricating a laminated microfluidic flow device. In the method, flow elements are formed in rigid sheets and abutting surfaces of the sheets are bonded together.

Owner:UNIV OF WASHINGTON

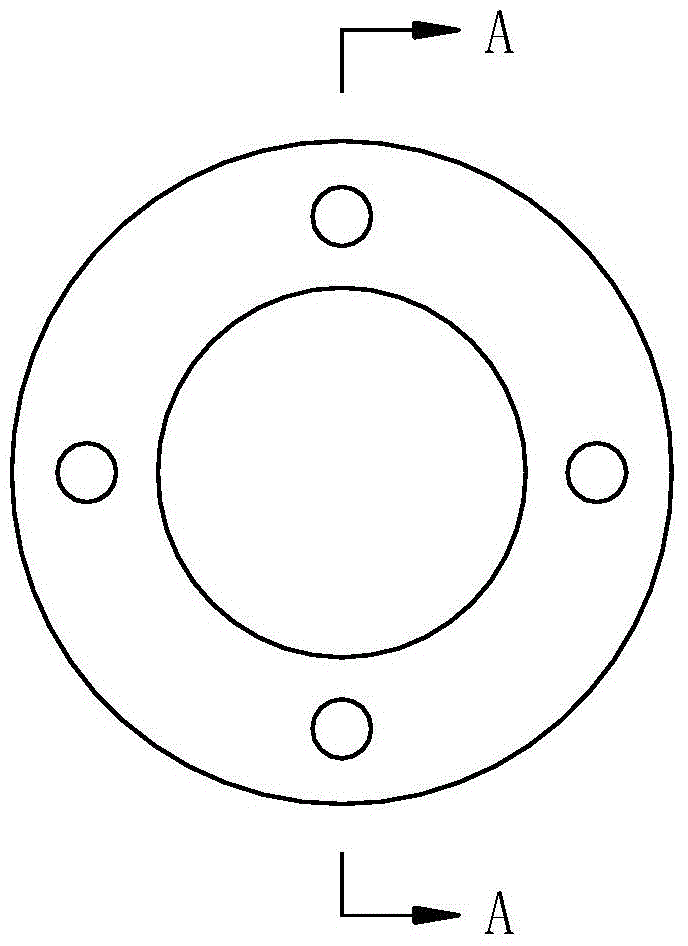

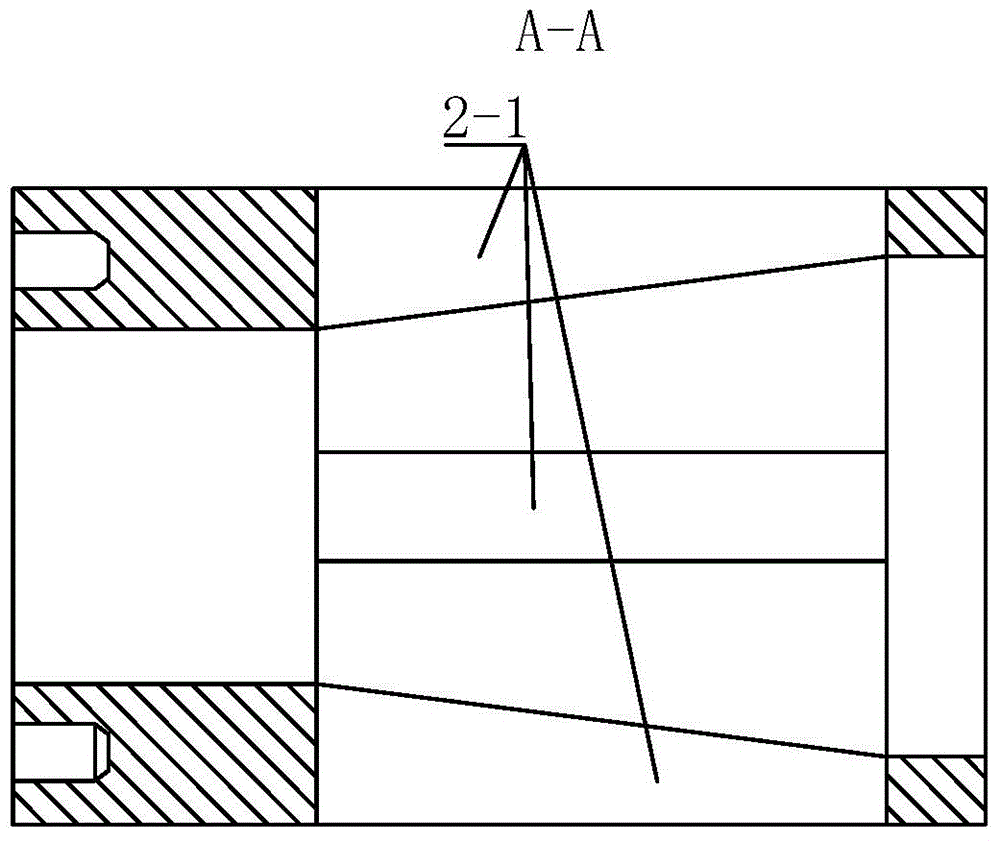

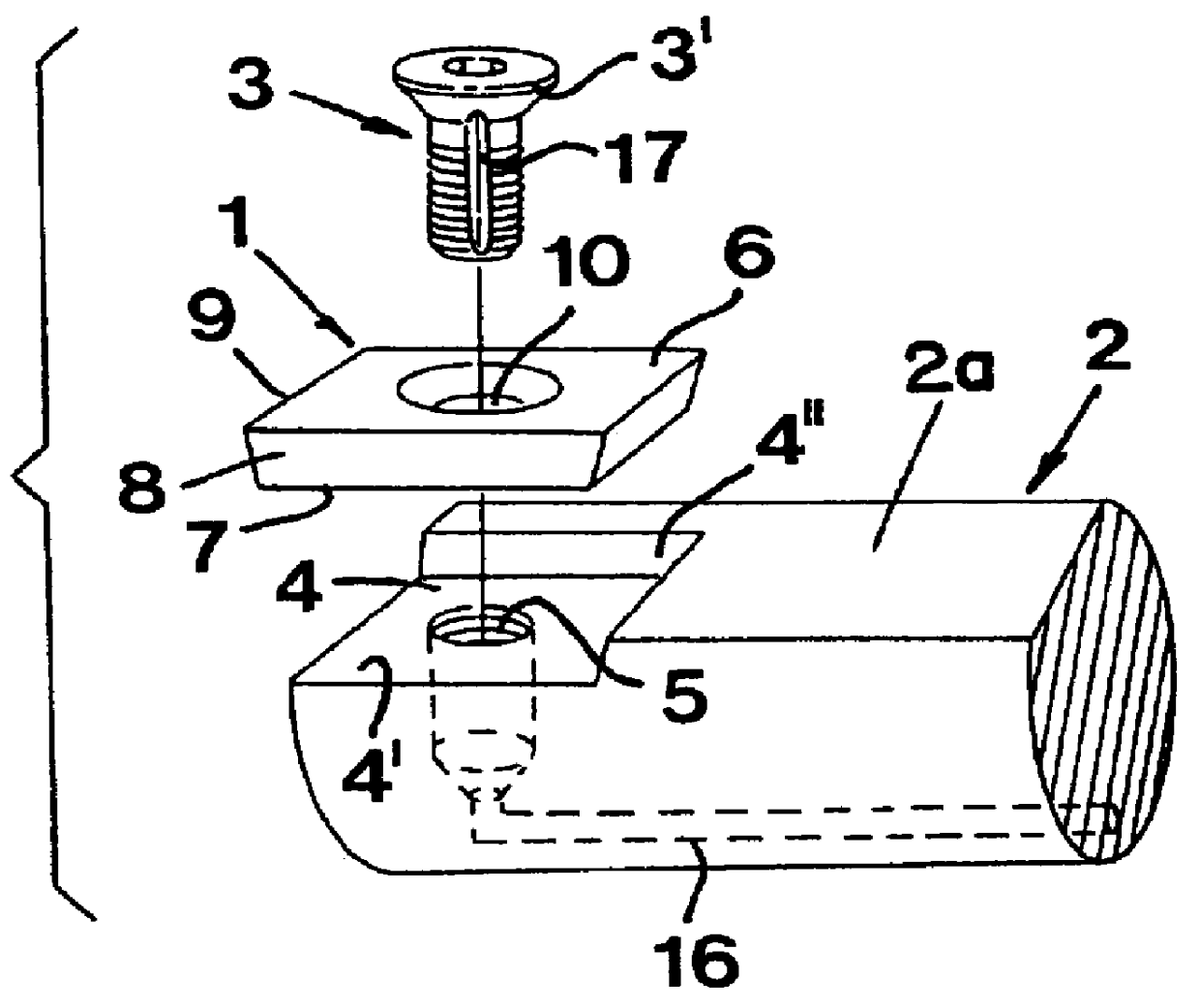

Thin-wall round pipe turning and clamping device

InactiveCN104607681AReasonable designCompact structureExpansion mandrelsEngineeringUltimate tensile strength

The invention discloses a thin-wall round pipe turning and clamping device. The thin-wall round pipe turning and clamping device comprises a slide block bracket for slidingly mounting inclined surface slide blocks, a screw rod for slidingly mounting and supporting taper sleeves, and a clamping base, wherein the slide block bracket and the screw rod are both fixedly mounted at one end of the clamping base; the taper sleeves are slidingly mounted on the screw rod; at least two inclined surface slide blocks fitting the taper sleeves to tightly eject workpieces from the inner sides are slidingly mounted on the slide block bracket; elastic cushion blocks are respectively arranged between all the inclined surface slide blocks and the workpieces; fastening nuts for tightly pressing the taper sleeves are arranged at the ends of the screw rod; and antiskid washers are arranged between the fastening nuts and the end surfaces of the taper sleeves. The thin-wall round pipe turning and clamping device has the characteristics of reasonable design, simple structure, good use effect, high machining precision, convenience for disassembly of the workpieces, low labor intensity, high production efficiency, low production cost and convenience for promotion and application.

Owner:XIAN ZHIYUE ELECTROMECHANICAL TECH

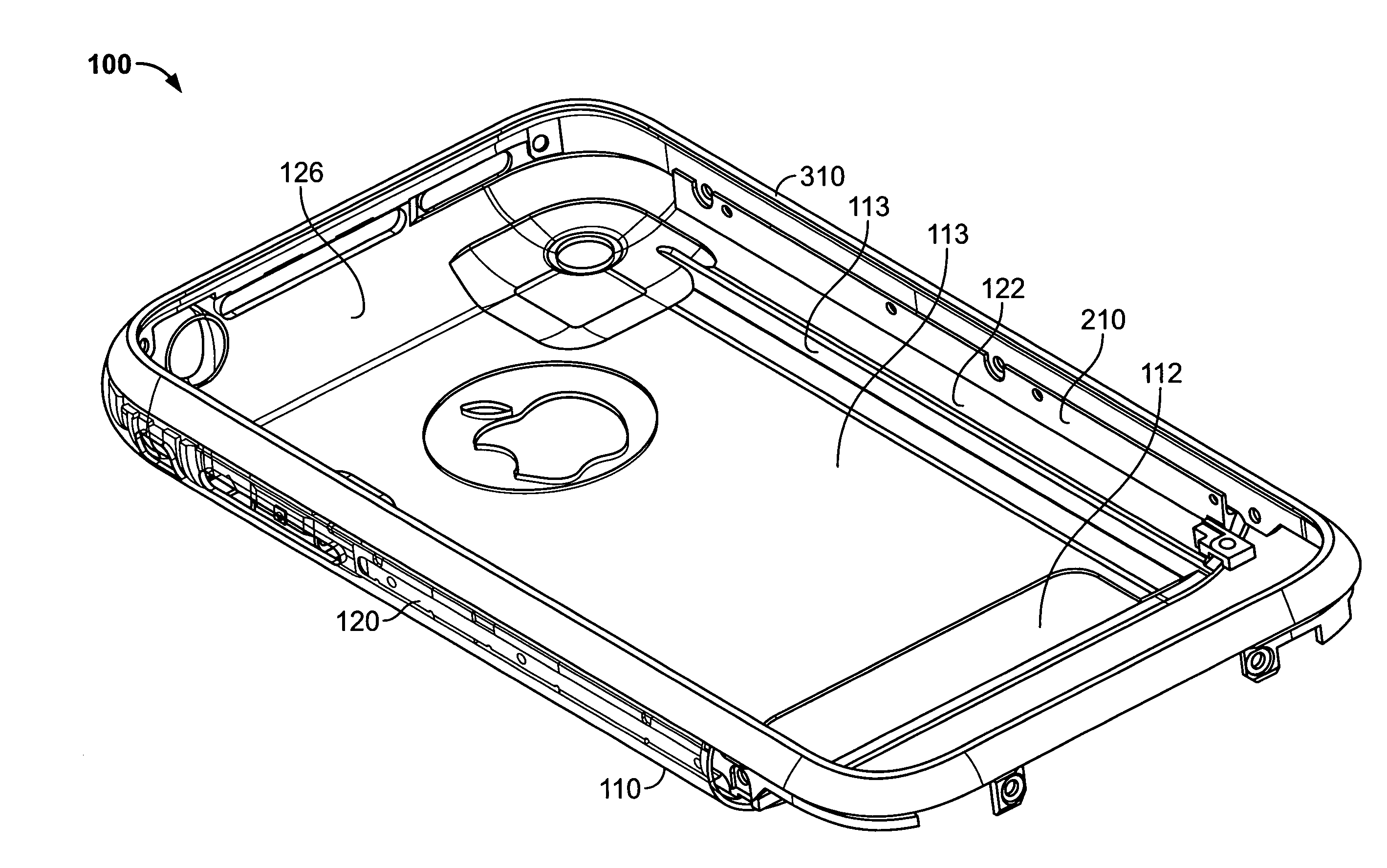

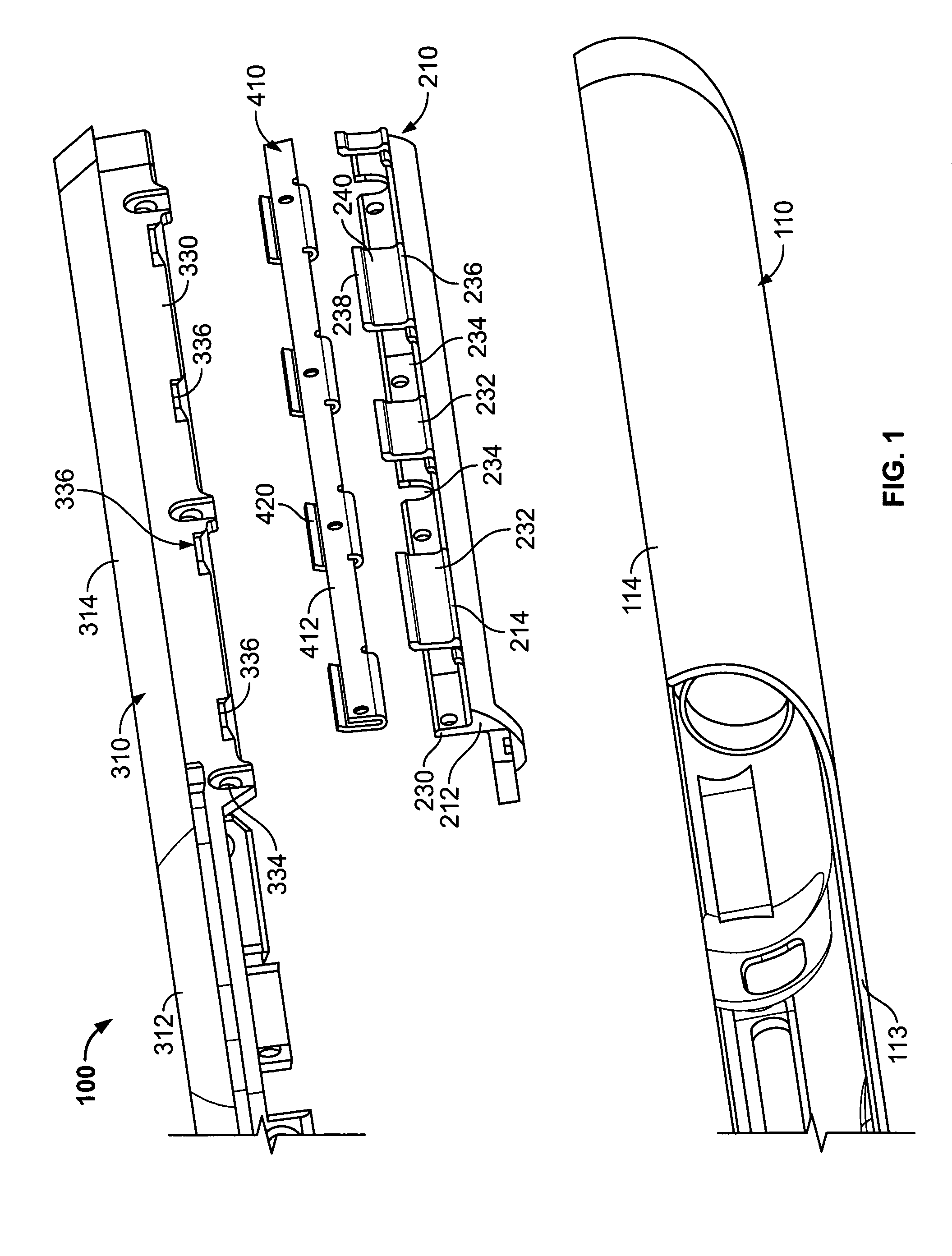

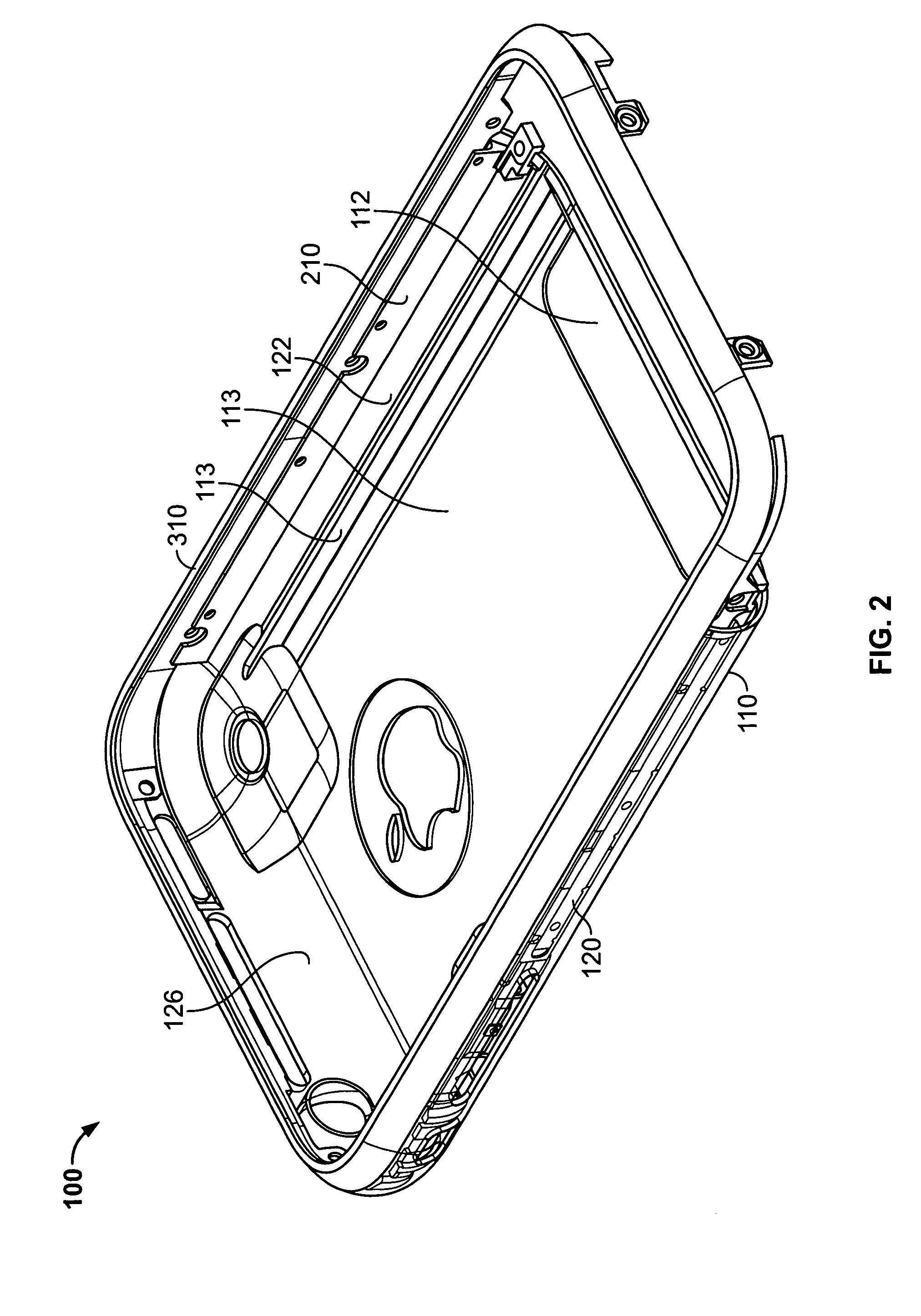

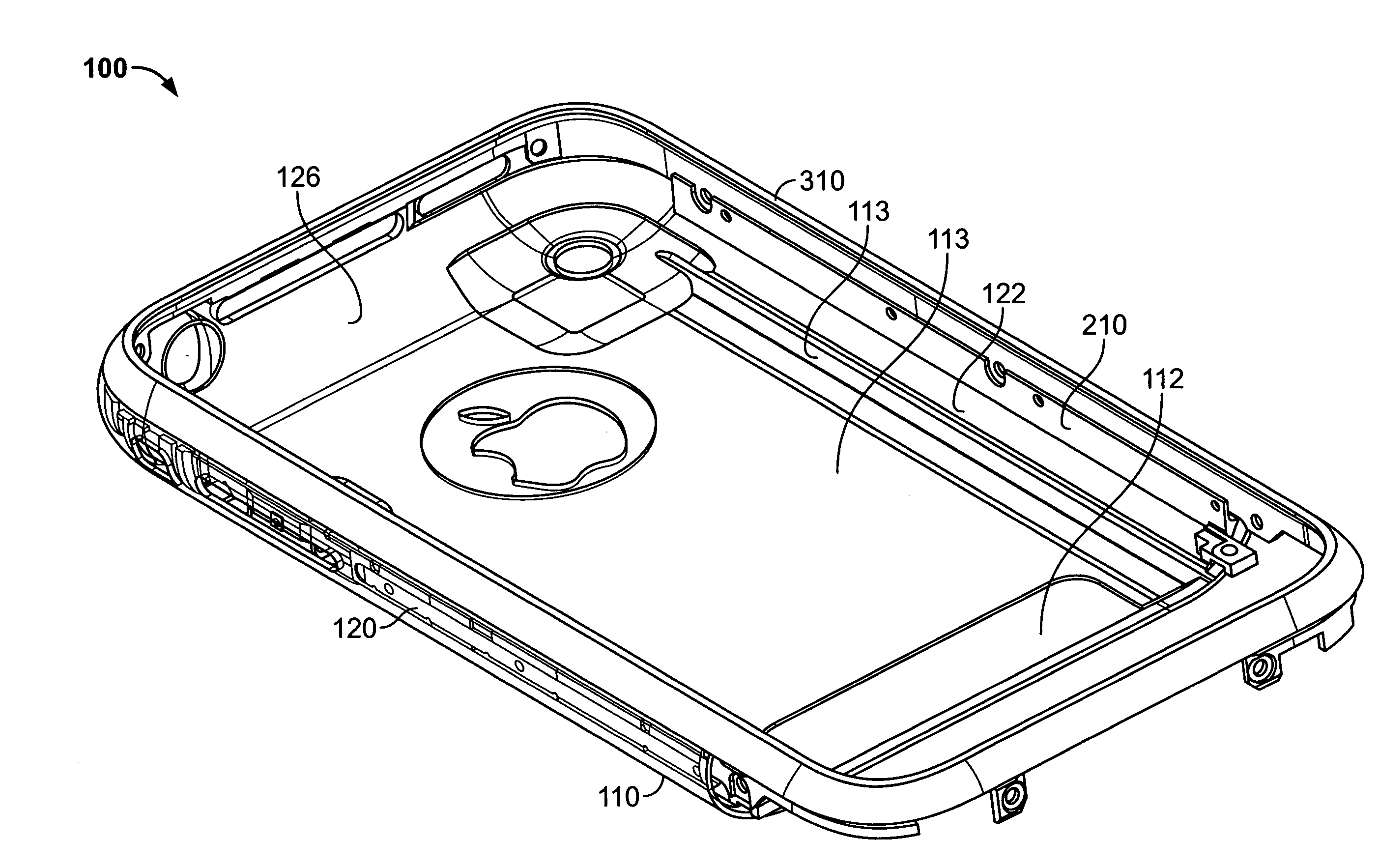

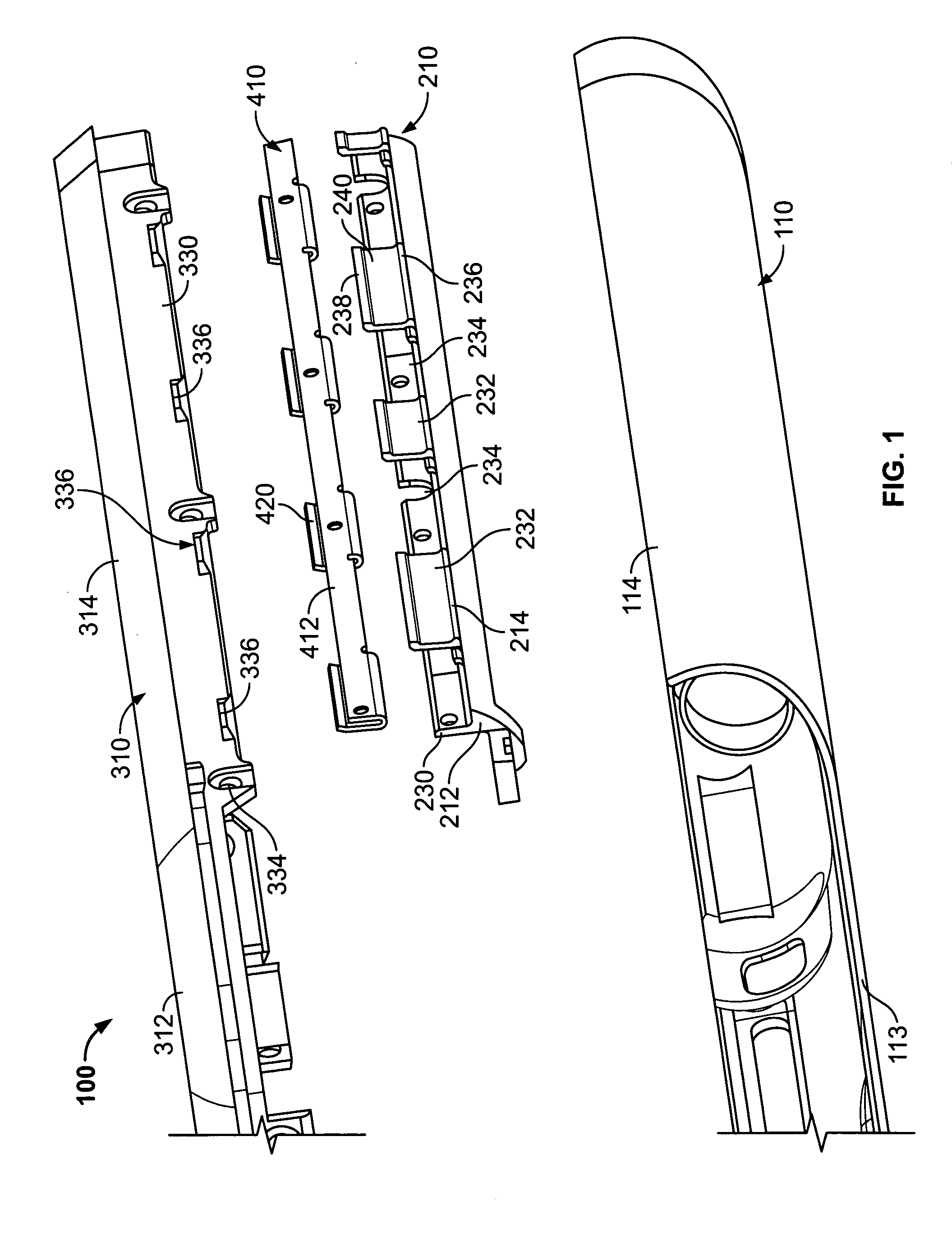

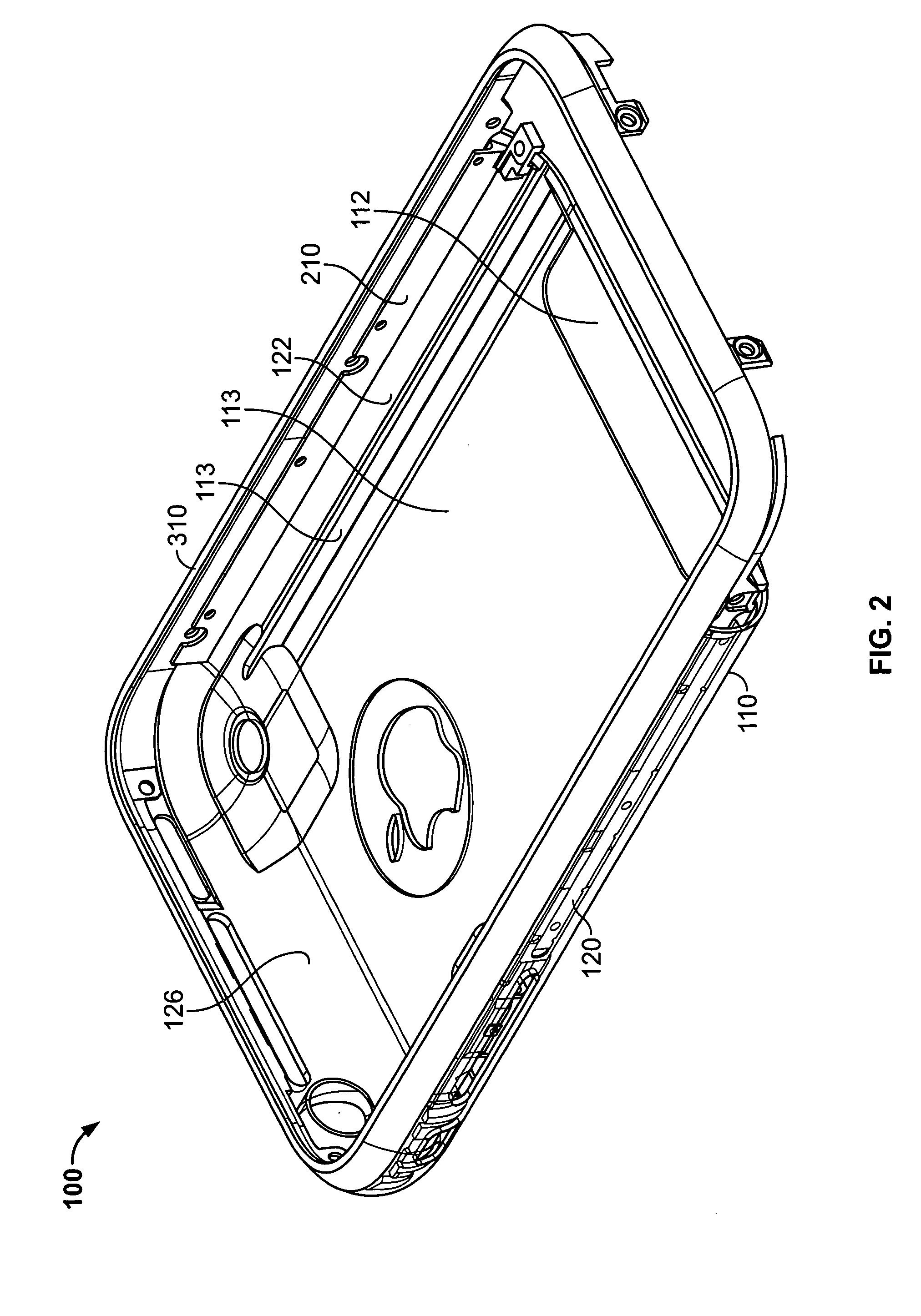

Cold worked metal housing for a portable electronic device

ActiveUS7688574B2High hardnessDesired impact and scratch resistant propertyClosed casingsDigital data processing detailsEngineeringMachining

A cold worked stainless steel bezel for a portable electronic device is provided. The bezel is secured flush to a housing to form part of the case of the portable electronic device. A brace that includes a slot for receiving a wall extending from the bezel is fixed to the housing. When the bezel engages the housing, the wall of the bezel is inserted in the slot of the brace and releasably held by a spring that engages both the brace and the wall. The bezel can be released by disengaging the spring, (e.g., using a special tool or a magnetic field). Because the bezel is manufactured from cold worked stainless steel, it is hard and resistant to impacts. Cold worked steel also facilitates manufacturing within design constraints and tolerances, and requires very little machining after manufacturing to comply with those constraints. The portable electronic device may include a personal media device, a mobile telephone, or any other suitable device or combination thereof.

Owner:APPLE INC

Electroactive polymers transducers and actuators

InactiveUS6940211B2Speed up the conversion processImprove mechanical responseTransducer detailsPiezoelectric/electrostriction/magnetostriction machinesPre strainActive polymer

The present invention relates to electroactive polymers that are pre-strained to improve conversion from electrical to mechanical energy. When a voltage is applied to electrodes contacting a pre-strained polymer, the polymer deflects. This deflection may be used to do mechanical work. The pre-strain improves the mechanical response of an electroactive polymer. The present invention also relates to actuators including an electroactive polymer and mechanical coupling to convert deflection of the polymer into mechanical work. The present invention further relates to compliant electrodes that conform to the shape of a polymer. The present invention provides methods for fabricating electromechanical devices including one or more electroactive polymers.

Owner:SRI INTERNATIONAL

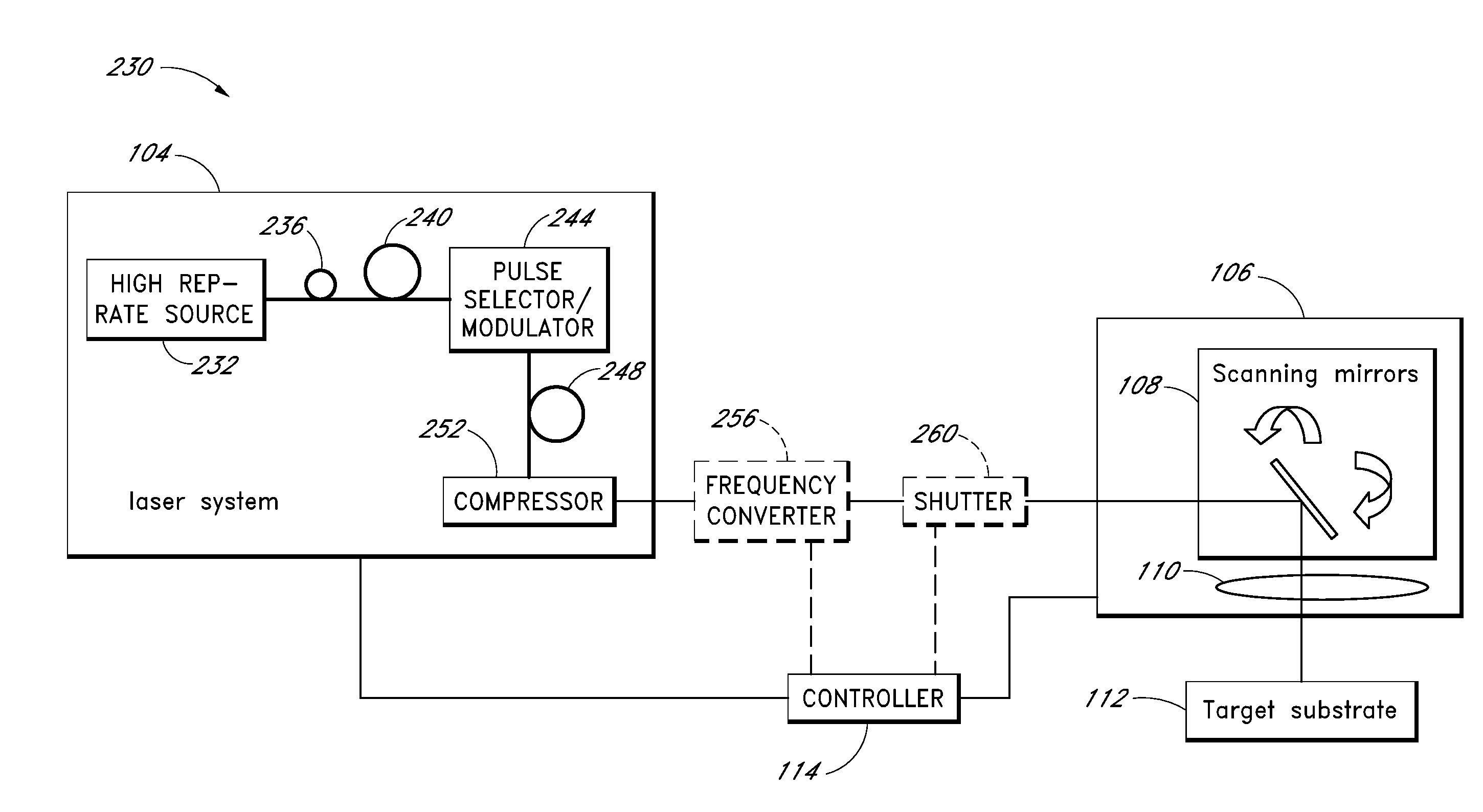

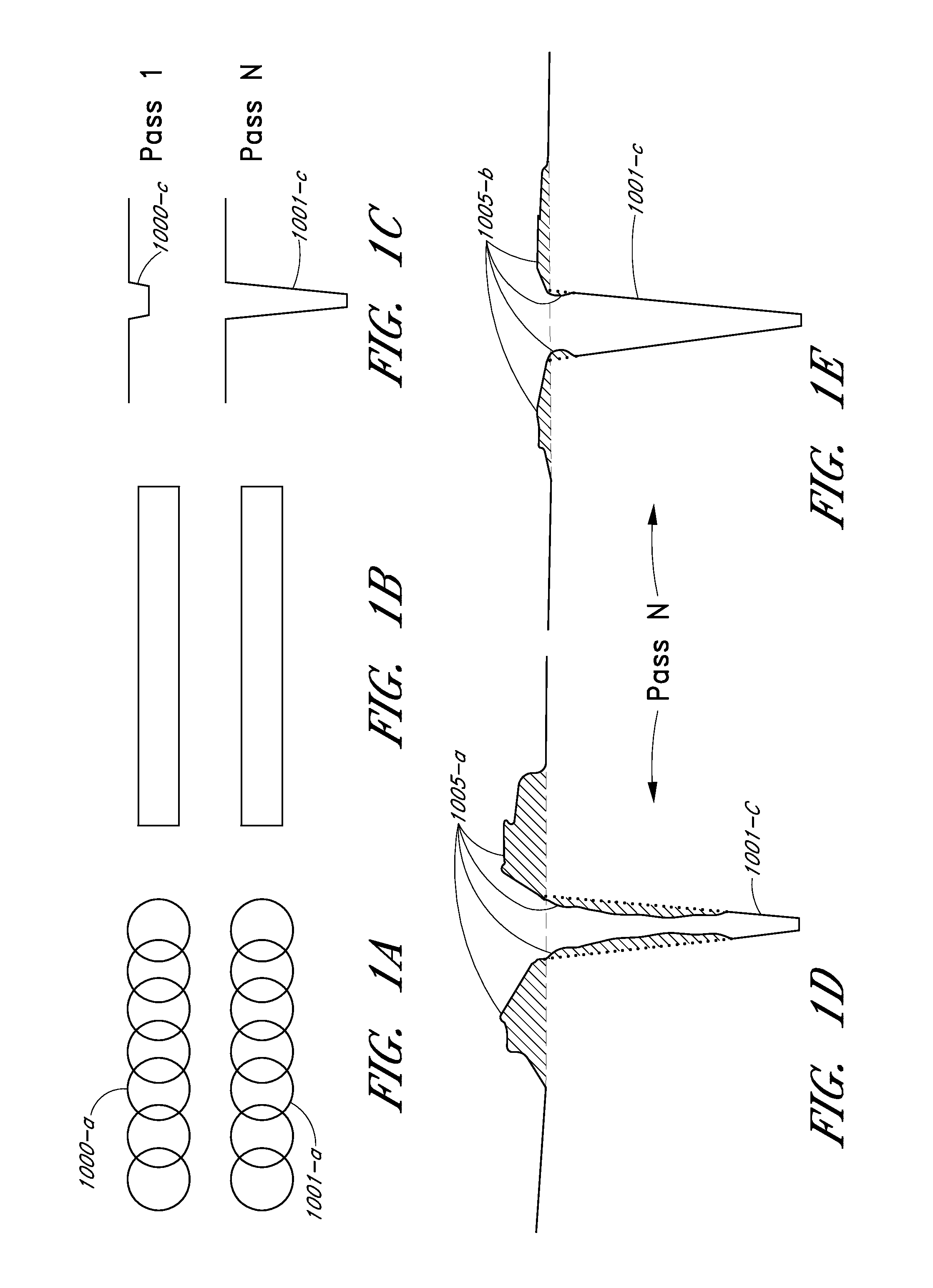

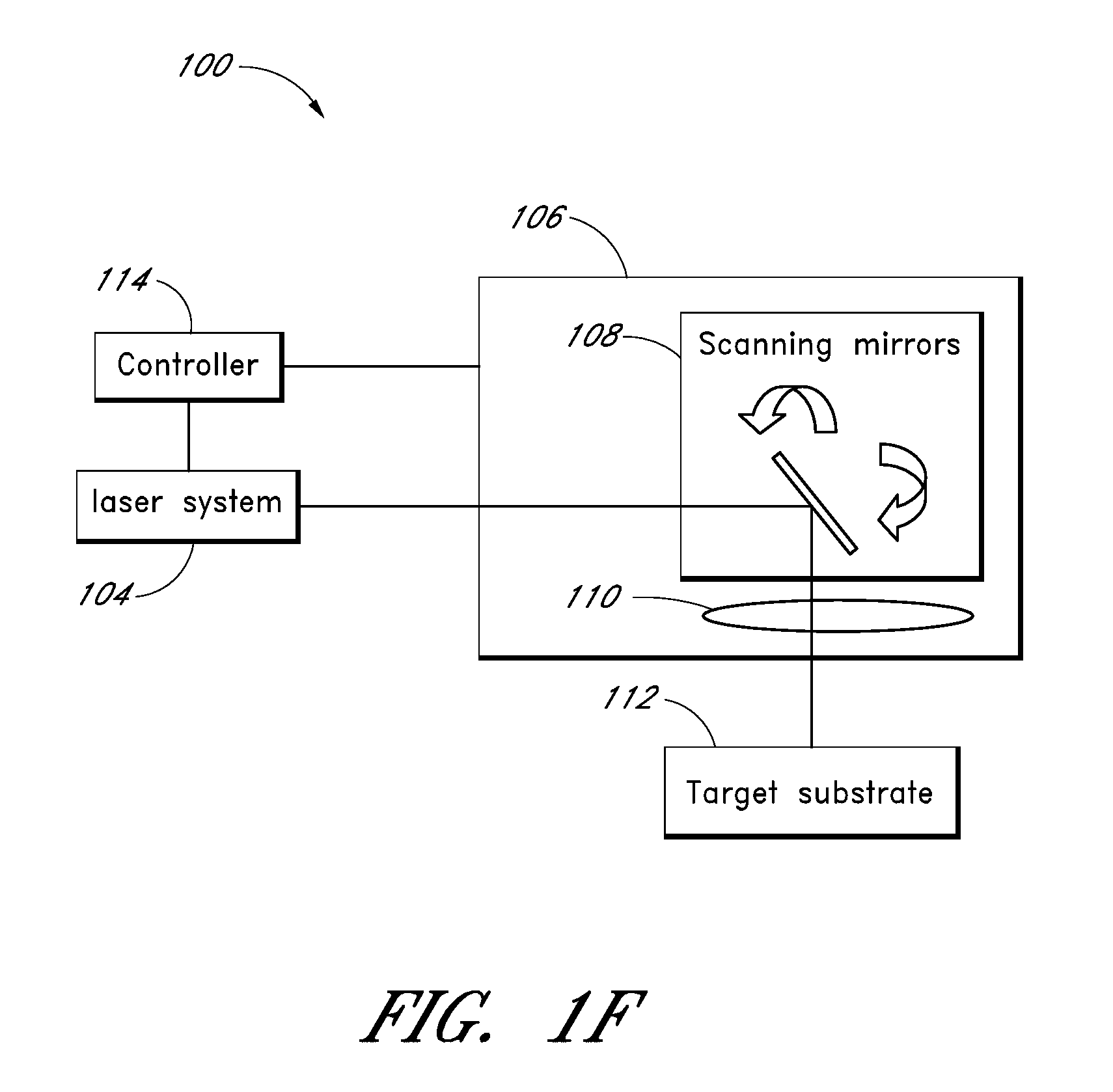

Laser-based material processing methods and systems

ActiveUS20100197116A1Efficient removalAvoid accumulationSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesDielectricMaterials processing

Various embodiments may be used for laser-based modification of target material of a workpiece while advantageously achieving improvements in processing throughput and / or quality. Embodiments of a method of processing may include focusing and directing laser pulses to a region of the workpiece at a pulse repetition rate sufficiently high so that material is efficiently removed from the region and a quantity of unwanted material within the region, proximate to the region, or both is reduced relative to a quantity obtainable at a lower repetition rate. In at least one embodiment, an ultrashort pulse laser system may include at least one of a fiber amplifier or fiber laser. Various embodiments are suitable for at least one of dicing, cutting, scribing, and forming features on or within a semiconductor substrate. Workpiece materials may also include metals, inorganic or organic dielectrics, or any material to be micromachined with femtosecond and / or picosecond pulses, and in some embodiments with pulse widths up to a few nanoseconds.

Owner:IMRA AMERICA

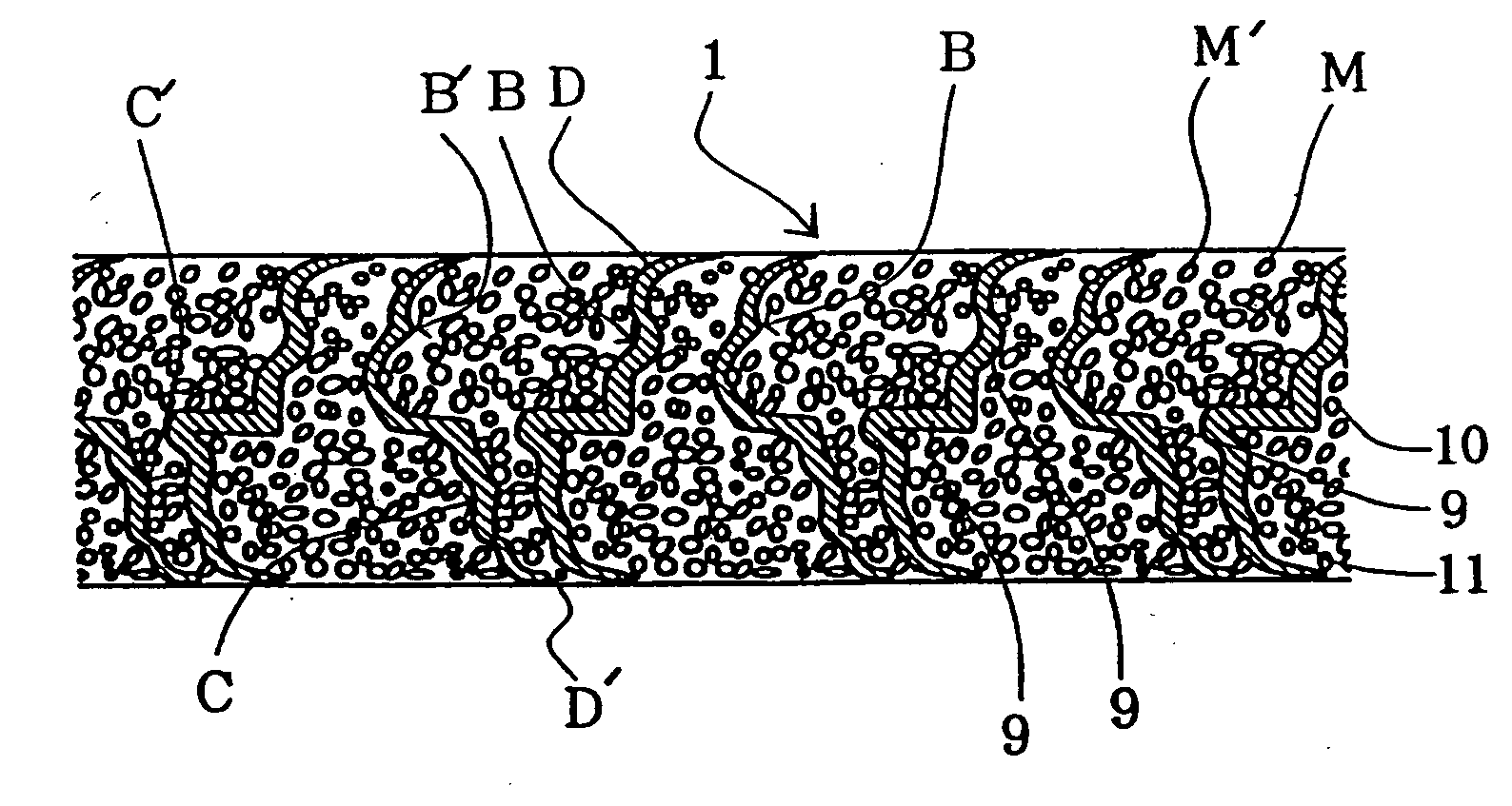

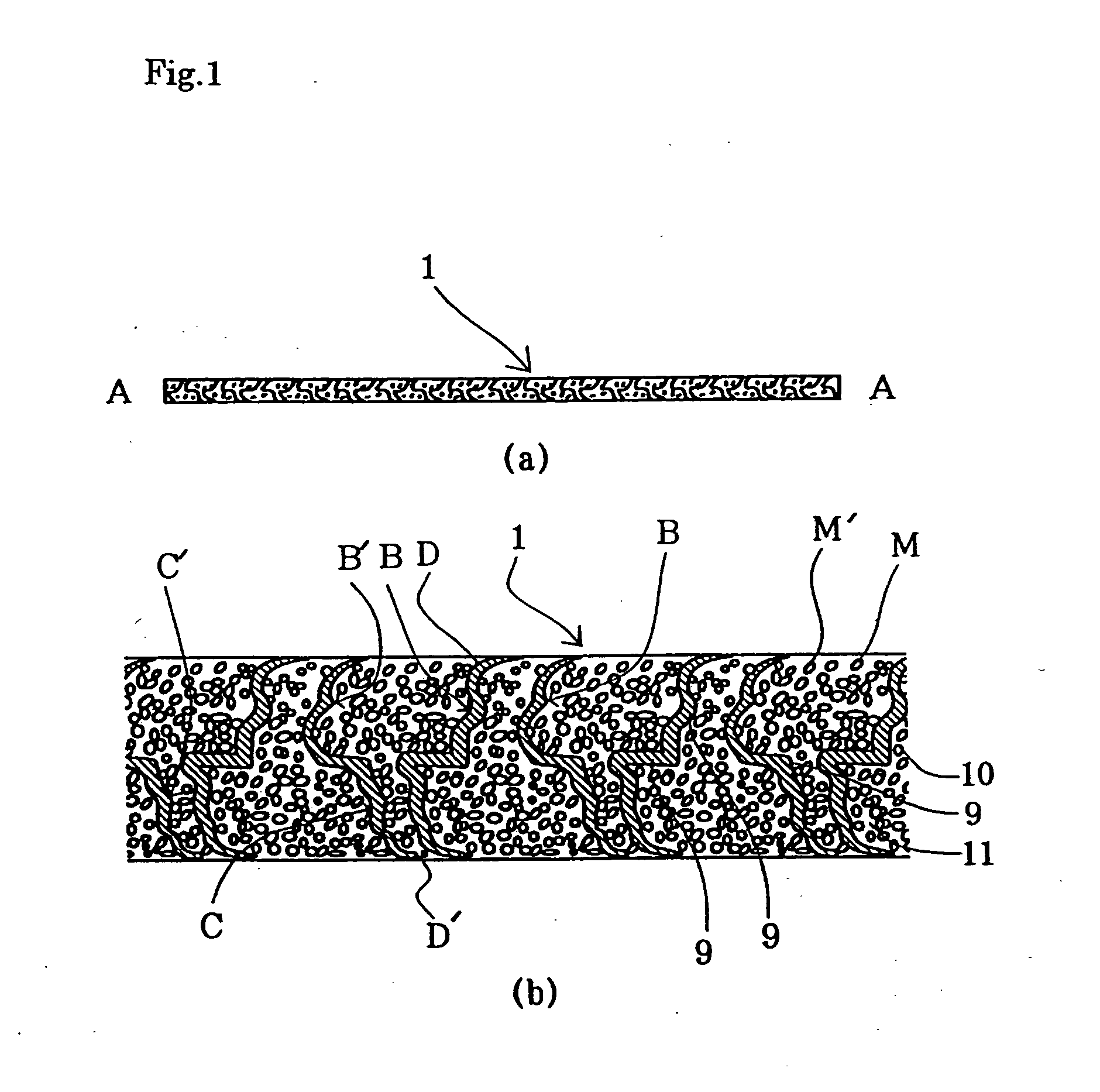

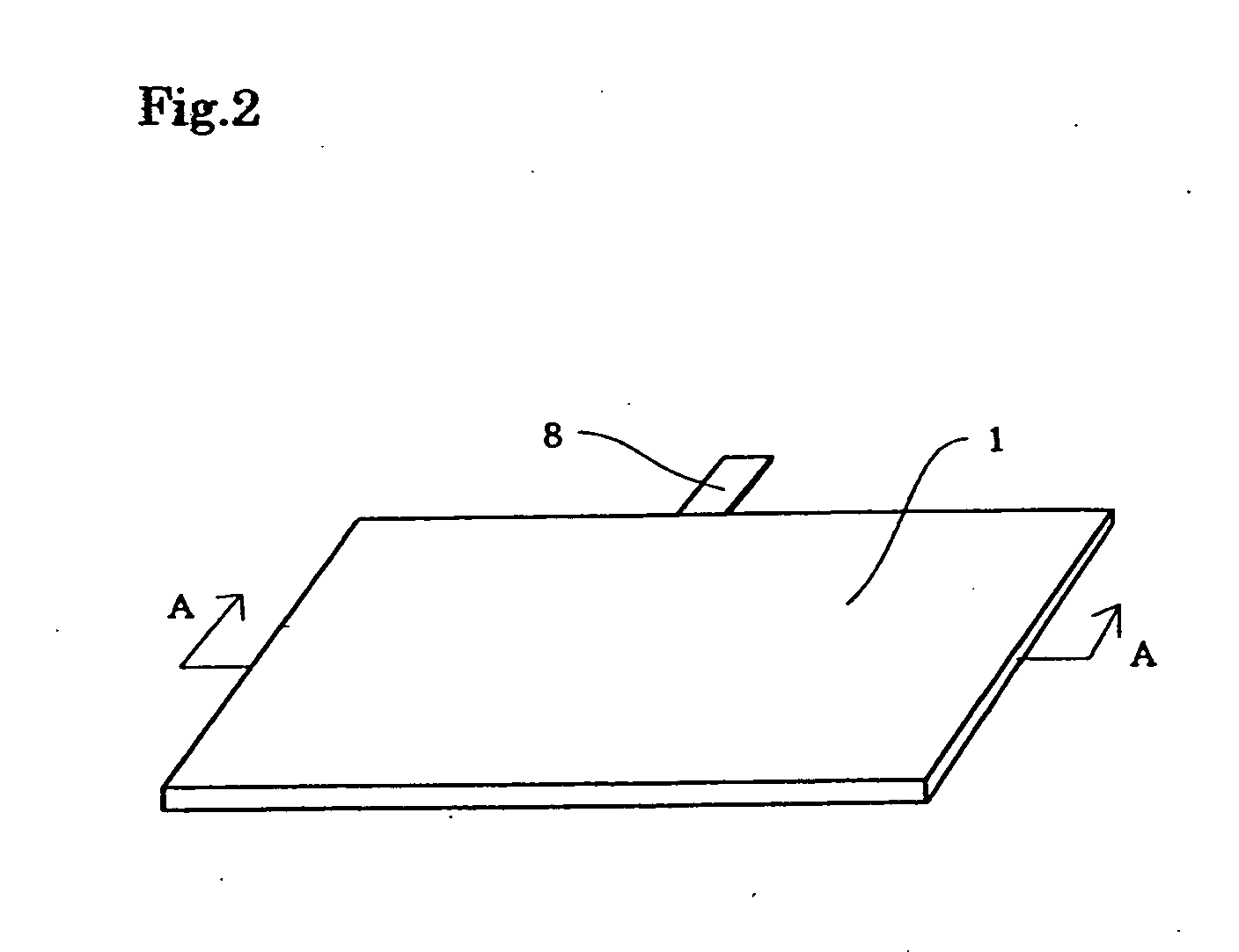

Non-sintered type thin electrode for battery, battery using same and process for same

InactiveUS20050019664A1Prevent peelingPrevent materialElectrode carriers/collectorsActive material electrodesElectrical batteryEngineering

An electrode substrate is formed by mechanically processing a nickel foil so as to be made three dimensional through the creation of concave and convex parts, and then, this substrate is filled with active material or the like so that an electrode is manufactured, wherein the above described concave and convex parts are rolling pressed so as to incline in one direction. Furthermore, an electrode for secondary battery is formed by using the above described method.

Owner:THE UNIV OF QUEENSLAND

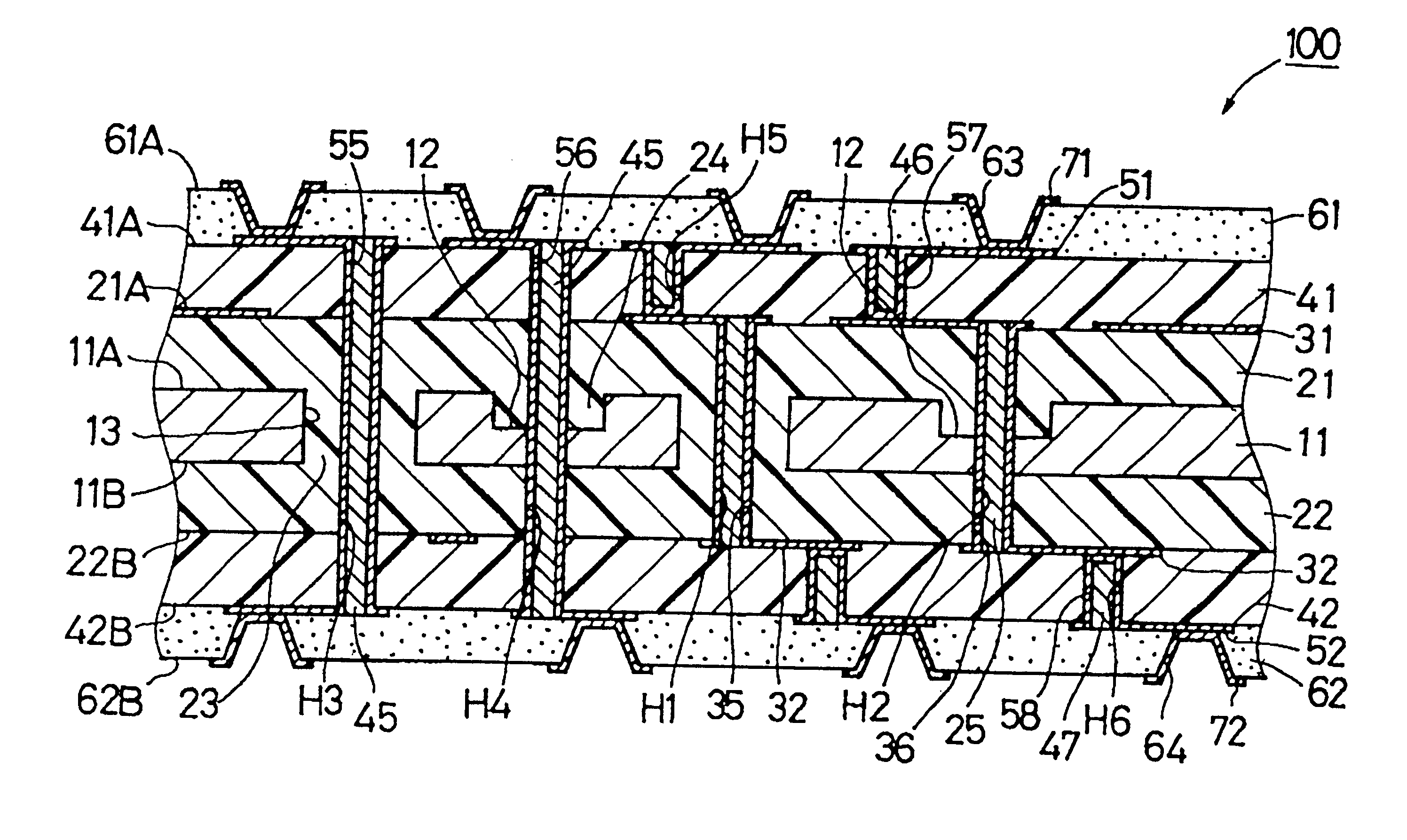

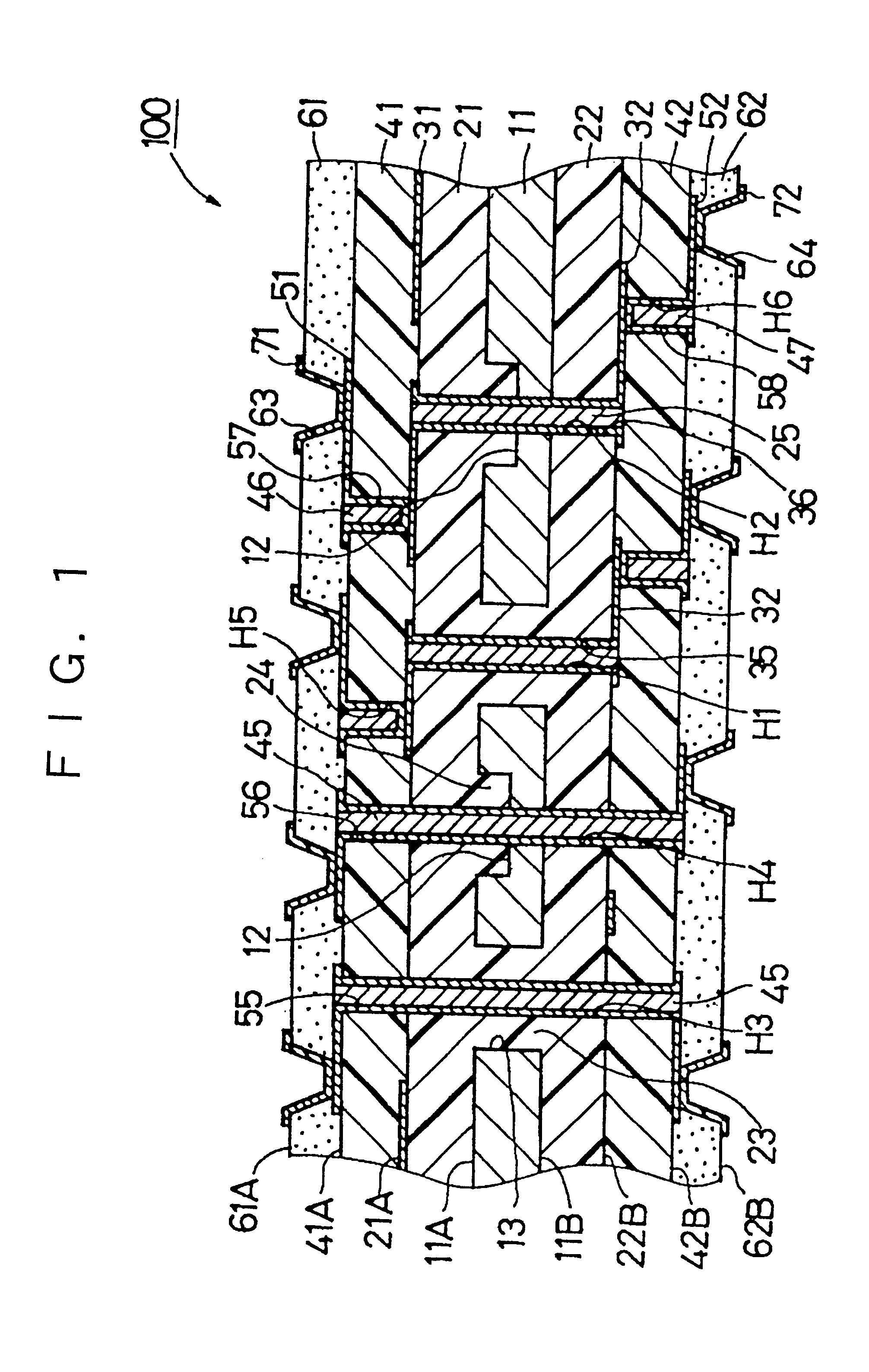

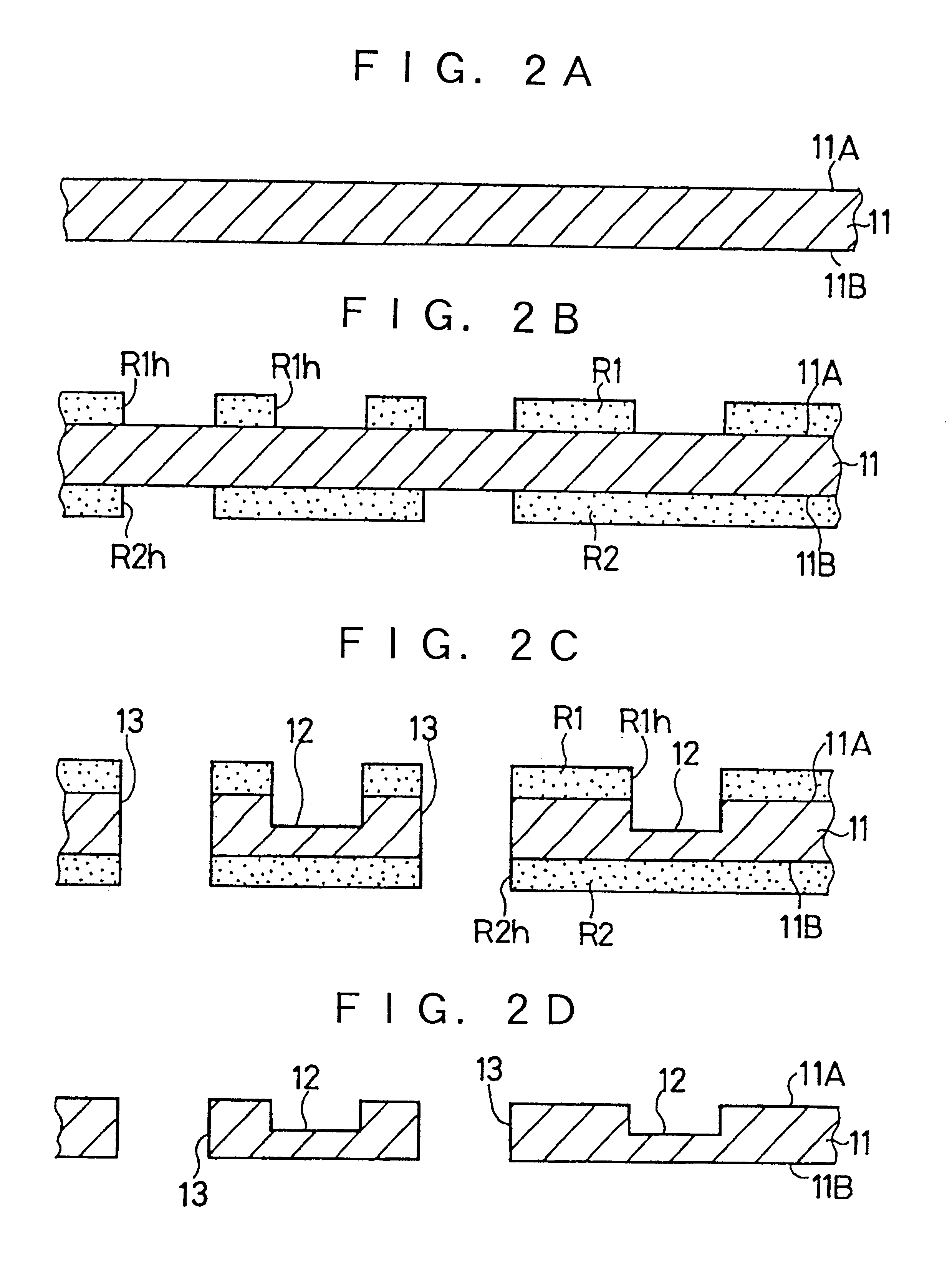

Metal core multilayer resin wiring board with thin portion and method for manufacturing the same

InactiveUS6323439B1Improve rigidityFirmly connectedElectrically conductive connectionsPrinted circuit aspectsEngineeringMachining

A multilayer resin wiring board includes a metal core substrate having a first main surface and a second main surface; a plurality of wiring layers located on the first and second main surfaces of the metal core substrate; a plurality of insulating resin layers, each intervening between the metal core substrate and the wiring layers and between the metal core substrate and the wiring layers and between the wiring layers; and a via formed on the wall of a through hole for connection to the metal core substrate extending through the insulating resin layers and the metal core substrate so as to establish electrical conductivity to the metal core substrate. The metal core substrate has a thin portion which is thinner than the remaining portion of the metal core substrate. The through hole for connection to the metal core substrate is formed through the thin portion by laser machining.

Owner:NGK SPARK PLUG CO LTD

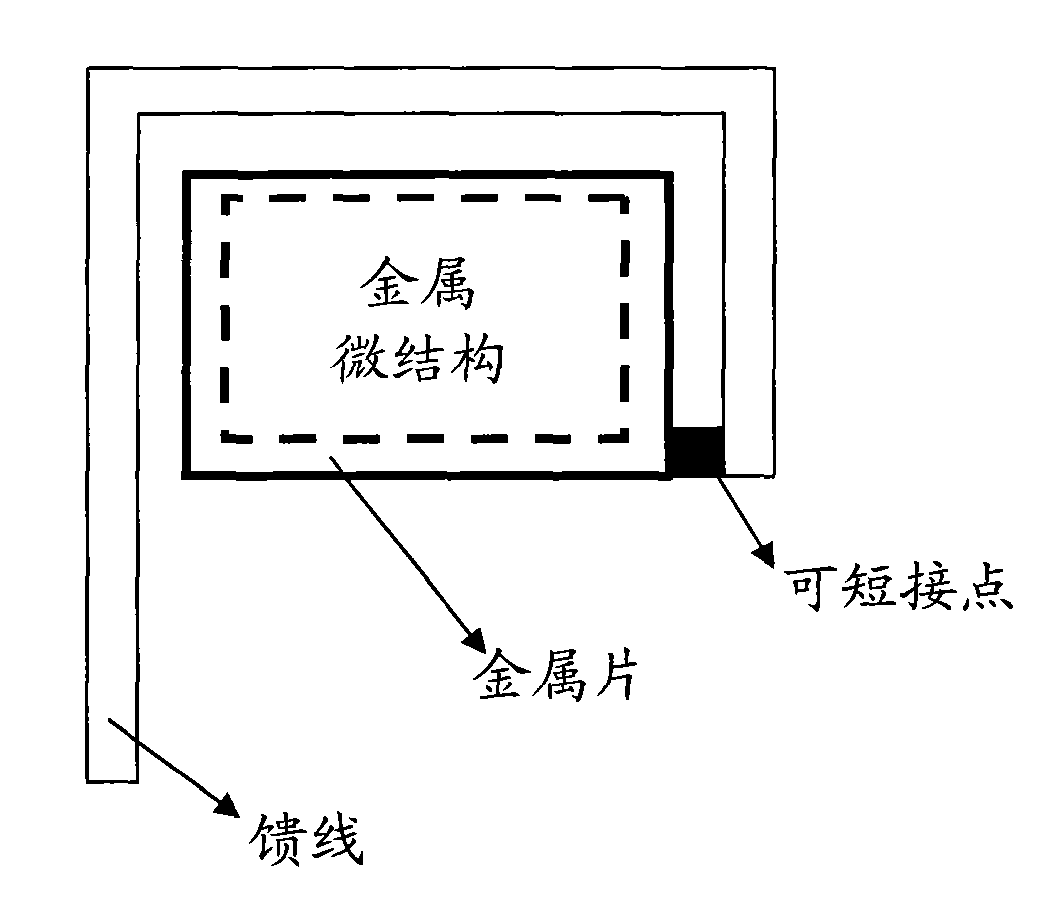

Monopole radio frequency antenna

InactiveCN101667680AImproving Impedance MatchingReduce the impactElongated active element feedCouplingMetal sheet

The invention discloses a monopole radio frequency antenna comprising a metal sheet, a feeder line and a medium for the placement of the metal sheet and the feeder line. The feeder line is fed into the metal sheet through a coupling mode. The monopole radio frequency antenna has the advantages of small size, simple machining, low cost, high utilization rate of an antenna radiation area, easy matching design of a multimode antenna, high interference resisting capability and the like.

Owner:深圳大鹏光启科技有限公司

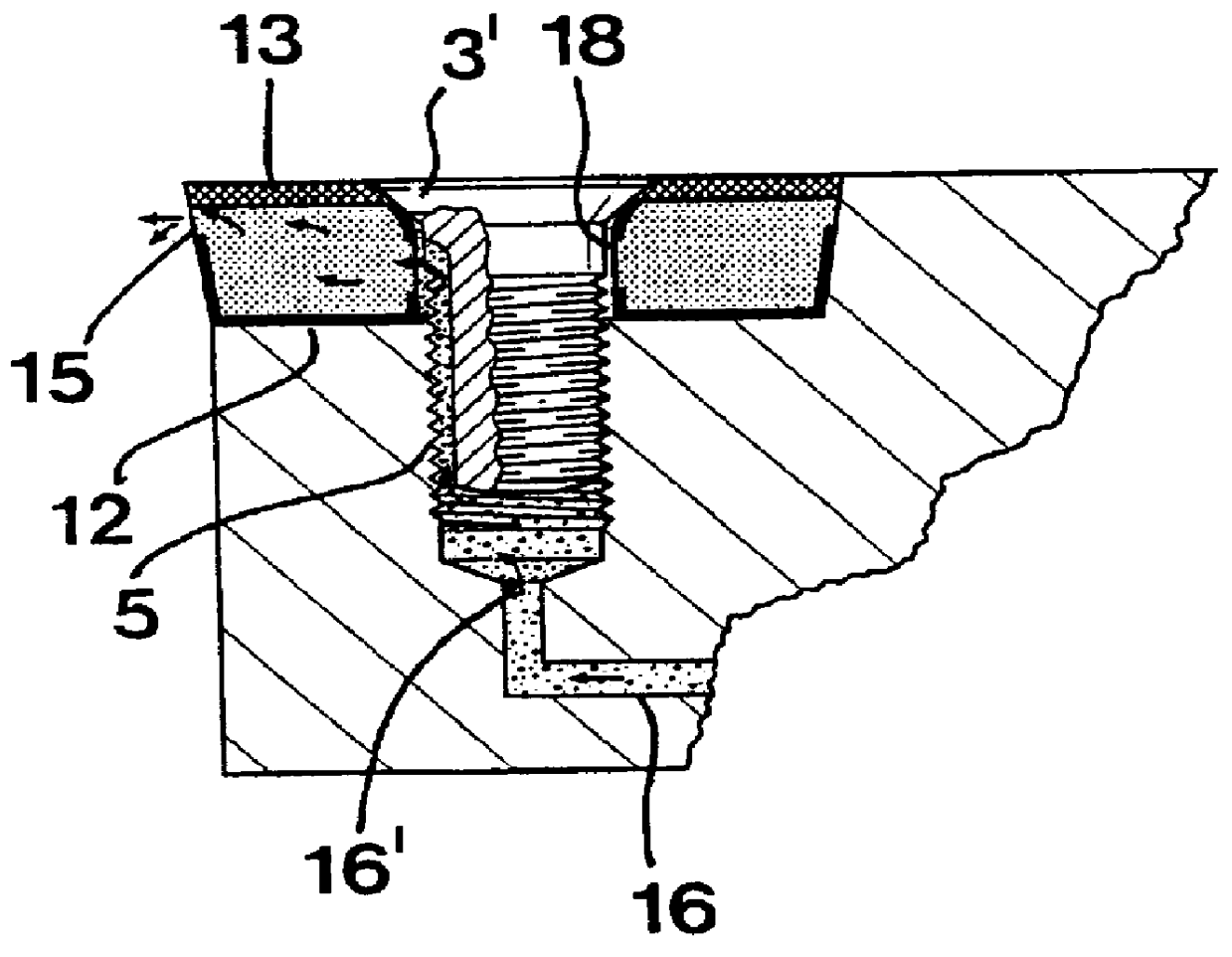

Chip forming cutting insert with internal cooling

InactiveUS6053669ADrawback can be obviatedEffective steeringCutting insertsTurning toolsEngineeringMachining

A cutting insert is cooled during chip removing machining of a workpiece by conducting cooling medium through a porous supporting body of the insert. The cooling medium enters the insert through an inlet formed therein at a location remote from a cutting edge of the insert and exits the insert through an outlet formed in the insert at a location proximate the cutting edge. The discharged cooling medium impinges on, and cools, the workpiece.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Self-supporting unitary feed assembly

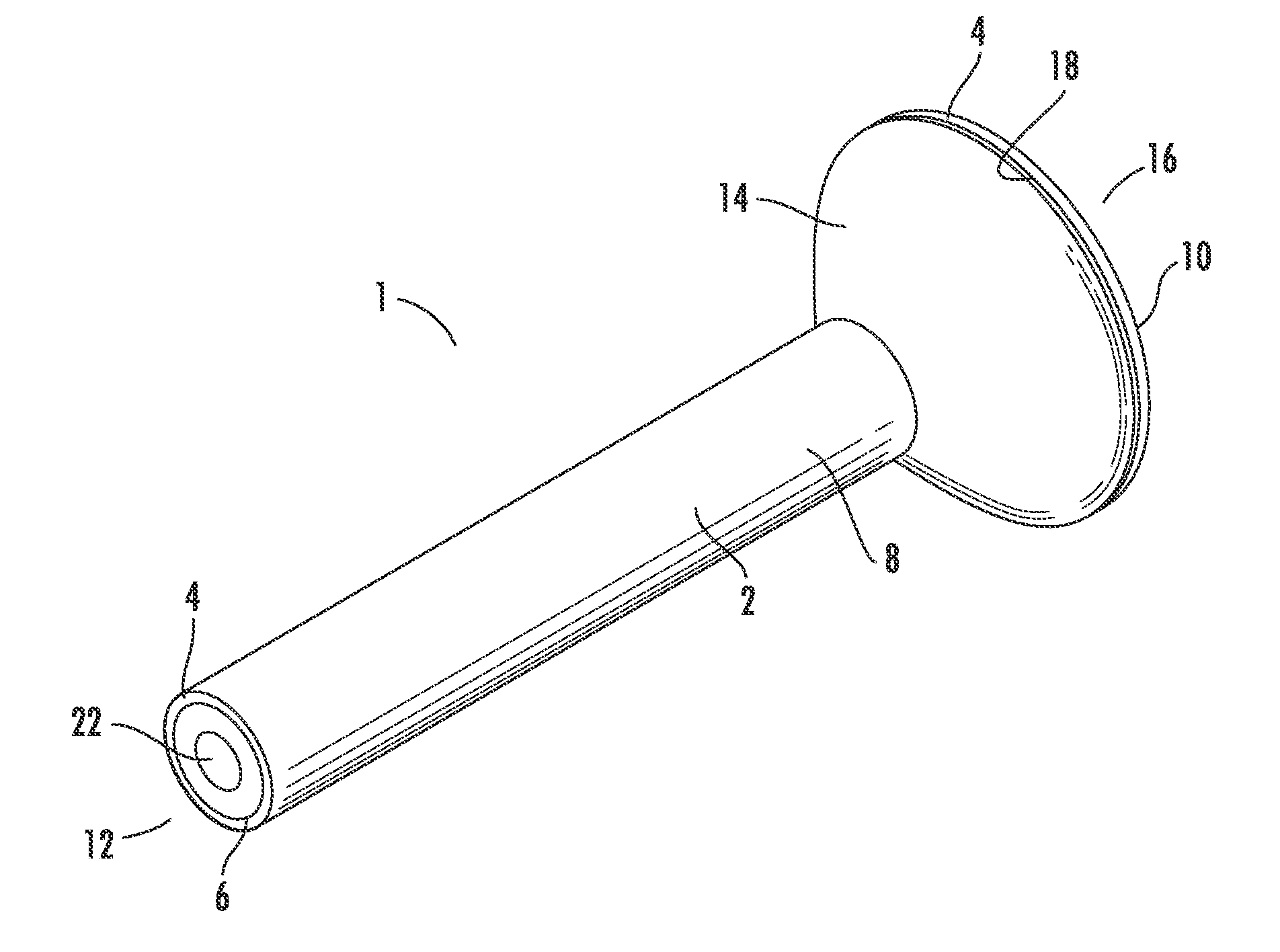

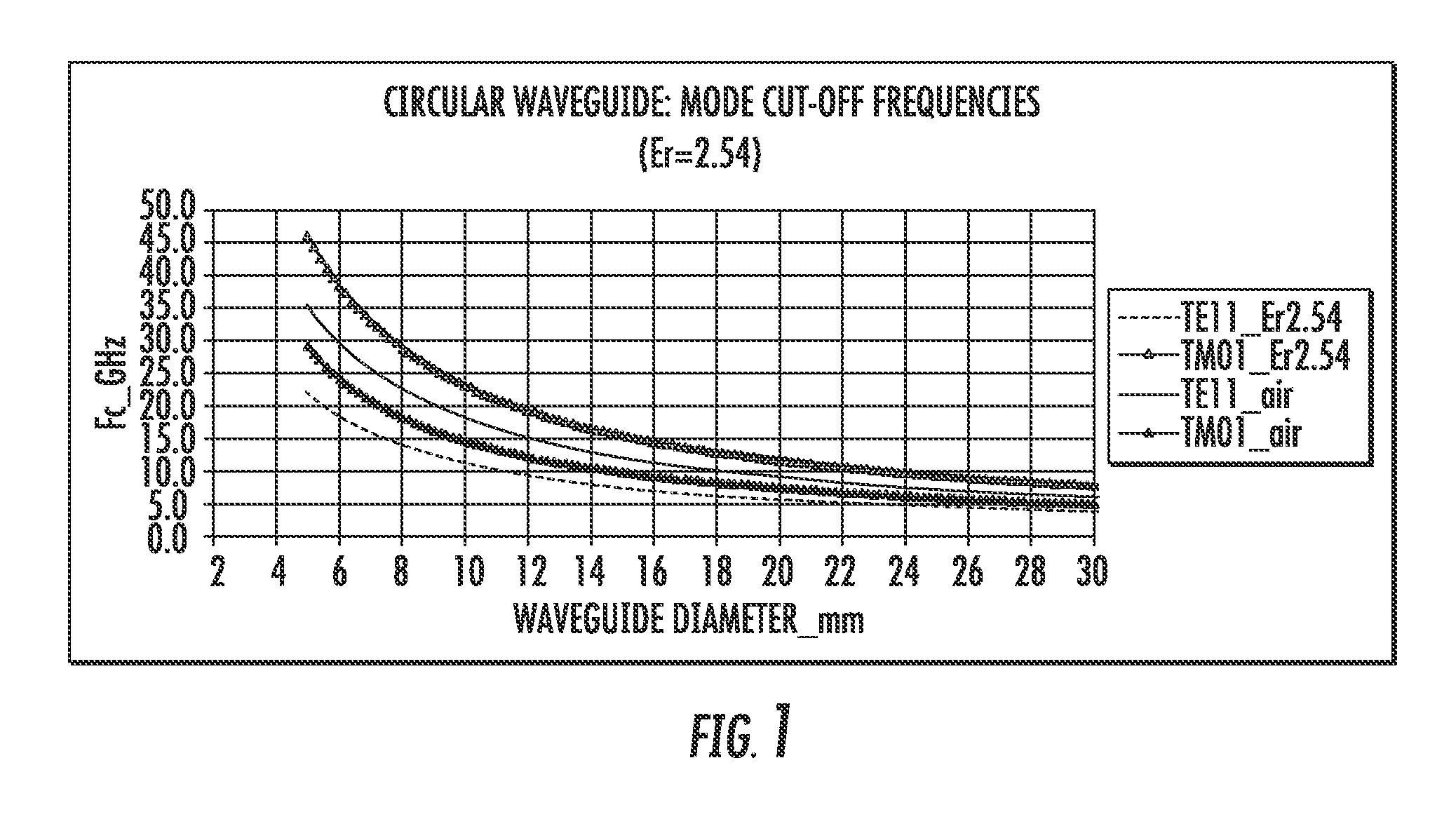

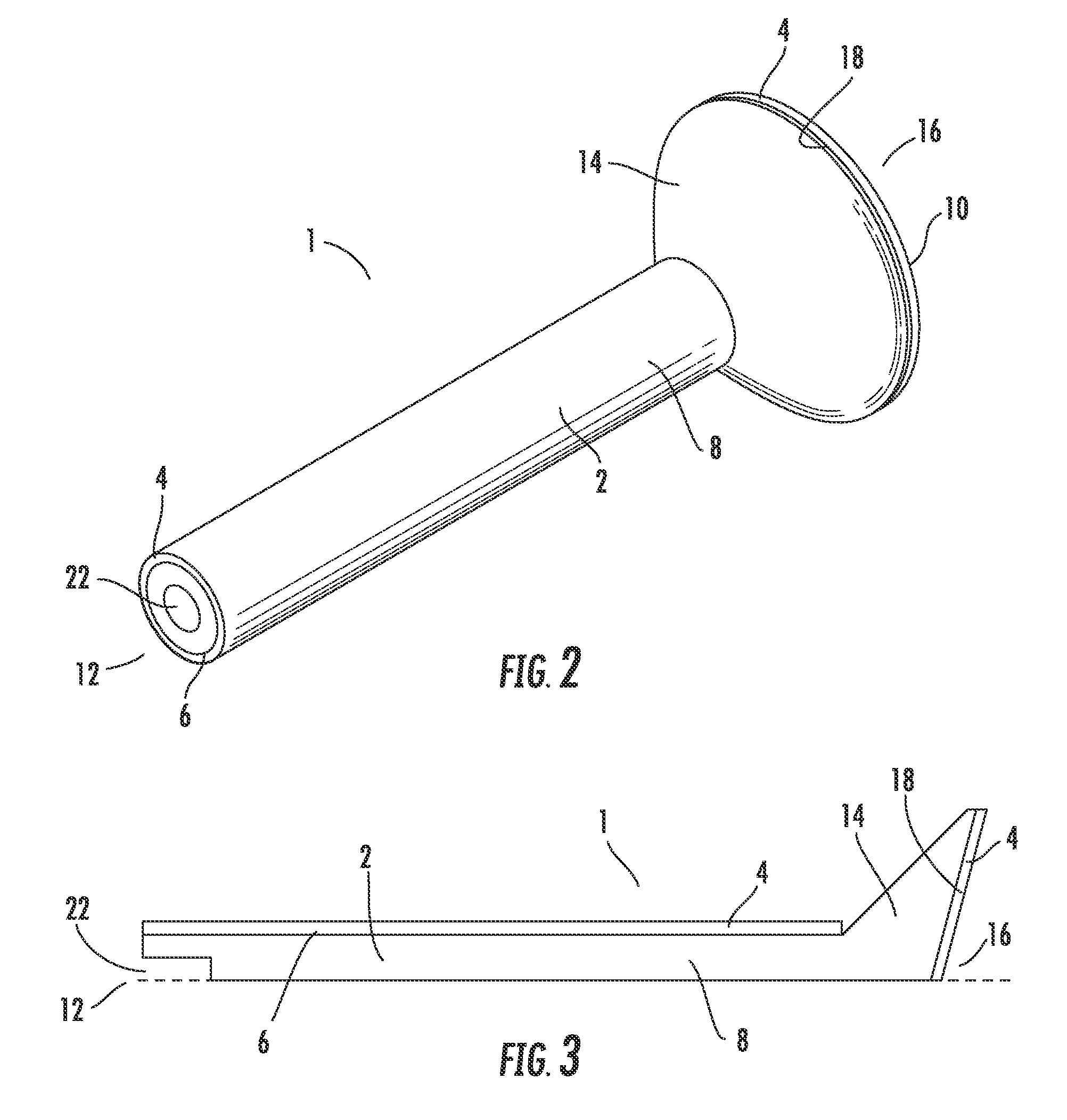

InactiveUS7907097B2Minimize impedance mismatchRepeatedly cost efficiently manufacturedAntenna supports/mountingsEngineeringMachining

A feed assembly for a reflector antenna having a unitary portion of dielectric material, a proximal end of the unitary portion configured for connection with the reflector antenna. The unitary portion having a waveguide portion extending between the proximal end and a sub reflector support having a sub reflector surface at a distal end. The waveguide portion and the sub reflector surface covered with an RF reflective material. The unitary portion may be cost effectively formed via, for example injection molding and or machining. Alternatively, the feed assembly may be formed as a horn feed, without a sub reflector.

Owner:COMMSCOPE TECH LLC

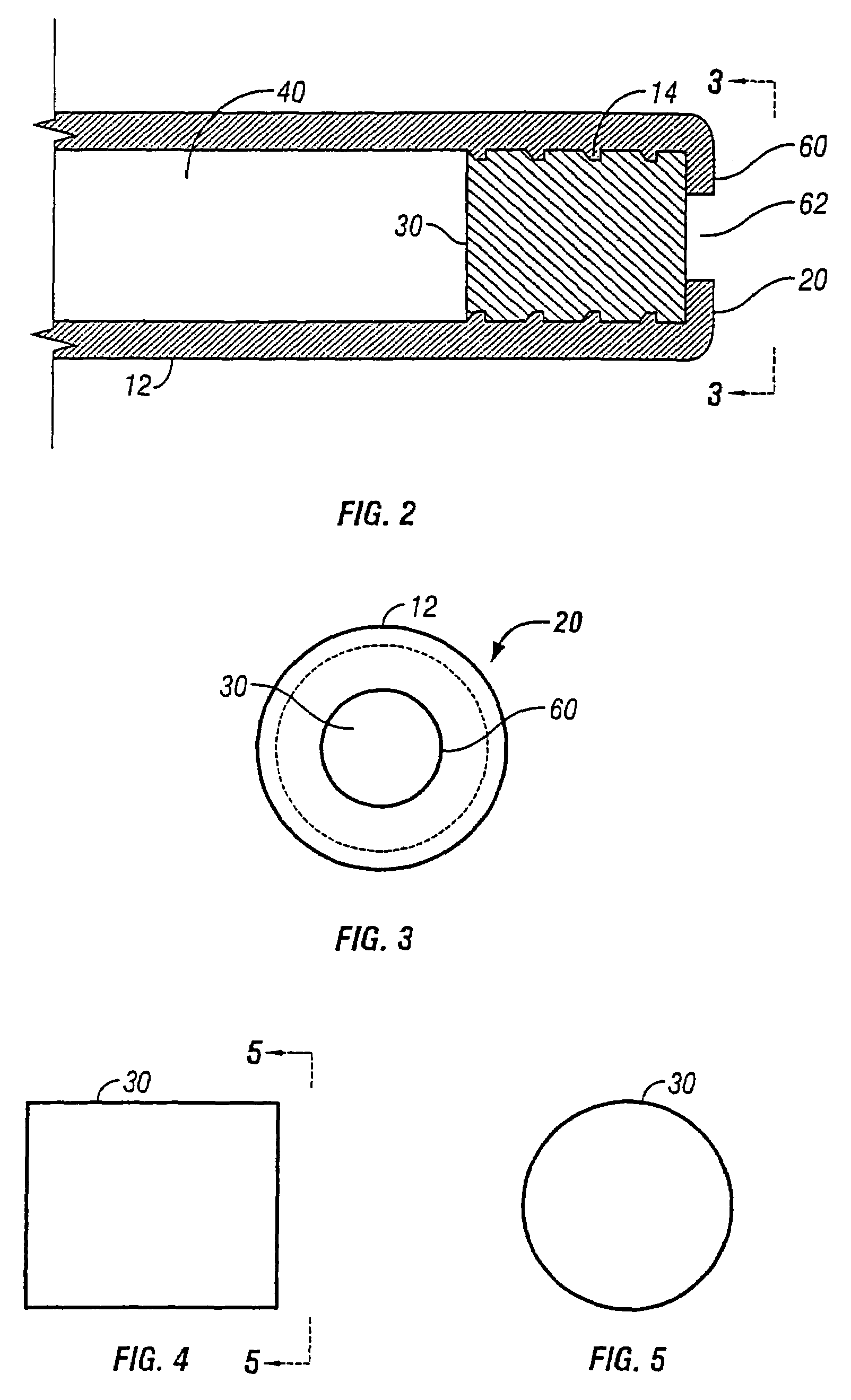

Osmotic implant with membrane and membrane retention means

InactiveUS7163688B2Prevent ejectionReduces expulsionMedical devicesCapsule deliverySystems designMedicine

An osmotic delivery system for controlled delivery of a beneficial agent includes an implantable capsule containing a beneficial agent and an osmotic engine that swells on contact with water, thereby causing the release of the beneficial agent over time. The osmotic delivery system has a membrane material that allows a controlled amount of fluid to enter from an exterior of the capsule, while preventing the compositions within the capsule from passing out of the capsule. The osmotic delivery system is designed to meet at least the operating pressures of 1000 psi. The membrane material is cast, calendered or extruded followed by machining (i.e., die-cutting, stamping or otherwise cutting to shape) to provide a uniform nonribbed membrane material. The capsule also includes a membrane material-retaining means that is positioned at a fluid uptake end to retain the membrane material within the capsule, even under periods of high pressure.

Owner:INTARCIA THERAPEUTICS INC

Cold worked metal housing for a portable electronic device

ActiveUS20080165485A1High hardnessDesired impactClosed casingsDigital data processing detailsMachiningElectron

A cold worked stainless steel bezel for a portable electronic device is provided. The bezel is secured flush to a housing to form part of the case of the portable electronic device. A brace that includes a slot for receiving a wall extending from the bezel is fixed to the housing. When the bezel engages the housing, the wall of the bezel is inserted in the slot of the brace and releasably held by a spring that engages both the brace and the wall. The bezel can be released by disengaging the spring, (e.g., using a special tool or a magnetic field). Because the bezel is manufactured from cold worked stainless steel, it is hard and resistant to impacts. Cold worked steel also facilitates manufacturing within design constraints and tolerances, and requires very little machining after manufacturing to comply with those constraints. The portable electronic device may include a personal media device, a mobile telephone, or any other suitable device or combination thereof.

Owner:APPLE INC

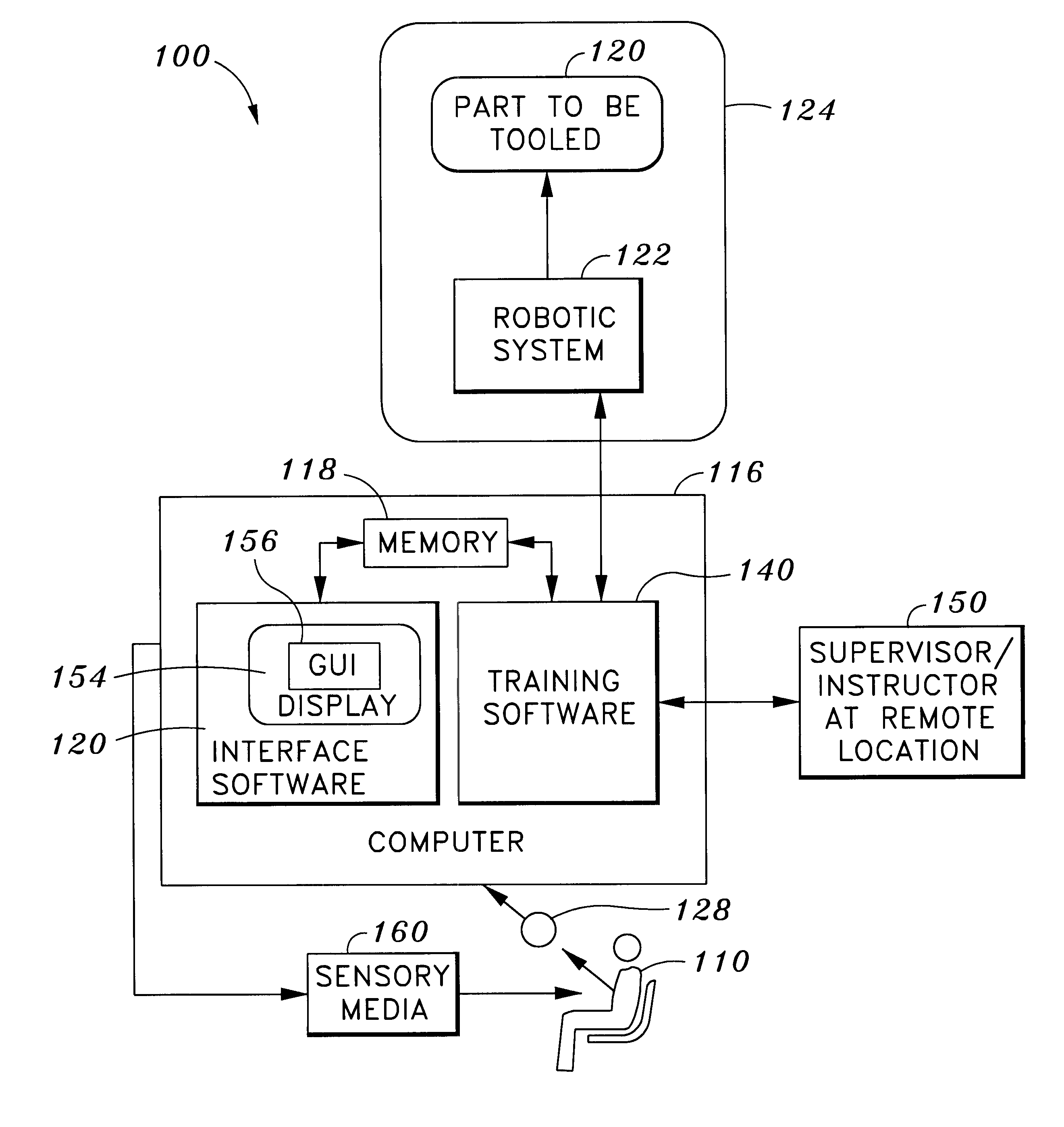

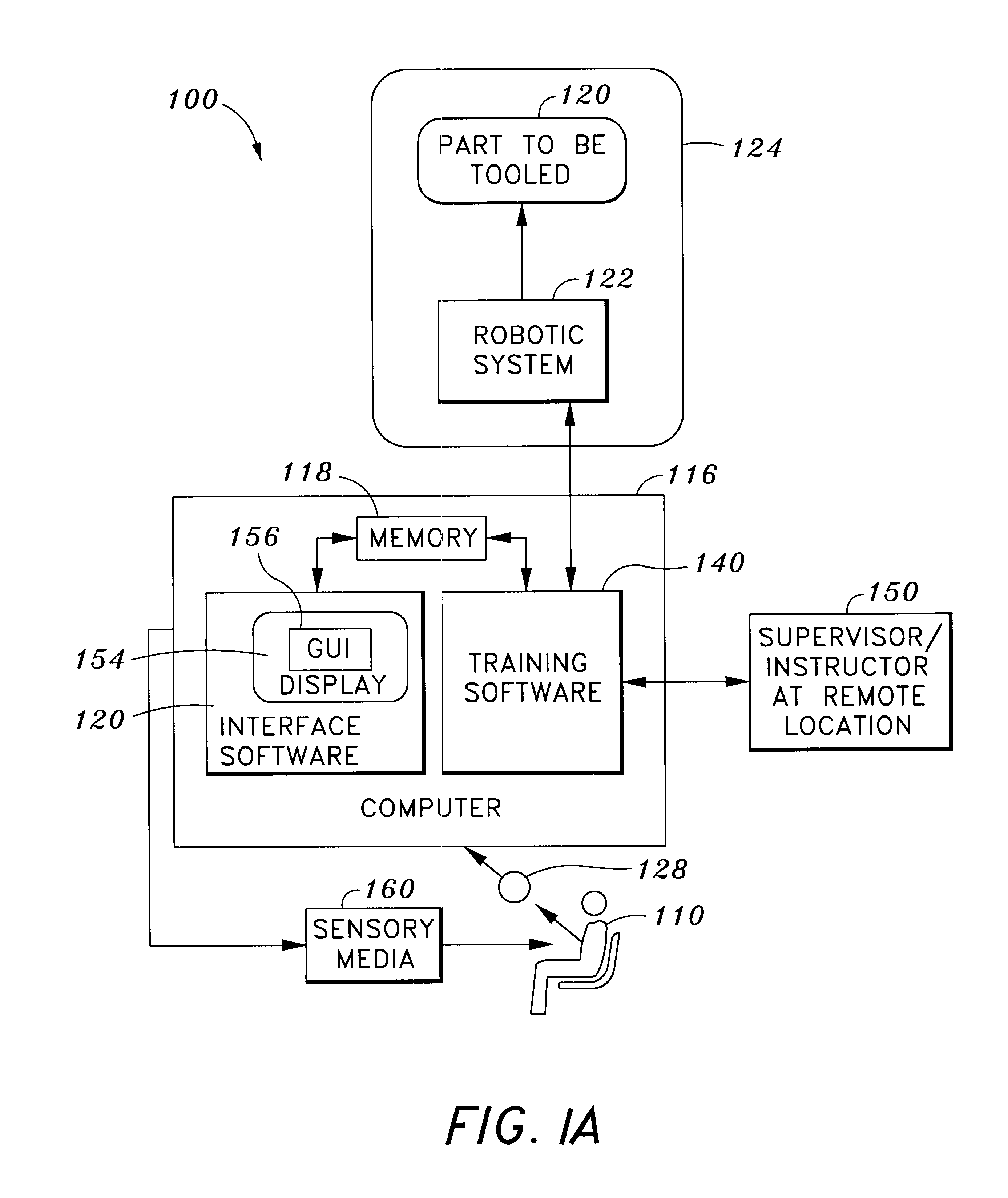

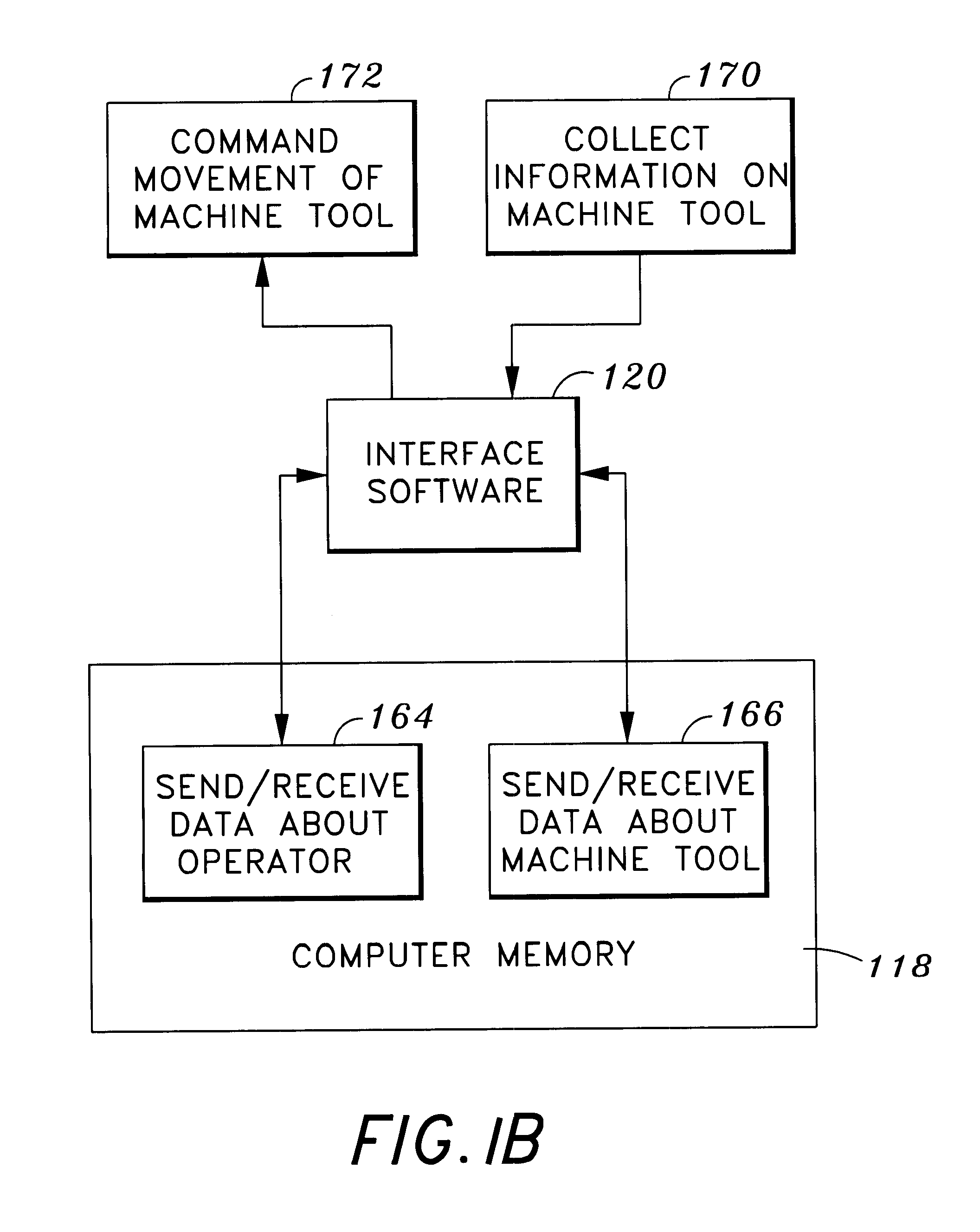

Computer interface system for a robotic system

InactiveUS6292712B1Reduce amountEasy to operateProgramme controlComputer controlPointing deviceWorkstation

The present invention is an interactive multi-media interface system which incorporates text, audio, and video graphics animation and other tools to interface a user with a device in an outside environment, such as a robotic device, machining or other tool. The interface system includes a computer workstation to allow inputs from a user, such as a machine operator, computer memory, and an interface computer program operating on the computer. The computer has a graphical user interface for interfacing the operator with the workstation and to allow interactive operation and control of the machine tool. The operator can provide inputs to the interface system by various input devices such as a keyboard, cursor, mouse, a stylus pointing device or a touch sensitive screen. The interface software shares access to and exchanges data with the computer memory.

Owner:NORTHROP GRUMMAN SYST CORP

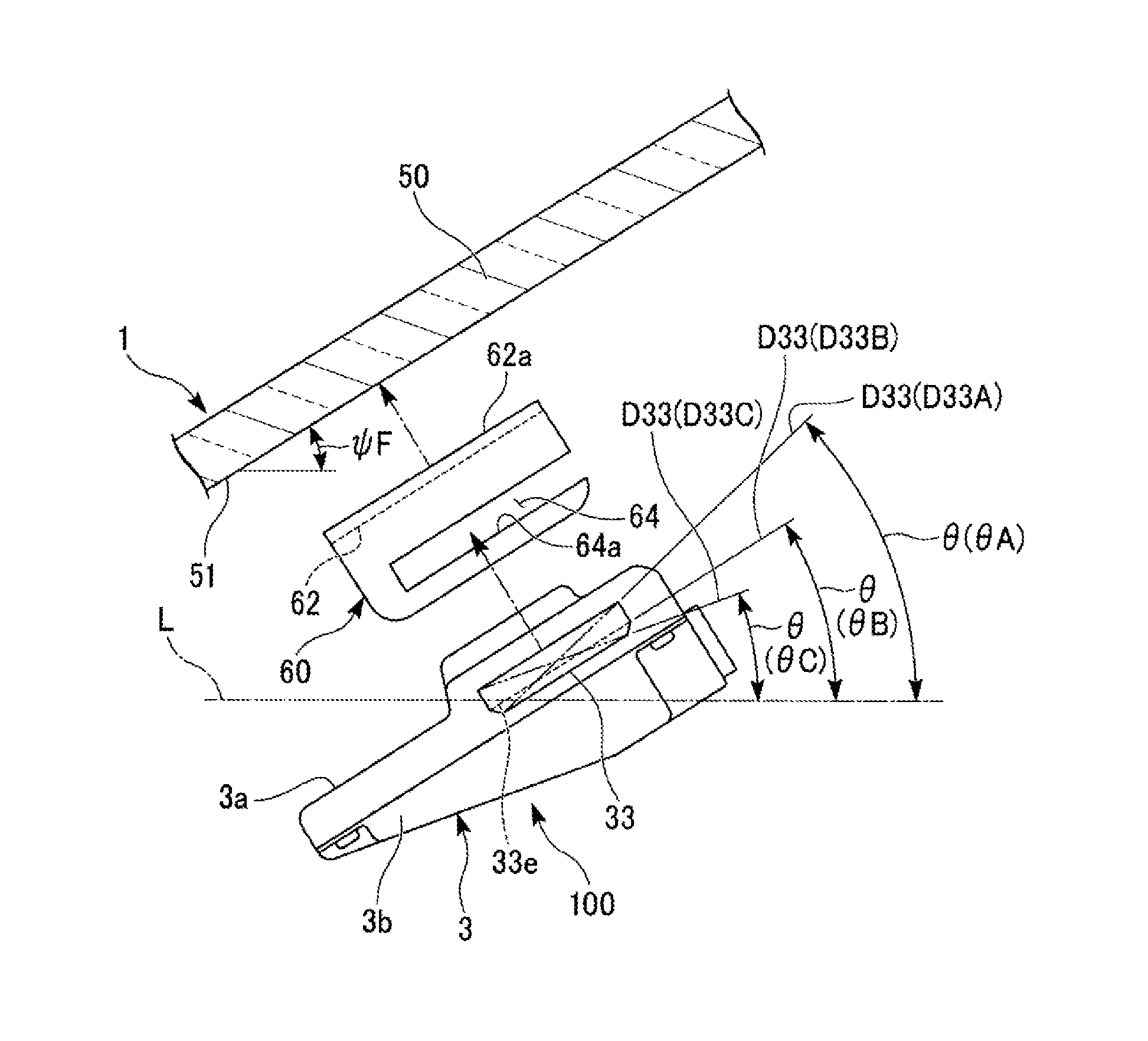

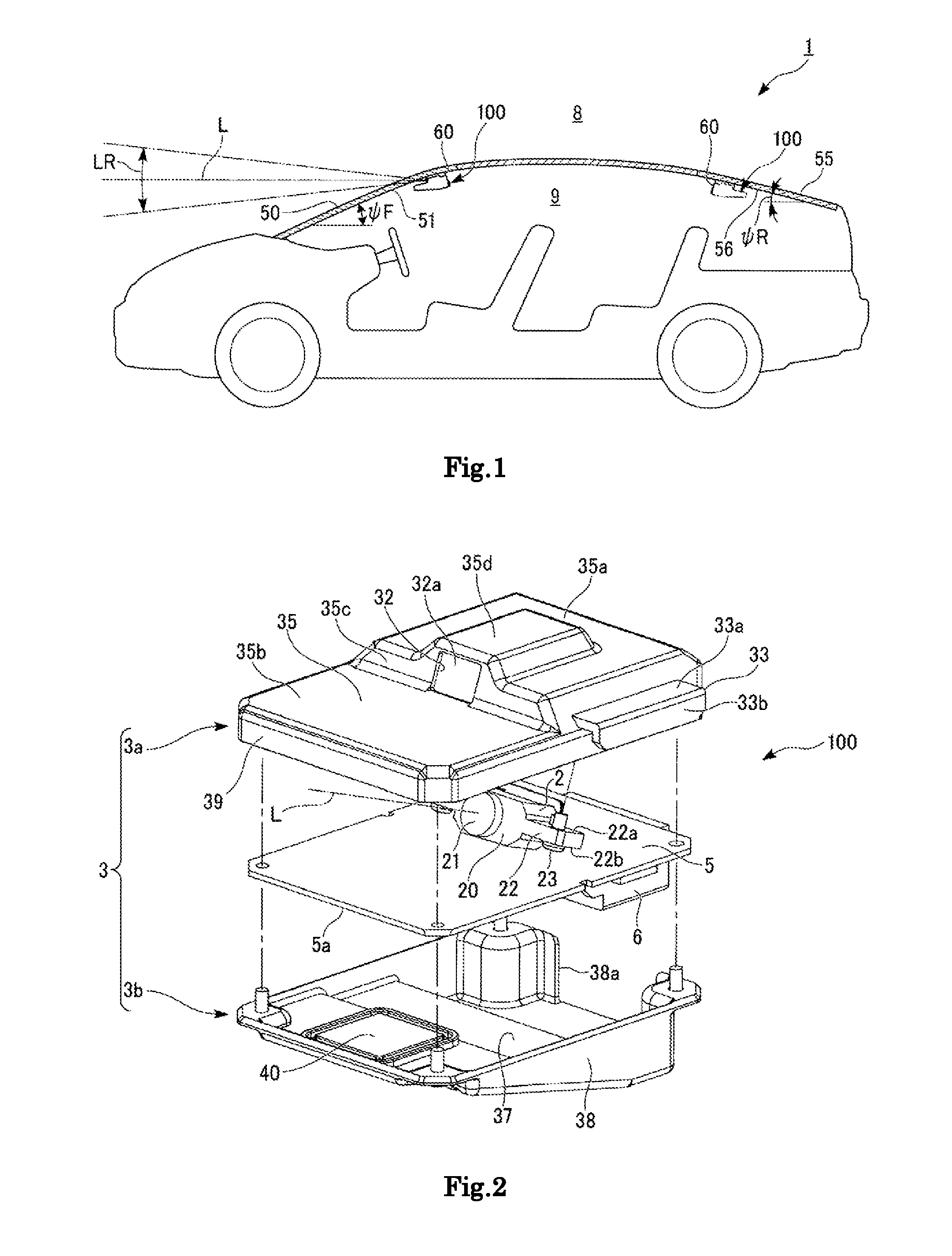

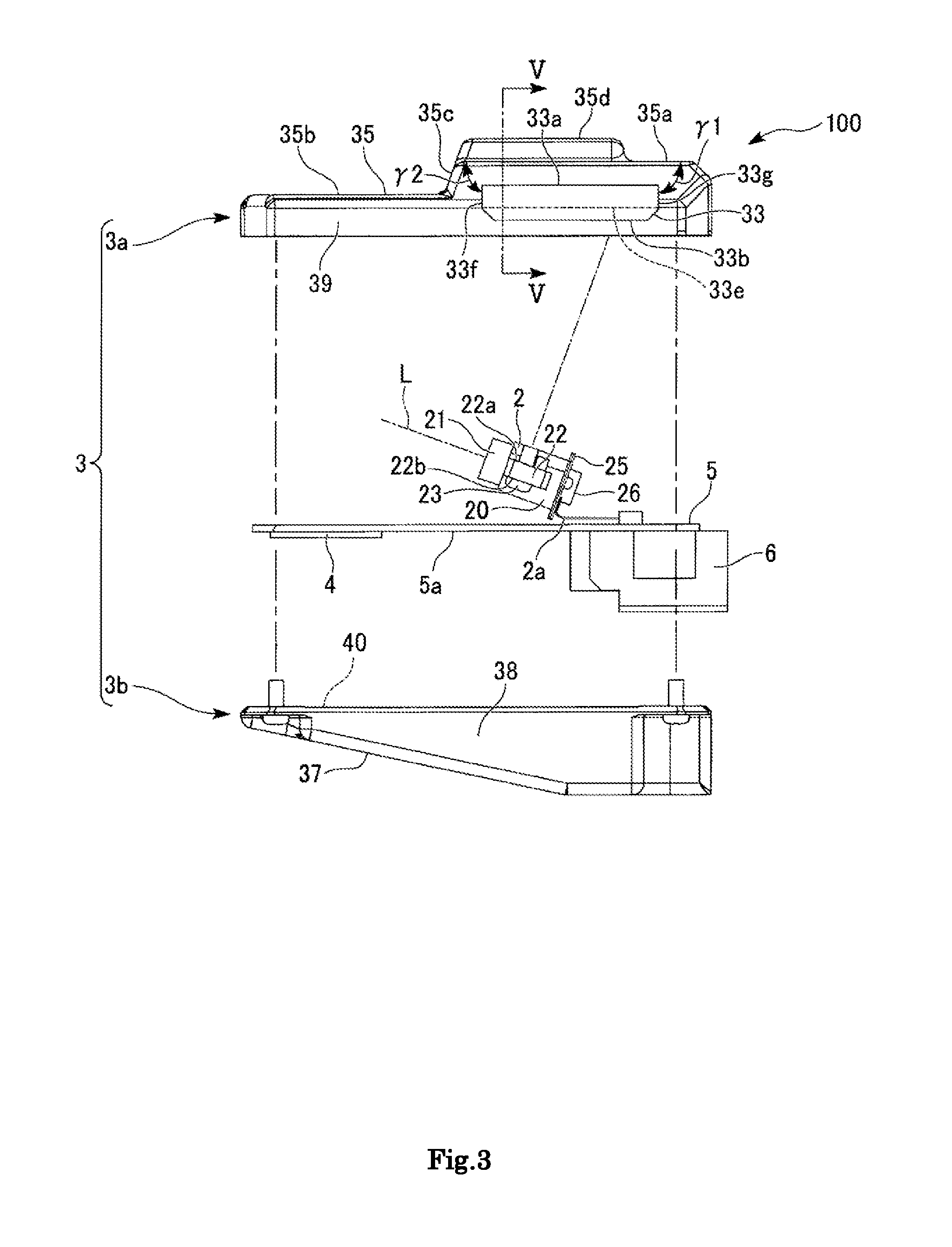

Method of manufacturing vehicle

ActiveUS20170057422A1Low costEasy to adjust the angleTelevision system detailsColor television detailsOptical axisEngineering

A method of manufacturing a vehicle in which a vehicle-mounted camera is attached to a glass surface on a vehicle interior side of a window glass of a vehicle body, and includes a seat fixed to the glass surface and including a seat surface extending along a predetermined direction and preferably formed by machining, includes determining the predetermined direction on the basis of an inclination angle of the glass surface to set an optical axis direction of the vehicle-mounted camera in any direction. The method of manufacturing provides a vehicle-mounted camera that is low in costs and includes an optical axis with an angle which is easy to adjust.

Owner:NIPPON DENSAN CORP

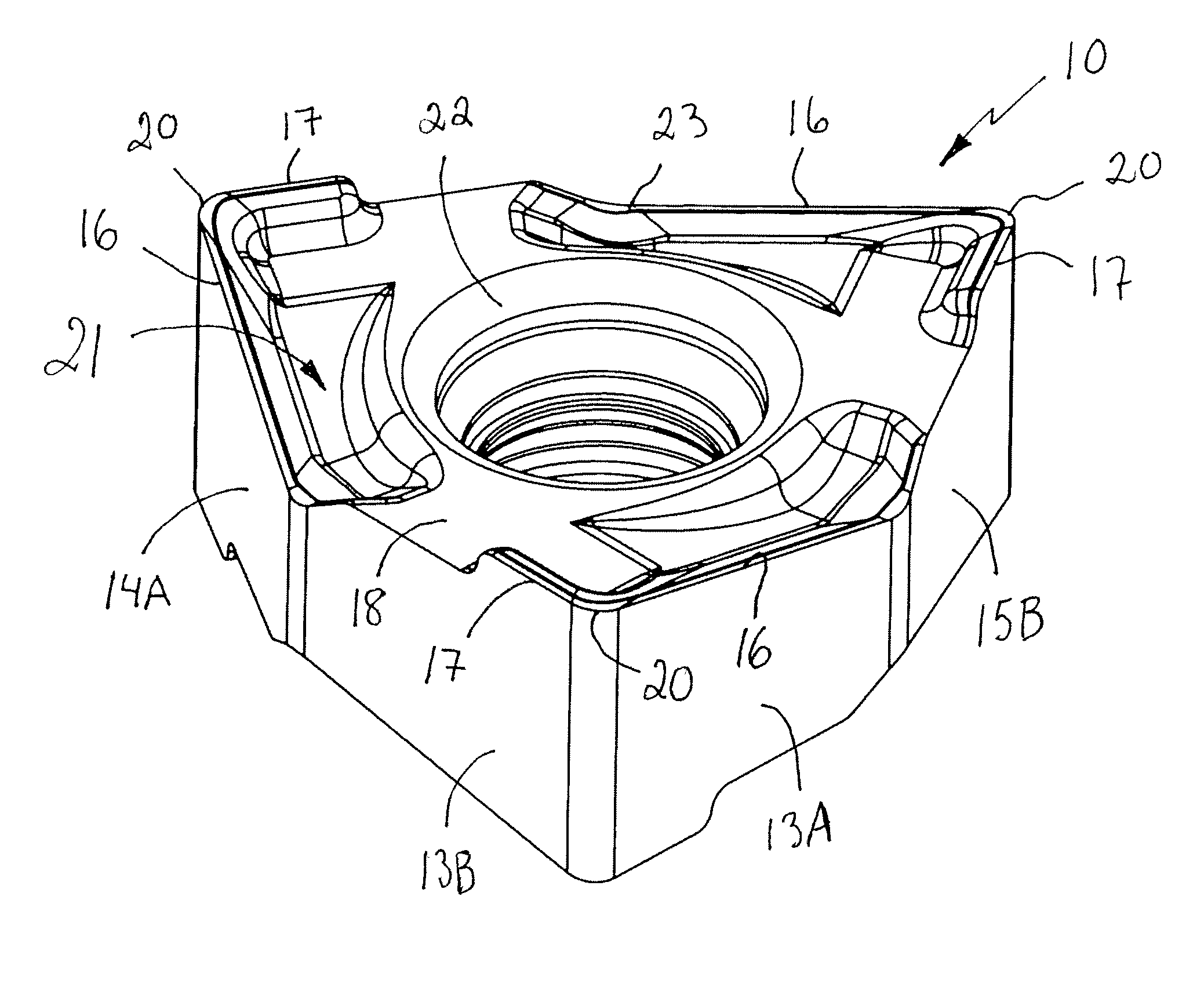

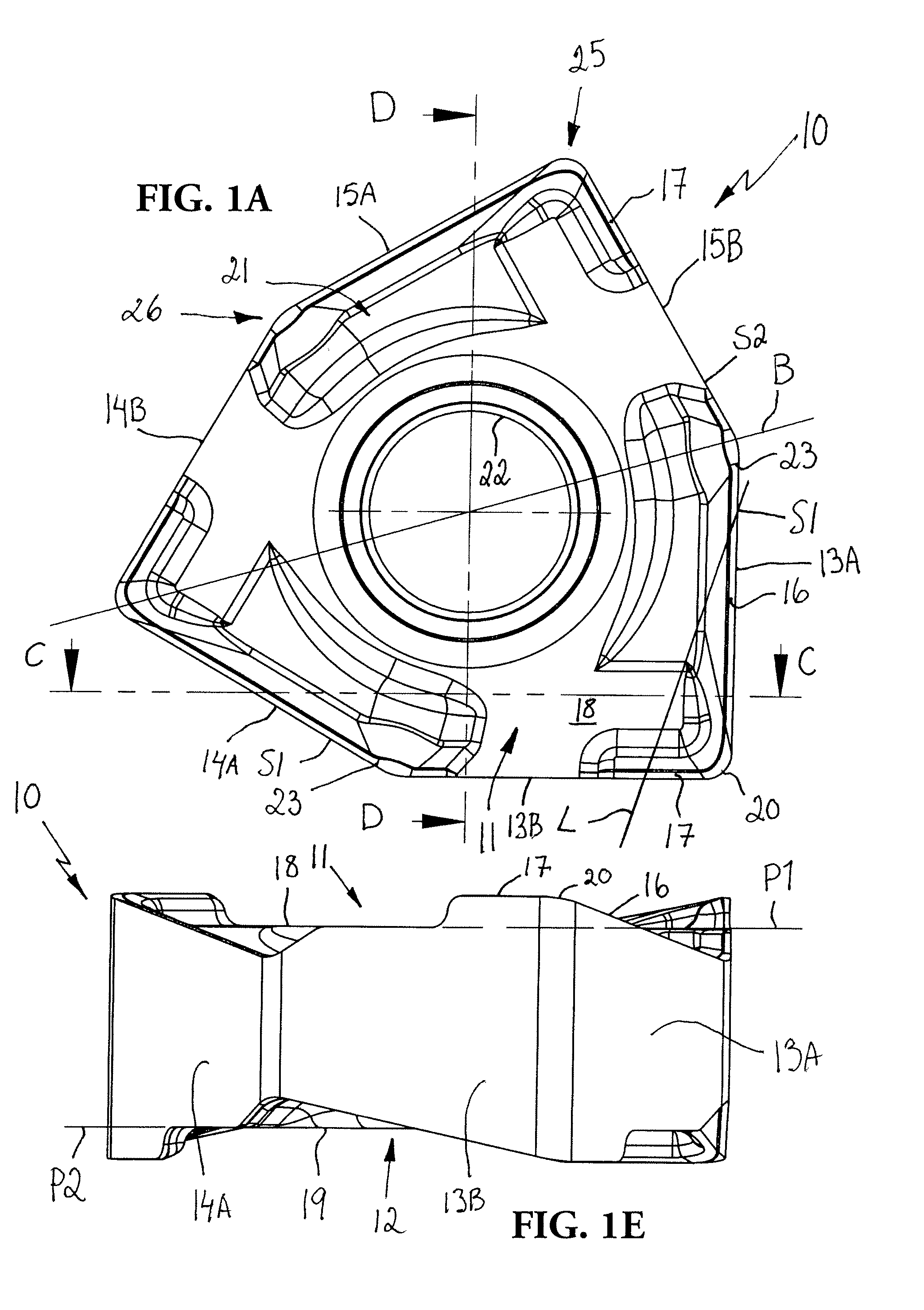

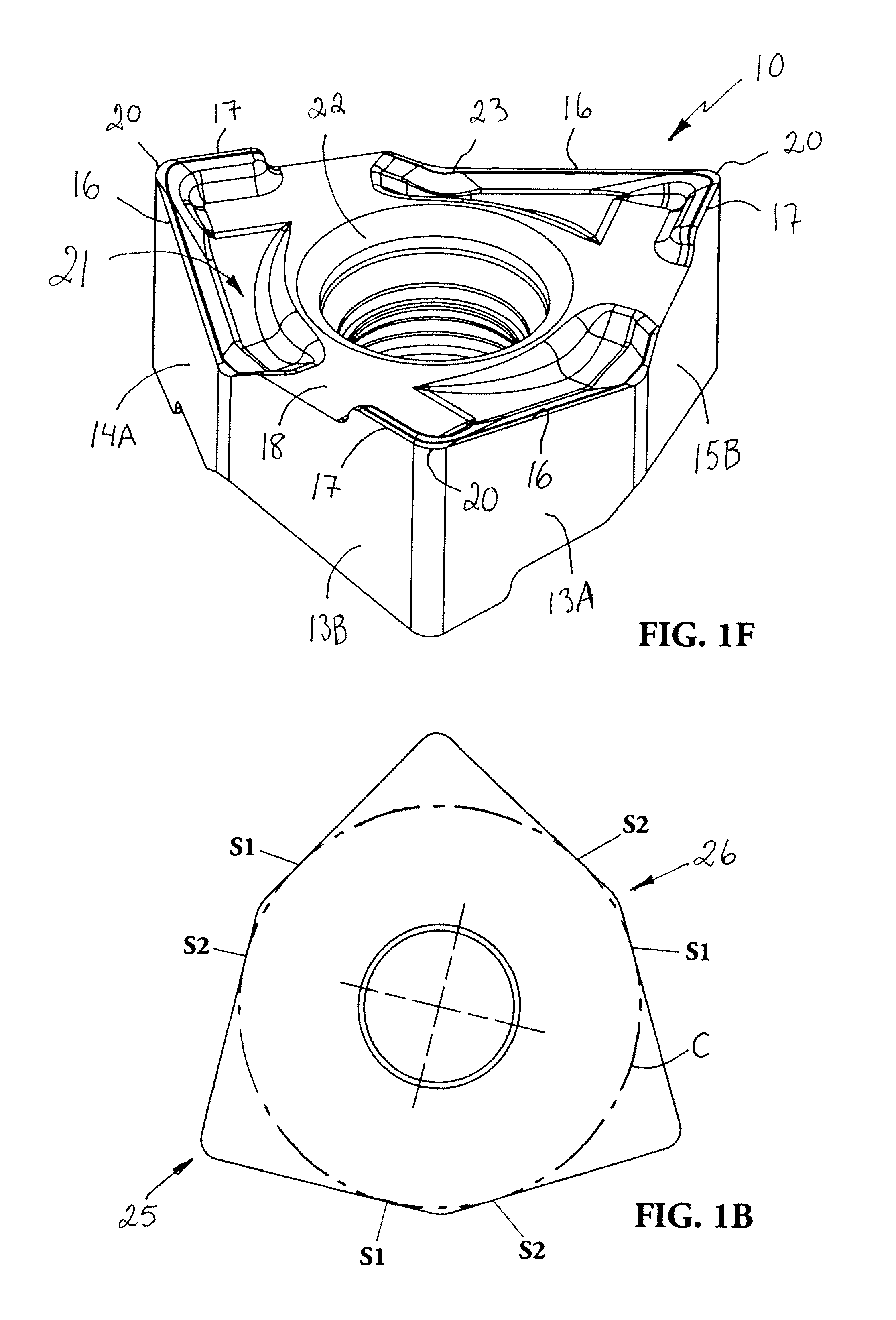

Milling insert and a milling tool

The present invention relates to an indexable milling insert and a milling tool for chip removing machining. The milling insert is intended to be able to mill substantially perpendicular corners in a work piece. The milling insert comprises an upper side, a lower side and edge surfaces extending therebetween. The upper side and the lower side are substantially identical. An imaginary circle inscribed in the milling insert touches the milling insert periphery in four to six points. Lines of intersection between the edge surfaces and the sides form relative to each other substantially perpendicular main cutting edges and minor cutting edges. Each of the sides includes a support surface, each of which being provided in a plane. Each minor cutting edge projects from the plane of the associated support surface. Each major cutting edge intersects the plane of the associated support surface.

Owner:SECO TOOLS AB

Laser ablation feedback spectroscopy

InactiveUS20050061779A1Precise depth controlReduce the amount requiredWelding/soldering/cutting articlesMetal working apparatusMass spectrometryAblation plasma

Methods, for use with a laser ablation or drilling process, which achieve depth-controlled removal of composite-layered work-piece material by real-time feedback of ablation plasma spectral features. The methods employ the use of electric, magnetic or combined fields in the region of the laser ablation plume to direct the ablated material. Specifically, the electric, magnetic or combined fields cause the ablated material to be widely dispersed, concentrated in a target region, or accelerated along a selected axis for optical or physical sampling, analysis and laser feedback control. The methods may be used with any laser drilling, welding or marking process and are particularly applicable to laser micro-machining. The described methods may be effectively used with ferrous and non-ferrous metals and non-metallic work-pieces. The two primary benefits of these methods are the ability to drill or ablate to a controlled depth, and to provide controlled removal of ablation debris from the ablation site. An ancillary benefit of the described methods is that they facilitate ablated materials analysis and characterization by optical and / or mass spectroscopy.

Owner:BLUMENFELD WALTER +2

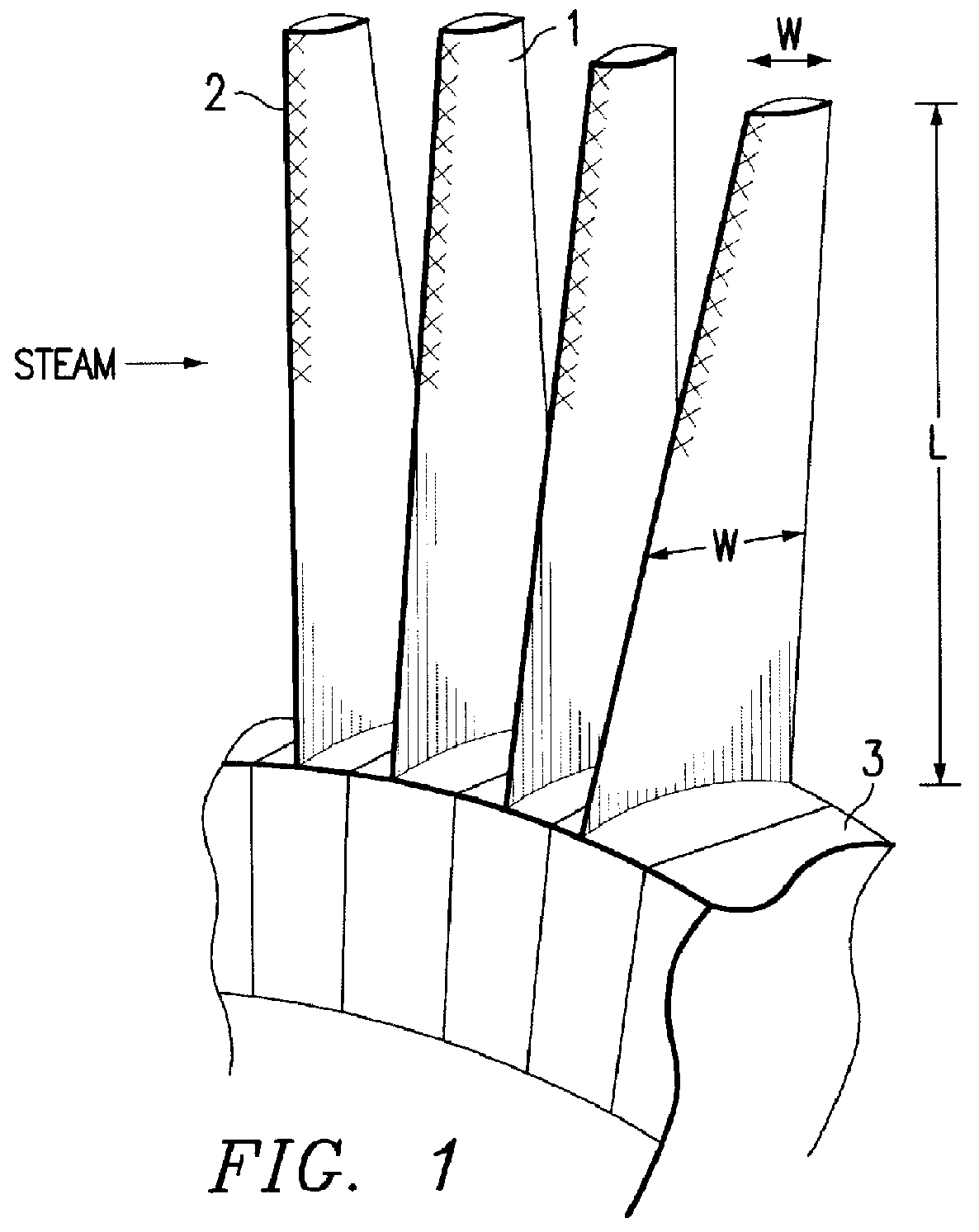

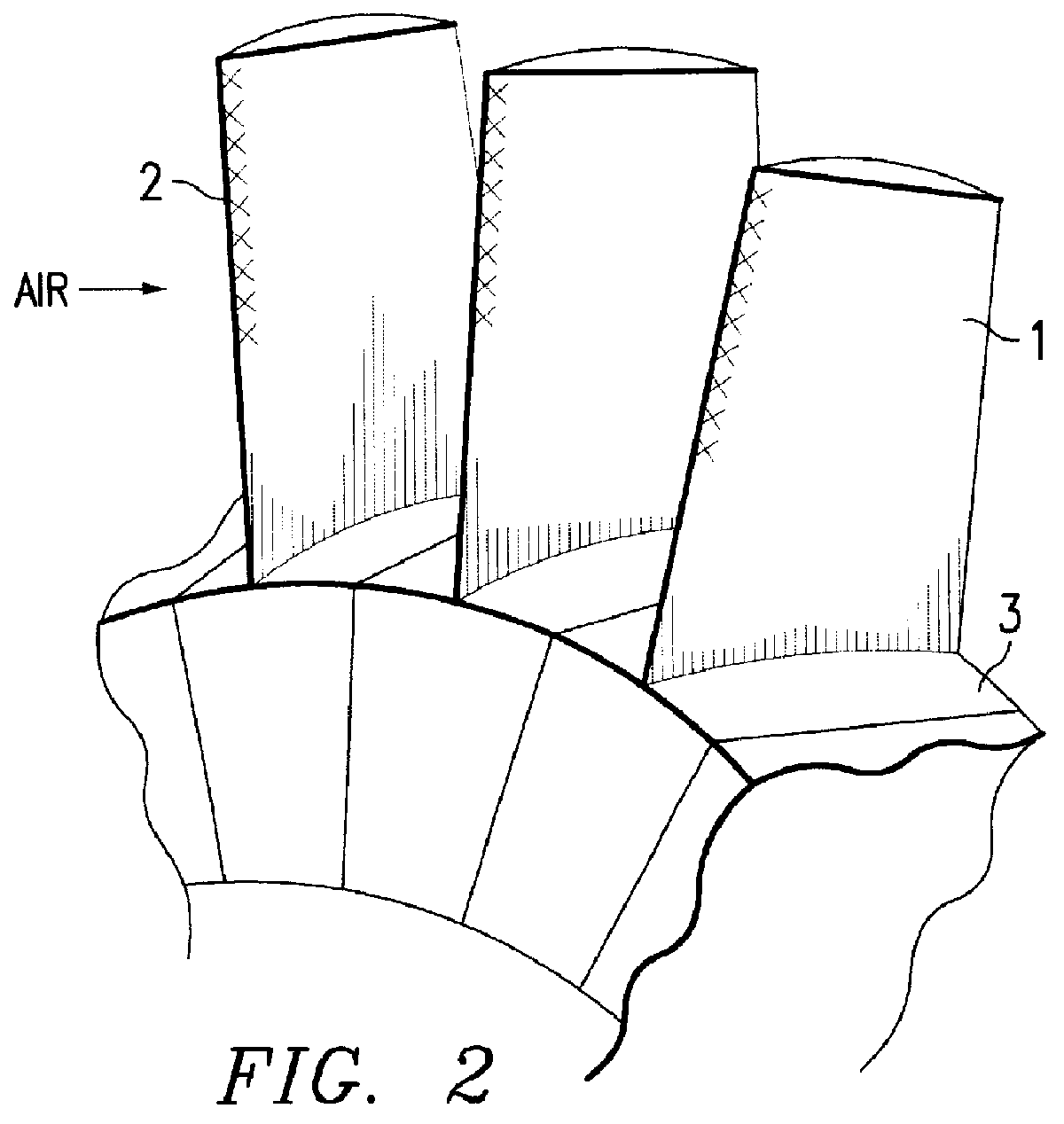

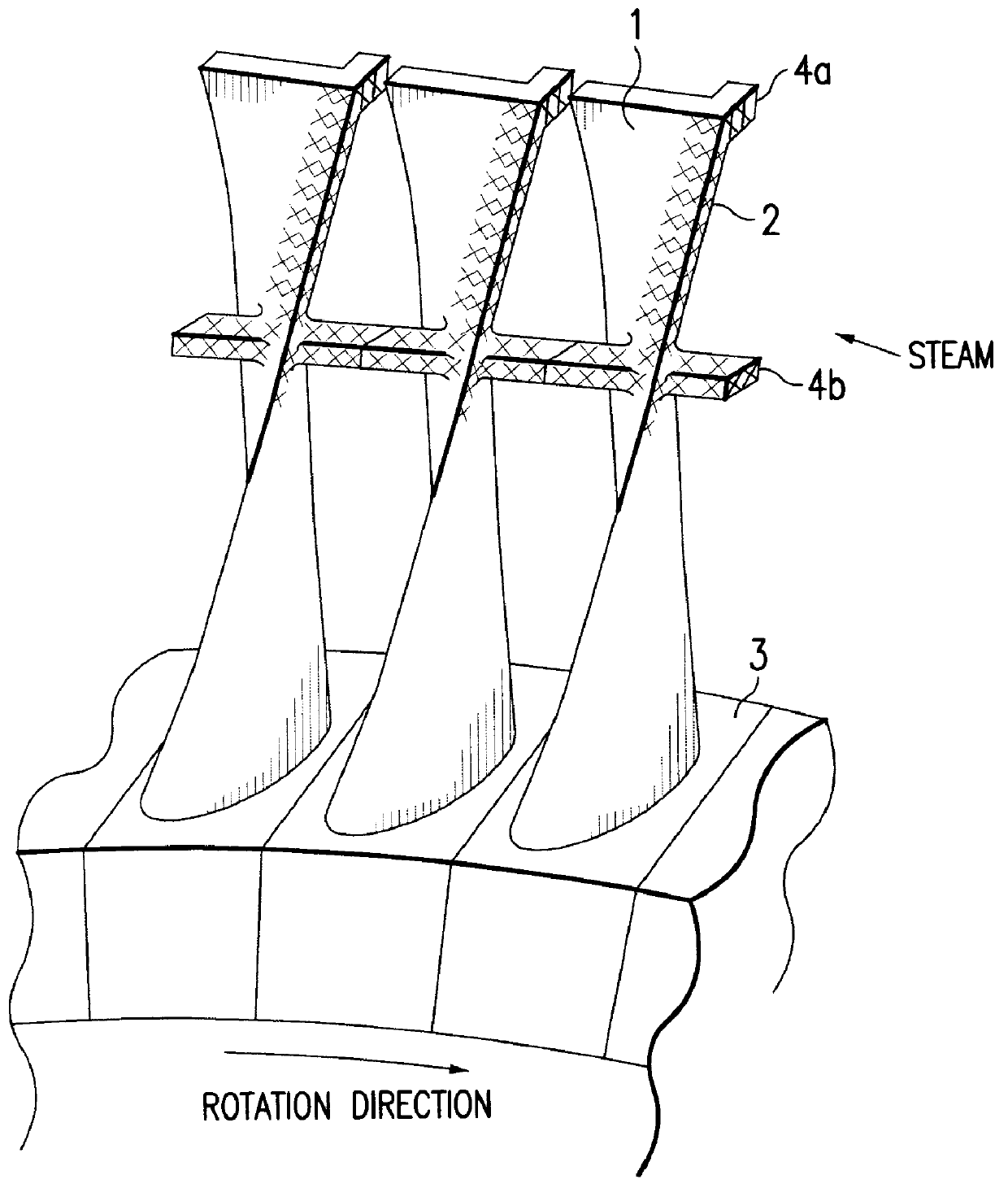

Method for producing titanium alloy turbine blades and titanium alloy turbine blades

InactiveUS6127044ALess abrasionSuperior in water droplet erosion resistancePropellersEngine manufactureLeading edgeTurbine blade

PCT No. PCT / JP95 / 01817 Sec. 371 Date Jun. 2, 1998 Sec. 102(e) Date Jun. 2, 1998 PCT Filed Sep. 13, 1995 PCT Pub. No. WO97 / 10066 PCT Pub. Date Mar. 20, 1997A method for producing titanium alloy turbine blades comprising the steps of (a) forming turbine blades of titanium alloy through hot forging or machining, (b) cooling leading edges on tip portions of the turbine blades including covers thereof formed through hot forging or machining faster than blade main body after final hot forging or solid solution treatment, and (c) heat treating the cooled turbine blades. With this method, it is possible to manufacture titanium turbine blades in an economical fashion and obtain titanium alloy turbine blades superior in reliability by preventing erosion.

Owner:KK TOSHIBA +1

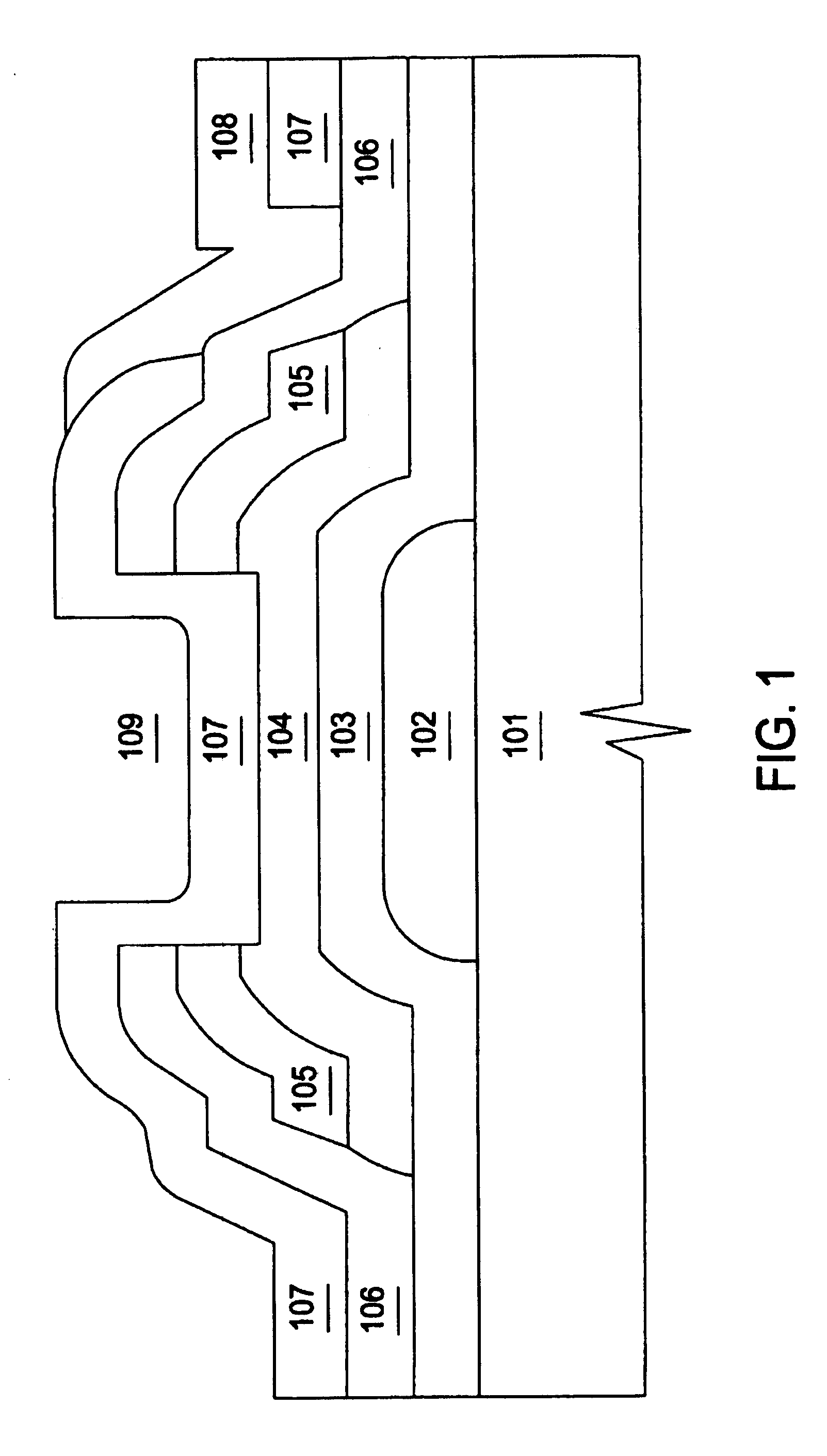

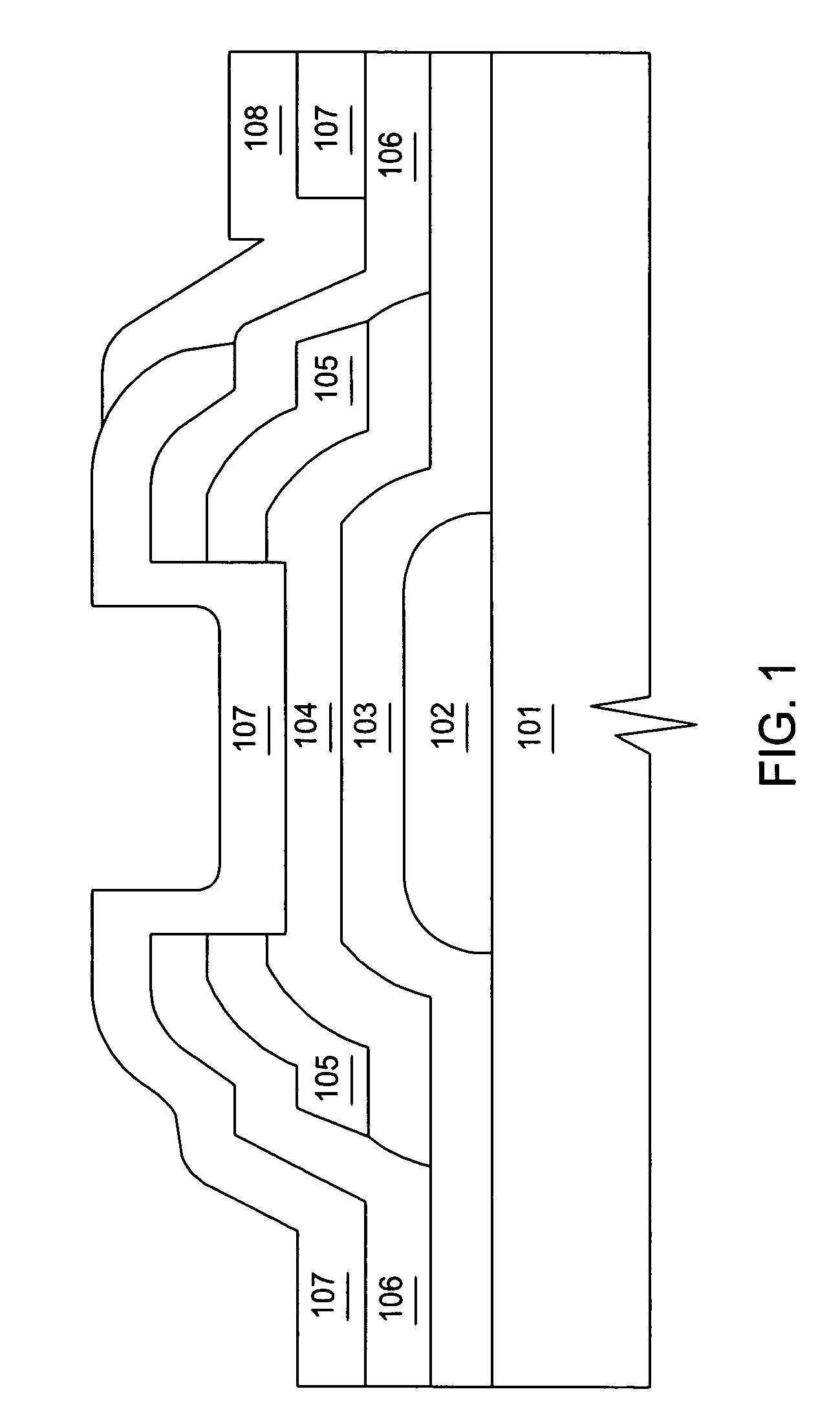

Method for producing a part and device for carrying out this method

InactiveUS7003864B2Faster machinabilityReduced tool wearMouldsWood working apparatusEngineeringRapid prototyping

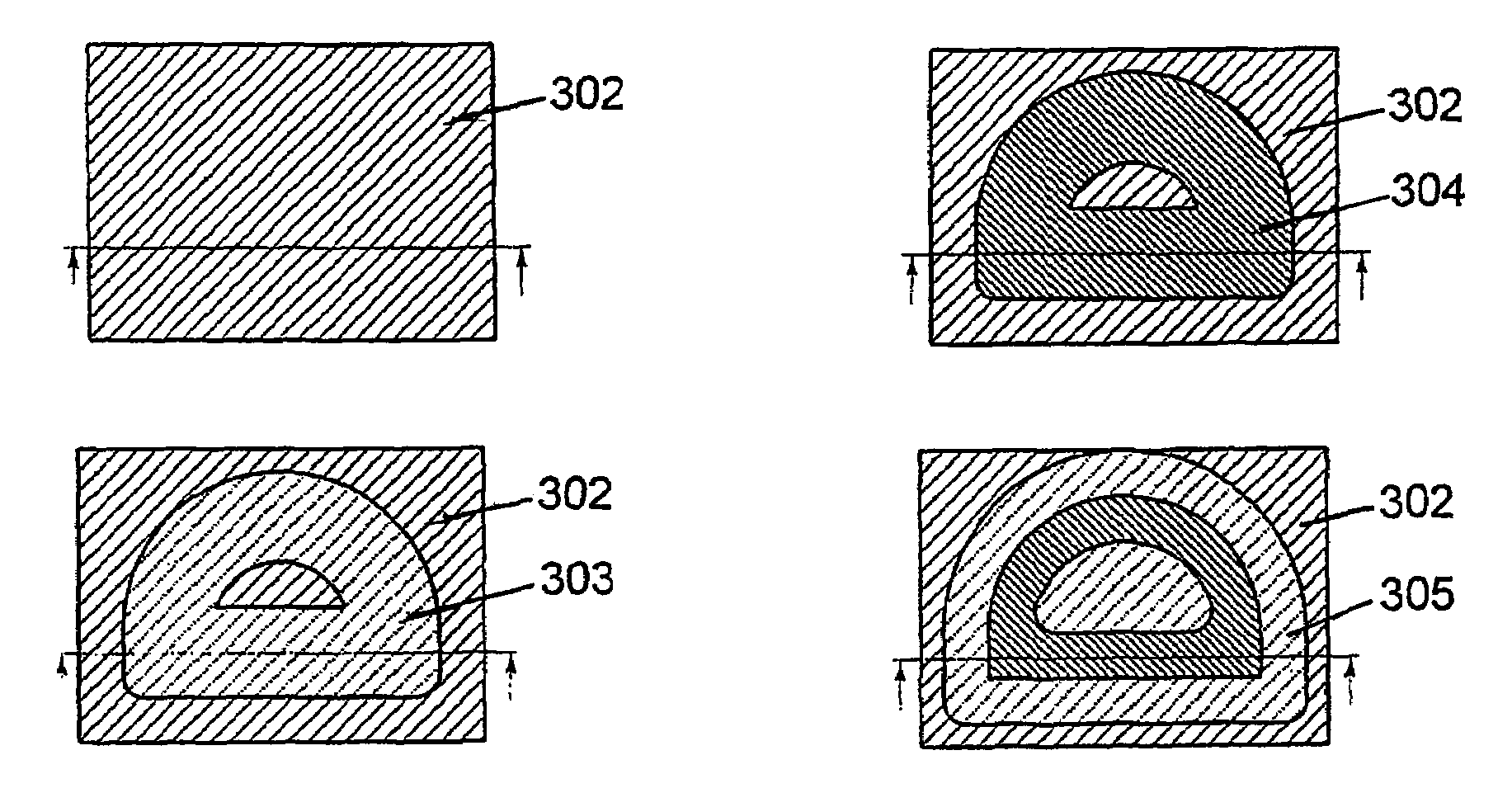

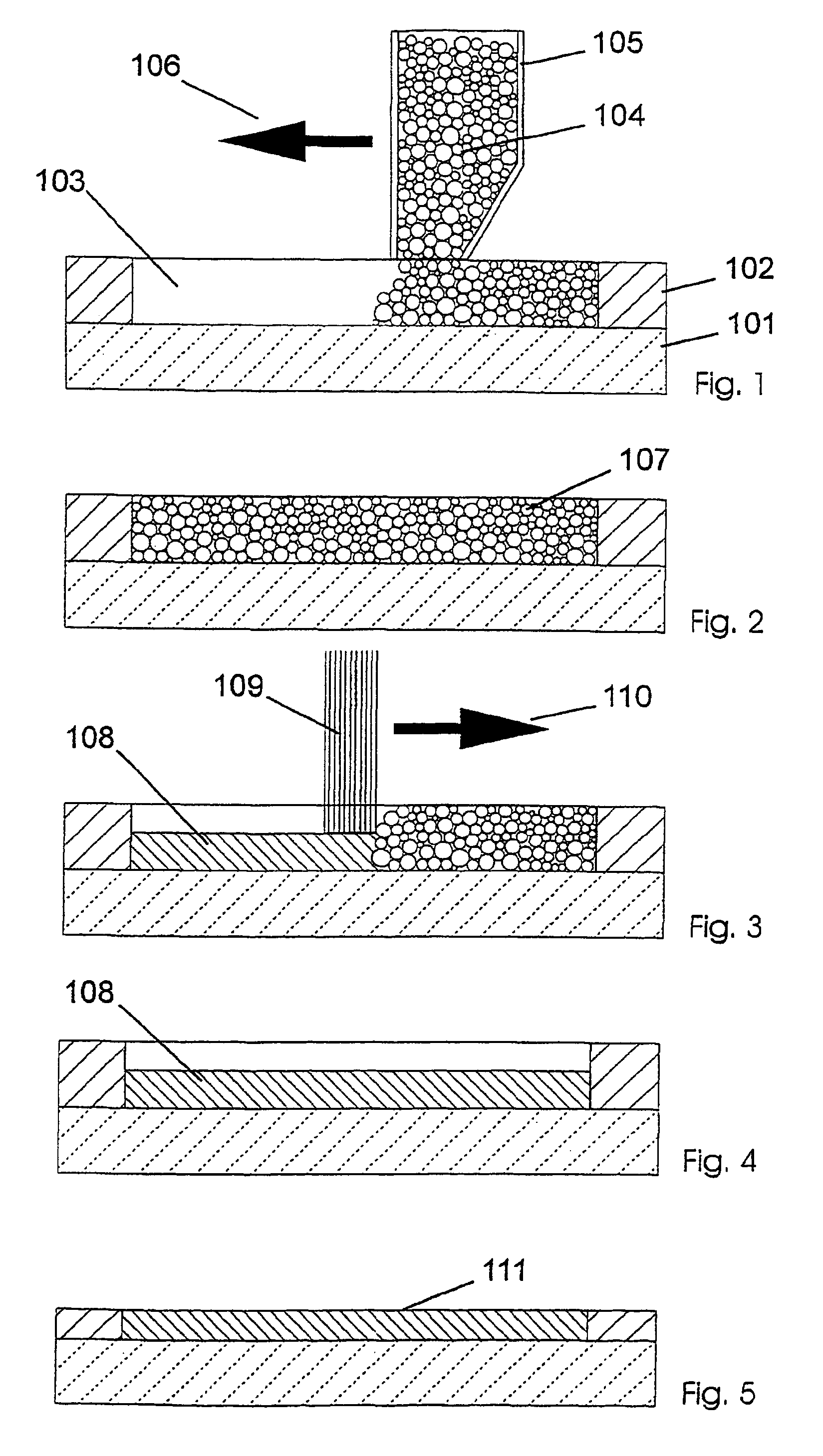

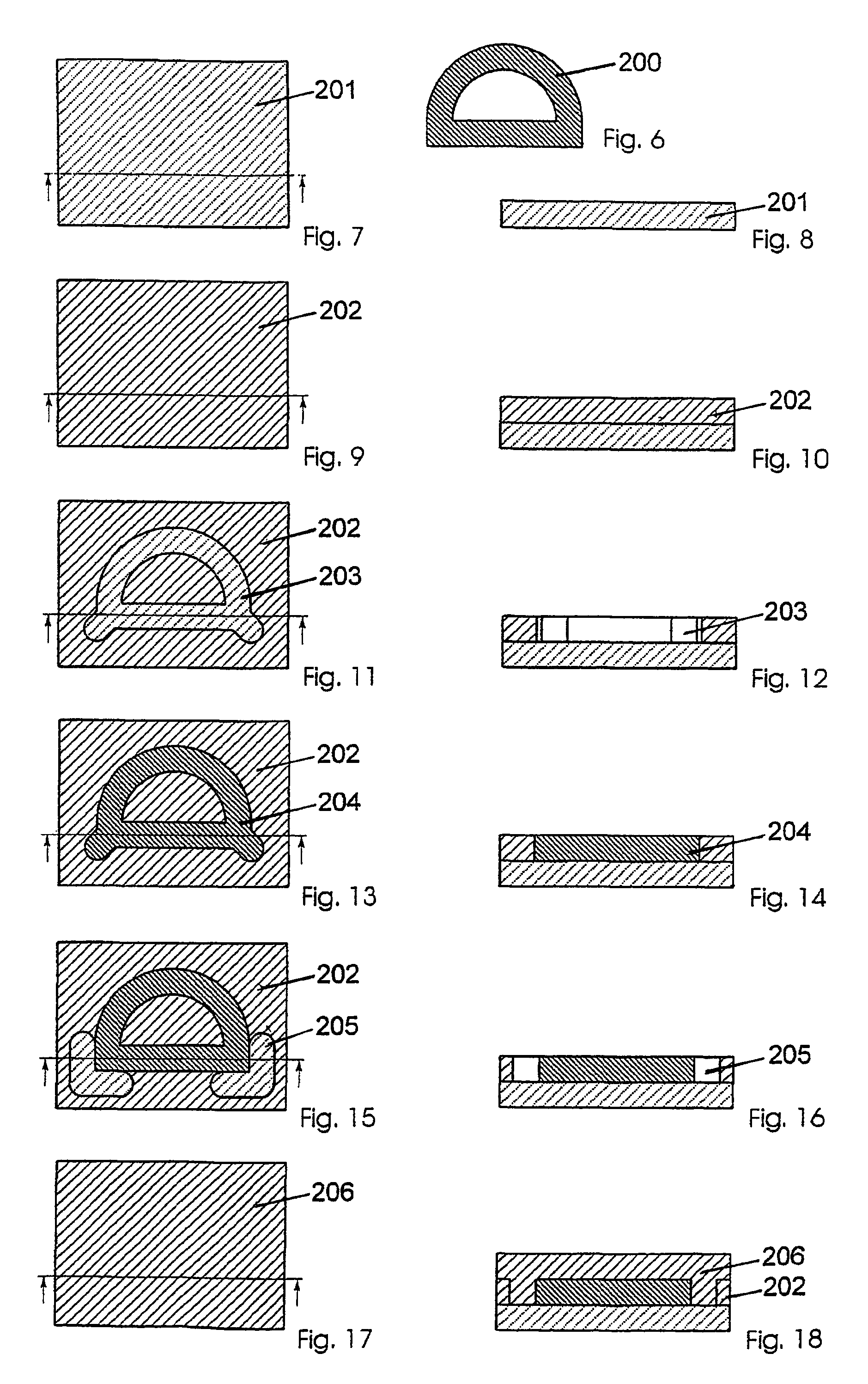

The present invention relates to a method for producing a part (108, 200, 300), comprising the following steps:a) applying a first flat layer consisting of a support material (102, 202, 302), to a construction platform (101, 201, 301),b) introducing at least one recess (103, 203, 303) into the support material (102, 202, 302),c) filling the recess (103, 203, 303) with a construction material (104, 204, 304),d) applying a further layer of support material (102, 202, 302),e) repeating steps b) through d) until completion of the part (108, 200, 300), andf) removing the support material (102, 202, 302).This method is to provide a manufacturing method and a device that combine the advantages of the layerwise construction (rapid prototyping) with the advantages of machining (e.g. high-speed cutting) and particularly permit the production of sharp-edged contours.Furthermore, the present invention relates to a device for carrying out the method.

Owner:HERMLE MASCHENBAU

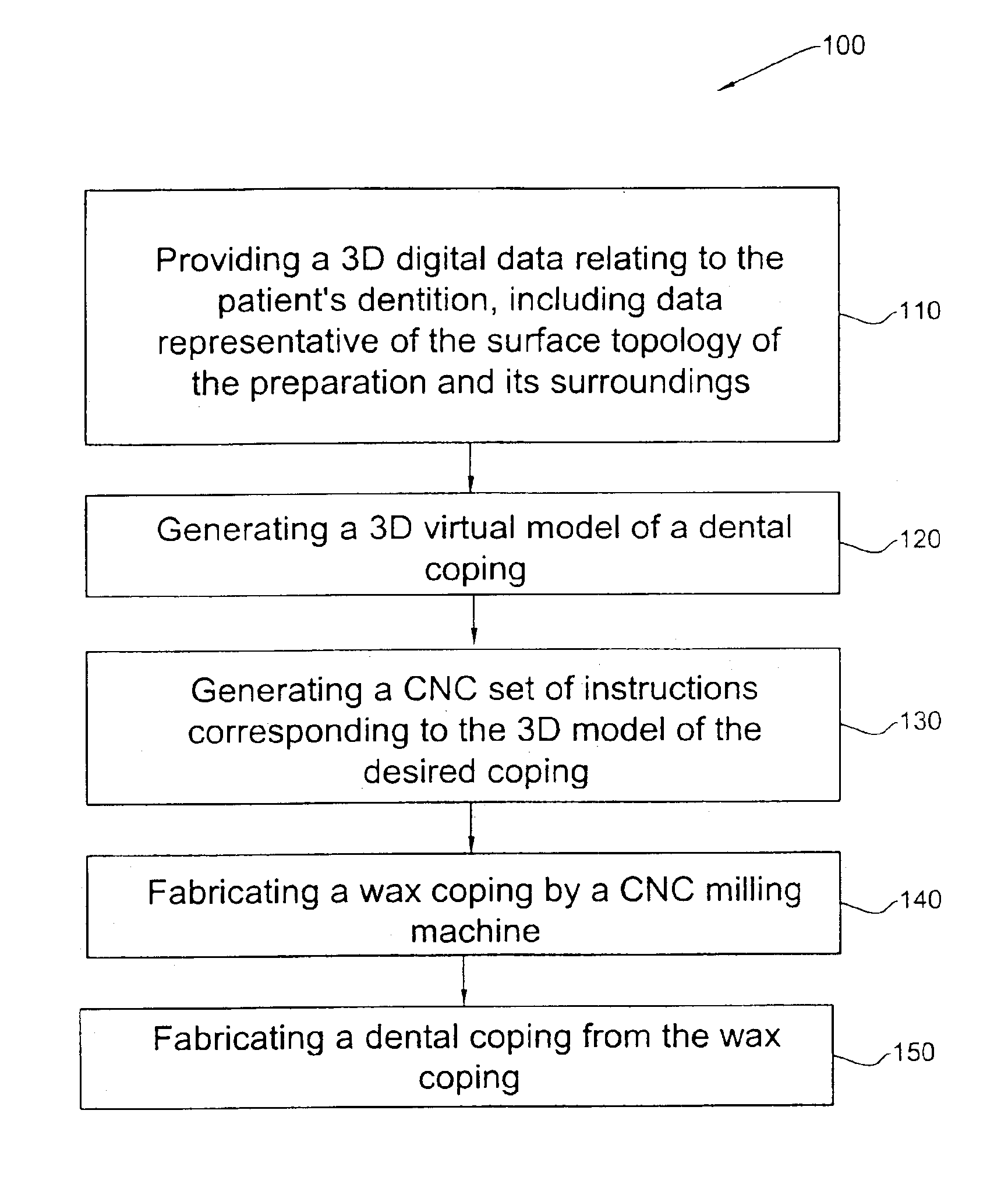

Method and system for fabricating a dental coping, and a coping fabricated thereby

A wax model of a required coping is produced using CNC machining techniques based on a virtual model of the coping created from digital data obtained from the intraoral cavity. The dental coping is then fabricated from the wax model.

Owner:ALIGN TECH

Methods for making bearings, races and components thereof having diamond and other superhard surfaces

InactiveUS20030019106A1Easy to polishReduce coefficient of frictionShaftsMetal-working apparatusPolycrystalline diamondHigh pressure

Method for making diamond bearings and diamond bearing components. Some methods include sintering diamond feedstock and a substrate under high pressure and high temperature to create a sintered polycrystalline diamond compact with a non-planar bearing and articulation surface. Various machining, grinding and polishing methods for finishing the compact are provided.

Owner:DIAMICRON

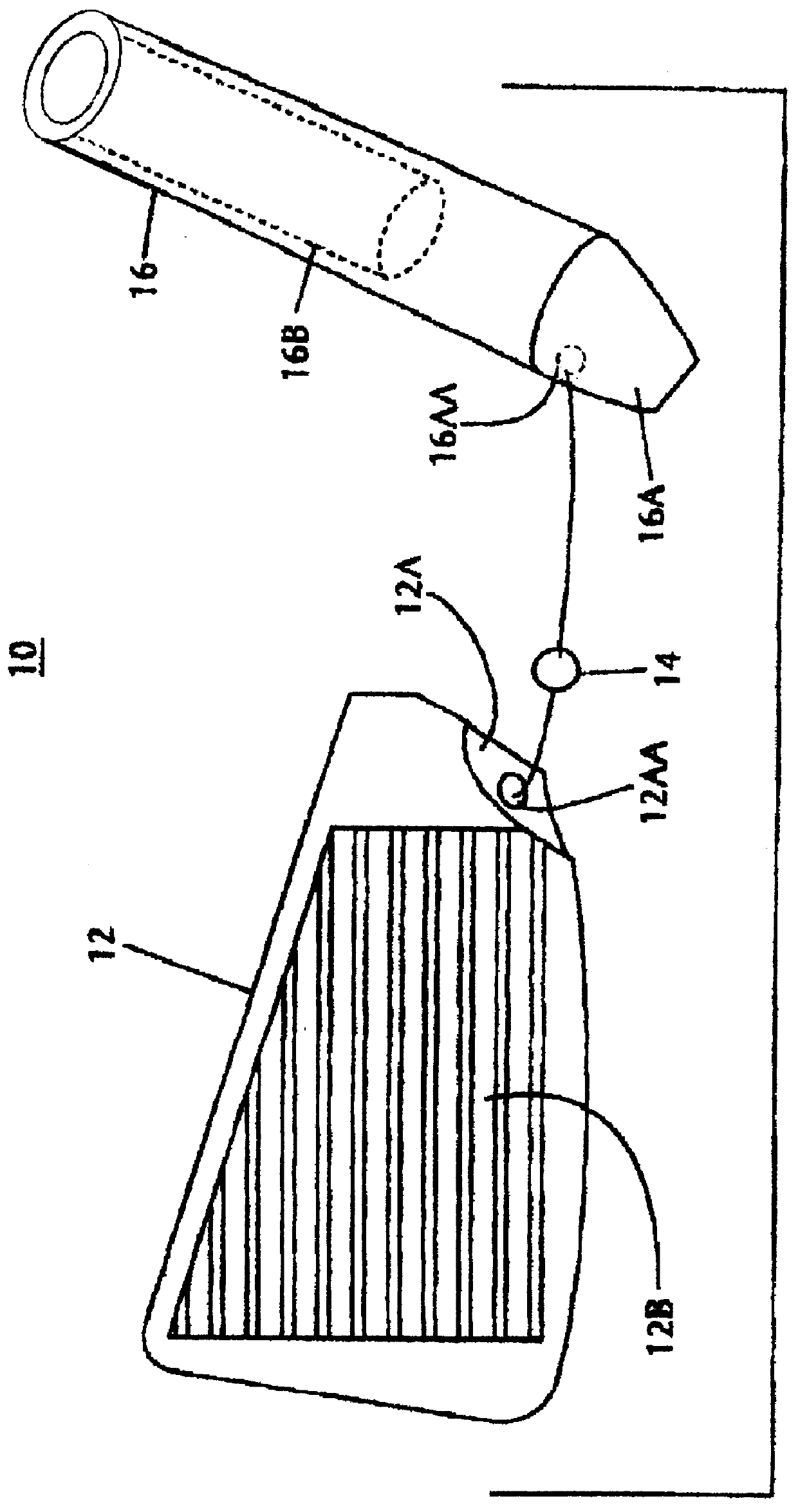

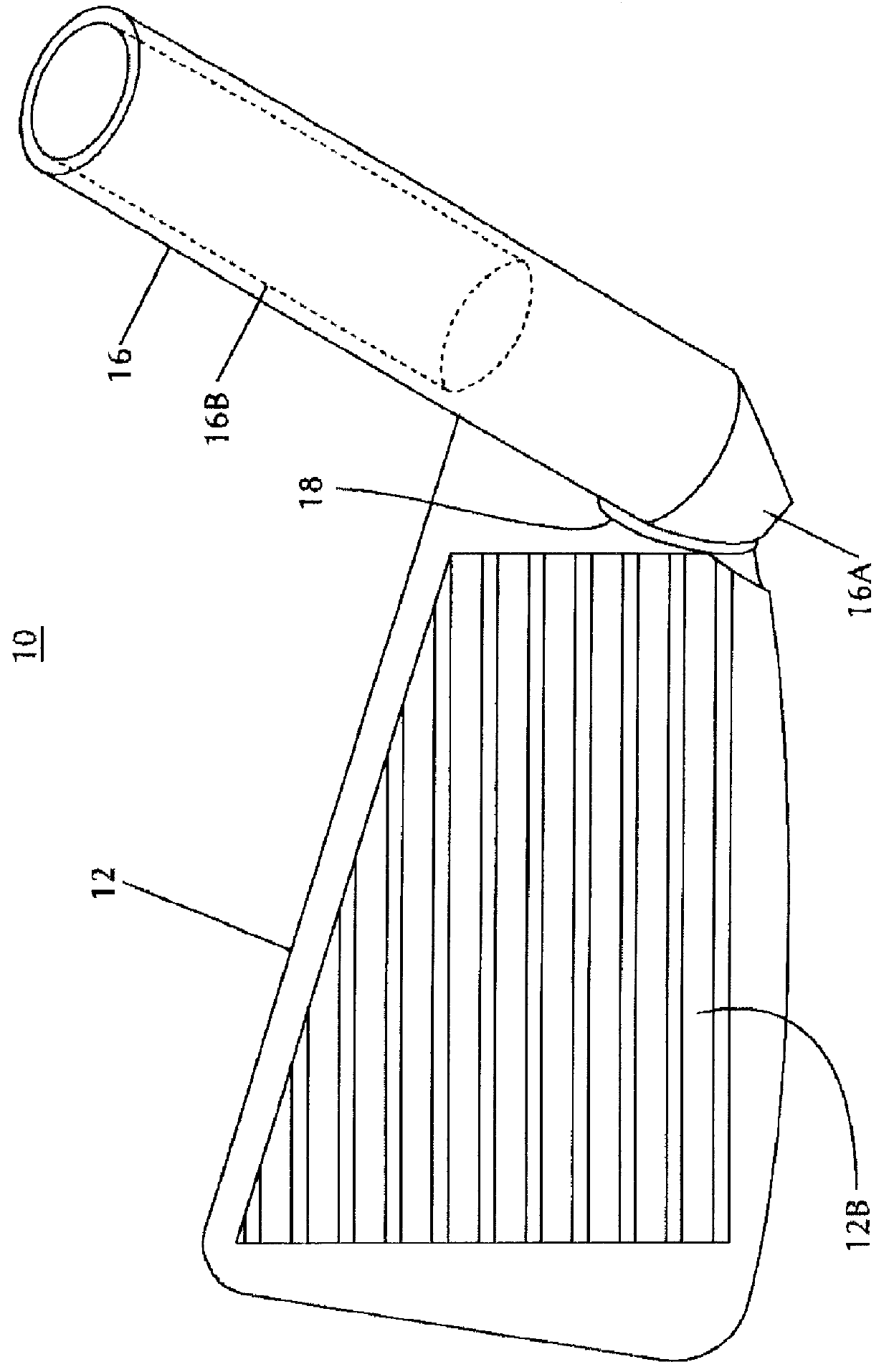

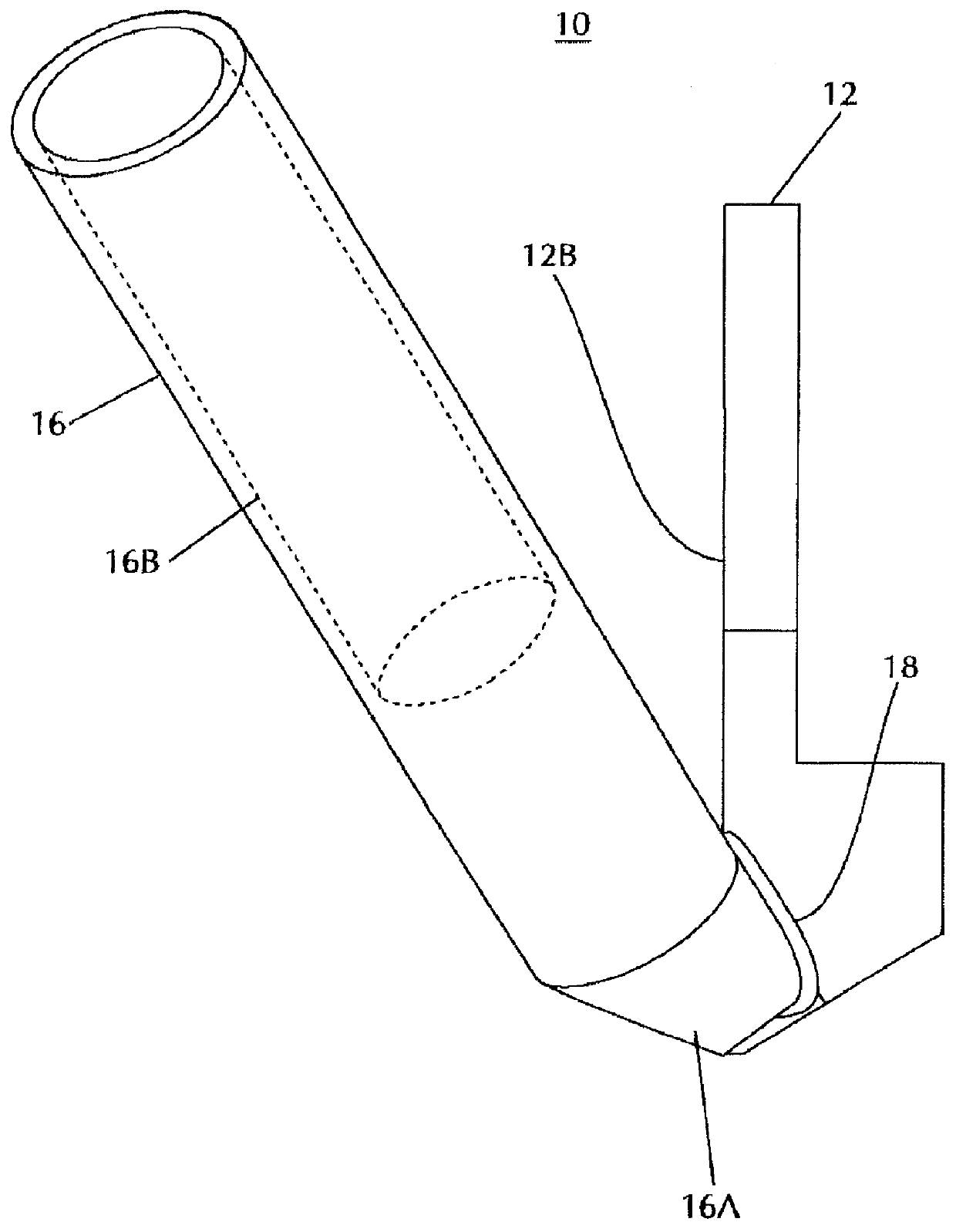

Custom-fabricated golf club device and method

InactiveUS6120384AWide rangeAccurate resolutionGolfing accessoriesGolf clubsManufacturing technologyCombined use

A custom-fabricated golf club device comprising a golf club head with a recessed portion located at the front heel portion of the head and machined therein, the recessed portion comprising a substantially semi-spherical aperture. A hosel assembly has a lower portion, having a substantially semi-spherical aperture that aligns with the aperture of the head recessed portion, the hosel assembly further having a recessed portion at an upper portion thereof. A steel ball is located securely within the aperture of head recessed portion and the aperture of the hosel assembly lower portion, functioning to provide positive location of the club head and hosel assembly. In the preferred mode, a permanent weldment functions to securely affix the lower portion of the hosel assembly to the club head at the heel portion of the club head. The device is utilized in conjunction with golf clubs of both the iron and wedge variety to provide a cost-effective and convenient way to custom-fabricate golf clubs to the unique physical characteristics of individual players. By taking advantage of machining, rather than forging or casting the components, a wide range of lie angles with precise resolution can be achieved. In addition, the manufacturing techniques of the present invention diligently conform to the USGA rule that clubs other than putters shall not be designed to be adjustable except for weight.

Owner:DRAKE STANLEY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com