Patents

Literature

48786 results about "Pressure sensor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pressure sensor is a device for pressure measurement of gases or liquids. Pressure is an expression of the force required to stop a fluid from expanding, and is usually stated in terms of force per unit area. A pressure sensor usually acts as a transducer; it generates a signal as a function of the pressure imposed. For the purposes of this article, such a signal is electrical.

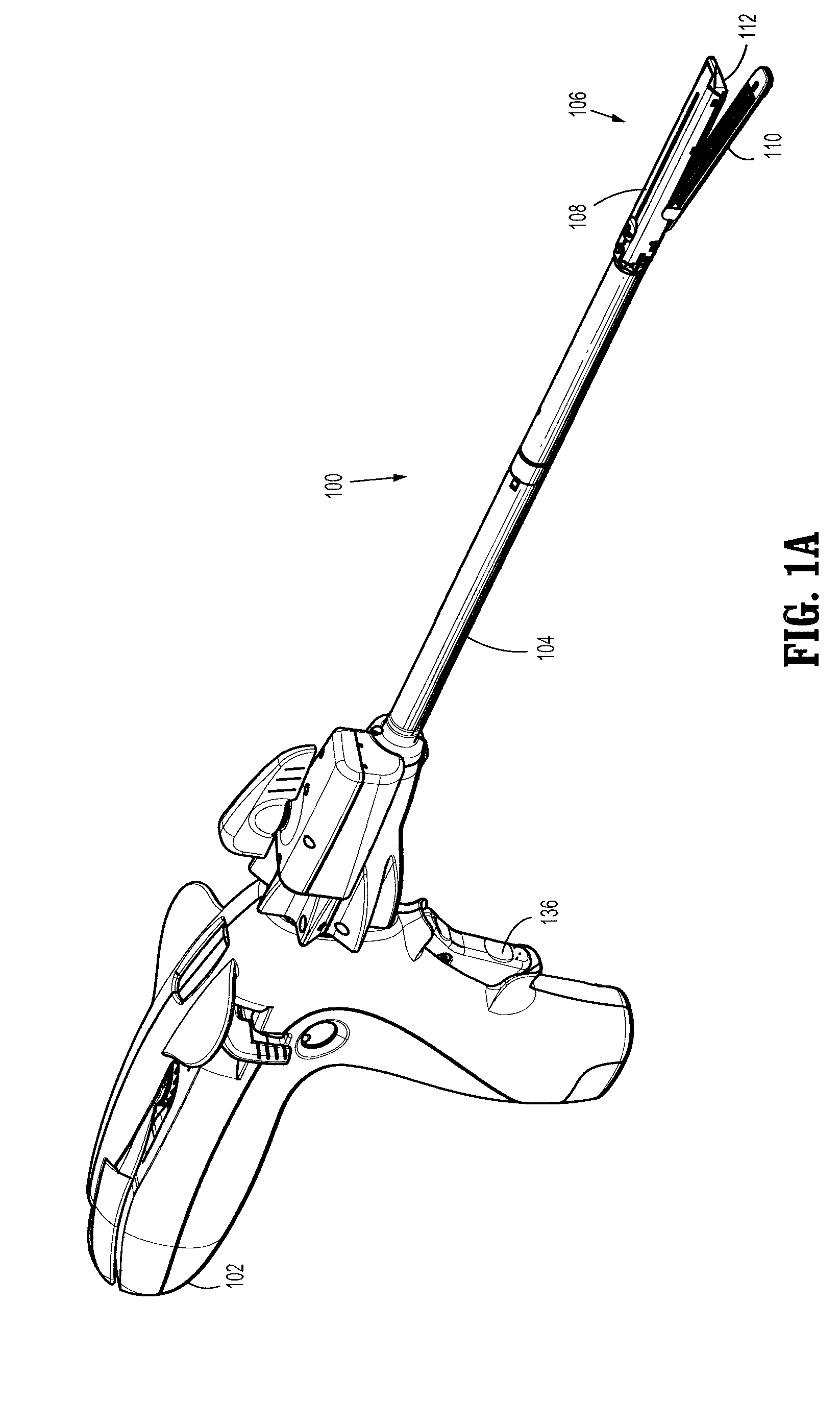

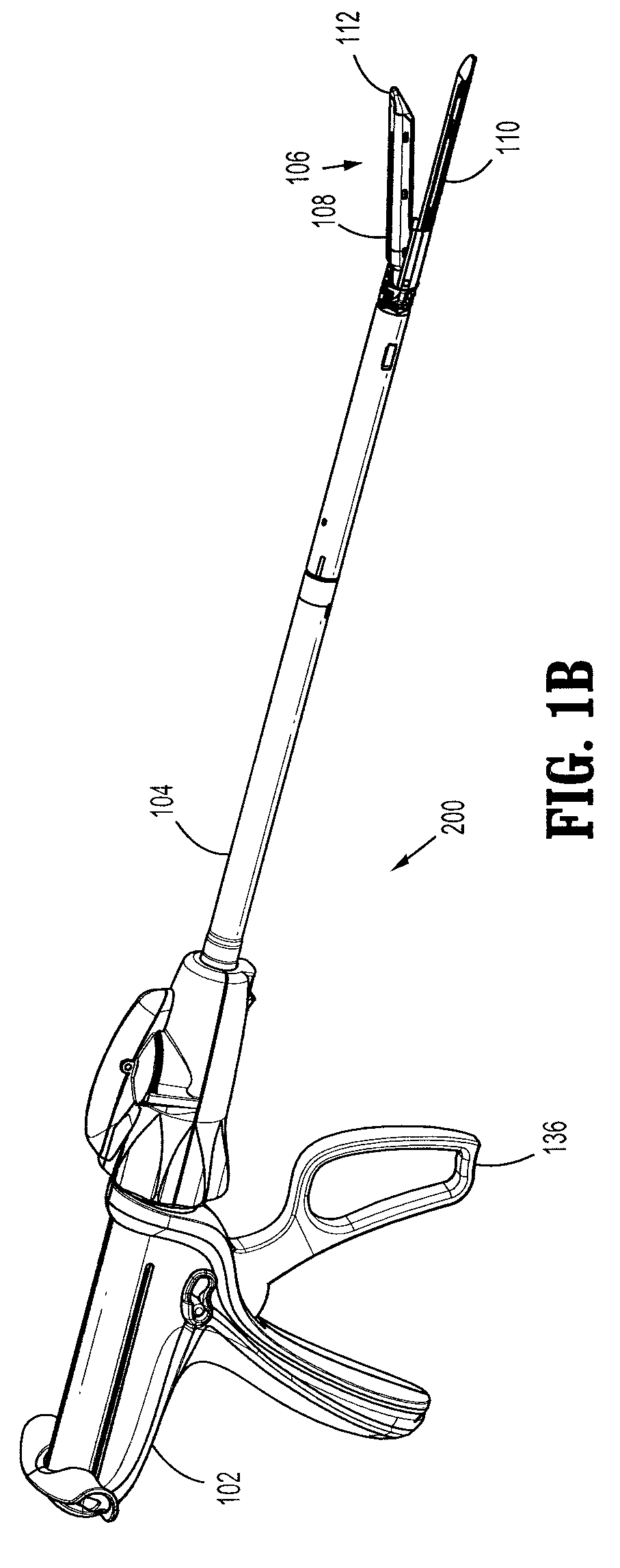

Surgical stapling apparatus

Owner:COVIDIEN LP

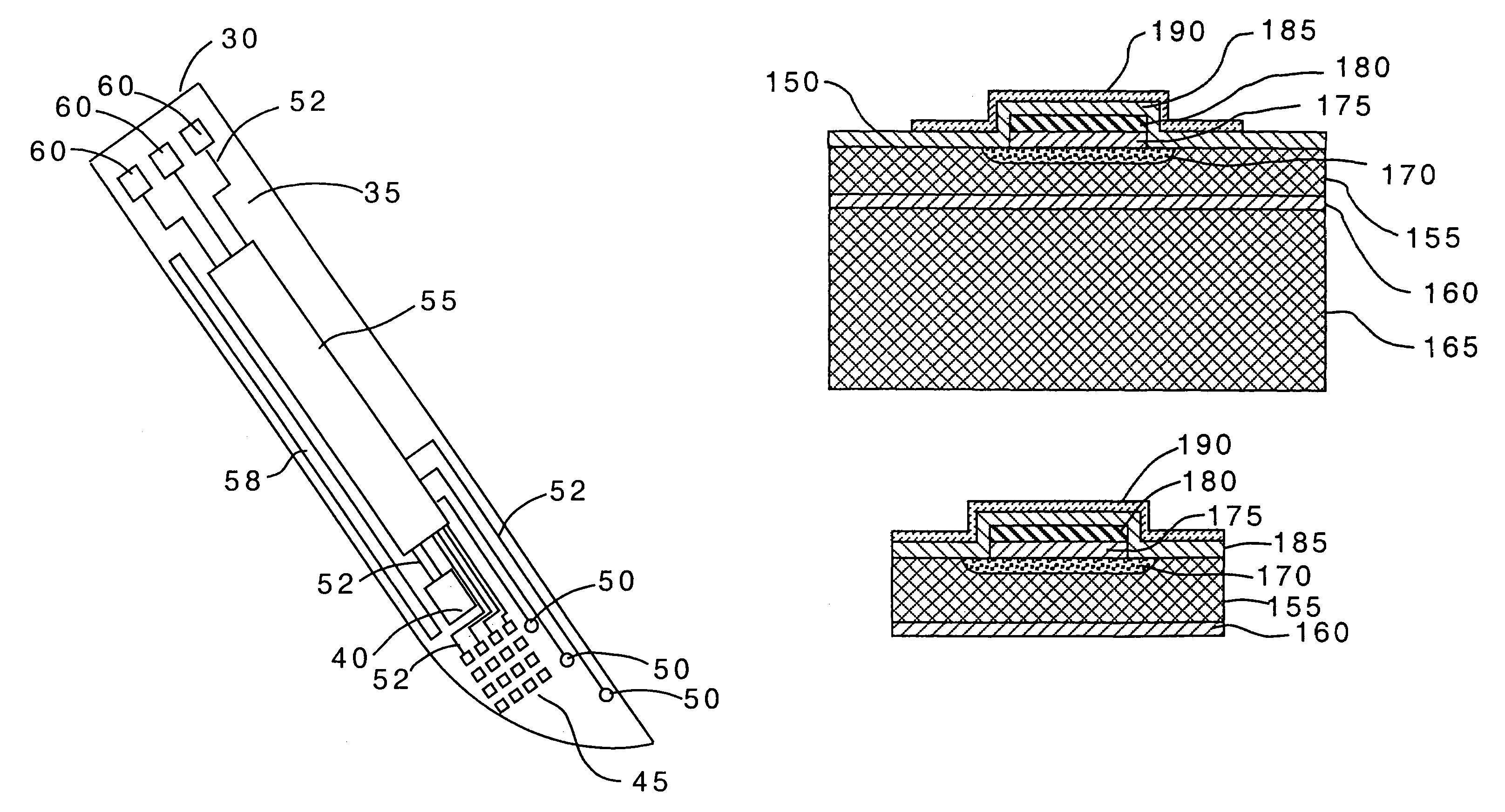

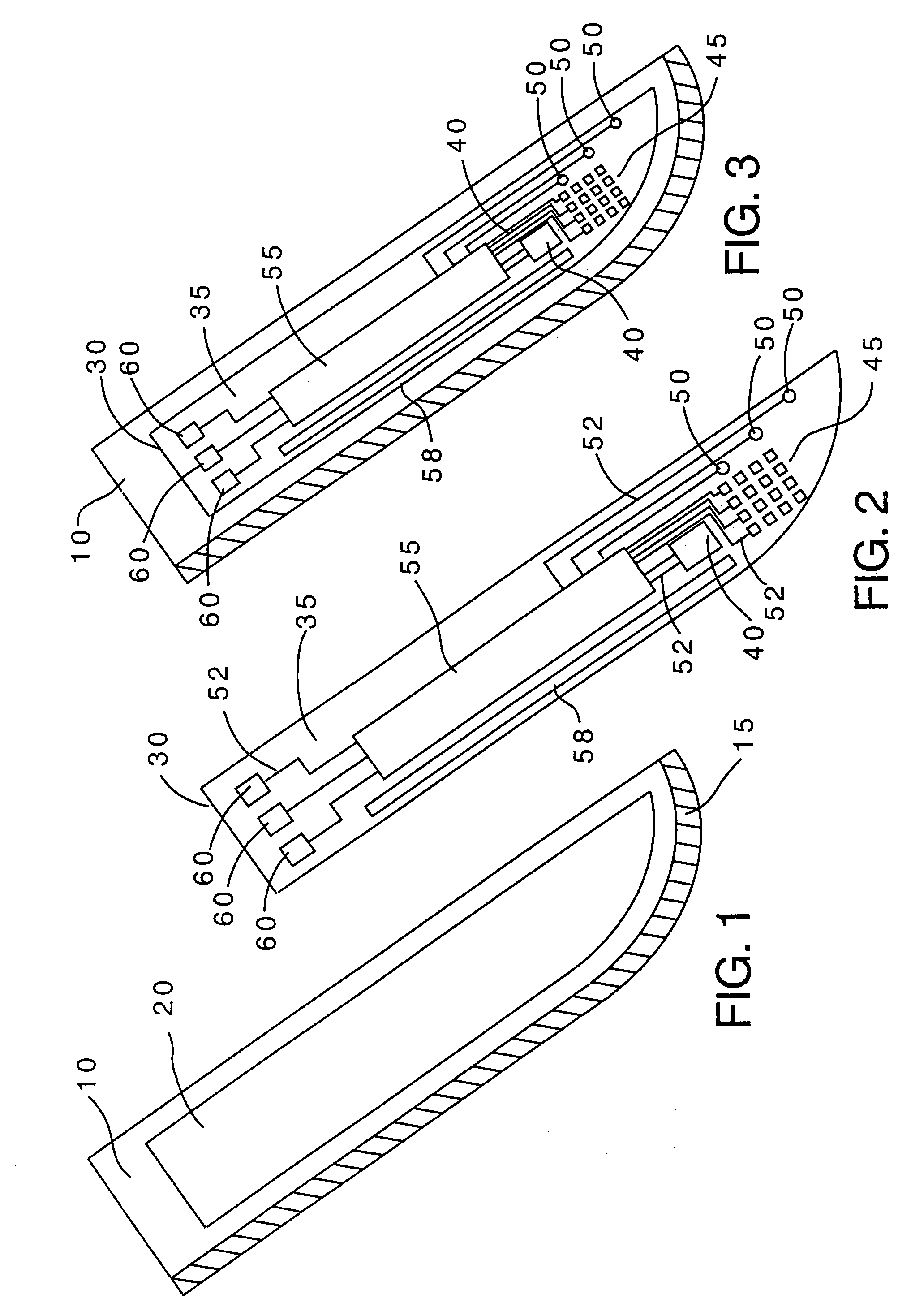

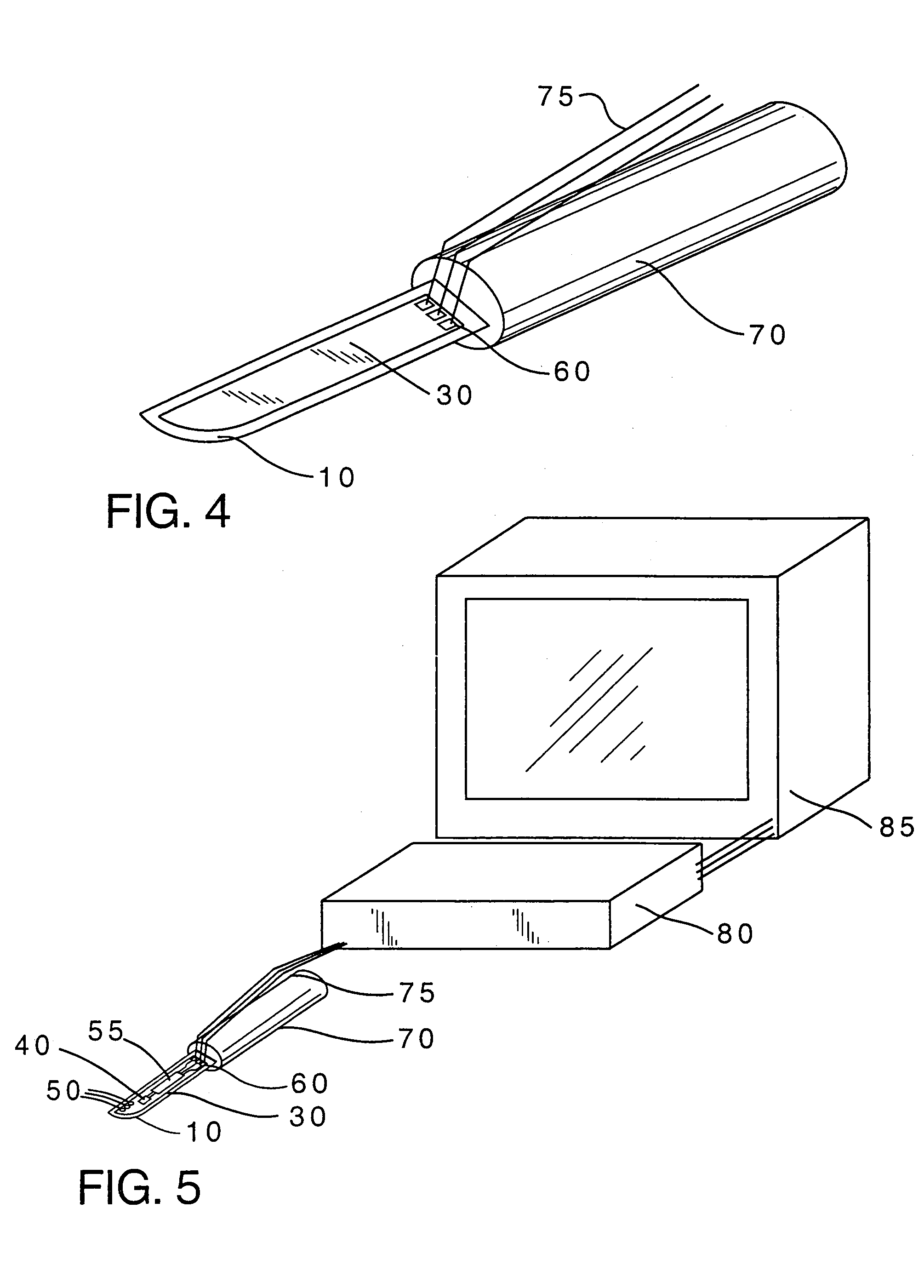

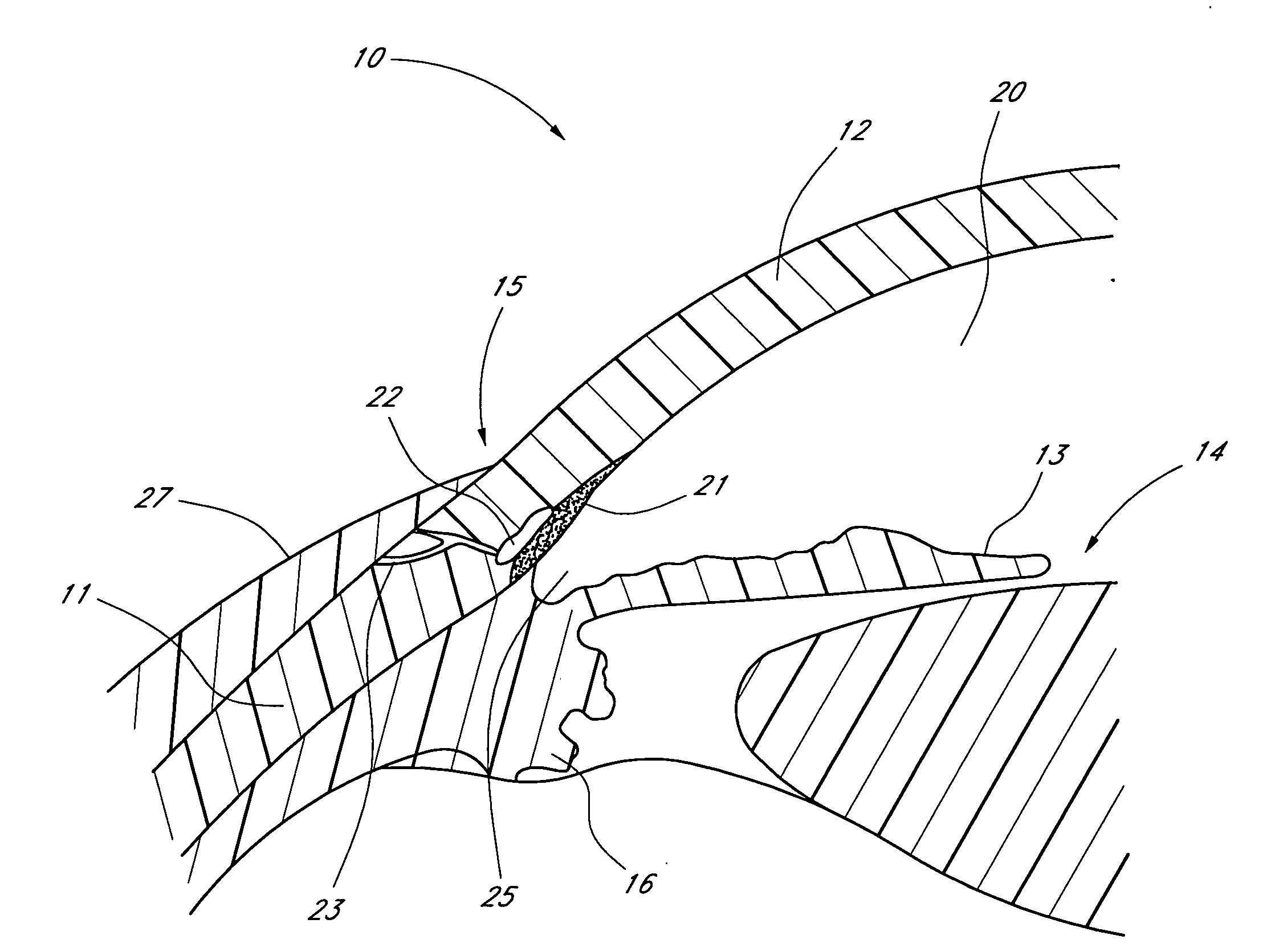

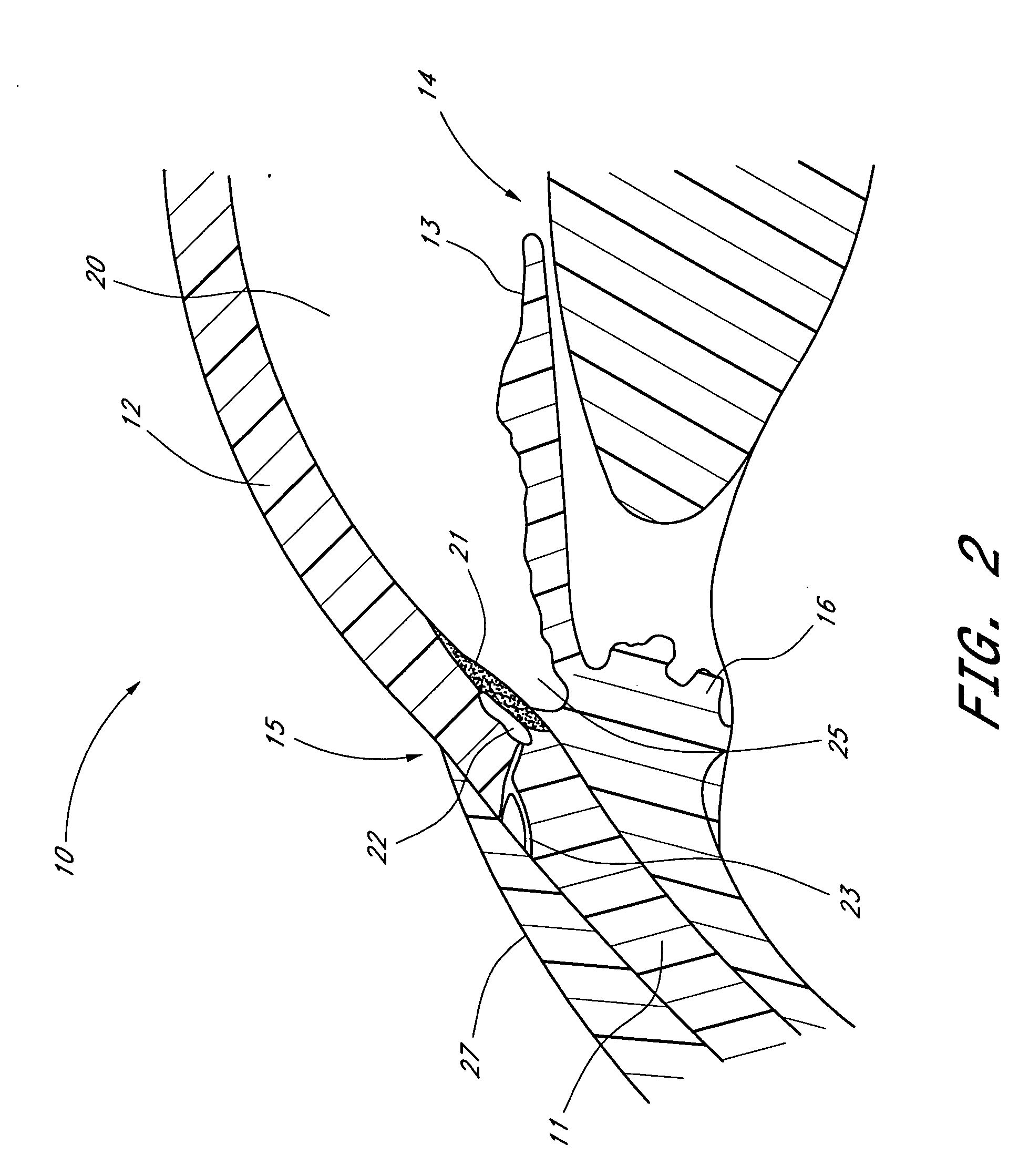

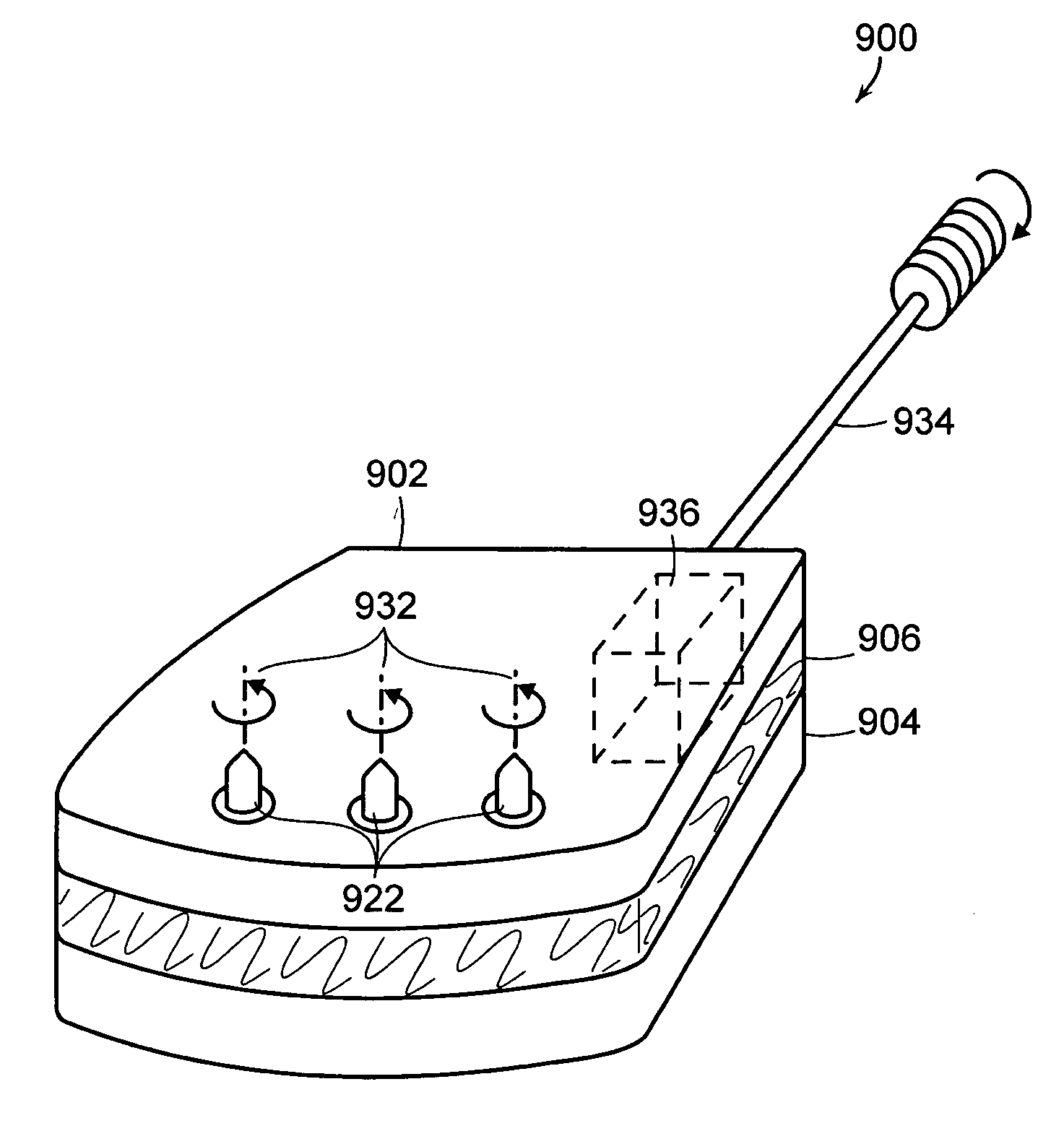

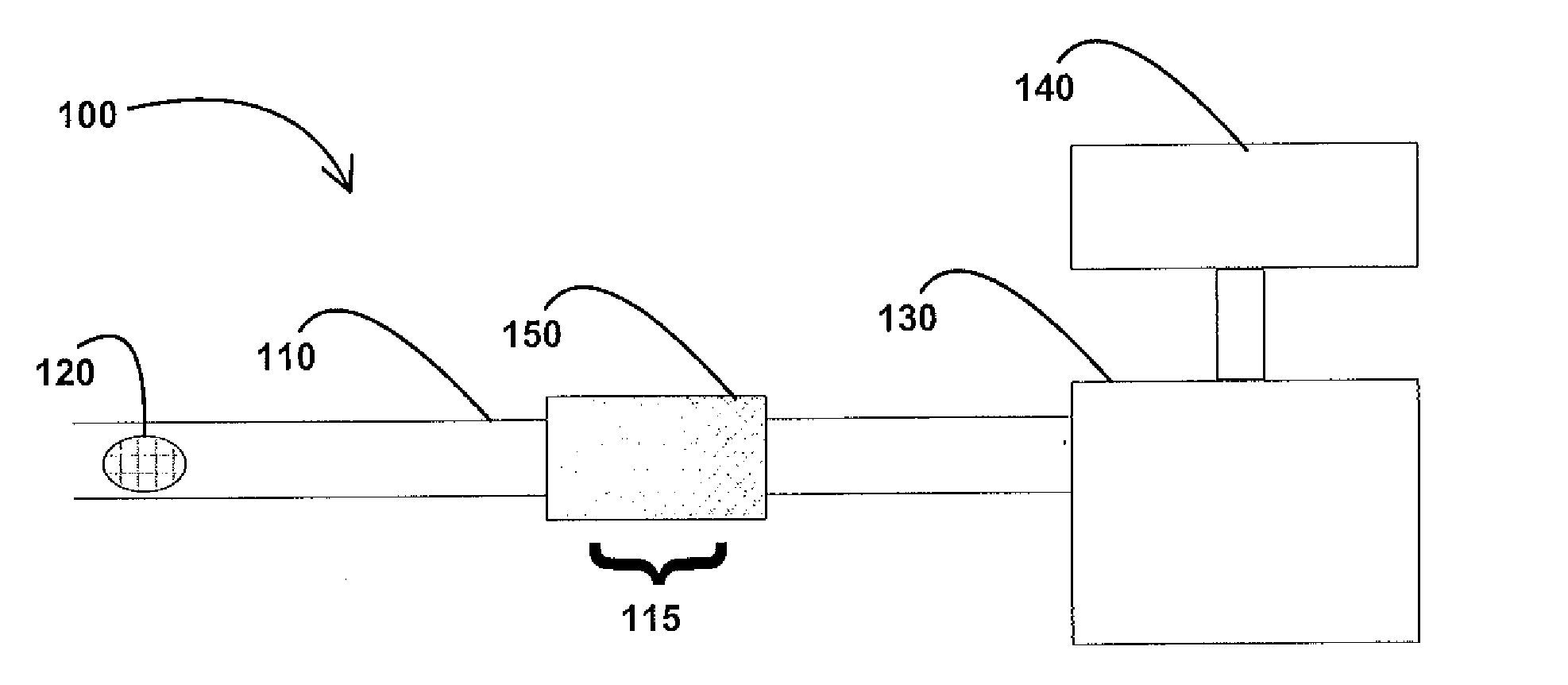

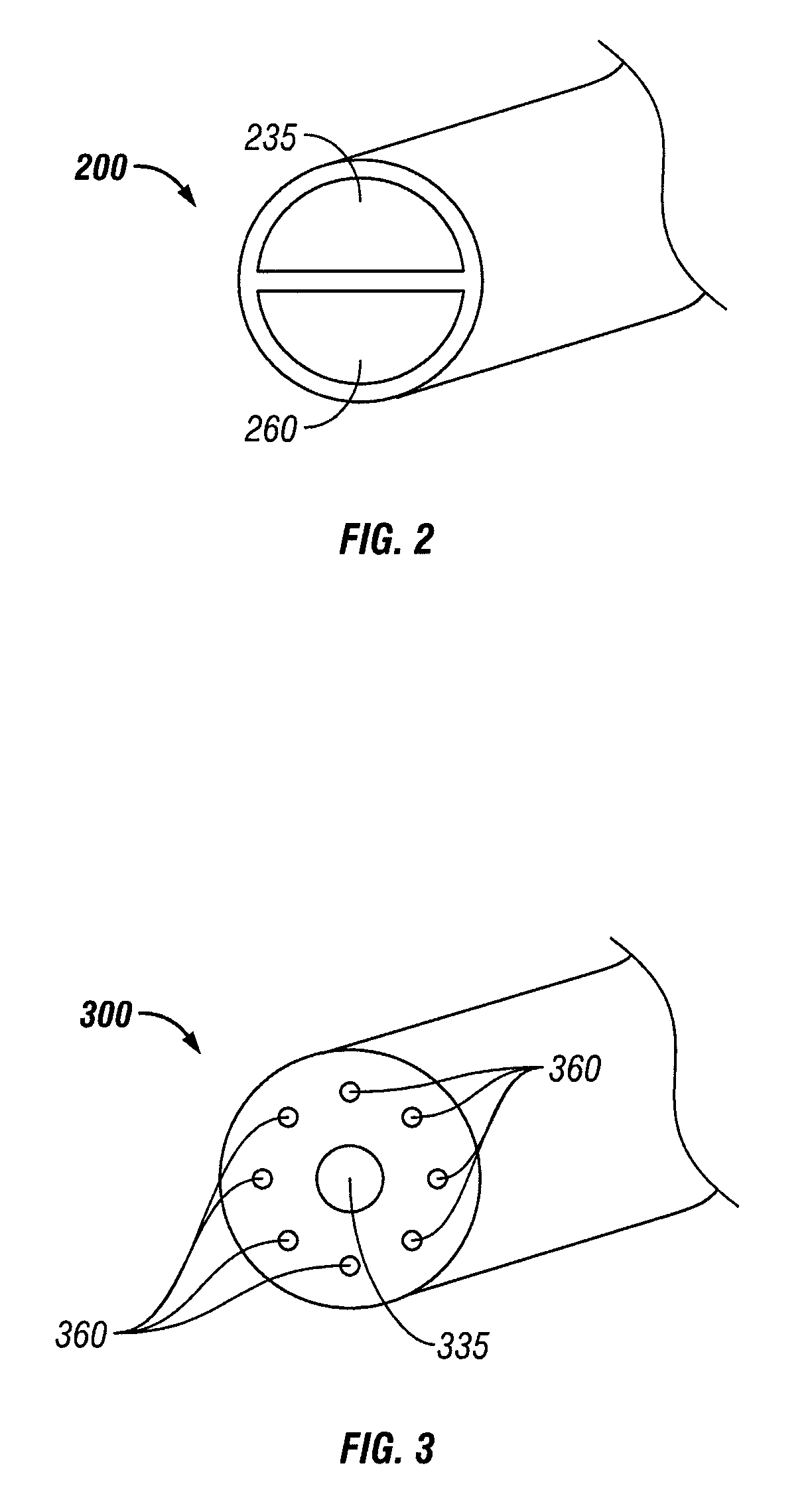

Method of making a cutting instrument having integrated sensors

A cutting instrument including a metal blade has a recess formed therein and a semiconductor substrate affixed to the blade in the recess. The semiconductor substrate includes at least one sensor formed thereon. The sensor formed on the semiconductor substrate may comprise at least one or an array of a strain sensors, pressure sensors, nerve sensors, temperature sensors, density sensors, accelerometers, and gyroscopes. The cutting instrument may also further include a handle wherein the blade is affixed to the handle and the semiconductor substrate is electrically coupled to the handle. The handle may then be coupled, either physically or by wireless transmission, to a computer that is adapted to display information to a person using the cutting instrument based on signals generated by one or more of the sensors formed on the semiconductor substrate. The computer or handle may also be adapted to store data based on the signals generated by one or more of the sensors. A method of making said cutting instrument includes the steps of at least one sensor being formed on a semiconductor wafer and a layer of photoresist being applied on a top side of the semiconductor wafer according to a pattern that matches the defined shape of the semiconductor substrate. The portion of the semiconductor wafer not covered by the photoresist is removed and thereafter the photoresist is removed from the semiconductor wafer, thereby leaving the semiconductor substrate having a defined shape and at least one sensor formed thereon. The semiconductor substrate having a defined shape and at least one sensor formed thereon is then affixed to a metal blade in a recess formed in said blade.

Owner:VERIMETRA

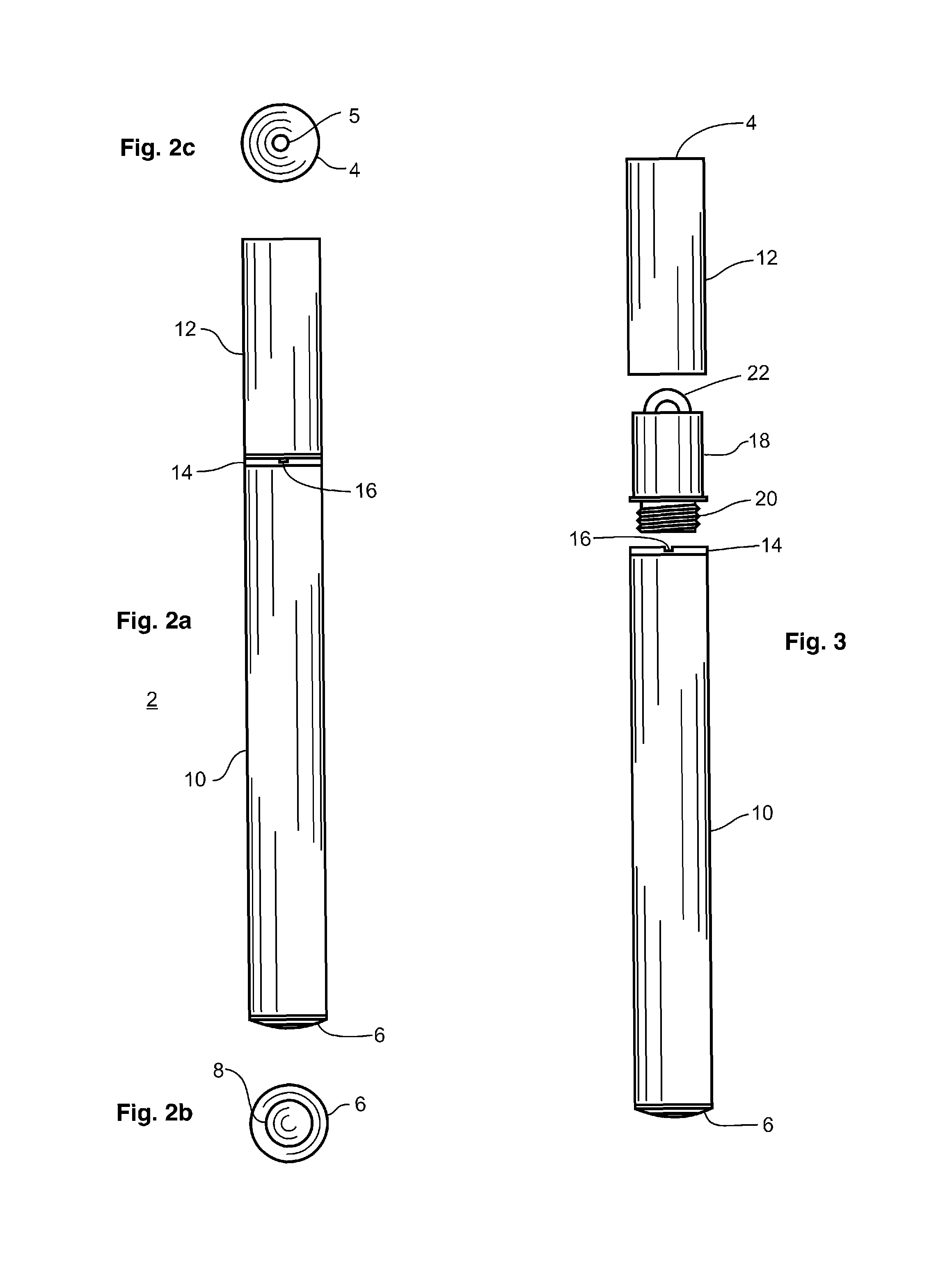

Electronic cigarette with function illuminator

An electronic cigarette with an illumination function, and that generates an aerosol of a fluid when air is drawn through it, includes a housing with a translucent tip, a mouthpiece, and a battery. A fluid reservoir and an atomizer assembly selectively generate an aerosol of the fluid. A draw pressure sensor generates a draw signal in response to a pressure change induced while air is drawn out of the mouthpiece. A draw control circuit activates the atomizer assembly in response to the draw signal. The draw circuit also outputs a lamp signal in response to the draw signal. A lamp circuit with an actuator, a first color lamp, and a second color lamp that are both aligned to illuminate the tip. The lamp circuit selectively, and alternatively in response to subsequent actuations of the actuator, selects between illuminating the first color lamp and the second color lamp in response to the lamp signal.

Owner:JUUL LABS INC

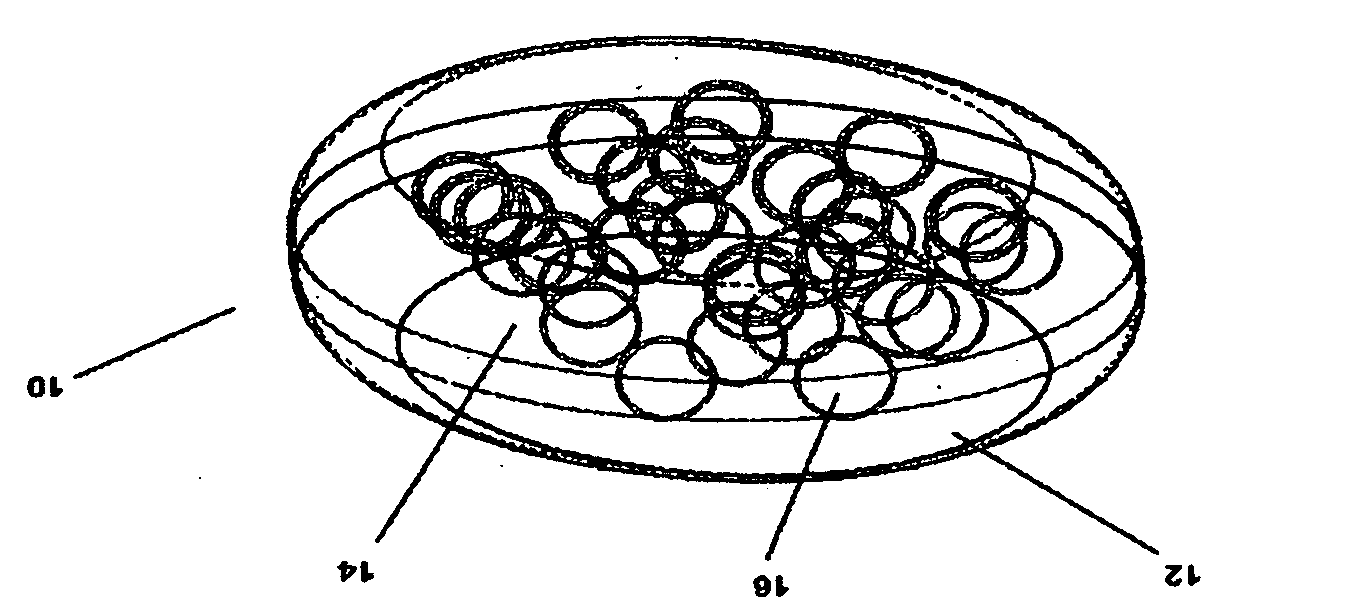

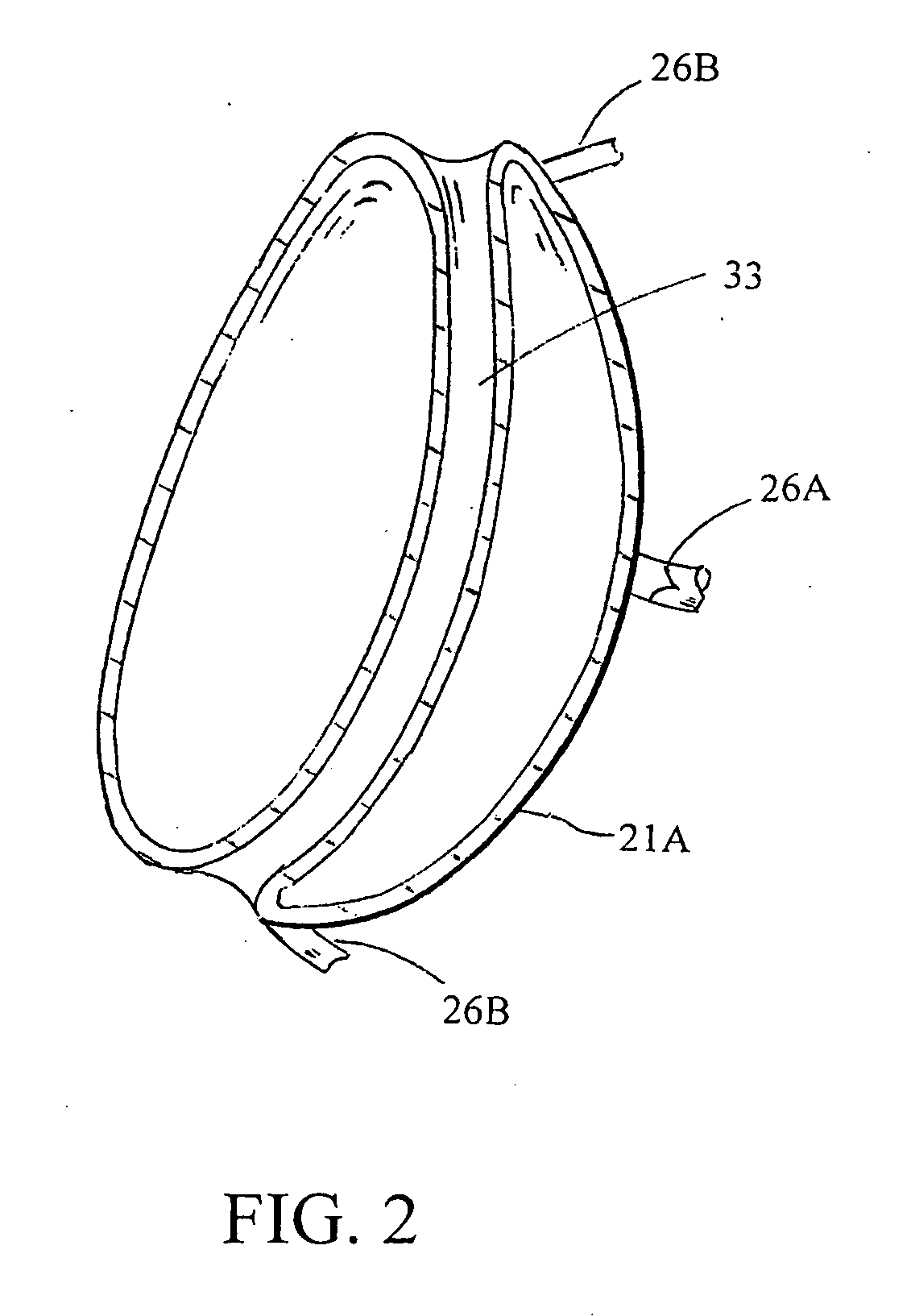

Closed system artificial intervertebral disc

An artificial intervertebral disc and disc nucleus are described herein having chambers and dampening members. The dampening members may be within or outside of the main body of the device. The chambers may be filled with a suitable liquid, gas, or both, and separated by valves to regulate flow of fluid between chambers, within a dampening member, between the main body and dampening member, or all of the above. Chambers may be filled with responsive hydrogels, EPAM, or other suitable materials, and the device may have activation plates or members, a strain gauge, a pressure sensor, or other means for detecting changes in the materials and / or triggering desired changes in the materials in order to mimic the behavior of a healthy native disc or disc nucleus. A control system may be in communication with the device for receiving feedback and delivering stimuli to initiate desired changes in the fluids or other materials. Membranes may be of variable permeability and may be metallized to ensure as low permeability as possible. Dampening members may be filled during manufacture with carbon dioxide or other suitable gas which may be in a supercritical state and allowed to return to ambient temperature and gaseous state or by other means. Methods of manufacture, delivery of the artificial disc and related structures, and methods of treatment are also described.

Owner:SYNECOR LLC

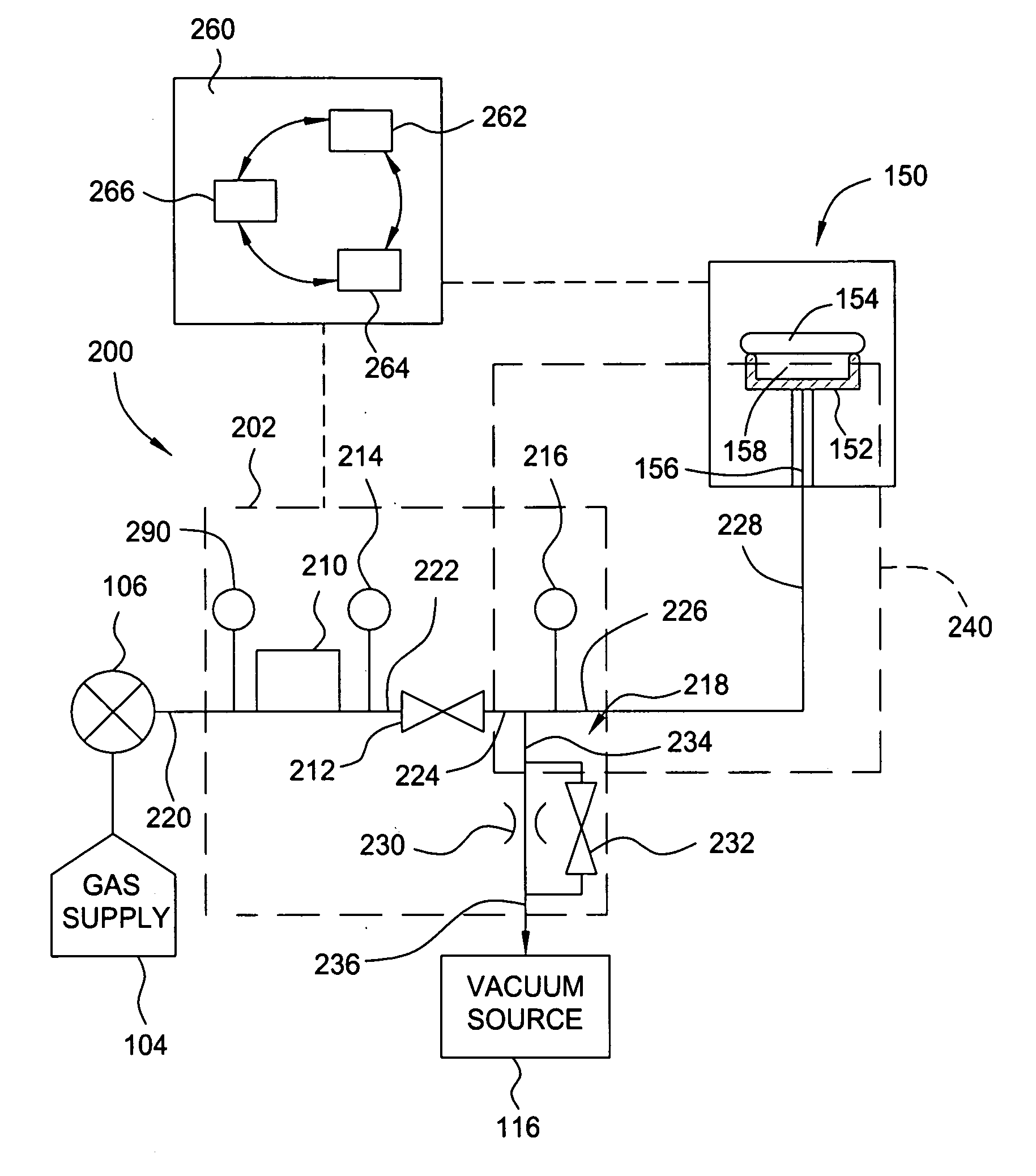

Method for wide range gas flow system with real time flow measurement and correction

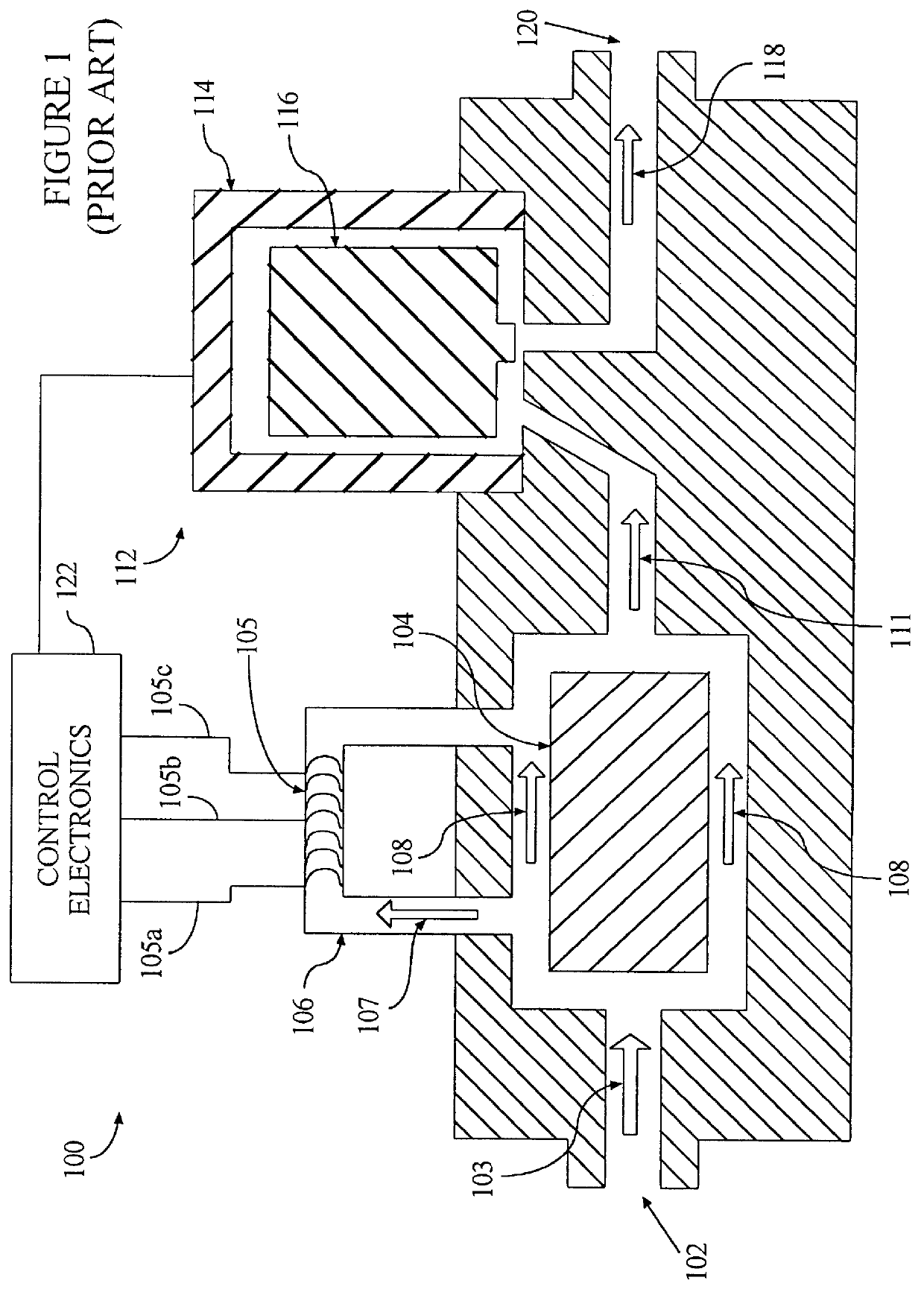

InactiveUS6119710AAccurate measurementAccurate flowOperating means/releasing devices for valvesVolume/mass flow by thermal effectsDifferential pressureInlet valve

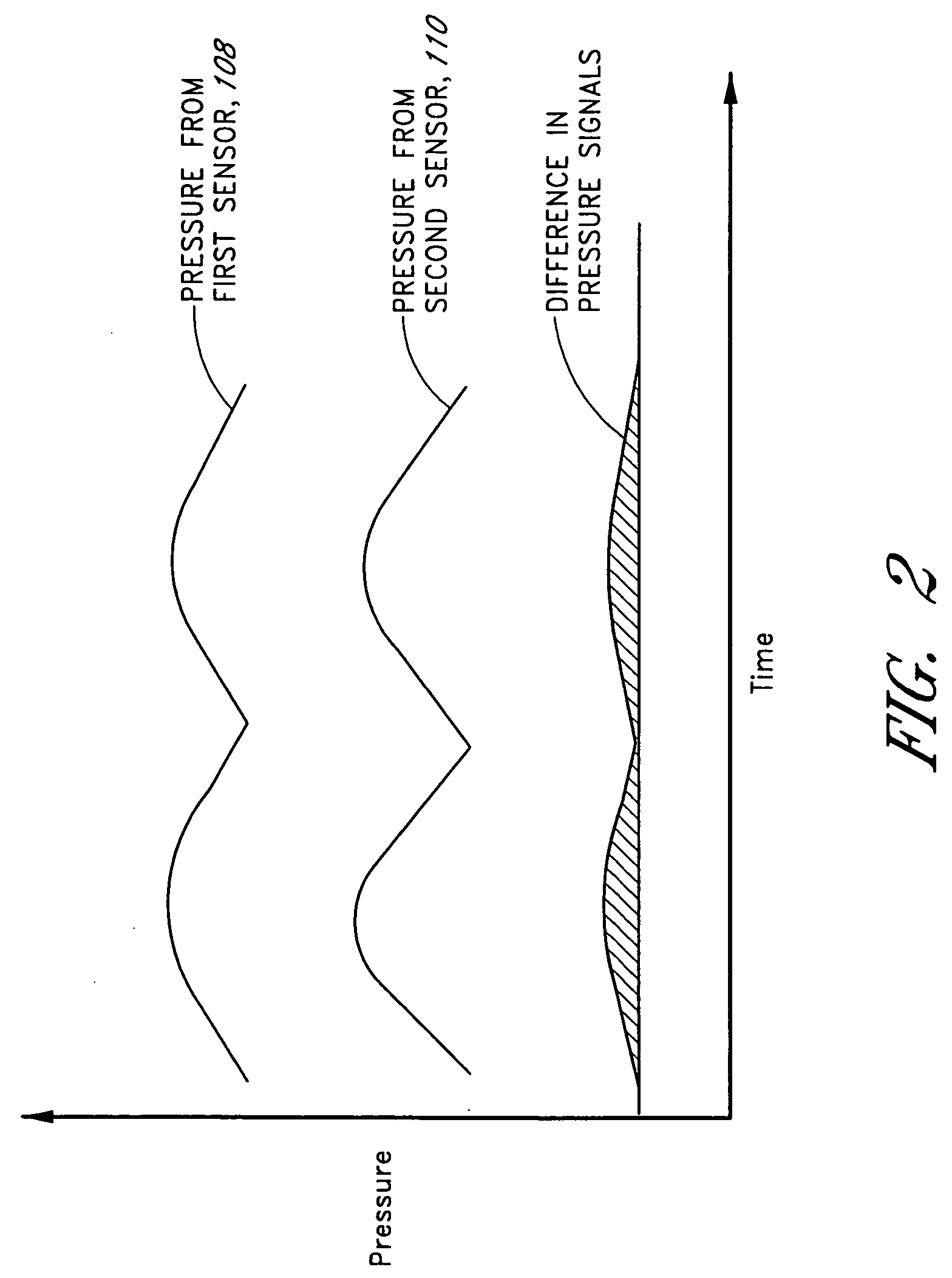

A gas delivery system accurately measures and optionally regulates mass flow rate in real time. A fluid conduit connects an inlet valve, calibration volume, flow restrictor, and outlet valve in series. Pressure and temperature sensors are coupled to the calibration volume. One or more pressure sensors may be attached across the flow restrictor. Alternatively, an absolute pressure sensor may be attached upstream of the flow restrictor. One embodiment of differential pressure sensors comprises a floating reference differential pressure sensor, including a first transducer attached to the fluid conduit upstream of the flow restrictor and a second transducer attached to the conduit downstream of the flow restrictor. In this embodiment, each transducer receives a reference pressure from a reference source, and optionally, after the calibration volume is charged, the floating reference differential pressure transducers are calibrated. When gas flow is initiated, differential and / or absolute pressure measurements are repeatedly taken, and a measured mass flow rate calculated thereon. Gas flow is adjusted until the measured mass flow rate reaches a target mass flow. Using the temperature / pressure sensors at the calibration volume, repeated calculations of actual flow rate are made to uncover any discrepancy between actual and measured mass flow rates. Whenever a discrepancy is found, the manner of calculating measured mass flow is conditioned to account for the discrepancy; thus, the measured mass flow rate more accurately represents the actual mass flow rate thereby providing an actual mass flow rate more accurately achieving the target mass flow rate.

Owner:CYBER INSTR TECH LLC AN ARIZONA LIMITED LIABILITY +1

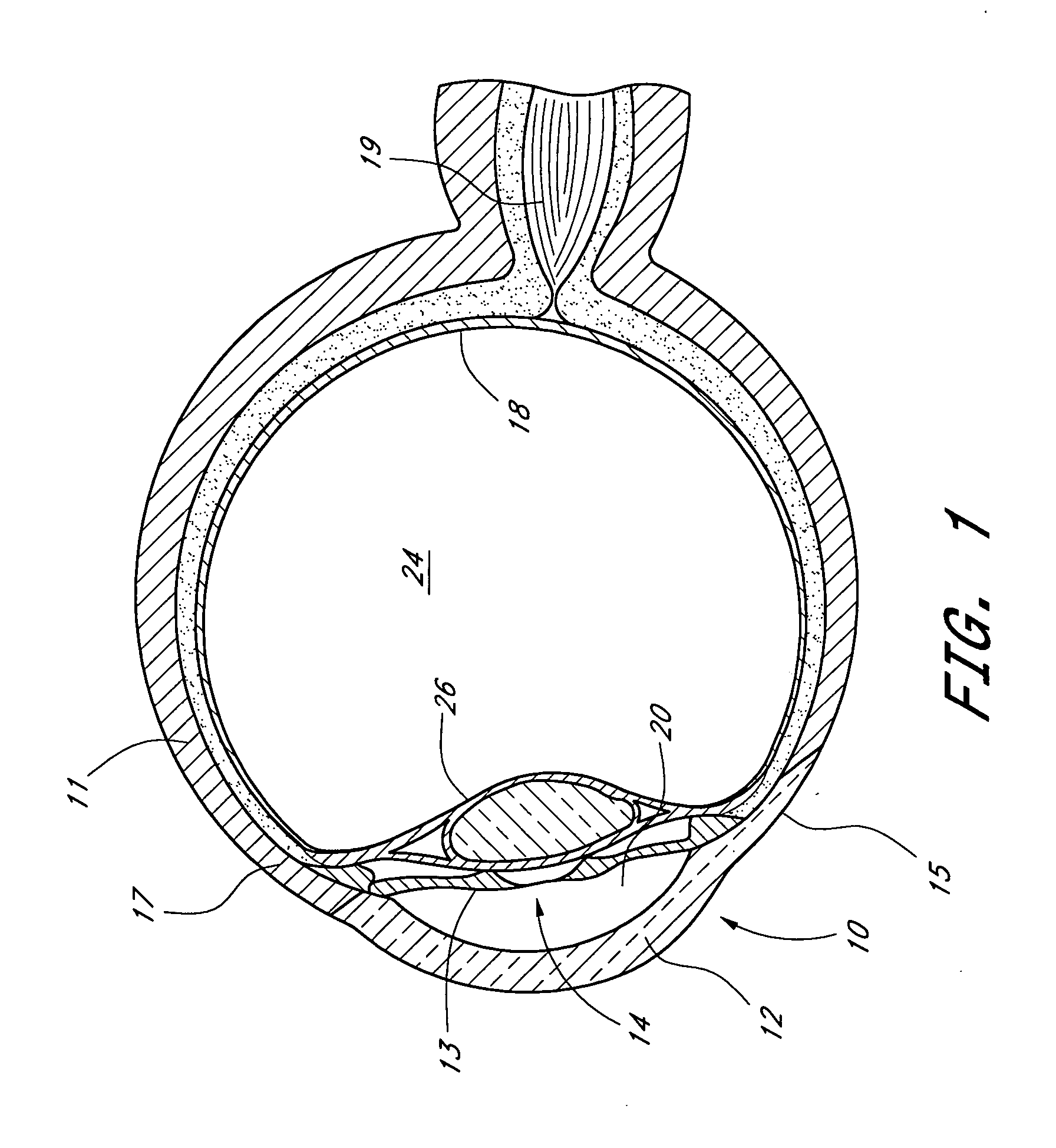

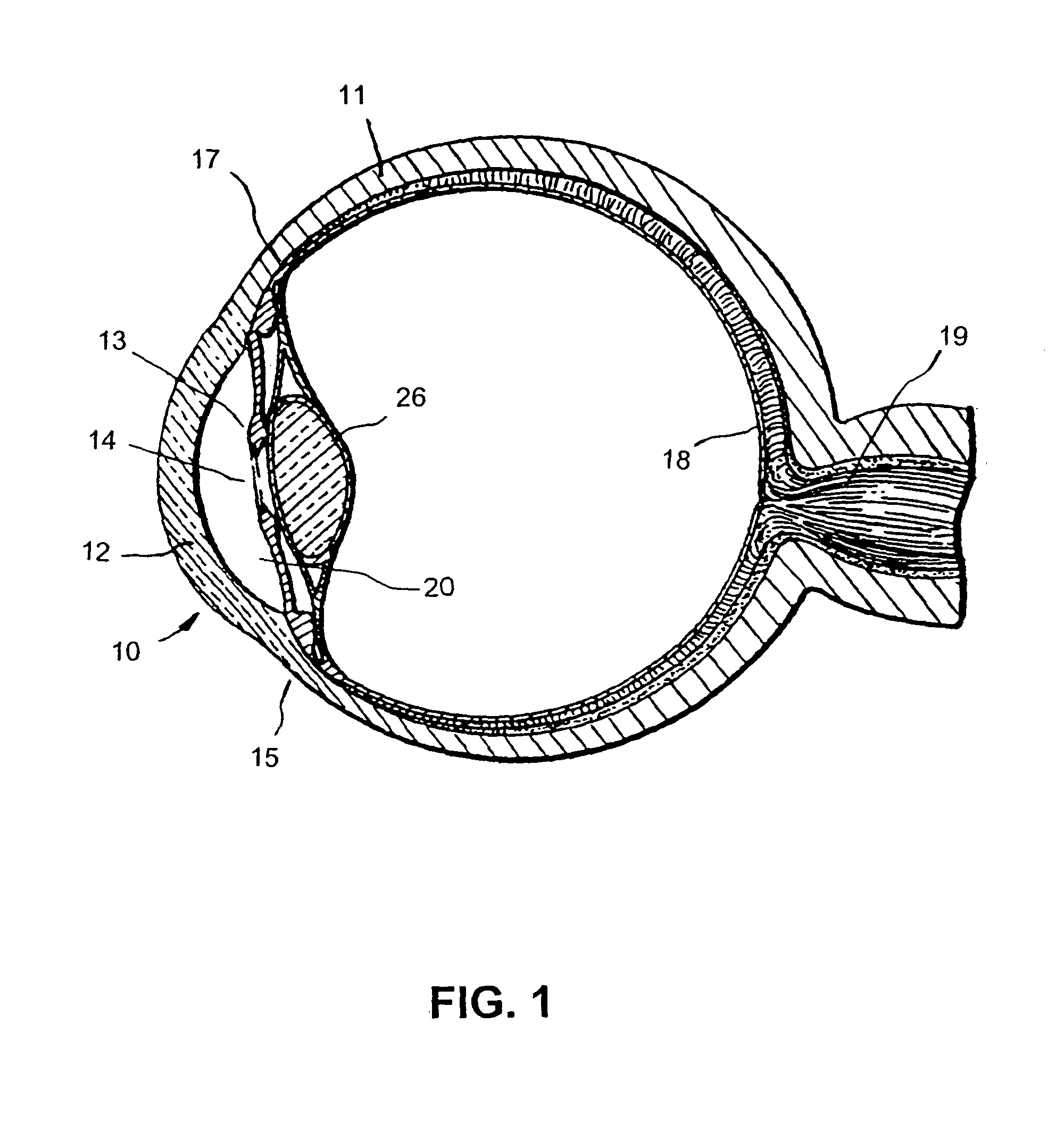

Implantable ocular pump to reduce intraocular pressure

A trabecular pump is implantable in the eye to reduce intraocular pressure. The pump drains aqueous humor from the anterior chamber into outflow pathways, such as Schlemm's canal. A feedback system includes the intraocular pump and a pressure sensor in communication with the pump, for regulating intraocular pressure.

Owner:GLAUKOS CORP

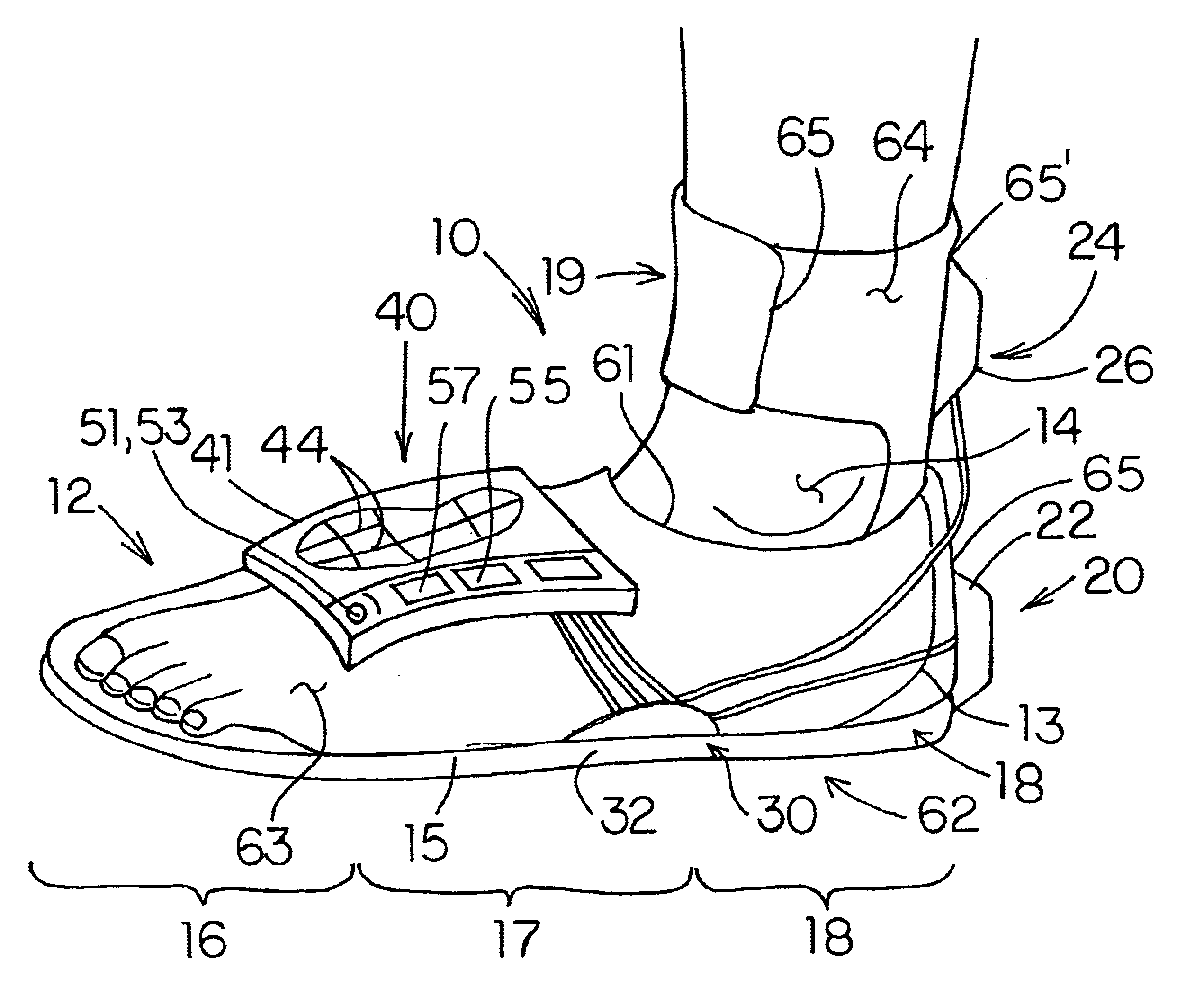

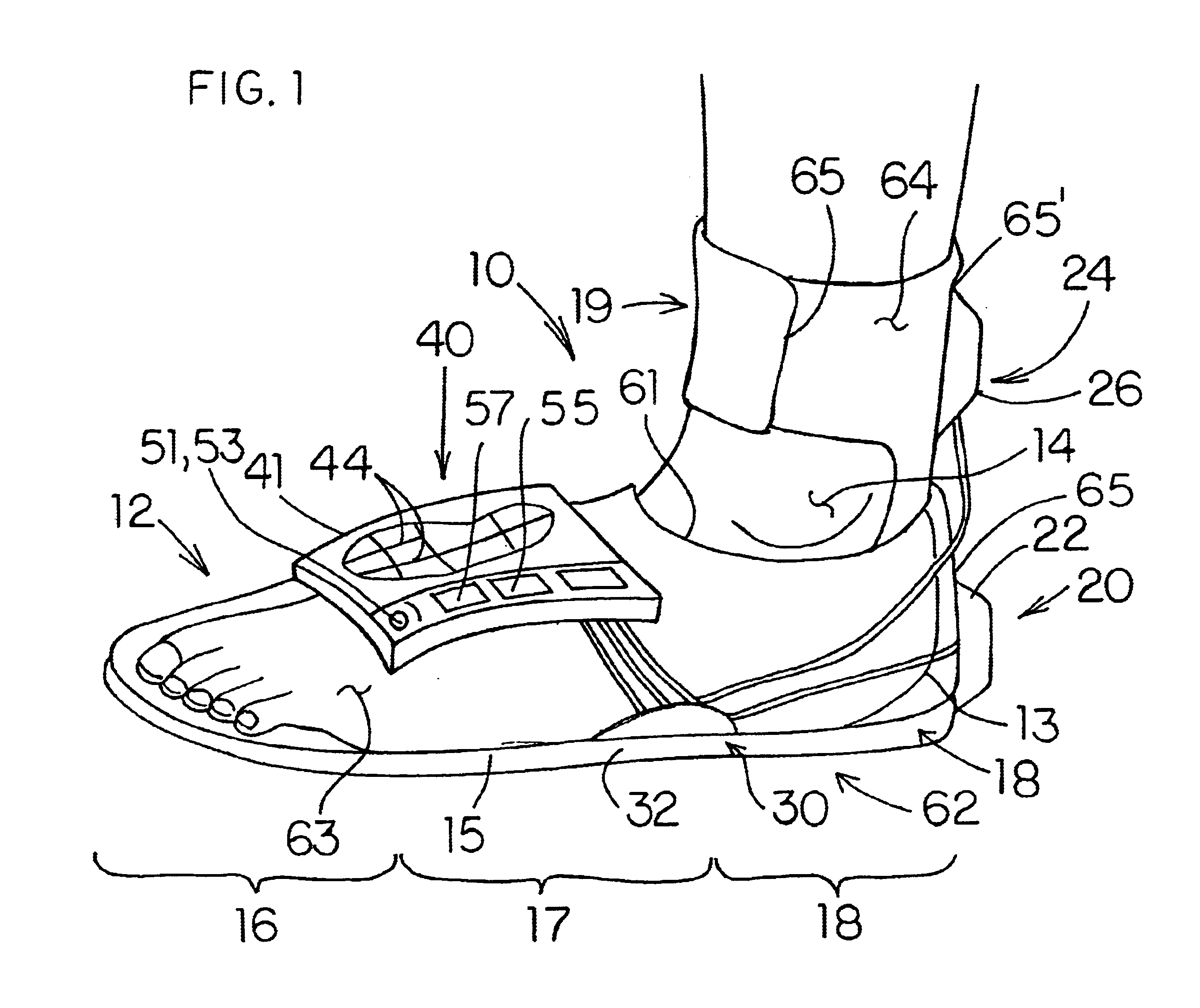

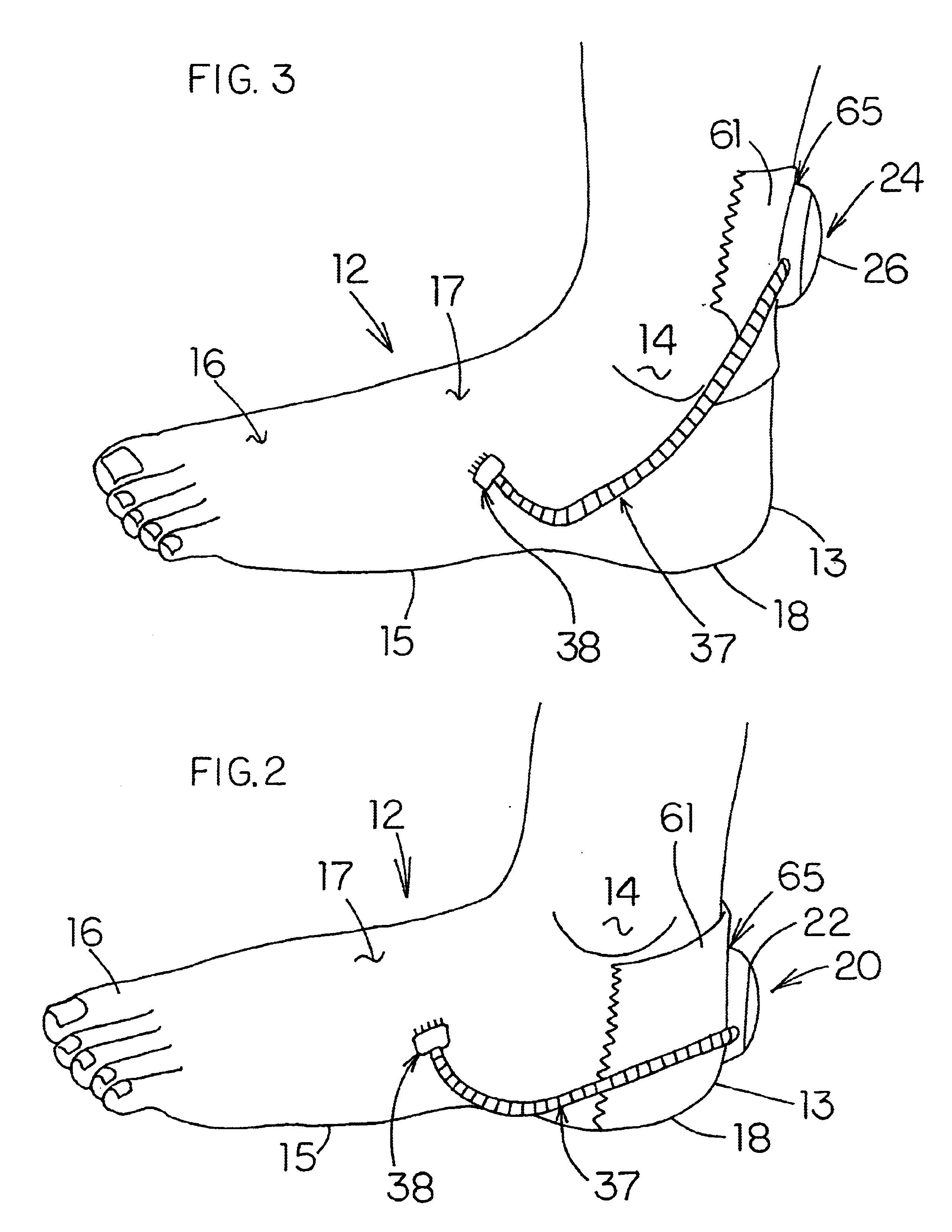

Portable system for analyzing human gait

InactiveUS6836744B1Input/output for user-computer interactionInertial sensorsAccelerometerAngular velocity

The invention is a portable gait analyzer comprising of at least one independent rear foot motion collection unit, at least one independent lower shank motion collection unit, plantar pressure collection unit, at least one processing and display unit, and a soft casing unit. A plurality of accelerometers, rate sensors, force sensor resistors, and pressure sensors provide for the acquisition of acceleration signals, angular velocity signals, foot force signals, and foot pressure signals to be processed. At least one central processing unit, a plurality of memory components, input / output components and ports, telemetry components, calibration components, liquid crystal displays components for the processing and outputting of three dimensional acceleration, angular velocity, tilt, and position. The rearfoot motion collection unit and lower shank motion collection unit interact with the processing and display unit to calculate rear foot kinematic data crucial to identify the motions of pronation and supination. The plantar pressure collection unit interacts with the processing and display unit to calculate plantar pressure data crucial to identify the center of pressure line and excessive and abnormal loads on the sole of the foot. These factors of rear-foot kinematics and plantar pressure lead to gait style identification.

Owner:ADVANCED MOTION TECH INC

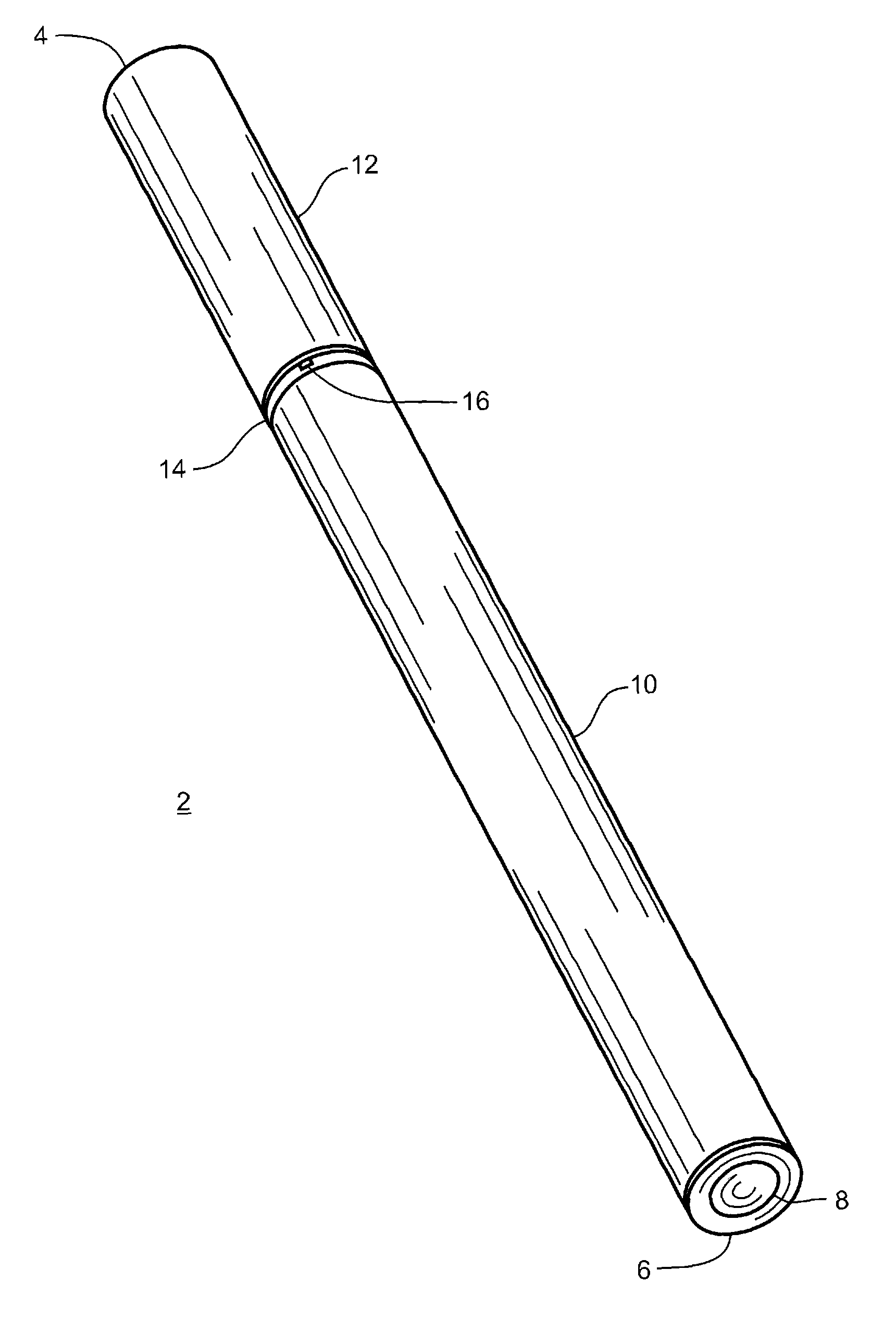

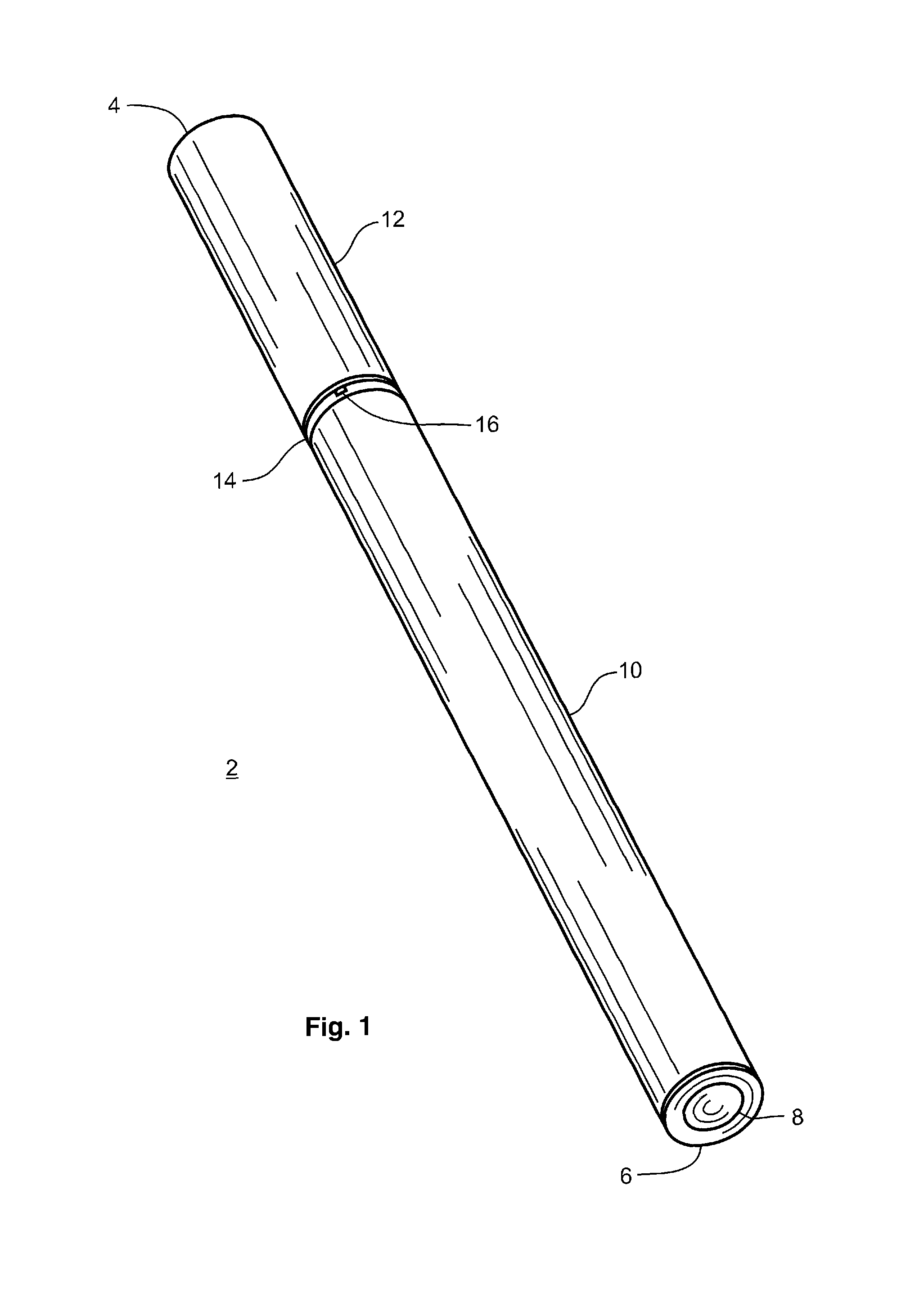

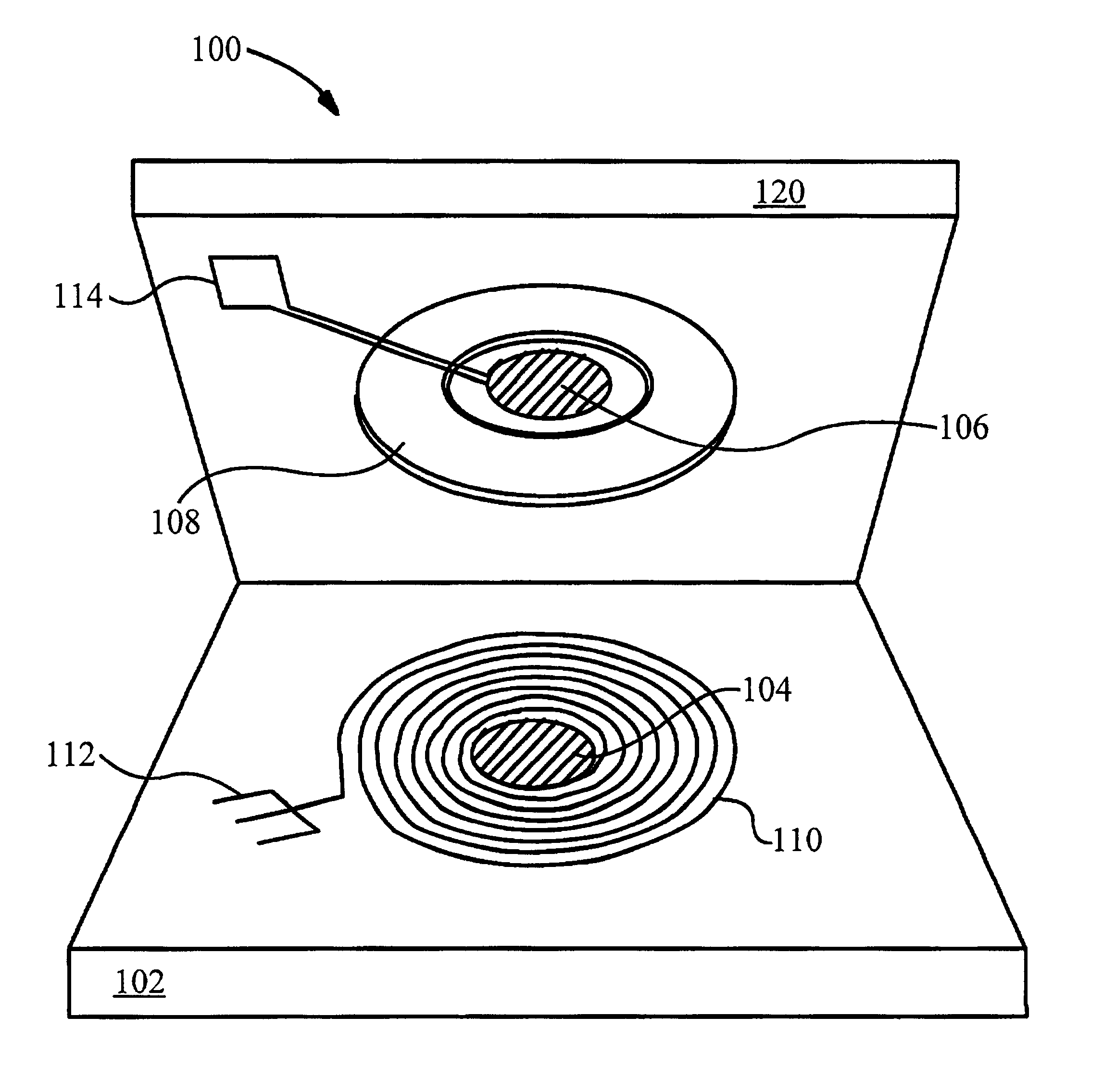

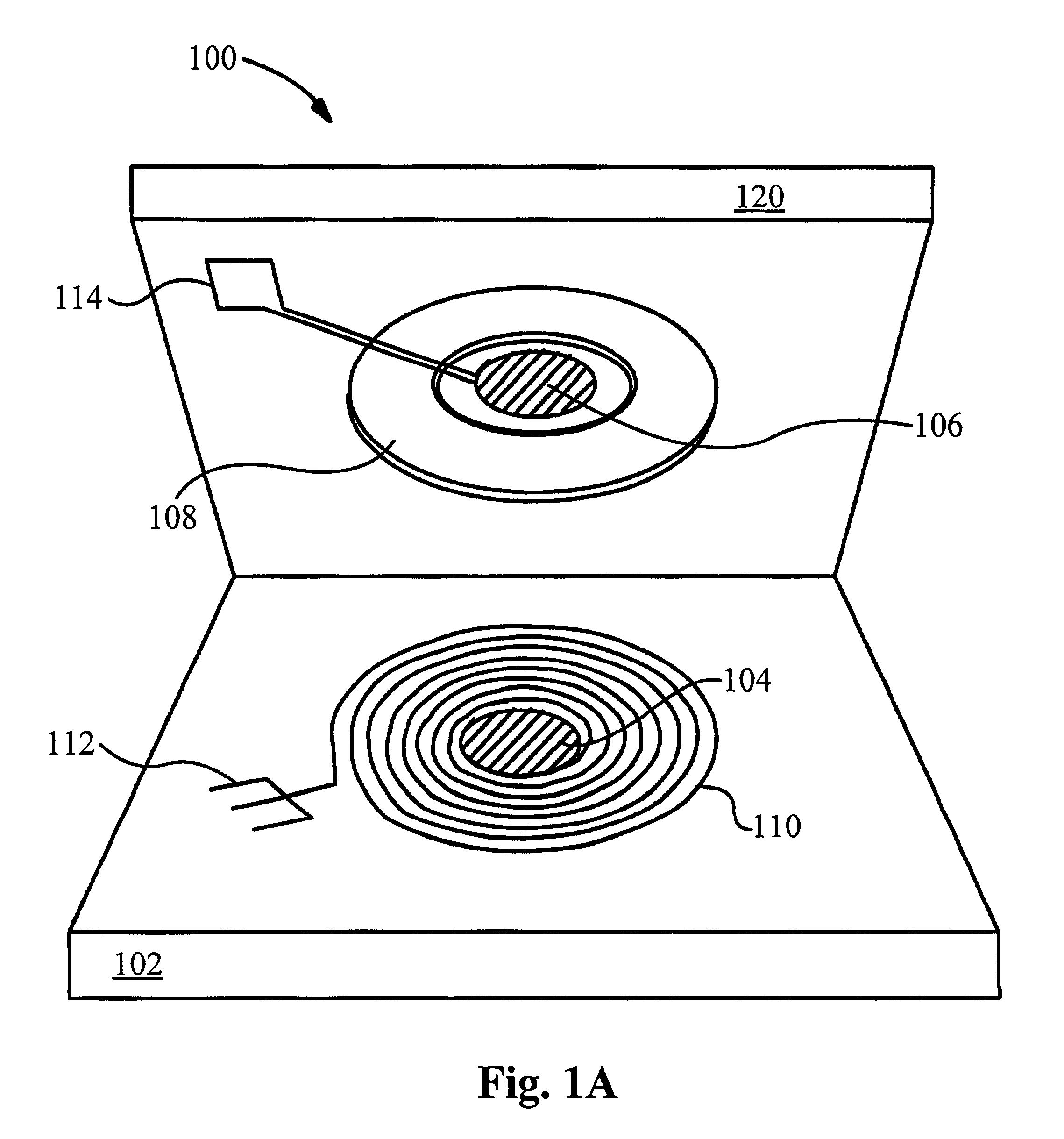

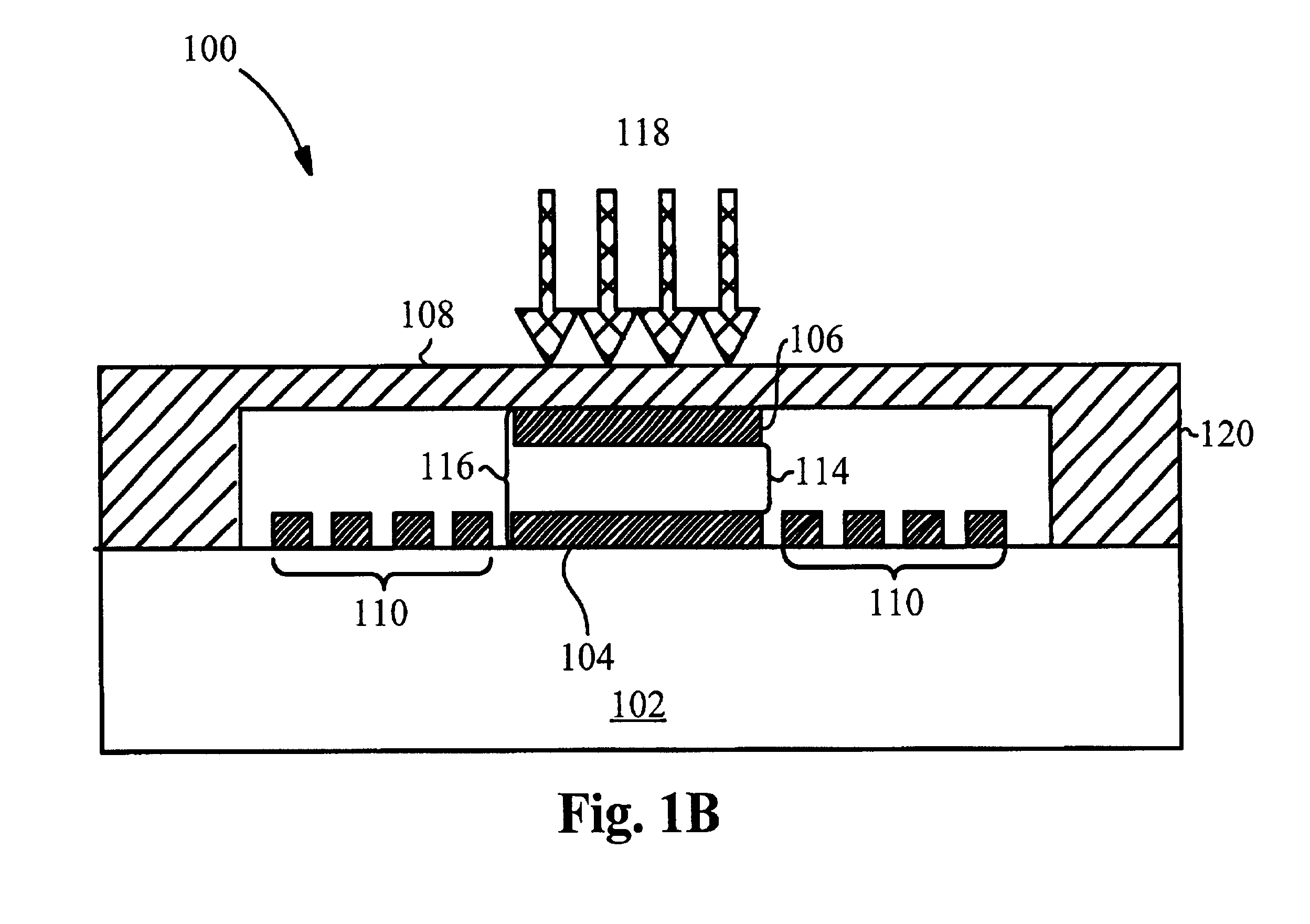

Implantable continuous intraocular pressure sensor

InactiveUS6939299B1Worn safely and comfortably and convenientlyPerson identificationTonometersIntraocular pressureSpiral inductor

An implantable miniaturized pressure sensor integrates a capacitor and an inductor in one small chip, forming a resonant LC circuit having a Q value of 10 or greater. The capacitor has an upper capacitor plate and a lower capacitor plate disposed proximate thereof. The upper and lower capacitor plates are connected to one or more spiral inductor coils. The sensor is micromachined from silicon to form a thin and robust membrane disposed on top of the upper capacitor plate. The sensor is hermetically sealed and the membrane is deflected relative to the upper capacitor plate by an external fluid, gas, or mechanical pressure. The resonant frequency of the sensor can be remotely monitored and continuously measured with an external detector pick up coil disposed proximate the sensor. The sensor can be smaller than 2×2×0.5 mm and is particularly useful for intraocular applications.

Owner:IOSENSOR

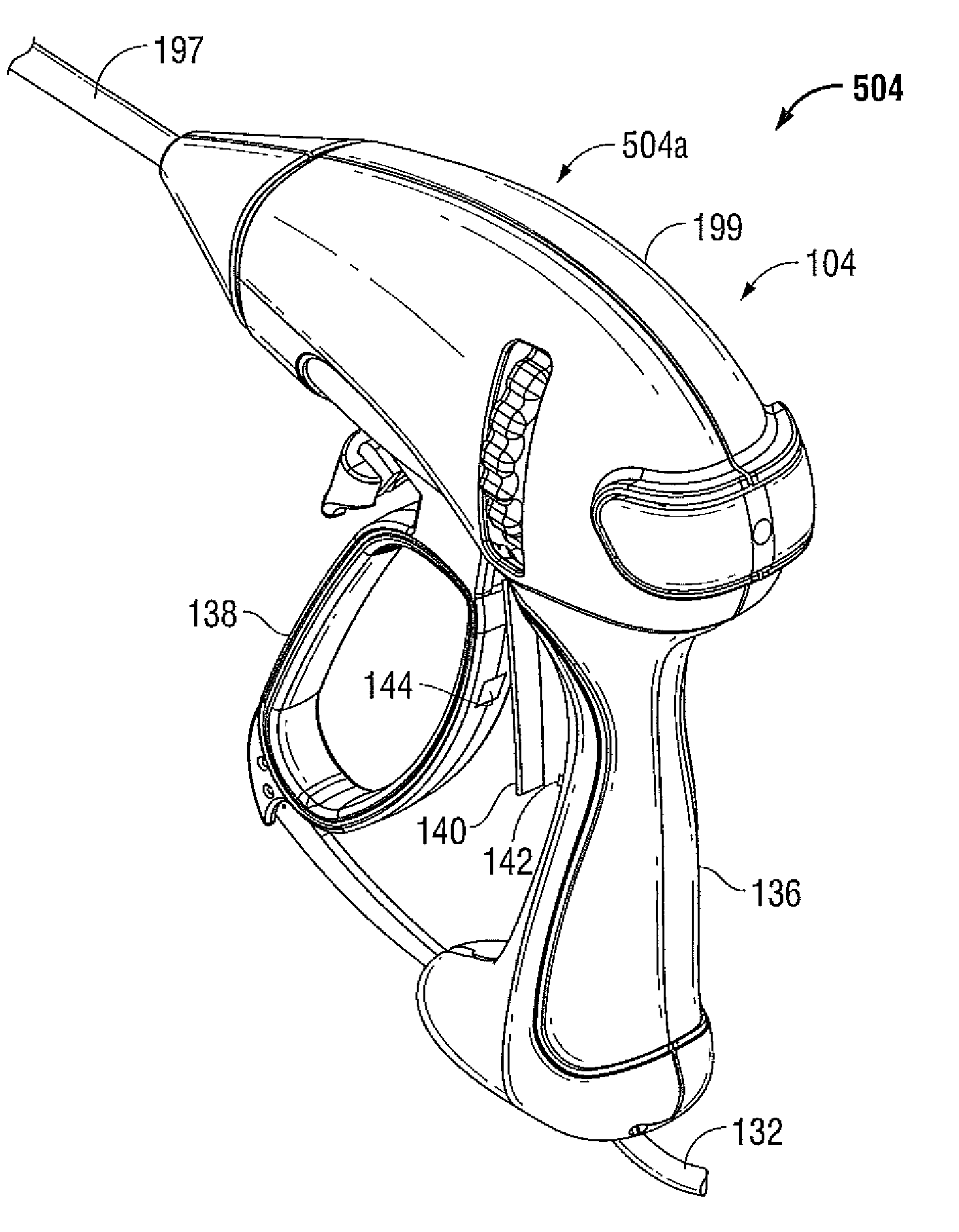

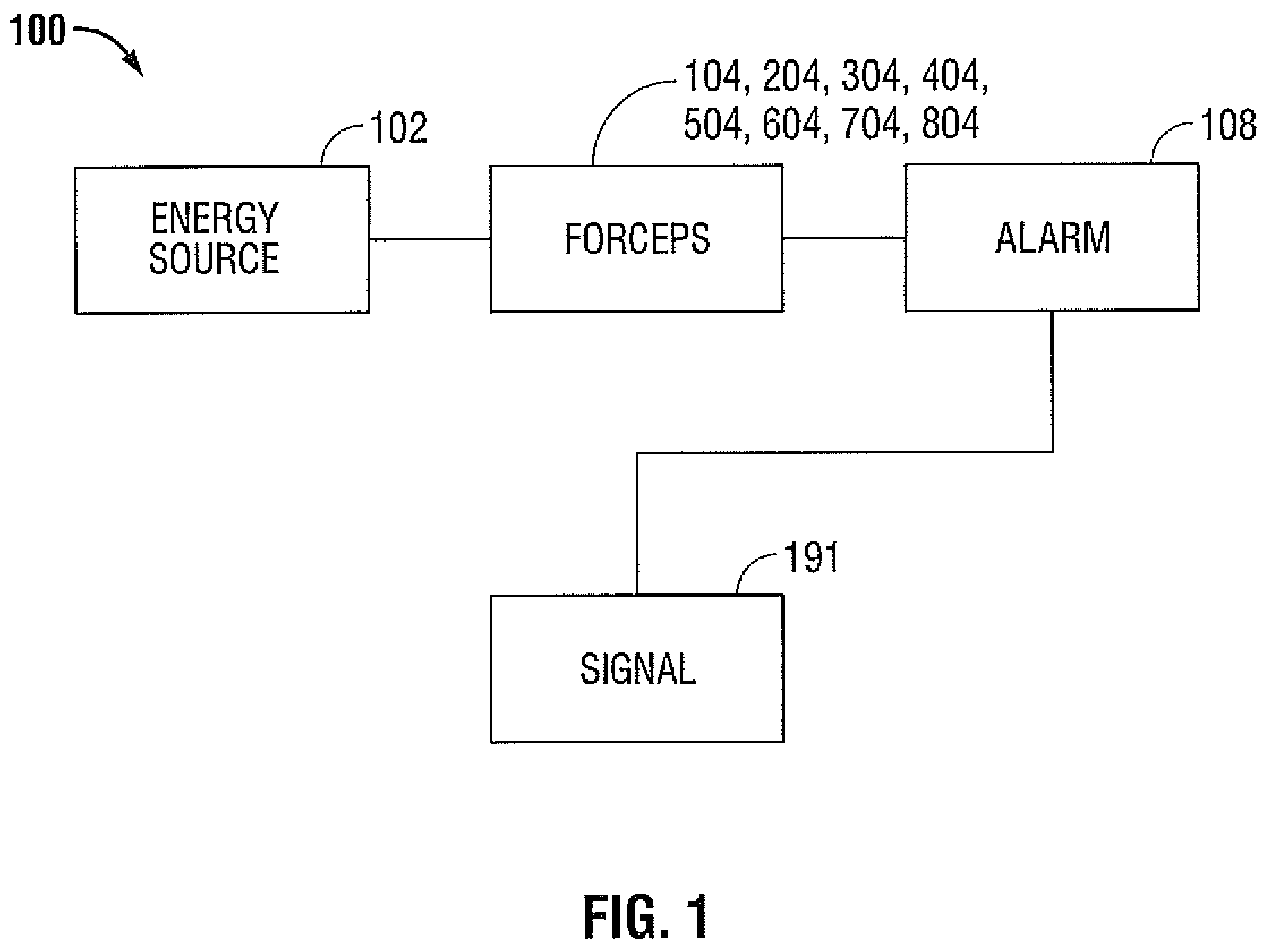

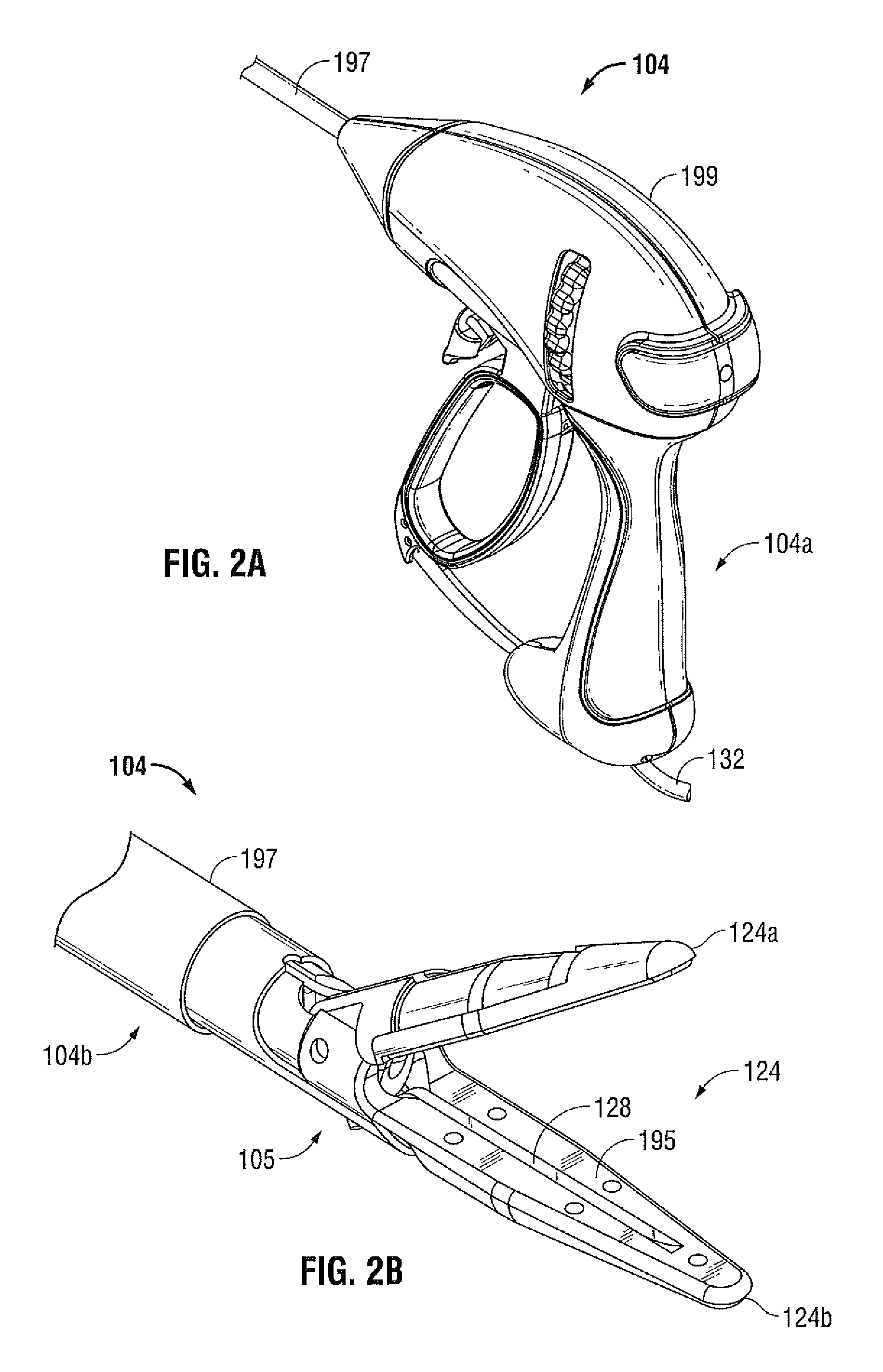

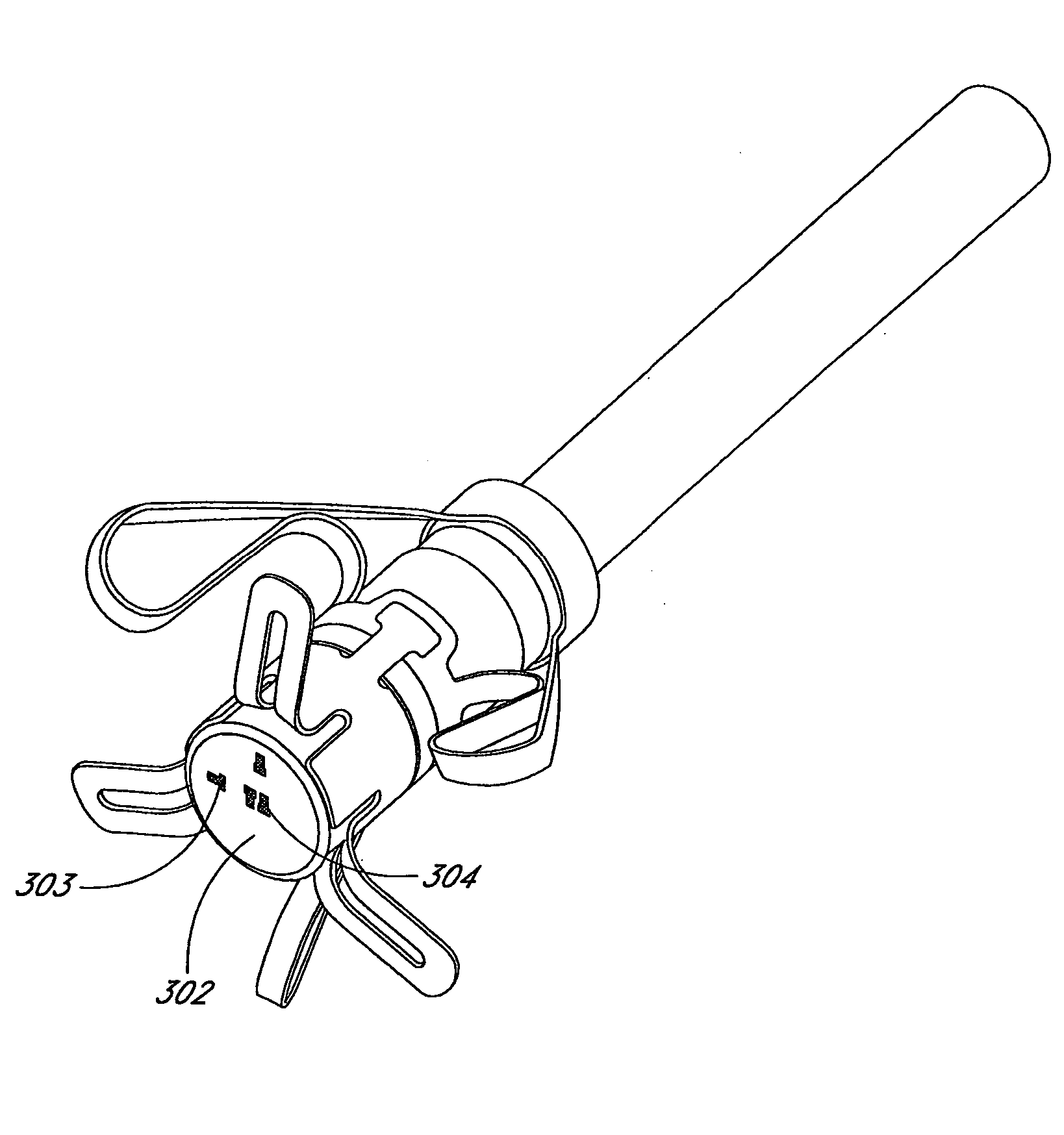

Vessel sealer and divider with blade deployment alarm

ActiveUS8251994B2DiagnosticsSurgical instruments for heatingElectrical resistance and conductanceElectricity

An electrosurgical forceps includes a selectively advanceable knife and a knife deployment alarm configured to emit a signal under predetermined conditions. An alarm is configured to emit a signal when the cutting blade moves relative to the blade channel. A series of resistances are arranged so that a shorting of each resistor is indicative of a predetermined operating condition triggering the alarm to emit a signal. Pressure sensors, optical measurement devices, and electrical contacts are envisioned for determining blade or trigger actuation or translation.

Owner:TYCO HEALTHCARE GRP LP

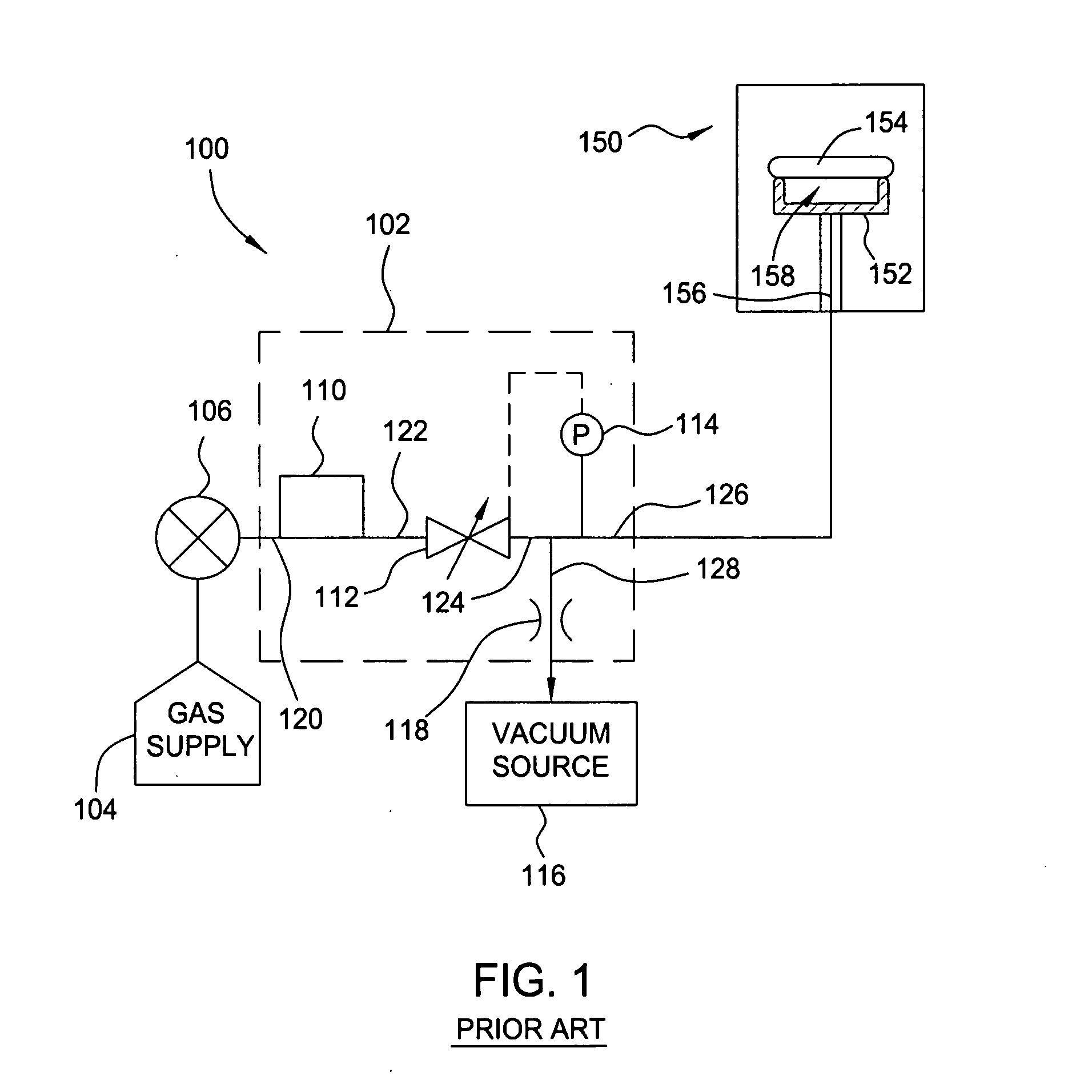

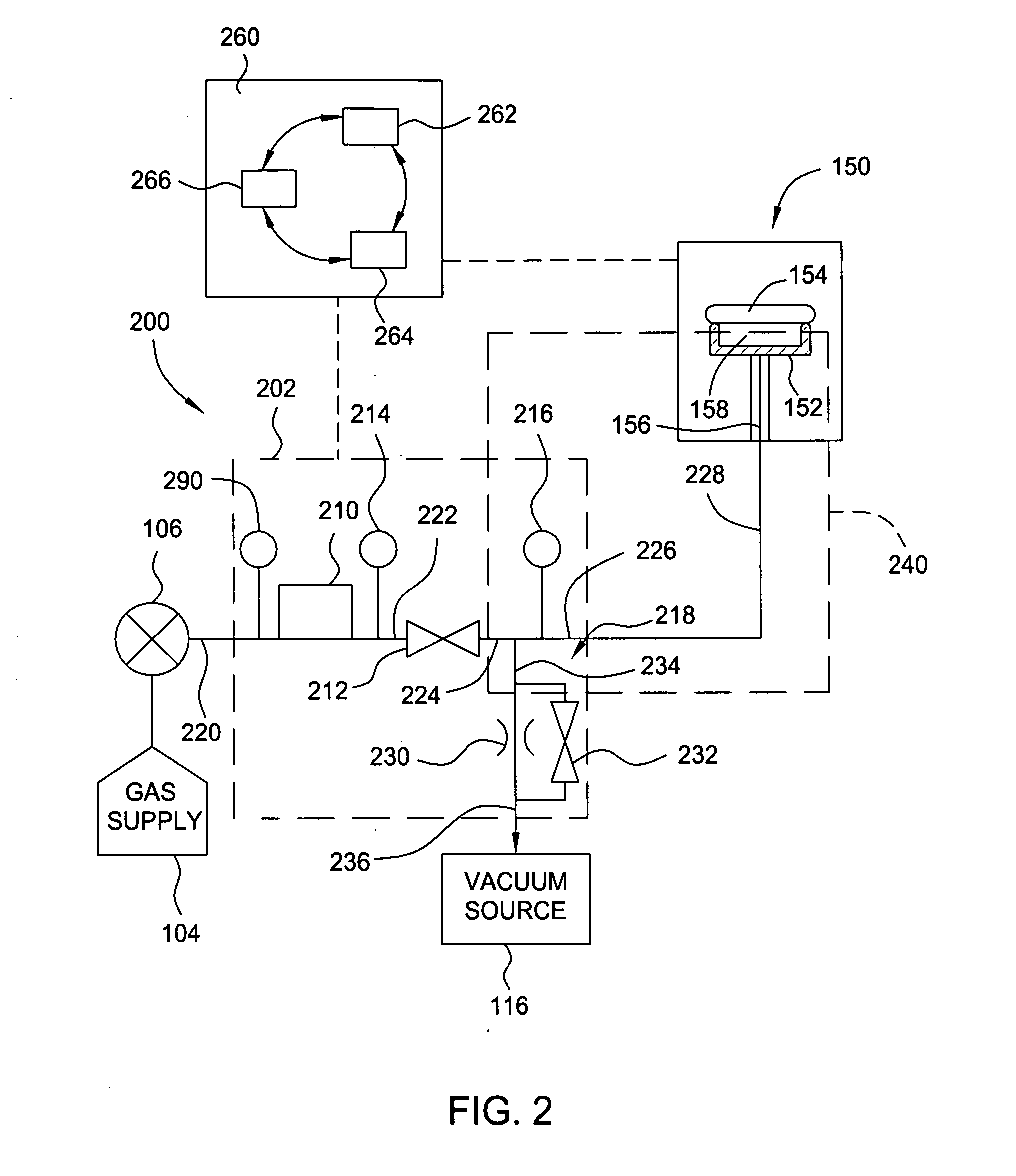

Method and apparatus for substrate temperature control

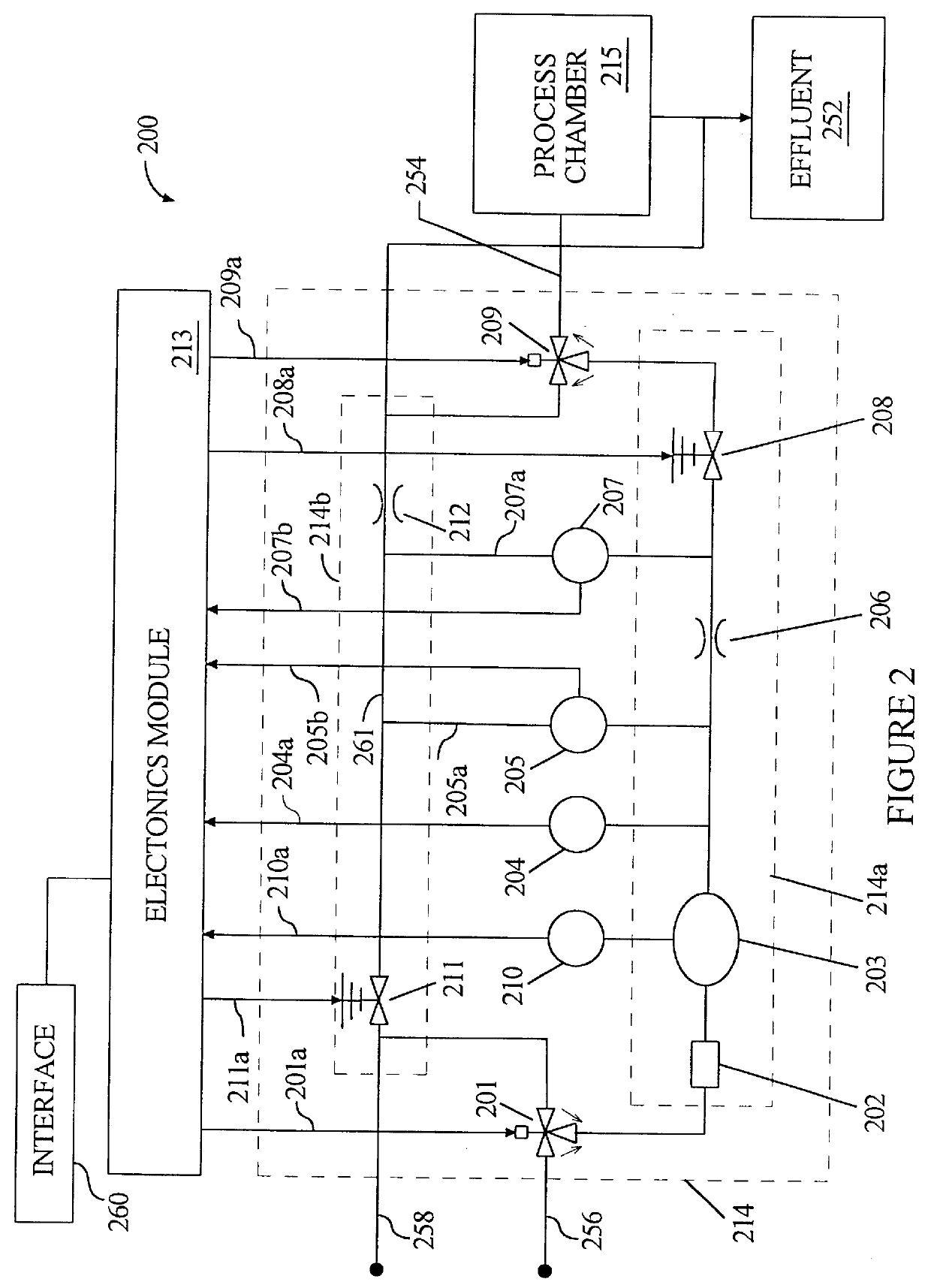

InactiveUS20050120805A1Electric discharge tubesAerodynamic testingTemperature controlFlow transducer

A method and apparatus for gas control is provided. The apparatus may be used for controlling gases delivered to a chamber, controlling the chamber pressure, controlling the delivery of backside gas between a substrate and substrate support and the like. In one embodiment, an apparatus for controlling gas control includes at least a first flow sensor having a control valve, a first pressure sensor and at least a second pressure sensor. An inlet of the first flow sensor is adapted for coupling to a gas supply. A control valve is coupled to an outlet of the flow sensor. The first pressure sensor is adapted to sense a metric indicative of the pressure upstream of the first flow sensor. The second pressure sensor is adapted to sense a metric indicative of the pressure downstream of the control valve.

Owner:APPLIED MATERIALS INC

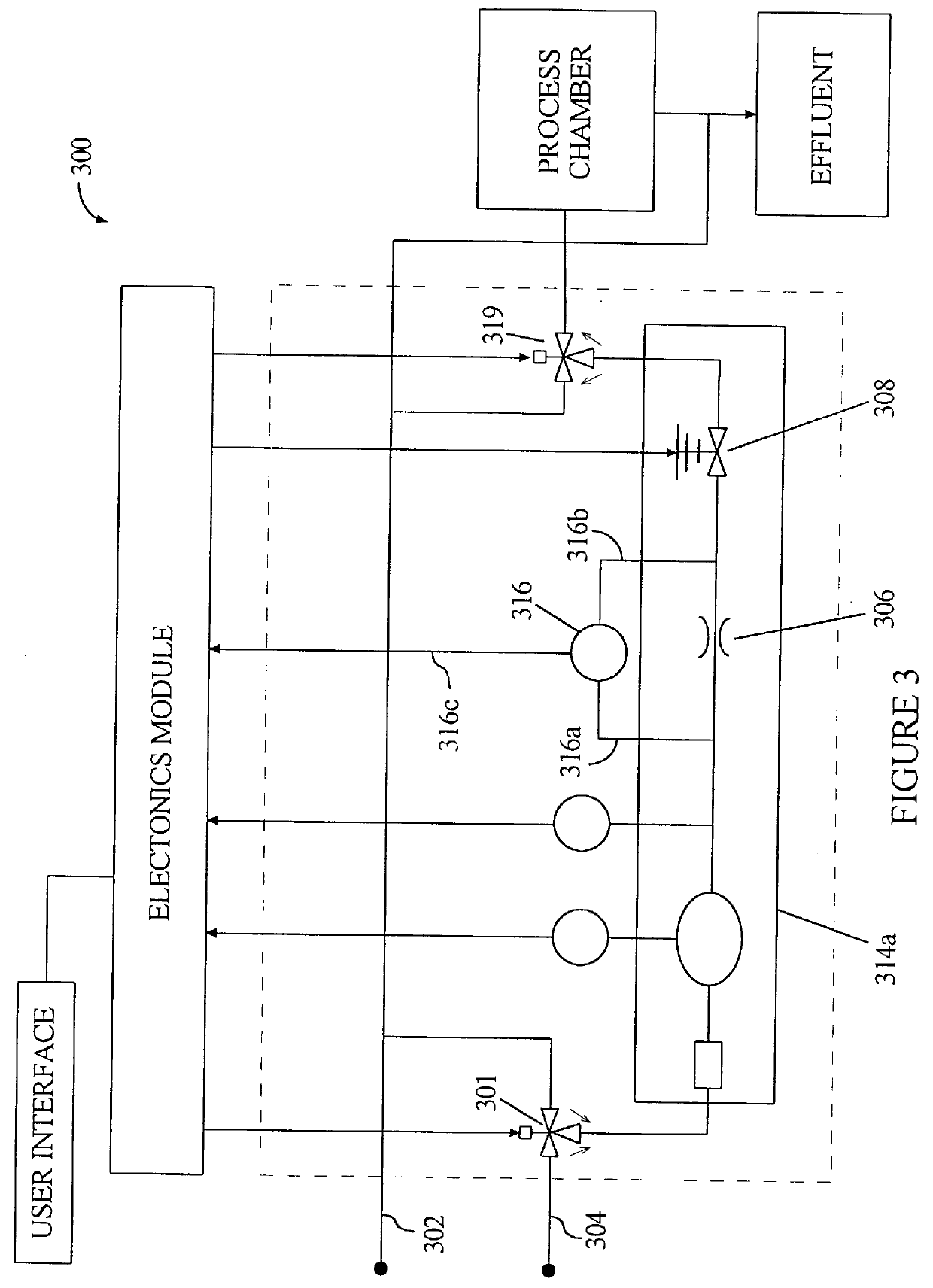

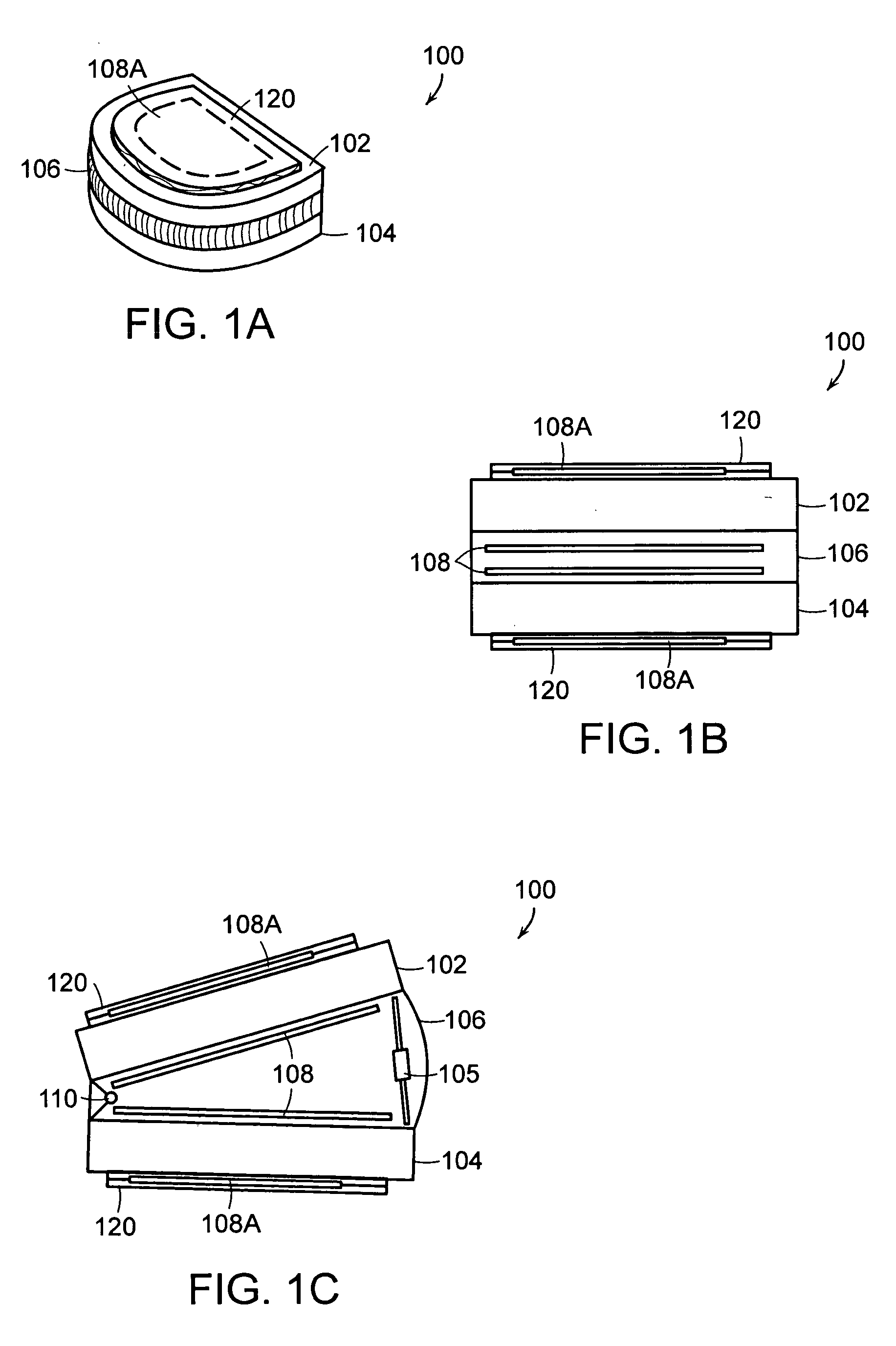

Method and apparatus for measuring consumption of reactants

InactiveUS20060107898A1Liquid surface applicatorsChemical vapor deposition coatingEngineeringForce sensor

A method and apparatus for measuring the consumption of reactants includes a partial pressure sensor for measuring the partial pressure of a reactant in a reactant stream. The partial pressure sensor includes a first pressure sensor that has a first sensitivity to the composition of the gas stream and a second pressure sensor that has a second sensitivity to the composition of the reactant stream, the second sensitivity being greater than the first sensitivity. A control unit is configured to compare a first pressure signal from the first pressure sensor to a second pressure signal from the second pressure sensor to determine the partial pressure of the reactant in the reactant stream.

Owner:BLOMBERG TOM E

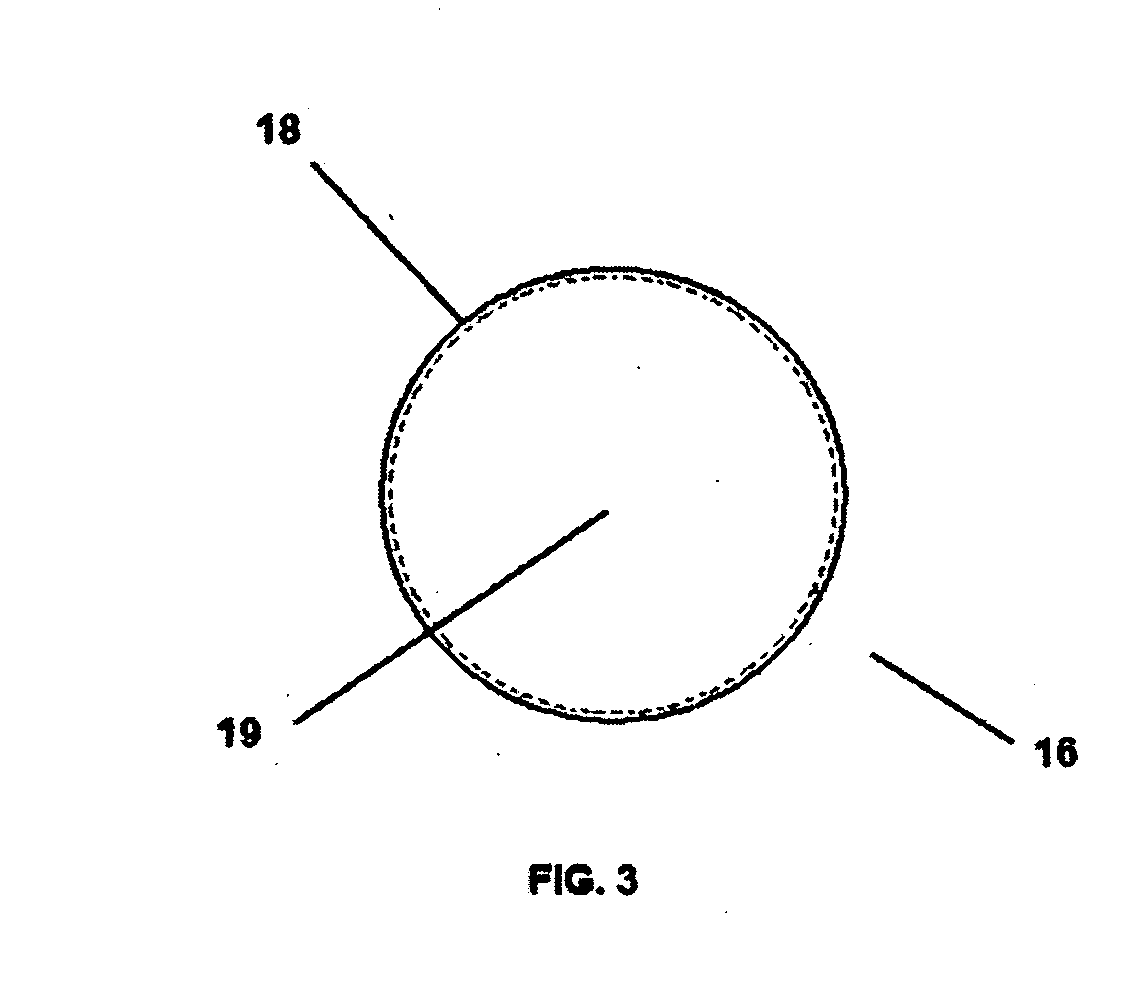

Trial disk implant

InactiveUS20060069436A1Minimize changesReduce dependencePerson identificationJoint implantsSpinal Disk ImplantIntervertebral disk

A trial intervertebral disk implant includes a first plate, a second plate, adjacent to the first plate, a conformable layer between the first and the second plates, and a pressure sensor within the conformable layer. The pressure sensor measures a distribution of compression force exerted by the first and the second plates on the conformable layer. The trial implant includes indicating means for indicating a position of the first and the second plates relative to each other, and locating means, for locating a position of the trial implant relative to the vertebrae between which said trial implant has been placed. The trial implant further includes at least one retractable member, connected to at least one of the first and the second plates. The retractable member can be extended or retracted through an aperture defined by a surface of the plate that is proximal to an abutting vertebra.

Owner:DEPUY SPINE INC (US)

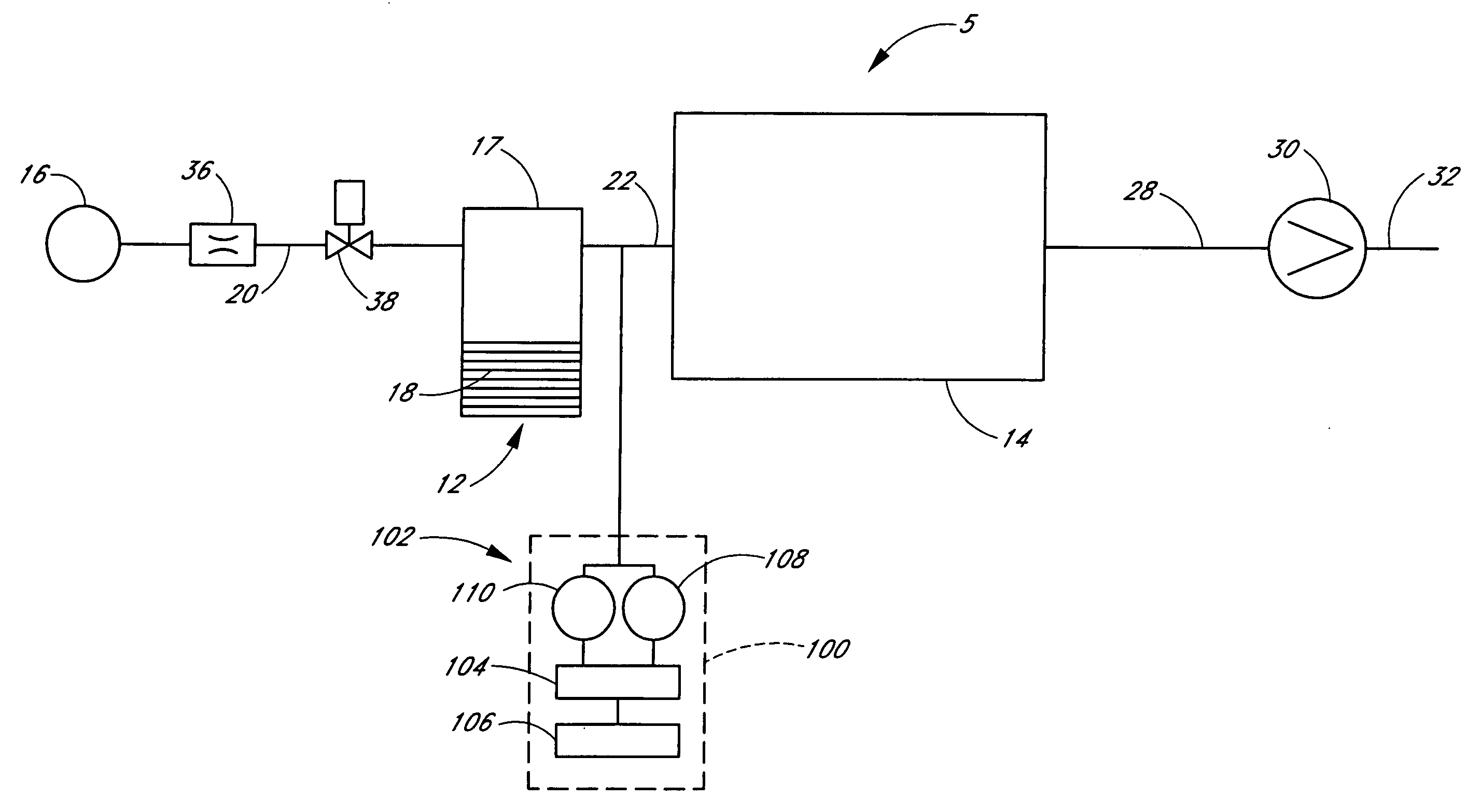

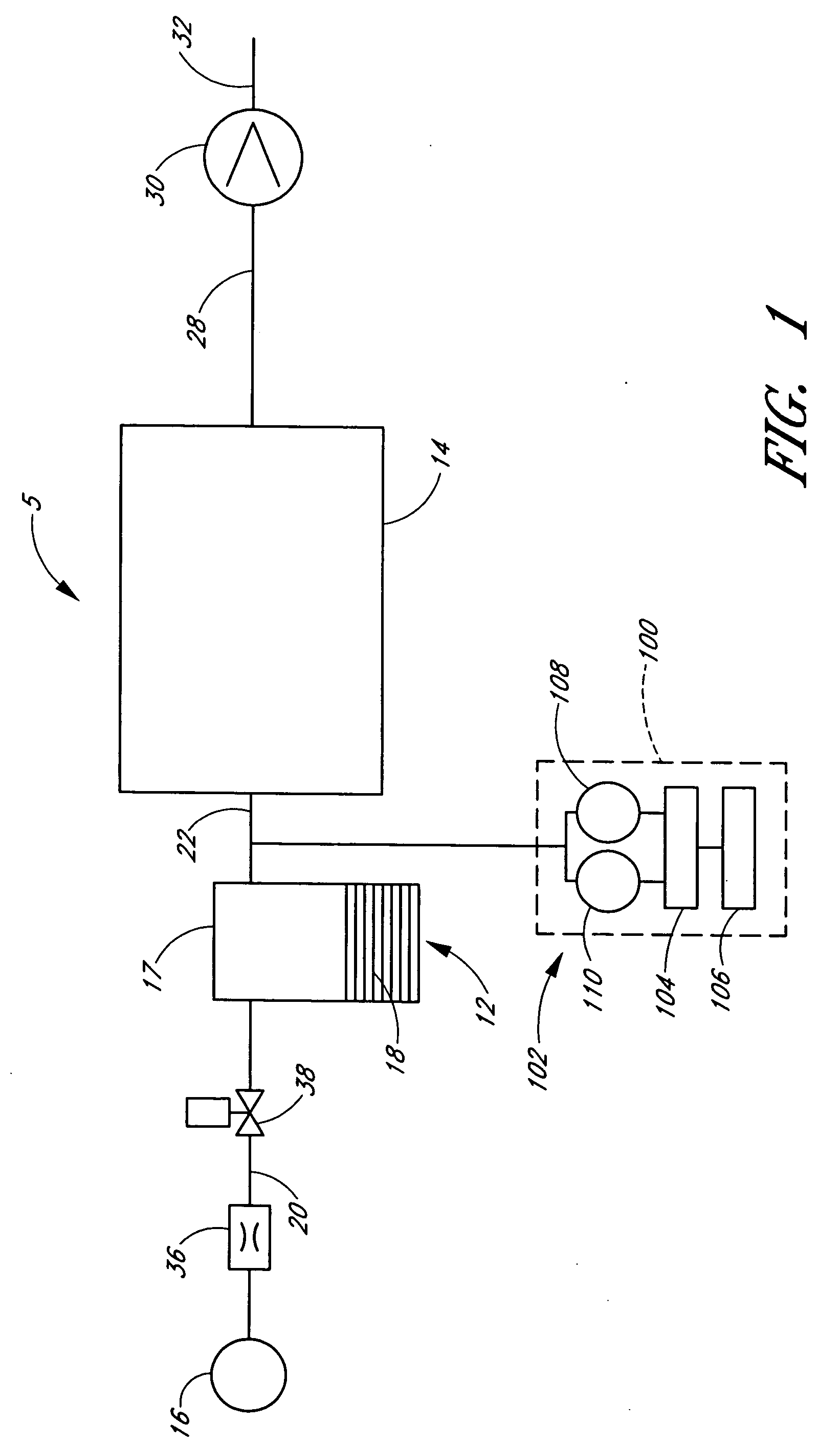

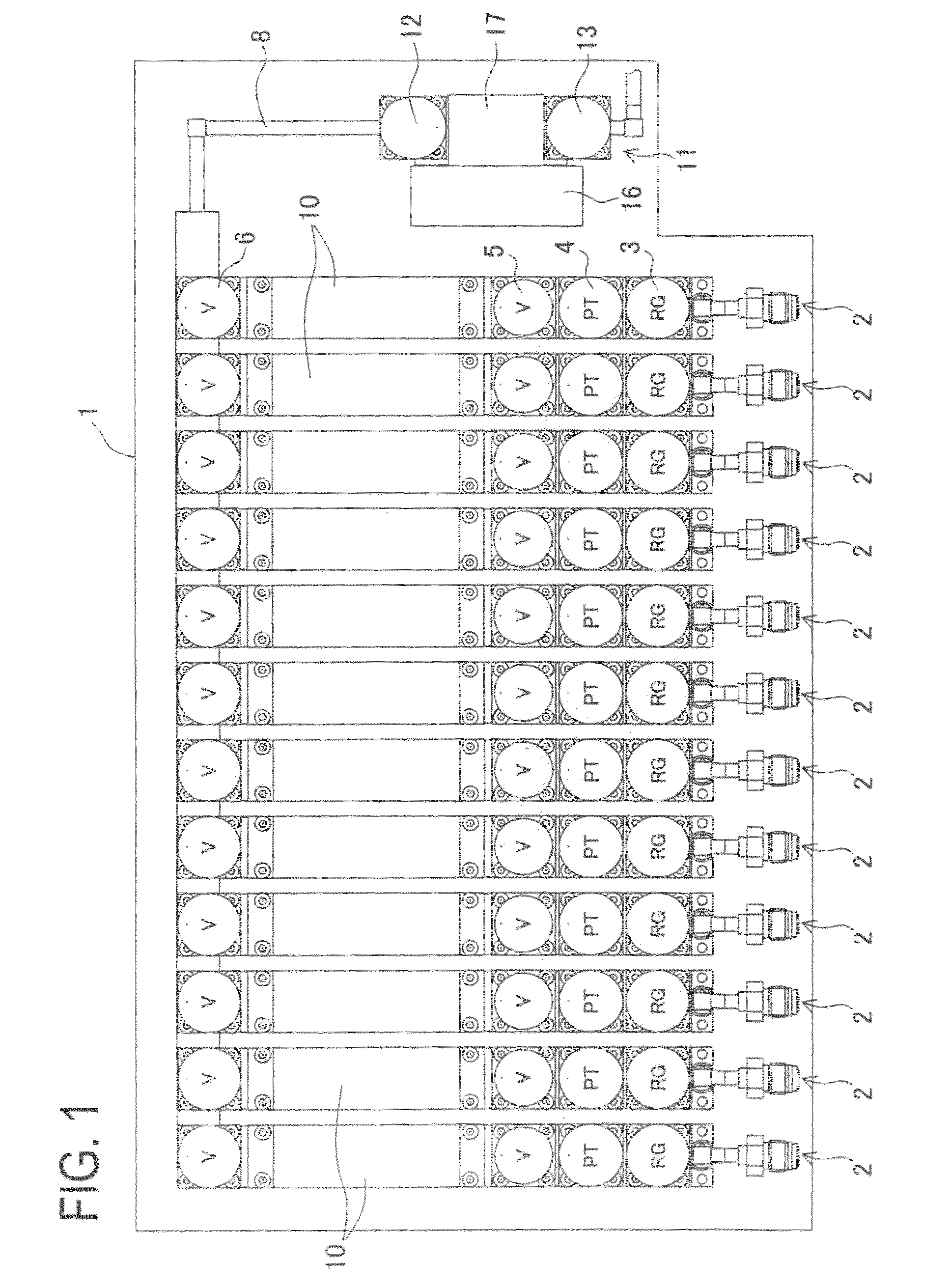

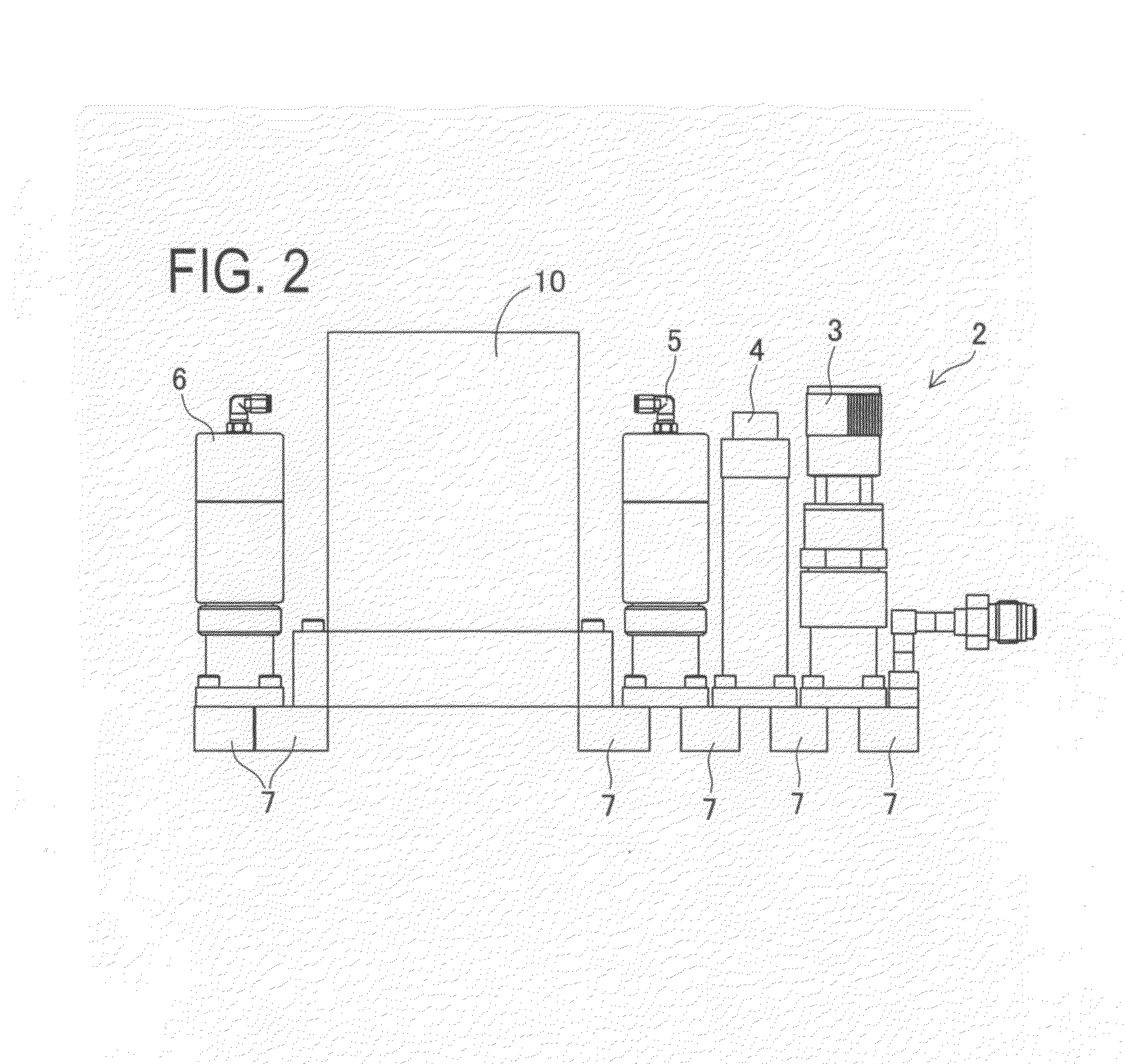

Gas flow rate verification unit

ActiveUS7716993B2Increase flow rateUniform pressureMultiple way valvesPipeline systemsEngineeringGas supply

A gas flow rate verification unit capable of enhancing reliability of gas flow rate verification. The gas flow rate verification unit has a first cutoff valve that is connected to a flow rate control device and to which gas is inputted, a second cutoff valve for discharging the gas, a communication member for allowing the first cutoff valve and the second cutoff valve to communicate with each other, a pressure sensor for detecting the pressure of the gas supplied between the first cutoff valve and the second cutoff valve, a temperature detector for detecting the temperature of the gas supplied between the first cutoff valve and the second cutoff valve, and a control means for verifying the flow of the gas flowing in the flow control device, the verification being performed by using both the result of the pressure detected by the pressure sensor and the result of the temperatures detected by the temperature detector. The volume (Vk) between the valve seat of the first cutoff valve and the valve seat of the second cutoff valve is equal to or less than the volume (Ve) between the outlet of the flow control device and the valve seat of the first cutoff valve.

Owner:CKD

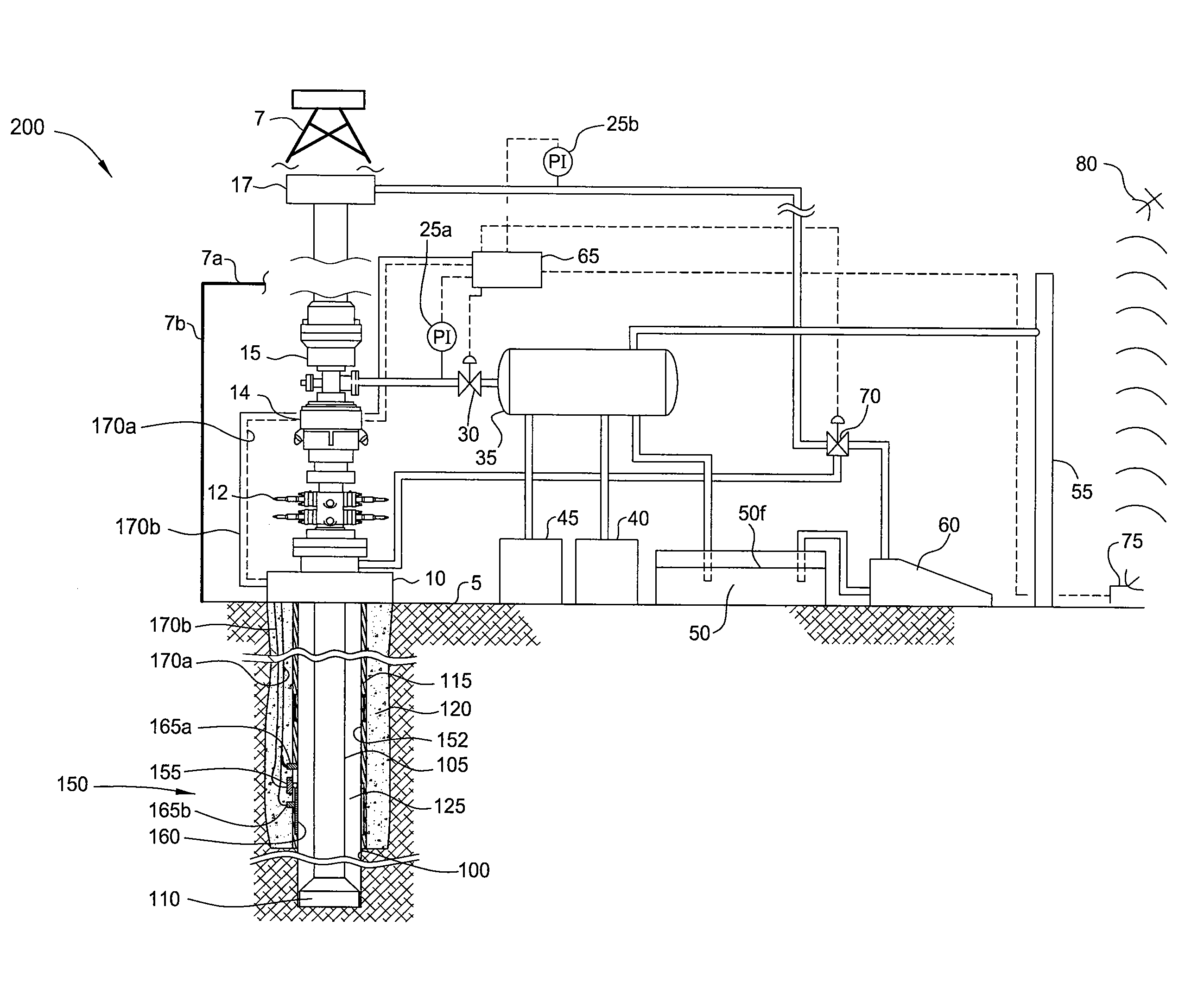

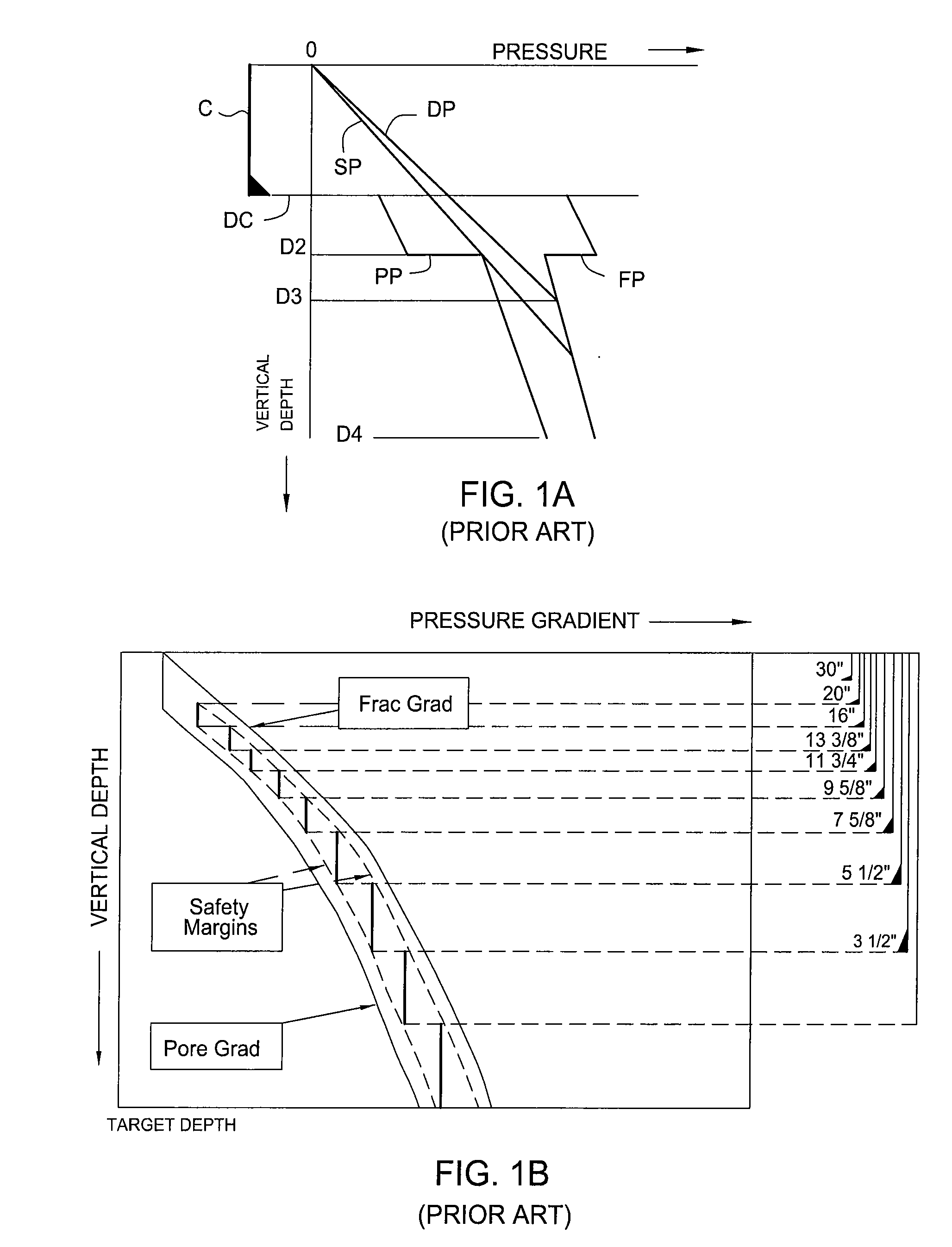

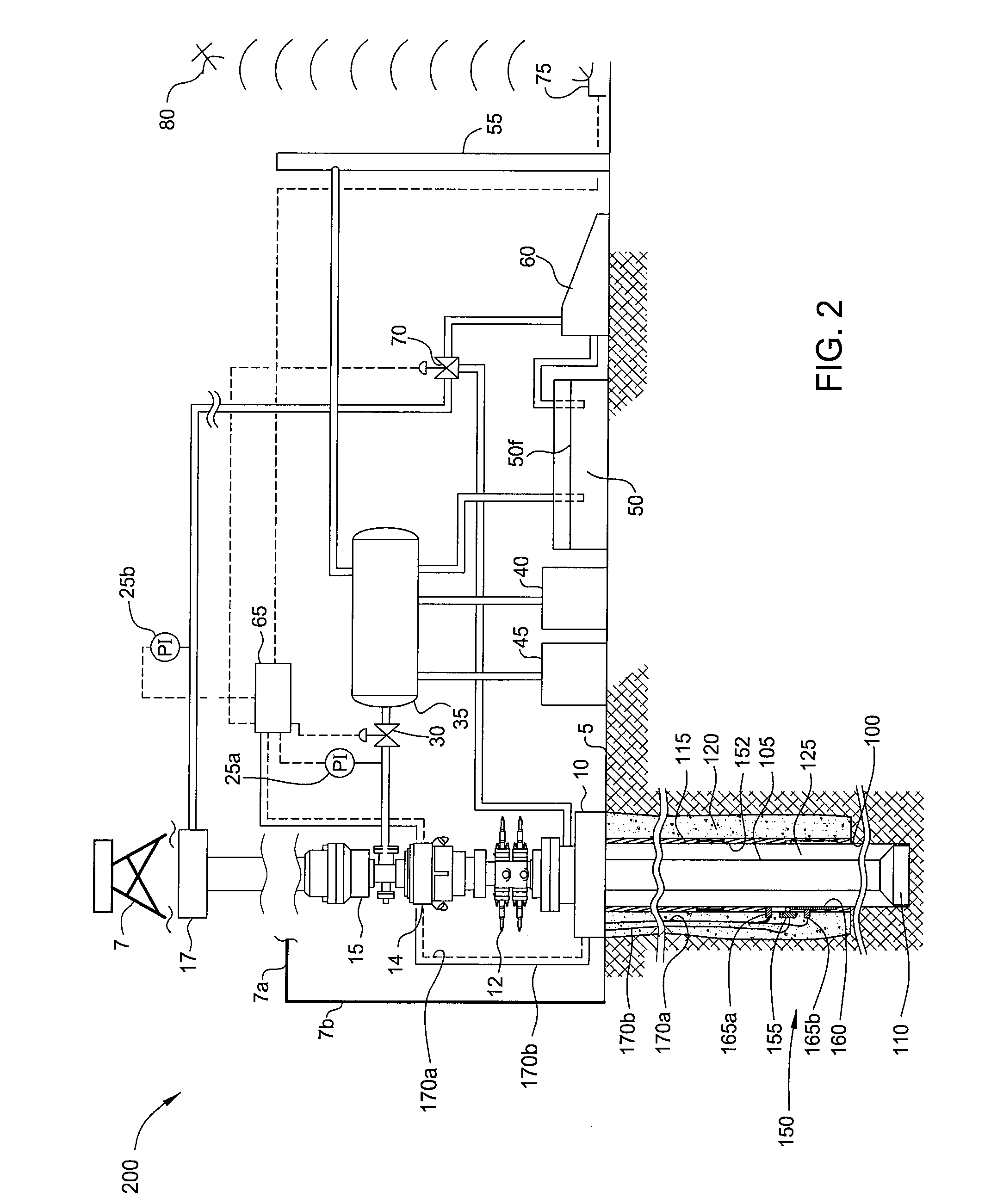

Annulus pressure control drilling systems and methods

In one embodiment, a method for drilling a wellbore includes an act of drilling the wellbore by injecting drilling fluid through a tubular string disposed in the wellbore, the tubular string comprising a drill bit disposed on a bottom thereof. The drilling fluid exits the drill bit and carries cuttings from the drill bit. The drilling fluid and cuttings (returns) flow to a surface of the wellbore via an annulus defined by an outer surface of the tubular string and an inner surface of the wellbore. The method further includes an act performed while drilling the wellbore of measuring a first annulus pressure (FAP) using a pressure sensor attached to a casing string hung from a wellhead of the wellbore. The method further includes an act performed while drilling the wellbore of controlling a second annulus pressure (SAP) exerted on a formation exposed to the annulus.

Owner:WEATHERFORD TECH HLDG LLC

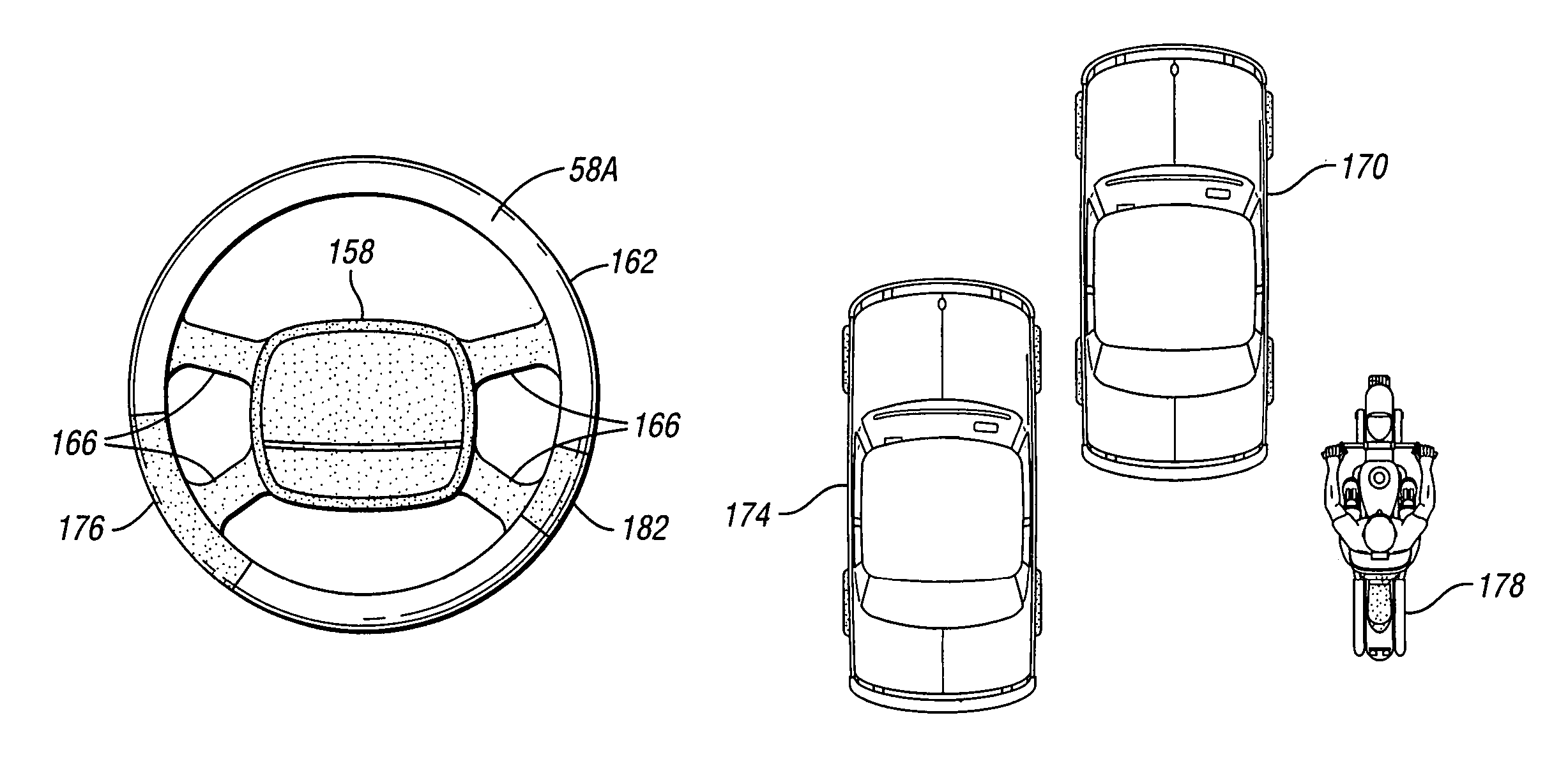

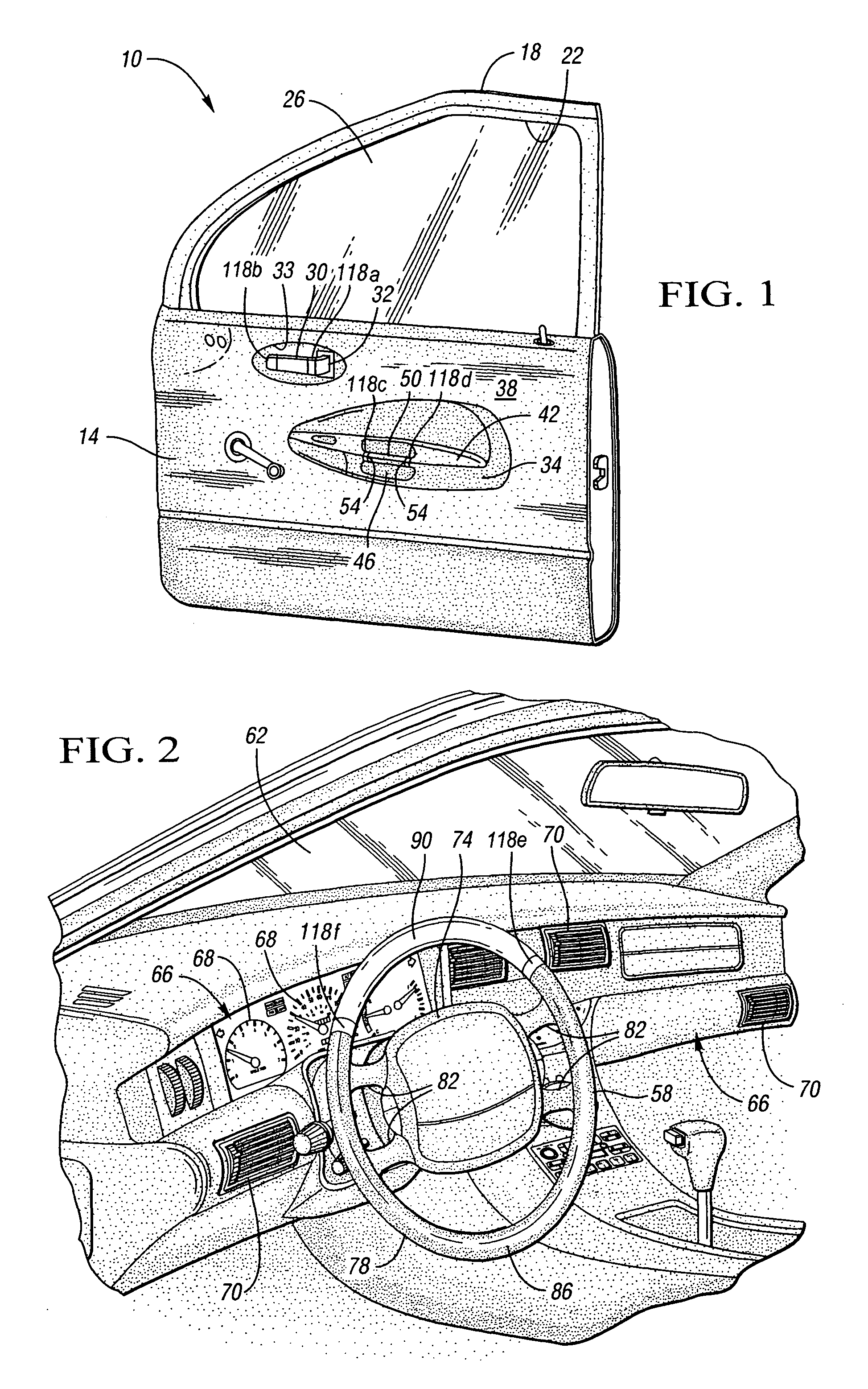

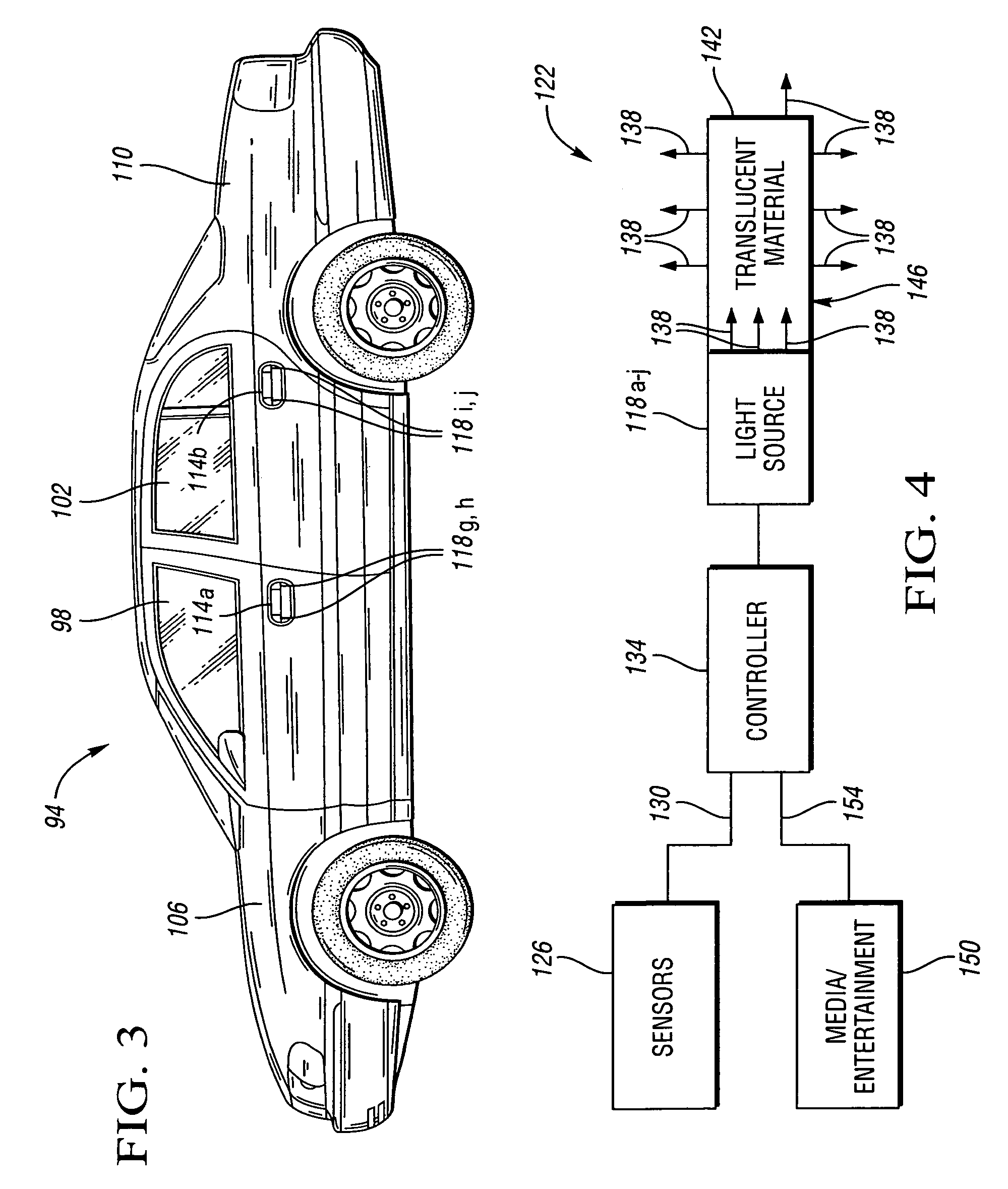

Vehicle illumination system and method

InactiveUS7987030B2Avoid interferenceConvenient lightingLighting circuitsPassenger/driving compartment lightingsSteering wheelControl system

An apparatus and method for illuminating a vehicle including a light source connected to an illuminatable component such as an interior or exterior vehicle door handle or steering wheel, and a control system including a plurality of sensors that monitor the vehicle and surroundings for predetermined conditions and selectively illuminate the component as a means of conveying information or warnings about the vehicle or its surroundings. Illumination may be enhanced by other auditory signals such as audio alarms or vibration. Predetermined conditions may include the proximity of a vehicle user, key fob activation or proximity, input from an entertainment system, activation of a pressure sensor, the presence of a person or object in proximity to the vehicle, or the vehicle's ignition or gear state.

Owner:GM GLOBAL TECH OPERATIONS LLC

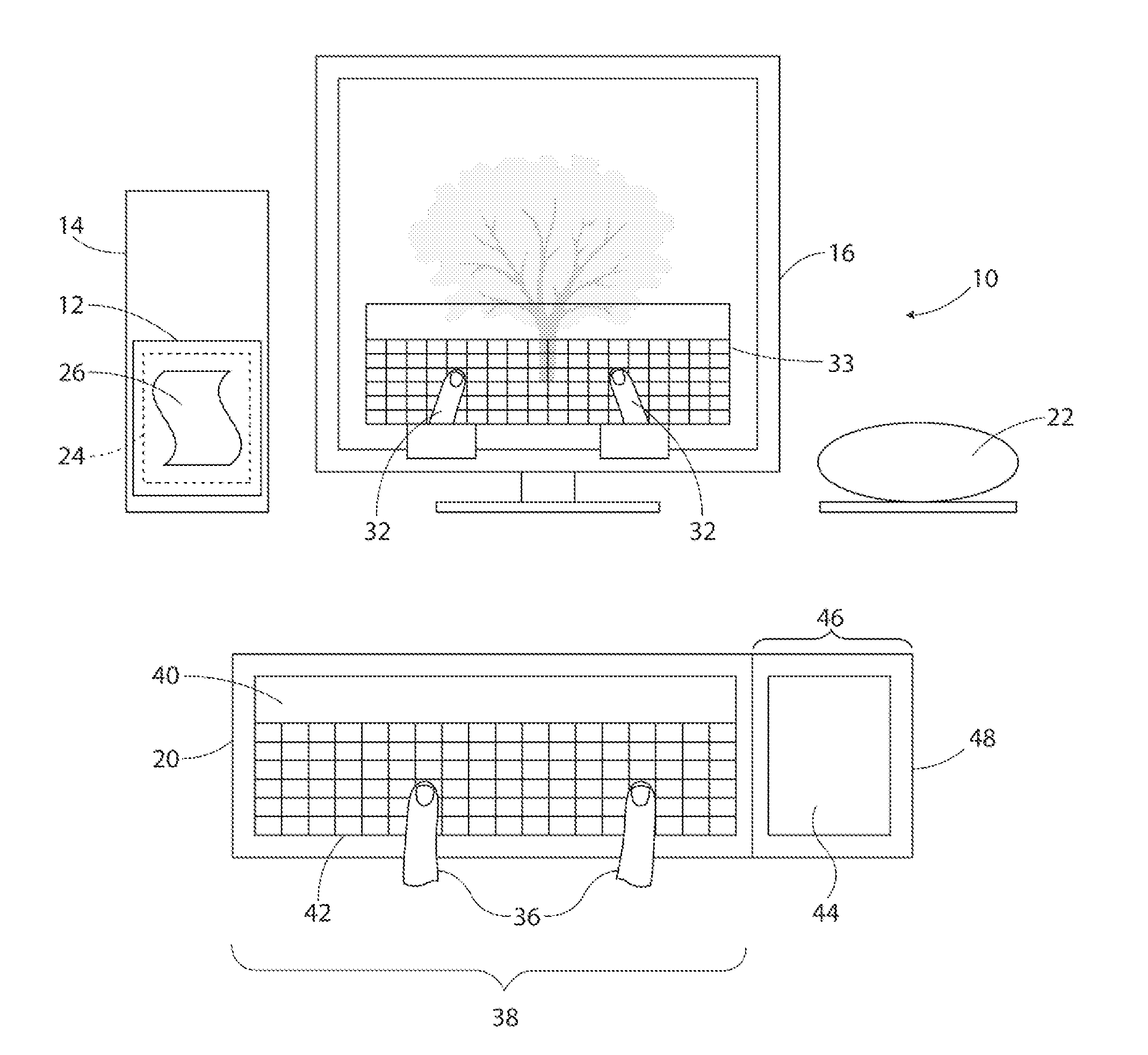

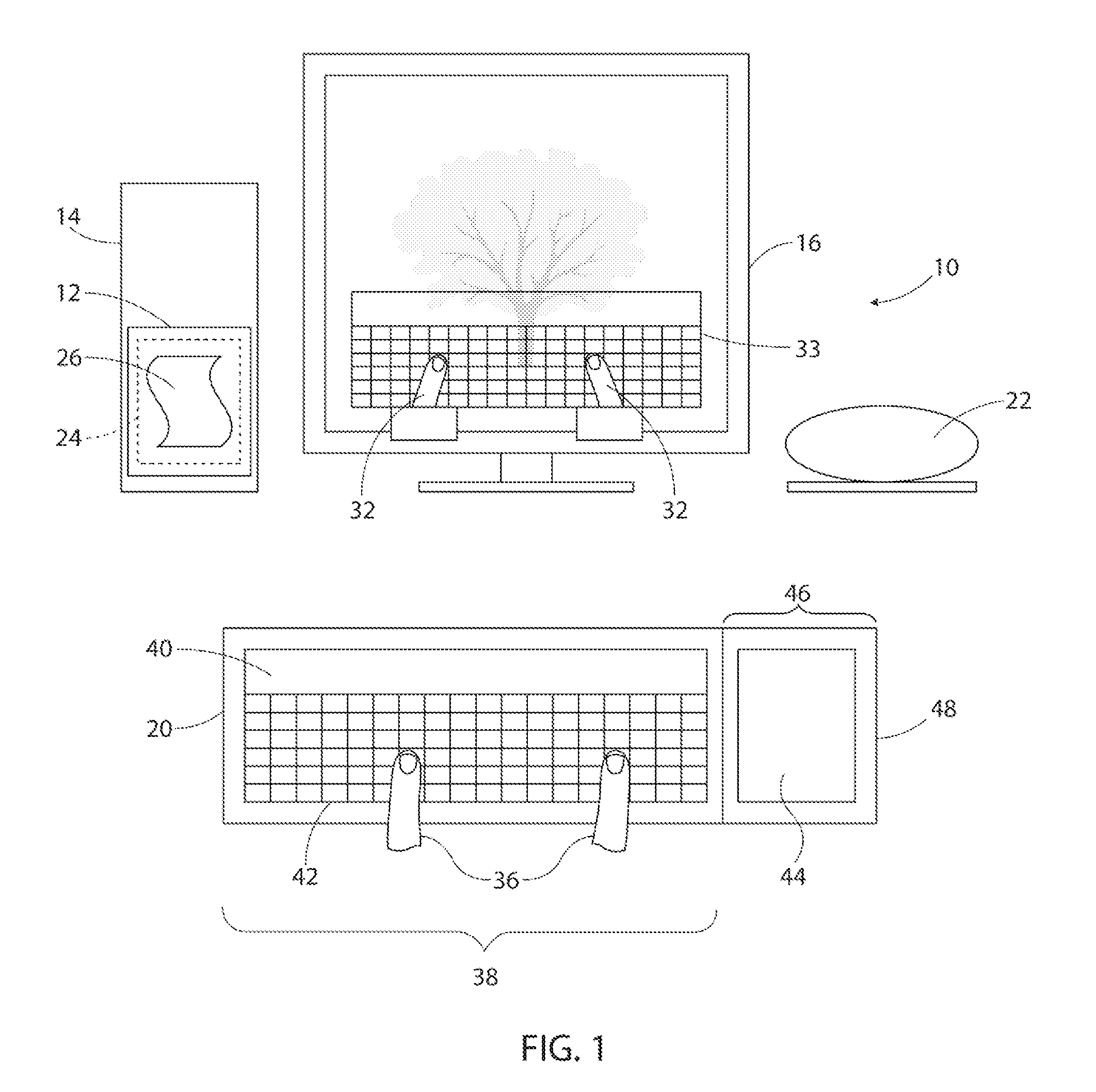

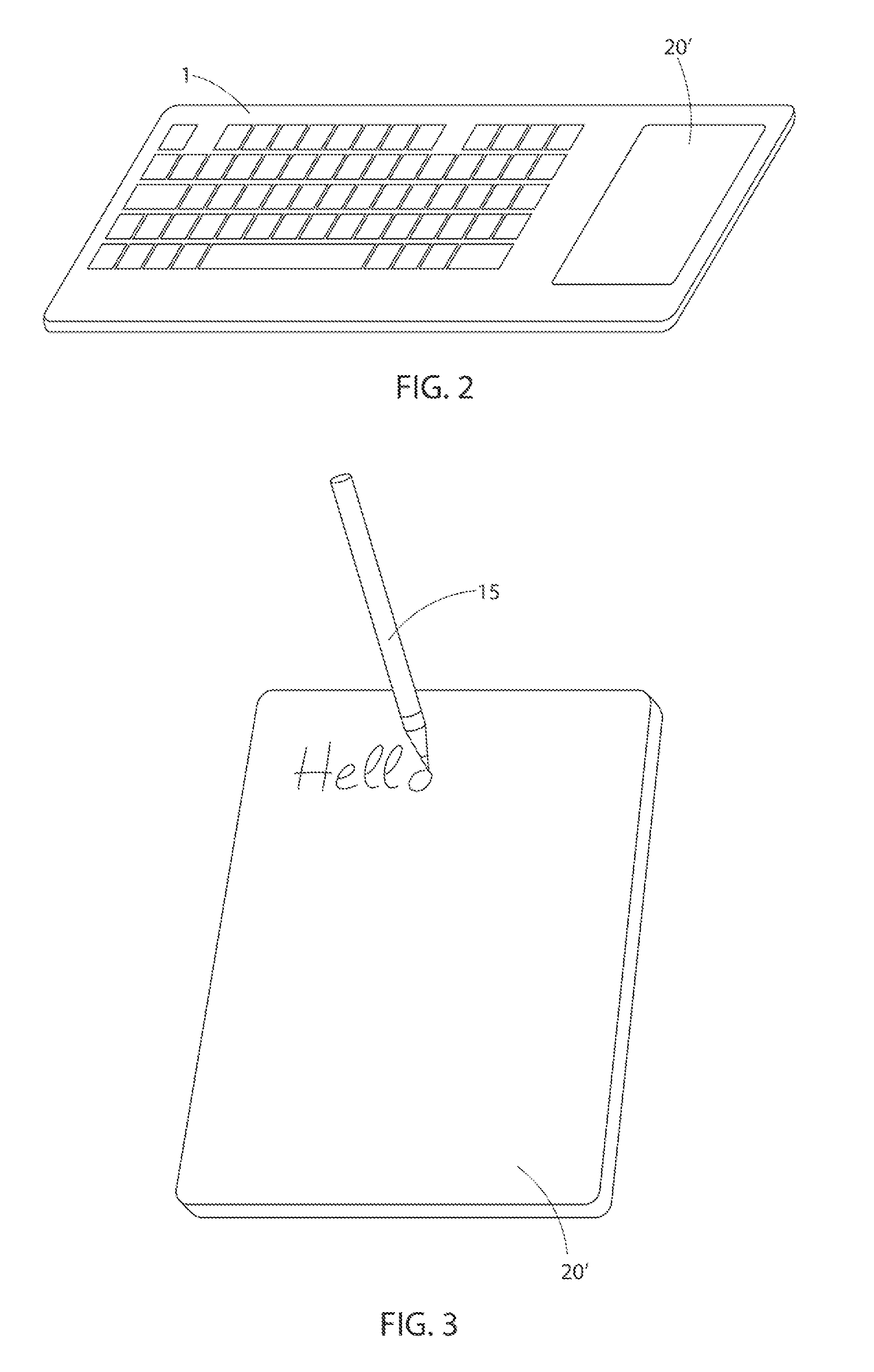

System and method for capturing hand annotations

ActiveUS20110248941A1Simplified entryLow costInput/output processes for data processingGraphicsJava annotation

A capture device for remote, virtual on screen data input by hand annotation comprises at least three functional layers including a bottom rigid layer, a middle pressure sensor layer and a top flexible layer. The bottom rigid layer has a surface that provides a mechanical support for writing. The middle pressure sensor layer is adapted to measuring a pressure array or map on the capture active area and to send data representing the measured pressure to a personal computer. The top flexible touch-sensitive passive LCD display layer includes an LCD surface by which whatever is written down on the LCD is impressed graphically due to its liquid crystal physical properties wherein applied pressure changes the crystal particles orientation and light properties, such that when a stylus presses against a writing surface thereof, it leaves a visible trace allowing the user to produce a drawing though no real ink has flown.

Owner:LOGITECH EURO SA

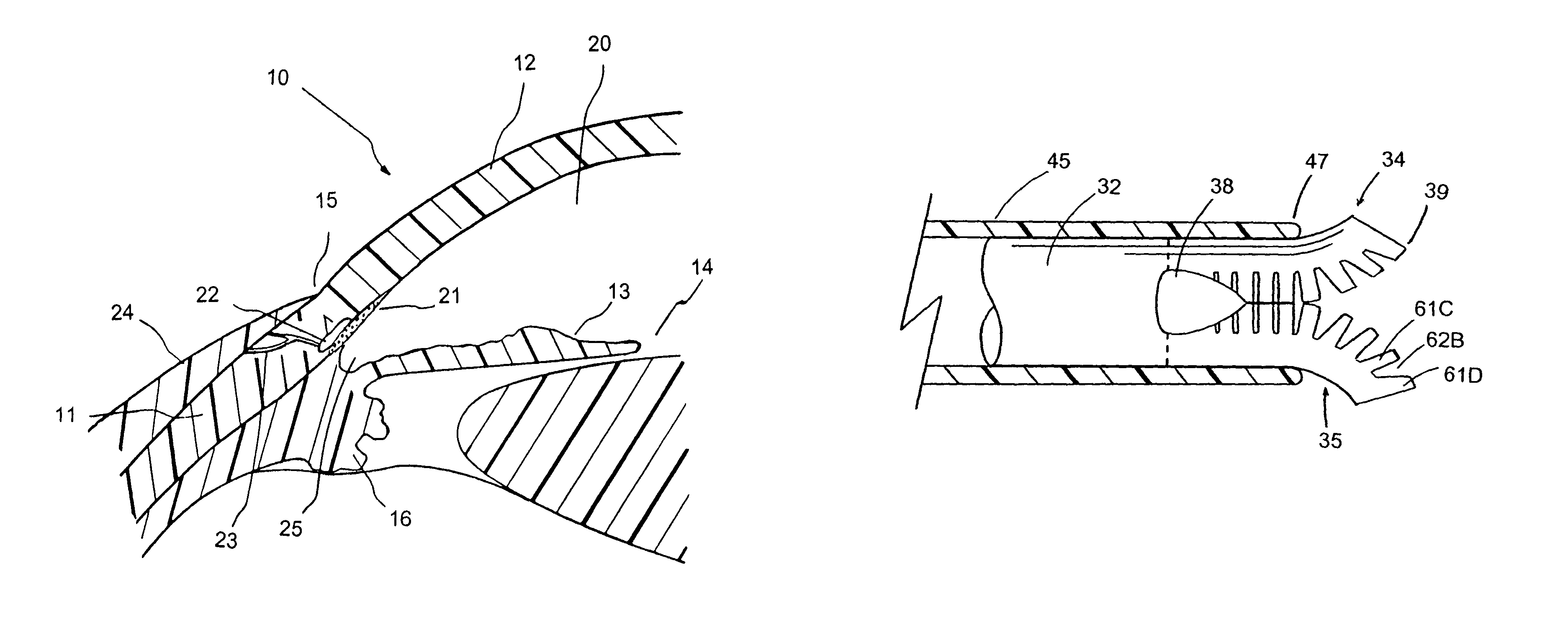

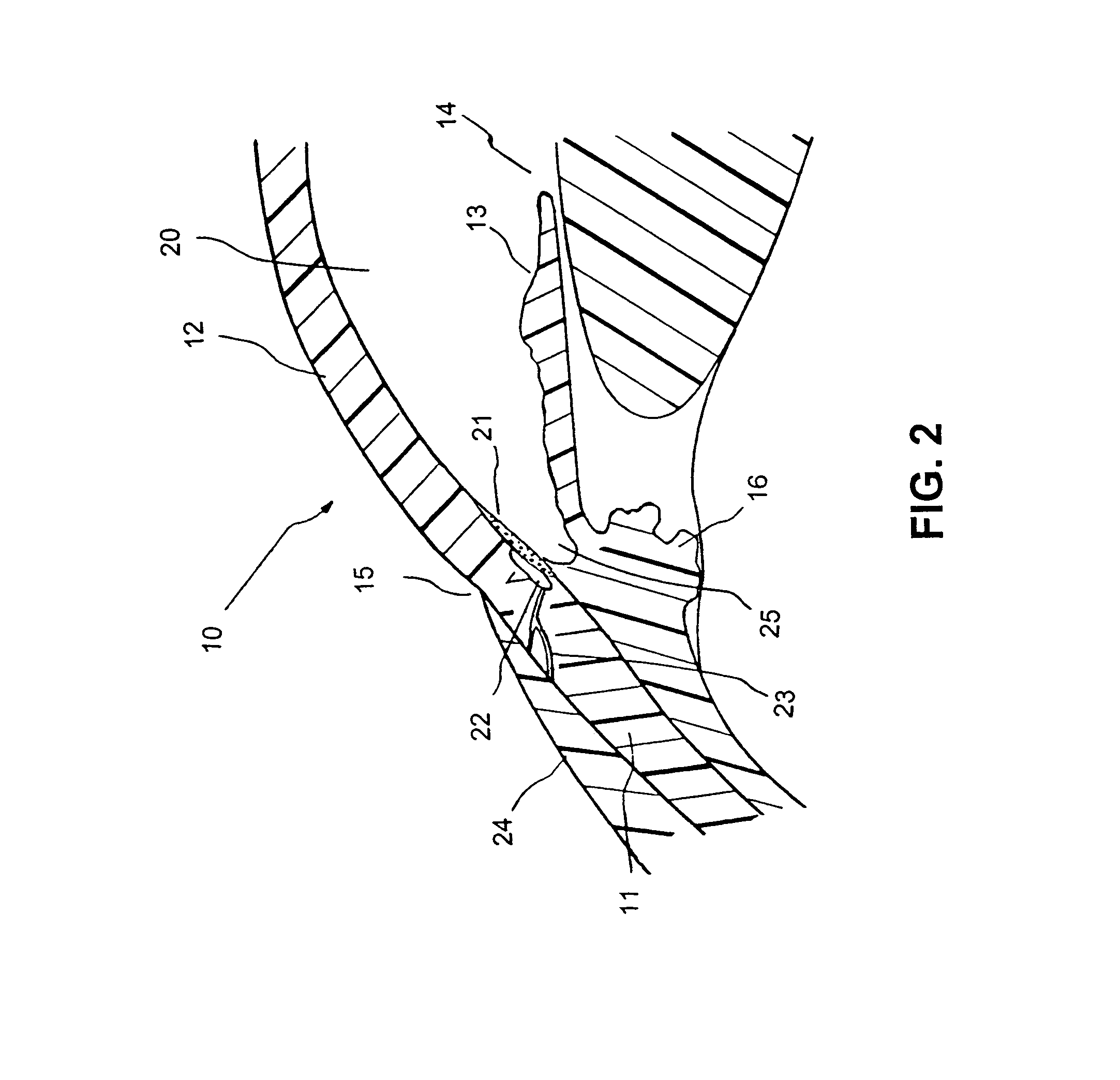

Implant with pressure sensor for glaucoma treatment

InactiveUS6981958B1Reduce morbidityAvoiding hypotonyEye surgeryInfusion needlesSchlemm's canalIntraocular pressure

A trabecular shunt and methods for treating glaucoma are disclosed. One of the methods comprises transporting fluid from the anterior chamber of an eye to Schlemm's canal through an implant, the implant extending between the anterior chamber and Schlemm's canal; sensing an intraocular pressure using a sensor incorporated into the implant; and transmitting a signal indicative of the sensed pressure to an external receiver.

Owner:GLAUKOS CORP

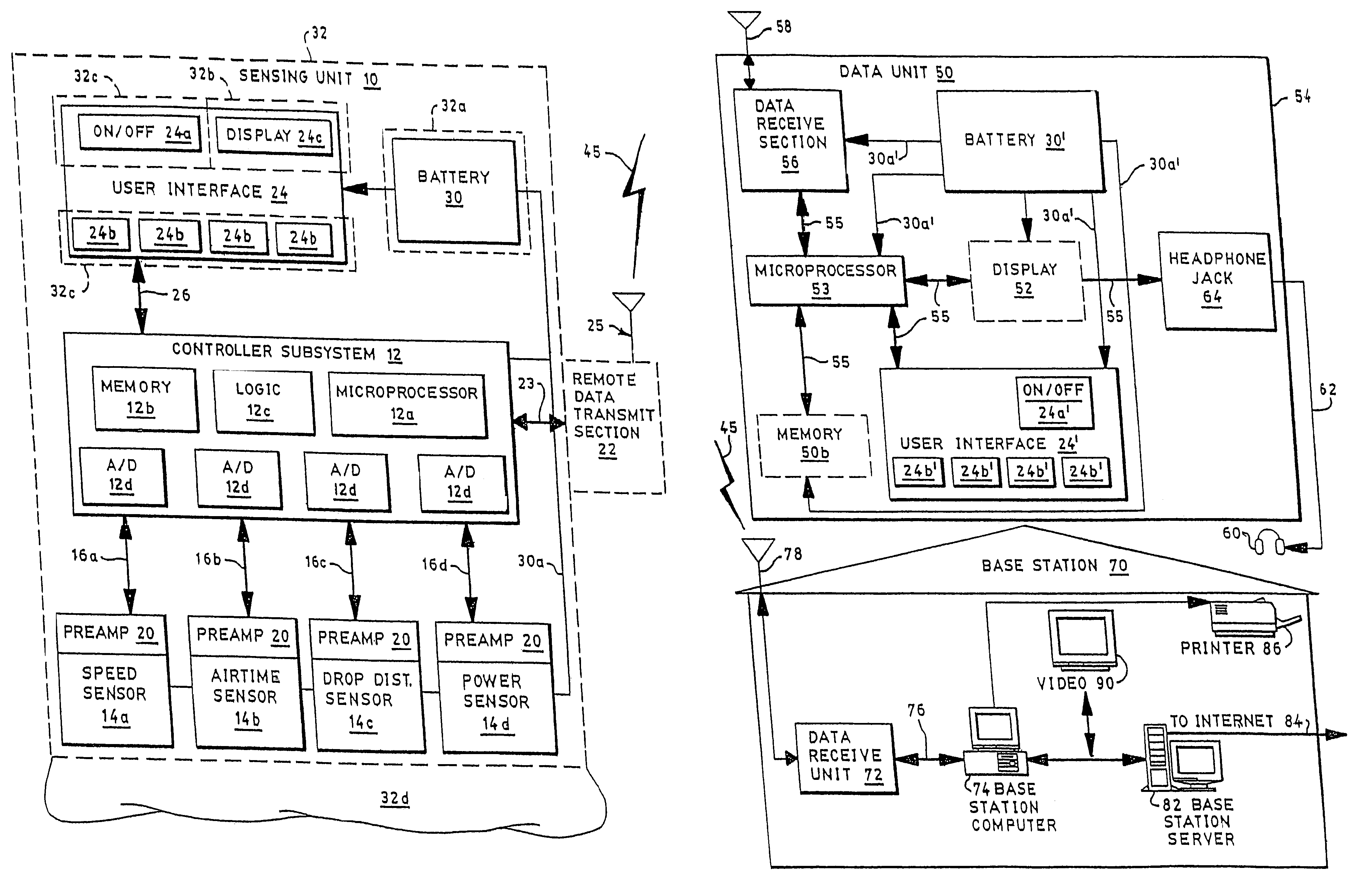

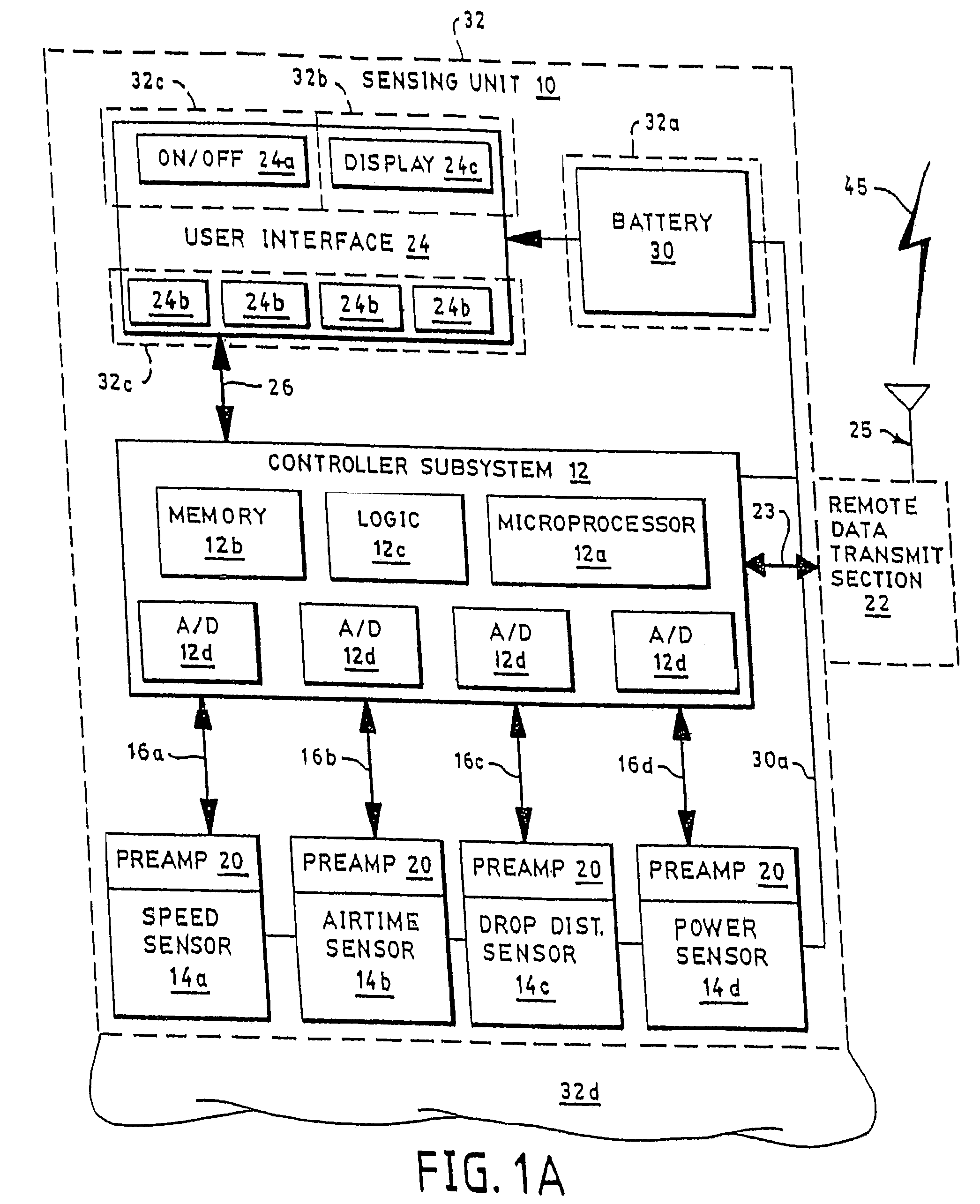

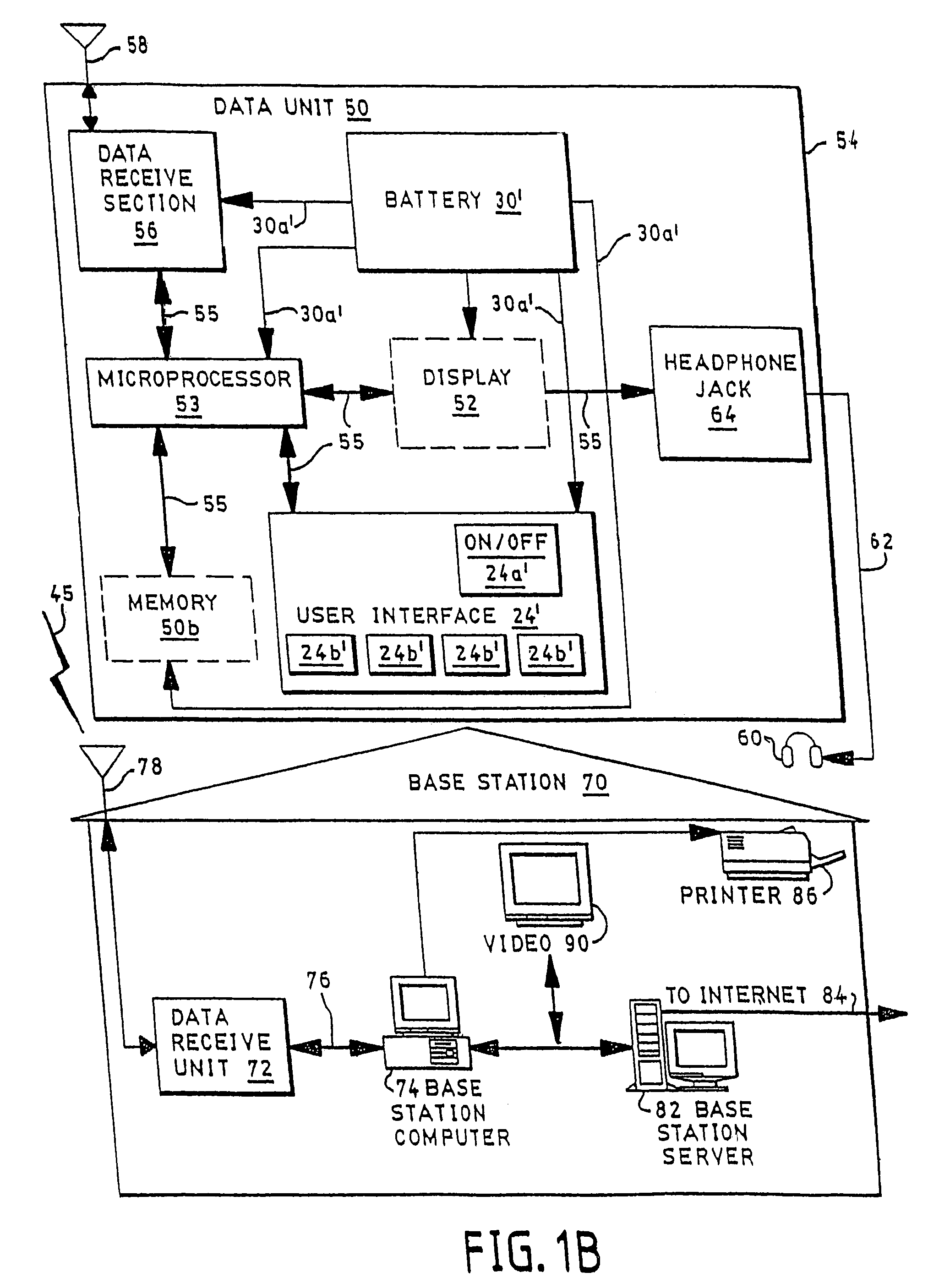

Sport performance systems for measuring athletic performance, and associated methods

InactiveUS7162392B2Electromechanical unknown time interval measurementNuclear monitoringAccelerometerExercise performance

System determines impact of a helmet, comprising: accelerometer and processor, the accelerometer detecting acceleration of the helmet, the processor configured to process the signals from the accelerometer to determine impact of the helmet. System determines athletic performance, comprising: pressure sensor for sensing change in elevation; microprocessor for processing signals from the pressure sensor to determine vertical speed corresponding to the change in elevation; and display for reporting the vertical speed to a user. System assesses athletic performance, comprising: protective housing configured for attachment to a human-powered sport vehicle; GPS sensor configured with the housing for generating earth position signals; microprocessor configured with the housing for processing the signals to determine speed and distance traveled of the sport vehicle; and display configured with the housing for displaying one or both of the speed and distance traveled to a user of the human-powered sport vehicle.

Owner:NIKE INC

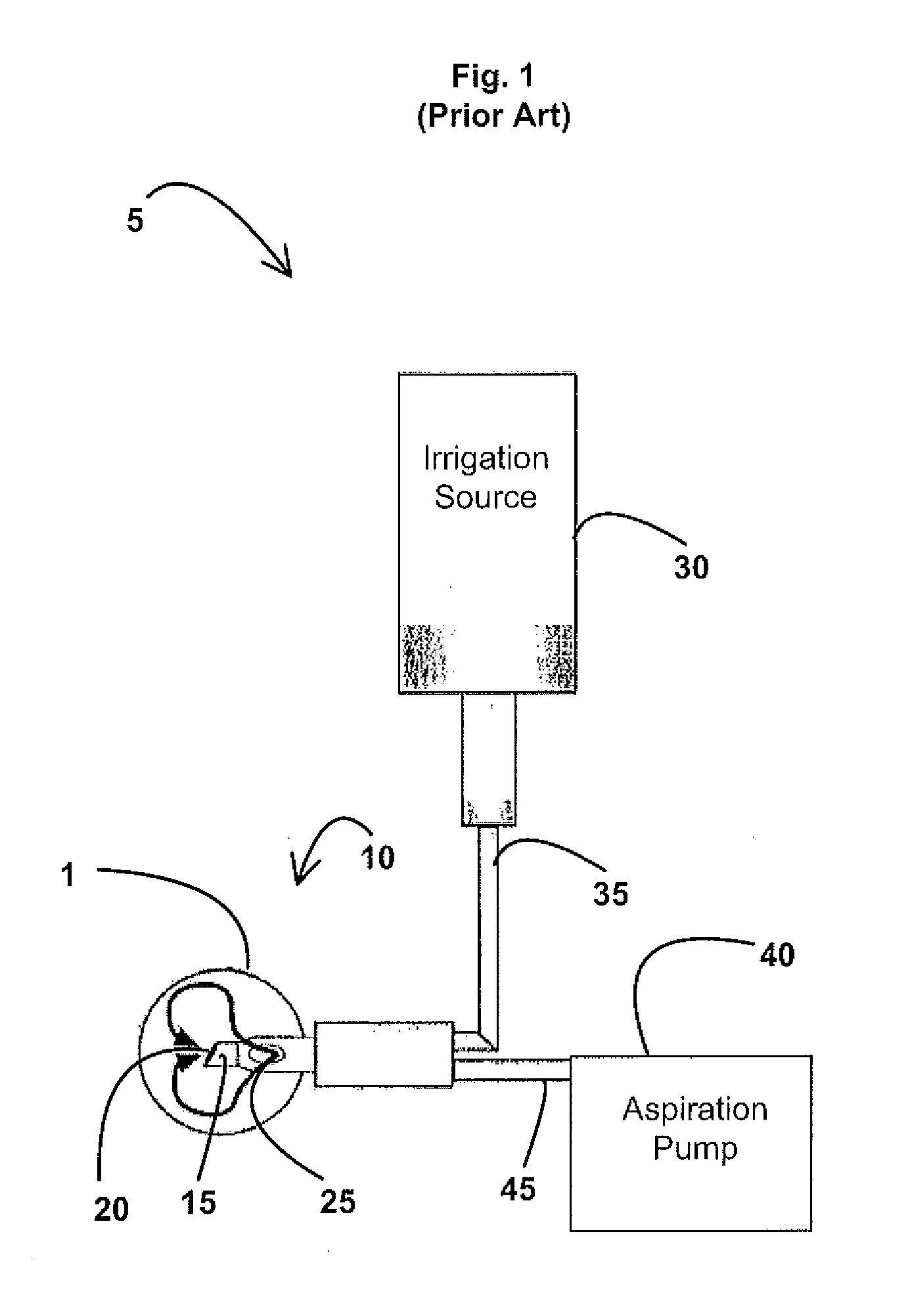

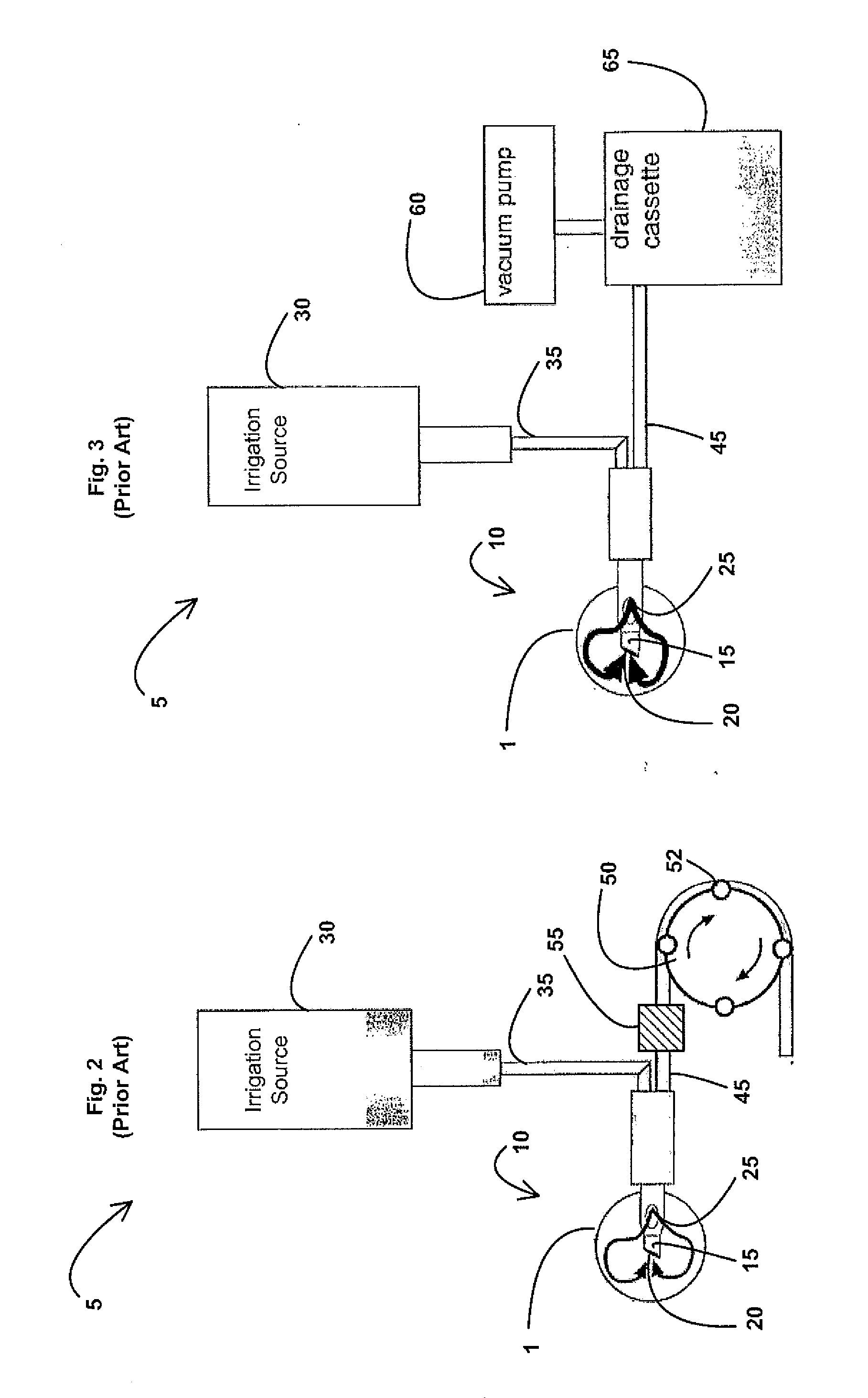

Systems and methods for power and flow rate control

The invention is generally directed to systems and methods for fluid control, and more particularly to systems and methods for power and flow rate control for aspiration. In accordance with one embodiment, an aspiration system includes an aspiration line having distal and proximal ends and an aspiration port defined in the distal end; a fluid transport device operatively coupled to the proximal end of the aspiration line; and a flow restrictor operatively coupled to the aspiration line in between the fluid transport device and the aspiration port. To measure occlusion within the line, first and second pressure sensors are utilized, the first sensor being operatively coupled to the aspiration line between the port and the restrictor and the second sensor being operatively coupled to the aspiration line between the restrictor and the fluid transport device. The pressure differential between the two sensors can provide an indication of the onset, presence, and / or elimination of an occlusion.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

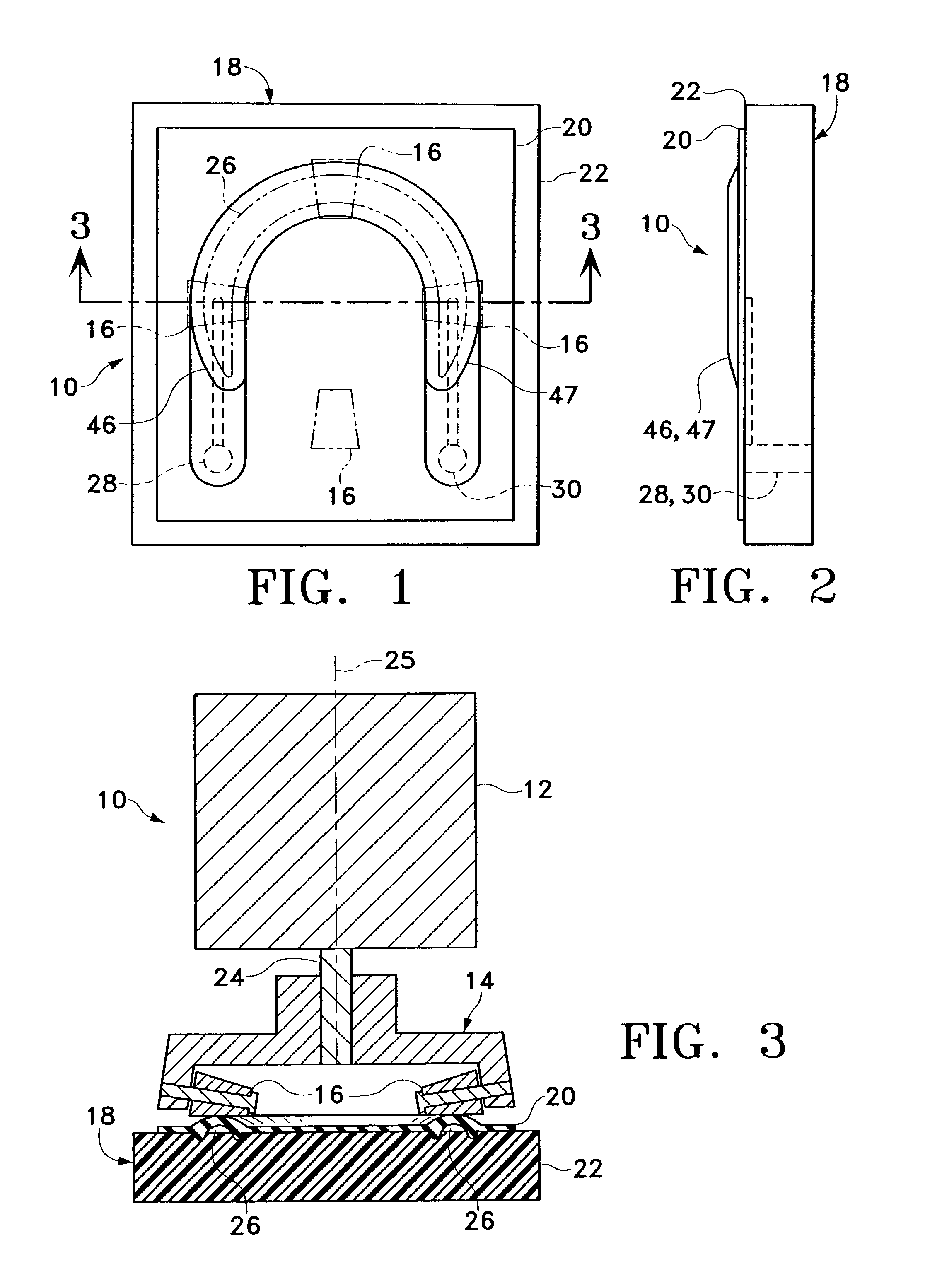

Implantable pressure sensor and method of fabrication

A body implantable pressure sensor attached to an endocardial lead for implantation in a heart chamber or cardiac blood vessel for sensing blood pressure and providing blood pressure signals to an implanted or external hemodynamic monitor and / or therapy delivery device and method of fabrication thereof. A pressure sensor module is formed of an elongated receptacle having an elongated receptacle cavity for receiving a calibrated, micro-machined pressure transducer having a pressure responsive element. The receptacle cavity is covered by a diaphragm disposed alongside the lead body and in parallel with the lead axis. The receptacle cavity is filled with a incompressible oil for transferring pressure forces that are applied to the diaphragm to the pressure transducer. The oil is introduced through a fill port, and the fill port is sealed after the oil is introduced to prevent leakage of the oil from the receptacle cavity and to complete the hermetic sealing of the receptacle cavity. The fill port further comprises a fill tube having a fill tube lumen extending outward of an end wall of the receptacle cavity to a fill tube end, and said sealing step further comprises the steps of crimping or otherwise obstructing the fill tube end to close the fill tube lumen, fitting a fill port cover having an abutting edge over the crimped fill tube end and against the end wall of the receptacle to enclose the sealed fill tube end within a fill port cover cavity, and sealing the abutting edge against the receptacle end wall to hermetically enclose the sealed fill tube end within the fill port cover cavity.

Owner:MEDTRONIC INC

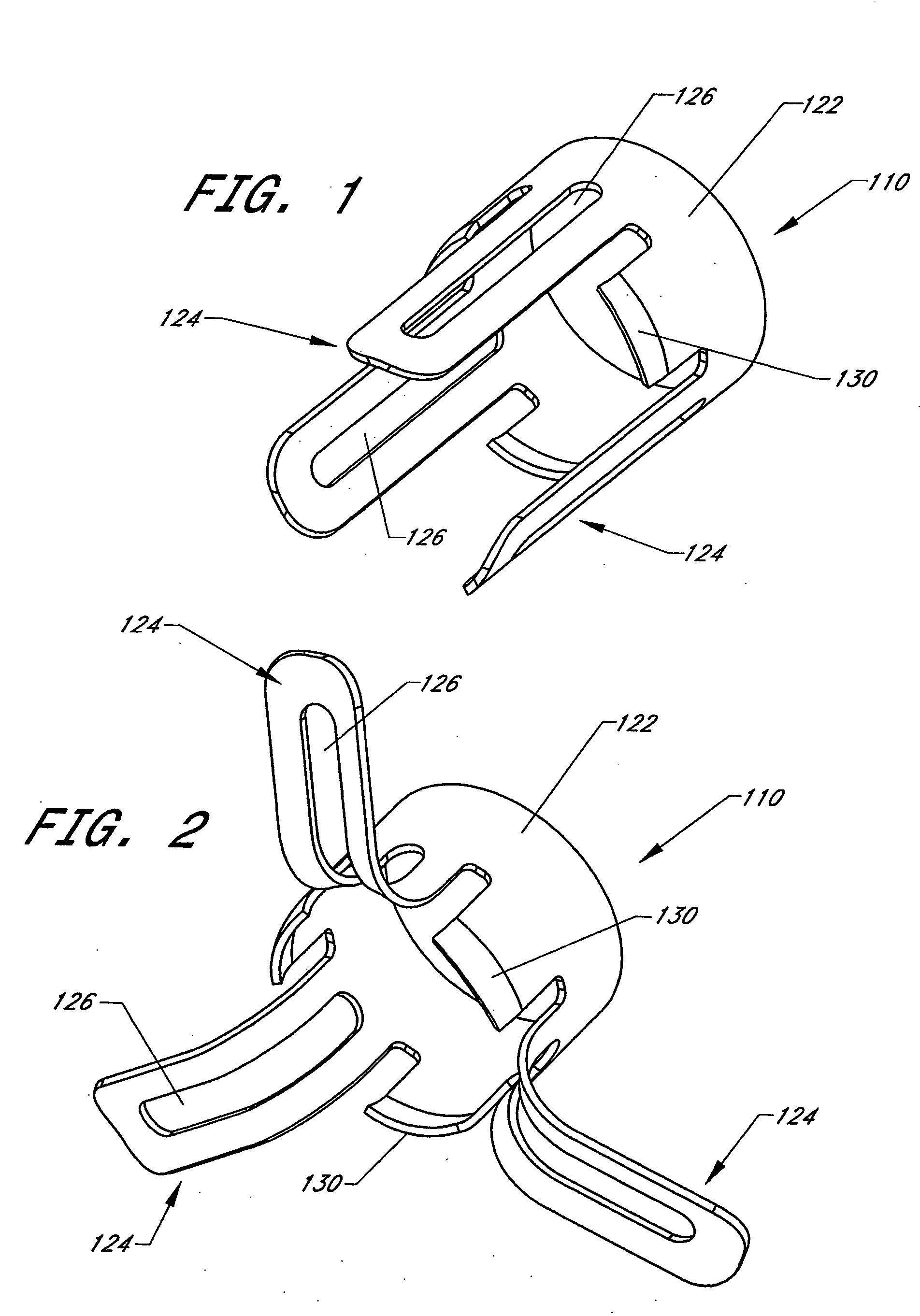

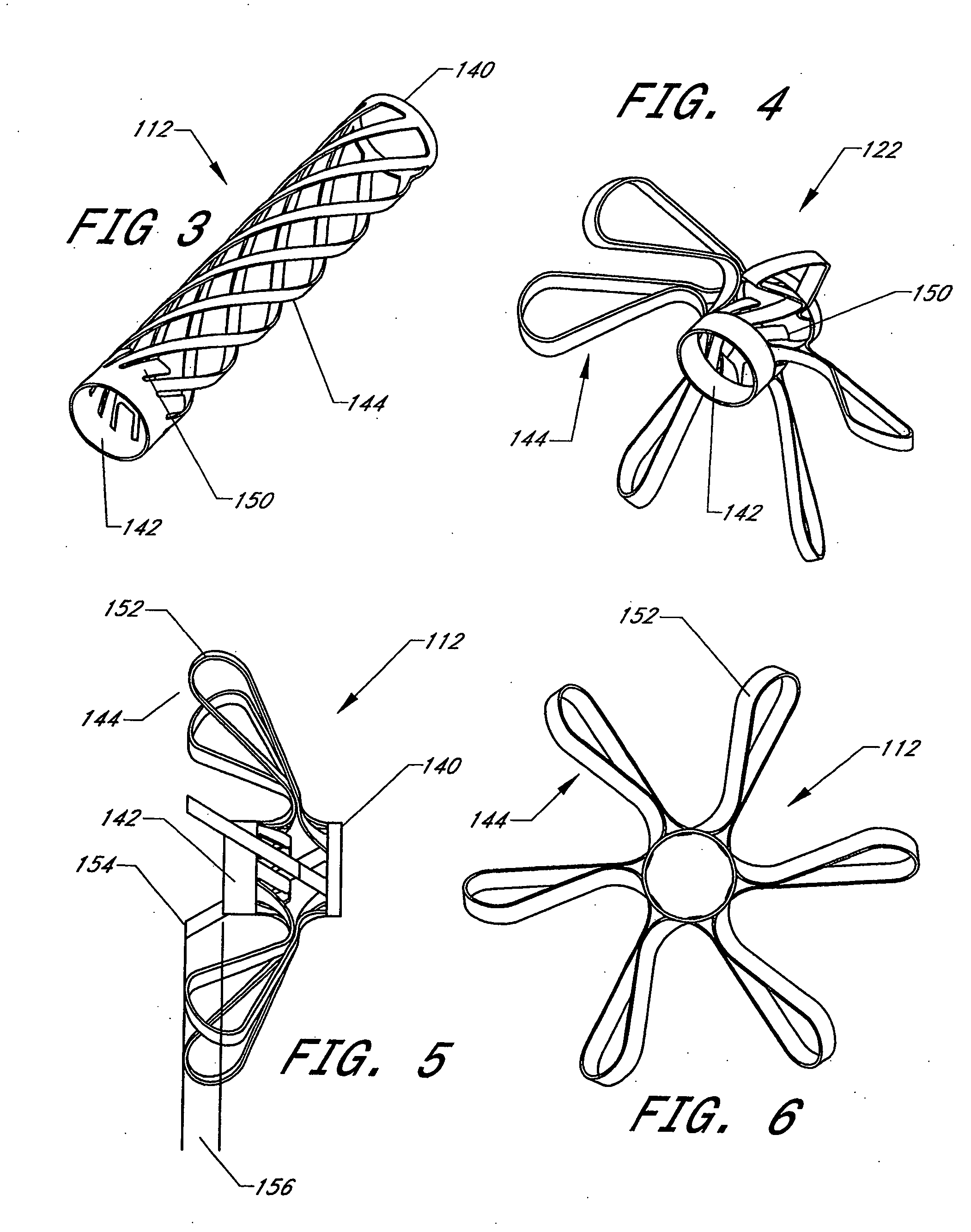

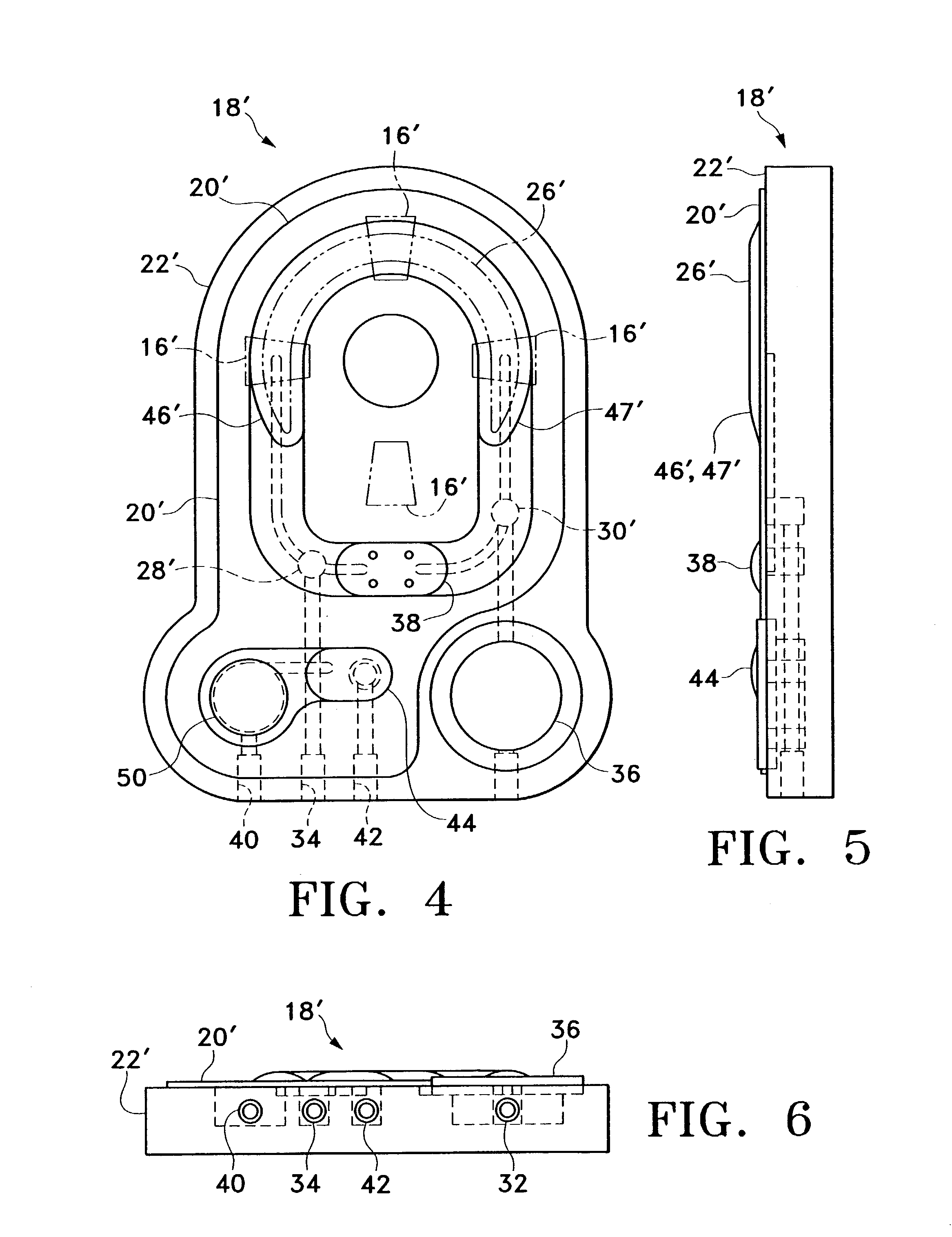

Implantable pressure transducer system optimized for anchoring and positioning

InactiveUS20050288722A1Long-term stabilityFacilitate optimal healingTransvascular endocardial electrodesSurgical needlesTransducerBiomedical engineering

This invention relates generally to systems and methods for optimizing the performance and minimizing complications related to implanted sensors, such as pressure sensors, for the purposes of detecting, diagnosing and treating cardiovascular disease in a medical patient. Systems and methods for anchoring implanted sensors to various body structures is also provided.

Owner:PACESETTER INC

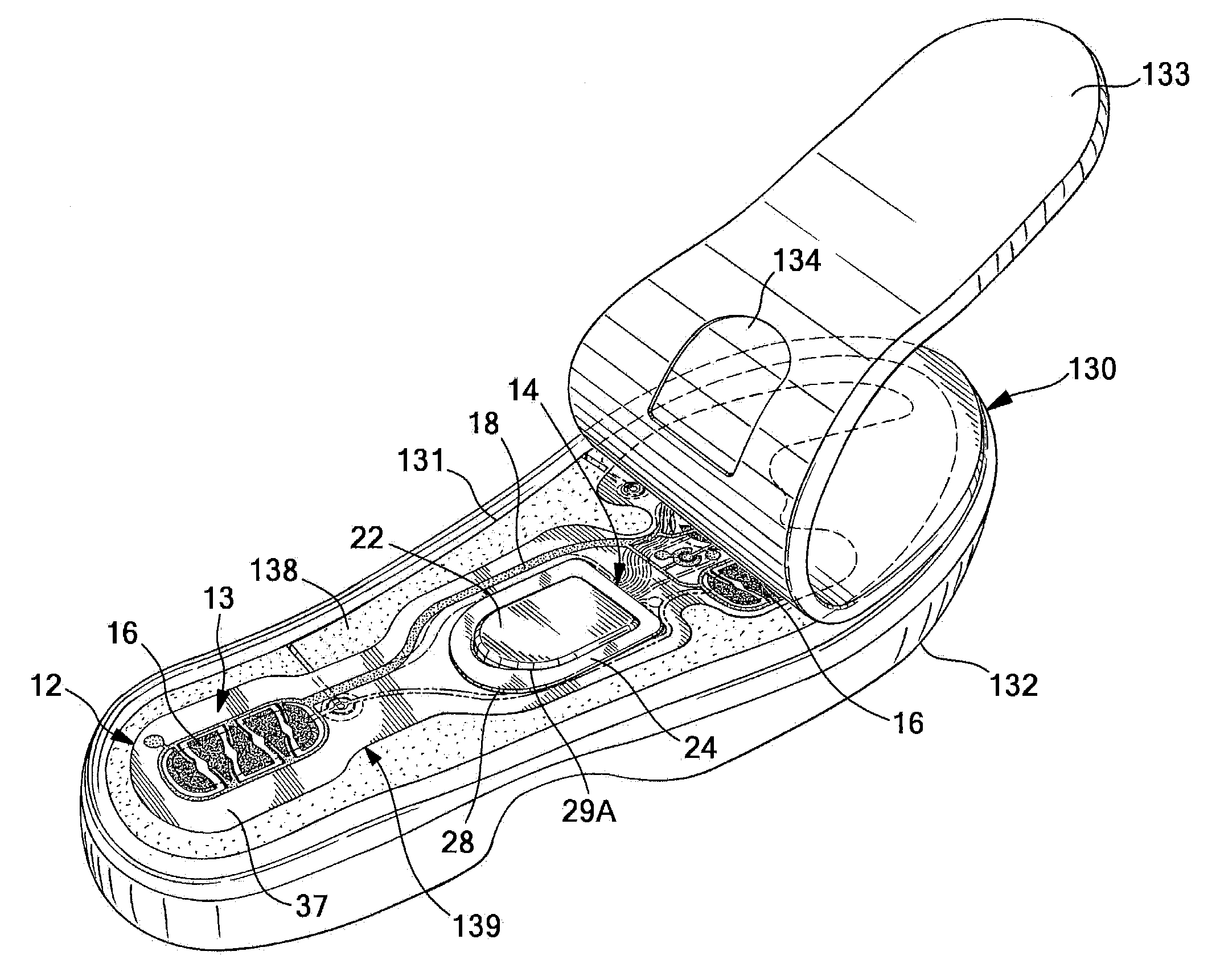

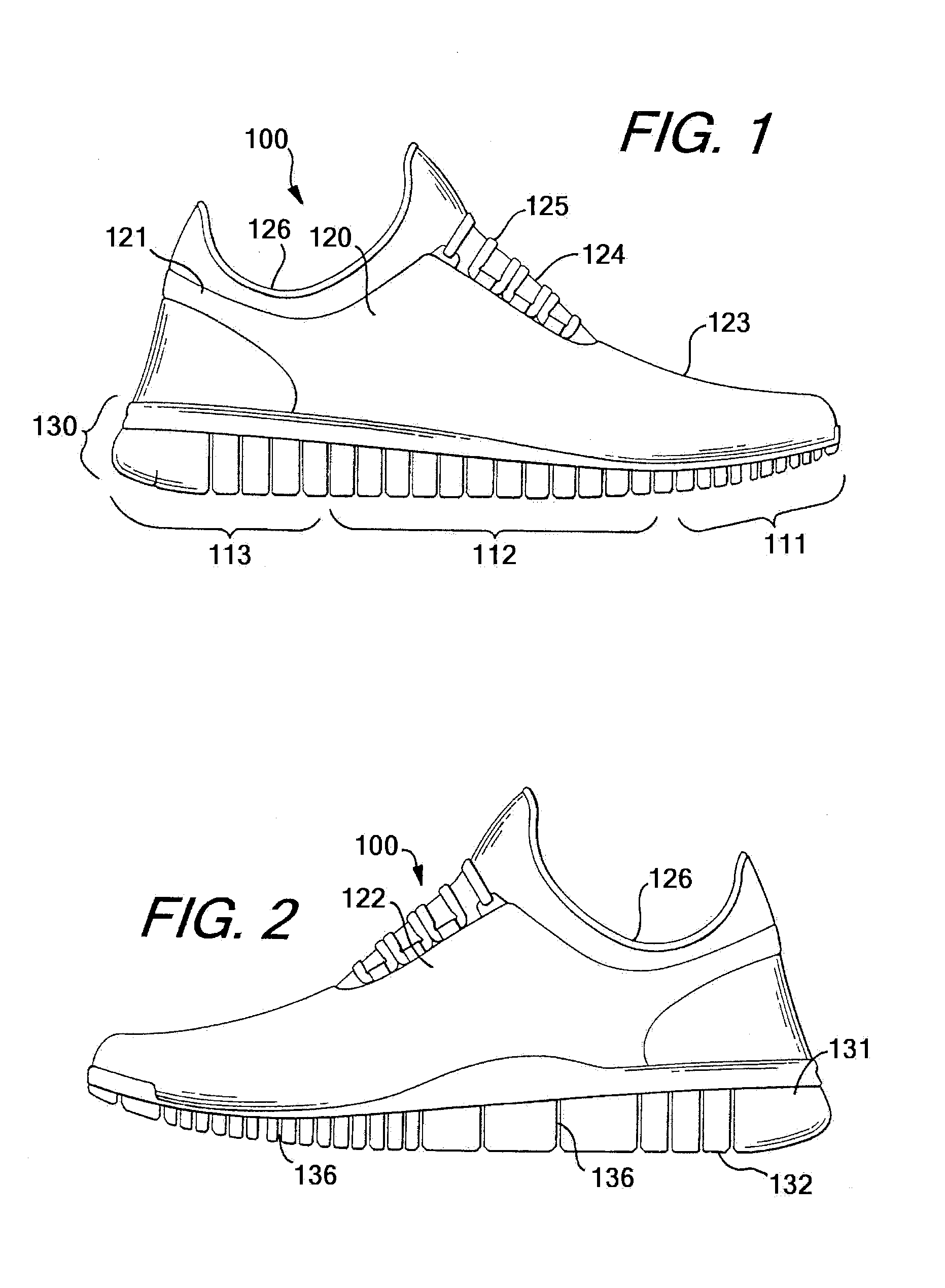

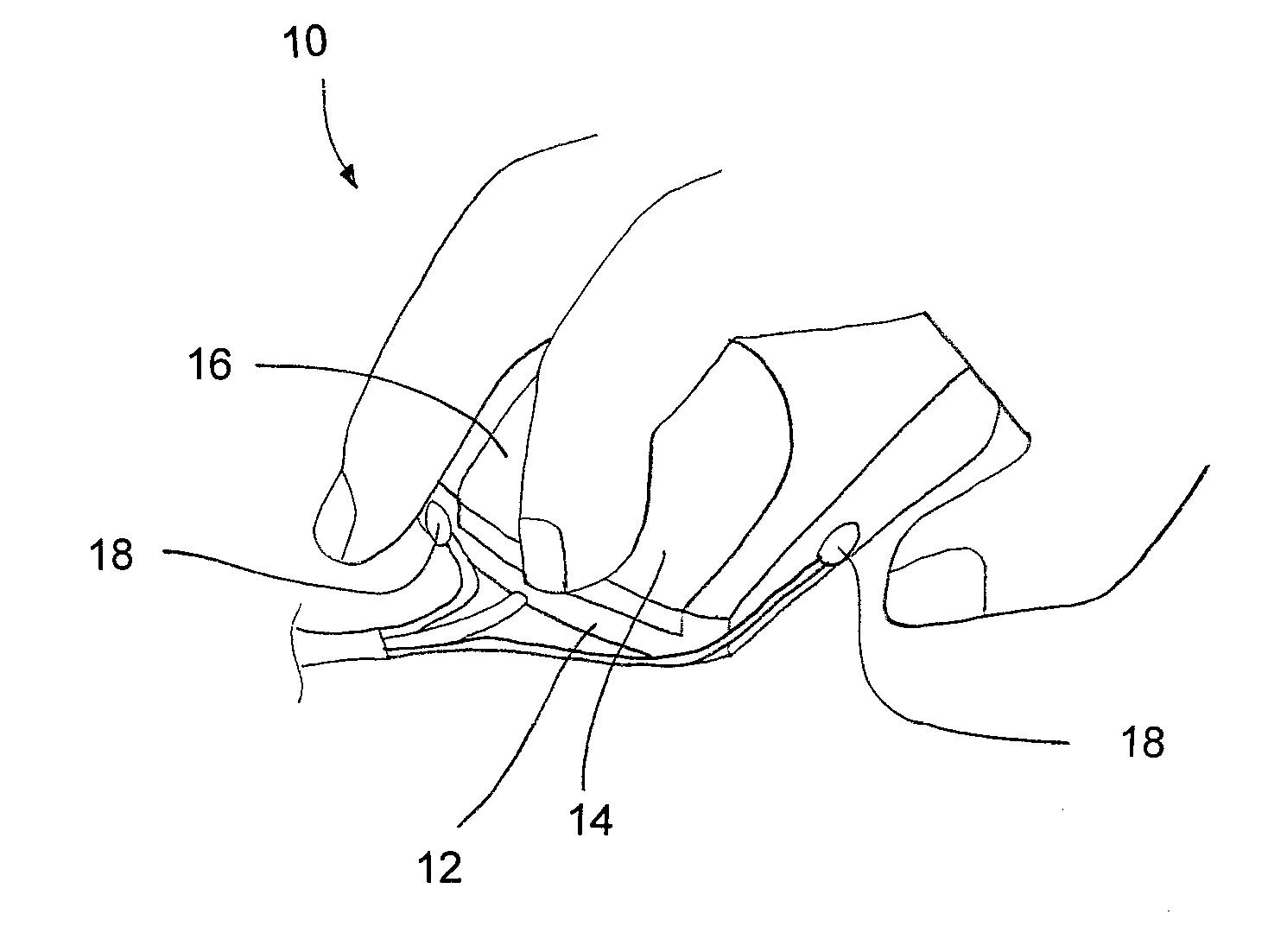

Footwear Having Sensor System

InactiveUS20130213147A1Reinforcement and wear resistance to the bend areaProvide wear resistanceSolesForce measurementEngineeringSensor system

A sensor system is adapted for use with an article of footwear and includes an insert member including a first layer and a second layer, a port connected to the insert and configured for communication with an electronic module, a plurality of force and / or pressure sensors on the insert member, and a plurality of leads connecting the sensors to the port.

Owner:NIKE INC +1

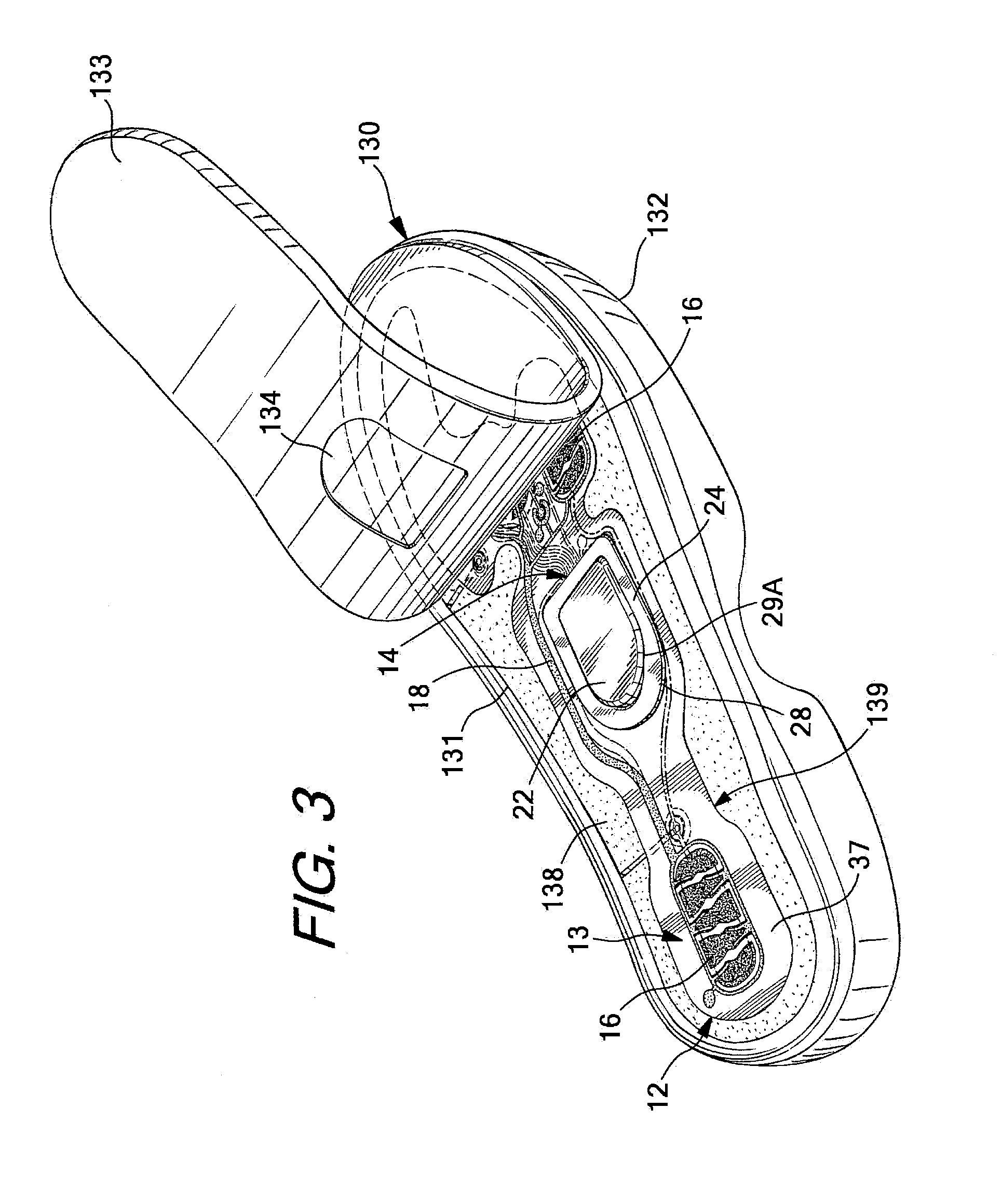

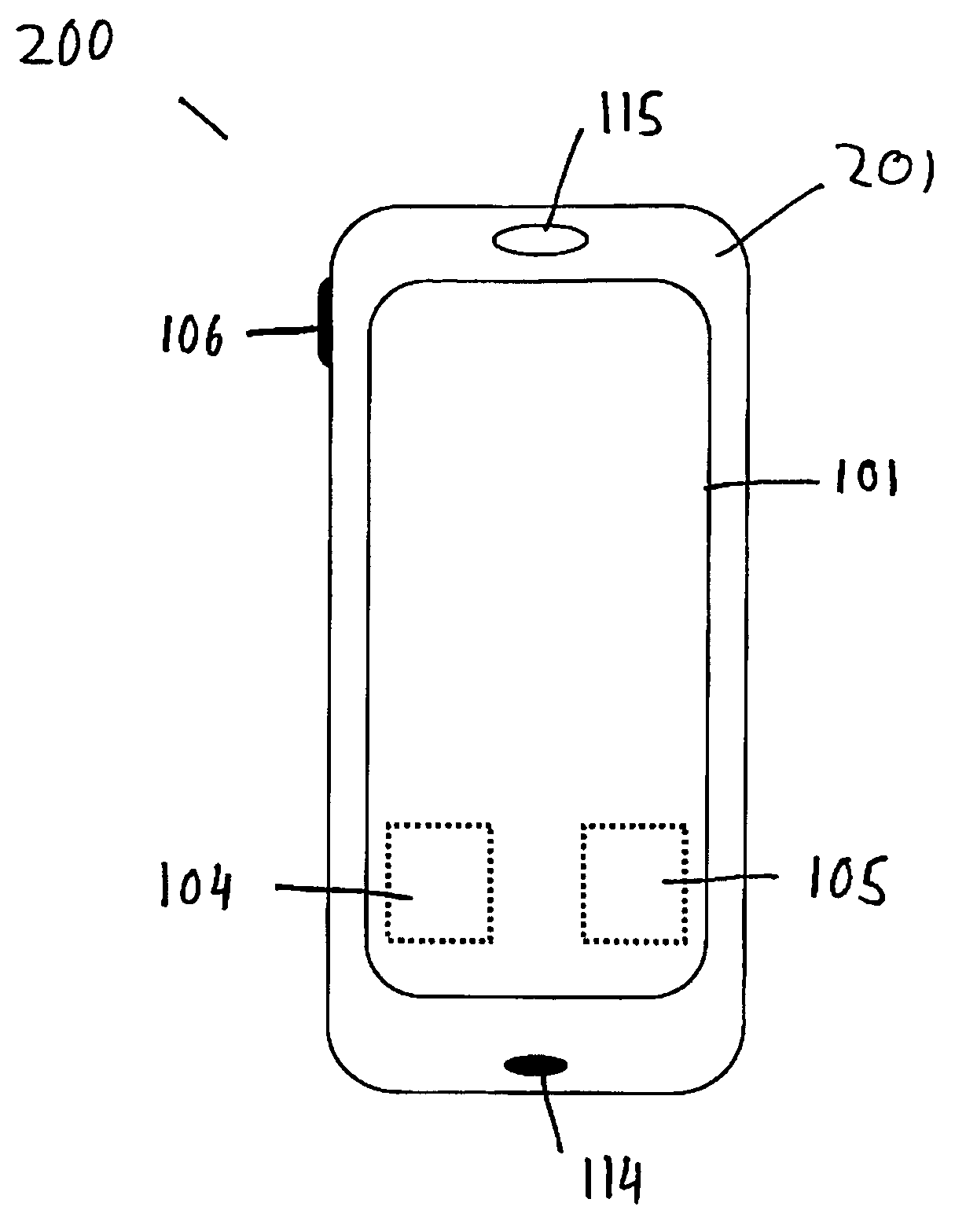

Method of unlocking a mobile electronic device

ActiveUS20100099394A1Easy to unlockReduce power consumptionPower managementUnauthorised/fraudulent call preventionTouchscreenMobile electronics

A method of unlocking a mobile electronic device and a mobile electronic device are disclosed. The mobile electronic device is operable in a locked state with the touch screen of the mobile electronic device being deactivated. In an embodiment, the mobile electronic device comprises a pressure sensor coupled to the touch-screen for detecting an application of pressure to the touch screen.

Owner:SNAPTRACK

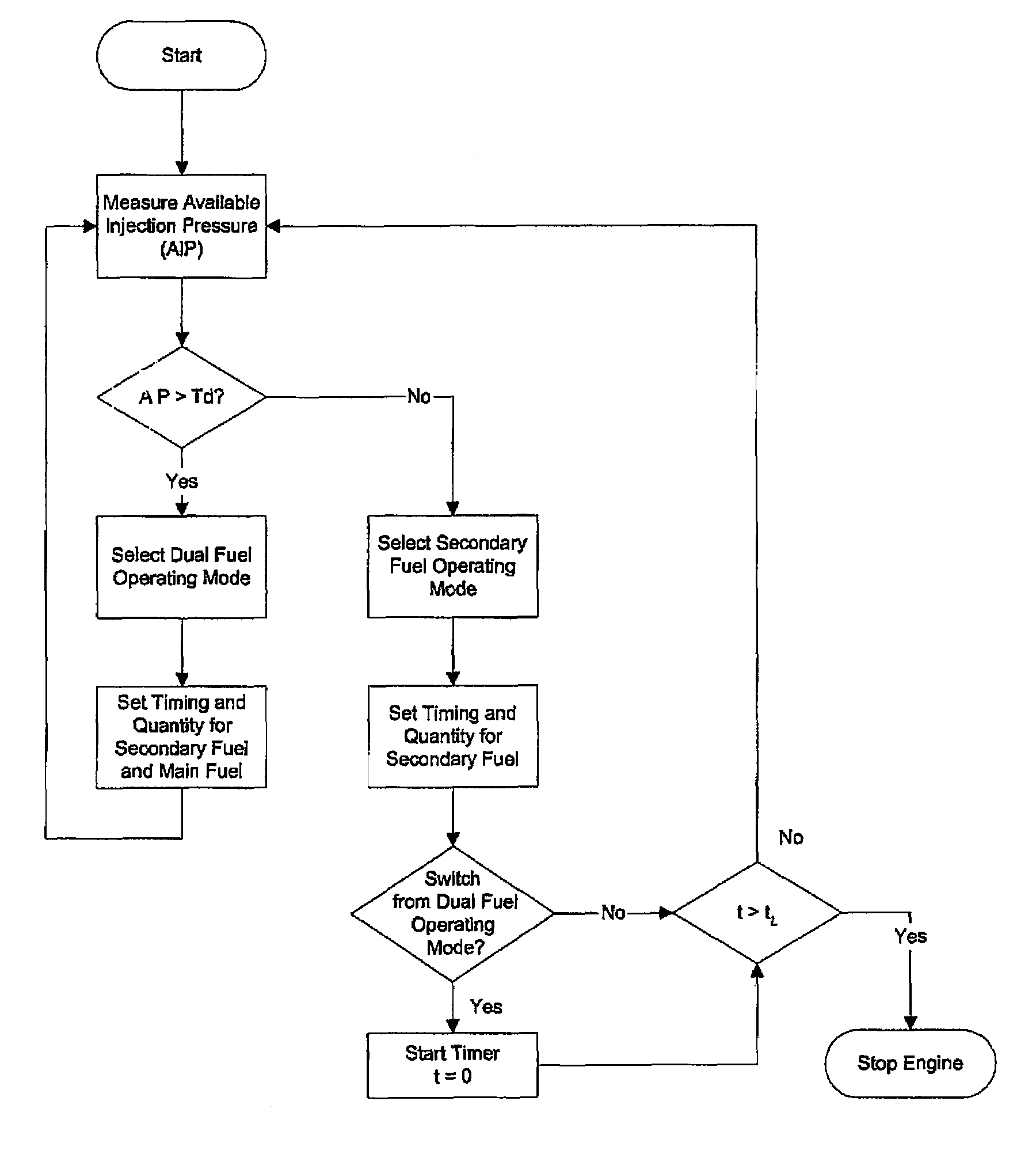

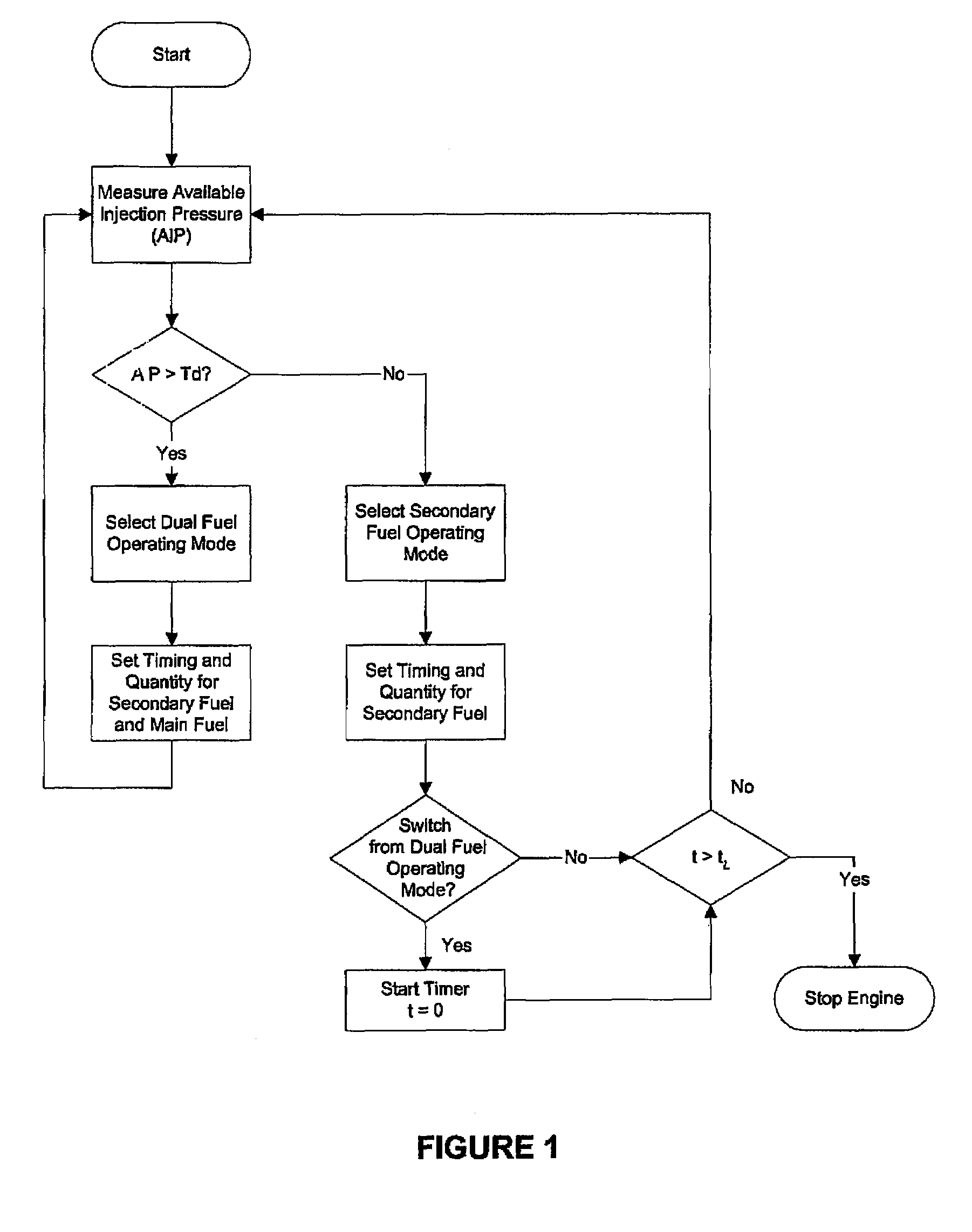

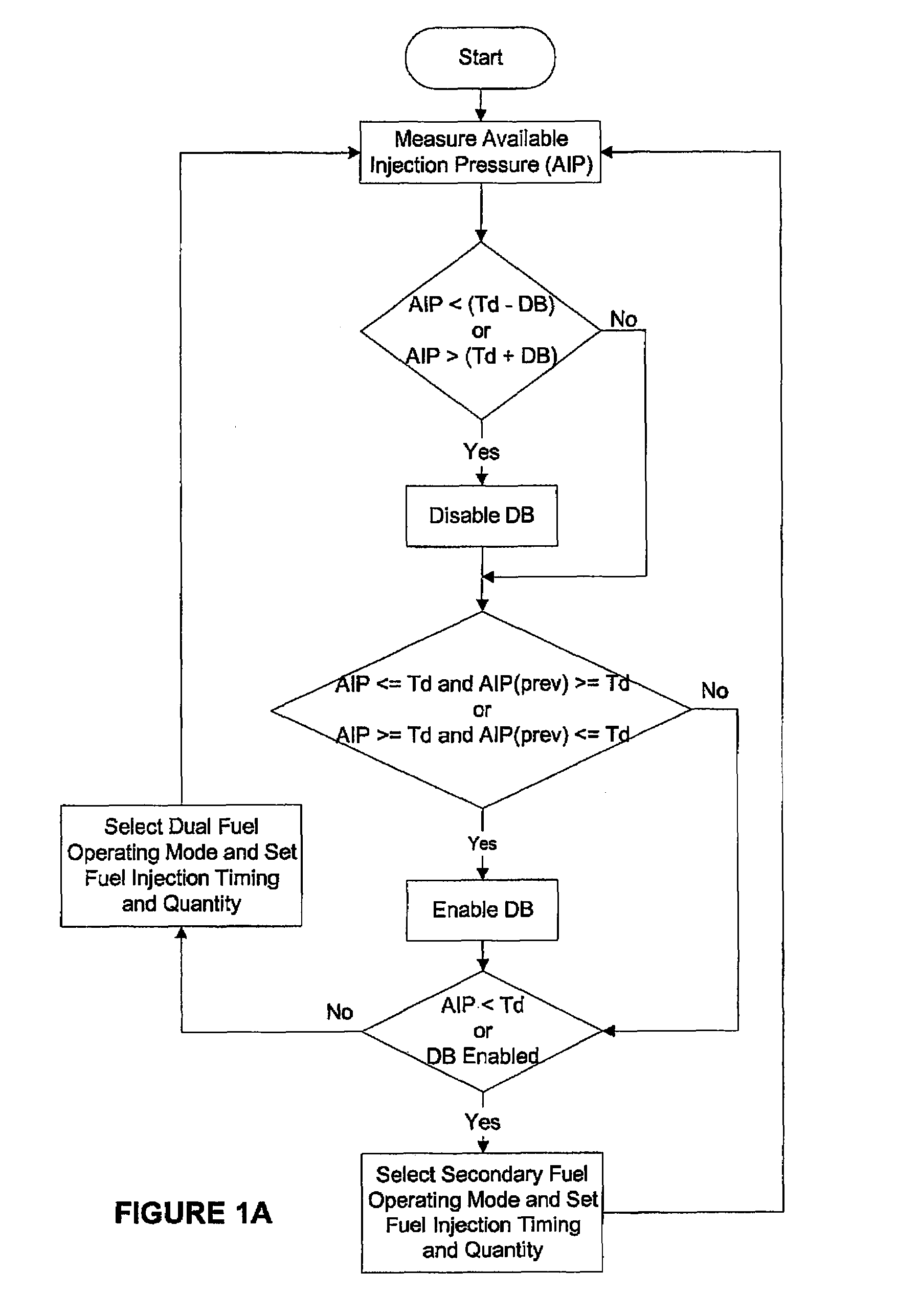

Method and apparatus for operating a dual fuel internal combustion engine

ActiveUS7627416B2Reduce modificationShorten the timeElectrical controlInternal combustion piston enginesCombustion chamberElectronic controller

In an internal combustion engine that can burn two fuels, the main fuel may become unavailable, either temporarily or until the main fuel is replenished. The present apparatus determines when to fuel an engine with main fuel and secondary fuel, or secondary fuel alone. The apparatus includes a main-fuel supply system comprising a main-fuel injection valve that introduces main fuel into an engine combustion chamber; a secondary-fuel injection system comprising a secondary-fuel injection valve that introduces secondary fuel directly into the combustion chamber; a pressure sensor associated with the main-fuel supply system for determining injection pressure inside the main-fuel injection valve; and an electronic controller in communication with the pressure sensor and programmable to separately command actuation of the secondary-fuel and the main-fuel injection valve when injection pressure is greater than a predetermined threshold, and to otherwise command actuation of the secondary-fuel injection valve and not the main-fuel injection valve.

Owner:WESTPORT FUEL SYST CANADA INC

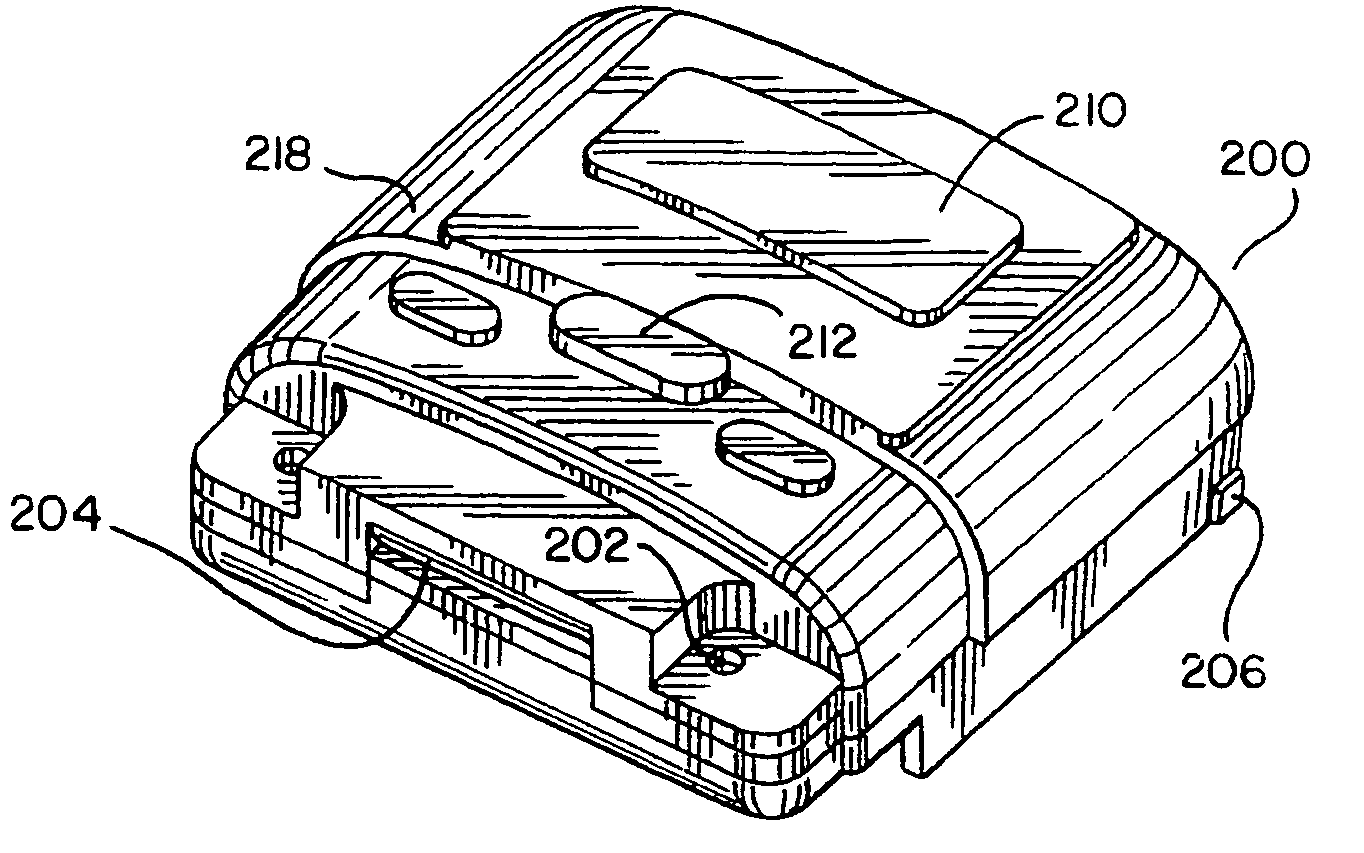

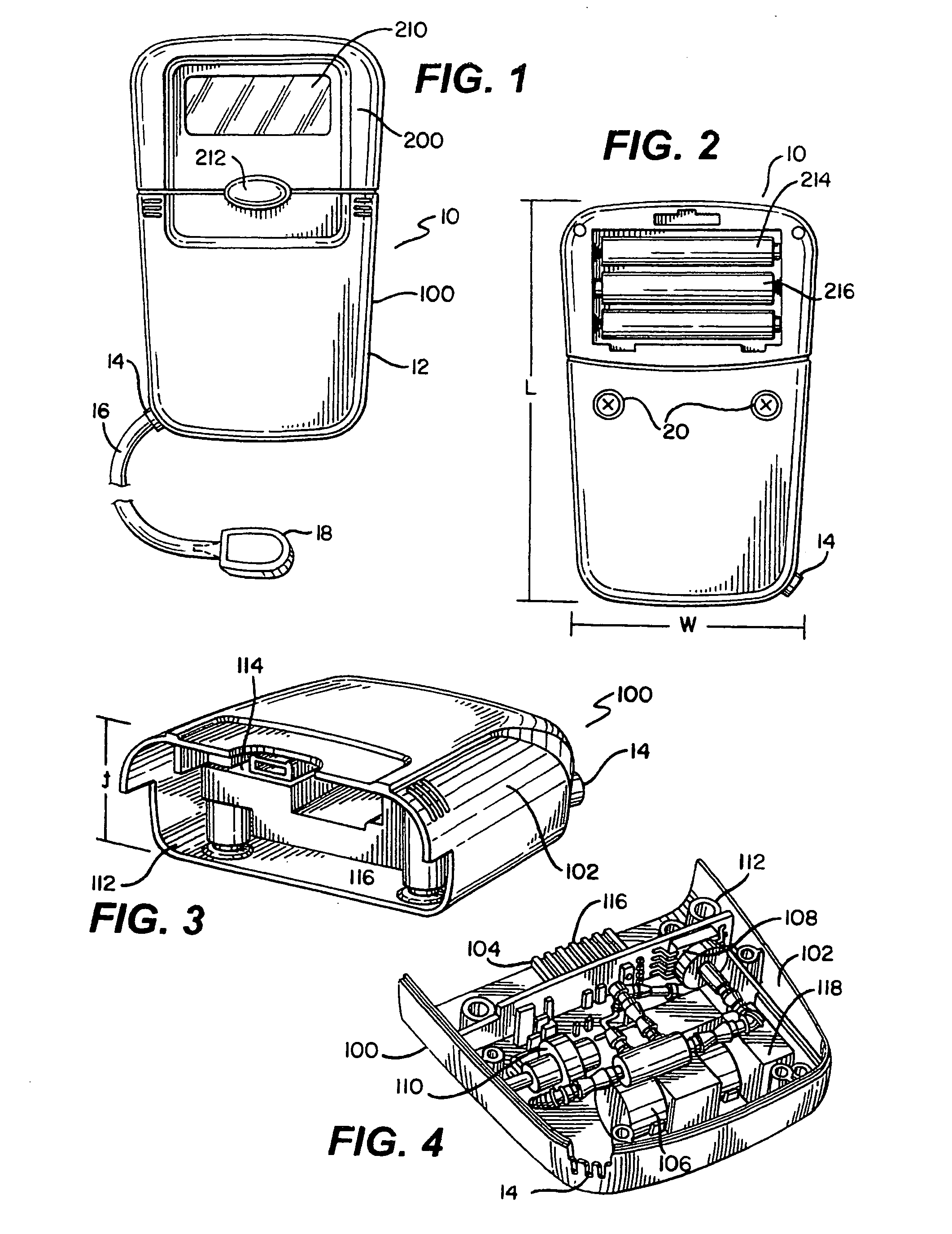

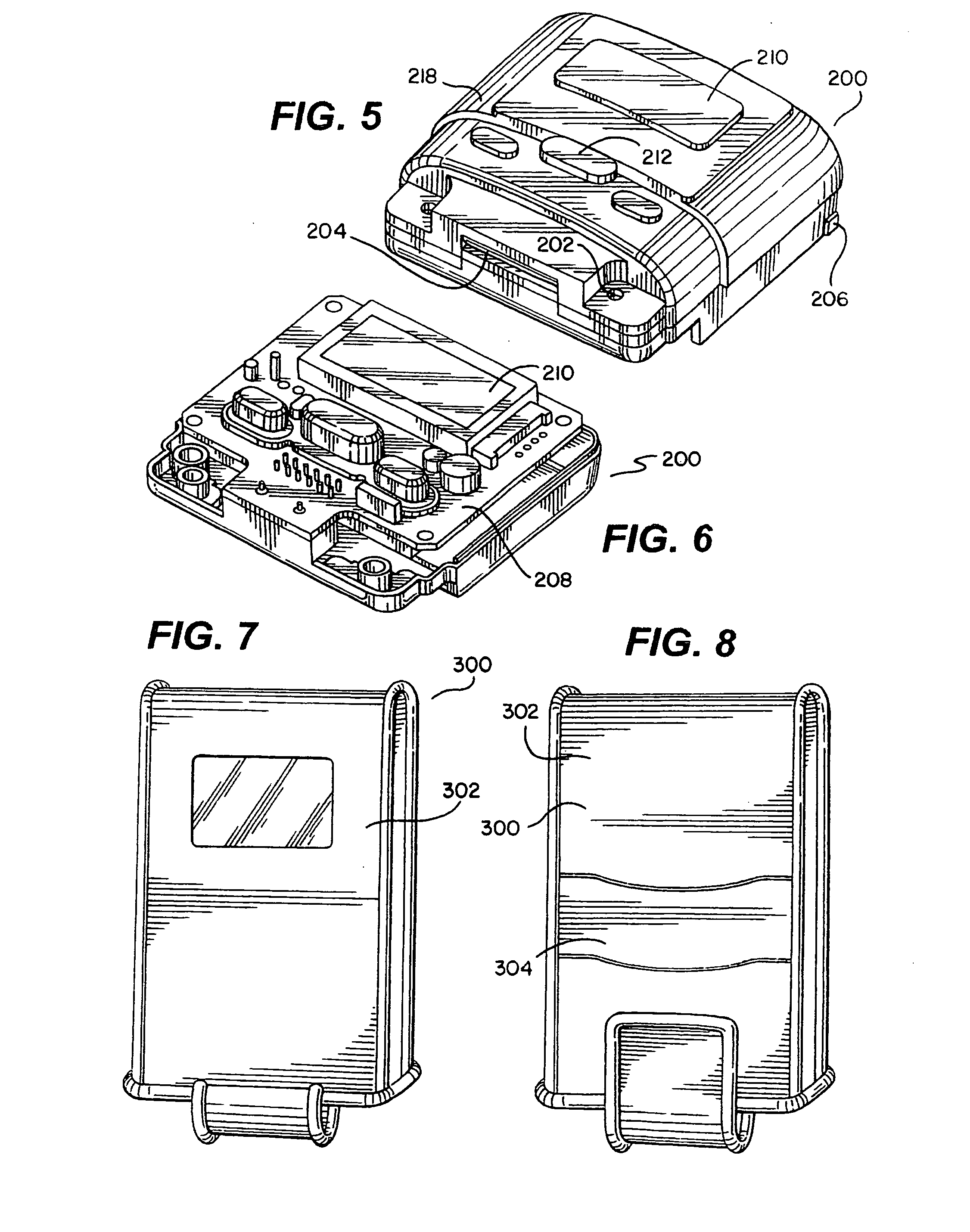

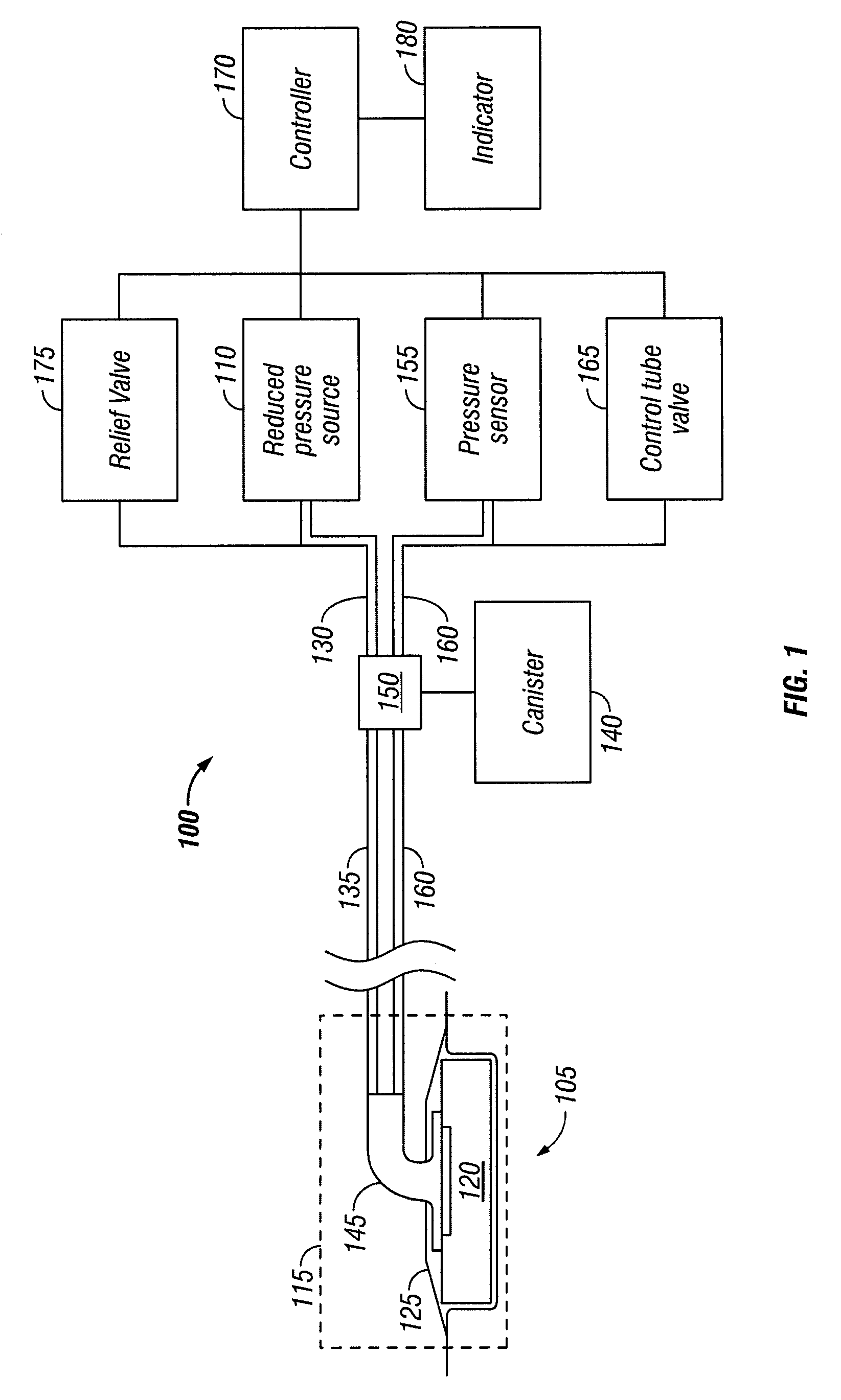

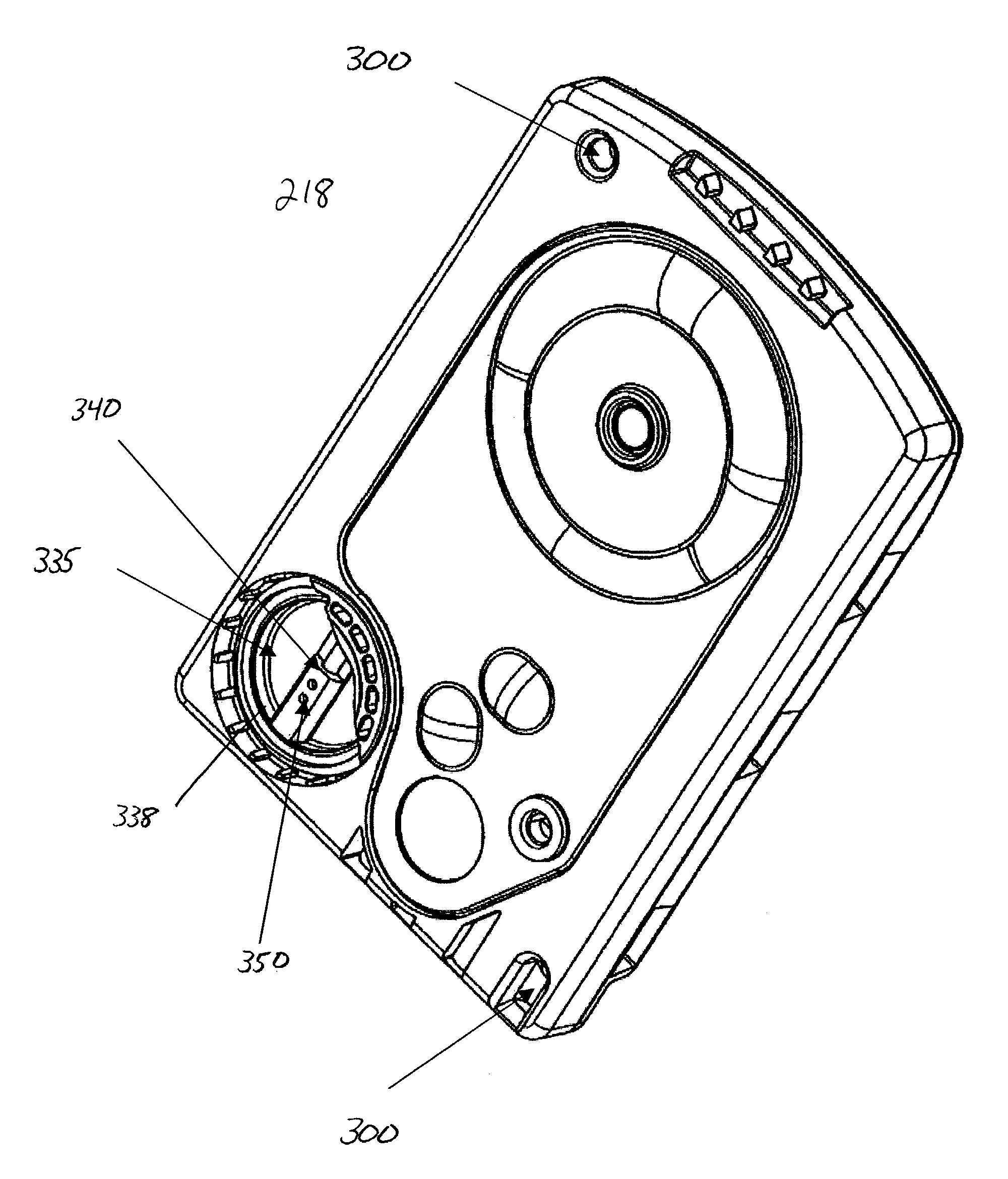

Control unit with pump module for a negative pressure wound therapy device

InactiveUS20090299306A1Improve efficiencyAccelerated churnMedical devicesIntravenous devicesControl cellWound therapy

An apparatus including a pump and control unit to be used to provide negative pressure for a wound therapy device. The pump module includes a pump and a pressure sensor, and the control unit module is capable of determining the pump in the pump module. The apparatus has a handheld size.

Owner:SMITH & NEPHEW INC

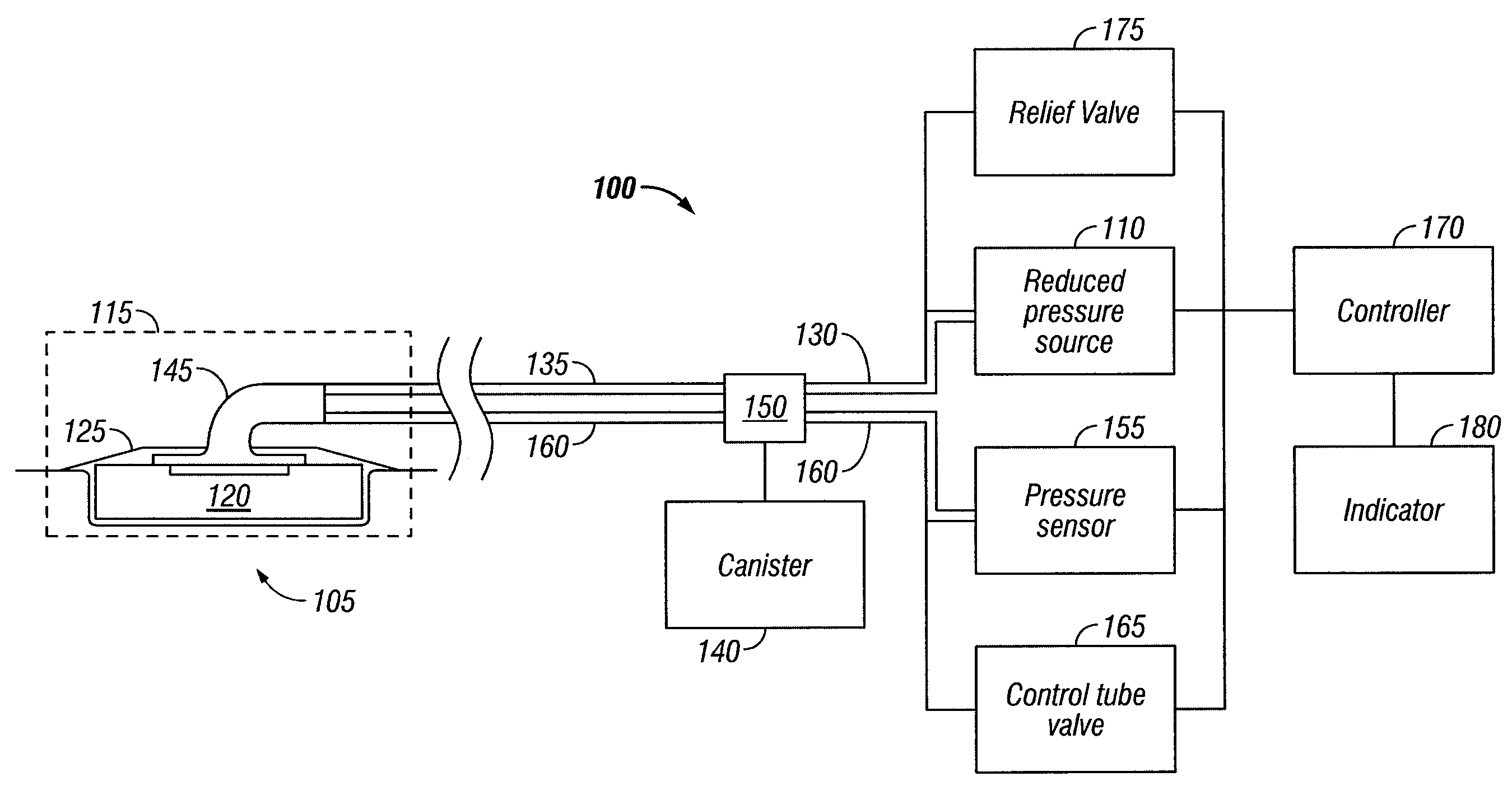

System and method for managing reduced pressure at a tissue site

ActiveUS20080234641A1Reduce pressureReduced pressure treatmentWound drainsMedical devicesEngineeringPressure sensor

The illustrative embodiments described herein are directed to an apparatus and method for managing reduced pressure at a tissue site. The apparatus includes a reduced pressure source that generates reduced pressure. The reduced pressure is delivered to the tissue site via a delivery tube. The apparatus includes a single pressure sensor. The single pressure sensor detects an actual reduced pressure at the tissue site. The apparatus also includes a controller. The controller determines a responsiveness of the actual reduced pressure measured by the single pressure sensor to an increase in reduced pressure generated by the reduced pressure source. The apparatus includes an indicator. The indicator emits a signal when the controller determines that the actual reduced pressure measured by the single pressure sensor is nonresponsive to the increase in reduced pressure generated by the reduced pressure source.

Owner:3M INNOVATIVE PROPERTIES CO

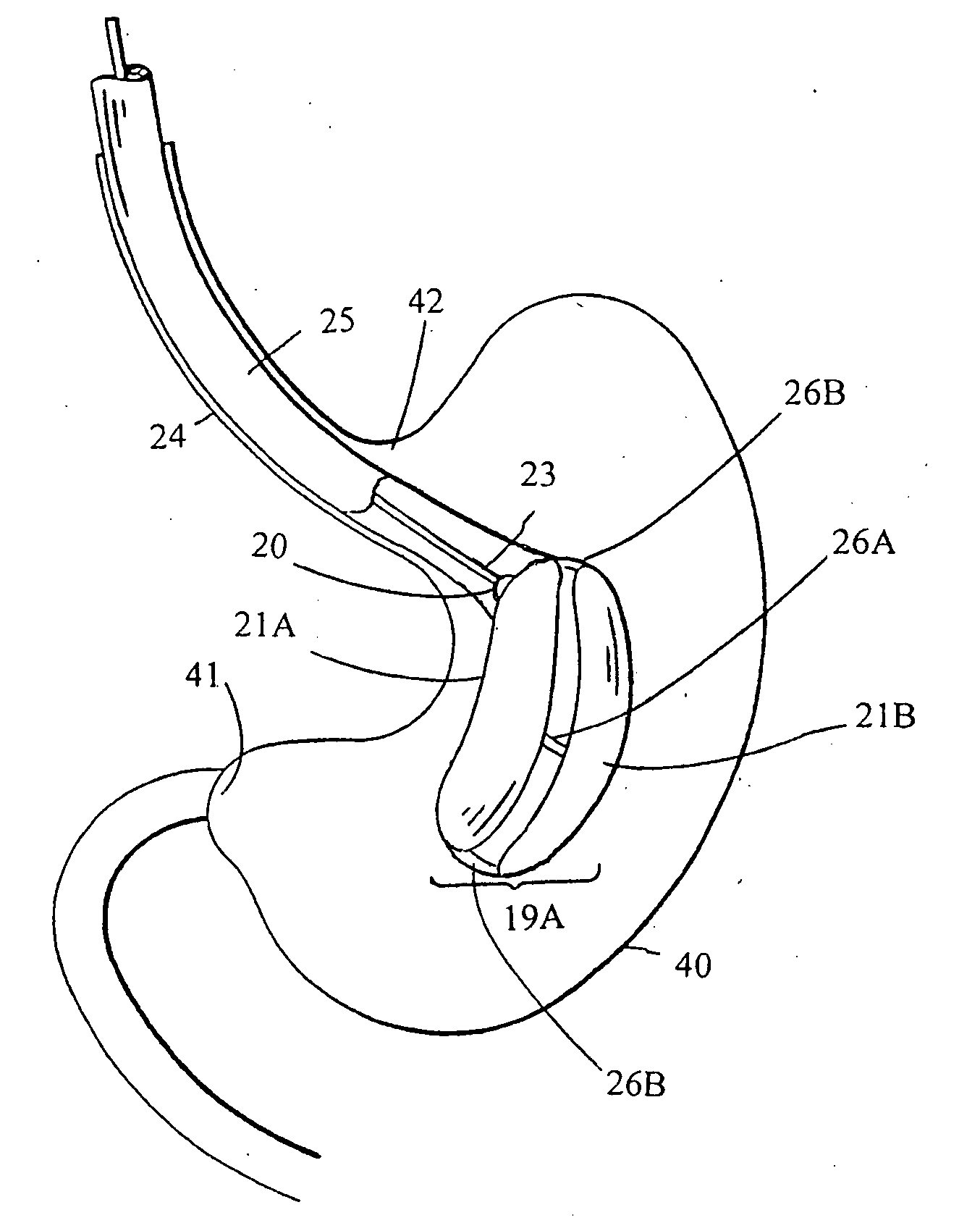

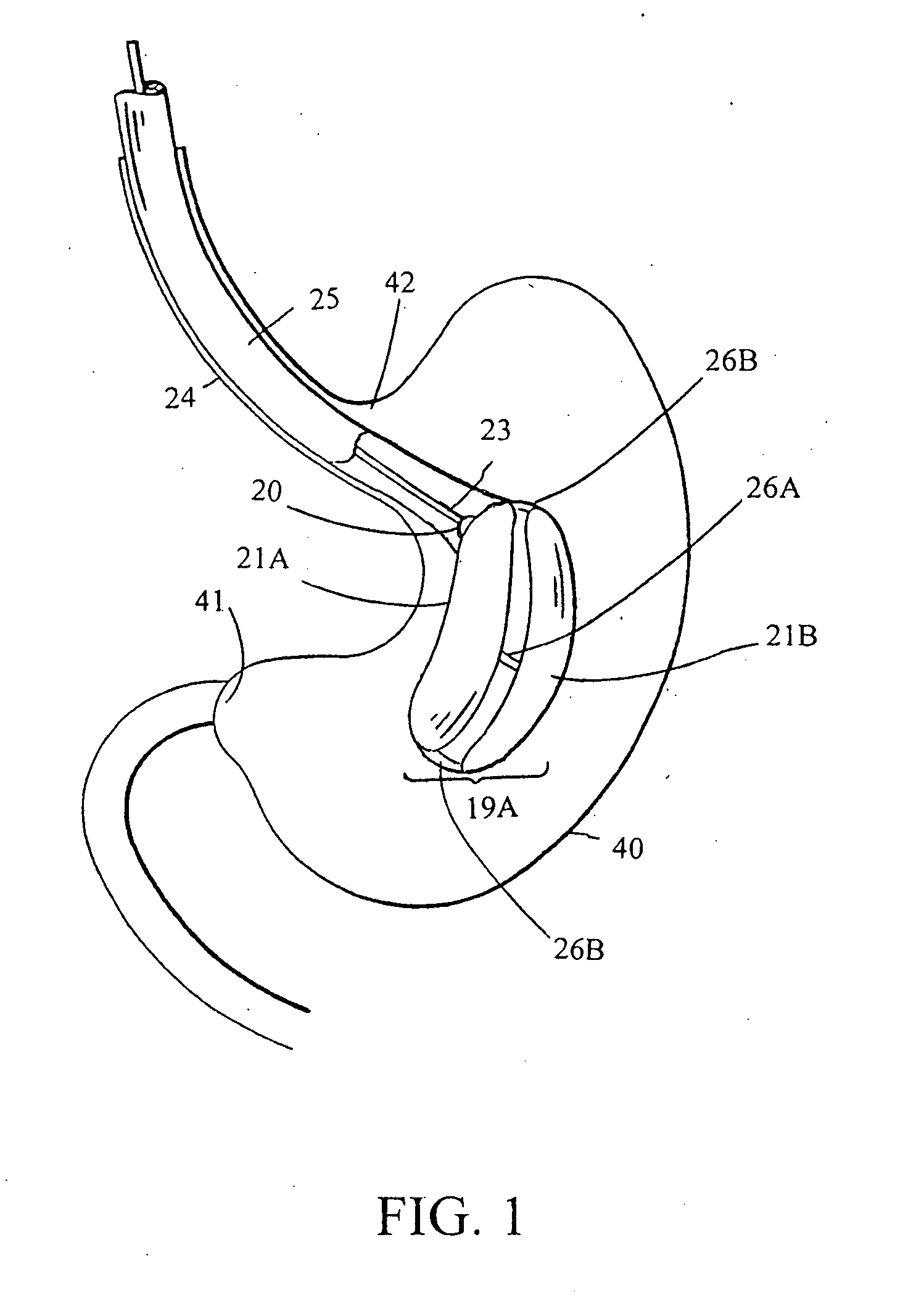

Intragastric space filler and methods of manufacture

InactiveUS20070149994A1Little and minimal effectReducing stomachDilatorsObesity treatmentPressure sensorUrology

Owner:RESHAPE MEDICAL CORP

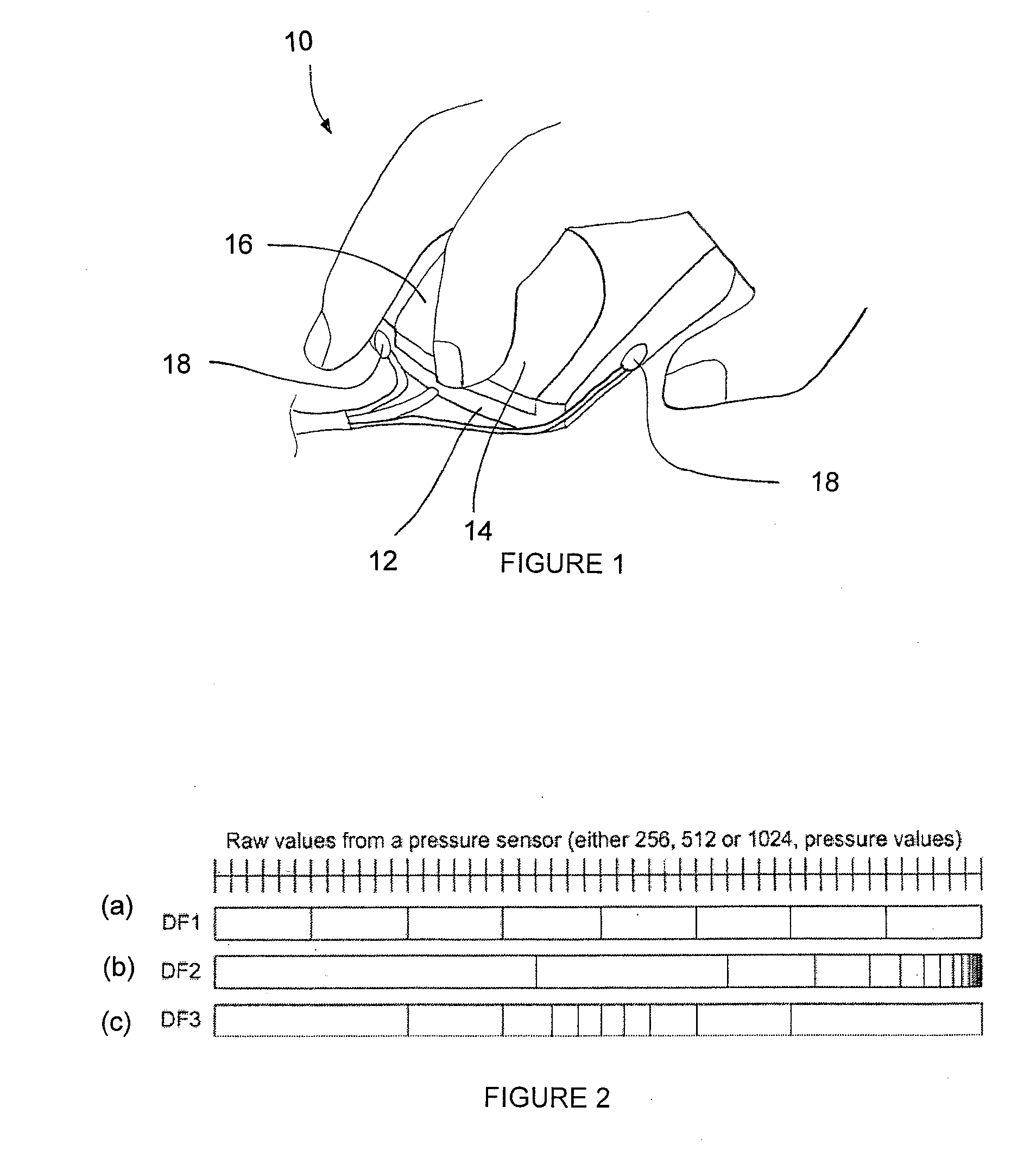

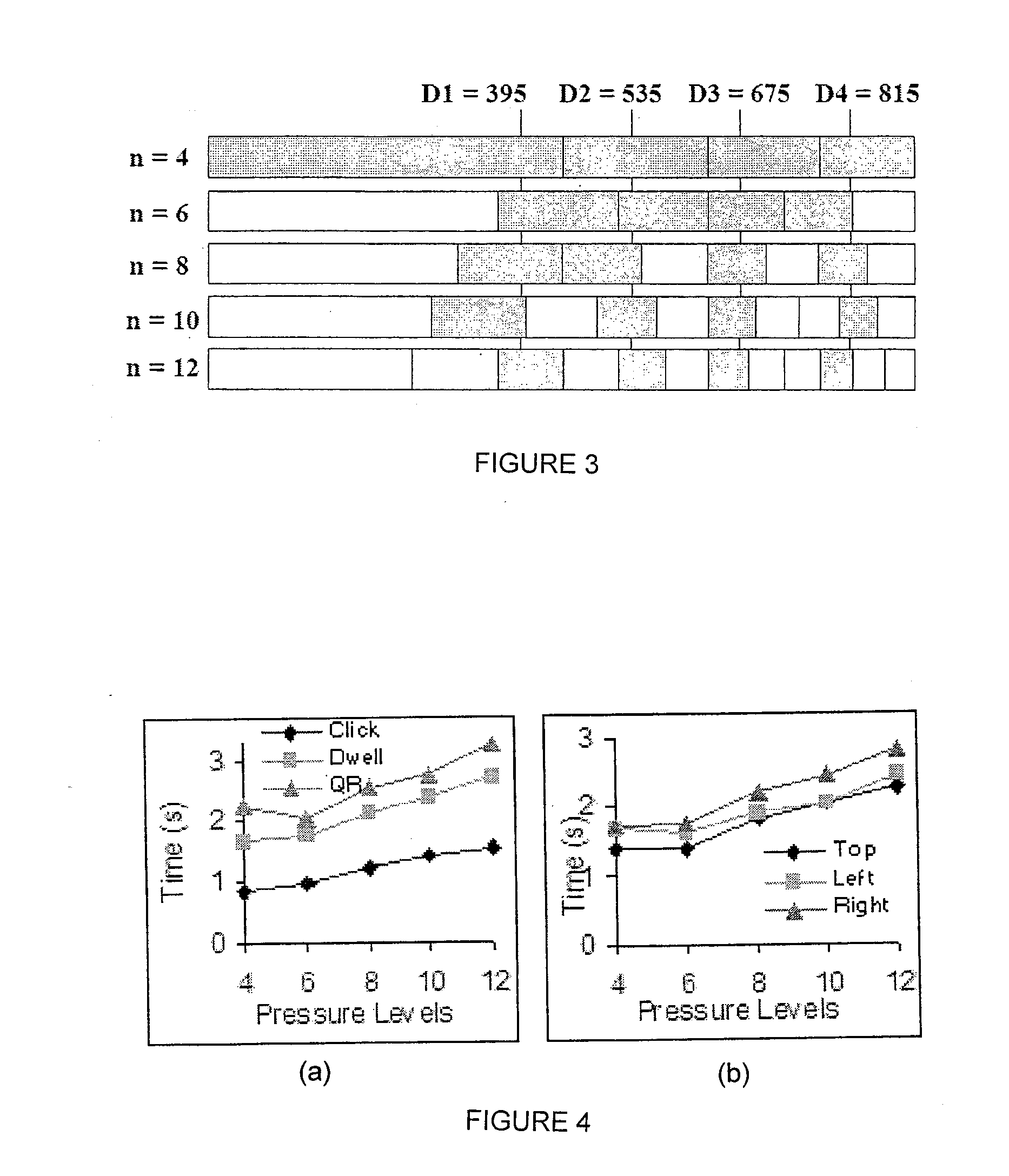

Pressure Augmented Mouse

InactiveUS20100127983A1Cathode-ray tube indicatorsInput/output processes for data processingHuman–computer interactionDiscrete action

The use of a uni-pressure and dual-pressure augmented mouse permits users to simultaneously control cursor positions as well as multiple levels of discrete action modes for common desktop application tasks. One, two or more independent pressure sensors can be mounted onto several locations on the body of the mouse. Various selection techniques are described to control many discrete levels and to simultaneously control different variable functions with pressure sensors on an input device for an electronic device.

Owner:IRANI POURANG +3

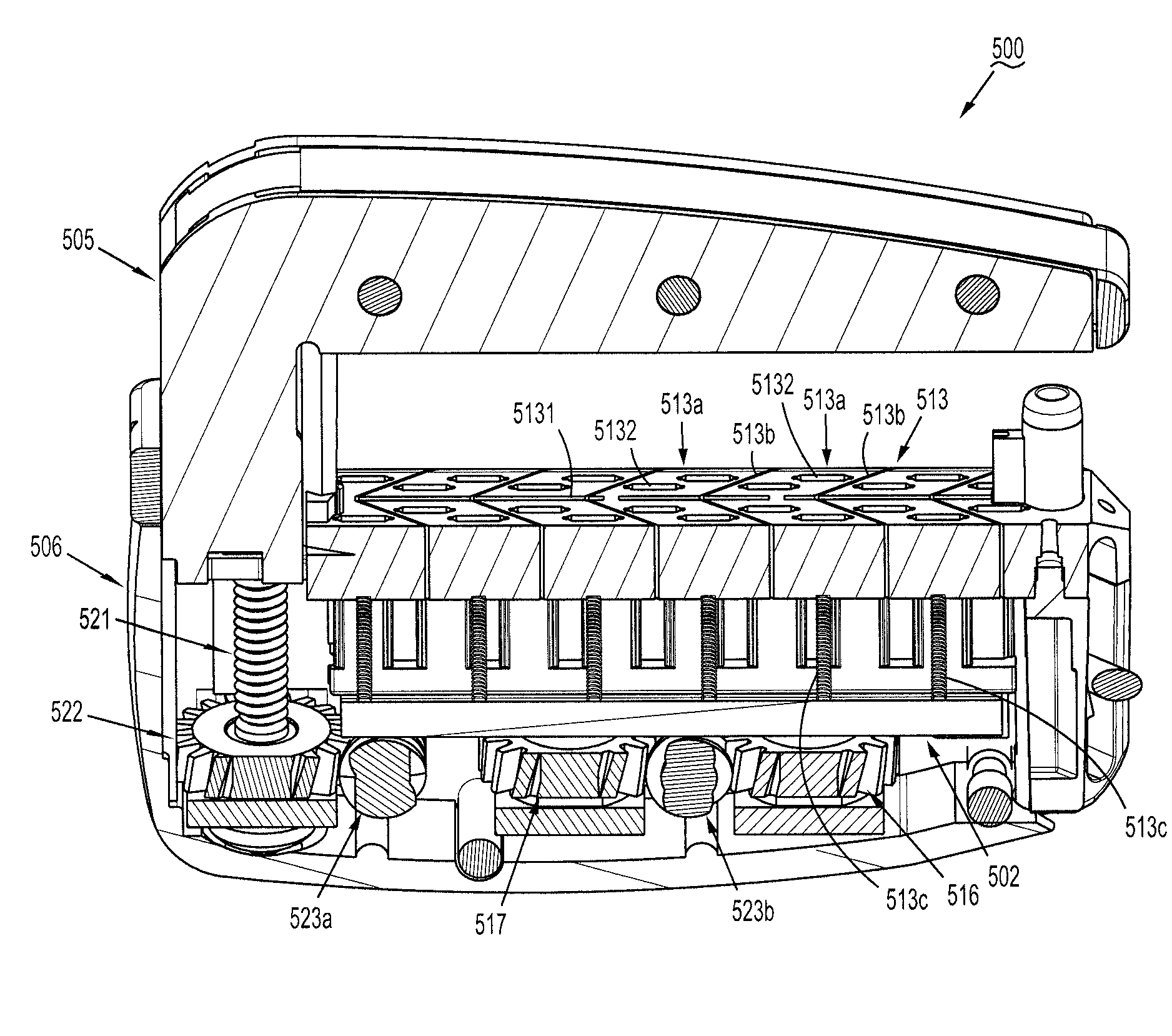

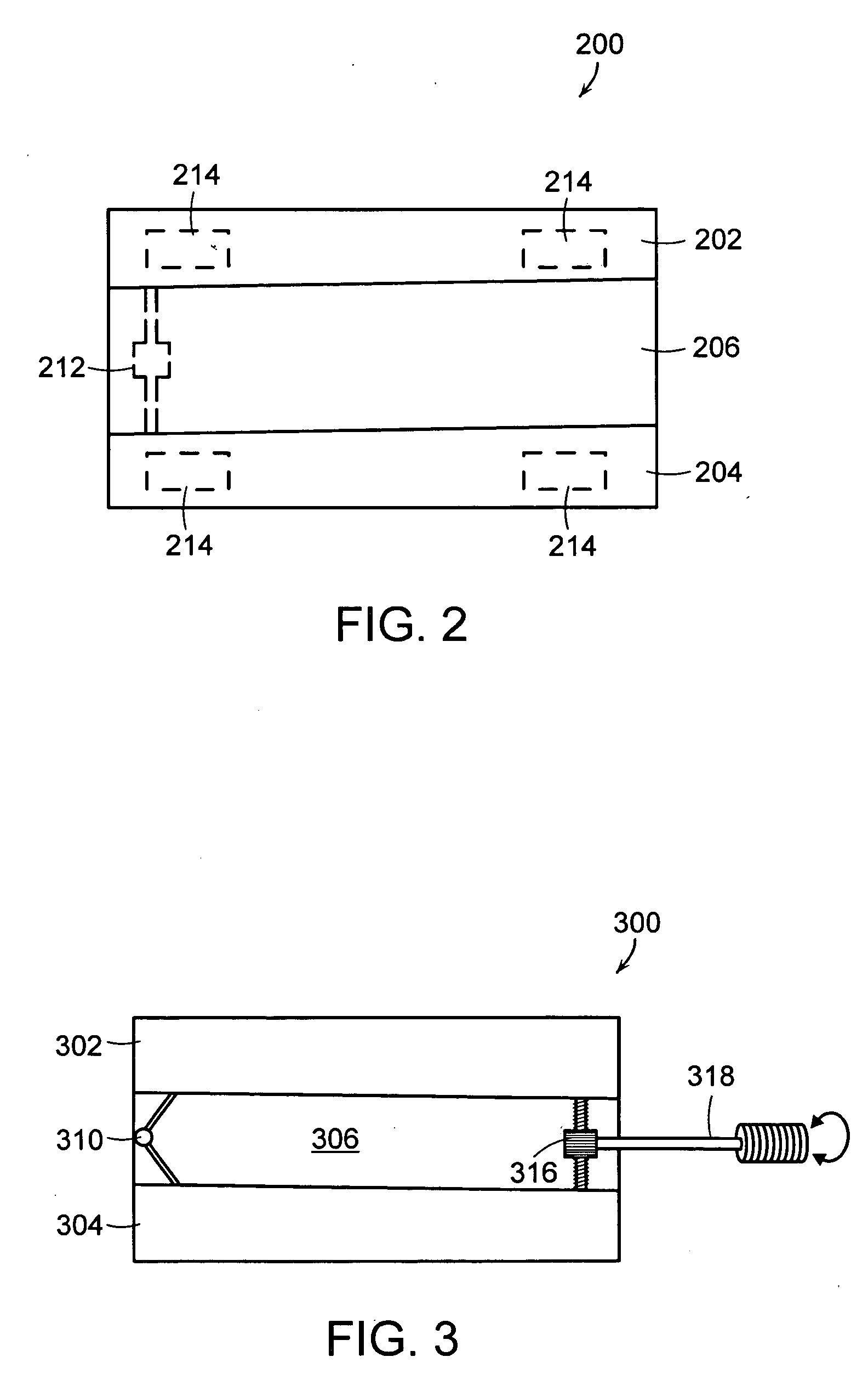

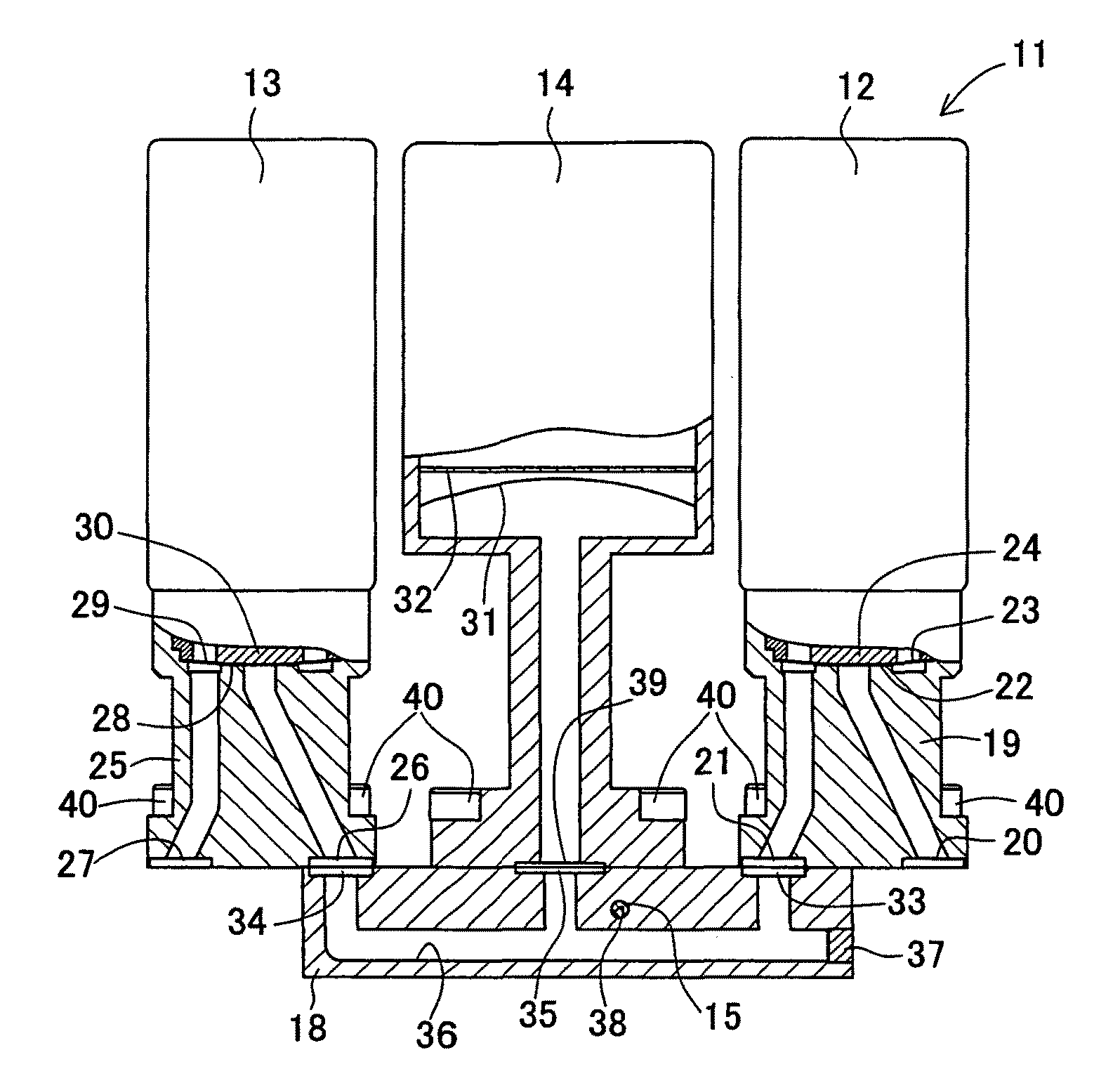

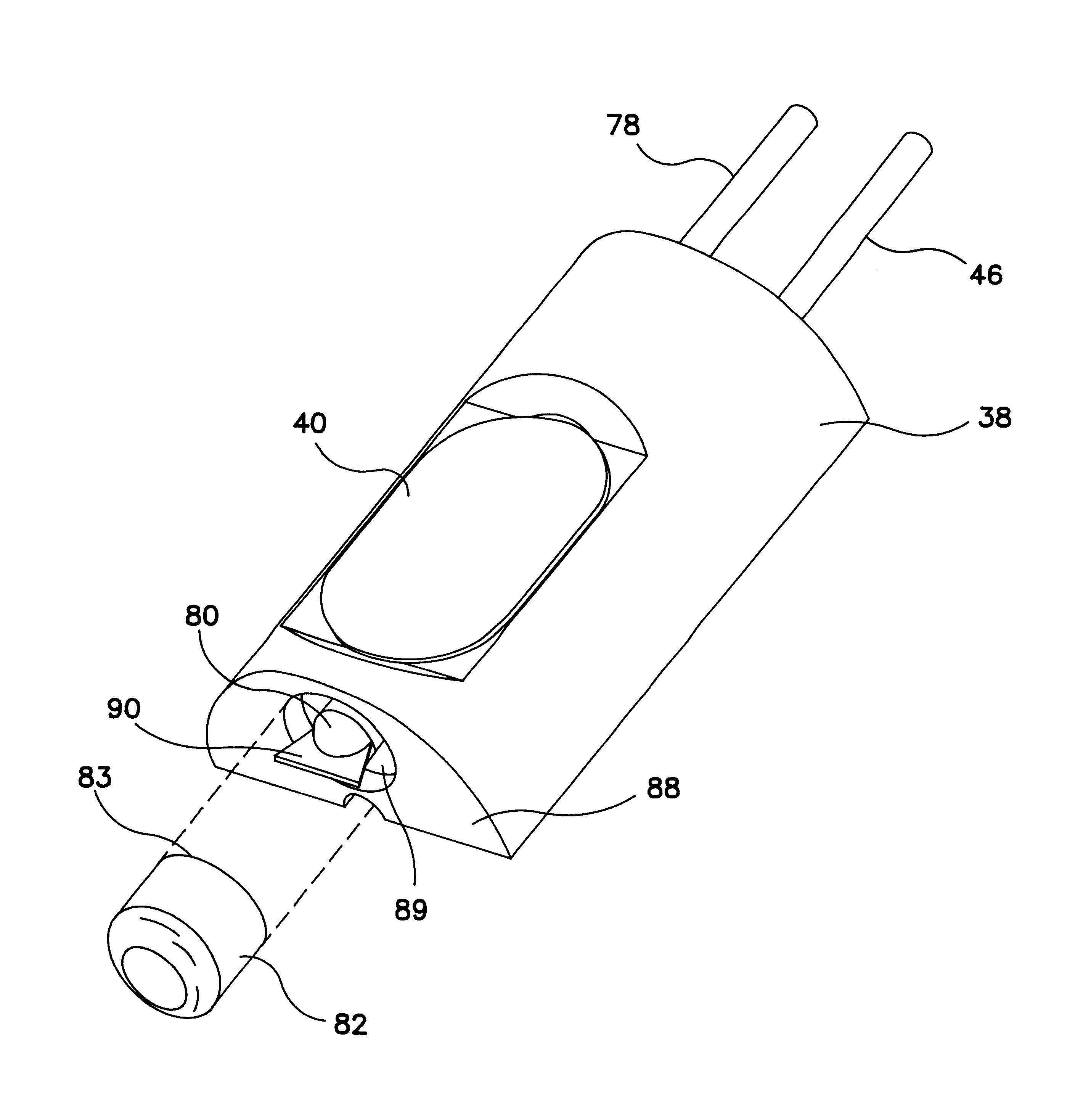

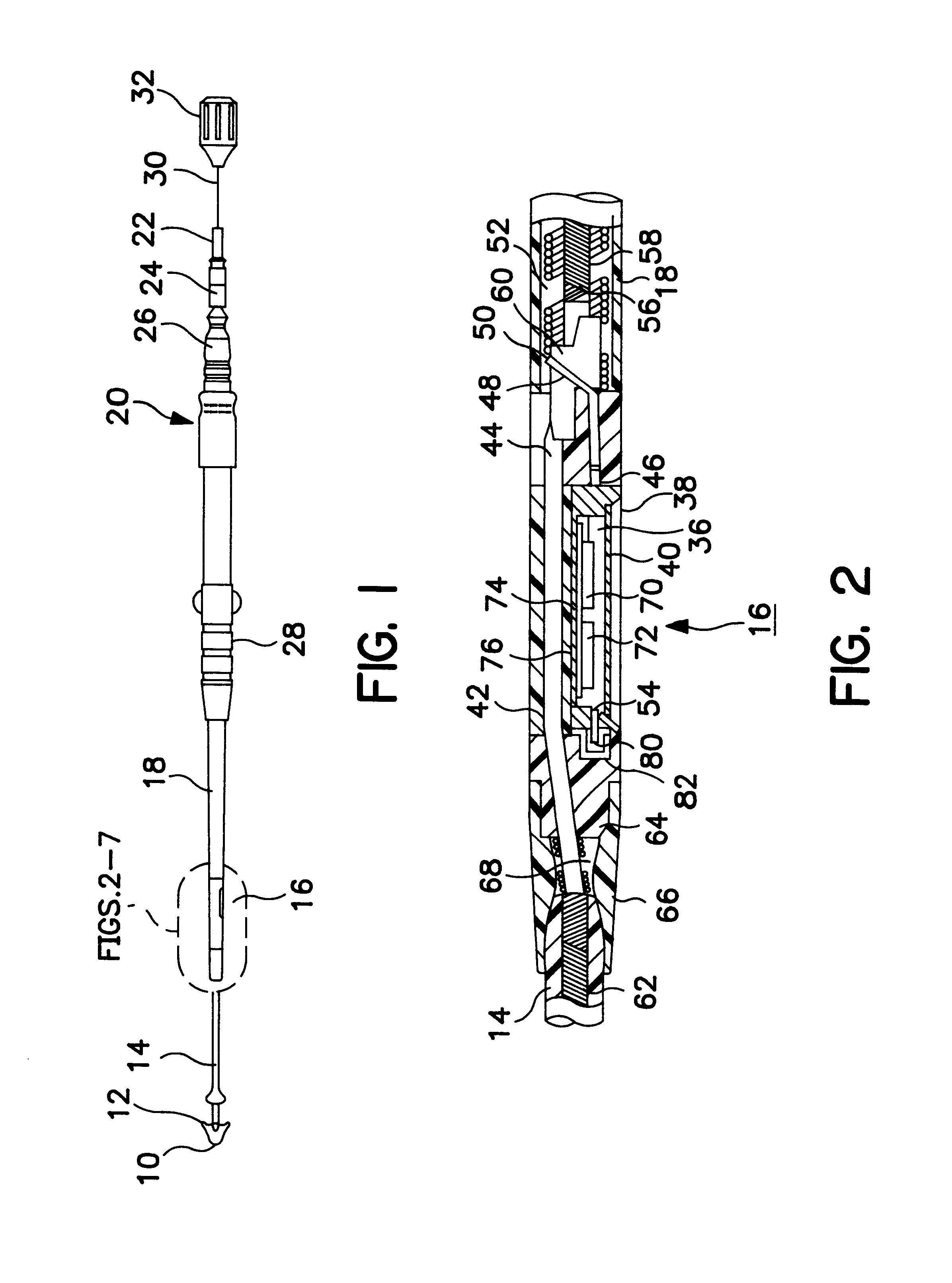

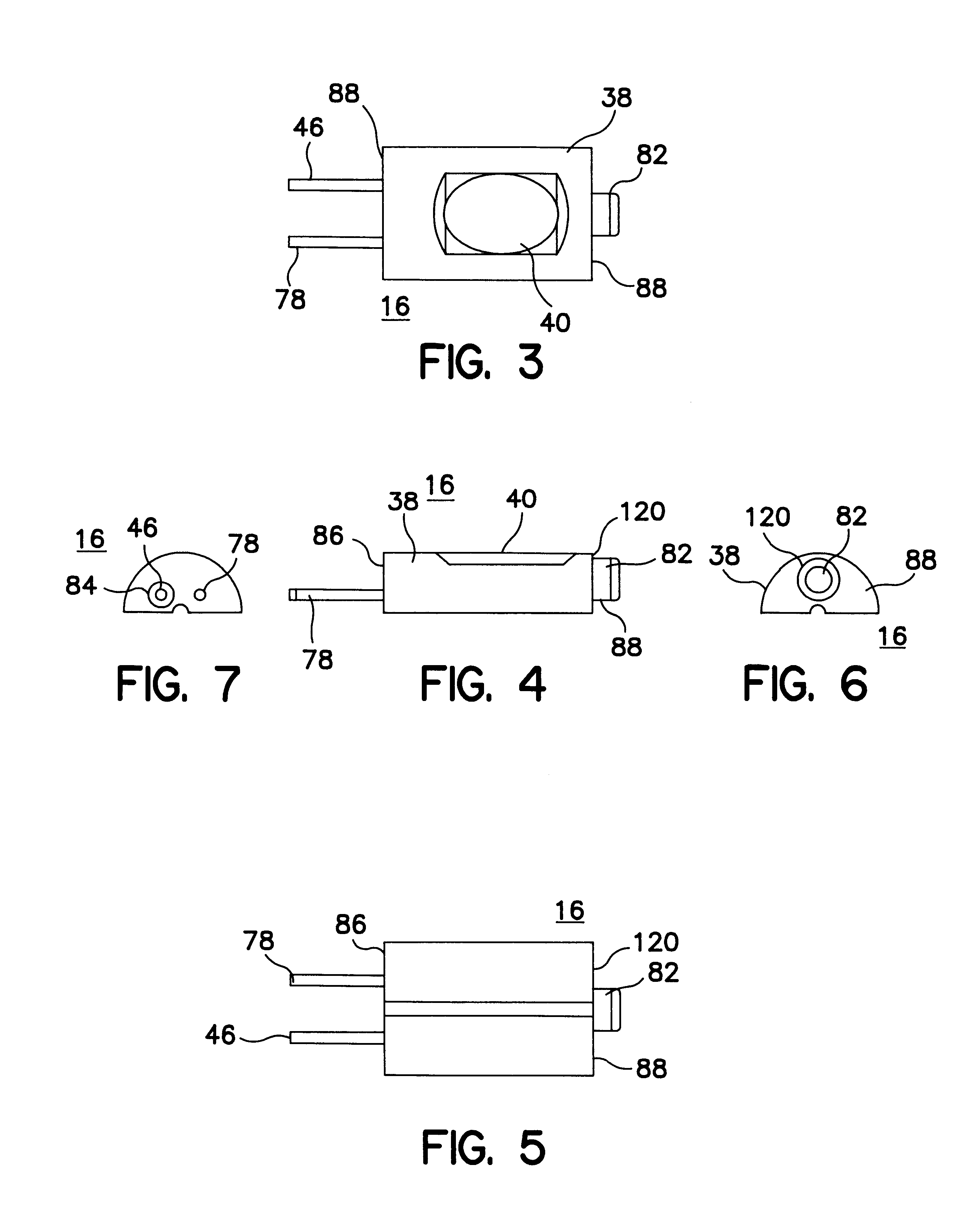

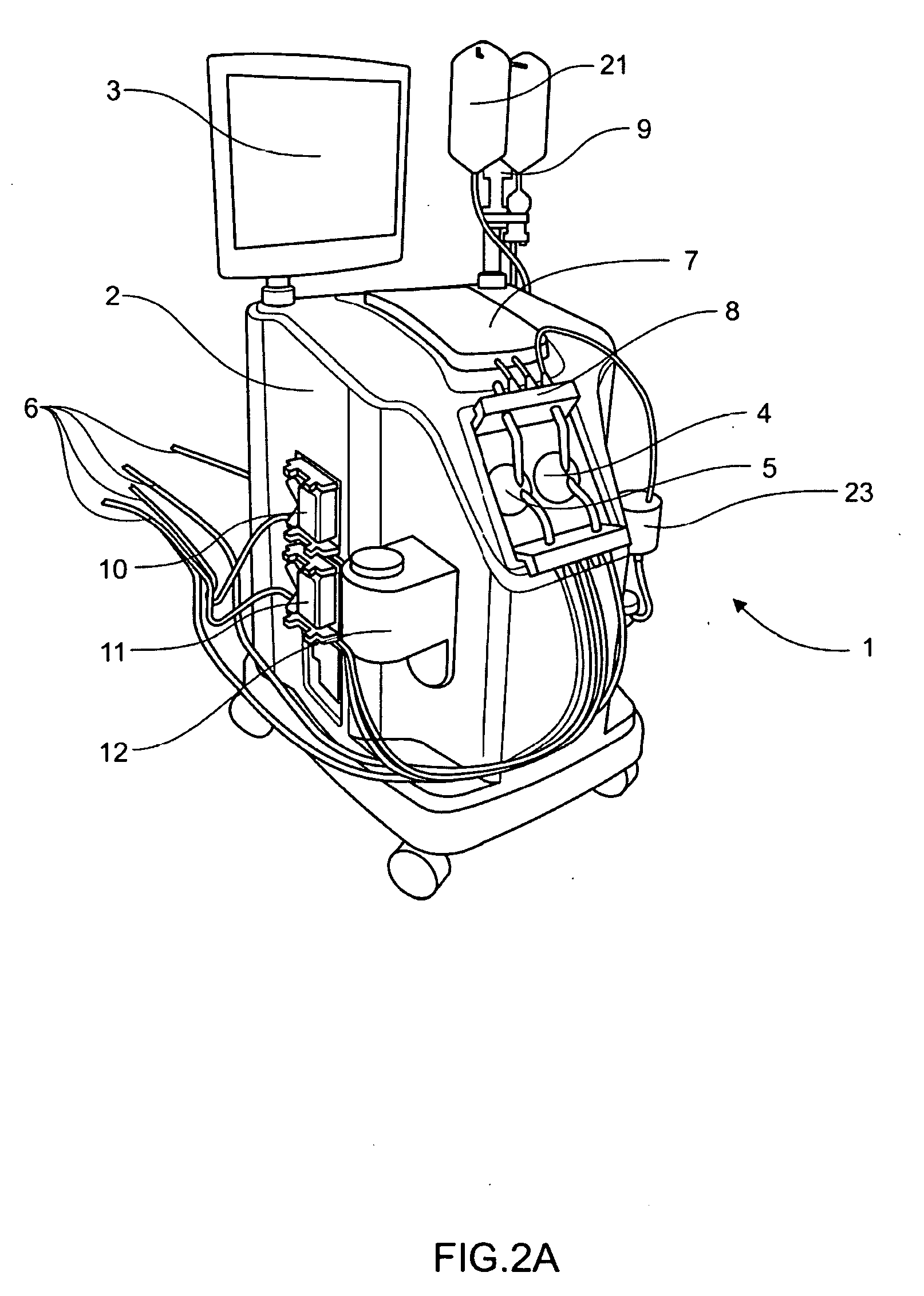

Surgical cassette having an aspiration pressure sensor

A cassette having a molded flow channel contained on an elastomeric sheet that is bonded or mechanically attached to a rigid substrate. The flow channel projects outwardly from the exterior of the cassette so that a peristaltic pump having pump head rollers mounted radially from the axis of rotation of the pump motor compress the elastomeric flow channels against the rigid substrate during operation.

Owner:ALCON INC

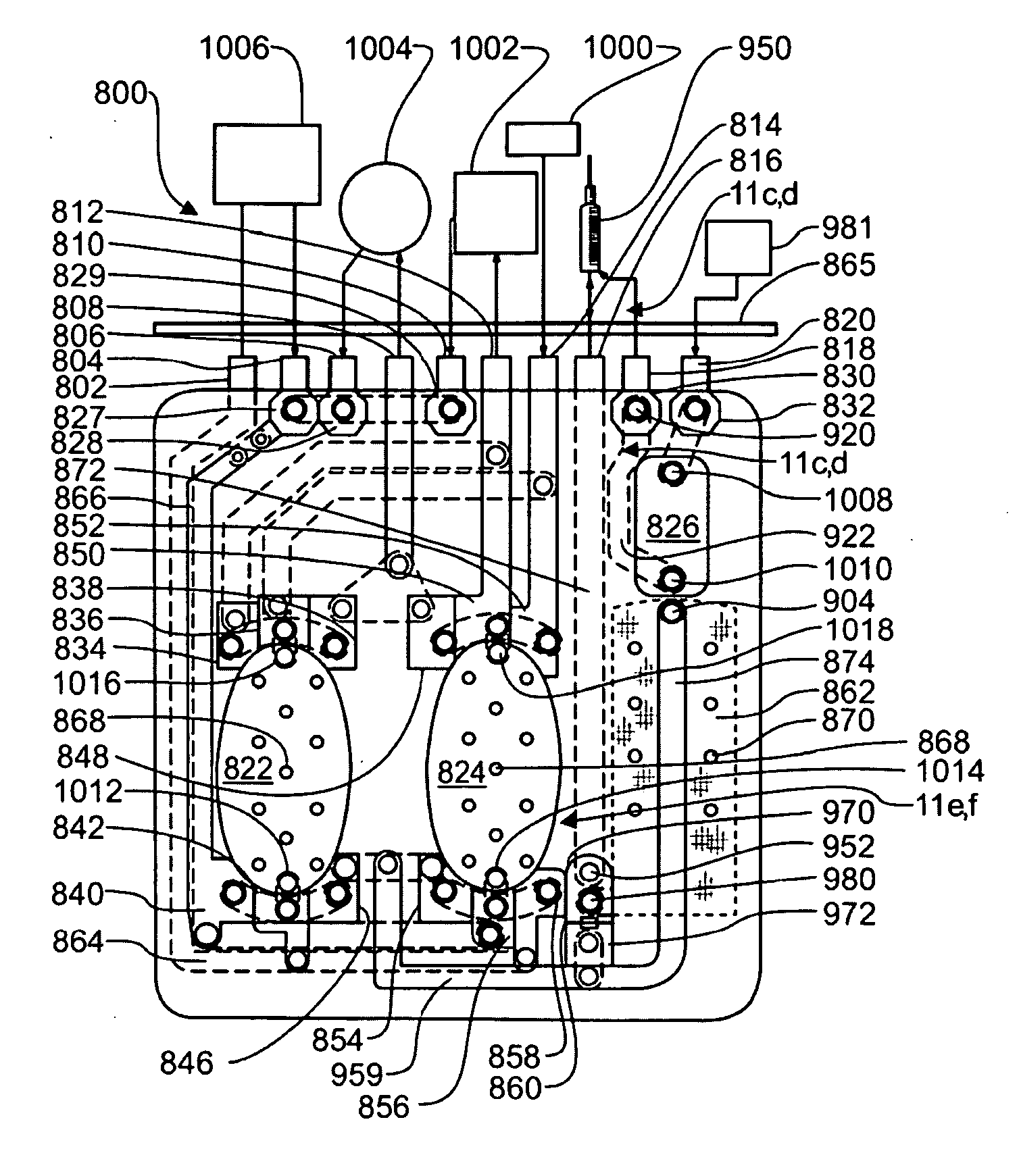

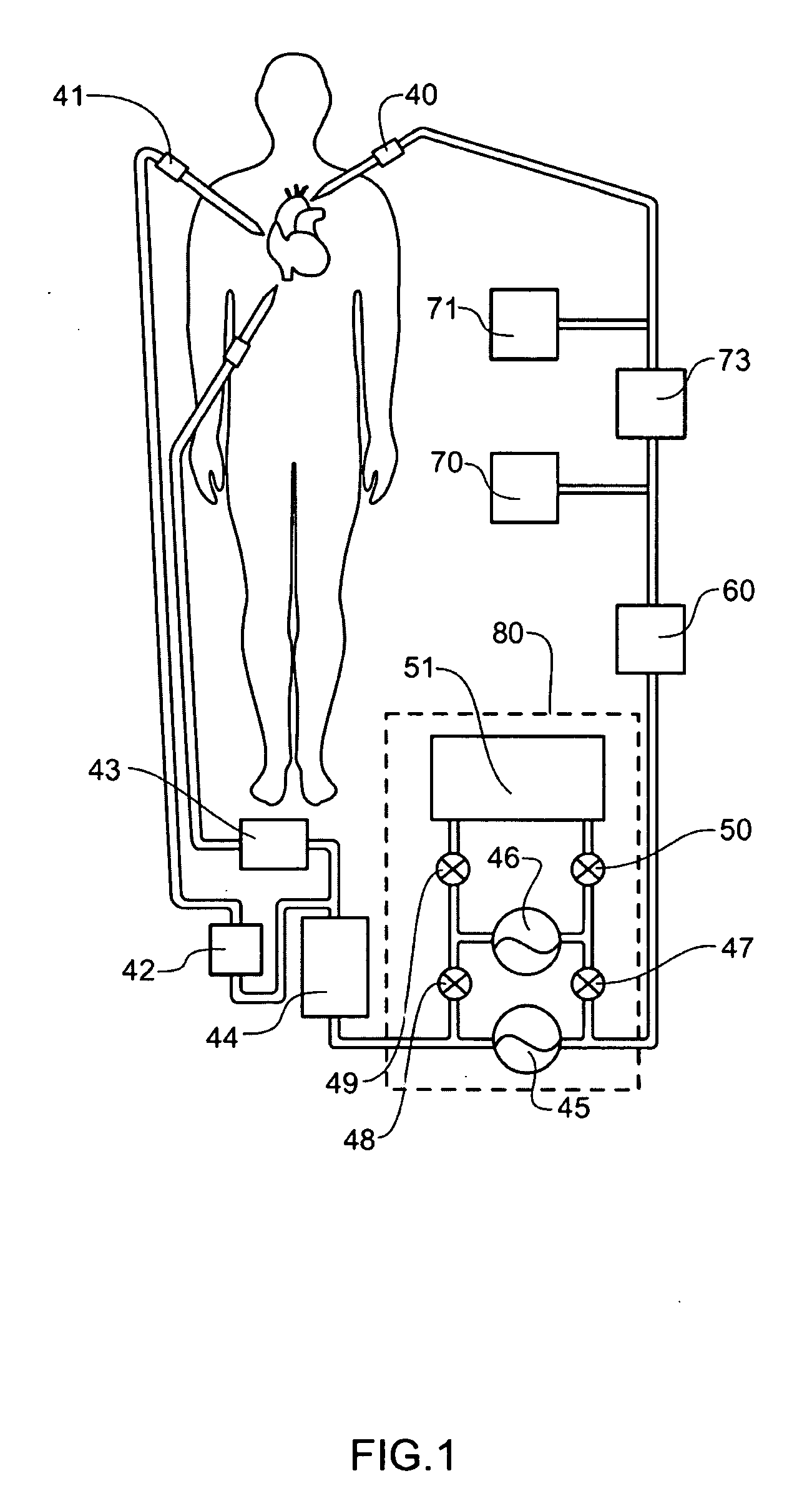

Systems, Devices and Methods for Cardiopulmonary Treatment and Procedures

ActiveUS20090099498A1Reduces hard snappingReduce shear forceVolume measurement apparatus/methodsControl devicesBlood pumpControl room

A cardiopulmonary bypass system utilizing membrane-based reciprocating positive displacement blood pumps (“pod pumps”). In one aspect, the pod pumps are constructed to provide reduced shear forces on the blood being pumped. In another aspect blood flow through the pod pumps can be controlled by a controller using information from pressure sensors in the control chamber of the pod pumps. In another aspect, the pod pumps are included on a disposable unit that can be received and held by a receptacle means on a base unit, the base unit also providing pressurized control fluid to the pod pumps on the disposable unit through the receptacle means.

Owner:DEKA PROD LLP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com