Patents

Literature

1878 results about "Pump head" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

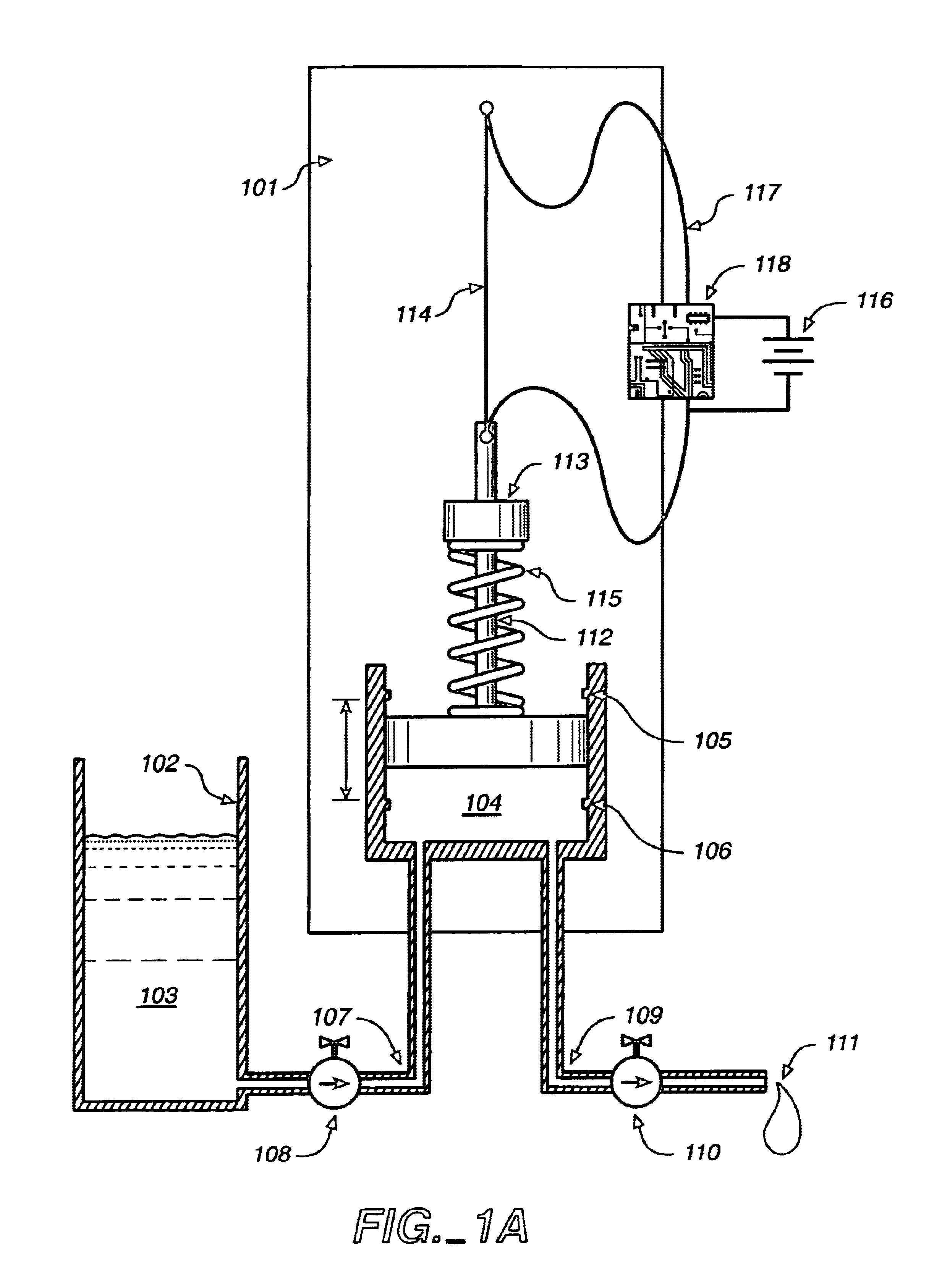

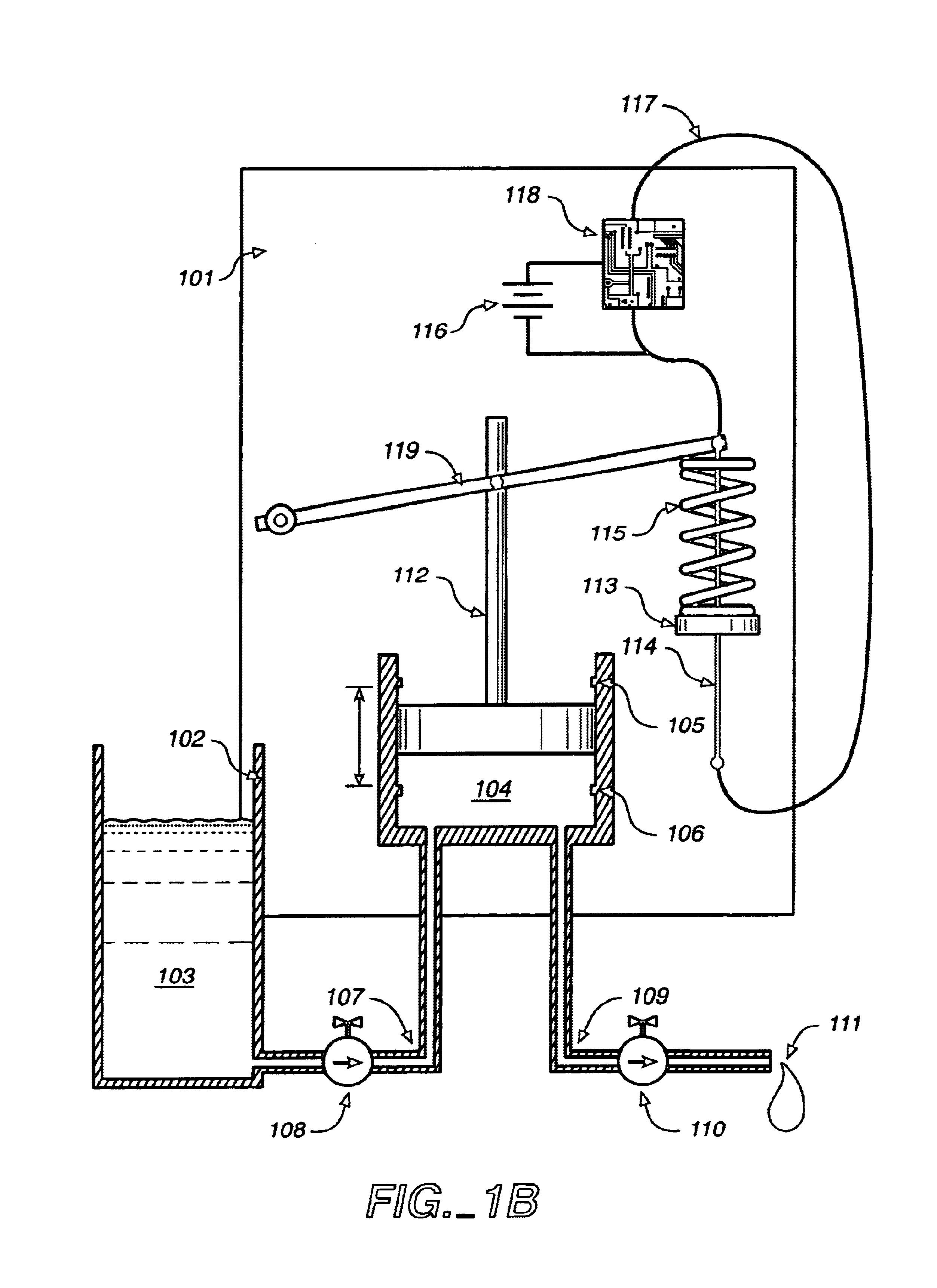

Device and method employing shape memory alloy

InactiveUS6916159B2Low costSmall size and weightTesting/calibration apparatusVolume/mass flow measurementShape-memory alloyEngineering

Owner:THERASENSE

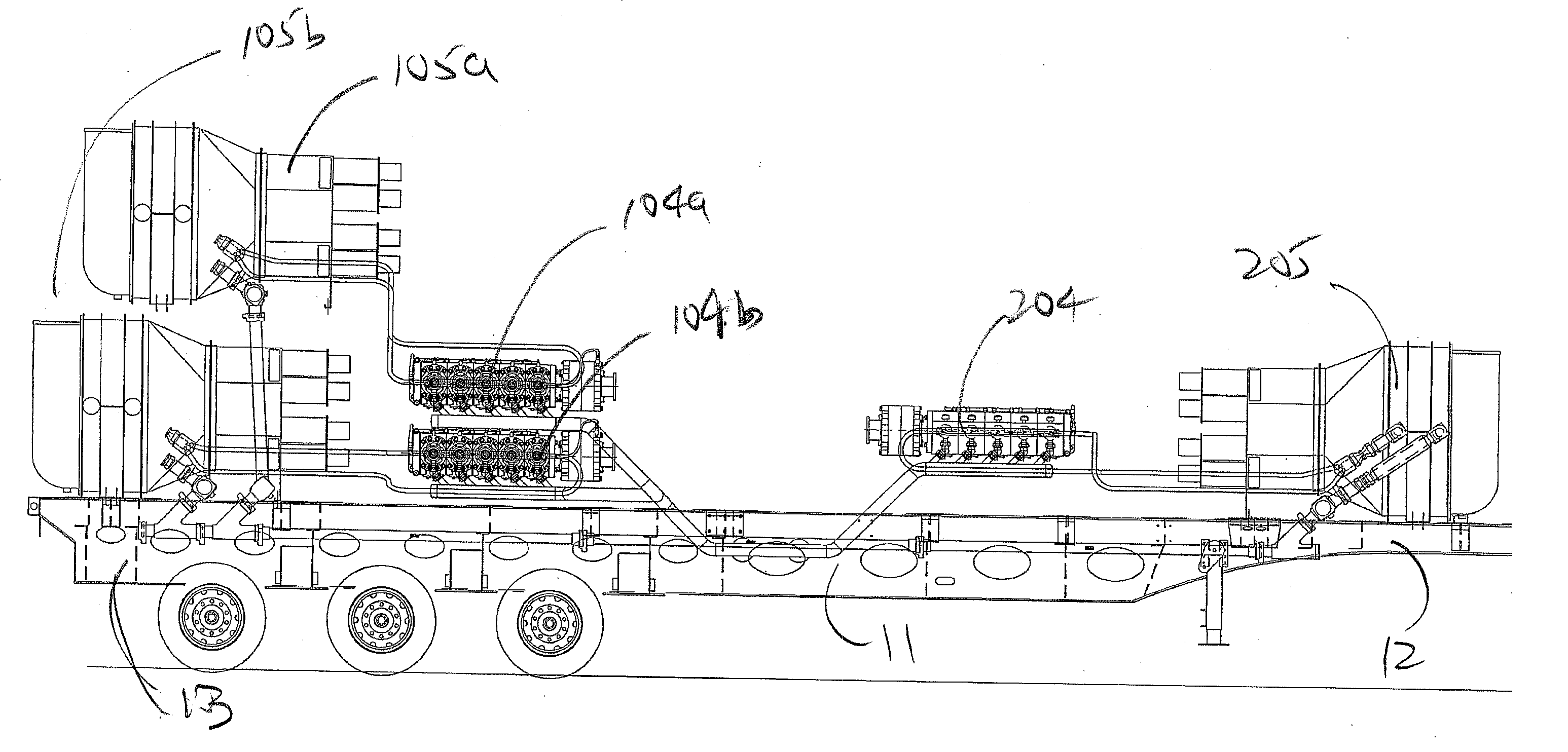

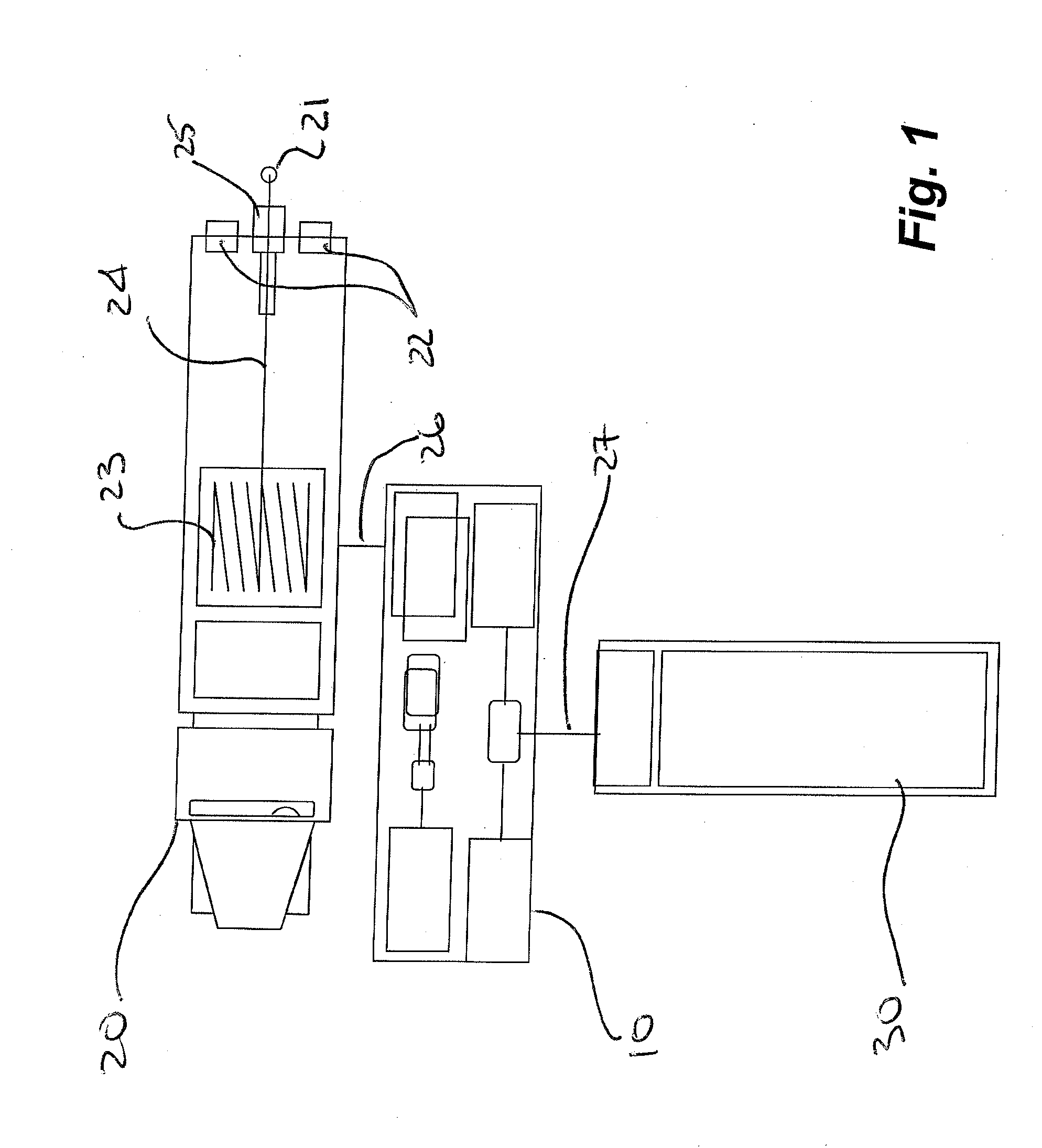

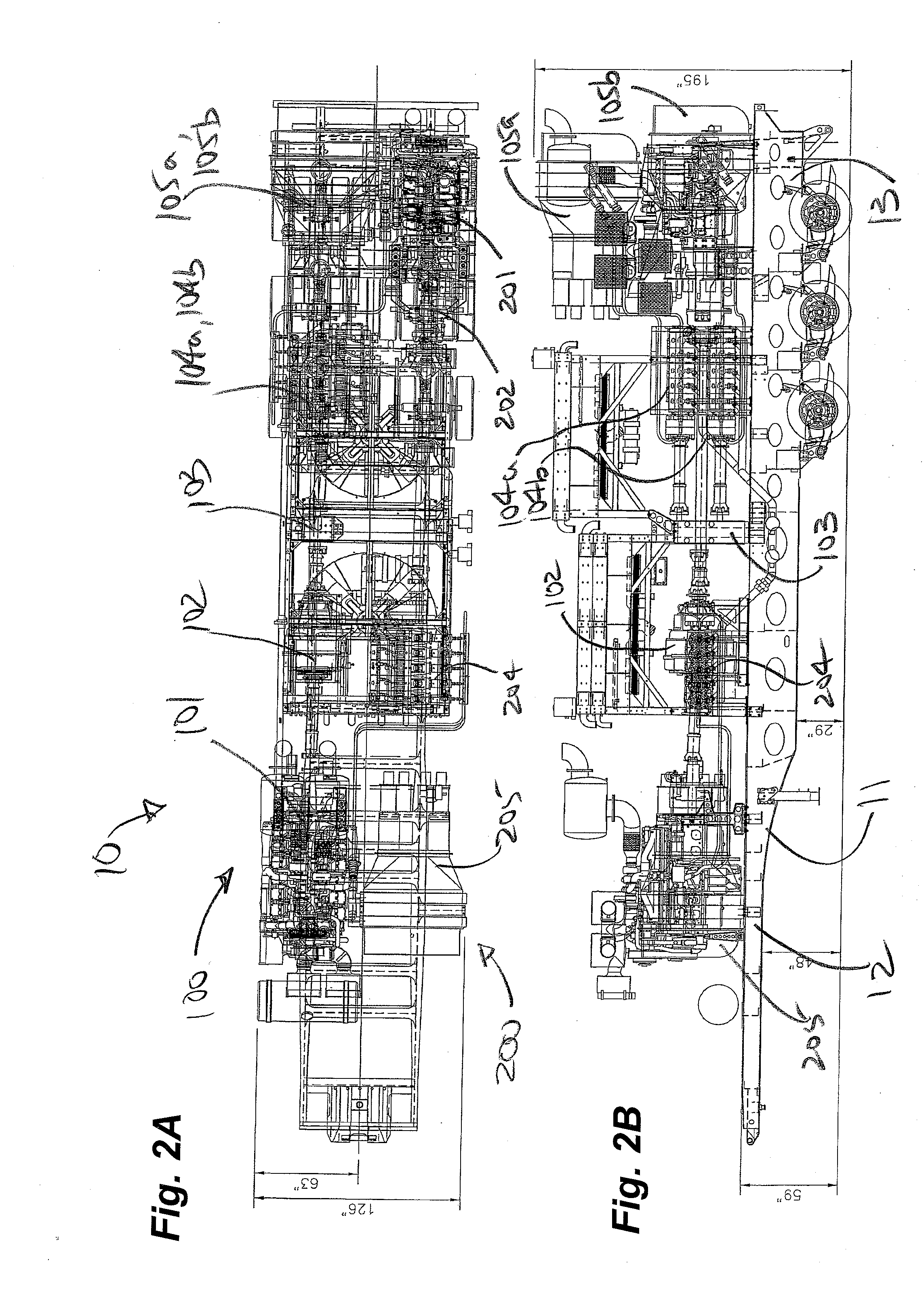

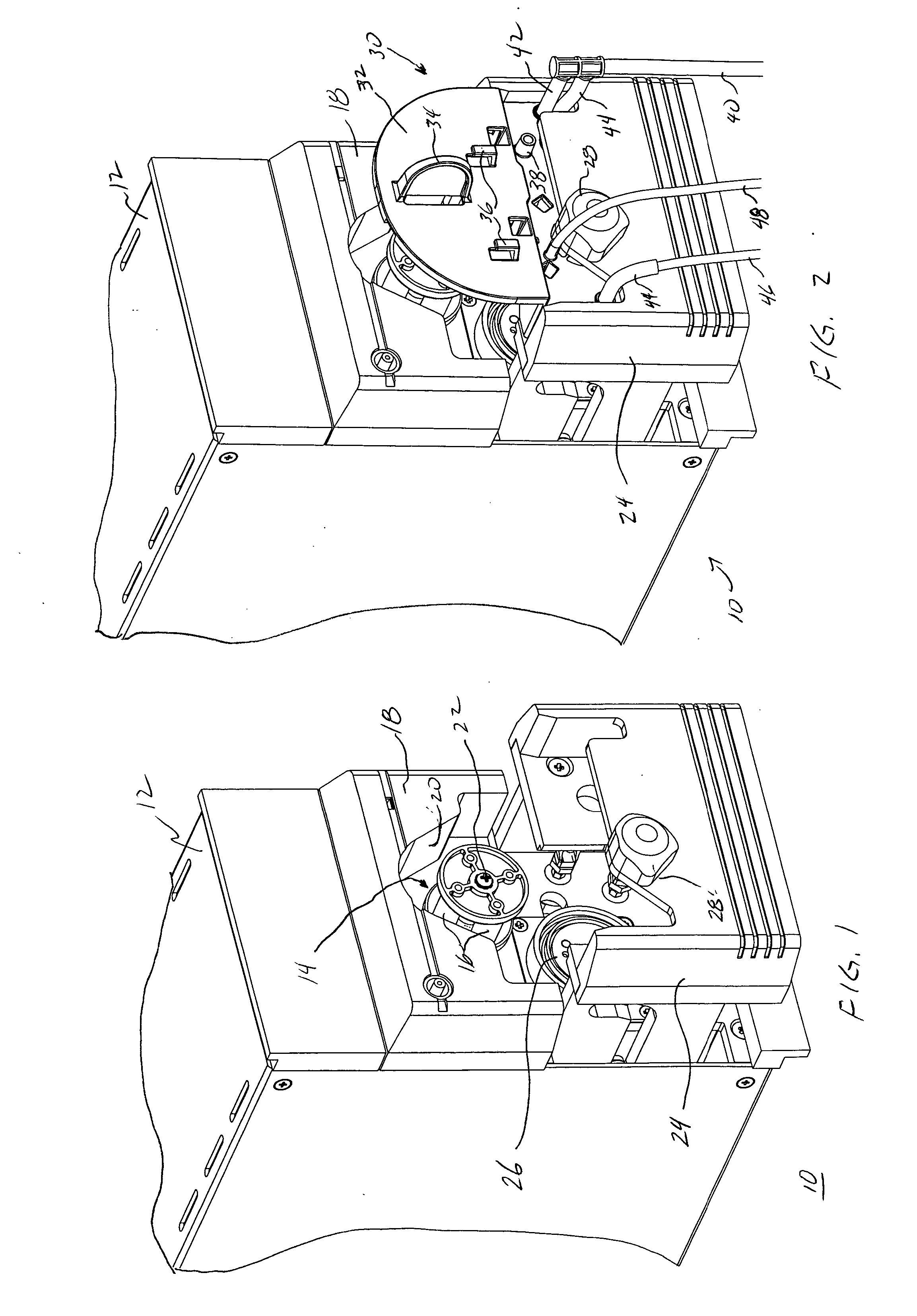

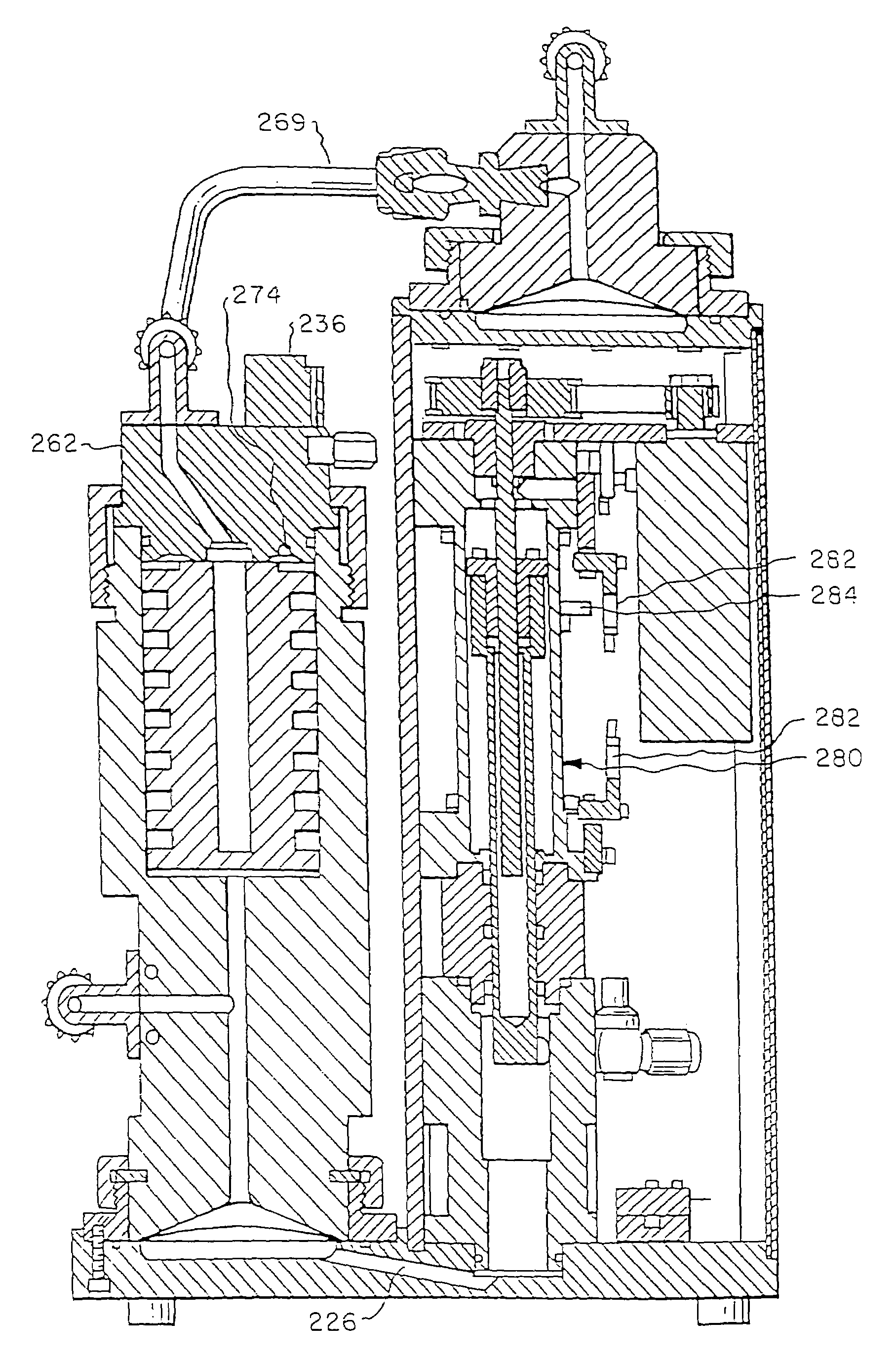

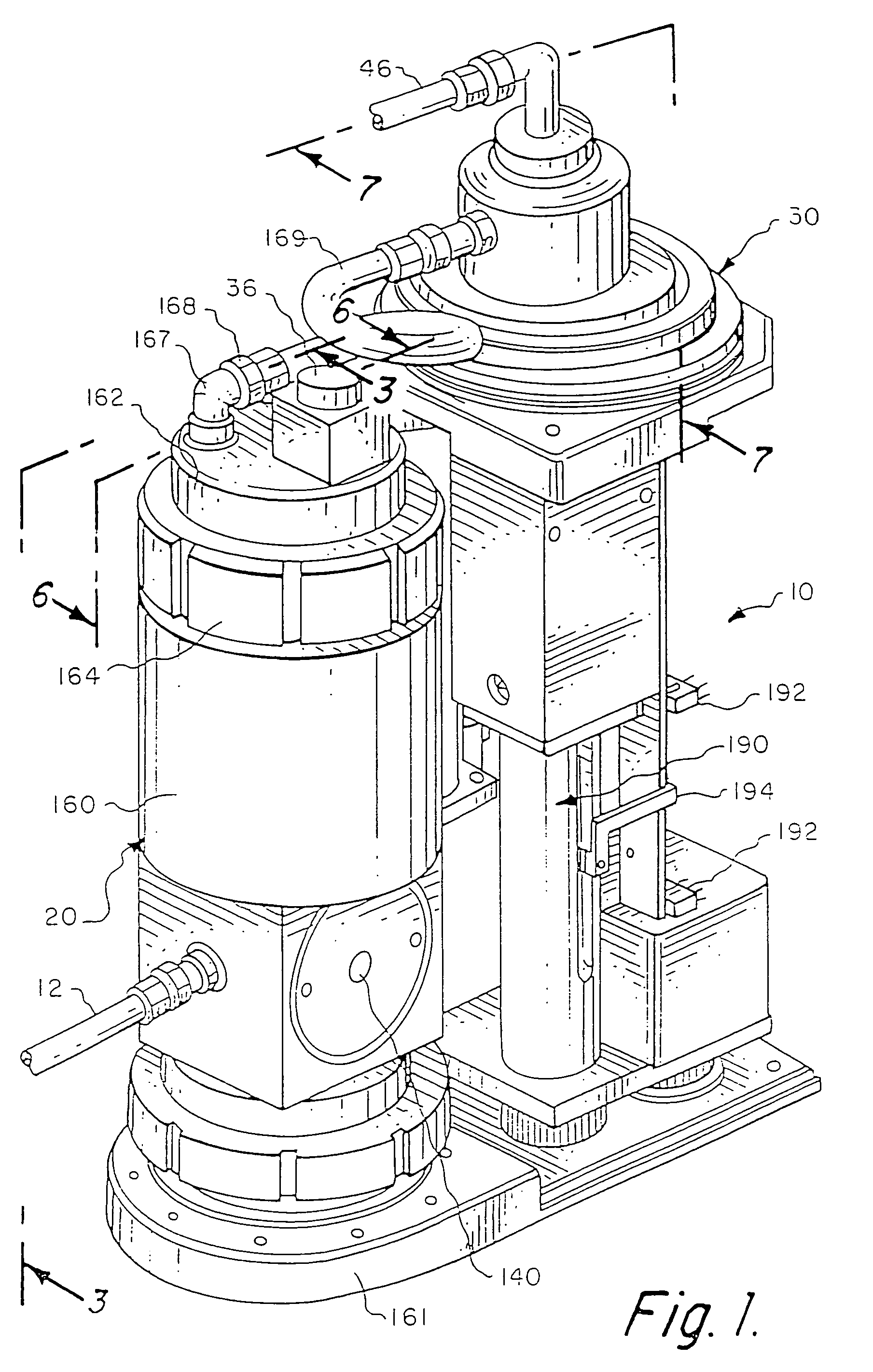

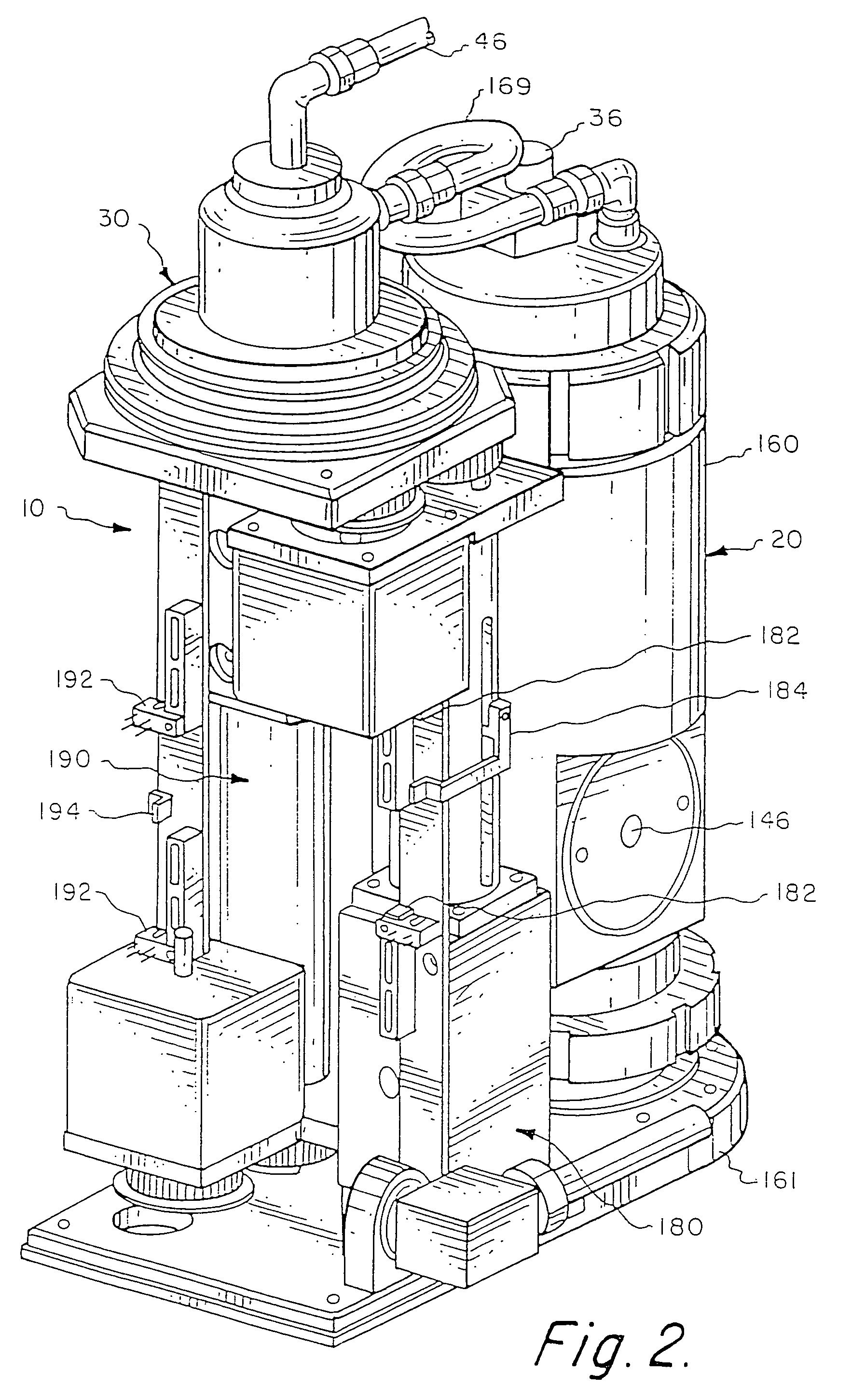

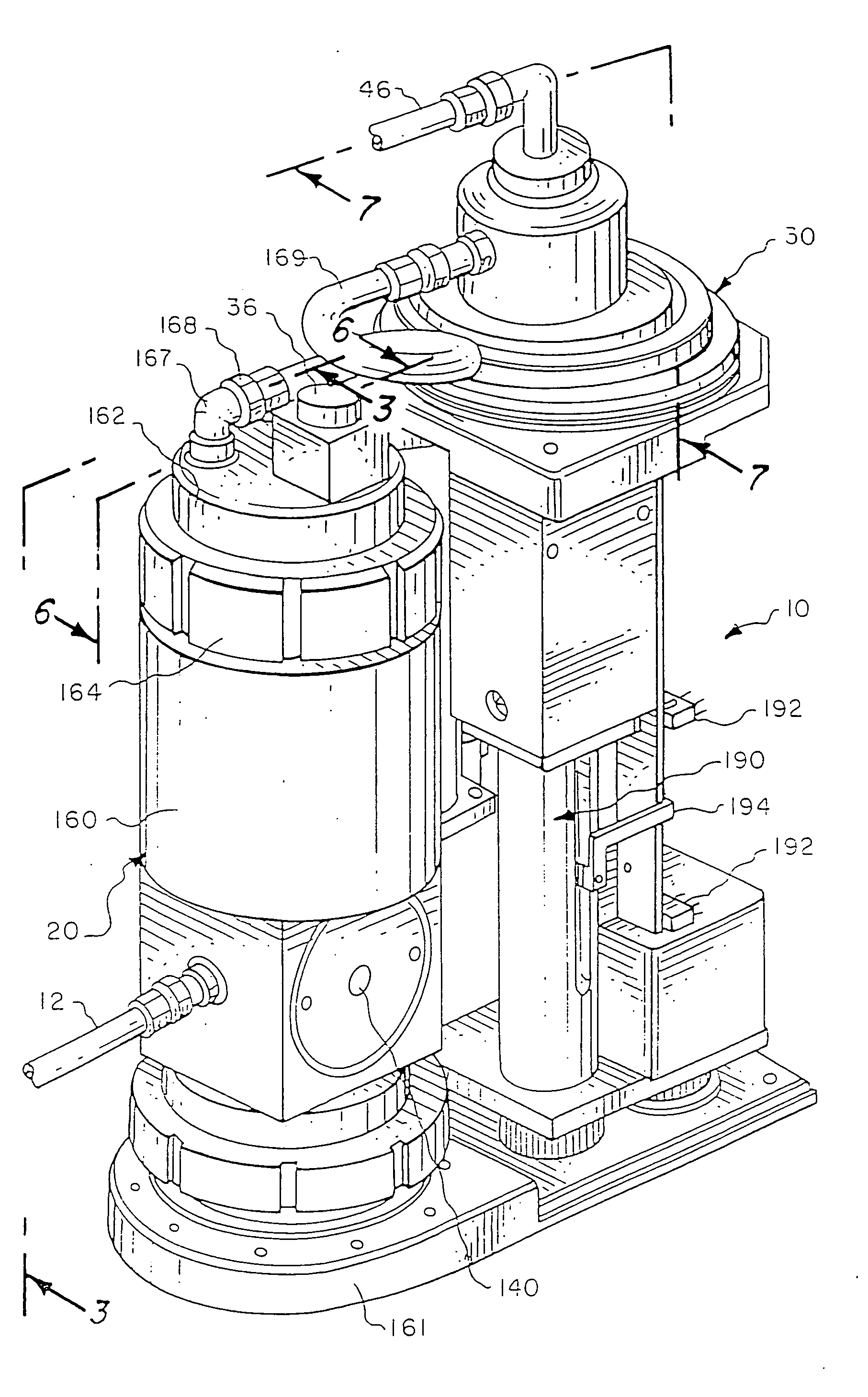

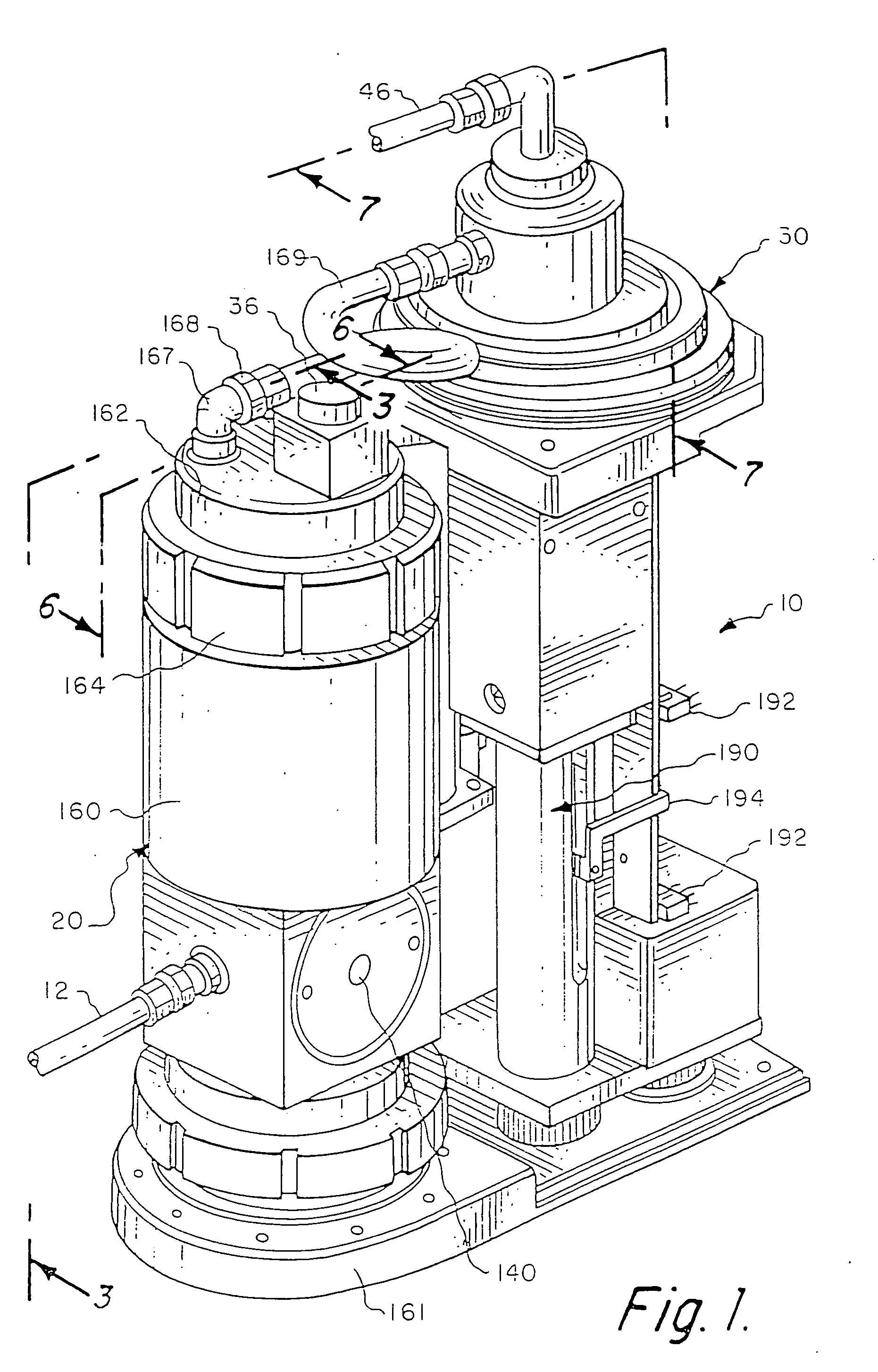

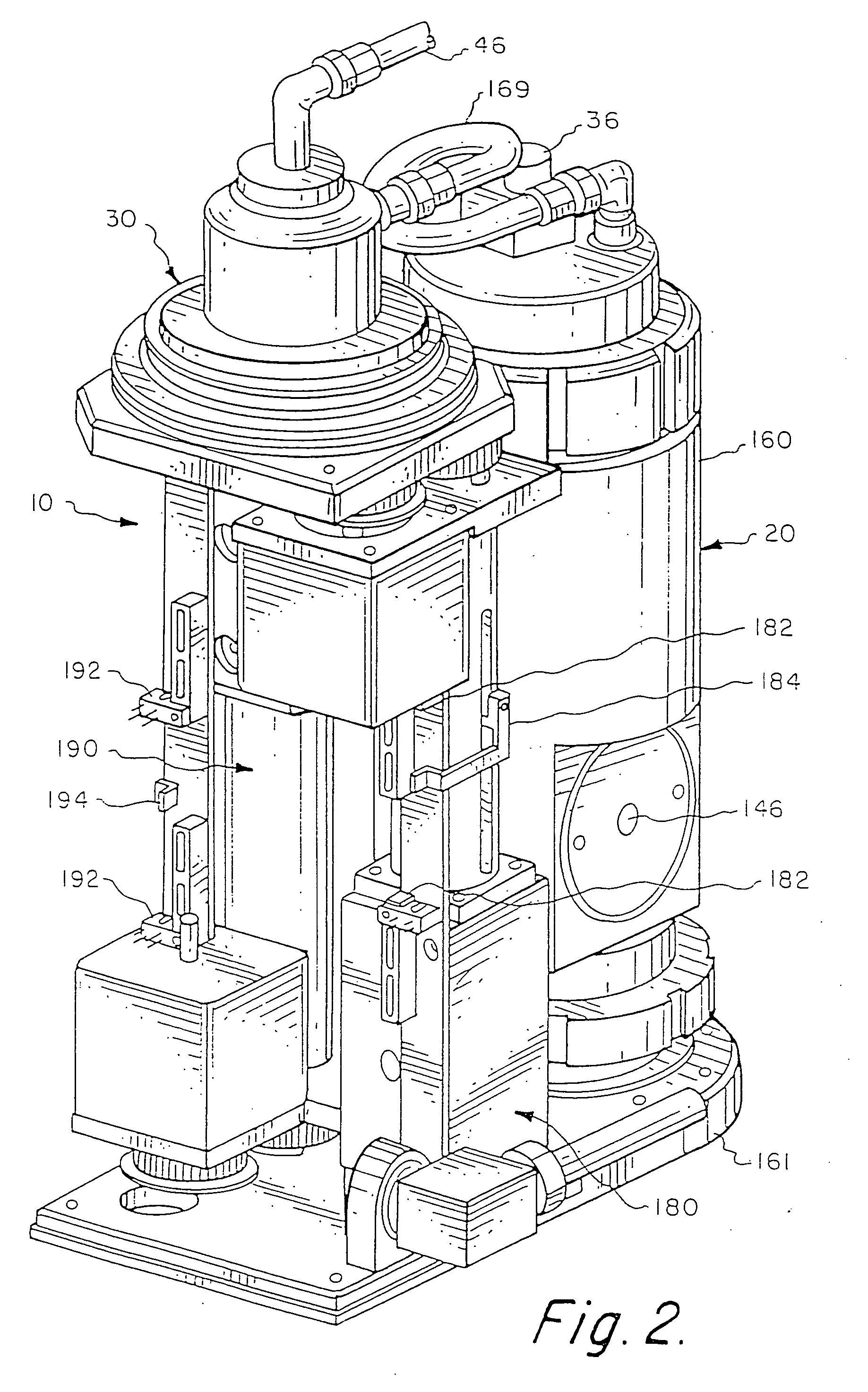

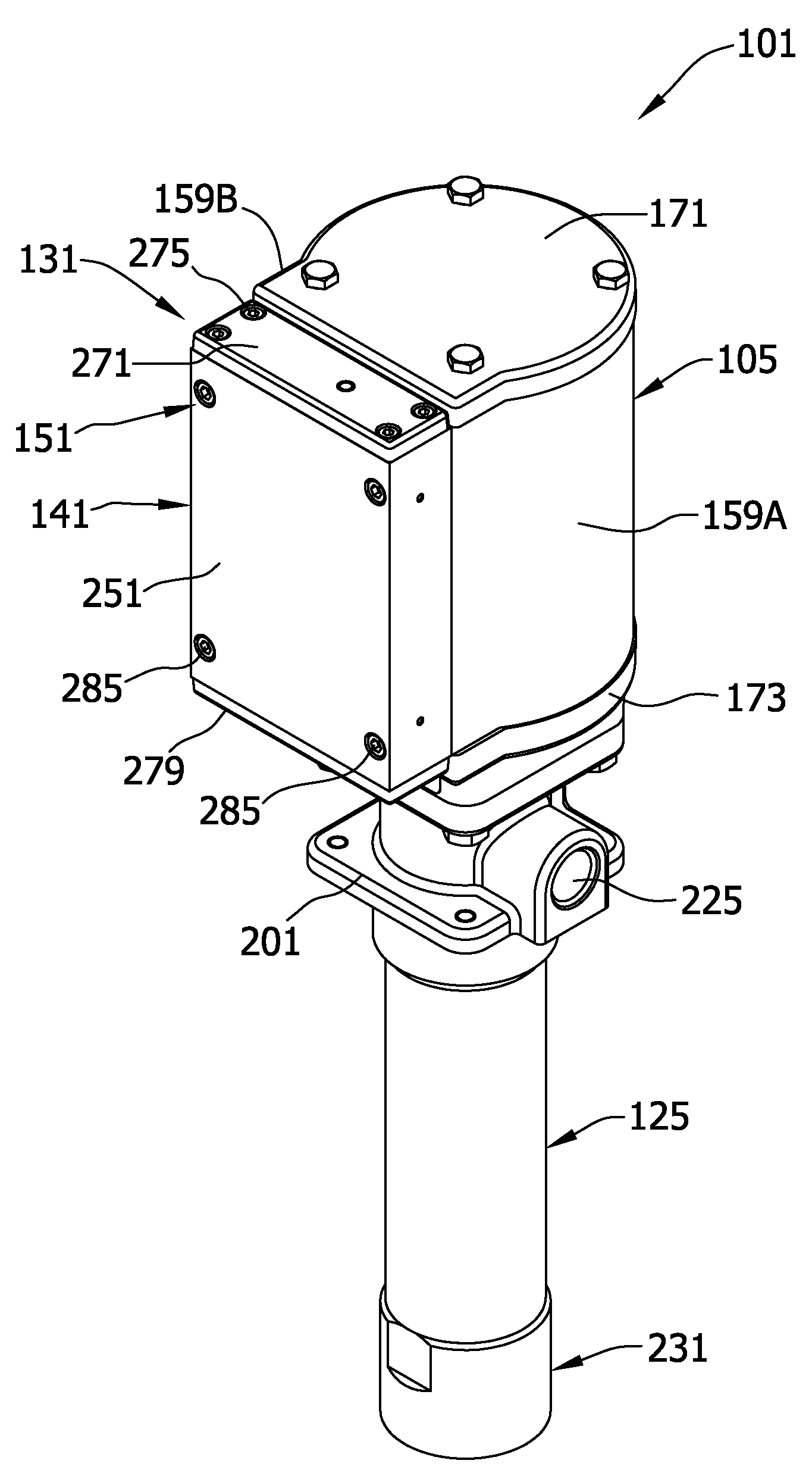

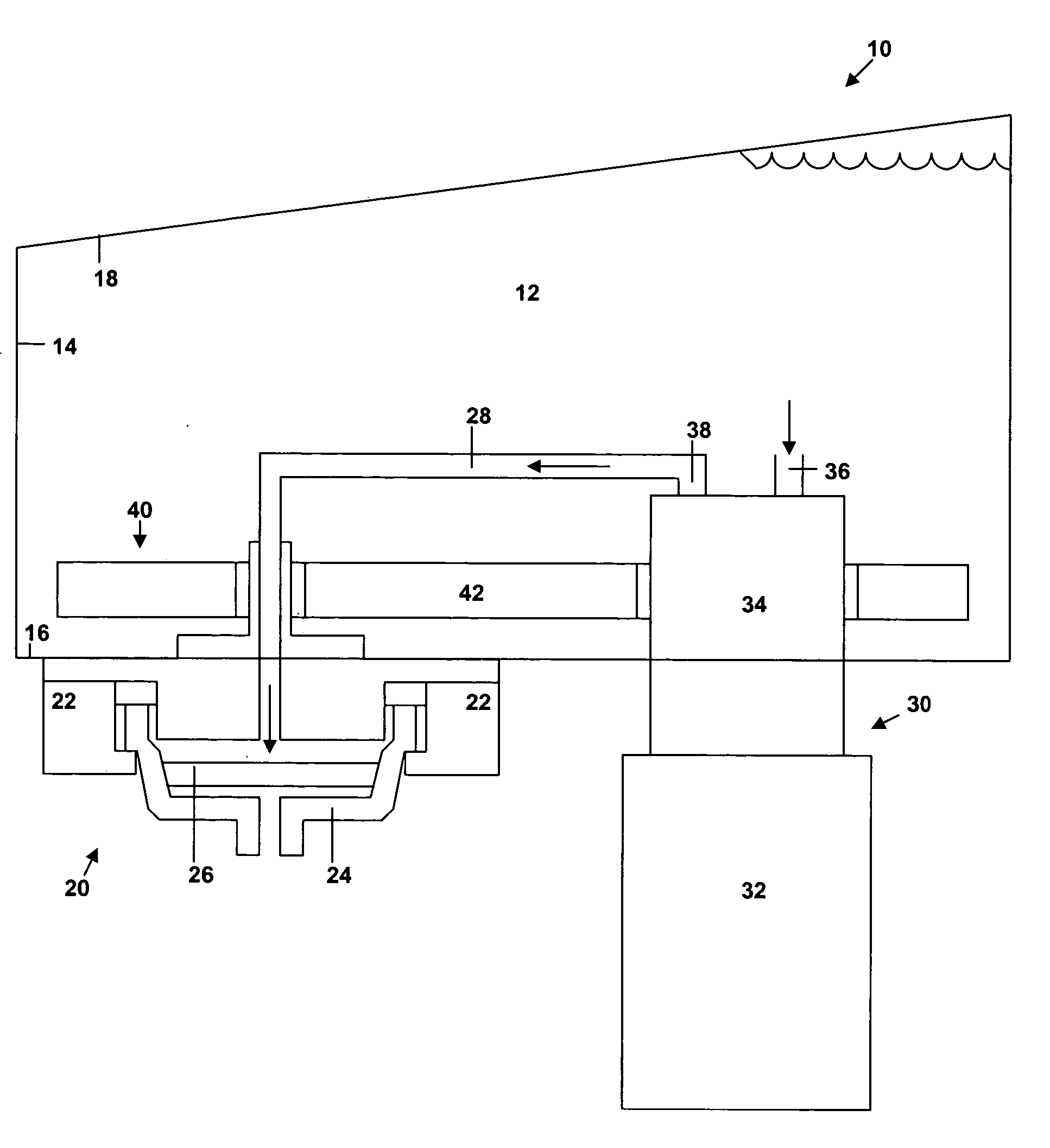

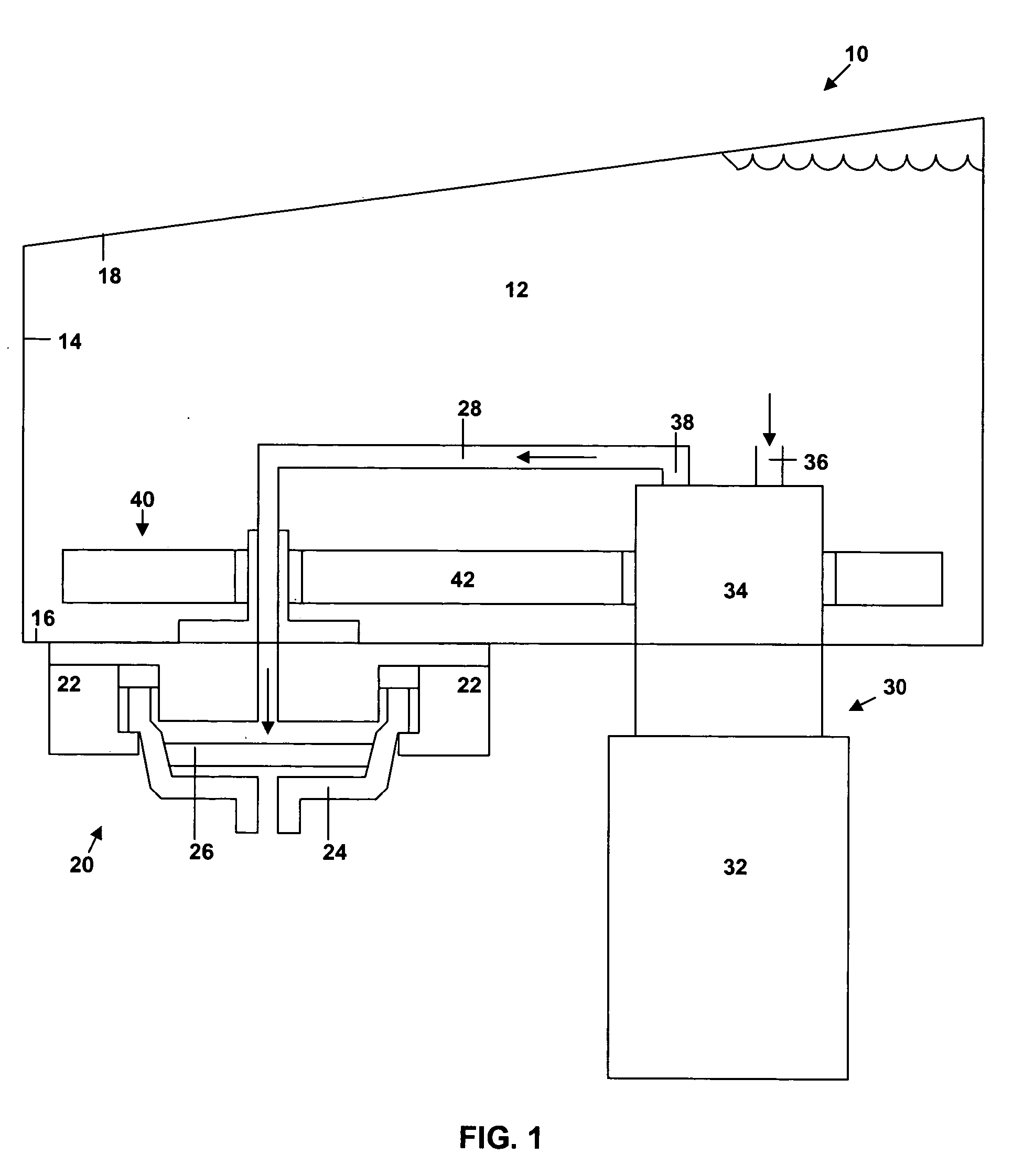

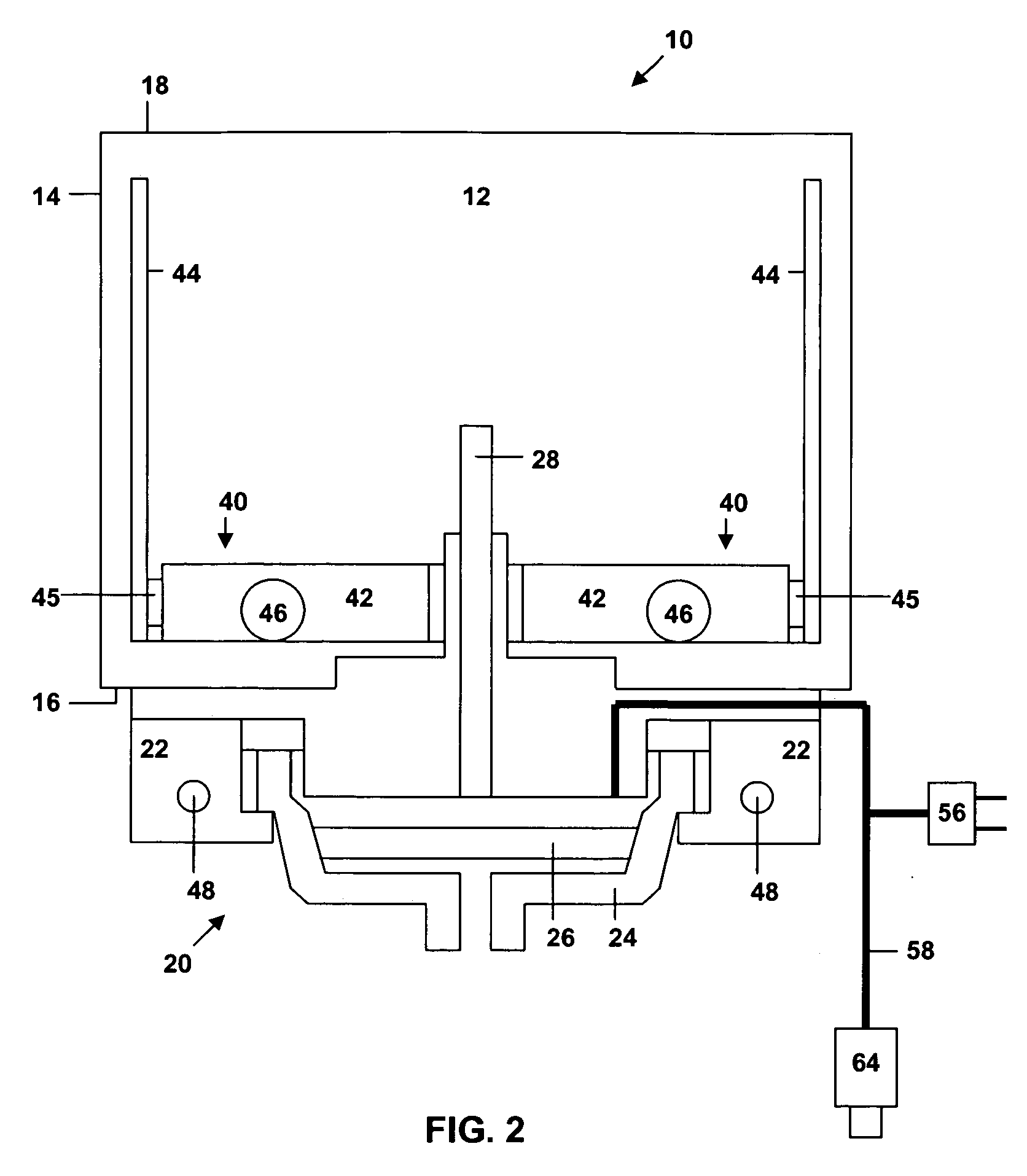

Transportable pumping unit and method of fracturing formations

InactiveUS20060260331A1Increase chanceReduced operating requirementsNon-pressured vesselsPumpsCombustorControl system

A high capacity pumper for liquefied gas incorporates multiple pumping systems distributed in a parallel arrangement and in opposing orientation on a transportable platform such as a trailer. Vaporizers incorporate a burner control system utilizing a primary set of burners operating a baseline and a secondary set of burners providing fine regulating control. A system for fracturing formations is now possible using a minimum number of components including the high capacity pumper, a coiled tubing rig and a source of liquefied gas. An improved manifold for a cryogenic plunger pump includes unions and angled connectors between a supply conduit and each of a plurality of pump heads.

Owner:CENTURY OILFIELD SERVICES

Surgical cassette having an aspiration pressure sensor

A cassette having a molded flow channel contained on an elastomeric sheet that is bonded or mechanically attached to a rigid substrate. The flow channel projects outwardly from the exterior of the cassette so that a peristaltic pump having pump head rollers mounted radially from the axis of rotation of the pump motor compress the elastomeric flow channels against the rigid substrate during operation.

Owner:ALCON INC

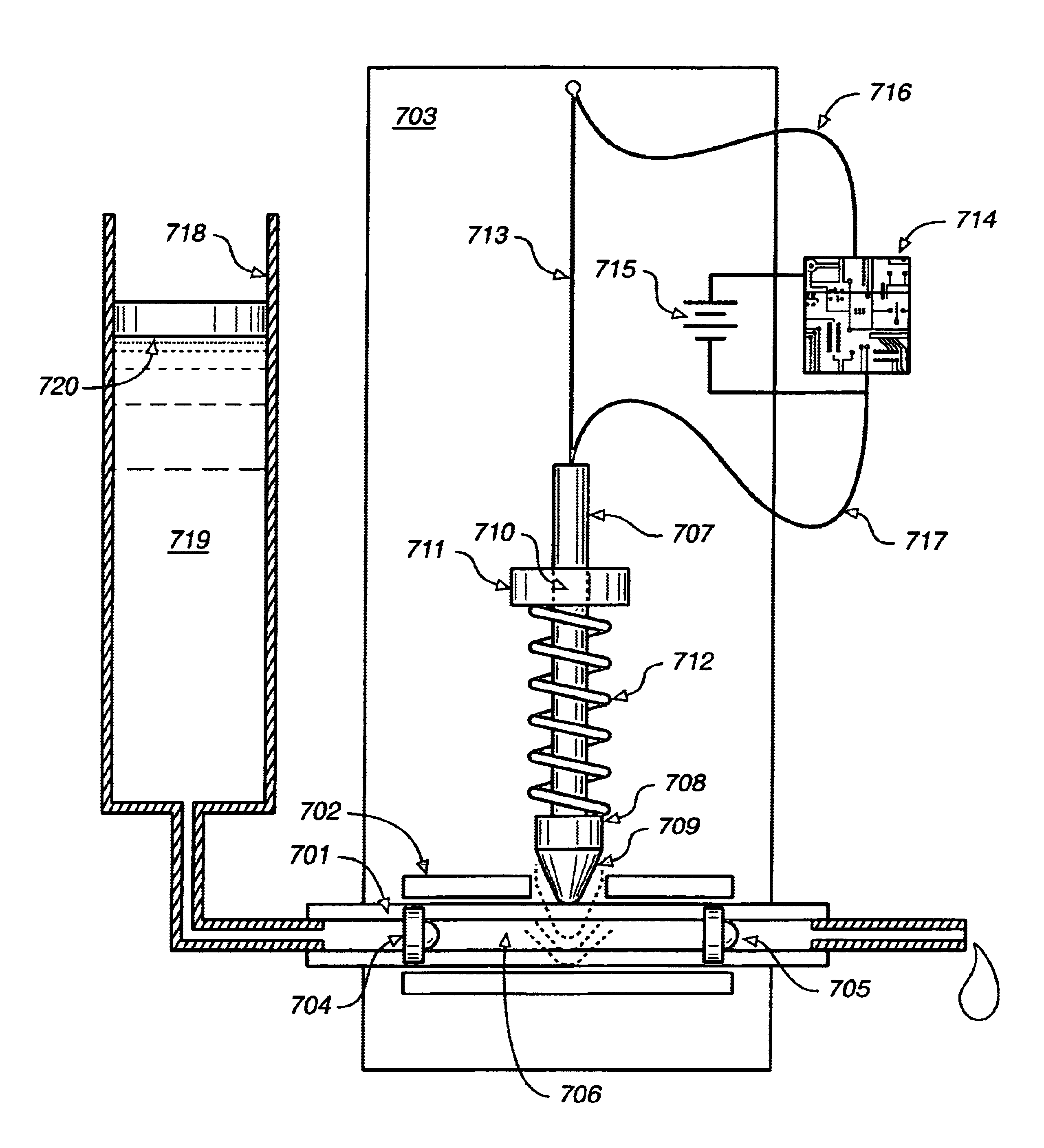

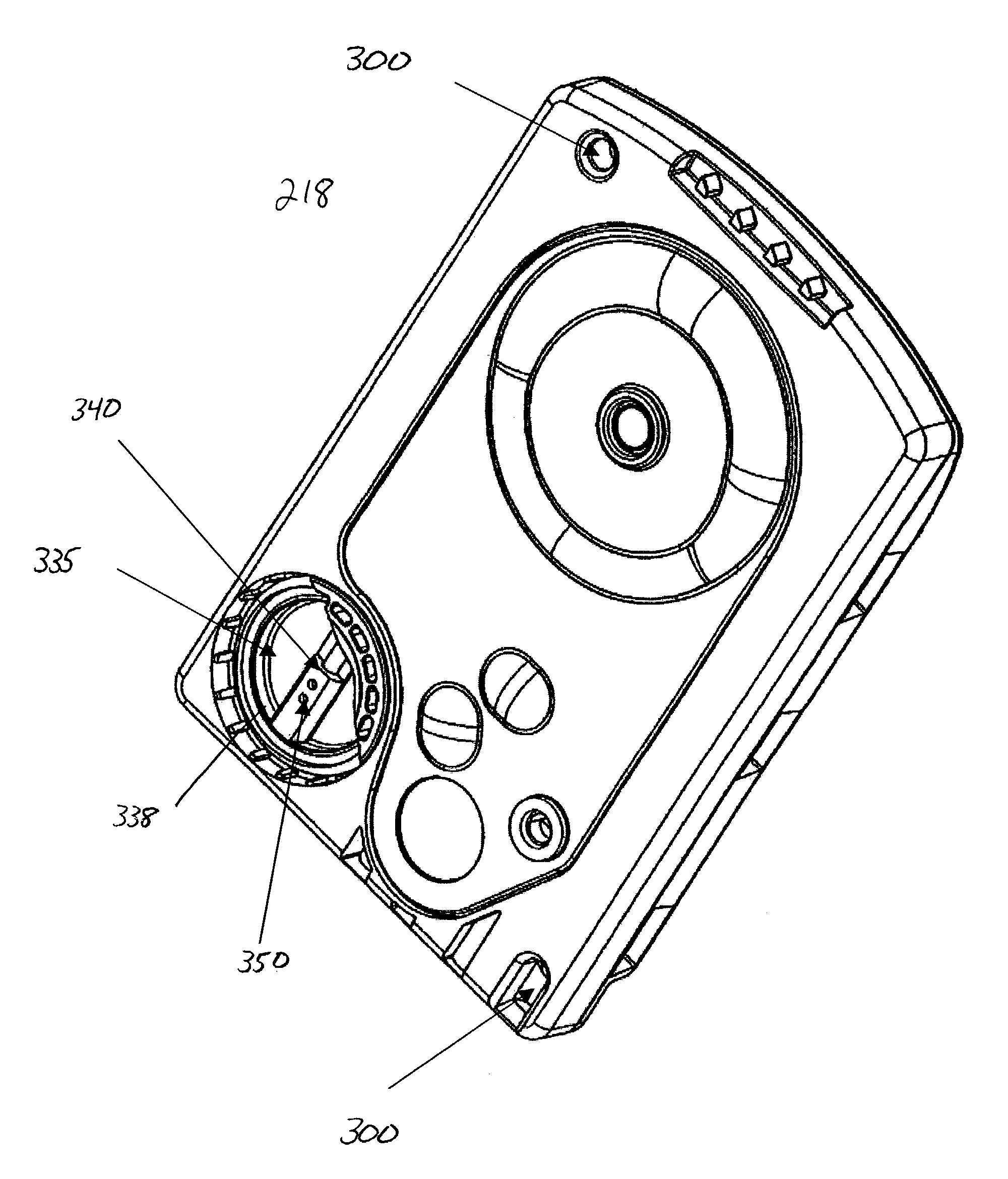

Fluid delivery device, system and method

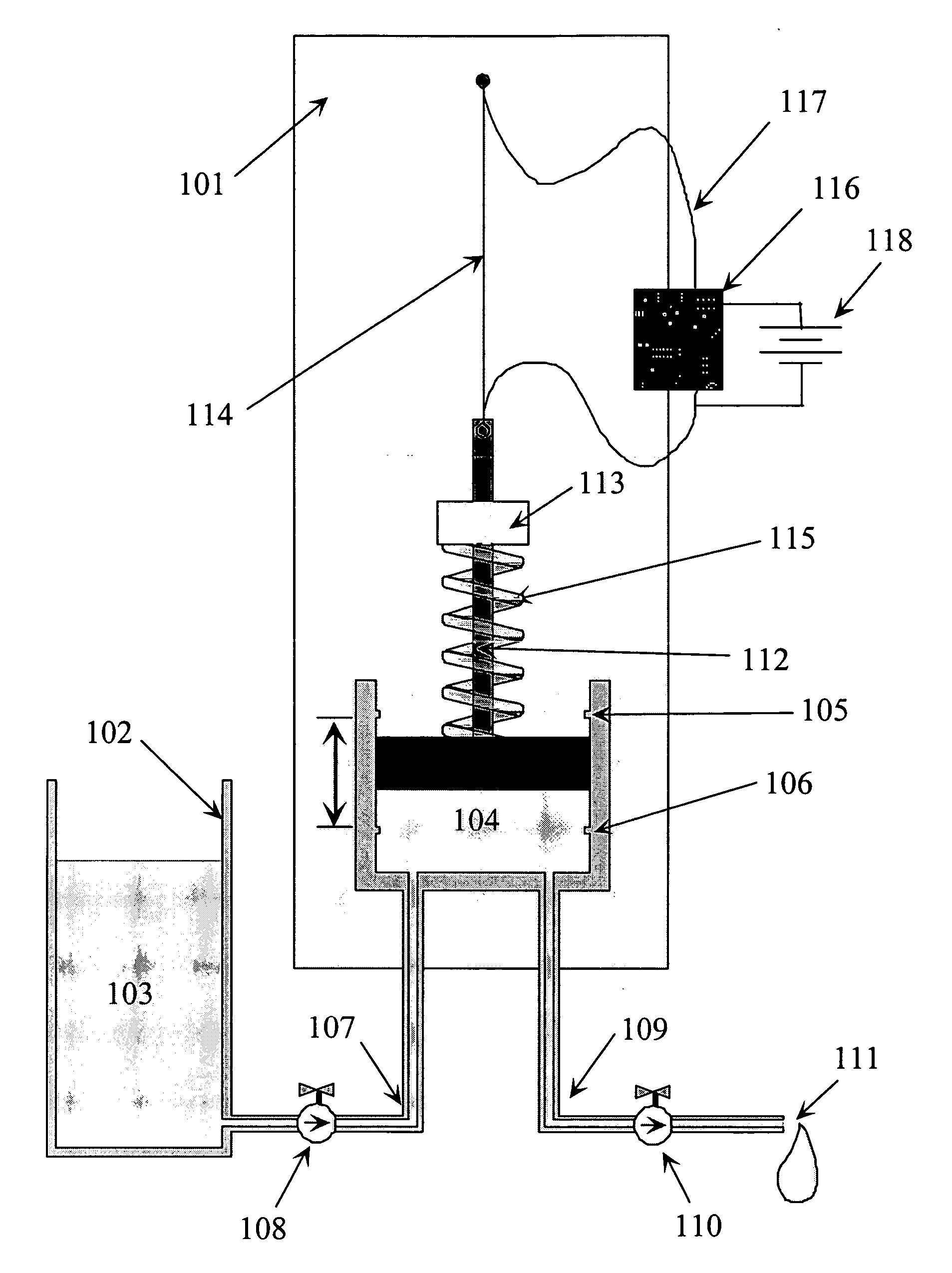

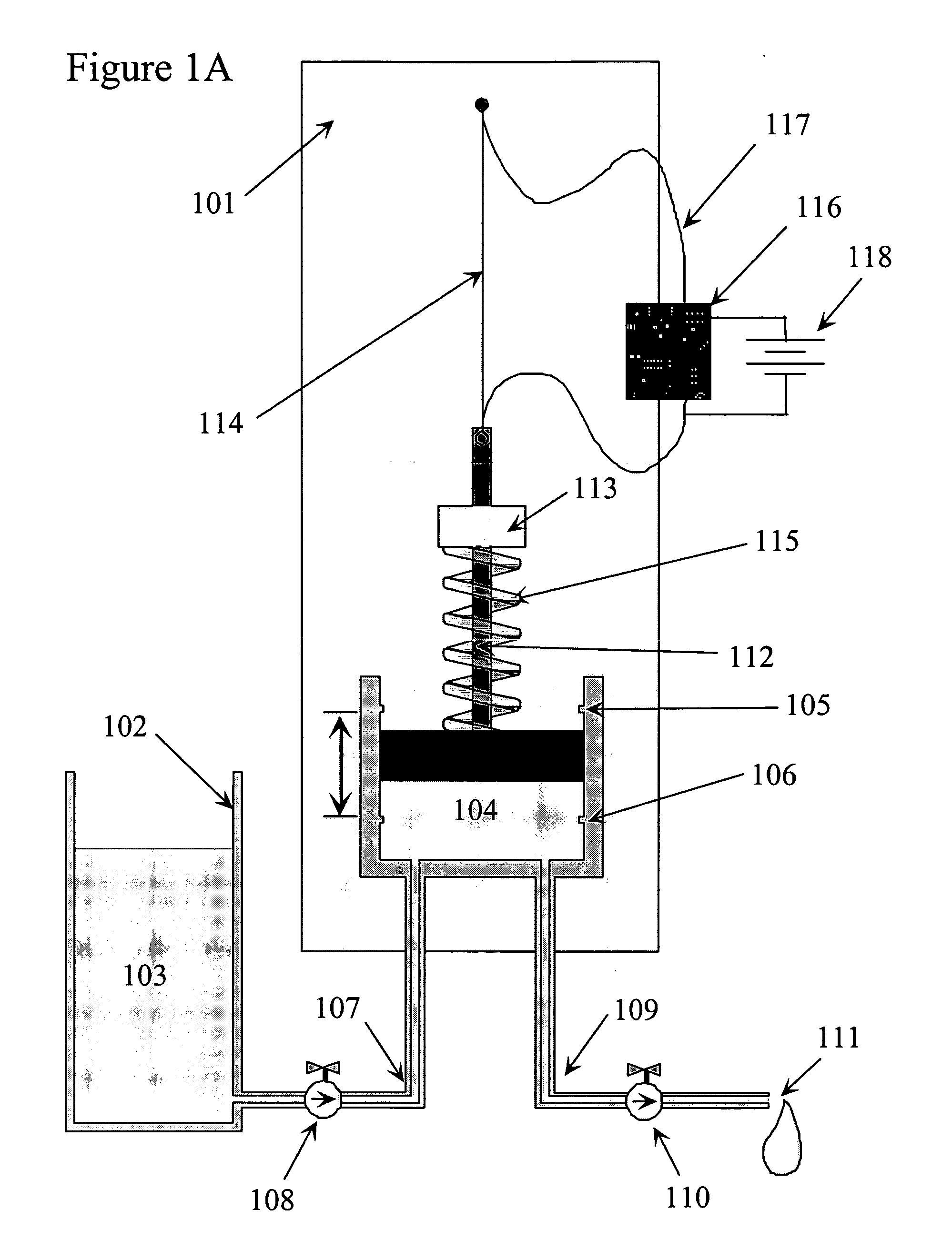

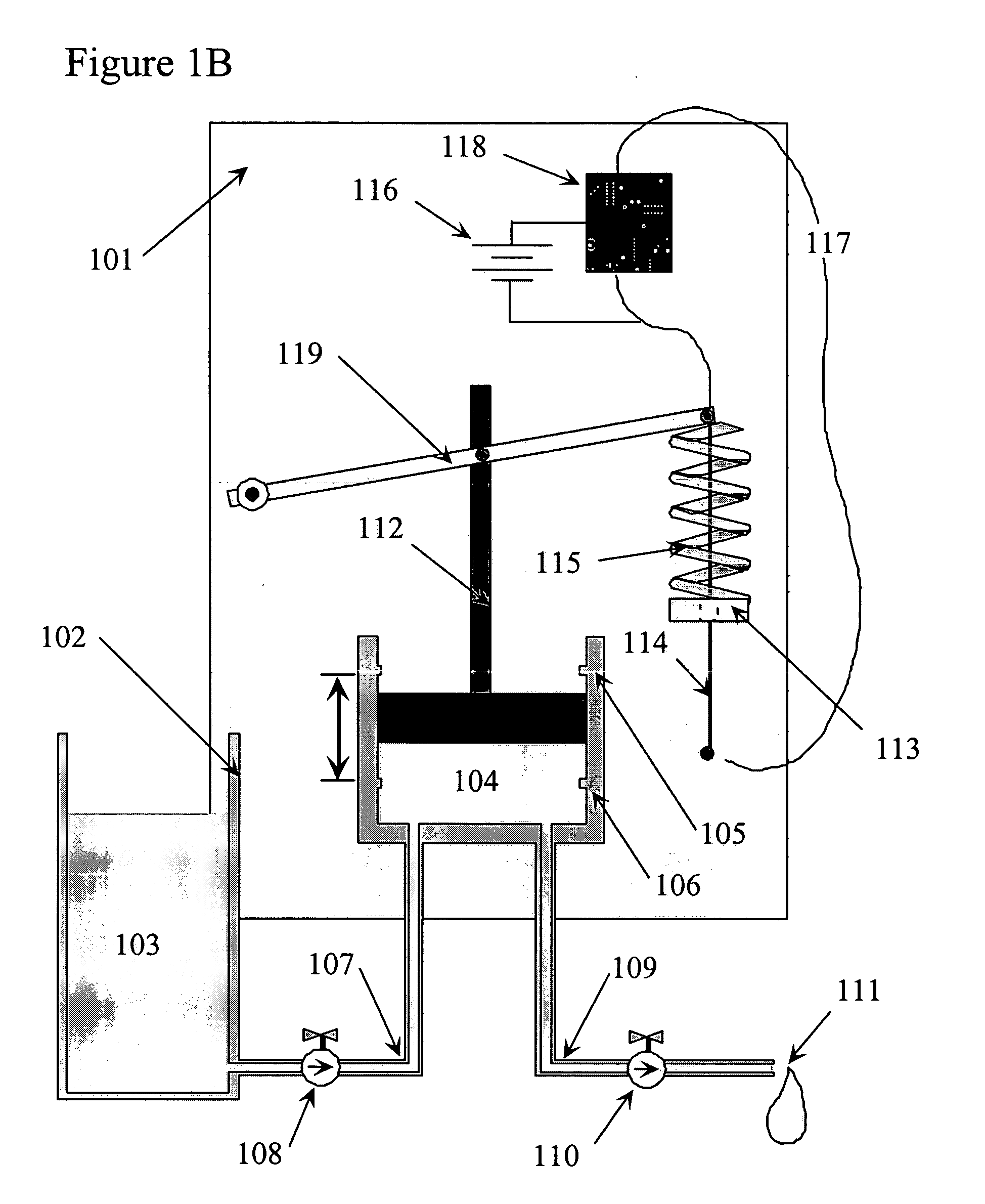

ActiveUS20040115067A1Low costSmall sizeTesting/calibration apparatusVolume/mass flow measurementShape-memory alloyAlloy

A system for the metering and delivery of small discrete volumes of liquid is comprised of a small or minimal number of inexpensive components. One such component is a movable member, such as a miniature precision reciprocating displacement pump head, which is driven by an actuator that comprises a shape memory alloy material. The operating mechanism of the system is of little or minimal complexity. The system facilitates the precise metering and delivery of the small discrete volumes of liquid. Potential applications for the system include subcutaneous, long-term, automated drug delivery, for example, the delivery of insulin to a person with diabetes. In such an application, the small, simple and inexpensive nature of the invention would allow for its use as both a portable and a disposable system.

Owner:THERASENSE

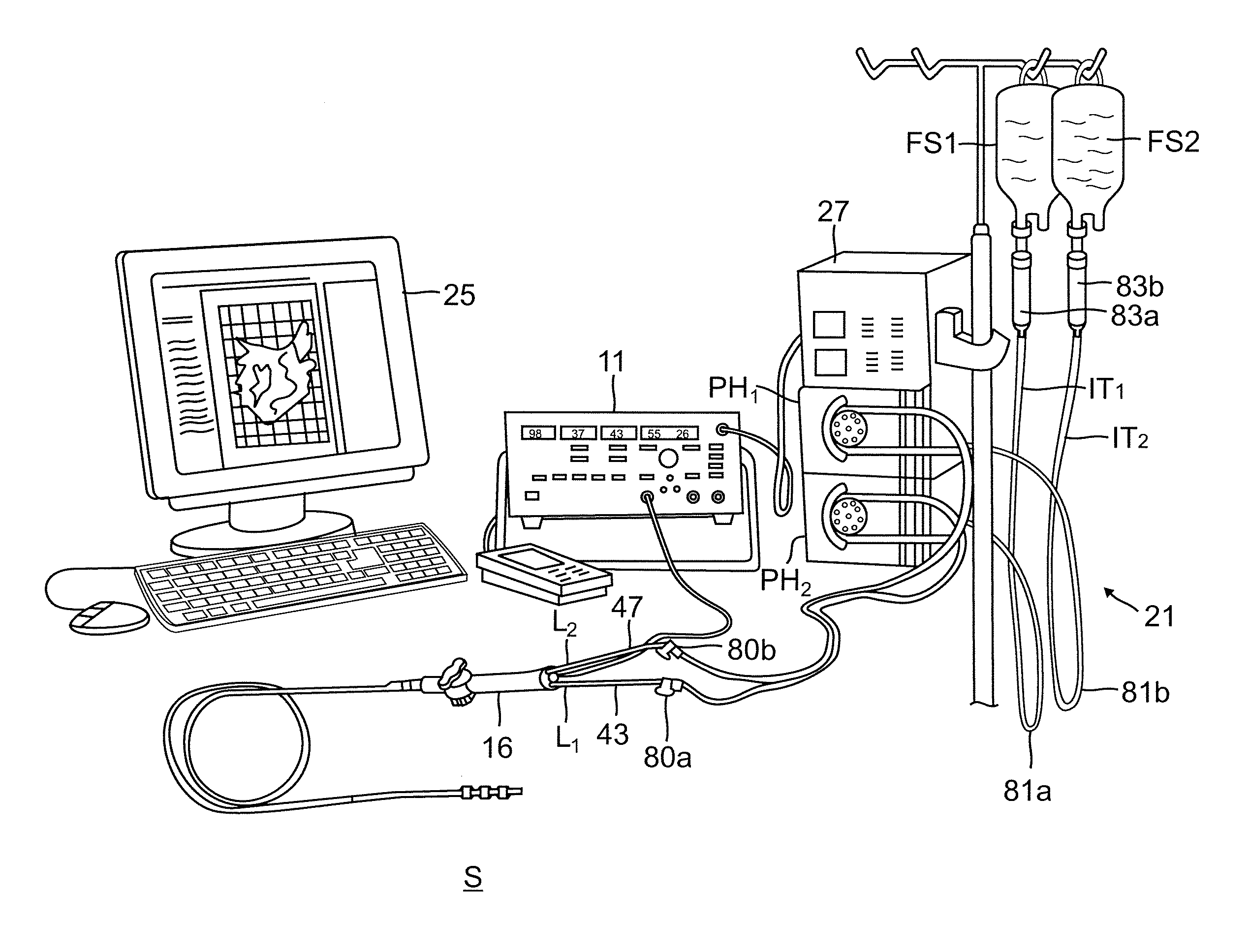

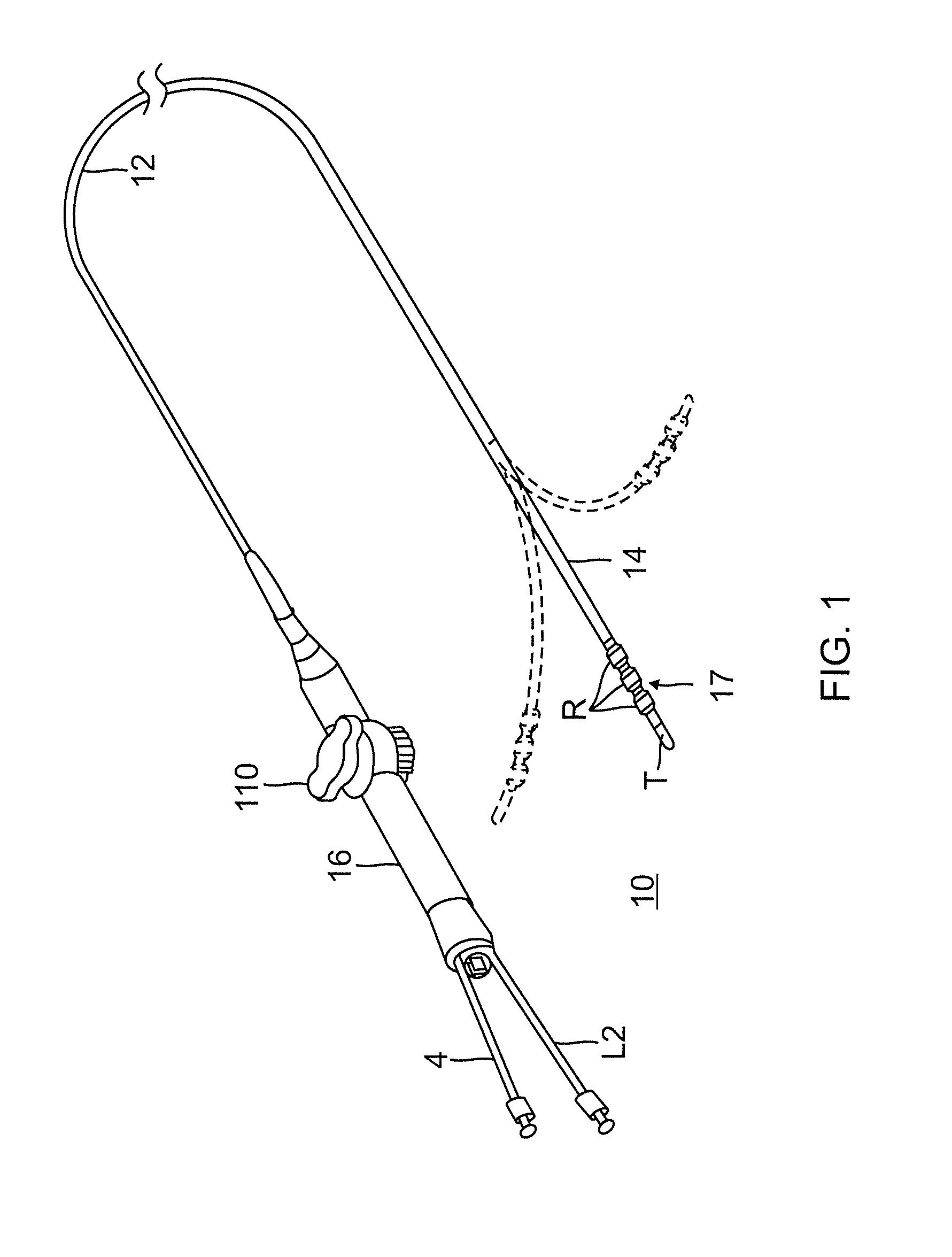

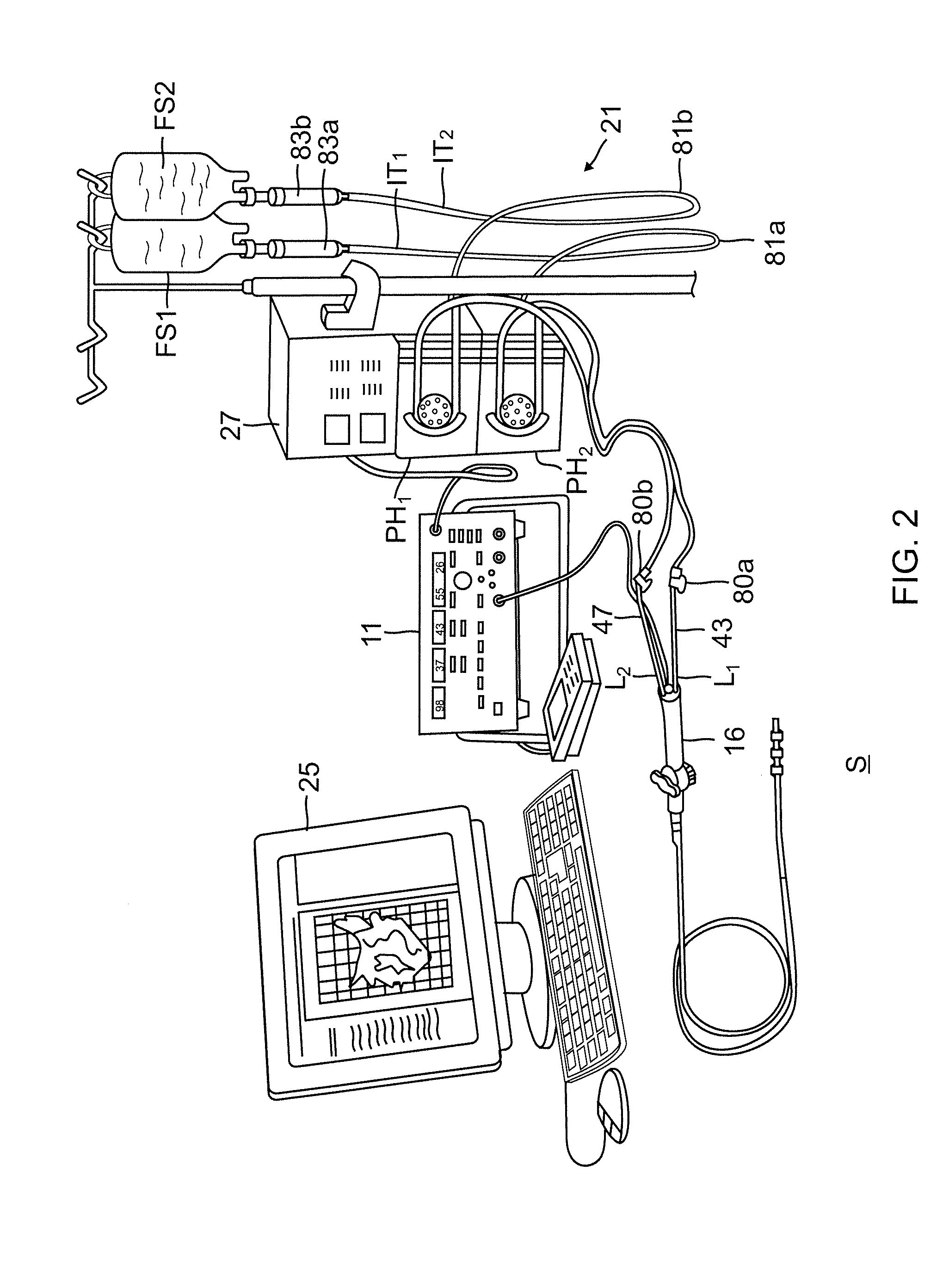

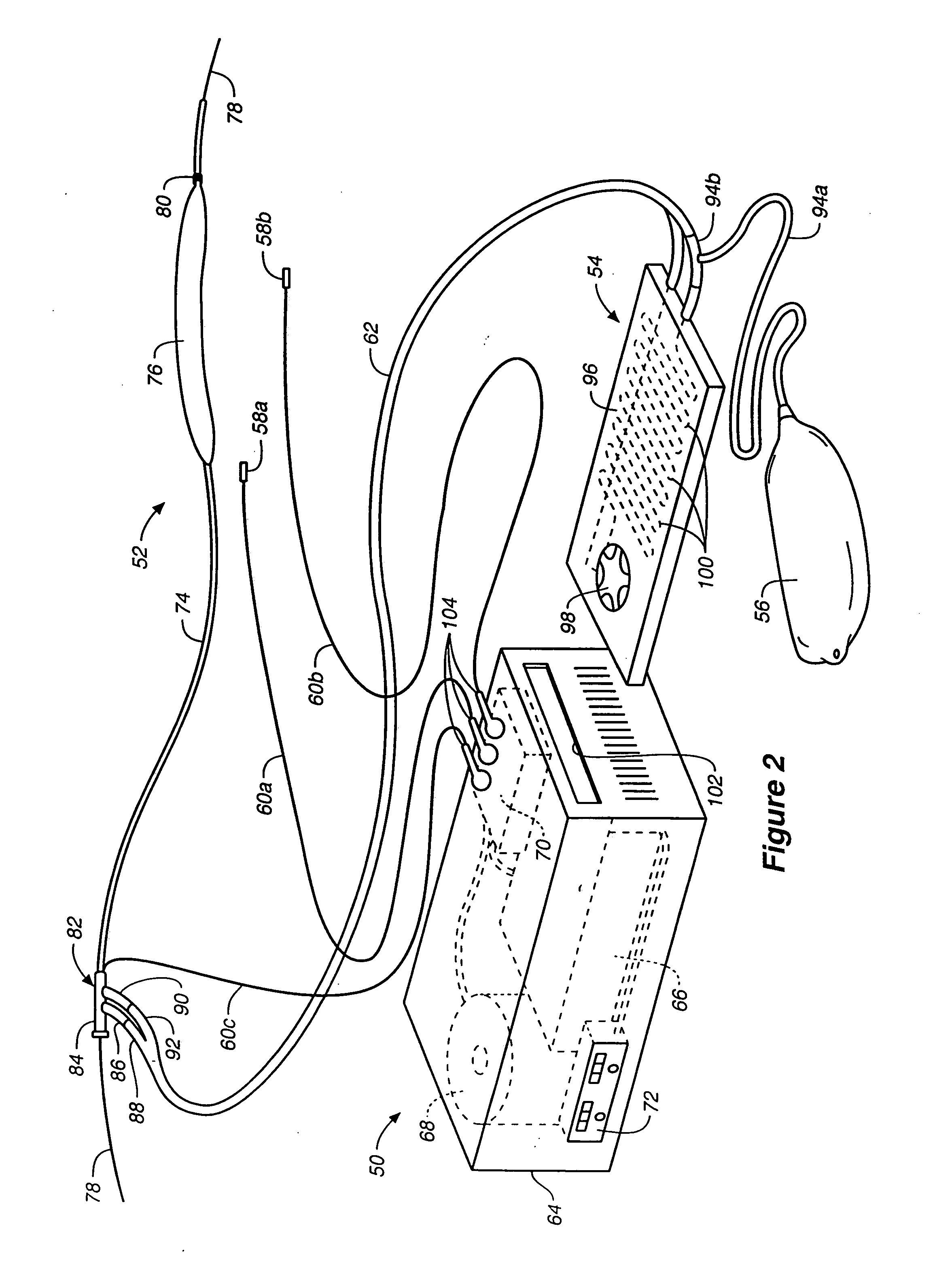

Integrated ablation system using catheter with multiple irrigation lumens

ActiveUS20130030426A1Limiting fluid loadingReduce driving stressDiagnosticsSurgical instruments for heatingPump headIrrigation fluids

A catheter adapted for ablation has multiple dedicated irrigation tubings to supply fluid to their respective electrode or set of electrodes. The tubings provide parallel flow pathways through the catheter where irrigation fluid is delivered to irrigated tip and / or ring electrodes which can accomplish uni-polar or bi-polar ablation. Such separate and dedicated fluid pathways allow fluid to be delivered to the corresponding electrode or set of electrodes at different flow rates. An integrated ablation system using such catheter has an ablation energy source and an irrigation pump with multiple pump heads that can operate independently of each other. An integrated irrigation tubing set is included to extend between the fluid source and the catheter, with each pump head being able to act on a different tubing that delivers fluid to a different electrode or set of electrodes.

Owner:BIOSENSE WEBSTER (ISRAEL) LTD

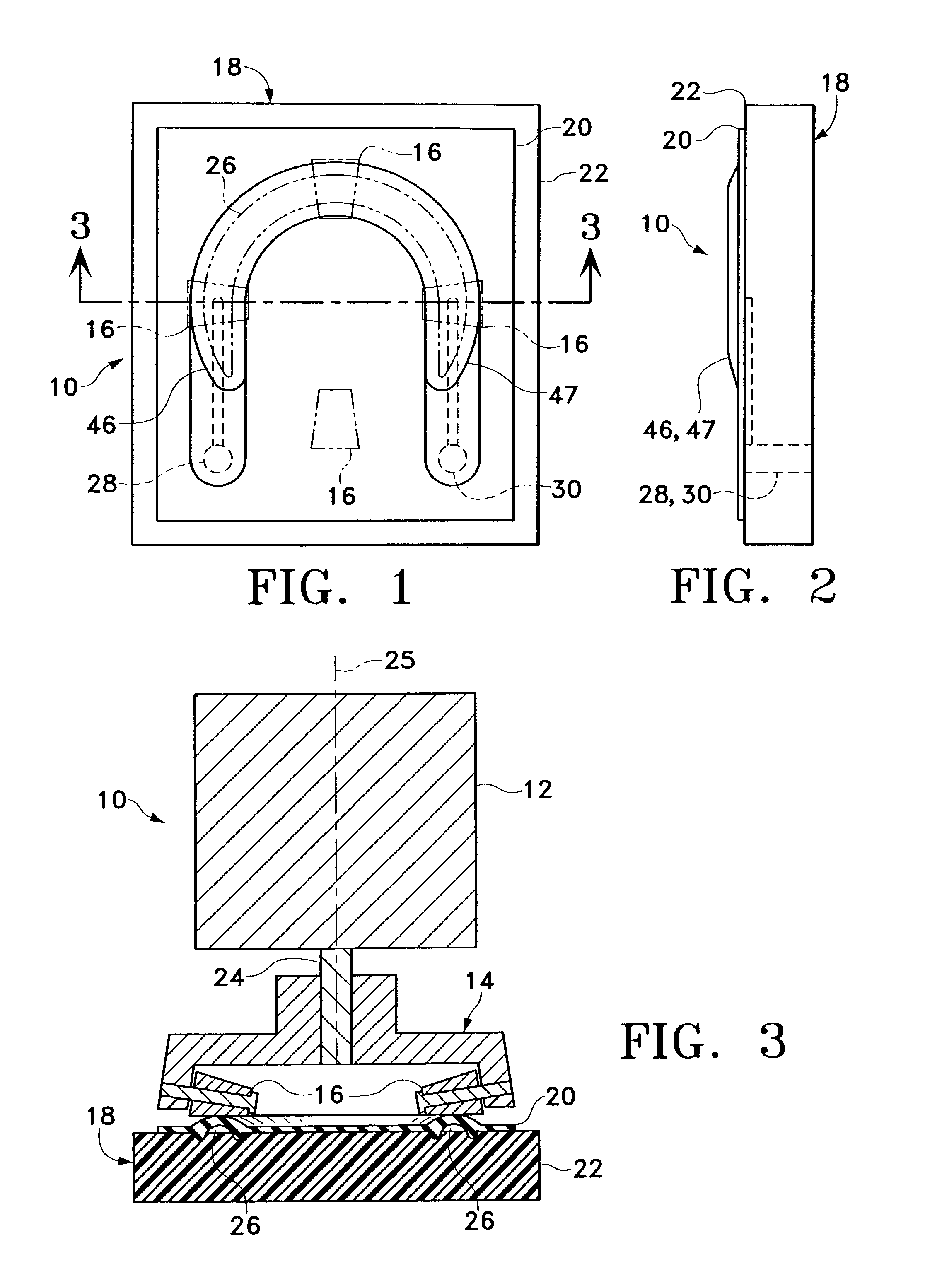

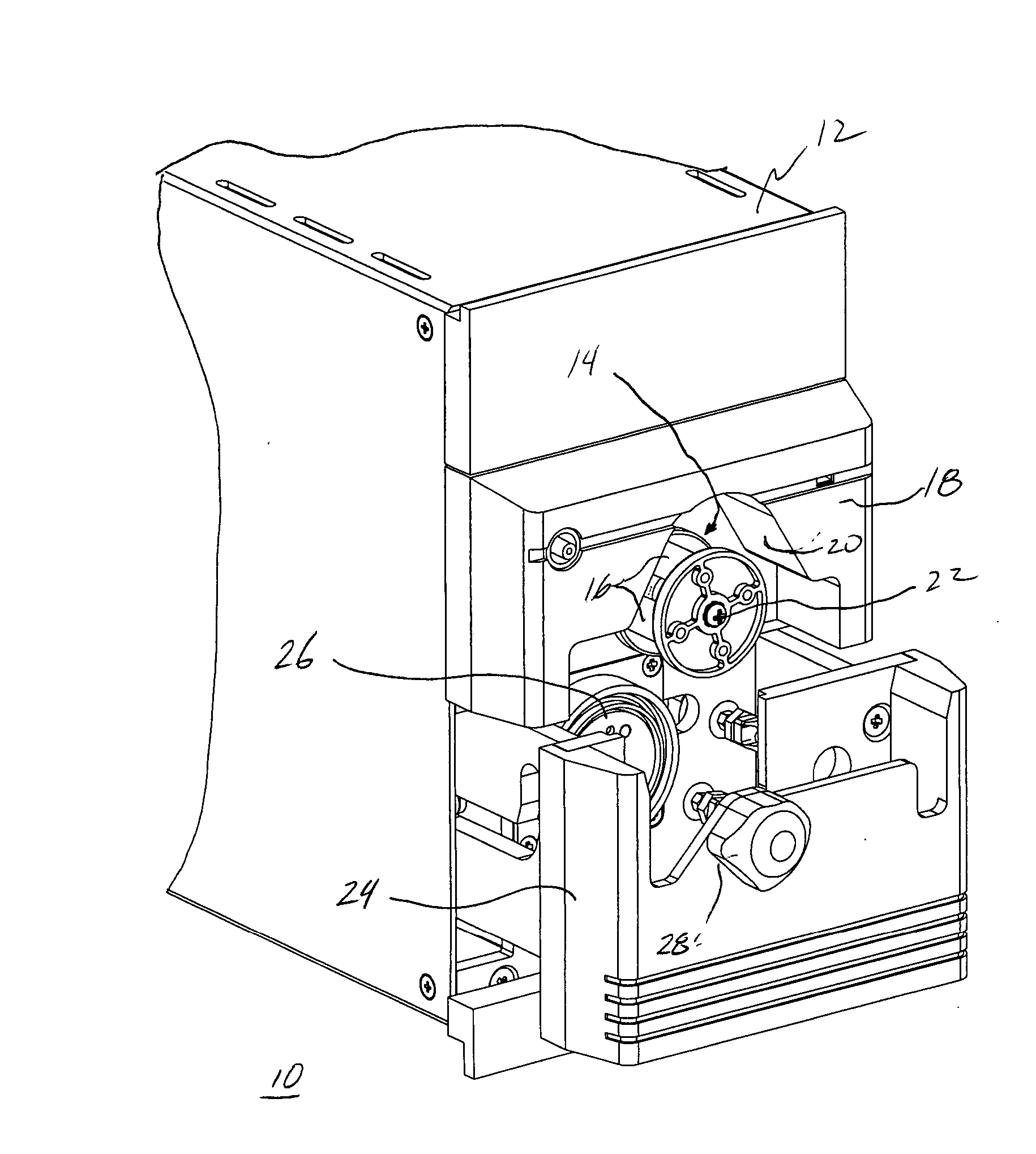

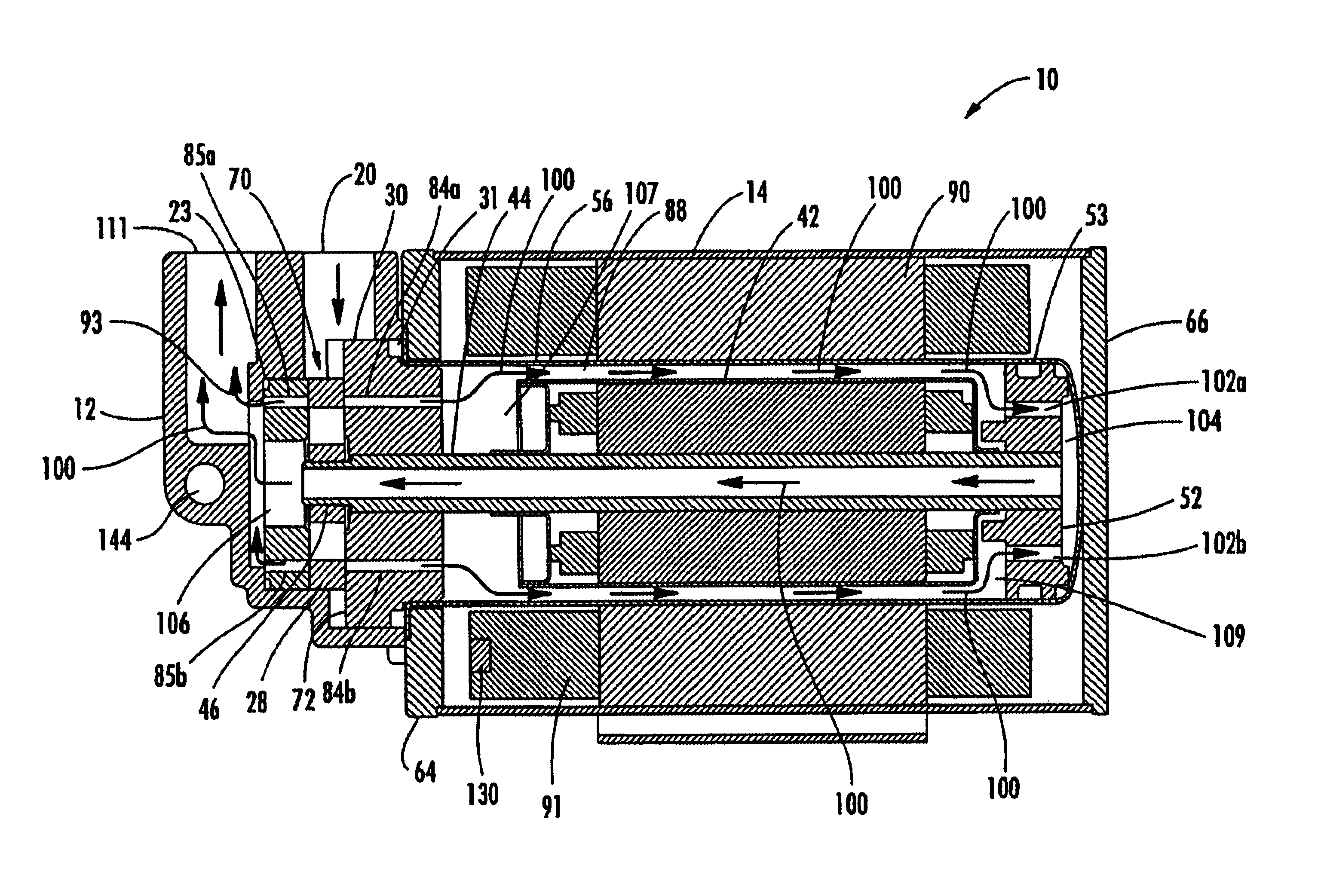

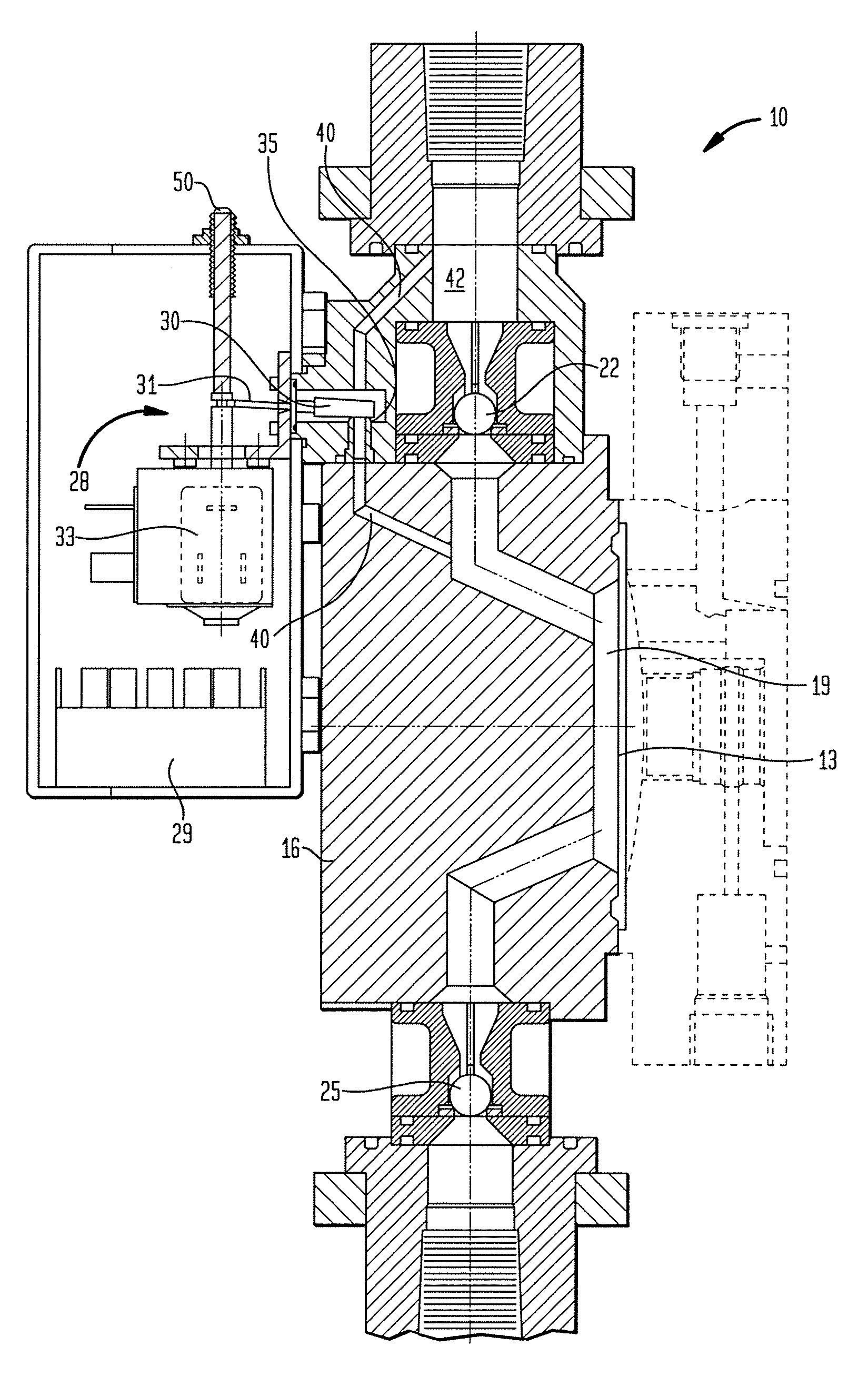

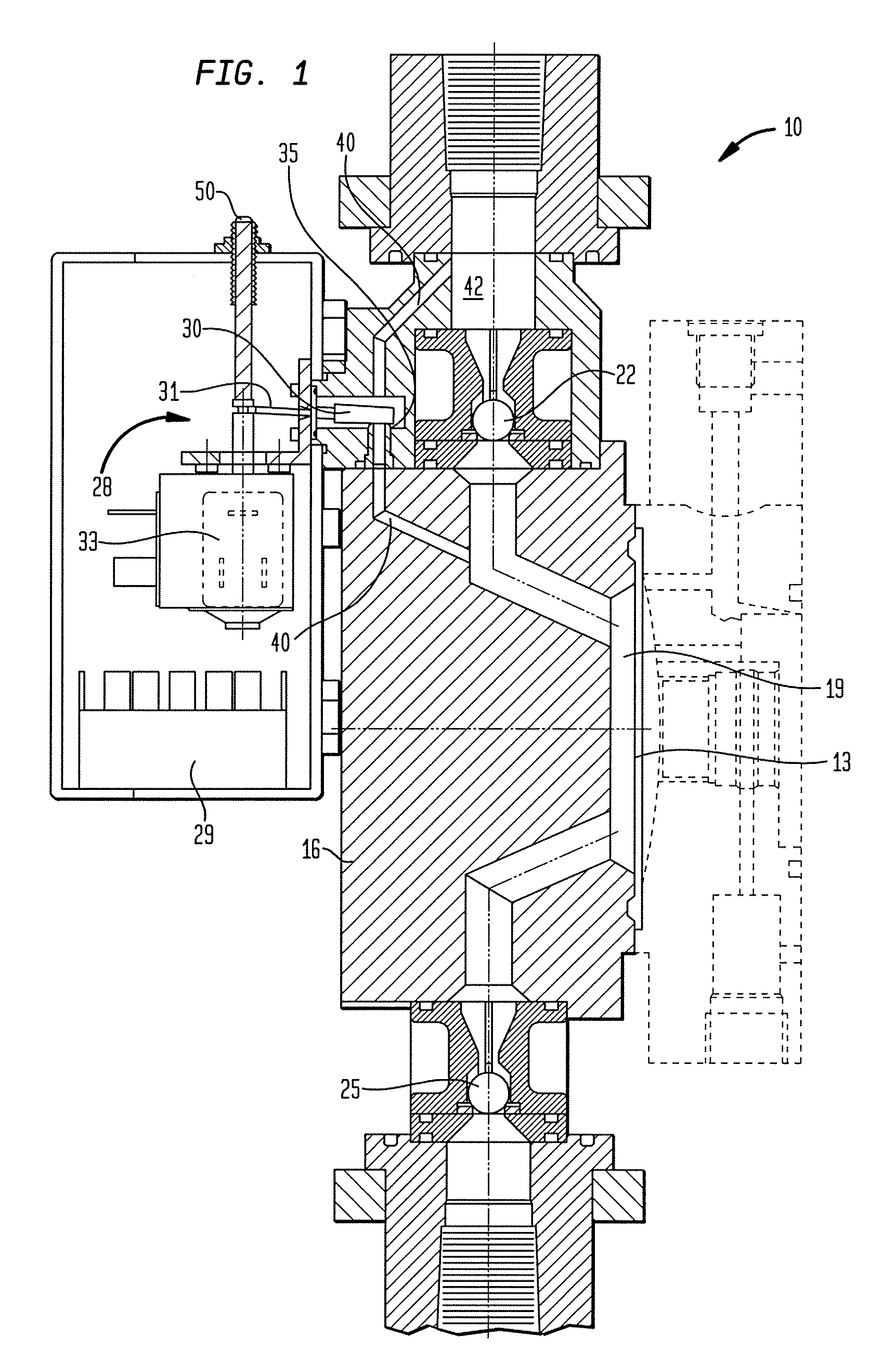

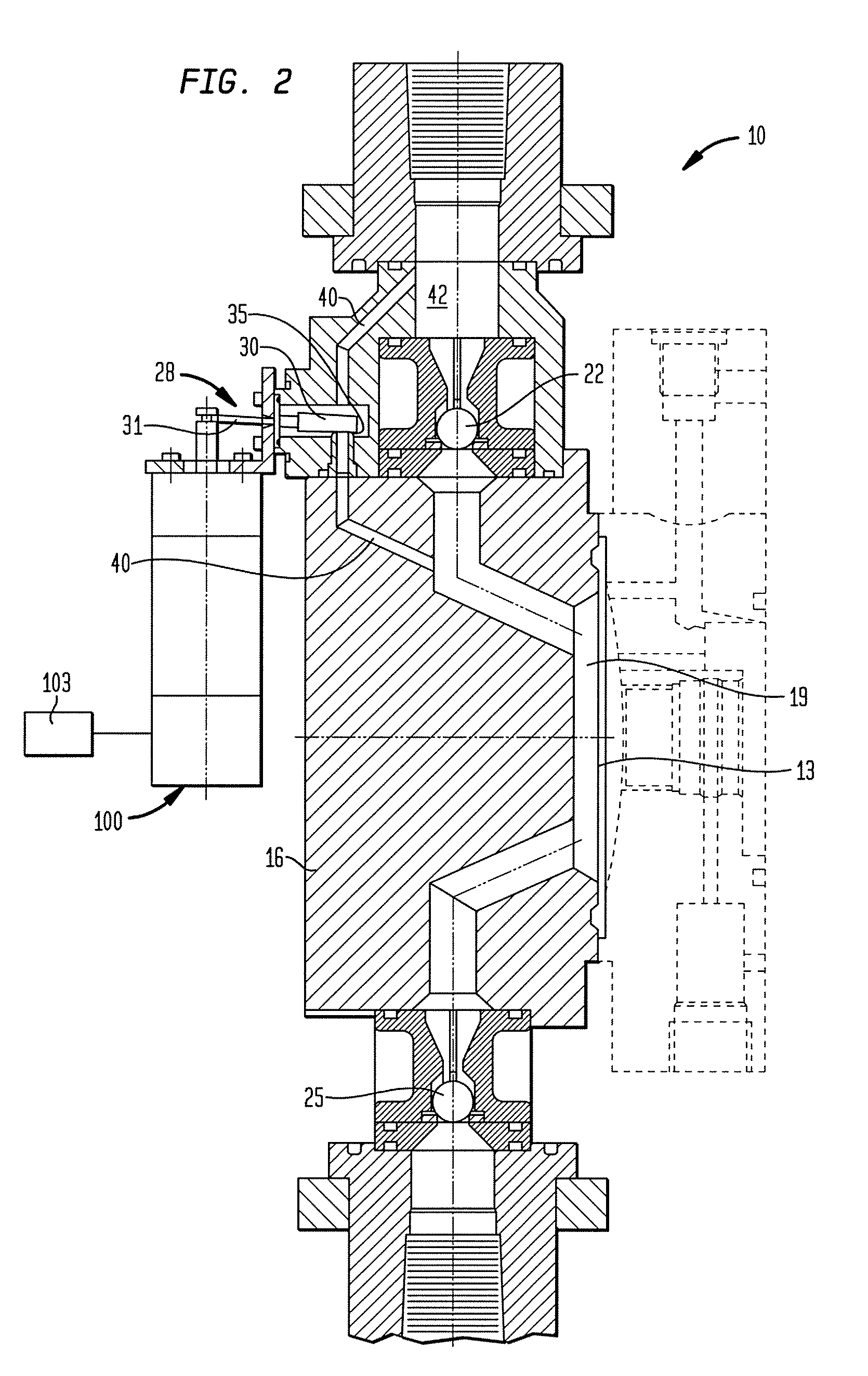

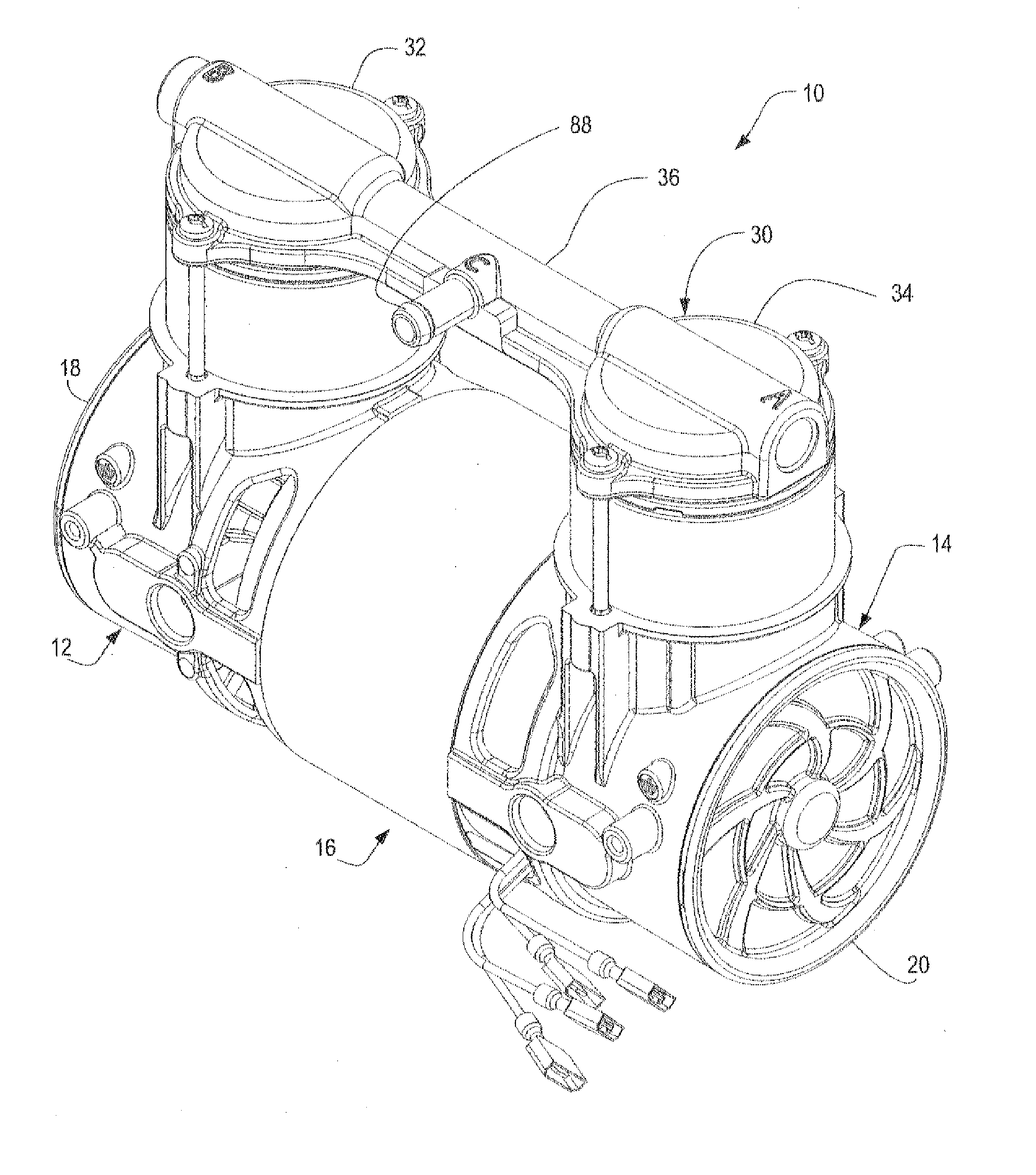

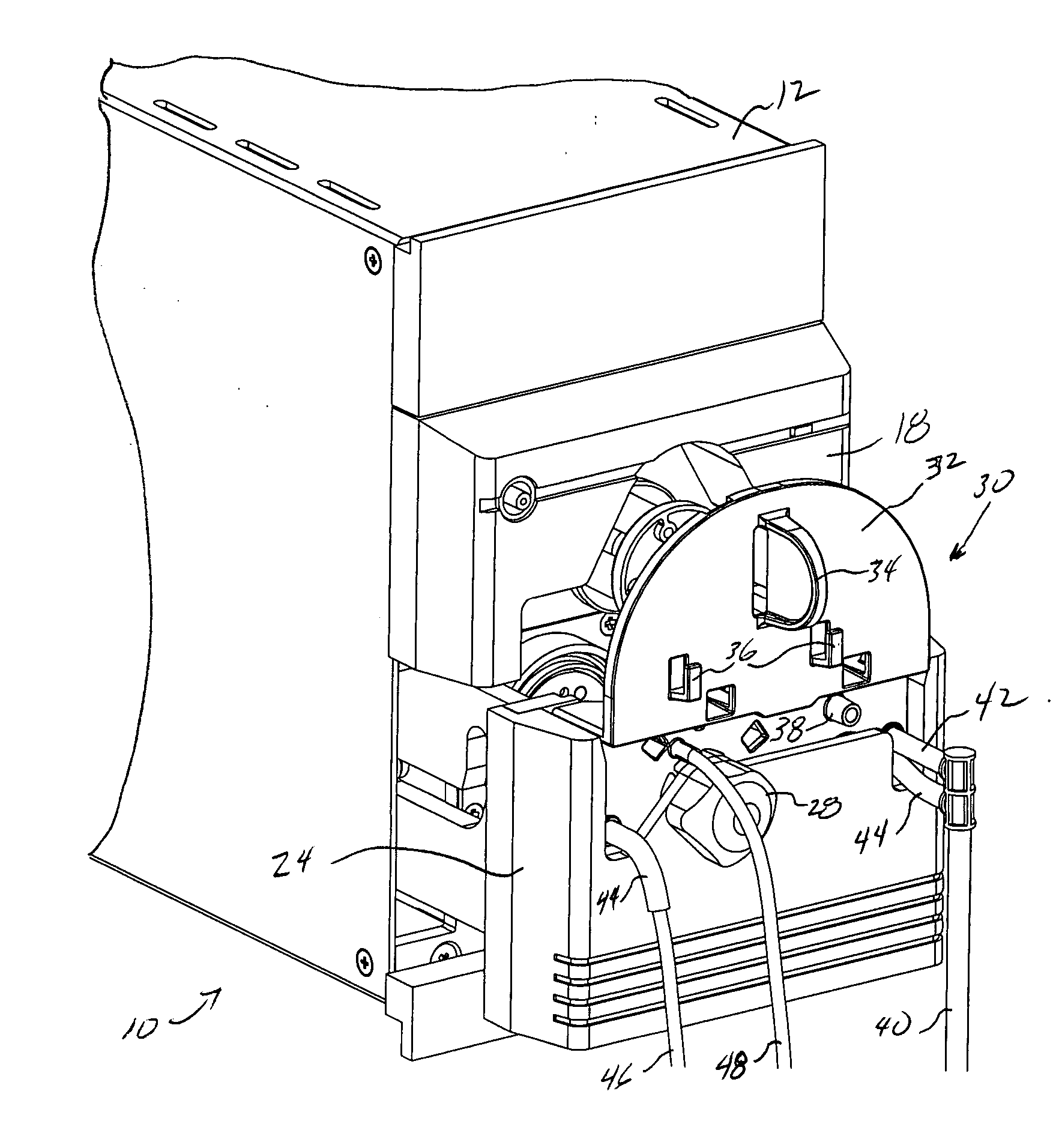

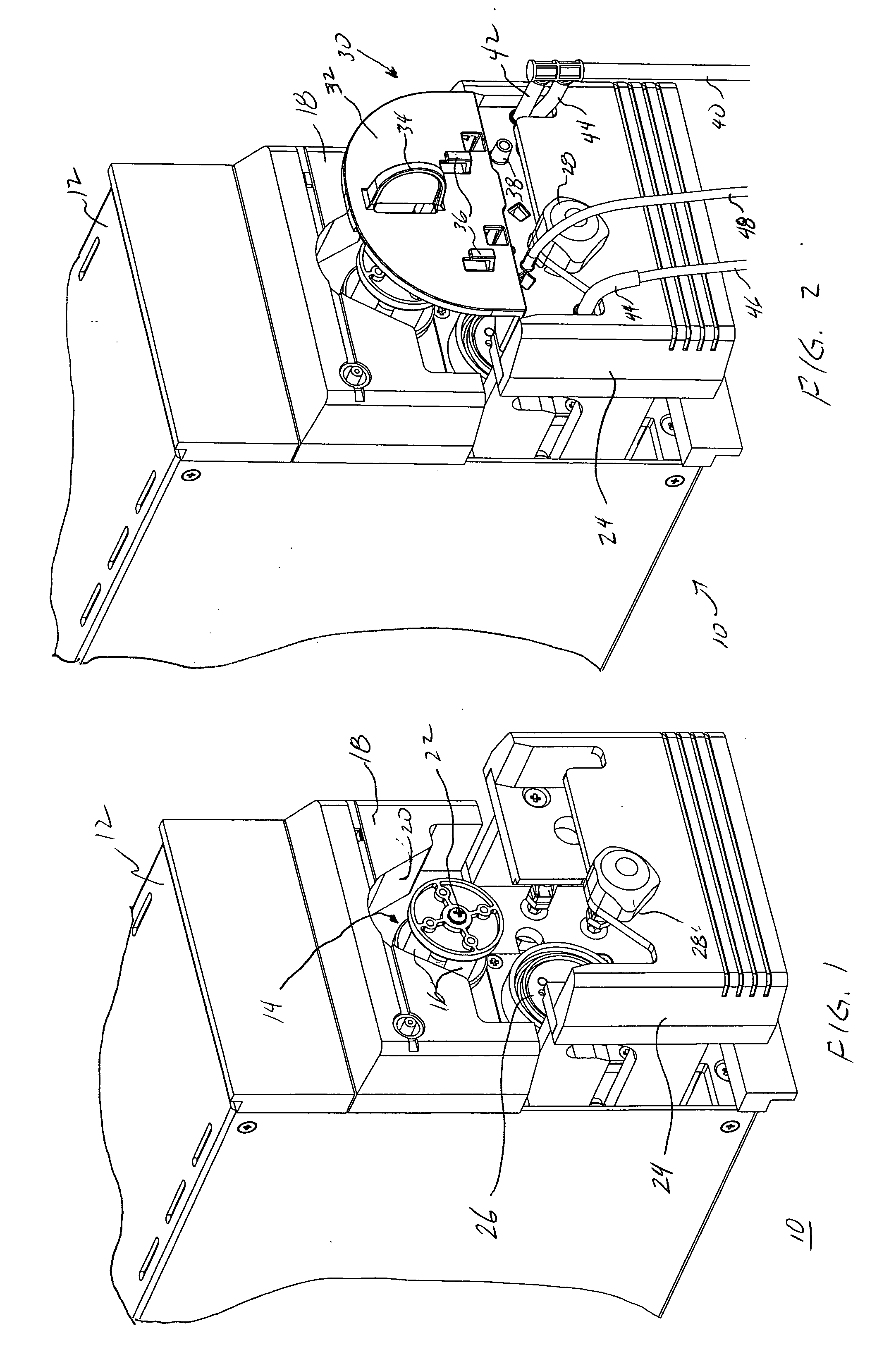

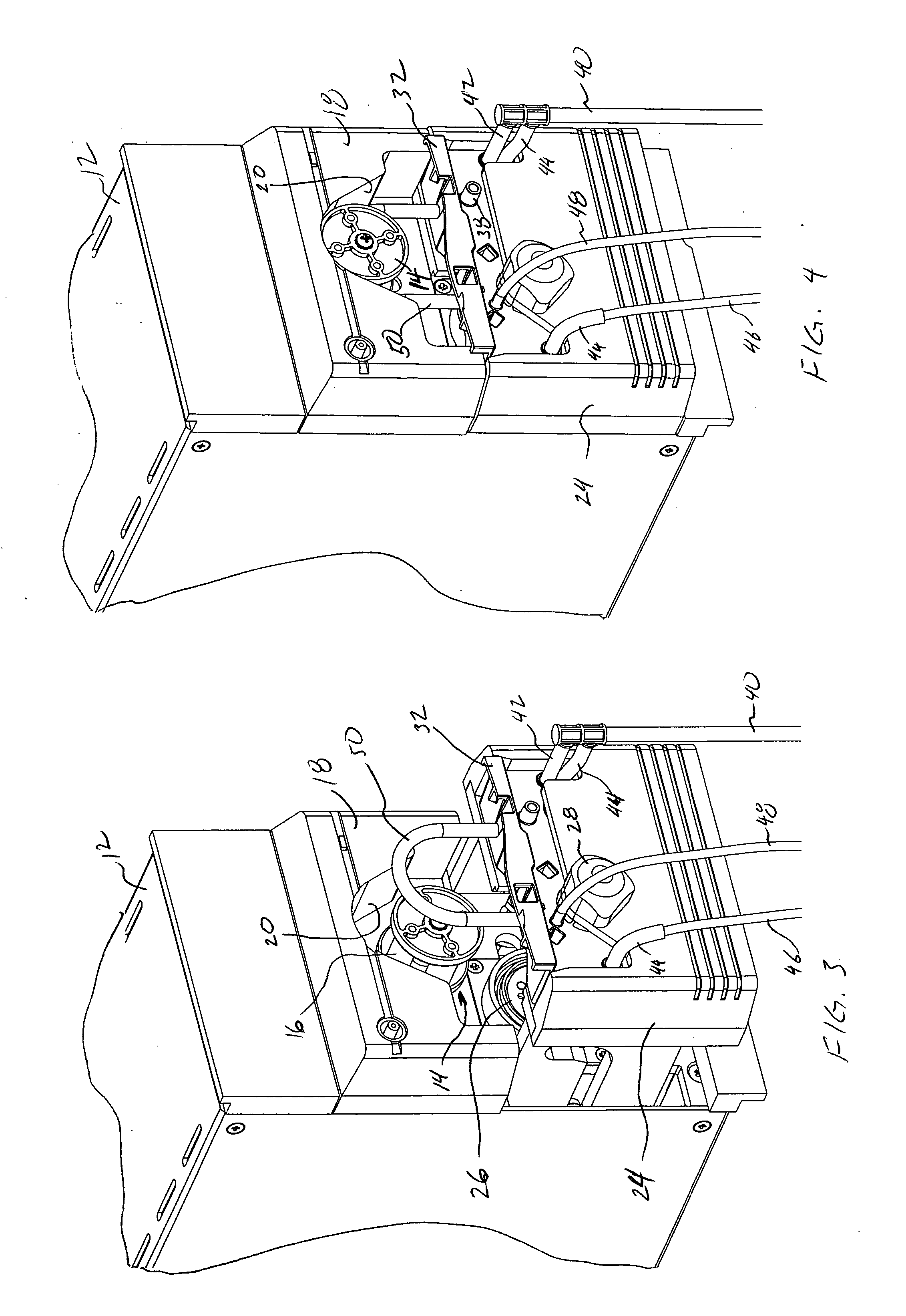

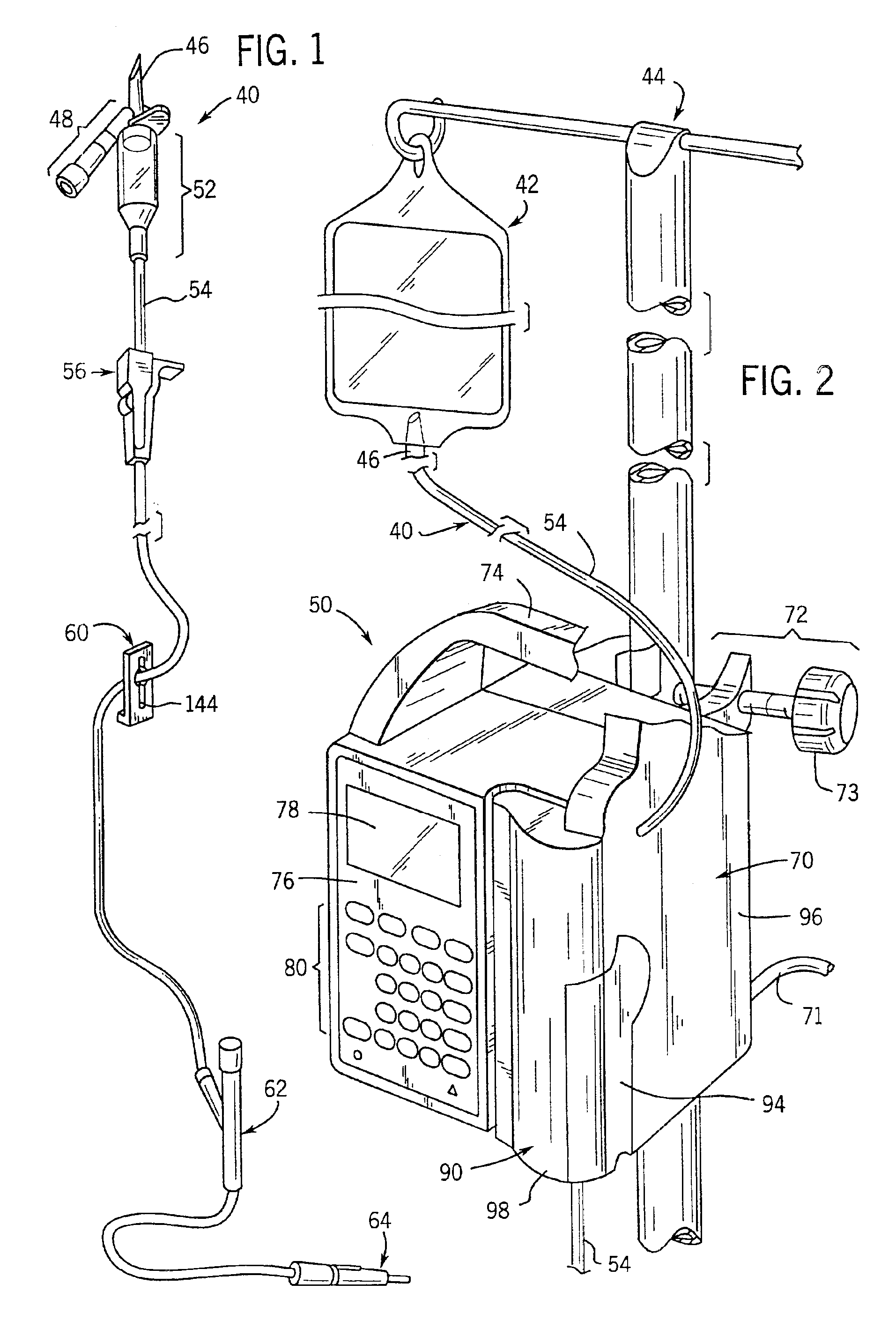

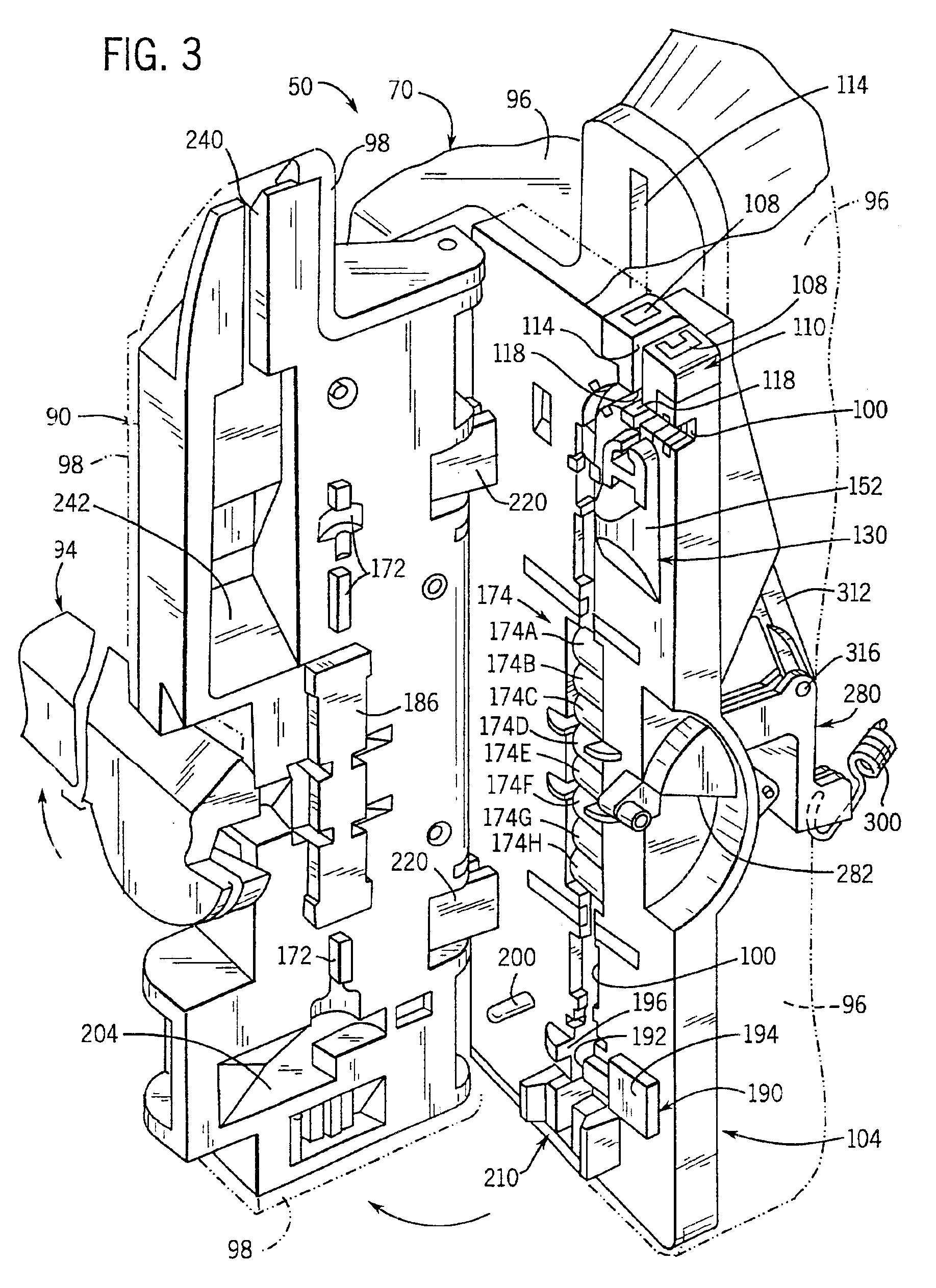

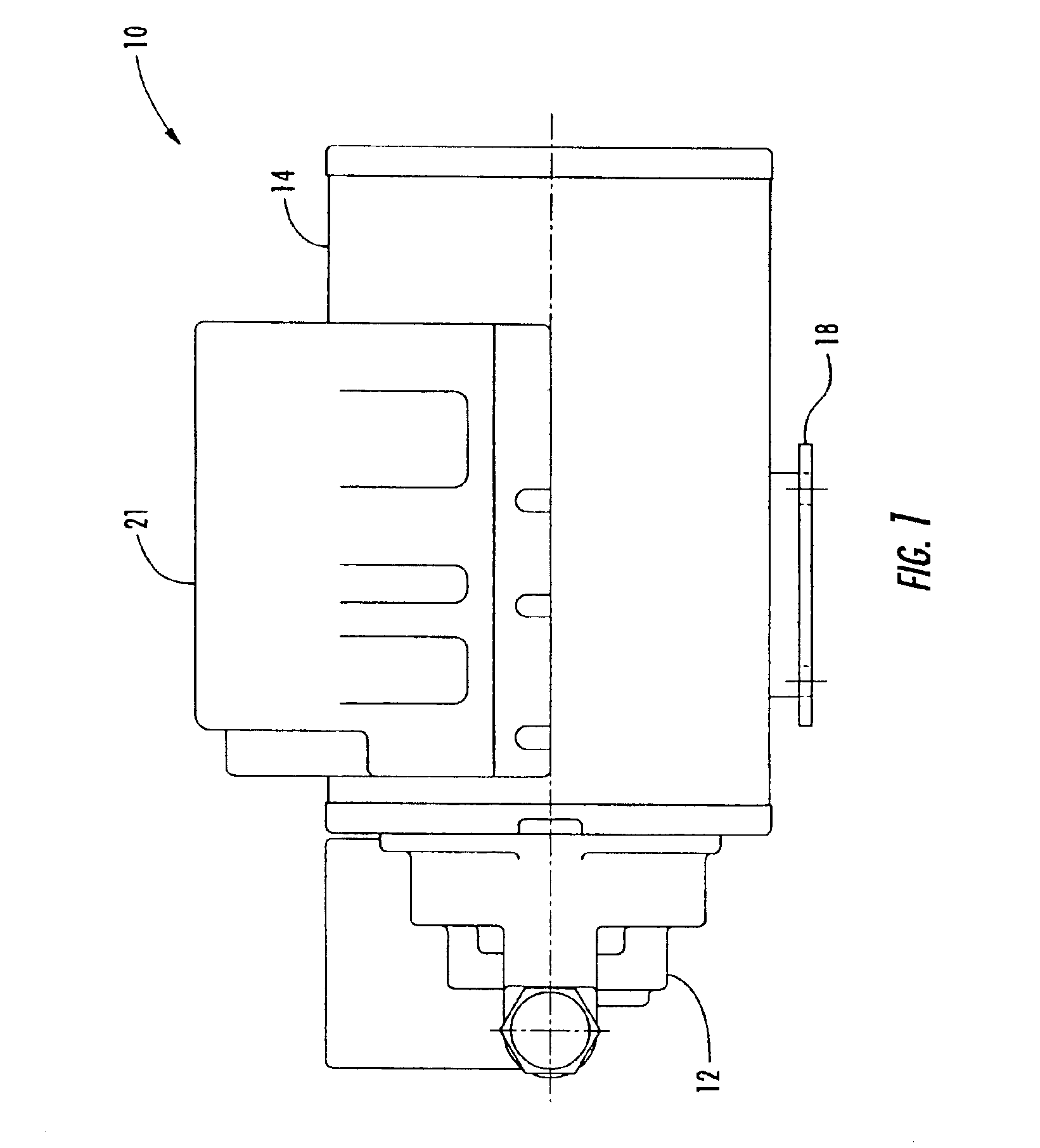

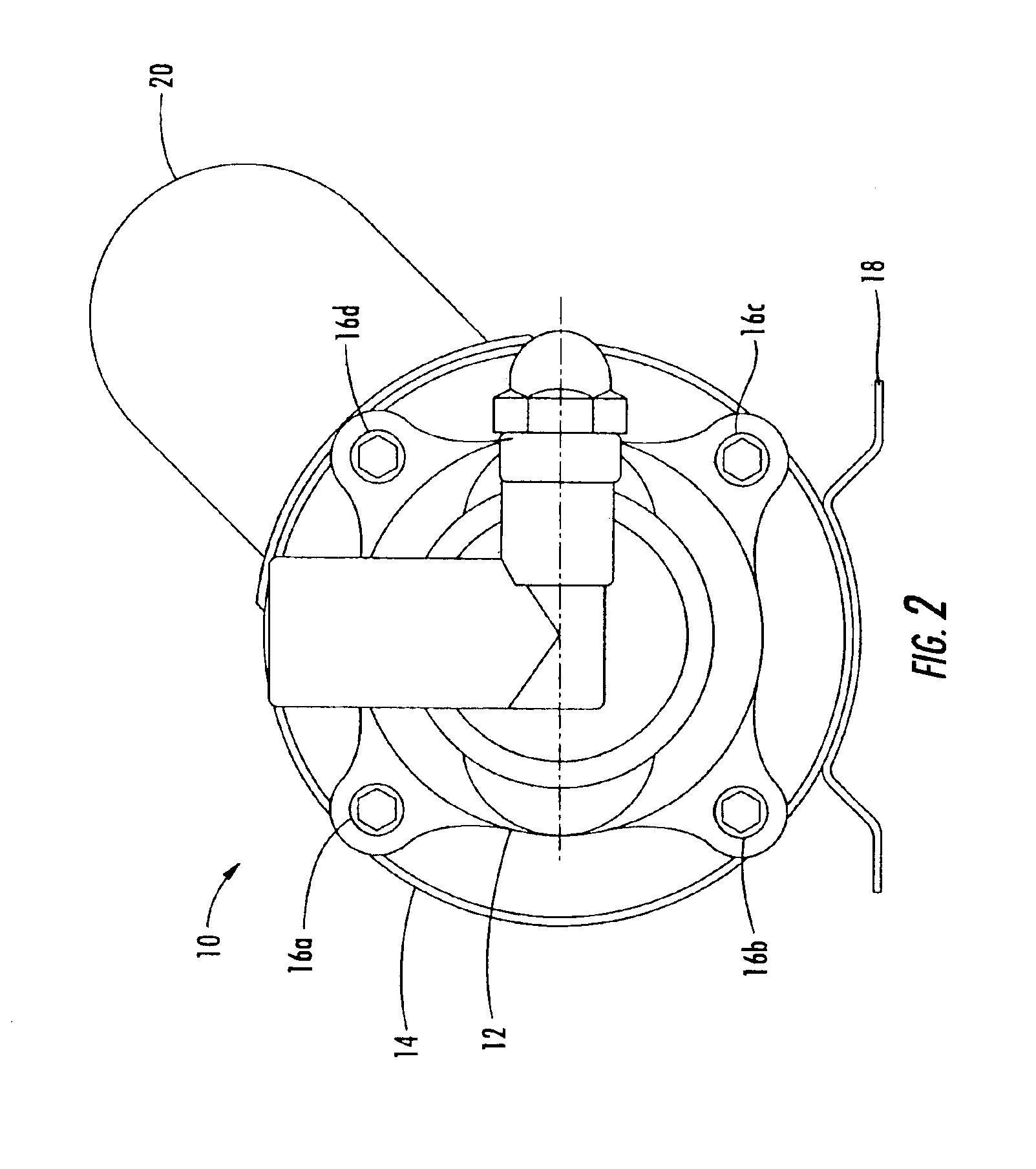

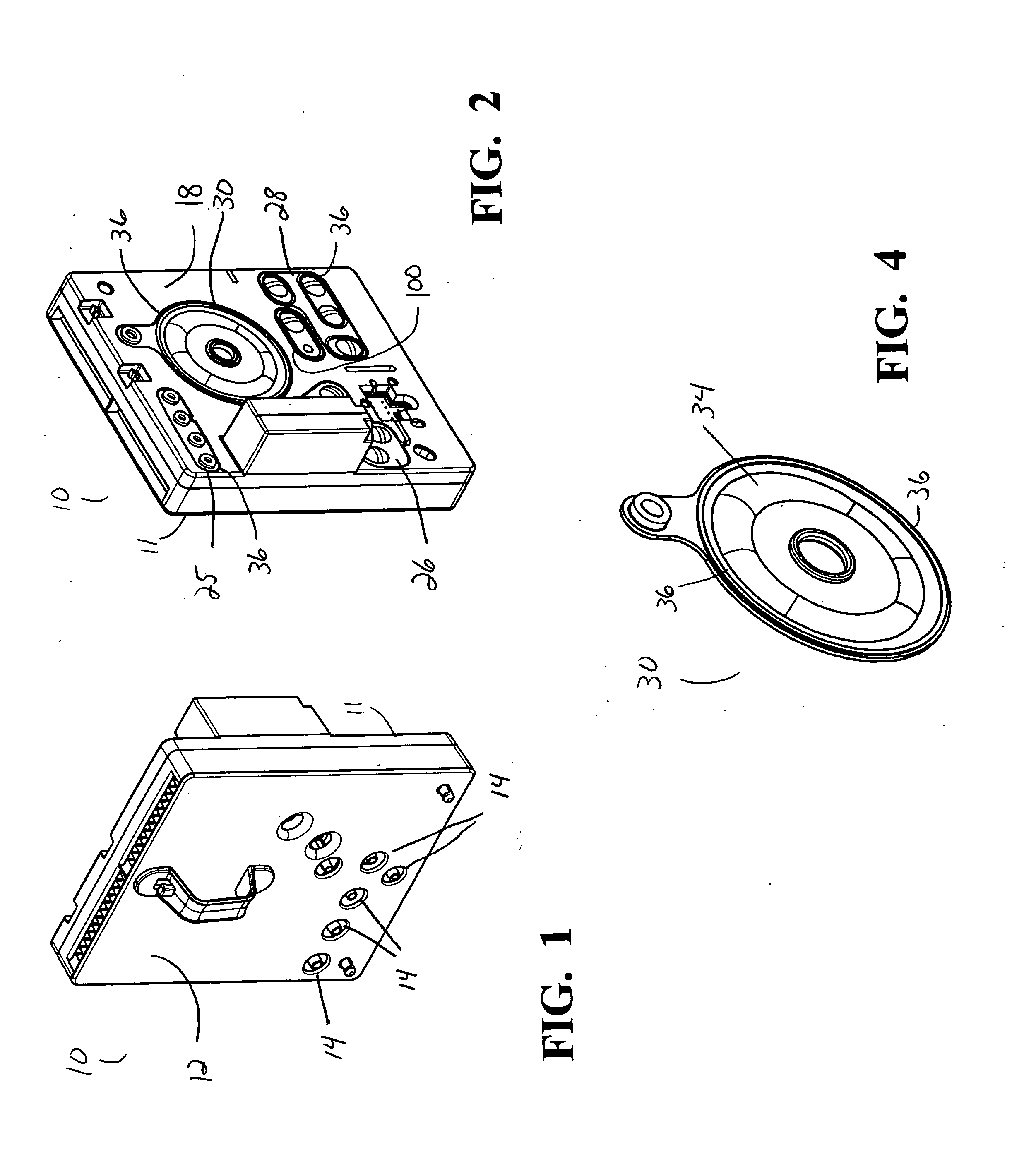

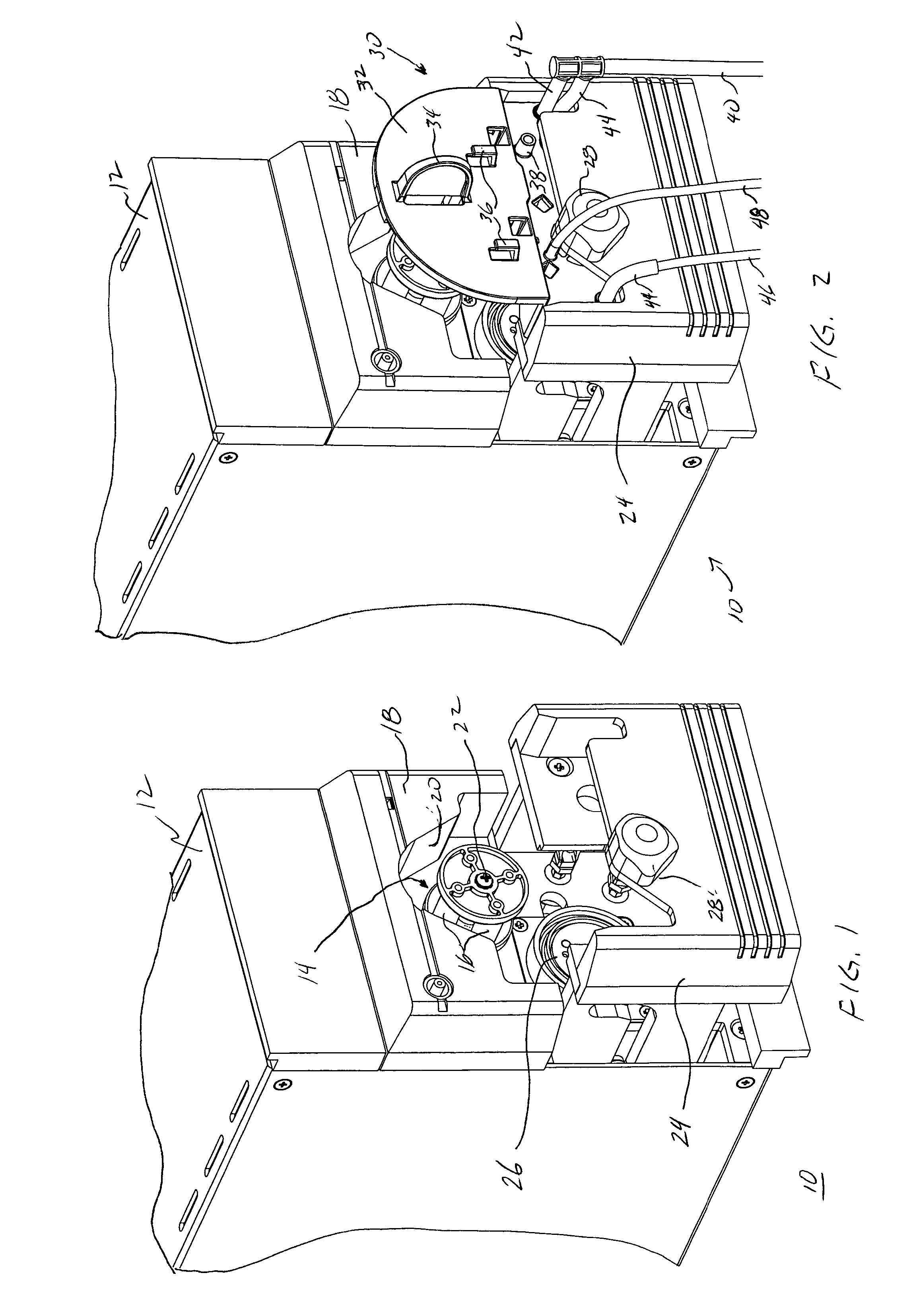

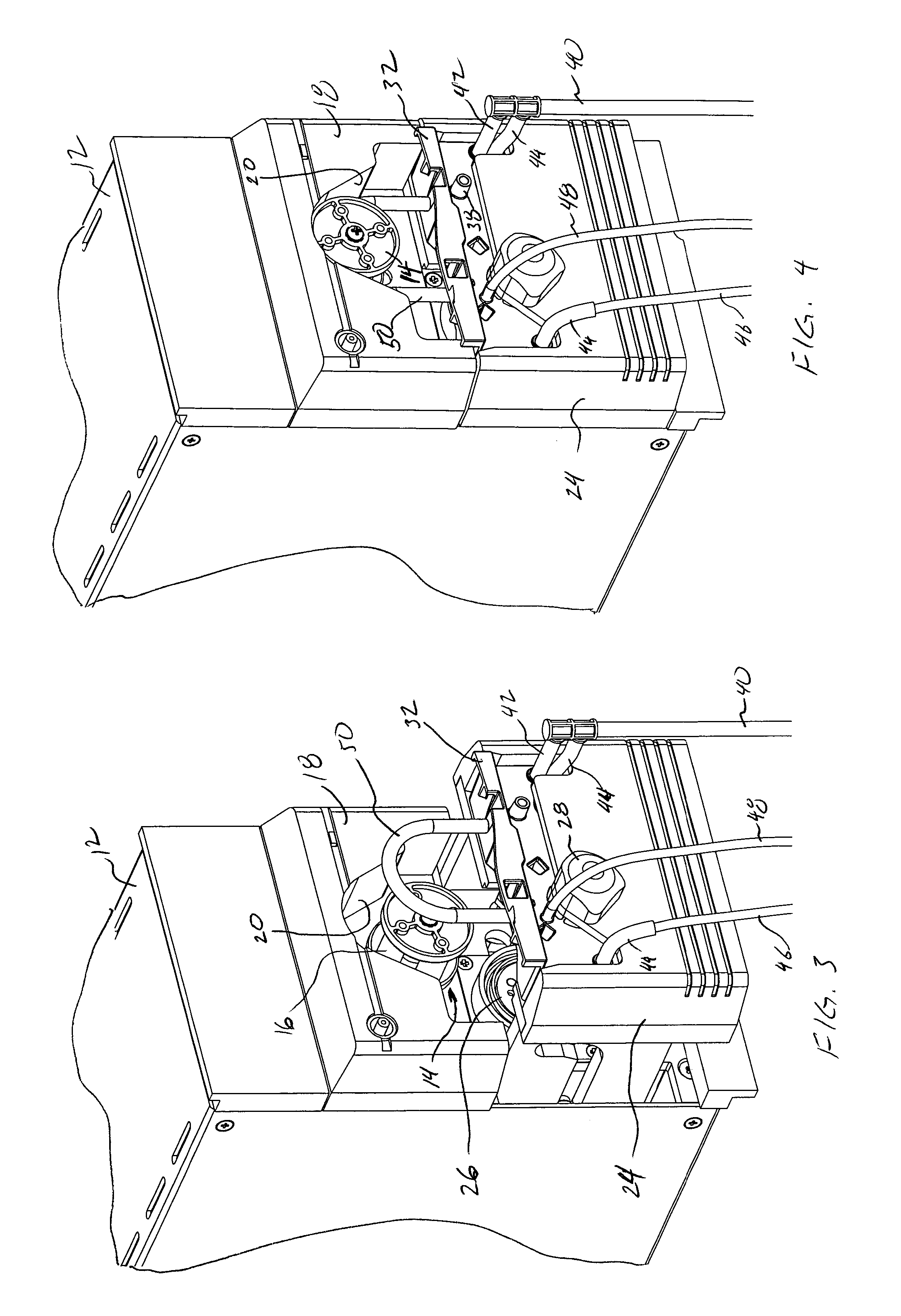

Peristaltic pump with air venting via the movement of a pump head or a backing plate during surgery

ActiveUS20050069419A1Low costShort timePositive displacement pump componentsFlexible member pumpsPeristaltic pumpEngineering

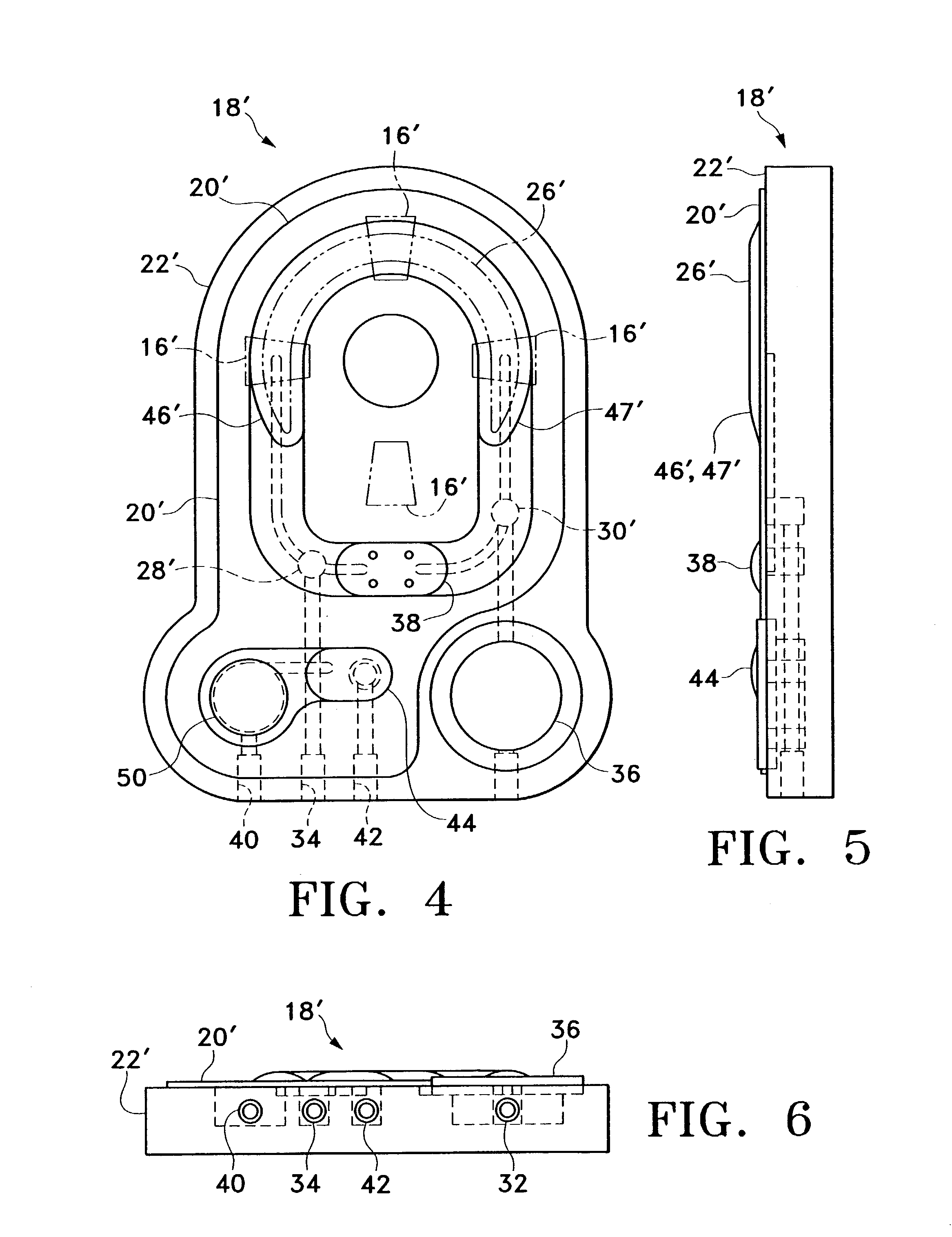

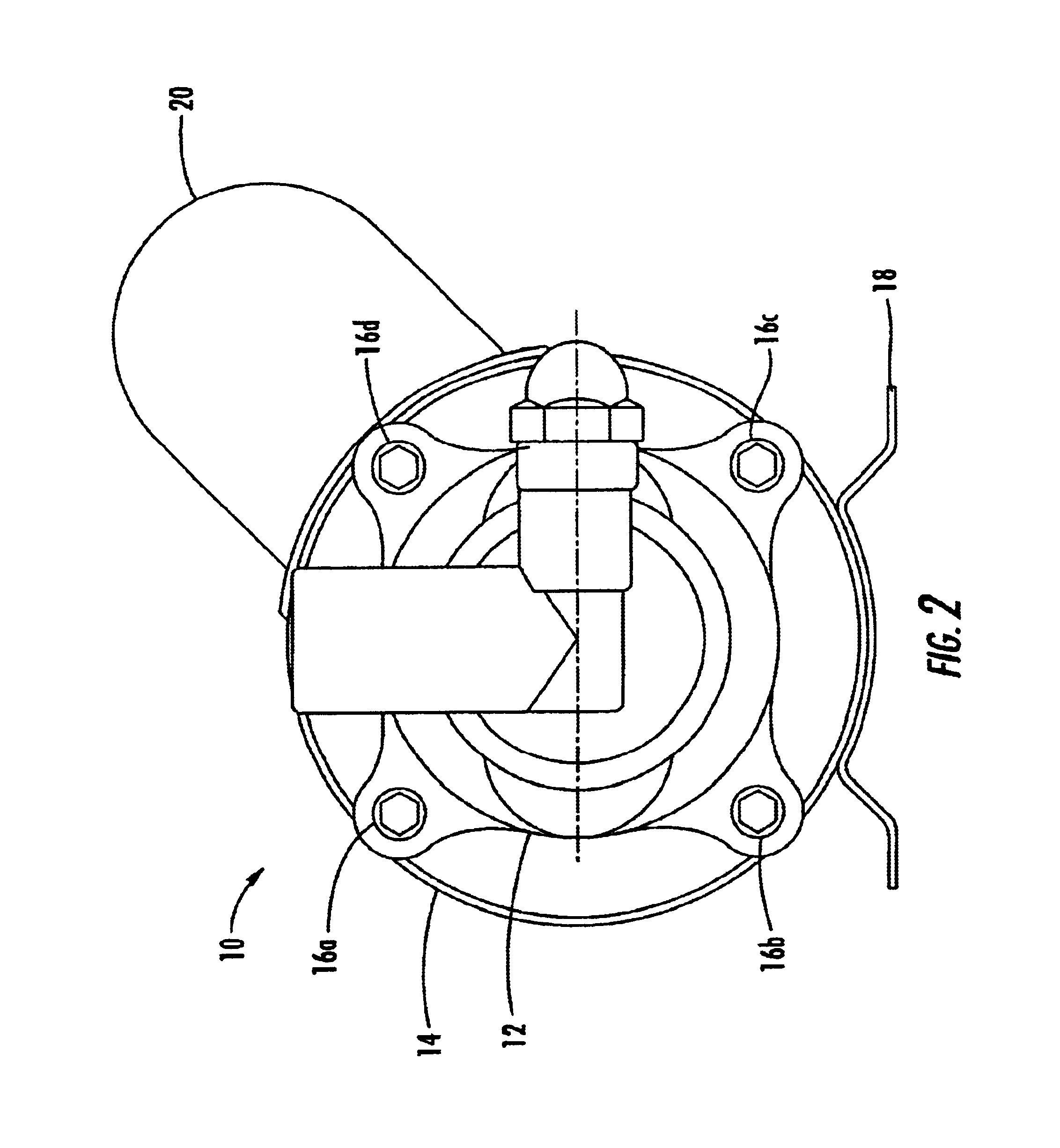

A peristaltic pump 10 for use in ophthalmic surgery includes a housing 12, a pump head 14 having plurality of rollers 16, a backing plate 18 attached to the housing 12, and a length of surgical tubing 50. The rollers 16 and backing plate 18 cooperate to pinch the length of surgical tubing 50 to peristaltically pump fluids from a surgical site to a collection bag 64. At least one of the pump head 14 and the backing plate 18 is moveable, during operation of the pump 10, from a tubing pinched position to a tubing vent position. This movement allows the tubing 50 to be vented by removing the pinched closure of the tubing 50.

Owner:BAUSCH & LOMB INC

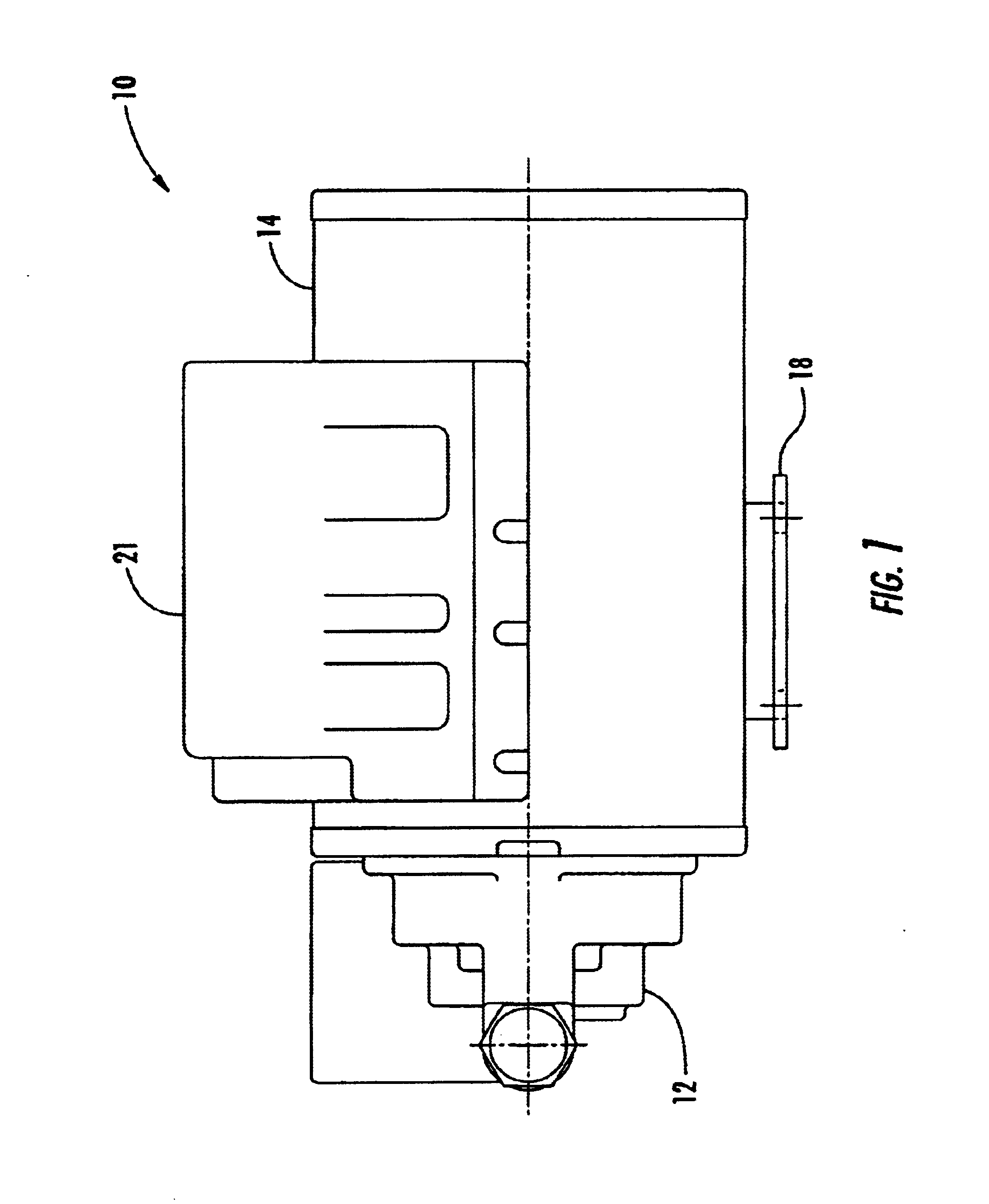

Overheat protection for fluid pump

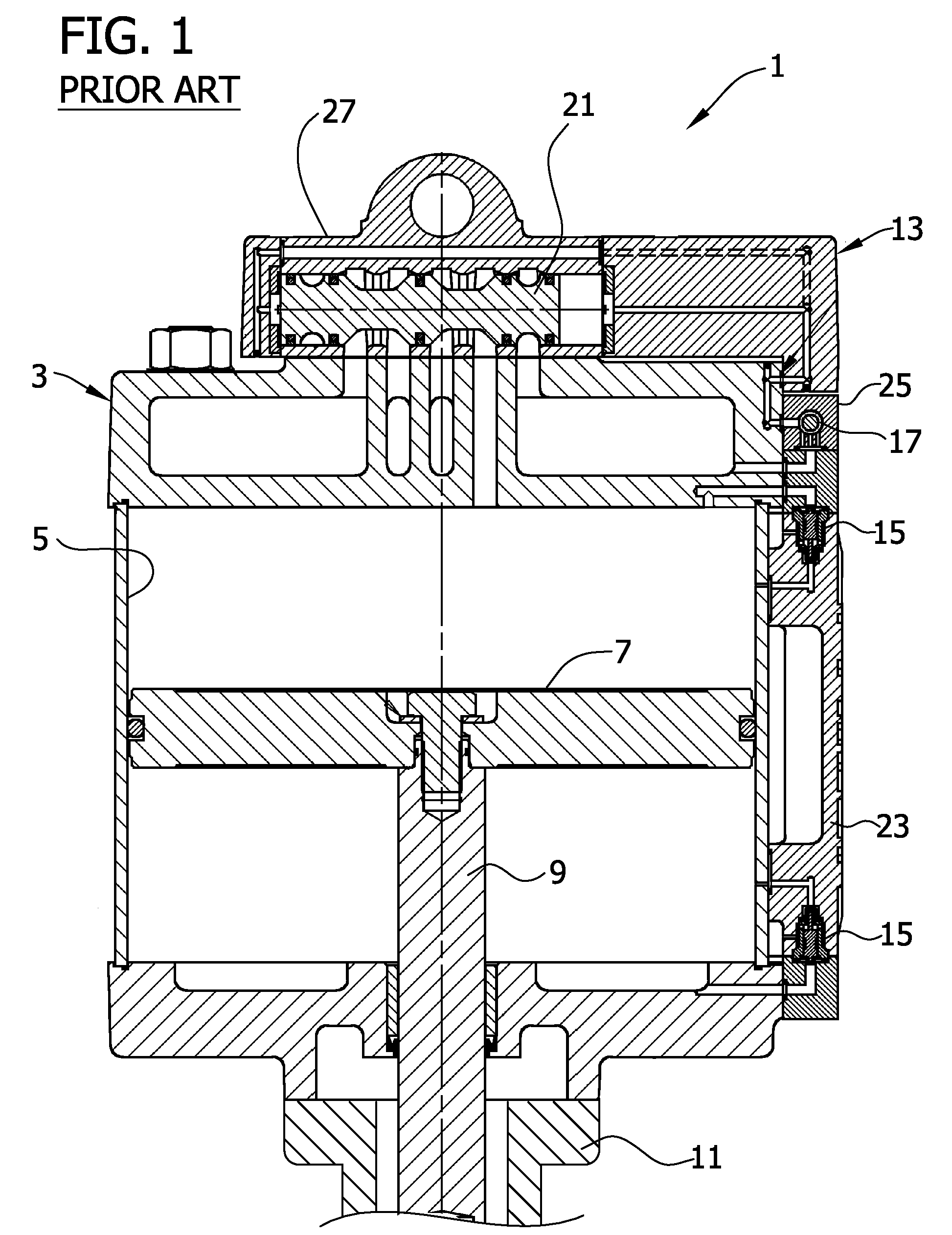

InactiveUS6837688B2Avoid damageReduce stepsRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsPump headThreshold temperature

An apparatus for detecting the presence of an overheat condition in a fluid pump includes a pump head for receiving a fluid at a first pressure and outputting the fluid at a second pressure that is greater than the first pressure. A motor is positioned adjacent the pump head to drive the pump head to pressurize the fluid. A single overheat sensor senses an overheat condition in the pump head and an overheat condition in the motor. When a threshold temperature is sensed by the overheat sensor, a switch is activated to prevent operation of the motor. In one embodiment, the overheat sensor and switch are integral and may, for example, take the form of a bi-metal switch formed in the stator windings of the motor. In alternate embodiments, the overheat sensor and switch are separate.

Owner:STANDEX INT CORP

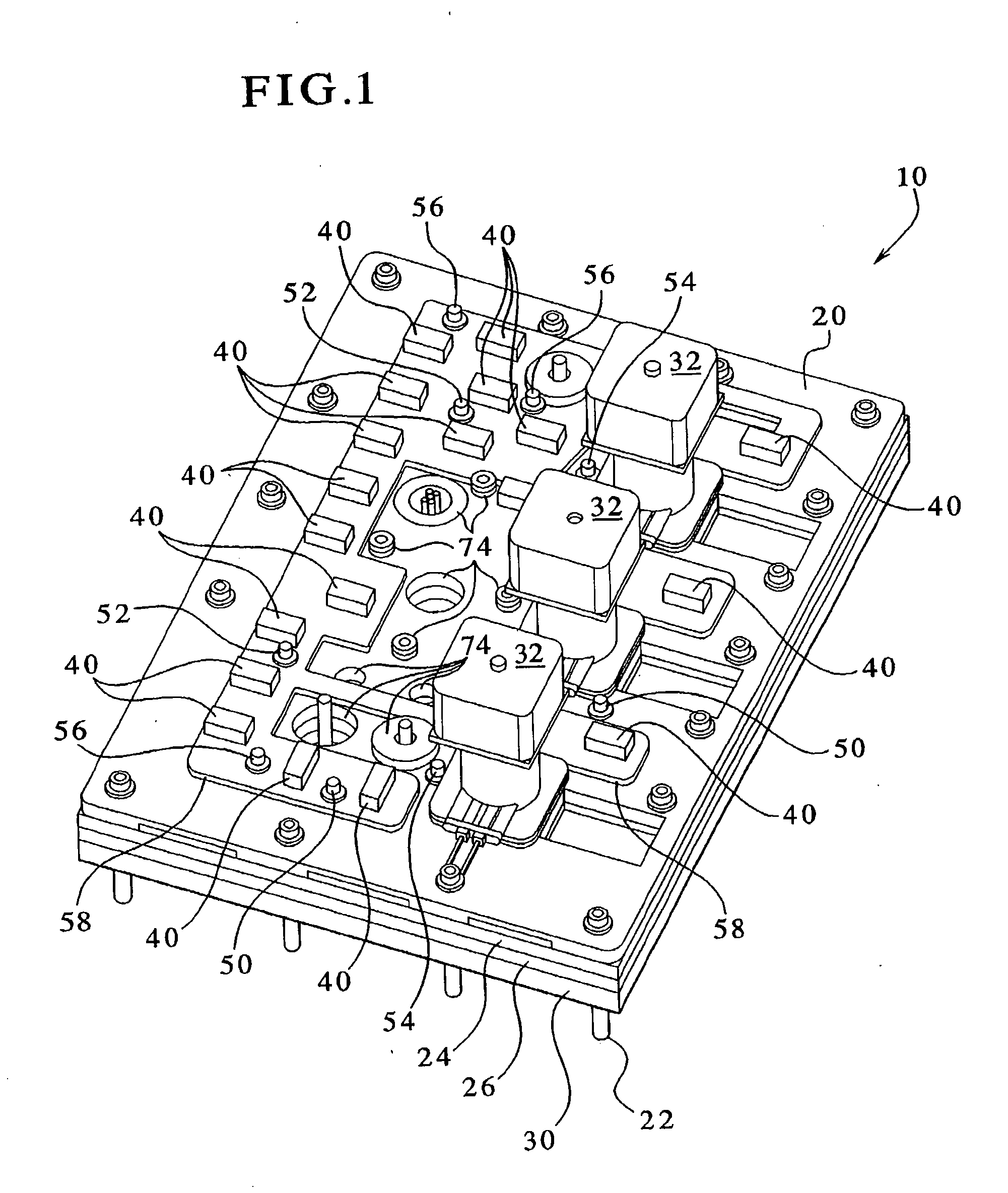

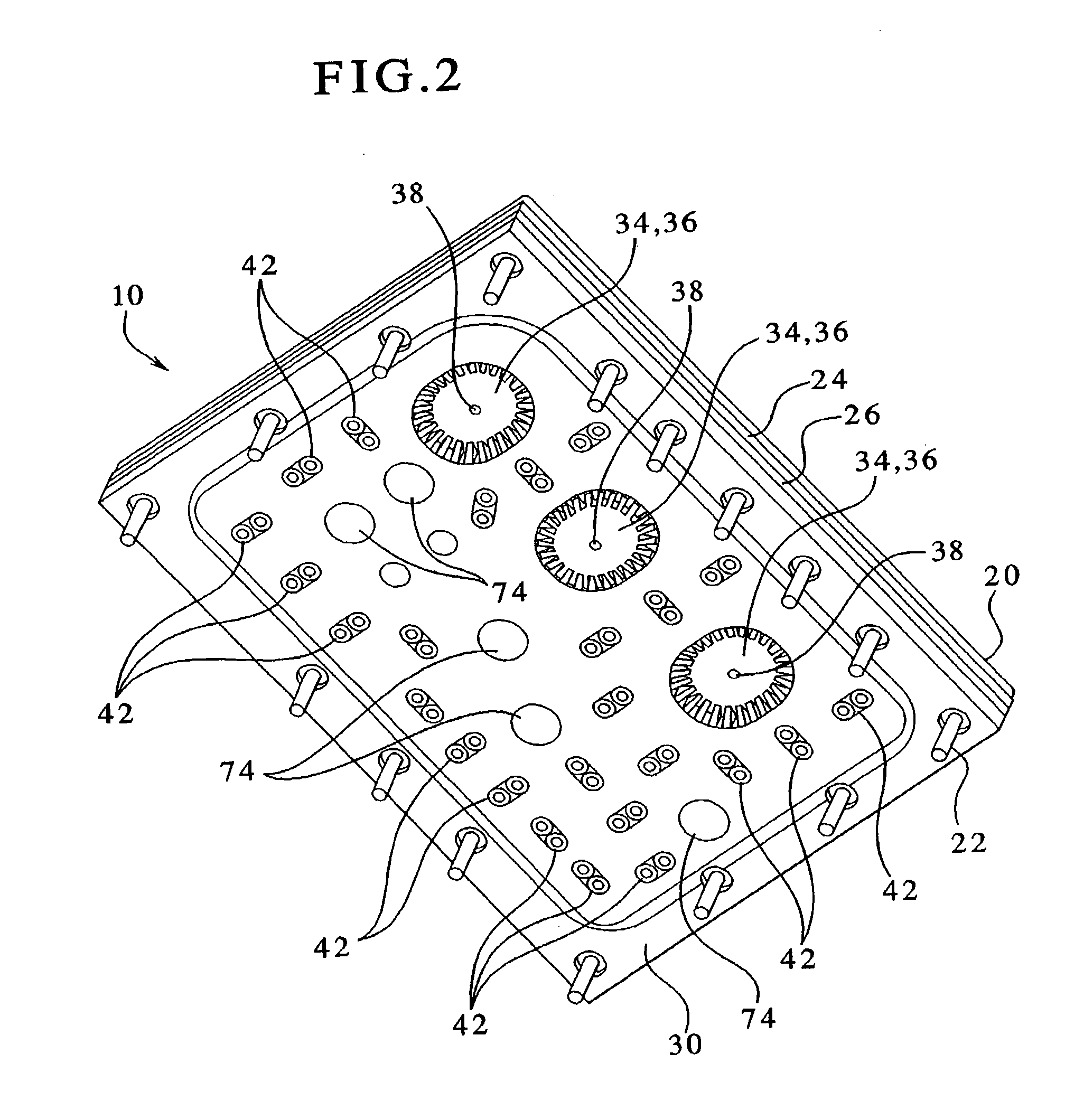

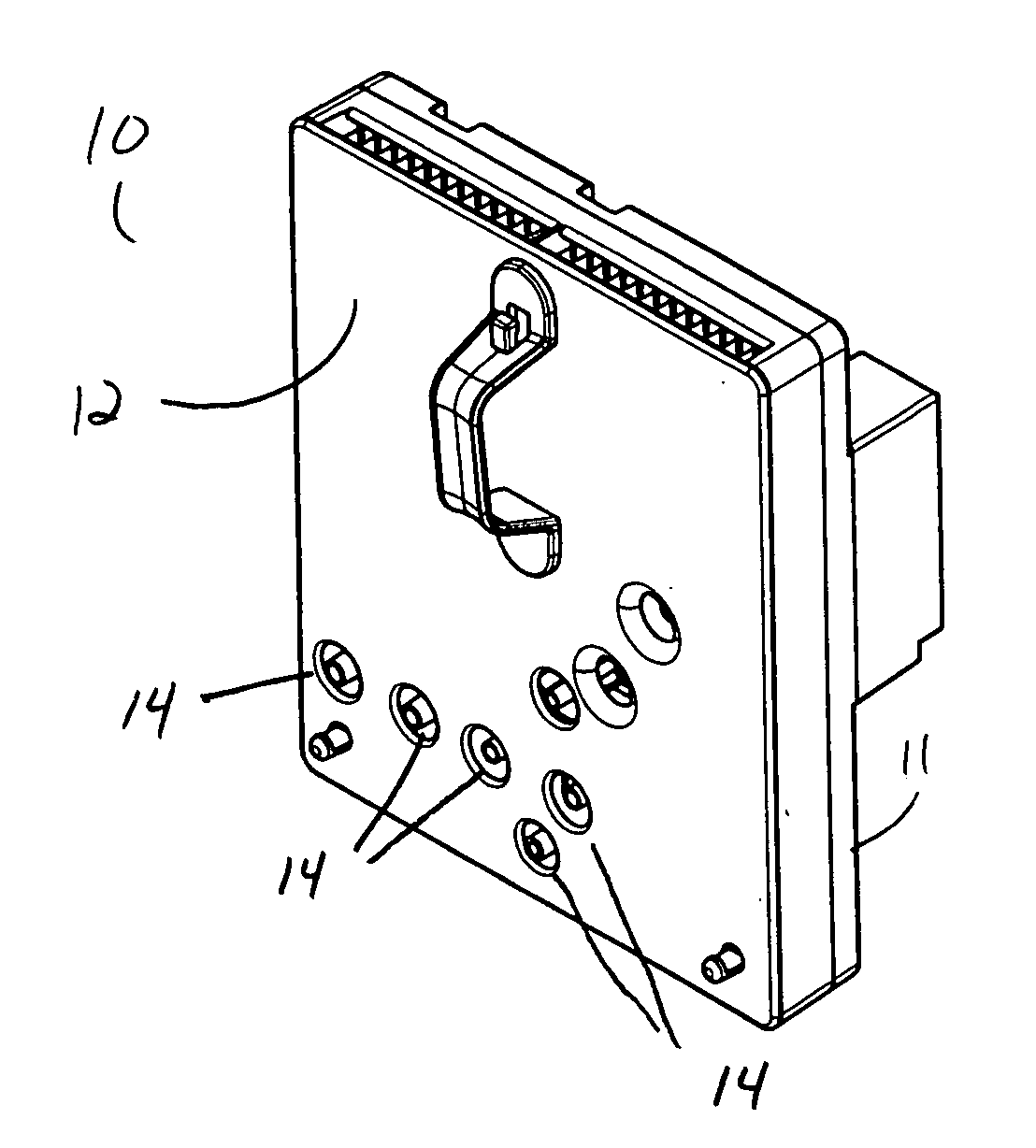

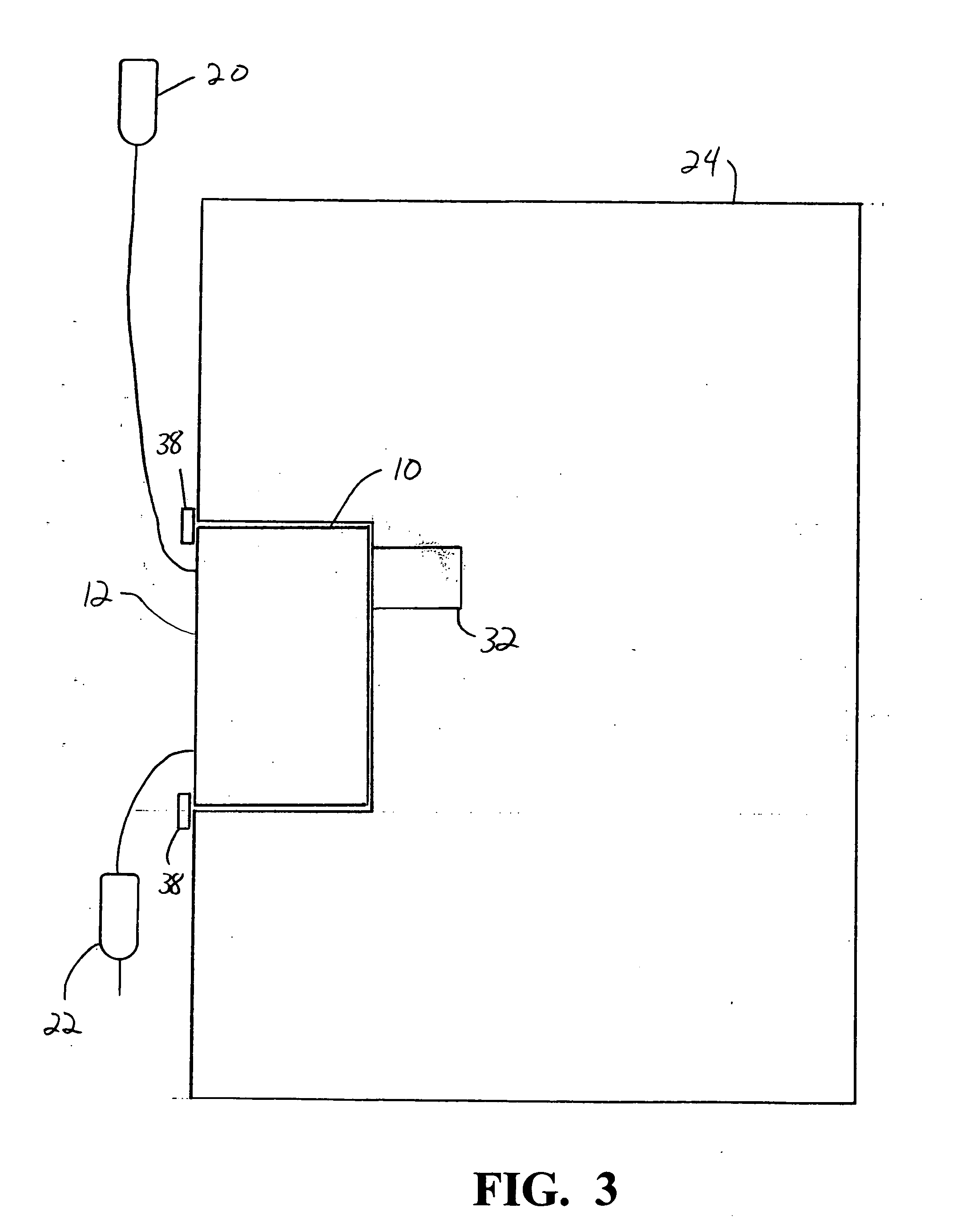

System including machine interface for pumping cassette-based therapies

A dialysis machine includes: a hardware unit including at least one pump actuator, at least one valve actuator and a cassette interface, the cassette interface including: (i) a plate that abuts the cassette; (ii) at least one pump aperture defined by the plate; (iii) at least one pump head moveable out of and retractable into the at least one pump aperture to operate a pumping portion of the cassette; (iv) at least one valve aperture defined by the plate; (v) at least one valve apparatus moveable out of and retractable into the at least one valve aperture to operate a valve portion of the cassette; (vi) at least one sensor aperture defined by the plate; and (vii) at least one sensor located in the least one sensor aperture, the at least one sensor operable with a sensor portion of the cassette.

Owner:BAXTER HEALTHCARE SA +1

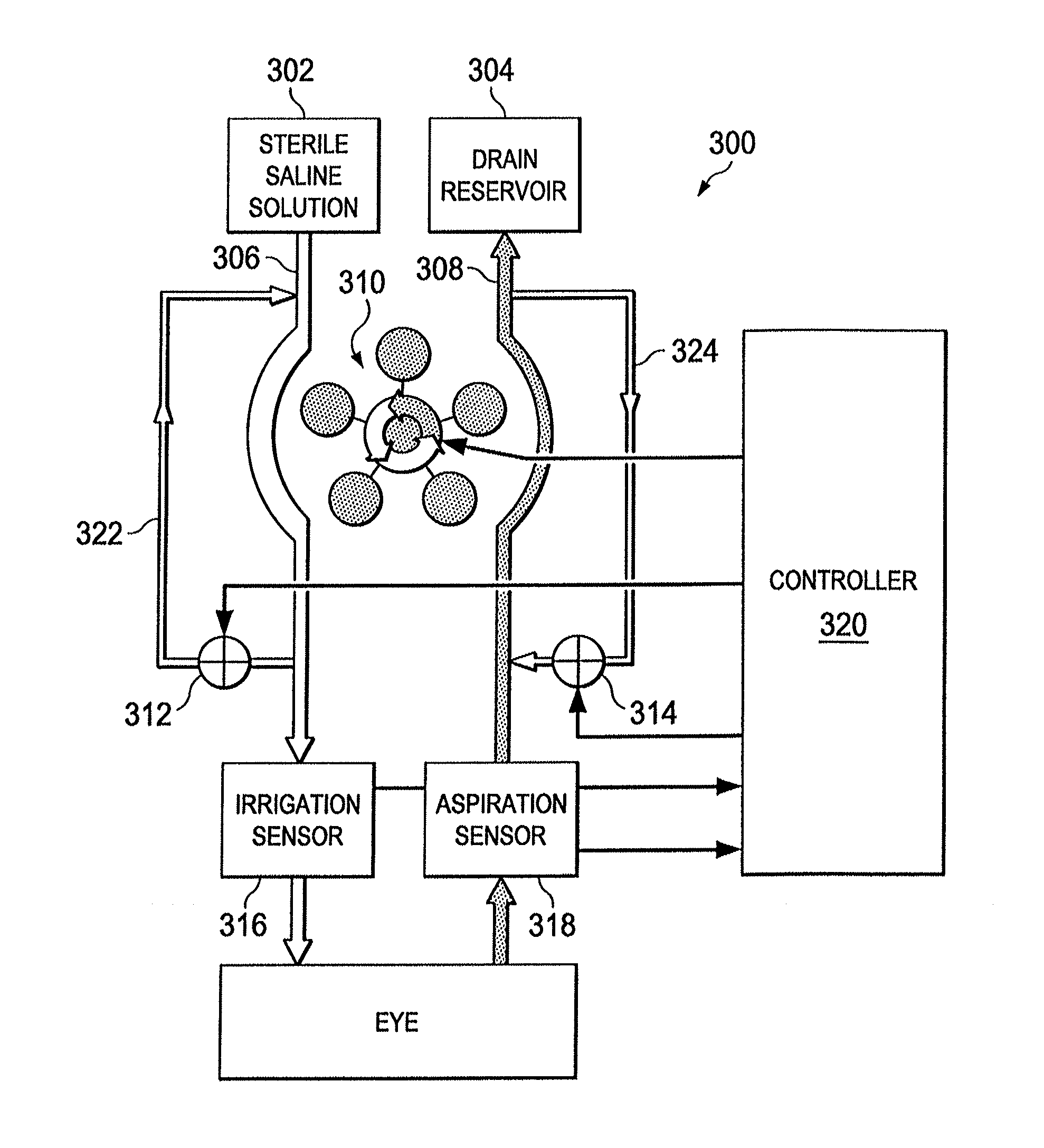

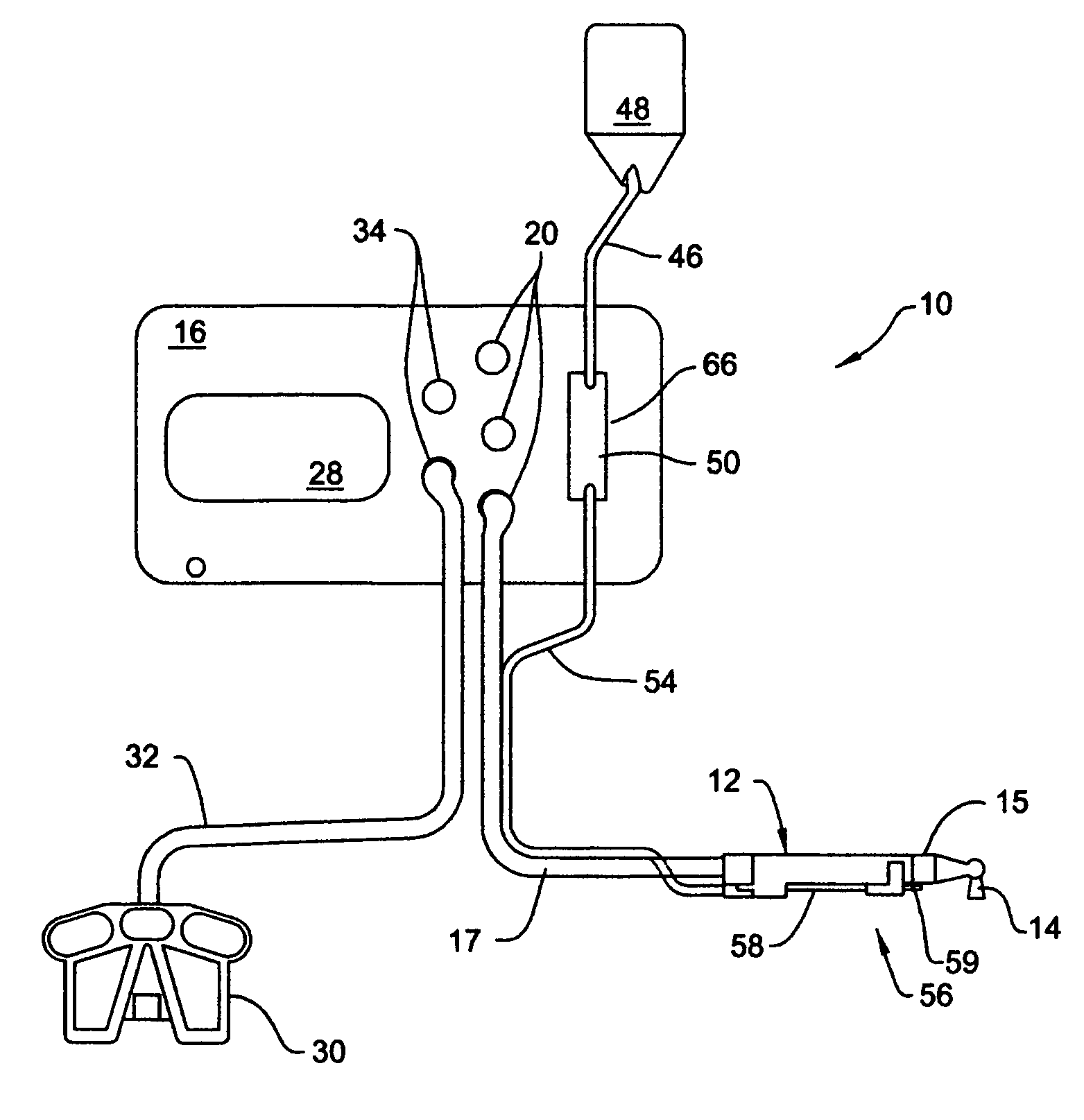

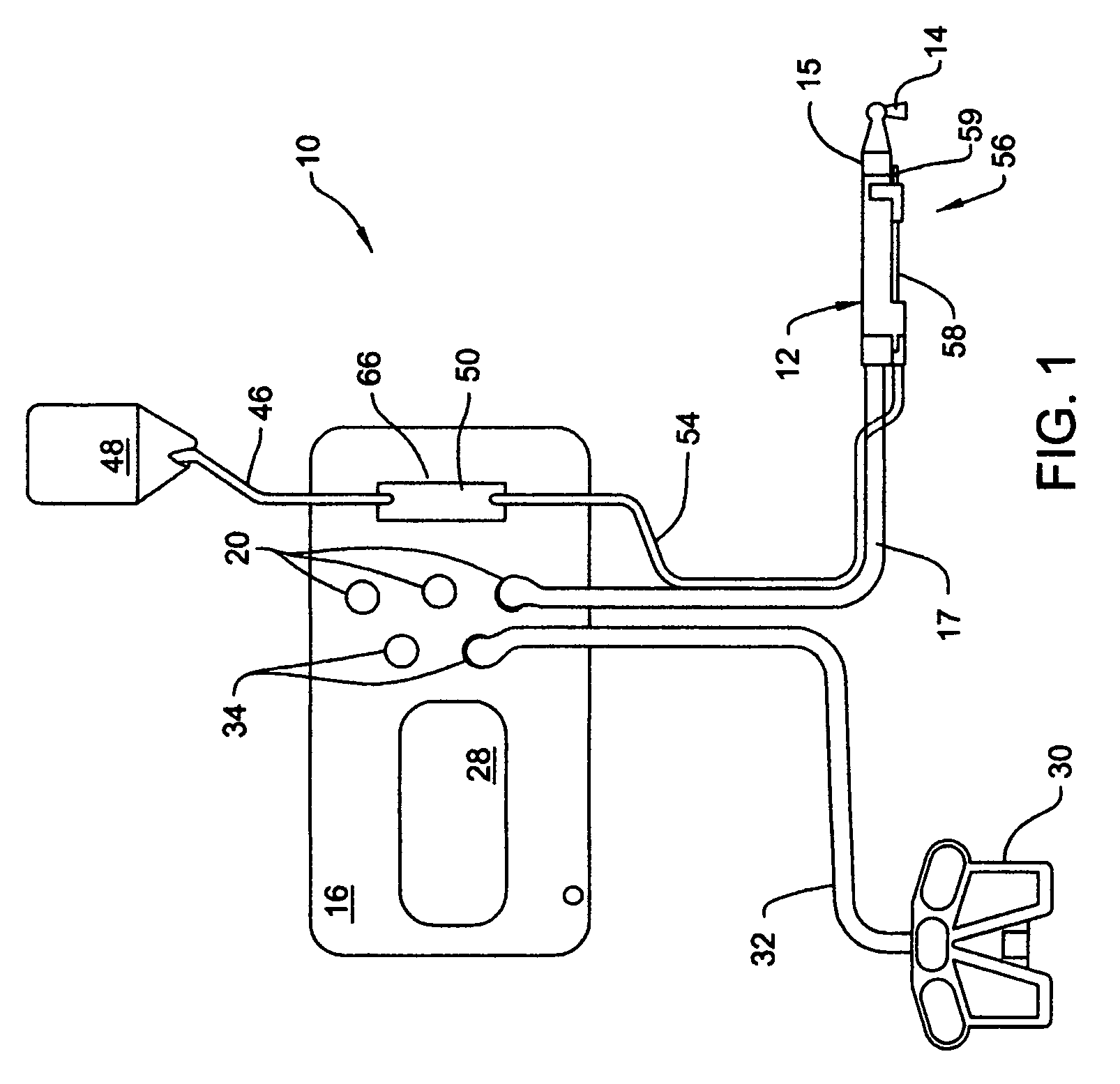

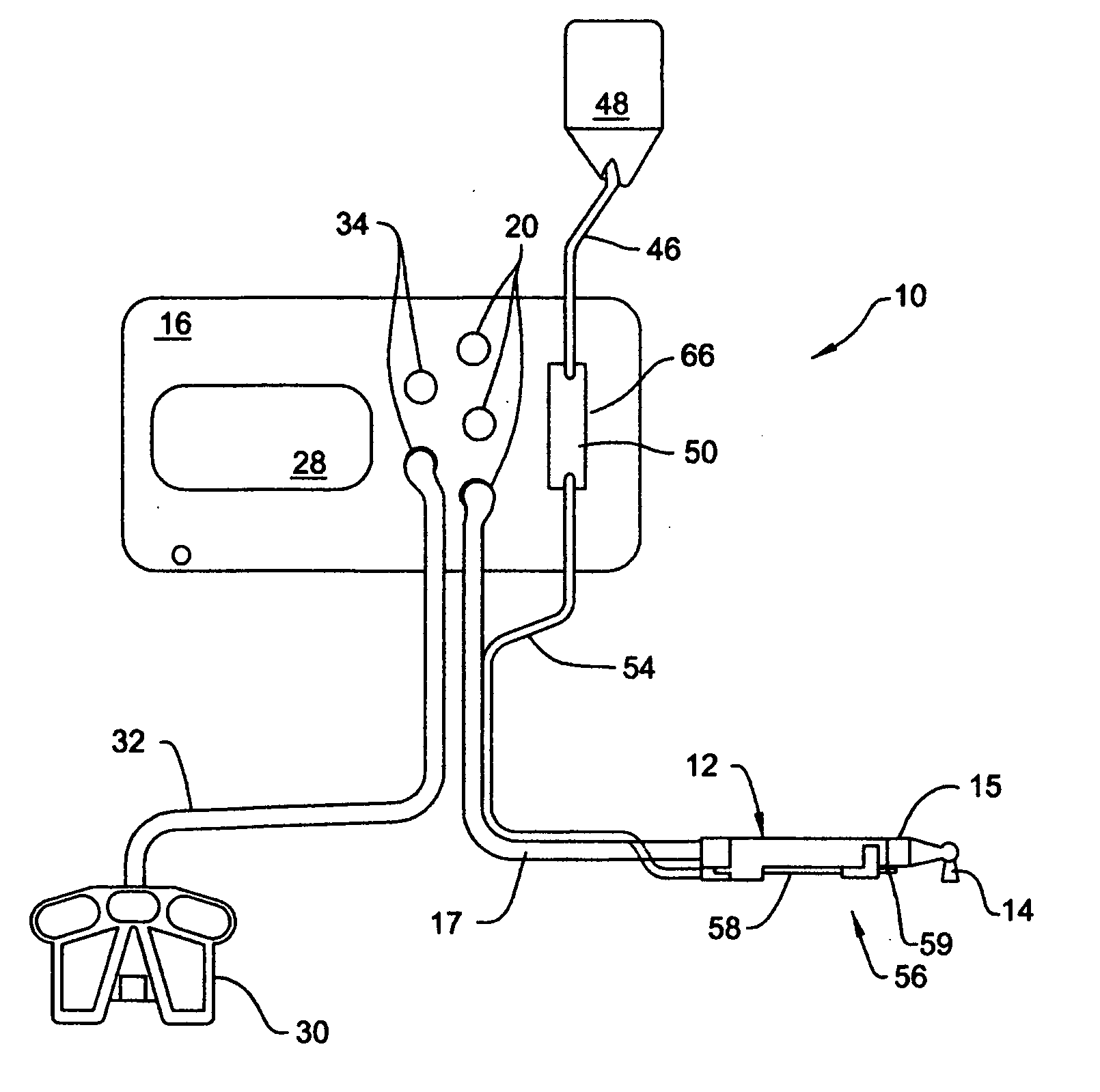

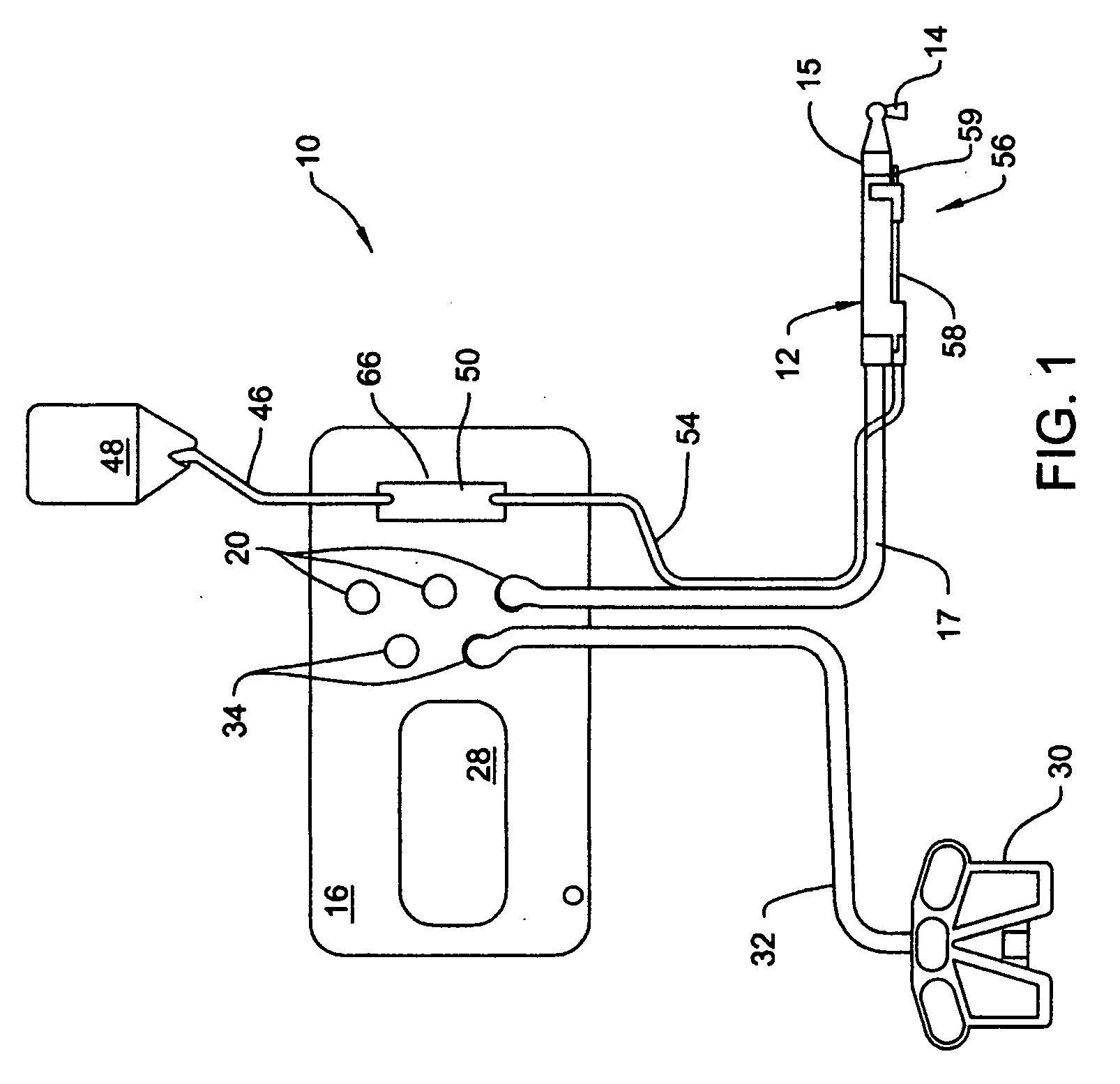

Phacoemulsification Fluidics System Having a Single Pump Head

A phacoemulsification fluidics system for irrigating and aspirating a surgical site includes a sterile solution reservoir, an irrigation path configured to extend from the sterile solution reservoir to the surgical site, and an aspiration path configured to extend from the surgical site. The system also includes a single flow control pump head associated with both the irrigation path and the aspiration path. The flow control pump head is arranged within the system to simultaneously pressurize the irrigation path in a manner that drives the irrigation fluid to the surgical site and pressurize the aspiration path in a manner that vacuums waste fluid from the surgical site.

Owner:ALCON RES LTD

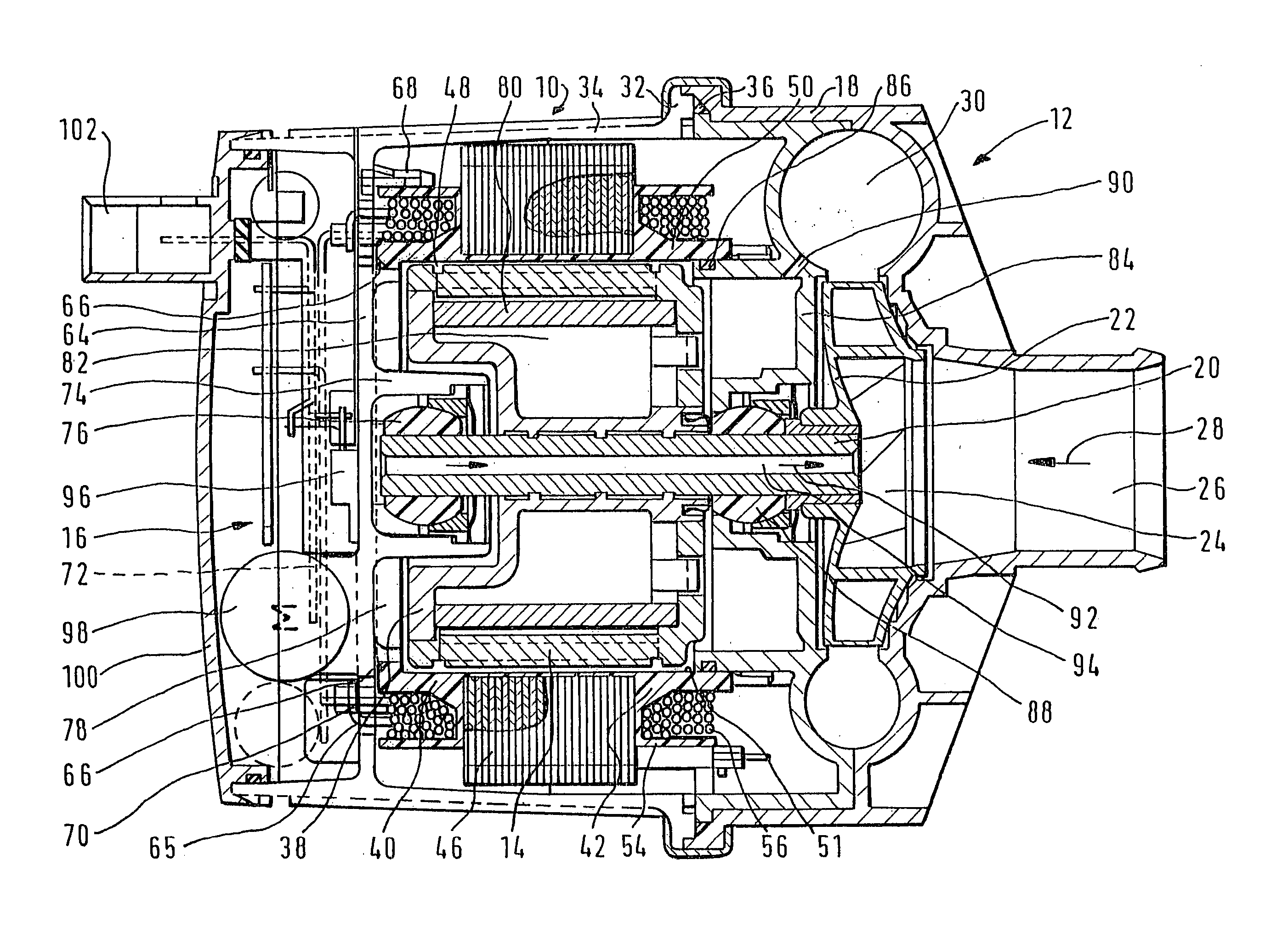

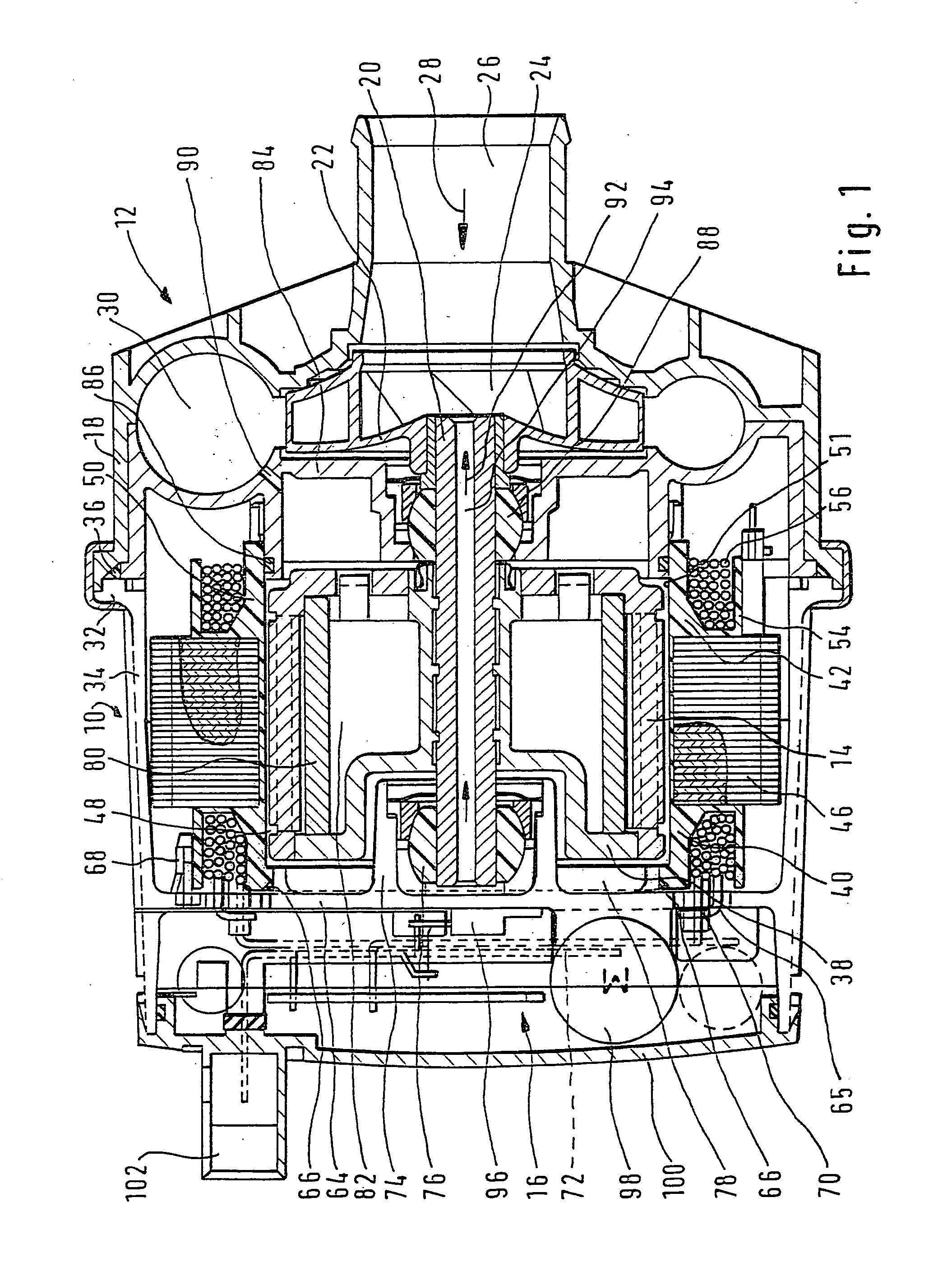

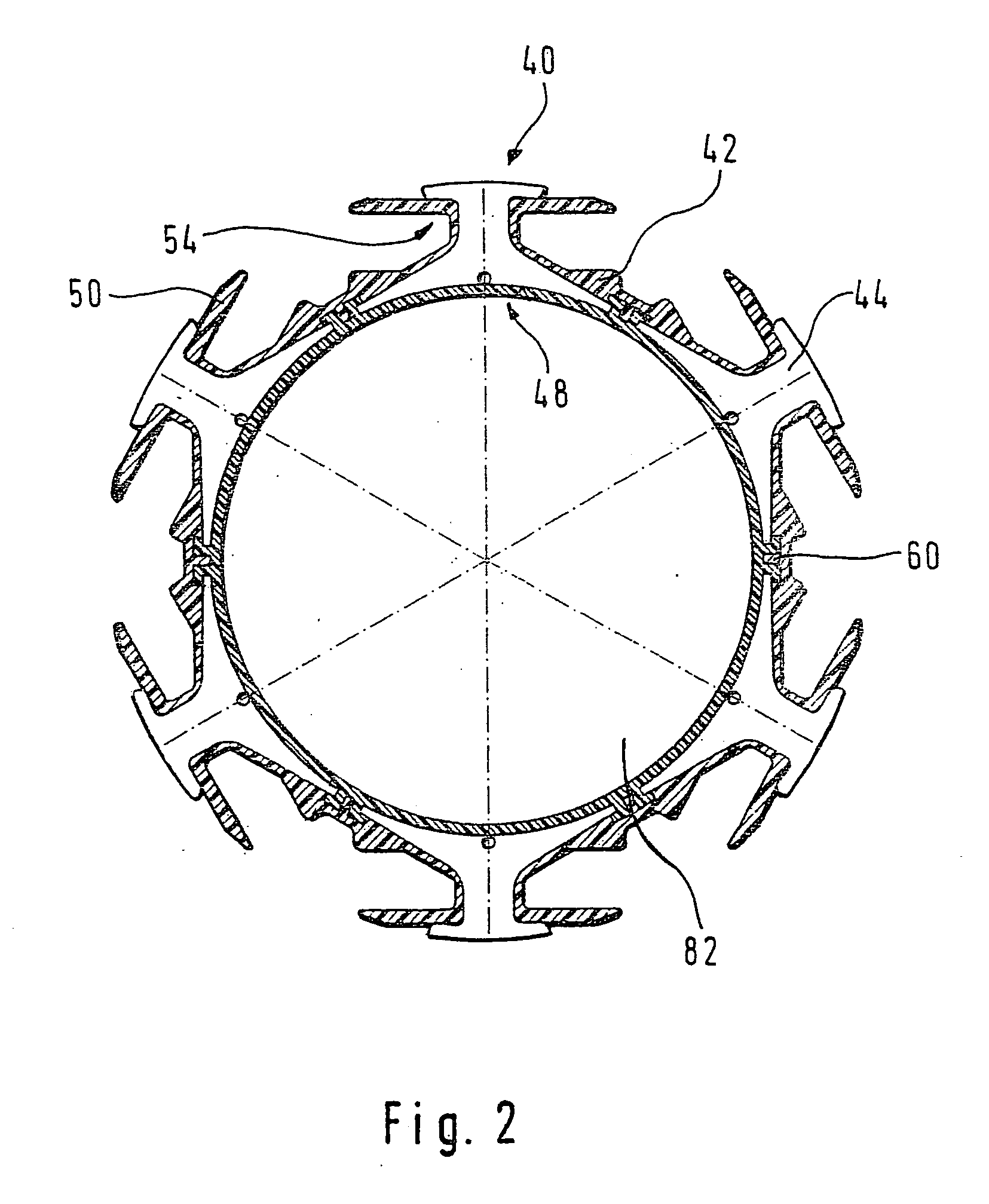

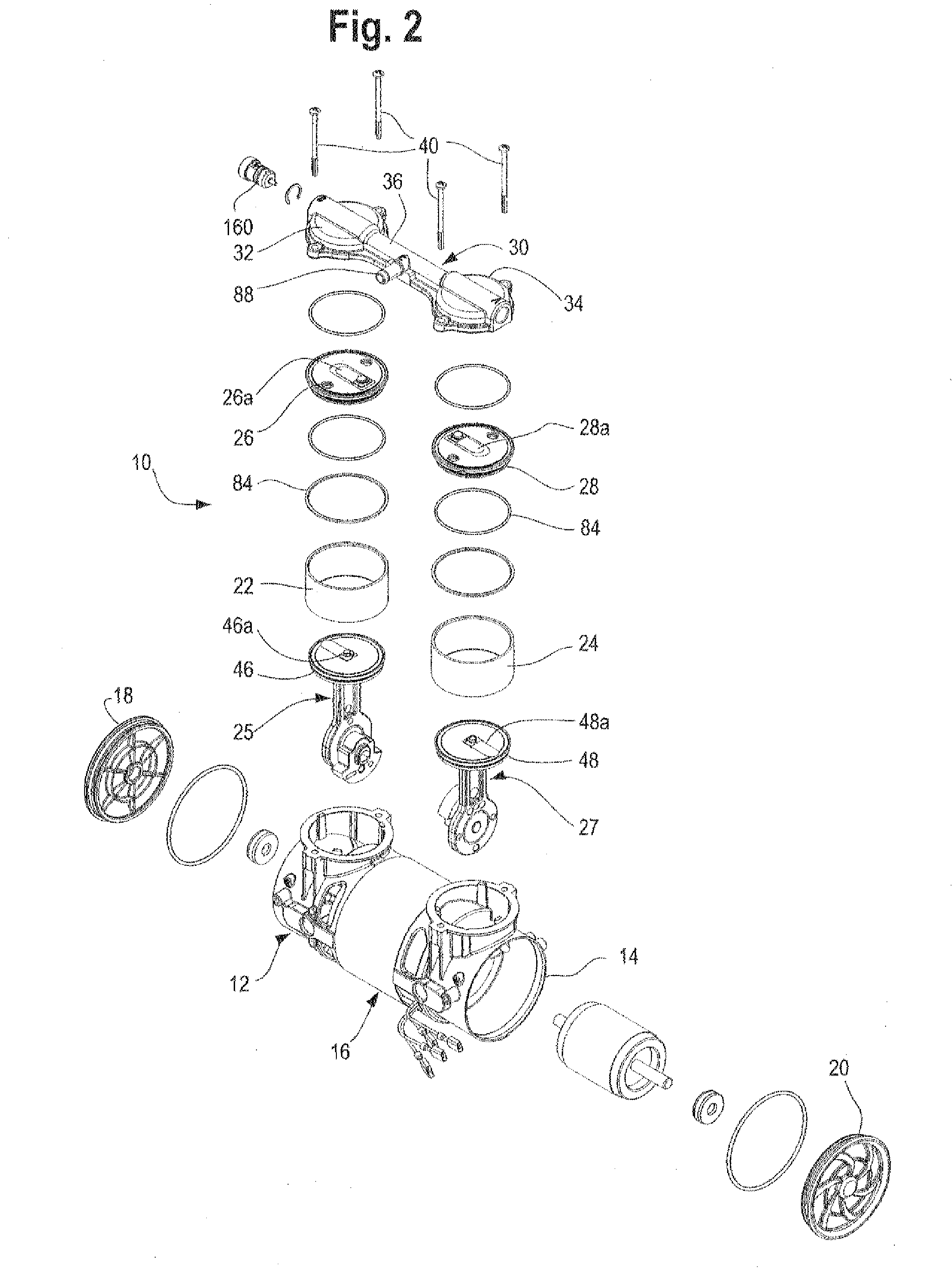

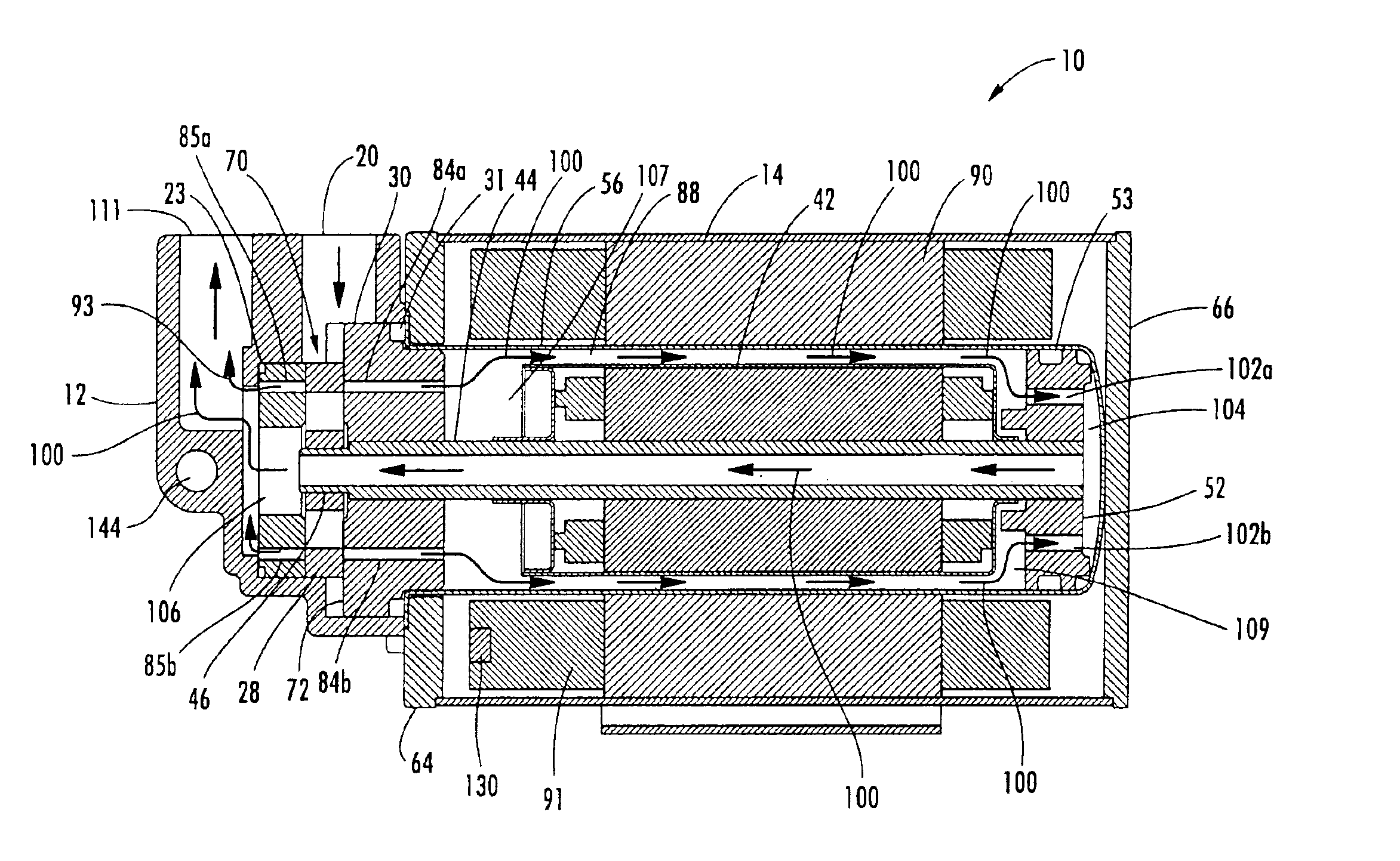

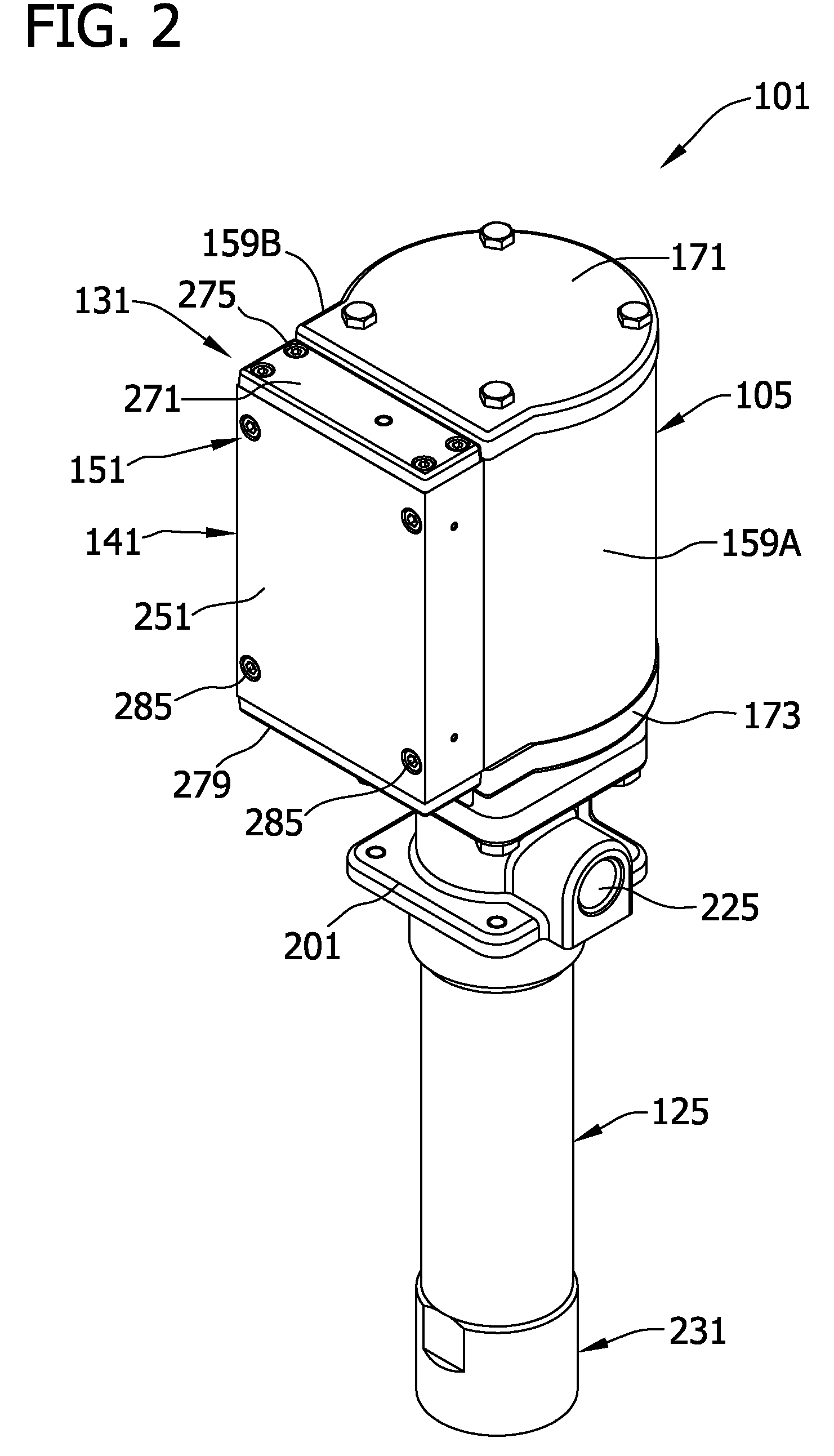

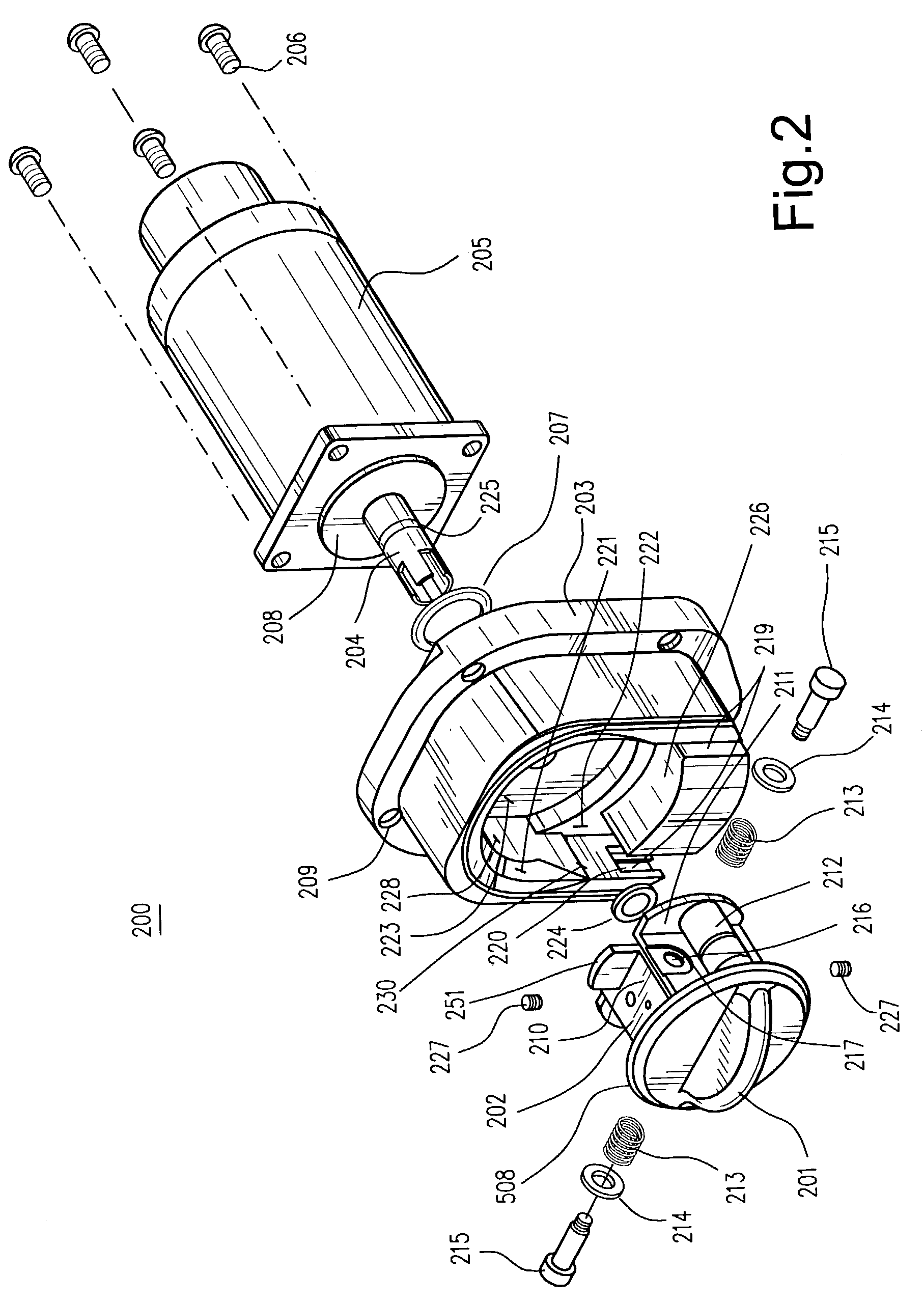

Pump driven by an electromotor and method for producing a pump of this type

The invention relates to a pump (10), having a pump head (12), which has a pump chamber (11), and having an electric motor (14), which drives the pump head (12) and has a stator (40) and a rotor (38), the rotor (38) being connected to the pump head (12) and being disposed in a rotor chamber (82) open toward the pump chamber (11). It is proposed that the stator (40) is disposed radially around the rotor chamber (82), and the rotor chamber (82) is sealed off from the pump chamber (11) by a sealing wall (51) belonging to the stator (40) and by at least one wall (64) of the pump housing (18).

Owner:ROBERT BOSCH GMBH

Method of operating a surgical irrigation pump capable of performing a priming operation

Owner:STRYKER CORP

Effervescent gas bleeder apparatus

InactiveUS7175397B2Positive displacement pump componentsFlexible member pumpsReciprocating motionInlet valve

A diaphragm metering pump suitable for metering an effervescent gas. The pump has a pump head with a product chamber having an inlet end with a one-way inlet valve and an outlet end with a one-way outlet valve. A displaceable diaphragm member defines a boundary of the product chamber. The diaphragm member is capable of being reciprocated to cause pumping displacements. A discharge side is disposed downstream from the outlet valve. A passageway is disposed in fluid communication between the discharge side and the product chamber. A valve is disposed in the passageway. The valve is opened intermittently to allow liquid to re-enter the product chamber in an amount effective to purge gas from the product chamber to prevent loss of prime.

Owner:PULSAFEEDER

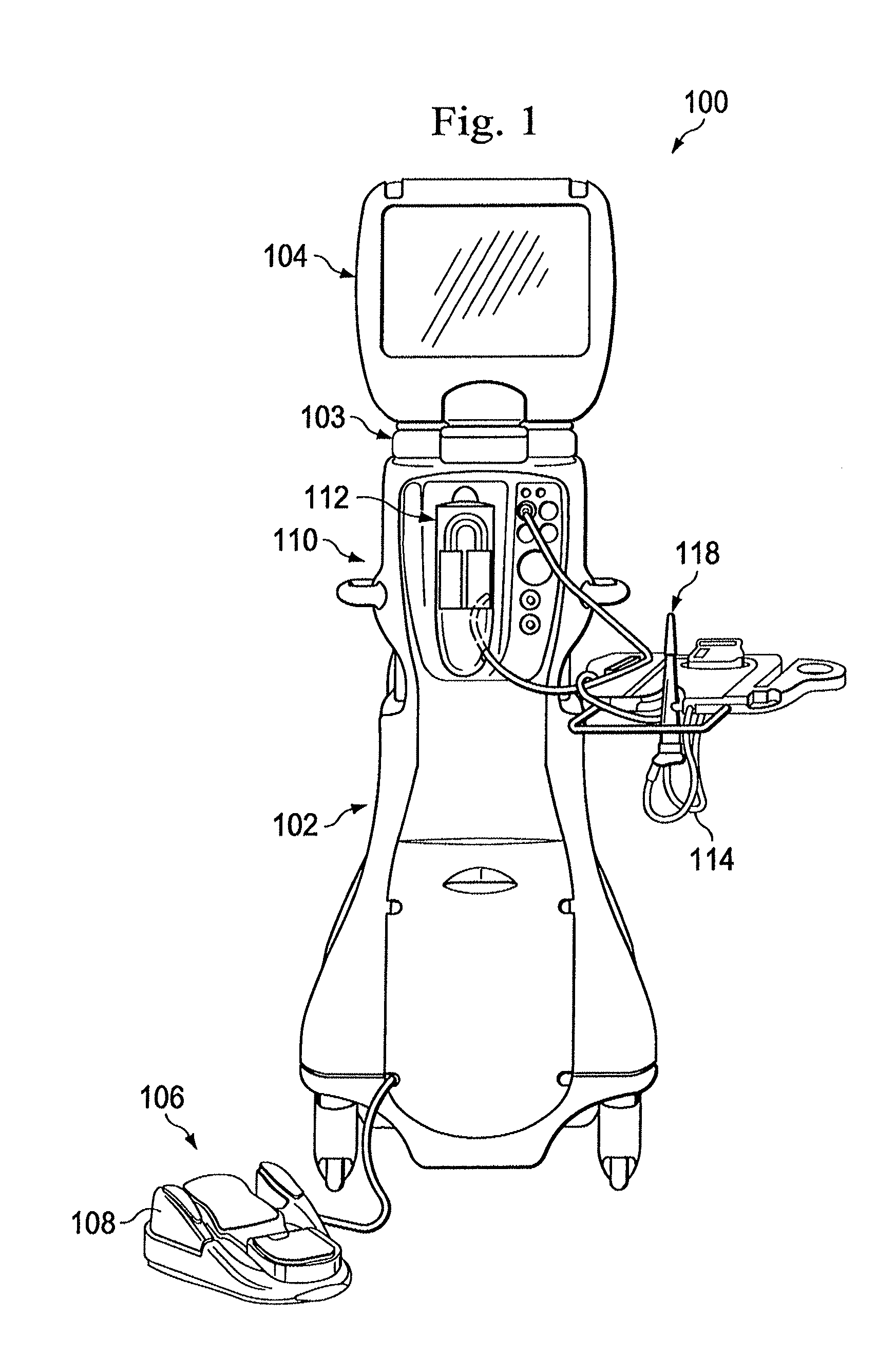

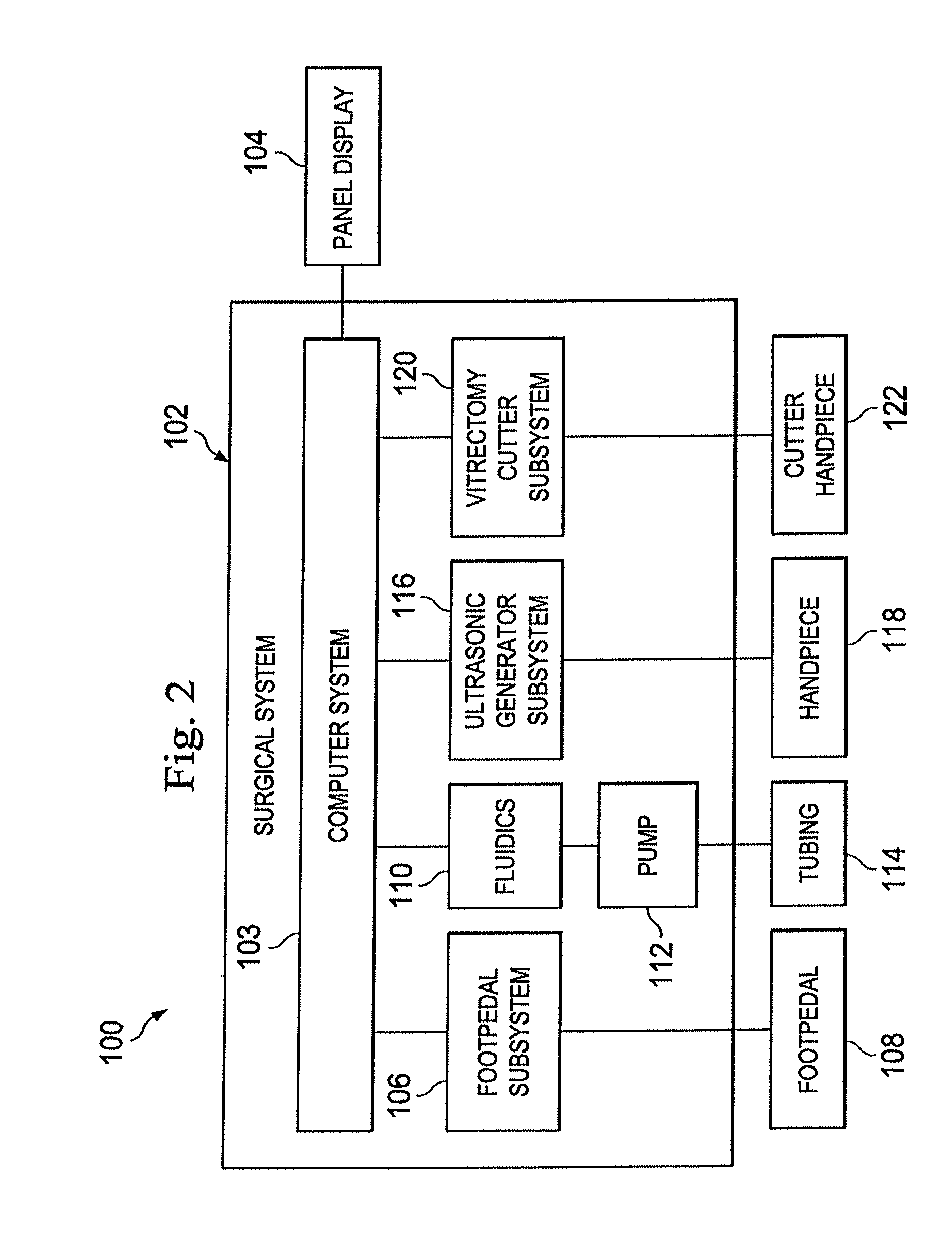

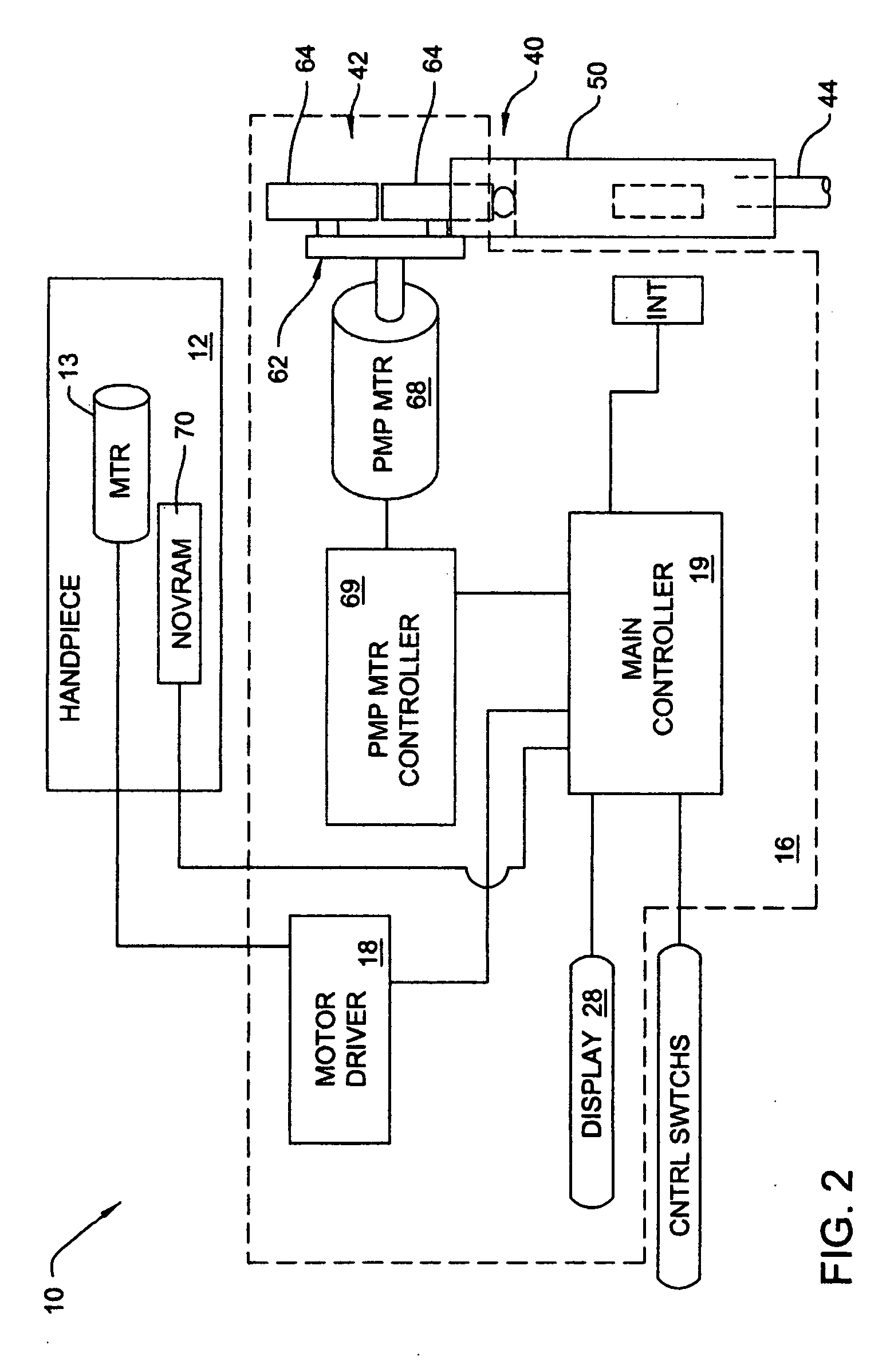

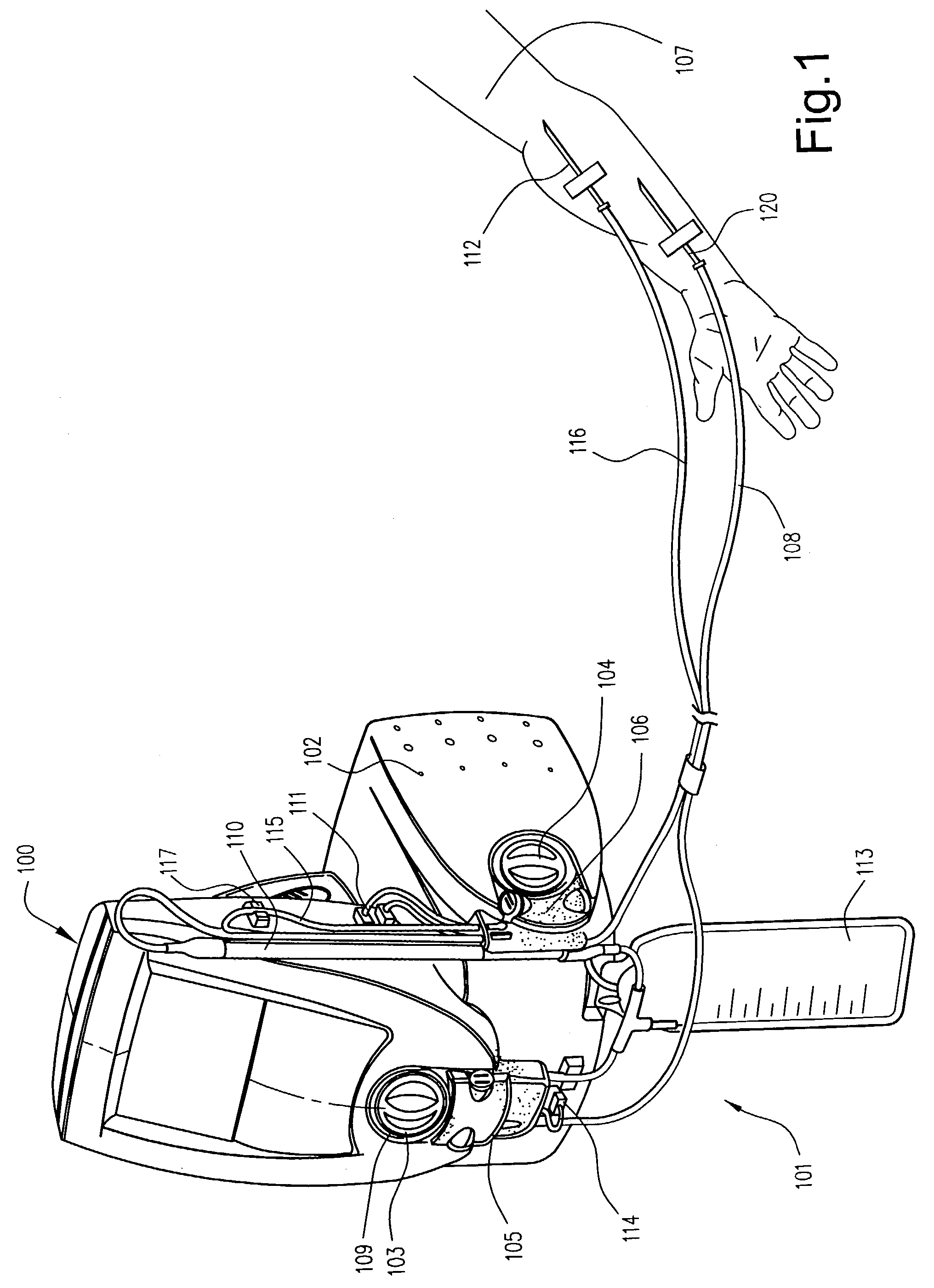

Surgical tool system with integrated pump

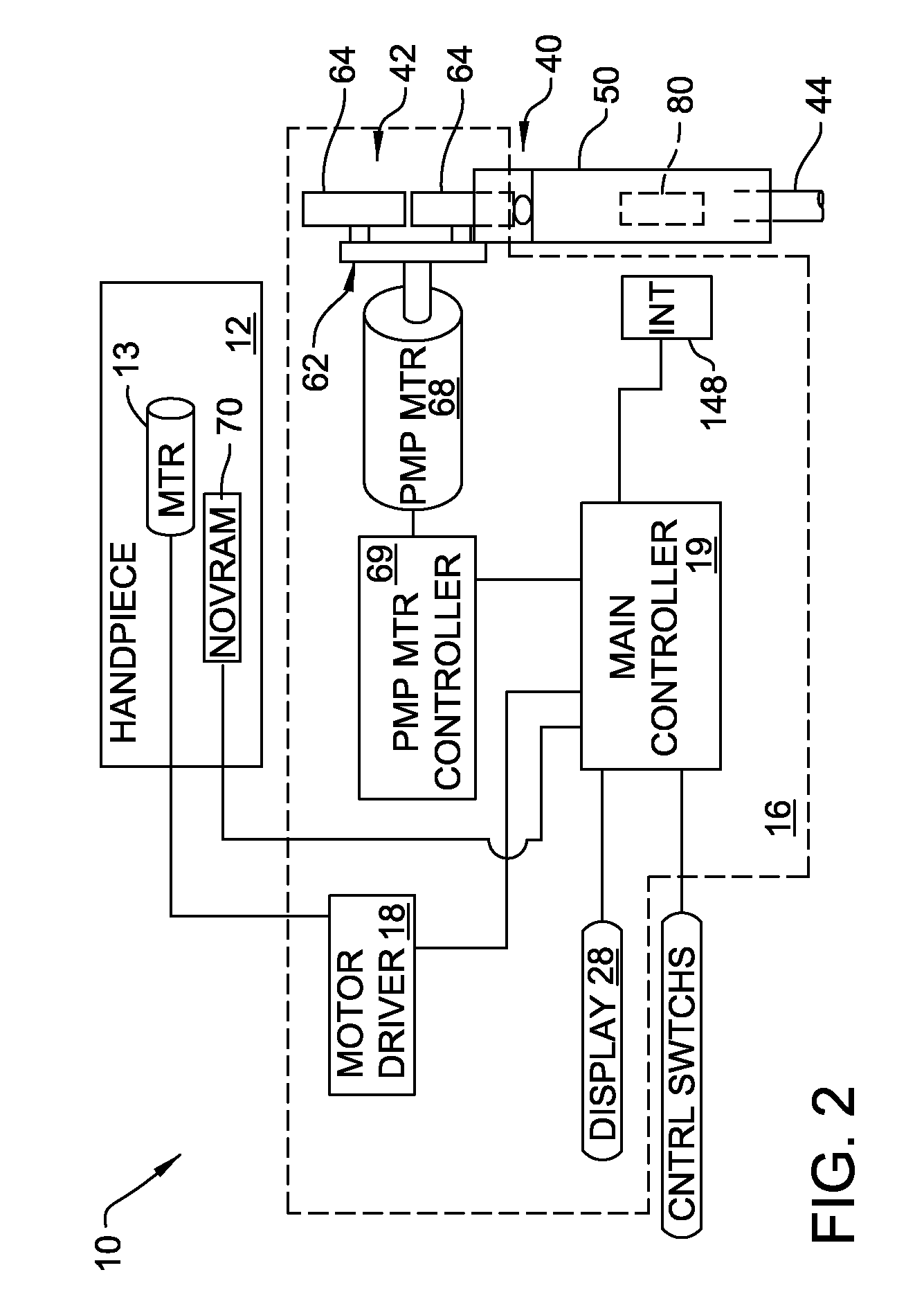

A tool system for both powering a handpiece and operating an irrigation pump. The pump includes a fixed pump head driven by a pump motor and a removable tube set. A readable memory such as RFID is integral with the tube set. The tube set memory contains data describing the physical characteristics of the tube set. A control console reads the data in the tube set memory. Based on these data, data from the handpiece and the characteristics of the motor driving the pump head, the control console determines if the pump, including the tube set can provide irrigation fluid at appropriate flow rates for the handpiece. If the assembled pump, specifically the pump head and tube set, can provide fluid at the appropriate flow rates, the control console then regulates the operation of the pump motor so that fluid, when required, is delivered at those flow rates.

Owner:STRYKER CORP

Apparatus and methods for pumping high viscosity fluids

A system for dispensing and filtering fluid is disclosed, in which the fluid flow path is substantially vertical from the fluid inlet through fluid dispense. Substantially all wetted surfaces are Teflon® or some similar non-contaminating fluid, for applications such as cleanroom processes. A valve and a filter chamber are incorporated into a pump head to simplify the flow path and reduce potential contamination points. Preferred methods, and chips or other microelectronic devices fabricated from the apparatus or methods, are also disclosed.

Owner:ENTEGRIS INC

Pump improvements

InactiveUS20060275160A1Avoid interferencePositive displacement pump componentsWorking fluid for enginesPump headPiston

A pump has a boltless cover that is held on the end of a housing of the pump by only a compressed ring between the cover and the housing. The pump has a flageless valve plate, meaning that the valve plate has no flange through which bolts that secure the head to the pump extend The pump has eccentrics and pistons that all have holes in them so that the pistons at opposite ends of the pump can be assembled to the shaft of the motor 180° out of phases. The pump further has a monolithic head that includes the two head members of the pump and the tube that connects them also has an integrally formed port. The pump is supported by elastomeric tubular members from its ports. The pump has a push-in fitting that can be pushed into a hole in a member such as the heads the housing or the base so that once pushed in, a ring around the fitting expands outwardly behind an edge of the body to trap the fitting in the opening.

Owner:LEU SHAWN A +1

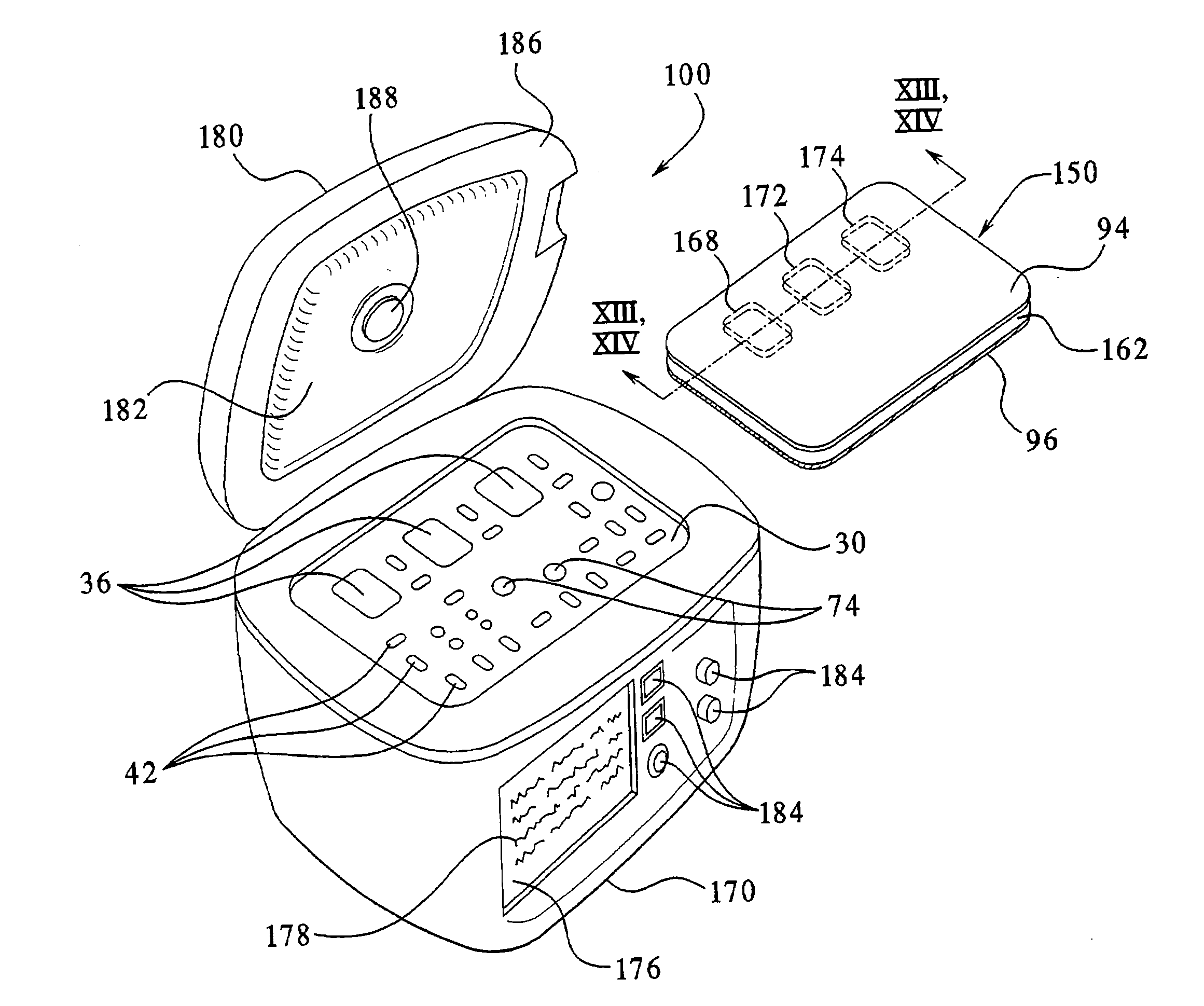

Peristaltic pump cartridge including an aspirant collection bag for use in ophthalmic surgery

A peristaltic pump cartridge 30 for use in ophthalmic surgery includes a housing 62, a length of surgical tubing 50 attached to the housing 62 for engagement with a pump head 14 of a peristaltic pump 10, and an aspirant collection bag 64 attachable to the housing 62. The bag 64 includes a fitment 98 heat-sealed to the bag 62. No adhesive is required to form a liquid-tight seal between the bag 62 and the fitment 98. The fitment 98 is attachable to the housing 62 for providing a conduit for aspirant to be pumped through the tubing 50 and into an interior of the bag 64.

Owner:BAUSCH & LOMB INC

Device, system and method for on-line monitoring of flow quantities

InactiveUS20050031443A1Improving monitoring and control and diagnosingEasily integrated into existing equipmentWind motor controlPump controlTotal efficiencyMotor drive

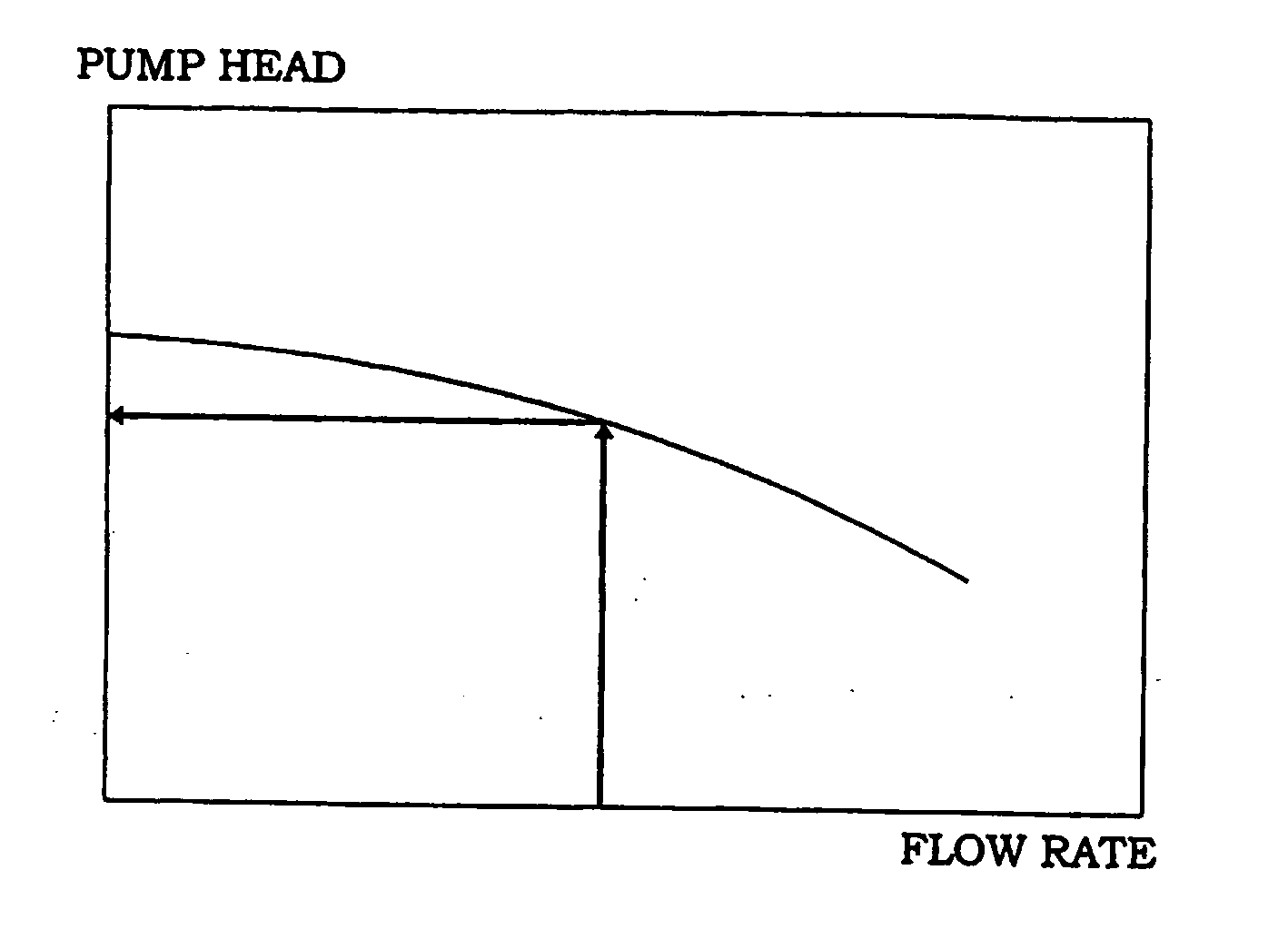

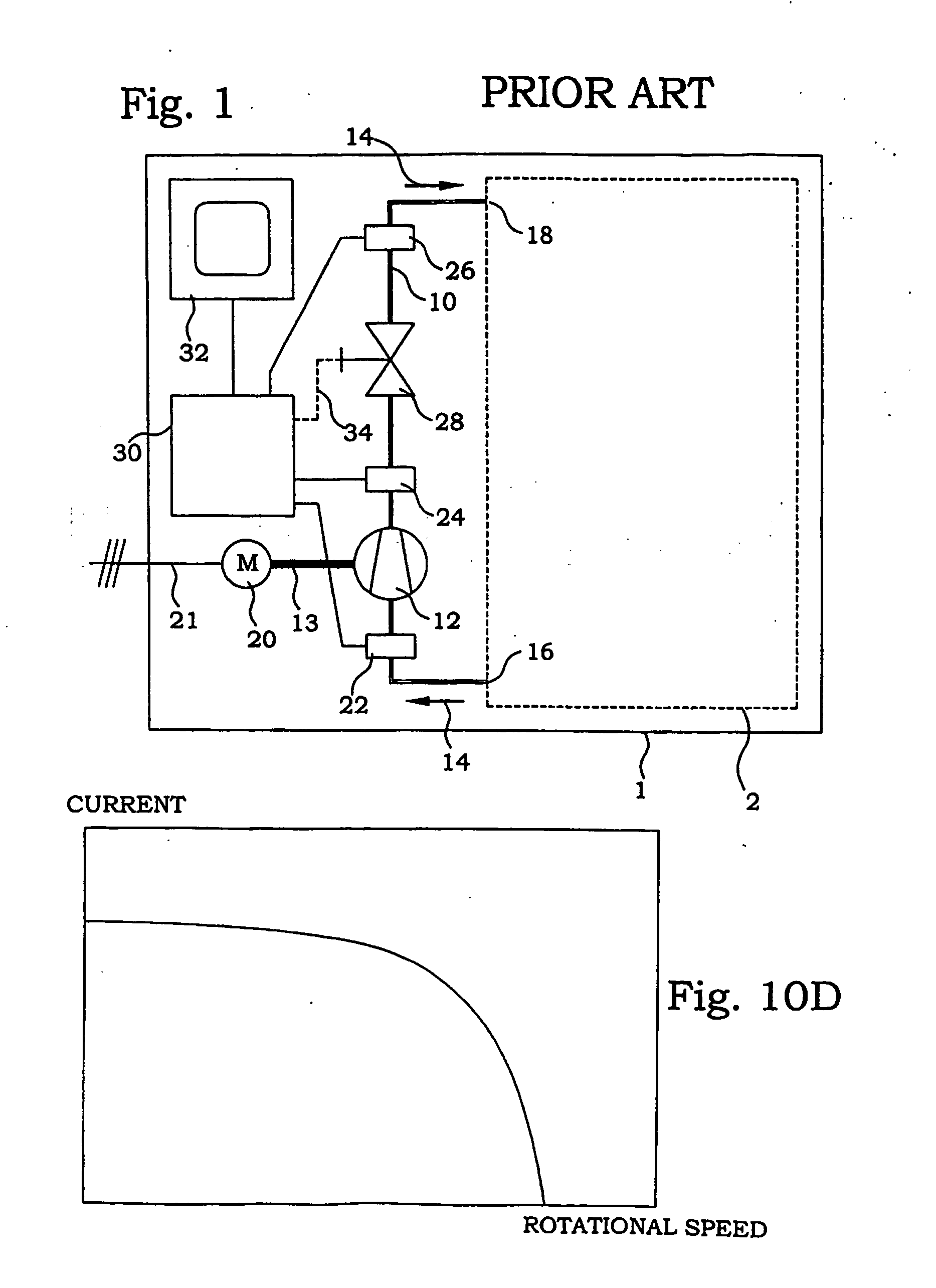

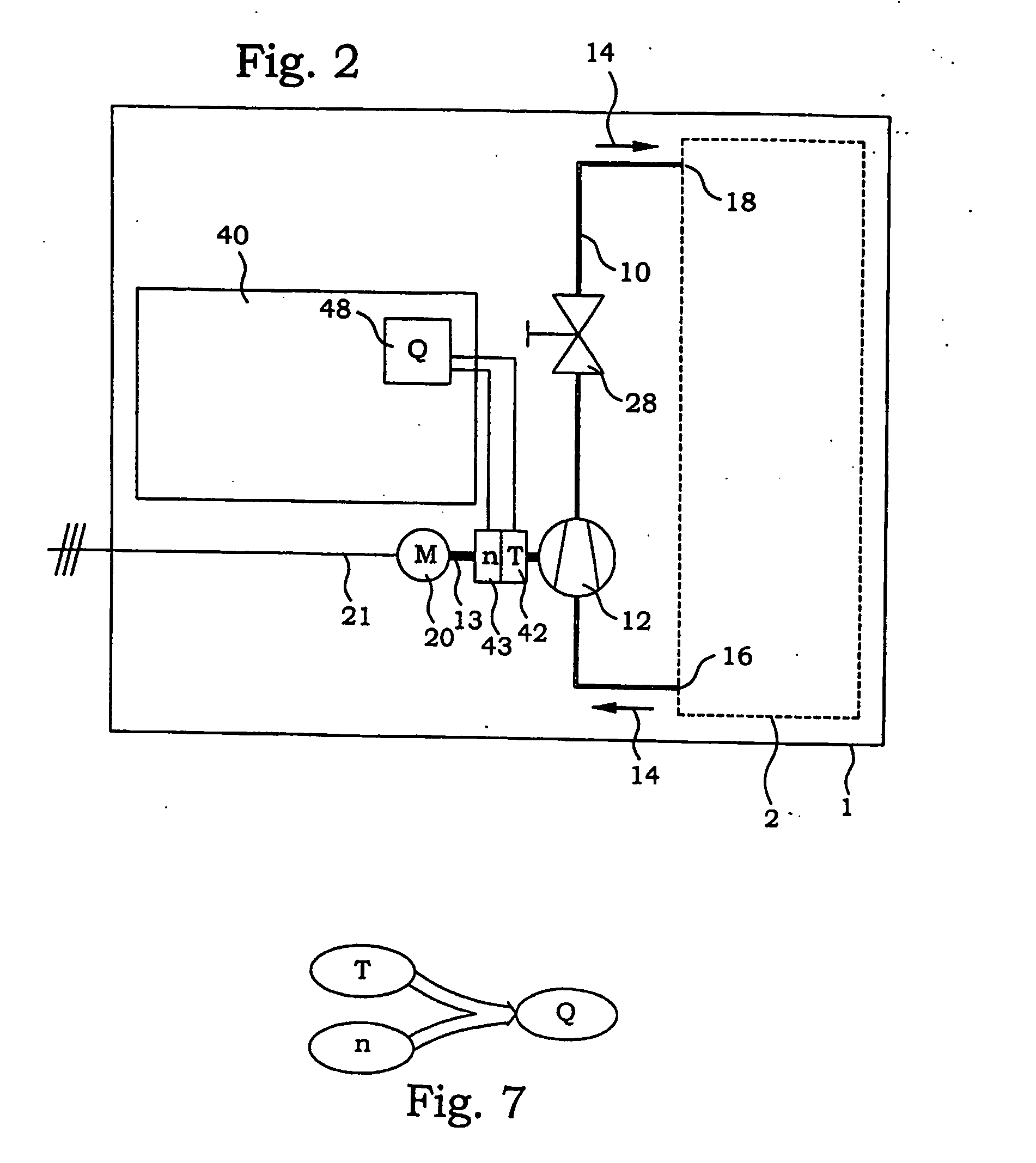

Measures of a torque and rotational speed of a pump or fan are obtained, from which a mechanical input power can be calculated. By further using predetermined relations between mechanical input power and flow rate through the pump or fan, a measure of the flow rate can be derived without use of in-line flow or pressure sensors. In preferred embodiments the torque and / or rotational speed is obtained by measuring the input current and voltage of a motor driving the pump or fan and using predetermined relations between on the one hand current and voltage and on the other hand torque and rotational speed. Furthermore, also other flow properties, such as pump head, pump efficiency and total efficiency can be determined in this manner.

Owner:ABB (SCHWEIZ) AG

Temperature compensation system for regulating flow through tubing in a pump

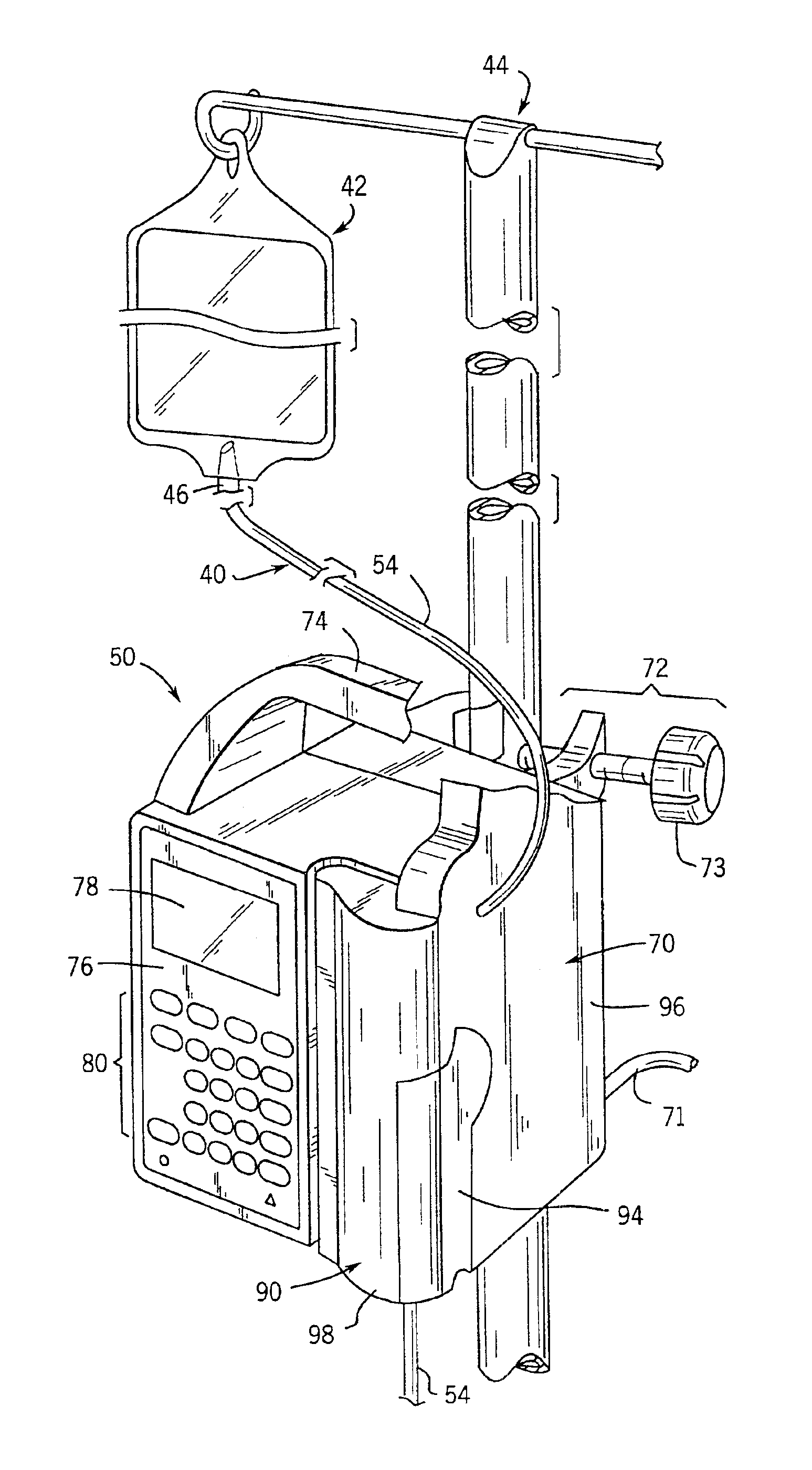

InactiveUS6869425B2Easy to operateEasy to set upFluid parameterOther blood circulation devicesPeristaltic pumpHeat flow

A peristaltic pump is provided with a housing, a pump head in the housing, and a receiving path defined along a housing and pump head for receiving tubing. Two spaced-apart temperature sensors are provided. One temperature sensor is located adjacent the tubing in a heat conduction path along which heat flows between the sensor and the tubing. The other sensor is located outside of the heat conduction path for sensing ambient temperature. The pump operating speed is adjusted as a function of the sensed temperatures. This accommodates the temperature-dependent rate of recovery of the tubing from its peristaltically deformed configuration to its original configuration.

Owner:ICU MEDICAL INC

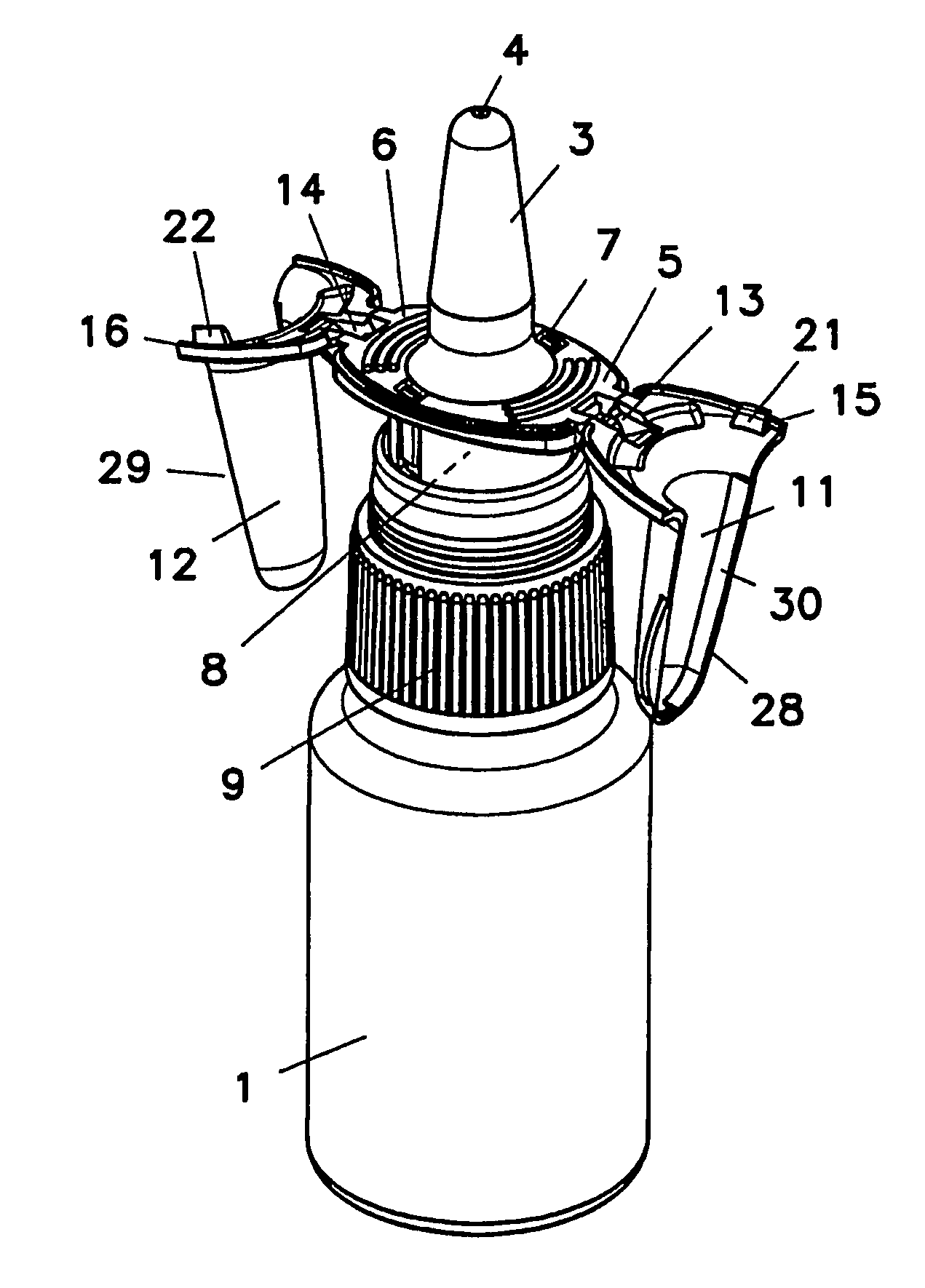

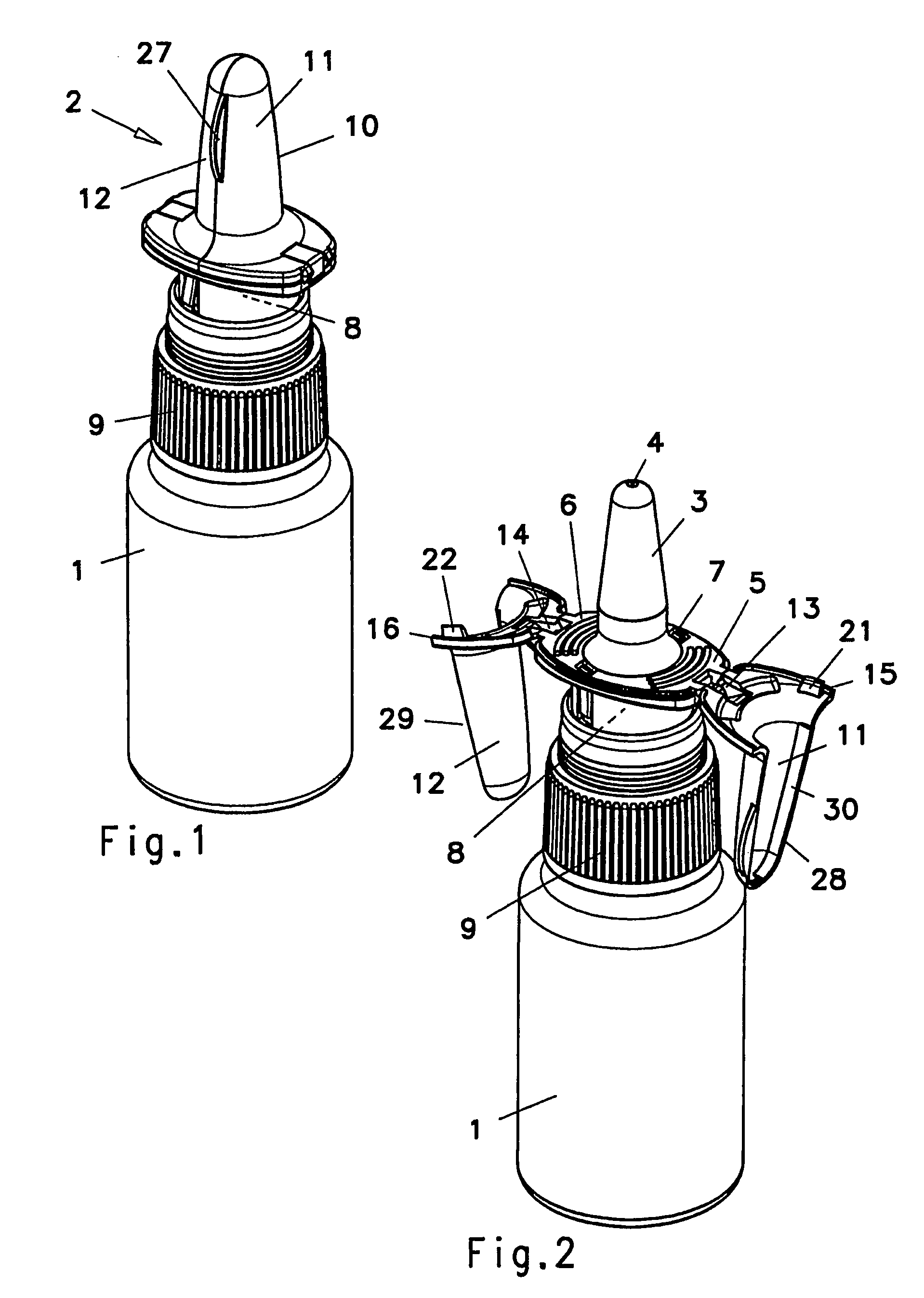

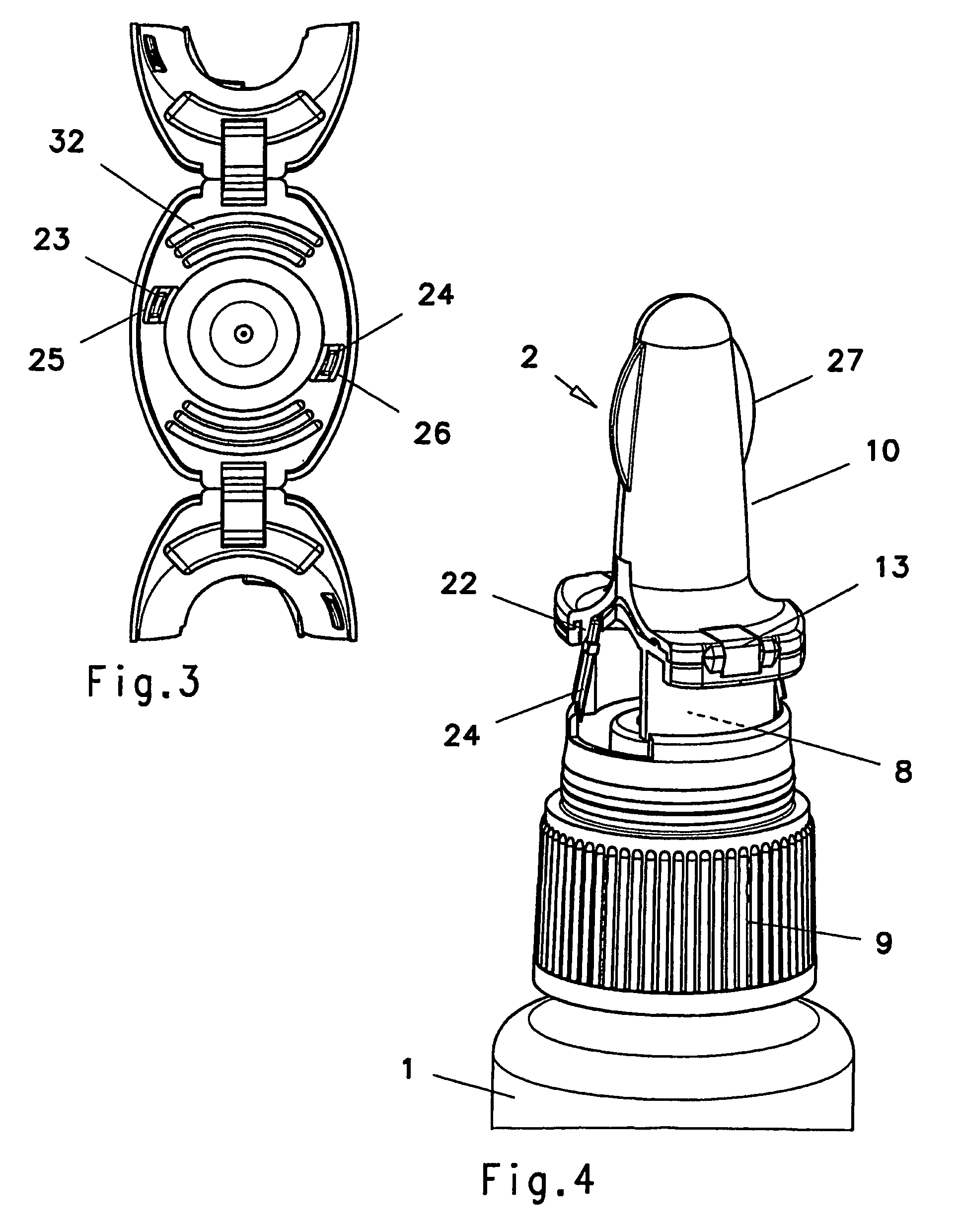

Manually operated dispenser comprising a protective cap

ActiveUS7757901B2Overcomes drawback and deficiencySolve the real problemClosure using stoppersLarge containersPump headHinge angle

A manually operated dispenser for flowable media, having a container which has a supply chamber, and a pump head which can be fastened thereto and has a dispensing section with a nozzle-shaped nasal adapter having an outlet opening designed as a spray diffuser, and gripping surfaces protruding laterally from the nasal adapter, and having a protective cap, which has two wings which can be unfolded and are matched in terms of shape, for the nasal adapter, the gripping surfaces having, on opposite sides, end edges which are connected as a single piece to a wing of the protective cap via a respective spring hinge, and the wings have base surfaces which overlap the gripping surfaces.

Owner:SILGAN DISPENSING SYST HEMER GMBH

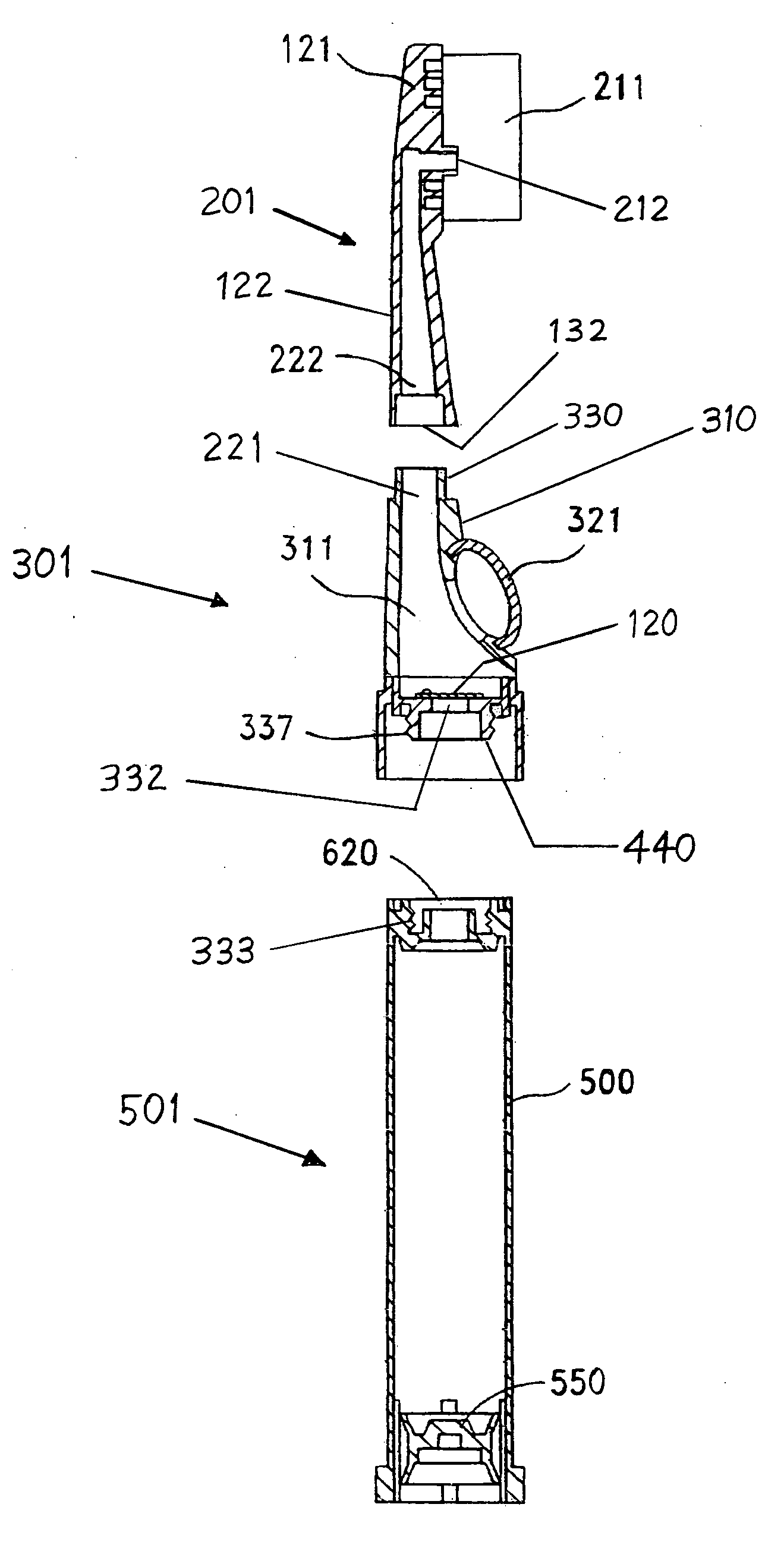

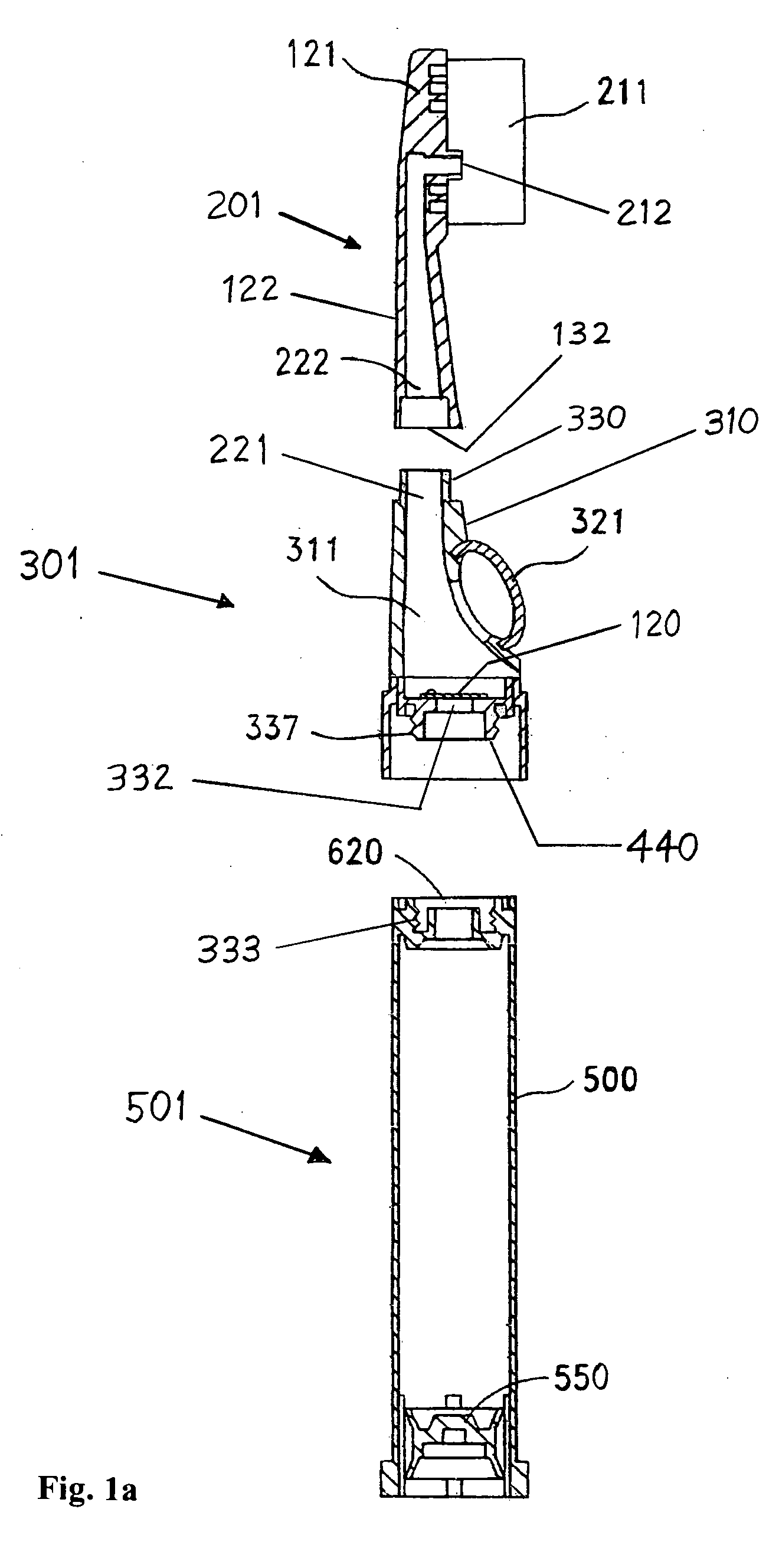

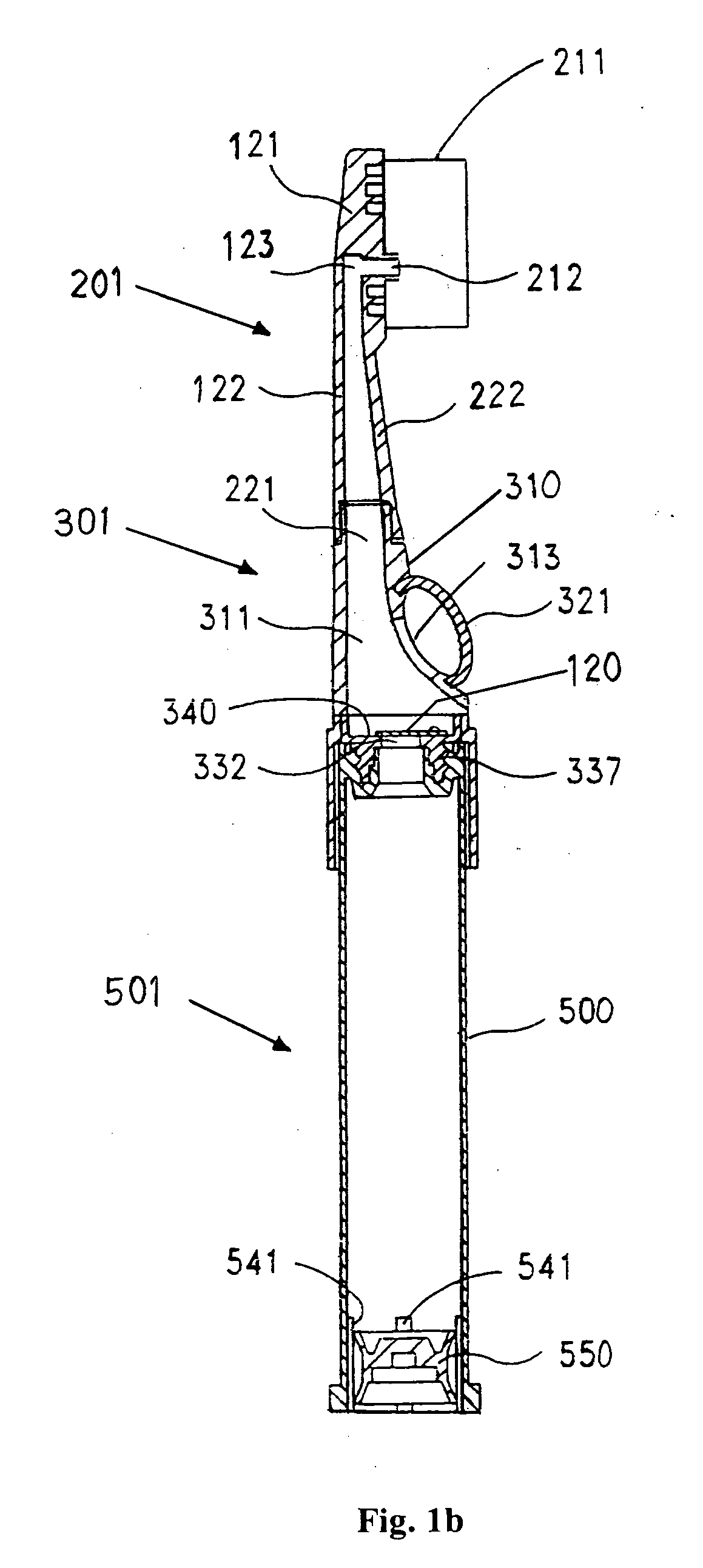

Manual and electrical pump toothbrushes for dispensing liquid and paste dentifrices

InactiveUS20070041779A1Prevent backflowPrevent dryingCarpet cleanersFloor cleanersToothpasteEngineering

Pump toothbrush being provided for maximizing the benefit of brushing with liquid dentifrice by conveniently dispensing the dentifrice incrementally with one-hand to teeth surfaces and spaces between teeth without interrupting the continuous brushing motion. Common pump head and cartridge structure enable dispensing any kind of liquid and paste dentifrices. The pump head is equipped with an elastic compressible button for pumping with thumb and an inlet connector for mounting a refillable piston cartridge. A built-in self-closing slit valve in the brush head prevents backflow and drying of dentifrice material at the spout opening. The slit valve opens and closes automatically with the pumping action. The dispensing mechanism and cartridge structure are applicable to manual and electrical pump toothbrushes which use common cartridges. A toothbrush container having vent-tube and vent-caps is also provided for selective venting and sealing a pump toothbrush.

Owner:KUO YOUTI

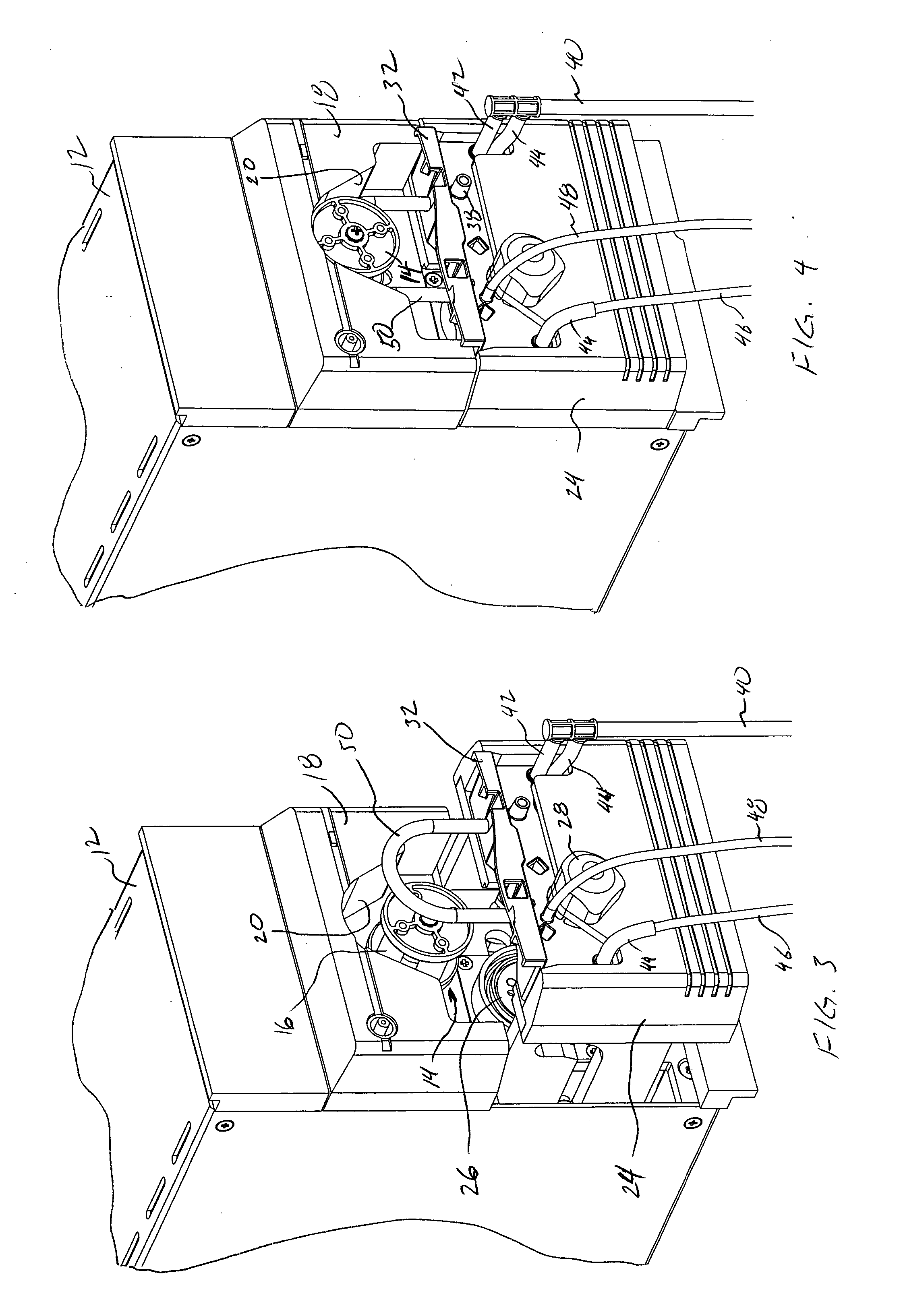

Fluid circulation path for motor pump

InactiveUS6884043B2Rotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringPump head

A fluid pump includes a pump head having an inlet for receiving fluid at a first pressure and an outlet for outputting fluid at a second pressure greater than the first pressure. Pressurized fluid is directed through a first passage to the outlet without the pressurized fluid leaving the pump head prior to reaching the outlet. A second passage directs pressurized fluid to a fluid circulation path which is at least partially external to the pump head with the fluid circulation path terminating adjacent the outlet. Pressurized fluid passing through the first and second passages is directed to the outlet without being re-pressurized by the pump head. The first and second passages are in opposed relation to one another to provide balancing of thrust produced by the flow of pressurized fluid through the passages. An electric motor drives the pump head. The fluid circulation path may include portions of the electric motor.

Owner:STANDEX INT CORP

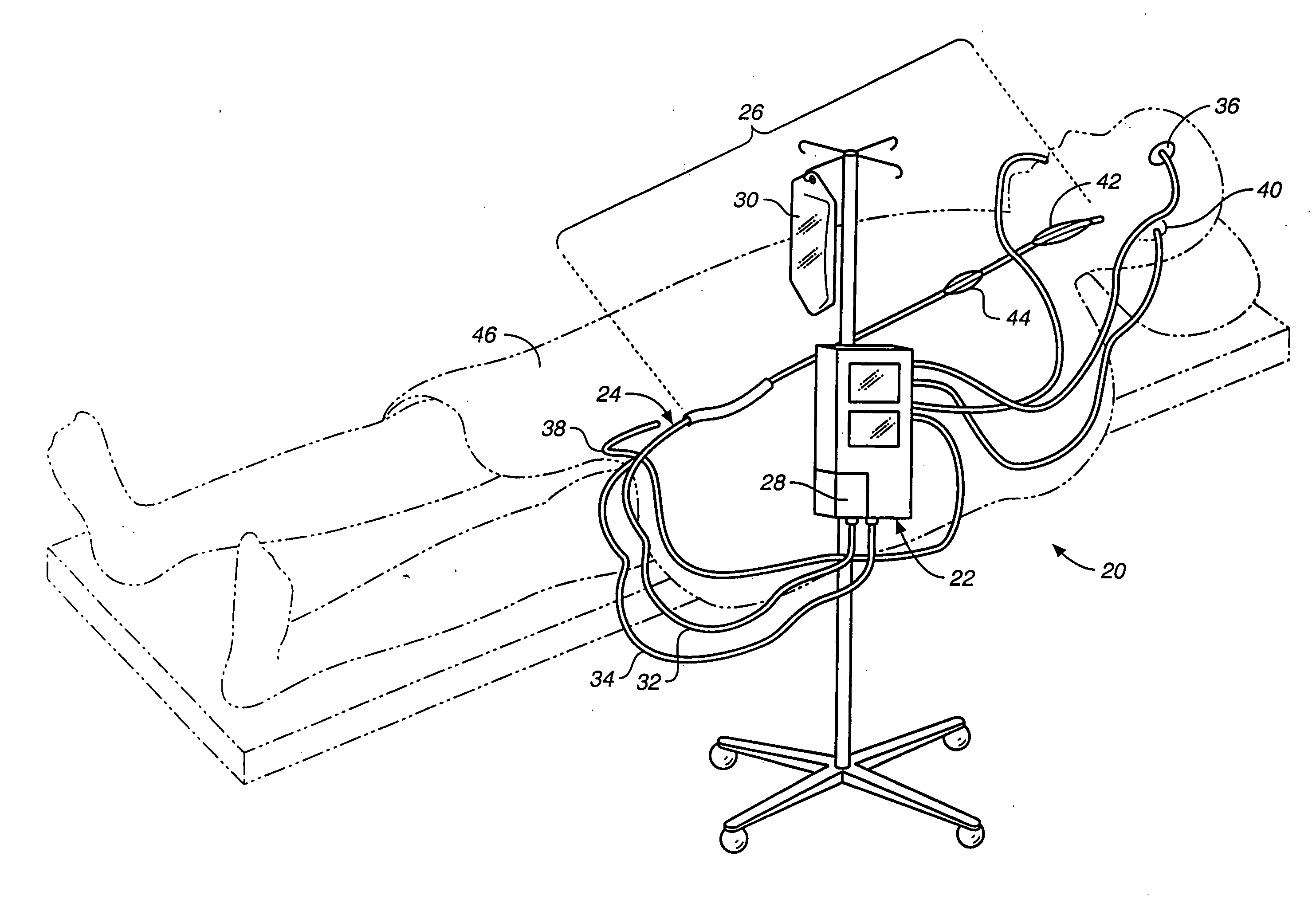

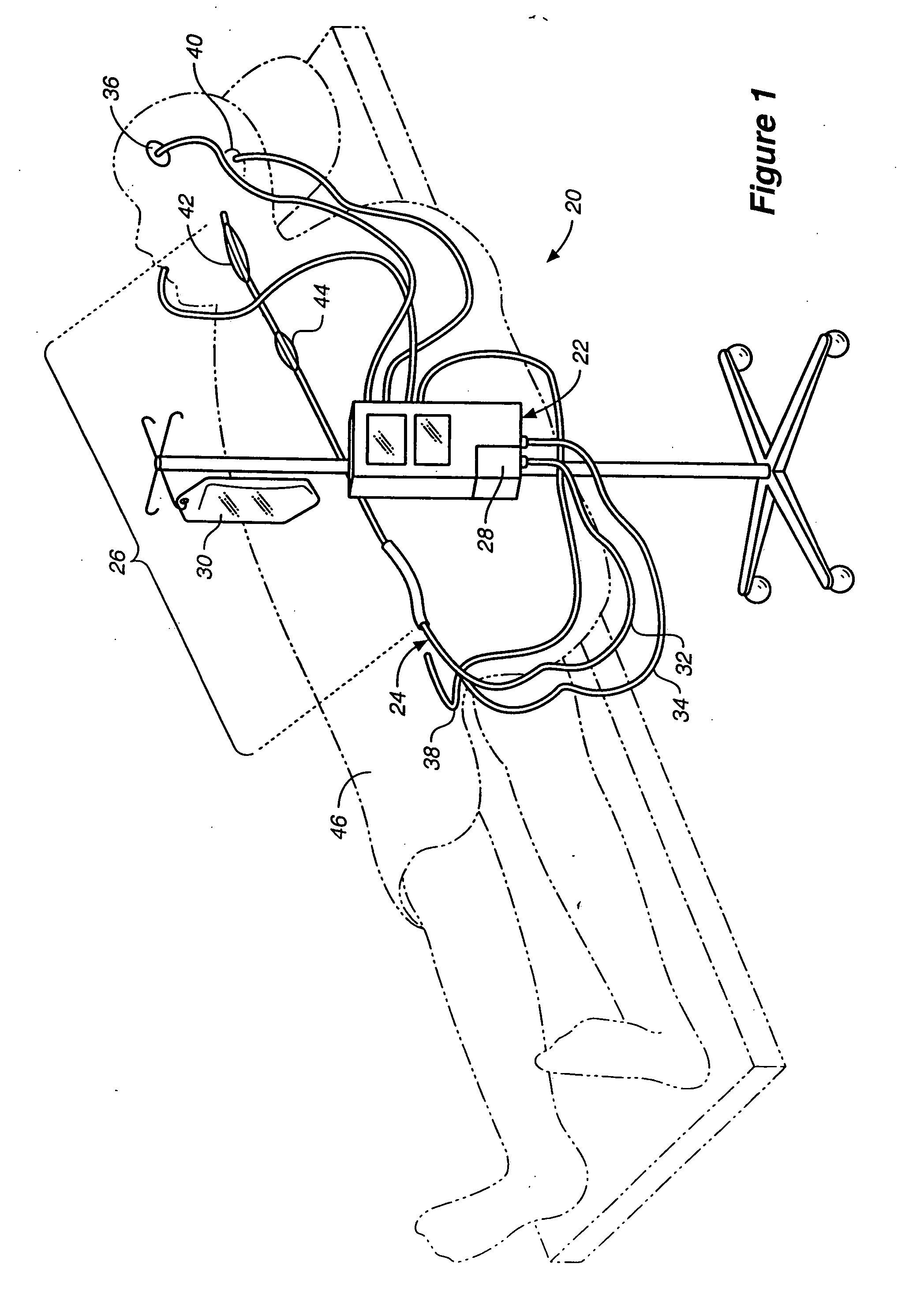

Method and system for control of a patient's body temperature by way of a transluminally insertable heat exchange catheter

Methods and apparatuses for temperature modification of a patient, or selected regions thereof, including an induced state of hypothermia. The temperature modification is accomplished using an in-dwelling heat exchange catheter within which a fluid heat exchange medium circulates. A heat exchange cassette of any one of several disclosed variations is attached to the circulatory flow lines of the catheter, the heat exchange cassette being sized to engage a cavity within one of various described re-usable control units. The control units include a heater / cooler device, a user input device, and a processor connected to receive input from various sensors around the body and the system. The heater / cooler device may be thermoelectric to enable both heating and cooling based on polarity. A temperature control scheme for ramping the body temperature up or down without overshoot is provided. The disposable heat exchange cassettes may include an integral pump head that engages with a pump drive mechanism within the re-usable control unit. More than one control unit may be provided to receive the same heat exchange cassette so that a large capacity control unit can be used initially, and a smaller, battery-powered unit can be substituted once the patient reaches the desired target temperature.

Owner:ZOLL CIRCULATION

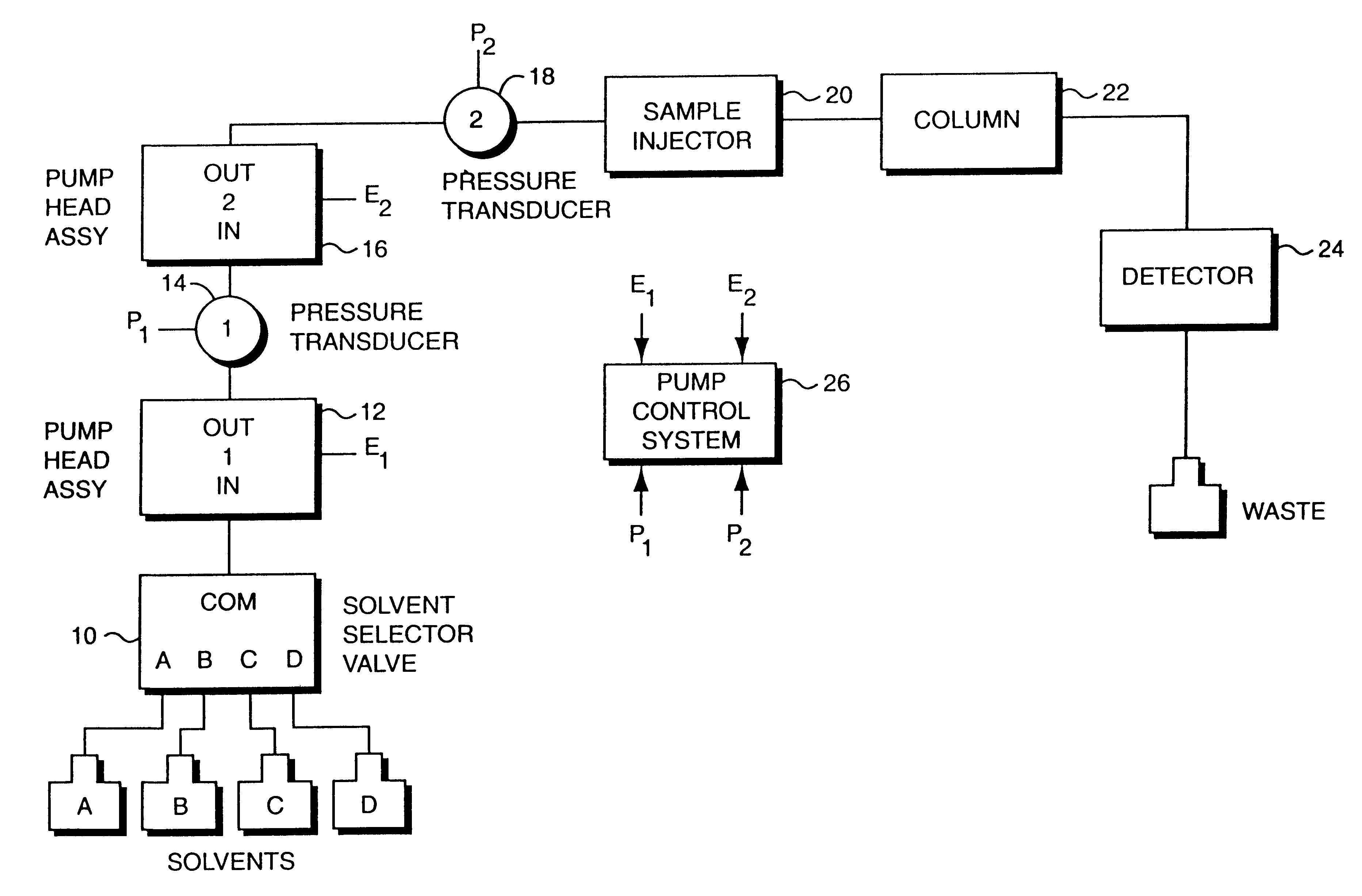

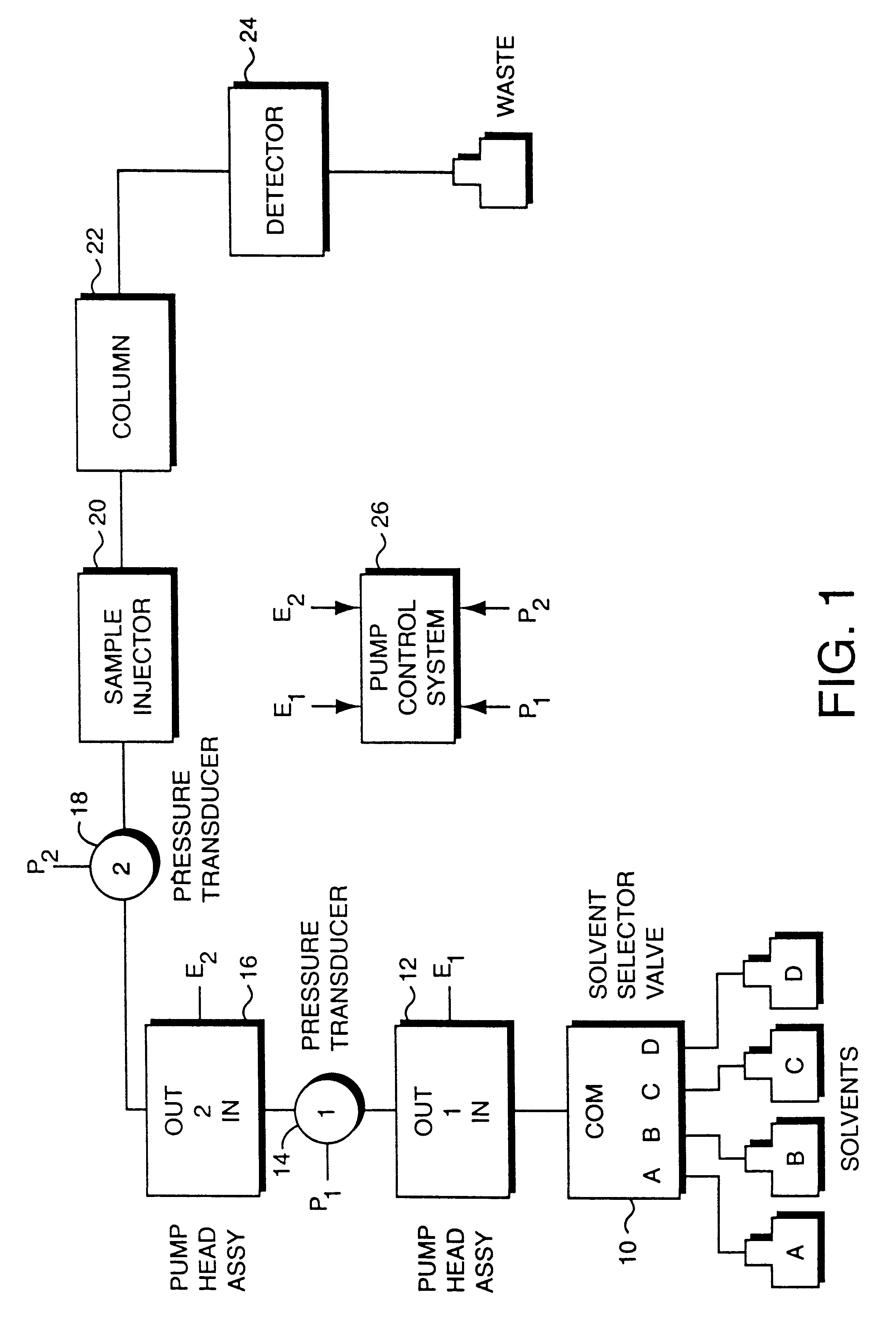

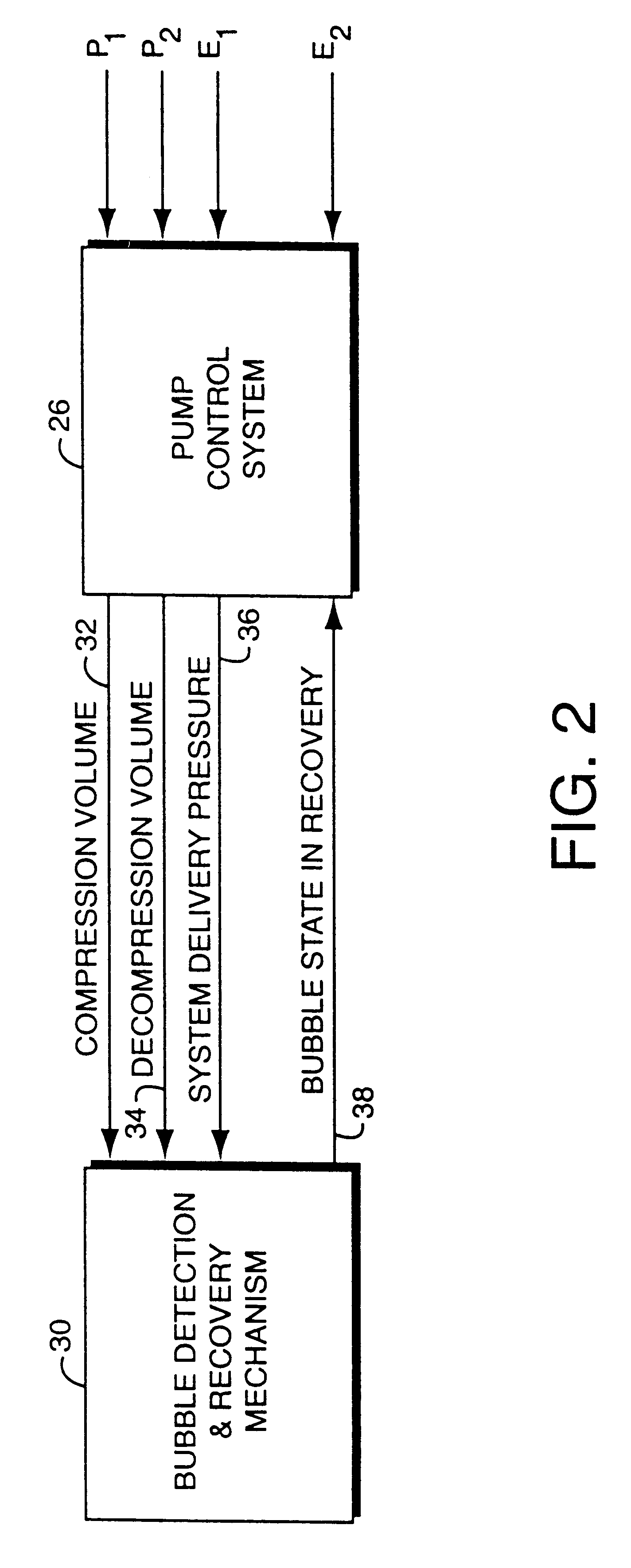

Bubble detection and recovery in a liquid pumping system

InactiveUSRE37553E1Minimizes delay volumeMinimizes compositional rippleIon-exchanger regenerationLoose filtering material filtersGas to liquidsEngineering

A serial, dual piston high pressure fluid pumping system that overcomes the difficulties of gas in the fluid stream without the need for added mechanical valves or fluid paths. A bubble detection and recovery mechanism monitors compression and decompression volumes of the serially configured dual pump head pump, and the overall system delivery pressure. Bubble detection is effected by sensing a ratio of compression to decompression volume and determining if the ratio exceeds an empirical threshold that suggests the ratio of gas-to-liquid content of eluent or fluid in the system is beyond the pump's ability to accurately meter a solvent mixture. The magnitude of the ratio of compression to decompression volume indicates that either the intake stroke has a bubble or that the eluent has a higher-than-normal gas content. Once a bubble has been detected, recovery is effected by forcing the pump into a very high stroke volume with the compression and decompression stroke limits constrained to obtain the largest delivery stroke compression ratio that will expel a bubble or solvent that has detrimental quantities of gas.

Owner:WATERS INVESTMENTS

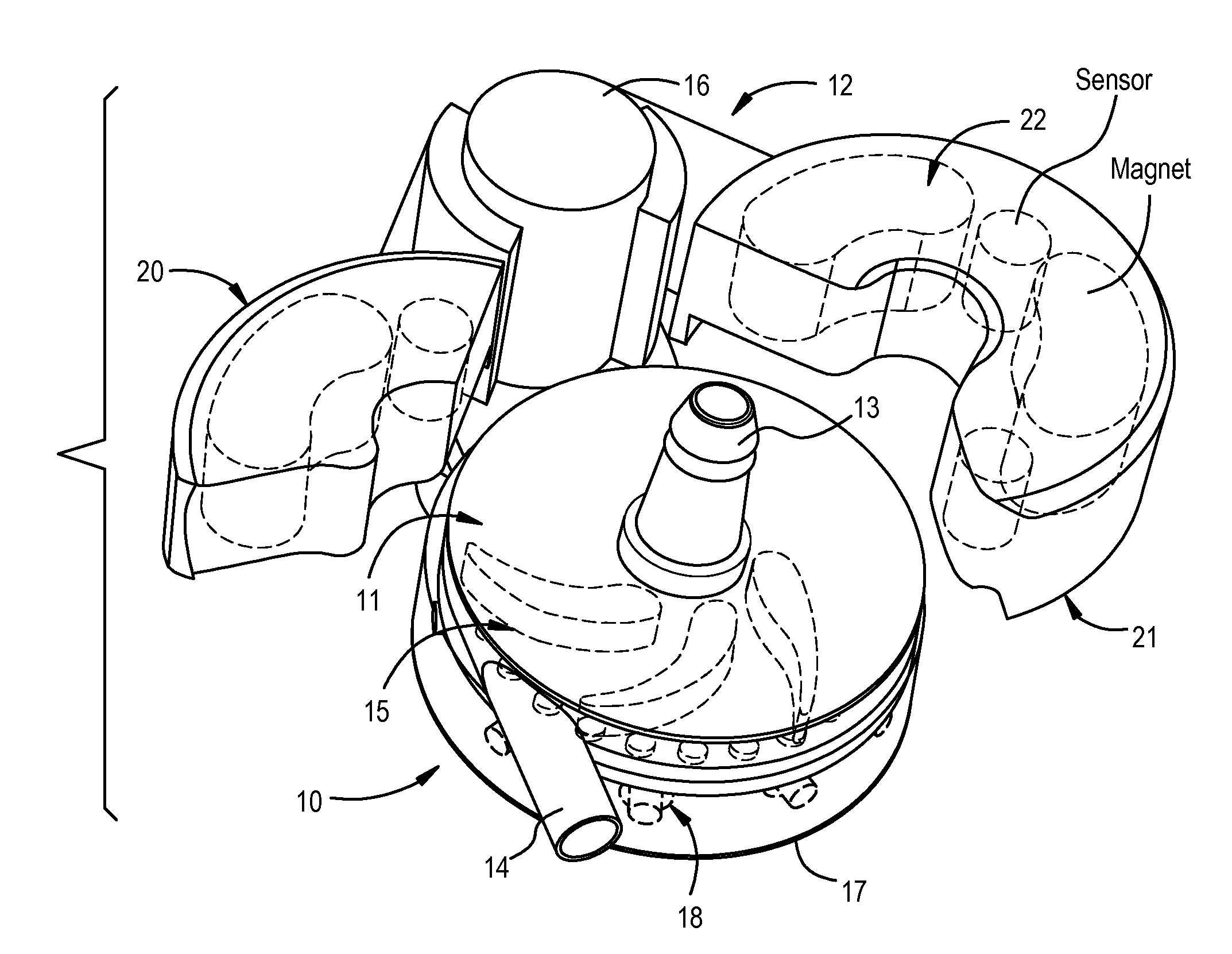

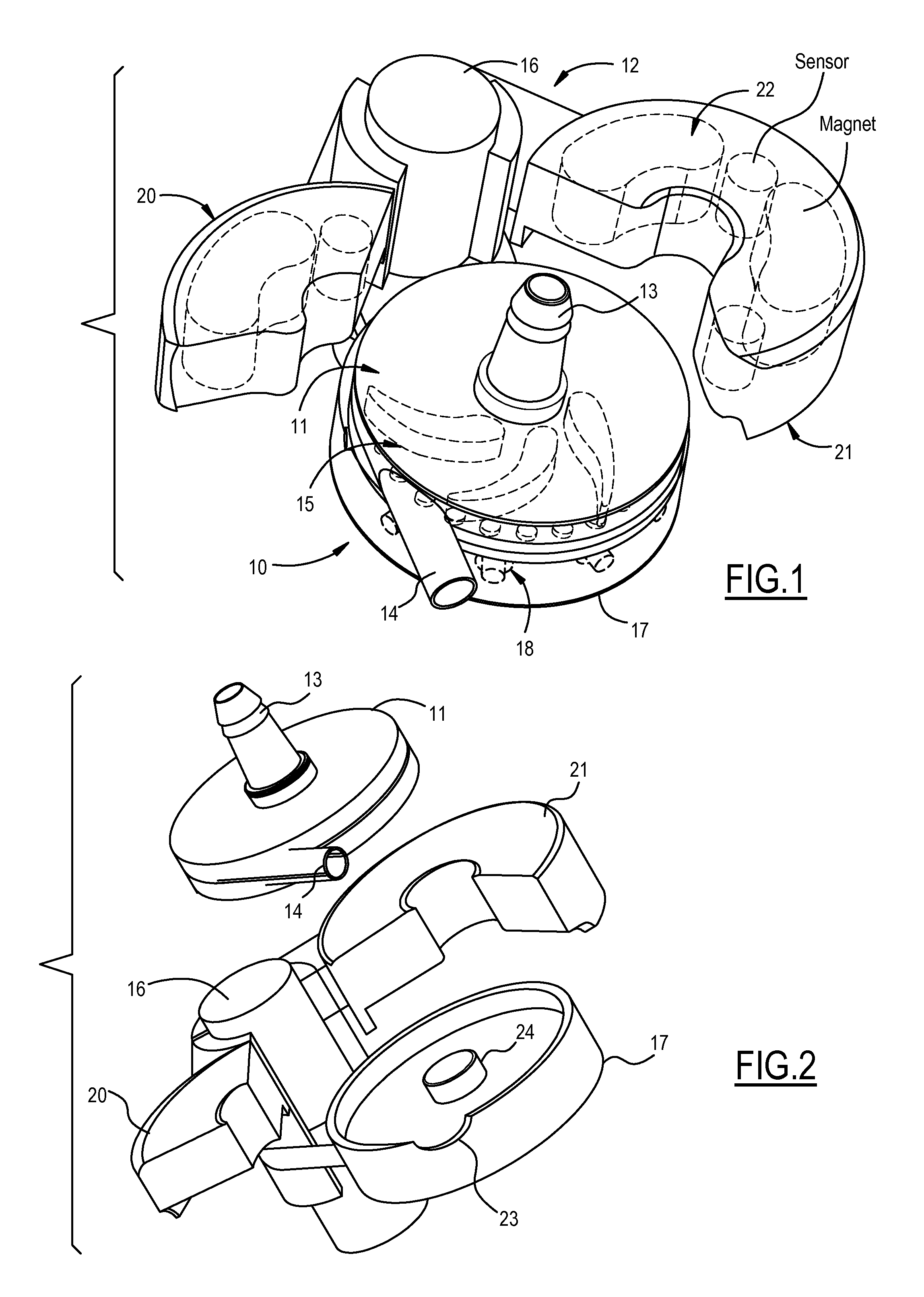

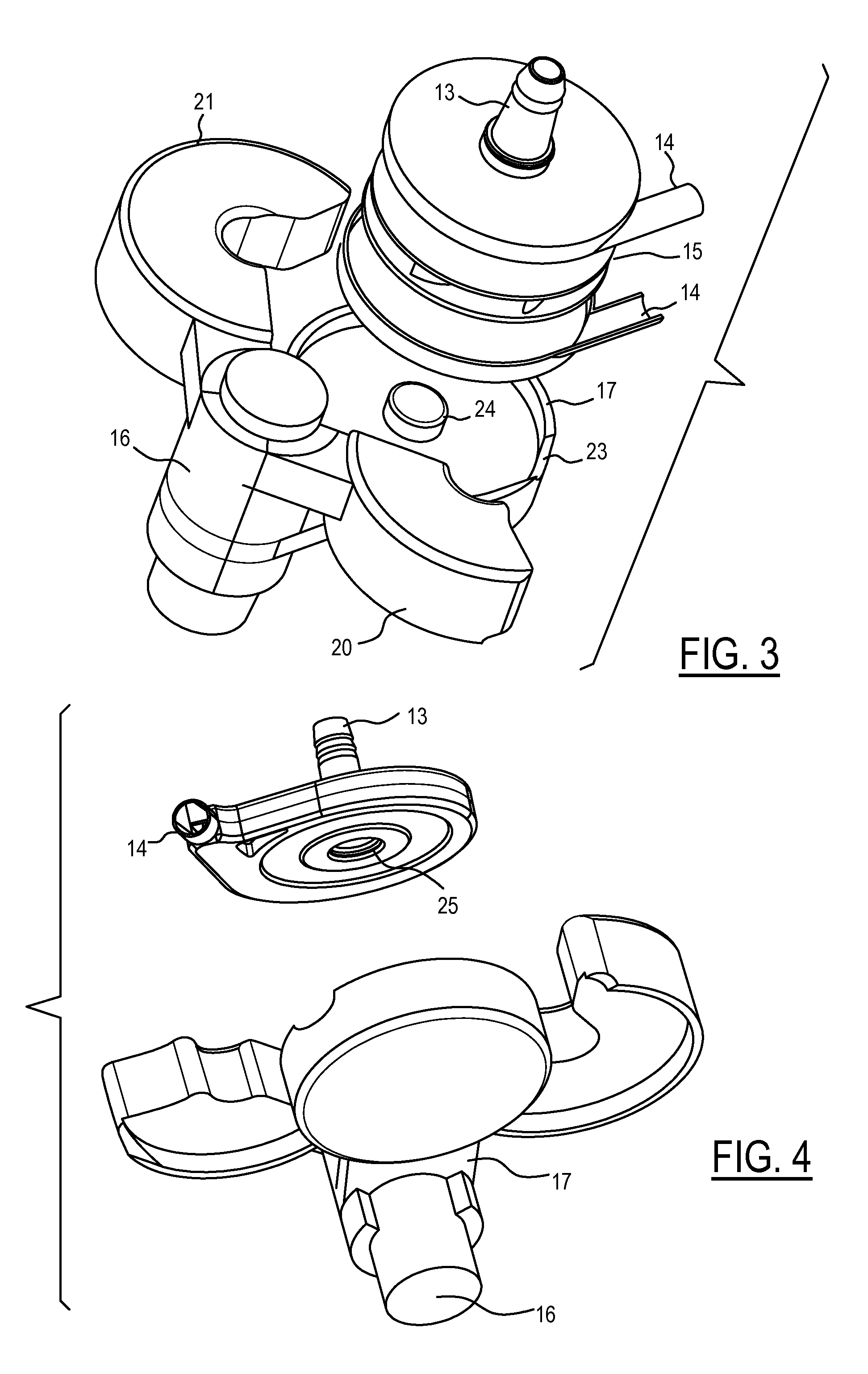

Extracorporeal Blood Pump with Disposable Pump Head Portion Having Magnetically Levitated Impeller

A pump drive unit has an openable housing that accommodates a disposable impeller unit which is pre-connected with tubing, while maintaining the tight tolerances and close spacing. A levitation system (magnets and sensors), drive motor and drive magnets, and control electronics are all re-usable and housed within relatively permanent structures. In one embodiment, a hinged top separates the levitating magnets to allow the impeller unit to be captured and retained with positional accuracy and in close proximity to the desired locations when the hinged top is closed. The top may be separated into sections covering unequal arcs to coincide with the organization of the magnetic subcomponents in the upper drive unit housing.

Owner:TERUMO CARDIOVASCULAR SYST CORP

Apparatus and methods for pumping high viscosity fluids

InactiveUS20060070960A1Good benefitImprove performanceSpecific fluid pumpsPower operated devicesPump headViscosity

A system for dispensing and filtering fluid is disclosed, in which the fluid flow path is substantially vertical from the fluid inlet through fluid dispense. Substantially all wetted surfaces are Teflon® or some similar non-contaminating fluid, for applications such as cleanroom processes. A valve and a filter chamber are incorporated into a pump head to simplify the flow path and reduce potential contamination points. Preferred methods, and chips or other microelectronic devices fabricated from the apparatus or methods, are also disclosed.

Owner:ENTEGRIS INC

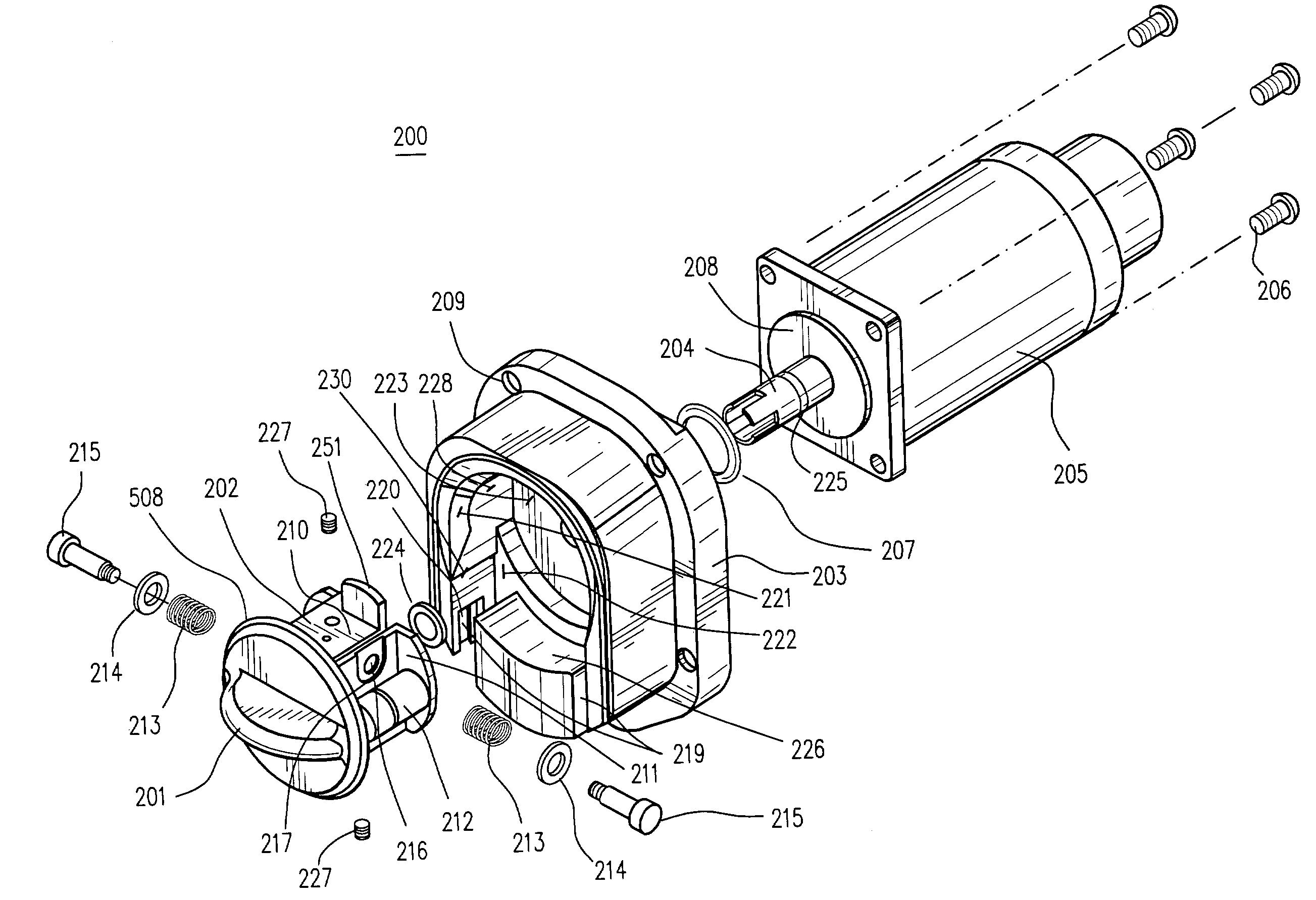

Air-Operated Pump

An air-operated pump for pumping material such as oil or grease. The pump is powered by an air motor which operates to reciprocate a piston and plunger to effect a pumping action. The air motor is modular in that the air valve system is contained in a single housing fastened to the pump head. The housing is removable as a unit from the pump head to facilitate servicing of the air valve system.

Owner:LINCOLN INDUSTRIES CORP

Self-loading peristaltic pump for extracorporeal blood circuit

InactiveUS7018182B2Flexible member pumpsPositive-displacement liquid enginesPeristaltic pumpEngineering

Owner:GAMBRO LUNDIA AB

Cassette having elastomeric clamping ribs

A cassette having a molded flow channel contained on an elastomeric sheet that is bonded or mechanically attached to a rigid substrate. A surgical console contains a cassette receiving area having a pump head with rollers that are mounted radially from the axis of rotation of the pump motor and compress the elastomeric flow channels against the rigid substrate. The cassette is held in place against the pump head by a latching mechanism that draws the cassette against the pump head. The periphery of the elastomeric sheet contains a raised ridge or boss integrally formed as part of the elastomeric sheet at or near the area(s) of the elastomeric sheet that is / are subject to high transient or static pressures. The ridge allows the elastomeric sheet to be firmly pressed against the cassette receiving portion of the surgical console, yet still allow the cassette to be drawn against the pump head. The firm engagement of the sheet ridge against the cassette receiving portion of the surgical console helps to ensure that the elastomeric sheet does not become dislodged when the cassette is exposed to high transient pressures.

Owner:ALCON INC

Espresso machine and method of use thereof

InactiveUS20060037481A1Minimize temperature lossReduce the temperatureBeverage vesselsImpellerEngineering

An espresso machine having a brew water tank and a heating block located within the brew water tank. The heating block is preferably made of a thermally conductive material such as copper and will preferably have a body and thermally conductive vertical members extending vertically from the body within the brew water tank. The heating block will be associated with a heat source which can be an electric heater. The espresso machine may also include a pump head consisting of an input, and output, and an impeller mechanism, positioned within the brew water tank and in contact on at least one side with heated brew water. In addition, the brew water conduit connecting the pump to the brew head will be located substantially within the brew water tank. Thus, temperature loss in the brew water conduit or in the pump head will be minimized. In addition, a second heat source may be operatively associated with the bayonet or portafilter. Thus, a reduction in the temperature of brew water as it passes through the ground coffee in the portafilter can be minimized. A separate and distinct exhaust conduit may also be placed in fluid communication with the brew head, allowing the exhaustion of pressurized water from the brew head, after the preparation of a shot of espresso, entirely through a conduit which is separate from the clean water supply.

Owner:BICHT JOHN

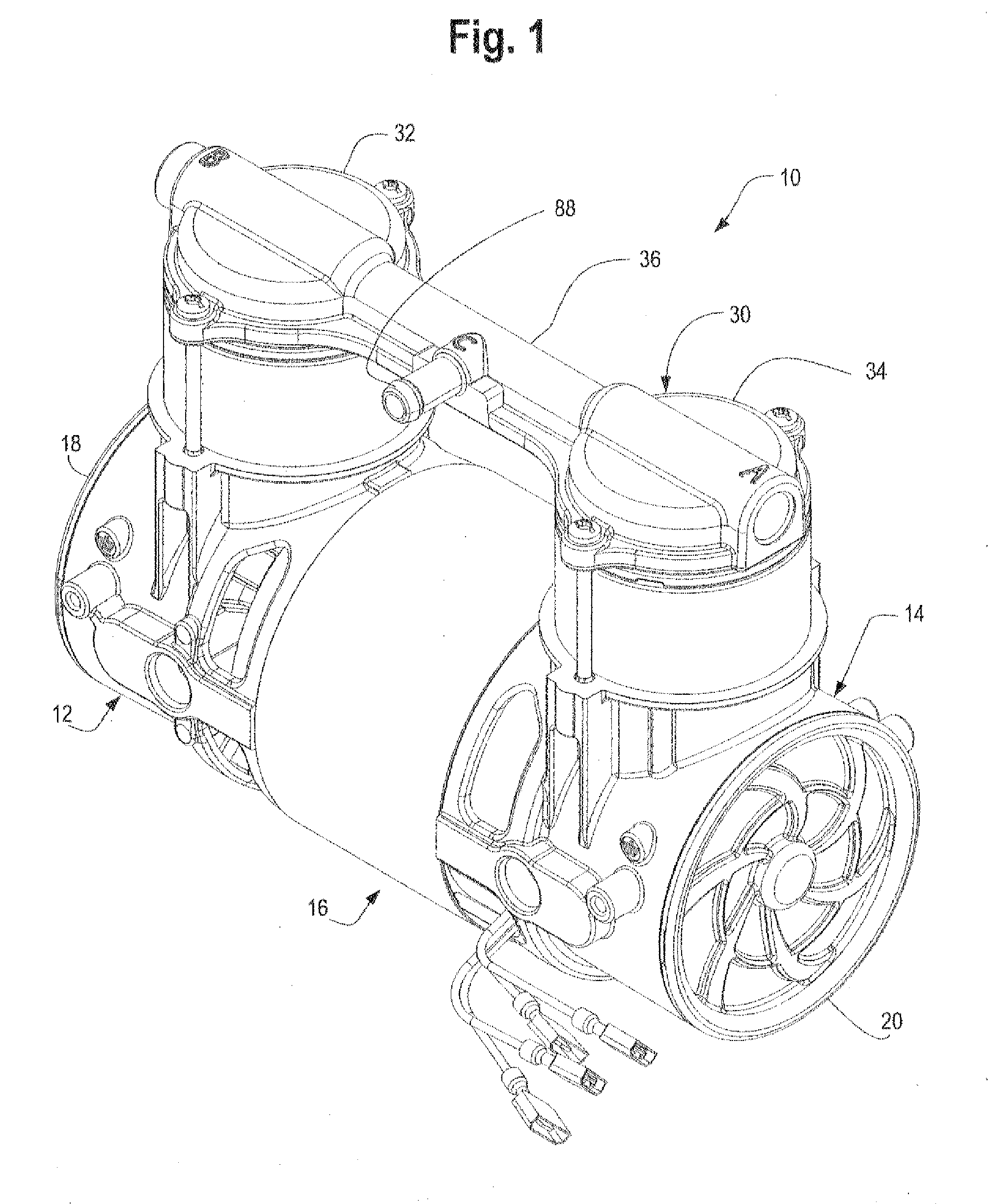

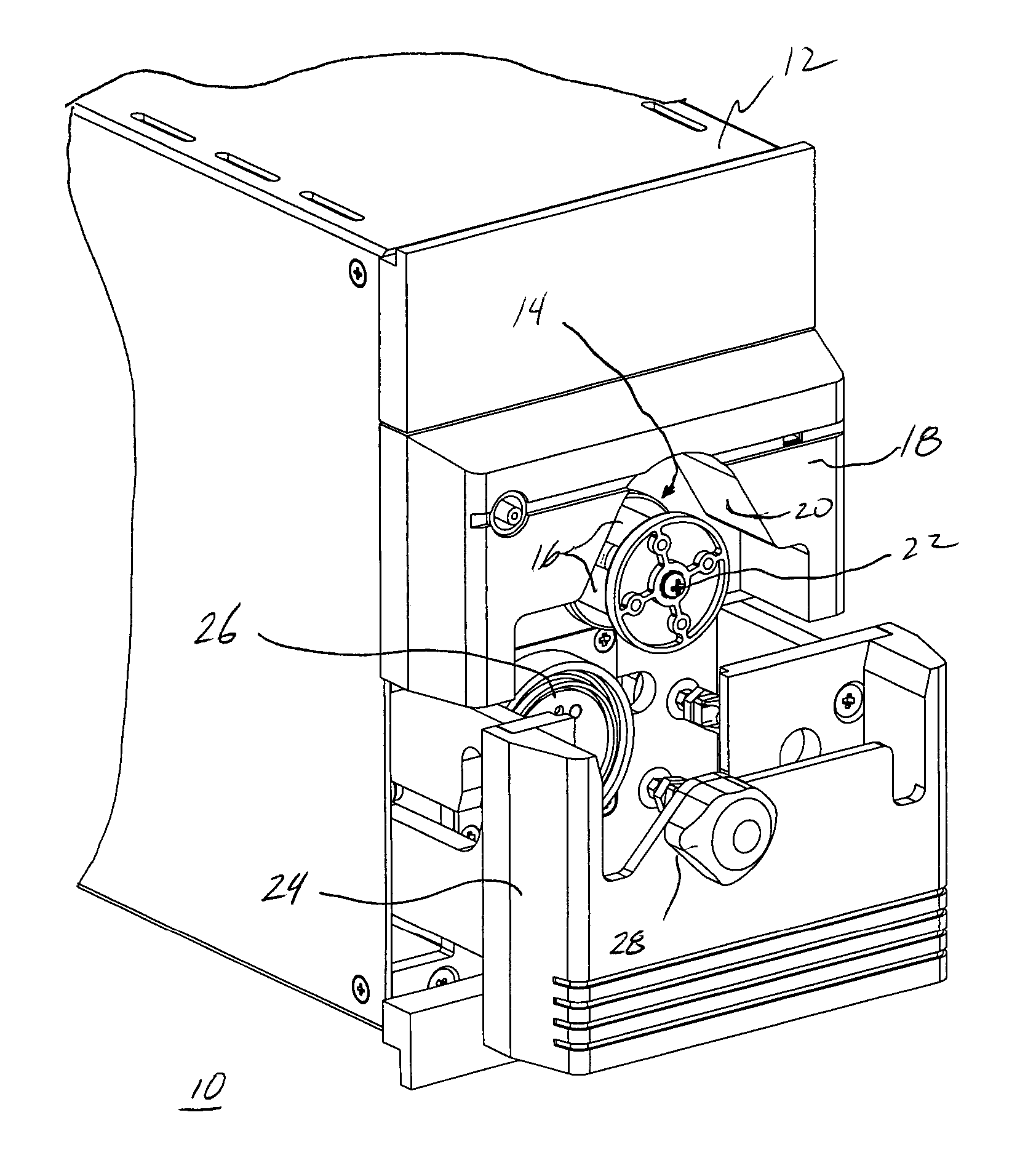

Peristaltic pump with air venting via the movement of a pump head or a backing plate during surgery

ActiveUS7168930B2Low costShort timePositive displacement pump componentsFlexible member pumpsPeristaltic pumpSurgical site

A peristaltic pump 10 for use in ophthalmic surgery includes a housing 12, a pump head 14 having plurality of rollers 16, a backing plate 18 attached to the housing 12, and a length of surgical tubing 50. The rollers 16 and backing plate 18 cooperate to pinch the length of surgical tubing 50 to peristaltically pump fluids from a surgical site to a collection bag 64. At least one of the pump head 14 and the backing plate 18 is moveable, during operation of the pump 10, from a tubing pinched position to a tubing vent position. This movement allows the tubing 50 to be vented by removing the pinched closure of the tubing 50.

Owner:BAUSCH & LOMB INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com