Pump driven by an electromotor and method for producing a pump of this type

a technology of electromotor and pump, which is applied in the direction of piston pumps, positive displacement liquid engines, magnetic circuit shapes/forms/construction, etc., can solve the problems of reducing the air gap by lessening the thickness of the material, affecting the efficiency of a split pot motor of this kind, and reducing the air gap. , the risk of mechanical instabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

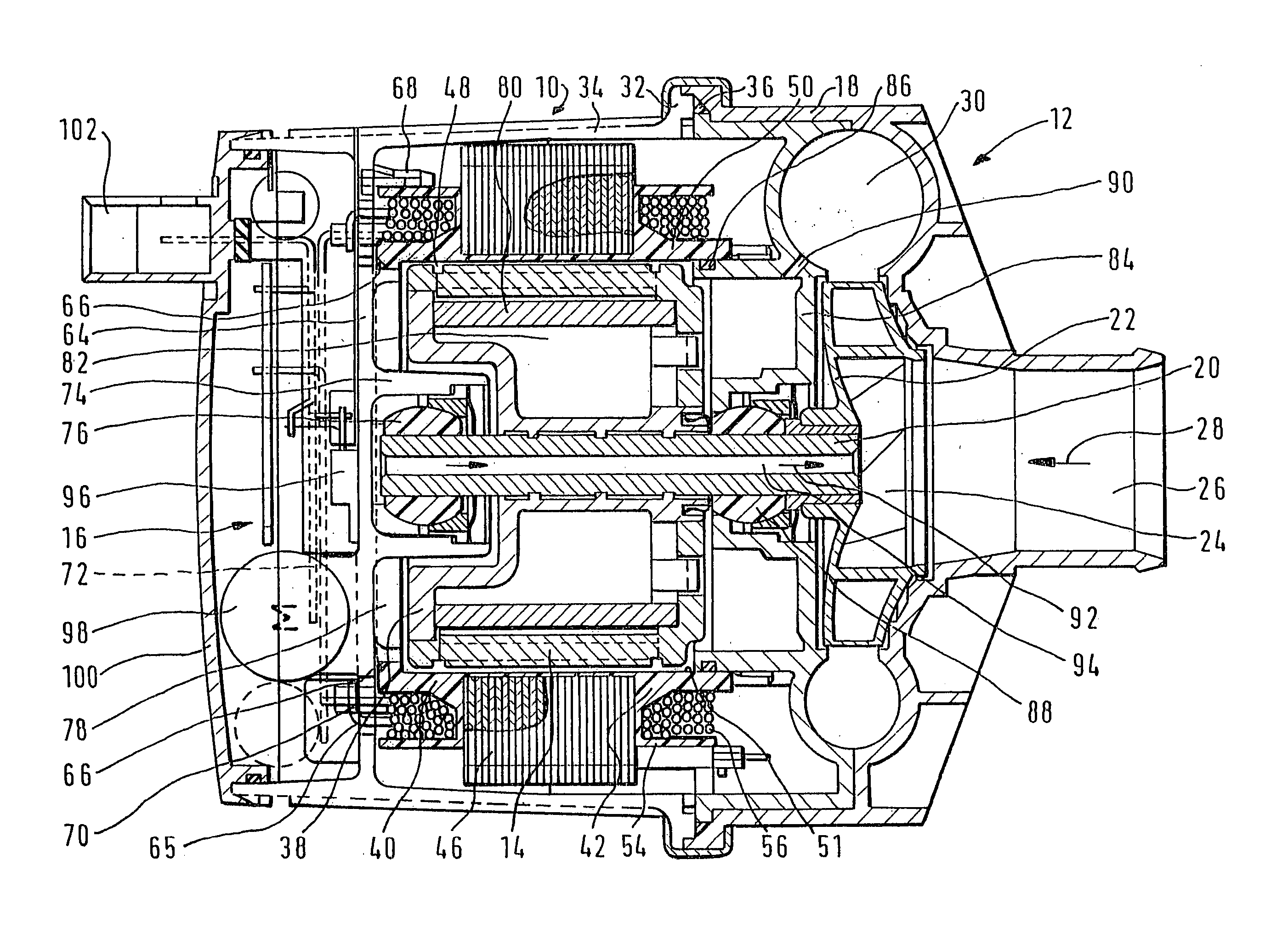

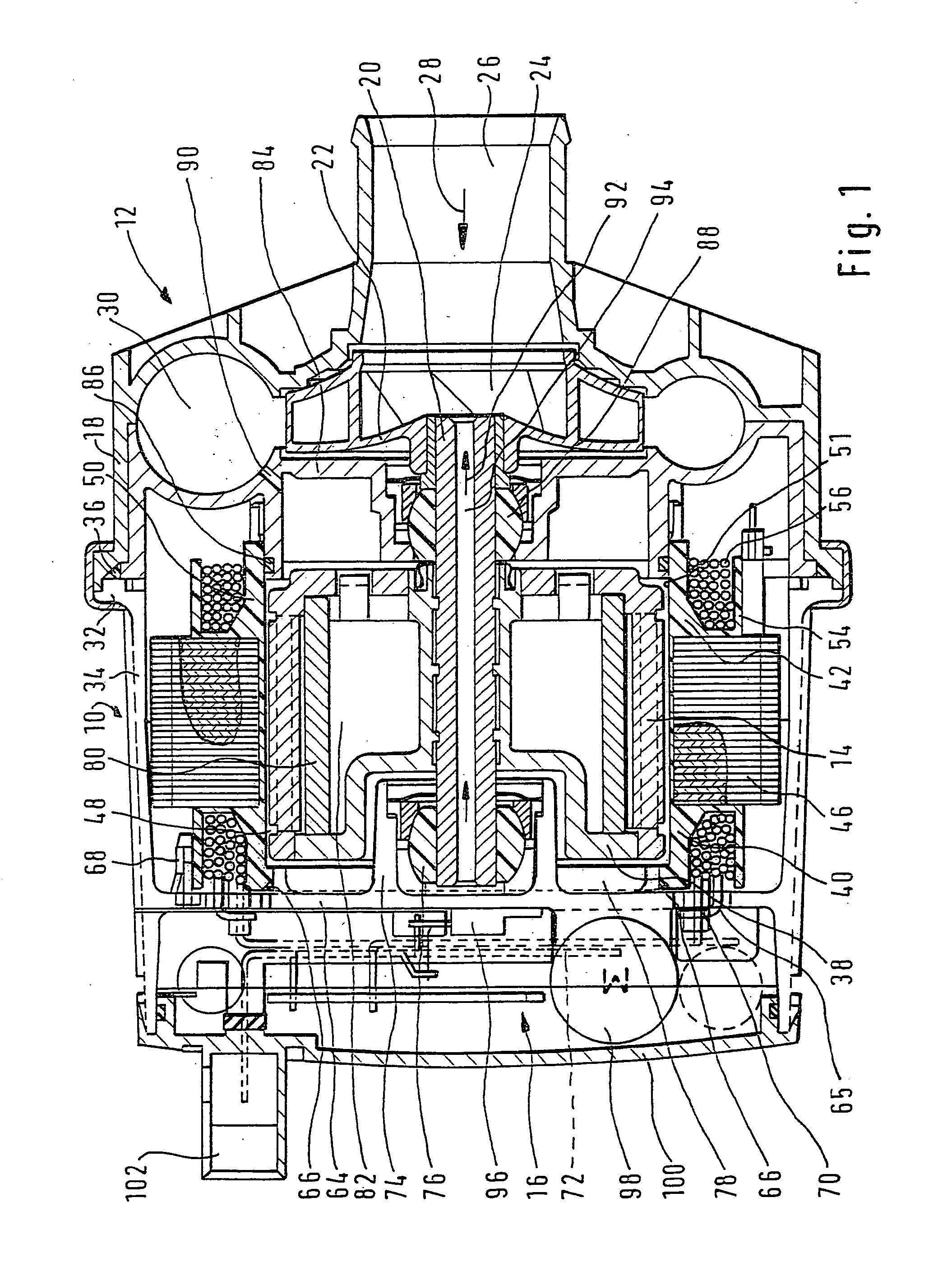

[0023] The exemplary embodiment, shown in longitudinal section in FIG. 1, of an electric-motor-driven pump 10 of the invention comprises a pump head 12, which is driven by a brushless, electronically commutated electric motor 14, and a switch mechanism 16 for controlling the electric motor 14.

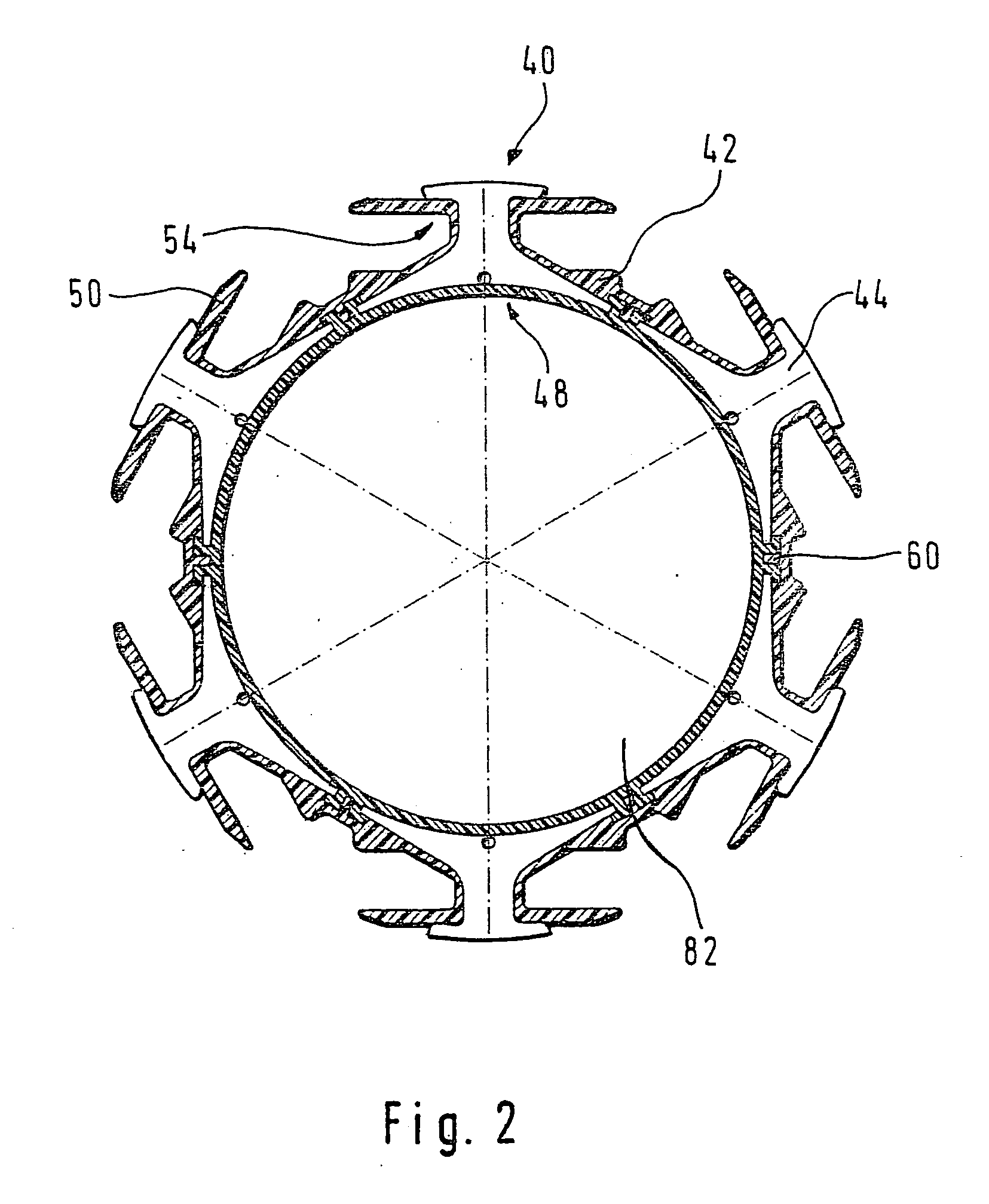

[0024] The pump head 12 has a pump housing 18, in which an impeller 22, secured to a drive shaft 20, is located in a pump chamber 11. The impeller 22 is provided with vanes 24 for transporting and increasing the pressure of a fluid to be recirculated. An opening 26 for aspirating the fluid in the direction of the arrow 28 leads into the pump housing 18. The pump housing also has an outlet opening 30, not completely shown in FIG. 1, on the compression side of the pump. The intake opening 26 discharges at the vanes 24 of the impeller 22 of the pump 10. In the exemplary embodiment of the motor pump 10 of the invention shown, the pump housing 18 is connected via a flange 32 to the motor housing 34 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com