Cassette having elastomeric clamping ribs

a cassette and rib technology, applied in the field of peristaltic pumps, can solve the problems of typical unplanned pressure pulsation and failure at the elastomer/substrat interfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

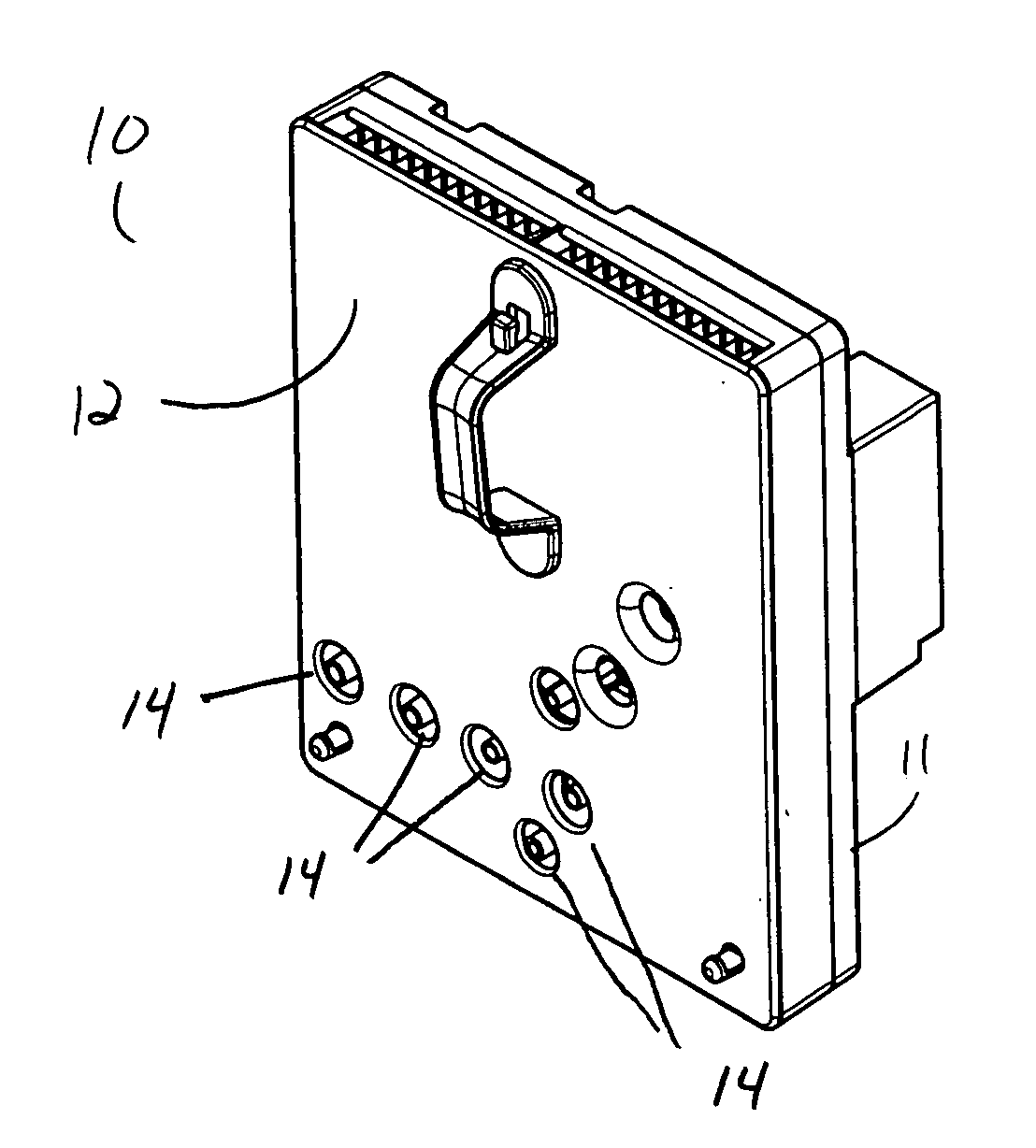

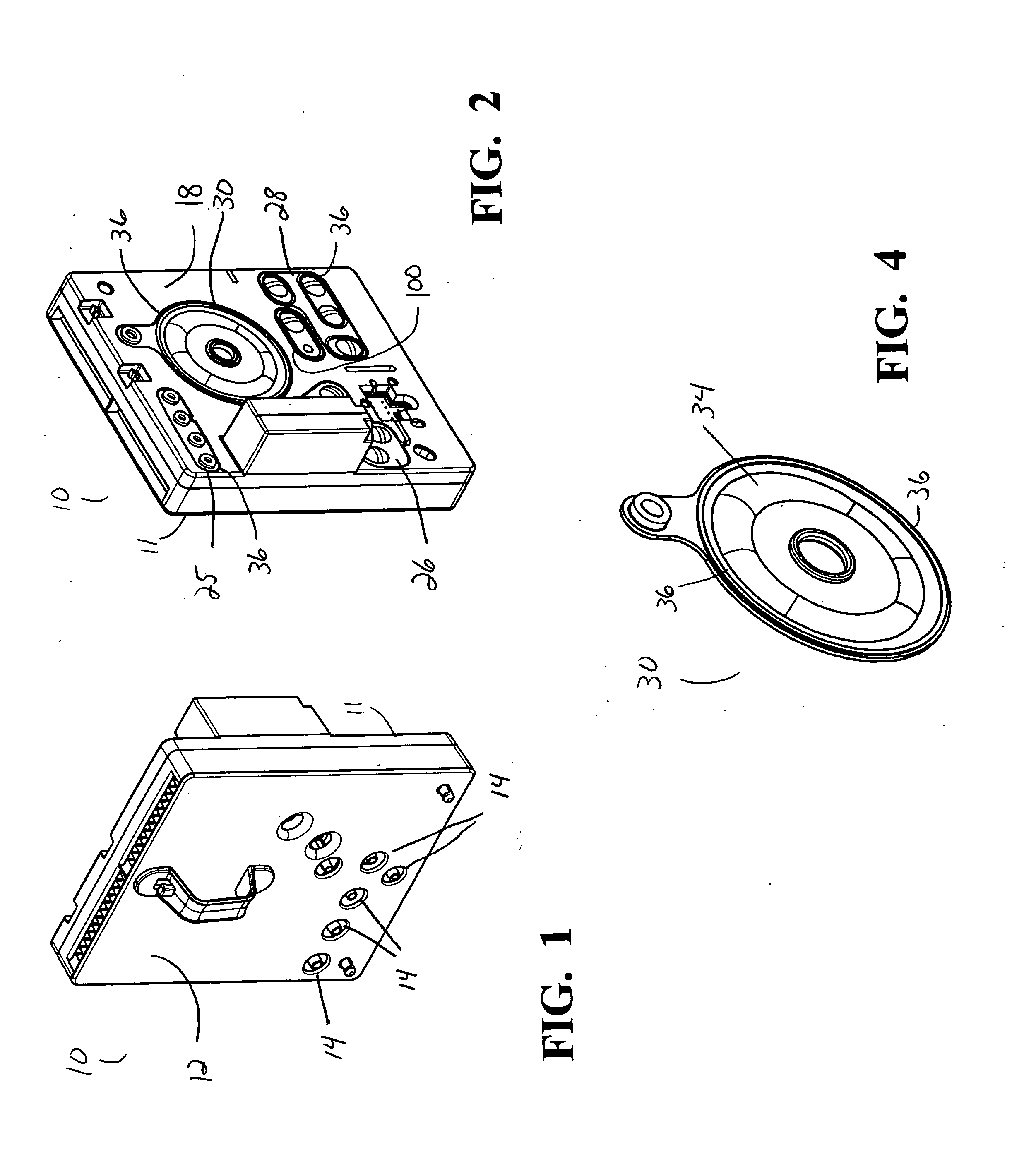

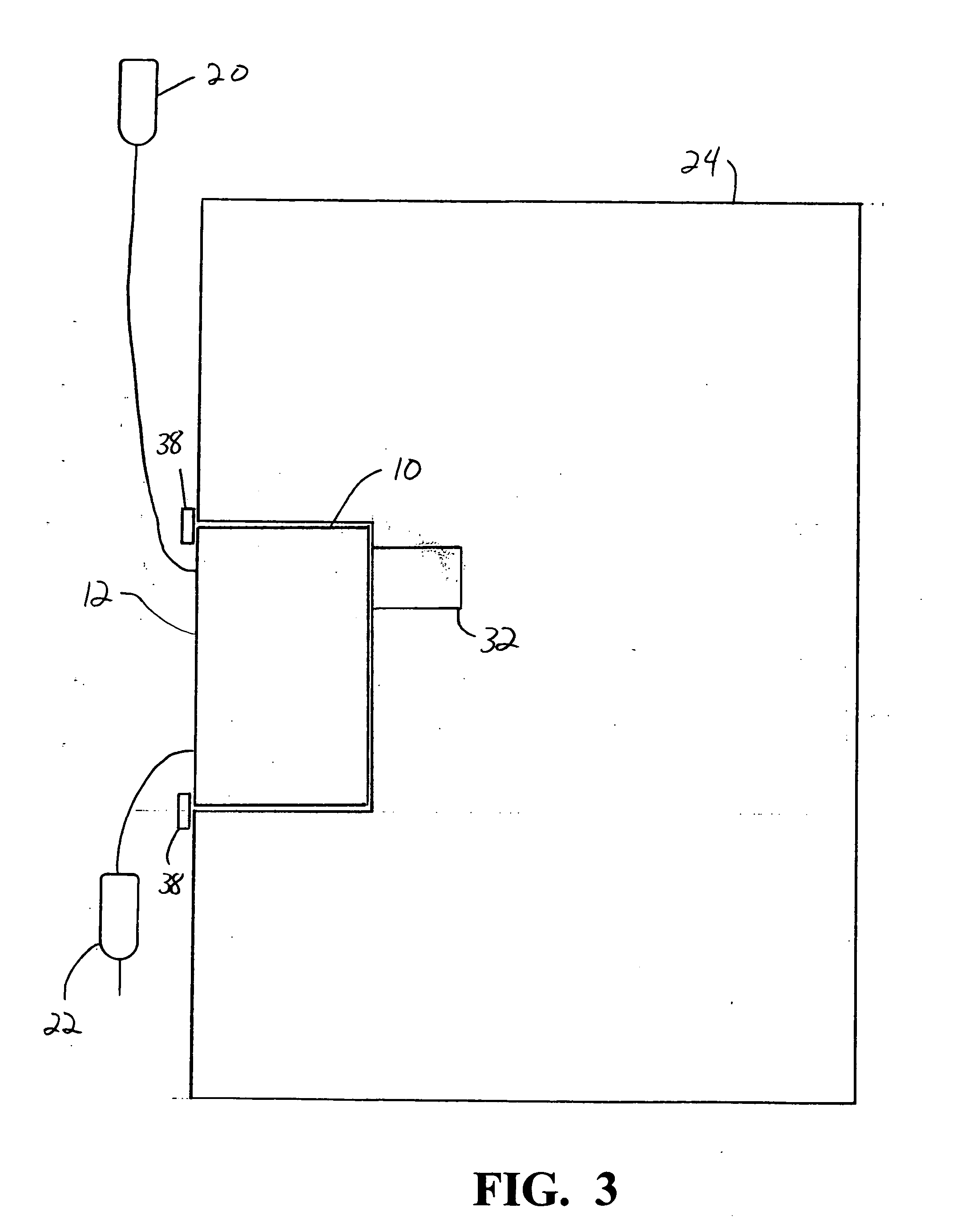

[0017] As best seen in FIGS. 1-3, cassette 10 of the present invention generally includes body 11 having front face 12 containing a plurality of fluidic connections 14 for fluidically connecting cassette 10 to infusion fluid source 20 and surgical handpiece 22 used during a surgical procedure. Cassette 10 may also include handle 16 for assisting in installing and removing cassette 10 from surgical console 24. As best seen in FIG. 2, cassette 10 has rear face 18 opposite front face 12 and adapted for mechanical and fluidic interaction with surgical console 24. Frictionally mounted on rear face 18 of cassette 10 are a plurality of elastomeric interface-forming sheets, such as pneumatics elastomer 25, infusion elastomer 26, aspiration elastomer 28, valve elastomer 100 and pump elastomer 30. Cassette 10 is mounted within console 24 so that pump elastomer 30 is pressed against pump mechanism 32 mounted in console 24 by latches 38. Cassette 10 may be molded from any suitable material, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com