Patents

Literature

4746 results about "Magnetic tape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnetic tape is a medium for magnetic recording, made of a thin, magnetizable coating on a long, narrow strip of plastic film. It was developed in Germany in 1928, based on magnetic wire recording. Devices that record and play back audio and video using magnetic tape are tape recorders and video tape recorders respectively. A device that stores computer data on magnetic tape is known as a tape drive.

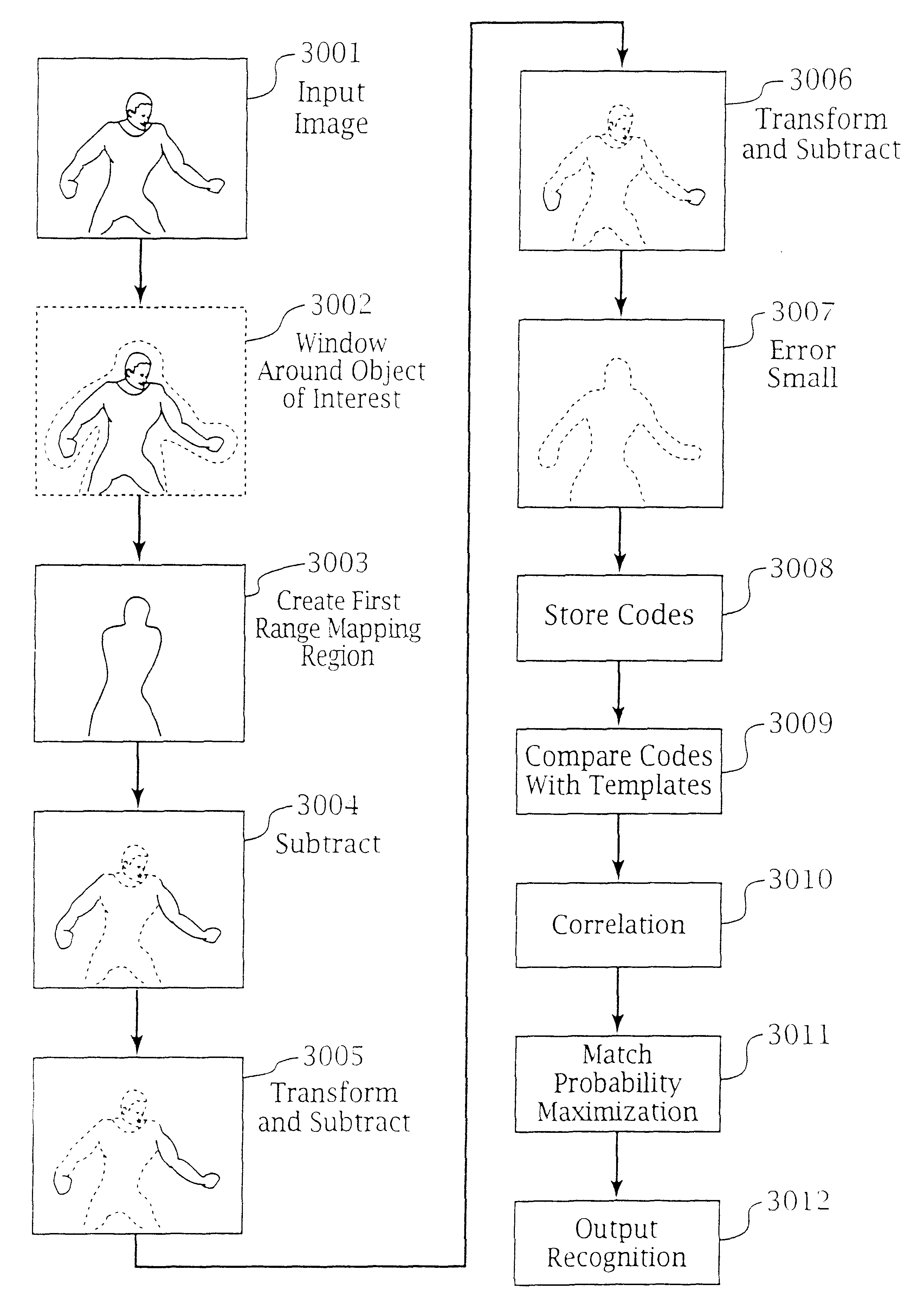

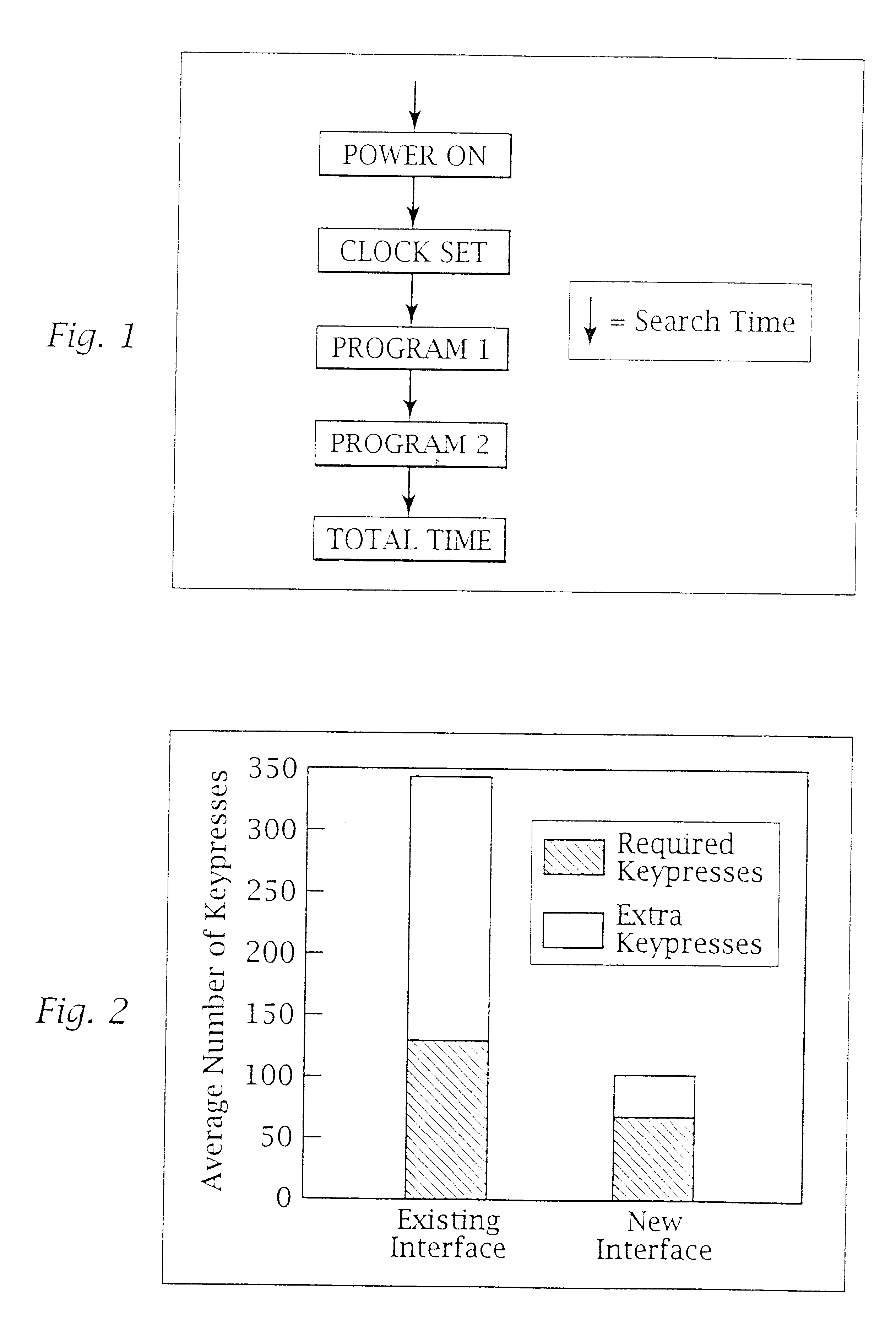

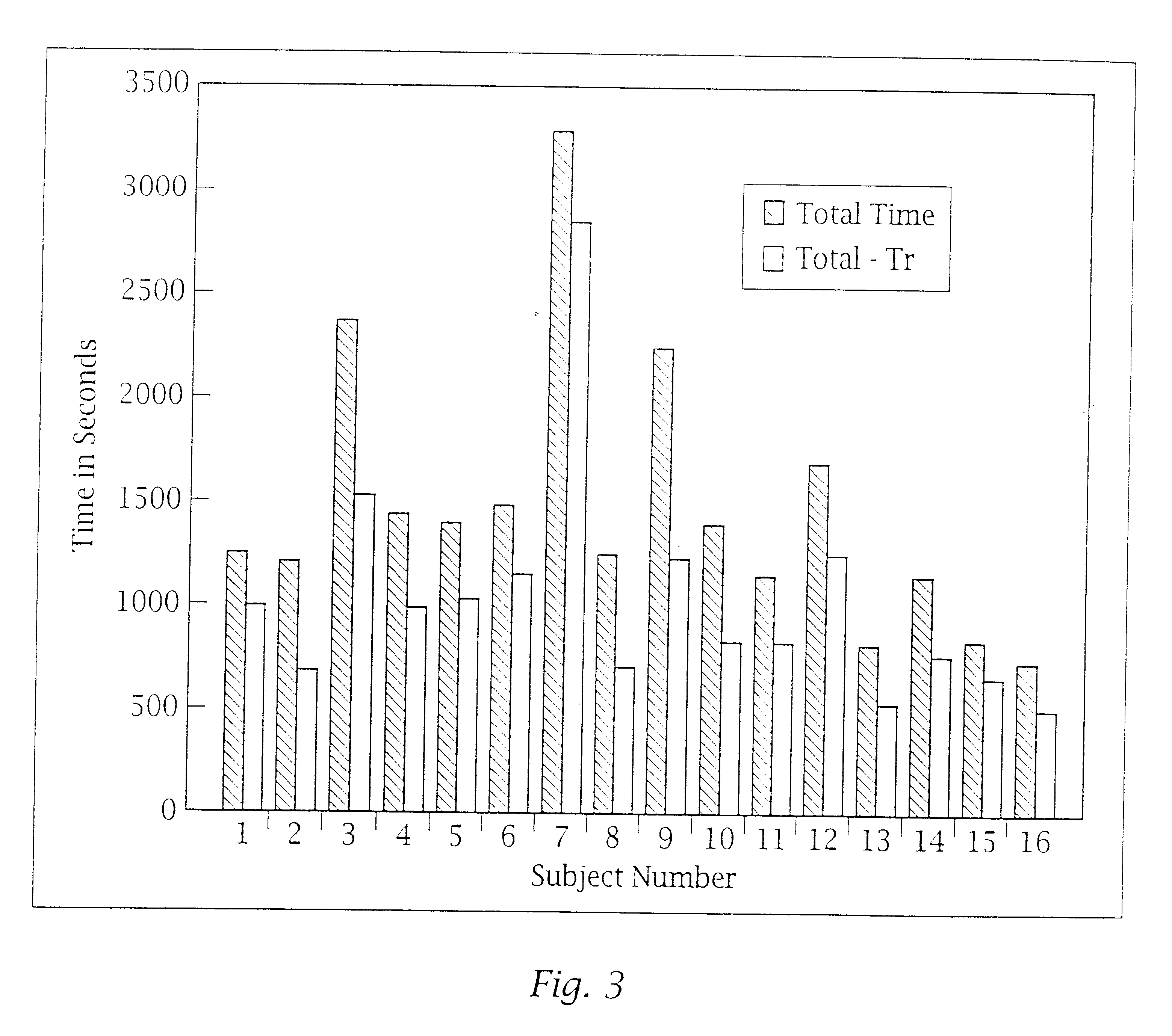

Adaptive pattern recognition based control system and method

InactiveUS6400996B1Minimize timeEasy to implementError preventionFrequency-division multiplex detailsData streamSmart house

An adaptive interface for a programmable system, for predicting a desired user function, based on user history, as well as machine internal status and context. The apparatus receives an input from the user and other data. A predicted input is presented for confirmation by the user, and the predictive mechanism is updated based on this feedback. Also provided is a pattern recognition system for a multimedia device, wherein a user input is matched to a video stream on a conceptual basis, allowing inexact programming of a multimedia device. The system analyzes a data stream for correspondence with a data pattern for processing and storage. The data stream is subjected to adaptive pattern recognition to extract features of interest to provide a highly compressed representation that may be efficiently processed to determine correspondence. Applications of the interface and system include a video cassette recorder (VCR), medical device, vehicle control system, audio device, environmental control system, securities trading terminal, and smart house. The system optionally includes an actuator for effecting the environment of operation, allowing closed-loop feedback operation and automated learning.

Owner:BLANDING HOVENWEEP

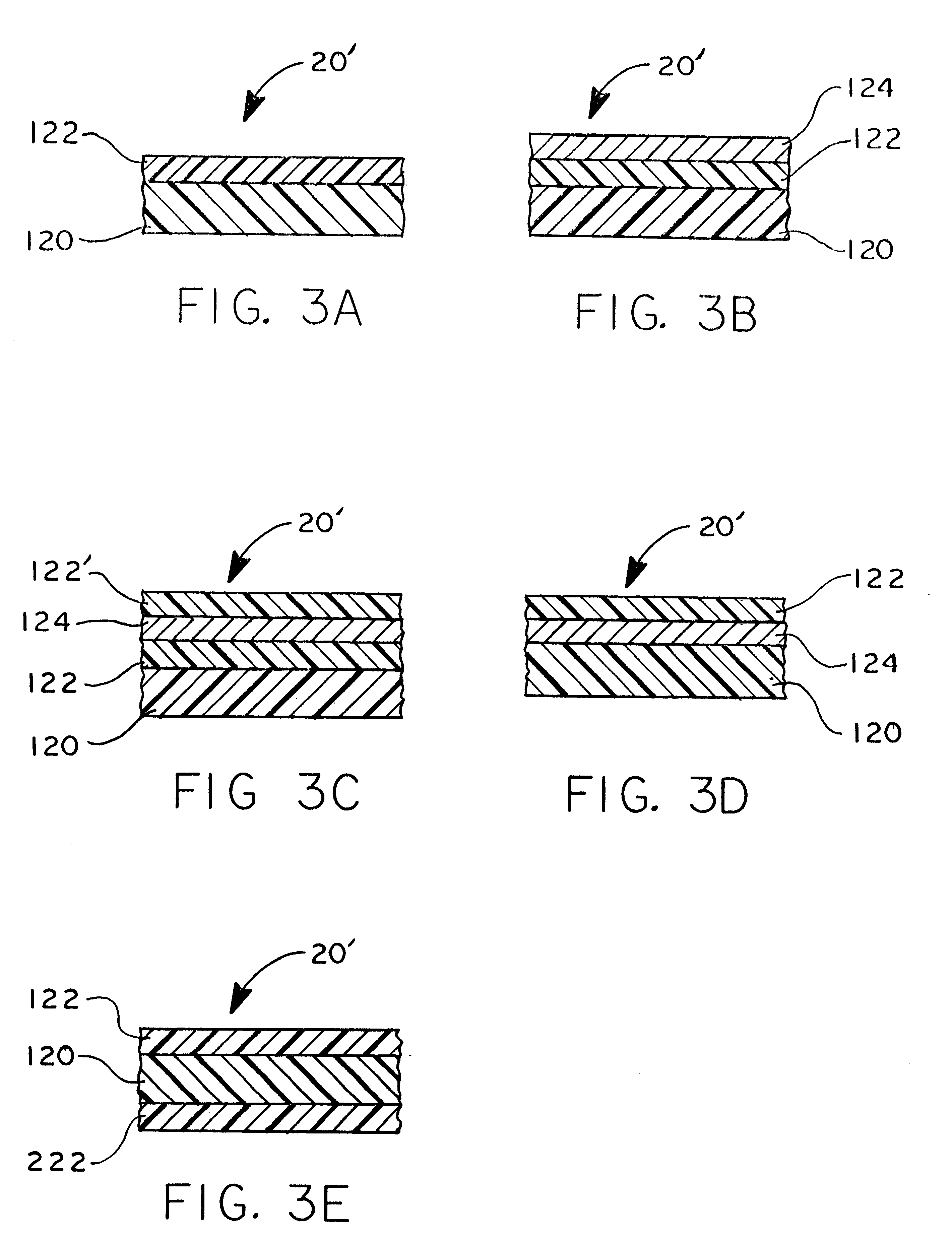

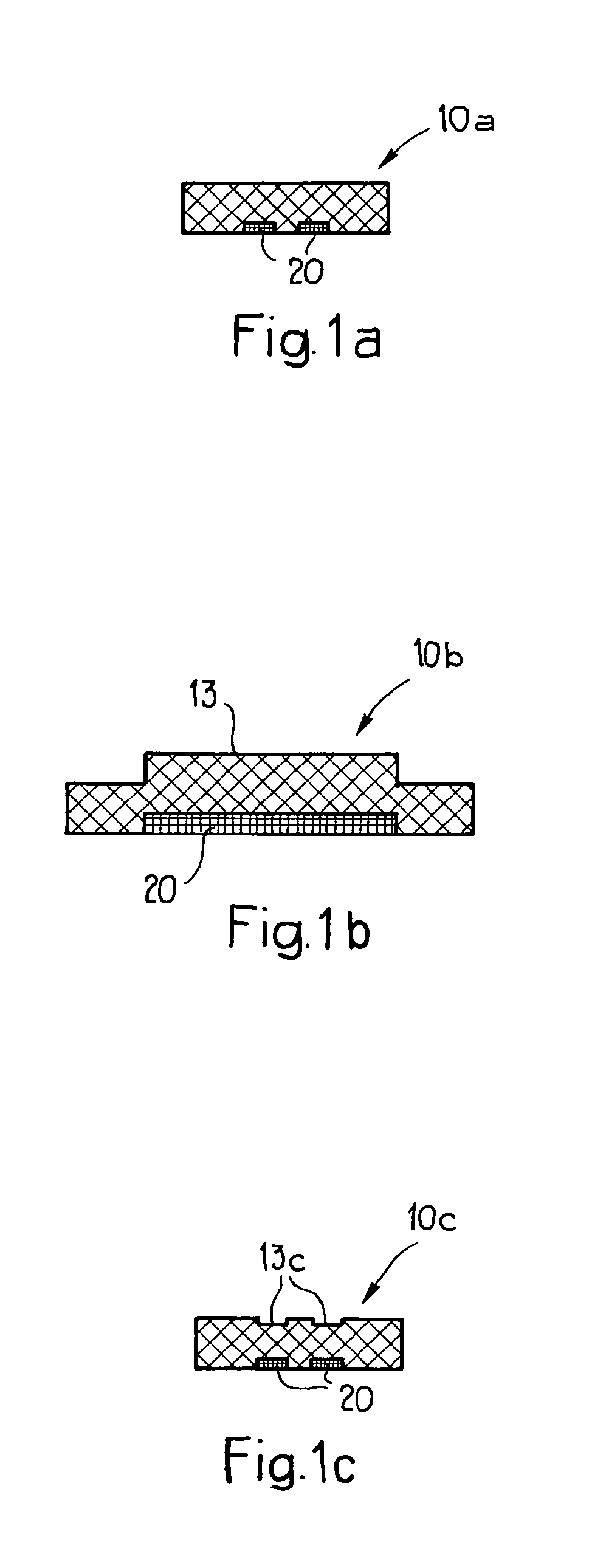

Method of forming a hybrid polymer film

InactiveUS6214422B1Fine surfaceLow costFixed capacitor dielectricSynthetic resin layered productsThermoplasticCross-link

A hybrid film, comprising a first polymer film having a plasma-treated surface and a second polymer film having first and second surfaces, with the first surface of the second polymer film being disposed along the first plasma-treated surface of the first polymer film, has superior thermal and mechanical properties that improve performance in a number of applications, including food packaging, thin film metallized and foil capacitors, metal evaporated magnetic tapes, flexible electrical cables, and decorative and optically variable films. One or more metal layers may be deposited on either the plasma-treated surface of the substrate and / or the radiation-cured acrylate polymer A ceramic layer may be deposited on the radiation-cured acrylate polymer to provide an oxygen and moisture barrier film. The hybrid film is produced using a high speed, vacuum polymer deposition process that is capable of forming thin, uniform, high temperature, cross-liked acrylate polymers on specific thermoplastic or thermoset films. Radiation curing is employed to cross-link the acrylate monomer. The hybrid film can be produced in-line with the metallization or ceramic coating process, in the same vacuum chamber and with minimal additional cost.

Owner:SIGMA LAB OF ARIZONA

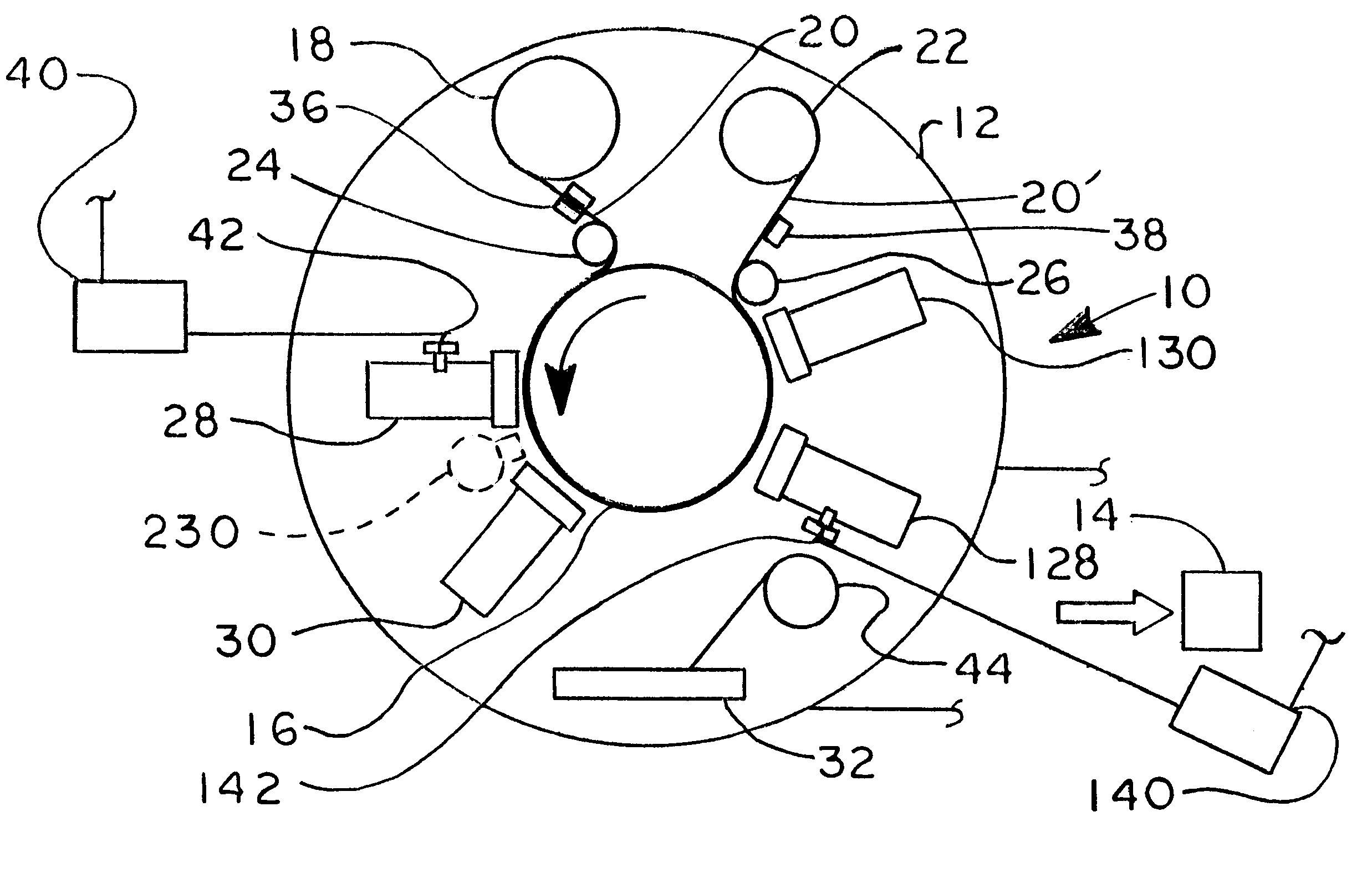

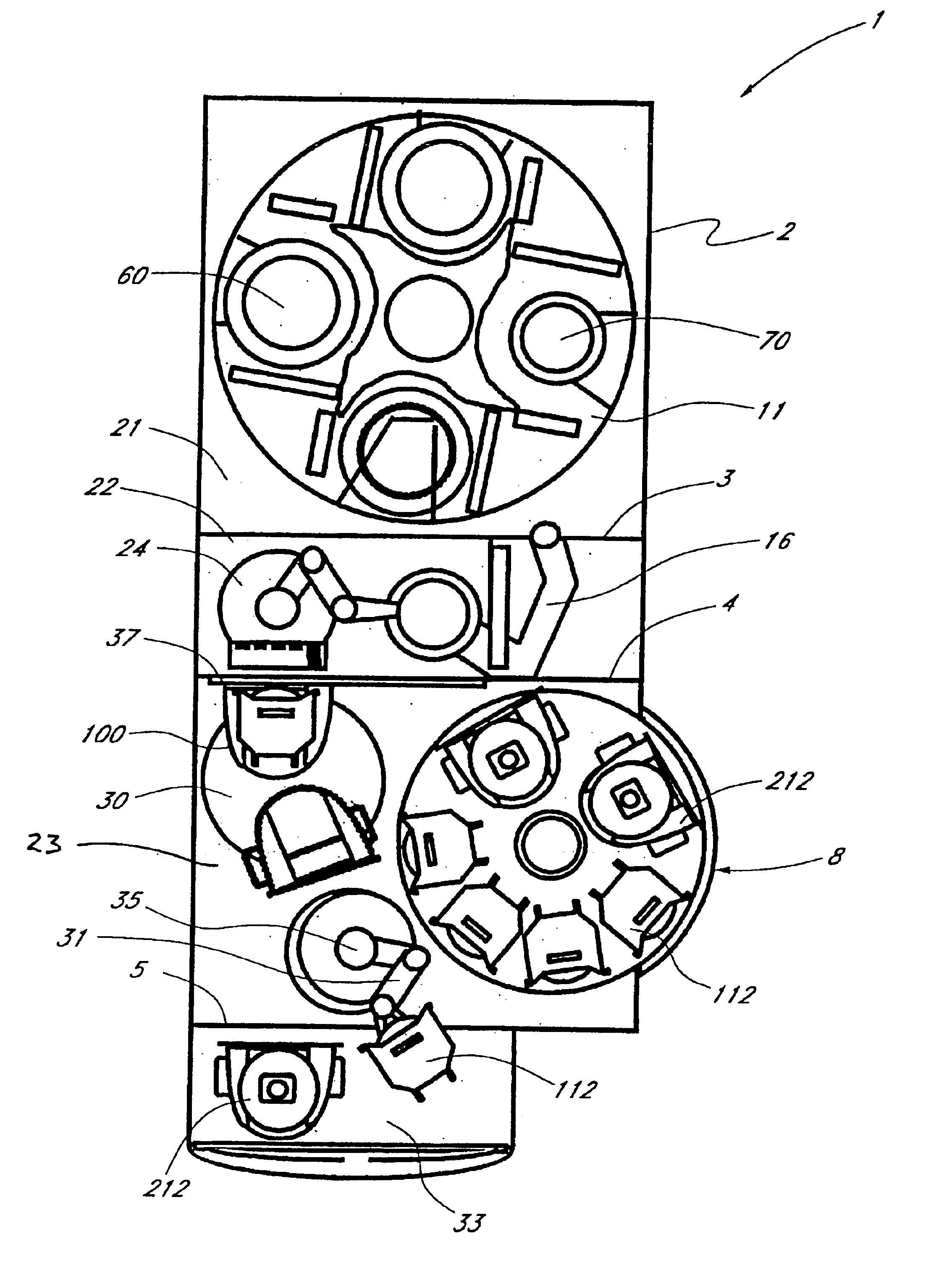

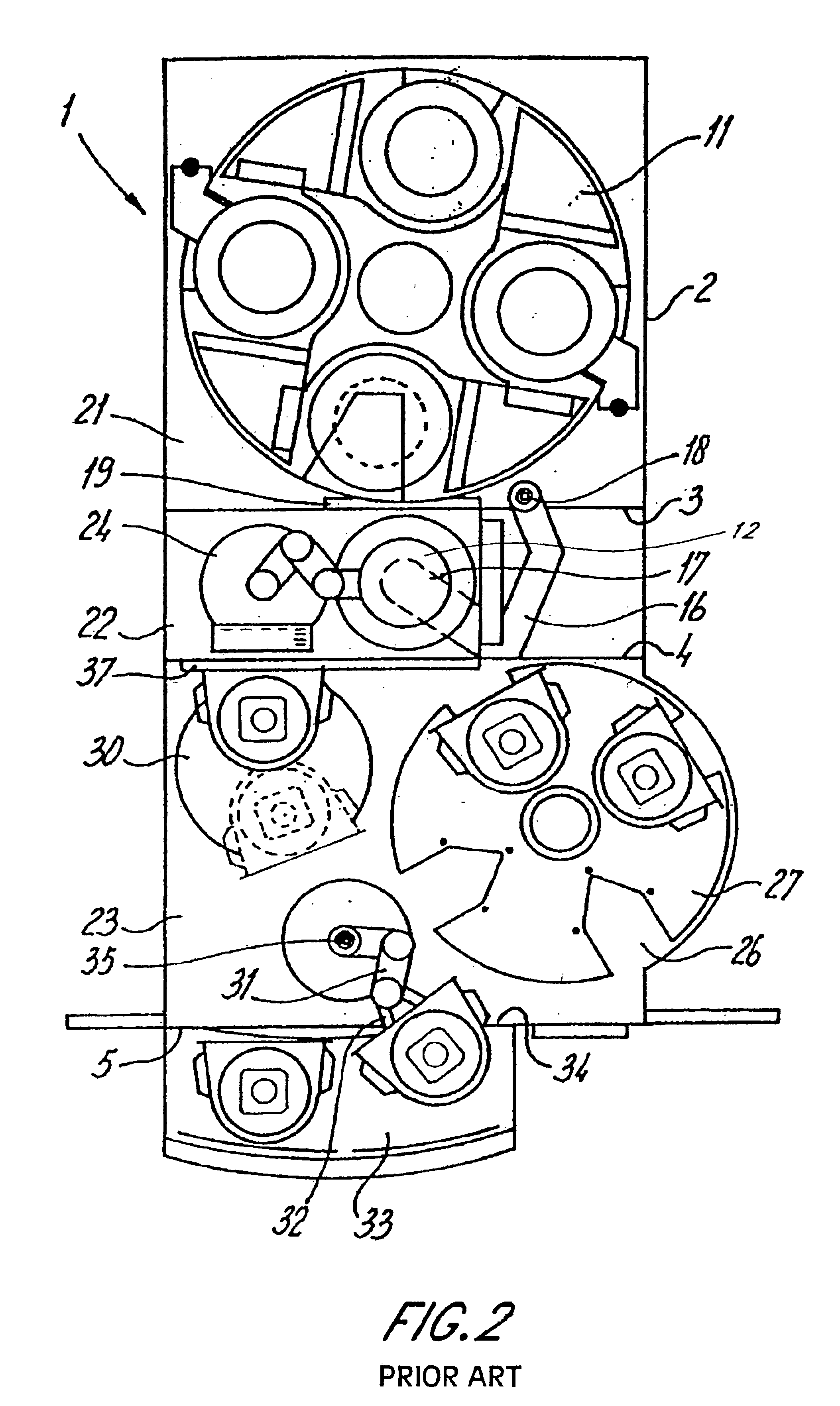

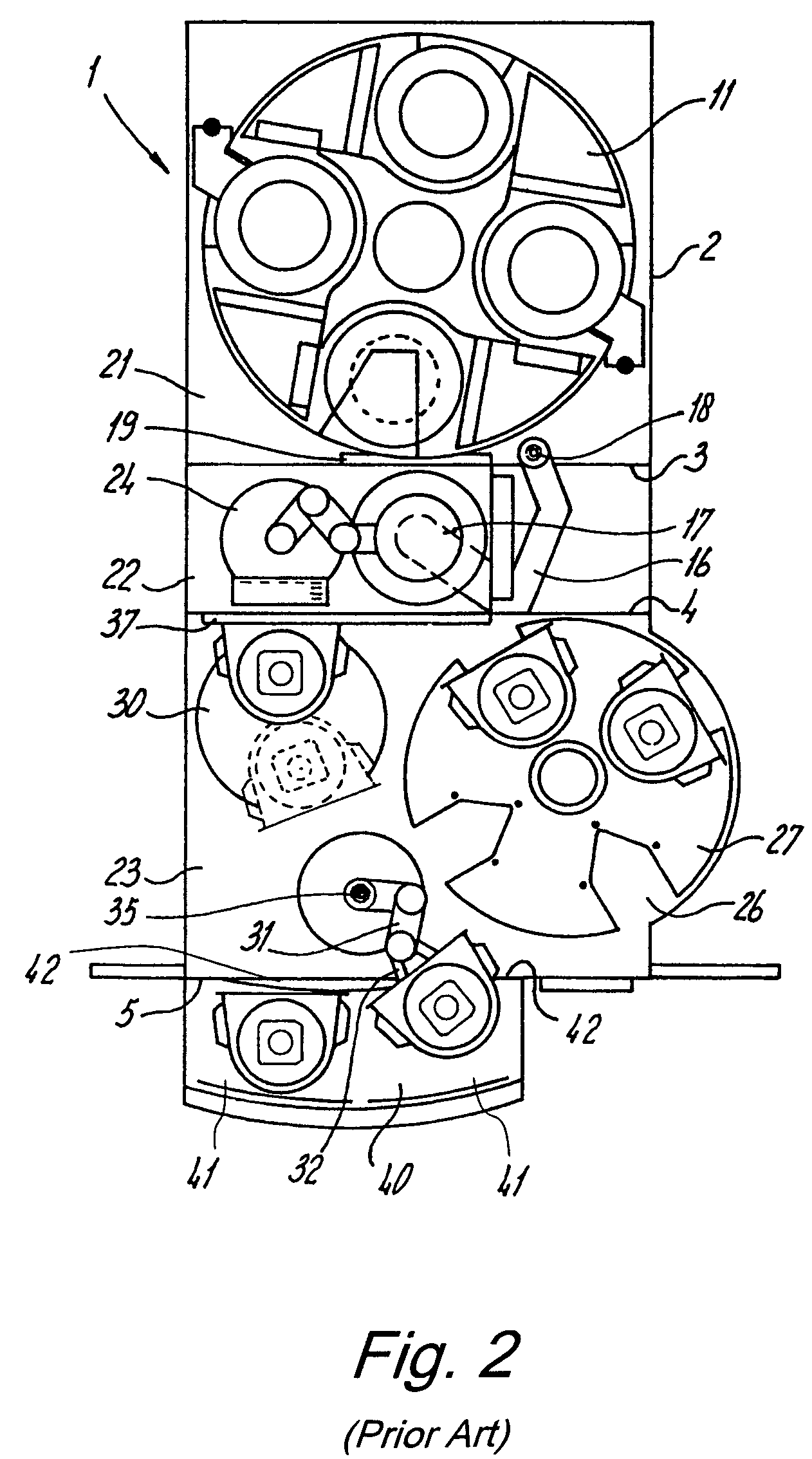

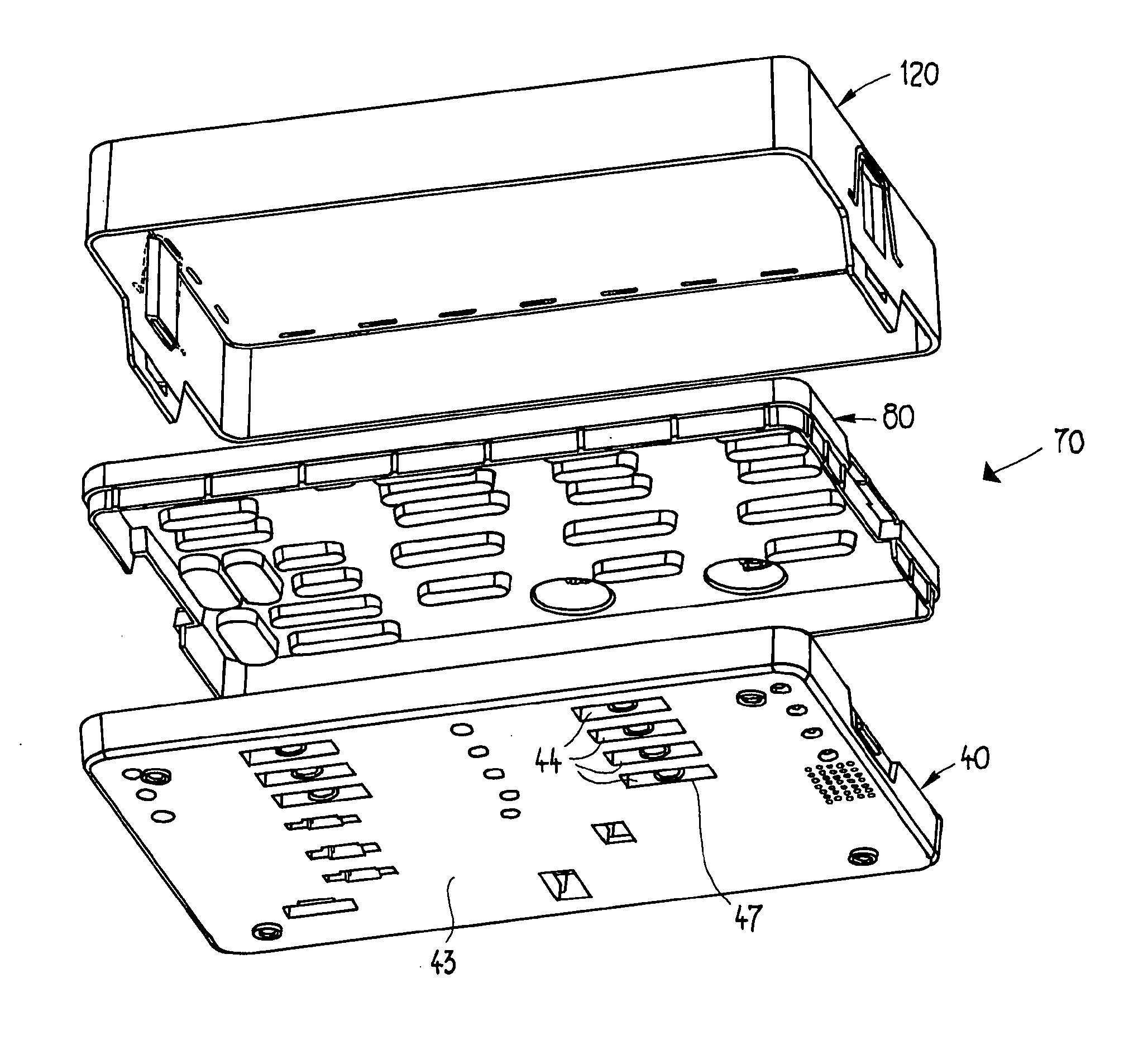

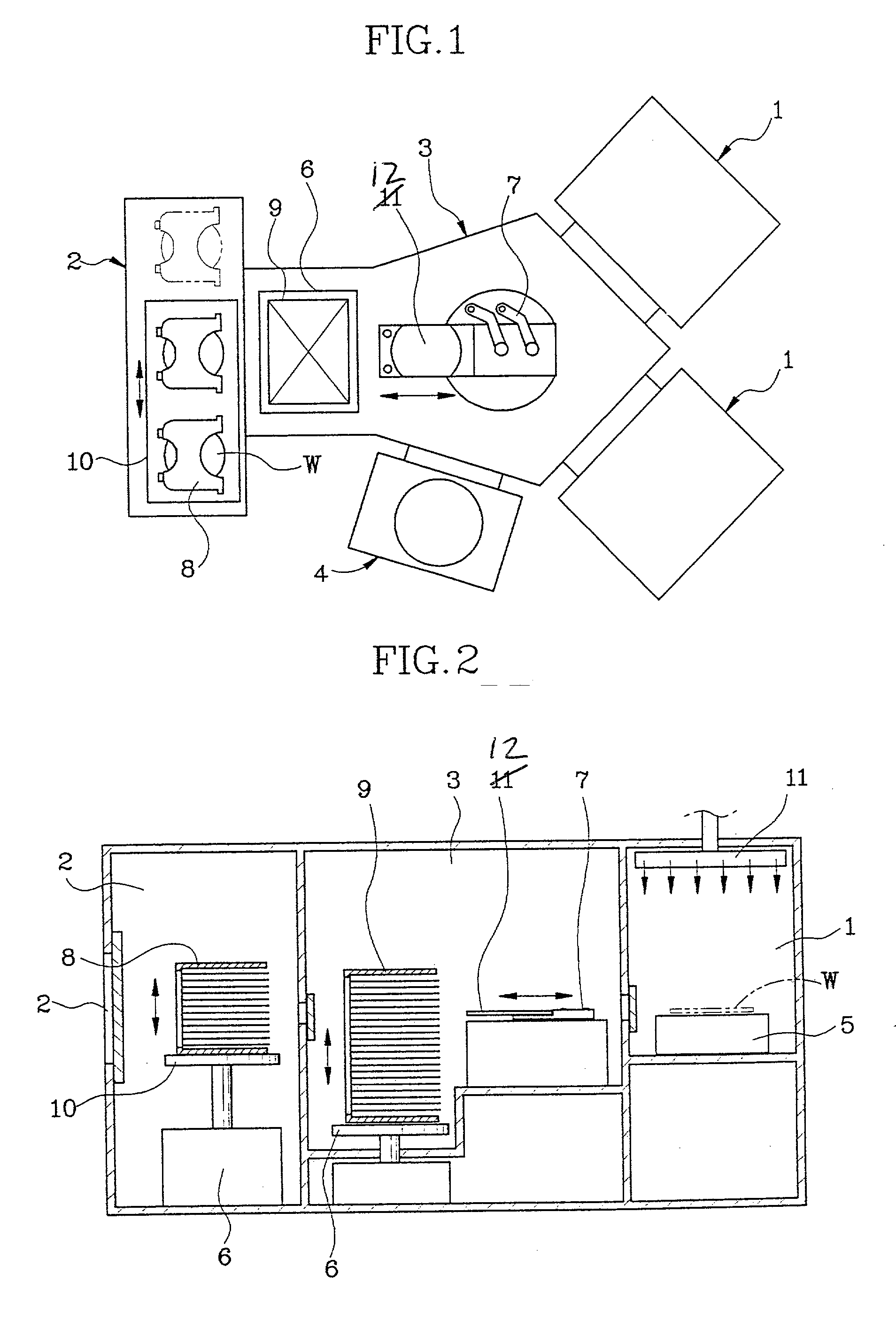

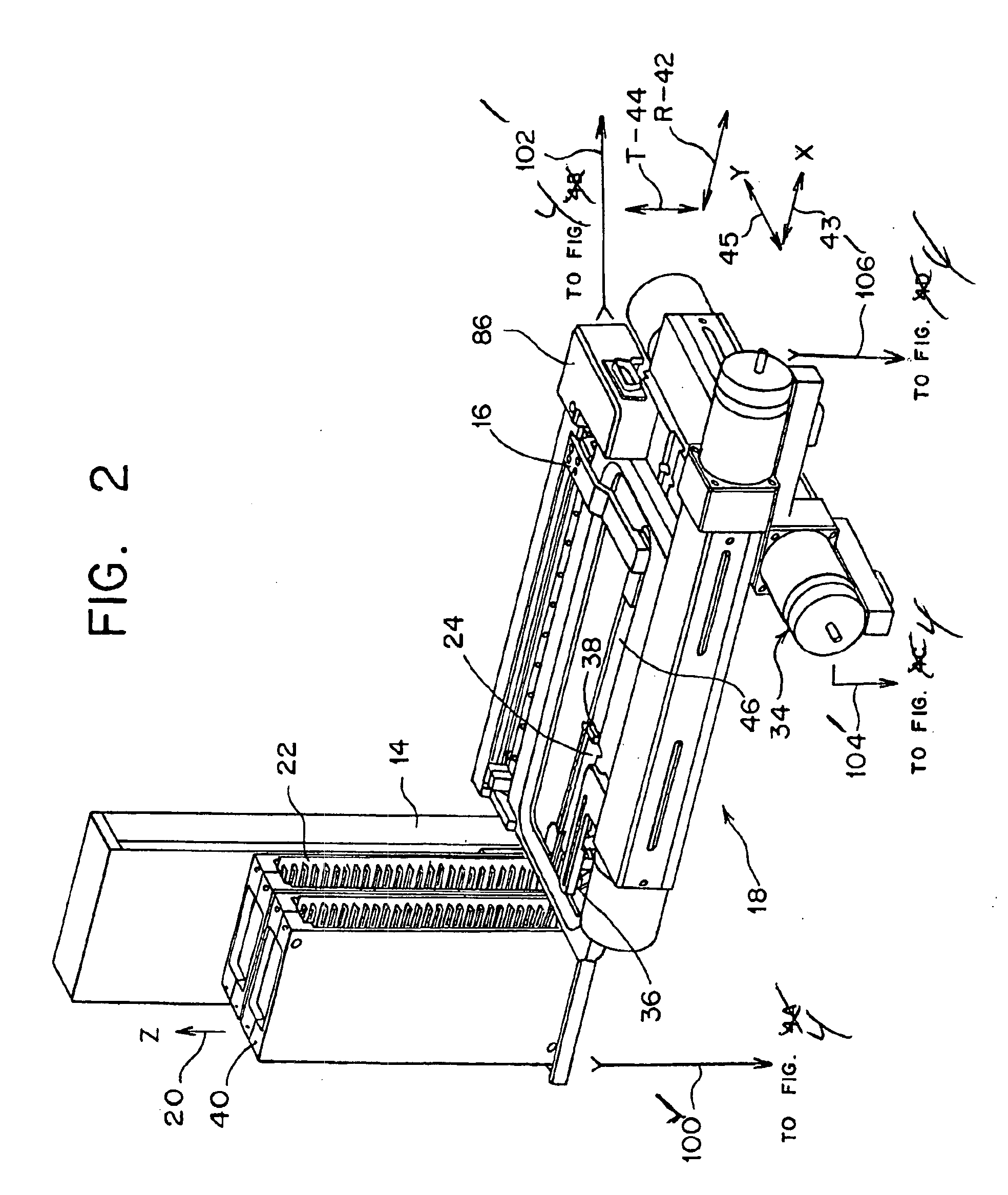

Wafer handling system

InactiveUS6981832B2Semiconductor/solid-state device manufacturingStorage devicesMagnetic tapeEngineering

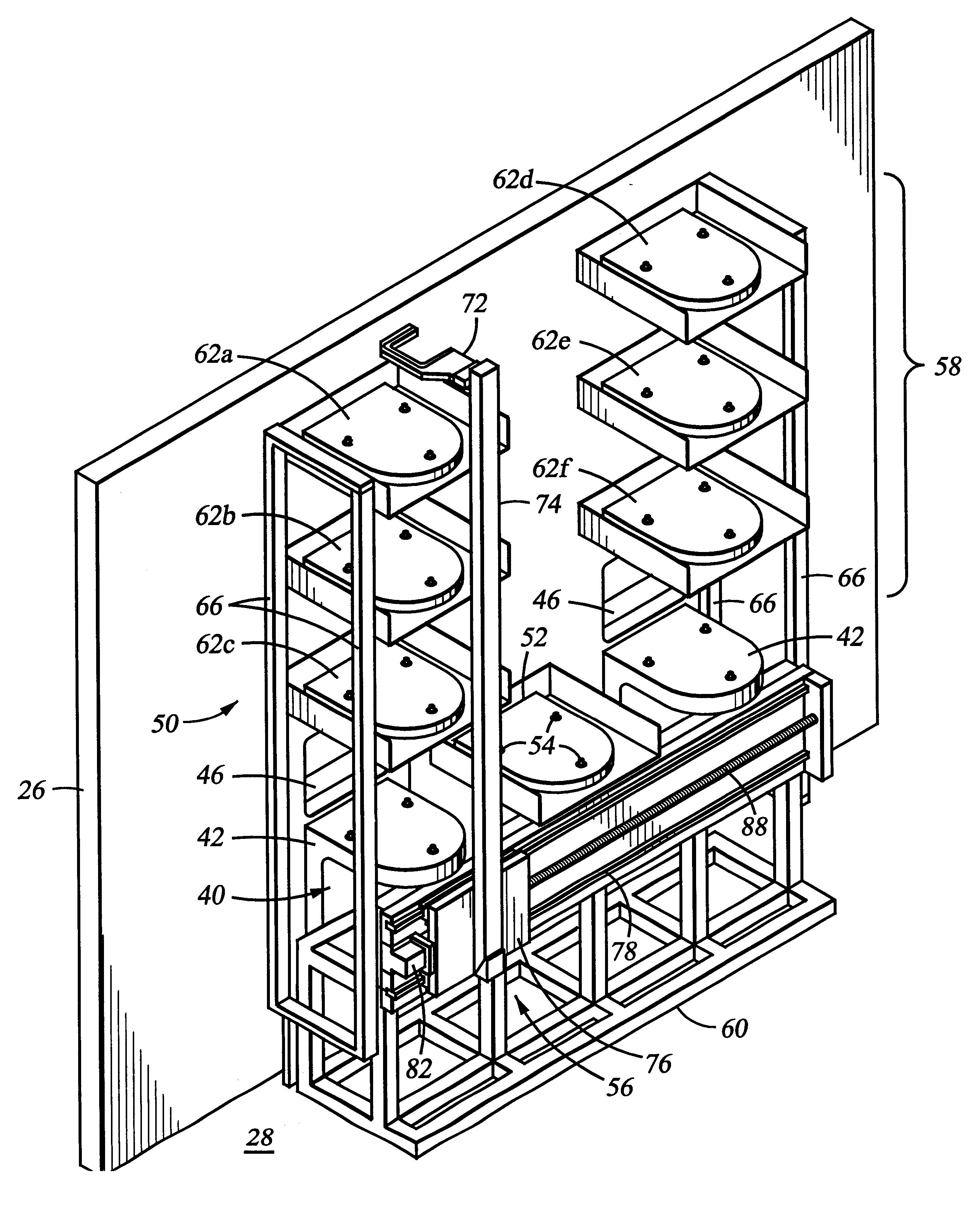

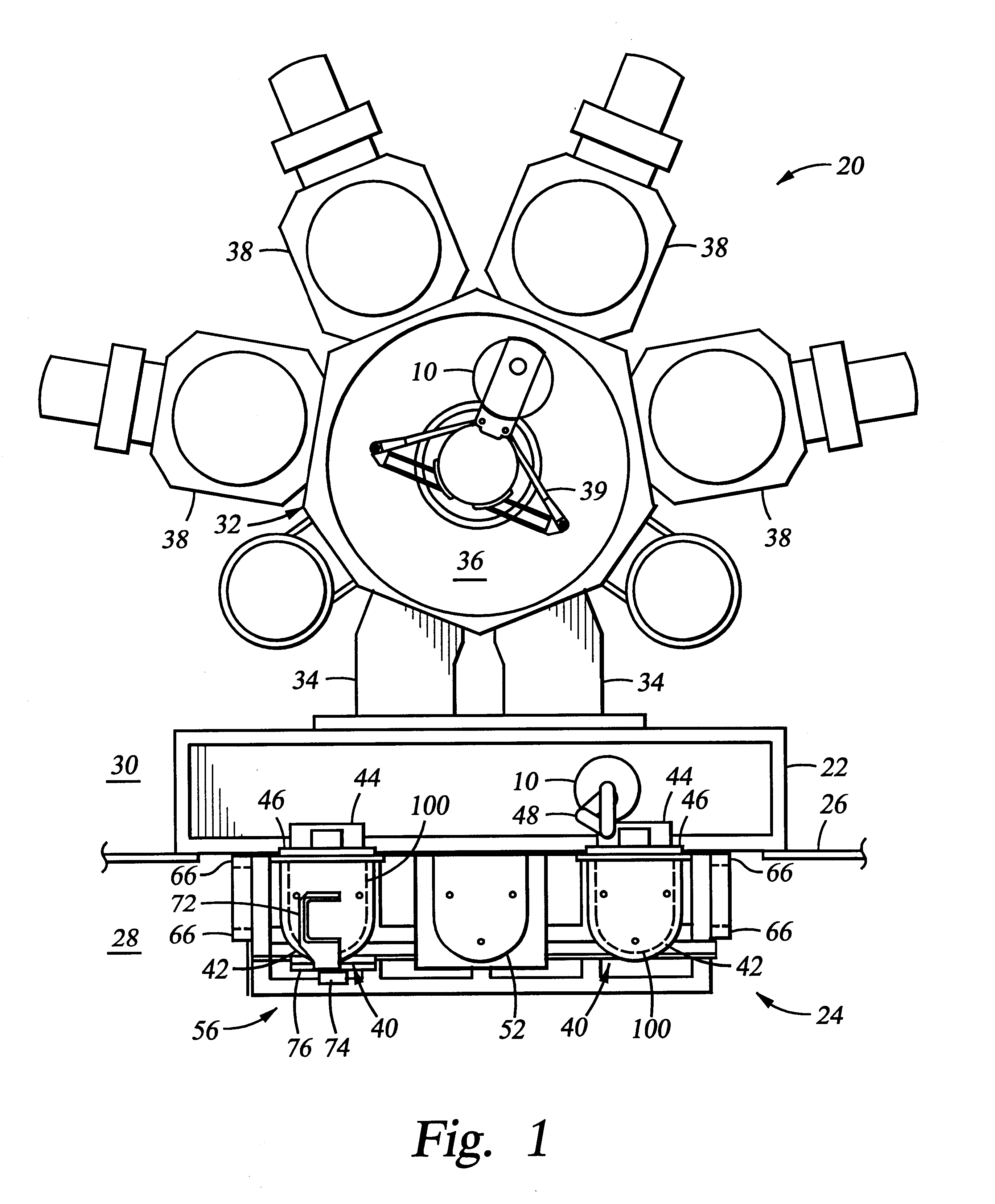

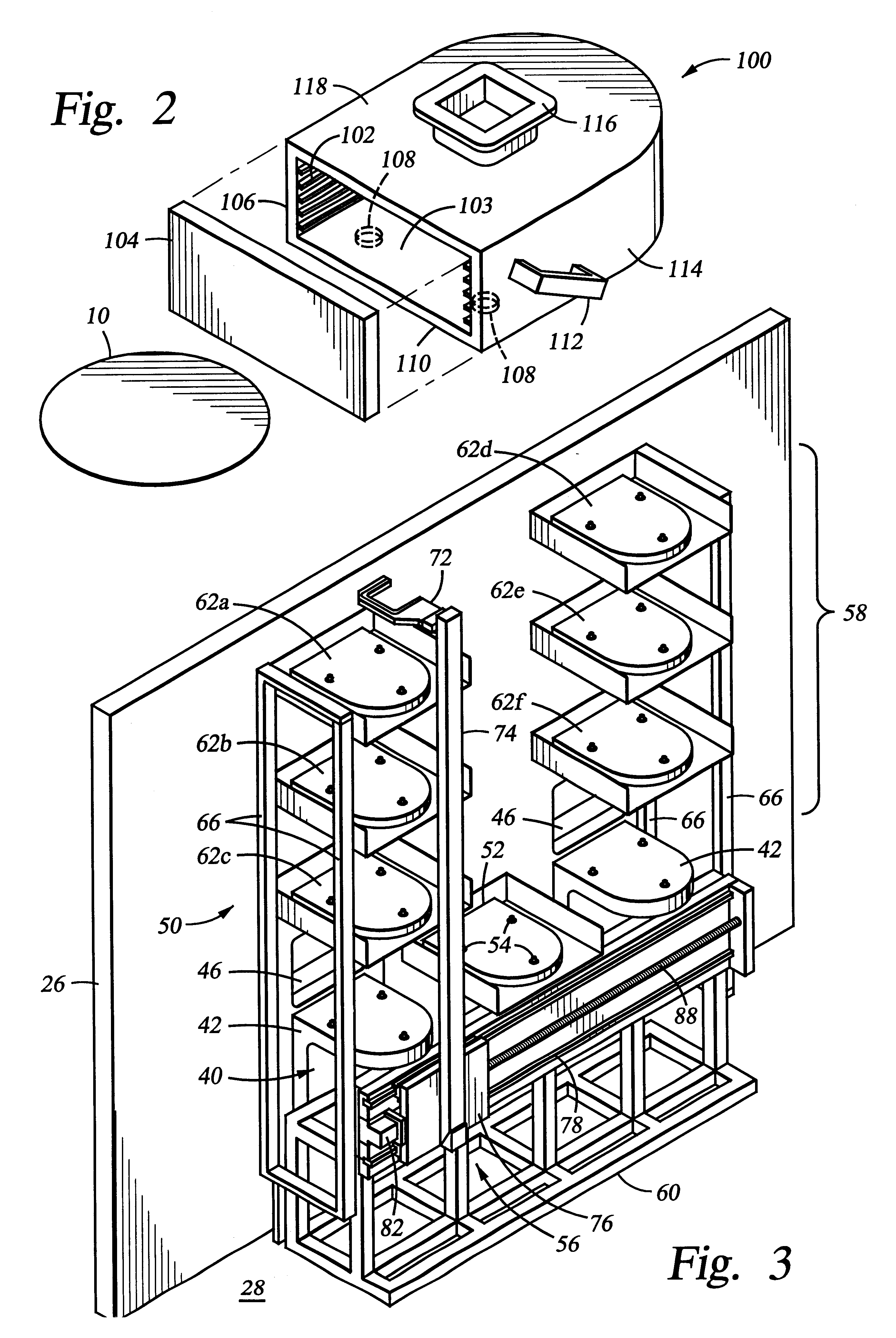

A system for processing semiconductor wafers includes adaptations allowing the selective handling of cassettes for both 200-mm wafers and 300-mm wafers. The system is configured initially for handling standard 300-mm FOUP cassettes. Adaptions for handling 200-mm wafer open cassettes include a load port adapter frame for receiving such cassettes on a input / output platform; a cassette handler adapter configured for reversibly mounting on a cassette handler end effector and for receiving 200-mm open cassettes; a store adapter frame for converting 300-mm FOUP storage compartments into compartments for storing 200-mm open cassettes; and a Transhipment FOUP for holding 200-mm open cassettes upon a cassette transfer platform and bringing such cassettes into an interface with a wafer handler. The Transhipment FOUP has outer surfaces resembling a standard 300-mm FOUP cassette, but is configured to receive a 200-mm open cassette therein.

Owner:ASM INTERNATIONAL

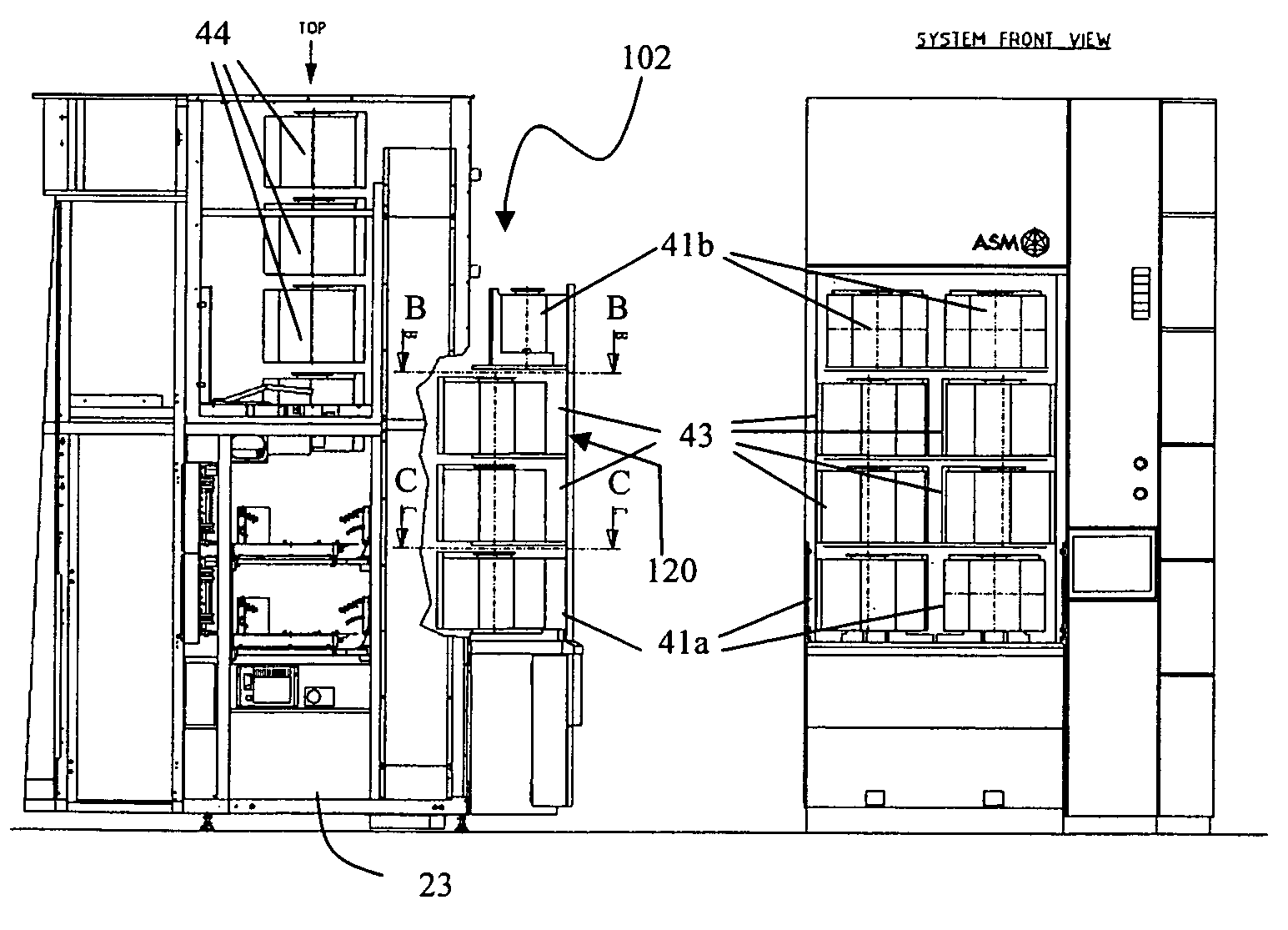

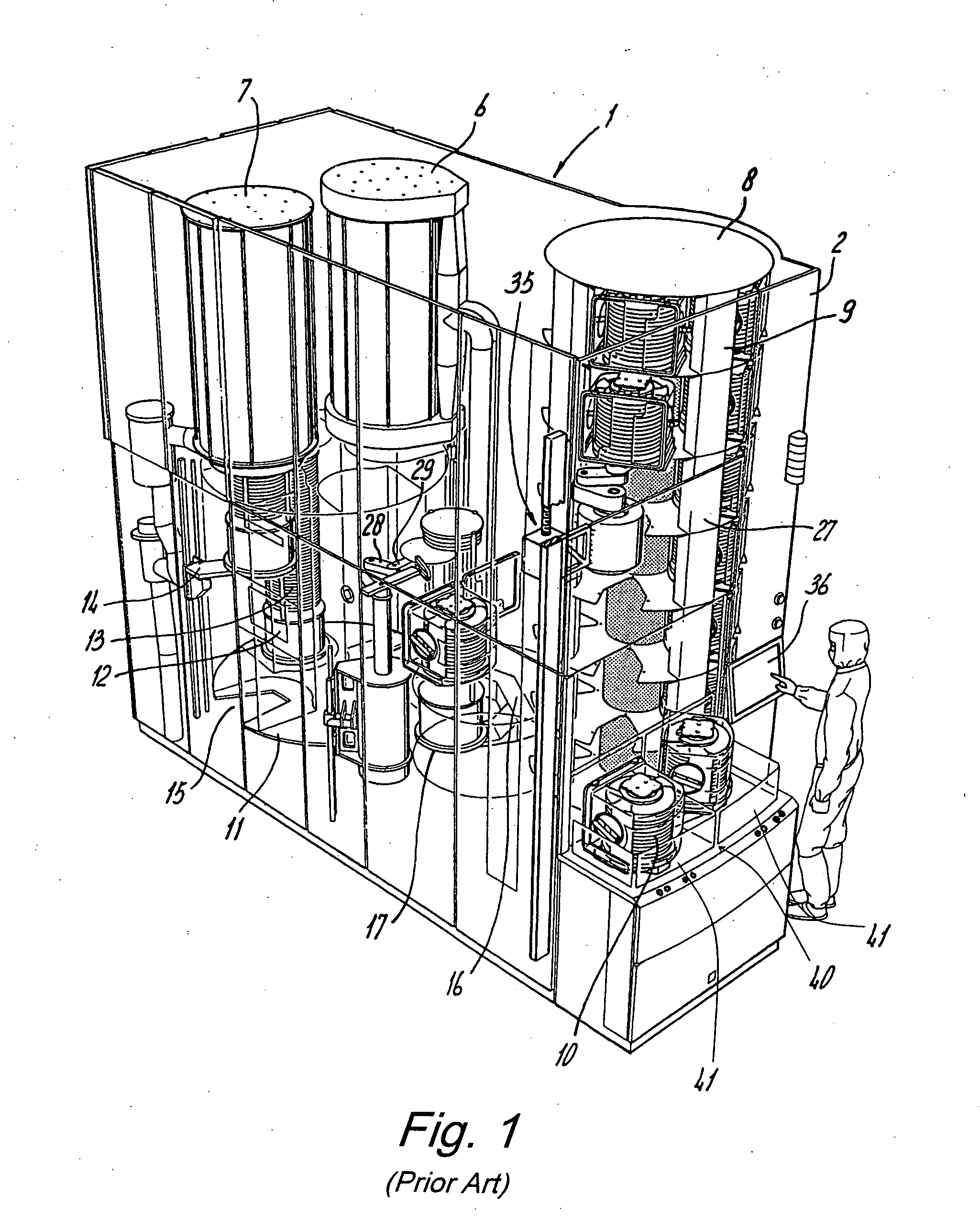

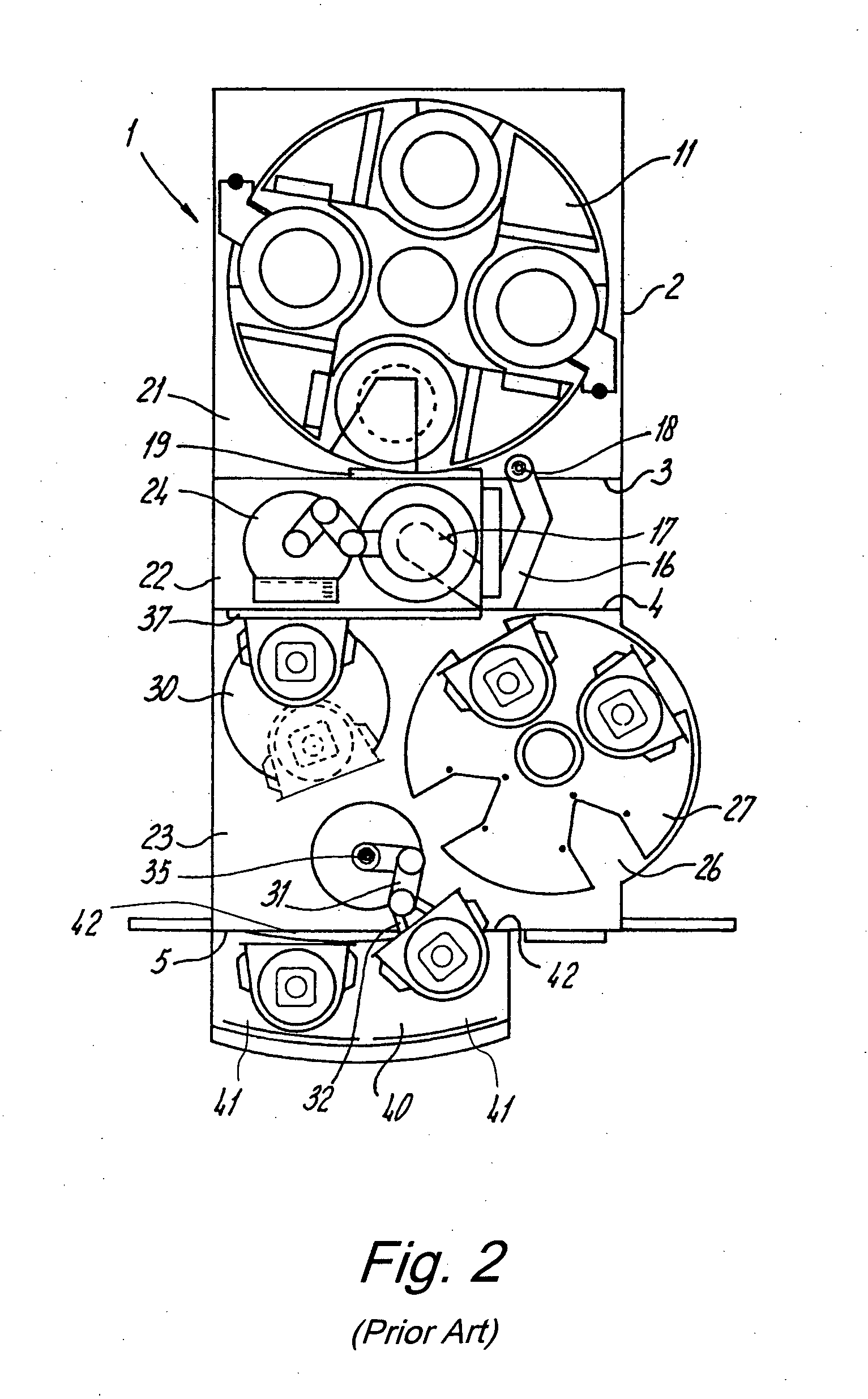

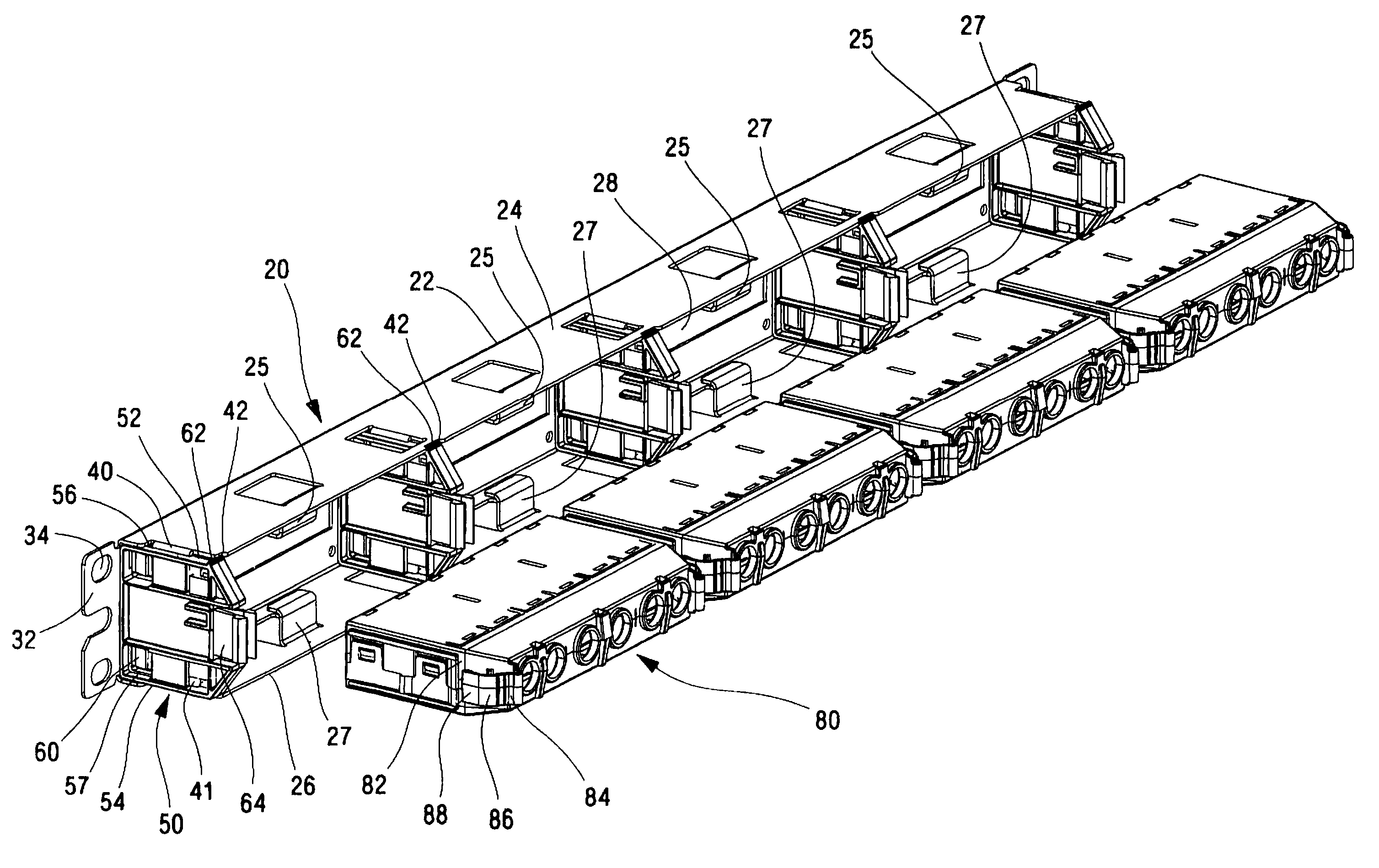

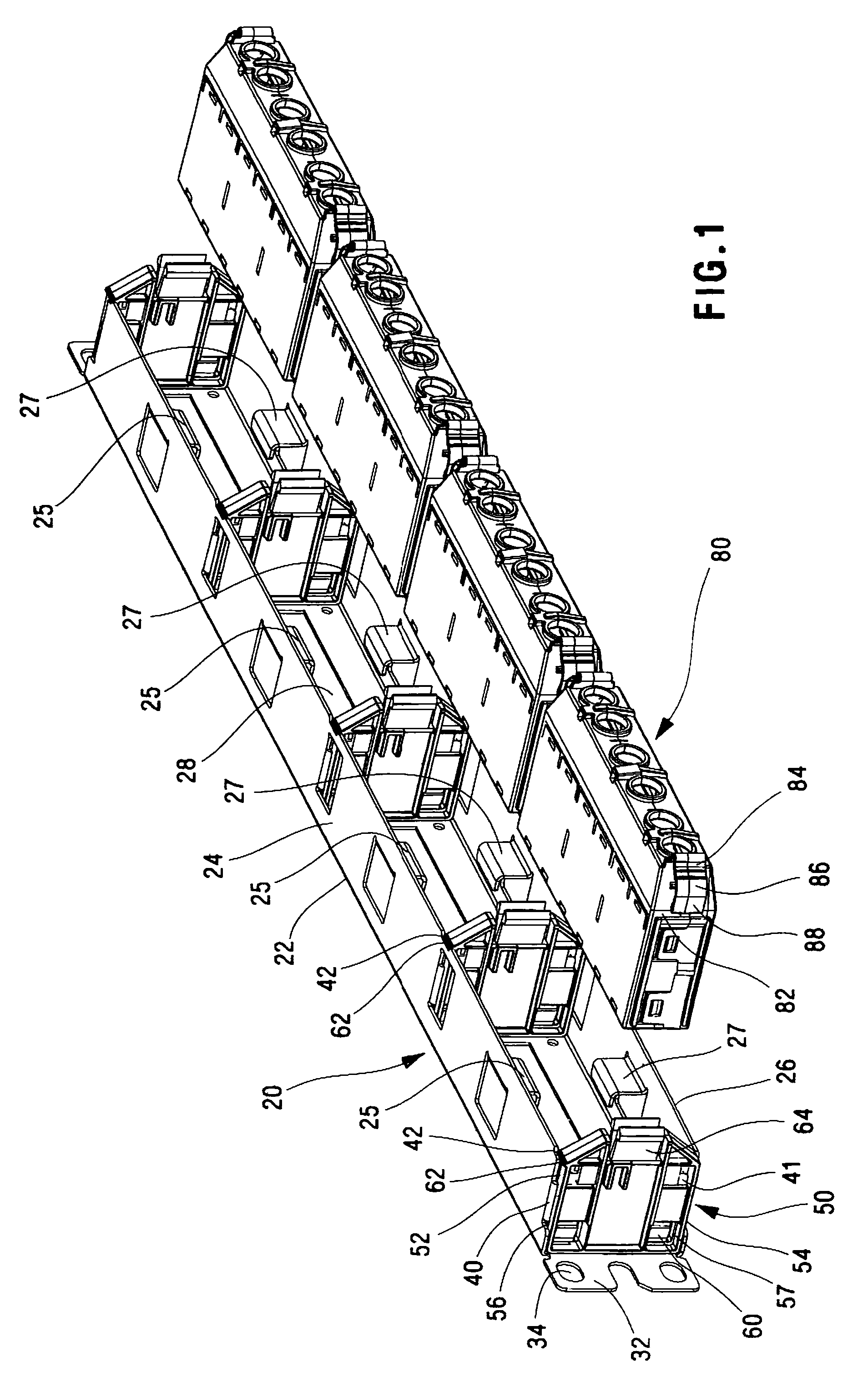

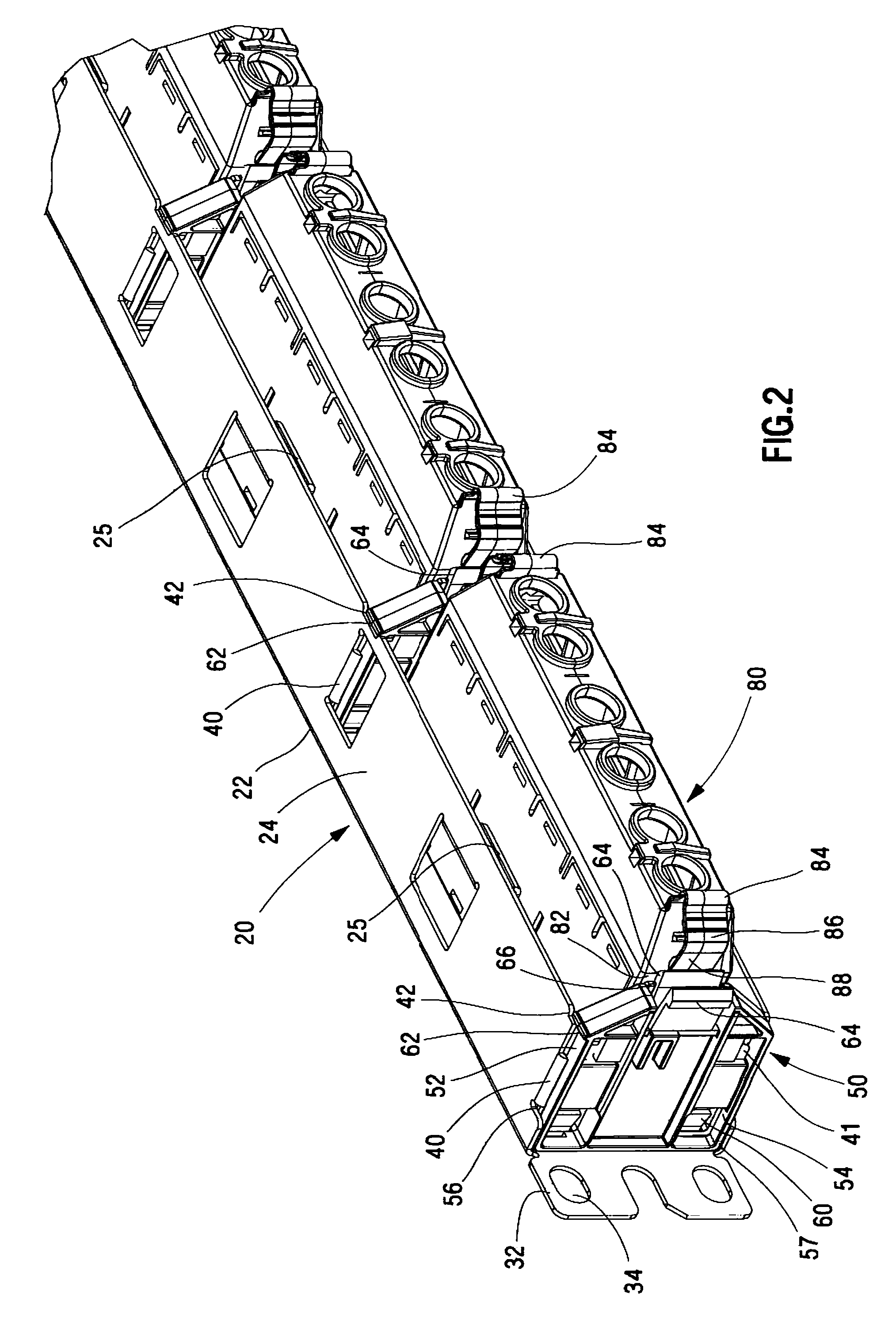

Processing system with increased cassette storage capacity

ActiveUS7740437B2Semiconductor/solid-state device manufacturingCharge manipulationMagnetic tapeEngineering

Owner:ASM IP HLDG BV

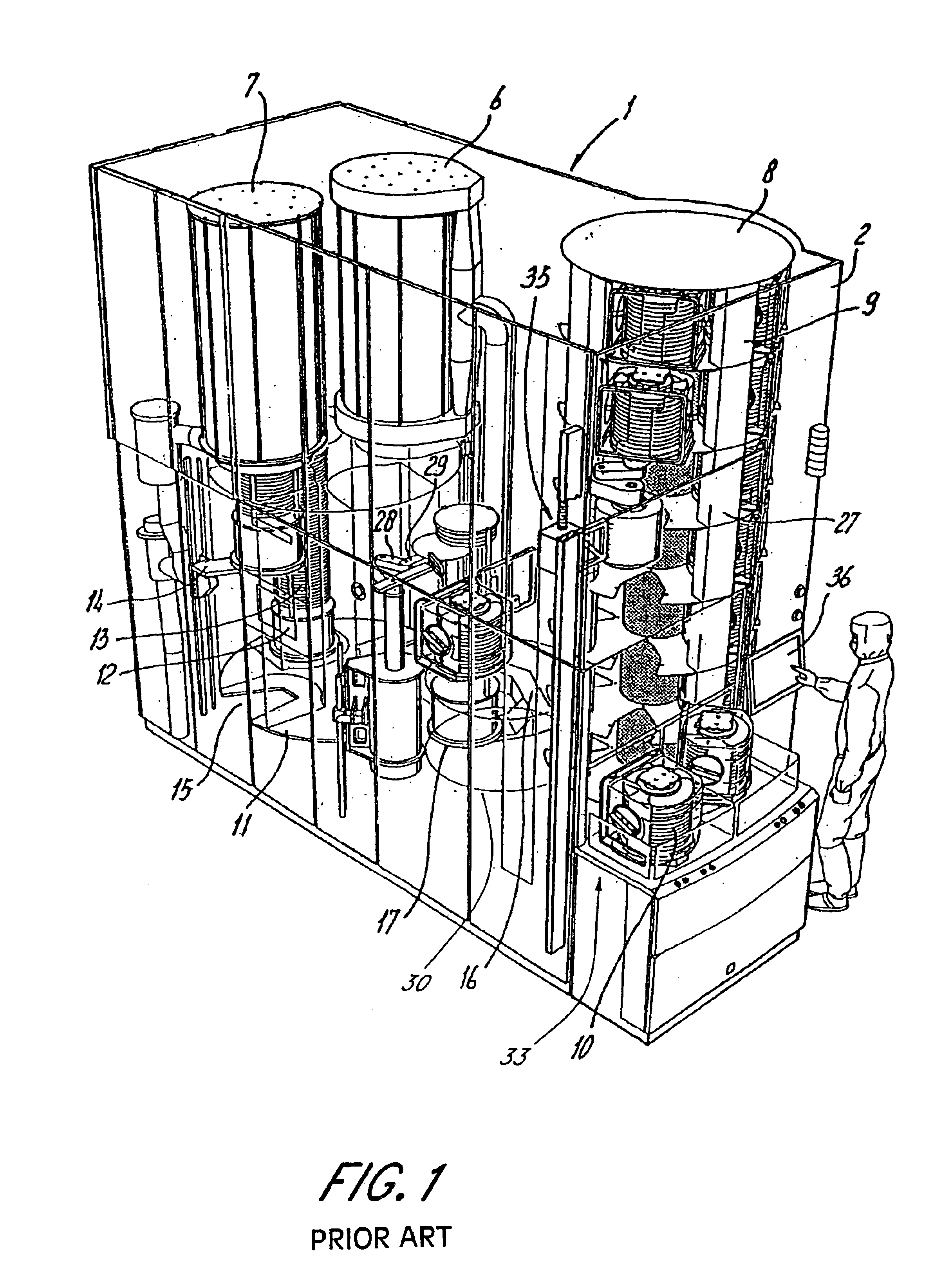

Apparatus for storing and moving a cassette

InactiveUS6283692B1Semiconductor/solid-state device manufacturingCharge manipulationDocking stationMagnetic tape

A cassette stocker includes a plurality of cassette storage shelves positioned adjacent a cleanroom wall above a cassette docking station, and a cassette mover to carry a cassette between the shelves and the docking station. An interstation transfer apparatus includes an overhead support beam and a transfer arm adapted to carry a cassette between processing stations.

Owner:APPLIED MATERIALS INC

Processing system with increased cassette storage capacity

ActiveUS20080075562A1Semiconductor/solid-state device manufacturingStorage devicesMagnetic tapeEngineering

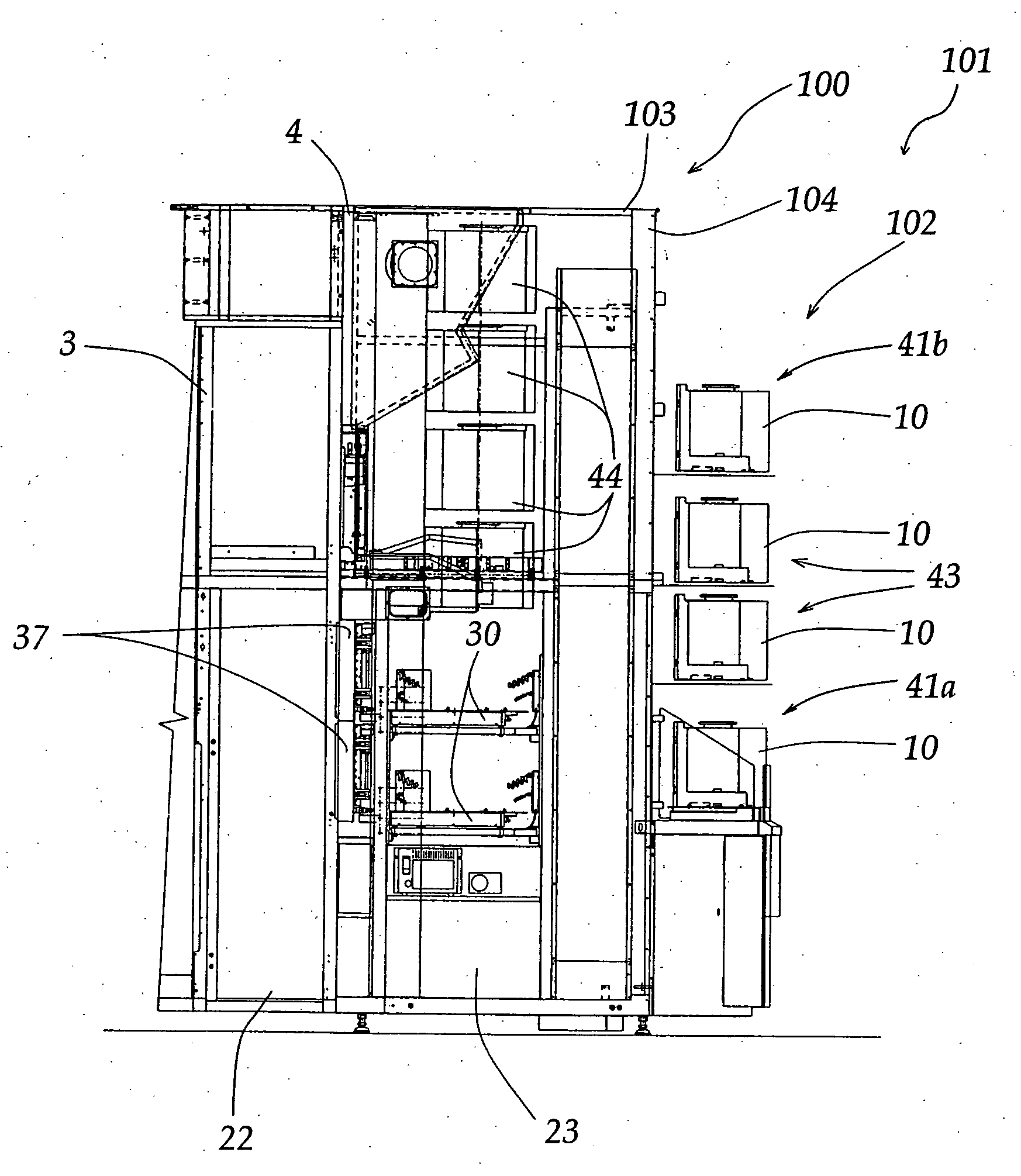

A system for processing semiconductor substrates includes a front-end with at least two vertical levels of input / output ports for transferring substrate cassettes into or out of the housing of the processing system. The front-end also includes at least one level of storage positions, e.g., two levels of storage positions, which can be disposed between the two vertical levels of the input / output ports. The two vertical levels of storage positions can each be provided with two storage positions and each of two levels of input / output ports can be provided with accommodations for two cassettes, allowing for a total of eight cassettes to be accommodated at the front-end of the processing system. Inside the housing of the processing system, interior storage positions can be provided adjacent a wafer handling chamber and spaced apart from a cassette store having rotary platforms for housing cassettes. A single cassette handler can be used to access cassettes at each of the input / output ports and the interior storage positions.

Owner:ASM IP HLDG BV

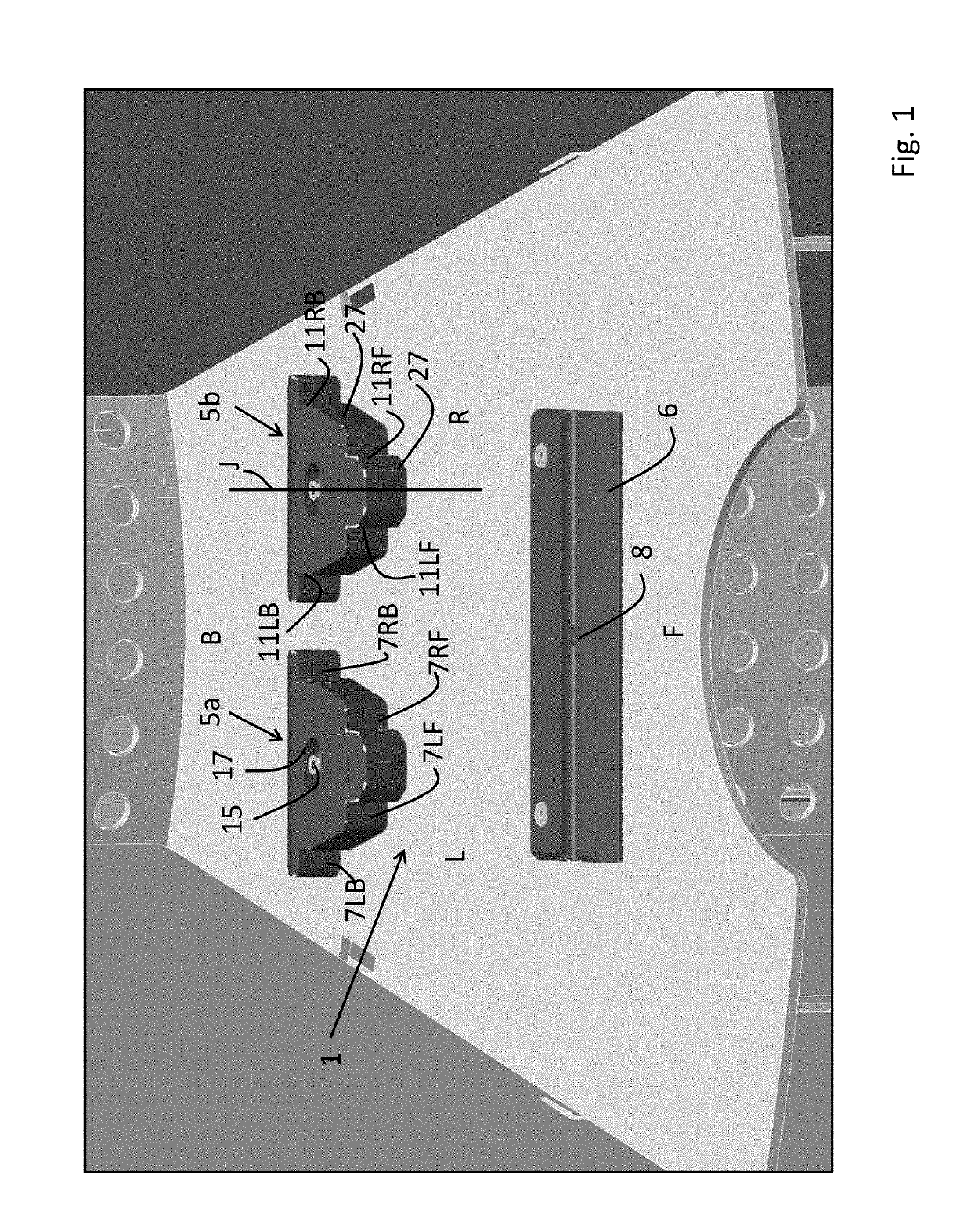

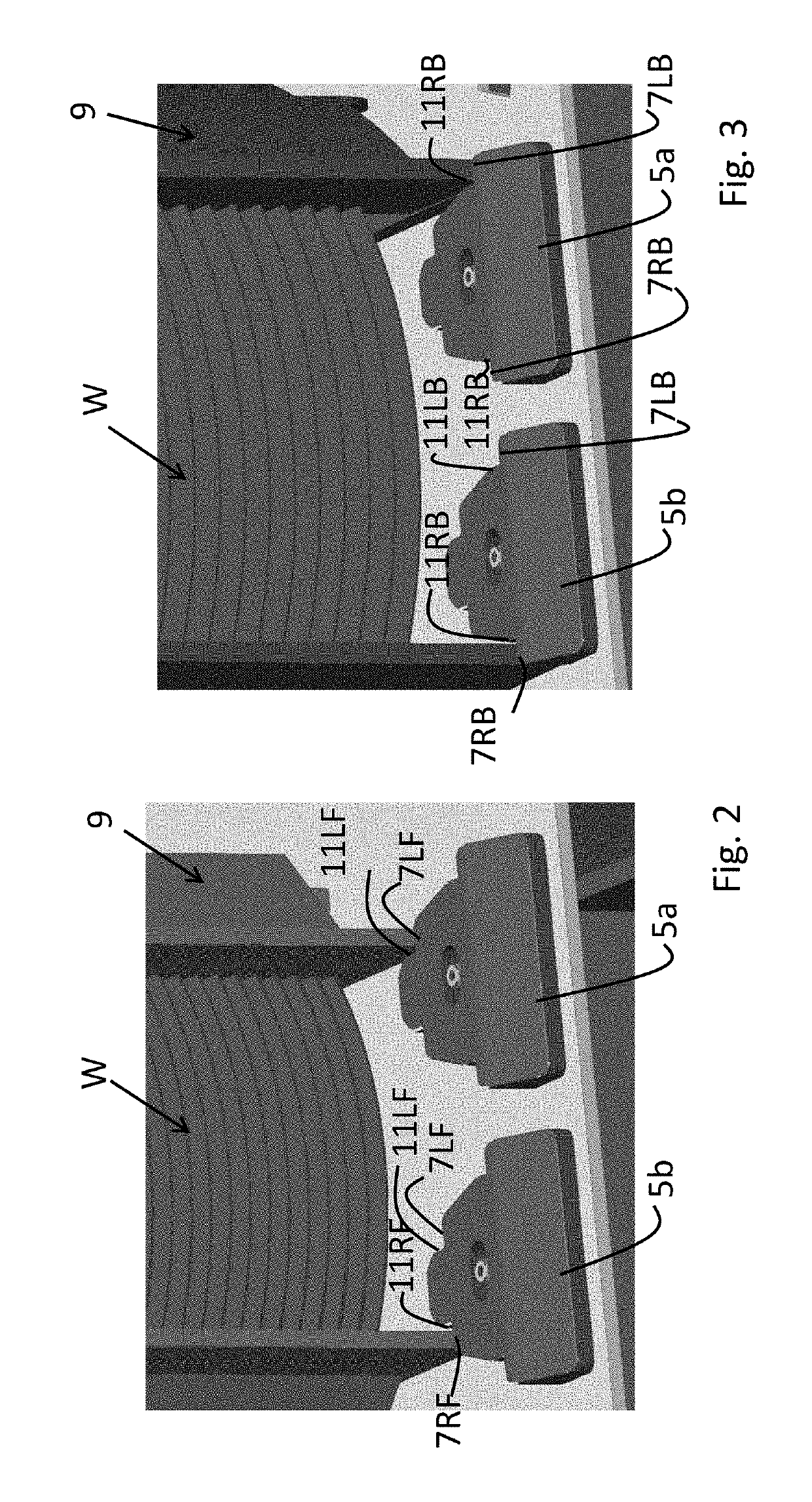

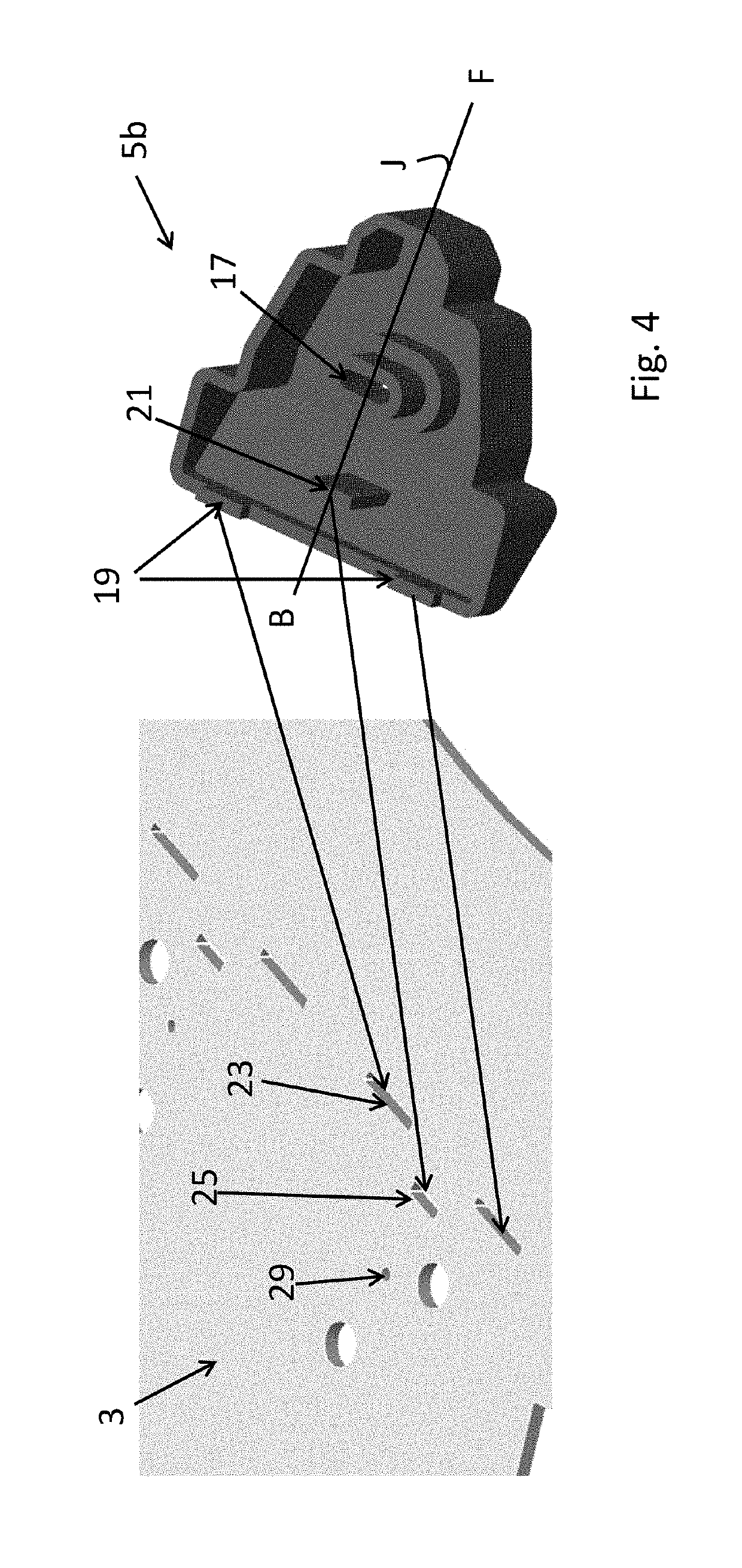

Cassette holder assembly for a substrate cassette and holding member for use in such assembly

ActiveUS10249524B2Increase the number ofEasy maintenanceSemiconductor/solid-state device detailsSolid-state devicesInterior spaceSemiconductor materials

The invention relates to a cassette holder assembly for holding a cassette for storing at least one semiconductor material substrate in an interior space accessible from a front end of the cassette. The cassette holder assembly may have a base plate for receiving the cassette. Two holding members supported by the base plate may be positioning the cassette on the plate in the assembly. The holding members may be substantially identical to each other.

Owner:ASM IP HLDG BV

Hybrid polymer film

InactiveUS6083628AFine surfaceLow costFixed capacitor dielectricSynthetic resin layered productsThermoplasticCross-link

A hybrid film, comprising a first polymer film having a plasma-treated surface and a second polymer film having first and second surfaces, with the first surface of the second polymer film being disposed along the first plasma-treated surface of the first polymer film, has superior thermal and mechanical properties that improve performance in a number of applications, including food packaging, thin film metallized and foil capacitors, metal evaporated magnetic tapes, flexible electrical cables, and decorative and optically variable films. One or more metal layers may be deposited on either the plasma-treated surface of the substrate and / or the radiation-cured acrylate polymer. A ceramic layer may be deposited on the radiation-cured acrylate polymer to provide an oxygen and moisture barrier film. The hybrid film is produced using a high speed, vacuum polymer deposition process that is capable of forming thin, uniform, high temperature, cross-linked acrylate polymers on specific thermoplastic or thermoset films. Radiation curing is employed to cross-link the acrylate monomer. The hybrid film can be produced in-line with the metallization or ceramic coating process, in the same vacuum chamber and with minimal additional cost.

Owner:SIGMA LAB OF ARIZONA

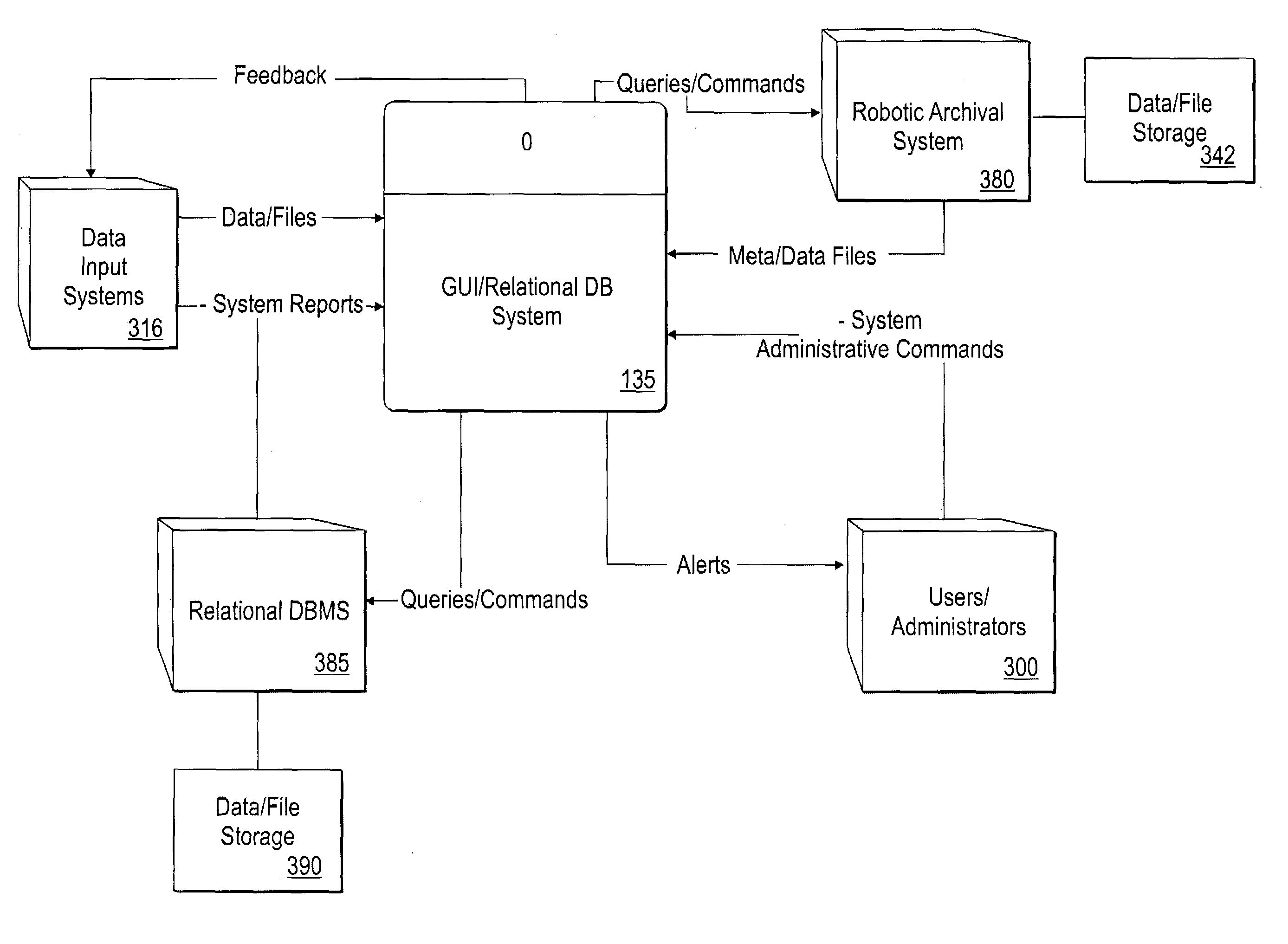

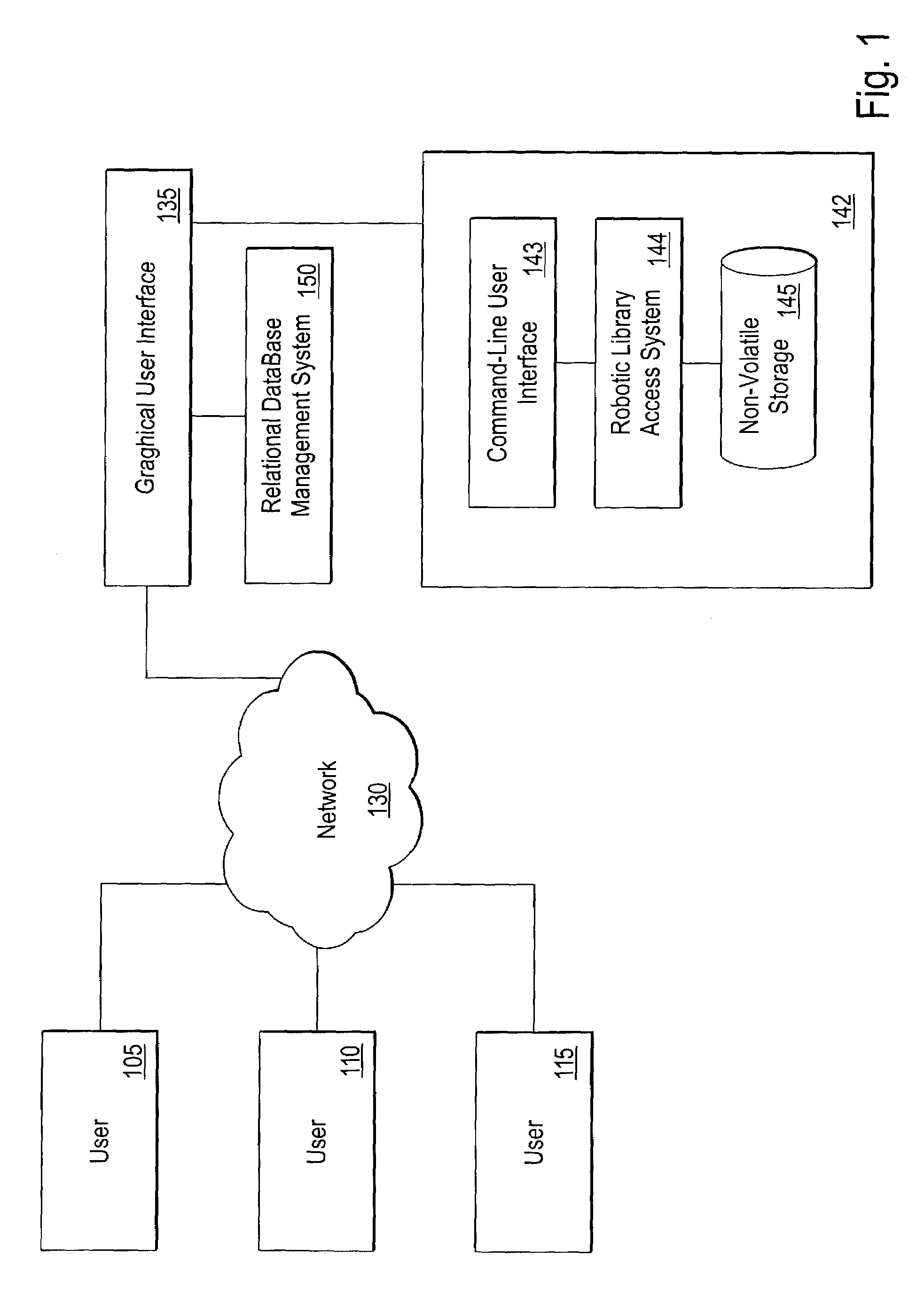

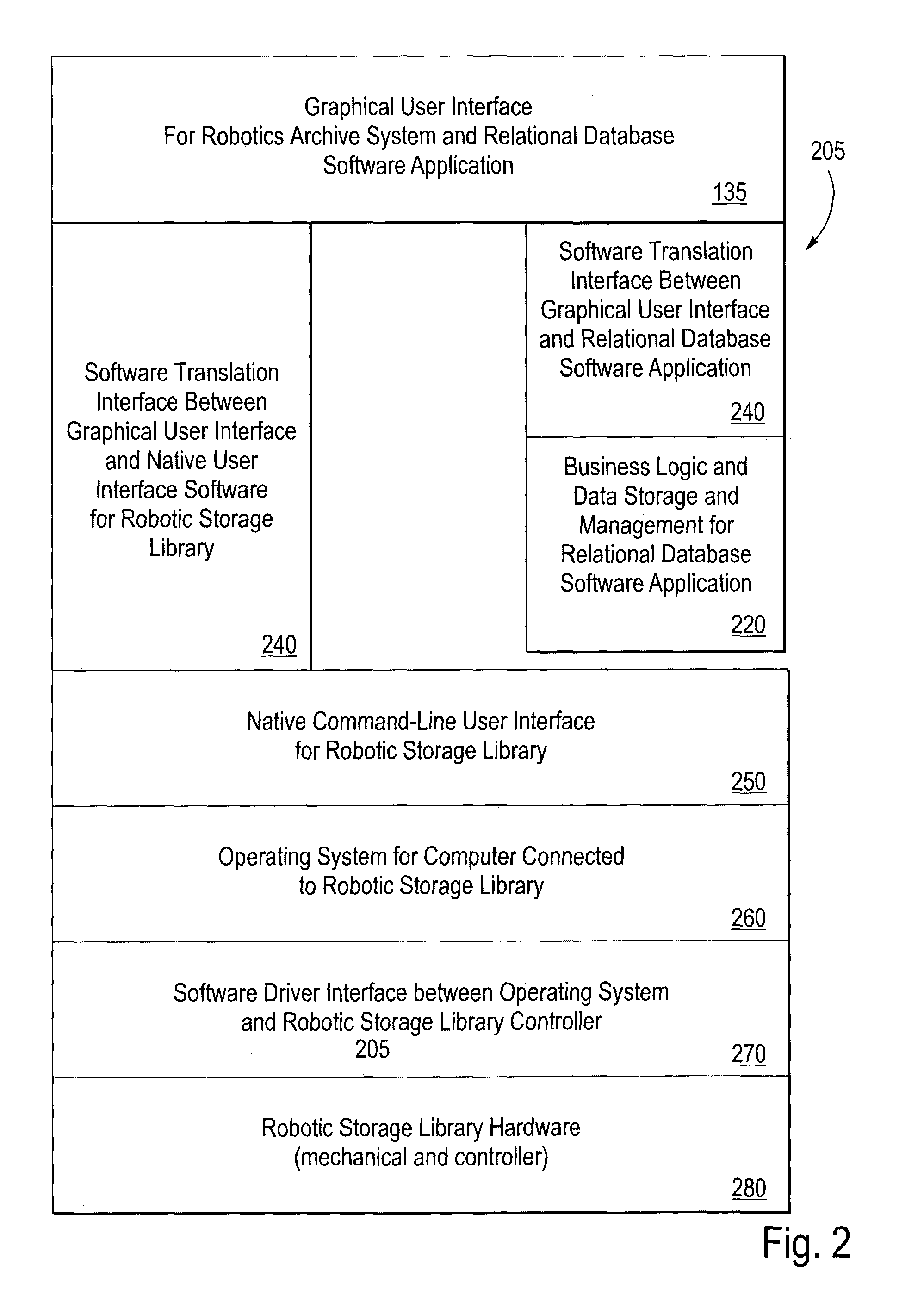

Graphical user interface-relational database access system for a robotic archive

InactiveUS6980987B2Shorten the timeData processing applicationsDigital data processing detailsRelational databaseNetwork connection

The invention includes a system for data file archival management including: a robotic data storage system having multiple non-volatile storage media, input and output means for reading and writing to the storage media, adapted and configured for storing data files, and having a command-line software code portion adapted and configured to provide a command-line user interface to control the robotic tape data storage system; a server; a business logic software code portion resident in memory on the server, configured and adapted for adding and searching metadata about the data files, where the metadata is organized as a relational database; a plurality of personal computers or workstation clients connected to the server computer over a network; a GUI software code portion resident in the memory of the personal computers, workstations, or of a server in communication with the personal computers or workstations, configured and adapted for providing a graphical user interface to at least a portion of the business logic software code portion; and a translation software code portion resident in the memory of the database server adapted and configured for translating adding, deleting, updating, and searching messages from a format compatible with the business logic code portion into and from a format compatible with the command-line code portion.

Owner:ALTO TECH RESOURCES

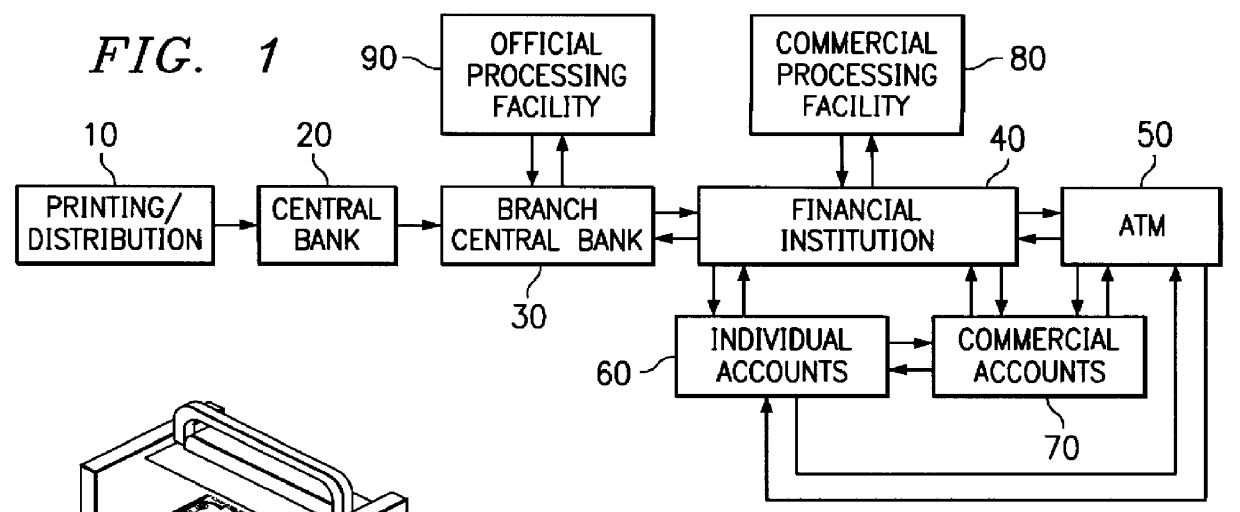

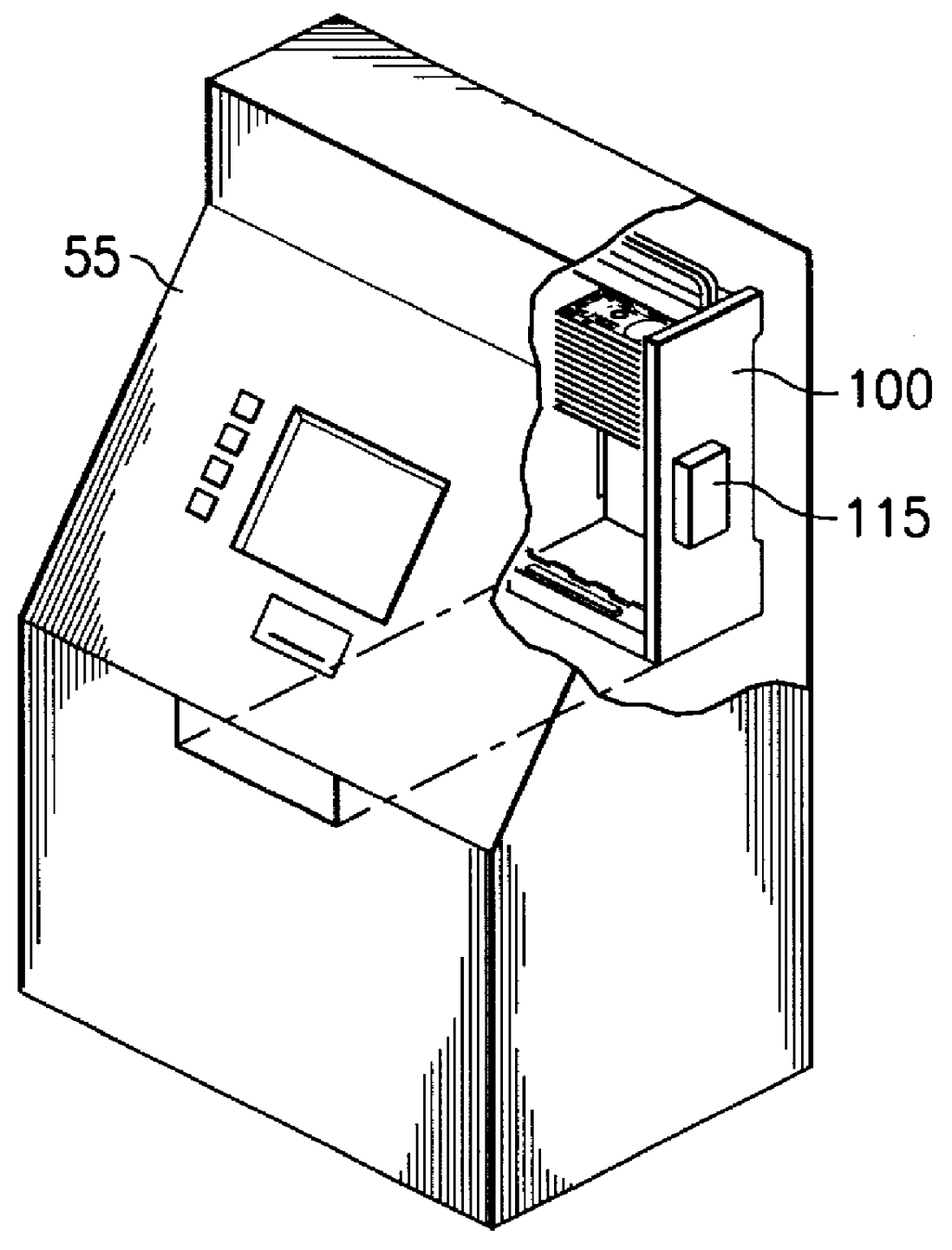

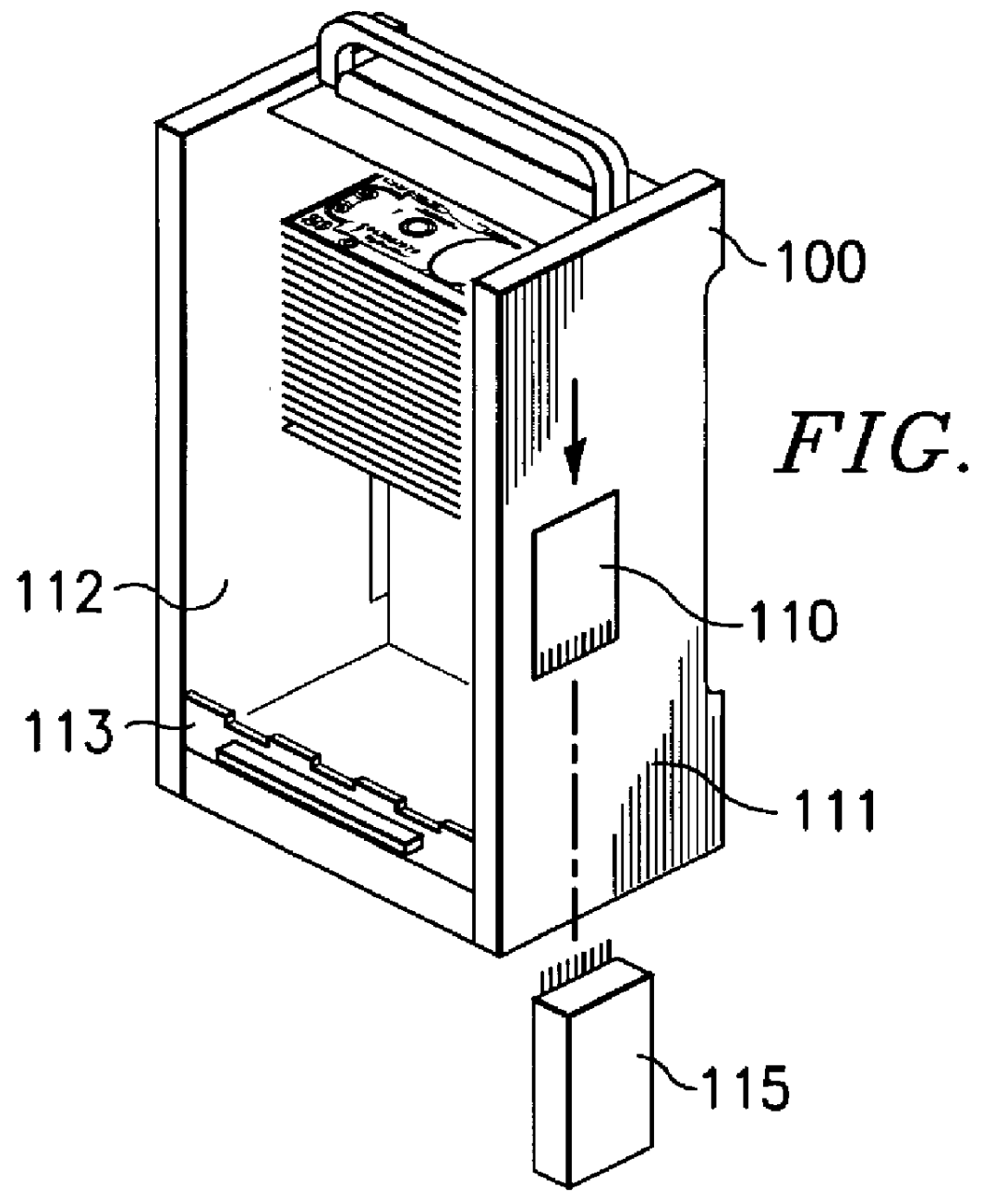

Method for currency distribution and management

InactiveUS6065672AImprove efficiencyImprove securityComplete banking machinesTicket-issuing apparatusMagnetic tapeSmart card

A method for currency management and tracking utilizing a unique standardized cassette for the transportation of note bundles and loading of note bundles into currency processing apparatus, the cassette having an accompanying smart card on which data regarding the individual note history of each note contained therein and distributed therefrom is recorded. The invention further provides for the uploading of data stored on cassette smart cards to a central data bank, thus allowing for the management and statistical modeling of the currency pool.

Owner:DE LA RUE NORTH AMERICA

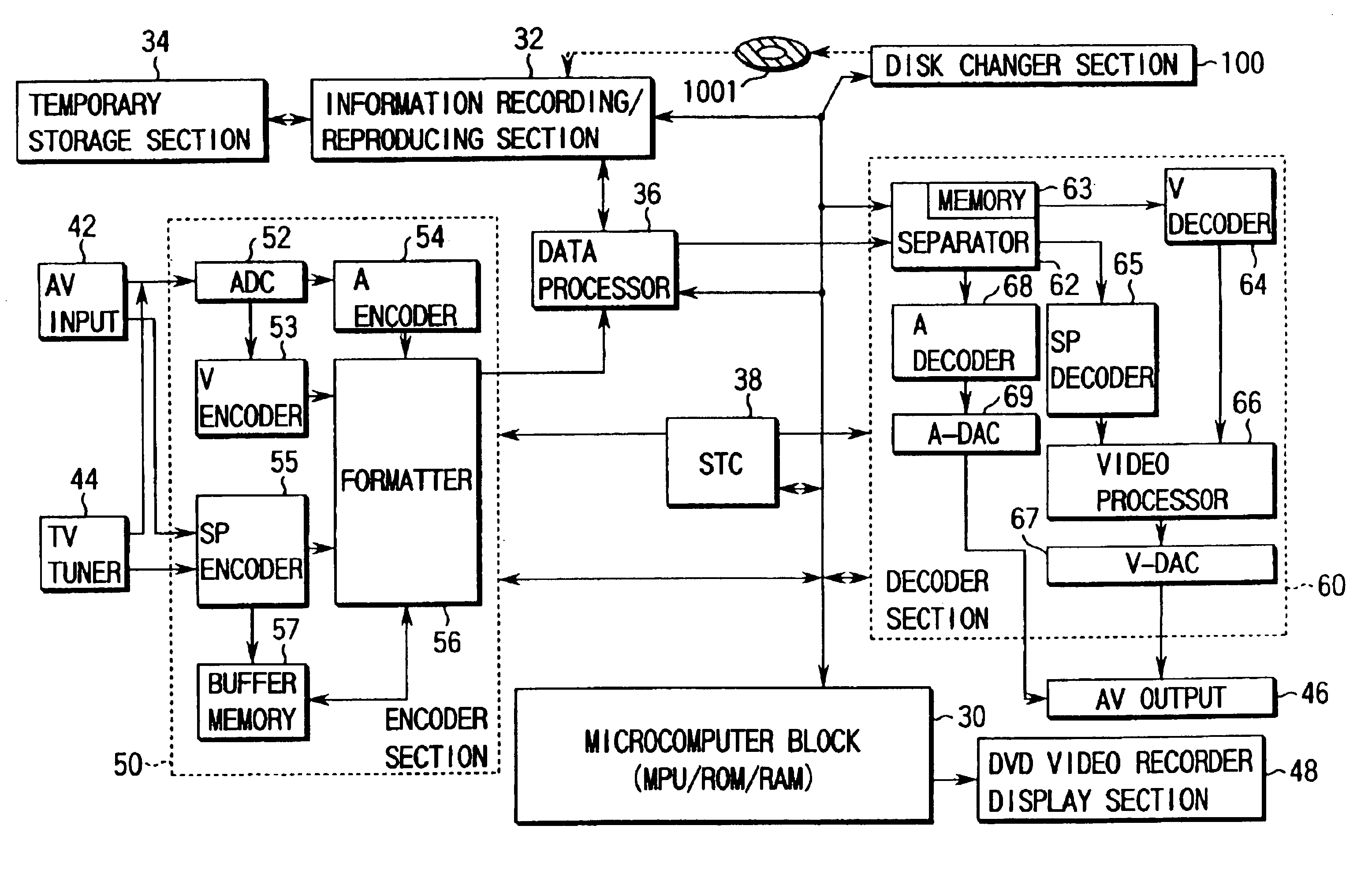

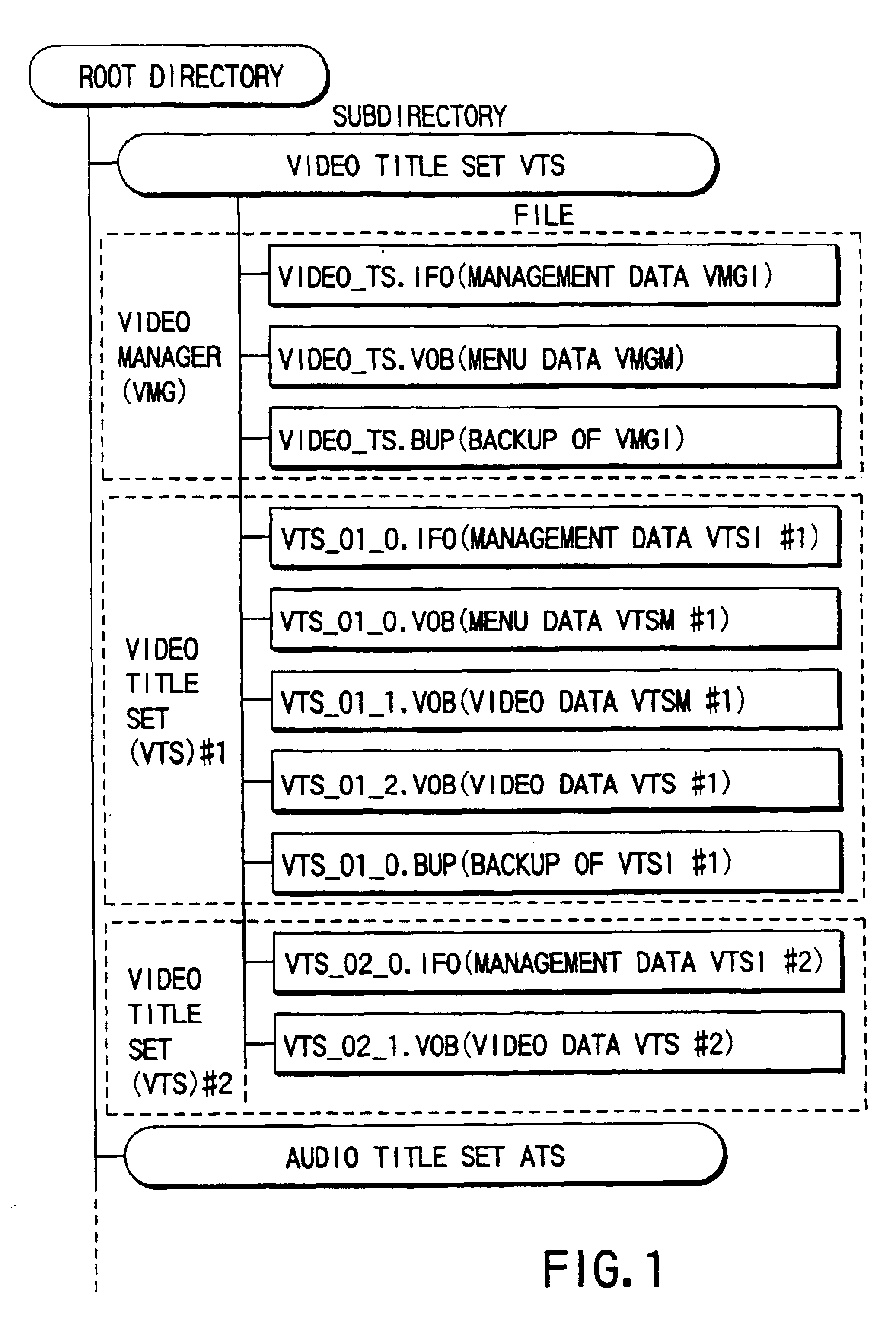

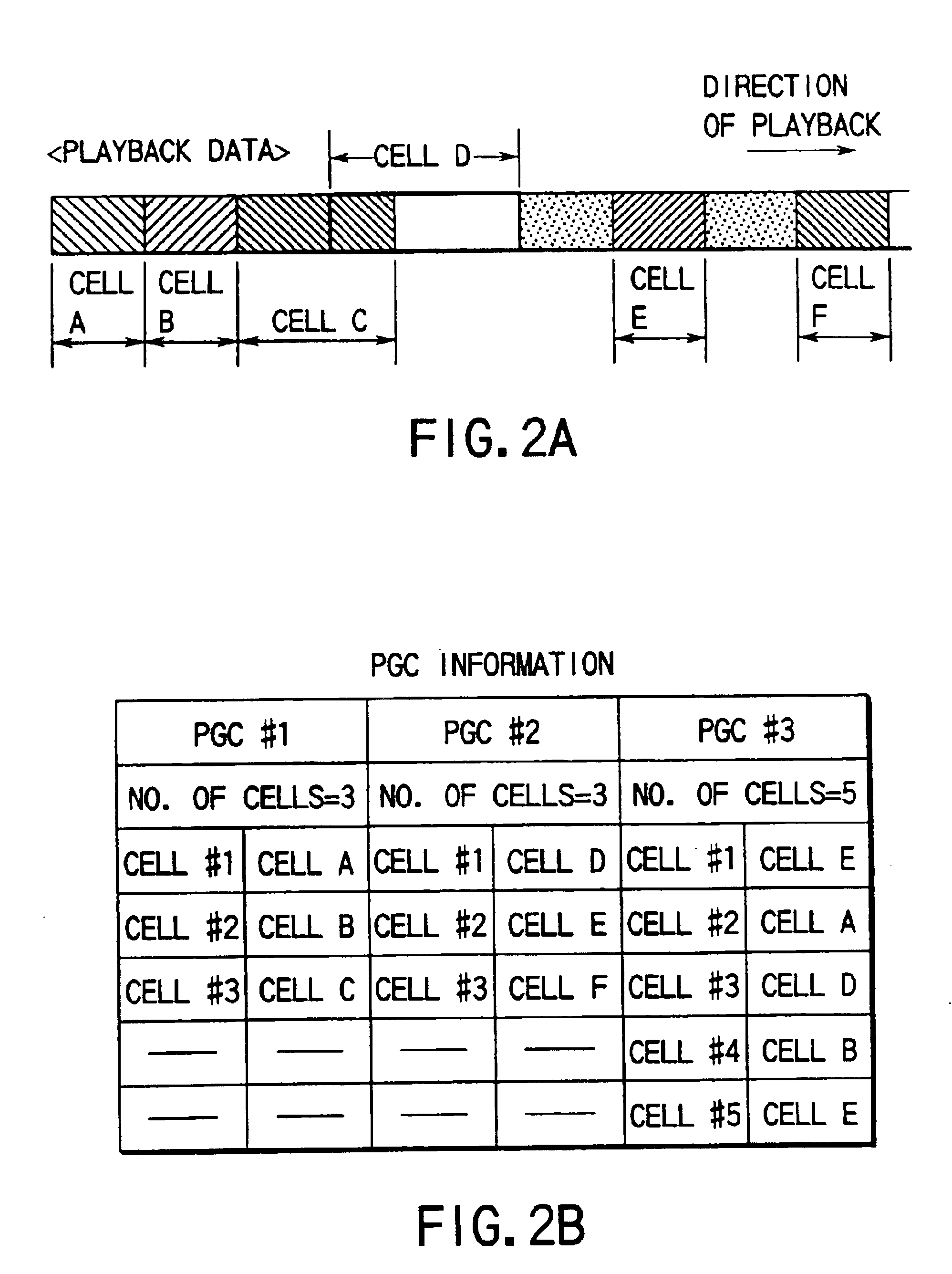

Information recording method and information reproducing method

InactiveUS6915066B2Easy to findTelevision system detailsElectronic editing digitised analogue information signalsMagnetic tapeDatabase

With this invention, at least one of a video file containing video information, a still picture file containing still picture information, and an audio file containing audio information and a management file having management information on a control method of reproducing the information in the file are recorded on an information storage medium. This realizes a data structure that causes the recording and deleting places on the information storage medium to correspond spuriously to places on a single tape, such as a VTR tape. Use of the data structure provides users with an easy-to-use interface.

Owner:KK TOSHIBA

Cassette for storage of medical instruments

InactiveUS20140014544A1Easy to cleanReliable, long lasting and secureSurgical furnitureDispensing apparatusMagnetic tapeBiomedical engineering

Owner:STRAUMANN HLDG AG

Release latch for pre-terminated cassette

ActiveUS7689089B2Increase deflectionEasy to removeOptical light guidesSelection arrangementsPatch panelMagnetic tape

A release latch for a pre-terminated cassette is described. The pre-terminated cassette includes a release latch to allow removal of the pre-terminated cassette from a patch panel, where the patch panel includes a retaining feature for retaining the pre-terminated cassette. The release latch includes a cantilever beam located on the sidewall of the pre-terminated cassette. The cantilever beam has a hinge point that allows the beam to deflect with respect to the sidewall. The release latch further includes a depressing tab provided at the distal end of the cantilever beam and a latch tab protruding from the surface of the cantilever beam between the hinge point and the depressing tab. The latch tab is capable of engagement with the retaining feature of the patch panel when the cassette is installed in the patch panel.

Owner:PANDUIT

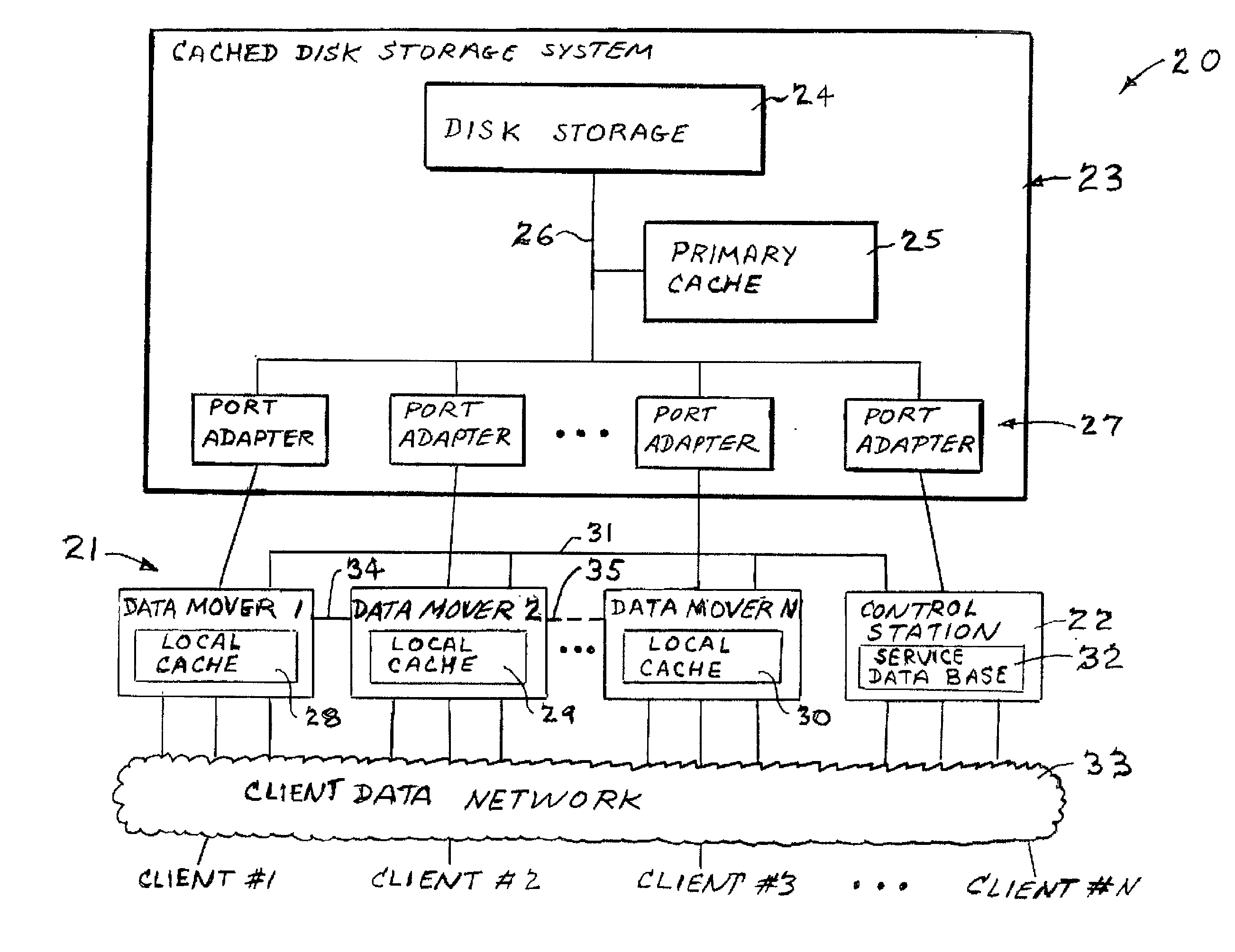

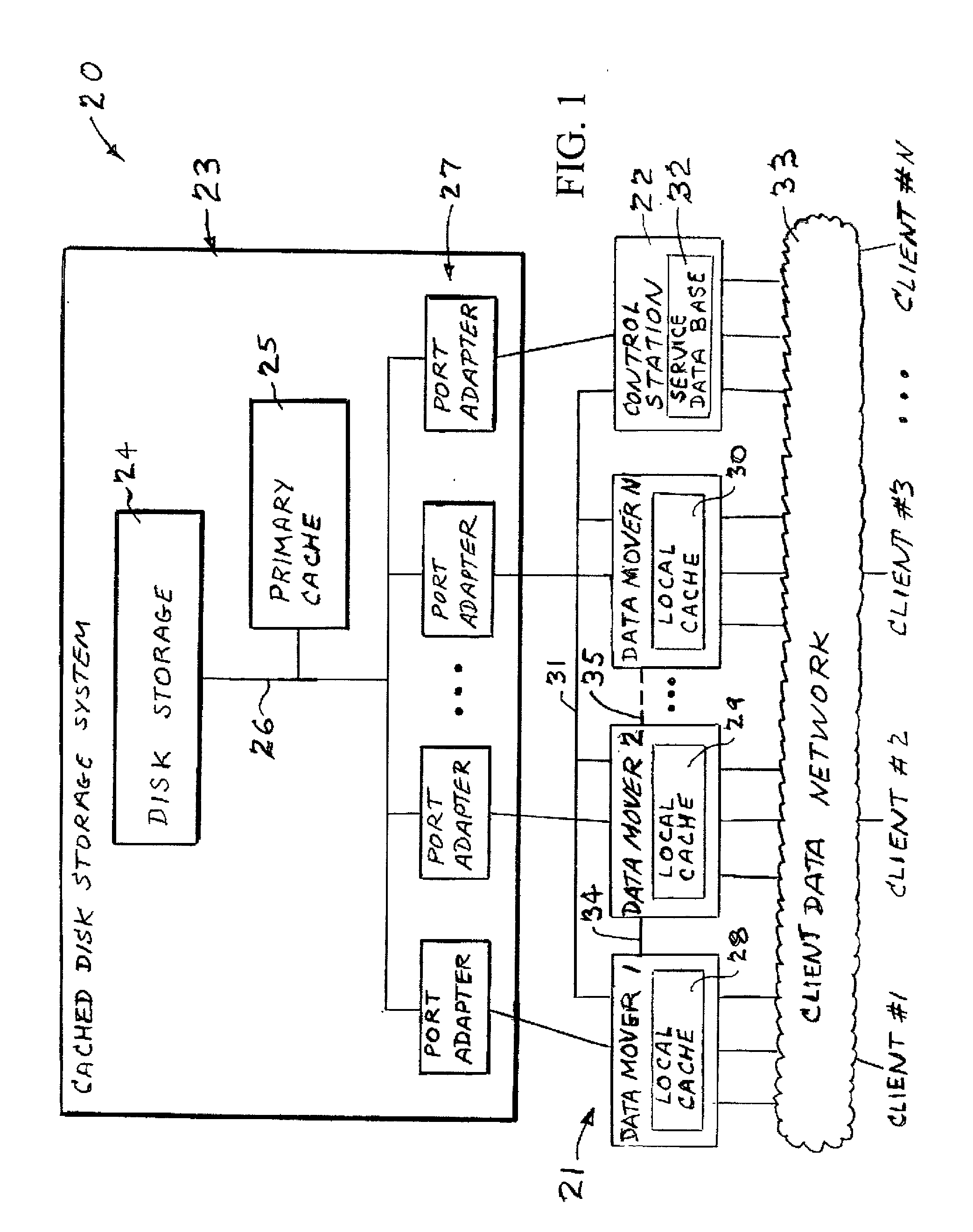

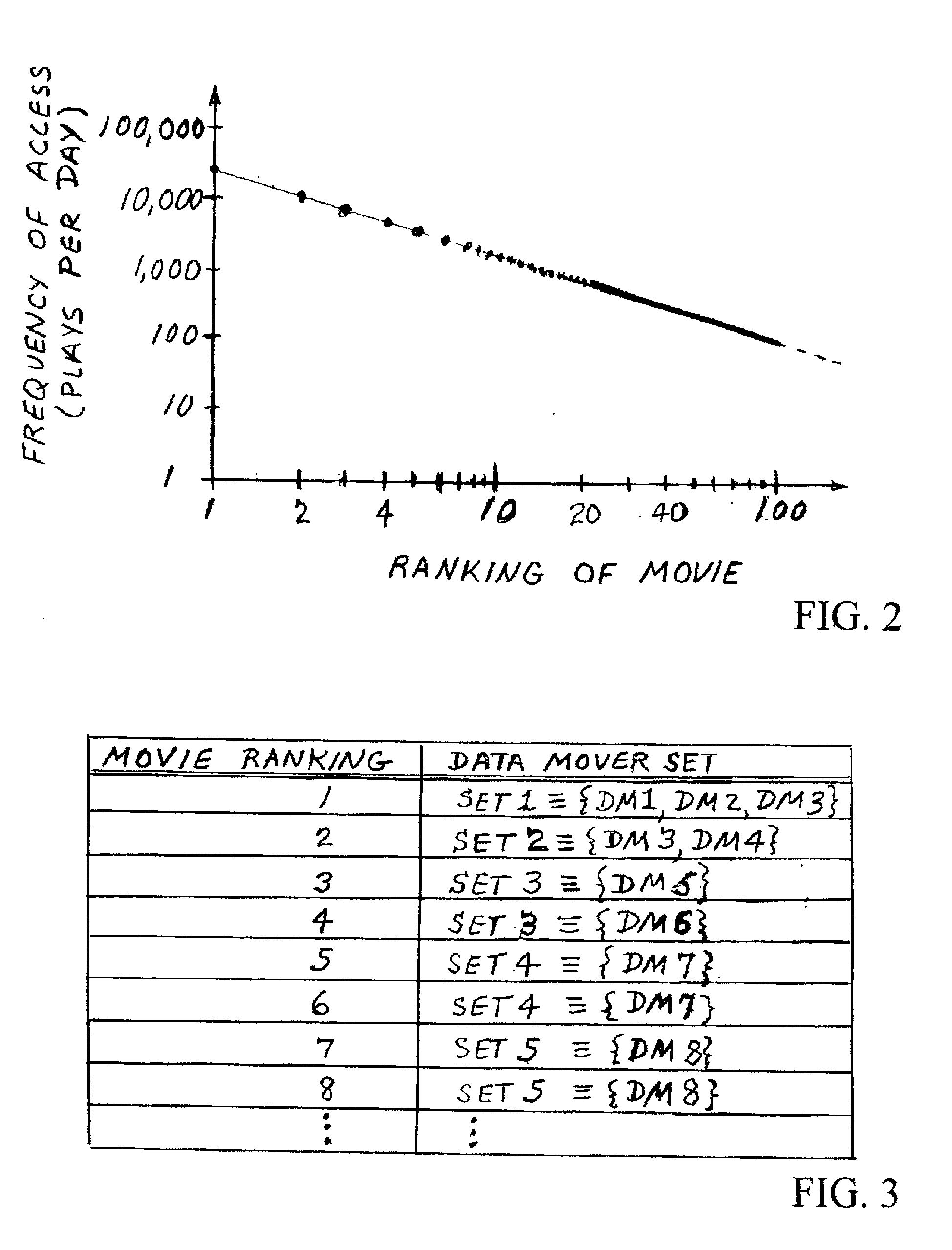

Video file server cache management using movie ratings for reservation of memory and bandwidth resources

ActiveUS20030005457A1Memory adressing/allocation/relocationMultiple digital computer combinationsMagnetic tapeRanking

Access to movies ranging from very popular movies to unpopular movies is managed by configuring sets of data movers for associated movie rankings, reserving data mover local cache resources for the most popular movies, reserving a certain number of streams for popular movies, negotiating with a client for selection of available movie titles during peak demand when resources are not available to start any freely-selected movie in disk storage, and managing disk bandwidth and primary and local cache memory and bandwidth resources for popular and unpopular movies. The assignment of resources to movie rankings may remain the same while the rankings of the movies are adjusted, for example, during off-peak hours. A movie locked in primary cache and providing a source for servicing a number of video streams may be demoted from primary cache to disk in favor of servicing one or more streams of a higher-ranking movie.

Owner:EMC IP HLDG CO LLC

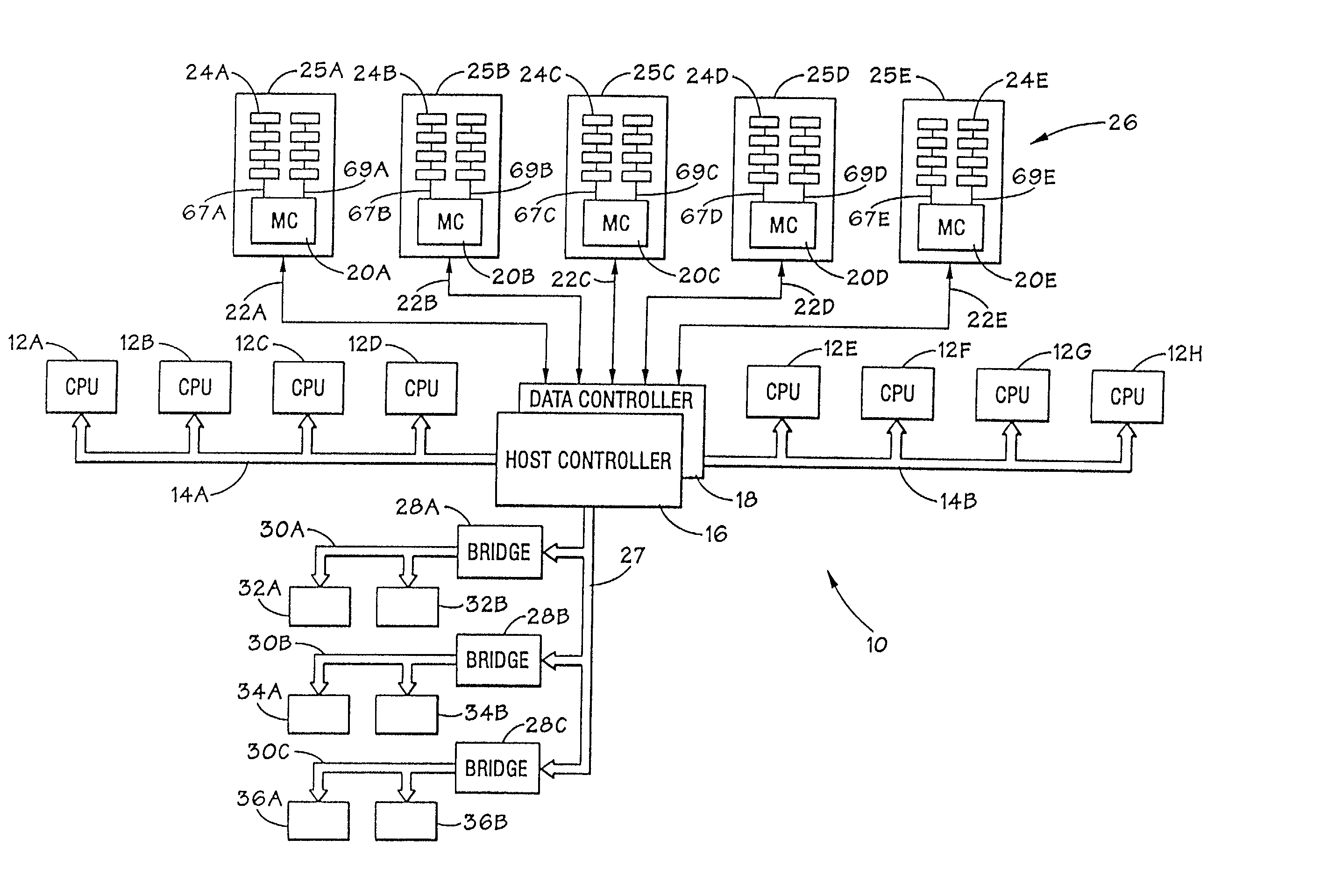

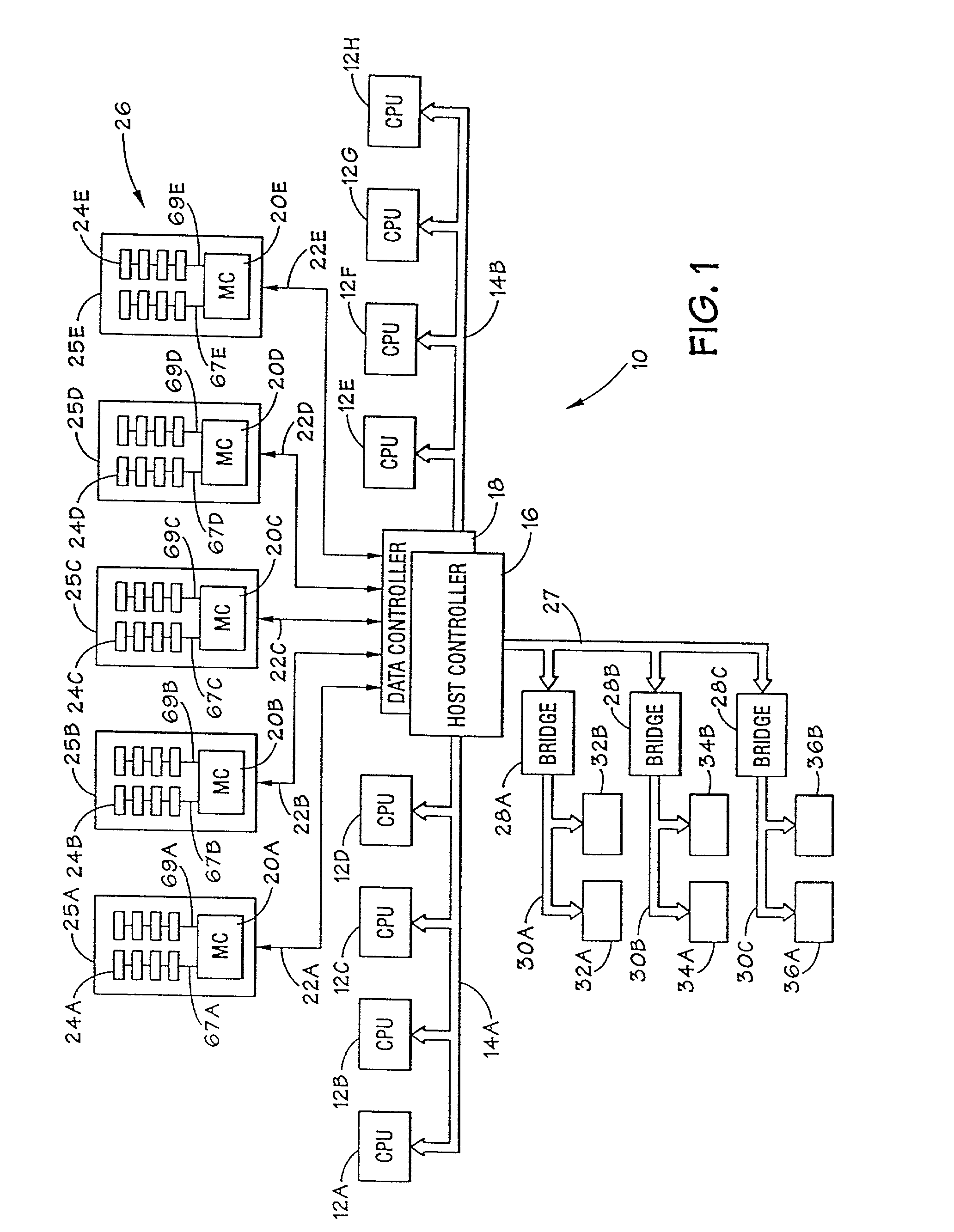

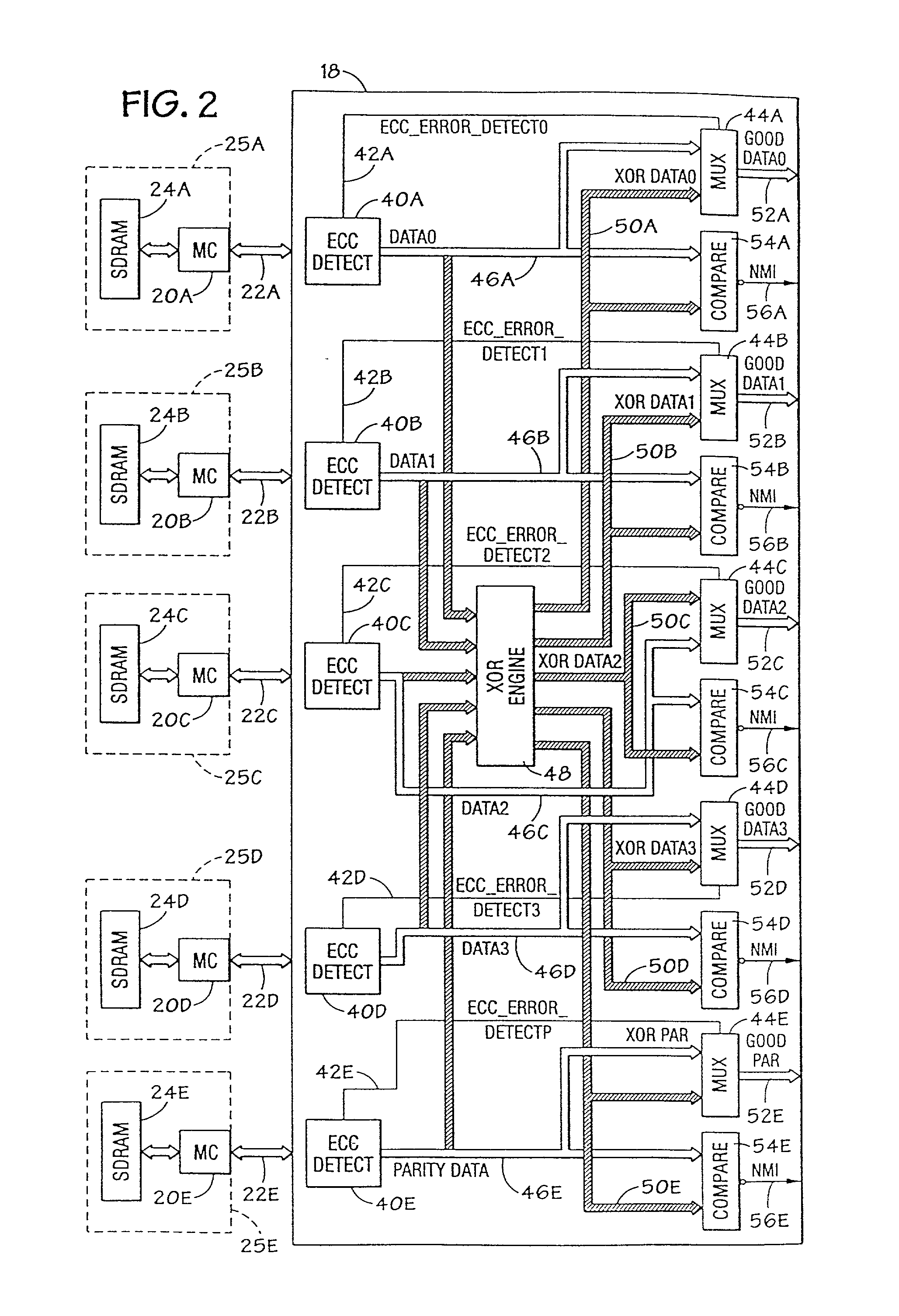

Error indication in a raid memory system

A computer system includes a plurality of memory modules that contain semiconductor memory, such as DIMMs. The system includes a host / data controller that utilizes an XOR engine to store data and parity information in a striped fashion on the plurality of memory modules to create a redundant array of industry standard DIMMs (RAID). The host / data controller also interleaves data on a plurality of channels associated with each of the plurality of memory modules. The system implements error interrupt control, ECC error reporting, cartridge error power down procedures in response to command errors, storage of error information in unused segments of each DIMM, hot-pug procedure indicator and remote tagging capabilities of memory cartridges and DIMMs.

Owner:SONRAI MEMORY LTD

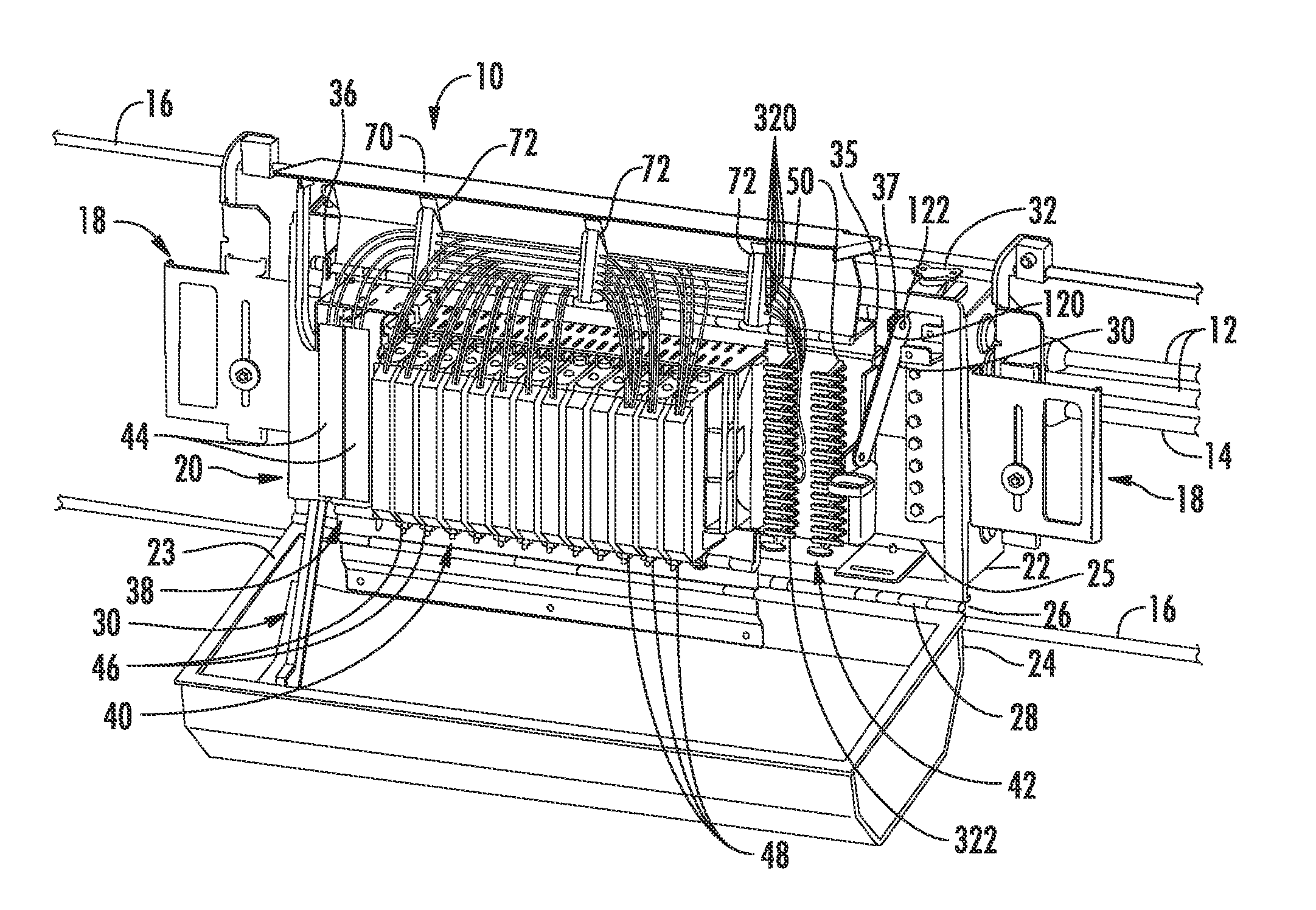

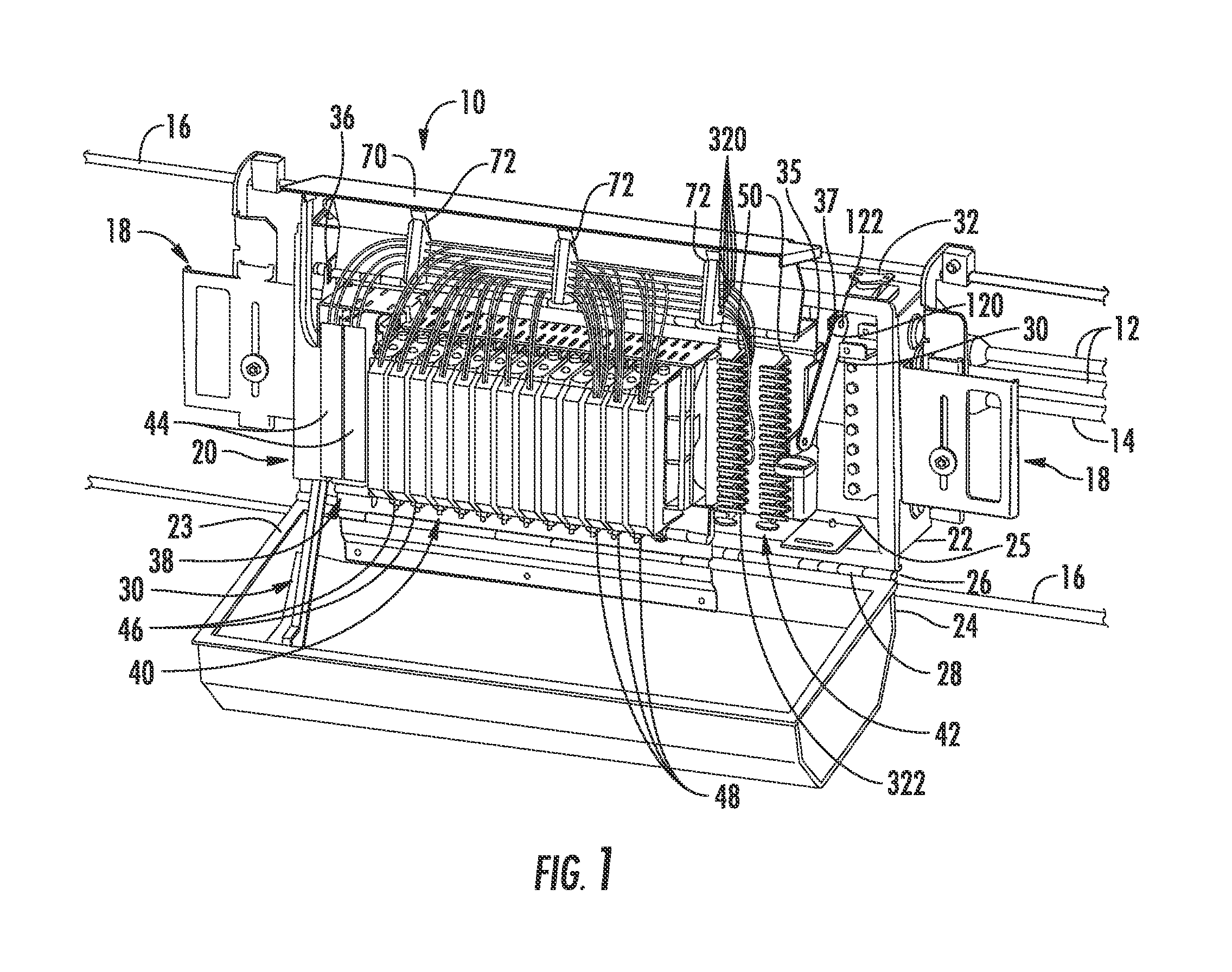

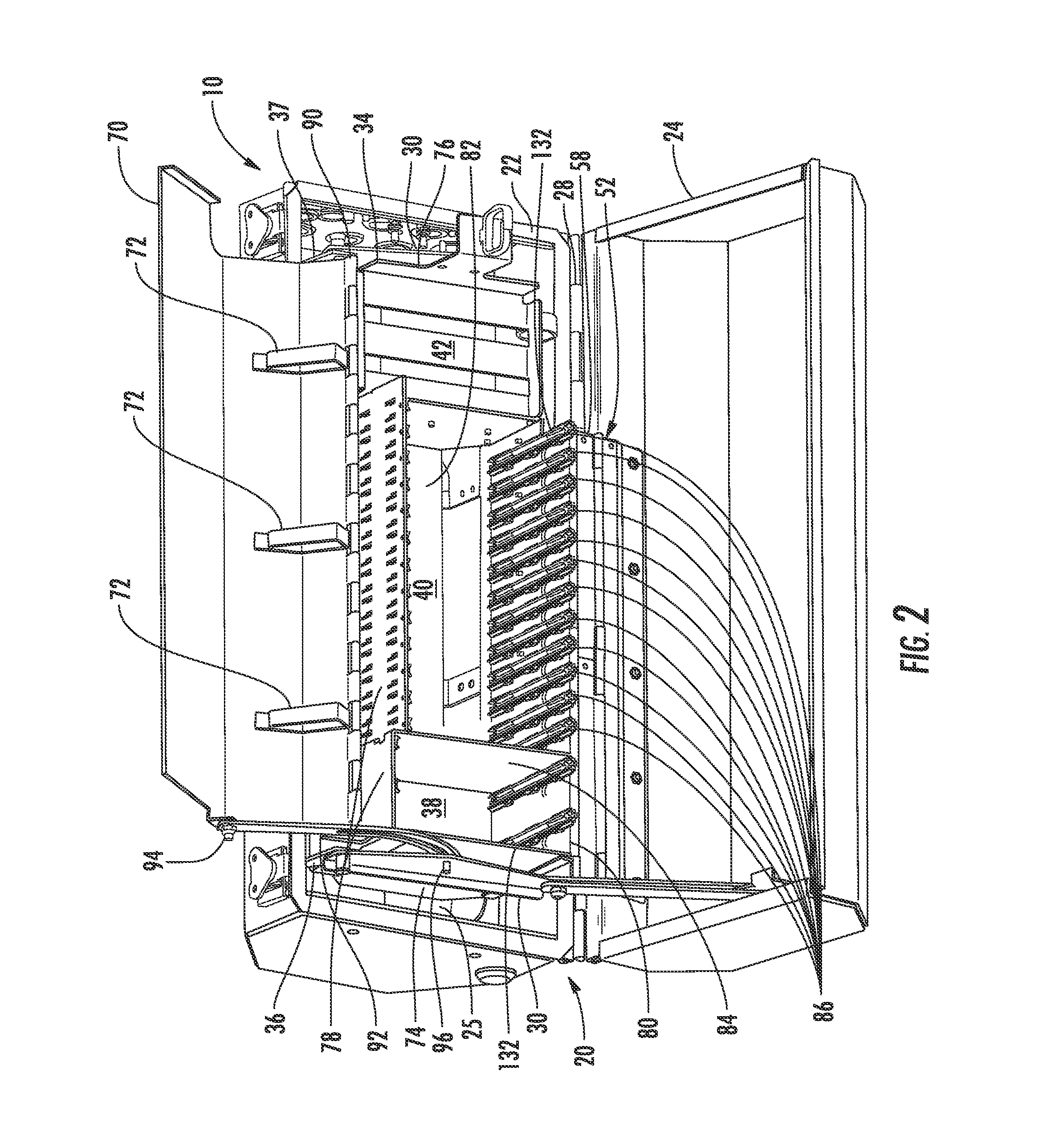

Variably configurable and modular local convergence point

ActiveUS20110211799A1Easy accessOptical fibre/cable installationMetal working apparatusInterior spaceParking area

A variably configurable fiber optic terminal as a local convergence point in a fiber optic network is disclosed. The fiber optic terminal has an enclosure having a base and a cover which define an interior space. A feeder cable having at least one optical fiber and a distribution cable having at least one optical fiber are received into the interior space through a feeder cable port and a distribution cable port, respectively. A movable chassis positions in the interior space and is movable between a first position, a second position and third position. The movable chassis has a splitter holder area, a cassette area and a parking area. A cassette movably positions in the cassette area. A splitter module holder having a splitter module movably positioned therein movably positions in the splitter holder area. The optical fiber of the feeder cable and the optical fiber of the distribution cable are optically connected through the cassette, which also may be through the splitter module. In such case, the optical fiber of the feeder cable optically connects to an input optical fiber to the slitter module, where the optical signal is split into a plurality of output optical fibers. One of the plurality of output optical fibers connects to the optical fiber of the distribution cable for distribution towards a subscriber premises. The interior space is variably configurable by changeably positioning the cassette and splitter modules in the movable chassis.

Owner:CORNING OPTICAL COMM LLC

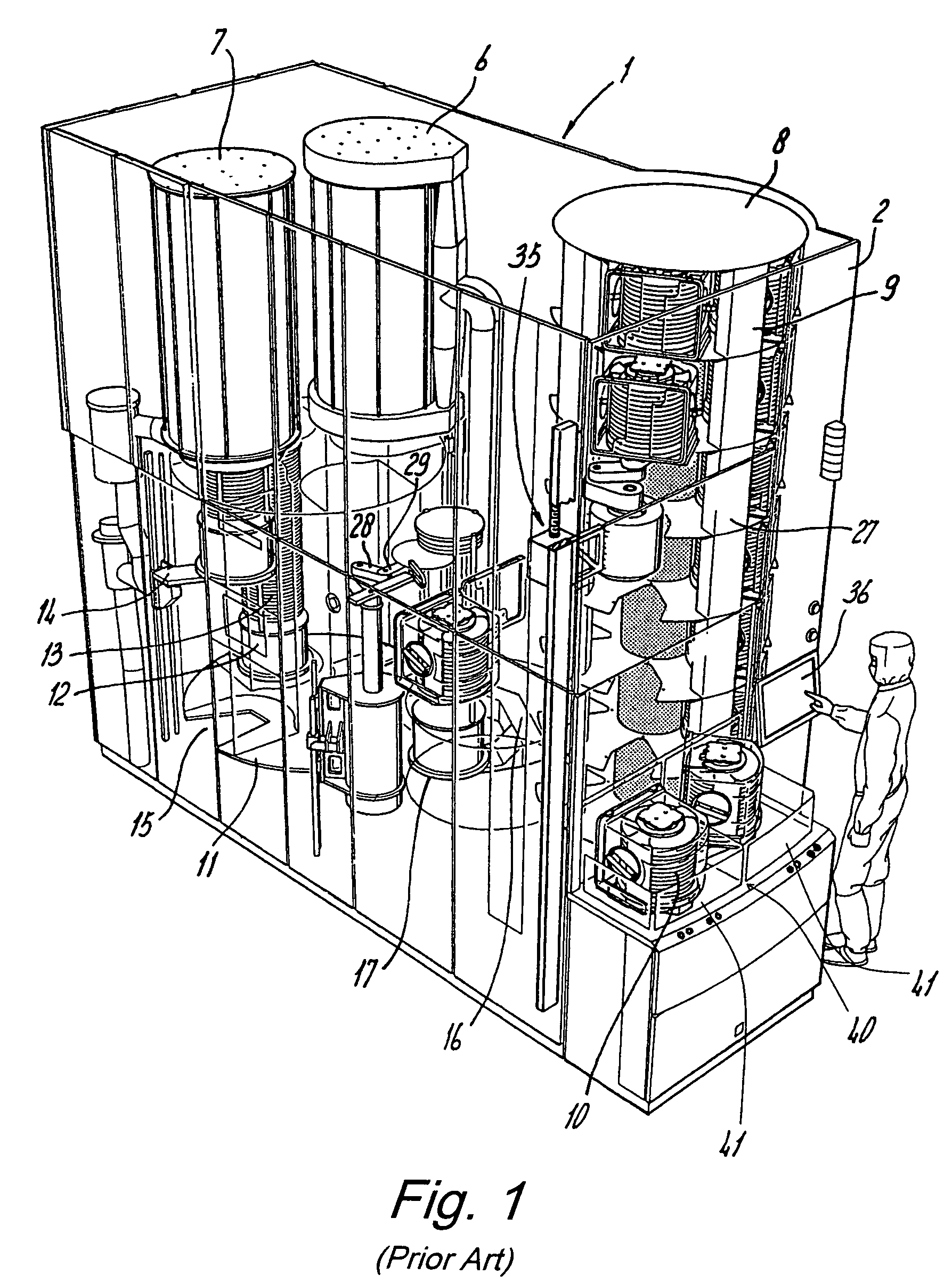

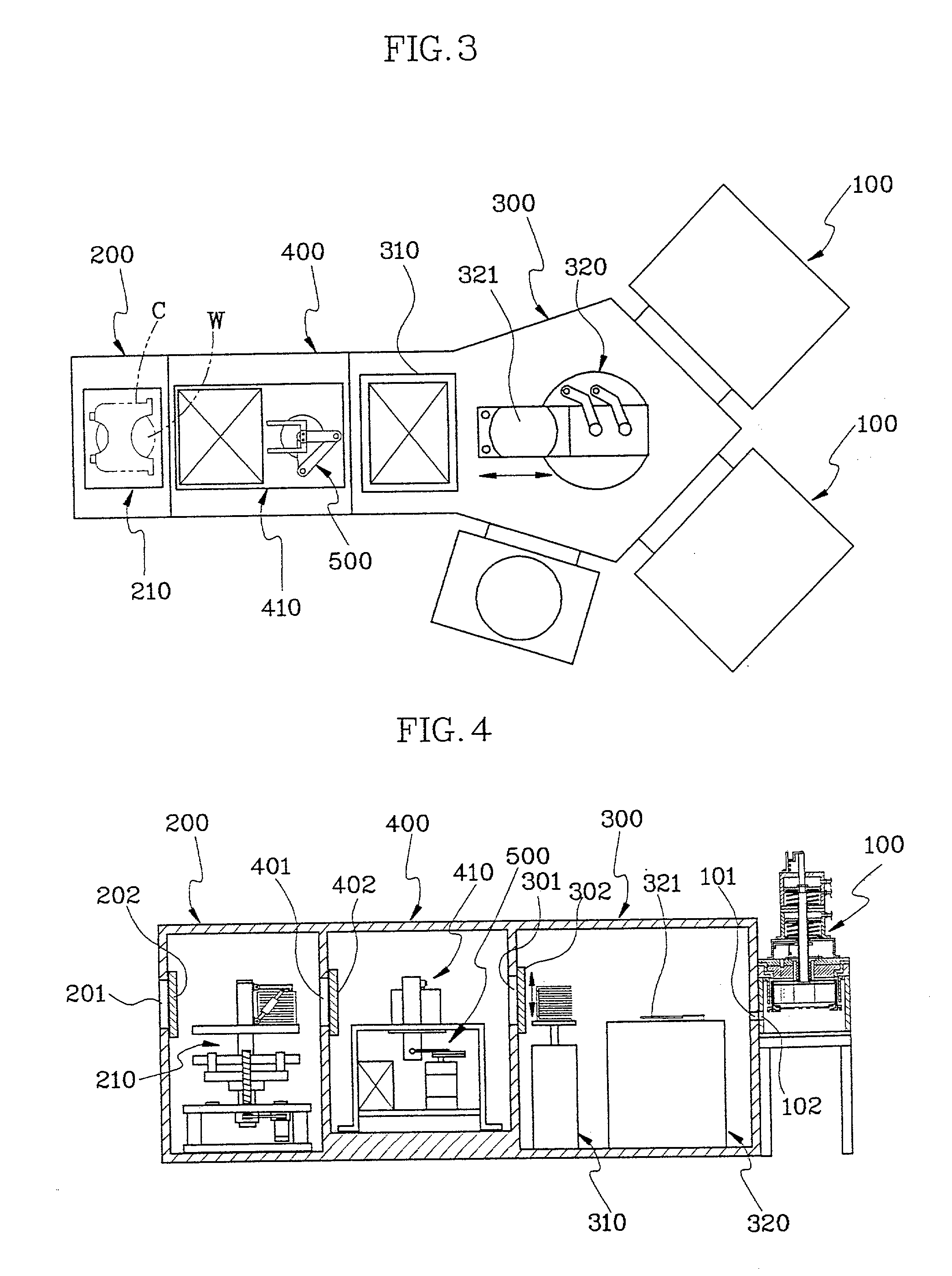

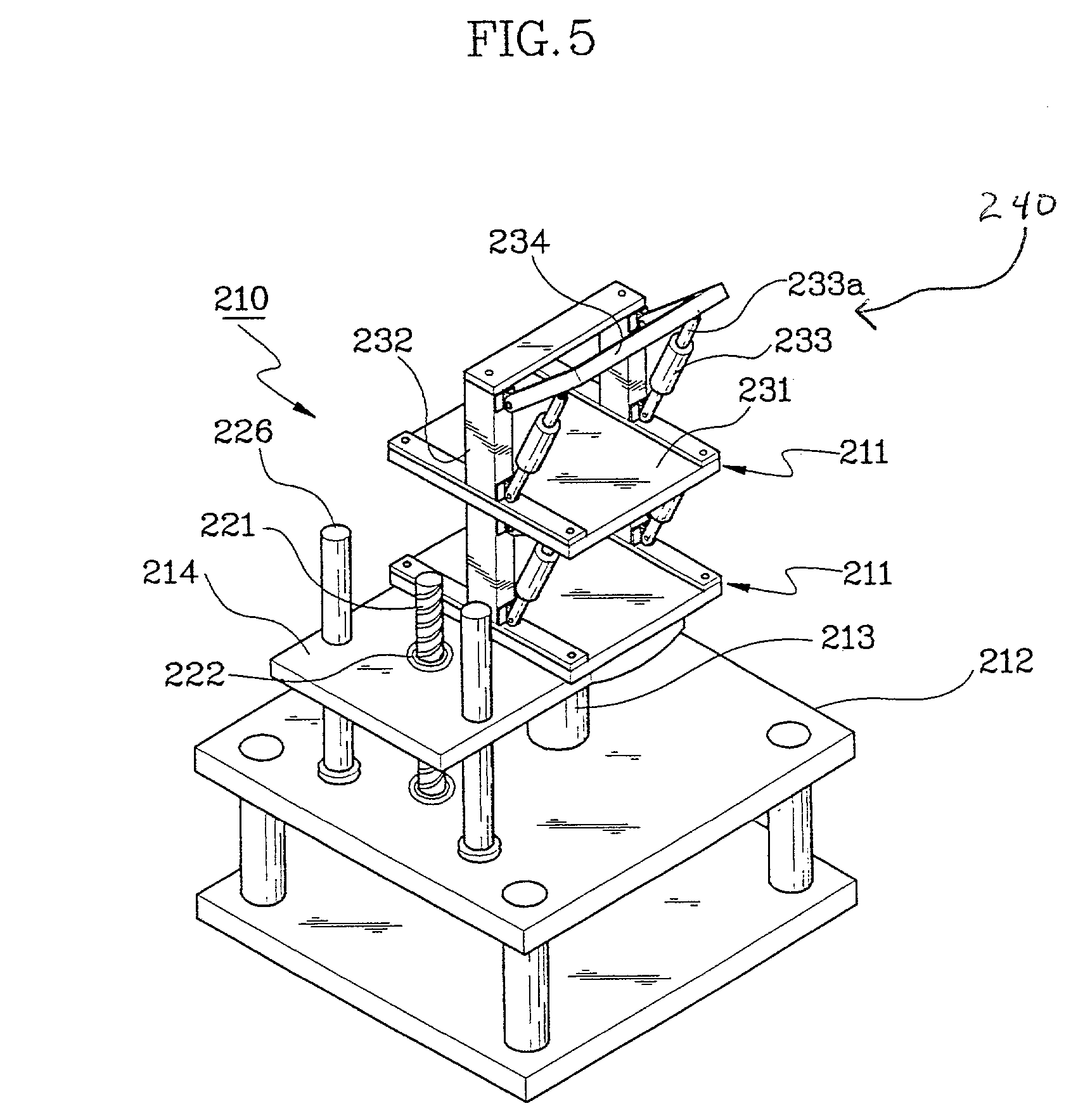

Etching apparatus for manufacturing semiconductor devices

InactiveUS20010037856A1Operation efficiency can be improvedReduce processing timeSemiconductor/solid-state device manufacturingCharge manipulationMagnetic tapeWafer stacking

An etching apparatus for manufacturing semiconductor devices which reduces contamination of the processing surface of a wafer by transporting a plurality of wafers stacked in a cassette with their processing surfaces facing down from the cassette supply chamber to one or more process chambers where the etching operation is performed on each wafer, one at a time. The apparatus has a load lock chamber for transferring the wafers stacked in the cassette from the cassette supply chamber, which is maintained under atmospheric conditions, to the process chamber, which is maintained under a strong vacuum. The process chamber has a cathode to which a wafer is clamped by a wafer holder with its processing surface facing down; the process chamber may also have a removable lower cover for easy repair and cleaning. The apparatus may also have a wafer aligning chamber installed between the cassette supply chamber and the load lock chamber for simultaneously aligning all of the wafers n the cassette before they are transported to the load lock chamber. The wafer aligning chamber also has a cassette transport mechanism for transferring the cassette from a cassette supply table in the cassette supply chamber to an elevator installed in the load lock chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

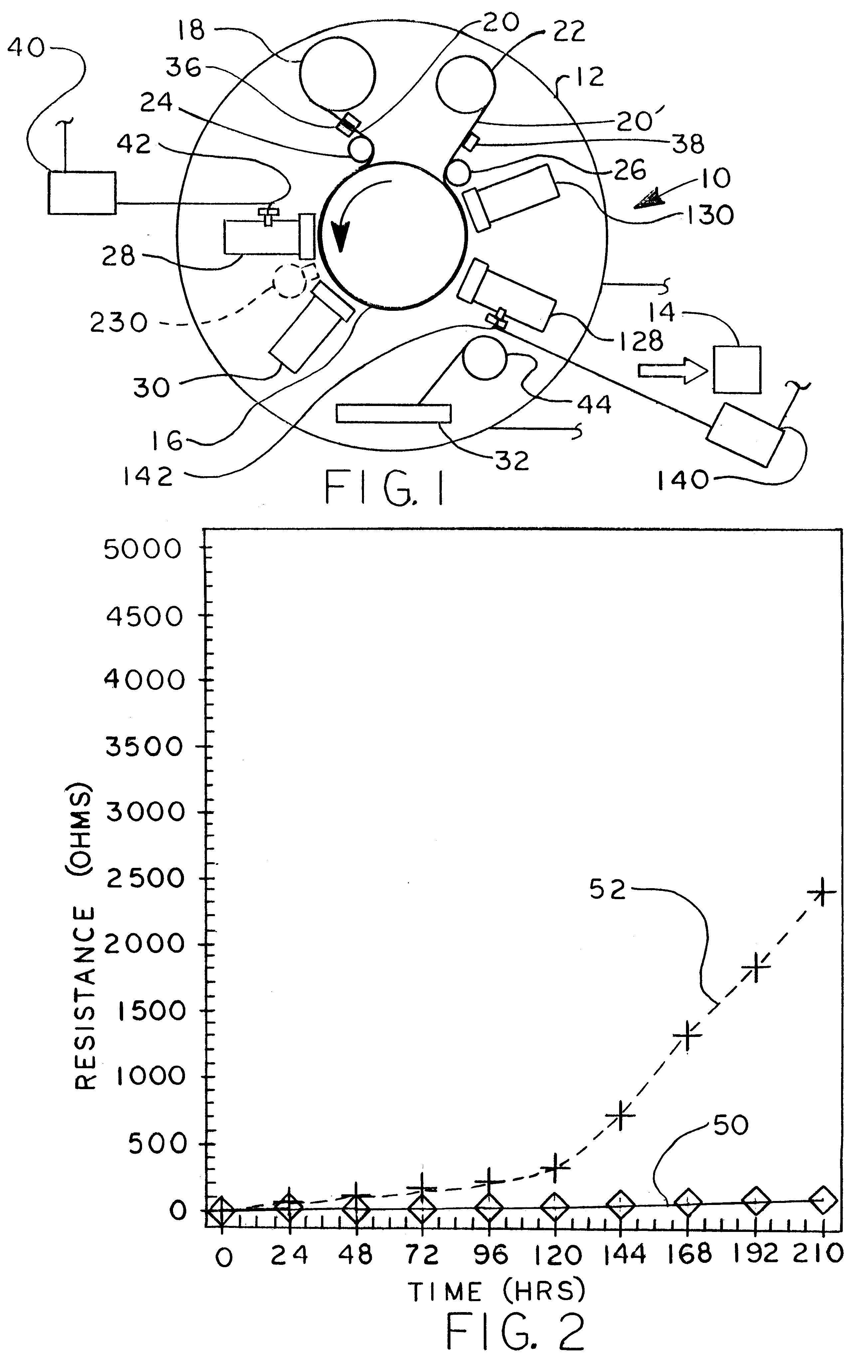

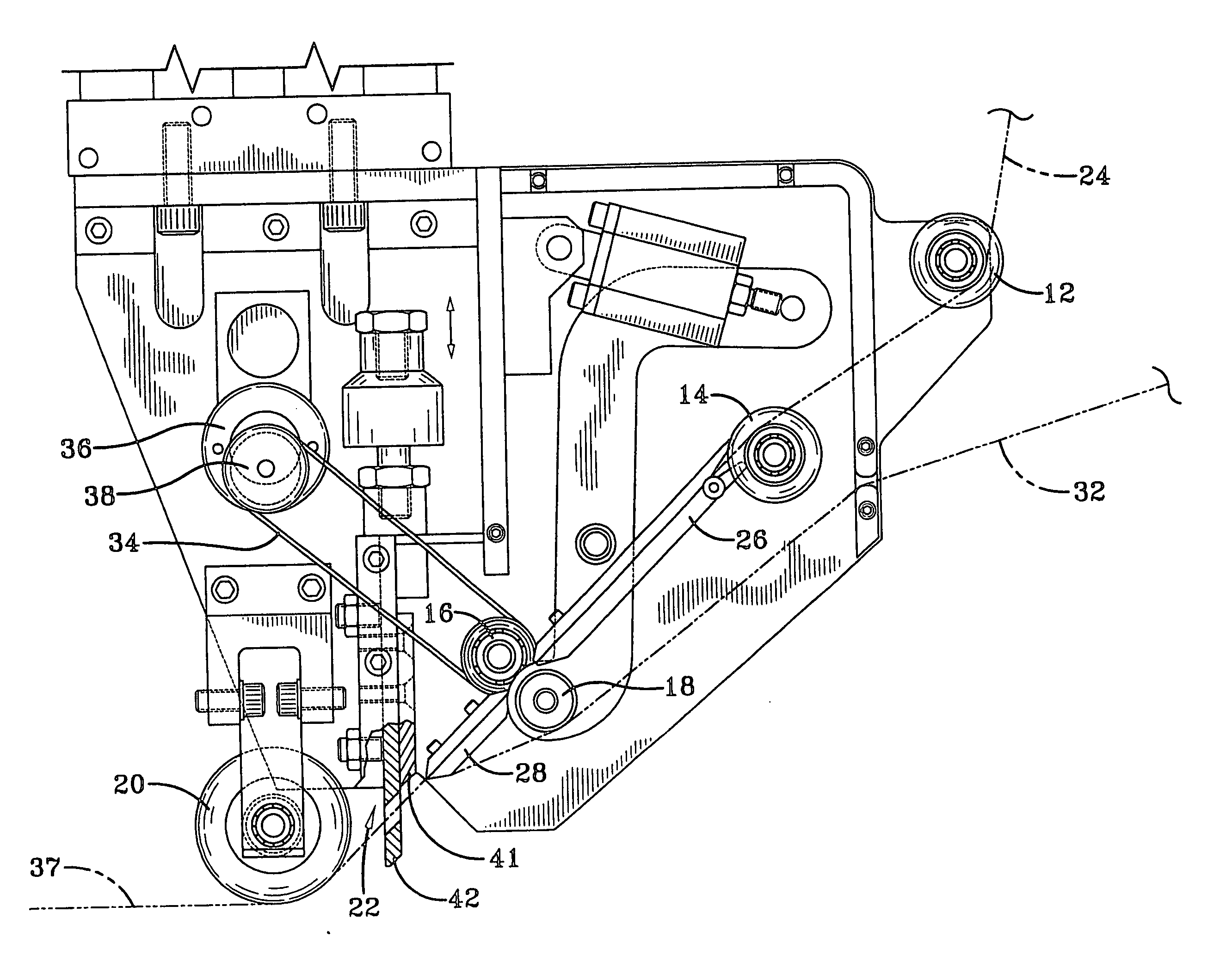

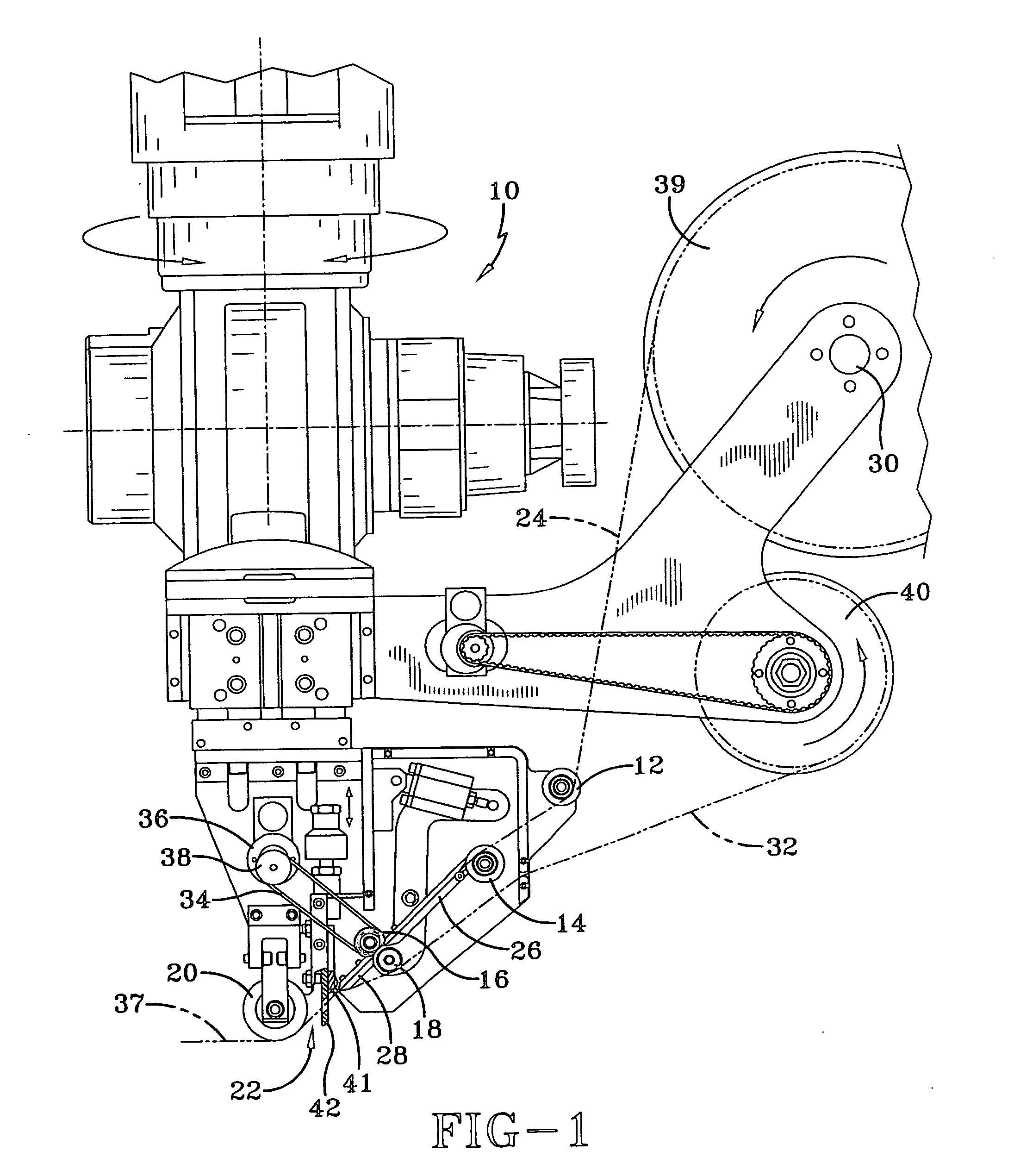

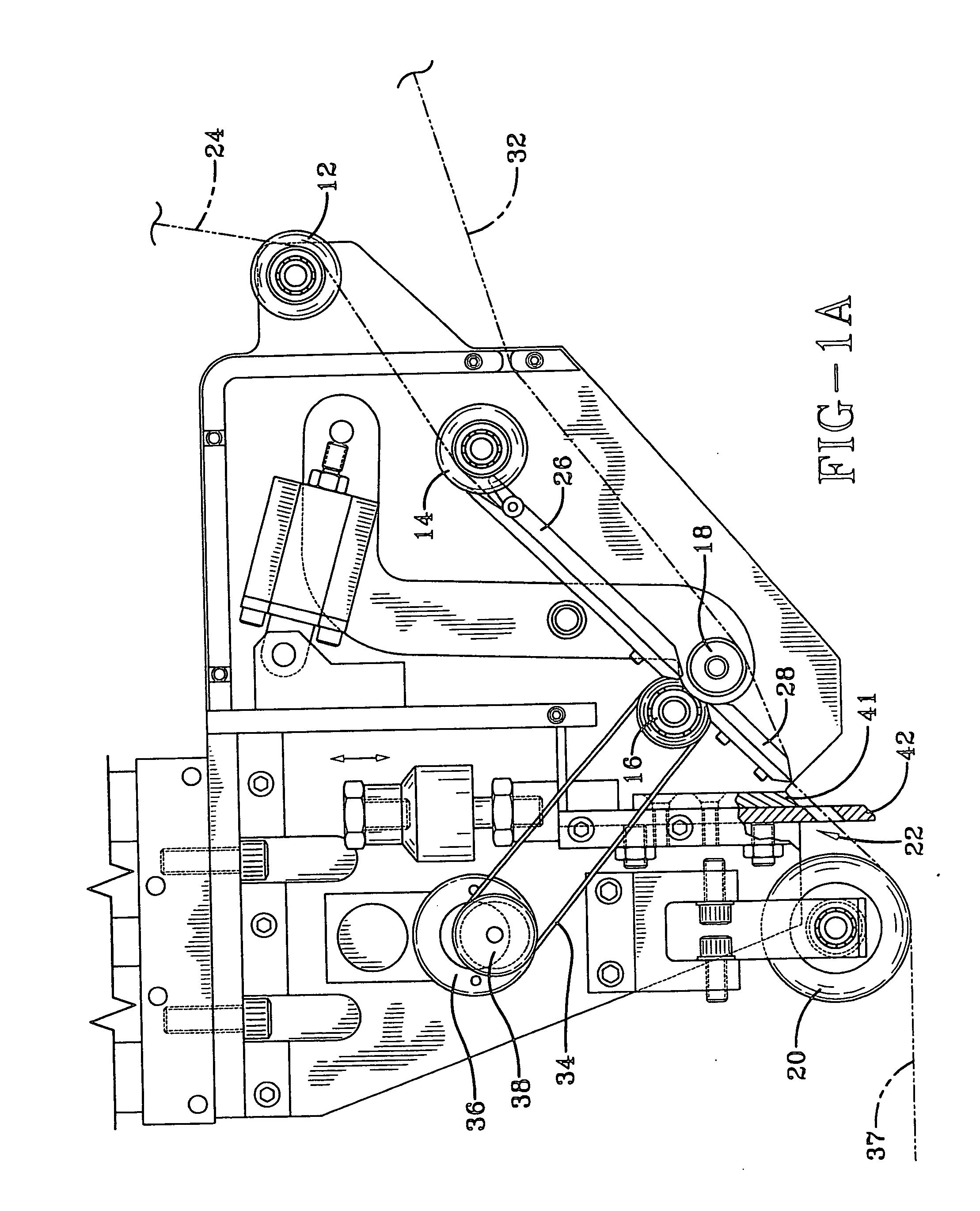

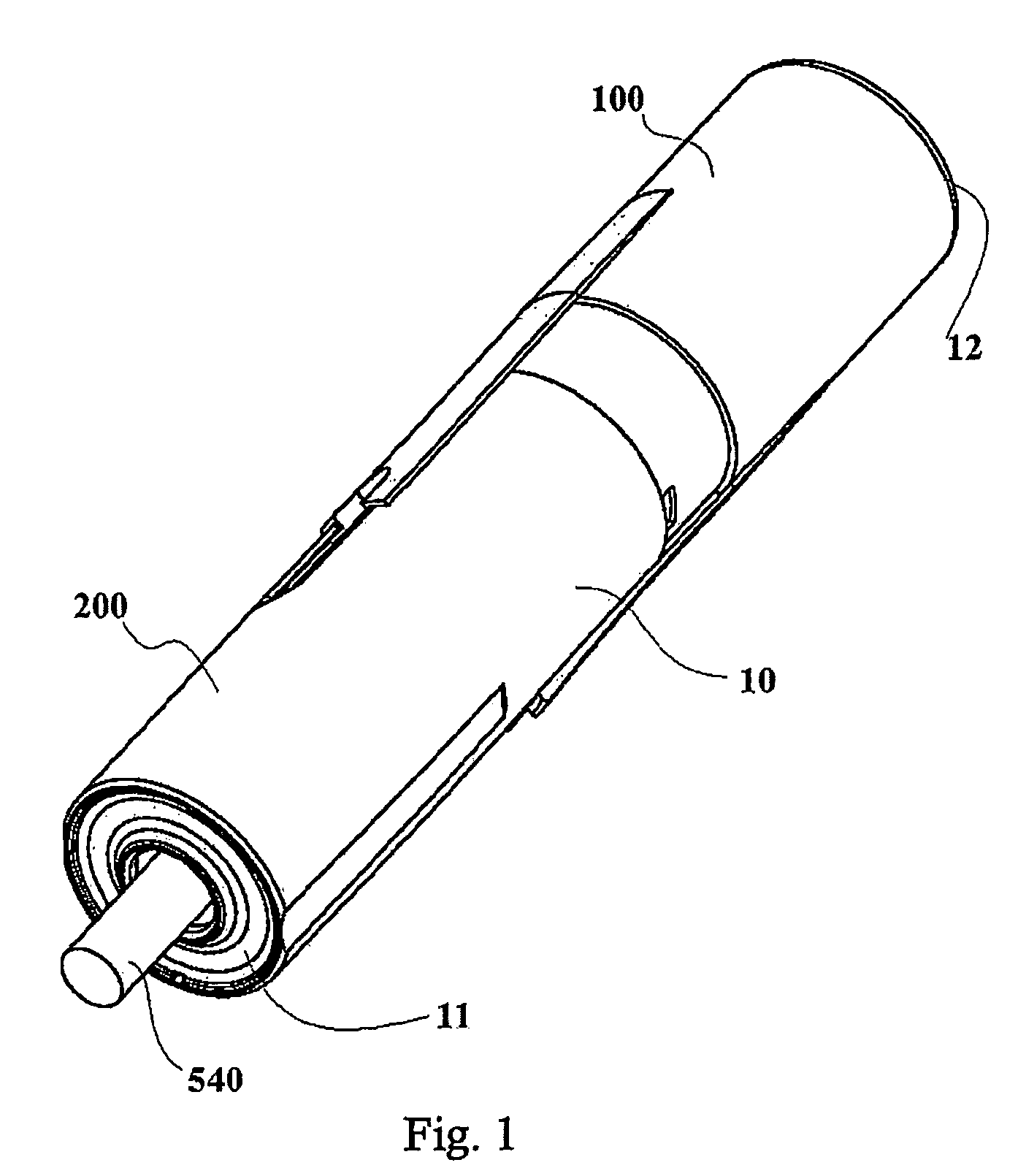

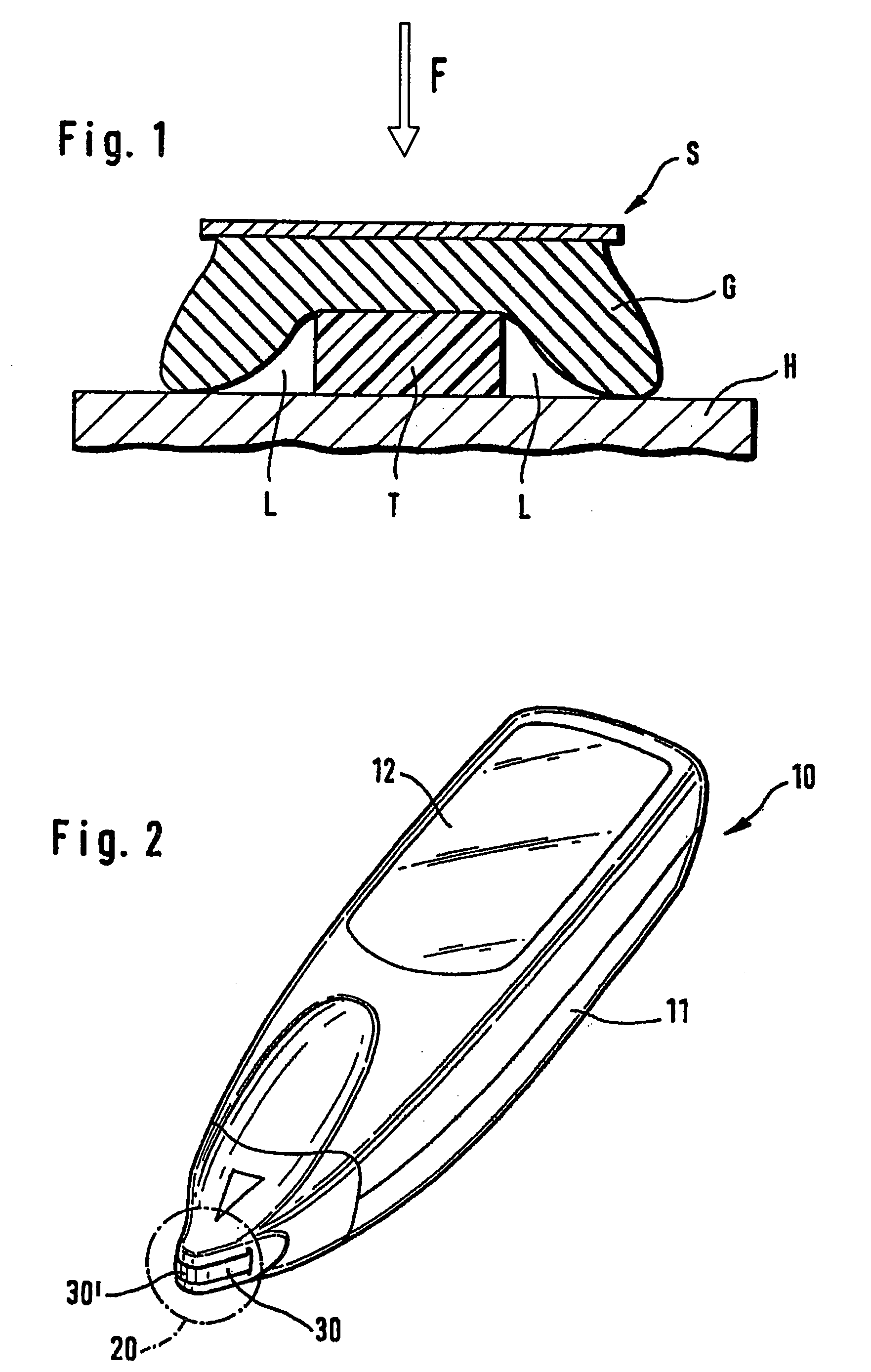

Composite tape laying apparatus and method

ActiveUS20050109451A1Simple procedureMaximizes material throughputLamination ancillary operationsControlling laminationFiberMagnetic tape

A fully automated method and apparatus is disclosed to laminate various structural articles with a layer of resin impregnated fiber tape. The tape laying member removes a releasable backing layer from the tape being employed, then deposits the unbacked tape on the surface of the structural article, and finally severs the end of the tape being deposited. An automated cut and restart procedure is employed in the present tape laying member to increase tape throughput.

Owner:TRELLEBORG SEALING SOLUTIONS GERMANY

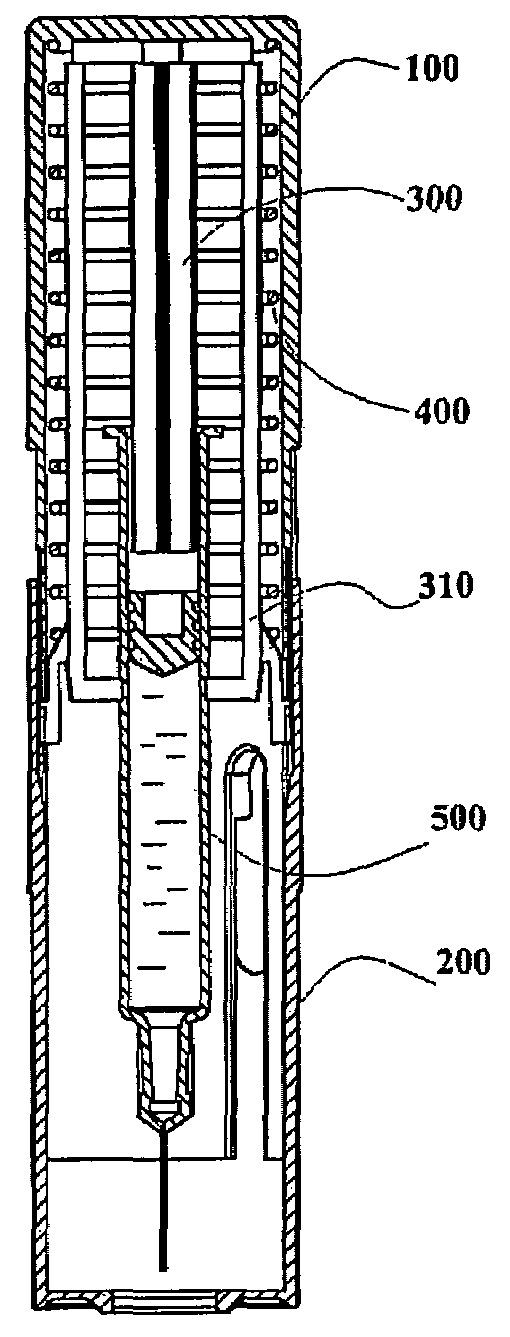

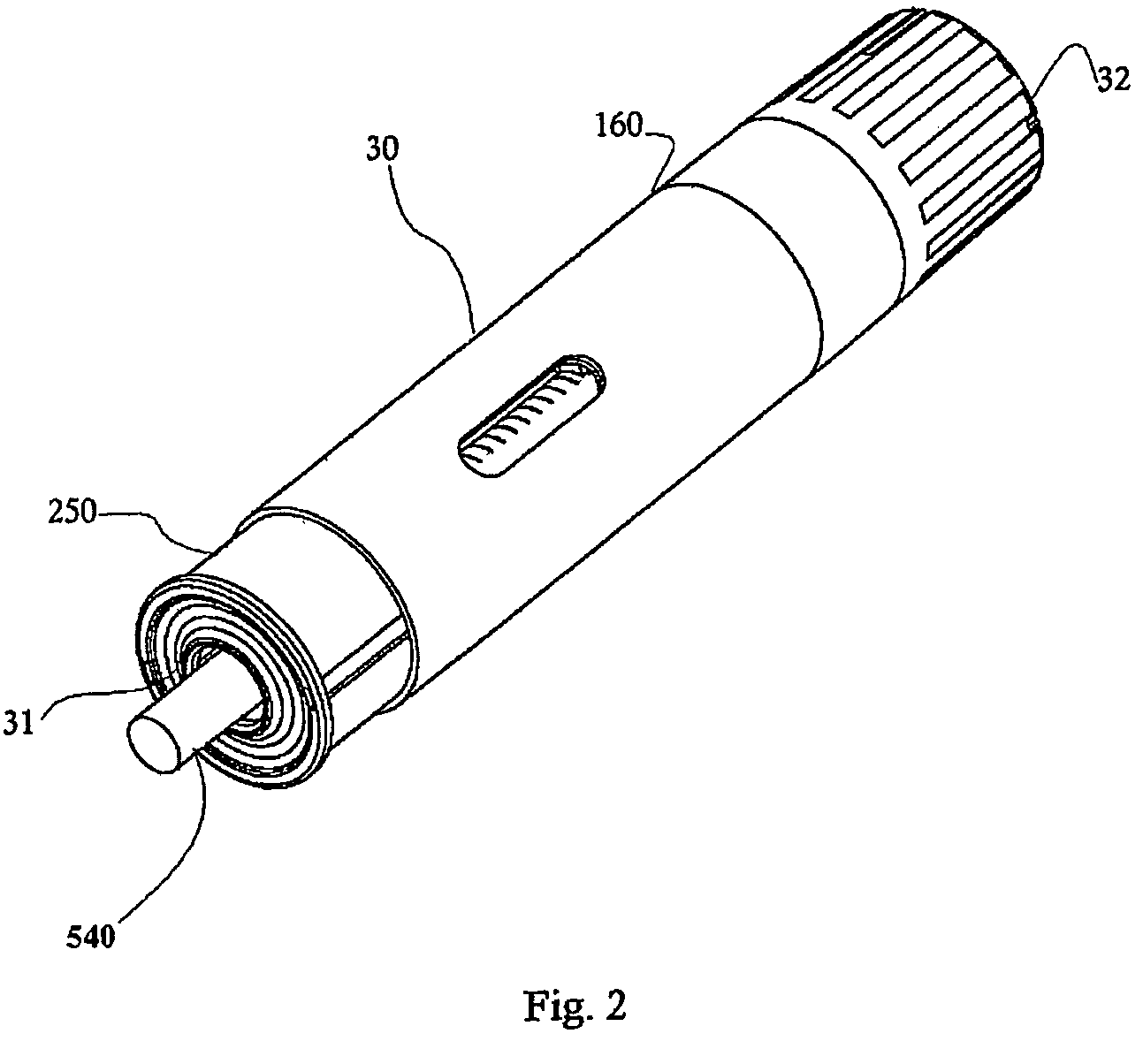

Injecting apparatus

ActiveUS7717877B2Facilitates automatic insertionAmpoule syringesAutomatic syringesCaregiver personInjection site

An injector is automatic in that the needle is inserted into the injection site (e.g., a patient's skin) with user or caregiver assistance, the delivery is automatically initiated upon needle insertion, and the needle is retracted automatically after the end of delivery. Preferably the needle is not seen by the user prior to, during or after injection. Prior to and after injection, the needle is hidden in the device so as to avoid any potential injury or health risk to the user or health care provider. The injector includes a housing and a shield arranged to slide relative to the housing and a driver moving during drug delivery. The housing and shield form a cartridge enclosure. The cartridge is shielded and locked after delivery is completed. A needle-locking mechanism can be used in any number of pen-like injectors or safety needles.

Owner:WEST PHARMA SERVICES OF DELAWARE

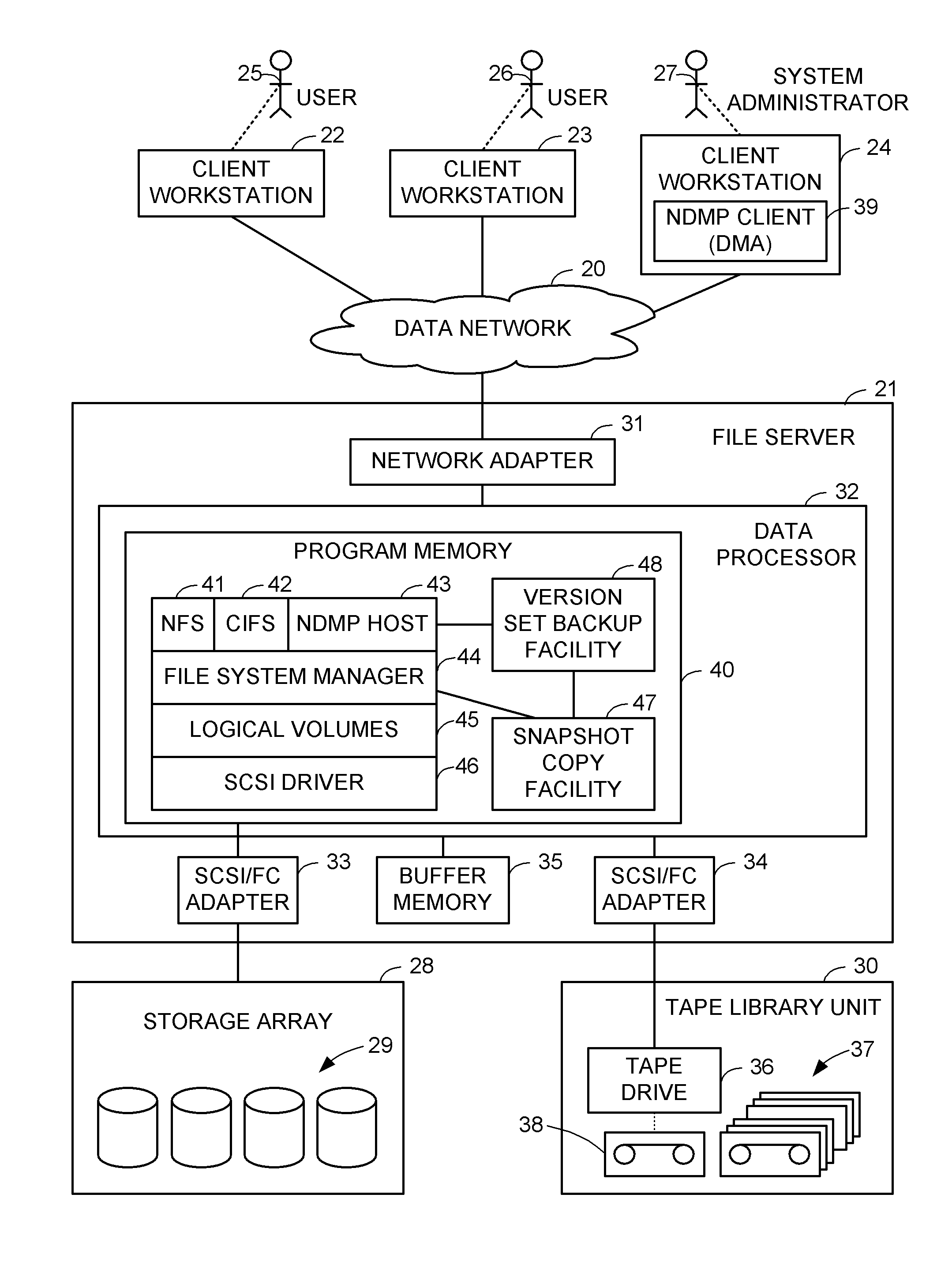

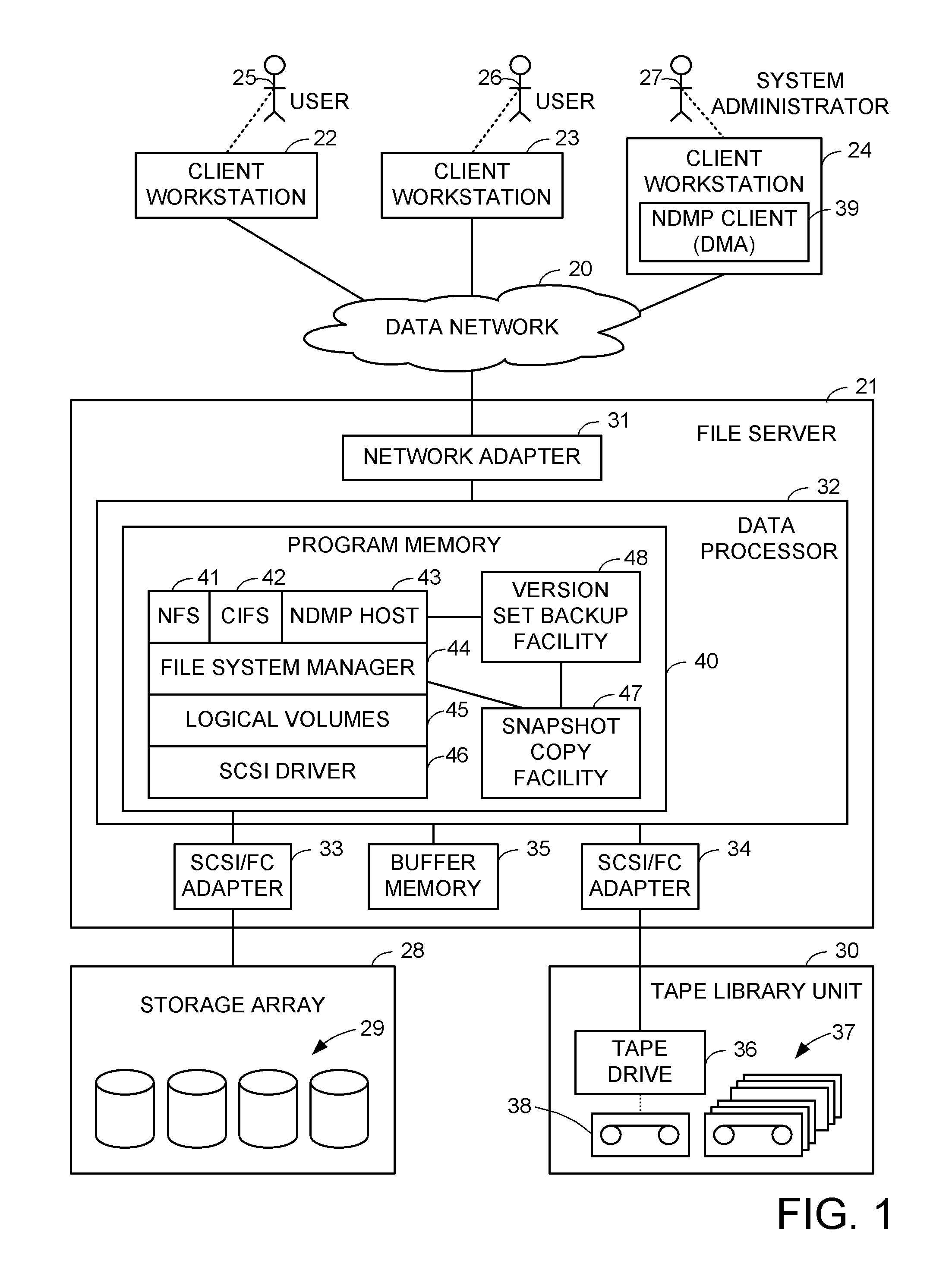

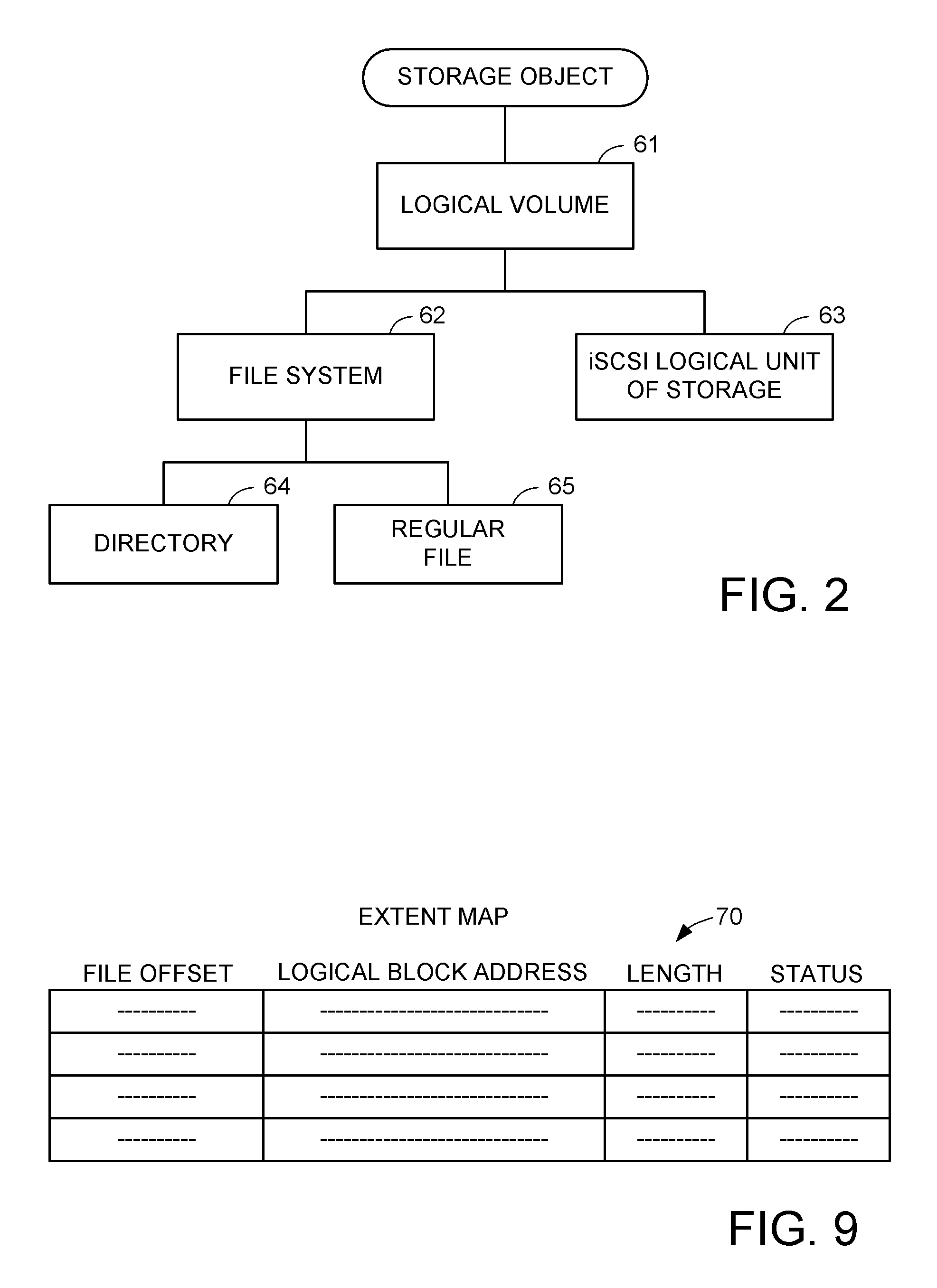

Efficient backup and restore of storage objects in a version set

ActiveUS8099572B1Efficient backupIncrease management costsDigital data processing detailsError detection/correctionLogical block addressingMagnetic tape

The version set backup and restore facility responds to a version set backup request by backing up multiple snapshot copies of a storage object concurrently from a storage array to backup storage media. The version set backup and restore facility responds to a version set restore request by restoring a plurality of snapshot copies of the storage object concurrently from the backup storage media to the storage array. The on-tape backup image of the version set includes variable-length extents of data for each of the multiple snapshot copies of the storage object. The variable-length extents of data for each of the snapshot copies of the storage object are grouped together and ordered in the on-tape backup image by increasing or decreasing logical block address.

Owner:EMC IP HLDG CO LLC

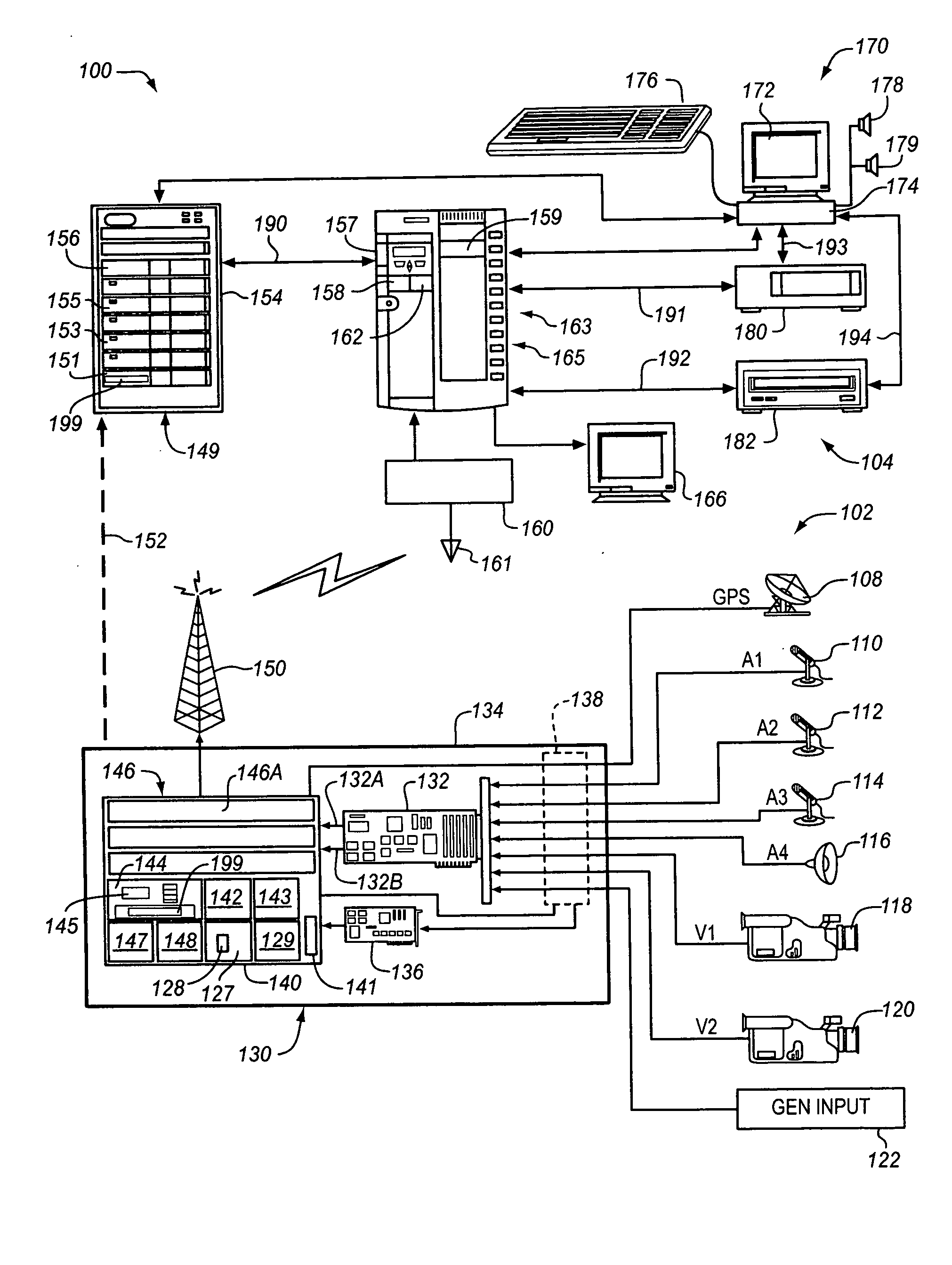

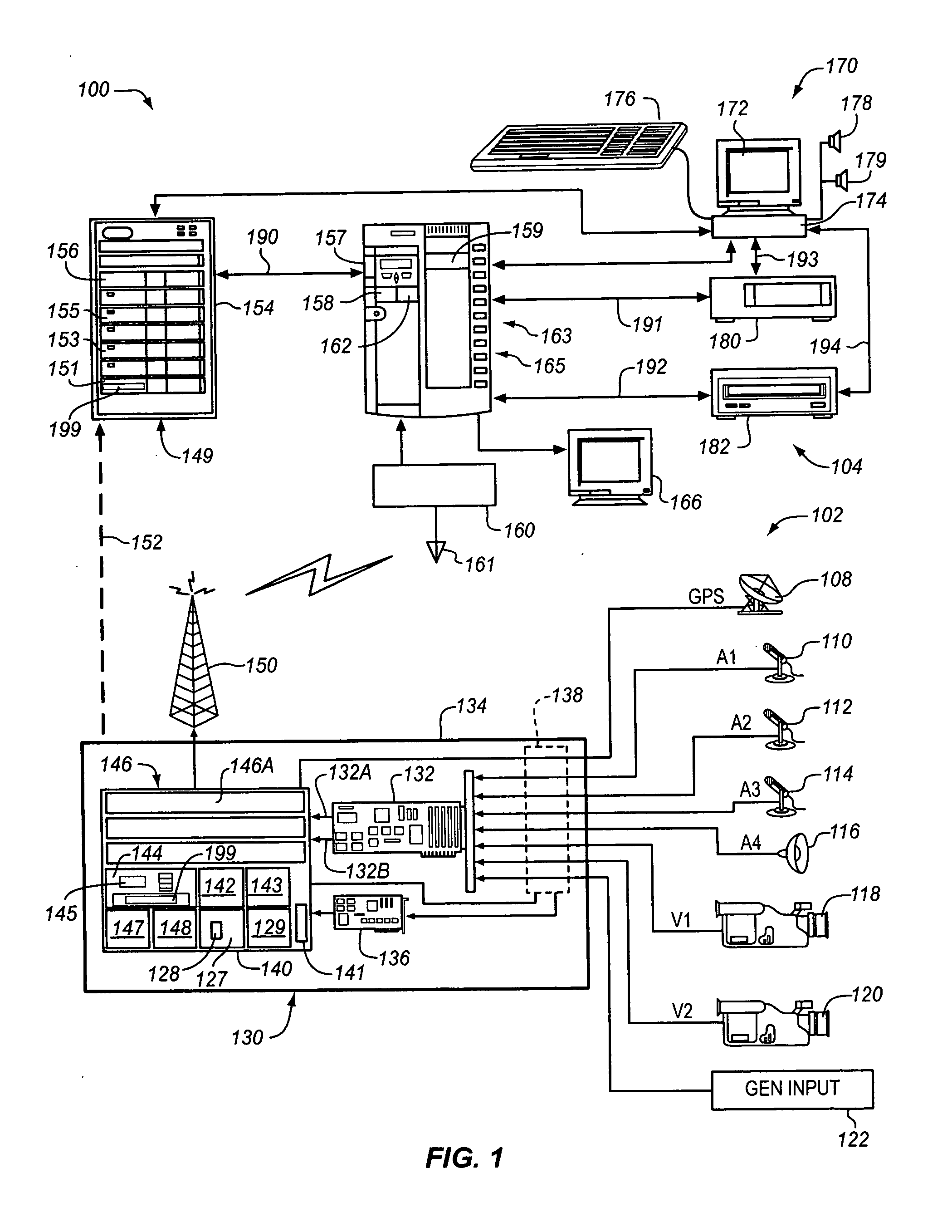

High capacity surveillance system with fast search capability

InactiveUS20060274828A1High speedTelevision system detailsRegistering/indicating working of vehiclesComputer hardwareData stream

A surveillance system having a plurality of MPEG compressed data streams each originating from a separate video / audio source. The data is stored on hard disk and streamed to tape in real time with time set markers readable independent of the compressed video signal. The data is partitioned on the tape, each partition including a plurality of data blocks, each data block including synchronized frames from each stream, a stream map, telemetry information, roster information and tape positioning data. Each partition includes a duplicate stream map and a duplicate partition directory, and each block within the partition includes duplicate telemetry information. Set marks readable in fast forward or rewind mode, are placed every second on the tape in a position just before the duplicate telemetry and a file mark is placed just before the duplication partition directory. The tape cassette includes an EEPROM, which holds a duplicate partition directory and redundant directory information useful for searching. In case of tape error, the tape automatically restores itself when inserted into the tape deck.

Owner:SECURITY WITH ADVANCED TECH

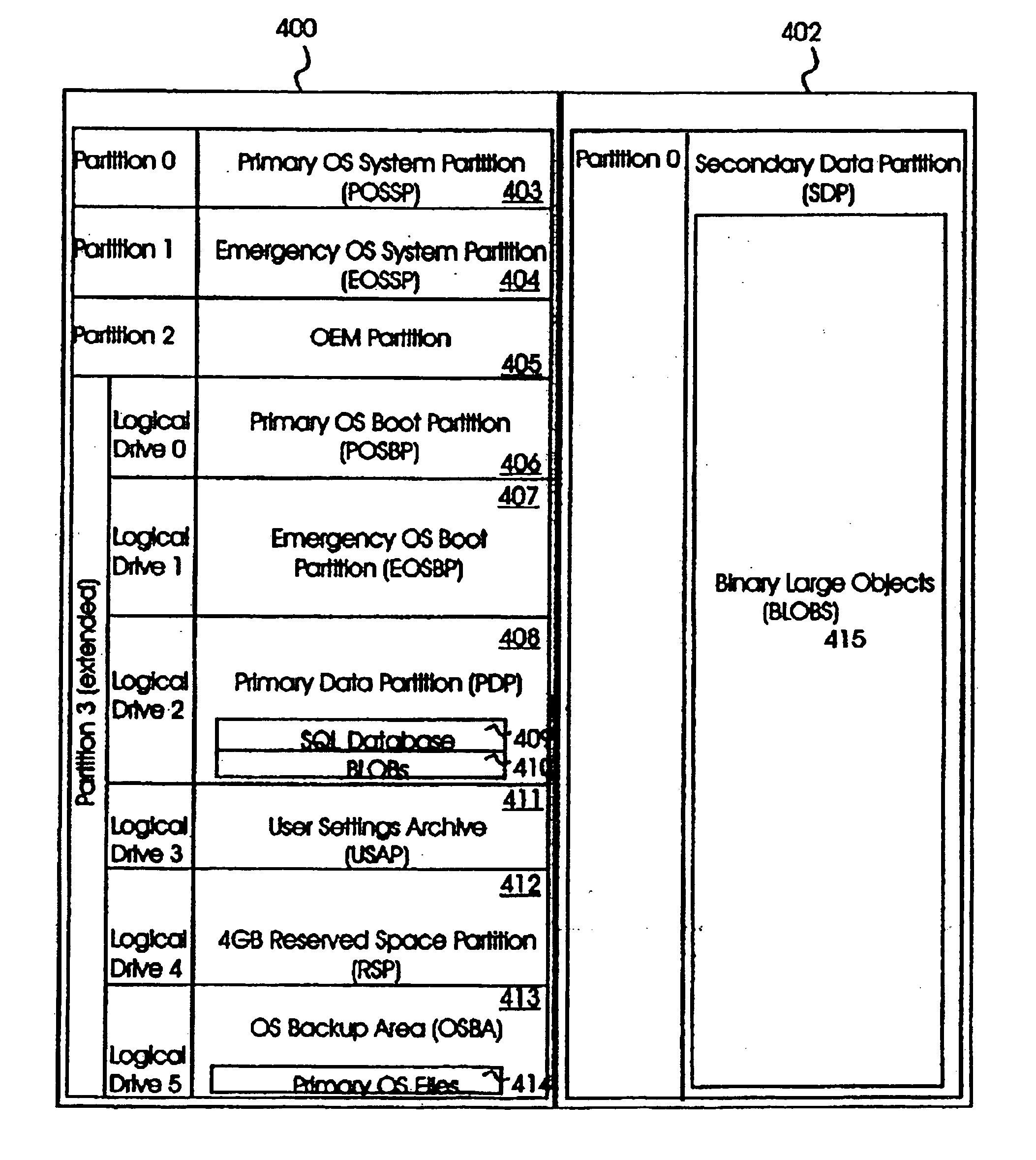

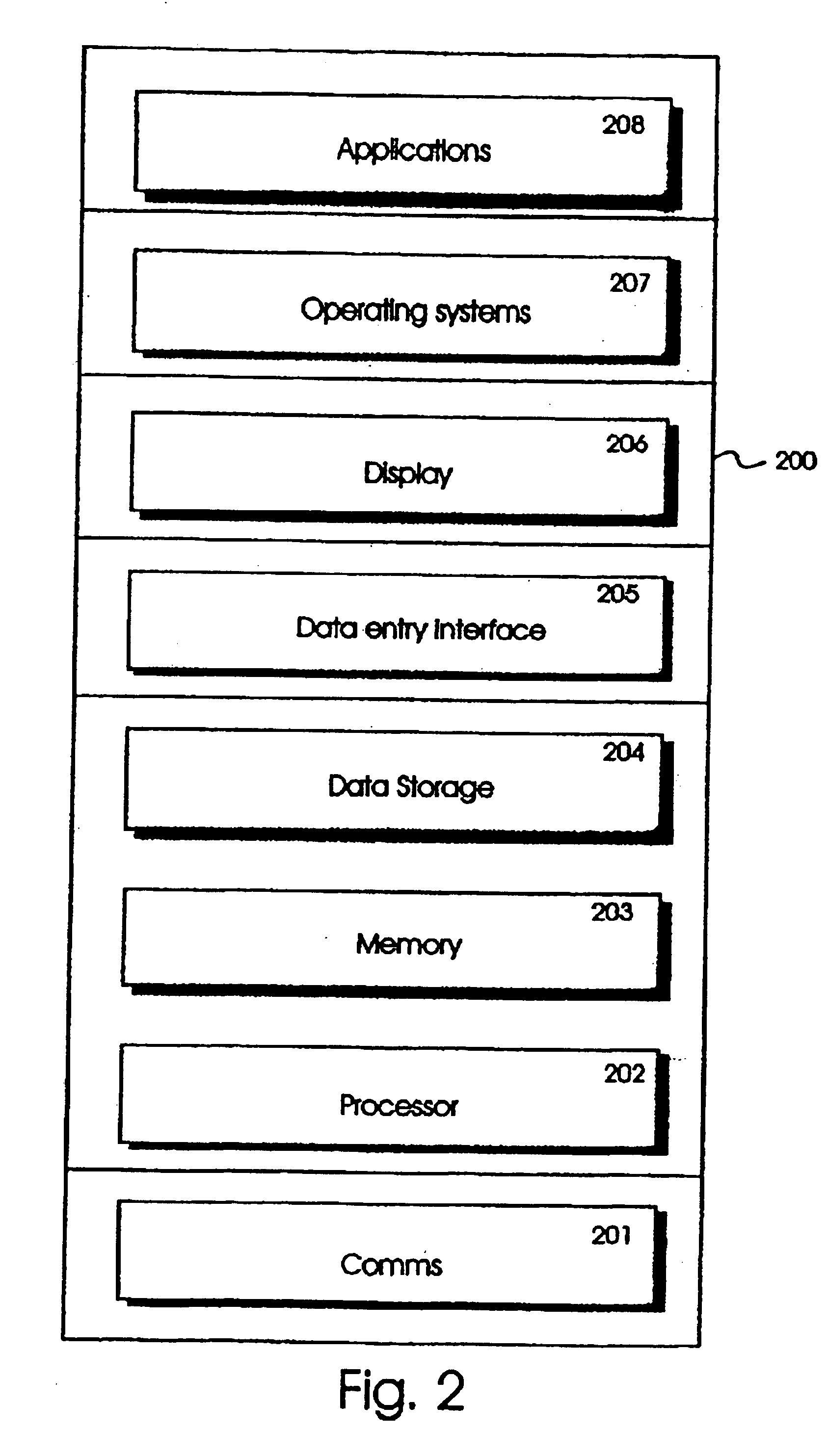

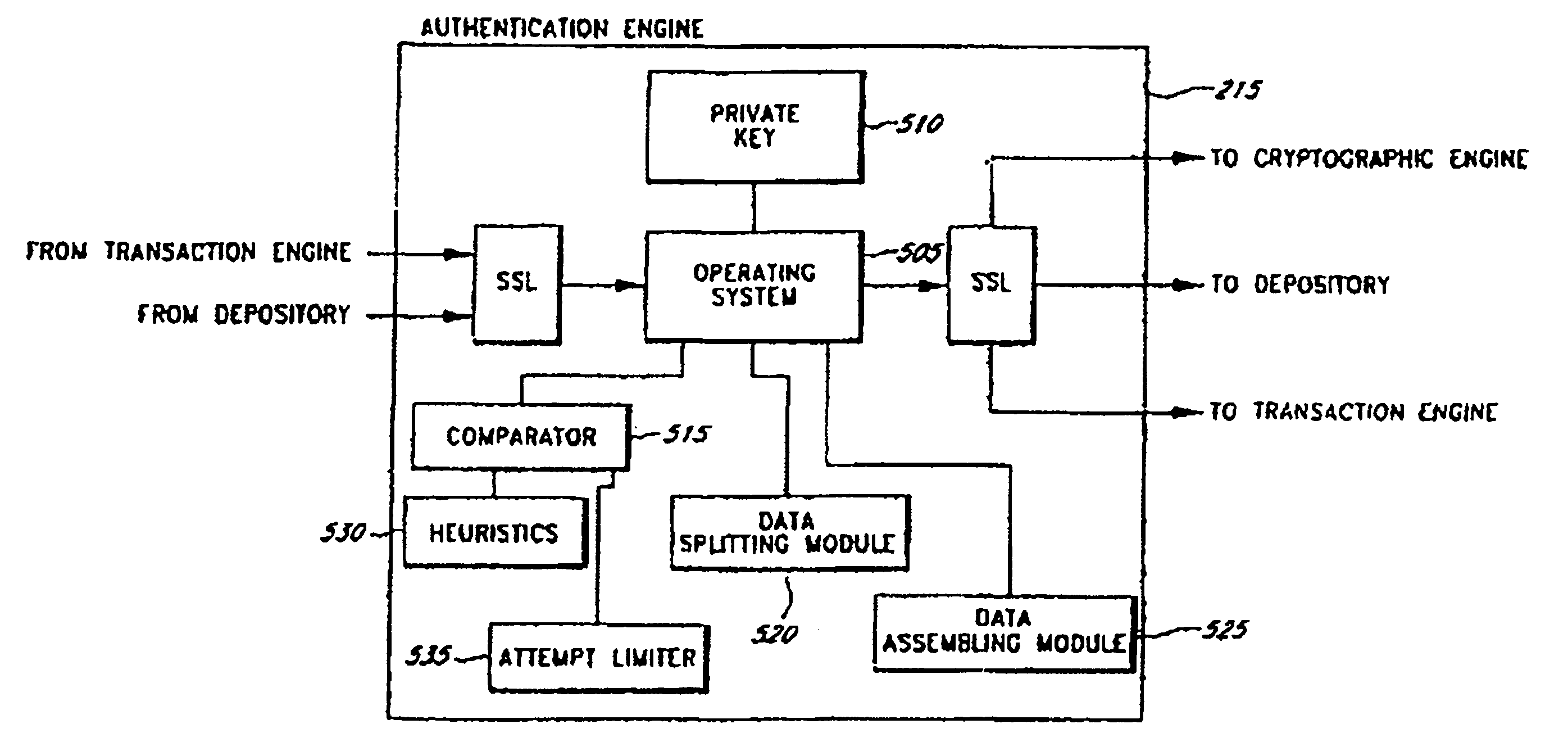

Performing operating system recovery from external back-up media in a headless computer entity

InactiveUS6845464B2Redundant operation error correctionMemory systemsHard disc driveOperational system

A computer entity, particularly but not exclusively a headless computer entity, has operating systems stored on a non-volatile data storage device e.g. a hard disk drive, and has a back-up data storage device. Operating system backup's are taken from an uncorrupted copy of an operating system stored in a separate partition on the data storage device to the primary operating system which is actually used to run the device, thereby ensuring that if the primary operating system of the computer entity becomes corrupted either gradually or catastrophically, the back-up copy which is stored on a back-up media is not effected. Under failure conditions of the computer entity, a pristine copy of the operating system can be reloaded from the back-up tape data storage media and the computer entity rebooted from the pristine operating system back-up copy.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

Tape backup method

InactiveUS20080183992A1Minimal compute resourceAvoid the needMemory architecture accessing/allocationMemory loss protectionOriginal dataMagnetic tape

A secure data parser is provided that may be integrated into any suitable system for securely storing and communicating data. The secure data parser parses data and then splits the data into multiple portions that are stored or communicated distinctly. Encryption of the original data, the portions of data, or both may be employed for additional security. The secure data parser may be used to protect data in motion by splitting original data into portions of data, that may be communicated using multiple communications paths.

Owner:SECURITY FIRST INNOVATIONS LLC

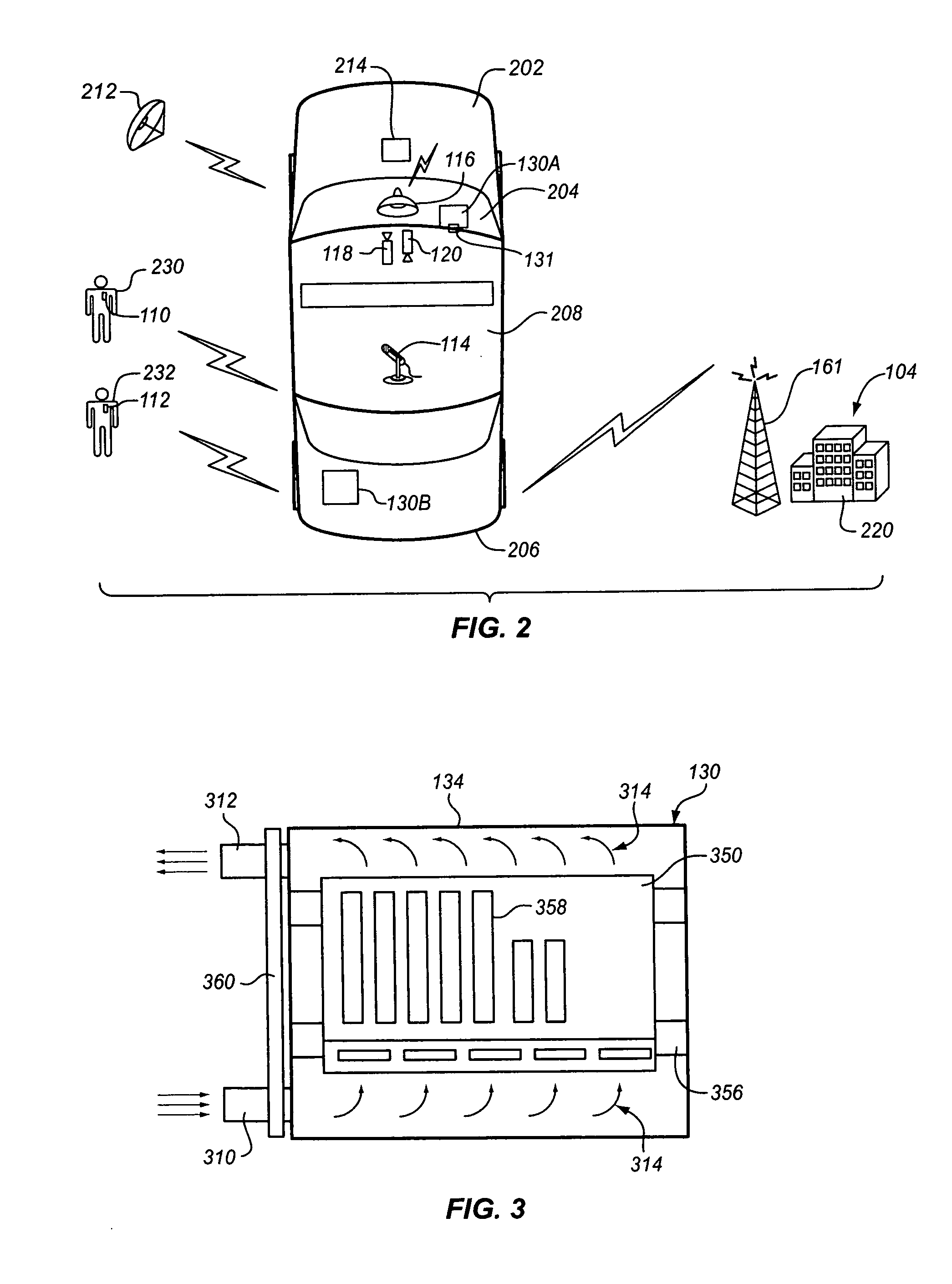

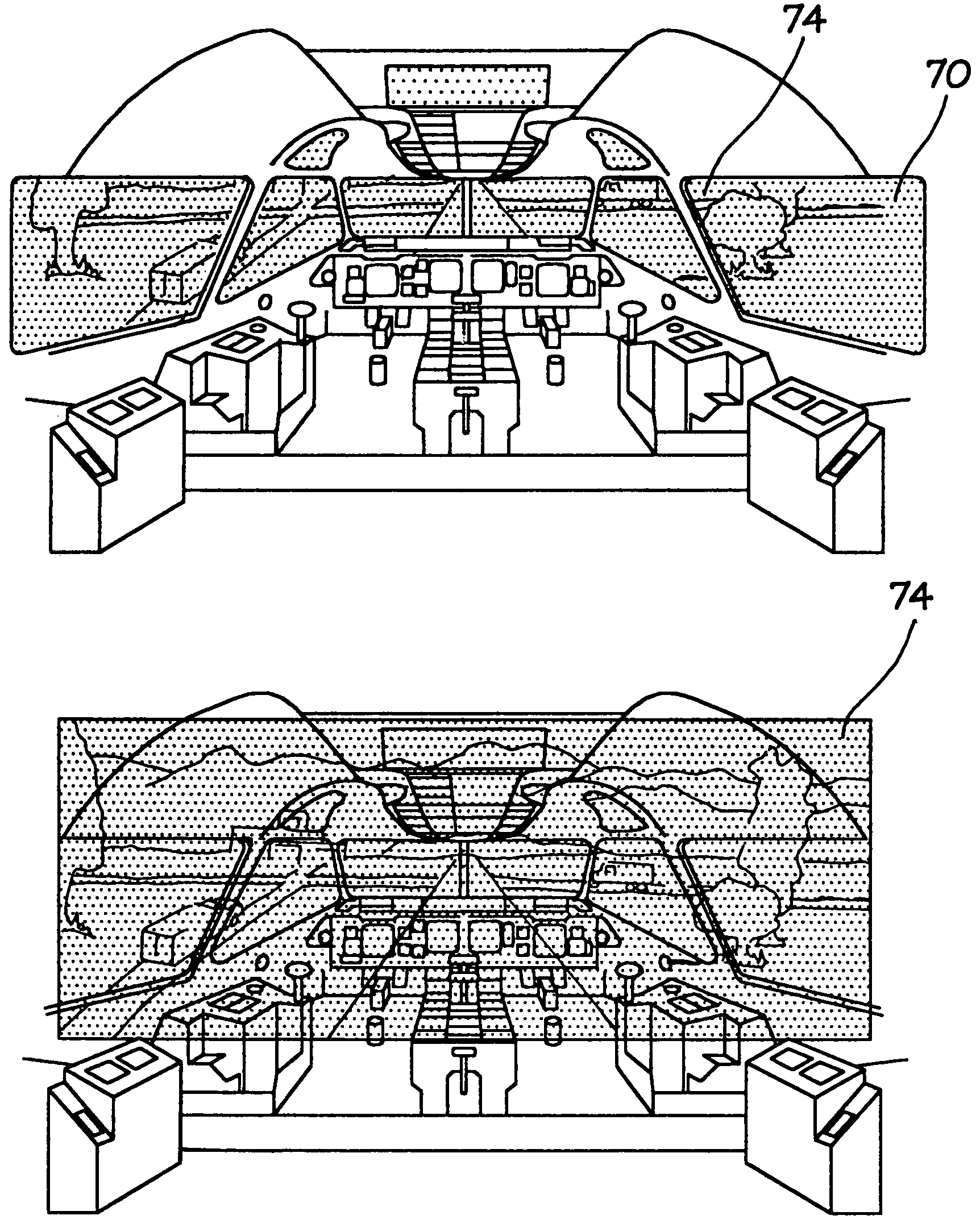

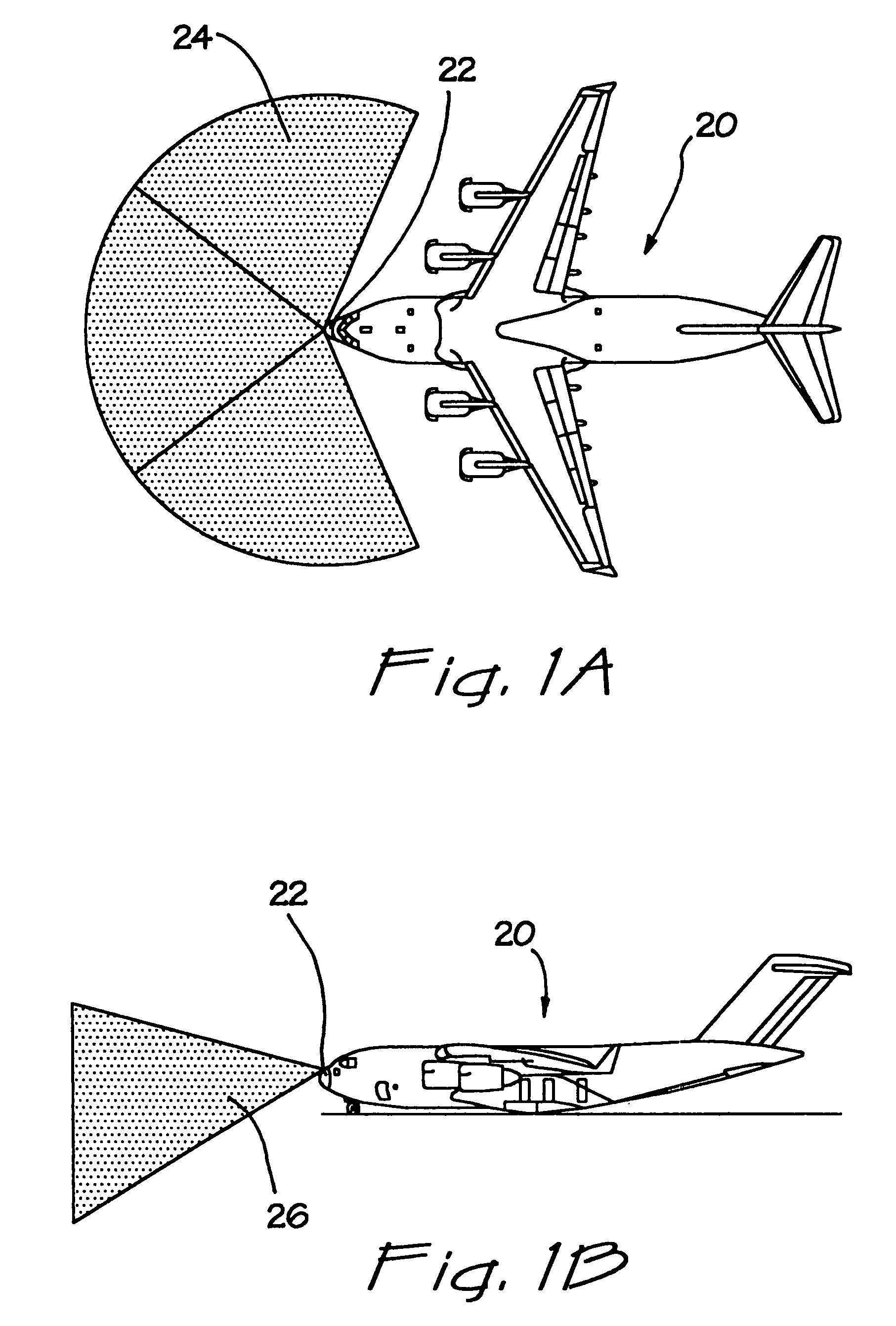

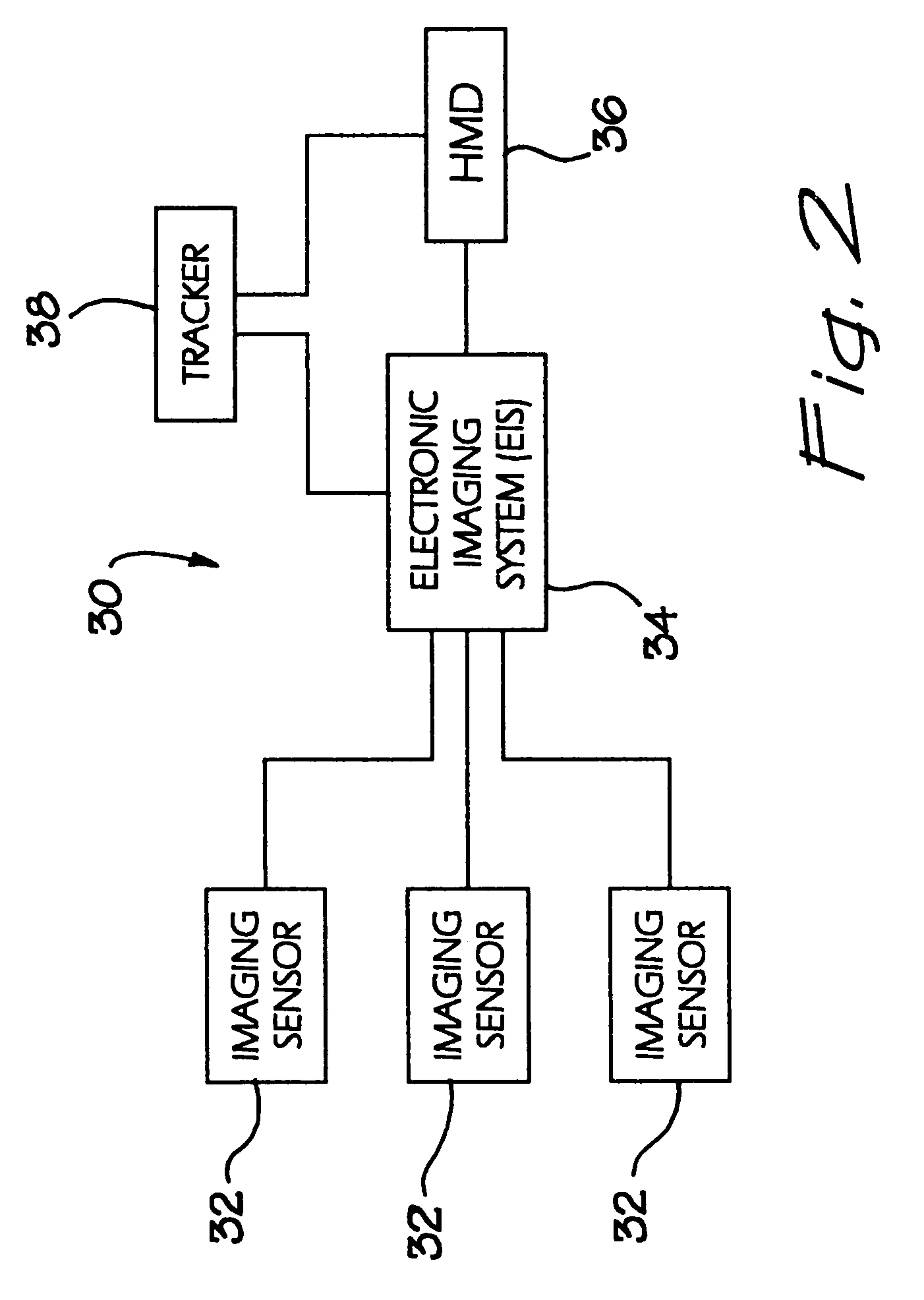

Exterior aircraft vision system using a helmet-mounted display

An improved multiple-sensor vision system for use on vehicles or aircraft. The system utilizes a plurality of fixed sensors, such as infrared sensors, that provide signals that are recorded on tape and / or stored in memory. A processor digitally samples the stored images and provides output to a helmet-mounted display. Desirably, the sensors are arrayed in series such that their images may be juxtaposed and blended to provide a wider field-of-view image. A tracking system desirably monitors the head position of the operator, which position is then used to select various images from the processor. In this way, the operator can select various views by simply looking in that direction. In one embodiment, the array of sensors is forward-looking and positioned close to the head position of the operator to minimize parallax issues. In addition to forward-looking sensors, other sensors mounted around the vehicle / aircraft may provide rearward, hemispherical, or complete spherical coverage. Sensors that monitor the status of various instruments on board the vehicle can also provide input to the helmet-mounted display, including a moving map tile that is displayed below or to the side of the main image.

Owner:THE BOEING CO

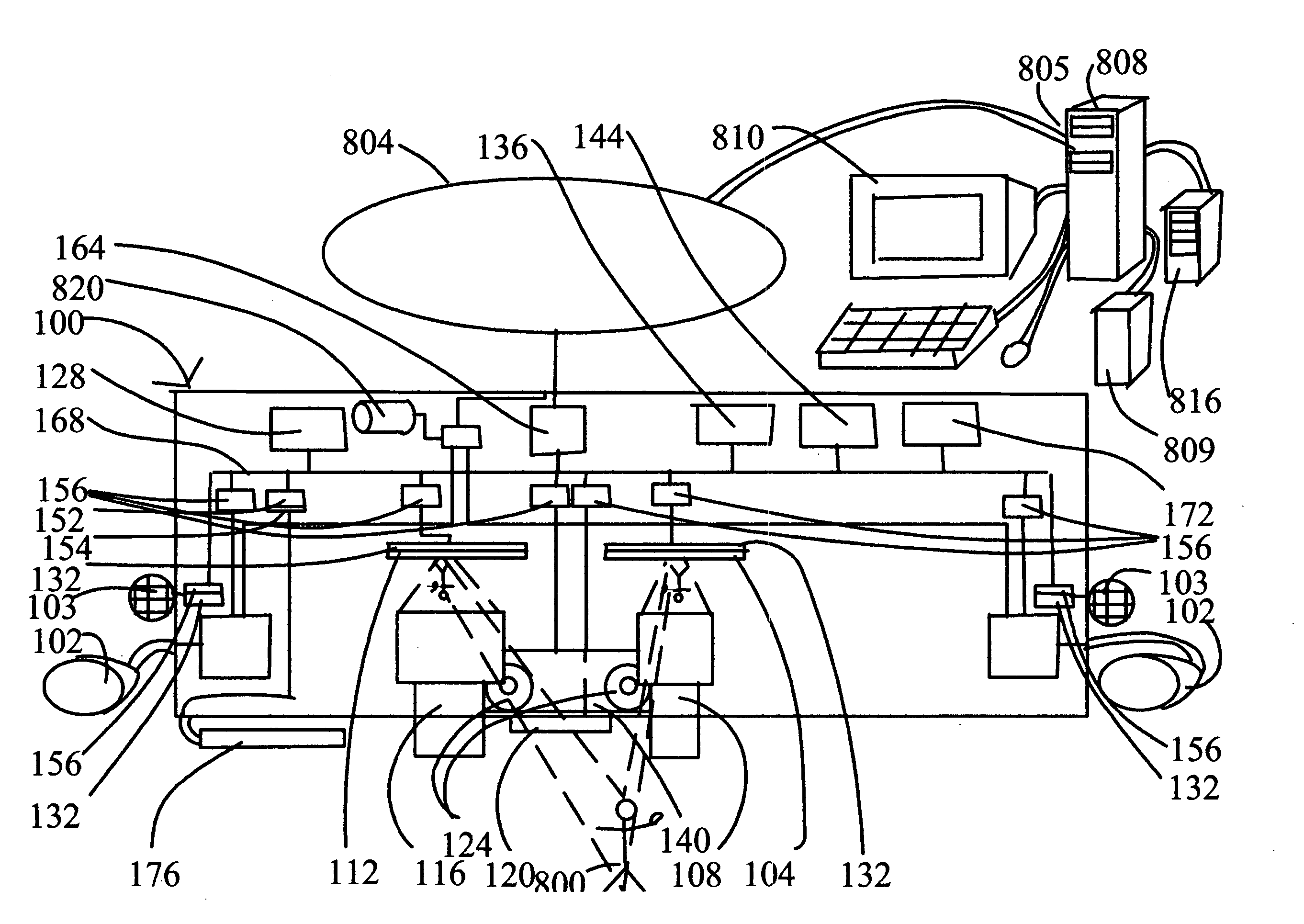

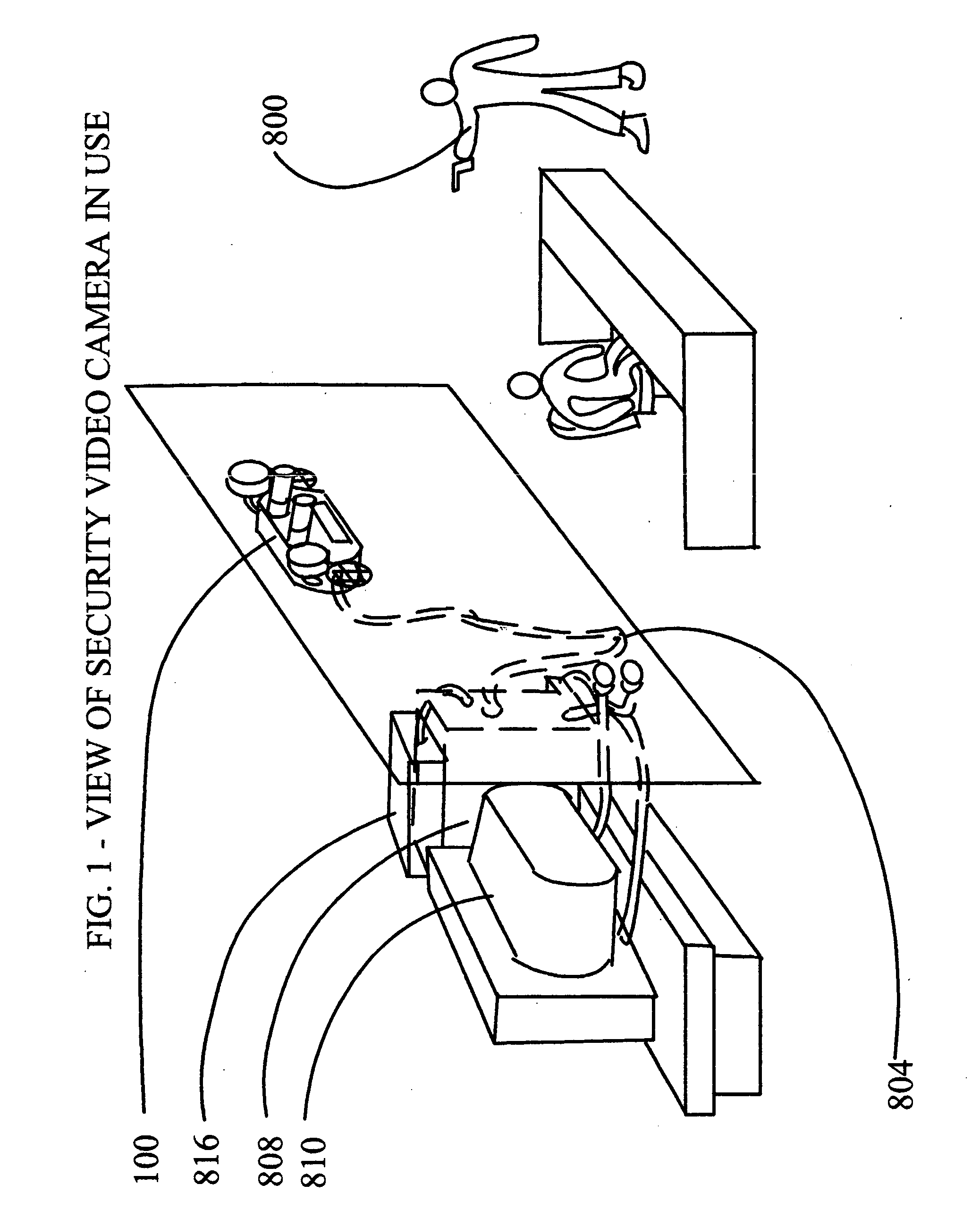

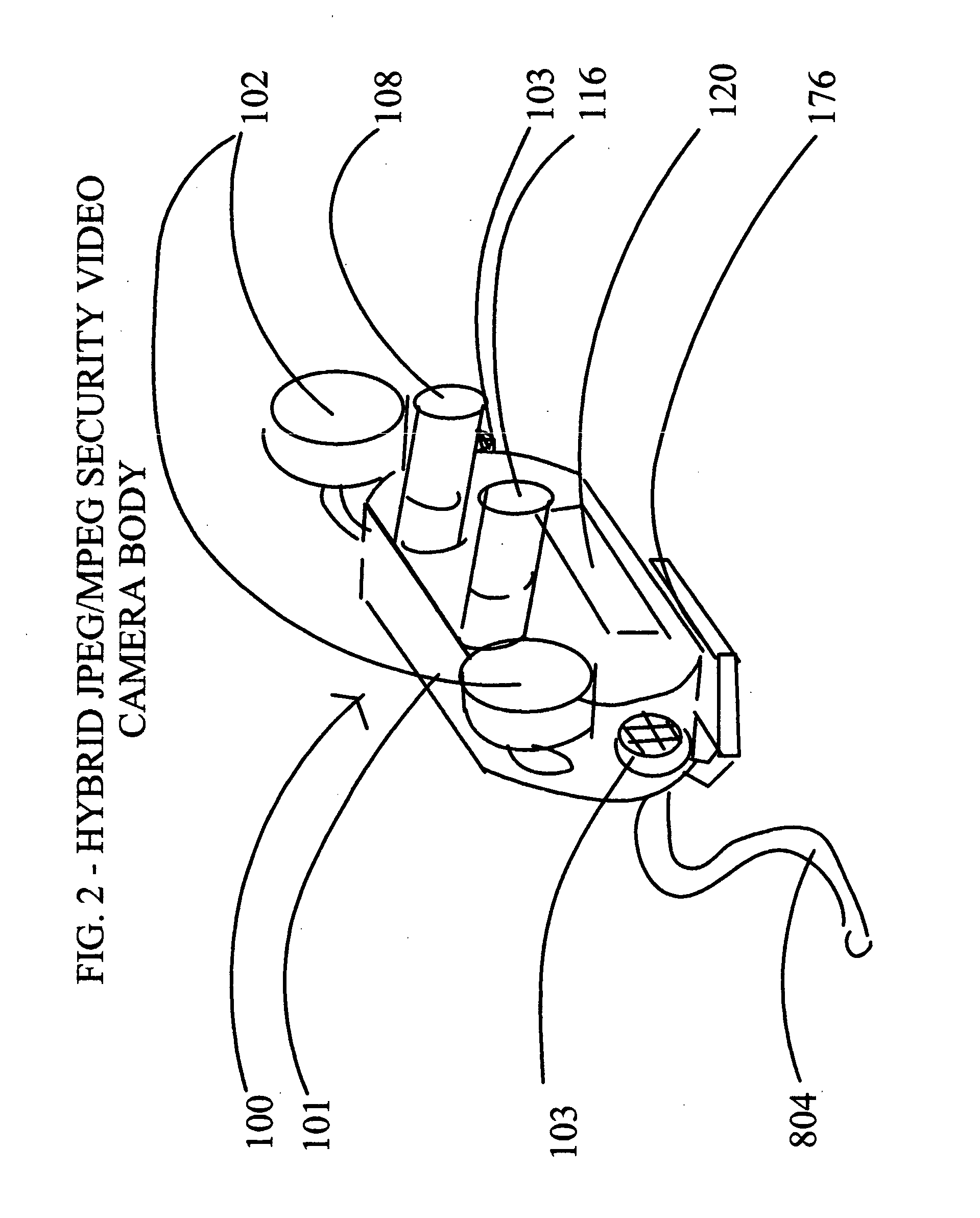

Hybrid joint photographer's experts group (JPEG) /moving picture experts group (MPEG) specialized security video camera

InactiveUS20040109059A1Enhanced eye-mind intuitive orientation and mental coordinationRapid responseColor television detailsClosed circuit television systemsMagnetic tapeJPEG

FIG. 1 is a diagram of an unmanned, fully automatic, security installation with electronic pan and tilt functions, the focal plane array based motion sensor (120) of the hybrid simultaneous-mode MPEG X / JPEG X security video camera (100) is positioned to capture moving suspects, the moving suspect (800) is shown, the local area network (LAN) cable (804) is shown leading away from the hybrid MPEG X / JPEG X security video camera (100), a security room personal computer viewing station (808) is shown, lastly a digital computer tape video logging station (816) is shown.

Owner:KAWABOINGO

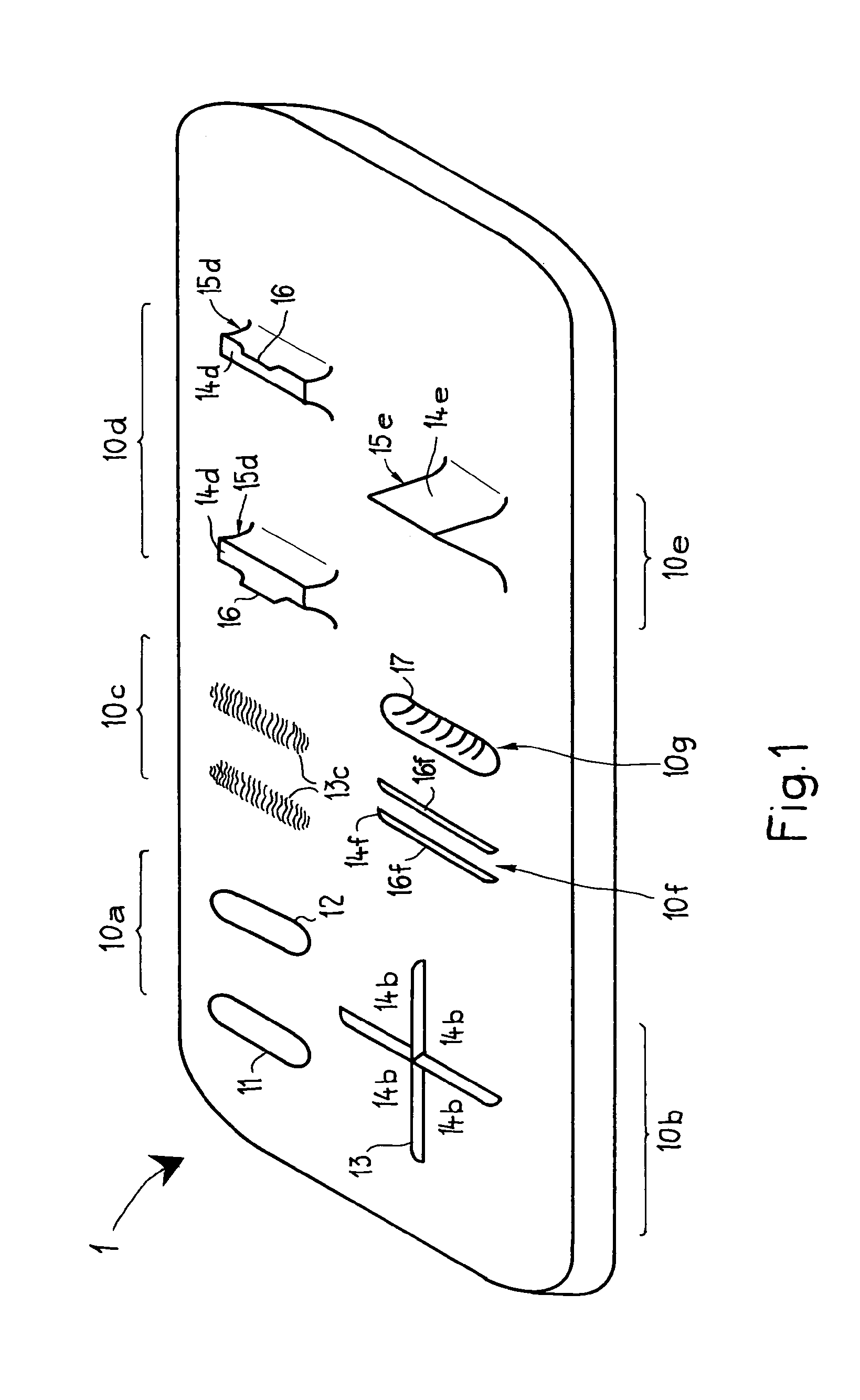

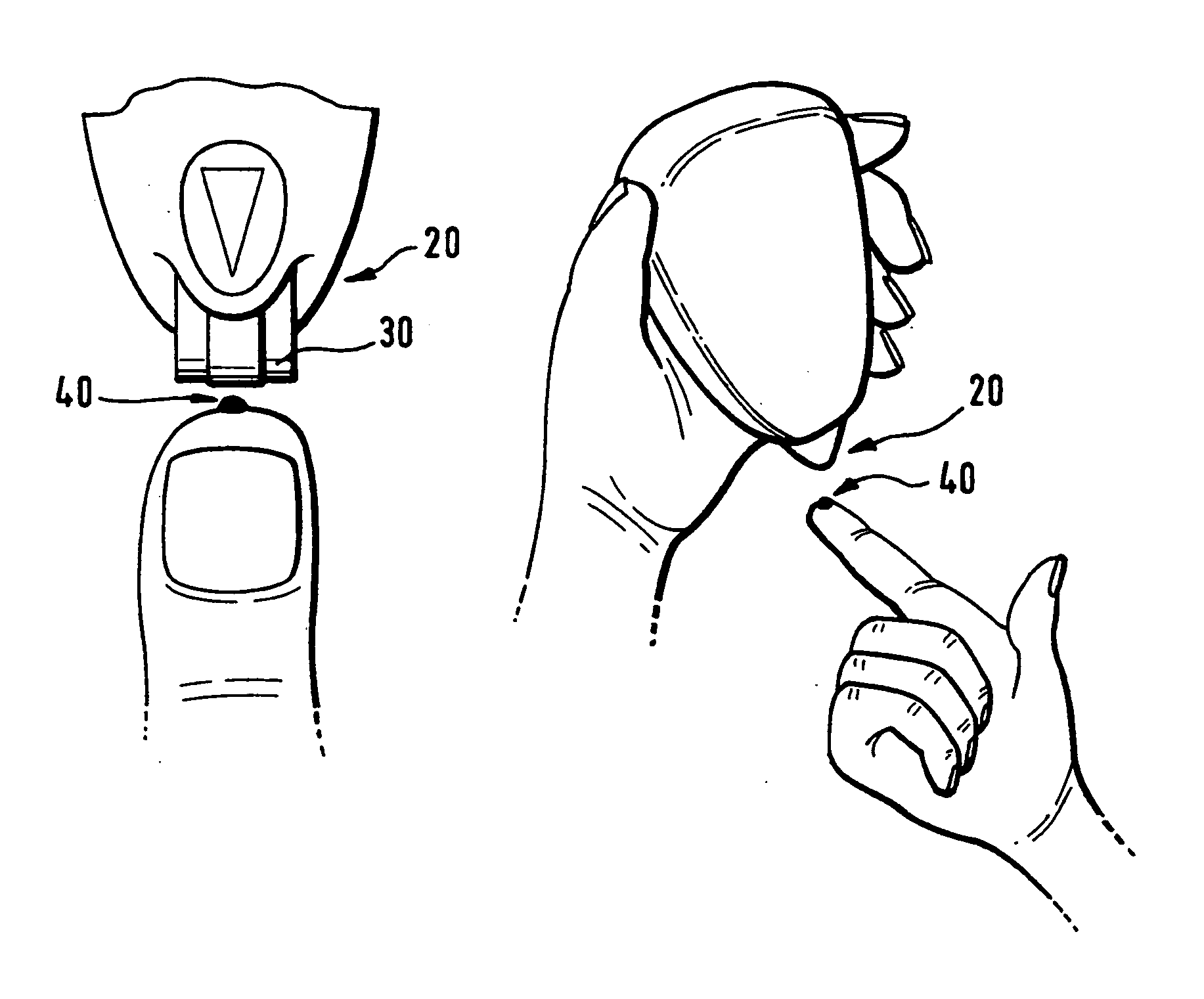

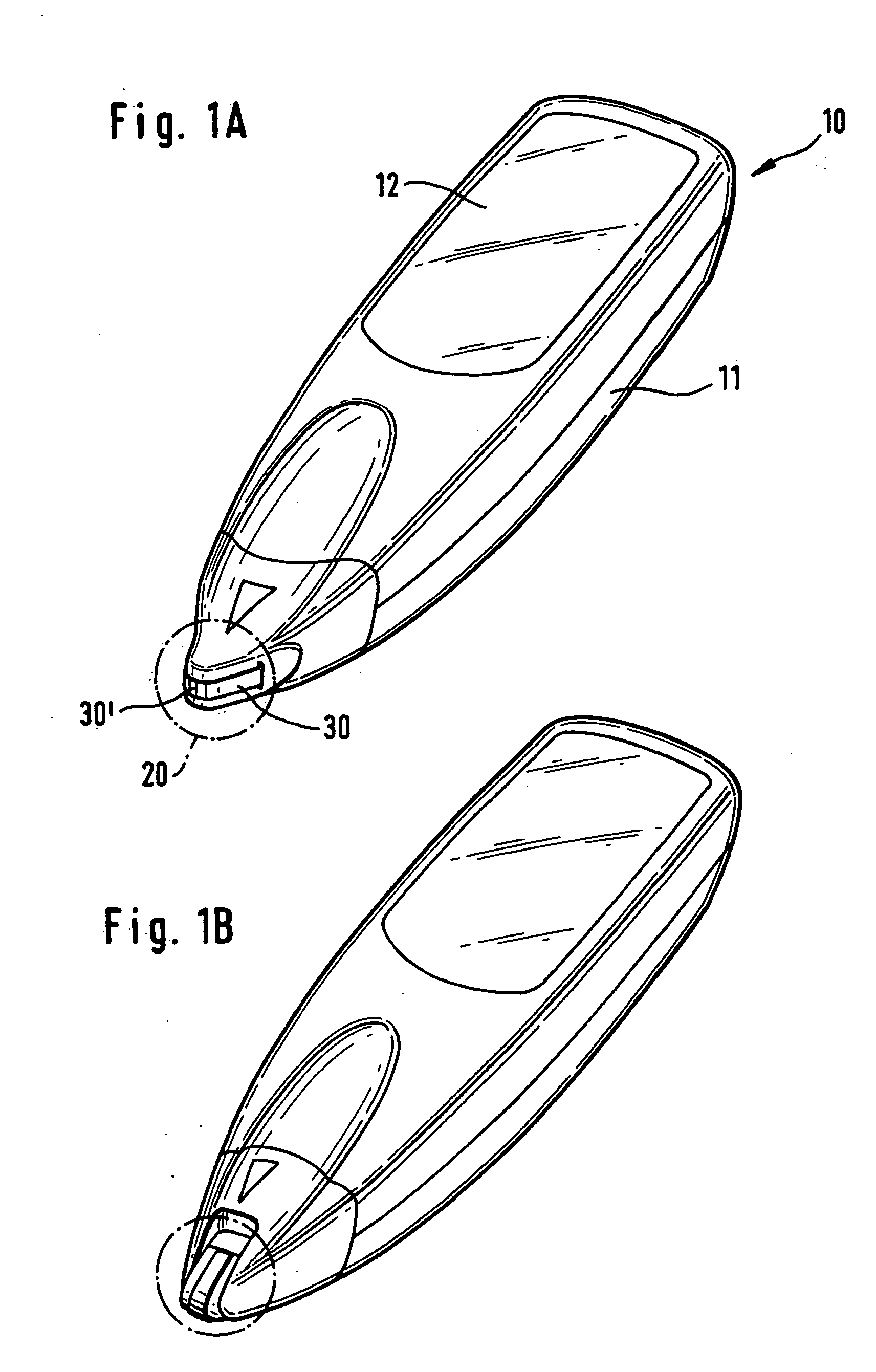

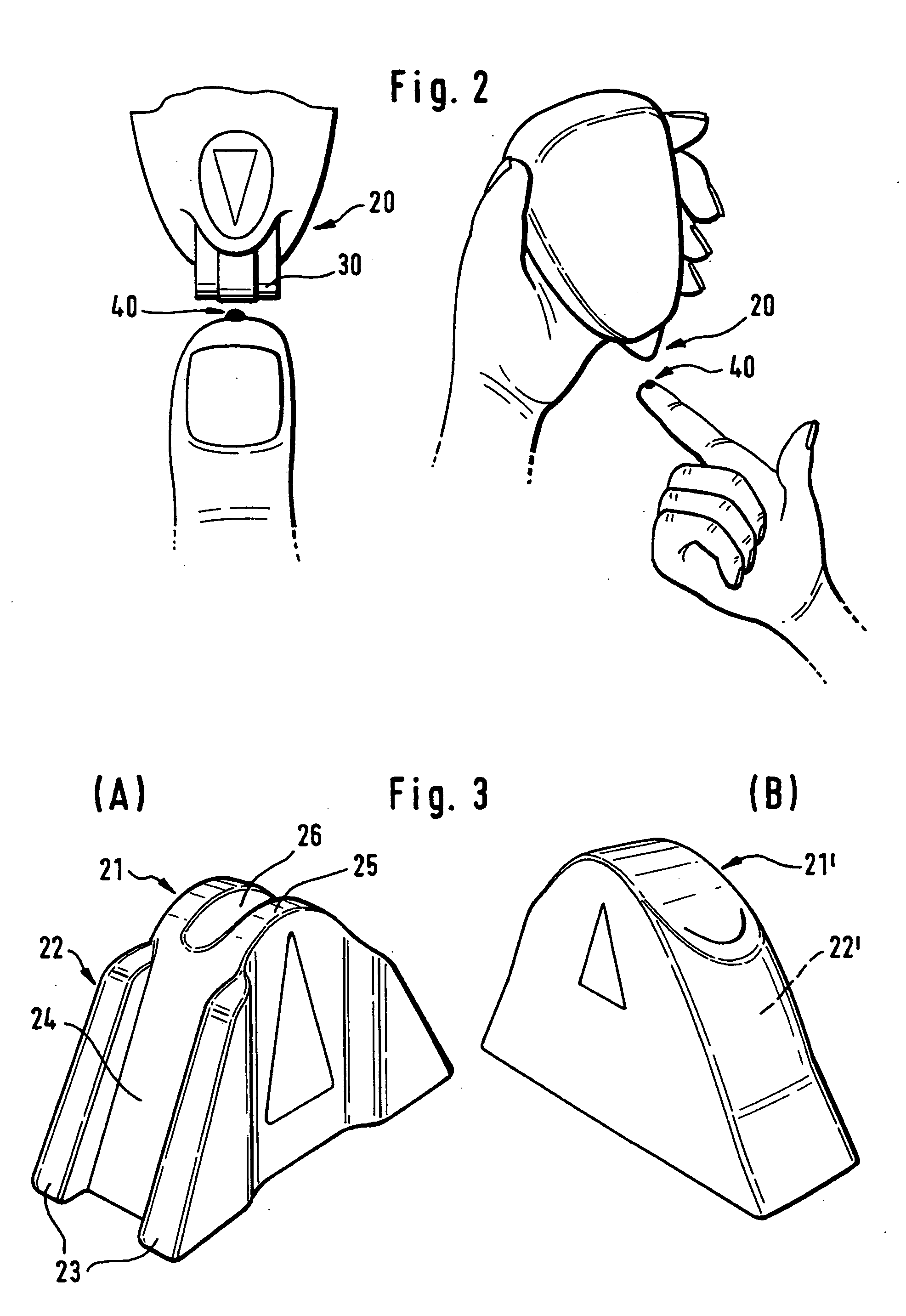

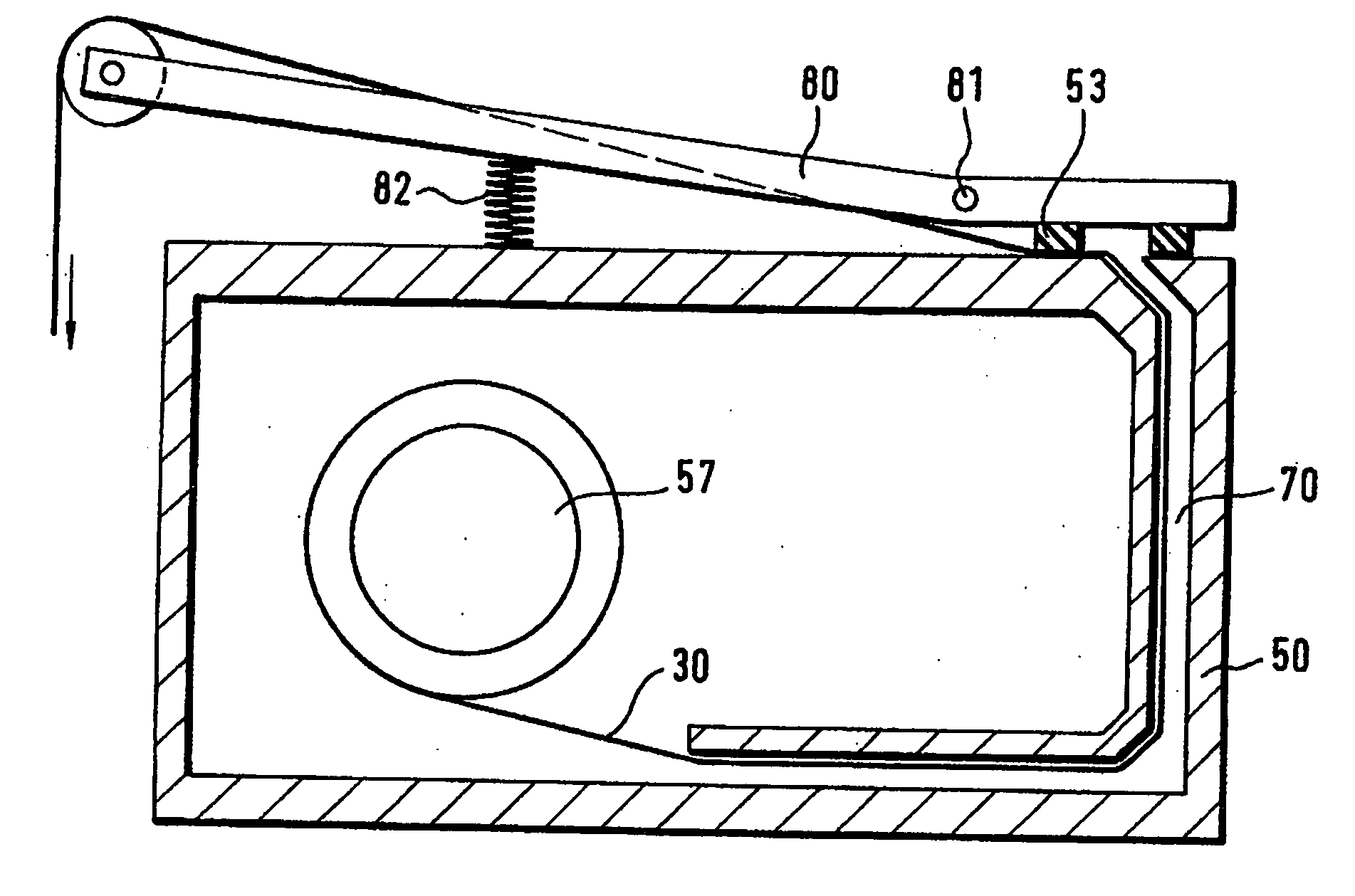

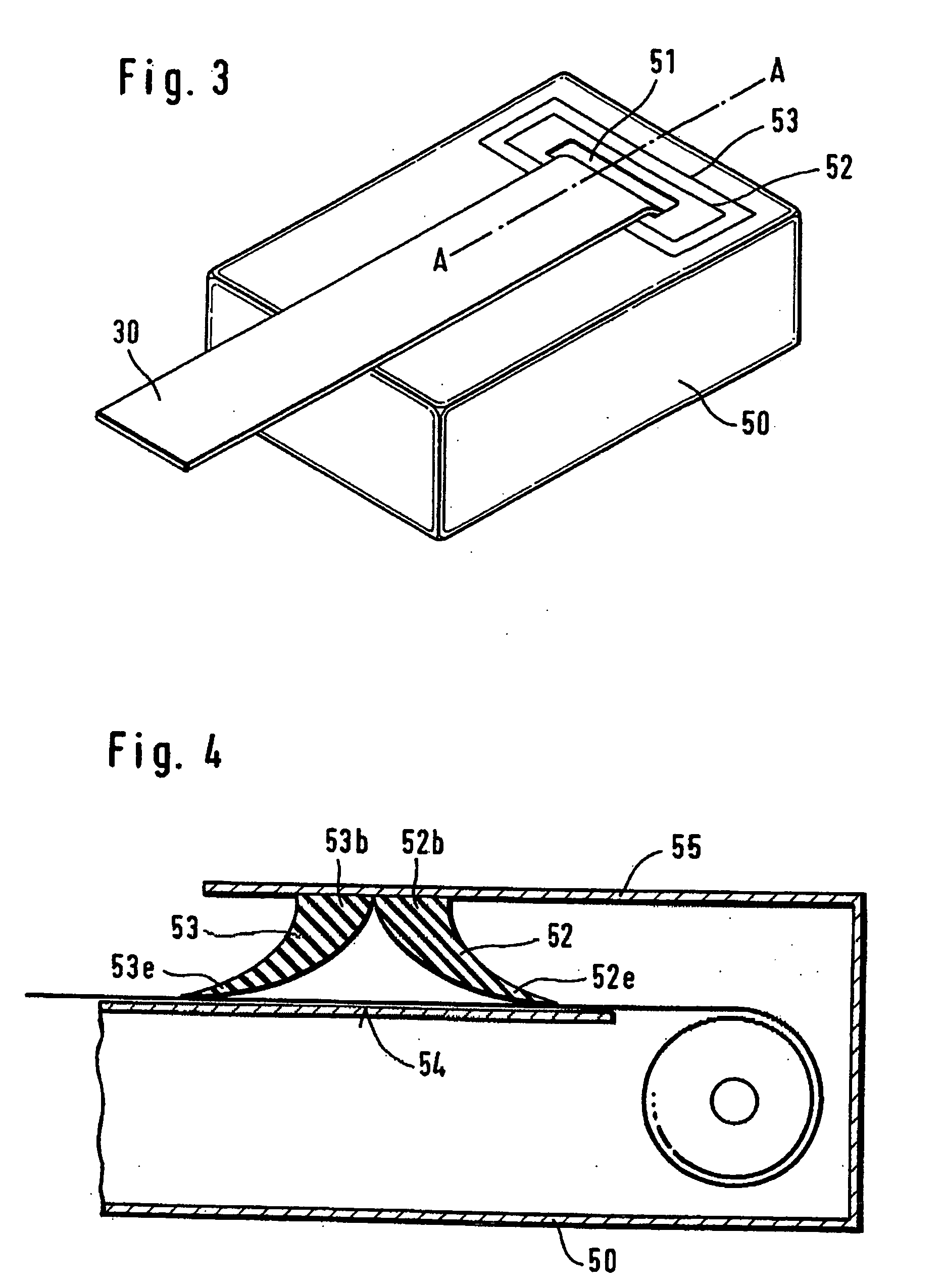

Body fluid testing device

InactiveUS20050201897A1Easy to moveBroaden applicationMaterial analysis by optical meansVaccination/ovulation diagnosticsMagnetic tapeEngineering

The present invention concerns a body fluid testing device (10) for analyzing a body fluids, comprising a test media tape (30) adapted to collect the body fluid, a supply portion (100) storing an uncontaminated section of the test media tape, a storage portion (110) for storing a contaminated section of the test media tape, an exposure portion positioned between the supply portion and the storage portion, the exposure portion being adapted to expose a section of the test media tape to the body fluid. An important aspect is a tip portion (20) for exposing a test medium to body fluid application. The application further concerns a test media cassette for housing test media. Another aspect is a testing device and method that employs illumination of a test medium at the site for body fluid application.

Owner:ROCHE DIABETES CARE INC

Body fluid testing device

ActiveUS20050232815A1Easy to testAdvanced conceptContainers for annular articlesFilament handlingMagnetic tapeEngineering

Body fluid testing device for analyzing a body fluid comprises a test media tape adapted to collect the body fluid. The test media tape comprises a tape and test media portions. A free tape portion without test medium is located between successive test media portions. The testing device further comprises a supply portion. The supply portion comprises a housing in which uncontaminated test media tape is contained. The housing further has an opening for withdrawing test media tape from the housing. The testing device further has a sealing means for closing the opening against the surrounding. A free tape portion of the test media tape is located between a wall of the housing and the sealing means when the sealing means closes the opening. Further aspects concern a test media cassette with sealing means and a method for providing test media while holding them sealed against humidity during onboard storage.

Owner:ROCHE DIABETES CARE INC

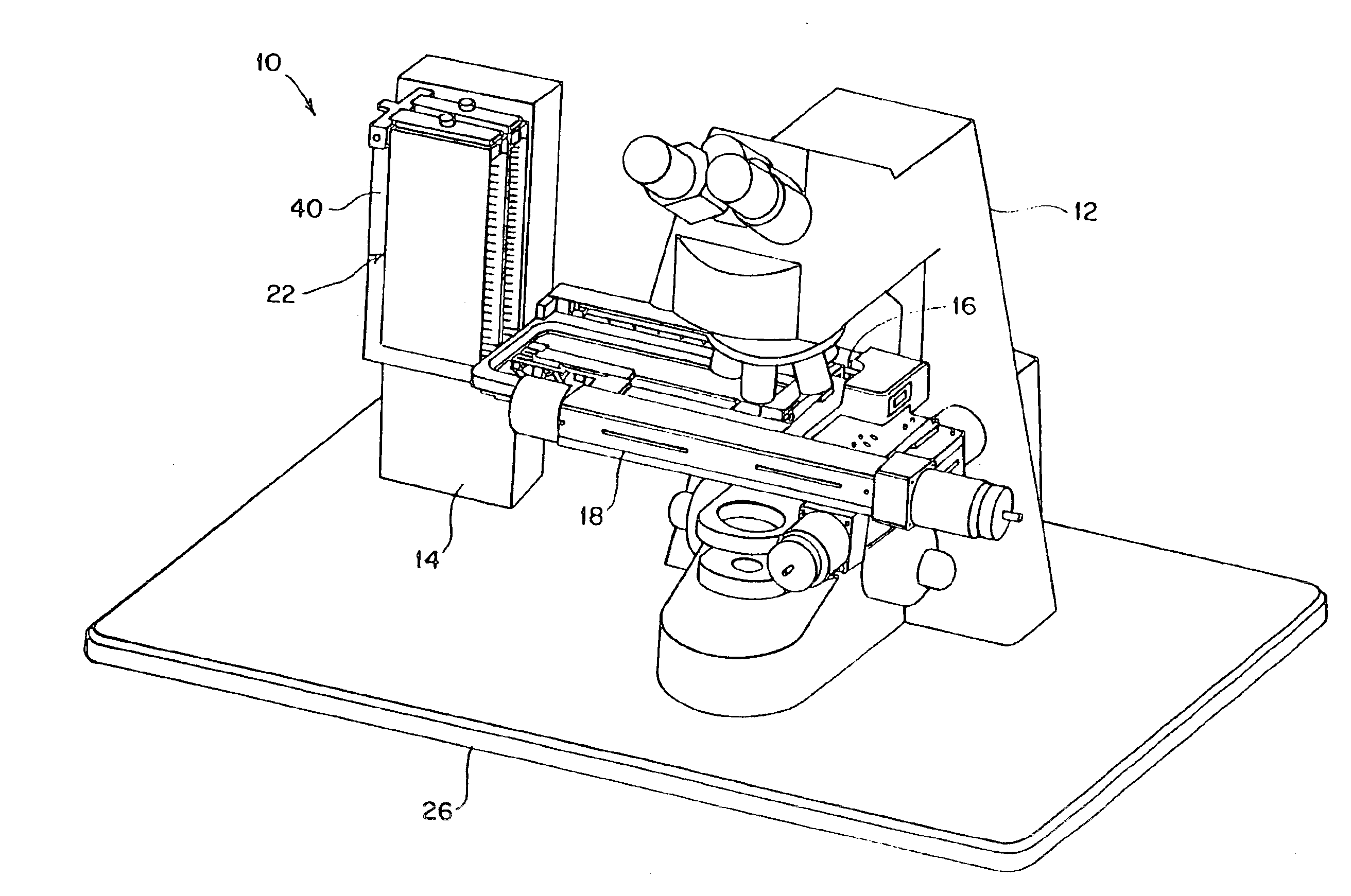

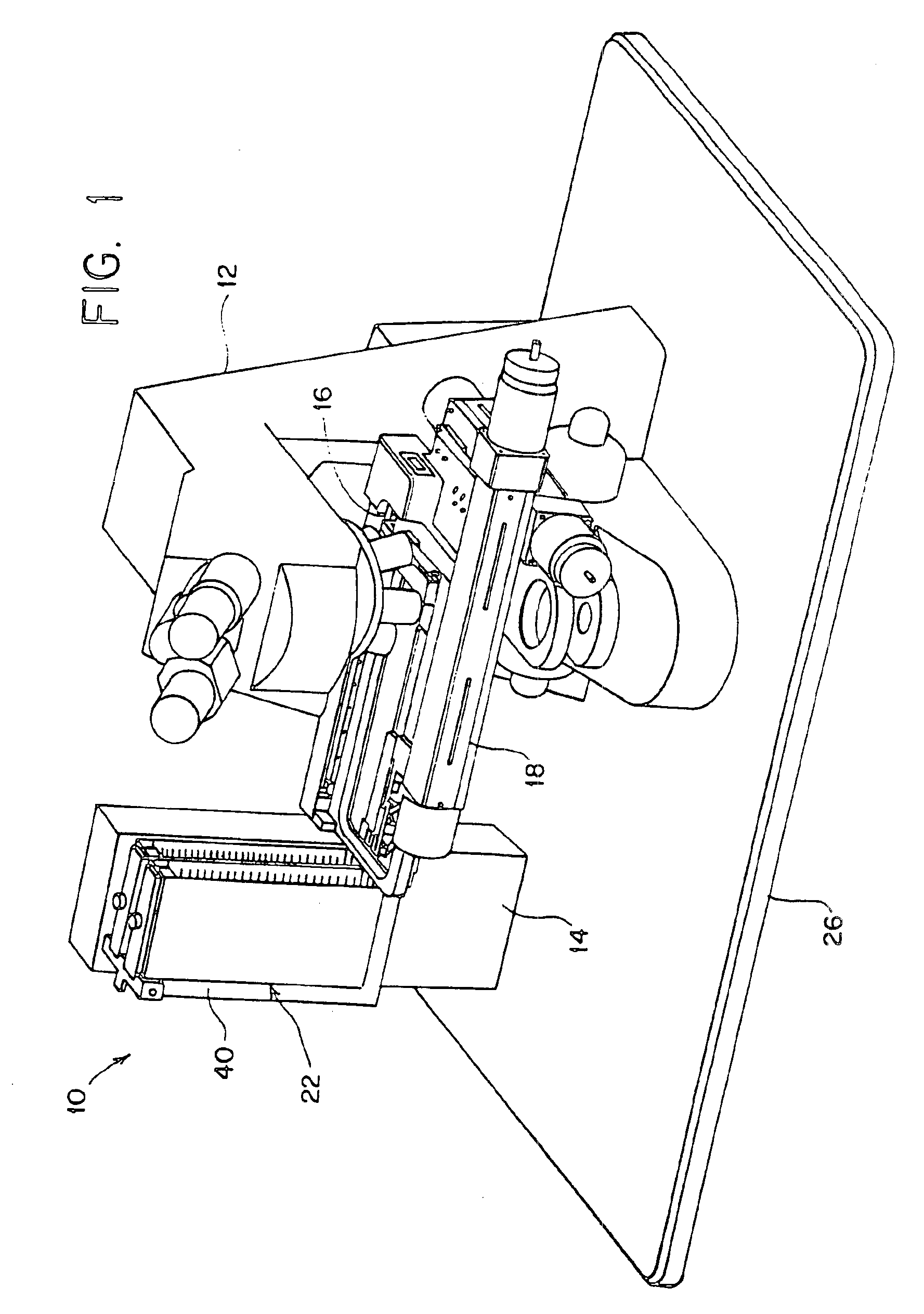

Automated slide loader cassette for microscope

InactiveUS6847481B1Enhance intrinsic valuePrecise positioningArticle unpackingMicroscopesMicroscope slideMagnetic tape

The slide handler is an instrument that automatically transfers glass microscope slides from a cassette or magazine to a motorized microscope stage and then returns the slide back into the second cassette. The use of this instrument permits the unattended computer control, measurement and inspection of specimens mounted to the slides. Full modular integration of the system components allows for the slide handler instrument to be utilized with any microscope. The instrument system has a minimum of three components; namely a slide cassette indexer, an XY-stage, and a slide exchange arm. The indexer, the arm and the XY-stage are connected together and integrated into one unitary modular instrument that can be moved from one microscope to another.

Owner:LUDL ELECTRONICS PRODS

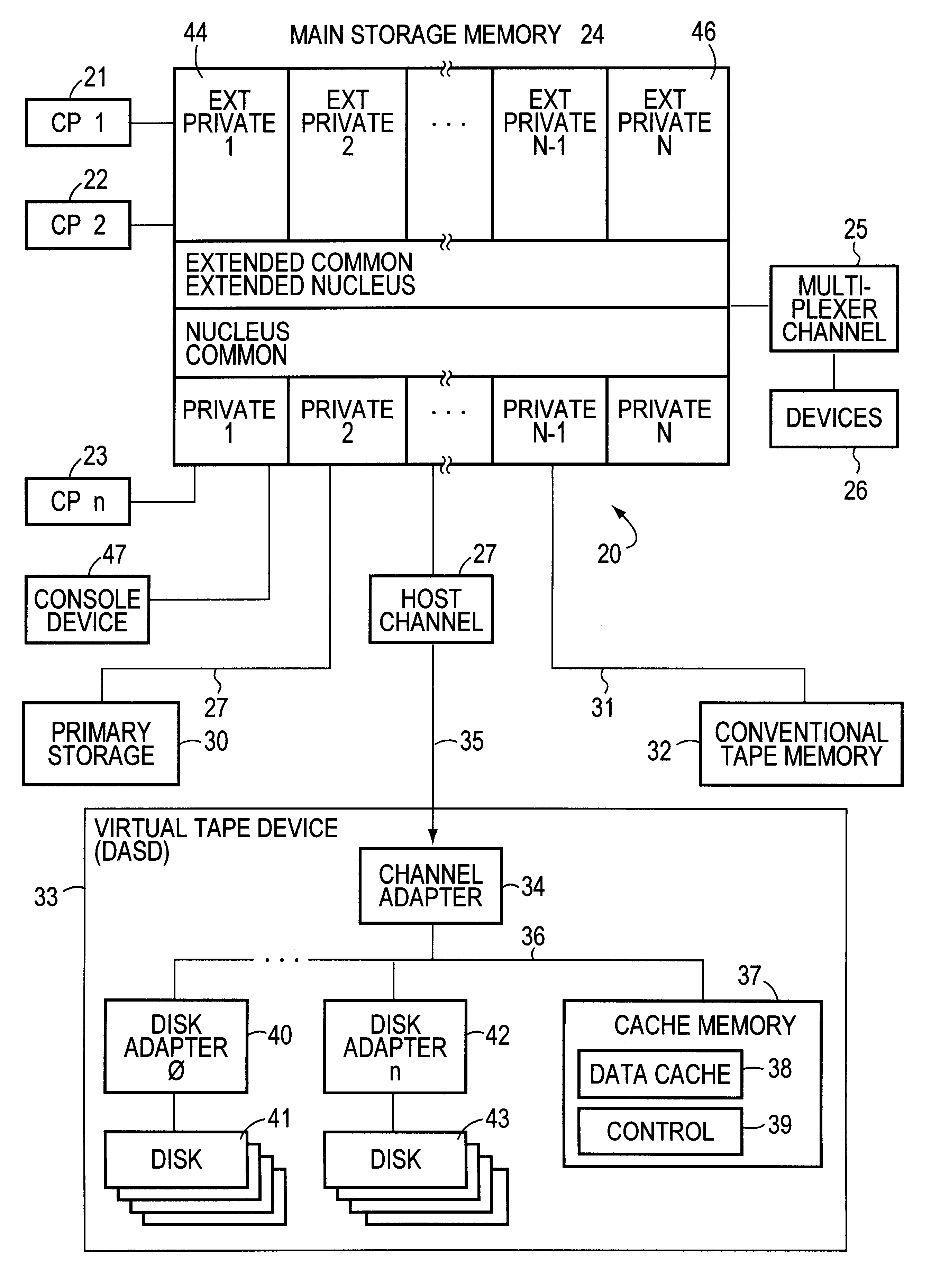

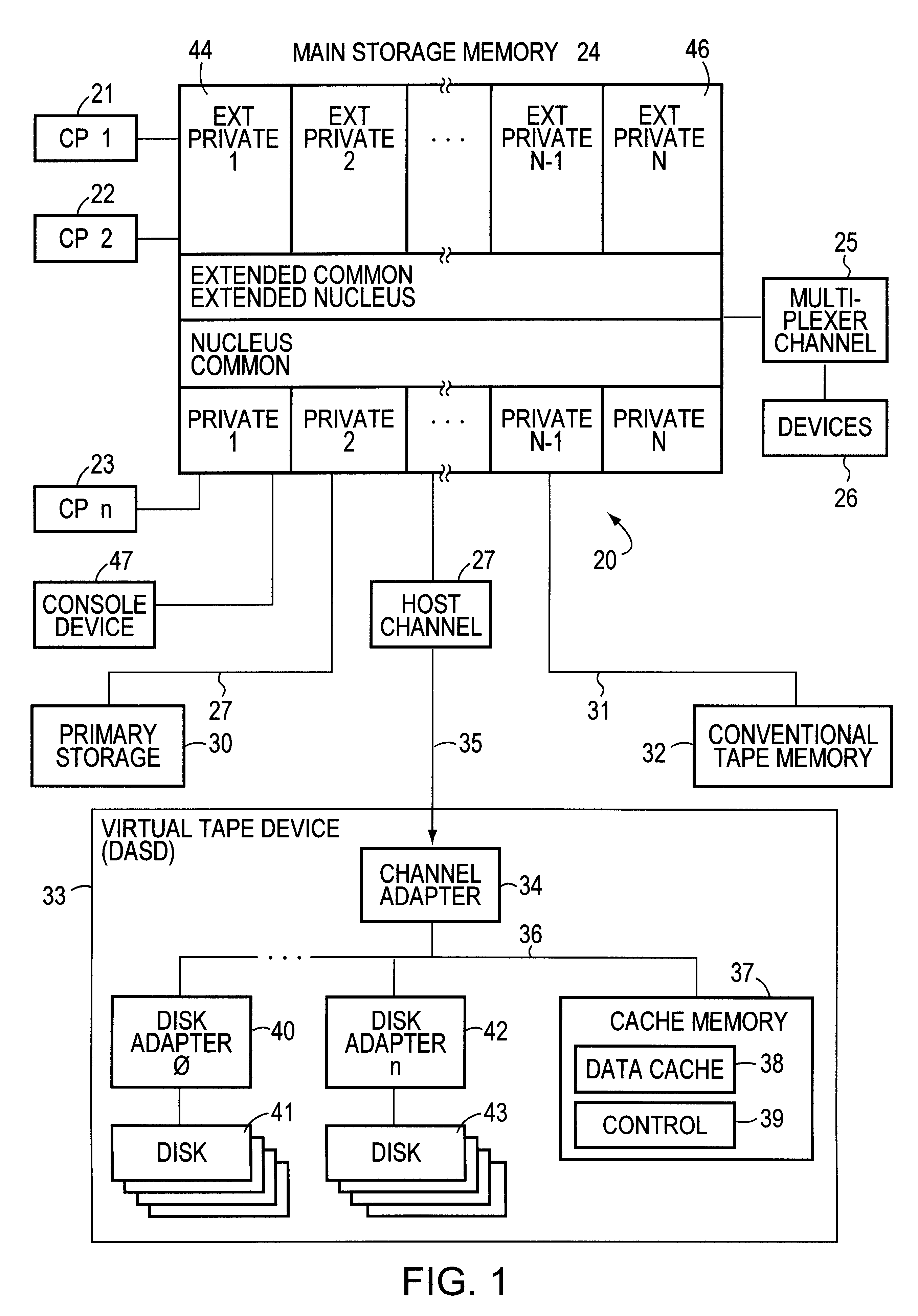

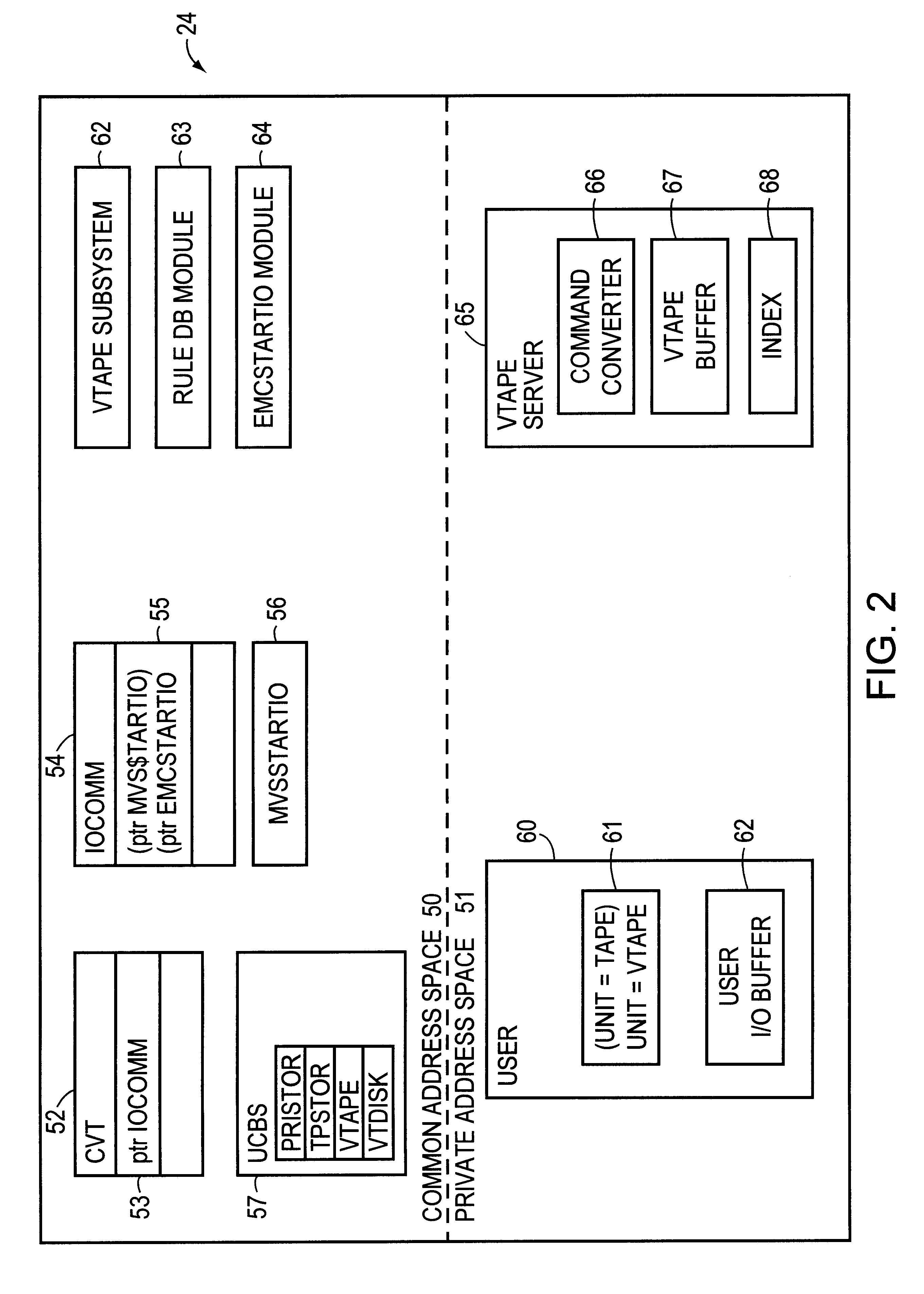

Virtual tape system

InactiveUS6341329B1Input/output to record carriersMemory adressing/allocation/relocationComputer hardwareMagnetic tape

A method and apparatus for emulating a magnetic tape storage device with a conventional, unmodified magnetic disk storage device. I / O output requests for the emulated magnetic tape storage device are intercepted to determine whether they involve a virtual tape resource that comprises a magnetic disk storage device. Tape requests to such a resource are converted into one or more conventional magnetic disk storage requests to effect an analogous operation.

Owner:EMC CORP

Multifunctional polymer coated magnetic nanocomposite materials

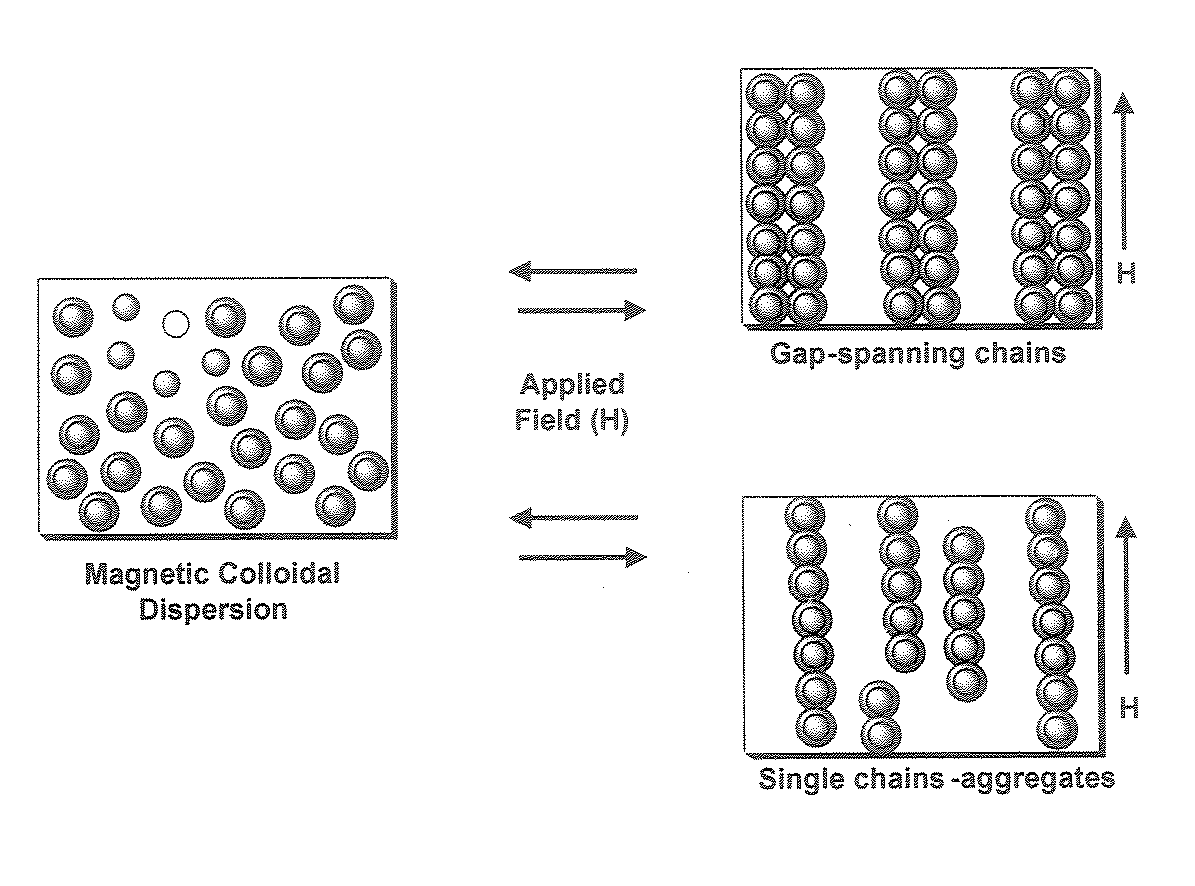

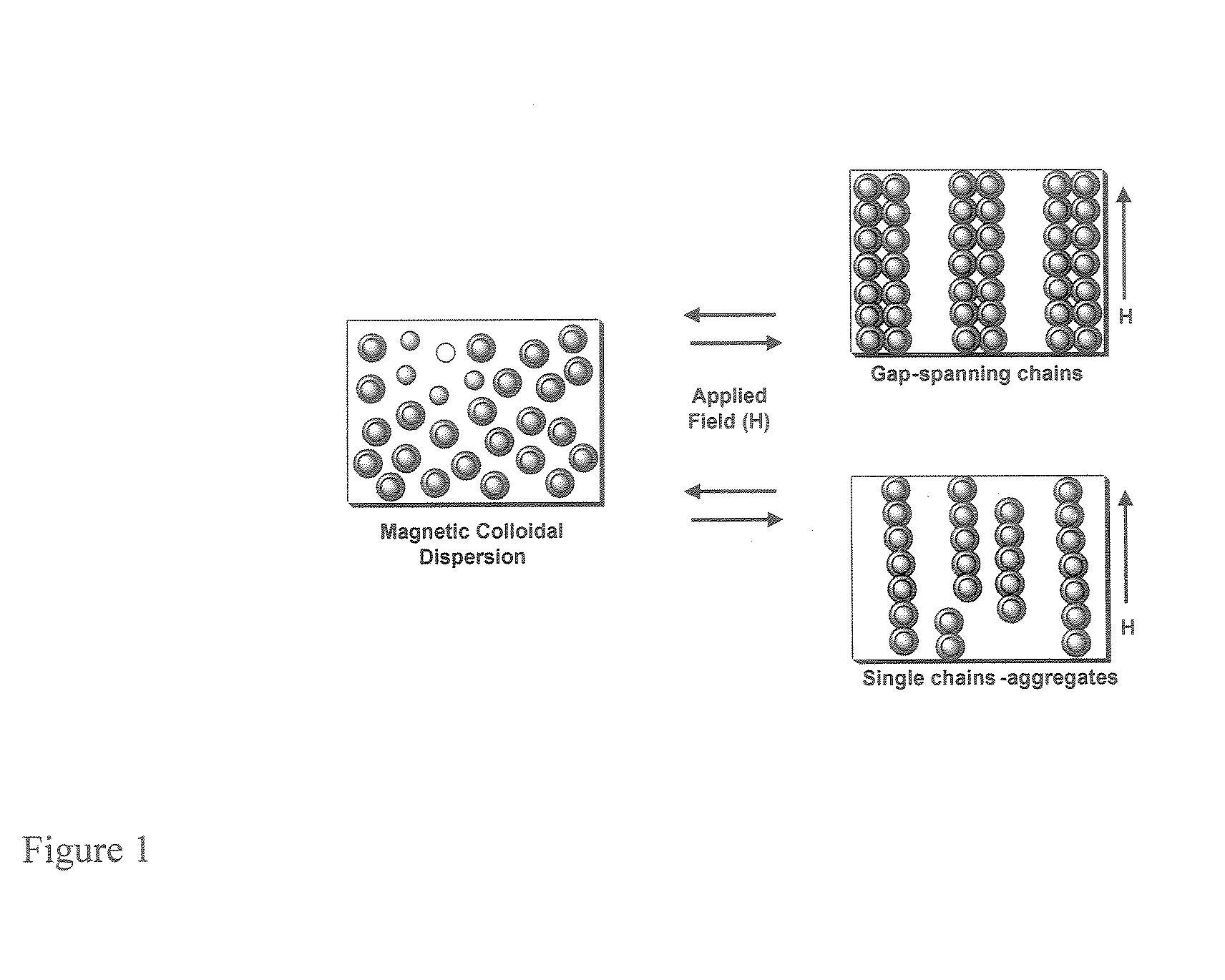

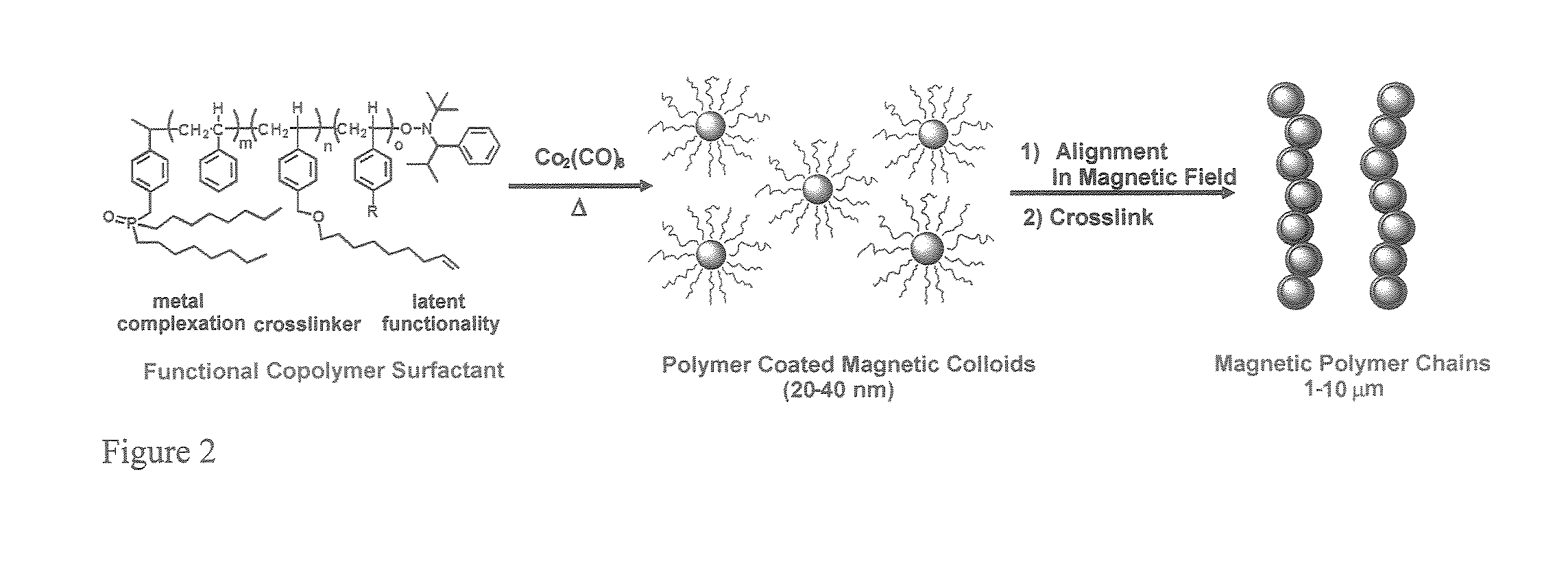

A polymer coated nanoparticle containing a metallic core and a polymer shell encapsulating said metallic core is useful, for example, in magnetic tapes and supercapacitors.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com