Patents

Literature

6109 results about "Food packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Food packaging is packaging for food. A package provides protection, tampering resistance, and special physical, chemical, or biological needs. It may bear a nutrition facts label and other information about food being offered for sale.

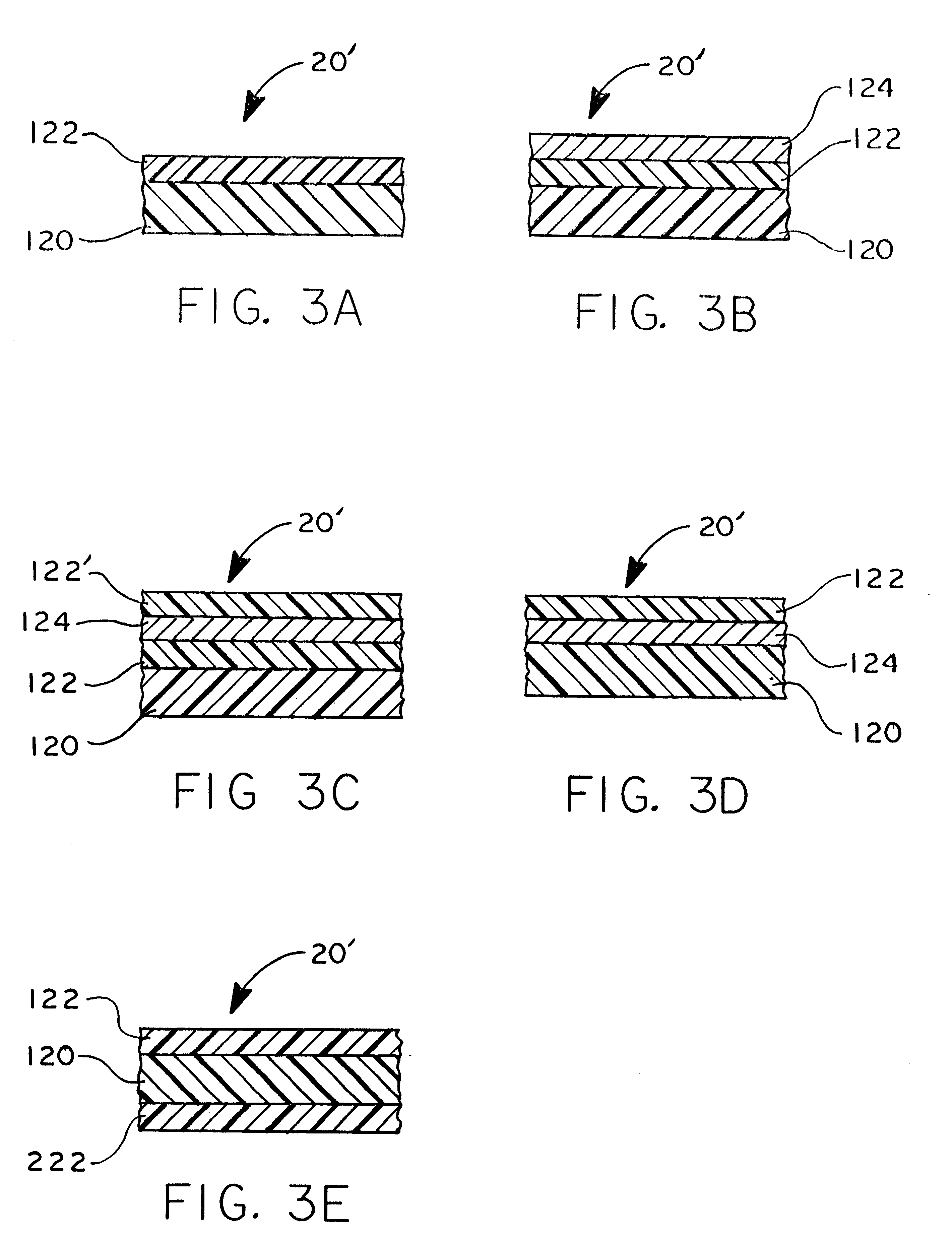

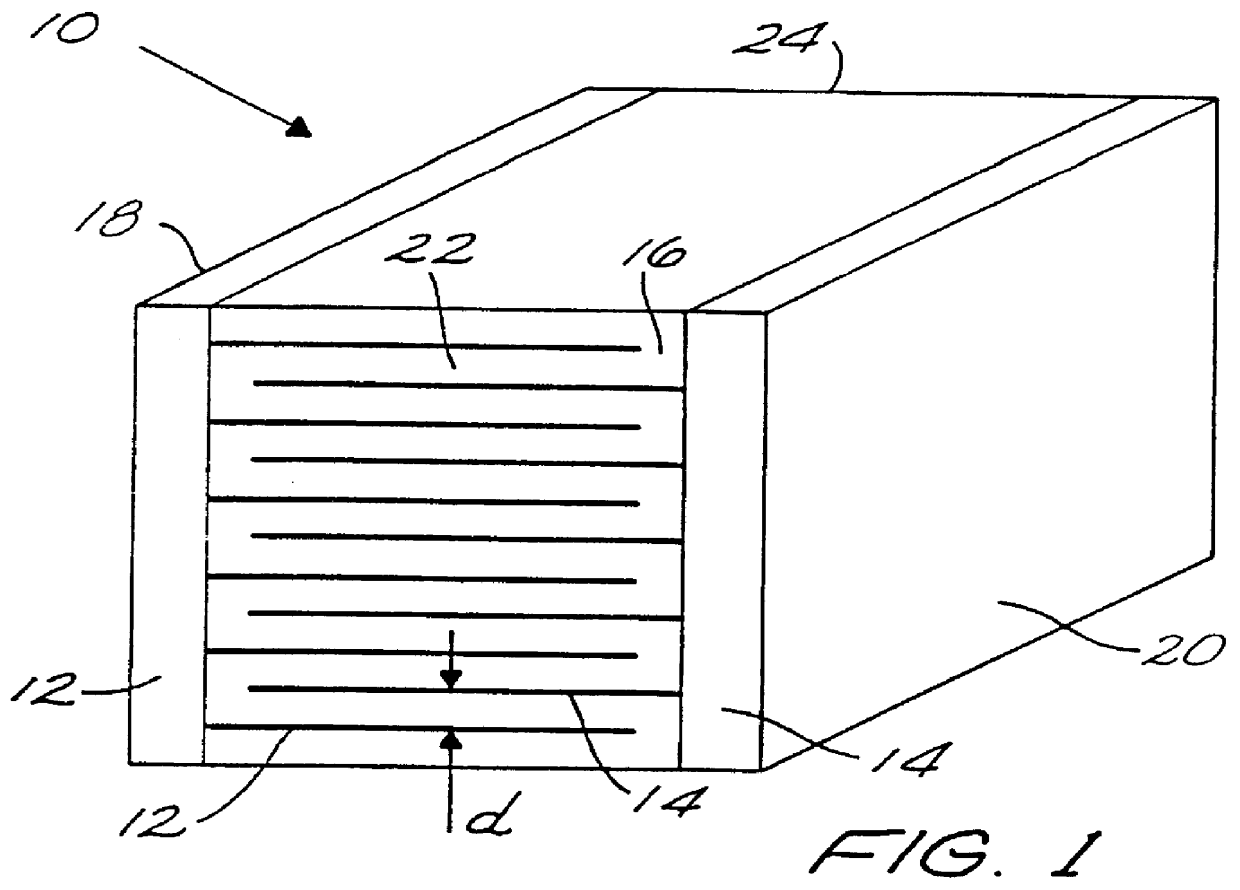

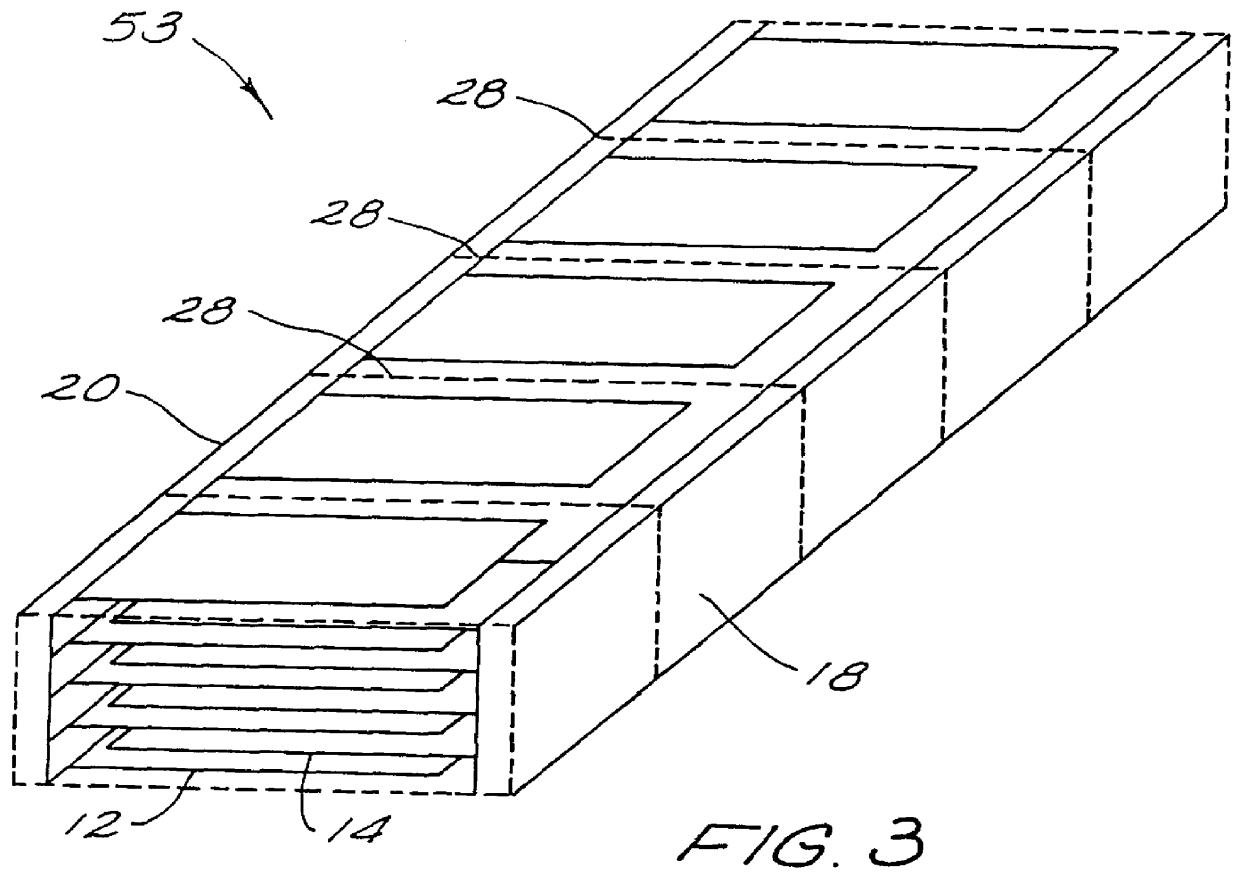

Method of forming a hybrid polymer film

InactiveUS6214422B1Fine surfaceLow costFixed capacitor dielectricSynthetic resin layered productsThermoplasticCross-link

A hybrid film, comprising a first polymer film having a plasma-treated surface and a second polymer film having first and second surfaces, with the first surface of the second polymer film being disposed along the first plasma-treated surface of the first polymer film, has superior thermal and mechanical properties that improve performance in a number of applications, including food packaging, thin film metallized and foil capacitors, metal evaporated magnetic tapes, flexible electrical cables, and decorative and optically variable films. One or more metal layers may be deposited on either the plasma-treated surface of the substrate and / or the radiation-cured acrylate polymer A ceramic layer may be deposited on the radiation-cured acrylate polymer to provide an oxygen and moisture barrier film. The hybrid film is produced using a high speed, vacuum polymer deposition process that is capable of forming thin, uniform, high temperature, cross-liked acrylate polymers on specific thermoplastic or thermoset films. Radiation curing is employed to cross-link the acrylate monomer. The hybrid film can be produced in-line with the metallization or ceramic coating process, in the same vacuum chamber and with minimal additional cost.

Owner:SIGMA LAB OF ARIZONA

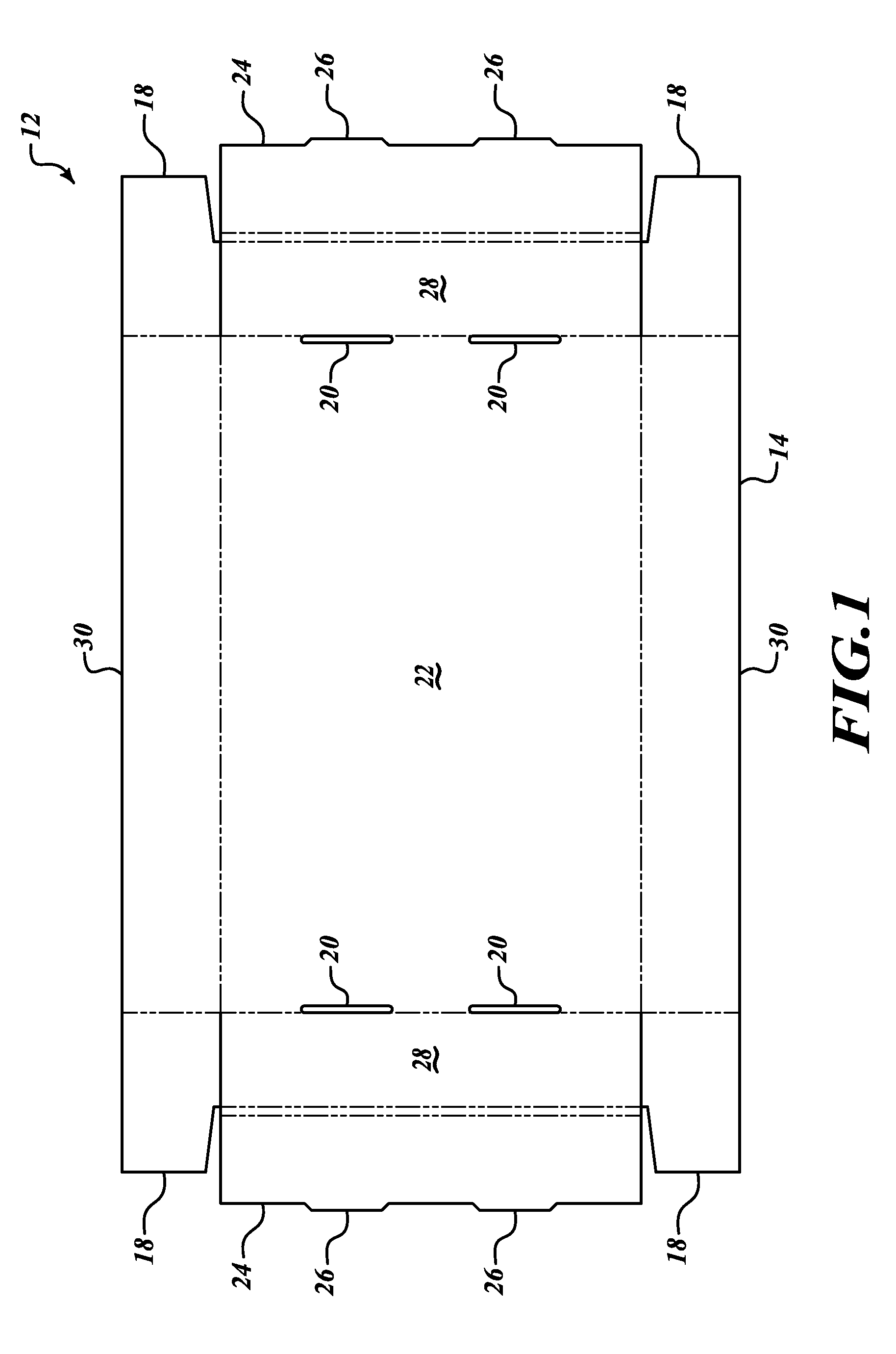

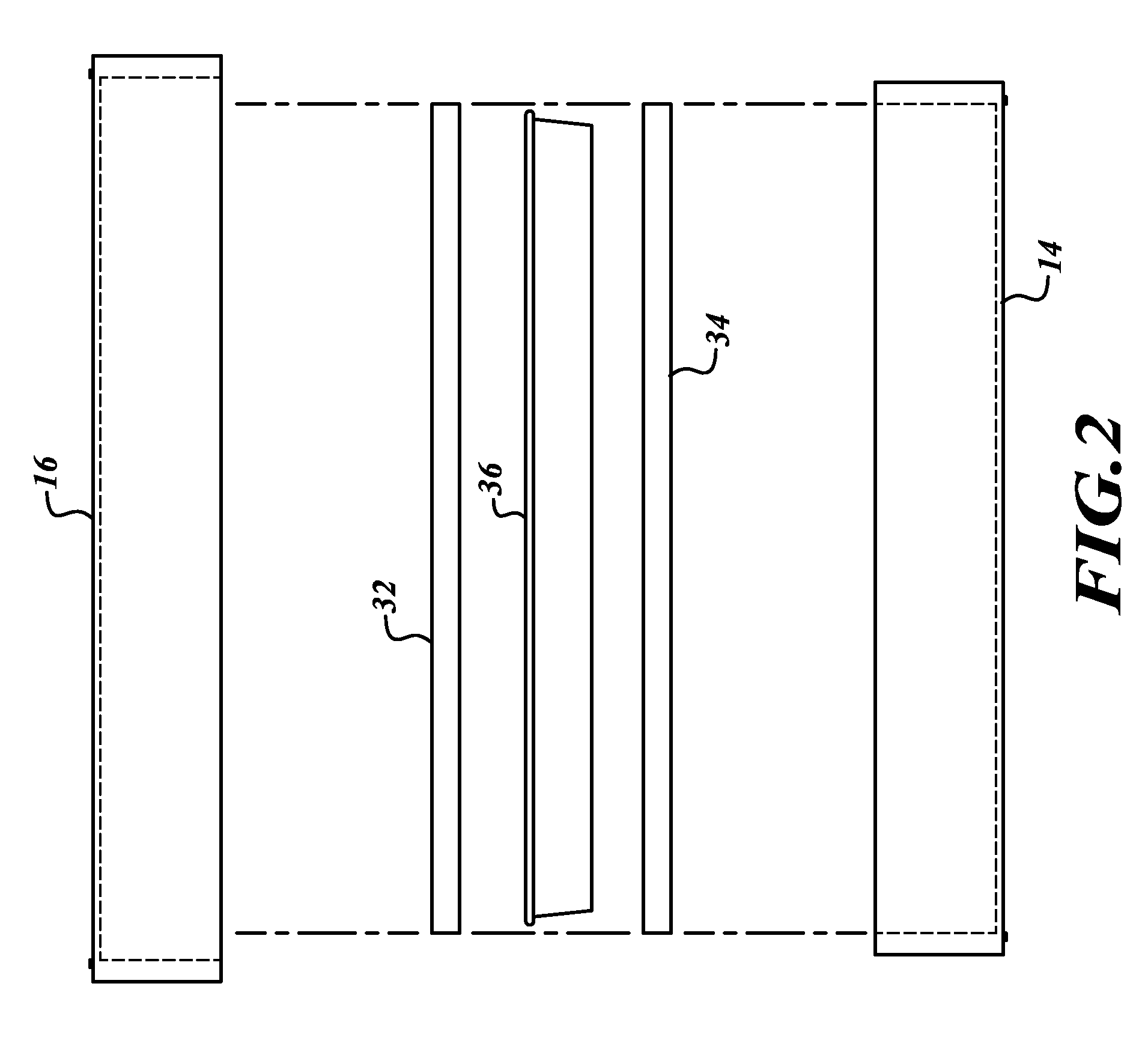

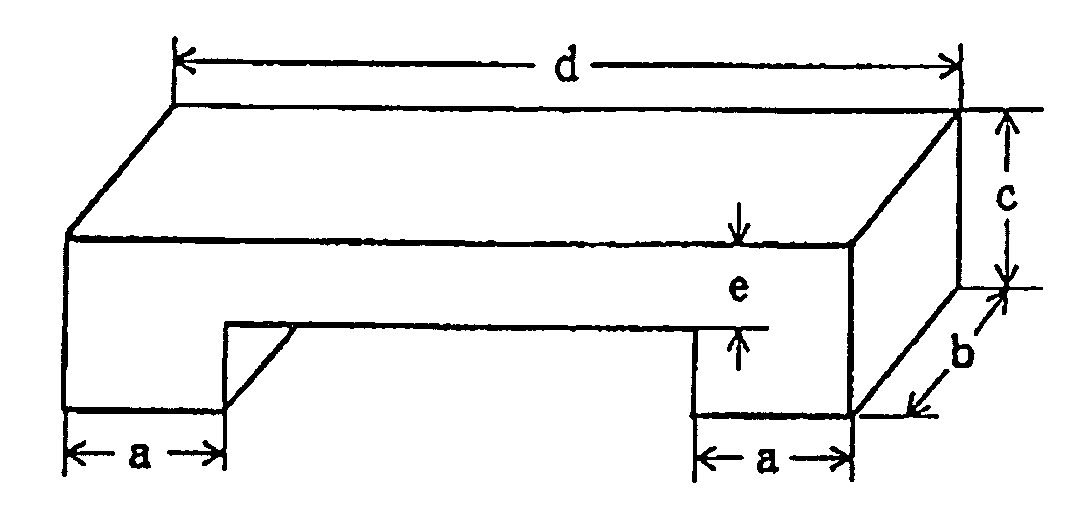

Insulating microwave interactive packaging

InactiveUS7019271B2Improve cooking resultsImprove the heating effectDomestic cooling apparatusLighting and heating apparatusMicrowave ovenEngineering

Owner:GRAPHIC PACKAGING INT +1

Hybrid polymer film

InactiveUS6083628AFine surfaceLow costFixed capacitor dielectricSynthetic resin layered productsThermoplasticCross-link

A hybrid film, comprising a first polymer film having a plasma-treated surface and a second polymer film having first and second surfaces, with the first surface of the second polymer film being disposed along the first plasma-treated surface of the first polymer film, has superior thermal and mechanical properties that improve performance in a number of applications, including food packaging, thin film metallized and foil capacitors, metal evaporated magnetic tapes, flexible electrical cables, and decorative and optically variable films. One or more metal layers may be deposited on either the plasma-treated surface of the substrate and / or the radiation-cured acrylate polymer. A ceramic layer may be deposited on the radiation-cured acrylate polymer to provide an oxygen and moisture barrier film. The hybrid film is produced using a high speed, vacuum polymer deposition process that is capable of forming thin, uniform, high temperature, cross-linked acrylate polymers on specific thermoplastic or thermoset films. Radiation curing is employed to cross-link the acrylate monomer. The hybrid film can be produced in-line with the metallization or ceramic coating process, in the same vacuum chamber and with minimal additional cost.

Owner:SIGMA LAB OF ARIZONA

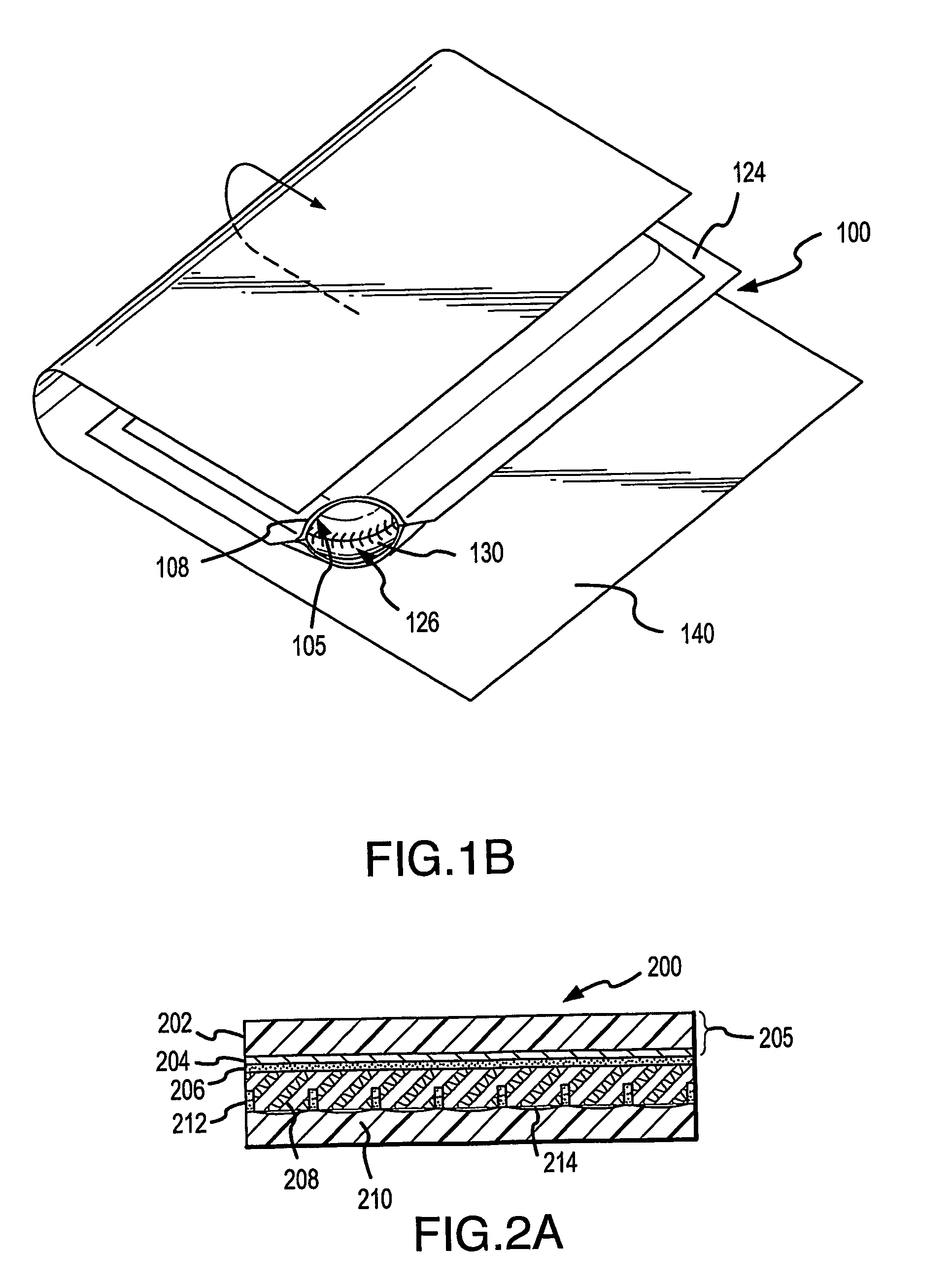

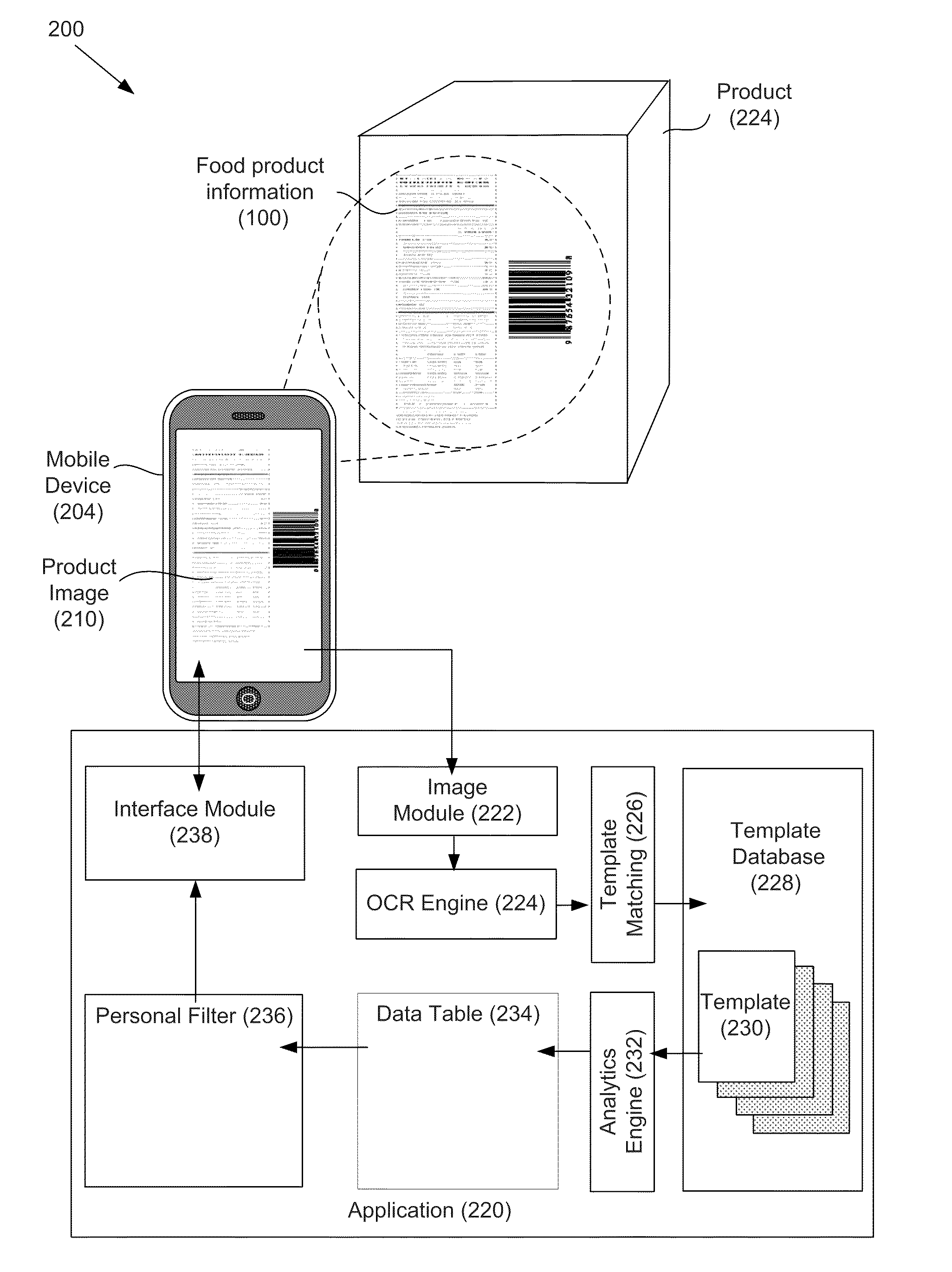

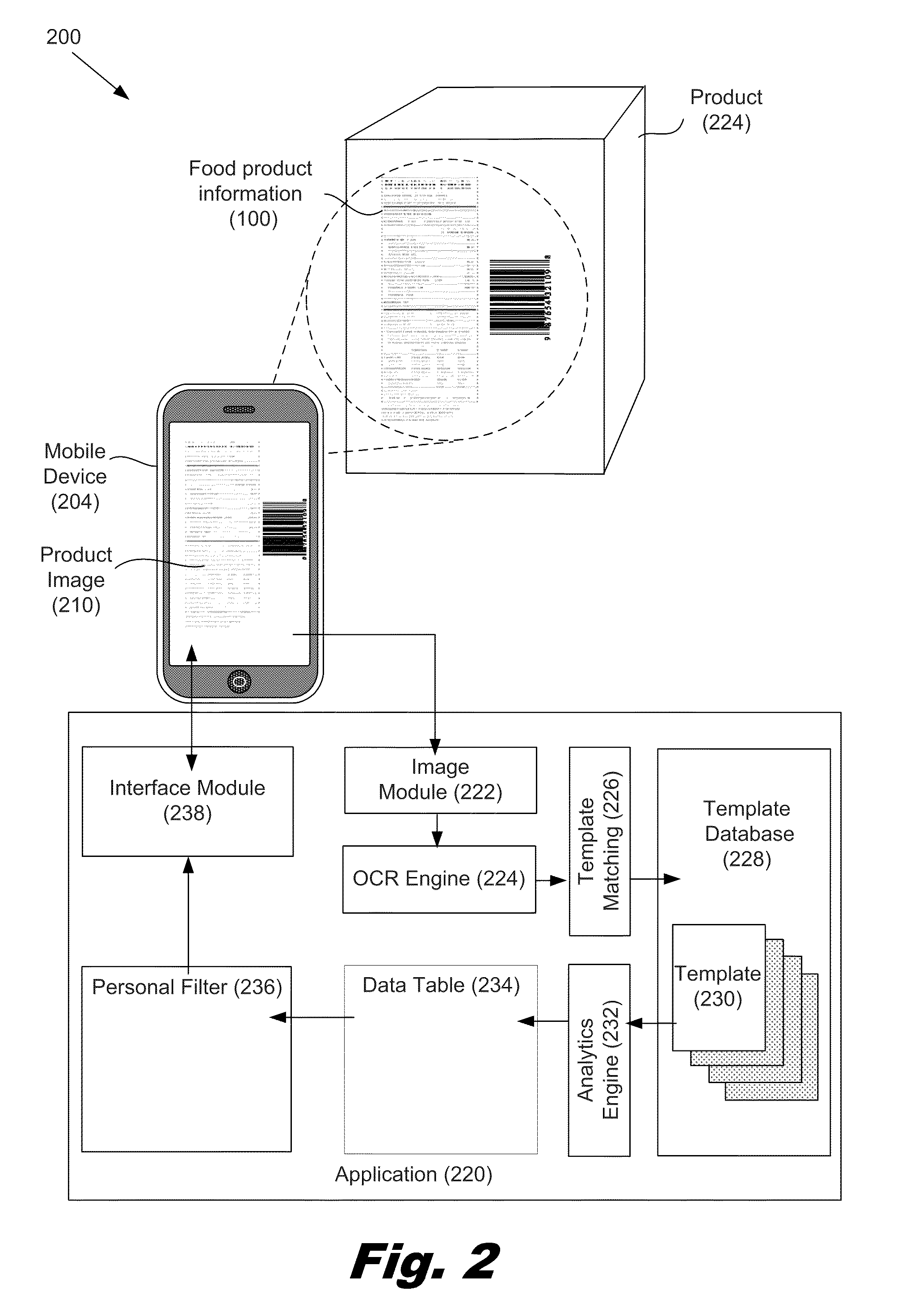

Template-based recognition of food product information

ActiveUS20120005222A1Digital data information retrievalDigital data processing detailsTemplate basedFood packaging

A method for template based recognition of food product information includes capturing an image of food product packaging and extracting an attribute from the image. The attribute is used to find a matching template in a template-database. The matching template is then used to extract food product information from the image.

Owner:NEC CORP

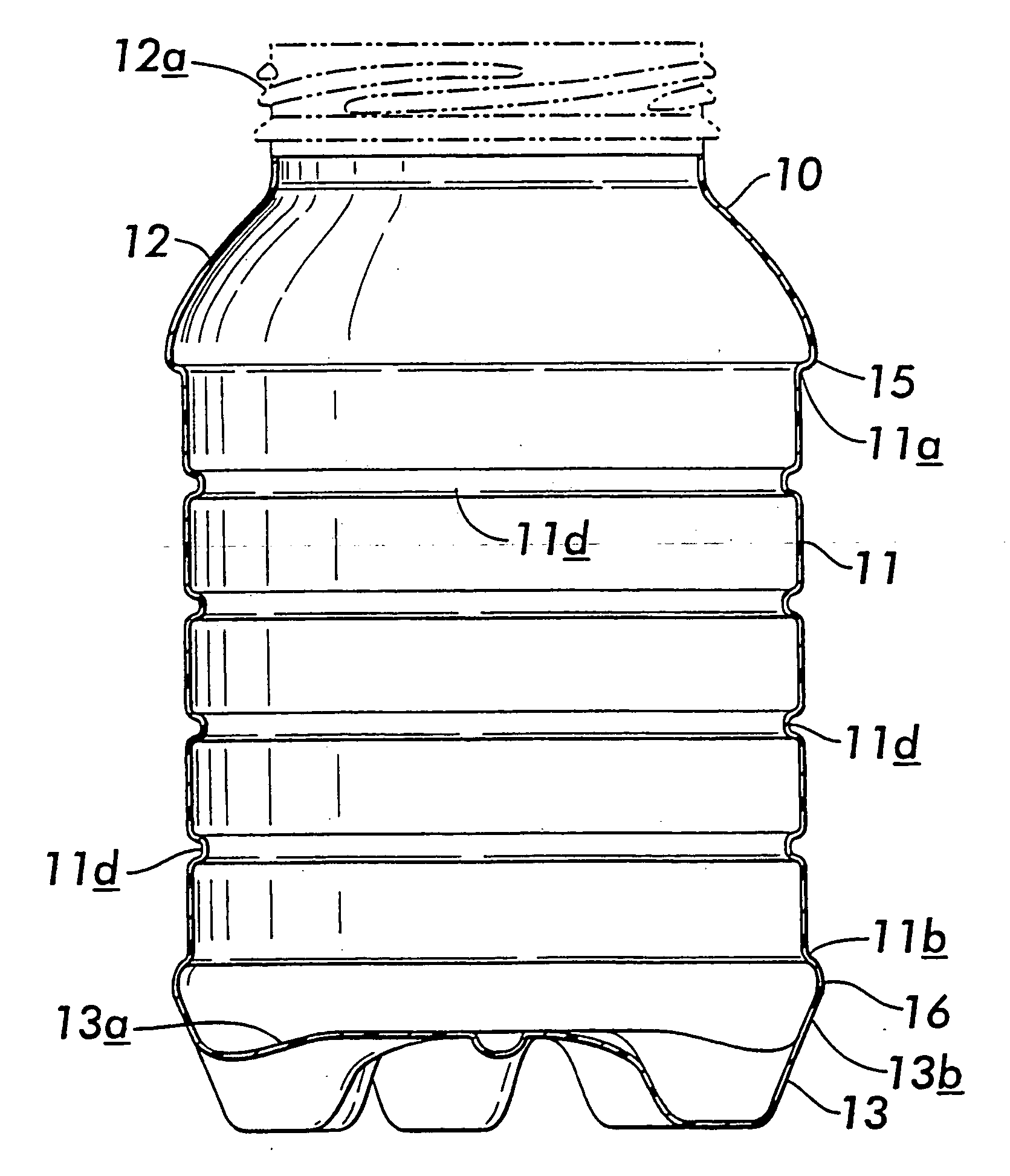

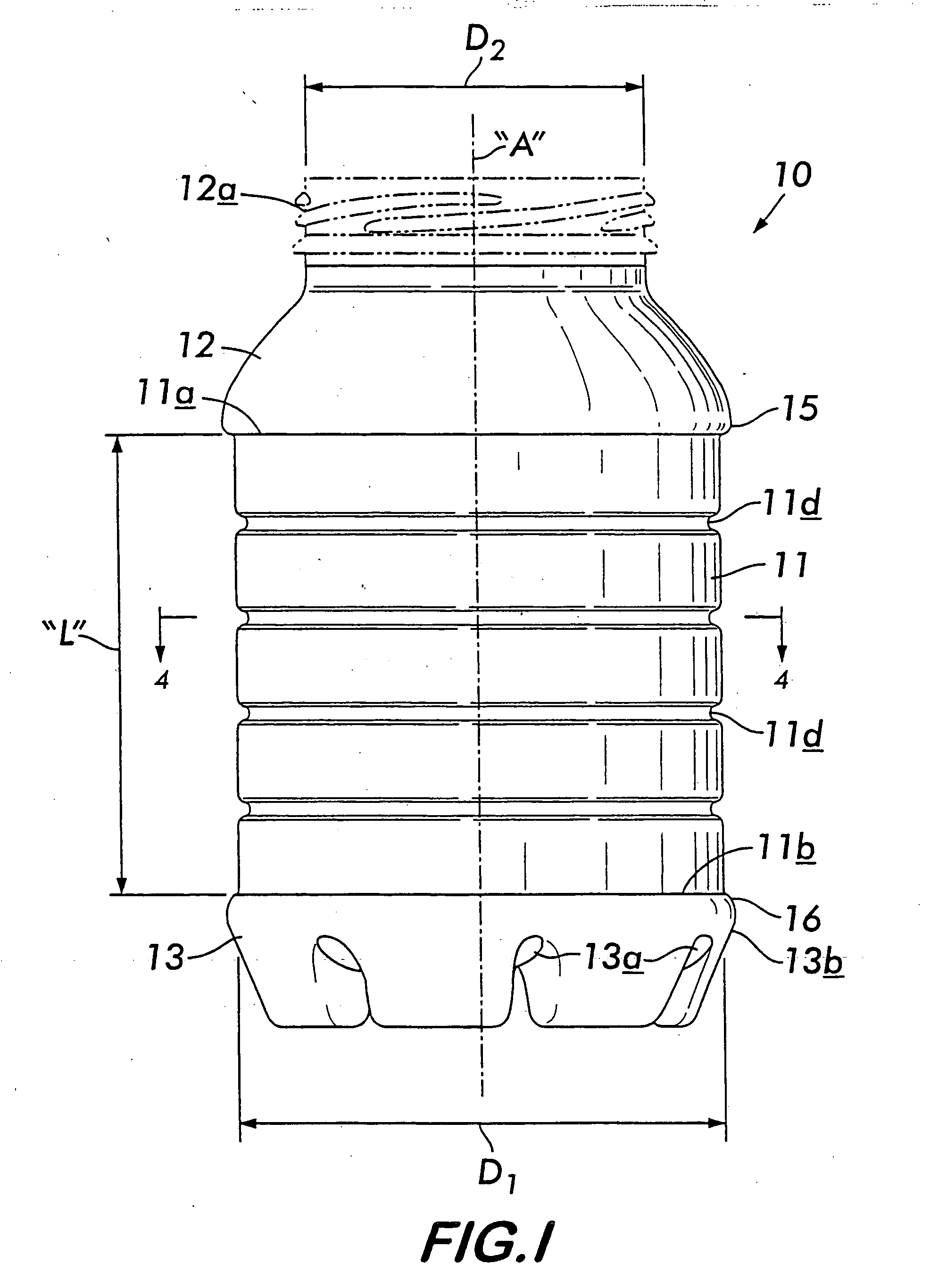

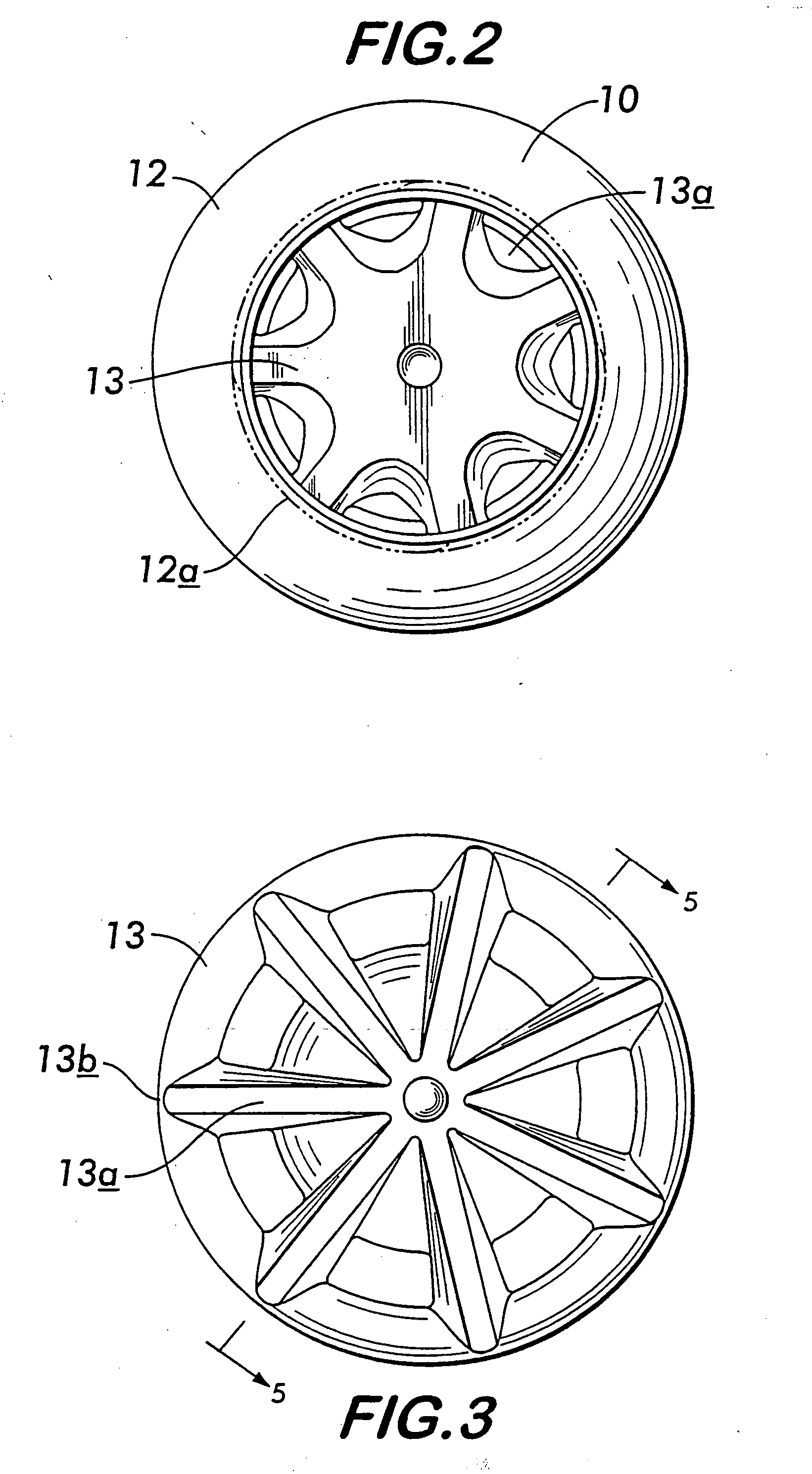

Pasteurizable wide-mouth container

A wide-mouth blow-molded plastic container capable of accommodating, without undesirable distortion, super-baric pressures when filled with volatile food products and pasteurized, and sub-baric pressures after cooling to ambient temperatures. A method of packaging a food product in the container is also disclosed.

Owner:GRAHAM PACKAGING CO LP

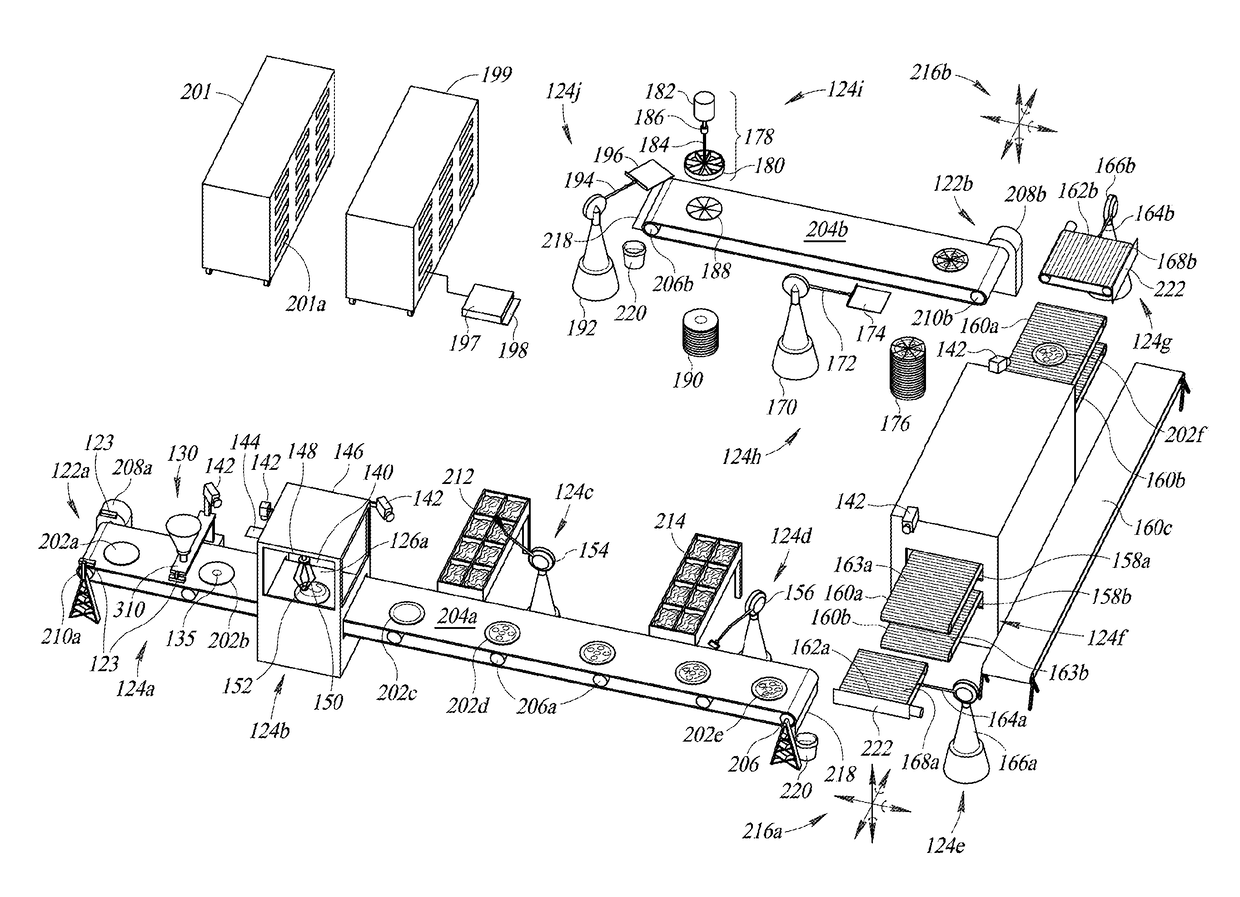

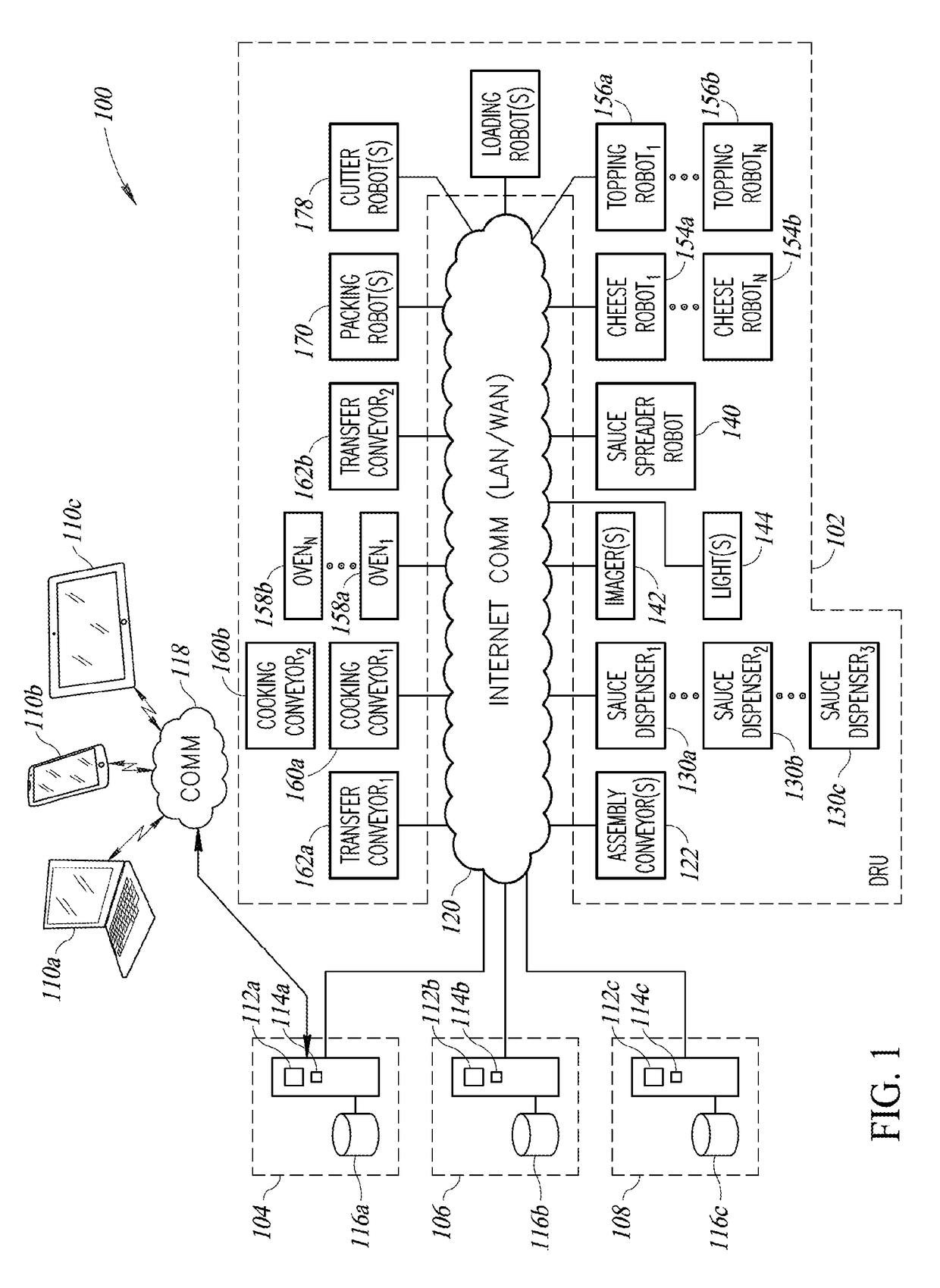

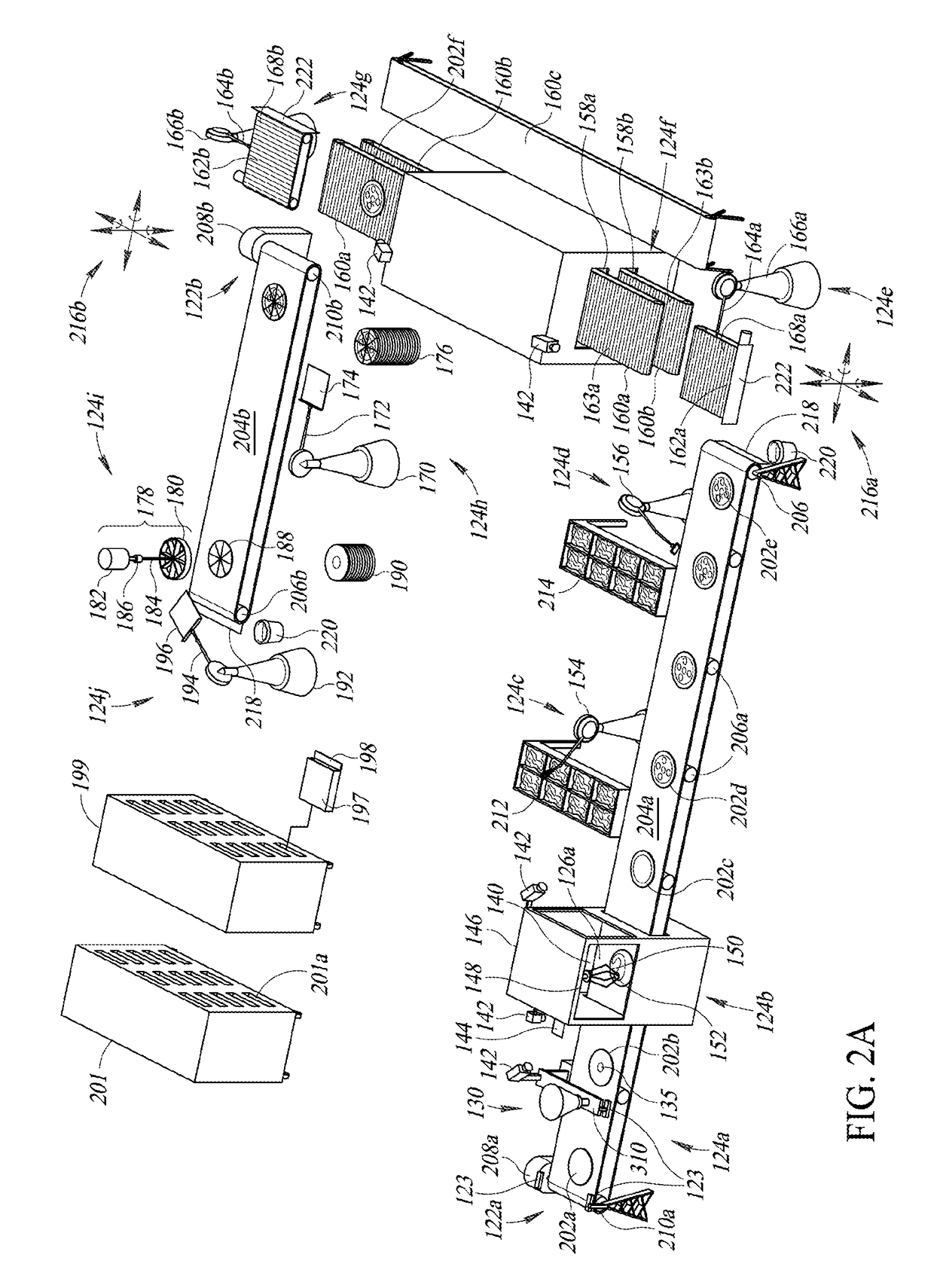

On-demand robotic food assembly and related systems, devices and methods

An on-demand robotic food assembly line can include one or more conveyors and one or more robots, operable to assemble food items in response to received orders for food items, and one or more ovens operable to, for example, partially cook assembled food items. The on-demand robotic food assembly line can optionally package the assembled and partially cooked food items in packaging, and optionally load the packaged partially cooked food items into portable cooking units (e.g., ovens) that are optionally loaded into racks that are, in turn, optionally loaded into delivery vehicles, where the food items are individually cooked under controlled conditions while en route to consumer destinations, such the cooking of each food item is completed just prior to arrival at the consumer destination location. A dynamic fulfillment queue for control of assembly is maintained based at least in part on estimated transit time for orders.

Owner:ZUME INC

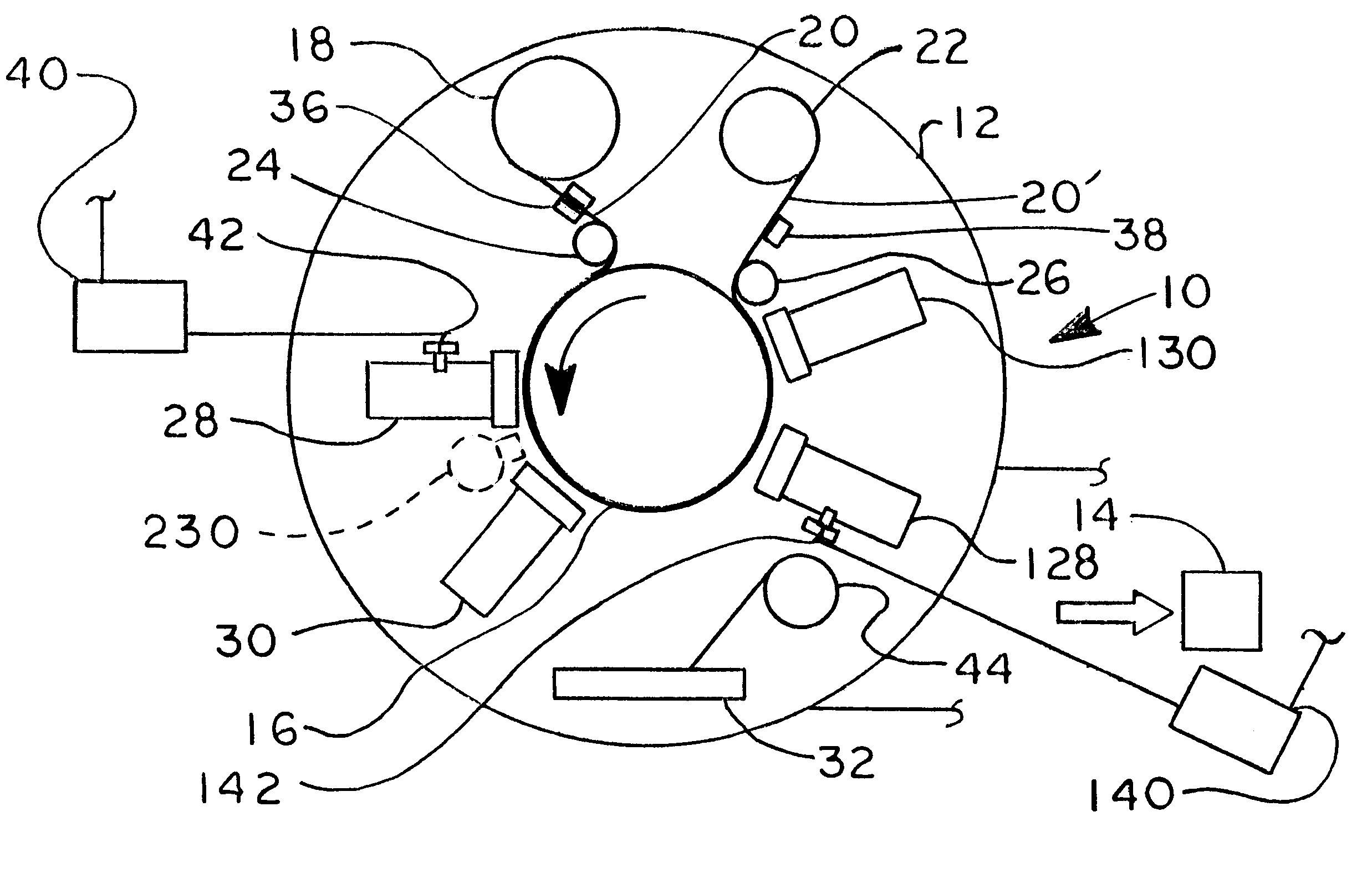

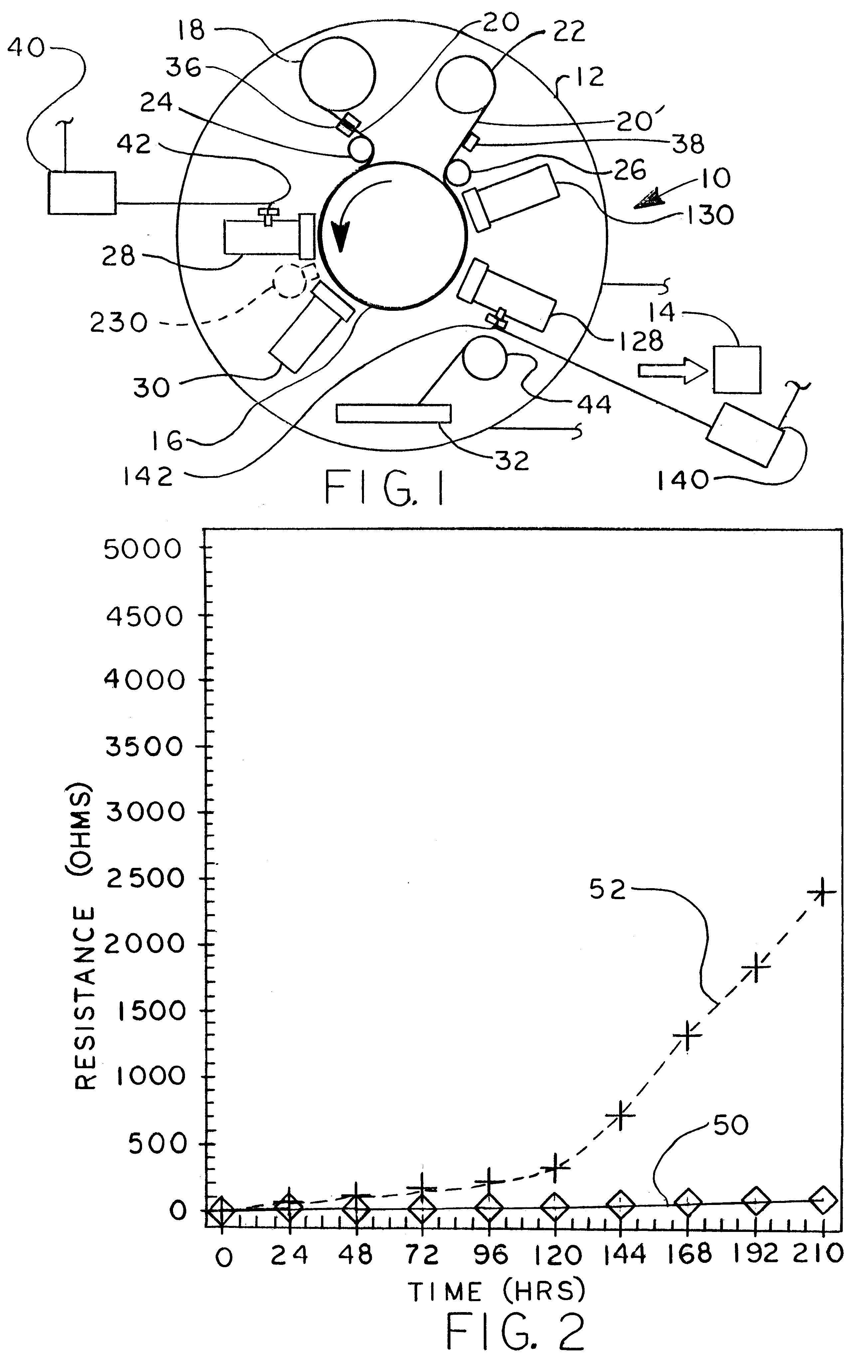

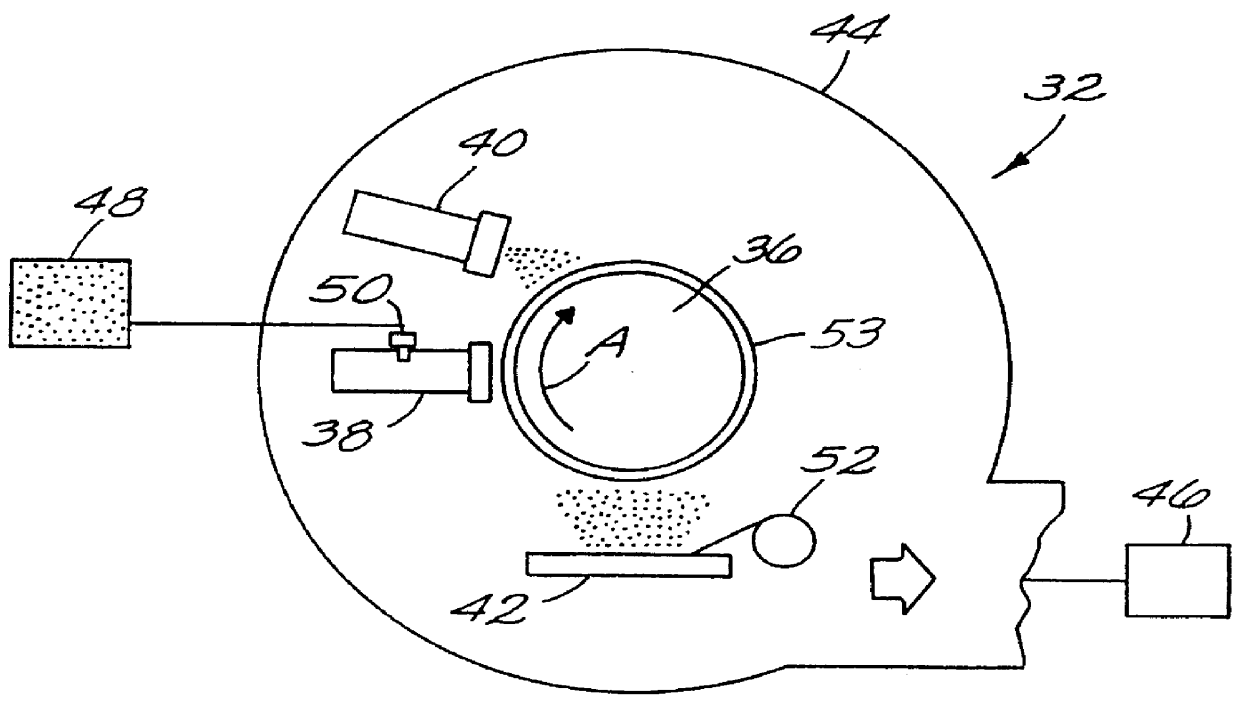

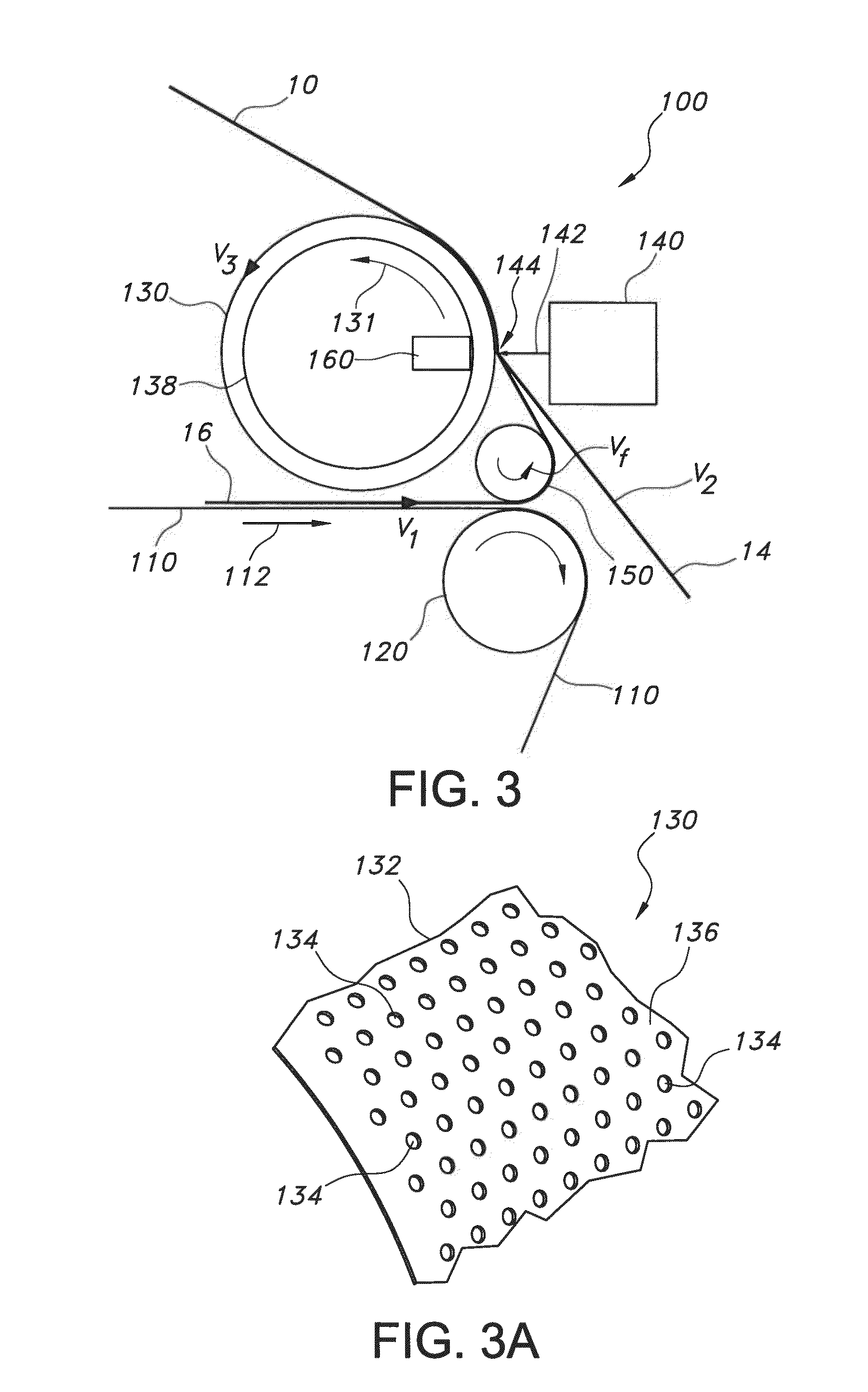

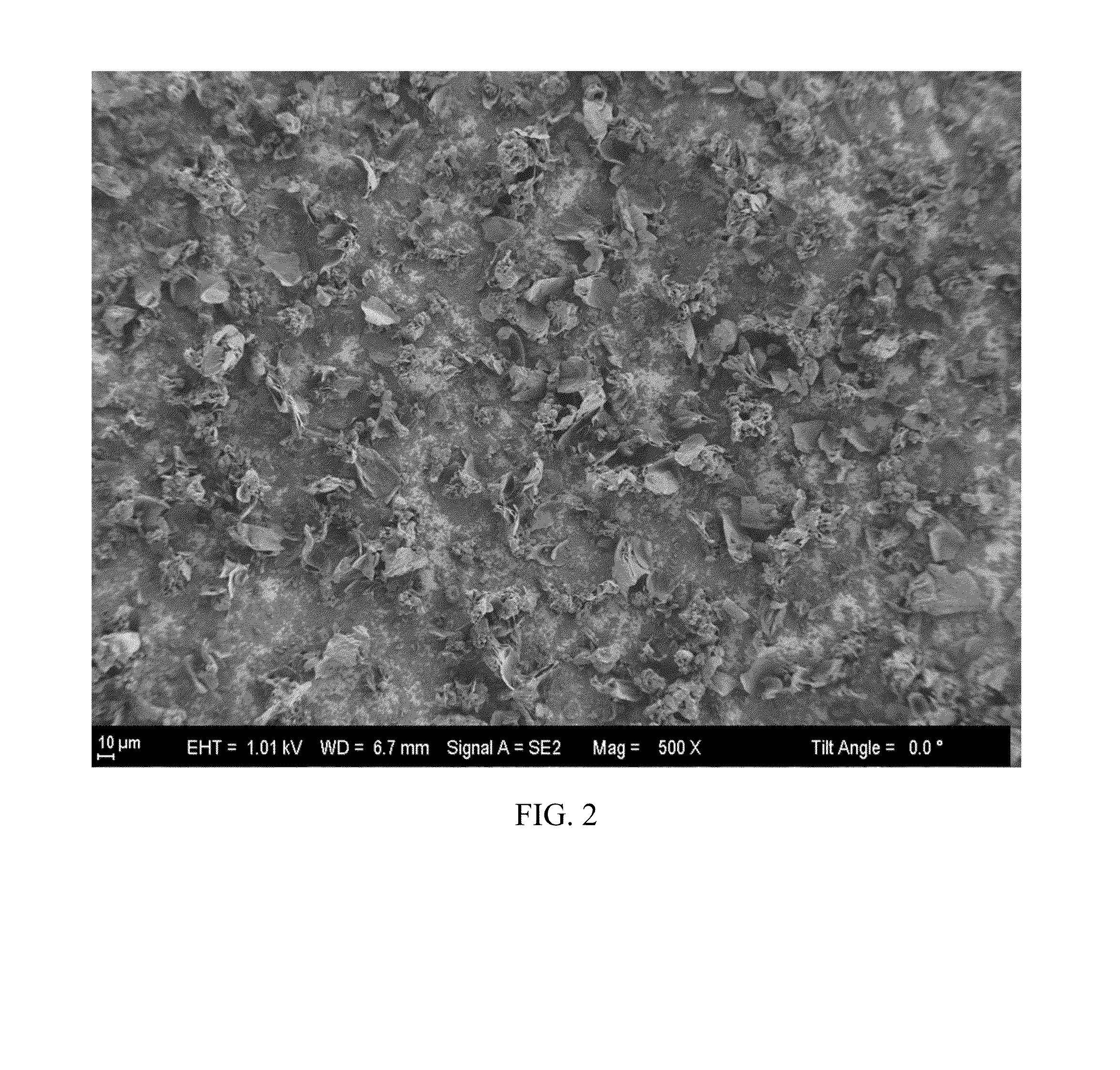

Apparatus for producing metal coated polymers

InactiveUS6106627AHigh breakdown strengthAvoid depositionRadiation applicationsVacuum evaporation coatingCross-linkBreakdown strength

A method of improving the breakdown strength of polymer multi-layer (PML) capacitors is provided and of providing a window in food packaging is provided. The method comprises patterning the aluminum coating, either by selective removal of deposited aluminum or by preventing deposition of the aluminum on selected areas of the underlying polymer film. Apparatus is also provided for patterning metal deposition on polymer films comprising masking for defining regions in which metal is deposited. The apparatus comprises: (a) a rotating drum; (b) a monomer evaporator for depositing a monomer film on the rotating drum; (c) a radiation curing element for curing the monomer film to form a cross-linked polymer film; and (d) a resistive evaporator for depositing a metal film on the cross-linked polymer film. The foregoing elements are enclosed in a vacuum chamber. The masking comprising one of the following: (e1) a web mask provided with openings for depositing the metal film therethrough, the web mask including a portion adapted for positioning between the resistive evaporator for depositing the metal film on the cross-linked polymer film and the rotating drum; or (e2) a rotating element for transferring liquid from a source to the rotating drum, the rotating element adapted to transfer the liquid to the rotating drum after the monomer evaporator for depositing the polymer film and before the resistive evaporator for depositing the metal film.

Owner:SIGMA LAB OF ARIZONE

Sulfonated aliphatic-aromatic copolyesters and shaped articles produced therefrom

ActiveUS20050027098A1High crystallinityHigh heat distortion temperatureLayered productsCeramic shaping apparatusPolymer scienceCopolyester

Sulfonated aliphatic-aromatic copolyesters and articles made therefrom, and processes for producing the sulfonated aliphatic-aromatic copolyesters and articles are provided. Articles that can be made from the sulfonated aliphatic-aromatic copolyesters include films, coatings and laminates. Some of the compositions and articles are biocompostable. The films can further be used to form shaped articles such as sheets, food packaging such as sandwich wraps, thermoformed containers, and coatings for, for example, films and other substrates. The sulfonated aliphatic-aromatic copolyesters are derived from copolyesters produced from aliphatic-aromatic copolyesters formed from an aromatic dicarboxylic acid component, an aliphatic dicarboxylic acid component, a first glycol component consisting of 1,4-butanediol, a second glycol component, and optionally, a polyfunctional branching agent.

Owner:DUPONT POLYMERS INC

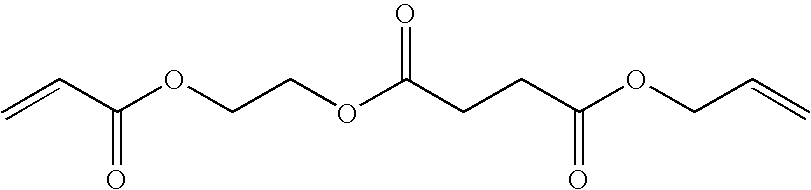

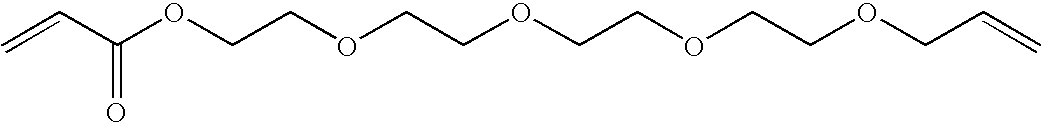

Curable liquids and inks for toys and food packaging applications

A free radical curable liquid for inkjet printing of food packaging materials includes no initiator or otherwise one or more initiators selected from the group consisting of non-polymeric di- or multifunctional initiators, oligomeric initiators, polymeric initiators, and polymerizable initiators; and a polymerizable composition of the liquid consists essentially of: a) 25-100 wt % of one or more polymerizable compounds A having at least one acrylate group G1 and at least one second ethylenically unsaturated polymerizable functional group G2 selected from the group consisting of a vinlyether group, an allylether group, and a allylester group; b) 0-55 wt % of one or more polymerizable compounds B selected from the group consisting of monofunctional acrylates and difunctional acrylates; and c) 0-55 wt % of one or more polymerizable compounds C selected from the group consisting of trifunctional acrylates, tetrafunctional acrylates, pentafunctional acrylates and hexafunctional acrylates. If the weight percentage of compounds B>24 wt %, then the weight percentage of compounds C>1 wt %, and all weight percentages of A, B, and C are based upon the total weight of the polymerizable composition. At least one polymerizable compound B or C is present in the polymerizable composition if the free radical curable liquid contains no initiator.

Owner:AGFA NV

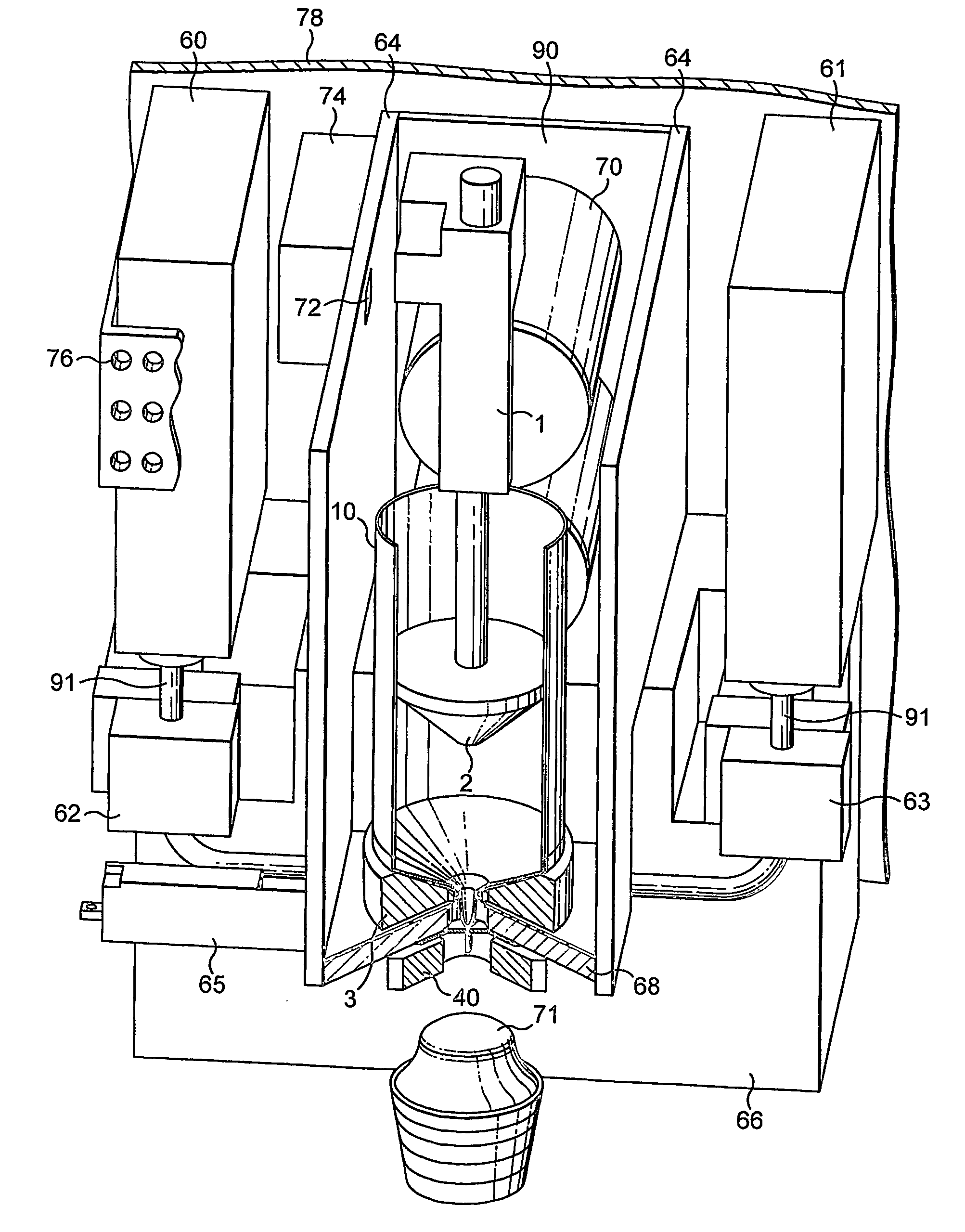

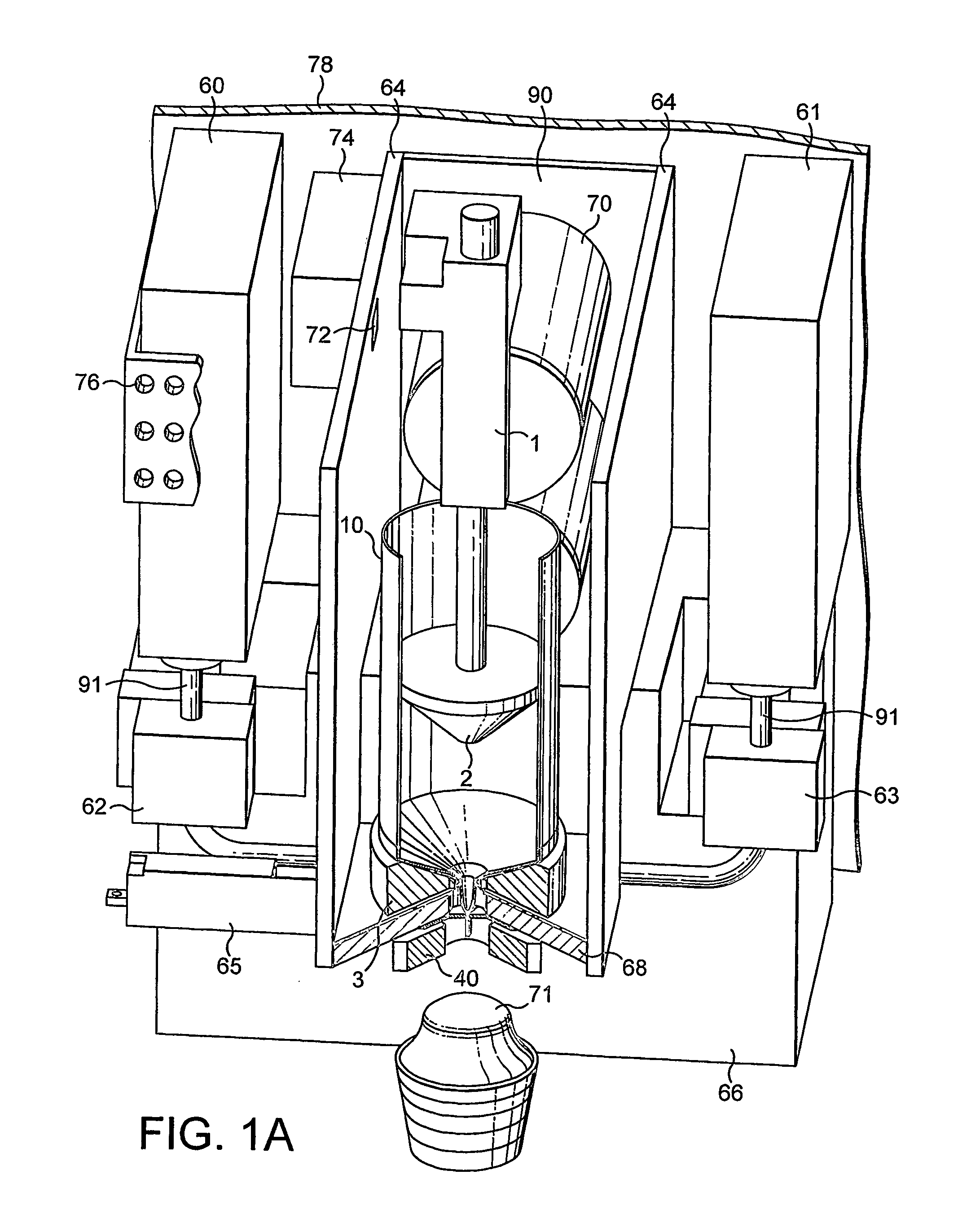

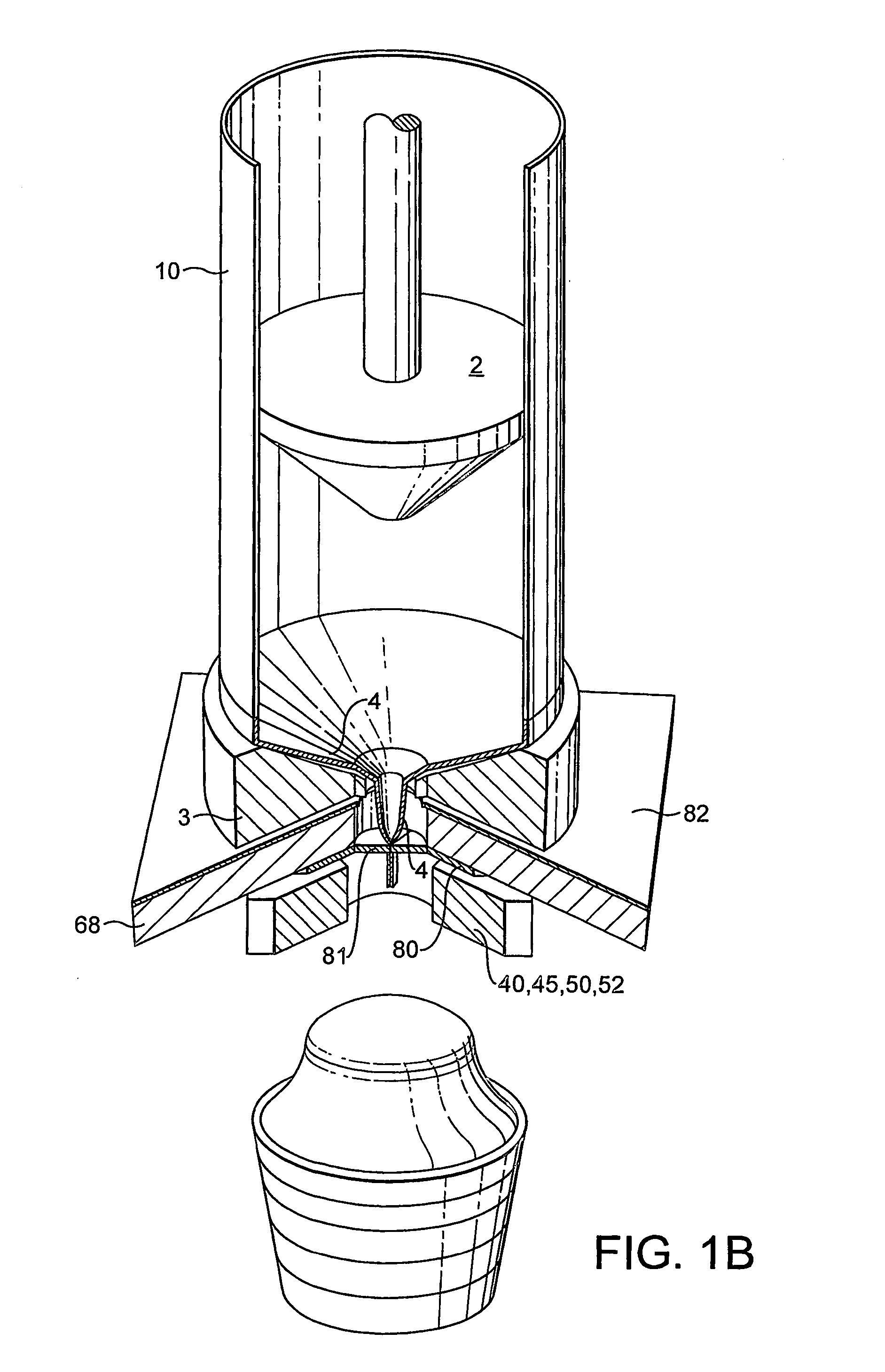

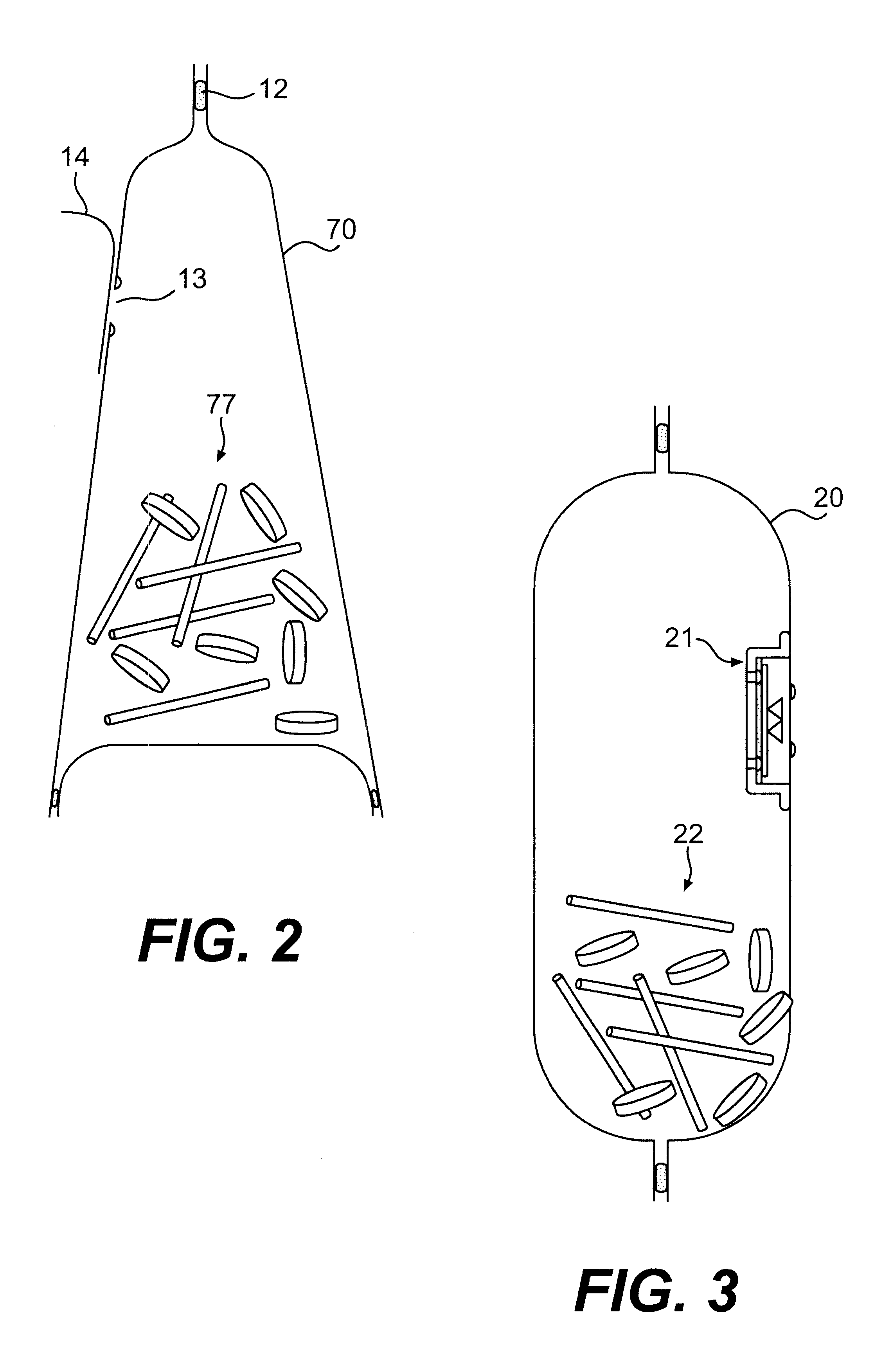

Food beverage dispensing system

InactiveUS20060255066A1More hygienic and more controlled mannerSimple and economical wayClosuresFrozen sweetsFood contactEngineering

A food or beverage delivery system comprising at least one disposable or recyclable package containing viscous food therein; a dispensing apparatus having a holder for holding the food package and a pressure-displacement device that forces the food out of the package; and a valve; wherein the food package comprises an outlet portion which is part of the package, and wherein the valve is adapted to act in closure on the outlet portion to cut off portions of food coming out of the package without the food contacting the apparatus. The system may deliver frozen confection more hygienically with or without flavourings. The frozen confection may be a layered product with flavouring forming separations, bottoms or toppings. It may also be used to more accurately dose viscous beverage concentrates in a beverage dispenser.

Owner:NESTEC SA

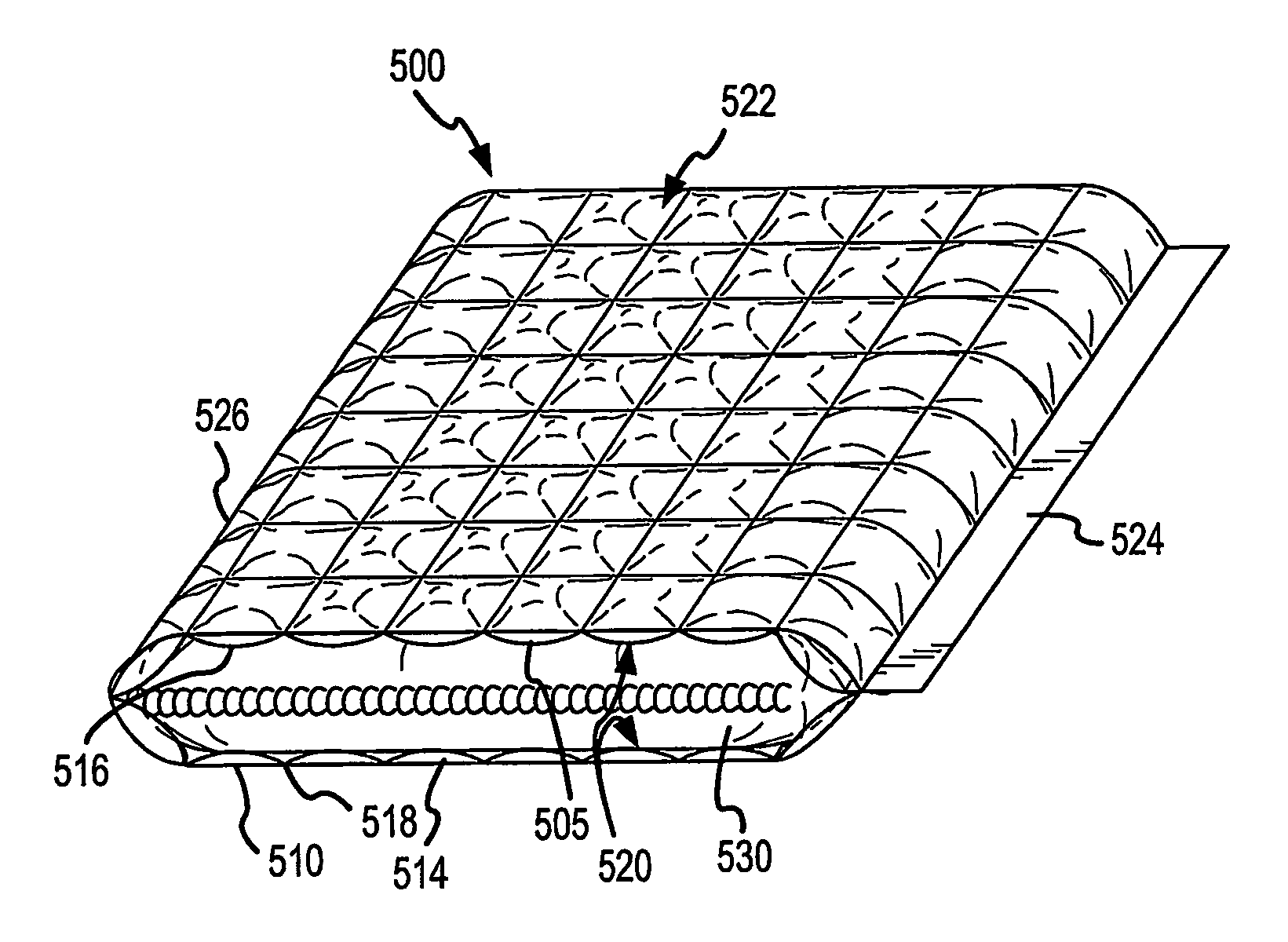

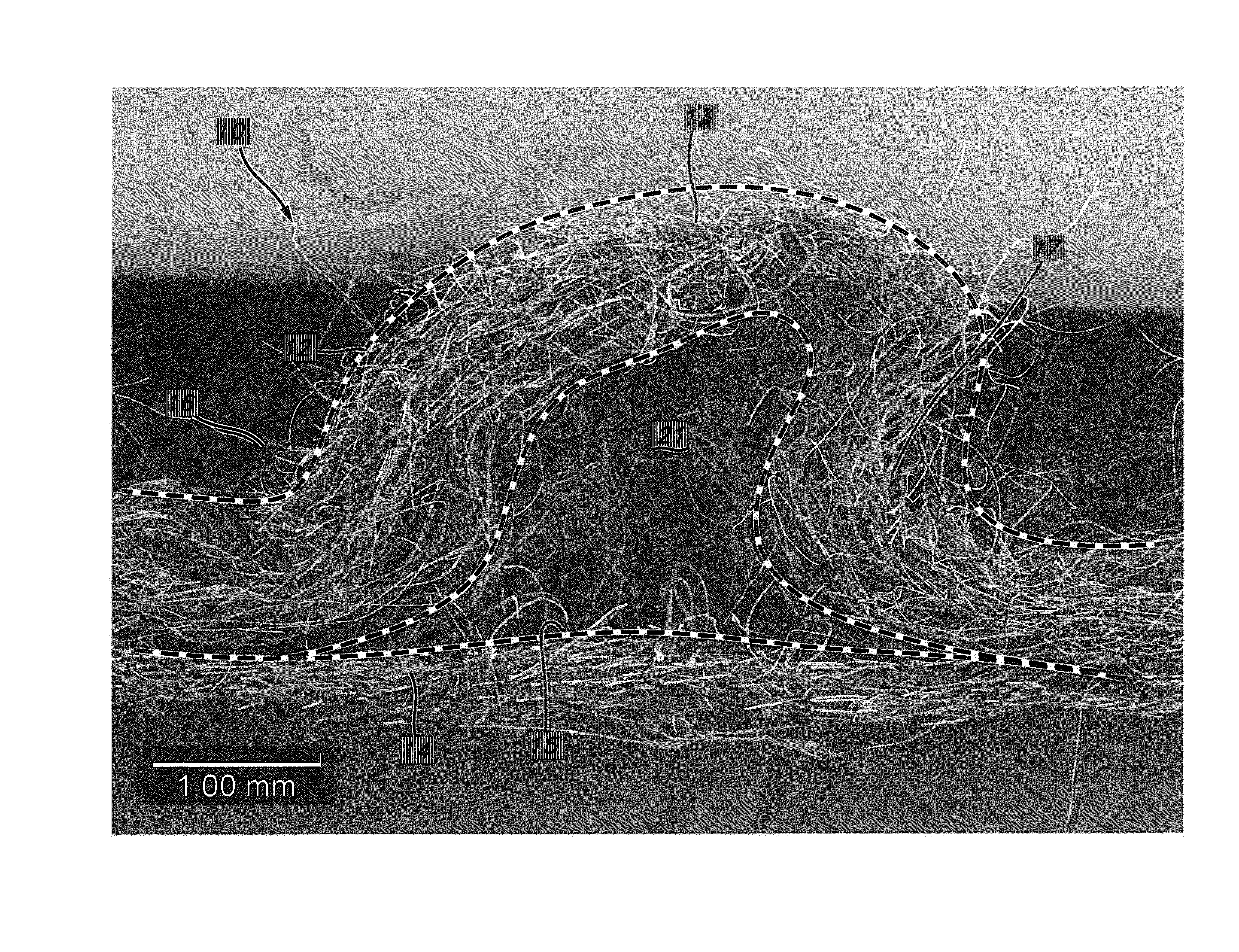

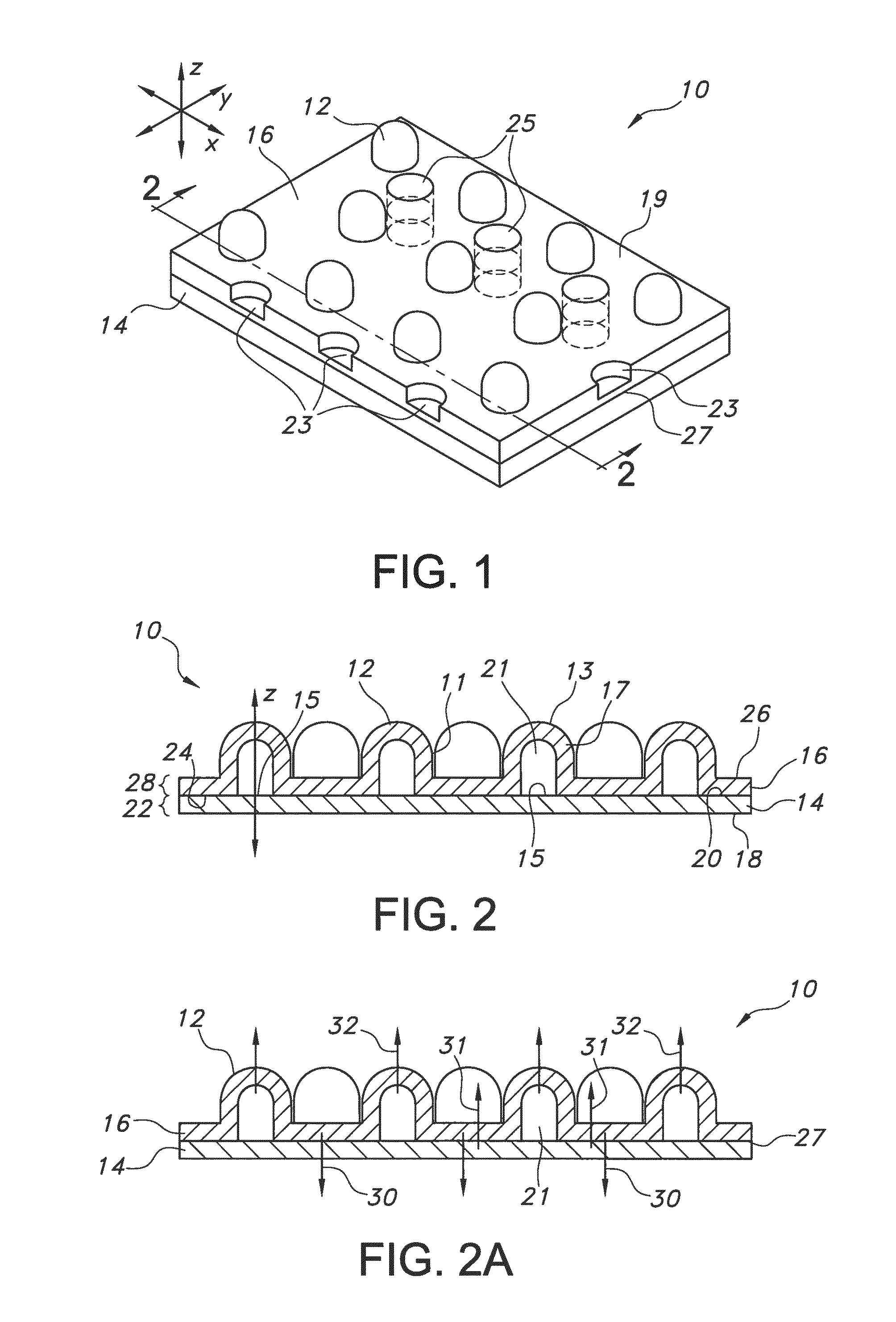

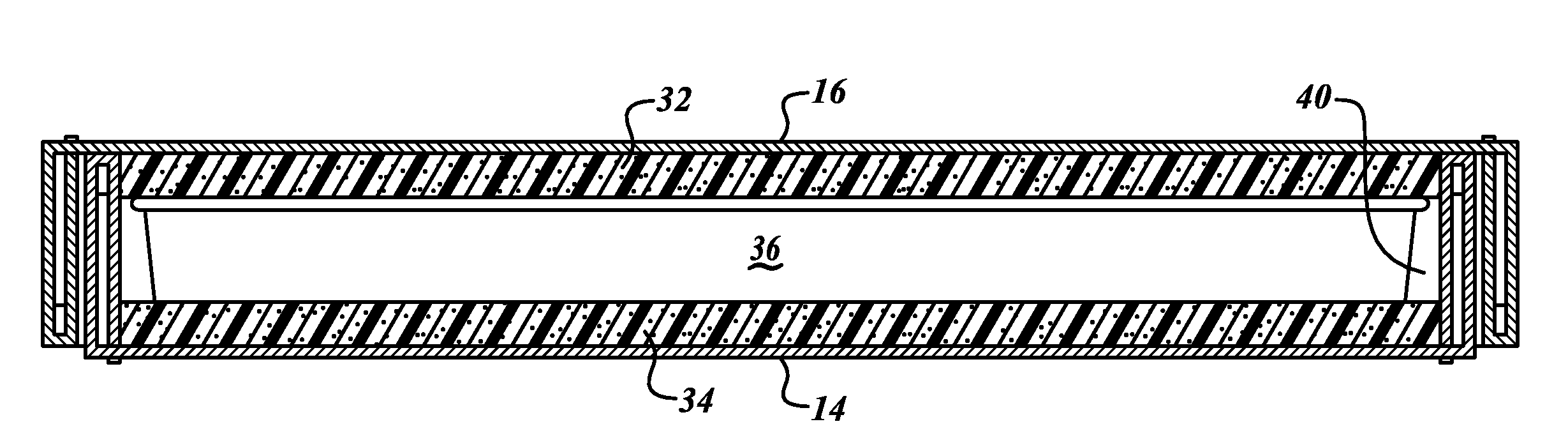

Fluid-Entangled Laminate Webs having Hollow Projections and a Process and Apparatus for Making the Same

ActiveUS20140121626A1Increase resistanceImprove rigidityLamination ancillary operationsPersonal carePersonal careFiber

The present invention is directed to a fluid-entangled laminate web and the process and apparatus for its formation as well as end uses for the fluid-entangled laminate web. The laminate web includes a support layer and a nonwoven projection web having a plurality of projections which are preferably hollow. As a result of the fluid-entangling process, entangling fluid is directed through the support layer and into the projection web which is situated on a forming surface. The force of the entangling fluid causes the two layers to be joined to one another and the fluid causes a portion of the fibers in the projection web to be forced into openings present in the forming surface thereby forming the hollow projections. The resultant laminate has a number of uses including, but not limited to, both wet and dry wiping materials, as well as incorporation into various portions of personal care absorbent articles and use in packaging especially food packaging where fluid control is an issue.

Owner:COMMONWEALTH SCI & IND RES ORG +3

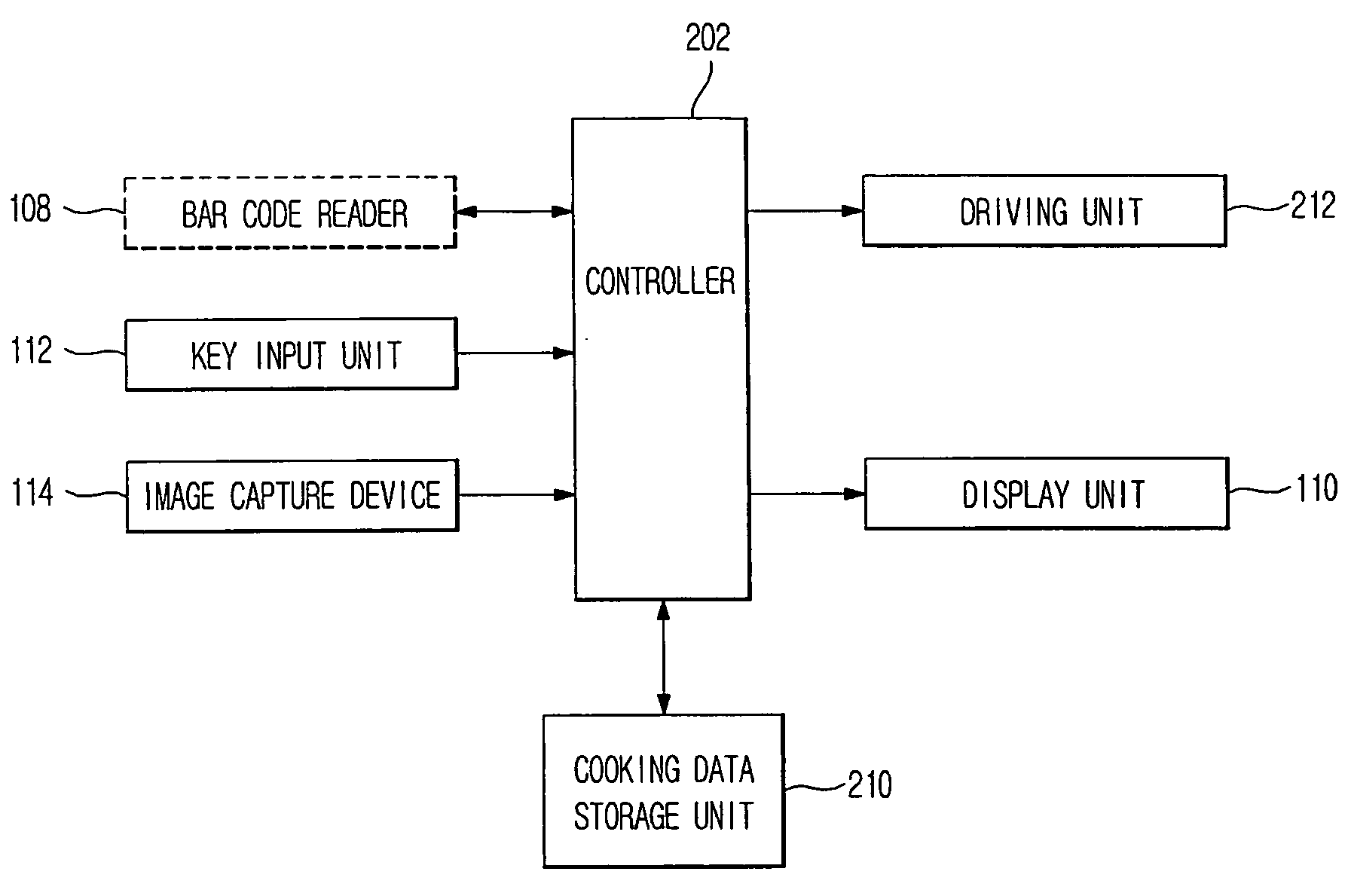

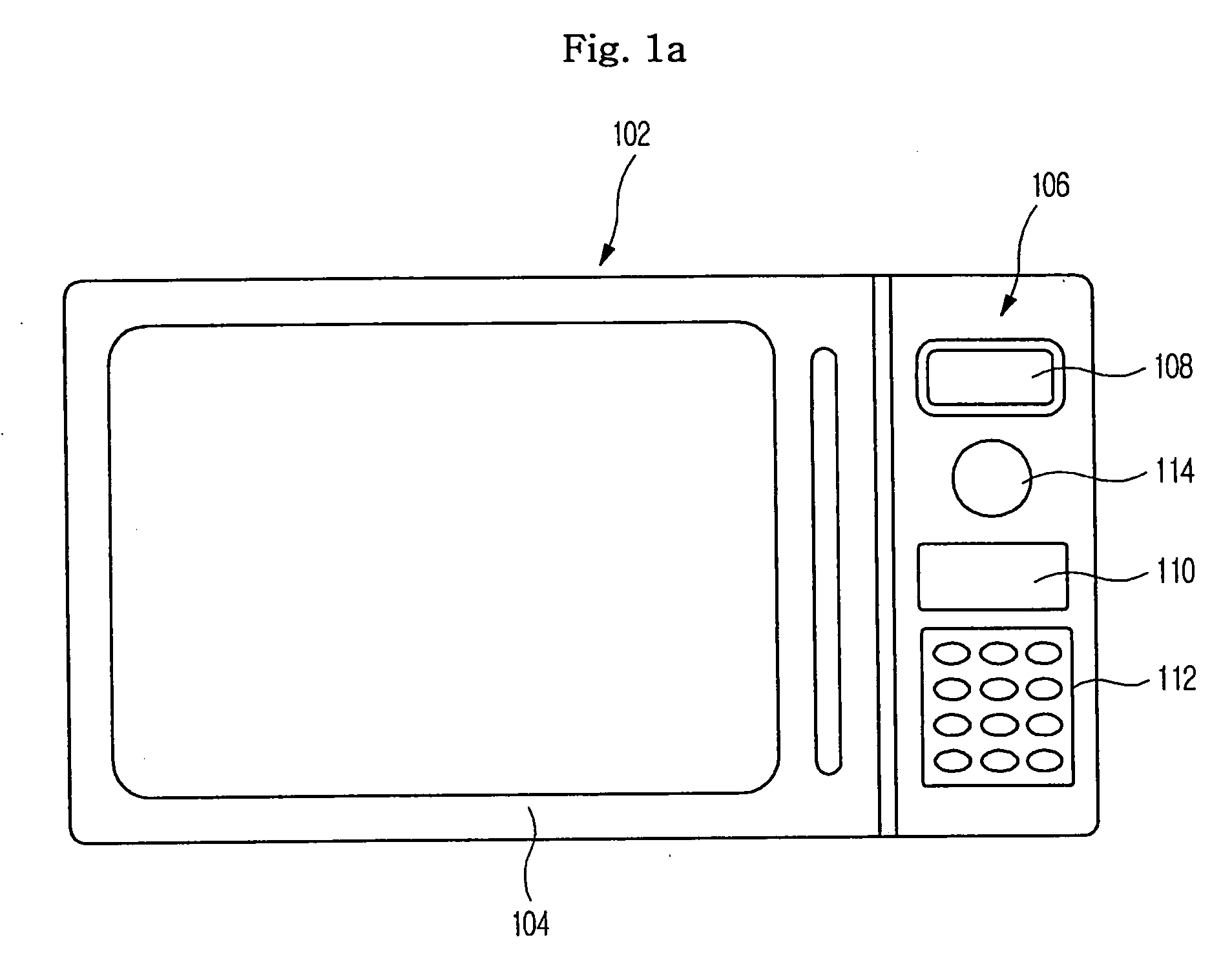

Cooking apparatus, cooking system, and cooking control method utilizing bar code

InactiveUS20070007279A1Domestic stoves or rangesLighting and heating apparatusEngineeringFood packaging

A cooking apparatus, cooking system, and cooking control method using a bar code, in which automatic cooking of food is performed when the bar code attached to a package of the food is lost or damaged. The cooking apparatus for cooking food using cooking data includes a memory for storing identification data and cooking data of the food; an image capture device for obtaining an image of the food; and a controller for identifying the food by comparing the image of the food to the identification data of the food, stored in the memory, obtaining the cooking data of the identified food, and controlling the cooking apparatus so that the cooking of the food is performed based on the cooking data.

Owner:SAMSUNG ELECTRONICS CO LTD

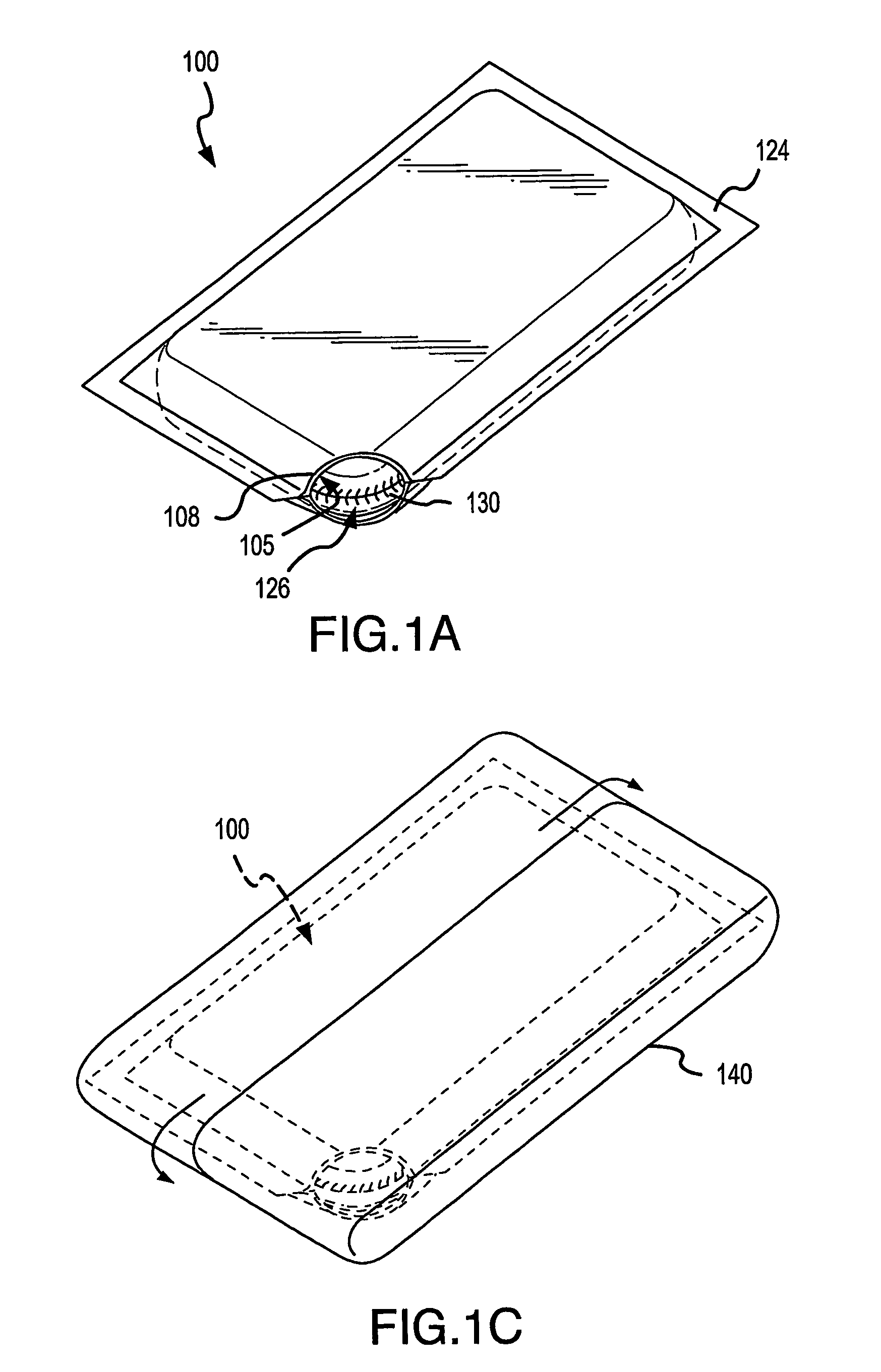

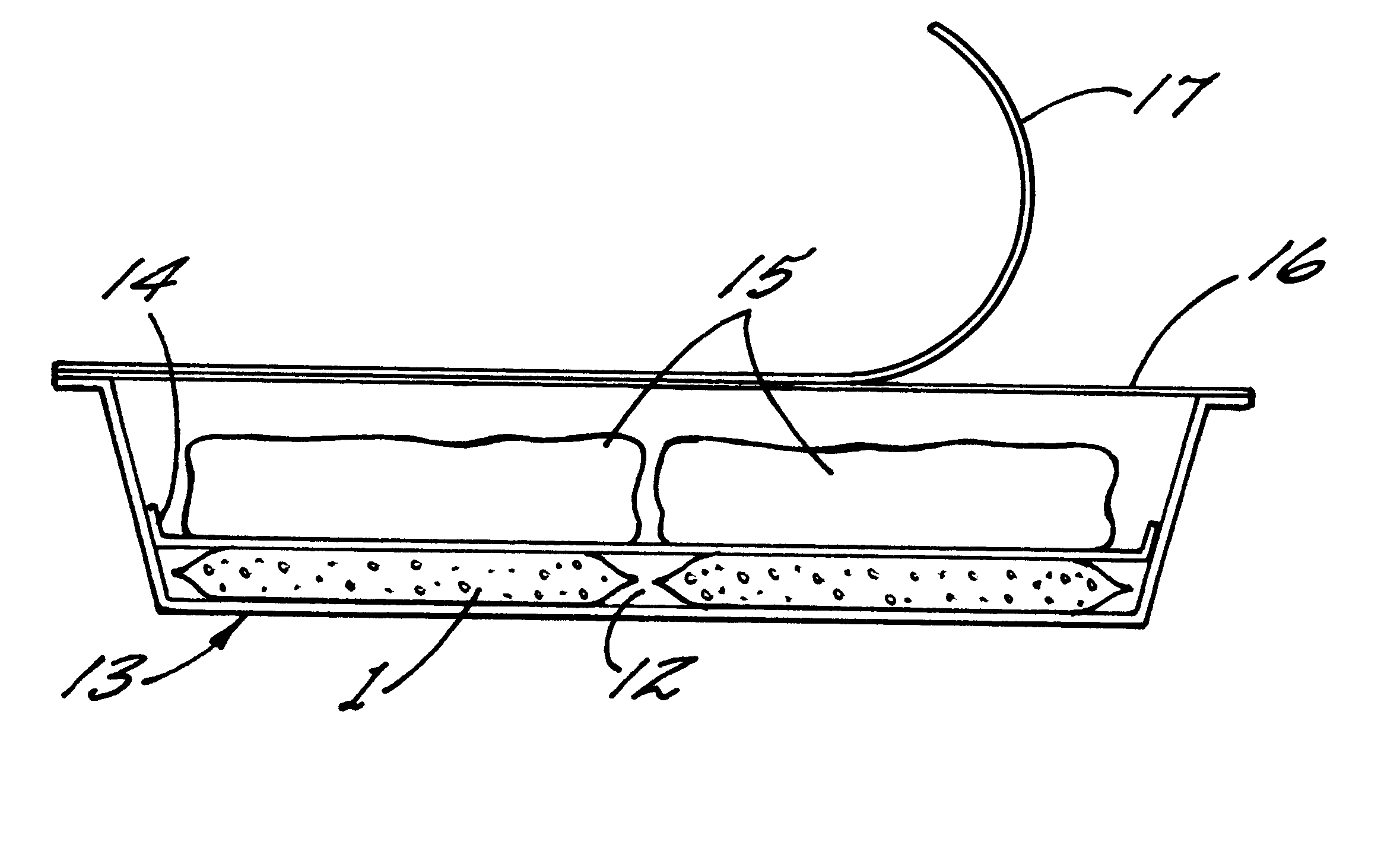

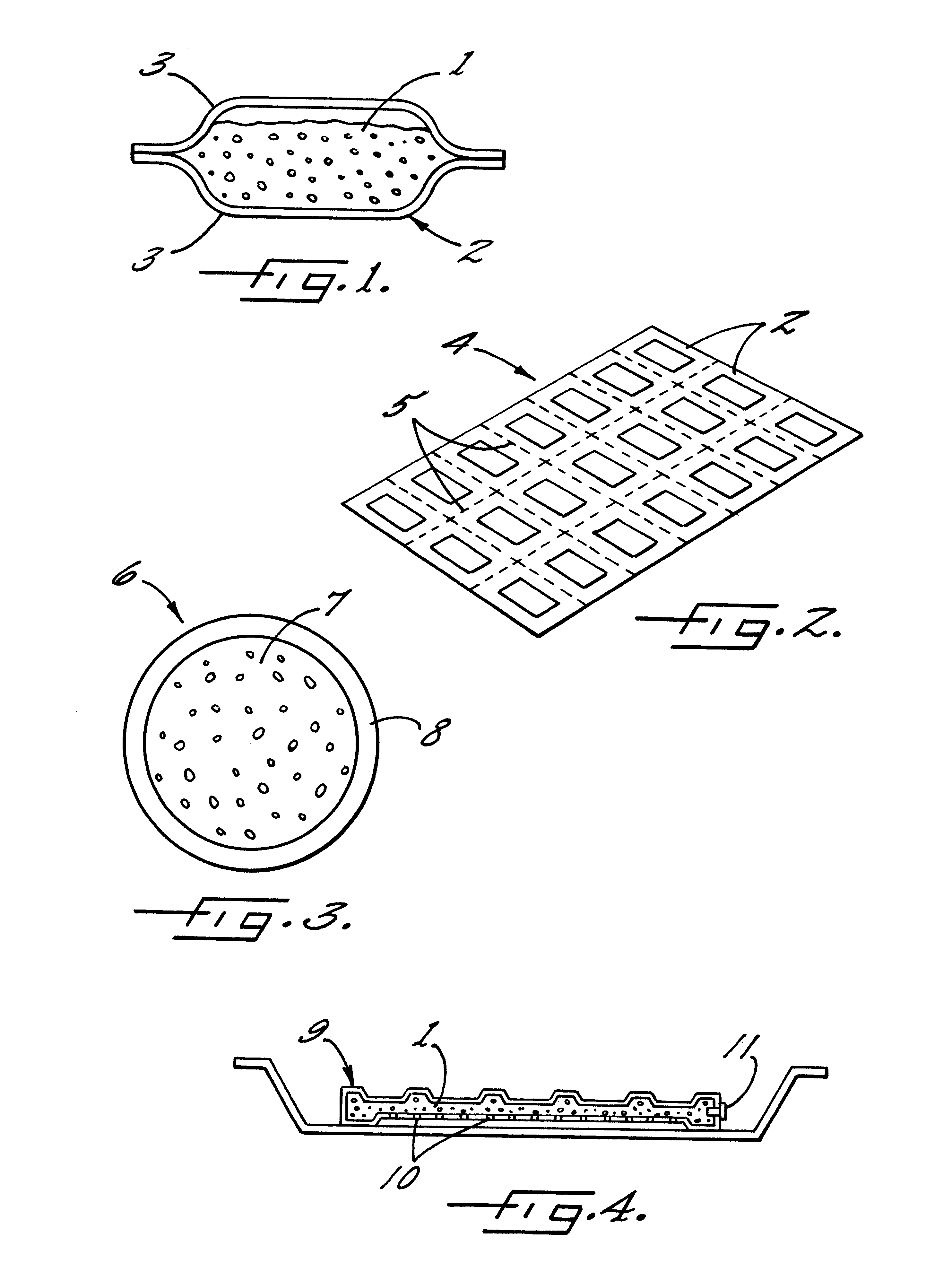

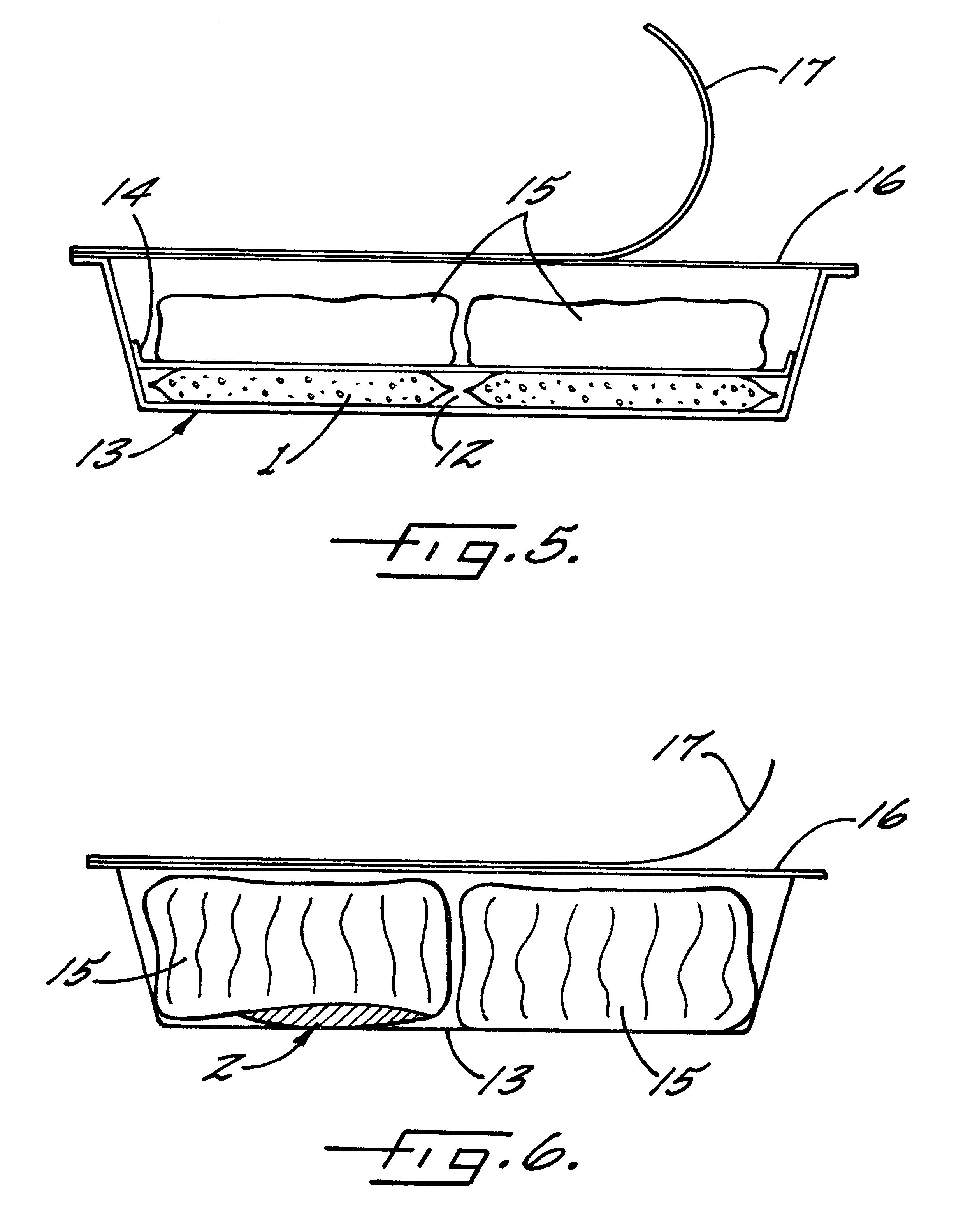

Packaging for meat and foodstuff

InactiveUS6447826B1Preventing inflationMaintain internal pressureReady-for-oven doughsFlexible coversFood packagingLow oxygen

Methodology for packaging and packages for meat or other foodstuffs in a carbon dioxide rich low oxygen environment by including without the packages carbon dioxide generating material and oxygen removing material where the production of carbon dioxide is not dependent upon removal of oxygen.

Owner:SEALED AIR NZ +1

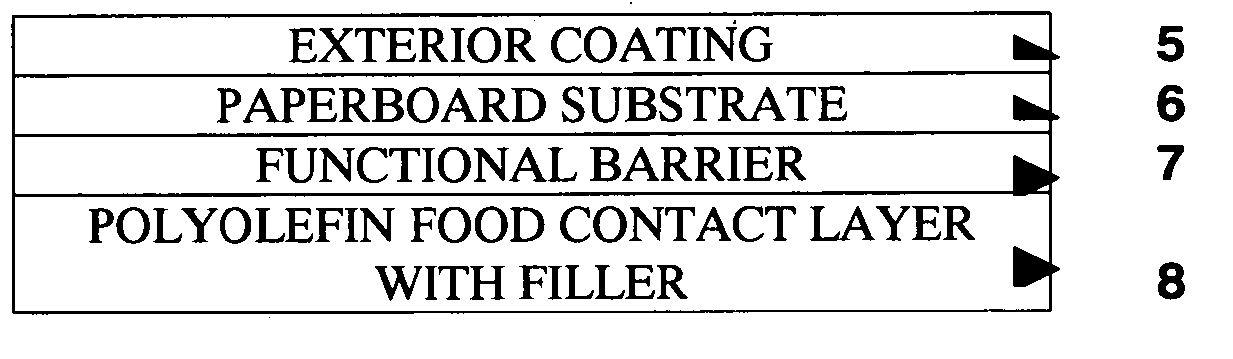

Oxygen-scavenging filled polymer blend for food packaging applications

InactiveUS6037022AOxygen transmission propertyLow oxygenDomestic containersThin material handlingPaperboardFood packaging

The specification discloses a polymer blend especially well-suited for coating paperboard substrates used in food packaging, particularly acidic or acid-generating foods such as fruit and vegetable juices. The blend contains an acid-activatable oxygen scavenger dispersed in a film-forming synthetic polymer such as an EVOH copolymer. When placed as a film or layer on the side of the substrate inside the container in contact with the food the blend is effective to reduce the oxygen in the container over time to a very low concentration, replacing the same with carbon dioxide, for an excellent preservative effect.

Owner:INT PAPER CO

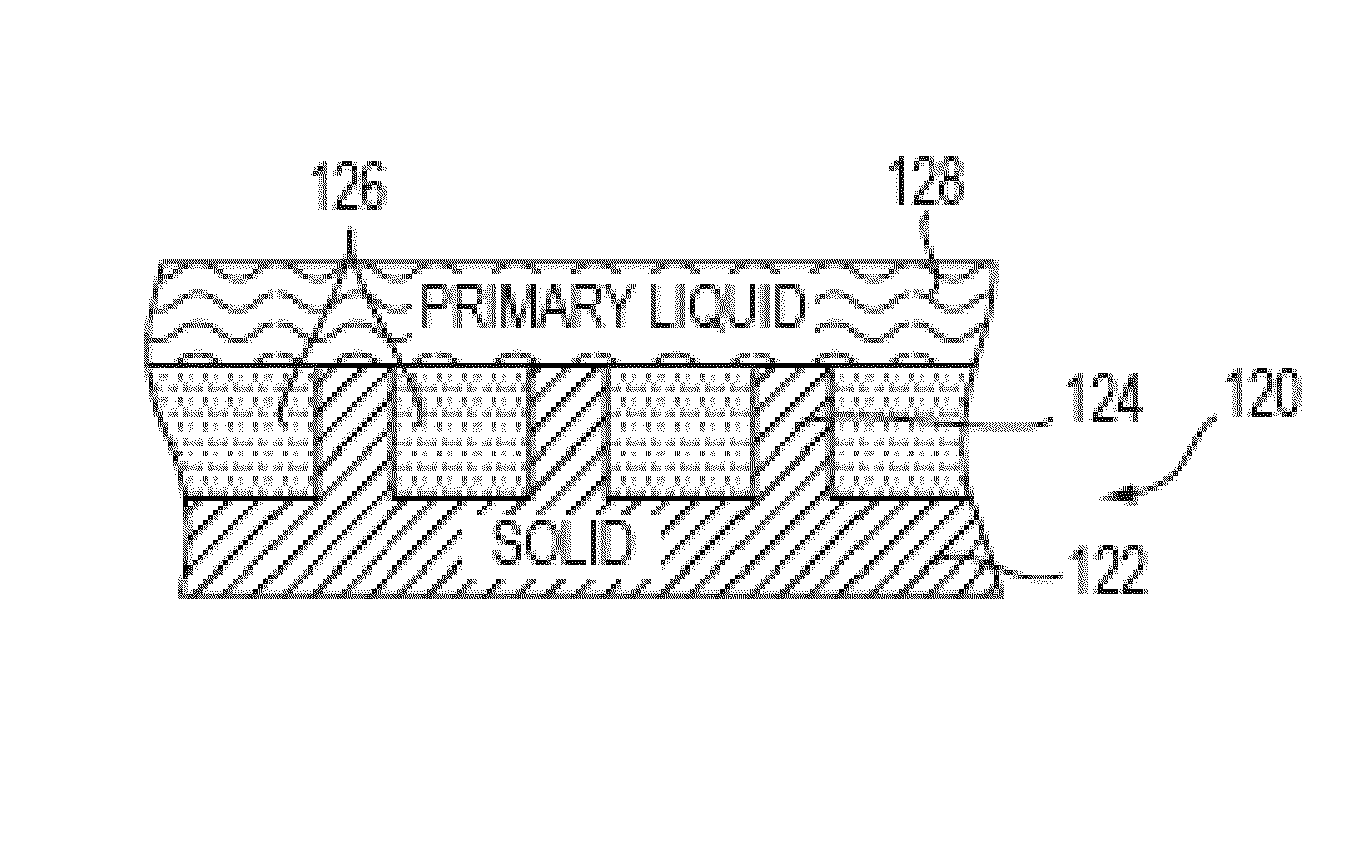

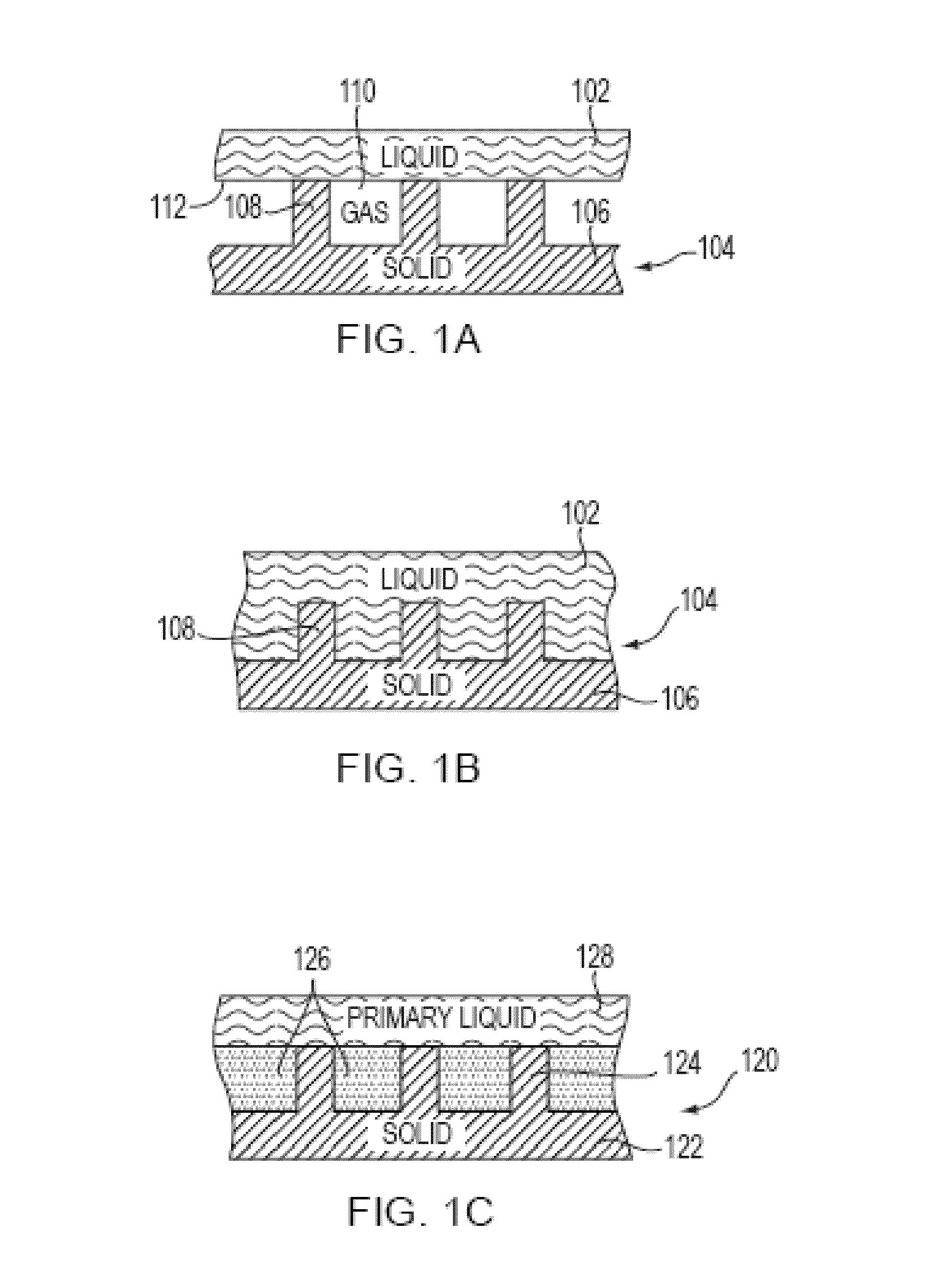

Self-lubricating surfaces for food packaging and food processing equipment

ActiveUS8535779B1Improve health and safetyAvoid leachingRecord information storageMagnetic recordingFood packagingTomato ketchup

In certain embodiments, the invention relates to an article having a liquid-impregnated surface. The surface includes a matrix of solid features (e.g., non-toxic and / or edible features) spaced sufficiently close to stably contain a liquid therebetween or therewithin, wherein the liquid is non-toxic and / or edible. The article may contain, for example, a food or other consumer product, such as ketchup, mustard, or mayonnaise.

Owner:MASSACHUSETTS INST OF TECH

Insulated food crate

InactiveUS20080296356A1Easy to cleanThe process is simple and effectivePackage recyclingBoxes/cartons making machineryDouble wallEngineering

An insulated food crate comprises a generally rectangular, typically cardboard box having separable top and bottom portions with double walls providing insulative properties and also insulating inserts fitted into the top and bottom portions. The box may also have ventilation holes or slots and / or compartments for serving utensils and may be disposable. In alternate embodiments, the insulated food crate may be made from a heat-resistant composite material, such as a reinforced plastic or stainless steel, as a more permanent, durable, and reusable solution. This inexpensive, accessible catering box keeps hot foods hot and cold foods cold while allowing quick and easy access to the foods inside.

Owner:HATCHER JOHN AUGUST +1

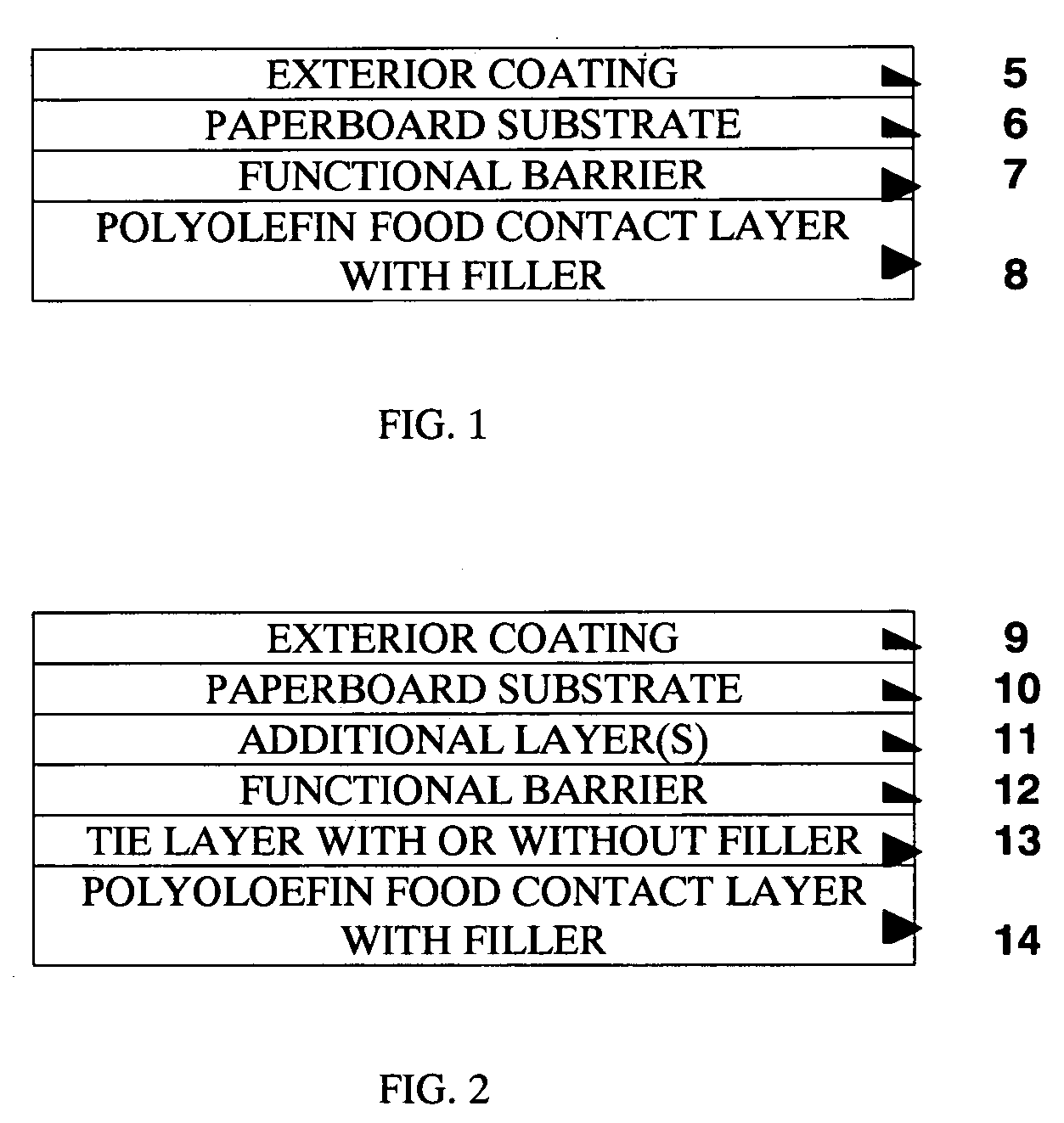

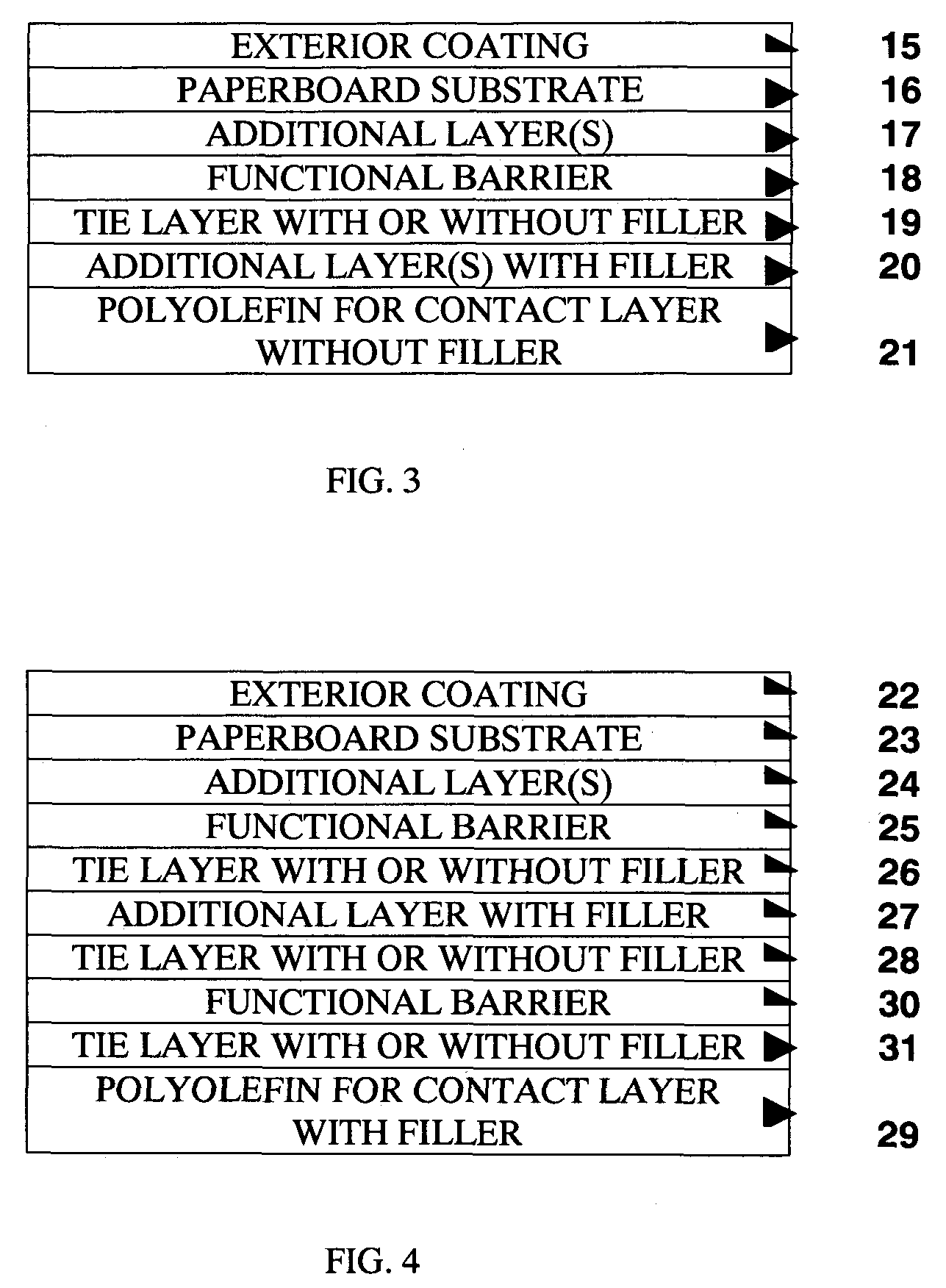

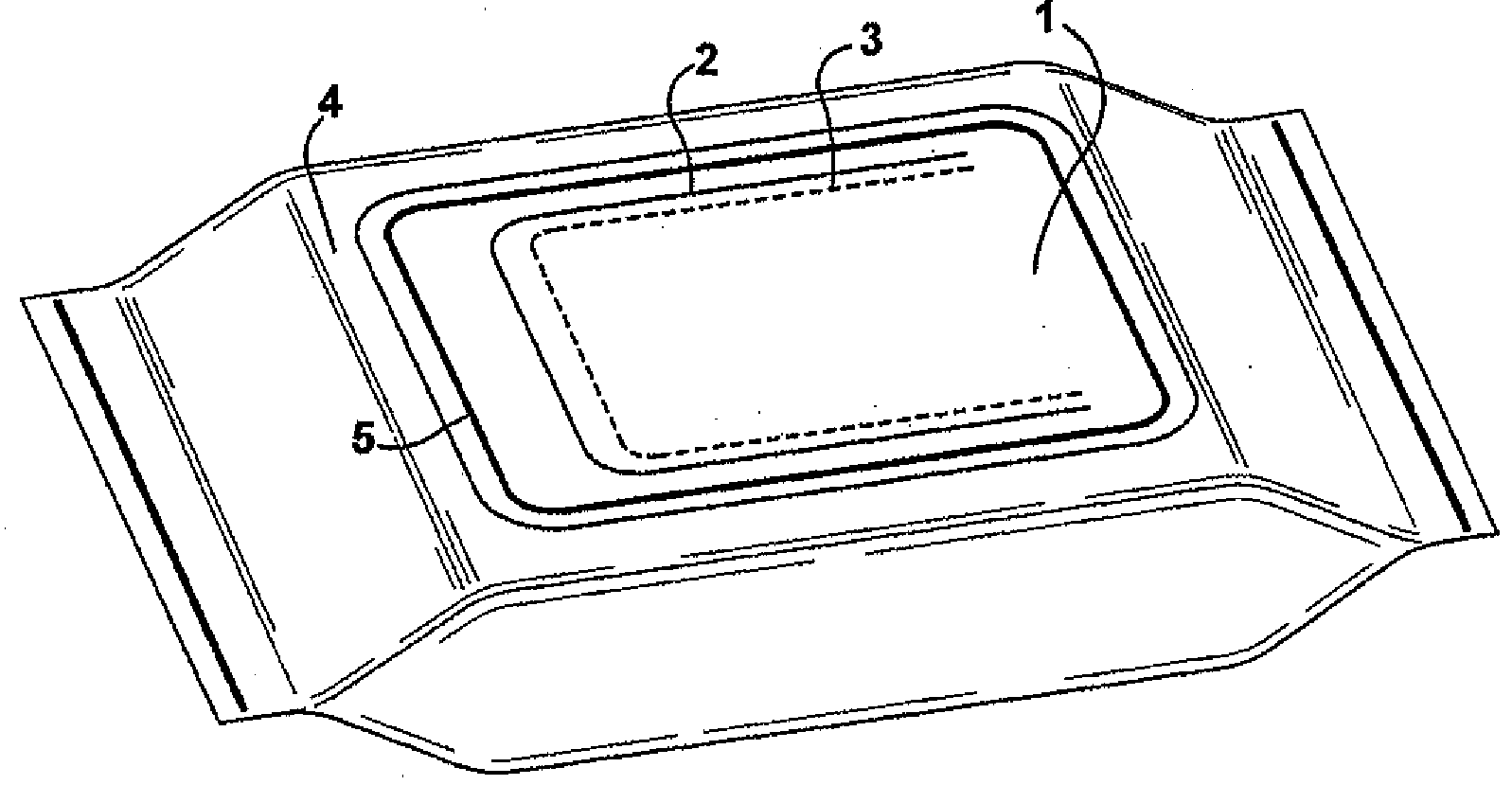

Paperboard laminate for food packaging applications

A laminate structure having improved resistance to the migration of essential oils, aromas and flavors and improved oxygen barrier characteristics for beverage packaging comprising an exterior coating of polyethylene applied onto the outer surface of paperboard substrate, a barrier layer of aluminum foil, EVOH, polyamide or PET applied directly or indirectly onto the paperboard and tie and other sublayers which may or may not contain inorganic filler applied intermediate the barrier layer and the innermost food contact layer which may or may not contain filler. The containers or cartons prepared from the laminate structures are characterized by minimized scalping and preserved product quality.

Owner:INT PAPER CO

Probiotic food, process for its preparation and dietary regimen

InactiveUS20070160589A1Easy maintenanceStrong feelingBiocideMetabolism disorderWater activityDietary regimen

A probiotic food item containing a beneficial amount of dry active probiotic cultures is provided. The food item also contains a substantial continuous fat-based coating with an effectively low water activity level. The food item is packaged in a substantially moisture impermeable package marked with a use by or sell by date, so as to ensure a desired minimal amount of probiotic colony forming units (CFUs) on the use by or sell by date. Methods for manufacturing the probiotic food product are also provided.

Owner:ATTUNE FOODS

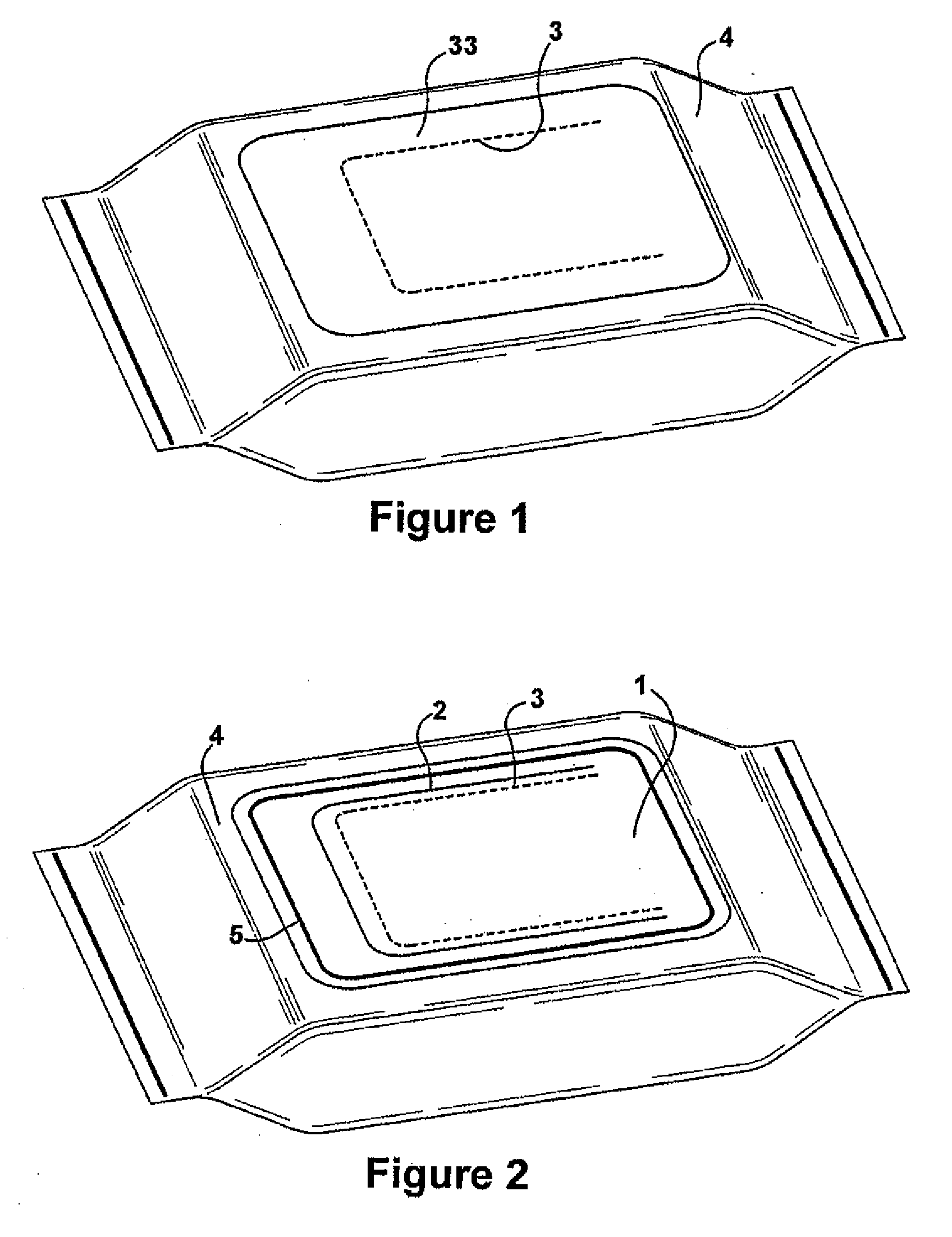

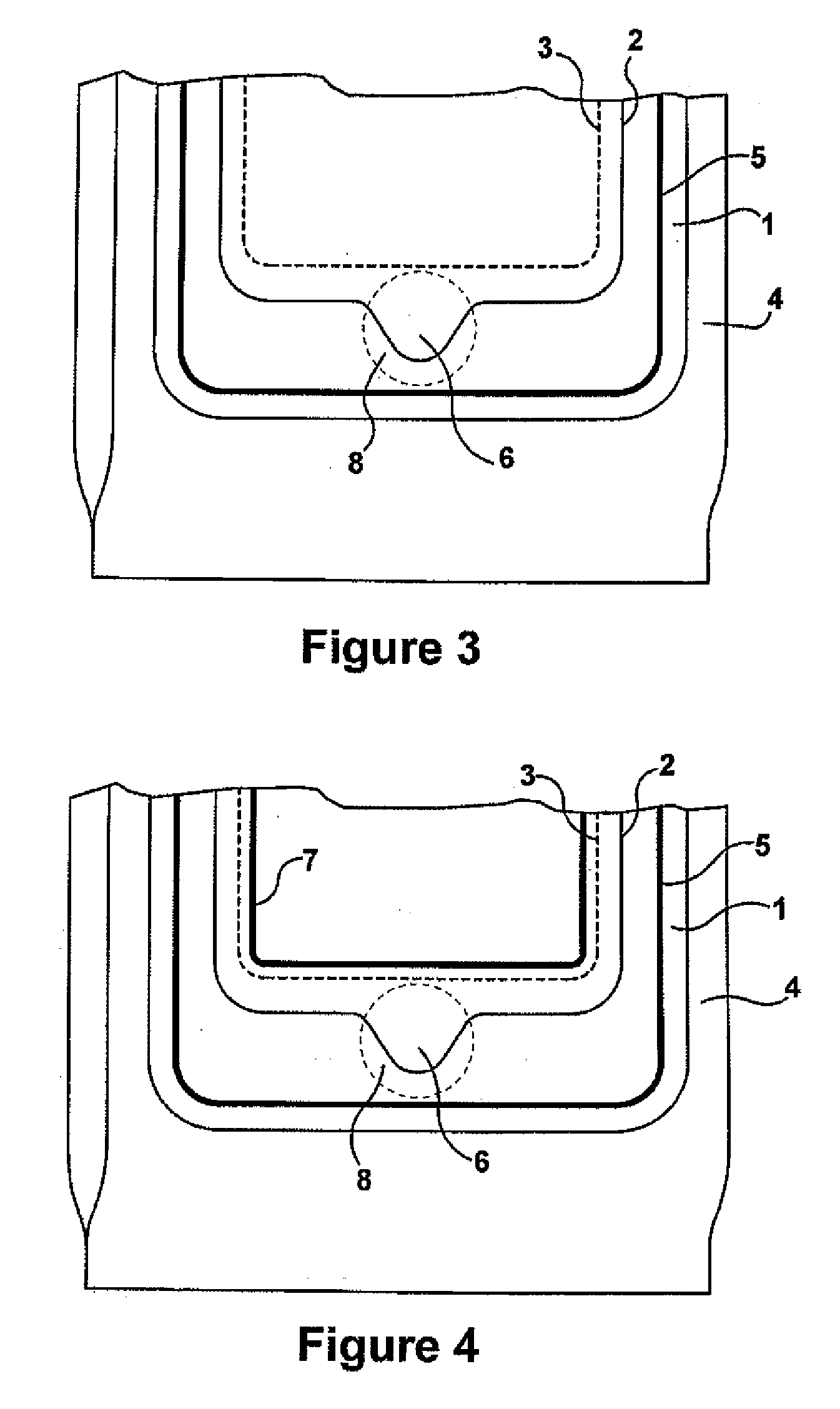

Reclosable food package with improved shelf life

InactiveUS20100002963A1Extended shelf lifeSufficient protectionEnvelopes/bags making machineryFlexible coversEngineeringFood packaging

A resealable container having an easily accessed yet airtight seal via the use of a tamper evident rupture strip which provides the container or package with improved shelf life for the product contained therein.

Owner:AVERY DENNISON CORP

Composition comprising ionomer and polyamide

A composition and an article made from the composition are disclosed. The composition comprises, or is produced from, an ionomer, a polyamide, and one or more esters of montanic acid. The article includes film, sheet, filament, tape, molded part, thermoformed product, and container for food or non-food packaging, or combinations of two or more thereof.

Owner:DOW GLOBAL TECH LLC

Aromatic sulfonium salt compound, photo-acid generator comprising the same and photopolymerizable composition containing the same, resin composition for optical three-dimensional shaping, and method of optically forming three-dimensional shape

ActiveUS7611817B2Not to amplify distortionAdditive manufacturing apparatusOrganic compound preparationBenzenePolymer science

Novel aromatic sulfonium salt compounds of general formula (I), photo-acid generators comprising the same, and photo-polymerizable compositions containing the same, capable of providing stereolithographic resin compositions which do not suffer from the hindrance to curing by oxygen, can easily give shaped articles having desired sizes by virtue of the high accuracy thereof in curing, can attain a satisfactory curing depth owing to the high sensitivity thereof for radiant energy and can be employed for wide usage, such as photoresist and ink for foods-packing medium, since the release of benzene is suppressed; and a stereolithographic process, using said stereolithographic resin composition.

Owner:ADEKA CORP

Water-based intaglio ink equal to plate engraving ink and uses thereof

ActiveCN101284965AOptimizing physical fastnessNo pollutionInksOther printing apparatusScreen printingSolubility

The invention is equivalent to water soluble intaglio ink of plate engraving ink and / or equivalent to water-soluble screen printing ink of the ink, suitable for a gravure printing machine. The ink has the advantages of nontoxicity, tastelessness, nonflammable property, water solubility, non-environmental pollution and rapid drying; the printing effect of the obtained presswork is the same as or equivalent to the printing effect of the plate engraving presswork; the materialized firmness of the presswork is superior to the materialized firmness of the plate engraving presswork; the ink is low in printing cost and suitable for printing secure and confidential documents with deep printing lines, such as bank notes, securities, stamps, food packing, etc.

Owner:北京万垟防伪技术有限责任公司 +2

Aliphatic-aromatic polyetherester compositions, articles, films, coating and laminates and processes for producing same

Aliphatic-aromatic polyetherester compositions, articles made from the aliphatic-aromatic polyetherester compositions, and processes for producing the aliphatic-aromatic polyetherester compositions and articles are provided. Articles that can be made from the aliphatic-aromatic polyetherester compositions include films, coatings and laminates. Some of the compositions and articles are biocompostable. The films can further be used to form shaped articles such as sheets, food packaging such as sandwich wraps, thermoformed containers, and coatings for, for example, films and other substrates. The aliphatic-aromatic polyetheresters are based on copolyesters produced from a mixture of aromatic dicarboxylic acids, aliphatic dicarboxylic acids, poly(alkyene ether) glycols, and glycols.

Owner:DUPONT IND BIOSCIENCES USA LLC

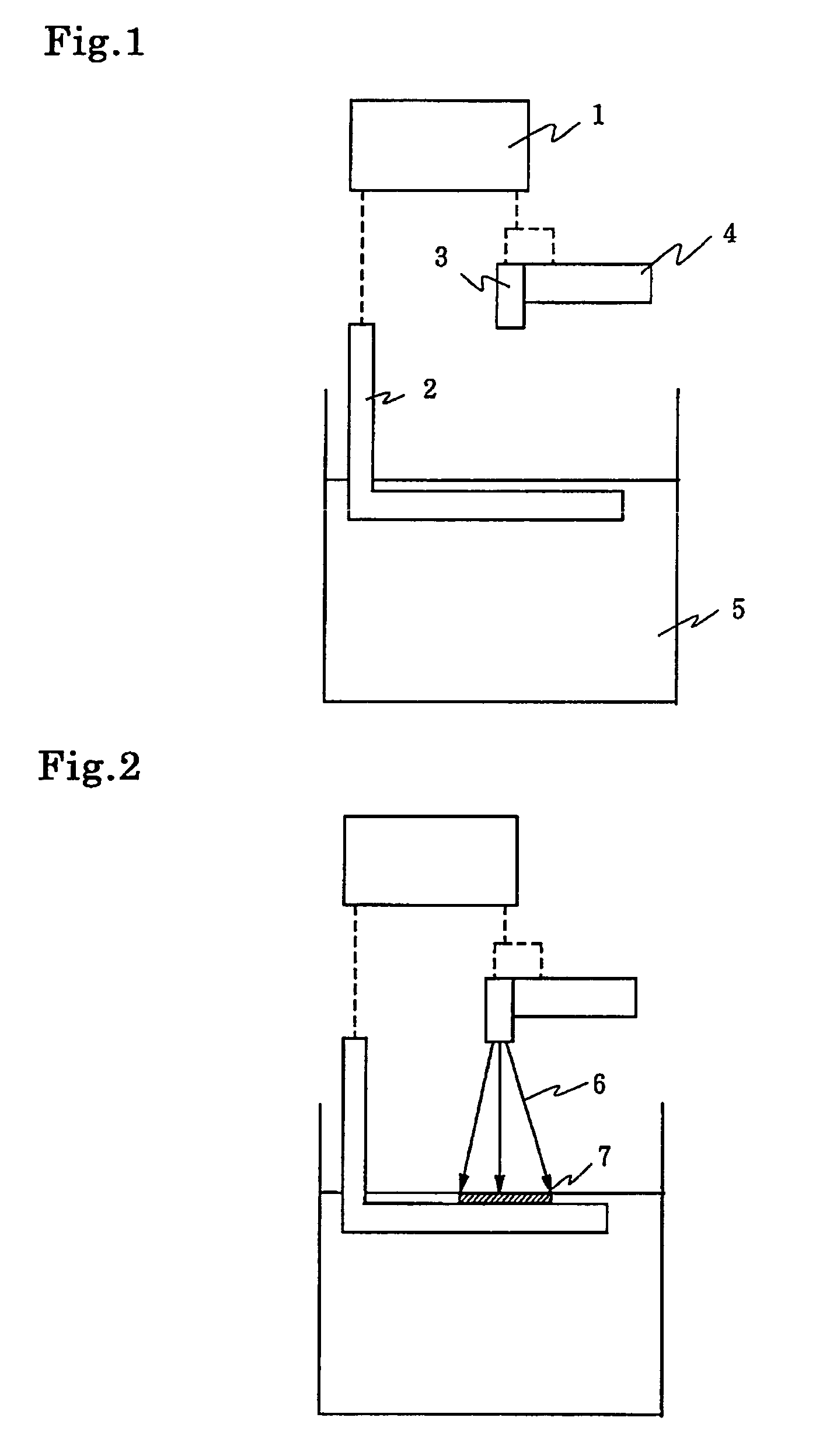

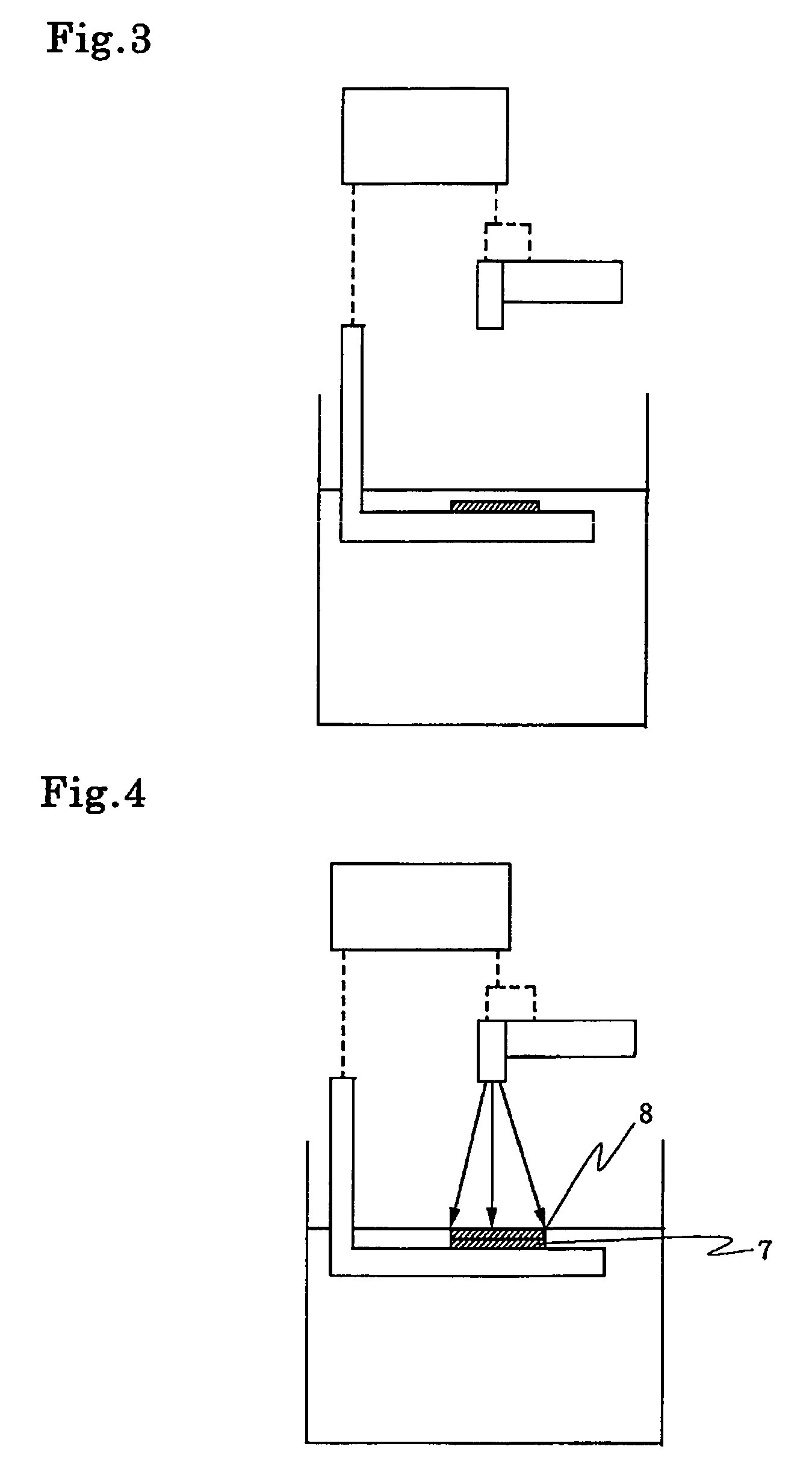

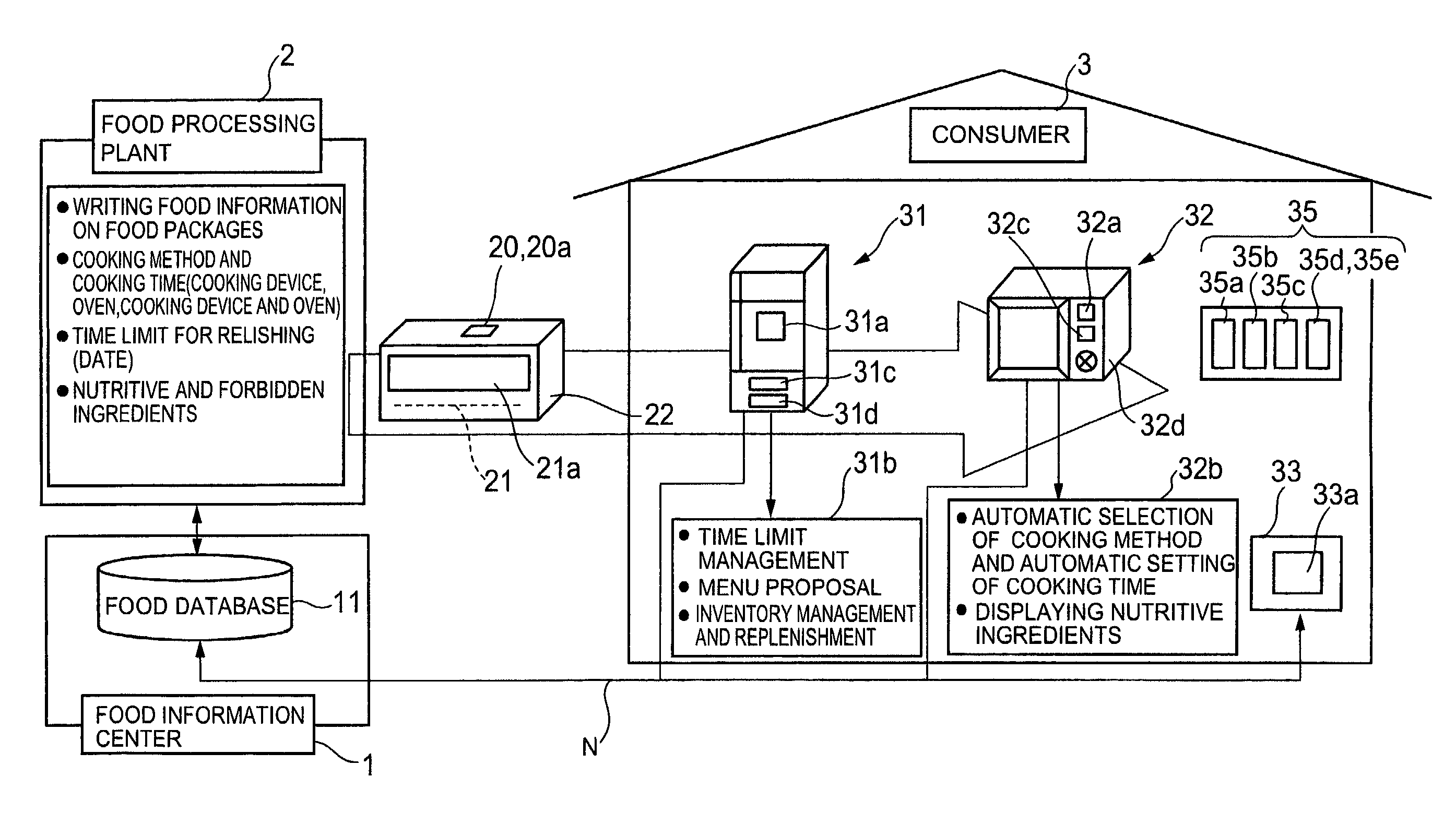

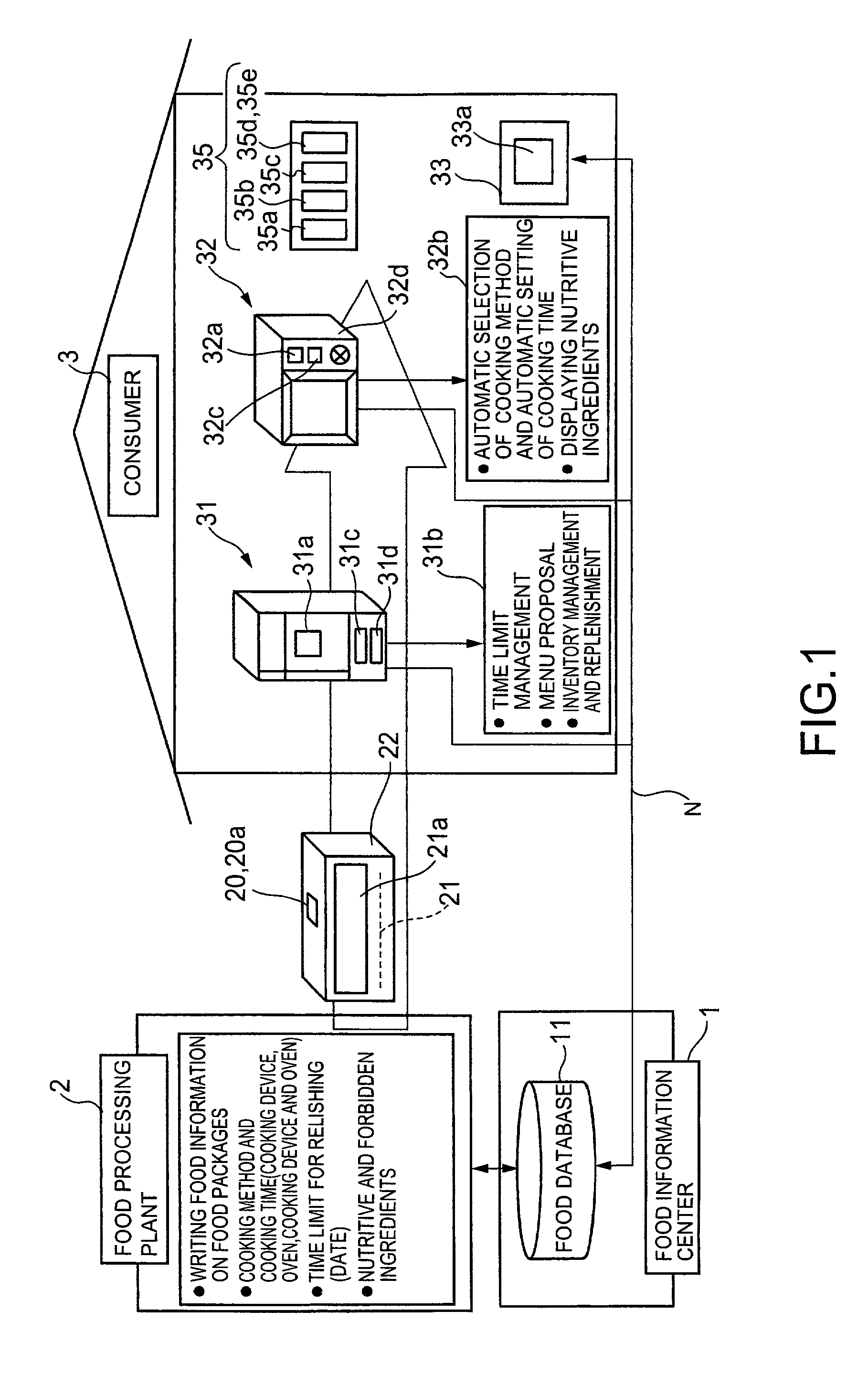

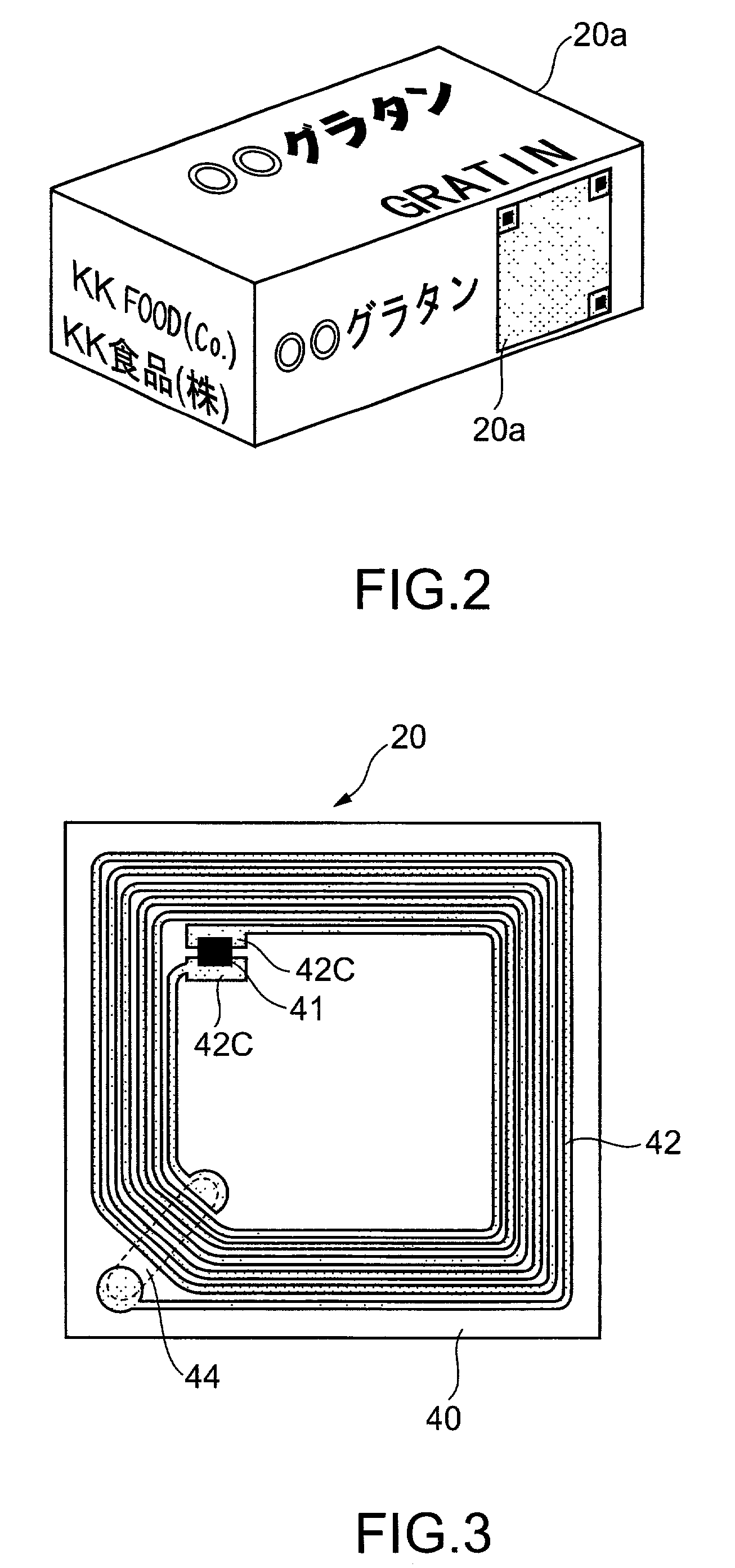

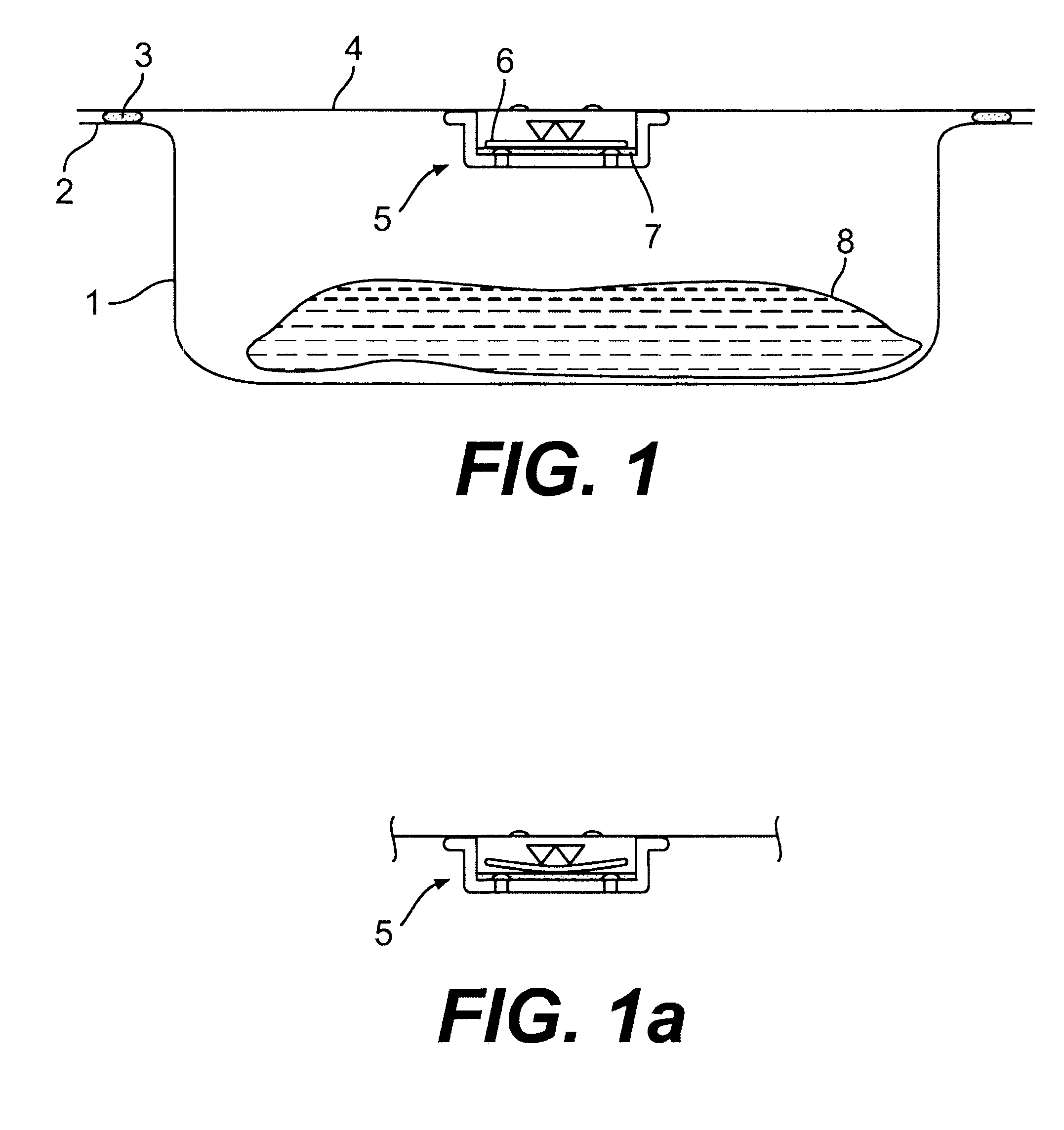

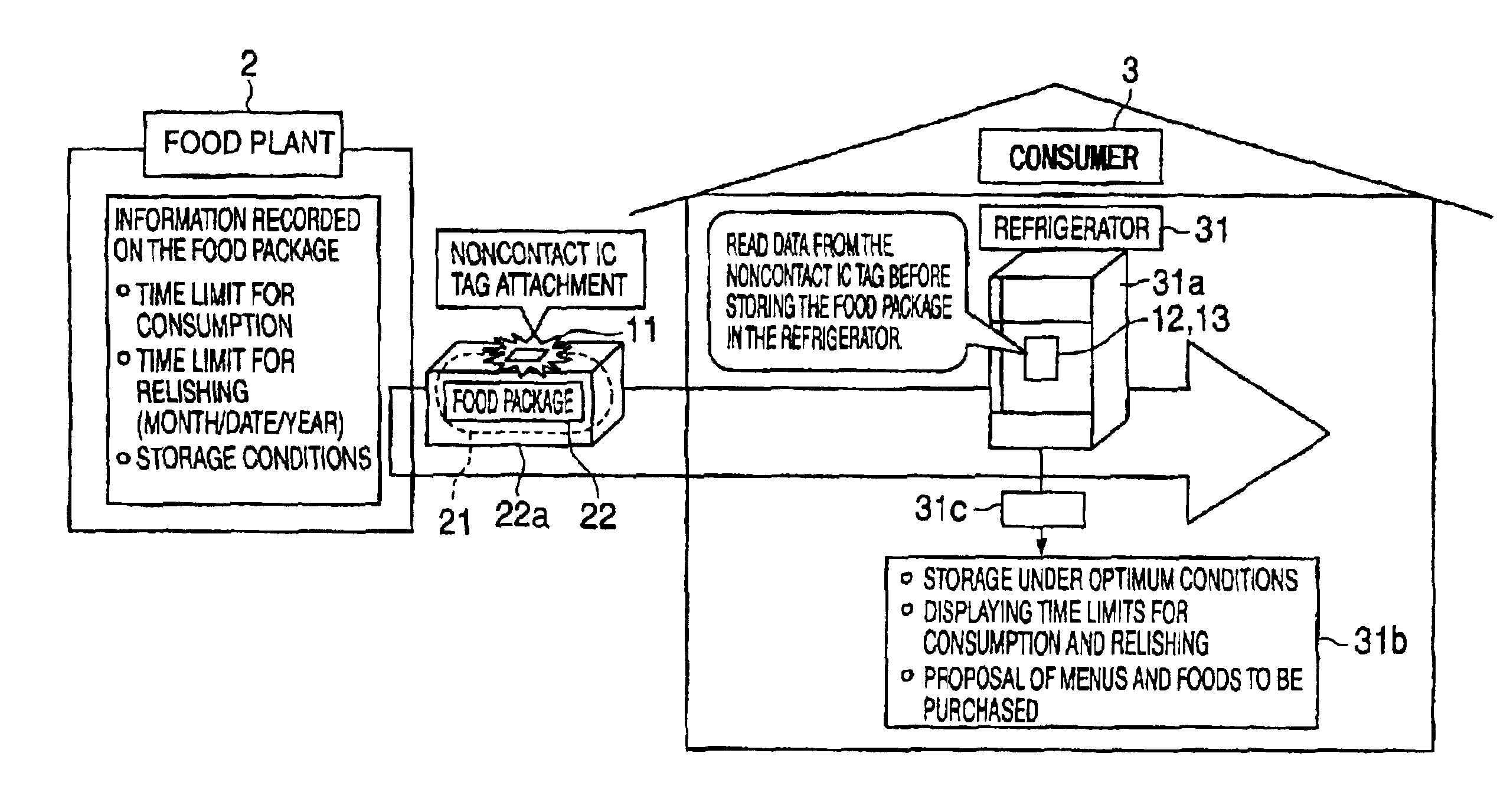

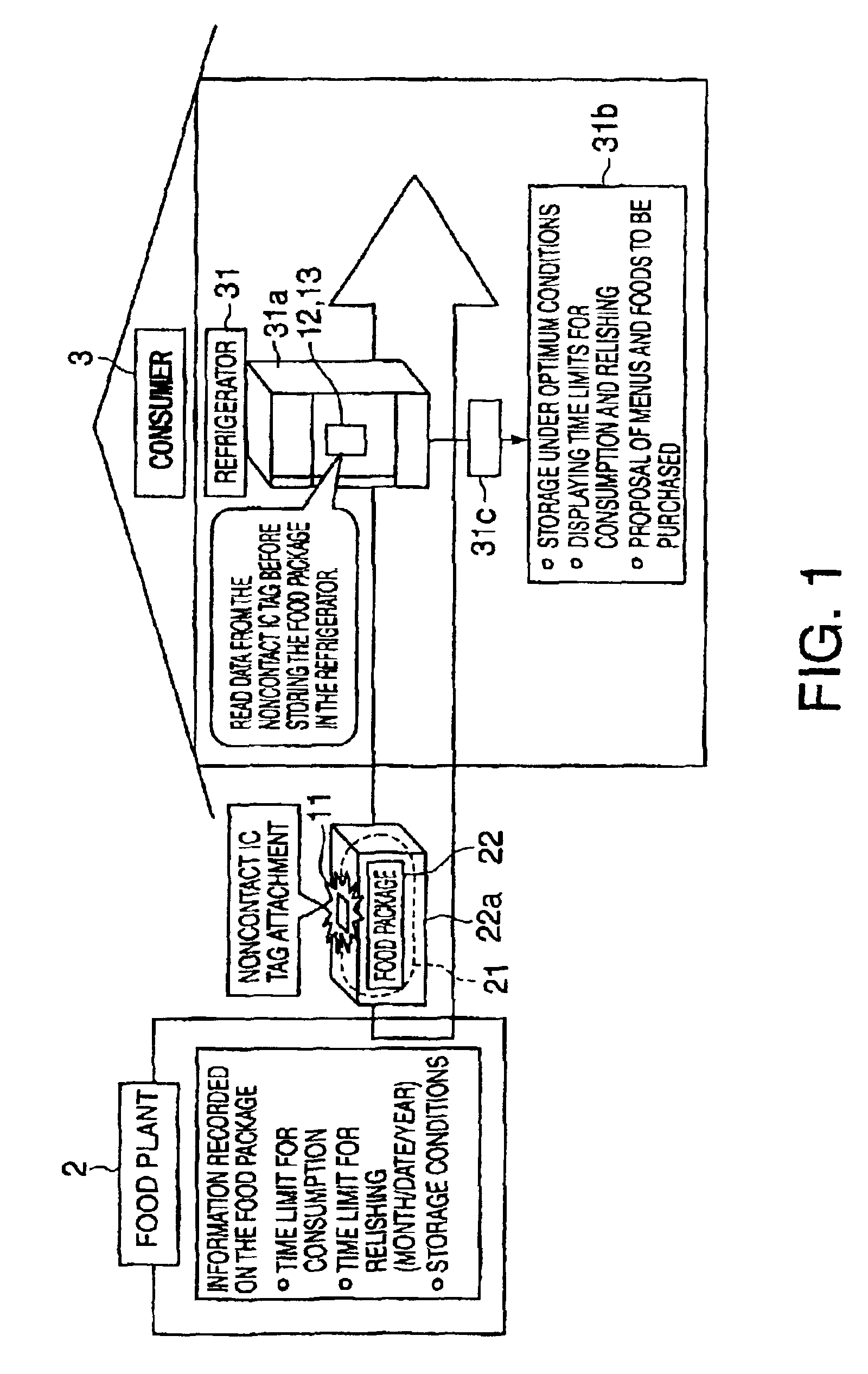

Food information management system

InactiveUS7096221B2Easy retrievalDomestic stoves or rangesLighting and heating apparatusAdditive ingredientEngineering

A food information management system includes a food database (11) containing food cooking conditions for cooking foods, and nutritive ingredients, energy-producing values and weight of foods, and information storage mediums (20, 20a). Each information storage medium is attached to a food package (21a) containing a processed food (21) and storing food information including food ID information specifying a food. When cooling the processed food (21), the food ID information stored in the food information storage medium (20, 20a) is read by a read means. Food information about a food specified by the food ID information is retrieved from the food database (11), an output means receives the food information, and a display means displays the food information.

Owner:DAI NIPPON PRINTING CO LTD

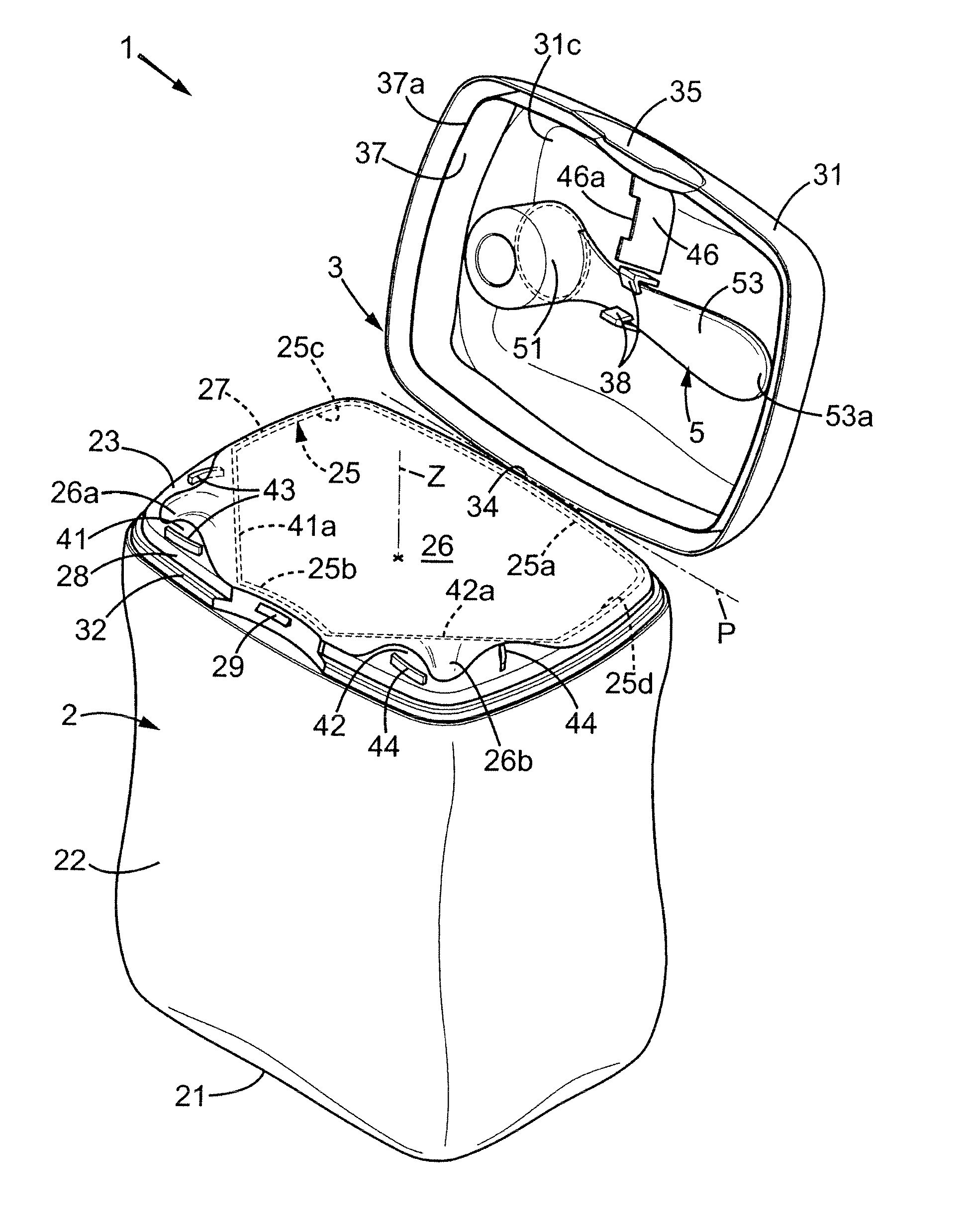

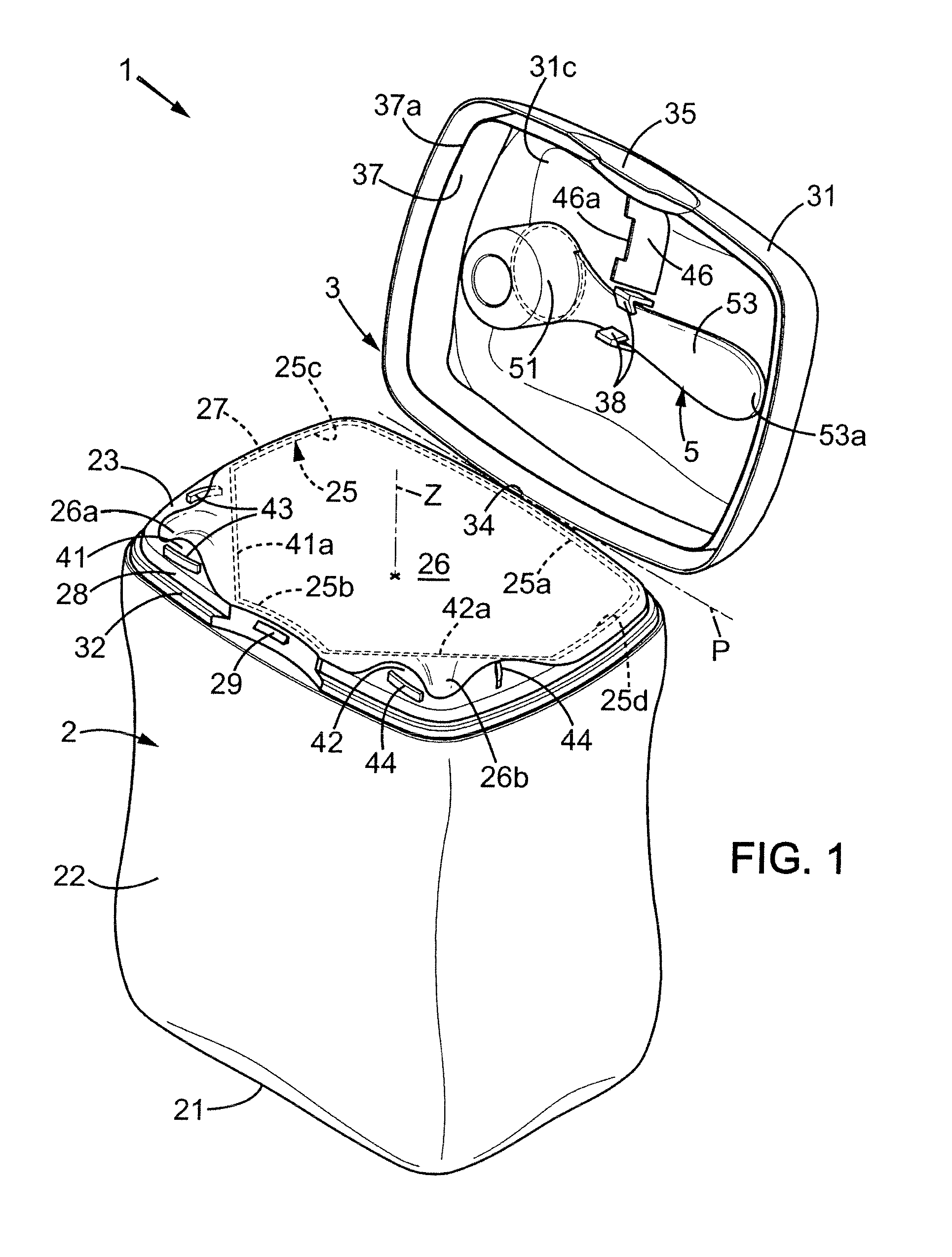

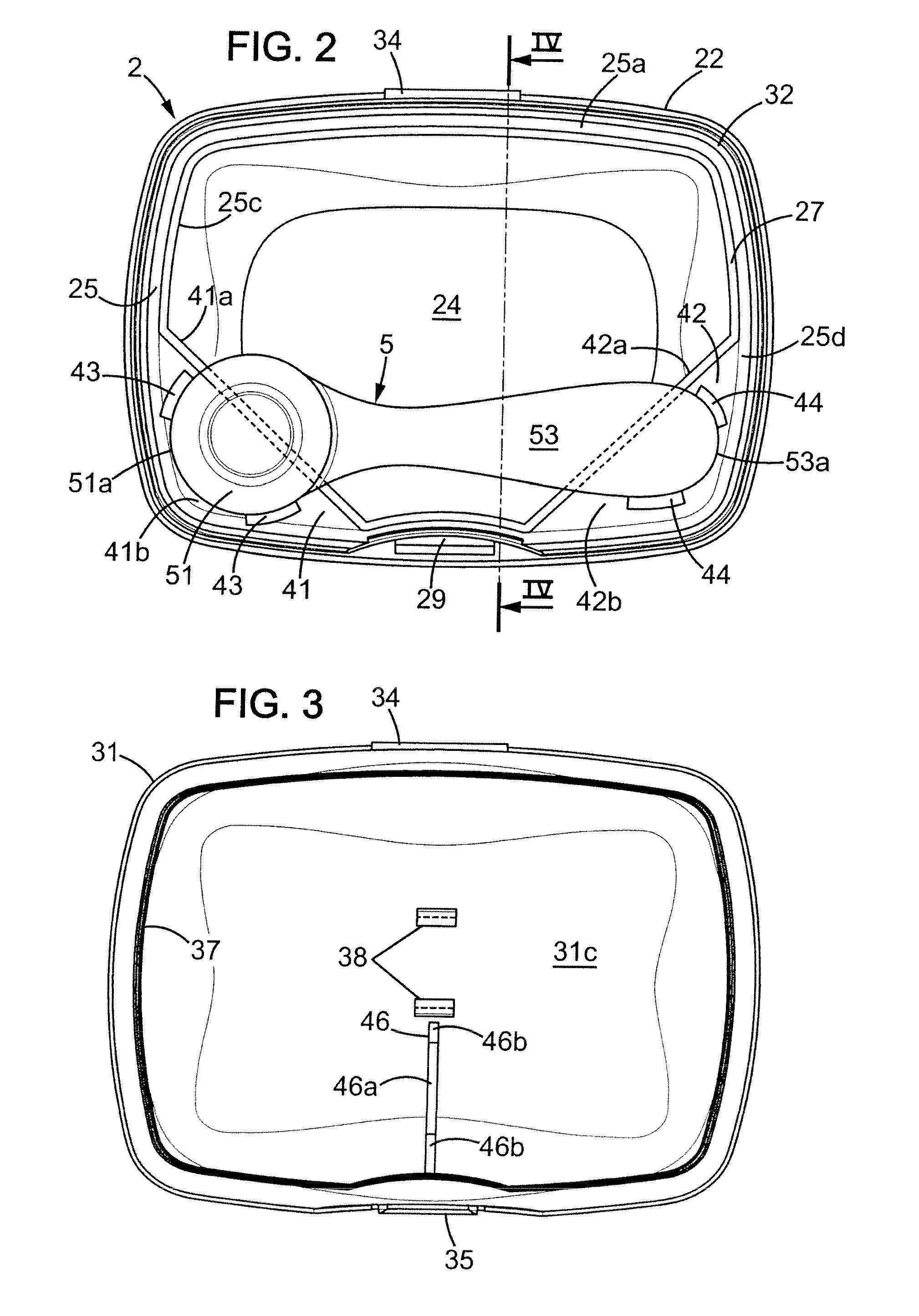

Package for food product taken out with a measuring device

A package for a food product sampled using a metering device, including a receptacle (2) having a wide top opening (24) and defined by a rim (25), a closure system (3) including a cover (31) that can be moved between an open position and a closed position, and a first levelling element (41) having a top face (41b) and a free edge (41a) situated in the space of the opening. The package also includes a second levelling element (42) spaced apart from the first and also having a top face (42b) and a free edge (42a), wherein the top faces (41b, 42b) of the first and second levelling elements (41, 42) each have a configuration and are mutually arranged in order to form two spaced-apart bearing zones substantially parallel to the plane of the opening for supporting the metering device.

Owner:DANONE

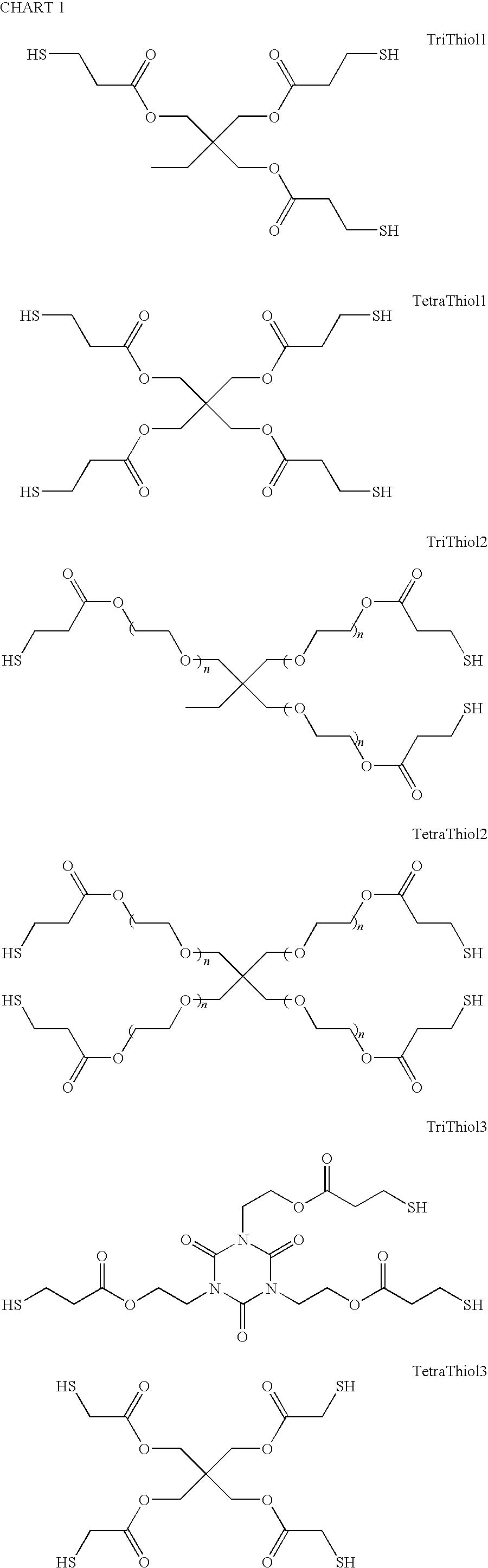

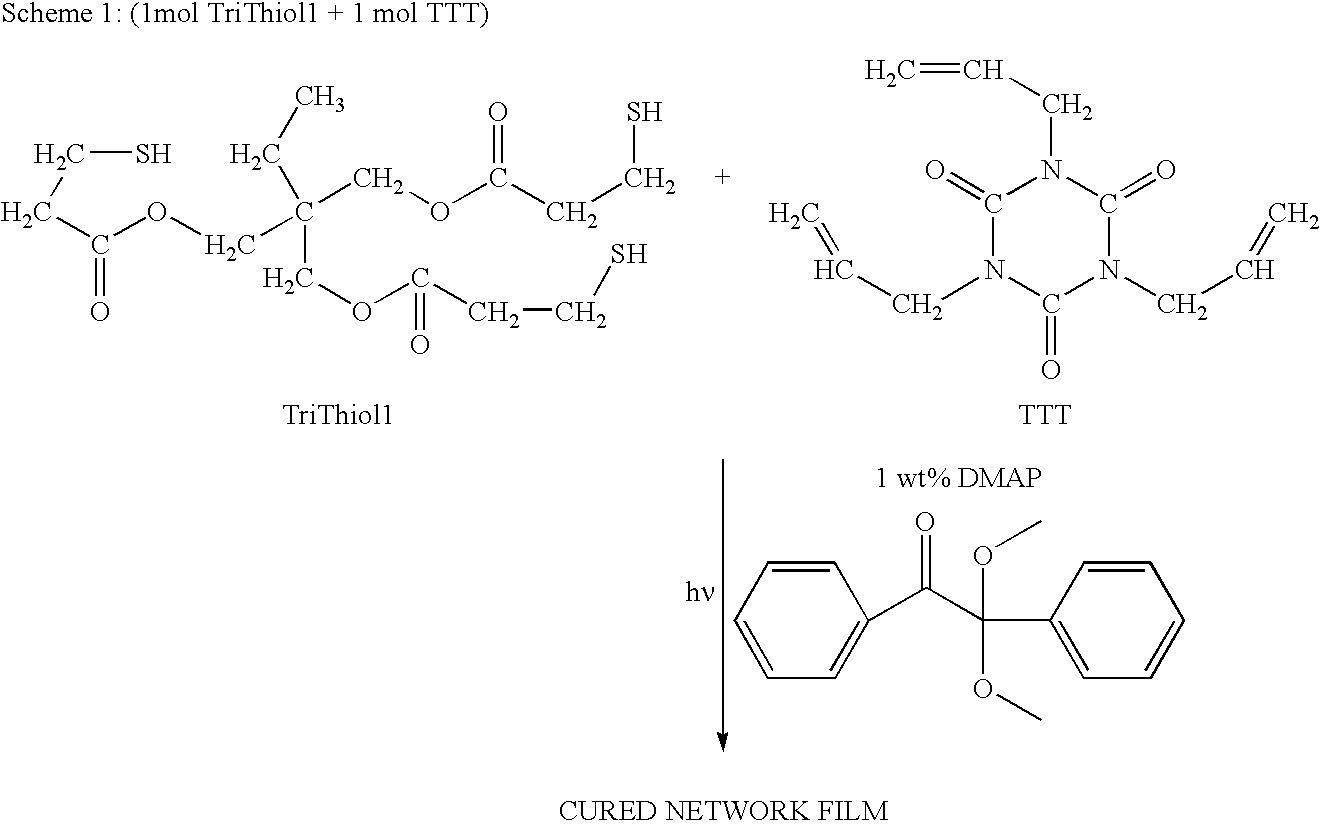

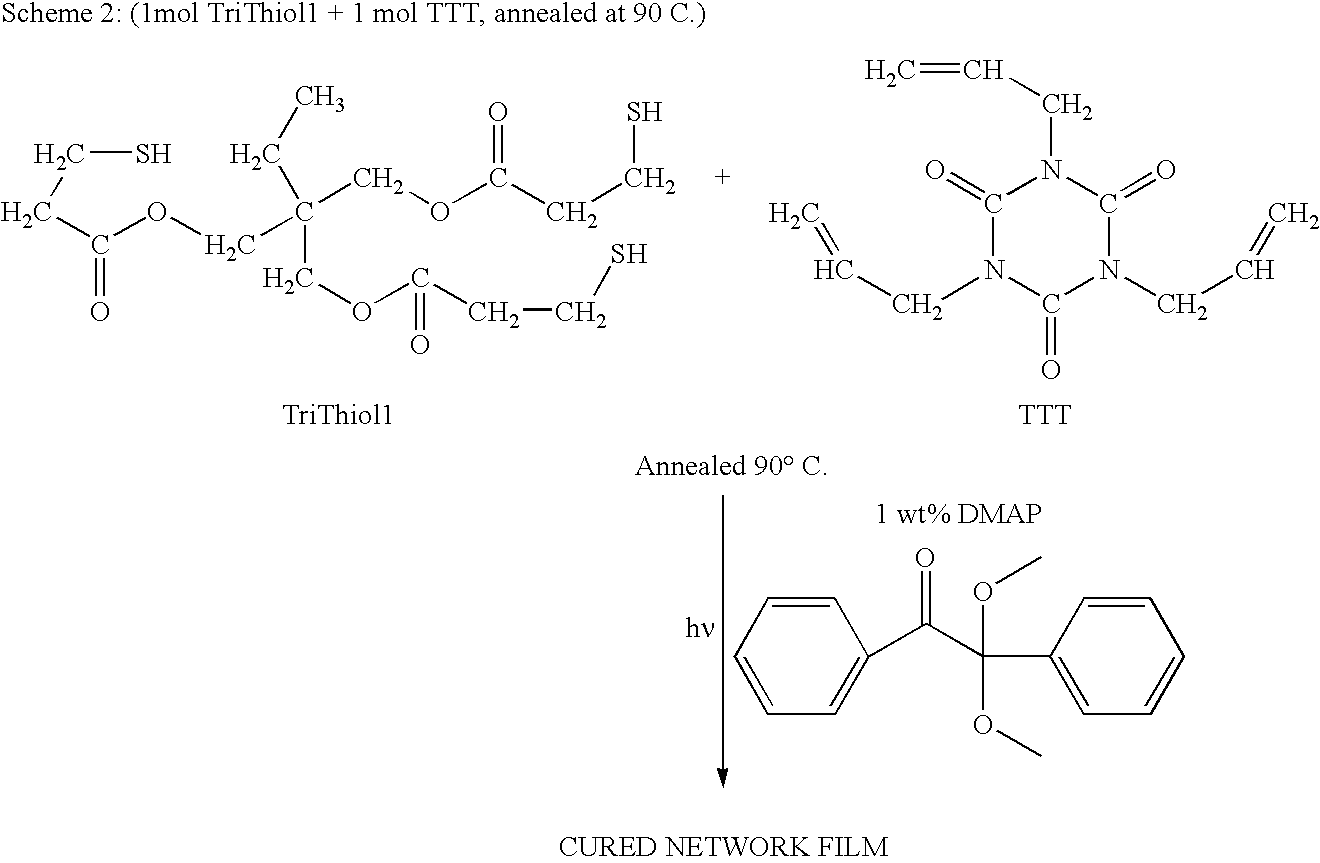

Photocurable Thiol-Ene Low Gas Permeability Membranes

InactiveUS20090253805A1Improve gas barrierExcellent substrate barrier resistanceOrganic chemistryPaper coatingThiolPolymer substrate

The present invention provides modified multifunctional thiol-ene monomers wherein one or more thiols are reacted with a Michael addition reactive double bond compound. The present invention further discloses photocurable thiol-ene formulations comprising thiol-ene monomers including the modified multifunctional thiols. The present invention further discloses photocurable thiol-ene formulations comprising thiol-ene monomers and Michael addition reactive double bond molecules and a Michael catalyst. The formulations of the present invention can be photocured to make films or coatings. In a further disclosure, the formulations, including those comprised of unmodified multifunctional thiols and multifunctional enes, are photocured to form films applied to non-flexible or flexible polymer or non-polymer substrates suitable for food packaging, electronic products, optical products and other applications and free-standing films. The present invention further discloses photocurable thiol-ene formulations comprising thiol-ene monomers and Michael addition reactive double bond molecules and a Michael catalyst. These formulations are disclosed to form free-standing films and coatings on substrates when applied to flexible substrates. Such materials are suitable for use in the packaging of food products and other products which are to be maintained in a hermetically sealed relationship to the atmosphere.

Owner:UNIVERSITY OF SOUTHERN MISSISSIPPI

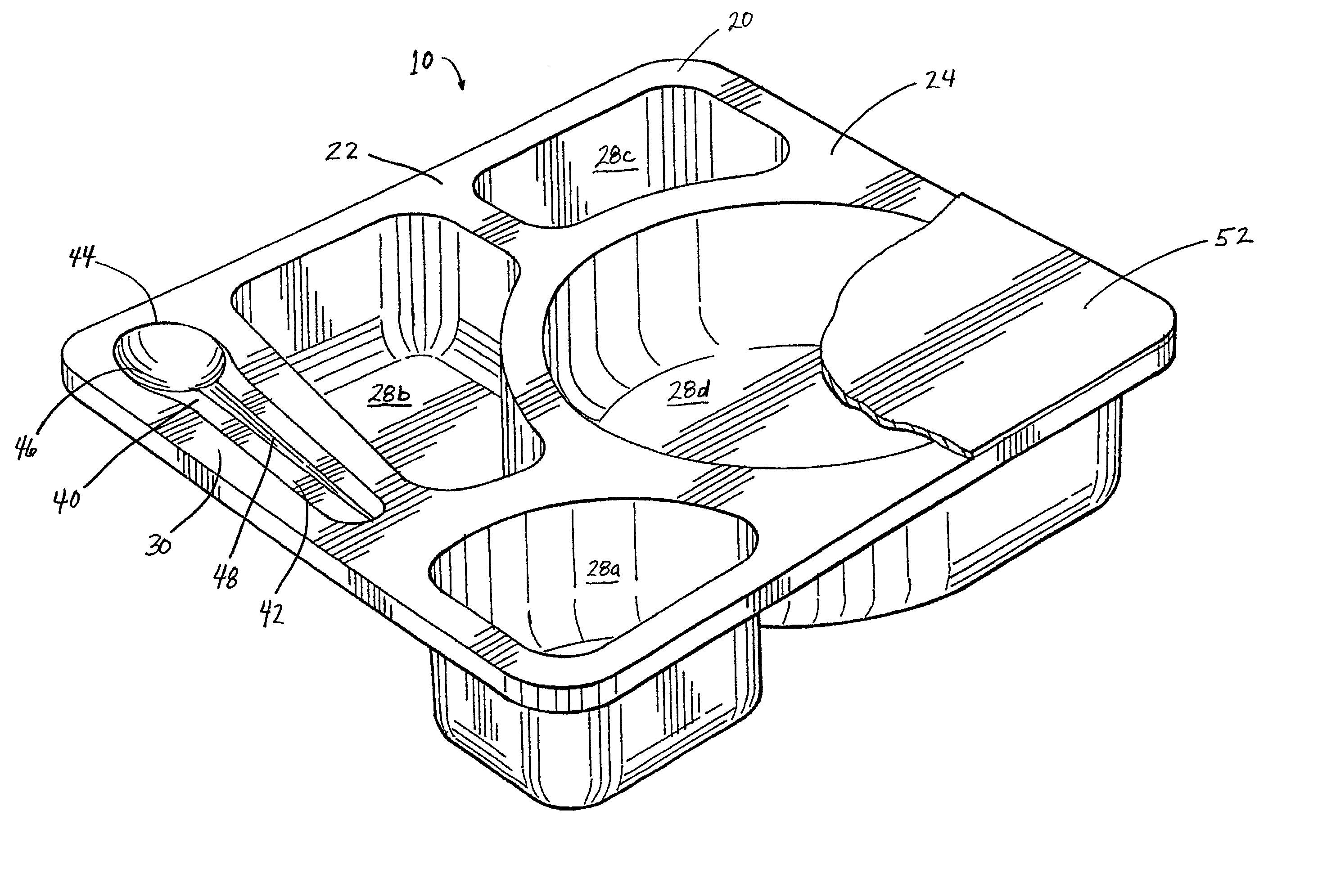

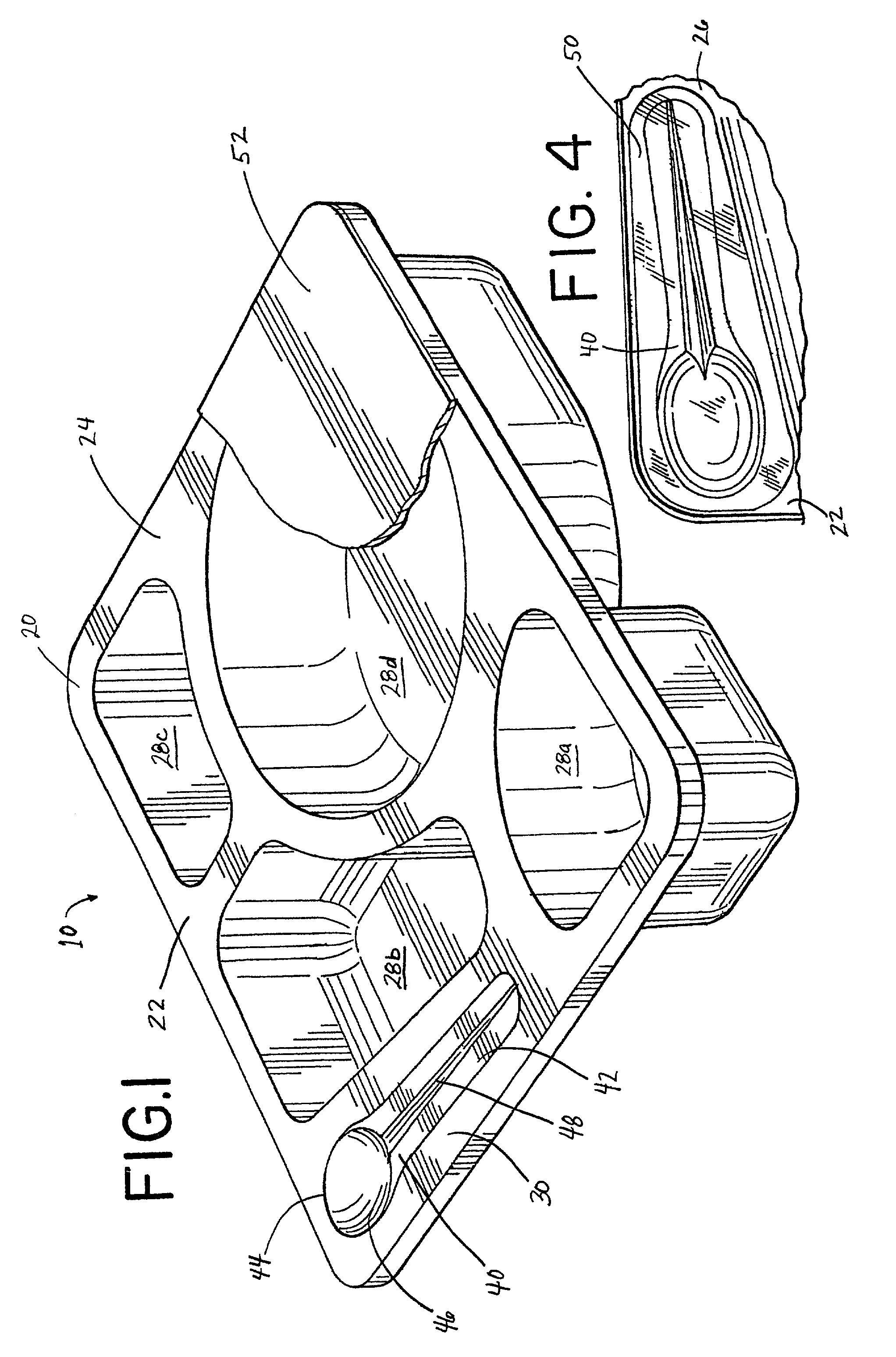

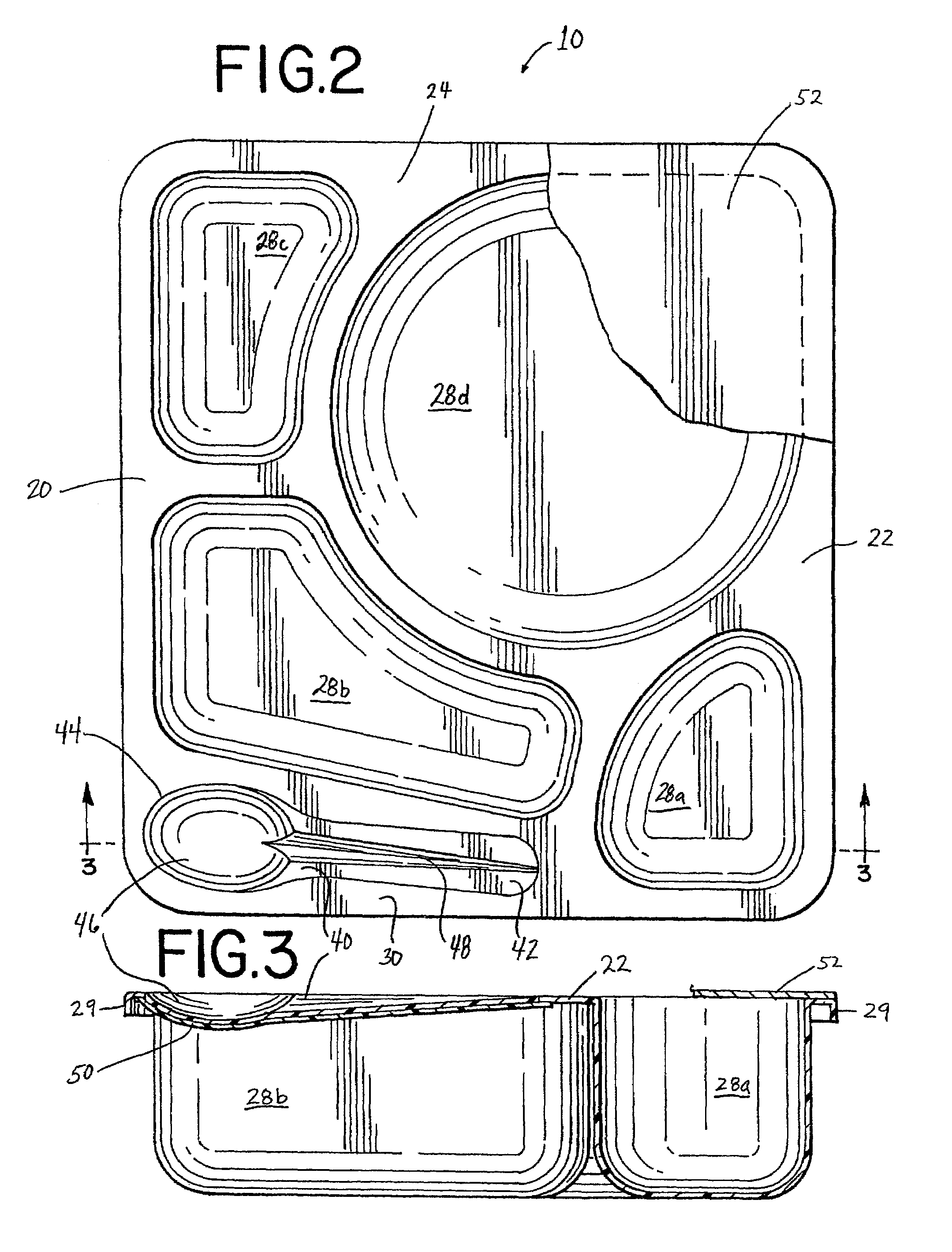

Tray with built in utensil

The present invention is directed to a pre-formed food packaging article, and method of manufacturing the same, useful in the packaging of individual food portions comprising a planar member having an upper surface and a lower surface, said planar member having a detachable utensil formed integrally in said planar member; and, said planar member having a sanitary membrane affixed to the lower surface covering and protecting the bottom of the utensil from contamination. The sanitary membrane of the present invention protects the lower surface of the integrally formed utensil, while a sealing film or lid protects the upper surface of the utensil, thus providing a food packaging article with a convenient, sanitary utensil for the consumer.

Owner:CURWOOD INC

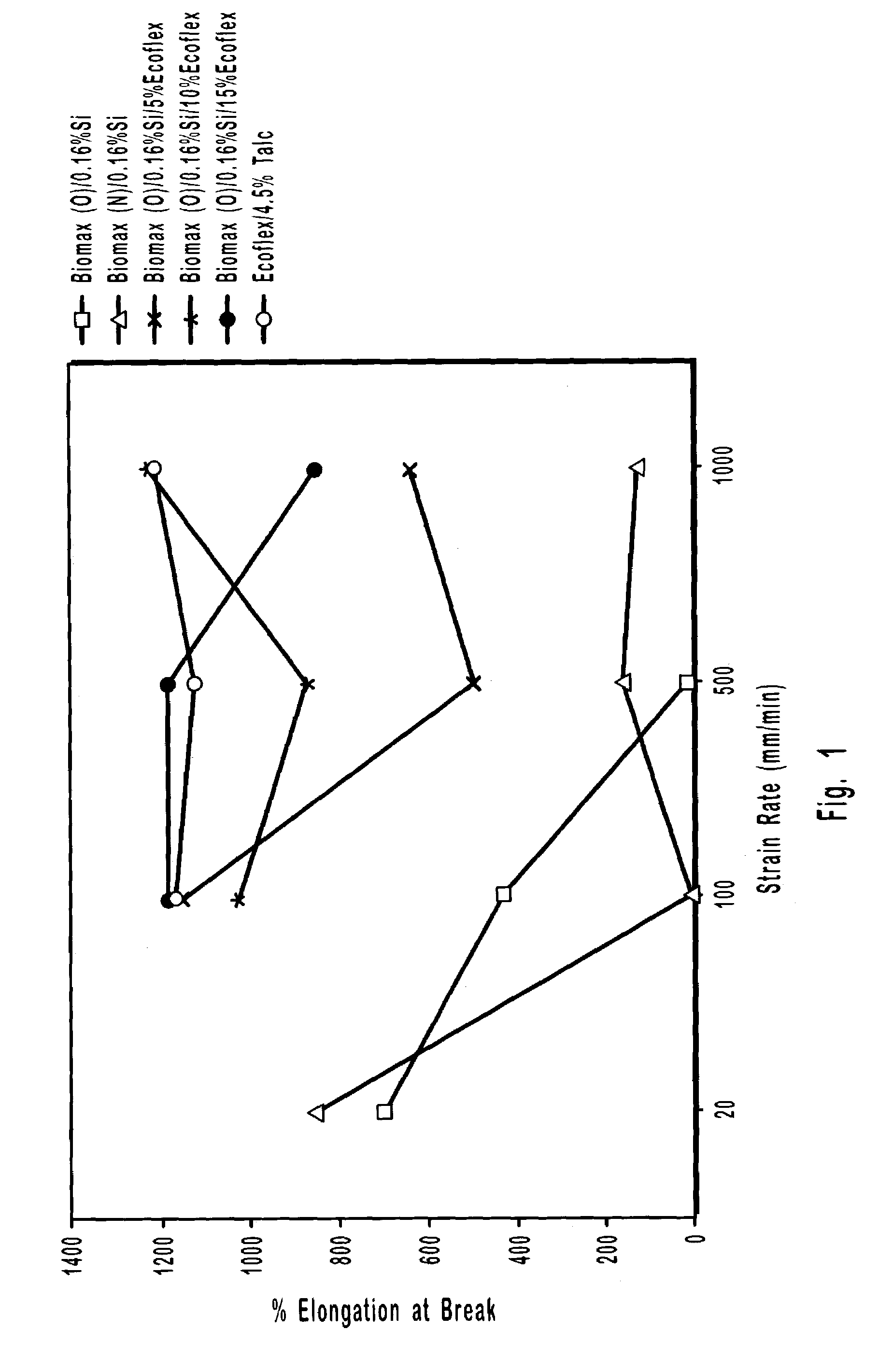

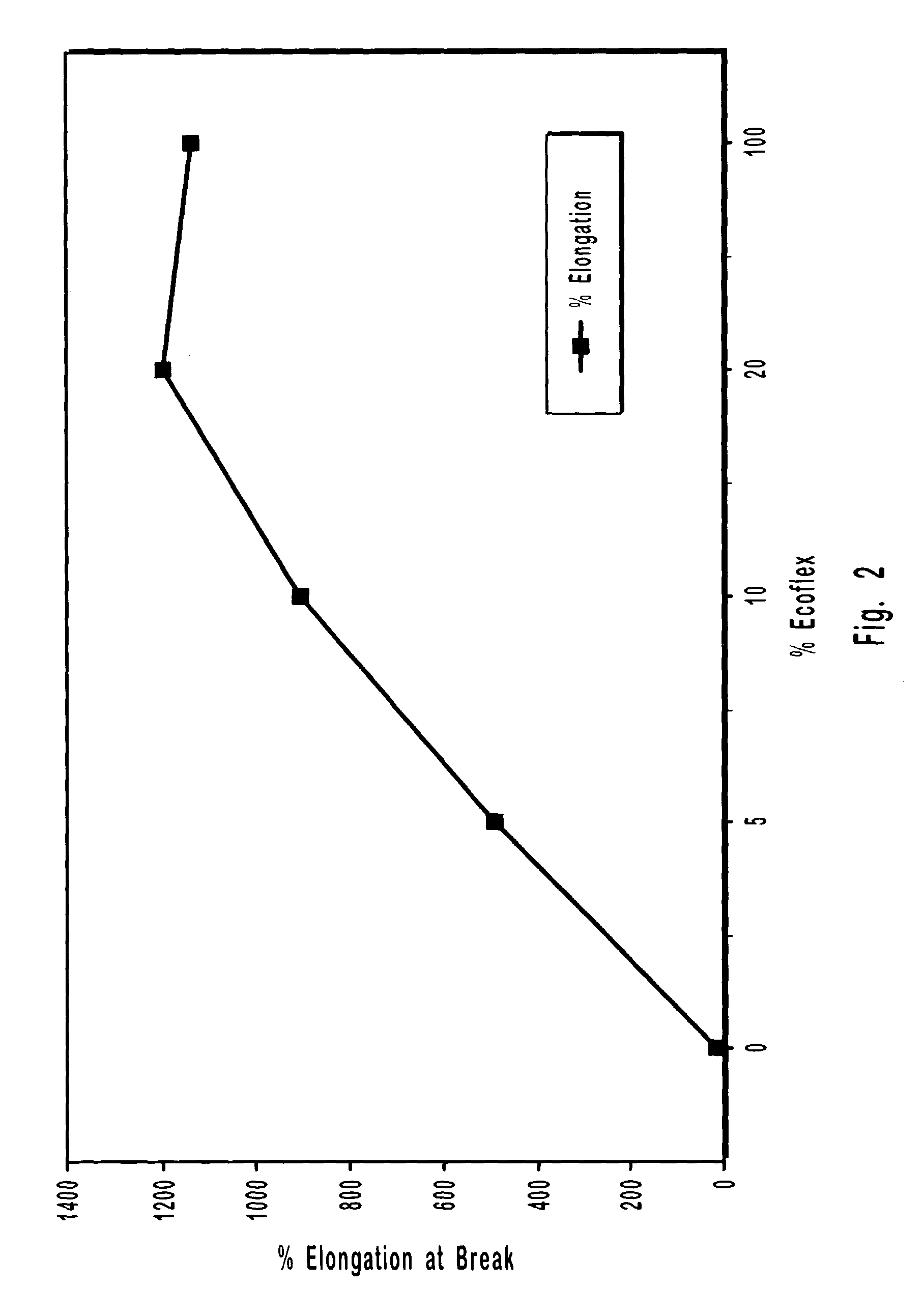

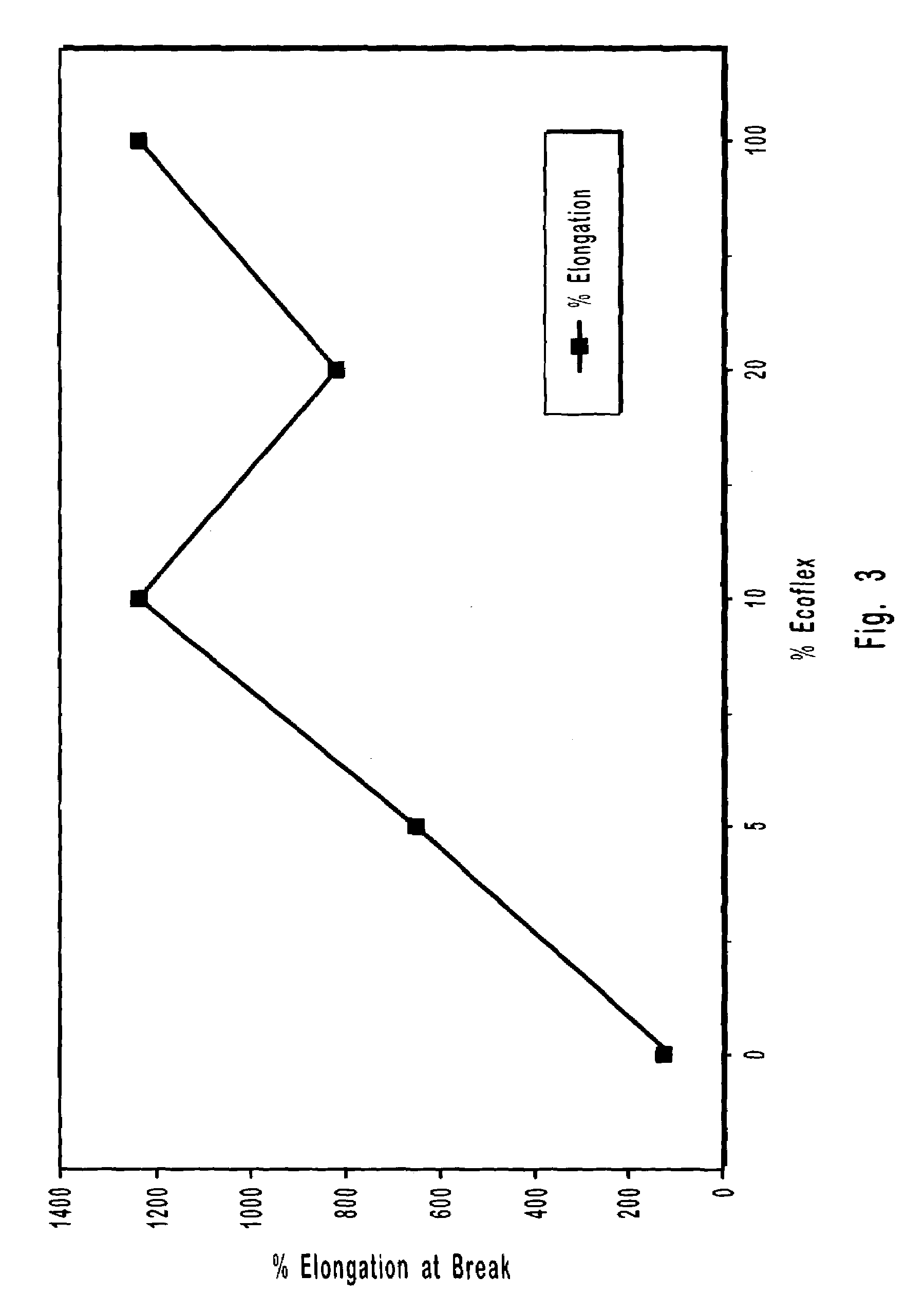

Fibrous sheets coated or impregnated with biodegradable polymers or polymers blends

ActiveUS7172814B2High glass transition temperatureImprove the crystallization processBio-packagingPaper coatingPolymer scienceBiopolymer

Fibrous sheets are coated or impregnated with a biodegradable composition to render the sheets more resistant to penetration by liquids. Biodegradable polymer blends suitable for use in coating or impregnating a fibrous sheet can be manufactured from at least one “hard” biodegradable polymer and at least one “soft” biodegradable polymer. “Hard” biopolymers typically have a glass transition temperature of at least about 10° C. “Soft” biodegradable polymers typically have a glass transition temperature less than about 0° C. Another useful biodegradable polymer composition includes one or more biodegradable polymers and sufficient inorganic filler so as to render the treated sheet microwaveable. The biodegradable polymer compositions are especially well-suited for coating or impregnating paper sheets, e.g., 12–15 lb / 3000 ft2 tissue paper to yield food wraps. Food wraps will typically be manufactured to have good “dead-fold” properties so as to remain in a wrapped position and not spring back to an “unwrapped” form.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

Ventable, microwave-safe food package

A package and a method for storing, venting, and heating consumable goods. The package includes a container defining an interior and a valve for venting gas during storage and heating. The container having sufficient stability to withstand heating conditions including microwave energy, vapor pressure, and a temperature of 150° Celsius. The valve has a well-defined, substantially constant flow resistance at vapor pressures and at a temperature of at least 150° Celsius developed in the interior during heating. Consumable goods are disposed in the interior of the container and comprise of at least two different fresh, raw foods that require different cooking times in water, and said consumable goods having an amount of water content of at least 30% by weight.

Owner:CREATIVE NEW FOOD DREAM STEAM

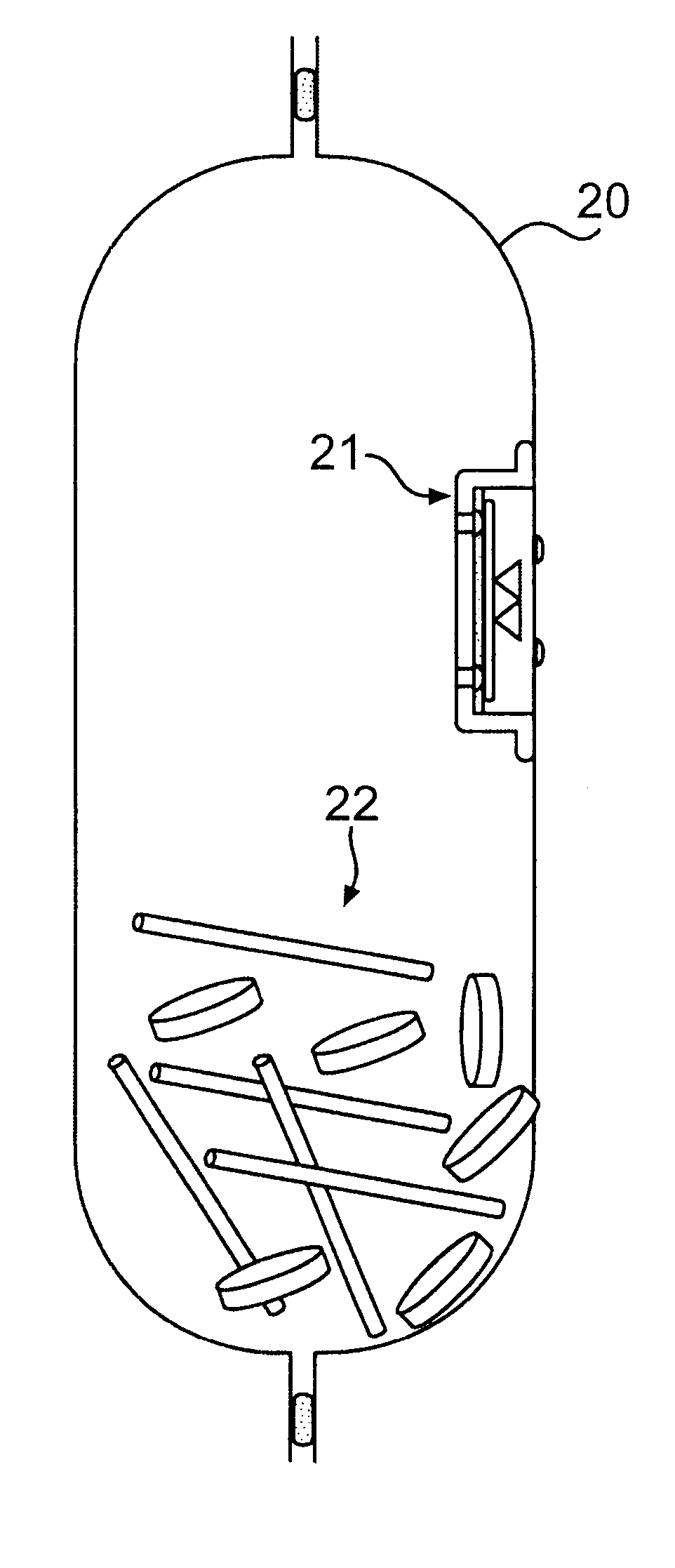

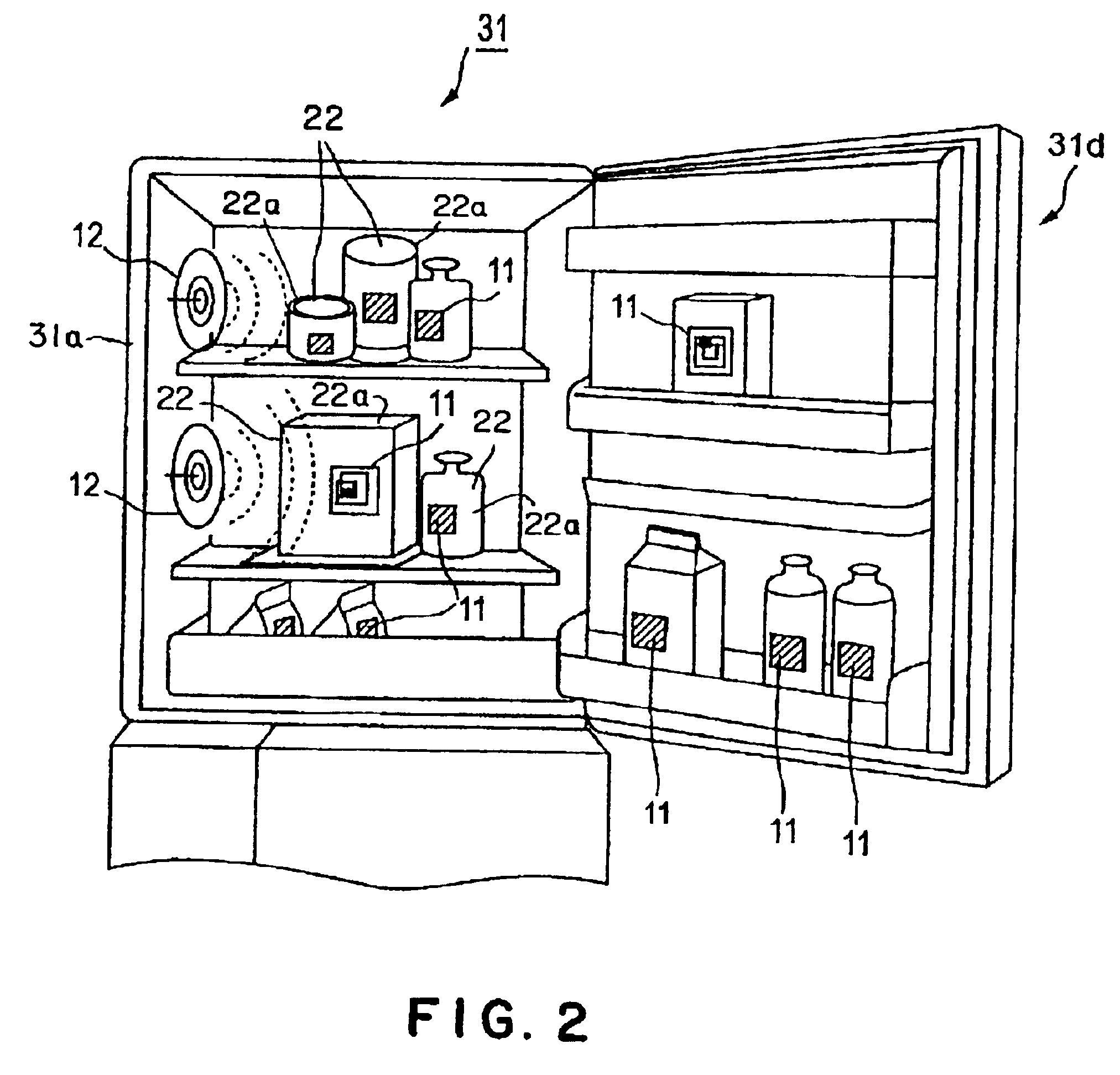

Automatic refrigerator system, refrigerator, automatic cooking system, and microwave oven

An automatic cold-storage system includes a food package (22) provided with a noncontact IC tag (11), and a refrigerator (31) for storing the food package (22). Information is read from the noncontact IC tag (11) by a noncontact IC tag reader (12) and is compiled to a database (31c). A managing means (31b) controls the refrigerator (31) on the basis of information contained in the database (31c). The managing means (31b) makes a display device (14) display a warning on the basis of information read by the noncontact IC tag reader (12).

Owner:DAI NIPPON PRINTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com