Patents

Literature

8136 results about "Cardboard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cardboard is a generic term for heavy-duty paper-based products having greater thickness and superior durability or other specific mechanical attributes to paper; such as foldability, rigidity and impact resistance. The construction can range from a thick sheet known as paperboard to corrugated fiberboard which is made of multiple corrugated and flat layers.

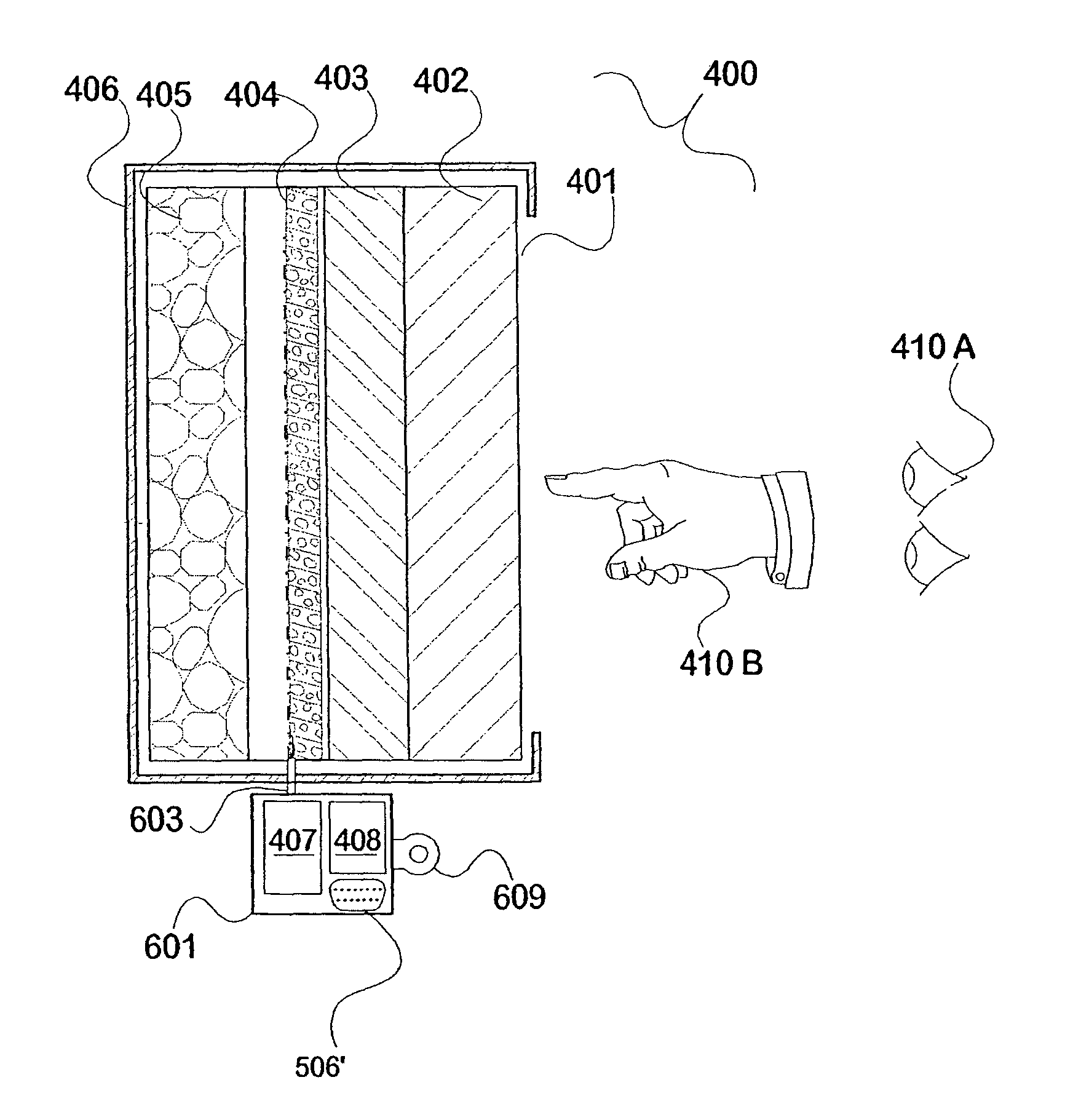

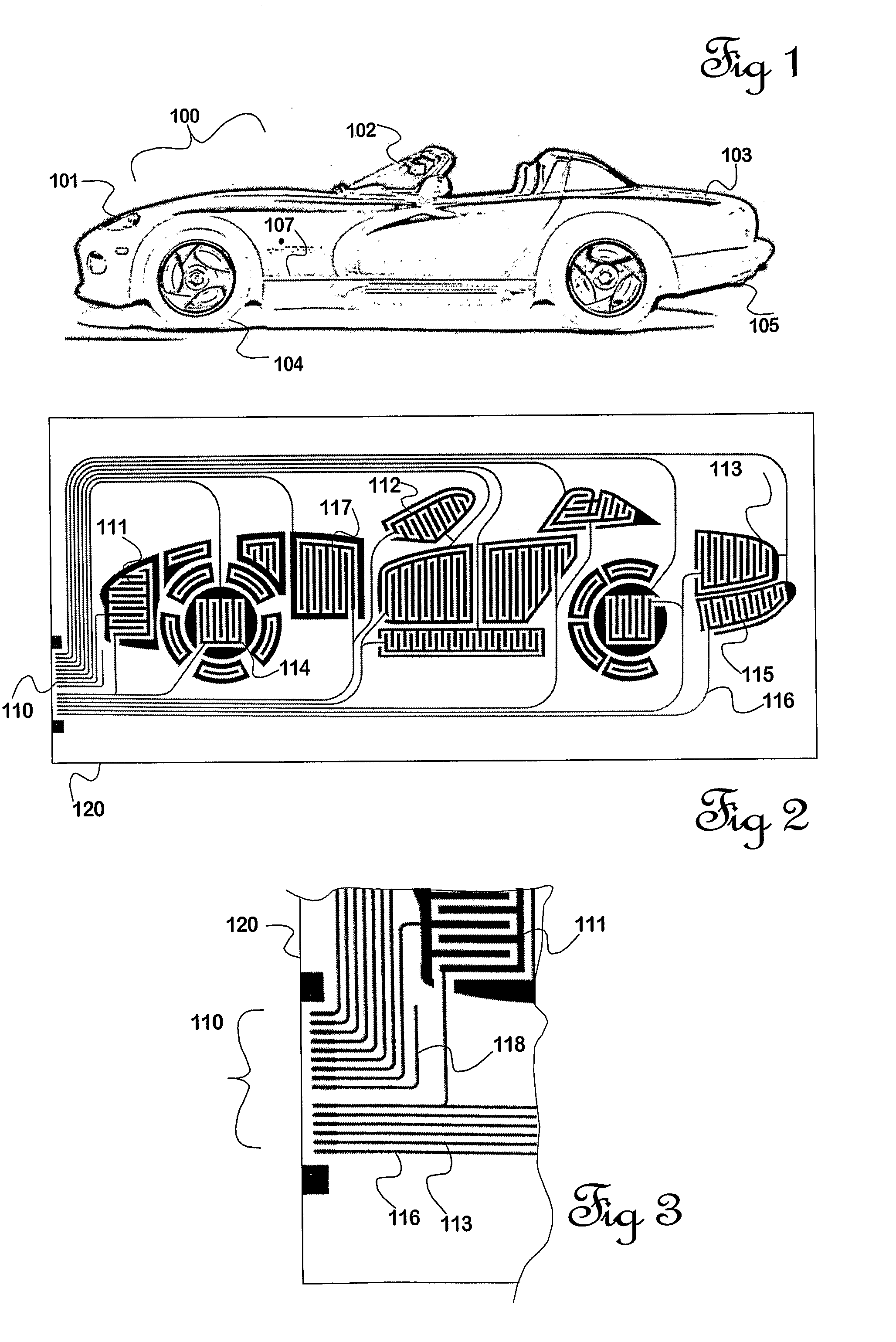

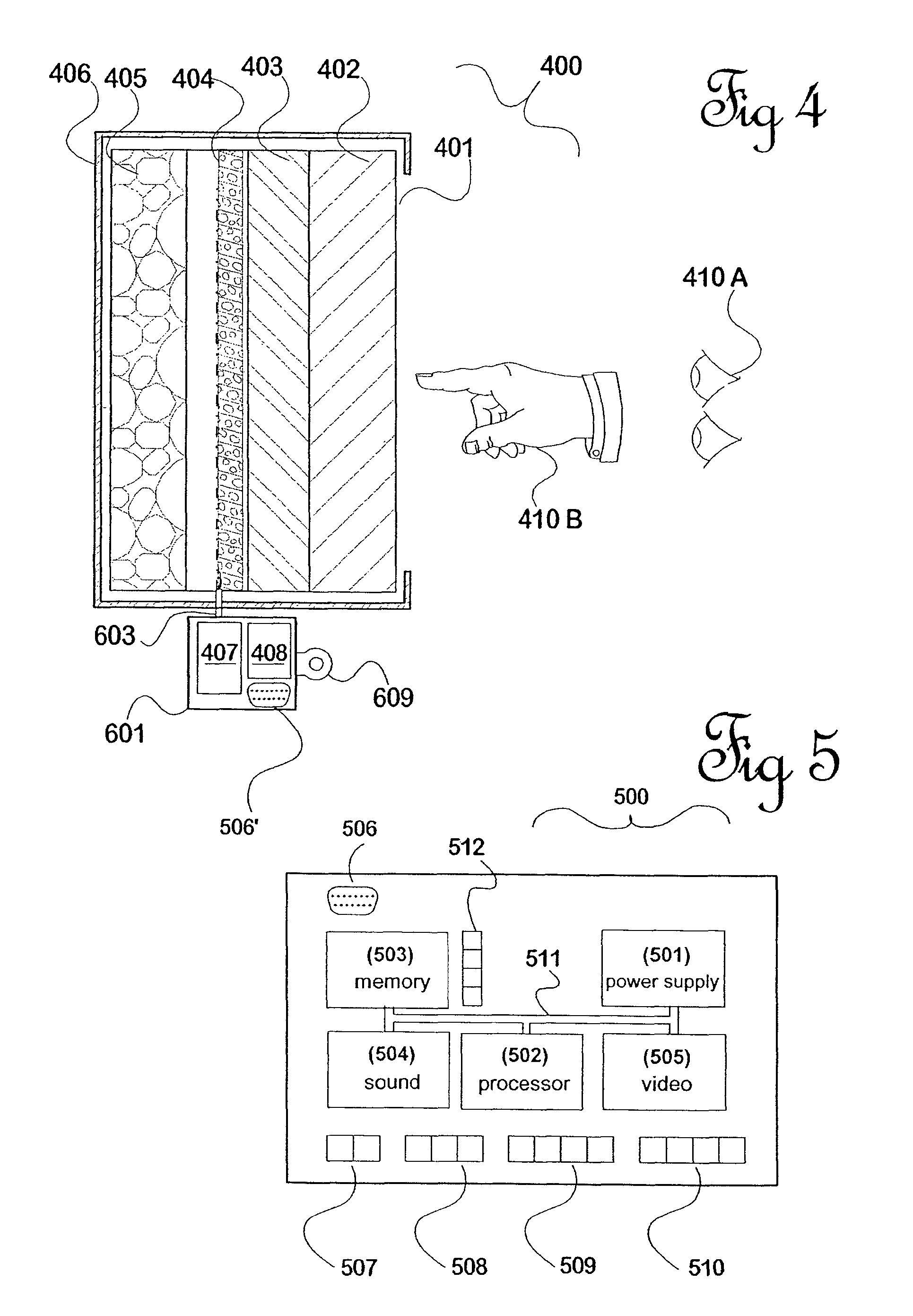

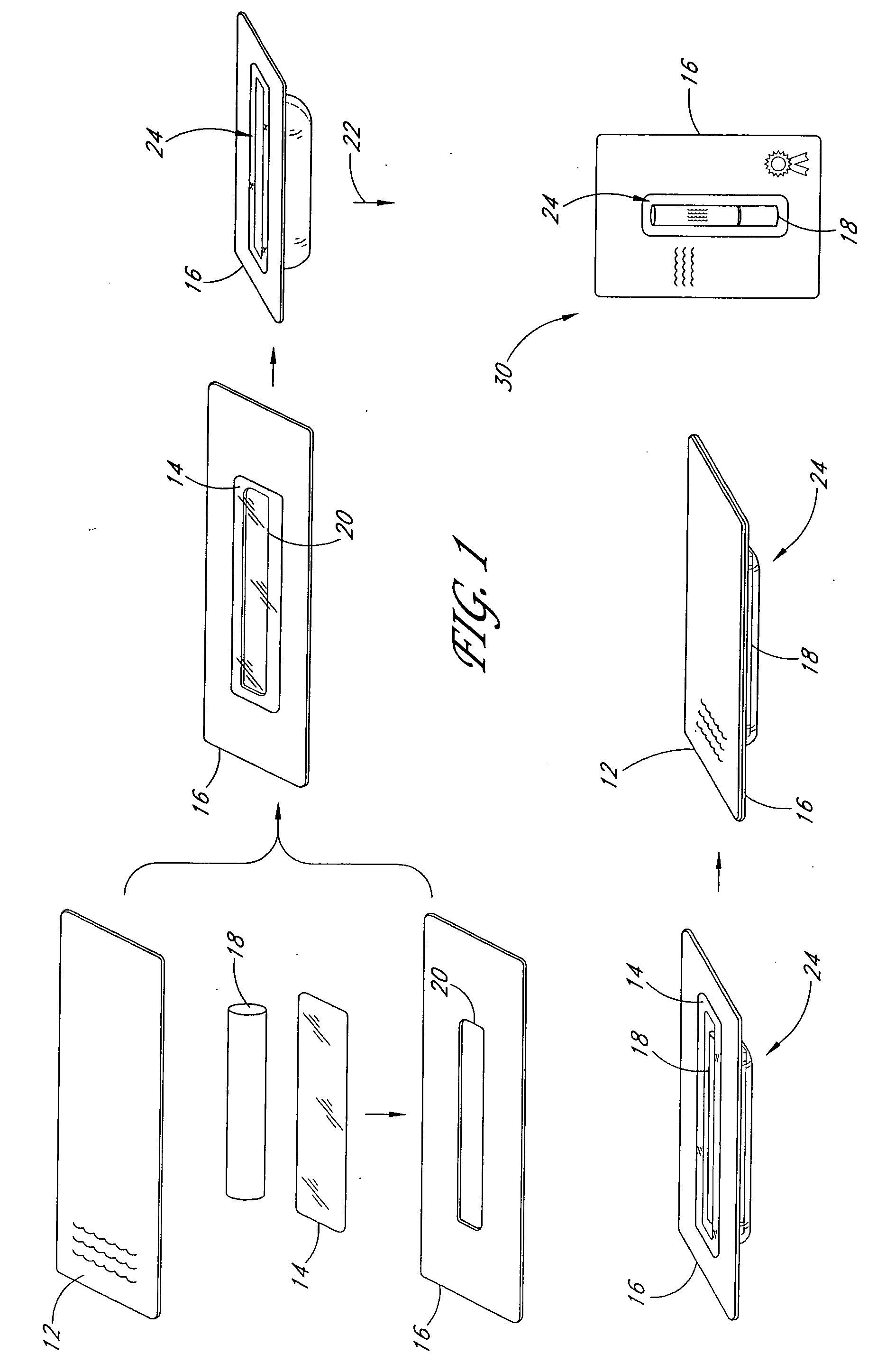

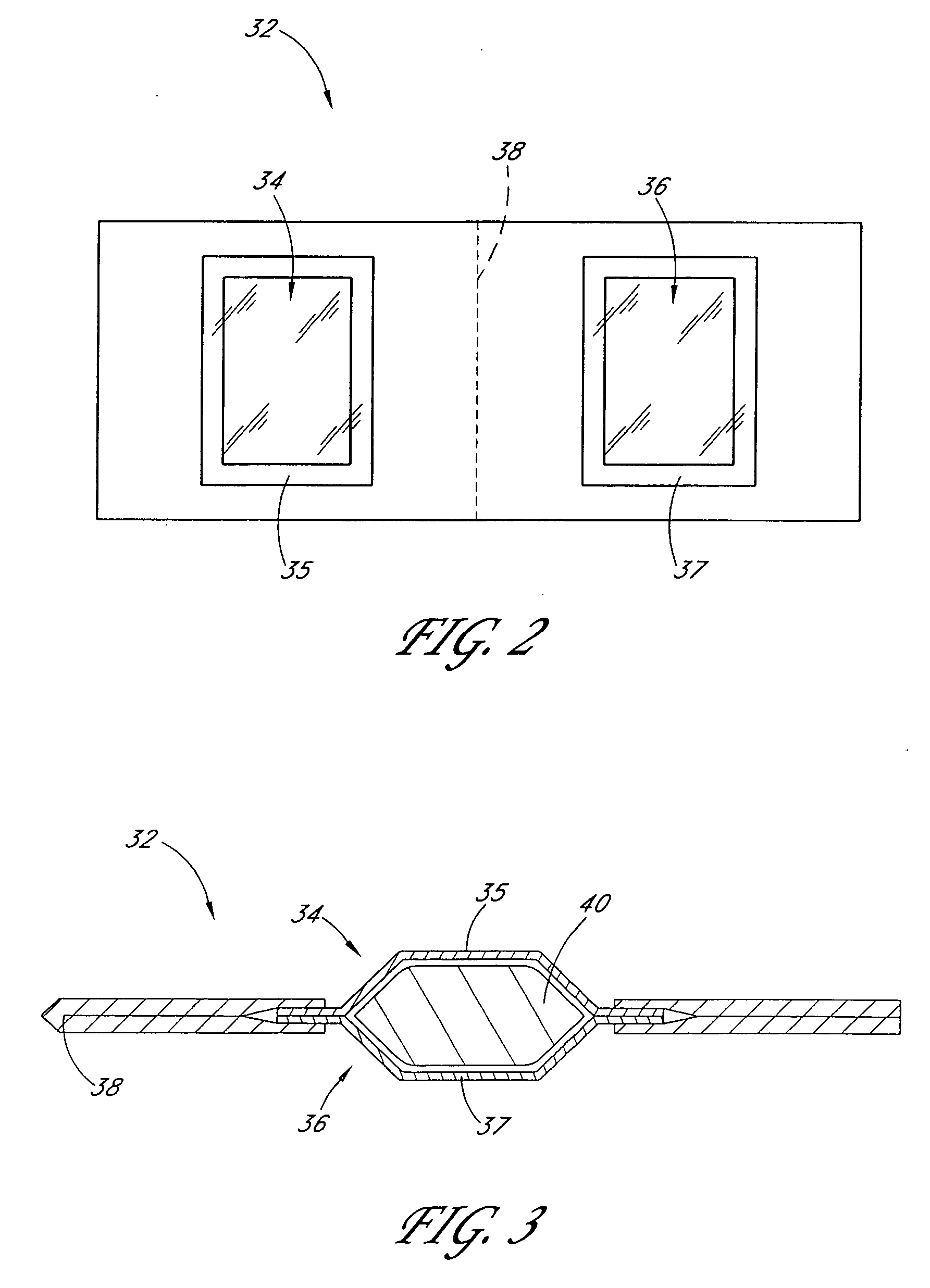

Apparatus and method for proximity-responsive display materials

InactiveUS7868778B2Easy to modifyEasy to replaceElectronic switchingAdvertisingCardboardDisplay device

Apparatus and a method for causing a printed display (poster, placard or promotional flier) to become interactive when a person points to part of the display. Behind the display a customized layout of capacitive proximity sensors printed with conductive inks on to a low-cost disposable, replaceable substrate (paper, plastic, cardboard) in alignment with visually significant features of the display is connected to proximity-sensing circuitry. Audio-visual or multimedia responses using pre-recorded or synthesized information are reproduced in event of a selection.

Owner:KENWRIGHT DAVID NORRIS

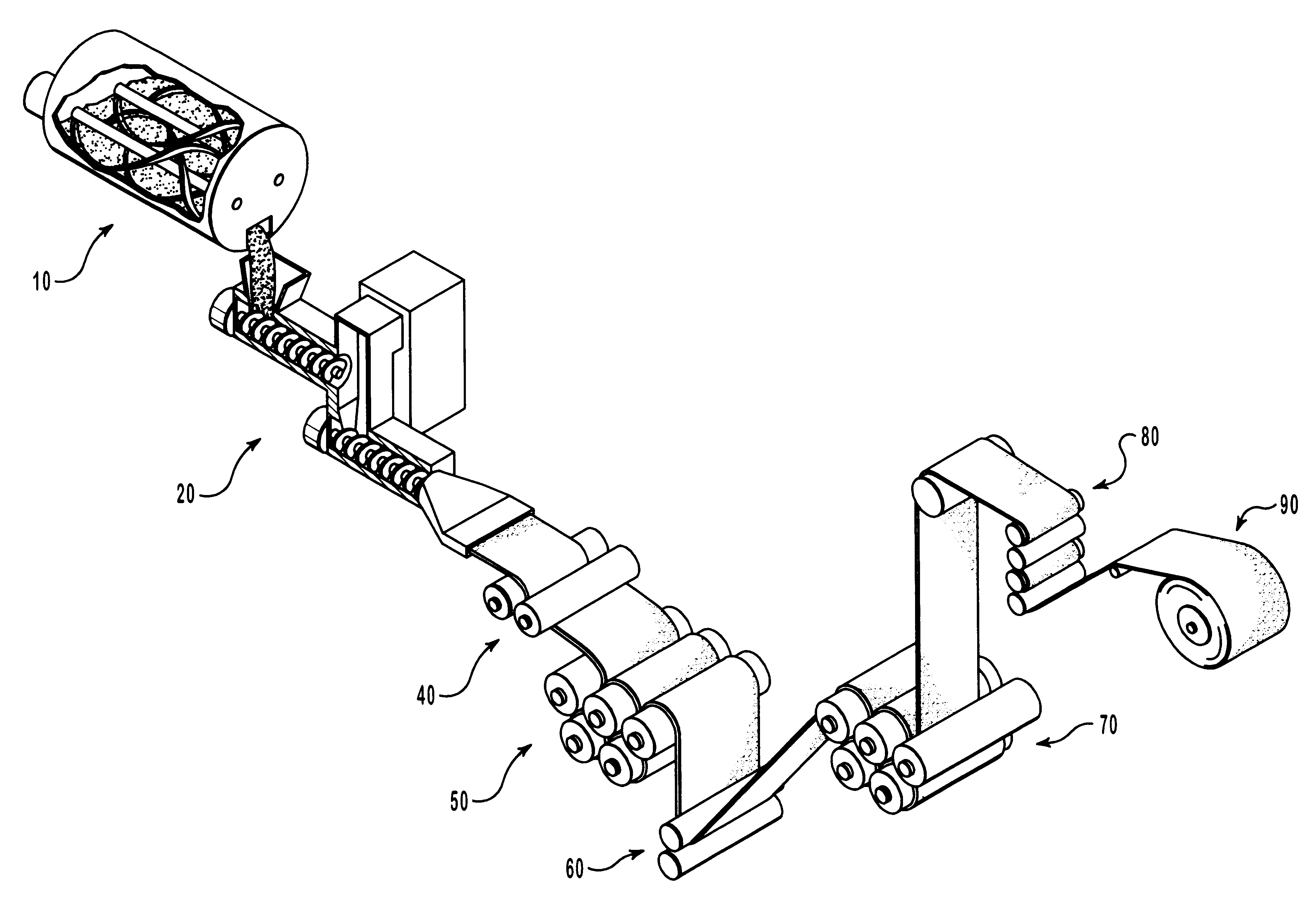

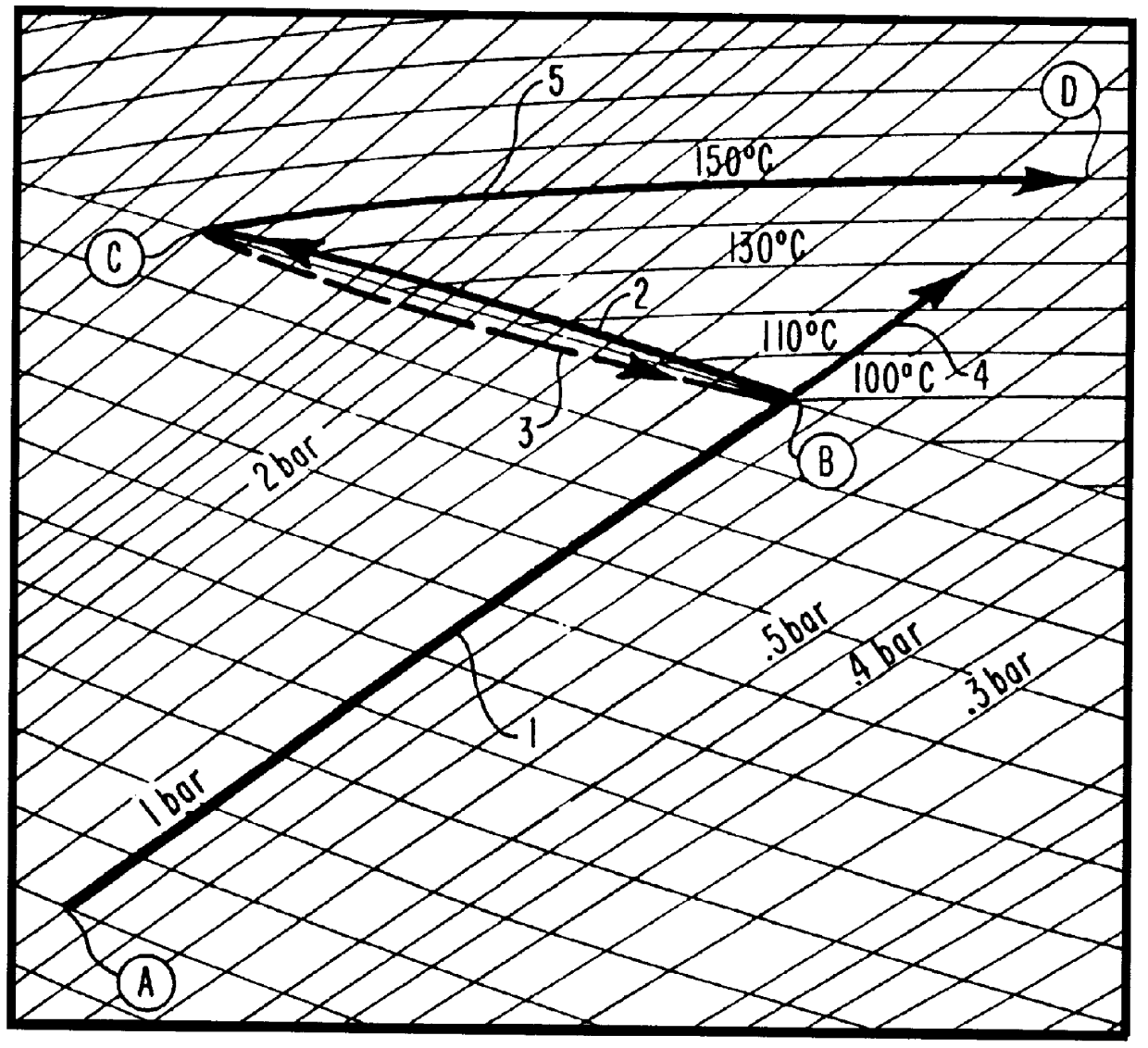

Methods for the manufacture of sheets having a highly inorganically filled organic polymer matrix

Compositions and methods for manufacturing sheets having a highly inorganically filled matrix. Suitable inorganically filled mixtures are prepared by mixing together an organic polymer binder, water, one or more inorganic aggregate materials, fibers, and optional admixtures in the correct proportions in order to form a sheet which has the desired performance criteria. The inorganically filled mixtures are formed into sheets by first extruding the mixtures and the passing the extruded materials between a set of rollers. The rolled sheets are dried in an accelerated manner to form a substantially hardened sheet, such as by heated rollers and / or a drying chamber. The inorganically filled sheets may have properties substantially similar to sheets presently made from traditional materials like paper, cardboard, polystyrene, plastic, or metal. Such sheets can be rolled, pressed, scored, perforated, folded, and glued. They have especial utility in the mass production of containers, particularly food and beverage containers.

Owner:E KHASHOGGI INDS

Molded starch-bound containers and other articles having natural and/or synthetic polymer coatings

Compositions, methods, and systems for manufacturing articles, particularly containers and packaging materials, having a particle packed, highly inorganically filled, cellular matrix are disclosed. Suitable inorganically filled mixtures are prepared by mixing together a starch-based binder, a solvent, inorganic aggregates, and optimal admixtures, e.g., fibers, mold-releasing agents, rheology-modifying agents, plasticizers, coating materials, and dispersants, in the correct proportions to form an article which has the desired performance criteria. The inorganically filled mixtures have a predetermined viscosity and are heated between molds at an elevated temperature and pressure to produce form-stable articles having a desired shape and a selectively controlled cellular, structure matrix. The molded articles may be placed in a high humidity chamber to obtain the necessary flexibility for their intended use. The articles may be manufactured to have properties substantially similar to articles presently made from conventional materials like paper, paperboard, polystyrene, plastic, or other organic materials. They have especial utility in the mass-production of containers, particularly food and beverage containers.

Owner:EARTHSHELL SPE

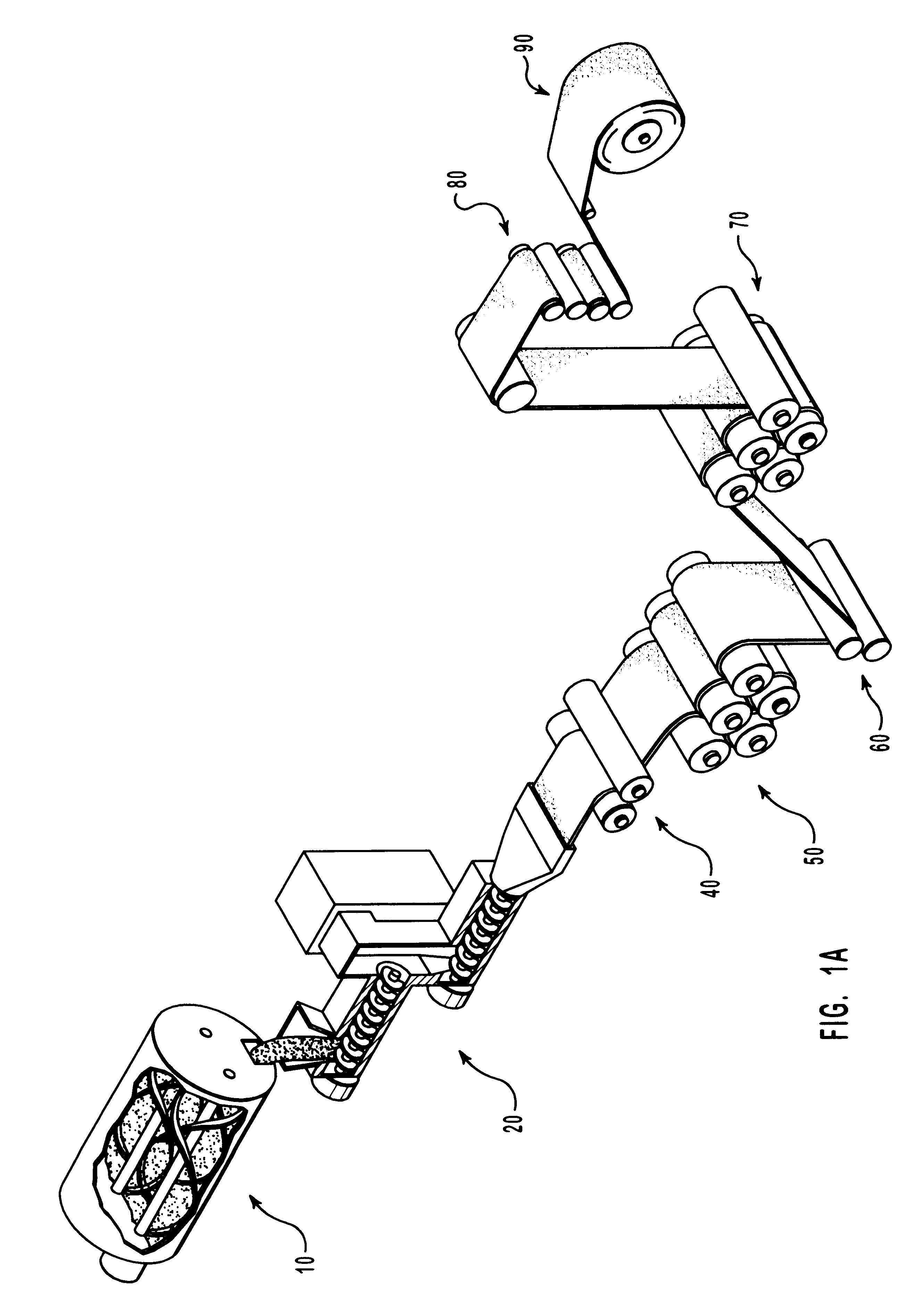

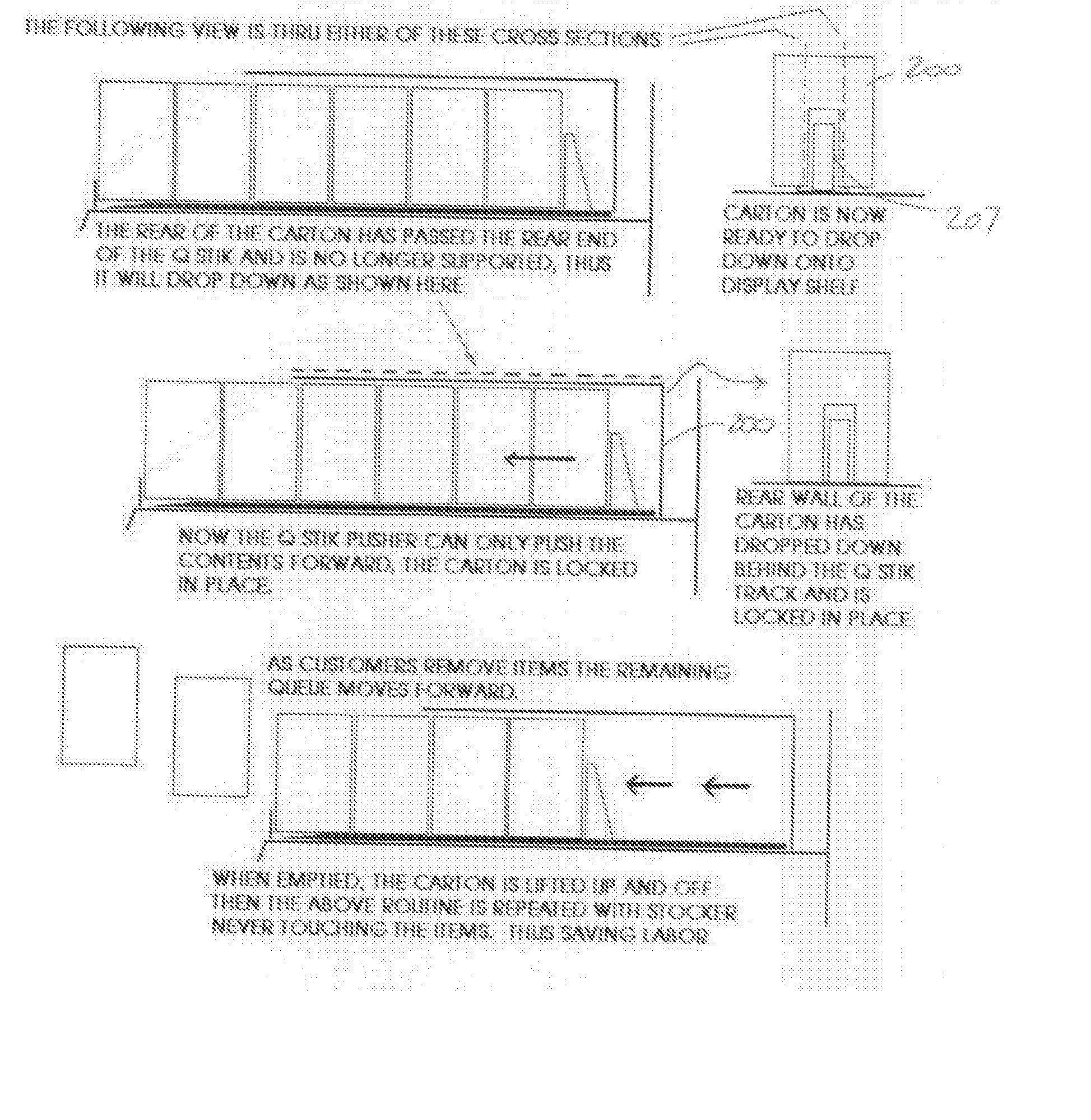

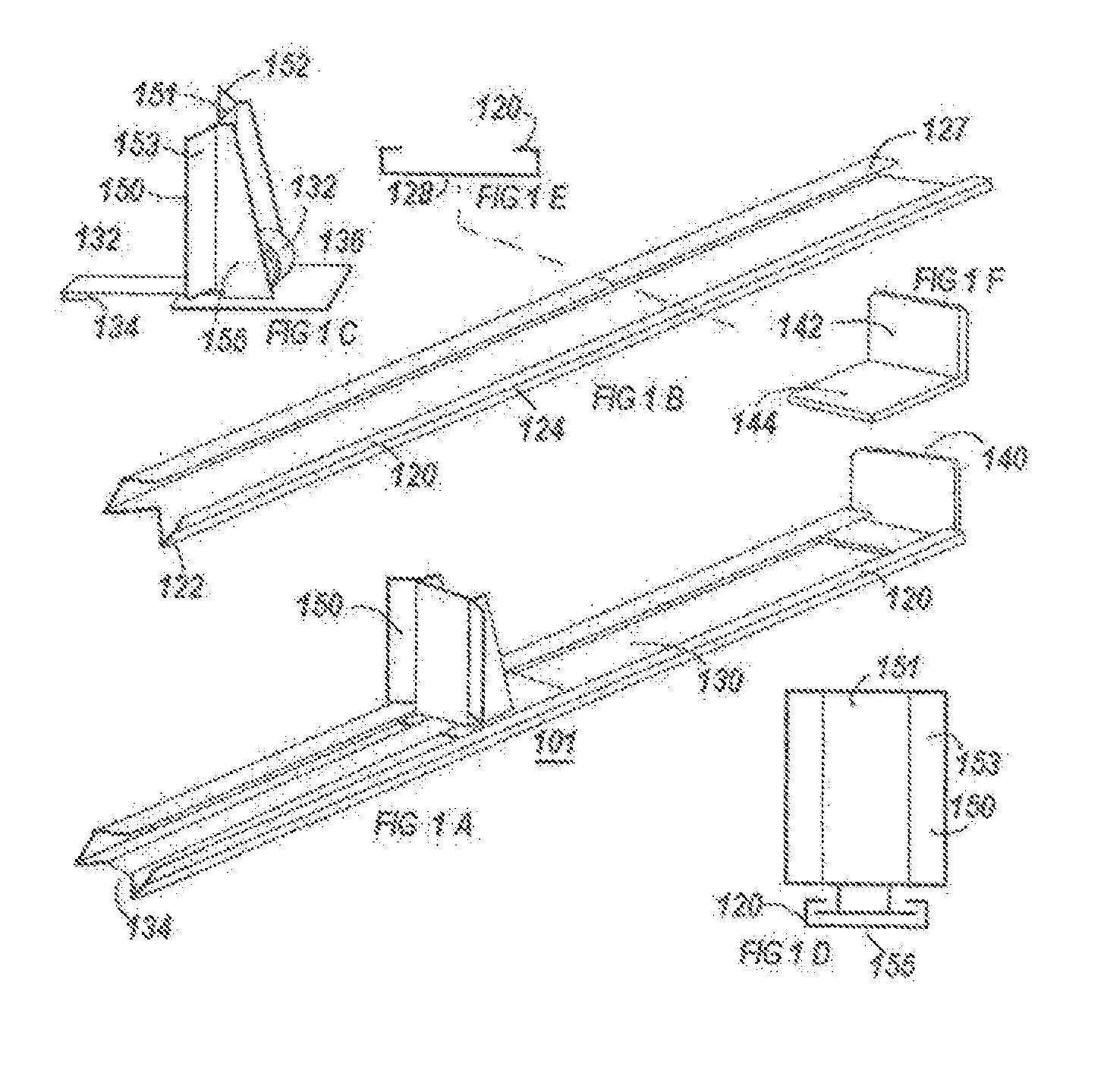

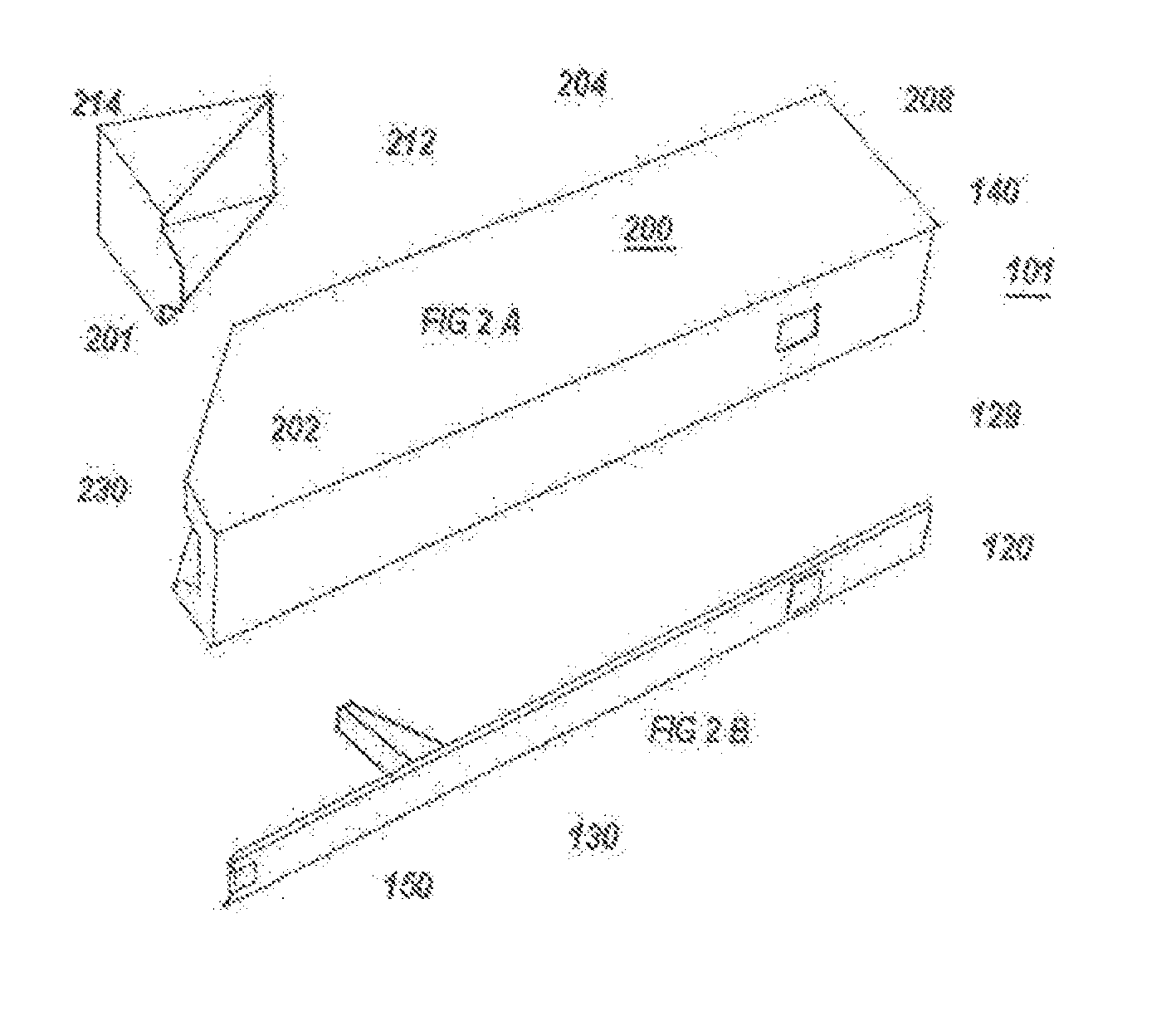

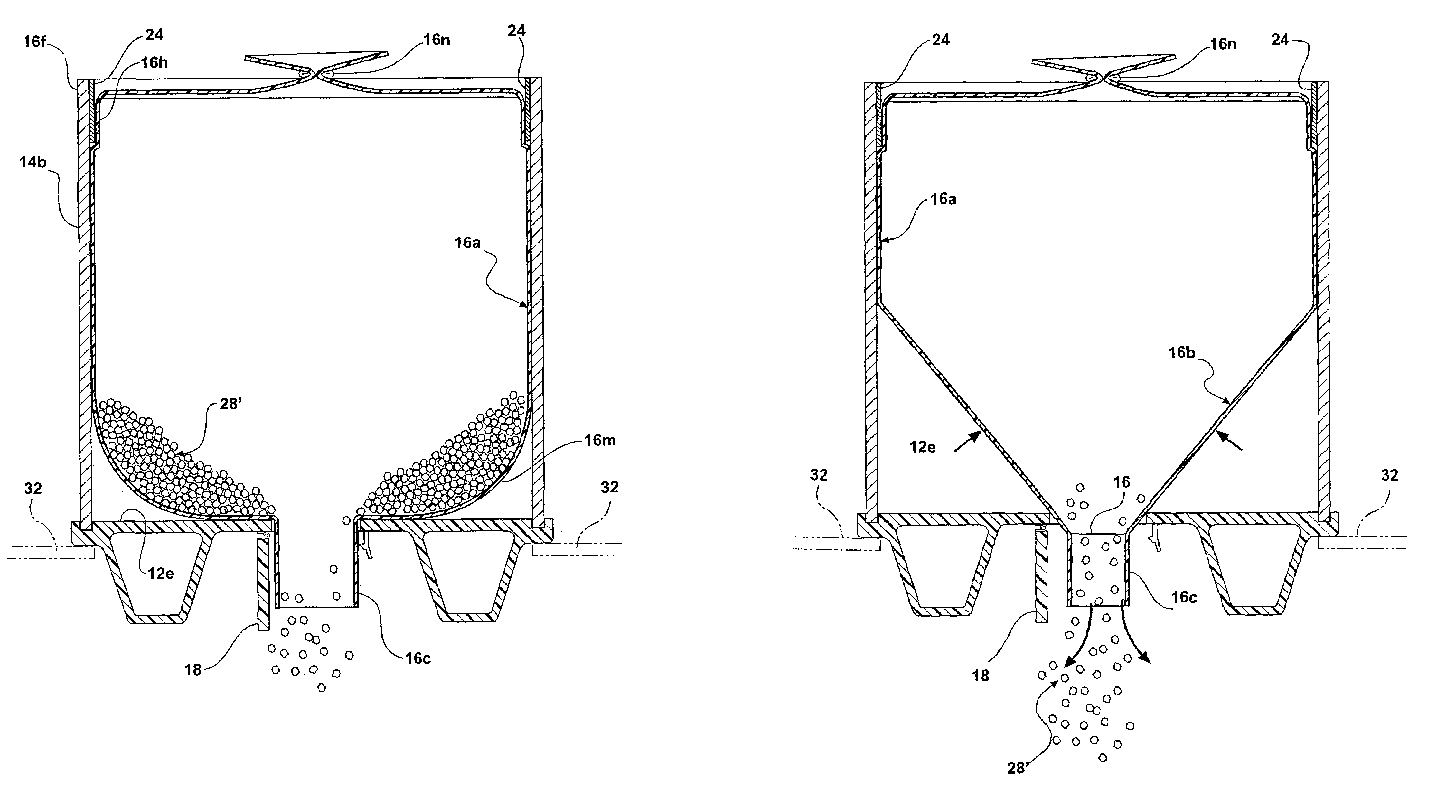

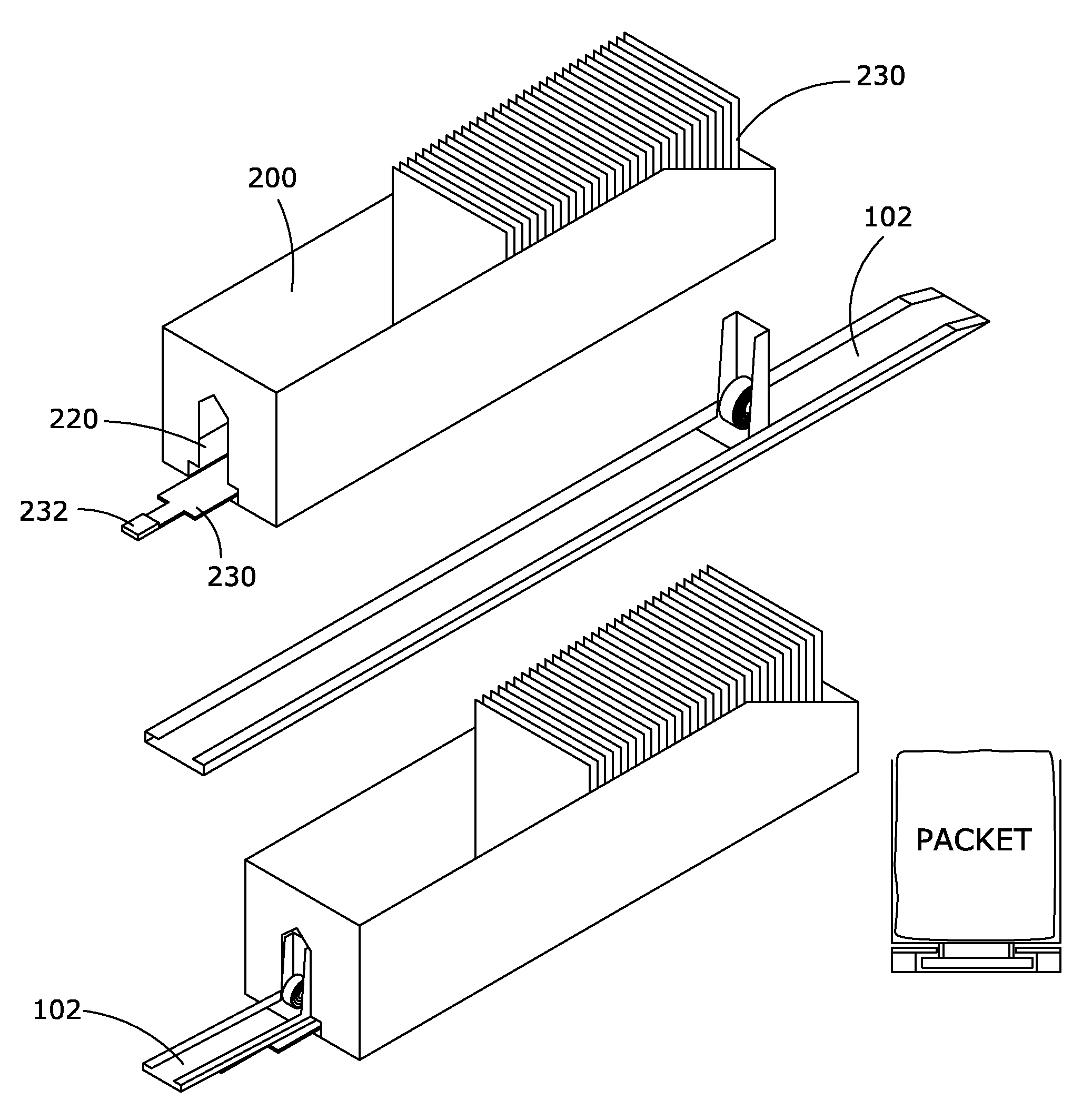

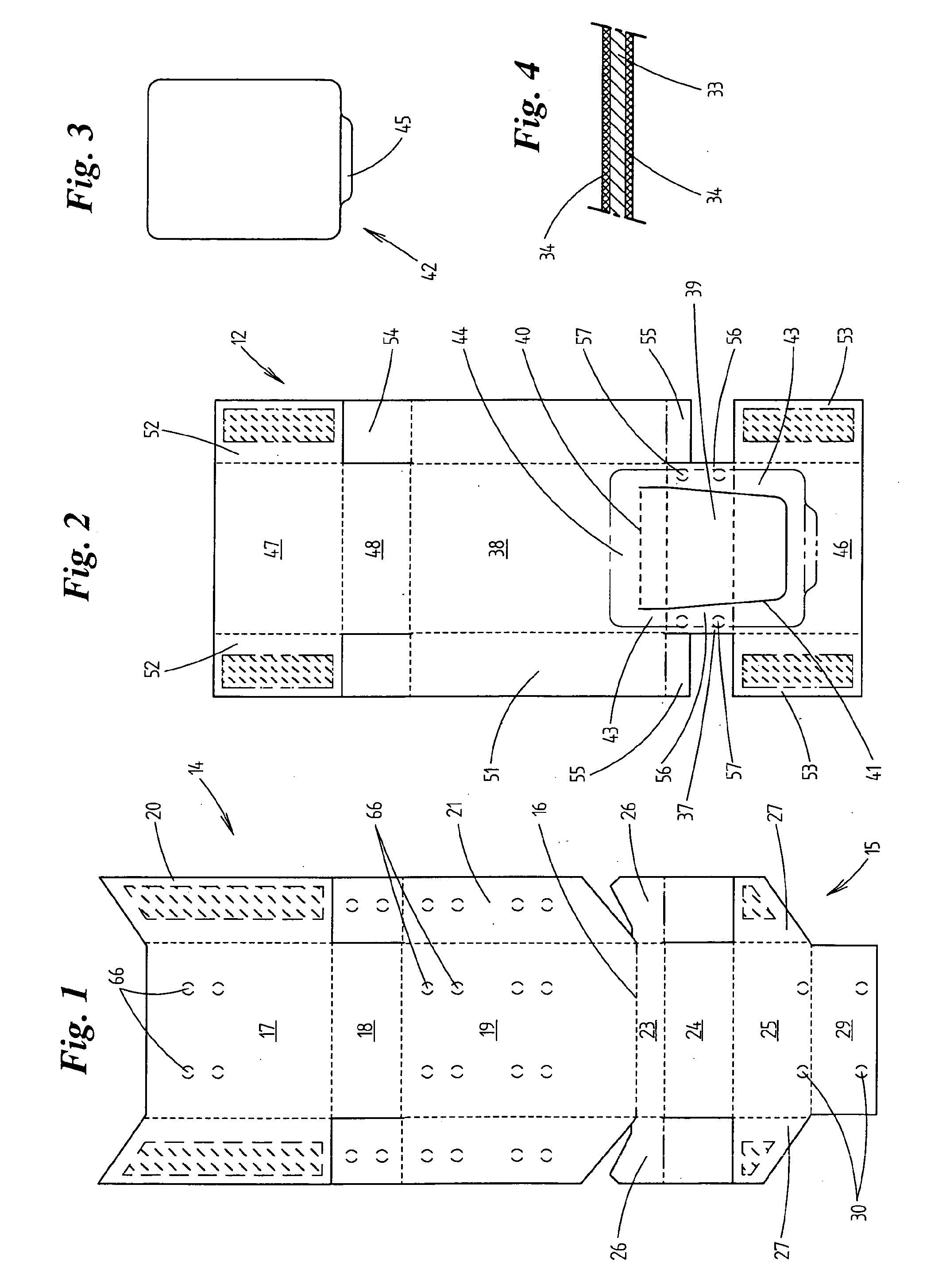

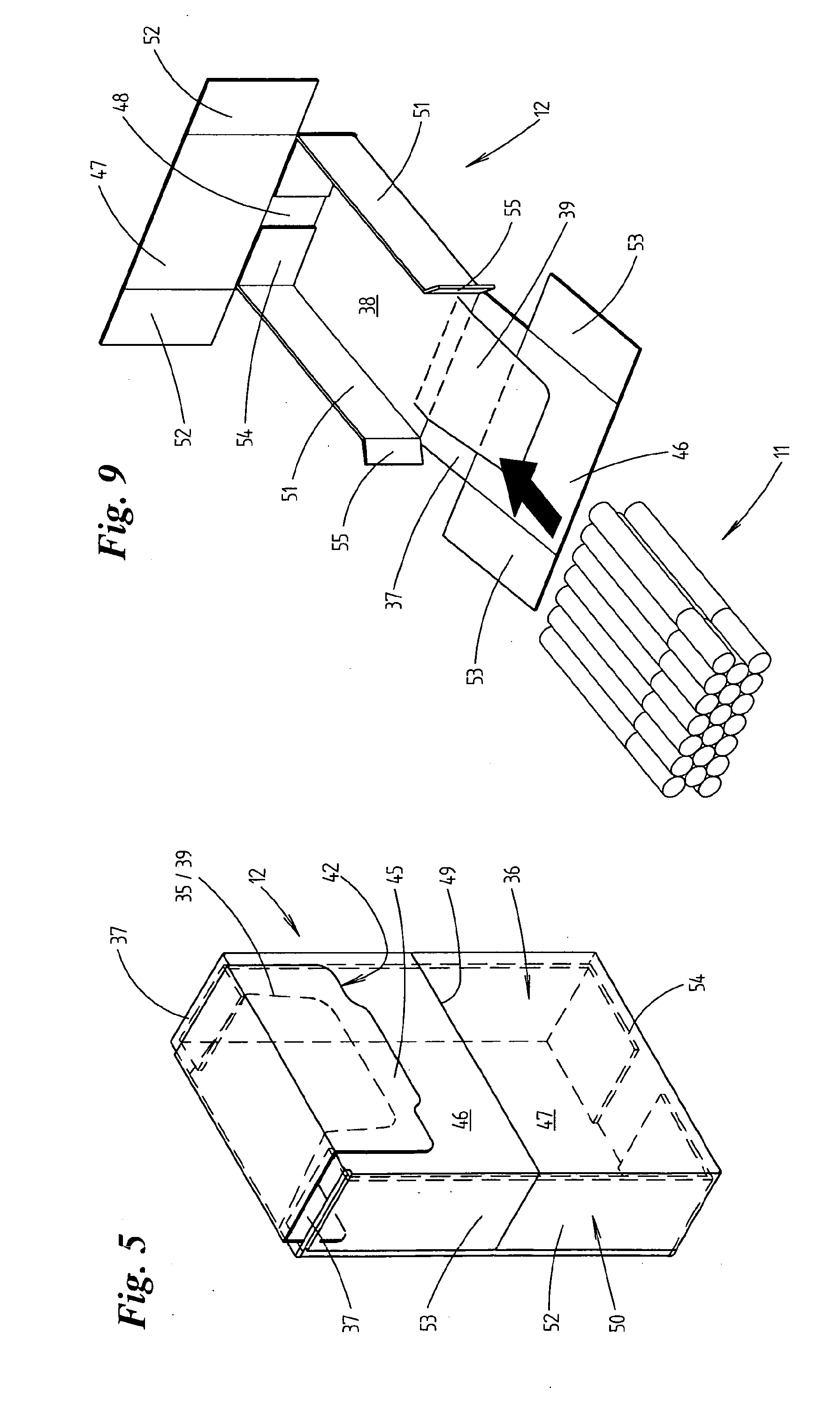

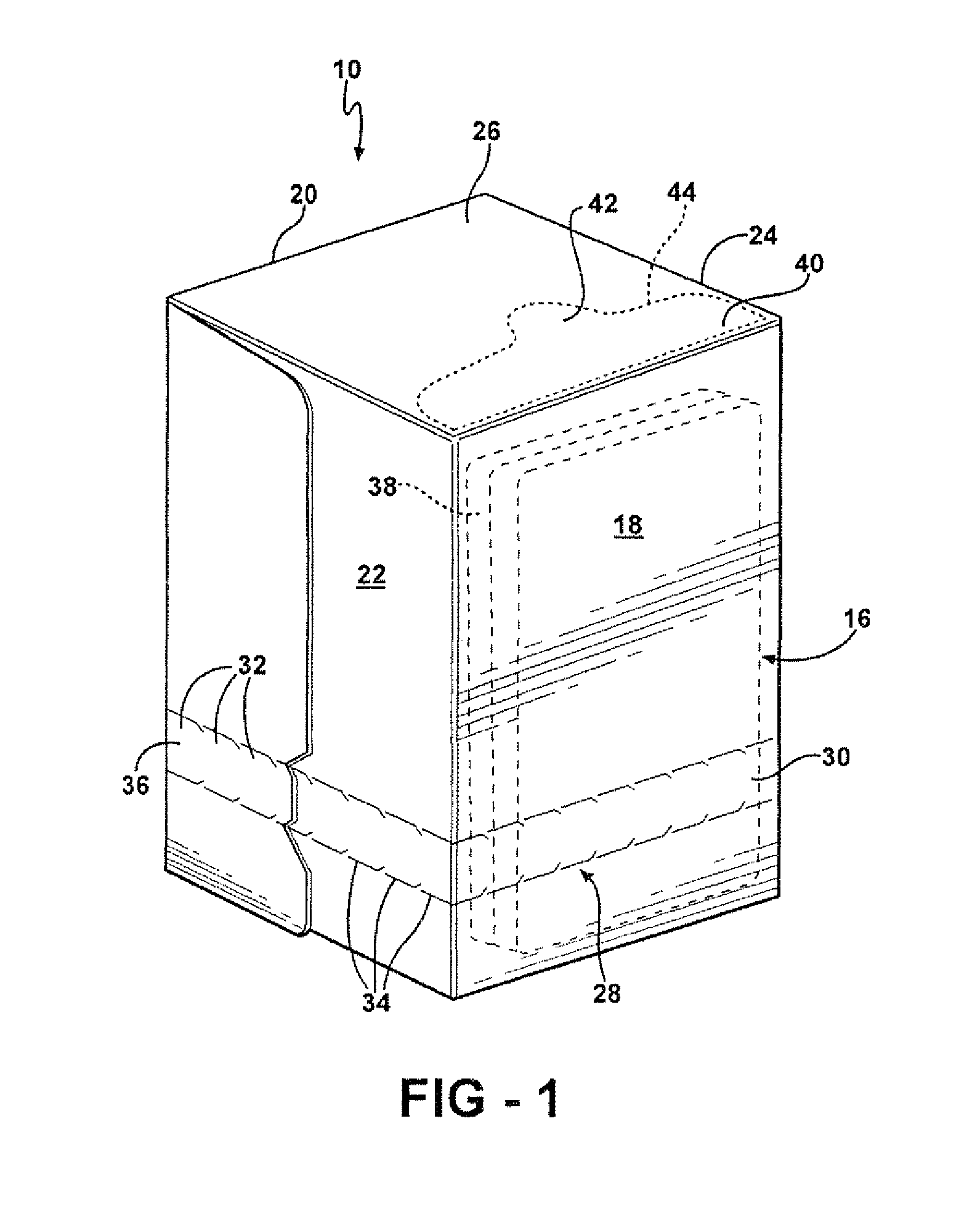

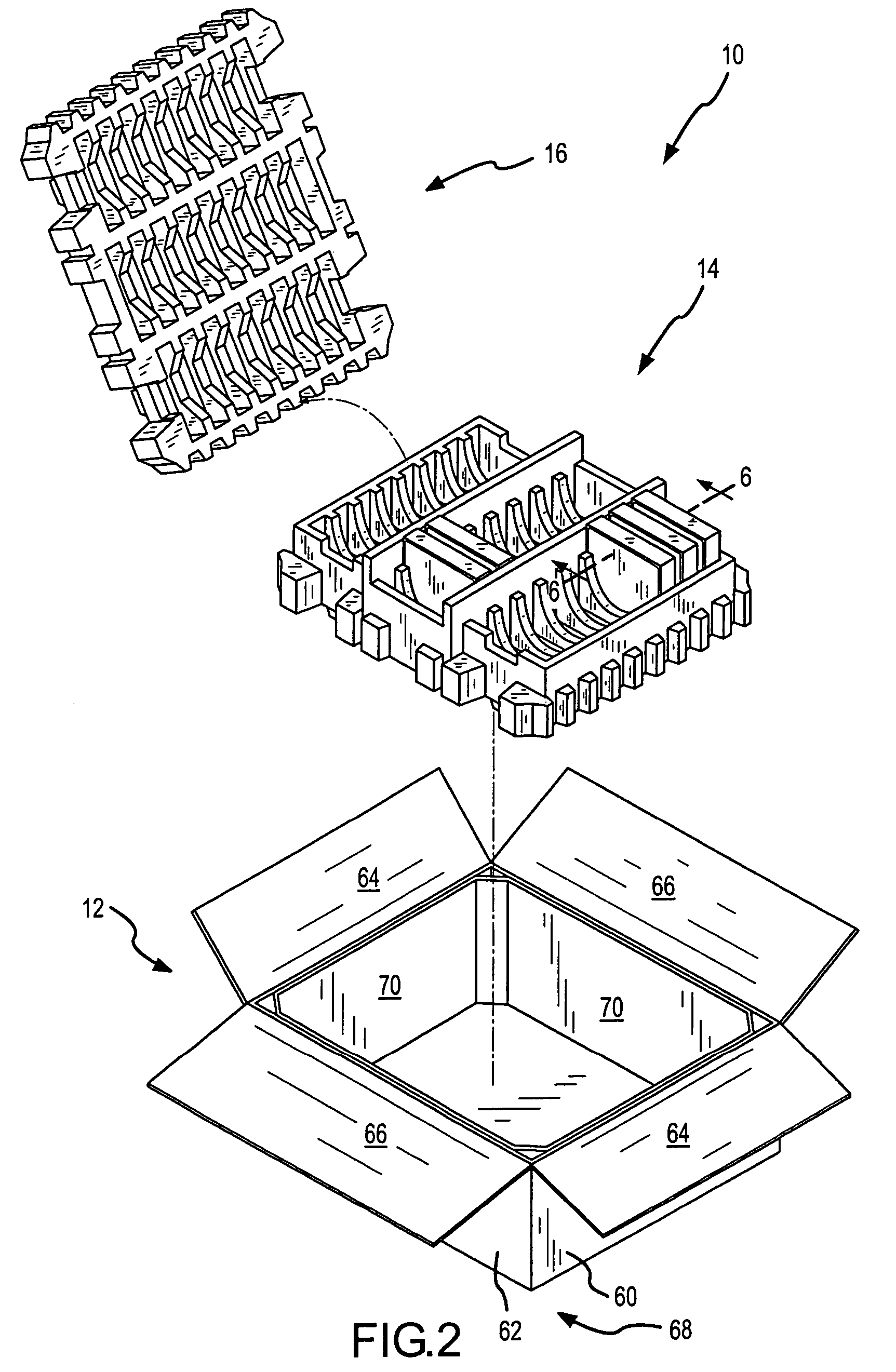

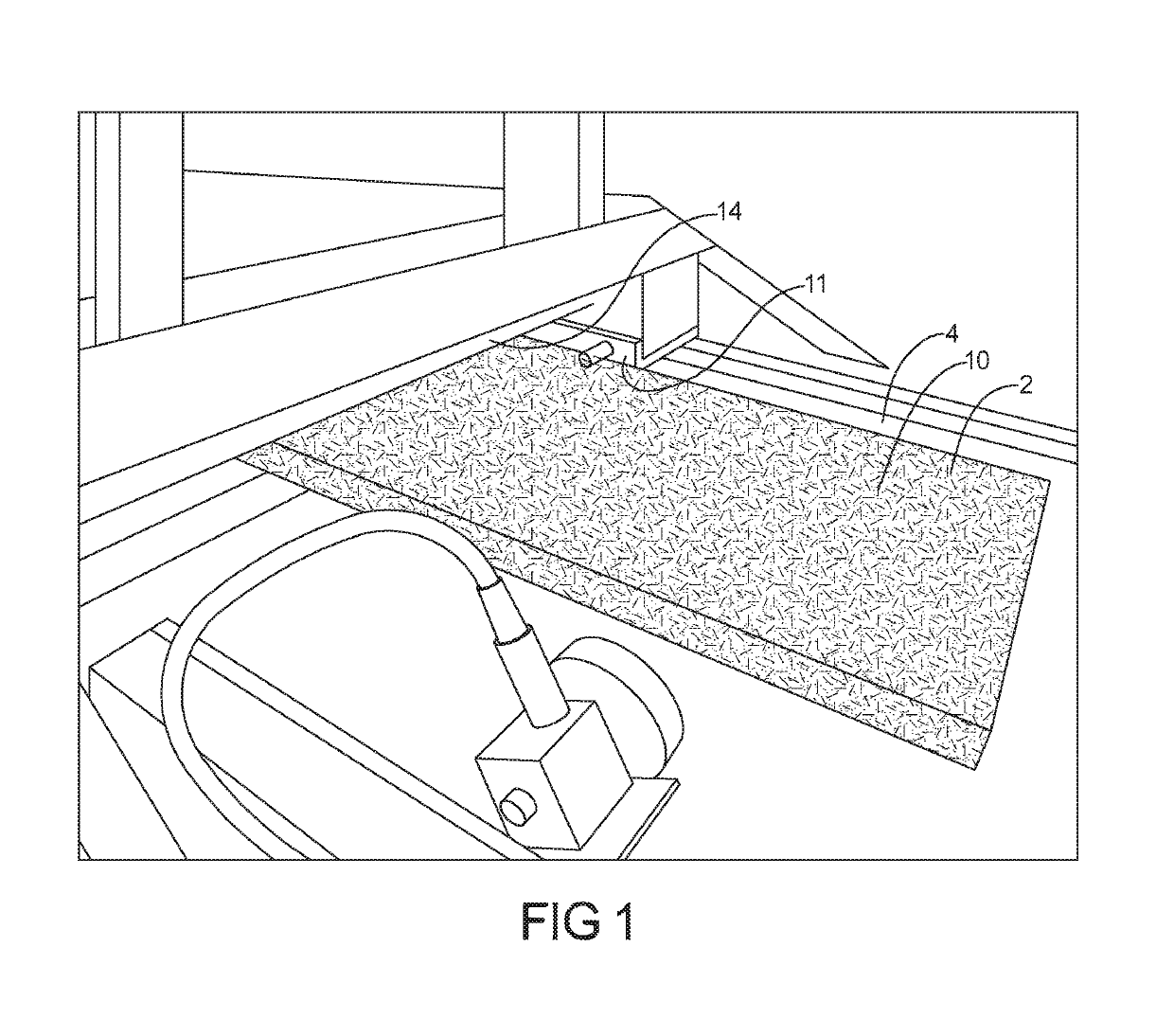

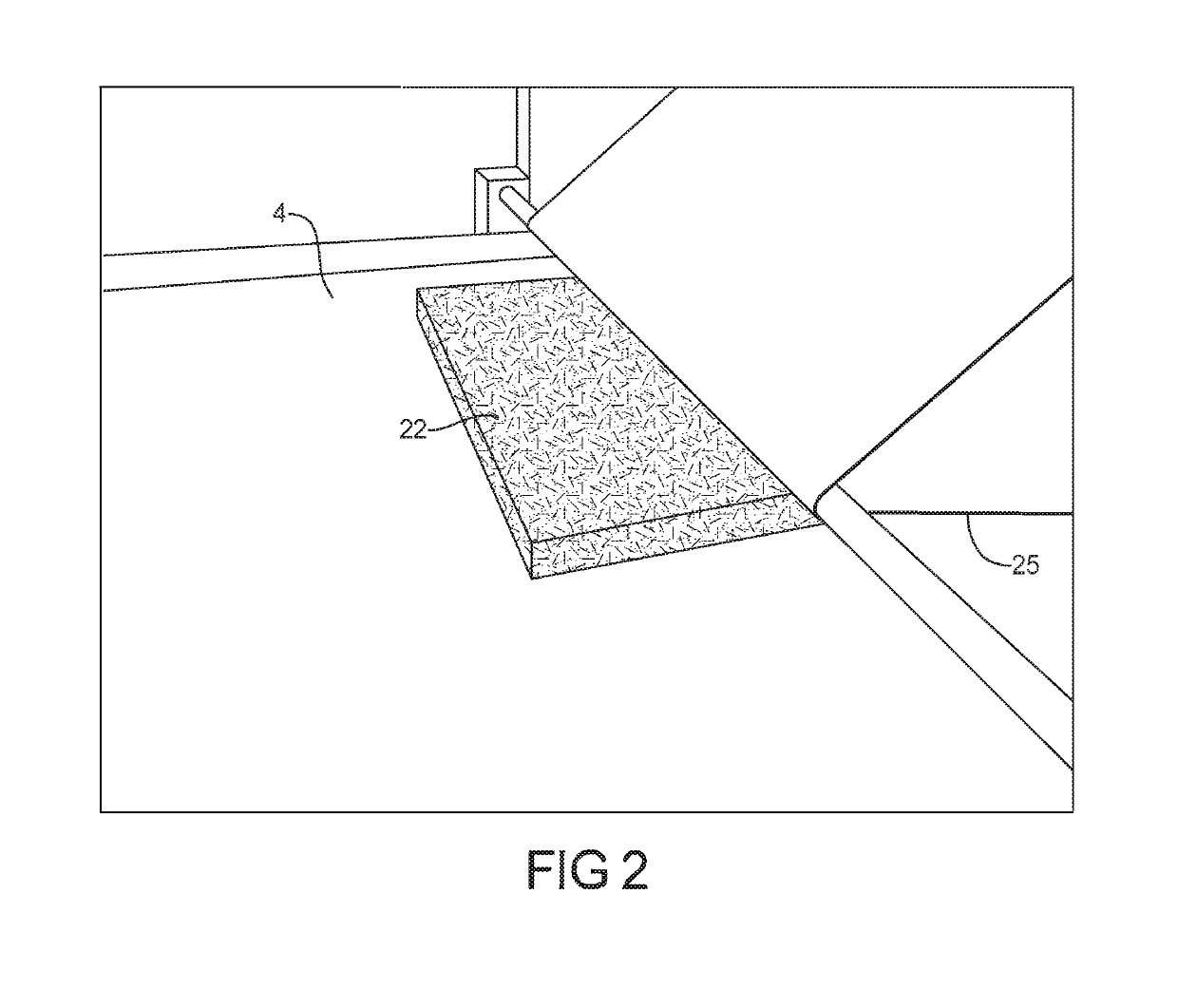

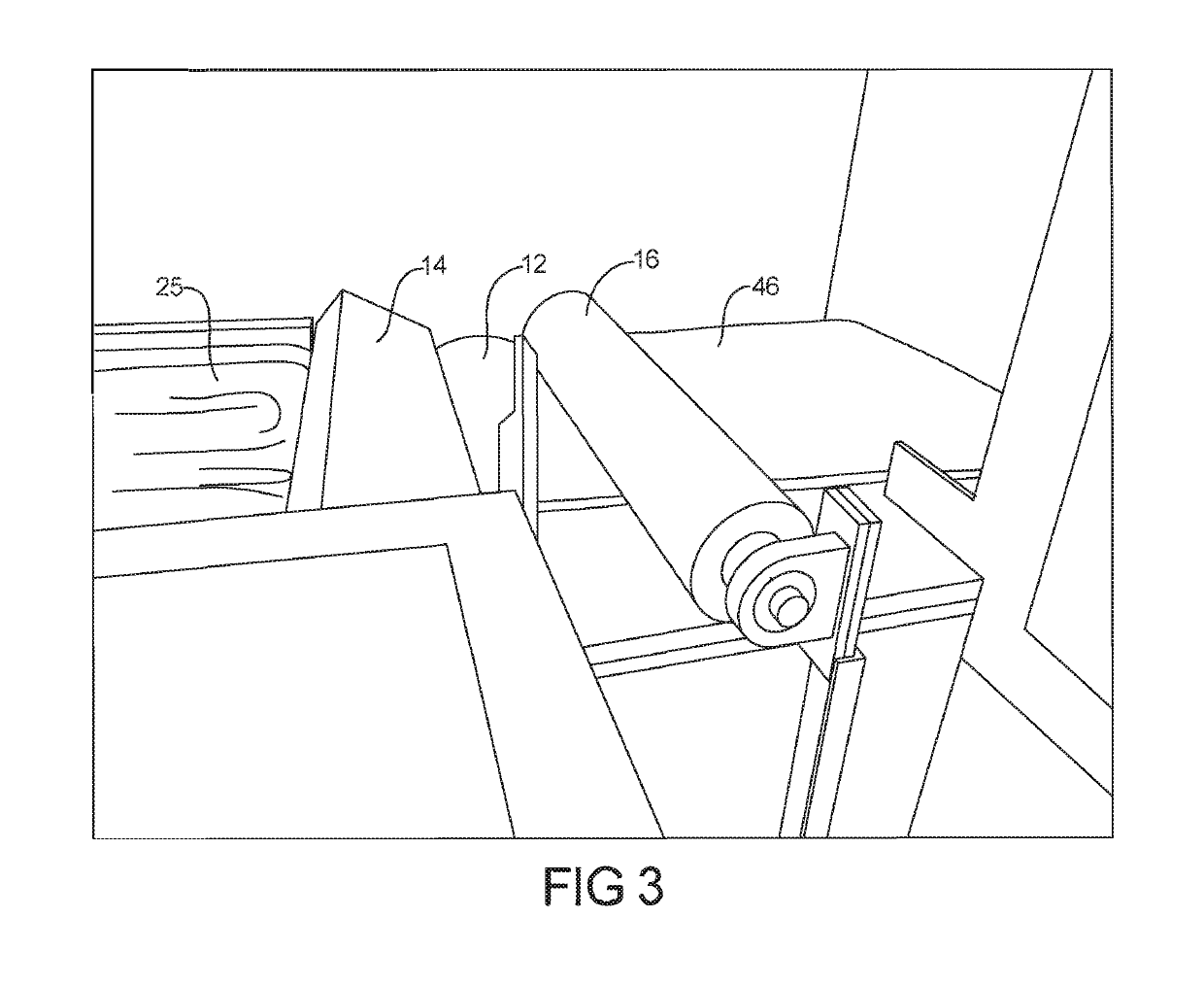

Spring driven method and apparatus for in-carton display and fronting of merchandise items

A spring alignment mechanism utilizes a guide inserted into a display carton below merchandise items. A spring-driven rear pull member travels on the guide so that as items are removed from the carton, remaining items are pulled forward. Merchandise items with rounded edges may rest on the directly on the carton, so that the guide may be inserted beneath the items. Other items may be supported on cardboard support ribs built into the bottom of the carton or provide on a carton insert.

Owner:CLOSE & SOLUTIONS

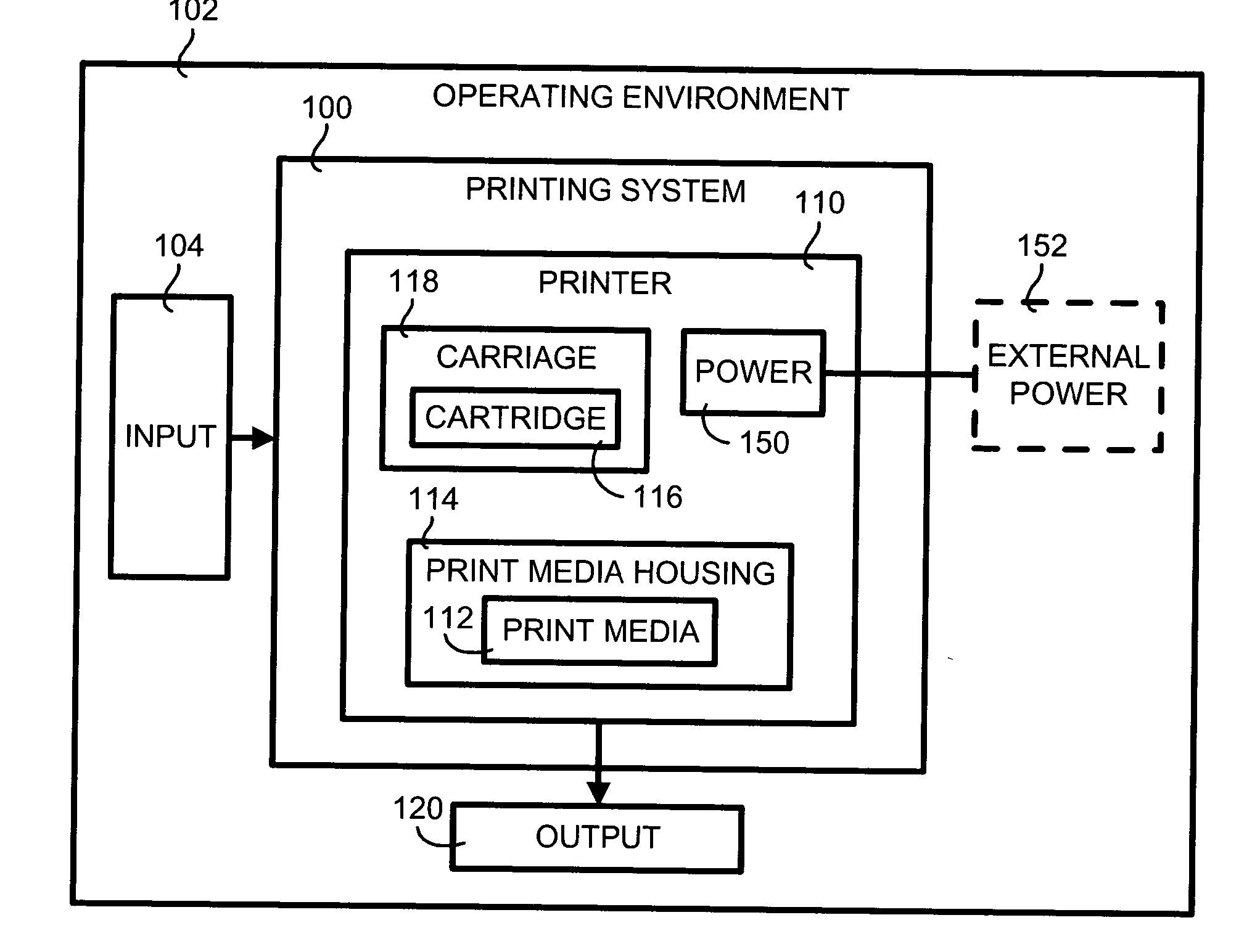

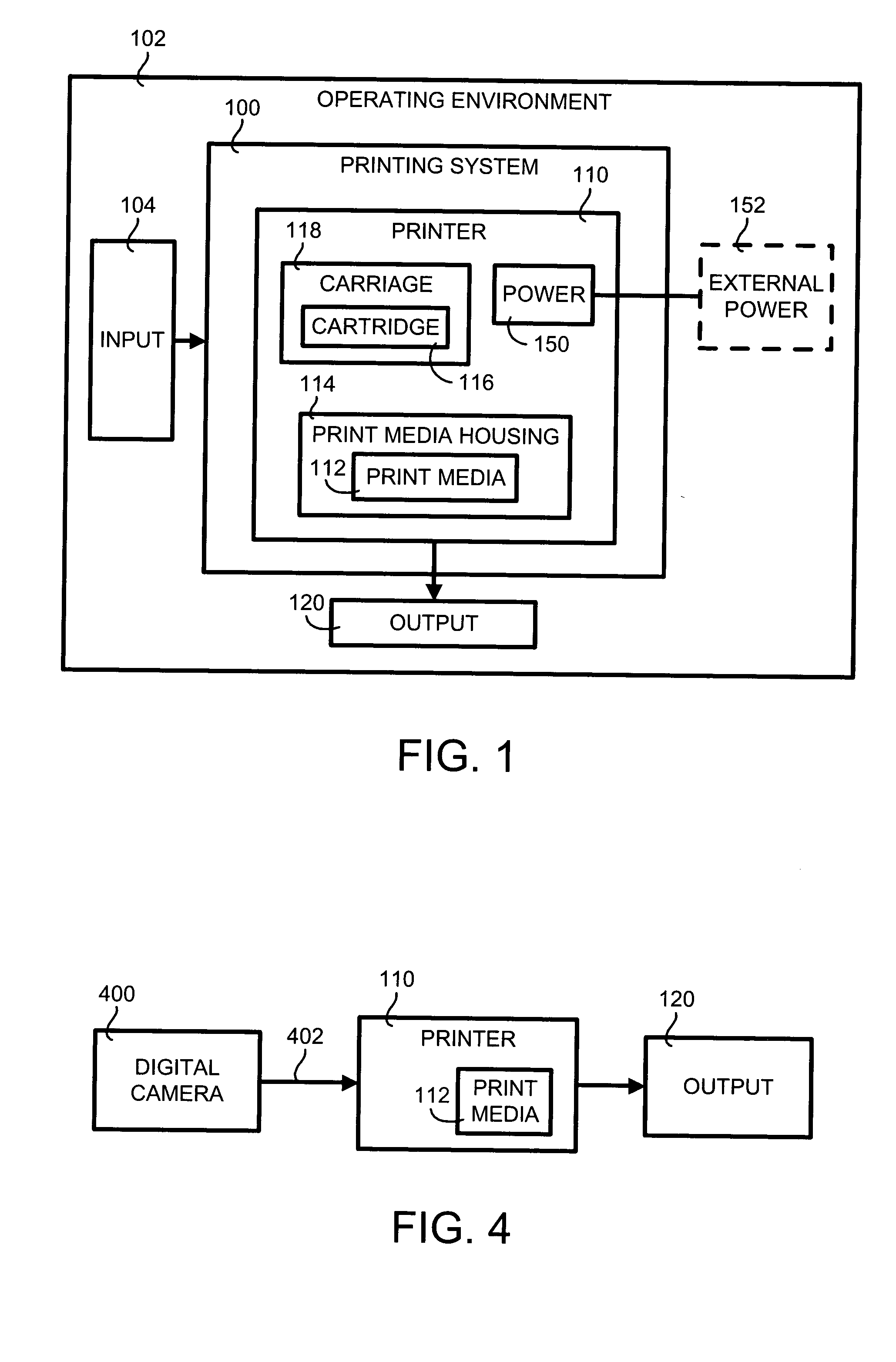

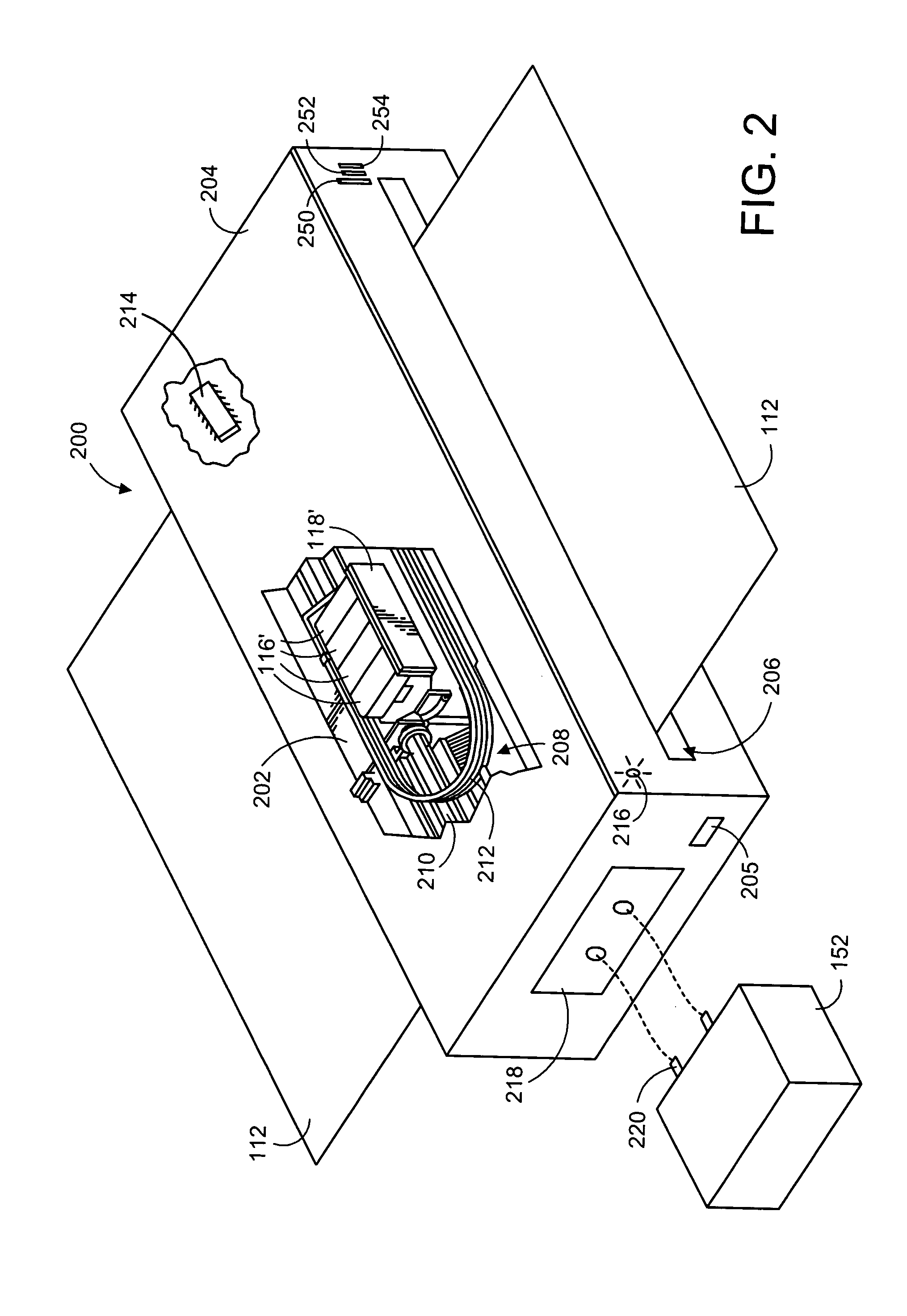

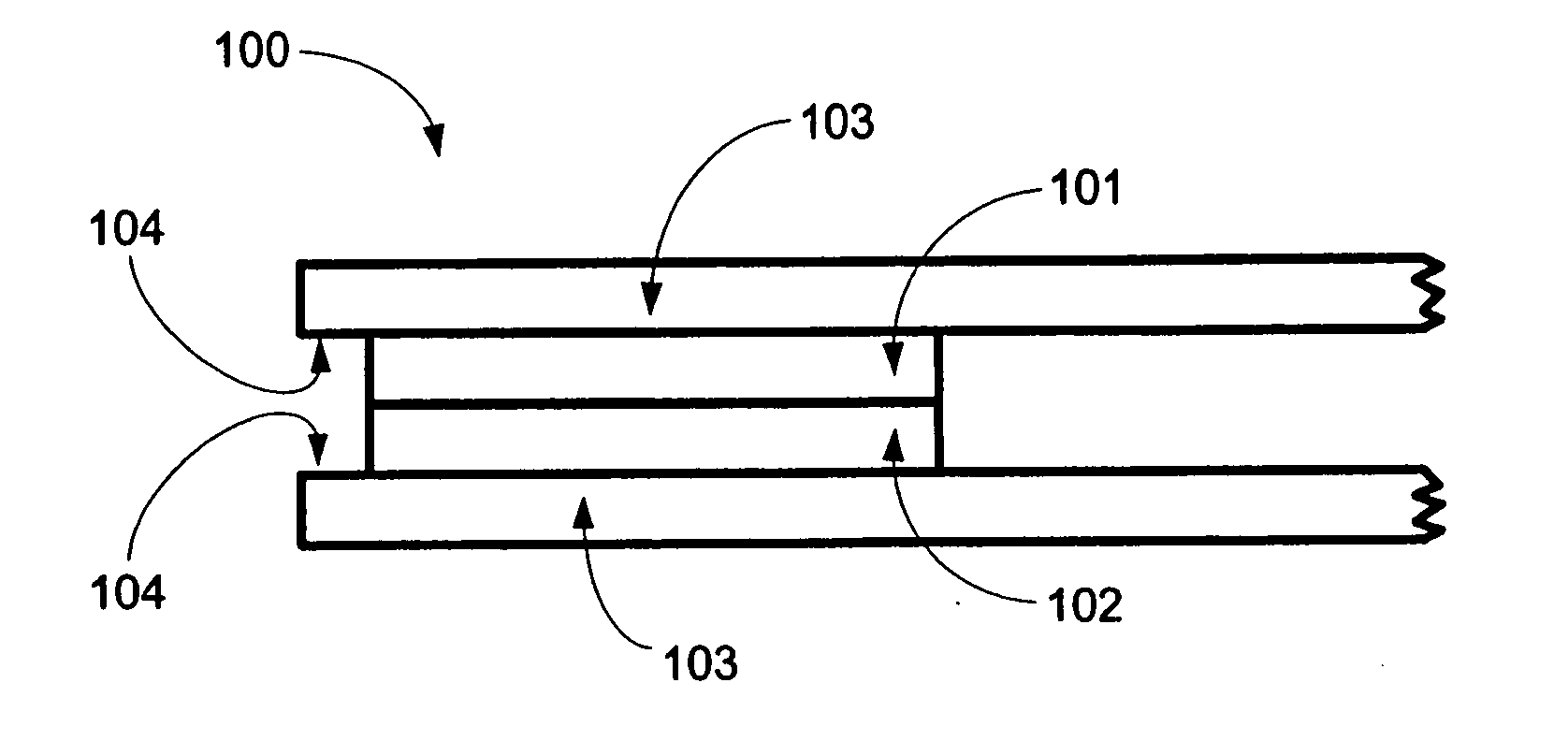

Recyclable printing mechanism and related method

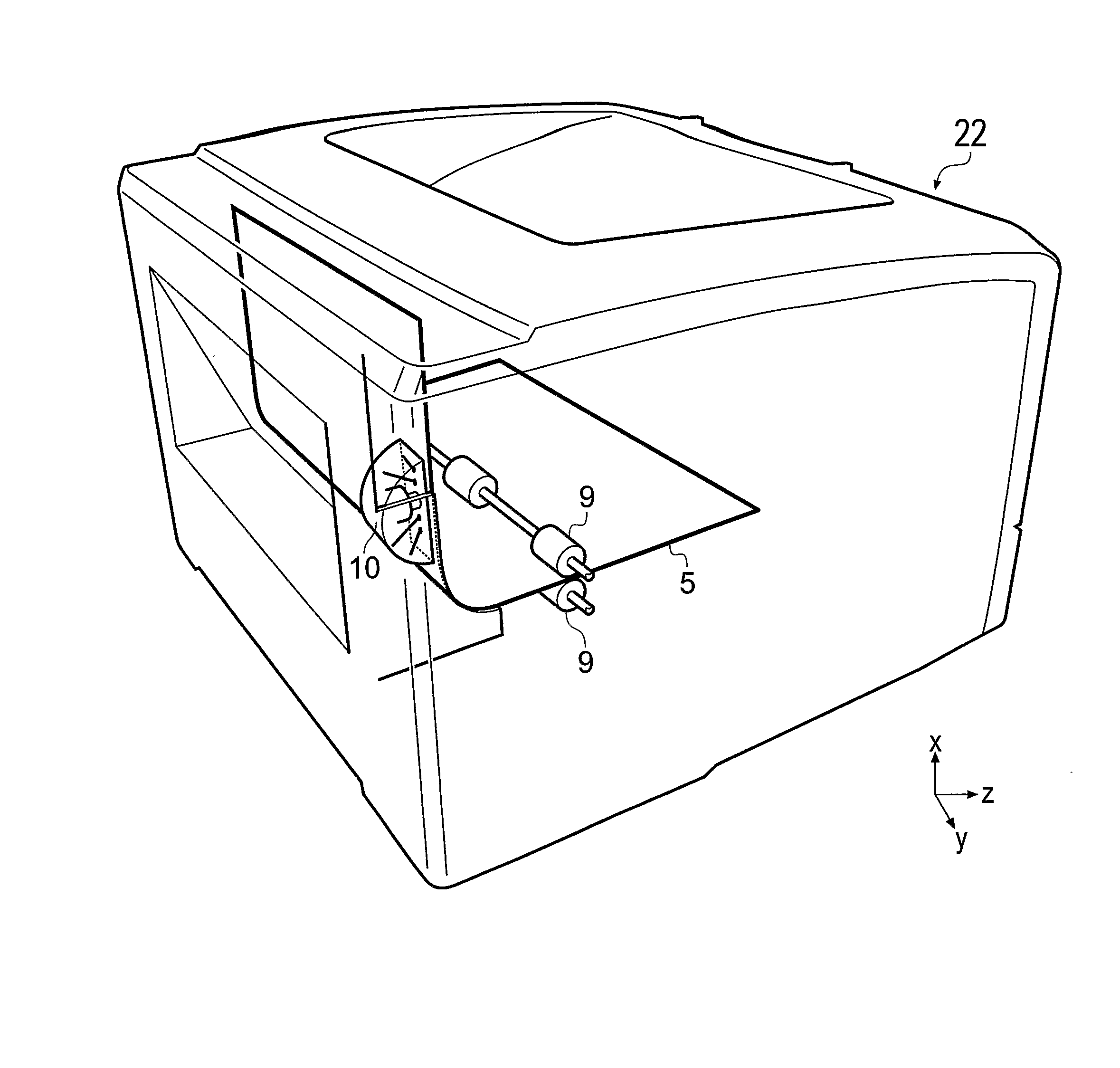

InactiveUS20050030554A1Digitally marking record carriersDigital computer detailsCardboardCellulose fiber

An embodiment of a printing apparatus is provided as including a chassis, a print engine supported by the chassis, and a casing of a cardboard material comprising cellulose fiber attached to the chassis and surrounding the print engine when attached to the chassis. A business method for recycling or refurbishing a recyclable printing mechanism is also provided.

Owner:HEWLETT PACKARD DEV CO LP

Cohesive reclosure systems and containers using same

This invention relates to resealable closure systems that are useful in containers, such as those used in packaging goods. The reclosure system features cohesive layers which are bonded to each other to provide a resealable closure. The cohesive bond layers are separable to provide opening of the container and access to the interior of the container and / or contents. The cohesive layers have low blocking characteristics. The reclosure systems are useful for flexible packaging, such as polymeric film and cloth packages, and rigid packaging, such as fiberboard, cardboard, paper, and polymeric foam. The reclosure systems may be opened and resealed multiple times. The closure system is resistance to contamination by oils, debris, solvents, and water. The reclosure is cold sealable with finger pressure.

Owner:AVERY DENNISON CORP

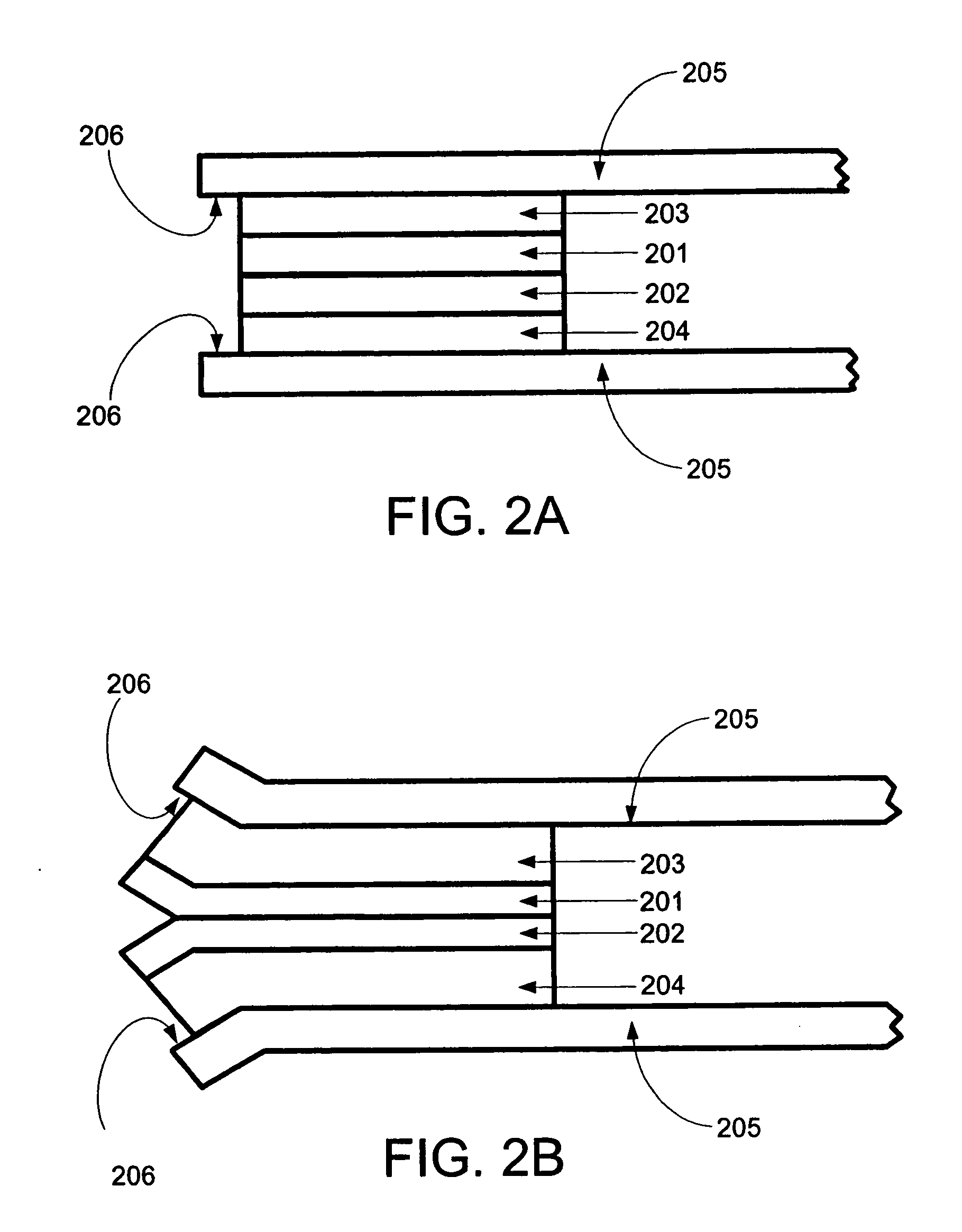

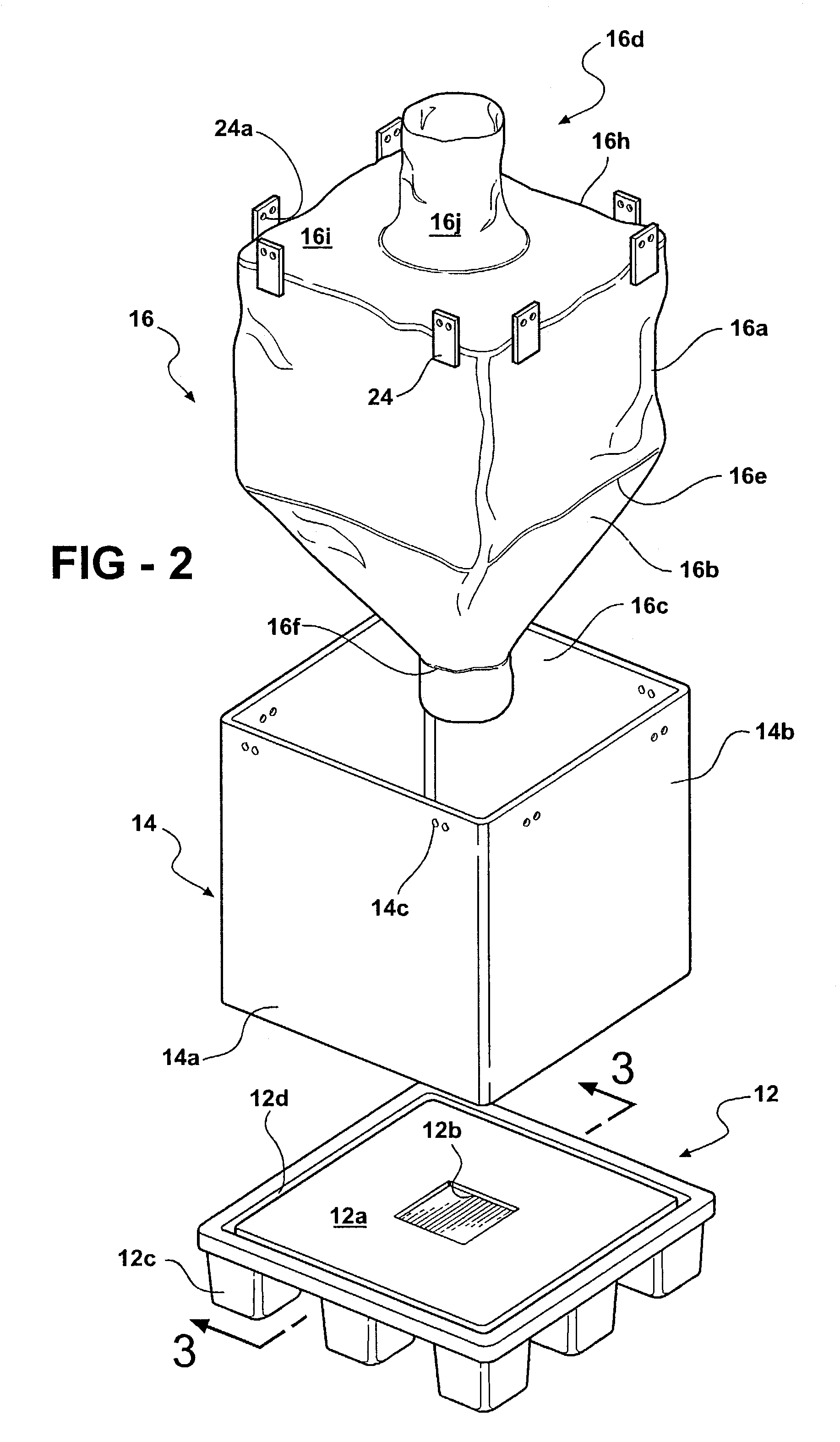

Bulk container with plastic liner

InactiveUS6968946B2Easy dischargeEasy to controlOther accessoriesLiquid transferring devicesCardboardEngineering

A container including a rigid plastic pallet having a platform portion defining a central discharge port, a tubular cardboard sleeve supported at a lower edge thereof on the pallet, and a flexible plastic liner positioned within the sleeve. The liner includes an upper portion of uniform cross-sectional configuration conforming to the cross-sectional configuration of the sleeve and a lower portion of downwardly and inwardly tapering configuration terminating in a bottom liner opening positioned proximate the pallet discharge port. The effective combined height of the upper and lower portions of the liner, with the upper edge of the upper liner portion secured to the upper edge of the sleeve, is greater than the distance from the upper edge of the sleeve to the upper face of the pallet so that the sides of the lower portion may bulge outwardly in response to the loading of contents into the liner to at least partially fill the annular void defined between the sleeve and the lower portion of the liner with the liner fully extended. The pallet port is selectively closed by a trap door pivotedly mounted on the pallet. The pallet port is selectively closed by a trap door pivotally mounted on the pallet and the liner includes a discharge spout extending downwardly from the lower portion of the liner for passage through the pallet discharge port.

Owner:SHUERT LYLE H

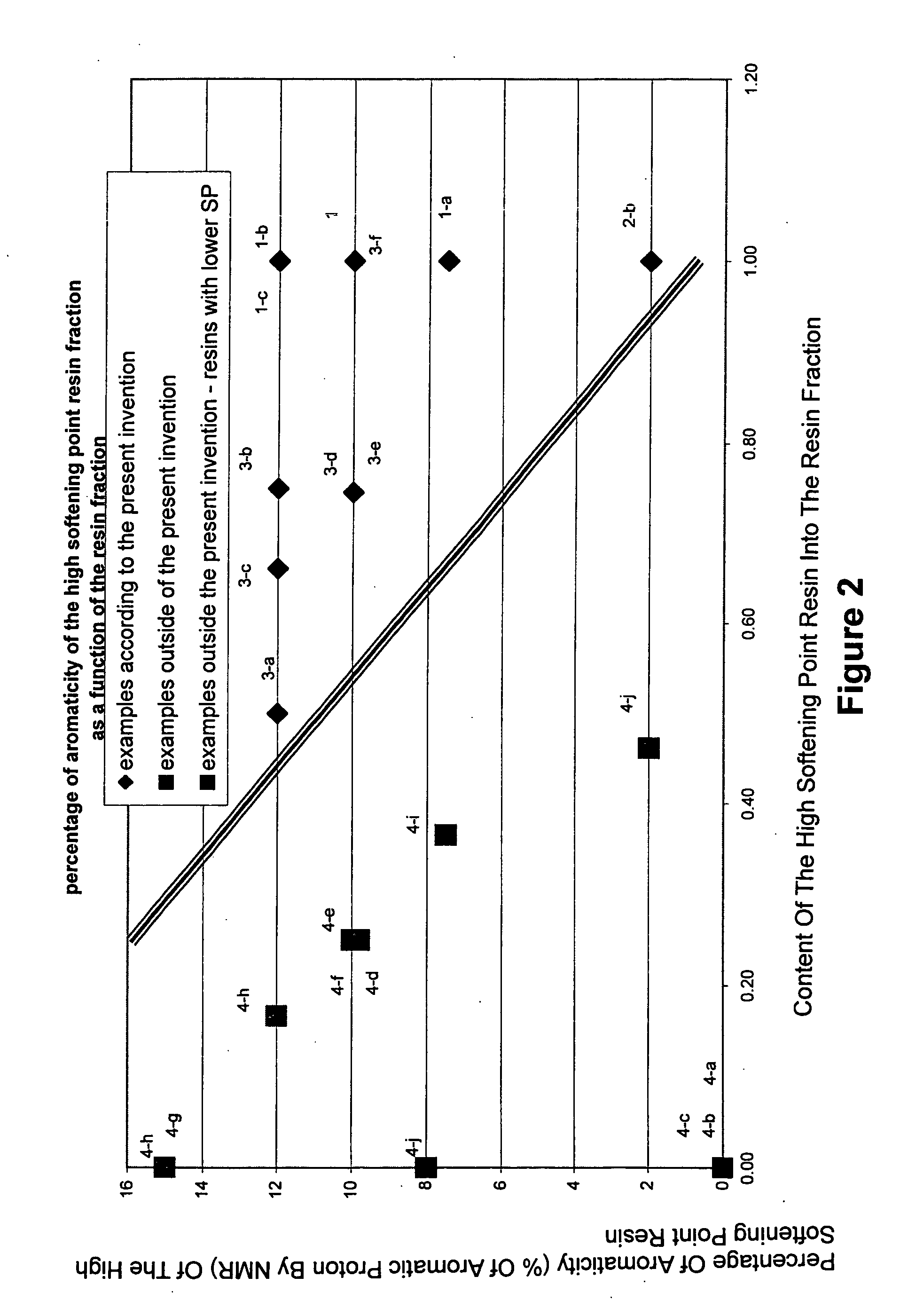

Hot Melt Adhesive Based on Olefin Block Copolymers

ActiveUS20110021103A1Improve spray characteristicsGood viscosity stabilityPersonal careLayered product treatmentCardboardCrystallinity

A hot melt adhesive composition, comprising a blend of components including about 5% to about 50% by weight of an olefin block copolymer; about 10% to about 70% by weight of a first tackifying resin having a softening point of at least about 95° C.; about 0 to 65% of a second tackifying resin that is different than the first tackifying resin; about 0% to about 60% by weight of a plasticizer; about 0% to about 20% by weight of an aromatic reinforcing resin having a softening point equal to or higher than 115° C.; about 0.1% to about 5% by weight of a stabilizer; and about 1% to about 40% by weight of a secondary polymer that is different from the olefin block copolymer, the first and second tackifying resins and the reinforcing resin, having relatively low crystallinity, which low crystallinity is equal to or less than 250 Joules / gram, wherein the components total 100% by weight of the composition, and the viscosity of the composition is equal to or less than about 20,000 mPa·s at 163° C. Laminates, especially those used in disposable soft goods, and methods of making such laminates using the hot melt adhesive composition are also described. The adhesive composition and / or laminate may be used in making a variety of end products such as a disposable diaper, a sanitary napkin, a bed pad, a bandage, a surgical drape, a tape, a label, a plastic sheet, a nonwoven sheet, a paper sheet, a cardboard, a book, a filter, or a package.

Owner:BOSTIK INC

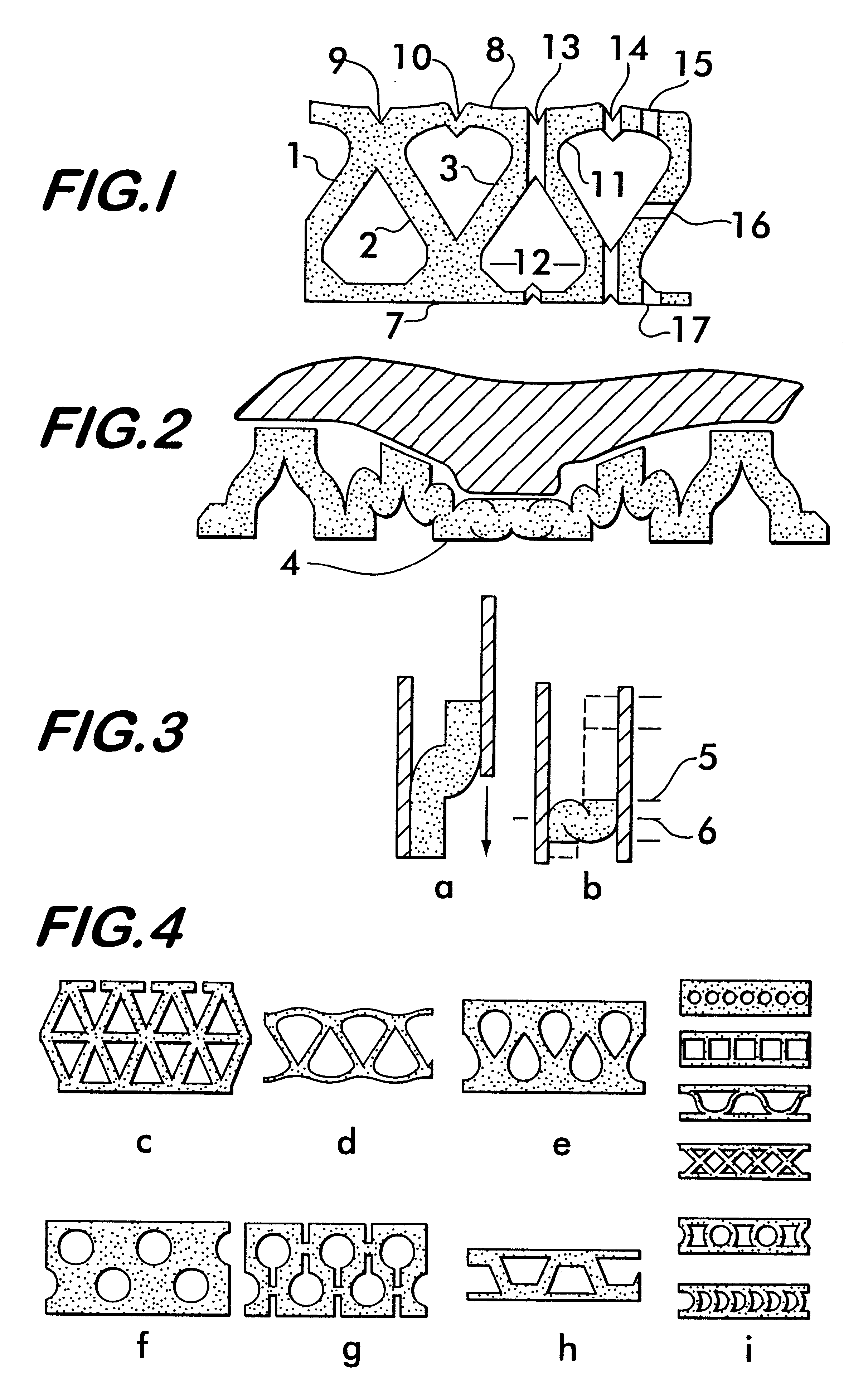

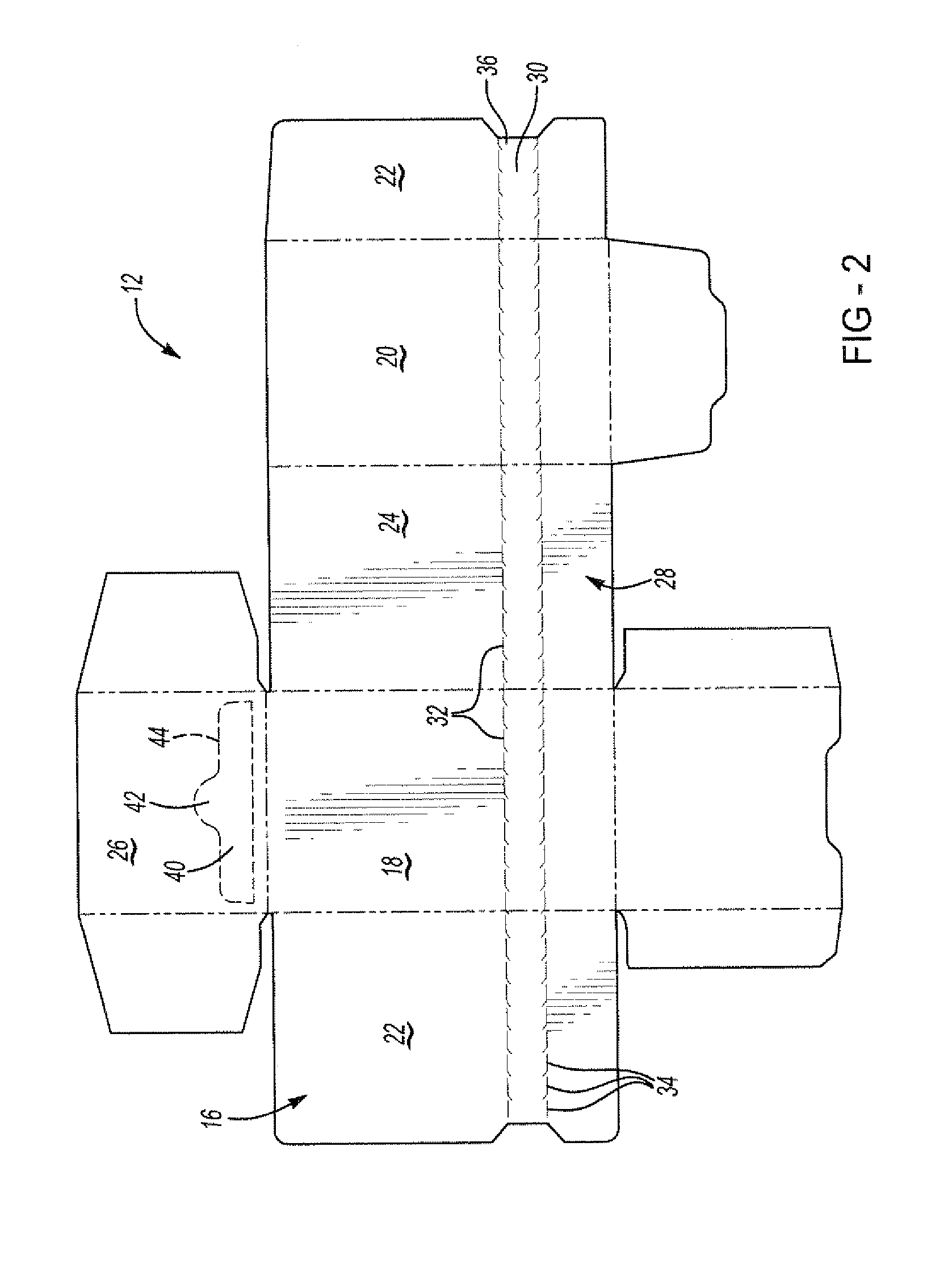

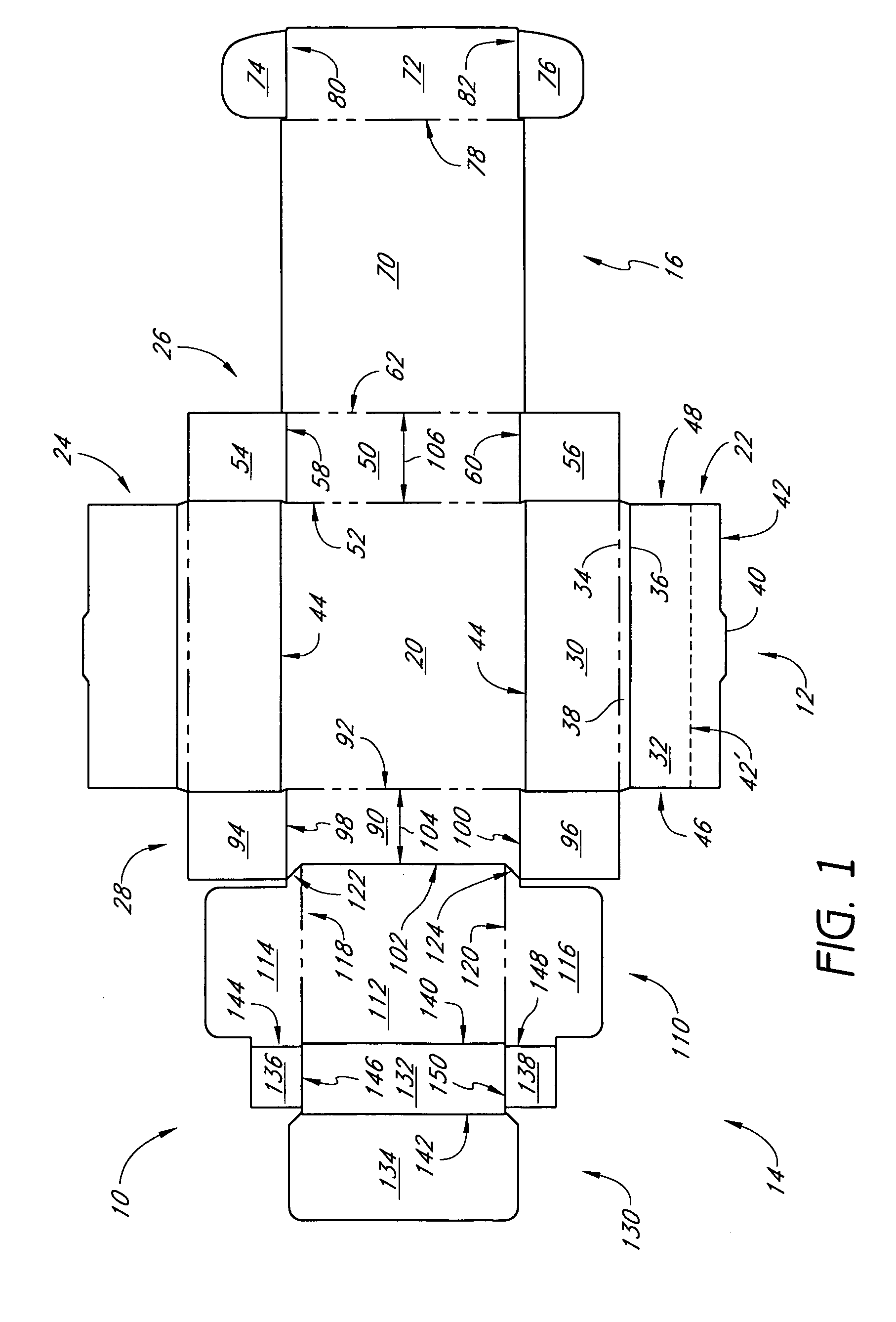

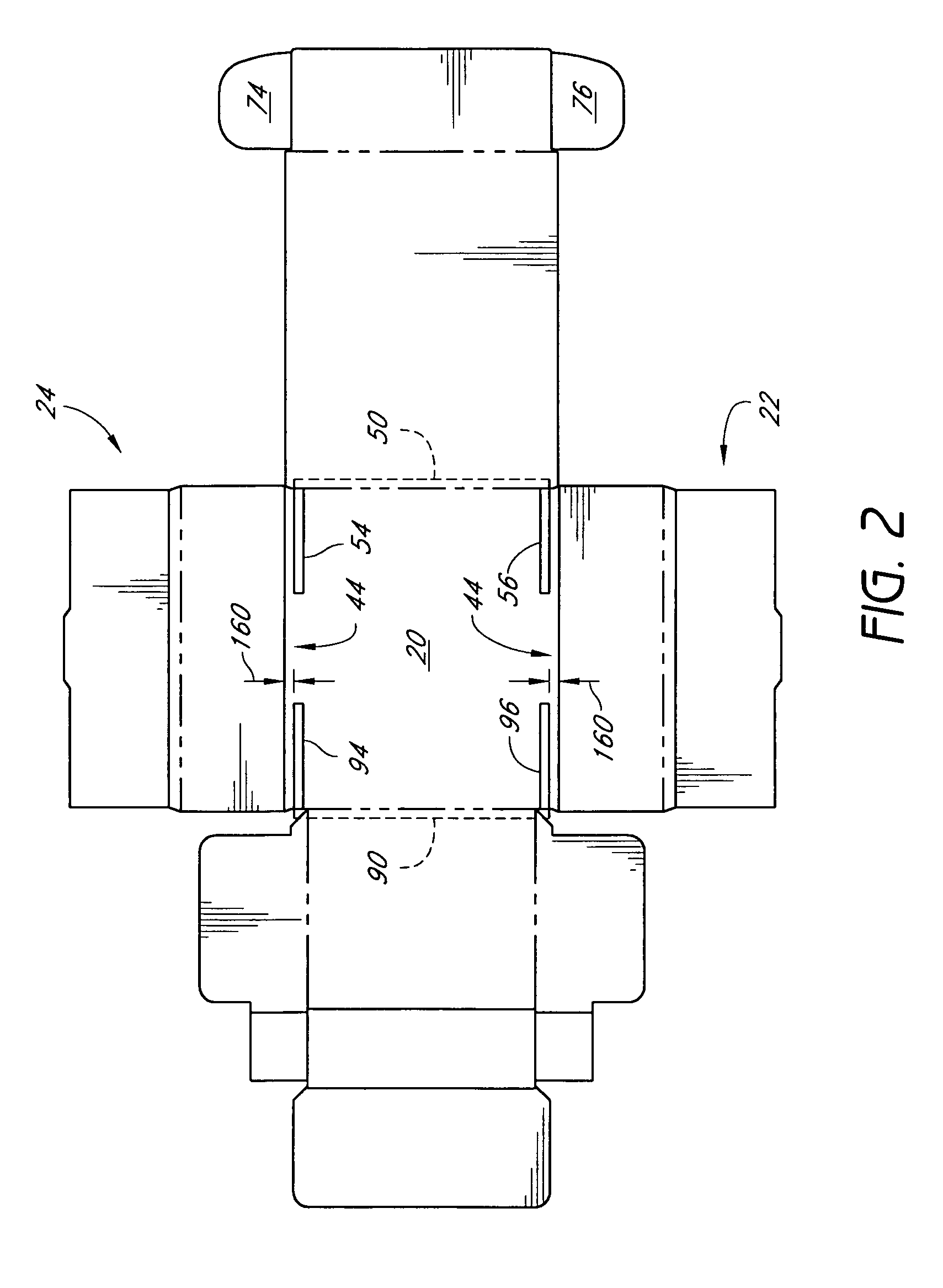

Folded corrugated container with reinforced quick-locking handles

ActiveUS20080173703A1Easily fold into ruggedized containerQuickly and foldably transformedRemovable lids/coversLidsCardboardCarton

A container comprises a knockdown carton made from a flat blank of corrugated material, and a knockdown lid. The carton comprises a center panel, foldable end panels, foldable side panels, and foldable corner panels. A pair of diametrically opposed corner panels are folded inwardly into contact with opposed end panels. The end panels comprise rectangular cutout holes surrounding foldable flaps. The lid has a central panel that is divided from integral end panels and integral side panels. A lid side panel extending vertically downwardly is coupled to the carton. Lid end panels have elliptical orifices that register with carton cutout regions and adjoining slots that align with handle anchor orifices. An alternative lid has flaps comprising major and minor segments separated by a diagonal fold line. The minor segment has an apex that releasably biases the flap in engagement with the end panel, yieldably locking the lid.

Owner:PRATT CORRUGATED HLDG

Process for production of paper or board

ActiveUS9605382B2Improve propertiesReinforcing agents additionPaper/cardboardCardboardPulp and paper industry

Owner:KEMIRA OY

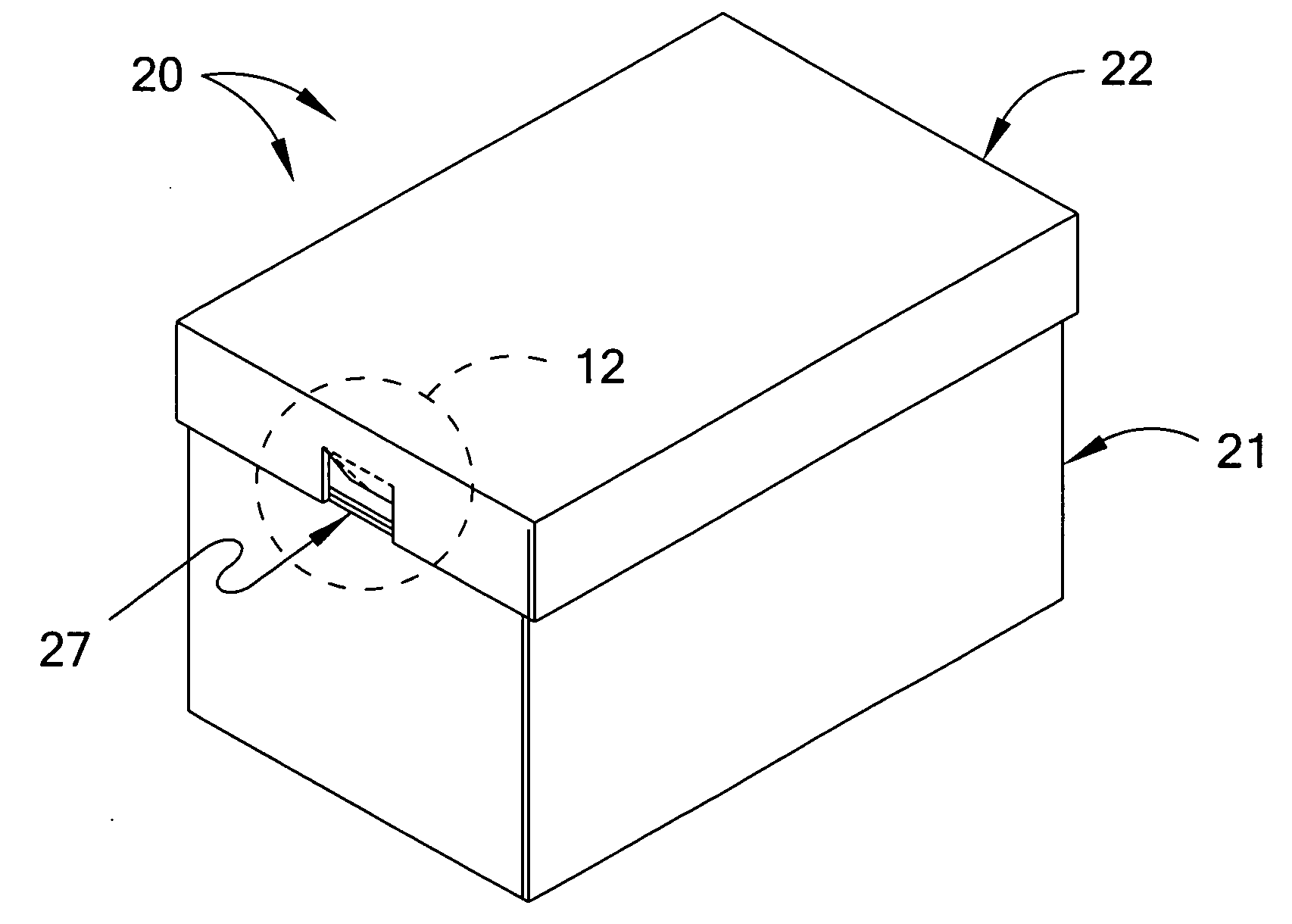

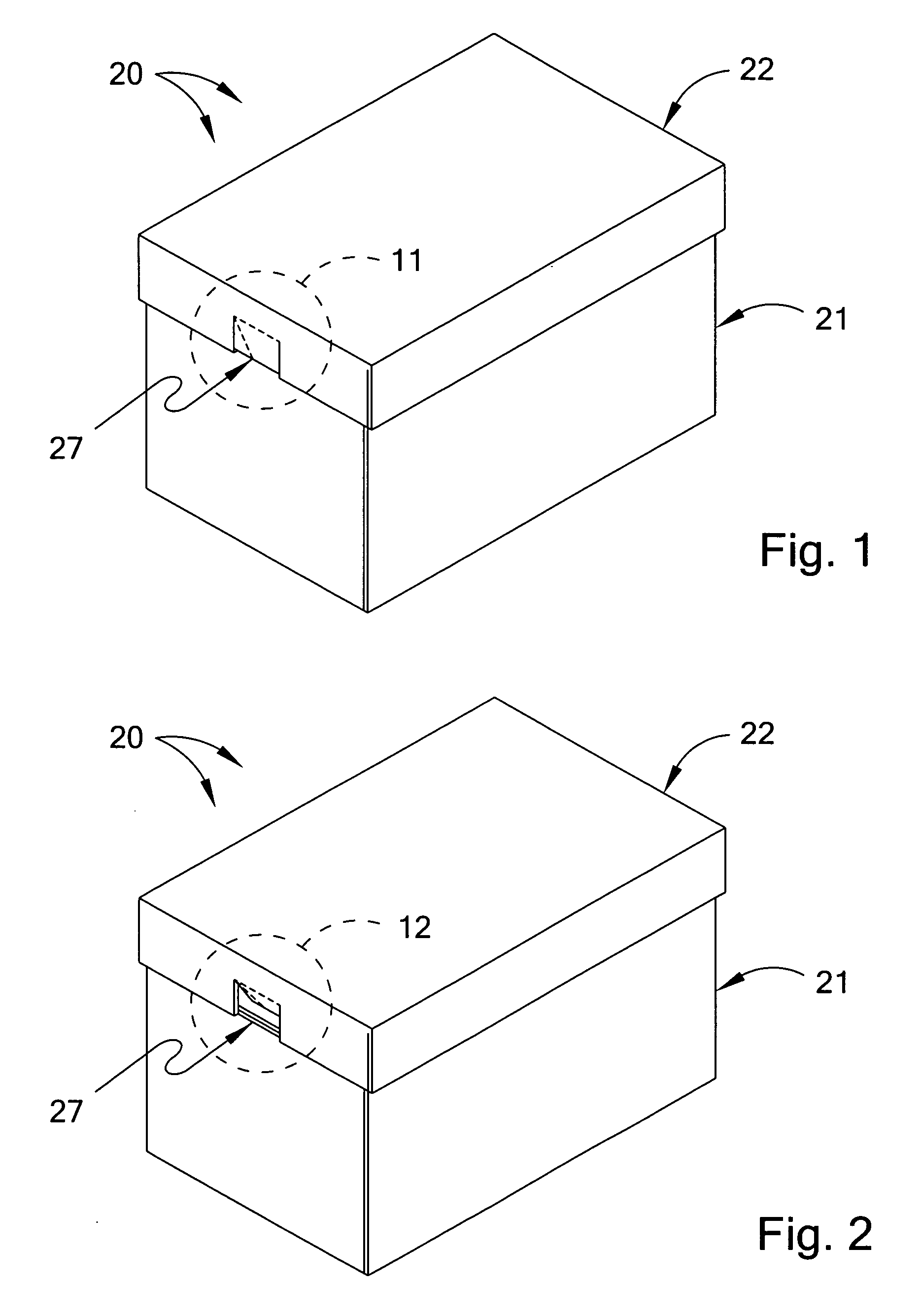

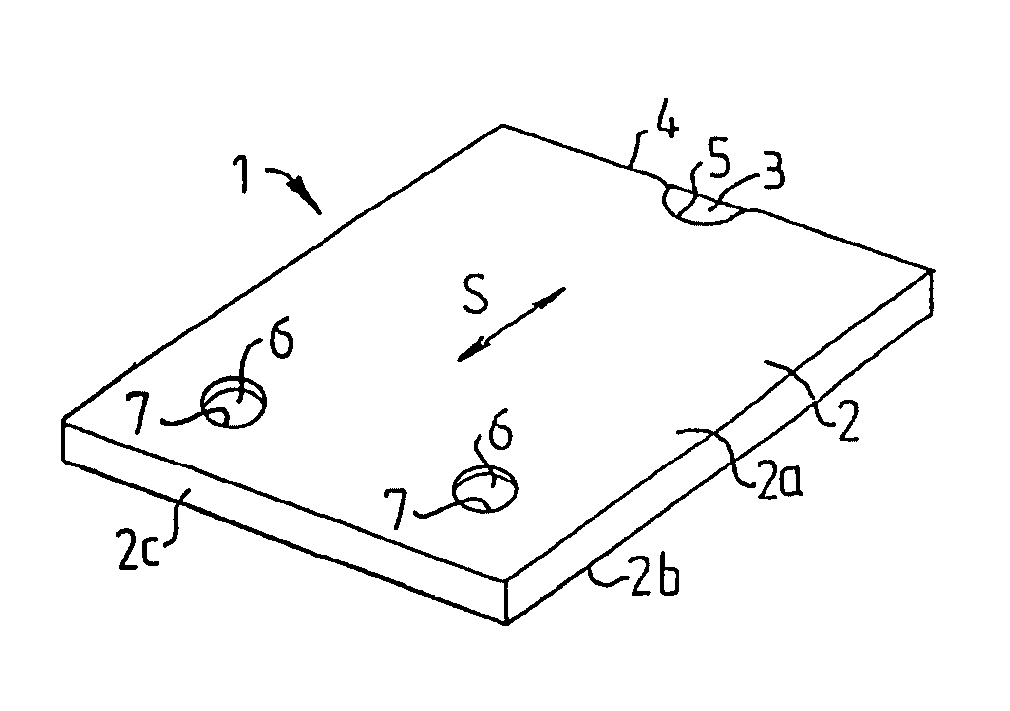

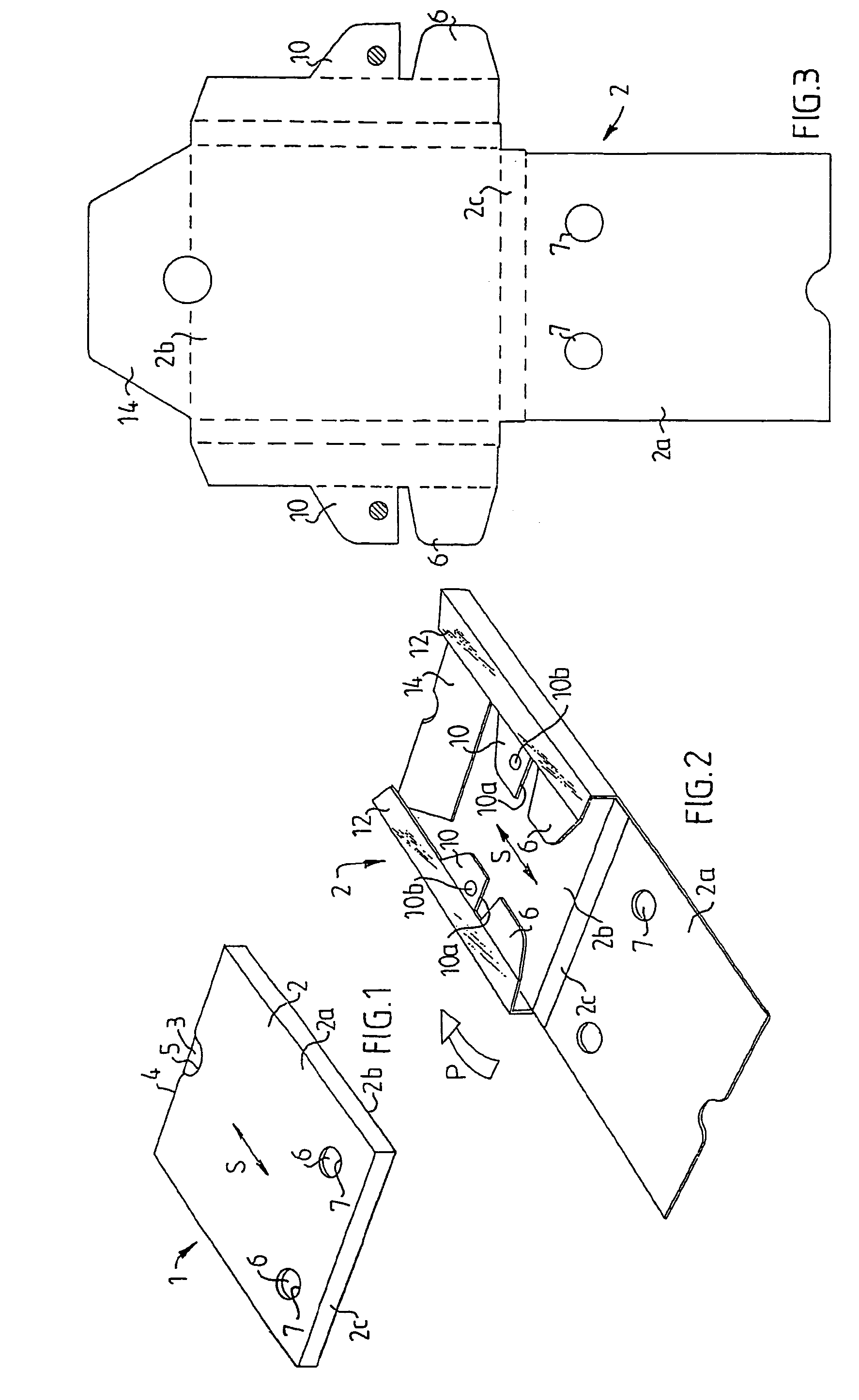

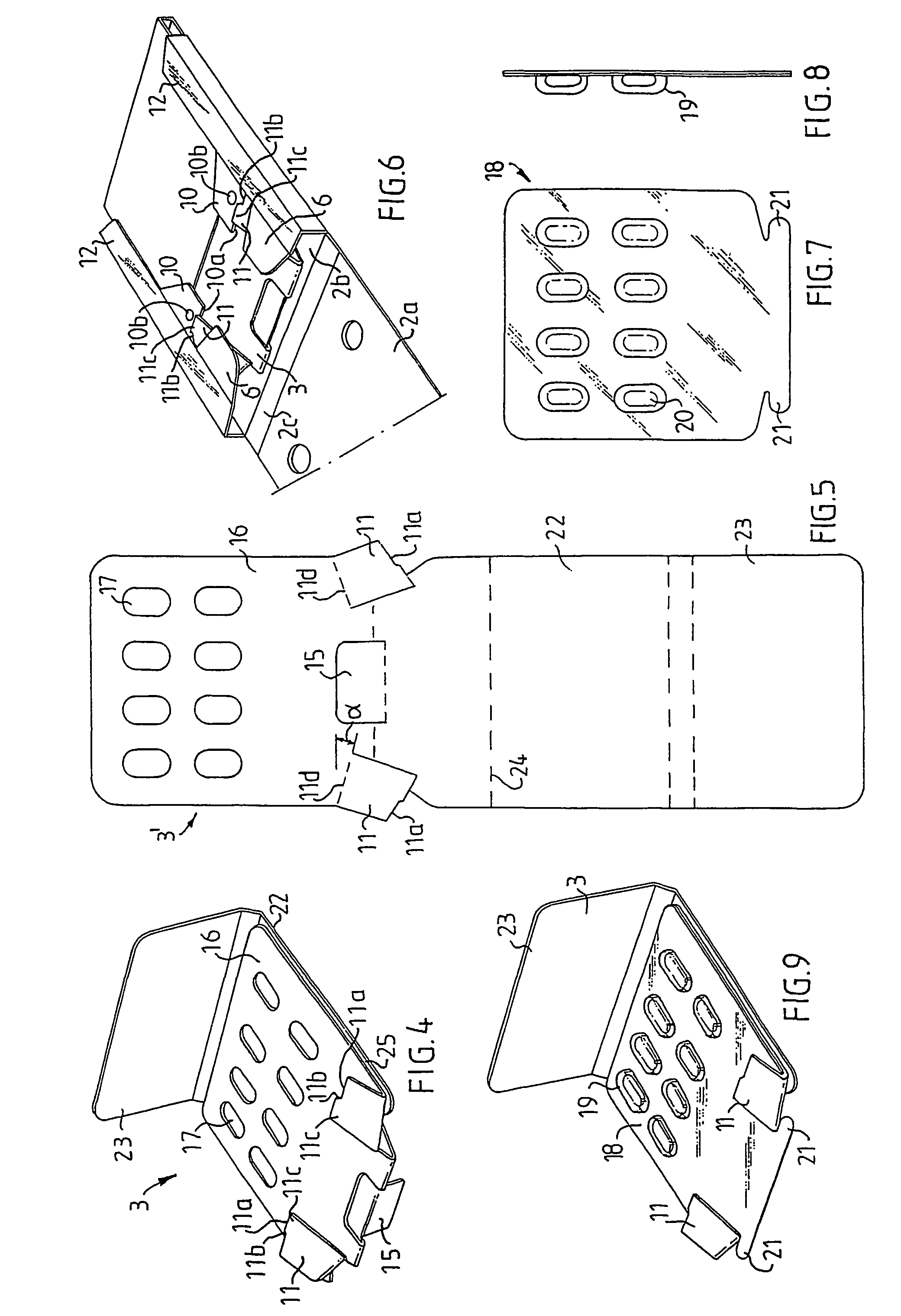

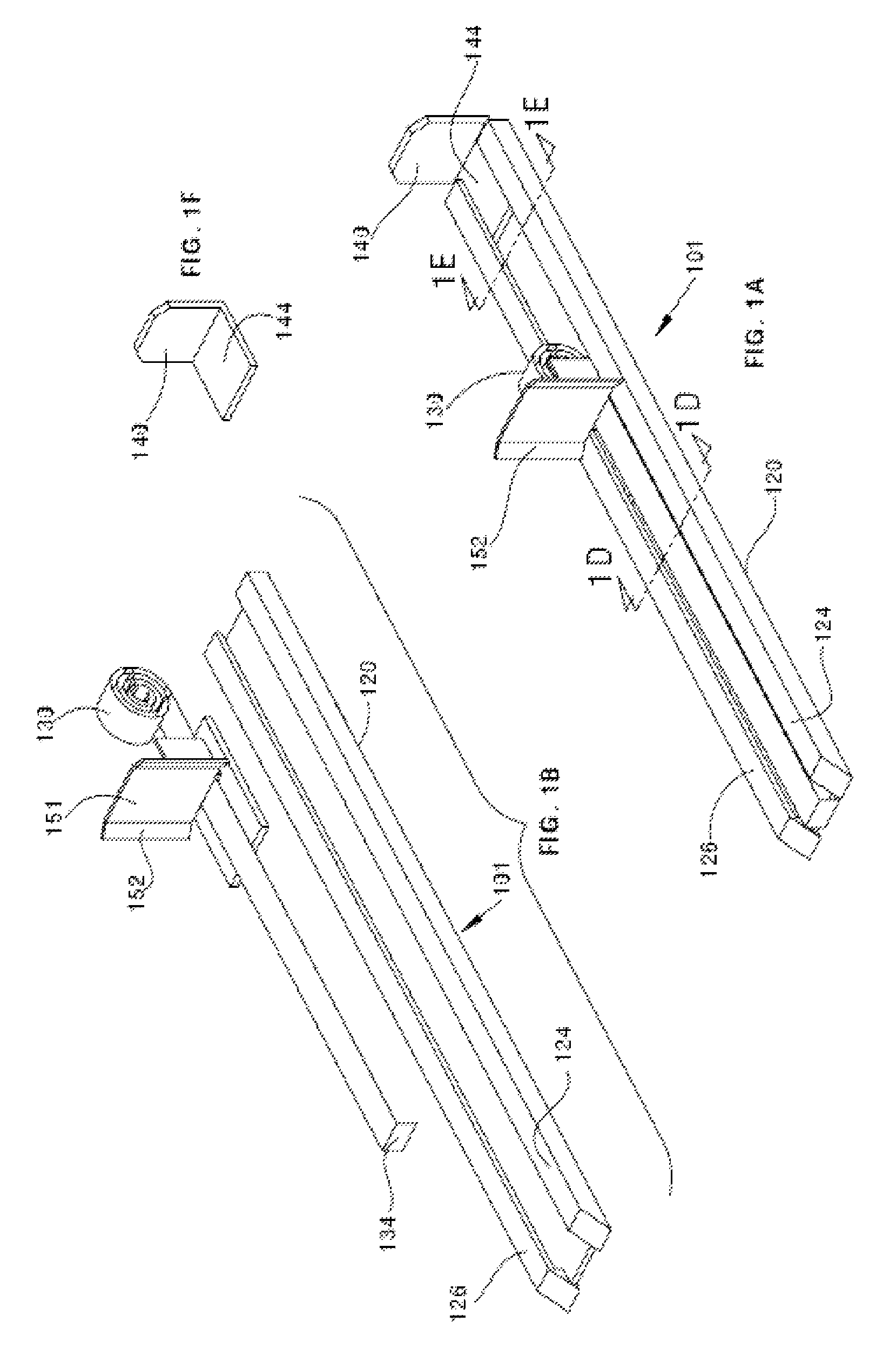

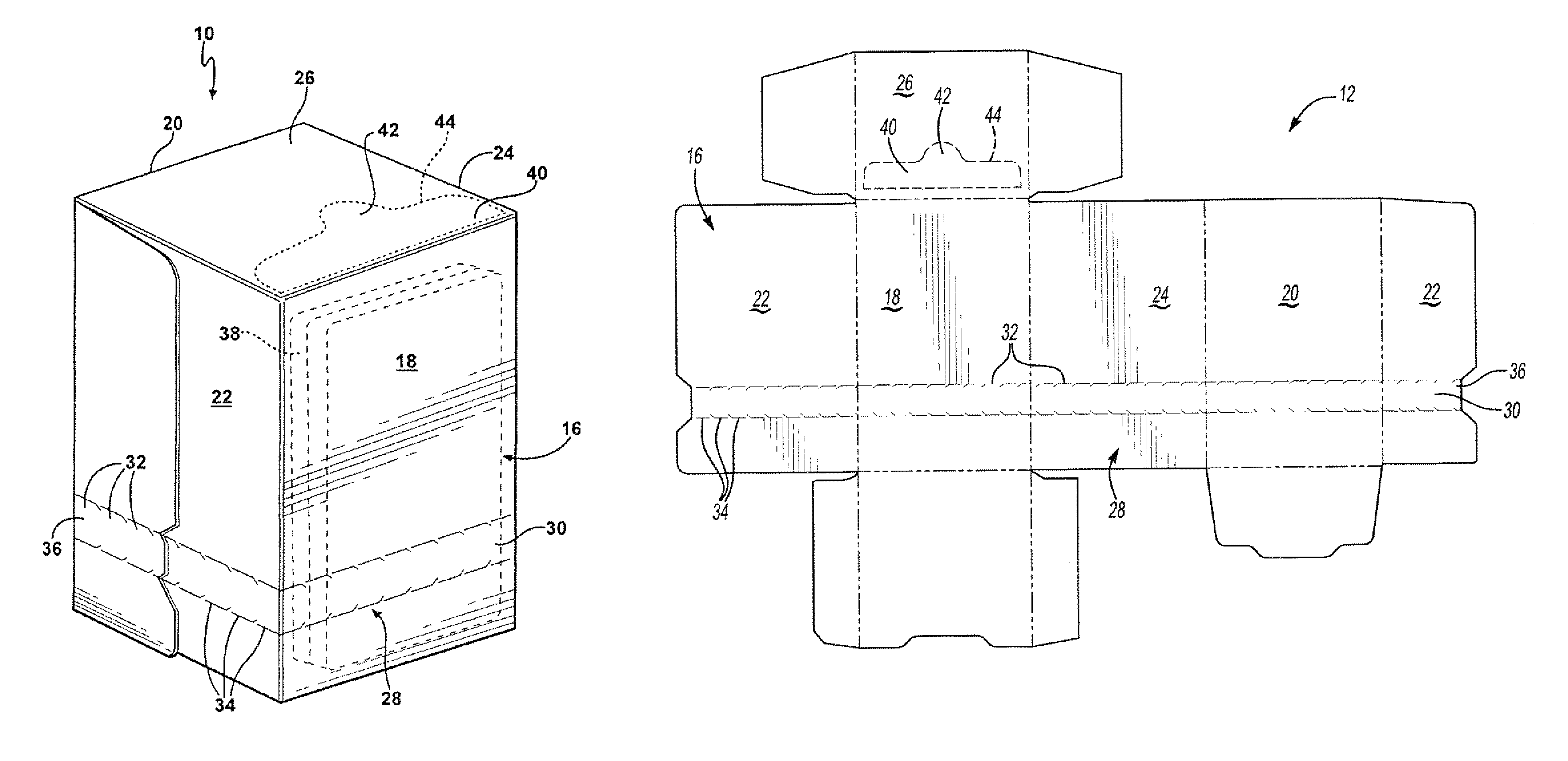

Child resistant package with slidable tray section

InactiveUS7090079B2Reliable lockingEasy to manufactureSmall article dispensingPharmaceutical containersCardboardEngineering

A package made of cardboard, includes a sleeve and an insert, the sleeve being provided with at least one catch tab located on the inside of the sleeve and provided with at least one projection, so that the catch tab forms an angle with the upper wall of the sleeve. At least one locking tab is provided on the insert, which is arranged so as to be at least in part inserted between the catch tab and the upper wall. At least one operating tab is provided, in addition to which the sleeve is provided with at least one cutout next to the operating tab, the operating tab being arranged so as to be pressed by a user against the locking tab, movement of the insert in the sliding direction (S) towards the opening being made possible.

Owner:STORA ENSO AB

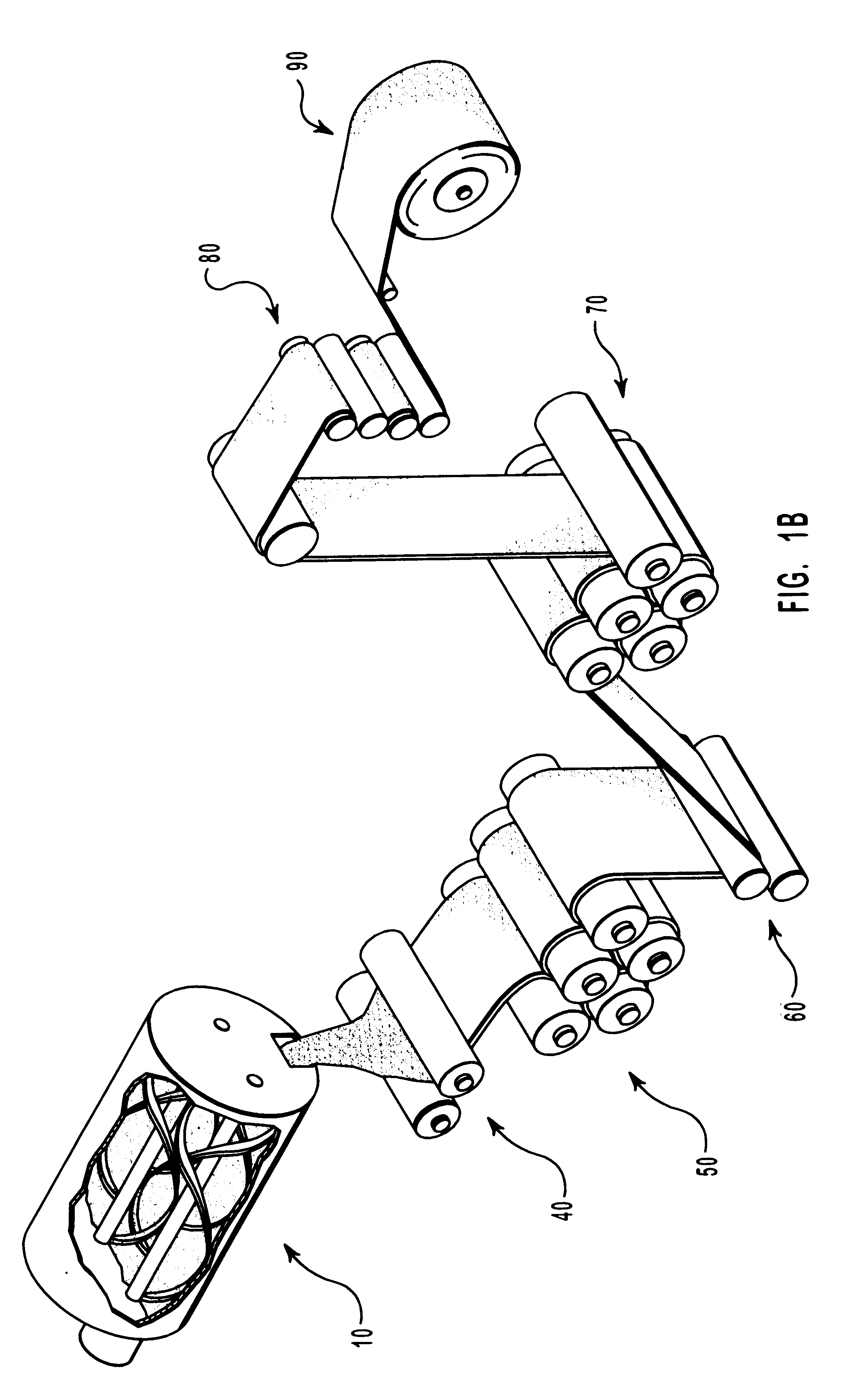

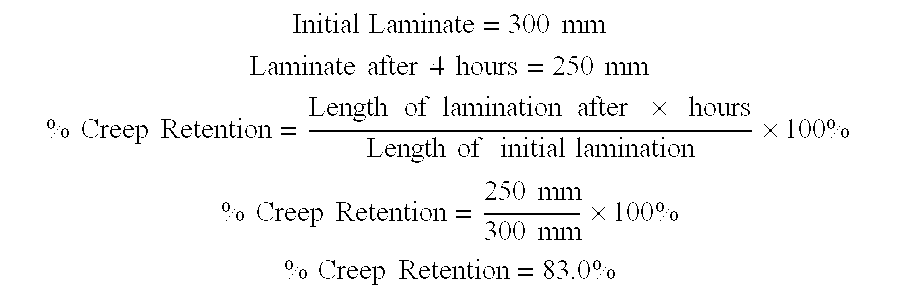

Low application temperature hot melt adhesive

InactiveUS20070088116A1High bond strength levelSame level of performanceAbsorbent padsAdhesivesElastomerCardboard

A hot melt adhesive composition, comprising a blend of components including about 10% to about 40% by weight of an elastomeric block copolymer, preferably styrene-isoprene-styrene (SIS) or styrene-butadiene-styrene (SBS), about 15% to about 70% by weight of a first midblock tackifying resin having a softening point of at least about 110° C. and having an aromatic content of at least about 1.5% by weight; about 0 to 55% of second midblock tackifying resin, about 5% to about 35% by weight of a plasticizer; and about 0% to about 20% by weight of an end block resin having a softening point lower than 125° C.; wherein the components total 100% by weight of the composition, the viscosity of the composition is equal to or less than about 20,000 mPa.s at 120° C., and is applied at a temperature lower that 150° C. and initial bond retention of the composition on elastic strands is at least about 60%. Also, the elastic modulus G′ of the composition is higher than about 5000 Pa, the vicous modules G″ is higher than about 50 Pa, and the tan delta value is between about 0.5 and about 60. Laminates, especially those used in disposable soft goods, and methods of making such laminates are also described. The adhesive composition and / or laminate may be used in making a variety of end products such as a disposable diaper, a sanitary napkin, a bed pad, a bandage, a surgical drape, a tape, a label, a plastic sheet, a nonwoven sheet, a paper sheet, a cardboard, a book, a filter, or a package.

Owner:BOSTIK INC

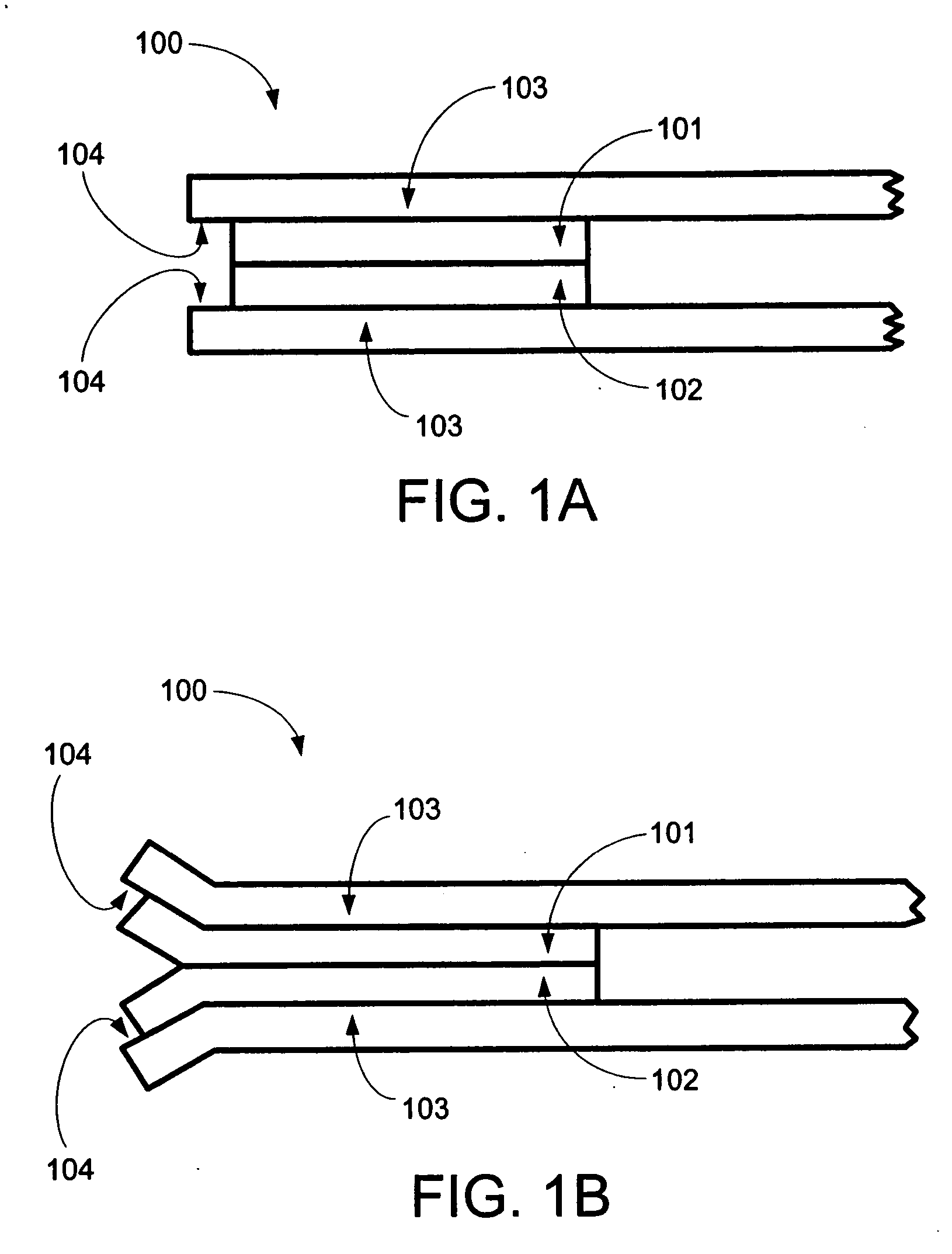

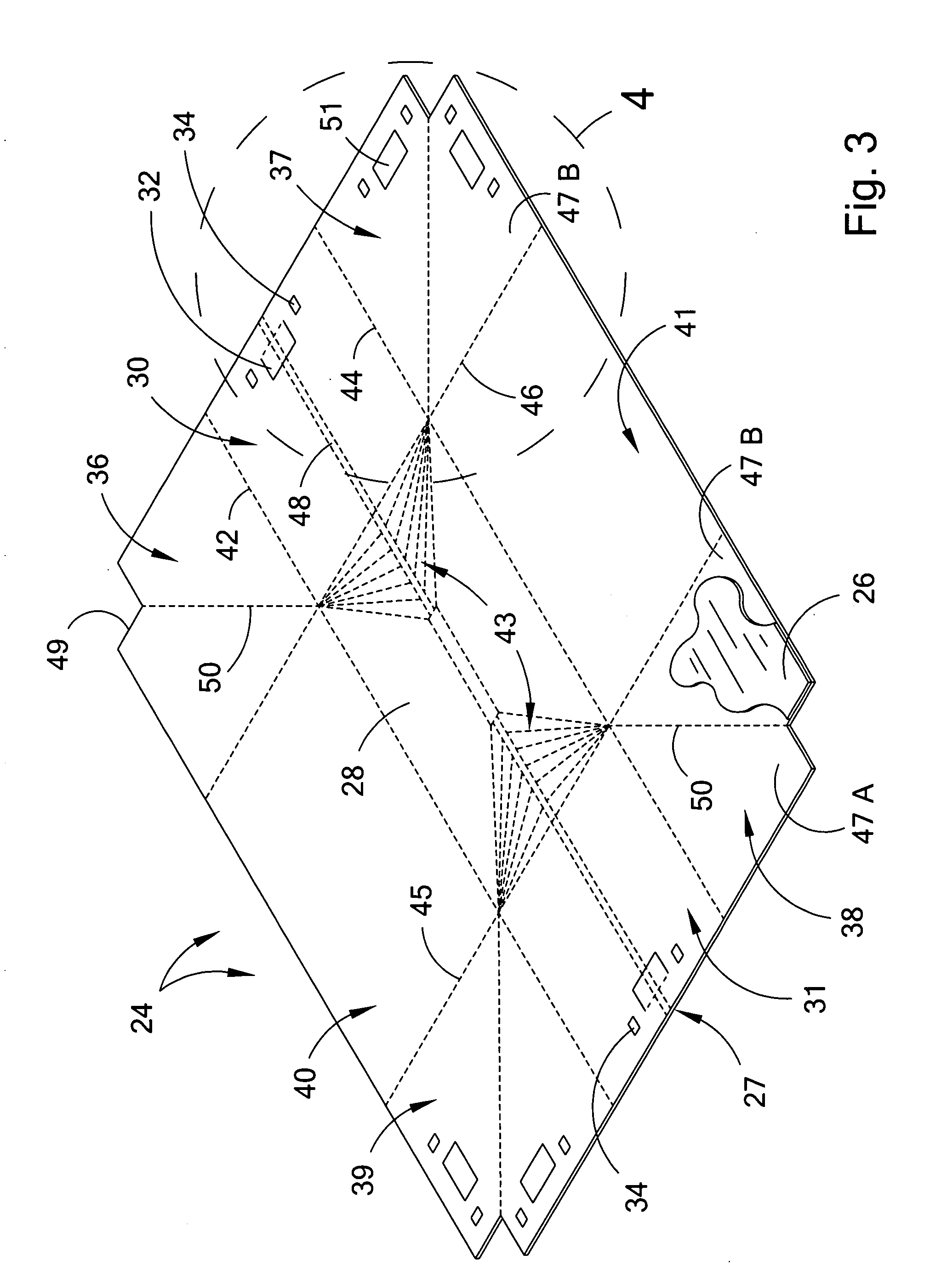

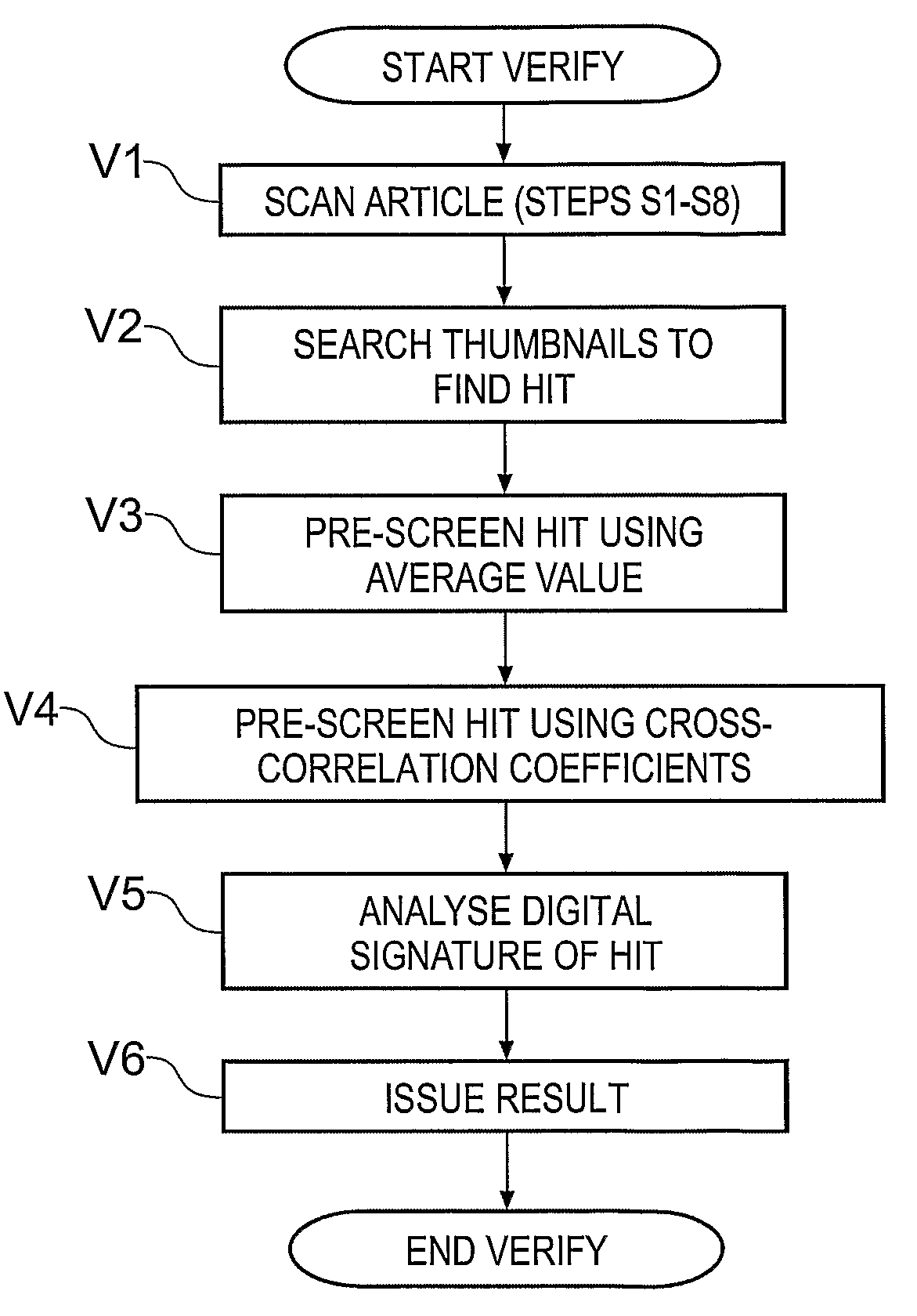

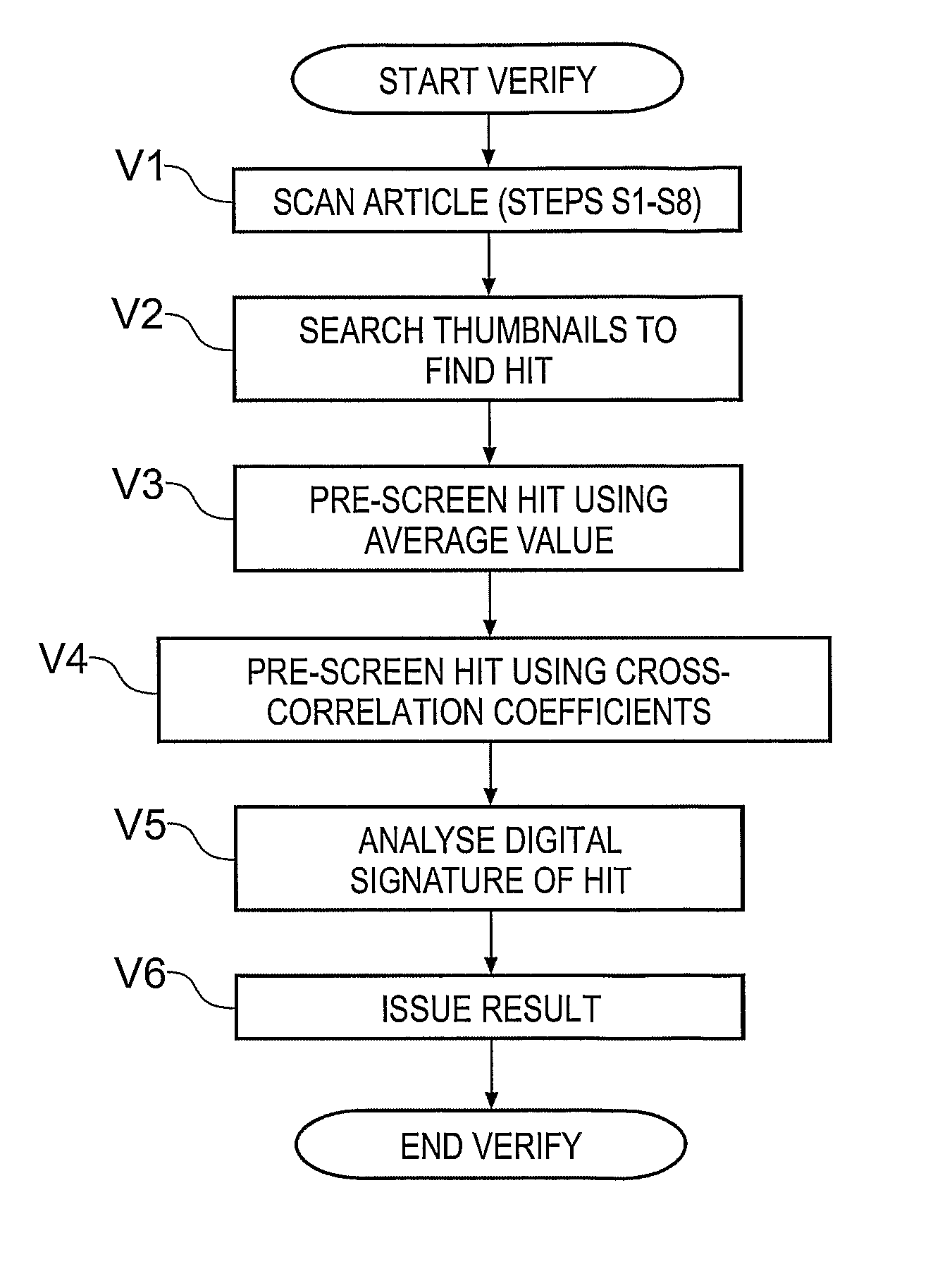

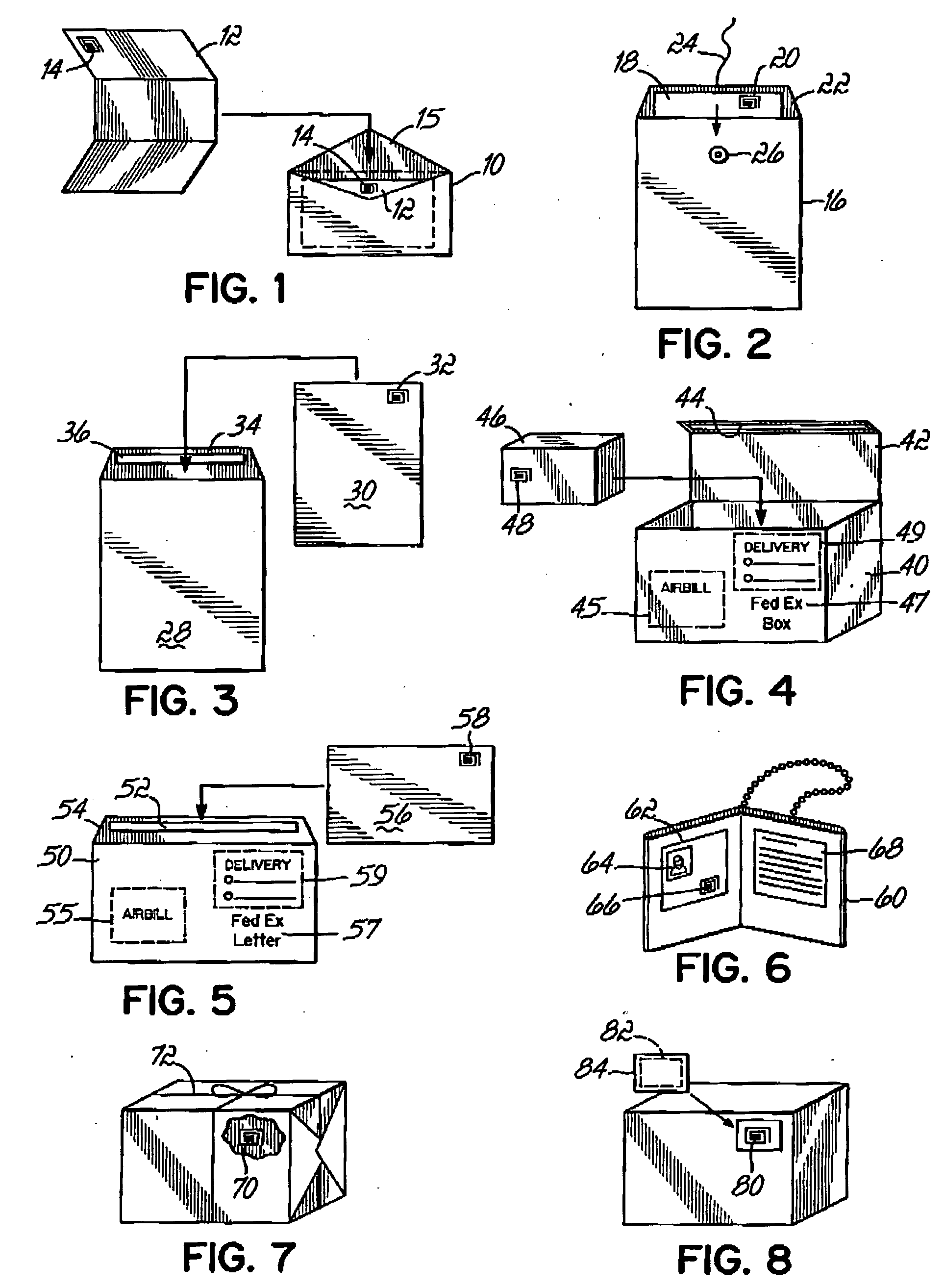

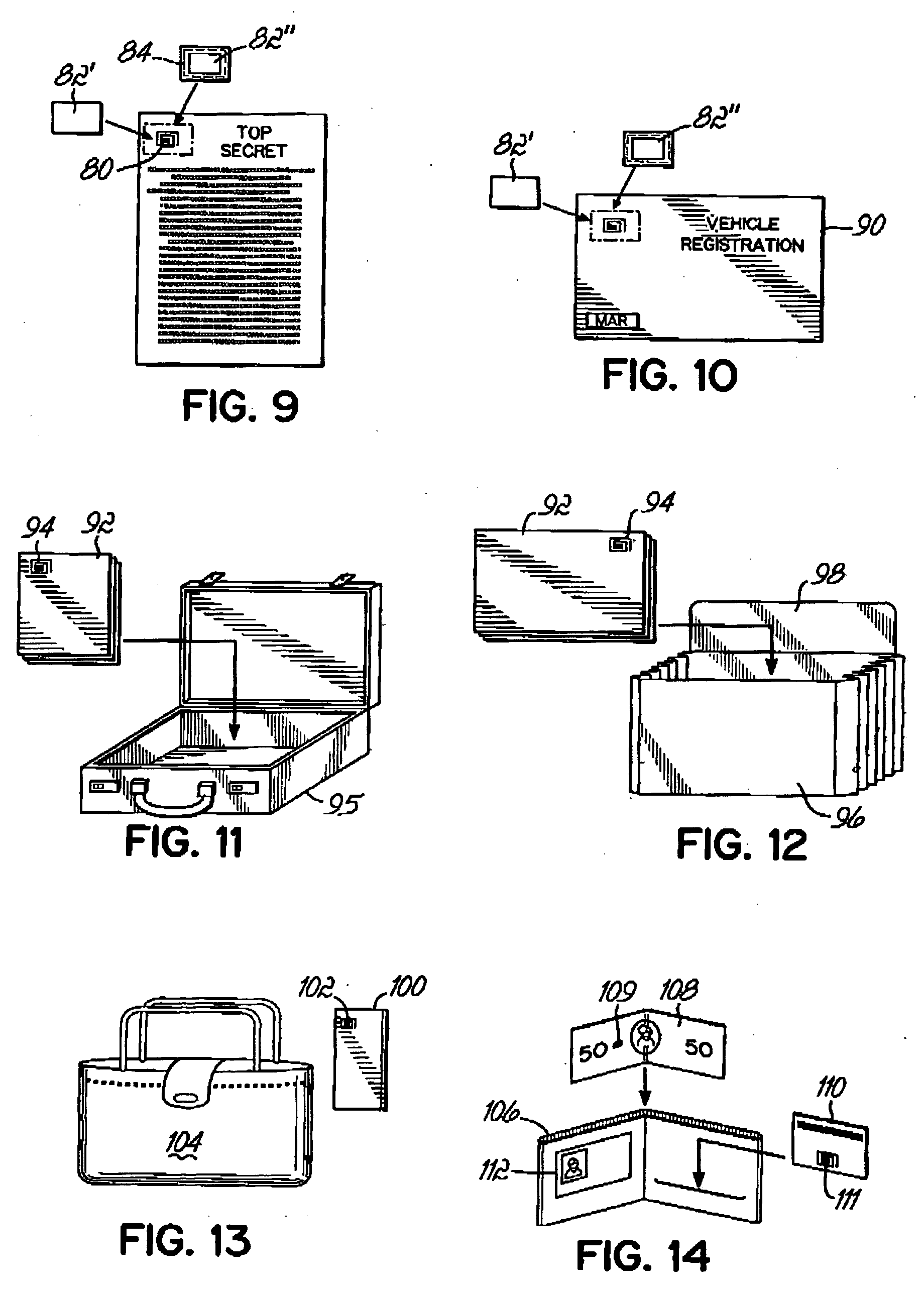

Authenticity verification methods, products and apparatuses

InactiveUS7853792B2Enhanced advantagePaper-money testing devicesUser identity/authority verificationCardboardMaterial type

Owner:INGENIA HLDG LTD

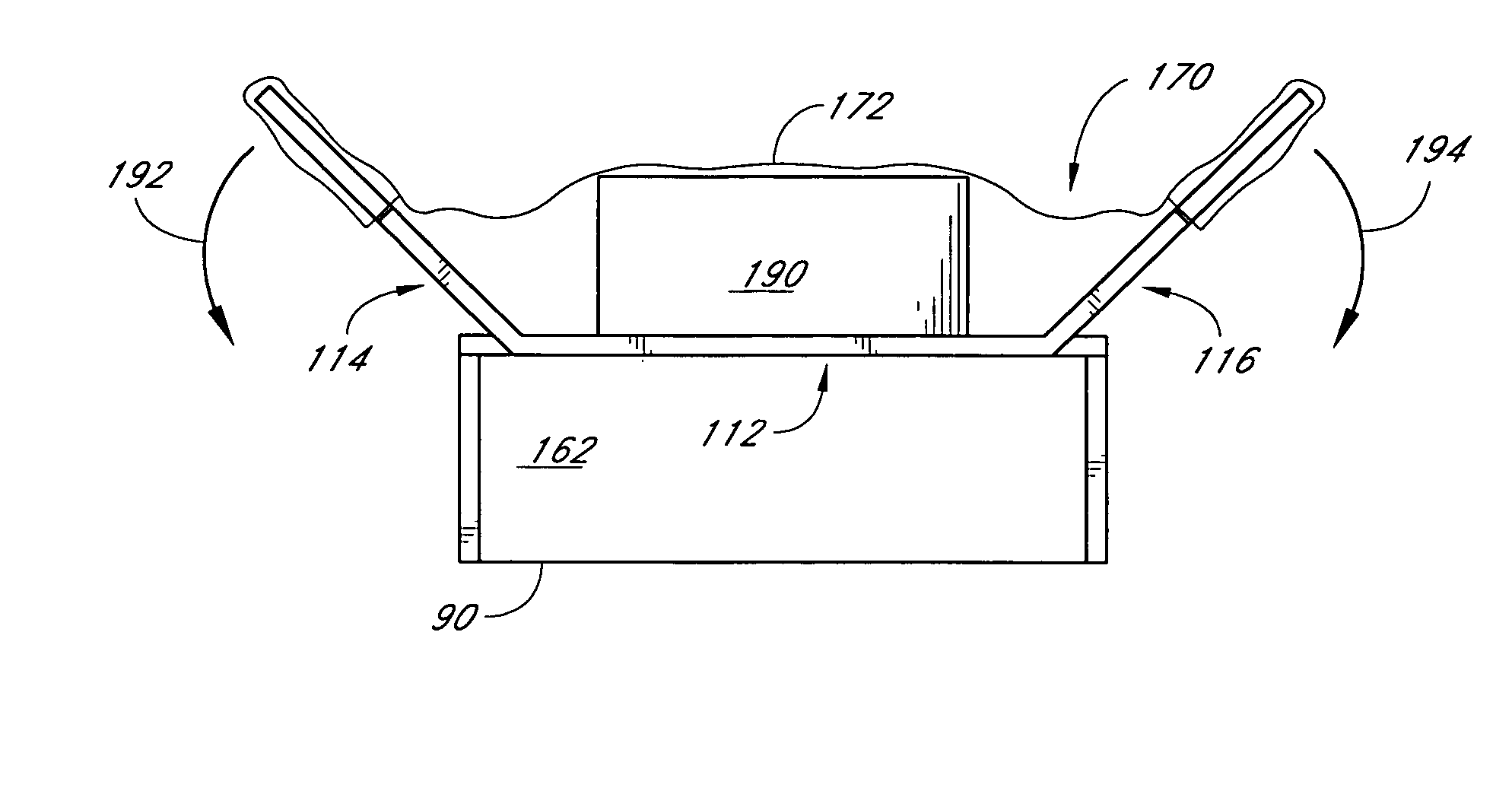

Spring driven method and apparatus for in-carton display and fronting of merchandise items

A spring alignment mechanism utilizes a guide inserted into a display carton below merchandise items. A spring-driven rear pull member travels on the guide so that as items are removed from the carton, remaining items are pulled forward. In one example, the guide is inserted between the bottom of merchandise items and the carton bottom. In another example, merchandise items are supported on cardboard support rails built into the bottom of the carton, or provided on a carton insert; and the guide is inserted between the cardboard support rails.

Owner:CLOSE & SOLUTIONS

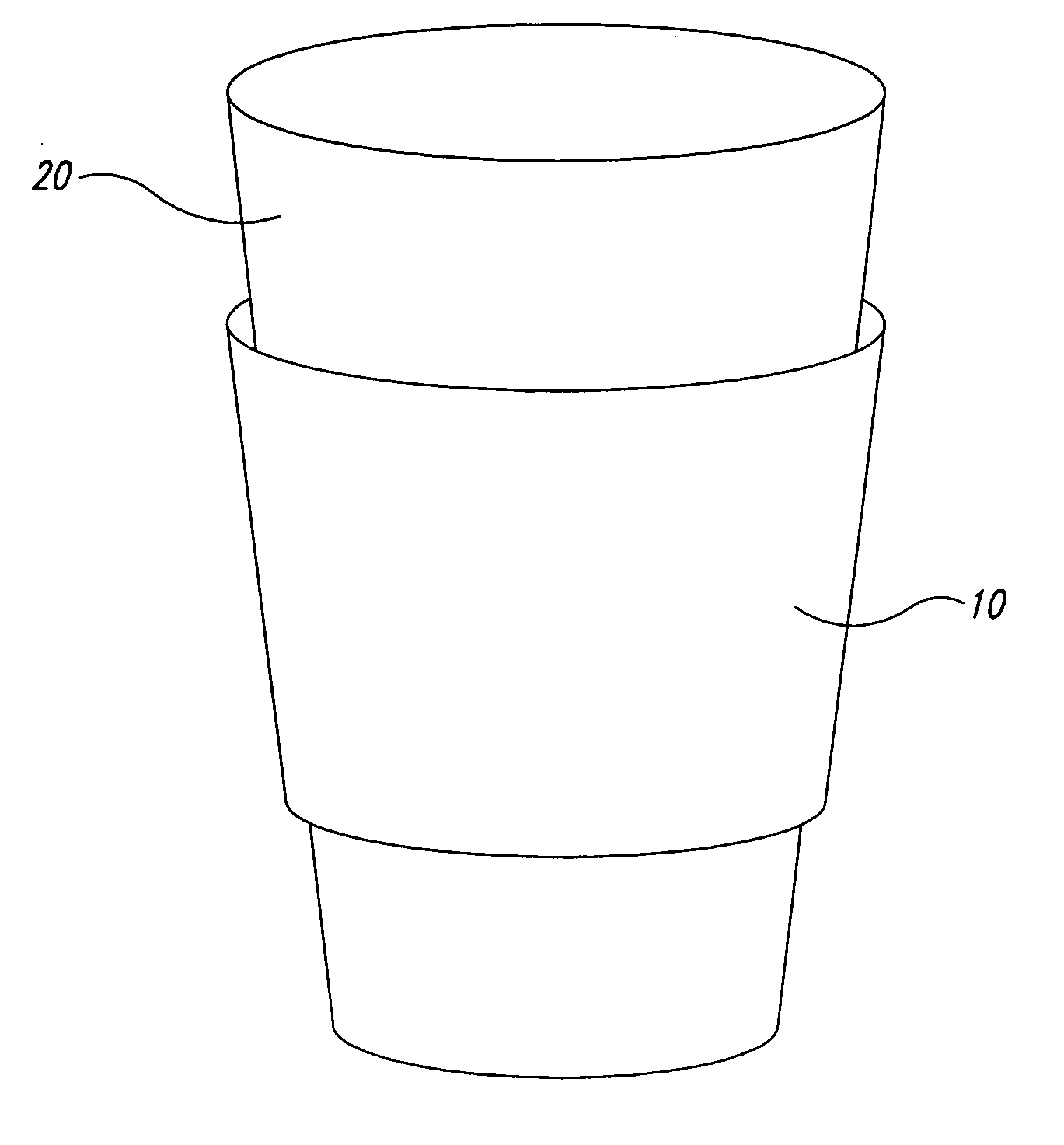

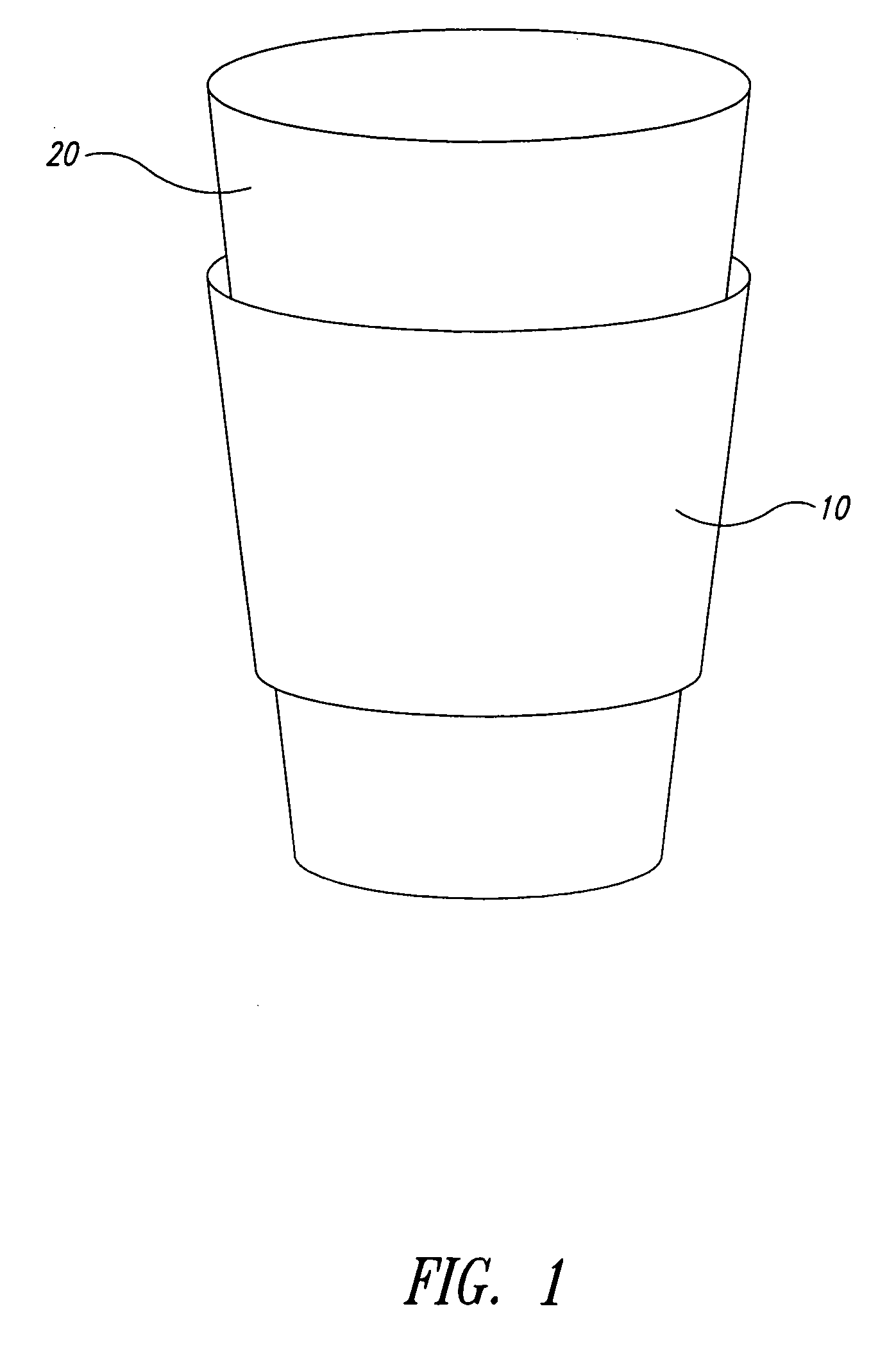

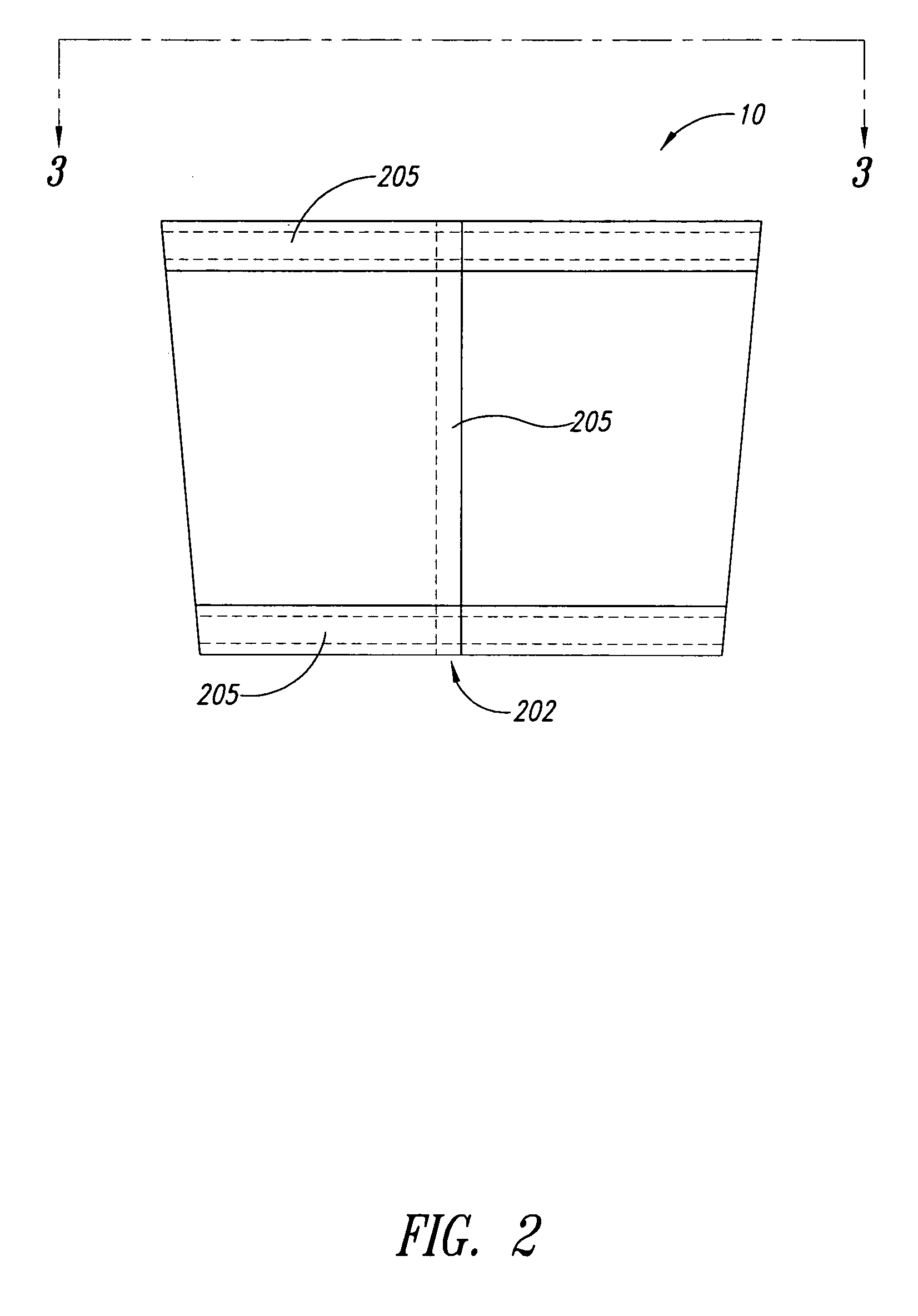

Reusable sleeve for a beverage container

InactiveUS20060186129A1Much insulationFit car glove compartmentPackage recyclingContainer/bottle contructionCardboardGift giving

A storable, reusable-insulating sleeve for a beverage container that provides insulation to the user from hot or cold beverages. The improved sleeve maintains insulation of hot temperatures approximately five and ten degrees higher for a thirty-minute interval, than, for example, cardboard counterpart sleeves. The improved sleeve comprises an integral storage-securing mechanism for storing the sleeve in a compact form. The compact form can easily fit into a pocket, purse, car glove compartment or desk drawer. The sleeve is made of various fabrics and is therefore reusable. Further, a pocket contained in the sleeve will accommodate a prepaid card or a key, for storage, transport and gift giving.

Owner:ALLNUTT ELENA G +1

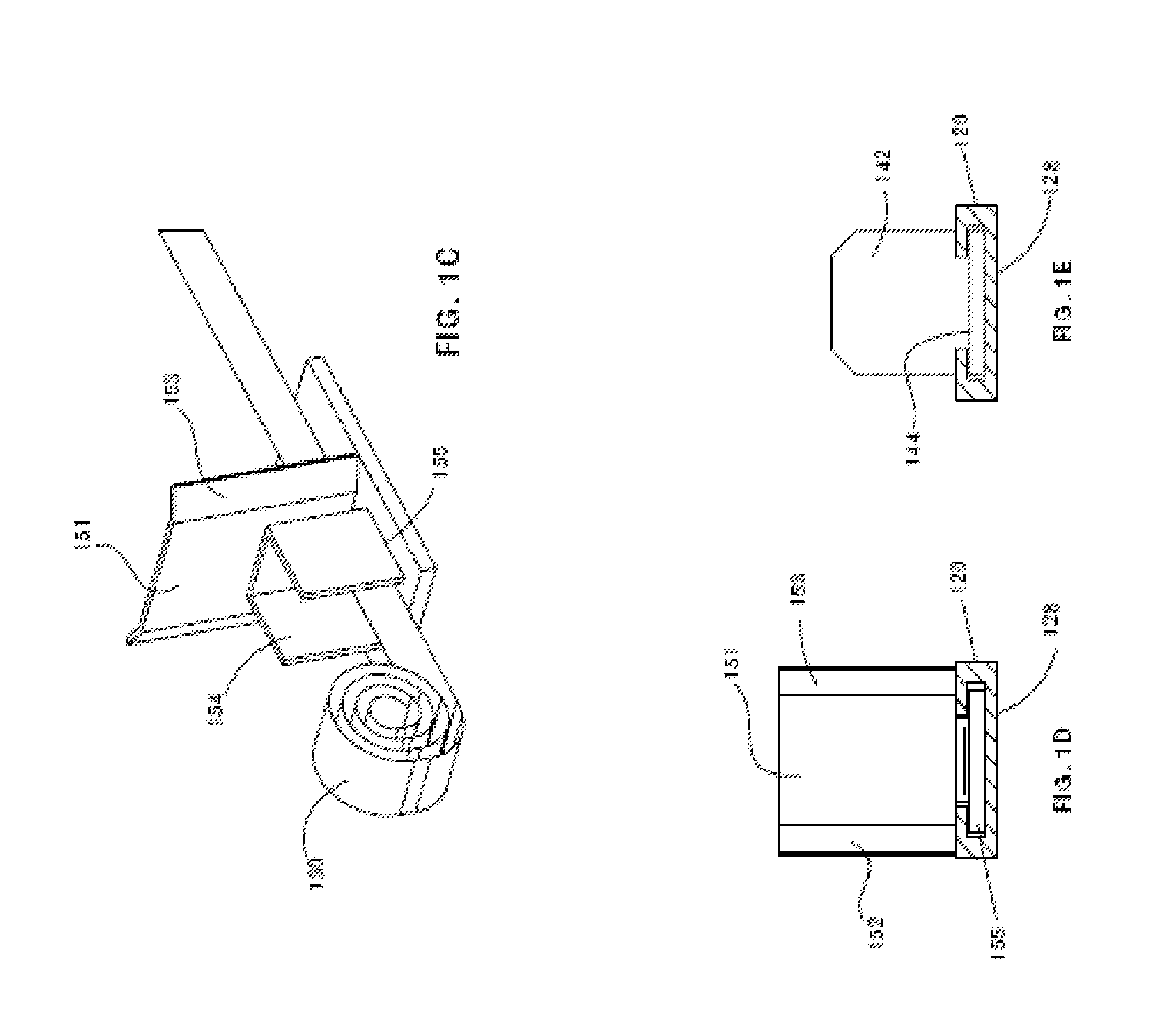

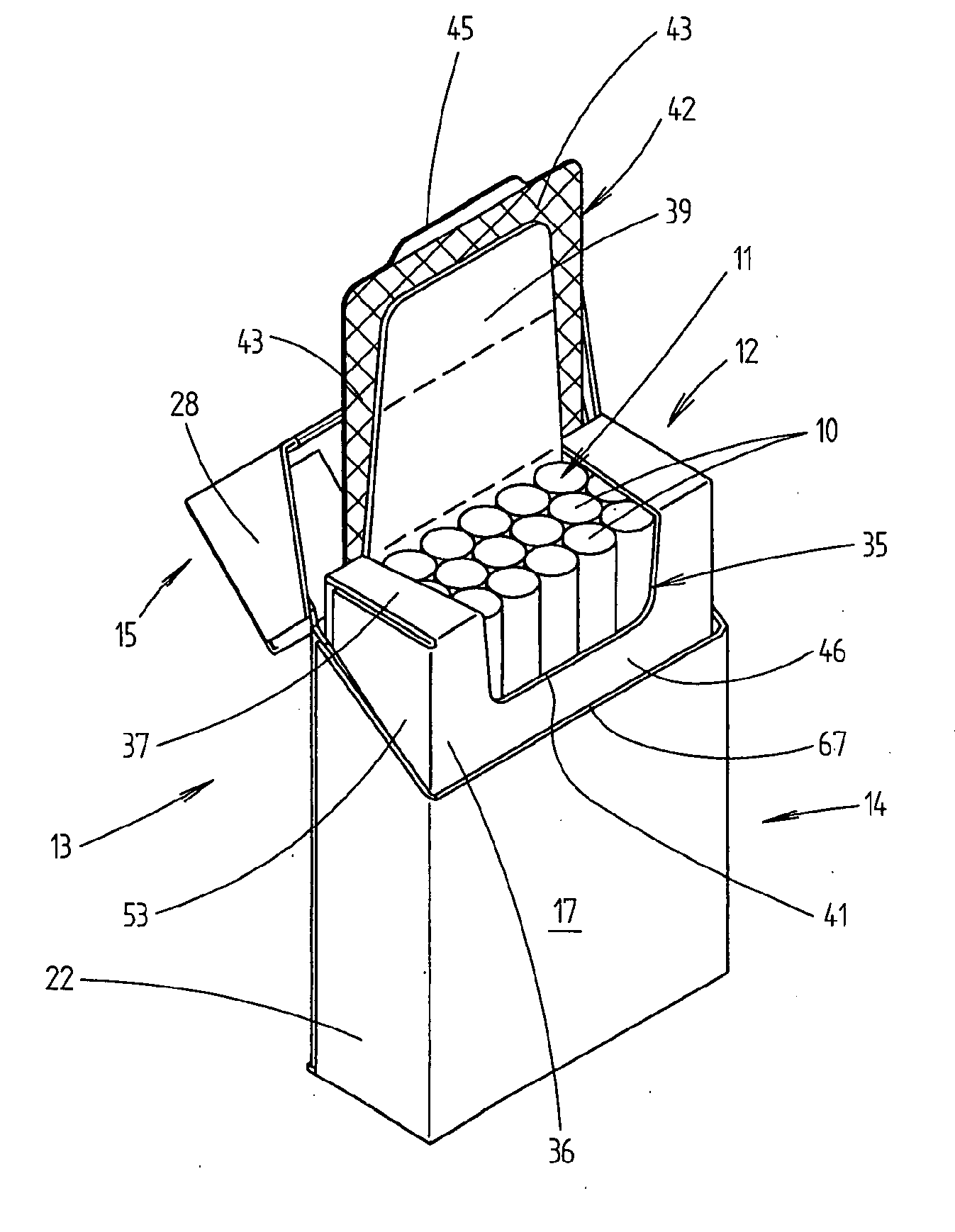

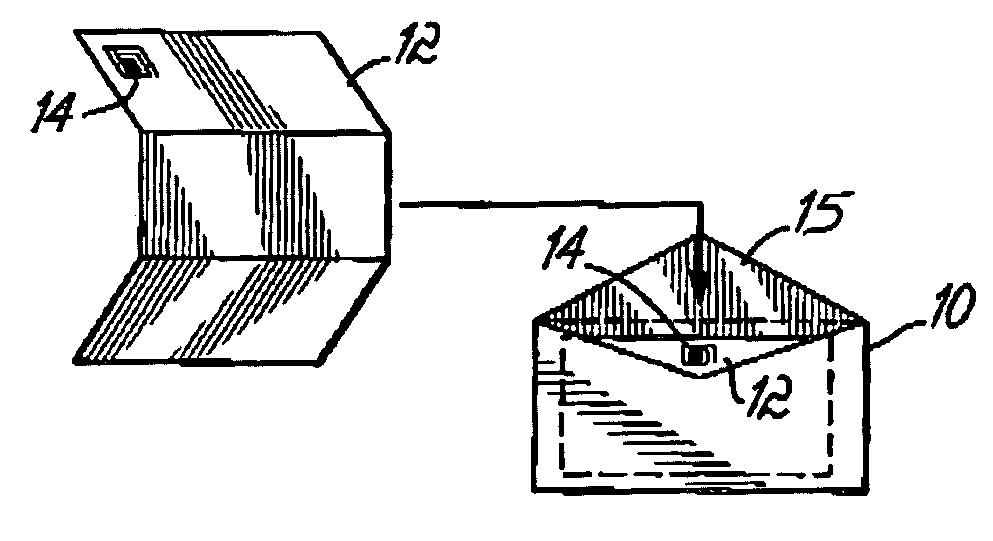

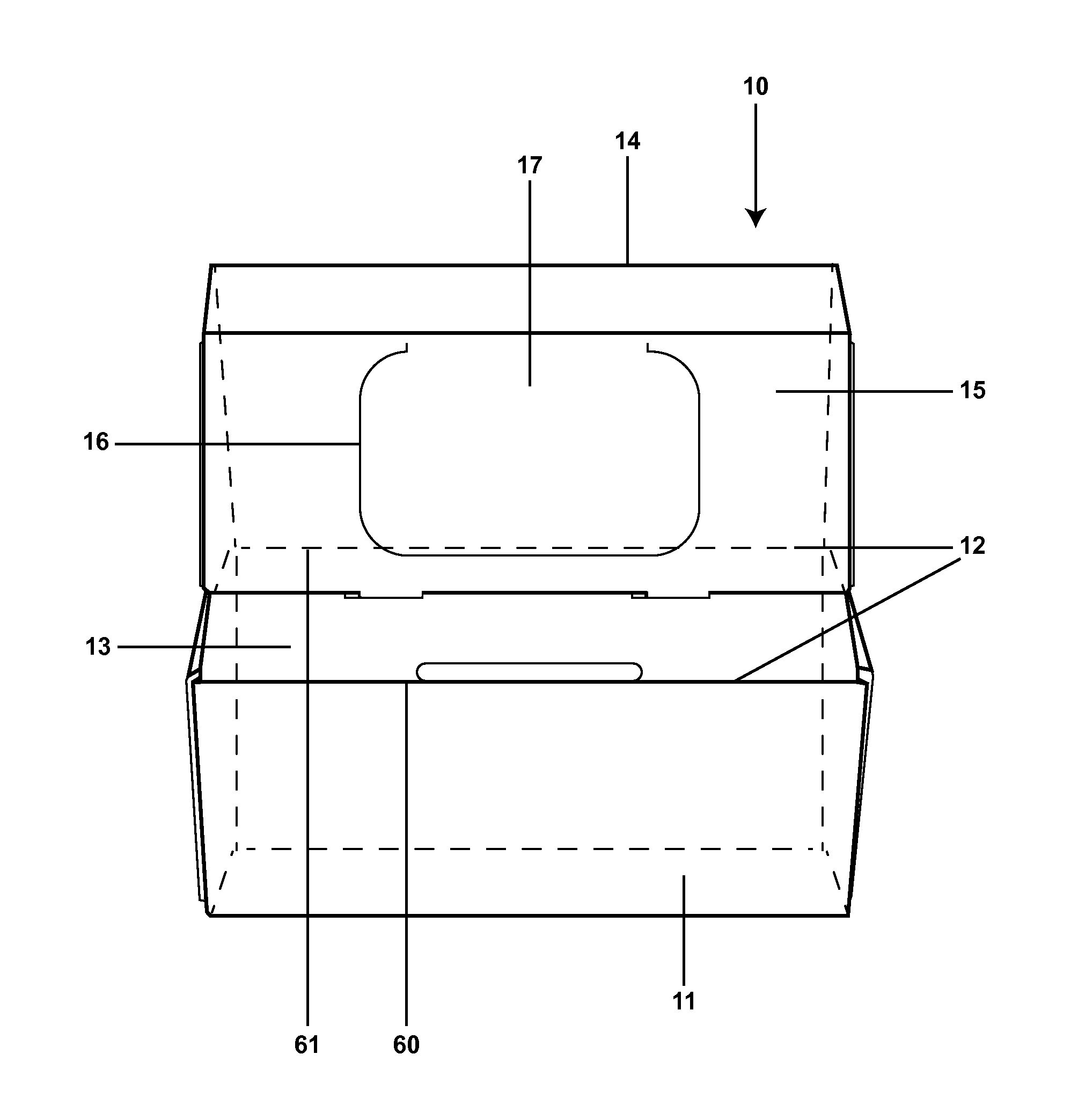

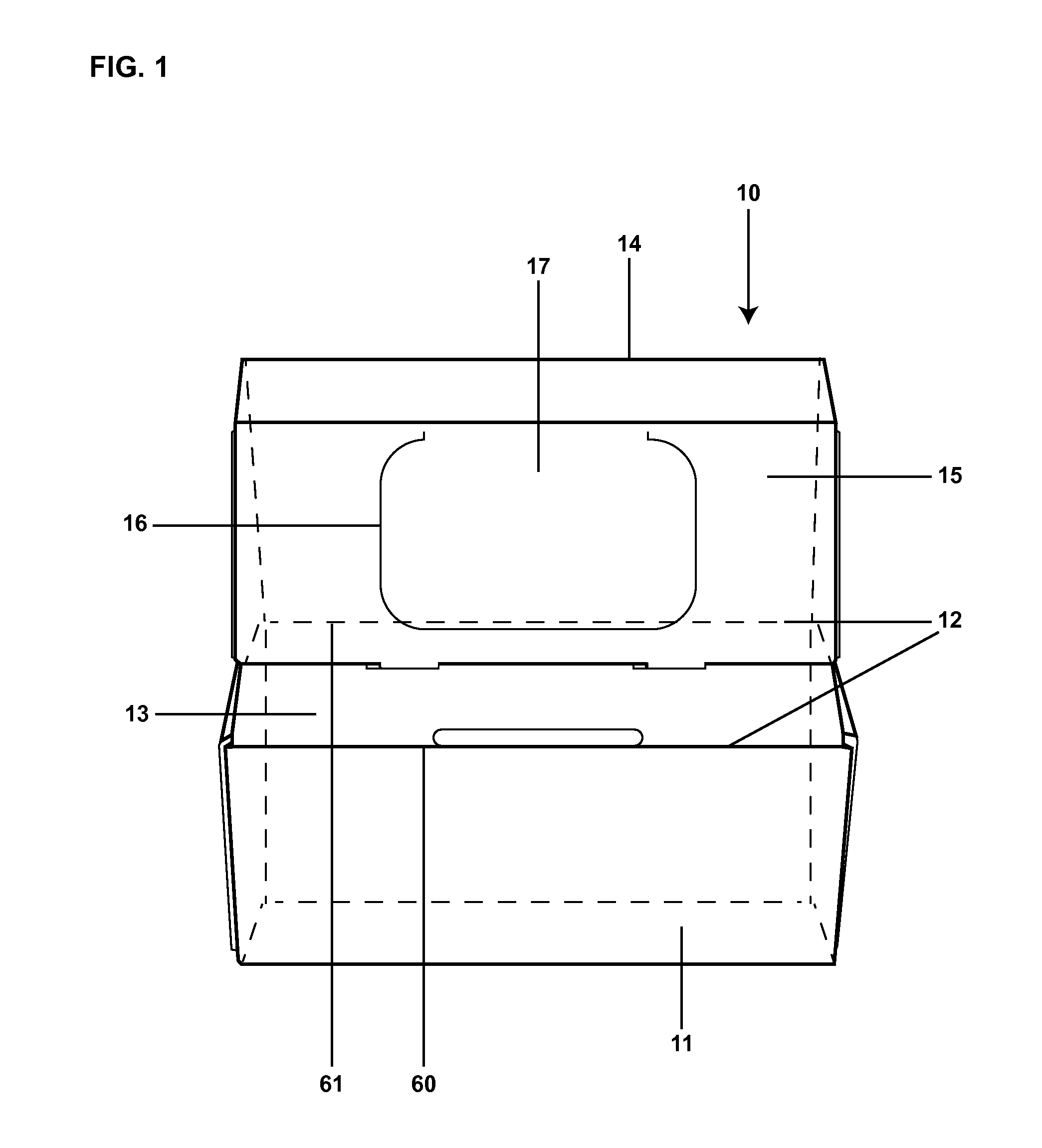

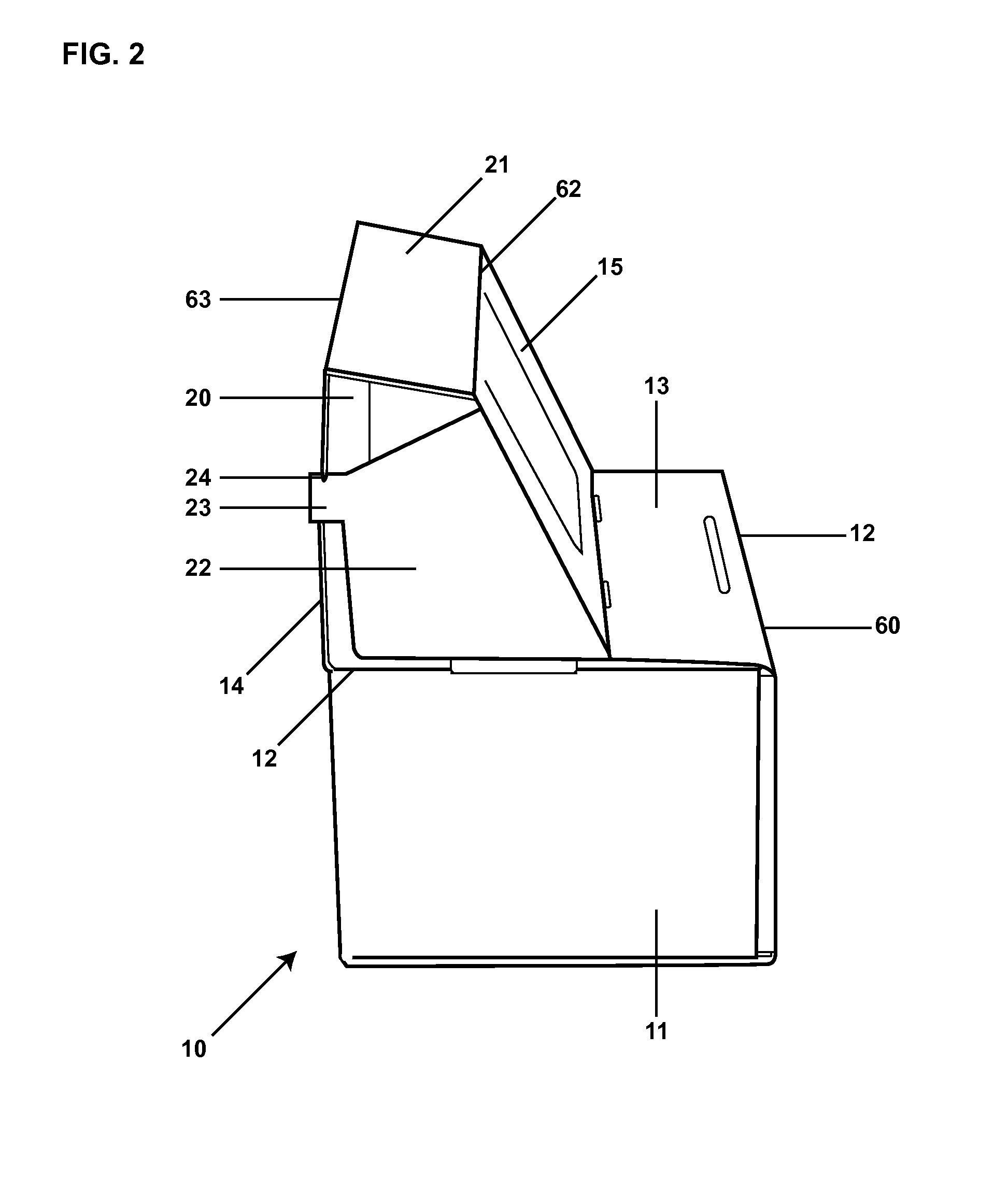

(cigarette) pack and process and device for producing it

ActiveUS20110114518A1Reduce materialKeep tightContainers for flexible articlesPackaging cigaretteCardboardEngineering

An aroma-tight or moisture-tight pack for cigarettes (10) having an inner pack (12), produced from cardboard or a comparable packaging material, made tight as a result of corresponding treatment, and an outer pack (13) in the form of a hinge-lid box, however without a collar. A cigarette group (11) is positioned directly, that is without an inner envelope, in the inner pack (12). The inner pack is provided in an upper region, namely in the region of a cover (15) of the outer pack (13), with a particular opening aid. A closure tab (39) of the inner pack (12) is covered over its entire surface area by an actuating tab (42) which is realized as tape and is produced from a separate blank.

Owner:FOCKE & CO (GMBH & CO KG)

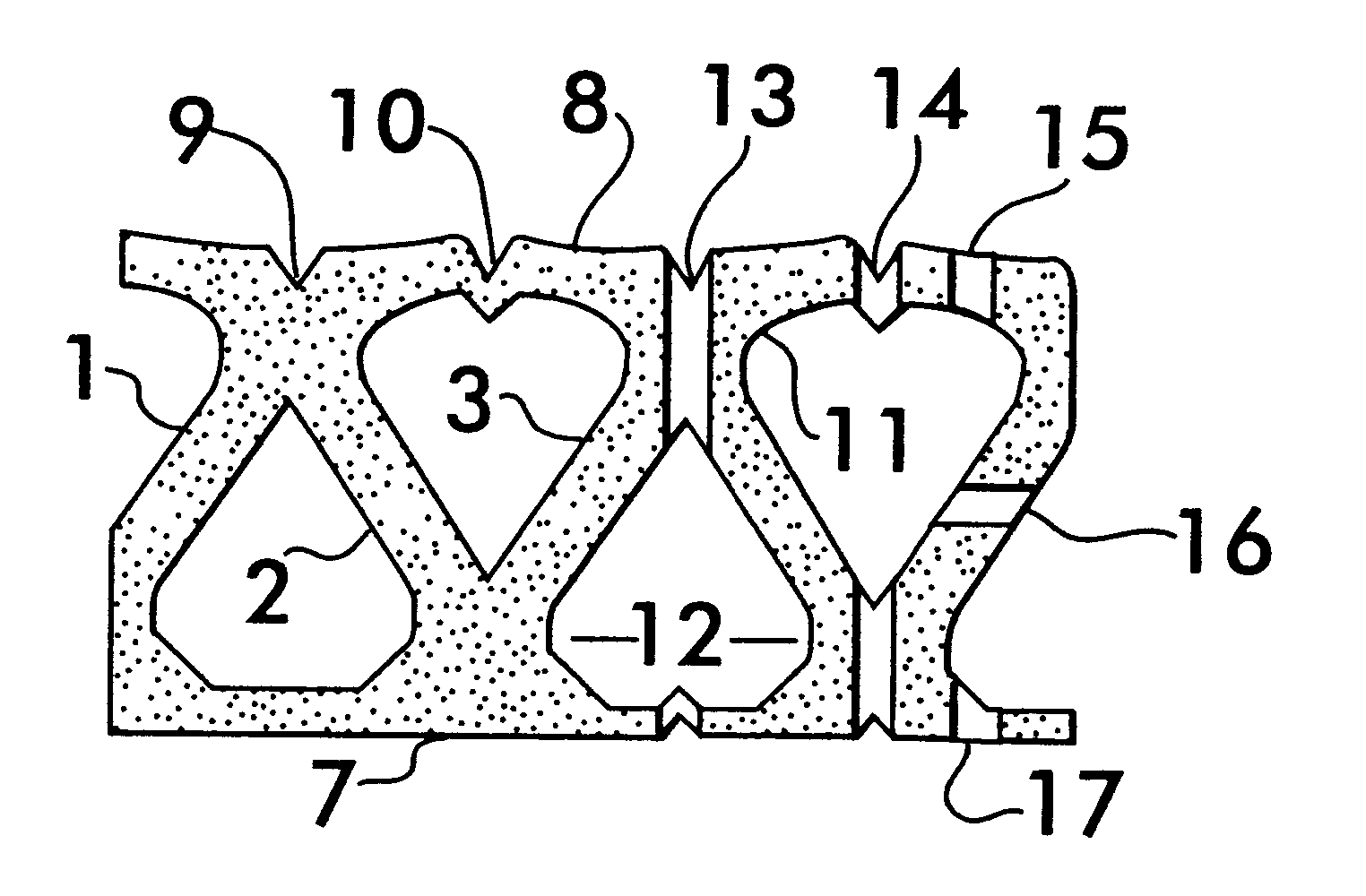

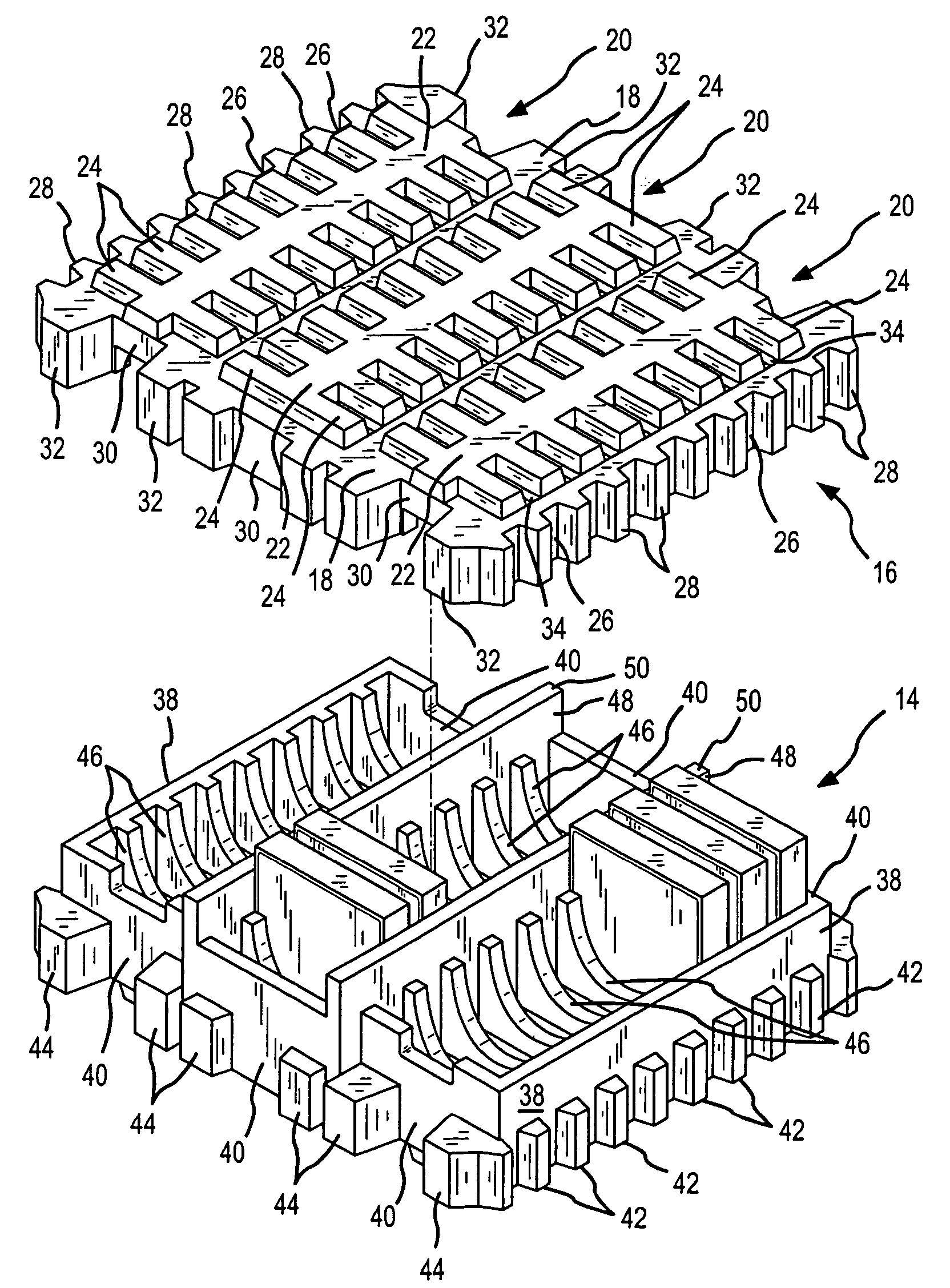

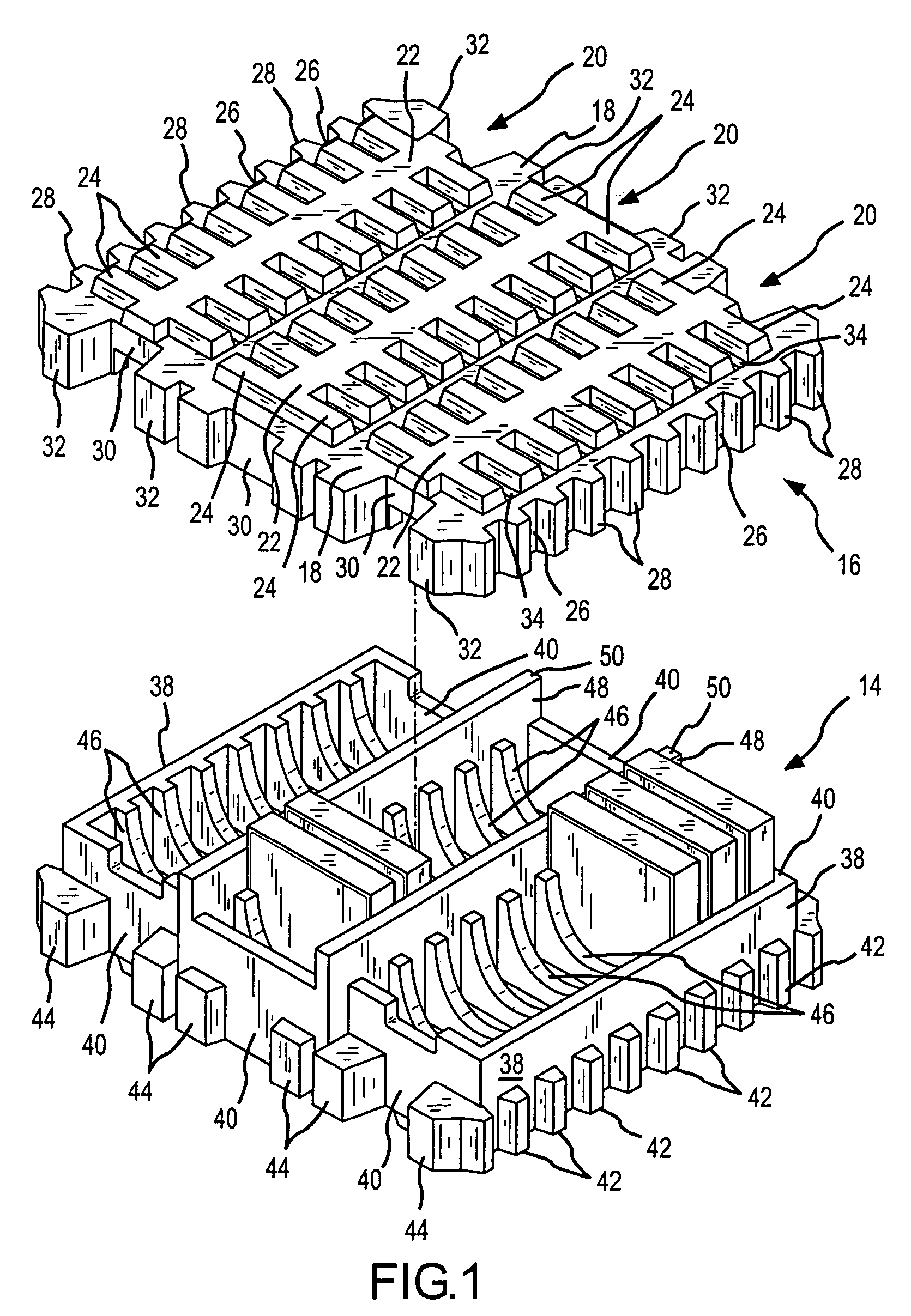

Macrocellular cushion and folding elastomer truss

InactiveUS6284346B1Reducing effective buckling lengthPreventing unnecessary outward (lateral) bucklingLayered productsLight effect designsElastomerCardboard

An improved closed-cell foam sheet stock and method for producing constant force characteristics in elastomer cushions. A closed cell foam is formed as a corrugated cardboard with regular cavities and support elements between two surface sheets. The resulting stock material possesses similar flexibility to foam stock but with an elongated force curve. A method for modifying this or other corrugated elastomers for efficient constant force curves is further provided where alternating support members are conjoined or buttressed to fold in controlled sigmoid shape under load. The resulting collapsible truss or space frame structure produces a cushion with improved cushioning, load distribution, shock absorption and resistance from lateral collapse while folding uniformly and efficiently to a smooth, compact and comfortable support under full compression. The orthopedic constant force profile allows uses in shoes, furniture, mattresses, sports padding, aircraft seats or packaging applications and extends the dynamic range of more resilient elastic, plastic or foam materials including very lightweight closed cell foam. For packaging applications both the collapsing truss or the less sophisticated corrugated profiles provide lighter weight and improved impact absorption over solid closed-cell foams.

Owner:SHERIDAN TIMOTHY BRIAN

Dual dispensing container

ActiveUS7988034B2Easy piercingImproved configuration of the perforations or slitsLidsRigid containersCardboardEngineering

A container of the present invention is designed for shipping and holding various items. The container is formed from a blank of a material, such as corrugated material, plastic, paperboard, etc. and includes side panels extending between a top portion and a bottom portion. A tear line extends around the side panels for disengaging the top portion from the container thereby exposing all of the items extending along the side panels. An improved configuration of the perforations or slits along the tear line prevents the corners defined between the side panels from being damaged and deformed and provides for smooth tearing of the tear line from the container. A second tear section is defined in the a portion of the container by a perforation line with the tear section being separable from the top portion thereby partially exposing the items contained in the container.

Owner:KELLOGG CO

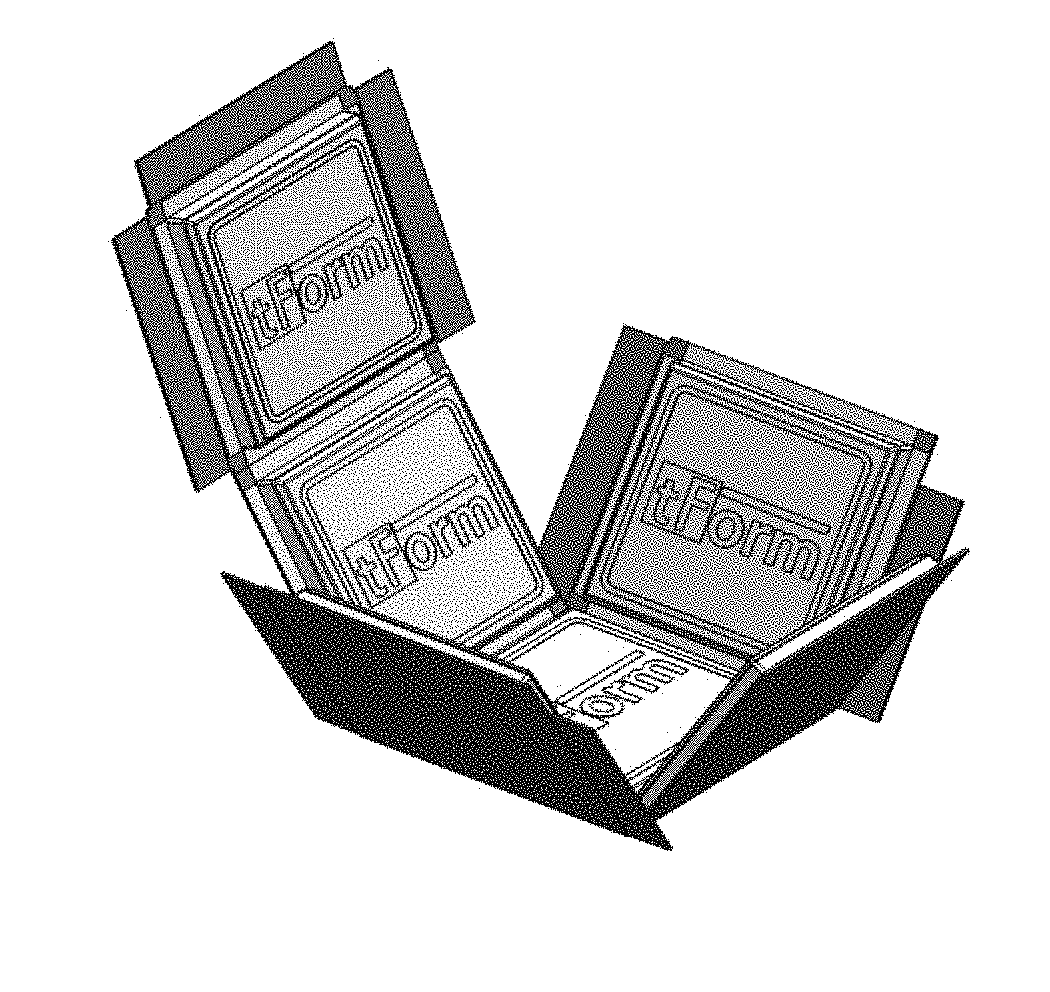

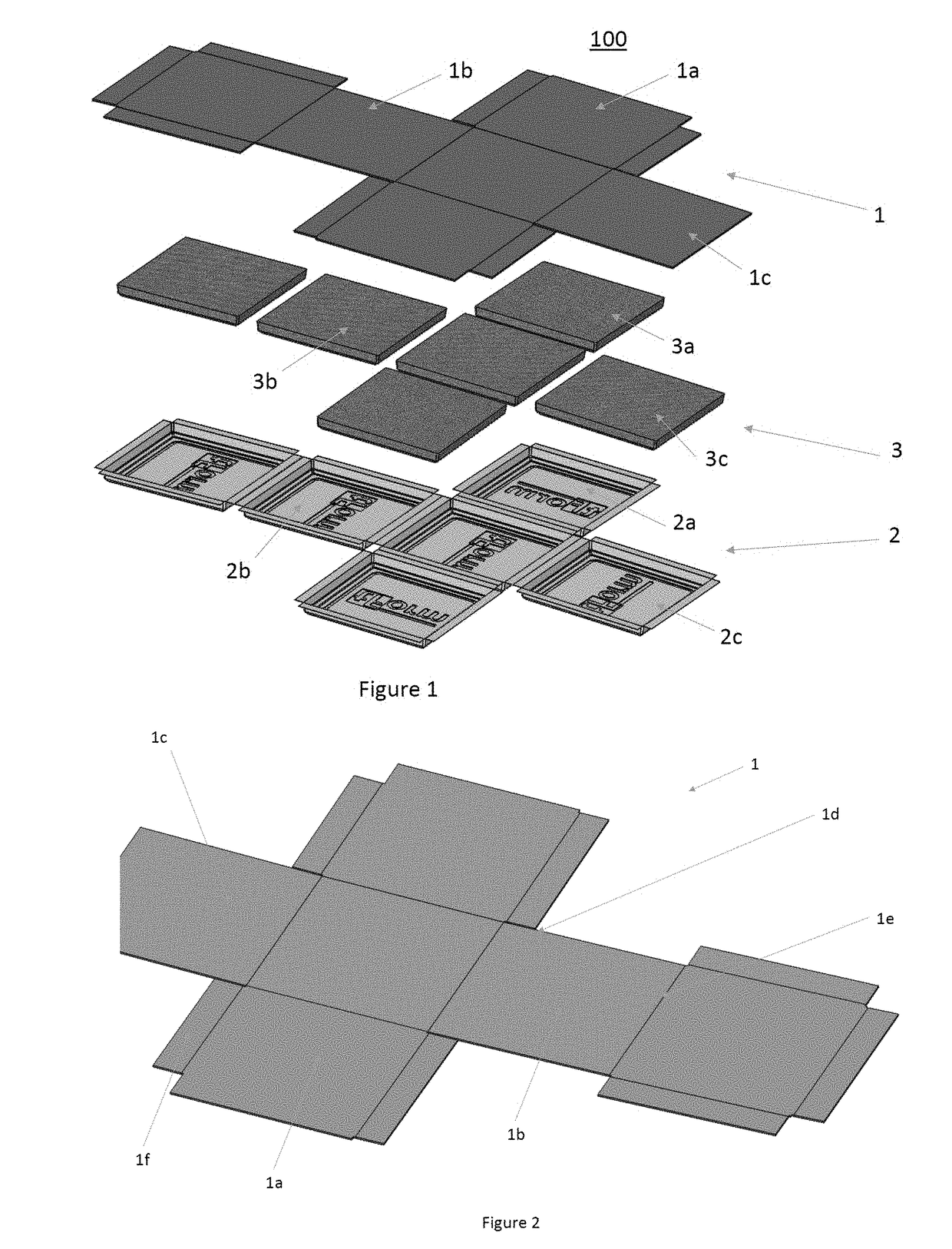

Fully recyclable insulated shipping container

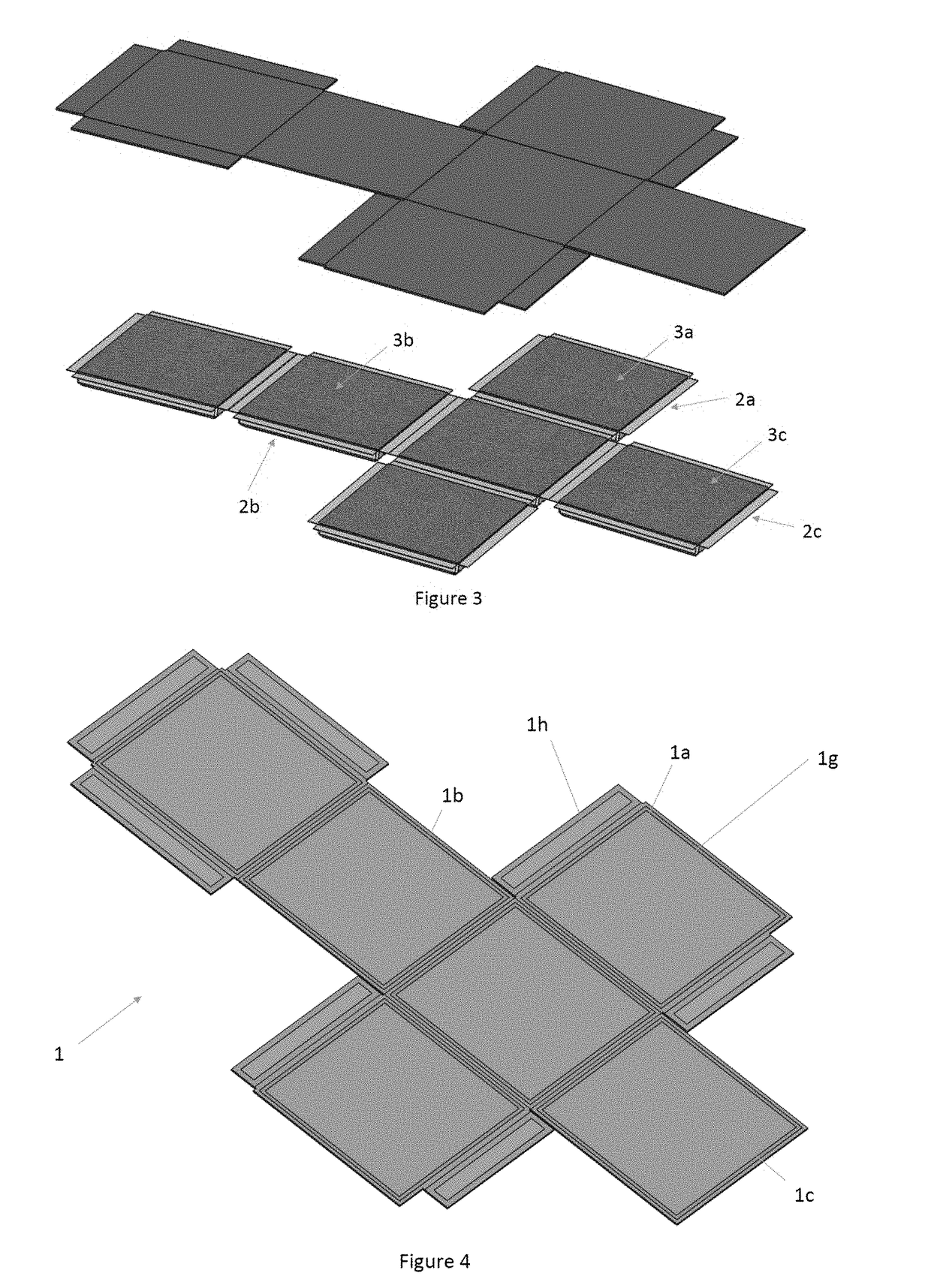

InactiveUS20180334308A1Easy to assembleCost advantageContainer decorationsLevel indicationsCardboardMultiple forms

The present invention generally relates to an insulated shipping container made entirely of standard recyclable materials for use in transporting heated or cooled payloads. The entire container and its insulation may be placed in a standard recycling bin after use, without any disassembly or separation of materials. The container comprises multiple layers that are easily folded together by the transporter prior to the additional of a payload for delivery to an end user. The container contains multiple formed paper panels that provide a tight seal for insulation purposes.

Owner:TFORM INC

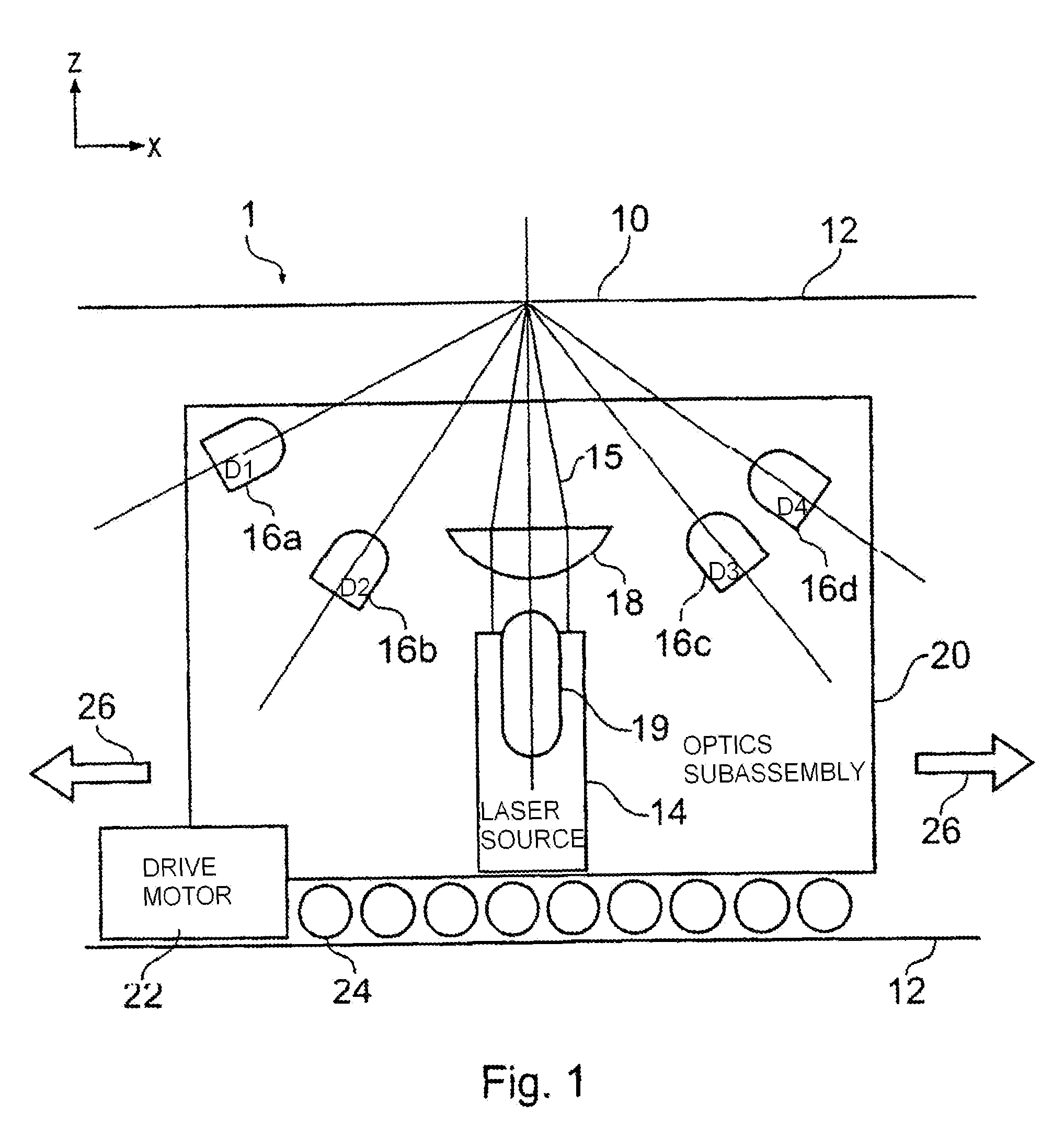

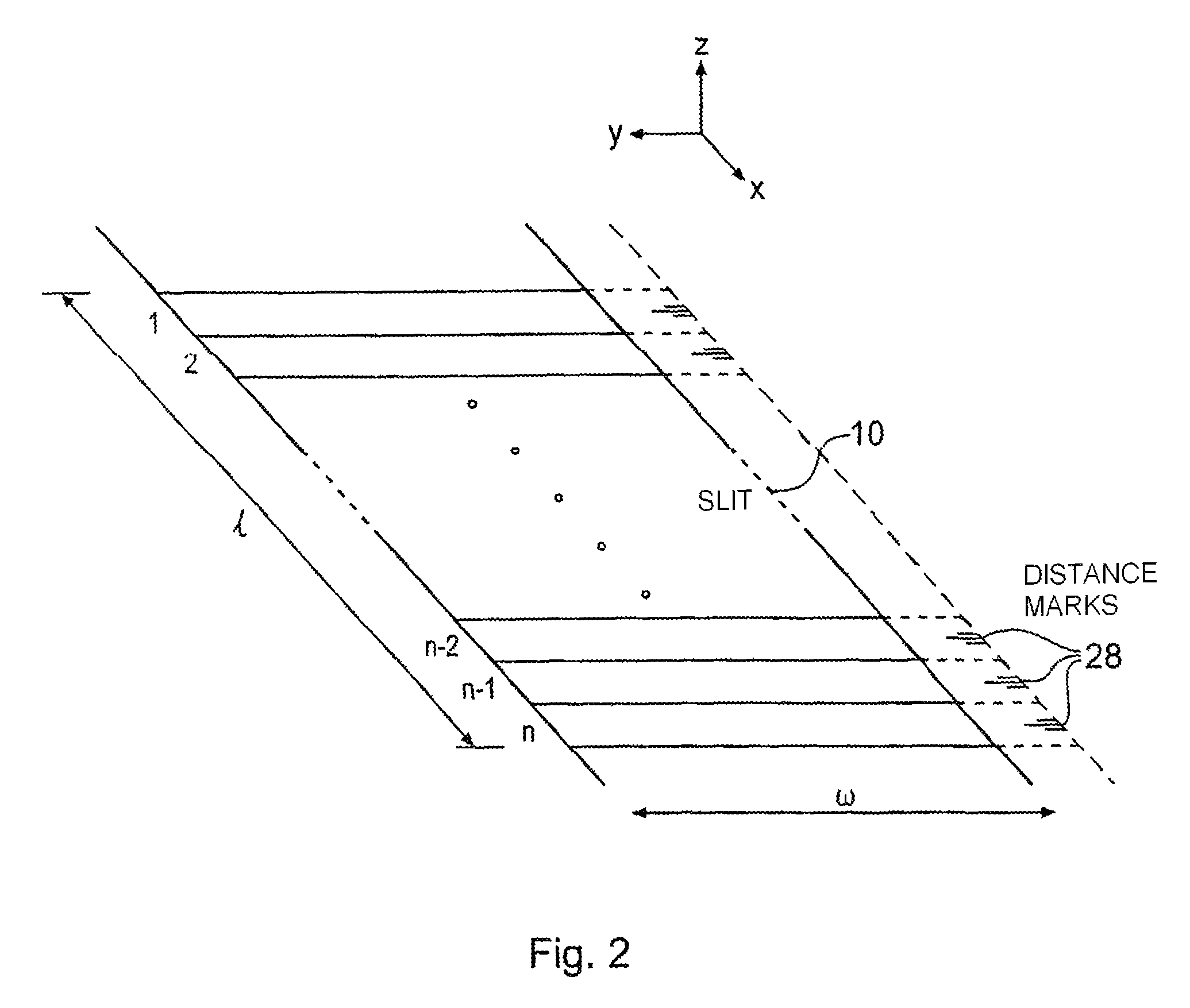

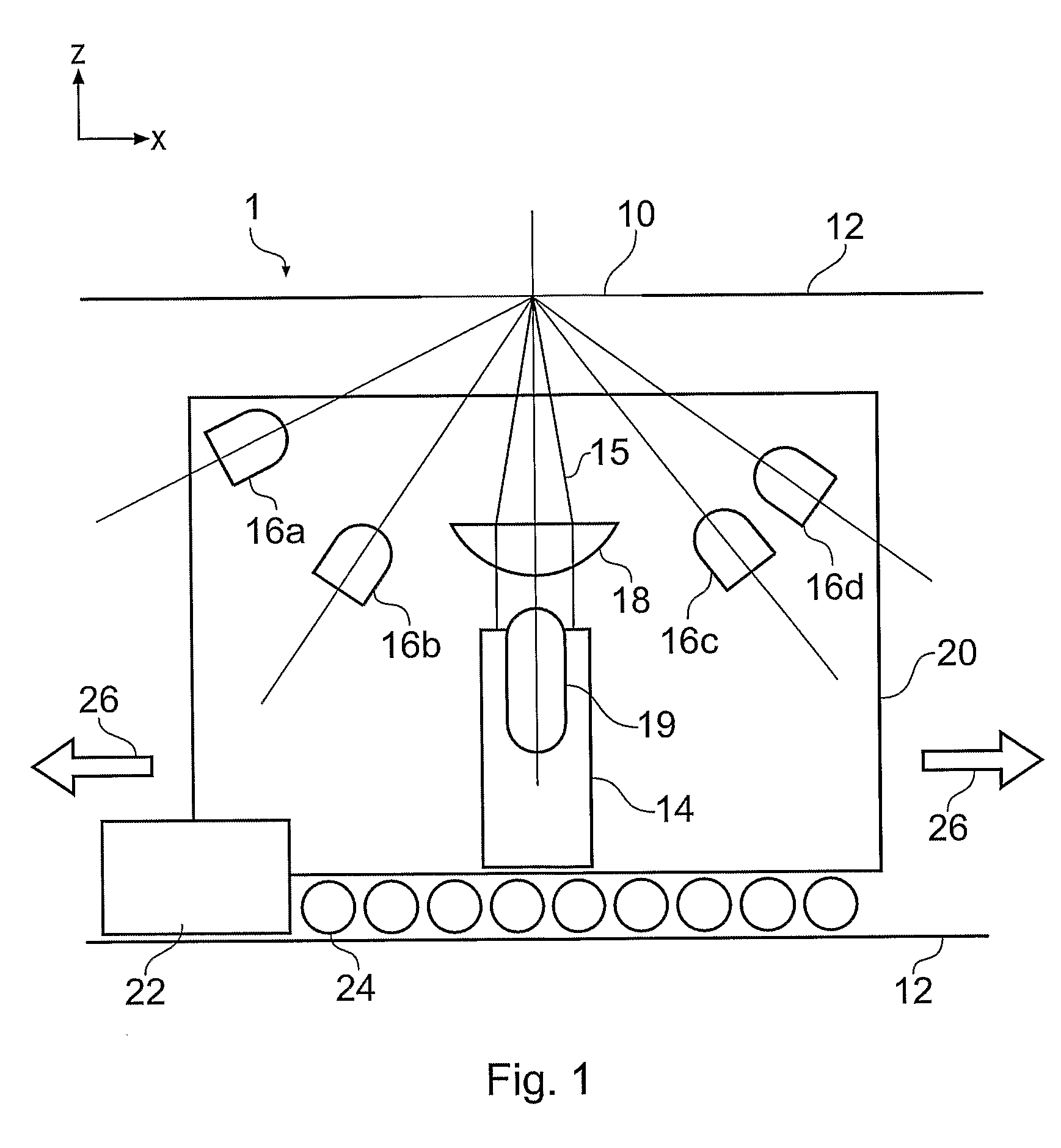

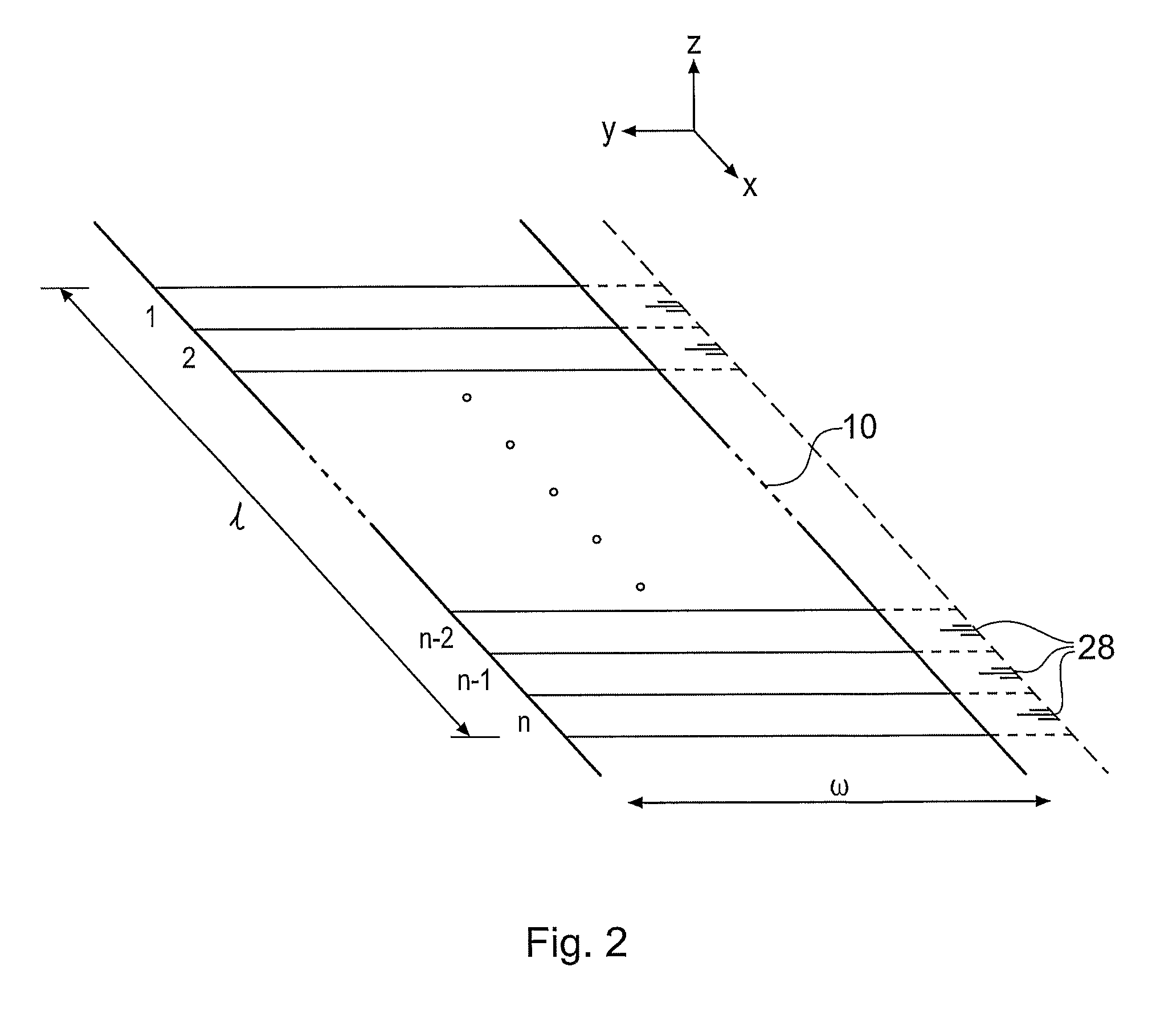

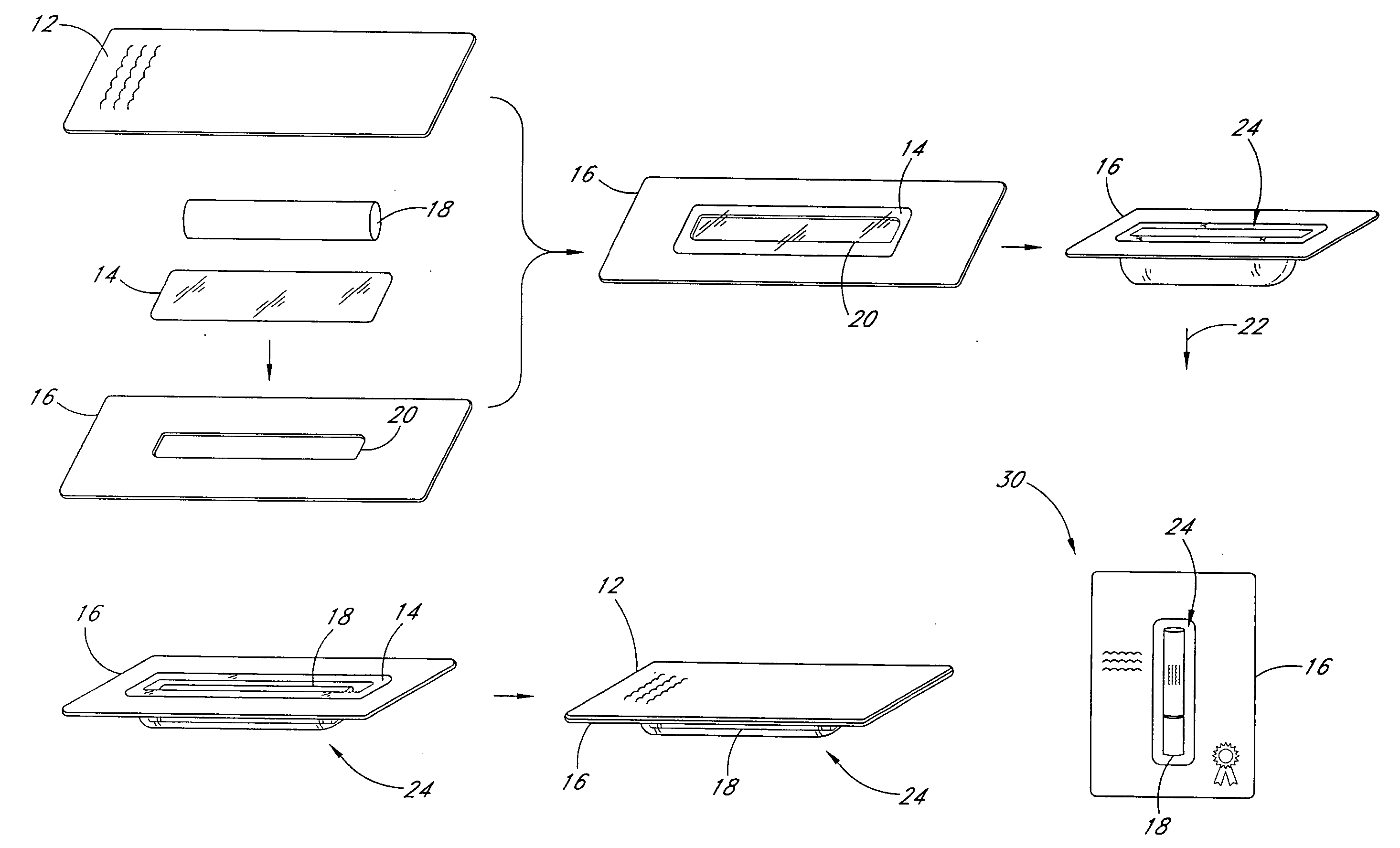

Methods and Apparatuses for Creating Authenticatable Printed Articles and Subsequently Verifying Them

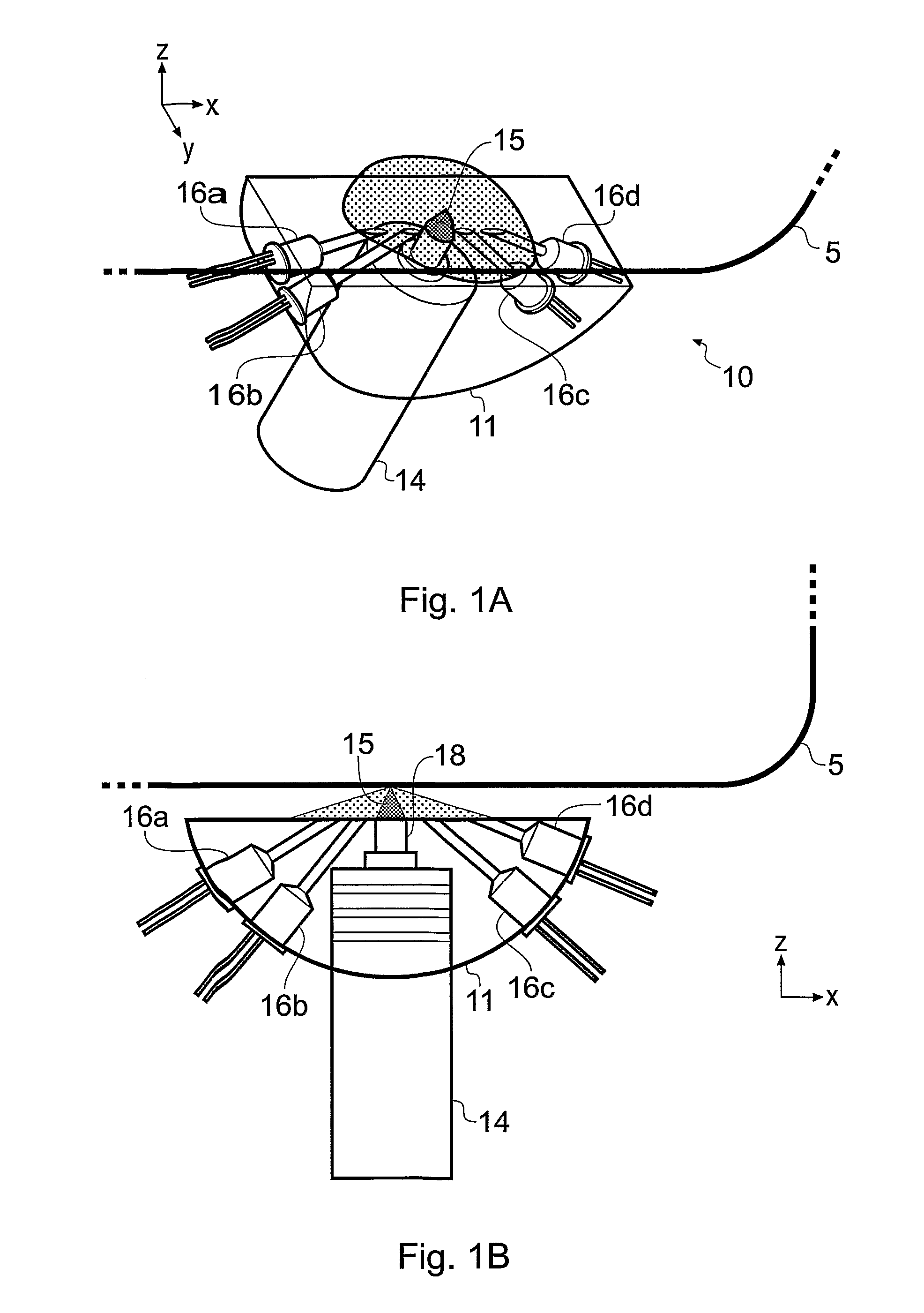

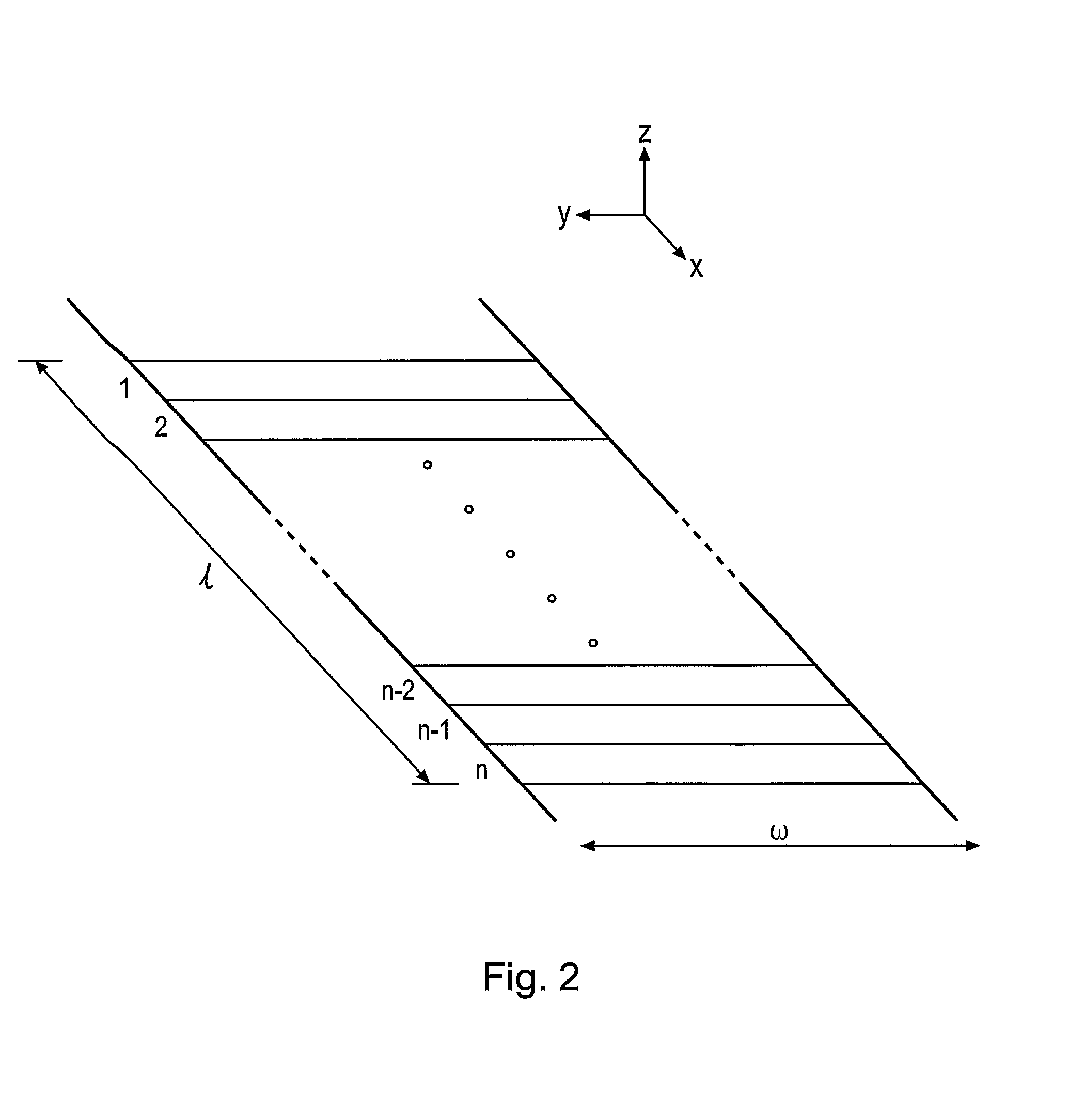

InactiveUS20080002243A1Improve security levelImprove security systemInking apparatusPaper-money testing devicesCardboardMaterial type

A method and apparatus for determining a digital signature from an article made of paper, cardboard, plastic or many other material types. A coherent source directs a beam to illuminate the article and a detector arrangement collects data points from light scattered from many different parts of the article to collect a large number of independent data points, typically 500 or more. By collecting a large number of independent signal contributions specific to many different parts of the article, a digital signature can be computed that is unique to the area of the article that has been scanned. This measurement can be repeated whenever required to test authenticity of the article. Using this method, it has been discovered that it is essentially pointless to go to the effort and expense of making specially prepared tokens, since unique characteristics are measurable in a straightforward manner from a wide variety of every day articles.

Owner:INGENIA HLDG LTD

Authenticity verification methods, products and apparatuses

InactiveUS20070192850A1Enhanced advantageDigital data processing detailsUser identity/authority verificationCardboardMaterial type

A method and apparatus for determining a digital signature from an article made of paper, cardboard, plastic or many other material types. A coherent light source directs a beam to illuminate the article and a detector arrangement collects data points from light scattered from many different parts of the article to collect a large number of independent data points, typically 500 or more. By collecting a large number of independent signal contributions specific to many different parts of the article, a digital signature can be computed that is unique to the area of the article that has been scanned. This measurement can be repeated whenever required to test authenticity of the article. Using this method, it has been discovered that it is essentially pointless to go to the effort and expense of making specially prepared tokens, since unique characteristics are measurable a in a straightforward manner from a wide variety of every day articles.

Owner:INGENIA HLDG LTD

Radiofrequency identification shielding

InactiveUS20060254815A1Increased riskPrivacy risk inherentMagnetic/electric field screeningRecord carriers used with machinesCardboardEngineering

Conductive materials, such as conductive paper, paperboard or plastic, are incorporated in a variety of known products such as luggage, file containers, bags, wrappings, stationery, men's and women's accessory clothing and other devices for carrying or storing papers and objects, so as to form a Faraday cage around the contents thereof to reduce the likelihood that those contents can be interrogated by RF-ID.

Owner:HUMPHREY THOMAS WARD +1

Container for disk drives

InactiveUS7584851B2Increase the effective heightReduce the overall heightOther accessoriesContainer/bottle contructionCardboardCushioning

A shipping container includes a main insert, a top cover and a cardboard or corrugated shell. The container is especially adapted for securing computer disk drives therein. Potential damage to the disk drives is minimized by isolating movement of the disk drives within the container. Each drive is loaded within a compartment defined by surrounding dividers formed on both the top cover and main insert. The overall container height is minimized by incorporating recesses in the inserts that can increase the effective height of exterior cushioning ribs thus reducing the thickness of the floorboard or base member. The incorporation of the recesses results in formation of relatively thin web sections that interconnect base portions of the cushioning ribs to base portions of the dividers.

Owner:SEAGATE TECH LLC

Lid assembly for shipping container

InactiveUS8579183B2Simplifies collection and shippingSimplify collectionUmbrellasPaper/cardboard articlesCardboardEngineering

A container for storage and shipping of objects includes a lid assembly having two configurations and an open-top box. In the first configuration the container can be loaded with objects for storage or collection while limiting physical and visual access to the contents of the box and in the second configuration, the container is sealed for shipping. The lid assembly contains side flaps which may be used to stabilize the lid assembly in the first configuration, and in the second configuration, secure the lid assembly to the open-top box. Preferably, the container is formed from one contiguous blank. The blank is preferably made of corrugated cardboard but may be formed from any substantially rigid material.

Owner:CALL2RECYCLE

Low density paperboard articles

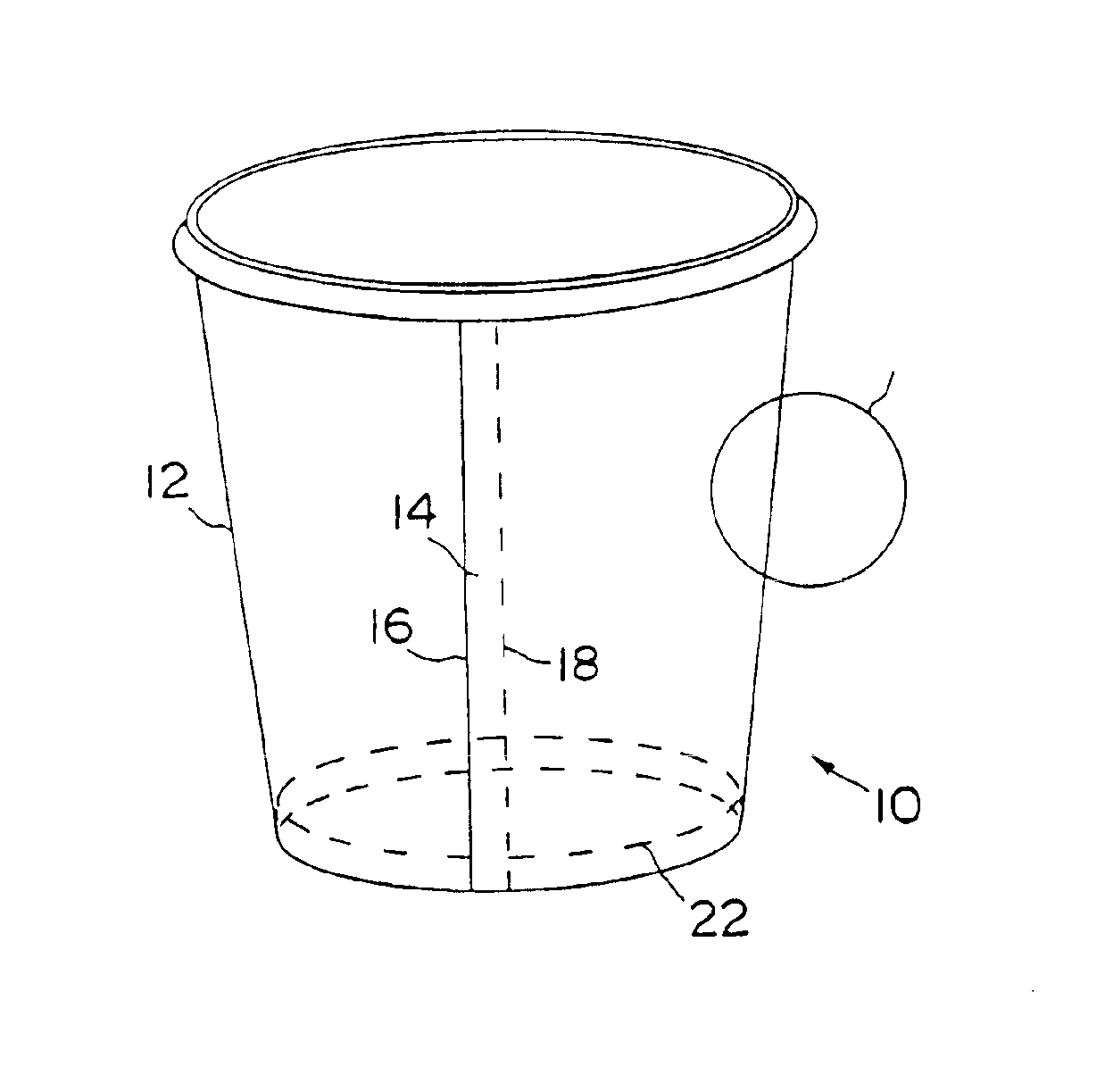

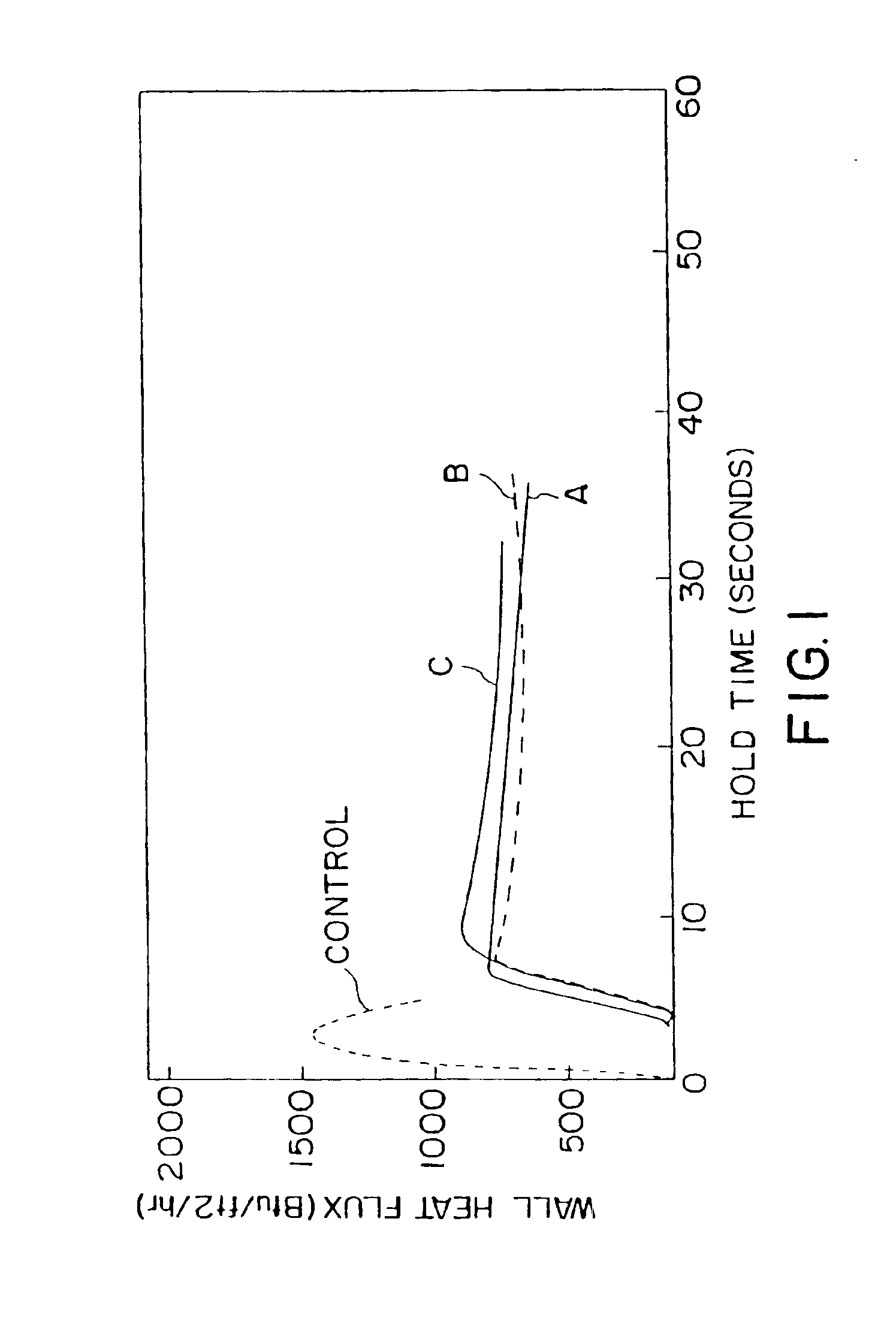

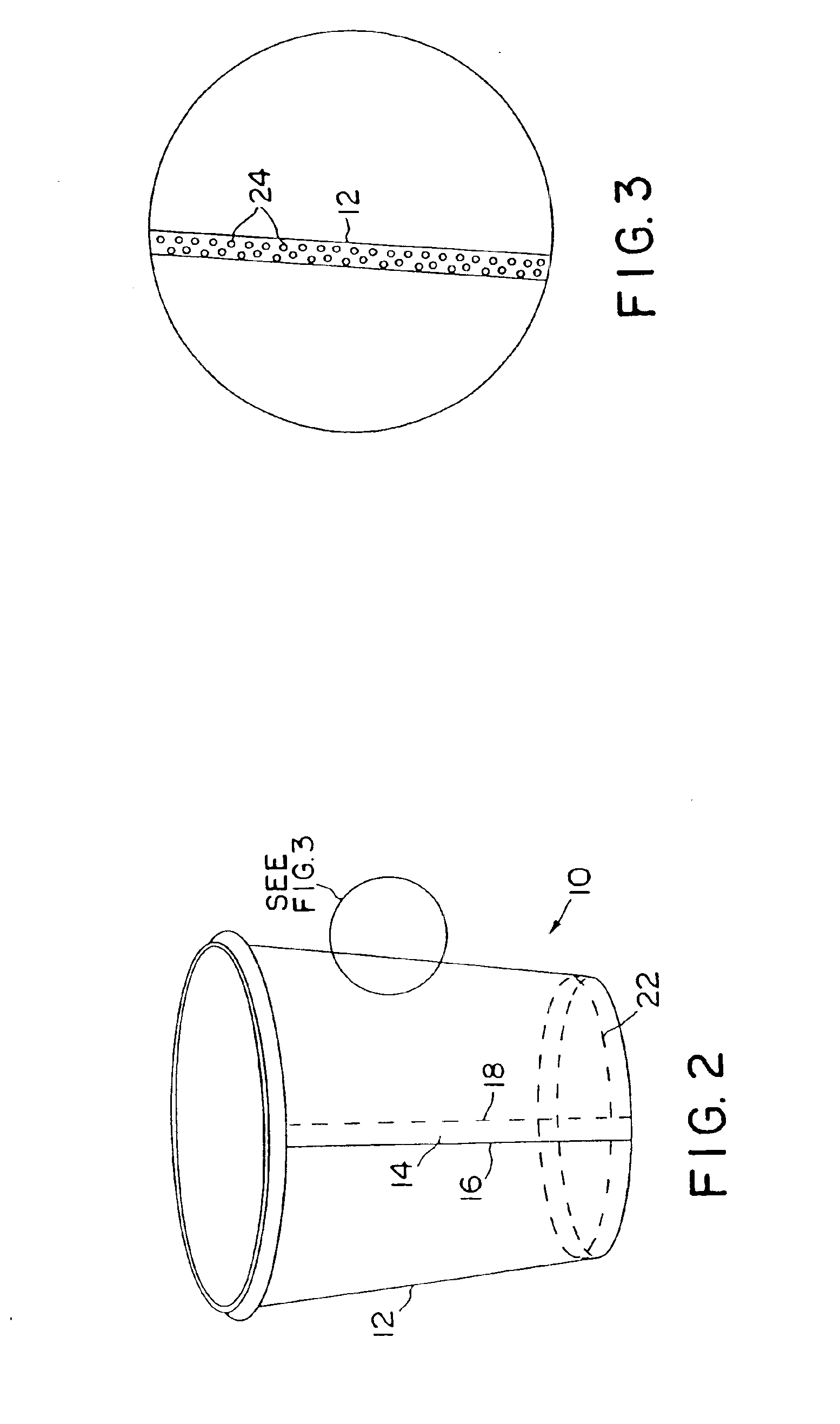

InactiveUS6846529B2Improve insulation performanceLess-expensive to produceNon-fibrous pulp additionNatural cellulose pulp/paperLow-density polyethyleneLinear low-density polyethylene

The invention provides a low density paperboard material for use in producing an insulated container, and is especially well-suited for making cups. The paperboard material comprises a paperboard web including wood fibers and expanded microspheres, and has a relatively low density ranging from about 6 to about 10 lb / 3MSF / mil, a relatively high caliper ranging from about 24 to about 35 mil, and an internal bond strength of at least about 80×10−3 ft-lbf preferably at least 100×10−3 ft-lbf. For applications such as cups the material is also coated on one or both sides with a barrier coating, preferably low density polyethylene, to limit liquid penetration into the web. The low density paperboard material of the invention is convertible for manufacture of containers, particularly cups, and the surface of the low density board may have a Sheffield smoothness of 300 SU or greater.

Owner:GRAPHIC PACKAGING INT

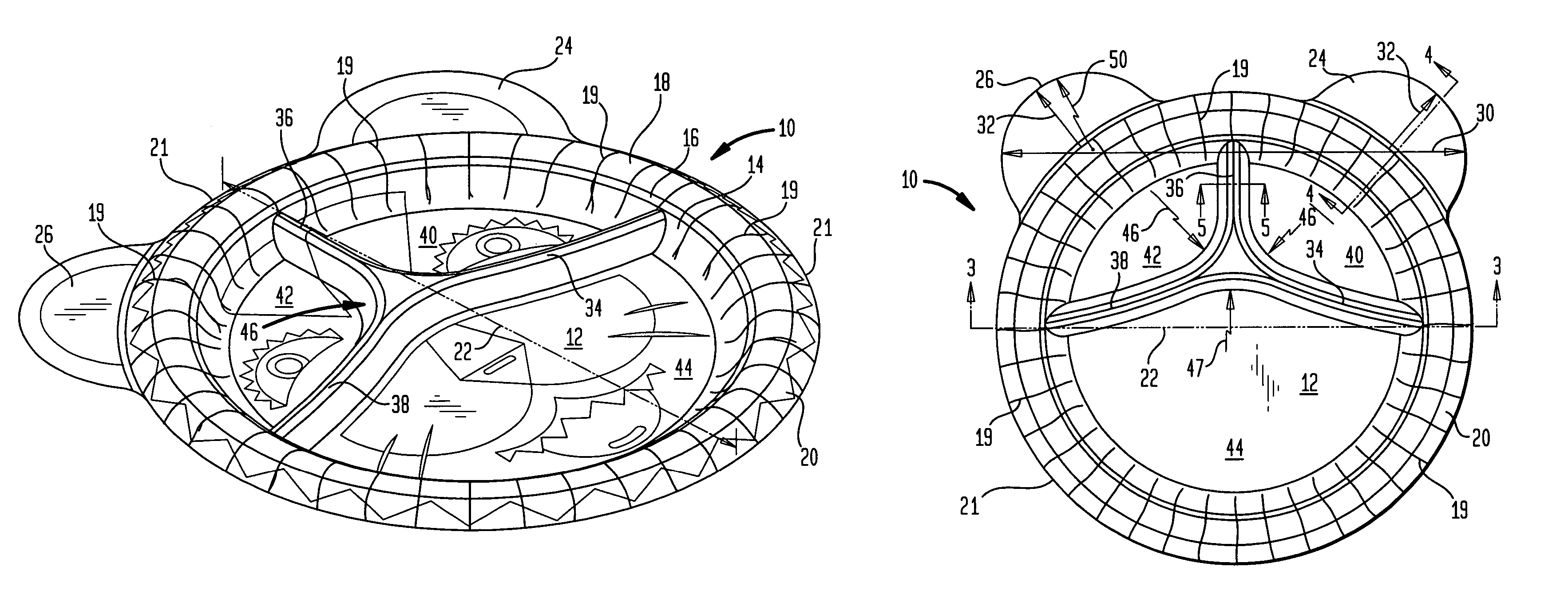

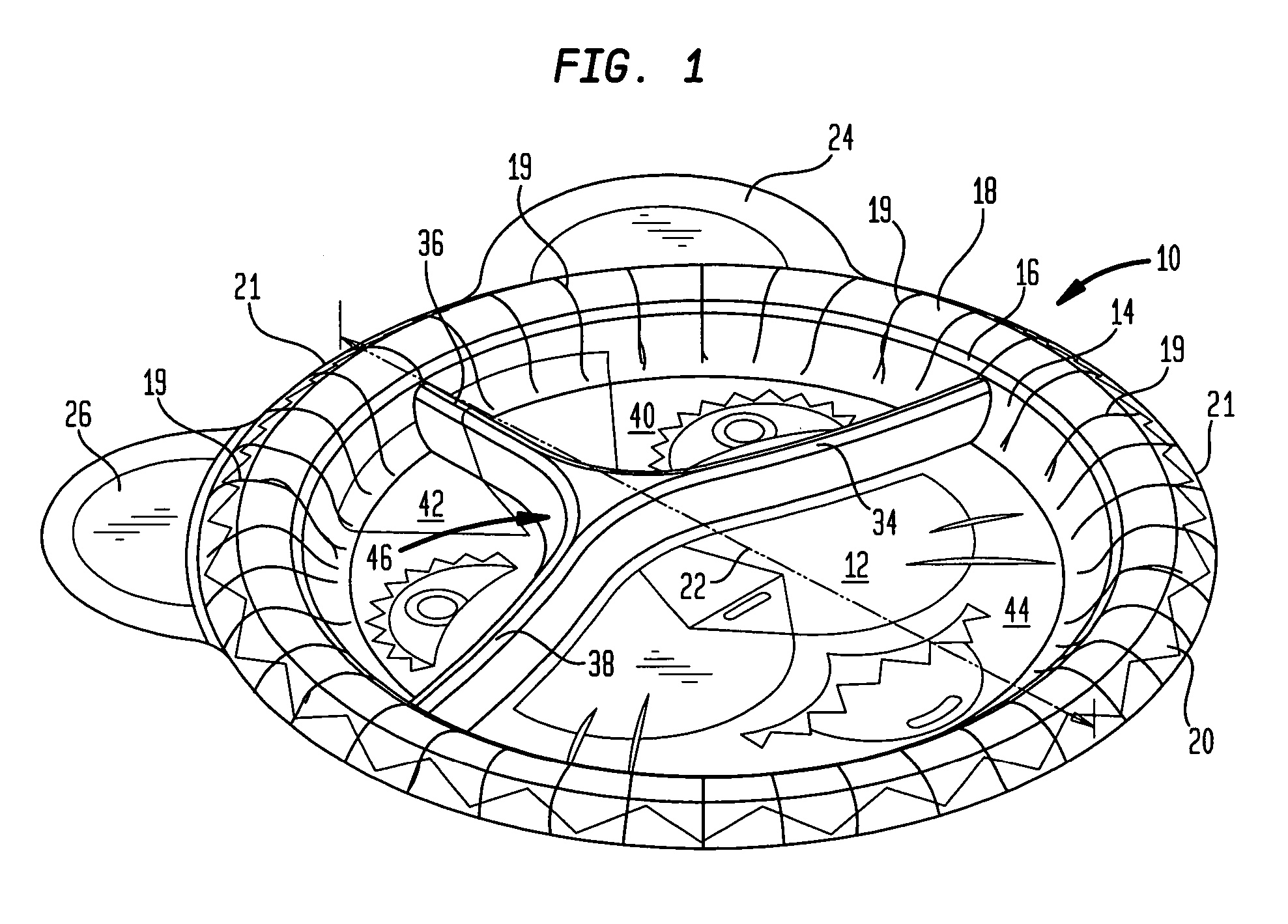

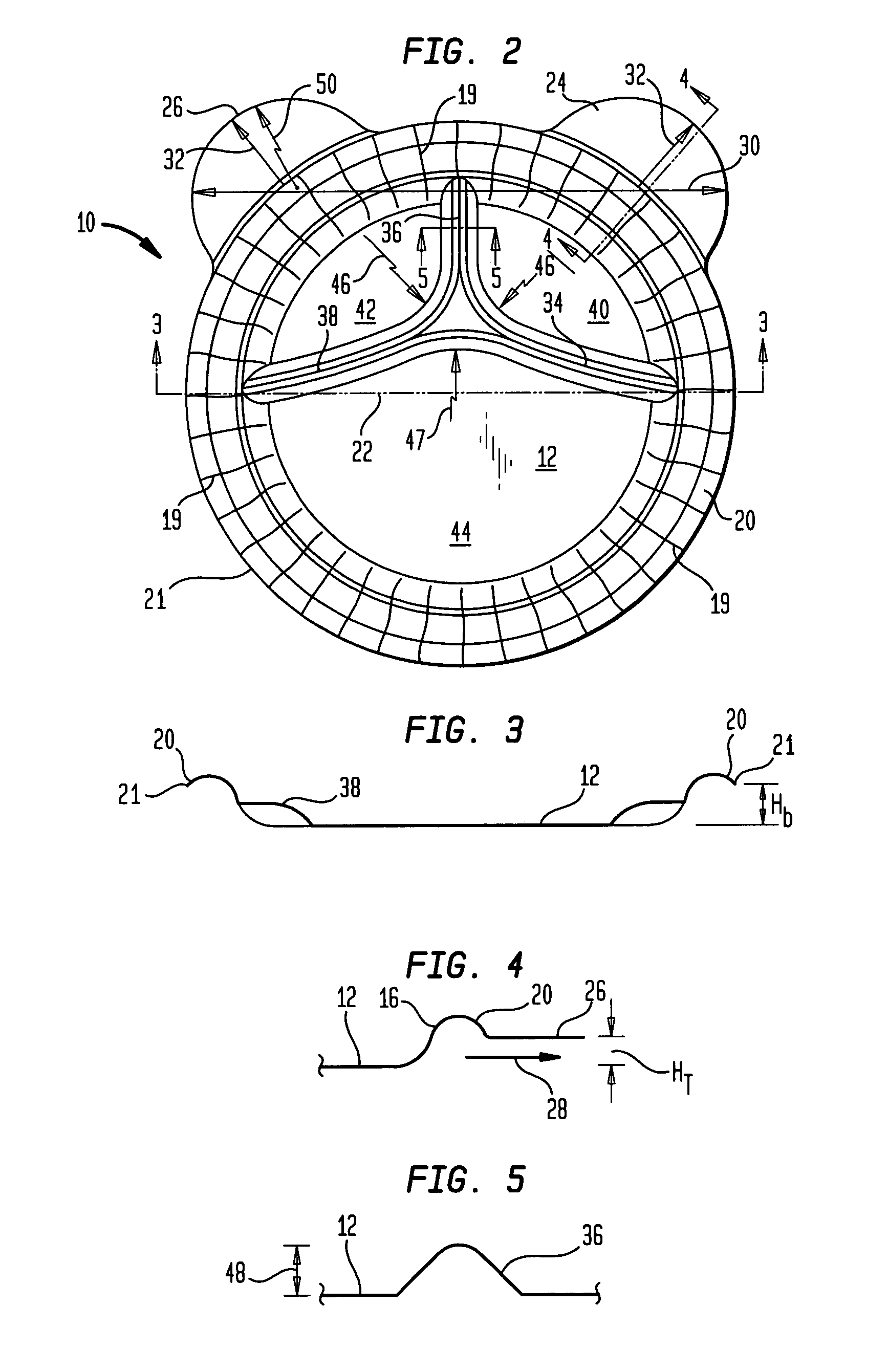

Disposable servingware containers with flange tabs

Disposable containers include peripheral tabs which are useful for positioning and processing the containers and operate as separators. In a preferred embodiment, the tabs correspond to tabs on a paperboard blank where the tabs are useful for controlling the orientation of the blanks so that printed and shape features may be kept in registration during manufacturing of a disposable servingware container.

Owner:GPCP IP HLDG LLC

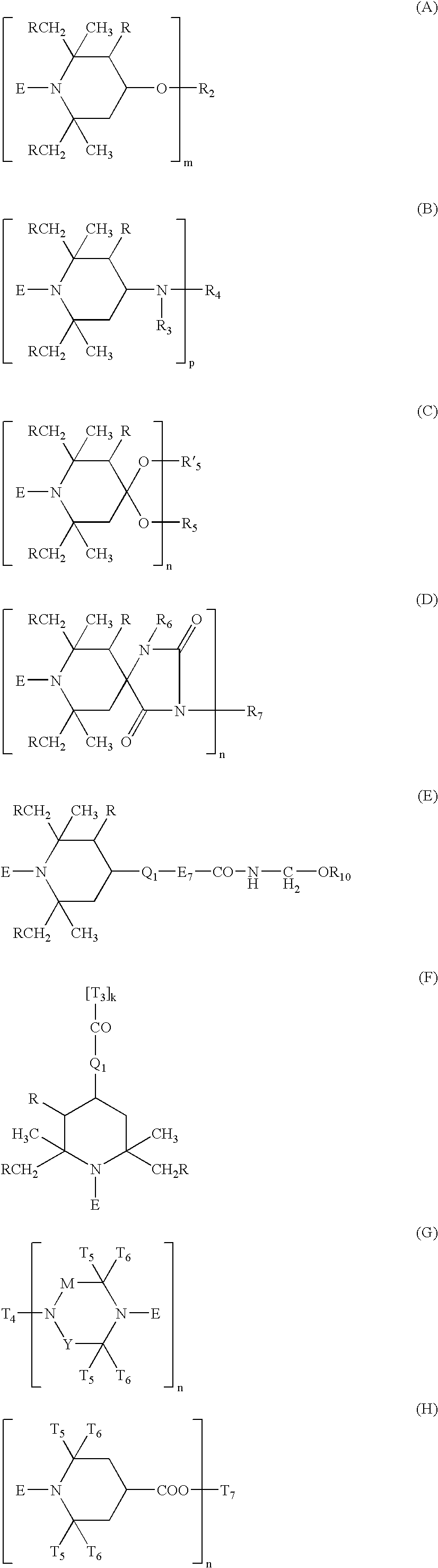

Flame retardant coatings

Provided are flame retardant coating compositions and articles coated therewith, which compositions comprise (A) a coating and (B) an effective flame retarding amount of a mixture of (i) at least one compound selected from the group consisting of the (a) sterically hindered nitroxyl stabilizers, (b) sterically hindered hydroxylamine stabilizers and (c) sterically hindered alkoxyamine stabilizers and (ii) at least one conventional flame retardant selected from the group consisting of (d) organohalogen flame retardants, (e) organophosphorus flame retardants, (f) isocyanurate flame retardants and (g) melamine based flame retardants. The coated articles are for example iron, steel, stainless steel, aluminum and other non-ferrous metals, wood, plywood, paper, cardboard, chip board, particle board, plastics, thermoplastics, epoxies, neoprene, rubber, composites, fiberglass reinforced composites, polyesters, polymeric foam, masonry, fabric or textiles, wire and cable constructions and circuit boards.

Owner:TROUTMAN MALISA +3

Suspension packaging system

InactiveUS7296681B2Easy to storeSimplifying transportationContainers to prevent mechanical damageRigid containersCardboardBiomedical engineering

A suspension packaging system can include a foldable member configured to form a cavity as well as a suspension device for suspending an article to be packaged within the cavity. The suspension portion can include foldable portions configured to cooperate with a retention member having pockets. The foldable portions can fit into the pockets and then be folded so as to generate tension in the retention member. The entire device, with the exception of the retention member, can be made from a single piece of material, such as corrugated cardboard, which thus reduces waste and simplifies bulk distribution of such a suspension packaging system.

Owner:CLEARPAK

Repulpable container

A repulpable insulated container assembly having a container formed of paper such as corrugated cardboard or varying paper materials and defining an interior; and a repulpable insert placed within the interior of the container and formed of a first paper layer; and a paper fiber pad coupled to the first paper layer.

Owner:PRATT RETAIL SPECIALTIES LLC

Printed packaging

InactiveUS20070051652A1Reduce manufacturing costHigh impact point-of-saleContainer decorationsLevel indicationsCardboardPlastic packaging

High visual impact plastic packaging is described as well as methods for producing such packaging. Printing on multiple surfaces of a package to obtain appealing visual effects is described. Methods of sealing plastic packages are described, including some that use heat sealing techniques. Plasticized or laminated paperboard materials can be used, as well as plastic materials such as recycled and / or recyclable polyurethane.

Owner:ONE SOURCE INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com