Patents

Literature

3207 results about "Fiberboard" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fiberboard (or fibreboard) is a type of engineered wood product that is made out of wood fibers. Types of fiberboard (in order of increasing density) include particle board or low-density fiberboard (LDF), medium-density fiberboard (MDF), and hardboard (high-density fiberboard, HDF).

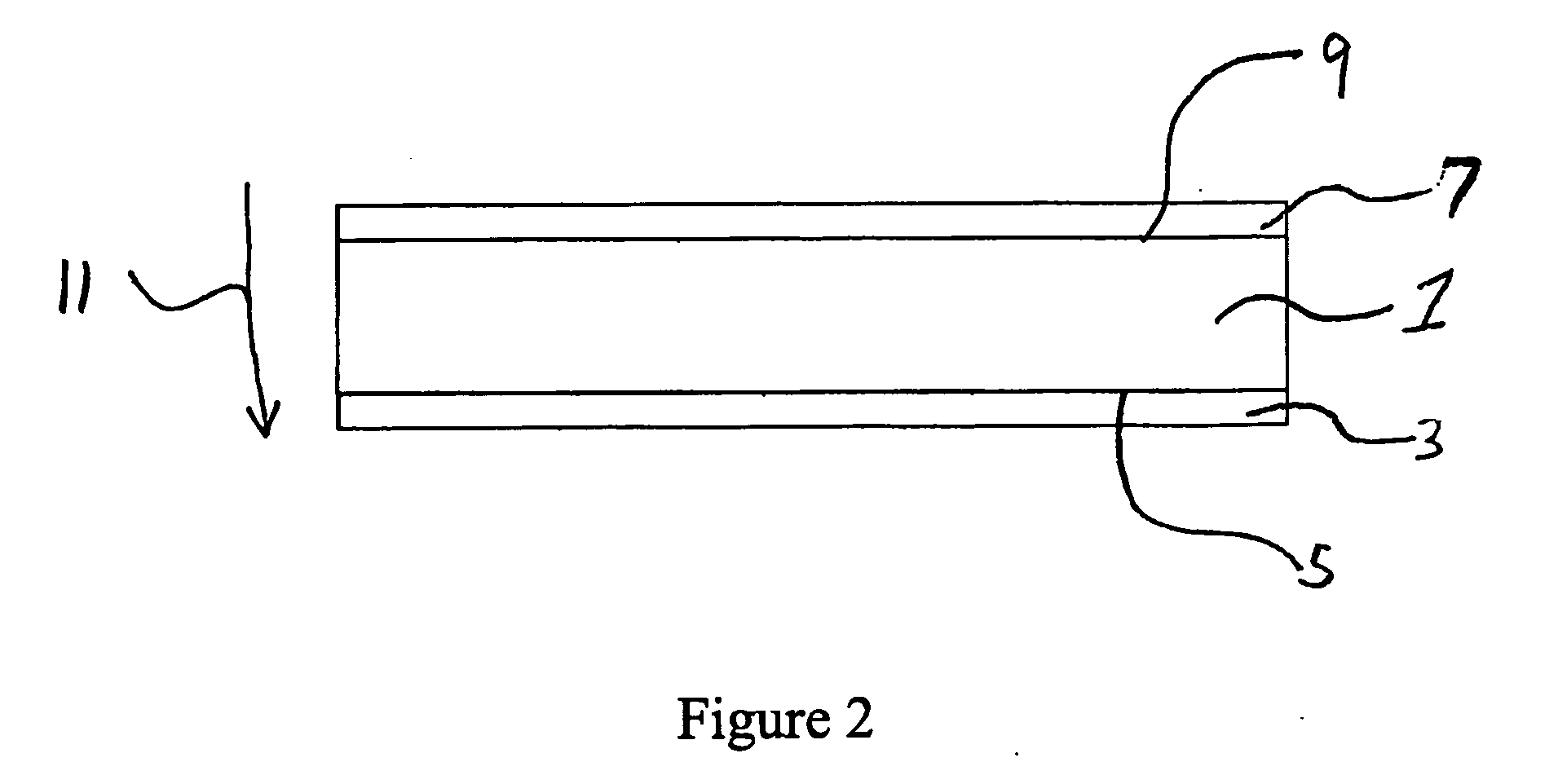

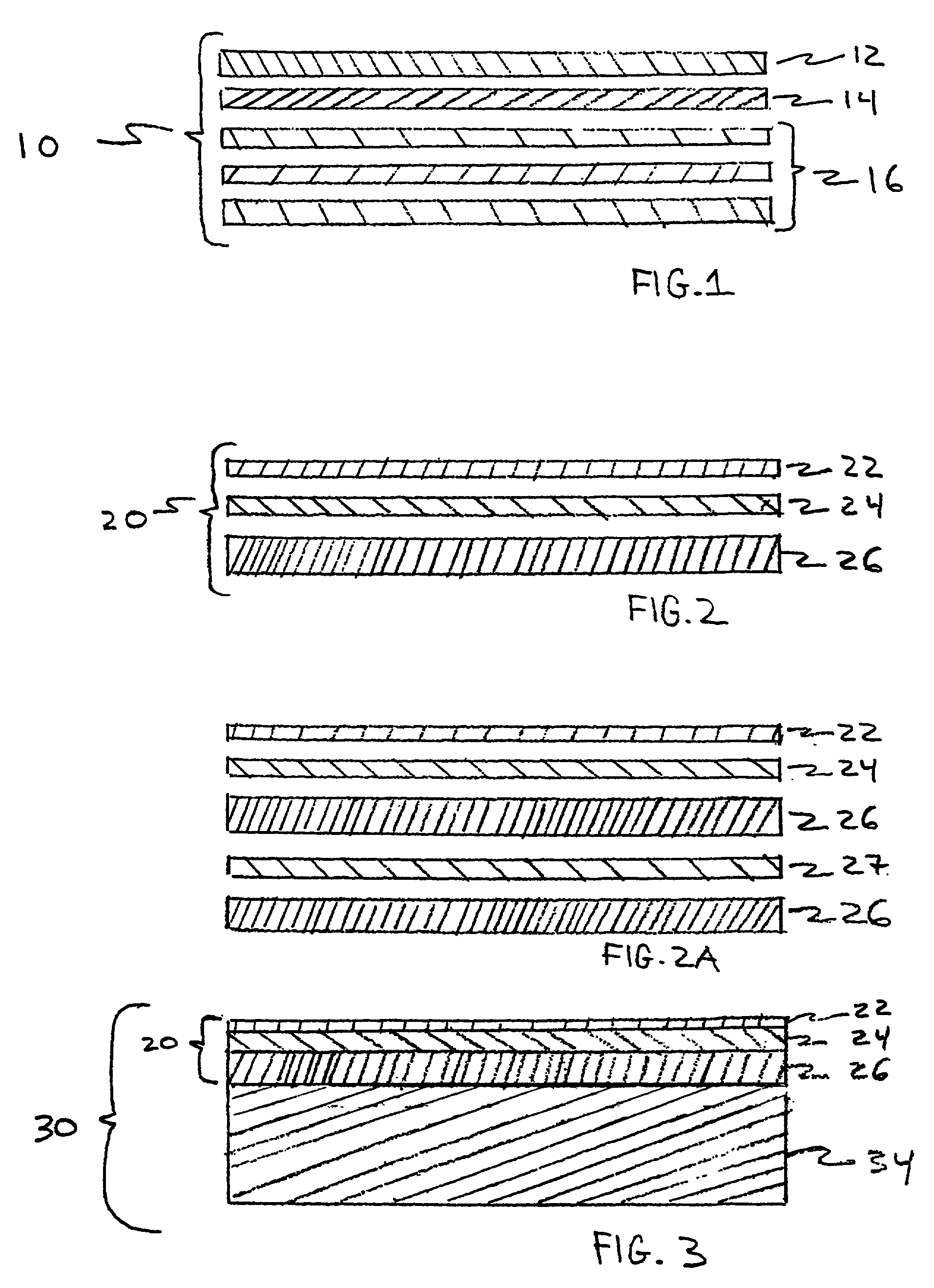

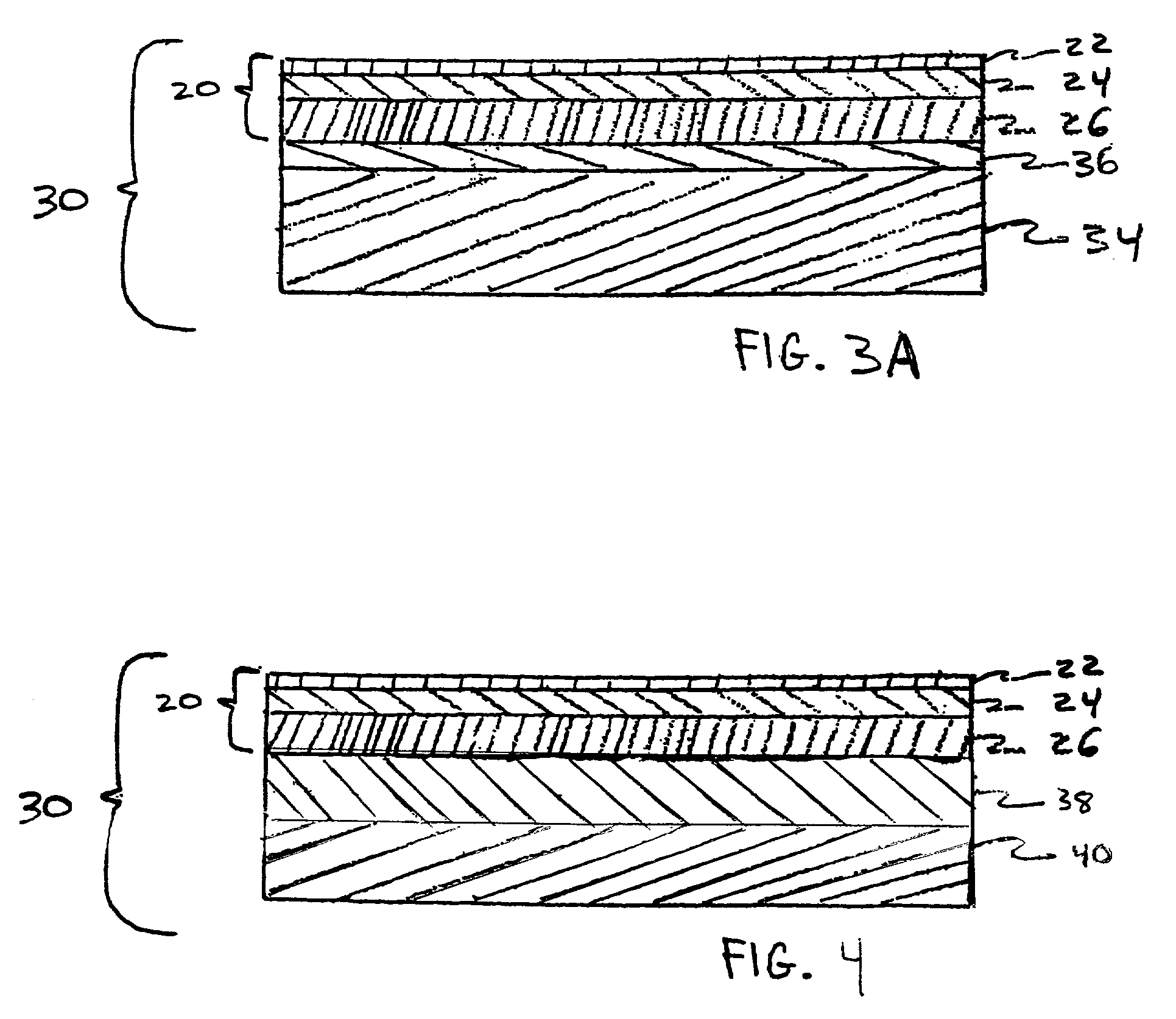

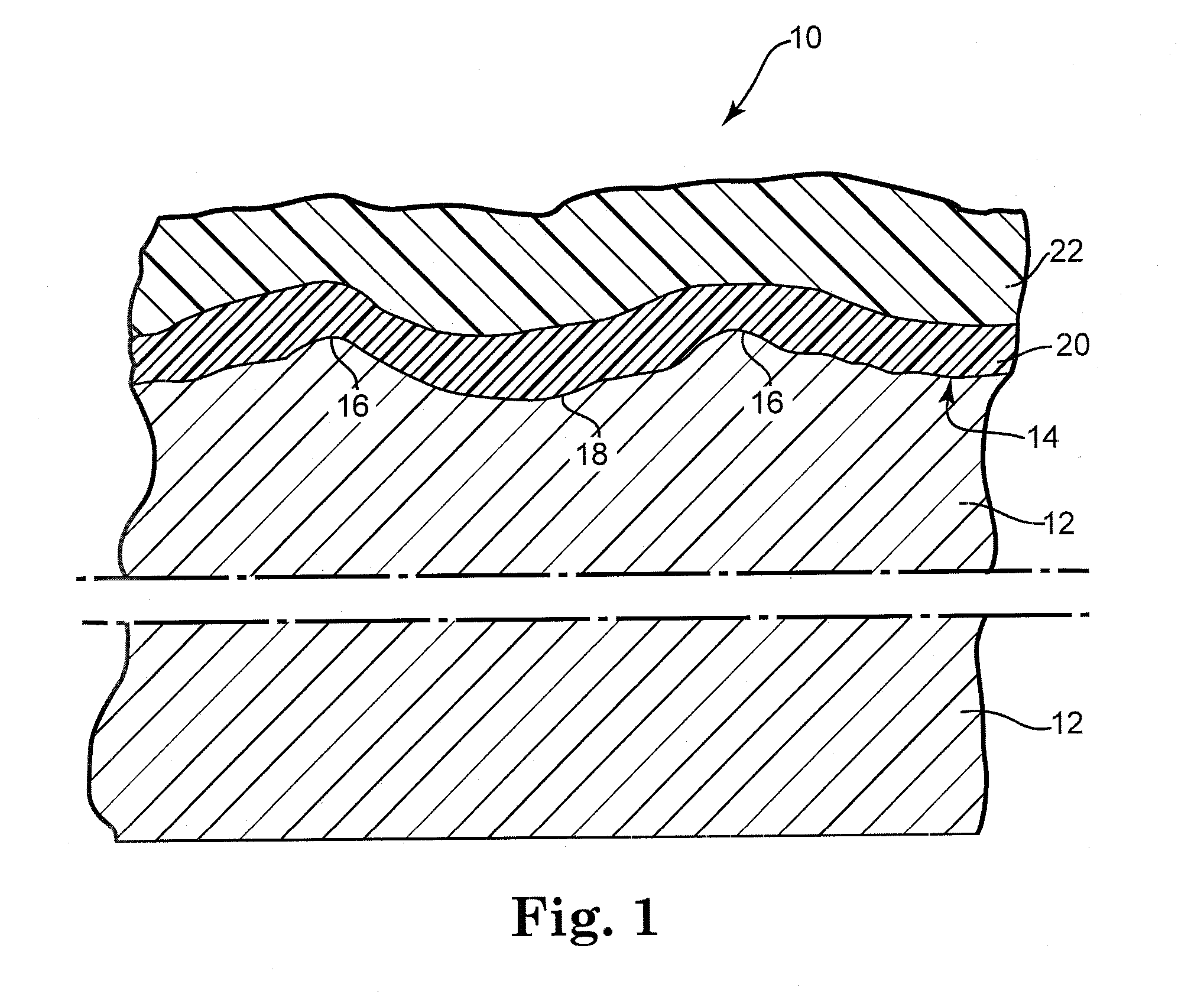

Bulk enhanced paperboard and shaped products made therefrom

An improved paperboard has been bulk enhanced by retaining a substantial portion of bulk-enhanced additives including expandable microspheres in a suitable distribution within the paperboard. The cellulosic paperboard web has an overall fiber weight (w) of at least 40 lbs. / 3000 square feet and at a fiber density of 3, 4.5, 6.5, 7, 8.3, and 9 pounds per 3000 square foot ream at a fiberboard thickness of 0.001 inch respectively, has a GM Taber stiffness of at least about 0.00716 w2.63 grams-centimeter / fiber mat density1.63 pounds per 3000 square foot ream at a fiberboard thickness of 0.001 inch, and a GM tensile stiffness of at least about 1890+24.2 w pounds per inch. The high retention of the bulk enhancing additives is believed to result from the incorporation of suitable retention aids. The resulting paperboard has better GM Taber stiffness values and GM tensile stiffness than prior art paperboards. The paperboard also has increased strain to failure and is able to be formed into suitable paperboard containers without loss of integrity. The resulting containers have increased hold times when they contain hot or cold food or drink.

Owner:DIXIE CONSUMER PROD

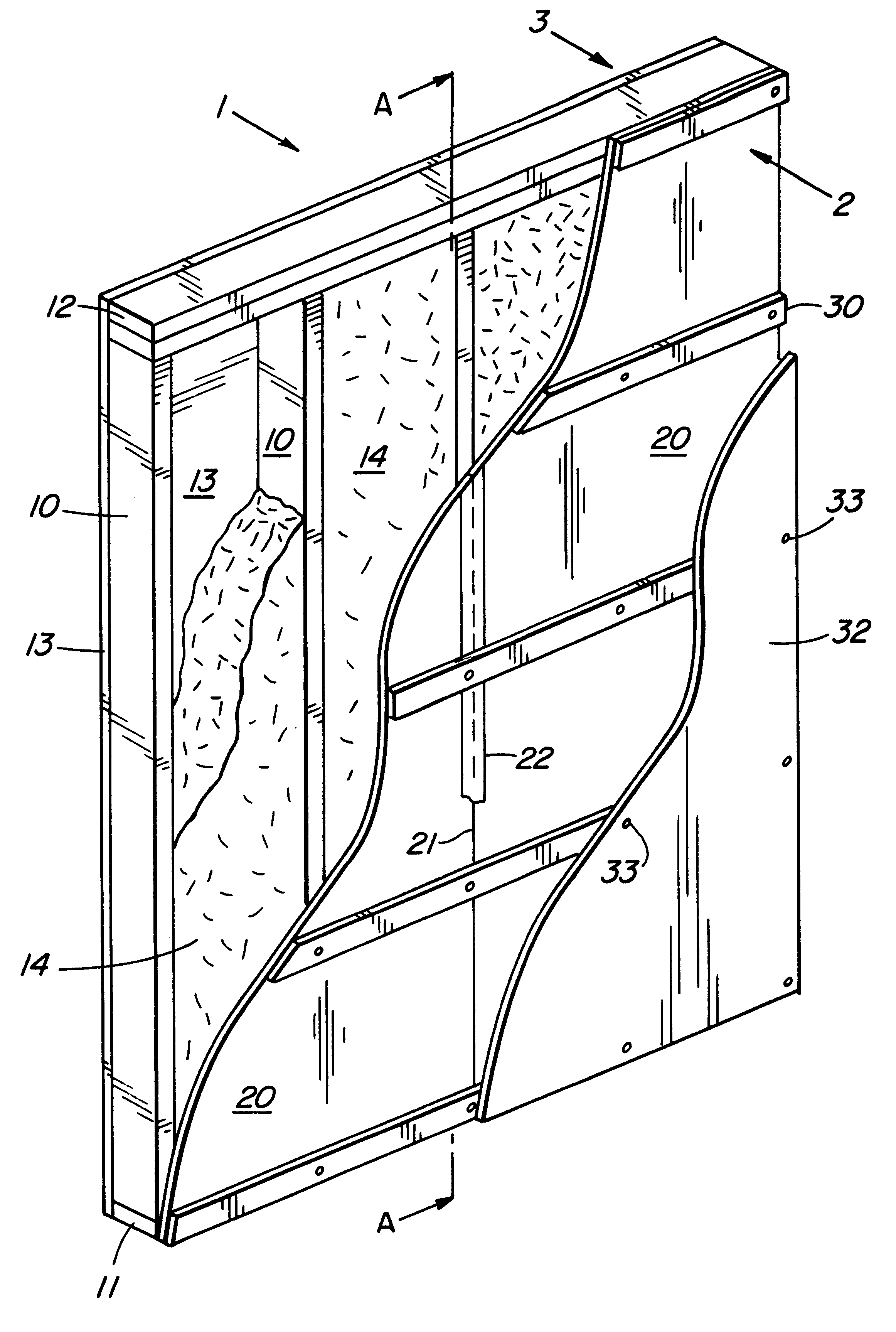

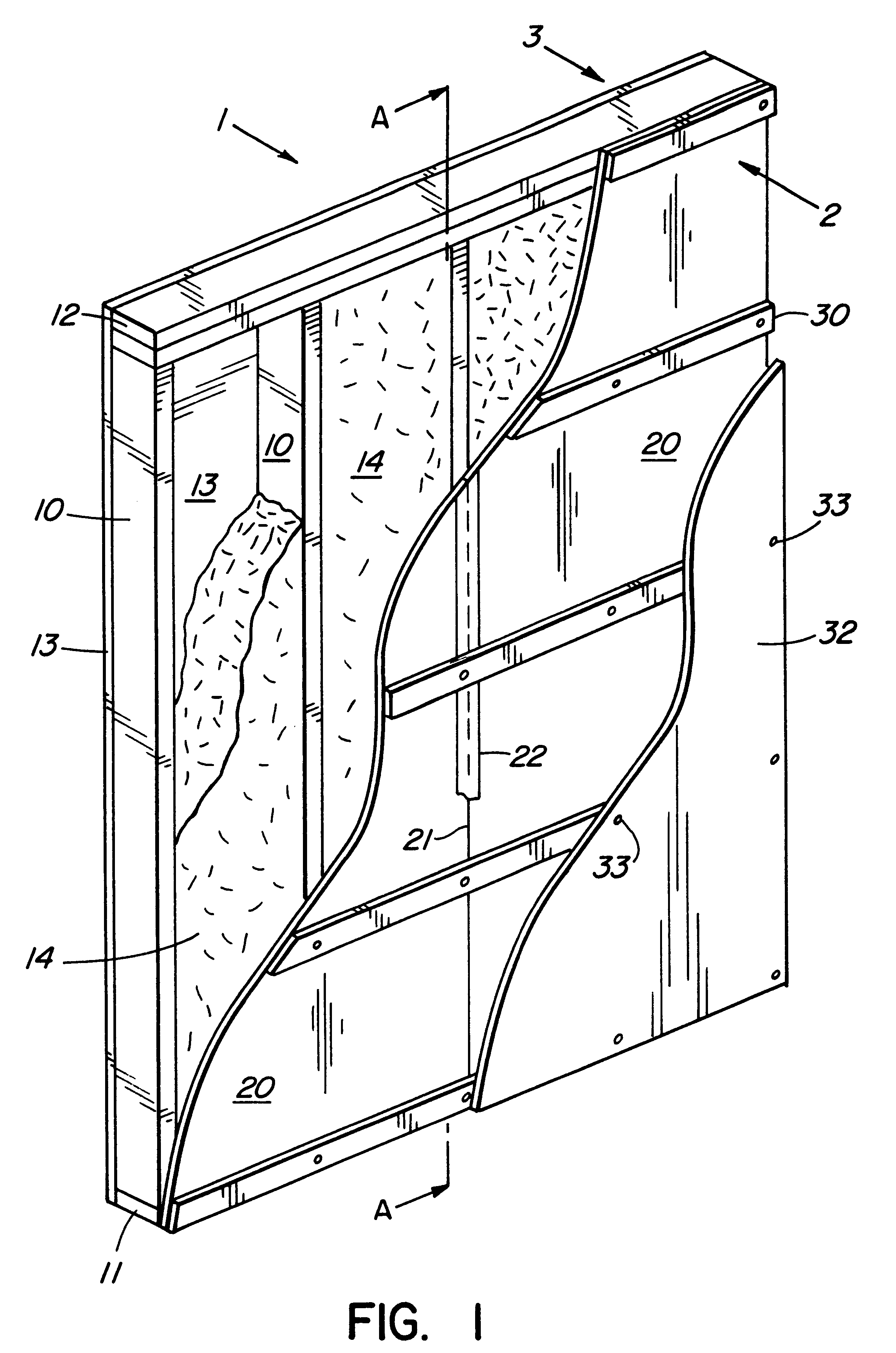

Composite vapor barrier panel

A fibreboard, insulating, wall panel includes an integral air and vapor barrier of metal foil or metallized plastic film adhered to one surface of the panel. Panels are attached to a stud wall frame. Abutting panel joints are taped to provide a continuance vapor barrier. Increased thermal and acoustic insulation as well as structural integrity of the barrier is provided by the panel.

Owner:BUILDING PROD OF CANADA CORP

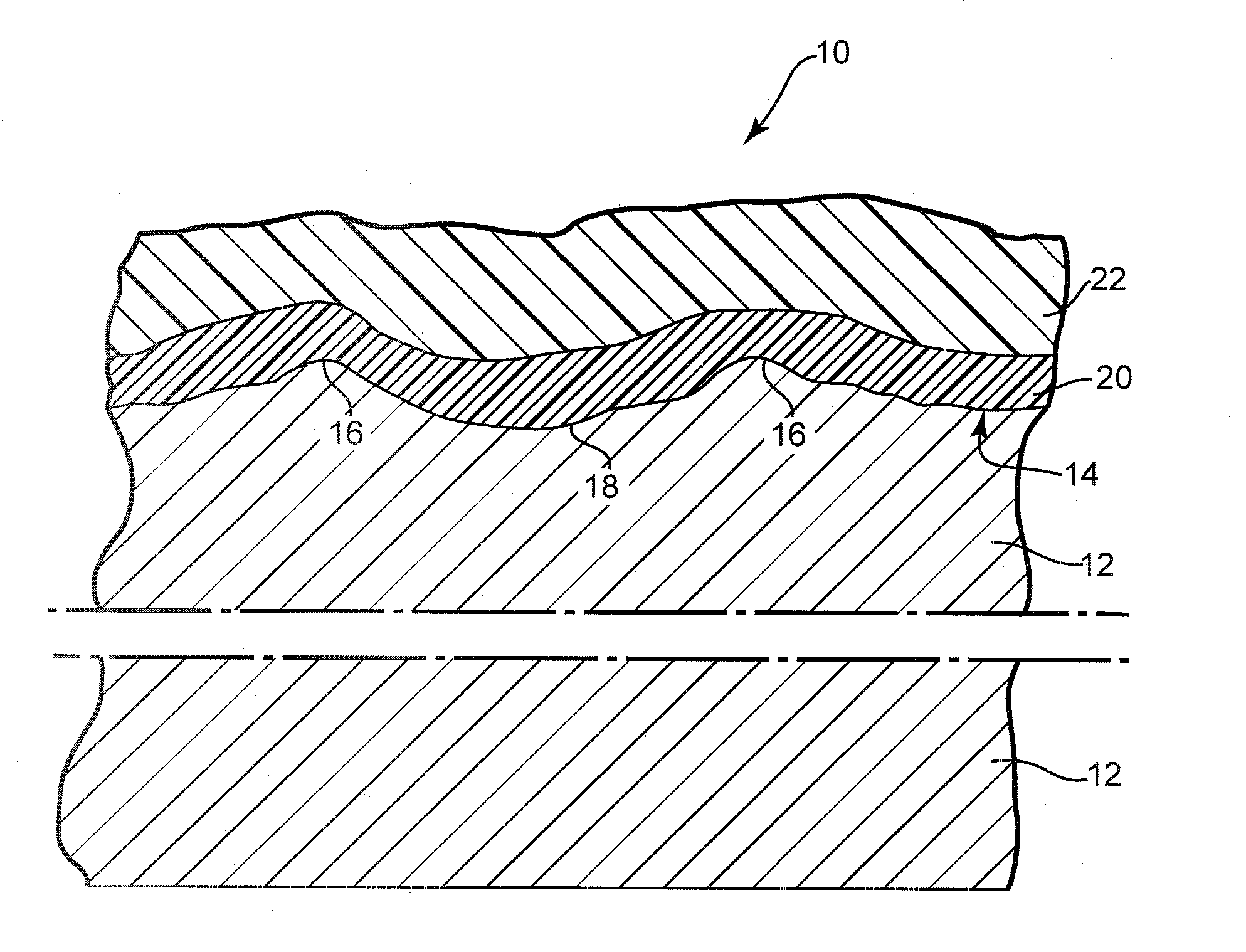

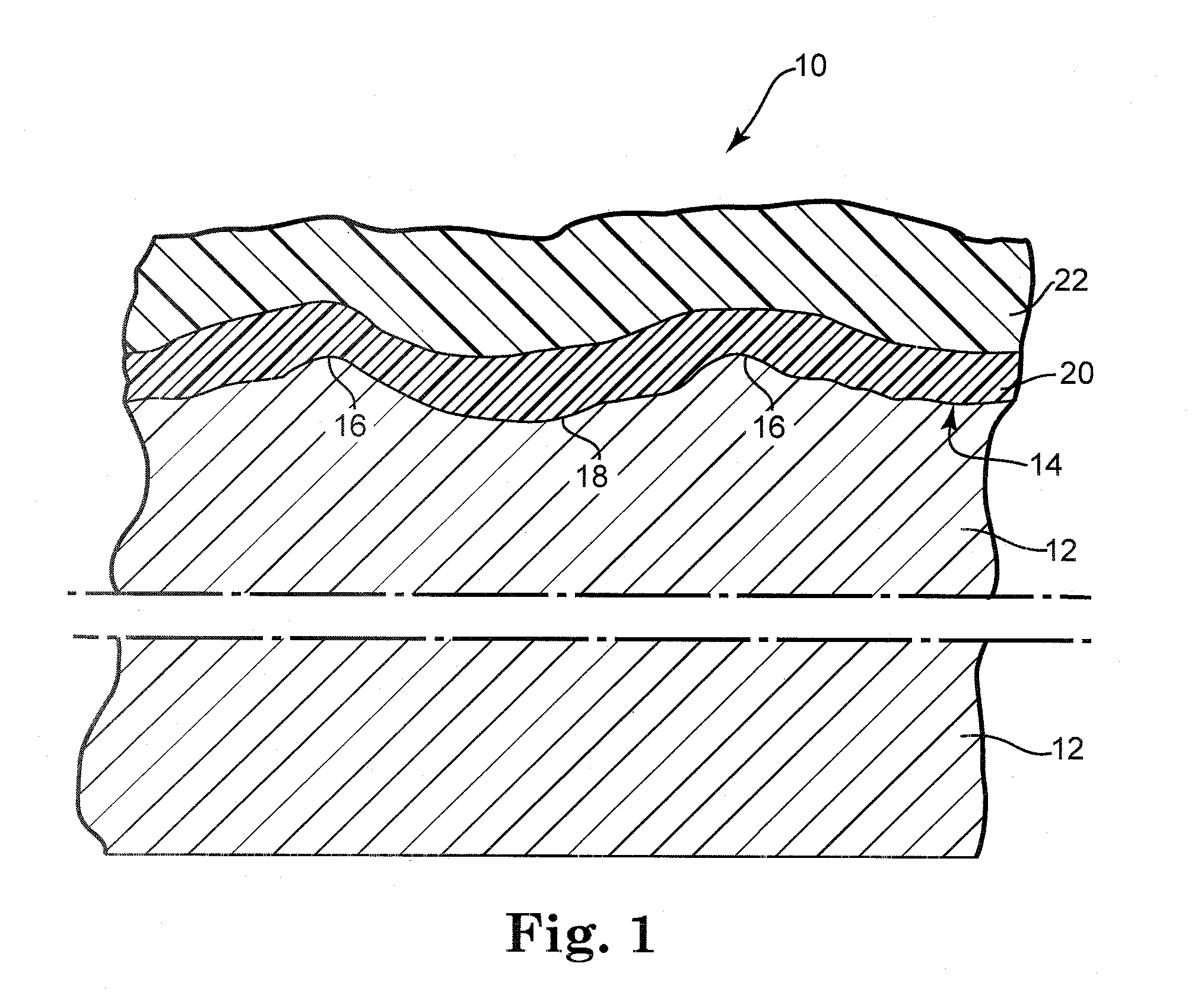

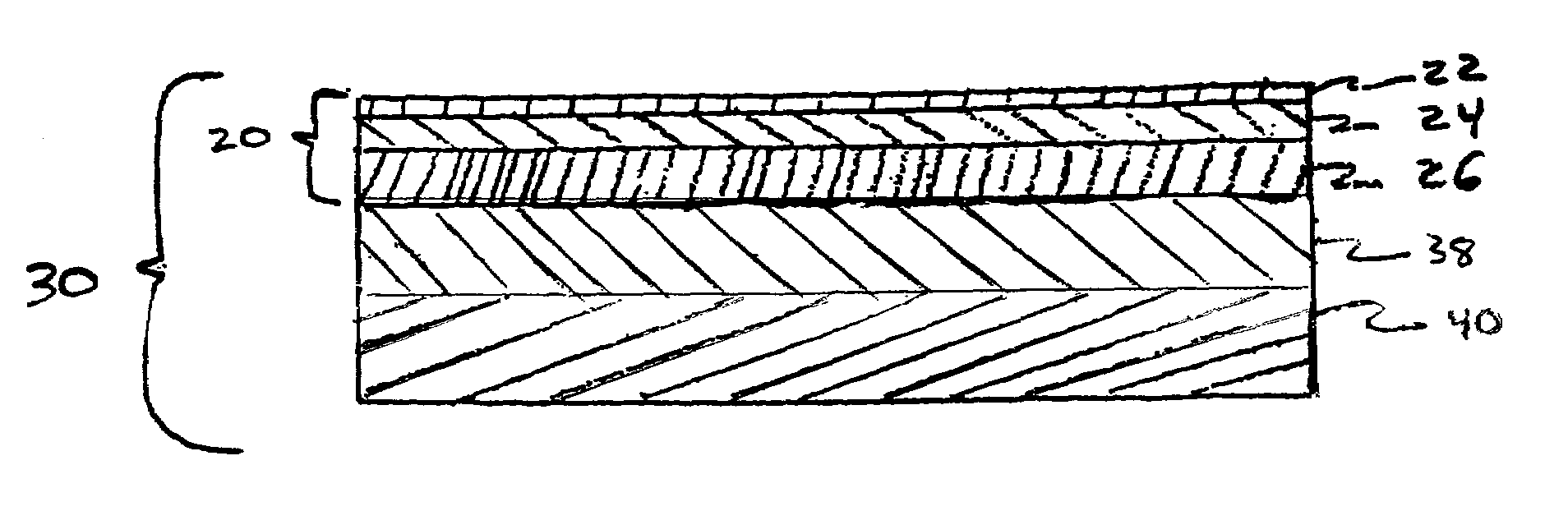

Coated paperboards and paperboard containers having improved tactile and bulk insulation properties

InactiveUS6919111B2Quality improvementImprove insulation performanceNon-fibrous pulp additionWrappersPaperboardEngineering

An improved paperboard has been bulk enhanced by retaining a substantial portion of bulk-enhanced additives including expandable microspheres in a suitable distribution within the paperboard. The cellulosic paperboard web has an overall fiber weight (w) of at least 40 lbs. per 3000 square feet and, at a fiber density of 3, 4.5, 6.5, 7, 8.3, and 9 pounds per 3000 square foot ream at a fiberboard thickness of 0.001 inches, has a GM Taber stiffness of at least about 0.00246 w2.63 grams-centimeter / fiber mat density1.63, and a GM tensile stiffness of at least about 615+13.18 w pounds per inch. The high retention of the bulk enhancing additives is believed to result from the incorporation of suitable retention aids. The resulting paperboard has better GM Taber stiffness values and GM tensile stiffness than prior art paperboards. The paperboard also has increased strain to failure and is able to be formed into suitable paperboard containers without loss of integrity. The resulting containers have increased hold times when they contain hot or cold food or drink.

Owner:DIXIE CONSUMER PROD

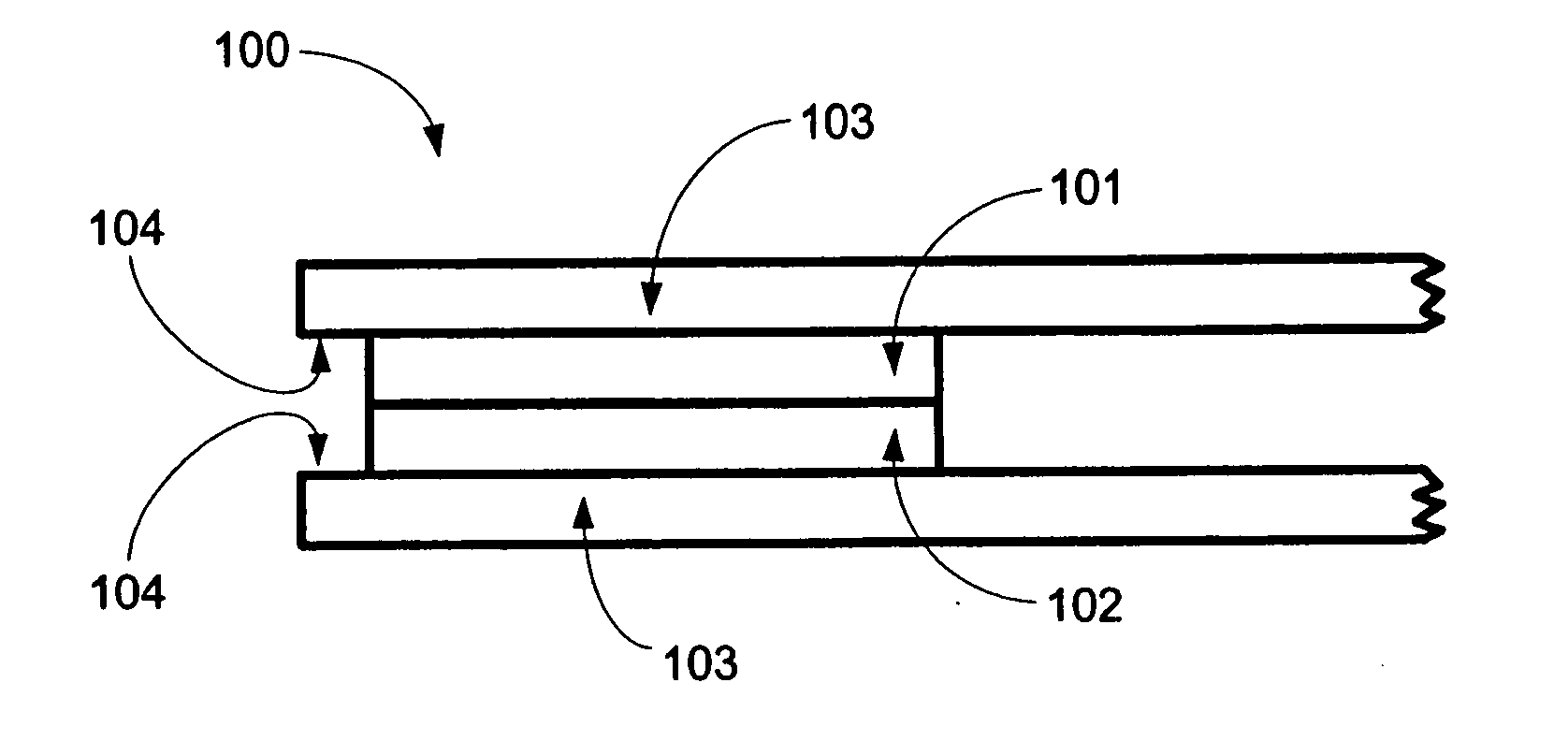

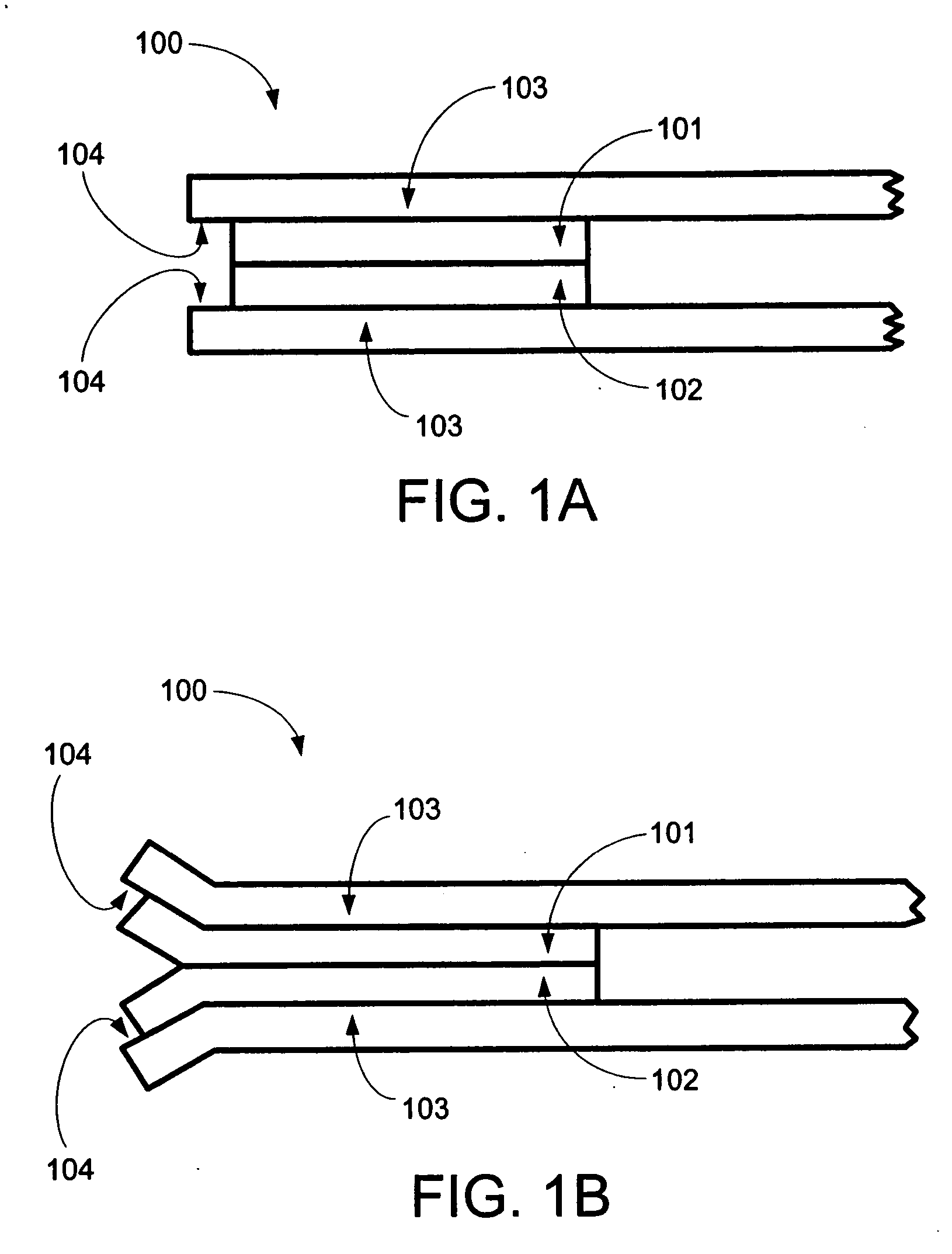

Cohesive reclosure systems and containers using same

This invention relates to resealable closure systems that are useful in containers, such as those used in packaging goods. The reclosure system features cohesive layers which are bonded to each other to provide a resealable closure. The cohesive bond layers are separable to provide opening of the container and access to the interior of the container and / or contents. The cohesive layers have low blocking characteristics. The reclosure systems are useful for flexible packaging, such as polymeric film and cloth packages, and rigid packaging, such as fiberboard, cardboard, paper, and polymeric foam. The reclosure systems may be opened and resealed multiple times. The closure system is resistance to contamination by oils, debris, solvents, and water. The reclosure is cold sealable with finger pressure.

Owner:AVERY DENNISON CORP

Wood adhesive and method of preparing thereof

InactiveUS20100258033A1Drying rate of adhesiveLow pour pointProtein waste adhesivesStarch adhesivesHigh densityAdhesive

A wood adhesive having a) 100 weight parts of water; b) between 3 and 45 weight parts of a proteinaceous material; c) between 0.01 and 15 weight parts of an acidity regulator; d) between 0.01 and 15 weight parts of an aromatic compound; e) between 0.01 and 15 weight parts of a curing agent; f) between 0.01 and 15 weight parts of a preservative; g) between 0 and 15 weight parts of a viscosity modifier; h) between 0 and 10 weight parts of a filler; and i) between 0 and 15 weight parts of a drier. The wood adhesive can be used for preparation of plywood, blockboard, oriented strand board (OSB), flakeboard, fiberboard, veneer plywood, middle density fibreboard, high density fibreboard, hardboard, flooring substrate, LVL, and so on. A method for preparing the wood adhesive is also provided.

Owner:YANG GUANG +1

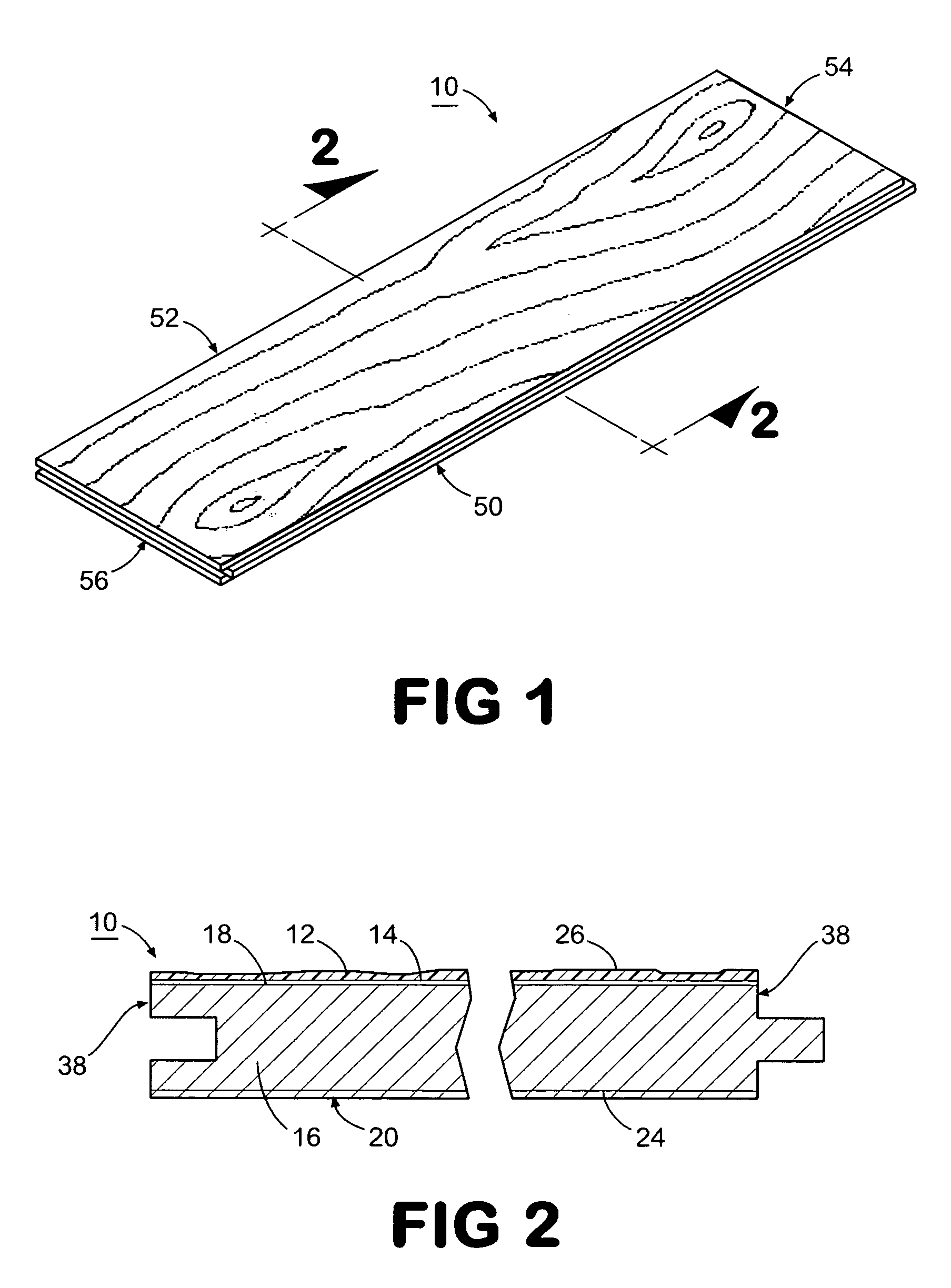

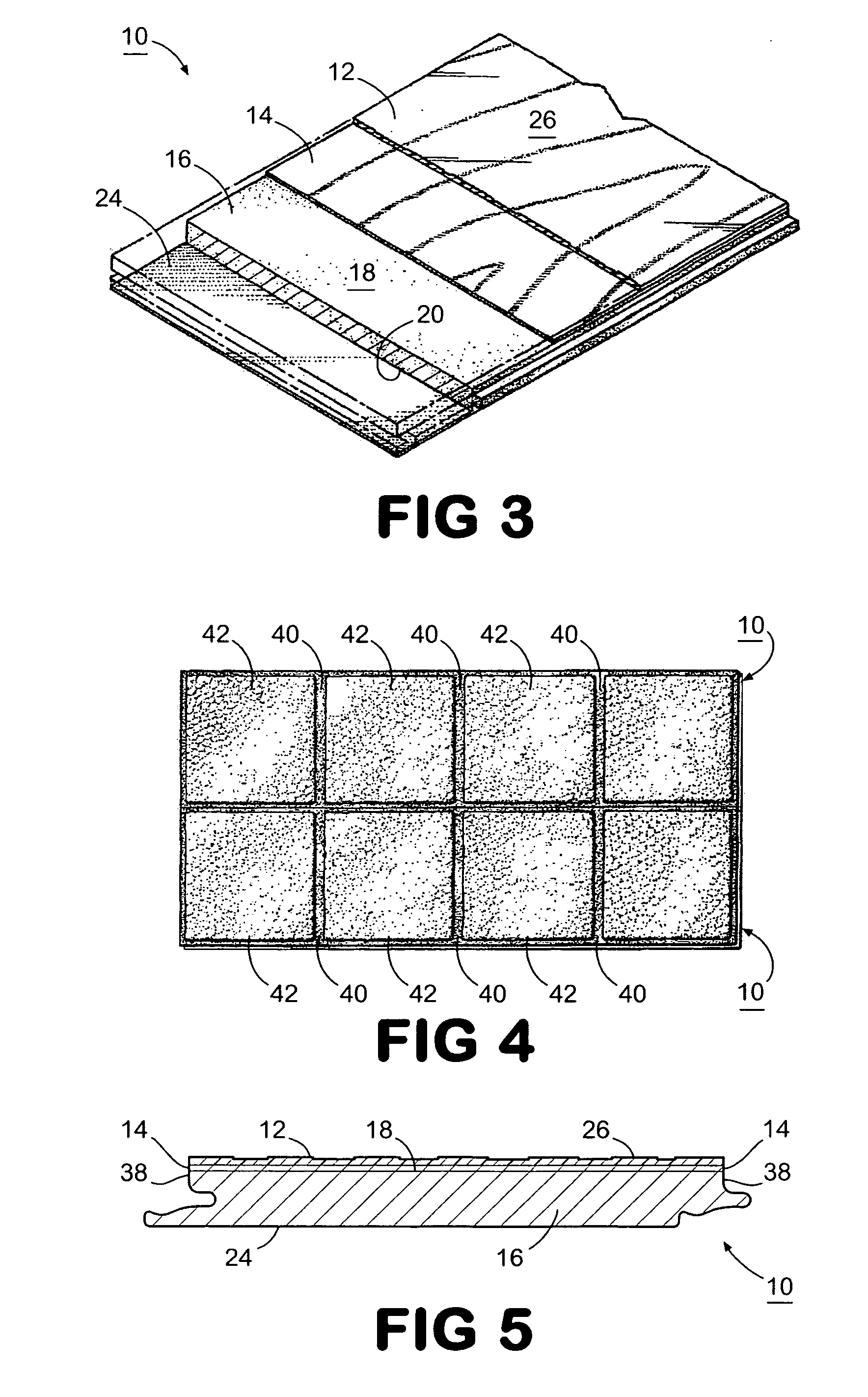

Laminate flooring members

InactiveUS20060024465A1Provide protectionSpecial ornamental structuresWood layered productsCost effectivenessHigh density

A decorated flooring member constructed using the DPL process and comprises a high density fiberboard (“HDF”) core and a wear layer that has an EPLF rating of AC5. In operation, the flooring member of the present invention will exhibit similar characteristics to an HPL constructed flooring member while retaining the cost benefits of a DPL constructed flooring member.

Owner:COLUMBIA INSURANCE CO

Coating system for sag resistant formaldehyde-free fibrous panels

ActiveUS20070055012A1Low costMaintain resistanceConstruction materialSynthetic resin layered productsFiberHydrophilic coating

A coating system on a fibrous substrate, such as a fibrous ceiling panel, having a first surface and a second surface. A first coating is disposed on the first surface of the substrate and includes a first binder and a first filler material. A second coating may be disposed on the second surface of the substrate. The second coating includes a second binder and a second filler material. The first coating and the second coating expand at different rates in the presence of humidity in order to help prevent sagging of the substrate in presence of humidity. The first coating is preferably a hydrophobic coating having a large particle size, high elastic modulus filler material. The second coating is preferably a hydrophilic coating having a lower concentration of high elastic modulus material and a polymer having a hydrophilic moiety.

Owner:AWI LICENSING

Fire-retardant coating, method for producing fire-retardant building materials

InactiveUS20050229809A1Simple materialIncrease resistanceFireproof paintsAntifouling/underwater paintsCalcium silicateFire retardant

The present invention relates to a fire-resistant coating and method thereof, which confers enhanced flame and heat resistance to substrate such as building materials. The invented coating is especially applicable to cellulose-based building materials including but not limited to fiberboards, wallboards, roofing materials, particleboards, ceiling tiles, soundproofing boards and hardboards. This novel composition is also useful in providing a fire-resistant coating for concrete, metals, foamed polymeric materials, gypsum and other substrates. A preferred embodiment generally comprising: mono potassium phosphate, magnesium oxide, silica powder, calcium silicate, rice hull ash and water. A method for imparting fire-retardancy to substrates using the invented composition is also described

Owner:BONE SOLUTIONS INC

Fiberglass non-woven catalyst

The present invention relates to novel catalysts for use with a fiberglass non-woven binder. The catalyst can be a Lewis acid, an organic acid salt, a free-radical generator, or a mixture thereof. The catalyst provides stronger bonding, increased crosslinking density, reduced curing times, and reduced curing temperatures. Fiberglass mats made with polymer binder compositions containing the catalyst exhibit both flexibility and elasticity, allowing the mats to be compressed for storage, yet return to original thickness once the compressive forces are removed. Formaldehyde-free wood composites, such as plywood and fiberboard, may also be produced with polymer binder compositions containing the catalyst.

Owner:SIEMENS AG +1

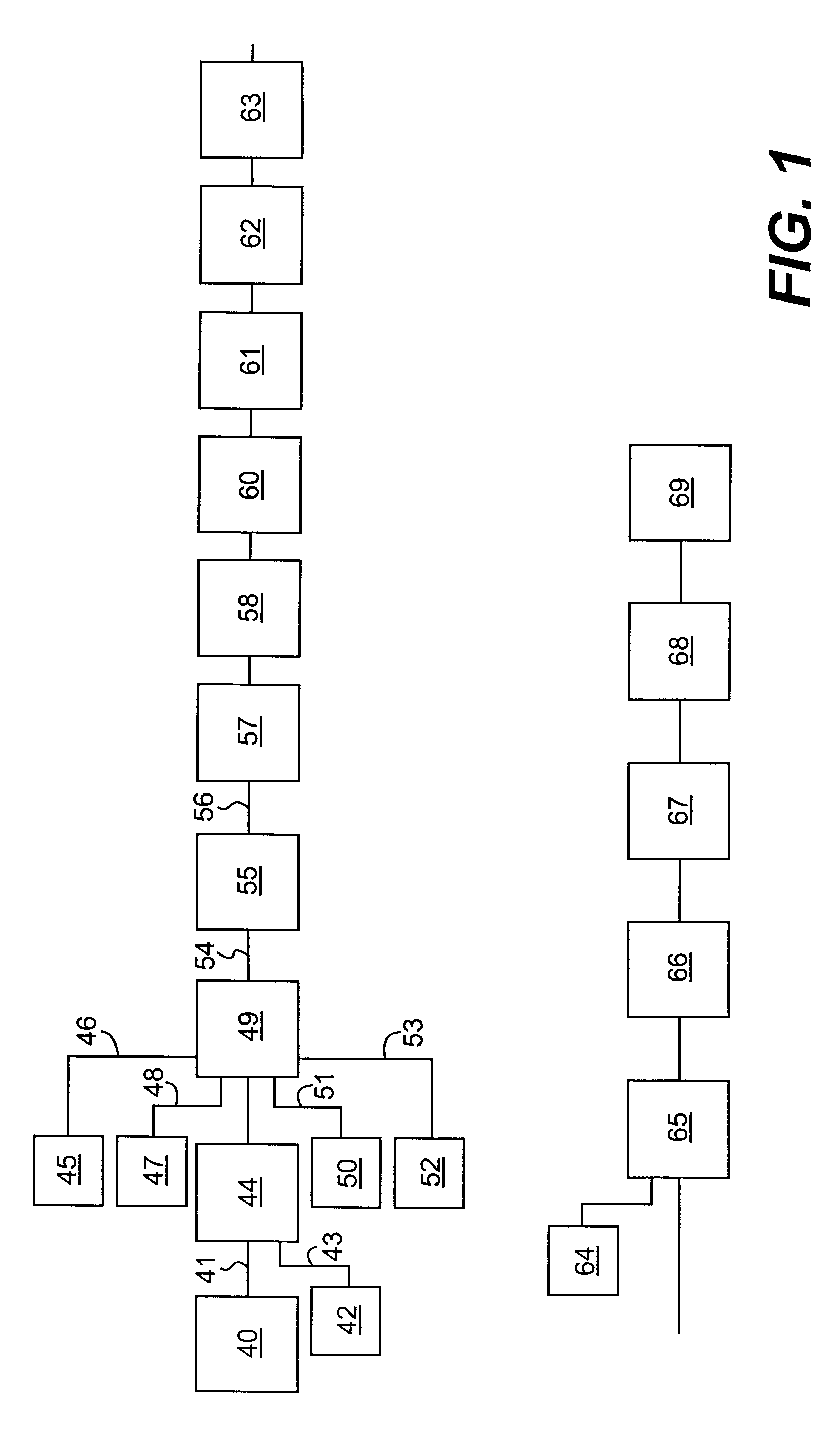

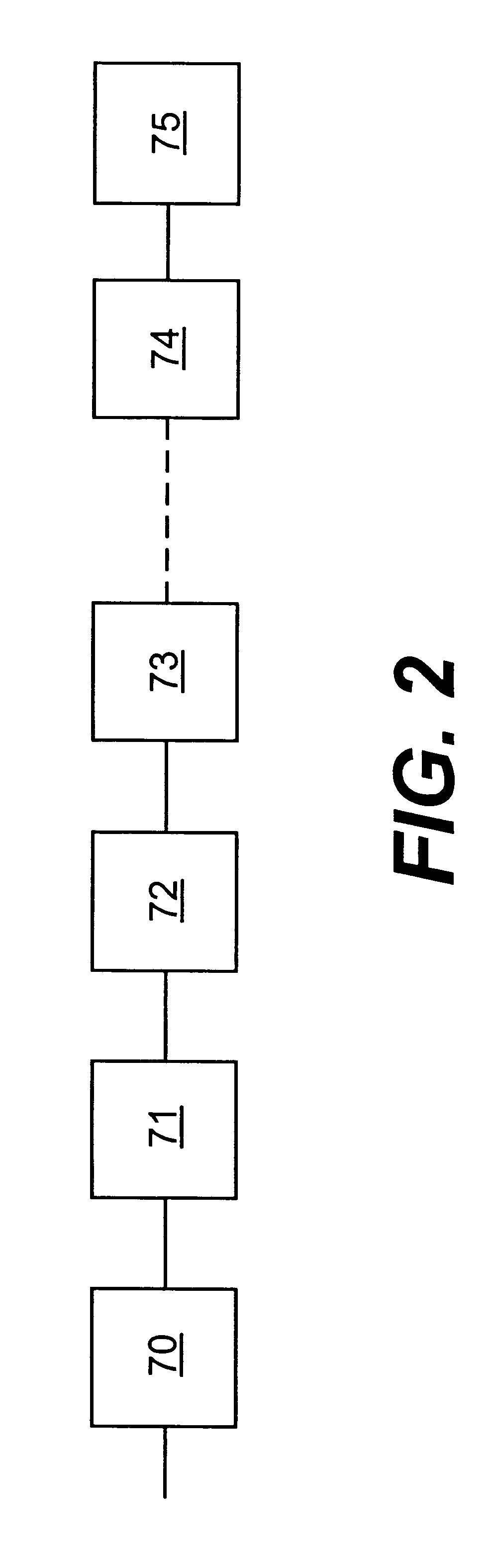

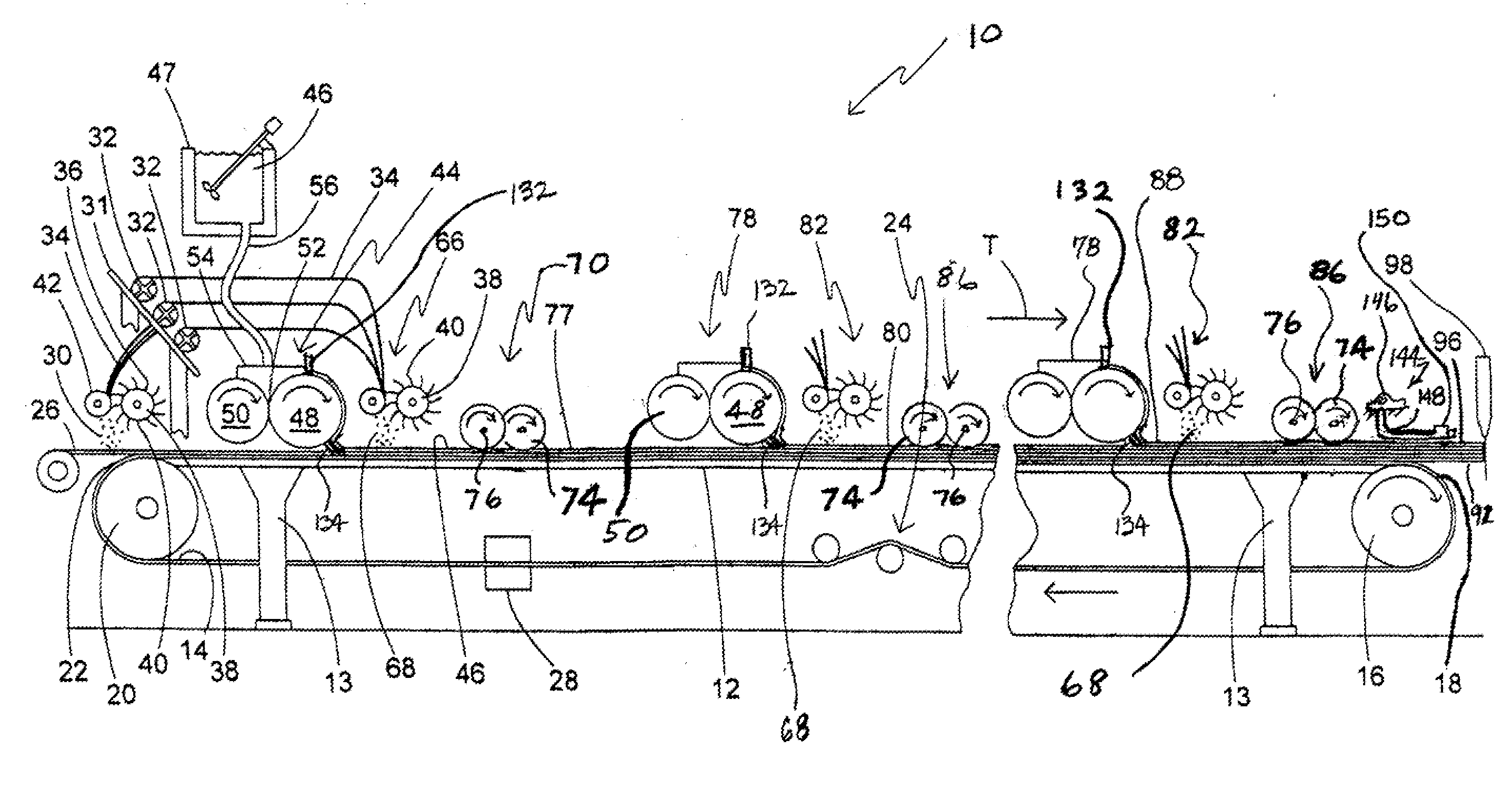

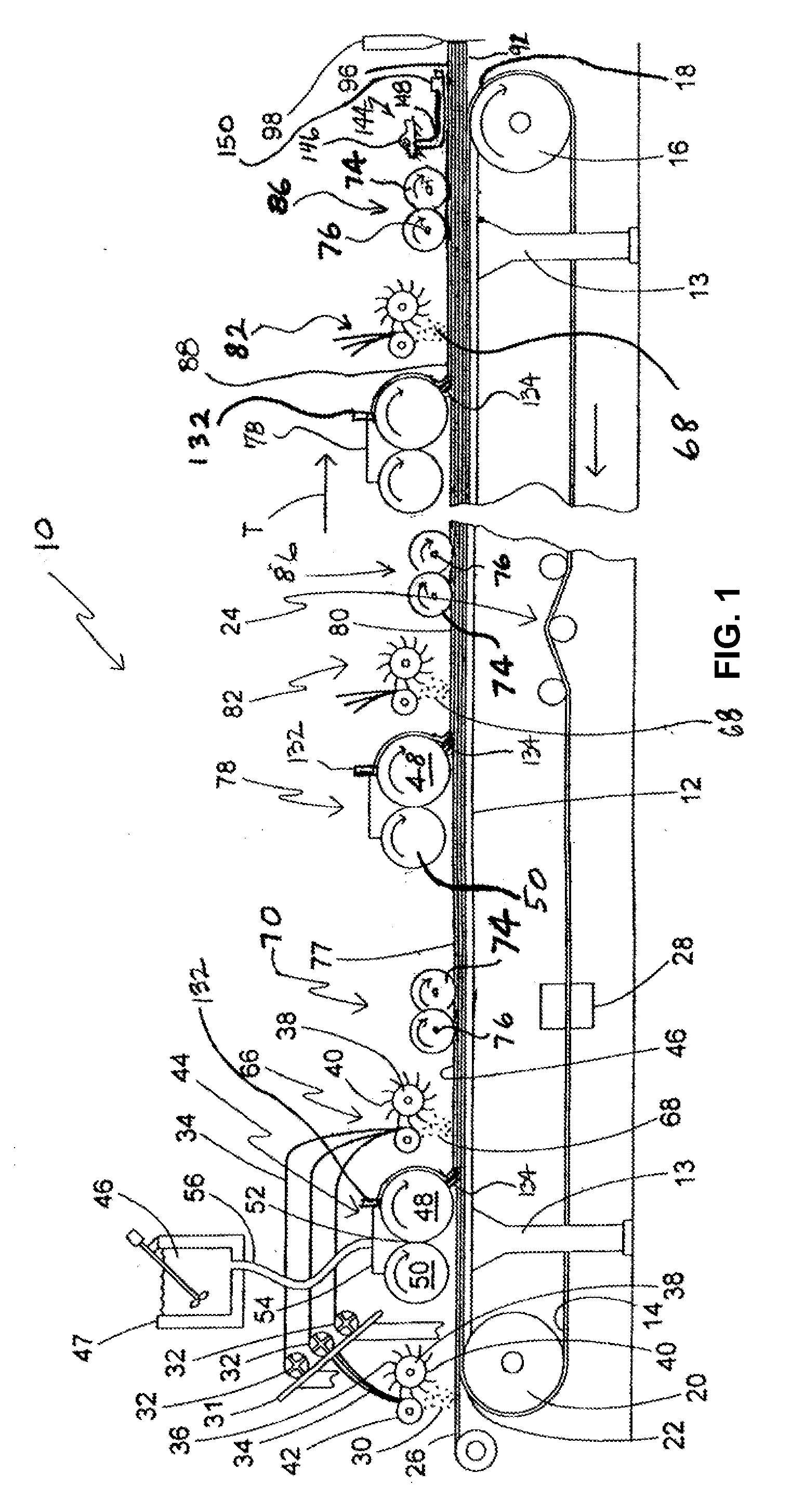

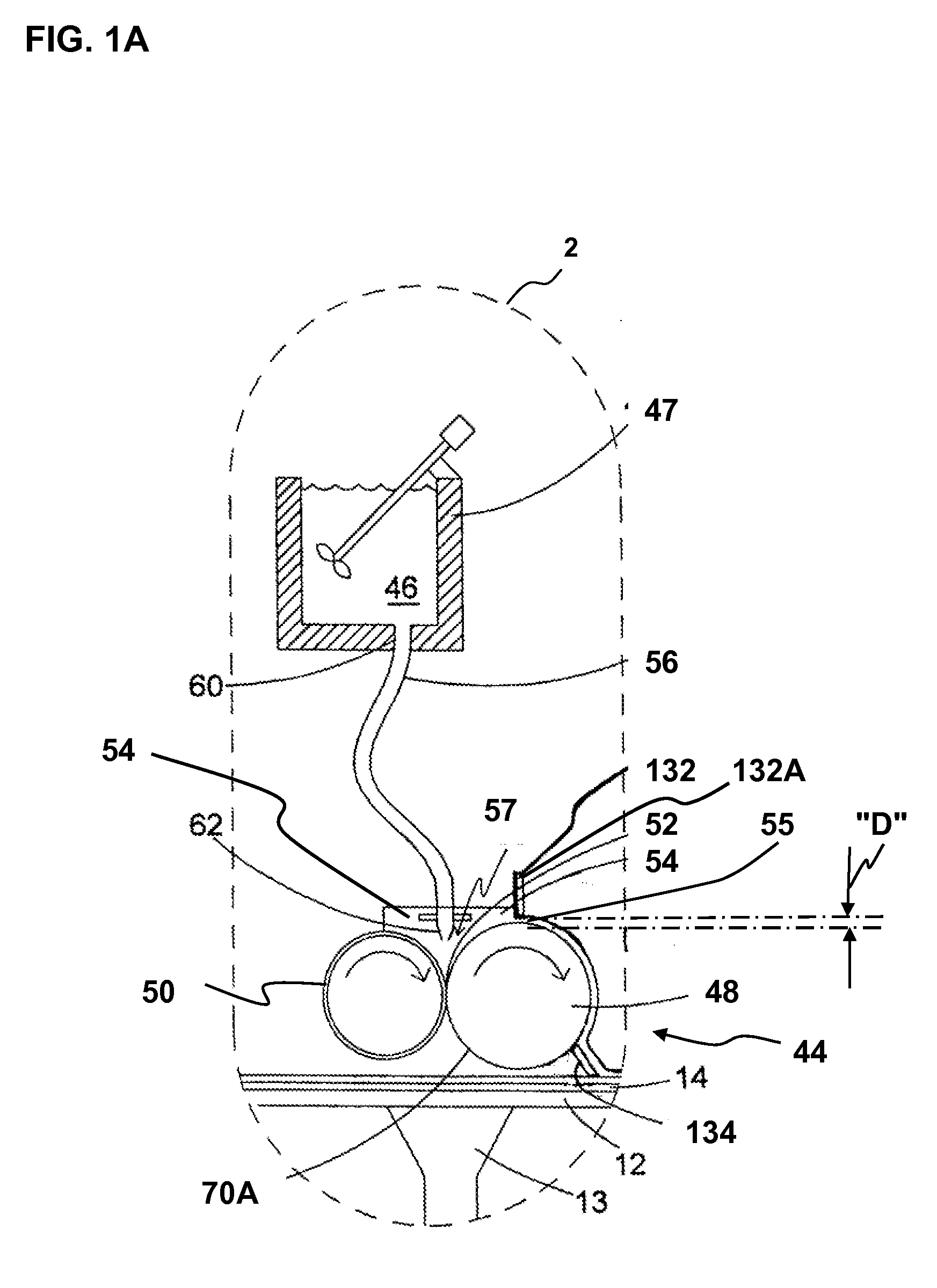

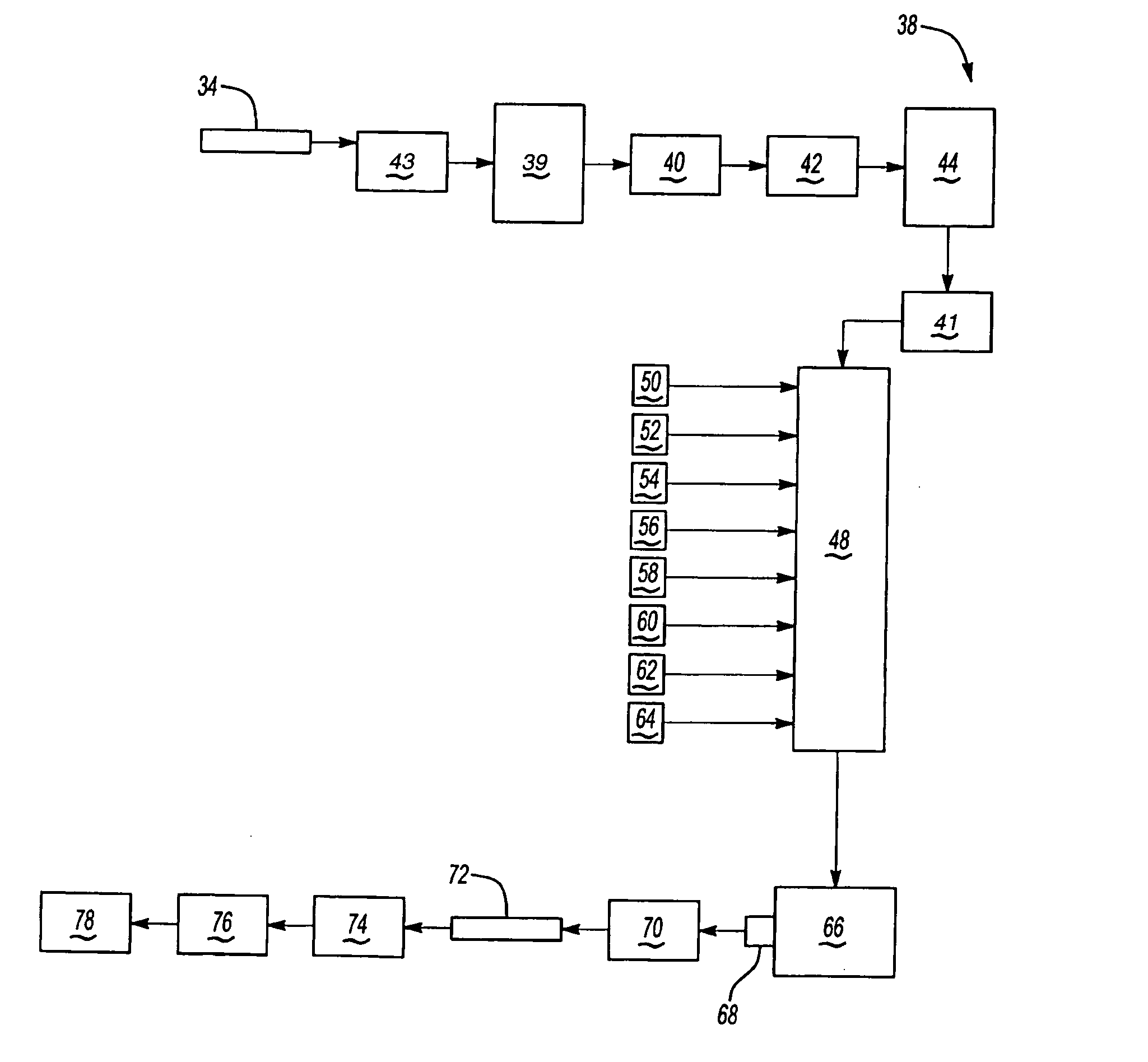

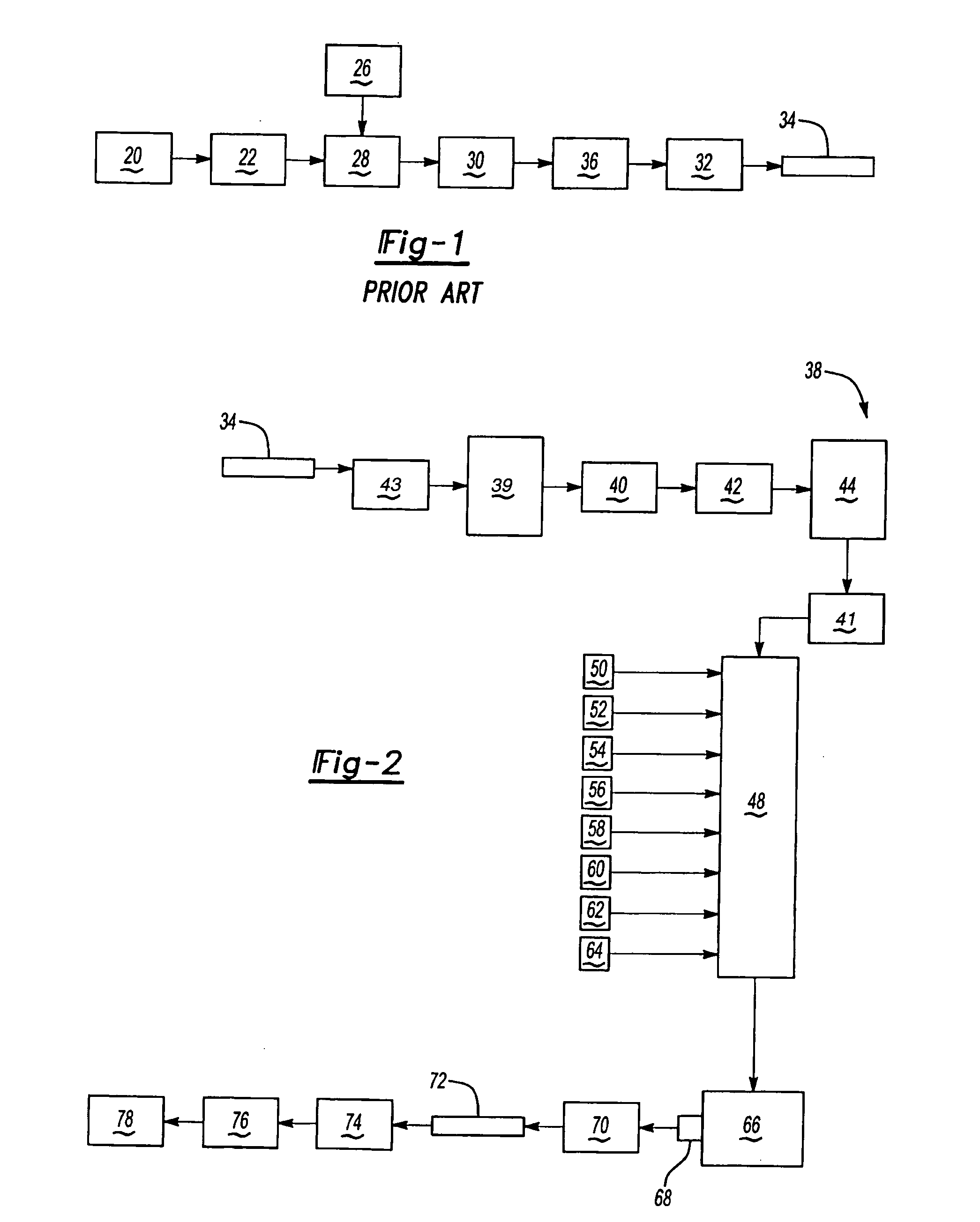

Panel smoothing process and apparatus for forming a smooth continuous surface on fiber-reinforced structural cement panels

InactiveUS20080099133A1Remove pock marks or groovesA large amountSolid waste managementTransportation and packagingProduction lineSurface layer

A vibrating flexible smoothing sheet or shroud disposed transversely of a direction of travel of a formed fiber panel including gypsum-cementitious slurry and embedded chopped fibers. The sheet is used to smooth the surface of the panel as it exits a fiber embedment station of a structural cementitious panel production line to remove grooves and other non-uniform surface imperfections to reduce the need for costly finishing after the panels are cured and cut to size. The flexible sheet is designed to float over the surface of the formed panel without tearing or otherwise damaging the surface of the heavily fiber reinforced surface layers of the panel. The vibrating sheet is pivotally mounted on the side dams of the web production line so it can float over the panel surface during use, but be raised off the line when not in use.

Owner:UNITED STATES GYPSUM CO

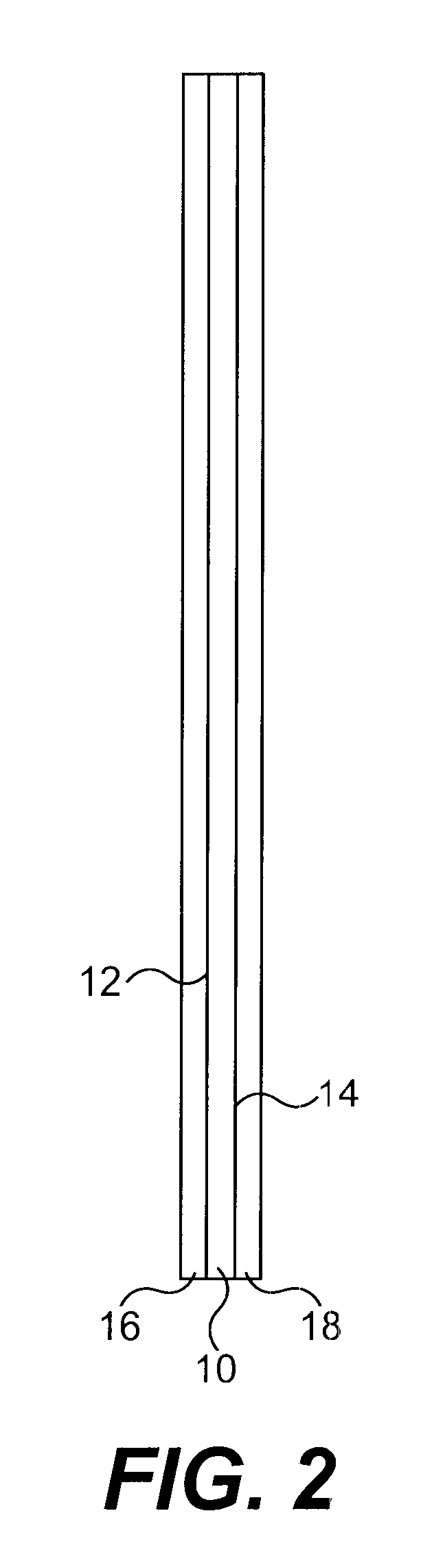

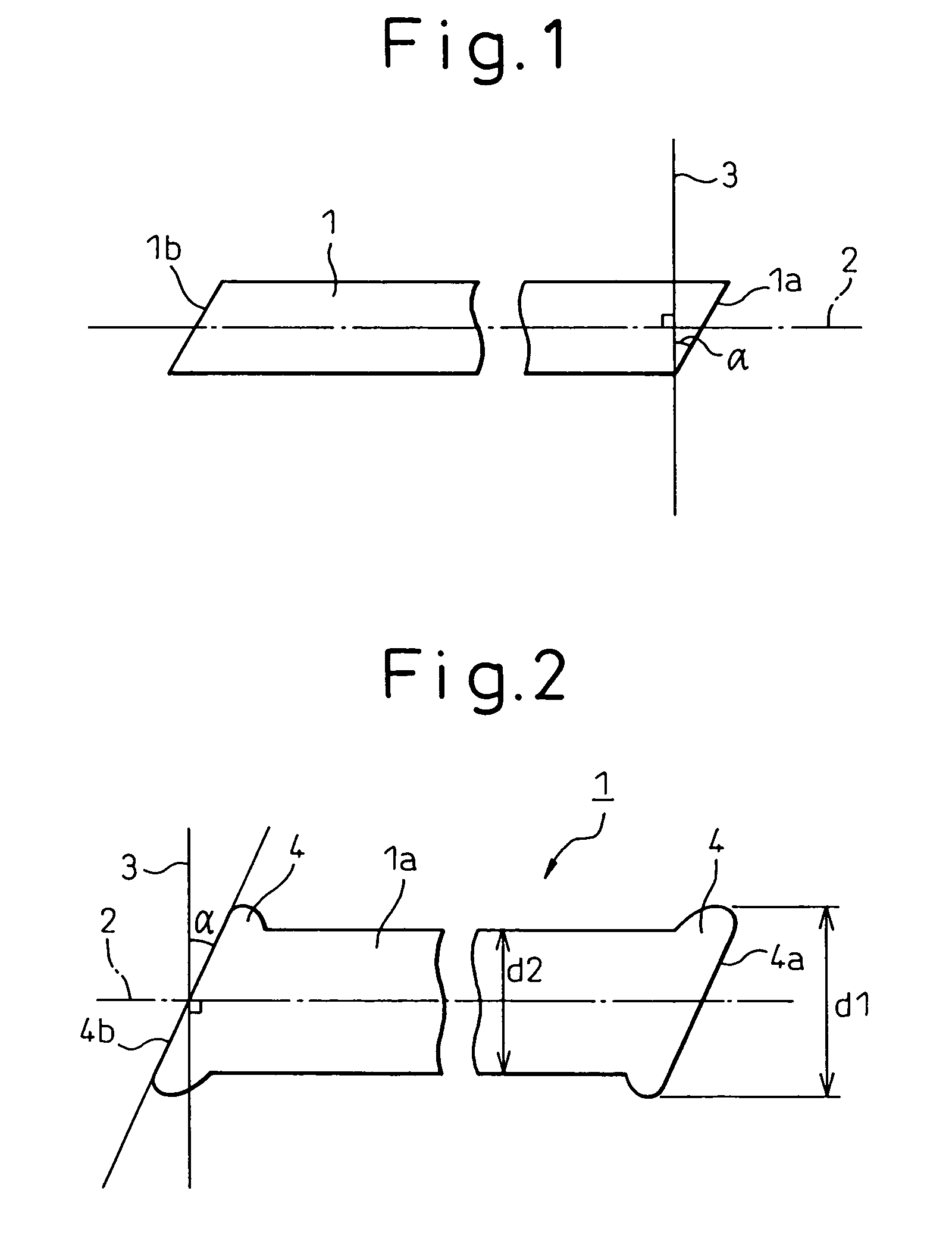

Heat-resistant synthetic fiber sheet

InactiveUS7026033B2Improve heat resistanceNon-fibrous pulp additionNatural cellulose pulp/paperPolymer scienceOrganic synthesis

A heat-resistant fiber paper-like sheet comprises 40 to 97% by mass of heat-resistant organic synthetic polymers staple fibers, 3 to 60% by mass of heat resistant organic synthetic polymer fibrid and or an organic resin binder, in a portion of the staple fibers, each staple fiber having two flat end faces having an inclining angle of 10 degrees or more from a plane crossing the fiber axis at a right angles, and is useful as a base material for laminate materials for electrical circuit boards.

Owner:TEIJIN LTD

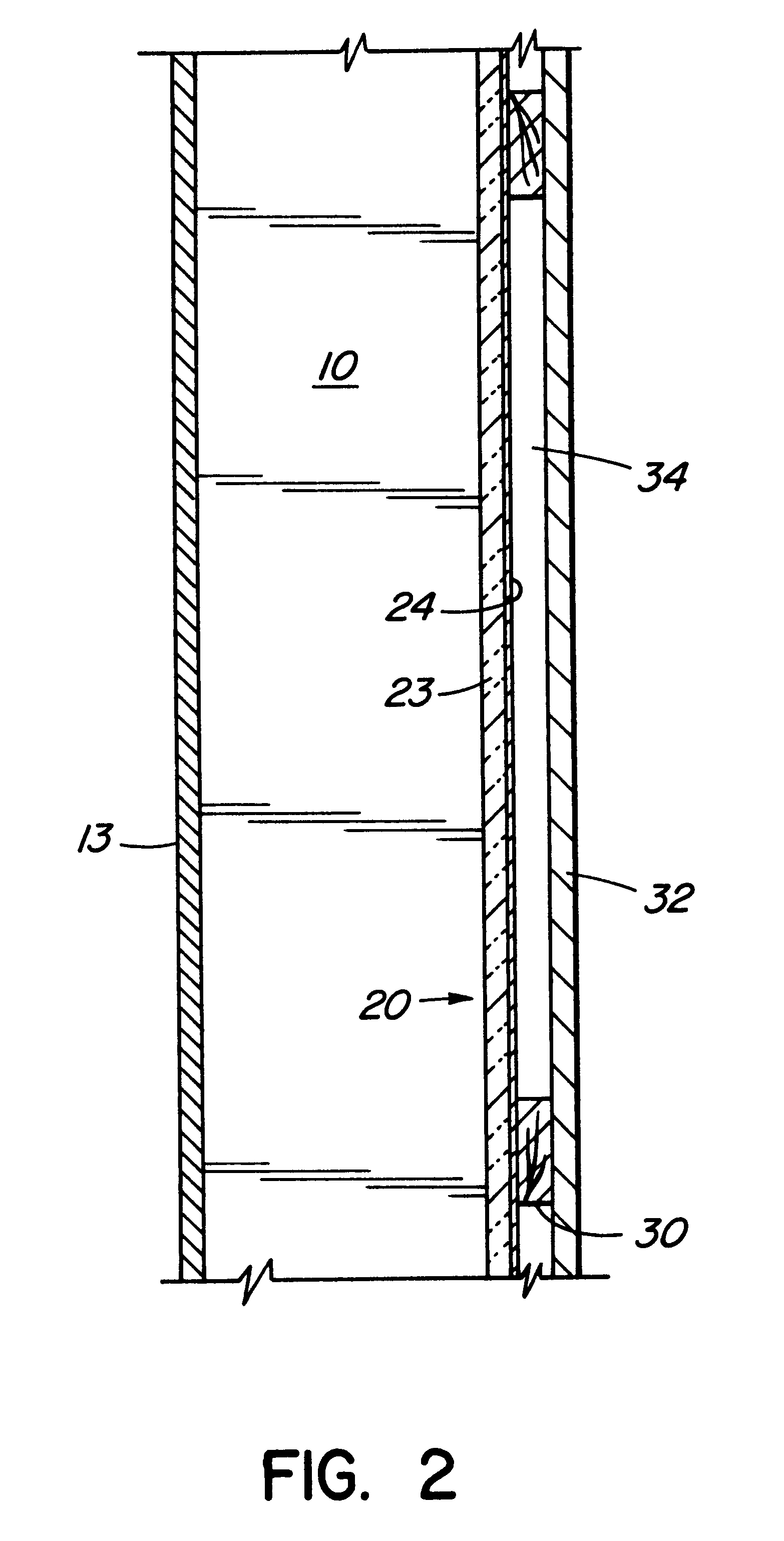

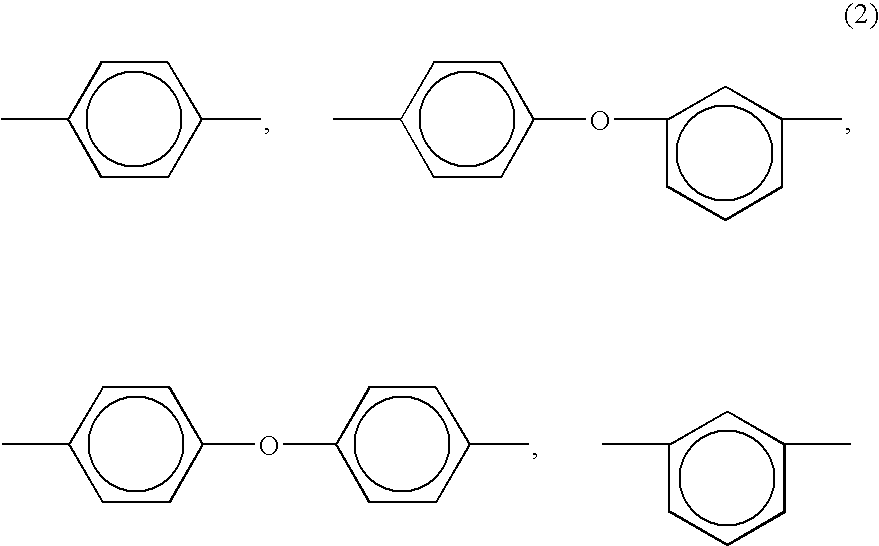

Gypsum wood fiber structural insulated panel arrangement

InactiveUS20080245007A1Low costHigh tensile strengthBuilding componentsMesh reinforcementCellulose fiber

A generally planar, structural insulated panel for building construction includes a pair of outer facings disposed on opposed surfaces of a plastic foam core. Both of the outer facings are gypsum cellulose fiber board such as gypsum wood fiber board. Disposed on the exterior surface of the gypsum wood fiber board on the exterior surface and between another expanded polystyrene insulation panel is a weather resistant barrier that is fastened to the gypsum wood fiber board. The exterior surface of the second insulation panel is fastened to the gypsum wood fiber board by mechanical fasteners. The insulation panels are then coated with a basecoat which has an embedded mesh reinforcement and then a finishing coat is applied to the base coating. Vinyl or aluminum metal siding can be fastened to the structural assembly by G screw fasteners or other mechanical fasteners.

Owner:UNITED STATES GYPSUM CO

Method of manufacturing composite board

InactiveUS20060145384A1Improve flow characteristicsIncreased flexural modulusMouldsFrozen sweetsFiberThermoplastic

A composite board is made from waste medium density fiber (MDF) board or waste particle board that includes solid urea formaldehyde. The waste board is chopped and milled into particles having a size between 20 mesh and 150 mesh, creating a waste flour. After removing moisture from the waste flour, the dried waste flour is mixed with a thermoplastic to bind and encapsulate the waste flour. Internal lubricants are added to improve the flow characteristics of the blended material, and external lubricants are added to present sticking of the mixture to an extruder or mold. Mineral fillers are added to improve the flexural modules of the composite board, and a plasticizer can be added to improve the physical properties or mechanical characteristics of the mixture. An ultraviolet absorber, a biocide, and a pigment can also be added. The blended material is extruded or molded into a desired shape. When cooled, the thermoplastic hardens to form a solid composite board.

Owner:MASCO CABINETRY

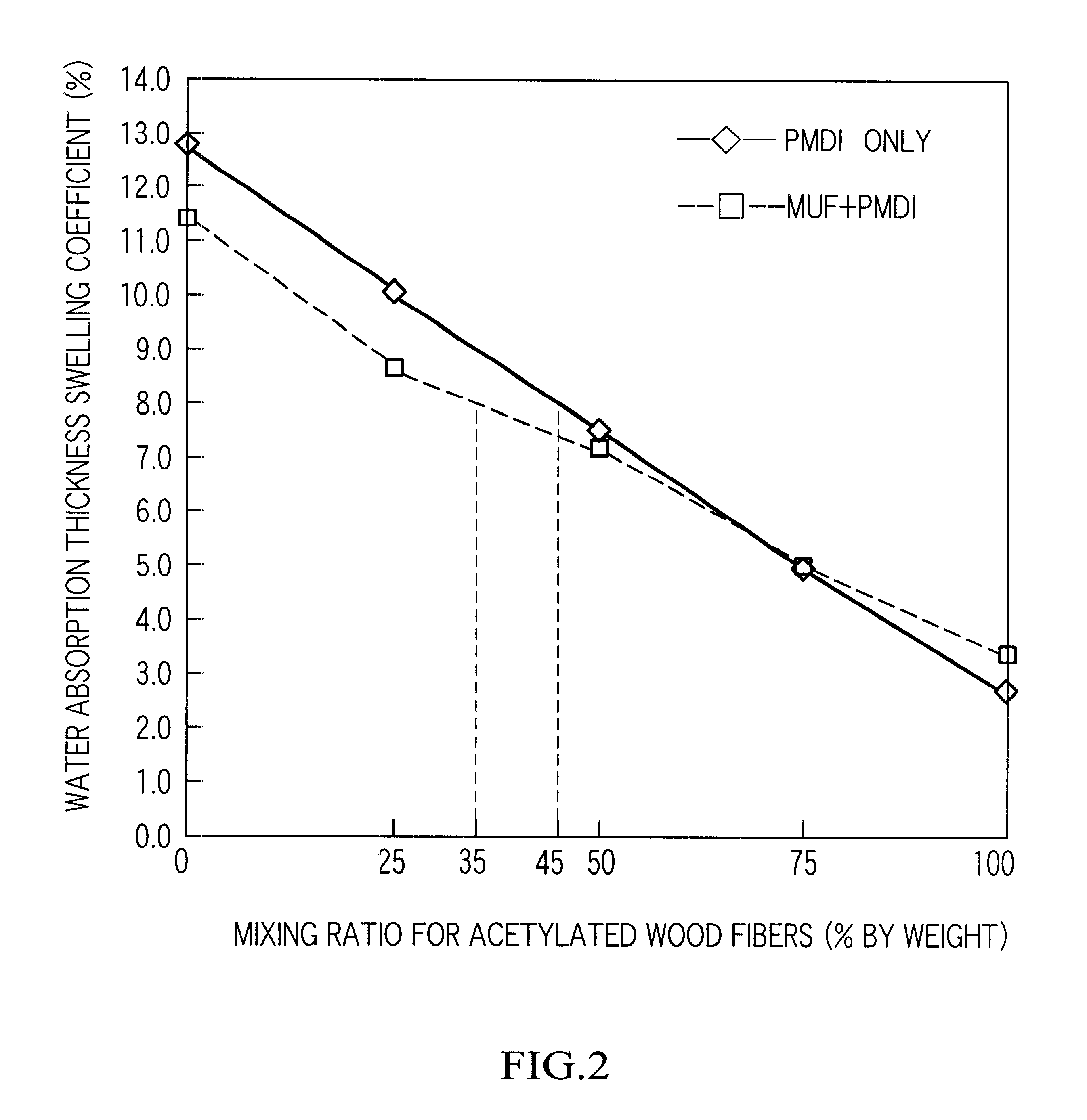

Fiberboard with improved water resistance

ActiveUS7413603B2High strengthImprove waterproof performanceSolid waste managementWood working apparatusSlurryWater resistant

Articles, including fiberboard, are made from a pumpable, flowable slurry including alpha-calcined calcium sulfate hemihydrate anchored in pores of host particles, alpha-calcined calcium sulfate hemihydrate, a silicone compound, magnesium oxide, and water. The magnesium oxide catalyzes the reaction of the silicone compound into a silicone resin. In a preferred method of making a water resistant fiberboard calcium sulfate dihydrate is combined with the host particles and water to form a slurry which is heated under pressure to calcine the calcium sulfate dihydrate to form alpha-calcined calcium sulfate hemihydrate. After relieving the pressure, a silicone compound and magnesium oxide are added to the slurry. The slurry is dewatered to form a filter cake, which is then formed into a desired shape and allowed to set.

Owner:UNITED STATES GYPSUM CO

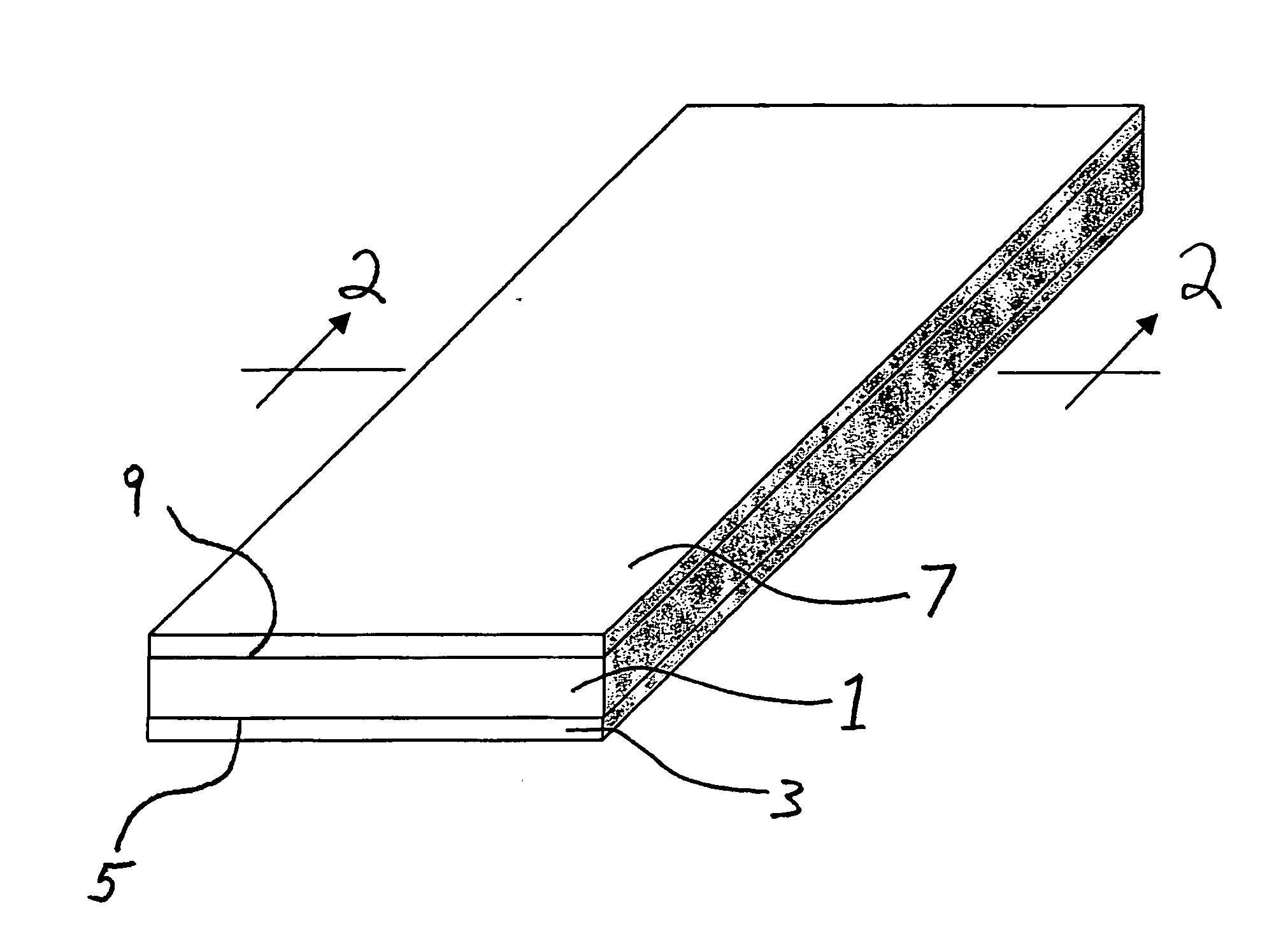

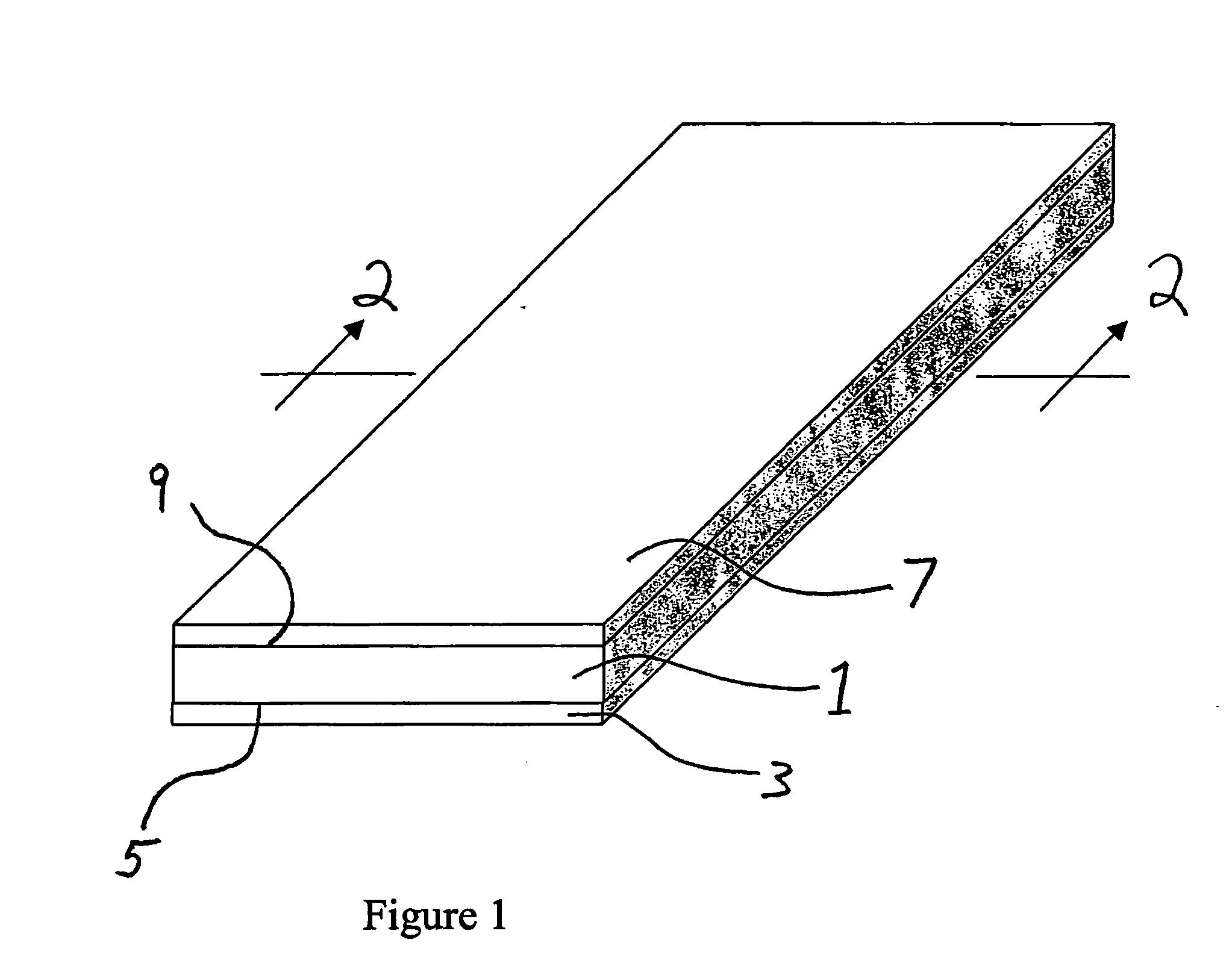

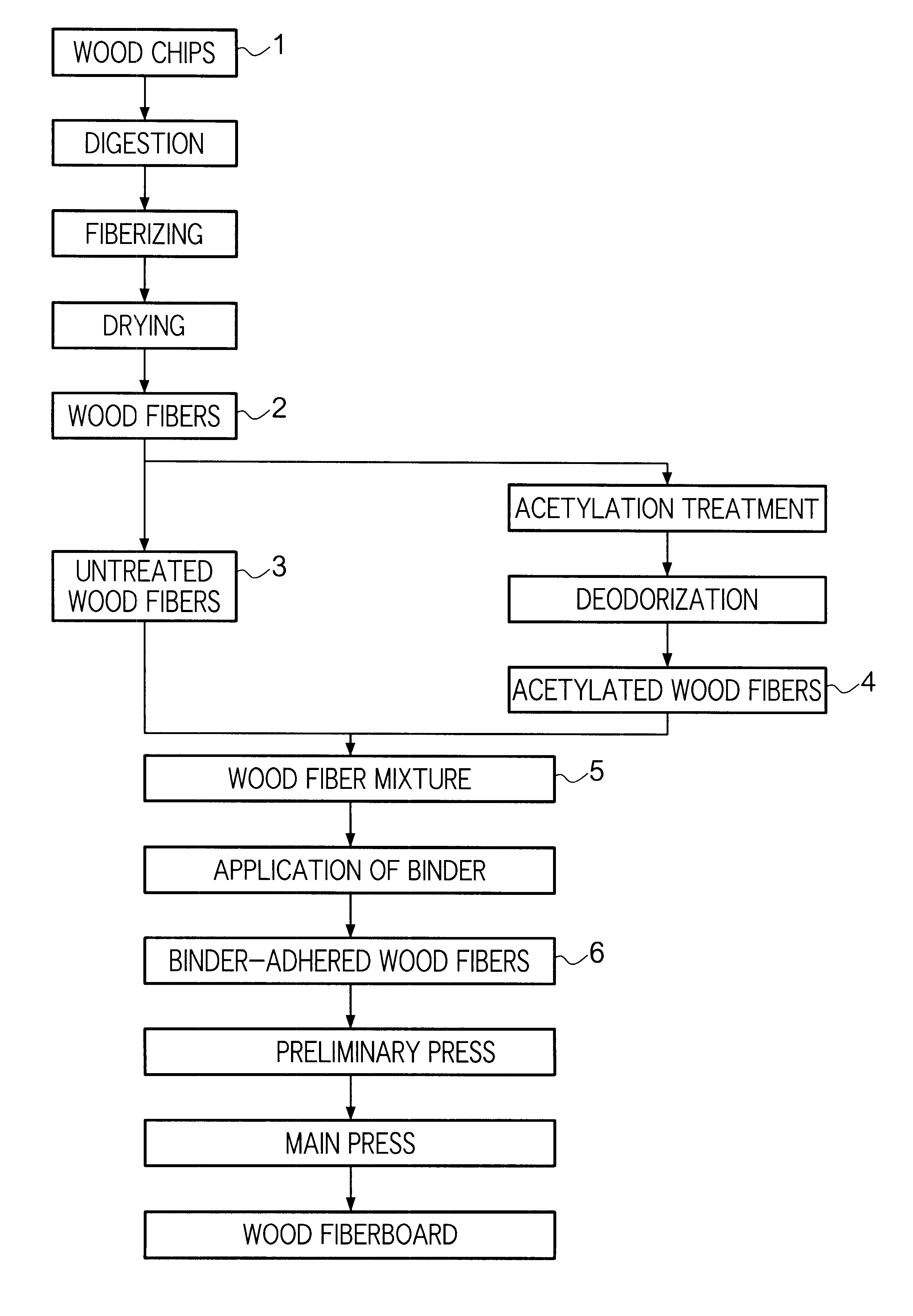

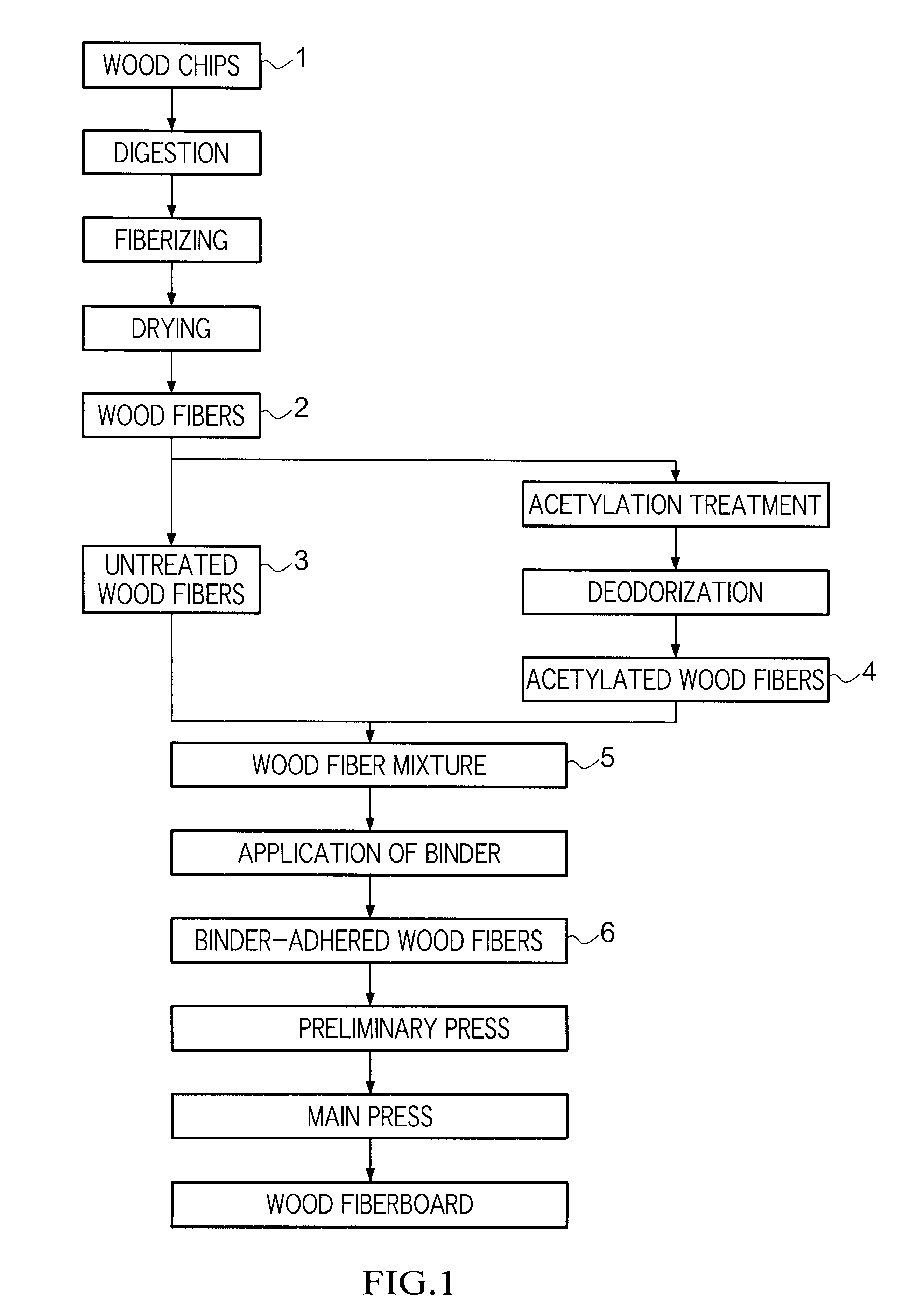

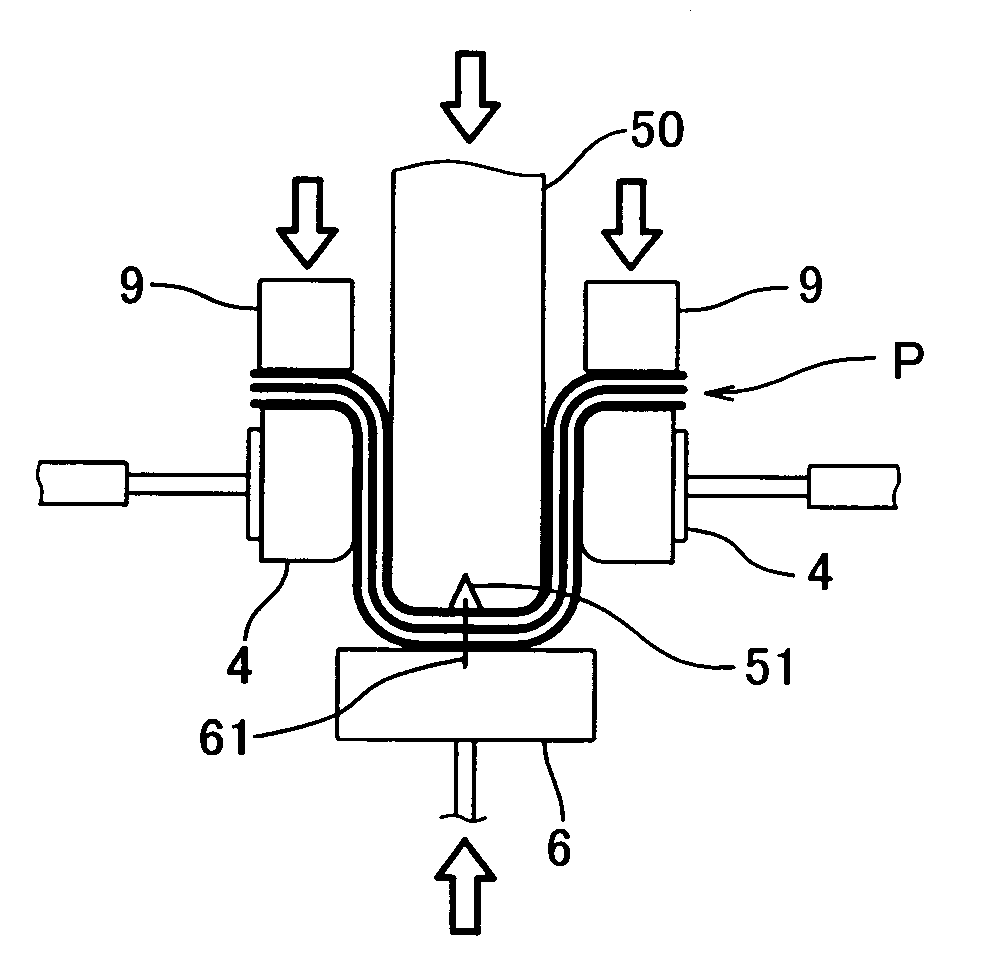

Wood fiberboard and manufacturing method therefor

InactiveUS6376582B1Improve balanceGood dimensional stabilitySynthetic resin layered productsPretreated surfacesPolymer scienceWood fibre

Owner:YAMAHA CORP

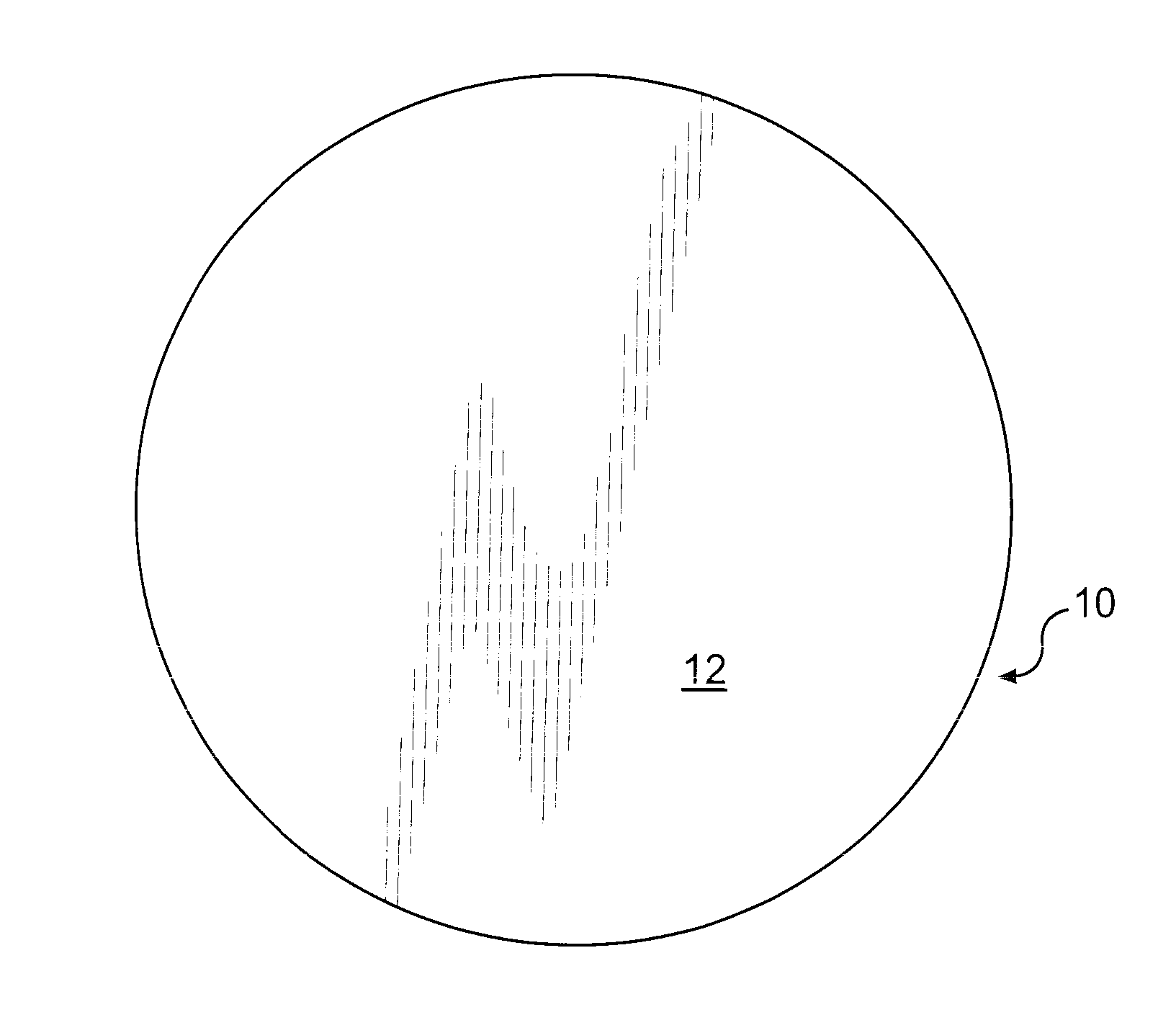

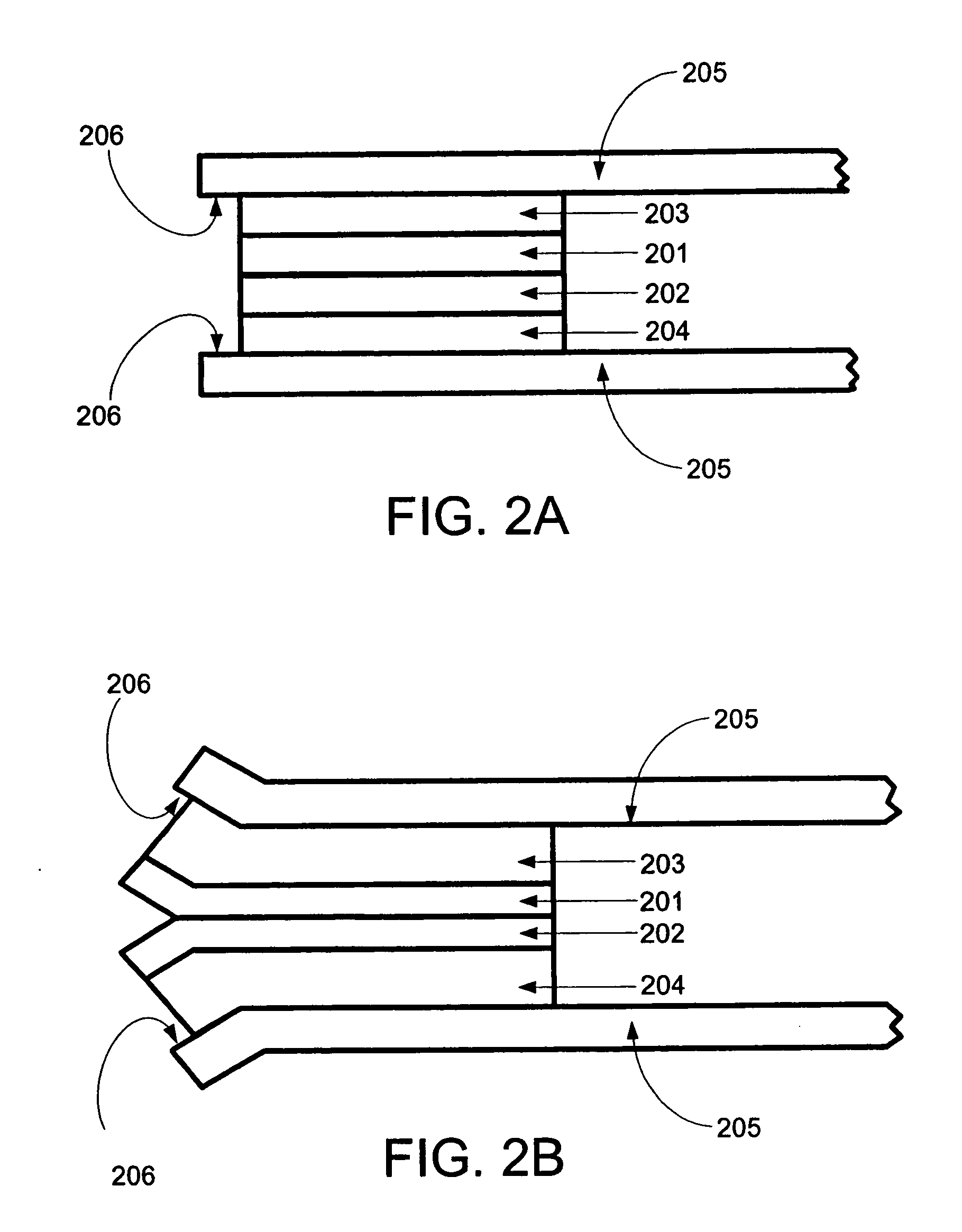

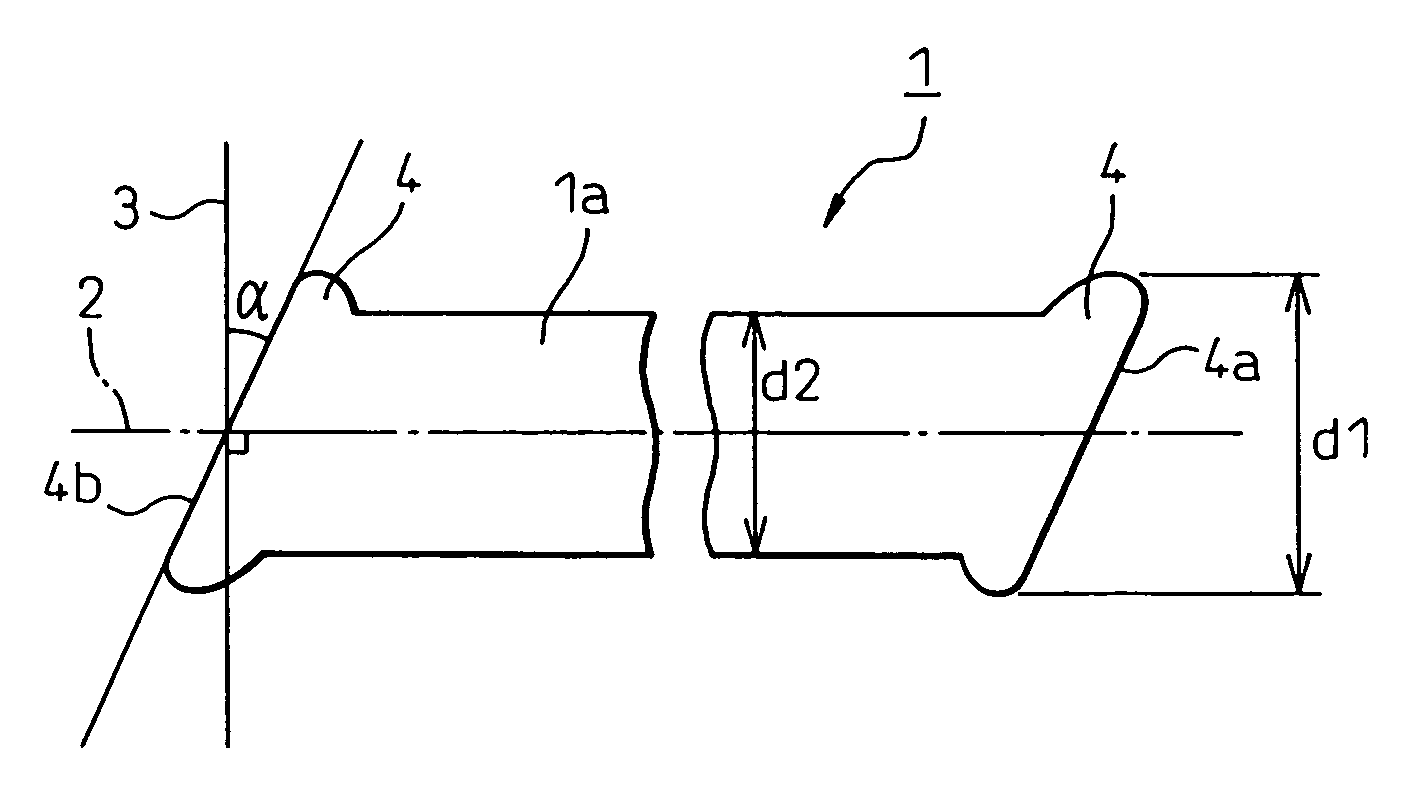

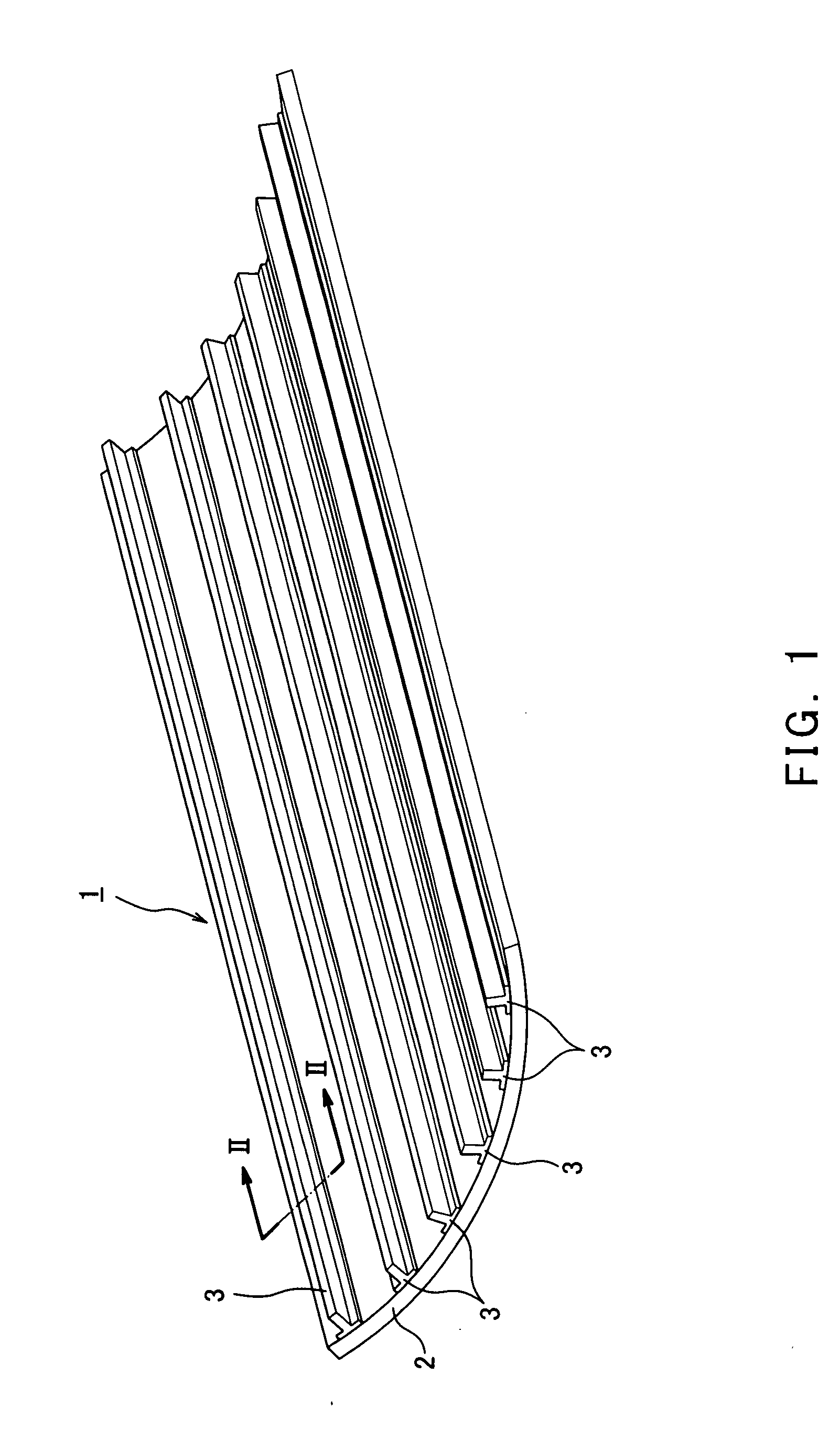

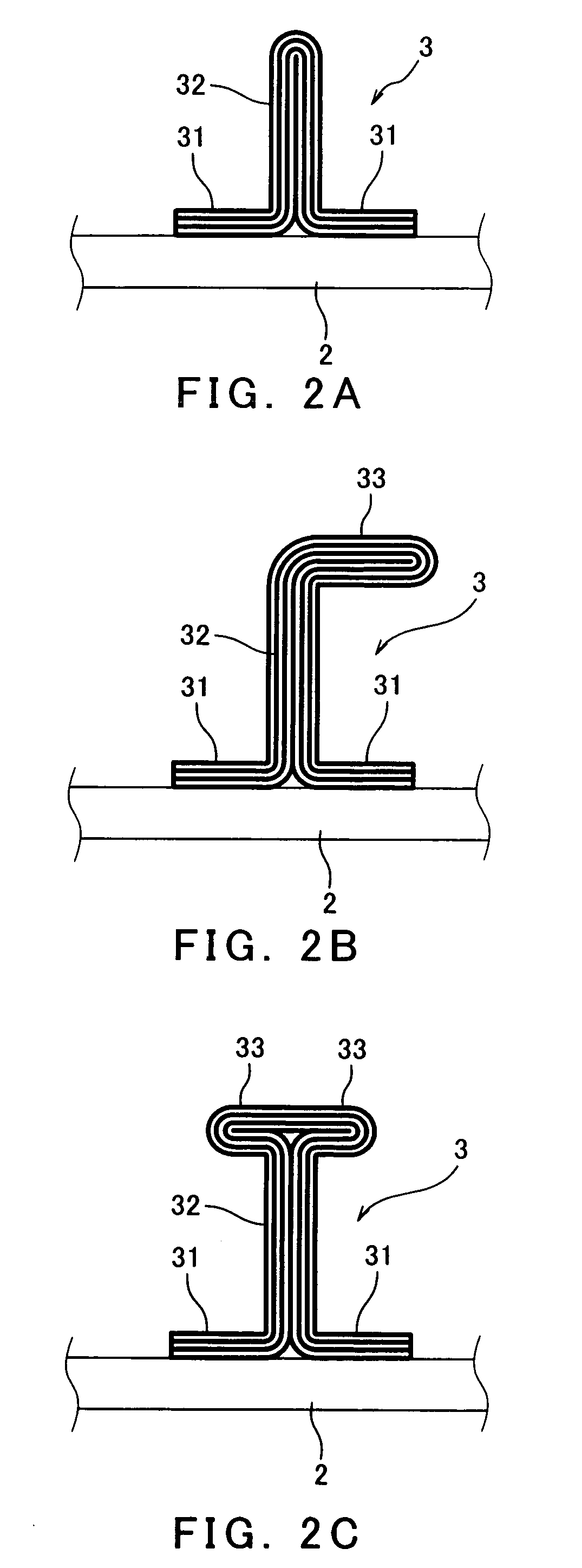

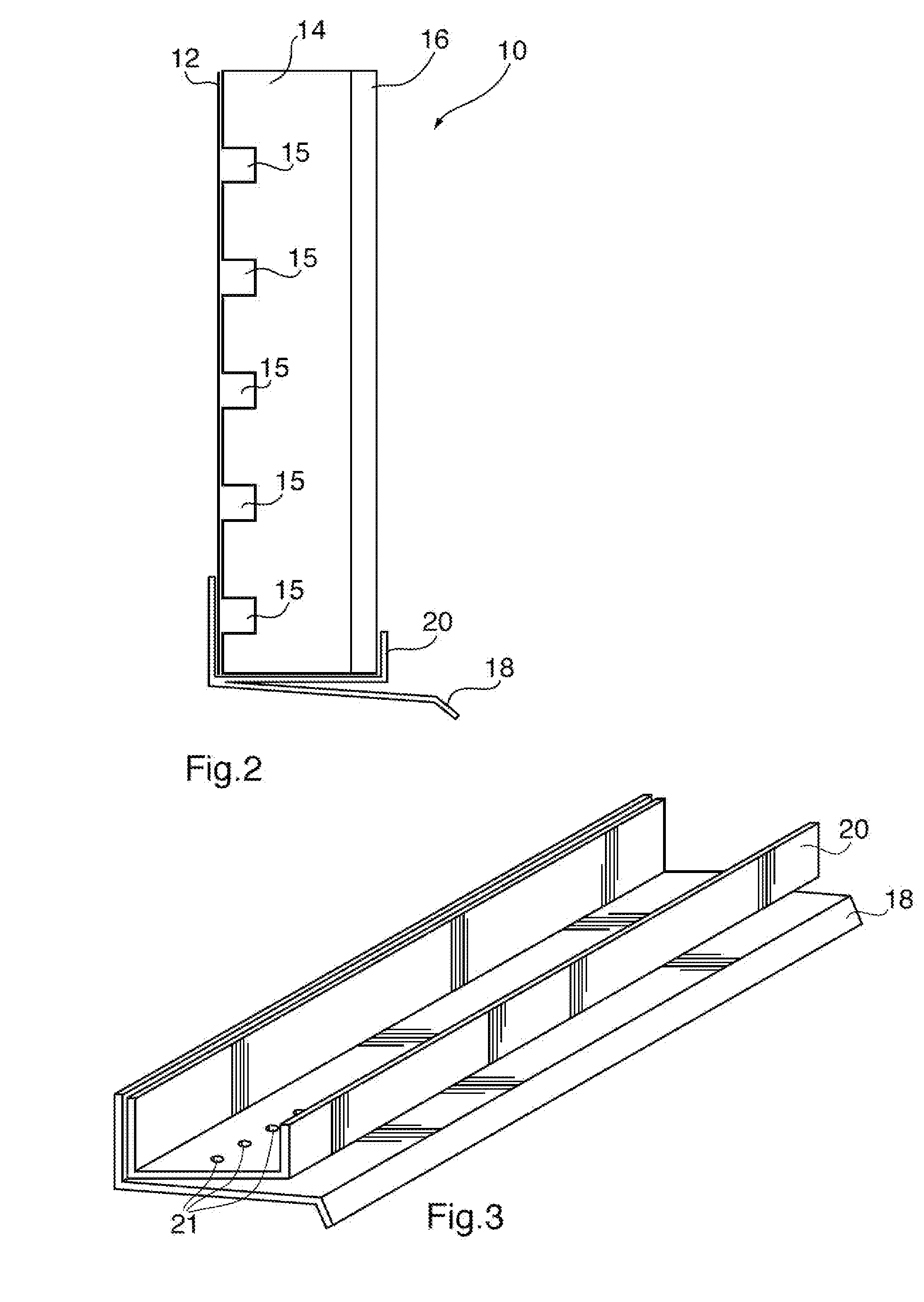

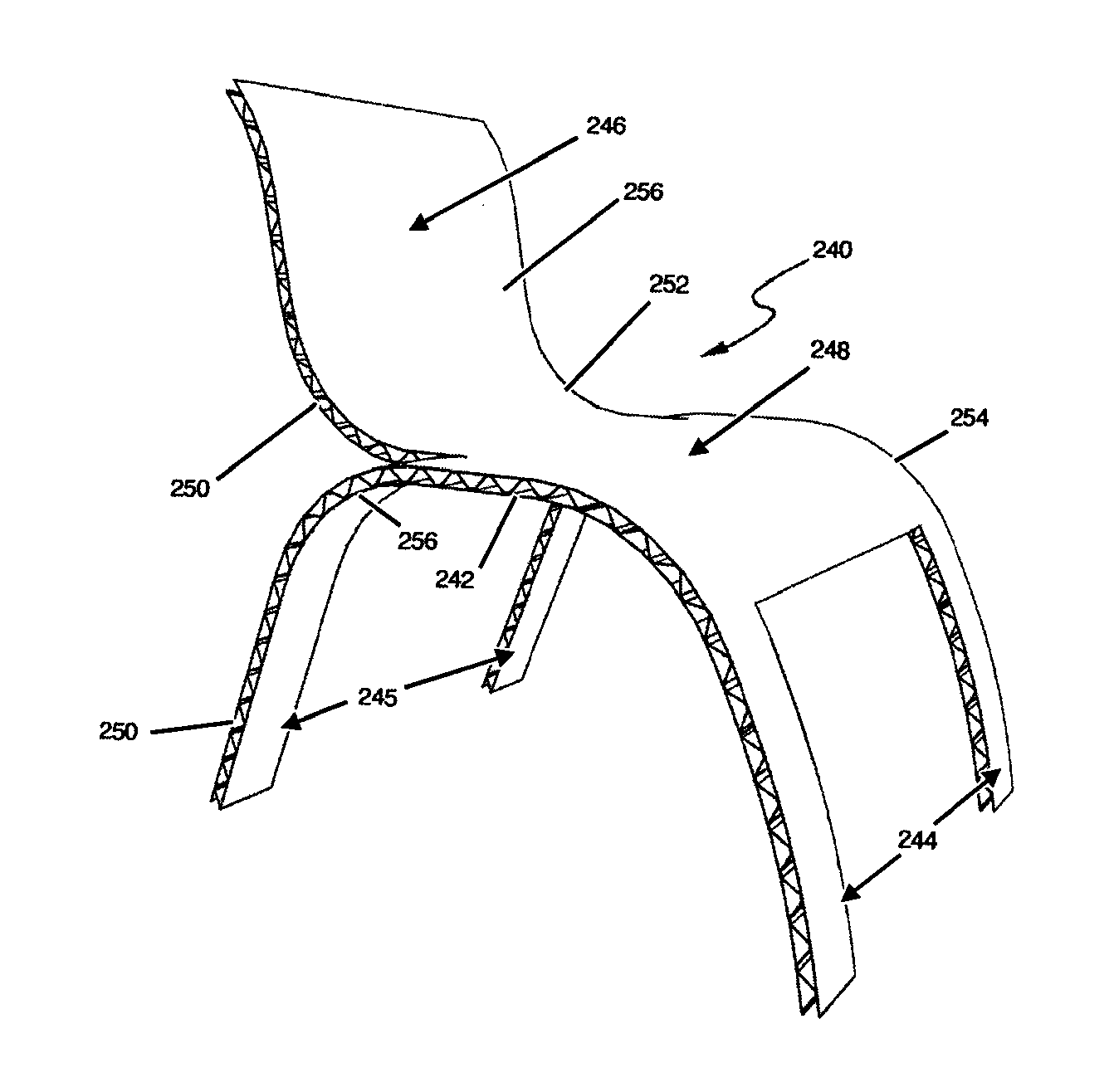

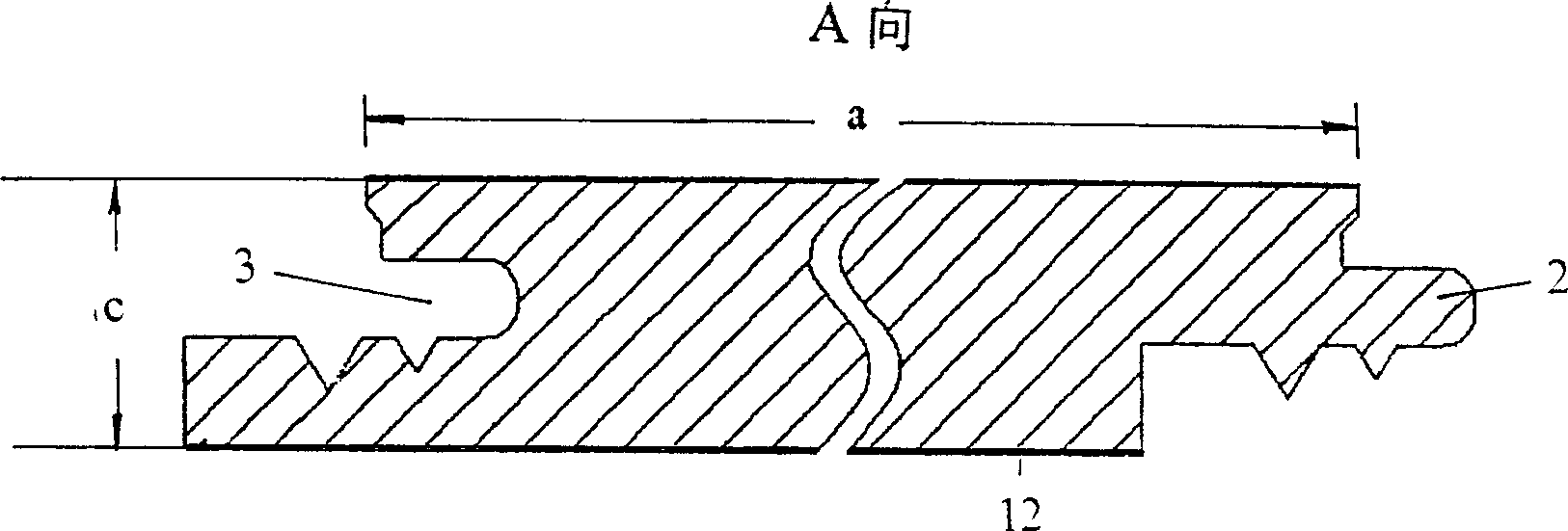

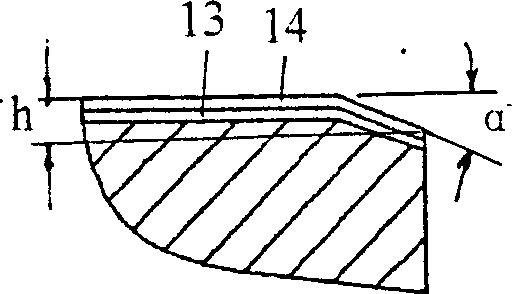

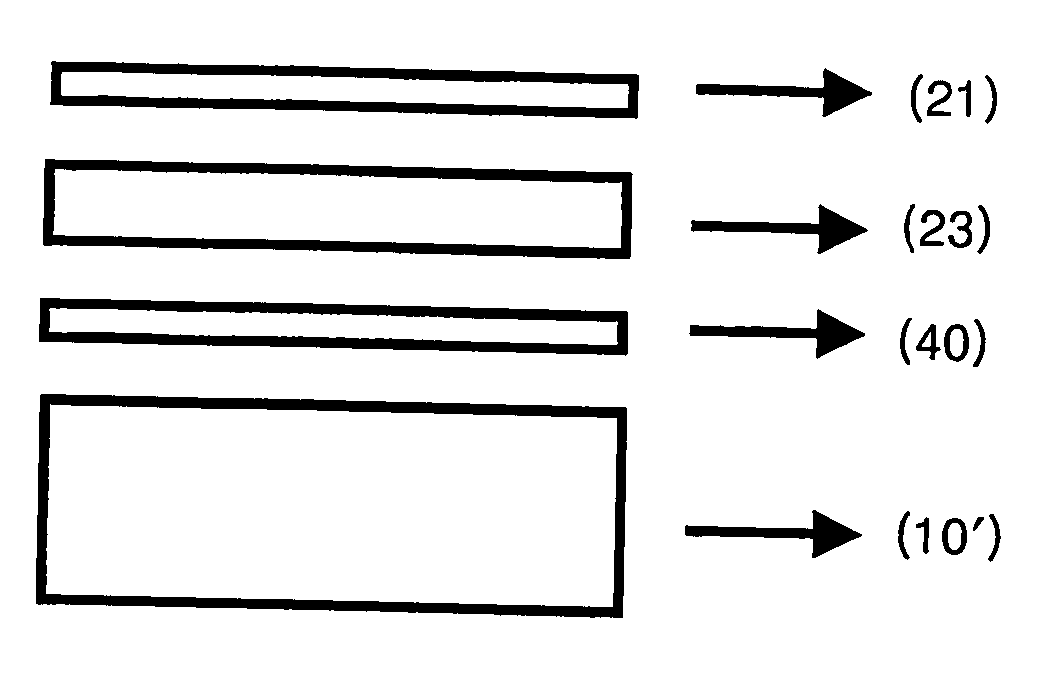

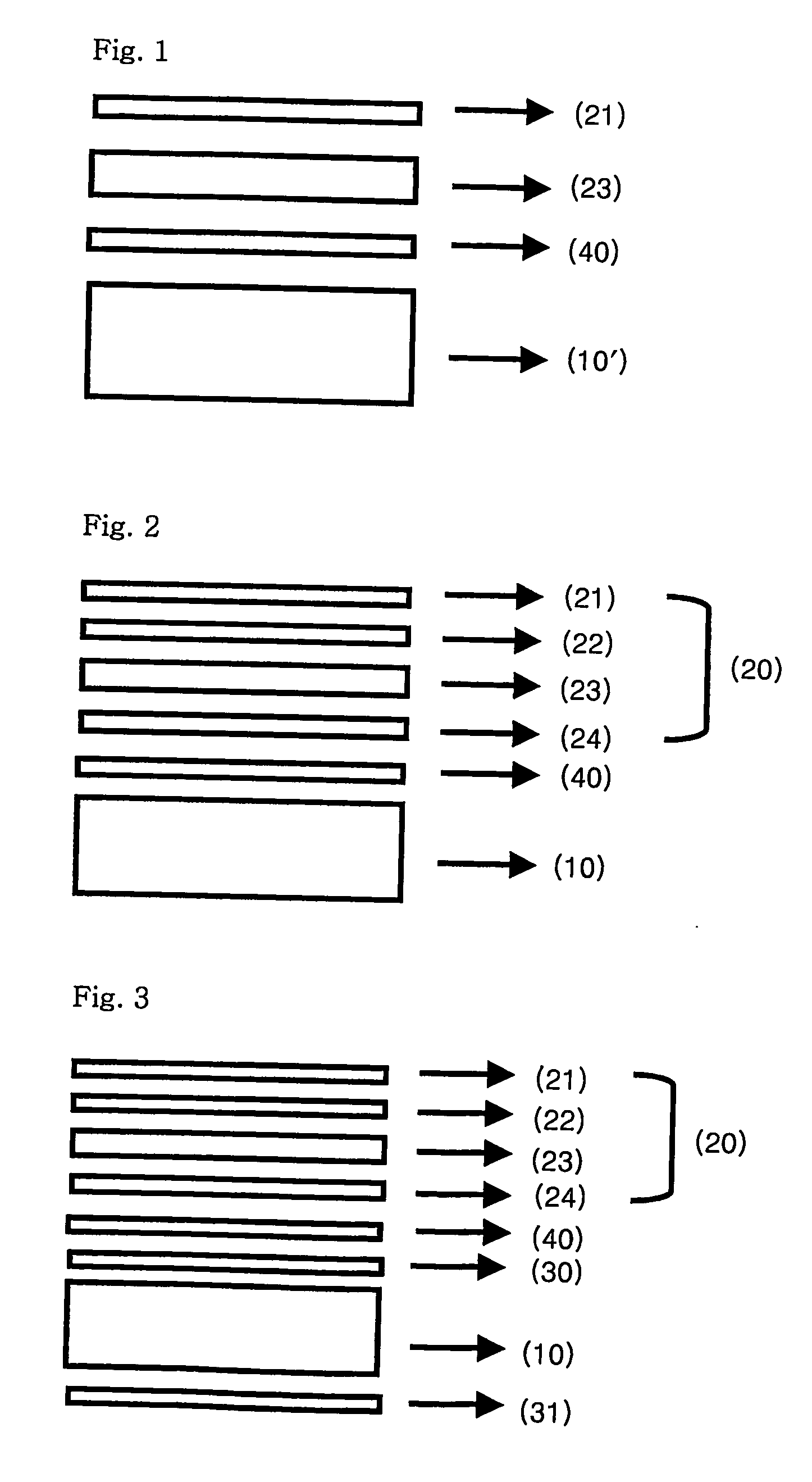

Method and apparatus for shaping section bar made of composite material and shaped product and I-shaped stringer thereof

A method and apparatus for shaping a section bar (for example, a “T-shaped” or “J-shaped” stringer) made of composite material is provided. The method comprising the steps of placing the stacked reinforced-fiber sheets on a pair of side presses opposing to each other with a predetermined gap; inserting a punch through the gap from above to fold the stacked reinforced-fiber sheets in half, while holding ends of the stacked reinforced-fiber sheets between upper surfaces of the side presses by block members; drawing out the punch upward and then pressing the stacked reinforced-fiber sheets folded by the side presses therebetween. A shaped product shaped thereby is high quality in which a distortion (“fluctuation”) of the stacked reinforced-fiber sheets in the inner side ply or plies of bending does not occur and ends of the stacked reinforced-fiber sheets are aligned between plies.

Owner:KAWASAKI HEAVY IND LTD

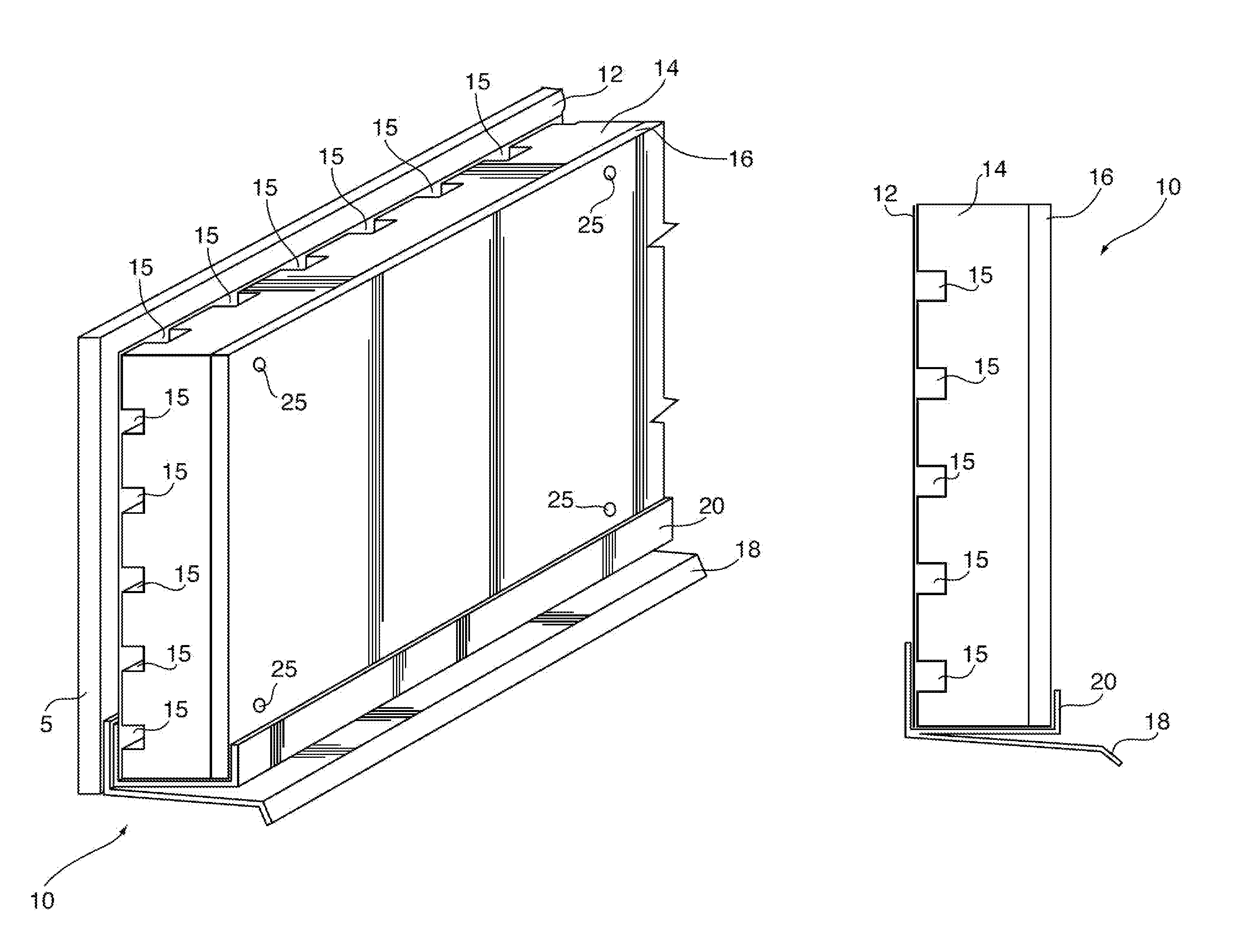

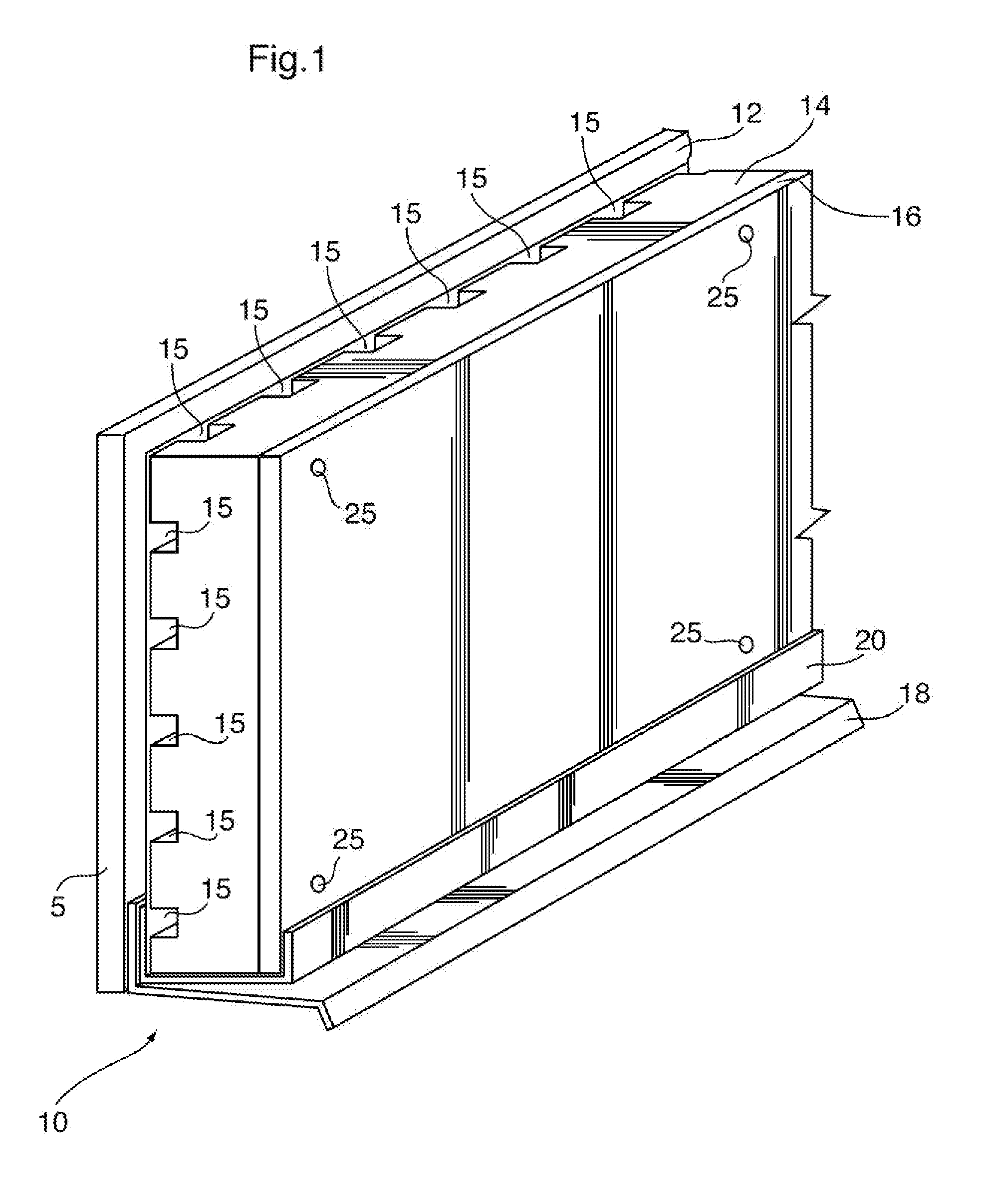

Exterior wall finishing arrangement

ActiveUS8555581B2Improve insulation performanceReduce penetrationCeilingsCovering/liningsMoistureFiberboard

Owner:1254453 ONTARIO INC

Coating systems for cement composite articles

The present invention provides a coating composition, a method of coating a substrate, and a coated substrate (e.g., a coated cement fiberboard article). In preferred embodiments the coating composition includes one or more latex polymers and an aliphatic epoxy resin system. The coating composition can include one or more coating compositions that may be applied in one or more layers. A coated article comprising a cement fiberboard substrate and a coating system applied to the substrate is also provided. The article includes a first coating system applied to the substrate, wherein the first coating system includes an aliphatic epoxy resin system having an aqueous dispersion of polymer particles, optionally a silicate additive, and optionally one or more olefinic compounds and initiator for same. The first coating system preferably includes one or more coating compositions that may be applied in one or more layers. In a preferred embodiment, the first coating system is applied to all the surfaces of the substrate (e.g., the front side, back side and edges of a board). The coated substrate may then be coated with other optional coatings, e.g., decorative or protective topcoats.

Owner:AXALTA COATING SYST IP CO LLC

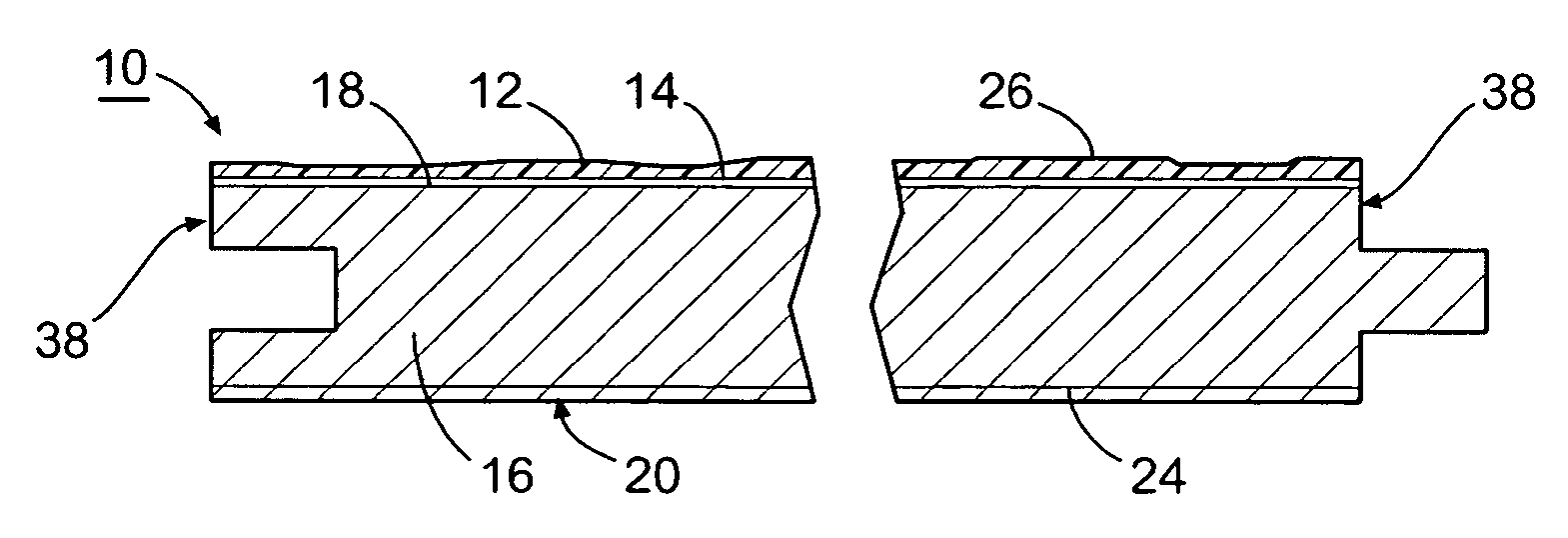

Decorative laminate assembly and method of producing same

InactiveUS7081300B2Improve wear qualityAvoid laborCovering/liningsOrnamental structuresWear resistantEngineering

A decorative laminate assembly having a decorative laminate top layer assembly. This top layer assembly includes, in descending superimposed relationship, a decorative layer and a core layer that includes PETG, or other polymeric material. Preferably, the top layer assembly also includes a wear resistant overlay layer on top of the decorative layer, and the core layer's PETG is in a sheet form. The top layer assembly may be directly bonded to a water resistant substrate. The decorative laminate assembly of the present invention can be used for a variety of purposes, including flooring applications. When the present invention is used for flooring applications, it is preferred that the overlay layer has enhanced wear resistant qualities and that the water resistant substrate comprise PVC or cement fiberboard.

Owner:THE DILLER +1

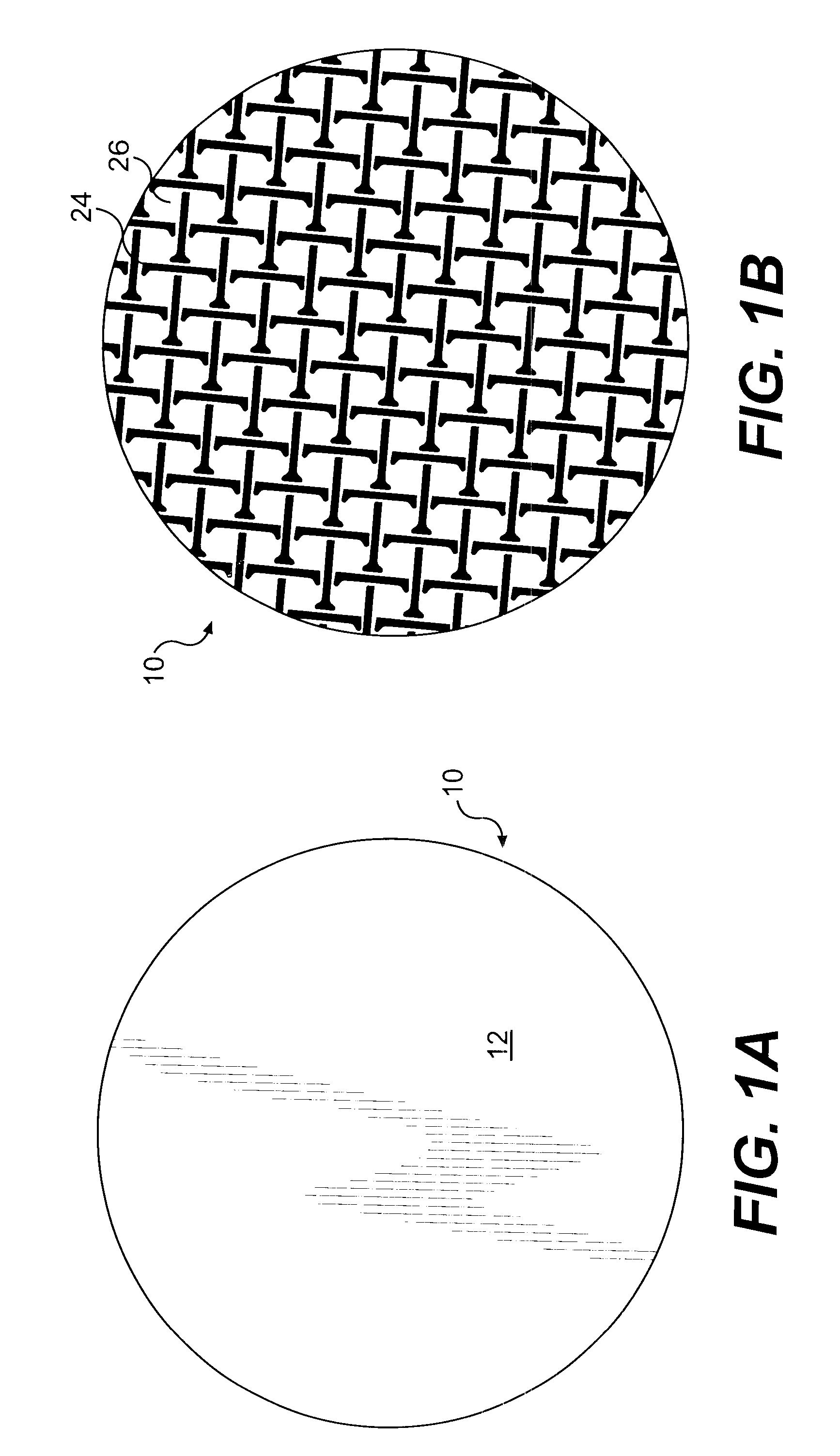

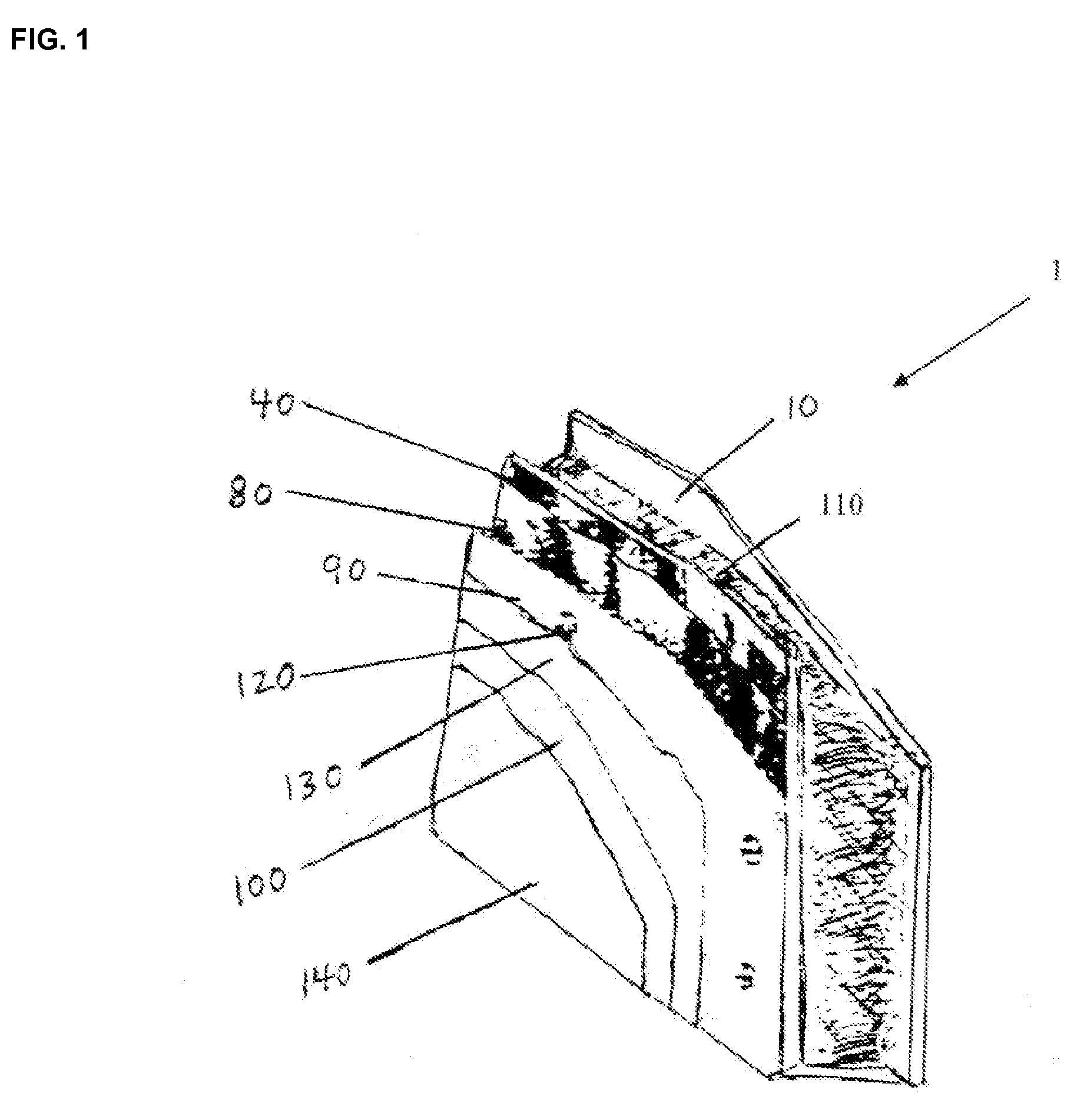

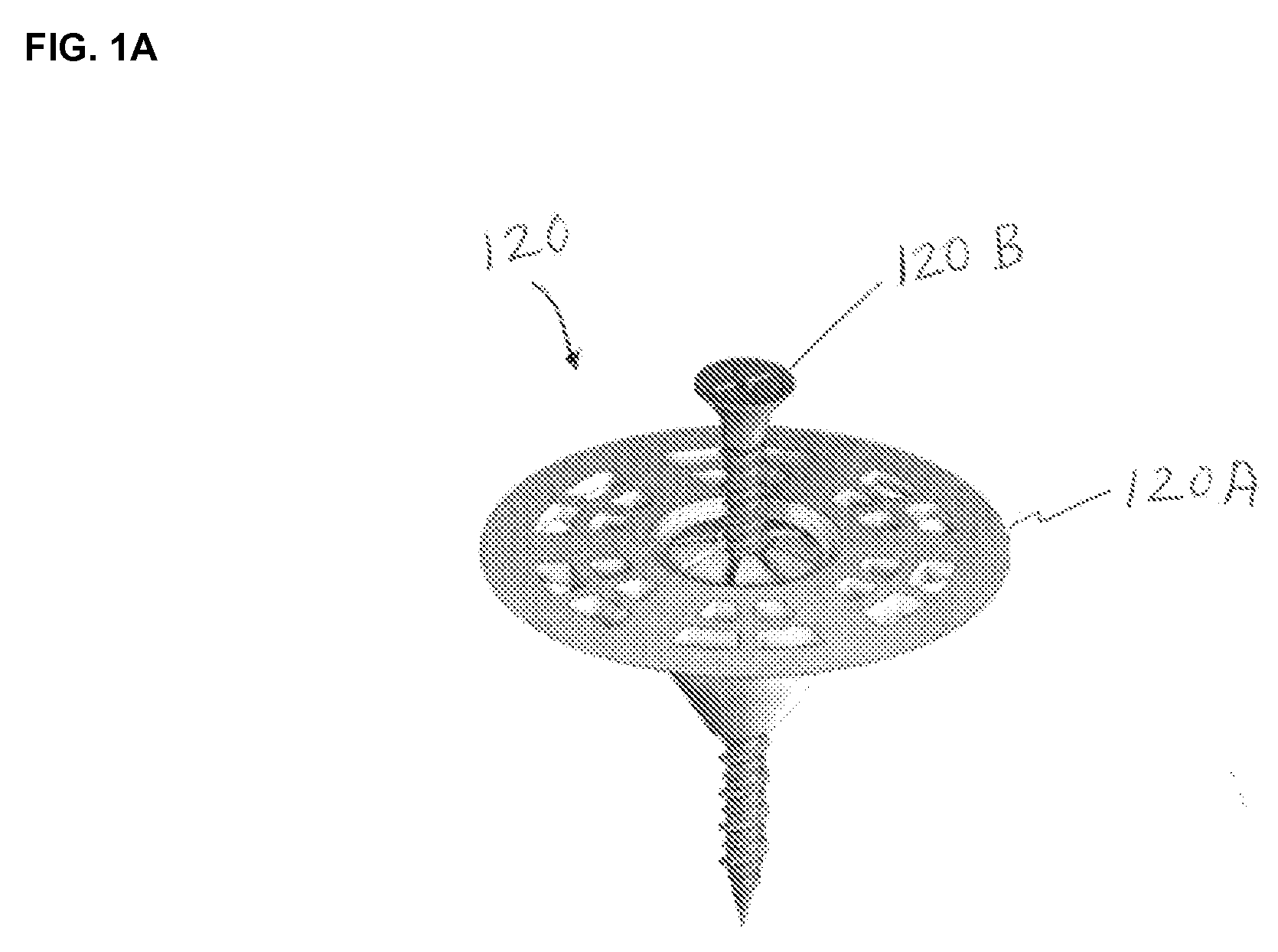

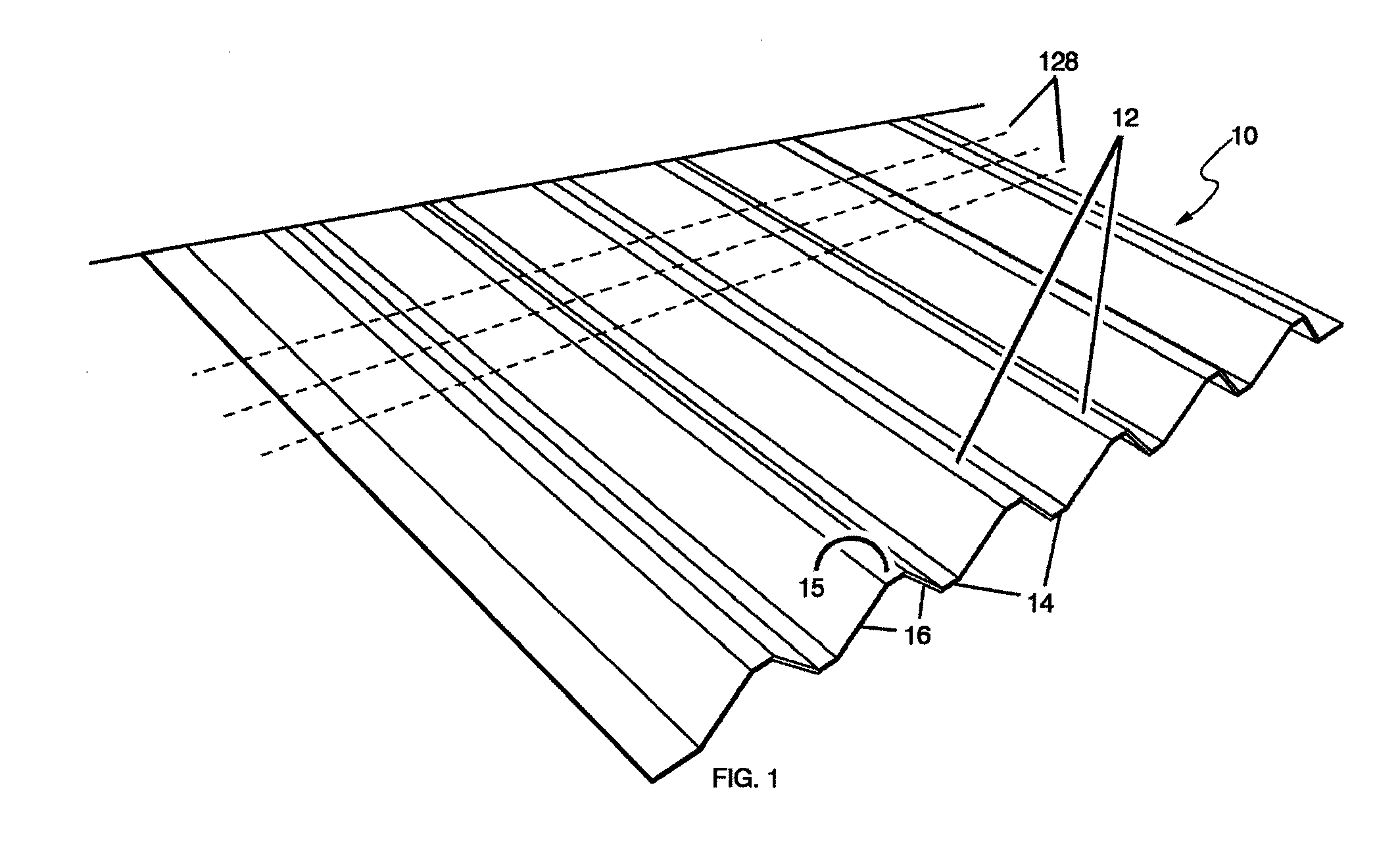

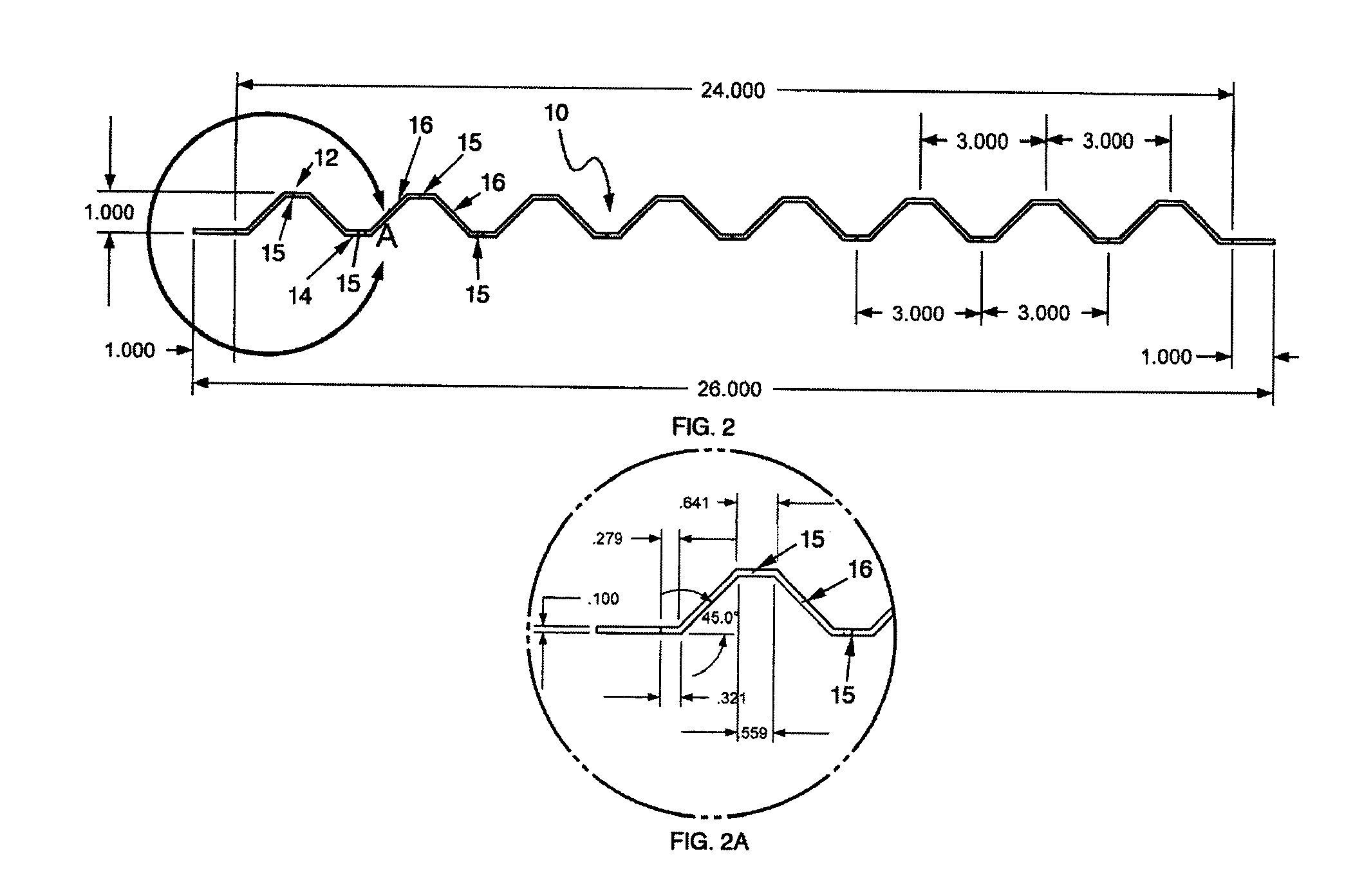

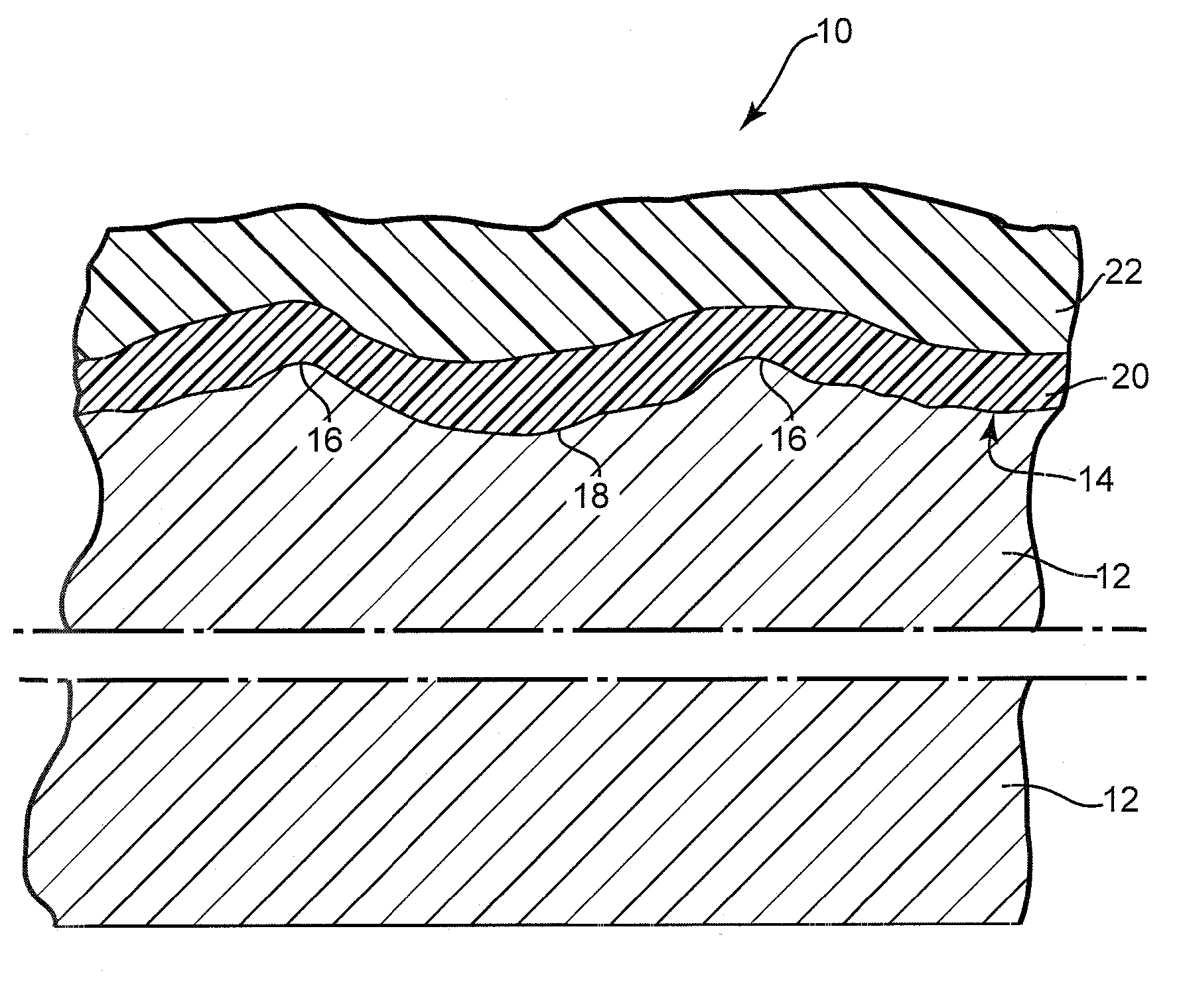

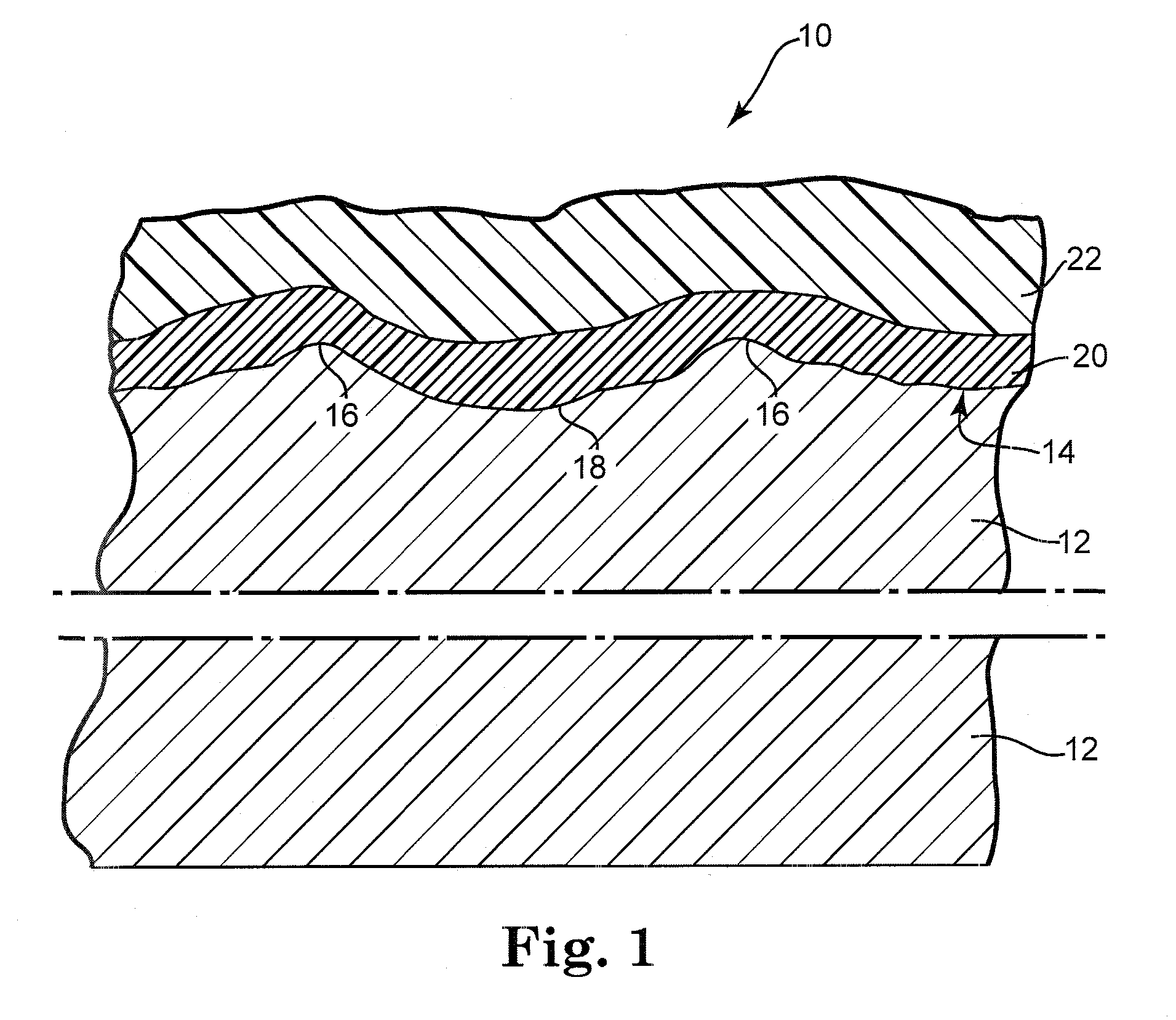

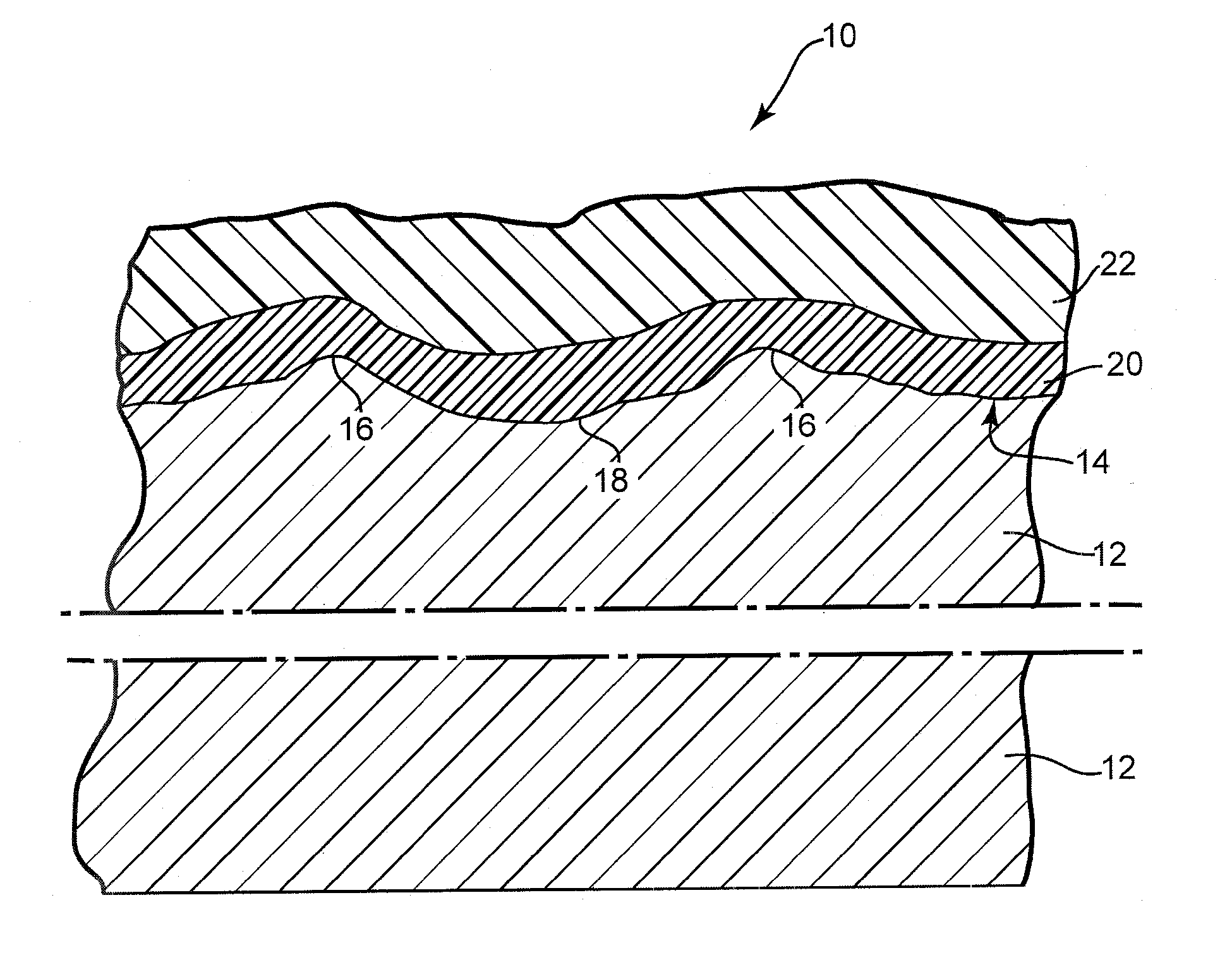

Engineered Molded Fiberboard Panels. Methods of Making the Panels, and Products Fabricated From the Panels

A honeycomb-shaped panel is formed from a plurality of generally sinusoidally shaped strips of molded fiberboard material each having spaced, oppositely directed flat peaks, the peaks of adjacent strips being secured together to form a plurality of hexagonally shaped cells extending perpendicular to the surfaces of the sheet. The strips may be cut from a single sheet of corrugated fiberboard sheet material and then secured together to form the honeycomb panel, or a plurality of such panels may be secured together face to face with their ribs aligned to form a stack, and selected cuts may be made through the secured, stacked panels to form a plurality of honeycomb panels of desired surface shape and height dimensions. The strips forming the cells are substantially rigid and resistant to collapse of the cells, and form a substantially rigid core when assembled between two flexible fiberboard skins, while the panel is bendable to adopt a desired panel curvature.

Owner:US SEC AGRI +1

Coating system for cement composite articles

A coated article which includes a cement fiberboard substrate and a radiation-curable coating system applied to the substrate. The coating system includes a latex polymer, one or more olefinic compounds and water, and may be provided in the form of one or more coating compositions that may be applied in one or more layers, wherein each of the coating compositions is preferably an aqueous composition, or can be mixed with another composition (e.g., on the substrate) to form an aqueous composition.

Owner:AXALTA COATING SYST IP CO LLC

Coating system for cement composite articles

ActiveUS20070259188A1Liquid surface applicatorsConstruction materialWater dispersibleCement composites

A coated article which includes a cement fiberboard substrate and a radiation-curable coating system applied to the substrate. The coating system includes an aqueous dispersion of water-dispersible polymer particles, one or more olefinic compounds and water, and may be provided in the form of one or more coating compositions that may be applied in one or more layers, wherein each of the coating compositions is preferably an aqueous composition, or can be mixed with another composition (e.g., on the substrate) to form an aqueous composition.

Owner:AXALTA COATING SYST IP CO LLC

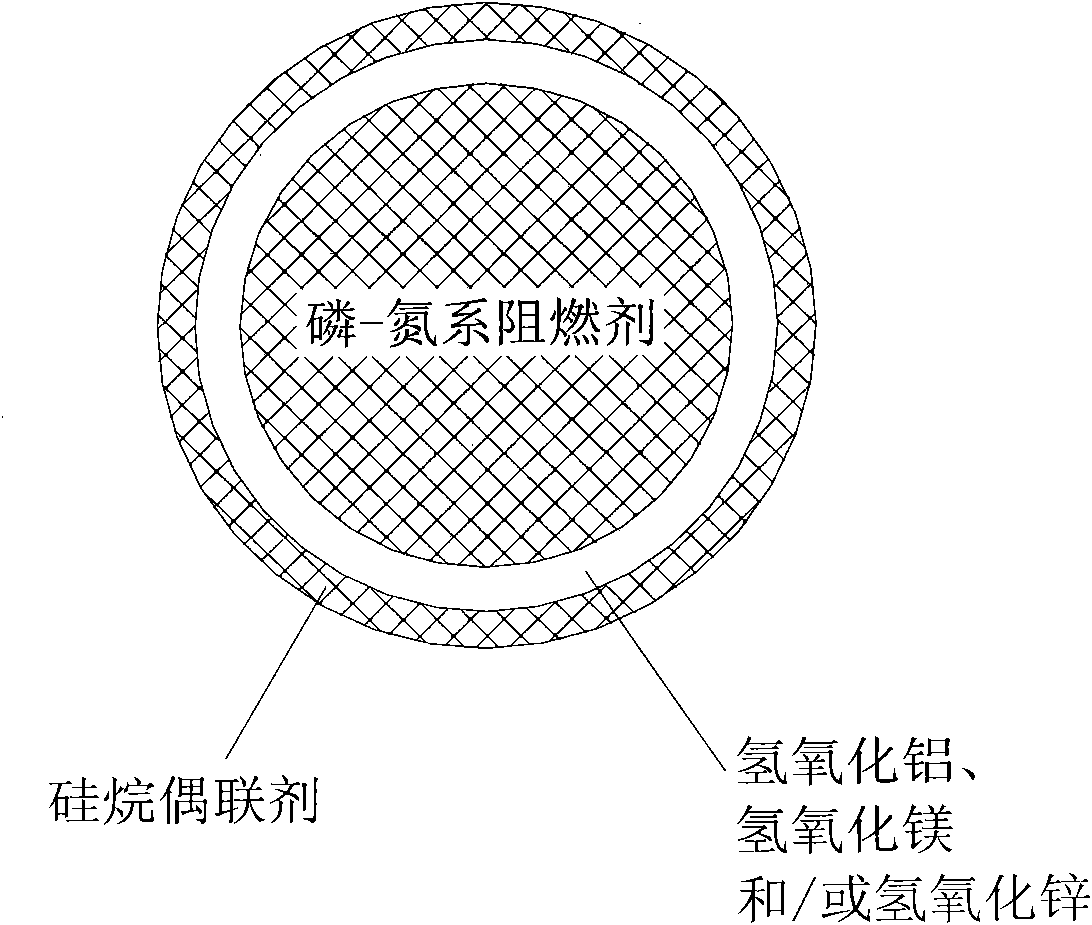

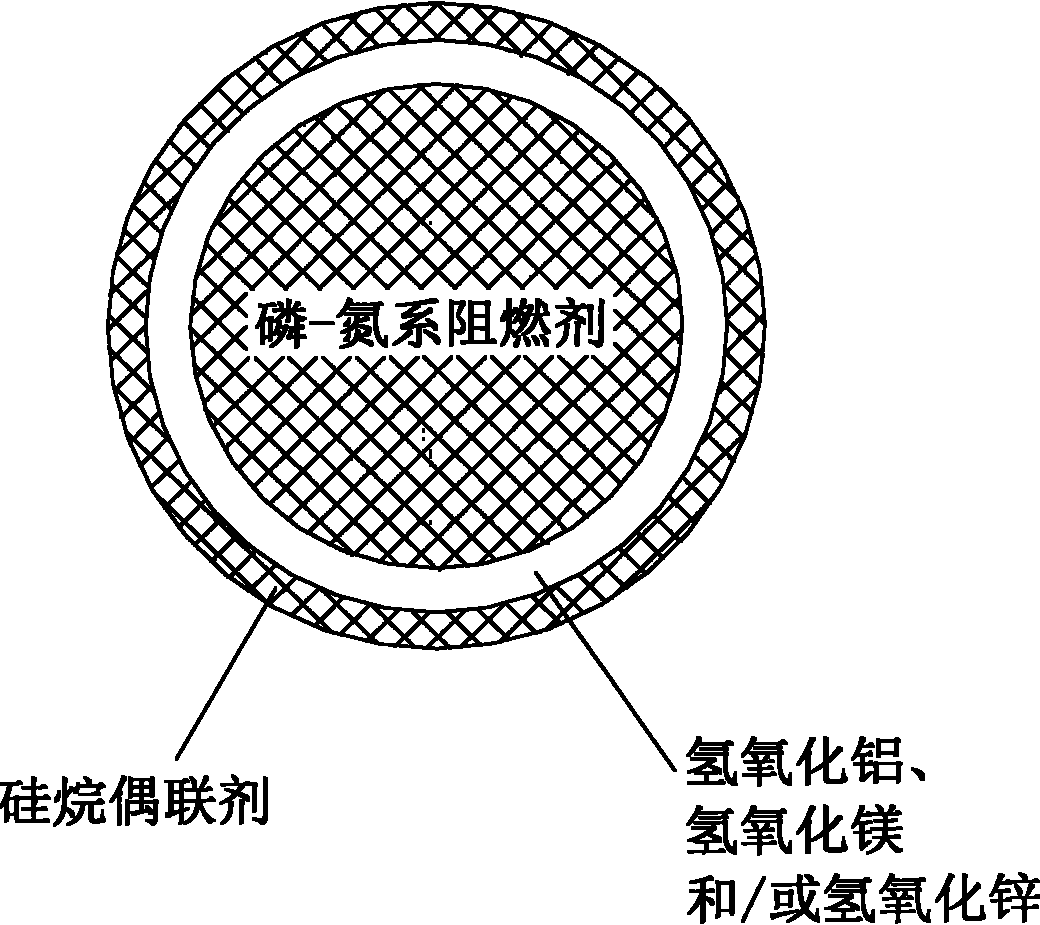

High-strength environment-friendly flame-retarding fiberboard and manufacturing method thereof

ActiveCN101905475AReduce the temperatureDelay in pyrolysis combustion reactionWood working apparatusDomestic articlesFiberSocial benefits

The invention discloses a high-strength environment-friendly flame-retarding fiberboard which comprises the following raw materials of plant fibers, flame retardants, adhesives and waterproofing agents, wherein the weight ratio of the plant fibers to the flame retardants to the adhesives to the waterproofing agents is 100:(3-30):(3-30):(0.1-4). The invention also discloses a manufacturing method of the high-strength environment-friendly flame-retarding fiberboard. Not only are the mechanical properties of the flame-retarding fiberboard obviously improved, but also the combustion property can conform to the regulations of GB8624 Class B or Class C, and the formaldehyde emission, the smoke volume produced and the smoke toxicity are also reduced. Thus, the high-strength environment-friendly flame-retarding fiberboard has good quality and low price, can be widely applied to the fields of building furnishings, flame-retarding furniture production, flame-retarding floor production, wooden fireproof door production, ship and vehicle furnishings and the like, and has good economical and social benefits.

Owner:北京盛大华源科技有限公司 +1

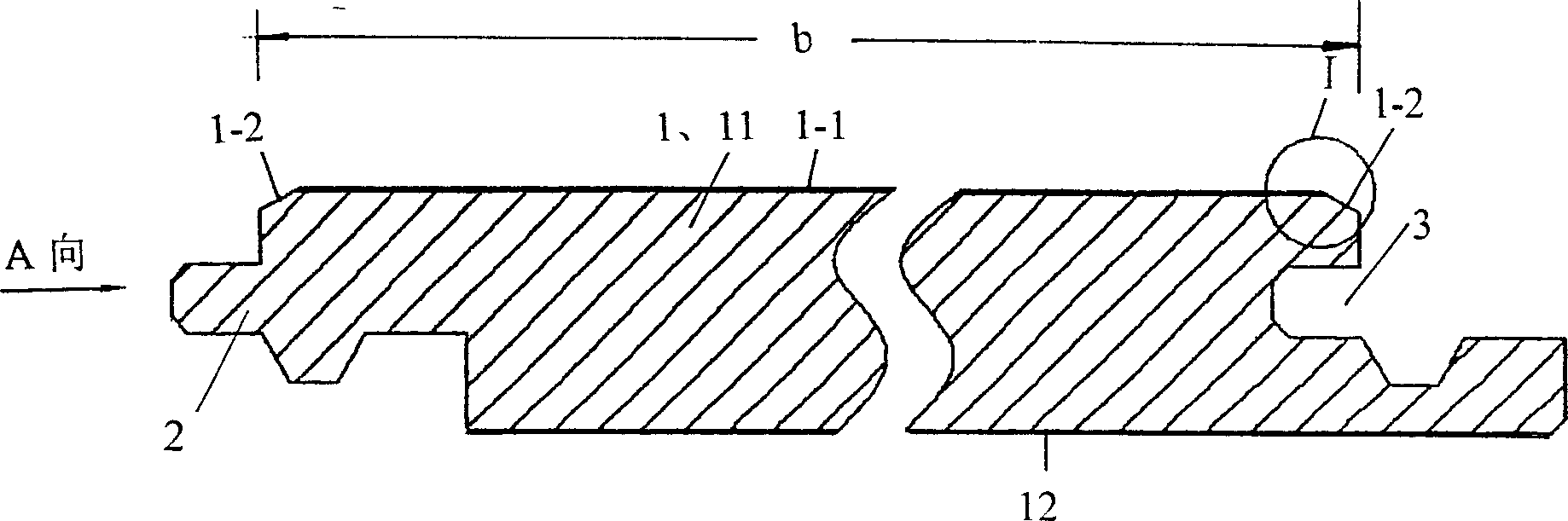

Stiffened timber floor and the manufacturing method thereof

InactiveCN1485184ALow priceExtended service lifeWood working apparatusWood layered productsSolid woodPulp and paper industry

An intensified wood floor board and its manufacturing method. One measure is, the upper surface of the floor mainbody is composed of the walking plane and inclined planes of the two sides of the walking plane; the upper surface of fiberboard has a paper layer with wood texture and a durable paper layer in sequence; by pressing mold, balanced paper layer, fiberboard, the paper layer with wood texture and a durable paper layer are adhered with each other. The second measure is, the upper surface of the floor mainbody is composed of the walking plane parallel to the base surface and inclined planes of the two sides of the walking plane, the upper surface of the upper surface of the fiberboard has a paper layer with wood texture and a durable paper layer in sequence; by bonding, the inclinedplanes on two sides are adhered with the paper layers with wood texture; resin varnish is coated on the paper layers with wood texture. due to inclined planes of two sides of the upper surface of floor mainbody, it is convenient to pave floor board. The floor board is durable, inexpensive and could use for a long time.

Owner:葛跃进

Process for production of gypsum/fiber board

ActiveUS20050161853A1Increase ratingsIncreased rehydration rateSolid waste managementWood working apparatusSlurryCellulose fiber

An improved process calcining a gypsum / cellulosic fiber slurry to produce a composite gypsum / cellulosic fiber product resides in adding a selected crystal modifier to the gypsum / cellulosic fiber slurry prior to the heating step to reduce the time necessary to carry out the calcination process, to reduce the temperature at which the calcination process is run or to increase the aspect ratio of the acicular calcium sulfate alpha hemihydrate crystals formed during the calcination process. Useful crystal modifiers include aluminum sulfate, aluminum chloride, chlorine, zinc sulfate, iron (III) sulfate, aluminum sulfate hexadecahydrate, iron (II) sulfate heptahydrate, iron (III) sulfate pentahydrate, zinc sulfate heptahydrate, copper sulfate pentahydrate, copper chloride dehydrate, manganese sulfate monohydrate and trisodium phosphate.

Owner:UNITED STATES GYPSUM CO

Thermosetting adhesives comprising a resin having azetidinium functional groups

InactiveUS20070054144A1Improve wet strengthFast curingCosmetic preparationsToilet preparationsAdhesiveEpichlorohydrin

Termosetting adhesives for use in e.g., particleboard or fiberboard, wherein the adhesives comprise a resin having azetidinium functional groups, can provide fast tack-building and curing, as well as ultimately excellent bonding characteristics. Preferably, the azetidinium-functional resin is formed from the reaction product of a polyamidoamine and epichlorohydrin.

Owner:GEORGIA PACIFIC CHEM LLC

Agronomic crop stalk medium density fiberboard using natural rubber and manufacturing method therefor

InactiveCN101367227AIncrease profitInhibition releaseFlat articlesDomestic articlesFiberStearic acid

The invention provides a crop straw medium density fiberboard by natural gum. Raw materials of the medium density fiberboard comprise crop straw fiber, a bonding agent, a waterproof and lubricating agent and a flame retardant, wherein the bonding agent is natural gum and comprises plant gum and animal gum; the waterproof and lubricating agent is natural wax, stearic acid or stearate; and the flame retardant is non-toxic and harmless flame retardant. The mixture ratio for all the raw materials by weight percent is: 75 to 93 percent of the crop straw fiber, 1 to 8 percent of the bonding agent (dried), 0.5 to 8 percent of the waterproof and lubricating agent, and 5.5 to 23.5 percent of the flame retardant. All the raw materials are produced into a finished product through mixing, sizing, spreading, prepressing, hot pressing and edge cutting; and microwave is used for auxiliary heating in the hot pressing phase. The crop straw medium density fiberboard by the natural gum can realize complete degradation under natural condition after the medium density fiberboard is abandoned or destroyed without any nonreversible destruction to the environment, so the production and application of the crop straw medium density fiberboard realize complete sustainability and recyclability, and have significant realistic and historic significance.

Owner:张东旭

Modifying method for wood elements

InactiveUS6632326B1Good dimensional stabilityReduce processing timeCellulosic pulp after-treatmentLiquid surface applicatorsManufacturing cost reductionAcetic acid

The present invention's modifying method for wood elements includes a step for soaking wood elements in one or a mixture of acetic anhydride, acetic acid, or chloroacetic acid; and a step for acetylating the impregnated wood elements in a gaseous phase. This method makes it possible to reduce the time required for the step of acetylating the wood elements, simplifies the process, reduces fabrication costs, and enables fabrication of a wood fiberboard having high dimensional stability.

Owner:YAMAHA CORP

Wood flooring composed of wpl, base and soundproof layer

InactiveUS20060172118A1Improve surface strengthEnhance natural textureCovering/liningsLighting and heating apparatusWood veneerHigh density

Owner:LG CHEM LTD

Method for using modified soy protein tackiness agent to prepare bamboo fiberboard

InactiveCN101186047AWide variety of sourcesEasily biodegradableDomestic articlesFlat articlesFiberQuality level

The invention discloses a bamboo fiberboard manufacturing method adopting a modified soy protein bond. The method includes the following steps: 1) glue mixing: 1 part of polyoxypropylene glycerin ether is added to 88 parts of modified reagent solution, and then 10 parts of soy proteins are added; then the solution is stirred for 2 to 3 hours; then 1 part of potassium sorbate is added as antiseptic and the solution is evenly stirred; 2) gluing: the bamboo fibers and the modified soy proteins are evenly mixed; 3) hot-pressing: a water-content of the acquisition of the step 2) is regulated to 24 to 27 percent to get a plate blank; then the plate blank is hot-pressed for shaping so as to get the bamboo fiber board. The adoption of the method of the invention can realize non-formaldehyde production, thus enhancing the quality level of fiberboard products.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com