Patents

Literature

553results about "Cellulosic pulp after-treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for sustainable energy and materials

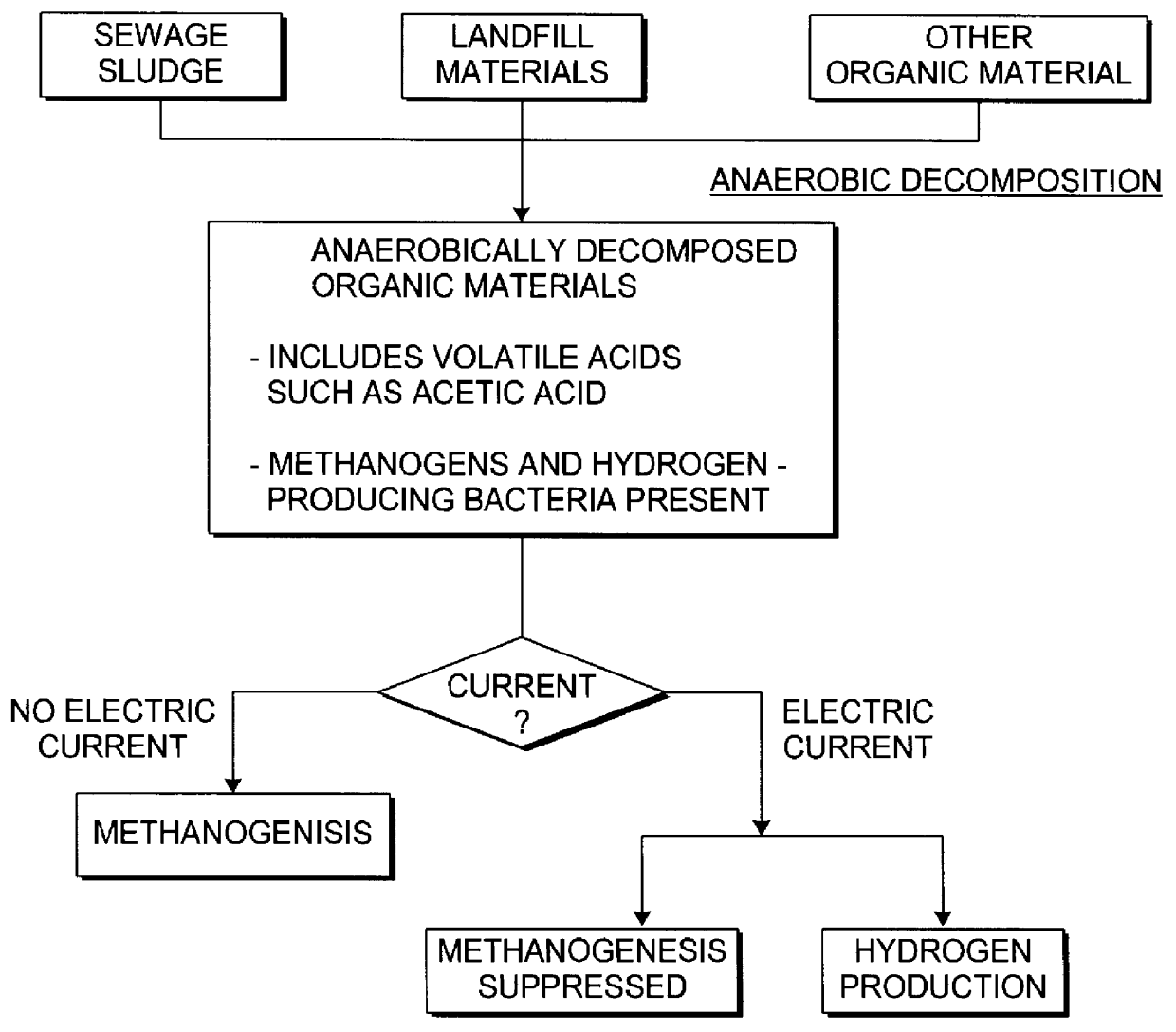

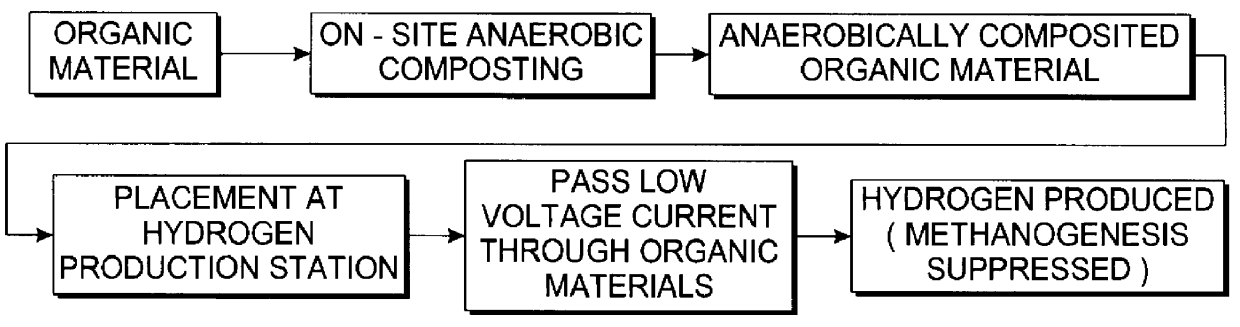

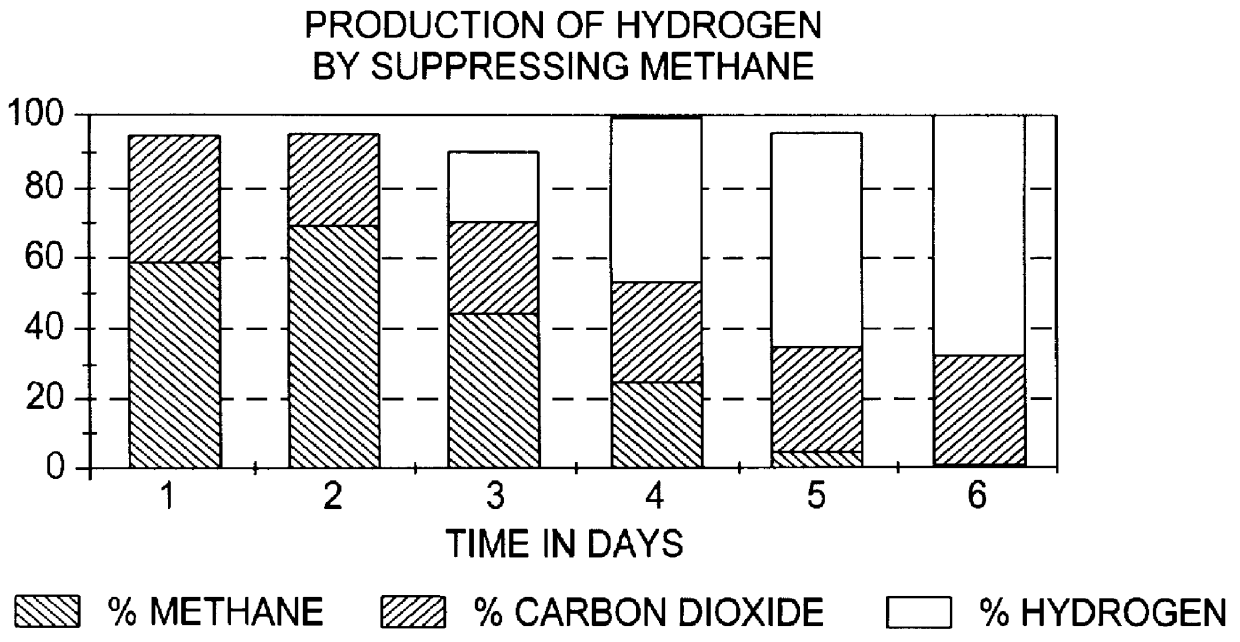

A process for the production of hydrogen from anaerobically decomposed organic materials by applying an electric potential to the anaerobically decomposed organic materials, including landfill materials and sewage, to form hydrogen, and for decreasing the time required to treat these anaerobically decomposed organic materials. The organic materials decompose to volatile acids such as acetic acid, which may be hydrolyzed by electric current to form hydrogen. The process may be continuously run in sewage digestion tanks with the continuous feed of sewage, at landfill sites, or at any site having a supply of anaerobically decomposed or decomposable organic materials.

Owner:MCALISTER TECH LLC +1

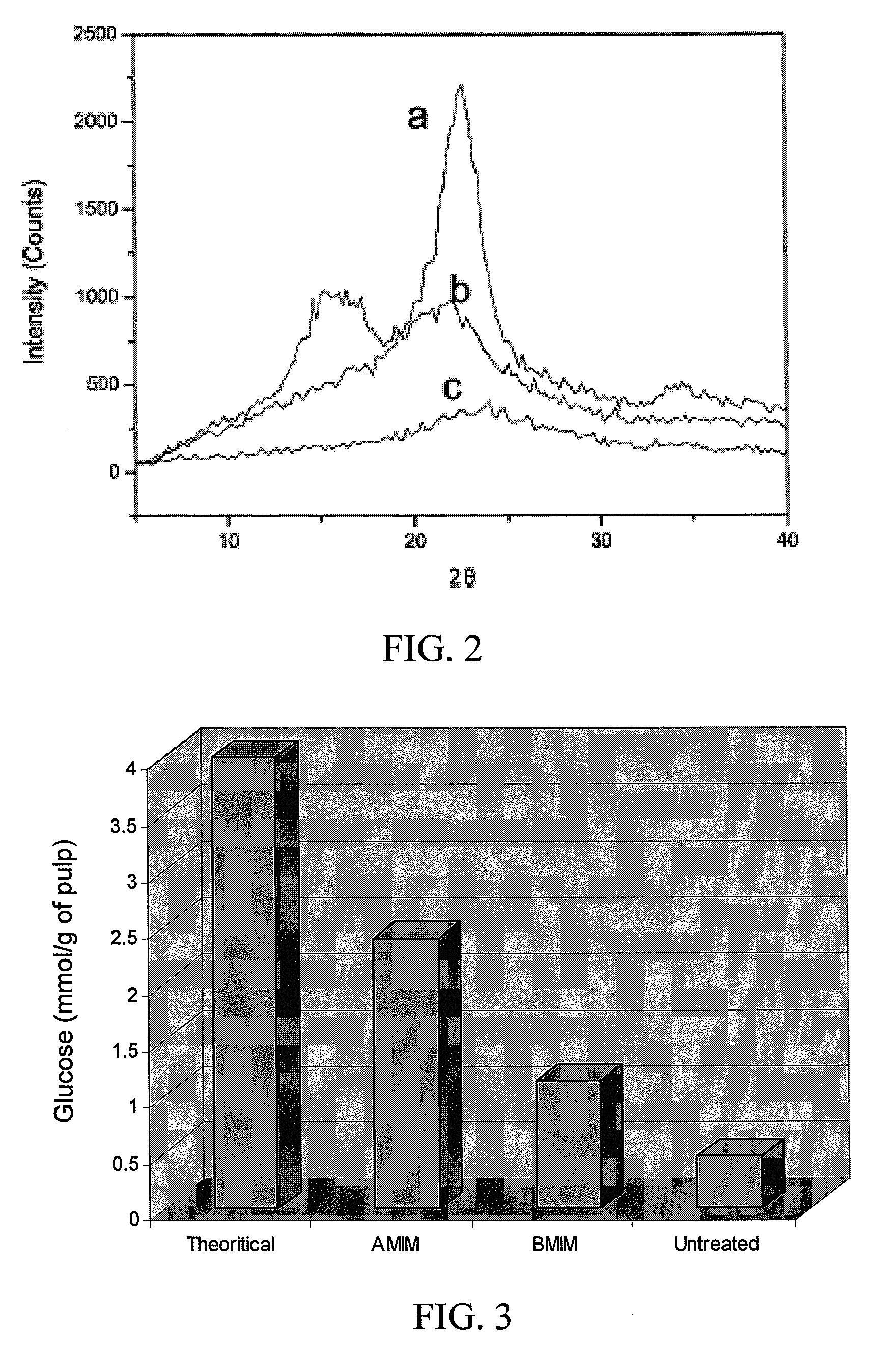

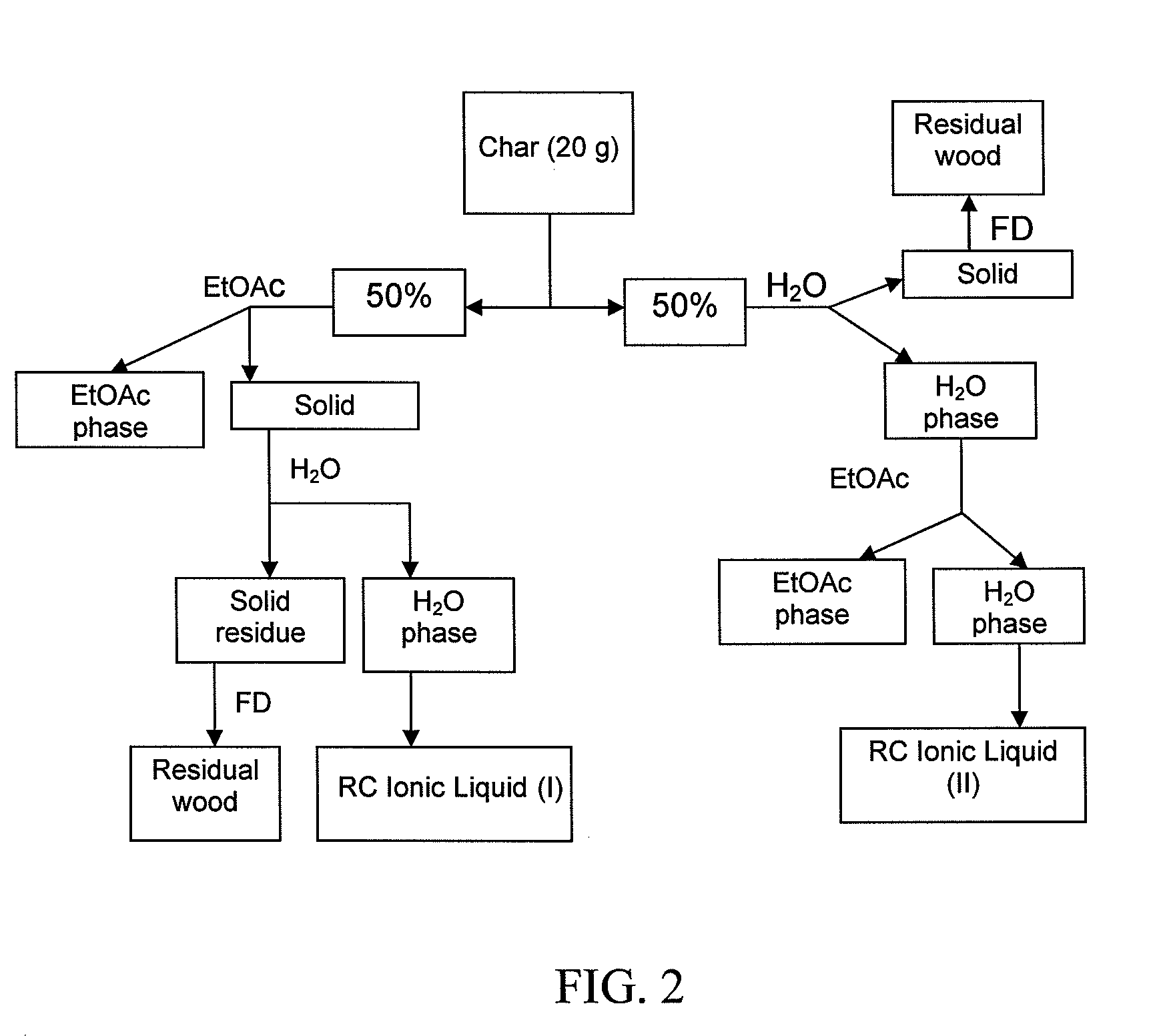

Use of lignocellulosics solvated in ionic liquids for production of biofuels

InactiveUS20080190013A1Guaranteed economic efficiencyReduced availabilityCellulosic pulp after-treatmentSugar productsBiofuelEvaporation

The present invention provides a method for converting lignocellulosic material into biofuel. In particular embodiments, the method comprises pre-treating lignocellulosic material by dissolving the material in ionic liquids. The pretreated lignocellulosic material can be isolated, such as by precipitation with a regenerating solvent (e.g., water), and be used directly in the formation of biofuel, including undergoing hydrolysis to form sugar and fermentation to form fuel, such as bioethanol. The ionic liquid can be recycled for further use, such as by evaporation of the water introduced during precipitation, and the recycling provides a route to a hemicellulose rich fraction and an ionic liquid of consistent quality and wood dissolution characteristics. The recovered hemicelluloses are of significant utilization potential toward commodity and specialty applications.

Owner:NORTH CAROLINA STATE UNIV

High Softness, High Durability Bath Tissue Incorporating High Lignin Eucalyptus Fiber

ActiveUS20130029106A1Less-wet lintOffsetting costsCellulosic pulp after-treatmentNon-fibrous pulp additionCellulose fiberMaterials science

A cellulosic tissue includes cellulosic fibers selected from the group consisting of chemically pulped fibers and mechanically pulped fibers, the cellulosic fibers have from about 10% to about 50% by weight eucalyptus fibers having a lignin content of at least about 20% by weight, and from about 3% to about 10% by weight regenerated cellulosic microfibers.

Owner:GPCP IP HLDG LLC

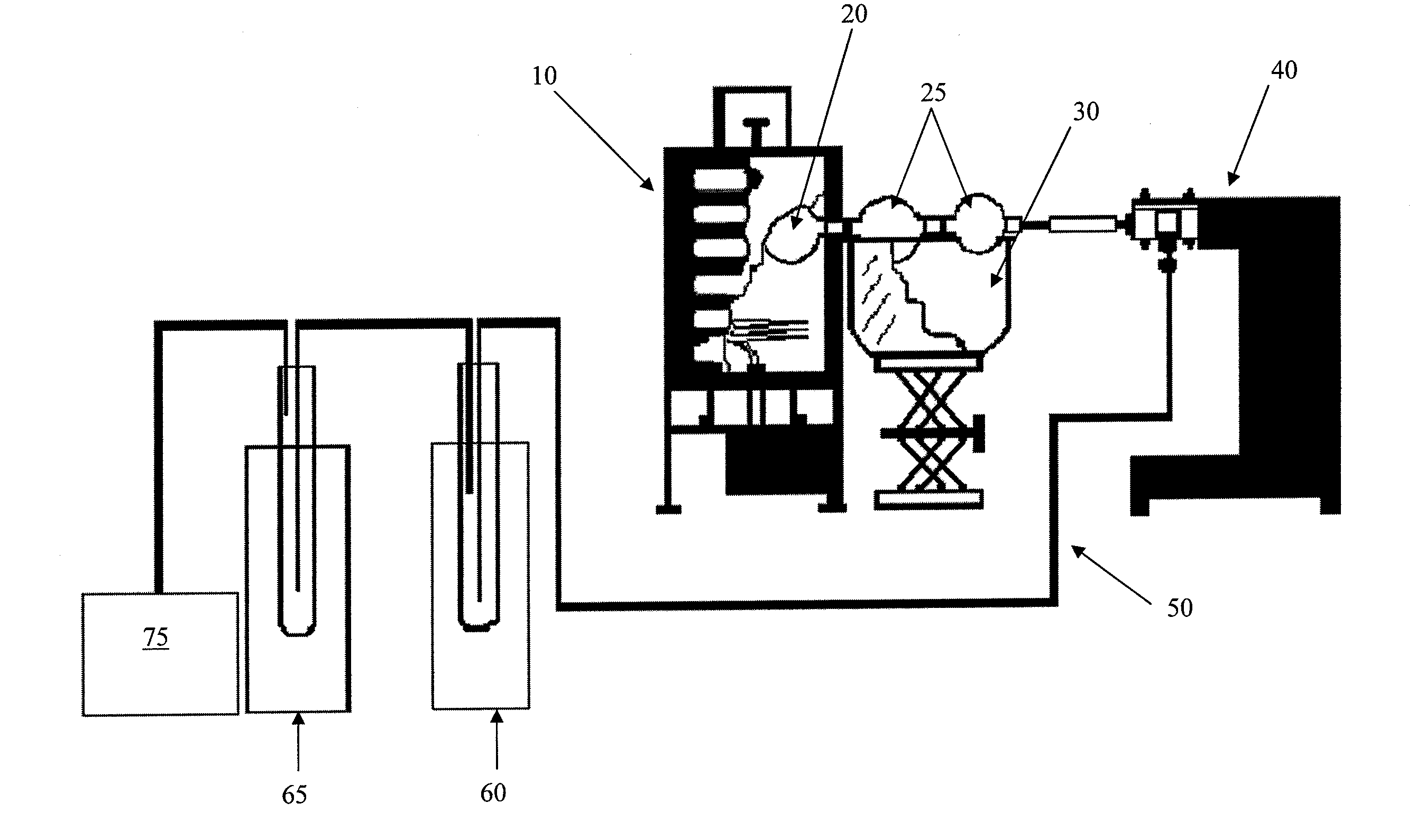

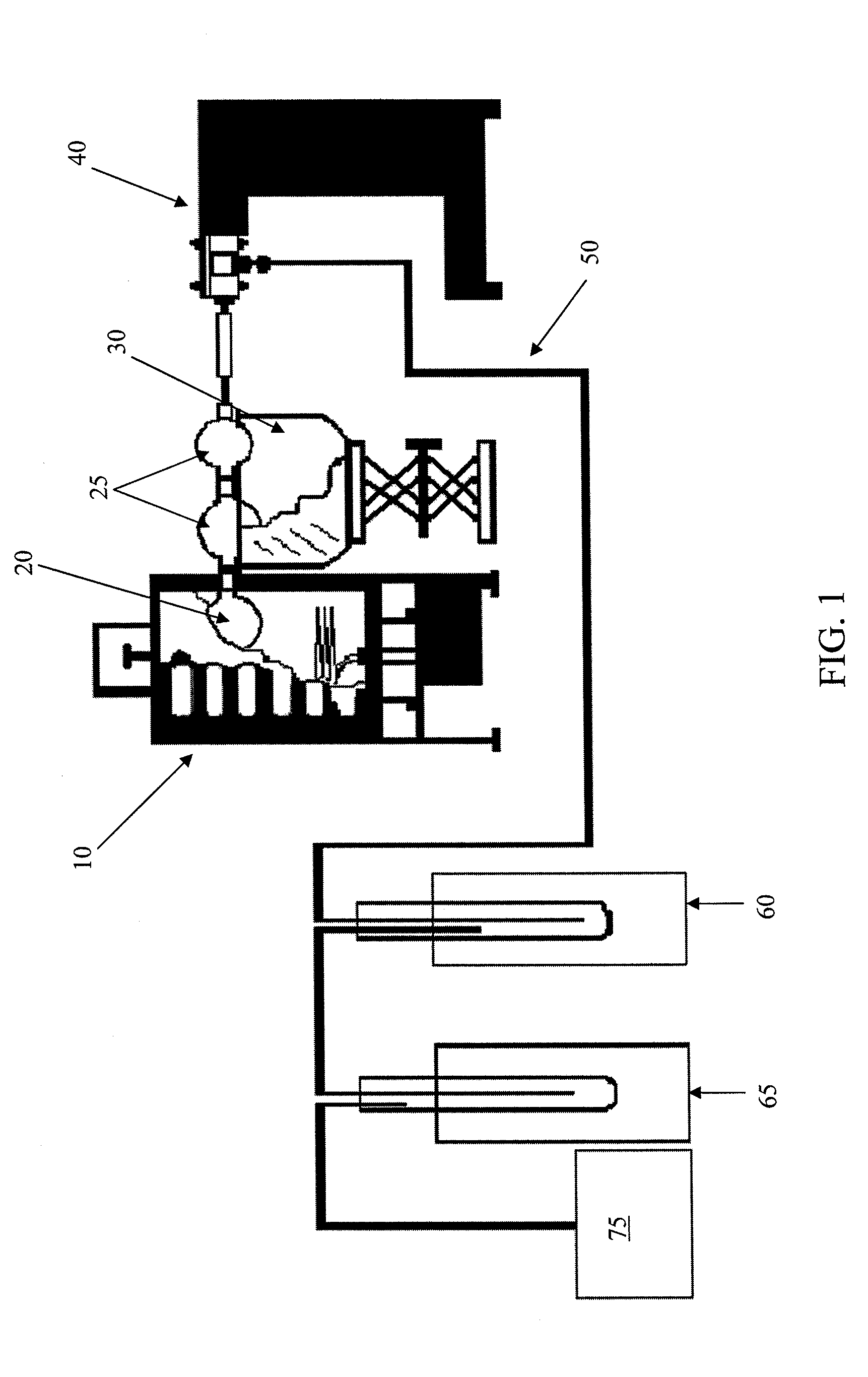

Product preparation and recovery from thermolysis of lignocellulosics in ionic liquids

InactiveUS20080185112A1Increase productionCellulosic pulp after-treatmentCoal charges mechanical treatmentCelluloseIonic liquid

The present invention provides methods for the thermolysis of lignocellulosic materials, such as wood, cellulose, lignin, and lignocellulose. In specific embodiments, the methods comprise combining the lignocellulosic material with an ionic liquid and subjecting the mixture of the lignocellulosic material and the ionic media to pyrolytic conditions to form a recoverable product, such as a commodity chemical.

Owner:NORTH CAROLINA STATE UNIV

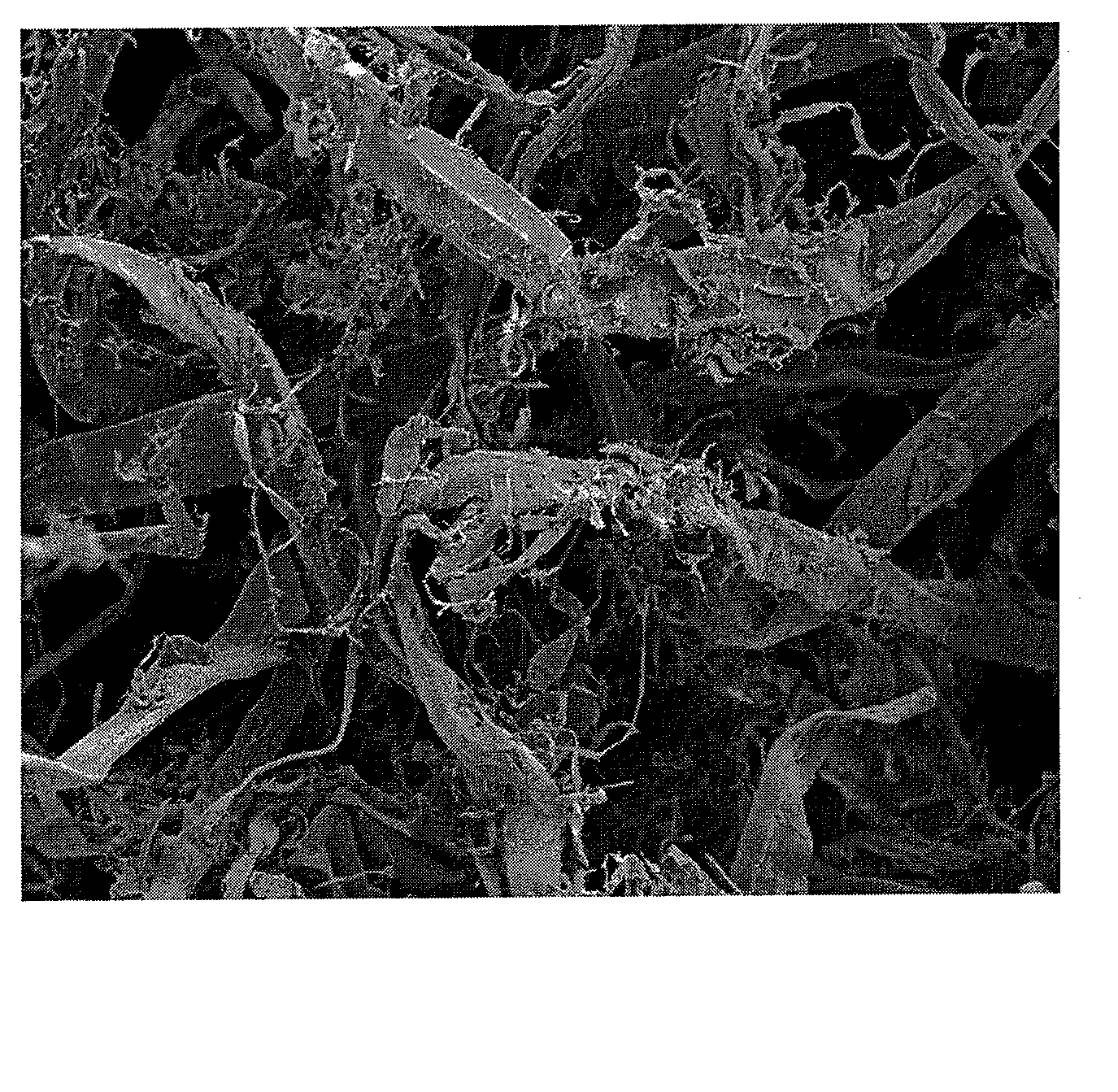

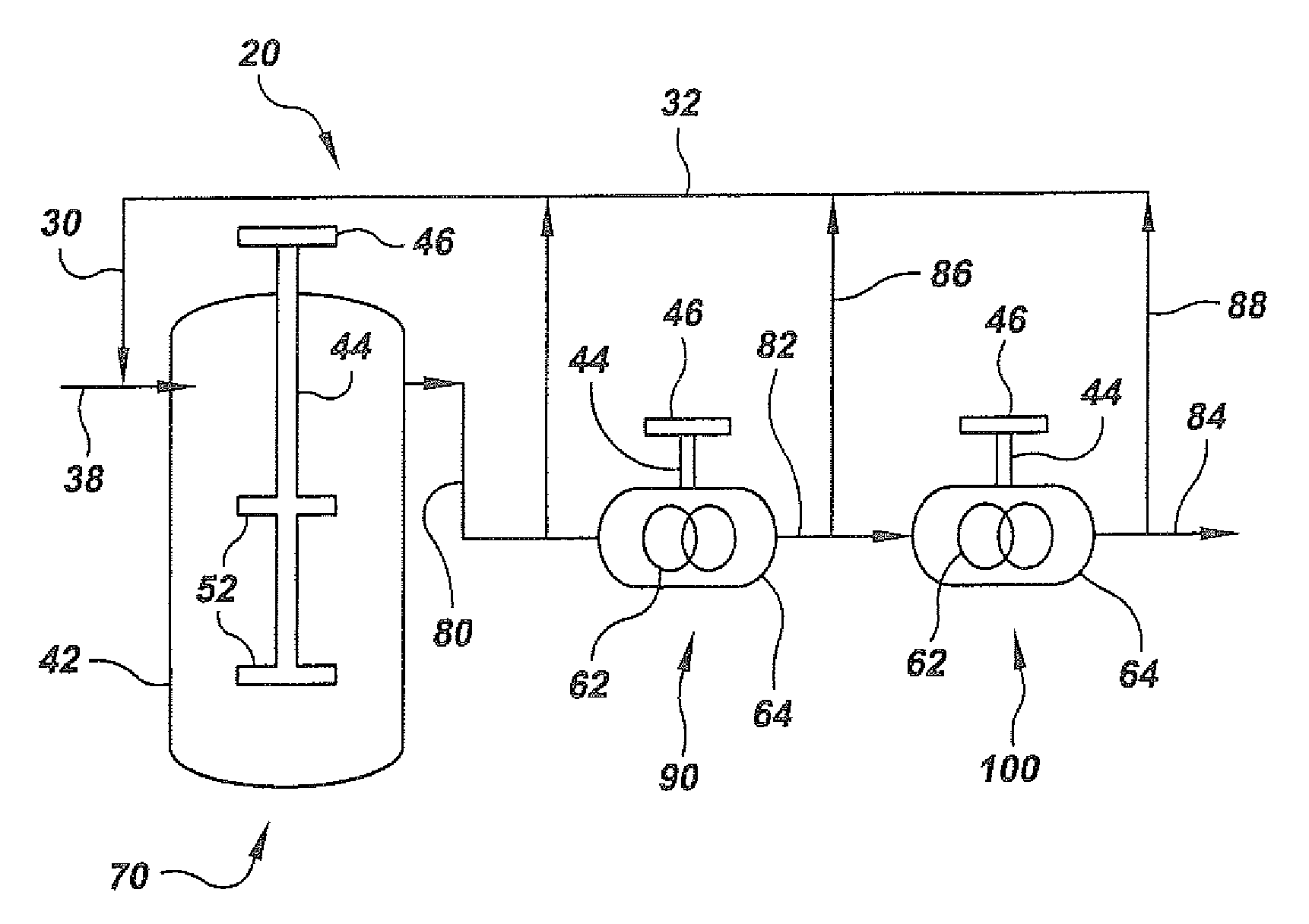

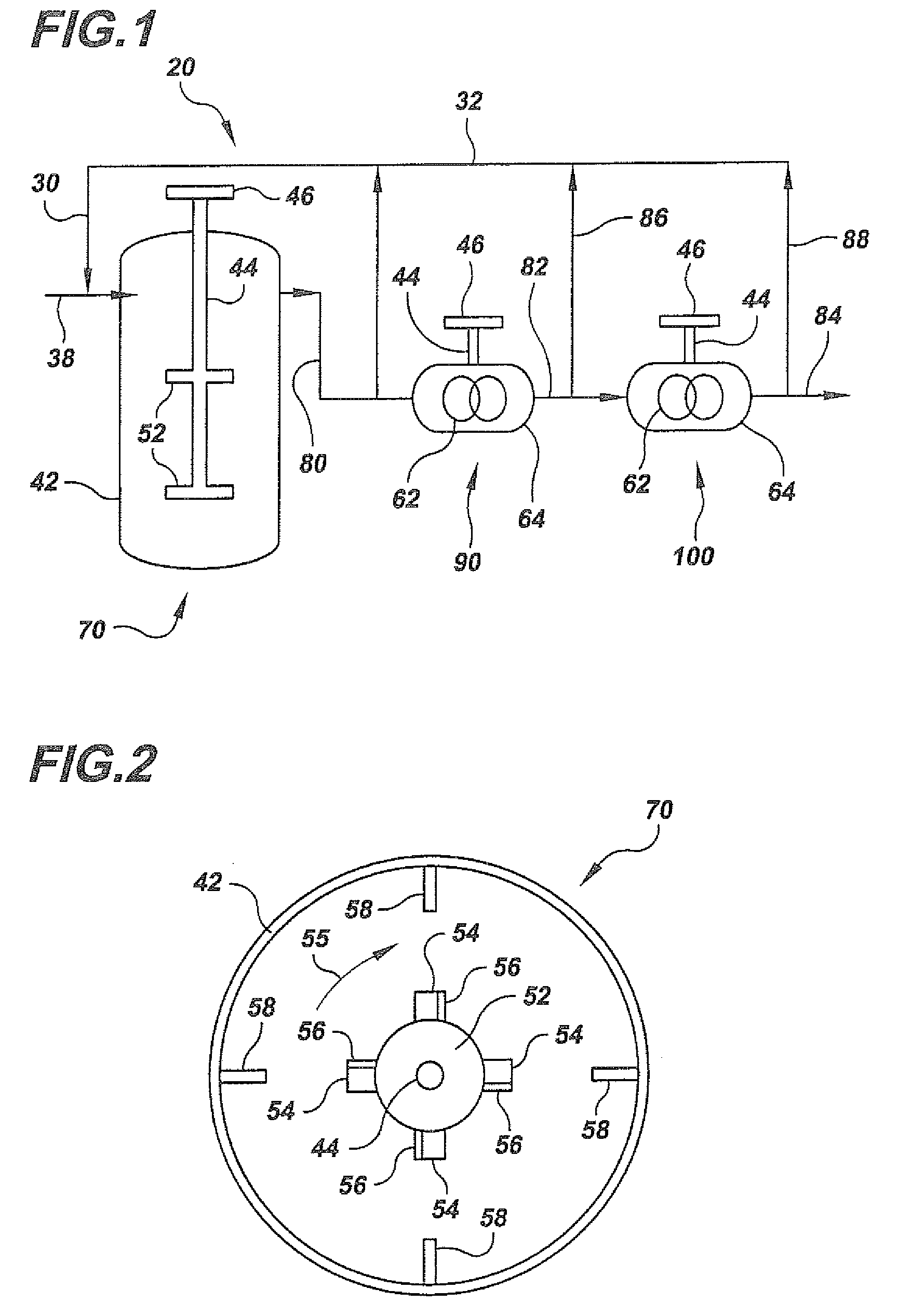

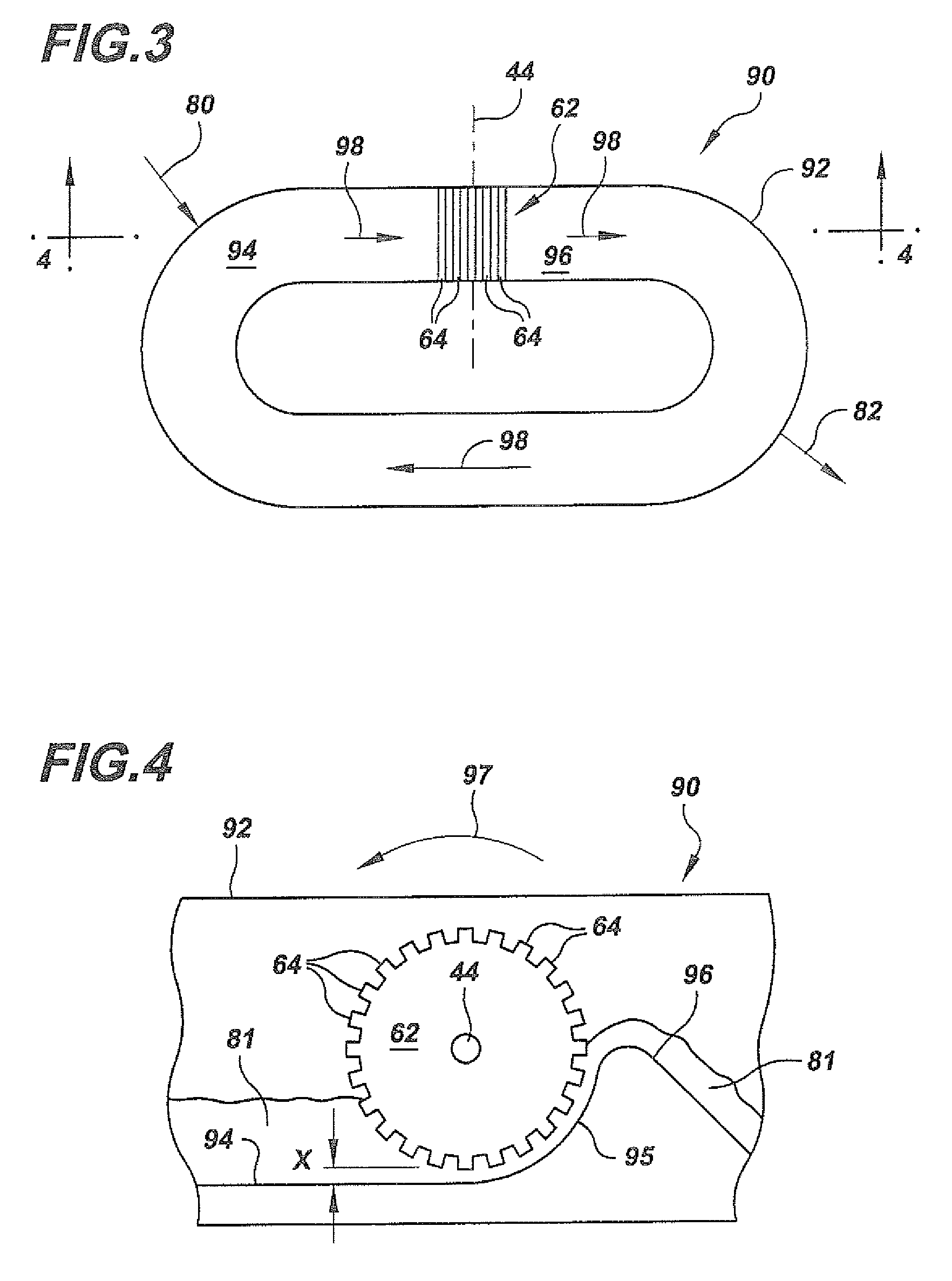

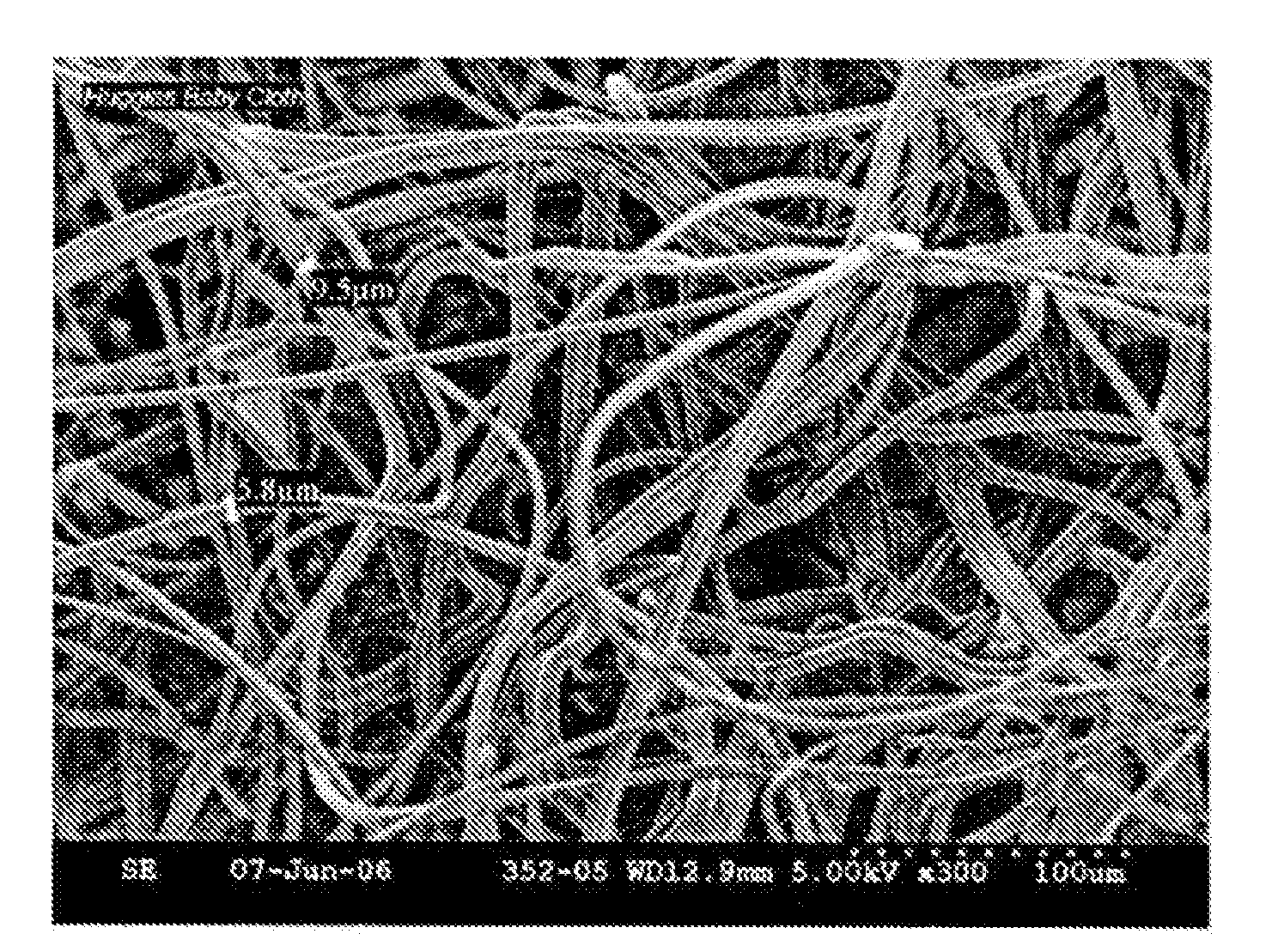

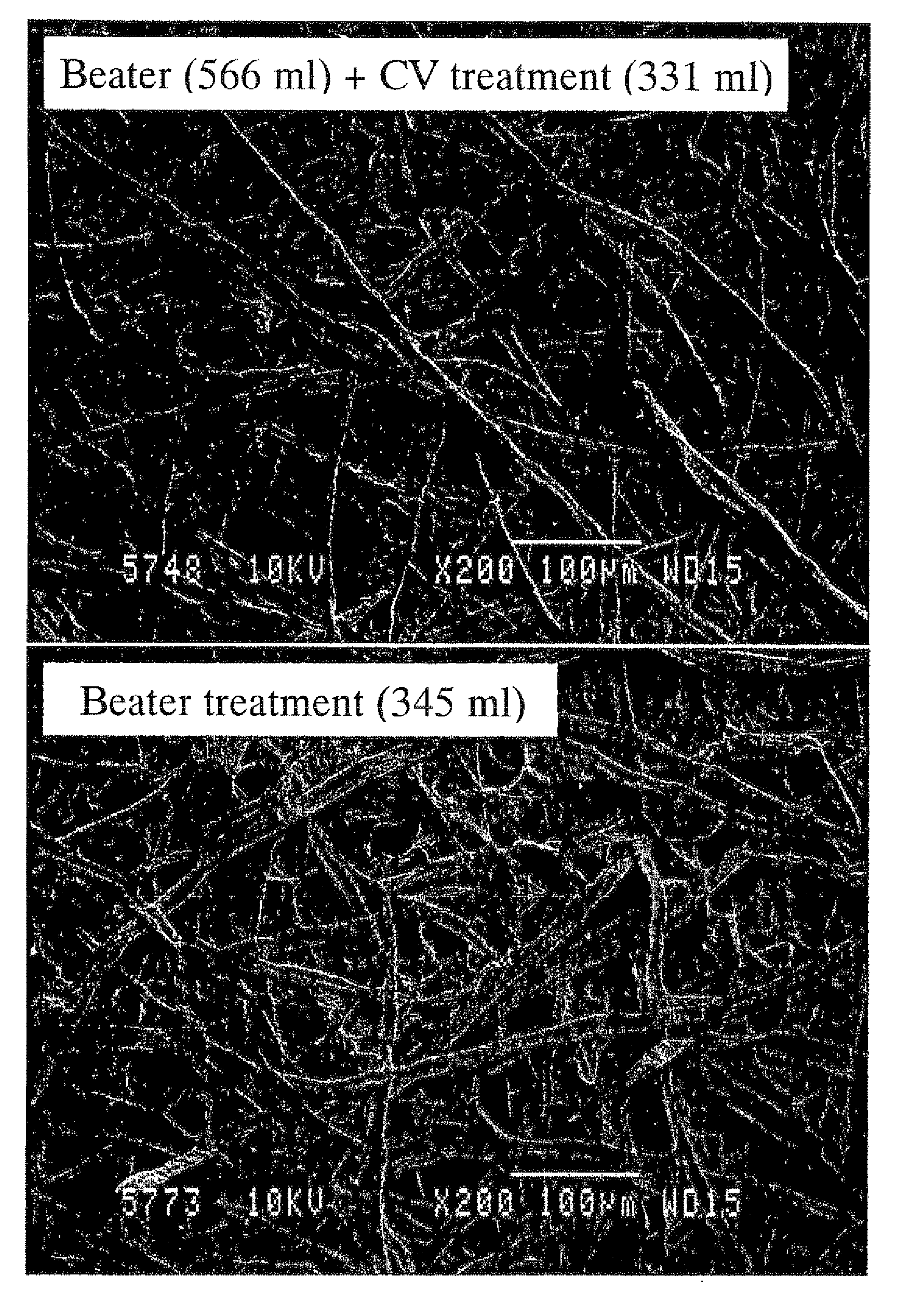

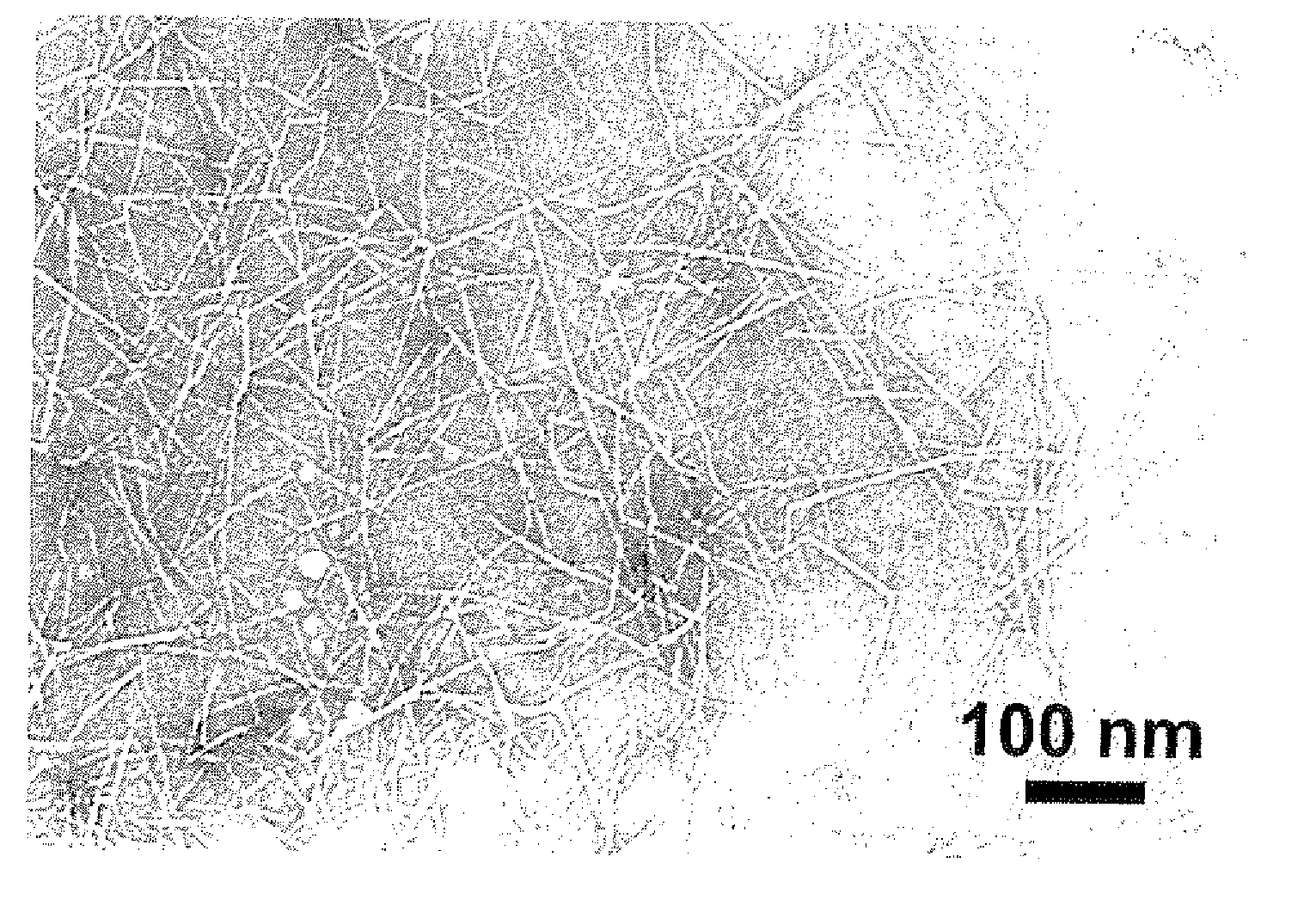

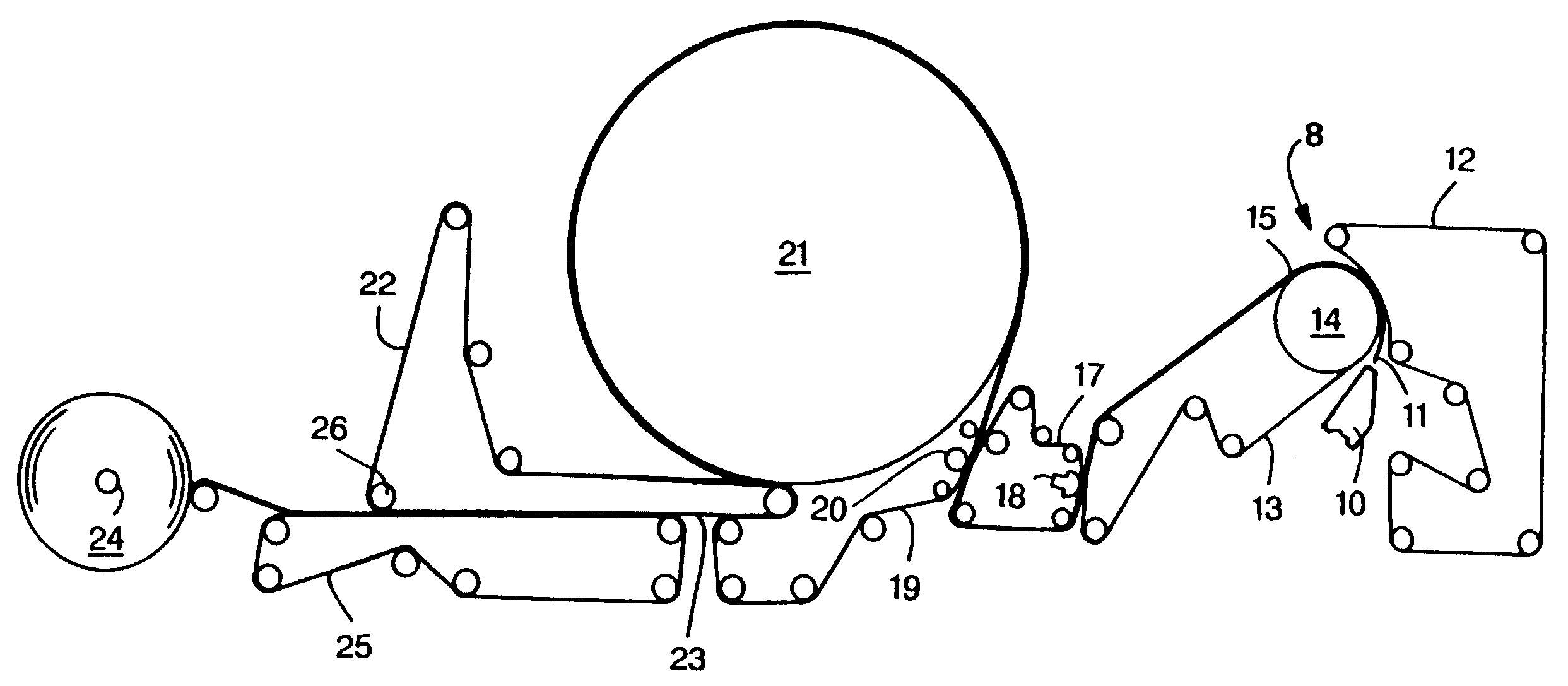

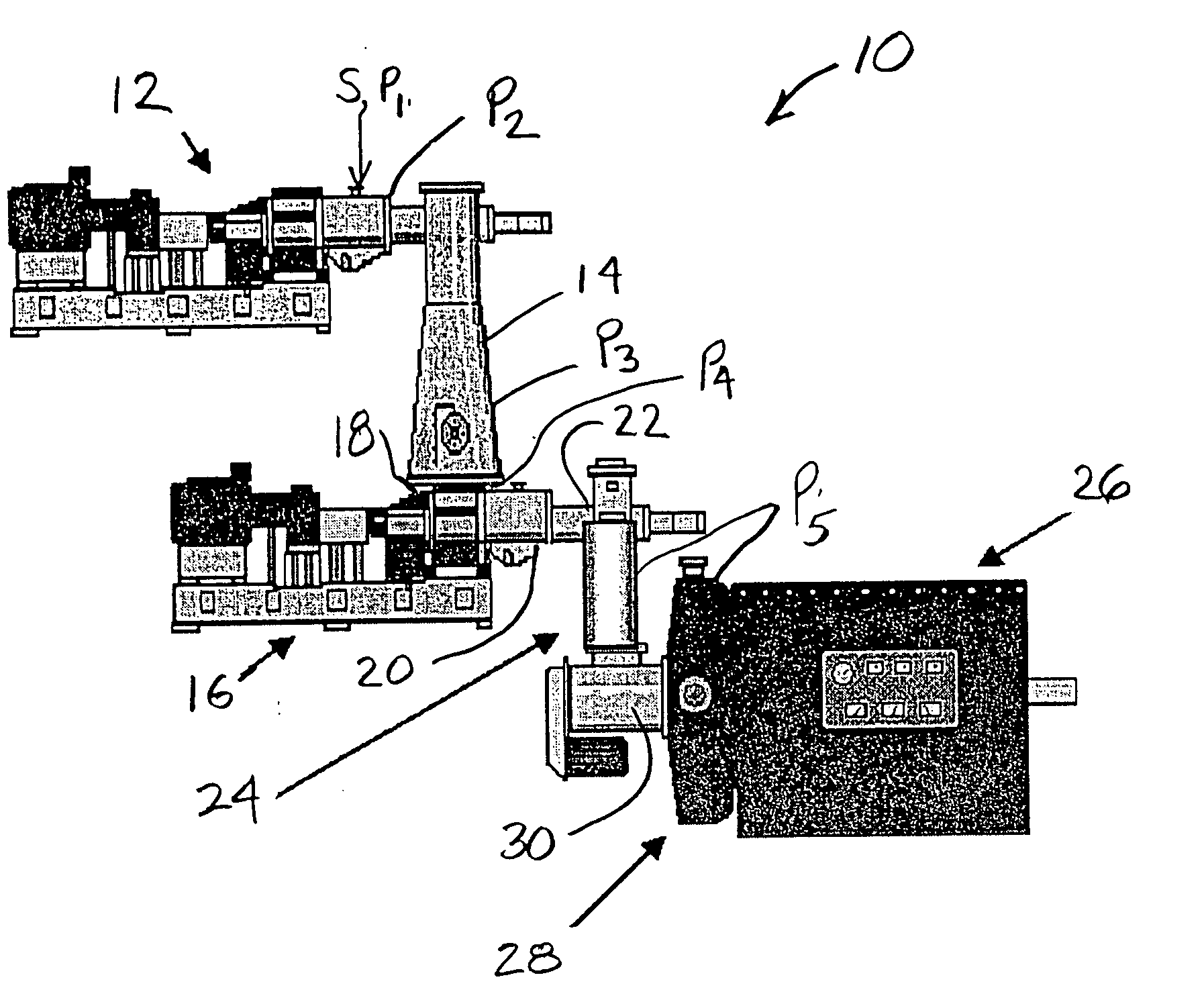

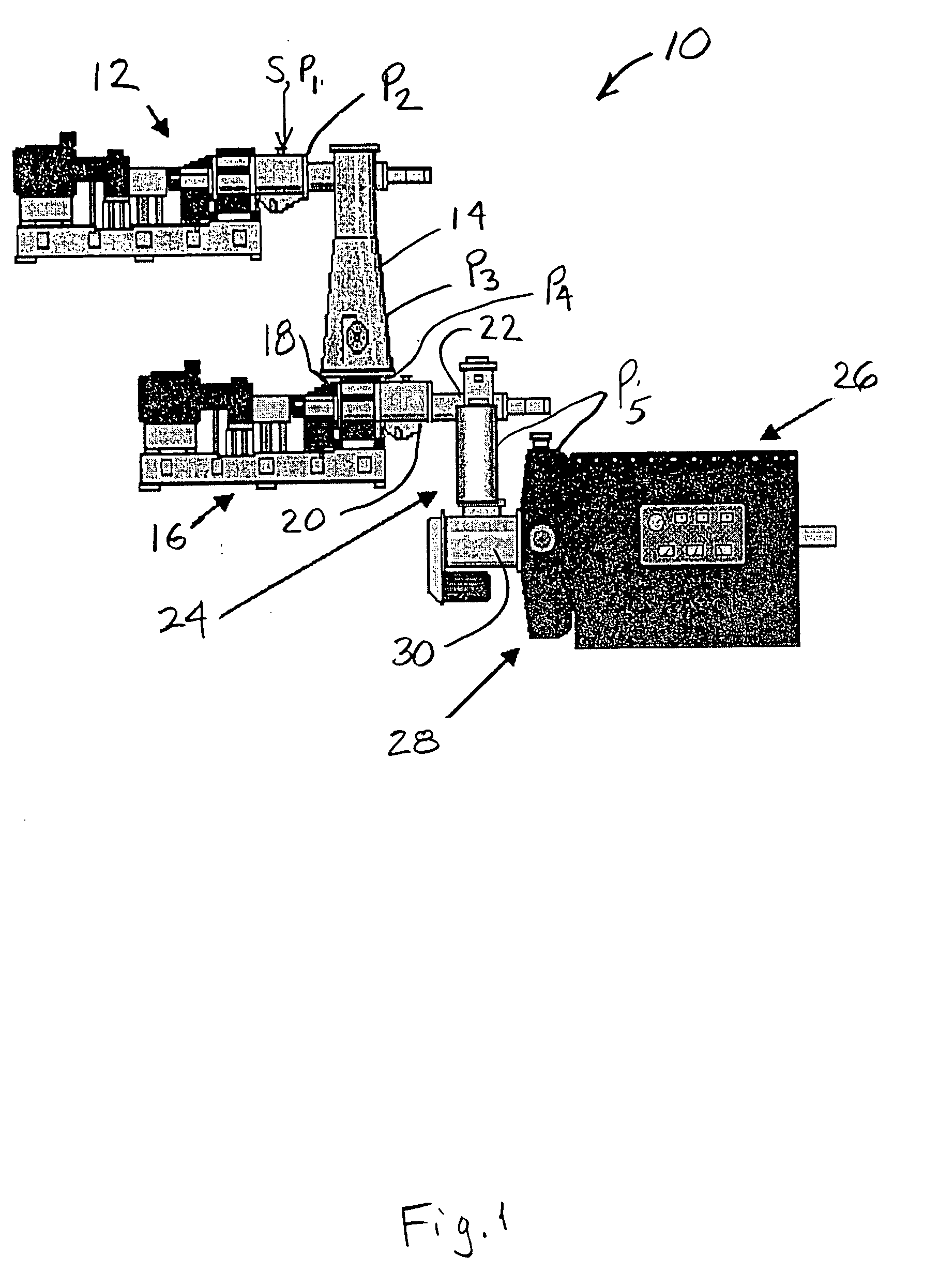

Process for producing nanofibers

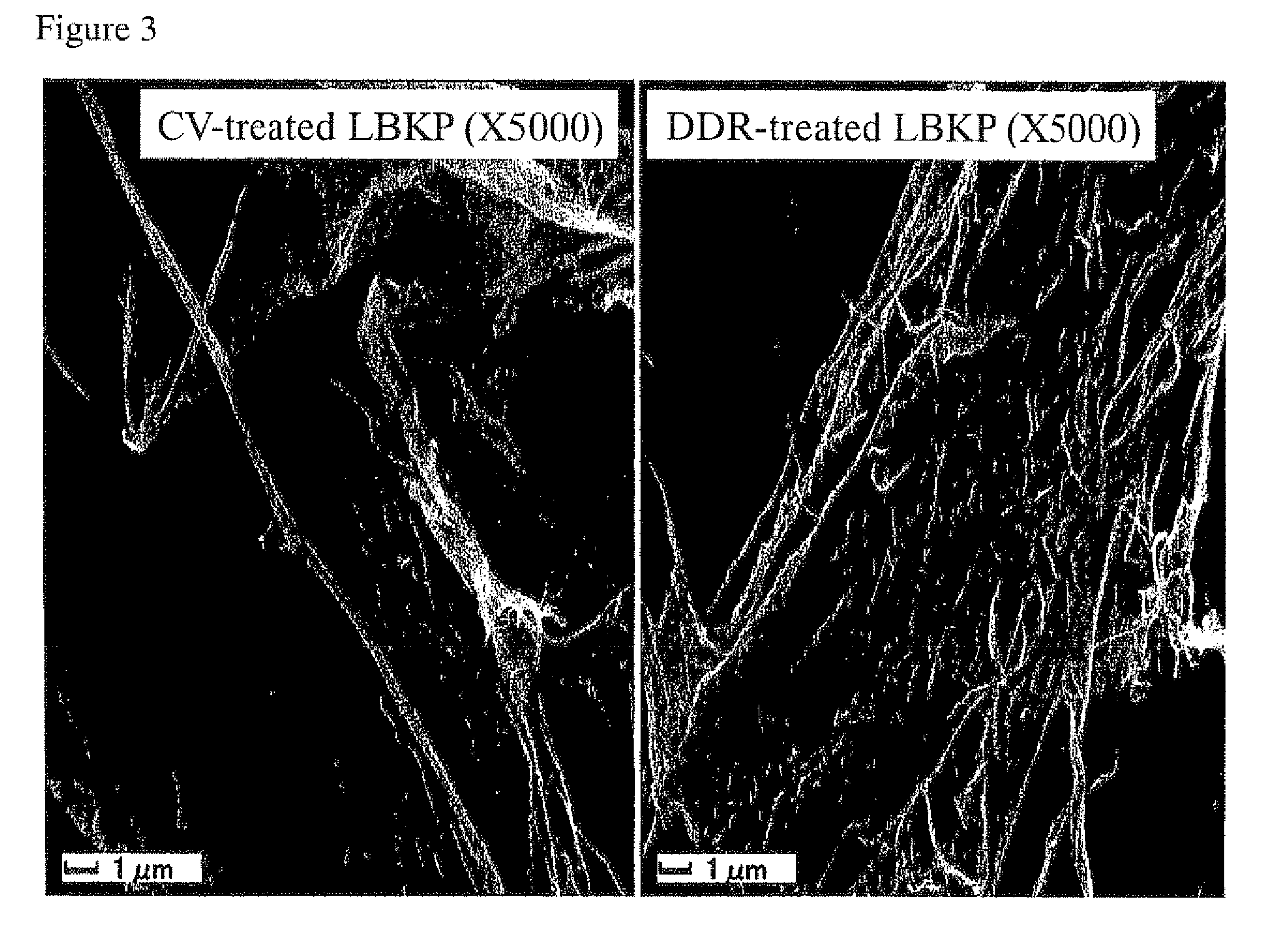

ActiveUS20080057307A1Good characterGreat flowabilityCellulosic pulp after-treatmentPulp beating methodsFiberNanofiber

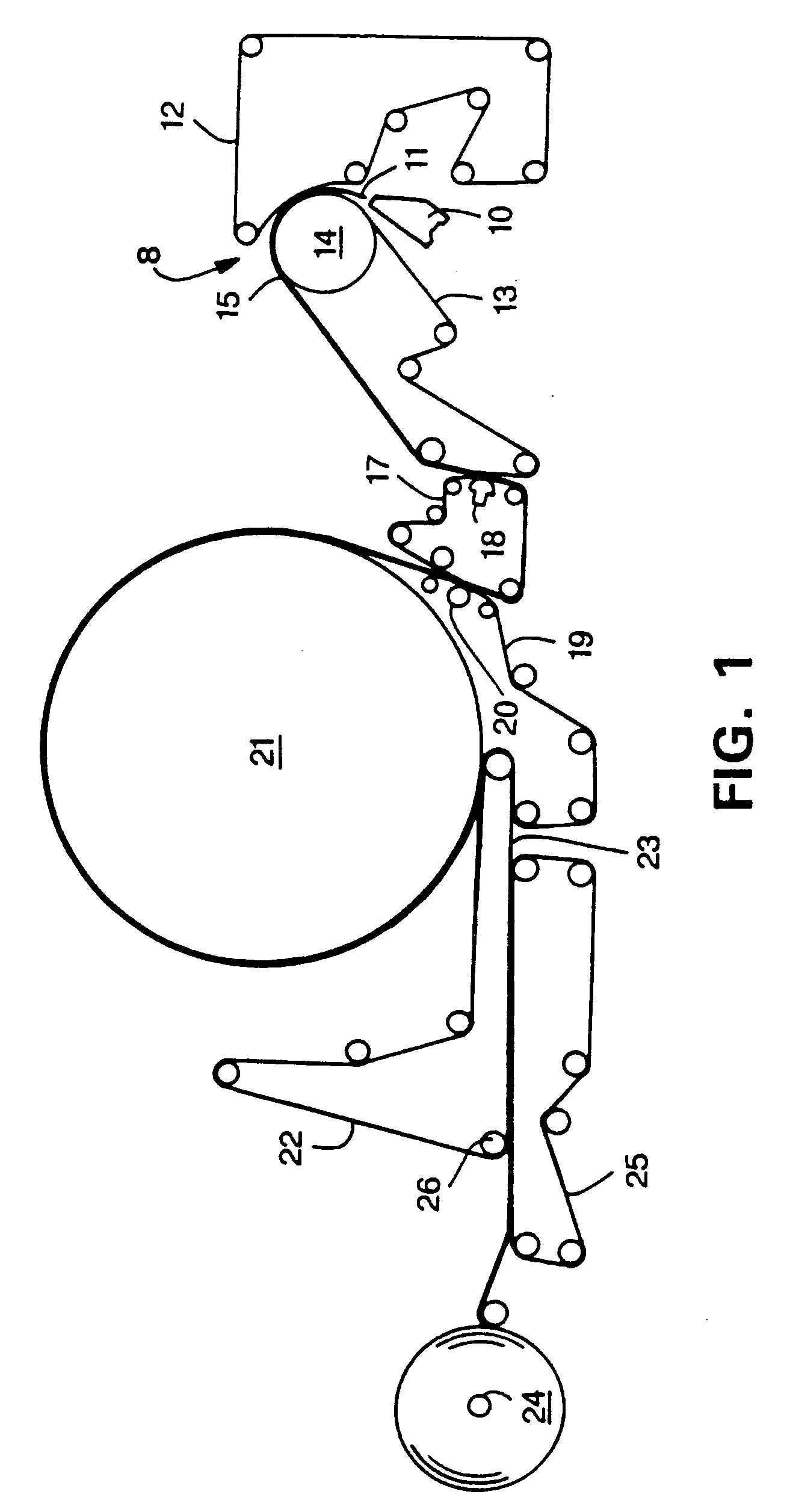

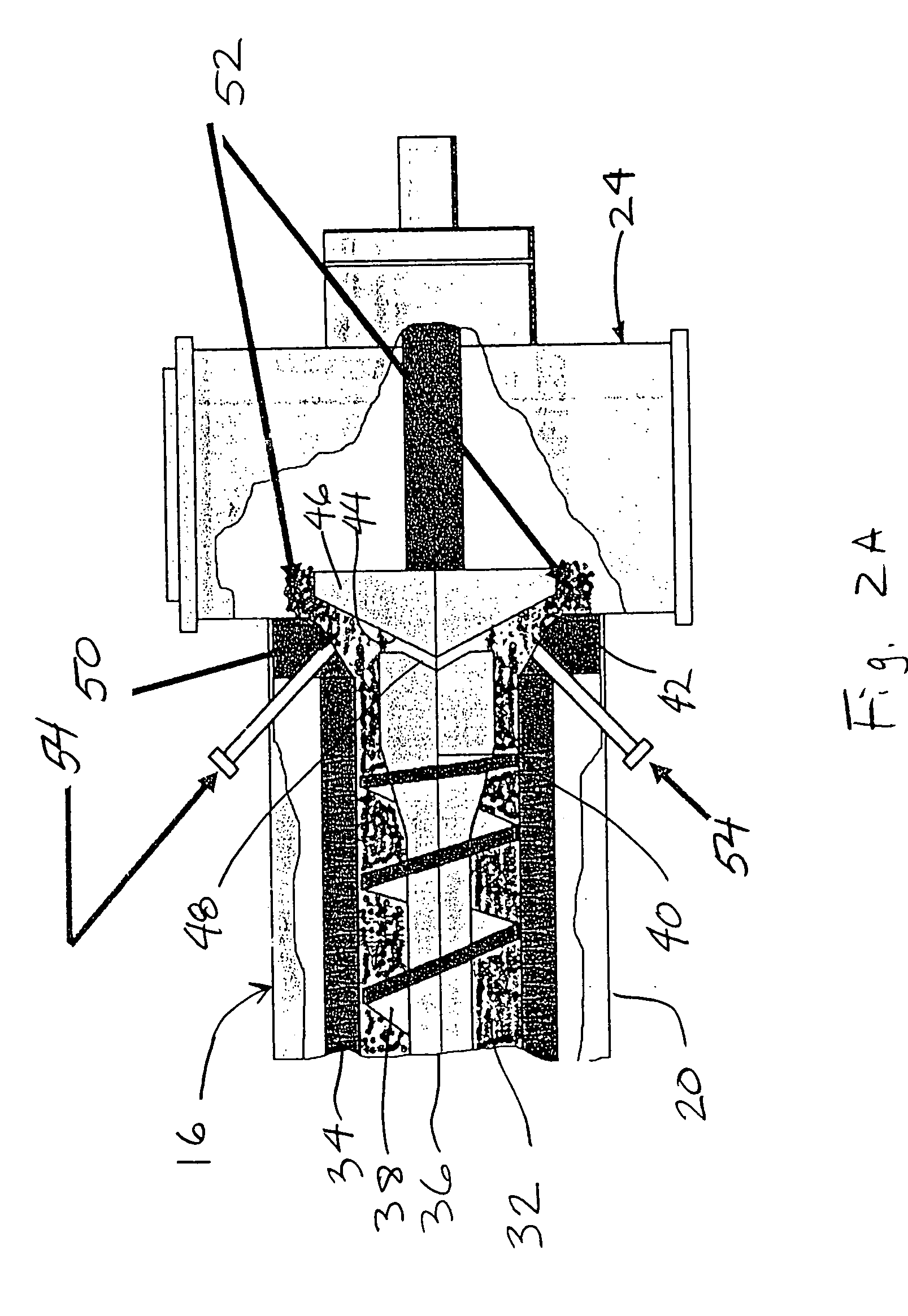

A process for making nanofibers includes preparing a fluid suspension of fibers, shear refining the fibers to create fibrillated fibers, and subsequently closed channel refining or homogenizing the fibrillated fibers to detach nanofibers from the fibrillated fibers. The shear refining of the fibers in the fluid suspension generates fiber cores having attached nanofibers. The closed channel refining or homogenizing of the fibrillated fibers is initially at a first shear rate and, subsequently, at a second, higher shear rate, to detach nanofibers from fiber cores and to create additional nanofibers from the fiber cores. The fiber suspension may flow continuously from the shear refining to the closed channel refining or homogenizing, and include controlling the rate of flow of the fiber suspension from the shear refining to the closed channel refining or homogenizing.

Owner:KX TECH LLC (DW US)

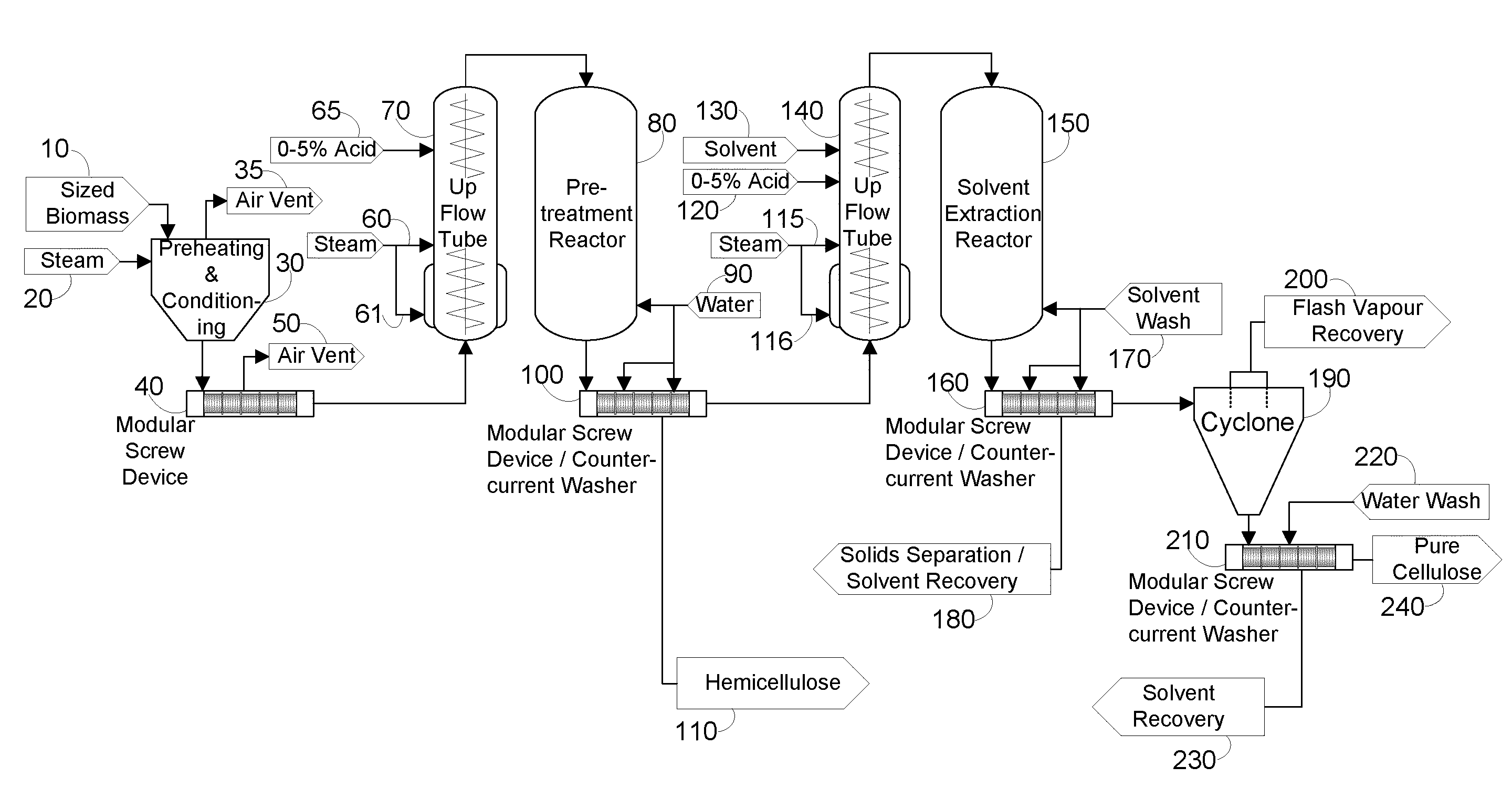

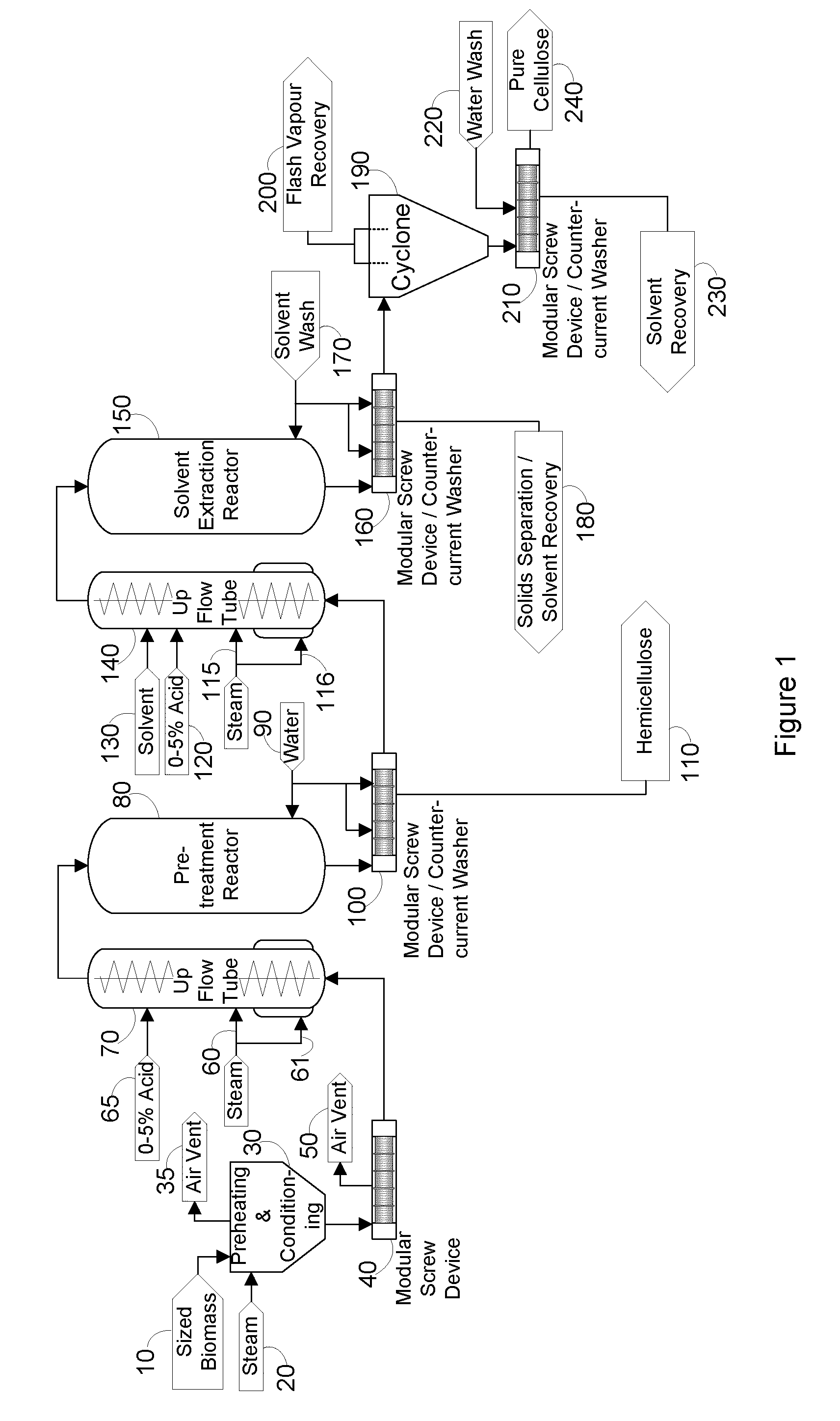

Separation of reactive cellulose from lignocellulosic biomass with high lignin content

InactiveUS20100269990A1Reduce inhibitionReduce extractionCellulosic pulp after-treatmentBiofuelsFiberLignocellulosic biomass

A process for separating the components of lignocellulosic biomass for the purpose of producing a pure reactive cellulose is disclosed. The process has two stages. In the first stage, the lignocellulosic biomass is pretreated with steam, with or without an acid catalyst, and then pressed, with or without the presence of an eluent, to remove hemicellulose and other impurities. In the second stage, the pretreated biomass is extracted with a solvent such as ethanol with or without acid catalysts in order to remove lignin and release a purified cellulose stream. The extracted cellulose is then rapidly decompressed to rupture the fibrous structure. The process provides a purified cellulose stream that is relatively easy to hydrolyze with enzymes and ferment to biofuels and other chemicals such as ethanol.

Owner:GREENFIELD SPECIALTY ALCOHOLS

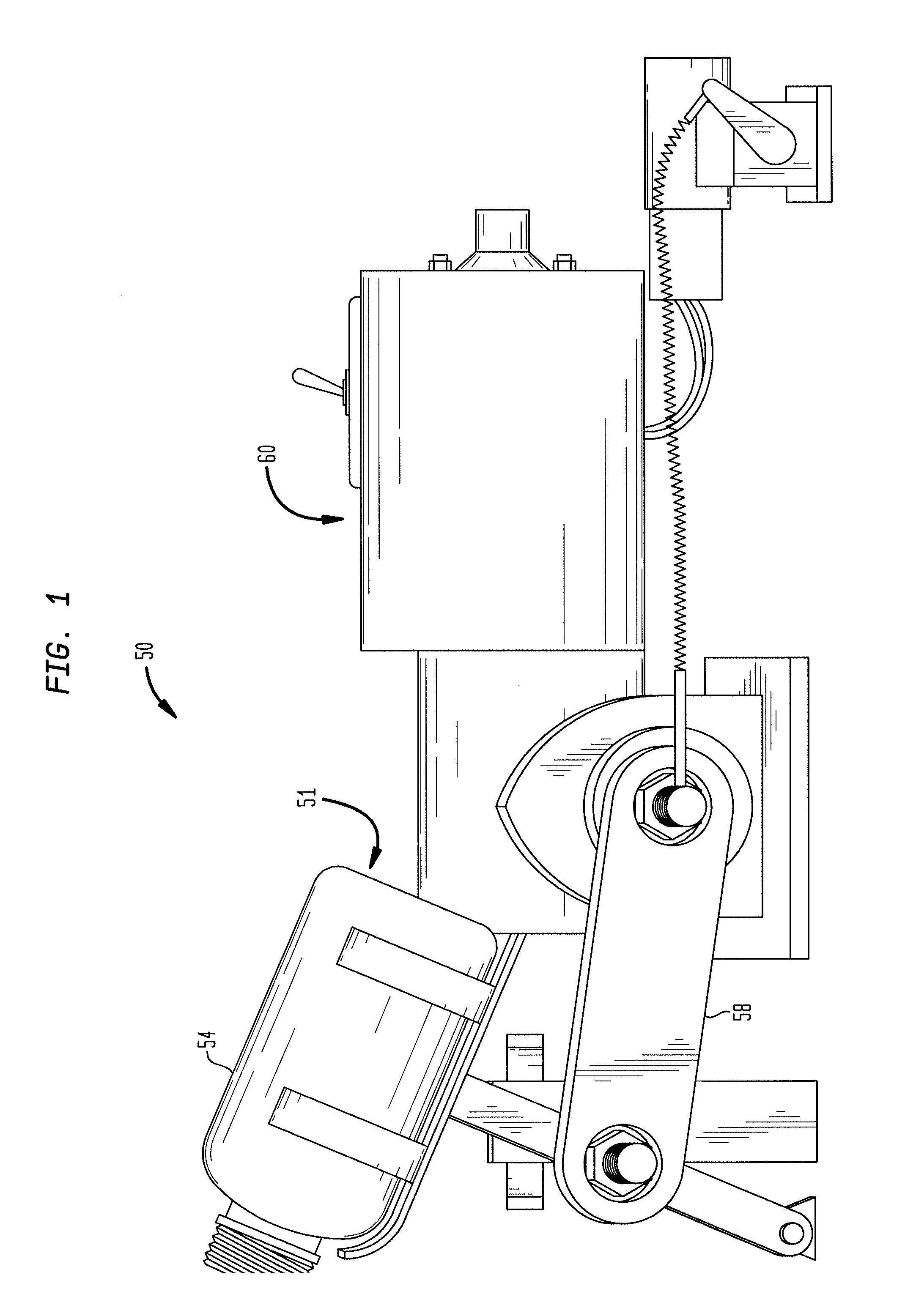

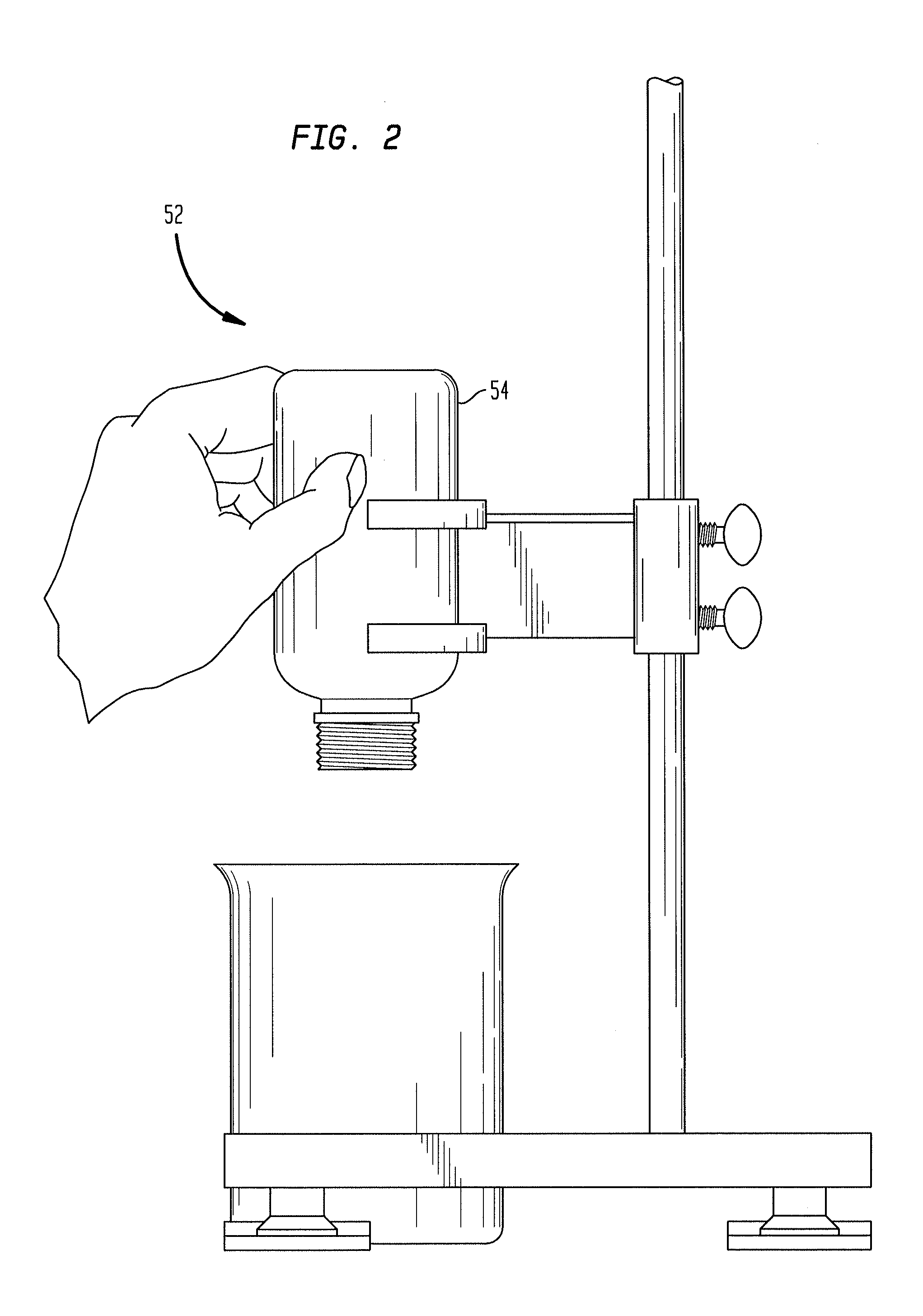

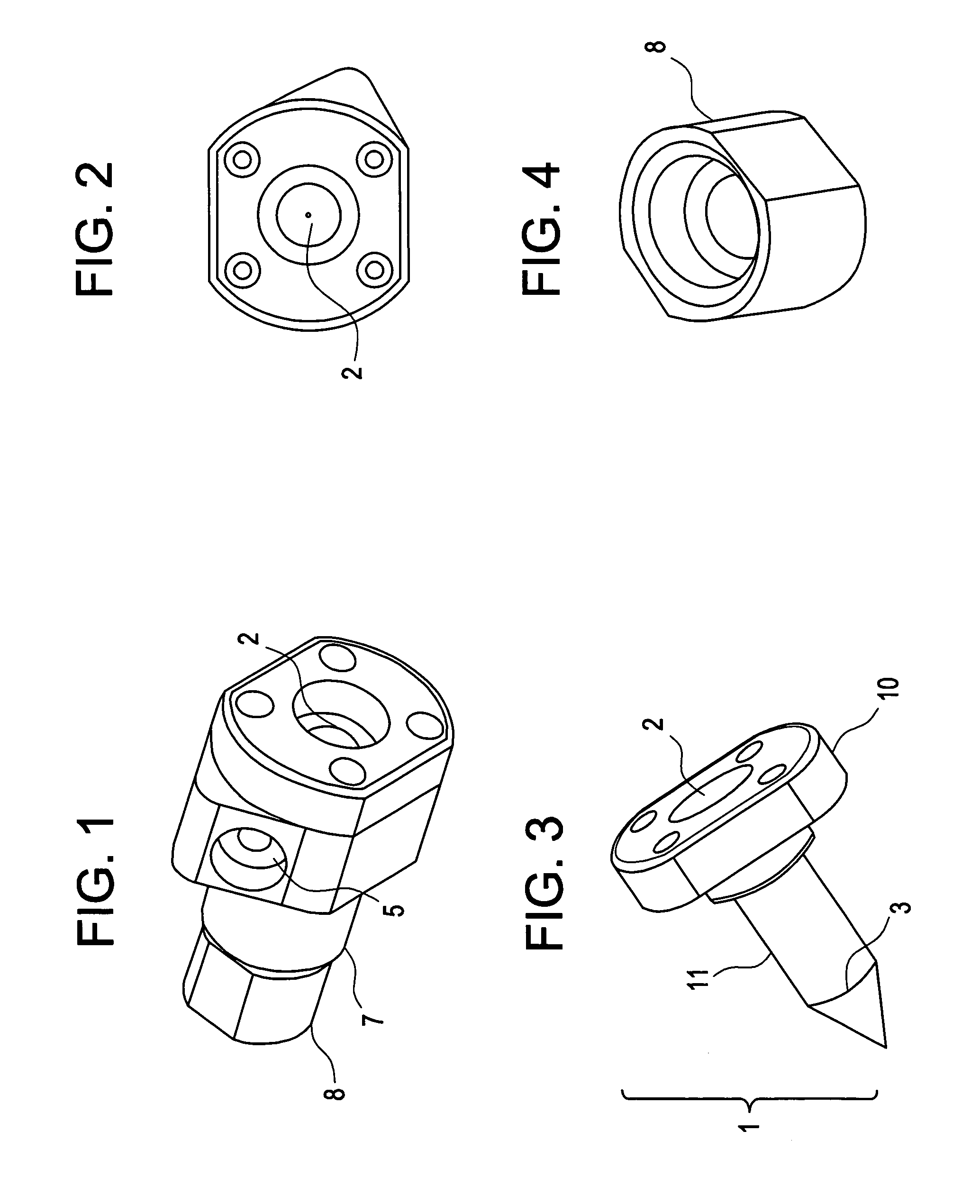

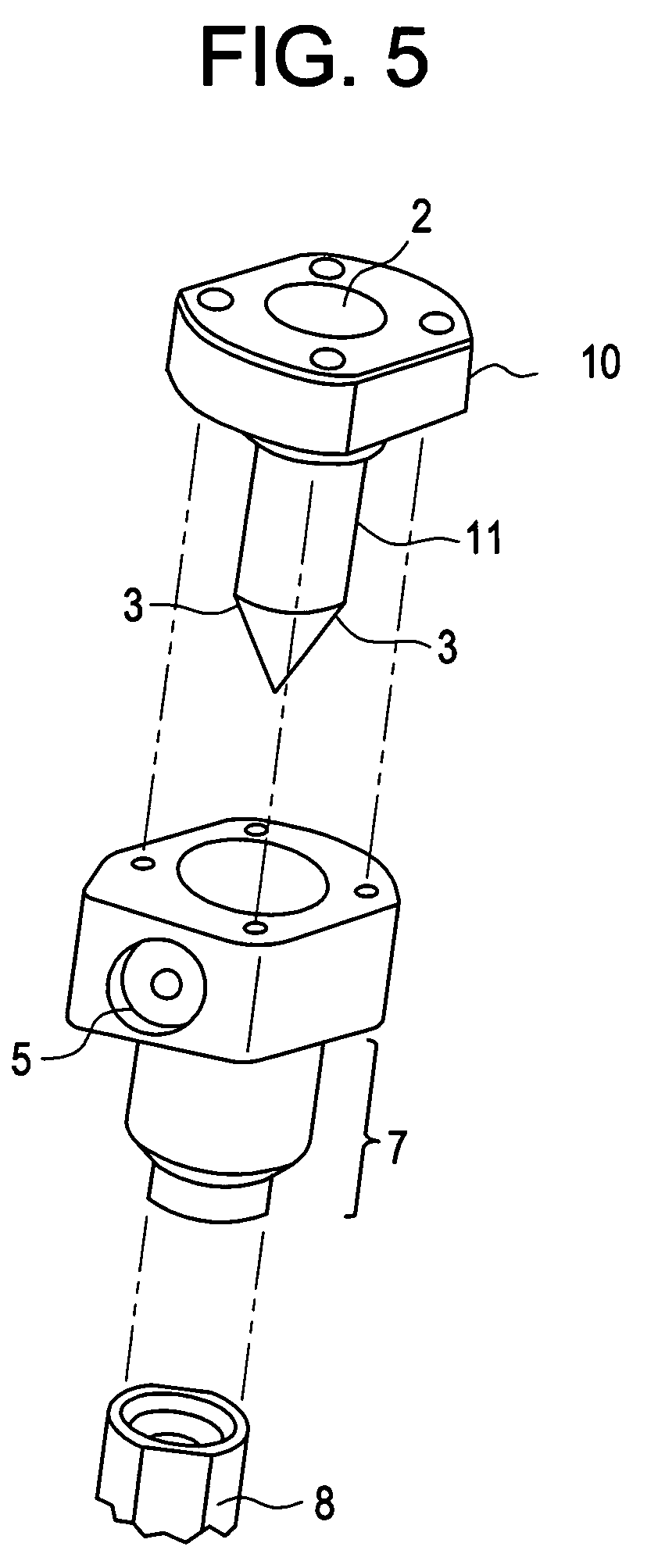

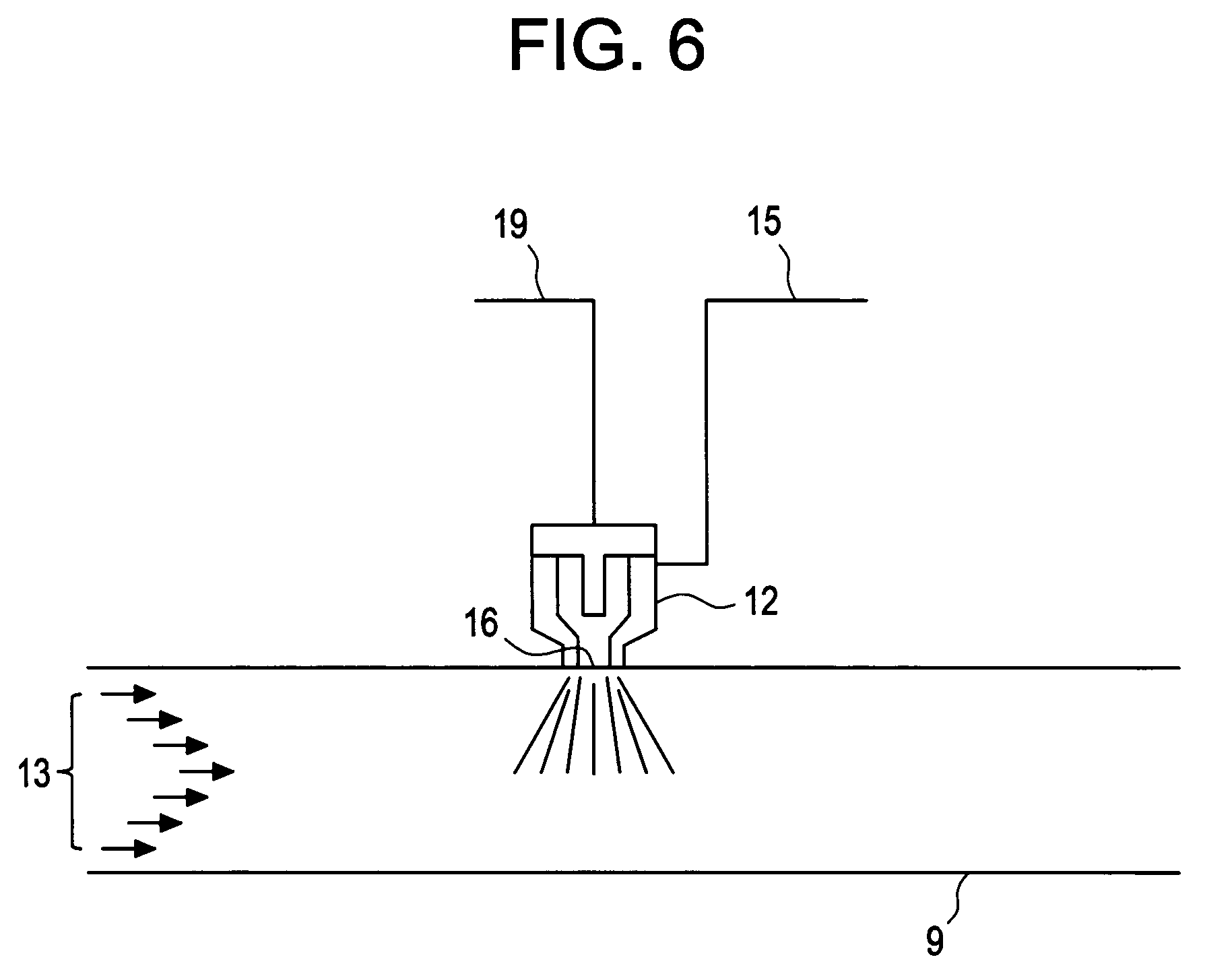

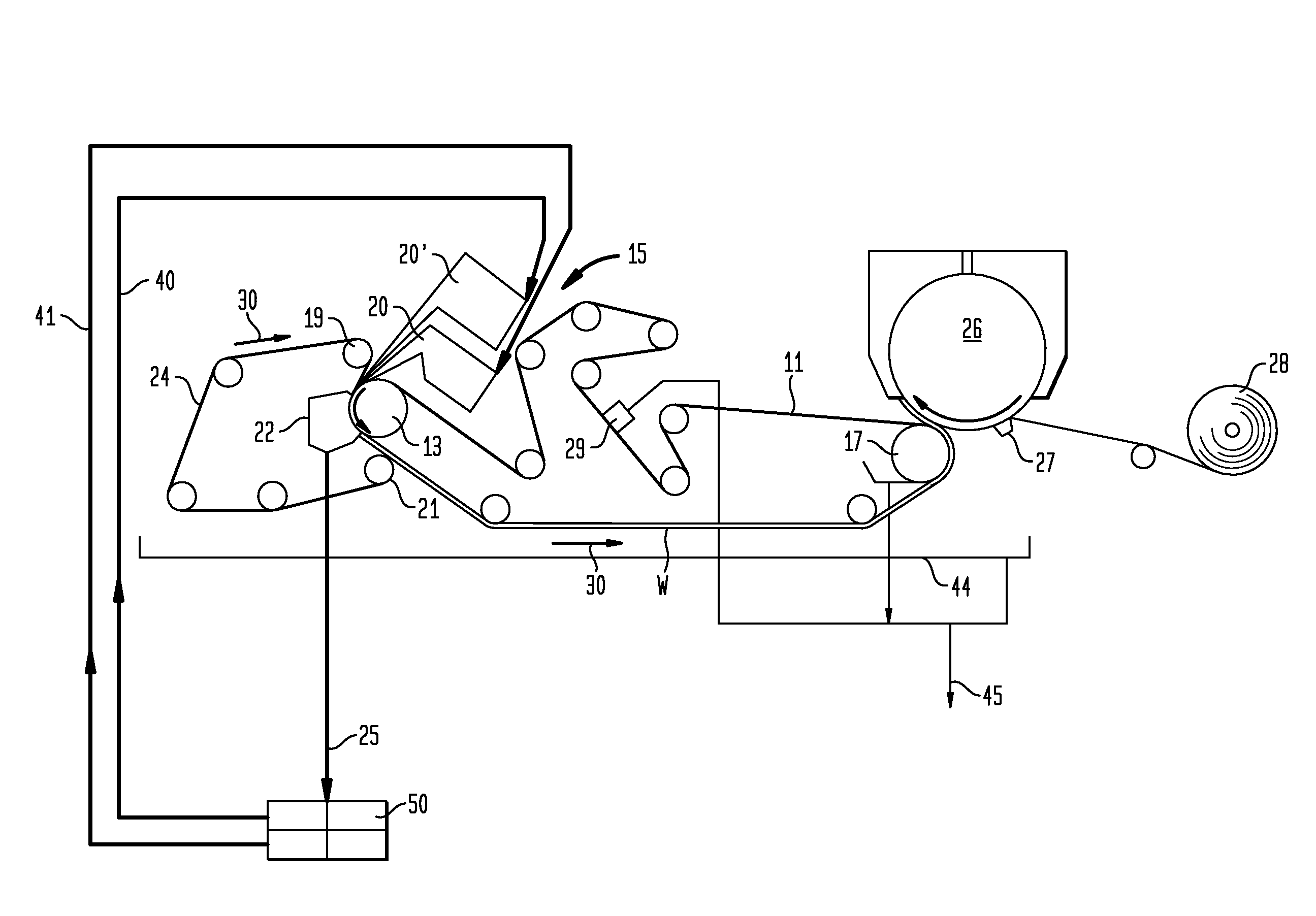

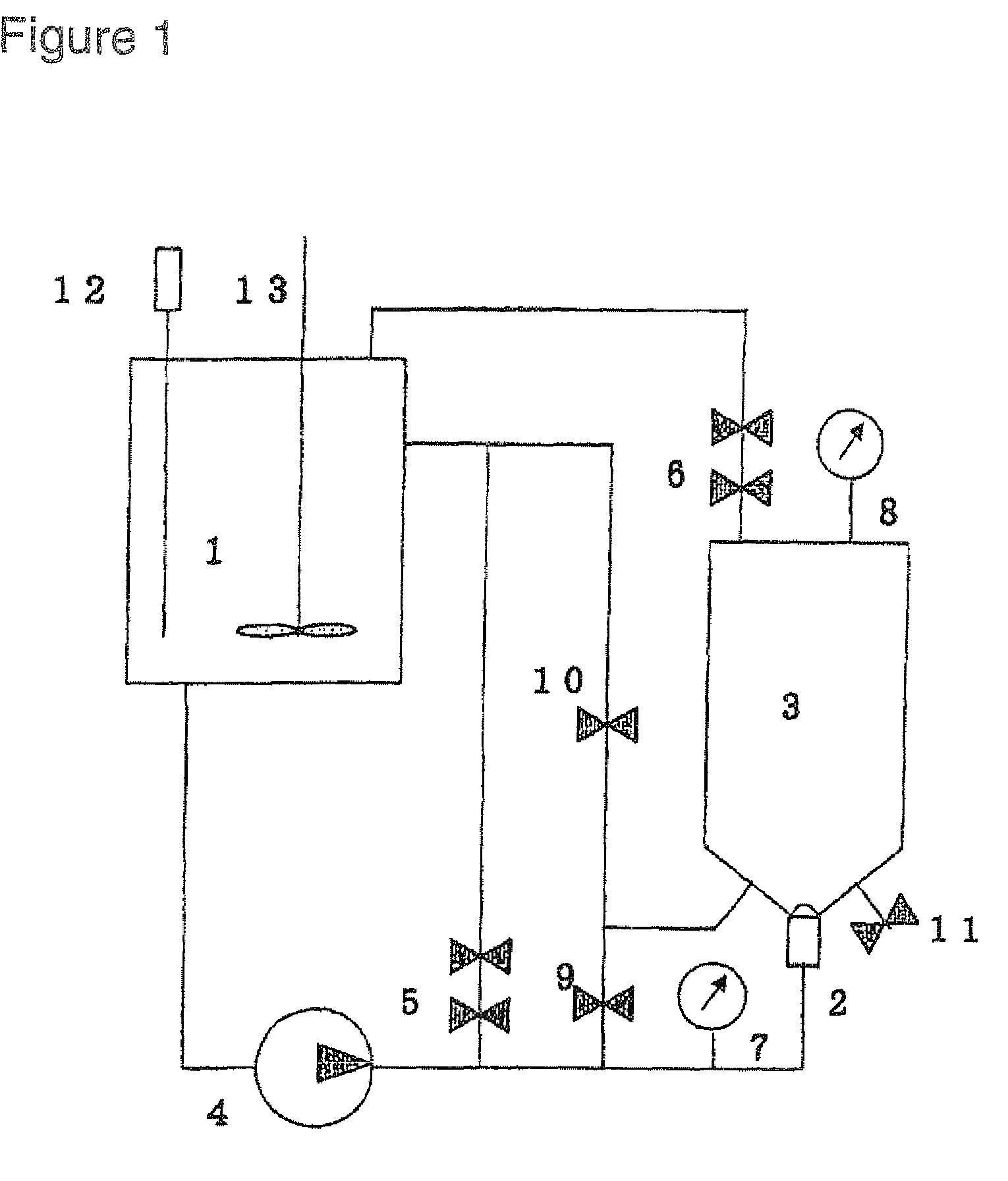

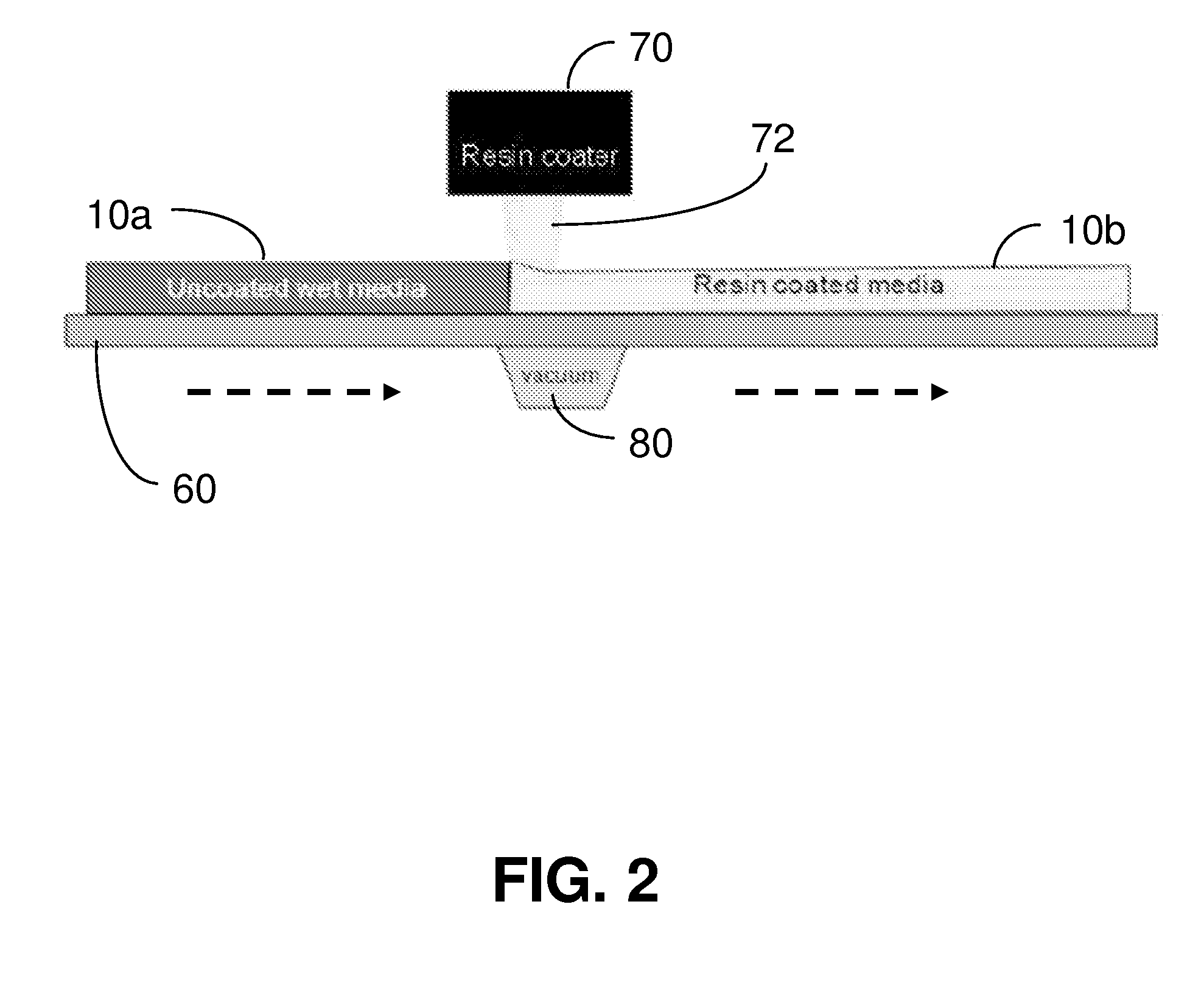

Method and arrangement for feeding chemicals into a process stream

An apparatus for feeding one or more chemicals into a process stream of a papermaking process is disclosed, as well as a method of utilizing the apparatus for feeding one or more chemicals into a process stream is disclosed.

Owner:ECOLAB USA INC

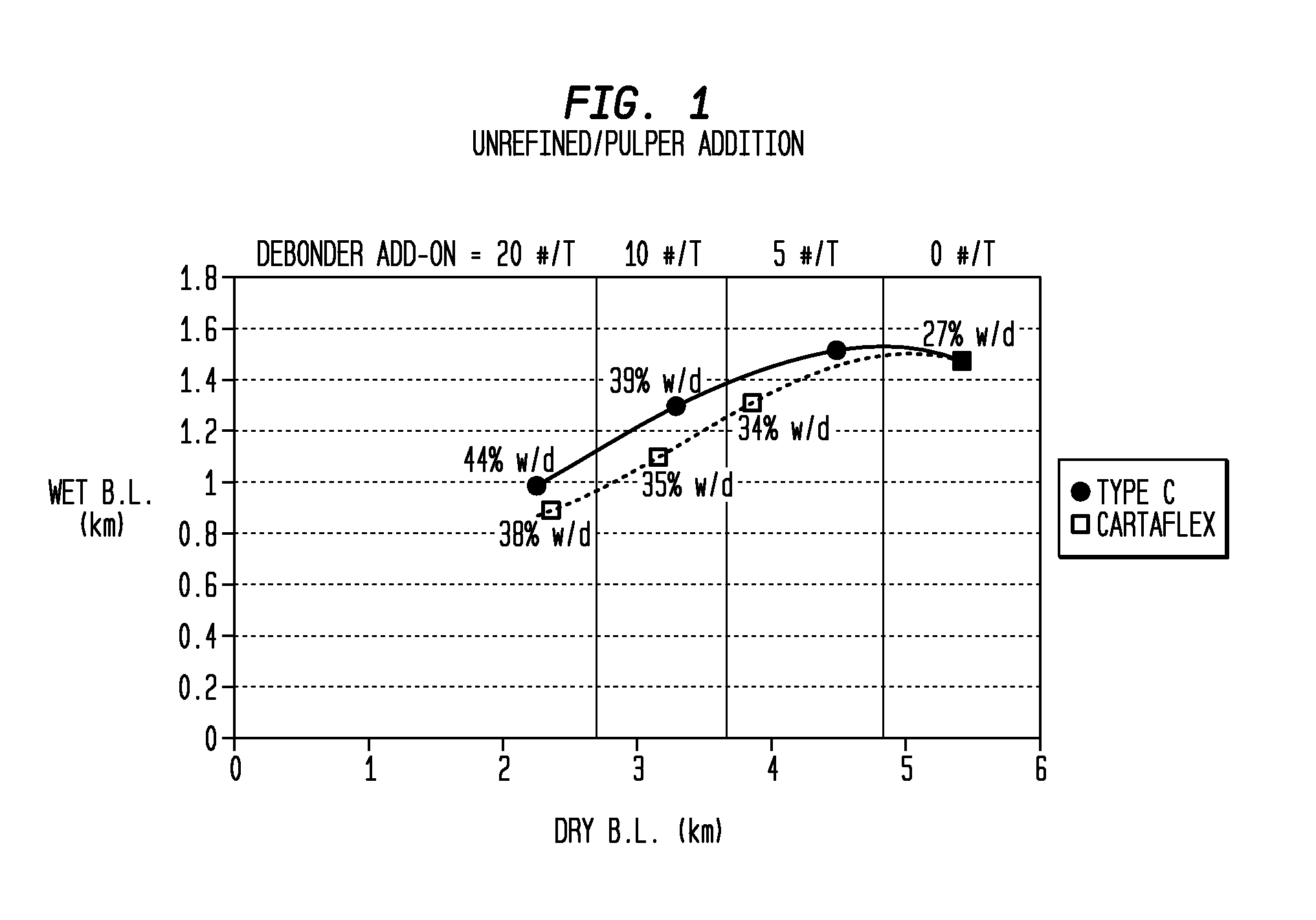

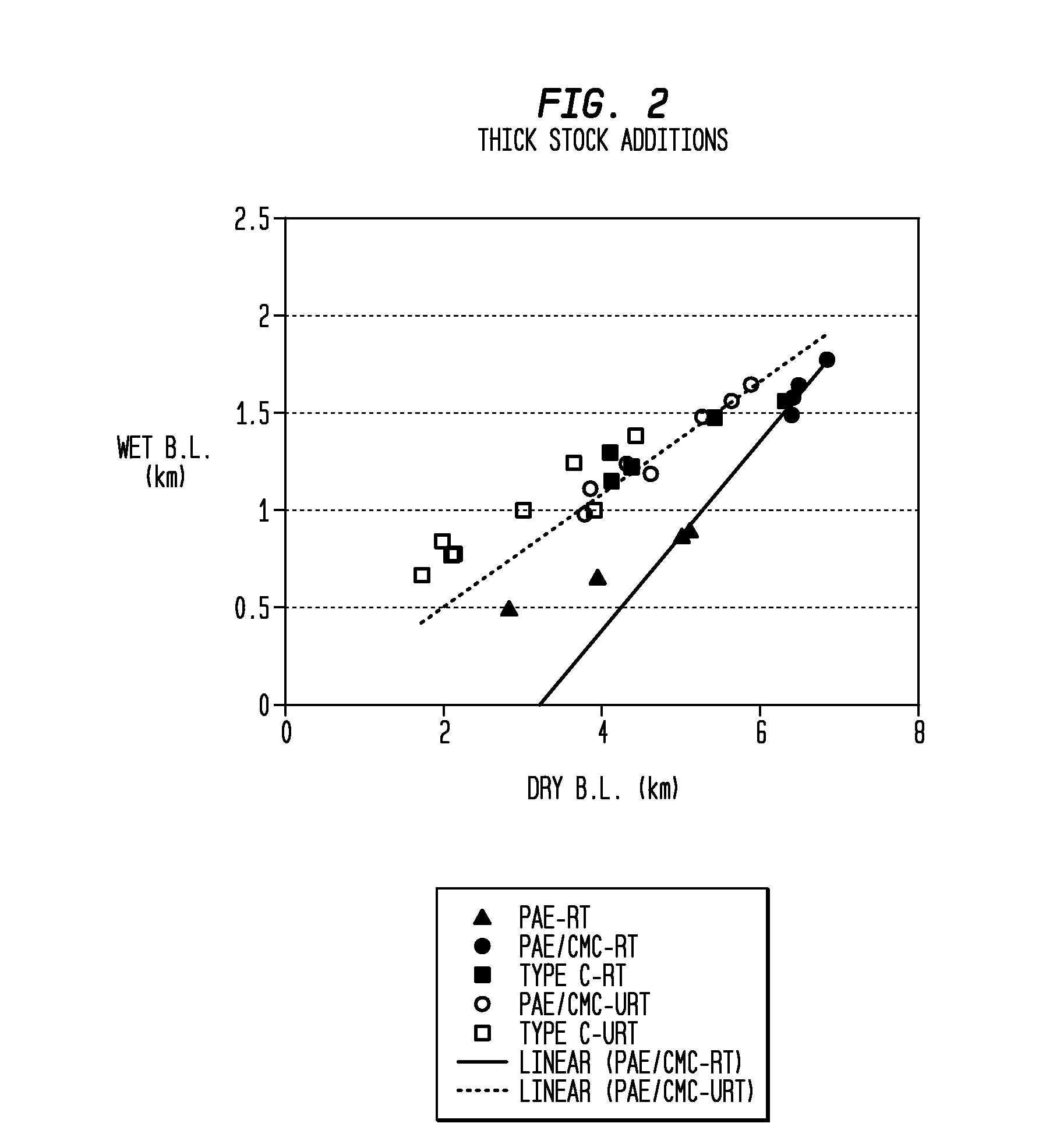

Method of Producing Absorbent Sheet with Increased Wet/Dry CD Tensile Ratio

ActiveUS20080083519A1Improve the level ofRaise the ratioCellulosic pulp after-treatmentNatural cellulose pulp/paperFiberEngineering

A method of making absorbent cellulosic sheet with increased wet / dry CD tensile ratio includes treating the fiber at high consistency with debonder in a pulper, for example. The process enables the use of large amounts of debonder in a wet-press process in order to achieve wet / dry CD tensile ratios of greater than 30%.

Owner:GPCP IP HLDG LLC

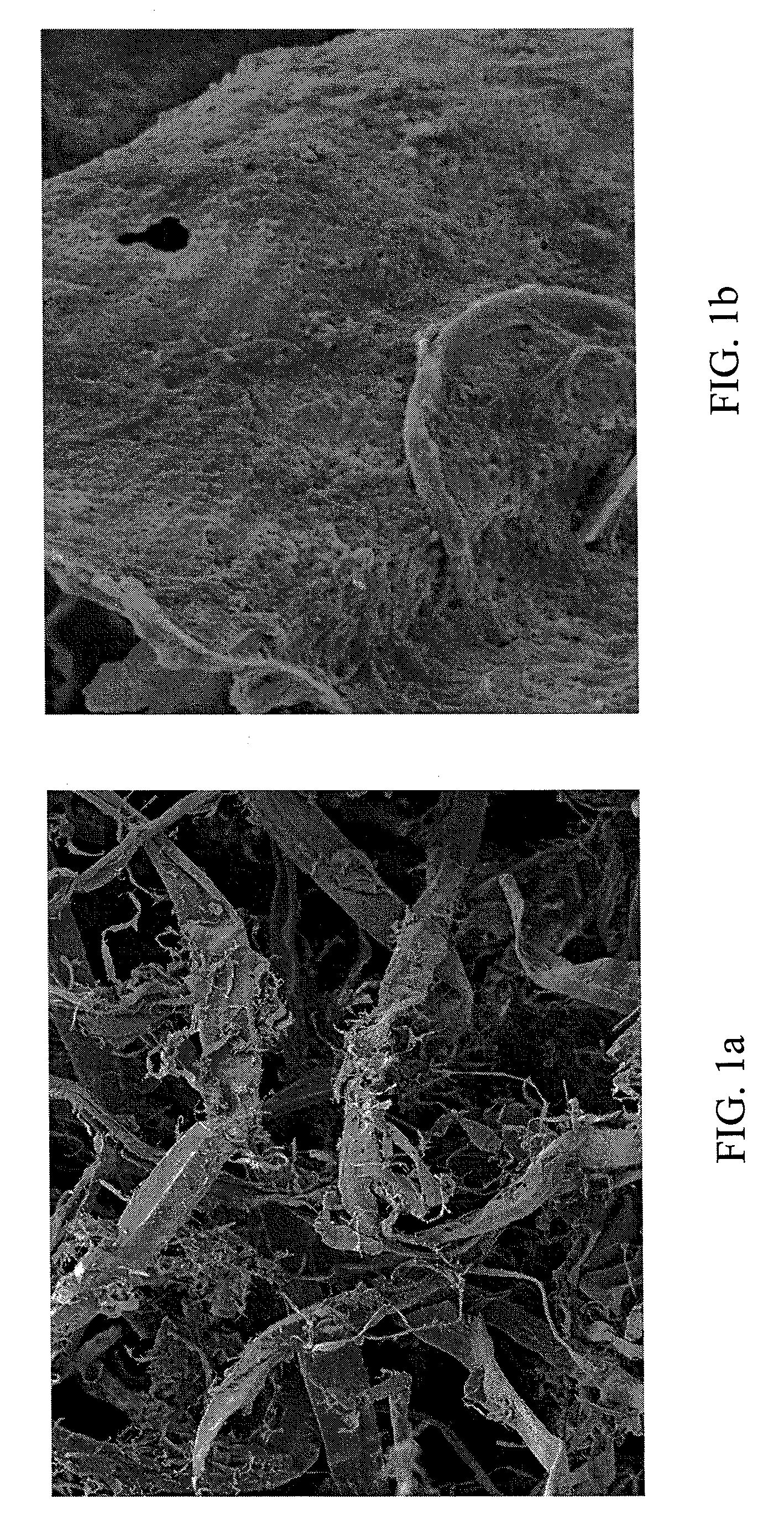

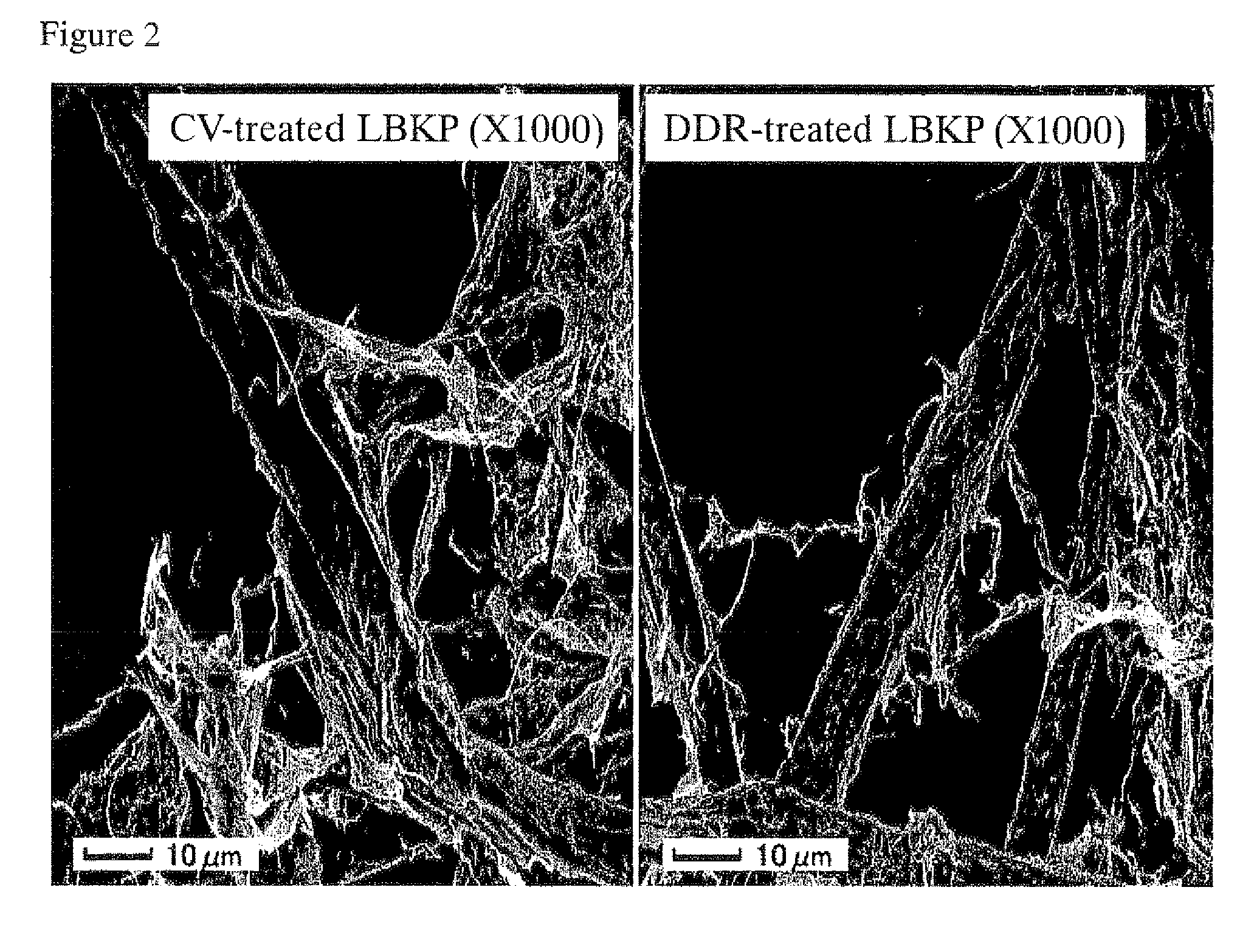

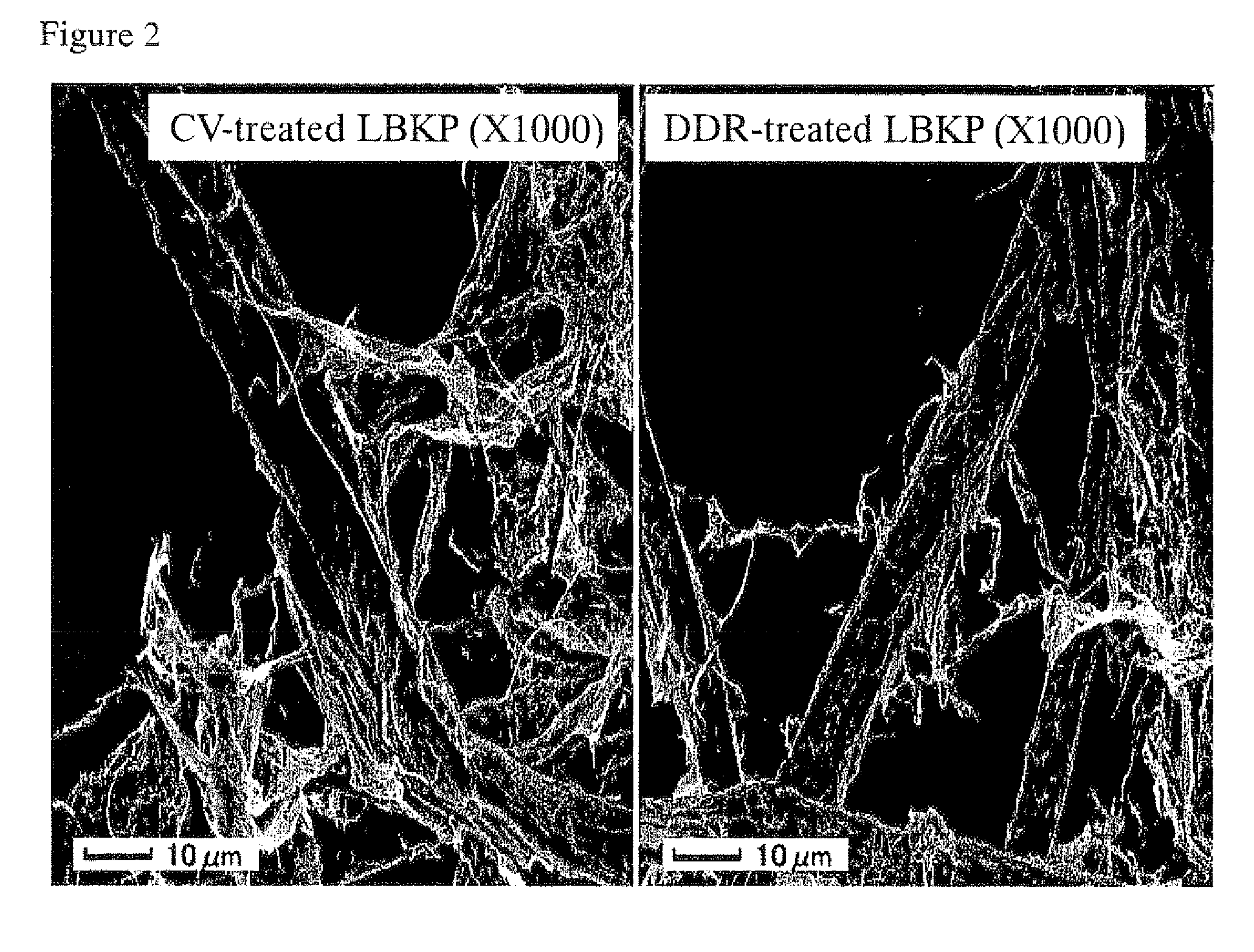

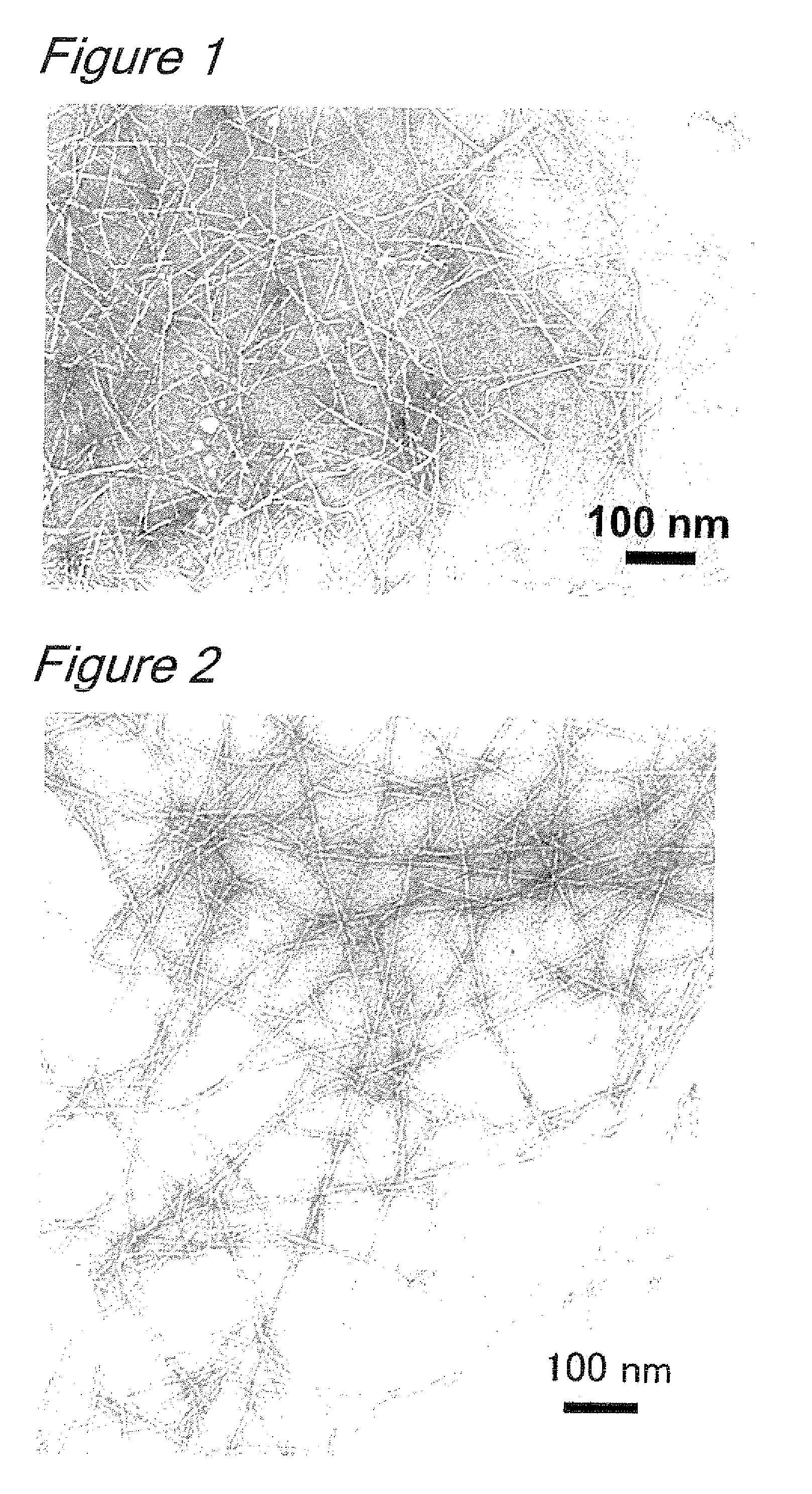

Cellulose-based fibrous materials

InactiveUS8012312B2Low densityImprove surface qualityCellulosic pulp after-treatmentCalendersFiberPolymer science

The present invention aims to provide cellulose-based fibrous materials for obtaining papers and sheets having low density, high surface quality, good size stability despite of high strength, and high opacity. Cellulose-based fibrous materials having external fibrils consisting of an assembly of scale-like microfibrils exhibit a higher fiber stiffness, a lower water retention value and a higher specific surface area as compared with fibrous materials having filamentous external fibrils at the same freeness. Papers and sheets having low density, high surface quality, good size stability and high opacity can be obtained by using such fibrous materials.

Owner:NIPPON PAPER IND CO LTD

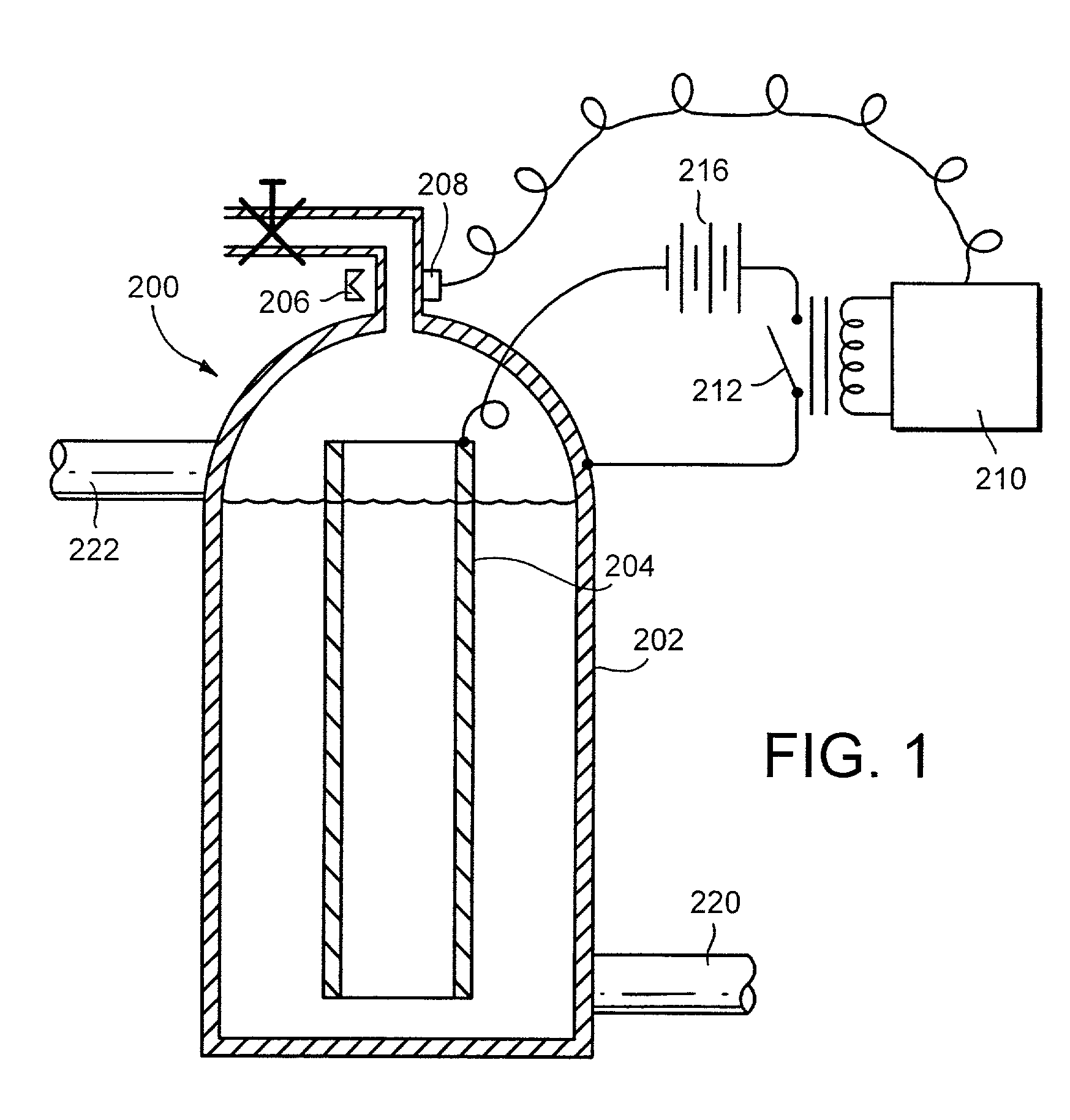

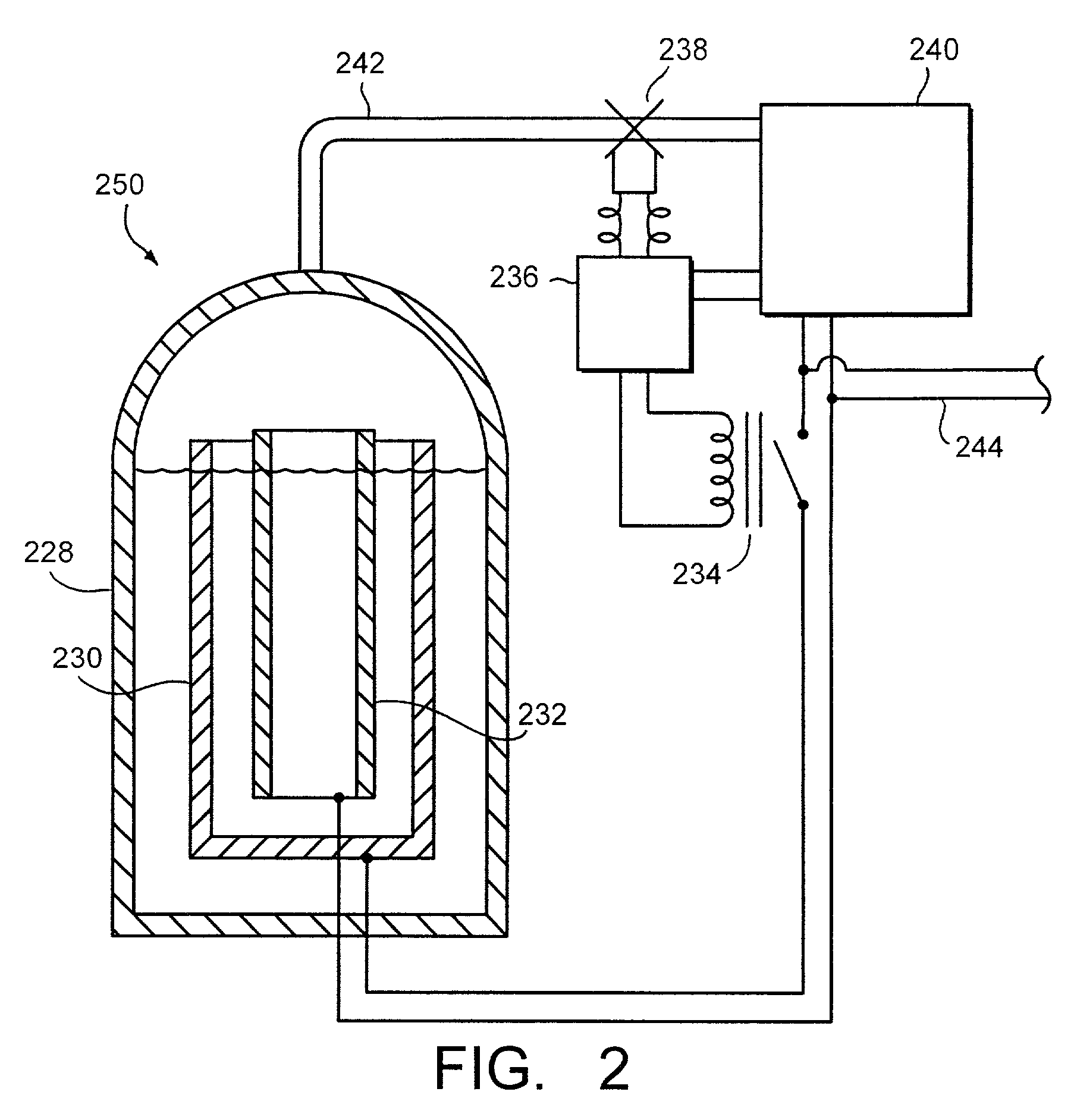

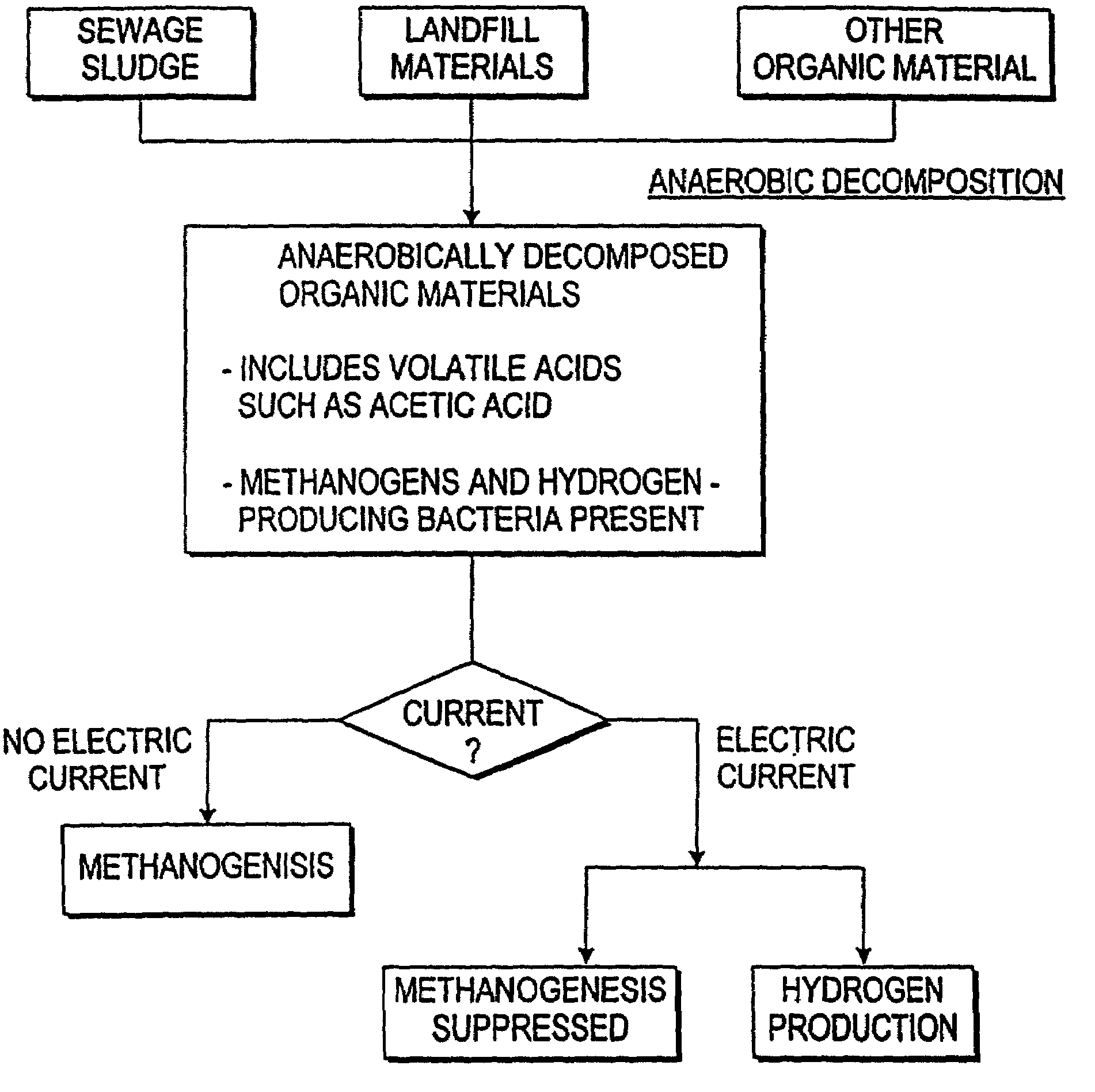

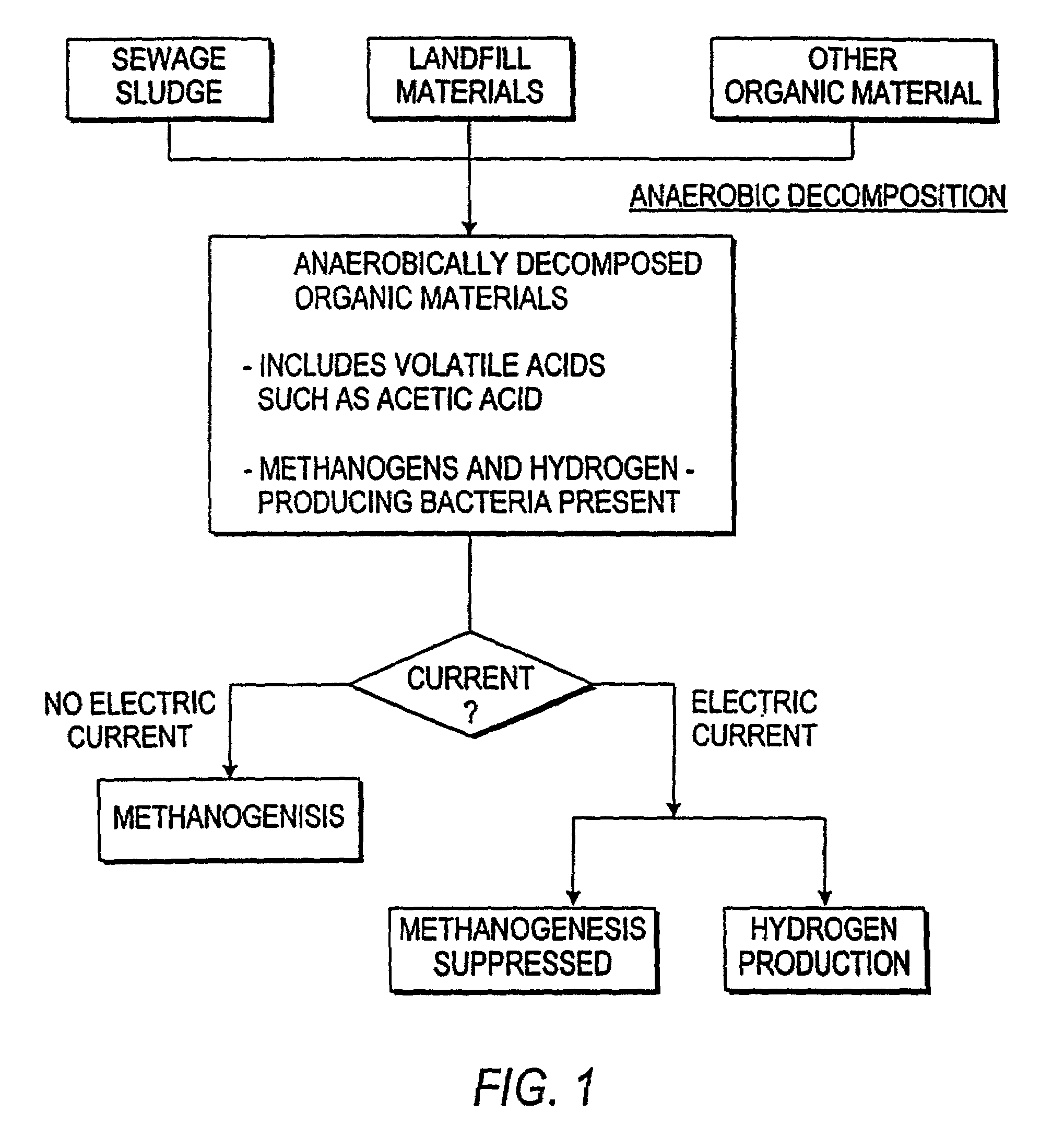

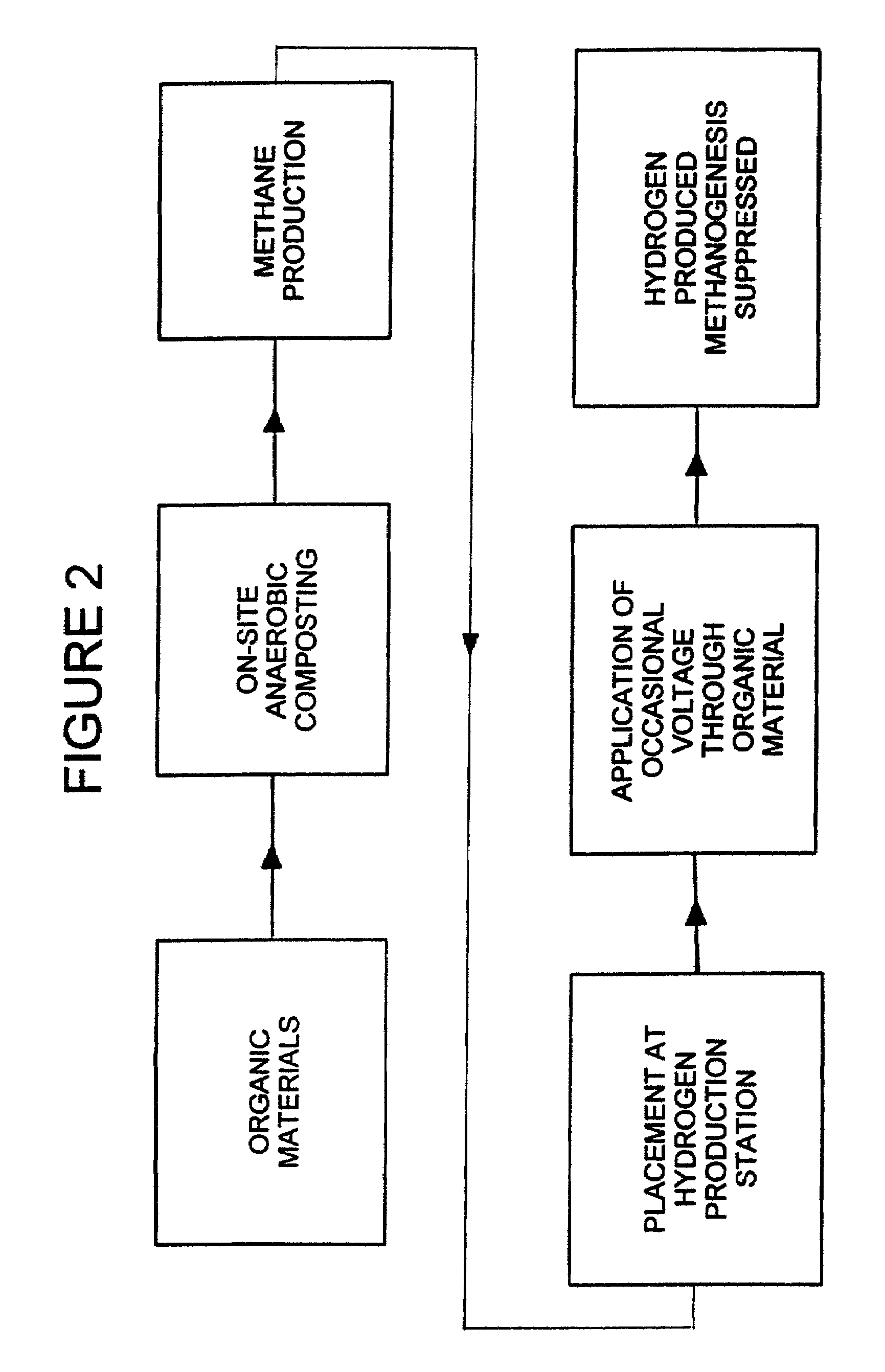

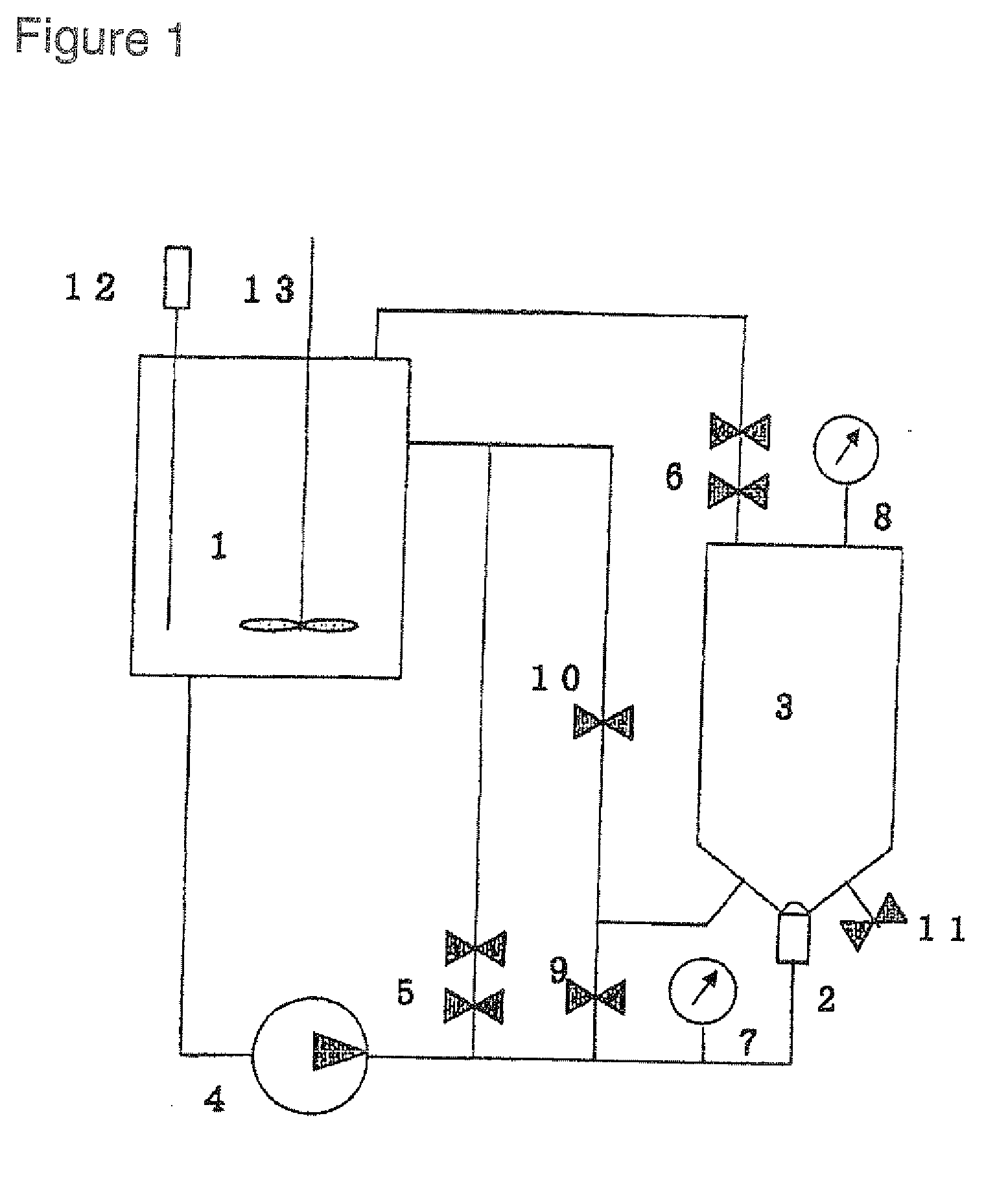

Process for production of hydrogen from anaerobically decomposed organic materials

InactiveUS6090266AReduce weightReduce volumeCellulosic pulp after-treatmentHydrogenAcetic acidHydrogen

A process for the production of hydrogen from anaerobically decomposed organic materials by applying an electric potential to the anaerobically decomposed organic materials, including landfill materials and sewage, to form hydrogen, and for decreasing the time required to treat these anaerobically decomposed organic materials. The organic materials decompose to volatile acids such as acetic acid, which may be hydrolyzed by electric current to form hydrogen. The process may be continuously run in sewage digestion tanks with the continuous feed of sewage, at landfill sites, or at any site having a supply of anaerobically decomposed or decomposable organic materials.

Owner:WORLD HYDROGEN ENERGY

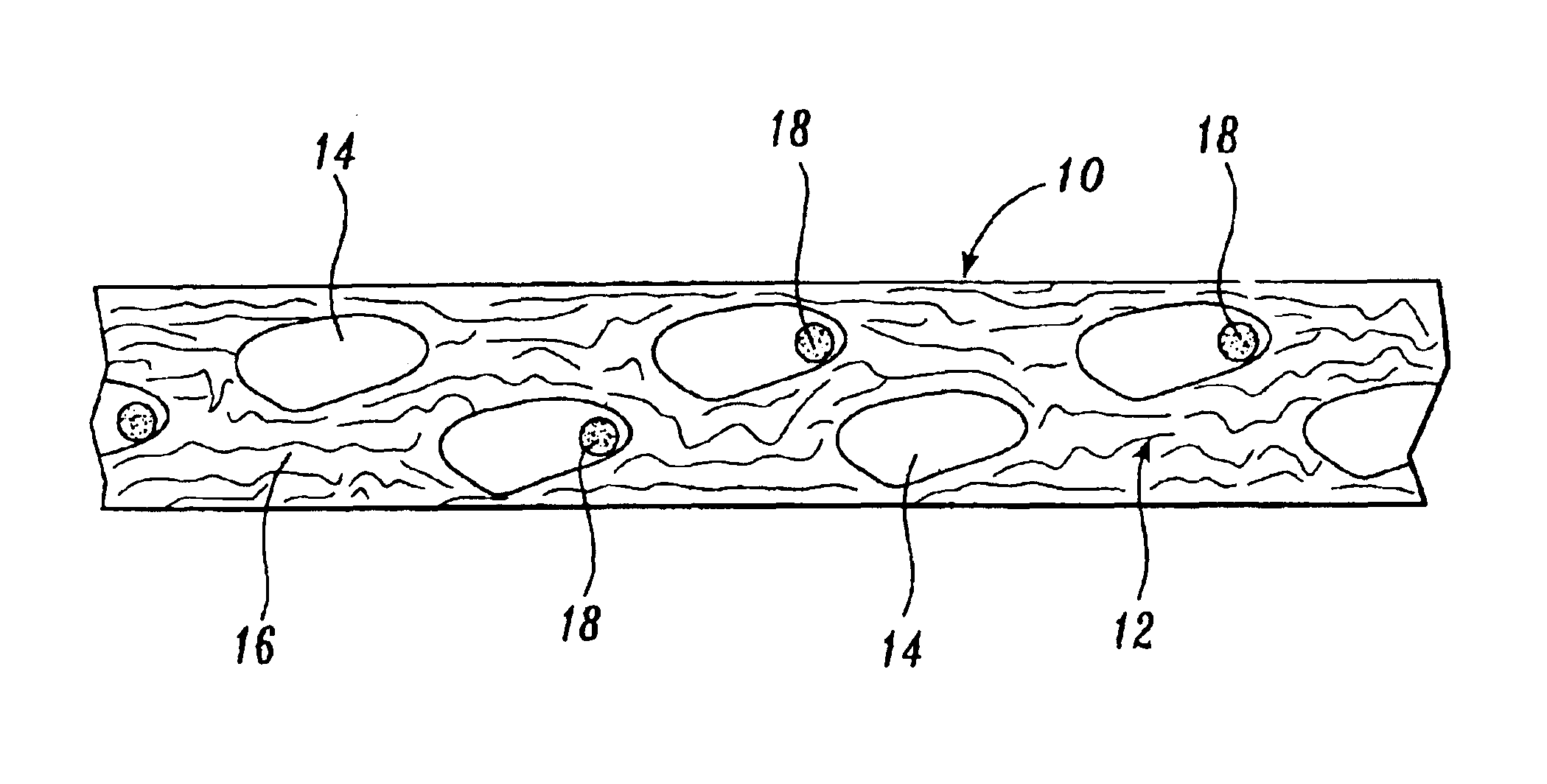

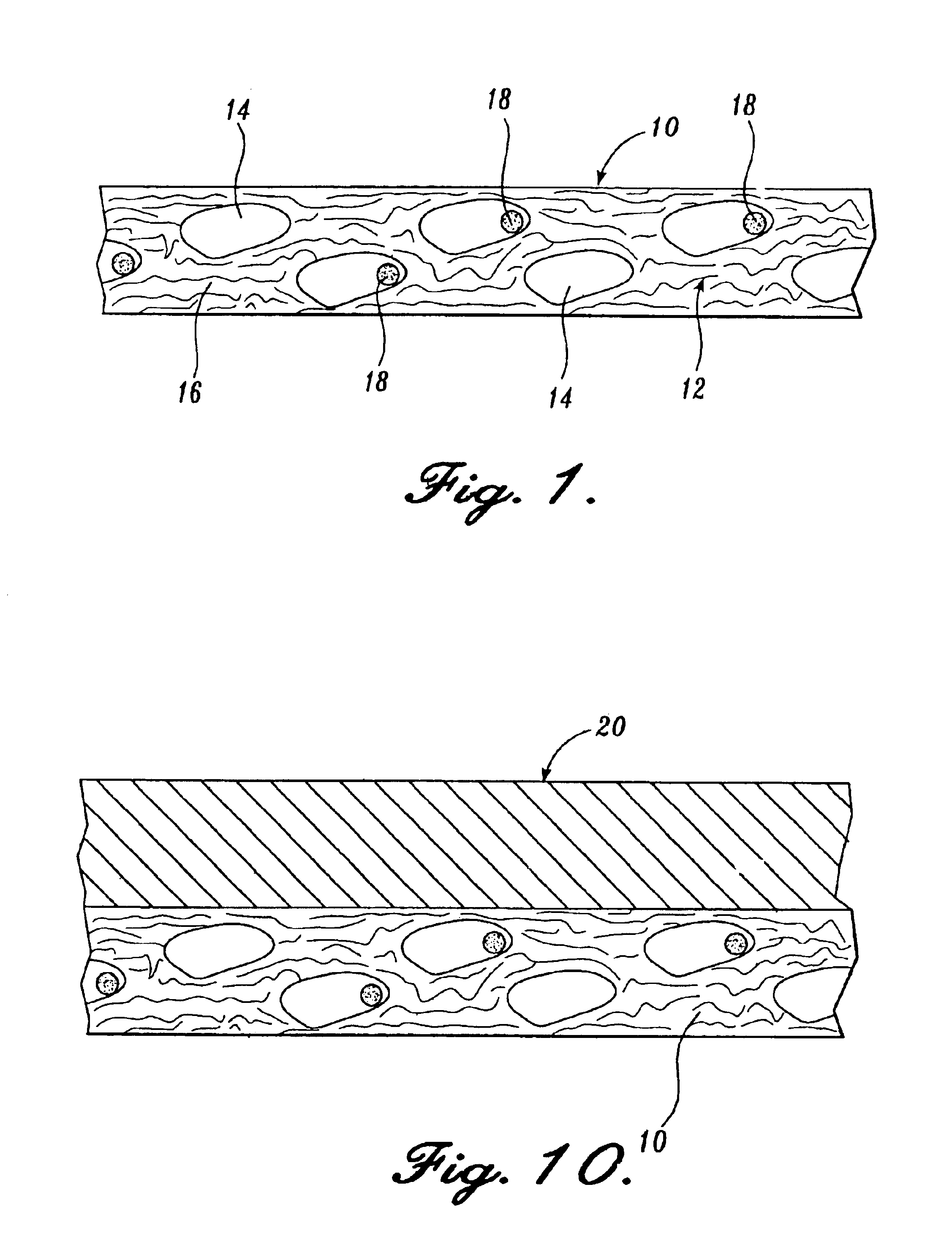

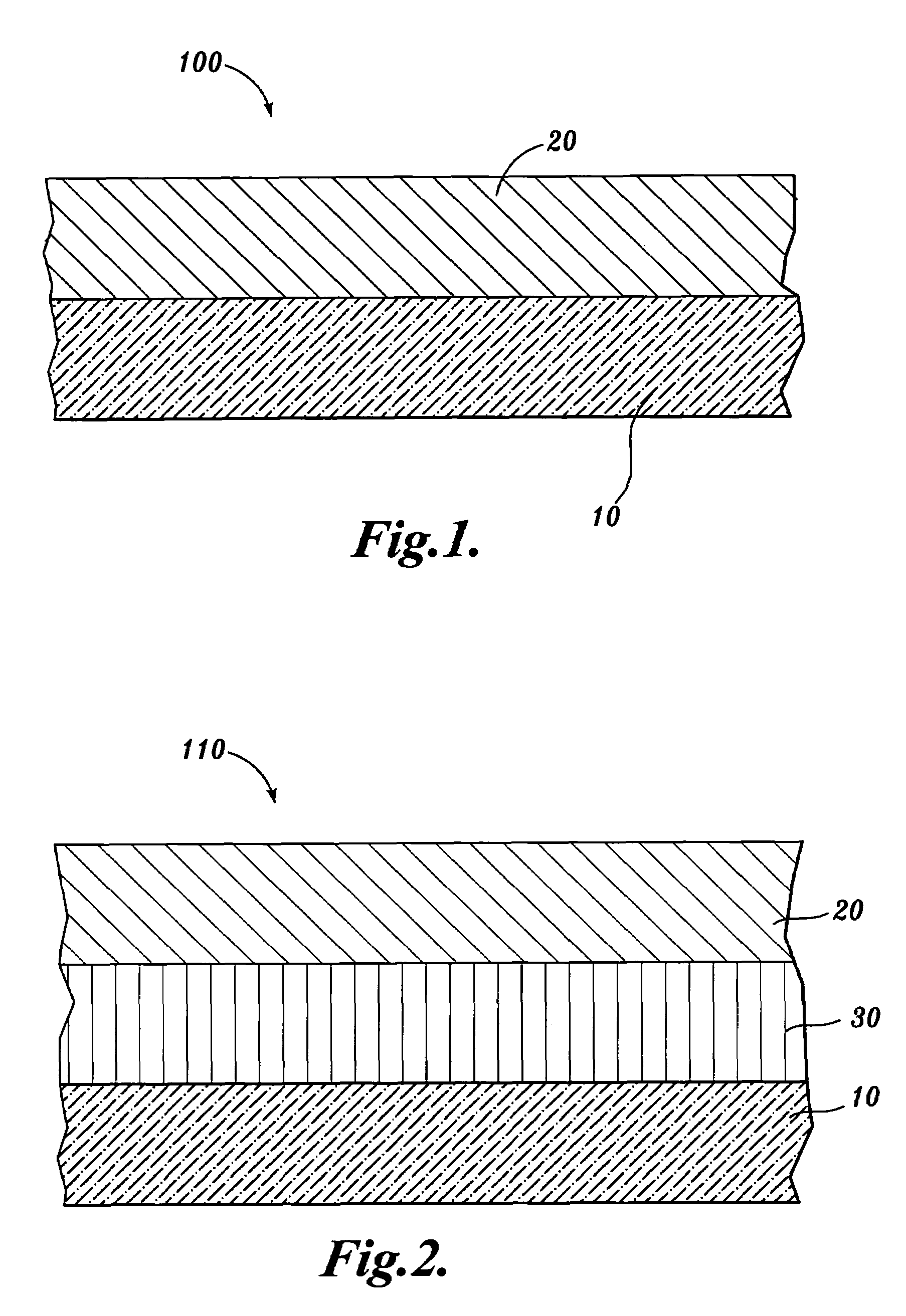

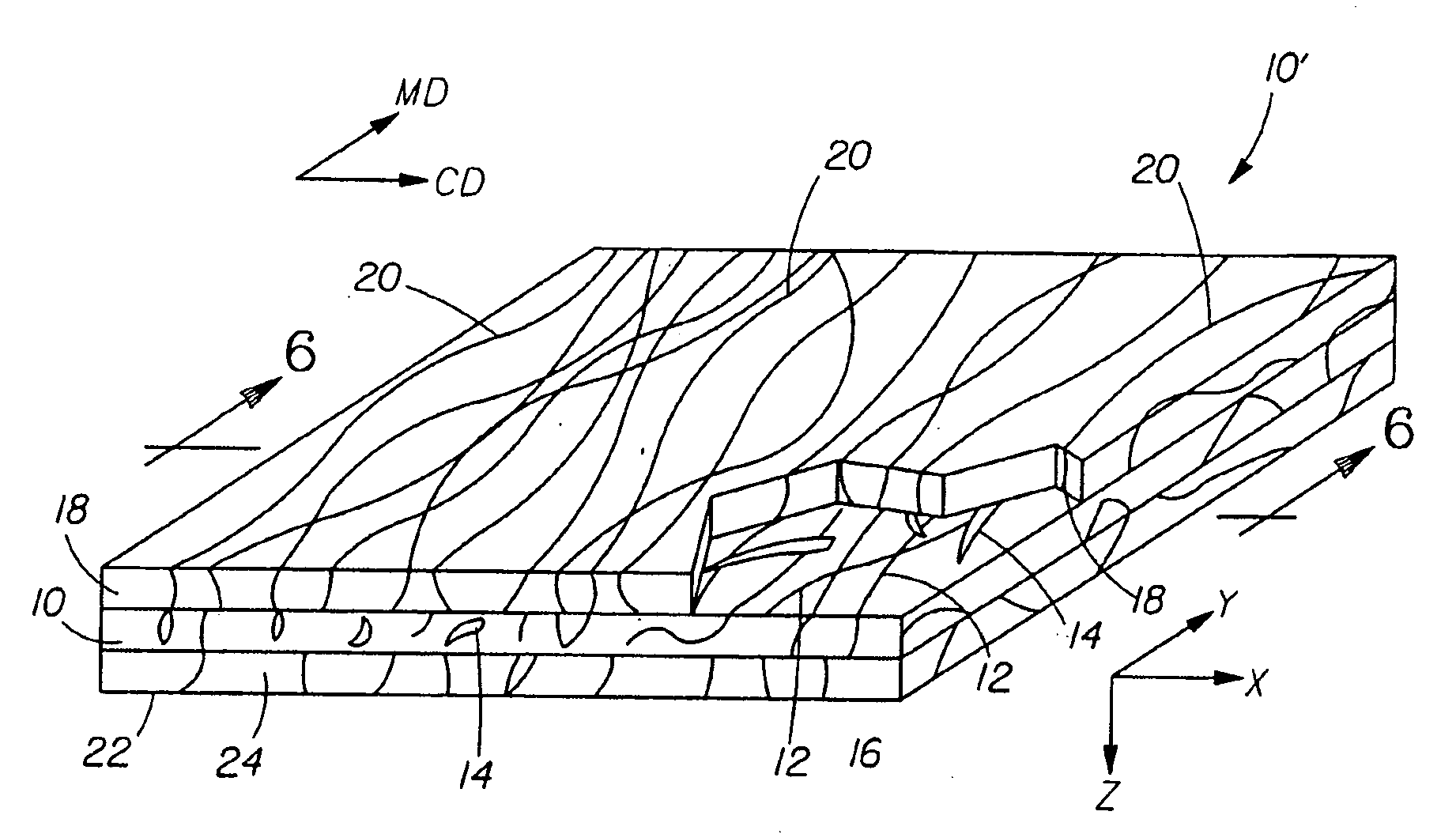

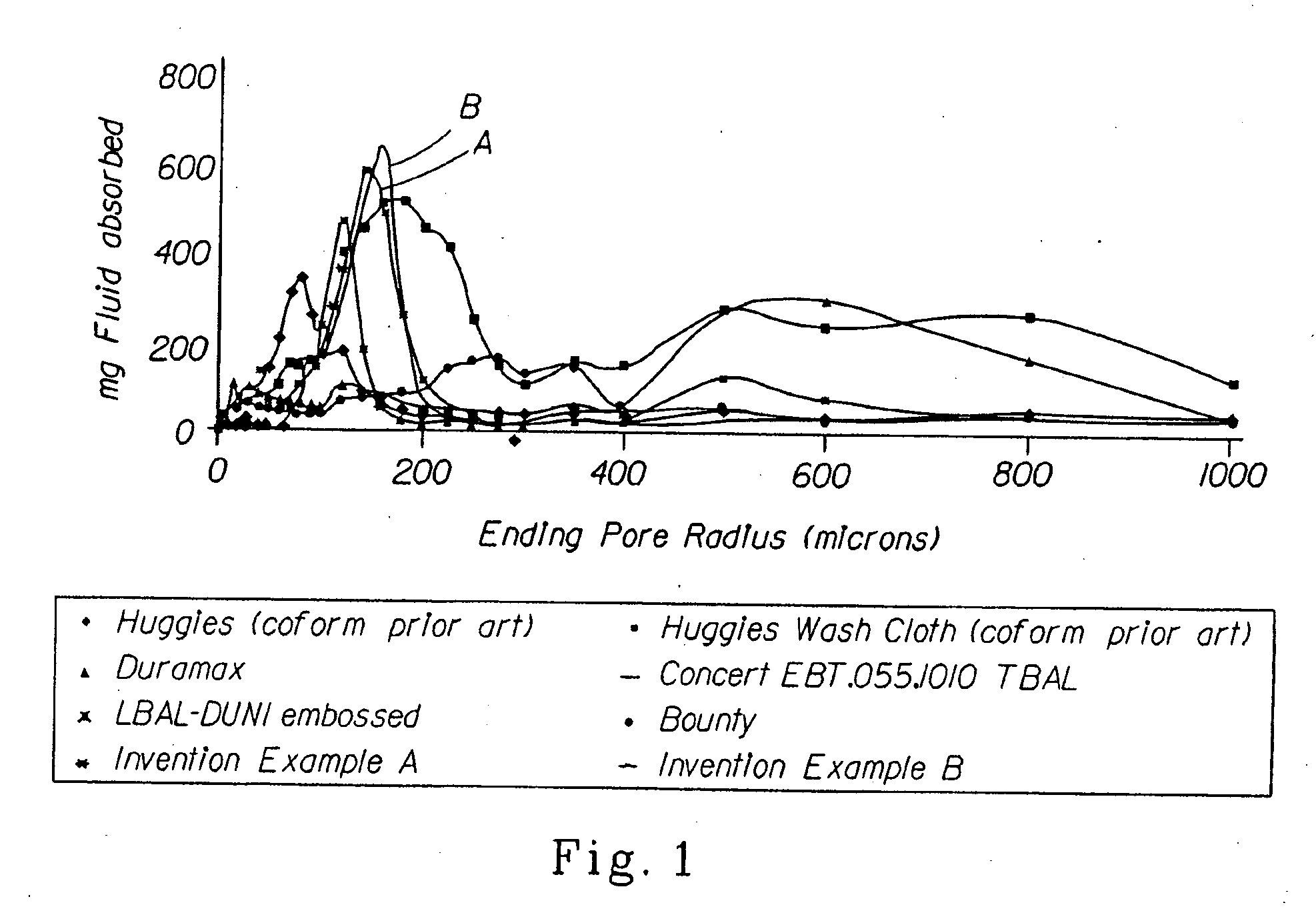

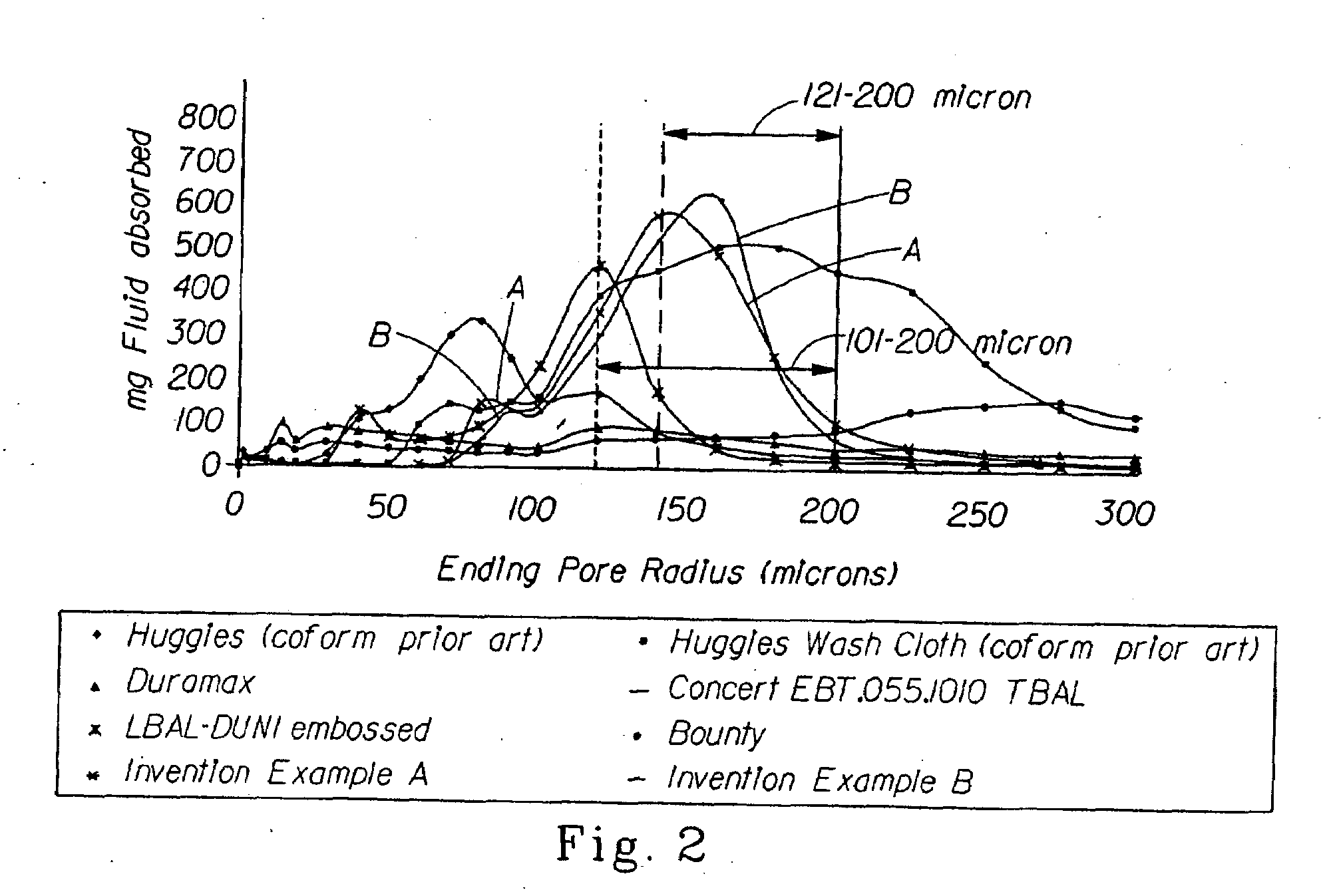

Reticulated absorbent composite

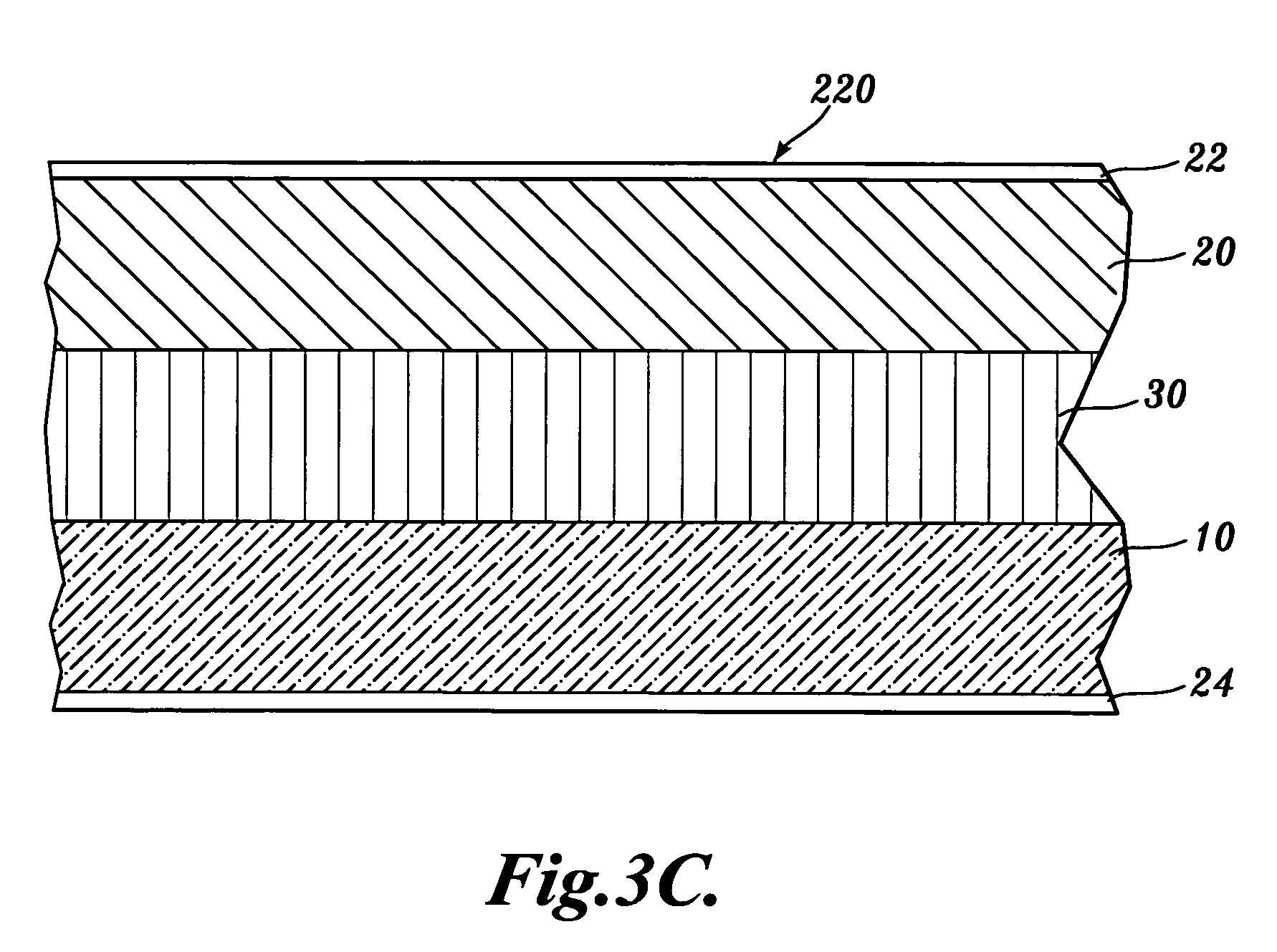

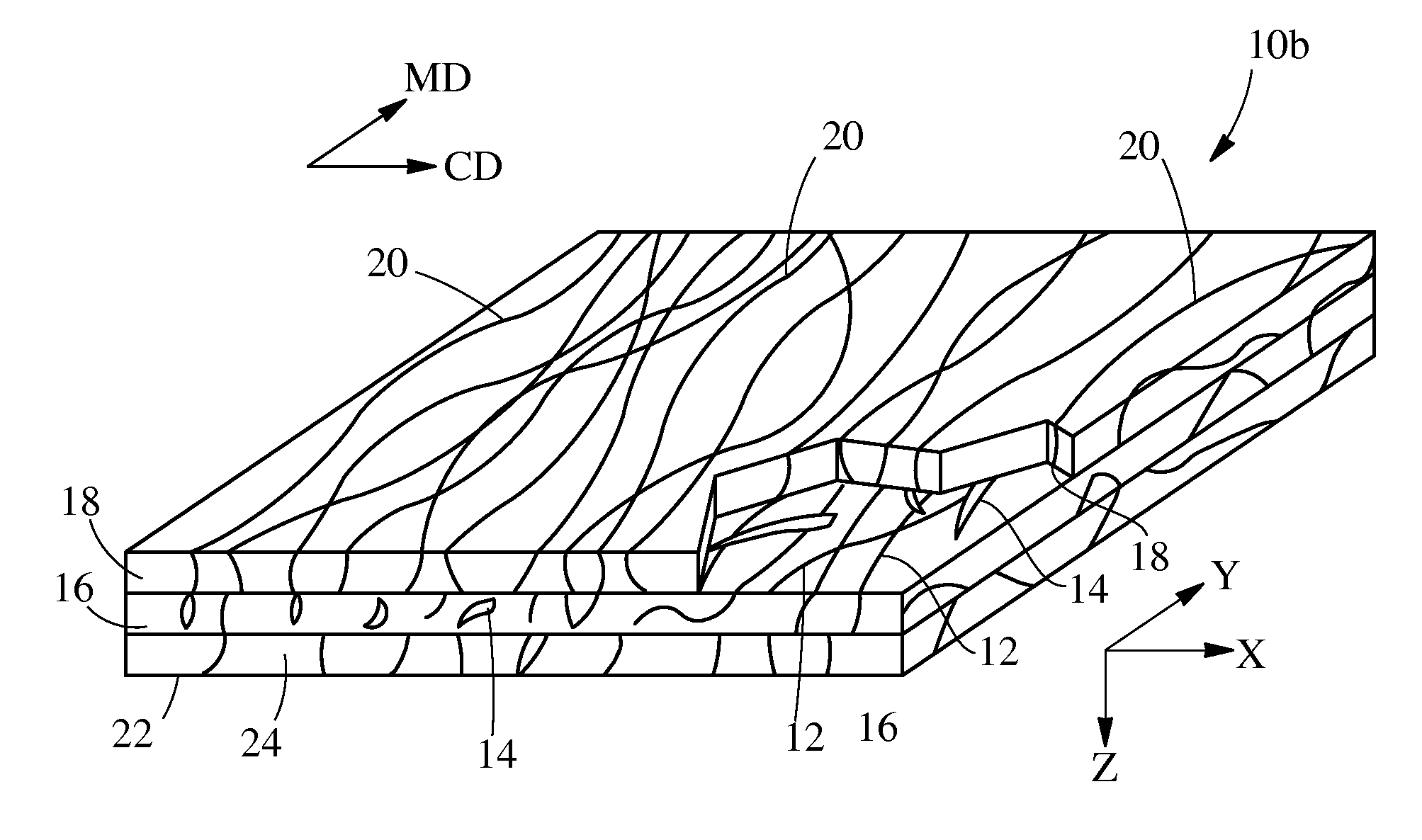

InactiveUS6962645B2Promote absorptionImprove acquisitionCellulosic pulp after-treatmentNon-fibrous pulp additionElastic fibresFiber

An absorbent composite (10) having a fibrous matrix that includes absorbent material is disclosed. The fibrous matrix defines voids (14) and passages between the voids, which are distributed throughout the composite. Absorbent material (18) is located within some of the voids (14). Absorbent material located in these voids is expandable into the void. In a preferred embodiment, the composite's fibrous matrix includes resilient and matrix fibers (16). The composite optionally includes a wet strength agent.

Owner:NAT INST FOR STRATEGIC TECH ACQUISITIONS & COMMLIZATION

Process for production of hydrogen from anaerobically decomposed organic materials

InactiveUS7138046B2Shorten the timeIncrease ratingsCellulosic pulp after-treatmentHydrogenAcetic acidHydrogen

A process for the production of hydrogen from anaerobically decomposed organic materials by applying an electric potential to the anaerobically decomposed organic materials, including landfill materials and sewage, to form hydrogen, and for decreasing the time required to treat these anaerobically decomposed organic materials. The organic materials decompose to volatile acids such as acetic acid, which may be hydrolyzed by electric current to form hydrogen. The process may be continuously run in sewage digestion tanks with the continuous feed of sewage, at landfill sites, or at any site having a supply of anaerobically decomposed or decomposable organic materials.

Owner:WORLD HYDROGEN ENERGY

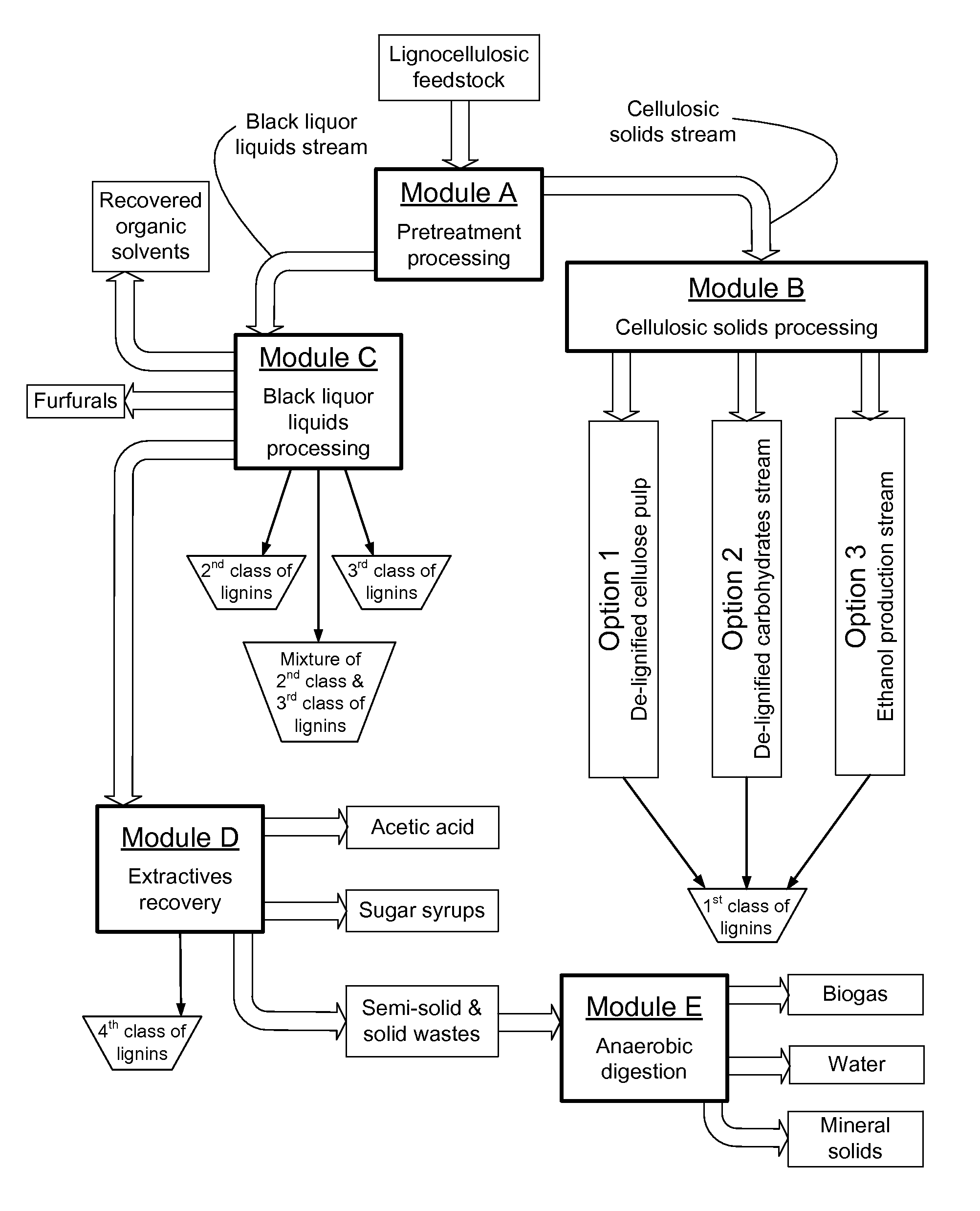

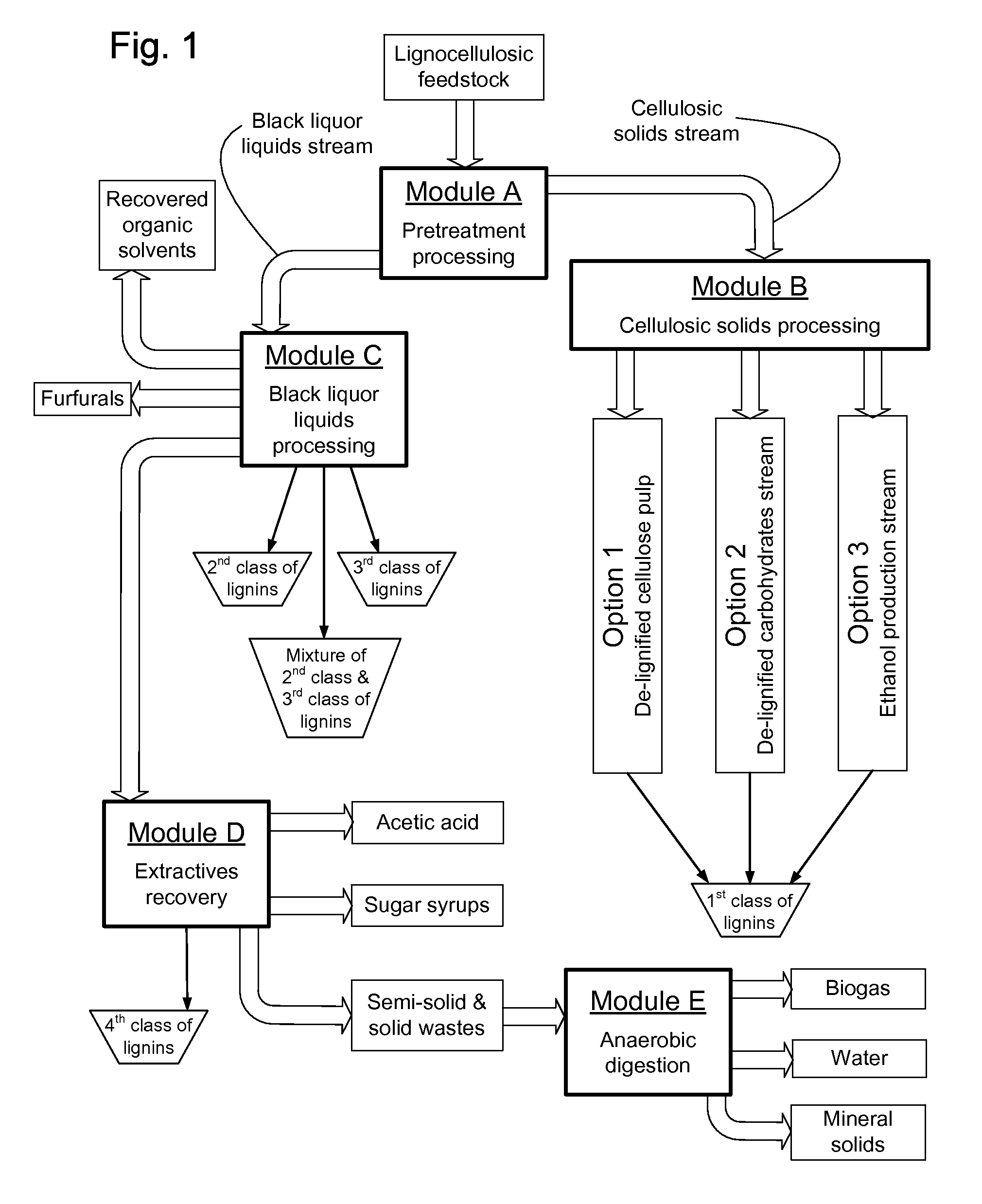

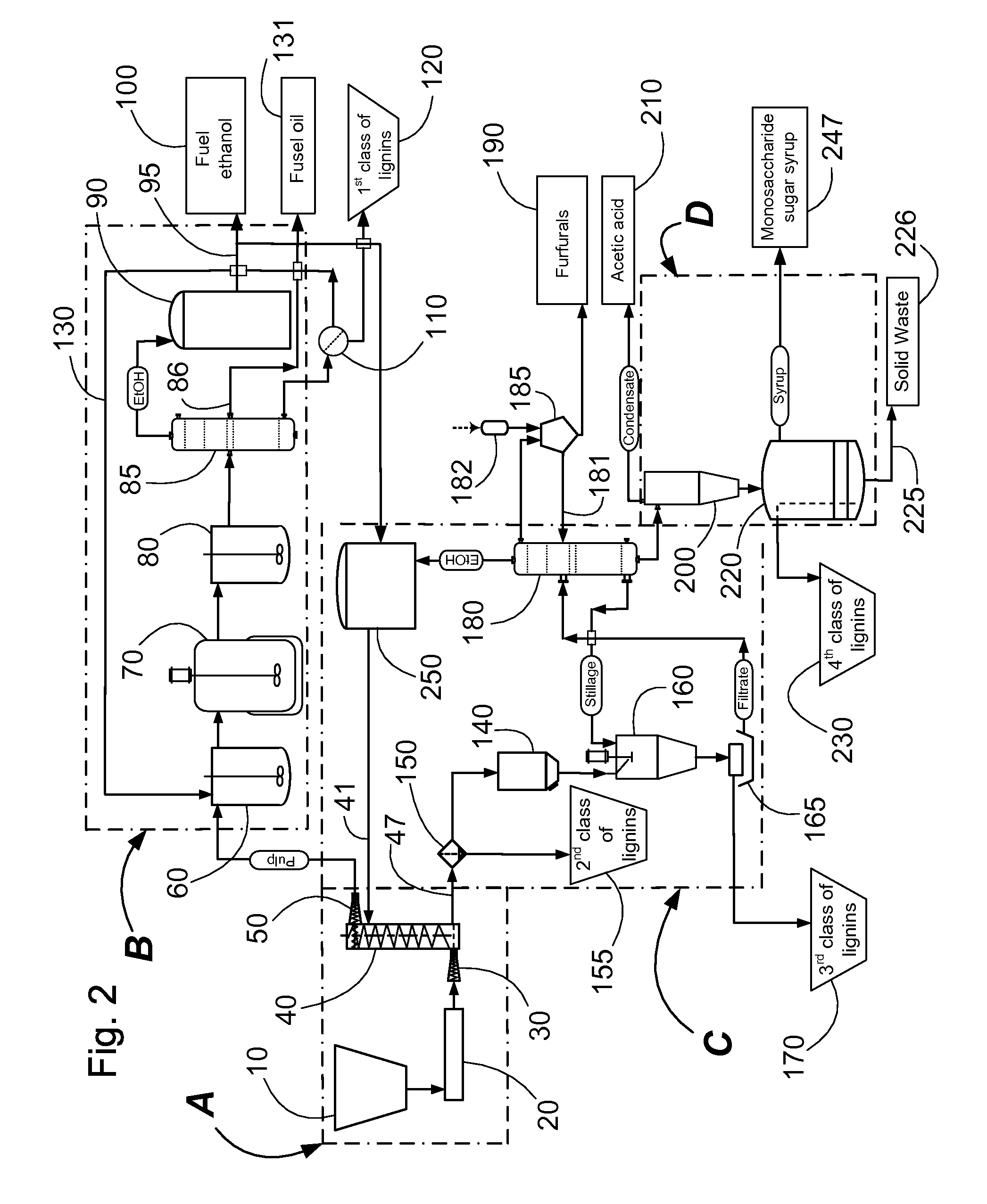

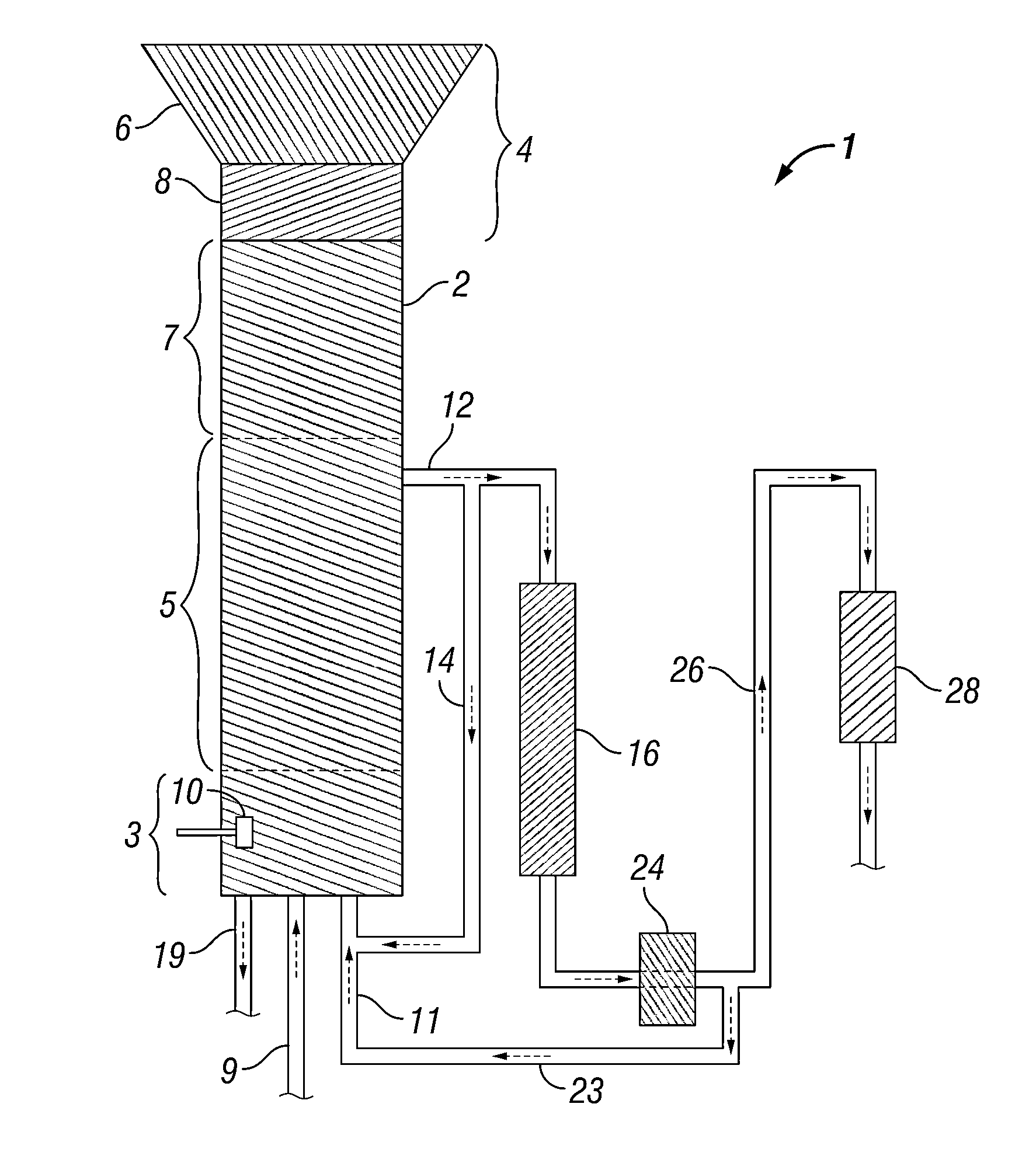

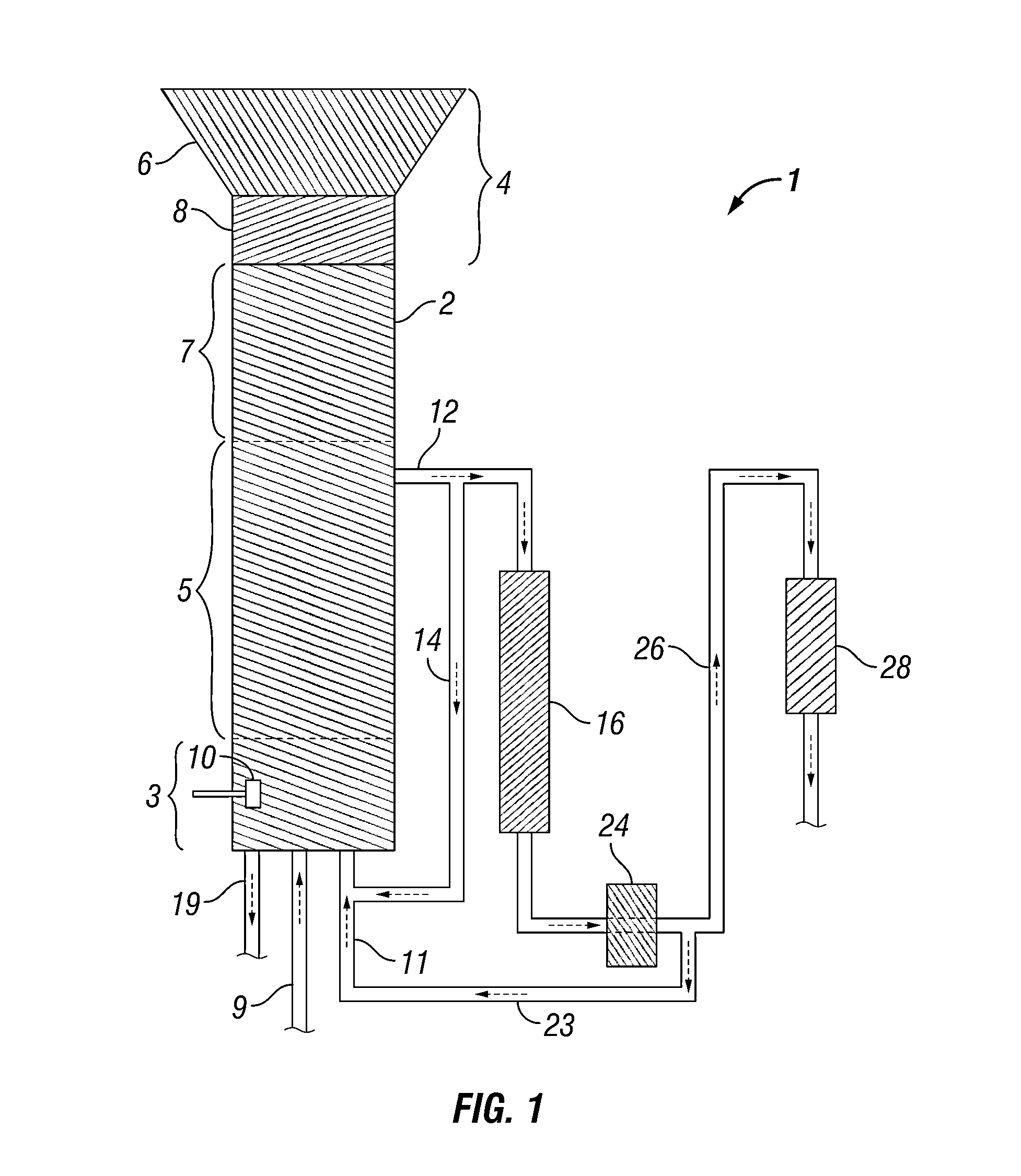

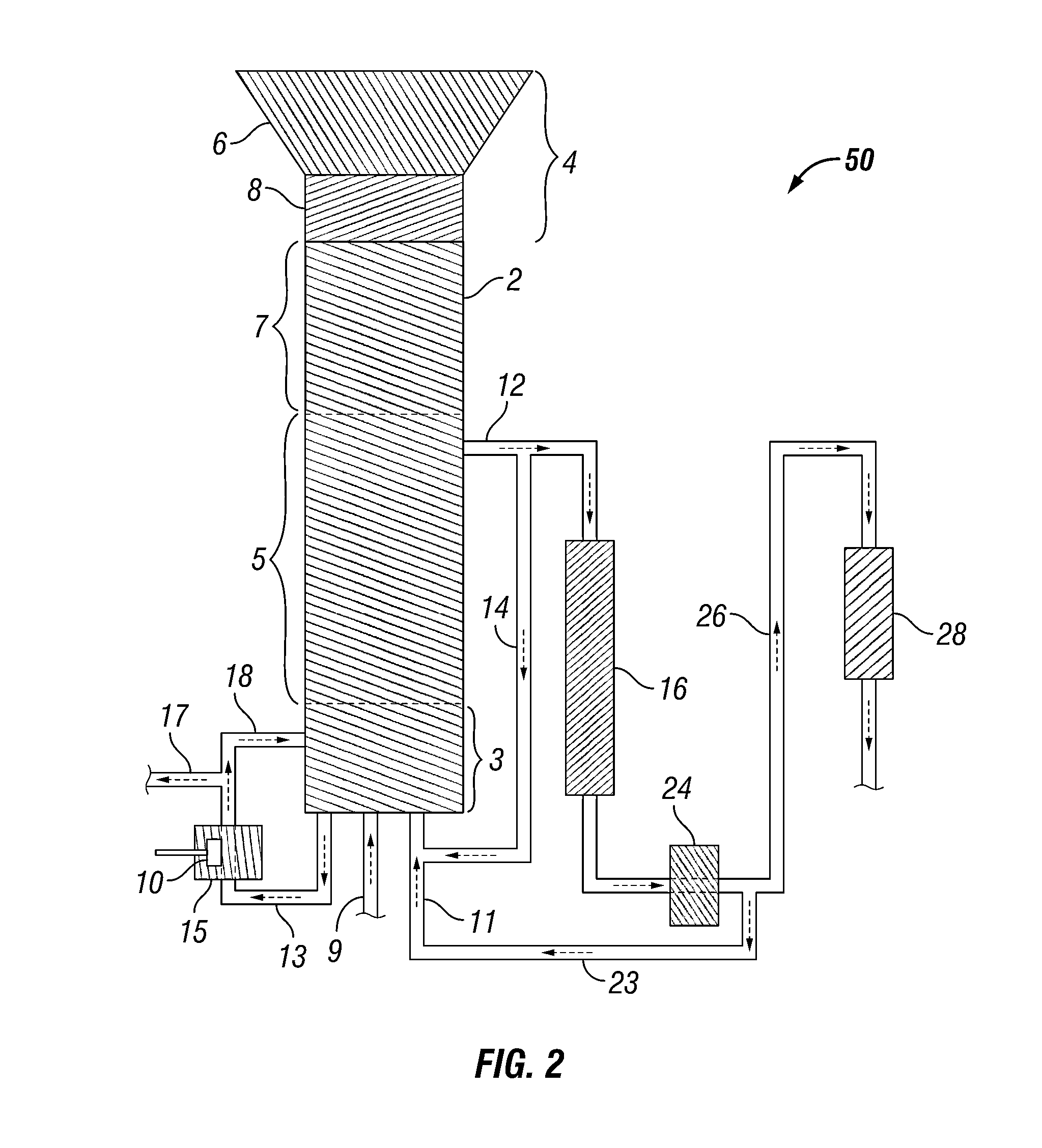

Continuous counter-current organosolv processing of lignocellulosic feedstocks

A modular process for organosolv fractionation of lignocellulosic feedstocks into component parts and further processing of said component parts into one or more of a de-lignified cellulose stream, a sugar stream, small-chain alcohol streams and four structurally distinct classes of lignin derivatives. The modular process comprises a first processing module configured for digesting lignocellulosic feedstocks with an organic solvent thereby producing a cellulosic solids fraction and a liquid fraction, a second processing module configured for recovering small-chain alcohols and optionally a first class of lignin derivatives from the cellulosic solids fraction, a third processing module configured for recovering from the liquid fraction at least one of a second class and a third class of lignin derivatives or mixtures thereof, and waste stream comprising a fourth class of lignin derivatives. The fourth processing module may optionally recover the fourth class of lignin derivatives.

Owner:SUZANO CANADA INC

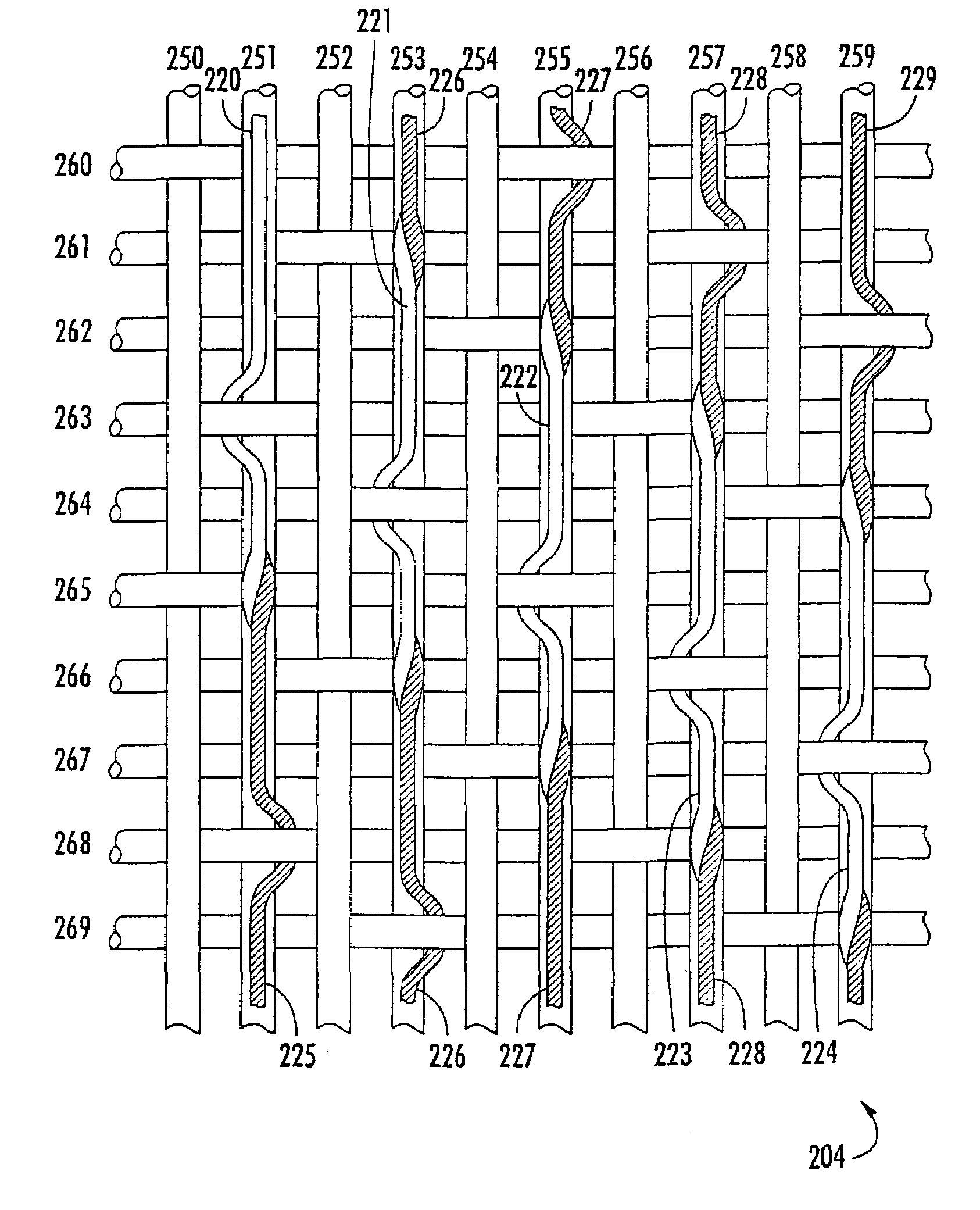

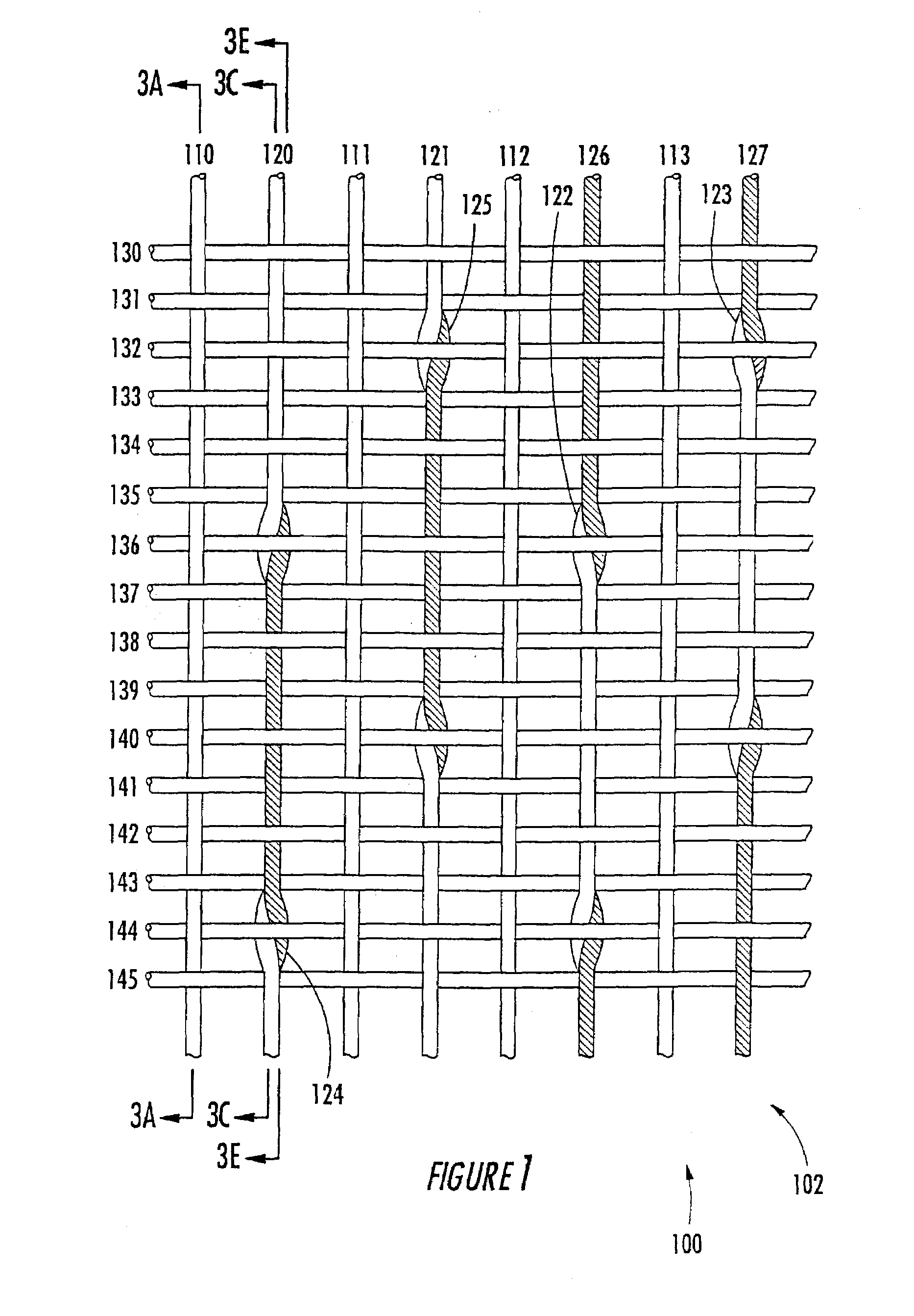

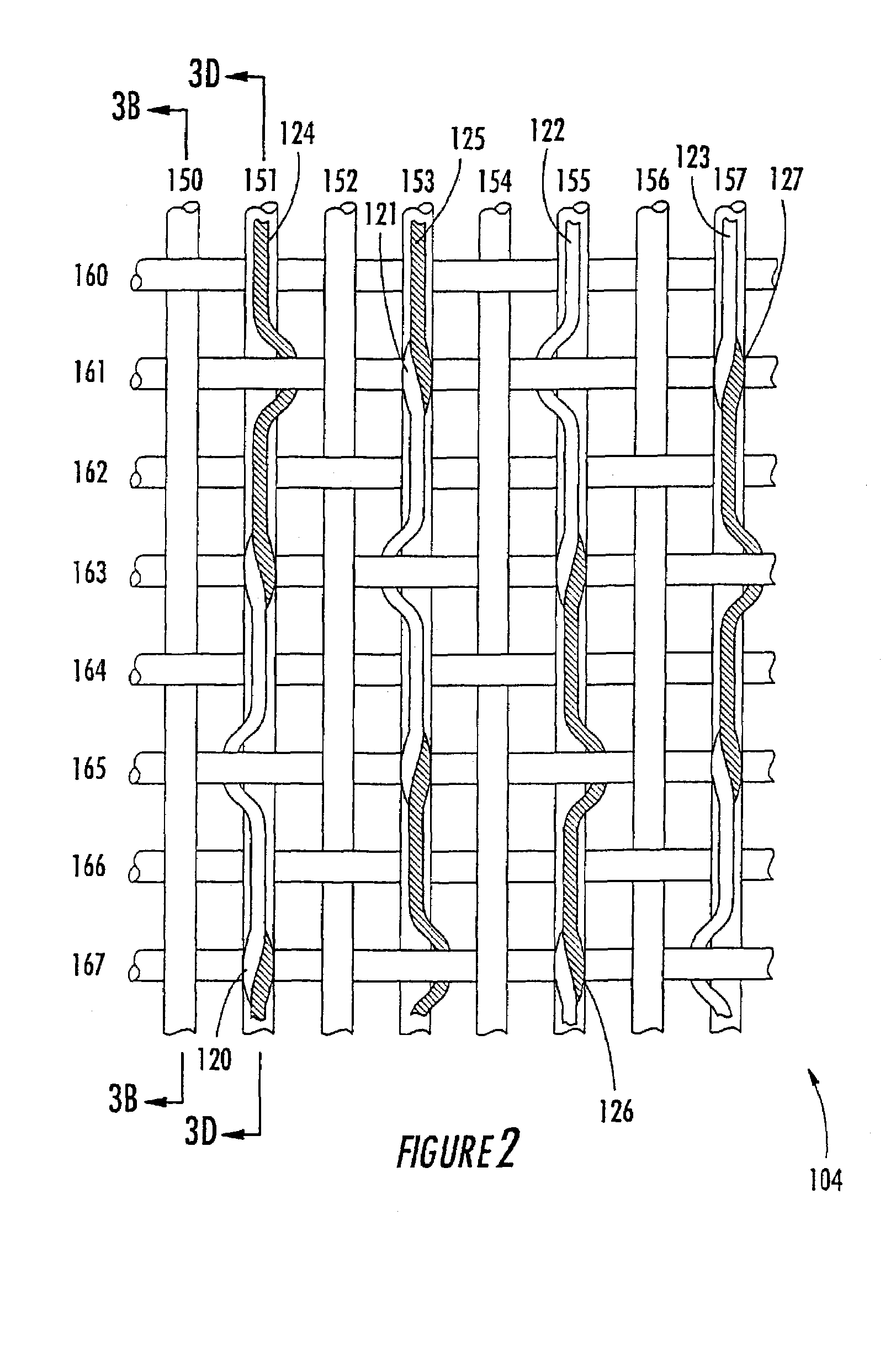

Warp-stitched multilayer papermaker's fabrics

InactiveUS7059357B2Easy to drainImprove joint strengthCellulosic pulp after-treatmentNon-fibrous pulp additionWeft yarnWarp knitting

A warp-stitched multilayer papermaker's fabric has a set of bottom warp yarns, a set of bottom weft yarns, a set of top weft yarns and a set of warp stitching yarn pairs. The bottom warp yarns are interwoven with the bottom weft yarns. The stitching warp yarns interweave with both the bottom weft yarns and the top weft yarns, and are woven such that at locations where the first of the stitching warp yarns in a pair weaves in the top fabric layer, the second stitching warp yarn in the pair drops below the top fabric layer to interweave with one or more bottom weft yarns to bind the top fabric layer and the bottom fabric layer together. The first stitching warp yarn of the stitching warp yarn pair may weave on a first side of one of the bottom warp yarns while the second stitching warp yarn of each stitching yarn pair may weave on the other side of that bottom warp yarn. Each stitching yarn pair may be substantially stacked above a bottom warp yarn. The fabric may further include a set of top warp yarns that interweave with the top weft yarns in the top fabric layer. The set of top warp yarns may be woven from a first warp beam, the set of bottom warp yarns may be woven from a second warp beam and the set of stitching warp yarns may be woven from a third warp beam.

Owner:WEAVEXX

Methods and systems for processing lignin during hydrothermal digestion of cellulosic biomass solids

InactiveUS20140117275A1Low viscosityCellulosic pulp after-treatmentOther chemical processesCelluloseFluid phase

Digestion of cellulosic biomass solids may be complicated by lignin release therefrom, which can produce a highly viscous phenolics liquid phase comprising lignin polymer. Methods for digesting cellulosic biomass solids may comprise: providing cellulosic biomass solids in the presence of a digestion solvent, molecular hydrogen, and a slurry catalyst capable of activating molecular hydrogen; at least partially converting the cellulosic biomass solids into a phenolics liquid phase comprising lignin, an aqueous phase comprising an alcoholic component derived from the cellulosic biomass solids, and an optional light organics phase; wherein at least a portion of the slurry catalyst accumulates in the phenolics liquid phase as it forms; and reducing the viscosity of the phenolics liquid phase.

Owner:SHELL OIL CO

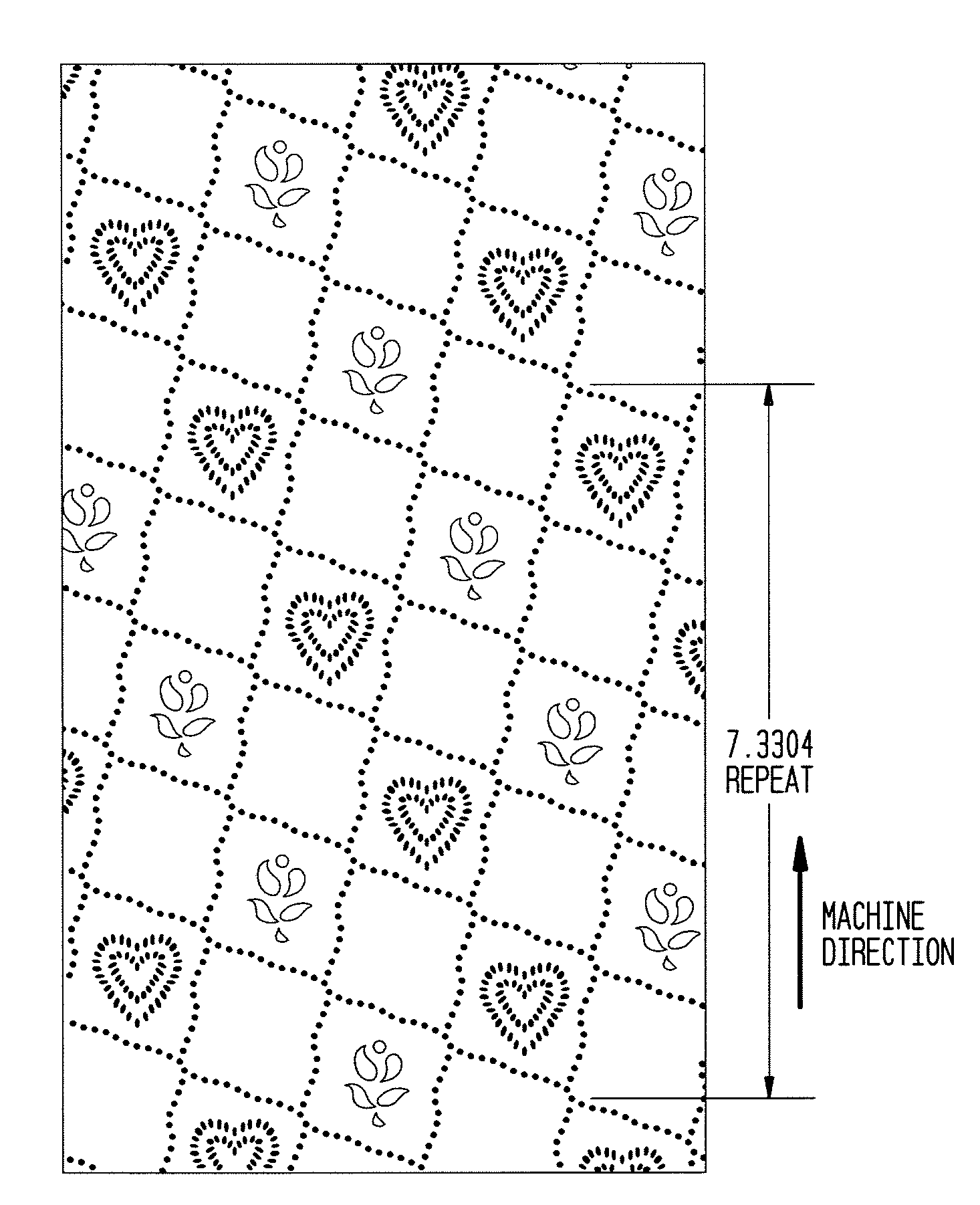

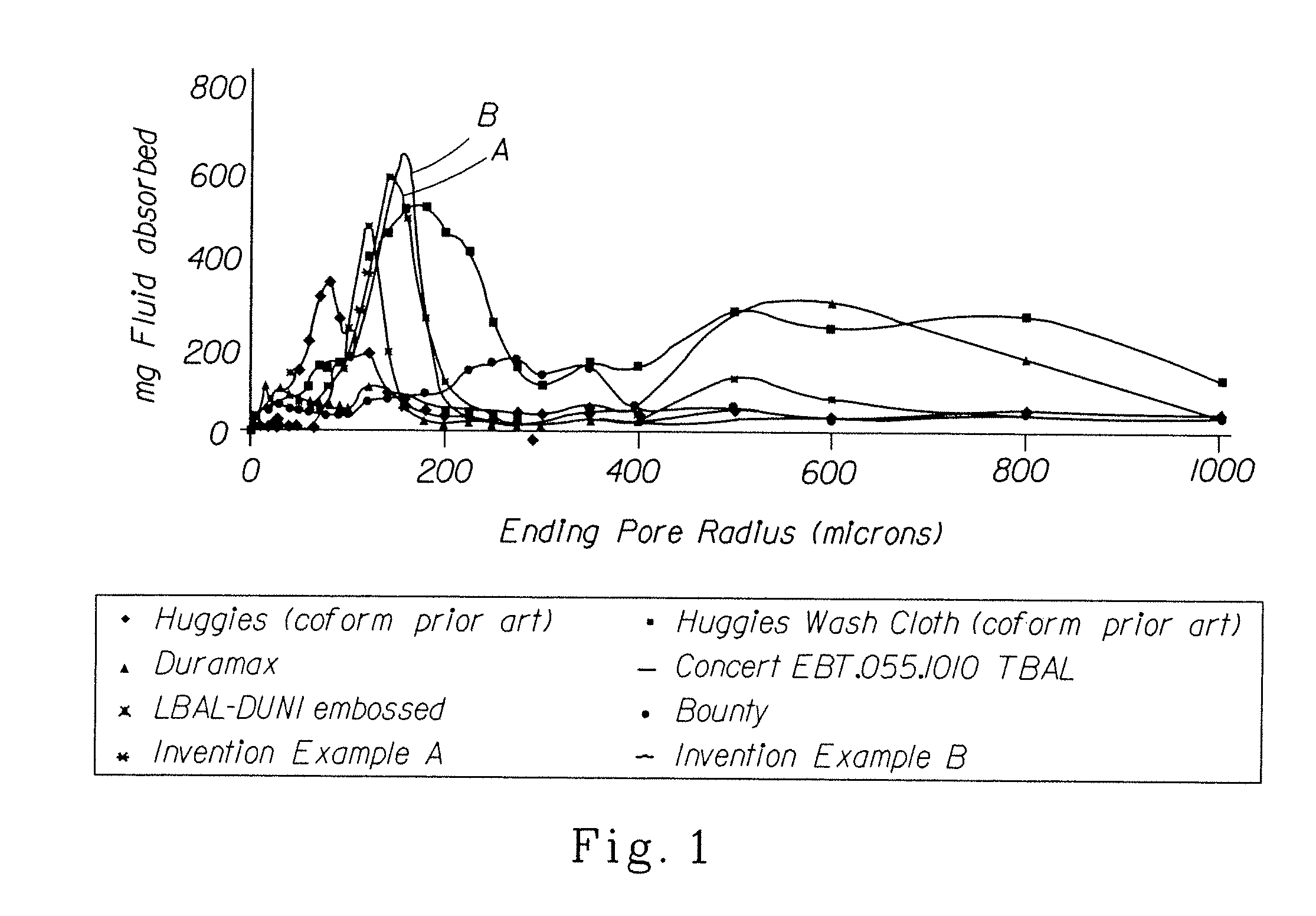

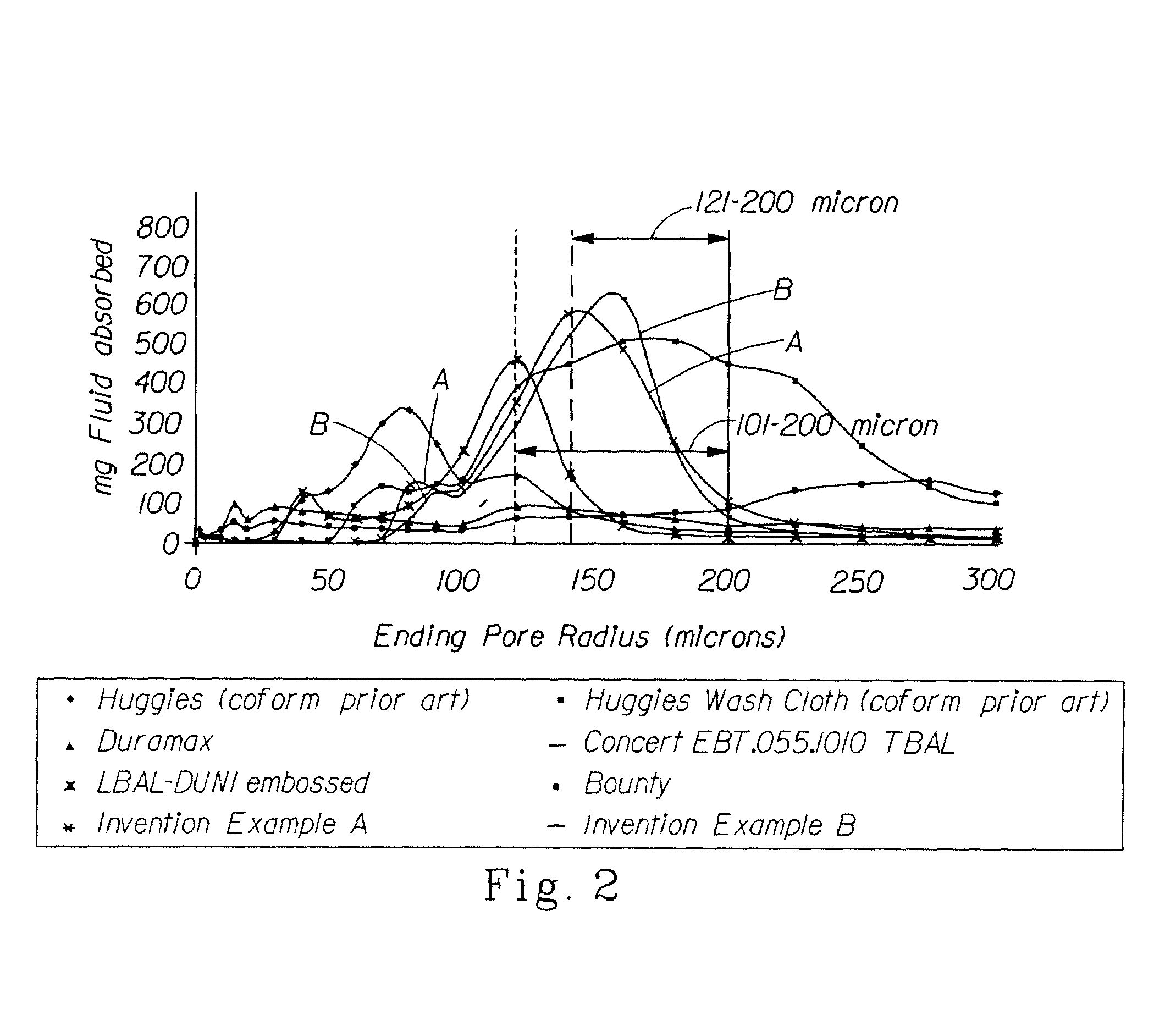

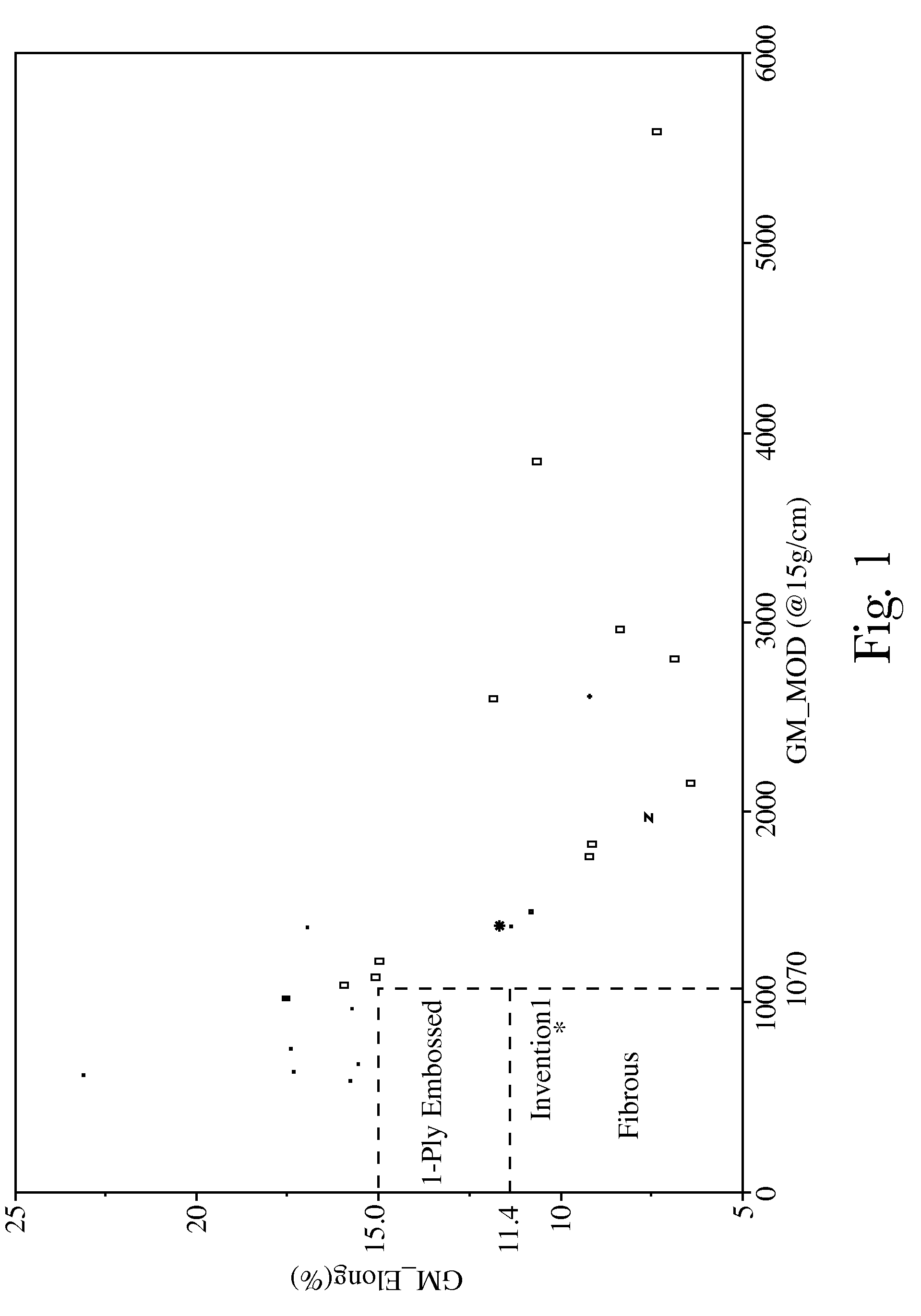

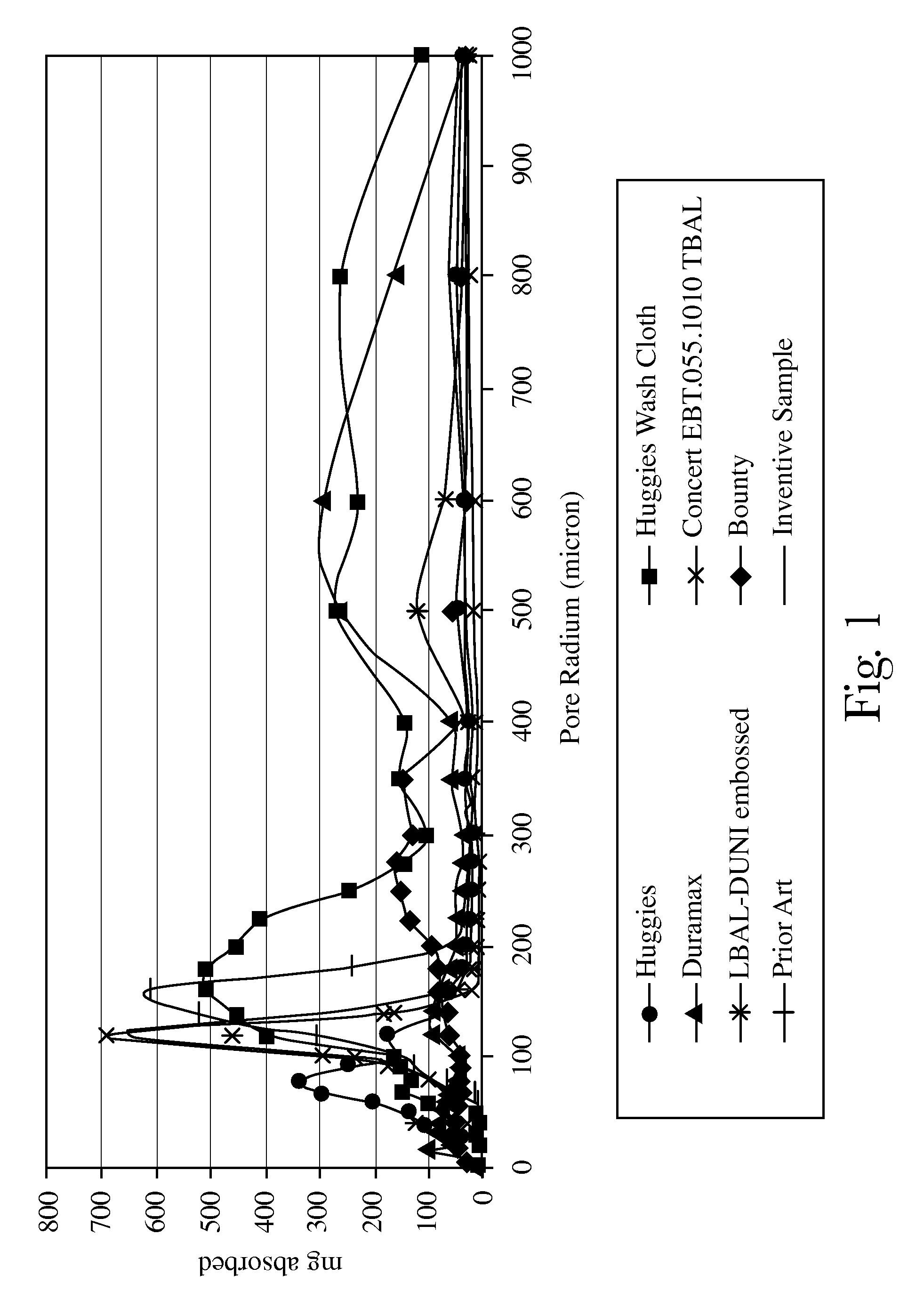

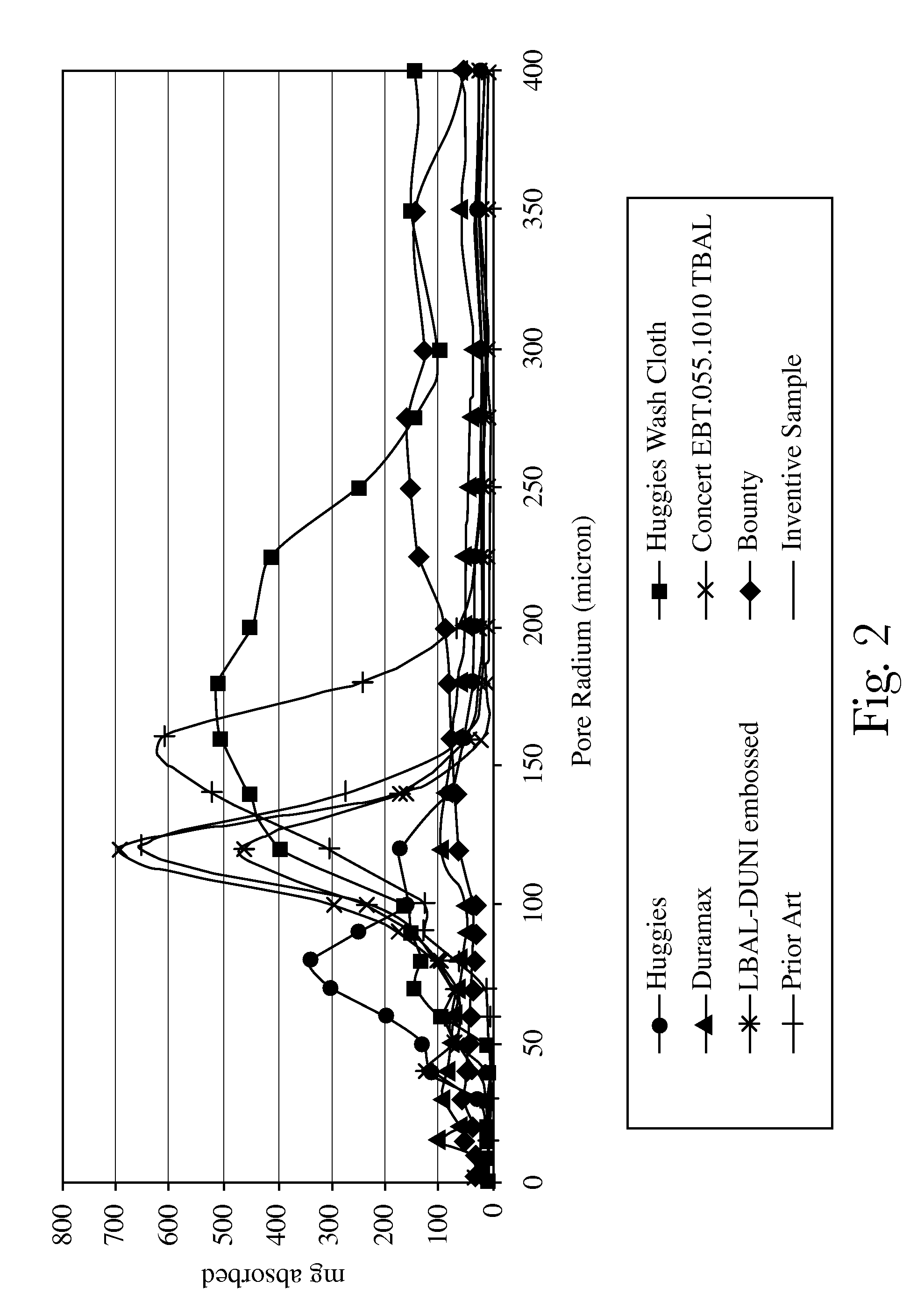

Fibrous structures and methods for making same

ActiveUS20090084513A1Improved absorbency and strength propertyCellulosic pulp after-treatmentNon-fibrous pulp additionFiberMaterials science

Fibrous structures that exhibit improved consumer recognizable properties, especially a VFS of greater than about 11 g / g, and to methods for making such fibrous structures are provided.

Owner:THE PROCTER & GAMBLE COMPANY

Cellulose-based fibrous materials

ActiveUS20090065164A1Low densityImprove surface qualityCellulosic pulp after-treatmentReinforcing agents additionFiberPolymer science

The present invention aims to provide cellulose-based fibrous materials for obtaining papers and sheets having low density, high surface quality, good size stability despite of high strength, and high opacity. Cellulose-based fibrous materials having external fibrils consisting of an assembly of scale-like microfibrils exhibit a higher fiber stiffness, a lower water retention value and a higher specific surface area as compared with fibrous materials having filamentous external fibrils at the same freeness. Papers and sheets having low density, high surface quality, good size stability and high opacity can be obtained by using such fibrous materials.

Owner:NIPPON PAPER IND CO LTD

Fibrous structures

Owner:THE PROCTER & GAMBLE COMPANY

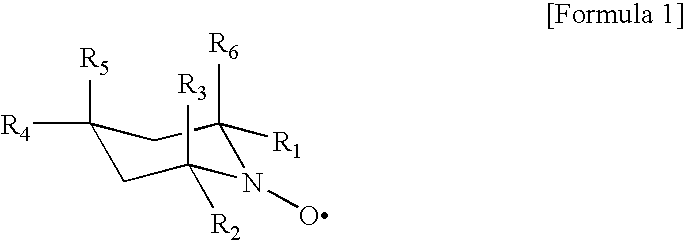

Processes for producing cellulose nanofibers, cellulose oxidation catalysts and methods for oxidizing cellulose

The present invention aims to provide a process for producing cellulose nanofibers using a 4-hydroxy TEMPO derivative less expensive than TEMPO and a process capable of rapidly producing homogeneous cellulose nanofibers. Wood cellulose can be efficiently converted into nanofibers by a process for producing cellulose nanofibers comprising treating a cellulosic material with an oxidizing agent in water in the presence of a cellulose oxidation catalyst comprising an N-oxyl compound represented by formula 1 below:wherein R1 and R2 are each independently hydrogen or a C1-C6 straight or branched alkyl group; and(i) one of R4 or R5 is —OR, —OCOR or —OSO2R wherein R is a straight or branched carbon chain having 4 or less carbon atoms, and the other of R4 or R5 is hydrogen, and R3 and R6 are methyl, or(ii) R4 is hydrogen, and R5, R3 and R6 are taken together with a piperidine ring to form an aza-adamantane compound having formula 2 below:or a mixture thereof, and a compound selected from the group consisting of bromides, iodides and mixtures thereof to prepare oxidized cellulose, and microfibrillating the oxidized cellulose to convert it into nanofibers.

Owner:NIPPON PAPER IND CO LTD

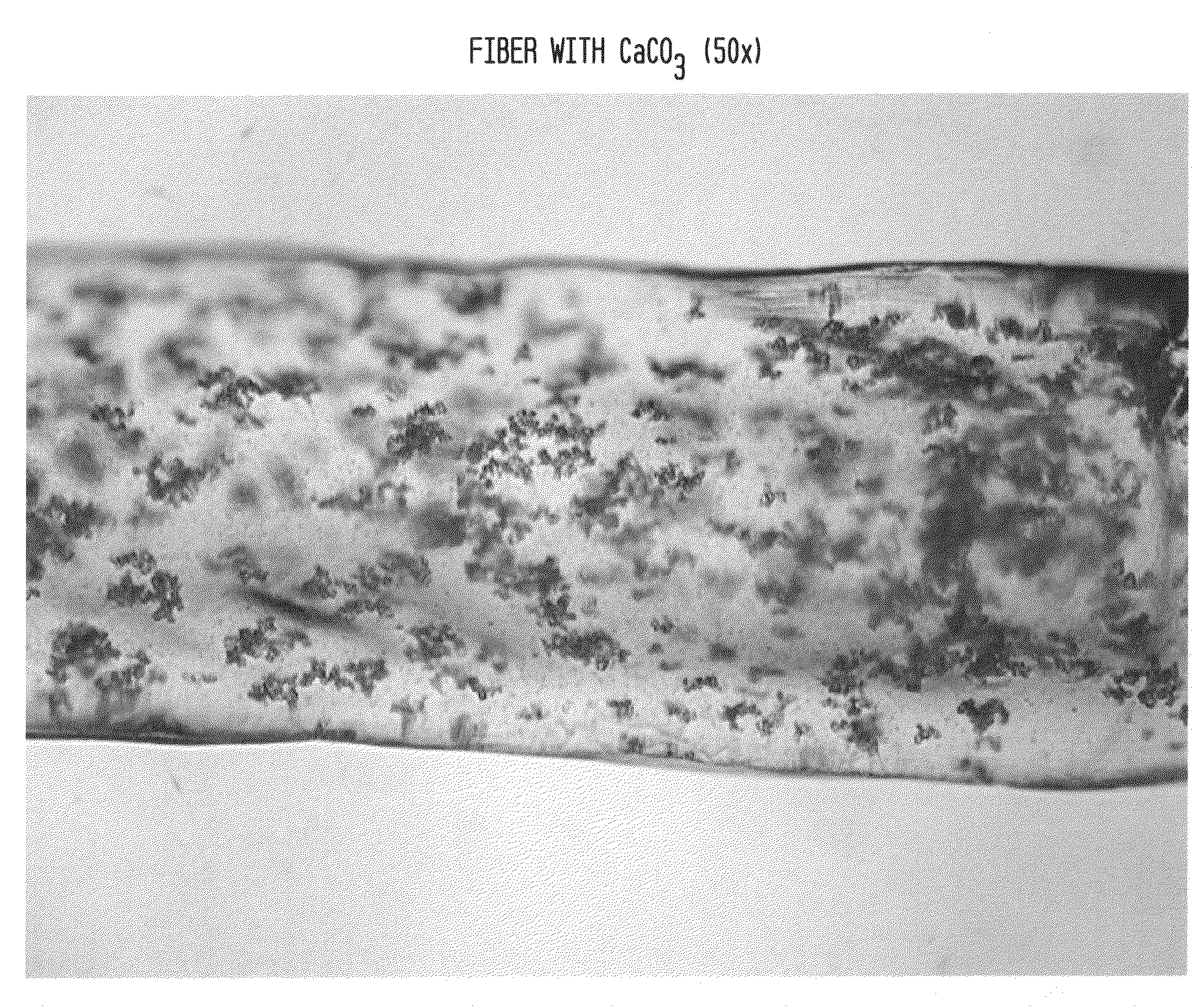

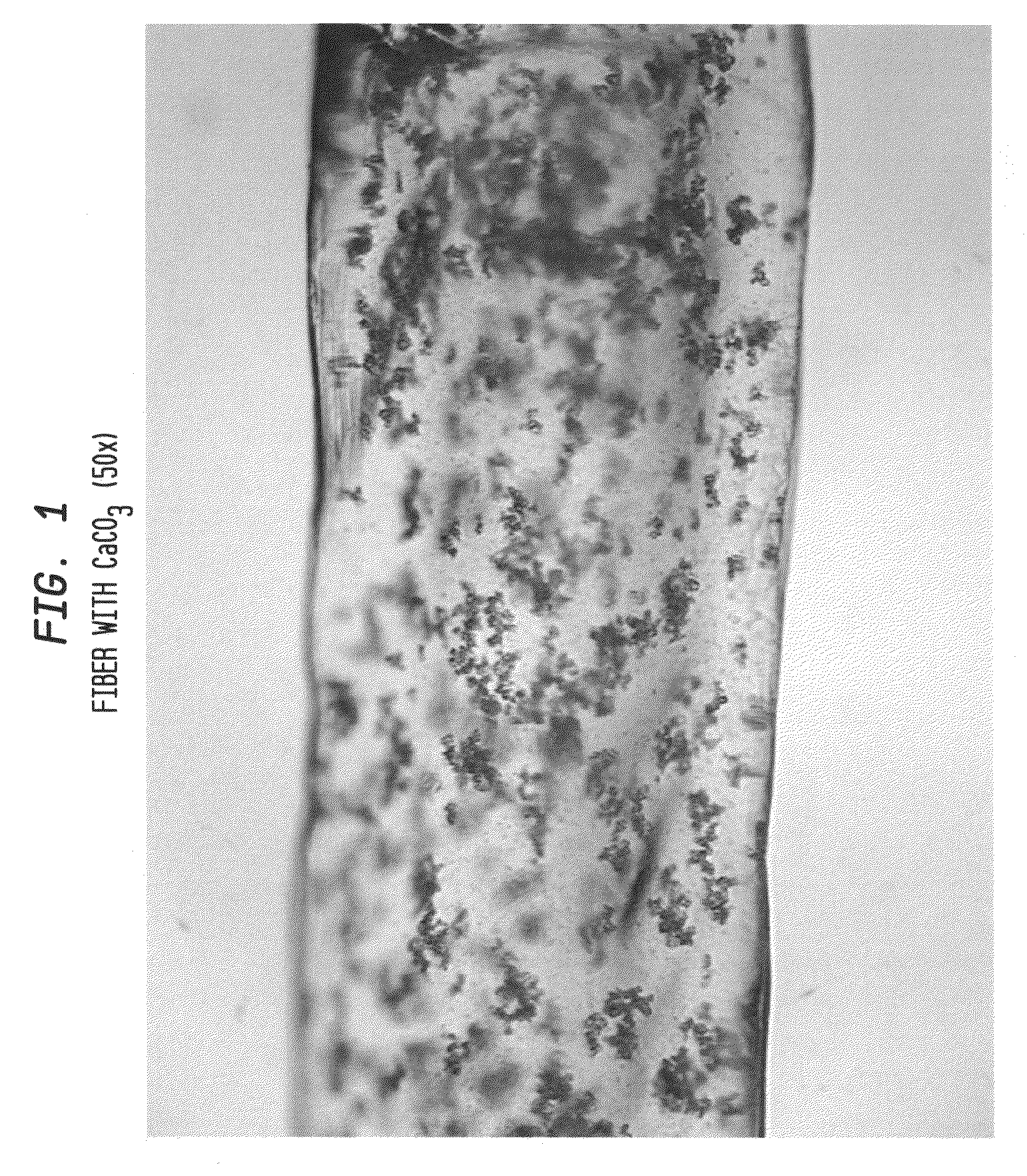

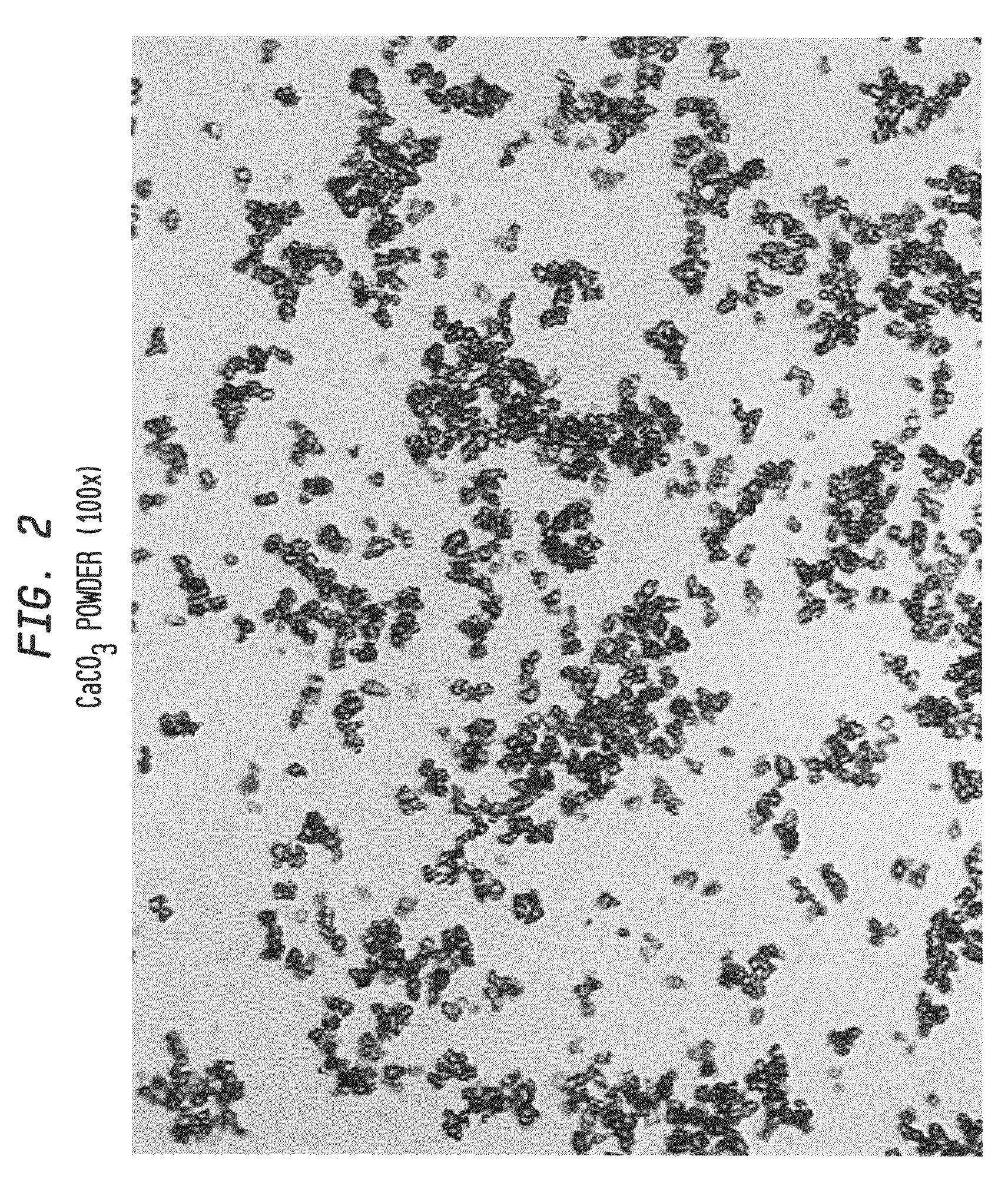

Filler-fiber composite

The present invention relates to a filler-fiber composite, a process for its production, the use of such in the manufacture of paper or paperboard products and to paper produced therefrom. More particularly the invention relates to a filler-fiber composite in which the morphology and particle size of the mineral filler are established prior to the development of the bond to the fiber. Even more particularly, the present invention relates to a PCC filler-fiber composite, wherein the desired optical and physical properties of the paper produced therefrom are realized.

Owner:SPECIALITY MINERALS (MICHIGAN) INC

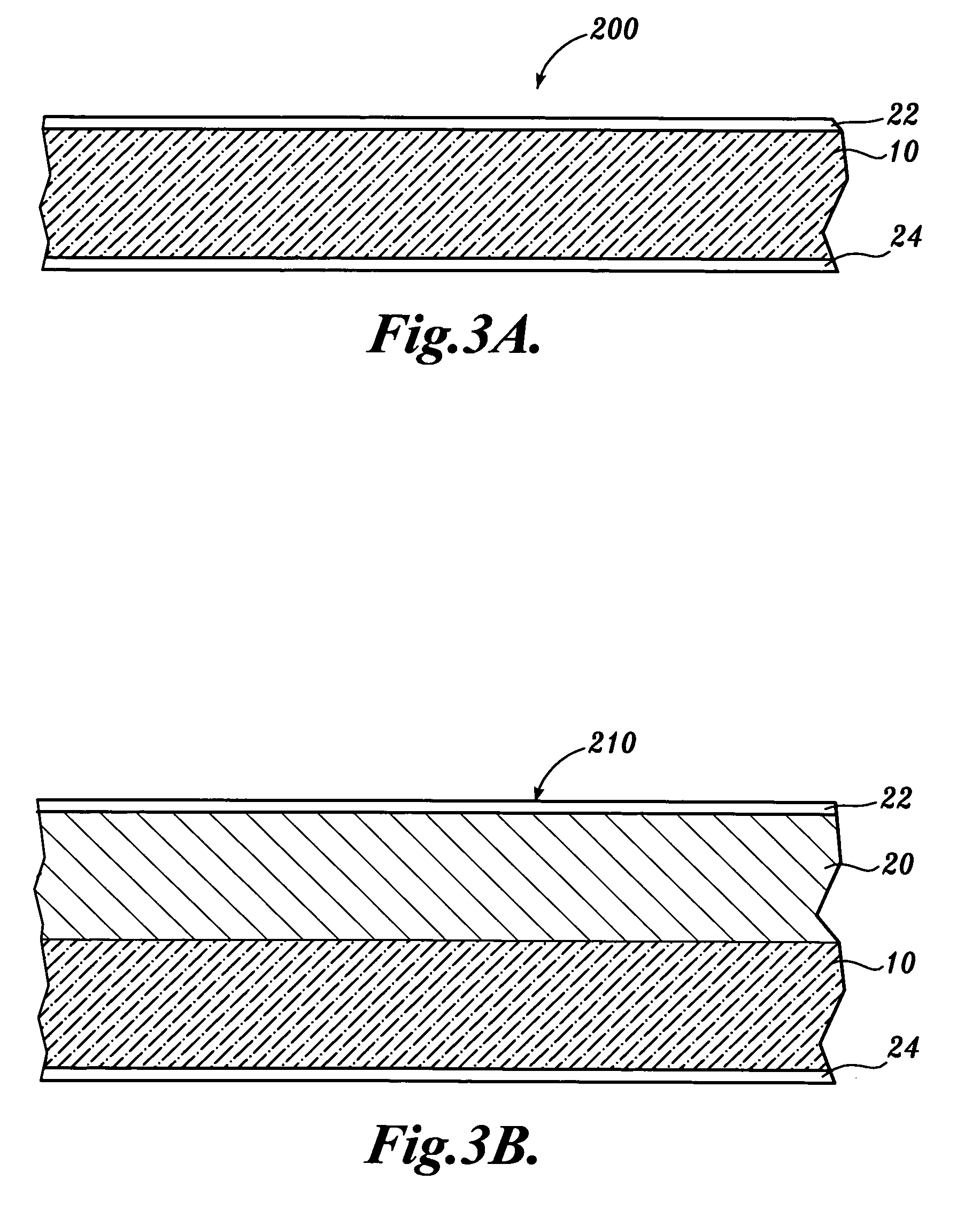

Soft Single-Ply Tissue

ActiveUS20100051218A1Low breaking lengthIncreased durabilityCellulosic pulp after-treatmentNon-fibrous pulp additionBiomedical engineeringPaper sheet

A soft single-ply tissue sheet is produced by making a textured, high bulk, through dried tissue sheet and calendering the sheet with a high level of compression energy to substantially reduce the bulk and impart improved properties to the sheet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Biorefinery Process for Extraction, Separation, and Recovery of Fermentable Saccharides, other Useful Compounds, and Yield of Improved Lignocellulosic Material from Plant Biomass

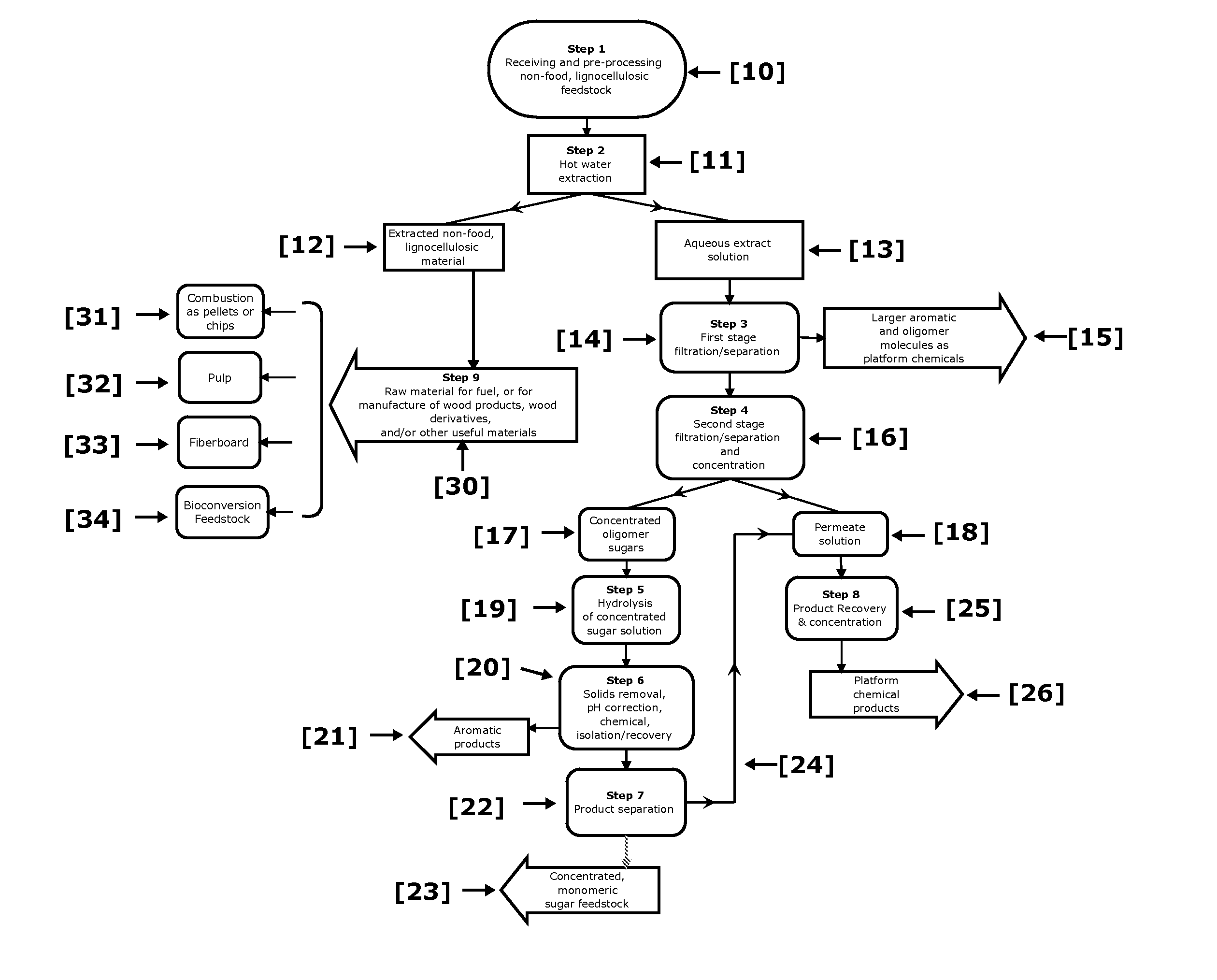

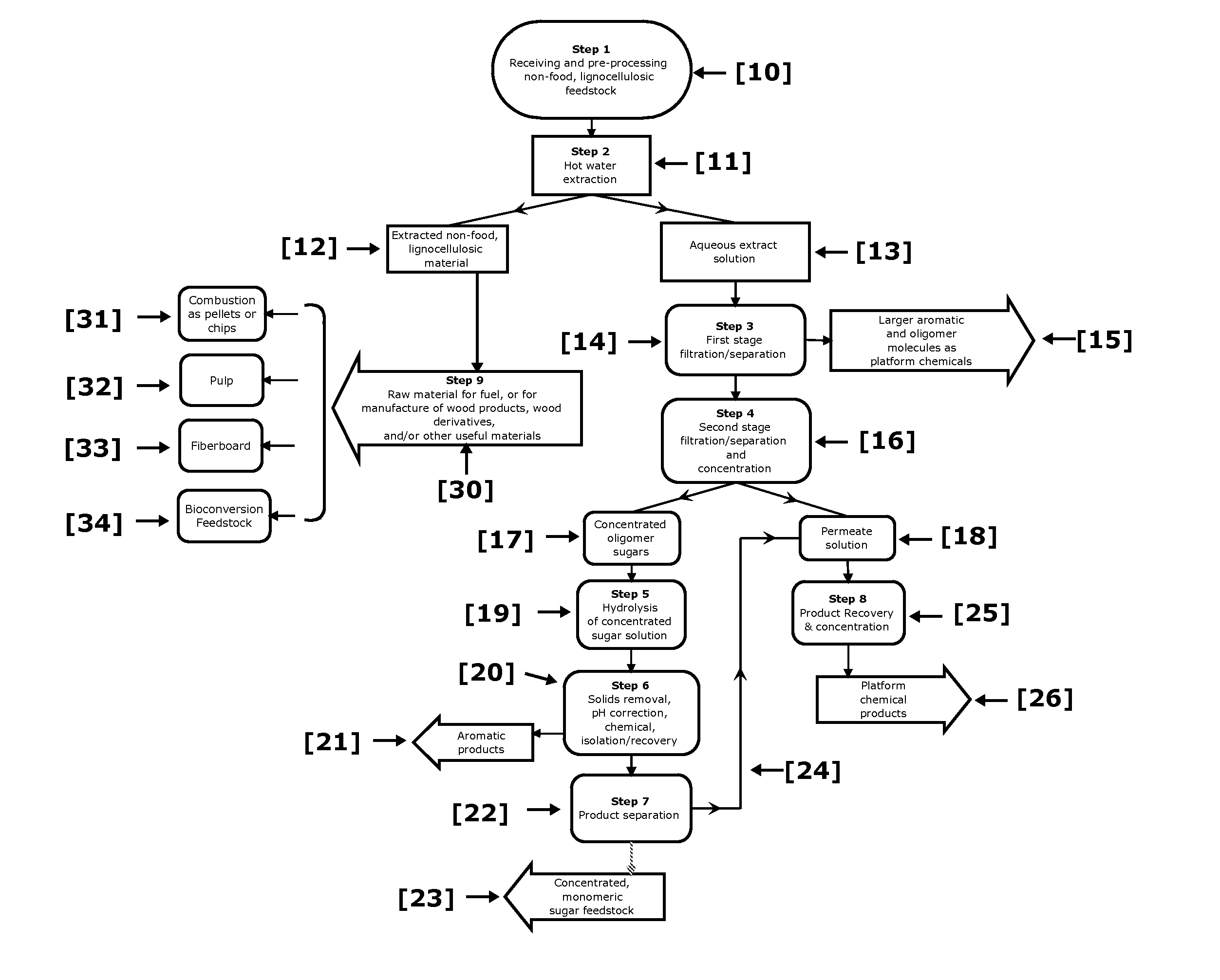

ActiveUS20110129886A1Increase diversityIncrease probabilityCellulosic pulp after-treatmentBiofuelsFurfuralAqueous extract

Non-food plant biomass is subjected to hot-water extraction in a pressurized vessel at an elevated temperature up to about 250° C. and at a pH below about 7.0, to yield an aqueous extract containing hemicellulosic components, other wood-derived compounds, and a lignocellulosic residue. The separated aqueous extract or liquor is purified and concentrated through a multi-step process producing fermentable sugars. At each stage, inhibitory chemicals such as acetic acid, lignin, and furfural are separated and eventually recovered as commercial chemicals. The lignocellulosic residue may be further processed, as a material with enhanced resistance to sorption of water, for manufacture of improved pulp and paper, construction materials, pellet fuel, and / or other useful products.

Owner:APPLIED BIOREFINERY SCI

Oxygen delignify treating method for grass group unbleached chemical pulp

ActiveCN101082187ALow percussionImprove water filtration performanceCellulosic pulp after-treatmentPulping with inorganic basesCelluloseMagnesium salt

The invention relates to an oxygen delignification processing method of grass unbleached chemical pulp. The oxygen delignification of the pulp is processed after cooking and before bleaching. Its rigidity before the oxygen delignification is potassium permanganate value 16-28 (equals to karber value 26-50). After pumping into the oxygen delignification reaction tower and inflating sodium hydroxide, magnesium salt and oxygen, the chemical pulp happen the oxygen delignification in the reaction tower. The chemical pulp with rigidity of potassium permanganate value 10-14 (equals to karber value 14-18) is achieved after the oxygen delignification. The invention can remove the lignin in the pulp effectively and the removal rate is 86-98%. It reduces the degradation of the cellulose to simplify the bleaching process and cut down the dosage of the chemicals. The bleached pulp has good rigidity and drainability. The breaking length of the pulp can reach 4500-8000m and its fold-resistant times can reach 20-70.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

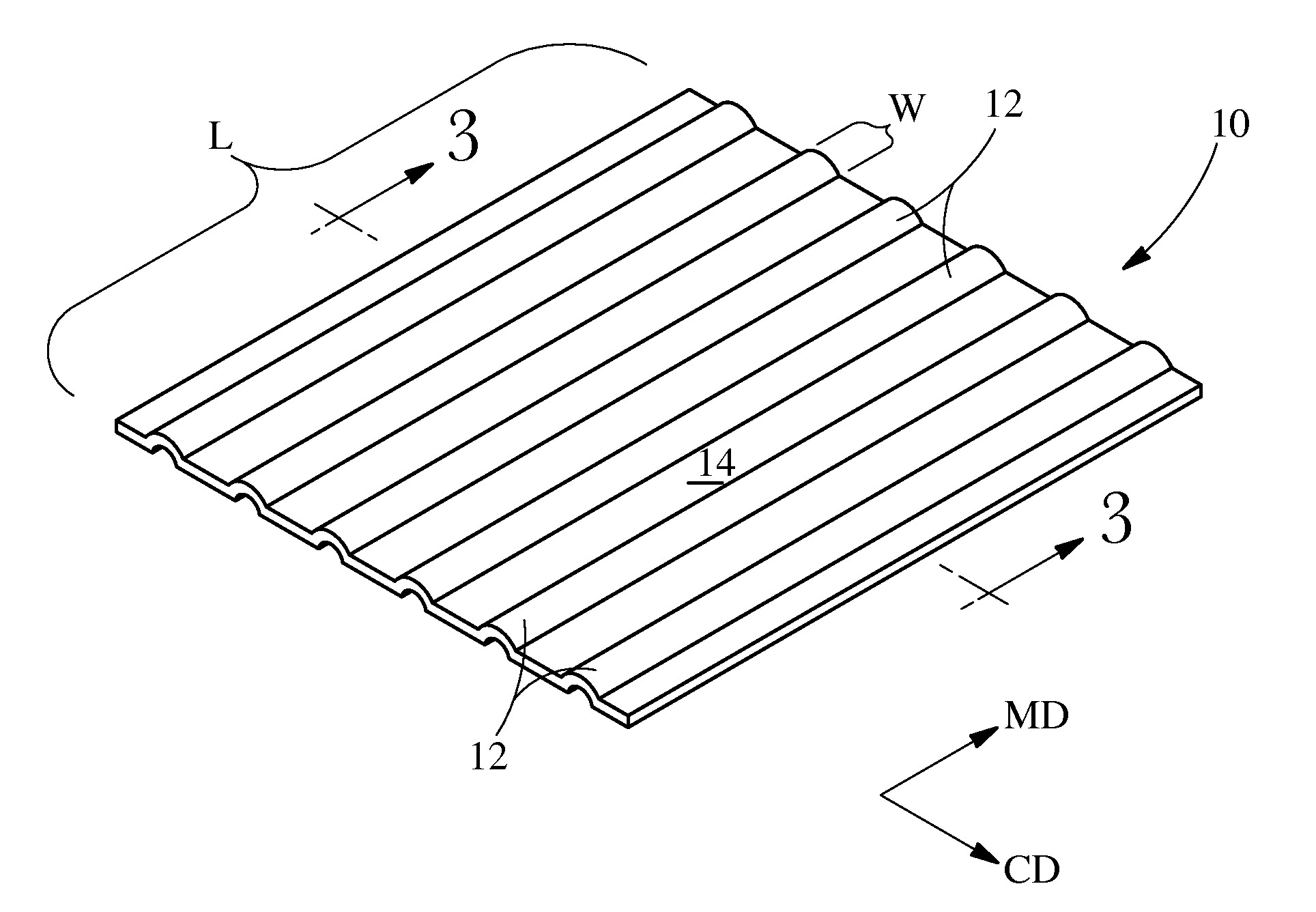

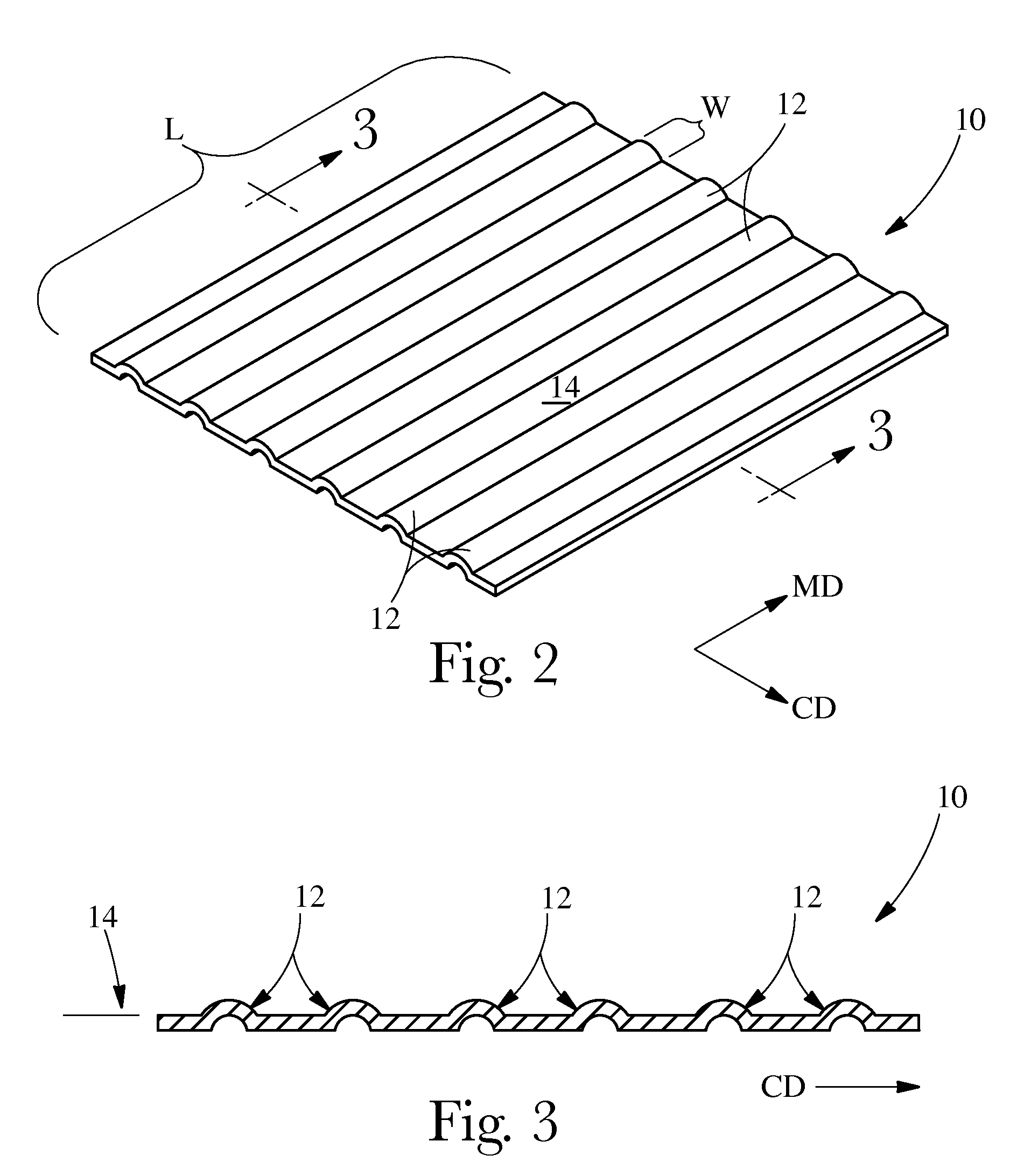

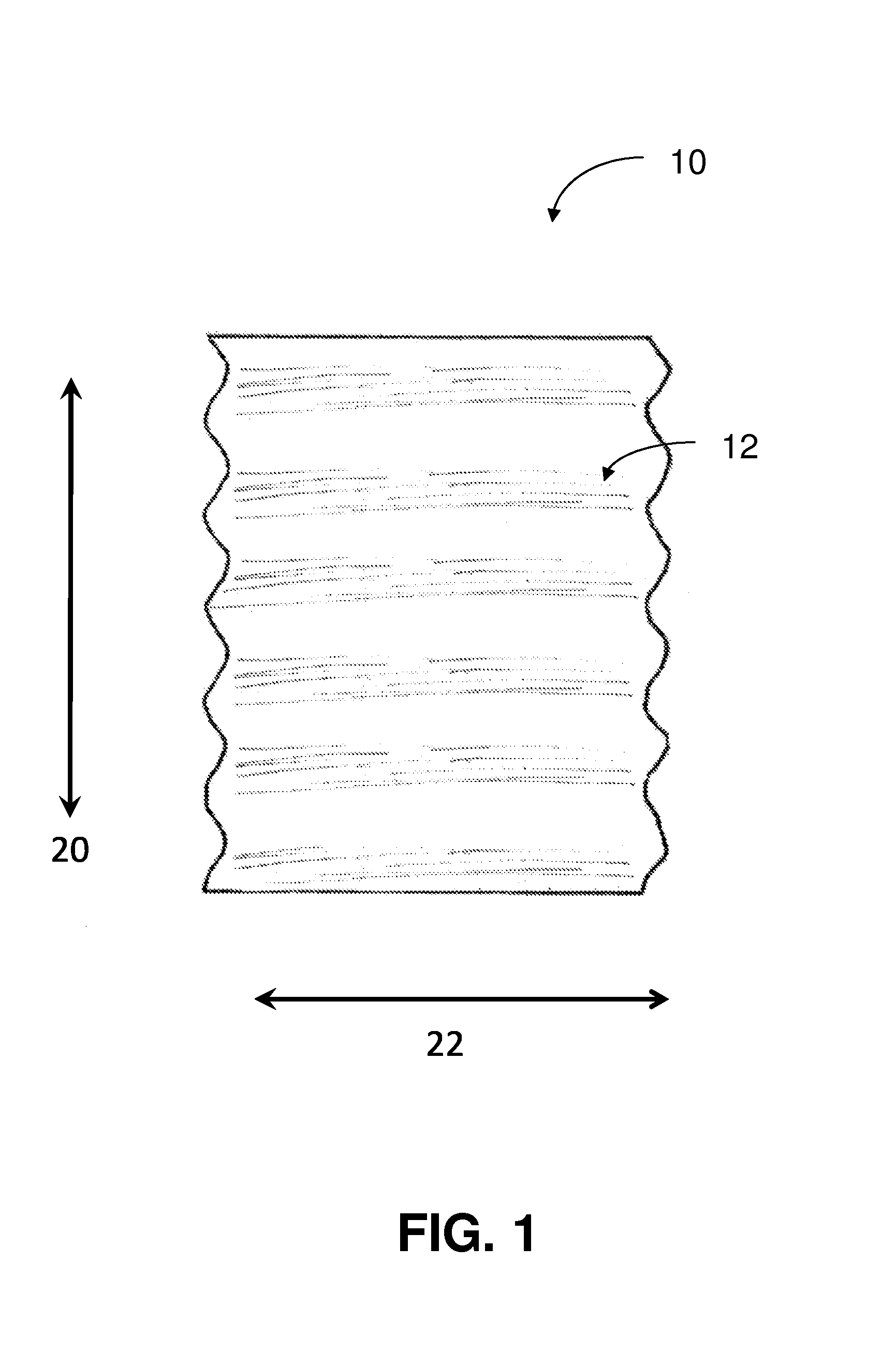

Flutable fiber webs with high dust holding capacity

The fiber webs described herein may be incorporated into filter media and filter elements. The fiber webs may exhibit a high dust holding capacity. The fiber webs may also exhibit a low thickness. The fiber webs may be sufficiently flexible and / or deformable so that they may be processed to include a series of waves (also known as flutes) that extend along the cross-machine direction.

Owner:HOLLINGSWORTH VOSE

Method for making carboxyalkyl cellulose

Owner:INT PAPER CANADA PULP HLDG ULC

Fibrous structures and methods for making same

Owner:THE PROCTER & GAMBLE COMPANY

Fibrous structures and methods for making same

Owner:THE PROCTER & GAMBLE COMPANY

Inflated filbers of regenerated cellulose formed from ionic liguid/cellulose dope and related products

Inflated fibers of regenerated cellulose and other regenerated structures are formed from ionic liquid / cellulose dope. Fibers so produced may be incorporated into absorbent sheet with other papermaking fibers to provide softness, bulk and absorbency.

Owner:GPCP IP HLDG LLC

Energy efficient TMP refining of destructured chips

InactiveUS20060006264A1Quality improvementReduce energy consumptionCellulosic pulp after-treatmentPretreatment with water/steamFiberRing pattern

A system and method for thermomechanical refining of wood chips comprises preparing the chips for refining by exposing the chips to an environment of steam to soften the chips, compressively destructuring and dewatering the softened chips to a solids consistency above 55 percent, and diluting the destructured and dewatered chips to a consistency in the range of about 30 to 55 percent. The destructuring partially defibrates the material. This diluted material is fed to a rotating disc primary refiner wherein each of the opposed discs has an inner ring pattern of bars and grooves and an outer ring pattern of bars and grooves. The destructured and partially defibrated chips are substantially completely defibrated in the inner ring and the resulting fibers are fibrillated in the outer ring. The compressive destructuring, dewatering, and dilution can all be implemented in one integrated piece of equipment immediately upstream of the primary refiner, and the fiberizing and fibrillating are both achieved between only one set of relatively rotating discs in the primary refiner.

Owner:ANDRITZ INC

High strength material using cellulose micro-fibril

InactiveUS20050067730A1Reduce amountHigh strengthFibreboardCellulosic pulp after-treatmentFiberPolymer science

The present invention relates to a high strength material and a high strength molded article comprising 65 to 100 wt. % of cellulose microfibrils; and products comprising these. The material, which is lightweight and has a very high strength, can be used for various purposes and can be produced by recycling wastepaper, used cloth and the like. Furthermore, by appropriately selecting the type and / or amount of binder, the material comprising microfibrils as a main component can be decomposed by microbes or the like after being dumped as waste, and is thus friendly to the global environment.

Owner:KYOTO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com