Patents

Literature

971results about "Pulp beating methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

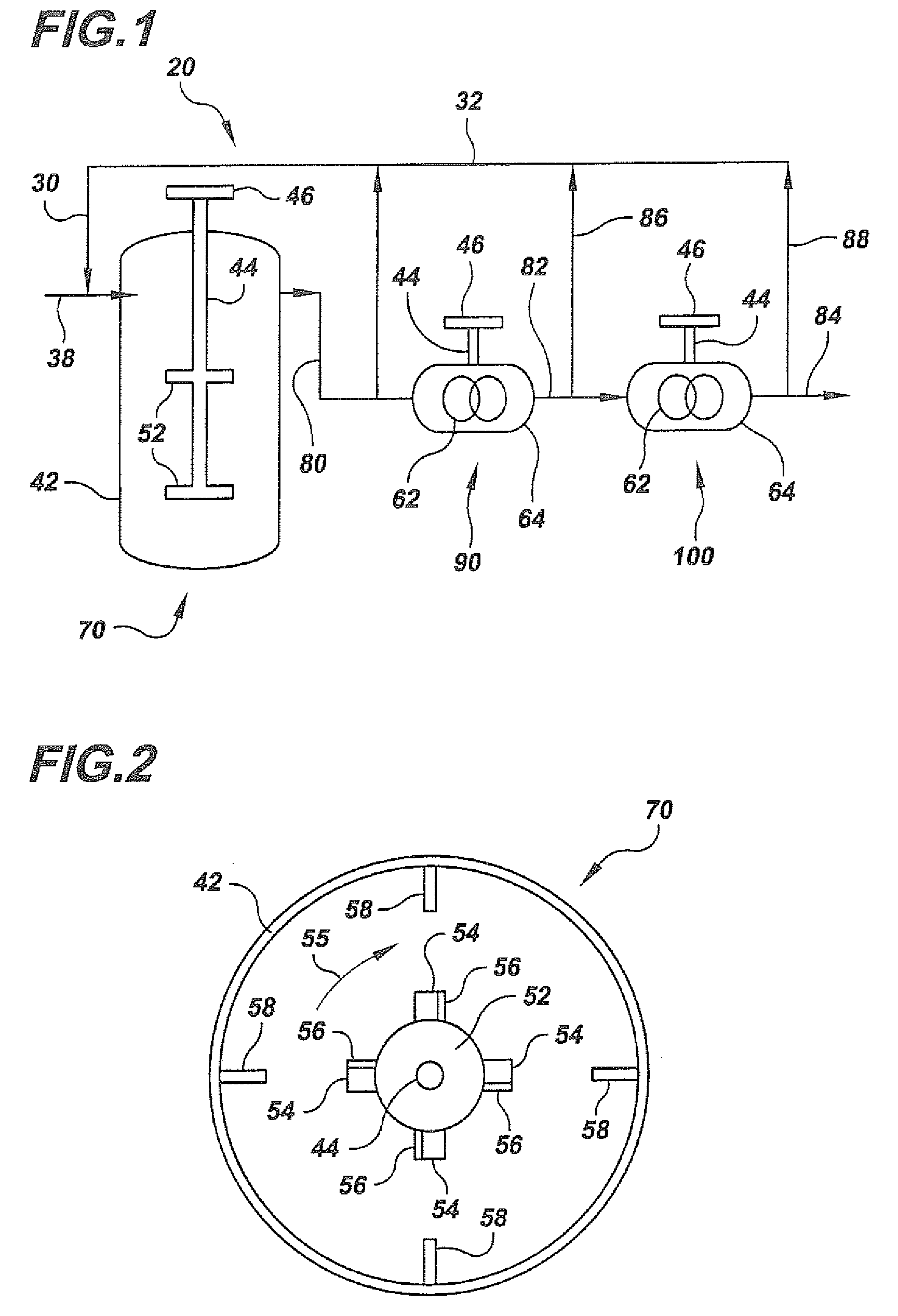

Process for producing nanofibers

ActiveUS20080057307A1Good characterGreat flowabilityCellulosic pulp after-treatmentPulp beating methodsFiberNanofiber

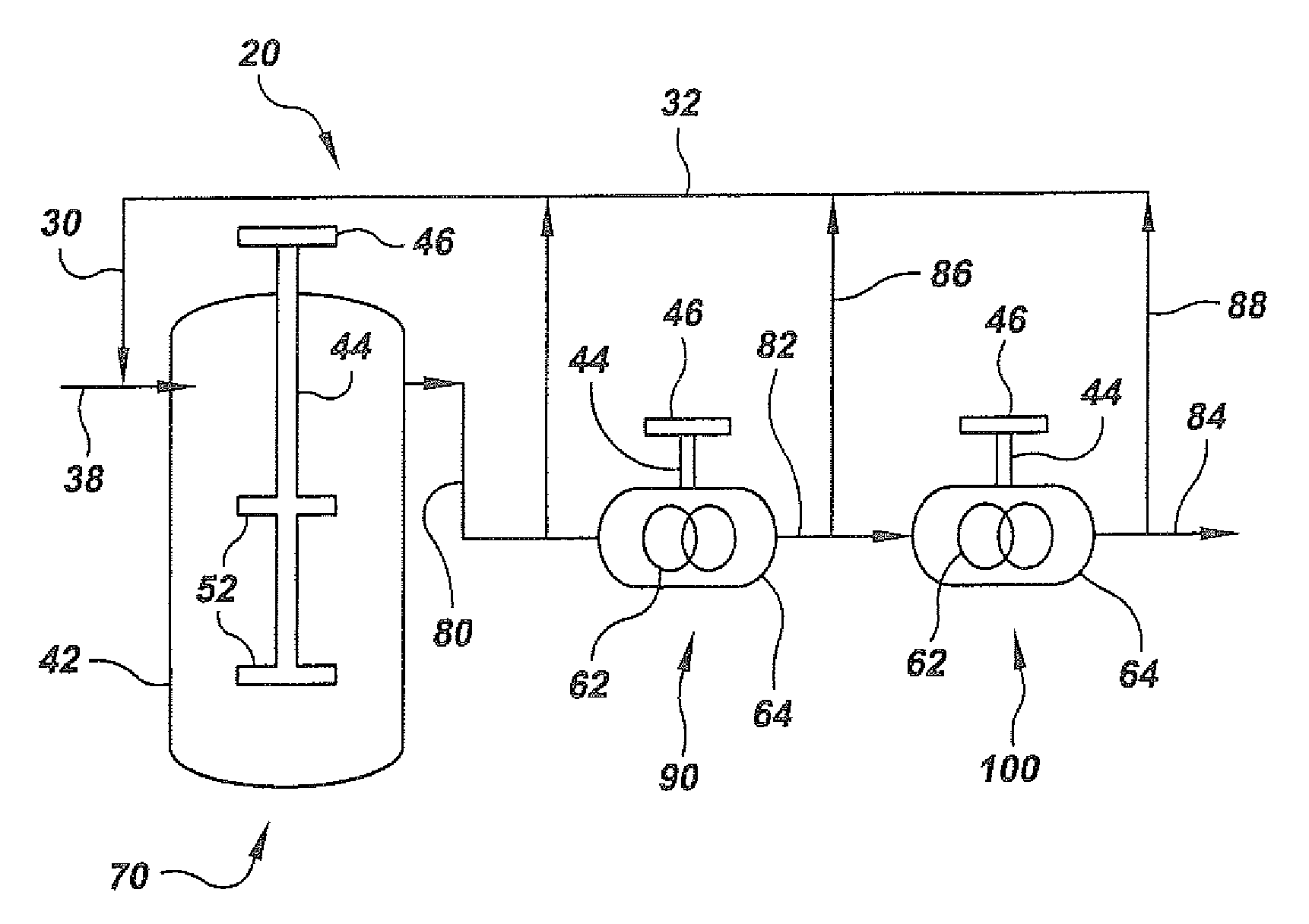

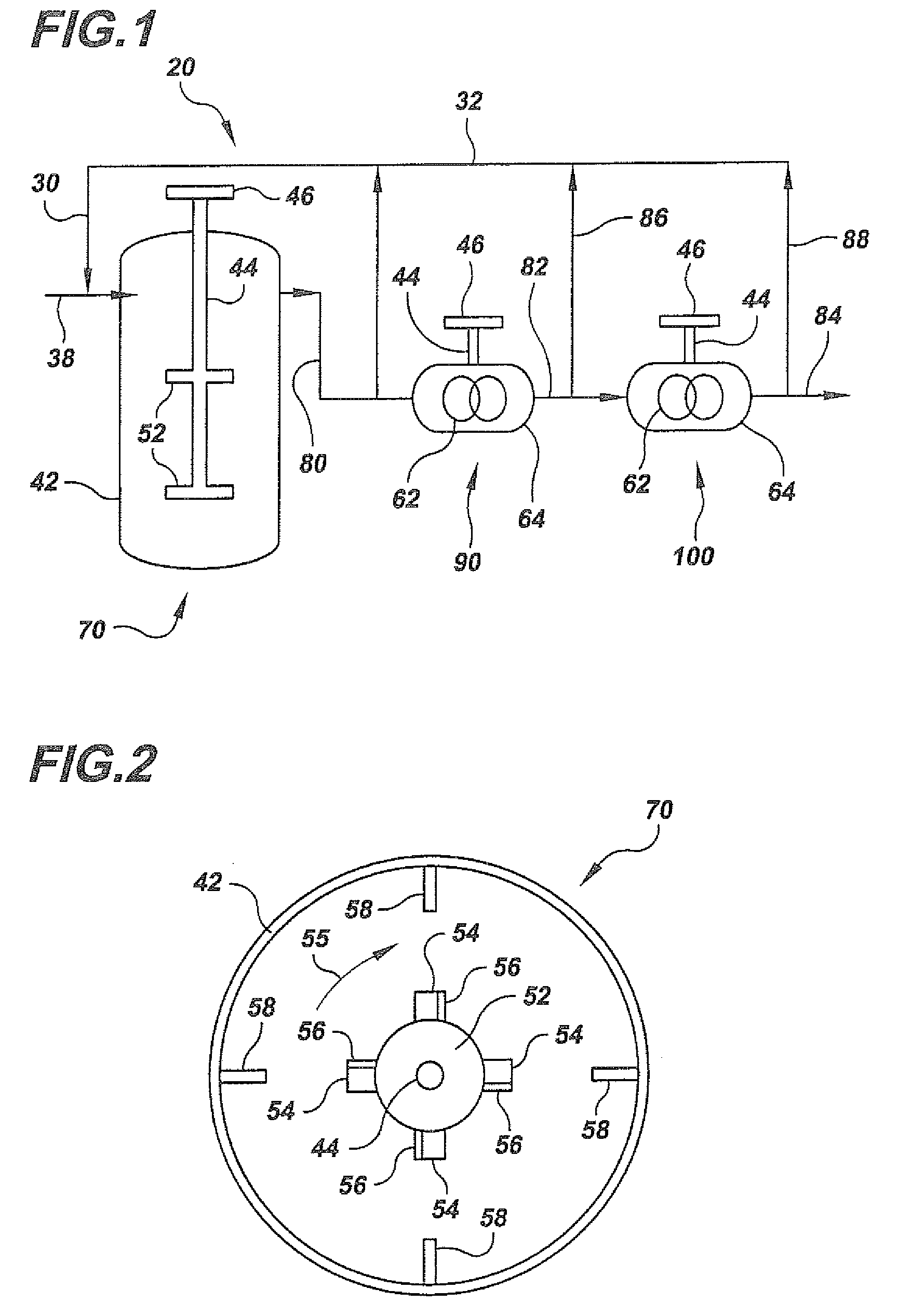

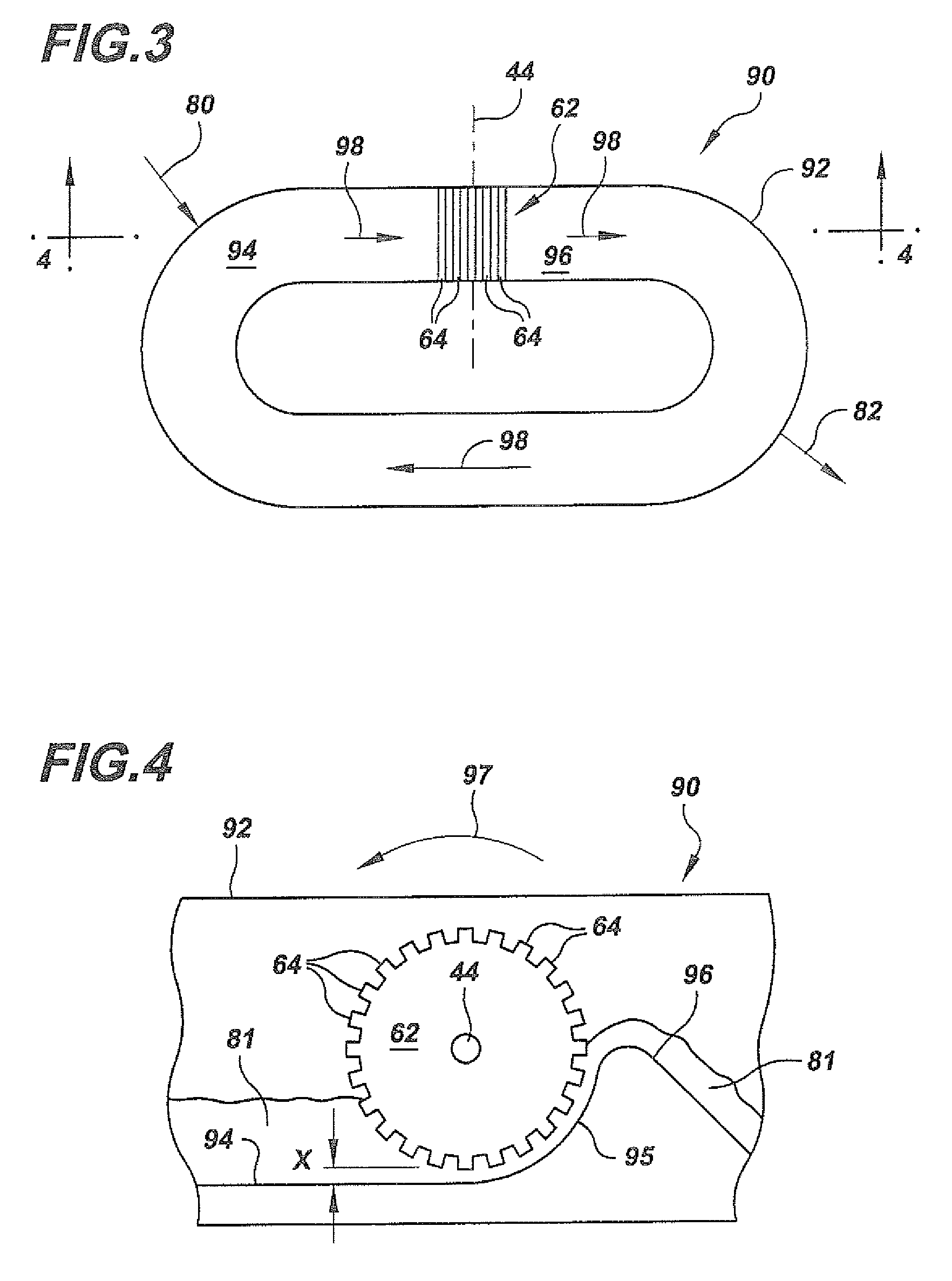

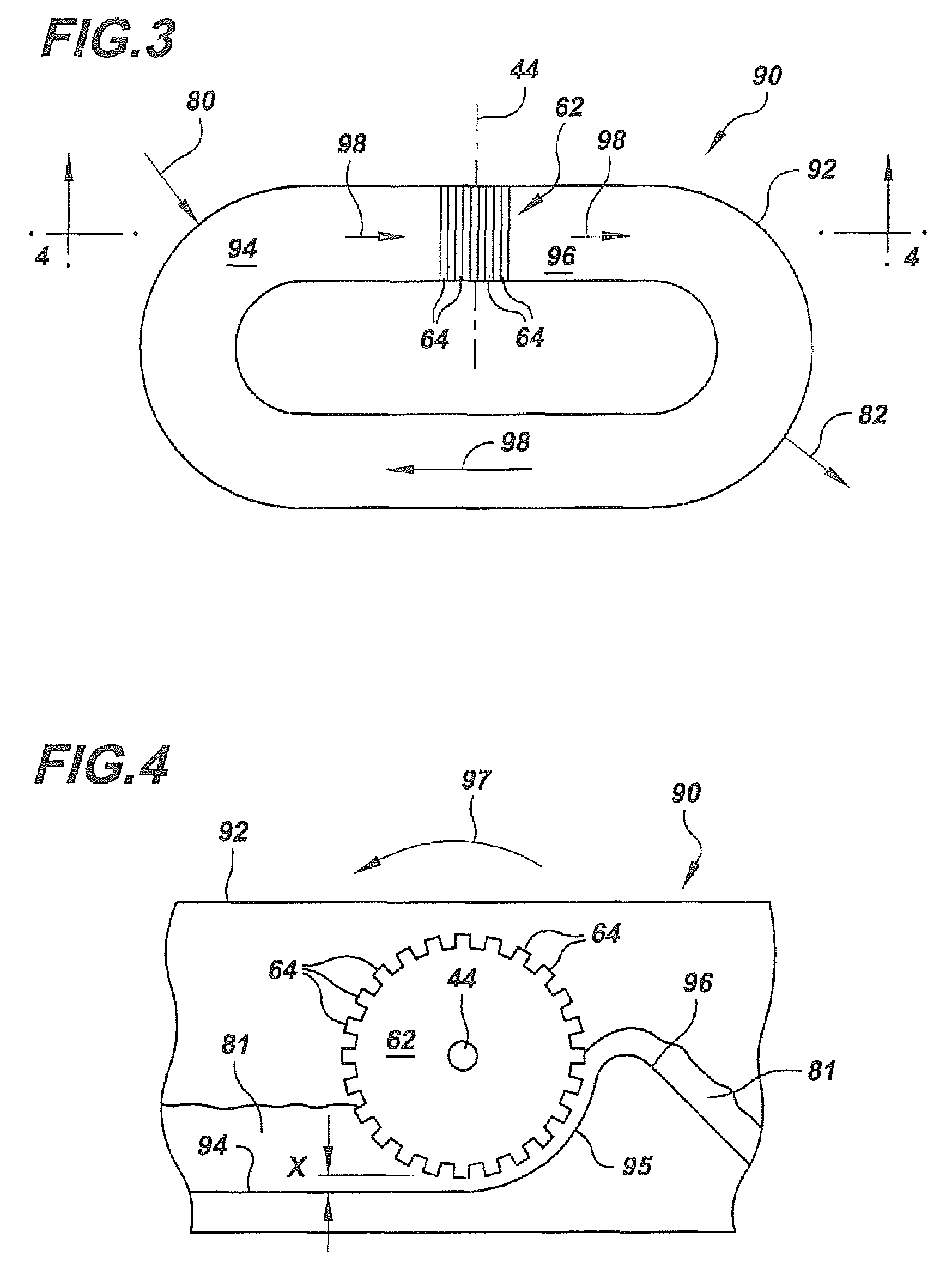

A process for making nanofibers includes preparing a fluid suspension of fibers, shear refining the fibers to create fibrillated fibers, and subsequently closed channel refining or homogenizing the fibrillated fibers to detach nanofibers from the fibrillated fibers. The shear refining of the fibers in the fluid suspension generates fiber cores having attached nanofibers. The closed channel refining or homogenizing of the fibrillated fibers is initially at a first shear rate and, subsequently, at a second, higher shear rate, to detach nanofibers from fiber cores and to create additional nanofibers from the fiber cores. The fiber suspension may flow continuously from the shear refining to the closed channel refining or homogenizing, and include controlling the rate of flow of the fiber suspension from the shear refining to the closed channel refining or homogenizing.

Owner:KX TECH LLC (DW US)

Novel pulping process for obtaining high performance fiber at high yield from plants

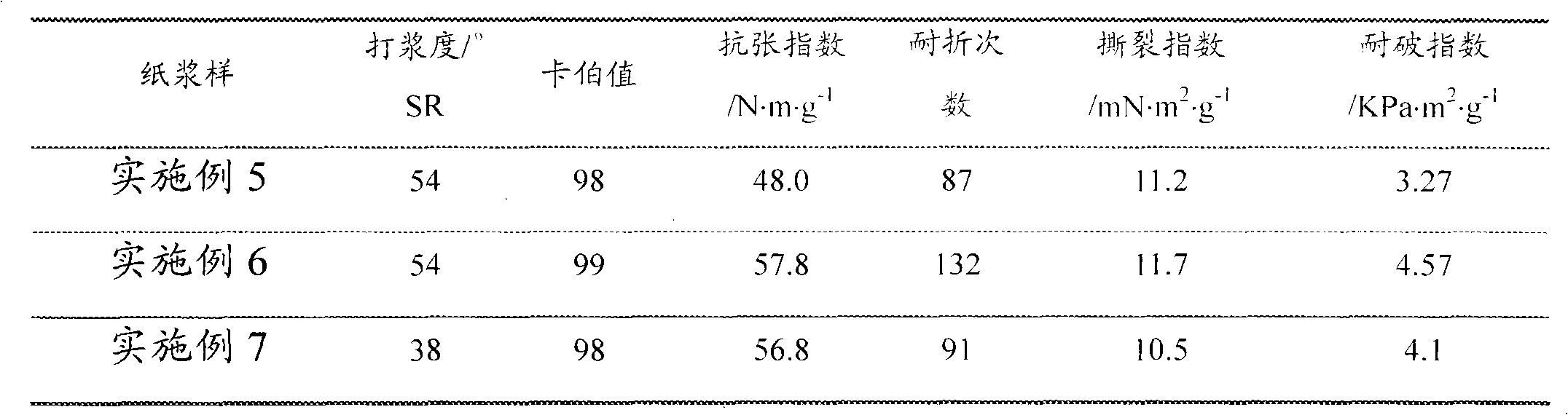

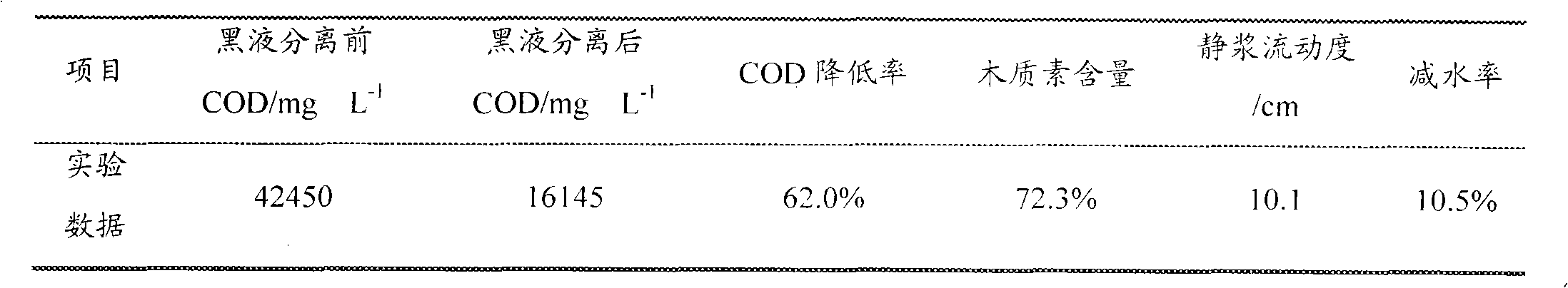

ActiveCN102337687AGood physical propertiesAvoid influencePulp beating methodsPulping with inorganic basesChemical treatmentFiber

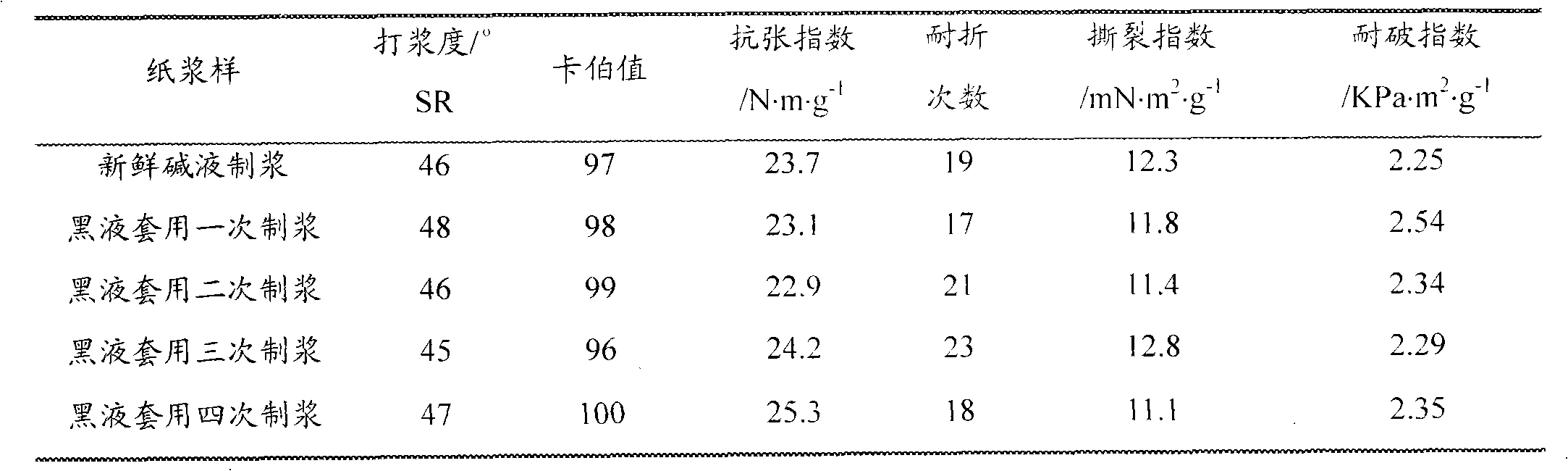

The invention relates to a cleaning process for extracting high quality fiber with high efficiency, high yield and low energy consumption from plant raw materials by a combination method of chemistry and machinery in a sectional type. The process comprises the following steps: a raw material is fully immersed in a NaOH solution or a KOH solution or limewater with low concentration (black liquor is used for supplementing into the corresponding alkaline for repeated and circular use) under the normal temperature or certain temperature, wherein the concrete immersion temperature and immersion time can be determined according to the types and the water content of the raw materials so that the alkaline liquor is fully, uniformly and properly absorbed and diffused into plants; steaming under normal pressure or steaming with pressure or no liquid steaming with pressure is used; the steamed material can be selected according to the paper quality requirement by using a blowout slurrying mode or a mode of pulp refining after blowing to form slurry or by using thread rolling and pulp refining to relief material once or multitime to prepare slurry. The novel process combines the advantages of chemical treatment and mechanical pulping, so that the uniform mass transfer and uniform heat transfer can be ensured and the damage to cellulose and hemicellulose by excessive alkali can be reduced, the yield of fiber is raised to about 75% from about 45% of the prior art, so that the novel pulping process is capable of avoiding the usage of auxiliary agents like sulfured and anthraquinone, conveniently extracting and using the cellulose and lignin in black liquor, and overcoming the influence on environment during the process of pulping and post-treating lignin.

Owner:BEIJING INSIGHT BIOMASS

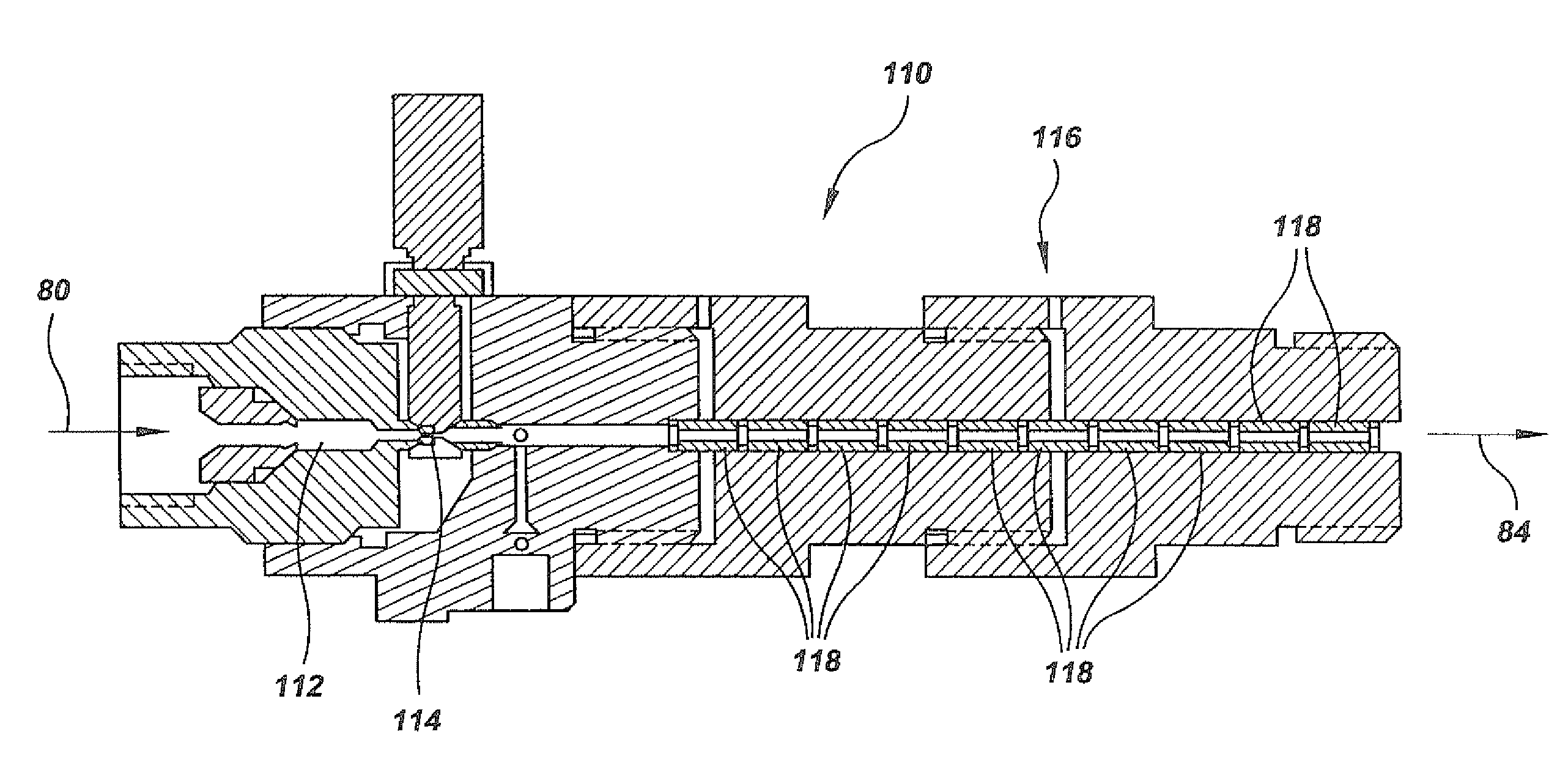

Process for producing nanofibers

ActiveUS8444808B2Good characterGreat flowabilityCellulosic pulp after-treatmentPulp beating methodsFiberShear rate

A process for making nanofibers includes preparing a fluid suspension of fibers, shear refining the fibers to create fibrillated fibers, and subsequently closed channel refining or homogenizing the fibrillated fibers to detach nanofibers from the fibrillated fibers. The shear refining of the fibers in the fluid suspension generates fiber cores having attached nanofibers. The closed channel refining or homogenizing of the fibrillated fibers is initially at a first shear rate and, subsequently, at a second, higher shear rate, to detach nanofibers from fiber cores and to create additional nanofibers from the fiber cores. The fiber suspension may flow continuously from the shear refining to the closed channel refining or homogenizing, and include controlling the rate of flow of the fiber suspension from the shear refining to the closed channel refining or homogenizing.

Owner:KX TECH LLC (DW US)

Corrugated paper produced by steam blasting straw to pulp and its production method

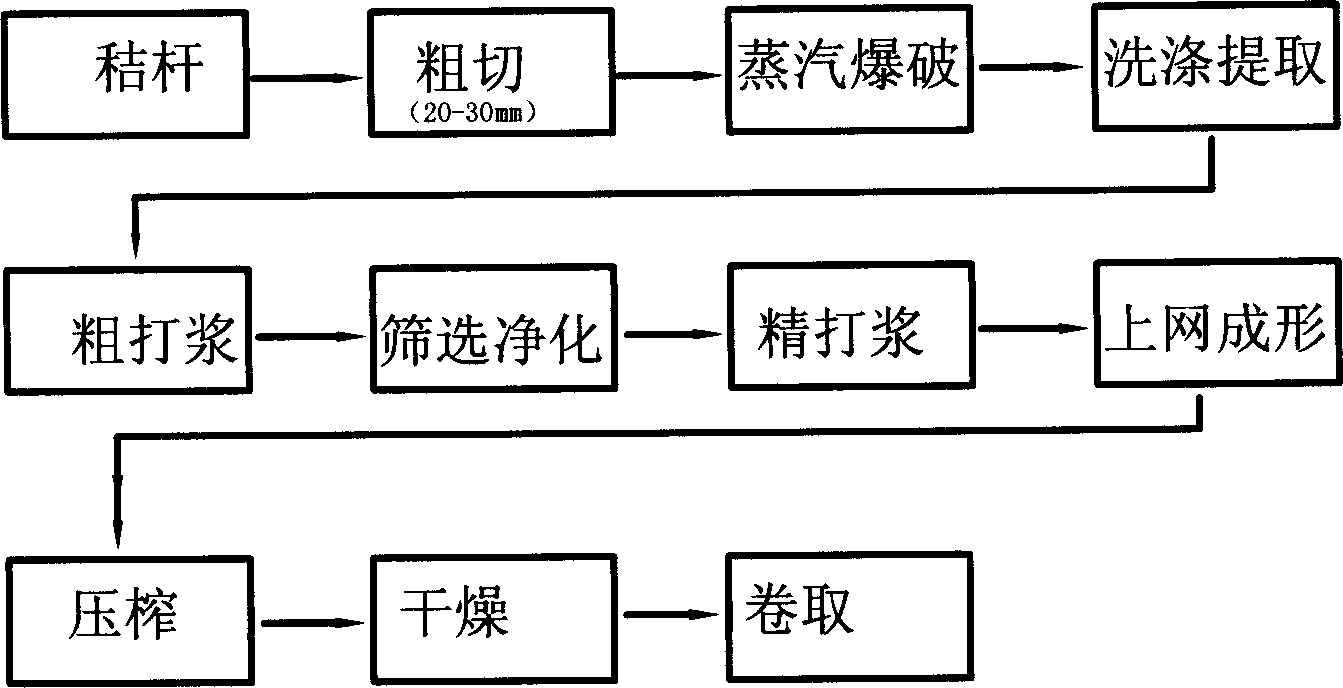

The invention relates to light weight high fatigue resistance semi-chemical corrugated paper produced by steam blasting stalk Kraft process and its manufacturing method. The method includes the following steps: using stalk as the raw material; do steam blasting after coarse cutting; adding its 0.5-2% bone dry weight into caustic soda; filling in steam blasting pot; vapor phase boiling temperature is 145-180 deg.C; pressure is 0.9-2.0MPa; treatment is time 12-18 min; gaining steam blasting stalk; washing and extracting; coarse beating; sieving; purifying; fine beating; gaining steam blasting ryegrass pulp; mixing the pulp and the existing natural color long fiber with 50-70% and 30-50% of their absolute dry percentages; facing wire and forming; pressing; drying; balling up to gain finished products. The invention has the advantages of low energy consumption, low pollution, and high yield. And it is good for environmental protection. The produced semi-chemical corrugated paper has the features of light weight, high fatigue resistance, and flat appearance.

Owner:山东丰源中科生态科技有限公司

Process for producing cotton dissolving pulp

The invention relates to a production technique of a dissolved cotton pulp, in particular to a production technique that utilizes the raw material of cotton linters and adopts simple techniques to produce the dissolved cotton pulp with even fiber length, high fibrillation degree, good intensity, less water soluble substances, high methylcellulose content, stable polymerization degree and less dust, has low COD discharge in waste water, and lowers environmental pollution. The dissolved cotton pulp produced by the production technique is mainly used for producing paper that is used for wiping upper-scale precise instruments, steel paper that is used for precise machining, a novel medicine loading agent of microcrystalline cellulose, explosive nitrocellulose, high-level nitrolacquer and building coating materials, etc.

Owner:山东银鹰股份有限公司

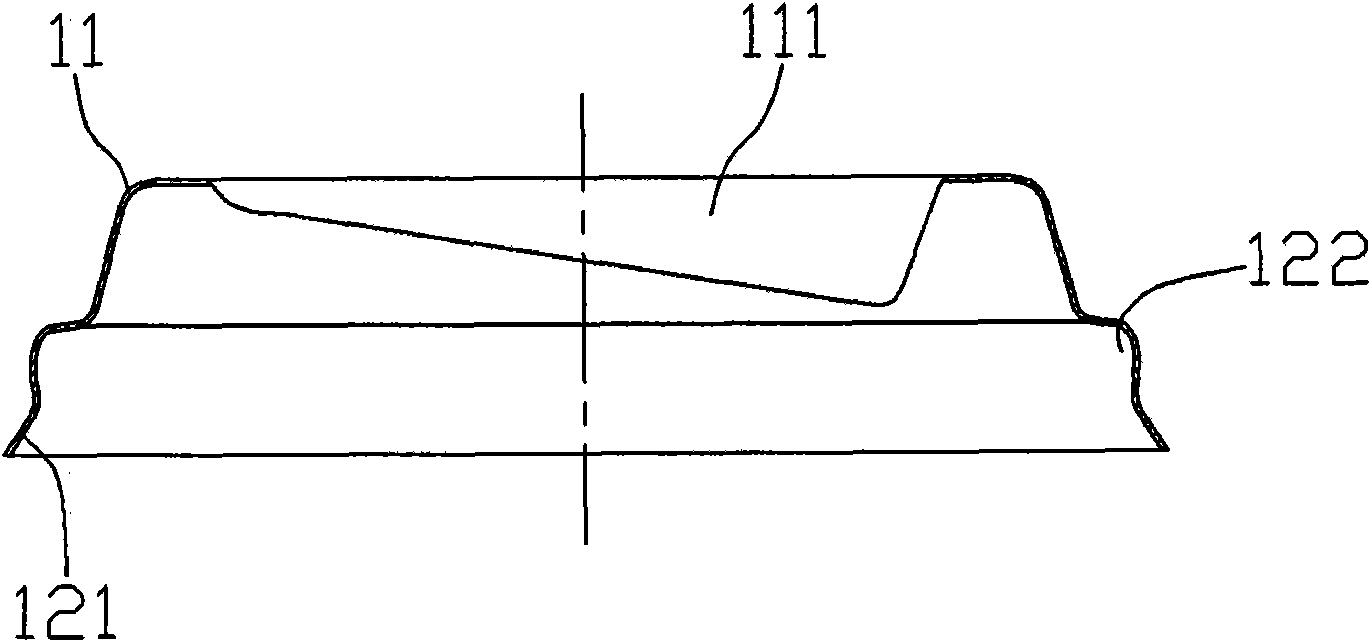

Manufacture process of disposable bowl cover and bowl cover made by same

InactiveCN101637982AReduce energy consumptionImprove waterproof performanceWater-repelling agents additionPaper/cardboard articlesMolded pulpHigh pressure

The invention provides a manufacture process of disposable bowl cover with high strength, strong stability and good water proof performance. The process includes the concrete steps of raw material beating-batching-compression molding-side shearing and punching-making back-off slot by pressing; wherein the material beating includes that: the used raw material is mainly bagasse paddle board accounting for 80-90% of total mass and supported by a small amount of wood pulp and bamboo pulp accounting for 10-20%, water dissociation beating is carried out by a beating engine, and the beating concentration is 4-6%; the compression molding includes: wet blank with water content of 65-75% is directly transferred into an aluminium or steel compression molding mold for high temperature high pressure dehydration, so that the water content of product can reach 5-7%, and the pressure thereof is 15-20x10<3>kgf, the temperature is 150+ / -10 DEG C, and the compression time is 45+ / -5 seconds. Compared withthe existing molded pulp process, the invention saves energy consumption; and the water proof performance, the strength and the stability of the product are greatly improved.

Owner:佛山浩博环保制品有限公司

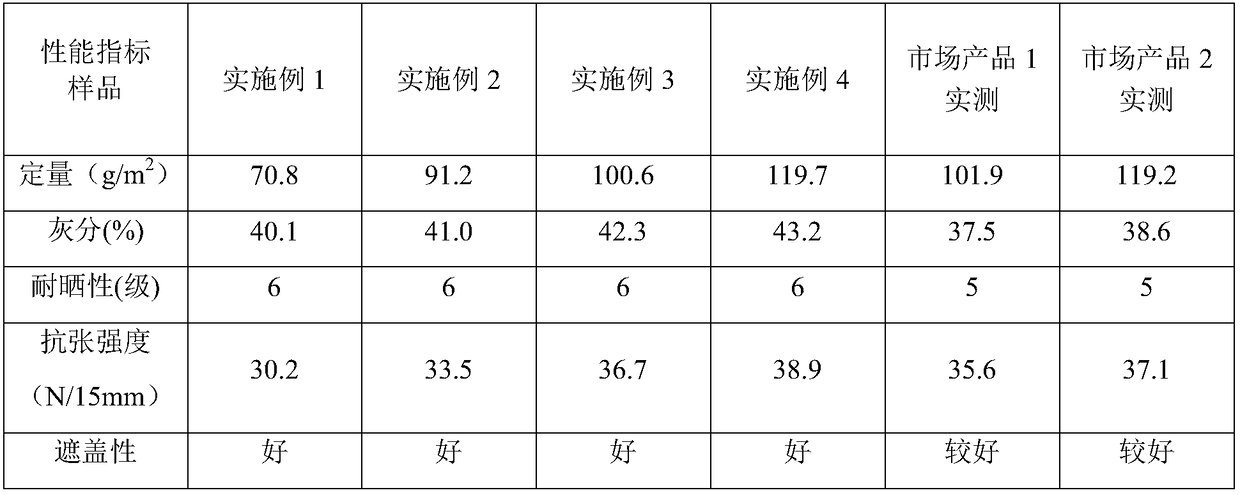

A kind of preparation method of wallpaper base paper

ActiveCN102268835AWith thermal insulation functionGood moisture absorption and release functionNon-fibrous pulp additionPulp beating methodsFiberFar infrared

The invention relates to a preparation method for environment-friendly type tile stocks. The preparation method is characterized in that: besides wood pulp fibers, a plurality of different fibrous raw materials and functional additives are added in the stuff of the tile stocks in the preparation process; and the environment-friendly type tile stocks are prepared through the operations of beating, paper making, squeezing, drying and reeling. Compared to common wallpaper, the tile stocks provided in the invention have the following advantages: the tile stocks have the functions of energy saving and heat insulation and can release negative ions and far infrared rays at the same time, thereby purifying air as well as benefiting health of human bodies.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

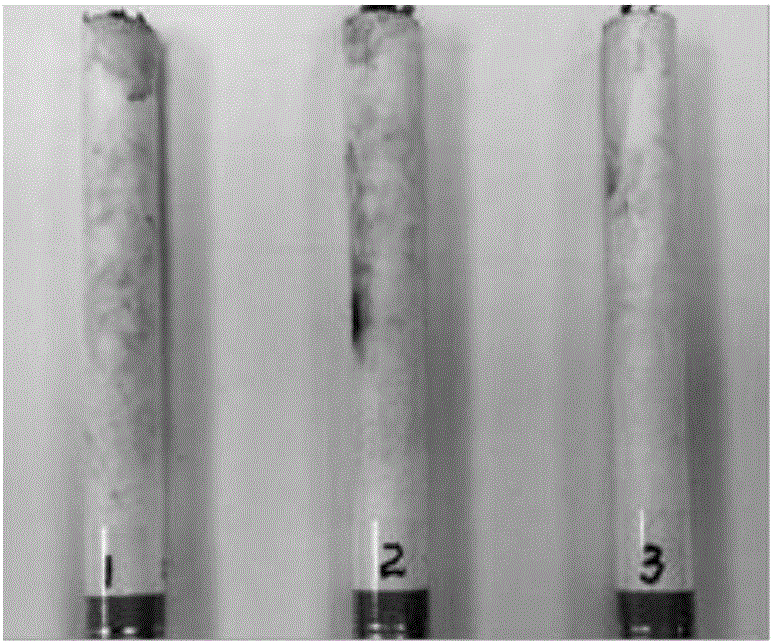

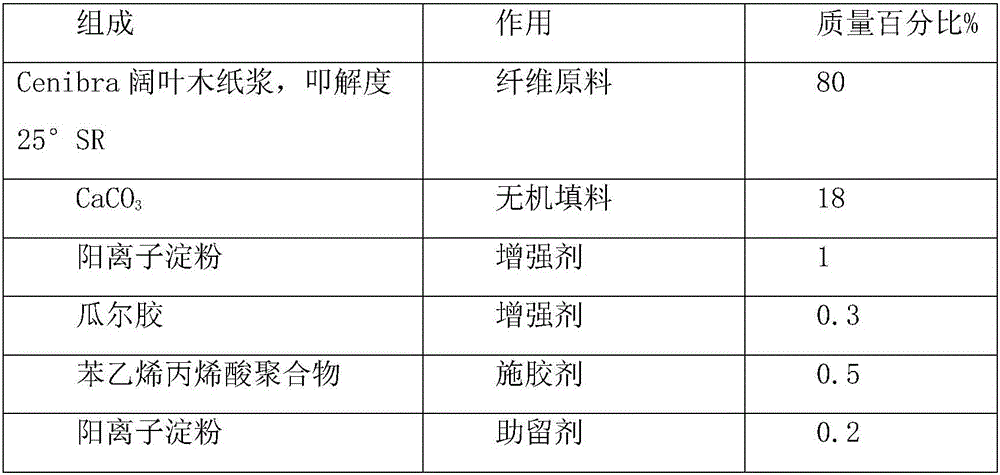

Heating non-combustible cigarette paper and preparation method thereof

ActiveCN106368069ANo tar spotsDoes not start carbonationInorganic fibres/flakesSpecial paperFiberBurn cigarette

The invention discloses heating non-combustible cigarette paper and a preparation method thereof. The preparation method of the heating non-burning cigarette paper comprises the following steps: 1) pulping the plant fiber with the length of 0.5 to 4mm, or adding the appropriate proportion of inorganic fiber; 2) adding the inorganic filler in the process of dilution of the pulp, wherein the addition ratio of the inorganic filler is 5 to 50% of the mass of the pulp; 3) sizing the paper to improve water and oil resistance, and cigarette paper is quantified at 50 to 120 g / m<2>. Compared with the existing heated non-combustible cigarette paper that is heated at 350 DEG C, the non-combustible cigarette paper of the present invention has very few yellow stitches, and no tar spots and carbonization, while the entire surface of the existing non-combustible cigarette paper turns yellow, with large tar penetrating and carbonized. In addition, the non-combustible cigarette paper of the present invention is rarely present broken in actual production, and there is almost no deformation and wrinkling after being sucked as the heated cigarette paper.

Owner:中烟摩迪(江门)纸业有限公司

Raw paper for thermal transfer paper and preparation process thereof

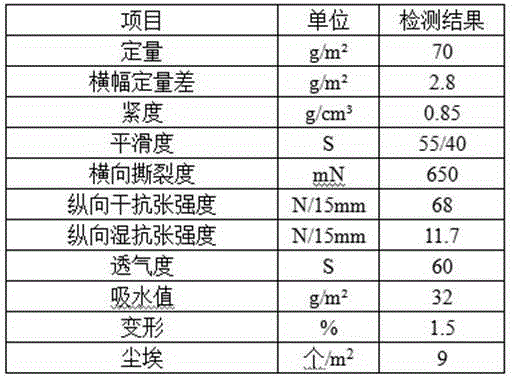

ActiveCN104085214AImprove tightnessControl the concentration of plagiarism onlinePulp beating methodsDuplicating/marking methodsApparent densityGrammage

The invention provides raw paper for thermal transfer paper and a preparation process thereof. The raw paper for the thermal transfer paper has grammage of 70 to 95 g / m2, cross file grammage tolerance of no more than 5 g / m2, apparent density of 0.8 to 0.85 g / cm3, smoothness of 45 / 36S, transverse tearability of no less than 600 mN, vertical dry tensile strength of no less than 70 N / 15mm, vertical wet tensile strength of no less than 12 N / 15 mm, air permeability of no less than 60 S, a water absorption value of 30 to 50 g / m2, a deformation rate of no more than 1.5% and dust of no more than 10 / m2. The preparation process for the raw paper for the thermal transfer paper comprises the steps consisting of pulping, mixing, beating and rewinding so as to prepare the raw paper for the thermal transfer paper, and then packaging is carried out, wherein a surface sizing solution and a filling material are added during beating. The raw paper for the thermal transfer paper prepared in the invention has the advantages of low cost, good paper formation, great apparent density, small air permeability, high tensile strength, high heat resistance, etc.

Owner:WEIFANG HENGLIAN SPECIALTY PAPER

Production method of base paper of tipping paper used by cigarettes with high natural air permeability

InactiveCN103103859AGood operating strengthGood flexibilityPulp beating methodsReinforcing agents additionWet strengthRaw material

The invention relates to a production method of tipping paper of base paper used by cigarettes with high natural air permeability and aims to provide the production method of the tipping paper of the base paper used by the cigarettes with the high natural air permeability of 80-300CU. The production method of the tipping paper of the base paper used by the cigarettes with the high natural air permeability is characterized by comprising the following steps: a, beating section, beating is conducted on needle pulp and eucalyptus pulp through fibrillation and cut of a millstone mill to reach the effects that the beating degree of the needle pulp is 20-300SR, the wet weight of the needle pulp is 9-10g, the beating degree of the eucalyptus pulp is 20-220SR, and the wet weight of the eucalyptus pulp is 1-2g, b, preparation of pulp. Raw material components of pulp material comprises, by weight, 20-30 of needle pulp, 70-80 of eucalyptus pulp, 50-80 calcium carbonate and 0.2-0.4 wet strength agent. The produced tipping paper of the base paper used by the cigarettes with the high natural air permeability of 80-300CU uses high natural holes to bring a large quantity of are into the main stream smoke of the cigarettes and enables injurious ingredients in the main stream smoke to be greatly reduced.

Owner:MUDANJIANG HENGFENG PAPER CO LTD

Method for preparing stainless steel lining paper

InactiveCN1936182AImprove performanceSolve the problem of only producing high-weight paperNatural cellulose pulp/paperFlexible coversFiberParaffin wax

The invention discloses a manufacturing method for a stainless steel lining paper that includes the following steps: adopting white wood pulp as raw material, and white sulfate softwood pulp: white hardwood pulp =70-80wt%: 30-20wt%; adopting short fiber shiny beating method, and 330 disc mill basalt stone lapping to take jordaning; using chemical auxiliary agent that adding 5-20wt% olefin emulsion, 0.5-1.0wt% positive ion starch, 0.5-1.0wt% AKD, 1.0-2.0wt% silicone emulsion, 0.3-0.5wt% CPAM, and 0.25-0.75wt% PAE. It has the advantages of high intension, laceration endurable, super smooth, clean and high temperature endurable. It could fit different manufacture technology requests of stainless steel.

Owner:樊运民

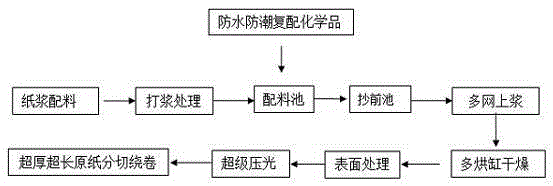

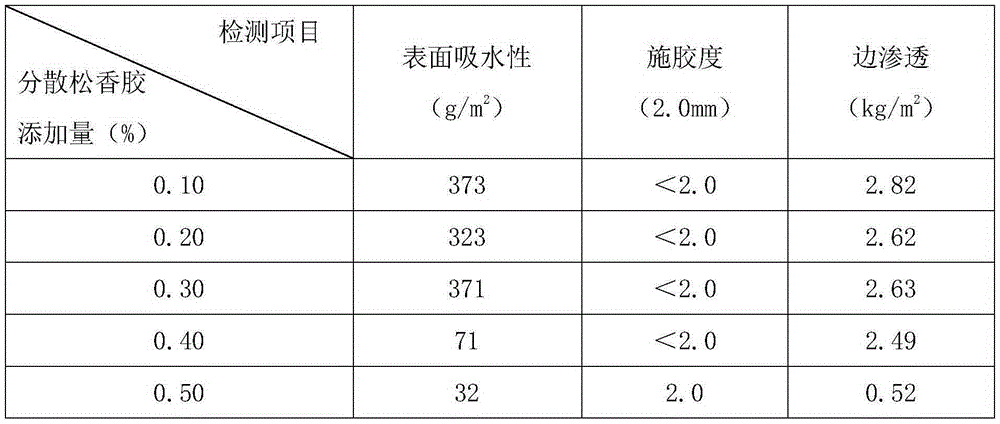

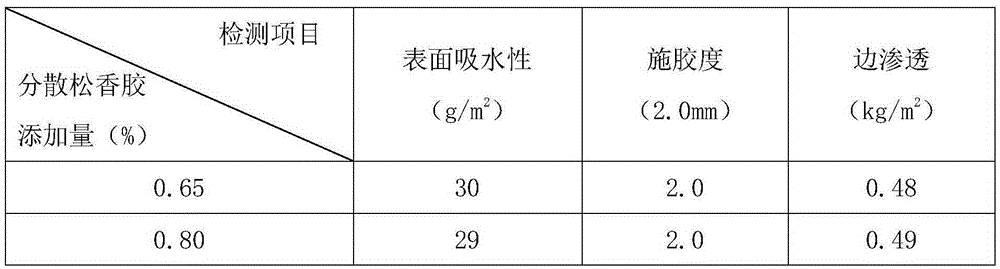

Waterproof and damp-proof raw paper dedicated for electronic paper tape, and preparation method thereof

InactiveCN105350375AGuaranteed StrengthImprove bondingWater-repelling agents additionPulp beating methodsFiberFibrillation

The present invention discloses a waterproof and damp-proof raw paper dedicated for electronic paper tapes, and a preparation method thereof. The method is characterized in that untwining and fibrillation are carried out on pulp fibers, fibrillation and cutting are further carried out so as to enable a pulp beating degree to reach 45 degree SR to 48 degree SR and a fiber wet weight to be reduced to 5.5 g to 8.0 g; and a water-resistant damp-proof composition is added in each layer, 1.0%-2.5% of the water-resistant damp-proof composition is added in relative to 100 parts of the pulp fibers, the water-resistant damp-proof composition including 0.15+-0.015 % of a wet strength agent PAE, 0.50+-0.05 % of gum rosin or an alkyl ketene dimer (AKD), 0.10+-0.01 % of silicon and fluorine type polymers, and 0.15+-0.015 % of ammonium zirconium carbonate. According to the above method, defibrination treatment is utilized, and a water-resistant damp-proof functional chemical is added in the pulp and coated on the surface of paper, surface water absorption and an edge permeation index of the raw paper are lowered than like products on the market, and water-resistance and damp-proofness of the raw paper are the best.

Owner:JIANGXI JIEMEI ELECTRONICS INFORMATION MATERIAL CO LTD

Production process of colored tissue paper

InactiveCN101748644AQuantitative lowGood strength requirementsCoatings with pigmentsPulp beating methodsFiber bundleColor tissue

The invention discloses a process for producing colored tissue paper by using 100 percent of wastepaper pulp. The process comprises the following steps of: pulp preparation: adding 100 percent of wastepaper pulp into a hydrapulper for breaking; removing impurities of thin films and the like by using a jig sieve; pulping through a high-frequency fluffer and a raffinator; and finally adding chemical raw materials and dye in a pulp blending tank, adjusting the density and feeding the mixture into a paper-making flow delivering system; paper making: diluting the pulp for making in a slushing tank by slushing, then removing sand by a deslagger and long fibers and fiber bundles by a selectifier screen, pumping into a head box and flowing into a net trough for filtering through a net; and finally squeezing, drying, reeling, splitting, packaging and warehousing. The quality of products reaches the national quality standard of 100 percent of wood pulp products and further reaches over B class according to the national standard.

Owner:福建省晋江优兰发纸业有限公司

Wine lees fiber paper pulp and paper made thereof

InactiveCN1844569ASave resourcesReduce manufacturing costNatural cellulose pulp/paperPulp beating methodsFiberSlurry

The invention relates to a lees fiber pulp and the method for producing paper with said pulp. Wherein, it uses the less generated by alcohol industry as raw material, via breaking, screening, braising, and washing, to produce the lees fiber pulp that containing the fibrin and hemicellulose; it can be mixed with the slurries made from wood, bamboo, straw, or recycled waste paper, into mixed pulp, to be fed to paper maker to produce paper; or it can only use the less as raw material to produce less fiber pulp, to be diluted and mixed with water to be fed to paper maker to produce paper. The invention enlarges the raw material resource of paper industry, reduce the producing cost of paper, and solve the problem of environment pollution.

Owner:肖剑鸣

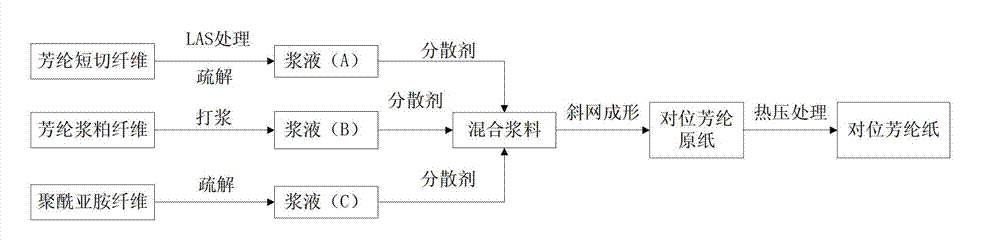

Para-position aramid fiber paper used for cellular material and preparation method thereof

ActiveCN102899959AReduce water repellencyImprove dispersion compatibilityPulp beating methodsPaper/cardboardPolyesterPapermaking

The invention discloses a para-position aramid fiber paper used for a cellular material and a preparation method thereof. The preparation process comprises the following steps: adding polyimide fibers, defibering and dispersing; papermaking together with para-position aramid fiber, wherein the papermaking proportion in parts by weight is as follows: 20-50% of para-position aramid short cut fiber, 35-60% of para-position aramid pulp fiber and 5-30% of polyimide fiber; and squeezing, drying and carrying out hot press moulding.. According to the preparation method, tear strength, temperature resistance and fire resistance of the para-position aramid fiber paper can be obviously improved, paper breaking during papermaking is reduced, operating speed of a paper machine and production efficiency are improved, and negative effects on properties of a paper sheet as a cohesive fiber such as a polyester fiber is introduced can be avoided.

Owner:SHAANXI UNIV OF SCI & TECH

Vulcanized fiber board and manufacturing process thereof

ActiveCN103103867AImprove electrical strengthHigh volume resistanceSpecial paperPulp beating methodsGlass fiberFiber

The invention relates to a vulcanized fiber board which is prepared from 94%-97% by weight of cotton fiber and 3%-6% by weight of glass fiber. The manufacturing process comprises the following steps: (1) beating and rinsing; (2) homogenating and papermaking; (3) colloidizing and aging; (4) desalting and washing; (5) pre-drying and drying; and (6) calendering and packaging. In comparison with the traditional vulcanized fiber board, the volume resistance of the vulcanized fiber board disclosed by the invention is increased by 50%, the electrical strength is increased by 21%, and the longitudinal and the transverse drying shrinkage rates are respectively reduced by 10% and 19.6%.

Owner:杭州特种纸业有限公司

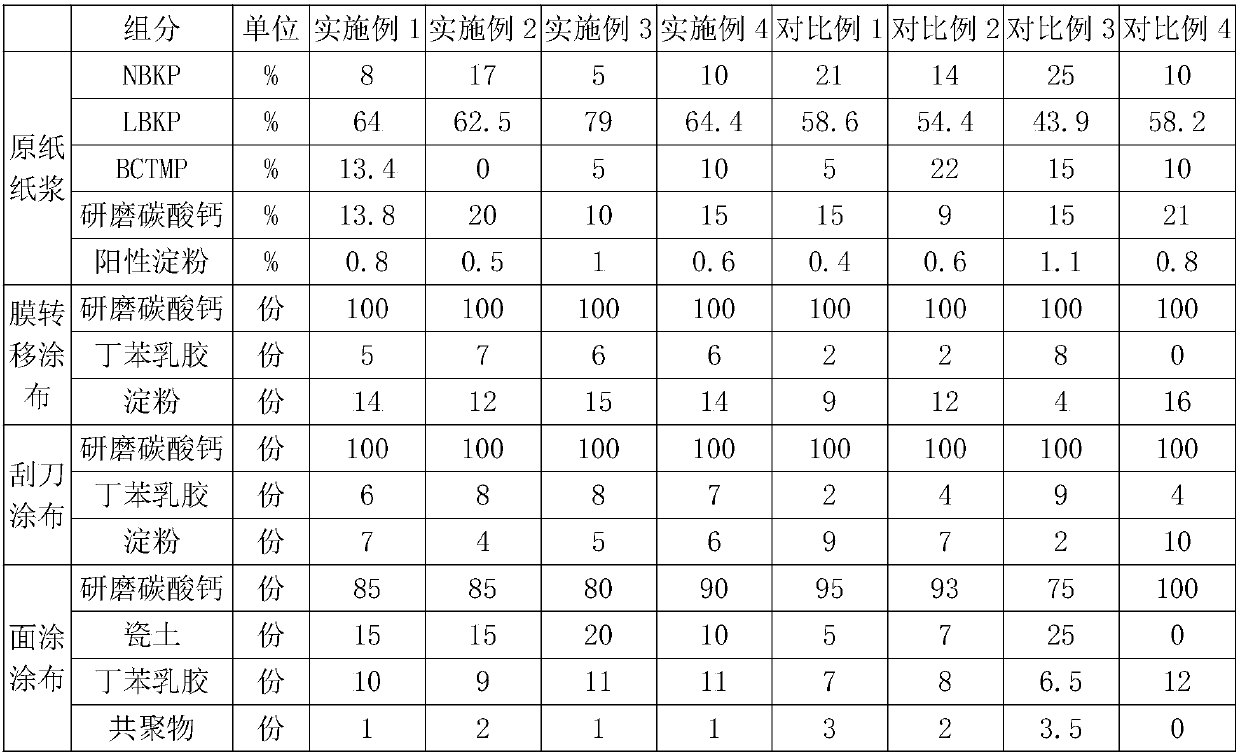

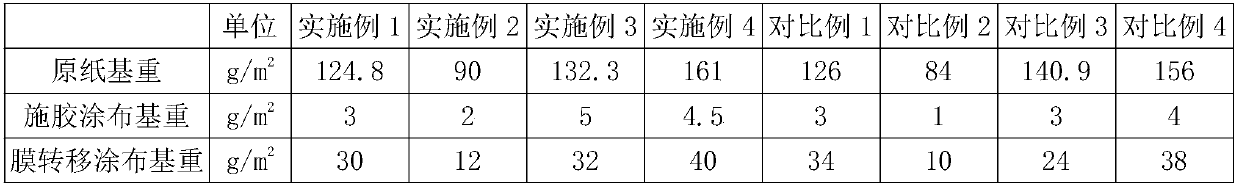

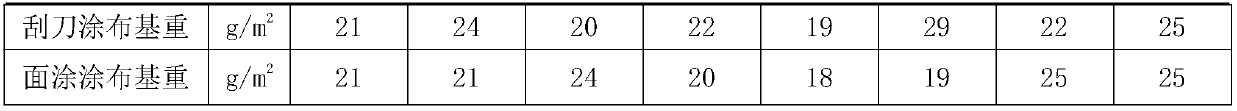

Double-side coated art printing paper with high smoothness and preparation method thereof

InactiveCN107829331AImprove smoothnessHigh image color saturationPulp beating methodsPaper coatingTO-18Gram

Owner:HAINAN JINHAI PULP & PAPER

Special anti-counterfeiting rice paper for postage stamp, postage stamp and production method thereof

ActiveCN101748642ARaise the gradeRich market needsStampsDefoamers additionBleachPulp and paper industry

The invention provides a production method of special anti-counterfeiting rice paper for a postage stamp, which comprises the following steps: adopting wingceltis barks and straws from sand fields as raw materials, preparing pulp through soaking, beating and bleaching with calcium hypochlorite bleach solution; purifying the prepared pulp, fetching paper, drying, and cutting to manufacture raw rice paper; performing the alum dragging treatment of the raw rice paper in alum solution, and naturally drying the rice paper to obtain non-absorbent rice paper; and applying glue on the back of the non-absorbent rice paper, and drying and flattening to manufacture the special anti-counterfeiting rice paper for the postage stamp. Since the production method in the invention is an improvement based on the conventional production process, the produced rice paper not only preserves the properties of the conventional rice paper, but also has excellent printing applicability. Therefore, the rice paper can be used as the special anti-counterfeiting rice paper for stamps, stamped postcards and other postage stamps.

Owner:北京邮票厂有限公司 +3

Mechanical method for making pulp by extruding sunflower stems

InactiveCN101586314AReduce the degree of beatingRemove light and heavy impuritiesPretreatment with water/steamPulp beating methodsHigh concentrationSlag

The invention relates to a mechanical method for making pulp by extruding sunflower stems, belonging to the field of paper making and aiming to provide a method for preparing paper making pulp by taking the sunflower stems as raw materials. Severed sunflower stems are firstly delivered into a vertical type depithing machine to carry out depithing by a half wet method and then washed to carry out depithing by a wet method, then the severed sunflower stems are steamed and then enter a twin-screw extrusion impregnating machine, slag charge sheets are extruded and grinded into mass-shaped rough pulp and also impregnated and absorbed by NaOH inside the twin-screw extrusion impregnating machine, the mixed rough pulp enters a reaction chamber to be continuously reacted and then enters a high-concentration attrition mill to mill the rough pulp into highly-concentrated pulp, and the milled pulp is delivered into a latency chest to be diluted, stayed and stirred and finally enters a screw press dewaterer to carry out screw type press and dewatering and extrude finished pulp. The invention has the advantages of low-energy consumption, no pollution, low water consumption (ton paper / 10 tons of water), high intensity, high yielding rate and high benefit.

Owner:杨宏

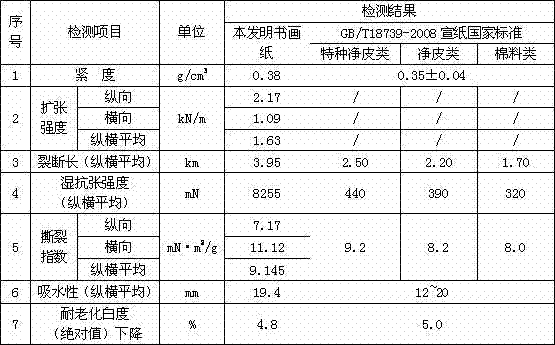

Water-resisting breaking-resisting oxidation-resisting calligraphy and painting paper

InactiveCN102454135AIncrease ink wettingReduce oxidative degradationNon-fibrous pulp additionSpecial paperFiberPaper manufacturing

The invention relates to the field of calligraphy and painting paper manufacturing, and specifically relates to a water-resisting breaking-resisting oxidation-resisting calligraphy and painting paper. The paper is prepared from raw materials and auxiliary materials through a pulping process and a paper making process. The raw materials comprise components of, by weight: 45-80 parts of bamboo pulp fiber, 10-30 parts of grass pulp fiber, 2-25 parts of wool pulp fiber, and 5-25 parts of viscose fiber. Each ton of the paper comprises auxiliary materials of, by weight: 0.5-2% of an antiseptic, and 3-15% of PVA. The calligraphy and painting paper provided by the invention has excellent water resistance, breaking resistance and oxidation resistance. The water-resisting and breaking-resisting functions are 10 times higher than a wet tensile strength index of a GB / T18739-2008 national standard of rice paper.

Owner:FUYANG JINYUAN PAPER

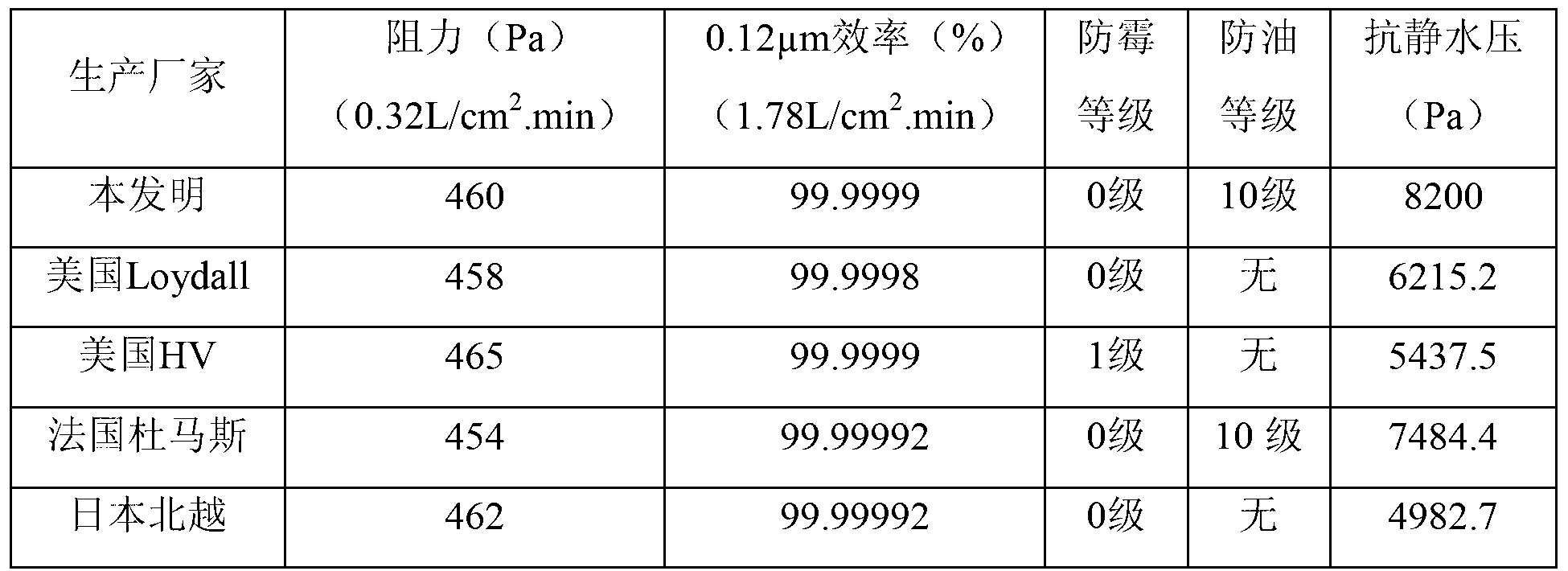

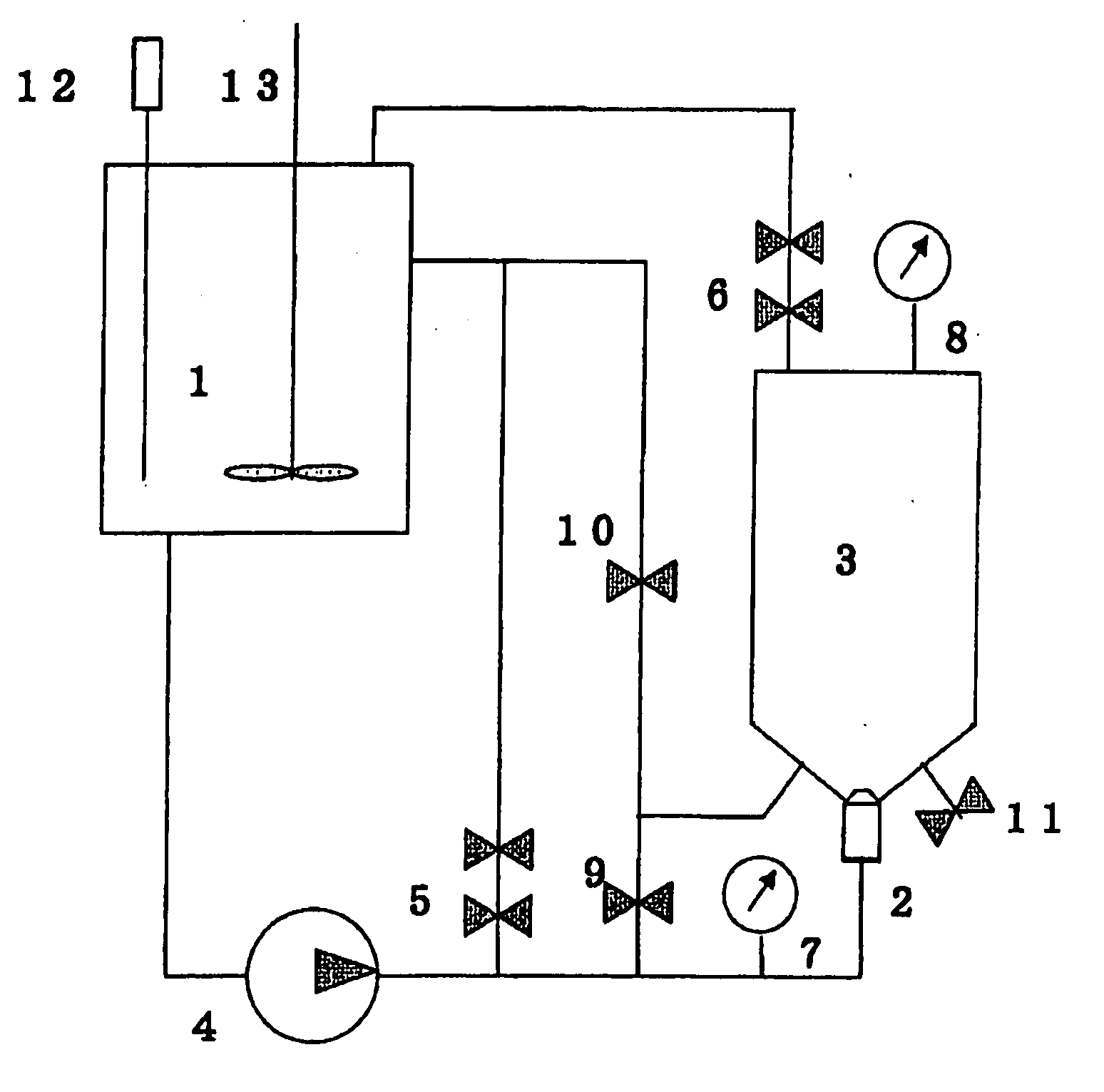

Highly-resistant-to-water core-level glass fiber air filtering paper and preparing method

ActiveCN103243612AReduce porosityLarge specific surface areaPulp beating methodsPaper coatingFiberGlass fiber

The invention discloses a piece of highly-resistant-to-water core-level glass fiber air filtering paper. The filtering paper comprises glass fiber filtering paper made from alkali-free glass fiber with the diameter being 0.1-0.3mu m, 0.5-0.7mu m and 0.8-1.0mu m and from alkali-free glass long fiber with the diameter being 1.4-1.6mu m, and a water-resistant layer attached to the face of the filtering paper and formed by hydrogen silicon oil and acrylic emulsion. The invention also discloses a preparing method for the air filtering paper, which comprises the steps of 1, selecting raw materials according to a proportion, 2, performing pulping to disperse the raw materials to obtain pulp, 3, diluting the pulp and adjusting the PH value, 4, performing slag-removing on the pulp in the step 3 and obtaining wet paper by wet forming, 5 dehydrating the wet paper in the step 4, 6, spraying mixing emulsion of the hydrogen silicon oil, the acrylic emulsion and water on the surface of the wet paper in the step 5; and 7, drying the wet paper in the step 6. The glass fiber air filtering paper has excellent water-resistant property and is suitable for severe environment.

Owner:CHONGQING ZAISHENG TECH CORP

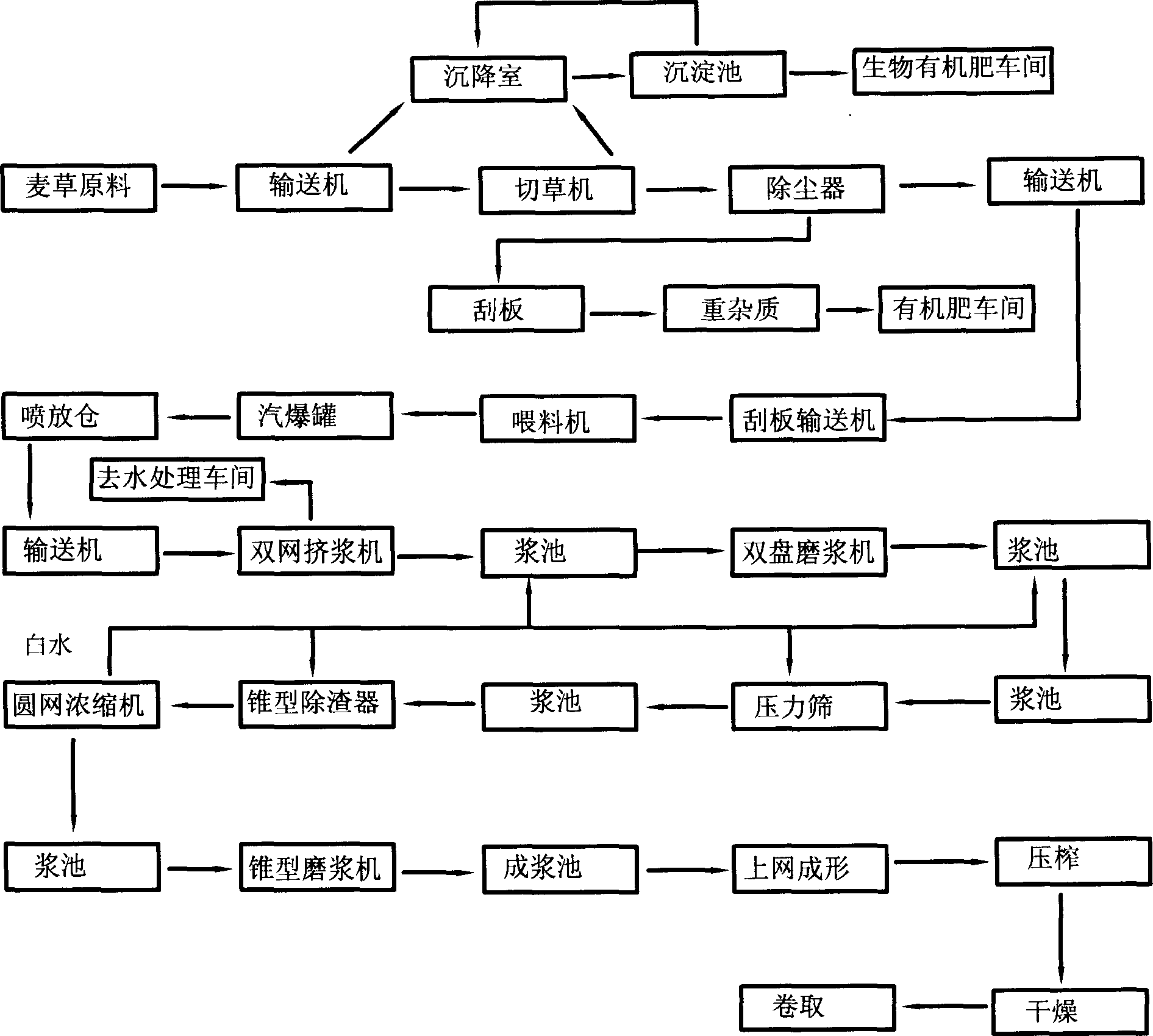

Pulping process for environment-friendly kraft board paper

InactiveCN106245395ABright colorStrong water resistancePulp beating methodsPaper recyclingFiberEnvironmental resistance

The invention discloses a pulping process for environment-friendly kraft board paper. The pulping process includes the steps that 1, the United States waste paper, England waste paper and European waste paper are mixed uniformly by a certain ratio, wood pulp of a certain ratio is added into the waste paper mixed uniformly, repulping is carried out, and a certain amount of bio-enzyme is added into the repulping process; 2, high-concentration residue removal and screening are carried out on the pulp obtained in the step 1; 3, pulp obtained through screening in the step 2 enters a grading workshop section and is divided into long fiber pulp, middle fiber pulp and short fiber pulp; 4, the three kinds of pulp obtained through grading in the step 3 sequentially pass through respective medium and low concentration residue removal devices to be purified in a residue removal mode; 5, pulp can be obtained by carrying out concentration, heat dispersion and disk milling on the pulp obtained after residue removal. The environment-friendly kraft board paper which is bright in color, high in water resistance and light resistance and consistent in color is manufactured by improving the original pulping process and strictly controlling the beating degree, the temperature and the pH value of the pulp.

Owner:JIANGSU LEE & MAN PAPER MFG

Environmentally friendly surface sizing agent capable of improving paper smoothness and barrier property and a preparation method and application of environmentally friendly surface sizing agent

InactiveCN108708207AFill in the gapsImprove surface propertiesWater-repelling agents additionPulp beating methodsMicro nanoCellulose

The invention discloses an environmentally friendly surface sizing agent capable of improving paper smoothness and barrier property and a preparation method and application of the environmentally friendly surface sizing agent. The method comprises the following steps: (1) preparation of micro-nano celluloses: pretreating bleaching wood pulp by a mechanical method, and carrying out enzymolysis treatment, nano grinding and homogenization treatment on the pretreated material to obtain the micro-nano celluloses; and (2) preparation of the surface sizing agent: pasting cationic starch under heatingand stirring conditions at first, cooling to a certain temperature, then adding the micro-nano celluloses, and continuously stirring at the temperature until the material is uniform to obtain the environmentally friendly surface sizing agent. An application process comprises the following steps: sizing paper by using a roll coater, naturally air-drying the sized paper, carrying out press polish treatment on the dried paper, and detecting influences of the sizing agent to the surface performance of the paper. By the disclosed environmentally friendly surface sizing agent with micro-nano cellulose / starch, the smoothness and barrier property of paper can be improved effectively.

Owner:SOUTH CHINA UNIV OF TECH

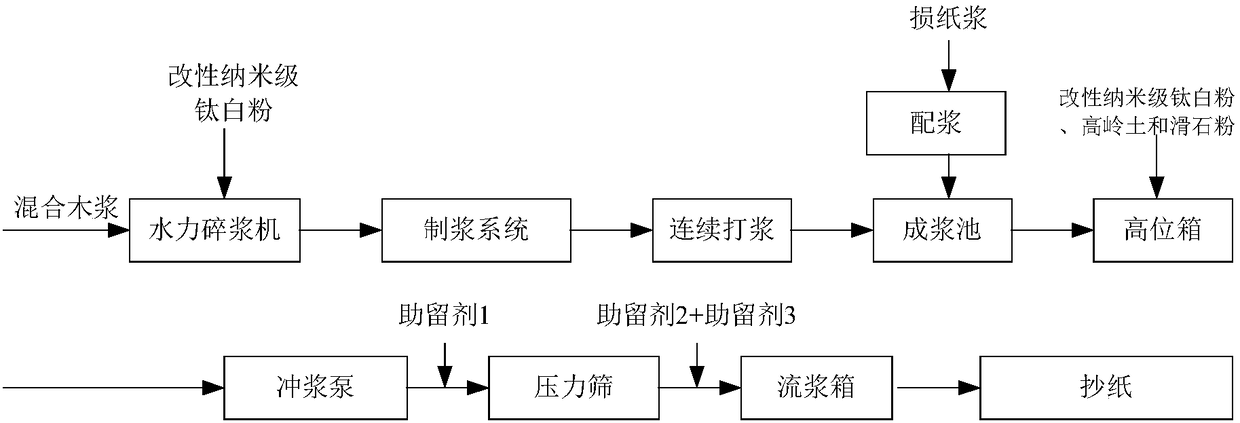

Special ecological board decoration base paper and preparation method thereof

ActiveCN108330720AImprove retentionEfficient mixingPulp beating methodsPaper recyclingSodium BentoniteSulfate

Owner:杭州华旺新材料科技股份有限公司

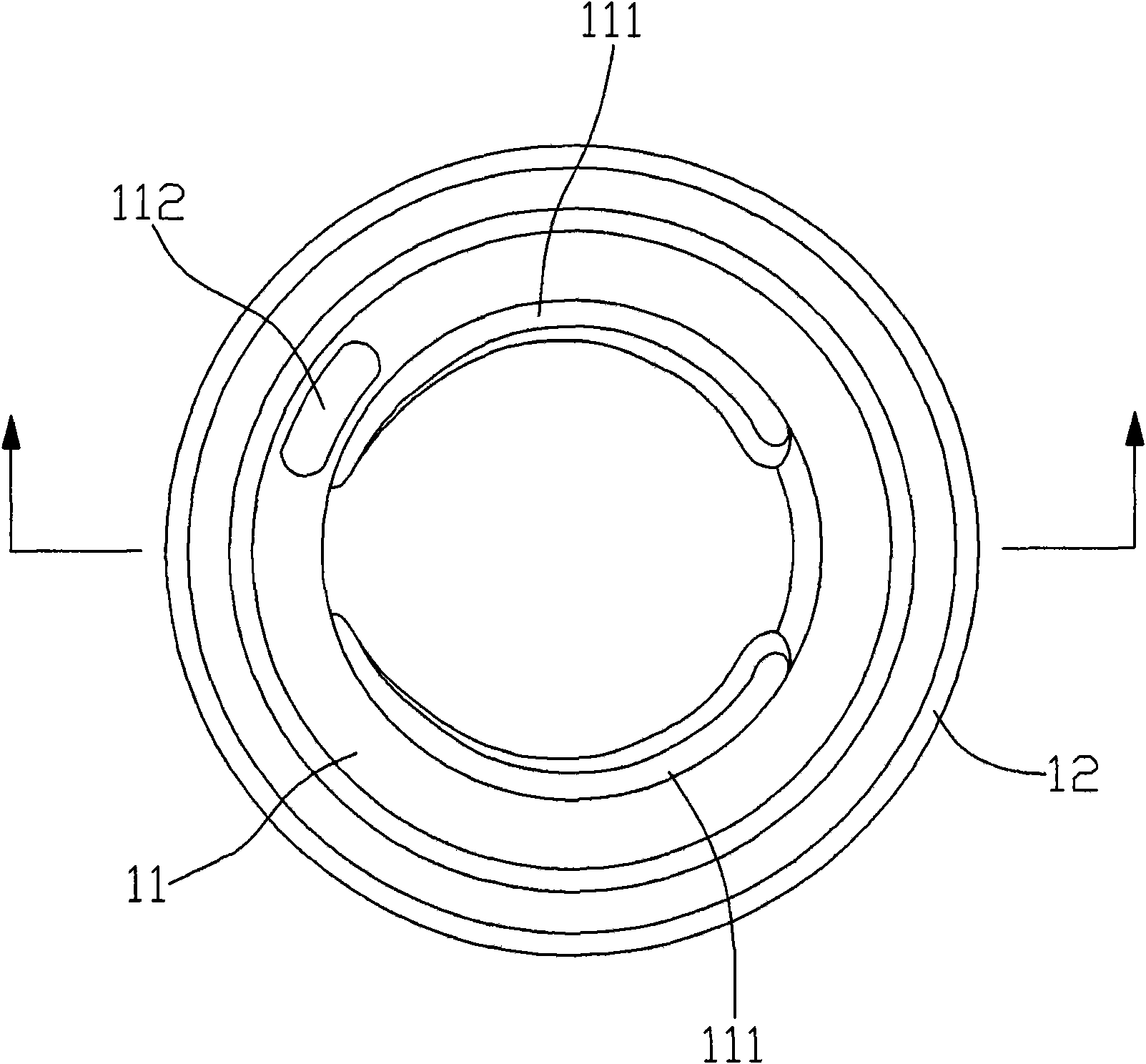

Methods for Beating Pulp, Methods for Treating Process Waters, and Methods for Producing Pulp and Paper

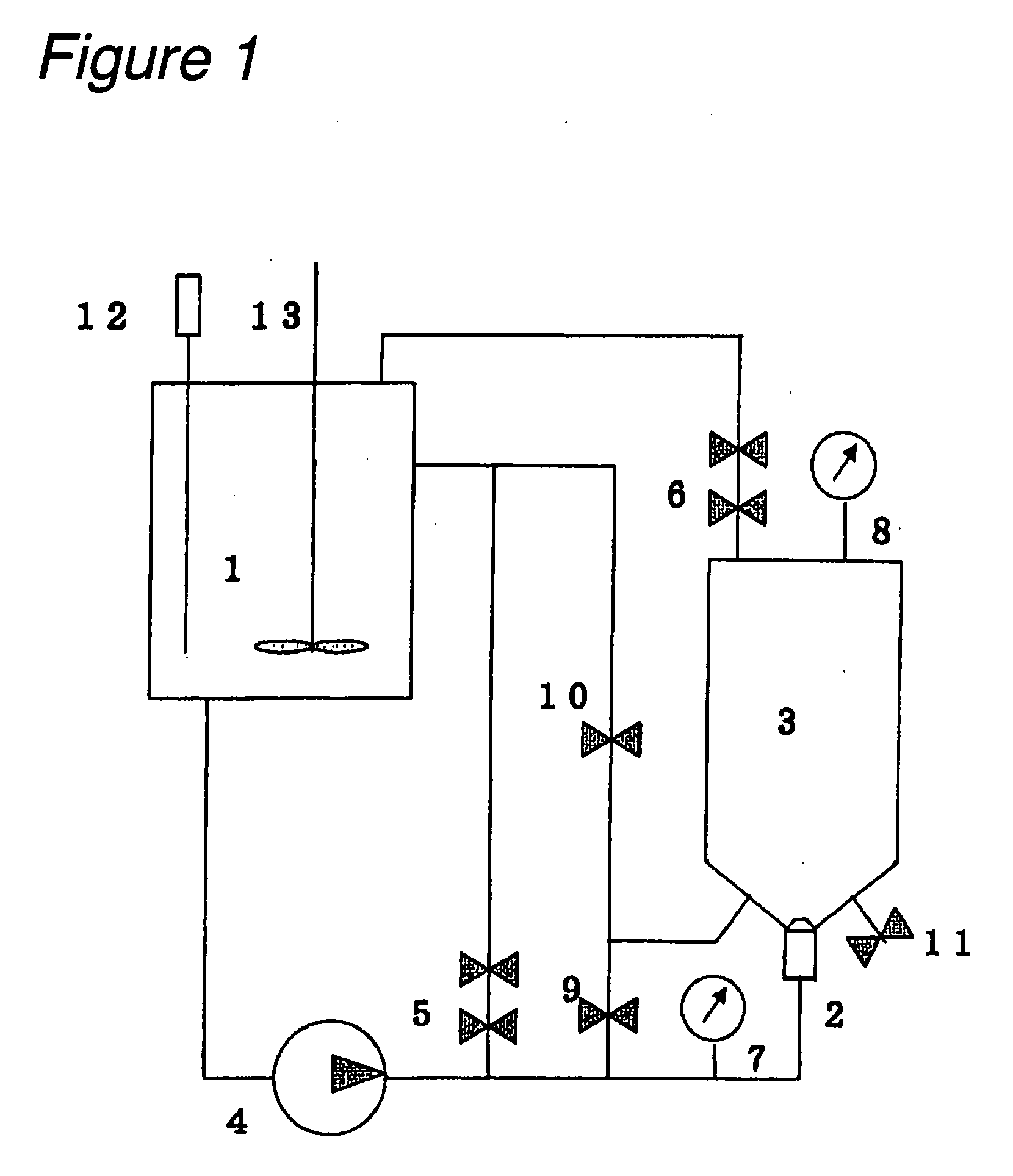

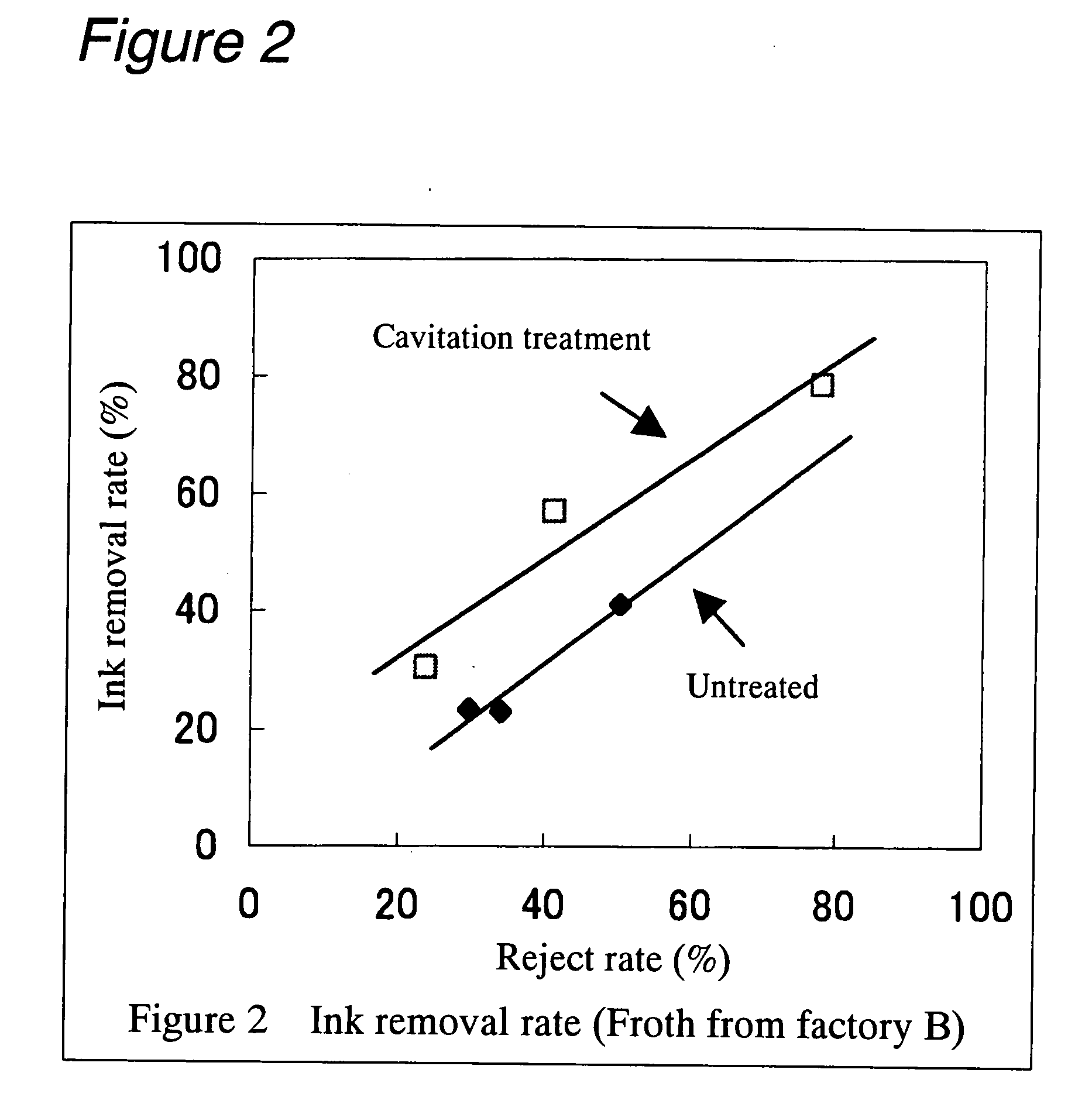

The first invention aims to provide a method for preparing stiffer bulky pulp at a freeness level comparable to that obtained by mechanical treatments to improve the bulkiness of product paper by searching for a method capable of adjusting freeness while suppressing damage to pulp fibers and internal fibrillation in a process for producing pulp. The second invention aims to strip contaminants deposited on pulp fibers and / or inorganic particles to reduce adhesion of the contaminants and decrease microorganisms in a treatment of process water containing long pulp fiber fractions used in a process for producing pulp and paper, thereby clarifying process water and thus preparing high-quality pulp and paper. According to the first invention, cavitation is generated in a pulp suspension preferably by a liquid jet and the resulting fine bubbles are introduced into the pulp suspension to adjust the pulp suspension to a desired freeness by means of the impact force induced by collapse of the fine bubbles in a process for producing pulp. According to the second invention, process water containing 50% by weight or less, based on total solids, of long pulp fiber fractions used in a process for producing pulp and / or paper is treated by cavitation generated by a liquid jet and then returned to the process for producing pulp and / or paper and reused.

Owner:NIPPON PAPER IND CO LTD

Manufacturing method heat sublimation transfer printing paper

InactiveCN105839465AStable thicknessHigh strengthCoatings with pigmentsSpecial paperHeat resistancePrinting ink

The invention discloses a manufacturing method of heat sublimation transfer printing paper. The method includes: respectively beating softwood pulp and hardwood pulp, mixing, adding auxiliary materials, manufacturing wet paper sheets, performing first drying, performing front-side coating and reserve-side glue application, performing post-drying, performing press polishing and finishing, and the like. The manufacturing method has the advantages that the heat sublimation transfer printing paper manufactured by the method is good in strength, stable in thickness, good in evenness, good in shape stability, good in flatness and good in heat resistance; the heat sublimation transfer printing paper is good in ink absorption performance and fast in ink absorption during digital printing, and images have no evident ink piling and color bleeding after the printing; the heat sublimation transfer printing paper overlaps with a substrate after the digital printing, and the printing ink transfer rate at the moment is high; the heat sublimation transfer printing paper can completely replace imported products.

Owner:YUEYANG FOREST & PAPER CO LTD

Preparation method of high-performance wear-resistant paper

InactiveCN102031723AReduce dosageReduce defects in appearance qualitySpecial paperPulp beating methodsPaper sheetWear resistant

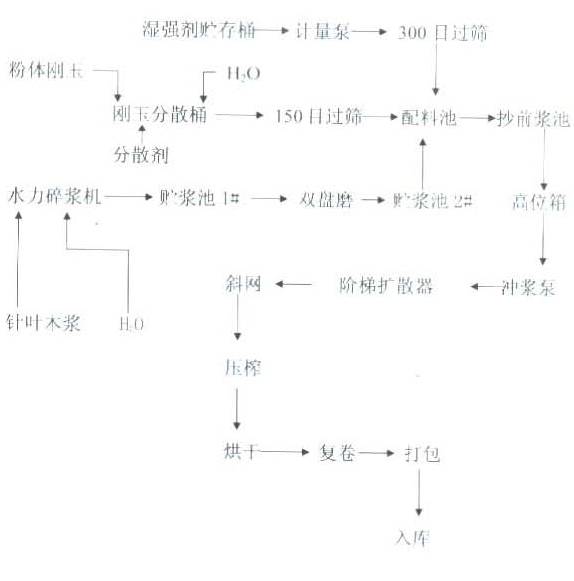

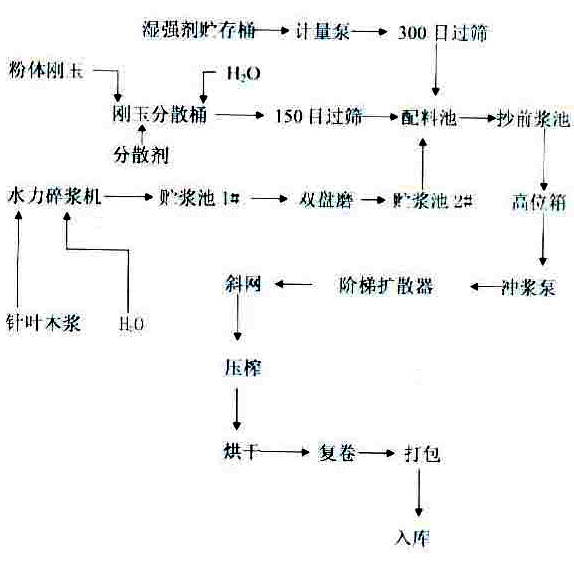

The invention relates to a preparation method of high-performance wear-resistant paper, comprising the following steps in sequence: the materials are prepared: powdered corundum, water and a dispersing agent are added in a dispersing barrel for mixing and sieved for spare use; an auxiliary agent is sieved for later use after being metered; soft wood pulp and water are crushed by a hydrapulper and pass through a first pulse storing pool and a double-disc grinder to enter a second pulp storing pool for later use; three types of spared pulp are mixed in a batching pool and mixed pulp is prepared; the mixed pulp passes through a papermaking pulp pool, a high-position box, a slushing pump and a step diffuser; the mixed pulp passes through an inclined net, and the netting concentration is 0.03-0.08%; and then squeezing and drying are carried out. The preparation method has the advantages that the mixed uniformity is improved by adopting the preparation technique of respectively preparing the soft wood pulp, the powdered corundum pulp and the auxiliary agent and then mixing, especially the powdered corundum is pre-dispersed, the pheonomenon that the bad dispersion of the corundum cause defects on the appearance quality brought by the finished wear-resistant paper, and the definition and the transparency are improved. In addition, the retention of the corundum is improved, and the used amount of the corundum is reduced.

Owner:JUNYUAN NEW MATERIAL

Method for papermaking utilizing waste paper containing wax

InactiveCN101067289AReduce pollutionReduce paper production costsNon-fibrous pulp additionWashing/displacing pulp-treating liquorsWaxSlag

The present invention discloses papermaking process with wax-containing waste paper. The papermaking process with wax-containing waste paper features the pulping process includes the steps of: compounding material, crushing, beating, extruding, washing, grinding and sieving to eliminate slag. The papermaking process with wax-containing waste paper as material has the effects of reusing waste paper resource and protecting environmental.

Owner:张书荣

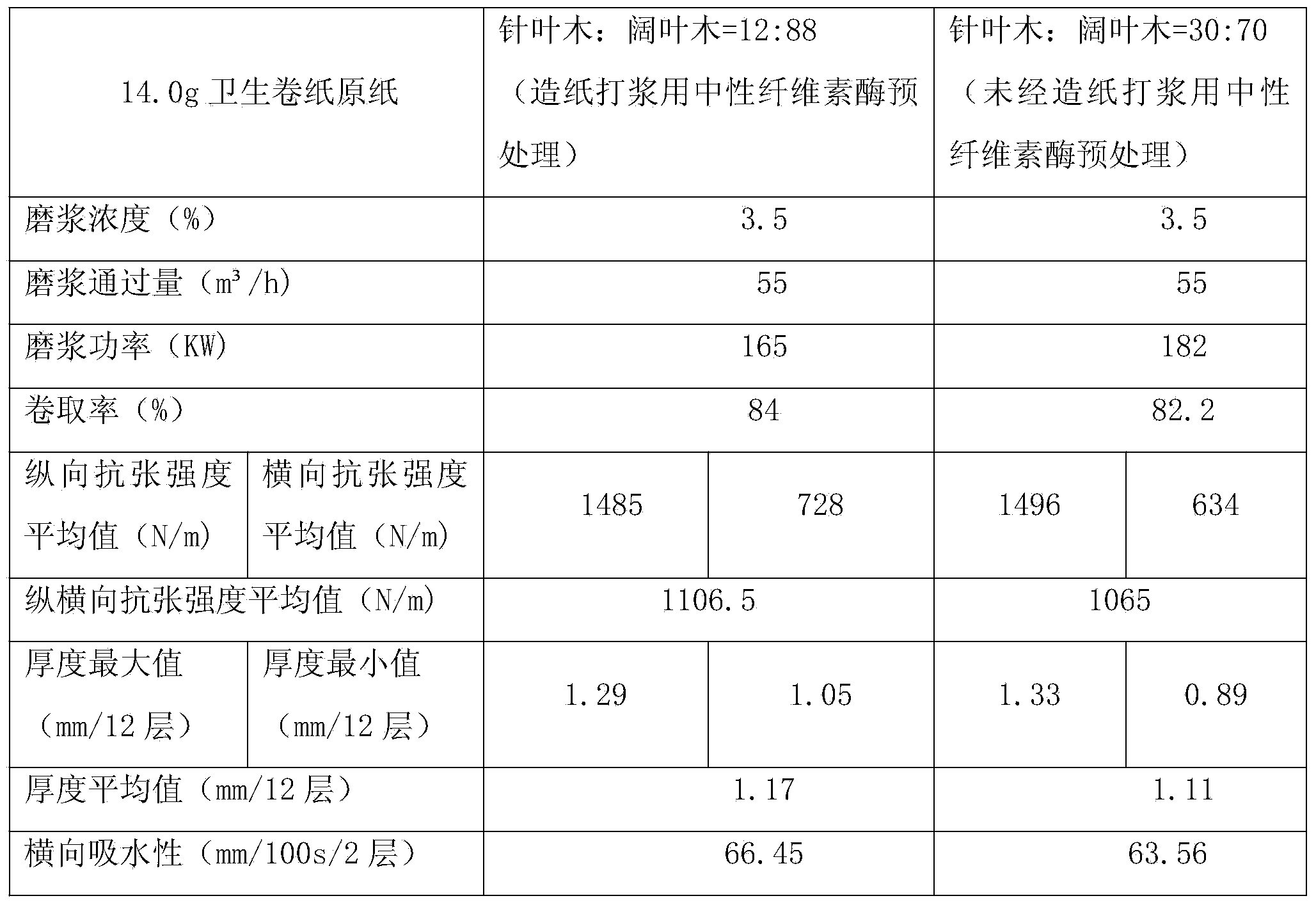

Needle pulp and broad leaf pulp pretreatment method with neutral cellulase

The invention belongs to the papermaking field, and particularly relates to a needle pulp and broad leaf pulp pretreatment method with neutral cellulase. The method comprises the following steps: adding repulping water into a groove body of a hydraulic repulper, wherein the volume of the pulp brushing water is 1 / 3-1 / 2 that of the groove body, the pH value of the repulping water is 5.5-8.5, and the water temperature is 30-50 DEG C; starting the hydraulic repulper, adding the neutral cellulase for papermaking beating into the hydraulic repulper, then putting mixed pulp of needle pulp and broad leaf pulp into the hydraulic repulper, and keeping the time of reaction between the neutral cellulase for the papermaking beating and the pulp in the hydraulic repulper to be 30-40 min, wherein 0.1-0.5 kg of the neutral cellulase for the papermaking beating is added into the pulp per ton; enabling the pretreated pulp to enter a front beating pool, sending into a fiberizer by a pulp pump and entering the next procedure. By pretreating the pulp with the neutral cellulase for the papermaking beating, ratios of long-fiber materials are reduced, material consumption is reduced, the product quality is improved, and energy conservation, consumption reduction and environment-friendly production are realized.

Owner:SHANDONG YOUTELL BIOCHEM

Leatheroid manufactured by papermaking sewage and cotton fibre and method thereof

InactiveCN101649573AWidely distributedRich sourcesPulp beating methodsSecondary cellulose fibresCardboardSludge

The invention provides leatheroid manufactured by papermaking sewage and cotton fiber and manufacturing method thereof, relating to the papermaking technical field. The used raw materials for leatheroid of the invention are papermaking sewage and cotton fiber. The manufacturing method of the leatheroid includes that: firstly size degradation is carried out on the cotton fiber; then the cotton fiber is mixed with papermaking sewage in proportion, the papermaking sewage accounts for 80-85% by weight percent and the cotton fiber accounts for 15-20% by weight percent, and beating and sizing are carried out; paper pulp is fed into a high-order net cage by a pump for manufacturing paper with pulp; laminated paper is sent onto a roller to be wound by a transmission system; the wound leatheroid ispeeled; and the leatheroid is subject to pressure polishing and cutting after mechanical dehydration. The leatheroid manufactured by the invention can be used as the cover of various books and also can be used as paper plate raw material of a packing box.

Owner:福建省晋江优兰发纸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com