Double-side coated art printing paper with high smoothness and preparation method thereof

A technology of coated paper and smoothness, applied in pulp beating method, papermaking, paper coating, etc., can solve the problems of dot enlargement, increase printing pressure, increase the amount of ink and ink fluidity, etc., to improve surface smoothness, reduce Amount, the effect of high color saturation of the image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method of high-smoothness double-sided coated paper, comprising the following steps:

[0035] Step 1: beating kraft softwood pulp, bleached kraft hardwood pulp and bleached chemical thermomechanical pulp respectively, and proportioning to form a slurry mixture;

[0036] Step 2: Add ground calcium carbonate and positive starch to the slurry mixture in step 1, and mix thoroughly to obtain base paper pulp;

[0037] Step 3: Use the base paper pulp obtained in step 2 to produce base paper, and the base paper produced has a quantitative value of 90-190g / m 2 , wherein the water content is 5-7%;

[0038] Step 4: Sizing the front and back surfaces of the base paper obtained in Step 3, with 2-5g of sizing layer per square meter of paper;

[0039] Step 5: On the basis of step 4, use film transfer coating for primer coating, the solid content of the coating is 61-66%, the shear viscosity is 400-600cps, the front and back surfaces are double-sided coated, and the tot...

Embodiment 1-4、 comparative example 1-4

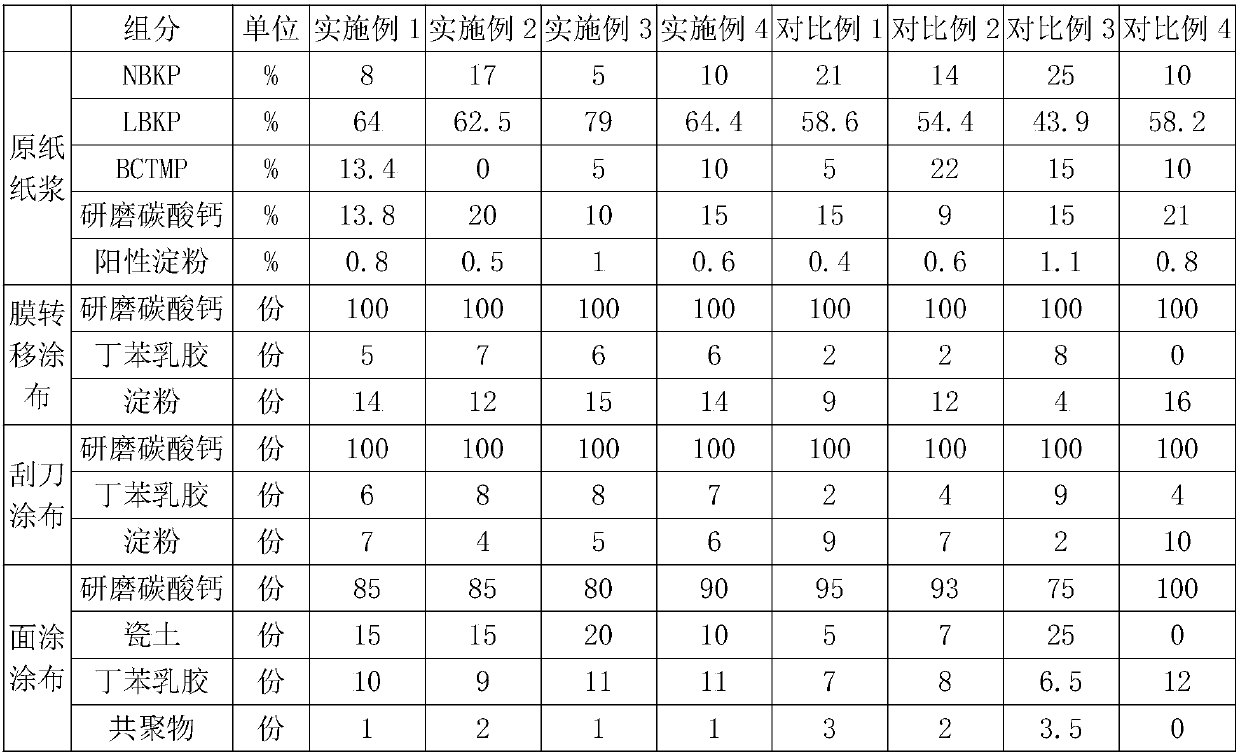

[0053] Table 1:

[0054]

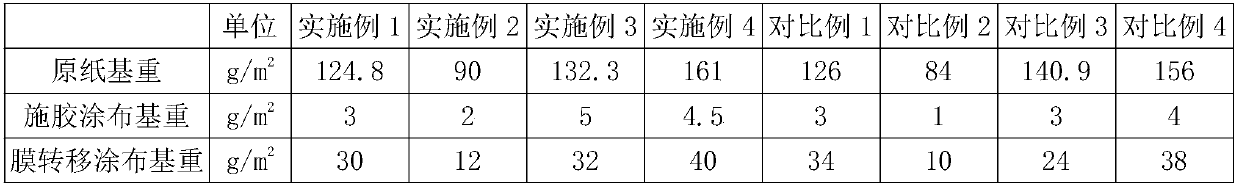

[0055] Table 2:

[0056]

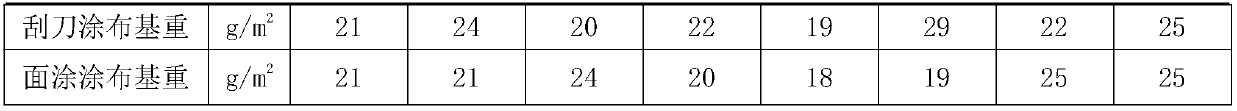

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freeness | aaaaa | aaaaa |

| Bulk | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com