Patents

Literature

1094results about "Calenders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

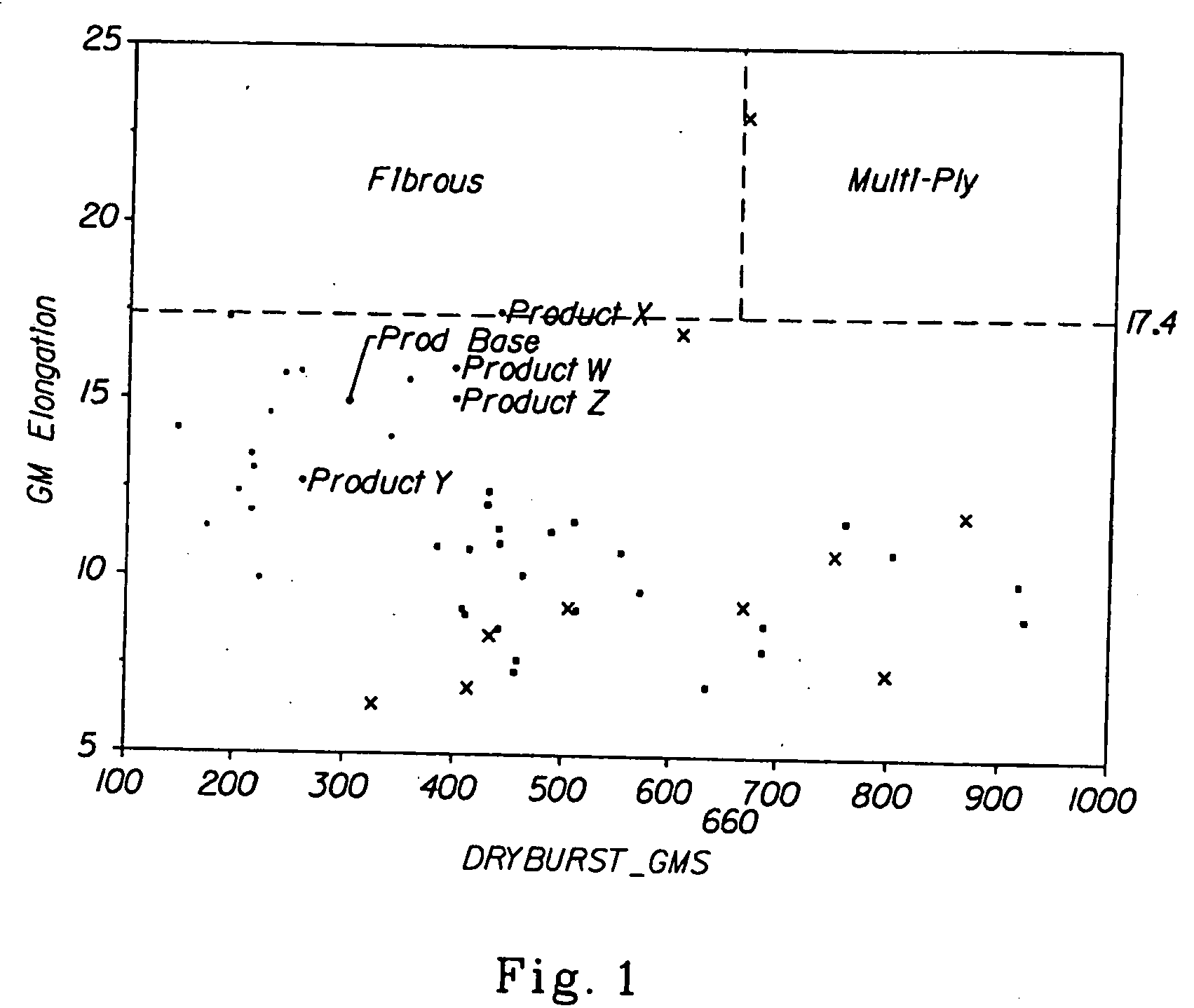

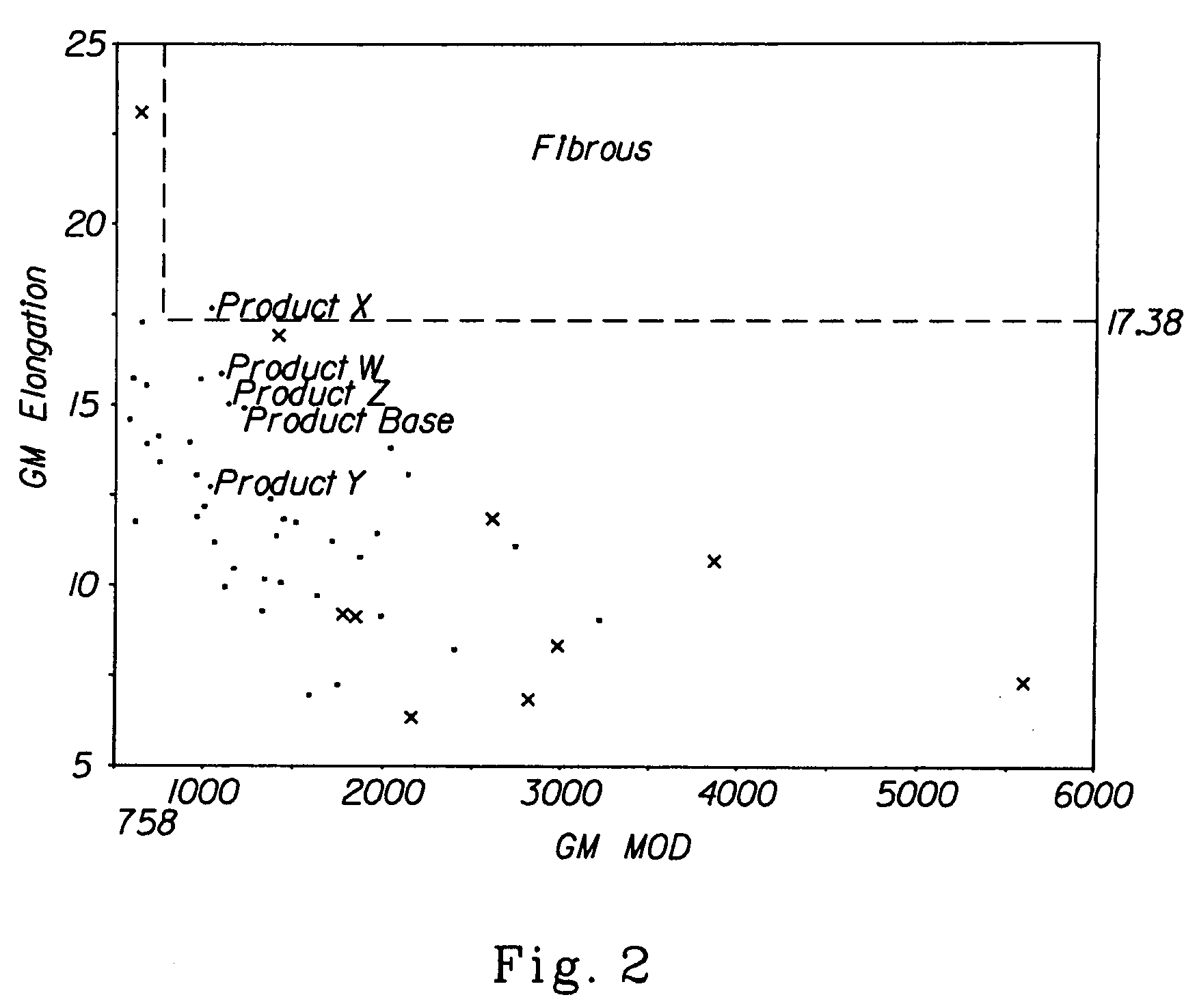

Fibrous structures

ActiveUS7687140B2Non-fibrous pulp additionNatural cellulose pulp/paperFiberUltimate tensile strength

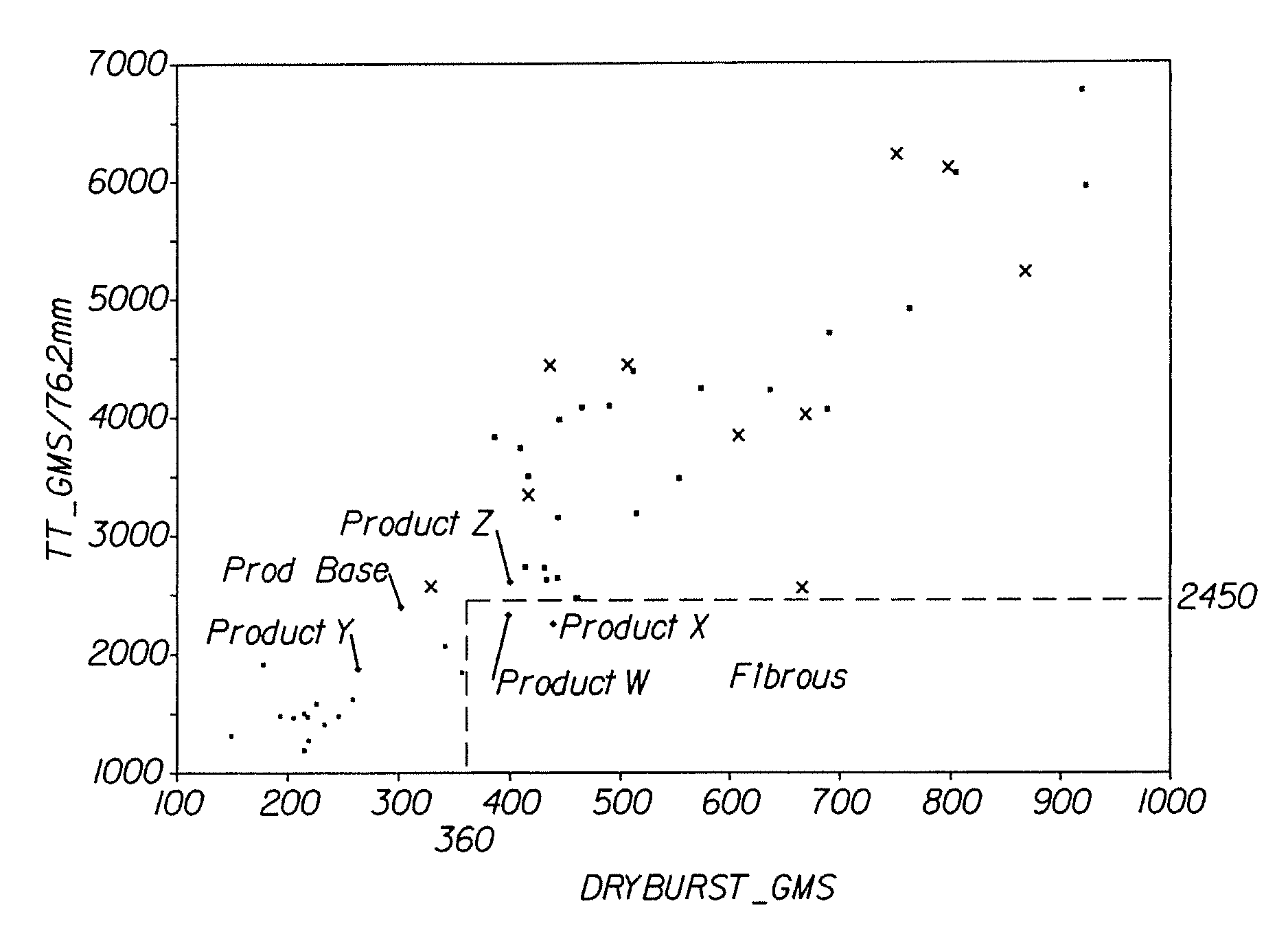

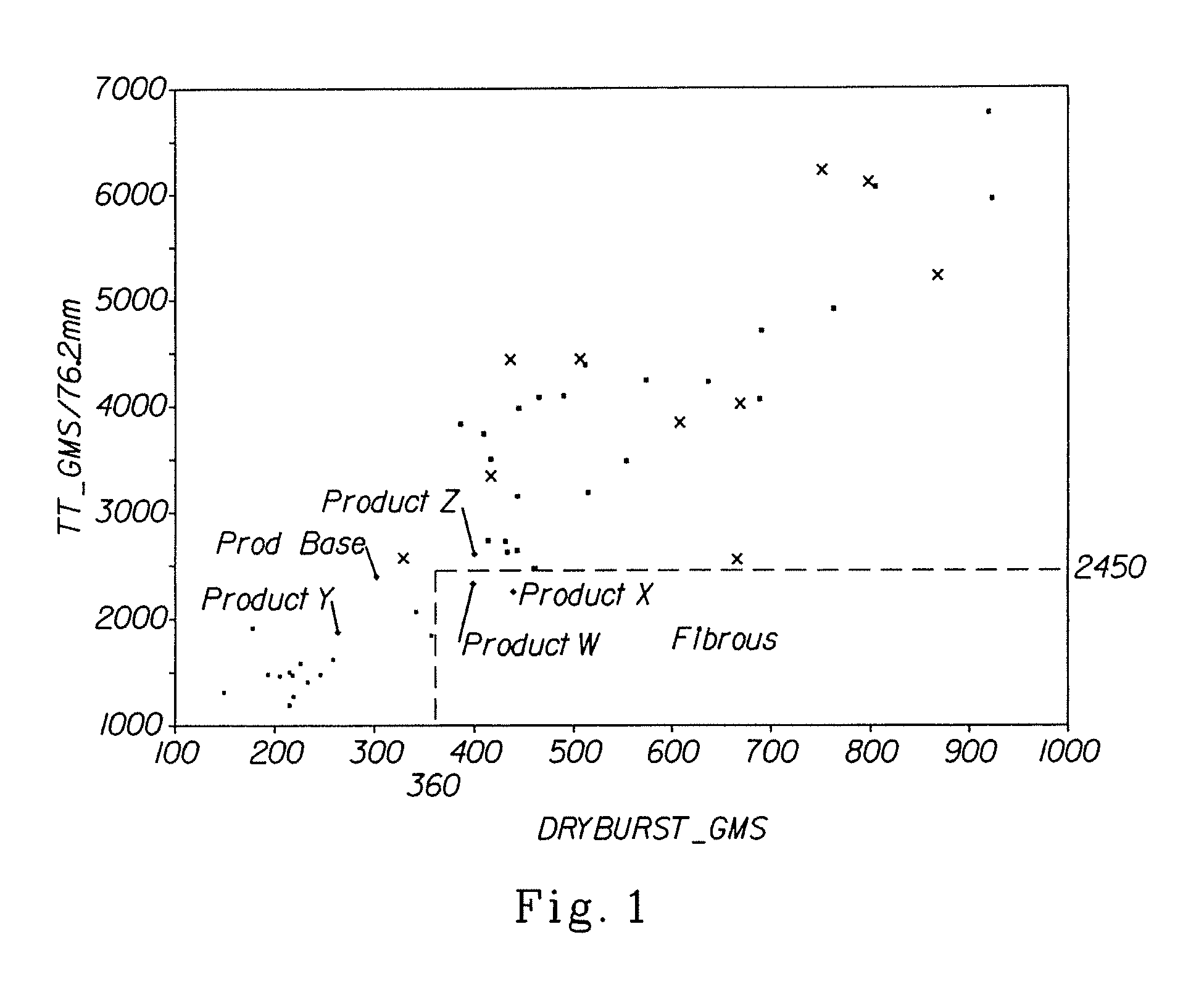

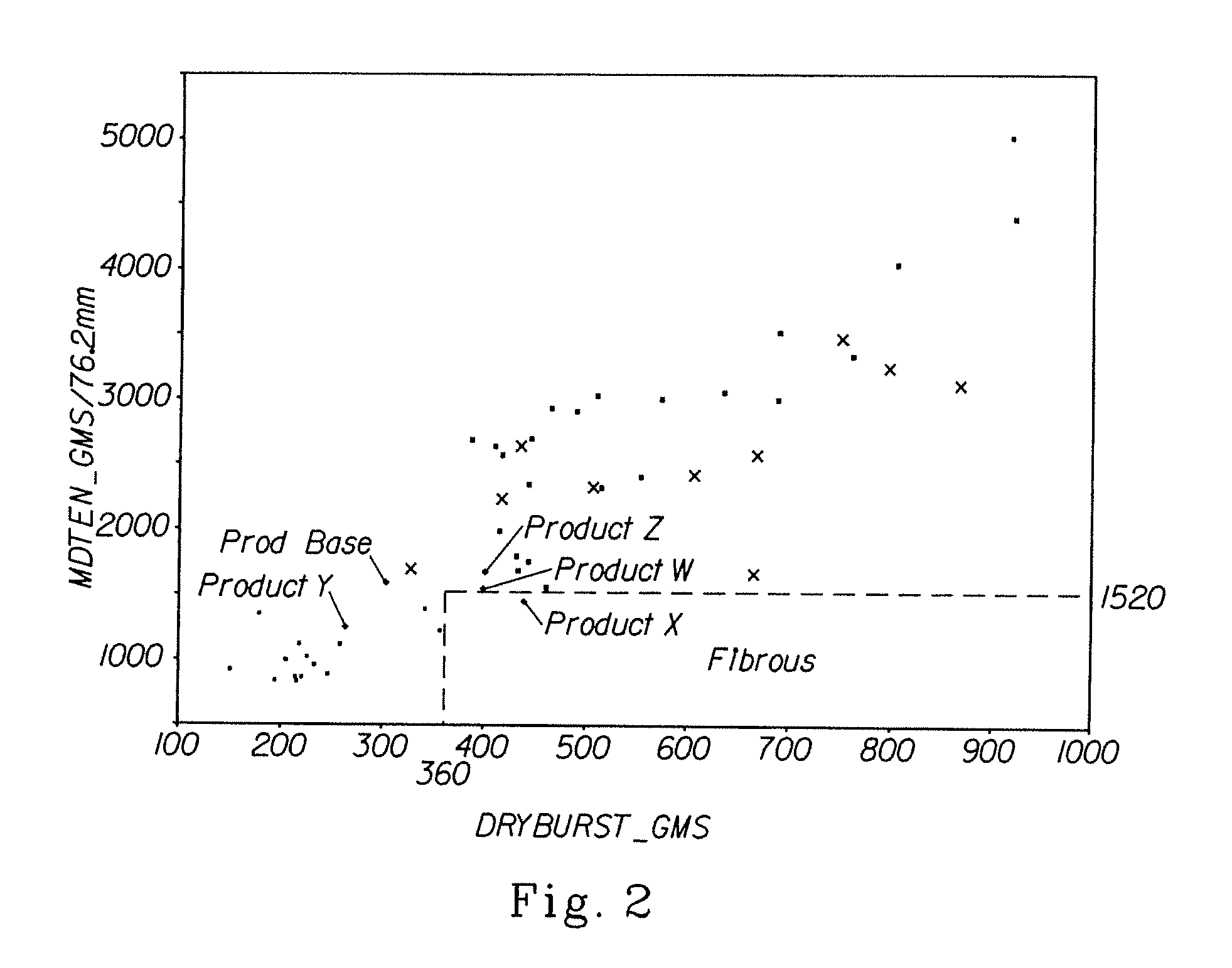

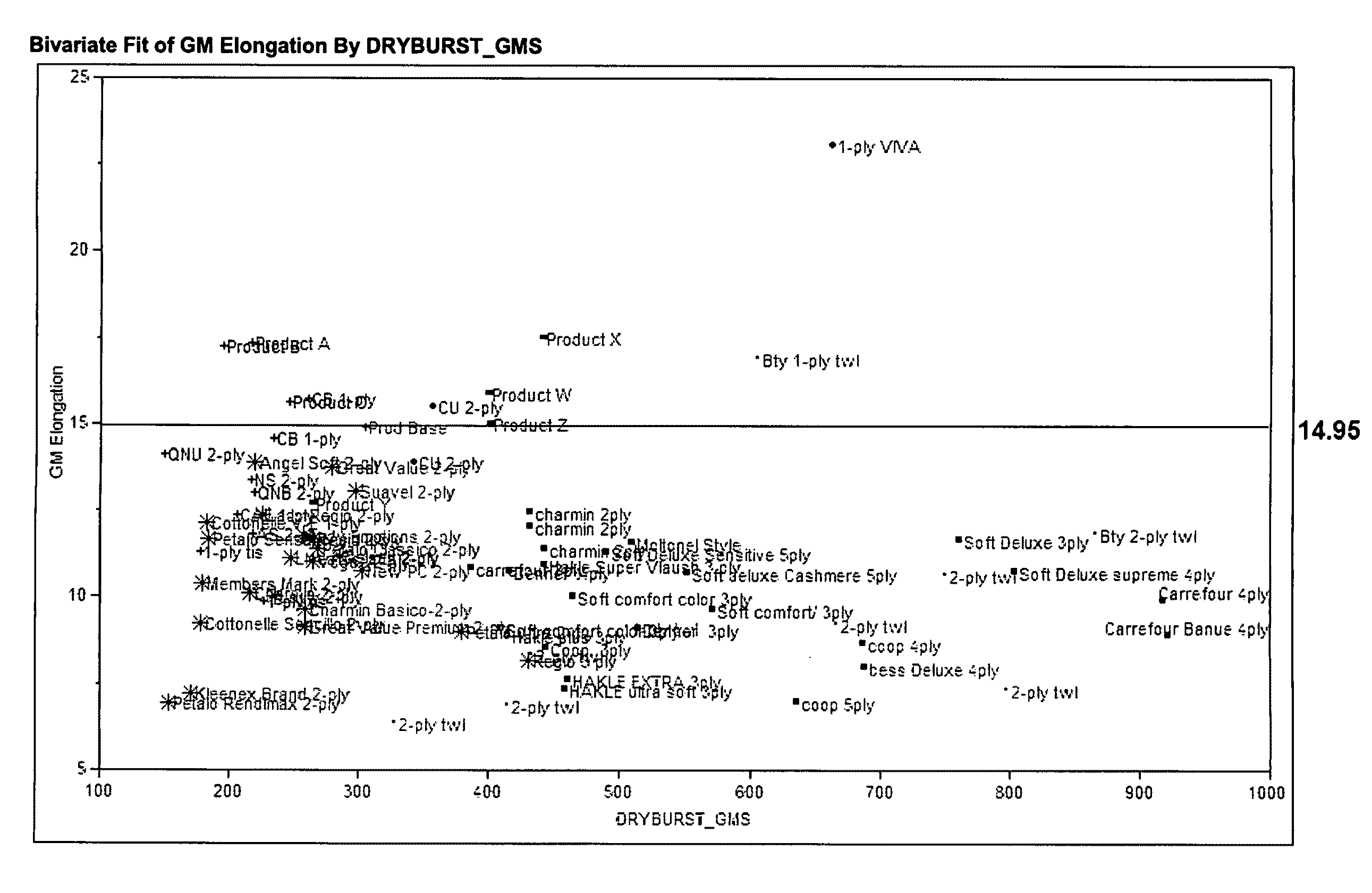

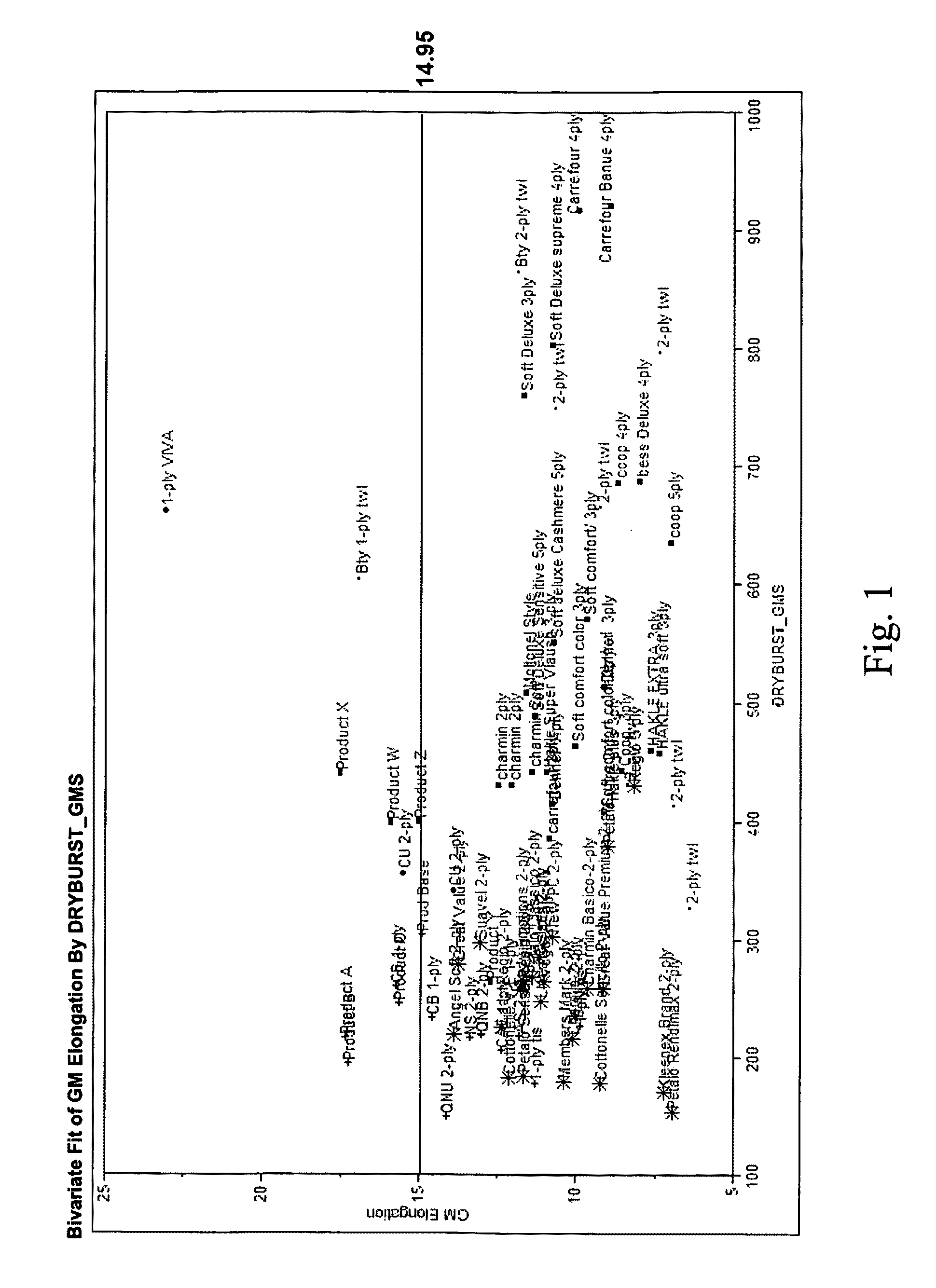

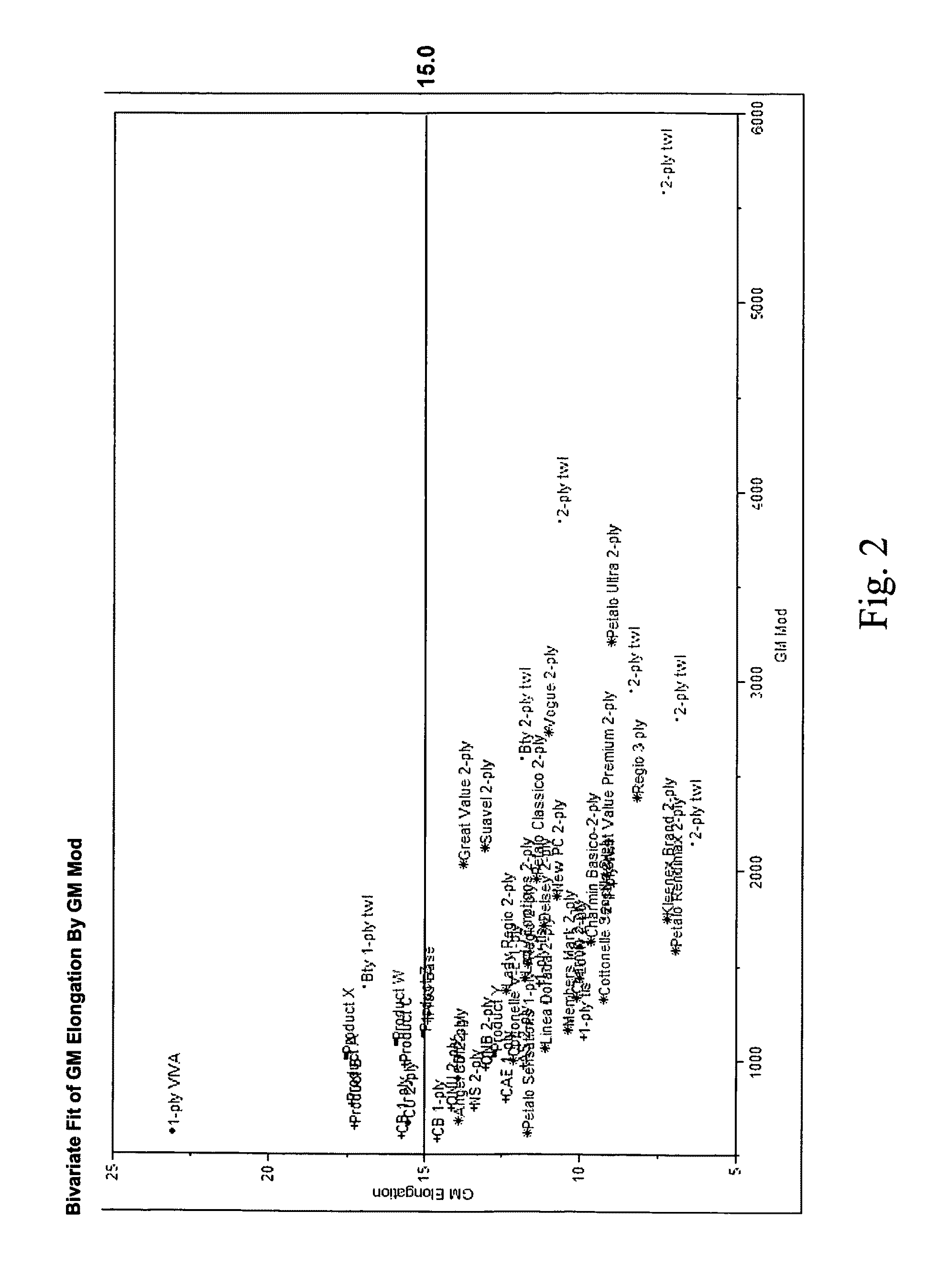

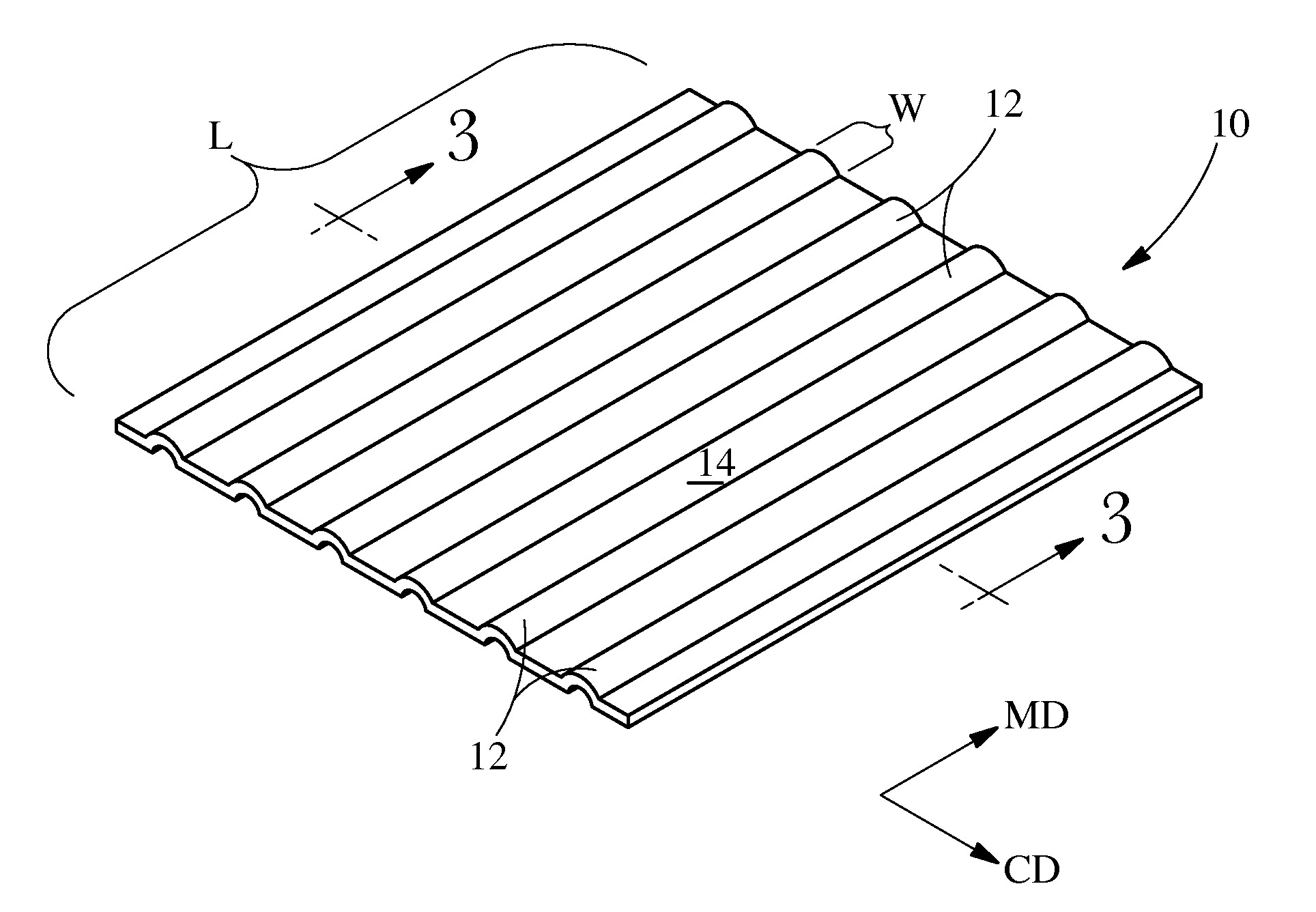

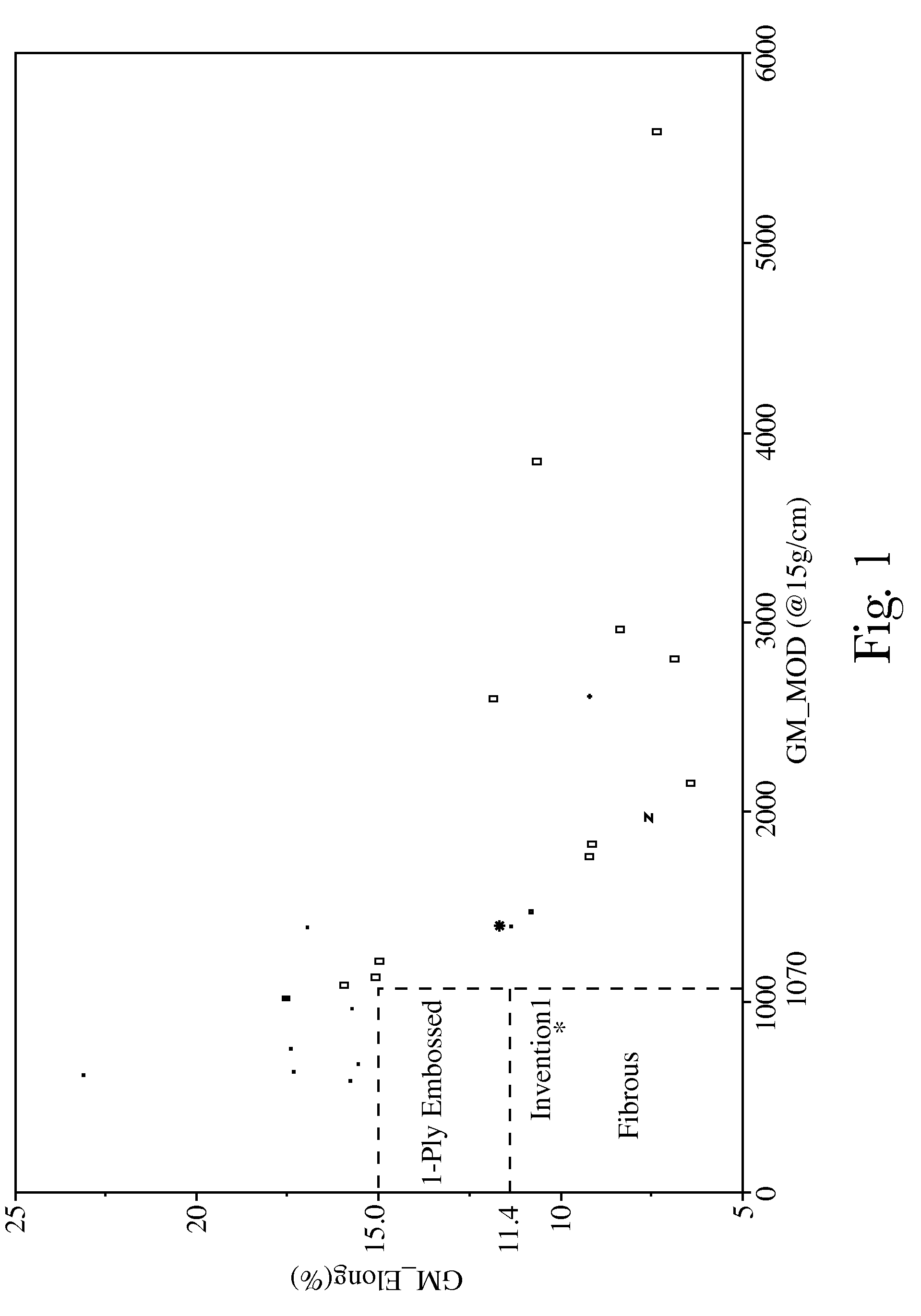

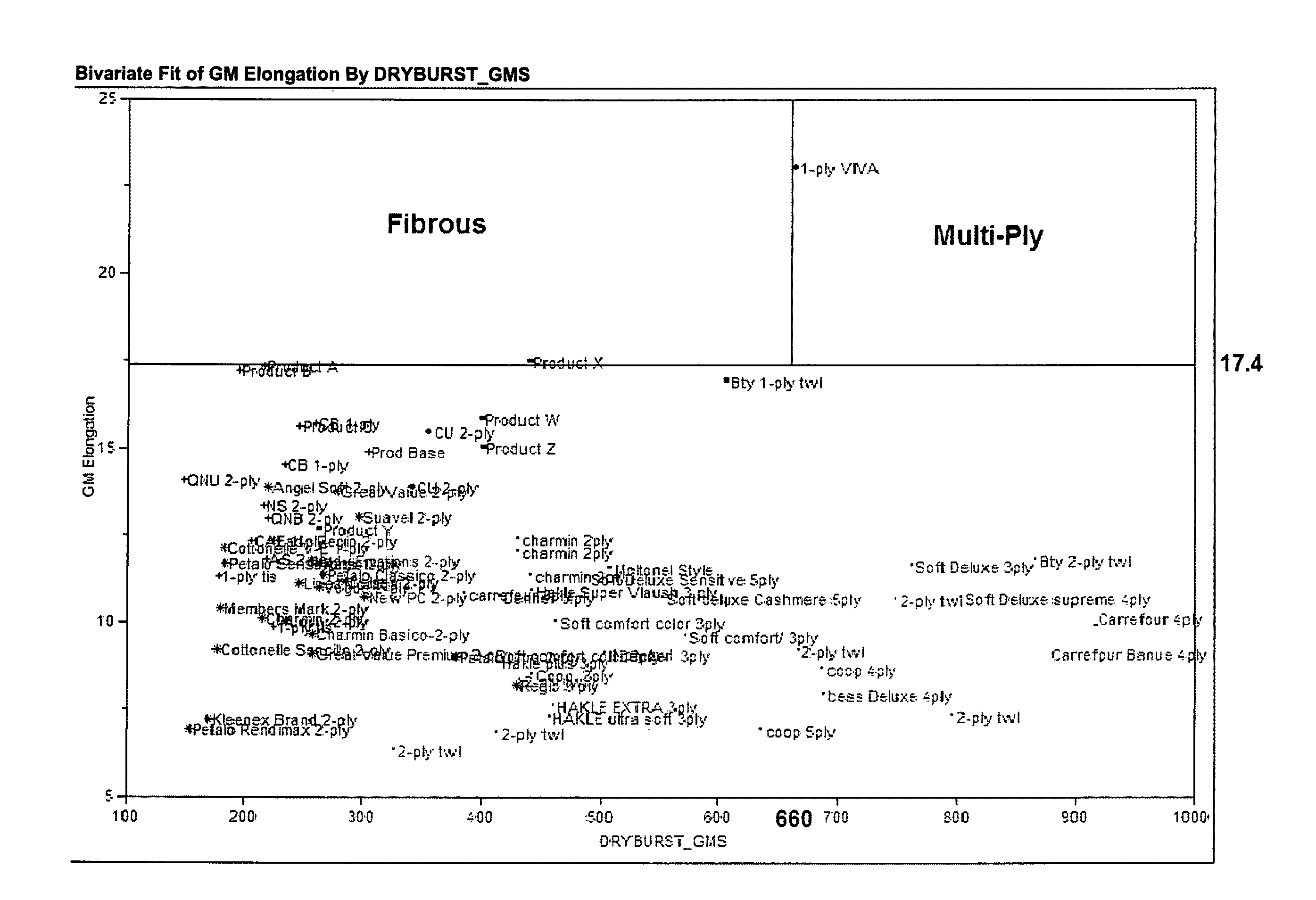

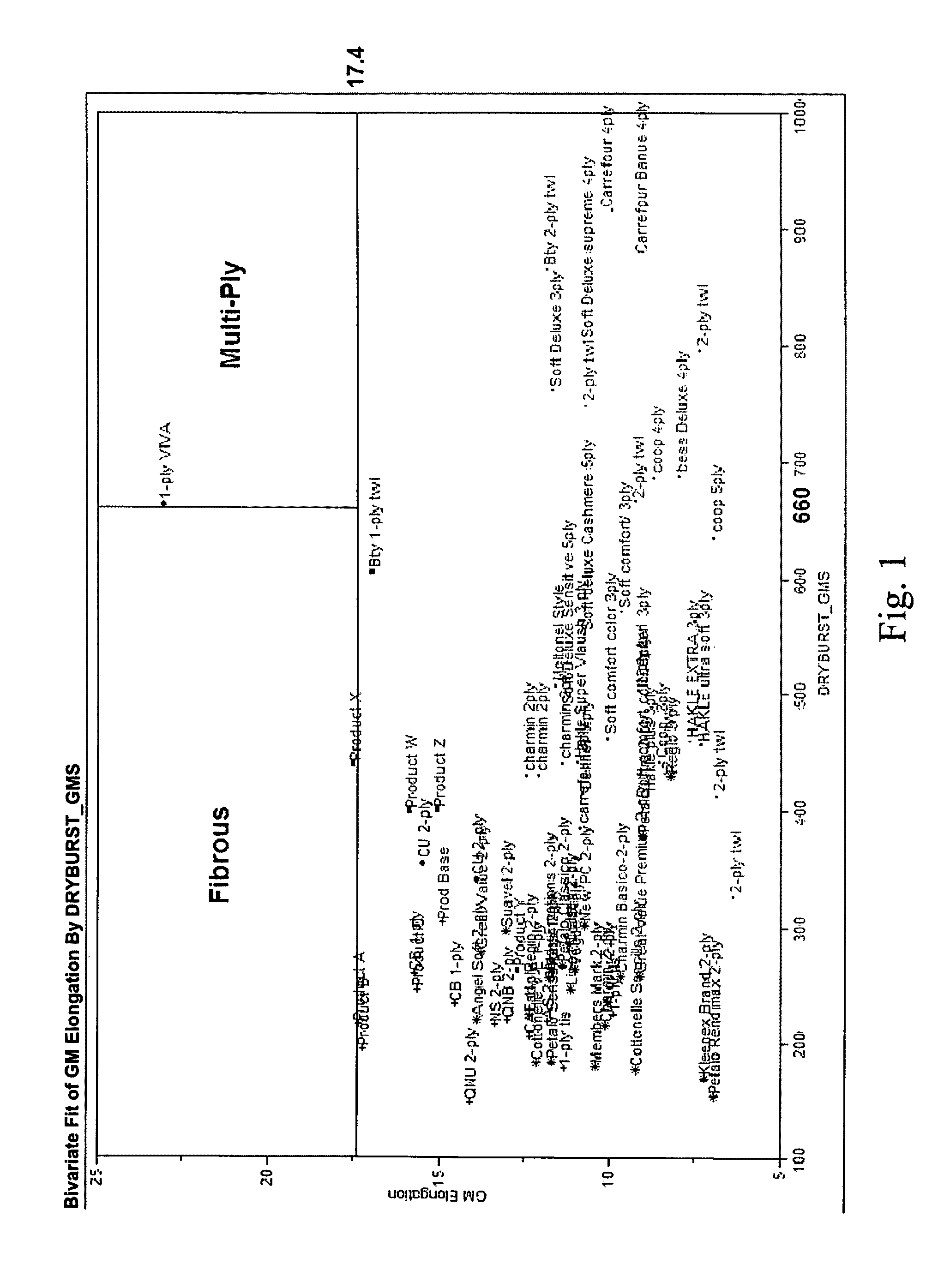

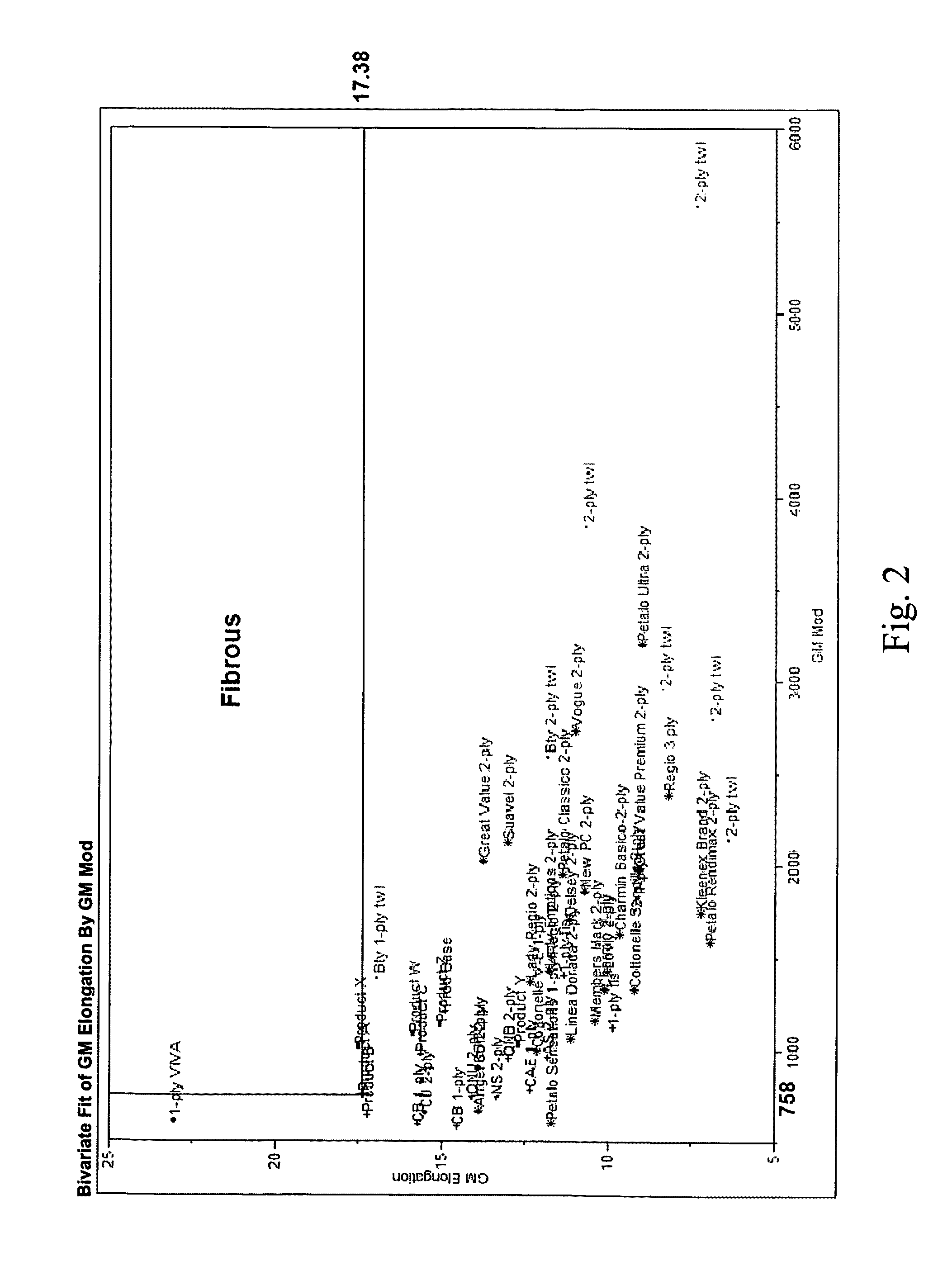

Fibrous structures that exhibit a Dry Burst of greater than 360 g as measured according to the Dry Burst Test Method and optionally, a Total Dry Tensile of less than 2450 g / 76.2 mm and / or a Machine Direction (MD) Dry Tensile of less than 1520 g / 76.2 mm and / or a Geometric Mean GM) Total Dry Tensile of less than 1180 g / 76.2 mm as measured according to the Tensile Strength Test Method are provided.

Owner:PROCTER & GAMBLE CO

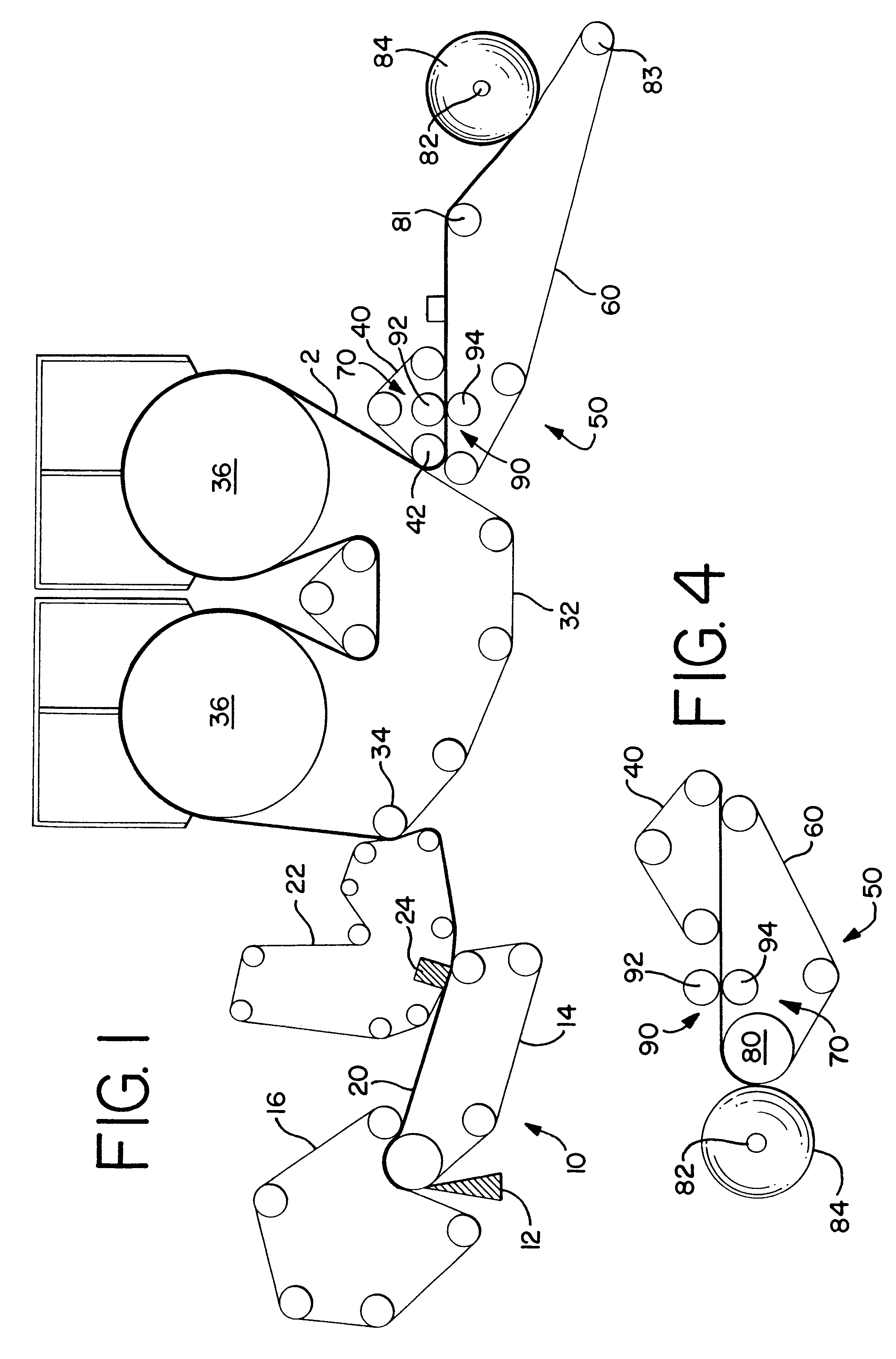

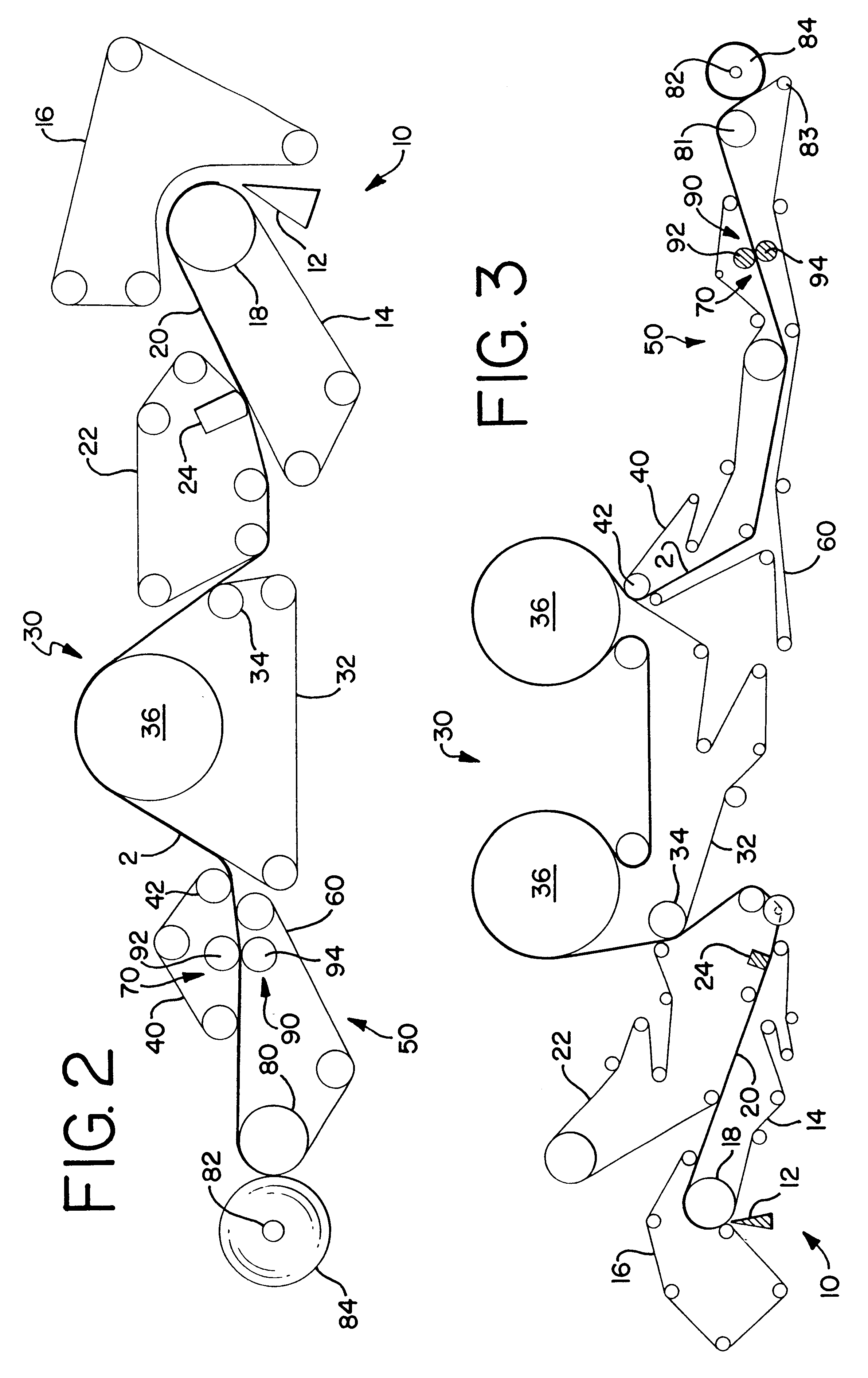

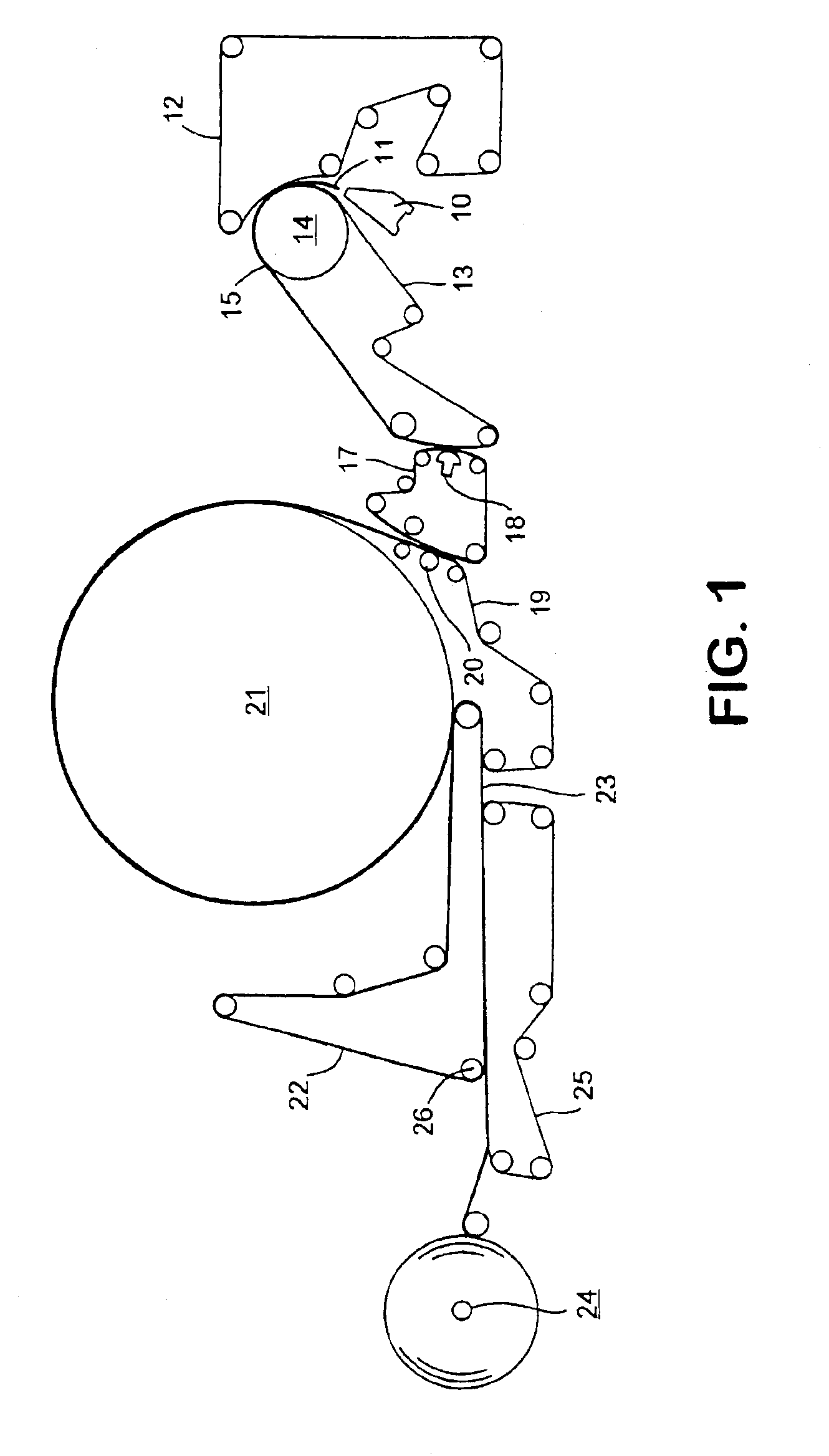

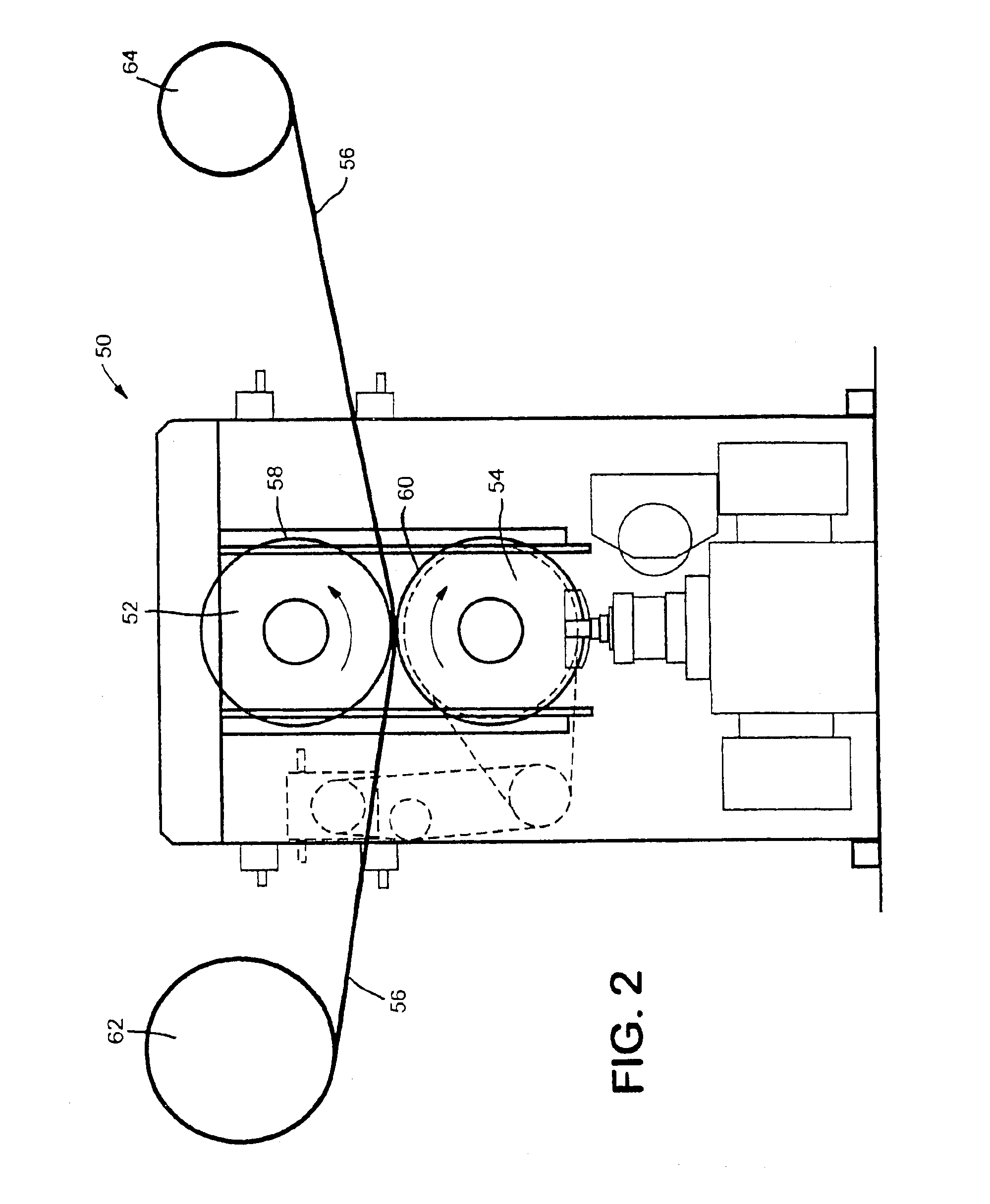

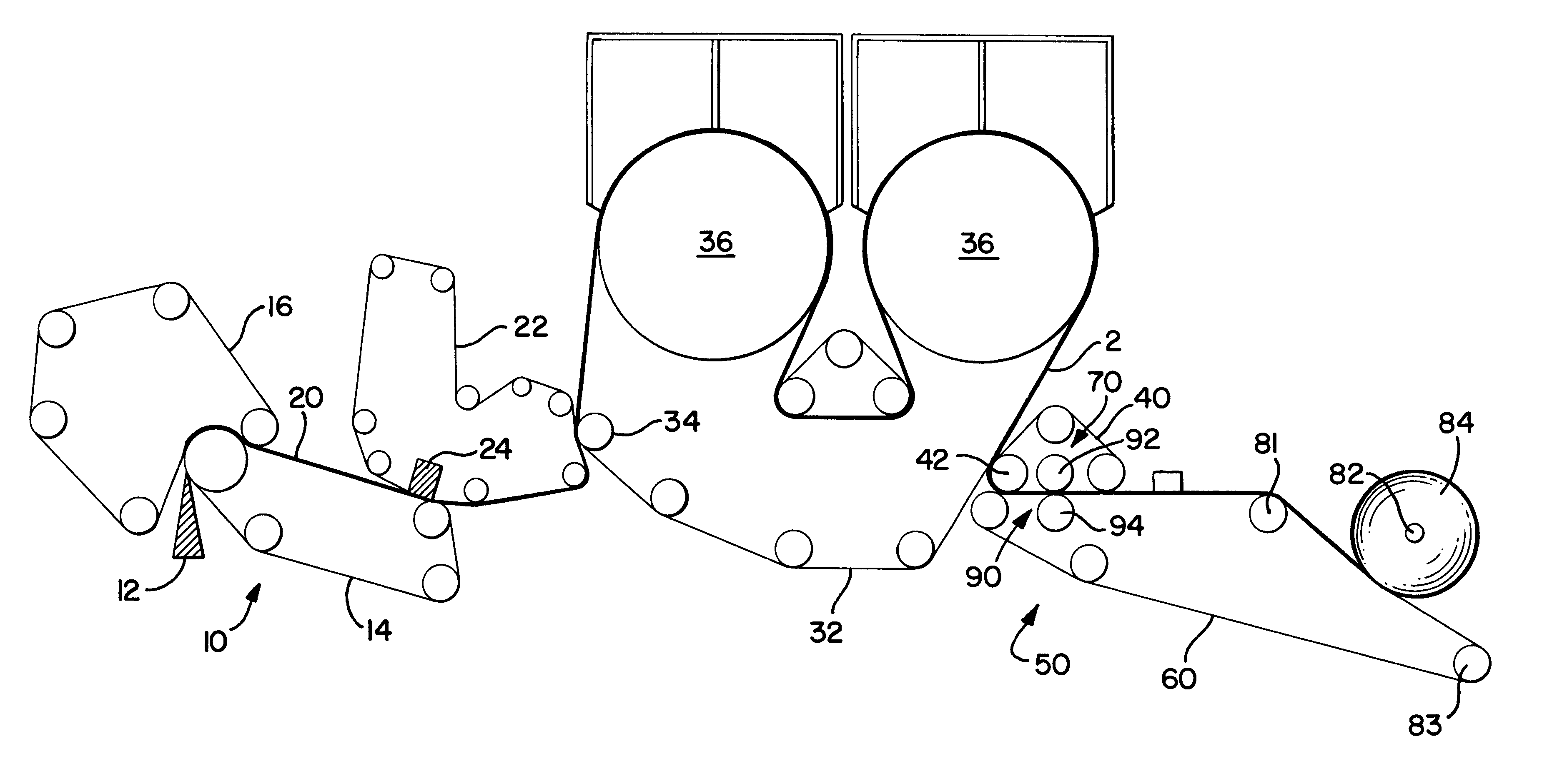

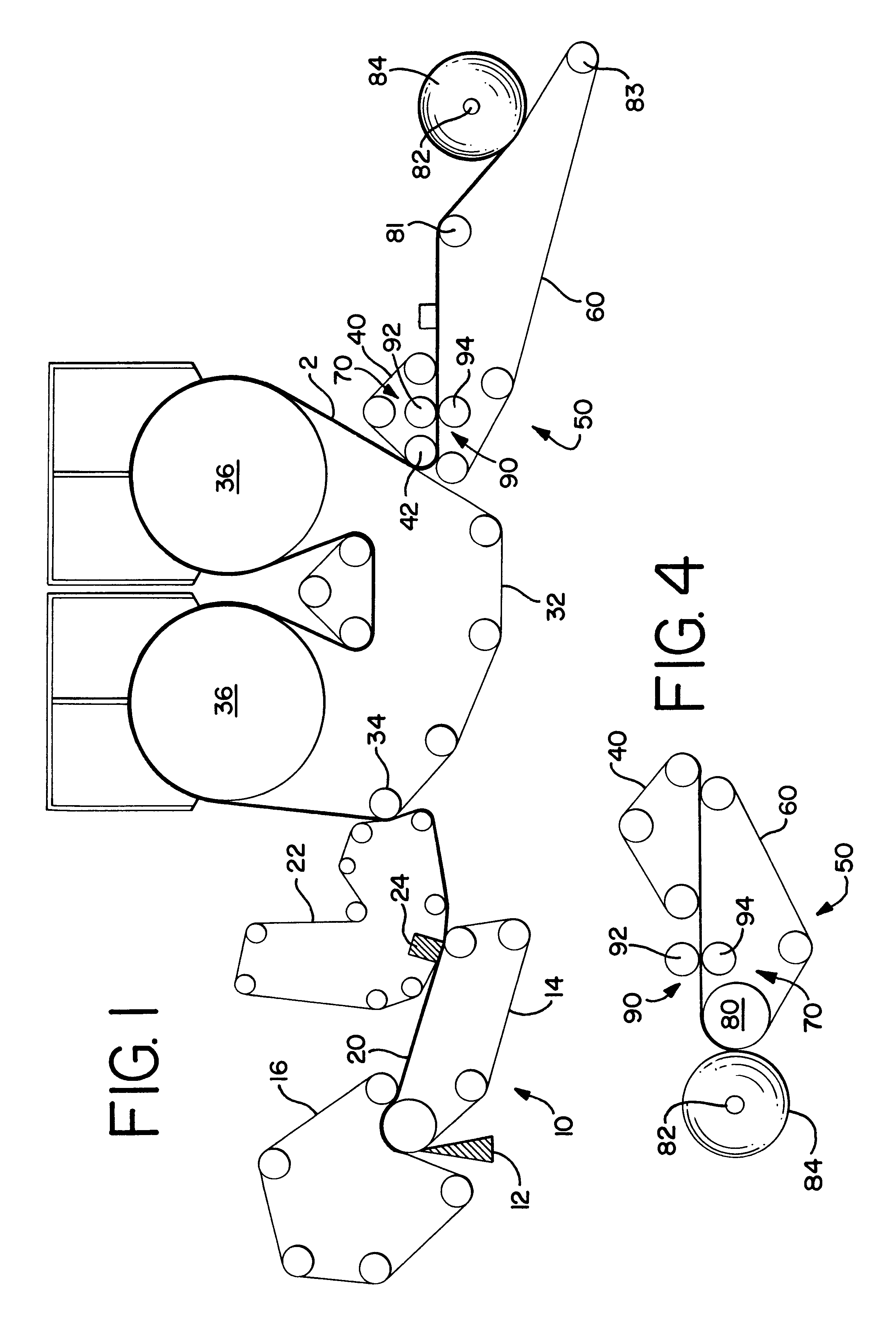

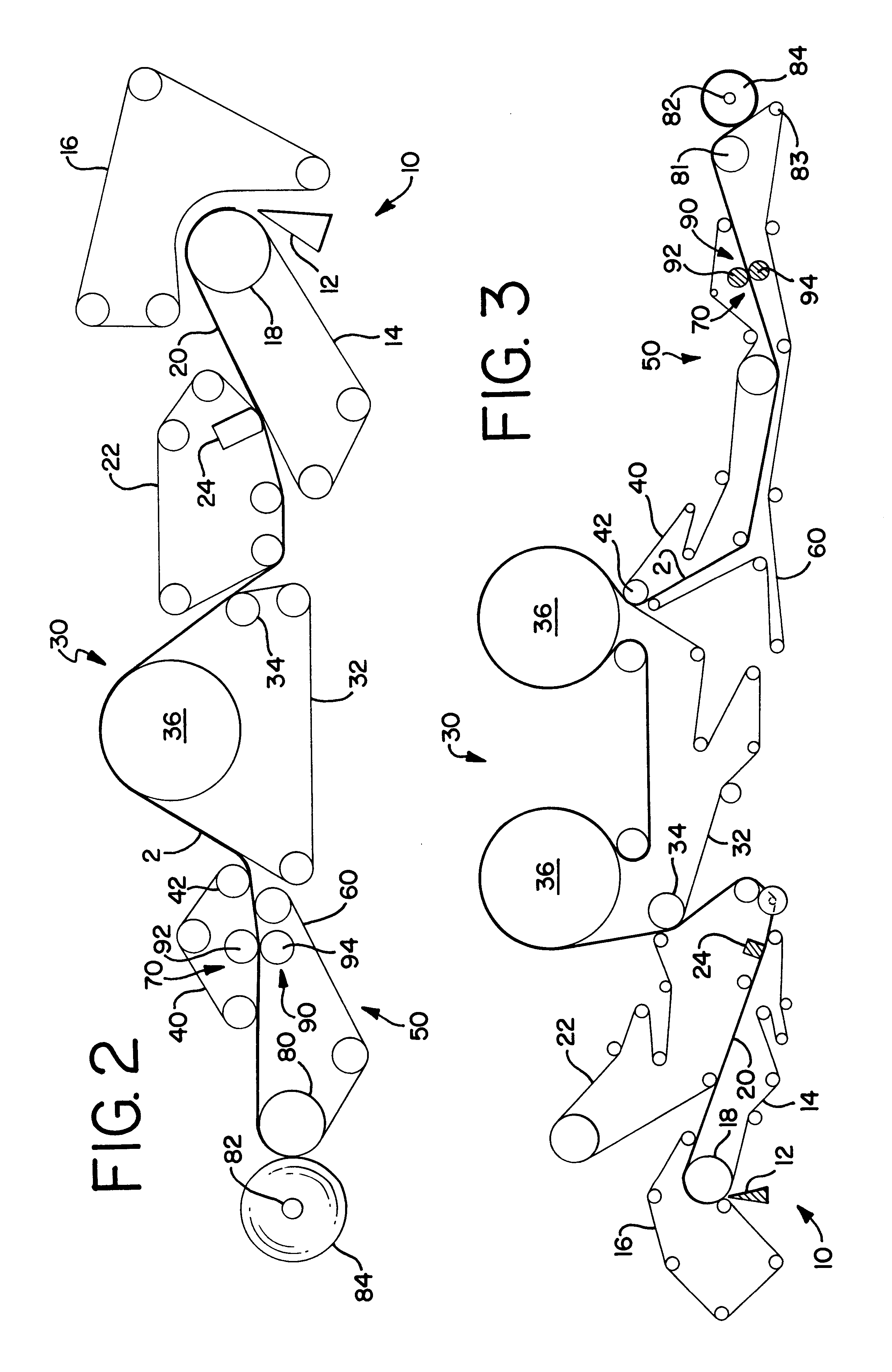

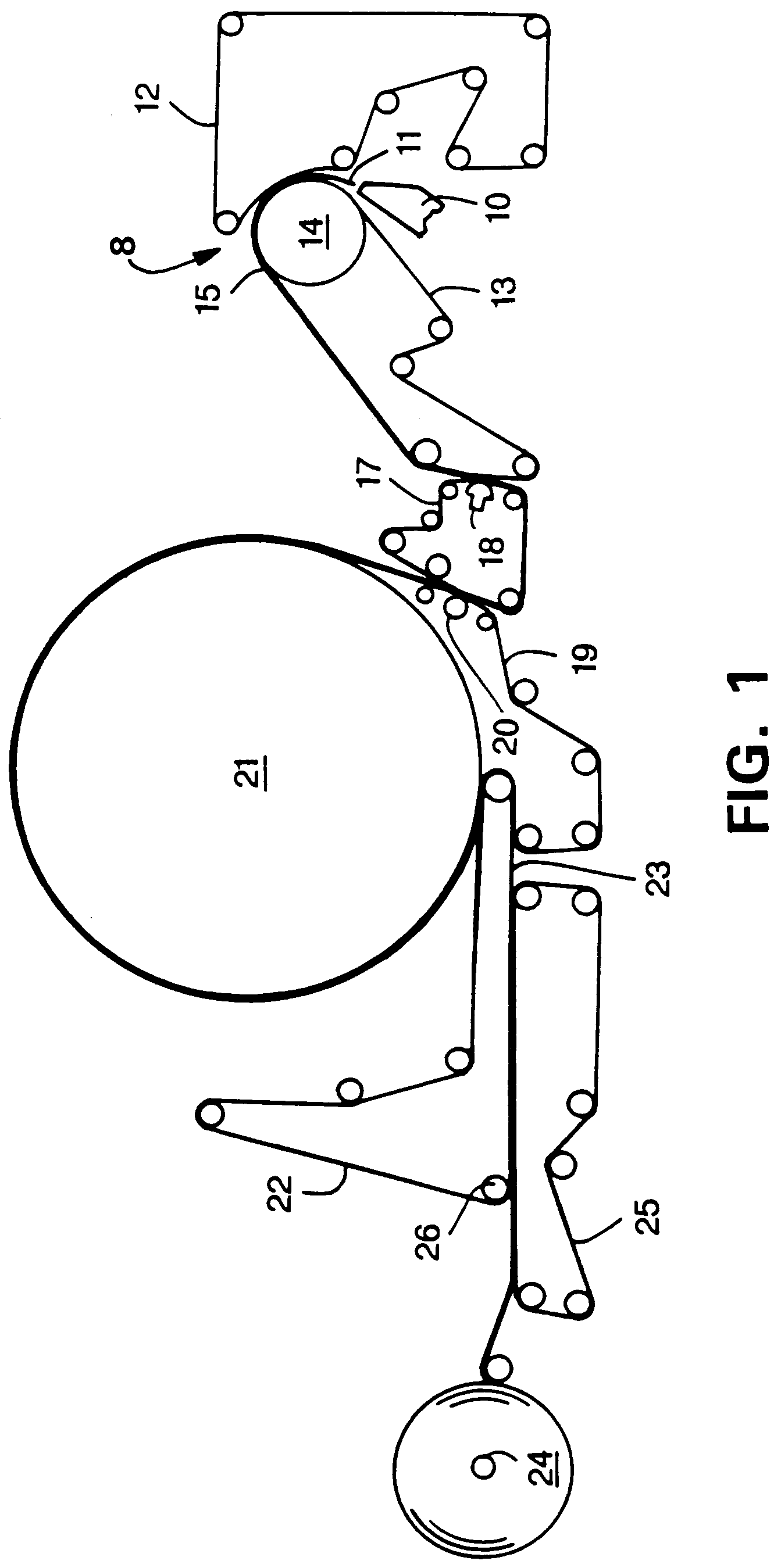

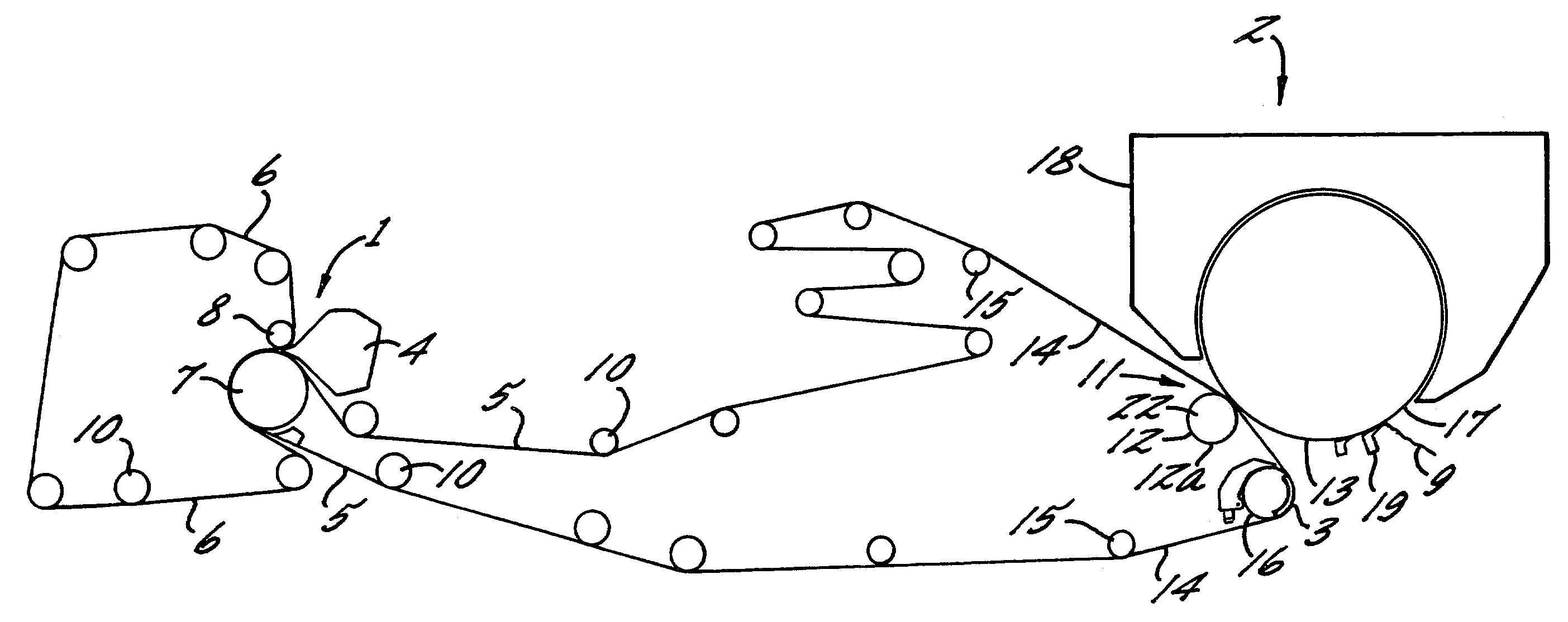

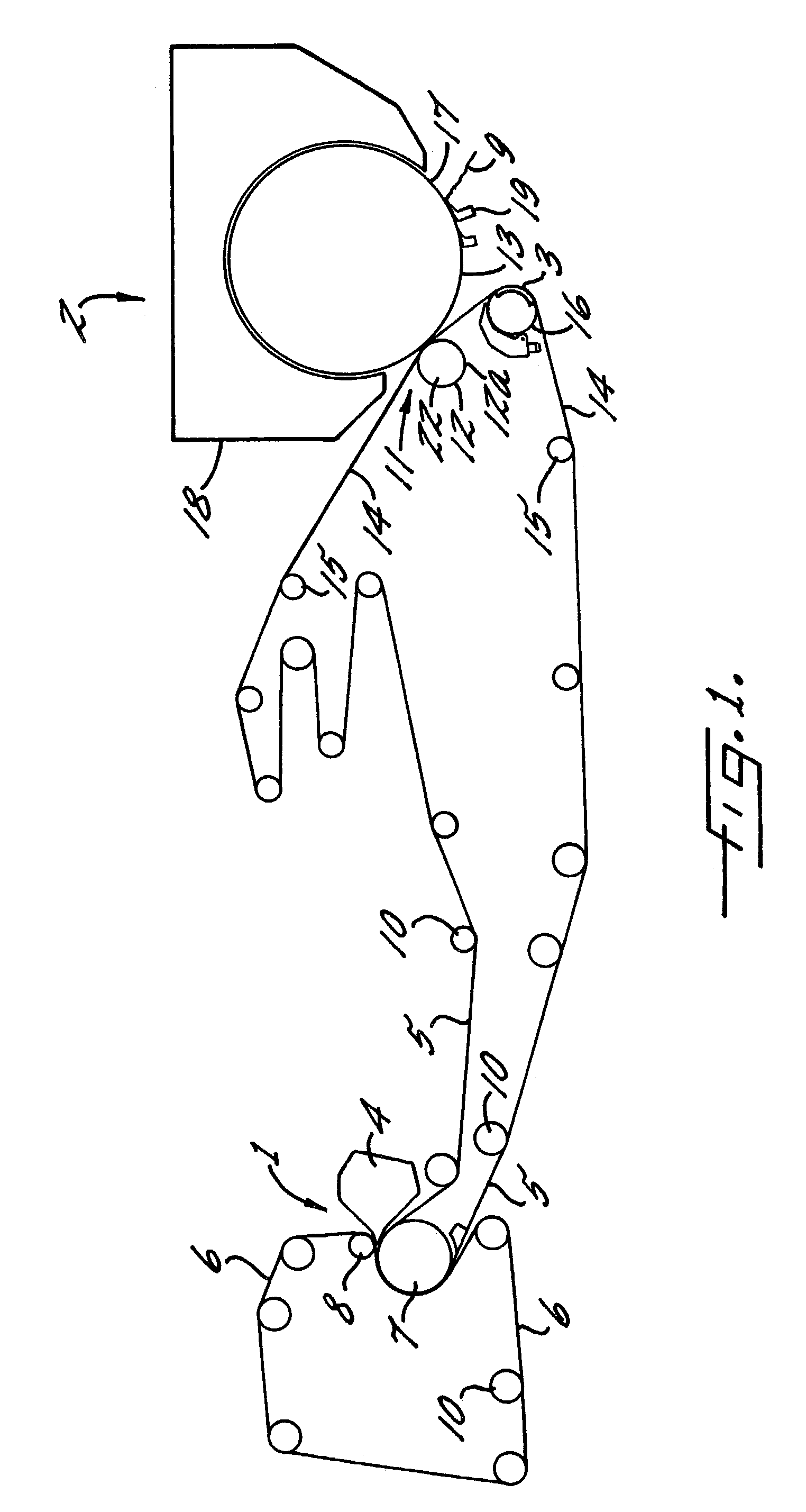

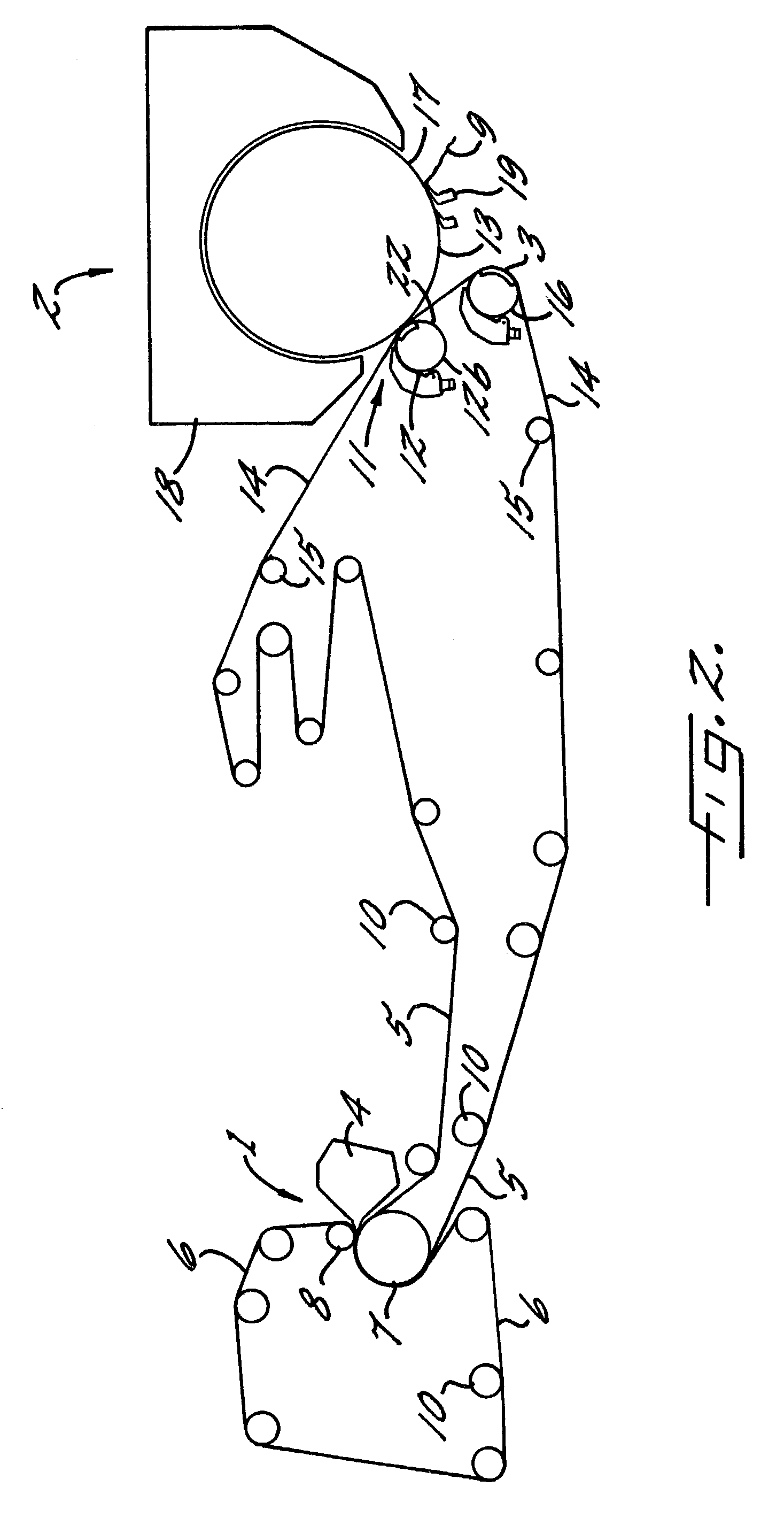

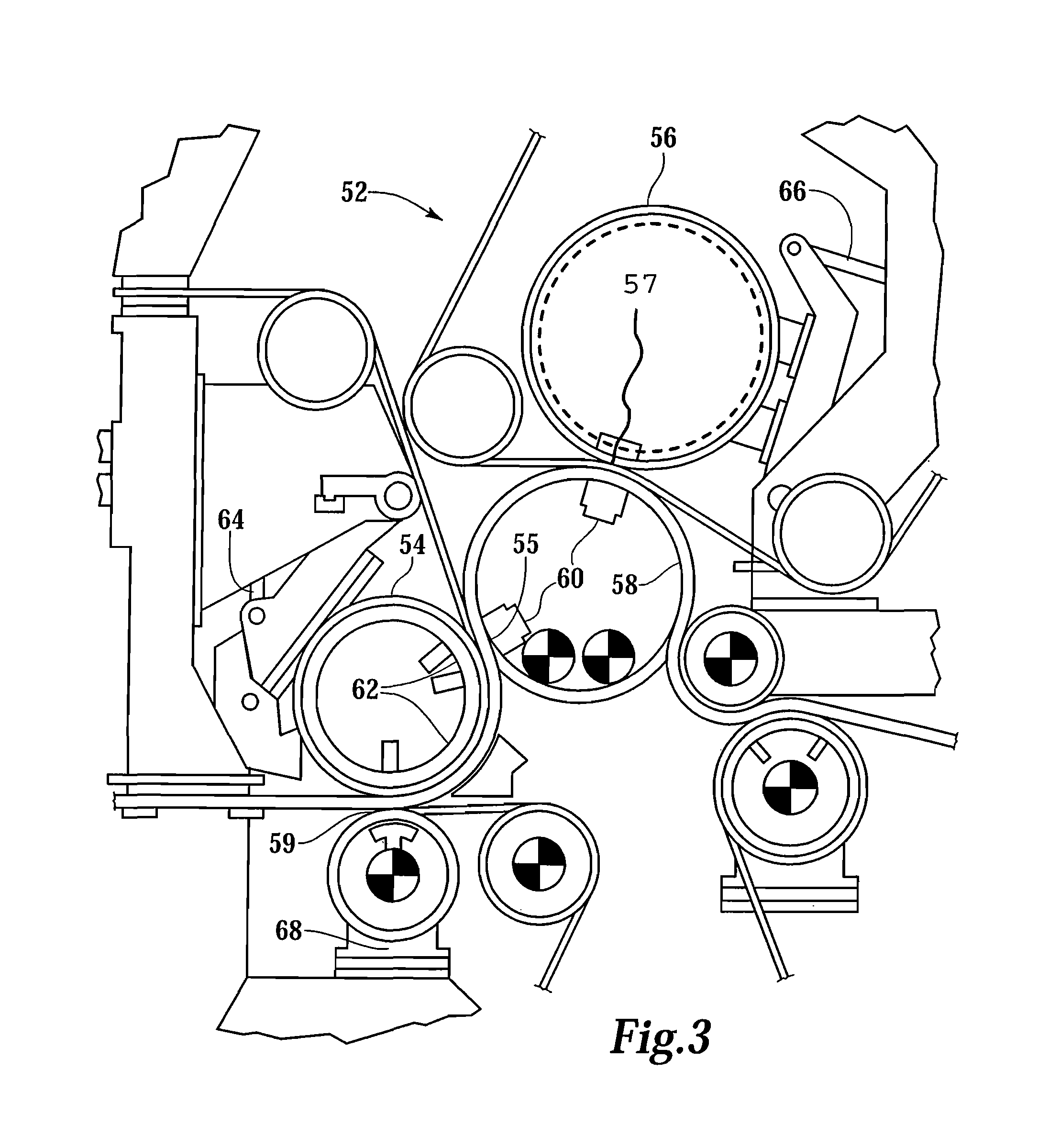

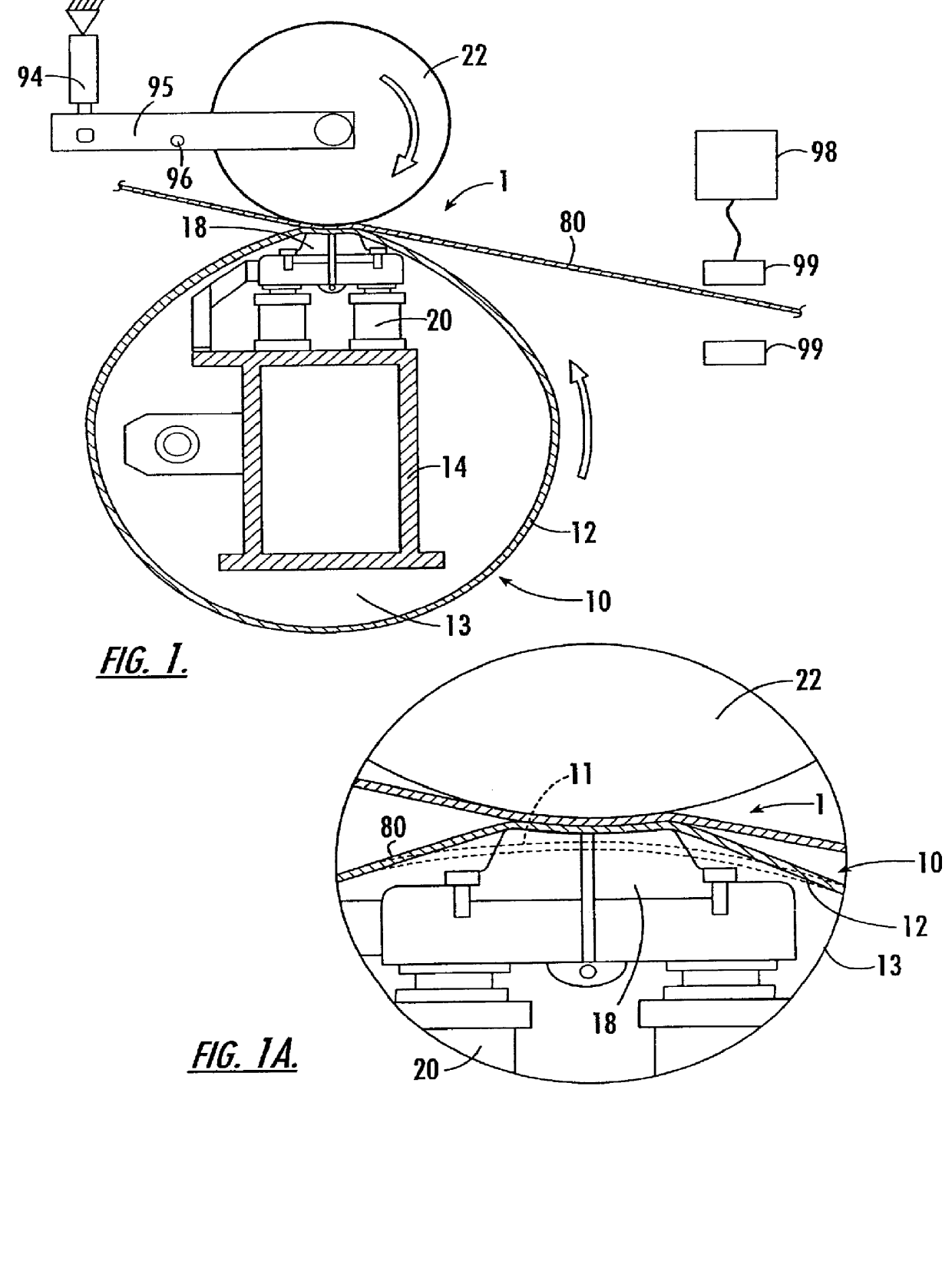

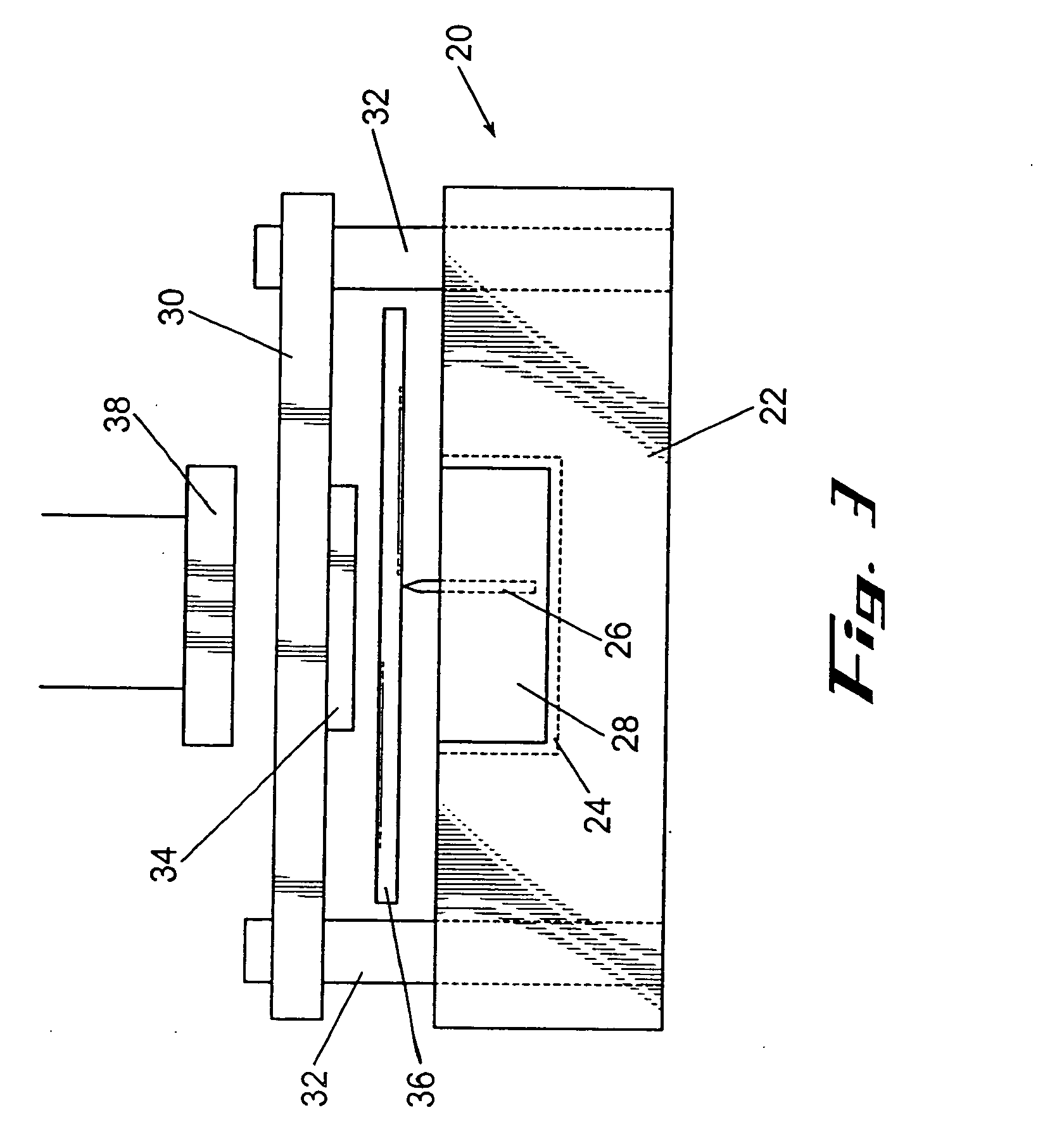

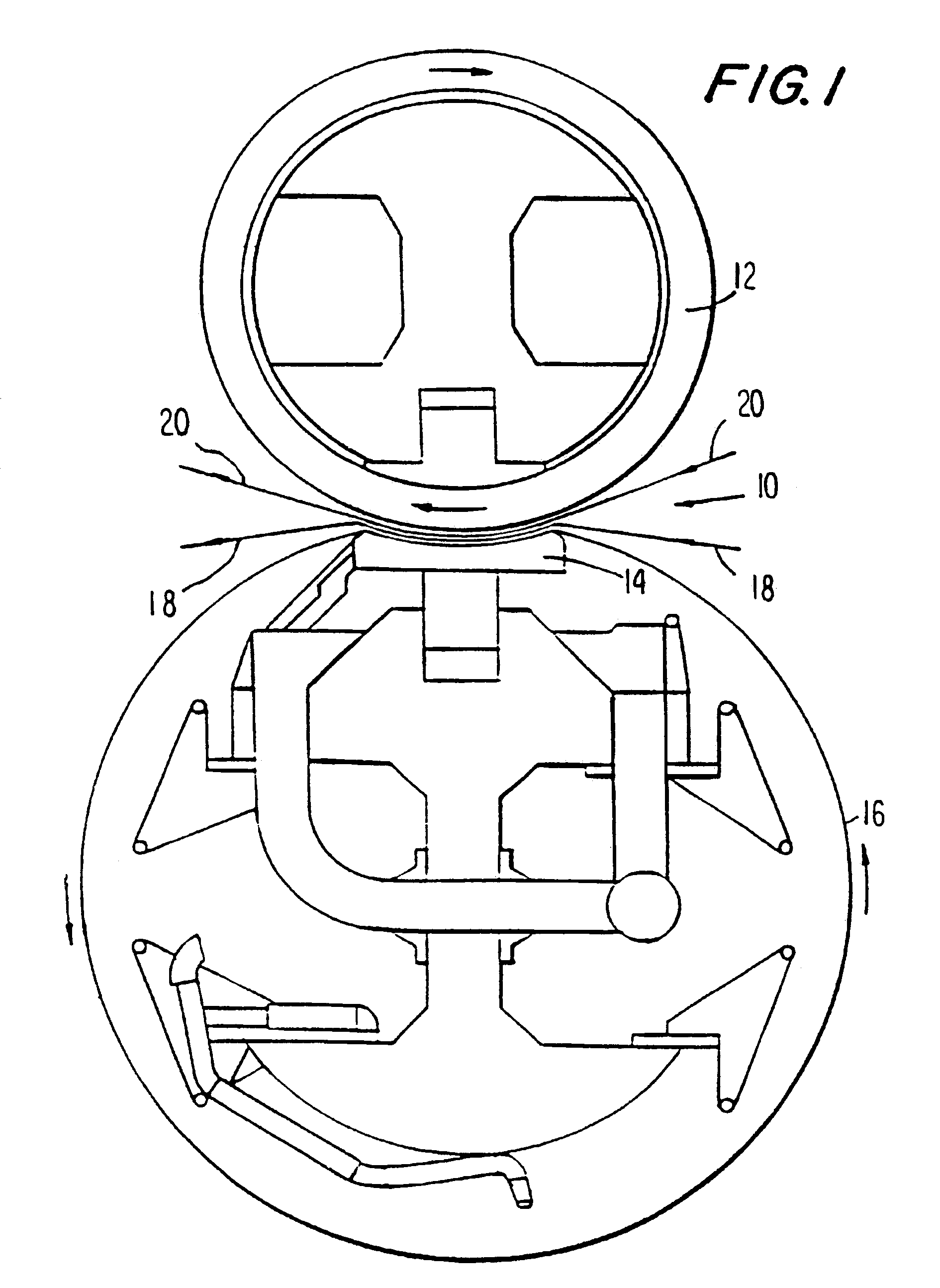

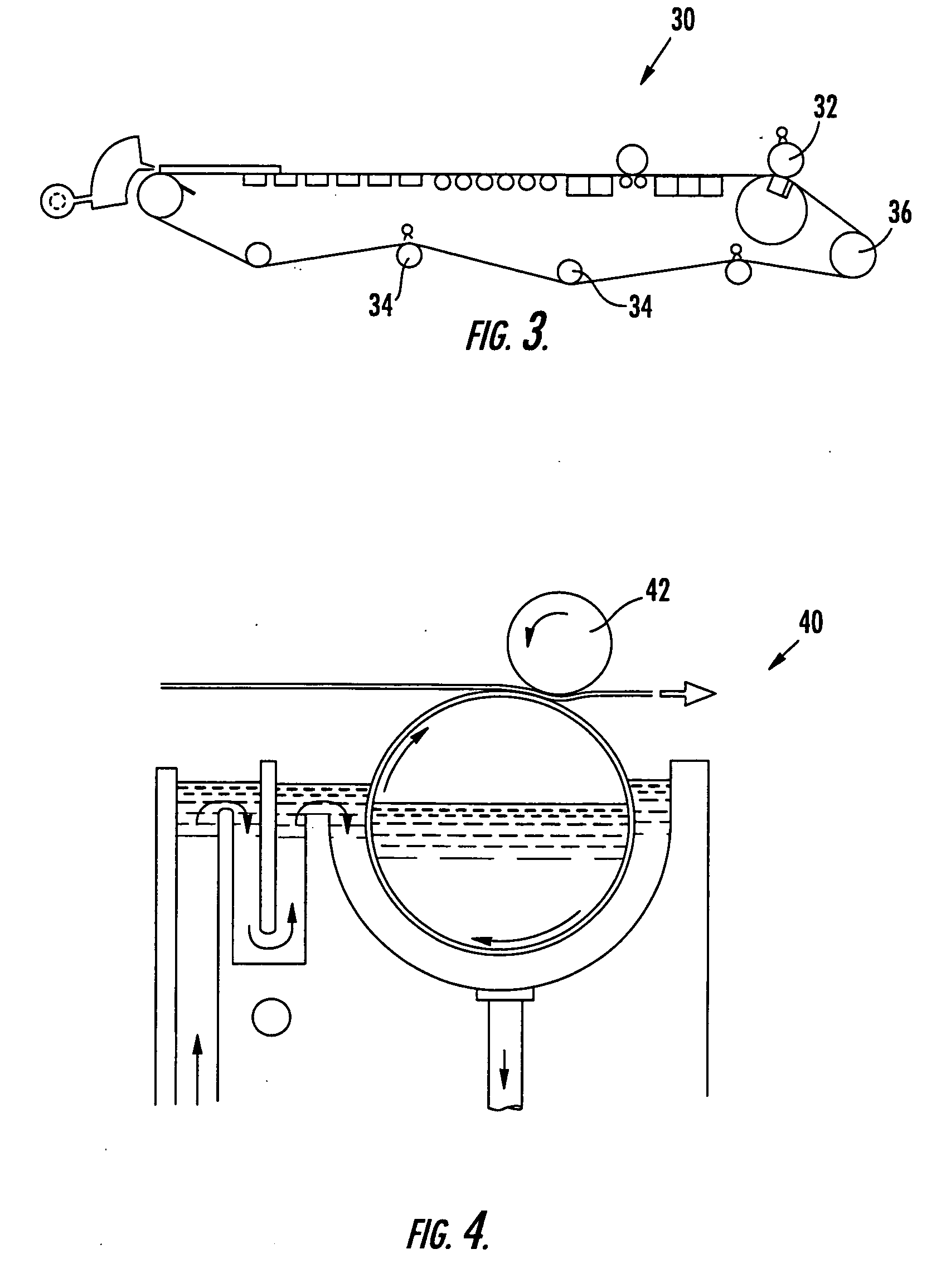

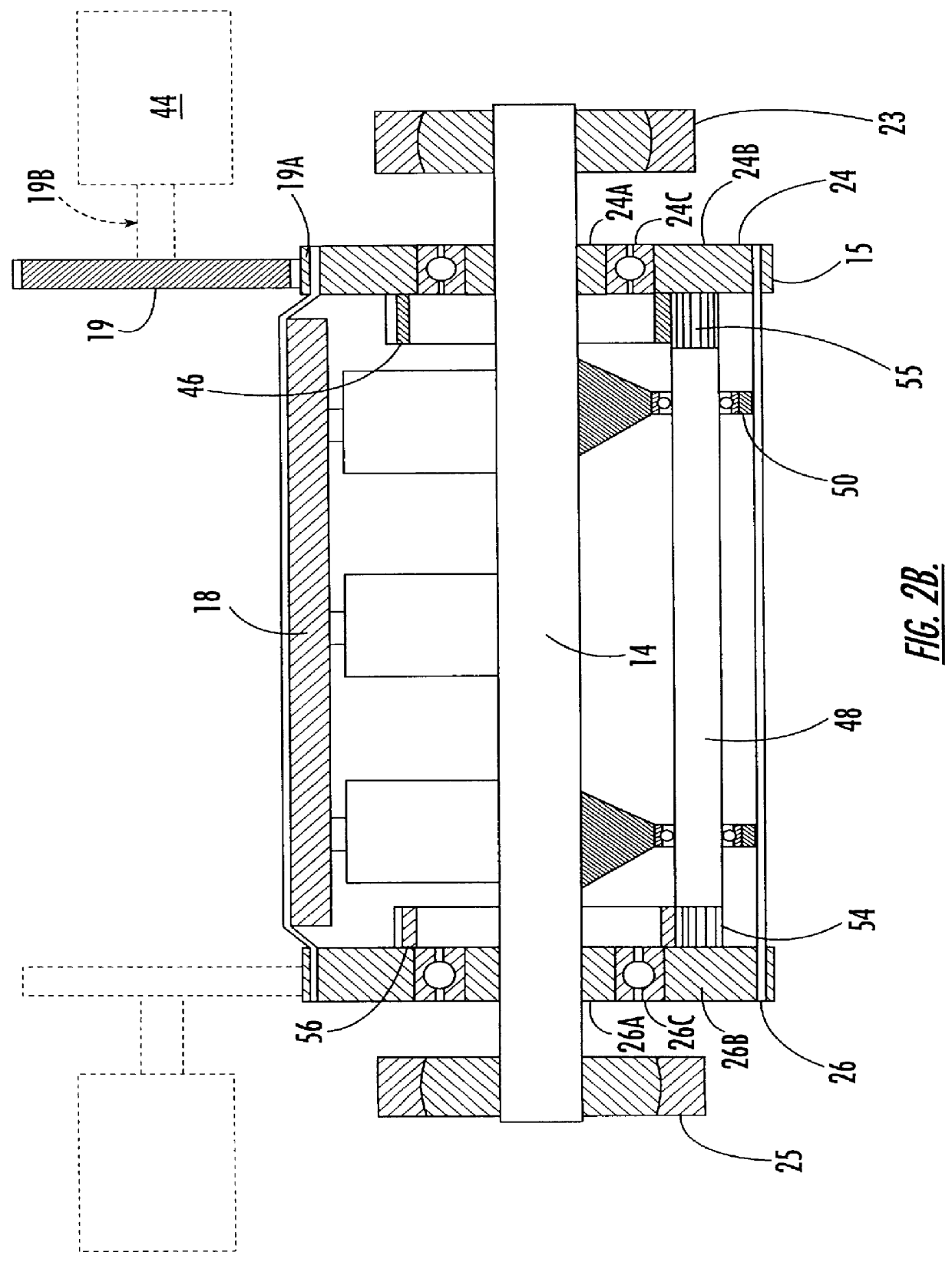

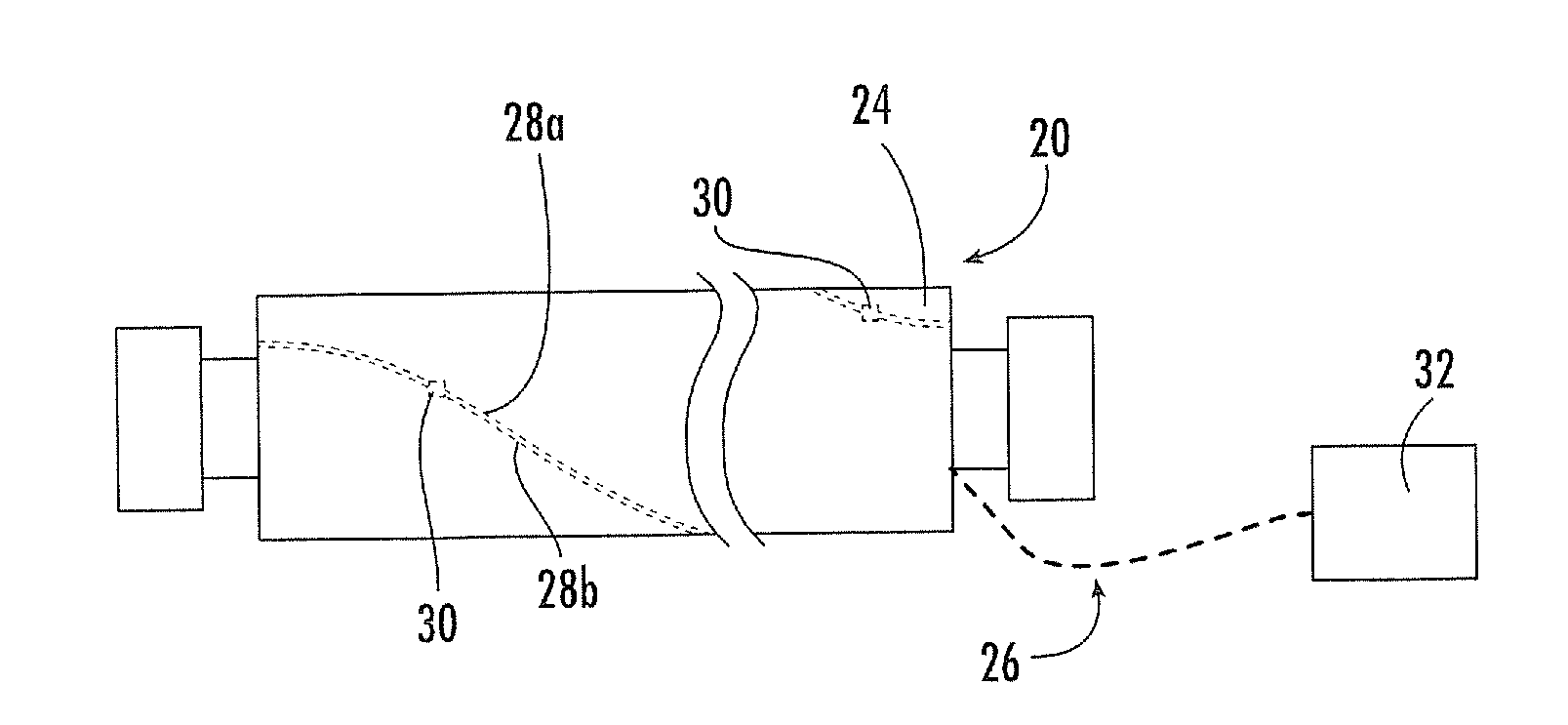

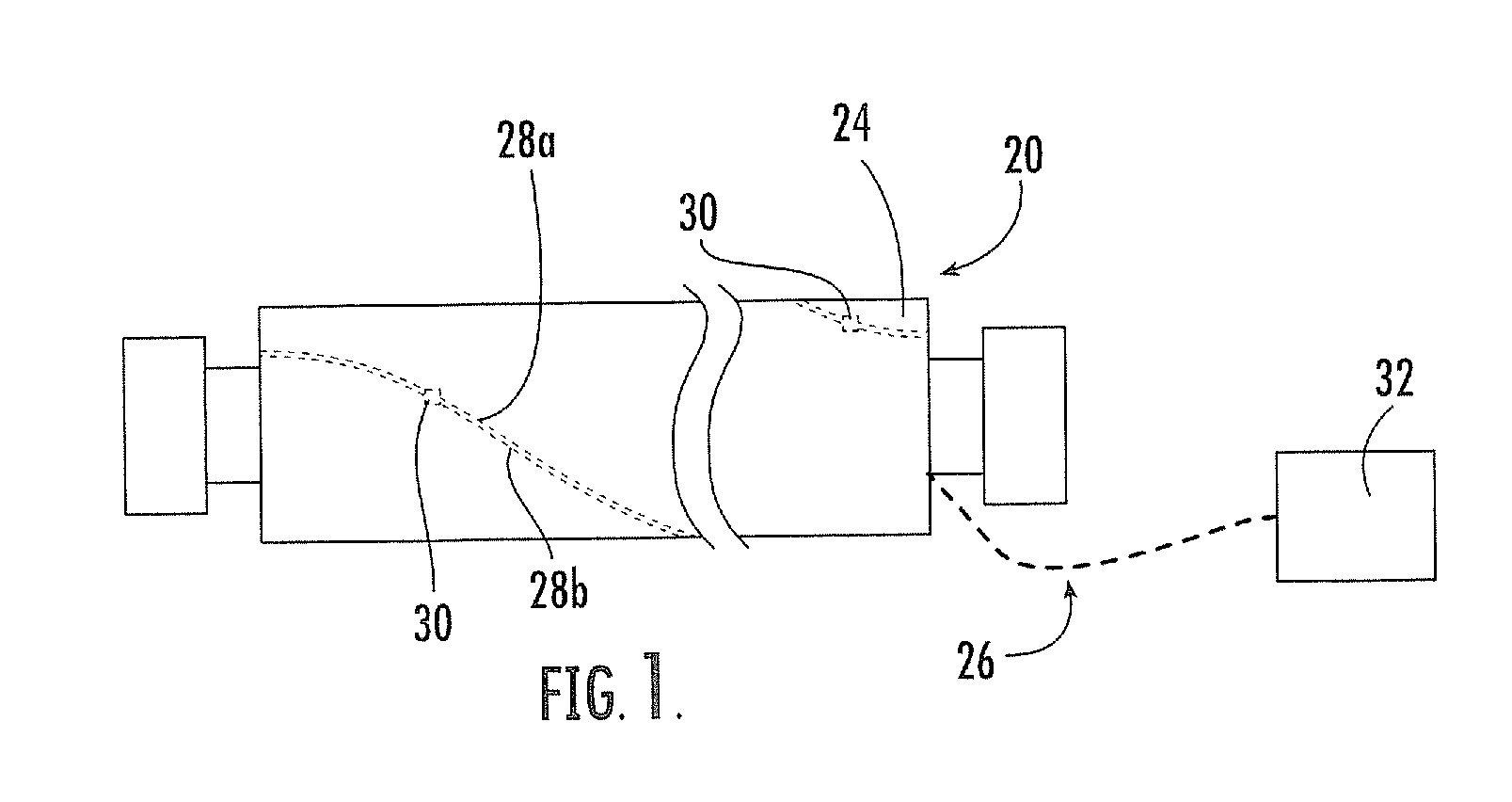

Apparatus for calendering a sheet material web carried by a fabric

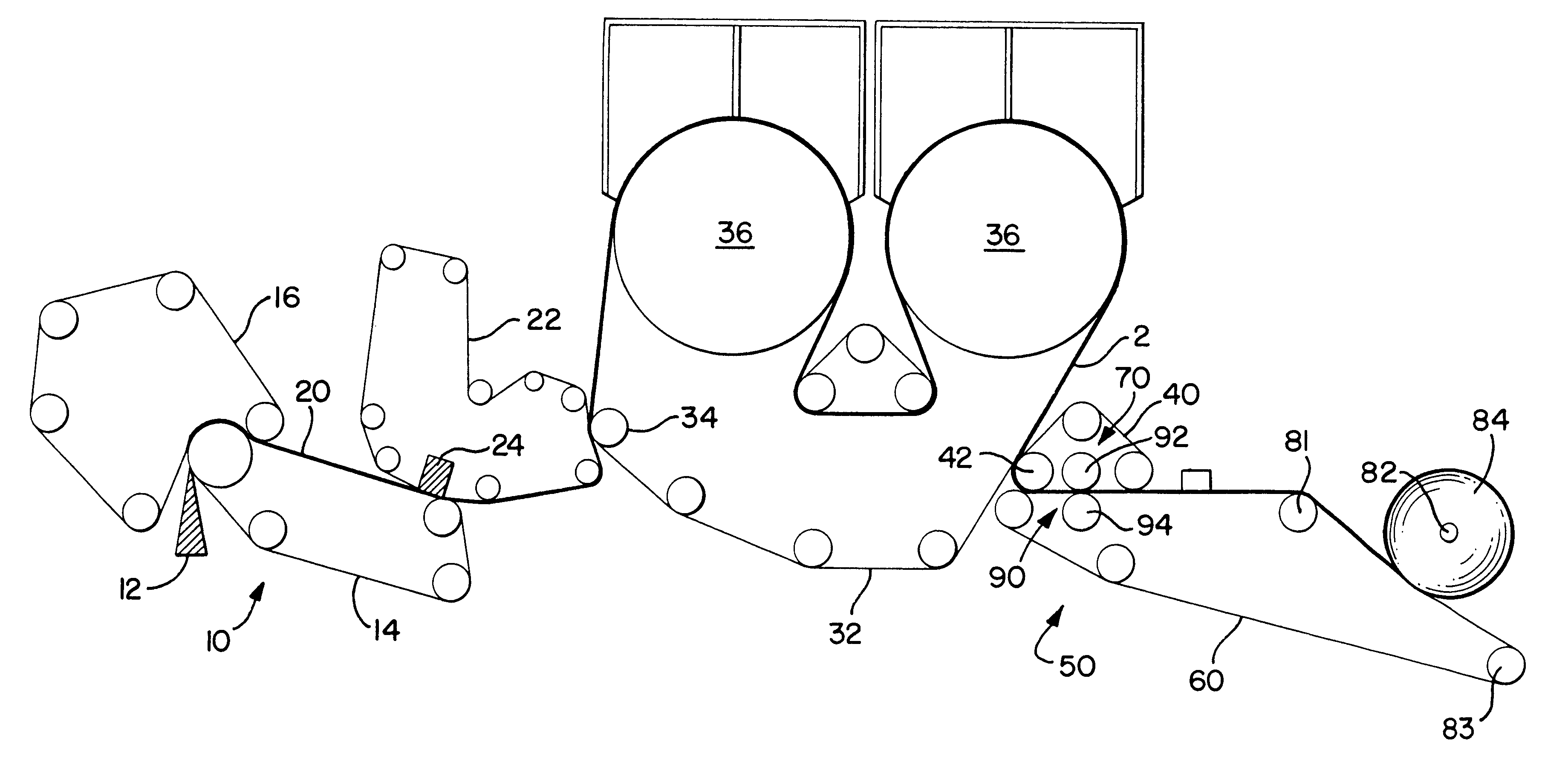

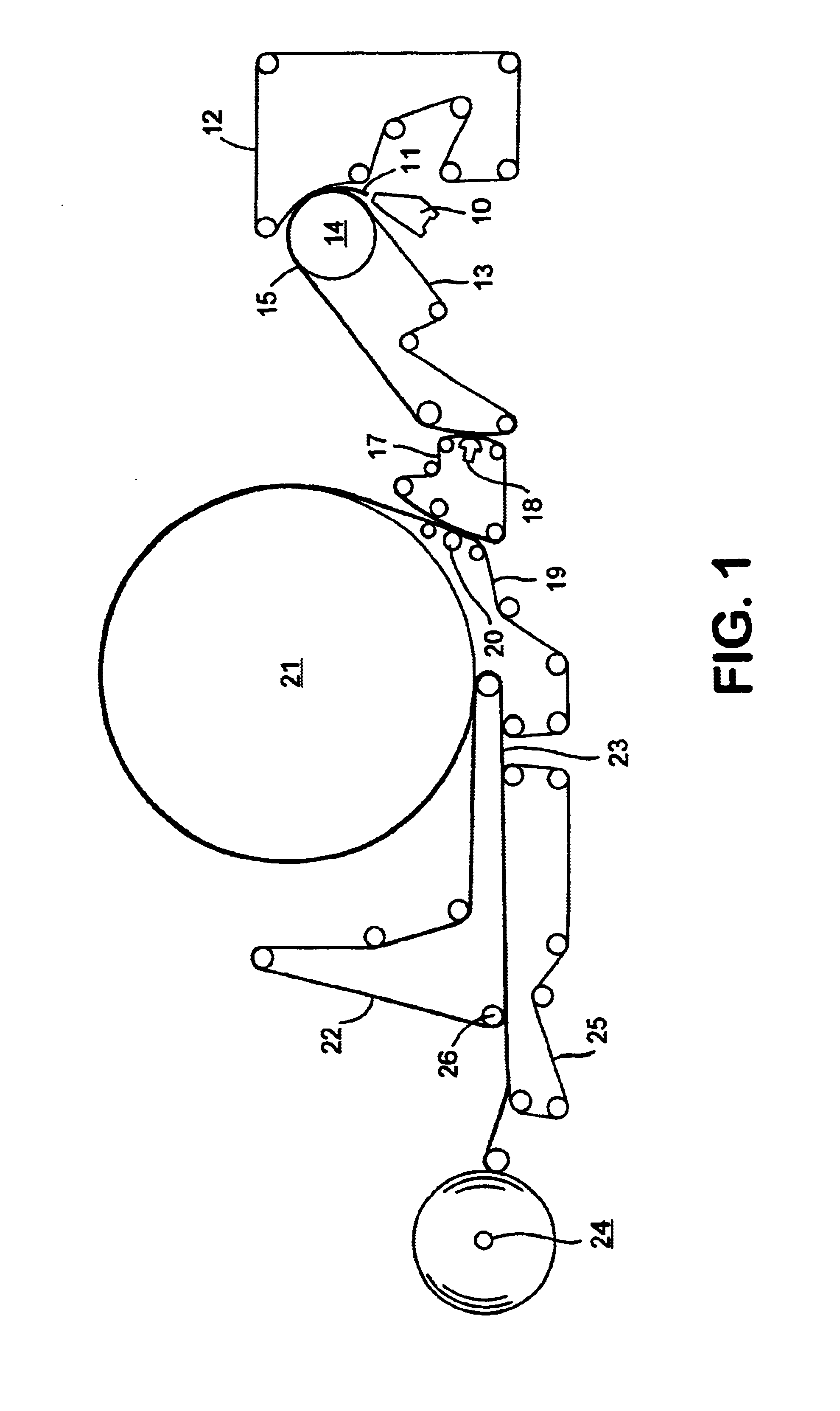

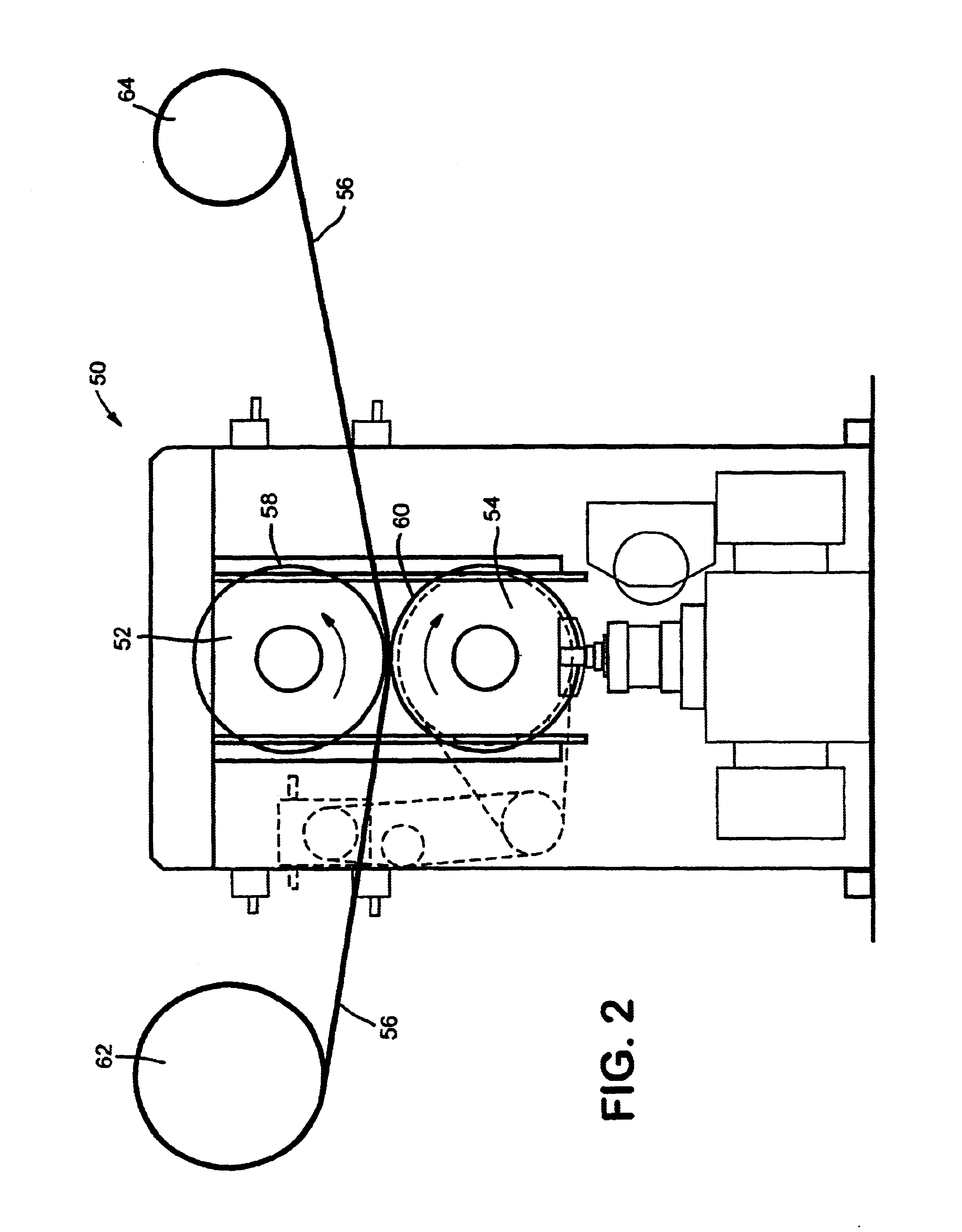

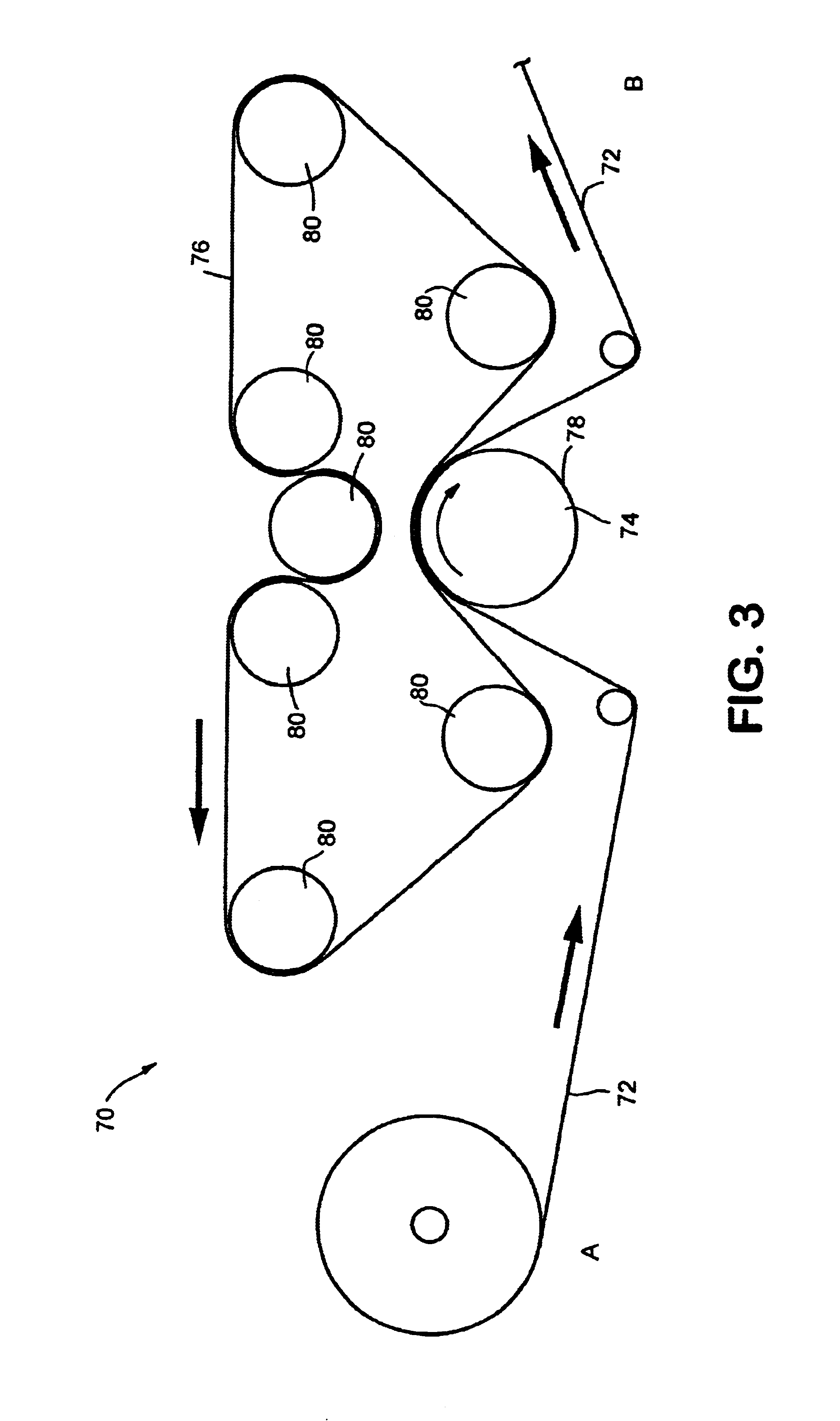

An apparatus for calendering a sheet material web being carried on or between one or more carrier fabrics. In a preferred embodiment, the apparatus includes a calender section having first and second calender rolls forming a nip therebetween. At least one carrier fabric is disposed between the first and second calender rolls. The first and second calender rolls apply a load to the carrier fabric and sheet material web as they pass through the nip between the calender rolls so as to reduce the caliper, or thickness, of the sheet material web. A method for calendering the sheet material web includes carrying the sheet material web on one or more carrier fabrics through the calender nip formed by the first and second calender rolls and applying a load to the carrier fabric, and sheet material carried thereby, so as to reduce the thickness of the sheet material web.

Owner:KIMBERLY CLARK WORLDWIDE INC

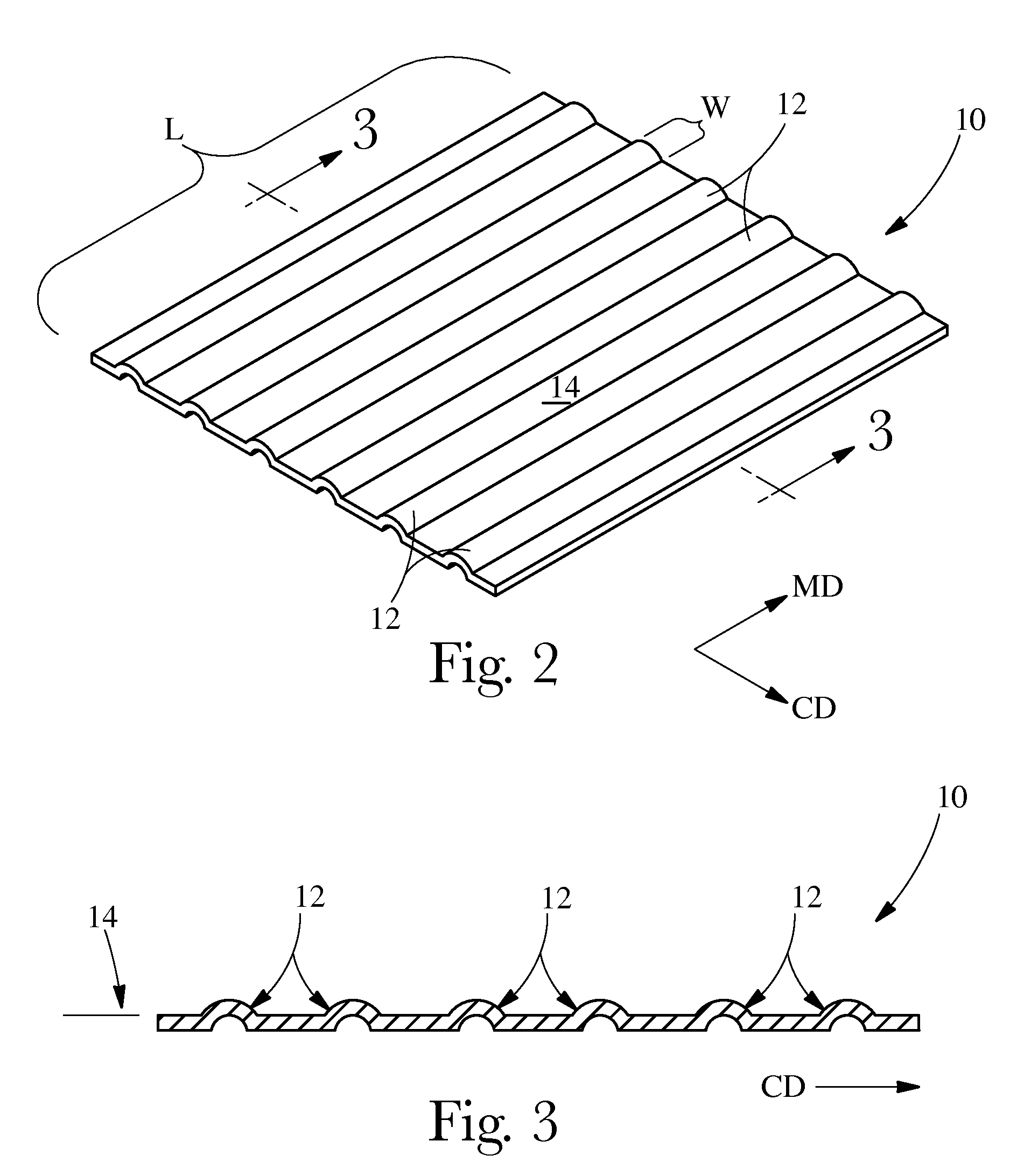

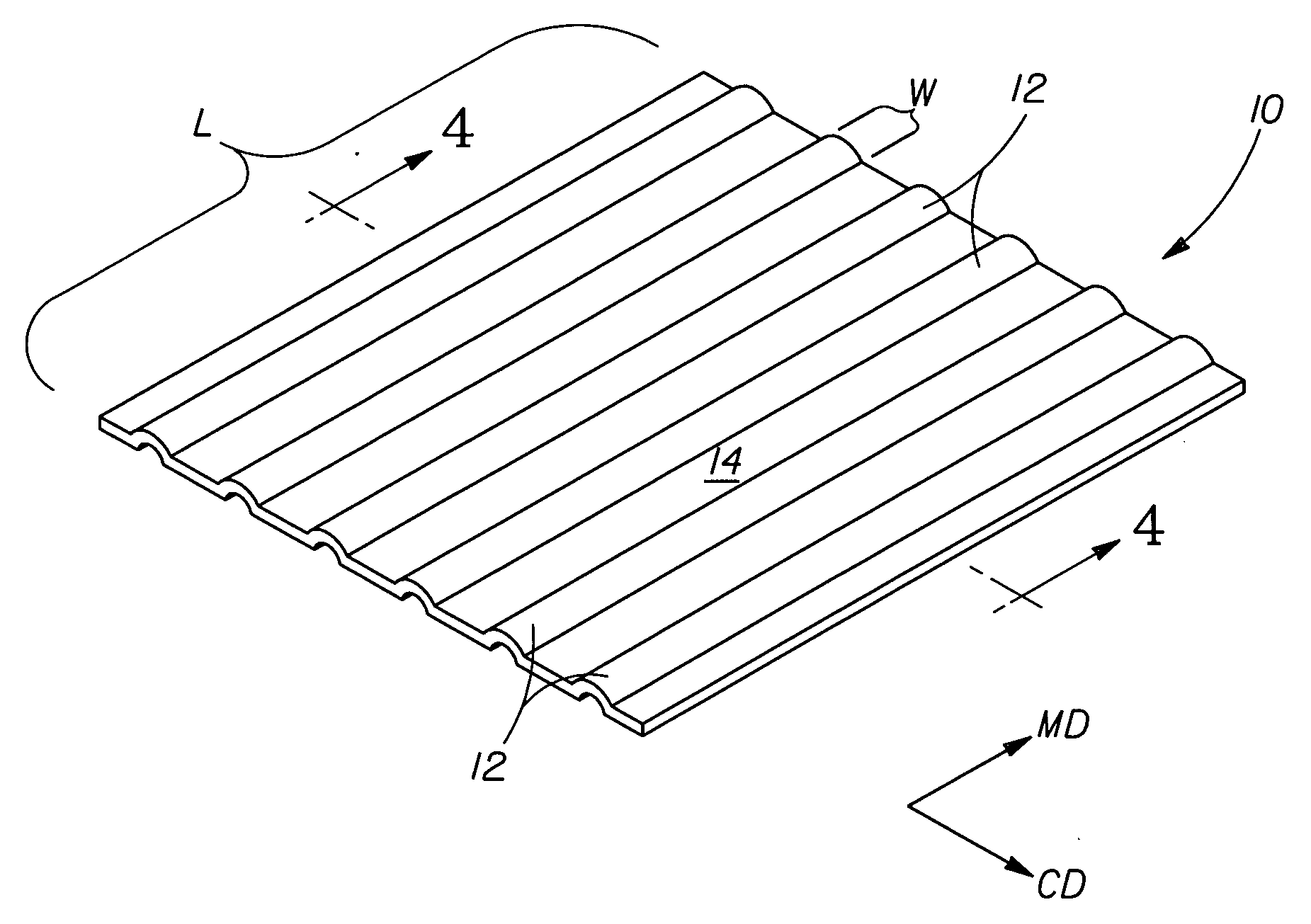

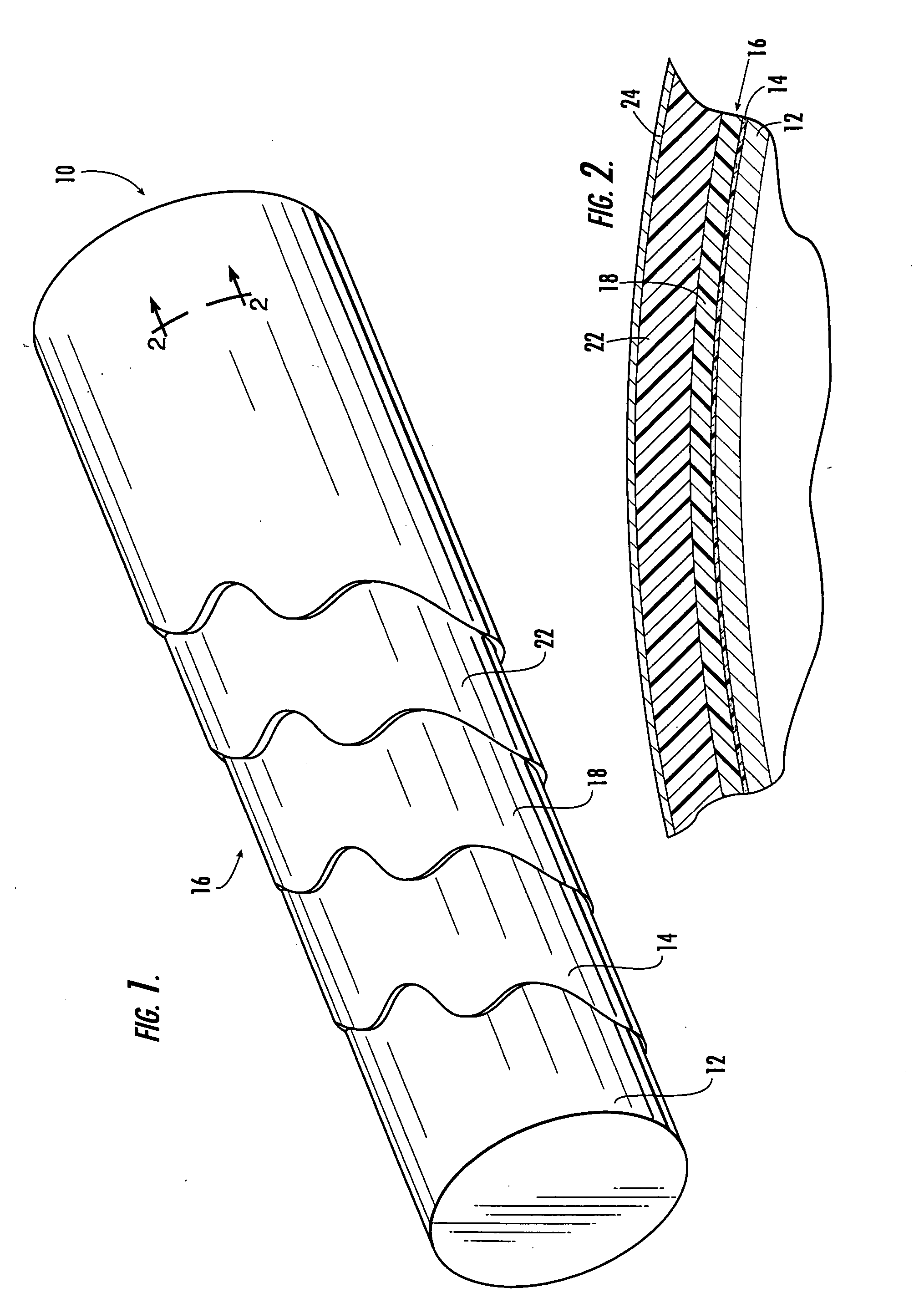

Embossed fibrous structures

Owner:PROCTER & GAMBLE CO

Cellulose-based fibrous materials

InactiveUS8012312B2Low densityImprove surface qualityCellulosic pulp after-treatmentCalendersFiberPolymer science

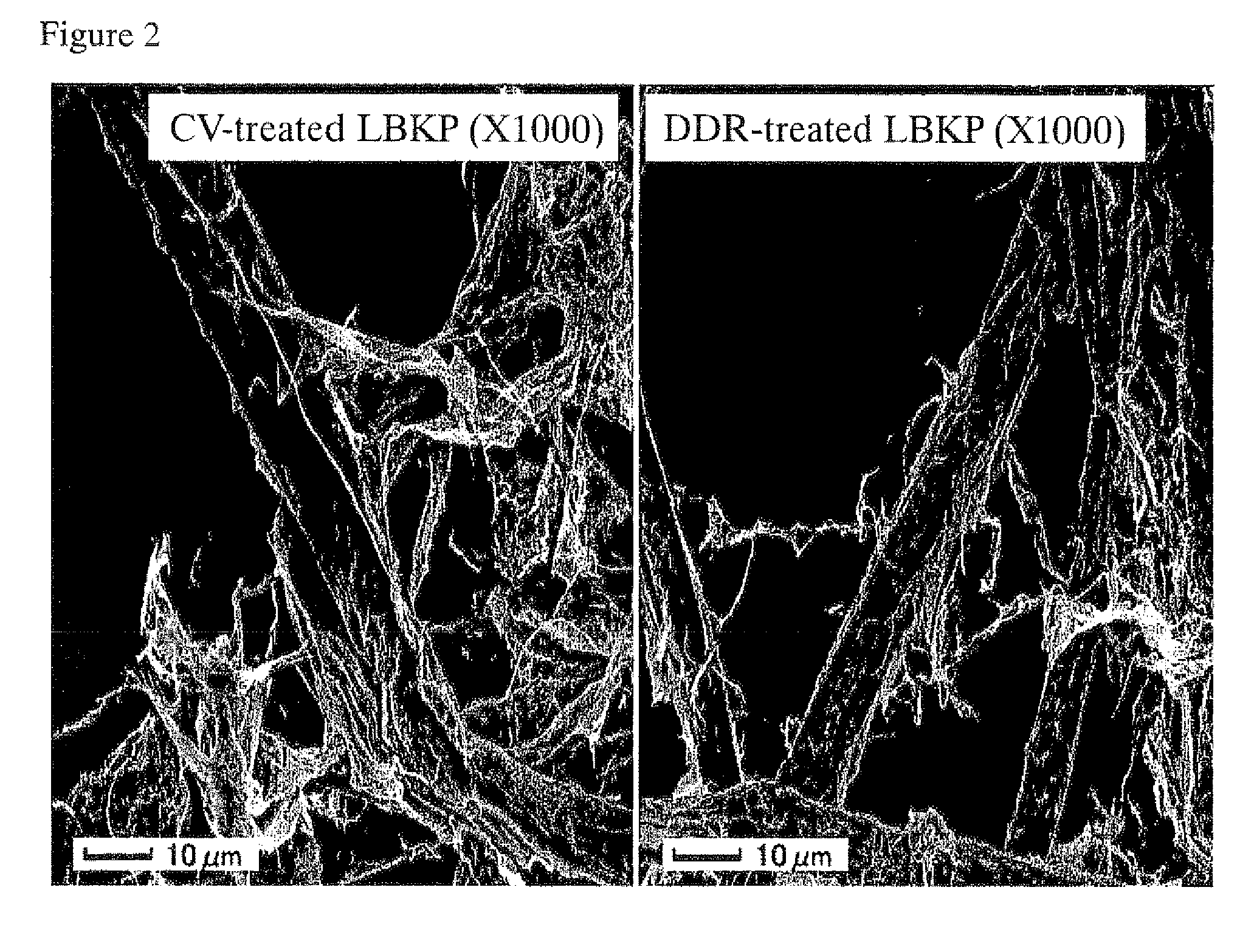

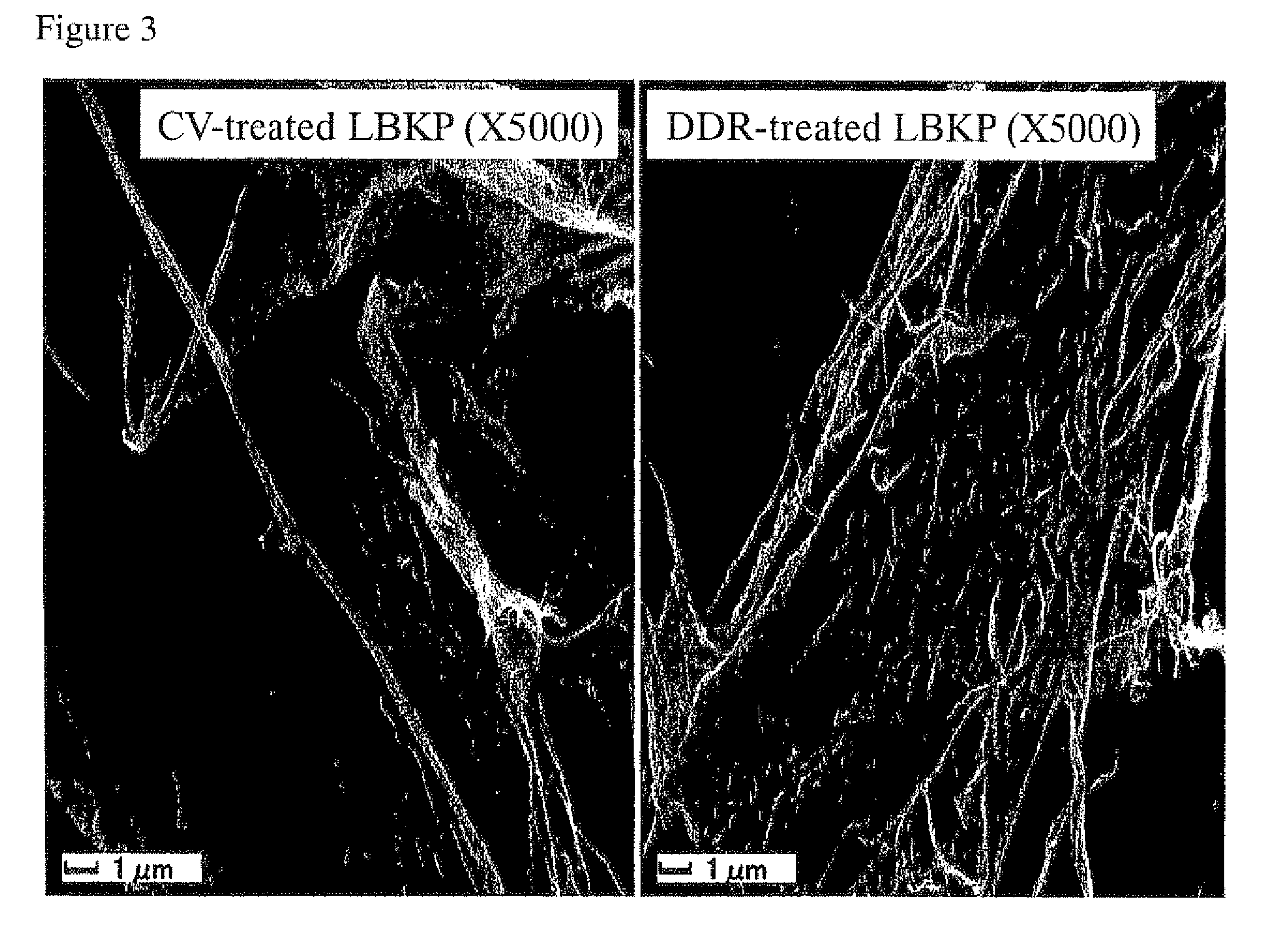

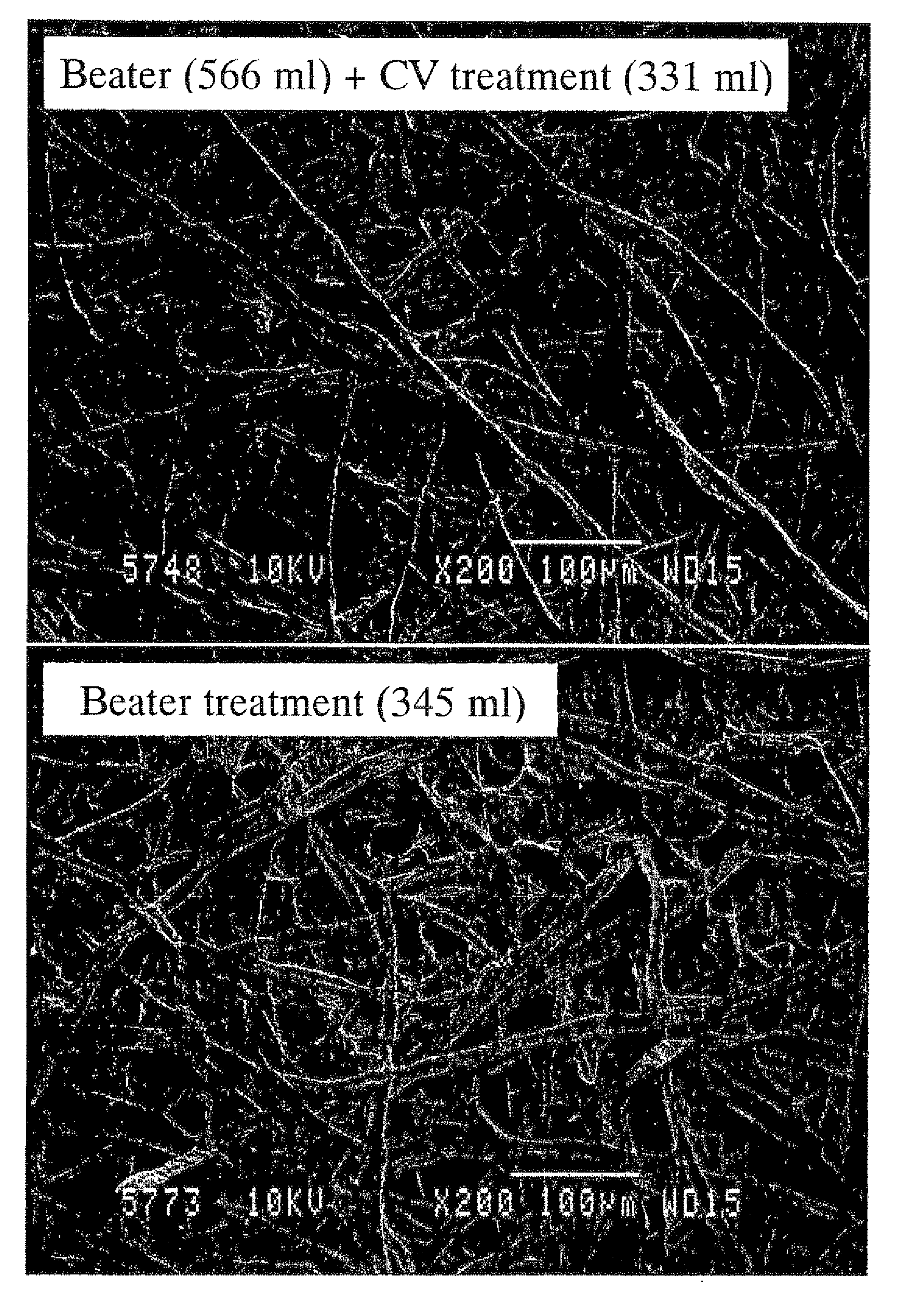

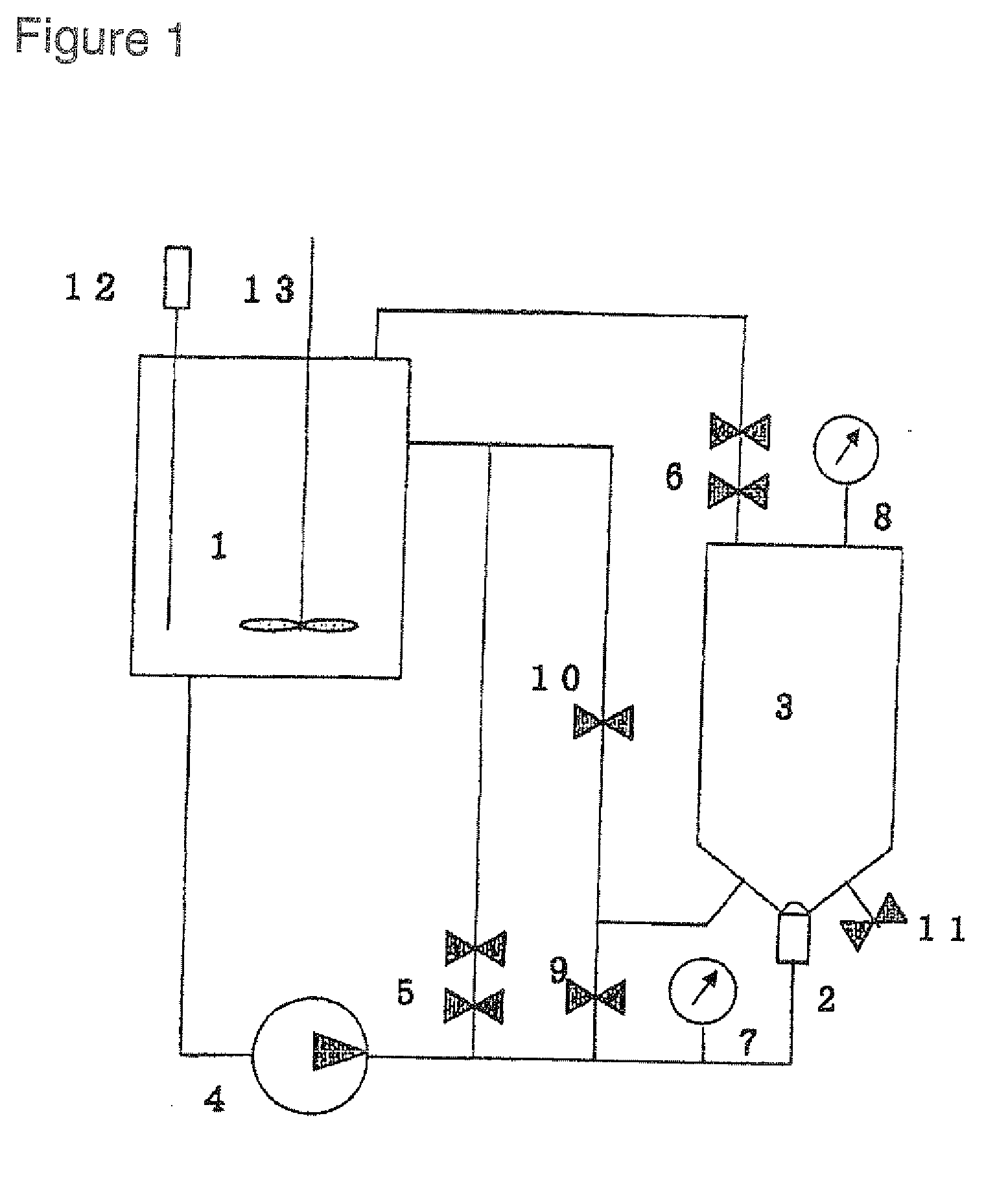

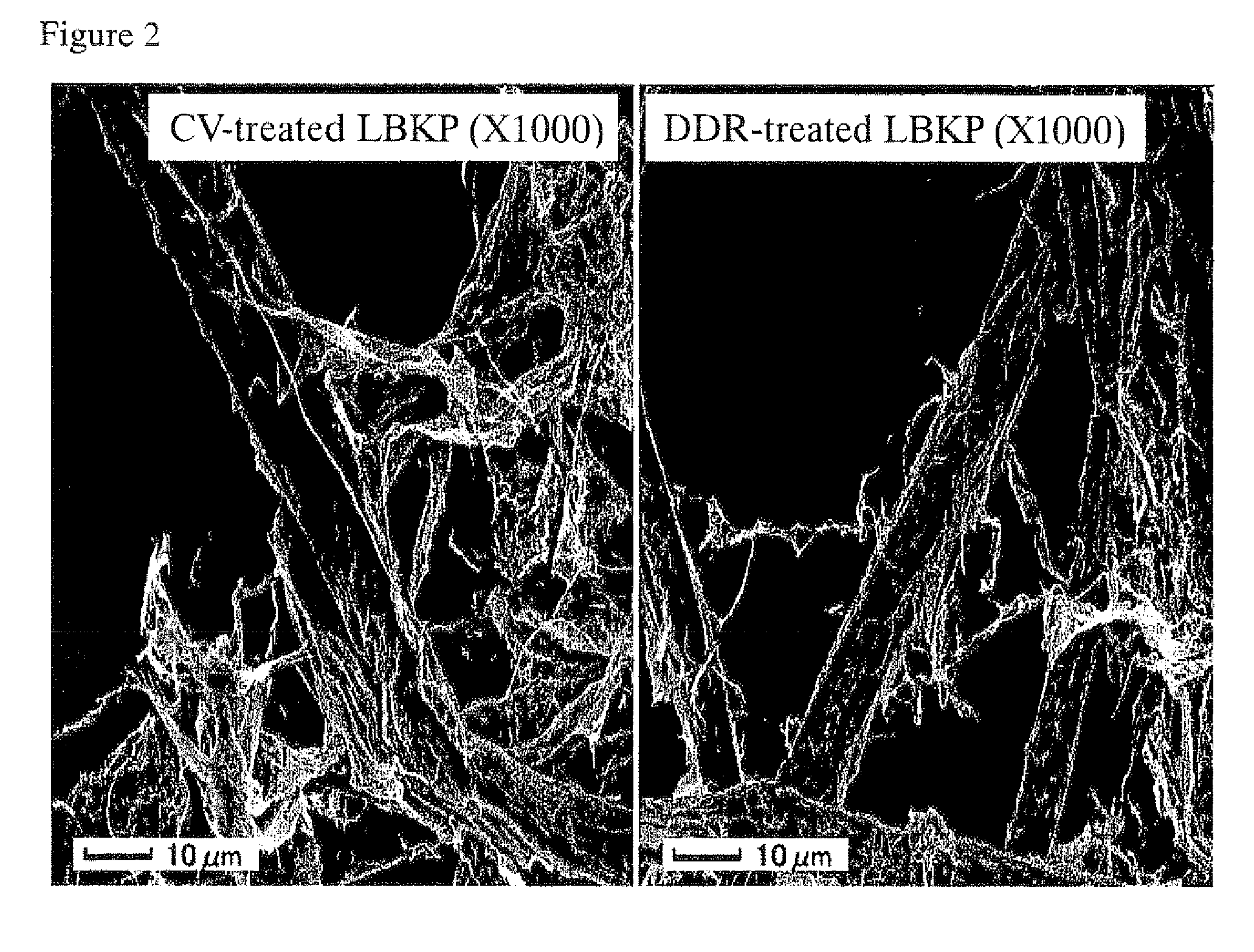

The present invention aims to provide cellulose-based fibrous materials for obtaining papers and sheets having low density, high surface quality, good size stability despite of high strength, and high opacity. Cellulose-based fibrous materials having external fibrils consisting of an assembly of scale-like microfibrils exhibit a higher fiber stiffness, a lower water retention value and a higher specific surface area as compared with fibrous materials having filamentous external fibrils at the same freeness. Papers and sheets having low density, high surface quality, good size stability and high opacity can be obtained by using such fibrous materials.

Owner:NIPPON PAPER IND CO LTD

Cellulose-based fibrous materials

ActiveUS20090065164A1Low densityImprove surface qualityCellulosic pulp after-treatmentReinforcing agents additionFiberPolymer science

The present invention aims to provide cellulose-based fibrous materials for obtaining papers and sheets having low density, high surface quality, good size stability despite of high strength, and high opacity. Cellulose-based fibrous materials having external fibrils consisting of an assembly of scale-like microfibrils exhibit a higher fiber stiffness, a lower water retention value and a higher specific surface area as compared with fibrous materials having filamentous external fibrils at the same freeness. Papers and sheets having low density, high surface quality, good size stability and high opacity can be obtained by using such fibrous materials.

Owner:NIPPON PAPER IND CO LTD

Fibrous structures

Owner:THE PROCTER & GAMBLE COMPANY

Fibrous structures

Owner:THR PROCTER & GAMBLE COMPANY ATTENTION CHEIF PATENT COUNSEL

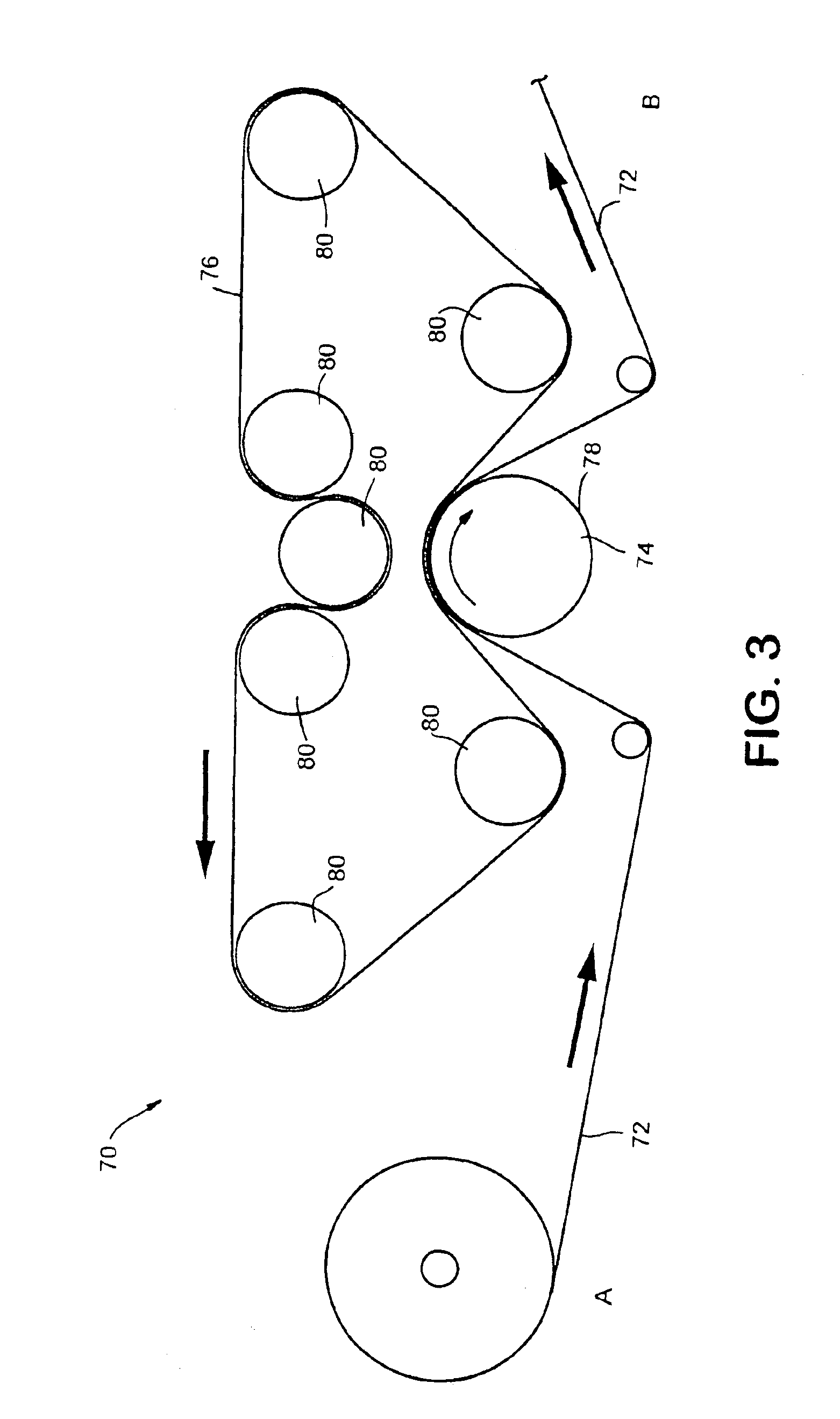

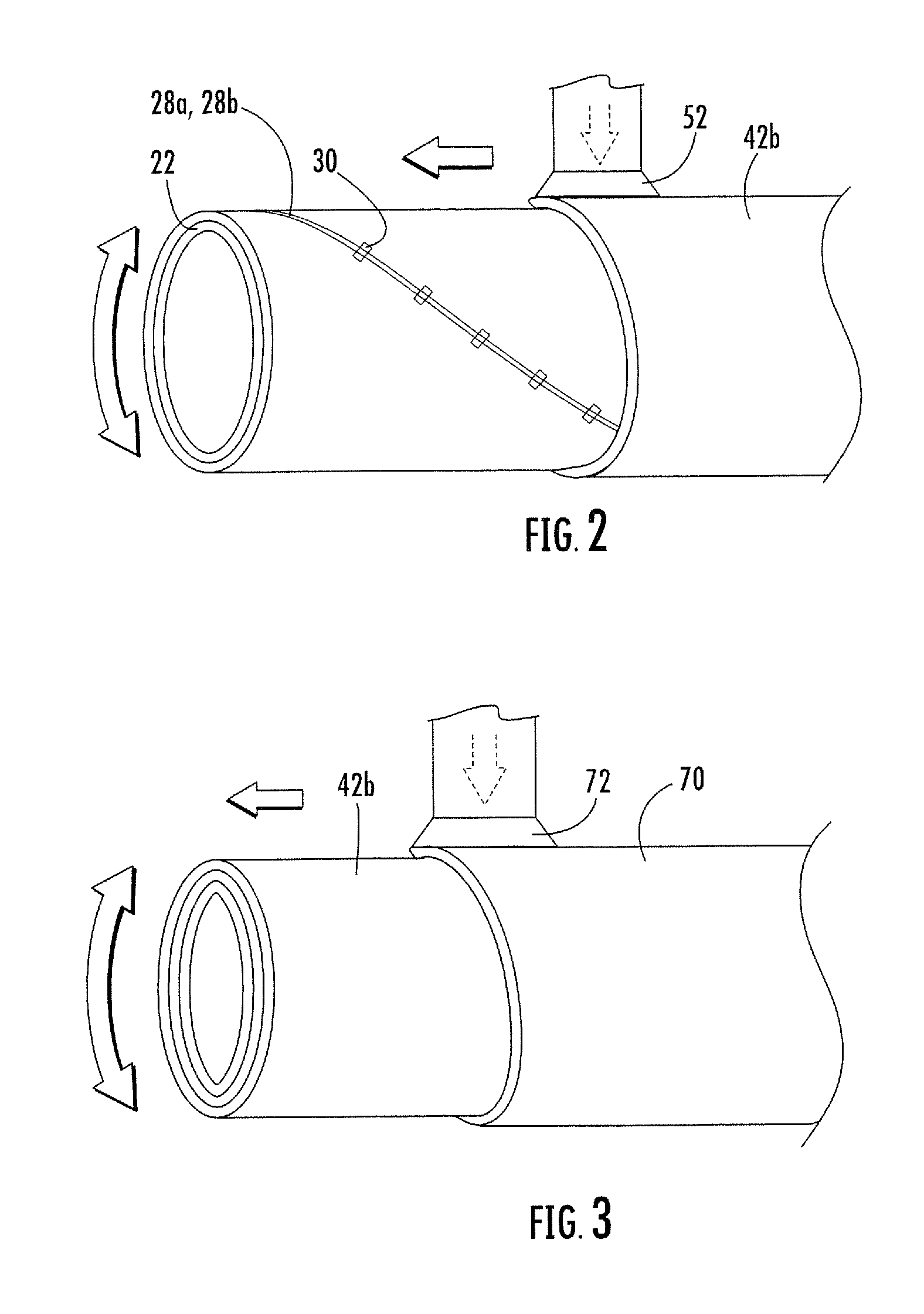

Rolled single ply tissue product having high bulk, softness, and firmness

InactiveUS6887348B2Good sheet softnessGood strength characteristicNon-fibrous pulp additionNatural cellulose pulp/paperMedicineHardness

Spirally wound paper products are disclosed having desirable roll firmness characteristics and softness properties. The rolled products can be made from a single ply tissue web formed according to various processes. Once formed, the tissue web is subjected to a shear-calendering device that increases the fuzz-on-edge properties of the web and preserves the bulk of the web when wound.

Owner:KIMBERLY-CLARK WORLDWIDE INC

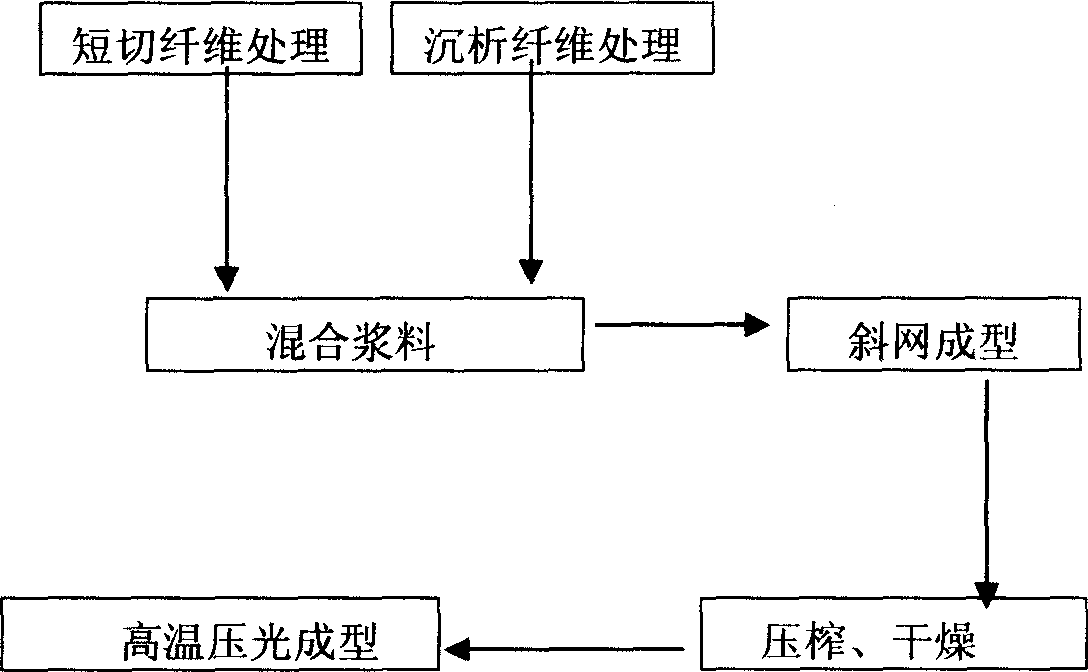

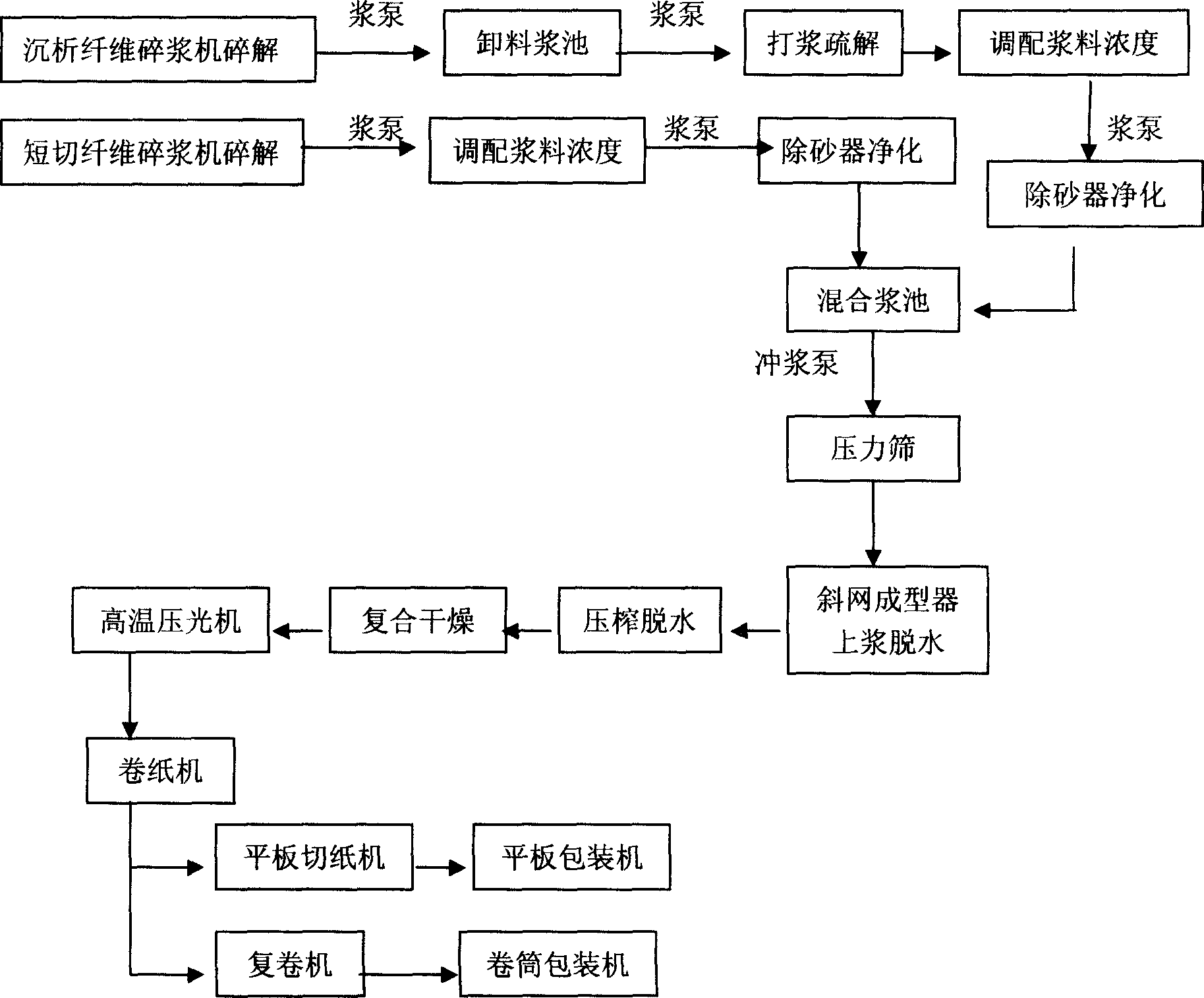

Meta aramid fibre paper and prepn. process

InactiveCN1834342ASolve the problem of increased processing burdenEvenly dispersedDryer sectionCalendersManufacturing technologySewage treatment

A method for preparing meta- PPTA paper includes forming a sizing material by adding 5-95 wt. % of meta- PPTA staple fiber into water and forming another sizing material by adding 5-95 wt. % of meta- PPTA precipitated fiber in water, mixing two said sizing materials, laying prepared sizing material on screen for forming, pressing and drying, pressing and polishing in high temperature for forming.

Owner:烟台泰和新材集团有限公司

Rolled tissue products having high bulk, softness, and firmness

Owner:KIMBERLY-CLARK WORLDWIDE INC

Method of calendering a sheet material web carried by a fabric

A method for calendering the sheet material web includes carrying the sheet material web on one or more carrier fabrics through the calender nip formed by the first and second calender rolls and applying a load to the carrier fabric, and sheet material carried thereby, so as to reduce the thickness of the sheet material web.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Soft single-ply tissue

InactiveUS20100051217A1Gram weight highLow stiffnessNon-fibrous pulp additionNatural cellulose pulp/paperBiomedical engineeringThin sheet

A soft single-ply tissue sheet is produced by making a textured, high bulk, throughdried tissue sheet and calendering the sheet with a high level of compression energy to substantially reduce the bulk and impart improved properties to the sheet.

Owner:KIMBERLY-CLARK WORLDWIDE INC

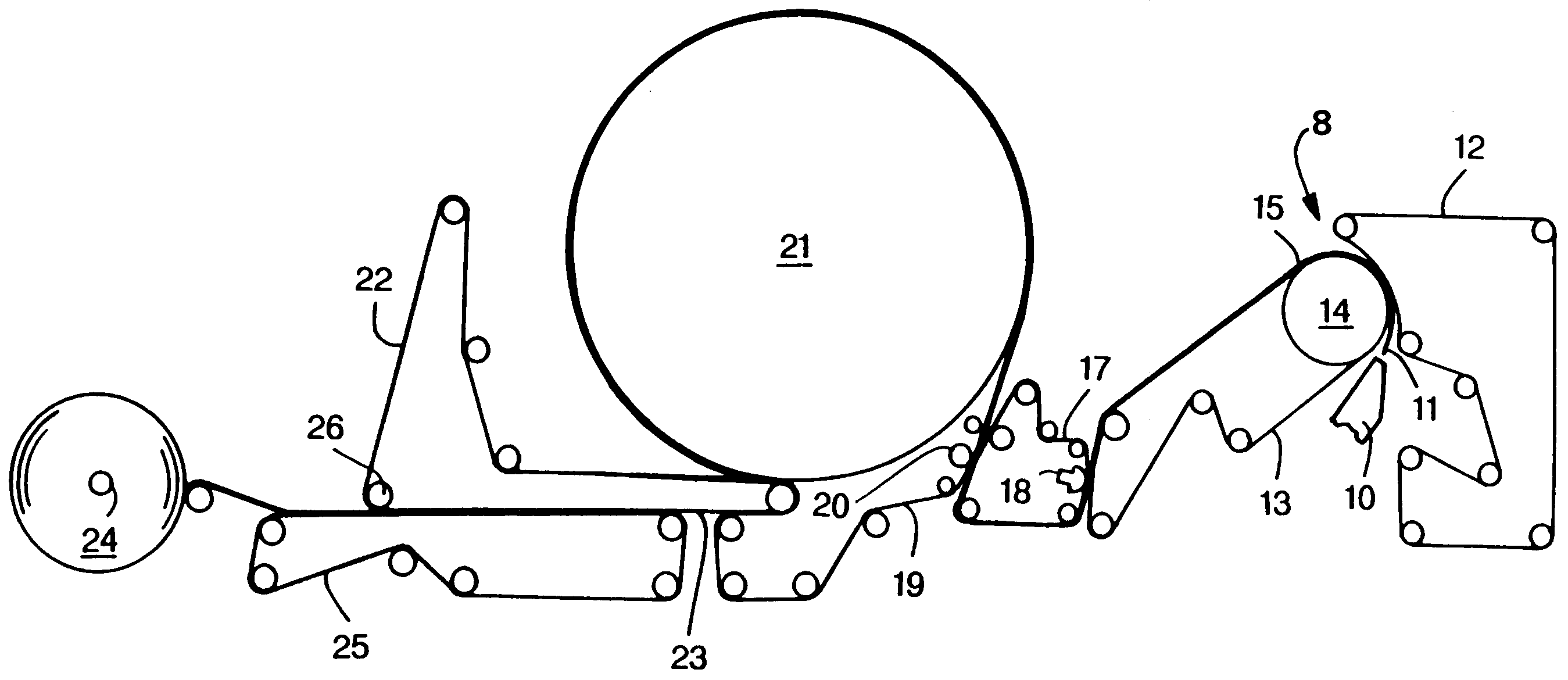

Paper machine and press section thereof

InactiveUS6998022B2Simple partsLower capital expenditureNon-fibrous pulp additionNatural cellulose pulp/paperCrêpe paperEngineering

A soft crepe paper machine comprises a wet section with a press section having a press defined by first and second press elements forming a press nip through which a press felt runs with a paper web. A suction roll is arranged in the loop of the press felt before the press nip at a distance from the second press element, and the felt with the web thereon runs around the suction roll with a large wrap angle. A drying cylinder forms the second press element. The first press element is either a solid press roll, a suction press roll, or a variable crown press roll.

Owner:METABO PAPER KARLSTAD

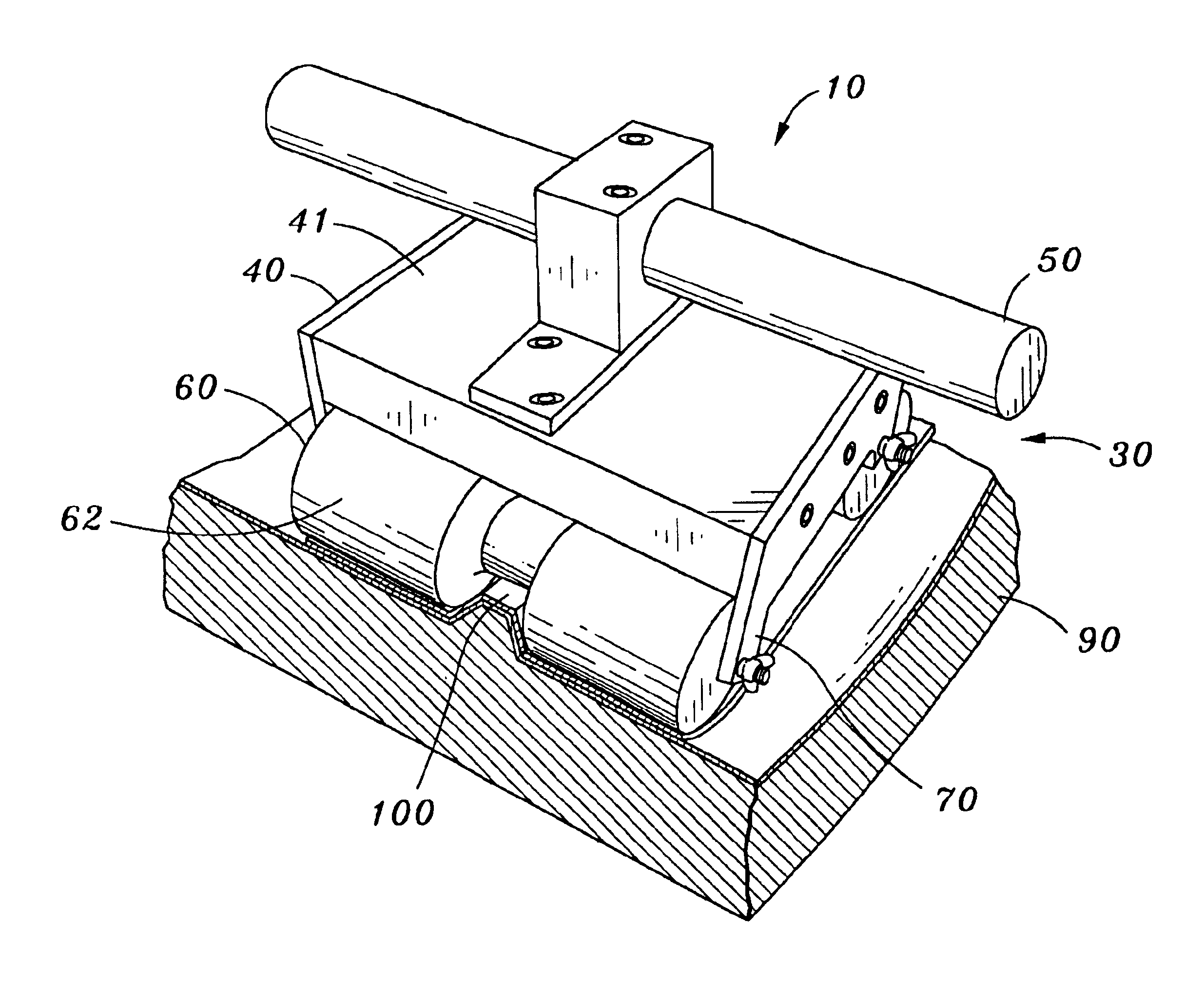

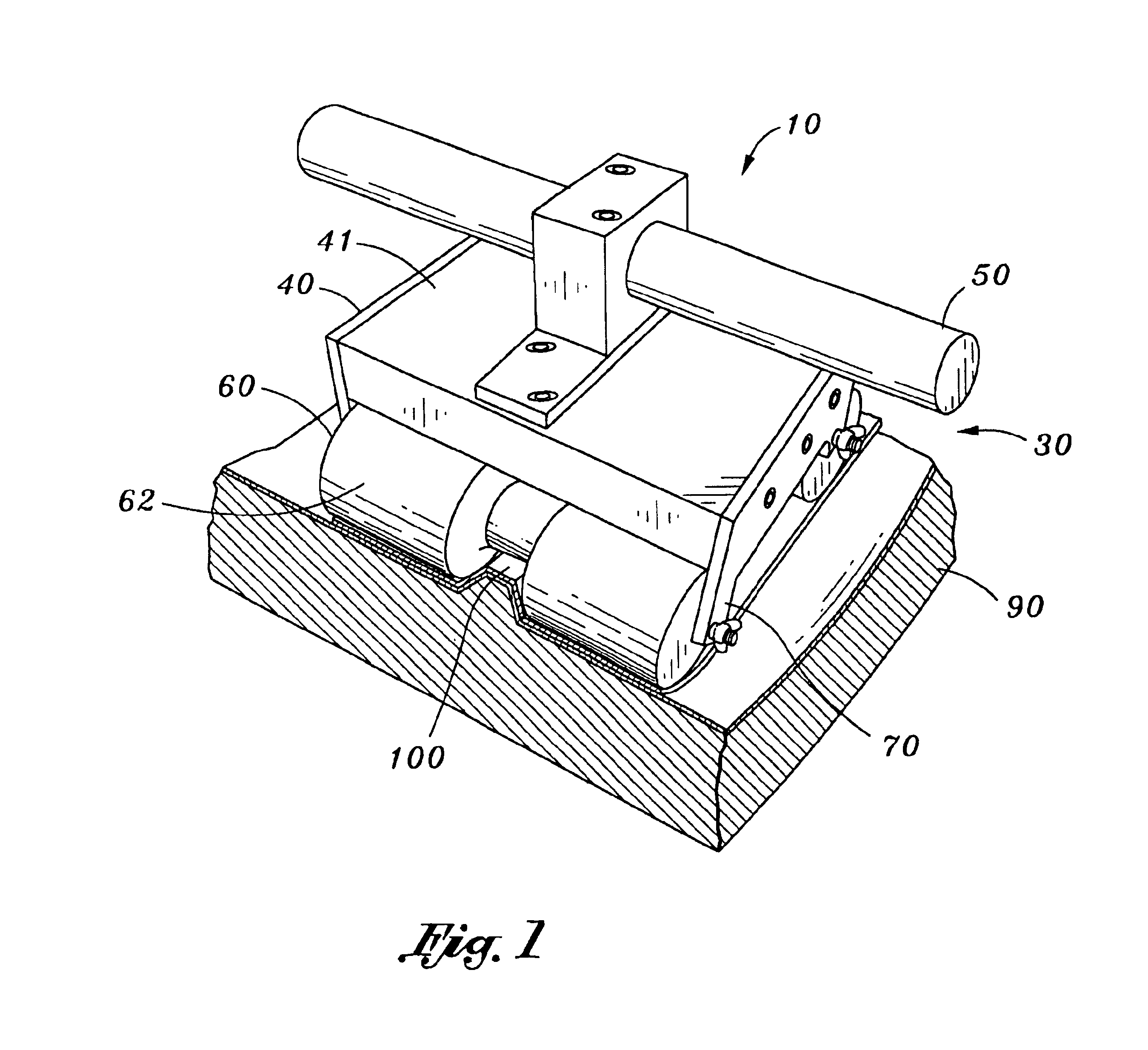

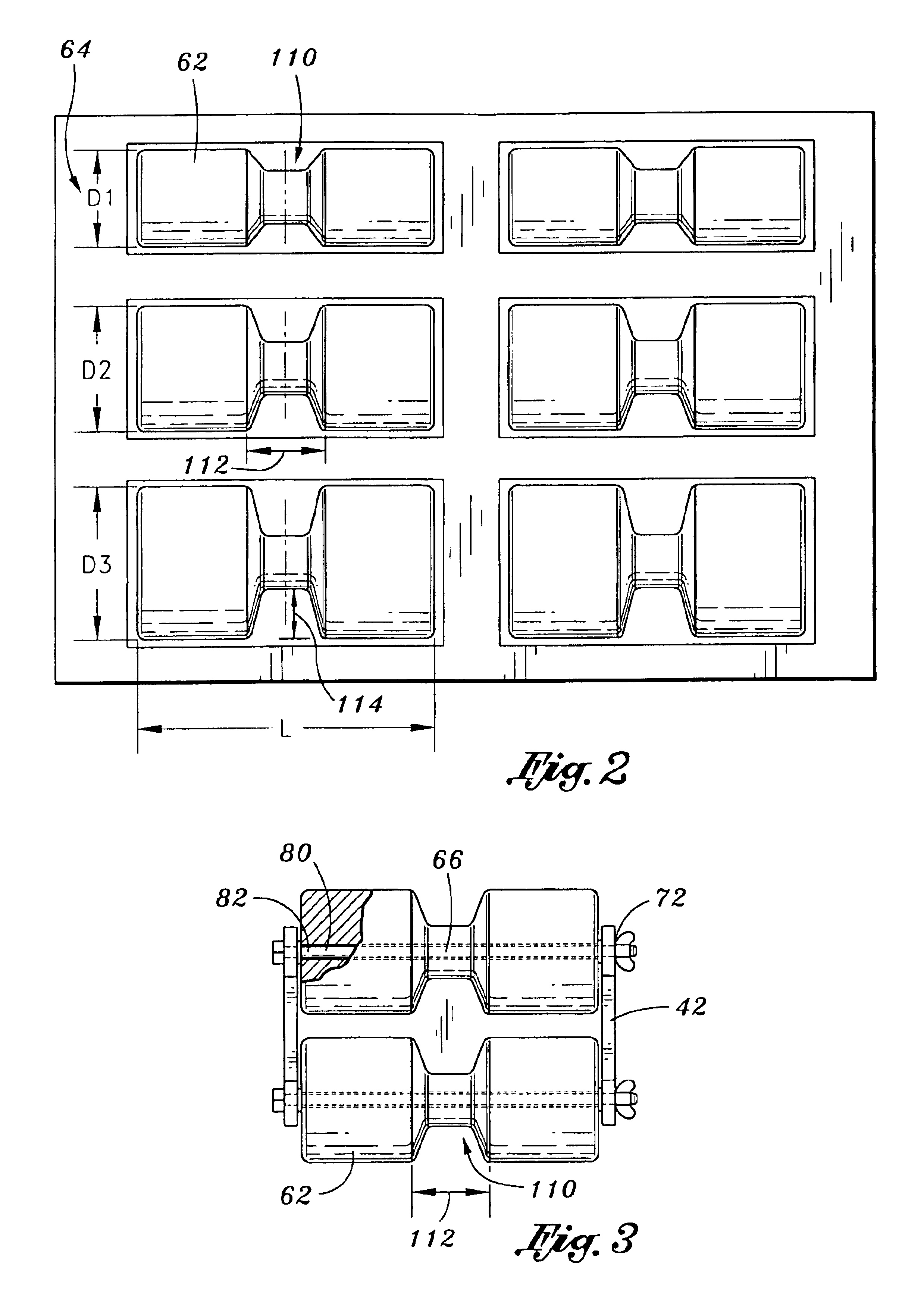

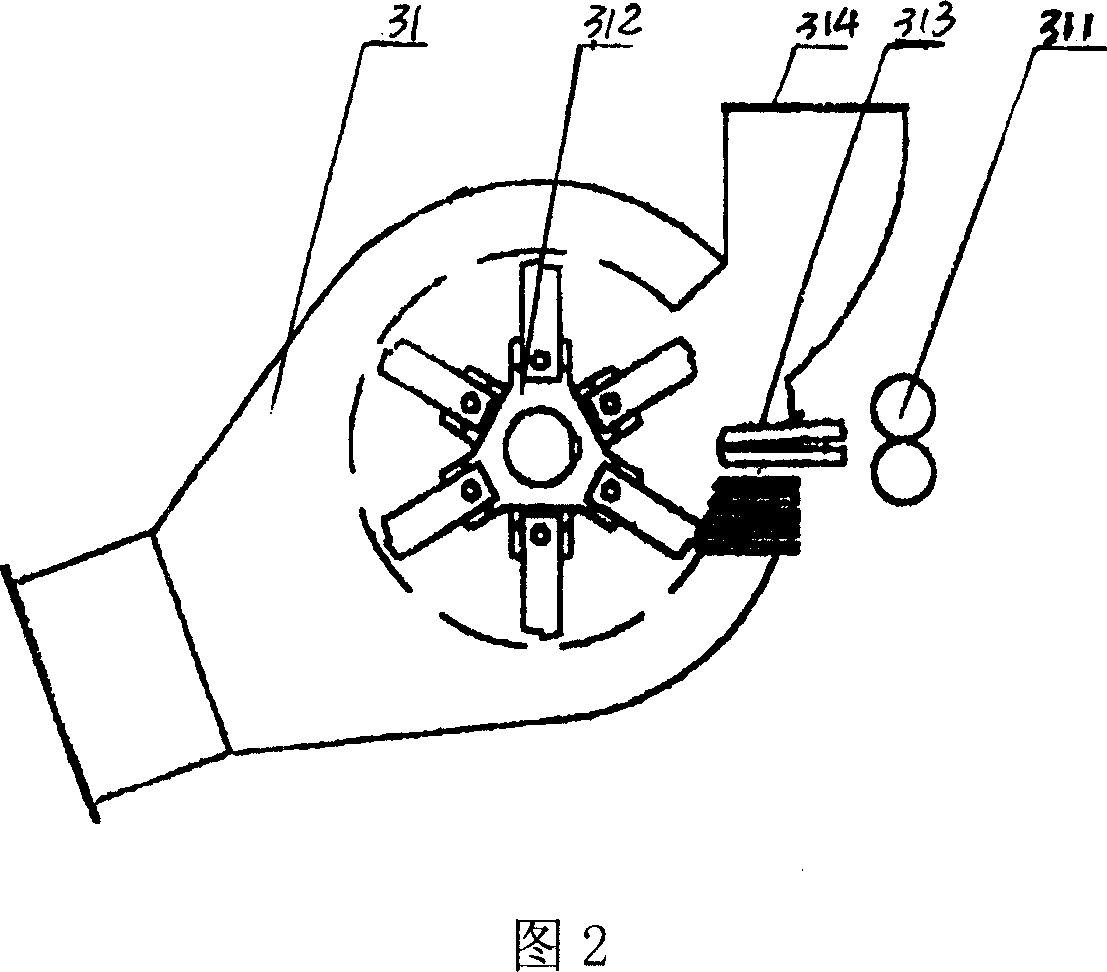

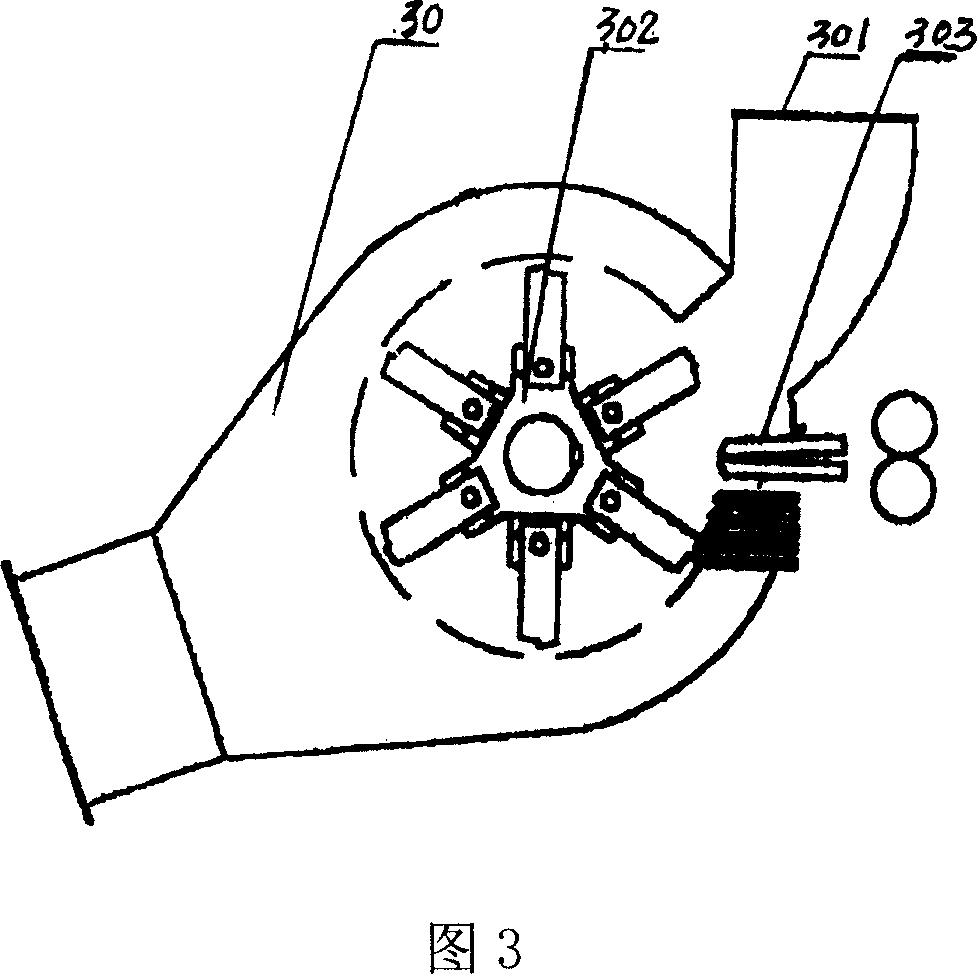

Conformal transverse hat profile roller

There is provided a variable pressure roller system for installing a preform having contact surfaces onto a configuration of a mold surface by applying pressure thereon. The roller system of the present invention comprises a roller carriage. A grasping handle may be mounted to the roller carriage. Moreover, the roller system may further comprise a plurality of rollers, wherein each respective one of the plurality of rollers is defined by a weight to generate a specific pressure corresponding thereto. Furthermore, each respective one of the plurality of rollers may be removably engageable to the roller carriage. Each respective one of the plurality of rollers may be adapted to uniformly distribute the specific pressure corresponding thereto on the contact surfaces for conforming the preform to the configuration of the mold surface when engaged to the roller carriage.

Owner:NORTHROP GRUMMAN SYST CORP

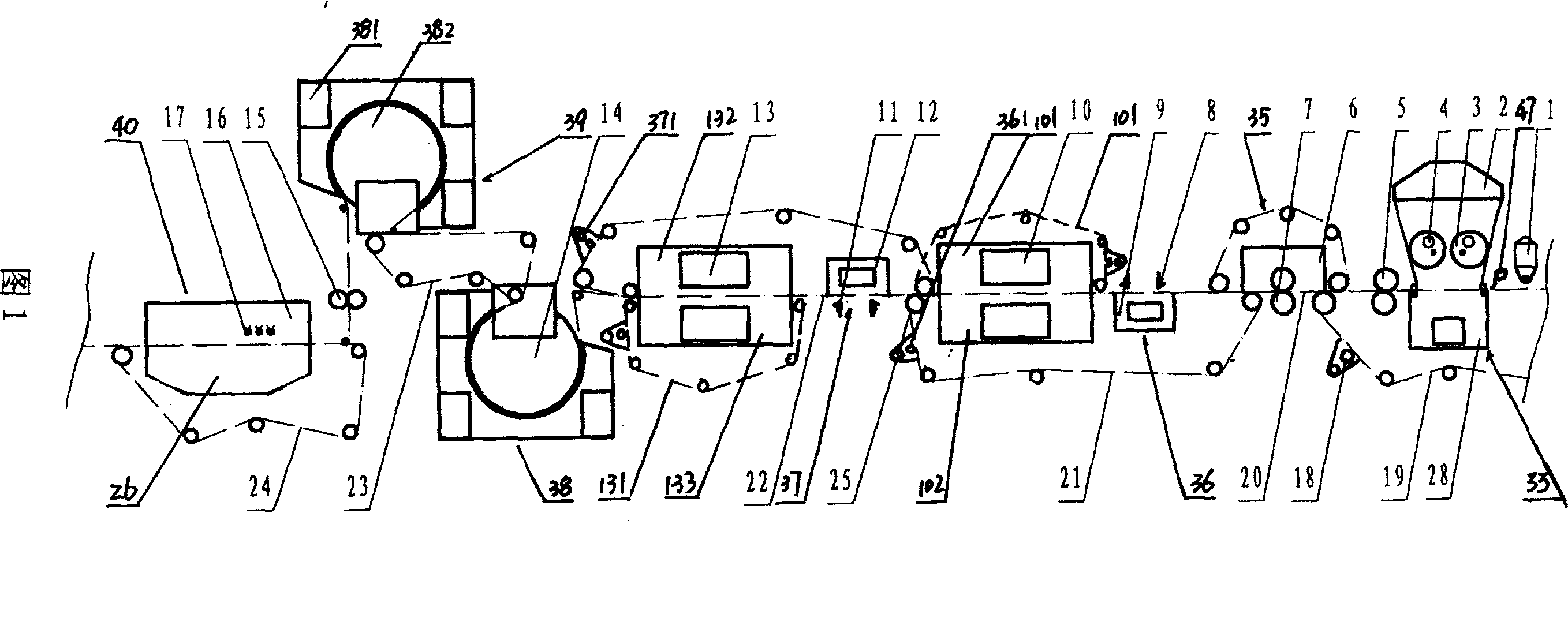

Dry-process papermaking machine through meshwork formed by airflow method

The present invention relates to an air-laying dry paper machine. It includes at least more then one forming device, sizing device, drying device and cooling device which are successively mounted on the machine frame from front to rear. Said sizing device includes at least more than two sizing devices and box type drying box. Between the forming device and sizing device an embossing device and pre-presing hot roller unit can be added, and between drying device and cooling device a calendaring device is added. Besides, it also includes fluff pulp fluffer, fibrids opening, conveying and metering device and powder additive device.

Owner:中丝(上海)新材料科技有限公司

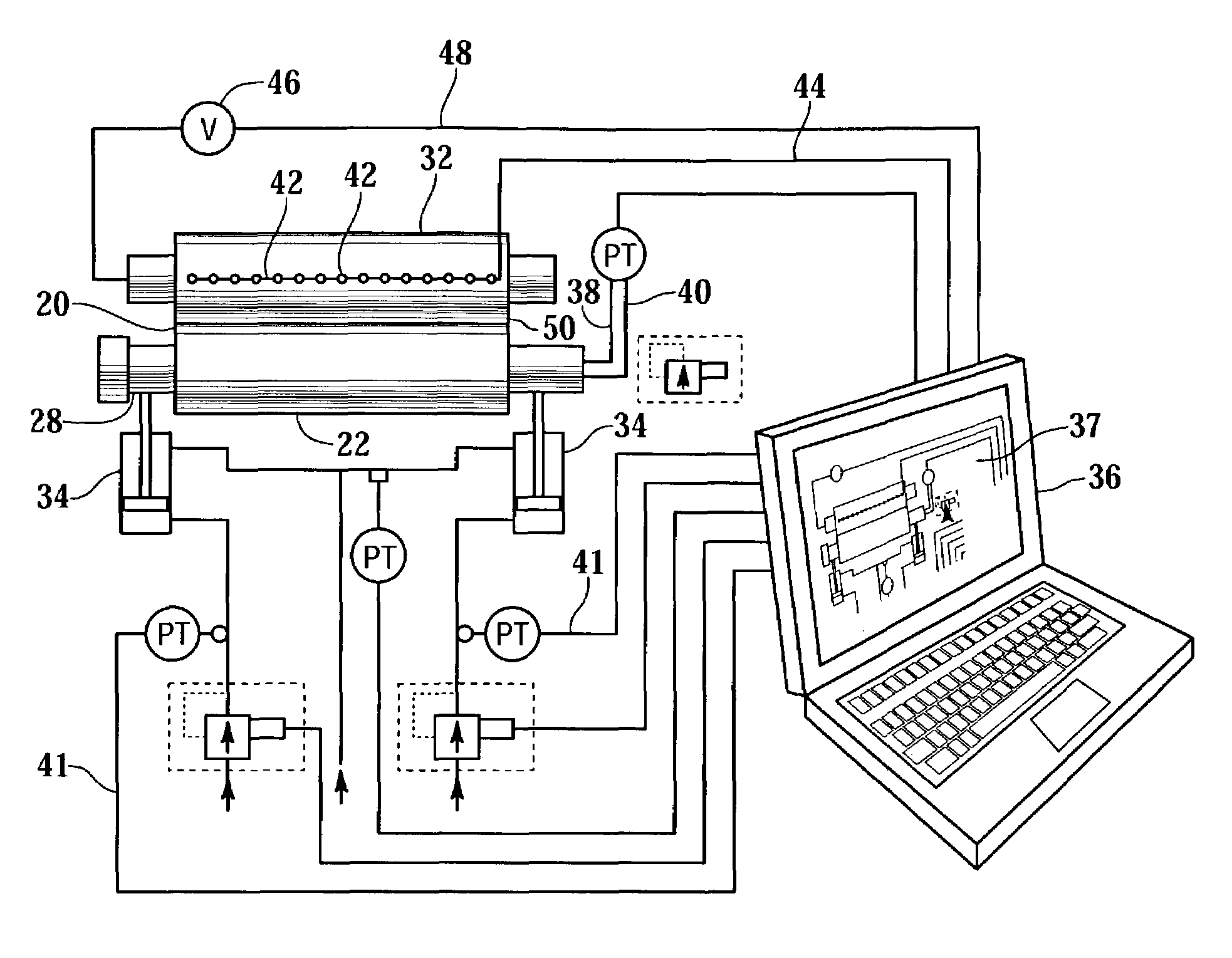

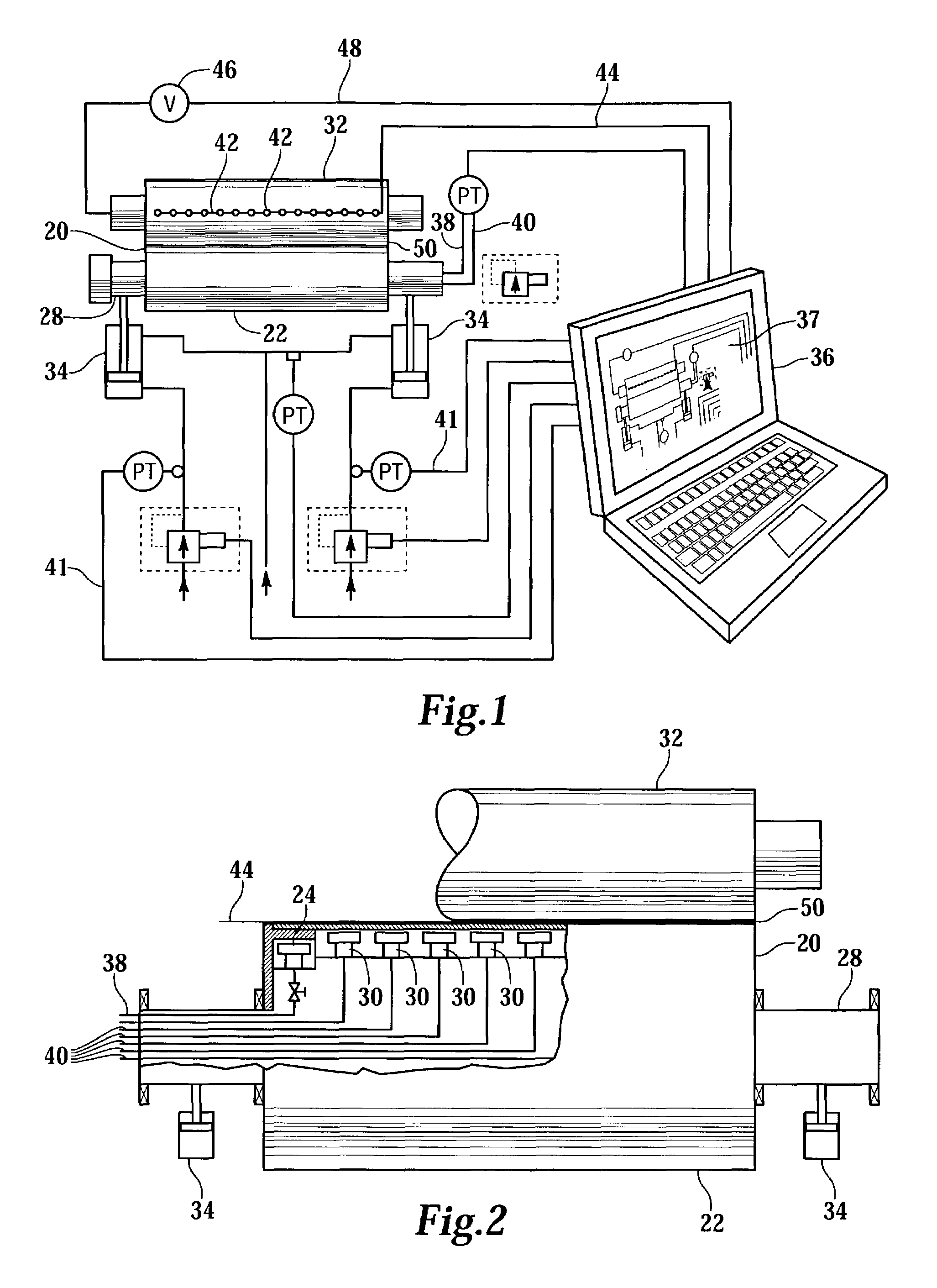

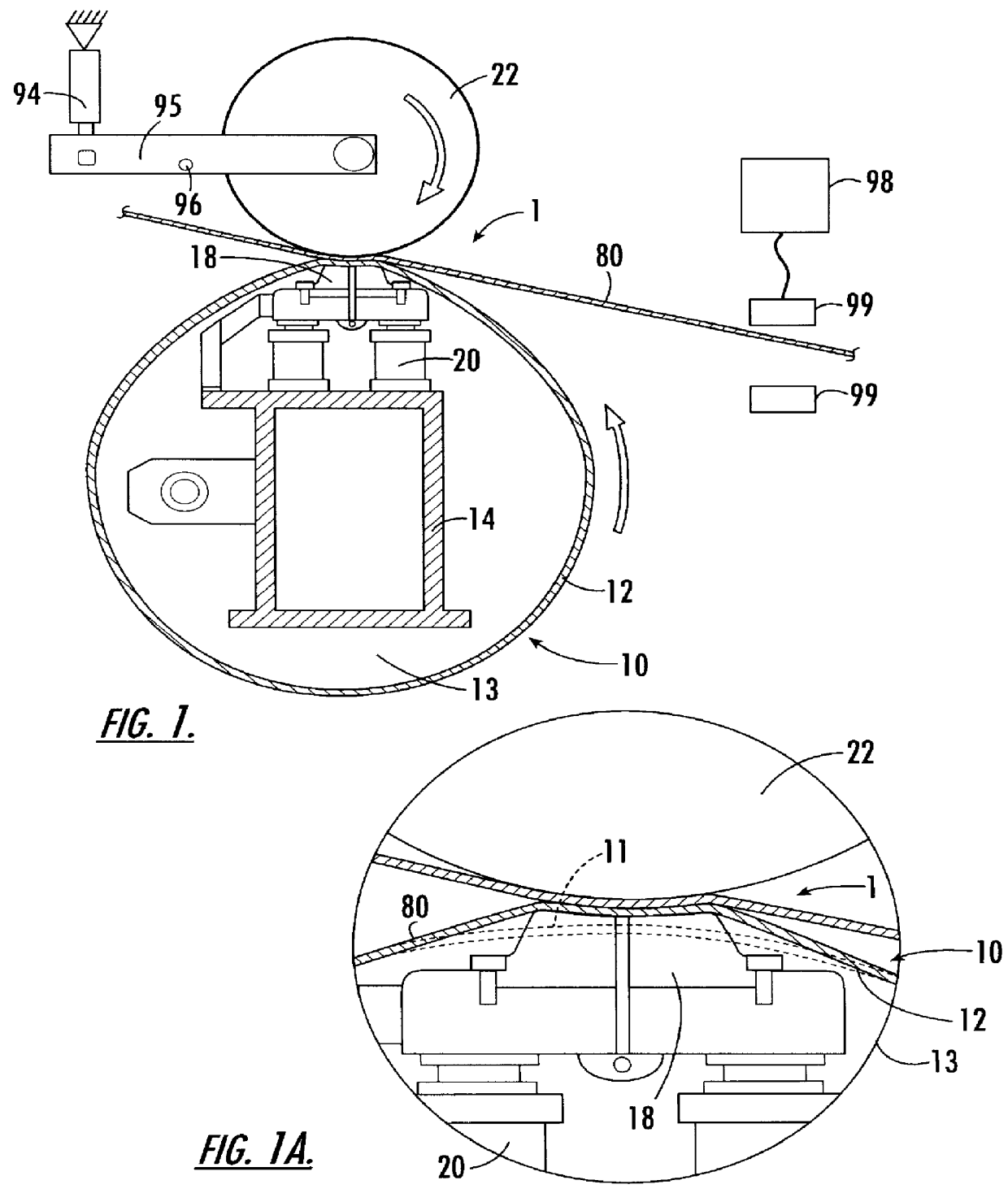

Nip and loading analysis system

InactiveUS7185537B2Improve assessmentBetter assessmentCalendersPress sectionEngineeringMechanical engineering

A nip characterization system which has as inputs the pressure applied to the nip by the hydraulic loading devices, and loads applied at the end bearings and / or the loads applied to the roll support beam, and in addition directly measures nip load, has more than sufficient information to completely characterize the nip.

Owner:VALMET TECH INC

Fibrous structures

Owner:THR PROCTER & GAMBLE COMPANY ATTENTION CHEIF PATENT COUNSEL

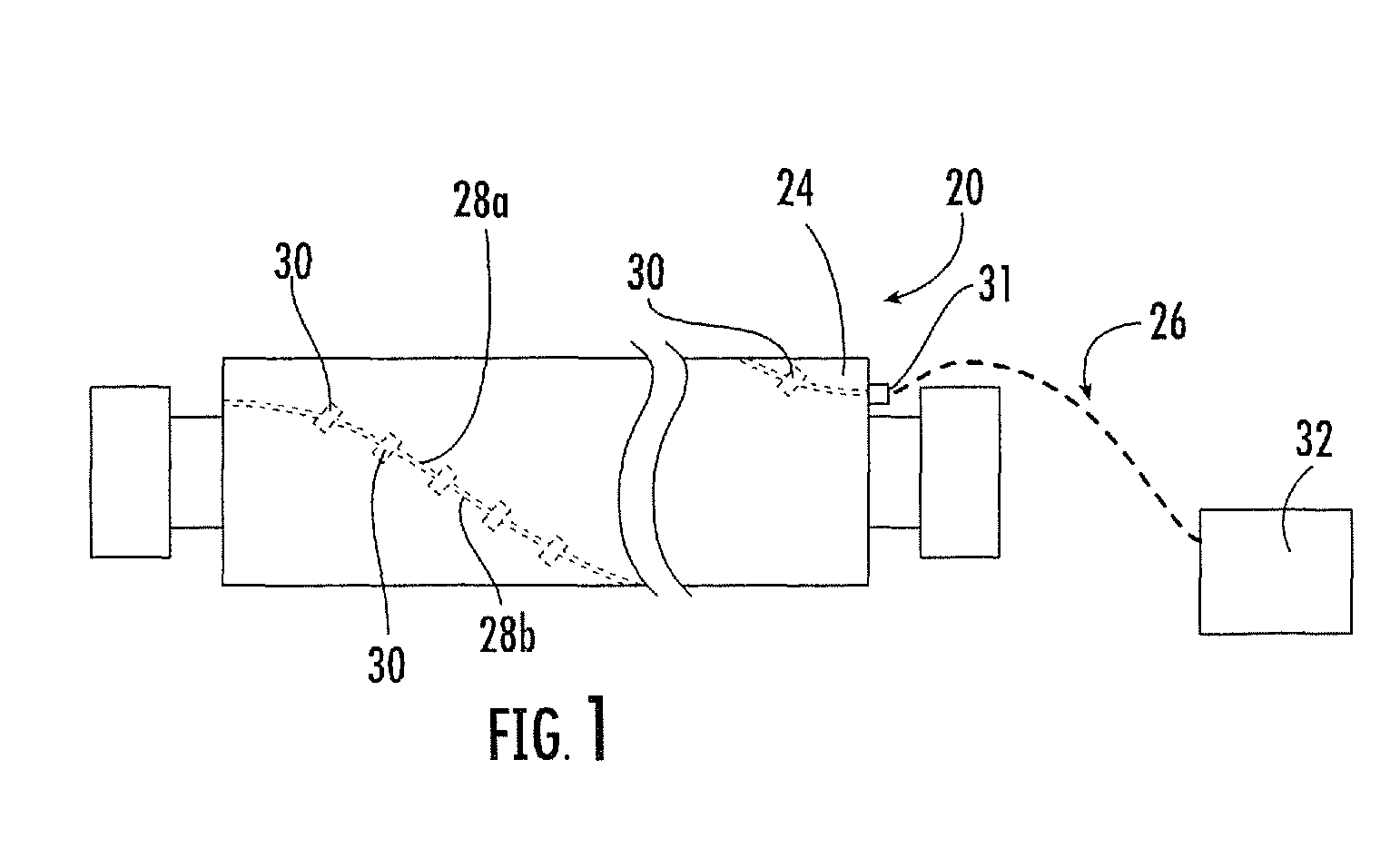

Apparatus for calendering paper

The invention relates to a method for operating a calender, comprising a cylindrical heated roll and a flexible belt surrounding a stationary support beam which supports at least one actuator which may urge a concave load shoe against the heated roll by means of said flexible belt to form an extended and heated nip through which a fiber web passes to be calendered and a separating mechanism for having at least one of the rolls movable into and away from the nip characterized in that said flexible belt is a flexible tubular jacket which forms a part of an enclosed shoe roll such that the ends of said jacket have end walls mounted thereto, which end walls are rotatably mounted in relation to said support beam, and in that at least one of said end walls is driven by means of a drive arrangement which drive arrangement may be activated to drive the end walls and thereby also the jacket independently of its position in relation to the fiber web or the heated roll.

Owner:VALMET TECH INC

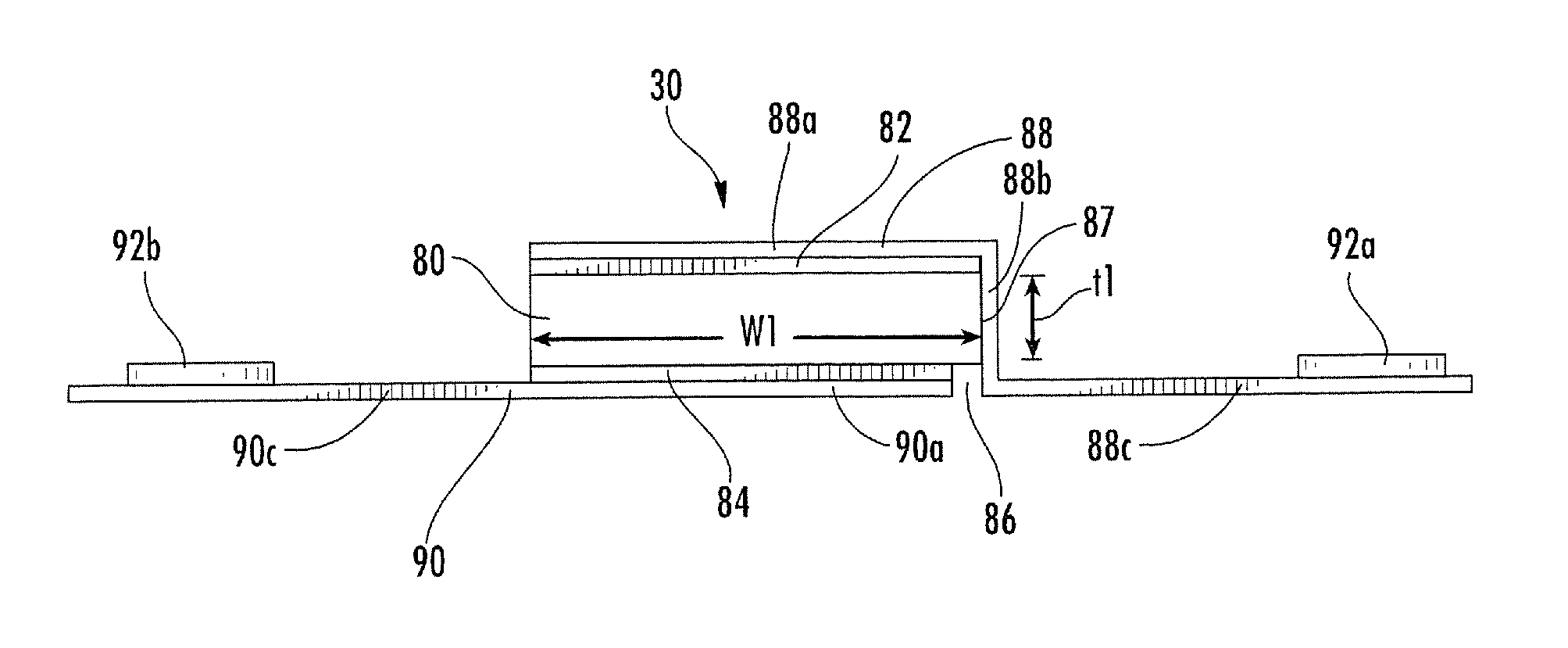

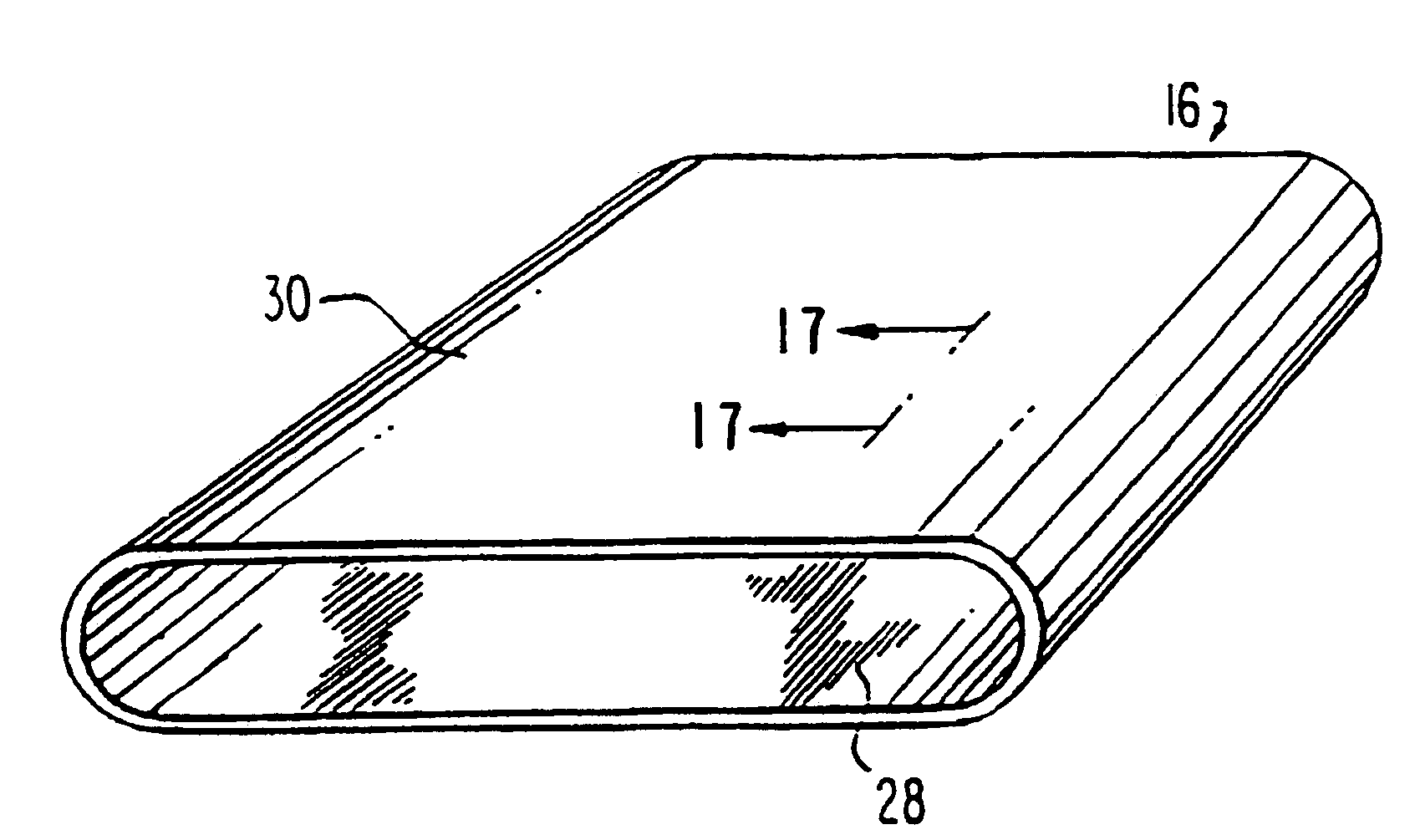

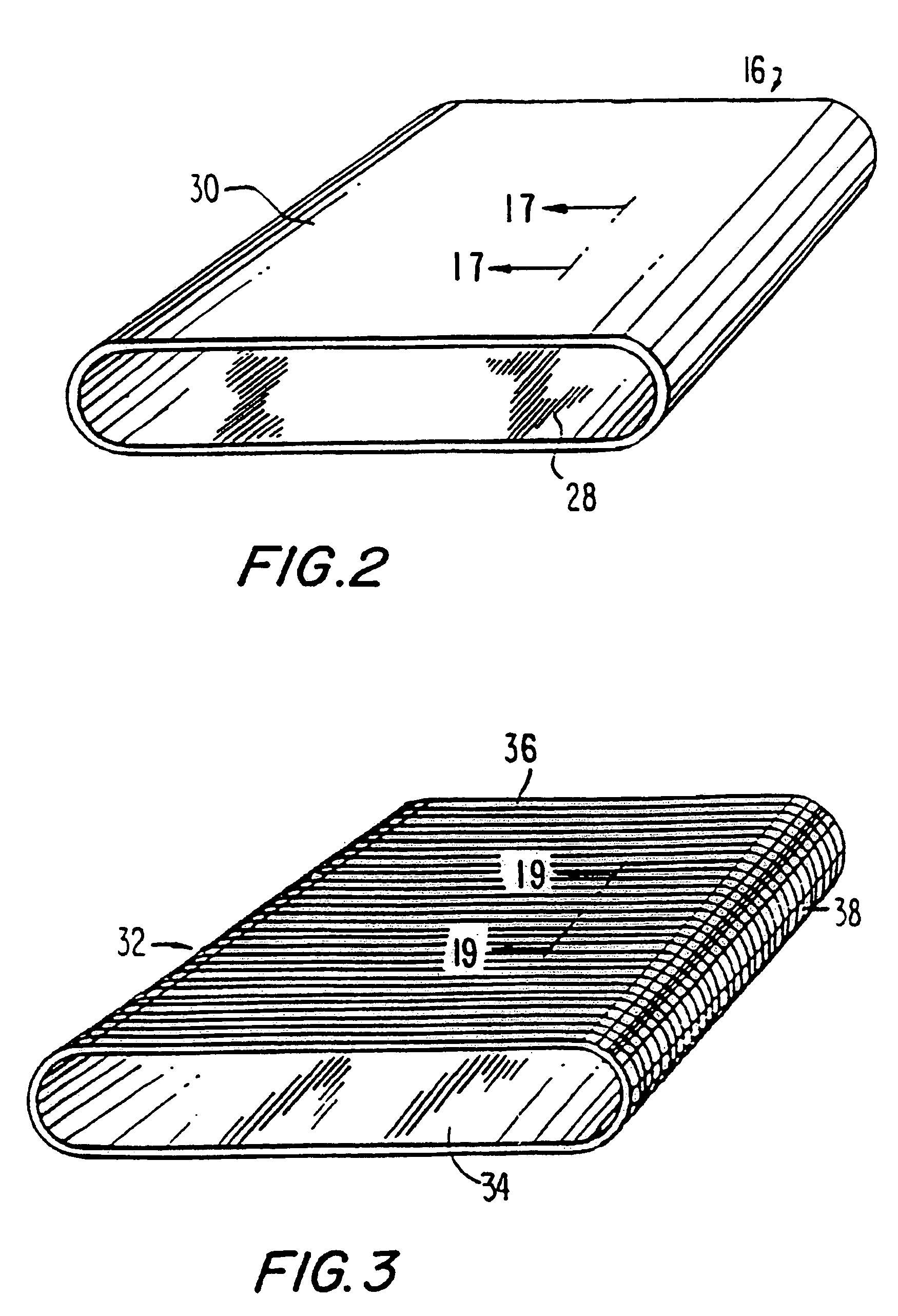

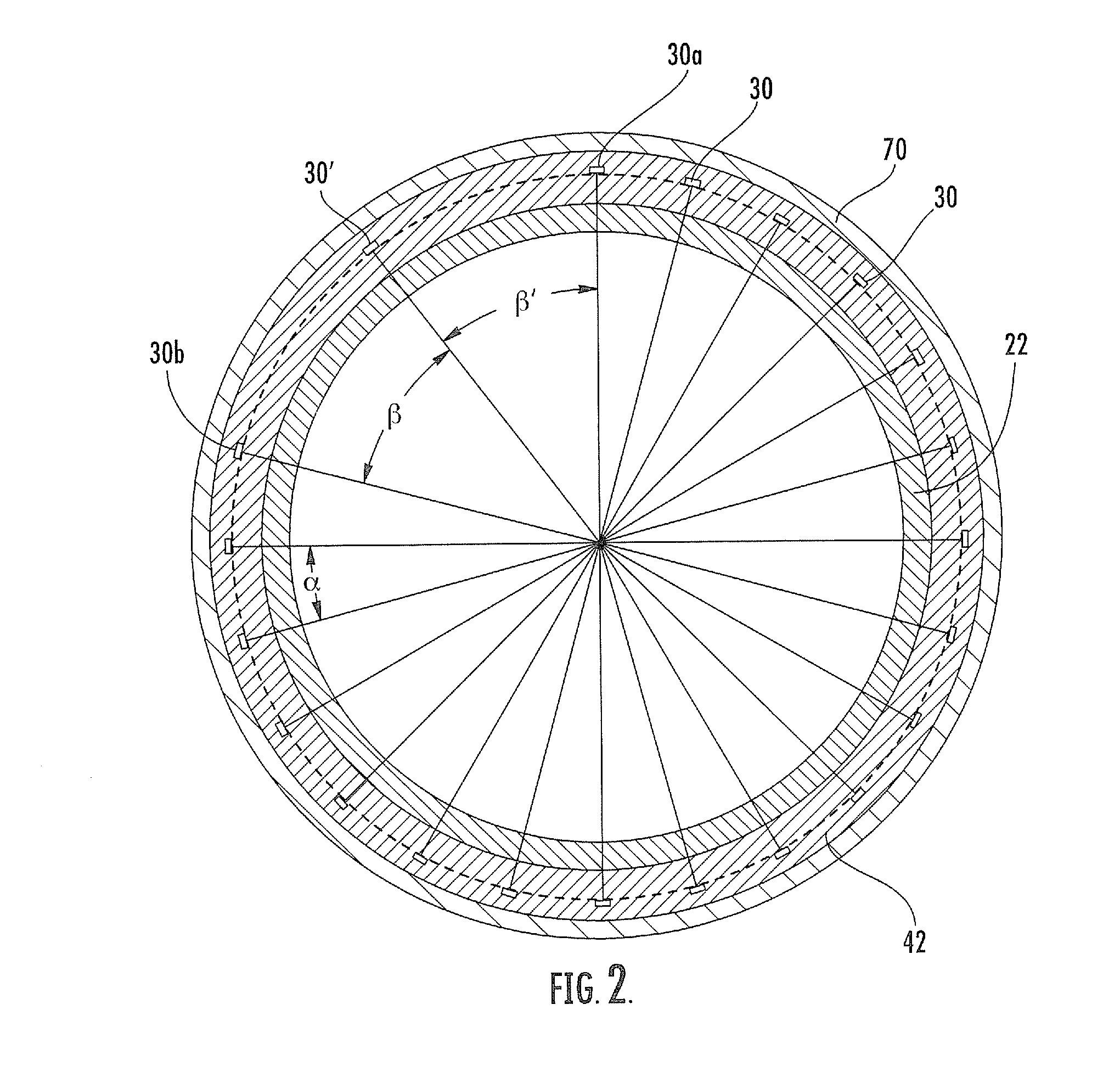

Industrial roll with sensors having conformable conductive sheets

ActiveUS8236141B2Force measurementMeasurement arrangements for variableConductive materialsEngineering

An industrial roll includes: a substantially cylindrical core having an outer surface and an internal lumen; a polymeric cover circumferentially overlying the core outer surface; and a sensing system. The sensing system includes: a plurality of sensors at least partially embedded in the cover, the sensors configured to sense an operating parameter of the roll and provide signals related to the operating parameter; and a processor operatively associated with the sensors that processes signals provided by the sensors. Each of the plurality of sensors includes: a first electrode overlying the top surface of a substrate and a second electrode underlying the bottom surface of the substrate, wherein the first electrode overlies the top surface of the substrate and the second electrode underlies only a portion of the bottom surface of the substrate, thereby forming a gap adjacent the bottom surface and a side surface of the substrate; a first sheet of conductive material attached to the first electrode and the side surface of the substrate and extended in a first direction away from the bottom surface of the substrate; and a second sheet of conductive material attached to the second electrode and extended in a second direction away from the bottom surface of the substrate, the second surface being opposite the first direction.

Owner:STOWE WOODWARD

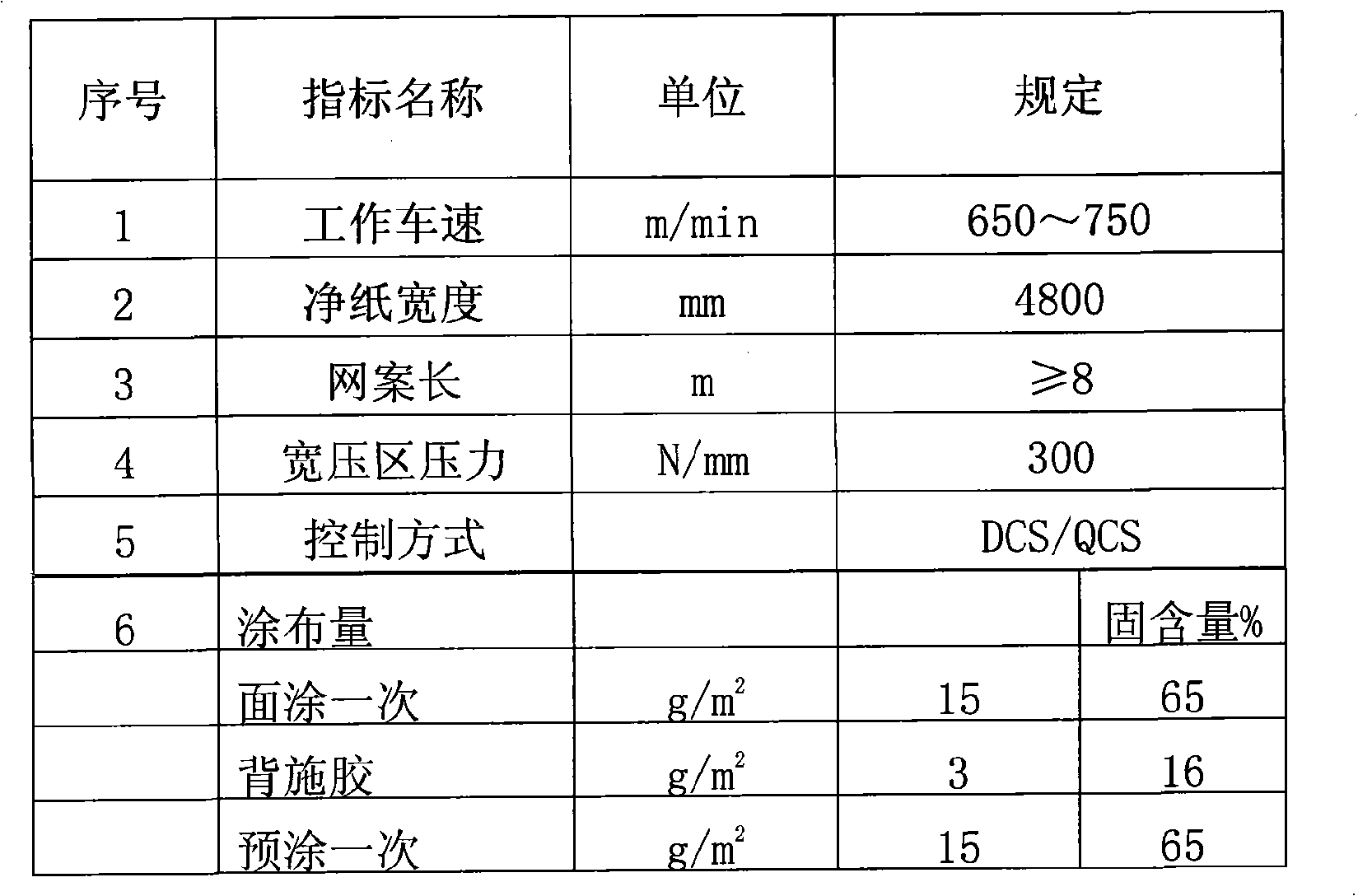

Method for producing coated kraft card board by home-made paper machine

The invention relates to technical field of coated kraft liner producing method. The producing method comprises feeding surface pulp, lining pulp, core pulp and bottom pulp pumped from machine chest of pulping workshop into respective machine chest; slushing and pressure screening the lining pulp, the core pulp and the bottom pulp by offline back water bank, then slushing and pressure screening the surface pulp by the offline back water bank after removing impurities in the surface pulp in a low concentration sand remover, finally all the pulp entering into a flow box to flow onto wire; after the pulp flowing onto wire, feeding the pulp into a coating system after forming by a four-long net forming machine, second shoe pressing, drying, glue blending, redrying, and press polishing by a two-roller hot pressing machine; feeding the coated paper into a state-regulating cylinder and a soft calendar to finish, then reeling by a horizontal paper reeling machine. The coated kraft liner producing method disclosed by the invention can greatly reduce use cost of the coated kraft liner to make the domestic market not dependent on import any longer.

Owner:ZHEJIANG YONGTAI PAPER IND GROUP

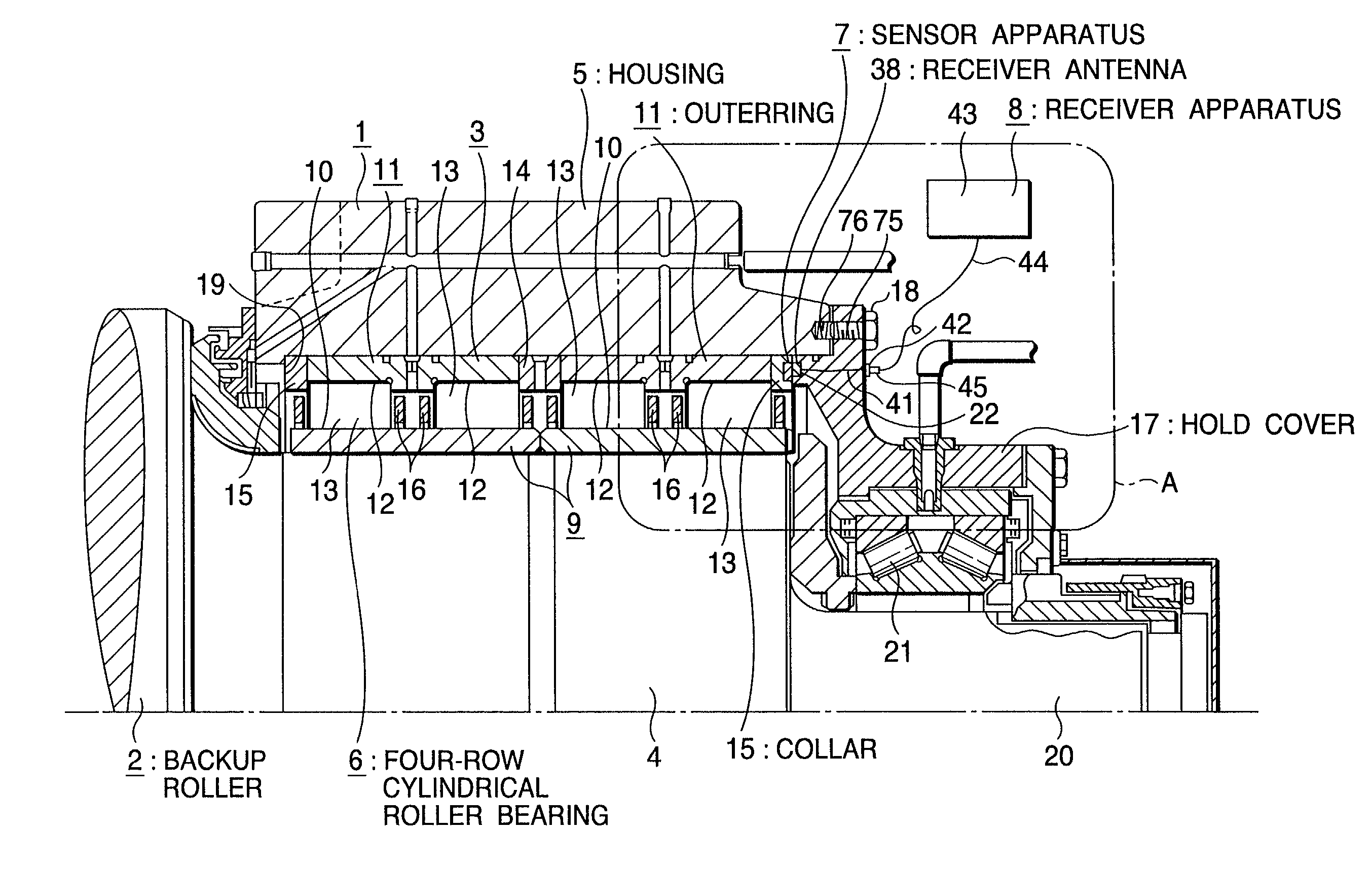

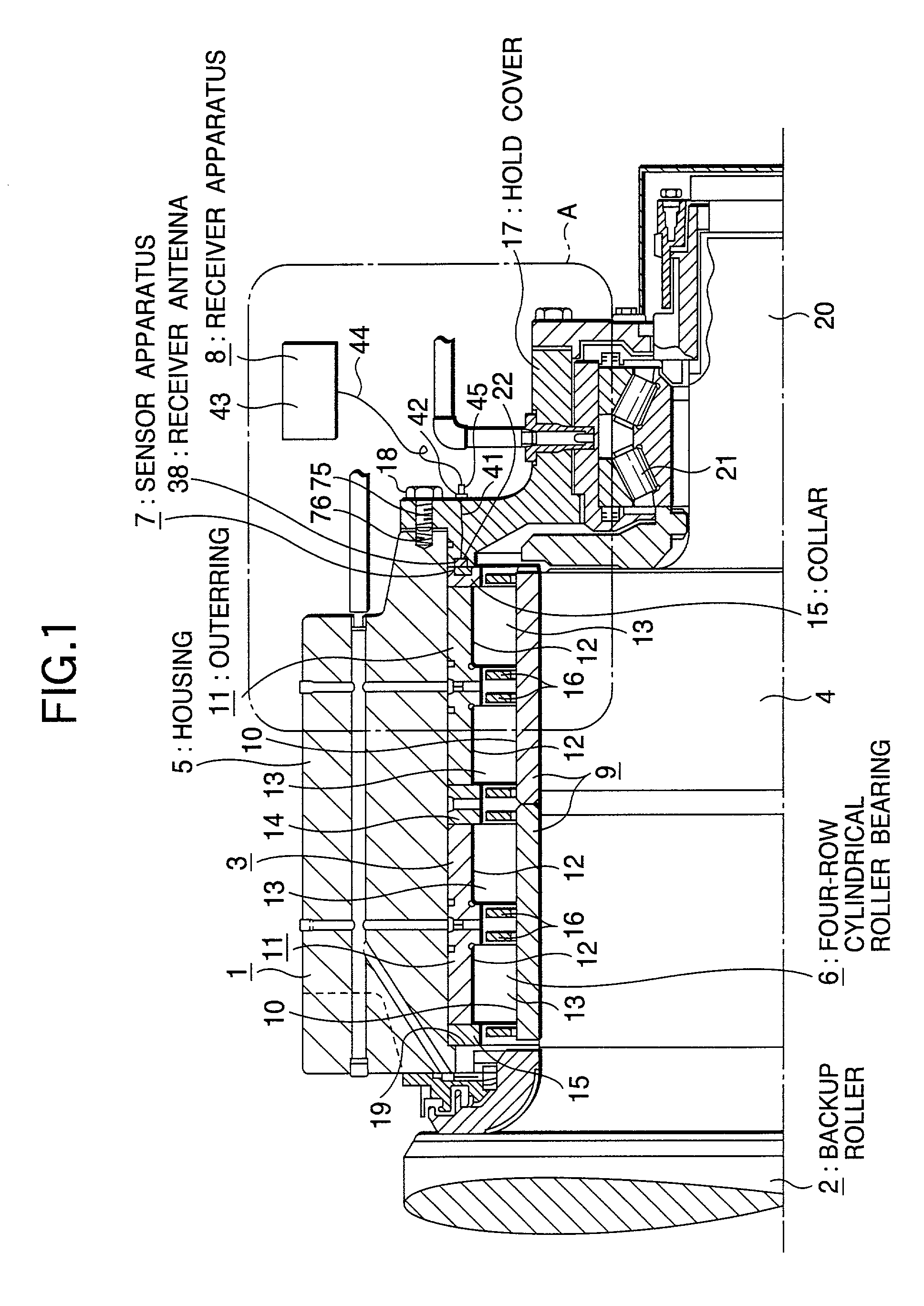

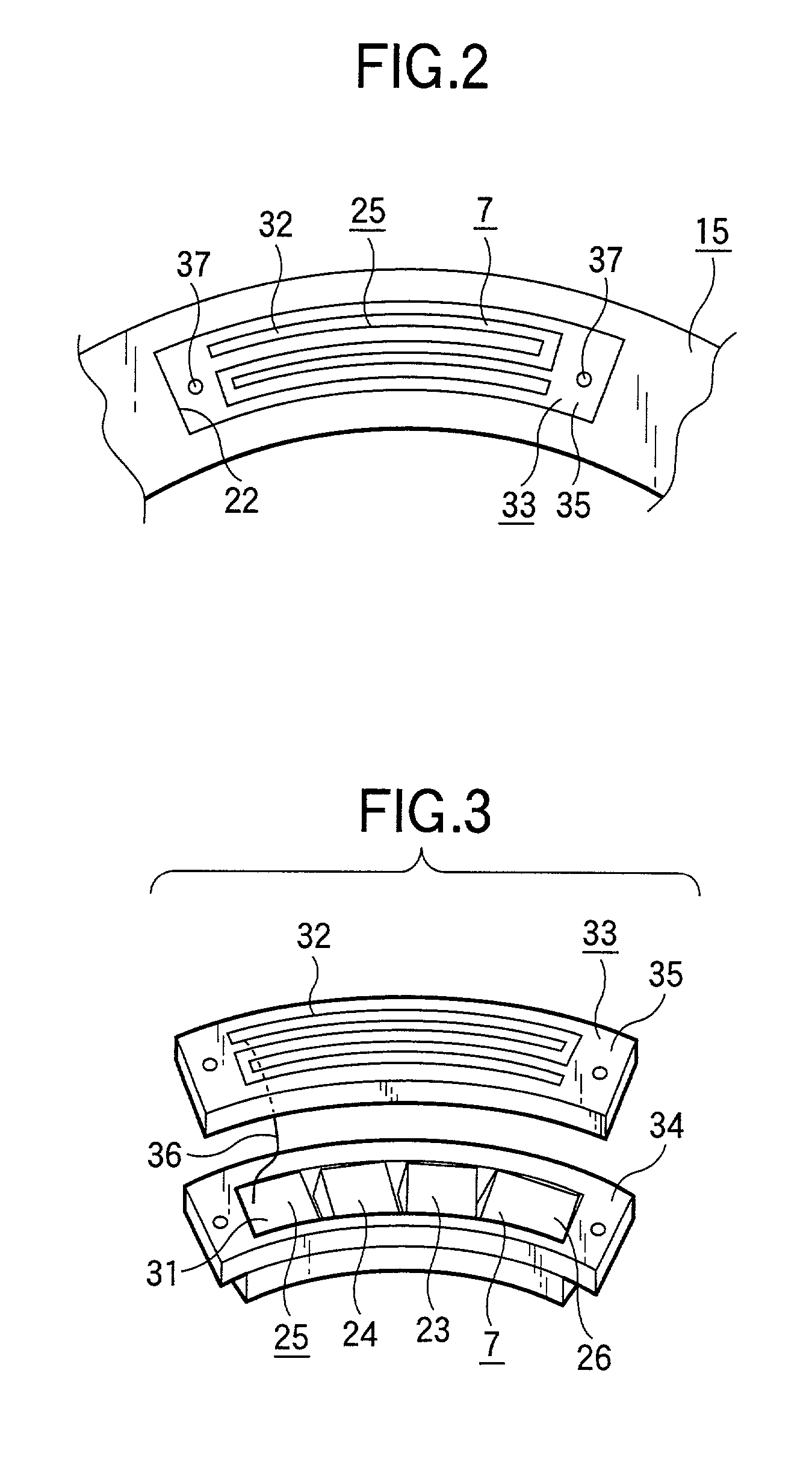

Rolling bearing unit with sensor

InactiveUS20030048962A1Easy to replaceEasy to confirmVibration measurement in solidsRotary bearingsRolling-element bearingEngineering

A four-row cylindrical roller bearing is incorporated into between the inner peripheral surface of a housing and the outer peripheral surface of a backup roller. A sensor unit 7 is held in a portion of a collar disposed in the axial-direction end portion of the four-row cylindrical roller bearing. The sensor unit comprises a detect part for detecting temperatures and vibrations and a transmitter device for transmitting signals, which are obtained after output signals taken out from the detect part are processed, as radio signals. On a portion of a hold cover which is a separate member from the collar, there is disposed a receive antenna which is part of a receiver apparatus for receiving the radio signals transmitted by the transmitter device.

Owner:NSK LTD

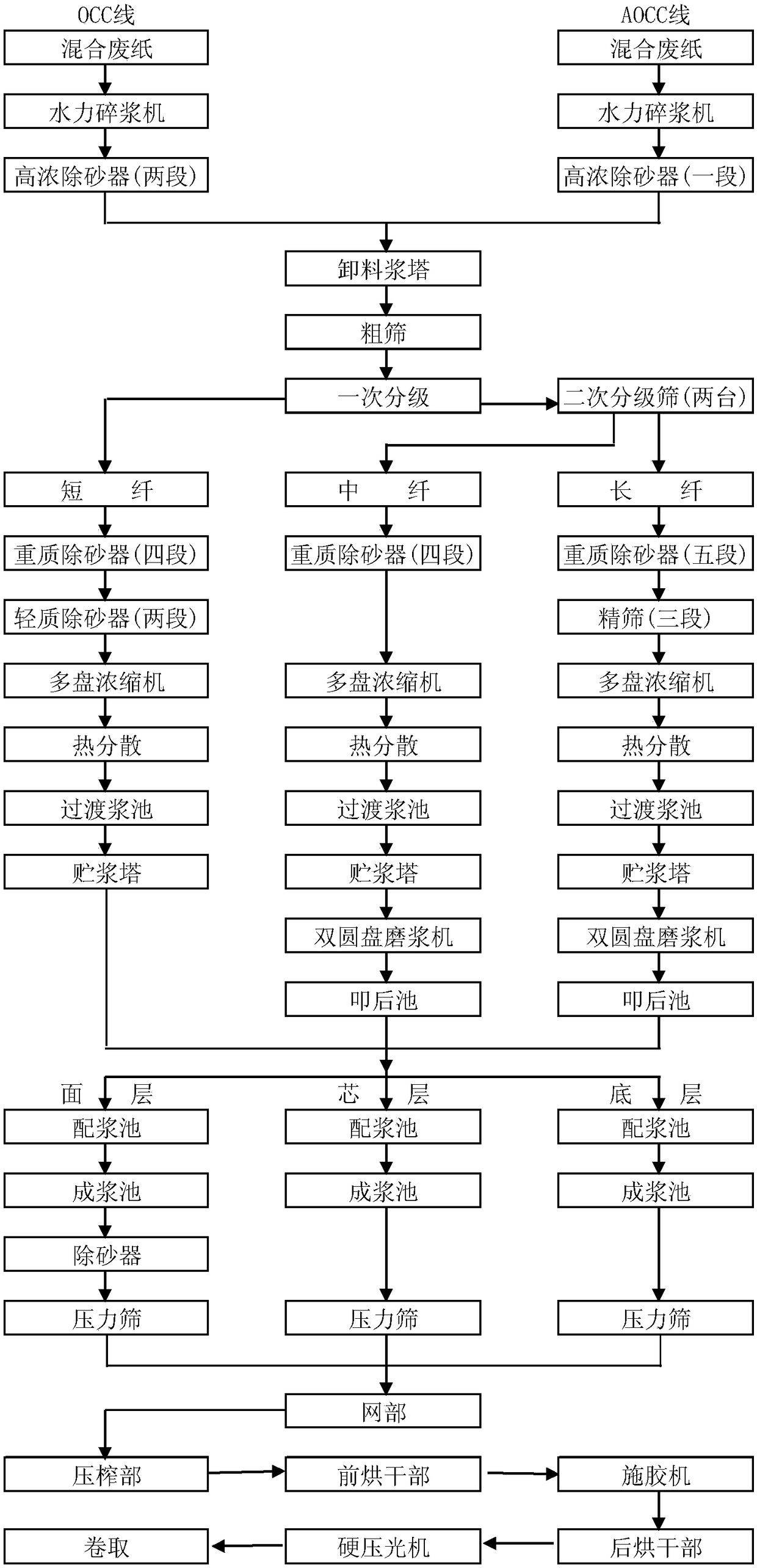

Preparation process of test-liner environment-friendly kraft cardboard paper

ActiveCN108252137AHigh burst resistanceReduce paper production costsDryer sectionPaper recyclingCardboardSlurry

The invention relates to a preparation process of test-liner environment-friendly kraft cardboard paper. The preparation process comprises the following steps: A, picking and selection of fine waste paper raw materials; B, crushing process; C, screening and purification; D, heat dispersion; E, treatment in a slurry storage tower; F, pulping process; G, treatment in a post-processing tank; H, treatment in a pulp distribution tank; I, treatment in a pulp forming tank; J, treatment by using a desander; K, treatment by using a pressure screen; L, treatment by using a net part; M, treatment by using a press part; N, treatment by using a front drying part; O, treatment by using a sizing machine; P, treatment by using a post-drying part; Q, treatment by using a hard calender; and R, reeling-up process. According to the preparation process provided by the invention, waste paper is recycled, and the obtained product with the same quality with test-liner environment-friendly kraft cardboard paper taking wood pulp as a raw material is produced, so that the cost is greatly reduced, the resources are saved, the effective circulation reuse of the renewable resources is guaranteed, and the damageto the environment is reduced. The preparation method has strong practicality and has strong promotion significance.

Owner:DONGGUAN JIANHUI PAPER CO LTD

Cut resistant paper and paper articles and method for making same

InactiveUS20050098286A1Reduce resistanceNon-fibrous pulp additionNatural cellulose pulp/paperMicrospherePapermaking

The specification discloses a method for making a paper material having a reduced tendency to cut human skin. The method includes providing a papermaking furnish containing cellulosic fibers and from about 0.5 to about 5.0 wt % by weight dry basis expandable microspheres, forming a paperboard web from the papermaking furnish, drying the web, and calendaring the web to a caliper of from about 11.0 to about 18.0 mils and a density ranging from about 7.0 to about 12.0 lb / 3000 ft2 / mil. Papers formed according to the method and articles formed therefrom are also disclosed.

Owner:INT PAPER CO

Belts and roll coverings having a nanocomposite coating

ActiveUS7413633B2Excellent characteristicsImprove fatigueSynthetic resin layered productsPretreated surfacesNanoparticleNanocomposite coating

The present invention relates to a urethane-based coating having nanoparticles for improving the characteristics of a papermaking process belt, roll cover and belts used in textile applications. For example, the present invention improves resistance to flex fatigue, crack propagation, groove closure and wear characteristics of urethane coatings on such belts and roll coverings. The present invention also improves the resistance to water and oil permeation characteristics of urethane coated belts and roll coverings.

Owner:ALBANY INT CORP

Abrasion-resistant rubber roll cover with polyurethane coating

ActiveUS20070111871A1Improve propertiesImprove toughnessMechanical working/deformationShaft and bearingsEngineeringWear resistance

An industrial roll includes: a substantially cylindrical metallic core; a rubber base layer that is adhered to and circumferentially overlies the core; a rubber top stock layer that circumferentially overlies the base layer; and a polyurethane coating that circumferentially overlies the top stock layer. In this configuration, the roll can provide improved abrasion-resistance, sheet release properties, and / or toughness compared to a roll with a rubber cover, but may provide these properties in a cover that is softer than a typical polyurethane cover.

Owner:STOWE WOODWARD

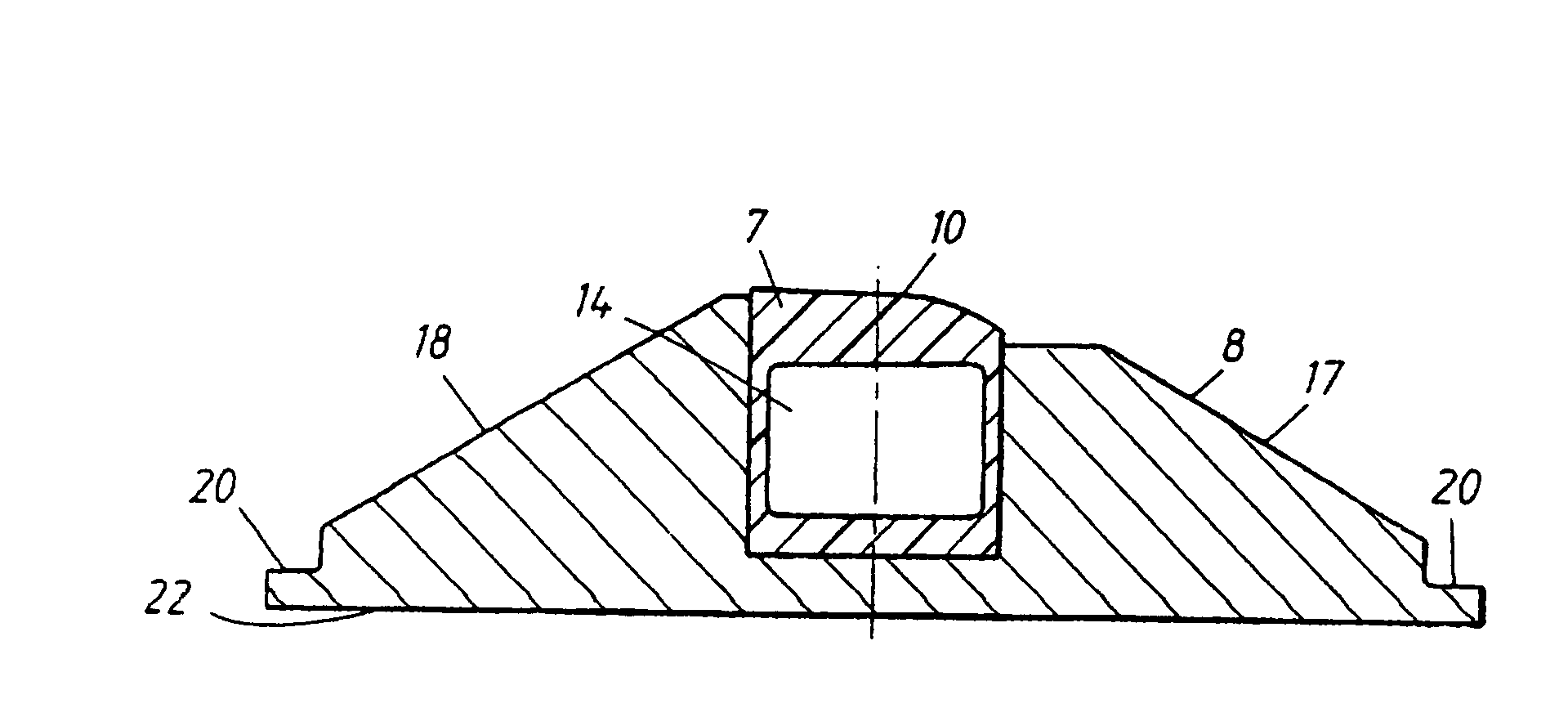

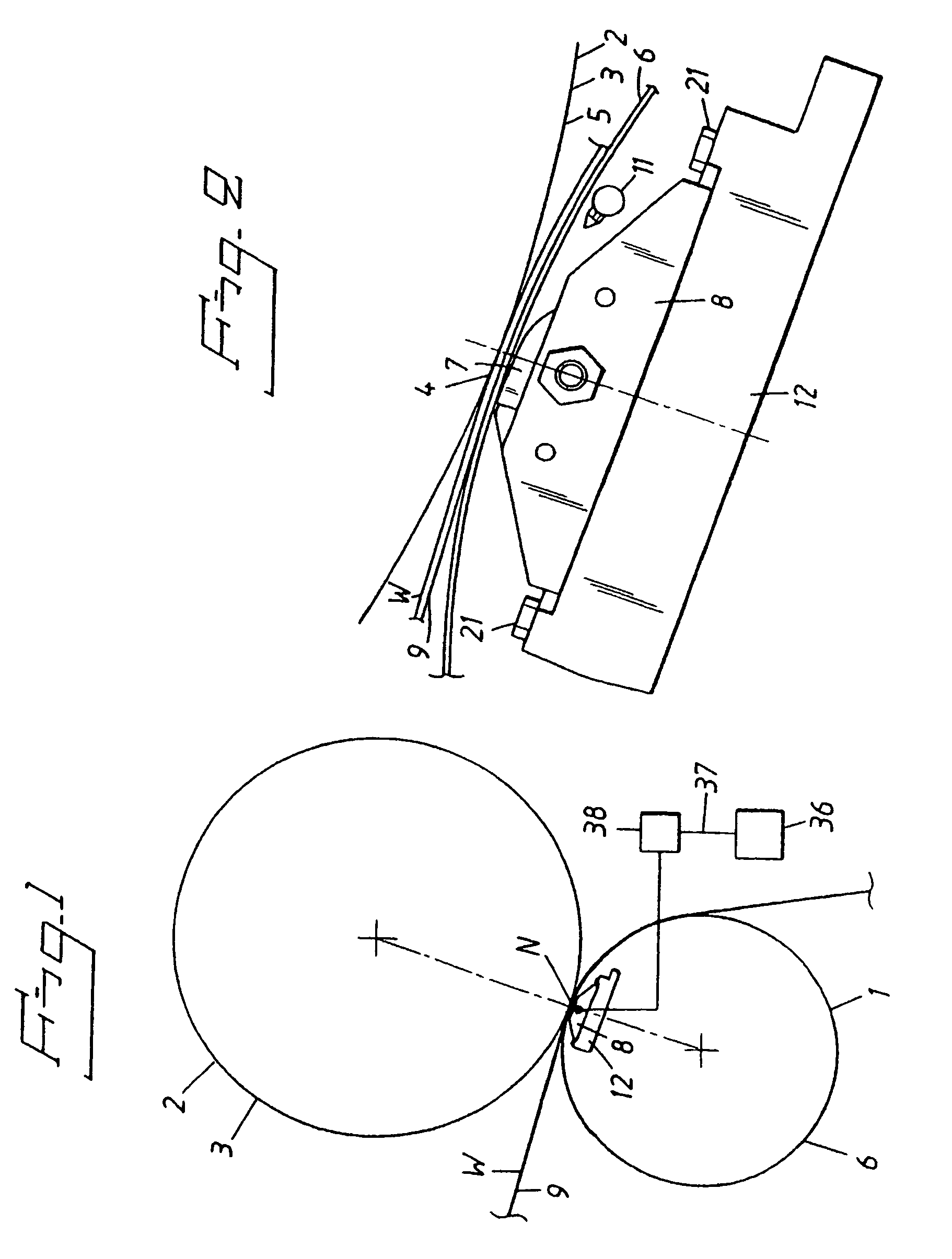

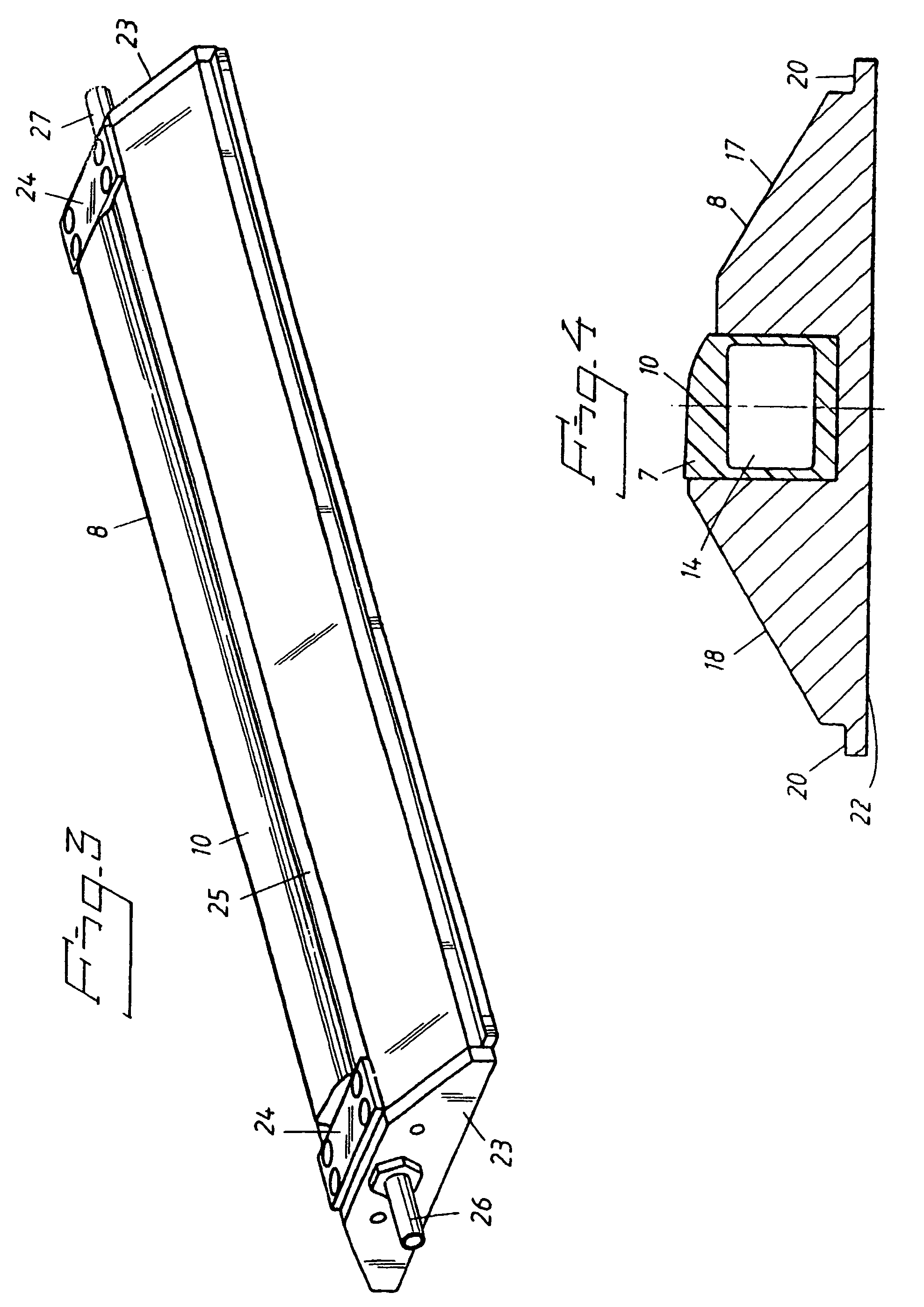

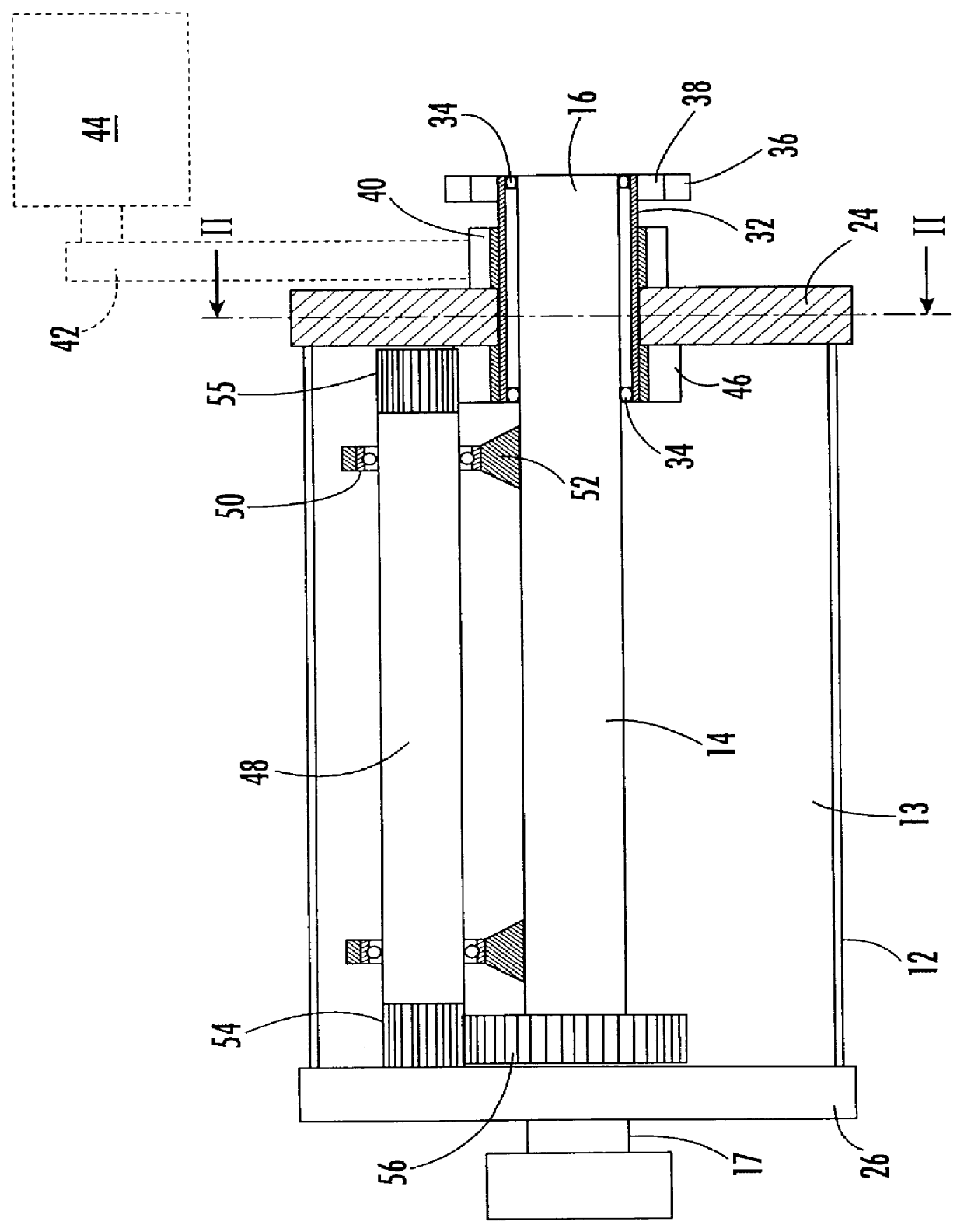

Method and apparatus for calendering paper

InactiveUS6158333AReduce disadvantagesIncrease incomeMechanical working/deformationCalendersFiberEngineering

The invention relates to a method and an apparatus calendering a fiber web, wherein the fiber web passes through an extended and heated nip, said nip being formed on one side by a cylindrical heated roll and on the other side by a flexible tubular jacket which is pressed against the heated roll by means of a concave load shoe, said tubular jacket surrounding a stationary support beam which supports at least one actuator which may urge said load shoe and said flexible tubular jacket against said heated roll, and wherein the extension of the load shoe in the axial extension is less than the axial extension of the jacket and the heated roll such that when the load shoe is urged against the heated roll there will be formed tapered sections at each side end of the jacket within the nip characterised in that said tapered section are substantially covered by said fiber web such that a small strips of the fiber web at each edge is not calendered in said extended nip.

Owner:VALMET TECH INC

Cut resistant paper and paper articles and method for making same

The specification discloses a method for making a paper material having a reduced tendency to cut human skin. The method includes providing a papermaking furnish containing cellulosic fibers and from about 0.5 to about 5.0 wt % by weight dry basis expandable microspheres, forming a paperboard web from the papermaking furnish, drying the web, and calendaring the web to a caliper of from about 11.0 to about 18.0 mils and a density ranging from about 7.0 to about 12.0 lb / 3000 ft2 / mil. Papers formed according to the method and articles formed therefrom are also disclosed.

Owner:INT PAPER CO

Shoe press belt

ActiveUS20100130701A1Resistance to crackingIncrease resistanceSynthetic resin layered productsCalendersElastomerNanoparticle

Owner:METSO FABRICS INC

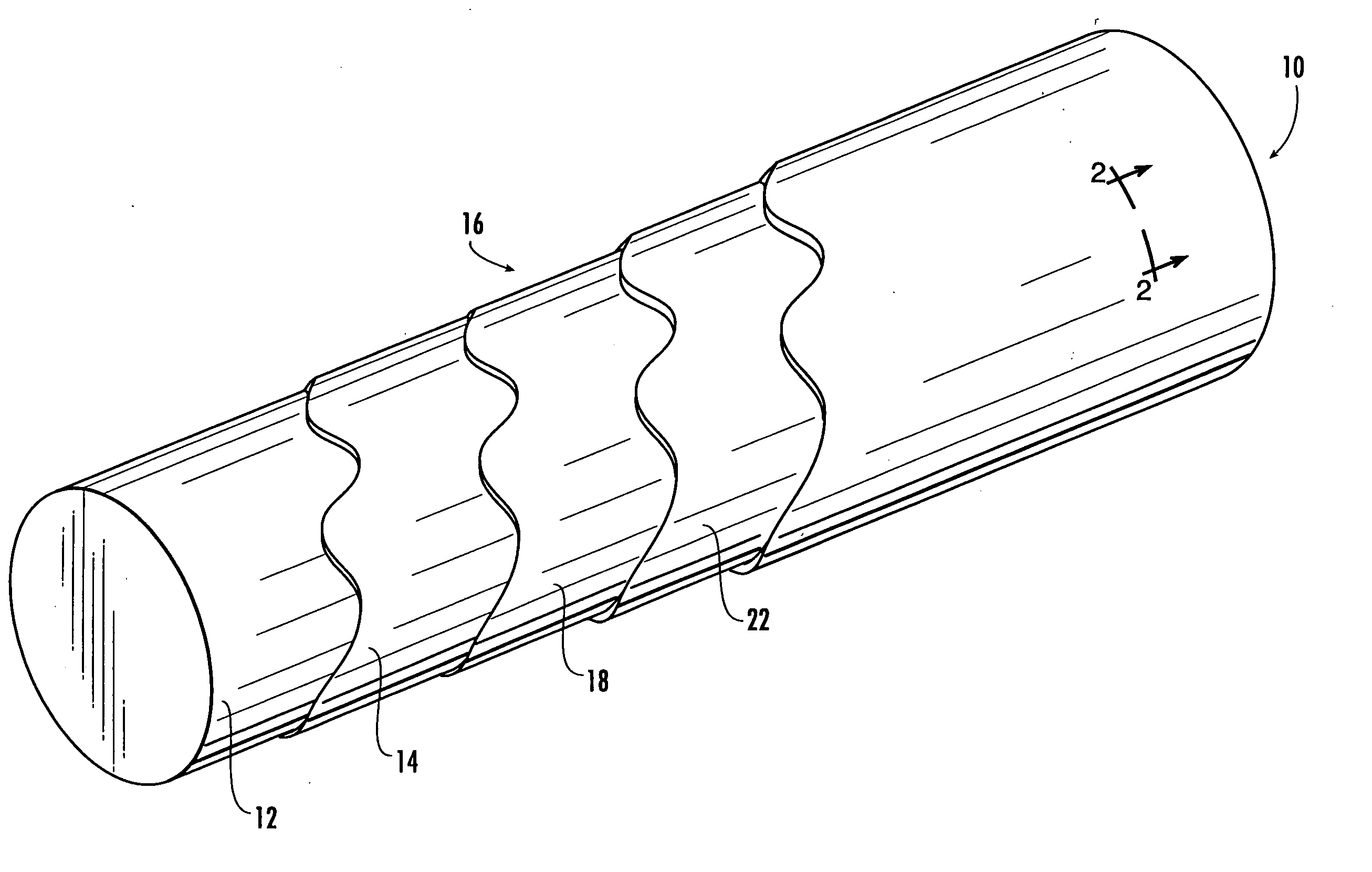

Industrial Roll With Sensors Arranged To Self-Identify Angular Location

ActiveUS20100324856A1Inflated body pressure measurementFluid pressure measurement by electric/magnetic elementsAccelerometerAngular distance

An industrial roll includes: a substantially cylindrical core having an outer surface; a polymeric cover circumferentially overlying the core outer surface; and a sensing system. The sensing system comprises: a plurality of sensors embedded in the cover, the sensors configured to detect an operating parameter of the roll and provide signals representative of the operating parameter, wherein one of the plurality of sensors is a tracking sensor and the remaining sensors are non-tracking sensors; and a processor operatively associated with the sensors that processes signals provided by the sensors. The sensors are arranged at a substantially equal radial distance from the core outer surface, such that they define a circle when viewed from an end of the roll. Each of the non-tracking sensors is further arranged at a substantially equal first angular distance from its immediate non-tracking sensor neighbors, two endmost non-tracking sensors defining an angular gap. The tracking sensor is disposed in the angular gap, such that a second angular distance defined by the tracking sensor and either of the endmost sensors differs from the first angular distance. In this configuration, the sensing system can identify from which sensor signals are generated without a trigger signal generator or accelerometer.

Owner:STOWE WOODWARD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com