Meta aramid fibre paper and prepn. process

A technology of aramid paper and aramid fiber, which is applied in the direction of papermaking, paper machine, textile and papermaking, etc., and can solve the problems of high degree of symmetry orientation and crystallinity of para-aramid fiber, easy flocculation of aramid fiber, and difficulty in forming hydrogen Key effects and other issues can be eliminated to eliminate the increased burden of sewage treatment, improve electrical insulation performance, and eliminate expensive costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiments of the present invention are given below in conjunction with the accompanying drawings to further illustrate the technical solutions of the present invention, but the embodiments of the present invention are not limited to the following specific embodiments.

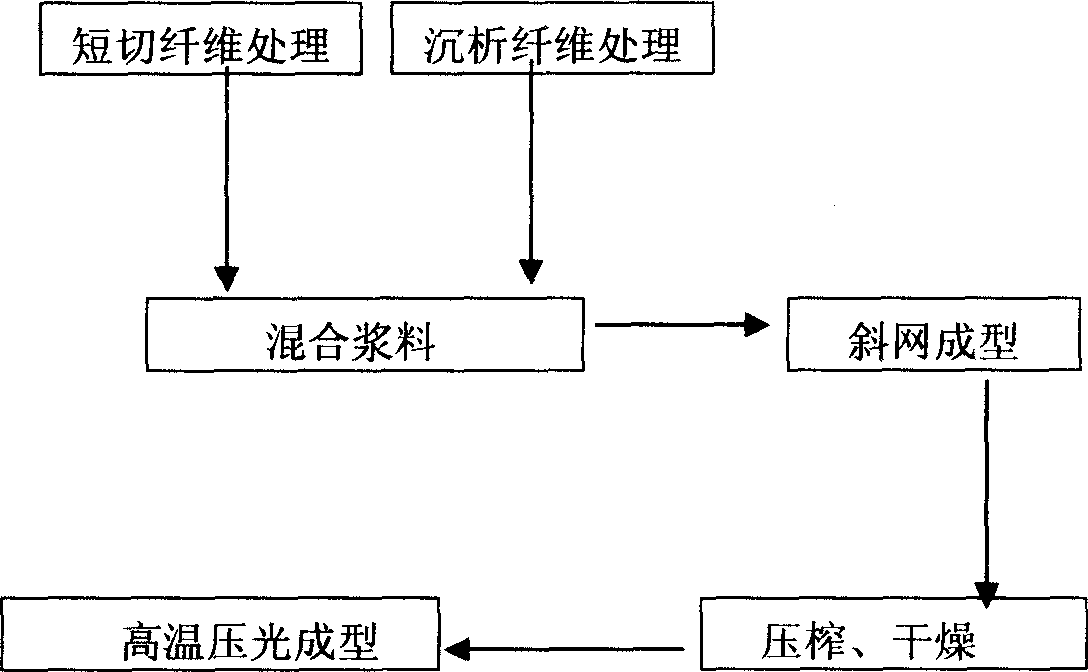

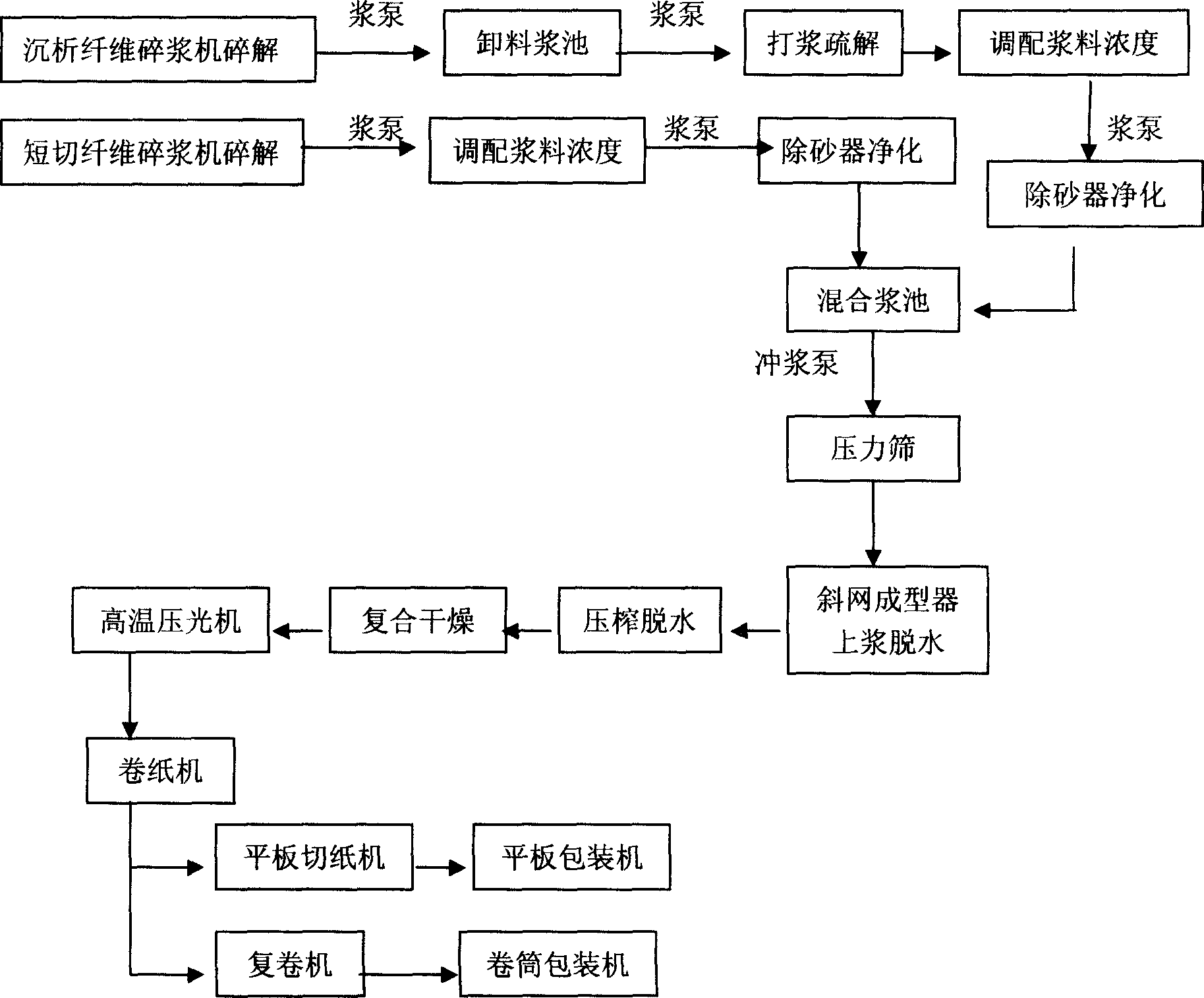

[0037] The method for preparing meta-aramid paper in this embodiment uses pure meta-aramid fibers to make meta-aramid paper. For the steps, seefigure 1 , figure 2 The preparation method flowchart is shown in:

[0038] 1. Add 5-95% (weight percent) meta-aramid chopped fibers in water to make slurry after being dispersed by dispersing equipment, and add 5-95% (weight percent) meta-aramid fiber in water for precipitation The fibers are dispersed by a dispersing device to make a slurry, and the above two dispersed slurries are mixed to obtain a mixed slurry;

[0039] The above-mentioned meta-aramid short-cut fibers are short-section fibers cut from continuous meta-aramid long fibers. Compare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com