Patents

Literature

363 results about "Paper quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Paper Quality. A paper mill monitors the quality of newsprint by applying ink to one side of the paper. By measuring the reflectance of light on the reverse side of the paper, a reliable, practical measure of how visible the ink is on the opposite side is obtained.

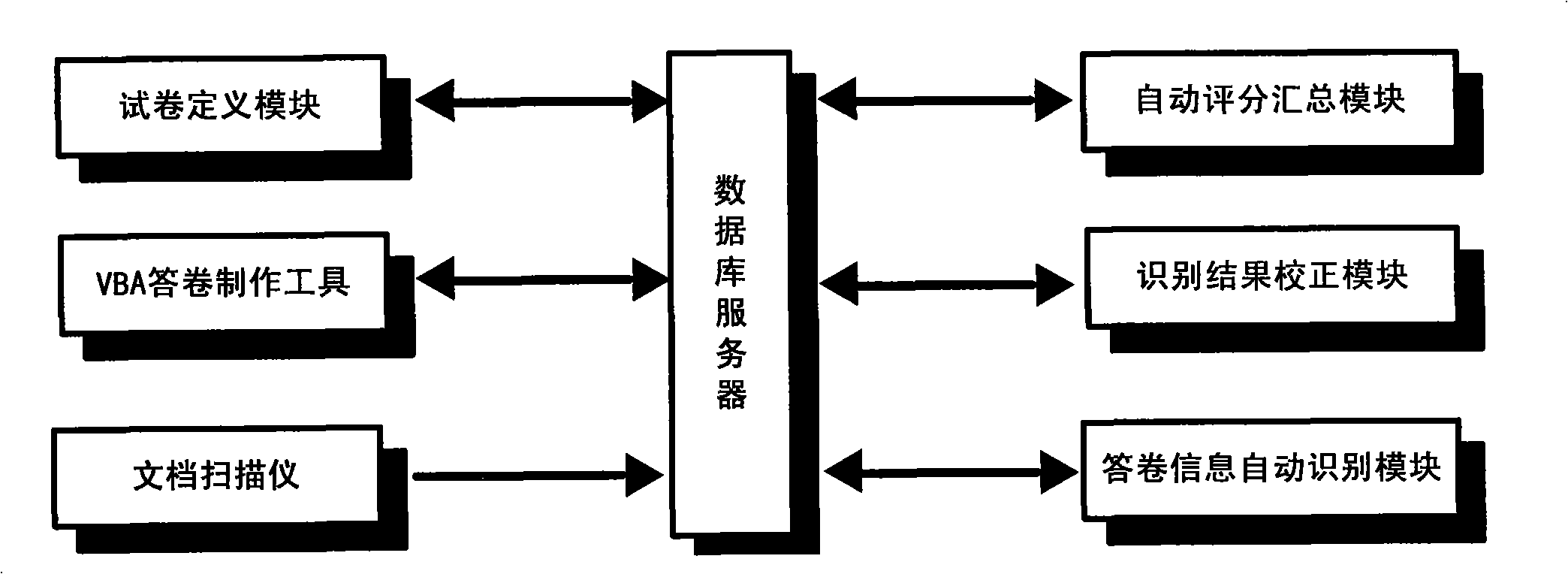

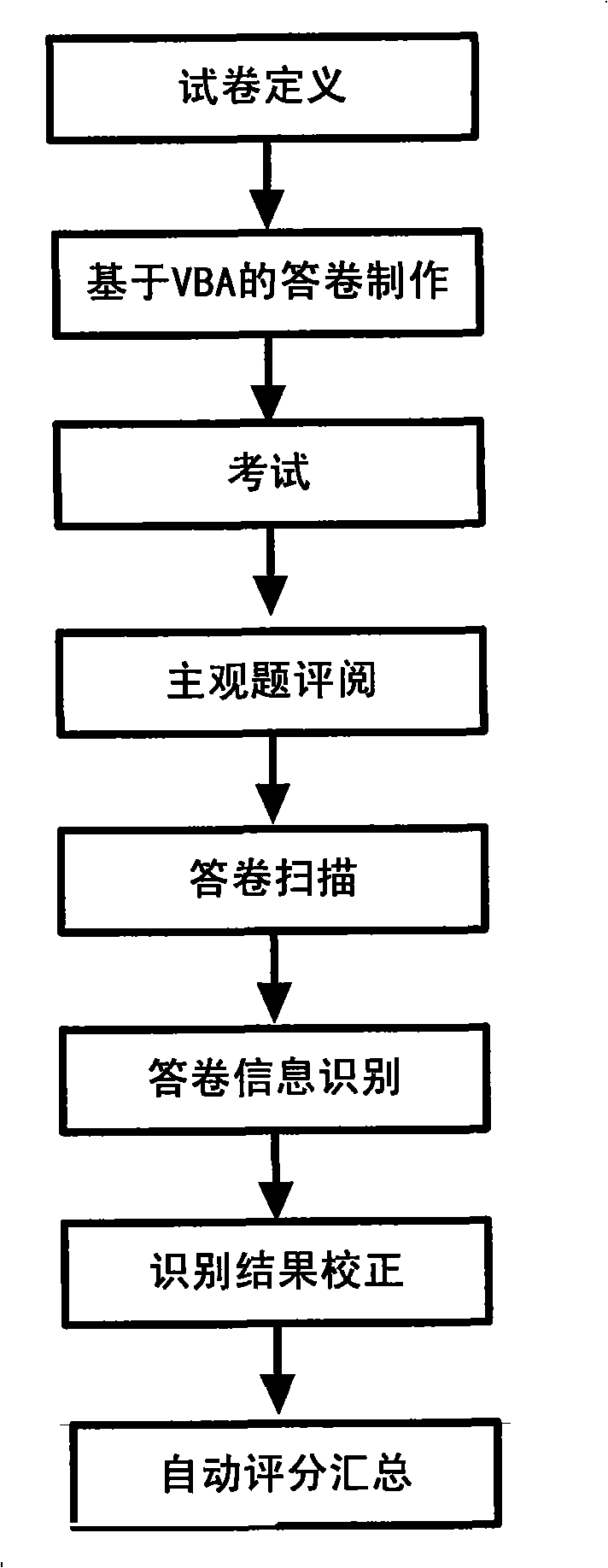

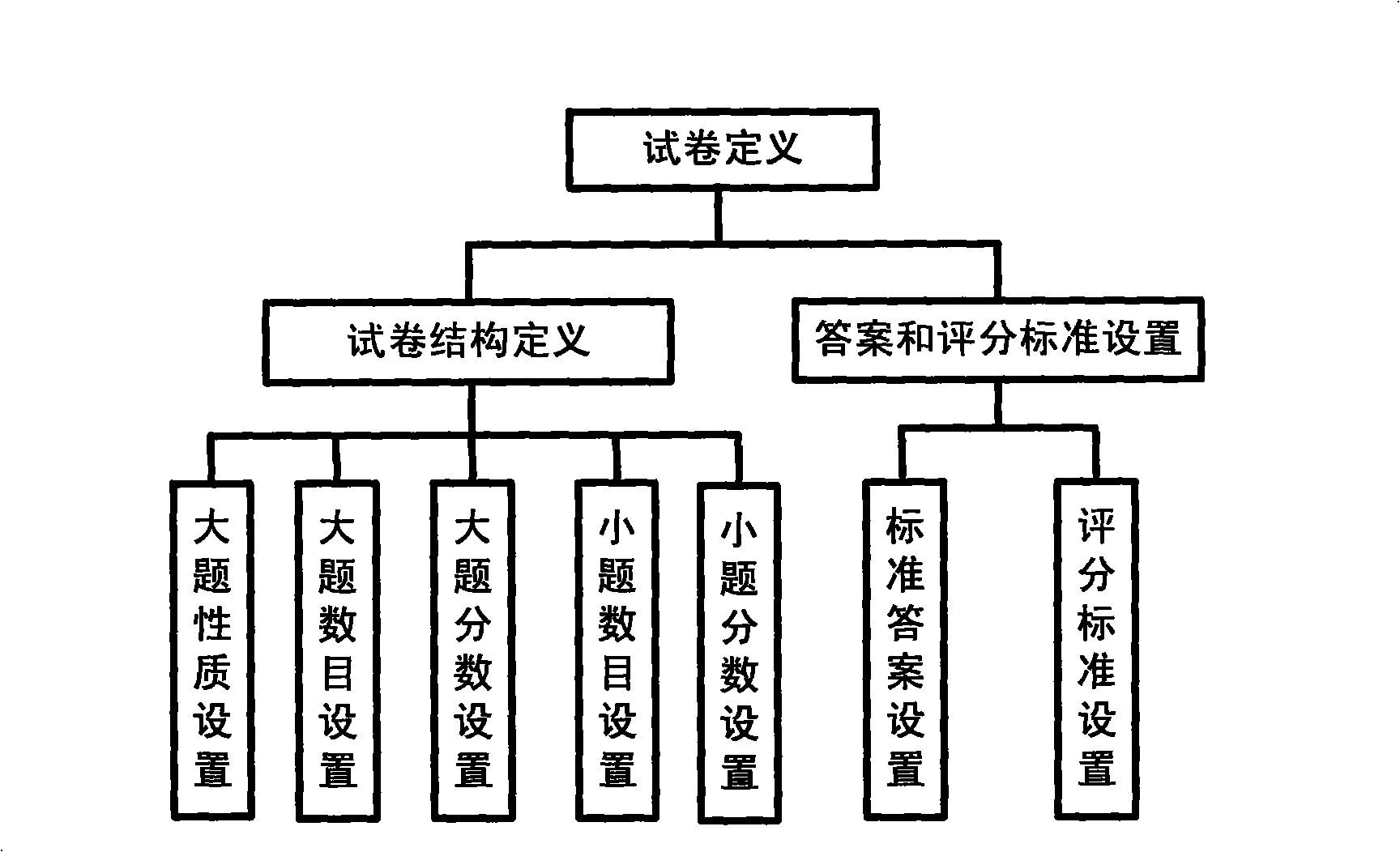

Automatic scanning and reading system and reading method

InactiveCN101334814ARealize identificationEasy to makeCharacter and pattern recognitionElectrical appliancesImaging processingInformation transmission

The invention discloses an automatic scanning examination paper marking system and a corresponding method, belonging to the image processing and mode identifying technique field. The system comprises a paper defining module, an answer sheet manufacturing tool based on VBA, a file scanner, a database server, an answer sheet information automatic identifying module, an answer sheet identified-result revising module and an automatic marking summarizing module. The whole structure of the automatic paper marking system appears as a star and the database server is the center of the system and other modules and apparatuses are respectively connected with the database server by network means and used for information transmission and network sharing. One automatic scanning examination paper marking method includes the following steps: paper defining, paper manufacturing based on VBA, examination, subjective question marking, answer sheet scanning, answer sheet information identifying, identified-result revising and automatic marking and summarizing. The advantage is that the invention can mark the paper including both subjective questions and objective questions; the requirements to the operation technique and apparatus are low; the requirements to the paper-quality of the answer sheet, pens and printing are low and the checking is convenient.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

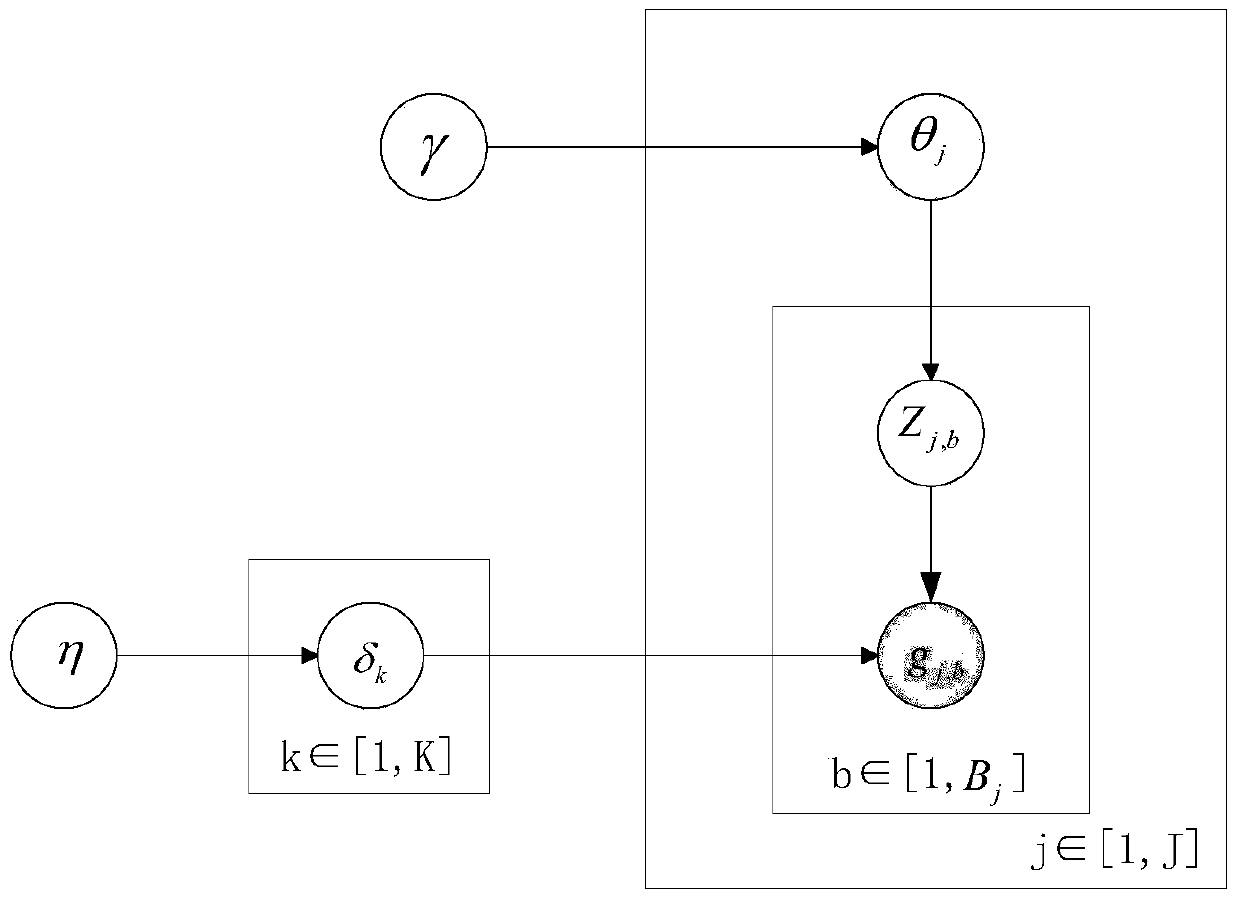

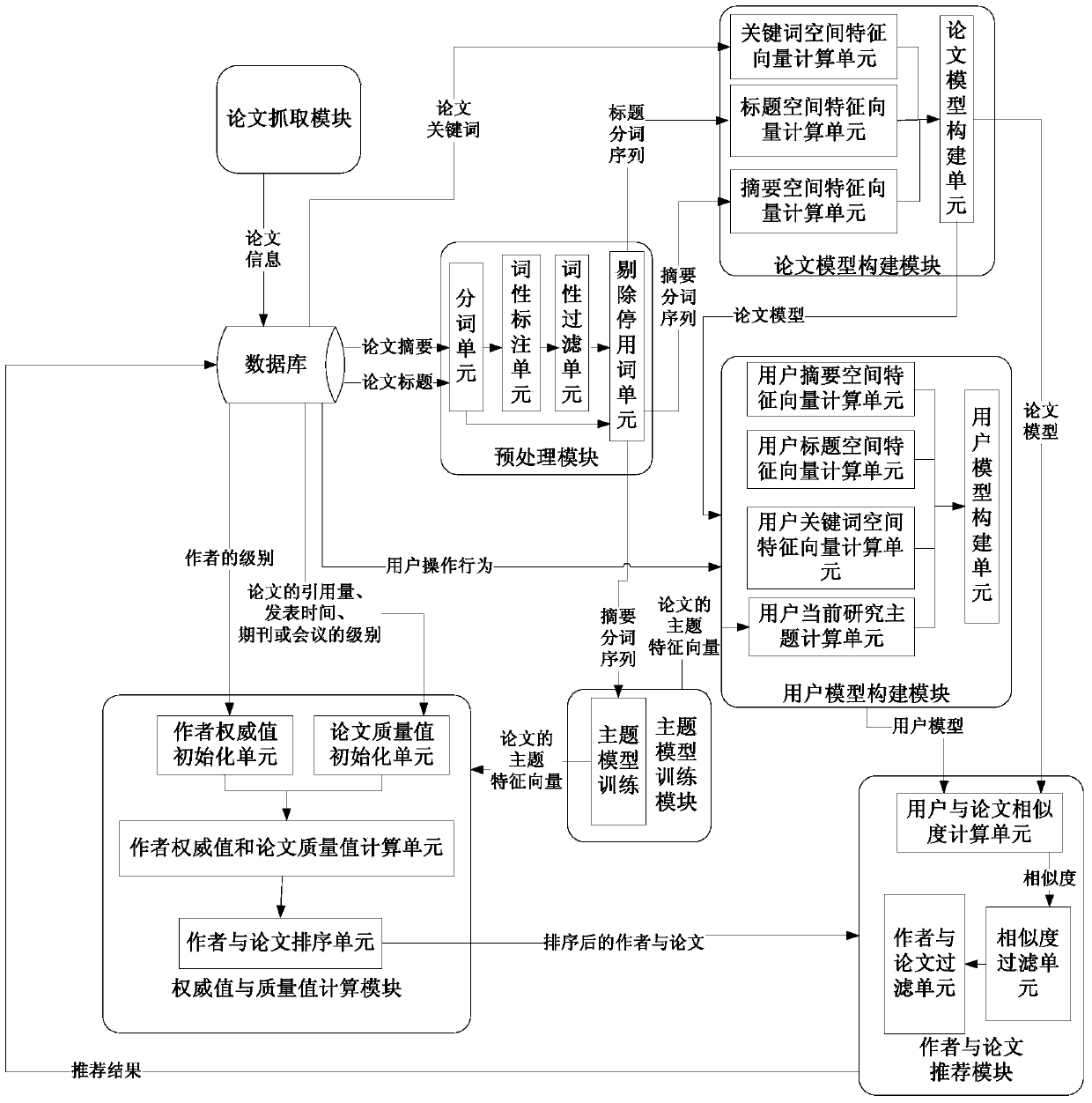

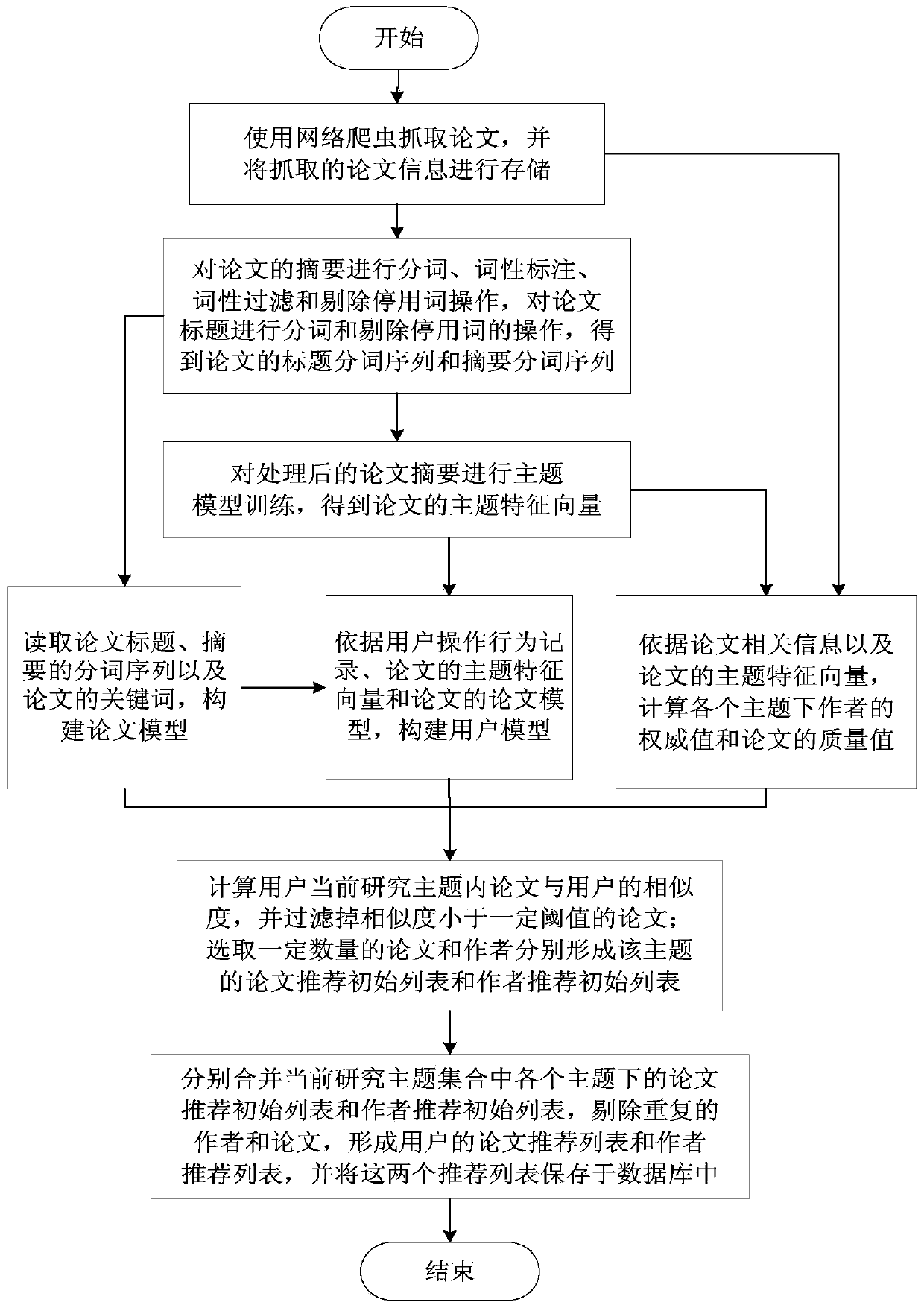

Authoritative author and high-quality paper recommending system and recommending method

ActiveCN103440329AThe initial value is reasonableImprove accuracySpecial data processing applicationsSubject matterField of view

The invention discloses an authoritative author and high-quality paper recommending system and recommending method. According to each preset theme, the recommending system calculates an author authoritative value and a paper quality paper through a plurality of factors including an author level, a citation rate, publish date and a publish periodical or a meeting level of a paper, and hereby recommends an authoritative author and a high-quality paper with the specified theme, so as to avoid authors with low authoritative values or papers with low quality values in an author or paper recommending list, and to reduce system calculation burden and improve system response time. The system and the method, on the basis of properties of academic papers, introduce relates algorithms after taking various factors affecting the author authoritative value and the paper high-quality value into comprehensive consideration, so as to improve accuracy of recommended results, which not only recommends high-quality papers to users but also remarkably shortens calculation time, and the system and the method are good in a real-time updating effect; furthermore, the system can enhance diversity of recommended results in the paper recommending list, and overcome a shortcoming of an existing system which is narrow in user view.

Owner:BEIJING UNIV OF POSTS & TELECOMM

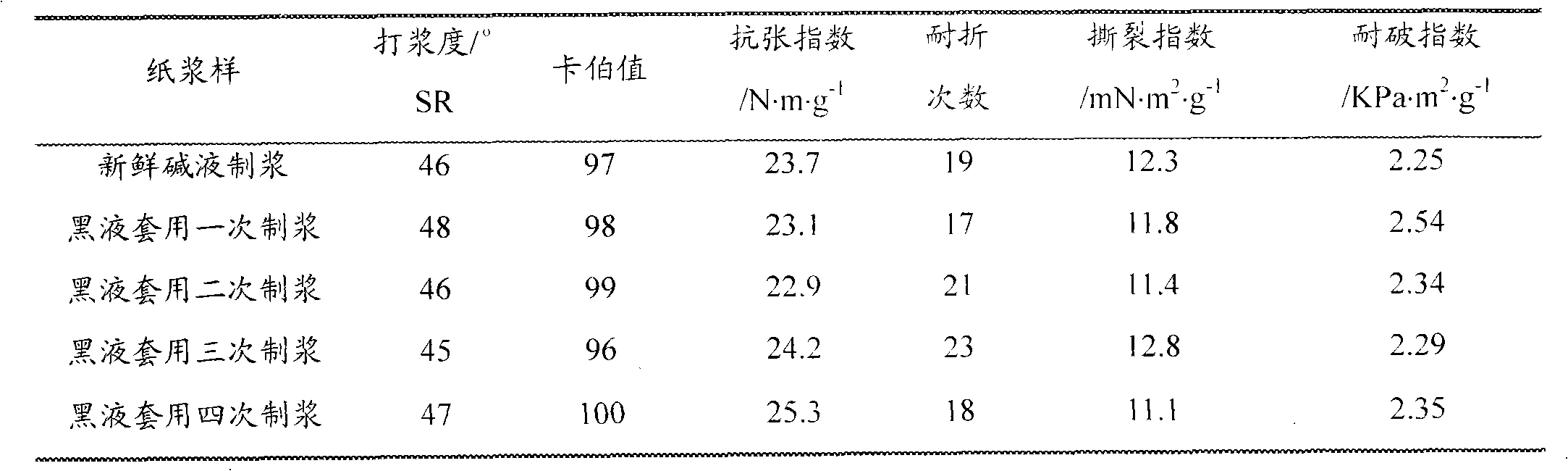

Enzymatic straw material pulping process

InactiveCN1421570AWell mixedChemical/chemomechanical pulpNon-woody plant/crop pulpLignin peroxidaseXylanase Y

The enzymatic straw material pulping process includes three stages of mechanical pre-treatment, enzyme treatment and chemical pulping or chemical-mechanical pulping. After being pretreated mechanically in a pulp grinder, the straw material is treated with hemicellulase liquid or mixed enzyme liquid comprising hemicellulase and lignin peroxidase at pH 3.5-6.5 and 40-60 deg.c for 1-10 hr. In chemical pulping, the material is presoaked with waste pulp-making liquor before extruding out wastes liquor and digested; and in chemical-mechanical pulping, the material is first treated with EDTA, NaOH and H2O2 at 40-80 deg.c for 30-120 min and then ground to form the pulp. The present invention is used in papermaking enterprises with straw as material and has the advantages of low pollution load, high, paper pulp quality, easy-to-process waste liquor, etc.

Owner:SHANDONG UNIV

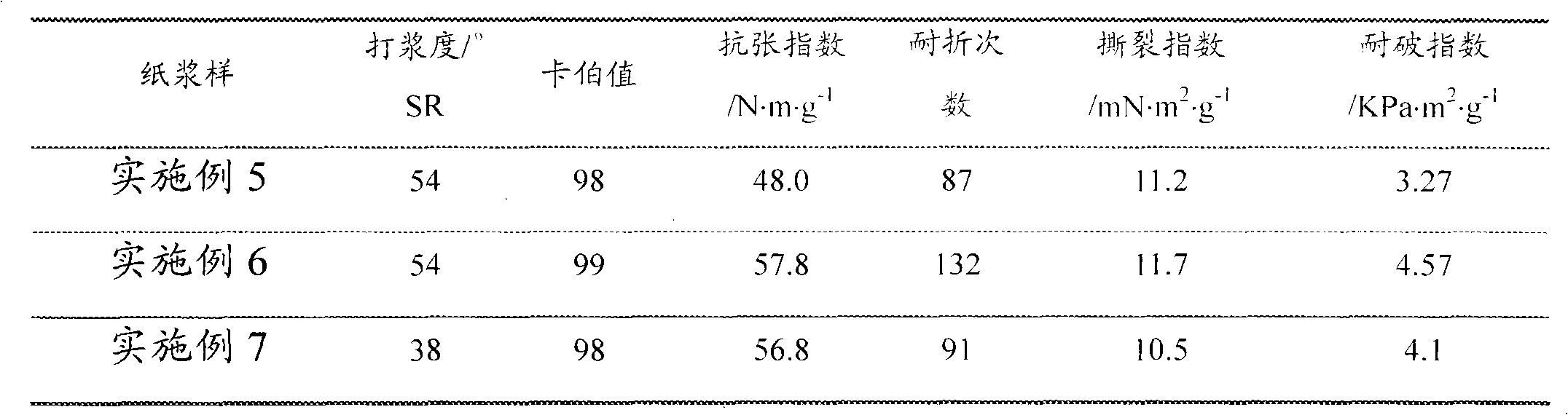

Novel pulping process for obtaining high performance fiber at high yield from plants

ActiveCN102337687AGood physical propertiesAvoid influencePulp beating methodsPulping with inorganic basesChemical treatmentFiber

The invention relates to a cleaning process for extracting high quality fiber with high efficiency, high yield and low energy consumption from plant raw materials by a combination method of chemistry and machinery in a sectional type. The process comprises the following steps: a raw material is fully immersed in a NaOH solution or a KOH solution or limewater with low concentration (black liquor is used for supplementing into the corresponding alkaline for repeated and circular use) under the normal temperature or certain temperature, wherein the concrete immersion temperature and immersion time can be determined according to the types and the water content of the raw materials so that the alkaline liquor is fully, uniformly and properly absorbed and diffused into plants; steaming under normal pressure or steaming with pressure or no liquid steaming with pressure is used; the steamed material can be selected according to the paper quality requirement by using a blowout slurrying mode or a mode of pulp refining after blowing to form slurry or by using thread rolling and pulp refining to relief material once or multitime to prepare slurry. The novel process combines the advantages of chemical treatment and mechanical pulping, so that the uniform mass transfer and uniform heat transfer can be ensured and the damage to cellulose and hemicellulose by excessive alkali can be reduced, the yield of fiber is raised to about 75% from about 45% of the prior art, so that the novel pulping process is capable of avoiding the usage of auxiliary agents like sulfured and anthraquinone, conveniently extracting and using the cellulose and lignin in black liquor, and overcoming the influence on environment during the process of pulping and post-treating lignin.

Owner:BEIJING INSIGHT BIOMASS

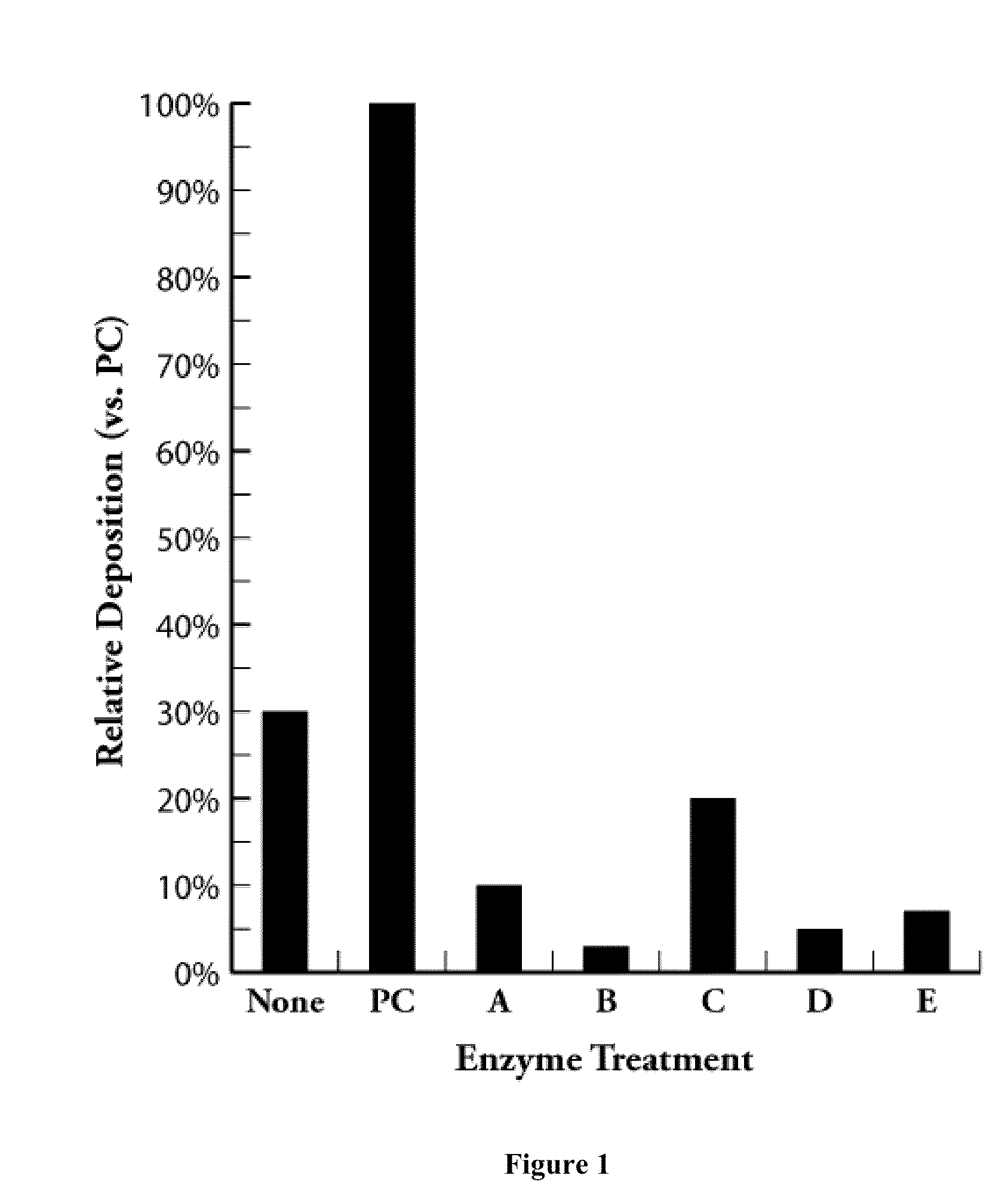

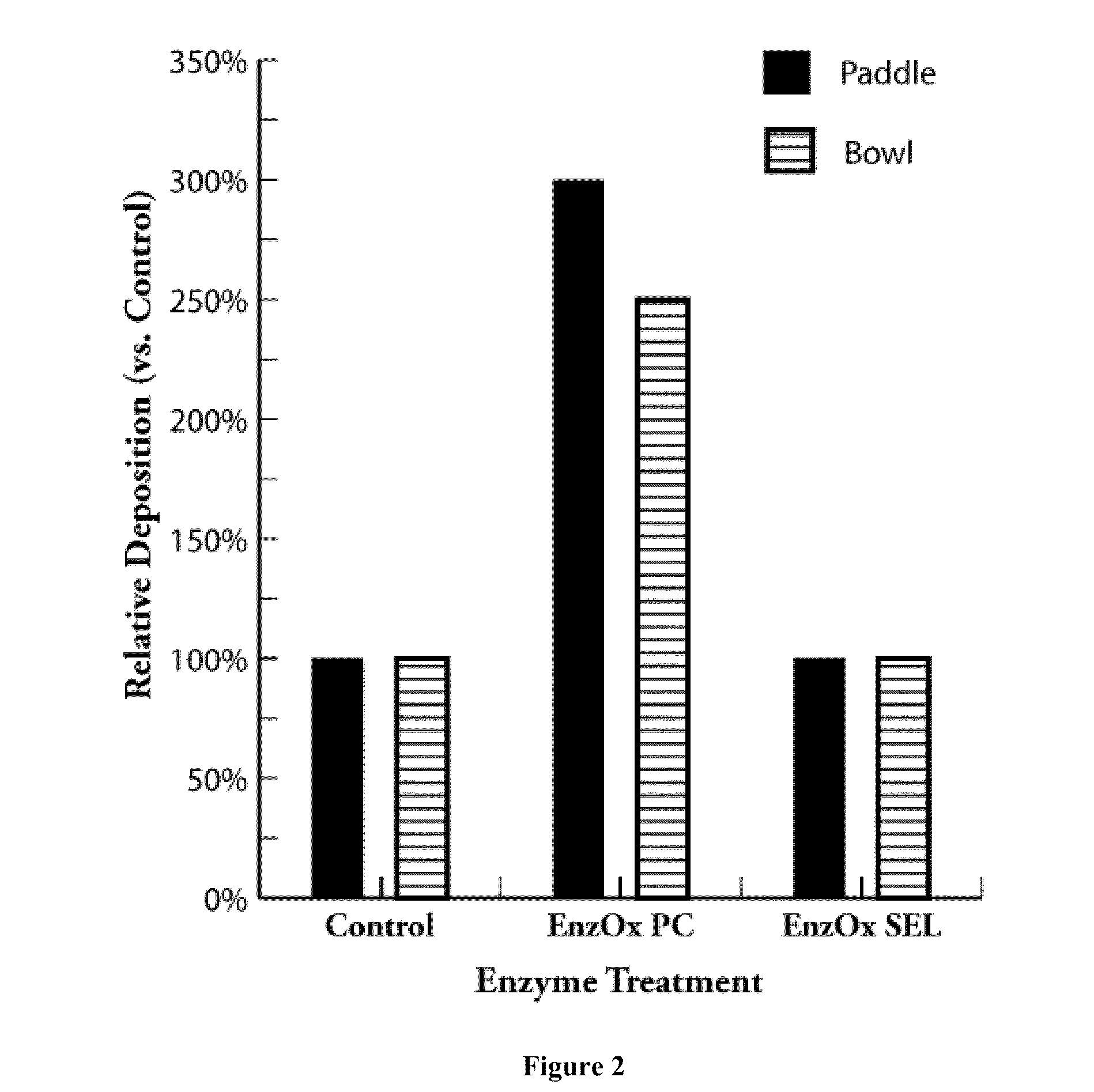

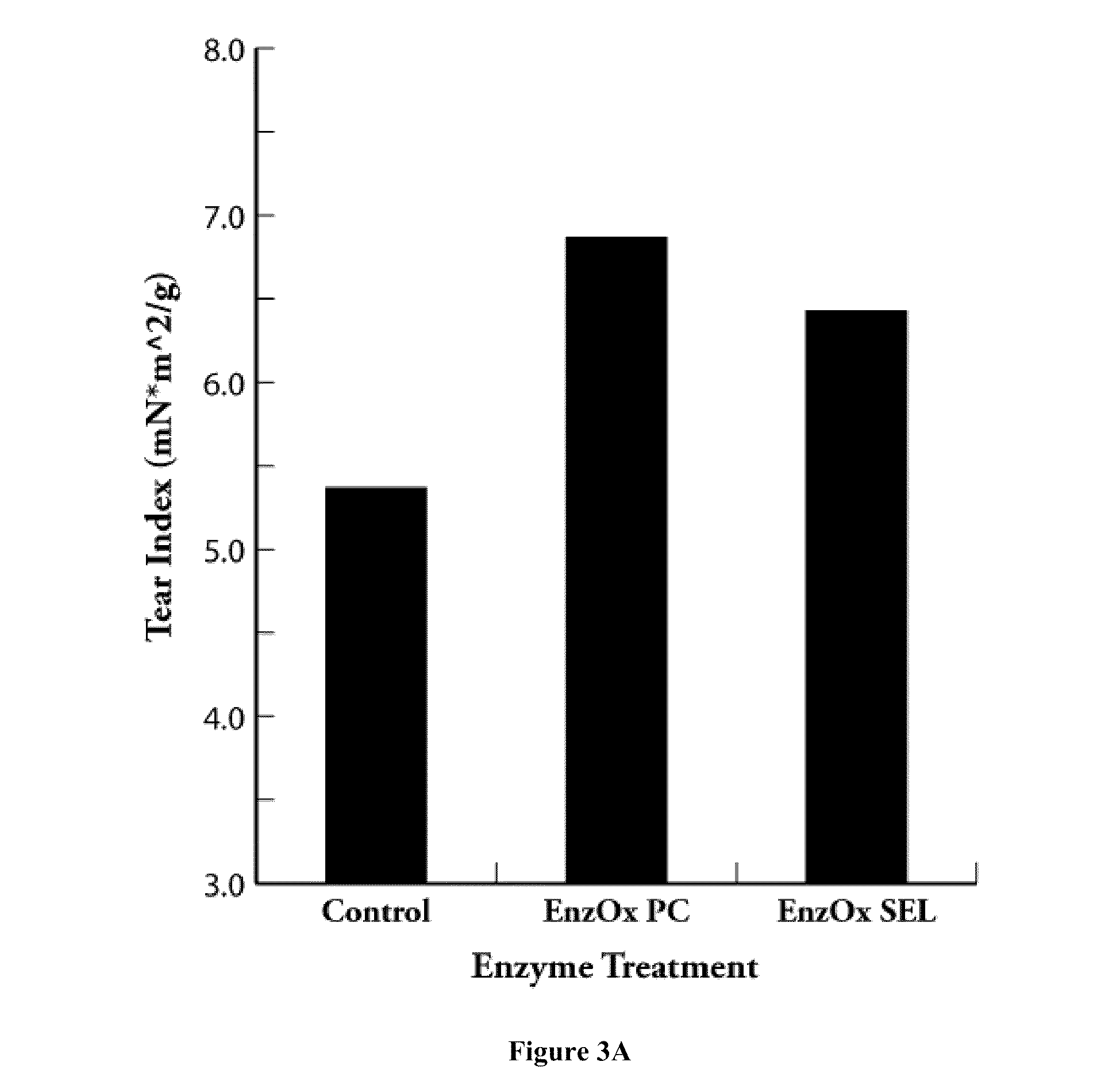

Use of 1,3-selective lipases for pitch control in pulp and paper processes

InactiveUS20100269989A1Reduce the amount requiredReduce concentrationNon-fibrous pulp additionFats/resins/pitch/waxes removal in pulpMonoglycerideSorbent

Formulations for pitch control, and methods of making and using thereof, are described herein. The formulations contains one or more 1,3-selective lipases. 1,3-selective lipases catalyze the hydrolysis of the terminal ester groups in triglycerides leaving the internal ester group intact. The enzyme formulations can contain one or more additives, such as dispersants, metal ions, absorbents, adsorbents, cationic polymers, and combinations thereof. The enzyme formulation is typically applied as a solution to the pulp stock. The enzyme formulations can be applied at any of one or more various points during the pulping and paper manufacturing processes. The use of selective lipase(s) decreases the total concentration of fatty acids in the system, and catalyzes the formation of monoglycerides, which are more effective at dispersing fatty acids than glycerol, the product of non-selective lipases, thereby improving pulp and paper machine runnability and pulp and paper quality.

Owner:ENZYMATIC DEINKING TECH LLC

Coating and coating used coated paper

ActiveCN103590282AHigh glossReduce the risk of bad printsDefoamers additionCoatings with pigmentsStrong acidsPaper sheet

The invention provides a coating used in the papermaking field. The coating contains nanometer microcrystalline cellulose, a pigment, a latex, an assistant and water, and the nanometer microcrystalline cellulose is highly-crystallized cellulose having a length of 100-500nm and a width of 3-100nm obtained by hydrolyzing a cellulose raw material in a strong acid; and the bone dry mass parts of the nanometer microcrystalline cellulose, the pigment, the latex, the assistant and water in the coating are 0.02-10, 75-95, 5-15 and 0.35-10 respectively. The invention also provides a coated paper made by using the coating. The coating is coated on the surface of paper to effectively improve the glossiness, the post-print glossiness and the roughness of the coated paper in order to improve the paper quality.

Owner:GOLD EAST PAPER JIANGSU

Method of controlling organic contaminants in pulp and paper making processes

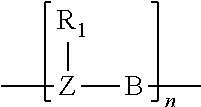

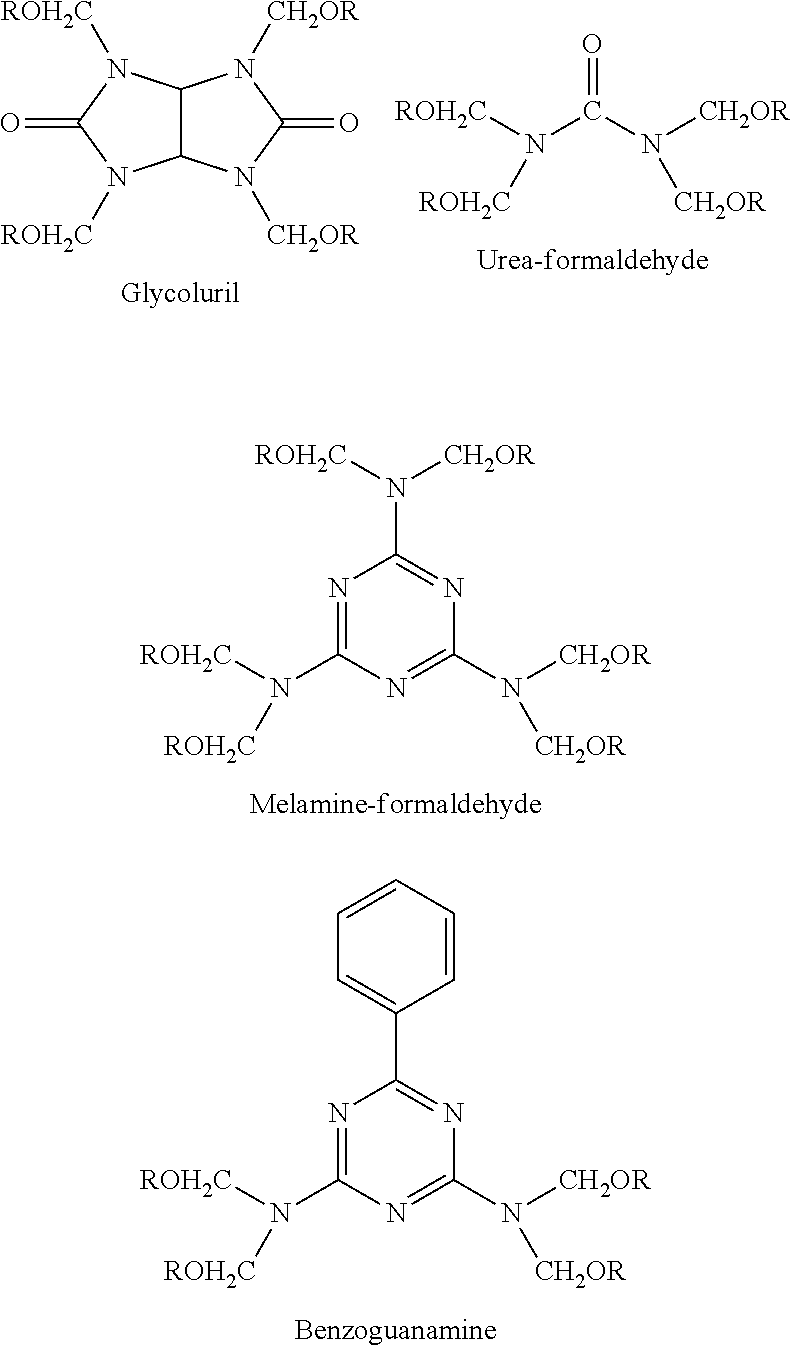

InactiveUS8048268B2Less hydrophobicLess tackyNon-fibrous pulp additionNatural cellulose pulp/paperEtherWater soluble

Method for controlling the deposition of organic contaminants from the pulp and papermaking systems using water soluble aminoplast ether copolymers is described herein. The aminoplast ether copolymer can be used alone or in combination with one or more additives. The pulps to be treated include mechanical, chemical, semi-chemical pulps; sulfide pulp; recycled old newspapers; mixed office wastes; corrugated boxes; and their combinations. The use of water soluble aminoplast ether copolymers to control or prevent pitch and stickies deposition improves down stream performance of papermaking equipment increasing mill efficiency and improving paper quality.

Owner:ENZYMATIC DEINKING TECH LLC

Film-transferring printing method

InactiveCN101148127AEffective peelingEfficient transferDecorative surface effectsPattern printingEngineeringPrinting ink

The film transfer printing process includes the following steps: 1. painting polyethylene terephthalate (PET) film with strippable layer of silica and methyl hydrazone acetaldehyde and in pH 7-8, solid content of 45+ / -2 % and proper viscosity; 2. printing graphic context on the PET film with intaglio printing or flexible plate printing ink; 3. painting water soluble glue of vinyl acetate-ethylene emulsion and in pH 8-10, solid content of 52+ / -2 % and proper viscosity; and 4. compounding the PET film to paper material and stripping to transfer the printed graphic context onto the paper material. The present invention can strip and transfer the printed ink layer effectively to obtain printed matter with strong metal texture in less influence of the paper quality on the printed matter quality.

Owner:SHENZHEN JINJIA GRP

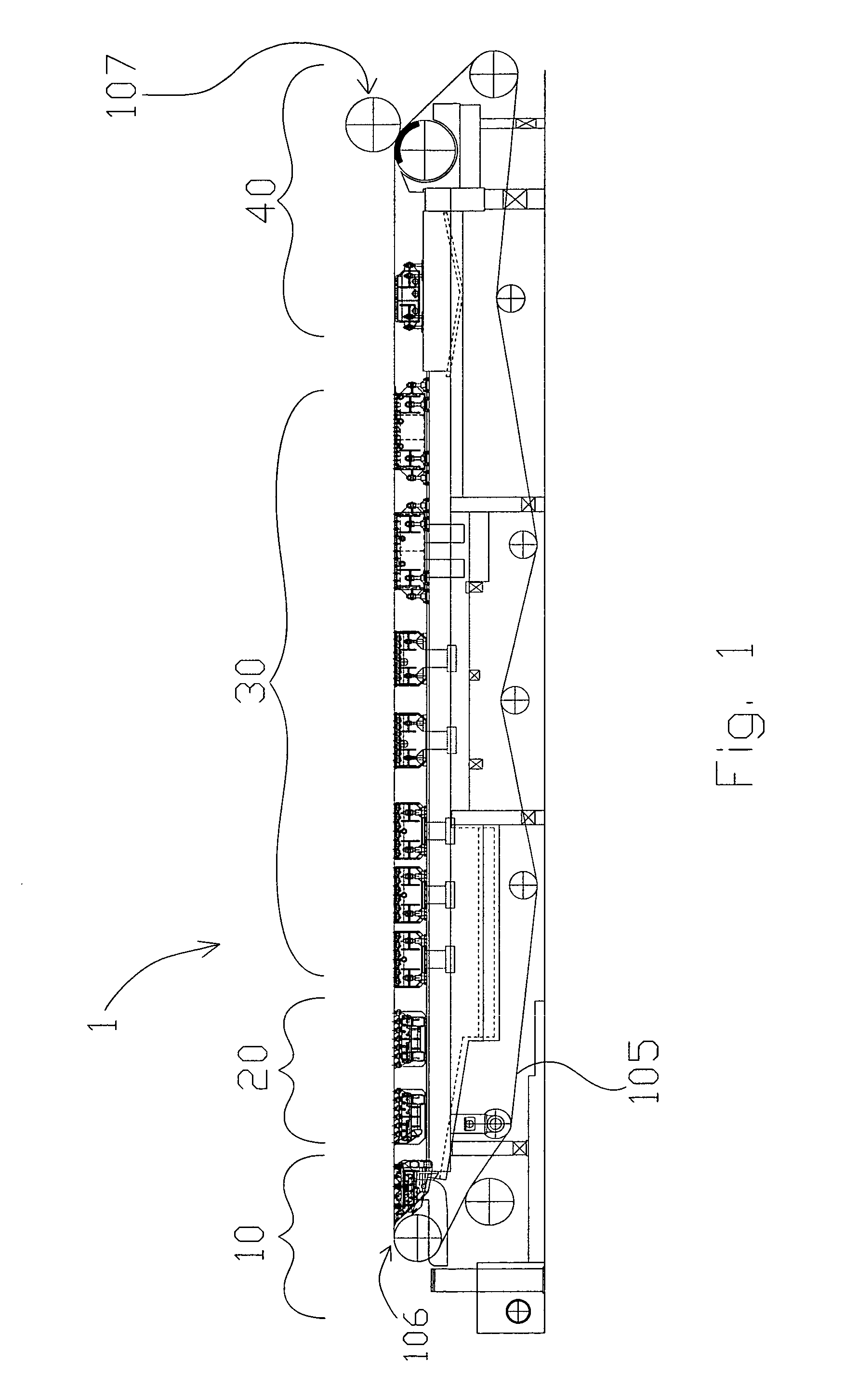

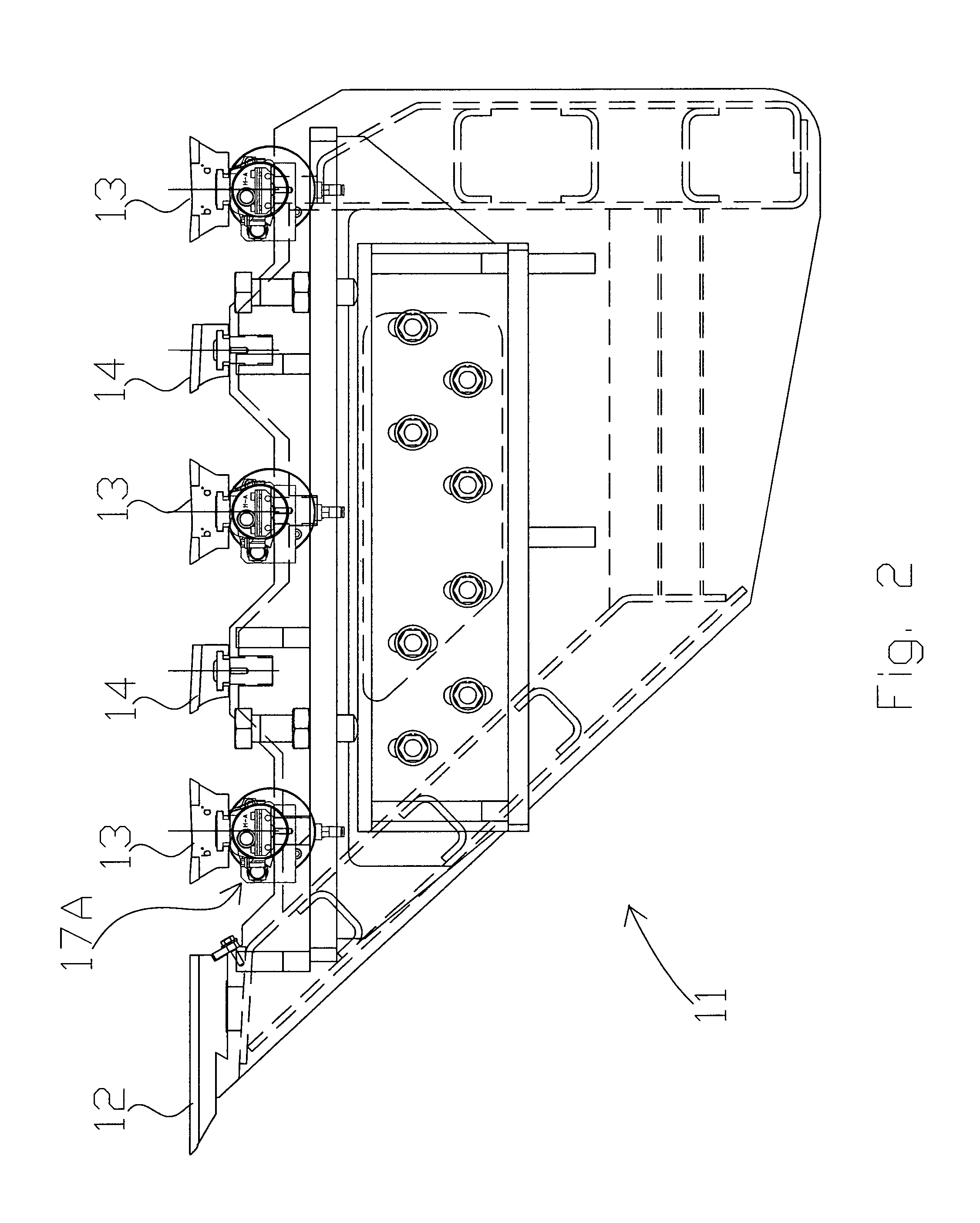

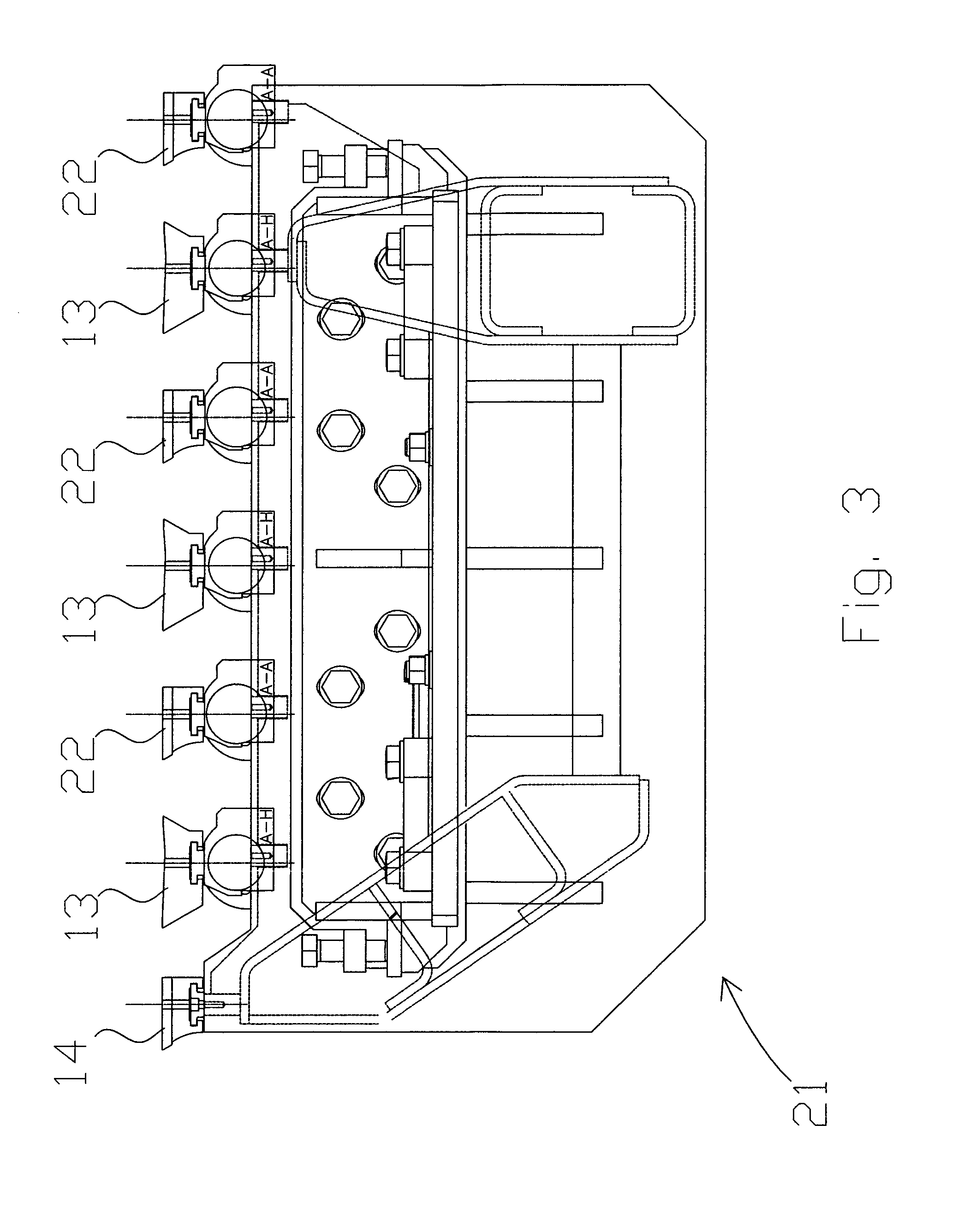

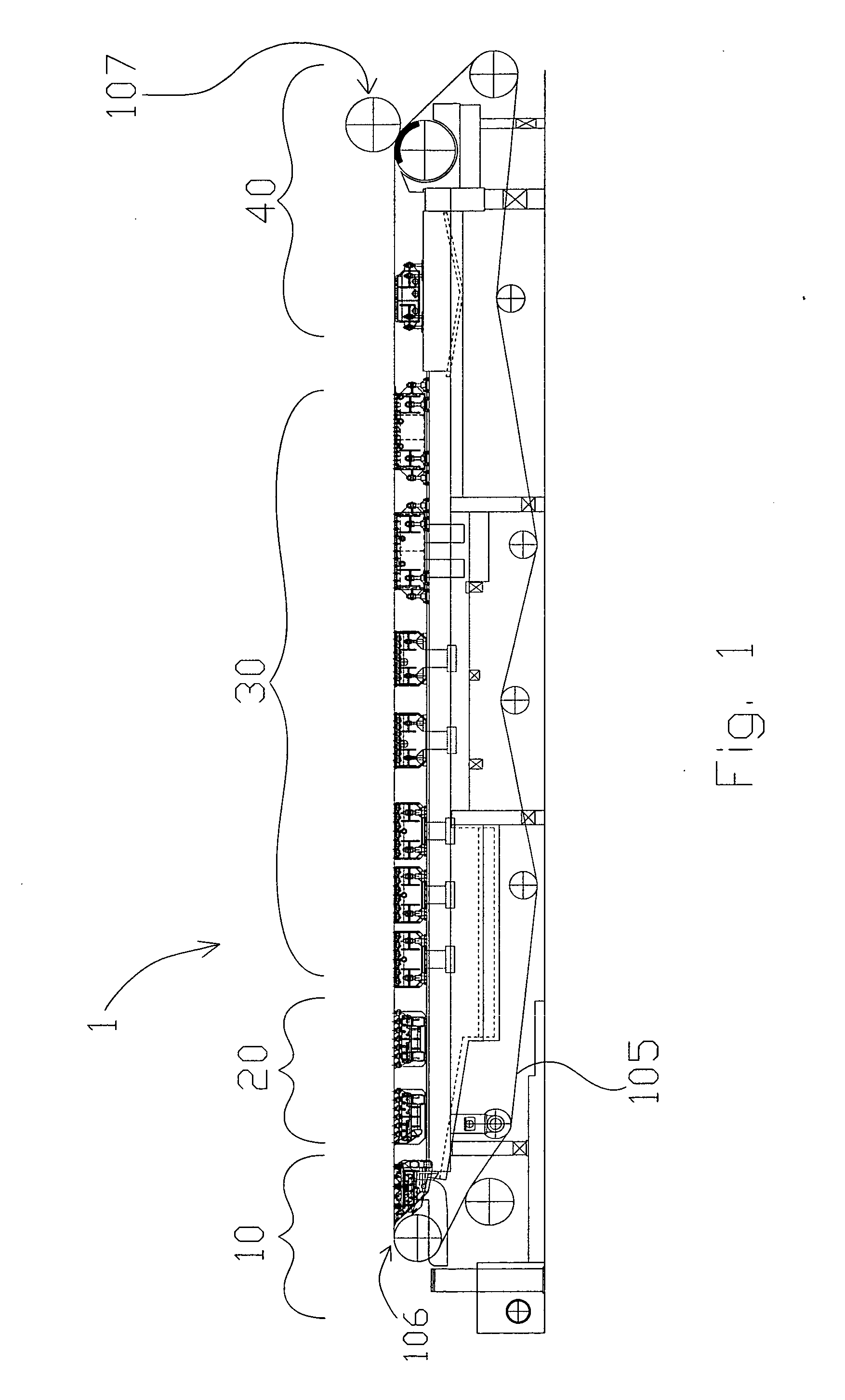

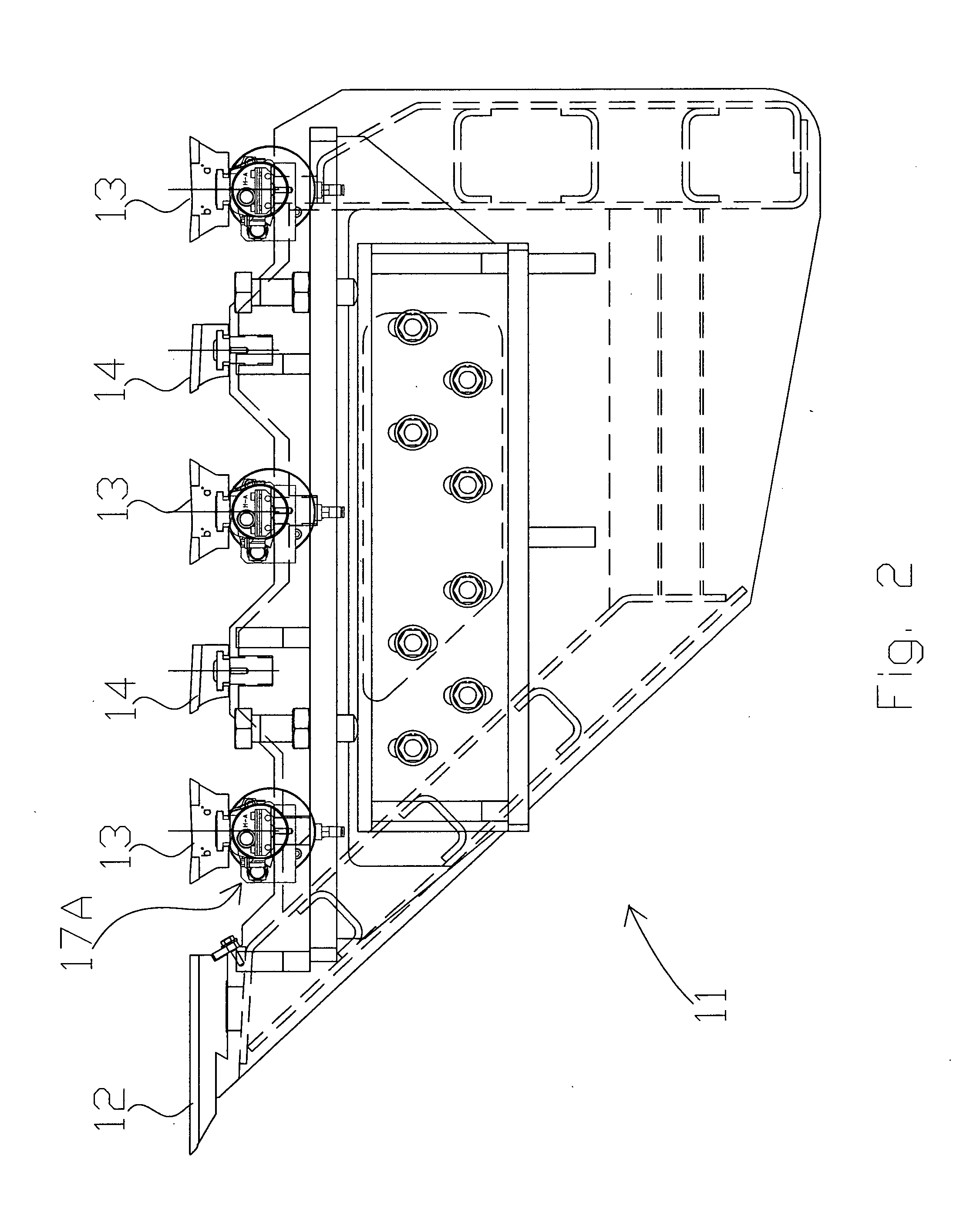

Method and machine for manufacturing paper products using Fourdrinier forming

An improved method for producing paper from pulp includes a plurality of subassemblies arranged in the forming or wet section of a Fourdrinier. The Fourdrinier includes a dewatering table having a plurality of blades that are static and on-the run adjustable in height and / or angle to control orientation of paper fibers in the stock to create a superior quality of paper and improved paper strength characteristics. Gravity and vacuum assisted drainage elements are equipped with on-the-run adjustable angle and height dewatering foil blades starting from a paper dryness of 0.1% and extending all the way to 5% dryness. The result of this process and machine is to improve the paper quality, save fibers and chemicals and fulfill the required paper properties.

Owner:IBS OF AMERICA

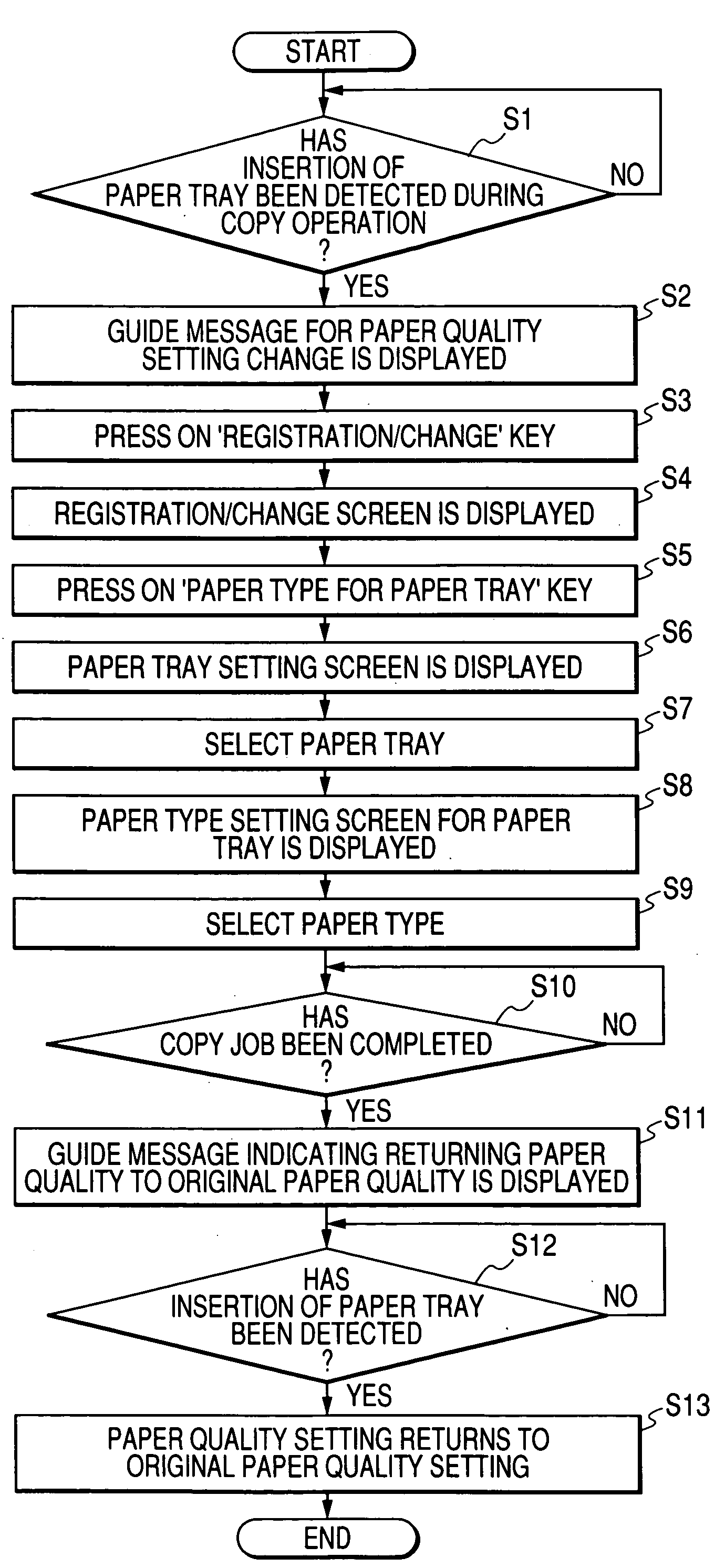

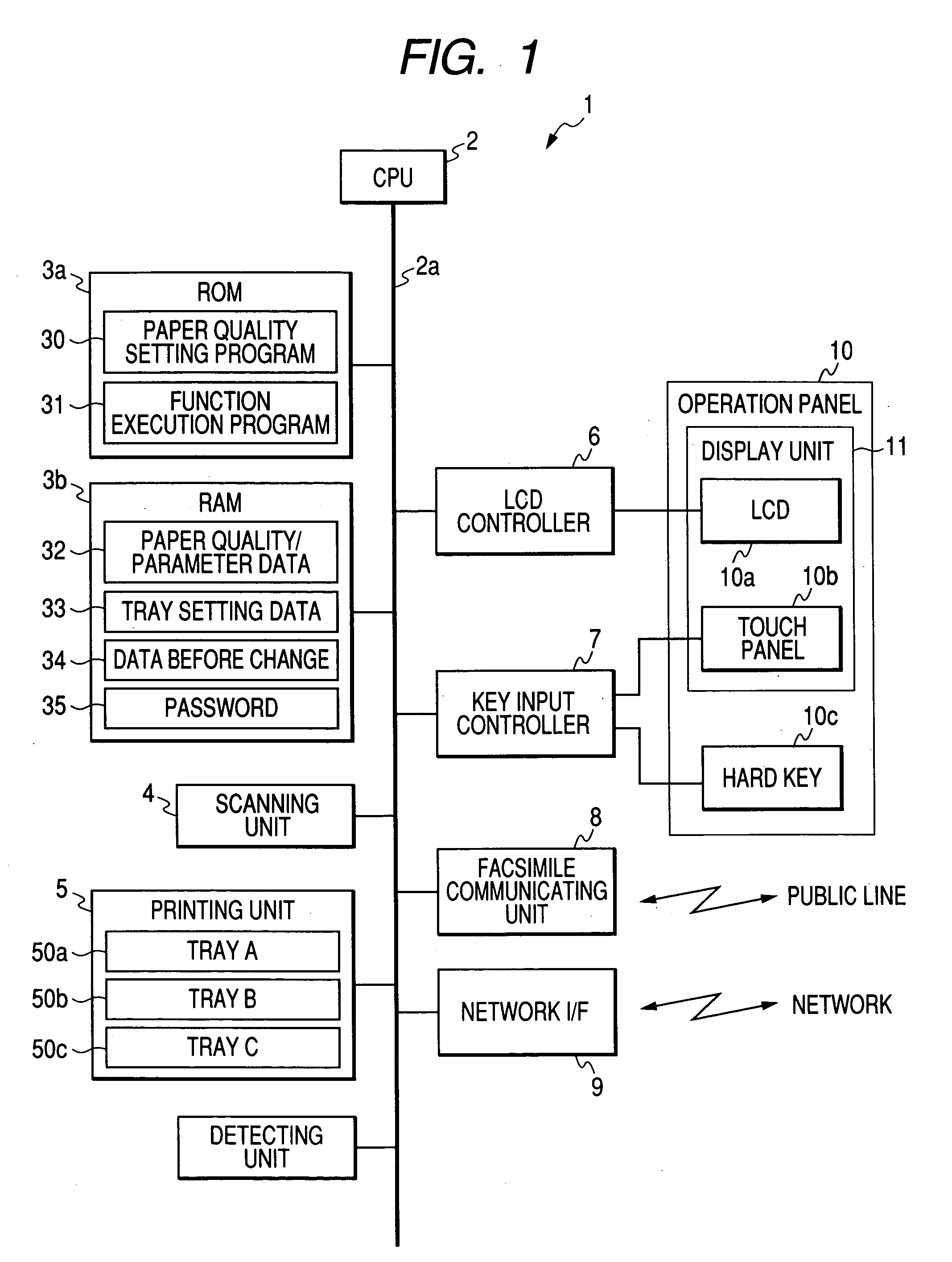

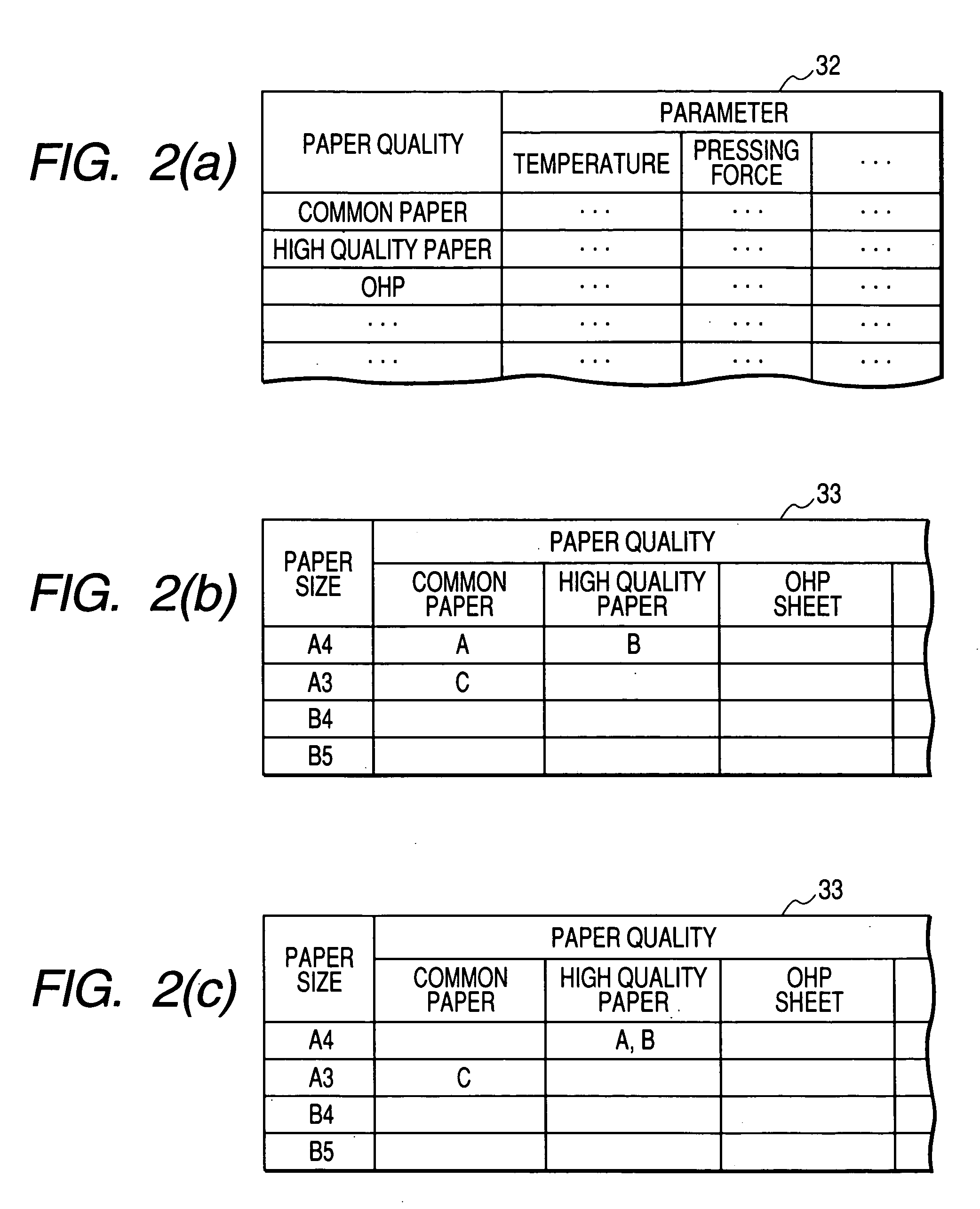

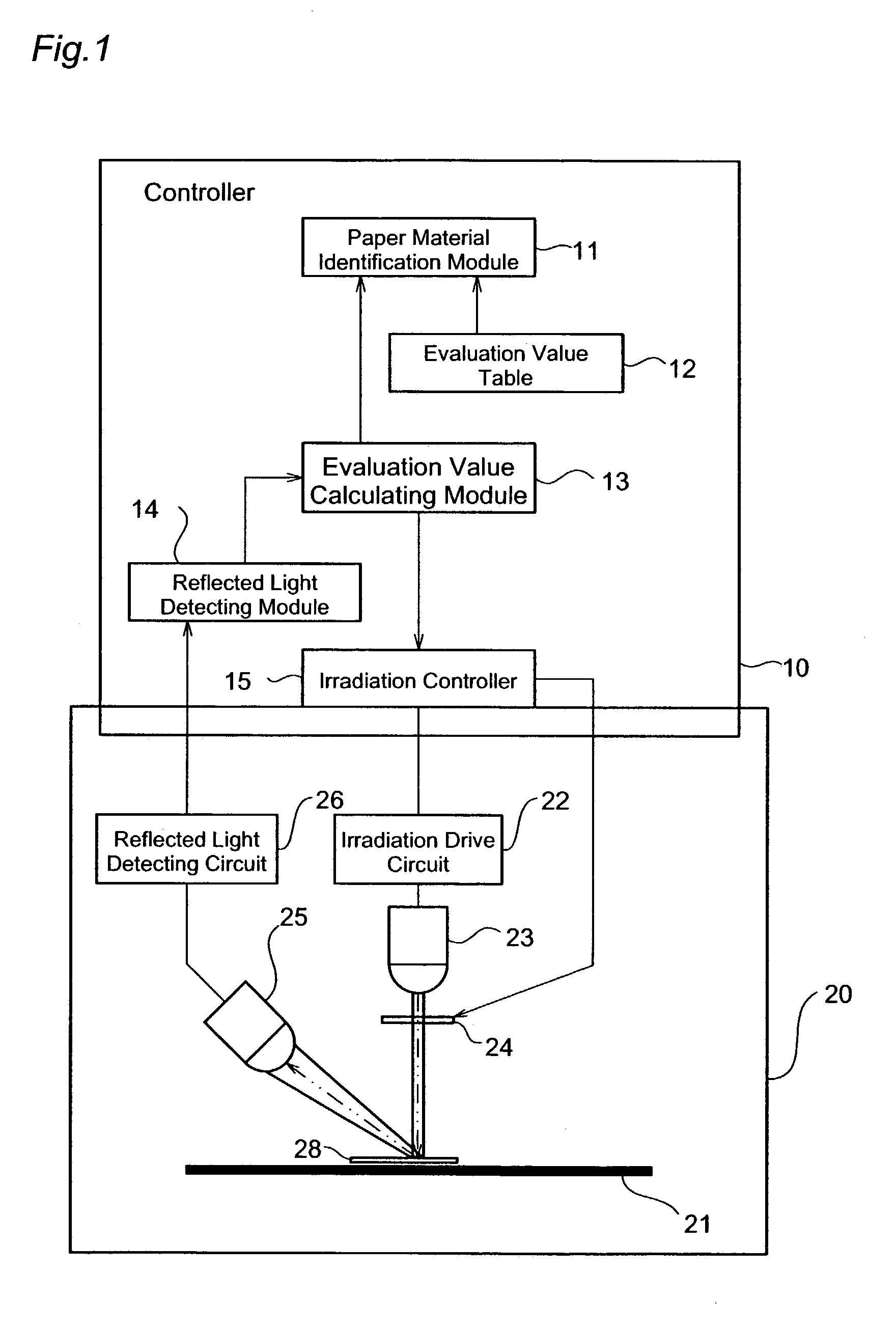

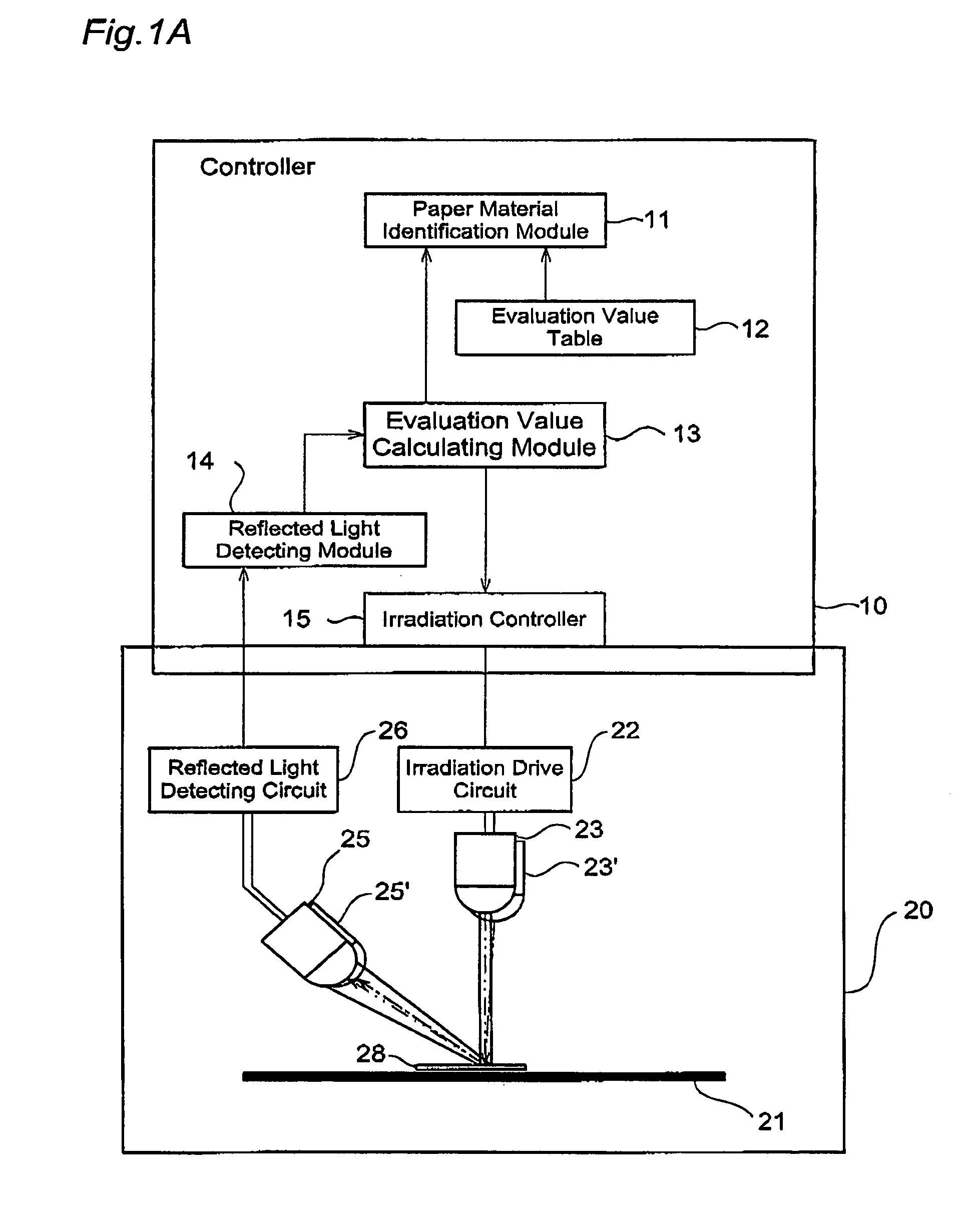

Image forming apparatus

InactiveUS20050213996A1Avoid troubleElectrographic process apparatusOther printing apparatusImage formationPulp and paper industry

In an image forming apparatus, when a general user pulls a paper tray out of the image forming apparatus, changes used paper with another paper having different paper quality to insert the paper tray into the image forming apparatus and operates a touch panel to change the paper quality setting, a CPU stores paper quality data before change in a RAM. The CPU returns the paper quality setting to the paper quality setting before change when a printing job is completed on the paper after paper quality change.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Wet-strength waste paper pulping method

ActiveCN103835174AAccelerate run upImprove permeabilityPaper recyclingWaste paper working-upFiberPapermaking

The invention discloses a wet-strength waste paper pulping method. The pulping method comprises the following steps: putting wet-strength waste paper in water and evenly mixing to obtain waste paper pulp; adjusting the pH value of the waste paper pulp to 3-10 and adding a biological enzyme for enzymolysis to obtain enzymatically degraded pulp, wherein the addition amount of the biological enzyme is 0.05-20kg per ton of wet-strength waste paper, the temperature of enzymolysis is 20-80 DEG C and the time of enzymolysis is 2-600 minutes; and pulping the enzymatically degraded pulp in a pulper to obtain paper pulp. According to the method, a wet-strength agent is selectively degraded by the biological enzyme, so that the combination between the wet-strength agent and fibers is destroyed, the moistening of the fibers is accelerated, and the pulping efficiency and the yield of fibers are enhanced; the pulping method is environmental friendly and safe since only biological enzyme needs to be added; all waste water during production can be recycled, and is not discharged to external, so that no environment pollution is caused; with the paper pulp produced by the method, the paper quality and the papermaking efficiency can be remarkably enhanced.

Owner:RISINGSTAR BIOTECH GUANGZHOU

Low-specific-gravity stone paper

ActiveCN102154932AIncrease coverageReduce weightCoatings with pigmentsCoated paper substrateManufacturing cost reductionGlass ball

The invention discloses low-specific-gravity stone paper relating to synthetic paper. The low-specific-gravity stone paper comprises a base paper layer and a coating layer, wherein the coating layer is coated on the base paper layer; the base paper layer comprises 15-30 parts by weight of synthetic resin and 70-85 parts by weight of mixing material, wherein the synthetic resin is polylactic acid, EVA (ethylene vinyl acetate copolymer), PP (polypropylene), PE (poly ehtylene) or a mixture of any two of the polylactic acid, the EVA, the PP and the PE; the mixing material is a hollow glass ball, coal ash or the mixture of the hollow glass ball and the coal ash; and the coating layer comprises 20-40 parts by weight of acrylic resin, 20-40 parts by weight of lithopone and 30-50 parts by weight of deionized water. The low-specific-gravity stone paper has the following benefits: the mixing material is the hollow glass ball or coal ash so that the mixing material has low specific gravity and good dispersity; the lithopone has good covering power, thus the weight of the paper is convenient to reduce, the paper quality is improved, and the manufacturing cost is reduced.

Owner:大正新型材料(肇庆)有限公司

Elaborate brown paper and producing method thereof

InactiveCN101100829AImprove physical strengthGood lookingPulp bleachingChemical/chemomechanical pulpFiberSulfate

The invention relates to elaborate works brown paper and its manufacturing method. It includes the following steps: using more than 60% masson pine, less than 15% cedar, less than 40% various broadleaf wood as material; steam boiling; washing screening; oxidizing delignify; bleaching to form sulfate micro drift wood pulp of which slurry brightness is 24-34%; pulping concentration is 3.5-4.0%; pumping degree is 26-34 degree SR; green weight is 10-15g; de-sanding; fixing; fine screening; forming; pressing; drying; coiling; recoiling; packing. The invention has the advantages of wide material source, low cost, satisfying the demands for cleaning production and food base paper quality.

Owner:YONGZHOU XIANGJIANG PAPER CO LTD

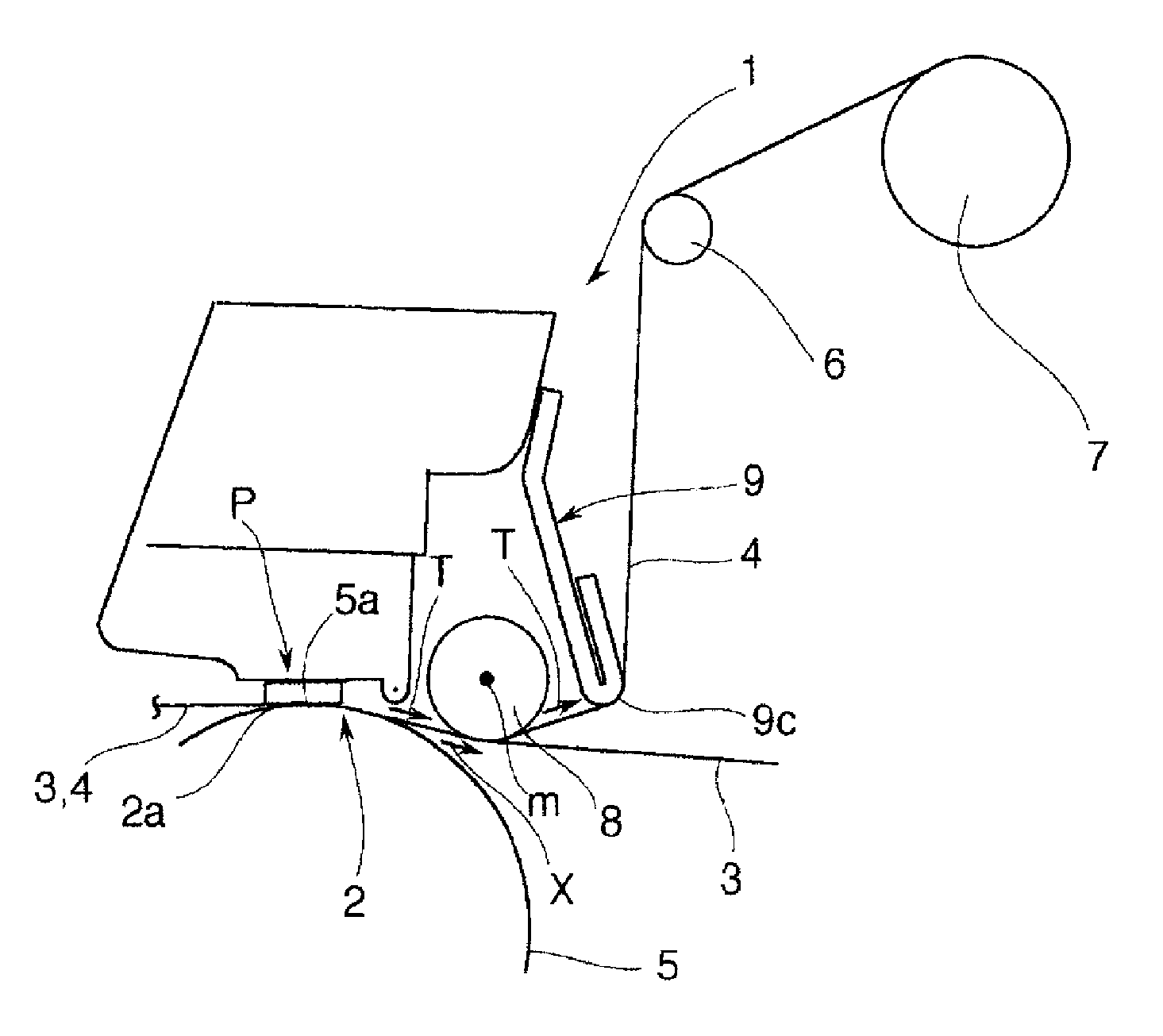

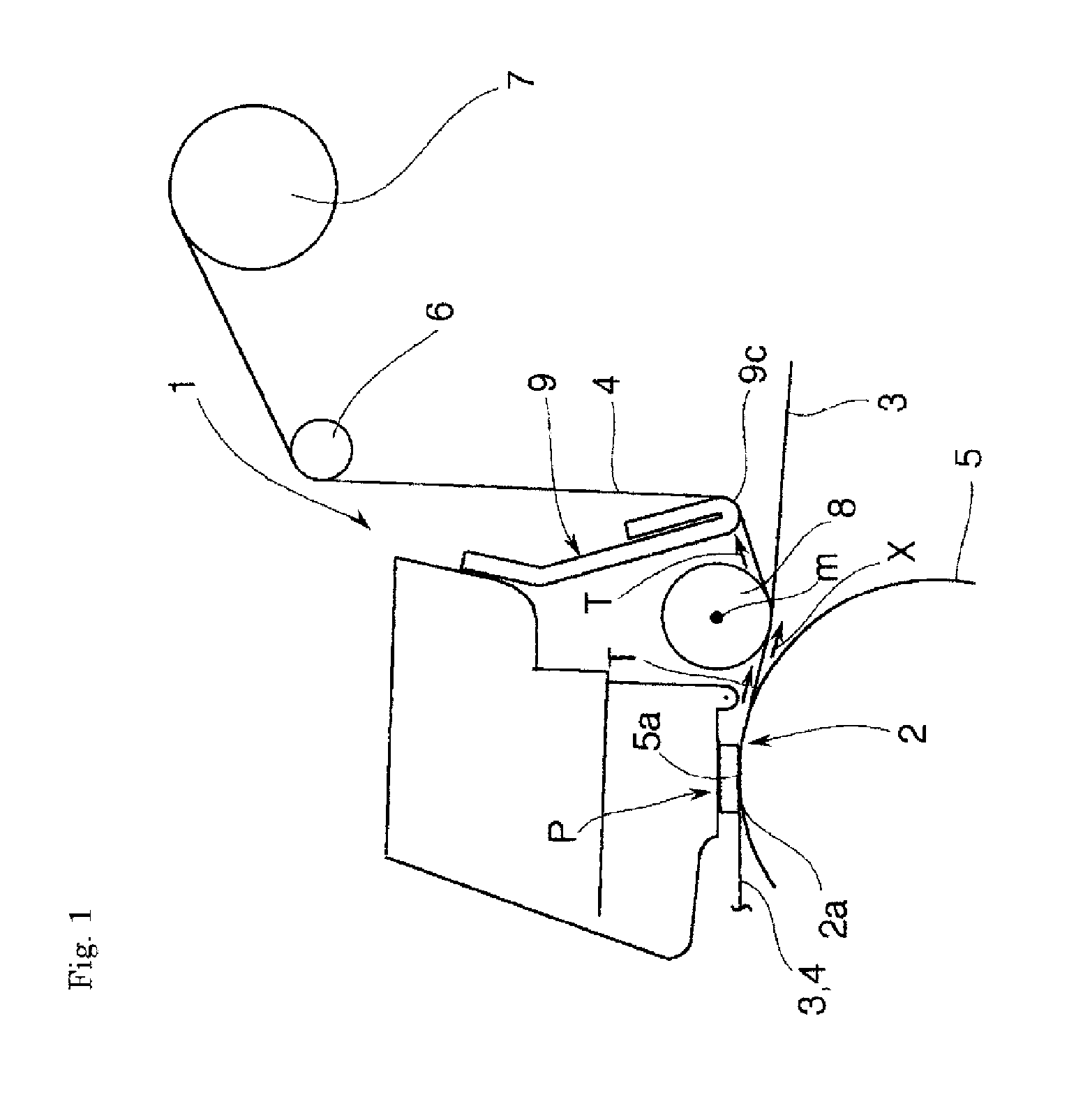

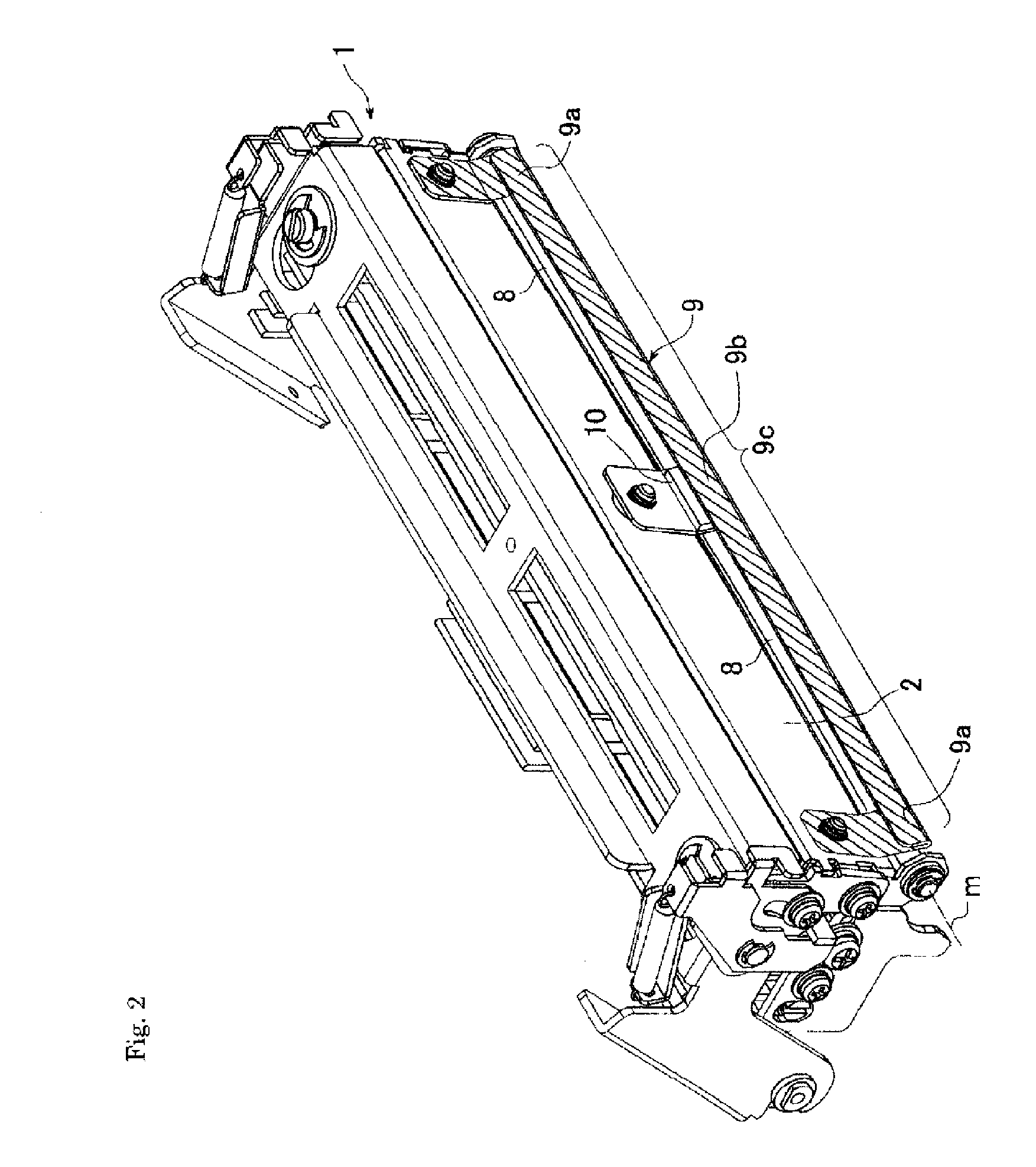

Thermal transfer printer

InactiveUS20090309949A1Eliminate lowered quality of paperMinimize occurrenceRecording apparatusPrinting mechanismsWrinkle skinHeat sensitive

A thermal transfer printer includes: a pealing roller which is disposed downstream of a printing position set between a thermal head and a platen roller and defines a peeling start position of an ink ribbon; and a tension plate which is disposed on a further downstream side than the peeling roller and slidably stretches the ink ribbon under a tension relative to the printing position, via the peeling roller. With a back tension being ensured by means of the tension plate to prevent slackness of the ink ribbon, the peeling roller performs peeling, thereby avoiding retention of dust or the like and the lowered quality of paper due to such retention. In this manner, problems such as wrinkles occurring with the ink ribbon are eliminated without damaging paper, and further, improvement of printing quality is compatible with that of paper quality, through a design based upon a mechanism concerning the occurrence of wrinkles.

Owner:SINFONIA TECHNOLOGY CO LTD

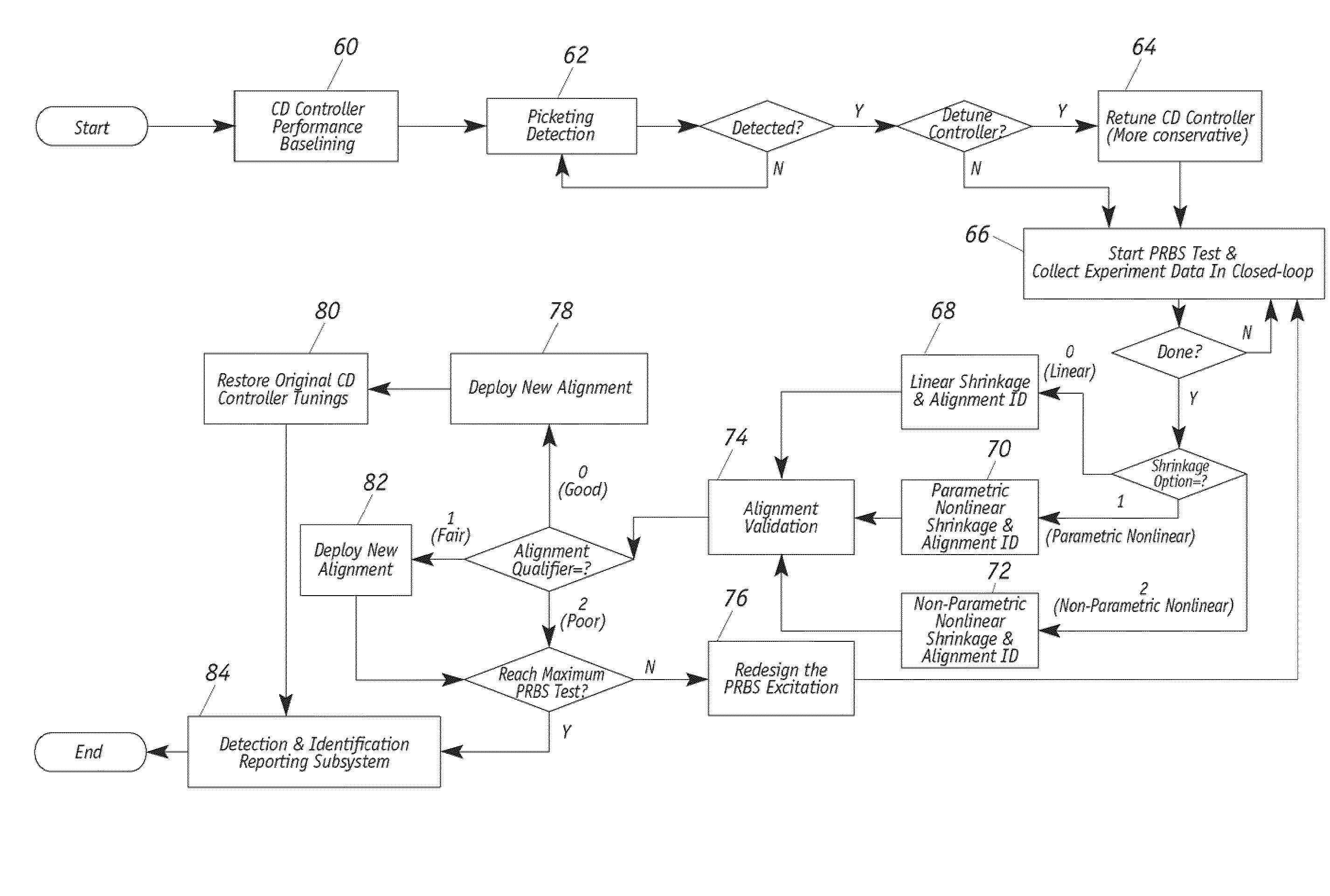

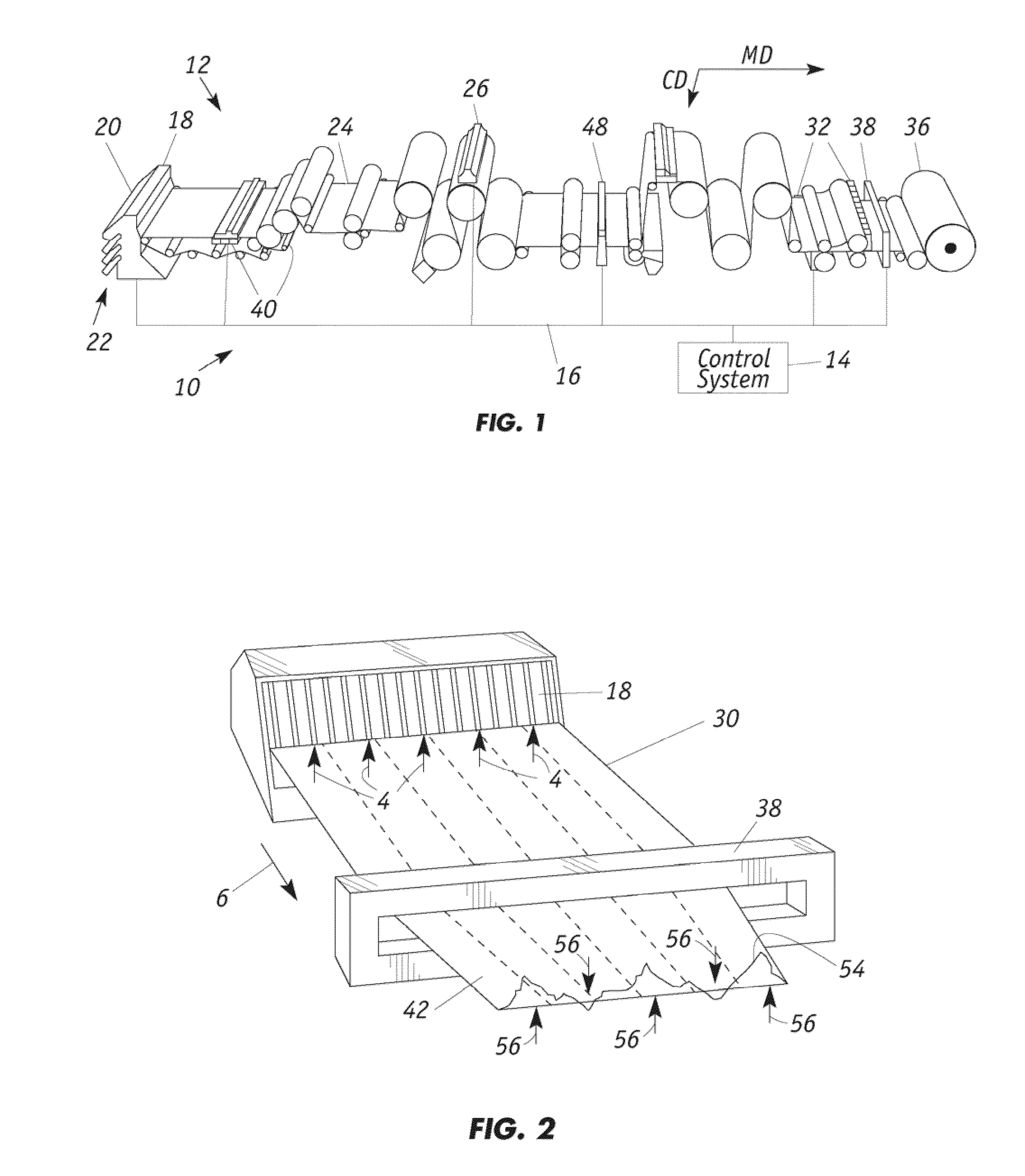

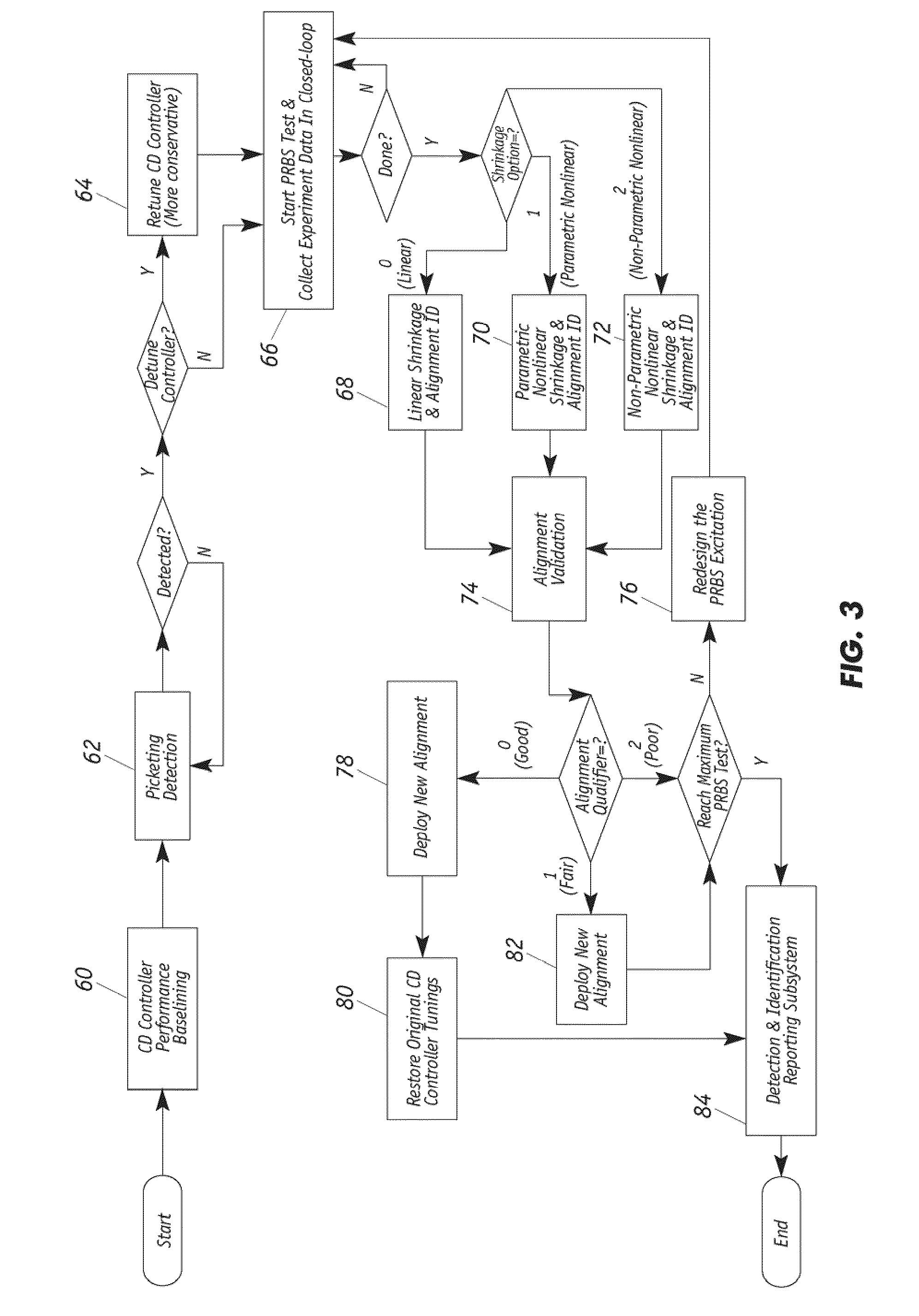

Closed-loop monitoring and identification of CD alignment for papermaking processes

ActiveUS8224476B2Improve robustnessAvoid detectionDigital differential analysersPaper-making machinesControl engineeringPapermaking

Owner:HONEYWELL ASCA INC

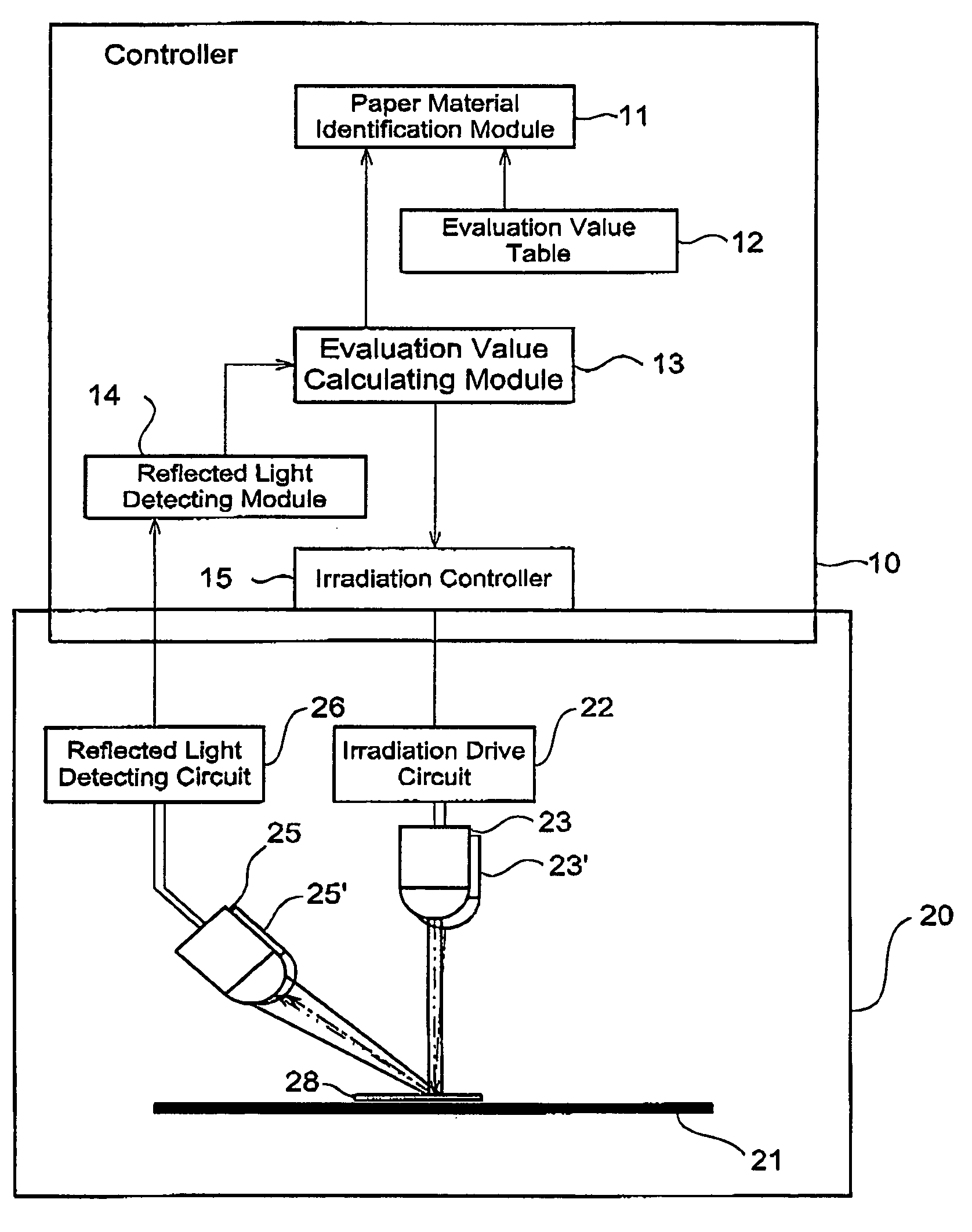

Paper quality discriminating machine

InactiveUS7167247B2Reduce the impactRecognition stabilityNon-fibrous pulp additionPaper-money testing devicesPulp and paper industryLength wave

The technique of the present invention enhances the stability of paper material identification of sheets. To achieve the above purpose, both short-wavelength light in the range of 370 nm and long-wavelength light in the range of 420 to 1000 nm are irradiated to paper to be identified in identifying the paper material. The identification is carried out, based on the difference in absorbance of the paper, which is obtained for each irradiated light. The absorbance of the paper varies according to the paper material, thereby enabling the identification of the paper material free from influence, which are caused by differences in manufacturing process, such as shading patterns. In addition, the simultaneous use of the short-wavelength light and the long-wavelength light declines influence on the absorbance, which are caused by environmental factors, such as humidity and deterioration of sheets, thereby resulting in stable identification of the paper material.

Owner:HITACHI OMRON TERMINAL SOLUTIONS CORP

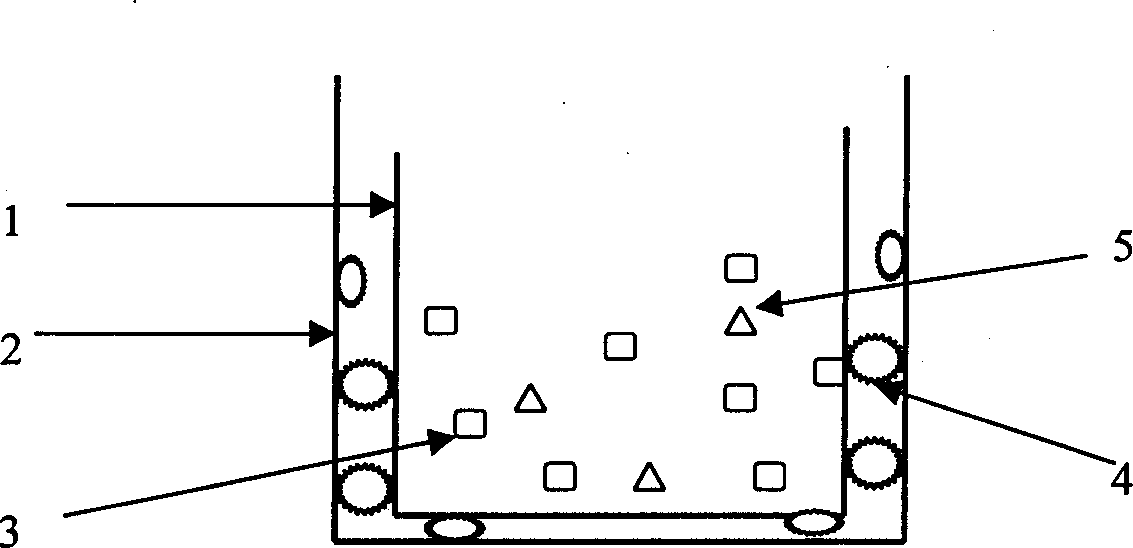

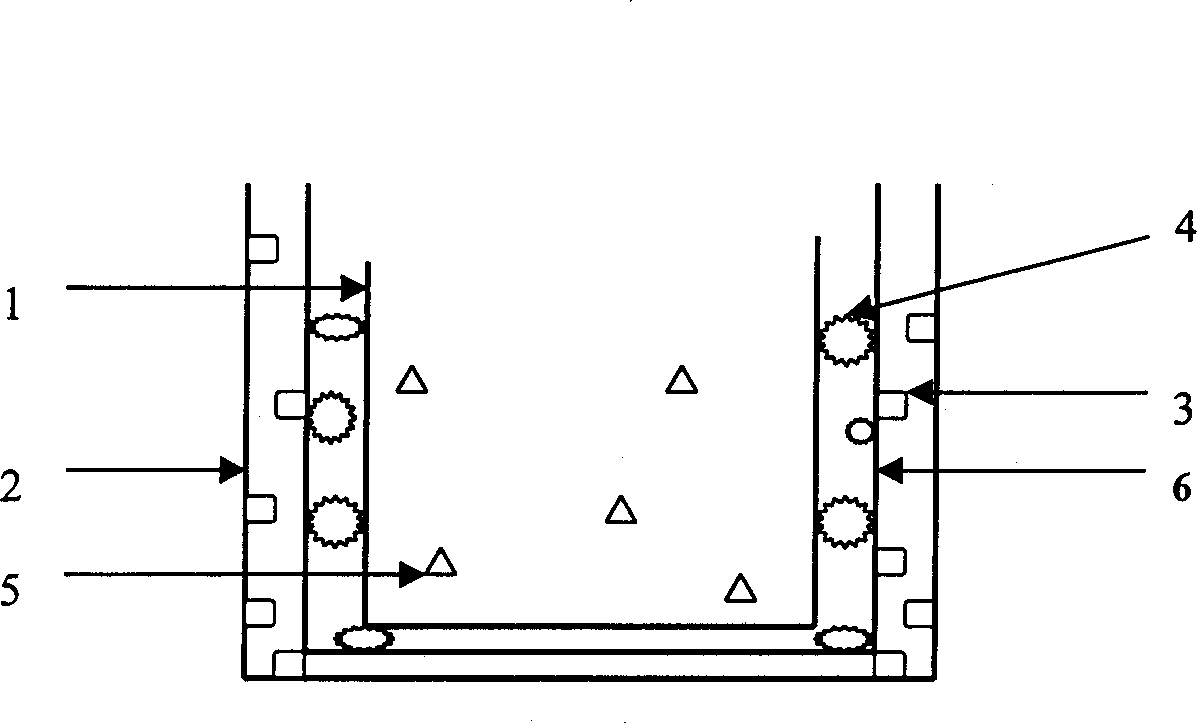

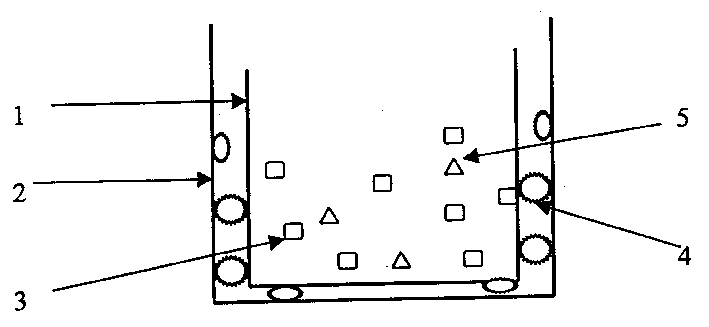

Water-saving seedling-nourishing water-retaining paper bag

InactiveCN1375186ASimple structureNo pollutionRoot feedersCultivating equipmentsGrowth plantWater saving

The invention provides an environmental paper bag applied to planting economic fruit trees and afforestation in drought and quasi-drought regions. It is characterized by that paper quality bags are adopted; water sucking resin is between internal bag and external bag; slow releasing nutrition 3 is between internal bag and the outside layer of multi-layer bag; plant growth regulator is within internal bag.

Owner:江苏纵横科技实业有限公司

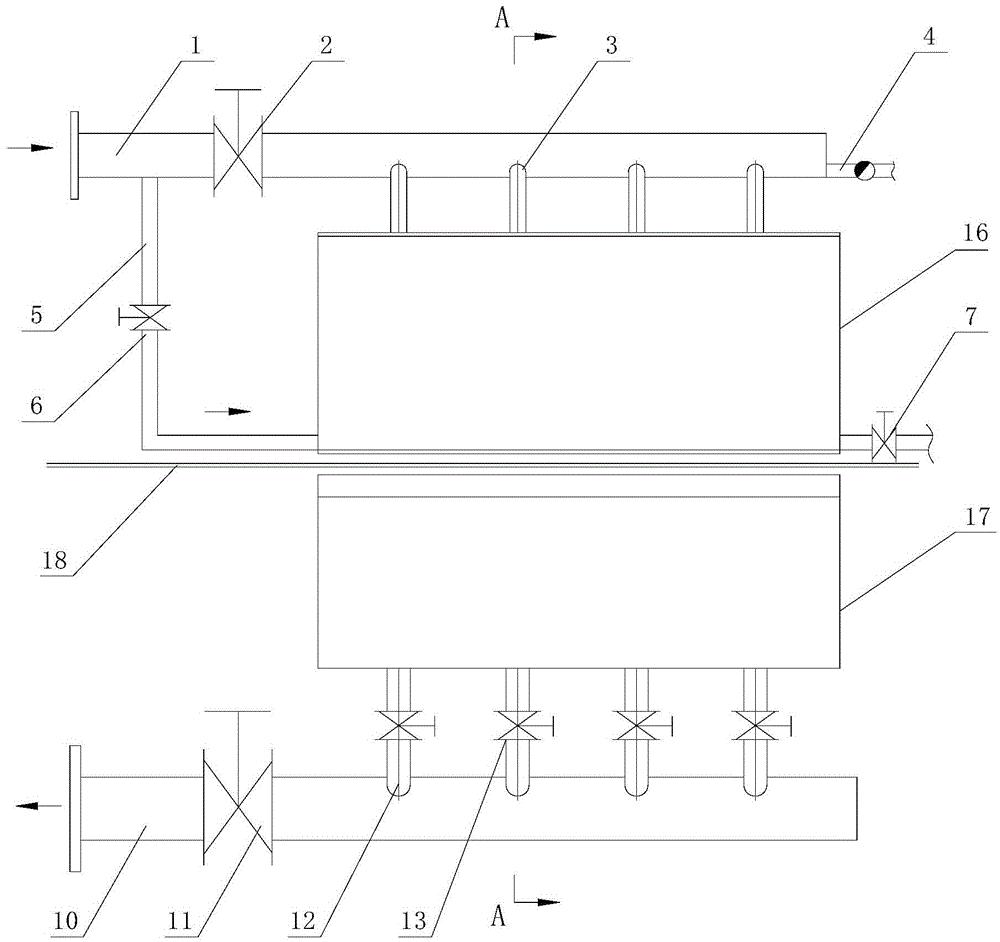

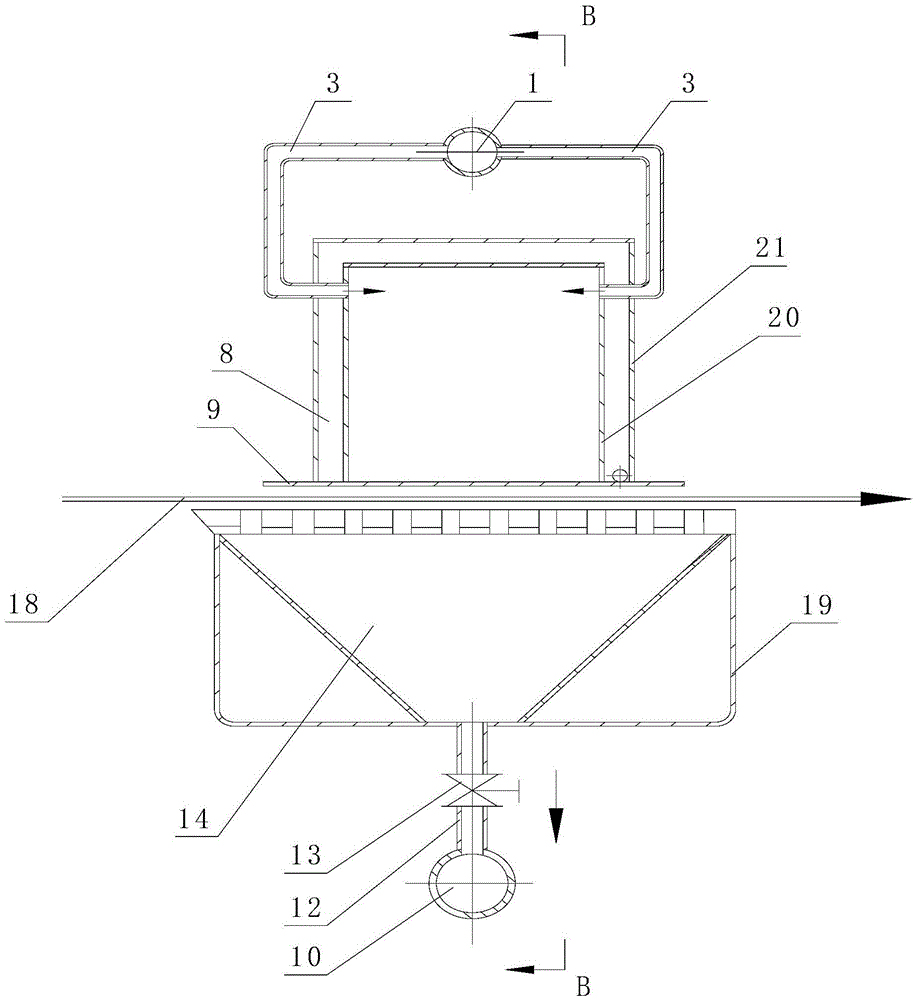

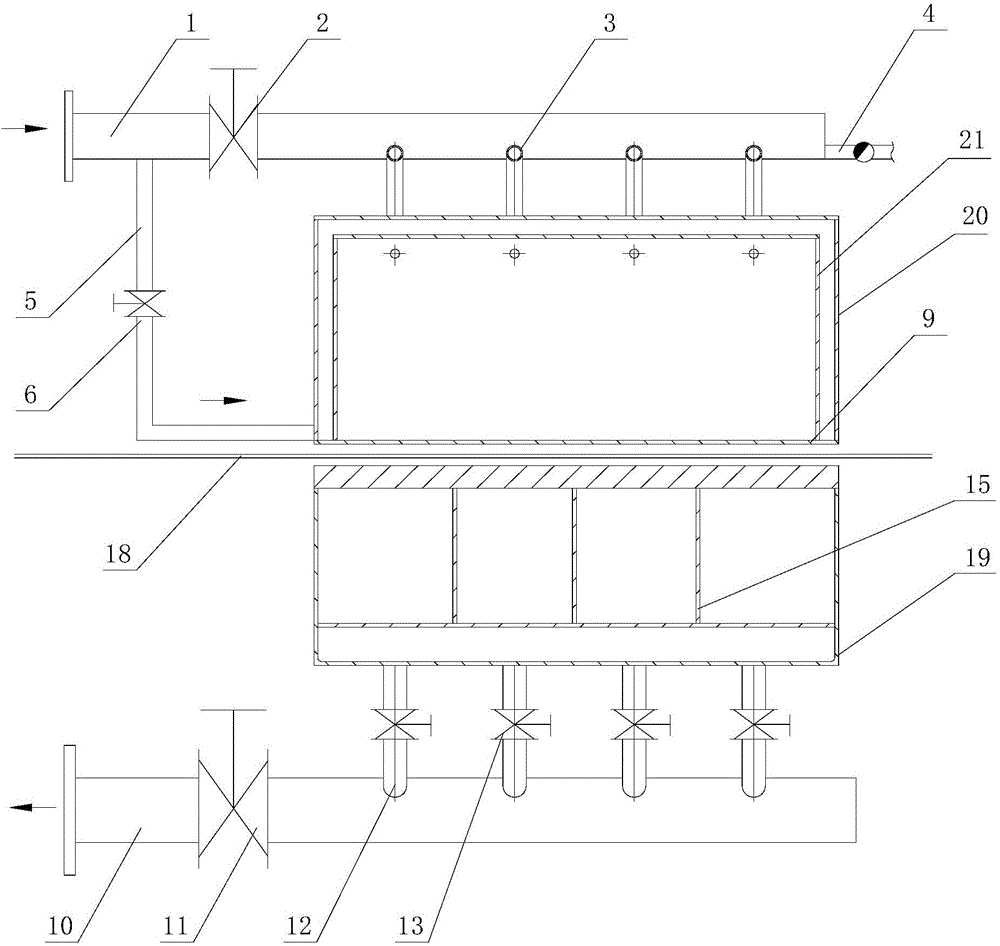

Steam device and method for adjusting moisture of paper sheet by using vacuum degree

InactiveCN104988787AIncrease profitQuality improvementDamping devicesPulp and paper industryMoisture

The present invention discloses a steam device and a method for adjusting moisture of a paper sheet by using a vacuum degree. The steam device comprises a steam box and a vacuum box which are matched for use; the steam box is arranged above a wet paper sheet and the vacuum box is arranged below the wet paper sheet; the bottom surface of the steam box is a steam spraying region; the top surface of the vacuum box is a pumping region; and the area of the pumping region is larger than that of the steam spraying region. The method comprises: continuously conveying the wet paper sheet between the steam box and the vacuum box; providing steam to the surface of the wet paper sheet in the direction from the upper side of the wet paper sheet by the steam box so as to improve the temperature and humidity of the wet paper sheet; pumping the wet paper sheet from the lower side of the wet paper sheet by the vacuum box; and controlling the temperature and humidity of the wet paper sheet by controlling pumping amount. According to the steam device and the method, disclosed by the present invention, the temperature and humidity of the wet paper sheet are adjusted by using a vacuum degree adjusting manner; the device has a simple structure and the utilization rate of the steam is high; and the better moisture adjusting effect can be realized and the quality of the paper sheet is effectively improved.

Owner:SOUTH CHINA UNIV OF TECH

Manufacturing method of environment protective paper

InactiveCN101328698AImprove toughnessHigh whitenessSpecial paperPaper/cardboardAtmospheric pressureMaterials science

The invention relates to a method for manufacturing environment-friendly paper, comprising the following steps that: two raw materials, which are 60 to 80 percent in weight of mineral composition powder and 19 to 37 percent of seaweed glue, are mixed first and with 1 to 3 percent of auxiliary material to form a mixture which is subjected to extruding, compounding and pelleting and thus a raw material of finished product is produced; the raw material of finished product is heated and softened inside a paper film making machine and is bleached by the auxiliary material as well as is extended to form a paper film by atmospheric pressure; the white paper is made by bi-directional extension molding and cooling as well as drying. The method takes the mineral composition powder and the seaweed glue as the main raw materials, thereby not only saving wood resources and other raw materials for making paper, lowering the cost for making paper and avoiding the pollution of chemical substances such as acid and alkali on the environment. In addition, the paper made by the method has the characteristics of good intensity, good flexibility, and high whiteness, thereby not only improving the paper quality but also lowering the production cost of the paper and having important benefits.

Owner:何静涛 +1

Quality evaluation method of color ink-jet paper based on multi-layer grey relational evaluation

InactiveCN102313698AConvenient and accurate evaluationAccurate evaluationColor/spectral properties measurementsUsing optical meansEvaluation dataPhysical performance

The invention relates to a quality evaluation method of color ink-jet paper based on multi-level grey relational evaluation. The quality evaluation method comprises the following steps of: selecting a plurality of types of the color ink-jet paper which needs to be evaluated, and measuring basic physical performances of the paper; selecting a professional photo printer to sequentially print professional test versions, color scales and images on paper samples; measuring attribute printing performance of the printed images by an instrument; based on modeling which applies the multi-level grey relation technology to a comprehensive evaluation system, analyzing a plurality of evaluation data of the paper samples, calculating the relation degree of each type of the paper samples, finally establishing a printing quality evaluation system of the color ink-jet paper according to a multi-level grey evaluation model and then testing sensitivity of the system; and distinguishing the relationship among various influence factors according to a relation degree matrix. The quality evaluation method has the following beneficial effects that: a qualitative and quantitative evaluation result is obtained by applying the model based on the multi-level grey system to quality evaluation of the color ink-jet paper, thus solving the difficult problem that the overall quality of the color ink-jet paper is difficult to be scientifically and accurately evaluated in the printing field, obtaining the scientific and quantized comprehensive evaluation result of the paper quality, reaching a more scientific and accurate effect without judgment depending on subjective consciousness of a person, and playing a certain reference role in establishment of quality standard of ink-jet printing of the color ink-jet paper.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Process for preparing electrolytic capacitor paper

InactiveCN1793508AEvenly arrangedHigh purityFlexible coversNatural cellulose pulp/paperFiberElectrolysis

The invention relates to a paper technology, especially for electrolytic capacitor paper manufacturing method. The method includes the following steps: absorbing layer pulping; using paper pulp to manufacture paper; pressure layer pulping; using paper pulp to manufacture paper; compositing absorbing and pressure layers; the pulping degree of the absorbing layer is 12degreeSR-50degreeSR. And it adopts side wave fourdrinier paper machine to copy paper. But the pressure layer respectively is 30degreeSR-98degreeSR and cylinder paper machine. Thus the invention resolves the problem that cross direction water uptake of electrolytic capacitor paper is not very good. And the invention has the advantages of high purity, uniform paper quality, thickness, tightness, and fiber array.

Owner:ZHEJIANG KAN SPECIALITIES MATERIAL

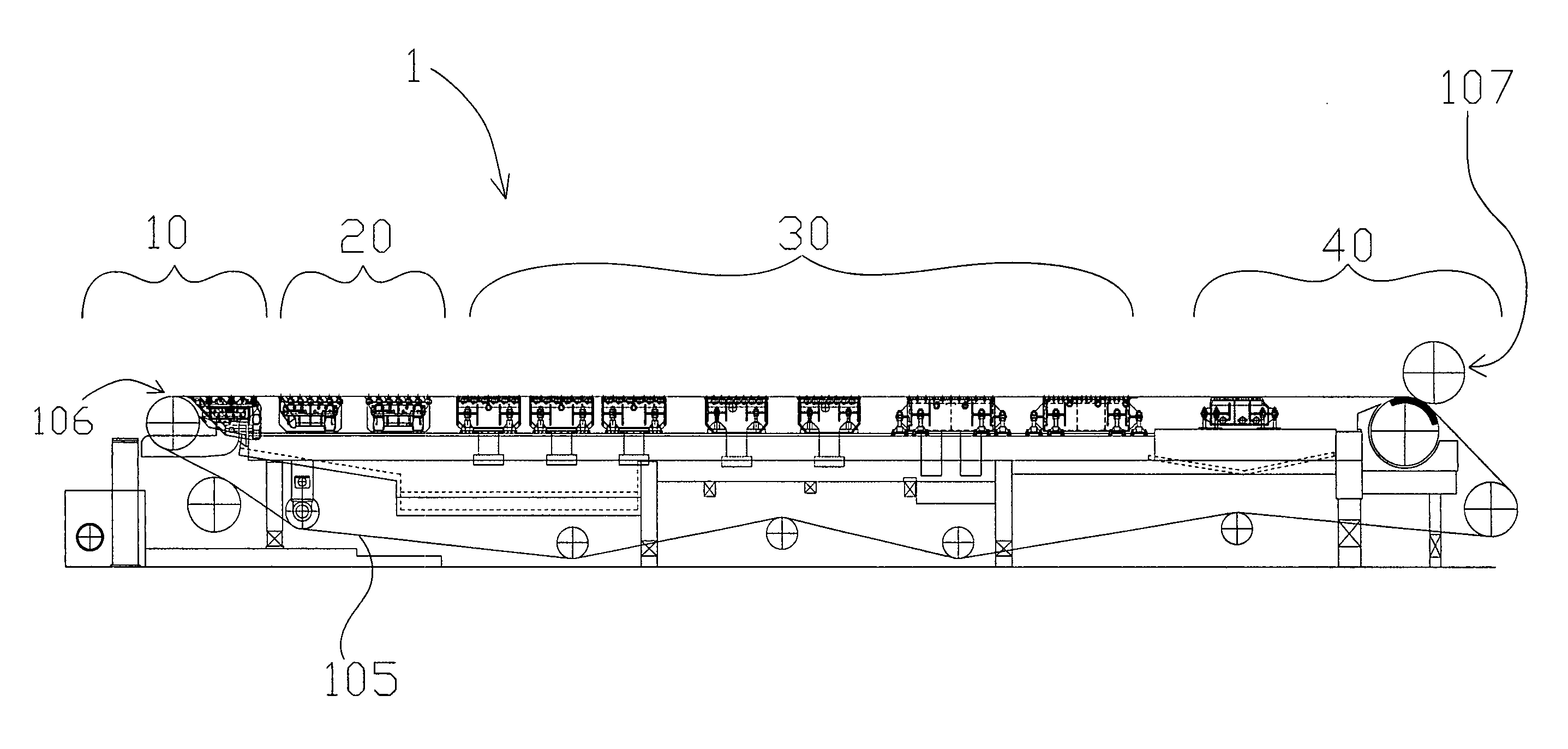

Method and machine for manufacturing paper products using fourdrinier forming

ActiveUS20120267065A1Improve paper strengthEasy to switchFibreboardMachine wet endFiberVacuum assisted

An improved method for producing paper from pulp includes a plurality of subassemblies arranged in the forming or wet section of a Fourdrinier. The Fourdrinier includes a dewatering table having a plurality of blades that are static and on-the run adjustable in height and / or angle to control orientation of paper fibers in the stock to create a superior quality of paper and improved paper strength characteristics. Gravity and vacuum assisted drainage elements are equipped with on-the-run adjustable angle and height dewatering foil blades starting from a paper dryness of 0.1% and extending all the way to 5% dryness. The result of this process and machine is to improve the paper quality, save fibers and chemicals and fulfill the required paper properties.

Owner:IBS OF AMERICA

Sizing agent for paper

InactiveCN103835184AQuality improvementImprove printing effectCoatings with pigmentsWater-repelling agents additionPolymer scienceEnzyme digestion

The invention provides a sizing agent for paper, which is mainly prepared by mixing glue, polyvinyl alcohol, cationic styrene acrylate, aluminum sulfate and fatty acid ester, wherein the glue is prepared by the following steps: adding a biological enzyme into a 20-25 wt% starch water solution, carrying out enzyme digestion at 80-85 DEG C for 10-20 minutes, heating to 130-140 DEG C, and boiling for 0.5-1 minute to inactivate the enzyme; and the polyvinyl alcohol accounts for 1-2 wt% of the glue, the cationic styrene acrylate accounts for 2-4 wt% of the glue, the aluminum sulfate accounts for 2-4 wt% of the glue, and the fatty acid ester accounts for 0.1-0.3 wt% of the glue. The sizing agent is simple in composition and easy to prepare; and after being applied to paper, the sizing agent can obviously improve the paper quality, enhance the breaking resistance, tear resistance and moisture absorption resistance of the paper, so that the paper has favorable smoothness and strong adaptability to surface printing.

Owner:NINE DRAGONS PAPER TAICANG LTD

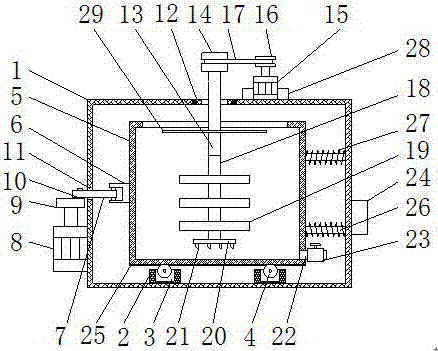

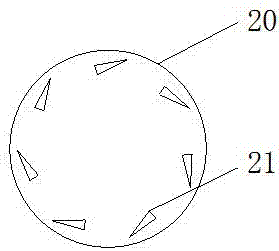

Wall paper production processing device

InactiveCN106943930AStir wellWell mixedShaking/oscillating/vibrating mixersTransportation and packagingFiberPaper production

The invention discloses a wall paper production processing device. The device comprises a support frame, two sides of the bottom of the inner cavity of the support frame are fixedly connected to roller blocks, the top of the roller block is provided with a roller groove, the inner cavity of the roller groove is movably connected to the roller through a rotation shaft, the top of the roller is fixedly connected to a stirring kettle, the centre axis in the left side of the stirring kettle is fixedly connected to a U-shaped block, and the inner cavity of the U-shaped block is movably connected to a connecting rod through a vertical rod. A second motor rotates and drives a second belt plate and a first belt plate to rotate so that a fixed rod and a stirring rod are driven to rotate and stirring blades further stir the materials. A cutting blade cuts fibers of the materials so that stirring and mixing are full. The device solves the problem that the traditional wall paper production device cannot fully stir fibers in paper pulp, further reduces stirring efficiency and seriously influences wall paper quality.

Owner:王娟

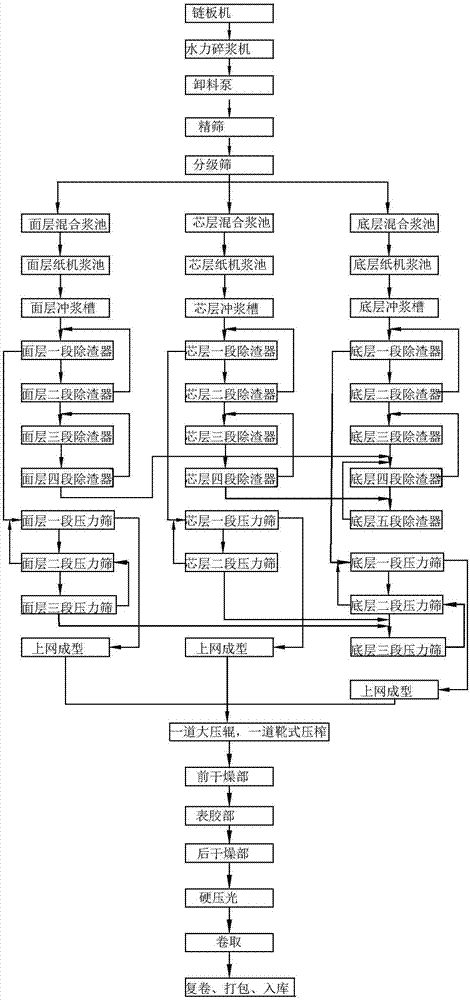

Production process for producing case board paper printing layer by waste paper

ActiveCN107268311AQuality improvementFacilitate cross-linkingPaper recyclingMachine wet endHigh concentrationFiber

The invention discloses a production process for producing a case board paper printing layer by waste paper. The production process is characterized by including the steps: waste paper fiber fluffing; classification; slag removal; screening by the aid of a pressure screen; core layer, surface layer and bottom layer preparation; composite forming; first drying; surface sizing; second drying; hard press polishing; bending; packaging; storing. The case board paper printing layer comprises a surface layer, a core layer and a bottom layer, the fiber lengths of three layers are combined by long, middle and short fibers of different proportions, impurities are repeatedly cleaned by high-concentration slag eliminator and a pressure screen, and finally formed paper is excellent in quality.

Owner:TAIZHOU FOREST PAPER CO LTD

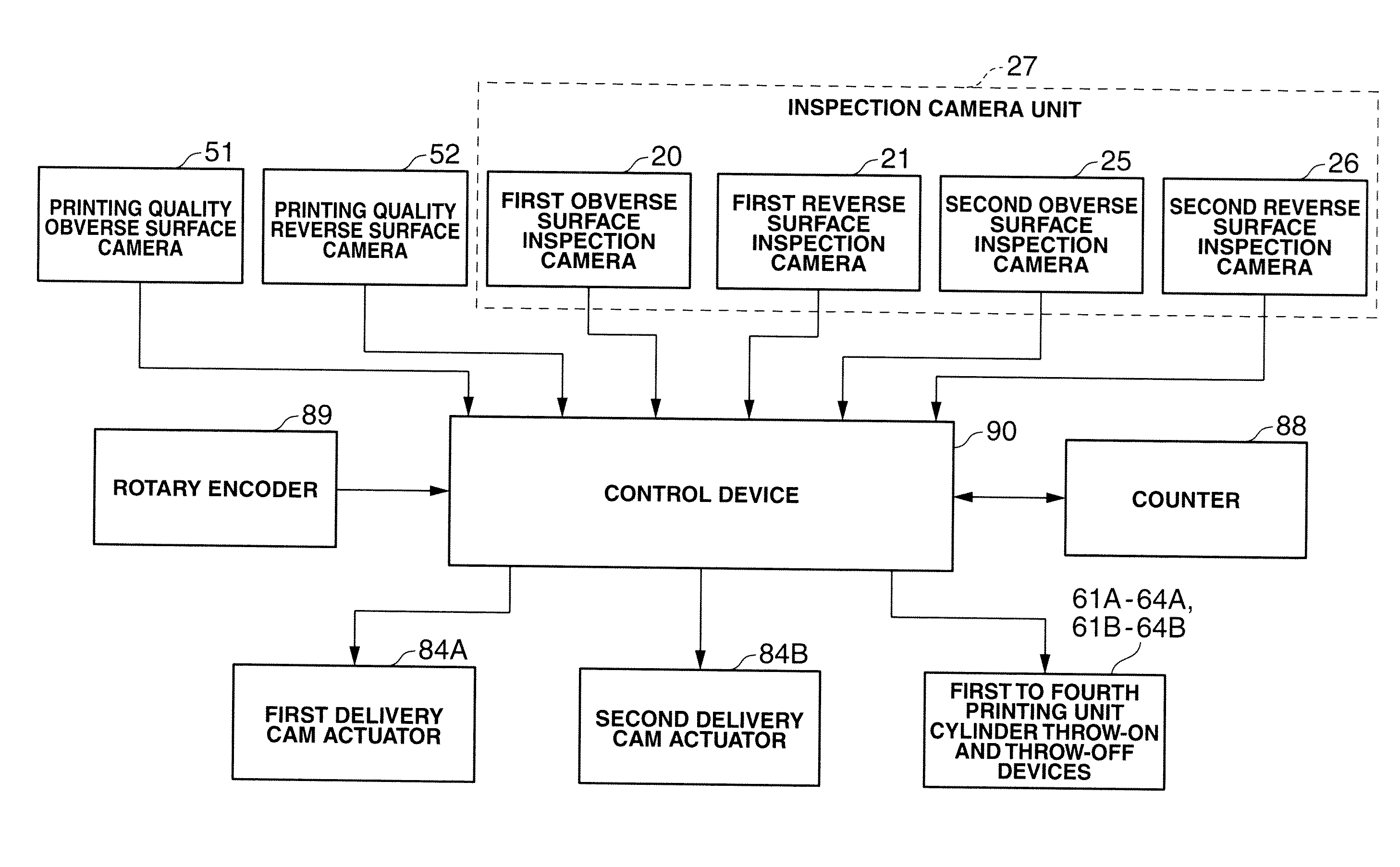

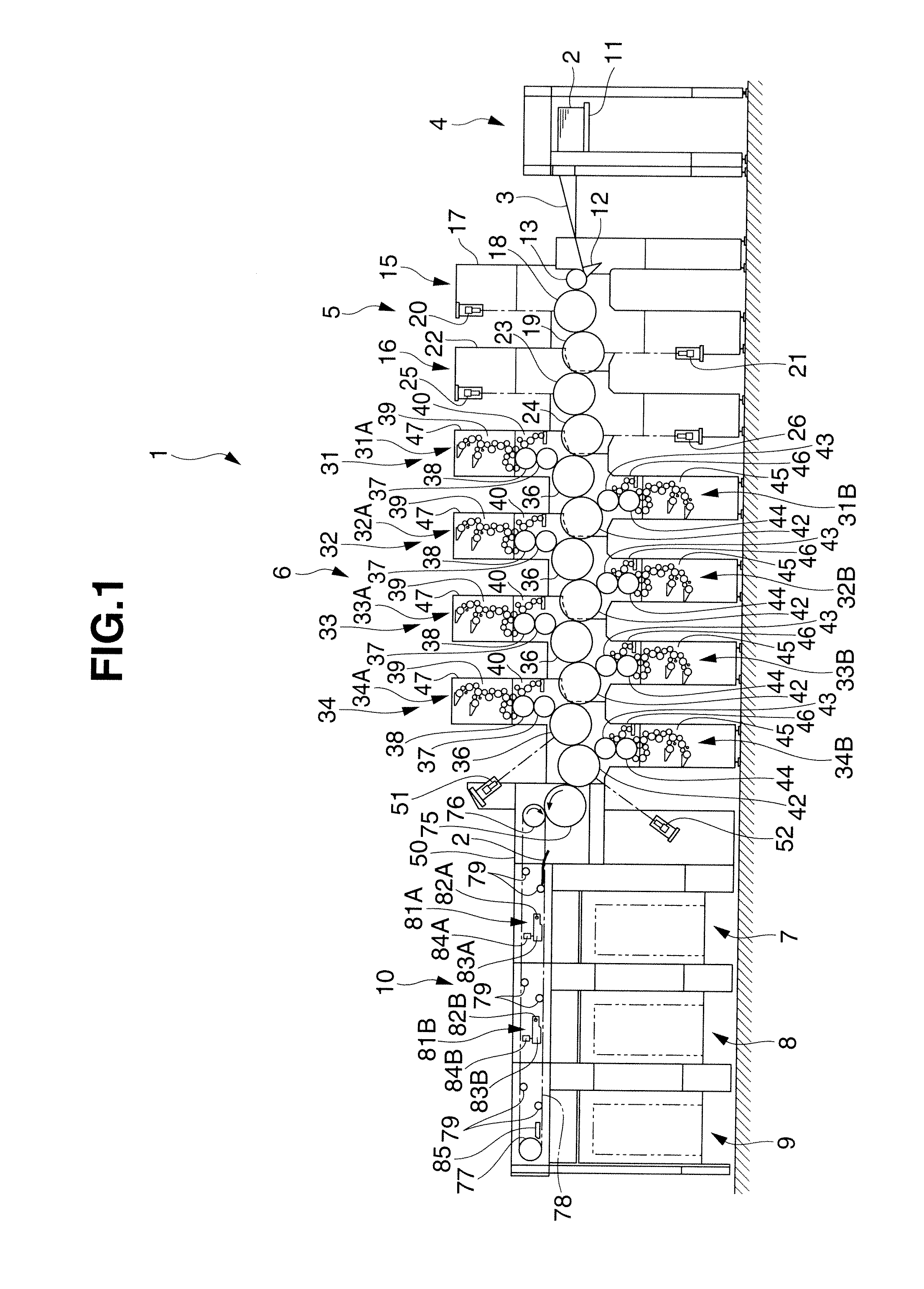

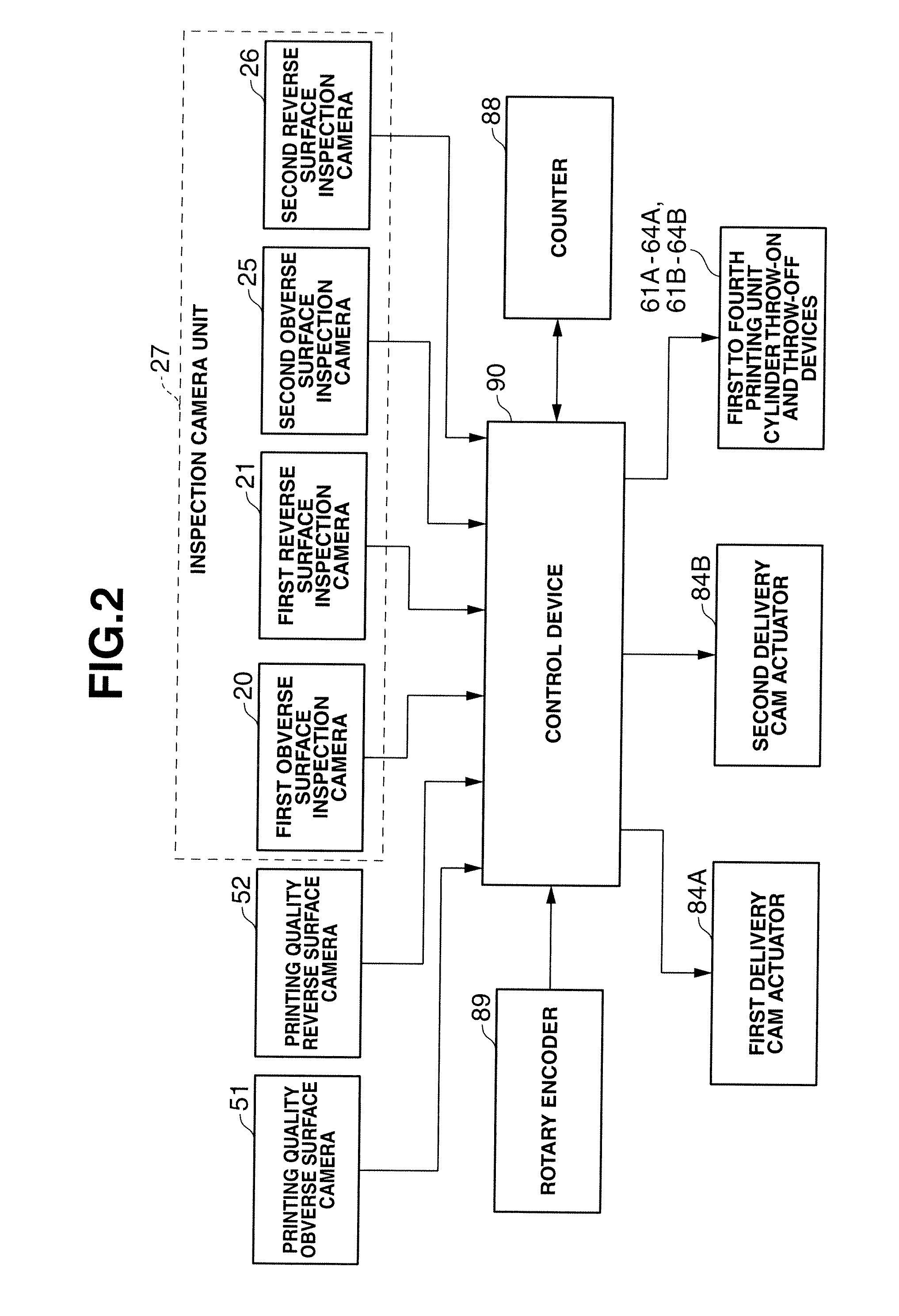

Offset printing press for printing securities

ActiveUS20120199025A1Reduce the burden onImprove productivityInvestigating moving sheetsRotary lithographic machinesPrinting pressImaging data

This invention discloses an offset printing press for printing securities, which includes an offset printing unit, inspection camera unit, and sheet quality determination unit. The offset printing unit prints a ground tint pattern on a transported paper sheet. The inspection camera unit is arranged upstream of the offset printing unit in the direction in which the paper sheet is transported, and captures an image of the paper sheet. The sheet quality determination unit determines the quality of the paper sheet based on image data output from the inspection camera unit.

Owner:KOMORI CORP

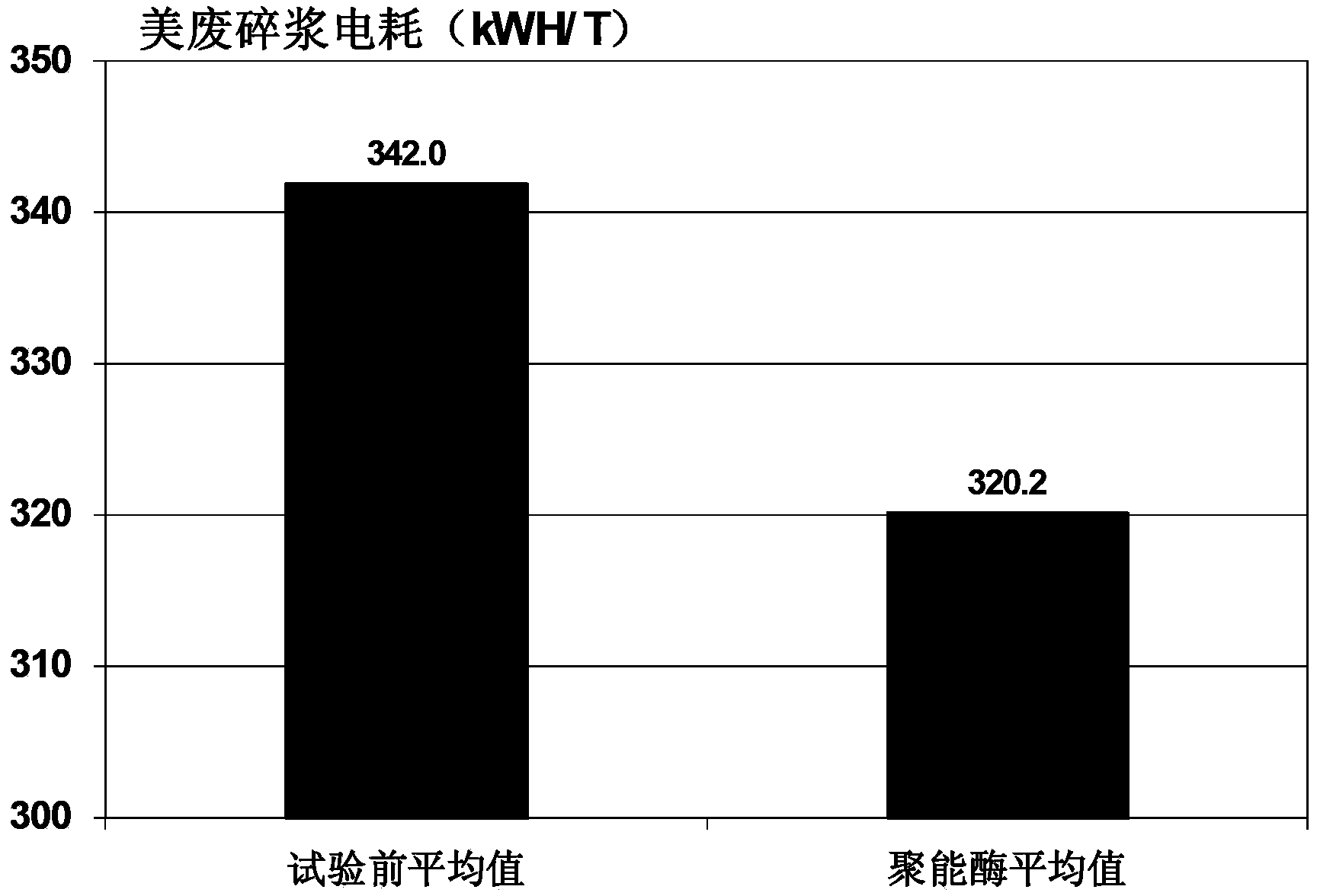

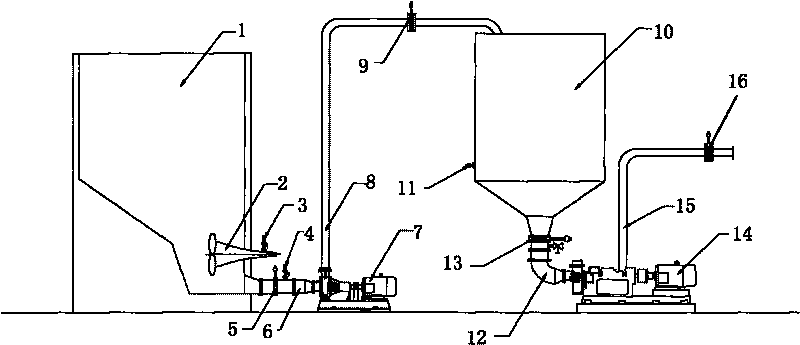

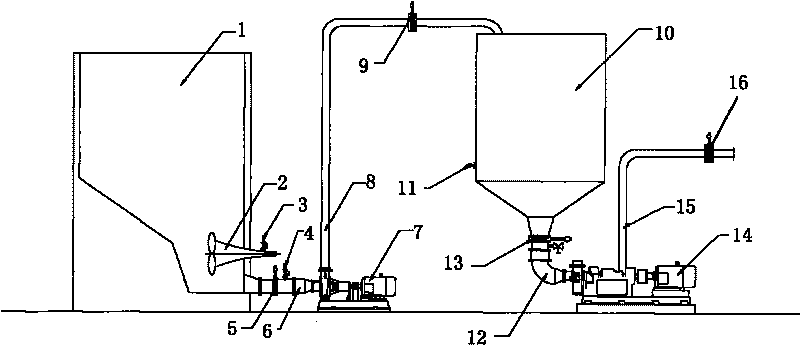

Device for controlling pulping process and control method thereof

InactiveCN101705633AQuality improvementImprove stabilityPulp beating methodsPulp and paper industryEnergy consumption

The invention discloses a device for controlling a pulping process and a control method thereof. The device comprises a first pulp tank, a pulp pump, a second pulp tank and a pulping machine sequentially connected with each other, wherein the first pulp tank is internally provided with a stirrer with dilution water, a pulp inlet tube of the pulp pump is provided with a dilution water tube, a pulp outlet tube of the pulp pump is provided with a paper pulp concentration meter, the second pulp tank is provided with a liquid level meter, and a pulp outlet tube of the pulping machine is provided with a flow meter. The method realizes the control of the pulping process through constant paper pulp concentration, constant paper pulp flux and constant pulping power. In the invention, the device and the method realize the pulping process under the set conditions of paper pulp concentration, flux, pressure and pulping power, thereby being beneficial to the stability of the pulping quality and the paper quality, reducing the energy consumption of the pulping process and improving the physical performance of papers.

Owner:SOUTH CHINA UNIV OF TECH

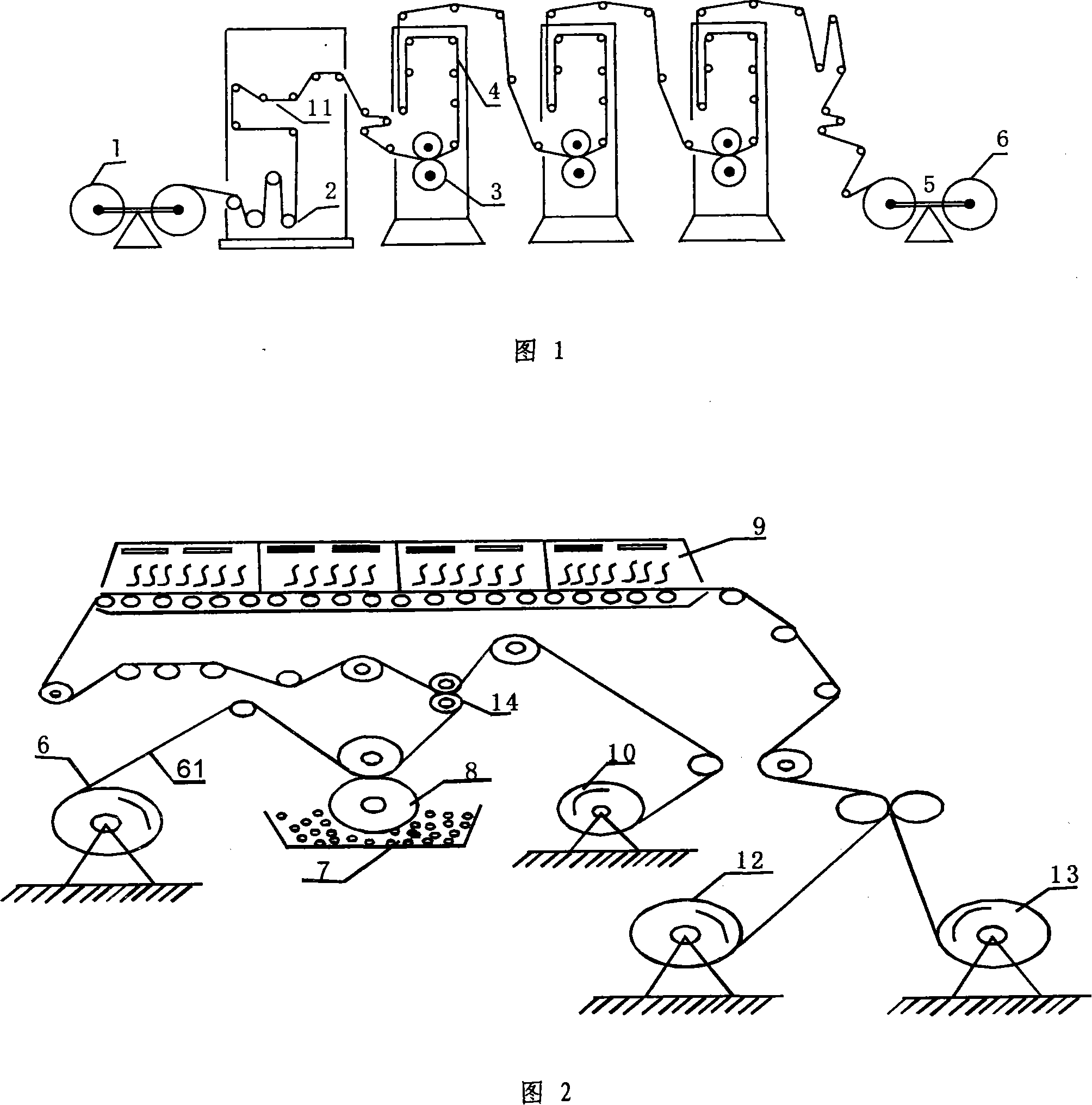

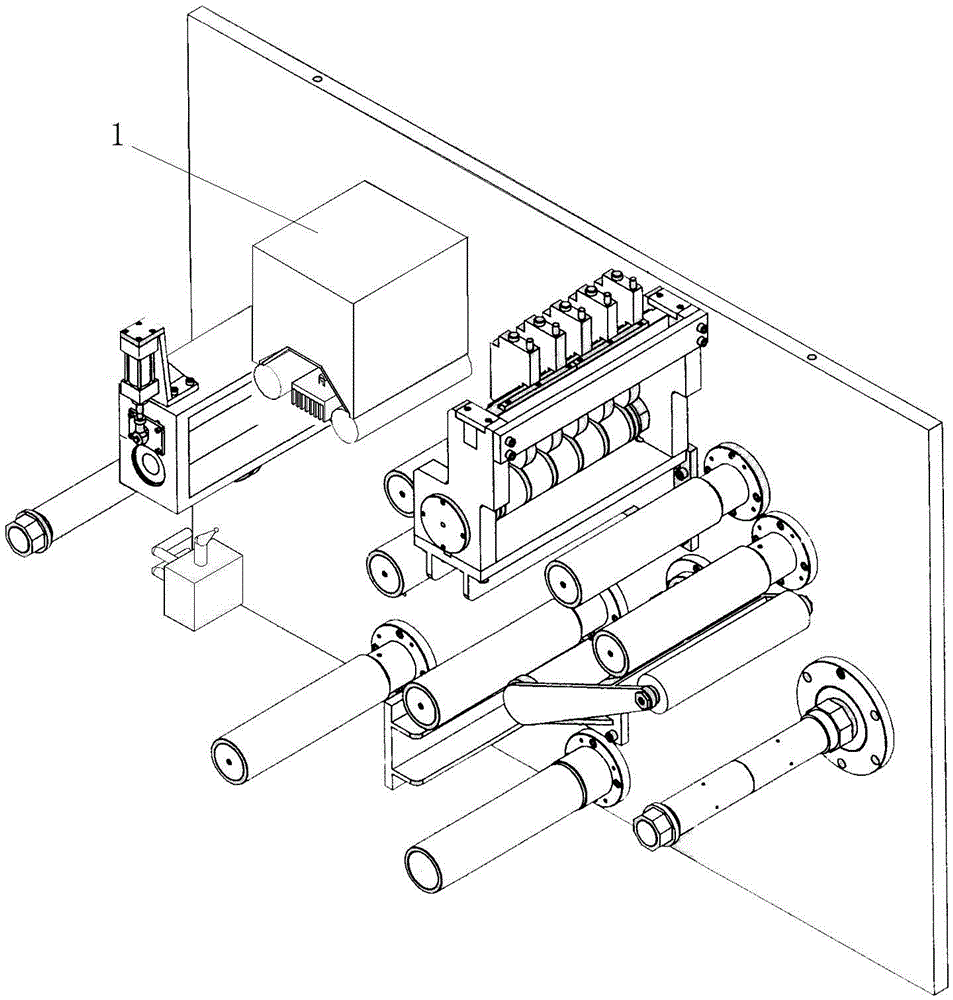

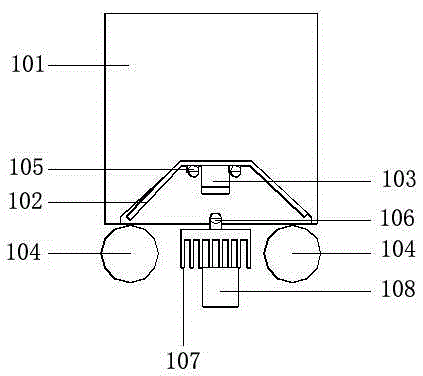

Tipping paper quality test warning system and on-line quality test method

InactiveCN105301008AEasy to removeFine and accurate detectionOptically investigating flaws/contaminationData centerComputer science

The invention provides a tipping paper quality test warning system and a corresponding test method, and belongs to the technical field of material measurement and analysis by optical means. The quality test warning system includes a reel splitting machine, a data center and a rewinding test device. The reel v machine is provided with an on-line test device (1); during splitting of the reel paper, information of paper with defects is recorded and stored in the data center; the data center is used as a connecting device for integration of the reel splitting machine and the rewinding test device; at the same time, for the defective products of small volume need rewinding test, a controller of the rewinding test device retrieves the corresponding information stored in the data center, and controls the rewinding test device to stop at a proper position, and conducts operations of removal and connection. The system and method achieve one-time test of a variety of processing defects, save investment in equipment, meet the quality requirements of tipping paper, quickly and accurately find and eliminate defects, and improve the test reliability, accuracy and efficiency of test.

Owner:ENDIAN SCI & TECH DEV OF YUNNAN

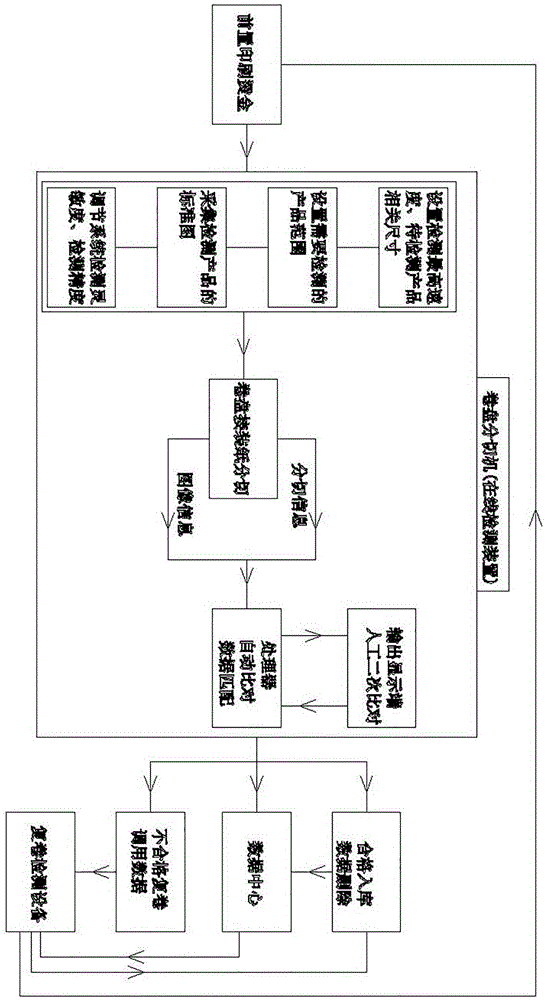

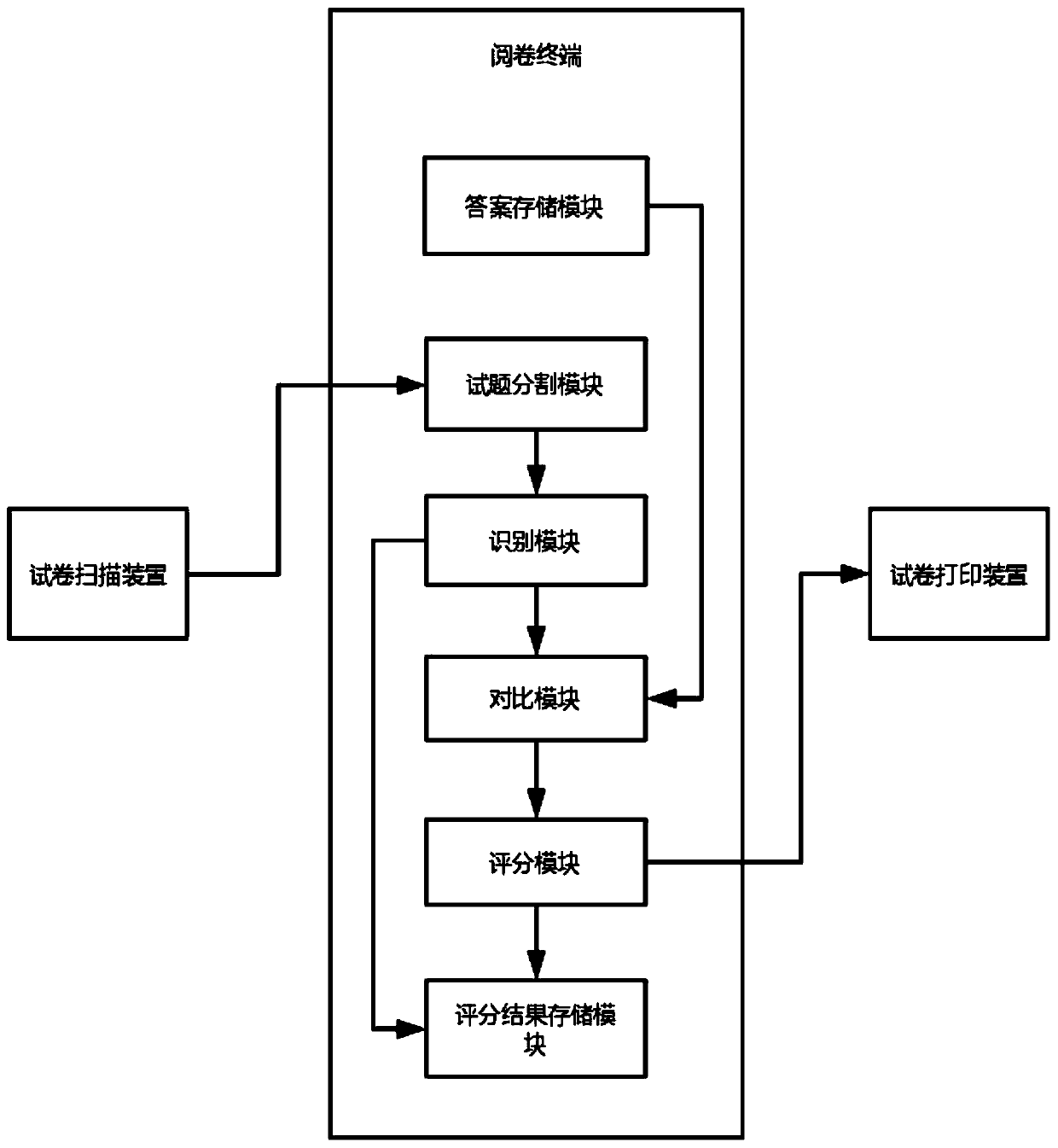

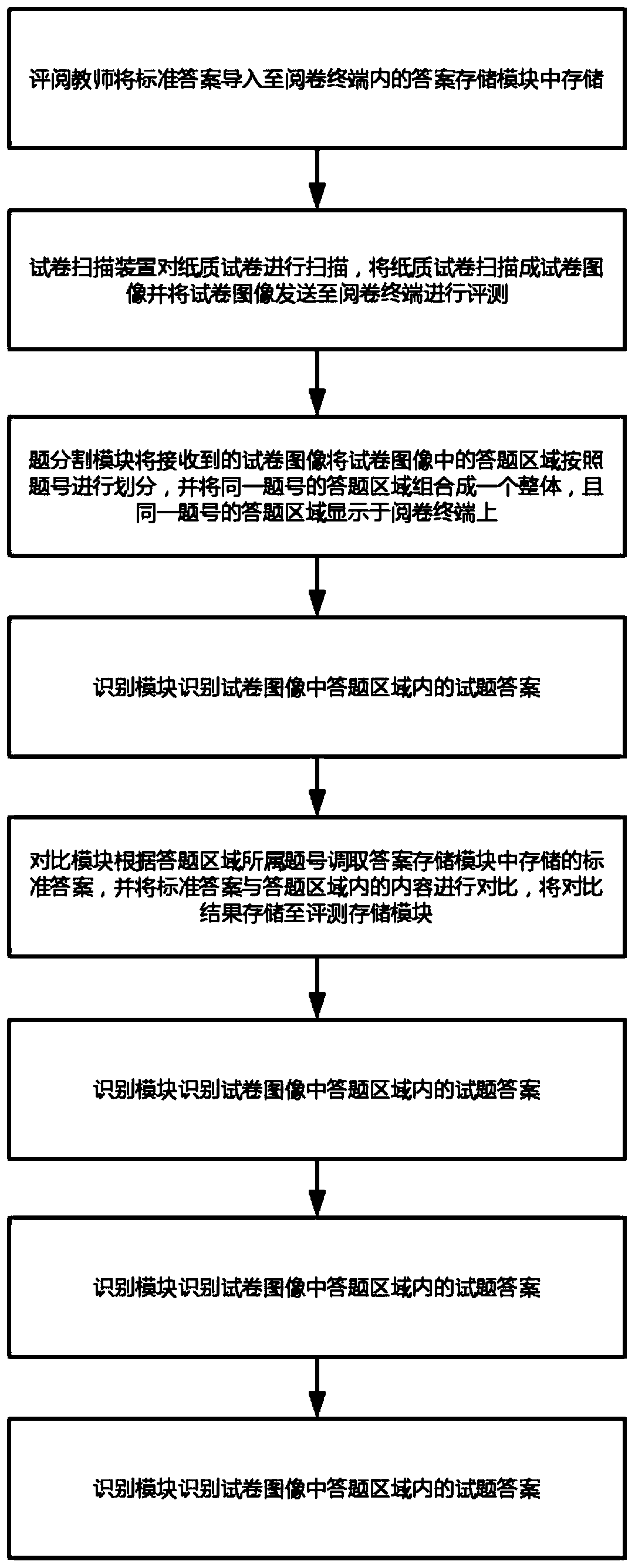

Intelligent paper marking system

PendingCN109740436AImprove teaching efficiencyReduce labor intensityCharacter and pattern recognitionResourcesEvaluation resultPulp and paper industry

The invention discloses an intelligent paper marking system including a test paper scanning device, the device is used for scanning paper test paper. scanning the paper test paper into a test paper image and sending the test paper image to the paper marking terminal; the paper marking terminal is used for receiving the test paper image sent by the test paper scanning device; comparing test question answers in the test paper image with correct test question answers; evaluation and scoring, calculating and storing scores of the test questions in the test paper image, and sending an evaluation result of the test paper image to the test paper printing device; the test paper printing device receives an evaluation result sent by the paper inspection terminal; the evaluation result is printed onthe test paper; through the arrangement of the examination paper scanning device, the examination paper marking terminal and the examination paper printing device, a traditional manual examination paper marking mode can be achieved, examination paper quality analysis and statistics can be conducted, a teacher can be freed from heavy repeated work, the teaching efficiency of the teacher is improved, and the labor intensity of teaching filing of the teacher is reduced.

Owner:李卫强

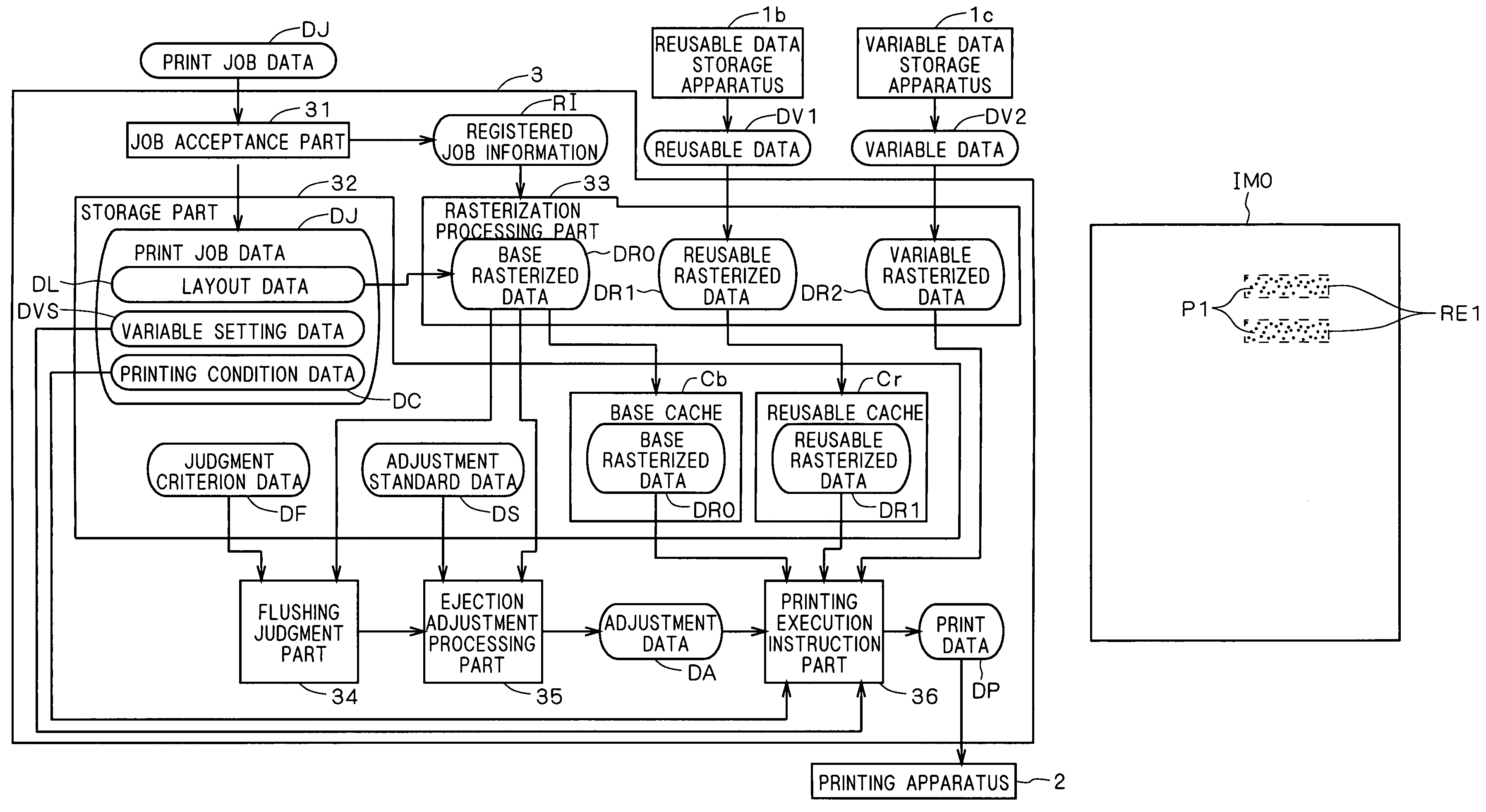

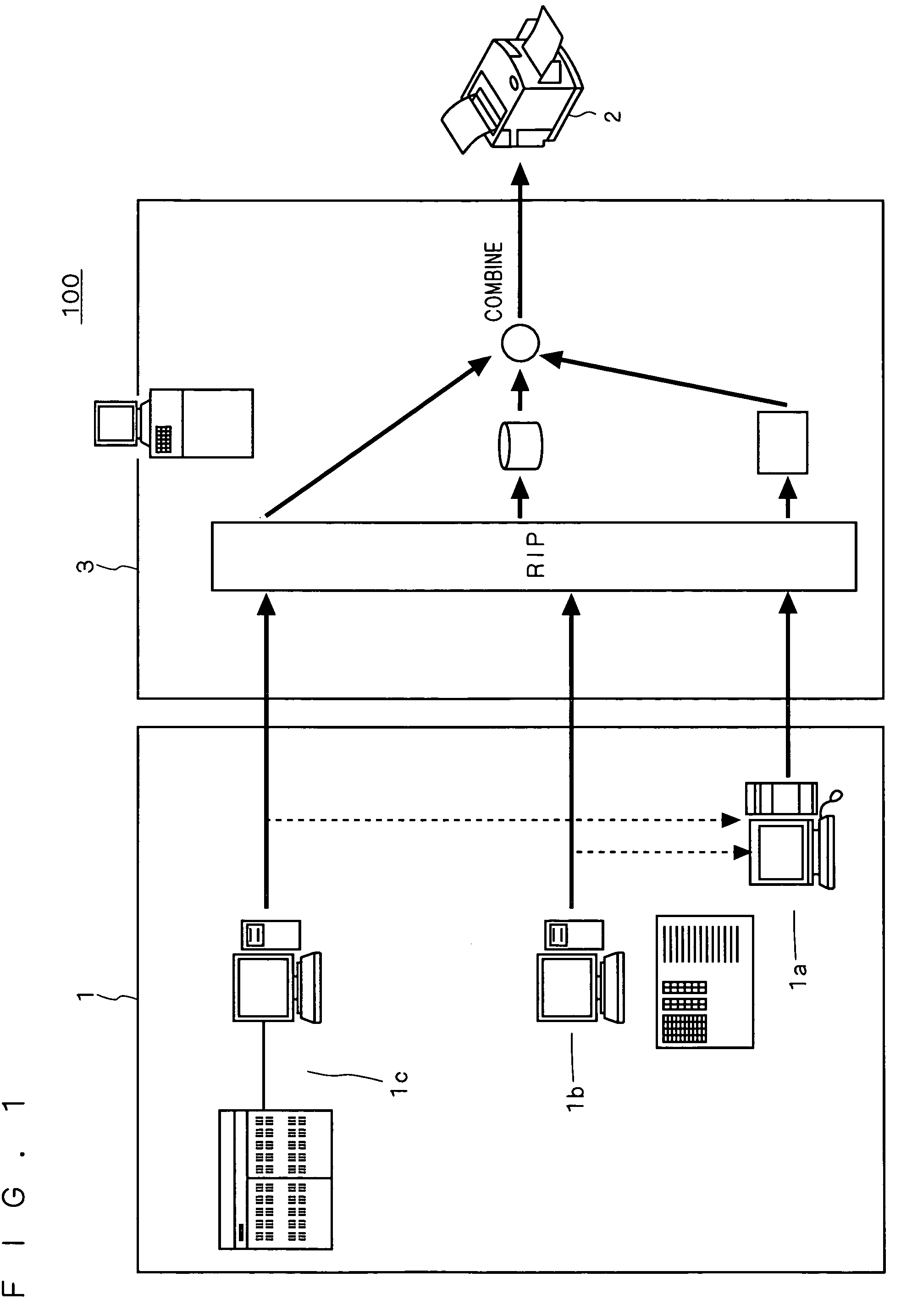

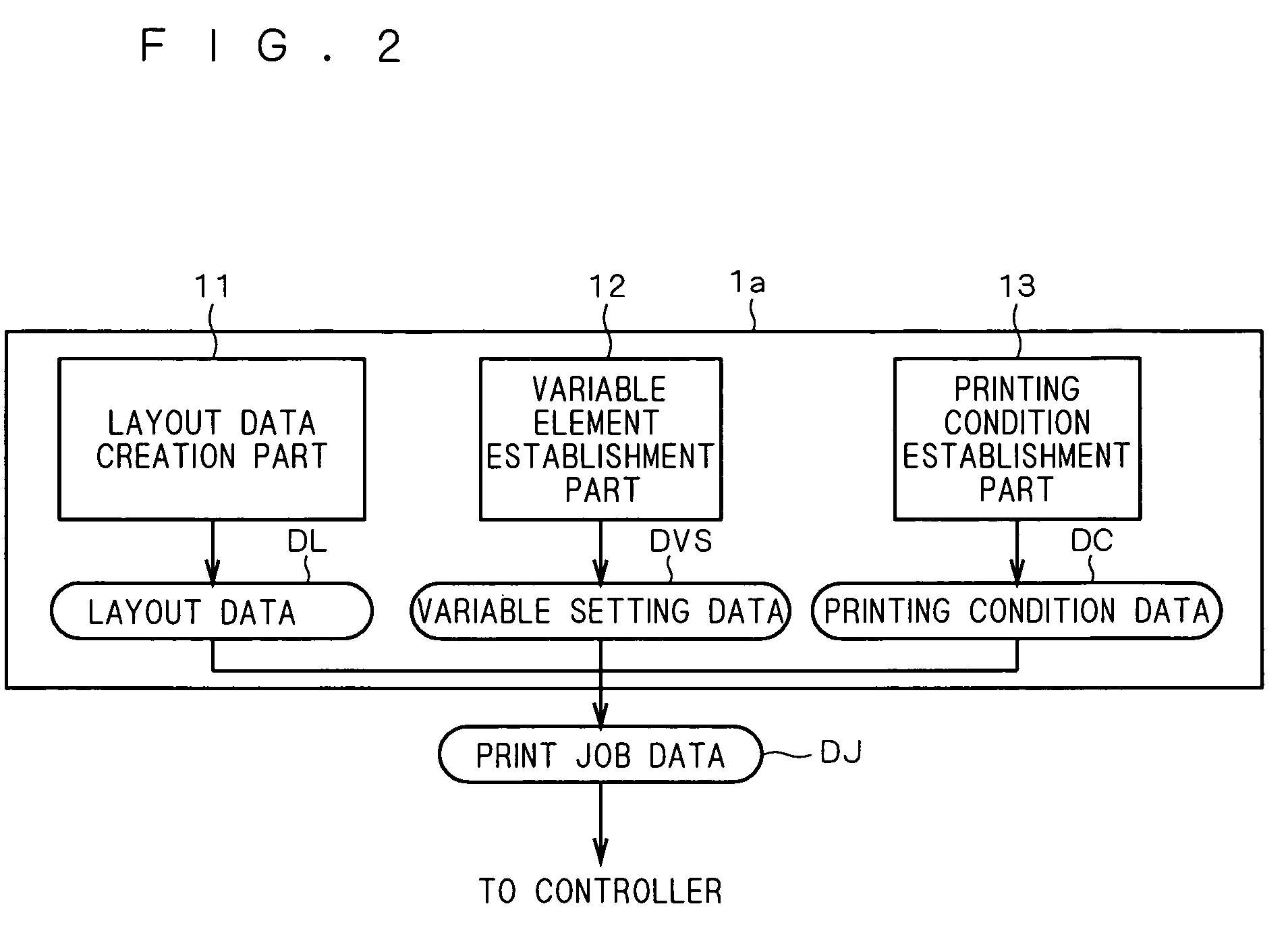

Printing system, controller for printing apparatus, method of executing printing process, and program for flushing ejection

For a low saturation and high density region in a printed sheet identified based on rasterized data, flushing ejection is executed, with landing positions dispersed in the region. For a region being low in saturation but not high in density, an edge portion of the region is determined as landing positions. During these processes, adjustment is made to the ejection from inkjet nozzels for color components which are not to be subjected to the flushing ejection, to maintian the original hue of the region. This achieves the flushing ejection minimizing the degradation of the quality of the printed sheet. Further, in the variable printing, necessity of the flushing ejection is judged based on details to be printed on a base page. This causes the evacution of the flushing ejection whenever individual printed sheets are produced. Therefore, the print quality is held uniform during the production of different printed sheets.

Owner:DAINIPPON SCREEN MTG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com