Novel pulping process for obtaining high performance fiber at high yield from plants

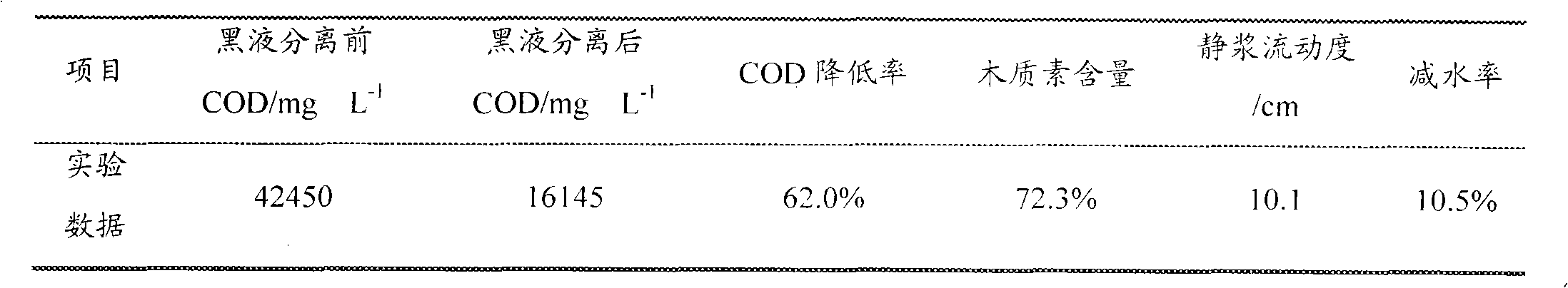

A process and fiber technology, which is applied in the new process field of segmented pulping, can solve the problems of difficult resource utilization of papermaking black liquor, destruction of effective components, and complex components, so as to achieve full-price development and comprehensive utilization, and reduce acid and alkali consumption. and stench, the effect of simplifying the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

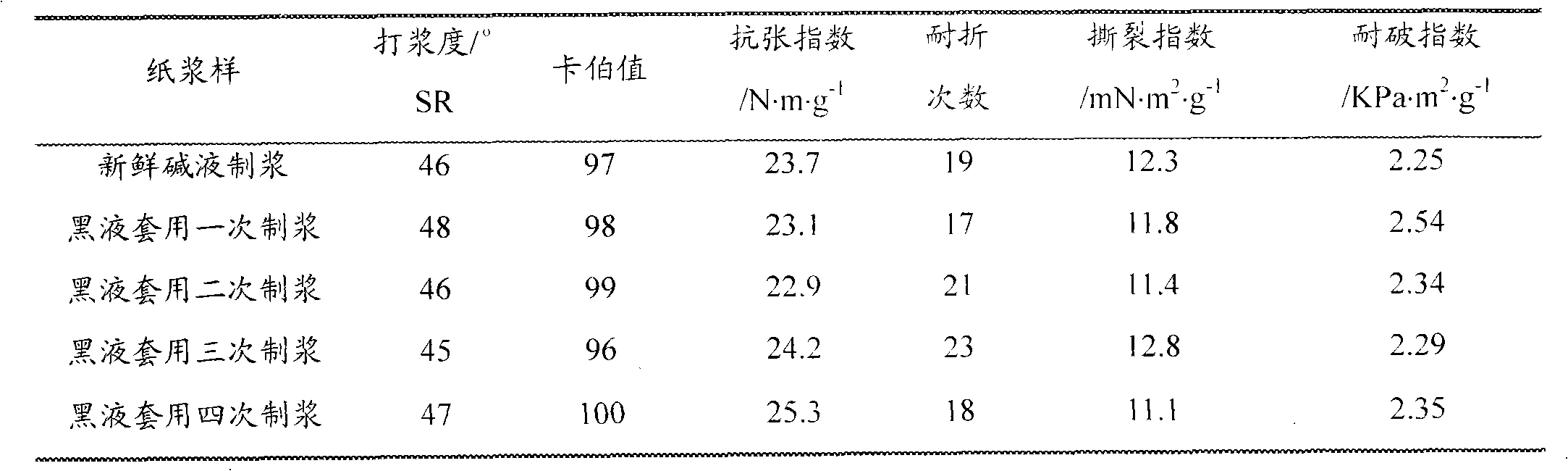

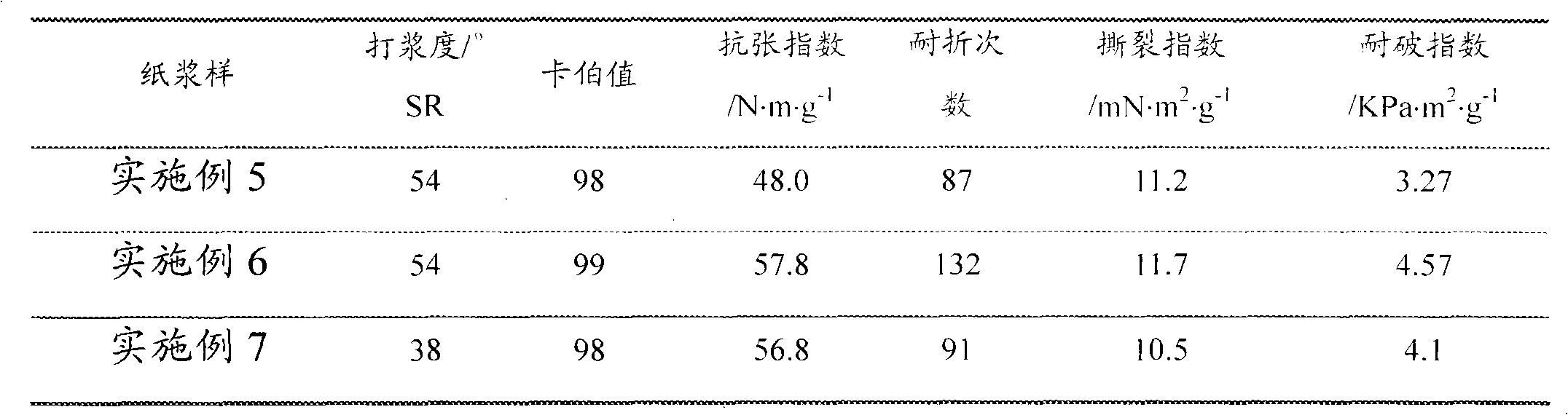

Examples

Embodiment 1

[0032] Take 50g wheat straw (dry) in 1L NaOH concentration of 0.5% solution and soak at room temperature for 12 hours, then cook at 103°C for 2h, filter out, beat, wash and filter to obtain 35.025g crude fiber, the crude fiber obtained The rate is 70.05%. Pulp papermaking test performance, the results are as follows: folding number 46 times, tensile index / N·m·g -1 48.8, tear index / mN m 2 g -1 9.20, burst index / KPa m 2 g -1 2.68.

Embodiment 2

[0034] Take 20Kg corn stalks (dry) and soak them in 200Kg of 0.8% NaOH solution at 60°C for 11 hours, raise the temperature to 90°C and soak for 1h, then heat up to 125°C and cook for 2.5h. The pulper refines the cooked corn stalks, and the yield of coarse pulp is 66.8% according to the weight measurement. Pulp papermaking test performance, the results are as follows: 9 fold times, tensile index / N·m·g -1 38.8, tear index / mN m 2 g -1 8.20, burst index / KPa m 2 g -1 1.68.

Embodiment 3

[0036] Take 2Kg of wood (dry) and soak it in 10L of NaOH solution with a concentration of 3% for 12 hours, then cook it at 100°C for 2h, filter out, refine, sieve, and wash to obtain 1.39Kg crude fiber, the yield of crude fiber was 69.5%. Coarse fiber beating, papermaking and other operations, and finally paper performance testing. Paper properties are as follows: degree of beating °SR 54, kappa number 96, folding endurance 152 times, tensile index / N·m·g -1 54.0, tear index / mN m 2 g -1 13.2, burst index / KPa m 2 g -1 3.57.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Burst index | aaaaa | aaaaa |

| Burst index | aaaaa | aaaaa |

| Burst index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com