Method for preparing tobacco sheet and application thereof

A technology for tobacco sheet and tobacco material, which is applied in the directions of tobacco, application and preparation of tobacco, can solve the problems such as affecting the use effect and adding amount of the sheet in cigarette products, the taste quality of the tobacco sheet is poor, and the tobacco powder treatment solution is not provided, and the like, To achieve the effect of improving aroma richness, good water filtration, and improving internal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The selection experiment of embodiment 1 tobacco sheet preparation conditions

[0048] 1. Selection of extraction conditions

[0049] There are many ways to extract tobacco waste, such as adding appropriate chemicals or direct cold and hot water. In order to ensure that the quality of tobacco active ingredients is less damaged and to achieve as much recycling as possible, the choice of extraction method very important. The present invention adopts extraction, which actually adopts a three-stage countercurrent extraction process.

[0050] Each part of the stem is extracted three times, and the secondary extraction solution, the first extraction solution and water are used as the extractant in turn; each part of the extraction agent is used to extract three parts of the stem, which are the second extraction stem, the first extraction stem and the new stem.

[0051] The extraction rate of each step of each stalk and each extract was studied, and one extraction was used a...

Embodiment 2

[0087] Example 2 Tobacco flakes with roasted sweet aroma

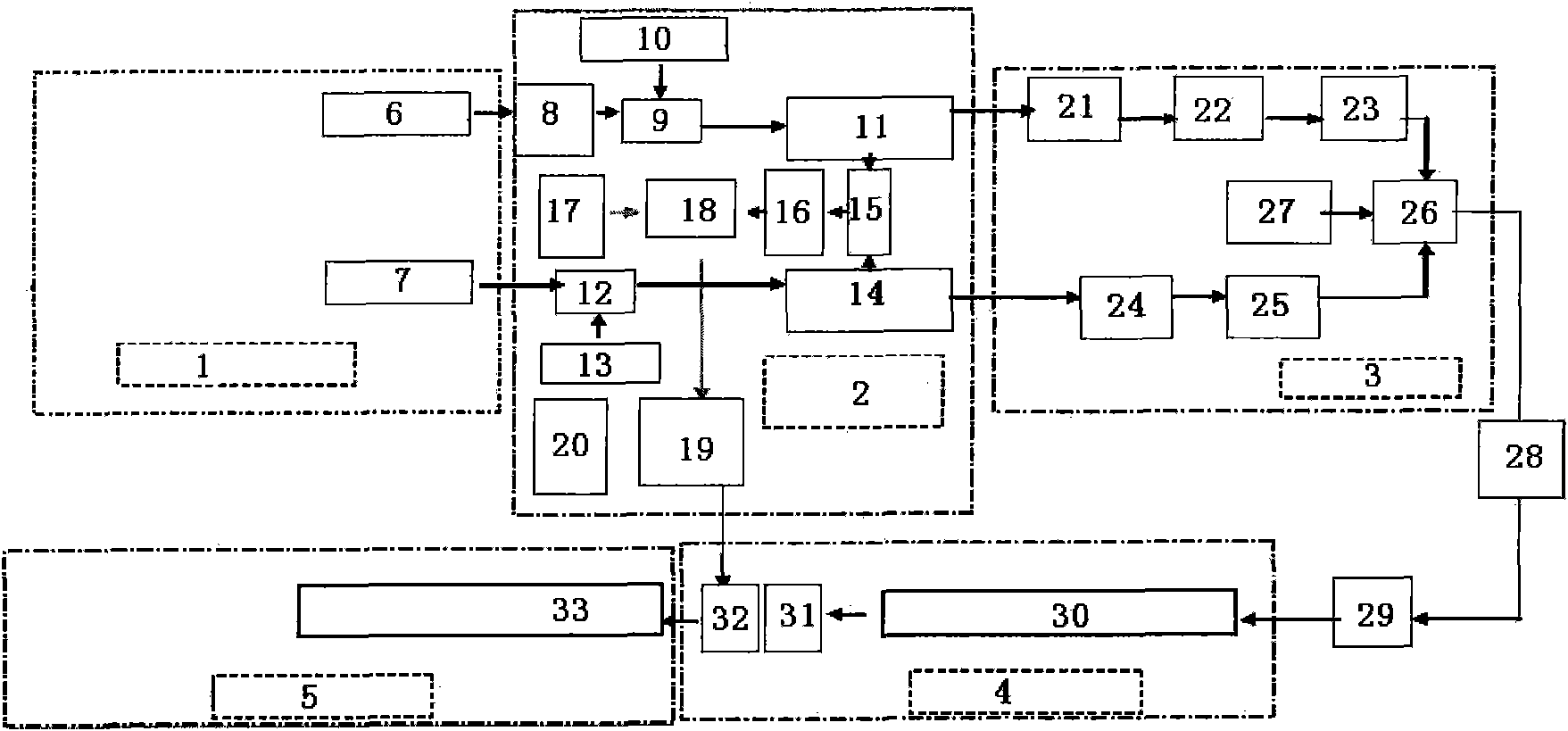

[0088] Tobacco sheet of present embodiment, preparation process flow chart sees attached figure 1 shown, with figure 1 Among them, 1 represents the raw material pretreatment section, 2 represents the extraction concentration reaction and blending section, 3 represents the slurry preparation section, 4 represents the papermaking forming coating section, and 5 represents the finished product post-processing section. The present invention mainly relates to the 2nd and 3rd sections . 6 is the prepared tobacco stem raw material, 7 is the prepared tobacco powder raw material; 8 represents the grinding and peeling of the tobacco stem raw material, 9 represents the soaking of the tobacco stem, 10 represents the enzyme treatment and extraction of the tobacco stem, and 11 represents the extraction of the tobacco stem extract Solid-liquid separation, 12 is the soaking of the tobacco powder, 13 is the enzymatic treatment and ext...

Embodiment 3

[0097] Example 3 Tobacco flakes with woody aroma and roasted sweet aroma

[0098] The tobacco sheet of this embodiment, the flow process is the same as that of embodiment 2, and the alcohol precipitation operation is set. It specifically includes the following steps:

[0099] (1) Tobacco stems and tobacco powders are prepared according to the mass ratio of tobacco stems and tobacco powders being 2:1. After the tobacco stems are polished and peeled, they are soaked in water (the solid-to-liquid ratio is 1: 15, Kg: L), and a compound enzyme (combination of compound pectinase and xylanase, the mass ratio of these two enzymes is added to the soaking solution) 1:2), the total amount of compound enzyme added is 1% of the total mass of the soaking solution, at 50°C, at a stirring speed of 5rmp, enzymatic hydrolysis treatment for 8 hours, using a three-stage countercurrent tank extraction process for extraction, at 50°C Extract for 60min.

[0100] The tobacco powder is soaked in wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com