Patents

Literature

273results about How to "Good filterability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing tobacco sheet and application thereof

ActiveCN101637298AGood physical propertiesExtract completelyTobacco preparationTobacco treatmentMaillard reactionFiber

The invention discloses a method for preparing tobacco sheets and an application of the method. In the method, enzymolysis is implemented when the tobacco stalk and the tobacco powder are soaked, solid-liquid separation is implemented after extraction, the solids are made into fiber sheet substrates, liquid is made into concentrated solution by alcohol precipitation and concentration, the concentrated solution is made into coating liquid by maillard reaction and coated on the fiber sheet substrates, and the fiber sheet substrates are dried and cut into tobacco sheets. In the invention, the macromolecular compounds that influence the quality of the tobacco sheets are sufficiently degraded by enzymolysis, the content of the impure taste in the tobacco sheets is decreased, the internal quality of the tobacco sheets is improved, and better aroma is obtained by the technical solution that produces prospective aroma by the maillard reaction to provide a rich aroma for the tobacco sheets so as to obtain tobacco sheet products fitting different types of cigarette products and having better internal quality. The tobacco sheets prepared by the method have excellent compatibility and harmonywith the conventional raw materials of the cigarettes, and have the advantages of good cigarette taste, various and rich aromas and less impure taste.

Owner:CHINA TOBACCO GUANGDONG IND

Filtering rod for cigarette and preparing method

InactiveCN101023811AGood filterabilityImprove mechanical propertiesTobacco smoke filtersN-vinyl-pyrrolidone polymer adhesivesPolyesterChemistry

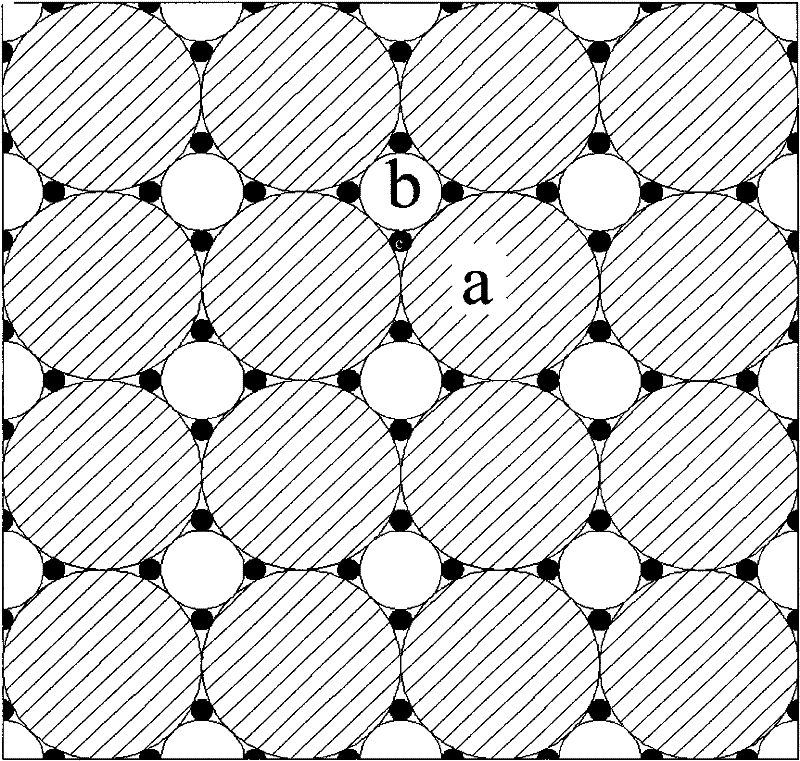

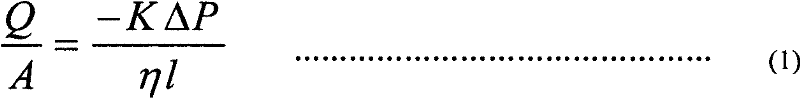

The present invention relates to a polylactic acid filter rod for cigarette. It is made up by using polylactic acid tow for cigarette through the processes of opening, adhesive bonding, bundling, cutting and after-treatment, its filament linear density is 2-8 dtex, its tow linear density is 3-6 ktex and its crimp ratio is 15-30 / 25 mm. The contacted parts of adjacent fibers are mutually bound and all fibers in the rod are cohesive together to form communicated 3-D network structure.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

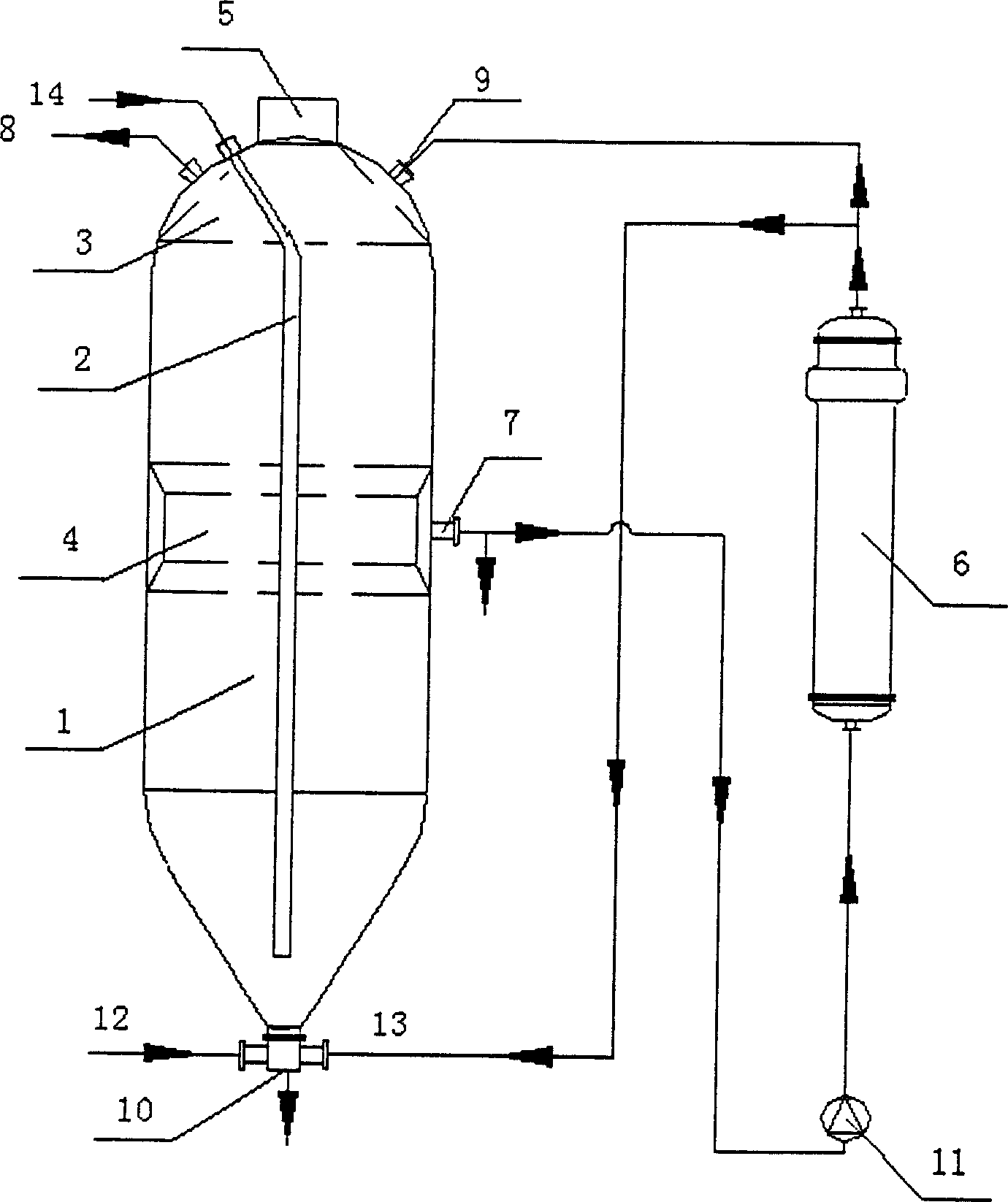

Oxygen delignify treating method for grass group unbleached chemical pulp

ActiveCN101082187ALow percussionImprove water filtration performanceCellulosic pulp after-treatmentPulping with inorganic basesCelluloseMagnesium salt

The invention relates to an oxygen delignification processing method of grass unbleached chemical pulp. The oxygen delignification of the pulp is processed after cooking and before bleaching. Its rigidity before the oxygen delignification is potassium permanganate value 16-28 (equals to karber value 26-50). After pumping into the oxygen delignification reaction tower and inflating sodium hydroxide, magnesium salt and oxygen, the chemical pulp happen the oxygen delignification in the reaction tower. The chemical pulp with rigidity of potassium permanganate value 10-14 (equals to karber value 14-18) is achieved after the oxygen delignification. The invention can remove the lignin in the pulp effectively and the removal rate is 86-98%. It reduces the degradation of the cellulose to simplify the bleaching process and cut down the dosage of the chemicals. The bleached pulp has good rigidity and drainability. The breaking length of the pulp can reach 4500-8000m and its fold-resistant times can reach 20-70.

Owner:SHANDONG FUYIN PAPER & ENVIRONMENTAL PROTECTION TECH

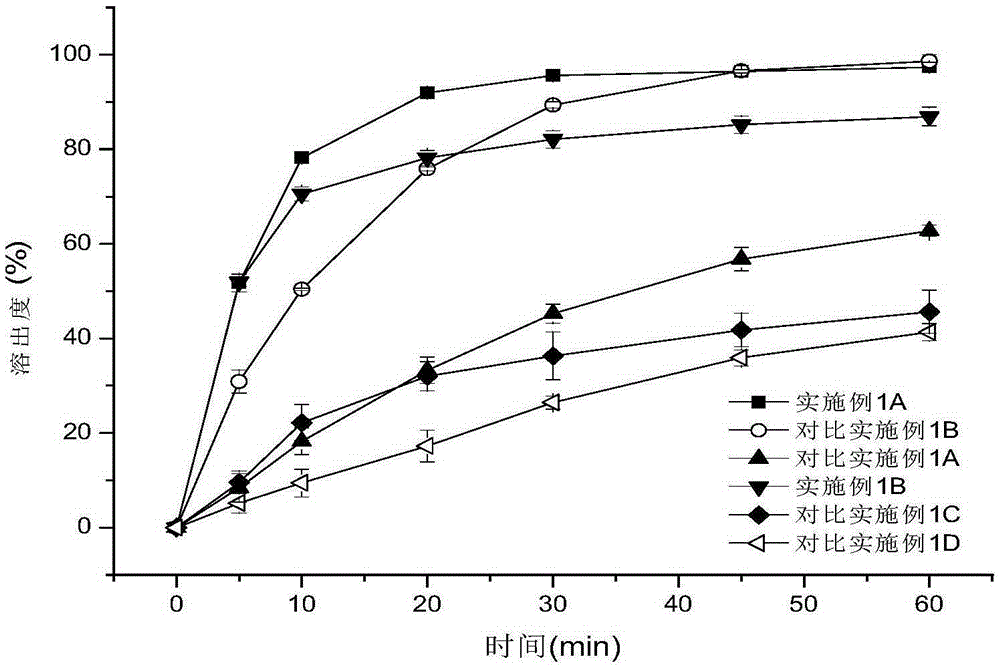

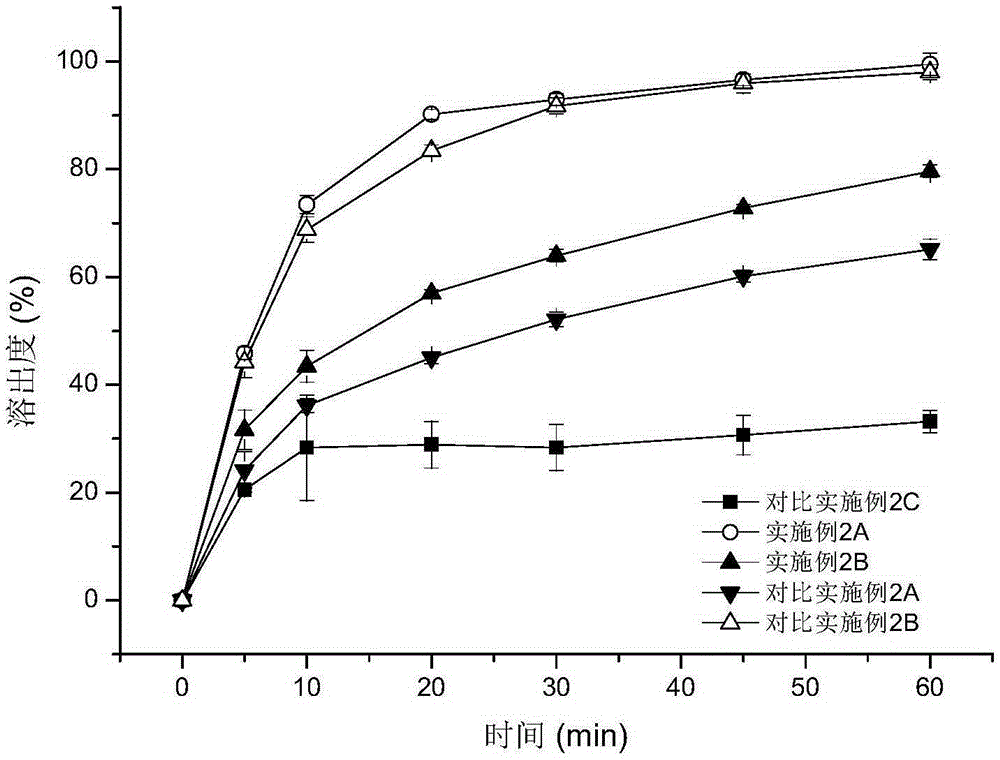

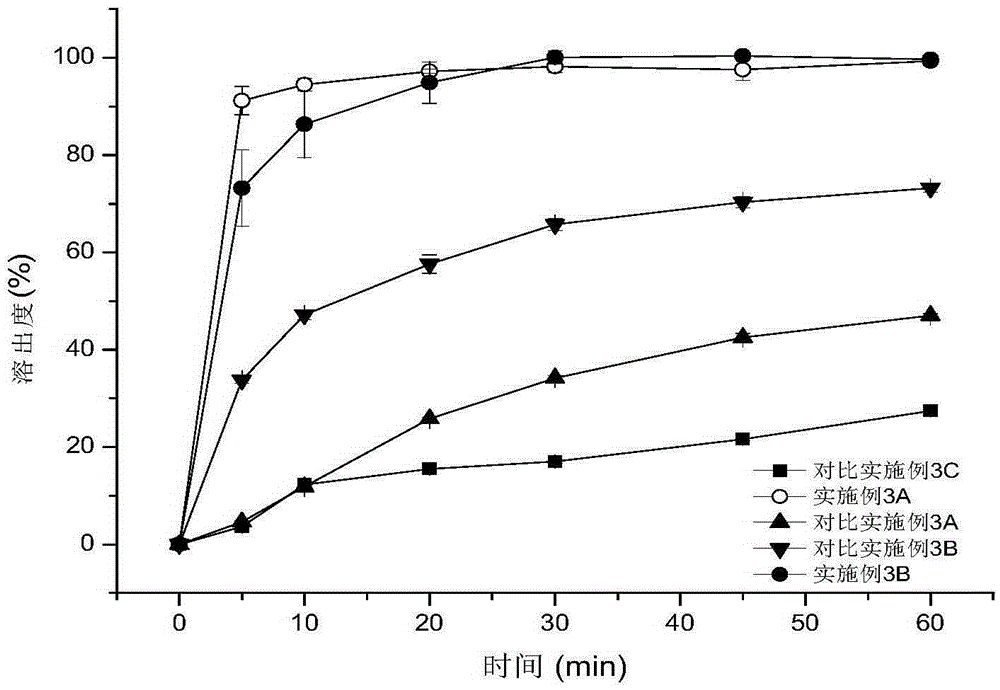

Sparingly soluble active component particle, particle preparation and preparation method thereof

ActiveCN105640890AChange natureChange releaseCosmetic preparationsPowder deliveryPolymer dissolutionActive component

The invention discloses a sparingly soluble active component particle, a particle preparation and a preparation method thereof. The preparation method of the sparingly soluble active component particle comprises the following steps: dissolving sparingly soluble active component and ionic polymer into an alkaline solution or an acidic solution, and then mixing the alkaline solution and acidic solution to change the pH value of solutions so as to precipitate the sparingly soluble active component and ionic polymer from the mixed solution to form particles; and the performance of the sparingly soluble active component particle is improved. According to the preparation method, sparingly soluble active component and ionic polymer are co-precipitated, at the same time, a preparation technology is adopted, and two technologies are tightly combined to prepare the sparingly soluble active component particle preparation. The prepared preparation has the advantages of excellent dissolving-out characteristic, high bioavailability, small individual difference, good stability, and good content uniformity.

Owner:SINOTHERAPEUTICS

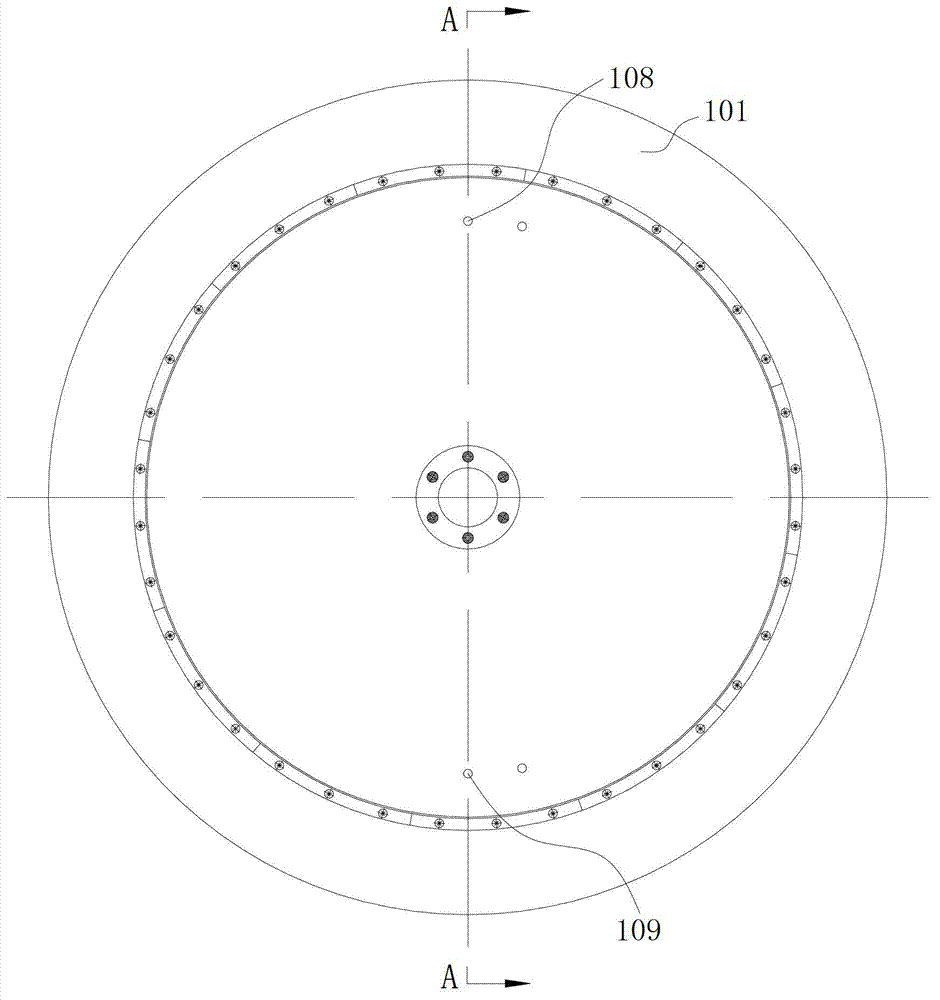

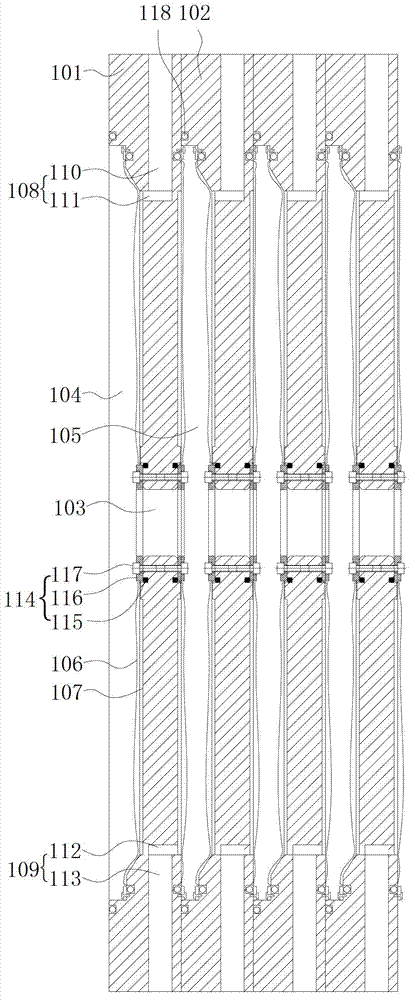

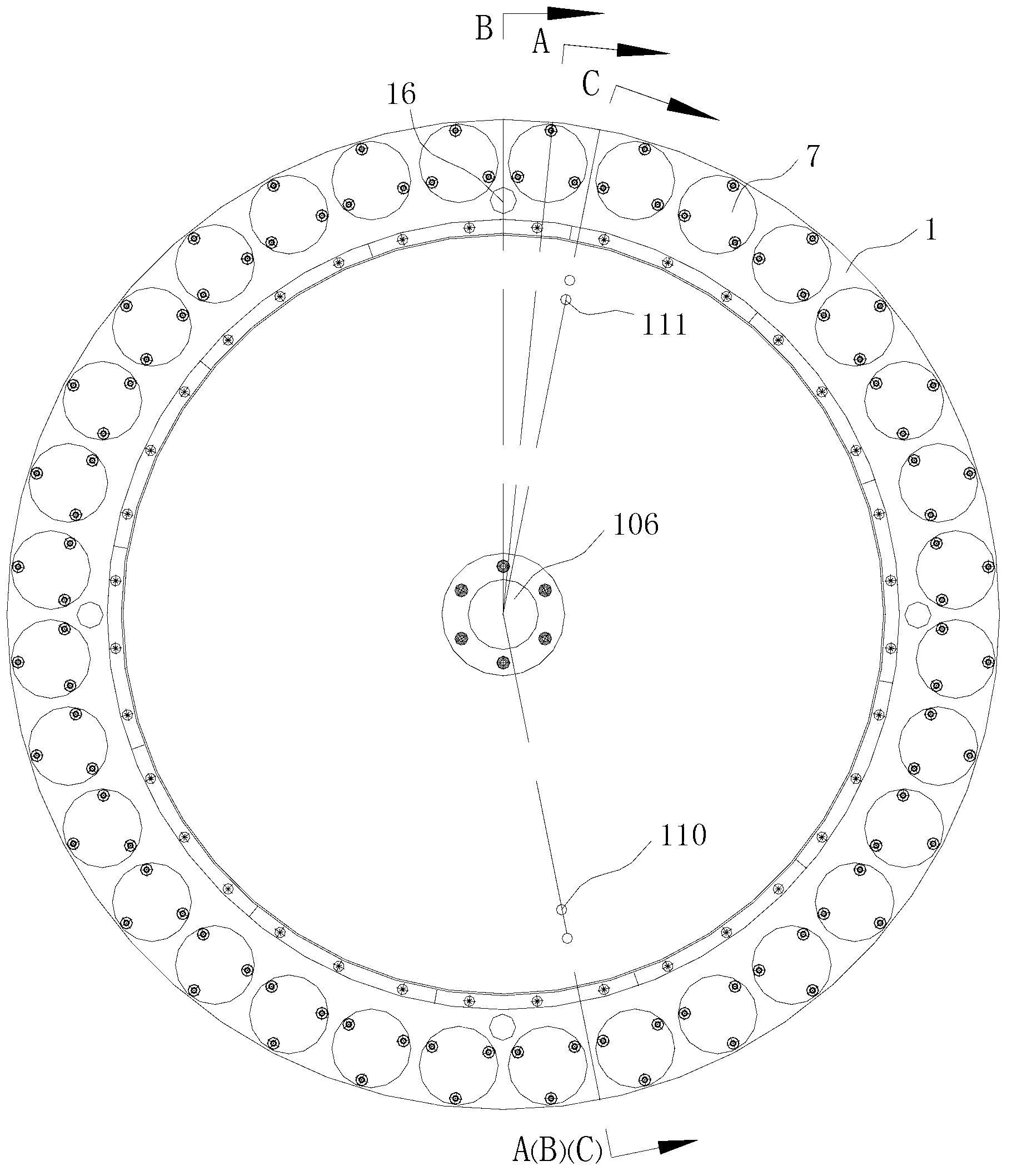

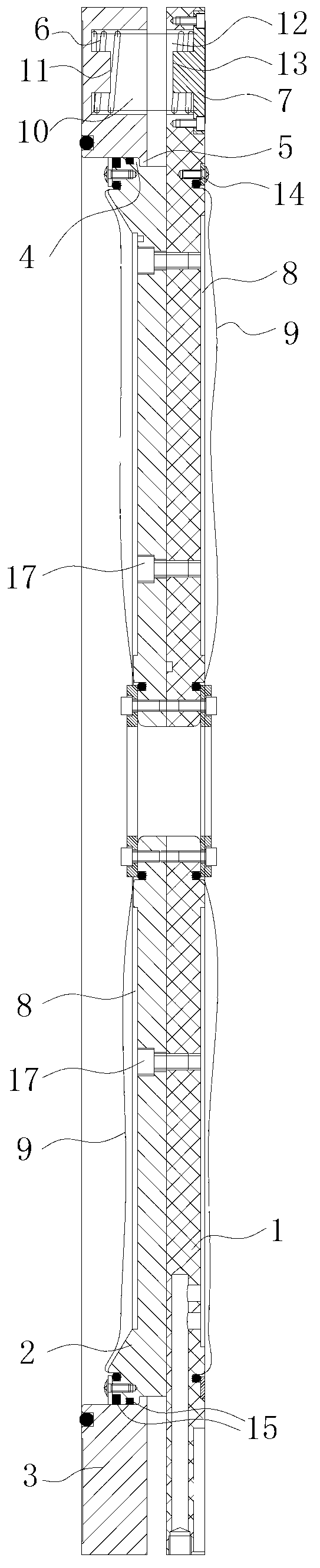

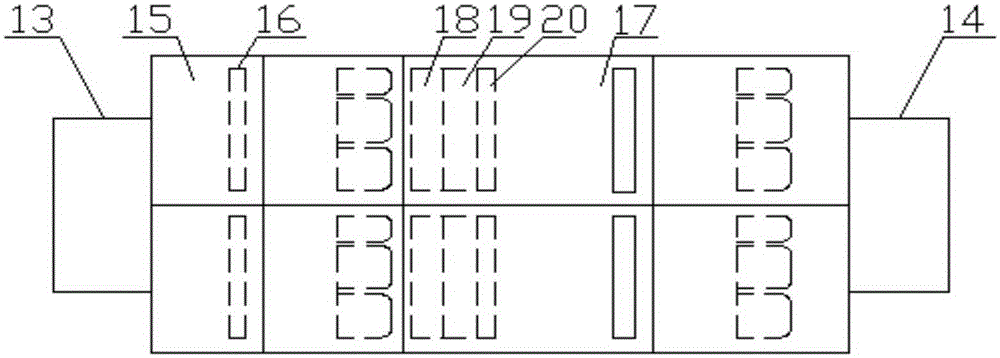

Pressure filter and pressure filtration method thereof

InactiveCN102814063AFew partsThe overall structure is simple and reliableFiltration separationPlate pressureFiltration

The present invention discloses a pressure filter, which comprises multiple groups of filter plates, wherein the adjacent filter plates are arranged in a contact manner, and each filter plate is provided with a material channel and a pressure filtration space with a variable volume and for accommodating a material. One end of the material channel is communicated with the pressure filtration space, and the other end is communicated with the pressure filtration space of the adjacent filter plate. Each filter plate is further provided with an air channel for communicating the filter plate pressure filtration space and a liquid channel for communicating the pressure filtration space of the adjacent filter plate. Filter screens are arranged on both sides of the filter plates and are positioned inside the adjacent pressure filtration space, wherein a filter cloth is covered outside the filter screen. The pressure filter of the present invention has characteristics of fewer components, simple and reliable structure, and low equipment maintenance workload. The present invention provides a pressure filtration method. According to the pressure filtration method of the present invention, two-stage pressure filtration and one-stage drying are adopted, wherein the first stage is that a driving pump is adopted to feed the material to carry out pressure filtration, the second stage is that high pressure air pressurizes the filter cloth to carry out pressure pressing, and the third stage is that the material is dried with high temperature air, such that pressure filtration efficiency is improved, and effects of automatic material unloading and filter cloth cleaning are achieved through the high pressure air.

Owner:FOSHAN JINKAIDI FILTRATION EQUIP CO LTD

Method for improving performance of paper stock in retention and drainage aiding

InactiveCN101634120AImprove retentionGood filterabilityInorganic compound additionPaper-making machinesFiberSlurry

The invention provides a method for improving the performance of paper stock in retention and drainage aiding. The method comprises the following steps: firstly, dispersing plant fiber materials for papermaking in water, beating the plant fiber materials with the beating degree being controlled to 25 to 70 DEG SR (Schopper-Riegler); secondly, feeding the evenly mixed slurry into the approach flow system of a paper machine, and adding CPAM (cationic polyacrylamide) as retention agent before feeding the slurry into a fan pump of the approach flow system; then, adding electronegative bentonite before feeding the slurry into a pressure screen or a head box, and adding APAM (anionic polyacrylamide) before feeding the slurry into the head box; and finally, papermaking forming on the paper machine, drying and obtaining the qualified paper. By adding excessive CPAM to the paper machine, the invention allows the action between CPAM and bentonite to form fine particles, and the further combination with APAM to form floccules, thereby providing draining channels in good conditions and further improving the drainage capacity during the forming process of the paper stock.

Owner:SHAANXI UNIV OF SCI & TECH

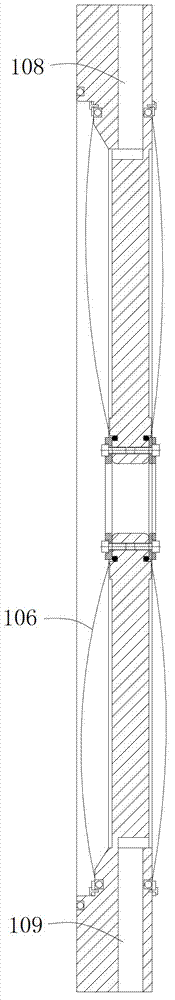

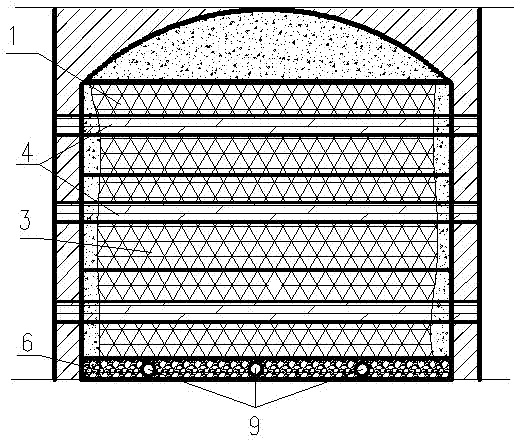

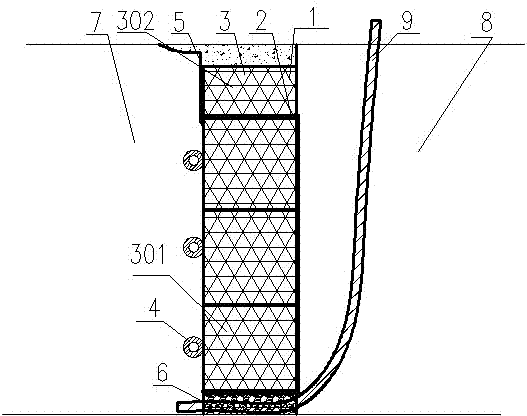

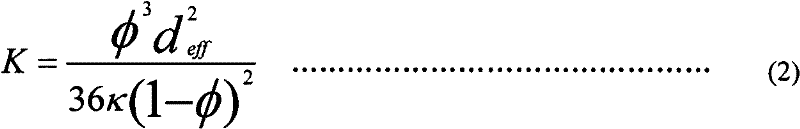

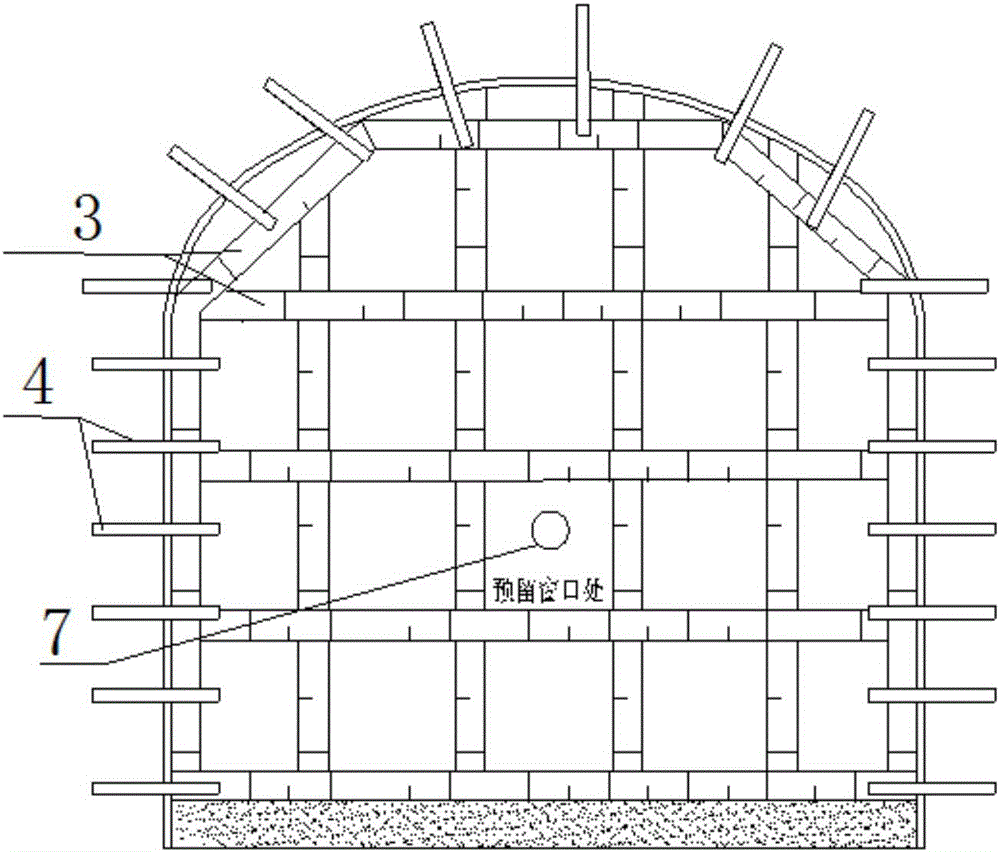

Tailing cemented and filled retaining wall device under mine

The invention relates to a tailing cemented and filled retaining wall device under a mine. The device comprises a roadway, a wall body and a plurality of dewatering pipes. The wall body divides the roadway into an internal part of a mining area and an external part of the mining area. The wall body comprises a filter fabric, a plurality of layers of stone cages and a plurality of retaining wall crosspieces. The stone cages are filled with mining waste rock. A concrete foundation is arranged below the lower layer of stone cages. The dewatering pipes are arranged in the concrete foundation. Water outlet ports of the dewatering pipes are arranged at the external part of the mining area and water inlet ports of the dewatering pipes are arranged at the internal part of the mining area. The filter fabric is laid on the outer surface of layers of stone cages at the internal part of the mining area. The retaining wall crosspieces are arranged at an upper layer and a lower layer and are fixedly arranged outside the layers of stone cages at the external part of the mining area. Gaps among the two sides and the top of the wall body and the walls of the roadway are blocked and sealed through concrete. The tailing cemented and filled retaining wall device under the mine has the characteristics of excellent wall body stress performance, good slurry retaining effect, good water filtering effect, high erection speed, simplicity and convenience in construction, low cost and the like. At an early filling stage, the dewatering capacity of the retaining wall device is 7-10 times of that of a concrete enclosure wall.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Organic high molecular composite flocculant and preparation method thereof

ActiveCN101973688ALow costSufficient sourceSludge treatment by de-watering/drying/thickeningChlorideSuspended matter

The invention discloses an organic high molecular composite flocculant which is mainly used for municipally or industrially dewatering sludge and a preparation method thereof, which solve the problems of complex treatment process, agent waste, secondary pollution and the like existing in the prior art. The flocculant comprises polyacrylamide, polydimethyldiallylammonium chloride and modified starch serving as raw materials and the dry weight ratio of polyacrylamide to polydimethyldiallylammonium chloride to modified starch is 4-9:0.5-5:0.5-5, wherein tap water or de-ionized water is used as a dispersing agent; and the liquid organic high molecular composite flocculant, of which the molecular weight is 4,000,000 to 12,000,000, the ionization degree is 40 to 80 percent and the effective content of the raw material is 1 to 5 percent based on dry weight, is prepared by dispersing the materials in a reactor at the temperature of between 10 and 50 DEG C with stirring and compounding for 0.5 to 3 hours. The flocculant has the advantages of sufficient raw material sources, low cost, simple process flow, stable performance and high suspension separation speed, is reasonably prepared and quickly dissolved and is safe to operate, and convenient to use, saves the amount, obviously improves the dehydration efficiency, expands the application range, prevents fluctuation of treatment effect and reduces secondary pollution.

Owner:国能辽宁环保产业集团有限公司材料分公司

Composition for changing and improving property of fiber surface and paper making method

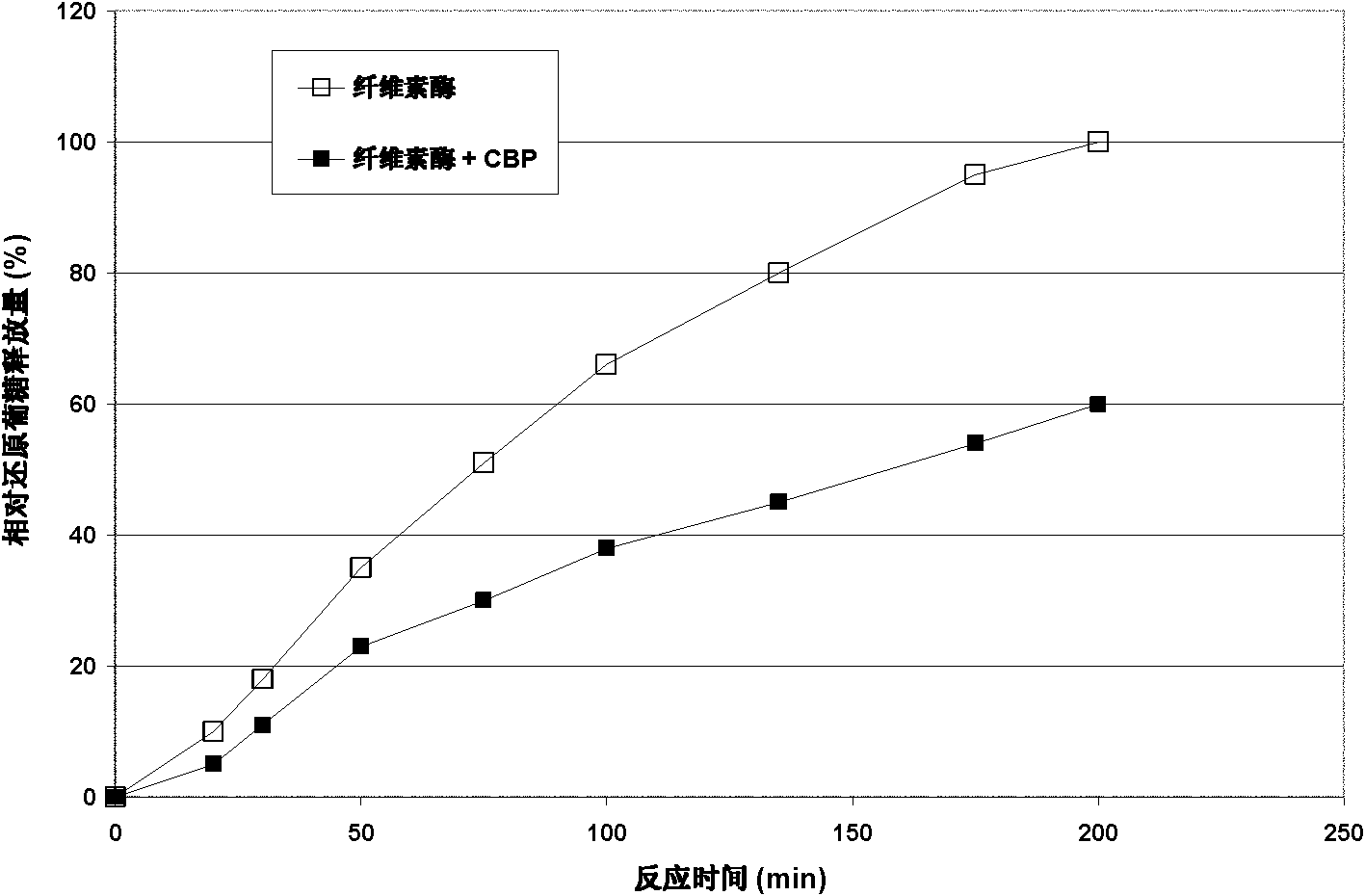

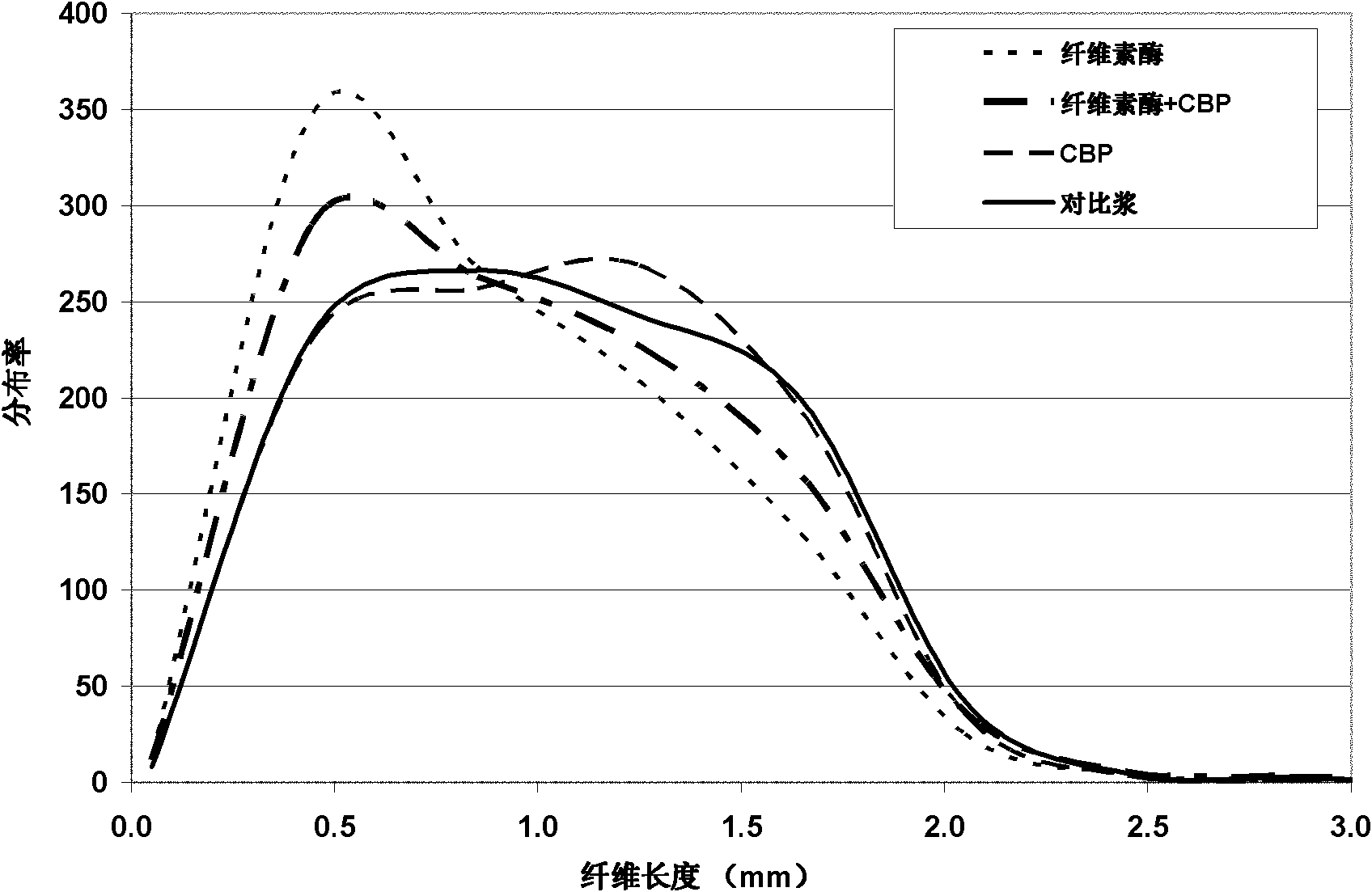

ActiveCN102086611AAvoid reactionIncrease fiber reactivityNon-fibrous pulp additionBiochemical fibre treatmentEnzymeChemistry

The invention discloses a composition for changing and improving the property of a fiber surface. The composition consists of the following components: a protein component without catalytic activity and a protein component with catalytic activity, wherein the protein component without catalytic activity is fibronectin with higher affinity to the fiber surface; the protein component with catalytic activity is fiber modified enzyme which can change the property of the fiber surface; and the weight ratio of the fibronectin to proteins of the fiber modified enzyme is between 1:(0.1-1:10). The invention also provides a method for applying the composition to paper making. When the composition is used for treating paper pulp, the drainage capacity of the paper pulp is greatly enhanced, and the intensive property of paper is remarkably enhanced.

Owner:RISINGSTAR BIOTECH GUANGZHOU

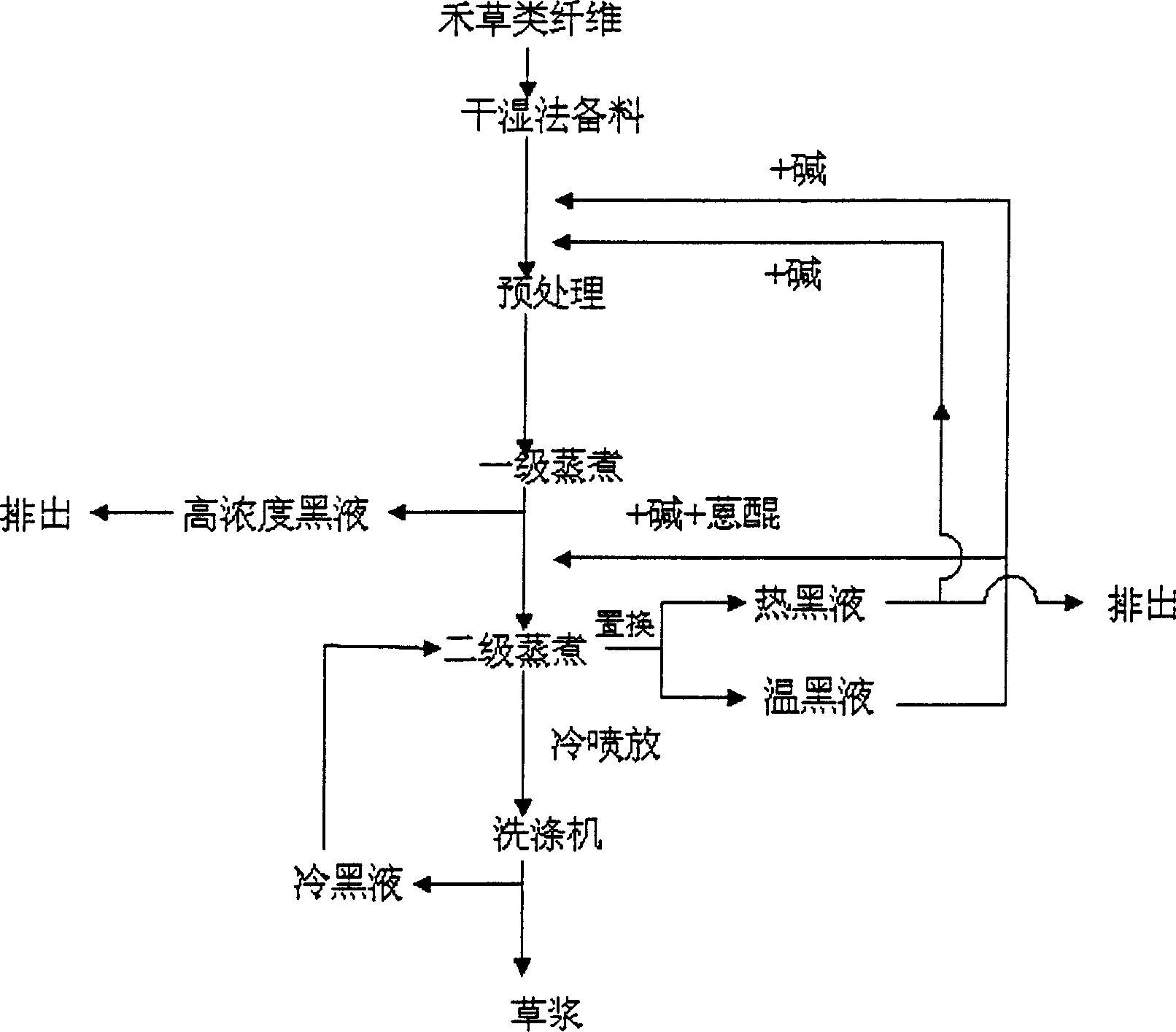

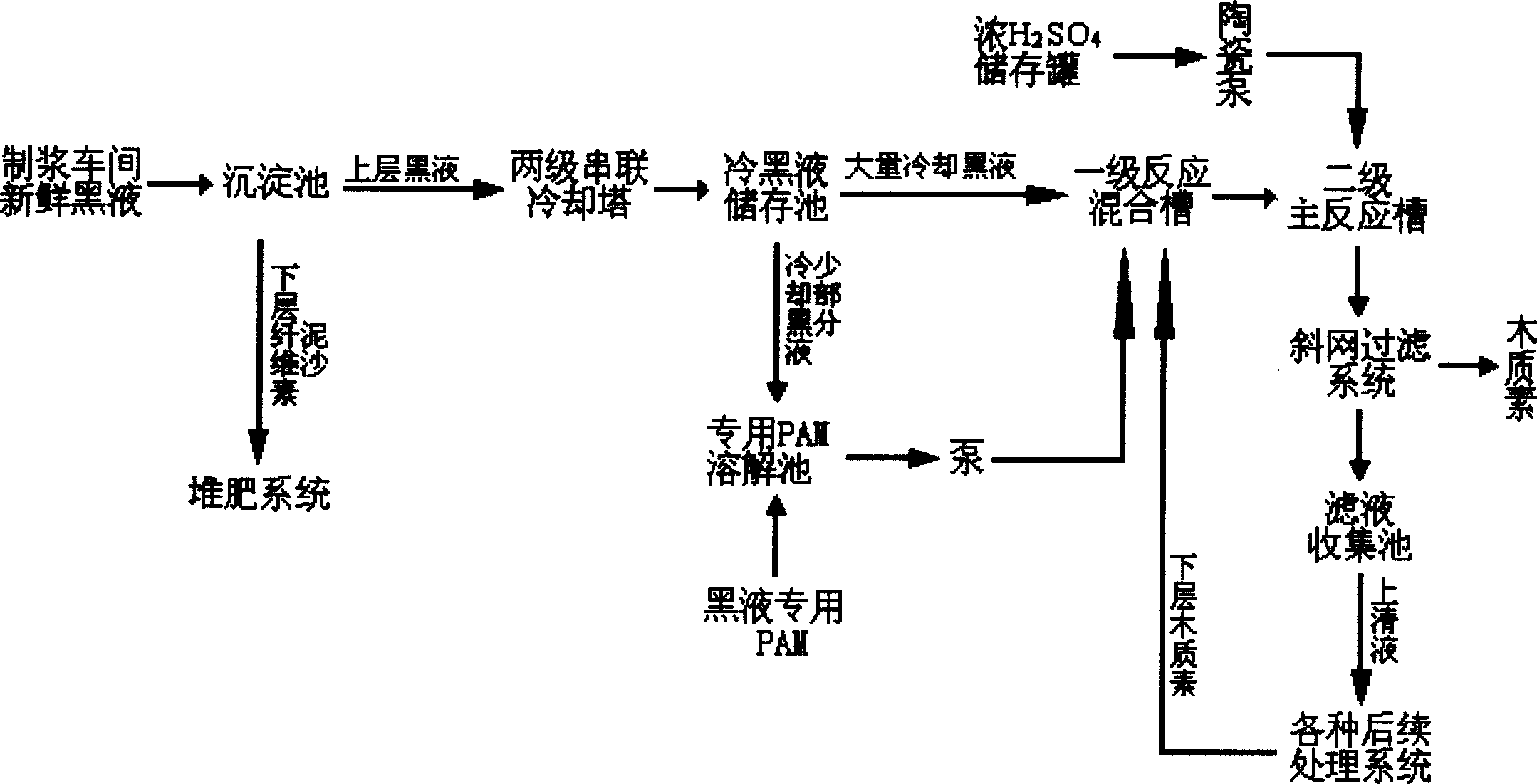

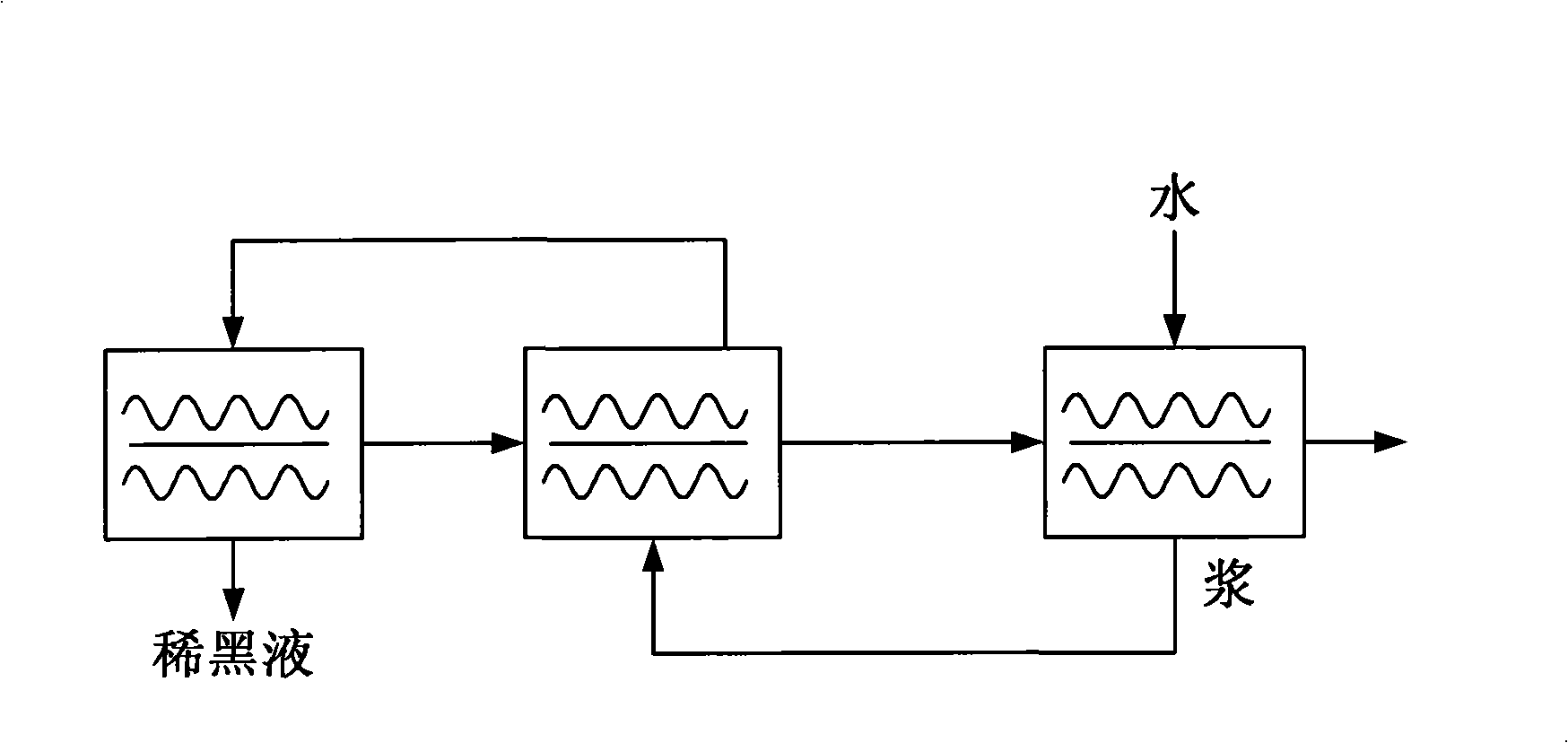

Whole black liqucd large liqucd rate cercal grass cooking technology with digester

ActiveCN1598127AReduce consumptionReduce hardnessFinely-divided material pretreatmentCellulose material pulpingHigh concentrationFiber

The invention relates to a whole black liquor large liquor rate cercal grass cooking technology with digester, comprising the following steps: after stocking, preimpregnating the grass raw fiber; loading the preimpregnated raw material into cooking equipment to perform first stage boiling washing to discharge black liqucd of high concentration to obtain straw pulp intermediate product; supplying cooking liquor to the said cooking equipment, and second stage boiling washing the straw pulp intermediate product, and then straw pulp being obtained through washing; repective cycle operating ryegrass large liquor rate displacement cooking and ryegrass large liquor rate displacement cooking black liquor and implementing grading displacement cooking in cooking pan, the research and design of cooking pan grading displacement cooking technology and the corresponding device design and parttern selection being done. The said technology can be used in rebuilting the domestic ryegrass pulp mill. The pulp strength can be enhanced and the quality of the waste liquor is improved. The invention benifits for recovery processing and reduces the discharge of the waste liquor and BOD, COD.

Owner:高唐绿荫环保科技有限公司

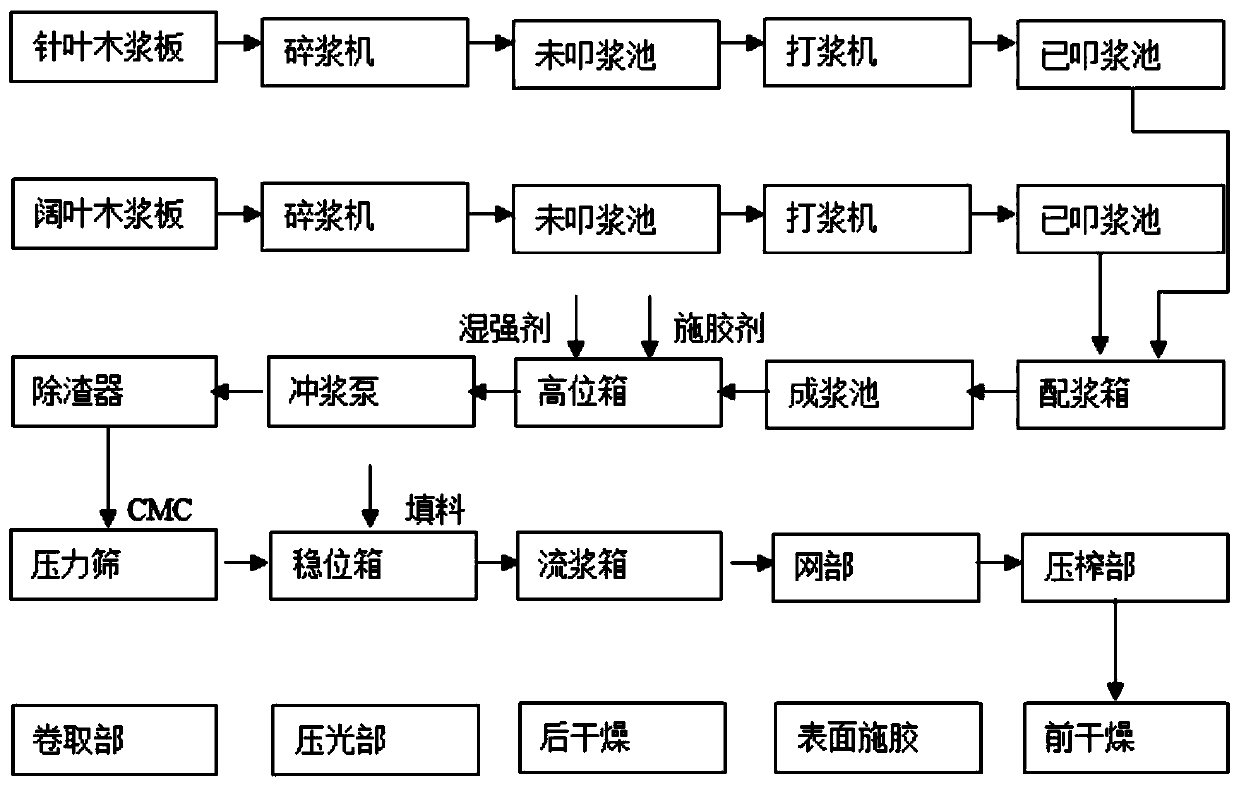

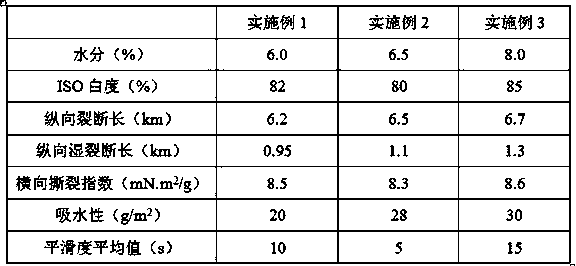

Manufacturing method of beverage drinking straw paper

InactiveCN110318302AImprove wet strengthIncrease paper dry strengthTextiles and paperHardwoodDrinking straw

The invention discloses a manufacturing method of a beverage drinking straw paper. The method comprises the technical processes of pulp beating, pulp blending, additive adding, wet paper making, pre-drying, surface sizing, after-drying, calendaring and rolling. The beverage drinking straw paper belongs to papers for foods and meets the sanitary requirements on the papers for foods. The beverage drinking straw paper is manufactured by choosing preferable raw and additive materials and chemicals and taking chlorine-free bleached softwood kraft paper pulp and chlorine-free bleached hardwood kraftpaper pulp as fiber raw materials, which contain no toxic chemical substances such as organic chlorides and are environmentally friendly, sanitary and free from damage to human body. The produced beverage drinking straw paper is high in dry strength and wet strength, free from breakage, high in humidity resistance and capable of being rapidly decomposed to meet the environmental requirements as we as the sanitary requirements on the papers for foods.

Owner:YUEYANG FOREST & PAPER CO LTD

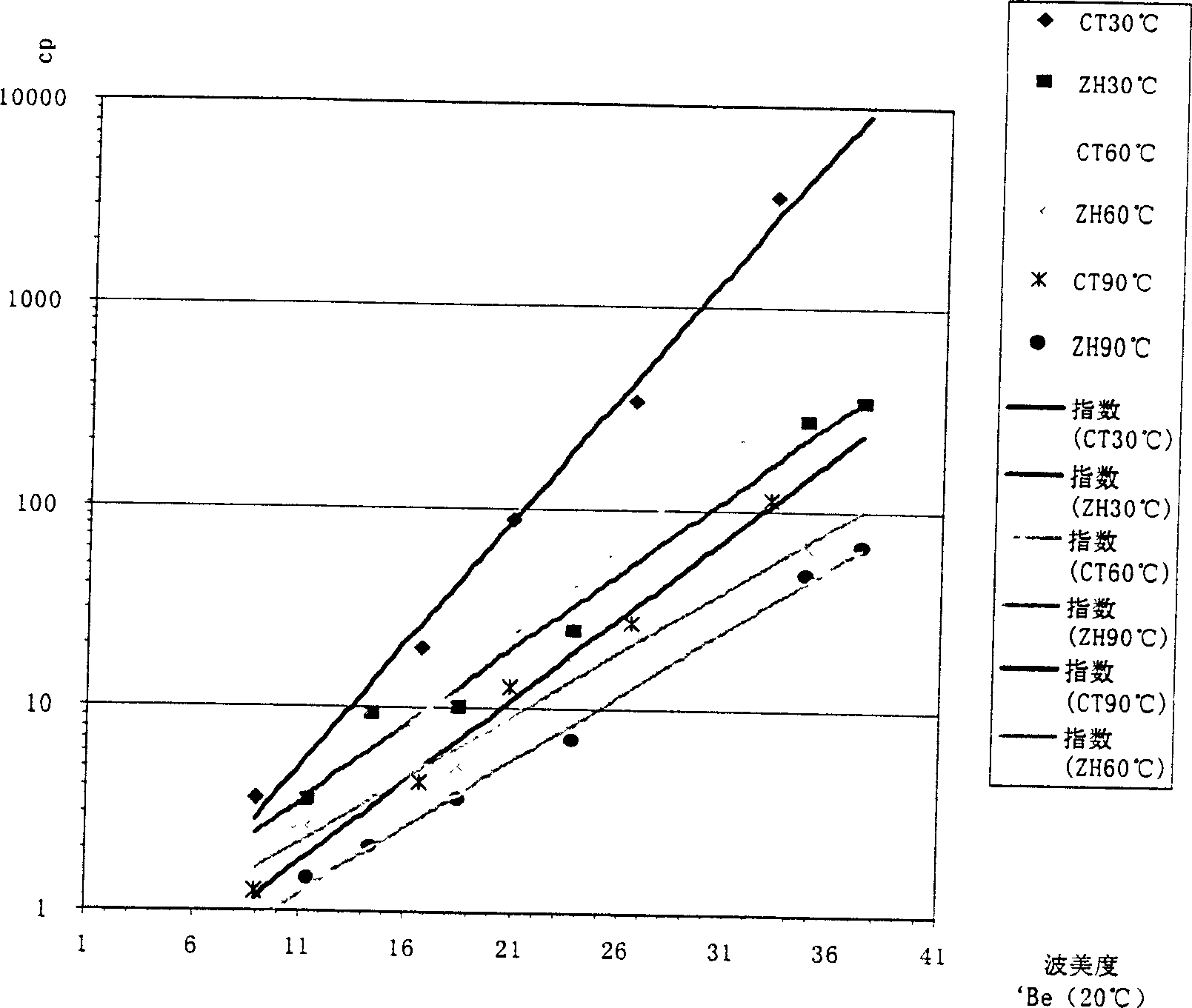

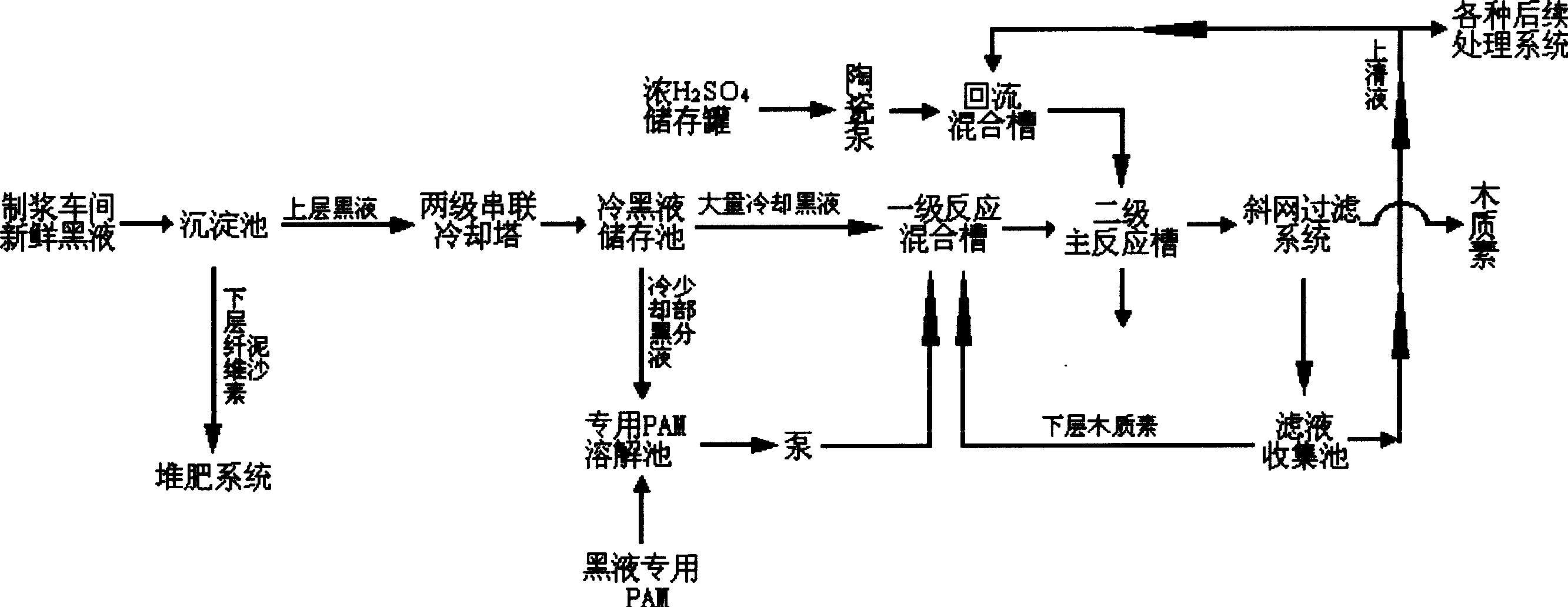

Process for extracting lignin by acid separation

InactiveCN1587077AGood filterabilityEasy to recycleLignin derivativesWater/sewage treatment by flocculation/precipitationLiquid wasteFiber

The present invention relates to the extraction process of acid out lignin, and is especially the process of treating waste digestion liquid produced during making paper pulp to extract lignin. The extraction process includes depositing separation to eliminate fiber mud and silt from black liquor, cooling black liquor containing lignin, adding flocculent and acid to deposit lignin, and filtering to obtain lignin containing product. The said process has high lignin extracting rate up to 95 %, and the obtained lignin has excellent water filtering performance and dryness over 25 %.

Owner:SHANDONG TRALIN PAPER

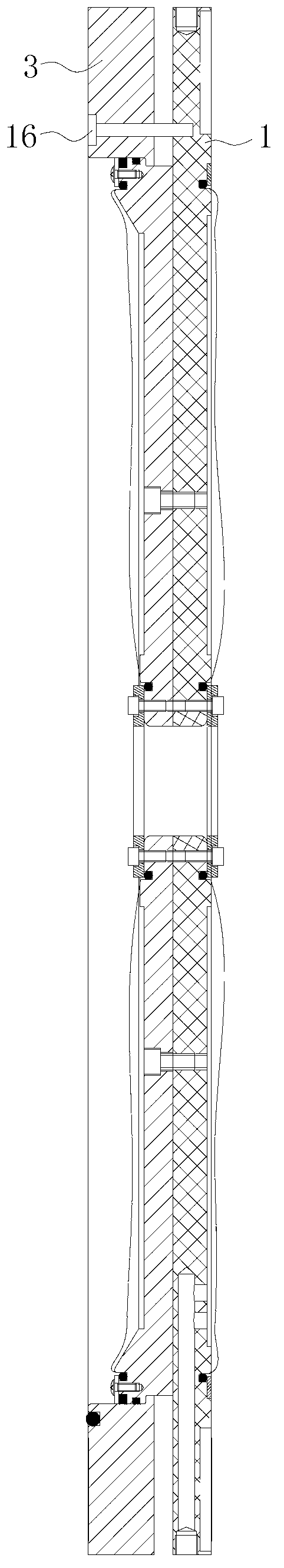

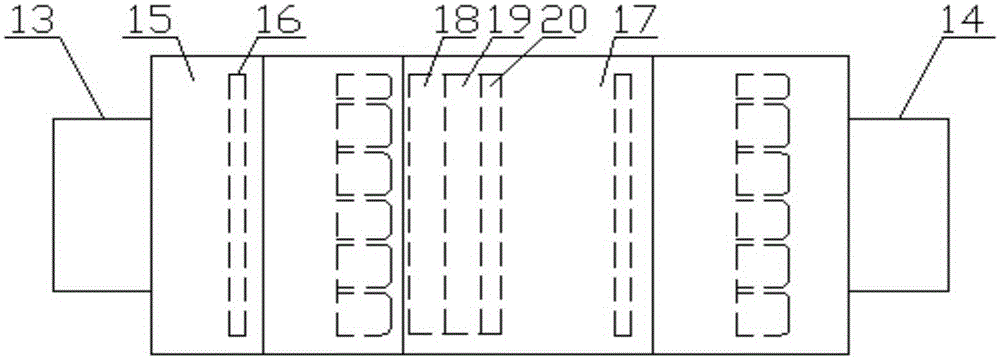

Pressure filter and pressing filtering method thereof

ActiveCN102836581AEasy resetGood pressure holding effectFiltration separationStructural reliabilityWater filter

The invention discloses a pressure filter comprising a plurality of filtering plate sets which are connected in sequence, wherein each filtering plate set comprises a main plate, an auxiliary plate, and an auxiliary frame, the auxiliary plate is fixed on one side of the main plate and on the same side of the main plate, the auxiliary frame is sleeved on the periphery of the auxiliary plate in a sliding mode, and the other side of the main plate is connected with the auxiliary frame of the adjacent filtering plate sets. Moreover, volume-changeable pressing filtering space used for containing materials is arranged between the adjacent filtering plate sets. Each filtering plate set is provided with a material channel which is communicated with the pressing filtering space. The other side of the main plate, opposite to the contact face of the auxiliary plate, is provided with a filtering mesh. Filter cloth wraps outside the filtering mesh. Each filtering plate set is also provided with a gas channel and a liquid channel which are communicated with the outside to the pressing filtering space. The pressure filter is high in structure reliability, has no leakage of the materials, and is convenient to maintain. The invention further provides a pressing filtering method. As pressing filtering and drying above the third level are adopted, water-filtering effect is better, size of the pressed and filtered material is larger, water containing rate of the materials is lower, work efficiency is higher, and production is higher.

Owner:FOSHAN JINKAIDI FILTRATION EQUIP CO LTD

Reynolds test instrument

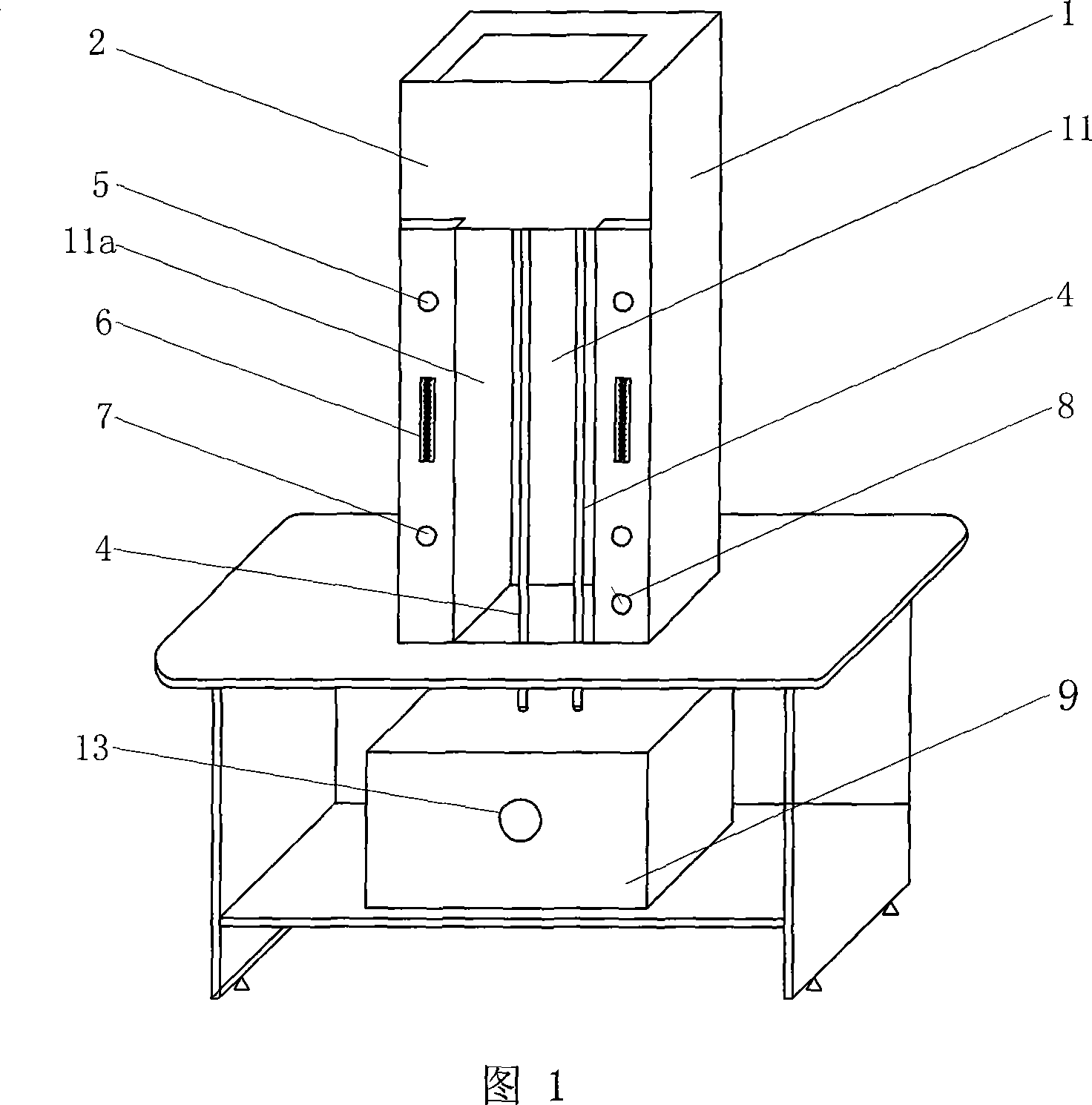

InactiveCN101051427AAvoid Vibration InterferenceImprove presentationEducational modelsEngineeringPermeation

The present invention discloses a Reynolds experiment instrument. It is characterized by that in the constant pressure zone of its constant pressure water tank a permeation cover is set, said permeation cover can be used for covering upper portion of water inlet of experiment tube, the space covered by said permeation cover is formed into a water-stabilizing zone, and the water body in the water-stabilizing zone of said experiment instrument can not be interfered by water of water inlet tube.

Owner:SOUTHWEST JIAOTONG UNIV

Poplar ultrasonic chemical mechanical pulping technique

ActiveCN106120418ALarge specific surface areaHigh bonding strengthPulping with organic compoundsMultistage pulping processChemistryPre treatment

The invention relates to a poplar ultrasonic chemical mechanical pulping technique. The pulping technique includes the steps: performing ultrasonic pretreatment on steamed poplar pulp after first stage impressafining; performing xylanase pretreatment on the pulp after the ultrasonic pretreatment; soaking the pulp in soda hydrogen dioxide solution after pretreatment; performing second stage impressafining after soaking; performing second stage soaking on the pulp in the soda hydrogen dioxide solution after the second stage impressafining; performing first stage refining on the pulp with the soaking liquid; performing high concentrated storage and bleaching after the first stage refining; and performing second stage refining to obtain high-brightness high-yield high-strength chemical mechanical pulp. The poplar ultrasonic chemical mechanical pulping technique can improve the mechanical pulping performance of fast-growing poplar, enlarge the application range of poplar high-yield pulp, improve the performance of poplar paper pulp, and improve the use value of the poplar.

Owner:QILU UNIV OF TECH

Ecological algae flocculating material

InactiveCN101234809AFast and efficient flocculation removalTotal Phosphorus and Nitrogen ReductionWater/sewage treatment by flocculation/precipitationAquatic animalFresh water organism

The invention relates to an algae setting material, which comprises 5 to 70 percent of natural fiber material and 30 to 95 percent of natural high polymer material, wherein, the natural fiber material is selected from plant fiber and / or animal fiber, and the natural high polymer material is selected from crab derivatives and / or shrimp derivatives and plant viscous juice with a proportion no less than 5 percent. The algae setting material is the natural substance without any harm to human bodies, livestock, environment as well as aquatic animals and plants, and has coagulation, adsorption, tangling and enmeshing function for the algae. When the use amount of the algae material is 0.1 to 10mg / L, the removal efficiency of the algae is over 95 percent. The obtained algae setting body of the flocculation has strong holding power, good performance of floating and drainability, little algae mug and convenient post-process, so the invention is applicable to urgent treatment of burst red tide in ease water and water bloom in fresh water.

Owner:合肥市东方美捷分子材料技术有限公司

VOCs (volatile organic compounds) waste gas treatment combination device

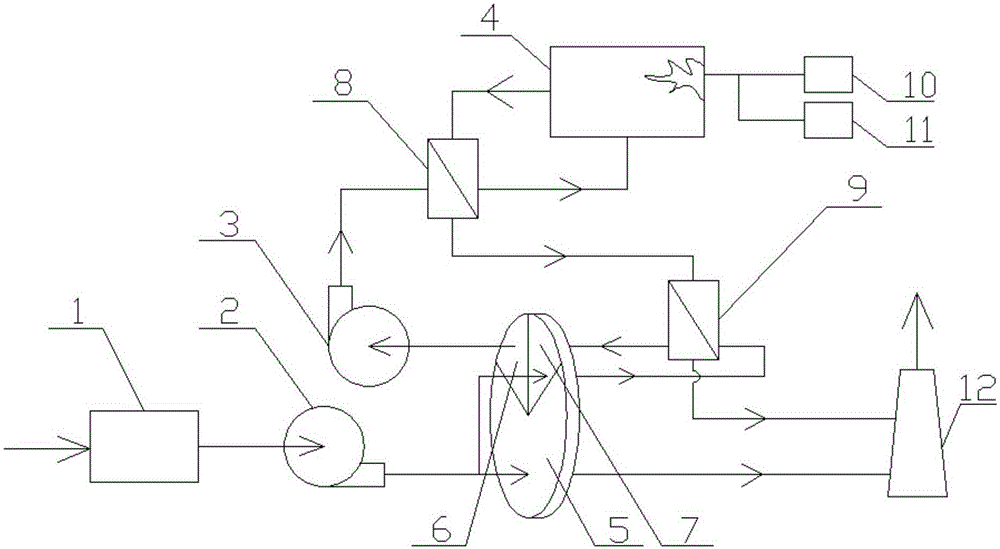

InactiveCN105194978AAvoid generatingGood filterabilityDispersed particle filtrationVapor condensationVolatile organic compoundPollutant

The invention relates to a VOCs (volatile organic compounds) waste gas treatment combination device and belongs to the technical field of air purification. A filter, an adsorption fan and a treatment zone of a concentration runner are connected sequentially through pipelines, gas is filtered, adsorbed, purified and released to the atmosphere, an output end of the adsorption fan is connected with a cooling zone, a heating pipeline of a second heat exchanger, a regeneration zone, a desorption fan, a heating pipeline of a first heat exchanger and an input end of a combustion device are connected sequentially through pipelines, an output end of the combustion device, a cooling pipeline of the first heat exchanger and a cooling pipeline of the second heat exchanger are sequentially connected, the concentration runner is driven by a motor to rotate, the filter comprises an upper chamber and a lower chamber, four filtering cavities are formed in the upper chamber from an inlet to an outlet sequentially, and coil pipes and water baffles are arranged in the filtering cavities respectively. The early filtration effect of the device is better, the conditions that other pollutants react with VOCs and impurities are decomposed and generate other pollutants when heated are prevented, and the waste gas treatment effect is remarkably improved.

Owner:TIANJUSHI ENG TECH GROUP

Integrated ecology renovation method for extratropical eutrophication marine site

InactiveCN1990394AImprove self-cleaning abilityRestoring eutrophic environmentsSeawater treatmentClimate change adaptationTemperate climateParticulates

The invention relates to a technique for treating polluted environment, which in detail is a comprehensive ecological restore method especially for etrophication waters in temperate zone in part of China. It combines the cultivation of large scale of algae and culture filter feeding animal of in etrophication waters to build a biological filter device and then restore polluted environment. The invention makes full use of ecological function of large scale algae absorbing dissolved nitrogen and phosphorus in large amount and ecological function of filter feeding animal filtering suspended particle and nutrient matter from water, to restore etrophication waters. The applied algae and filter feeding animal are important economical varieties, thus they can also bring economical benefit. The invention is characterized by both ecological benefit and economical benefit and suitability for etrophication waters in temperate zone in north of China.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

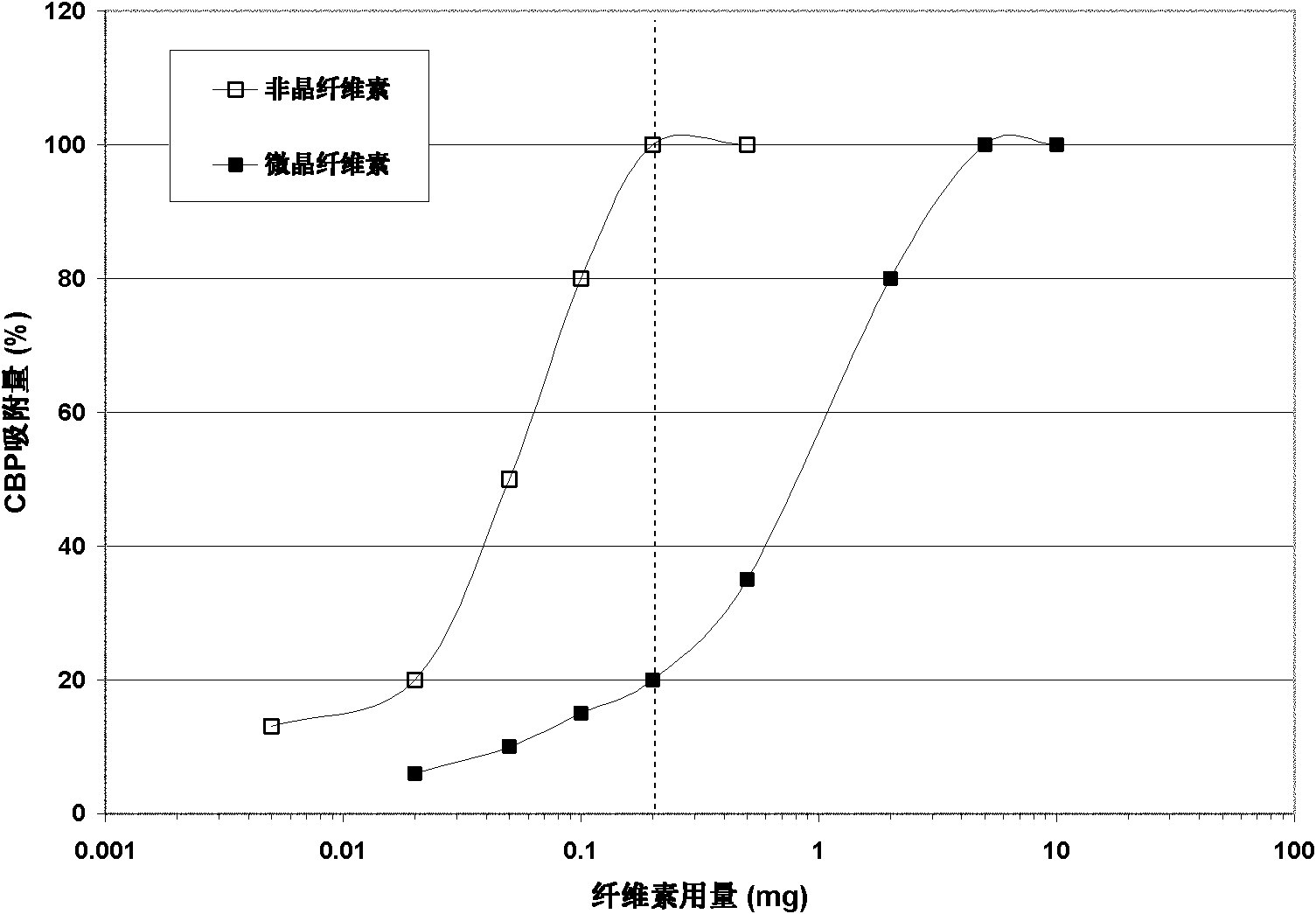

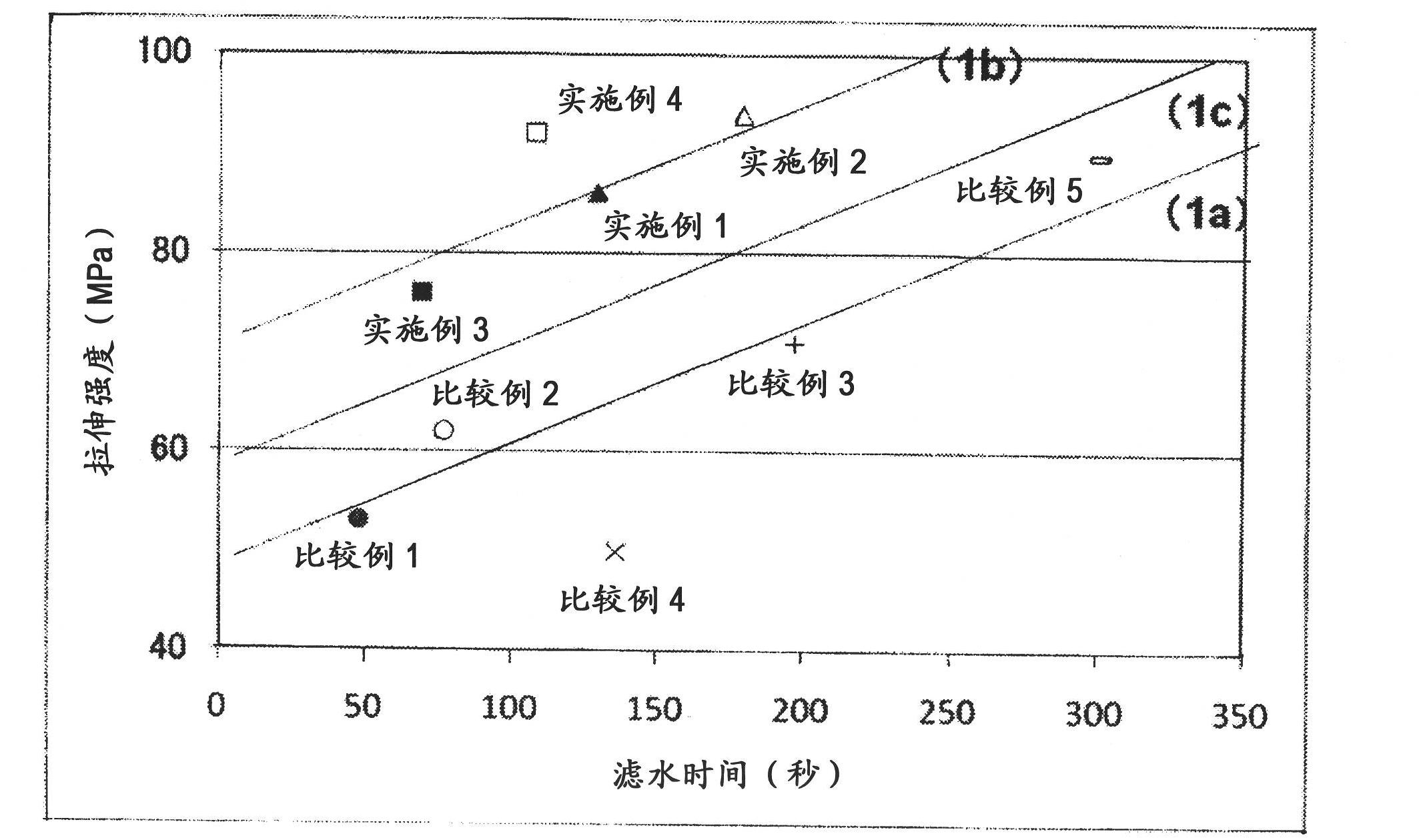

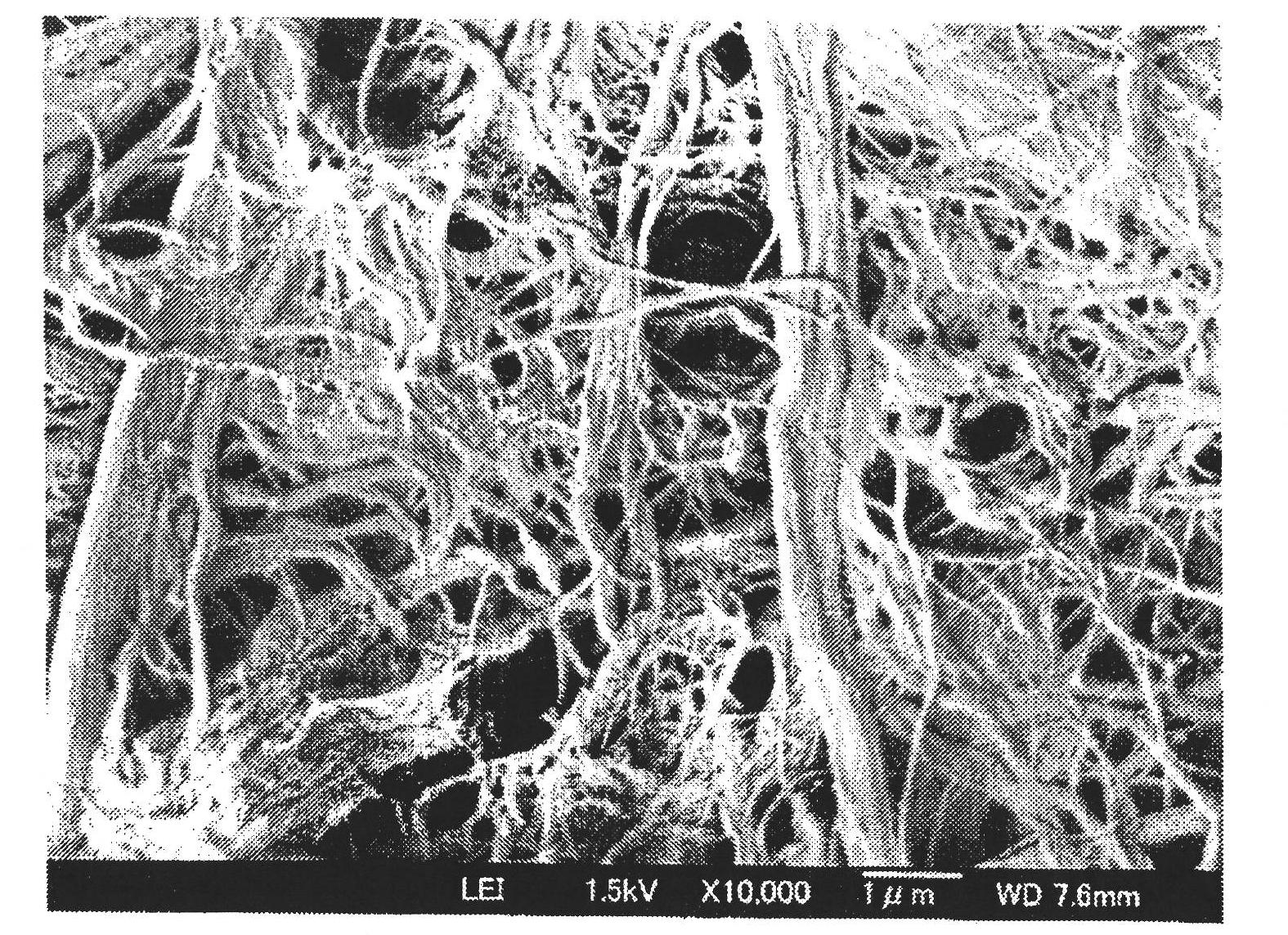

Cellulose nanofibers

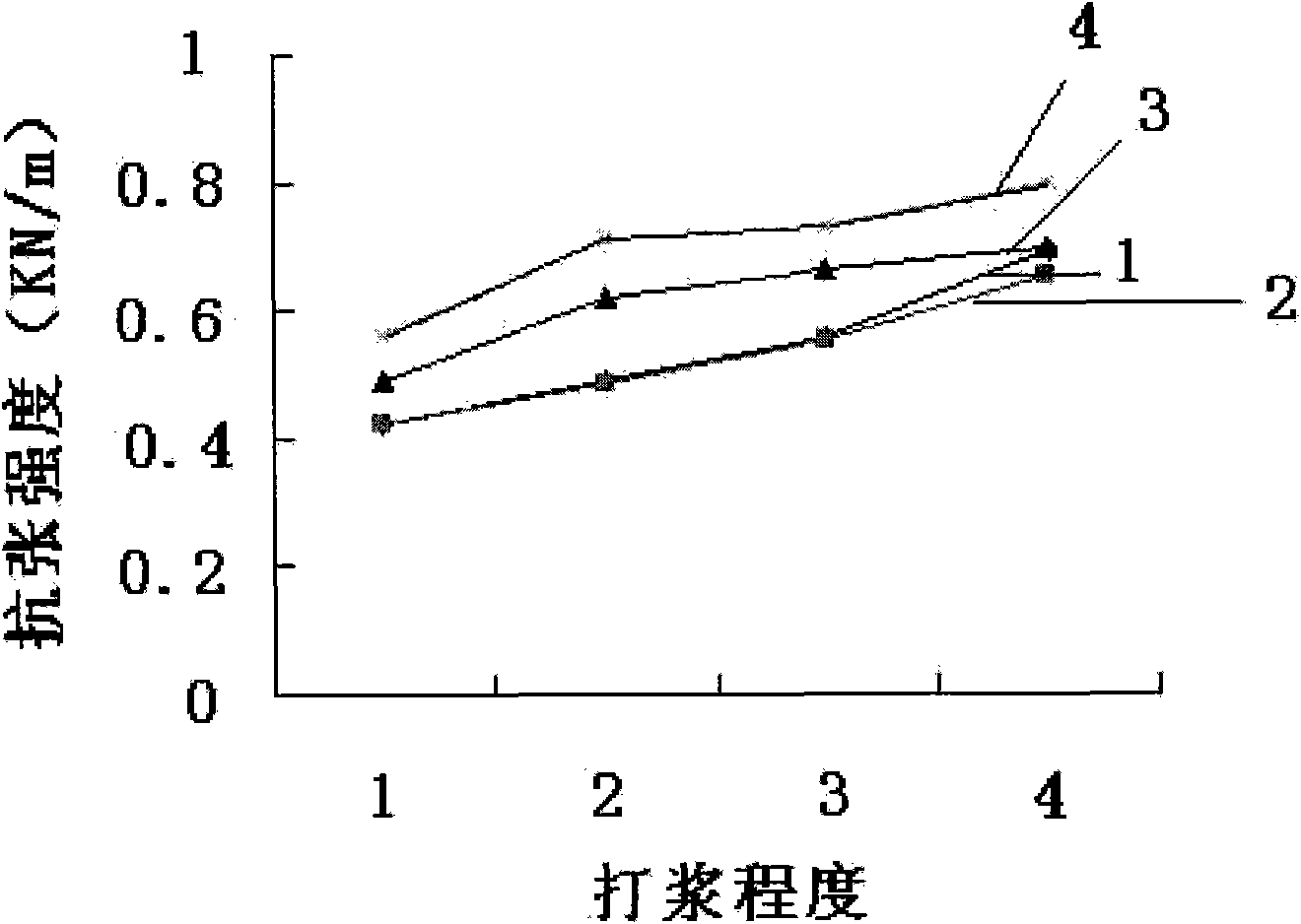

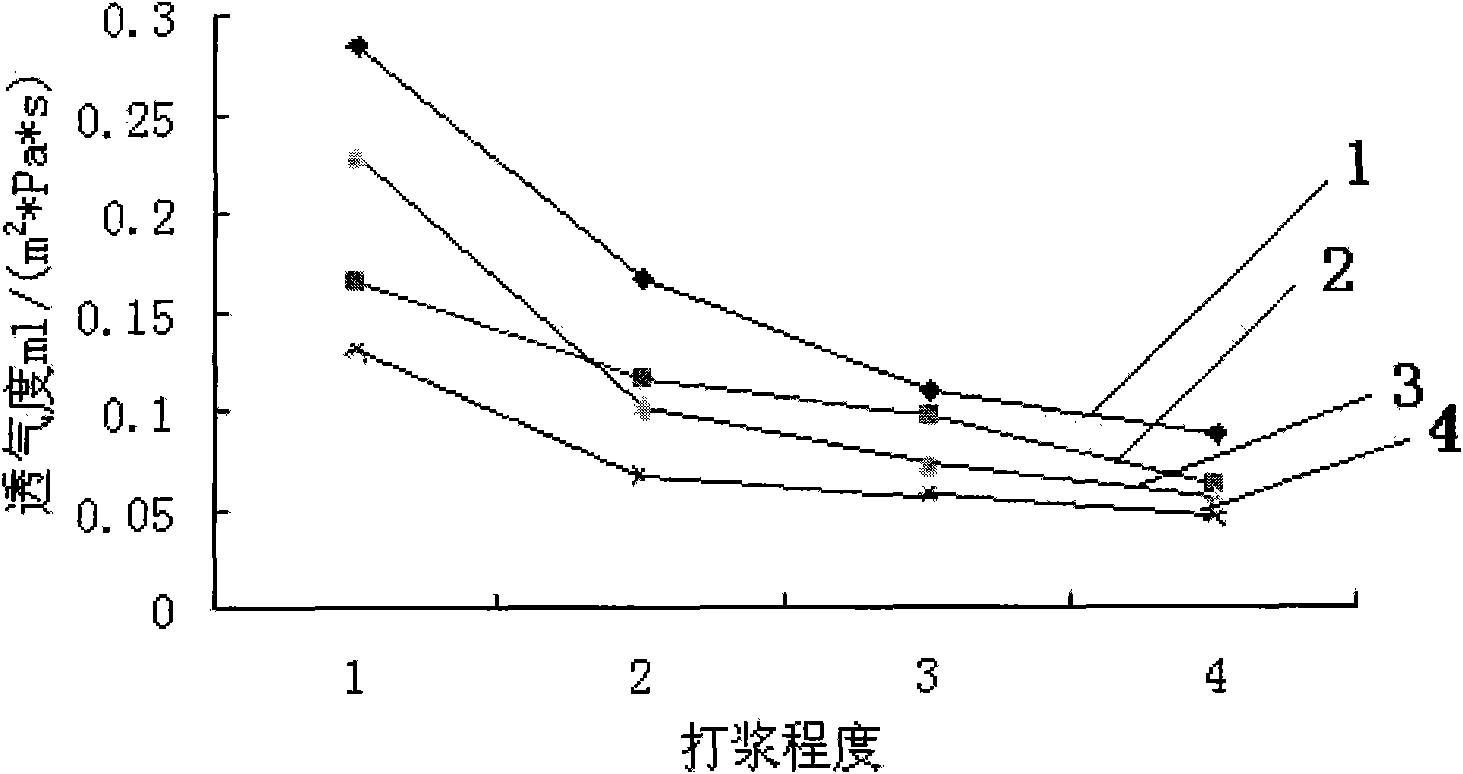

InactiveCN102656316AHigh mechanical strengthEasy to usePaper/cardboardPulp beating/refining methodsFiberCellulose

Provided are a novel process for producing cellulose nanofibers, and novel cellulose nanofibers. The process comprises fibrillating a pulp with a single-screw or multi-screw kneading machine in the presence of water to produce cellulose nanofibers, wherein the fibrillation is conducted in a manner such that the peripheral speed of the single-screw or multi-screw kneading machine is 45 m / min. Thus, cellulose nanofibers superior in both water filtration efficiency and sheet strength, which have been thought to be inconsistent properties, are obtained.

Owner:NIPPON PAPER IND CO LTD +2

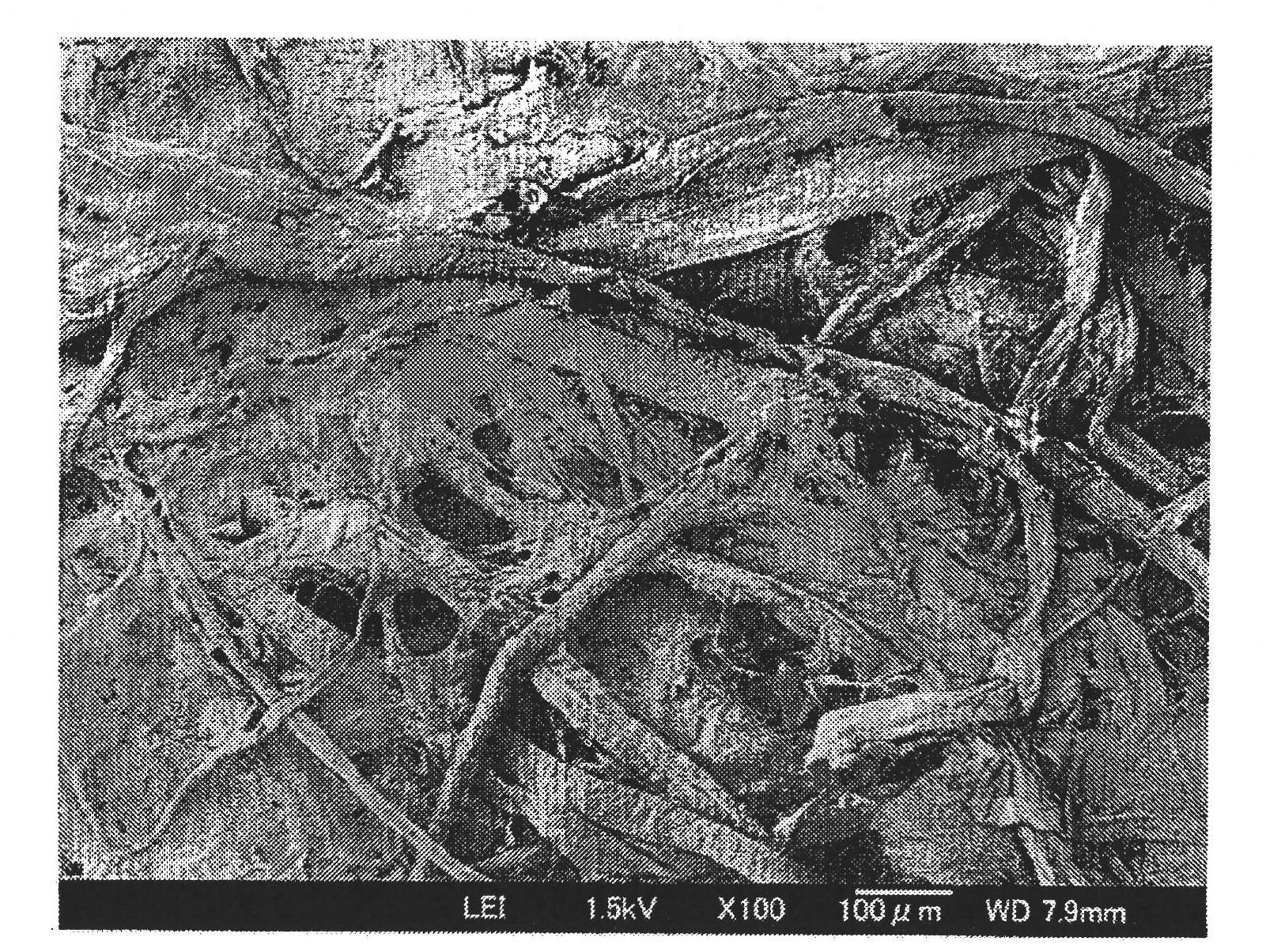

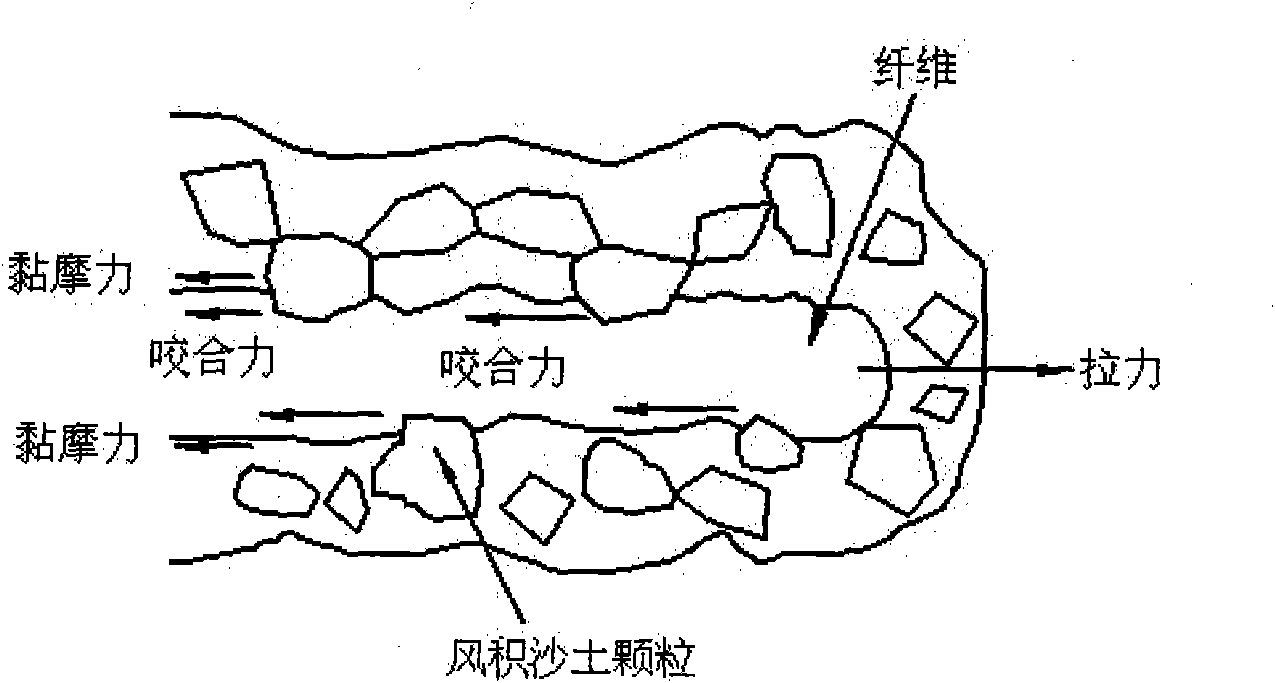

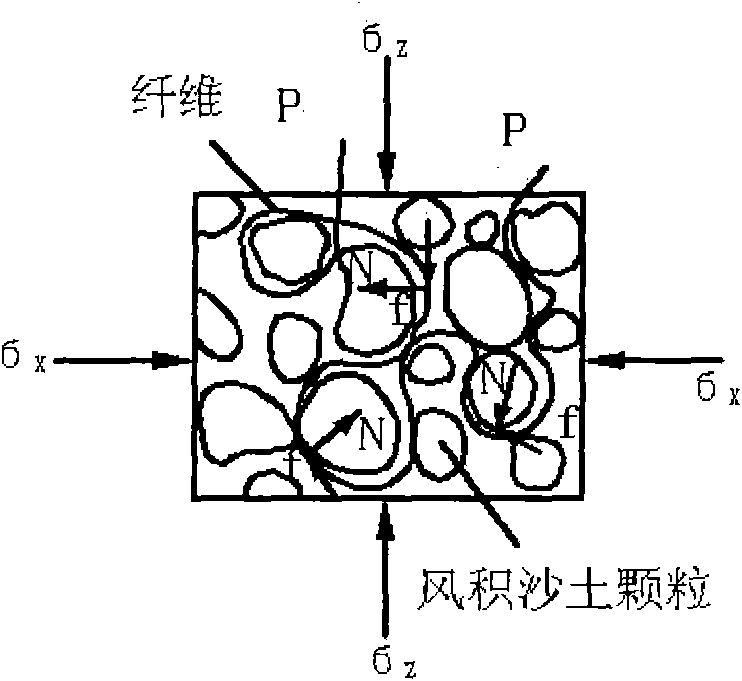

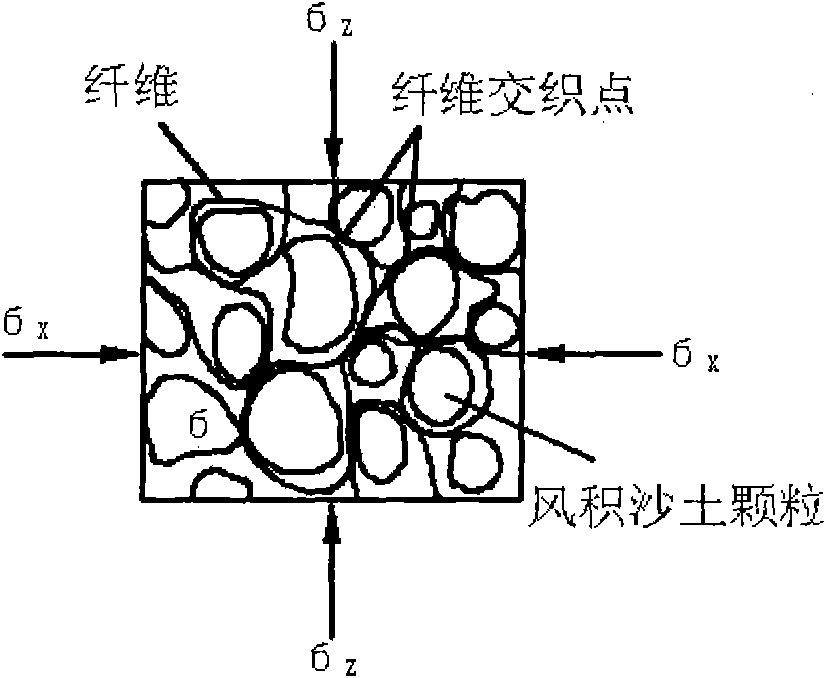

Method for reinforcing aeolian sandy soil by polypropylene fibers

The invention discloses a method for reinforcing aeolian sandy soil by polypropylene fibers. The method comprises the following steps: selecting materials for preparing fiber aeolian sandy soil, wherein the length of the polypropylene fiber is 18mm, the mix ratio of the fiber is 0.3 percent, and the aeolian sandy soil materials are air-dried aeolian sand or aeolian sandy soil (the moisture content accounts for 11.2wt%); according to the proportioning scheme, closely and completely mixing fine TEXSOL with aeolian sandy soil particles by way of spraying, so that a composite three-dimensional spatial structure is formed by the TEXSOL and the aeolian sandy soil; and carrying out mechanical compaction on the composite fiber aeolian sandy soil subjected to spraying, wherein the compaction method and standard of the composite fiber aeolian sandy soil are same as those of common soil, so that the compaction density of the aeolian sandy soil reaches 100 percent of the standard compaction density, and the fiber aeolian sandy soil is compacted closely. By utilizing the method in earth-filled dams, retaining walls and the drainage works of the earth-filled dams, the water stability of the interior of the soil body can be effectively improved, the shearing strength and tensile strength of the soil body can be obviously improved, and the construction process is simple; and because the fiber content of the fiber aeolian sandy soil is very low, the method has the advantages of cheapness and environmental protection.

Owner:HARBIN INST OF TECH

Pulping digestion agent production method

InactiveCN1508357AWide adaptabilityHigh degree of polymerizationCellulose material pulpingAlcoholSodium bisulfate

The invention is a producing method of paper pulp boiling agent, its raw materials comprising penetrating agent BS 4-10 weight shares, sodium bisulfate 4-10 weight shares, sodium chloride 4-10 weight shares, pleregal 0 15-25 weight shares, polyoxyethylenated alcohol 15-25 weight shares, alkyl sulphonate 40-55 weight shares, and water 60-80 weight shares. The producing process: adding the pleregal 0 and polyoxyethylenated alcohol in the 55-65 deg.C water, heating to 70-75deg.C, blending, and adding in alkyl sulphonate, blending and adding in BS, sodium bisulfate, sodium chloride, blending, cooling to 30-40deg.C, and blending to make the finished product.

Owner:湖南美莱精化有限公司

Non-asbestos fiber compound sealing material

InactiveCN102212332AImprove other performanceReduce porosityOther chemical processesFiberHeat resistance

The invention relates to a non-asbestos fiber compound sealing material, in particular to a high-performance paper-making method material, and belongs to the cross field of material science and paper-making technology. The non-asbestos fiber compound sealing material consists of non-asbestos fiber, rubber latex, mixed inorganic fillers and an auxiliary agent, wherein the mixed inorganic fillers are formed by the gradation of minimum two types, at most six types of fillers of different average grain sizes, and the average grain size of the bigger fillers is more than 2.5 times that of the adjacent smaller fillers. Because the closest packing theory is adopted in the invention and the fillers are formed by the gradation of the fillers of different average grain sizes, the close packing microporous material structure can be obtained while less rubber latex is consumed, various important indexes, such as the sealing property, mechanical strength and heat resistance, of the product are greatly improved, and the high-performance non-asbestos fiber compound sealing material is obtained. By the gradation of the fillers, the paper machine paper-making property of the pulp is improved.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

Recyclable steel structure filled retaining wall

The invention discloses a recyclable steel structure filled retaining wall which comprises a composite wall formed by overlaying a plurality of wall fixing round steel bars, an I-shaped steel structural wall, a mesh and water filtering cloth together in sequence, wherein the composite wall is mounted between a goaf and a roadway; I-shaped steel supports and a plurality of supporting and fixing round steel bars are arranged on the back surface of the composite wall for fixation; the composite wall fixing round steel bars are arranged on the periphery of the composite wall at intervals; the tail ends of the composite wall fixing round steel bars are anchored into surrounding rocks to be fixed; the supporting and fixing round steel bars are anchored into the bottom of the roadway; shotcrete is arranged between the composite wall and the roadway. The recyclable steel structure filled retaining wall is novel and reasonable structural design, convenient to construct, high in supporting strength, high in safety performance, good in sand blocking and water filtering effects, capable of being detached and reused, and low in comprehensive cost.

Owner:ANHUI KAIFA MINING IND

Preparation method of heat-resistance and salt-tolerance polyacrylamide

InactiveCN104387527AGuaranteed Molecular WeightMeet the standards of tertiary oil recoveryDrilling compositionMeth-Polyacrylamide

The invention discloses a preparation method of heat-resistance and salt-tolerance polyacrylamide. The preparation method comprises the following steps: taking the aqueous solution of acrylamide with the mass concentration of 20-30 percent, adding acrylic acid accounting for 1-2 percent of the mass of an acrylamide monomer and 2-acrylamide-2-methylpropane sulfonic acid (AMPS) accounting for 2-6 percent of the mass of the acrylamide monomer, adding sodium hydroxide for regulating a pH value to 5.5-6.5, cooling to 0-4 DEG C, introducing nitrogen to remove oxygen out of the system, sequentially adding a complexing agent, an azo initiator, an efficient chain transfer agent, a reducing agent and an oxidant when the oxygen content in the system is smaller than 0.01 percent, sealing after reaction is finished, preserving heat for 1-1.5h, then taking out colloid, putting the colloid in a hydrolyzer, adding an inorganic alkali liquor accounting for 6-13 percent of the acrylamide monomer, hydrolyzing at the temperature of 80-90 DEG C for 1-2h, and drying the colloid to prepare the product. The heat-resistance and salt-tolerance polyacrylamide is good in solubility and filterability, and the apparent viscosity of the heat-resistance and salt-tolerance polyacrylamide is above 11mPa.s.

Owner:ANHUI TIANRUN CHEM CO LTD

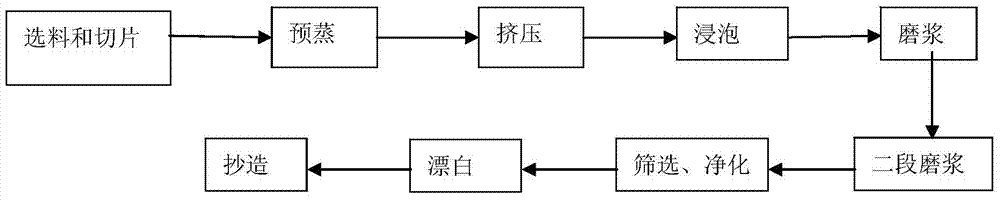

Method for preparing super-high-bulk paper pulp from fir slabs

ActiveCN104711884AReasonable useImprove toughnessPretreatment with water/steamPretreatment with alkaline reacting compoundsPulp and paper industryCompressibility

The invention discloses a method for preparing super-high-bulk paper pulp from fir slabs. The method is a process for producing bleached pulp boards according to the chemical hot-grinding technology, and comprises the following steps: slicing, pre-boiling, extruding, soaking, pre-heating, defibrination, secondary defibrination, screening and purifying, bleaching and papermaking. The method has the advantages that the prepared paper pulp is high yield, bulk, whiteness, drainability, tenacity, stiffness, ink absorption and compressibility, so that the print performance of the prepared paper pulp can be improved; the production cost and the sewage emission are low; the sewage is easy to treat; the prepared paper pulp can be used for producing of light paper, cup base paper and other types of paper requiring high bulk.

Owner:福建腾荣达制浆有限公司

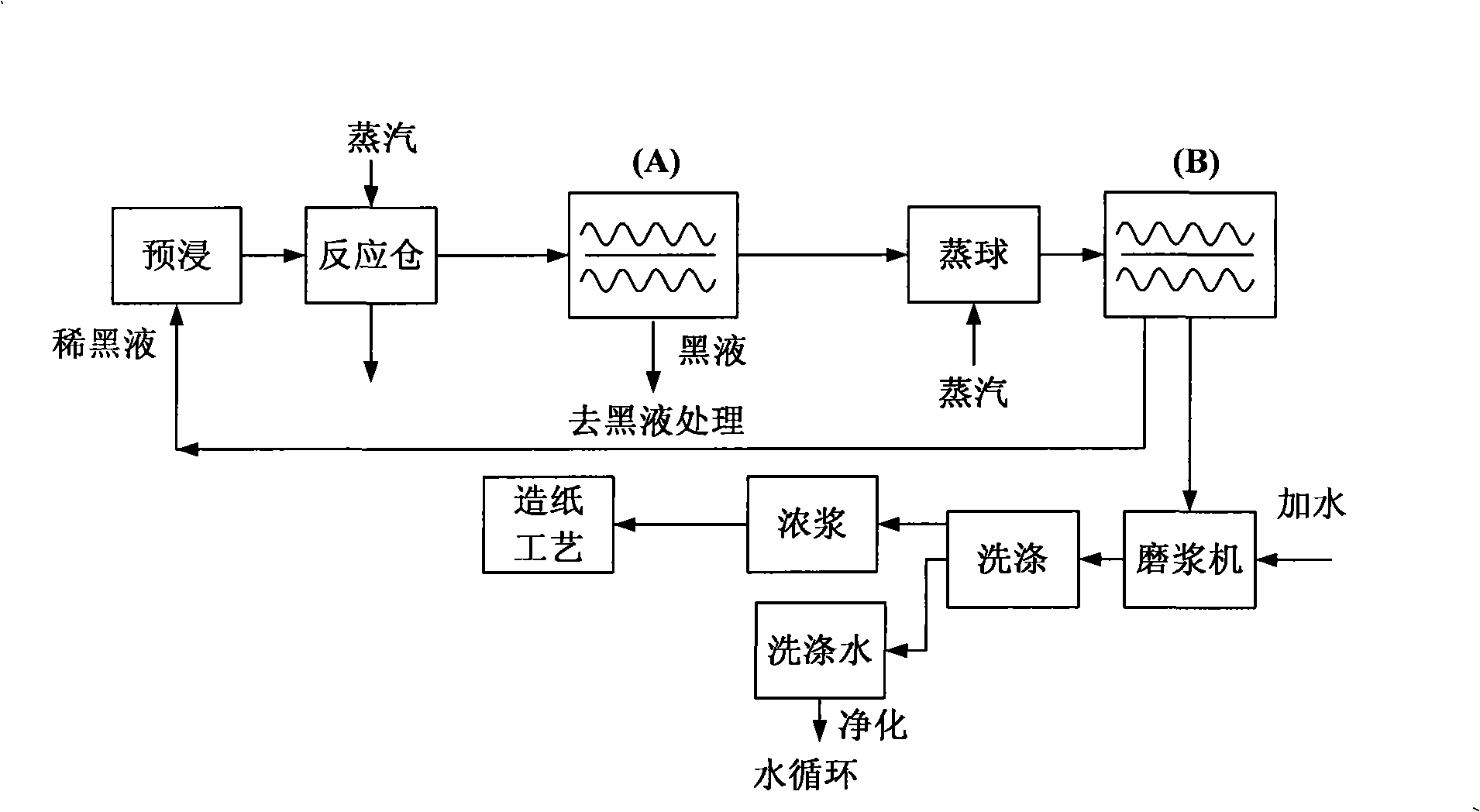

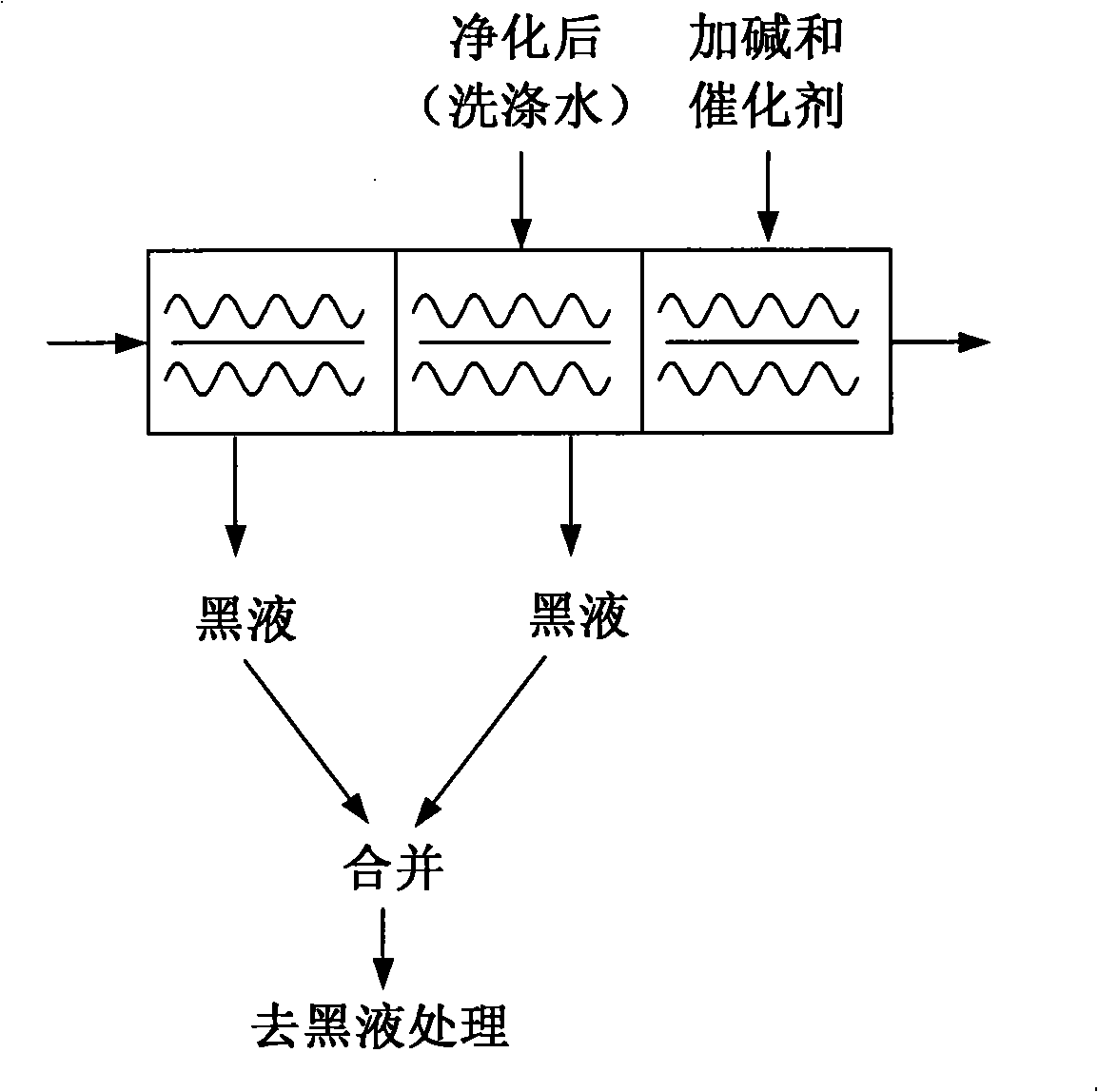

Pulping paper-making process with zero discharge of sewage water

InactiveCN101314924ASimplify the concentration processLess investmentPulp liquor regenerationWashing/displacing pulp-treating liquorsZero emissionAfter treatment

A pulp and paper preparation method with zero-emission of sewage comprises the steps as follows: (1) stewing for the first time: mixing materials for preparing the pulp with a thin black liquid obtained from stewing of the second time, pre-soaking the mixture, dewatering and then stewing at a low temperature; milling and devillicating the materials after stewing for the first time by adopting a double screw pulp milling and pressing machine, extracting a thick black liquid, concentrating and drying the thick black liquid, selling the same as a commodity, adding alkali and a catalyst, intensively mixing with the materials for making the pulp to obtain a material (B); (2) stewing for the second time: stewing the material (B) at a high temperature through steam; pressing the stewed material and extracting the thin black liquid by adopting at least two double screw extruders or filter presses connected in series; using the thin black liquid in stewing for the first time for pre-soaking the materials; (3) washing the pulp and treating the water for washing the pulp: grinding the pulp material through stewing for the second time in a high consistency pulping machine; washing the pulp; the water for washing pulp is reutilized for washing the pulp after anaerobic treatment, aeration treatment, and materialized and flocculation treatment; and (4) preparing paper and treating white water: purifying thick pulp, fine-grinding by adopting a double disc refiner, using the ground thick pulp for preparing paper, and reutilizing the paper-preparing white water after treatment.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

High-strength modified energy-saving biological enzyme paper pulp and pulping process

ActiveCN103898795AImprove performanceImprove percussionDefoamers additionPaper/cardboardEngineeringDefoaming Agents

The invention discloses high-strength modified energy-saving biological enzyme paper pulp and a pulping process thereof. The paper pulp comprises 0.5-5 parts of an antibacterial agent, 1-3 parts of a toughening agent, 1-5 parts of a thickening agent, 40-60 parts of regenerated paper pulp, 10-20 parts of a packing, 1-5 parts of a defoaming agent, 2-8 parts of a stabilizing agent, 1-3 parts of a retention aid, 10-30 parts of fibers and 5-20 parts of biological enzyme. According to the paper pulp, a biological enzyme technique is adopted for beating the pulp, and the biological enzyme with the high pertinence is selected for performing synchronous pulp beating treatment on the pulp, so that not only is the energy consumption reduced and is the yield increased, but also the fibers can be modified, for example, when wood pulp beating enzyme is adopted to be matched with the beating of the wood pulp, the beating degree is improved, the fiber strength is ensured, and the power consumption in beating each ton of the pulp is reduced; when the biological enzyme is adopted for beating OCC pulp, the beating degree is reduced, the fiber strength is improved, the drainability, the pulp beating capability and the flowability of the fibers are improved, and meanwhile, the production energy consumption is reduced, the properties of the pulp are improved, and thus the quality of paper is improved.

Owner:JIANGSU LEE & MAN PAPER MFG

Method for preparing non-asbestos latex sheet

InactiveCN101105022AGood water filtration performanceGood dehydration and forming effectFibreboardPaper/cardboardCarbon blackPolyacrylamide

A preparation method of non-asbestos latex beater sheets comprises: firstly dispersing non-asbestos fibers in water and pulping after adding a filler; then adding carbon black and mixing thoroughly; sequentially adding latex, sulphur and anti-aging agent and mixing thoroughly; and finally feeding the resulting mixture to the approach system of a paper making machine, adding a cationic polyacrylamide retention aid prior to the fan pump or press screen or head-tank of the approach system, adding bentonite prior to the headbox, making paper, and drying. In the invention, an appropriate amount of cationic polyacrylamide retention aid is added prior to the fan pump or press screen or head-tank of the approach system of paper making machine and sequentially an appropriate amount of bentonite prior to the headbox, so that the drainage property of beater sheet is improved after the raw material flows into the wire section of paper machine from the headbox and the beating degree of raw material in the wire section is reduced below 50oSR, thereby realizing excellent drainage and molding of raw materials in the wire section.

Owner:SHAANXI UNIV OF SCI & TECH

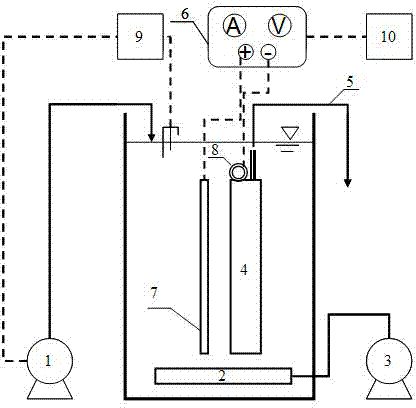

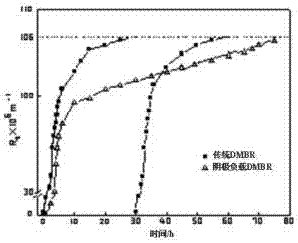

Cathode load self-generated dynamic membrane bioreactor

InactiveCN102874978ASignificant progressSignificant positive effectMultistage water/sewage treatmentAutomatic controlAutomated control system

The invention relates to a cathode load self-generated dynamic membrane bioreactor which comprises a biological treatment system, a cathode load system and an automatic control system. The biological treatment system comprises a water inlet pump, a perforated aeration pipe, an aeration pump, a dynamic membrane module and a water outlet pipe; the aeration pump is connected with the perforated aeration pipe; the perforated aeration pipe is arranged under the dynamic membrane module; and water collection port on the upper end of the dynamic membrane module is connected with the water outlet pipe. The cathode load system comprises a direct-current voltage-stabilizing power supply, an electrode plate and a cathode load interface, wherein the anode outputted by the direct-current voltage-stabilizing power supply is connected with an electrode plate, and the cathode outputted by the direct-current voltage-stabilizing power supply is connected with the cathode load interface. The automatic control system comprises a liquid level controller and a time relay, wherein the liquid level signal outputted by the liquid level controller is used for controlling the water inlet pump to start and adjusting the water inlet amount, and the time relay is connected with the direct-current voltage-stabilizing power supply and used for controlling the electroflocculation running time. Due to the adoption of the cathode load self-generated dynamic membrane bioreactor, the stable operation cycle of the dynamic membrane is prolonged significantly.

Owner:NORTHEAST DIANLI UNIVERSITY

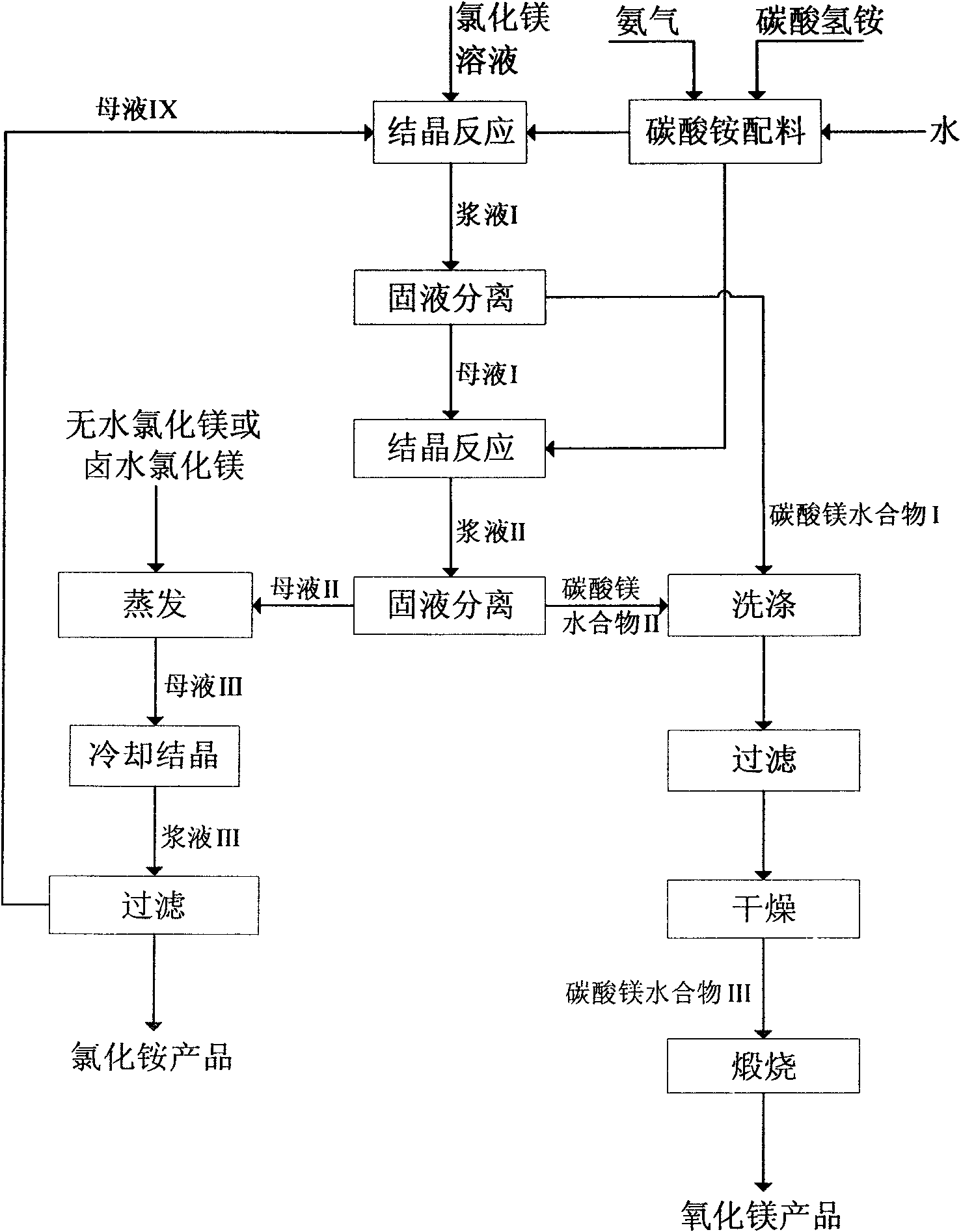

Method for producing magnesium oxide with co-production of ammonium chloride by taking magnesium carbonate hydrate as intermediate

InactiveCN101993097AHigh purityGood filtration propertiesMagnesium carbonatesAmmonium halidesMagnesium saltSeawater

The invention belongs to the field of inorganic salt chemical industry and fertilizer production, particularly relates to a method for producing magnesium oxide with co-production of ammonium chloride by taking magnesium carbonate hydrate as an intermediate. The method comprises the following steps of: with anhydrous magnesium chloride or bittern magnesium chloride as a raw material and with ammonia and ammonium bicarbonate as precipitating agents, obtaining the magnesium carbonate hydrate intermediate (the purity reaches 97-99 percent) with favorable crystal form by controlling process conditions; calcining the obtained magnesium carbonate hydrate intermediate to prepare magnesium oxide (the purity reaches 95-99 percent); adding salt to mother liquor enriched with ammonium salts and evaporating, salting out and cooling to separate out ammonium chloride, and filtering to obtain the ammonium chloride, wherein the mother liquor is circularly taken as a raw material. The method aims at producing needle-shaped or spherical magnesium carbonate hydrate by utilizing rich magnesium chloride brine from salt lakes, or magnesium chloride brine from seawater, or anhydrous magnesium chloride used for producing titanium sponge by-products, and other magnesium salt materials, thereby preparing high-purity magnesium oxide with the simultaneous co-production of ammonium chloride fertilizer. The method of the invention has strong maneuverability and is easy to realize industrialization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com