Patents

Literature

7478 results about "Water filter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

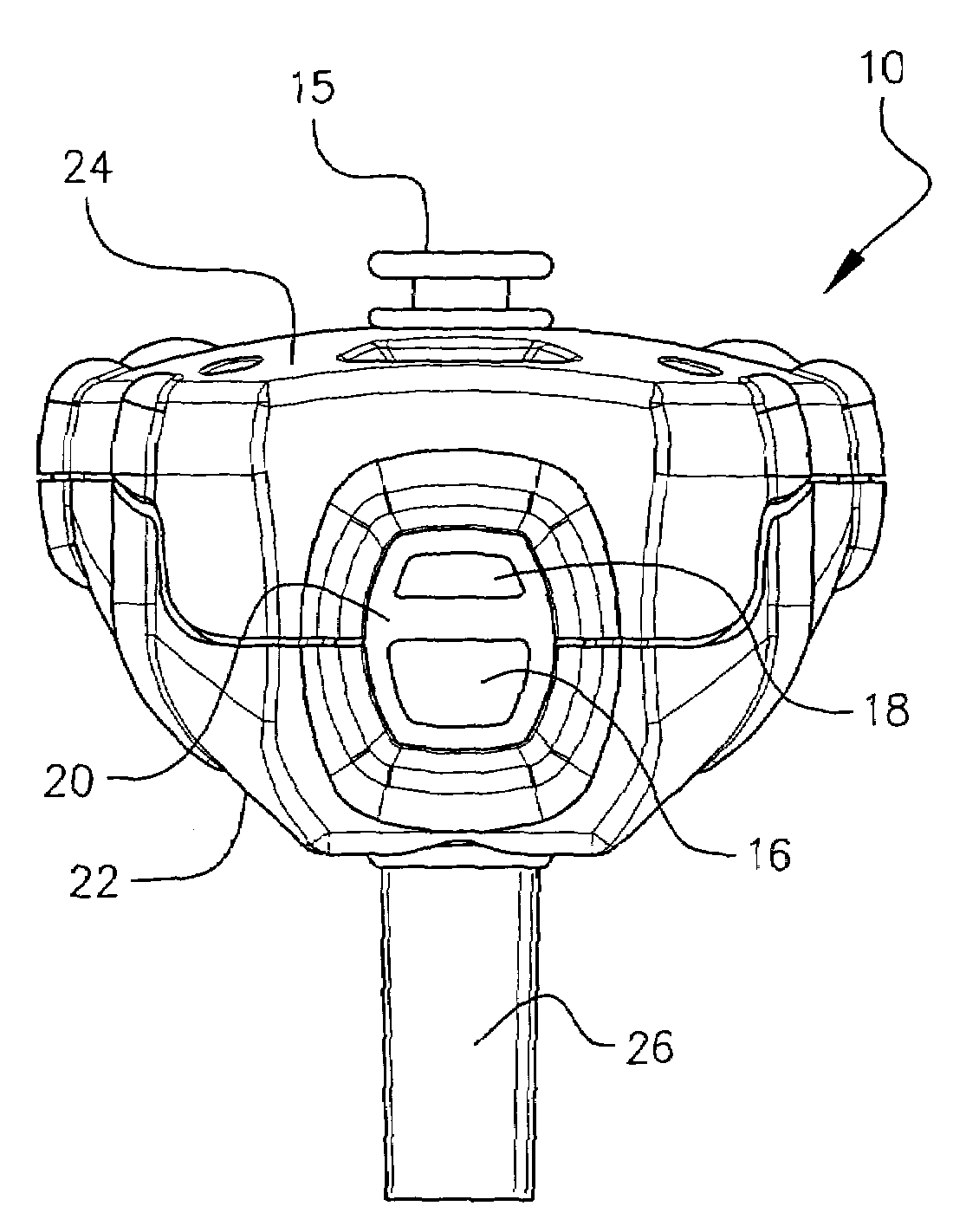

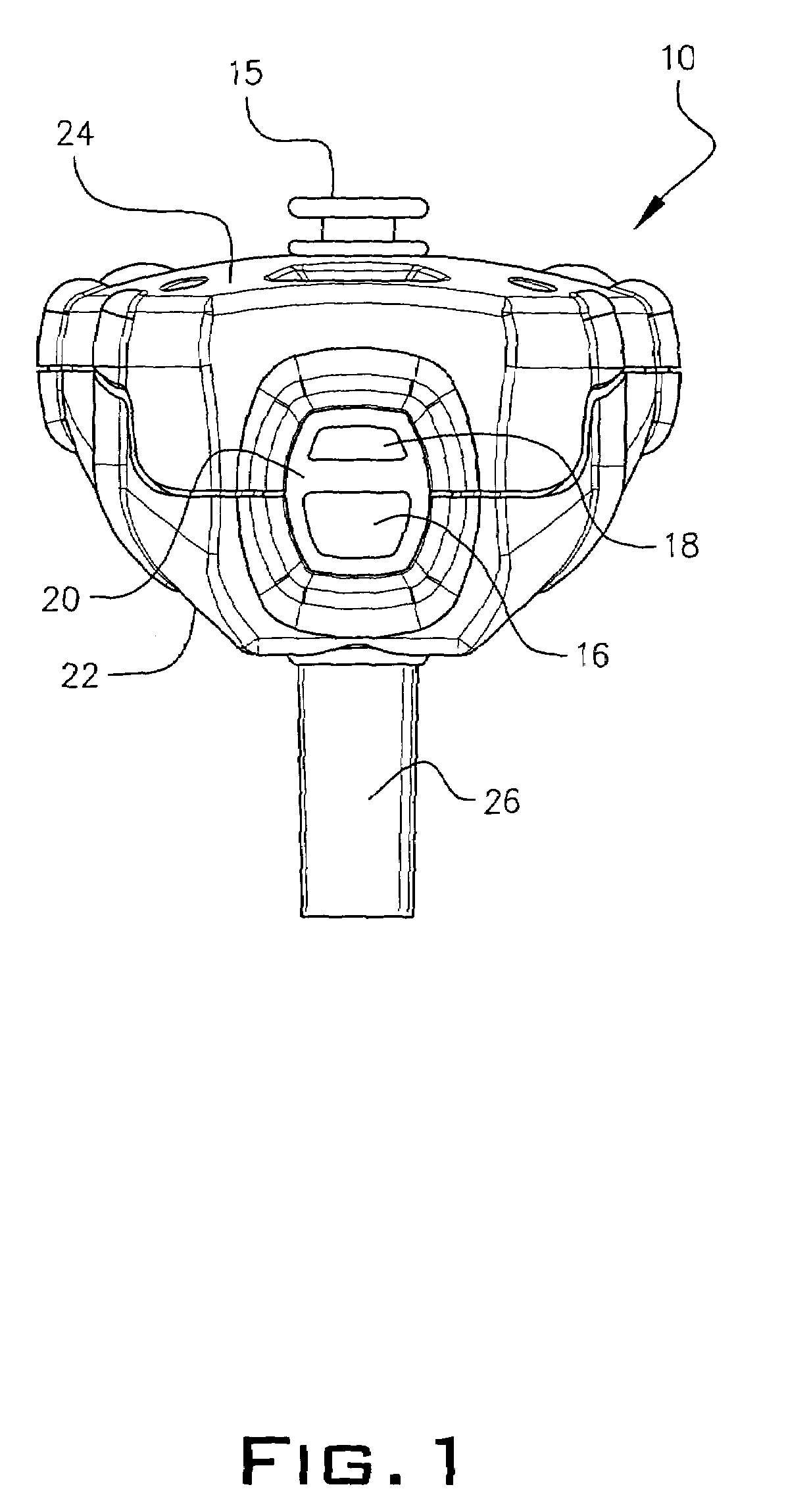

Water filter

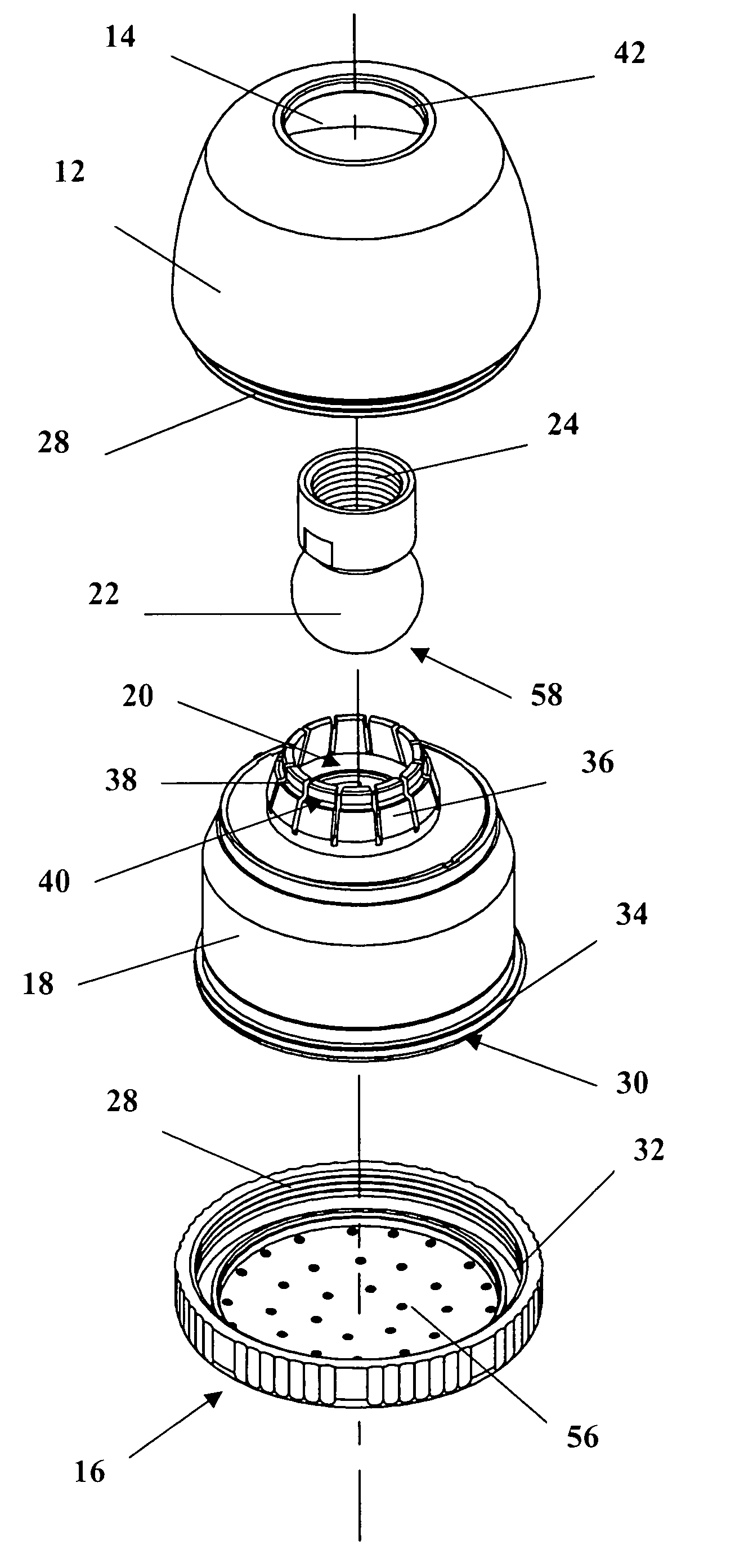

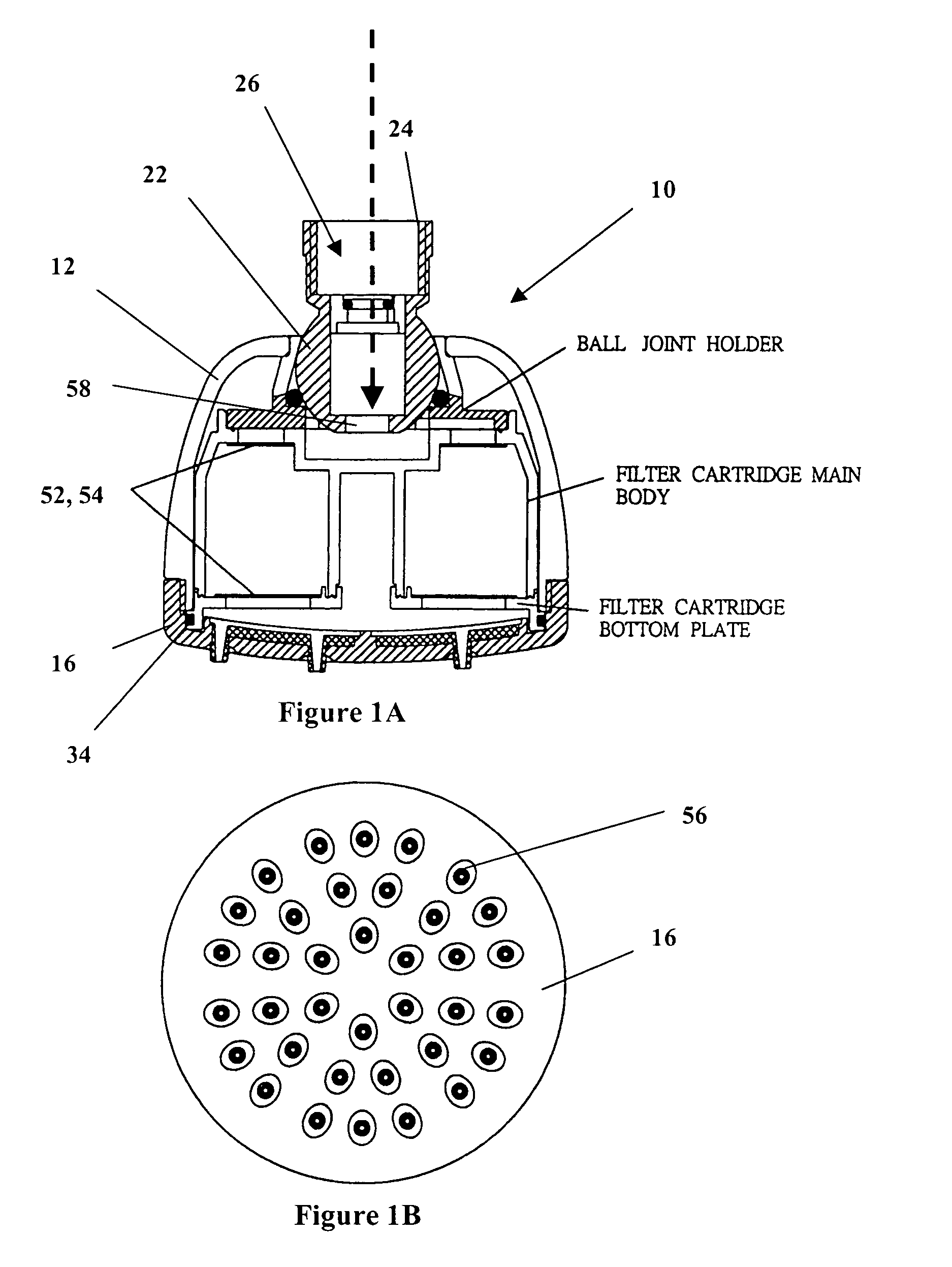

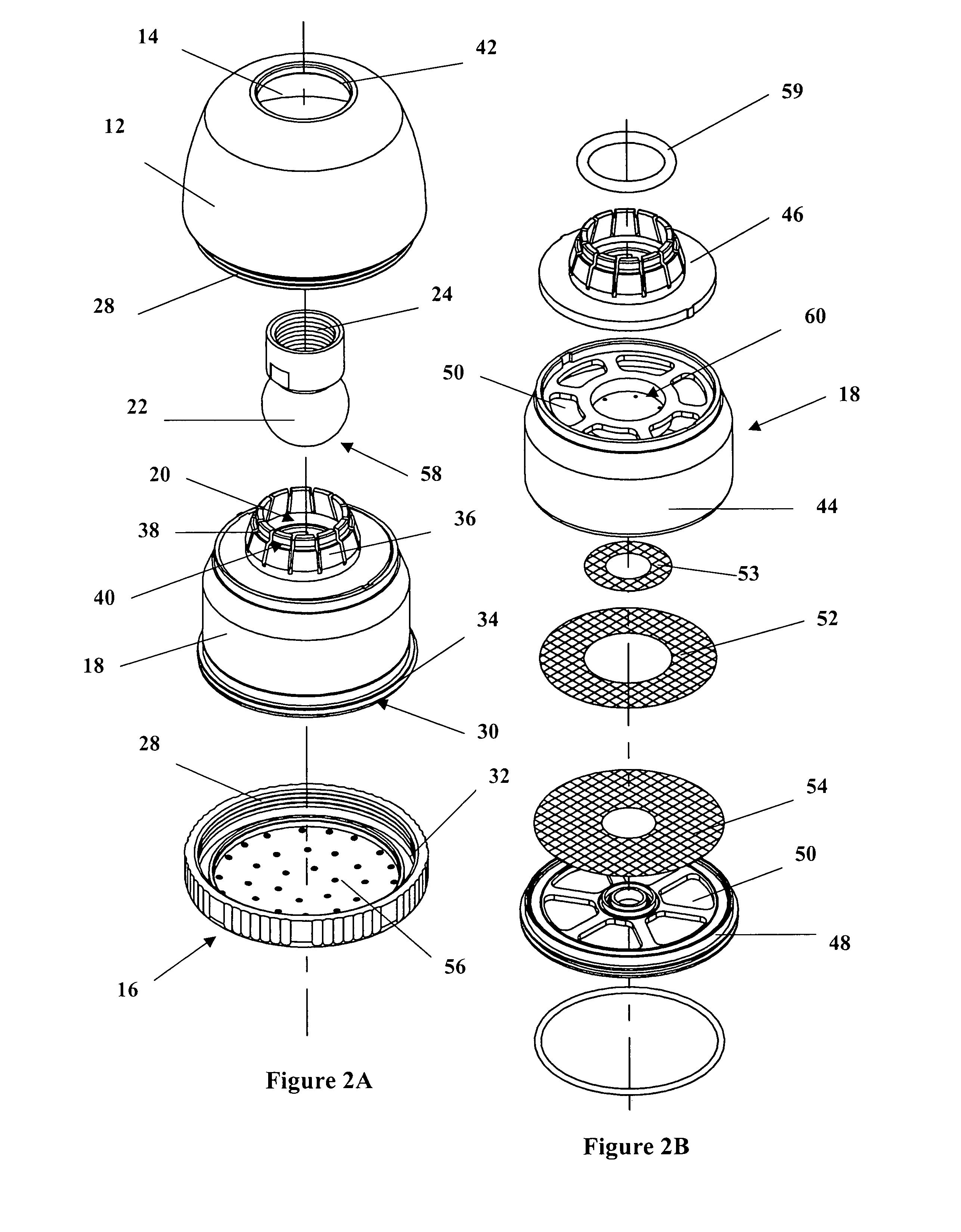

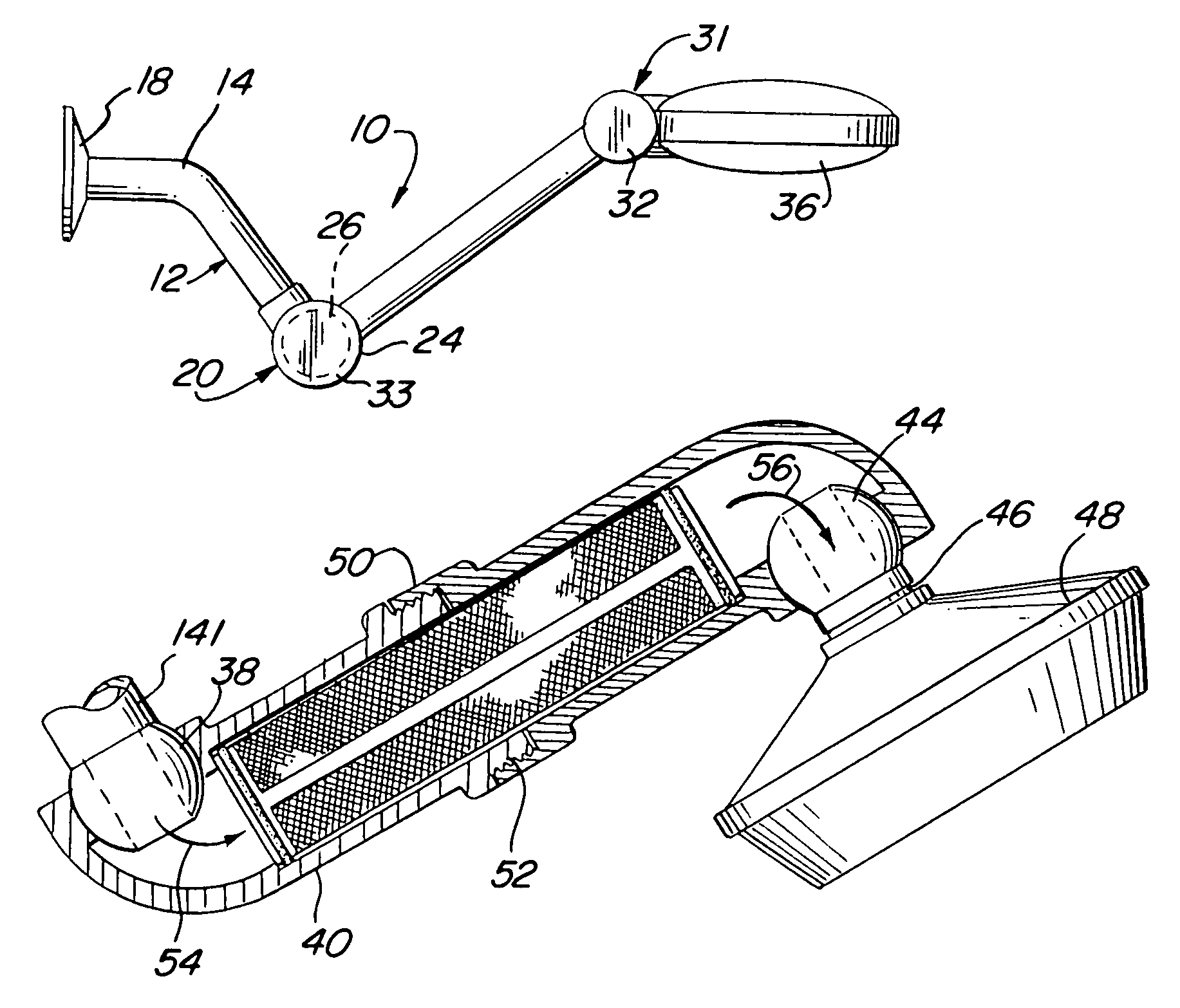

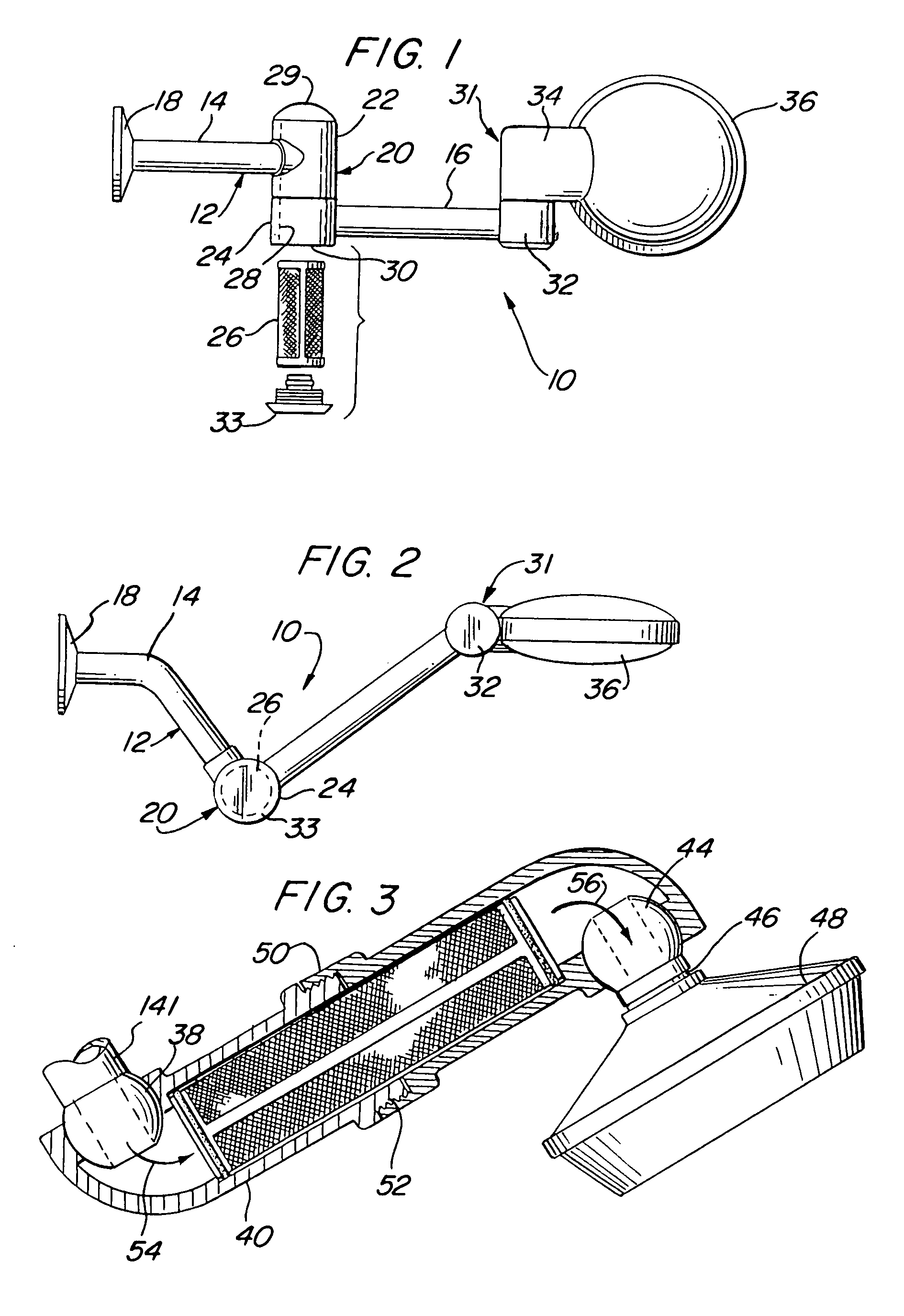

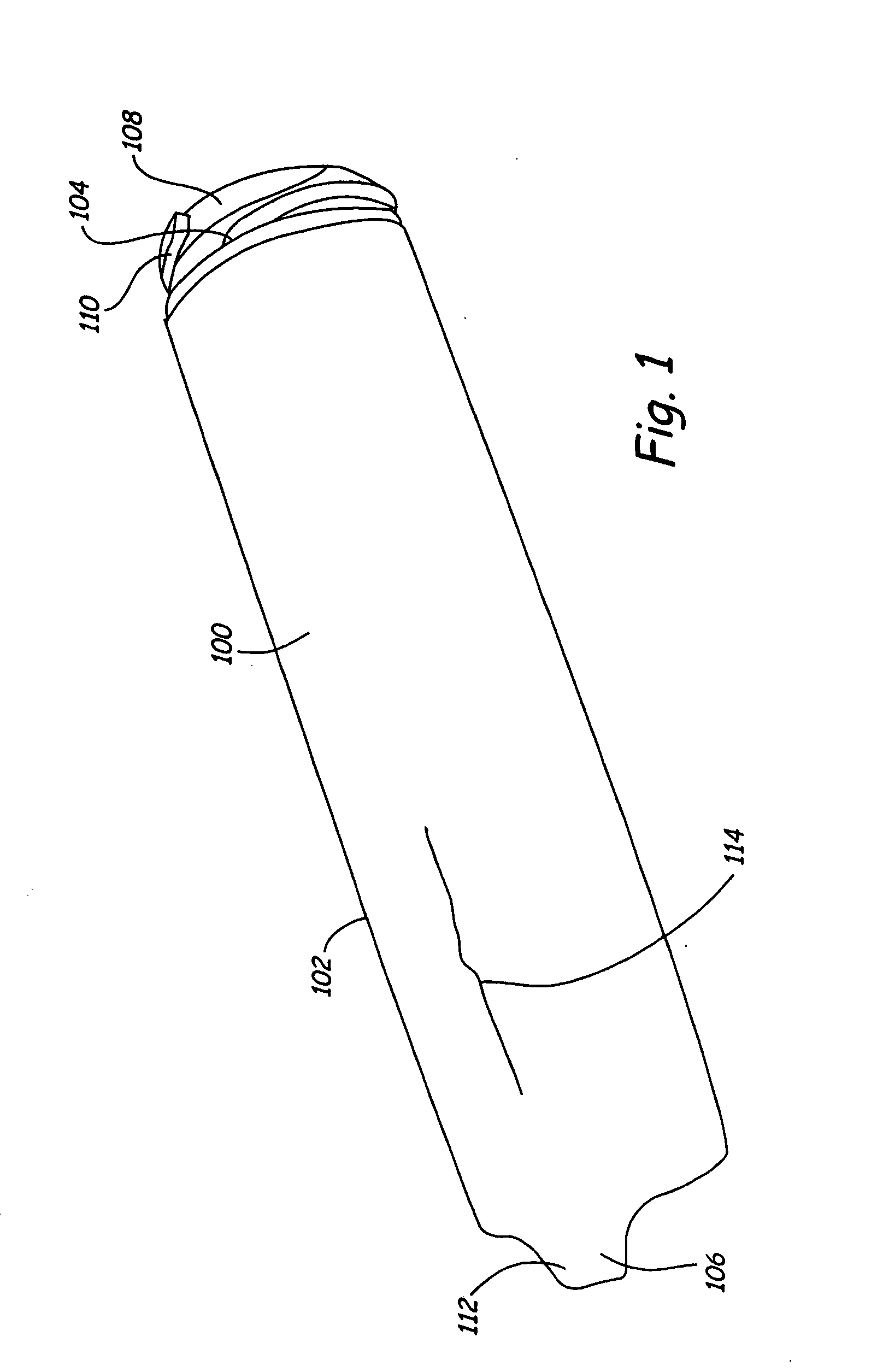

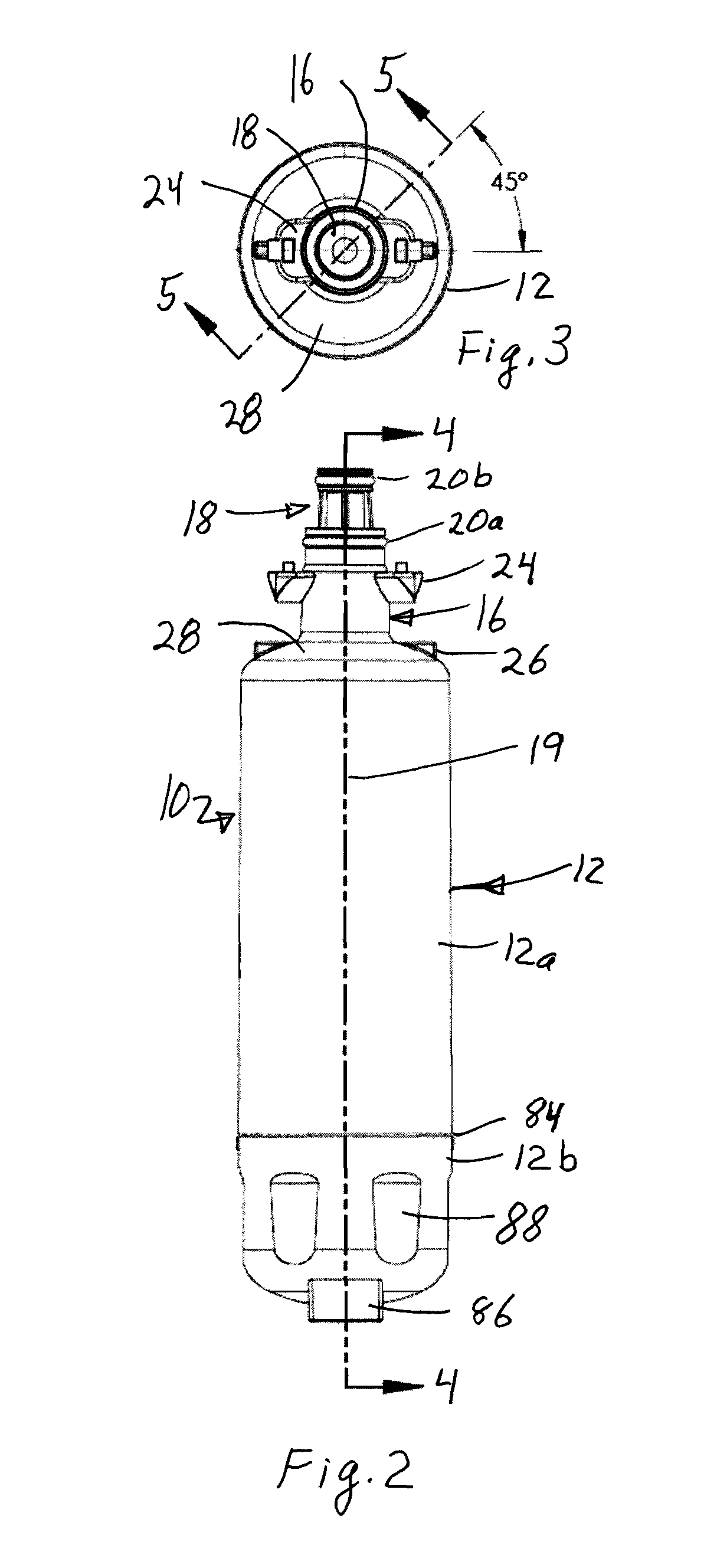

A showerhead having a replaceable water filter assembly. The showerhead having a compact body with releasably coupled pivotable element connected to the water filter assembly.

Owner:H2O INT

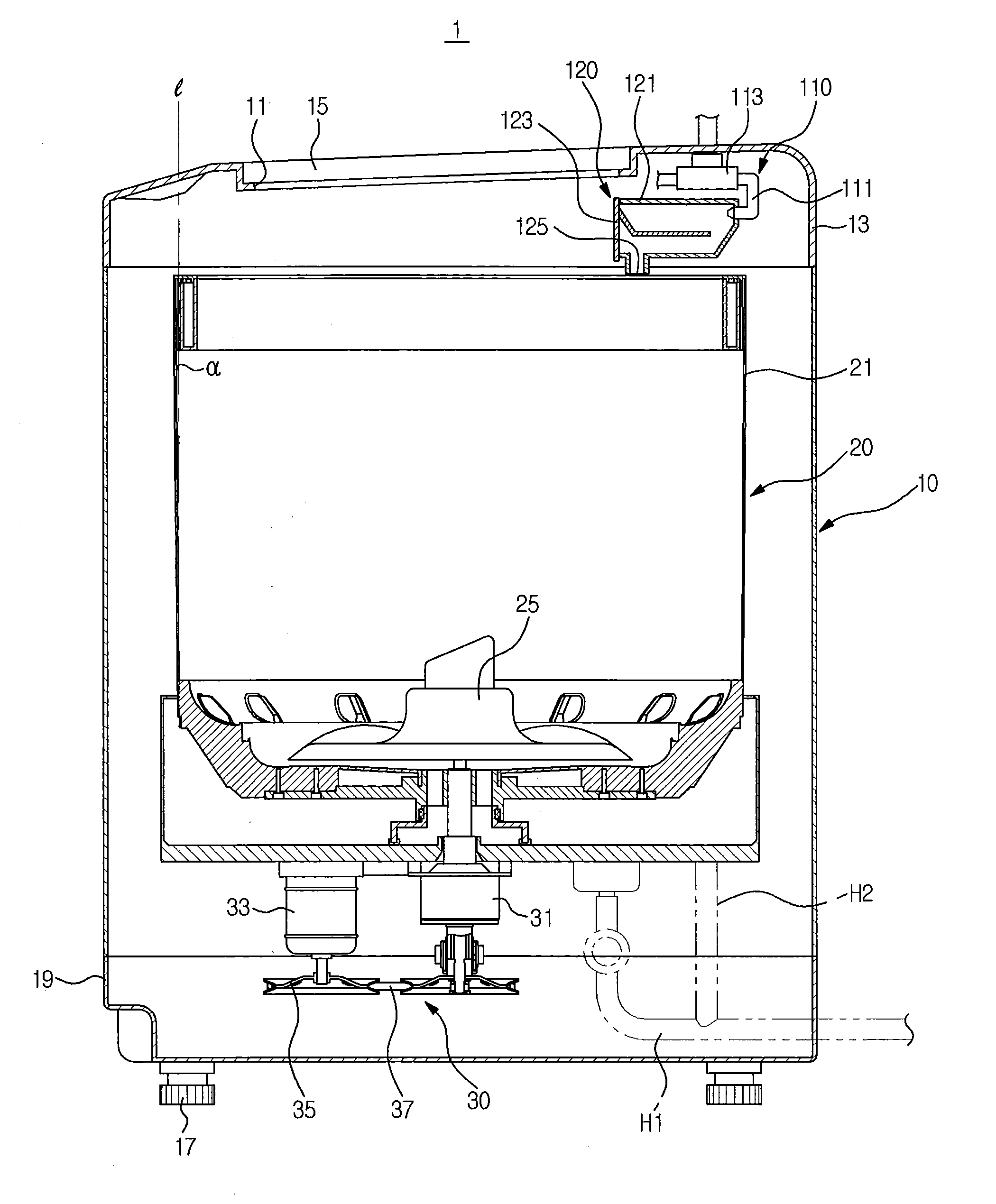

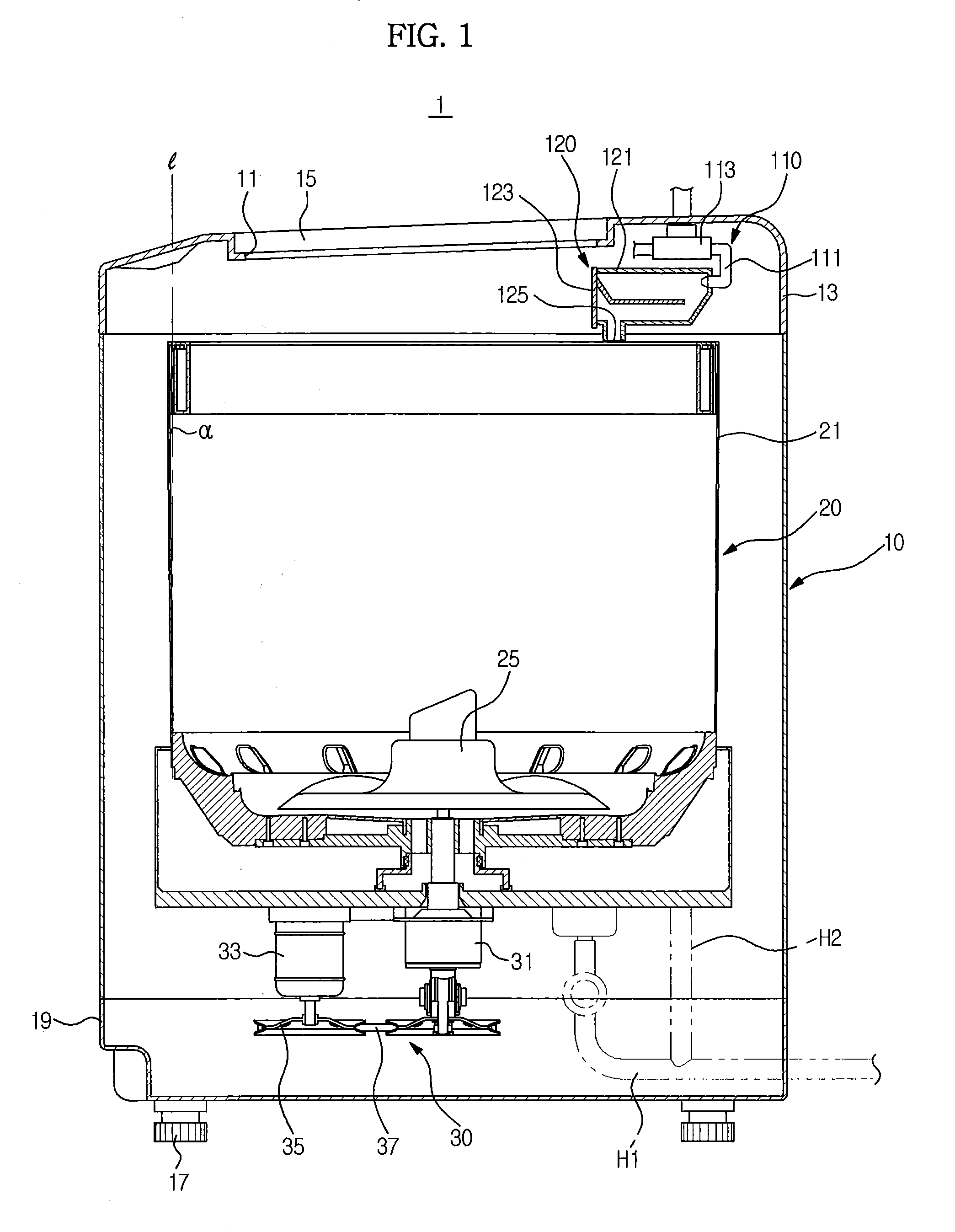

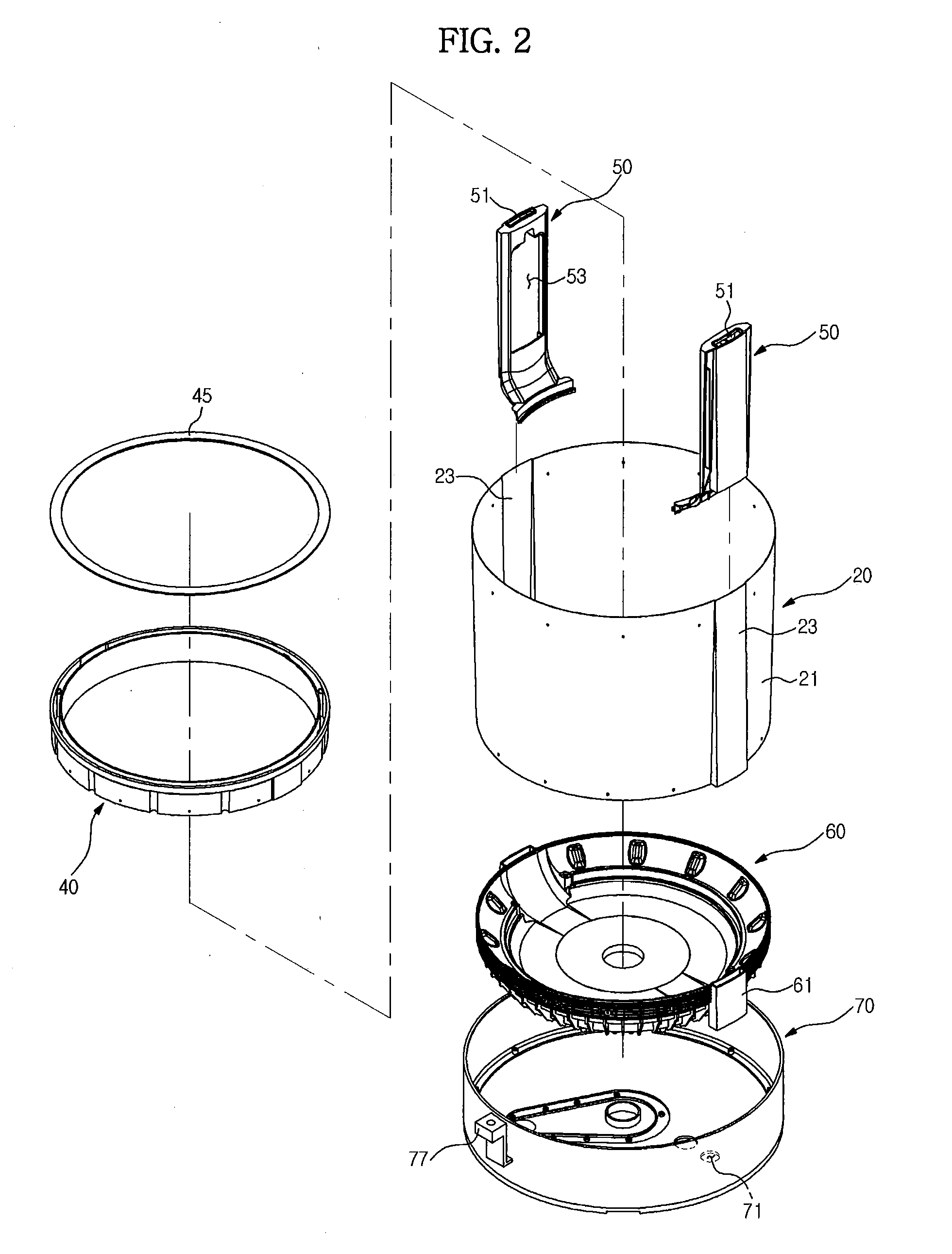

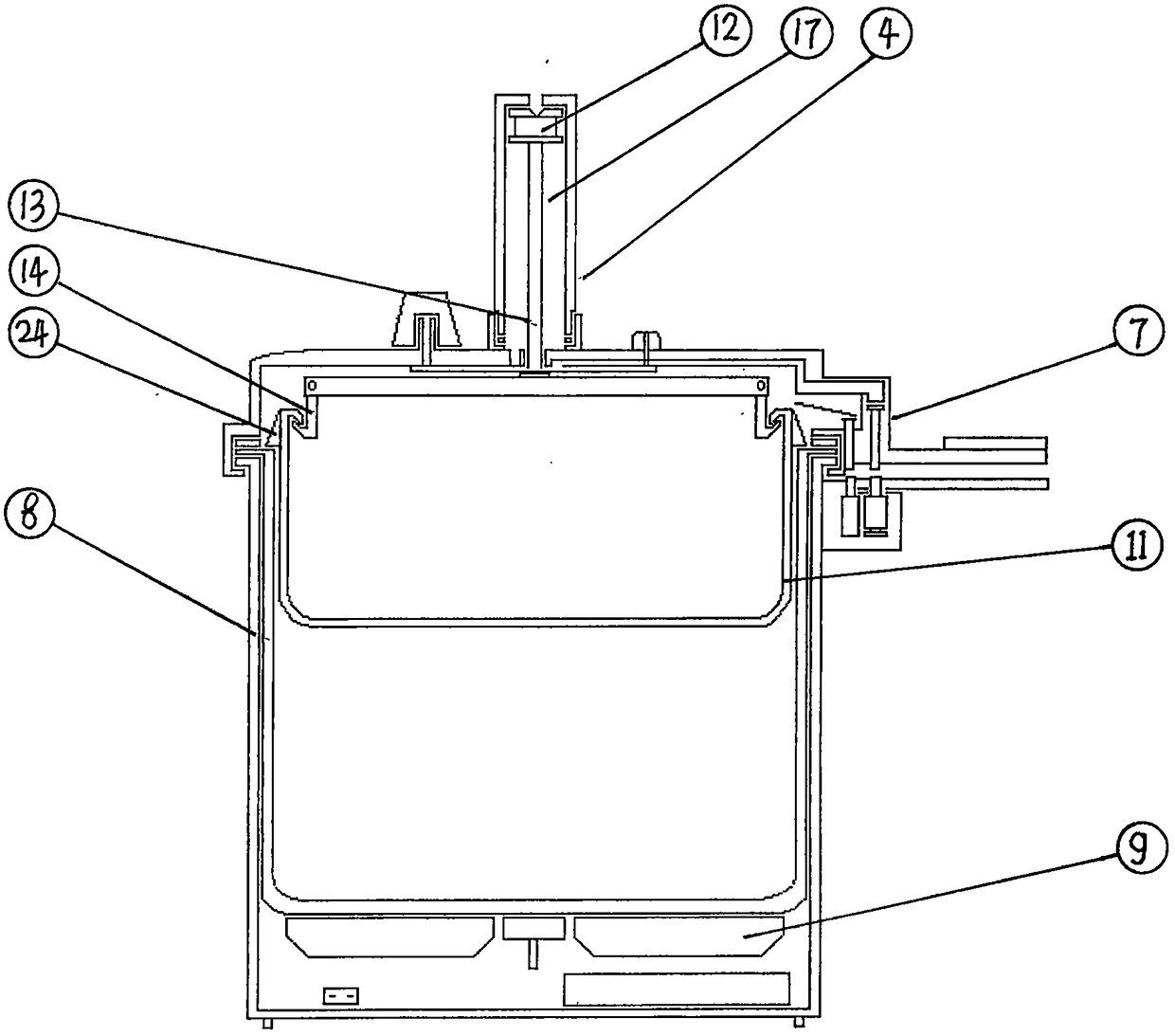

Washing machine

InactiveUS20130036776A1Reduce water consumptionImprove washing effectOther washing machinesInterengaging clutchesWater dischargeDrive shaft

A washing machine includes a cabinet forming an external appearance of the washing machine, a rotary tub disposed to rotate around a driving shaft vertically provided inside the cabinet and including a sidewall, which extends with inclination to have a diameter increasing from a lower side to an upper side of the washing machine, and at least one protrusion part, which protrudes from the sidewall with inclination to have a diameter increasing from an upper side to a lower side of the sidewall. A guide water filter is mounted on at least one protrusion part inside the rotary tub and provided at a rear surface thereof with a drain passage to discharge the washing water discharged from the balance ring to outside. A base is installed at the lower side of the rotary tub and includes a guide part and a support plate.

Owner:SAMSUNG ELECTRONICS CO LTD

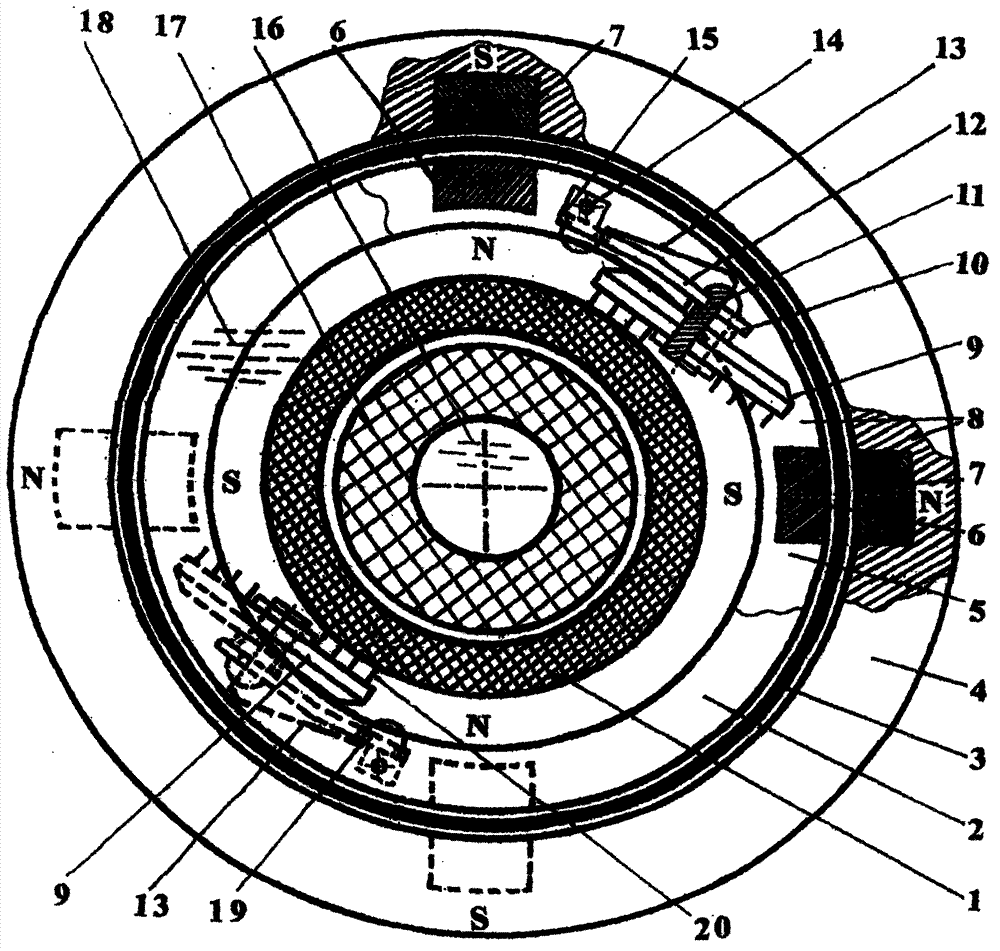

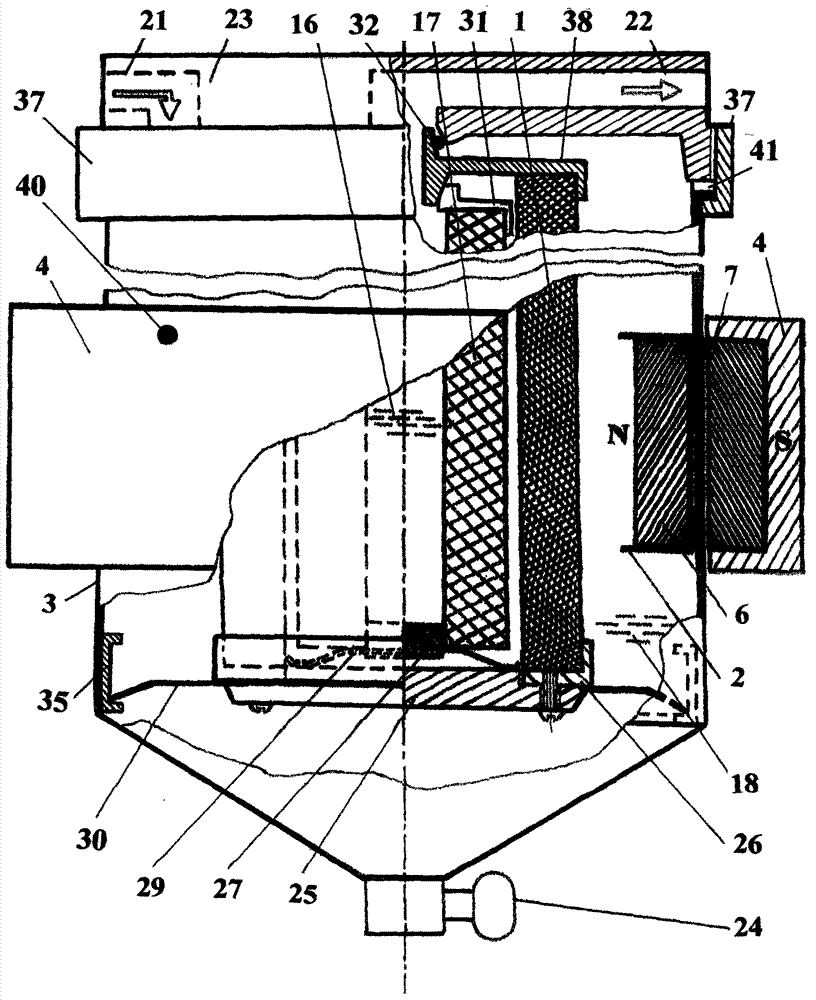

Disassembly-and-washing-free durable ceramic filter element water purifier

InactiveCN103157318AExtended service lifeAvoid damageLoose filtering material filtersGravity filtersWater filterEngineering

The invention discloses a disassembly-and-washing-free durable ceramic filter element water purifier which comprises a base 23, a ceramic filter element 1 and a non-magnetizer shell cylinder 3. The technical scheme is that a washing component is arranged in the shell cylinder 3 and is in mechanical linkage with an inner magnetic ring 2 which can slide along the shell cylinder 3, an outer magnetic ring 4 capable of sliding is sleeved outside the shell cylinder 3, and the two magnetic rings are separated by the cylinder wall and mutually absorbed. The outer magnetic ring 4 is pushed and rotated by hand, the inner magnetic ring 2 can be moved simultaneously and drives the washing component to wash the ceramic filter element 1, and sewage is discharged through a blowdown valve 24. Due to the fact that when the ceramic filter element 1 of the water purifier is washed, the outer cylinder 3 does not need to be disassembled, not only is operation convenient and fast, but also component damage possibly caused in the frequent washing and disassembling process is avoided, moreover, wearing strength imposed on the ceramic filter element by the washing component is reduced to the maximum, and active carbon which is inactive after a long time can be conveniently replaced, and therefore the service life of the water purifier can be greatly prolonged.

Owner:嘉兴市圣路易斯洁具有限公司

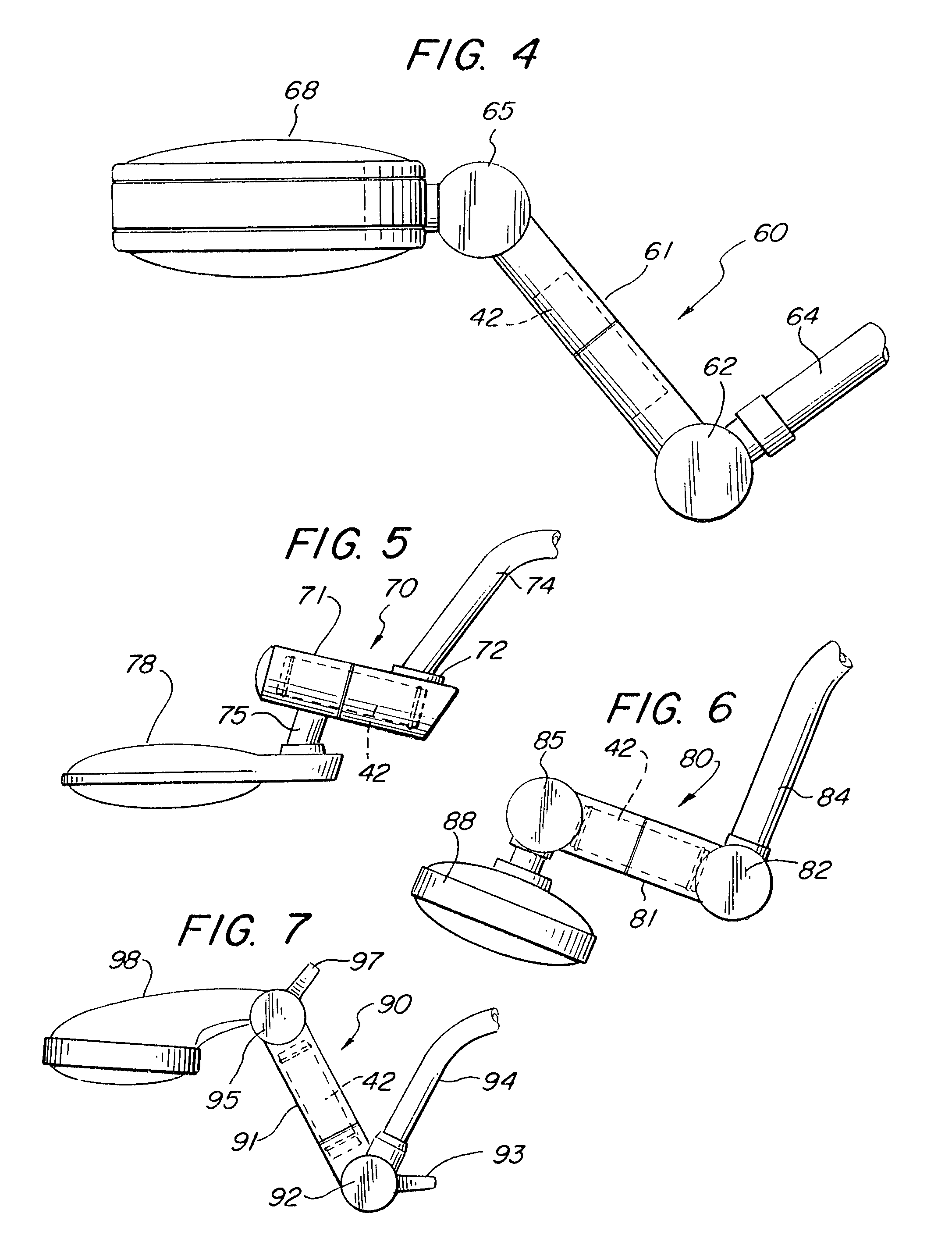

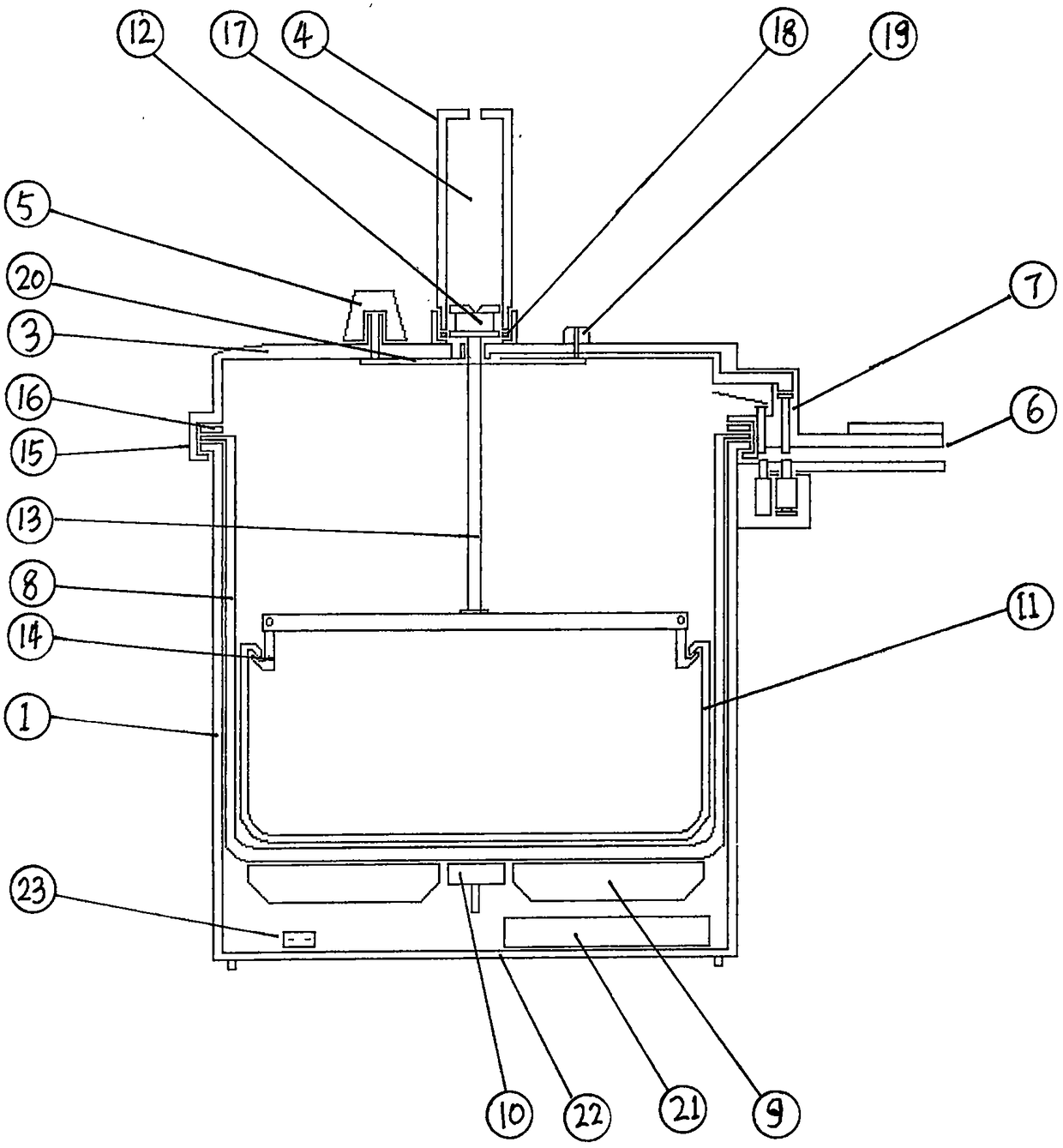

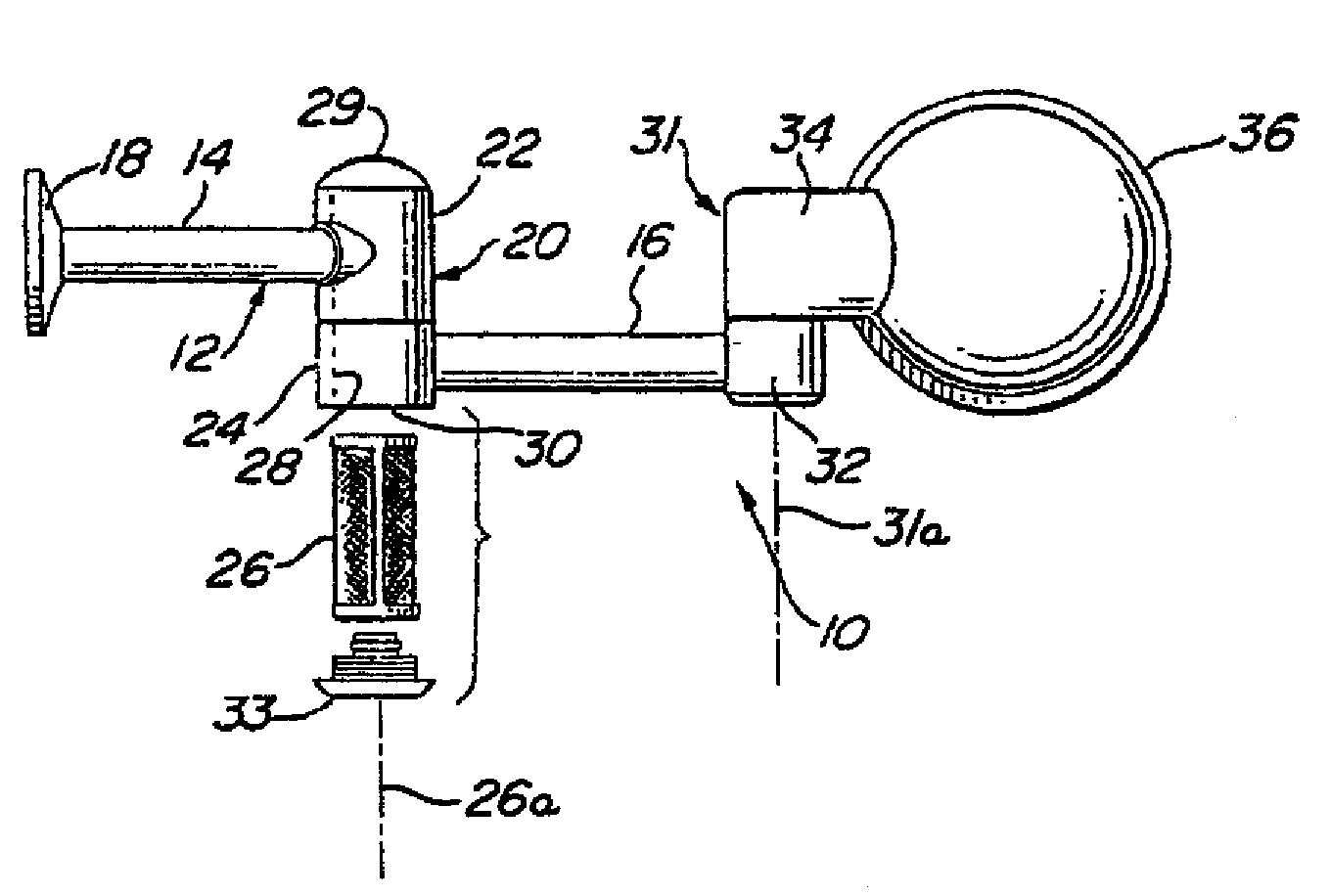

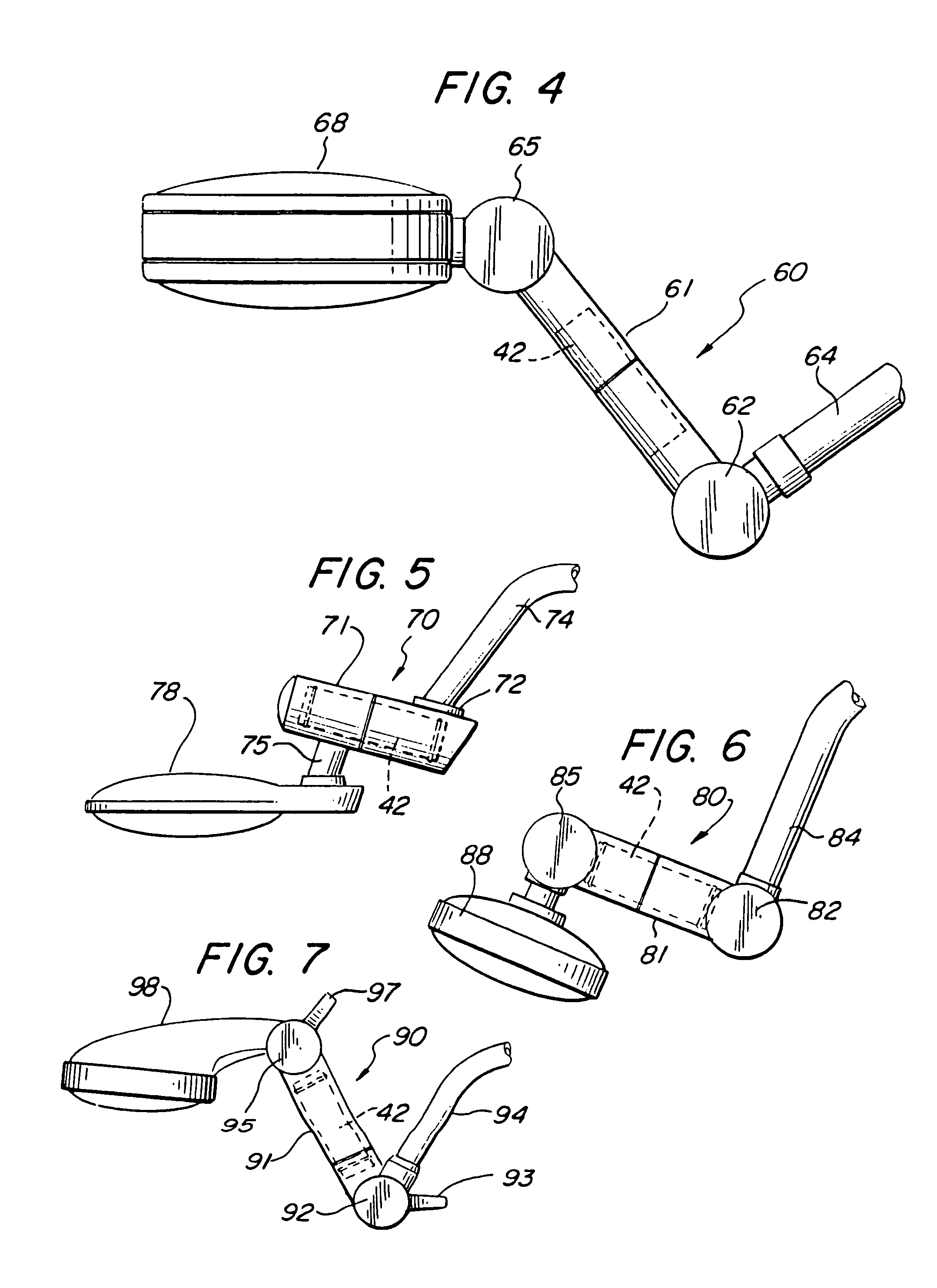

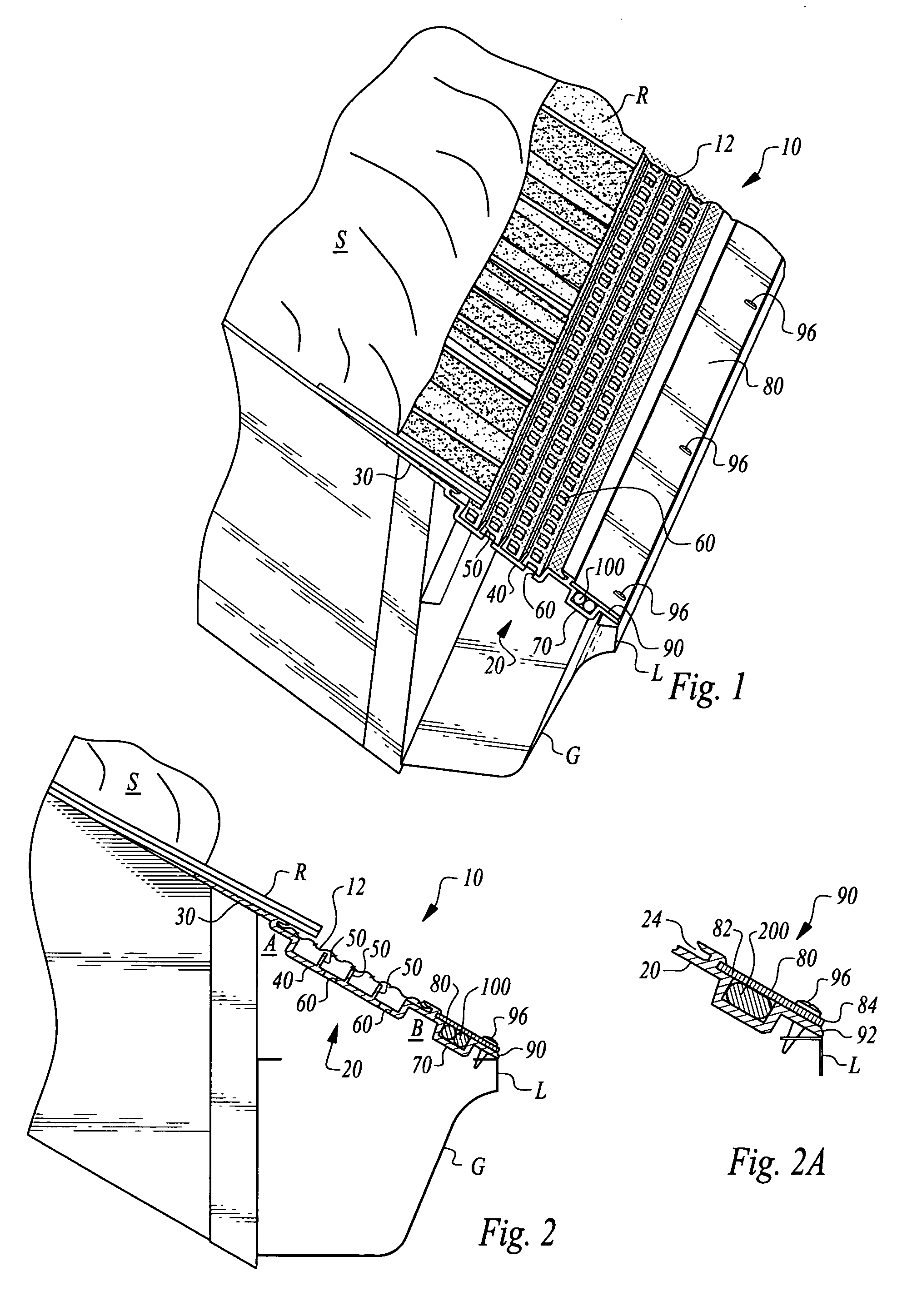

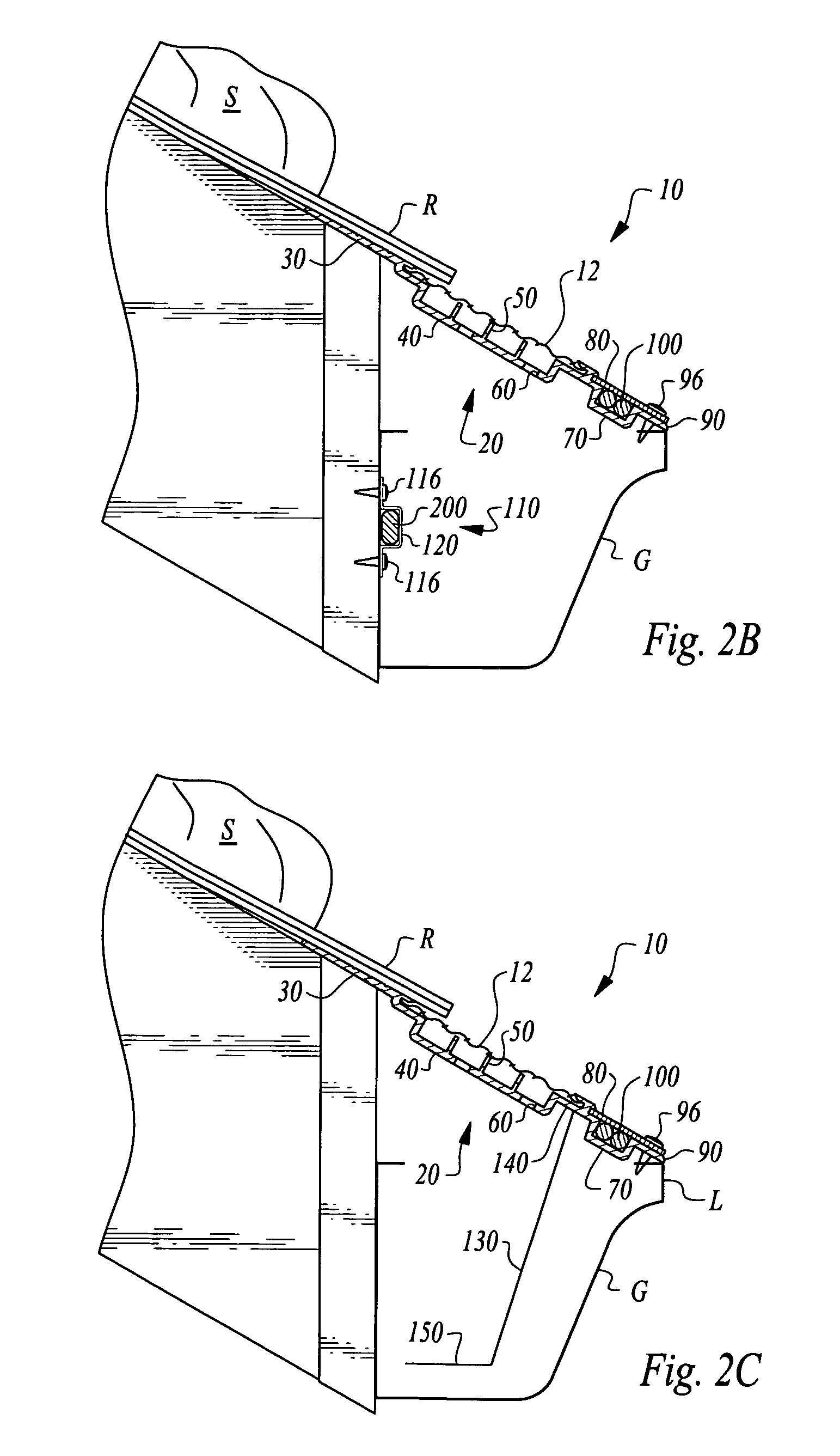

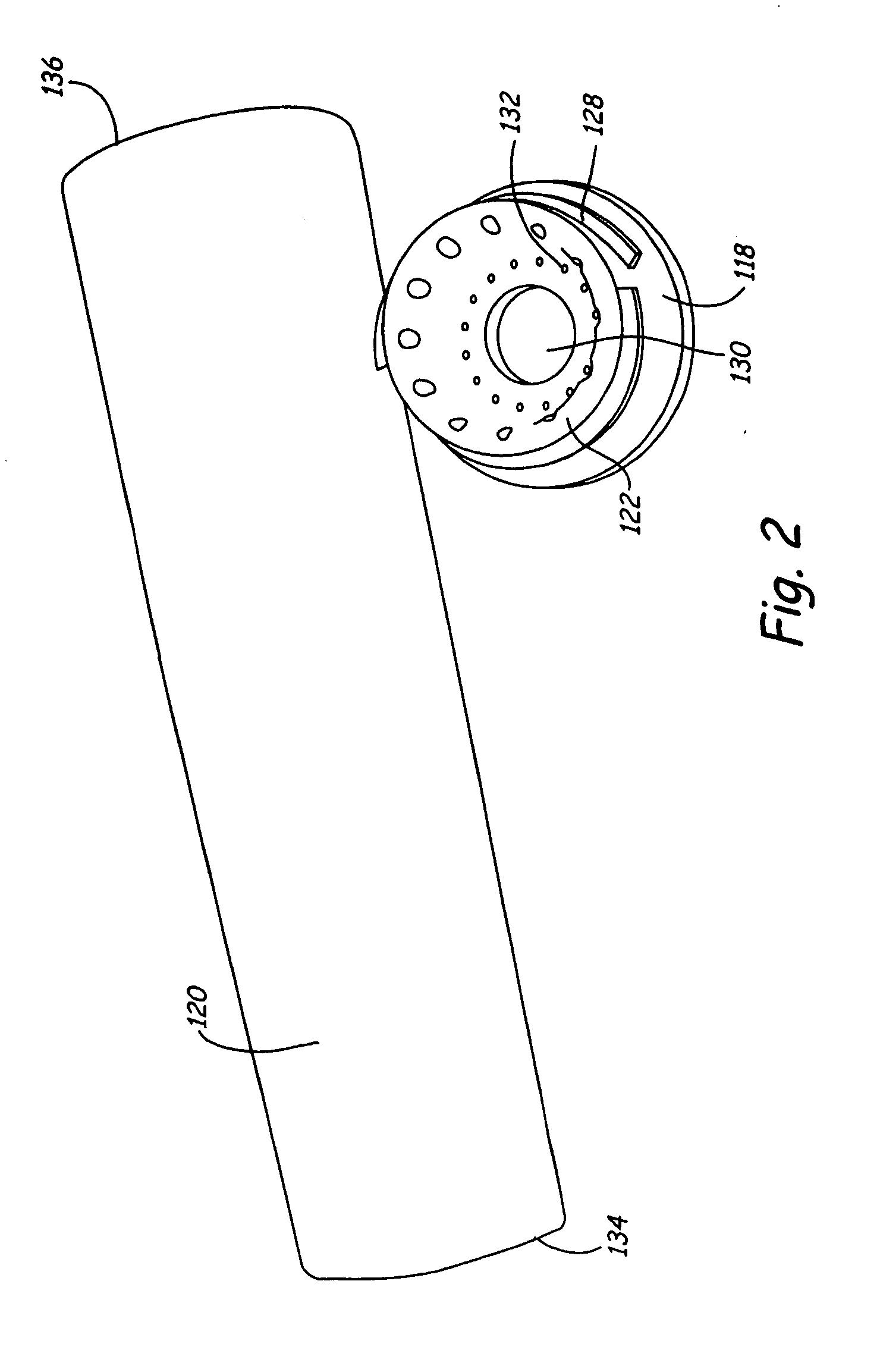

Filtered shower arm

A combination shower arm and water filter having an integrated design for attachment between a shower wall and a showerhead. The combination shower arm and water filter includes a housing having a number of components that may be easily manipulated, and which may be connected to any available showerhead, without the need of special tools. The combination shower arm and water filter allows an attached showerhead to be extended, moved or rotated into more accessible positions by actuation of the movable portions.

Owner:FARLEY DAVID K

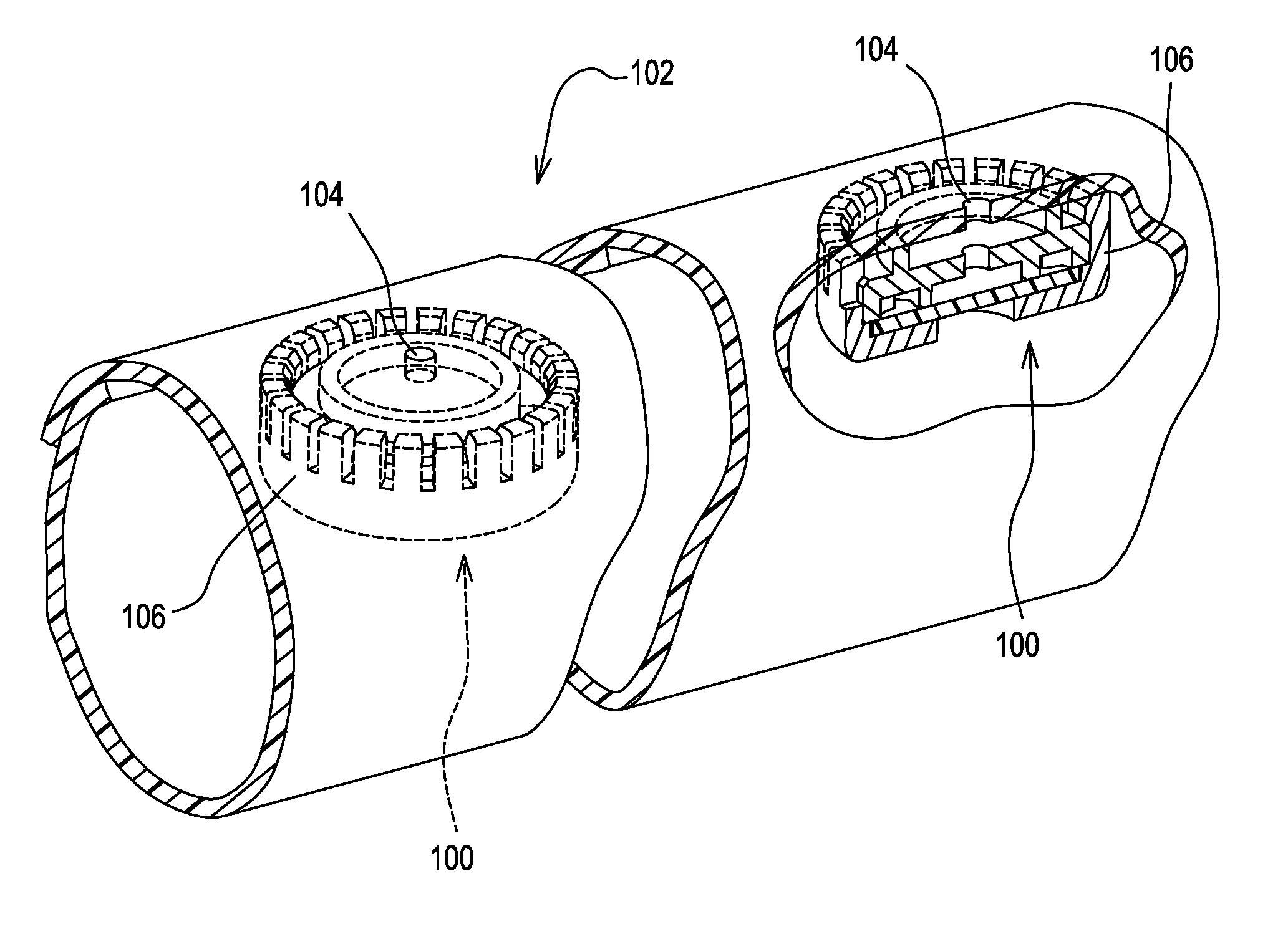

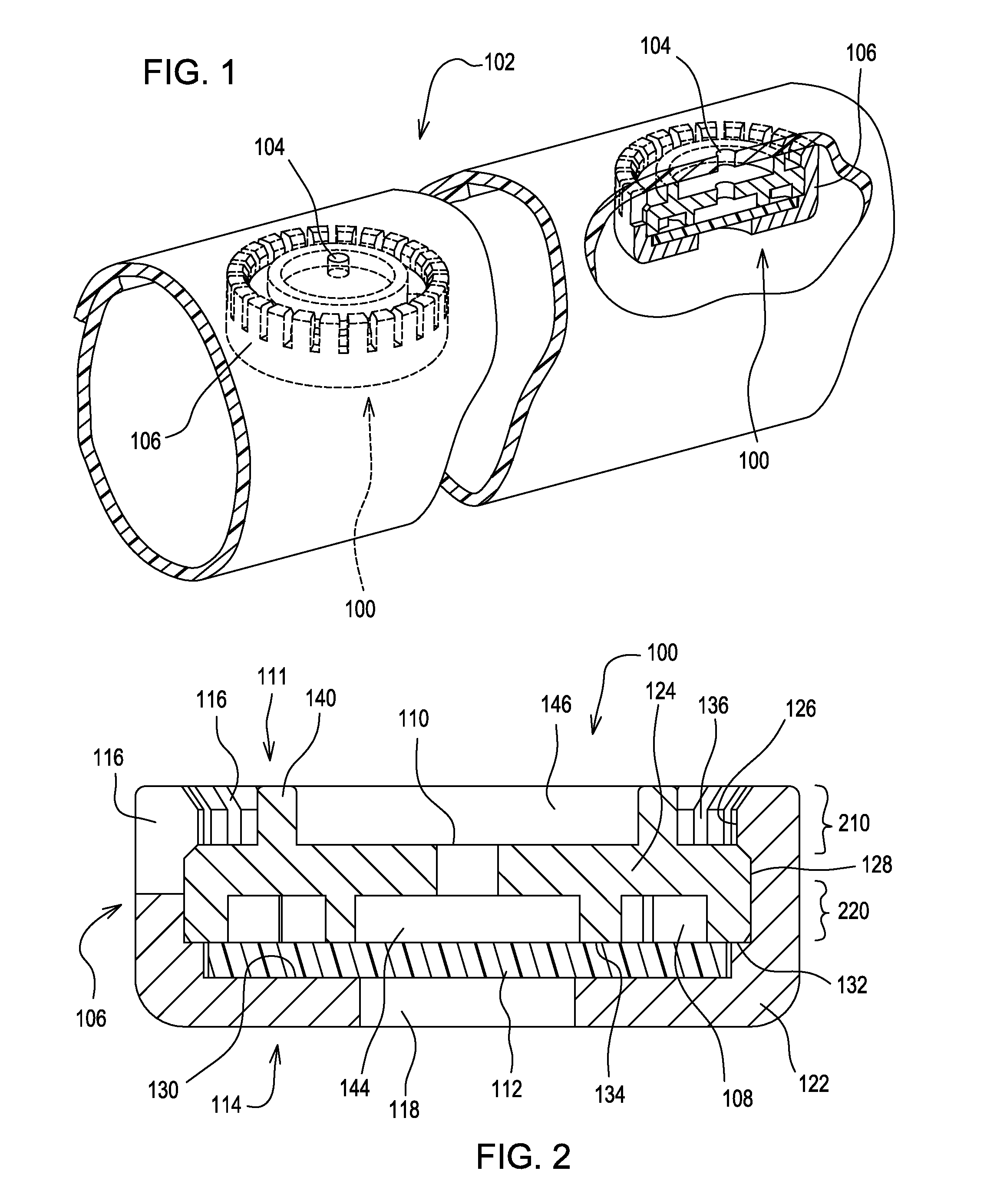

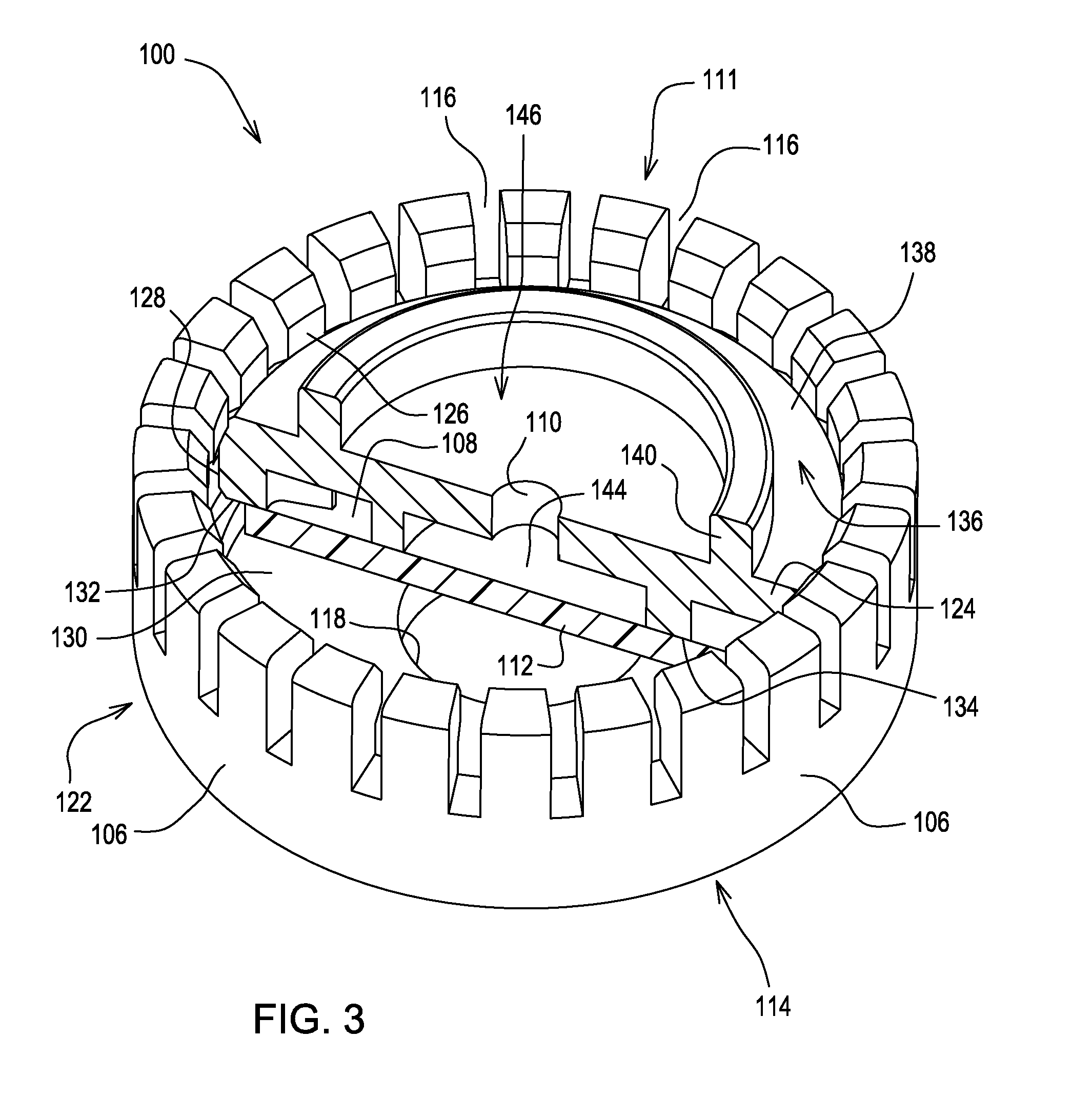

Water Filter Cartridge and Valve with Autobypass Feature

InactiveUS20080000820A1Avoid communicationSemi-permeable membranesOperating means/releasing devices for valvesWater filterValve actuator

A liquid filter cartridge system includes a housing, a valve body, a valve actuator, a filter, an inlet passage having a portion extending through each of the valve body and the valve actuator and into the filter, and an outlet passage having a portion leading out of the filter, and extending through each of the valve actuator and the valve body. An interface is located between the inlet passage portions in the valve actuator and the filter and an interface is located between the outlet passage portions in the valve actuator and the filter. The inlet passage interface and the outlet passage interface may lie in the same plane as each other. They may each comprise a face seal comprising an axial seal between the valve actuator and the filter. They may each comprise a seal between the valve actuator and the filter, wherein the two seals are sealed via compression and not via sliding contact.

Owner:WHIRLPOOL CORP

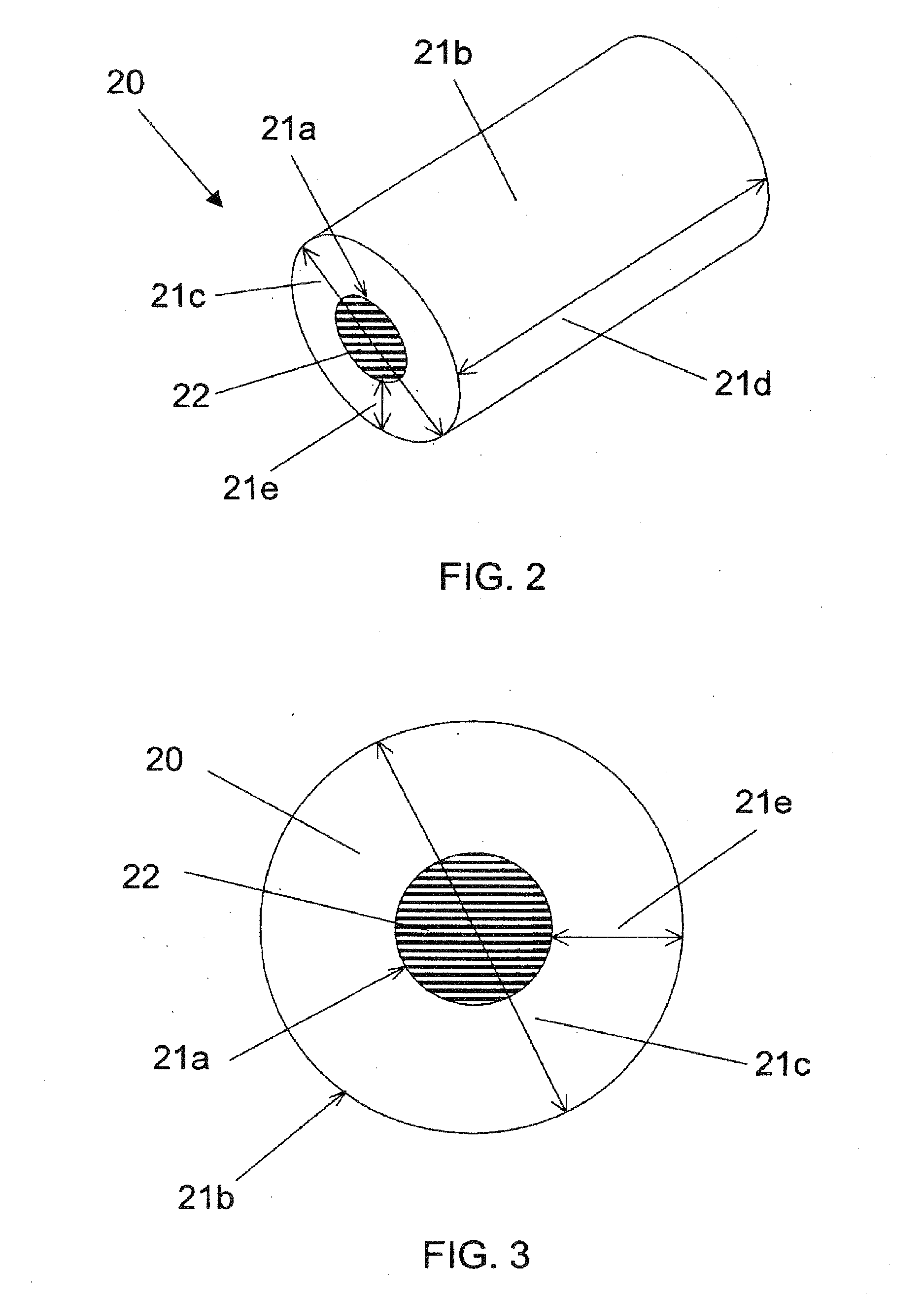

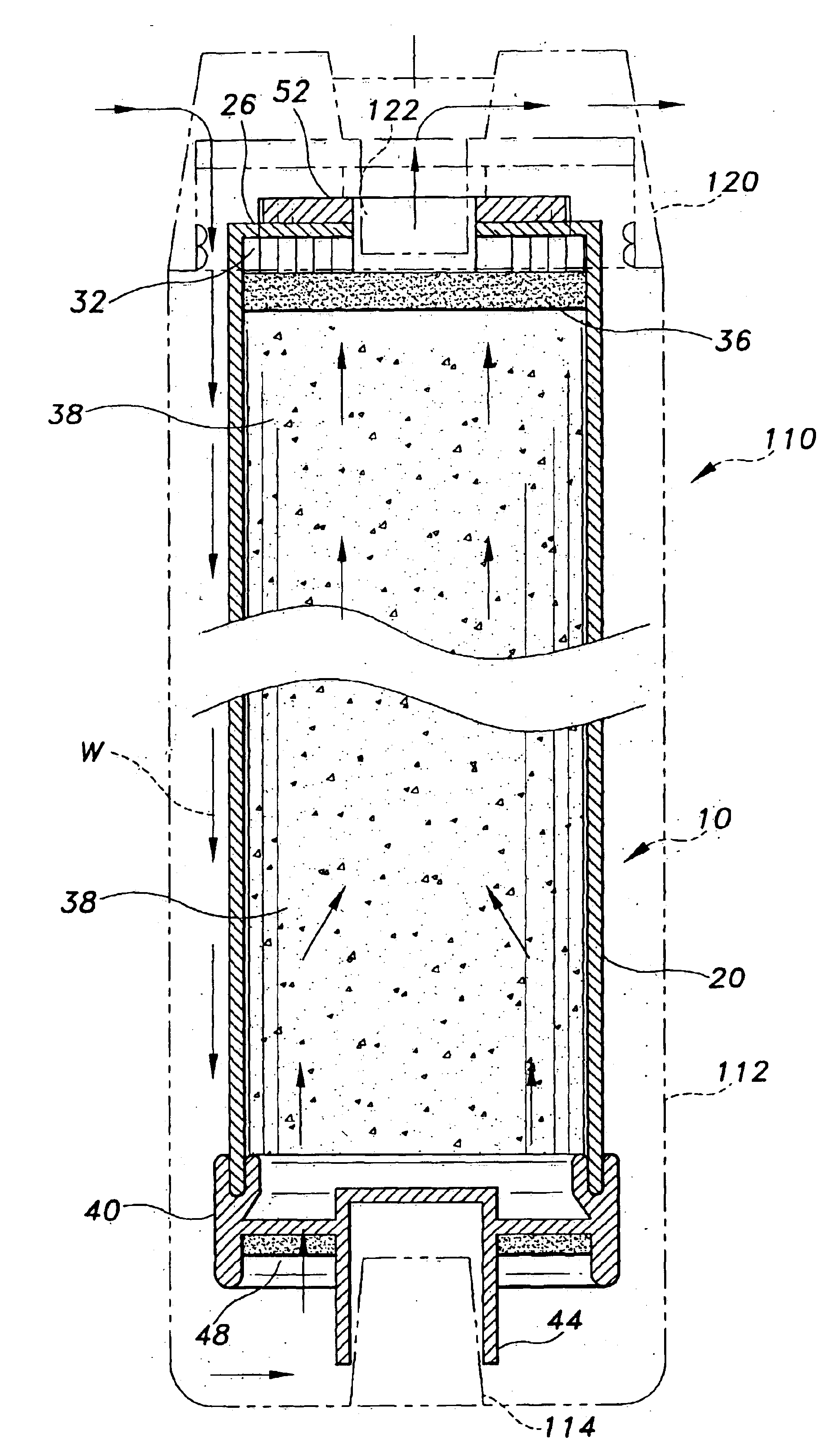

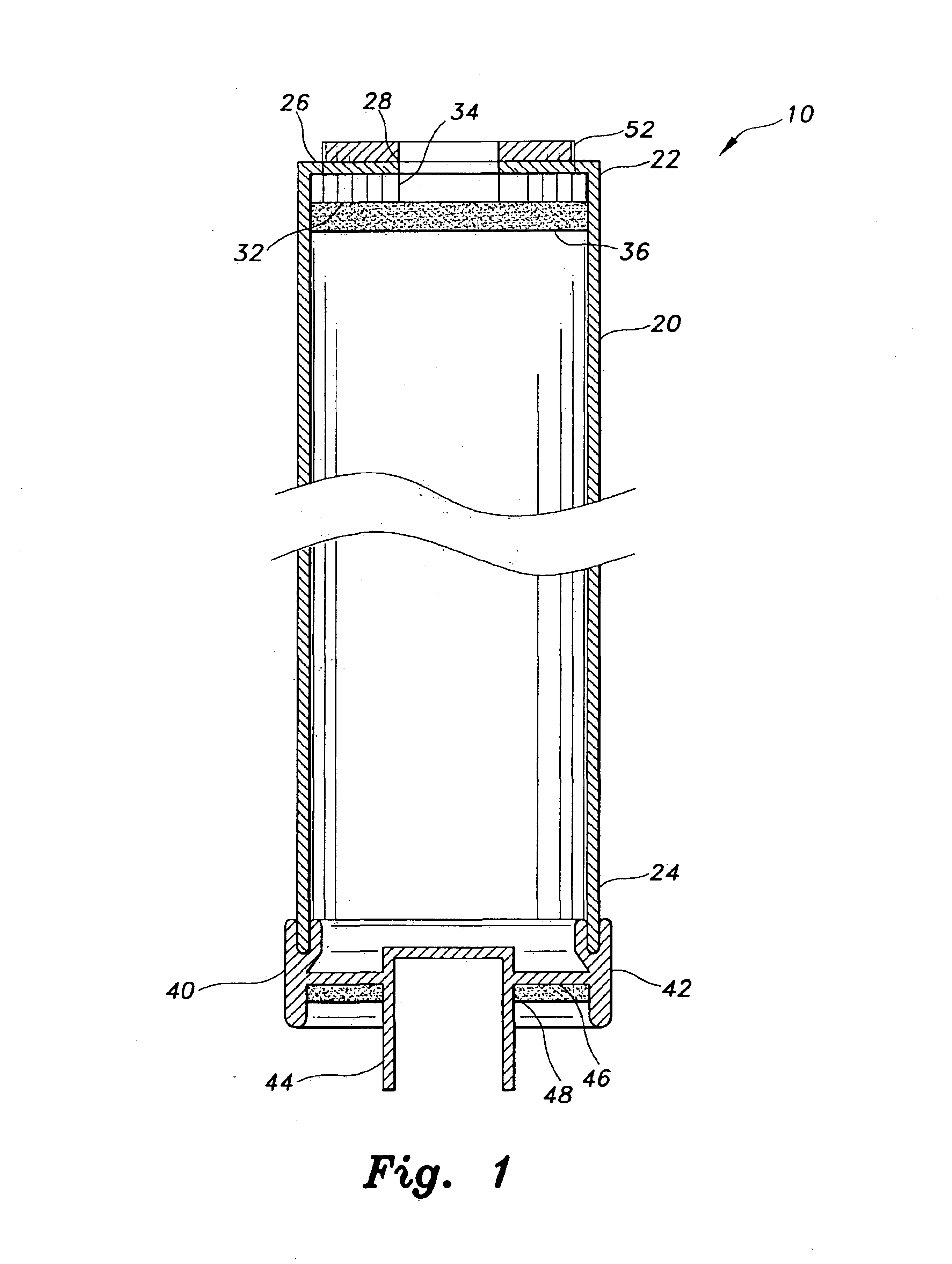

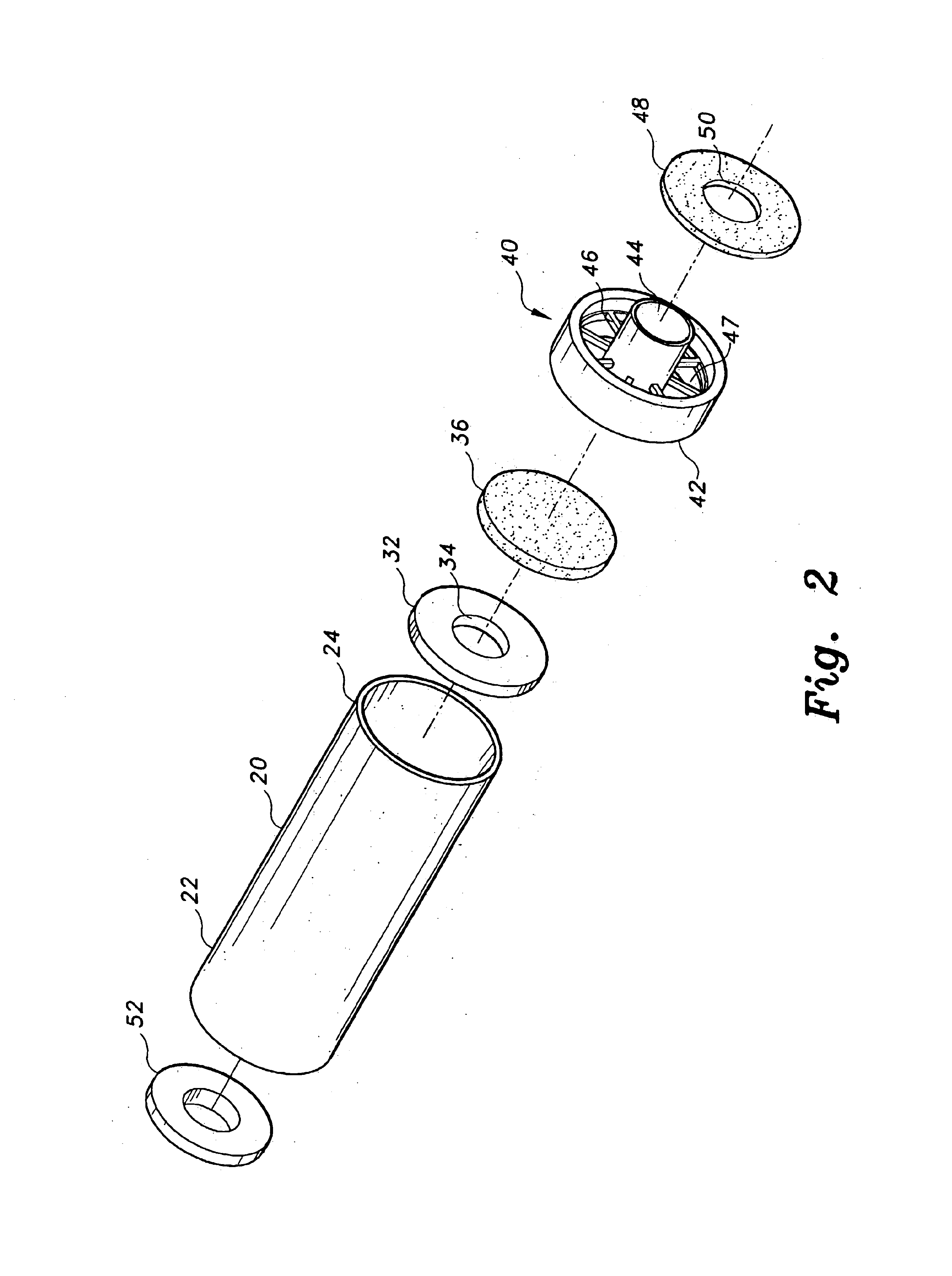

Water filter materials and water filters containing a mixture of microporous and mesoporous carbon particles

InactiveUS20050279696A1Reduce bacteriaReduce virusMembrane filtersLoose filtering material filtersWater filterActivated carbon filtration

A filter and filter material for providing or treating potable water is provided. The filter includes a housing having an inlet and an outlet, a filter material disposed within the housing, the filter material formed at least in part from a mixture of a plurality of mesoporous and microporous activated carbon particles. Preferably, at least some of the mesoporous activated carbon filter particles are coated with a cationic polymer, and even more preferably, at least some of the particles are coated with a cationic polymer and silver or a silver containing material. Kits comprising filters and information relating to the reduction, killing or removal of bacteria, viruses, microbials, and TTHM are also provided.

Owner:PUR WATER PURIFICATION PRODUCTS INC +2

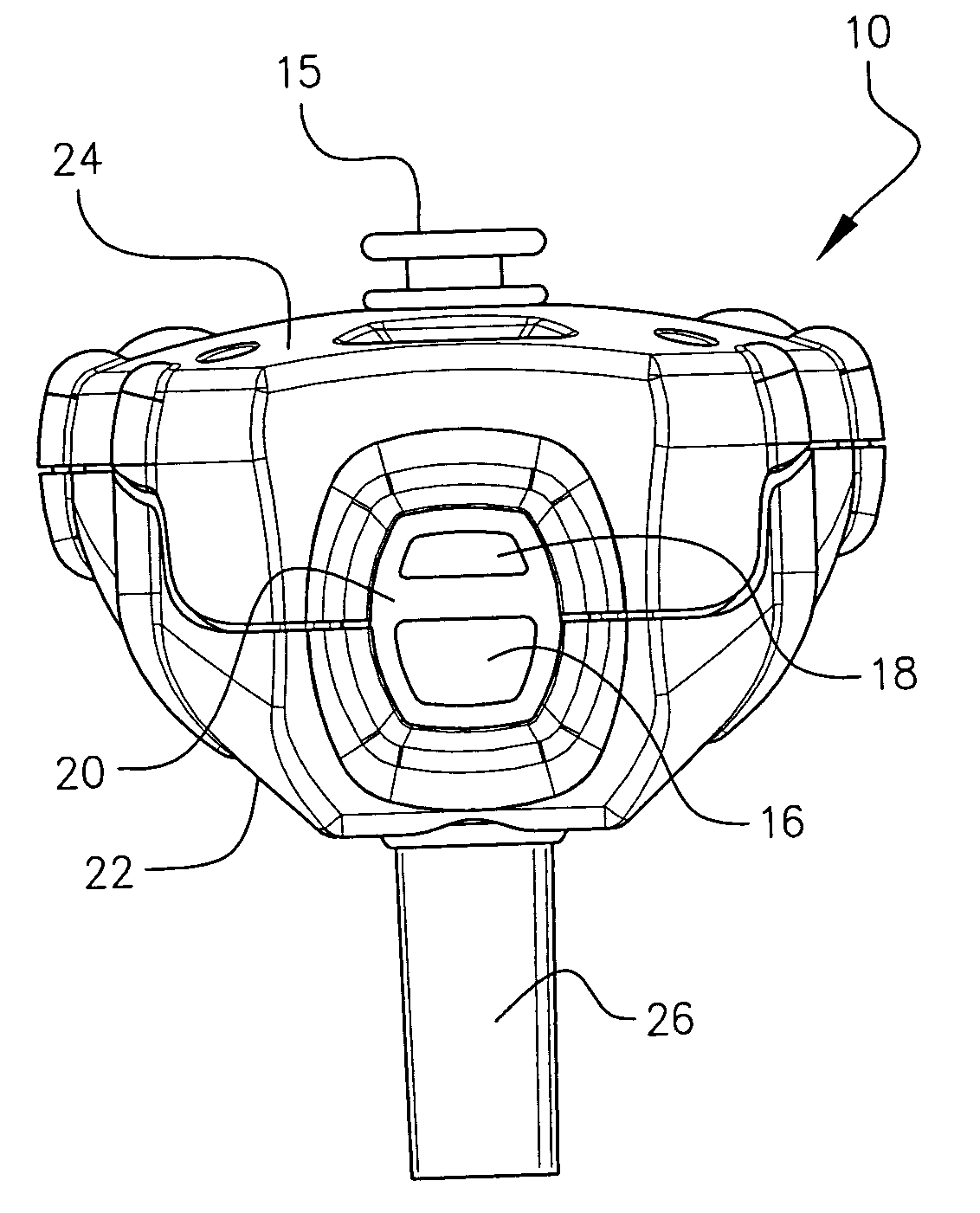

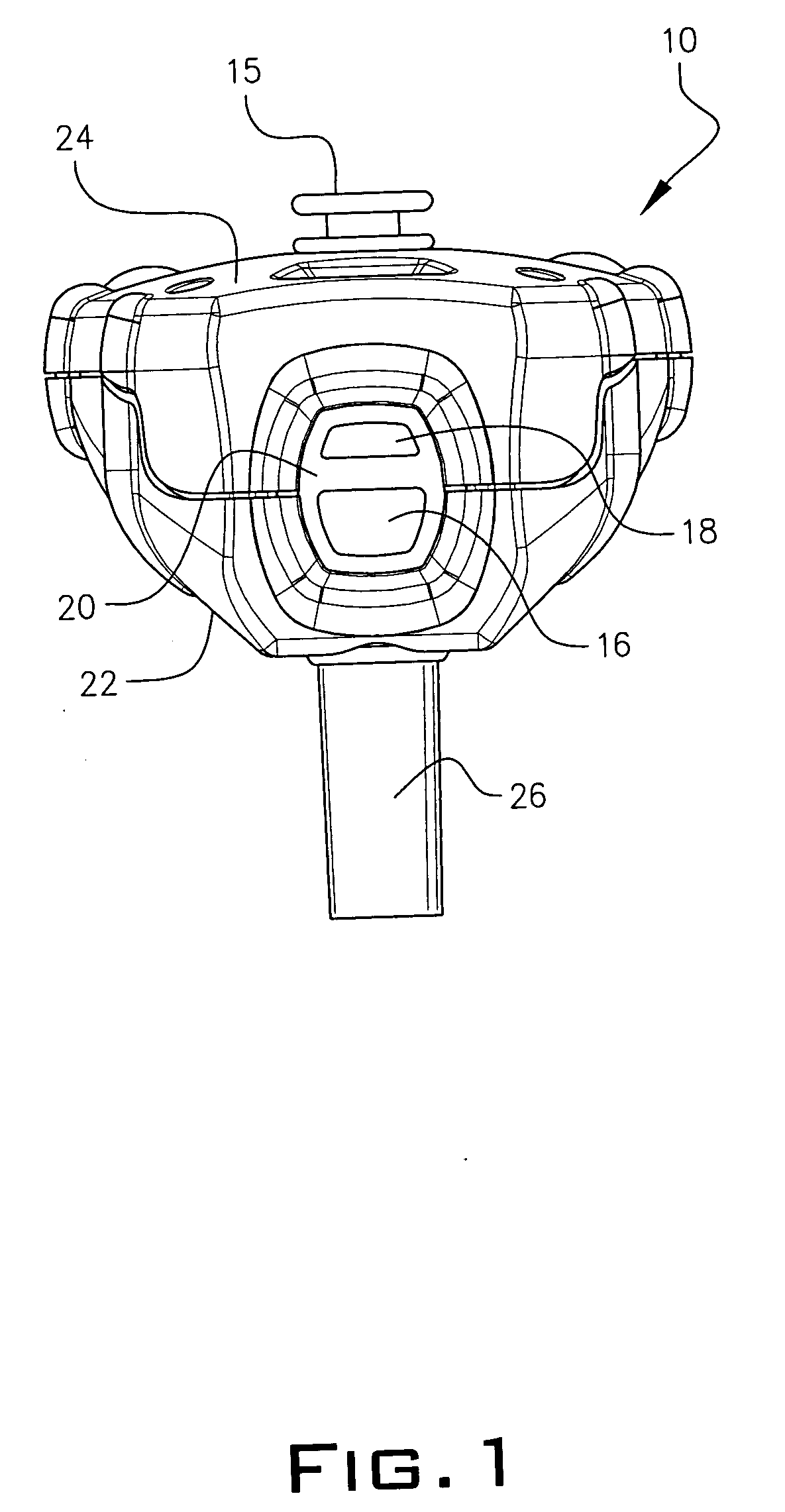

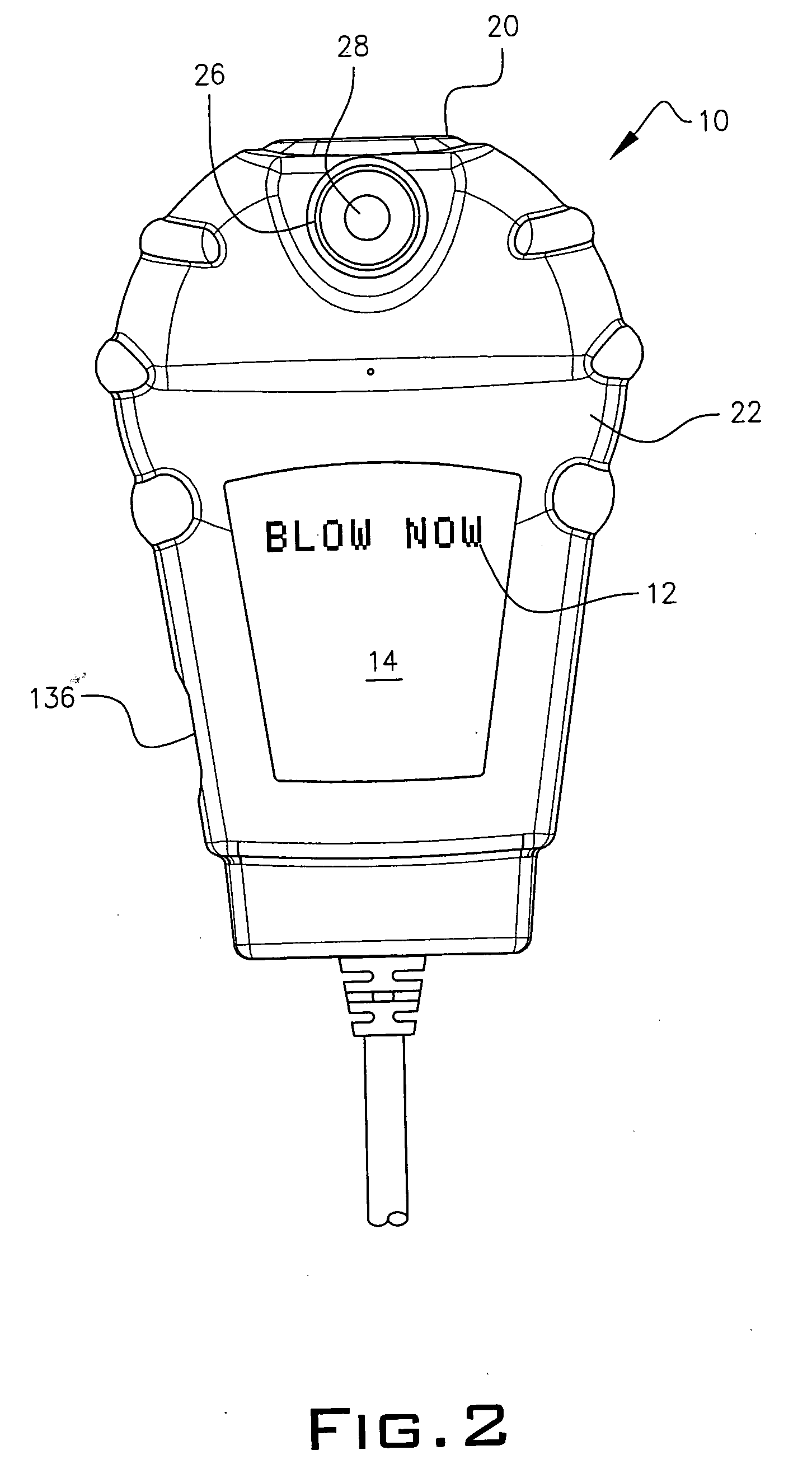

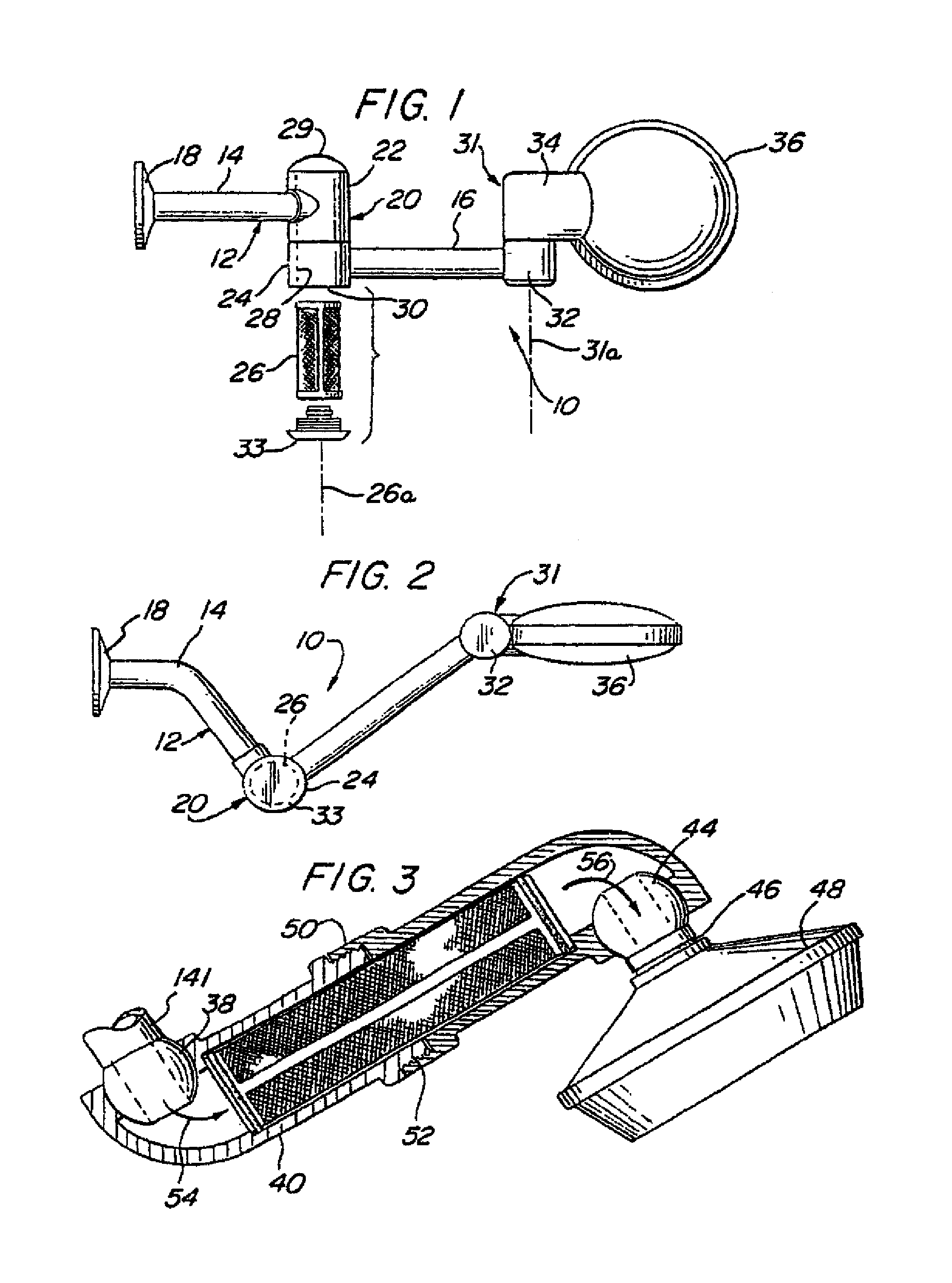

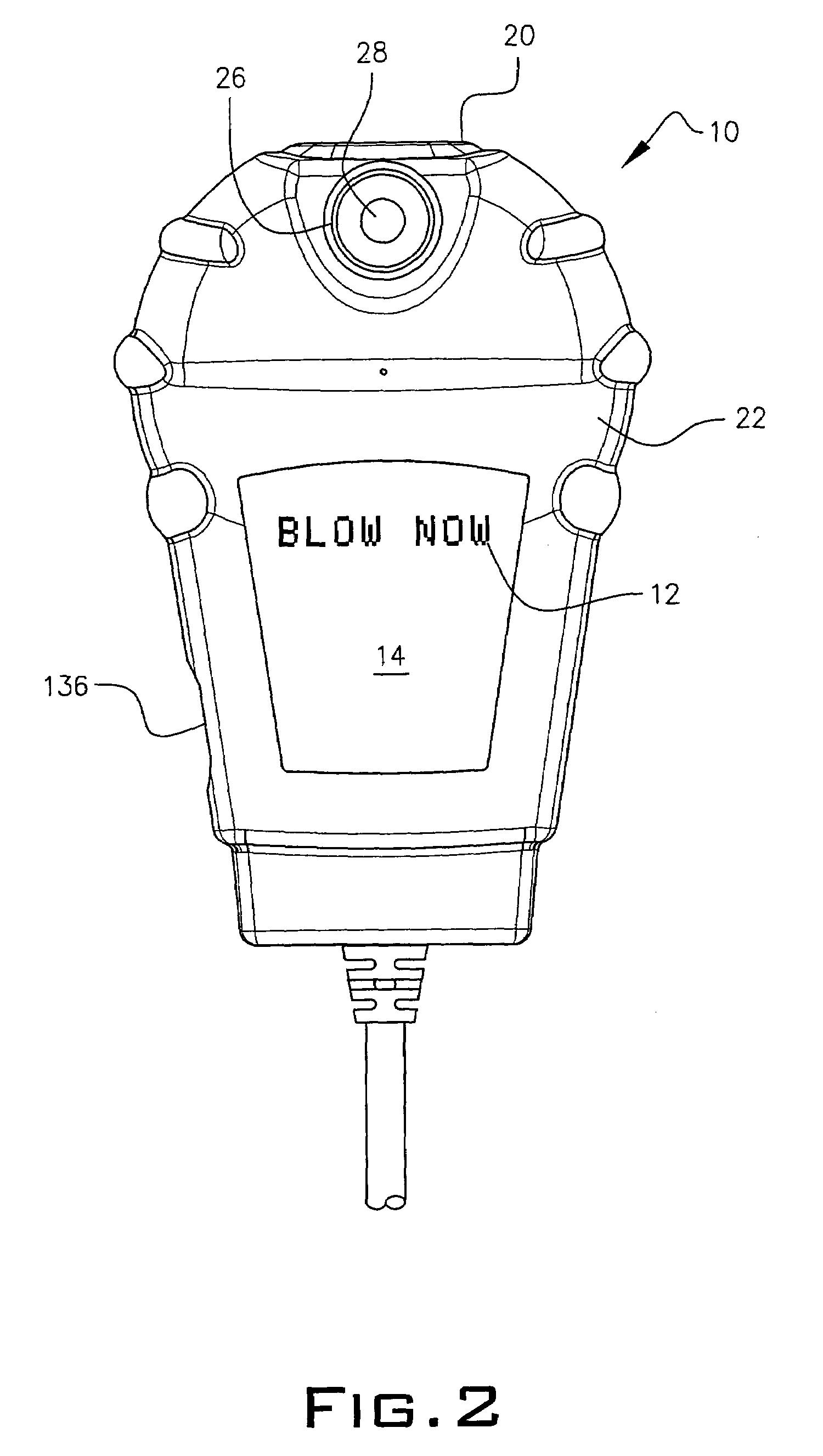

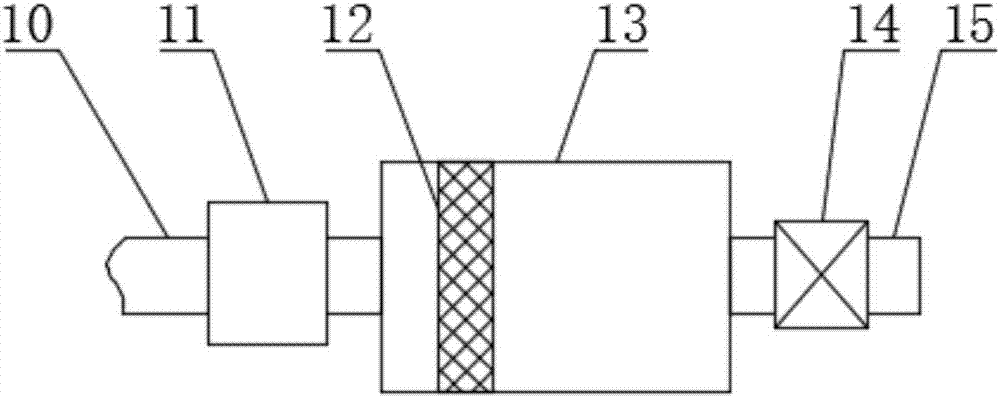

Vehicle sobriety interlock device

ActiveUS20050241871A1Accurate readingReduce moistureElectric devicesElectrical apparatusWater filterEngineering

An interlock device for measuring the sobriety of a potential vehicle operator is coupled to the starting mechanism of the vehicle. The interlock device includes a microprocessor controlled handset and base unit. The base unit encloses relays to preclude the starting mechanism from engaging if a predetermined acceptable threshold level of blood alcohol content has been exceeded. The relays receive a signal, through the base unit microprocessor, from the handset microprocessor which has calculated the blood alcohol content of a breath sample introduced into the handset by the vehicle operator. A breath sampling housing is enclosed within the handset in axial alignment with an intake port of the handset. A water filter and valve are positioned upstream from an electrochemical fuel cell. The fuel cell is coupled to the microprocessor. A pressure transducer measures the pressure of the breath sample. The handset microprocessor calculates a pressure offset through an algorithmic equation and applies the offset to the variable reading across the fuel cell to provide a normalized blood alcohol content measurement.

Owner:GUARDIAN INTERLOCK LLC

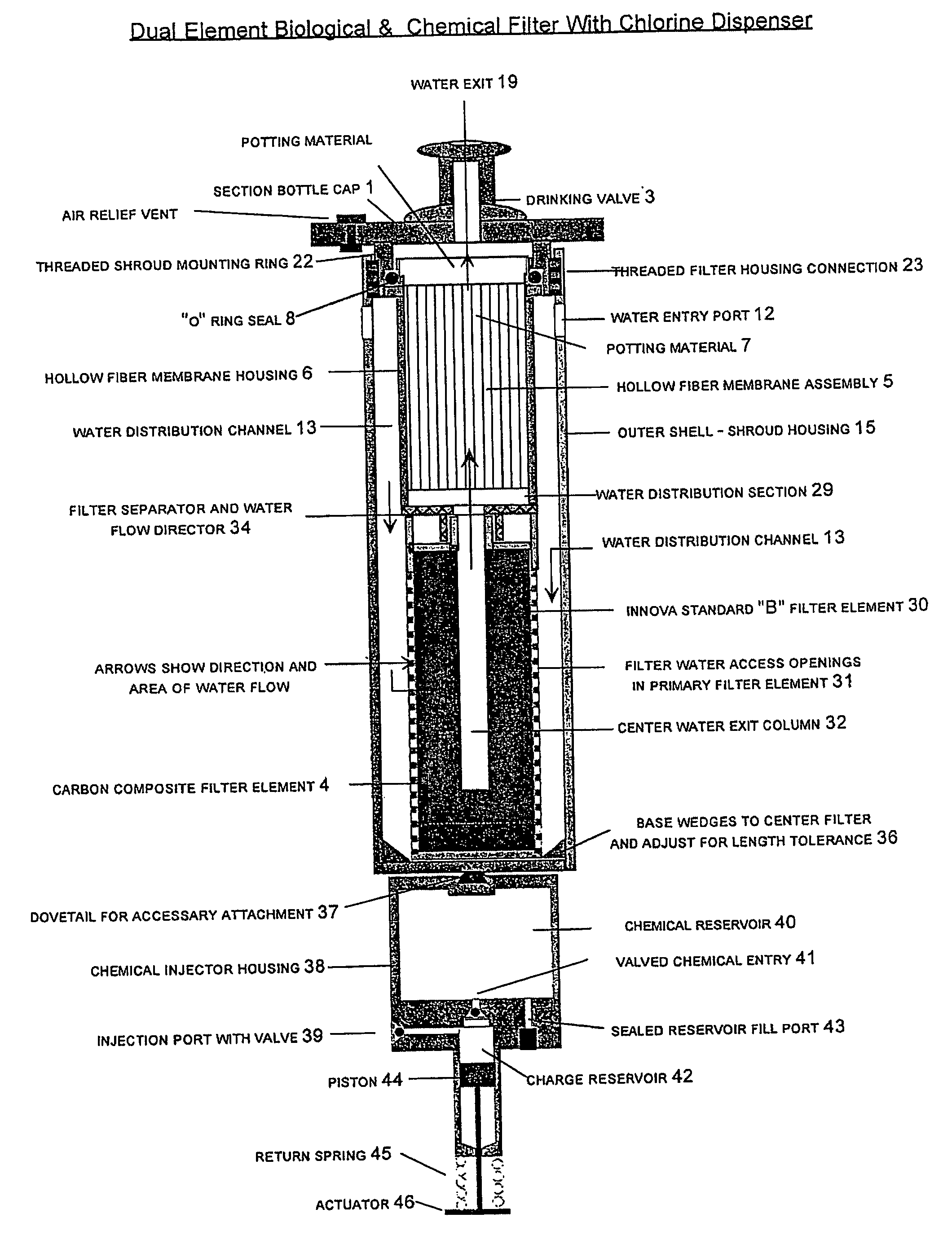

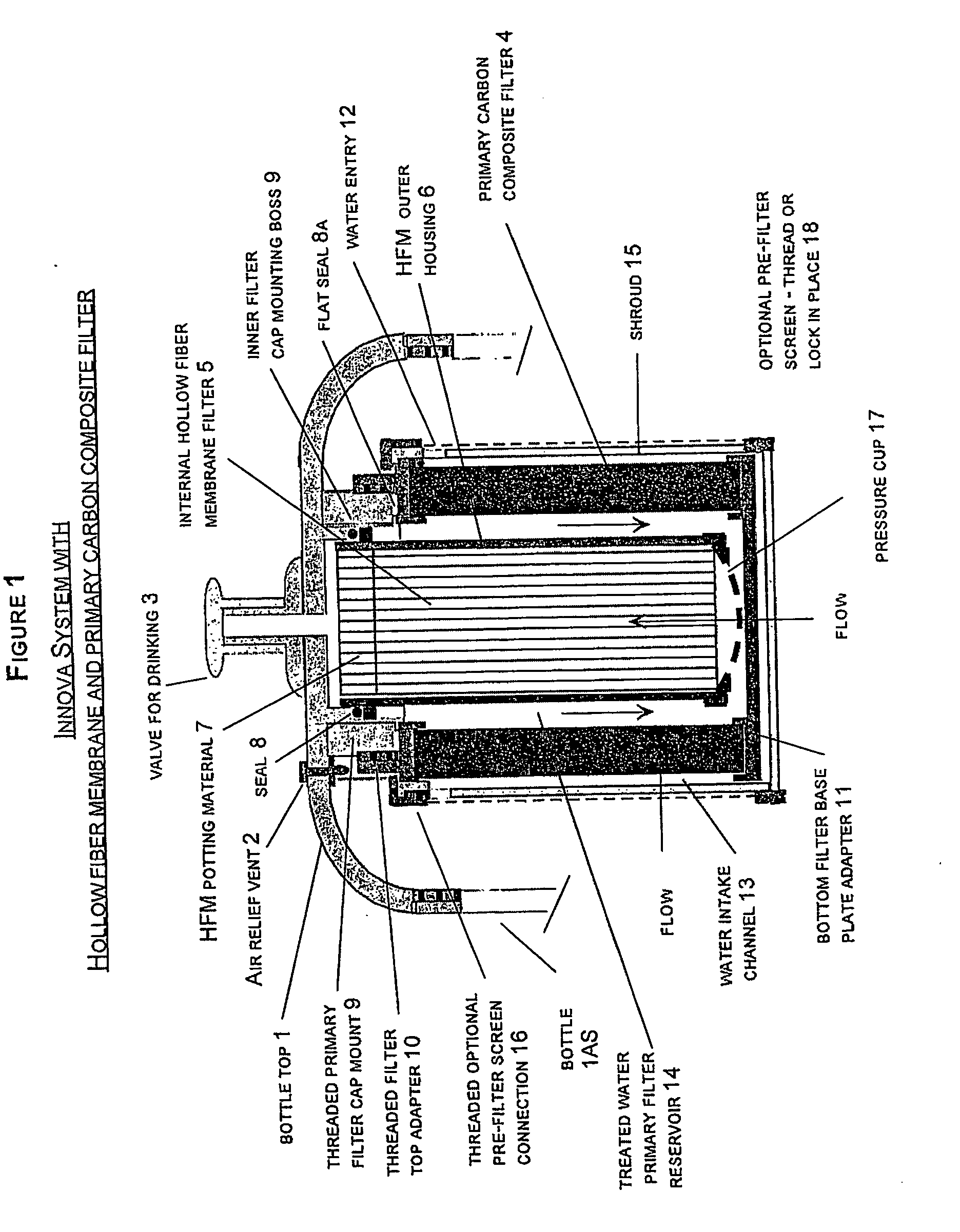

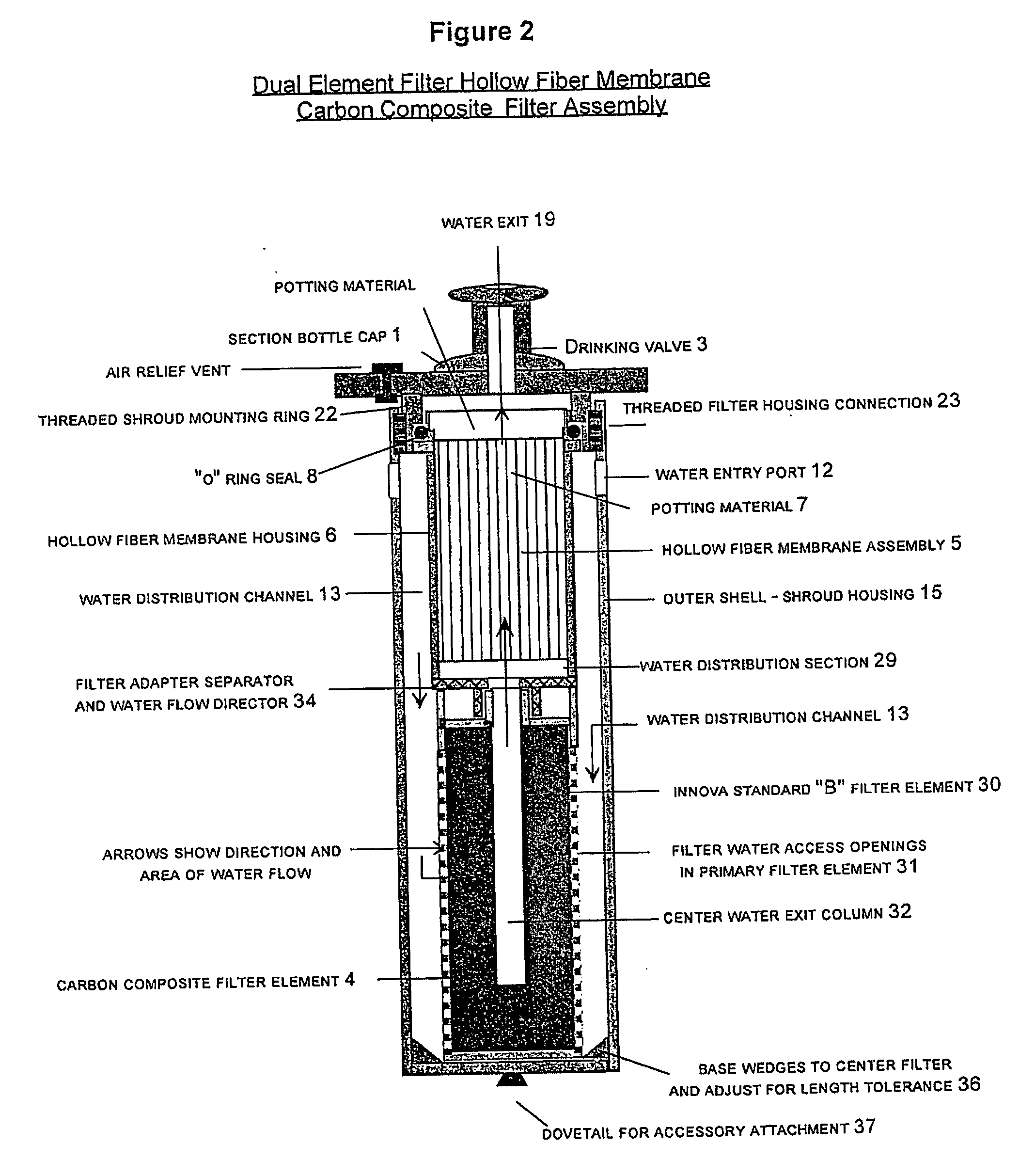

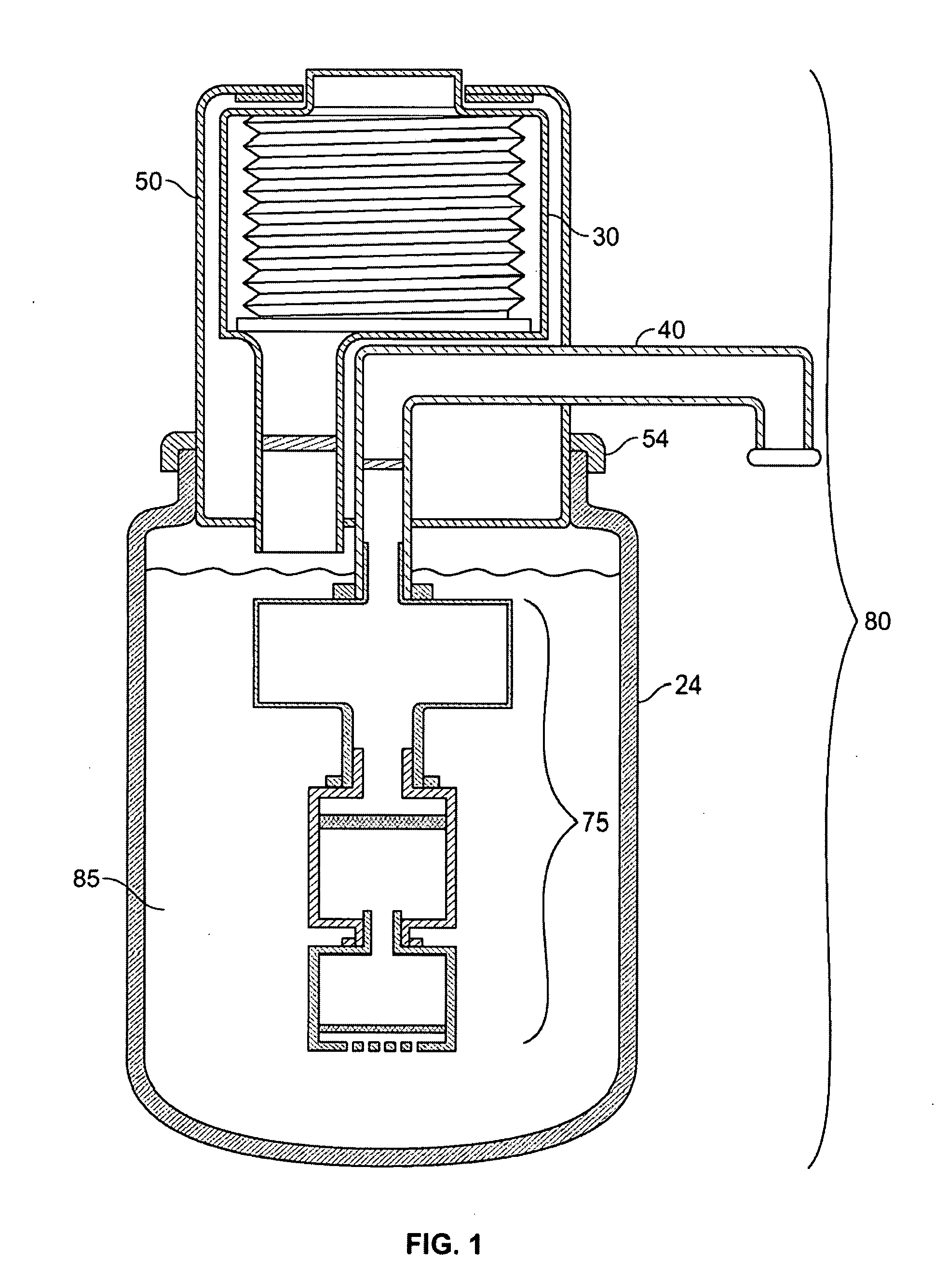

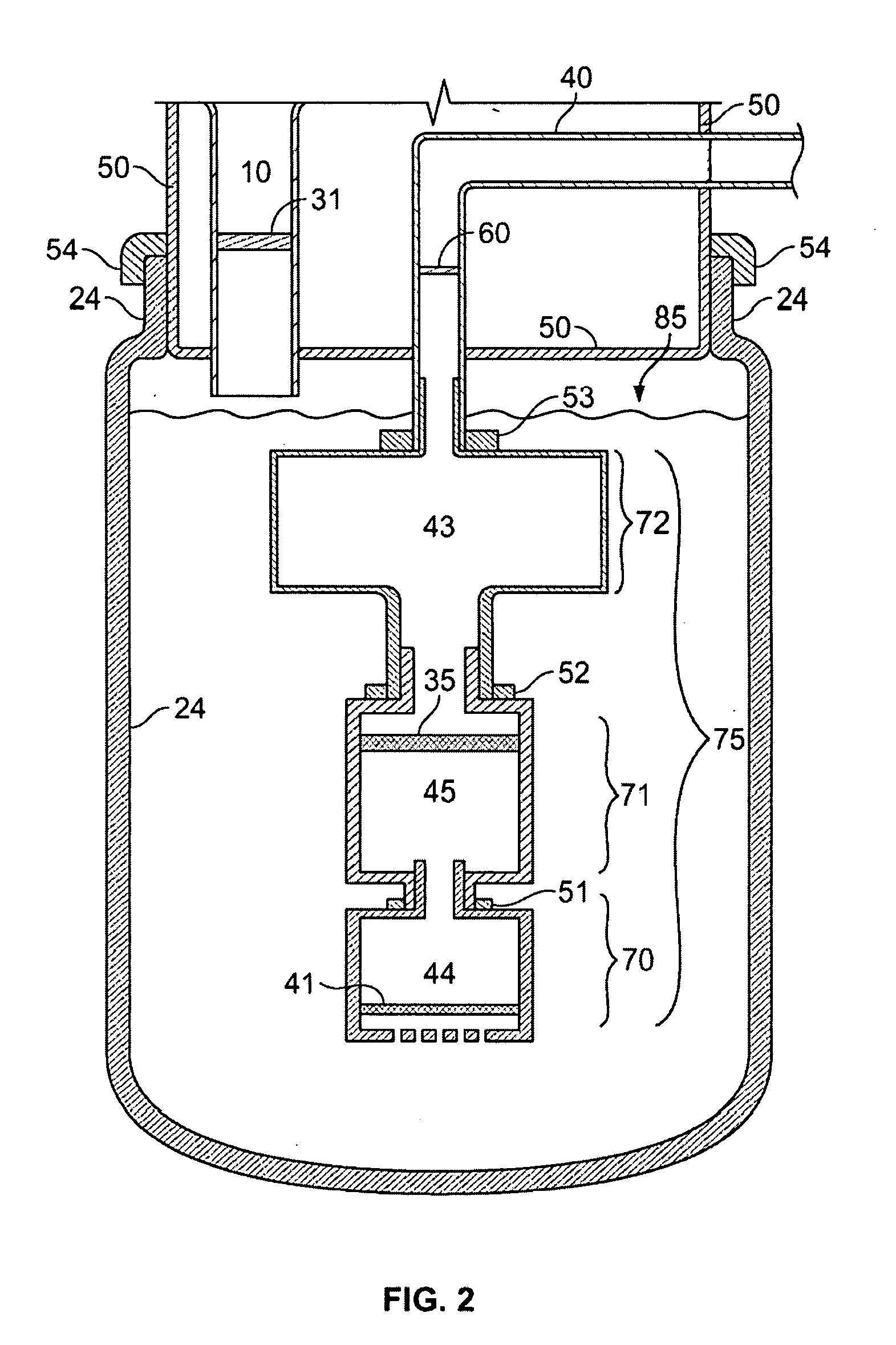

Hollow fiber membrane filters in various containers

InactiveUS20050035041A1Eliminate the problemAvoid accumulationTravelling sacksUltrafiltrationCarbon compositesWater filter

A water filter cooperable with a water container includes both a carbon composite filter (30) and a bundle of micro porous hollow fiber membranes (5) in fluid communication with the carbon composite filter (30). An influent side of the hollow fiber membrane (5) is continuously immersed in water whereby air is prevented from being reintroduced to the hollow fiber membrane (5).

Owner:INNOVAPURE WATER

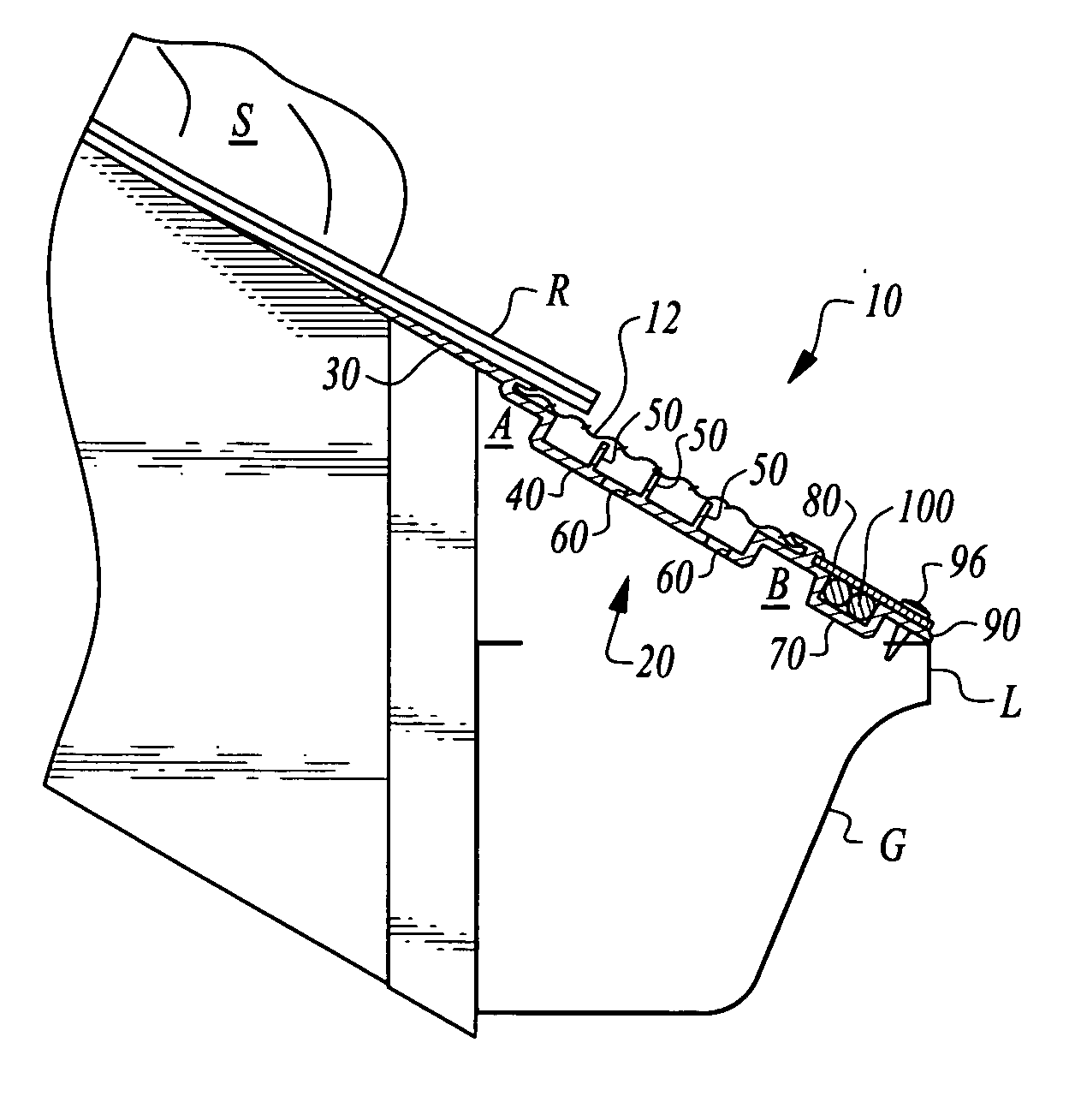

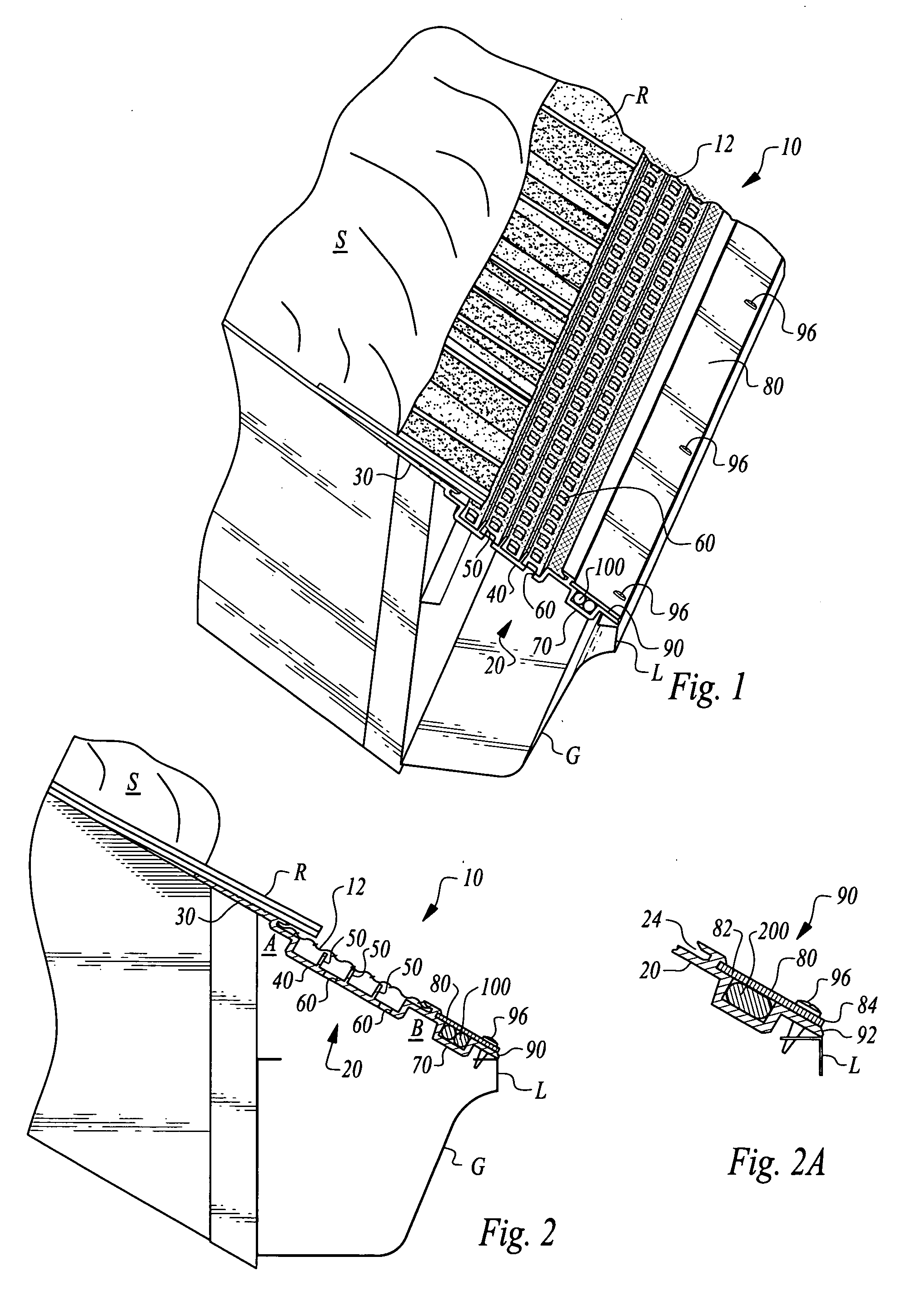

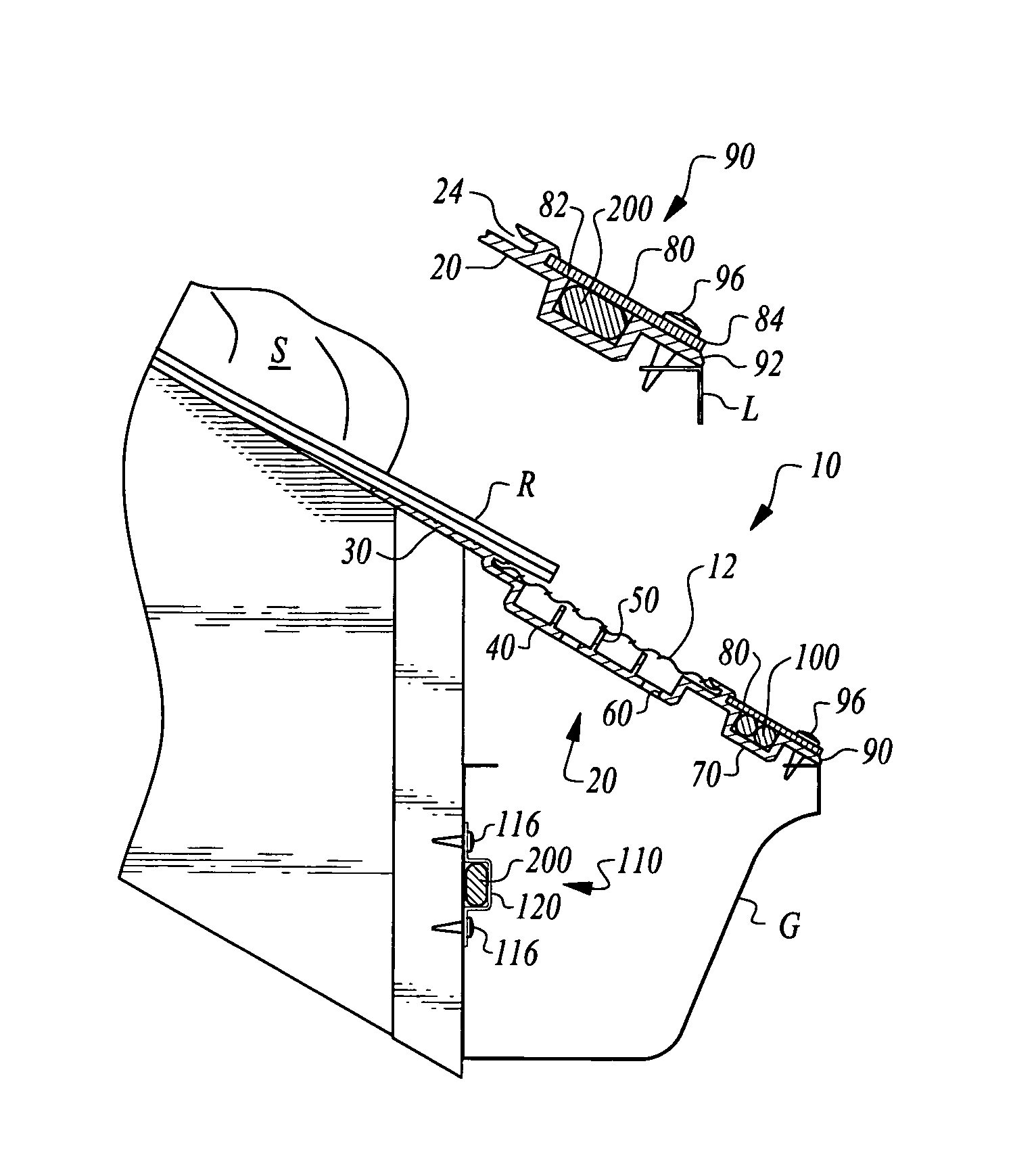

De-iced gutter debris preclusion system

ActiveUS20100287846A1Prevent icicle formationAvoid damageRoof coveringPipesElectrical resistance and conductancePower flow

The system includes a substantially rigid body providing underlying support for a filtering layer, such as in the form of a screen. The body includes a heating wire or other heat source coupled thereto with the body formed of heat conductive material. The body is configured with multiple ribs extending up from a floor so that heat transfer from the body to the screen can occur in a variety of different locations to keep the screen sufficiently heated. The body also includes a wing for interfacing with roofing and openings to allow water filtering through the screen to migrate down into the gutter. A cover overlies a channel which can contain one or more heating wires that experience resistive heating when an electric current is applied thereto.

Owner:ALL WEATHER ARMOUR LLC

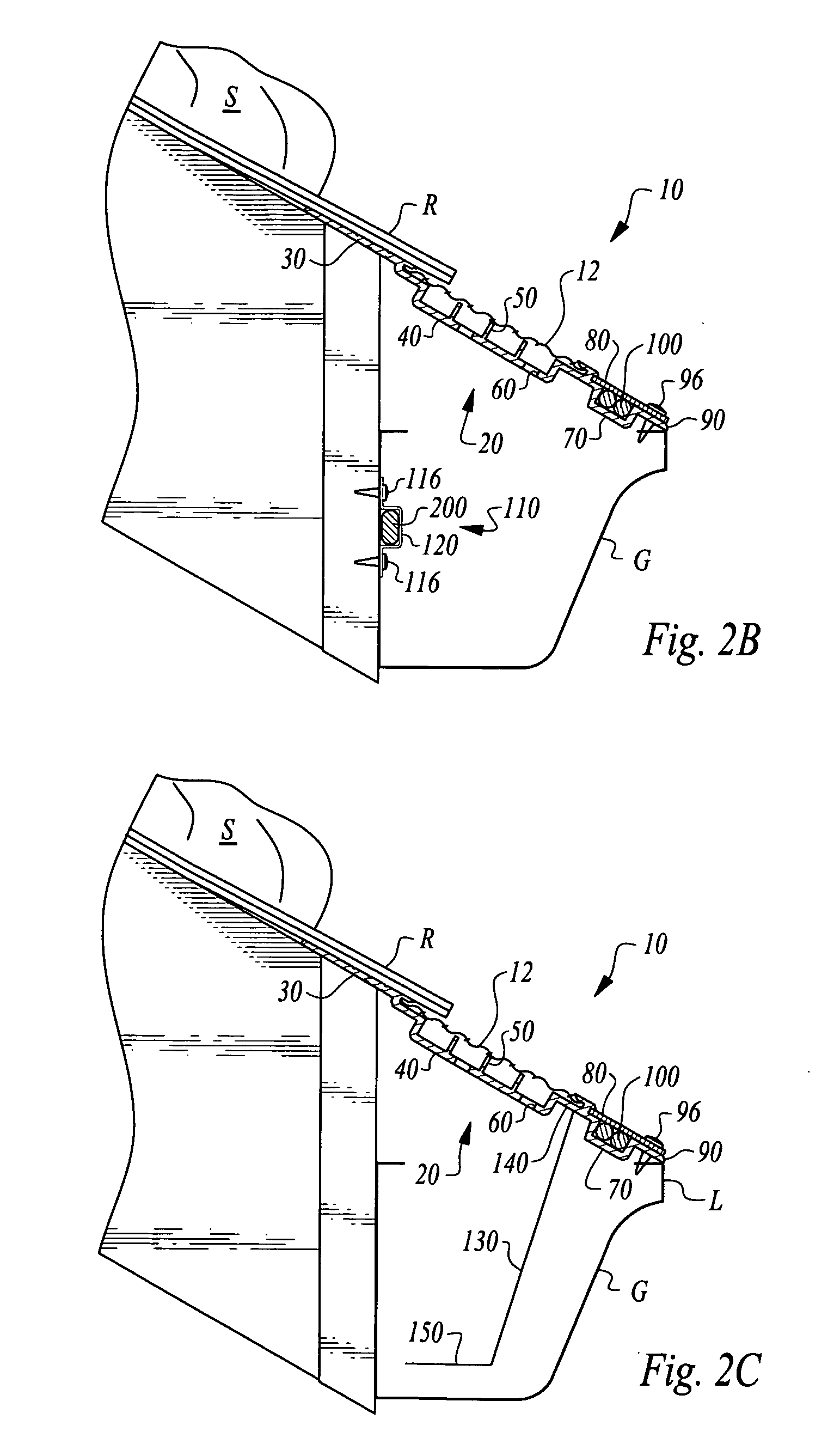

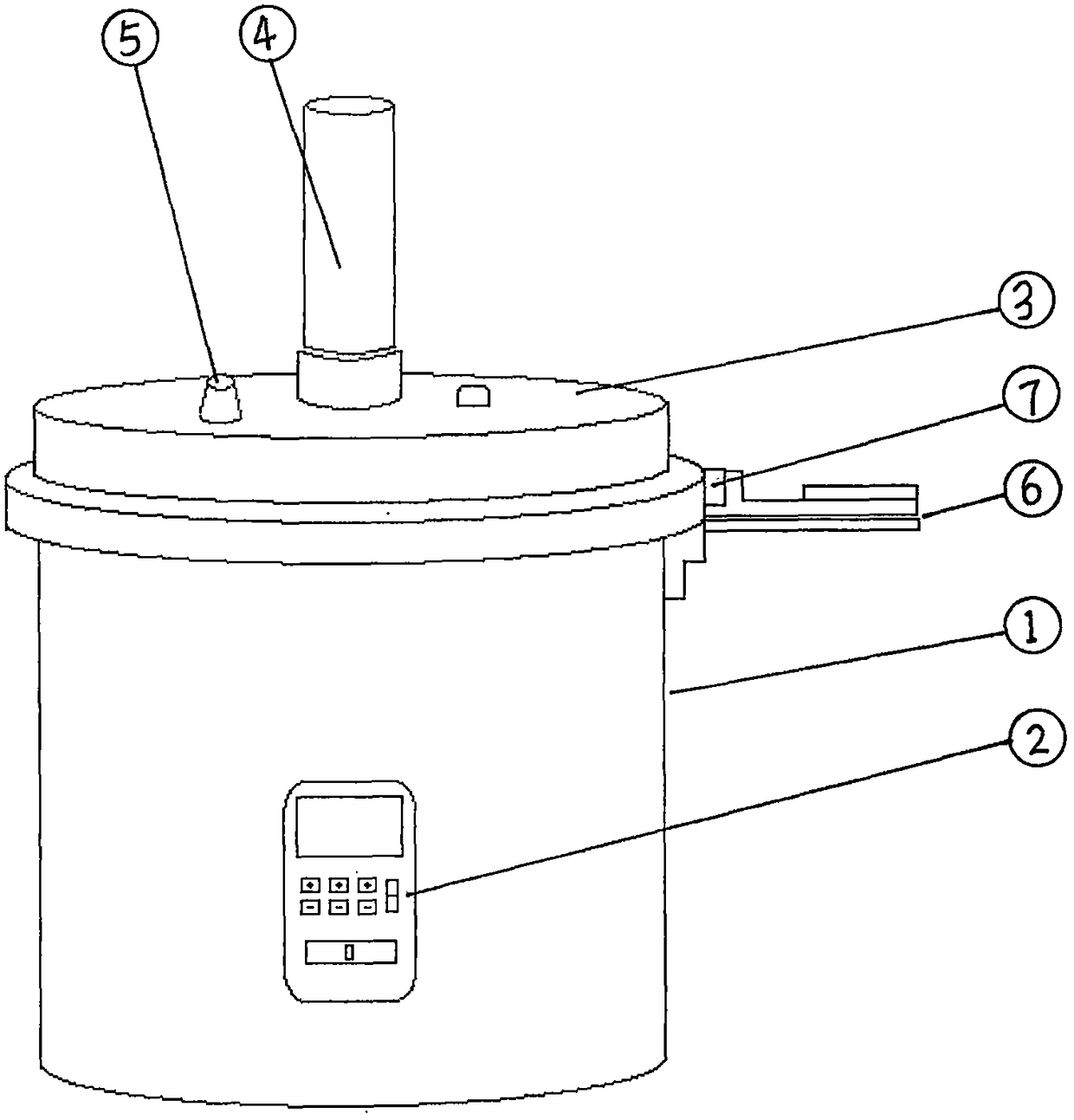

Water-filtering type high-pressure rice steamer

InactiveCN108497914AReduce viscosityNo cakingSteam cooking vesselsPressure-cookersWater filterEngineering

The invention relates to the fields of electric cookers and pressure cooker, and in particular to equipment for implementing water-filtering type rice steaming. According to a water-filtering type high-pressure rice steamer, an electric heating tray is arranged on a base plate of a pot body; a high-pressure inner body is arranged in the pot body; a rice steaming basket is arranged in the high-pressure inner body; a pressure piston lifting device is arranged on a top cap; an air cylinder and a piston are arranged in the pressure piston lifting device; and a piston and a hook are connected to alifting rod. During working of the equipment (the rice steamer), water and rice in the pot body are heated via the electric heating tray, so that a purpose of cooking rice can be achieved; an exhaustchannel in a gas control component is closed via a controller when the water in the pot body is heated to 100 DEG C, and meanwhile, a piston in the air cylinder is pushed to move upwards through high-pressure gas which is generated as the water in the pot body is continuously heated; the rice steaming basket is lifted upwards under the actions of the lifting rod and the hook, and rice, which is cooked by 70%, is filtered out from the water via the rice steaming basket and the rice is well cooked through high-pressure steam and heat energy generated from the water body; therefore, a purpose ofhigh-pressure water-filtering type rice steaming is achieved.

Owner:王明中

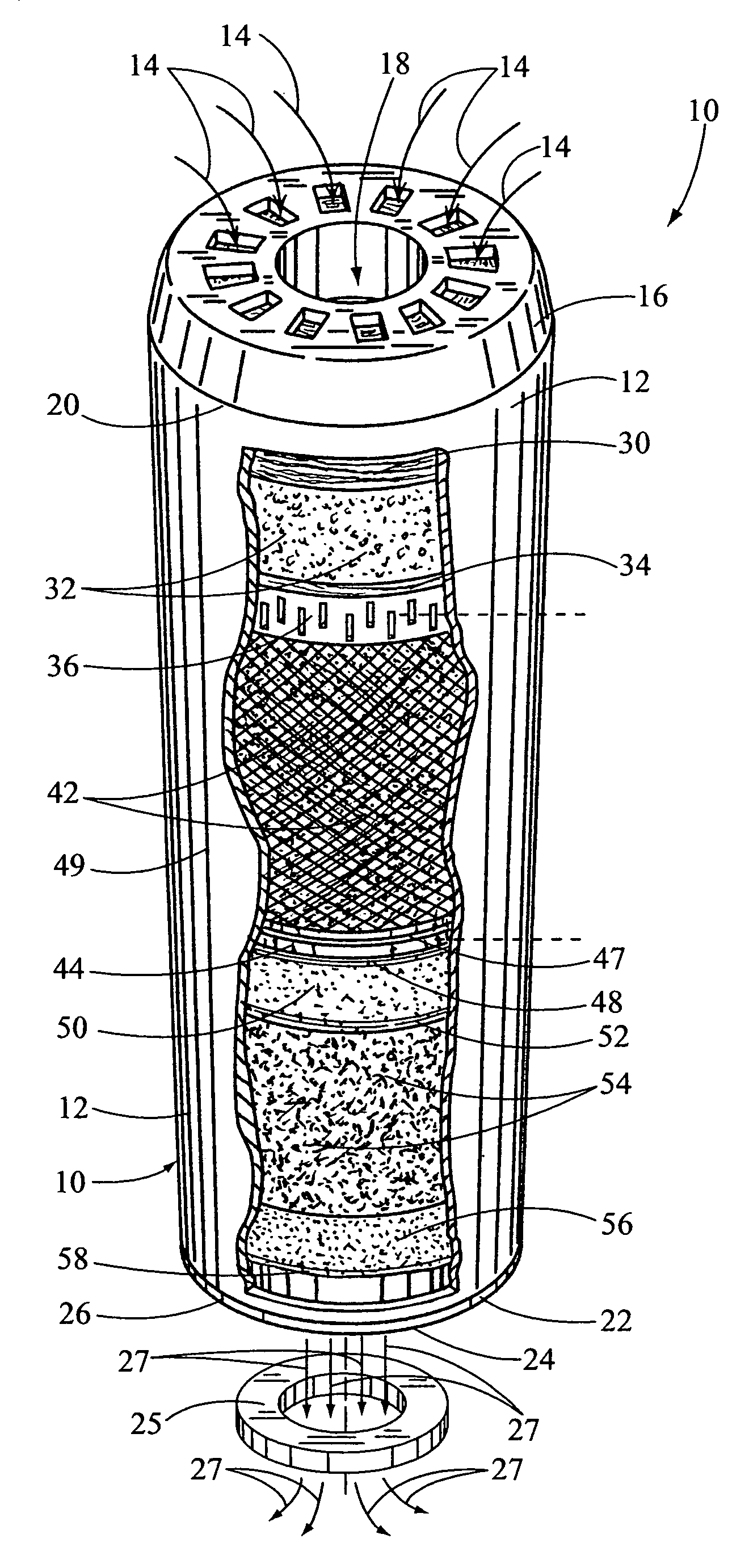

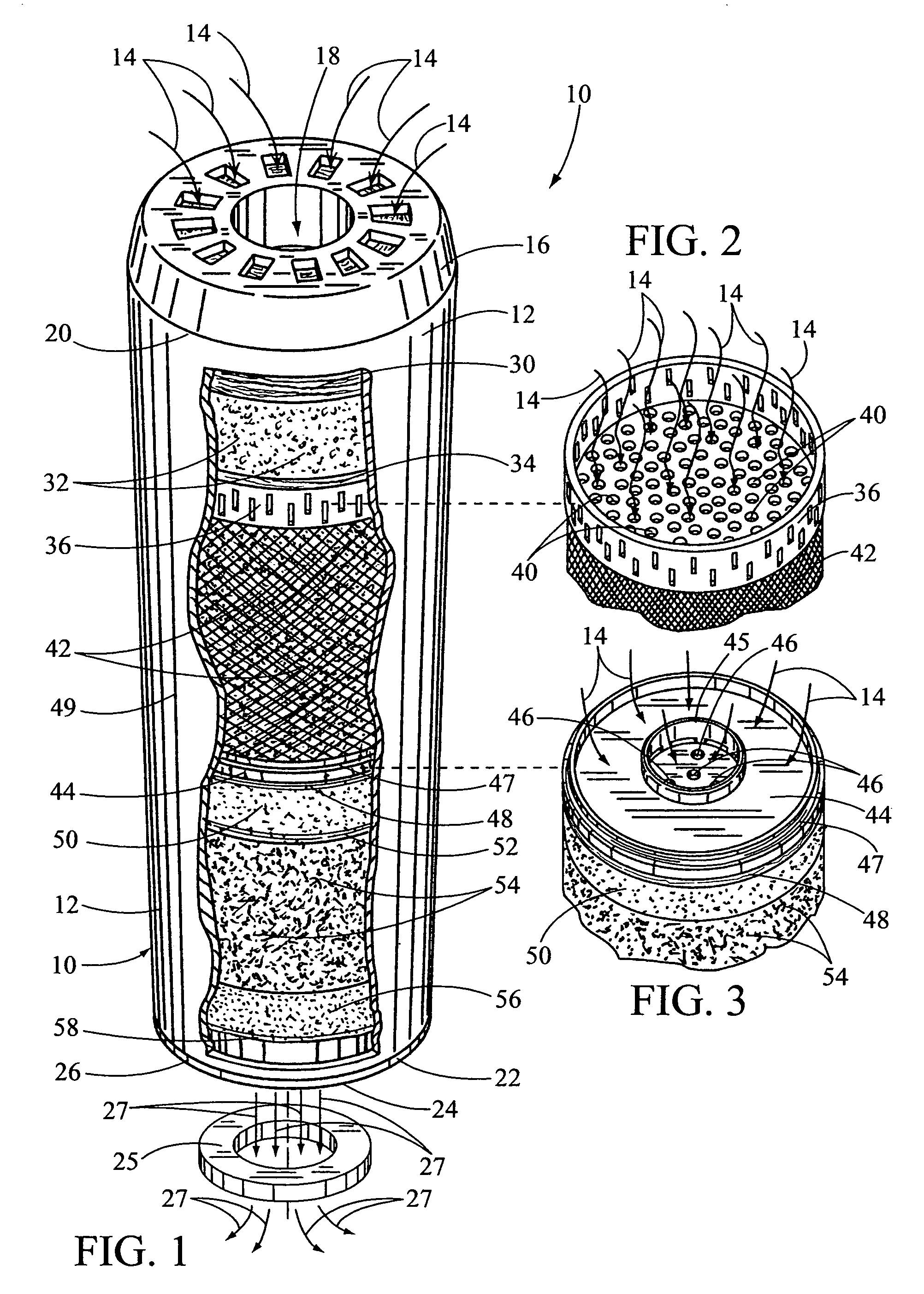

Drinking water filter used with tap water and other water sources

InactiveUS7156994B1Save spaceEliminate needTreatment involving filtrationWater/sewage treatment by ion-exchangeWater sourceFiltration

A drinking water filter for filtering major water contaminates from tap water and other drinking water sources. The water filter a cylindrical cartridge for receiving a plurality of sponge filters used as dividers between different layers of filtration material and along a length of the cartridge. The sponge filters are designed to remove large and small sediments in the water from 1 to 100 microns in size and greater when the water is introduced through the cartridge. The layers of filtration material includes a layer of granulated zinc and copper alloy, a fine mesh carbon block, a layer of granulated ion exchange resin, a layer of granulated activated carbon and layer of granulated activated calcite. The carbon block and the granulated carbon material is used for removing chlorine, odor, color, cysts, protozoa and organic contaminants such as pesticides, herbicides, arsenic, mercury, and trihalomnethanes. The zinc and copper alloy is used for removing chlorine and heavy metals in the water and reducing bacteria in the water. The calcite is used to raise the pH in the filtered water when the pH is below neutral.

Owner:ARCHER VIRGIL L

Gravity Flow Carbon Block Filter

A gravity fed carbon block water filter includes activated carbon particles; a binder material interspersed with the activated carbon particles; and a lead scavenger coupled to at least one of the activated carbon particles and binder material, the lead scavenger being for removing lead from water, where a lead concentration in a final liter of effluent water filtered by the filter is less than about 10 μg / liter after about 151 liters (40 gallons) of source water filtration, the source water having a pH of 8.5 and containing 135-165 parts per billion total lead with 30-60 parts per billion thereof being colloidal lead greater than 0.1 μm in diameter, and where the water has an average flow rate of at least 0.1 liter per minute through the filter with a head pressure of between approximately 0.1 and 1.0 psi.

Owner:BRITA LP

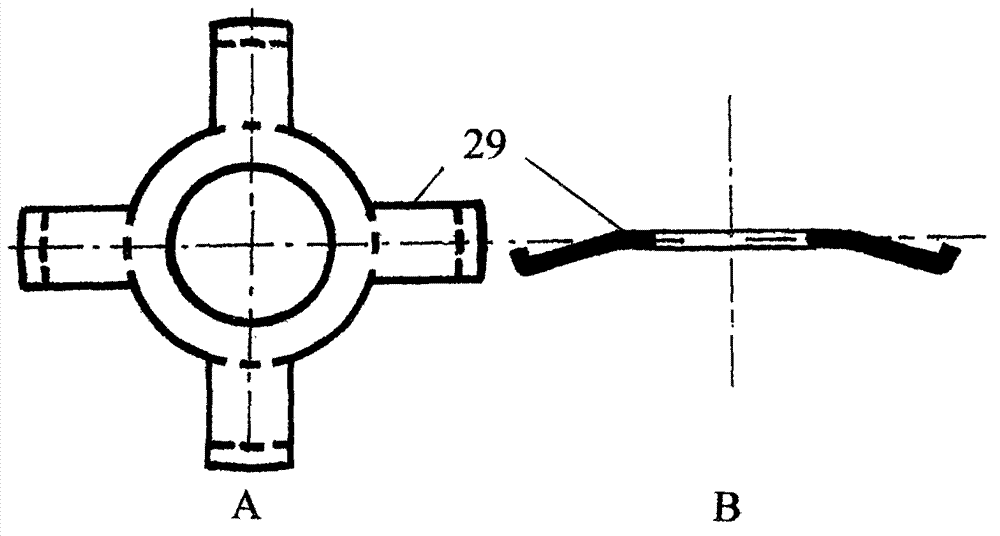

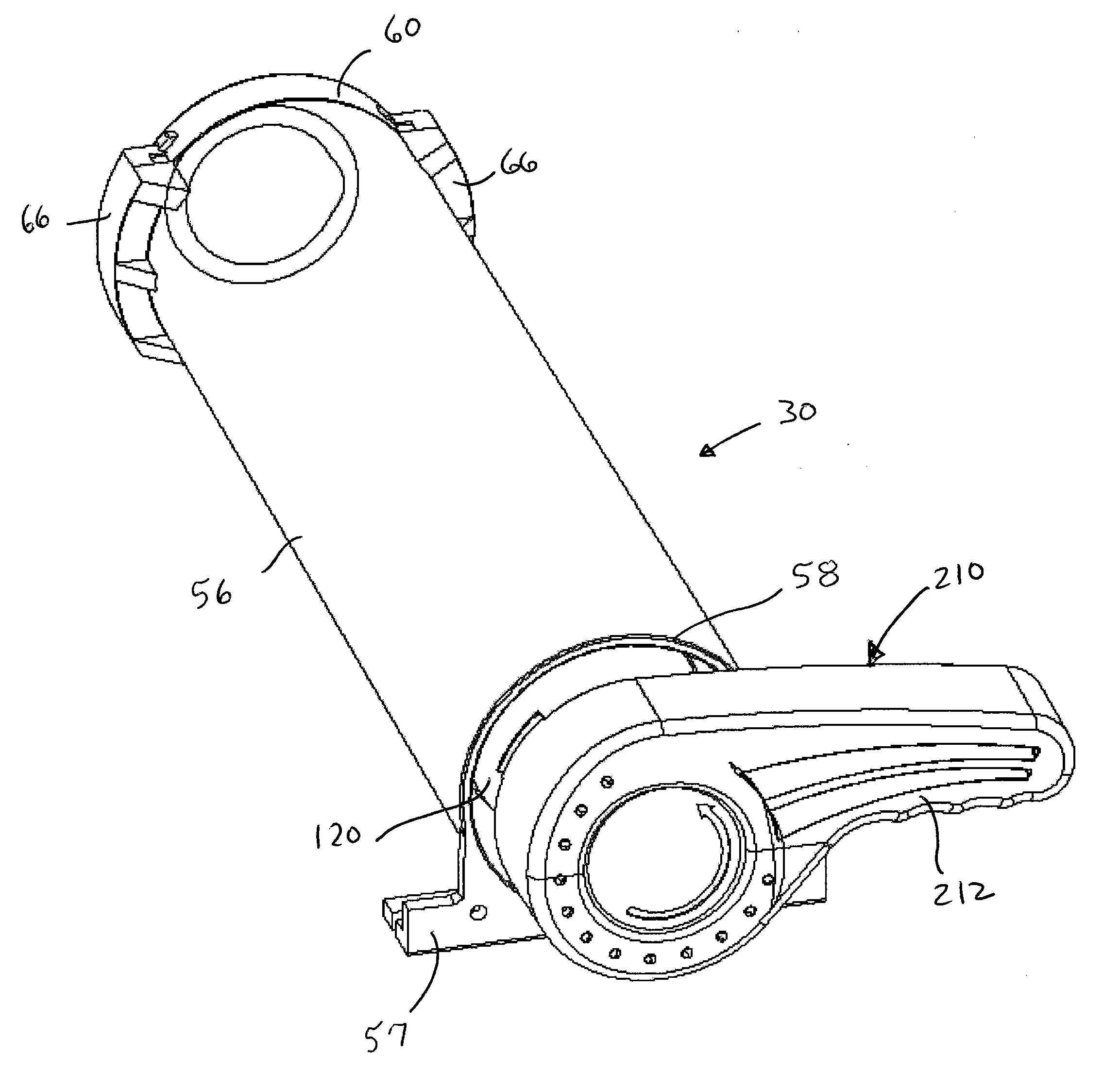

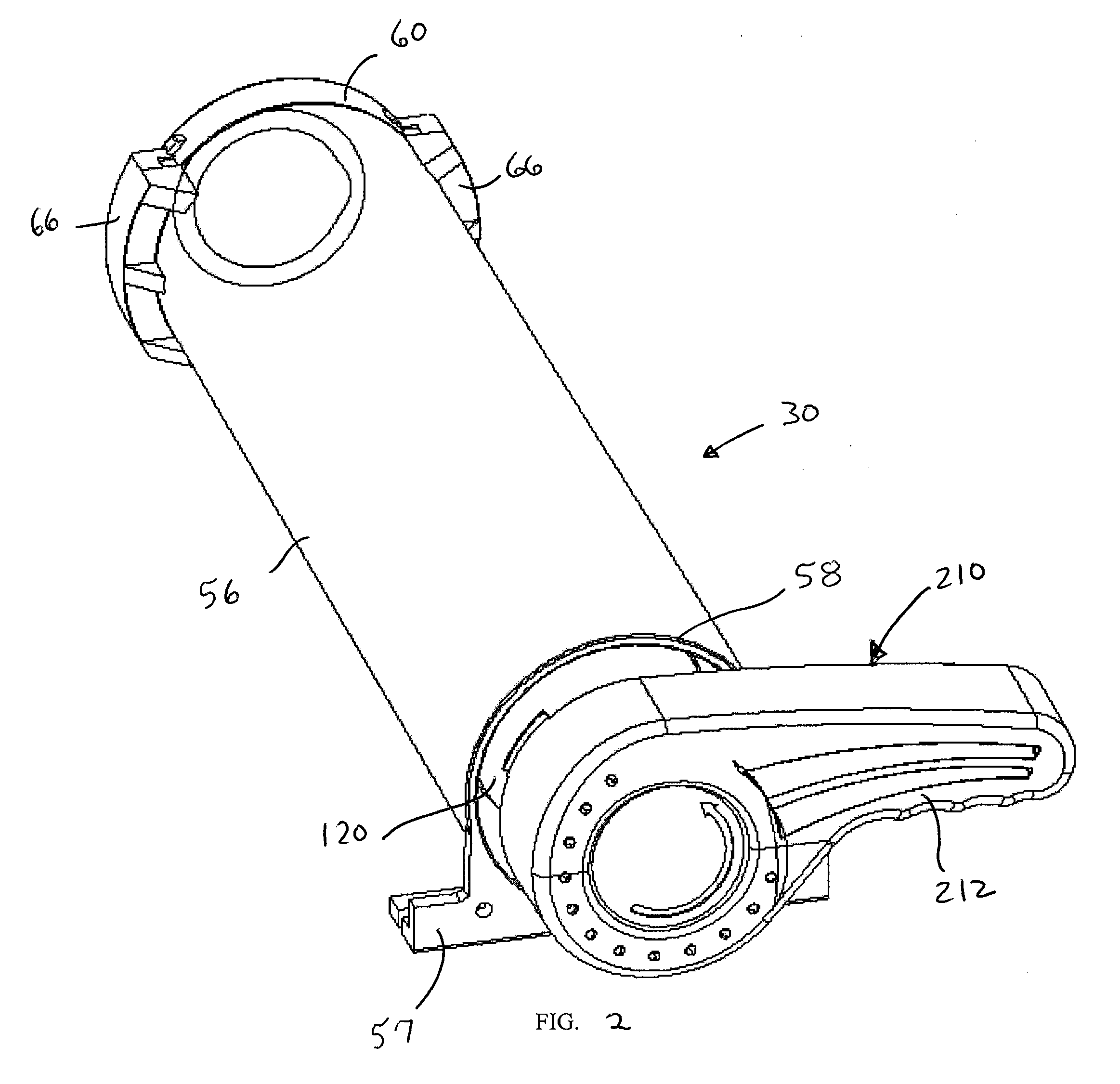

Filtered shower arm

A combination shower arm and water filter having an integrated design for attachment between a water pipe behind a shower wall and a showerhead. The combination shower arm and water filter including a body having a first hollow arm and a second hollow arm connected to a central cartridge holding portion. The filter holding portion has a central opening with a filter cartridge or element removably held in a hollow chamber formed above the filter holding portion by means of a cap that is removably secured to the an upwardly extending annular portion formed on the filter holding portion. Water entering the combined shower arm and filter assembly through the first hollow arm is directed into the hollow chamber for passage through filter media in the filter cartridge or element before it exits through the second hollow arm and out a showerhead.

Owner:FARLEY DAVID K

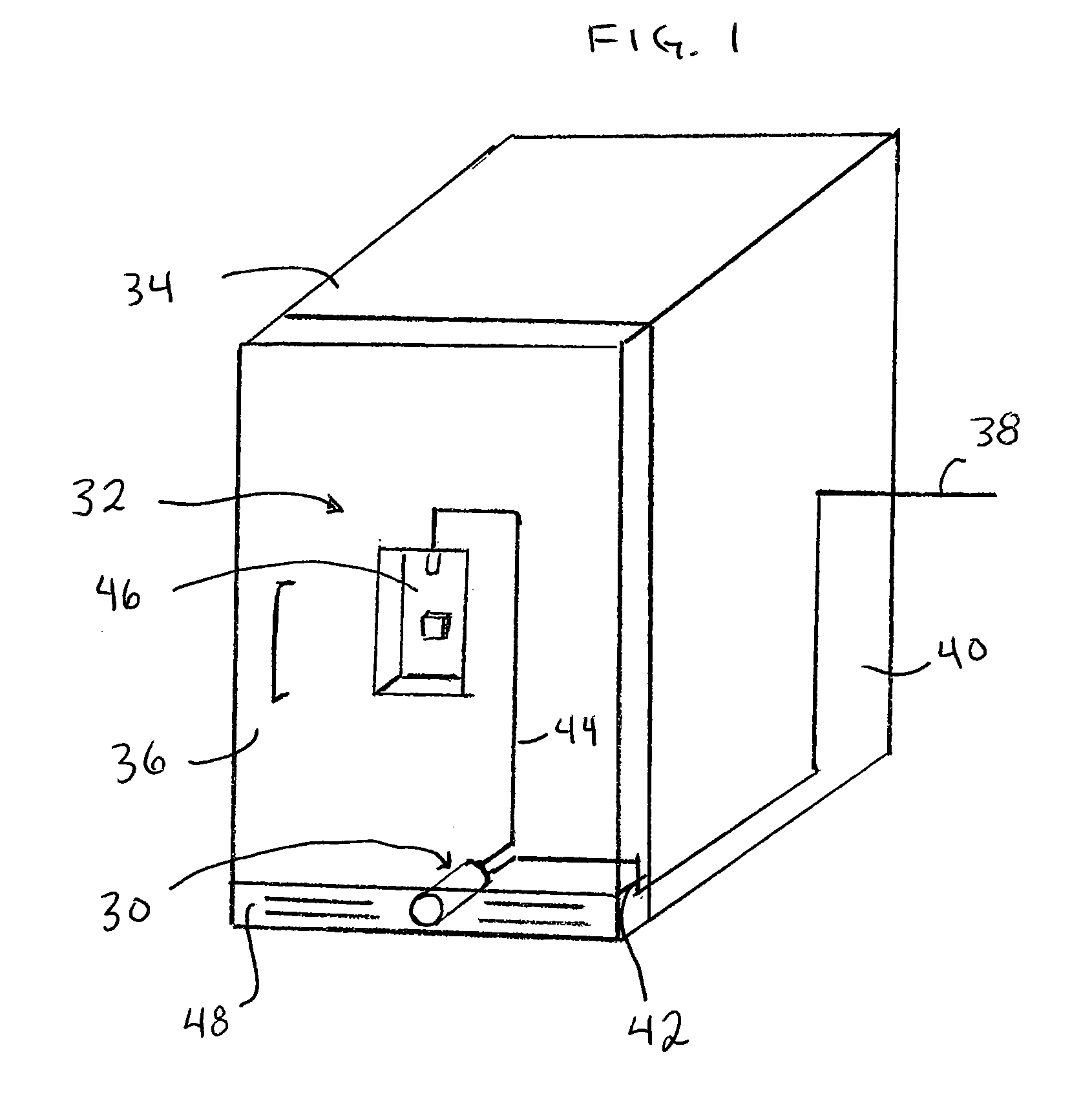

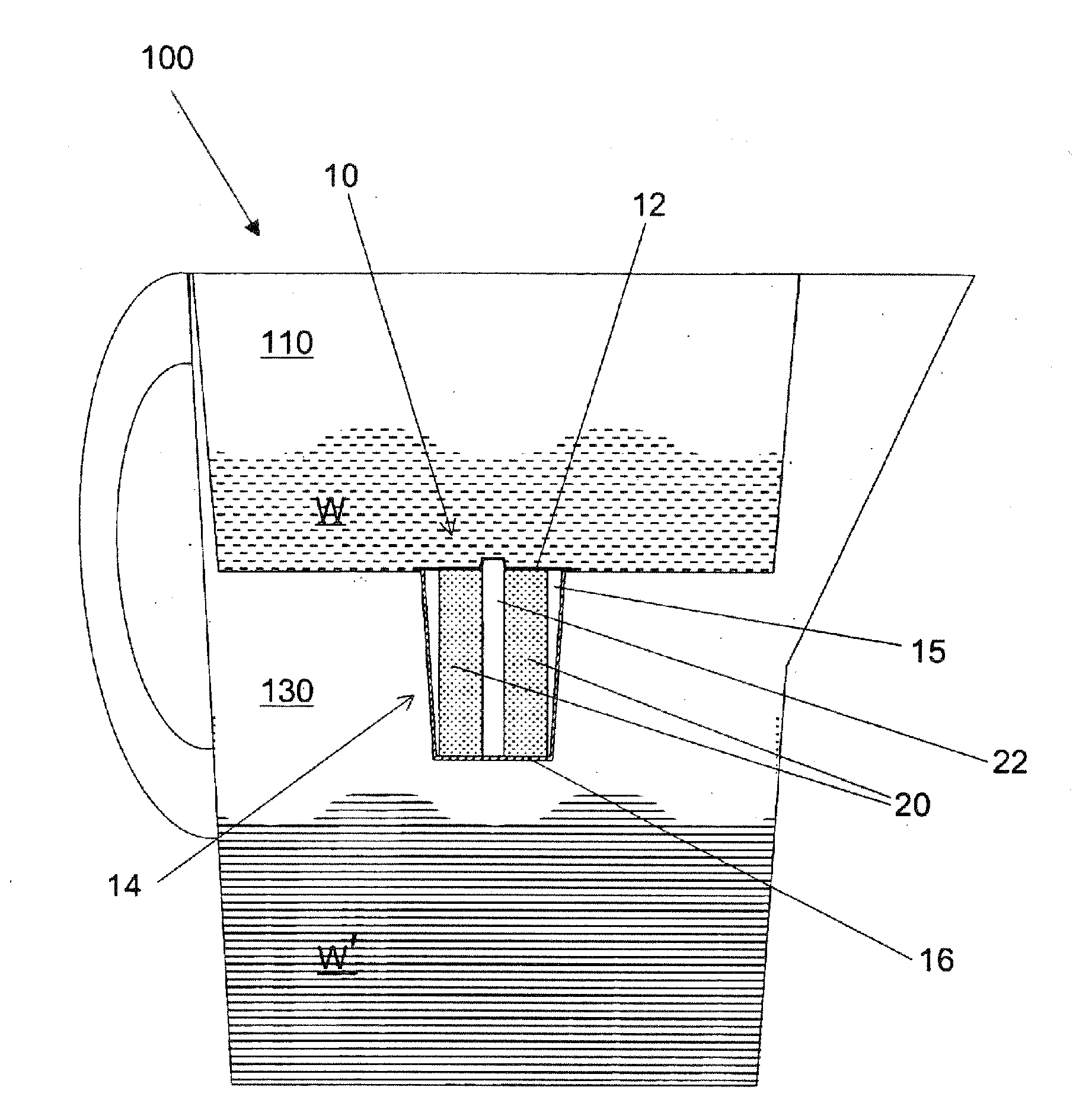

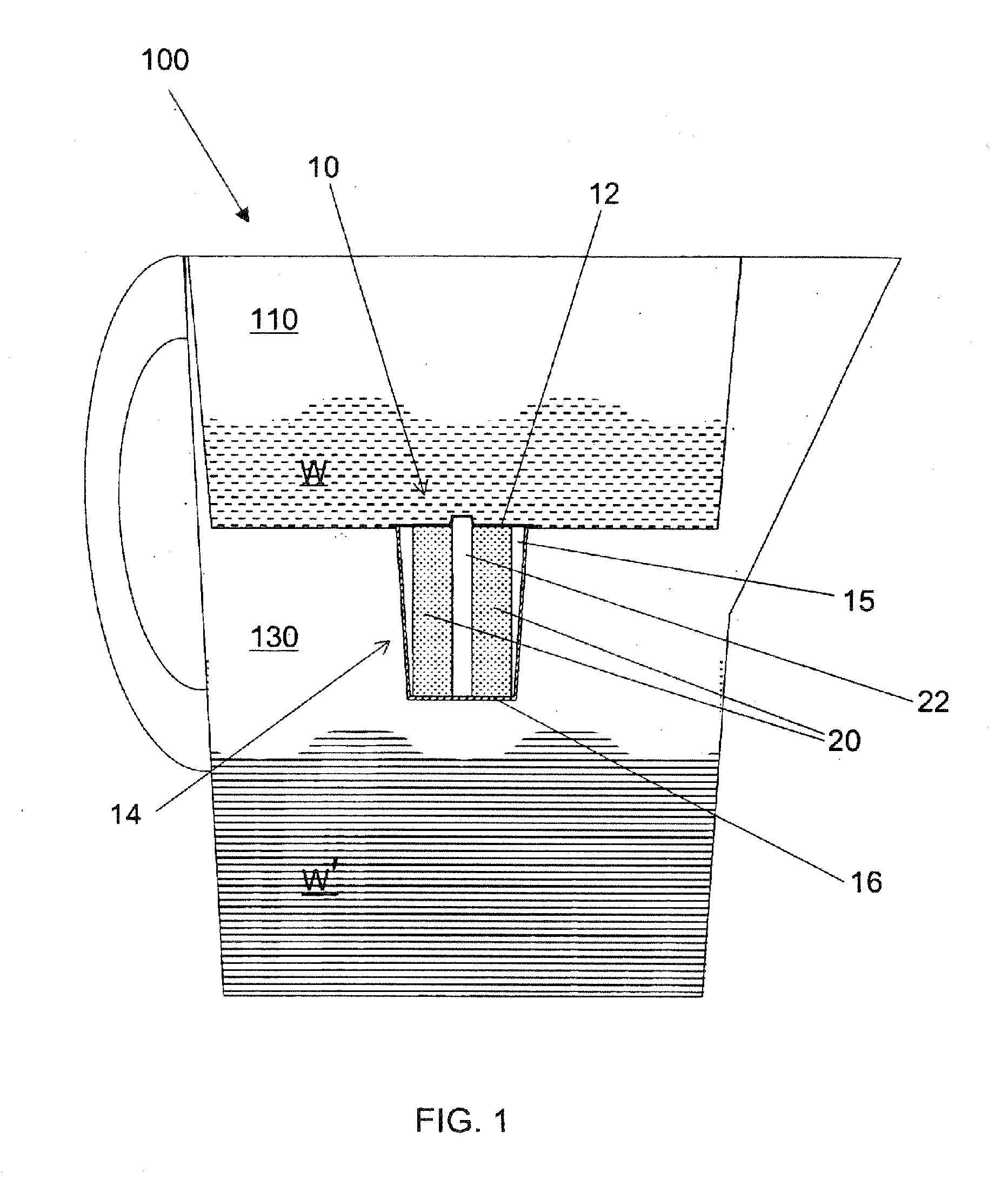

Water filter and dispenser system

InactiveUS20070278141A1Easy accessIncrease flexibilityLighting and heating apparatusTreatment involving filtrationWater filterRefrigerated temperature

The present invention relates to a low pressure water filter and dispenser system for use in a refrigerator which enables an effluent from said system exhibiting a log 6 bacteria reduction and a log 4 virus reduction with pressures as low as 0.35 kg / cm2 (5 psi). The system can be located in various places, for example it can sit on the shelf, it can be mounted to the ceiling of the refrigerator, or it can be attached to the wall or other internal components.

Owner:WHIRLPOOL MEXICO DE C V +1

Disc shaped regulated drip irrigation emitter

ActiveUS20120267454A1Low costMinimize sizeClimate change adaptationWatering devicesWater filterDrip irrigation

A drip irrigation emitter includes a disc shaped body having a pressure reducing labyrinth between a water inlet area and an outlet hole, and a pressure regulating diaphragm changing flow through the outlet hole in response to water pressure fluctuations in the water conduit where the emitter is mounted. The water filtering inlet of the emitter is located entirely at the sides of the disc shaped body.

Owner:RIVULIS PLASTRO LTD

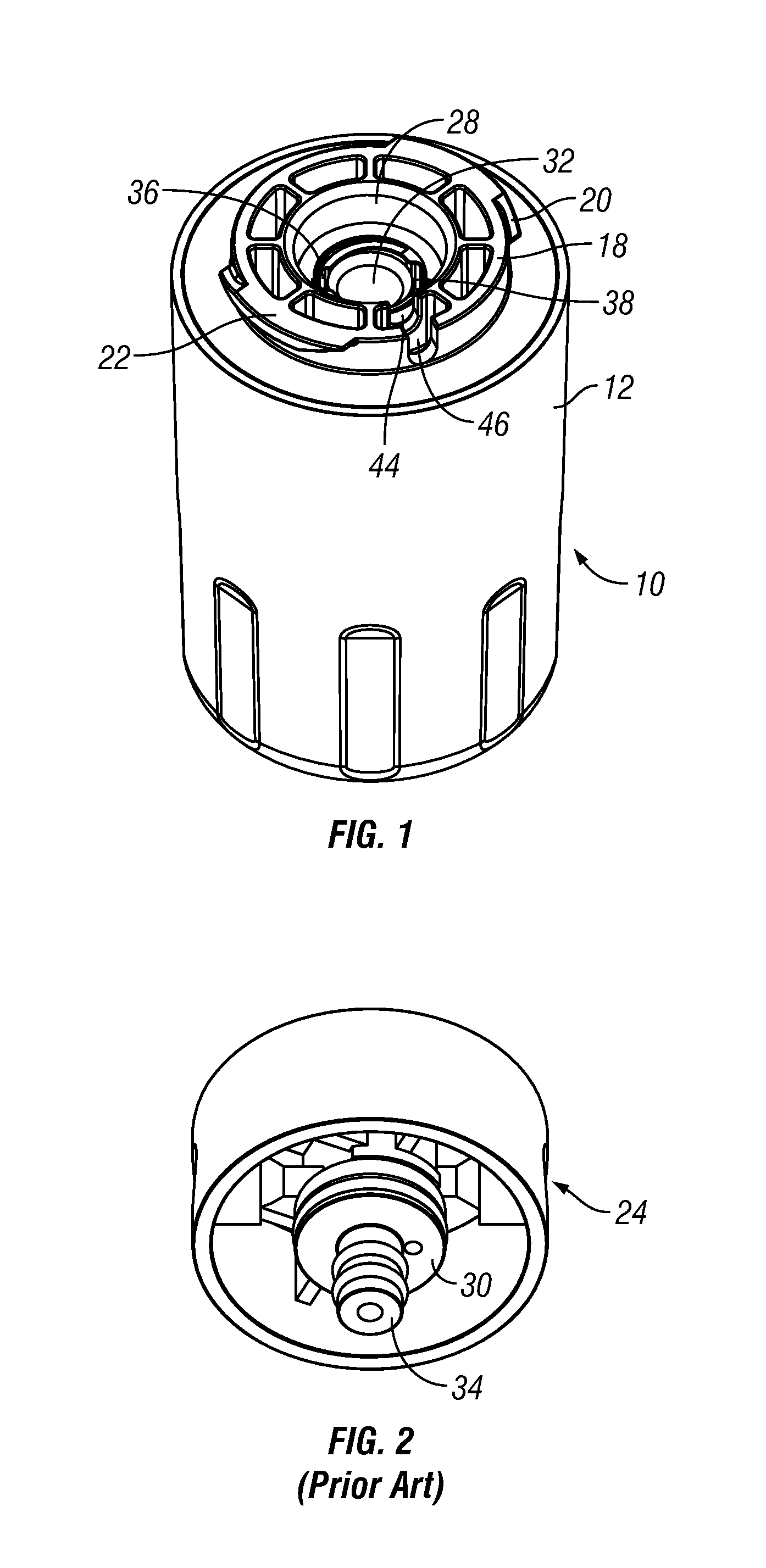

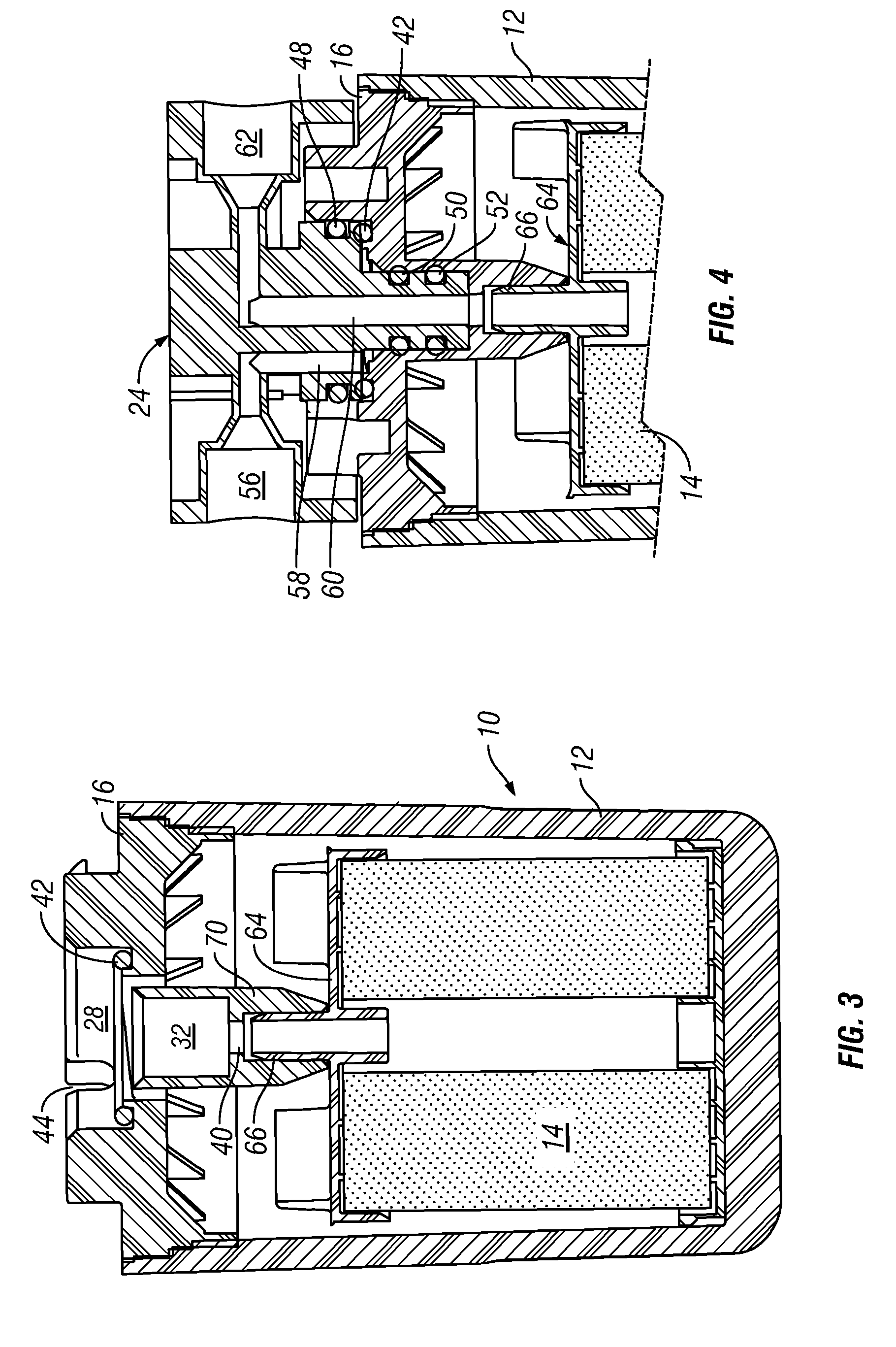

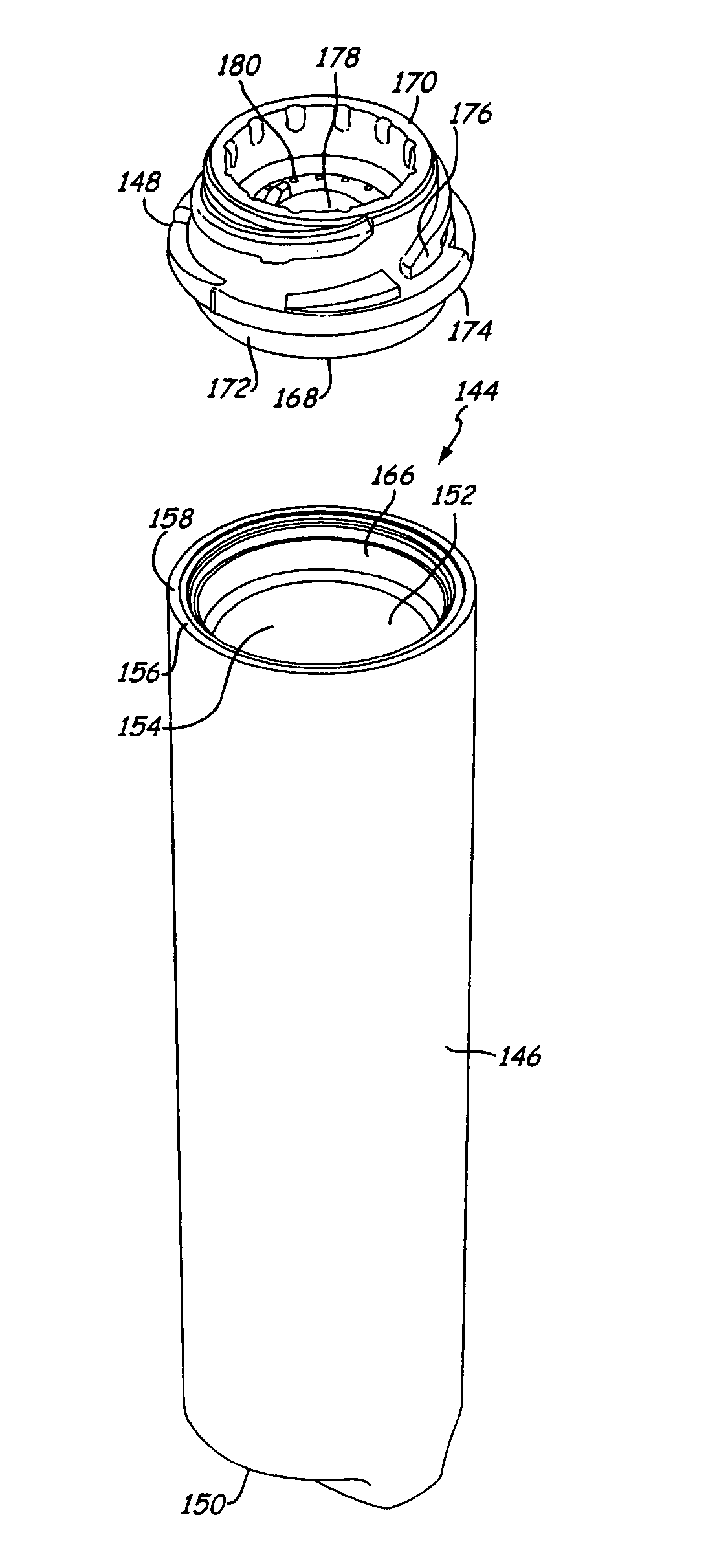

Refrigerator water filter cartridge with leakage indicator

ActiveUS8216463B1Improve manifold-to-cartridge water sealEasy to correctEngine sealsPiston ringsWater filterFiltration

A water filter cartridge particularly suited for a water filtration system incorporated into refrigerators includes an outer housing, a water filtration media inside the housing, and a cap affixed to an end of the housing to thereby enclose the filtration media. A portion of the cap defines a large cylindrical cavity having a channel formed therein which is positioned so that an O-ring provides a substantially water-tight seal when the filter cartridge is in an operative position in a manifold. The O-ring prevents water from otherwise flowing through the channel and externally of the water filtration system. Under normal water pressure the water filtration system will immediately visually exhibit a substantial leak if the filter cartridge is coupled to the manifold of the water filtration system in the operative position without the O-ring being positioned in the large cylindrical cavity.

Owner:BAIRD MICHAEL T

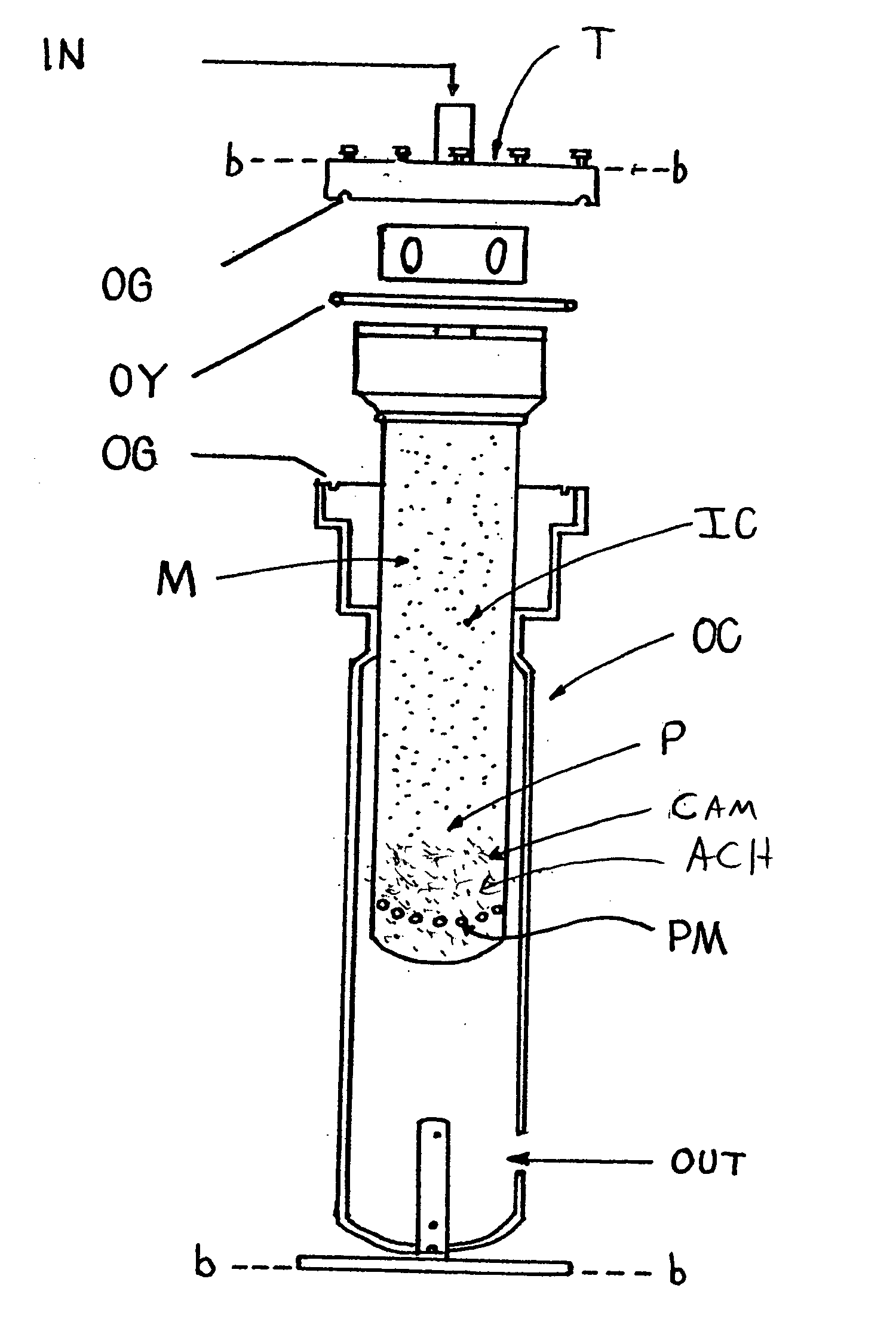

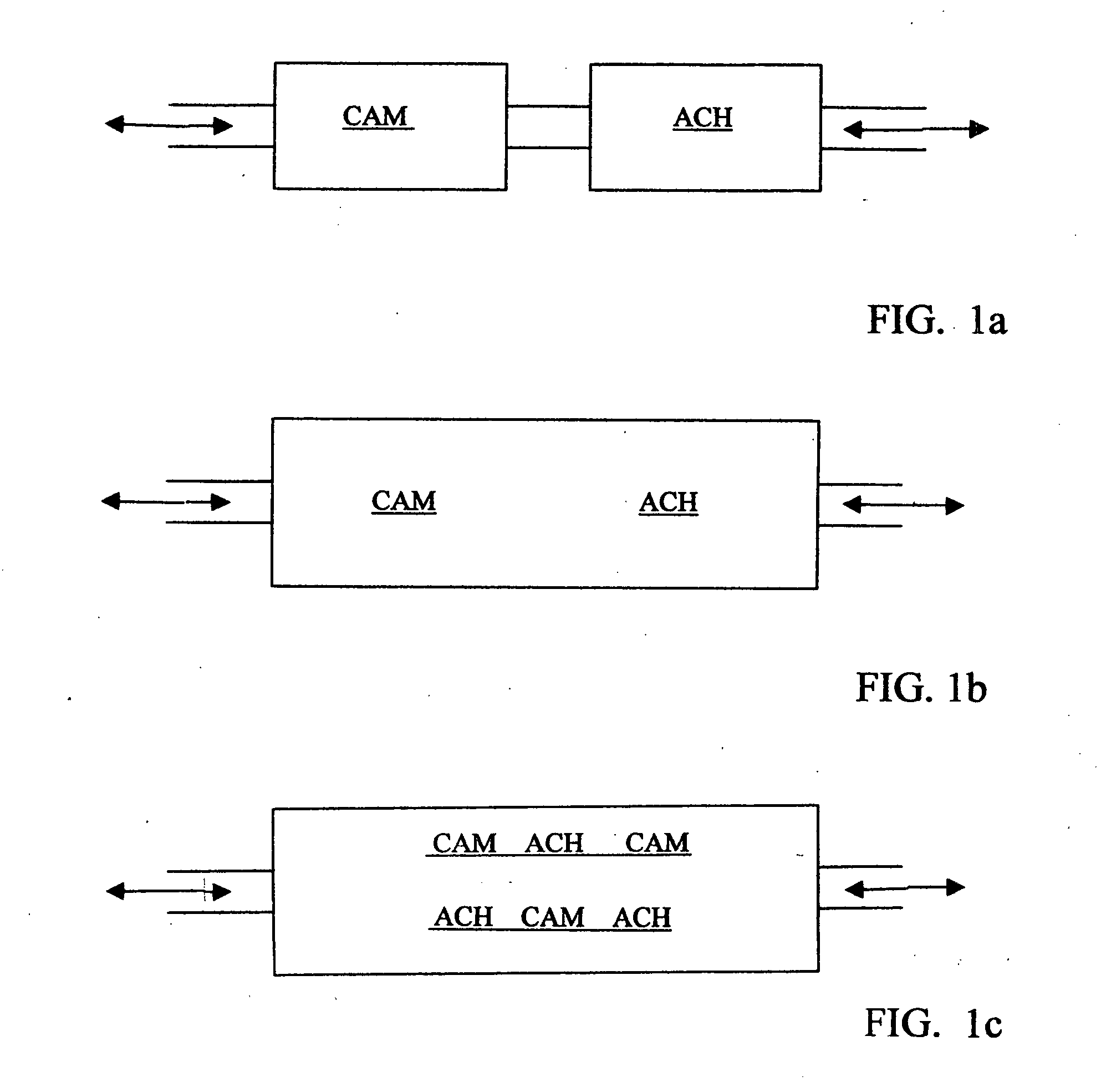

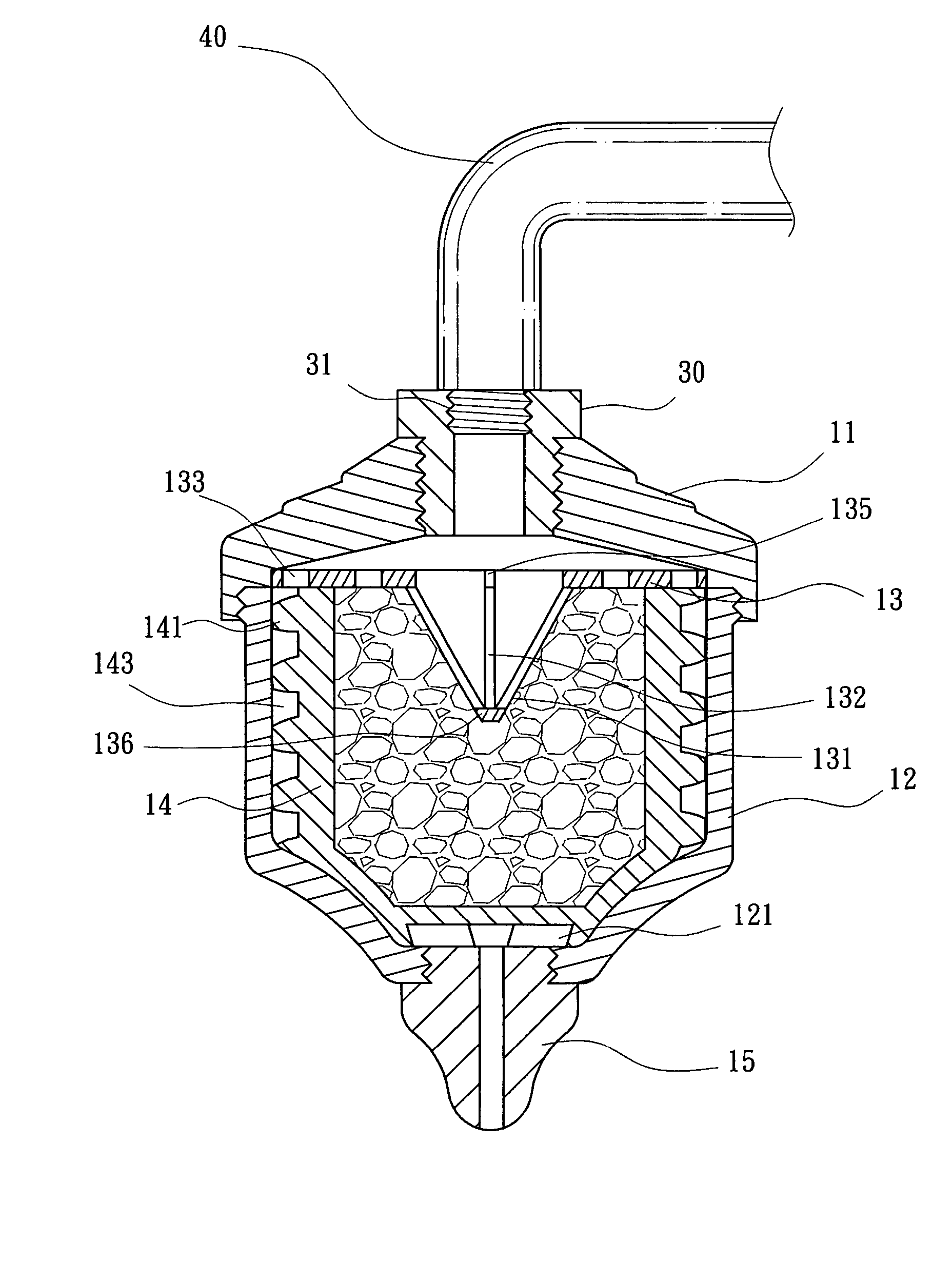

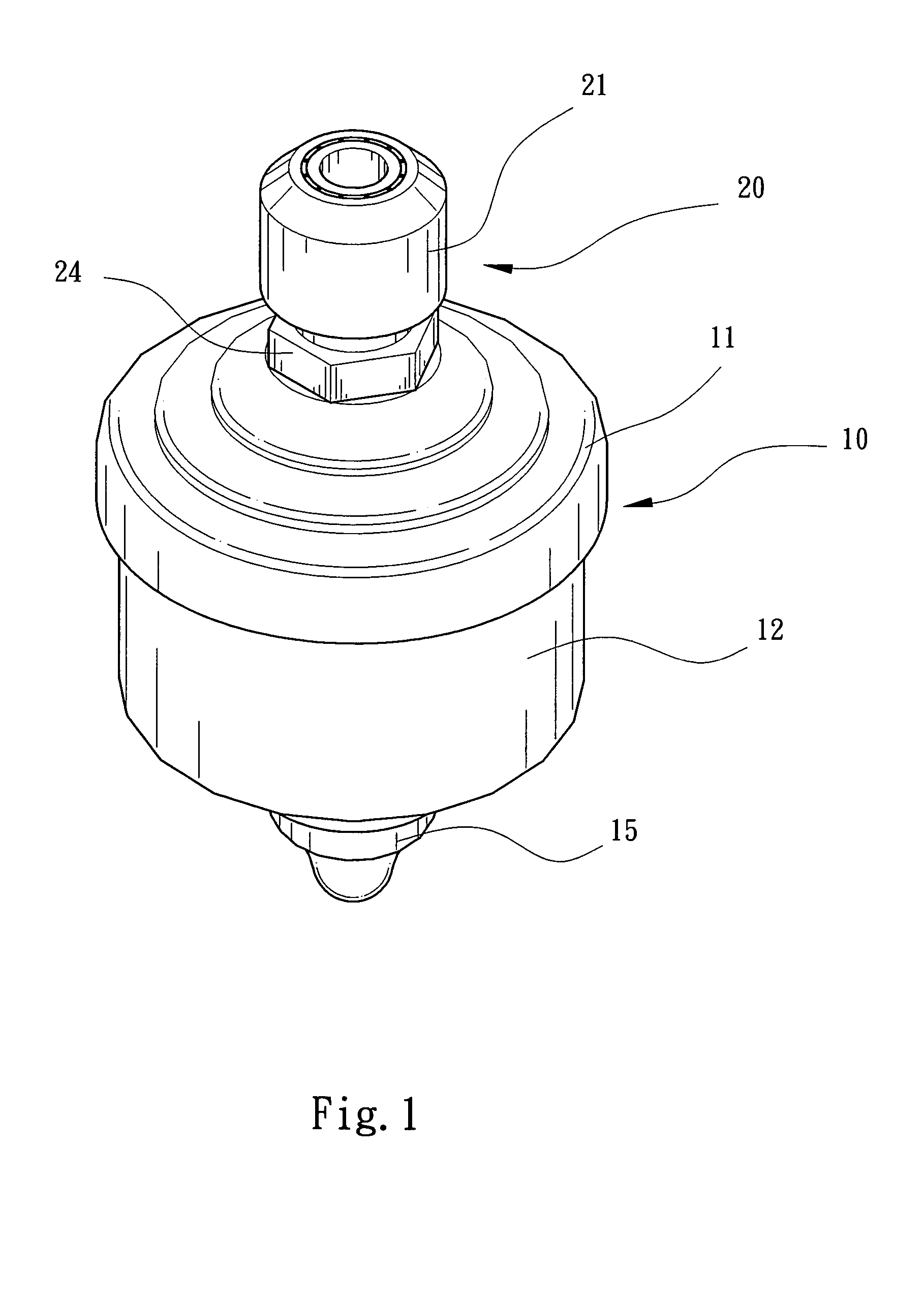

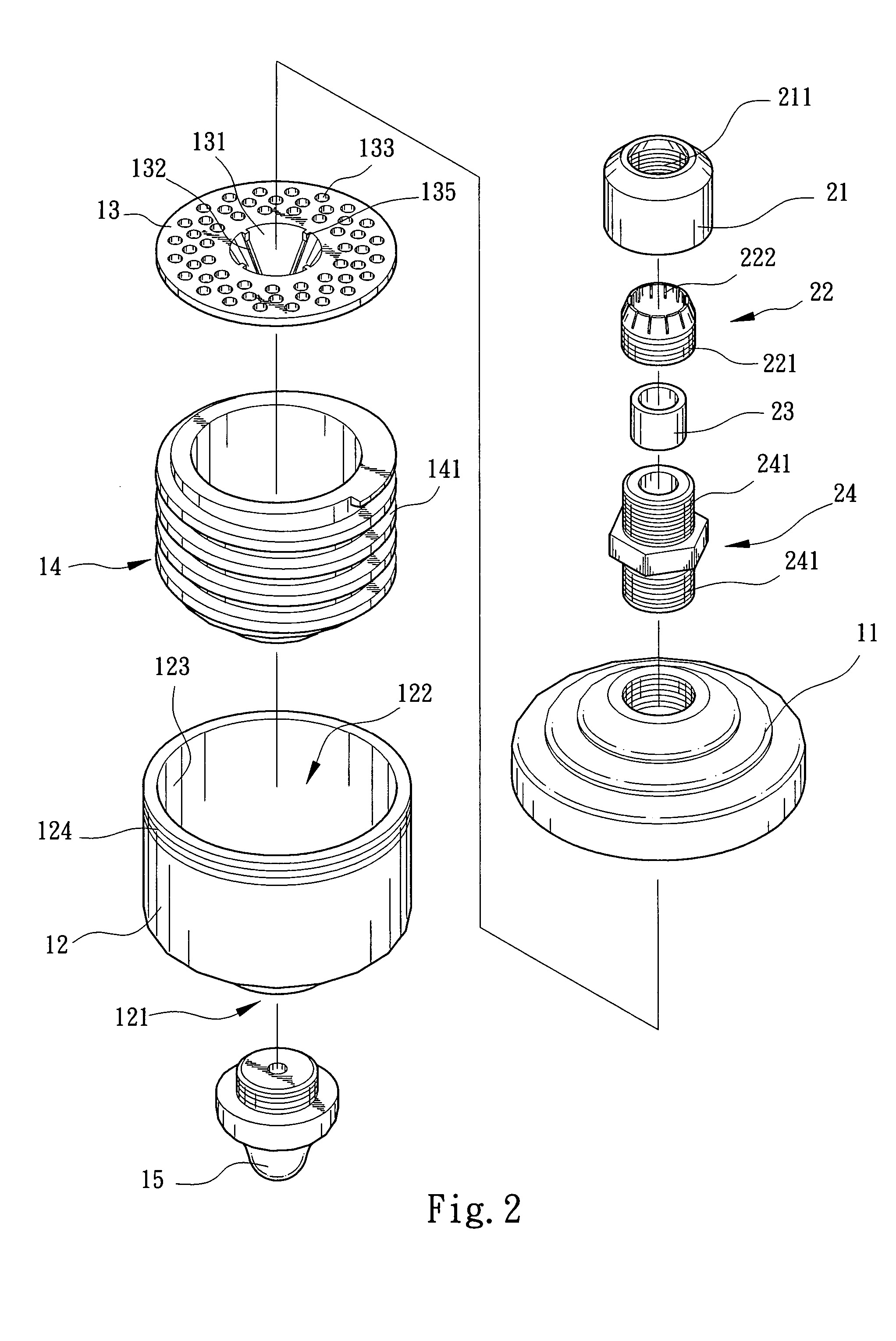

Water filter apparatus and methodology

InactiveUS20070295667A1Easy to disassembleEasy to changeSolid sorbent liquid separationSedimentation separationWater filterPotable water

Water filters systems for providing potable water including a combination of ceramic with anti-microbial embedded therewithin, and granular activated charcoal.

Owner:CLEAN & CLEAR CORP

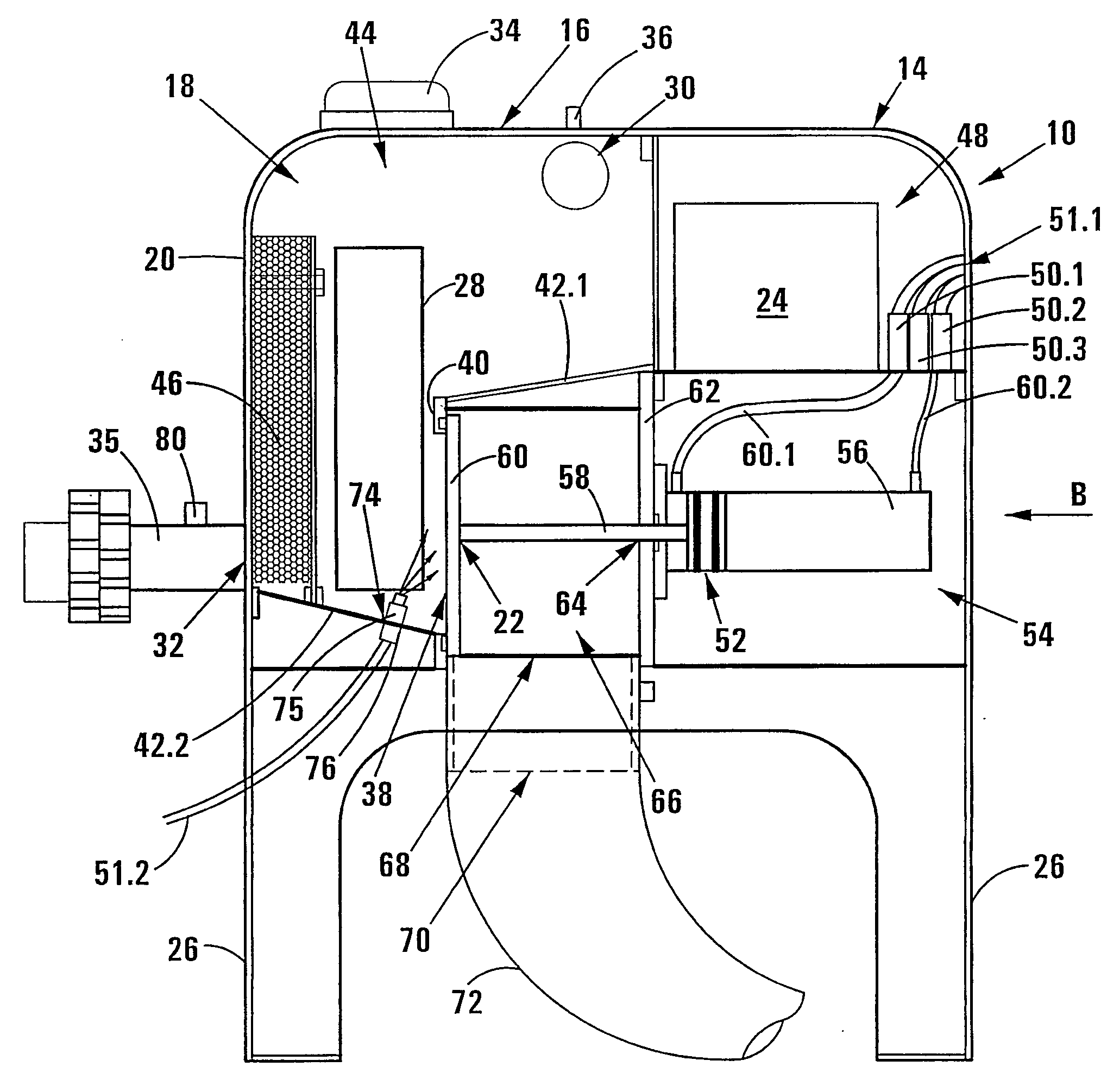

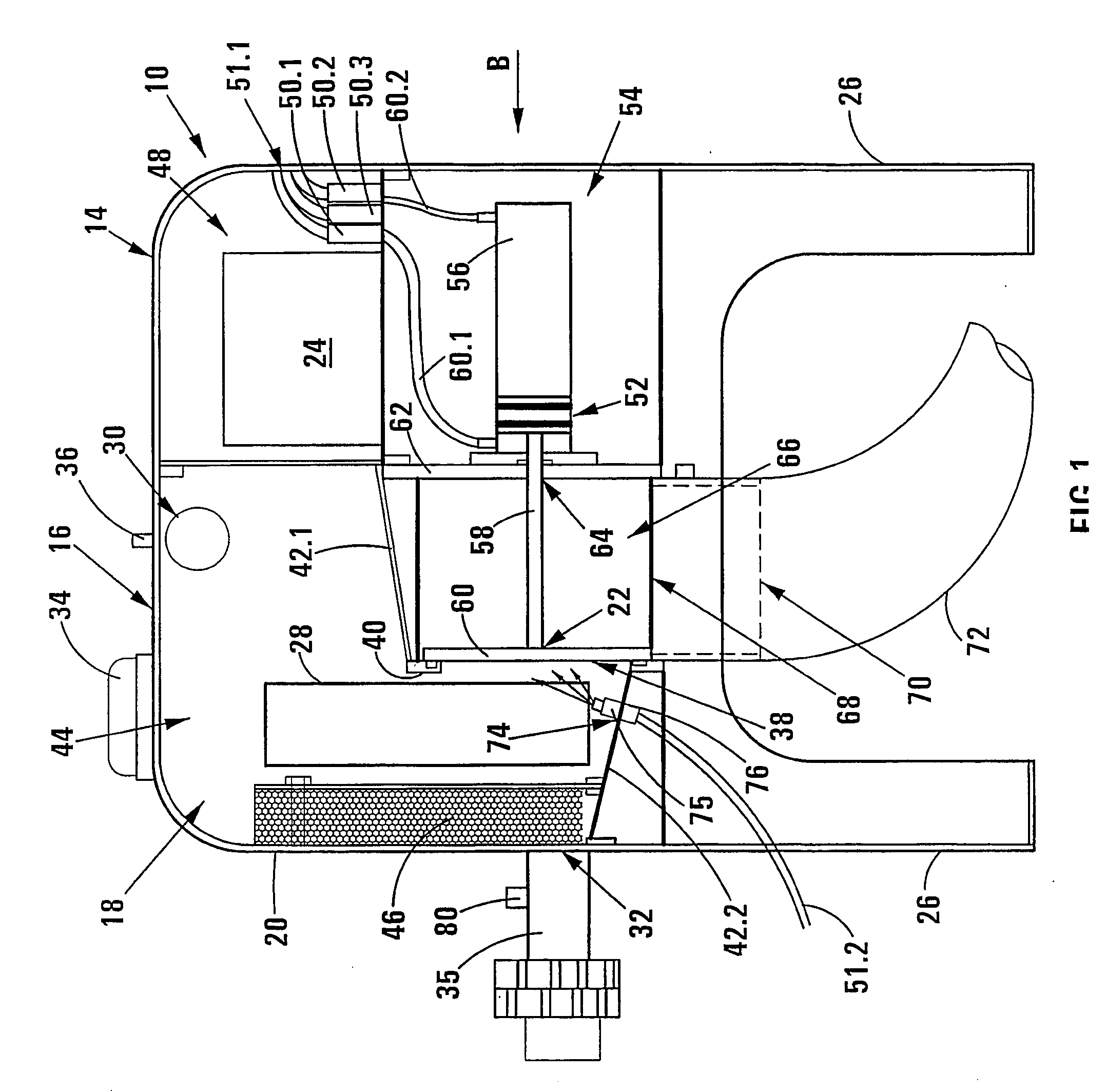

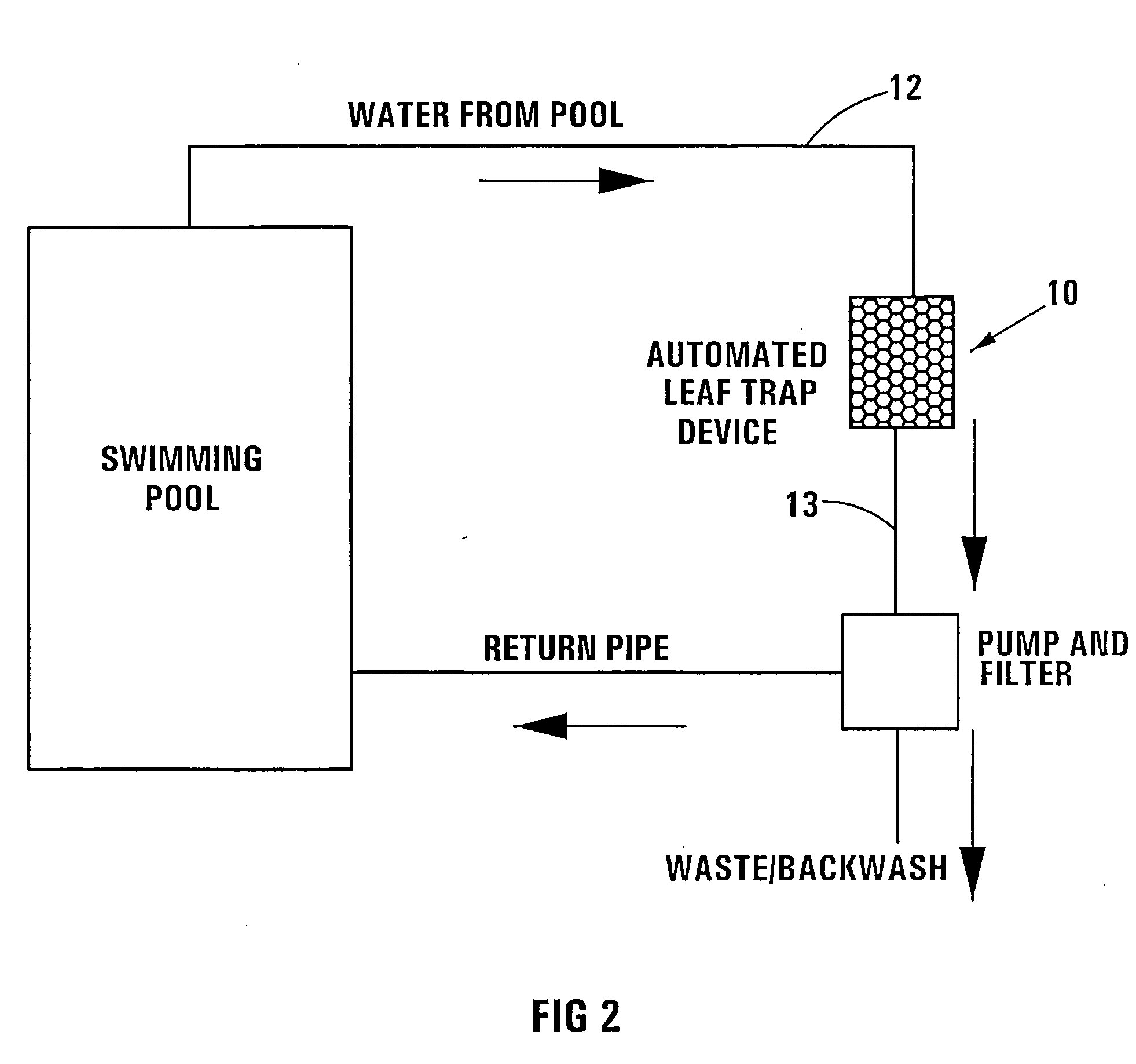

Leaf trap device

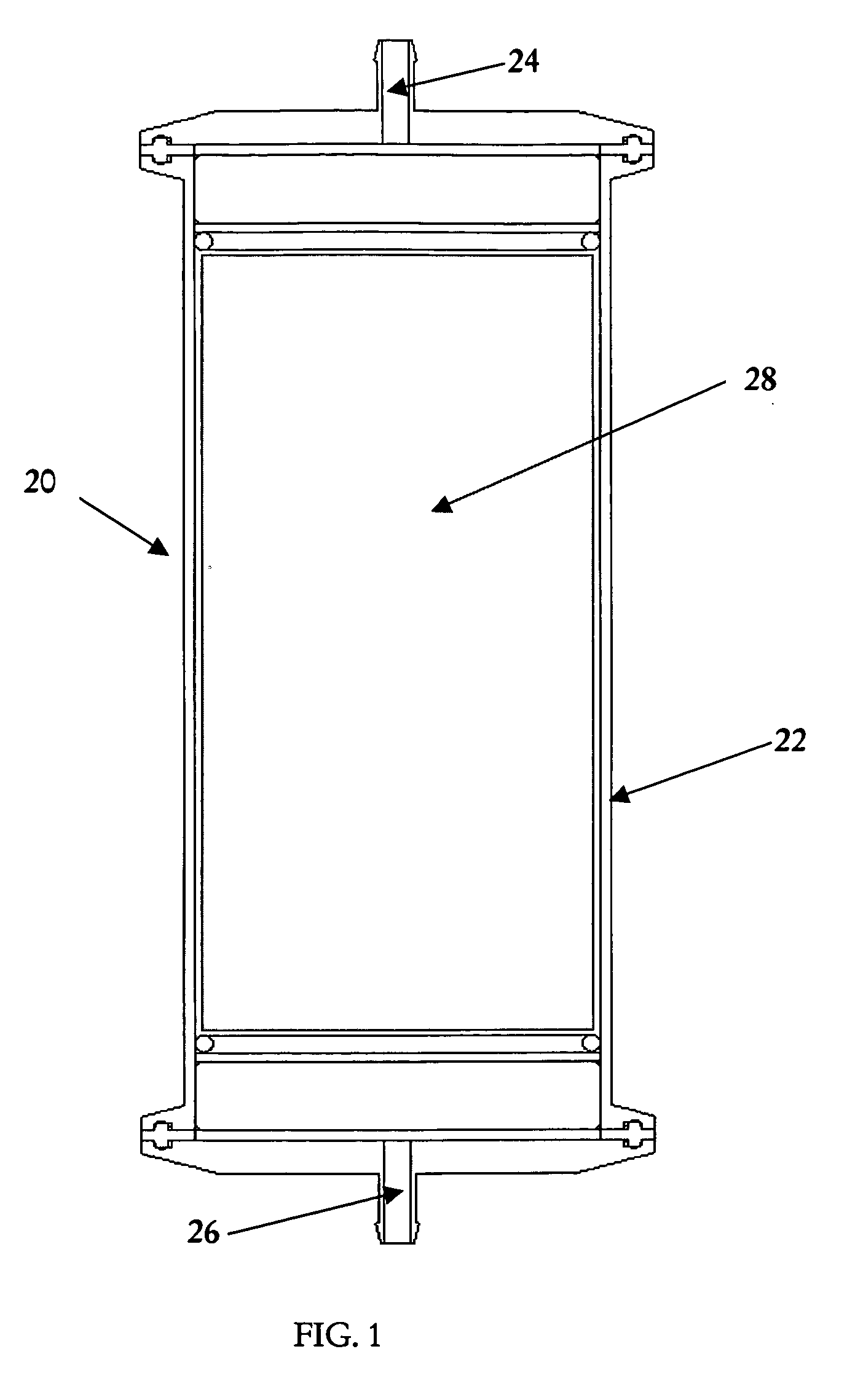

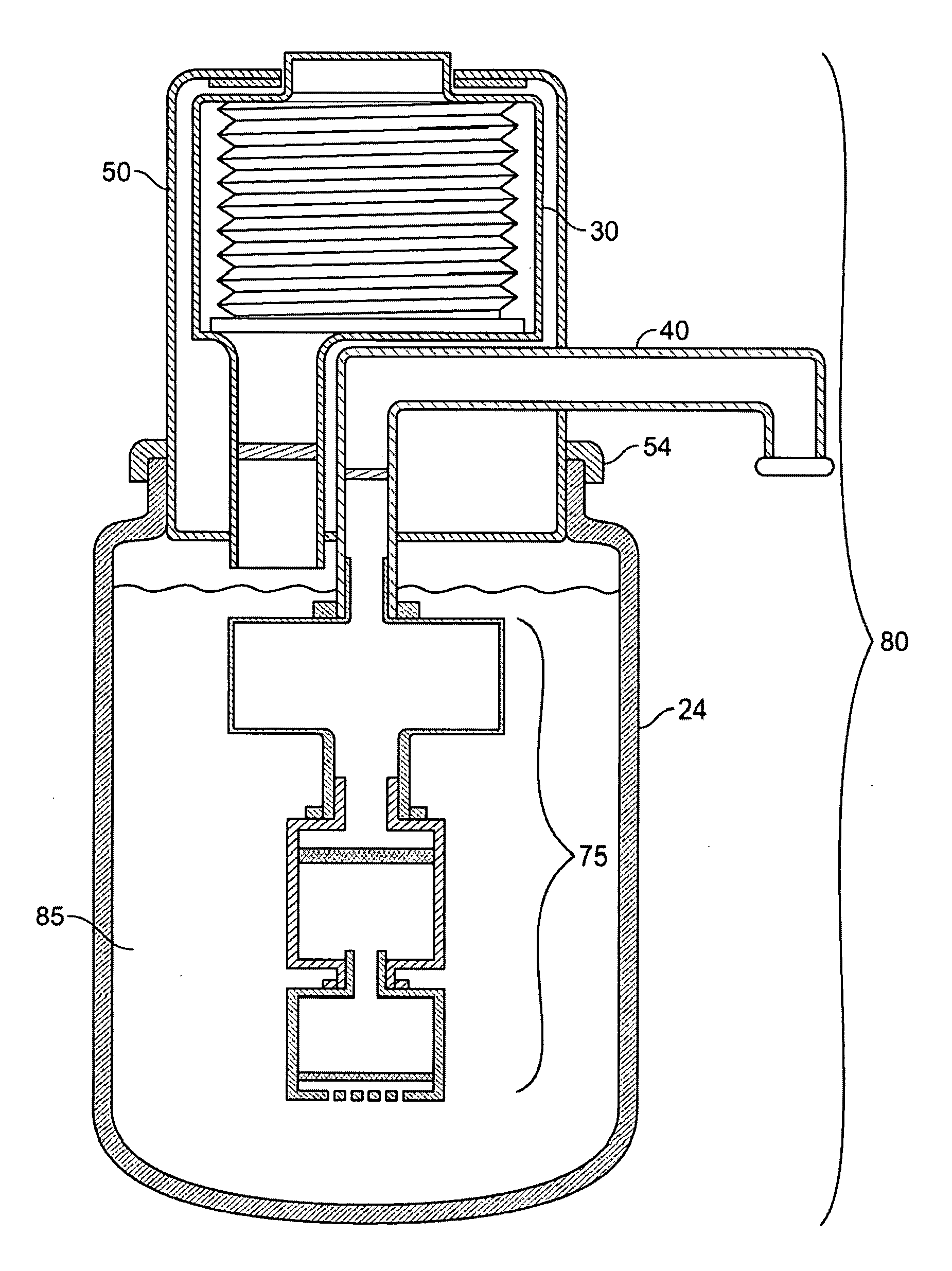

A leaf trap device 10 for use with a water recirculation system including pump and a water filter, for a swimming pool, comprises a housing structure 14 including a tank compartment 18, a filter device 20 mounted within the compartment 18, a discharge valve 22 and a control unit 24. The tank compartment 18 has a water inlet opening 30 and a water outlet opening 32. The control unit 24 is operable to control the operation of the pump and the discharge valve 22. The filter device 20 separates leaves from water entering the compartment 18. The leaves are collected in the tankcompartment 18. The control unit 24 switches off the pump and opens the discharge valve 22 at regular time intervals allowing leaves to be discharged from the tank compartment 18.

Owner:HOAL JOHN ANDREW VALENTINE +1

Porous polymer water filter and methods of use in refrigeration

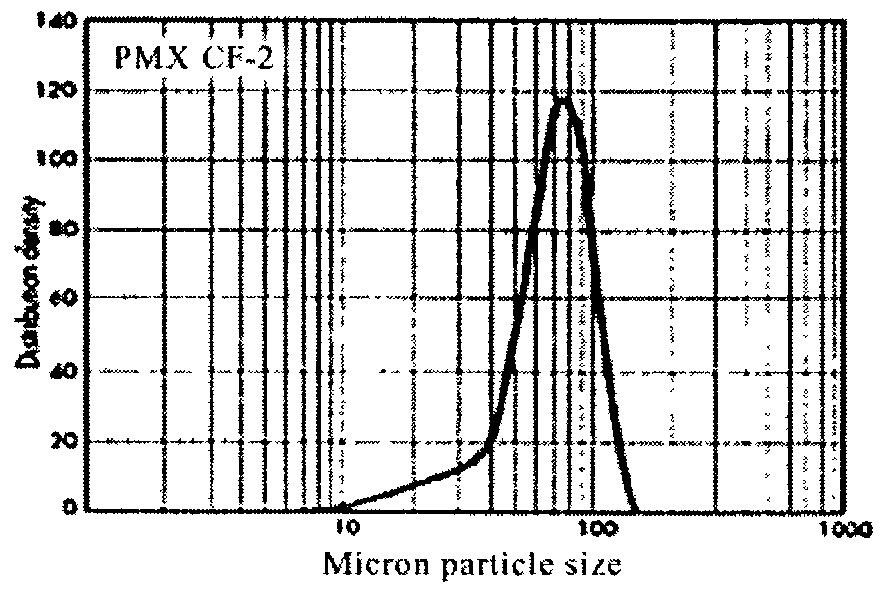

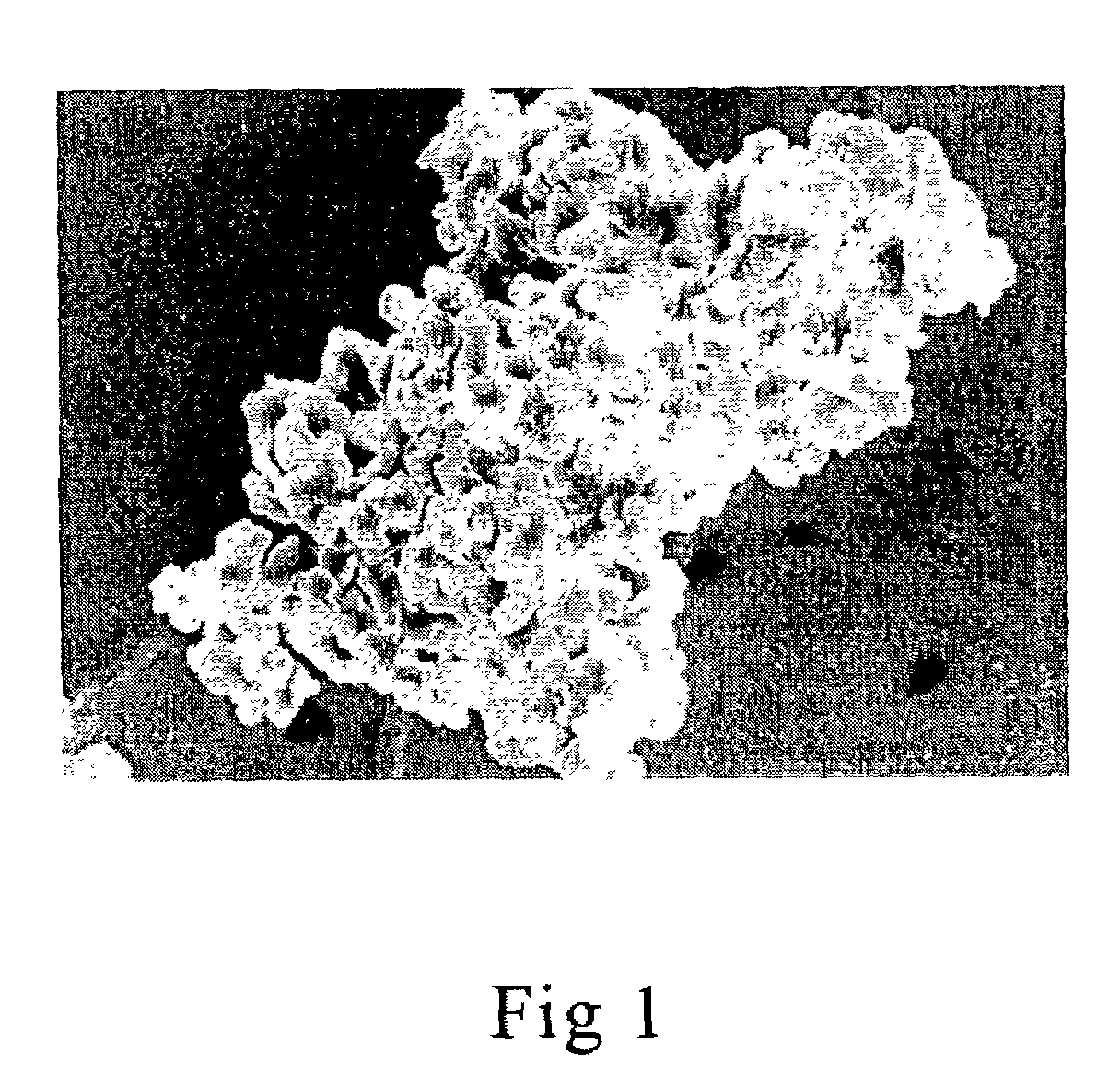

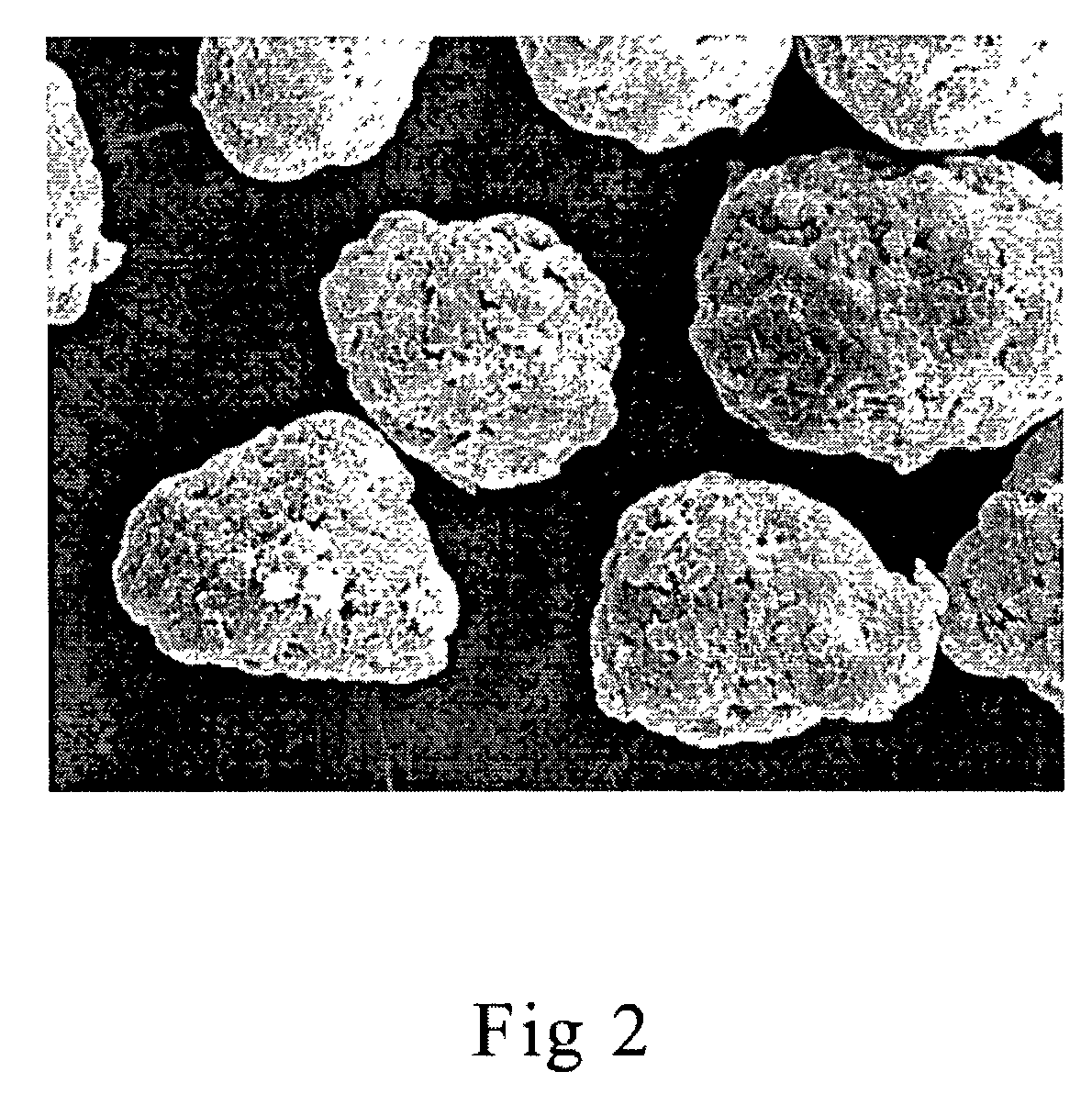

InactiveUS7169304B2Enhances bonding capabilityHigh densitySemi-permeable membranesLayered productsPolymer scienceFiltration

The filtration device of the present invention relies on materials and methodologies that achieve the formation of a structural matrix that may later accommodate the addition of other adsorbent materials as opposed to merely binding adsorbent materials together through the use of compression and / or binder materials. The filter device of the present invention relies on (i) a unique method of processing to achieve maximum density of materials, (ii) a polymeric material having a distinct morphology and (iii) a very small micron diameter of the polymeric material to create uniformity. For example, in place of compression to increase density, the materials comprising the filtration device of the present invention are instead vibrated into a mold cavity. Thus, the methodology of the current invention optimizes how all of the materials comprising the filtration device fit together without compaction. The material being processed is vibrated as it is gradually poured into the mold. Once the mold cavity has been filled to a point where it will hold no more material, it is heated and then cooled. In place of an external binder, the structural material adheres to itself as it softens. This results in a tortuous path matrix of pores rather than an absolute pore barrier.

Owner:3M INNOVATIVE PROPERTIES CO

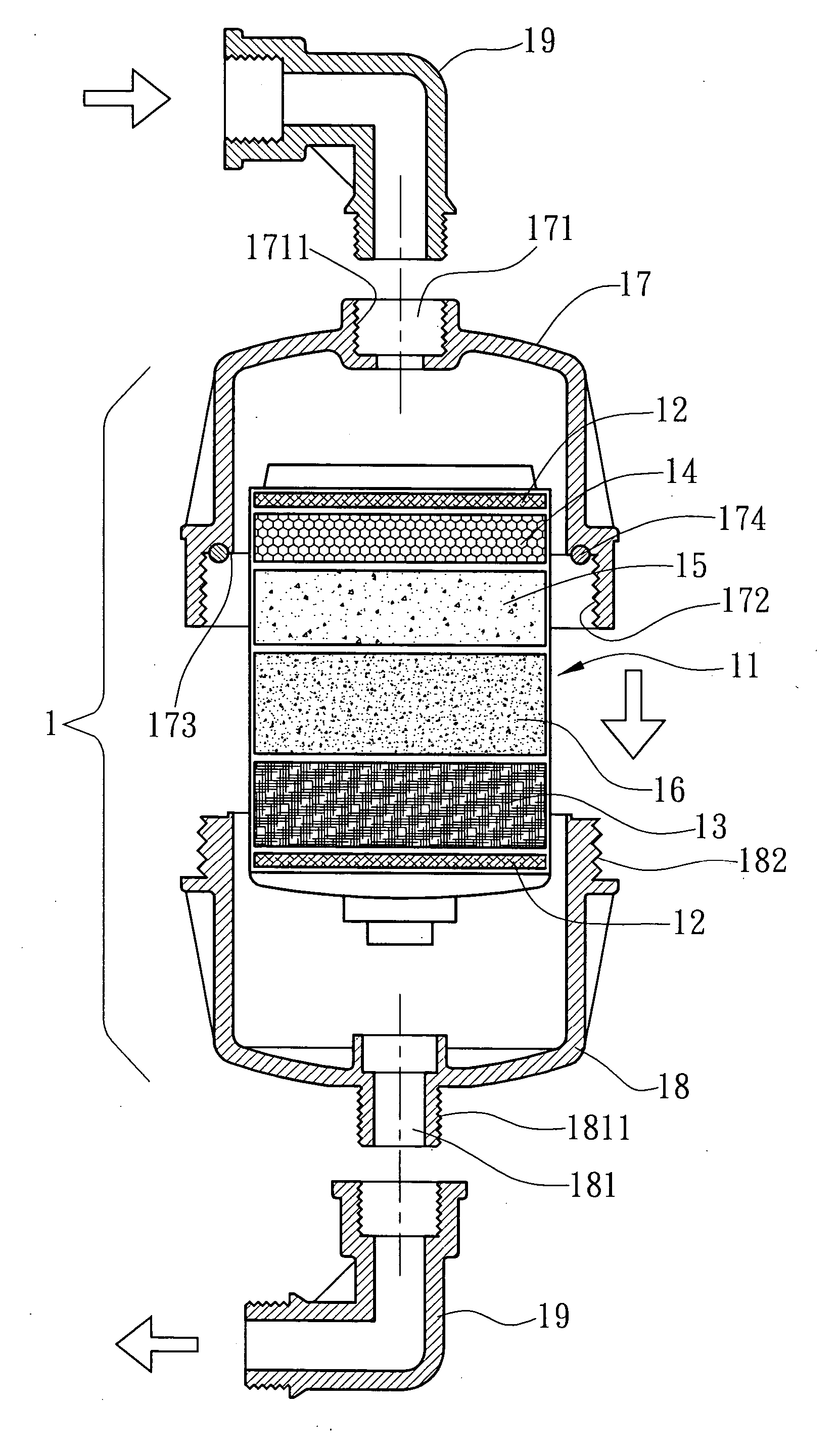

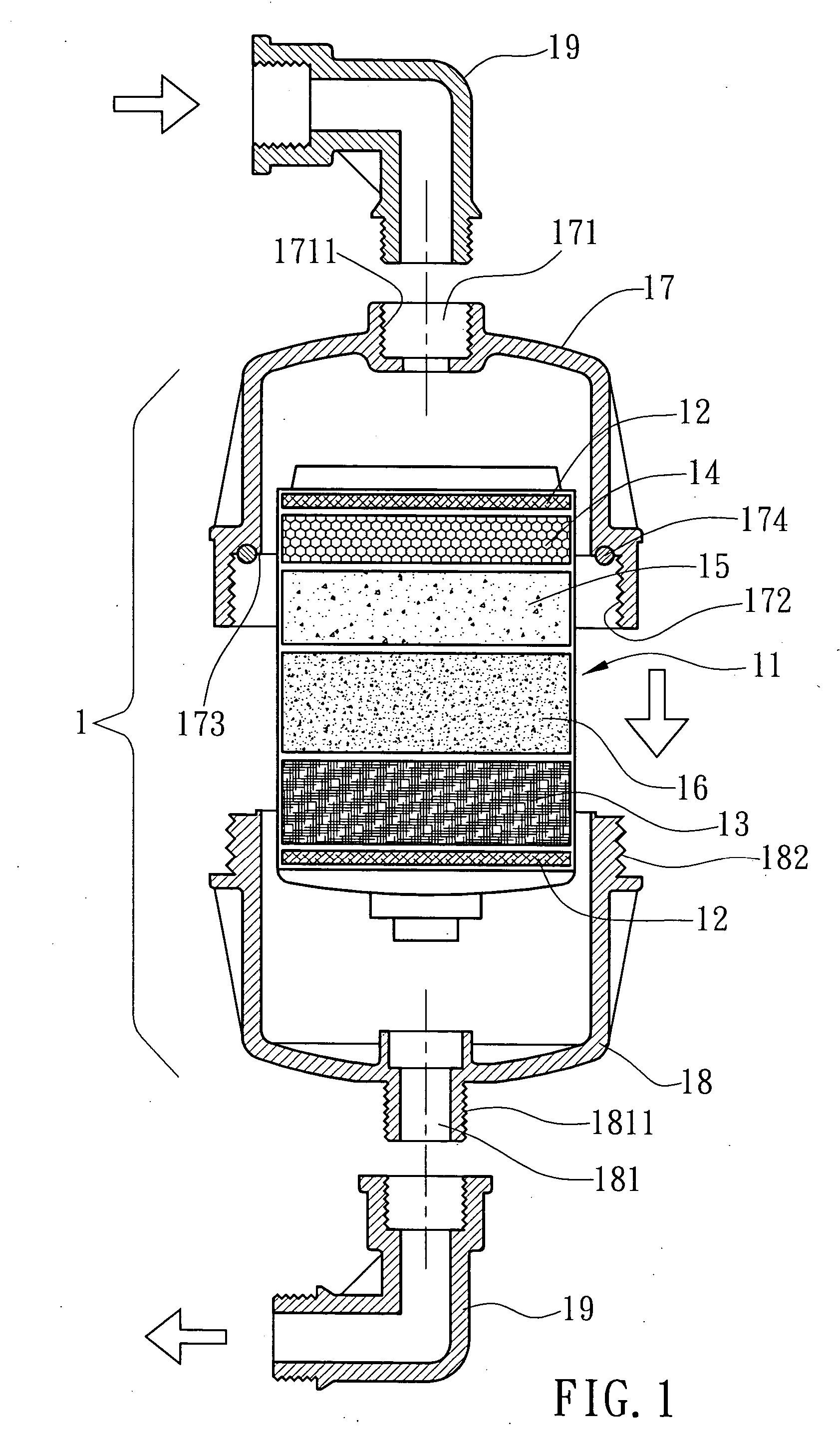

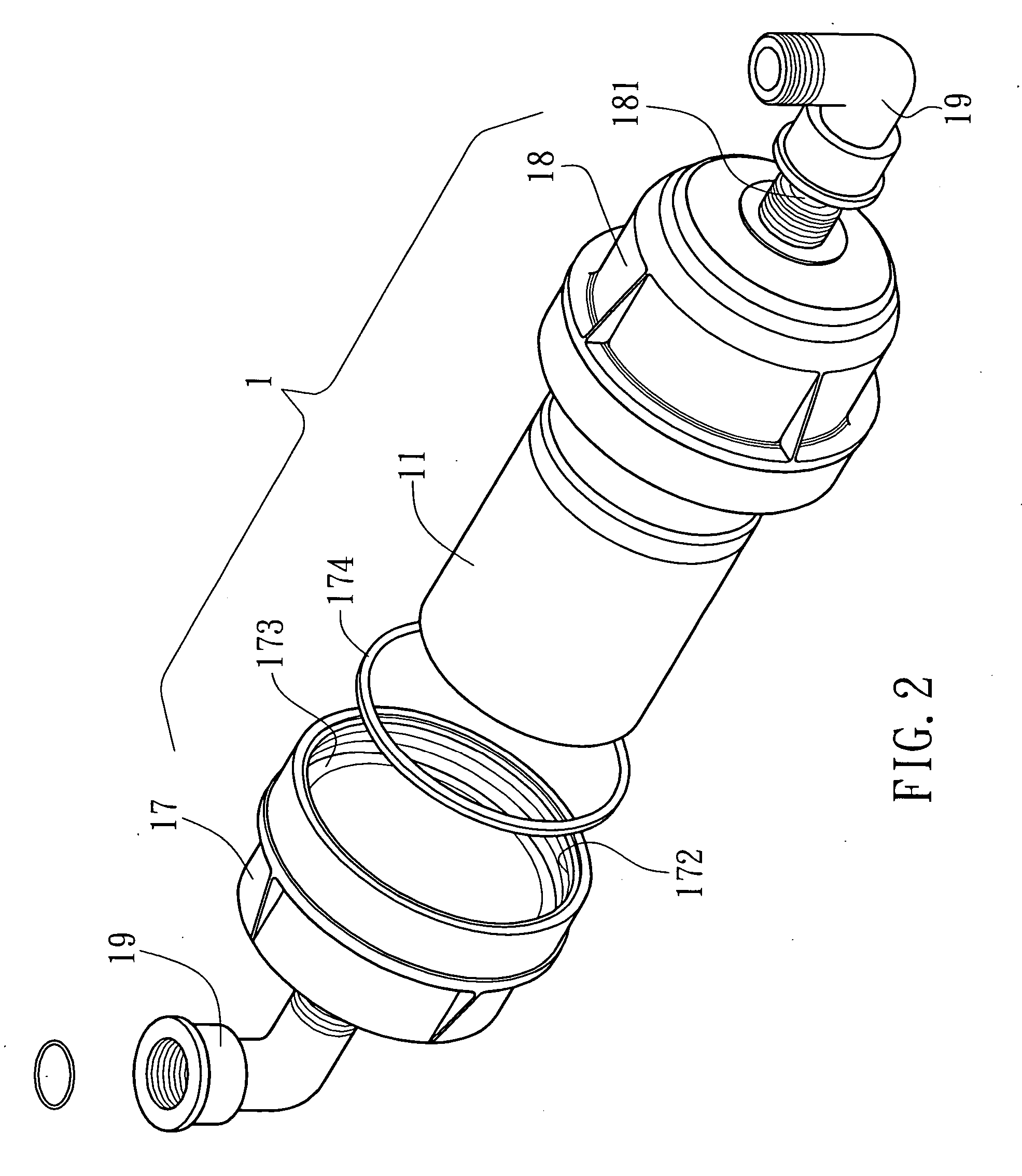

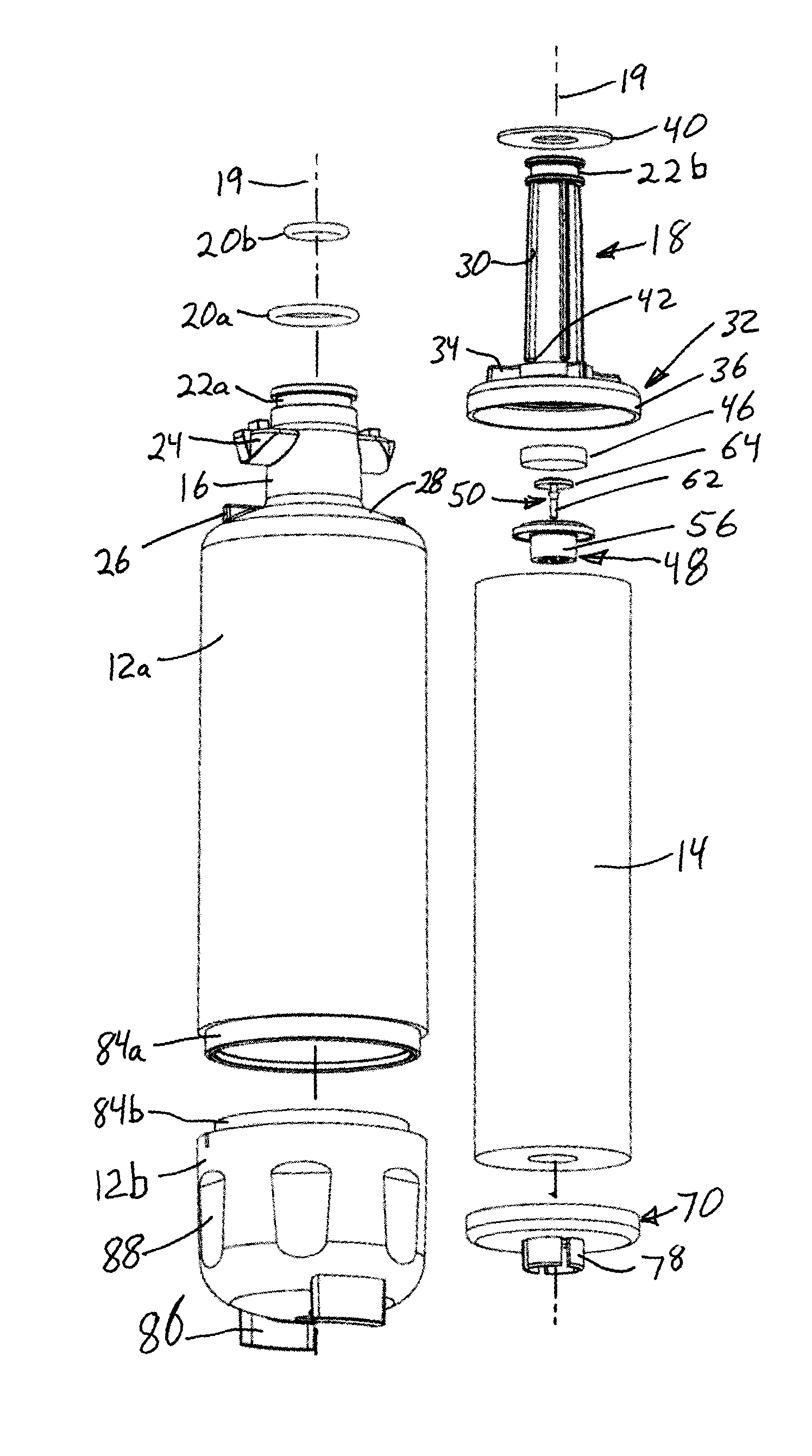

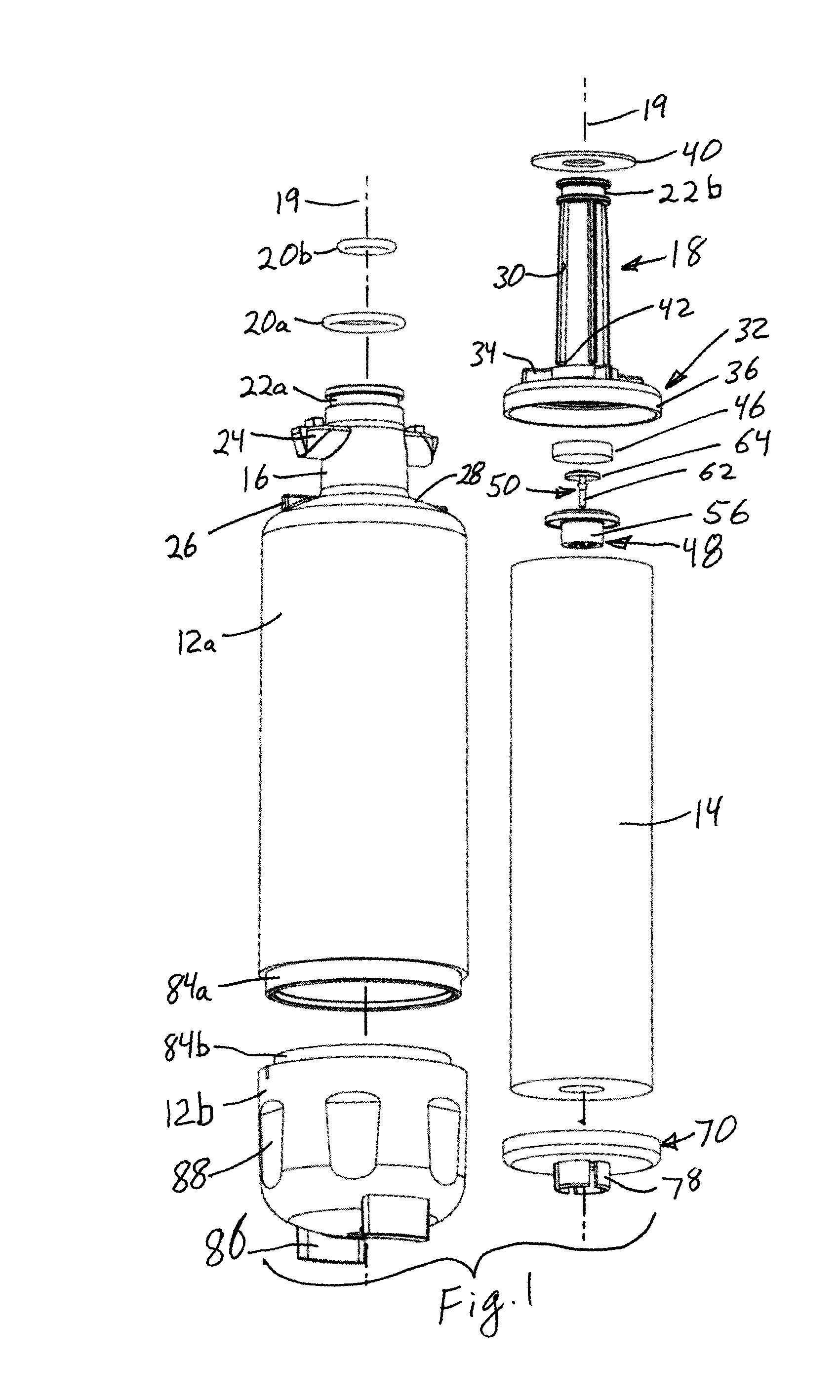

Universal water purifier unit assembly device

InactiveUS20080087596A1Easy to transportTreatment involving filtrationSolid sorbent liquid separationFiberWater filter

Owner:MARMON WATER SINGAPORE

Vehicle sobriety interlock device

ActiveUS7204335B2Reduce moistureAccurate readingElectric devicesElectrical apparatusFuel cellsWater filter

An interlock device for measuring the sobriety of a potential vehicle operator is coupled to the starting mechanism of the vehicle. The interlock device includes a microprocessor controlled handset and base unit. The base unit encloses relays to preclude the starting mechanism from engaging if a predetermined acceptable threshold level of blood alcohol content has been exceeded. The relays receive a signal, through the base unit microprocessor, from the handset microprocessor which has calculated the blood alcohol content of a breath sample introduced into the handset by the vehicle operator. A breath sampling housing is enclosed within the handset in axial alignment with an intake port of the handset. A water filter and valve are positioned upstream from an electrochemical fuel cell. The fuel cell is coupled to the microprocessor. A pressure transducer measures the pressure of the breath sample. The handset microprocessor calculates a pressure offset through an algorithmic equation and applies the offset to the variable reading across the fuel cell to provide a normalized blood alcohol content measurement.

Owner:GUARDIAN INTERLOCK LLC

Simple faucet water-filtering device

InactiveUS20050072728A1Simple structureEfficient removalServomotor componentsDomestic plumbingWater filterWater flow

A simple faucet water-filtering device including a main body and a connecting section. An upper end of the connecting section is adapted to connect with a spout of a faucet. A lower end of the connecting section is screwed with an upper cap of the main body. A lower end of the main body is formed with a water outlet. The main body has a casing defining a receiving space in which an energy cup is placed. An outer wall of the energy cup is formed with a spiral path, whereby a spiral water way is defined between the outer wall of the energy cup and inner wall of the receiving space. The water flows through the spiral water way and then flows out from the water outlet. The connecting section includes a faucet locking collar and an inner locking collar. The faucet locking collar has an inner conic opening at upper end. An upper end of the inner locking collar is formed with a conic section adapted to the inner conic opening of the faucet locking collar. An inner bushing is fitted in the inner locking collar.

Owner:CHANG CHIN CHING

Water filter

InactiveUS20070235381A1Efficient removalHarmful substanceTreatment involving filtrationWater treatment locationFiberWater filter

A water filter is disclosed to include a housing formed of a top cover shell and a bottom cover shell, and a filter element mounted in the housing for filtrating water passing through the housing, the filter element containing nanosilver fabrics, nanocarbon fibers, calcium sulfite, KDF-55, and coconut shell active carbon.

Owner:TSAI JACKIE

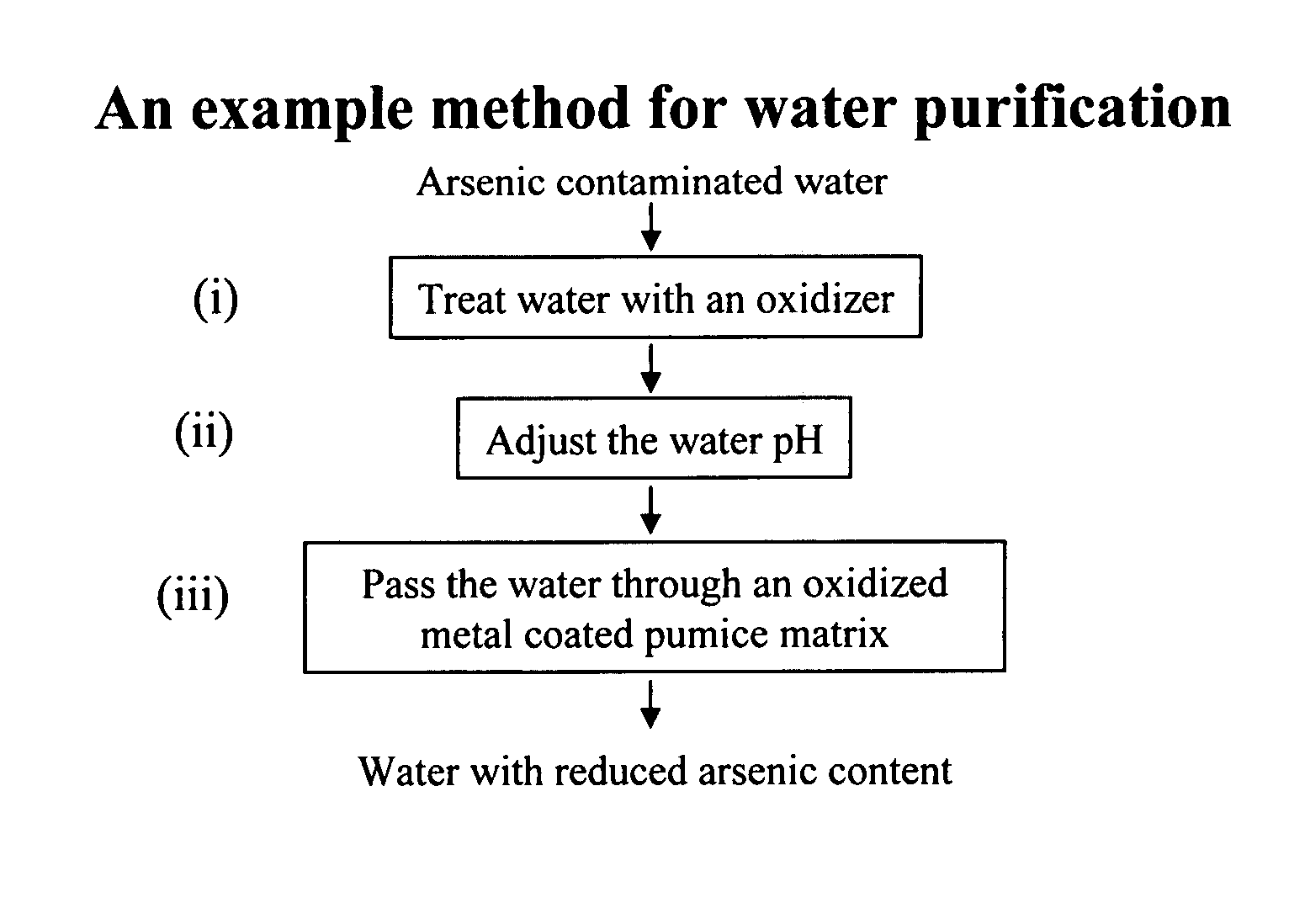

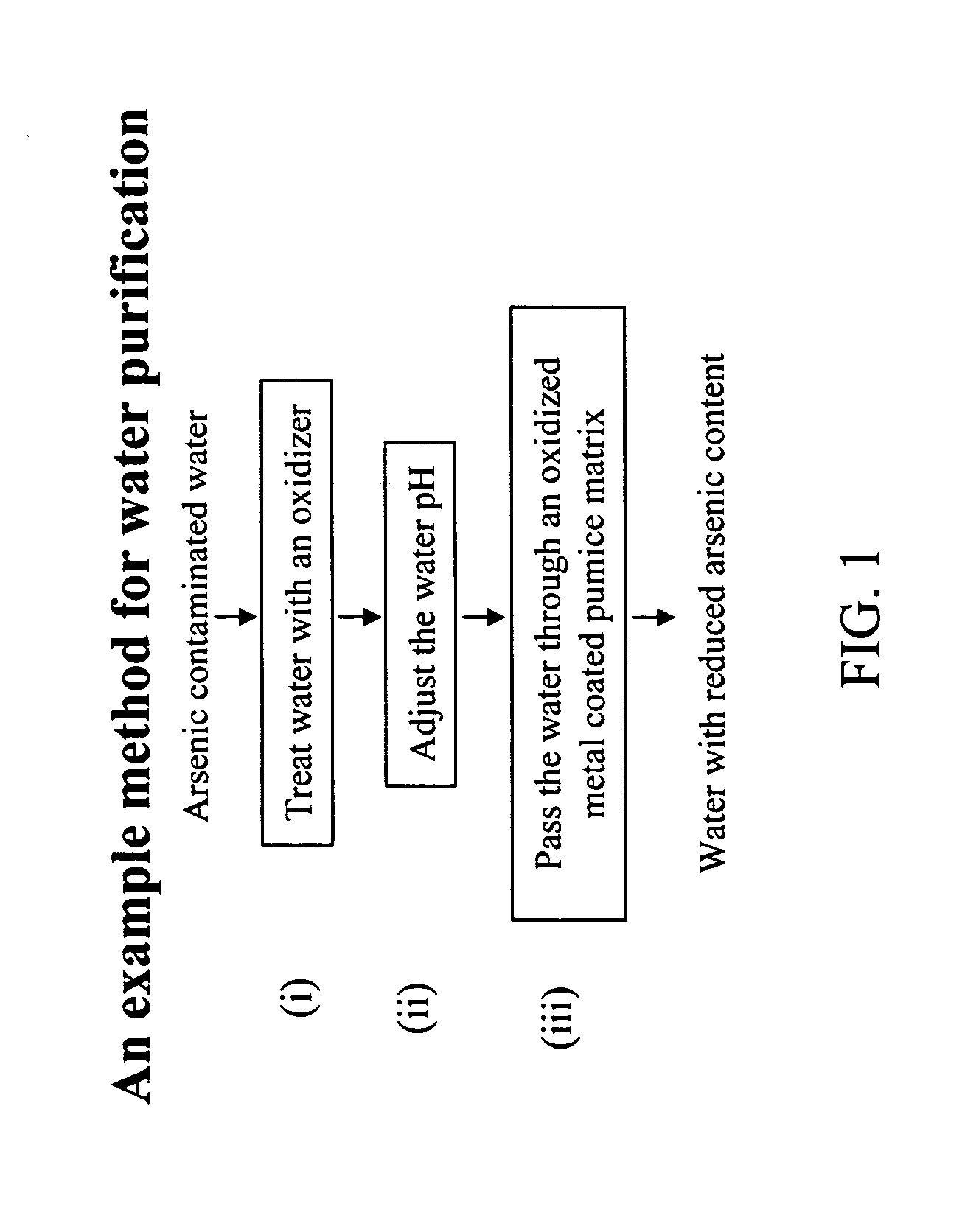

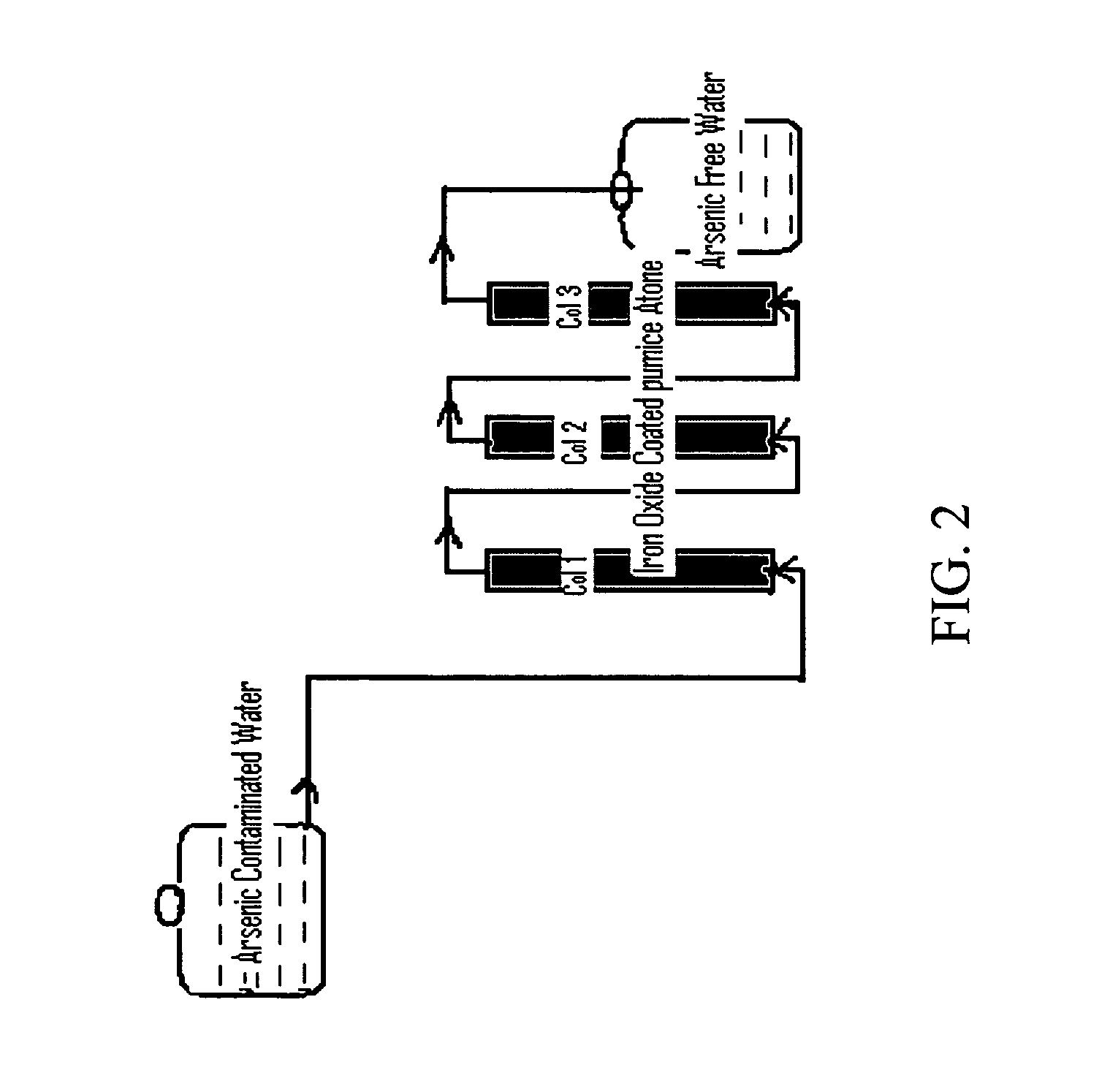

Removal of arsenic from water with oxidized metal coated pumice

InactiveUS20070017871A1Cheap disposalWithout environmental riskWater contaminantsSolid sorbent liquid separationContaminationMetal

The current invention is concerned with methods and compositions for the removal of arsenic contamination from water. A method for binding As to oxidized metal coated pumice and method for making the same are disclosed. Water filters comprising oxidized metal coated pumice, such as oxidized iron coated pumice, are also provided.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

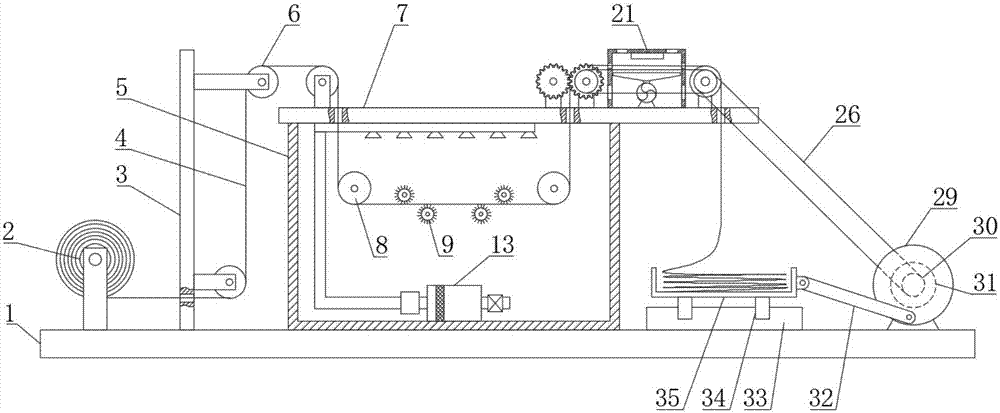

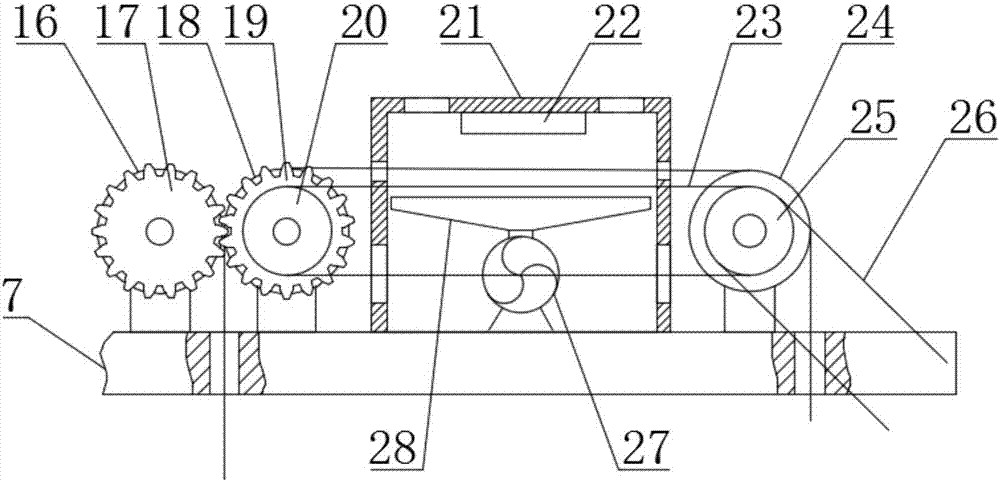

Cloth cleaning, drying and finishing integrated machine

InactiveCN107090680AImprove processing efficiencyEasy to cleanLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsWater filterPulp and paper industry

The invention discloses an integrated machine for cleaning, drying and finishing cloth, which comprises a base, a cleaning box is arranged on the base, two second guide rollers are rotatably connected to the front and rear side walls of the cleaning box, and a brush roller; the bottom of the cleaning box is provided with a filter box; the top of the cleaning box is provided with a top plate, and the right side of the top plate is provided with a drying box; A first gear is fixedly connected to the front end of a squeeze roller, and a second gear is fixedly connected to the front end of the second squeeze roller; a slide rail is also arranged on the base, and a fabric receiving basket is slidably connected to the slide rail through a slider , the right end of the fabric receiving basket is hinged with a connecting rod, and the other end of the connecting rod is rotationally connected with the front end of the motor. The invention integrates cloth cleaning, drying and sorting into one, which greatly improves the cloth processing efficiency; the washed water is filtered by a filter screen and then reused, which saves water resources.

Owner:王兴民

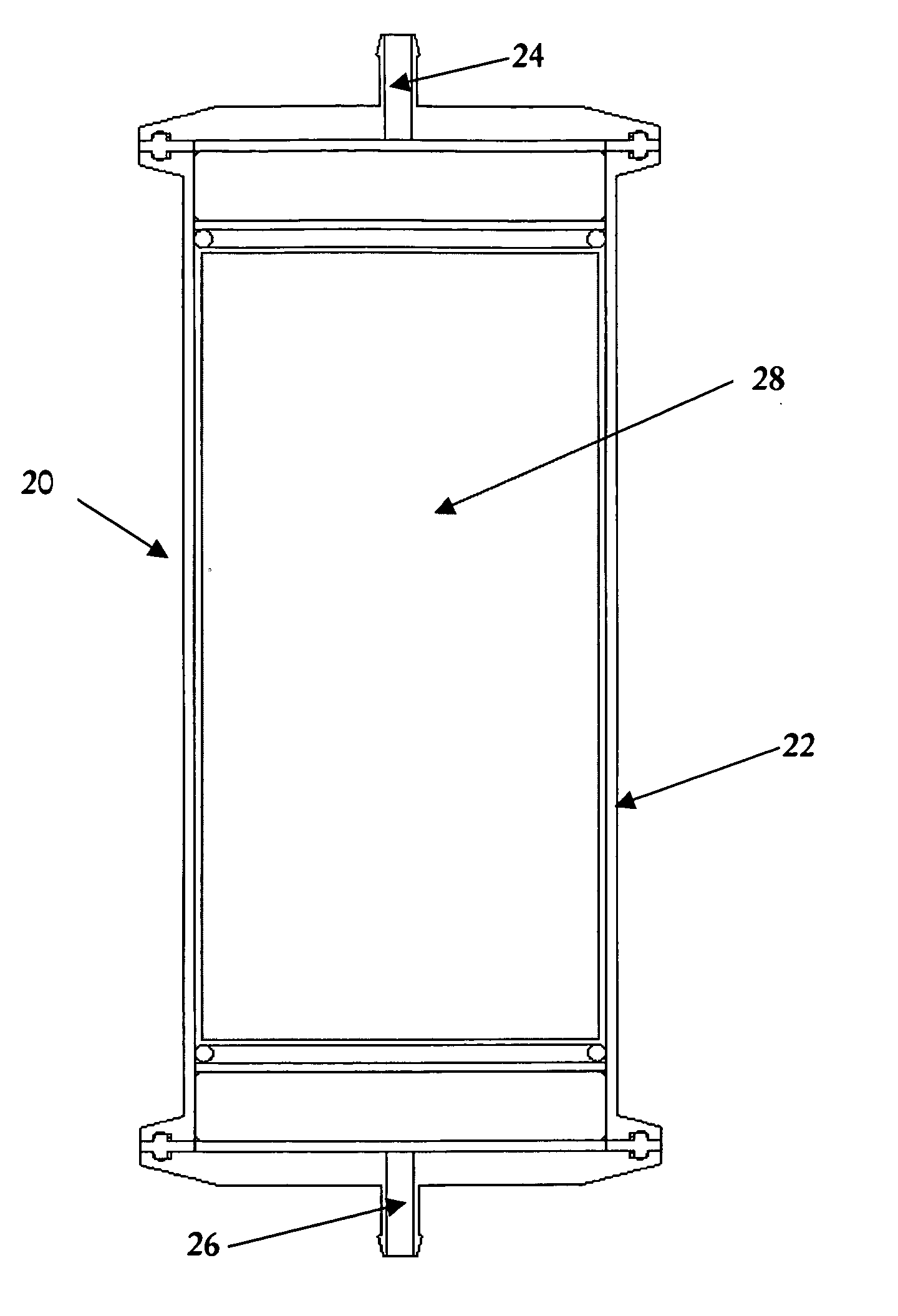

Water treatment cartridge

InactiveUS6872303B2Safe and easy and sanitizationSafe and easy treatmentTreatment involving filtrationSolid sorbent liquid separationChemical compositionChlorine dioxide

The water treatment cartridge is a cartridge adapted to fit into a conventional water filter housing to release a sanitizing dose of a water-treating chemical, and in particular chlorine dioxide, into a water treatment system or unit process. The cartridge is filled with a water treating media, comprised preferably of a mixture of an inert filler material and a chemical composition that releases chlorine dioxide on contact with water. The concentration of the chlorine dioxide released into the water, as well as the duration of the release, may be varied by the selection of the filler material and amount of the filler material in the water treating media.

Owner:RELIOX

De-iced gutter debris preclusion system

The system includes a substantially rigid body providing underlying support for a filtering layer, such as in the form of a screen. The body includes a heating wire or other heat source coupled thereto with the body formed of heat conductive material. The body is configured with multiple ribs extending up from a floor so that heat transfer from the body to the screen can occur in a variety of different locations to keep the screen sufficiently heated. The body also includes a wing for interfacing with roofing and openings to allow water filtering through the screen to migrate down into the gutter. A cover overlies a channel which can contain one or more heating wires that experience resistive heating when an electric current is applied thereto.

Owner:ALL WEATHER ARMOUR LLC

Freeze resistant water filter

InactiveUS20050161394A1Increase elasticityThin wallMembrane filtersCartridge filtersVitrificationPolyolefin

A freeze resistant filter cartridge assembly and methods for fabrication include a filter cartridge including a filter housing and a filter media and having at least one component selected from a list of components consisting of: the filter housing being formed of an increased elasticity polyolefin polymer having elongation and glass transition properties that allow for stretching of the housing during a freezing event rather than rupturing; a sleeve having a volume of air entrapped therein within and being disposed in the interior of the filter cartridge; and the filter housing formed of a conventional polyolefin having a wall thickness great enough to resist freeze induced expansion stresses. A disassemble cartridge filter includes a filter cap, a filter housing and a filter element. The filter cap and filter housing are rotatably attached wherein cap and housing engagement members prevent rotatable disengagement of the filer cap and filter housing.

Owner:3M INNOVATIVE PROPERTIES CO

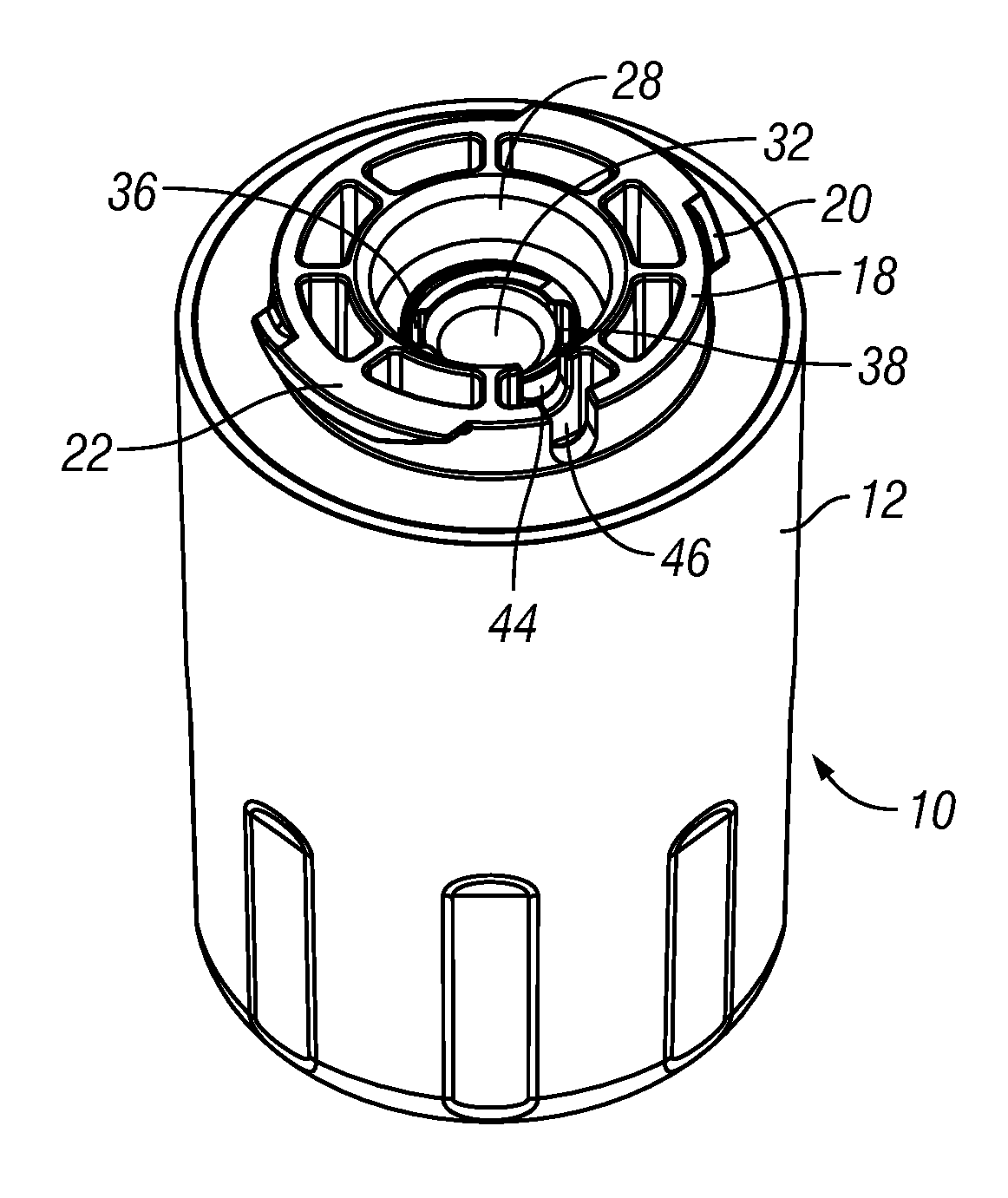

Water filter cartridge with valves

InactiveUS20140110331A1Reduce leakageChange flexibilityTreatment involving filtrationMembrane filtersWater filterEngineering

A water filter cartridge having a housing with an inlet nozzle with a concentric, smaller outlet nozzle extending through the inlet nozzle with a space therebetween defining an inlet to a flow path passing through a filter and through the outlet nozzle. A diaphragm valve mounted to the outlet nozzle blocks upstream flow out of the inlet when the cartridge is not in use. An umbrella valve mounted on the end of the filter blocks downstream flow out of the outlet nozzle when the cartridge is not in use, thus reducing leakage when the cartridge is removed from the appliance.

Owner:BAIRD MICHAEL T

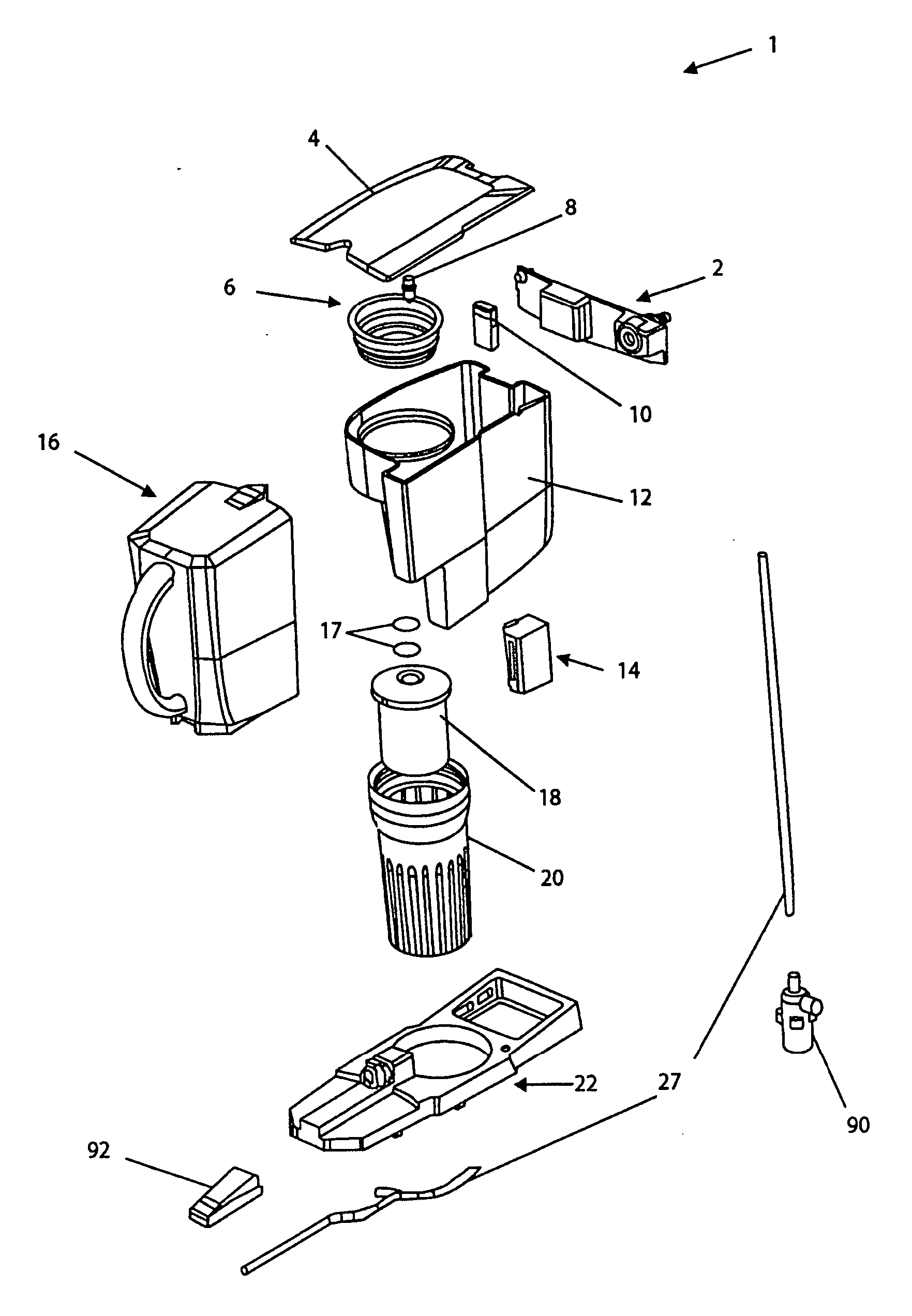

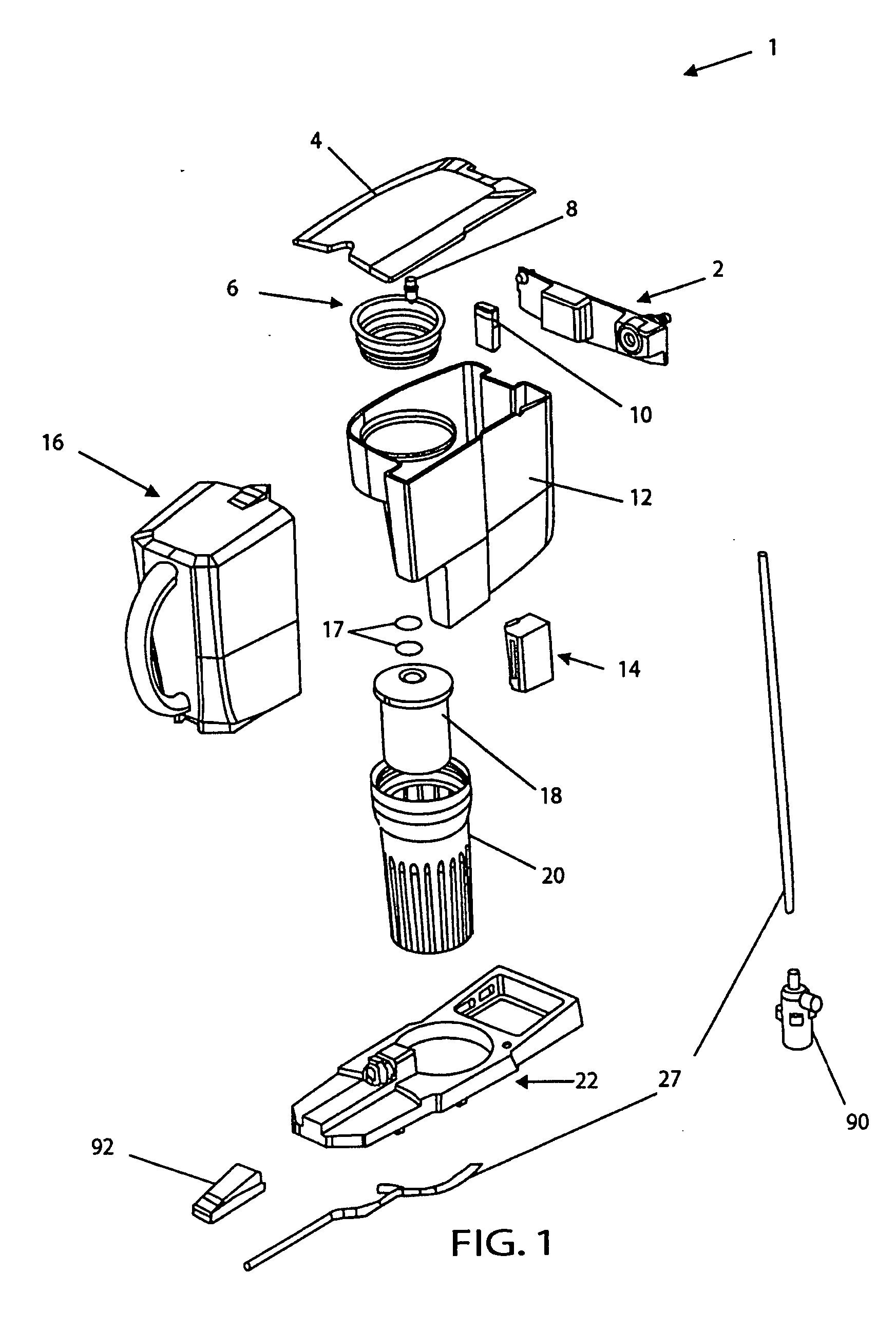

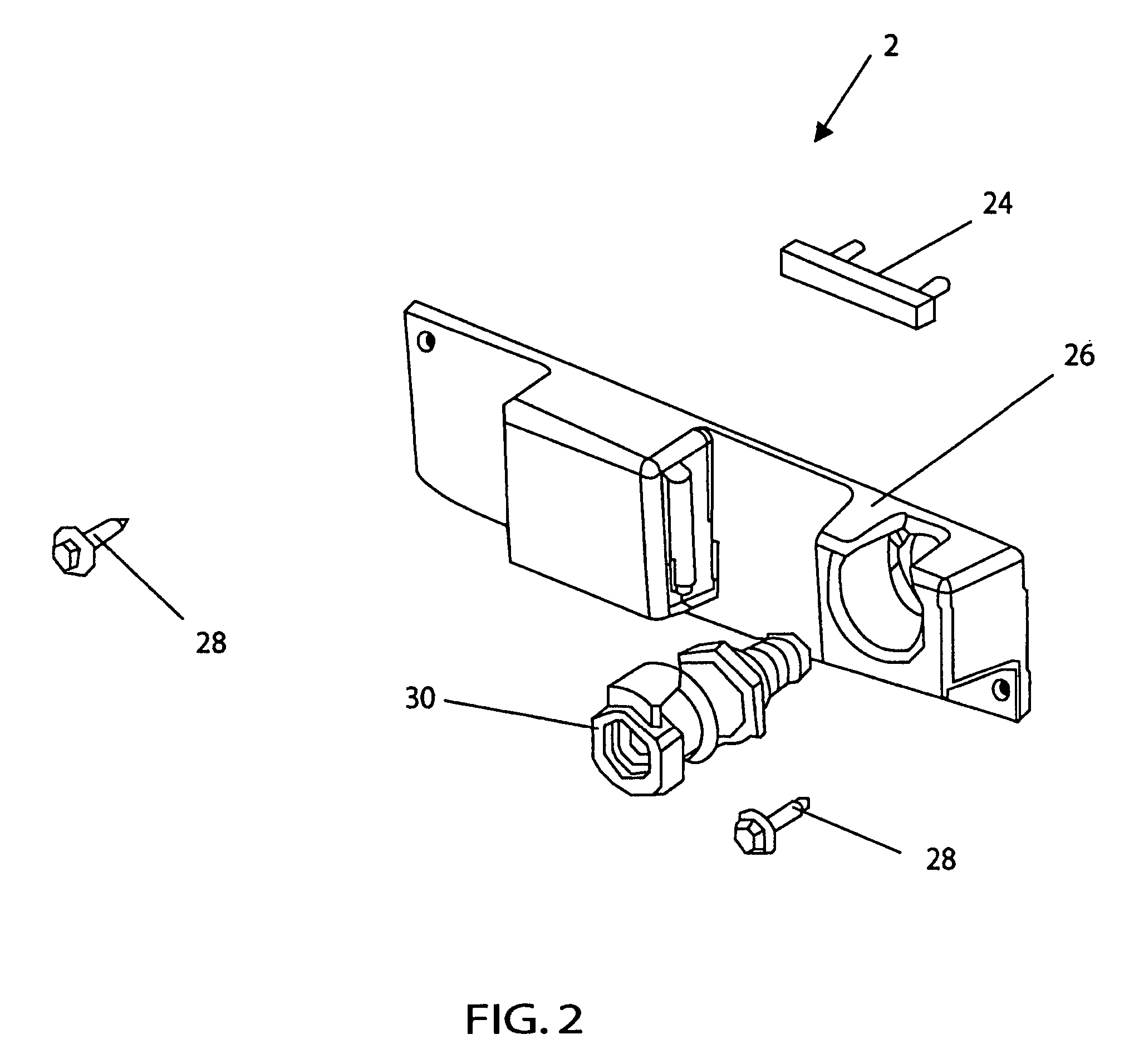

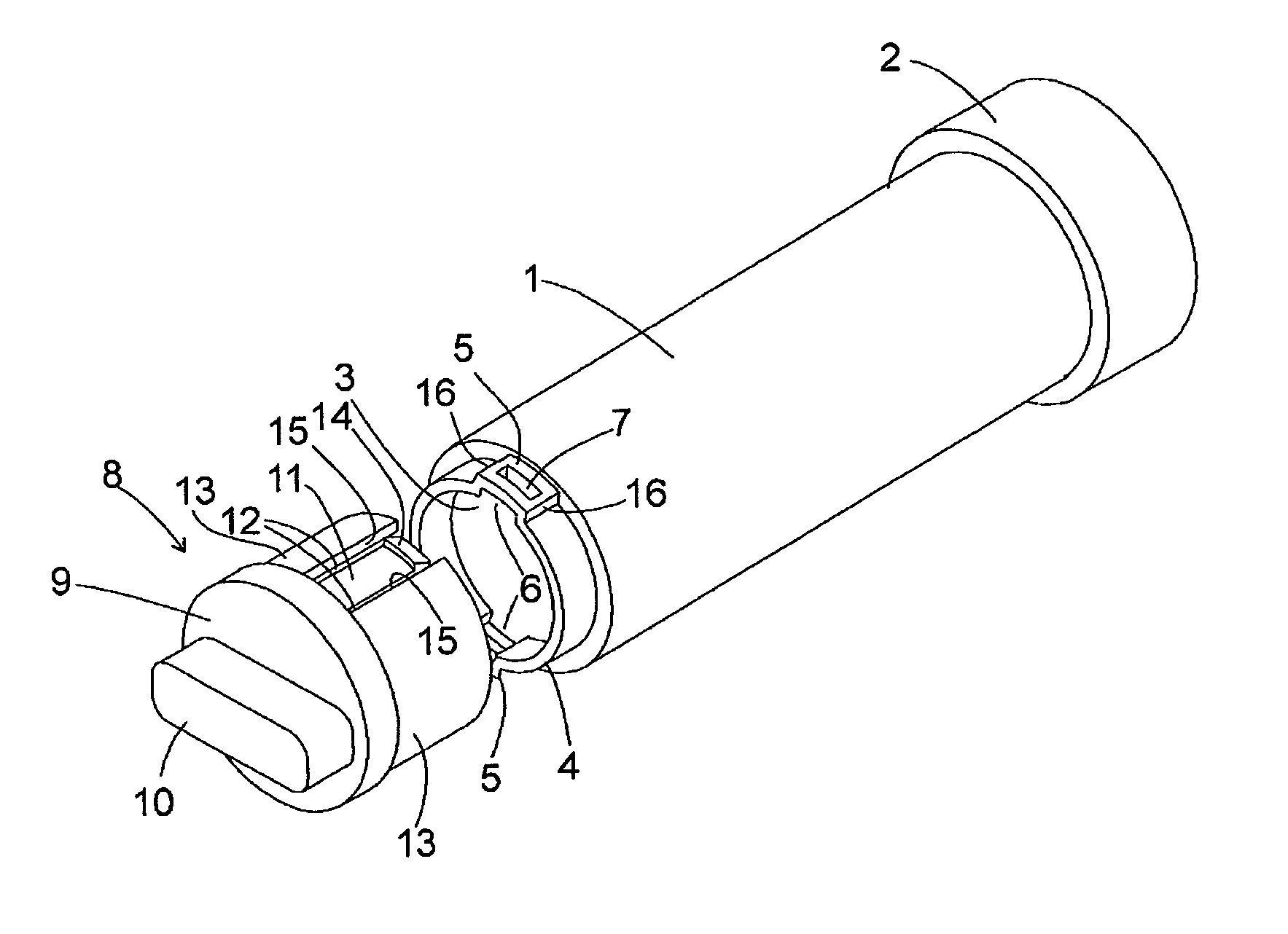

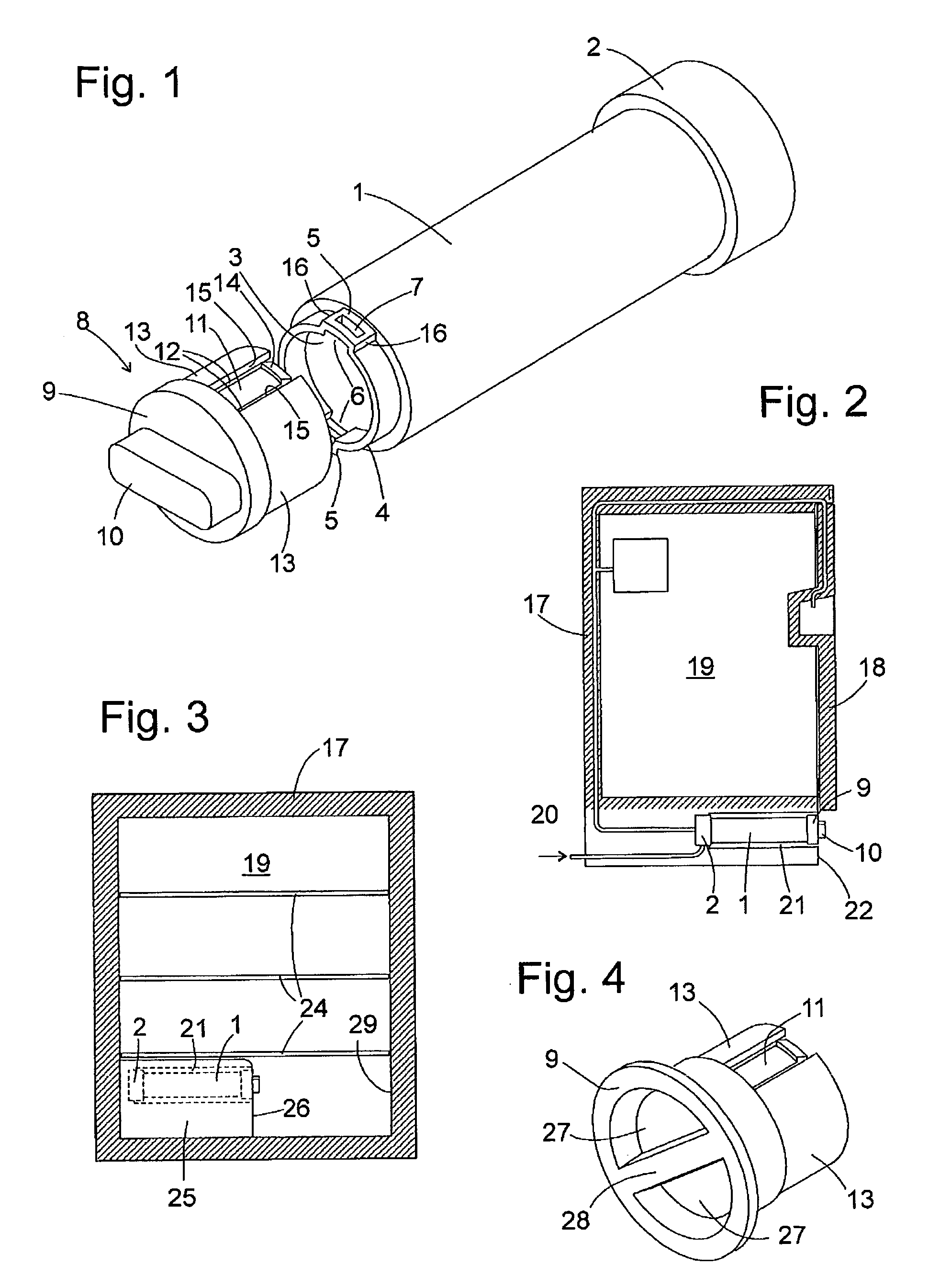

Refrigeration device and water filter for said device

InactiveUS8354024B2Clearly markedLighting and heating apparatusDomestic refrigeratorsWater filterEngineering

A water filter for a refrigeration appliance has a housing (1), which contains a filter material and has a fitting for mounting in a filter socket (2) at one end. A grip portion (8) is attached to an opposite end (3) of the housing (1).

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com