Patents

Literature

177results about How to "No caking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

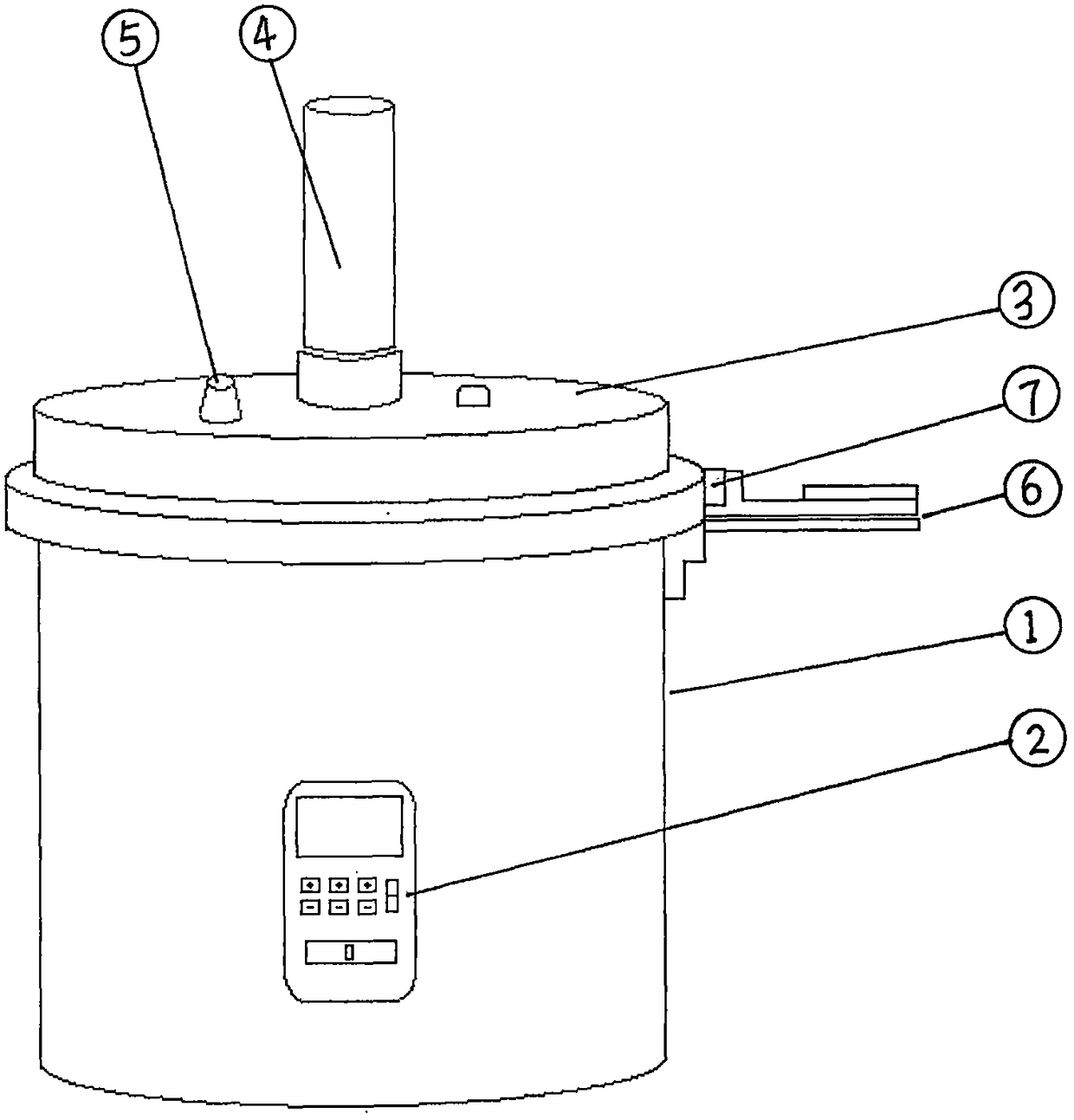

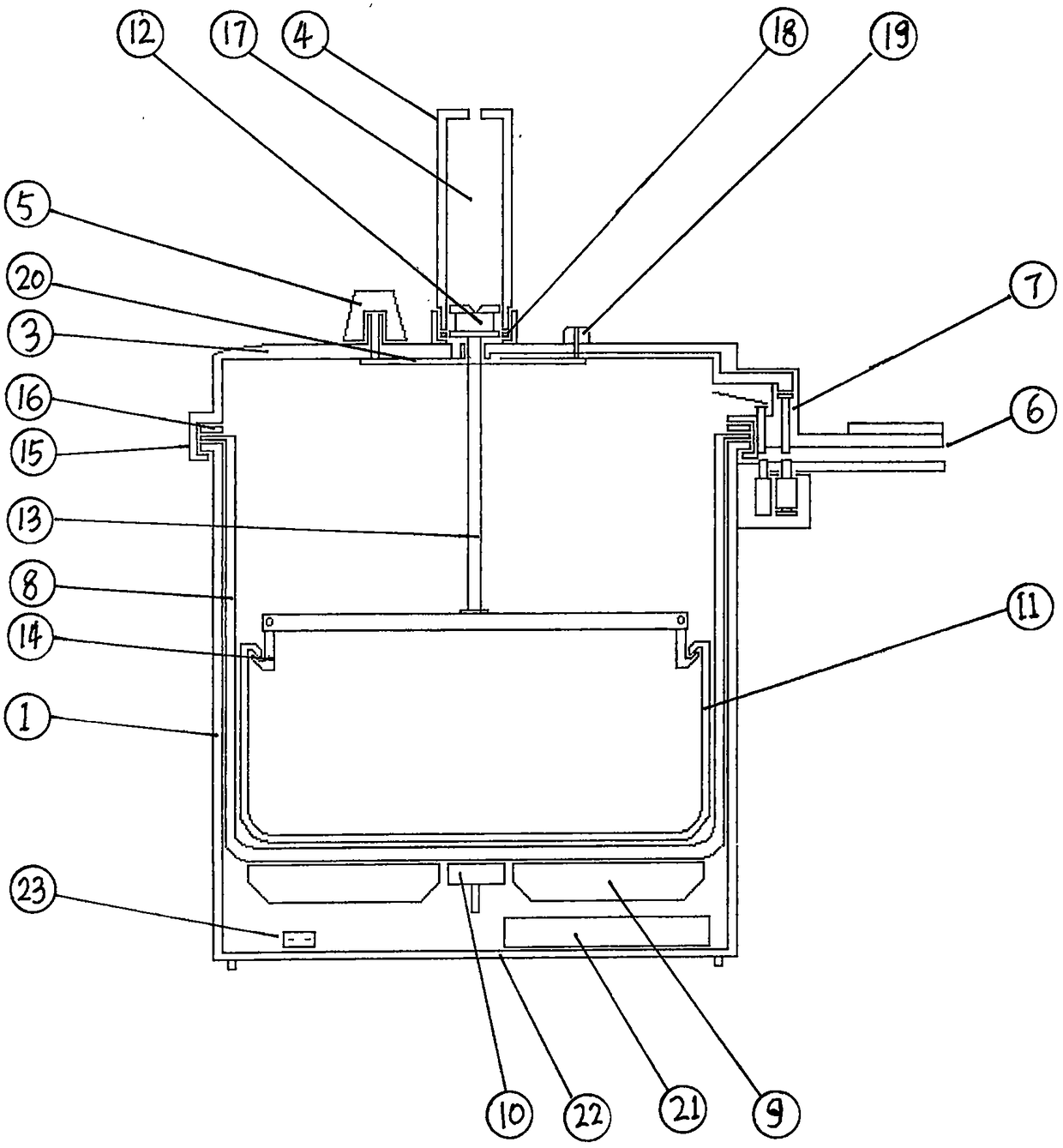

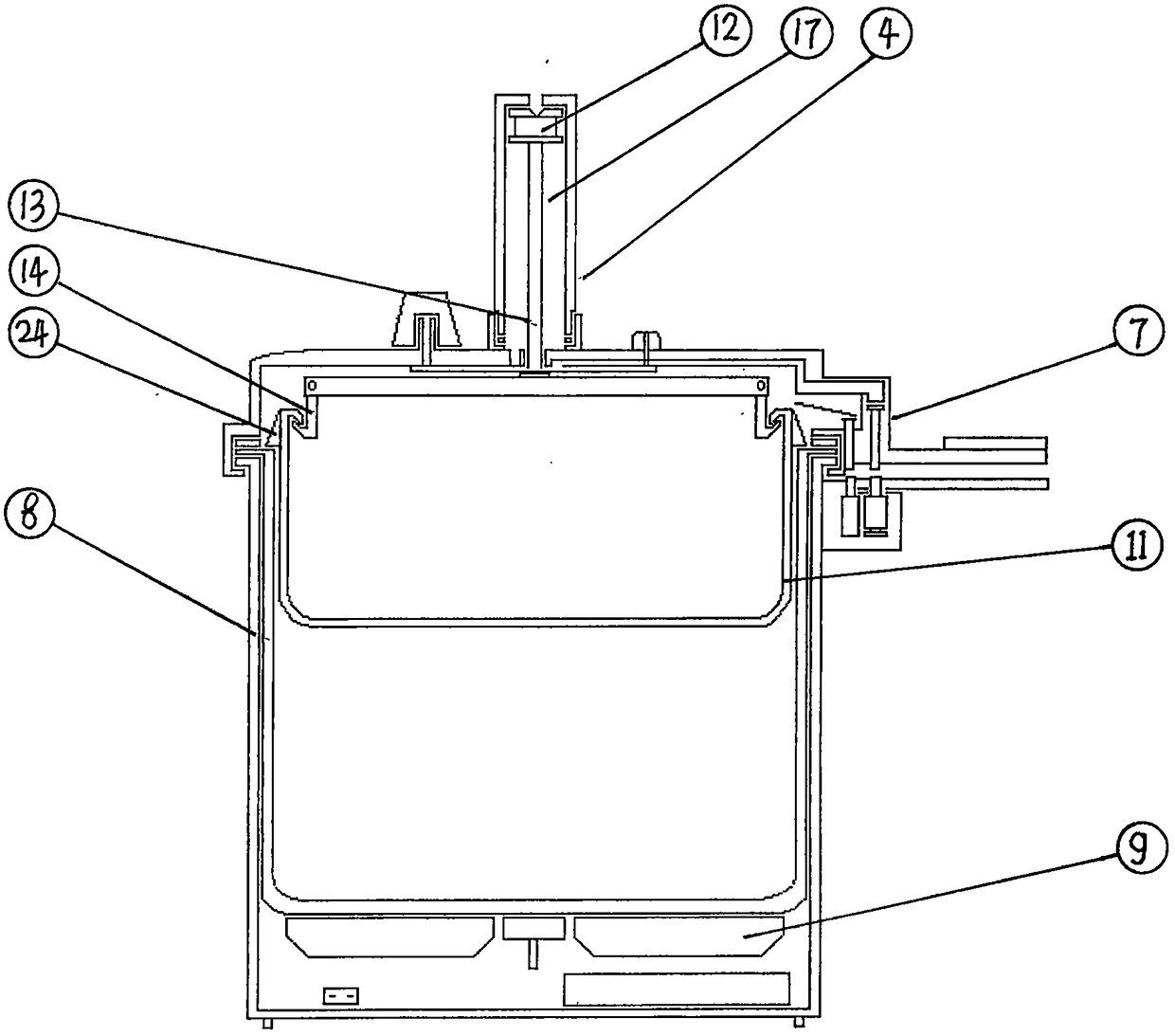

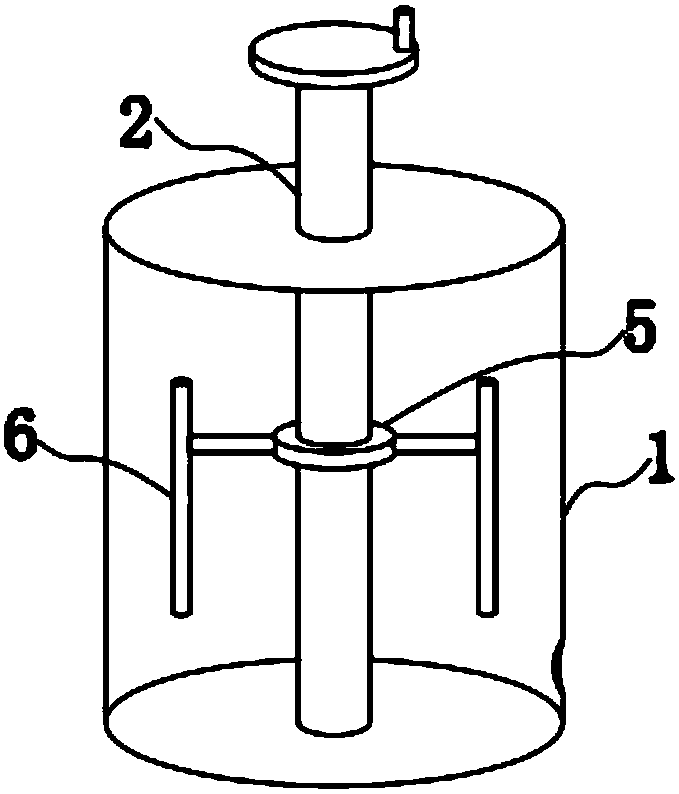

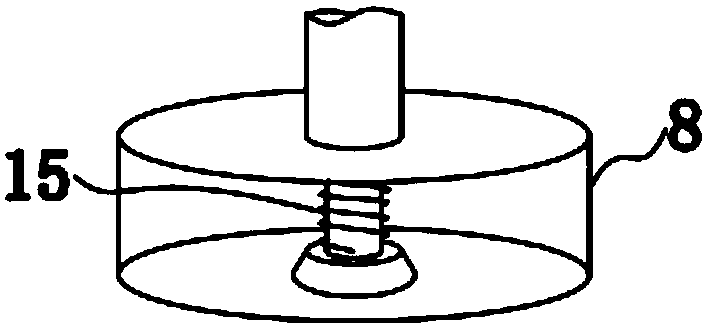

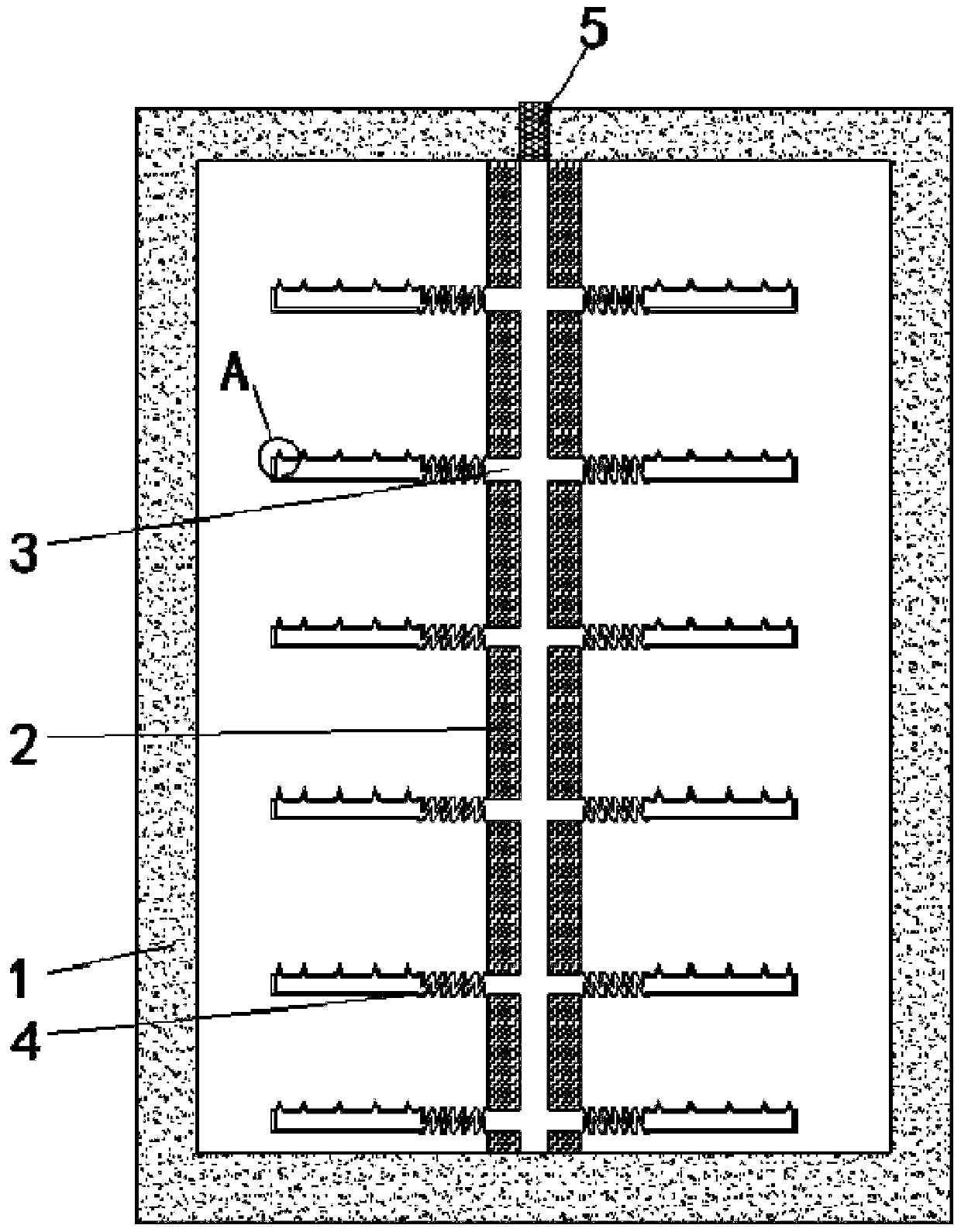

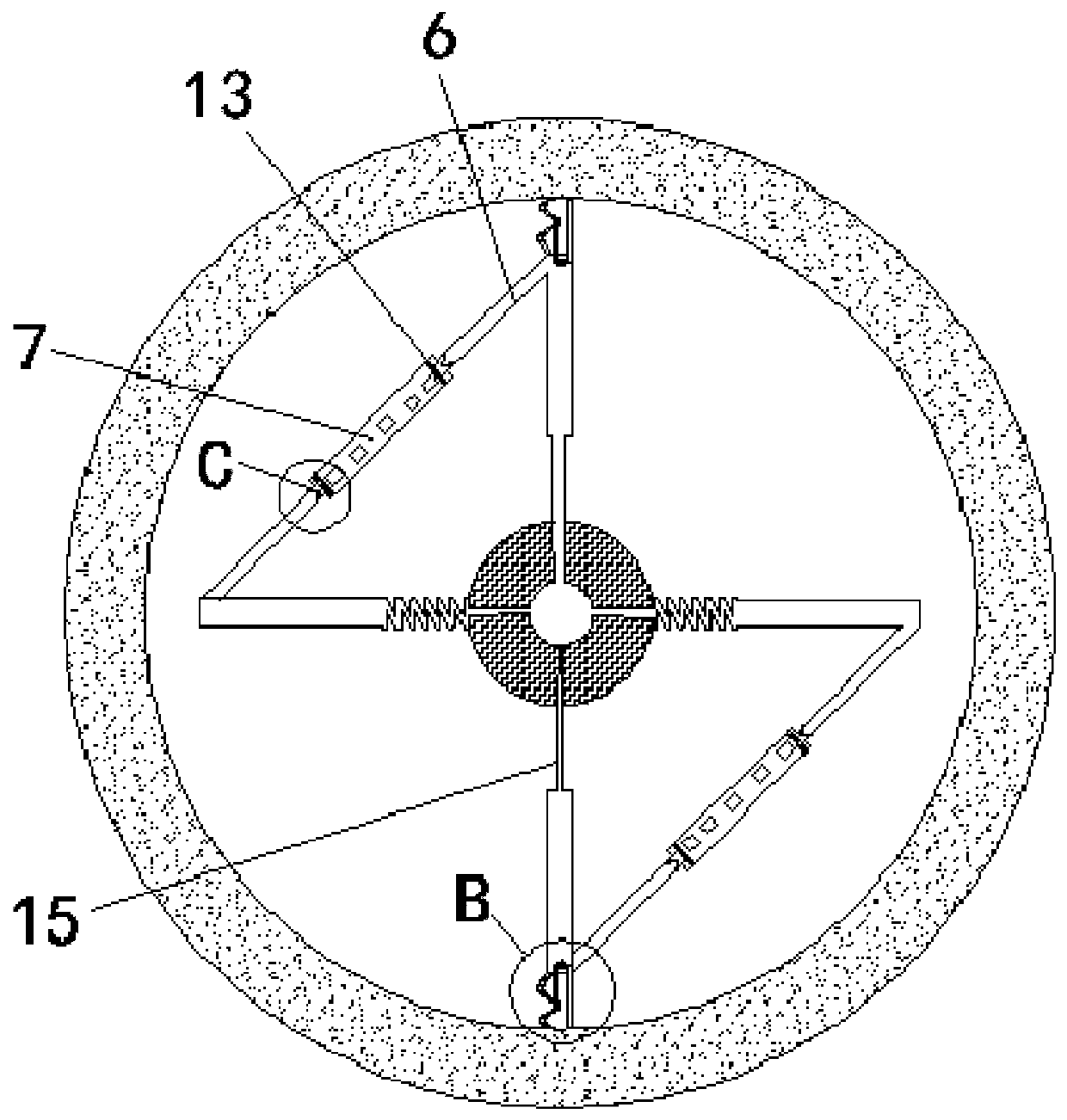

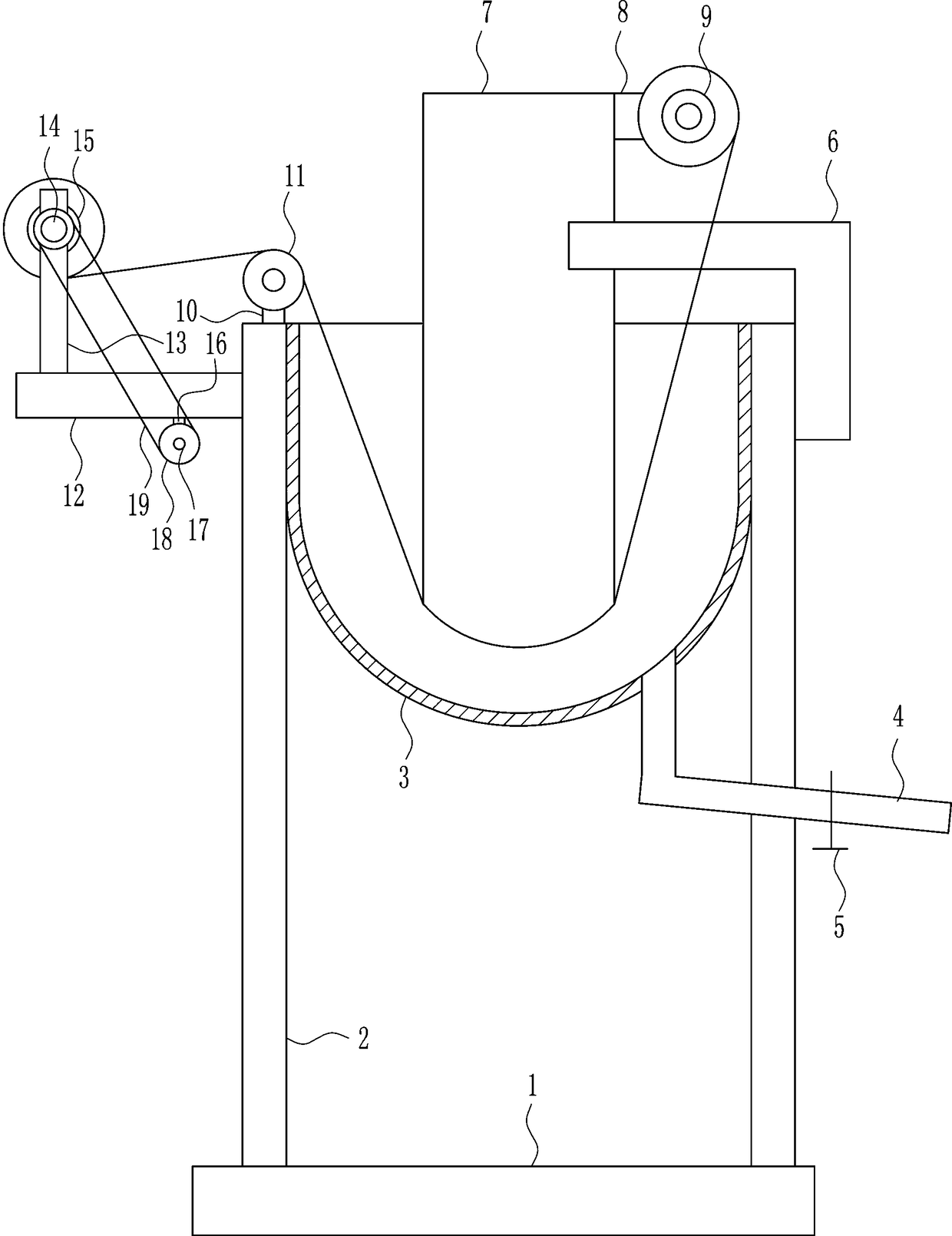

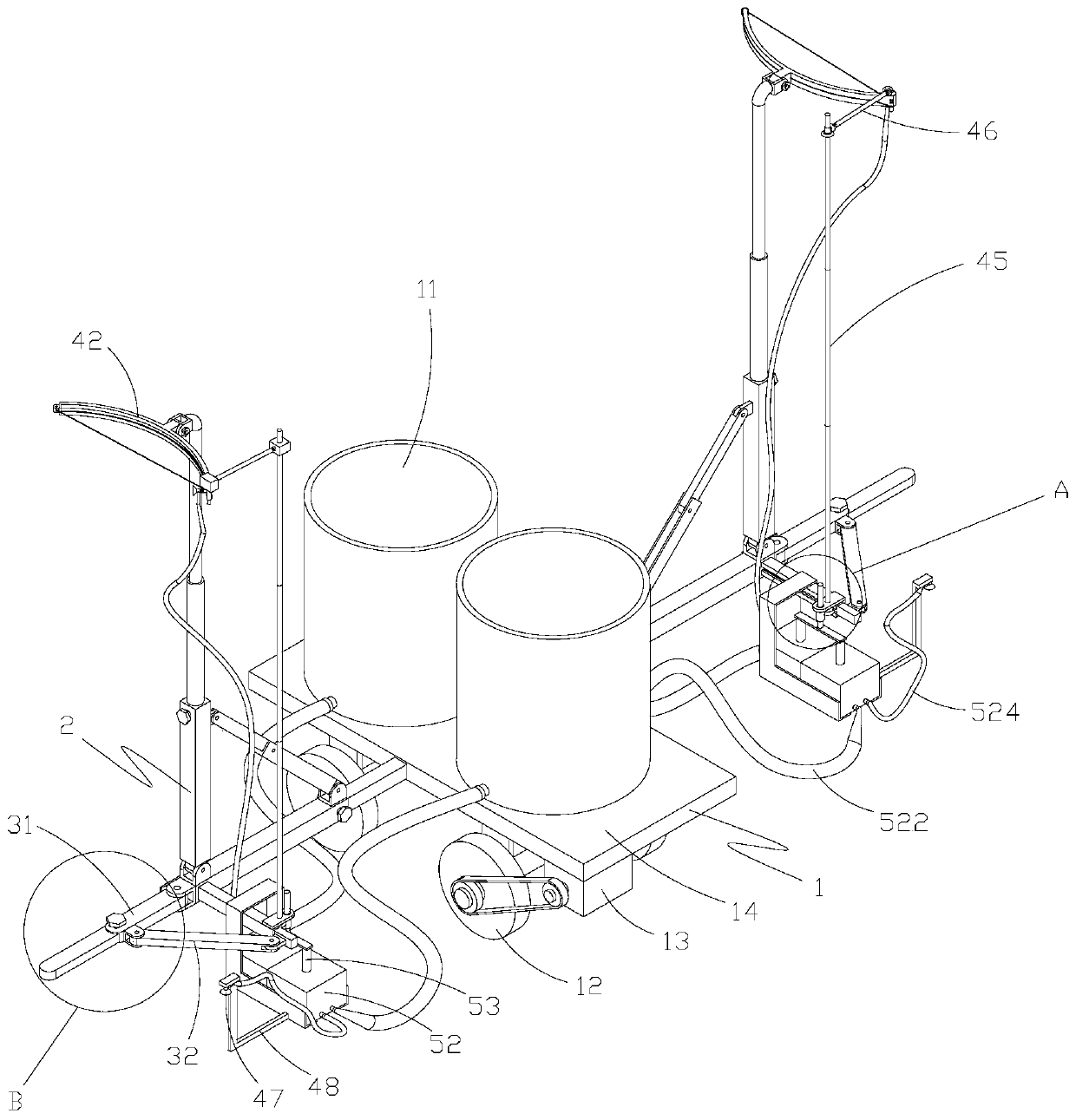

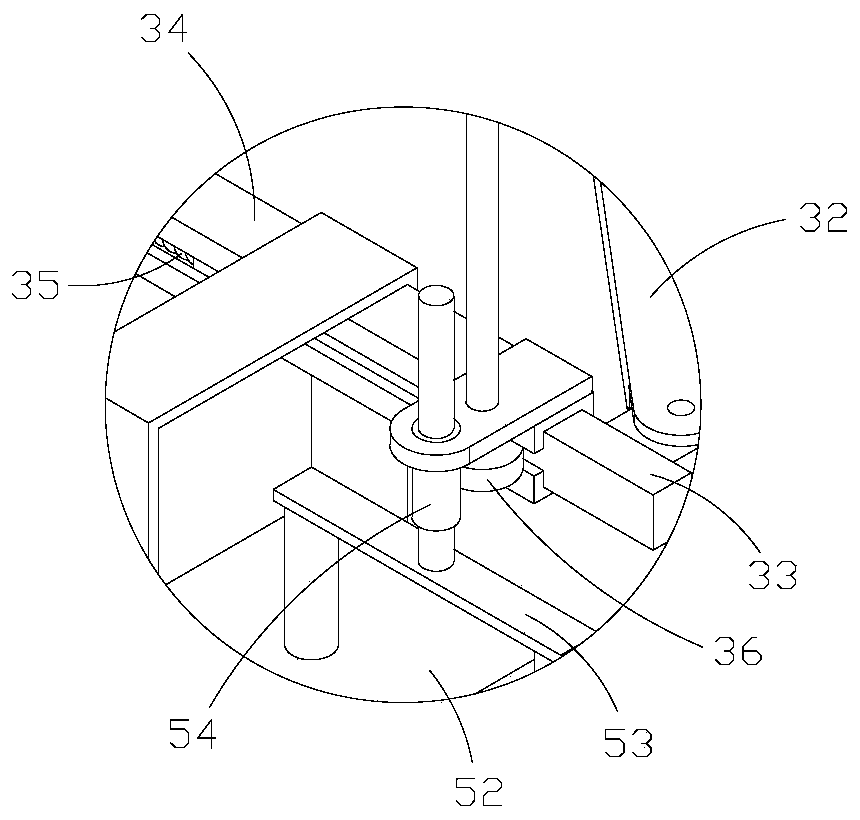

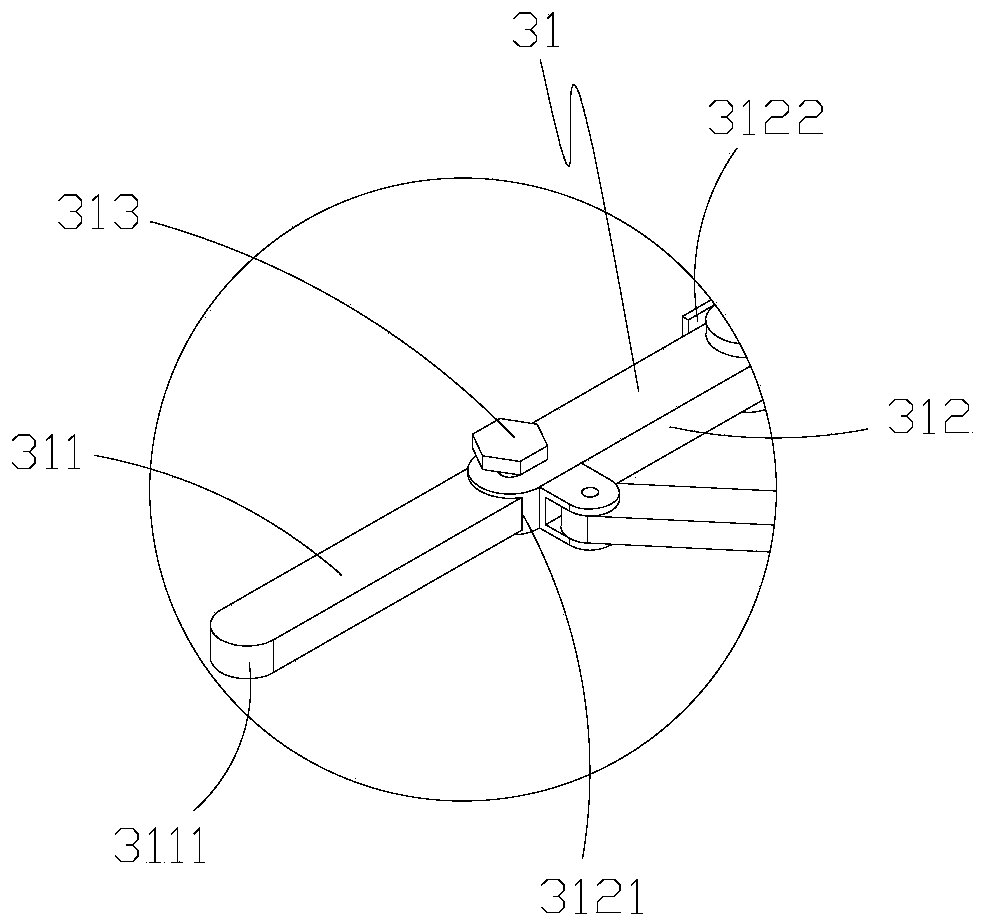

Water-filtering type high-pressure rice steamer

InactiveCN108497914AReduce viscosityNo cakingSteam cooking vesselsPressure-cookersWater filterEngineering

The invention relates to the fields of electric cookers and pressure cooker, and in particular to equipment for implementing water-filtering type rice steaming. According to a water-filtering type high-pressure rice steamer, an electric heating tray is arranged on a base plate of a pot body; a high-pressure inner body is arranged in the pot body; a rice steaming basket is arranged in the high-pressure inner body; a pressure piston lifting device is arranged on a top cap; an air cylinder and a piston are arranged in the pressure piston lifting device; and a piston and a hook are connected to alifting rod. During working of the equipment (the rice steamer), water and rice in the pot body are heated via the electric heating tray, so that a purpose of cooking rice can be achieved; an exhaustchannel in a gas control component is closed via a controller when the water in the pot body is heated to 100 DEG C, and meanwhile, a piston in the air cylinder is pushed to move upwards through high-pressure gas which is generated as the water in the pot body is continuously heated; the rice steaming basket is lifted upwards under the actions of the lifting rod and the hook, and rice, which is cooked by 70%, is filtered out from the water via the rice steaming basket and the rice is well cooked through high-pressure steam and heat energy generated from the water body; therefore, a purpose ofhigh-pressure water-filtering type rice steaming is achieved.

Owner:王明中

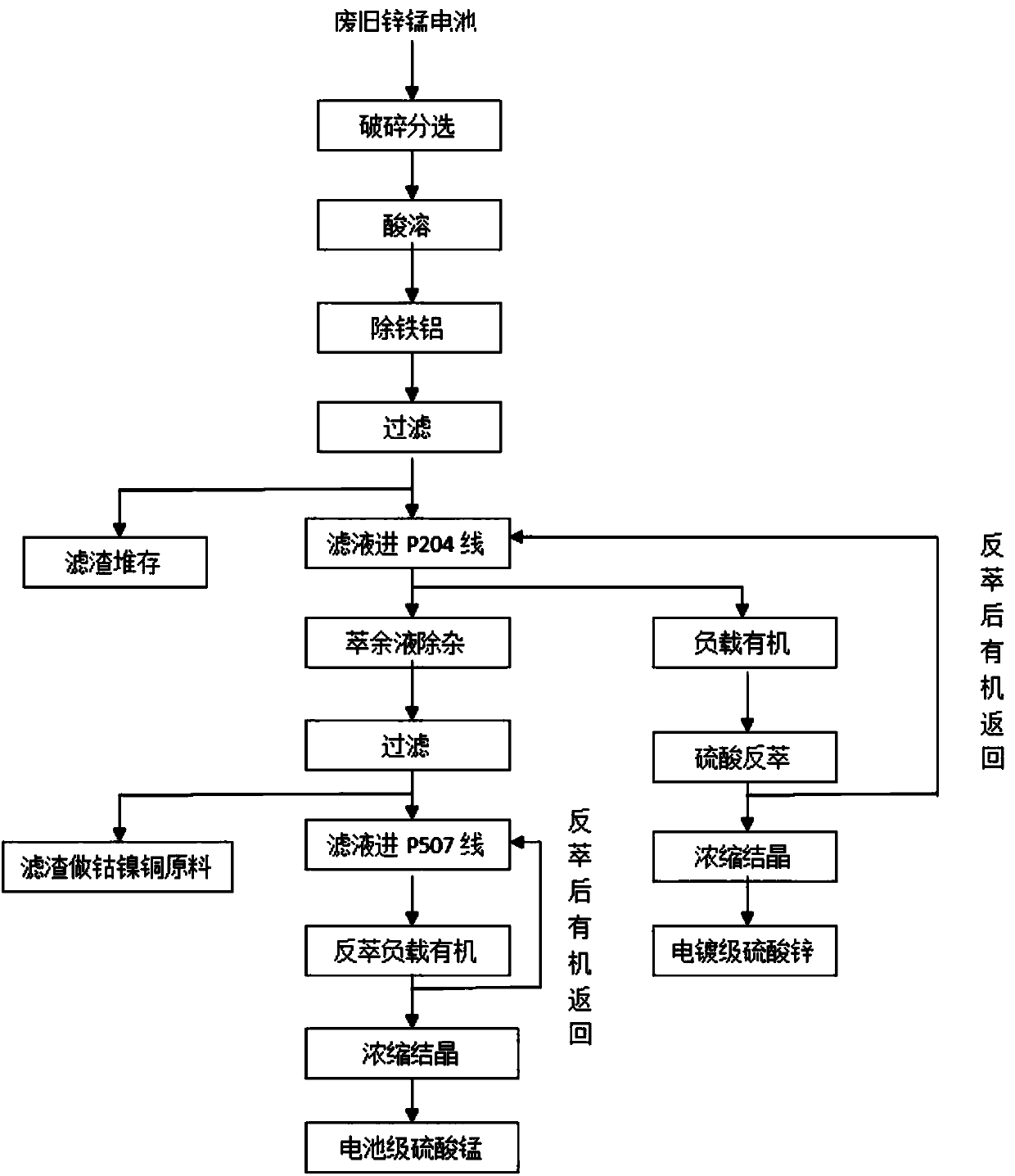

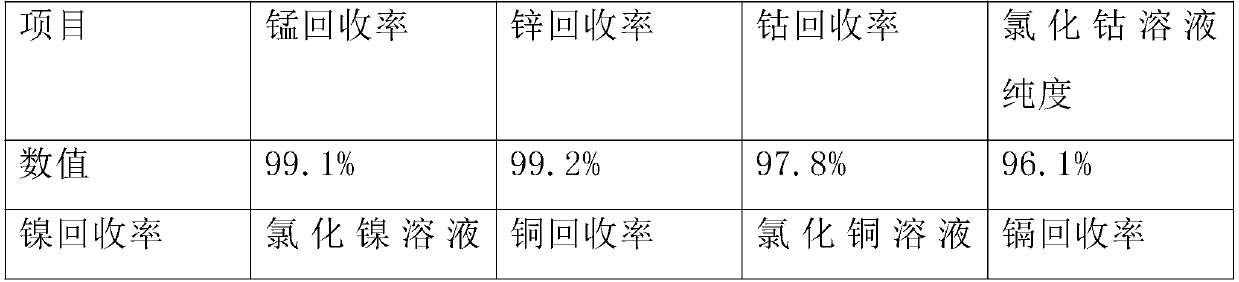

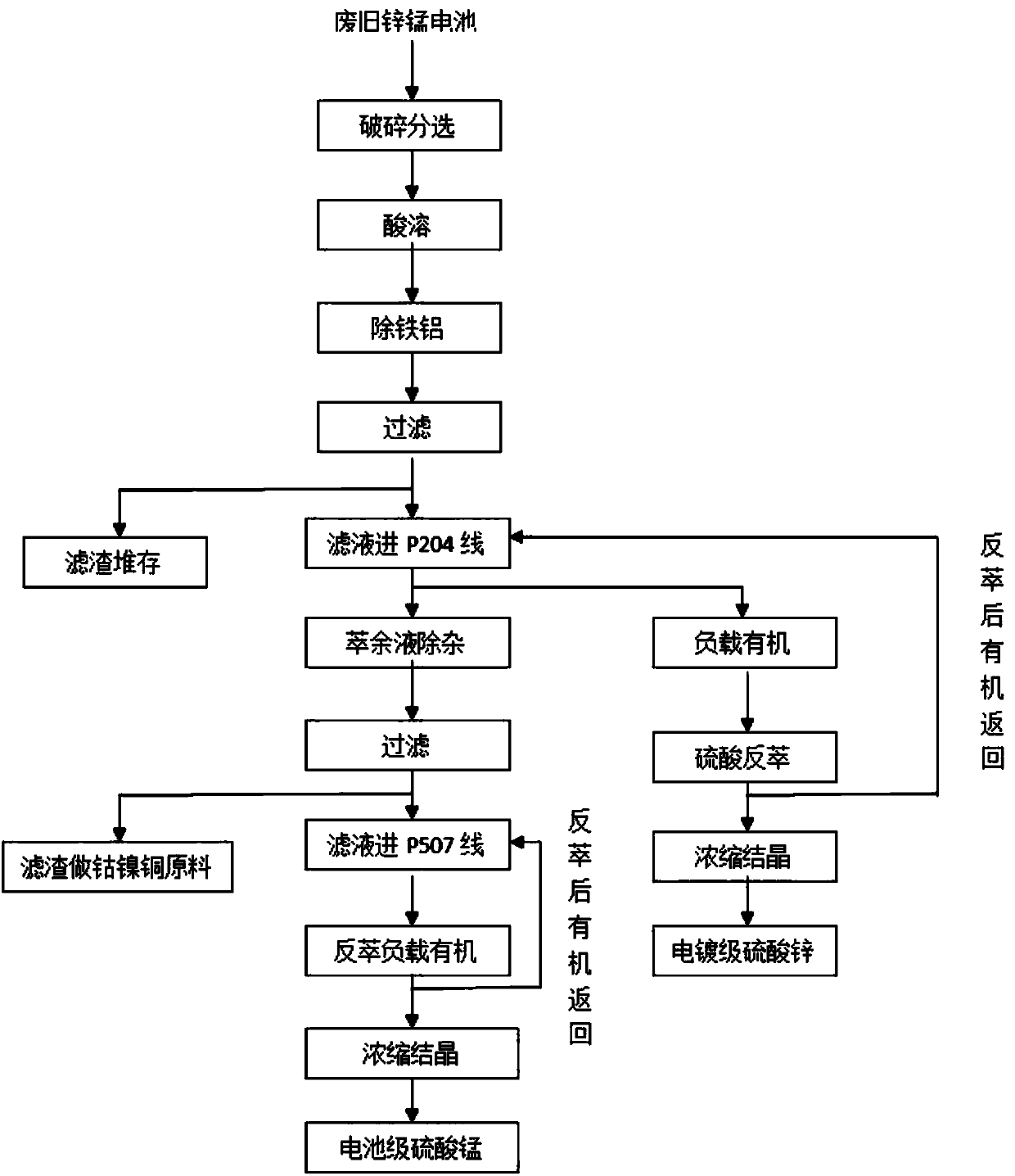

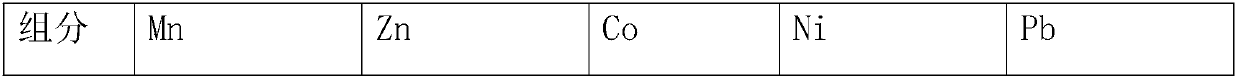

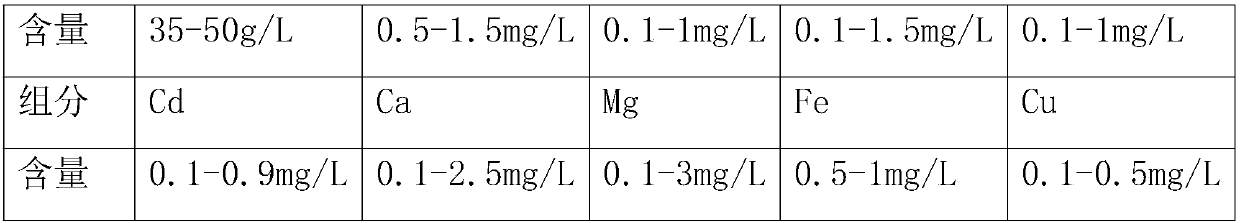

Method for producing battery-grade manganese sulfate and zinc sulfate with waste and used zinc-manganese batteries

ActiveCN107815550AHigh recovery rateAchieve recyclingZinc sulatesProcess efficiency improvementManganeseDissolution

The invention discloses a method for producing battery-grade manganese sulfate and zinc sulfate with waste and used zinc-manganese batteries and belongs to the technical field of waste and used battery utilization. The method comprises the steps that the waste and used zinc-manganese batteries are crushed, and the zinc-manganese batteries are placed into a crusher to be crushed into powder with the particle size being 200 microns or below; the zinc-manganese battery powder material is dissolved, and an acid and a reducing agent are added for dissolution; the pH is adjusted to remove iron and aluminum; zinc and manganese are separated, the zinc sulfate is prepared, and the zinc is extracted and separated through a P204 extraction agent; impurities are removed, a heavy metal trapping agent and fluoride are added, and heavy metal, calcium and magnesium are removed; a manganese sulfate solution is prepared, the manganese is extracted and separated through P507, then an obtained pure manganese solution is concentrated and crystallized, and the battery-grade manganese sulfate is obtained. By means of the method for producing the battery-grade manganese sulfate and the zinc sulfate with the waste and used zinc-manganese batteries, the battery-grade manganese sulfate and high-purity zinc sulfate crystals can be obtained, the obtained manganese sulfate crystals are in a particle shape and are free of the agglomeration phenomenon, the process is simple, and full-ingredient recycling is achieved.

Owner:蒋央芳

Grain mould-proof and insect preventive drier and production thereof

InactiveCN1644067ARound particlesLarge specific surface areaBiocideClimate change adaptationHot peppersMildew

An insecticiding mildew-inhibiting desiccant for grains is prepared from attapulgite, bentone, calcium oxide, anthracite, ginger, garlica cloves, tangerine peel, red hot pepper, Chinese prickly ash, fennel and anise through acidifying, grinding, granulating, calcining, baking and mixing. Its advantages are high effect, no pollution and poison, and low cost.

Owner:许庆华

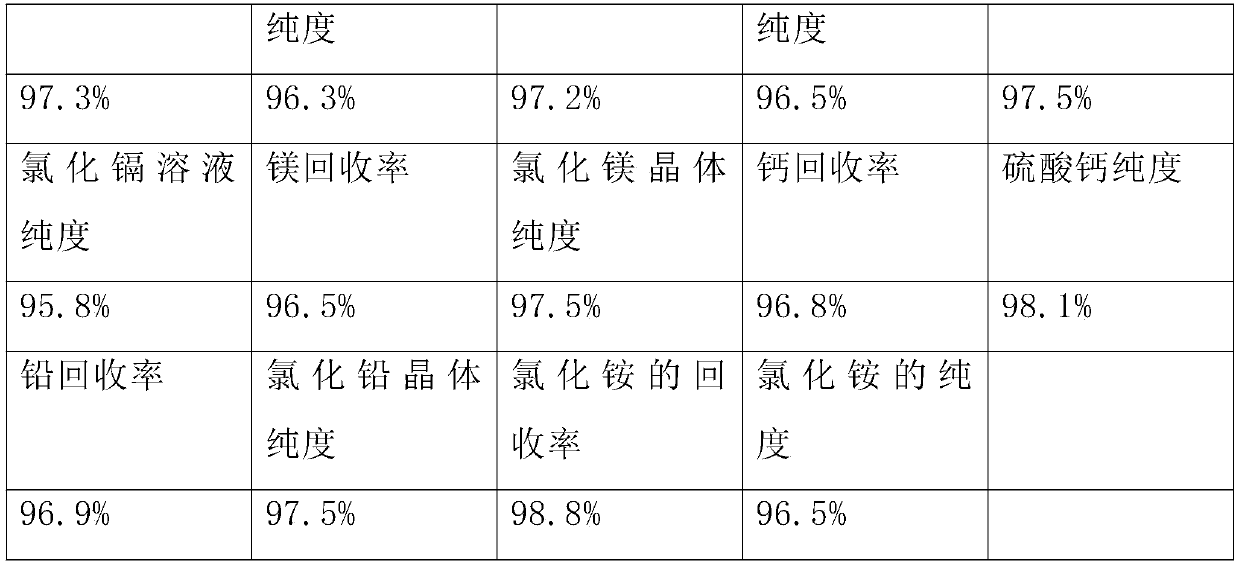

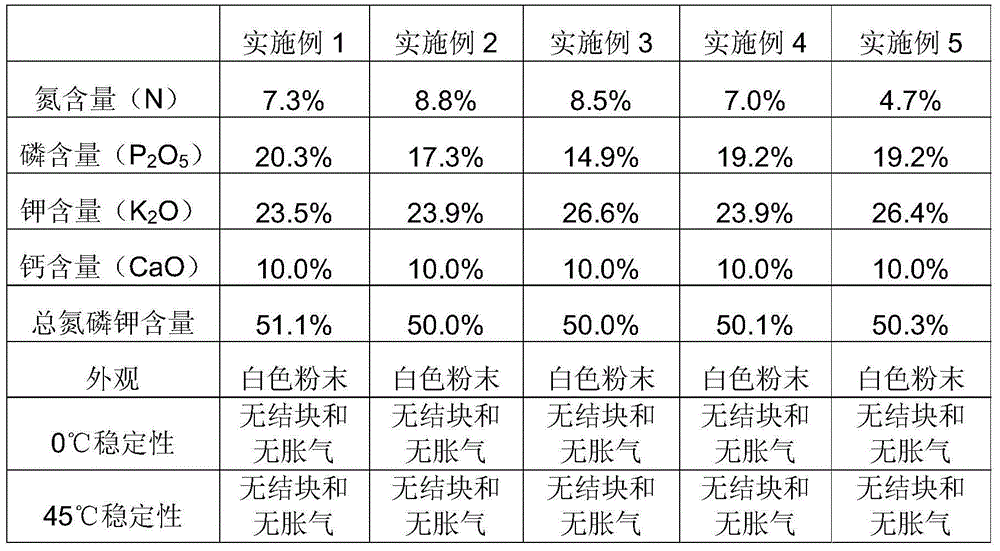

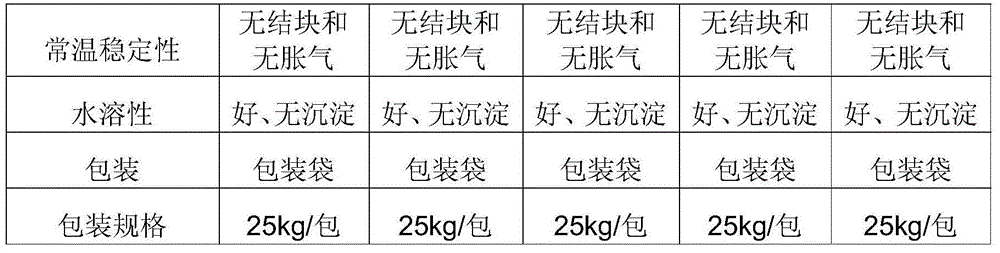

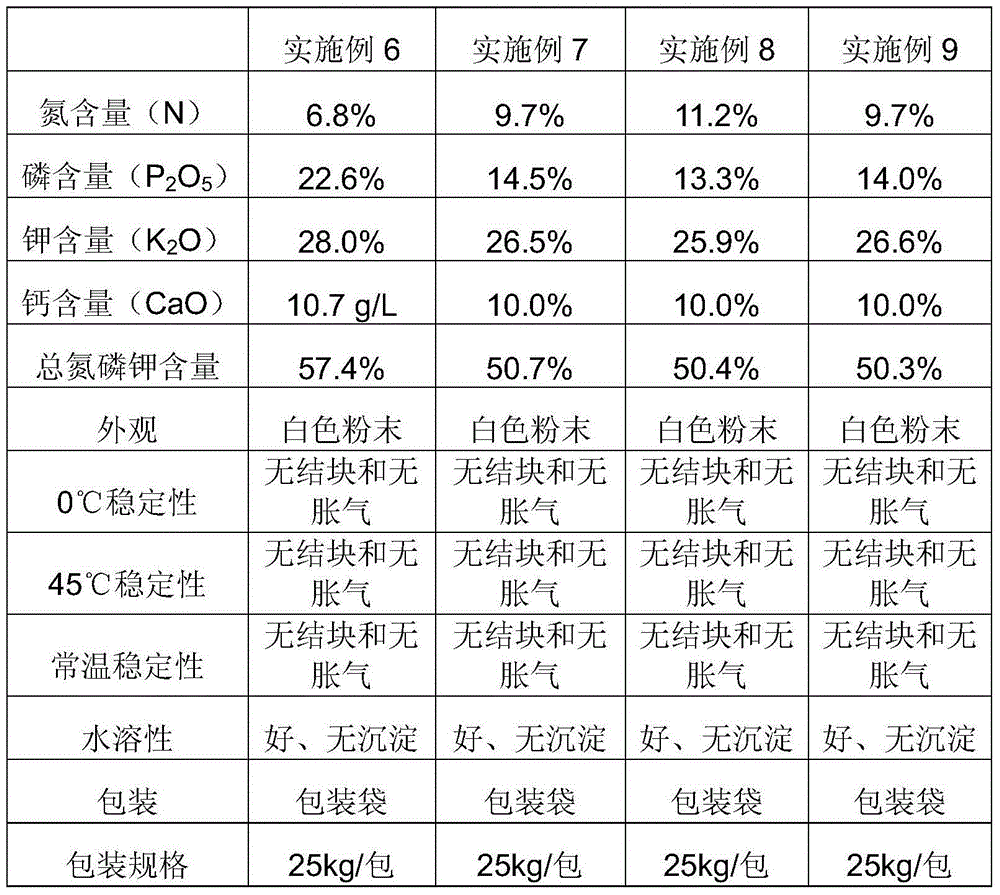

Water-soluble composite fertilizer with high phosphorus and calcium, and preparation method thereof

InactiveCN104478551AAvoid Insoluble PrecipitationAvoid it happening againCalcareous fertilisersAlkali orthophosphate fertiliserSolubilityAnticaking agent

The invention provides a water-soluble composite fertilizer with high phosphorus and calcium. The composite material comprises, by weight, 10-60 parts of a potash fertilizer, 10-60 parts of a phosphate fertilizer, 10-30 parts of a calcium fertilizer, 2-20 parts of urea and 0.1-5 parts of an anti-caking agent. The invention also provides a preparation method of the water-soluble composite fertilizer with high phosphorus and calcium. The composite fertilizer has the characteristics of high content of total nutrients, stable physical and chemical properties, good powder fluidity, no caking, precipitation or gas bloating at high temperature, low temperature or normal temperature, and good solubility. Phosphoric acid or phosphate is added to a solution obtained by dissolving the composite fertilizer in water to provide an acidic condition in order to make phosphate radicals and calcium ions simultaneously stably coexist in a liquid phase and avoid the generation of calcium phosphate and other insoluble precipitates. The water-soluble composite fertilizer effectively improves the fertilizer utilization rate, has highly concentrated nutrients, is suitable for large-area automatic fertilization, can obviously improve the fertilizing efficiency, and also has the advantages of time saving, labor saving, fertilizer saving and fast fertilizer efficiency.

Owner:GUANGZHOU YIXIANG AGRI TECH

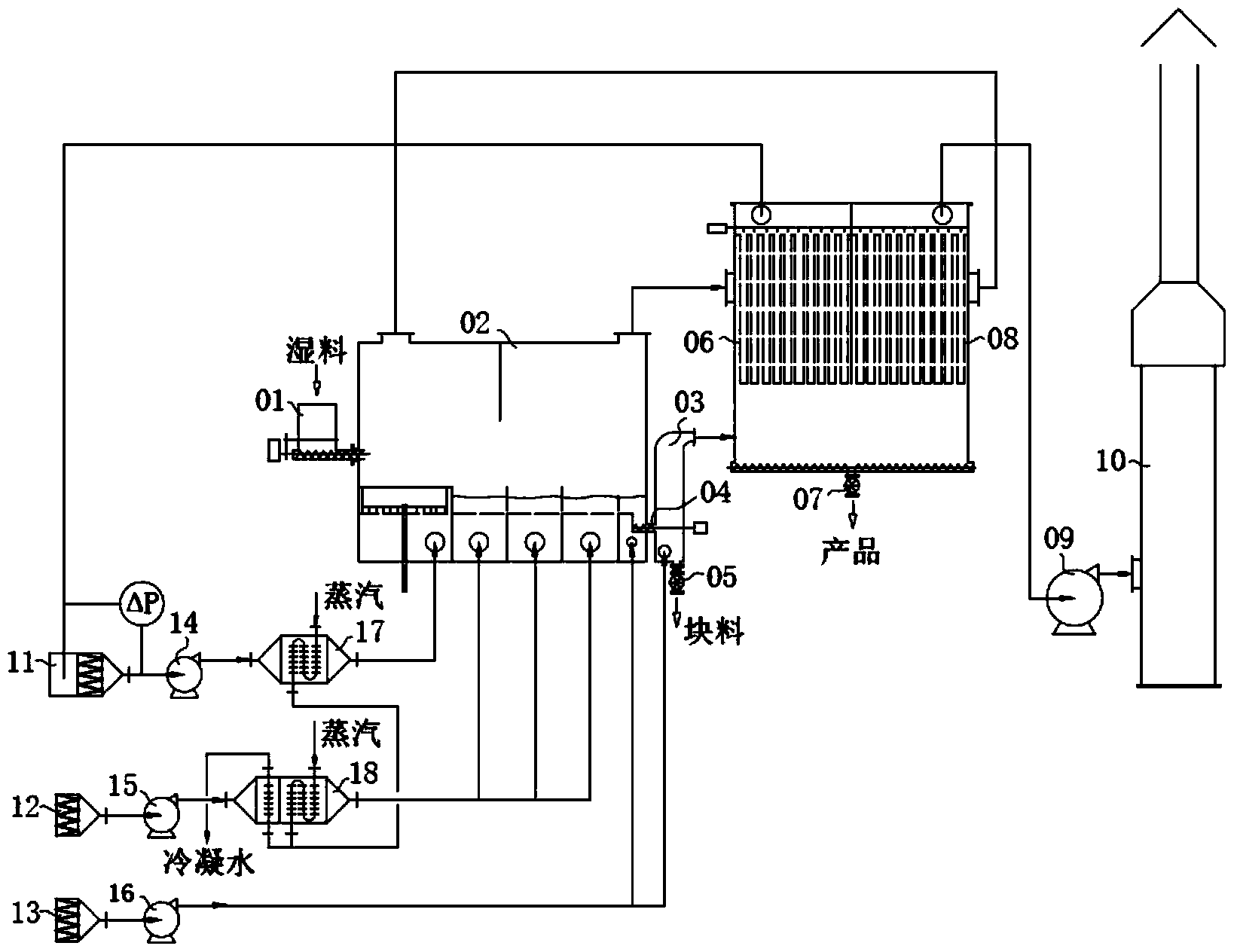

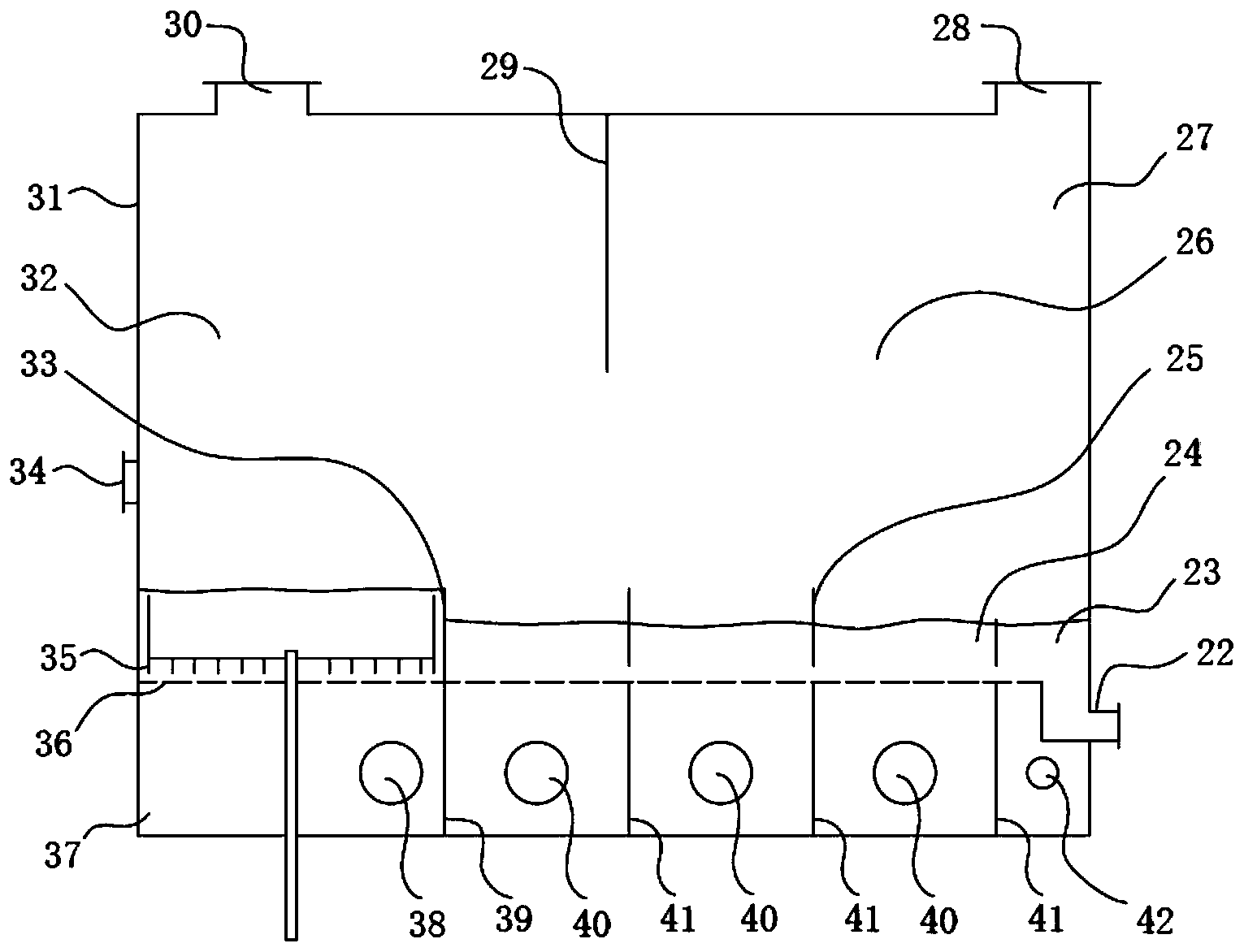

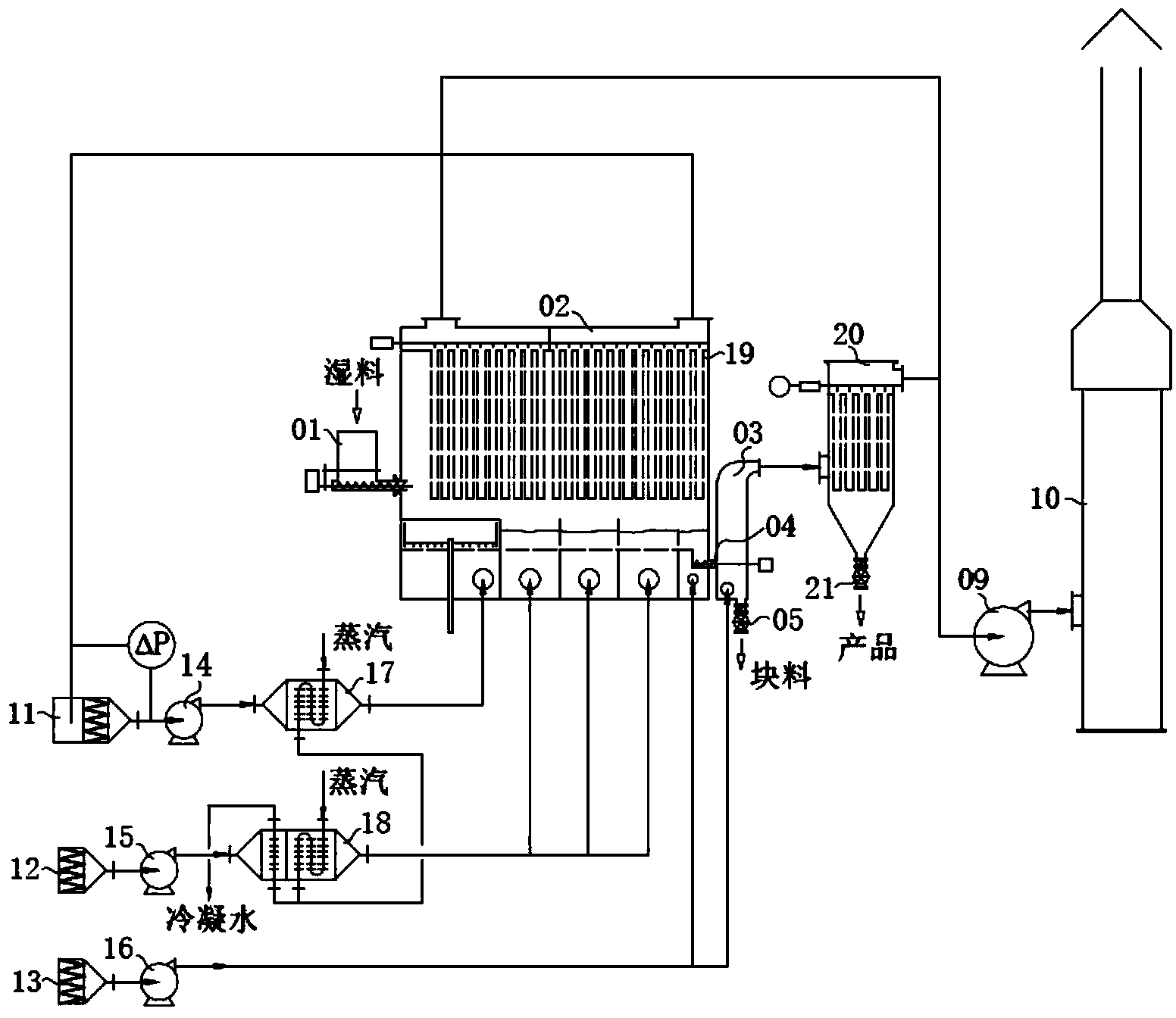

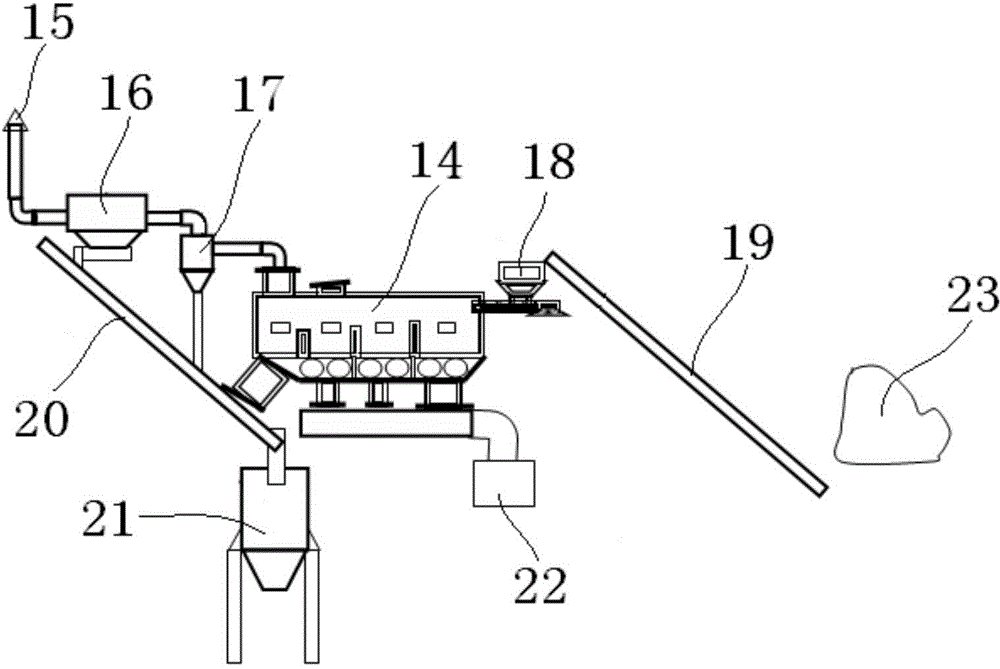

Partial tail gas circulation fluid bed drying method and equipment

ActiveCN104110941AAvoid contactAvoid problems such as blockingDrying solid materials with heatDrying gas arrangementsThermal energyFluidized bed drying

The invention provides a partial tail gas circulation fluid bed drying method and equipment. The method comprises the following steps of (1) material drying, (2) tail gas circulating, (3) tail gas discharging, (4) material cooling and (5) lump material separating. Air is filtered, pressurized and heated to be at the needed temperature and enters a deep drying section of a fluid bed drying machine to conduct deep material drying, tail gas which is discharged from the deep drying section of the fluid bed drying machine and is high in temperature and low in moisture content is dedusted, pressurized and heated and then enters a primary drying section of the fluid bed drying machine to conduct primary drying, and the tail gas which is discharged from the primary drying section of the fluid bed drying machine and is low in temperature and high in moisture content is dedusted and then discharged into the atmosphere. The equipment constructed based on the partial tail gas circulation fluid bed drying method comprises a fluid bed drying machine body, a first heating device, a second heating device, a cooling device and a dedusting device. The partial tail gas circulation fluid bed drying method and equipment have the advantages that the heat energy of drying media is fully used, drying heat efficiency is high, consecutive operation is reliable, energy is save, and emission is reduced.

Owner:ZHEJIANG UNIV OF TECH +1

Method for preparing mononaphthalenesulfonic acid and sodium salt of mononaphthalenesulfonic acid

InactiveCN1958567APromote absorptionHigh selectivitySulfonic acids salts preparationSulfonic acid preparationChlorosulfuric acidSODIUM NAPHTHALENESULFONATE

This invention discloses a method for synthesizing 1-naphthalene sulfonic acid and / or sodium 1-naphthalene sulfonate. The method comprises: (1) dissolving naphthalene in solvent, adding appropriate 1-naphthalene sulfonic acid seed crystals, cooling to 0 minus or plus 5 deg.C, stirring, dropping chlorosulfonic acid within 1-2 h, and keeping at -2-8 deg.C for 1.5-3 h; (2) cooling to 0 minus or plus 2 deg.C, and filtering to obtain the filter cake of 1-naphthalene sulfonic acid; (3) washing the filtrate with water, phase-separating to obtain the solvent and water scrubbing acid (for producing high-performance naphthalene water reducer); (4) neutralizing 1-naphthalene sulfonic acid and the solvent with 5-15% NaOH, keeping at 90 minus or plus 5 deg.C for 10-30 min, phase-separating the neutralization solution to obtain sodium 1-naphthalene sulfonate aqueous solution, cooling to lower than 35 deg.C, crystallizing, filtering to obtain the filter cake of sodium 1-naphthalene sulfonate, and utilizing the filtrate to prepare NaOH solution. The method has such advantages as high sulfonation selectivity, low product isomer content, easy operation and no wastewater.

Owner:江苏华达化工集团有限公司

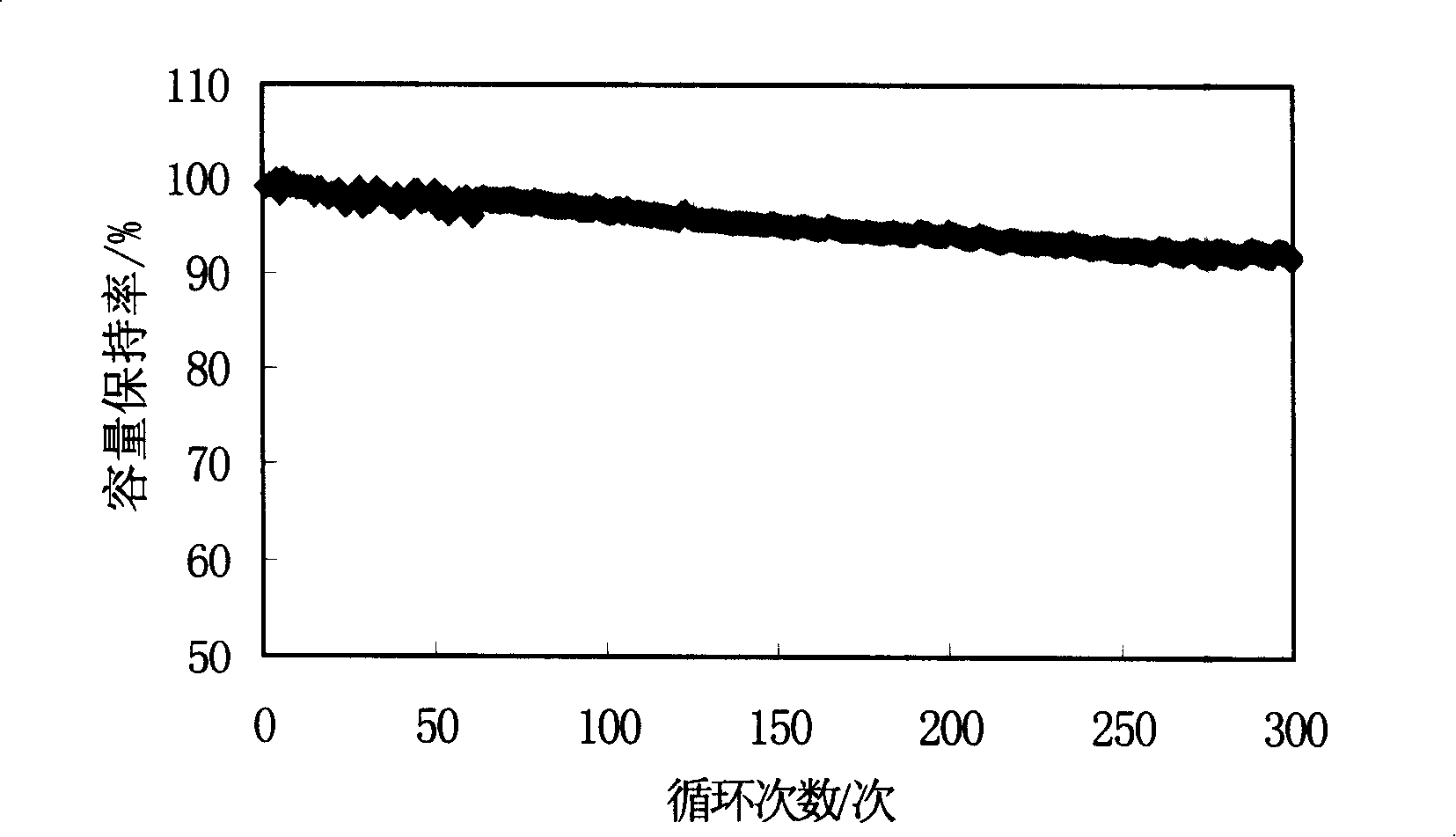

Plumbaginous modifying method and produced modified plumbago

The invention discloses a modification process of graphite. The graphite and polymer are mainly and thoroughly mixed and quickly heated to the temperature of the softening point of the polymer and then gradually heated to the temperature which can enable the mixture to be completely cured with a heating rate of 0.5-2 DEG C per minute, then the temperature of the mixture is preserved and the mixture is cured, the mixture is thoroughly stirred in the heating process for granulation, graphite composite the surface of which is coated with the polymer is obtained, and the graphite composite is normally carbonized and treated after being cooled to the room temperature. As the invention employs solid phase method to coat, no pollution problem of organic solvent exists, and the method is an environment-friendly preparation process. The produced modified graphite can not cake and needs no crushing treatment, which simplifies the technique and reduces the equipment investment and is favorable for mass production, further, the modified graphite of the invention, in particular modified natural graphite which is taken as carbon negative electrode material has relatively long cycle life.

Owner:内蒙古杉杉新材料有限公司

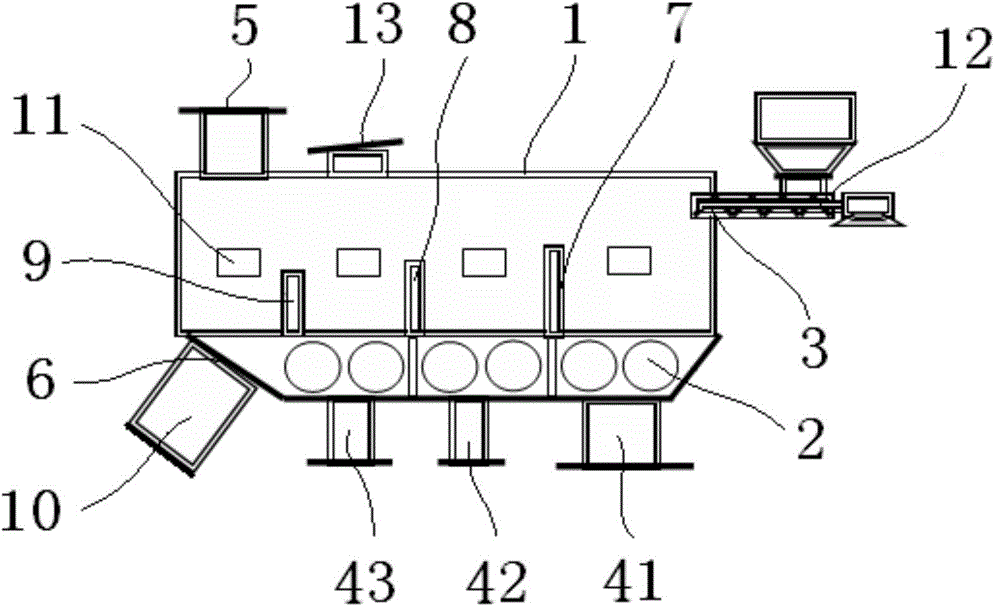

Mechanical dispersion fluidization drying method and equipment for coal slime

InactiveCN103604278AHigh calorific value utilizationIncrease productionDrying solid materials with heatDrying gas arrangementsParticulatesSmall footprint

The invention relates to a mechanical dispersion fluidization drying method and equipment for coal slime. The method is used for realizing fluidization drying of coal slime particulates by using hot smoke while dispersing coal slime to be dried into the coal slime particulates. The drying method is high in heat utilization rate and yield as well as wide in application range. The equipment comprises a drying box body and a stirring shaft, wherein the drying box body is provided with a feeding hole, a discharging hole, a gas outlet and a smoke inlet; the stirring shaft is used for dispersing the coal slime to be dried, is arranged at the bottom of the drying box body and is located above the smoke inlet; the coal slime to be dried is dispersed into the coal slime particulates by using the stirring shaft after entering the drying box body through the feeing hole, meanwhile, the hot smoke enters from the smoke inlet at the bottom of the drying box body at a proper flow rate and is discharged from the gas outlet after carrying out fluidization drying on the coal slime particulates, and at the same time, the dried coal slime is output from the discharging hole. The equipment is large in gas and solid drying contact area, long in drying time, high in heat utilization rate and yield and small in floor area.

Owner:CHANGAN UNIV

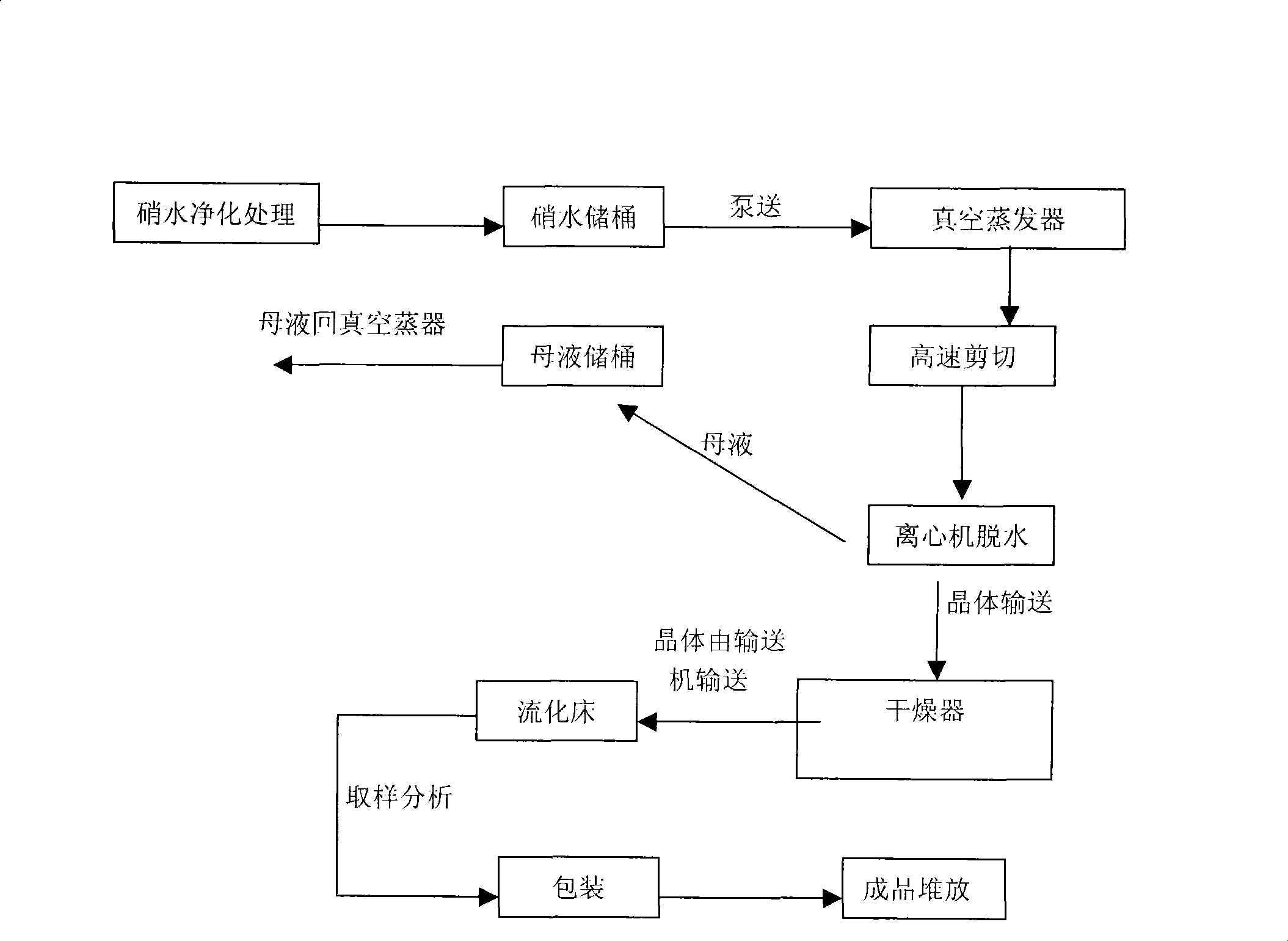

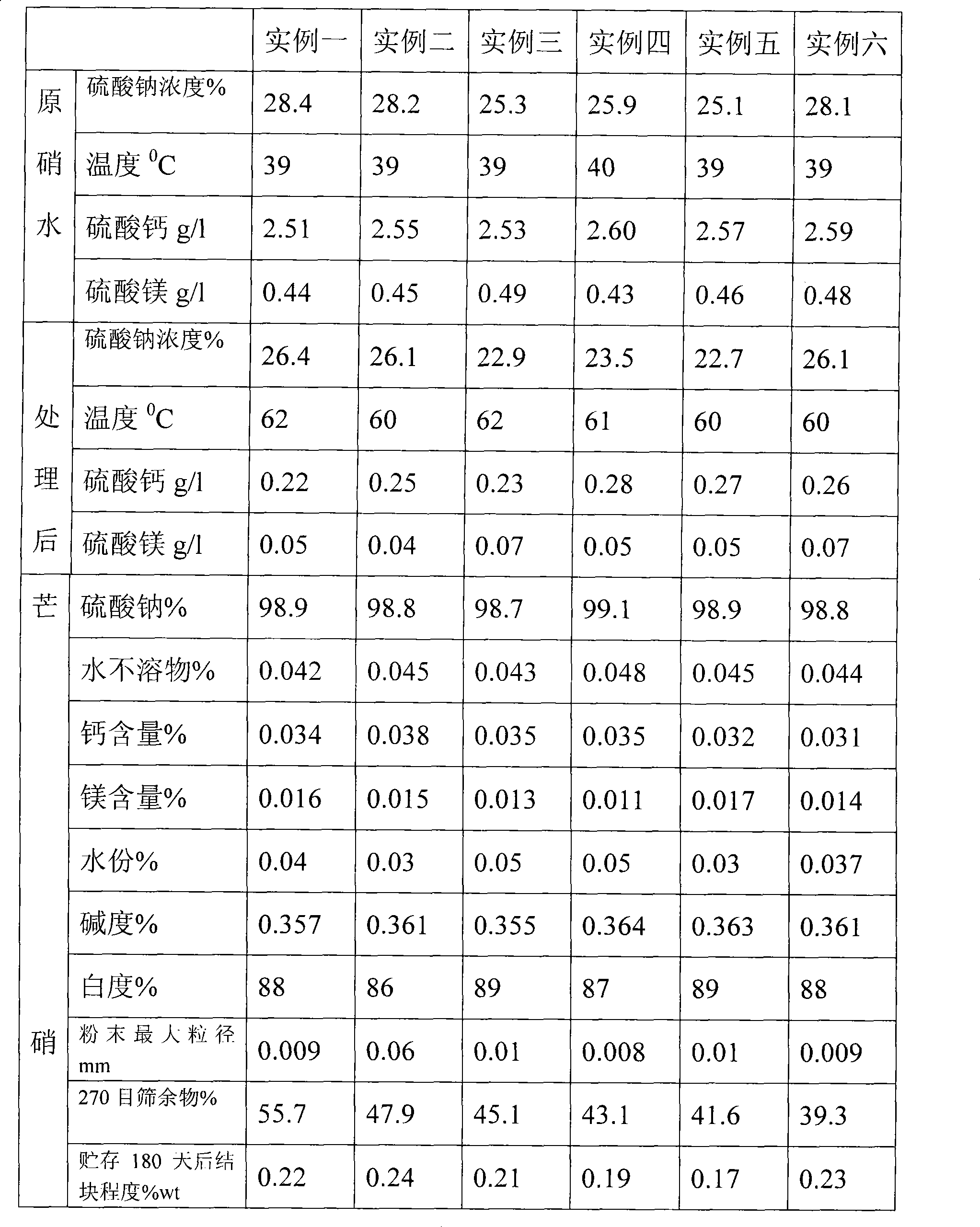

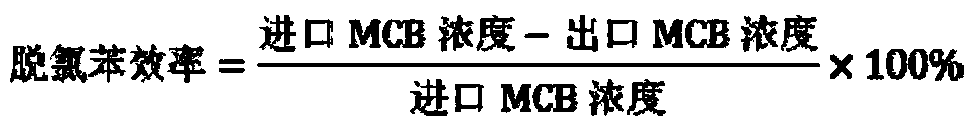

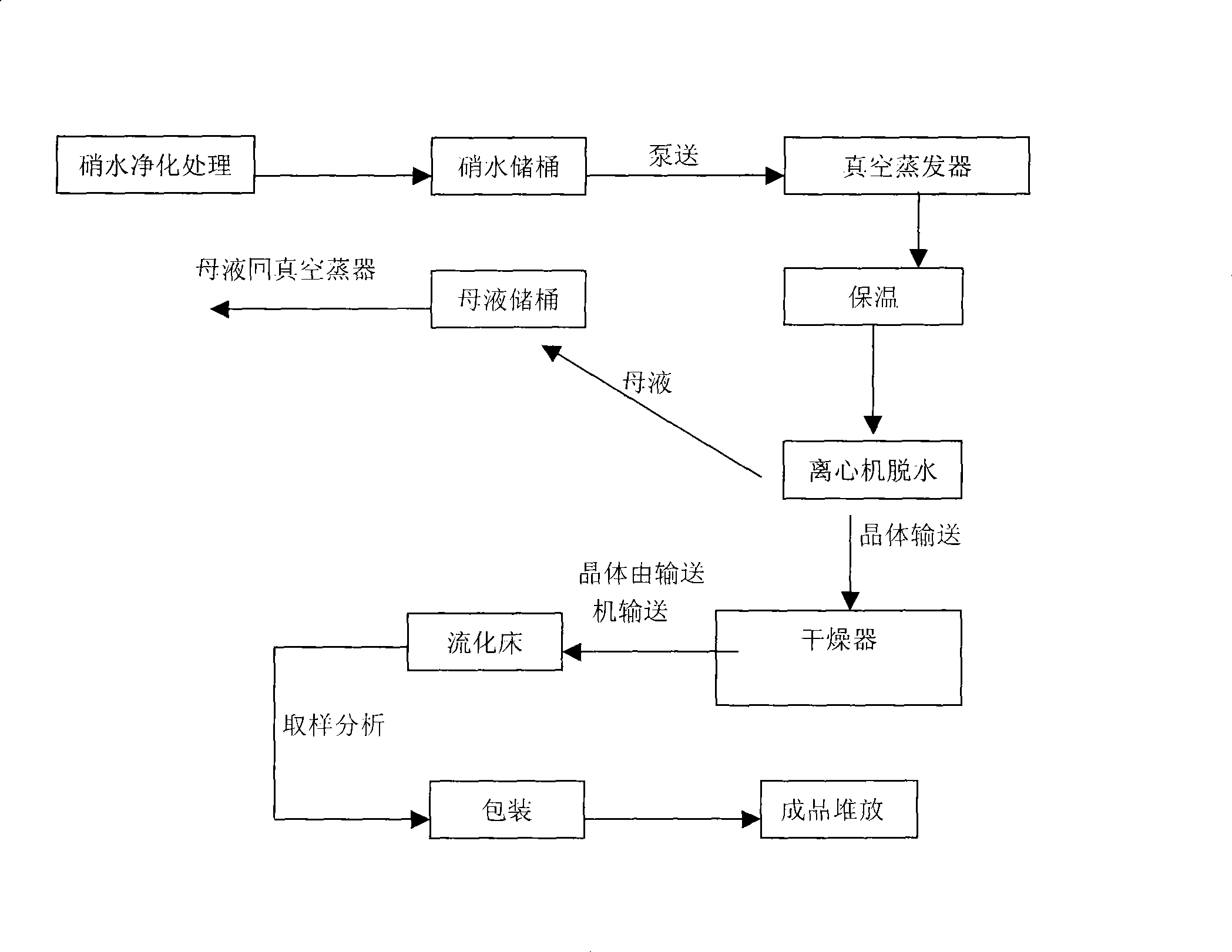

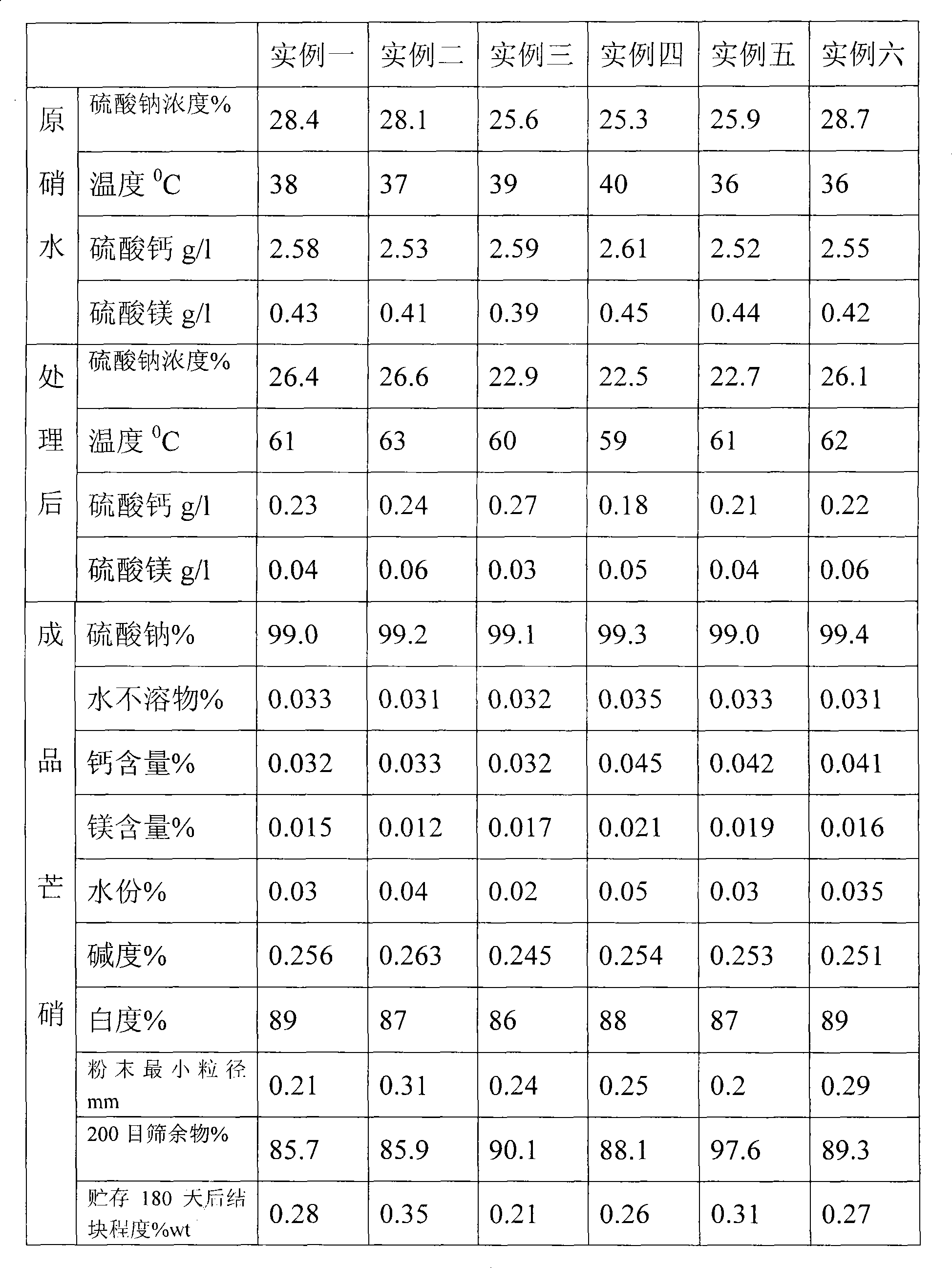

Method for producing ultrafine-grain special mirabilite

InactiveCN101428827AParticles have good fluidityNo cakingAlkali metal sulfite/sulfate purificationFluidized bedMirabilite

The invention discloses a method for preparing superfine granule special type saltcake, which includes the following technical steps: pumping hot water at 40-70 DEG C, and forming a saltcake solution containing a plurality of impurities; concentrating for crystallization by vacuum evaporation after refining impurities; cutting the saltcake solution at a high rotating speed; drying after centrifugal separation, processing by a fluidized bed, separating coarse granule saltcake and obtaining a superfine granule special type saltcake product. The anhydrous superfine granule special type saltcake product obtained by the process method of the invention after high rotating speed cutting and fluidized bed processing has the advantages of good granule fluidness and low possibility of agglomeration. The product can be widely used for preparing sodium sulfide, sodium silicate and the like, and is also used in industries of paper making, glass, printing and dyeing, synthetic fiber, hide manufacture, food, medicine and the like.

Owner:四川省川眉芒硝有限责任公司

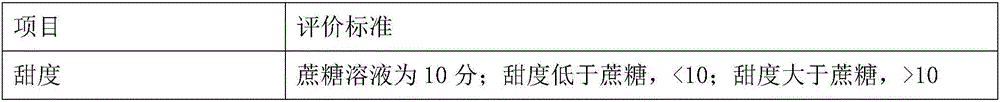

Natural compound sweetening agent with intestinal tract regulating function and preparation method thereof

PendingCN106820069APromote proliferationInhibit pathogenic bacteria such as Escherichia coliFood scienceFood ingredient functionsXyloseSucrose

The invention discloses a natural compound sweetening agent with an intestinal tract regulating function and a preparation method thereof. The natural compound sweetening agent is prepared from the following raw materials in parts by weight: 30 to 100 parts of xylooligosaccharide, 100 to 250 parts of L-arabinose, 50 to 150 parts of xylose, 80 to 200 parts of xylitol, and 0.3 to 0.6 part of stevioside. The preparation method of the natural compound sweetening agent comprises the following steps of reasonably proportioning natural functional sugar and a non-sugar sweetening agent, and performing wet granulation. The natural compound sweetening agent has the advantages that after taking, the effects of promoting proliferation of probiotics in intestinal tract, regulating microecology of bacteria colony in the intestinal tract, relaxing bowel and the like are realized, the calorie is low, the blood glucose is not increased, and the natural compound sweetening agent can be applied to diabetics patients and obesity people; the granularity is uniform, the fluidity is good, and the easiness in caking is avoided; because the sweet degree is equivalent to the sugarcane, the natural compound sweetening agent can be directly used by replacing the sugarcane, and more convenience in use is realized.

Owner:SHANDONG LONGLIVE BIO TECH CO LTD

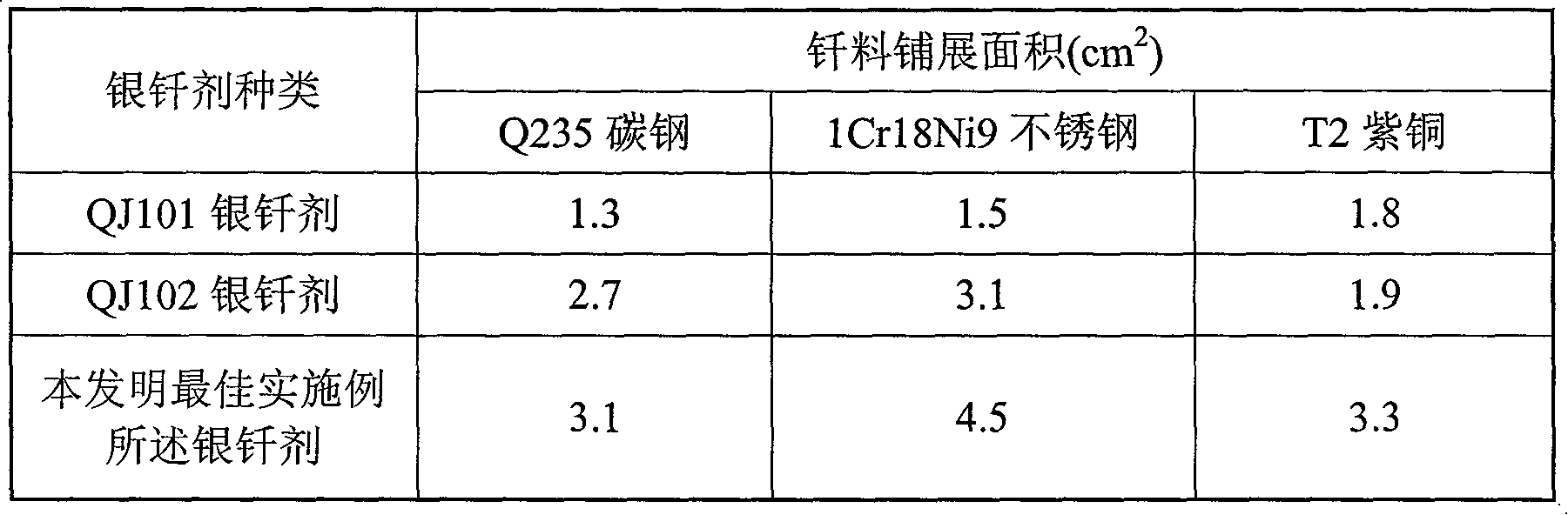

Cream-like silver brazing fluxes

ActiveCN101190483AHigh activityNo cakingWelding/cutting media/materialsSoldering mediaCarbon steelMaterials science

The invention relates to silver welding suitable for carbon-steel, stainless steel, copper and copper alloy. The paste-shaped silver flux has the composition of KF-KHF2-H3BO3 suitable for carbon-steel, stainless steel, copper and copper alloy. The composition (weight percentage) is 25% to 50% of K, 15% to 30% of KHF2, 15% to 30% of H3BO3 and the paste-shaped silver flux occupies residual quantity. The paste-shaped silver flux has the advantages of good activity and no agglomeration.

Owner:上海斯米克焊材有限公司

Packing powder for sintering ceramic core

ActiveCN104043770AGood wax removal ability and surface finishGood supportFoundry mouldsFoundry coresSurface smoothnessMass ratio

The invention aims to provide packing powder for sintering a ceramic core. The packing powder is characterized by being formed by mixing fine particle powder and ceramic balls, wherein the mass ratio of the fine particle powder to the ceramic balls ranges from (3:1) to (10:1). The packing powder has certain de-waxing capability in a biscuit de-waxing phase, has high supporting capability in a sintering process and guarantees that the finished product ceramic core has no gravity deformation and has certain surface smoothness; the yield in a production process of the ceramic core can be improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

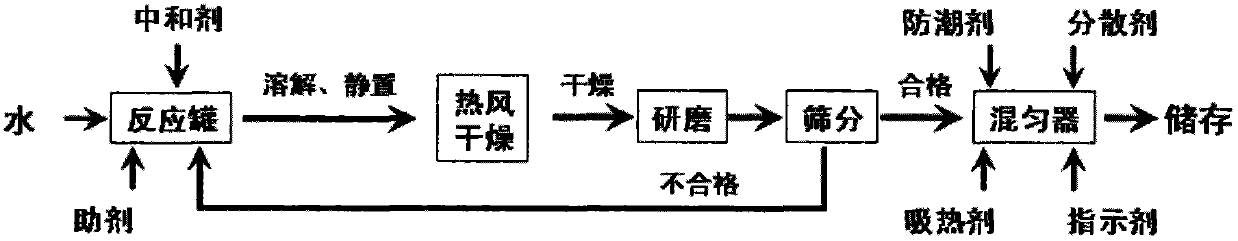

Alkaline powder for treating leaked sulfuric acid and preparation method of alkaline powder

ActiveCN102989114ANo cakingLow hygroscopicityDispersed particle separationMoisture absorptionEnergy consumption

The invention provides alkaline powder for treating leaked sulfuric acid and a preparation method of the alkaline powder. The alkaline powder is prepared from a neutralizer, an aid, a heat absorbent, a moisture-proof agent, a dispersant and an indicator in a certain ratio by a specific method. The raw materials for preparing the alkaline powder are readily available; the preparation method is simple, convenient and low in energy consumption; and the prepared powder does not cake, and is low in moisture absorption and good in settling performance after being sprayed. The alkaline powder can be used for effectively treating the leaked sulfuric acid of which the concentration is 50 to 98 percent or more; and the treatment process has the characteristics of high response speed, low temperature rise, secondary harm prevention, simplicity and convenience in endpoint judgment and the like.

Owner:ENG DESIGN & RES INST OF GENERAL ARMAMENTS DEPT +2

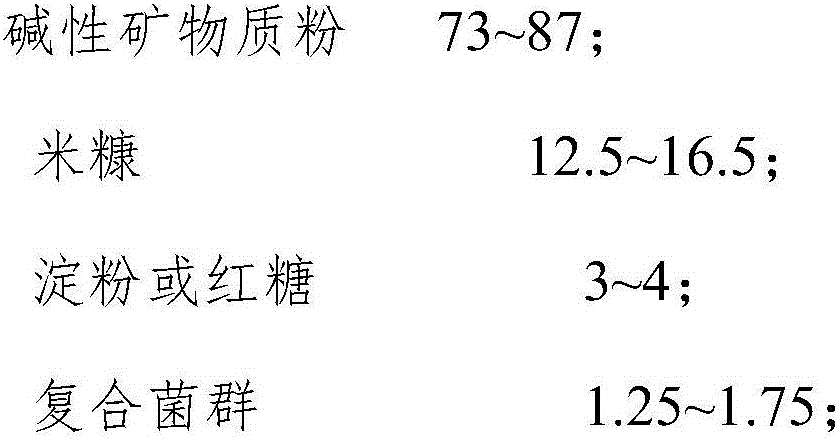

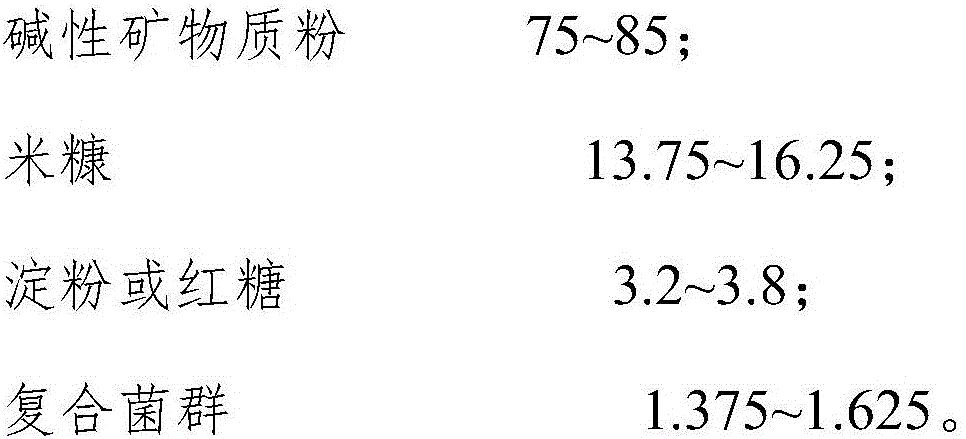

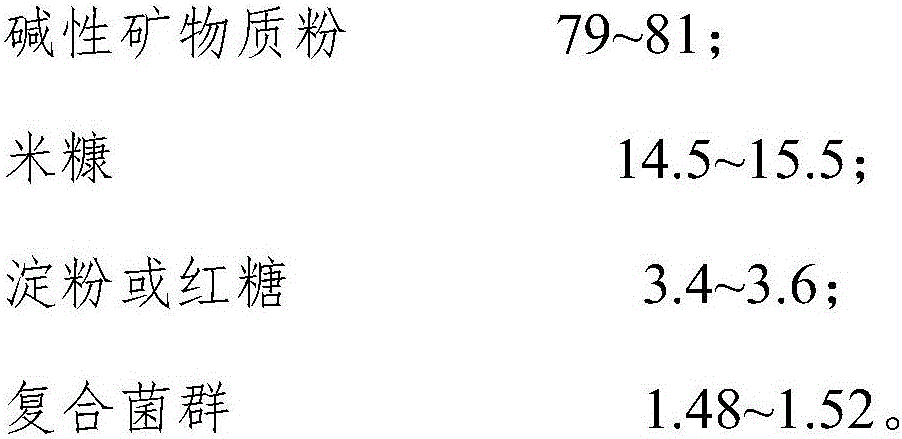

Microorganism acid soil restoration agent and preparing method and application thereof

InactiveCN106220400APromote conversionFacilitates conversion to solubleBioloigcal waste fertilisersFertilising methodsEcological environmentPotassium

The invention discloses a microorganism acid soil restoration agent. The microorganism acid soil restoration agent is prepared from alkali mineral powder, rice bran, starch or brown sugar, and enzyme bacteria. The microorganism acid soil restoration agent is applied to agricultural production to improve acid soil and improve soil, especially the ecological environment on the periphery of the root systems of crops, proper amounts of various nutrient elements such as nitrogen, phosphorus, potassium, calcium, magnesium, silicon, boron and zinc needed by growth of crops are provided, and soil is activated.

Owner:湖北嘉益田生物肥业有限公司

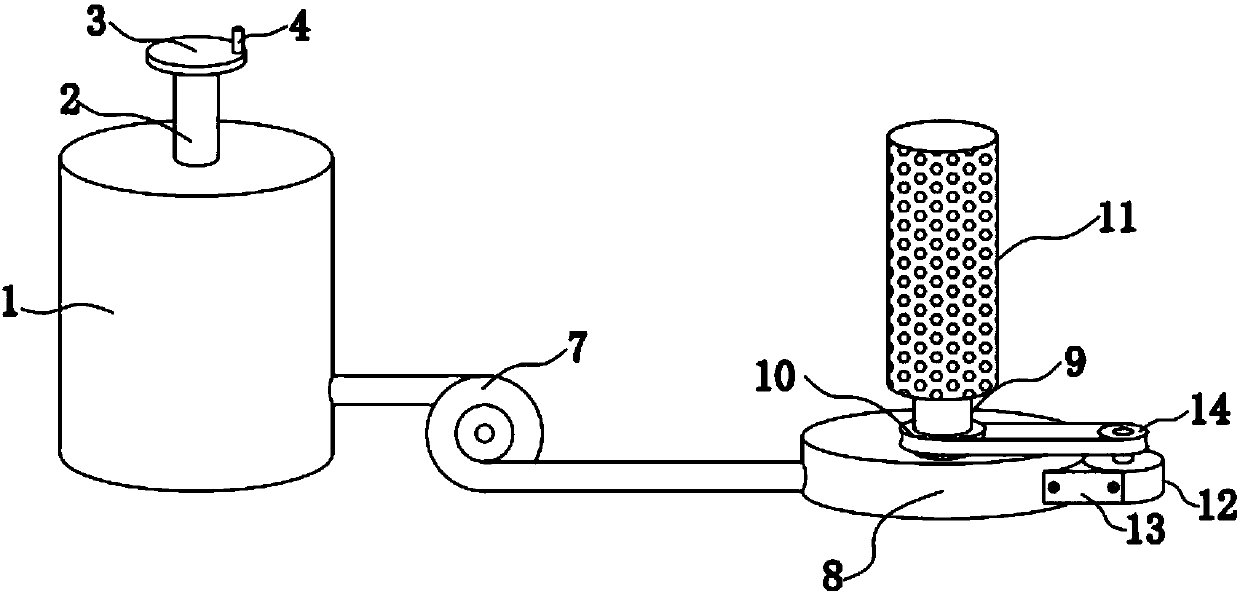

Pipe mold release agent spraying device

InactiveCN107790305APlay a protective effectNo cakingLiquid spraying apparatusEngineeringRelease agent

The invention discloses a spraying device for pipeline mold release agent in the technical field of spraying devices, which includes a liquid storage tank, a rotating shaft is plugged into the top of the liquid storage tank, and a rotating disc is fixedly connected to the top of the rotating shaft, and the rotating disc The right end of the top of the pipe is fixedly connected with a rocker, the outer wall of the rotating shaft is fixedly sleeved with a collar, and the collar is located in the inner cavity of the liquid storage tank, and the left and right ends of the collar are fixedly connected with a stirring rod. The spraying device of the release agent, the liquid storage tank is used to store the spray material, and the hand rocker is used to drive the turntable and the rotating shaft to rotate, and the rotating shaft and the stirring rod rotate synchronously to stir the spray material, so that the spray material will not agglomerate, which is convenient for spraying. And the spray particles are relatively fine, which makes the spray more uniform. The pressurized pump shifts the position of the spray material, and at the same time accelerates the spray material, so that the pressure between the spray material and the hose increases, so that it can be sprayed from the nozzle The spray material is more uniform and the flow rate is higher.

Owner:ANHUI WANAN ENVIRONMENT ENG

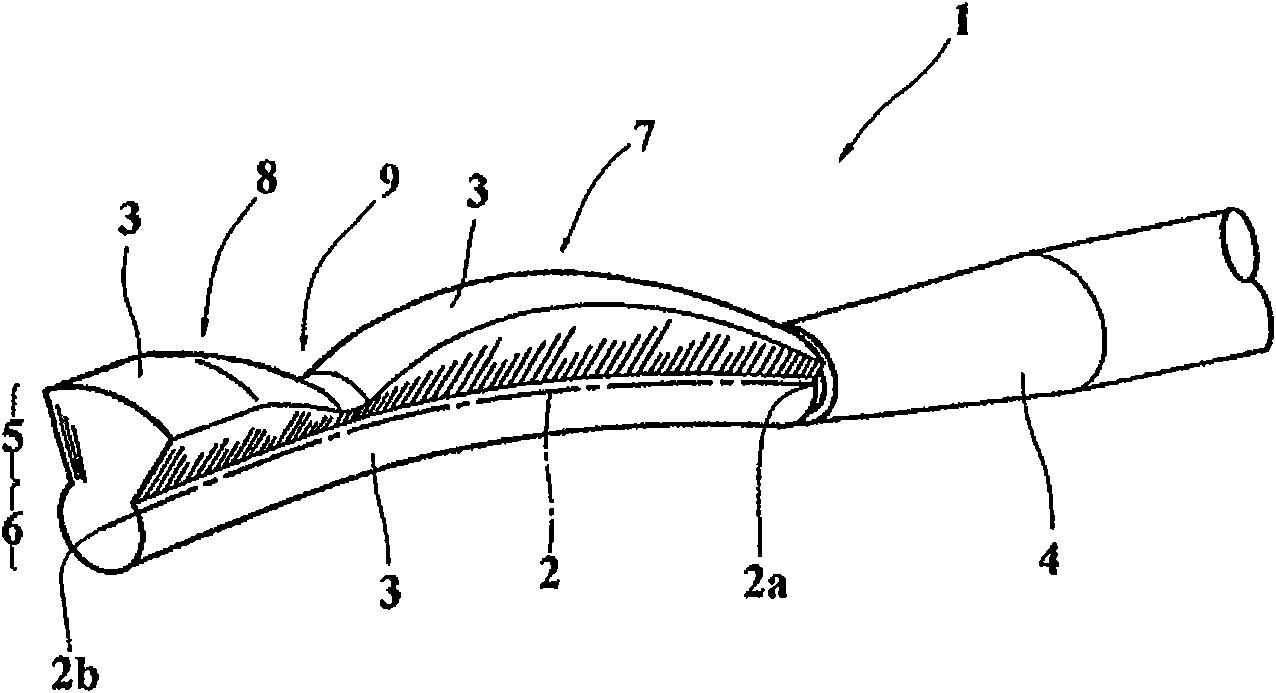

Mascara applicator

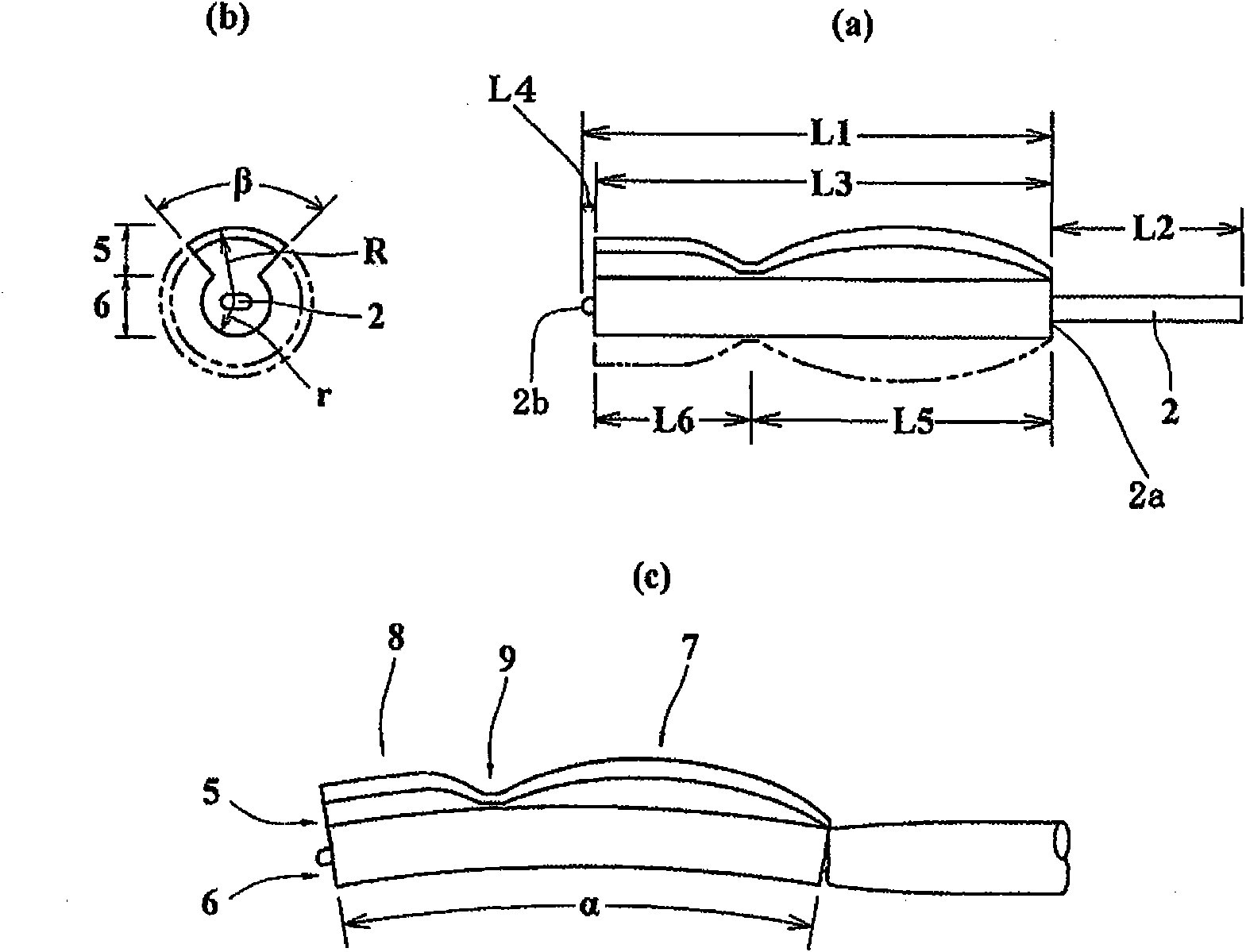

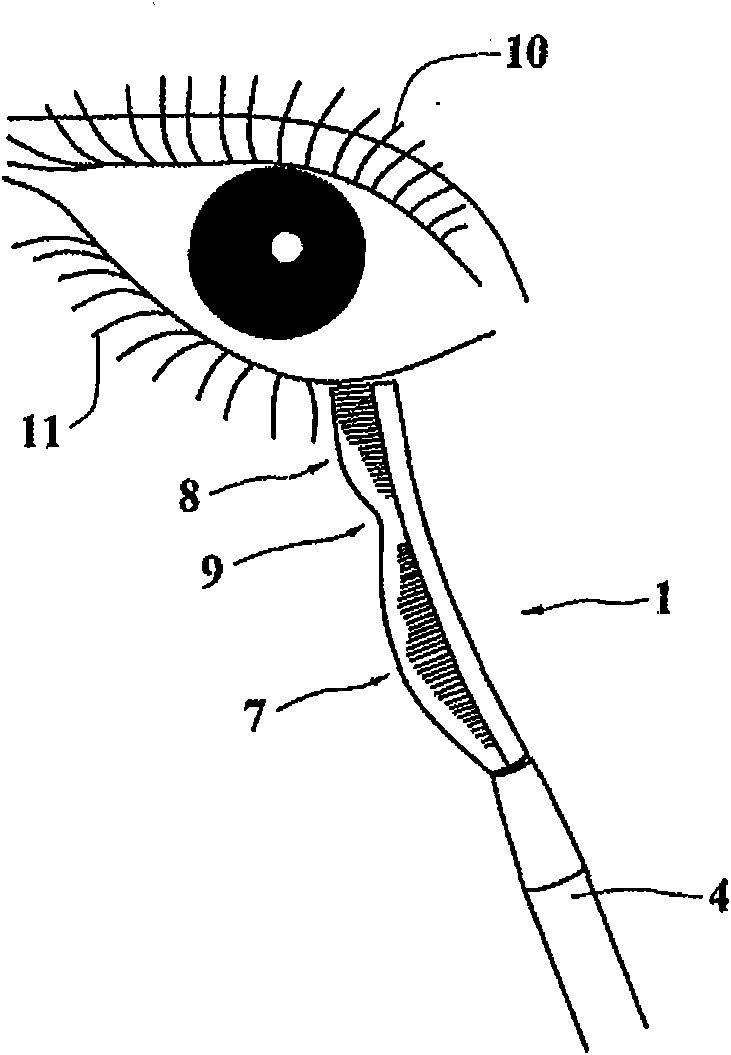

ActiveCN101909480AEasy to combBeautiful visual senseBristlePackaging toiletriesEyelashMechanical engineering

To provide a mascara applicator which is capable of, e.g., fitting the curve of the root of eyelashes to raise the eyelashes, adhering a mascara liquid to the root of the eyelashes to impart an increased volume thereto, spreading the mascara liquid on the eyelashes to widely fan out the eyelashes, and widely spreading the mascara liquid accurately on fine parts such as outer eye corners, inner eye corners, and lower eyelashes, and which can give a finish feeling of omnidirectional extension type mascara. [MEANS FOR SOLVING PROBLEMS] The mascara applicator (1) comprises a long core material (2) and an application part supported by the core material (2) and constituted of an upper application part (5) and a lower application part (6) which protrude from the core material cross-sectionally outward and are used to hold a mascara liquid and apply it to eyelashes, the applicator having a cross section in which the lower application part has a shorter length than the upper application part. The applicator is characterized in that the upper application part has a section along the longitudinal axial direction for the core material, the section being a hill-shaped section constituted of one and a half hills successively disposed along the longitudinal direction from a base end part to a tip part of the core material.

Owner:SHISEIDO CO LTD

Integrated filtering material, preparation method and applications thereof

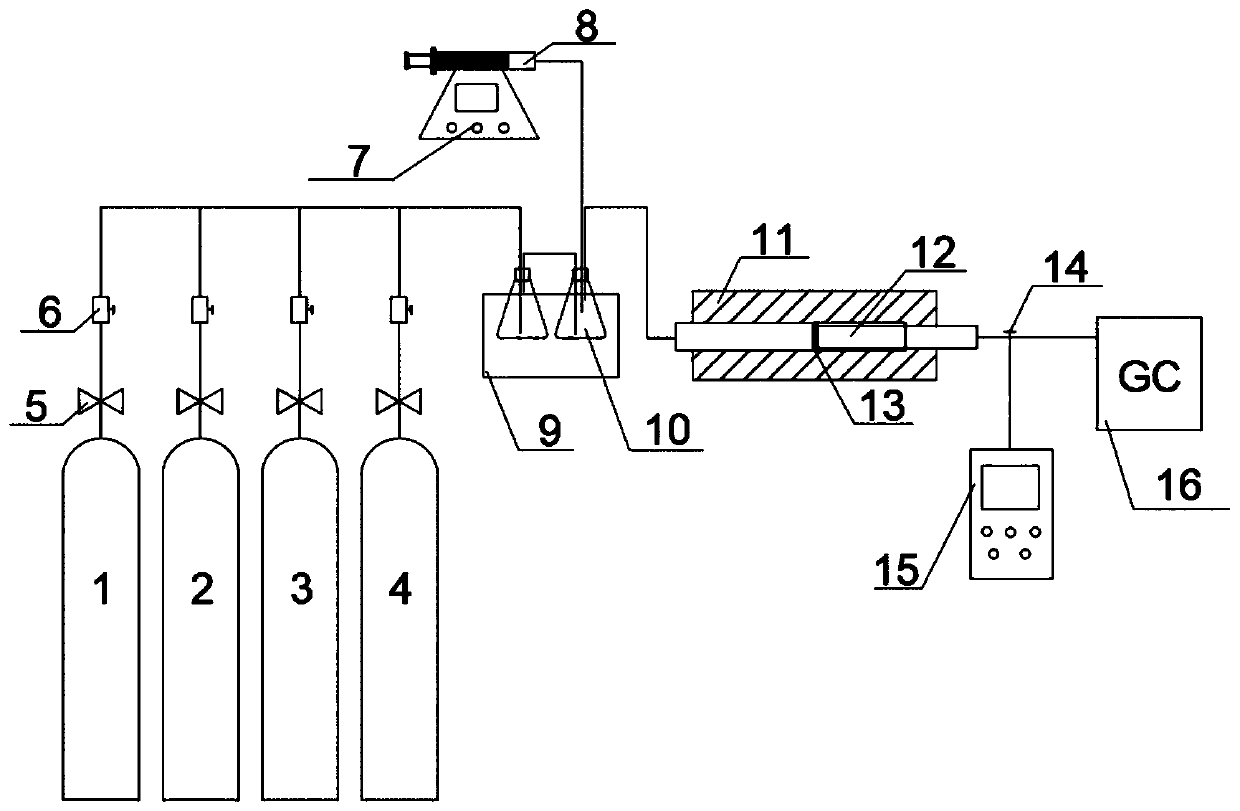

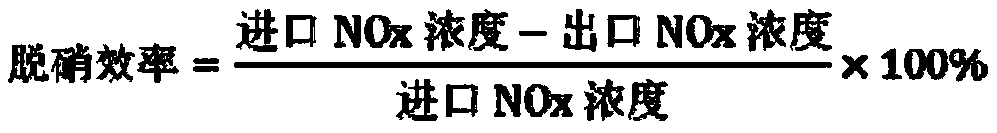

ActiveCN110975415ALarge specific surface areaProtect the physical structureGas treatmentDispersed particle filtrationPtru catalystChemical reaction

The invention provides an integrated filtering material, a preparation method and applications thereof, wherein the filtering material comprises a commercial dust removal filtering material and a catalyst growing on the filtering material and capable of simultaneously decomposing nitric oxide and dioxin. The preparation method comprises the following steps: impregnating a filtering material with aprecursor solution of manganese oxide and cerium oxide, and growing the manganese oxide and the cerium oxide on the filtering material through a chemical reaction; and impregnating the filtering material by using vanadium oxytrichloride as a precursor of vanadium oxide, carrying out a reaction in water, and carrying out drying, hydrothermal treatment and other processes to obtain the product. Theprepared composite filtering material can remove three pollutants in flue gas at the same time, and the catalyst is firm in loading and not prone to falling off.

Owner:NANJING UNIV OF TECH +1

Farmyard manure

InactiveCN102964161AApplicable productionGood fertilizer effectFertilizer mixturesFarmyard manureBran

The invention provides farmyard manure. The farmyard manure is formed by peanut bran, bone meal, fish meal and plant ash. The farmyard manure disclosed by the invention has high nitrogen-phosphorus-potassium content, and the elements are balanced in proportion; and the farmyard manure is very easily absorbed by plants and the generated fertilizer effect is very obvious, so that phenomena of soil caking, acidification, damages to a soil structure are not caused after the farmyard manure is used for a long period. The farmyard manure is completely harmless and is very suitable for producing organic foods.

Owner:徐华朝

Method for producing coarse-grain special mirabilite

InactiveCN101428828AParticles have good fluidityNo cakingAlkali metal sulfite/sulfate purificationMirabiliteVacuum evaporation

The invention discloses a method for preparing coarse granule special type saltcake, which includes the following technical steps: pumping hot water at 40-70 DEG C by a pump, and forming a saltcake solution containing a plurality of impurities; concentrating for crystallization by vacuum evaporation after refining impurities; obtaining a supersaturated solution containing saltcake crystals, keeping the temperature at 10-120 DEG C, and aging for 0.5-3.0 hours; drying after centrifugal separation, processing by a fluidized bed, separating fine granule saltcake and obtaining coarse granule special type saltcake. The anhydrous coarse granule special type saltcake product obtained by the process method of the invention has the advantages of good granule fluidness and low possibility of agglomeration. The product can be widely used for preparing sodium sulfide, sodium silicate and the like, and is also used in industries of paper making, glass, printing and dyeing, synthetic fiber, hide manufacture, food, medicine and the like.

Owner:四川省川眉芒硝有限责任公司

Method for preparing high-performance color anti-skid road surface paint and using method thereof

The invention discloses a method for preparing high-performance color anti-skid road surface paint. The method comprises the following steps: (1) dispersing and stirring dimethylbenzene, dispersing agent and epoxy resin, stirring the mixture with pigment, plasticizer and ground calcium carbonate, grinding the mixture after uniform stirring, filling the mixture in a filter screen for filtering to prepare the finished product paint; and 2) putting the finished product paint in a stirrer, adding 0.3-5mm quartz sand in the paint, stirring the paint, and dispersing and baking the colored quartz sands for 40 to 60 minutes after stirring so as to prepare the color particle material. The process for using the paint comprises the following steps: uniformly spraying the prepared paint on the road surface; uniformly spreading the color particle material on the paint; scraping the color particle material by a scraper tool; spraying the color road surface paint; spreading the color particle material; scraping the color particle material; and repeating the operation for 5 to 7 times. The prepared paint applied to road surface spraying has the advantages of abrasion resistance of the coating, low-temperature cracking resistance, good anti-skid performance and more bright color.

Owner:徐峰

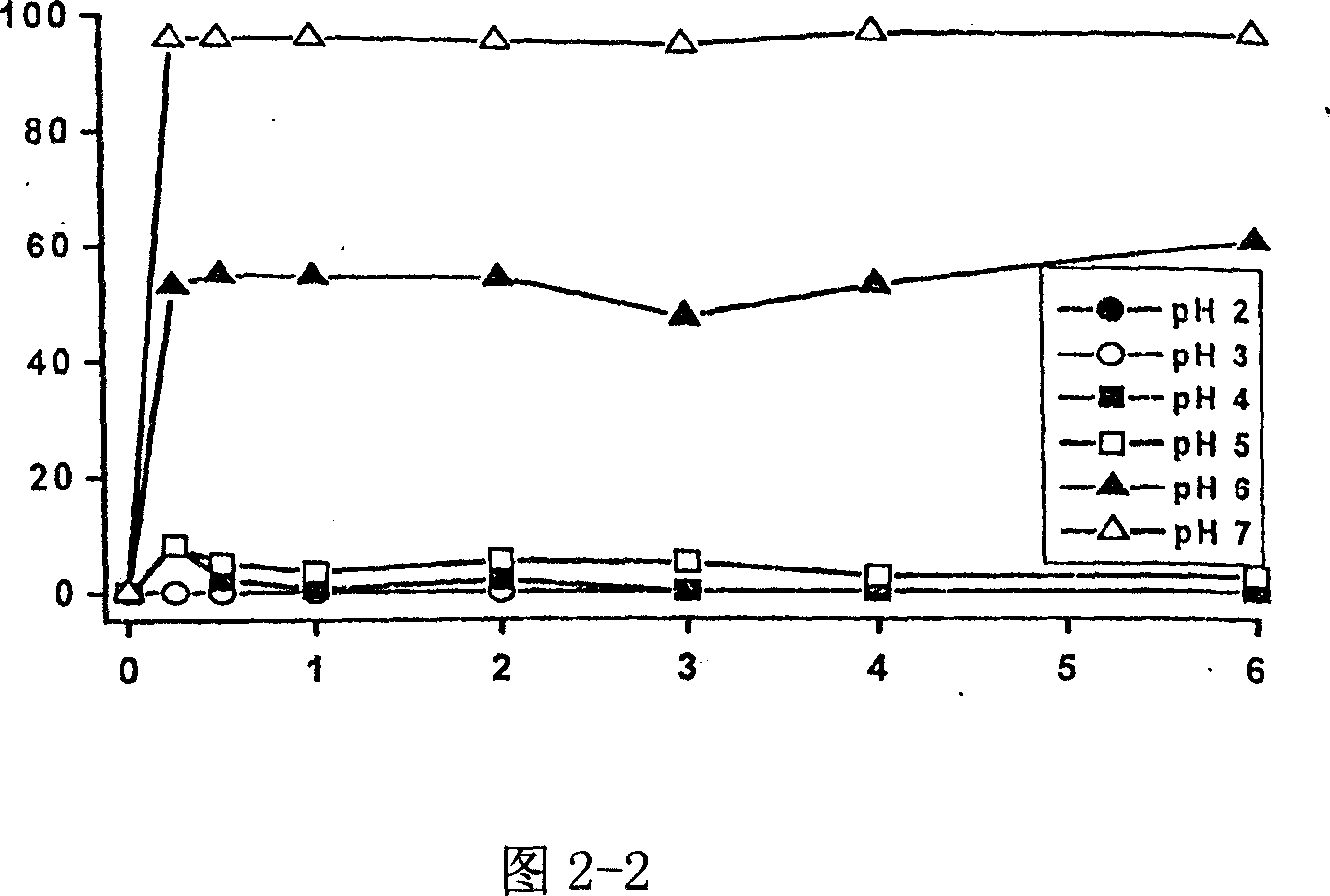

Probiotics components with enteric solubility gastric-acide-tolerance coatings

InactiveCN101077123AImprove survivabilityHas acid-resistant enteric coatingAnimal feeding stuffSolubilityFeed additive

The intestine soluble gastric acid resistant coated probiotics preparation consists of milk powder 15-20 wt%, corn starch 25-30 wt%, modified starch 8-15 wt%, ethyl cellulose 10-15 wt%, bacterial broth 5-10 wt% and talc powder 10-15 wt%. It is prepared into microcapsule, and has high gastric acid resisting and intestine solubility, high probiotics survival rate, high bacteriostasis property, high stability and less caking, and may be used as feed additive for farm animal.

Owner:BION TECH INC

Coating stirring barrel capable of preventing precipitation during stirring

InactiveCN110639395APrevent mixing bucketNo cakingRotary stirring mixersTransportation and packagingGear wheelInlet valve

The invention relates to the technical field of coatings, and discloses a coating stirring barrel capable of preventing precipitation during stirring. The coating stirring barrel comprises a barrel body; a dust filtering block is inserted into the top of the barrel body in a penetrating manner; the bottom of the dust filtering block is fixedly connected with a hollow rotating shaft; an air duct and a supporting air pipe are arranged on the surface of the hollow rotating shaft; an air inlet valve is fixedly connected to the interior of a hollow ejector rod; telescopic cylinders are fixedly connected to the opposite sides of the two hollow ejector rods, and compression springs are fixedly connected to the sides, away from the supporting air pipe, of the stirring rods; connecting rods are fixedly connected to the surfaces of the compression springs, gears are slidably connected to the opposite sides of the two connecting rods, and scraping rods are rotatably connected to the right sides of the gears. According to the coating stirring barrel capable of preventing precipitation during stirring, the stirring rod and the telescopic cylinder are used in cooperation, auxiliary use of the air inlet valve and the air outlet valve is combined, and thus the effect that a coating cannot precipitate at the bottom of the device during stirring is achieved.

Owner:杭州迪林网络科技有限公司

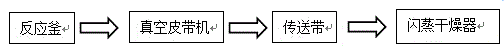

Method for carrying out solid-liquid separation on high-temperature alpha gypsum slurry

ActiveCN104310826AReduce moisture contentEliminate temperature and time conditionsGypsumTemperature control

The invention discloses a method for carrying out solid-liquid separation on high-temperature alpha gypsum slurry. The method comprises the following steps: (1) carrying out primary crystallization; (2) carrying out secondary crystallization; (3) carrying out high-temperature dehydration and solid-liquid separation; (4) conveying the material; (5) enabling dehydrated mud-like alpha gypsum to enter a flash dryer. The keys are as follows: heat insulation covers are additionally installed on a vacuum belt conveyor and a belt conveyor, and heat insulation and heating are achieved by injecting high-temperature steam or high-temperature air or directly heating air; the temperature of the high-temperature steam or the high-temperature air is 100-260 DEG C; the material temperature of alpha semi-hydrated gypsum when passing through the vacuum belt conveyor and the belt conveyor is controlled between 97 DEG C and 150 DEG C. Solid-liquid separation of alpha gypsum slurry under the condition of high temperature can be achieved by adopting the method.

Owner:湖南昌迅科技环保股份有限公司

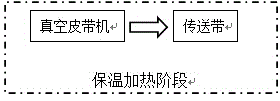

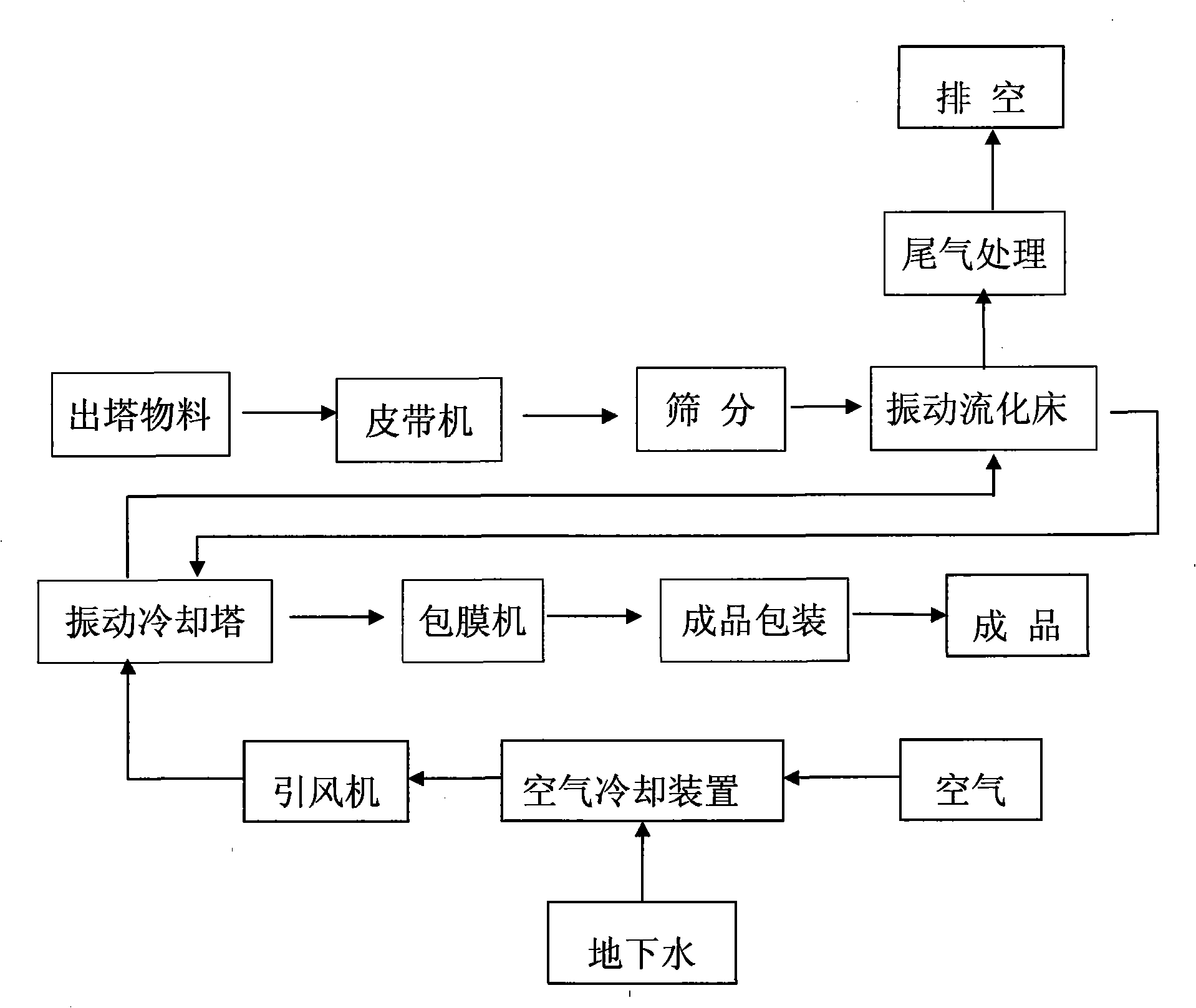

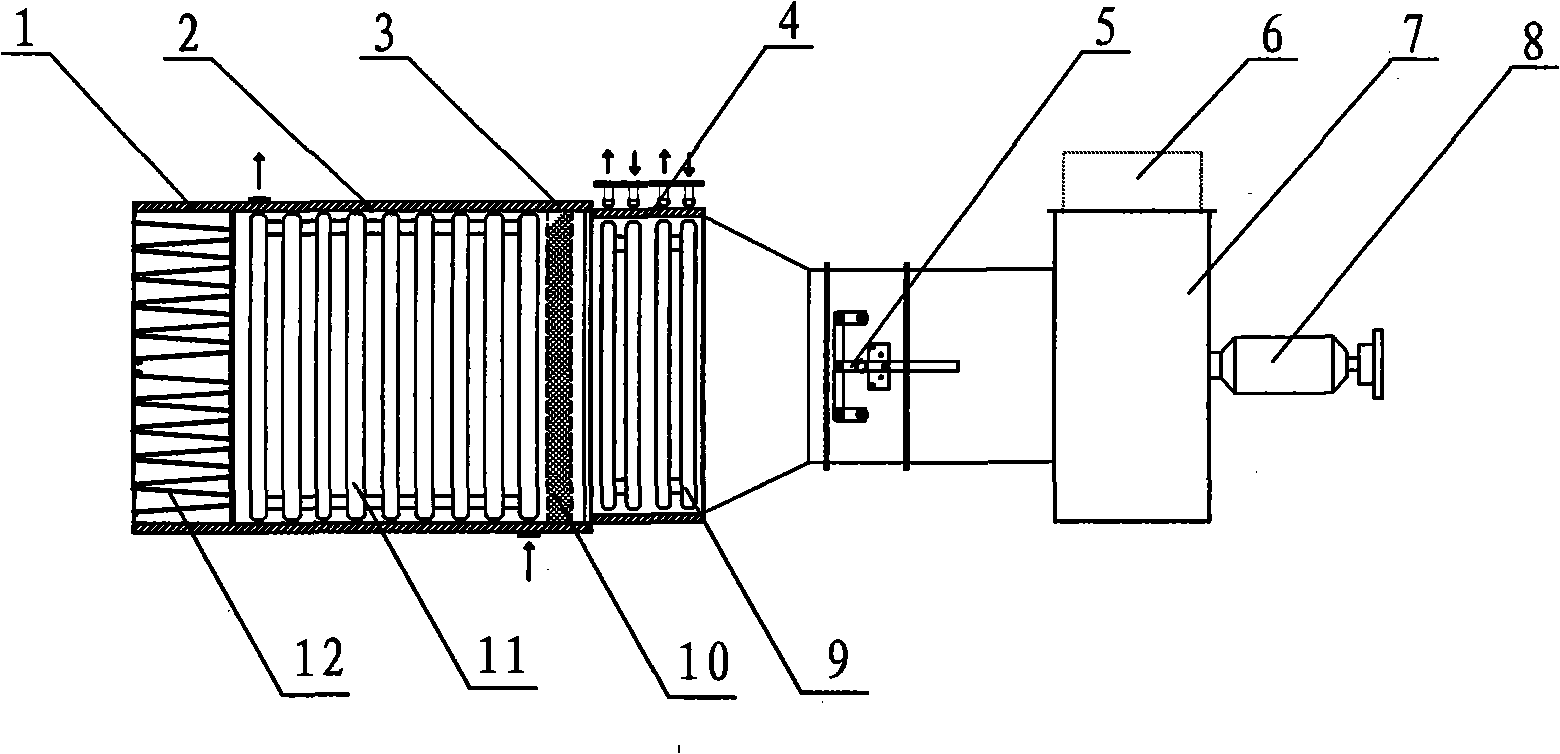

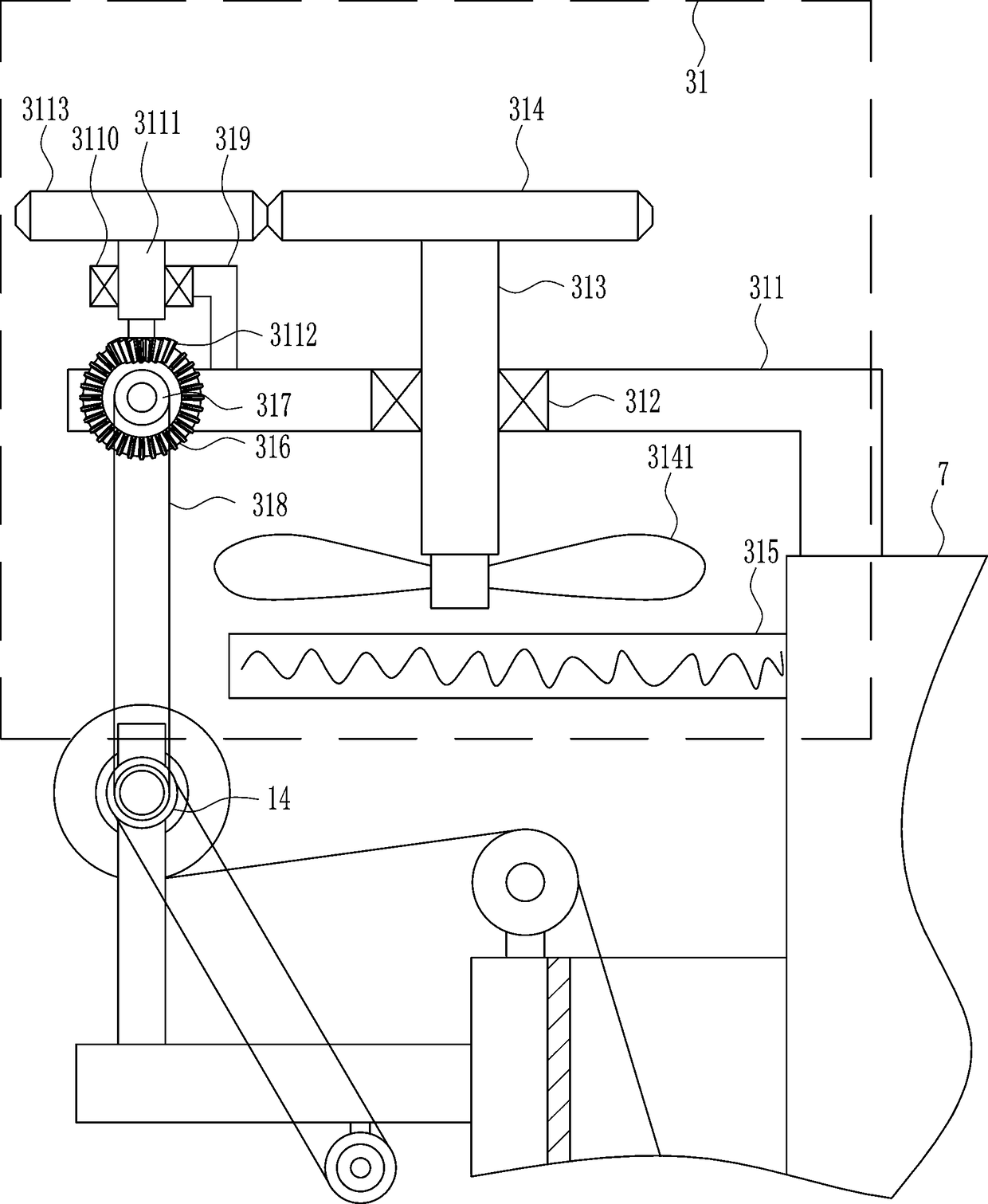

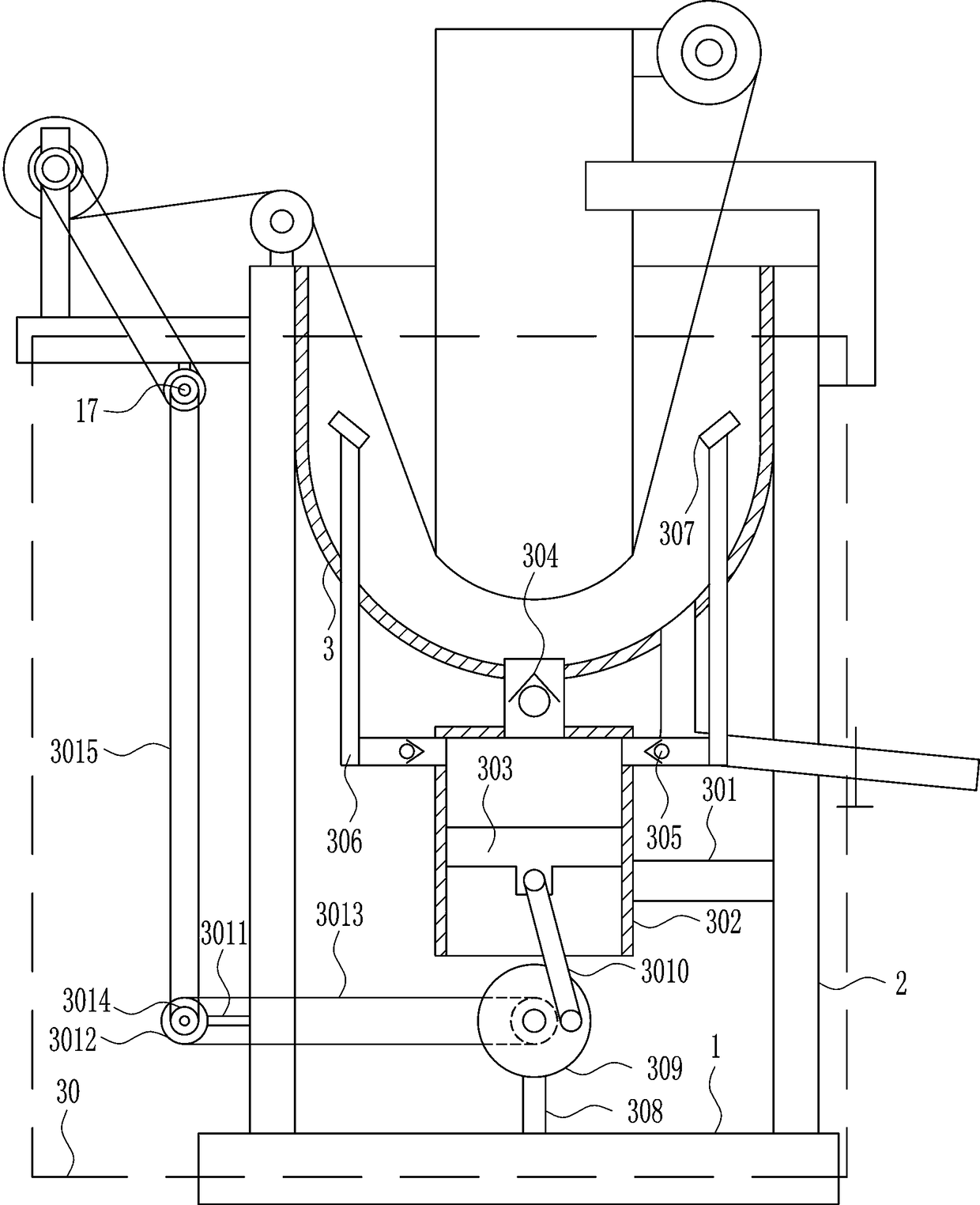

Air cooling device and novel process for cooling high tower granulation fertilizer

InactiveCN101303146AReduce particle breakageImproved particle finishDrying gas arrangementsGranulation by liquid drop formationFertilizerWater content

The invention relates to a new high tower fertilizer cooling technology of an air cooling device. The air cooling device comprises an air filter, a heat exchanger, an air dehumidifier, an air preheater and a draught fan, which are communicated sequentially, and a cooling pipe network is arranged in the heat exchanger. The technology comprises: (1) materials output from the tower, after a screen separation, are input into a vibrating fluidized bed for heat exchange with cold wind; (2) the cold air produced by the air cooling device is input into a vibrating cooling tower and then introduced into the vibrating fluidized bed, and exhaust gas discharged from the fluidized bed is collected and disposed; (3) materials output from the fluidized bed are input into the vibrating cooling tower for heat exchange with input cold wind and cooled materials are proceeded into a next working procedure. The technology of the invention has positive and beneficial effect that: while materials are cooled completely, the damage to material grains is reduced and the smoothness of the grains is improved; the water content of the cooled materials is reduced; energy is saved and consumption is reduced effectively, and production cost is reduced as well.

Owner:郑州阿波罗肥业有限公司

Line dyeing equipment for textile dyeing

ActiveCN108396473AWon't settleNo cakingTextile treatment containersTextile treatment machine arrangementsDying processesEngineering

The invention relates to textile processing equipment, in particular to line dyeing equipment for textile dyeing. The line dyeing equipment for textile dyeing can dry dyed lines, and turns dyestuff ina dying process so that the dyestuff cannot deposit. In order to solve the technical problem, the line dyeing equipment for textile dyeing comprises a bottom plate, supporting plates, a dyestuff box,a discharging tube, a valve, a first L-shaped rod, a guiding plate, a first connecting block, a first sleeve wheel, a second connecting block, a roller and the like; the left side and the right sideof the bottom plate are separately connected with the supporting plates; the dyestuff box is connected between the upper sides of the insides of the supporting plates; and the right of the lower sideof the dyestuff box is connected with the discharging tube. The dyed lines can be dried, and the dyestuff is turned in a dying process and thus cannot deposit.

Owner:台州佰伴制衣有限公司

Traditional Chinese medicine preparation for controlling pullorosis salmonellosis and preparation method thereof

InactiveCN103623134AUniform sizeSimple preparation processAntibacterial agentsAnimal feeding stuffBiotechnologySalmonella frintrop

The invention provides a traditional Chinese medicine preparation for controlling pullorosis salmonellosis. The traditional Chinese medicine preparation is characterized by being prepared from the following extracts in parts by weight: 3 to 5 parts of polygonum cuspidatum extract, 1 to 2 parts of fructus chebulae extract, and 1 to 2 parts of herba violae extract. The prepared traditional Chinese medicine compound particles are uniform in size, consistent in color and luster, and free of moisture adsorption, caking, deliquescence and other phenomena, meet the requirements of Chinese Pharmacopoeia, and are controllable in quality. The pharmacodynamics study shows that the traditional Chinese medicine preparation can be used for preventing and treating pullorosis salmonellosis.

Owner:SICHUAN AGRI UNIV

Preparation method of low-sulfur nano-iron powder

InactiveCN108018425AHigh recovery rateAchieve recyclingNanotechnologyProcess efficiency improvementManganese sulphateSulfate zinc

The invention discloses a preparation method of low-sulfur nano-iron powder, and belongs to the technical field of metal powder preparation. The preparation method comprises the following steps that breaking of a waste zinc-manganese battery is carried out, concretely, the waste zinc-manganese battery is put in a breaker to be broken into powder with the particle size being below 200 micrometers;the zinc-manganese battery powder is dissolved by adding acid and a reducing agent; pH is adjusted for removing iron and aluminum; zinc is separated from manganese and zinc sulfate is prepared, wherein zinc is subjected to extraction separation by adopting a P204 extraction agent; impurity removal is carried out, concretely, a heavy metal capturing agent and fluoride are added so as to remove heavy metal and calcium and magnesium; and preparation of a manganese sulfate solution is carried out, concretely, manganese is subjected to extraction separation by adopting P507, then an obtained pure manganese solution is condensed and crystallized, and thus battery-grade manganese sulfate is obtained. With the adoption of the preparation method of the low-sulfur nano-iron powder, the battery-grademanganese sulfate and high-purity zinc sulfate crystals can be obtained, the obtained manganese sulfate crystals are granular, an agglomeration phenomenon does not exists, a technology is simple andrecovery of full components is realized.

Owner:蒋央芳

Environment protecting bioceramics and its making process

The environment protecting bioceramics is used in the cultivation of plant and the purification of water, has pores and water absorption greater than 18%, and contains: SiO2 65-70- wt%, Al2O3 10-20 wt%, Fe2O3 and FeO 1.5-3 wt%, CaCo3 3-10 wt% and small amount of C. It is produced with the material including common red clay 10-25 wt%, low-viscosity soil 15-30 wt%, dolomite 5-15 wt%, carbon powder 5-30 wt% and viscous soil 18-24 wt%. Its production process includes successive six steps of preparing material, ball milling, sieving slurry, squeezing to dewater, forming and roasting. The present invention has the functions of maintaining tidy environment, eliminating bad smell, purifying water, etc. and the product has easily controlled color and high water absorption.

Owner:厦门益珈华艺术陶瓷有限公司

Agricultural equipment difficultly causing pesticide deposition for precise fertilization

InactiveCN111587867AWell mixedNo cakingPlantingTransportation and packagingAgricultural scienceAgricultural engineering

The invention discloses agricultural equipment difficultly causing pesticide deposition for precise fertilization. The agricultural equipment includes a vehicle body, a support arranged on the vehiclebody, a spray device arranged on the support, a fertilizing device arranged on the support and a valve device matched with the spray device and the fertilizing device; the vehicle body includes wheels that can move back and forth, a driving part for driving the wheels to move back and forth, and wheel shafts detachably connected to the wheels; the vehicle body includes pesticide barrels, stirringdevices arranged in the pesticide barrels and milling devices matched with the stirring devices; and each stirring device includes a stirring paddle that can move back and forth, a gear ring for driving the stirring paddle to move back and forth and a stirring transmission structure for transmission connecting of the gear ring and the wheel shafts. Through the arrangement of the stirring device and the milling device, liquid pesticides can be stirred, the pesticides are ensured to be evenly mixed, solid fertilizers can further be milled, it is ensured that the fertilizers are not agglomeratedue to moisture, the absorption of crops is facilitated, and the crops can grow better.

Owner:HANGZHOU LVCHENG TECH CO LTD

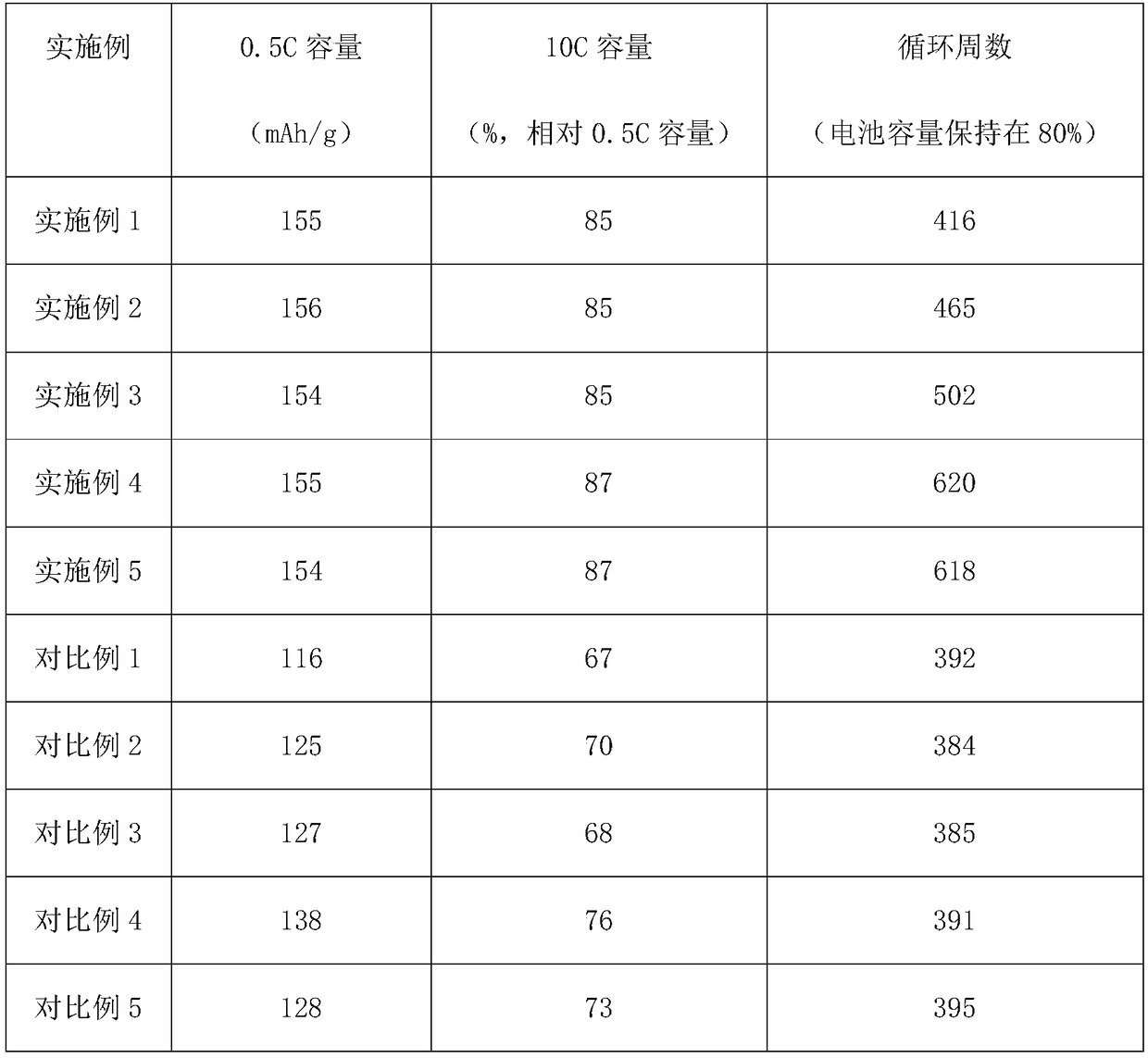

Preparation method of nickel-cobalt-aluminum ternary positive electrode material

ActiveCN108807967AAchieve co-precipitationIncrease concentrationCell electrodesSecondary cellsAluminum IonNickel salt

The invention discloses a preparation method of a nickel-cobalt-aluminum ternary positive electrode material. The preparation method comprises the steps as follows: adding a nickel salt solution, a cobalt salt solution, an aluminum salt solution and ammonia water into a sealed container respectively, pressurizing the container, adjusting the pressure to 0.2-0.5MPa, reacting at normal temperature until no precipitation is formed, and treating to obtain a nickel-cobalt-aluminum precursor; mixing the obtained nickel-cobalt-aluminum precursor with lithium carbonate to obtain a mixture, adding ethyl alcohol and glucose into the mixture, sintering after mixing uniformly to obtain the nickel-cobalt-aluminum ternary positive electrode material. According to the invention, the pressure of the reaction system is controlled to be 0.2-0.5 MPa, so that the reaction time is shortened, the preparation of the nickel-cobalt-aluminum ternary material precursor at normal temperature is realized, the energy consumption is reduced, the rate at which aluminum ions precipitate within the pressure range is enabled to be consistent with the rate at which nickel-cobalt ions co-precipitate, nickel-cobalt-aluminum co-precipitation is achieved, and the nickel-cobalt-aluminum ternary positive electrode material with uniform distribution of elements is obtained.

Owner:BINZHOU GRANDPRO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com