Patents

Literature

49results about How to "High calorific value utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

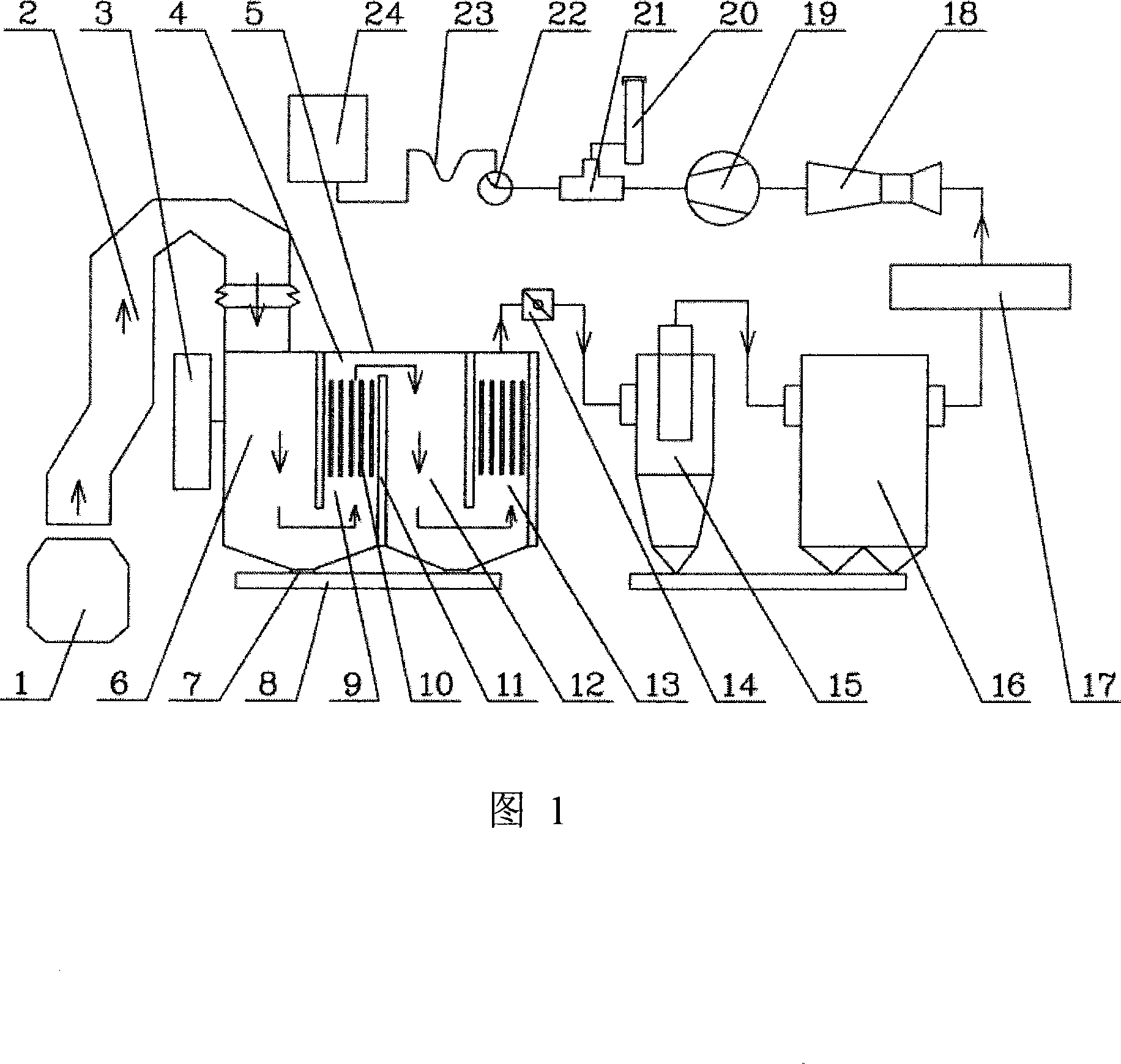

Pyrolysis garbage technology performed by means of double-cylinder rotary kiln

ActiveCN102706140AThe calcination process does not negatively affectGood pre-decomposition effectRotary drum furnacesEnergy inputPyrolysisWaste heat

The invention belongs to the technical field of environmental engineering, and provides a pyrolysis garbage technology performed by means of a double-cylinder rotary kiln. The pyrolysis garbage technology performed by means of the double-cylinder rotary kiln includes the double-cylinder rotary kiln, a cement production line and technology connection pipelines, wherein the double-cylinder rotary kiln includes a pyrolysis passage, an ash heat return passage, a kiln head cover and a kiln tail cover; the cement production line includes a cement rotary kiln, a clinker cooling machine and a predecomposition furnace; and the technology connection pipelines include a tertiary air pipeline for communicating the clinker cooling machine with the kiln tail cover, a composite gas pipeline for communicating the cement rotary kiln with the kiln tail cover, a composite gas shunting pipeline for communicating the ash heat return passage with a composite gas eduction pipe of the kiln tail cover, a waste gas waste heat pipeline for communicating a side hot air inlet of the predecomposition furnace with a waste gas exhaust connector of the kiln head cover, and a garbage slag pipeline for communicating a side feed opening of the predecomposition furnace with a garbage slag outlet of the kiln head cover. The technology is utilized for processing domestic garbage with the cement rotary kiln for cooperation, utilizes the high-temperature pyrolysis garbage cooled by cement clinker to effectively avoid the dioxin generation conditions during the garbage incineration, and effectively utilizes the heat value of garbage, and further completely utilizes the garbage ash in a recycling manner.

Owner:JIANGSU PENGFEI GROUP

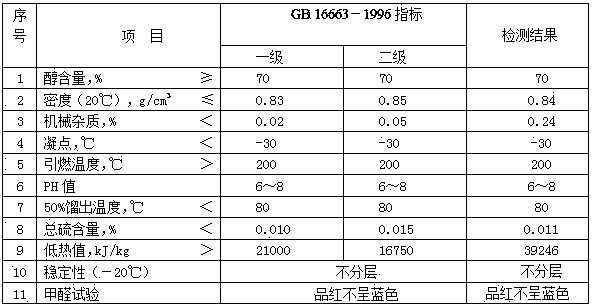

Alcohol-based fuel combustion improver and alcohol-based fuel

ActiveCN103265981ABurn fullyIncrease the calorific value of combustionLiquid carbonaceous fuelsCombustionAlcohol

The invention discloses an alcohol-based fuel combustion improver and an alcohol-based fuel. The alcohol-based fuel combustion improver consists of 4.9-93 parts by weight of co-solvent, 4.9-93 parts by weight of bio-oil, 0.1-0.3 part by weight of smoke suppression combustion improver and 1.0-3.0 parts by weight of combustion improver; and the alcohol-based fuel is formed by mixing and stirring 80-99 parts by weight of methanol and 1-20 parts by weight of alcohol-based fuel combustion improver. By adopting the combustion improver disclosed by the invention, the prepared alcohol-based fuel is a novel biological environment-friendly alcohol-based fuel, the calorific value is as high as 6,000-10,000 calories / g, and the combustion performance is good; and moreover, the alcohol-based fuel has high flash point and low volatility, and potential safety hazards in the prior art are eliminated. The alcohol-based fuel disclosed by the invention also has the characteristics of being safe and environment-friendly, reproducible, clean and sanitary, convenient to use, cheap and the like.

Owner:QINGYUAN JINGWANG ENVIRONMENTAL PROTECTION EQUIP

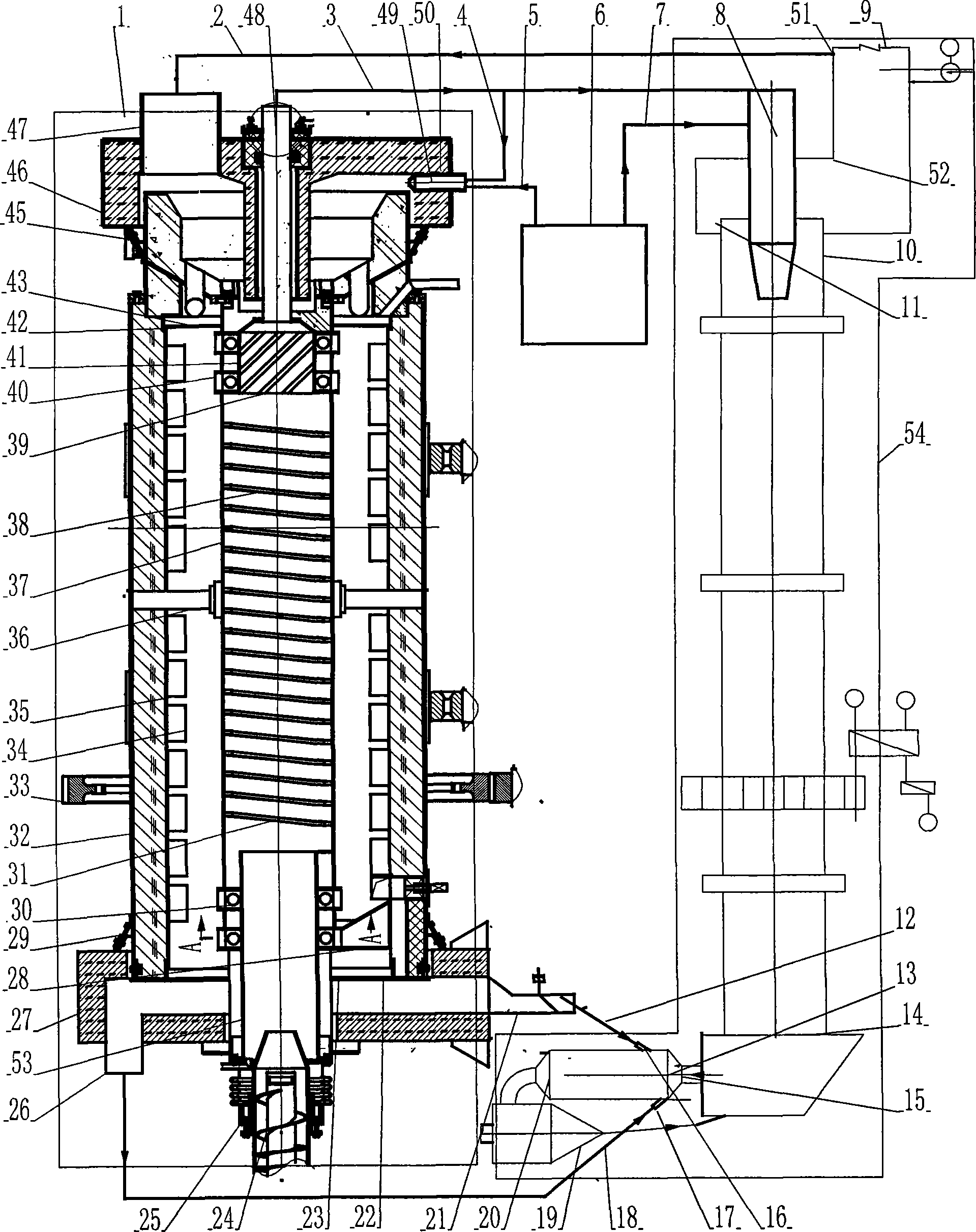

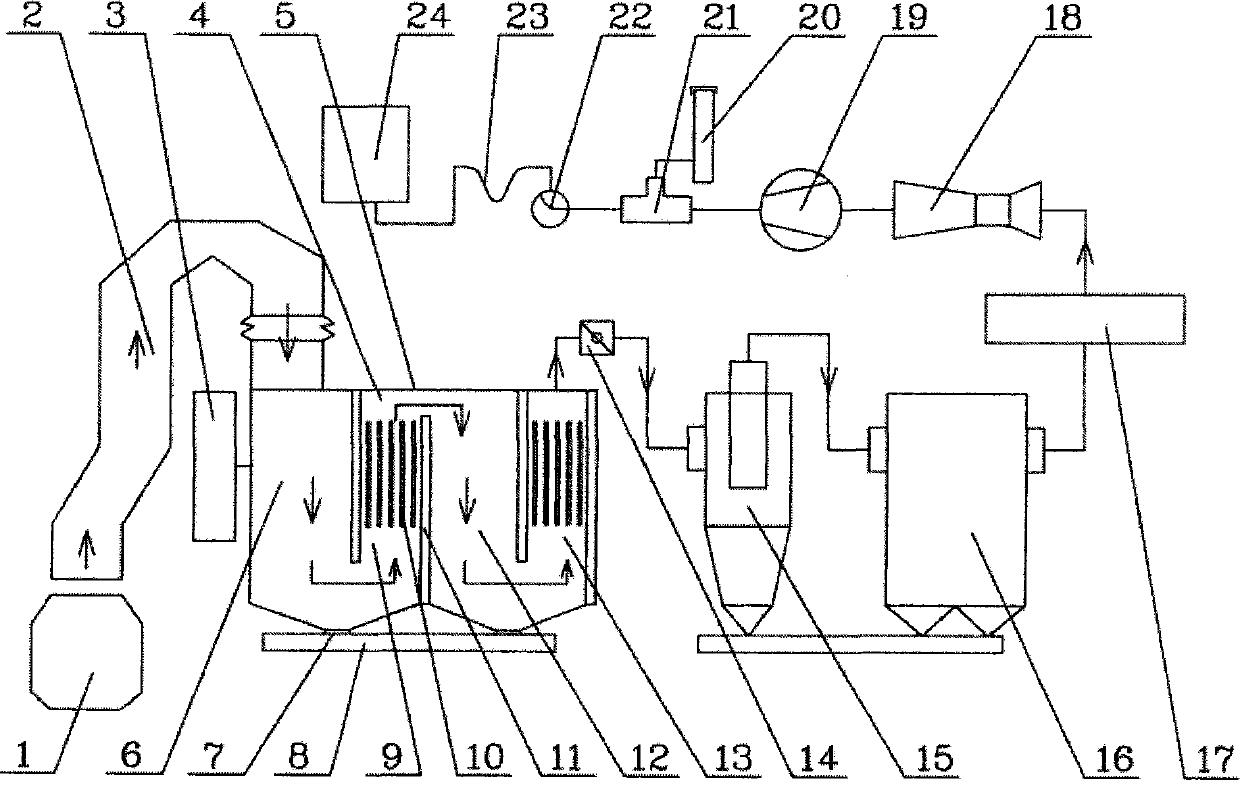

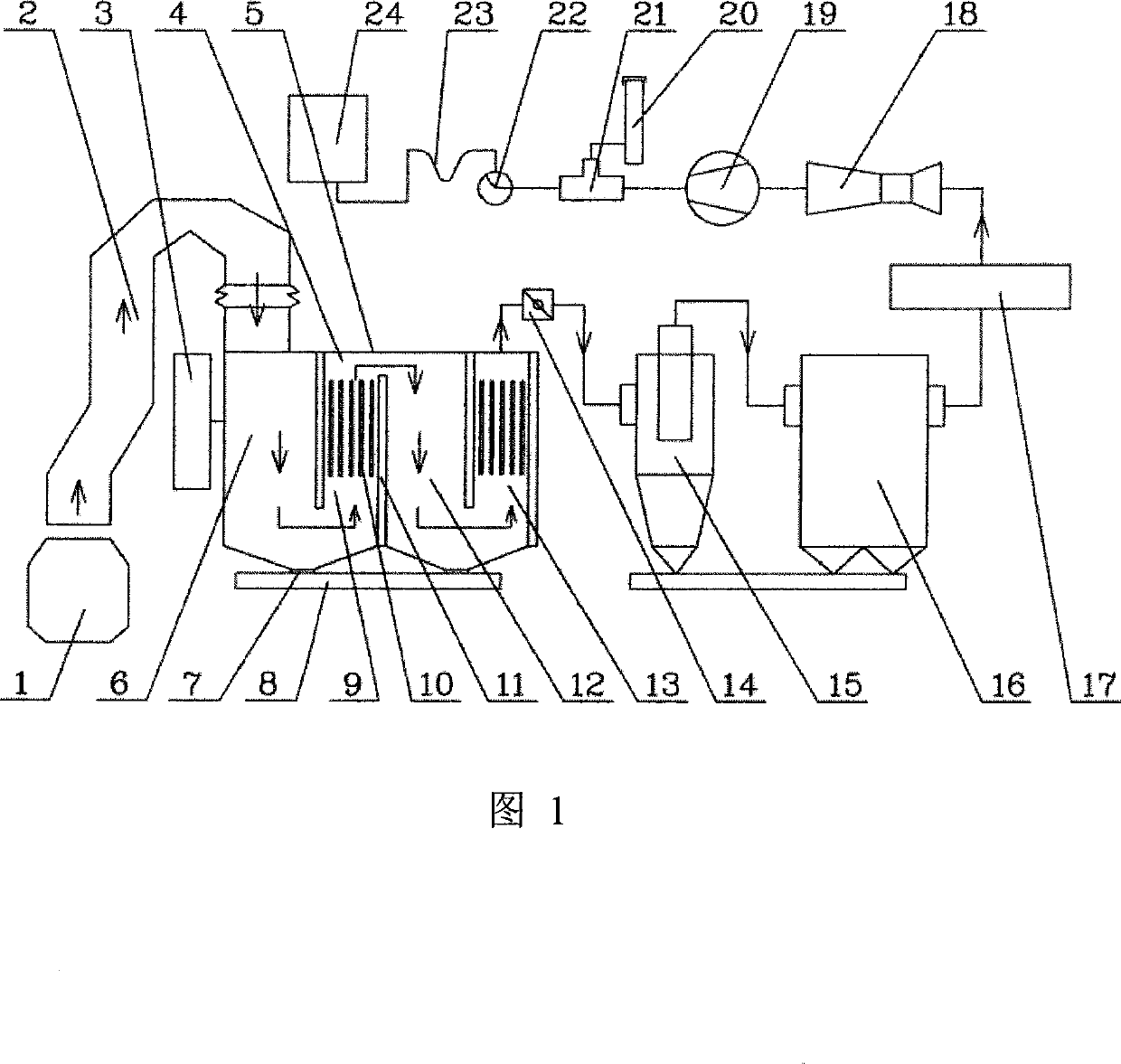

Coal gas anhydrous dust collecting equipment of revolving furnace and technique thereof

ActiveCN101195766AReduce consumptionHigh calorific value utilizationEnergy inputGas dust removalThermal energyTemperature control

The invention relates to a converter coal gas non-water dust removing equipment, which comprises a converter, a radiant type waste-heat boiler, an adjusting valve, a cyclone dust remover, a bag-type dust remover, a coal gas temperature controlling device, a flow meter, a main induced draft fan, a three-way valve, an emission chimney, a rotary water seal, a U-shaped water seal, and a coal gas tank. The invention is characterized in that a convection type waste-heat boiler is connected between the outlet position of the radiant type waste-heat boiler and the adjusting valve, and the convection type waste-heat boiler is composed of a settling chamber, a heat exchange component, a baffle plate, a box body, and an ash discharging opening. A process method comprises the steps that converter coal gas comes into the convection type waste-heat boiler via radiant type waste-heat boiler after recovery waste heat, the gravitational settling is performed to come into the adjusting valve, and the bag-type dust remover, etc to perform dust fining removal after the recovery waste heat, the emission is performed through the three-way valve or the converter coal gas comes into the coal gas tank to perform coal gas recovery, and the invention has the advantage that the energy consumption is reduced through recovering heat energy.

Owner:北京中冶设备研究设计总院有限公司

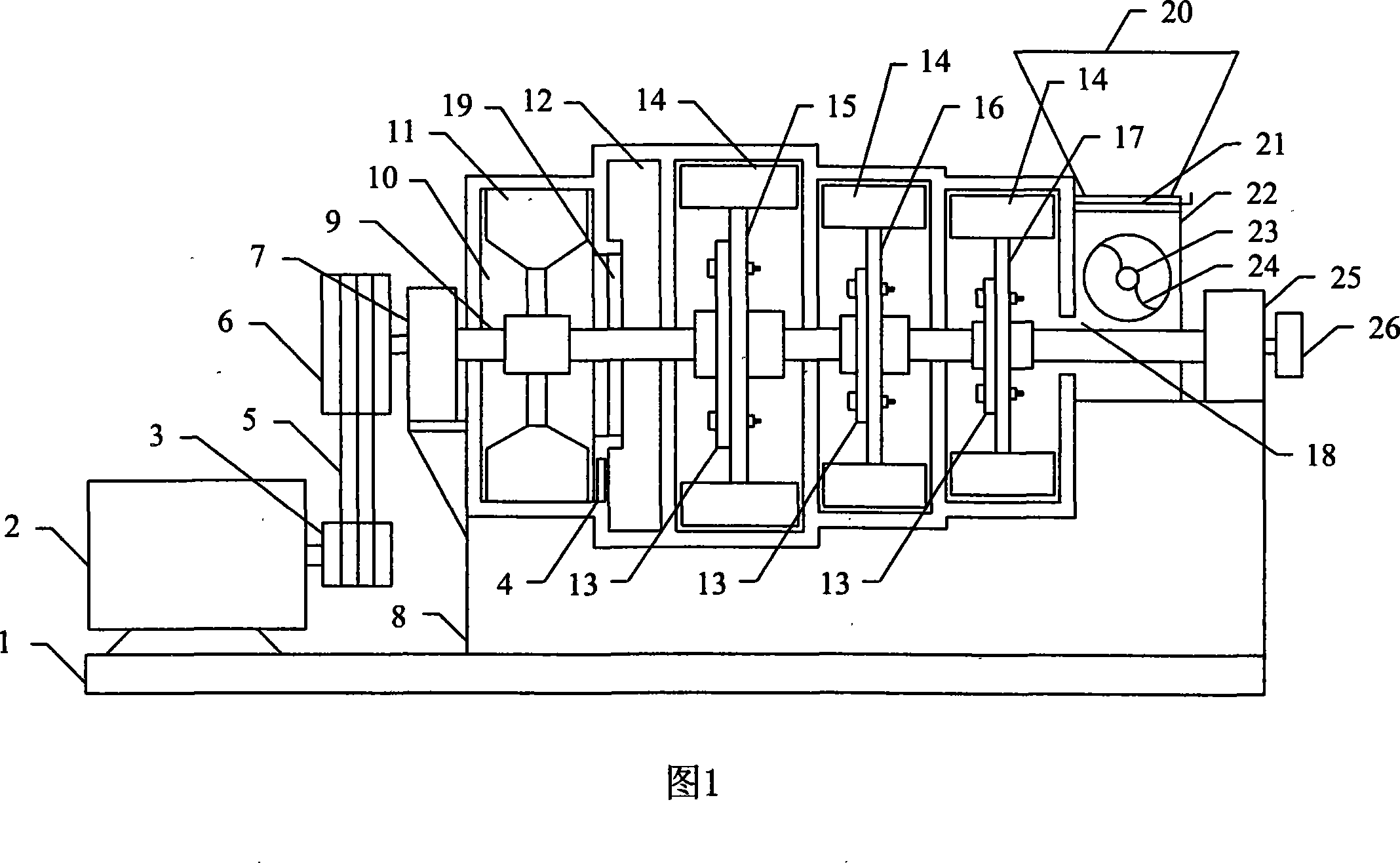

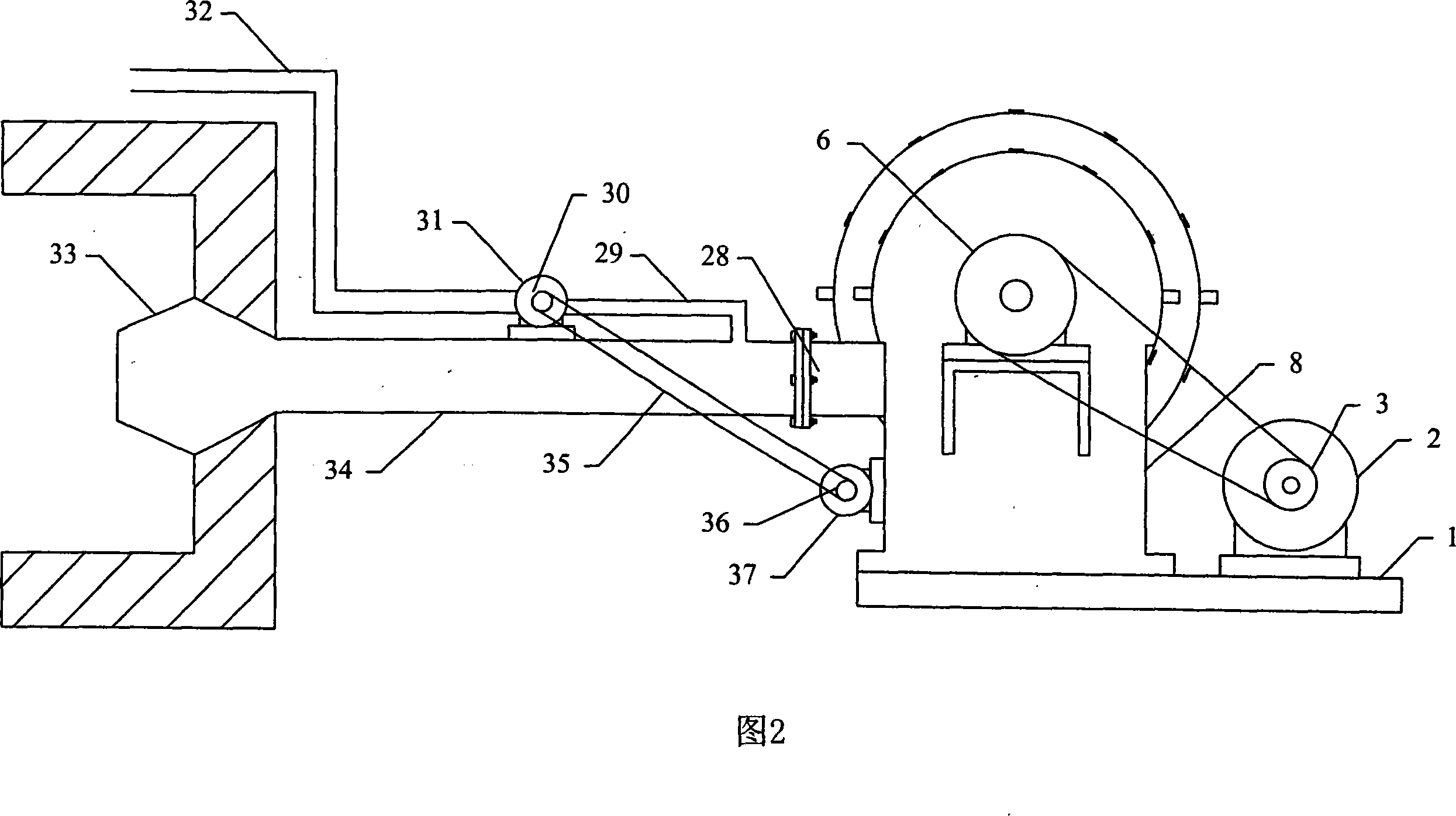

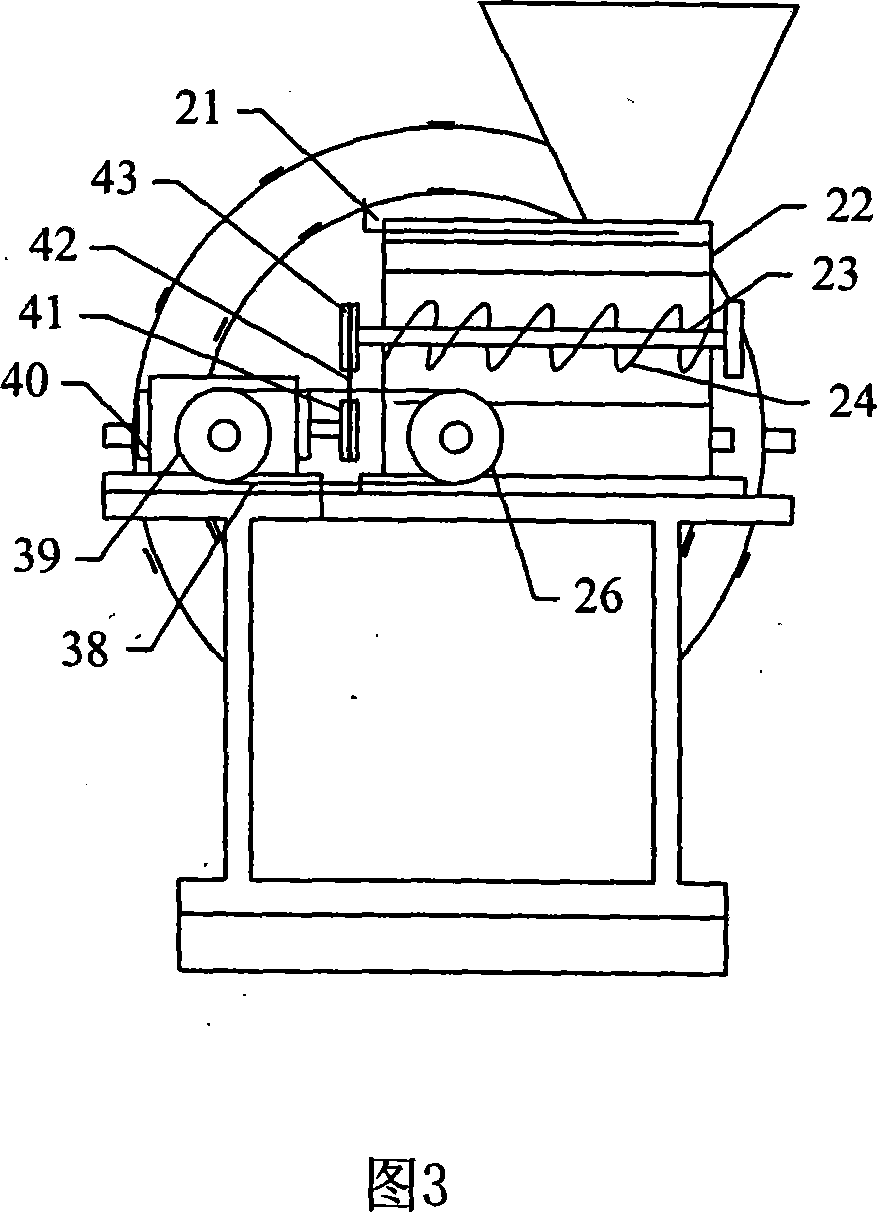

Centrifugal type composite coal-grinding and powder-spraying machine

InactiveCN101085428ABurn completelyReduce pollutionGrain treatmentsLump/pulverulent fuel feeder/distributionEngineeringGrind

The centrifugal compound grind coal powder machine has a main shaft at the base of the body, three sets of flying hammer of various diameters from the center of the shaft, linking as an integral with the vane by the bolt fastened tightly on the flange plate of the main shaft. Fan cabin set at the front of the machine, with wind introduction fan inside the fan cabin, with powder outlet at the left, and powder spraying barrel at the outlet. Rear of the machine sets spiral feeder whose left installs a worm decelerator, top of the feeder having the feeding hopper. It can be used together with the regeneration energy saving smelting-furnace, spraying coal powder into the furnace, reducing burning cost to over 66%. It is reduced in energy consumption, alleviated in contamination and increased in effect. It will be an ideal new generation product.

Owner:ANHUI HUAXIN LEAD IND GROUP

Coke oven coking method for improving ratio of long flame coal for chemical coke

ActiveCN104087328AHigh yieldMeet the requirements of chemical cokeSpecial form destructive distillationChemical industryAdhesive

The invention relates to a coke oven coking method for improving a ratio of long flame coal for chemical coke. The method comprises the following steps: a, performing secondary crushing on long flame coal, and mixing the long flame coal with an adhesive in a storage warehouse; b, performing pre-grinding on the long flame coal mixed with the adhesive, feeding the coal into a coal blending chamber, improving a ratio of the long flame coal mixed with the adhesive to 80 percent, adjusting a gas-fat coal ratio with high adhesiveness to 20 percent, and feeding the coal into a crusher for crushing after mixing; c, performing primary water injection on the prepared mixed coal, crushing the coal in a crusher chamber, performing secondary water injection on the crushed mixed coal, feeding coking coal into a charging car for tamping, so that the coking coal is smashed into a dense coal cake, and feeding the coal into a carbonization chamber for performing high-temperature dry distillation; and d, performing high-temperature dry distillation on the coking coal, performing coke quenching by adopting a dry method, and finally naturally cooling to obtain the chemical coke product. According to the method, low-cost smelting and chemical industry carbon materials can be produced, and the gap that smelting and chemical industry carbon materials are deficient is overcome.

Owner:新疆新鑫新能源化工有限公司

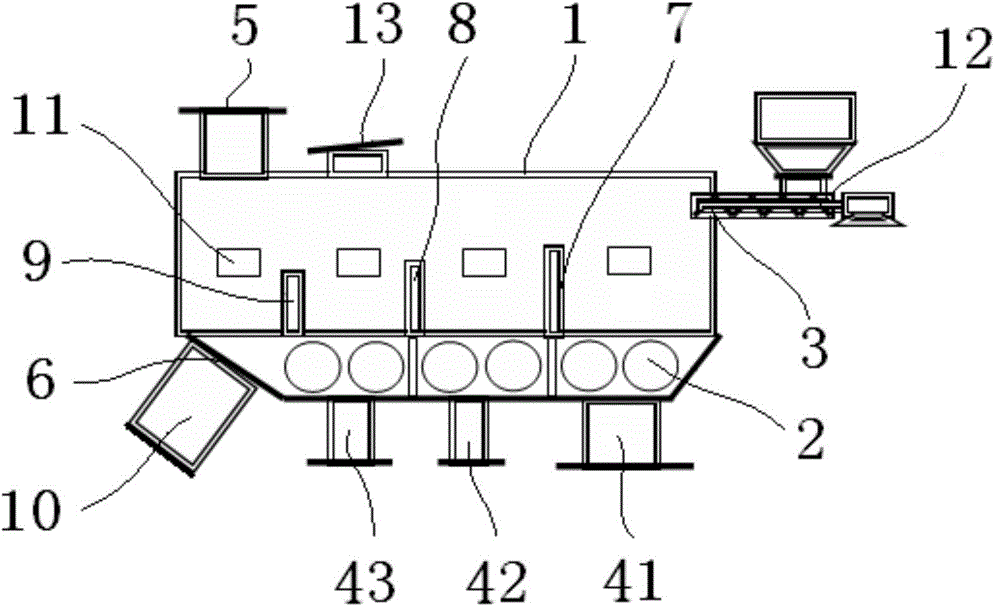

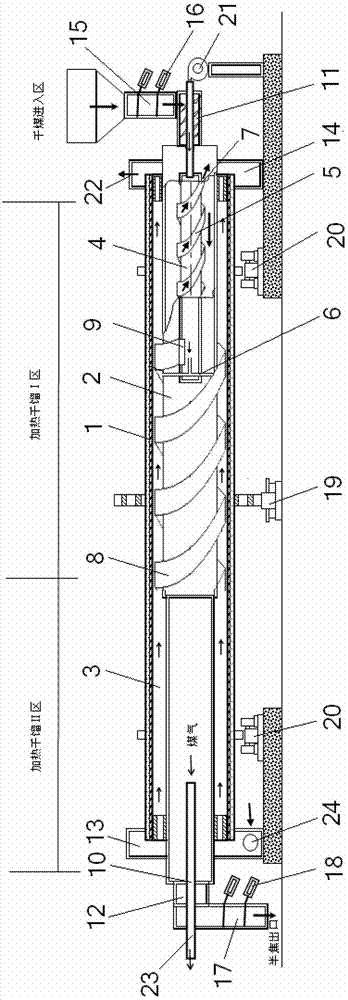

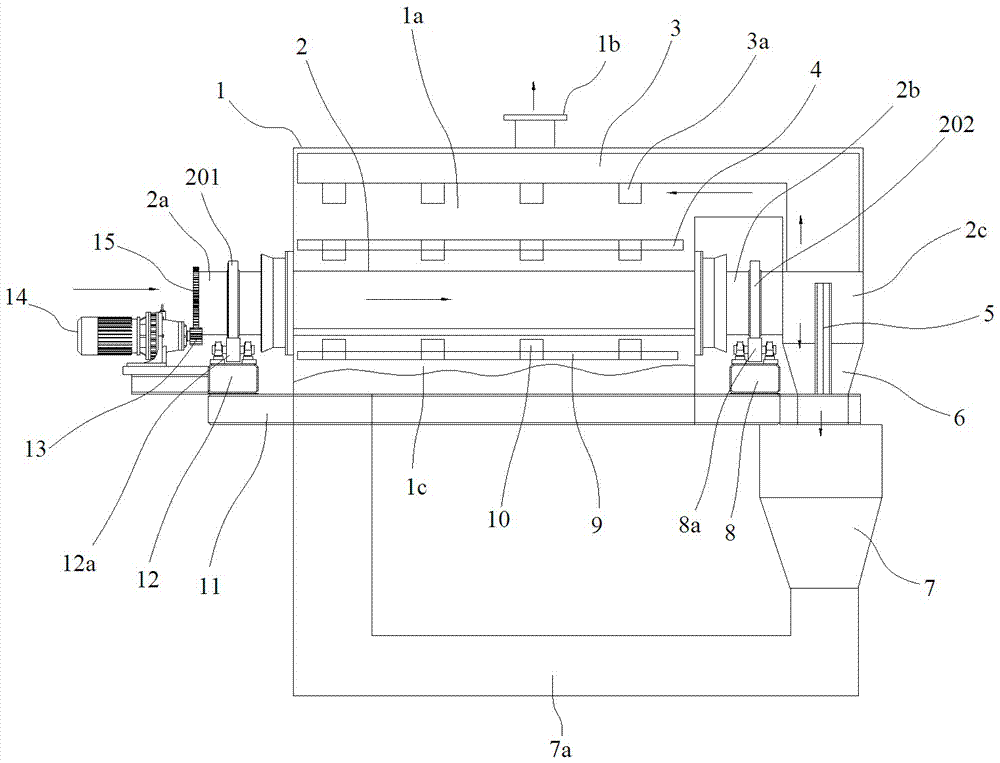

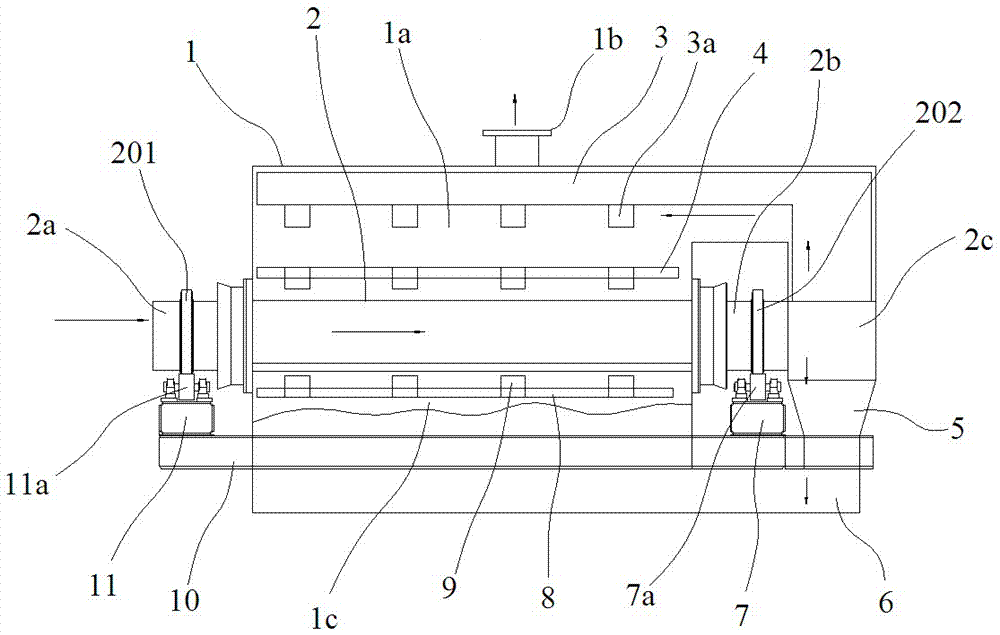

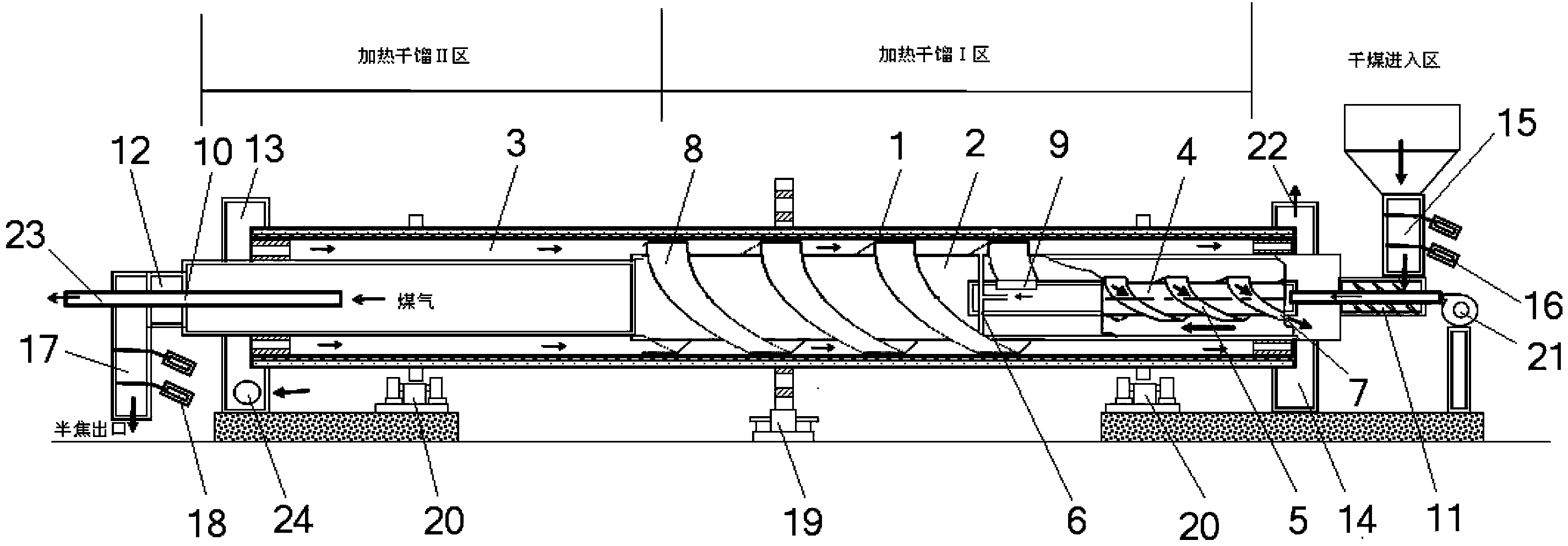

Mechanical dispersion fluidization drying method and equipment for coal slime

InactiveCN103604278AHigh calorific value utilizationIncrease productionDrying solid materials with heatDrying gas arrangementsParticulatesSmall footprint

The invention relates to a mechanical dispersion fluidization drying method and equipment for coal slime. The method is used for realizing fluidization drying of coal slime particulates by using hot smoke while dispersing coal slime to be dried into the coal slime particulates. The drying method is high in heat utilization rate and yield as well as wide in application range. The equipment comprises a drying box body and a stirring shaft, wherein the drying box body is provided with a feeding hole, a discharging hole, a gas outlet and a smoke inlet; the stirring shaft is used for dispersing the coal slime to be dried, is arranged at the bottom of the drying box body and is located above the smoke inlet; the coal slime to be dried is dispersed into the coal slime particulates by using the stirring shaft after entering the drying box body through the feeing hole, meanwhile, the hot smoke enters from the smoke inlet at the bottom of the drying box body at a proper flow rate and is discharged from the gas outlet after carrying out fluidization drying on the coal slime particulates, and at the same time, the dried coal slime is output from the discharging hole. The equipment is large in gas and solid drying contact area, long in drying time, high in heat utilization rate and yield and small in floor area.

Owner:CHANGAN UNIV

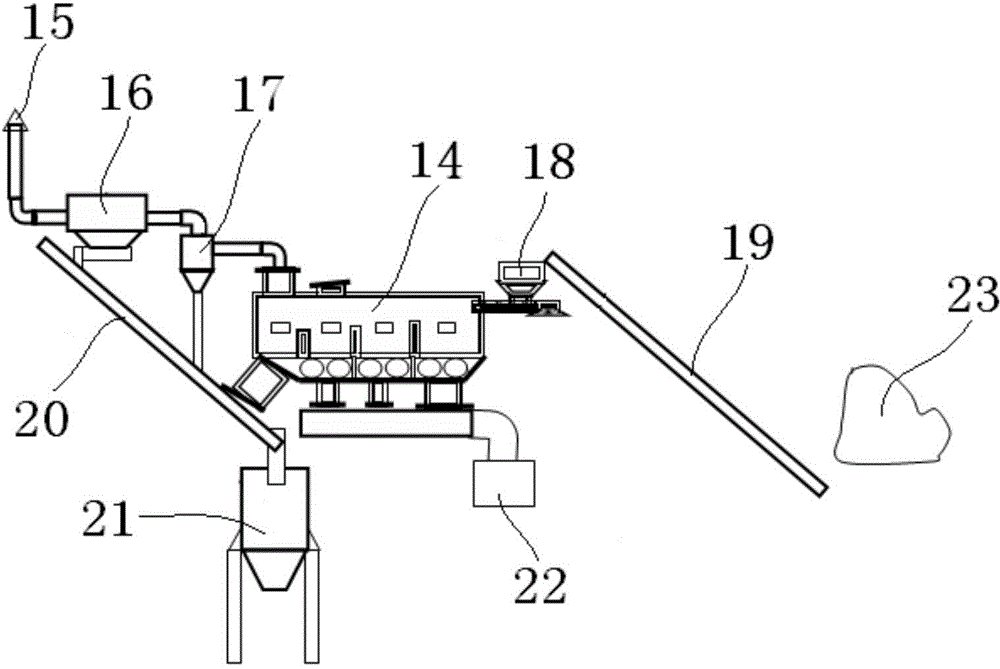

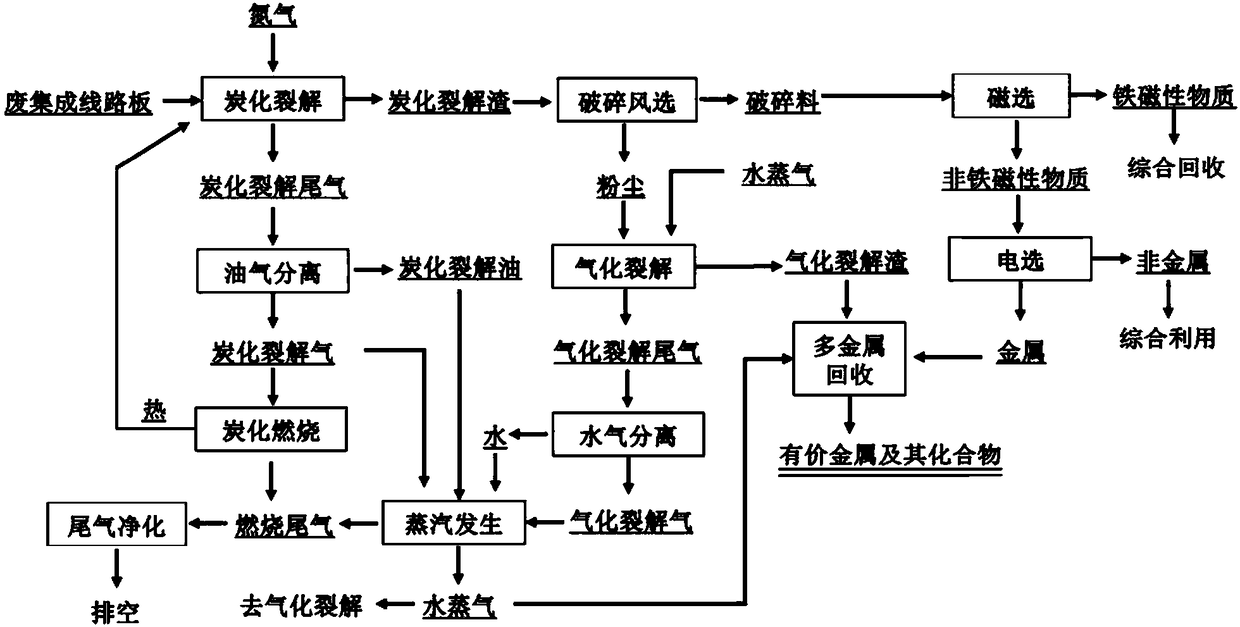

Caloric synergistic environment-friendly reclamation method for waste integrated circuit boards

ActiveCN108160665ARealize comprehensive utilizationIncrease profitElectrostatic separationSolid waste disposalPollutionIntegrated circuit

A caloric synergistic environment-friendly reclamation method for waste integrated circuit boards involves a carbonization pyrolysis system, a crushing separating system, a gasification pyrolysis system and a calorific value utilization and comprehensive recovery system. Compared with the prior art, the carbonization pyrolysis system can realize dry distillation pyrolysis of organic matter in thewaste integrated circuit boards, carbon, hydrogen and other elements can be converted into carbonization pyrolysis gas and pyrolysis oil serving as fuel. The combusting heat of the carbonization pyrolysis gas serves as energy needed by carbonization pyrolysis, and self-heating carbonization pyrolysis is achieved. Carbonization pyrolysis products are crushed and separated, the problem that crushingis difficult and metal is wrapped by organic matter brought by a traditional method of direct crushing and separation of circuit boards are solved, and the crushing effect and the separation effect are improved. The gasification pyrolysis system realizes comprehensive utilization of residual carbon, generated gasification pyrolysis gas can be used as a heat source needed by subsequent valuable metal recycling, and the utilization heat of the caloric value is further improved. The caloric synergistic environment-friendly reclamation method for waste integrated circuit boards has the characteristics of being high in caloric value utilization rate, low in energy consumption, high in metal recycling rate, capable of realizing short-process recycling of valuable metal, free of pollution in smoke and the like.

Owner:BEIJING UNIV OF TECH

Dehydrating combustion treating method for living refuse

InactiveCN1644986AHigh calorific valueImprove burnout rateIncinerator apparatusGrain treatmentsPretreatment methodCombustion

This invention is a dewatering burning treatment method of household garbage. Mechanical dewatering pretreatment method is adopted to replace the heat drying pretreatment method, household garage is broken up at first then efficient deep dewatering process is carried out by high speed centrifuge after removing water by filtering, the garbage dewatered is sent into the furnace to burning, the amount of the calorific power generated is increased by burning garbage through controlling the burning temperature and residence time of flue gas, the amount of generating dioxin is reduced too. The fluw gas generated by burning will be discharged after spray damp dry acid stripping and dsting. This invention can raise the burning temperature of garbage, and reduce the cost for flue gas treatment and environment pollution.

Owner:SHANGHAI JIAO TONG UNIV

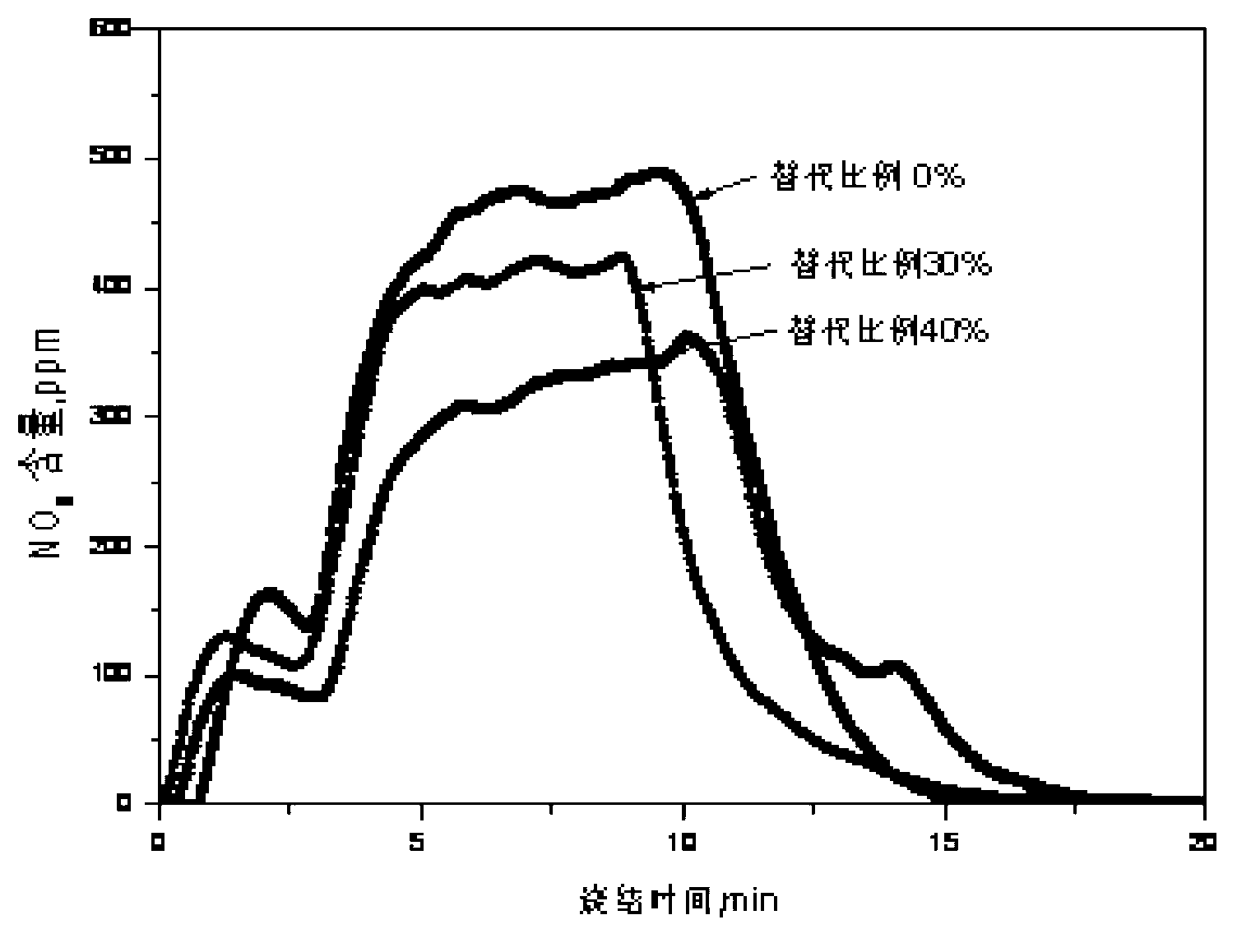

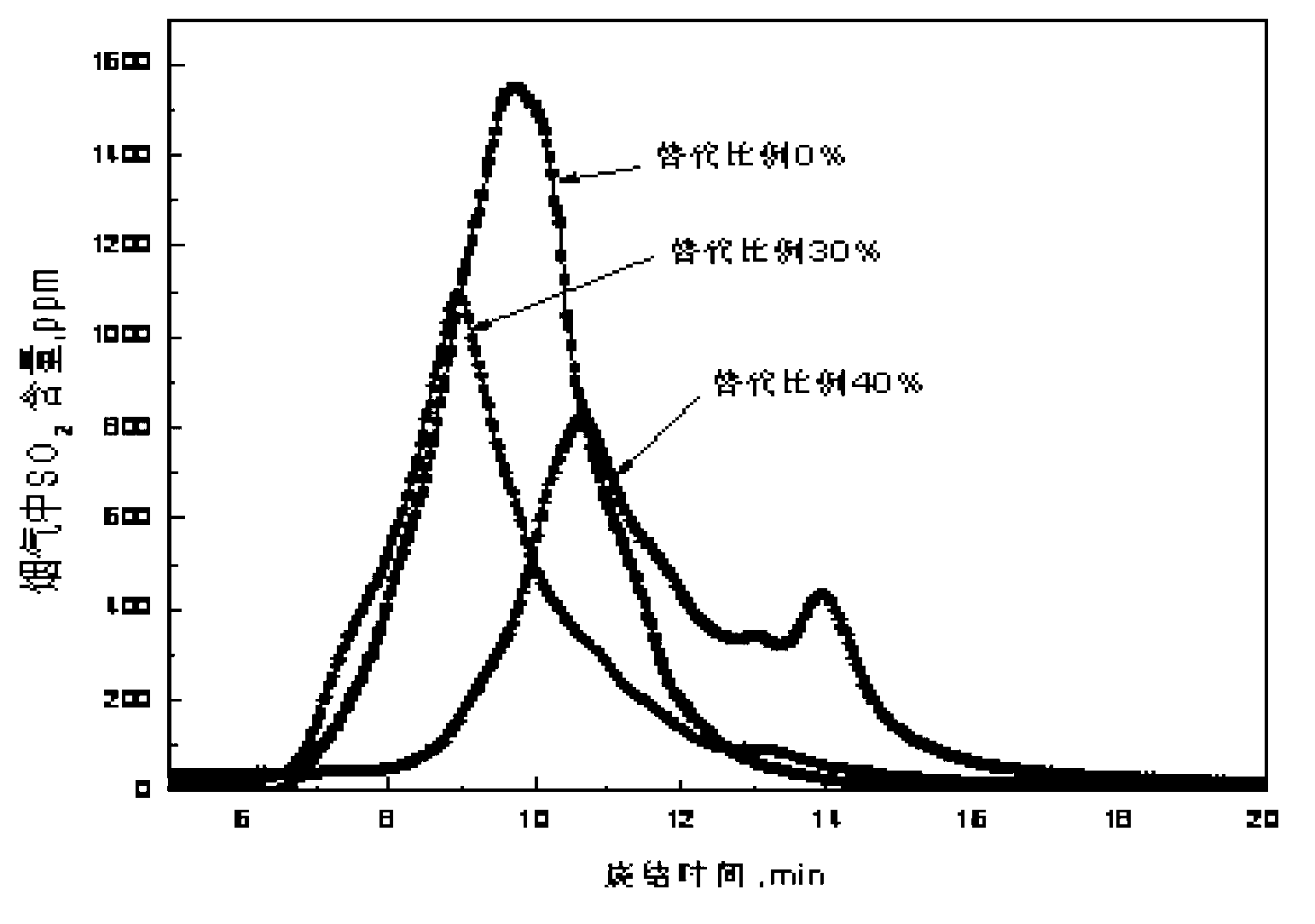

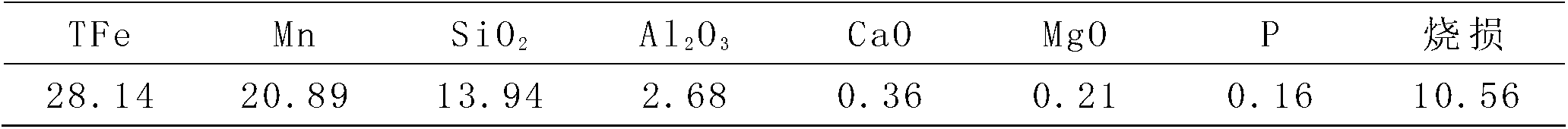

Method for energy conservation and emission reduction of manganese mineral powder sintering

The invention discloses a method for energy conservation and emission reduction of manganese mineral powder sintering. The method comprises the specific steps of fully and uniformly mixing biomass charcoal and coke powder according to a certain proportion to obtain mixed fuel, blending manganese mineral powder, the mixed fuel, return fines and a fusing agent, uniformly mixing, pelleting, distributing, igniting, sintering, cooling, and obtaining a finished sinter. According to the method, biomass charcoal fuel that is environment-friendly, low in price and high in renewability is used to partially replace the traditional fuel (the coke powder) for the manganese mineral powder sintering; a replacing proportion is 0%-65%; compared with the conventional sintering, on the premise that a quality index of sintering production is not reduced, the actual consumption of solid fuel is reduced obviously; and the emission amount of harmful gases such as SO2 and NOx in sintering flue gas is reduced greatly. With the method, the available sintering technological process is not changed basically; the operation is simple; the energy conservation and emission reduction of manganese mineral powder sintering production are achieved; and industrial production is facilitated.

Owner:CENT SOUTH UNIV

Biomass granular fuel and preparation method thereof

InactiveCN107641539AHigh calorific value utilizationImprove combustion efficiencyBiofuelsSolid fuelsRural areaNew energy

The invention relates to biomass granular fuel, which is prepared from the following raw materials in parts by weight: 40 to 50 parts of stalk powder, 40 to 50 parts of branch leaf powder, 20 to 30 parts of dahurian larch wood dust, 10 to 20 parts of redwood dust, 20 to 30 parts of hardwood dust, 8 to 15 parts of sulphur-fixing agents, 5 to 10 parts of lubricating agents and 4 to 8 parts of loosening agents. The invention also relates to a preparation method of the biomass granular fuel. The biomass granular fuel provided by the invention has the advantages of high calorific value, high combustion utilization rate and small environment pollution; the development of new energy resources can be promoted; the fuel can be used for providing life and production energy for rural areas.

Owner:TAISHAN HELI BIOMASS TECH CO LTD

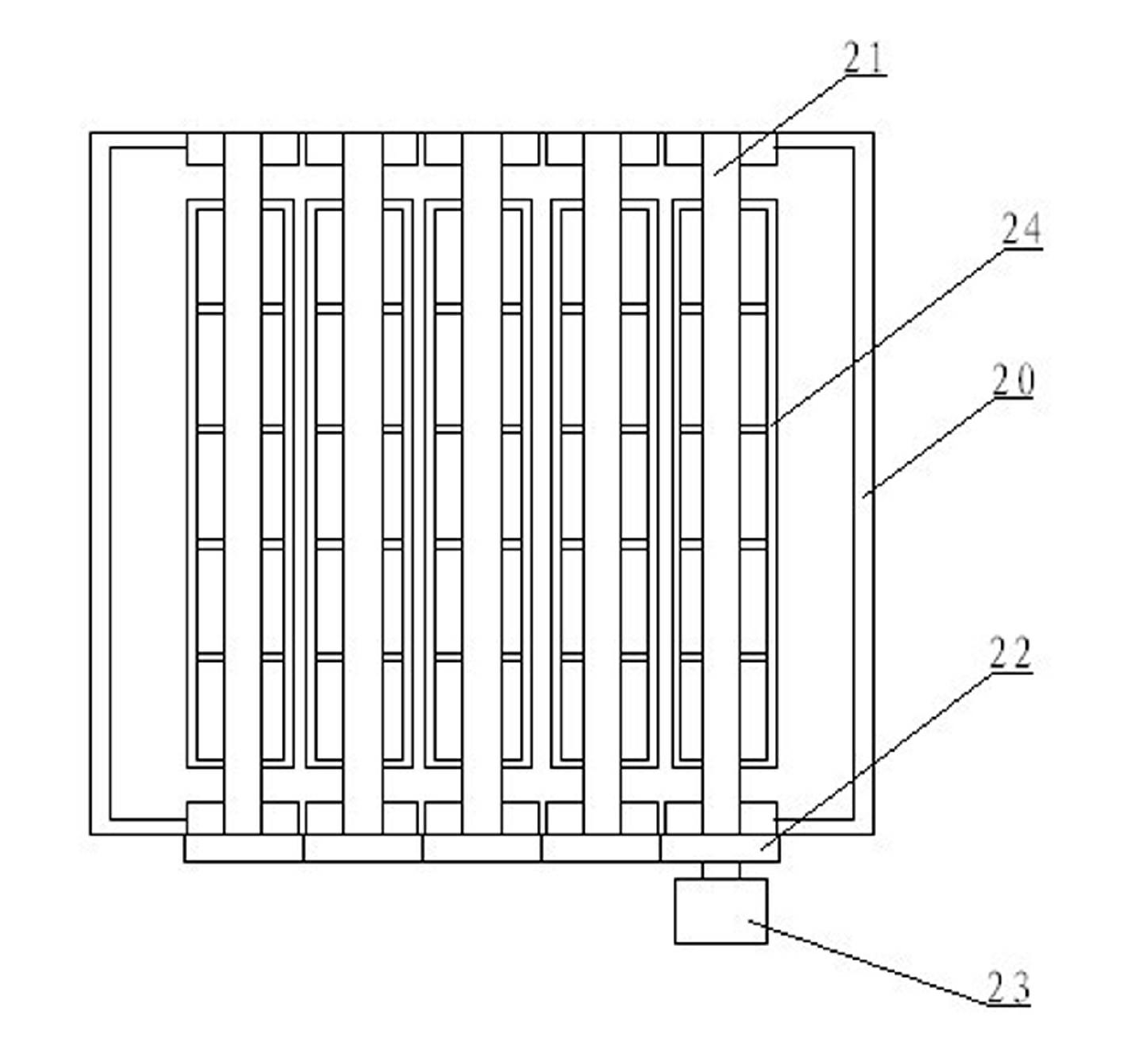

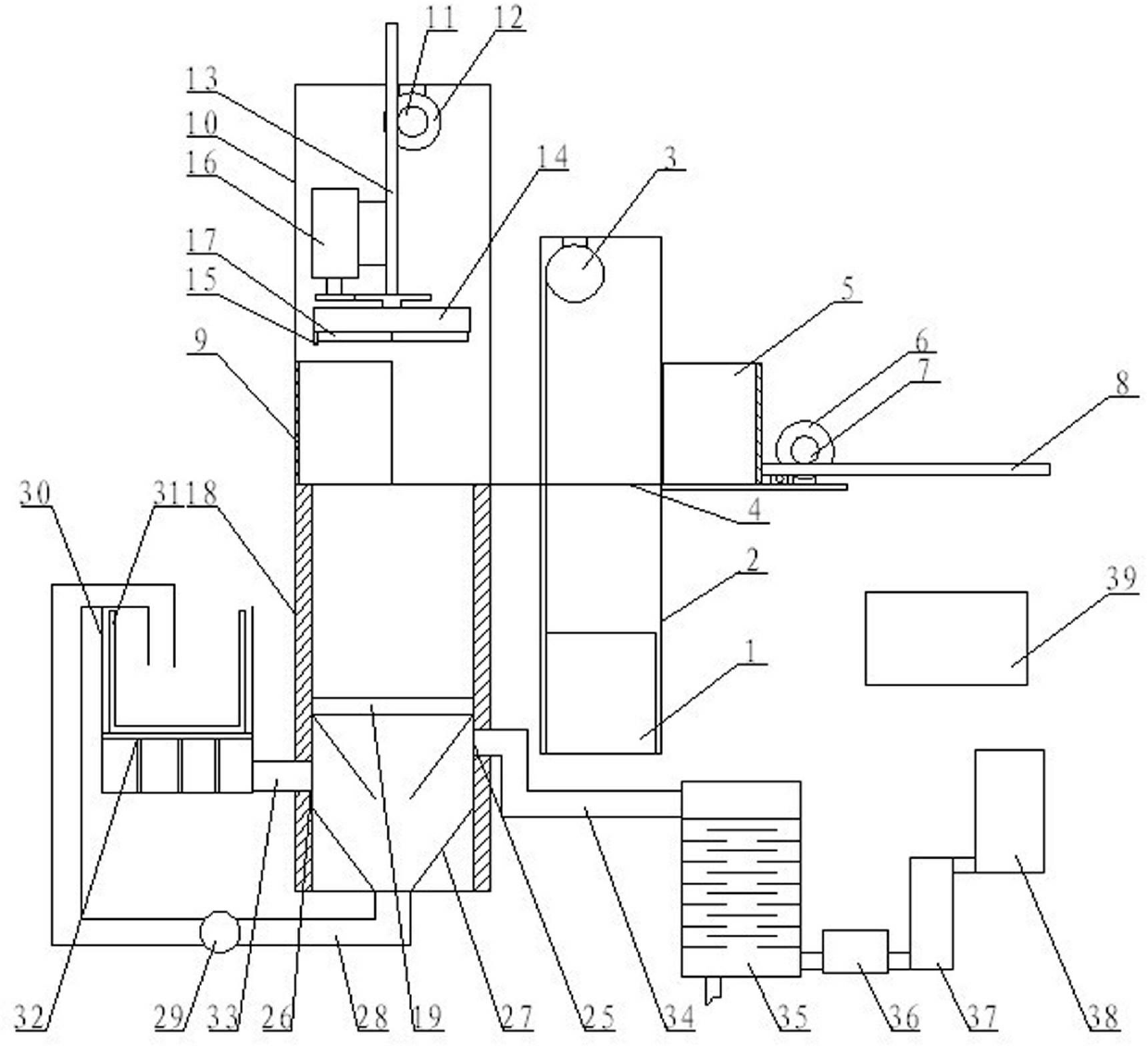

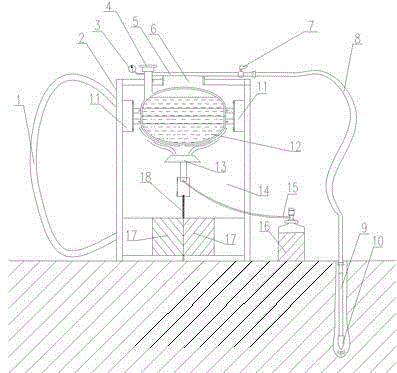

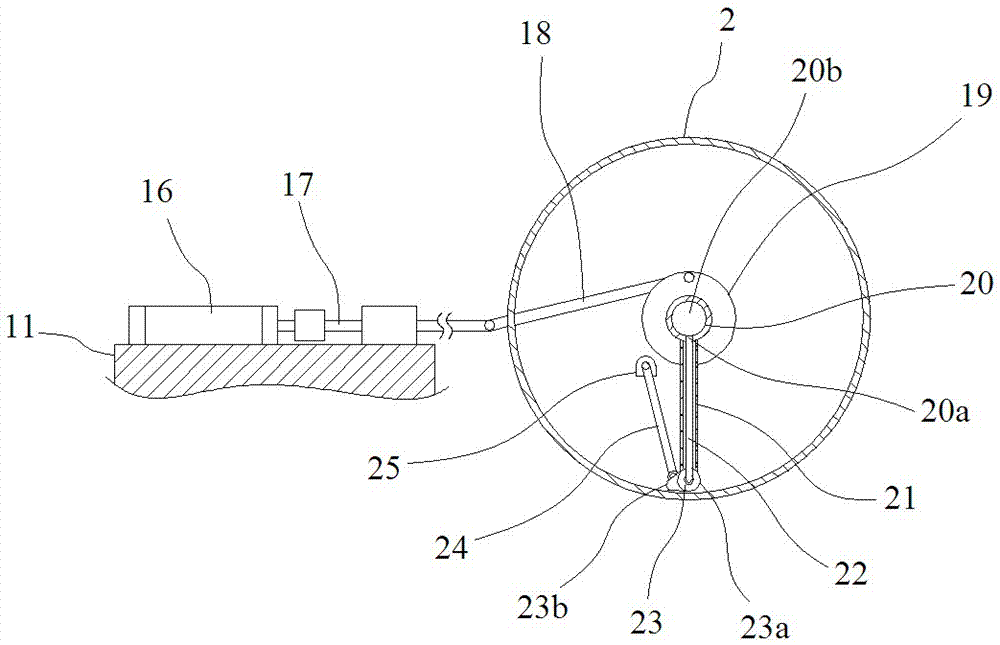

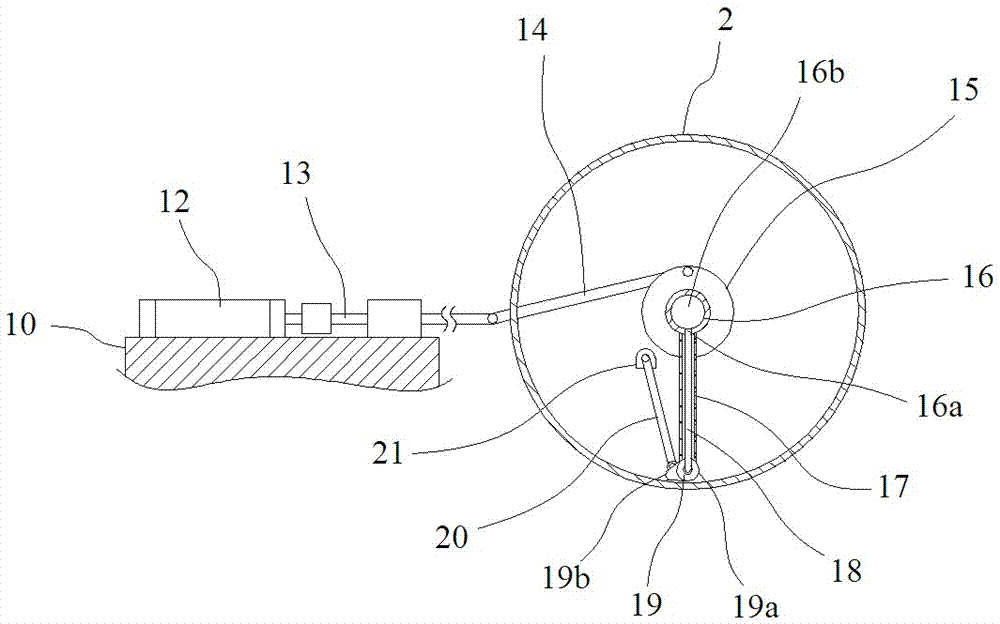

Novel straw direct gasification and poly-cogeneration device and preparation process

InactiveCN102329650AImprove gasification efficiencyUniform densitySpecial form destructive distillationFixed-bed gasificationFiltrationCogeneration

The invention relates to a novel straw direct gasification and poly-cogeneration device and preparation process. The device comprises a gasification furnace, a loading device, a pushing device, a pressing device, a distributing device, a carbon discharging device, a washing device, a fan, a water seal filtration device, a gas storage cabinet and a control cabinet. According to the invention, straw which does not need to be processed is directly fed into the gasification furnace for gasification through the loading, pushing, pressing and distributing devices, thereby effectively controlling straw cogenerated straw carbon and straw gas, matching a carbon shaving grate and the carbon discharging device to collect the straw carbon, carrying out labyrinth spraying and washing and separating the straw gas from straw extract, and filtering and collecting the straw gas in the water seal filtration device. The device has high reliability, good safety, strong practicability, simple gasification process, good gasification effect, high straw utilization ratio and low operation cost.

Owner:顾云江

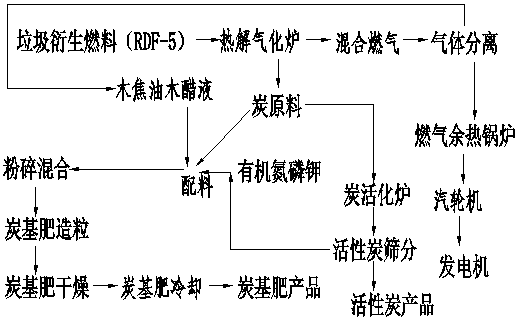

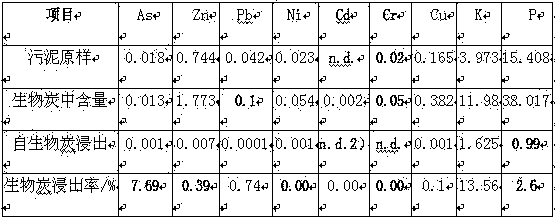

Heat and power cogeneration process for charcoal fertilizer and activated charcoal by taking municipal refuse derived fuel RDF-5 as raw material

InactiveCN108033446ACombined heat and powerEasy to storeCarbon compoundsOrganic fertilisersRefuse-derived fuelResource utilization

The invention discloses a heat and power cogeneration process for a charcoal fertilizer and activated charcoal by taking municipal refuse derived fuel RDF-5 as a raw material. The heat and power cogeneration process comprises the steps: 1) pyrolysis and gasification, namely delivering the fuel RDF-5 into a gasification furnace, carrying out pyrolysis and gasification under micro-aerobic conditionsthat the temperature is 600-800 DEG C and the equivalent ratio of air is 0.18-0.25 to obtain biomass mixed fuel gas and a biochar raw material, and discharging the biomass mixed fuel gas and the biochar raw material; 2) separation, namely purifying the biomass mixed fuel gas, and removing wood tar oil and a wood vinegar liquid to obtain a mixed liquid of the wood tar oil and the wood vinegar liquid and purified fuel gas; 3) combustion, namely delivering the purified fuel gas into a gas-fired boiler for combusting to generate steam; and 4) charcoal raw material treatment, namely delivering a part of the biochar raw material into a charcoal activation furnace to be heated to 900-960 DEG C, meanwhile, introducing the steam to the charcoal activation furnace to obtain activated charcoal; andmixing the other part of the biochar raw material with the mixed liquid of the wood tar oil and the wood vinegar liquid and an organic nitrogen, phosphorus and potassium fertilizer. The heat and powercogeneration process has the advantages of high calorific value utilization ratio and low emission pollution level and is not only capable of effectively solidifying poisonous heavy metals in the derived fuel, but also capable of obtaining a high-quality charcoal-based compound fertilizer or activated charcoal and increasing the resource utilization rate and the comprehensive economic benefit.

Owner:四川雷鸣生物环保工程有限公司

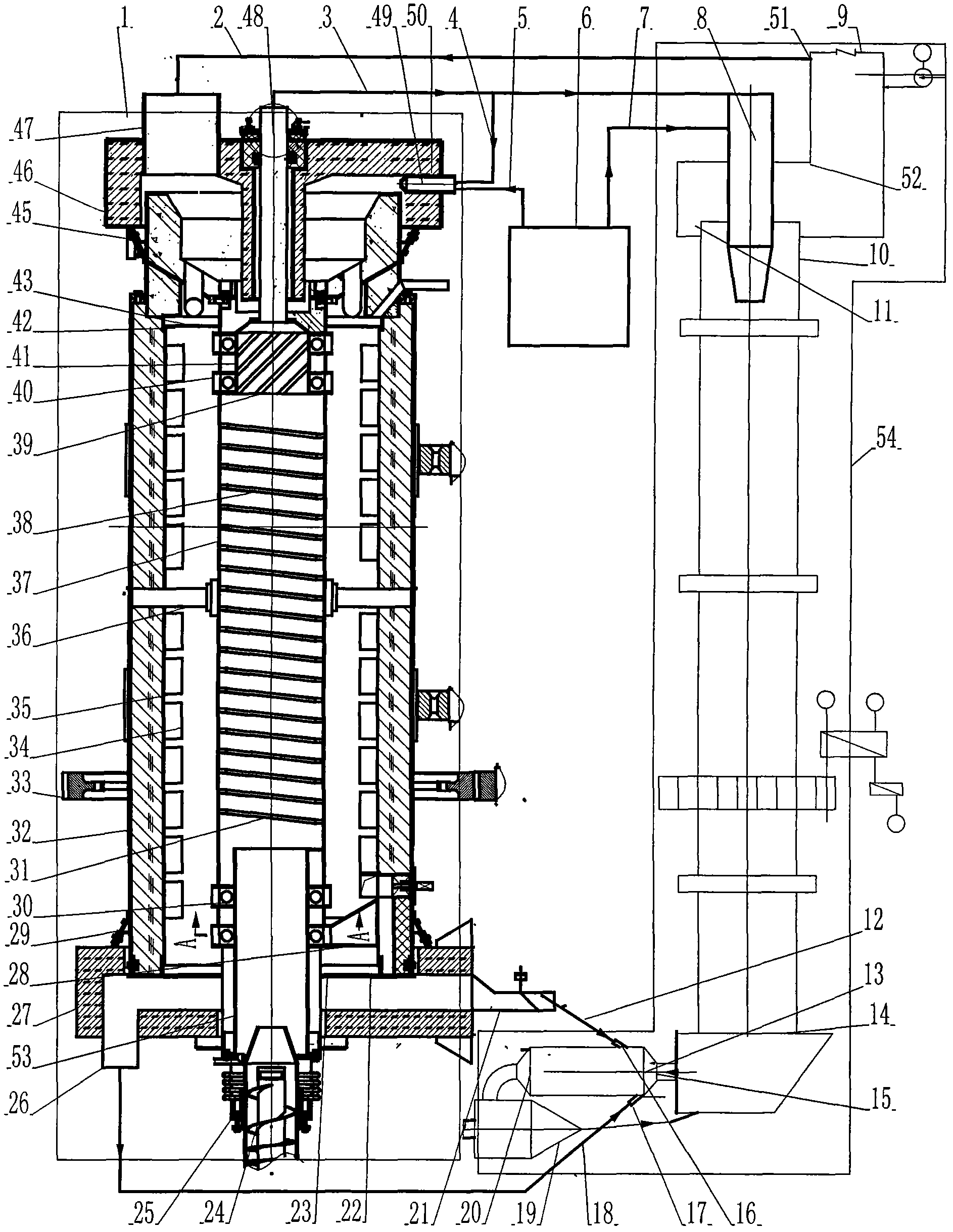

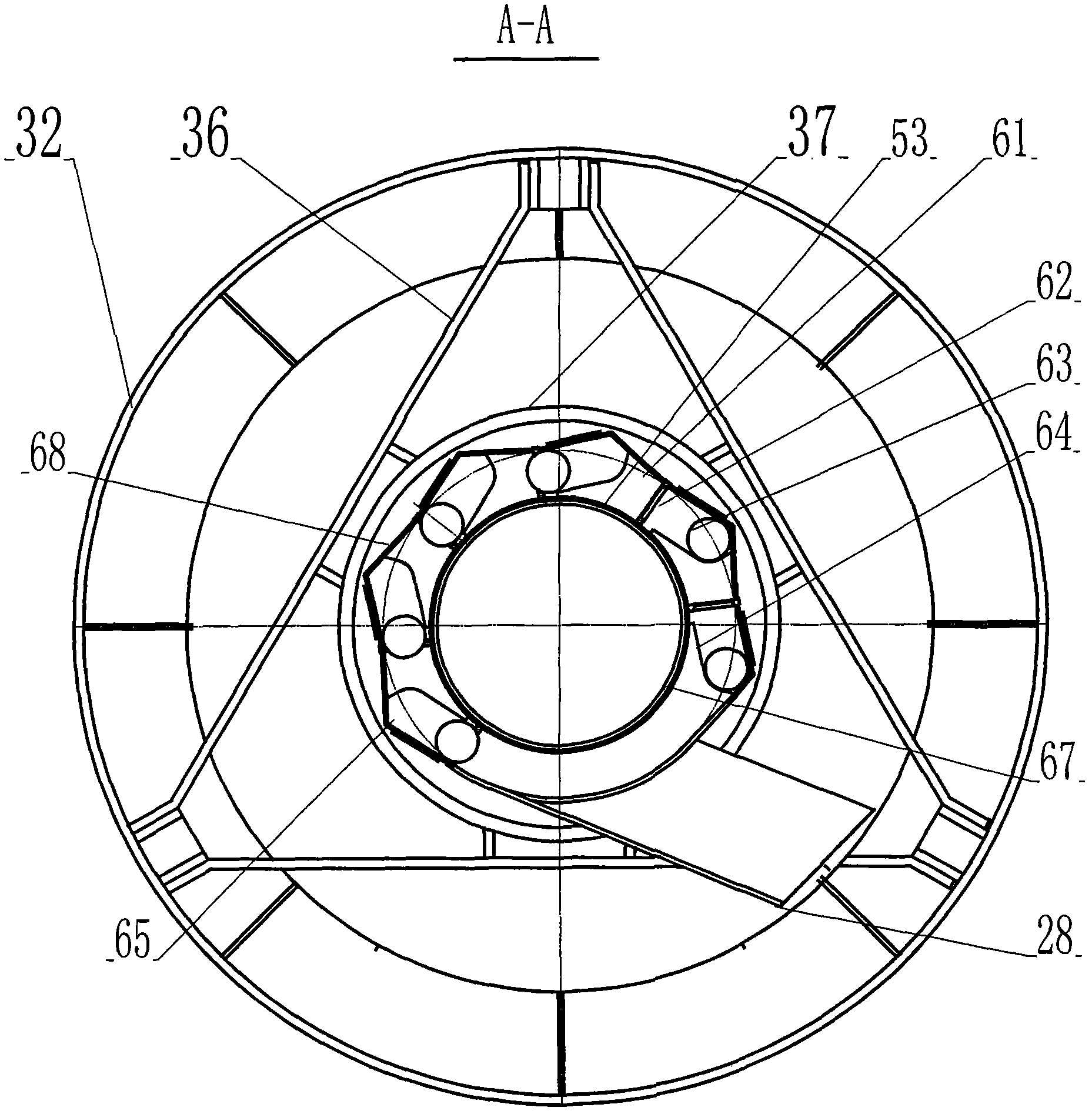

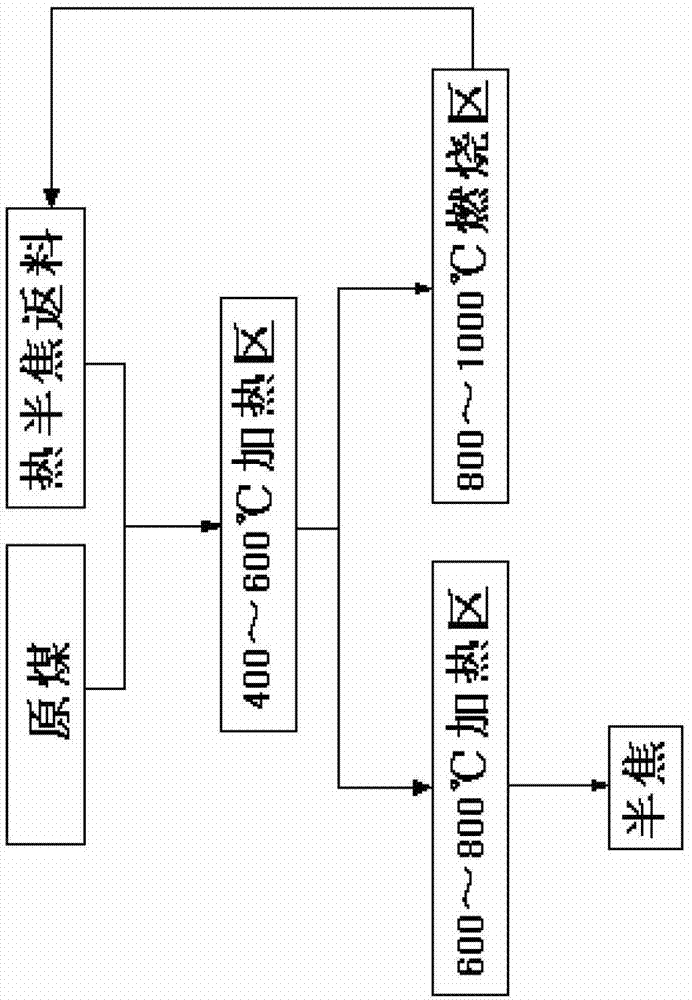

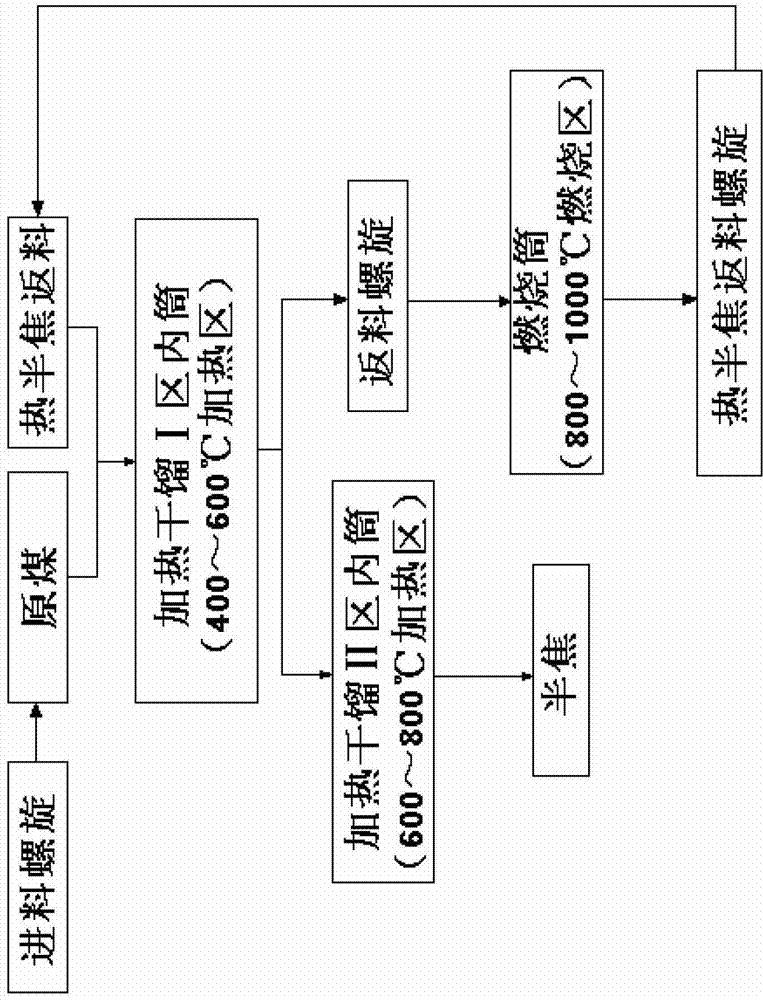

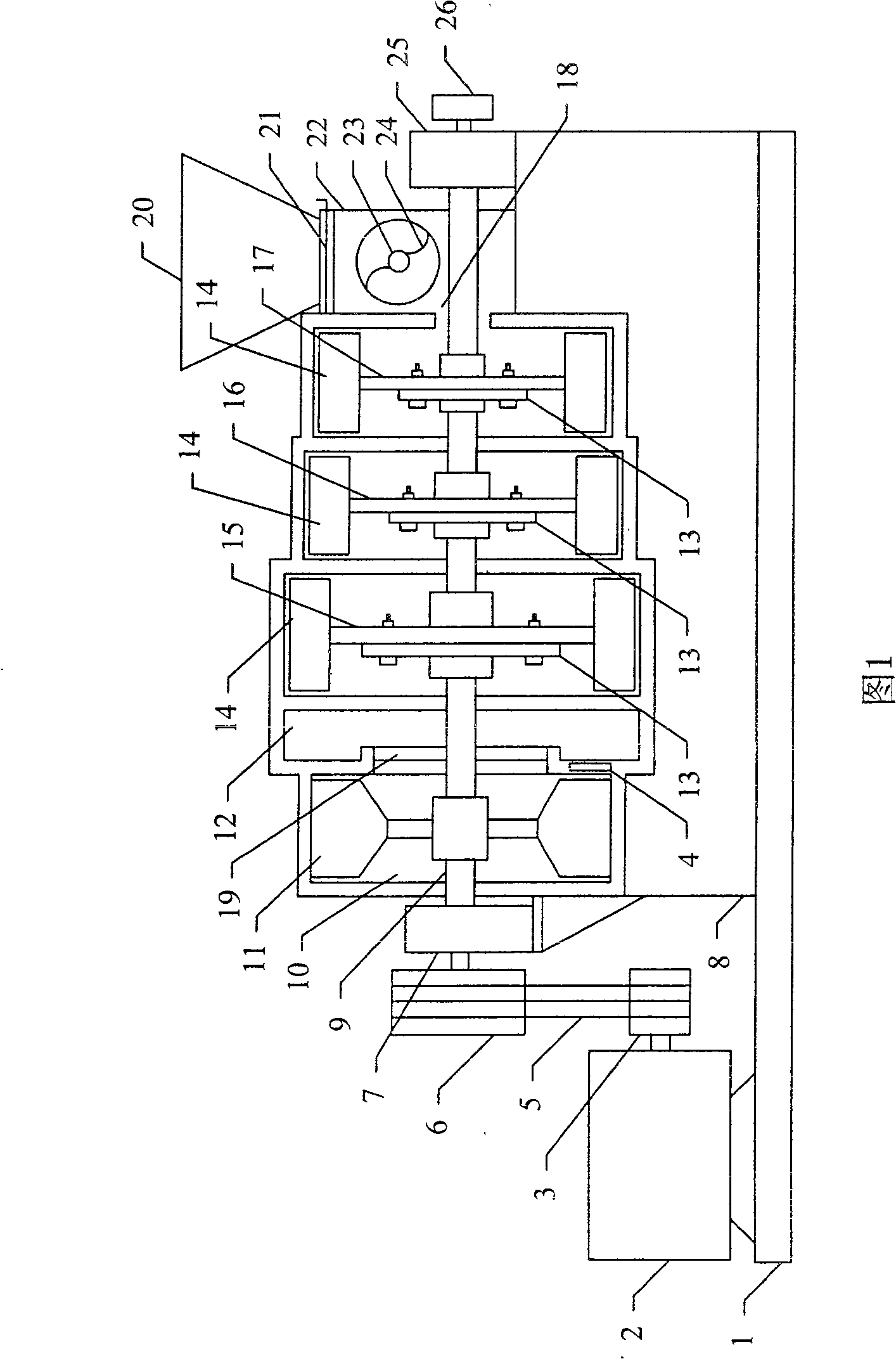

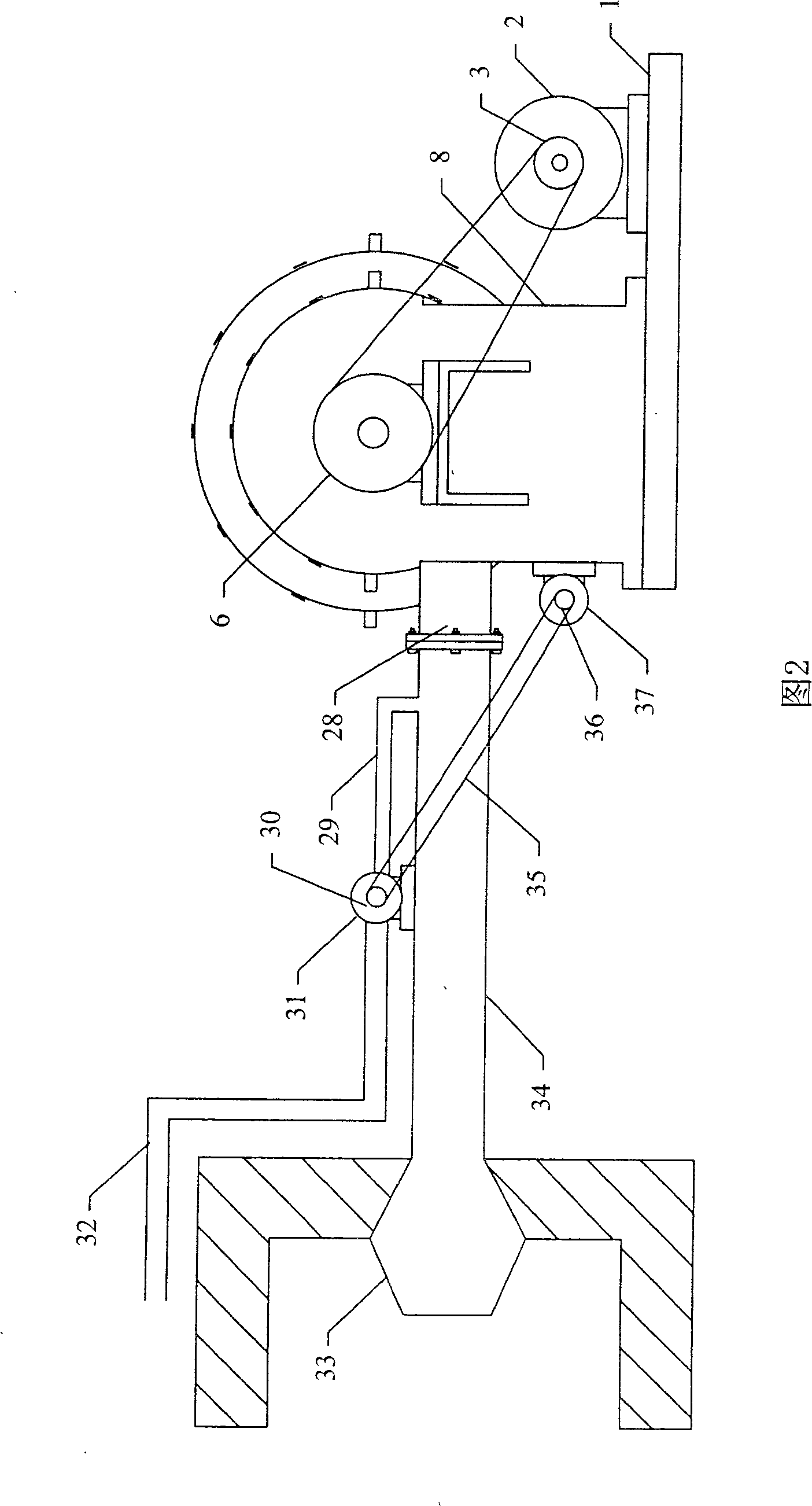

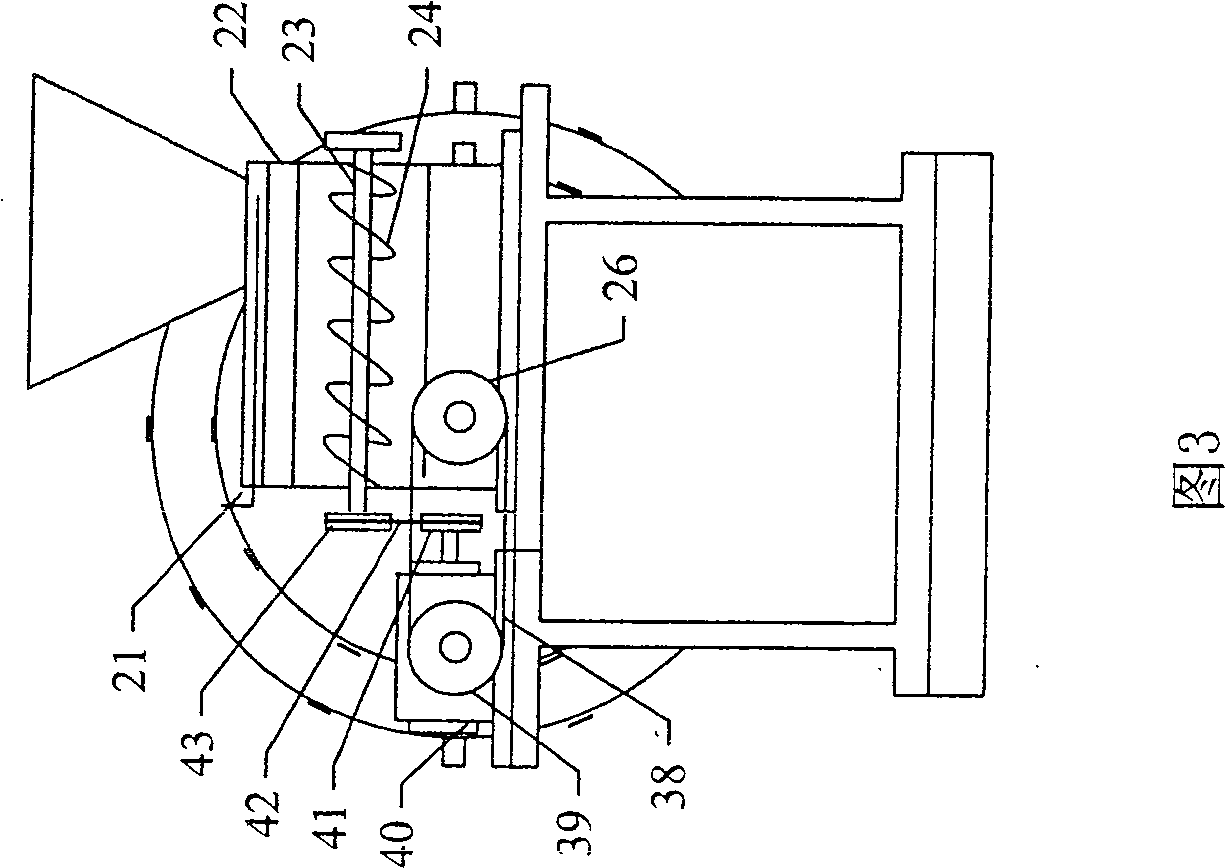

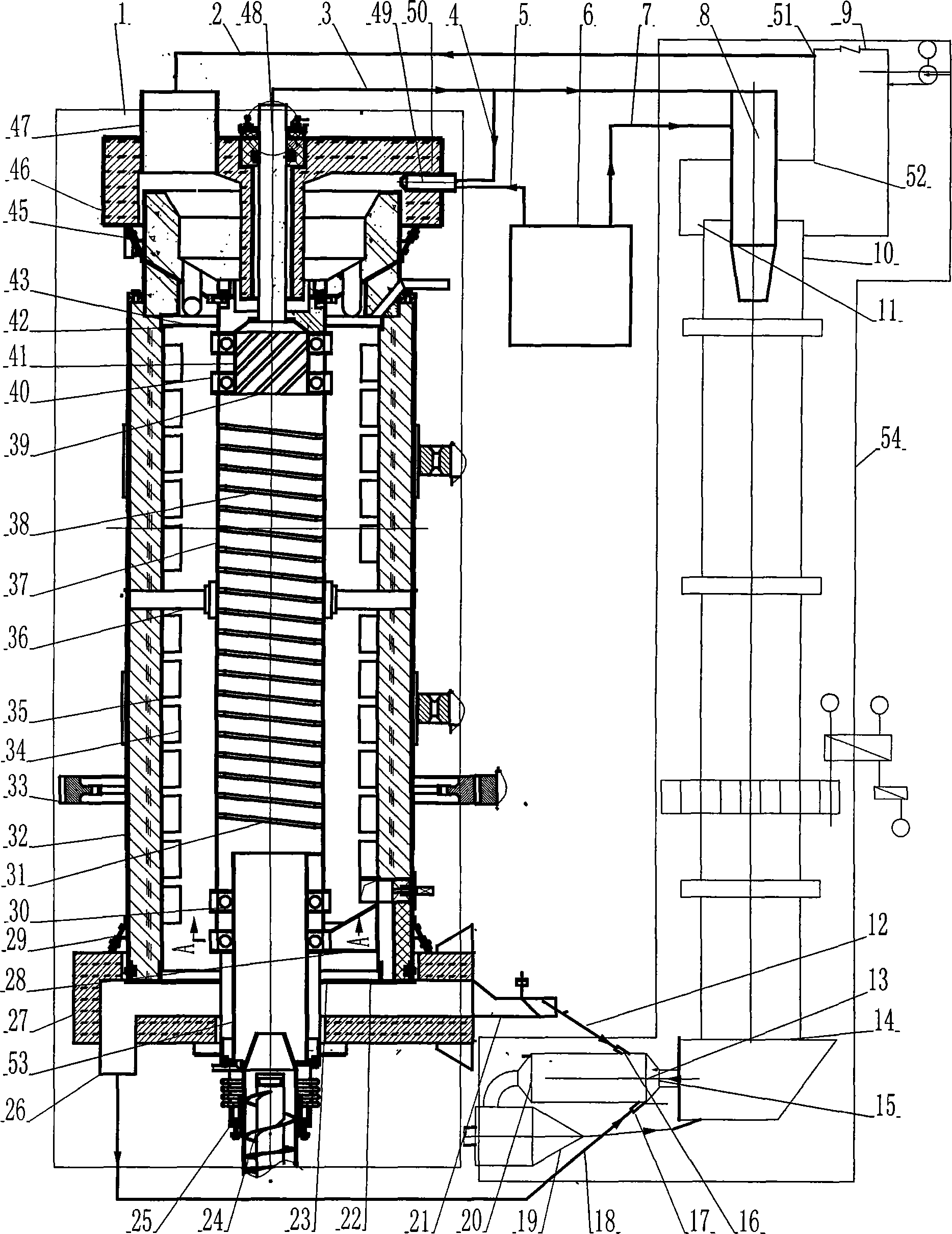

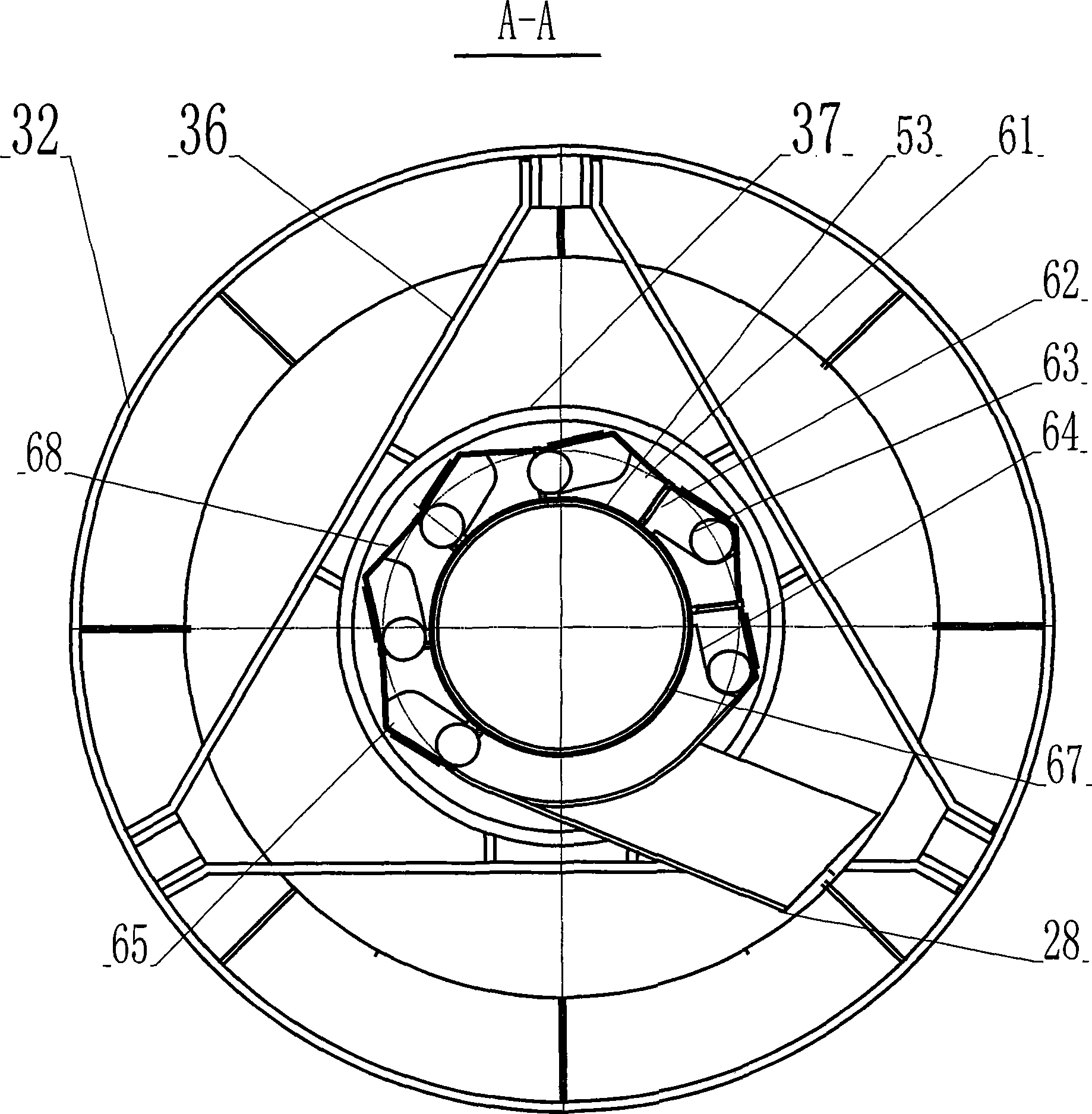

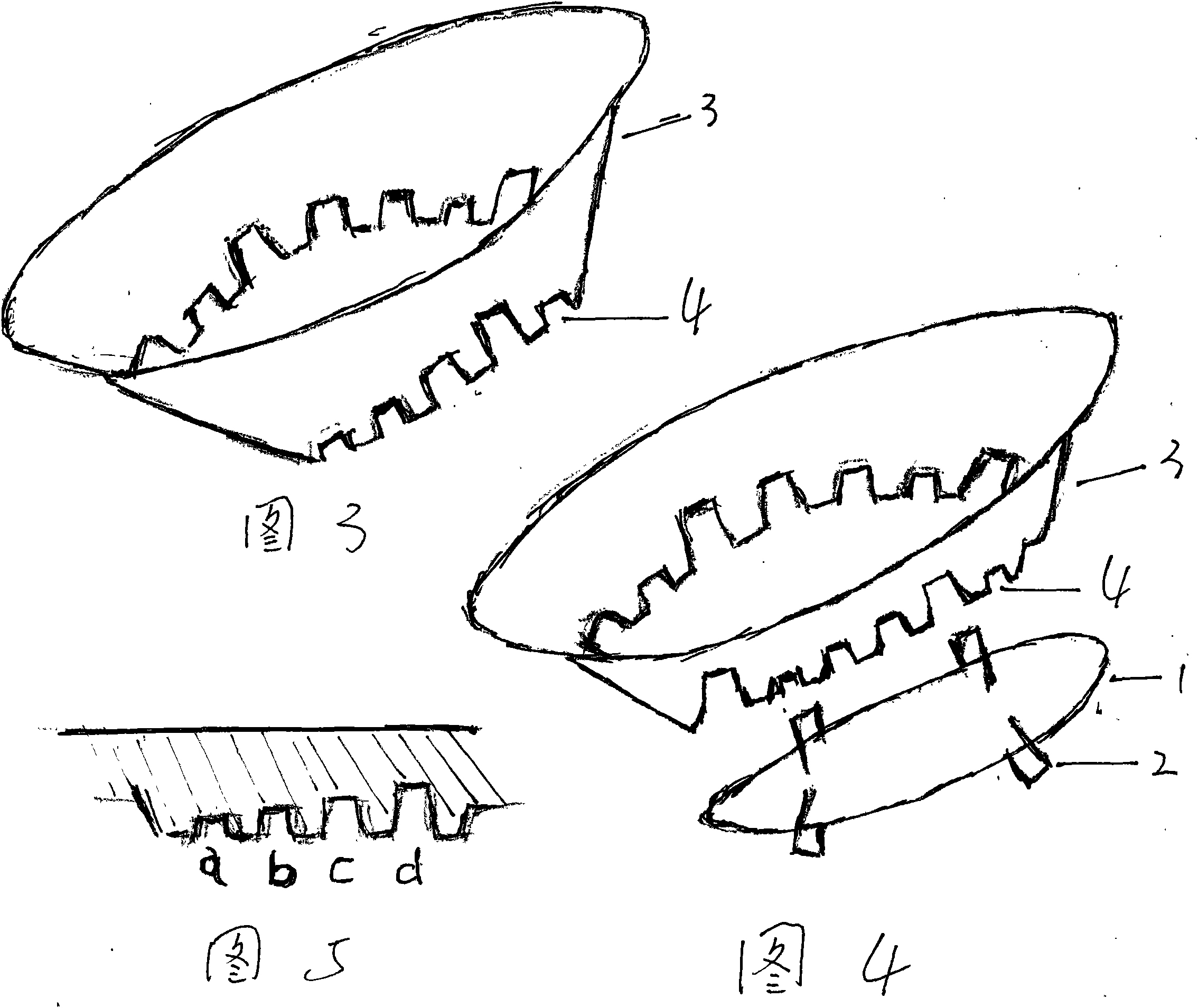

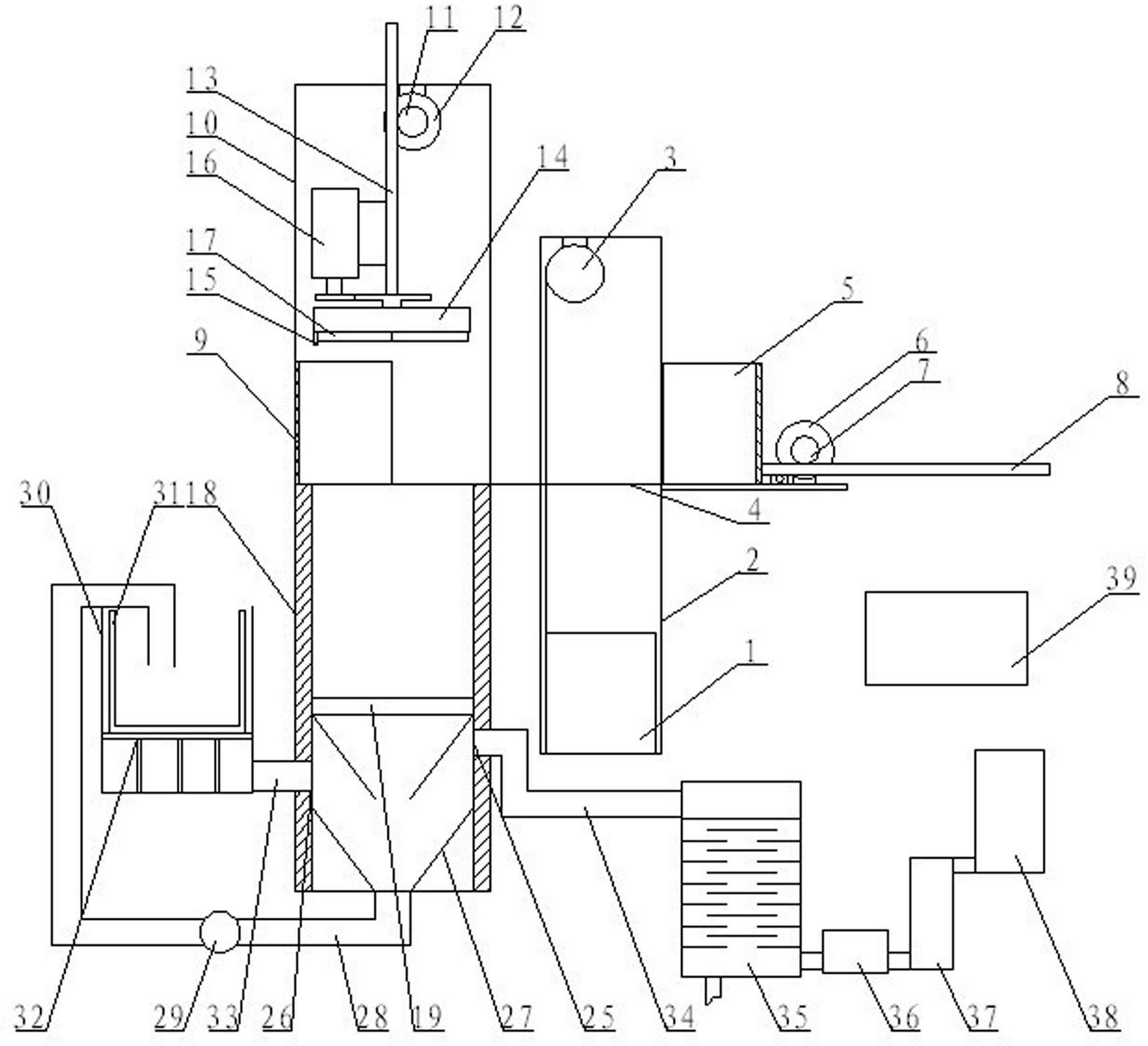

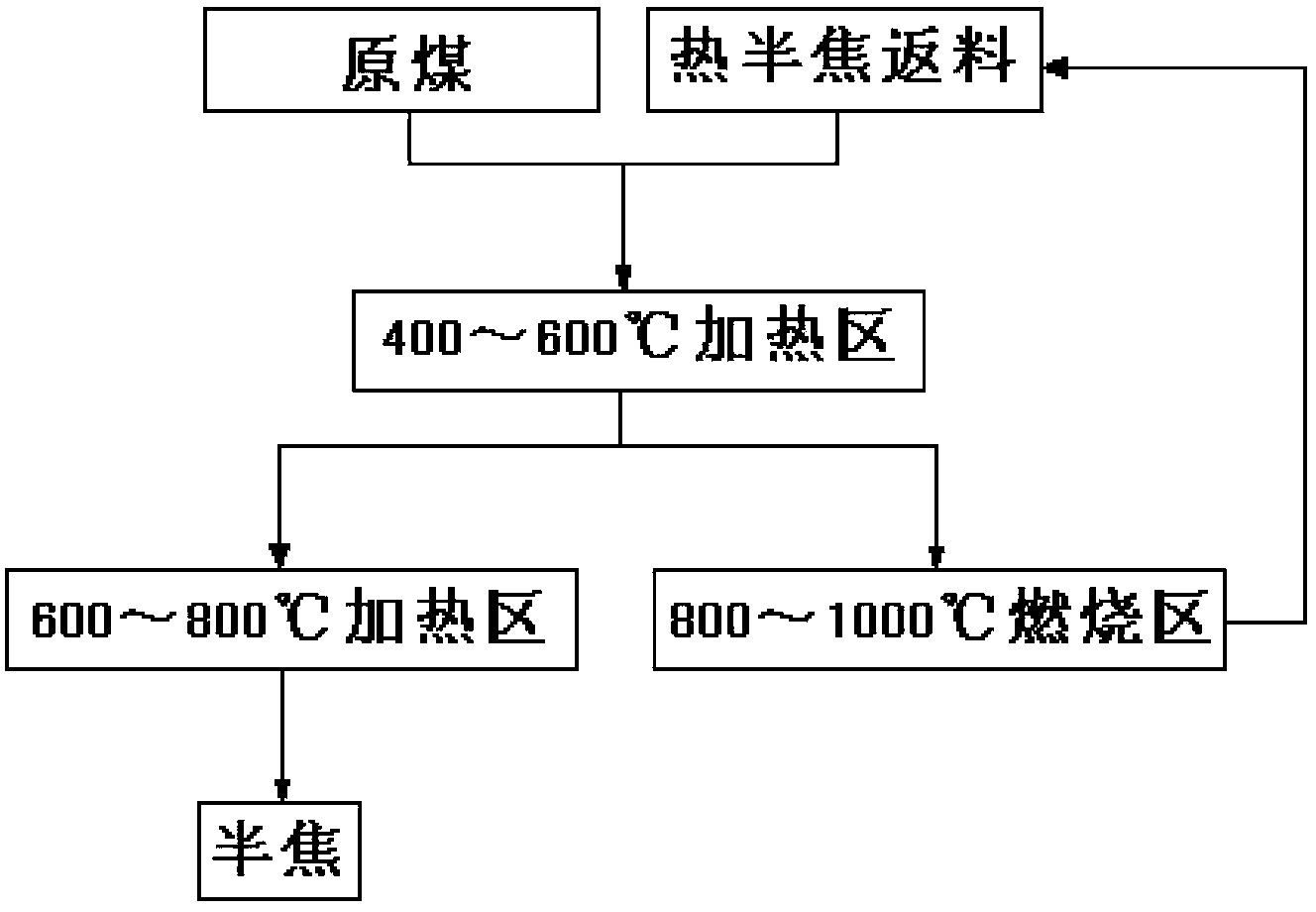

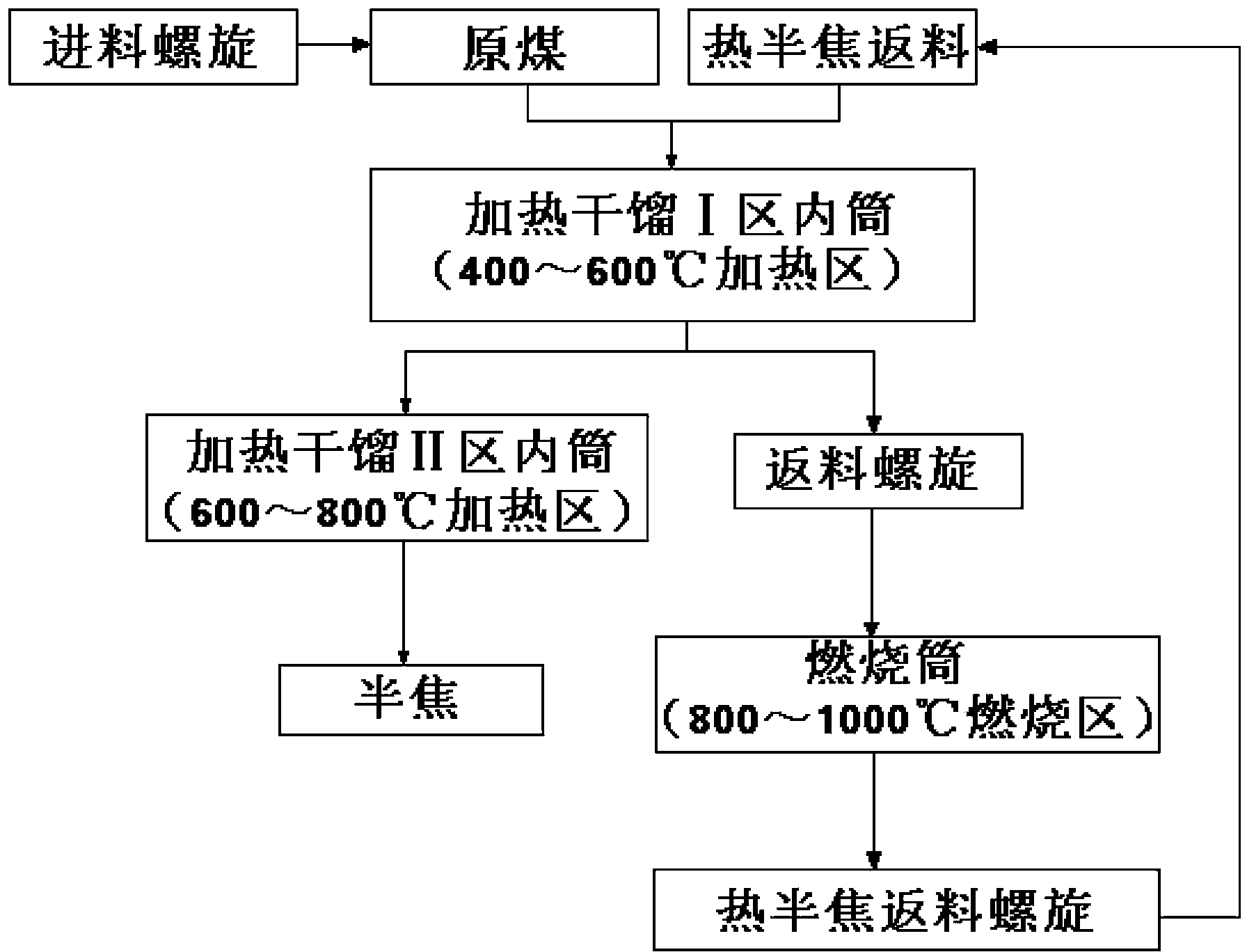

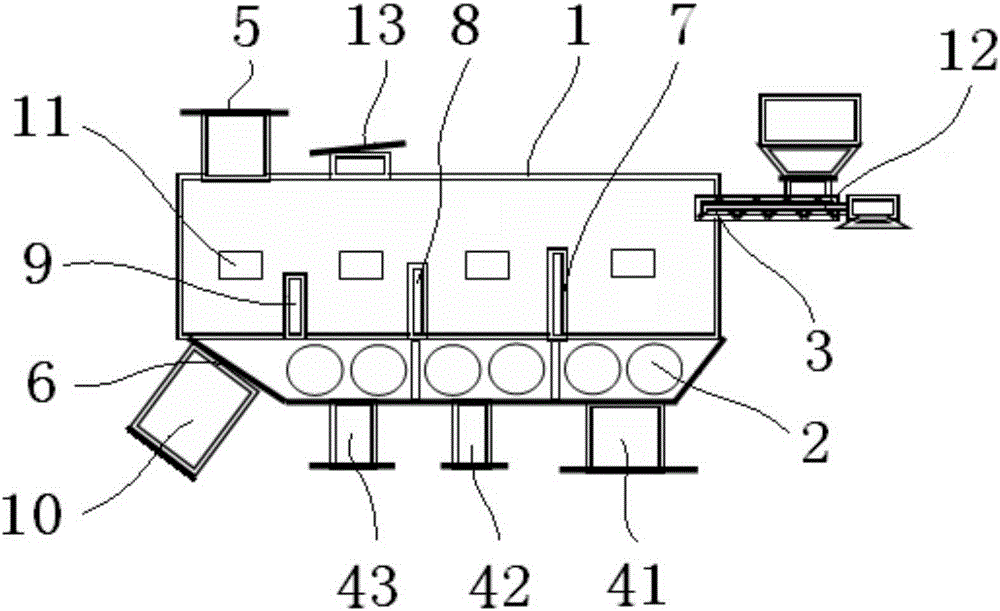

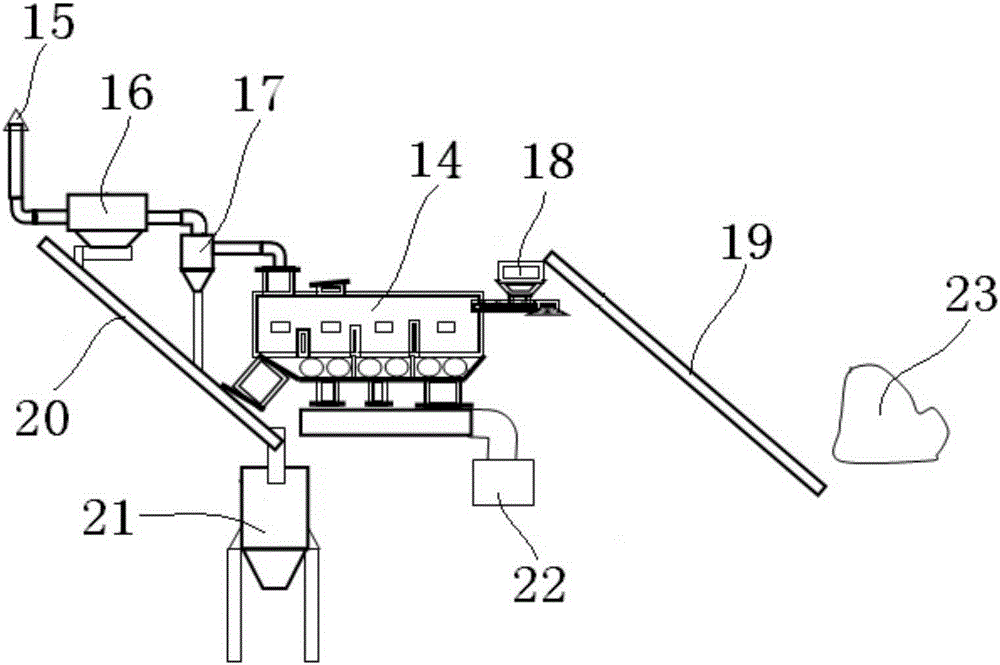

Coal dry distillation method and device for realizing same

ActiveCN102925175AImprove utilization efficiencyHigh calorific value utilizationCombustible gas coke oven heatingIndirect and direct heating destructive distillationFlueChemistry

The invention discloses a coal dry distillation method and a device for realizing the same, which are used for solving the problems of low heat value utilization rate and high equipment manufacturing cost of the existing external-heat dry distillation technology, coal gas mixing in nitrogen in the internal-heat dry distillation technology and difficult semi-coke conveying of the internal / external-heat combined dry distillation technology. In the invention, the coal is subjected to dry distillation sequentially through an external-heat heating area, an internal-heat combustion area and an external-heat heating area with different temperatures and is heated by taking the hot semi-coke generated in the internal-heat dry distillation area as raw material coal, and the smoke generated in the internal-heat heating area is discharged. The device comprises an outer barrel, an inner barrel and a flue between the outer barrel and the inner barrel, wherein a combustion barrel internally communicated with the flue is mounted in the inner barrel, and a horizontal return screw is arranged on the outer wall of the inner barrel and the combustion barrel, thus the coal heating and dry distillation time is prolonged; and meanwhile, the isolation between the direct and indirect heating of the smoke and the coal gas is realized, the quality of the coal gas is guaranteed, and the production efficiency and the dry distillation heat efficiency are improved.

Owner:榆林市榆神工业区能源科技发展有限公司

Centrifugal type composite coal-grinding and powder-spraying machine

InactiveCN100534625CBurn completelyReduce pollutionGrain treatmentsLump/pulverulent fuel feeder/distributionImpellerDusting powders

The invention discloses a centrifugal compound coal pulverizing machine, which is equipped with a main shaft in the base of the machine body, and three groups of flyweight bodies with different diameters are successively arranged in the middle of the main shaft. Fastened to the flange of the spindle. The front end of the machine body is provided with a fan compartment, and an induced fan is arranged in the fan compartment, and a powder outlet is arranged on the left side of the fan compartment, and a powder spray tube is installed on the powder outlet. The rear end of the machine body is provided with a screw feeder, the left side of the screw feeder is provided with a worm gear reducer, and the upper end of the screw feeder is provided with a feeding hopper. The invention is matched with the regenerated lead energy-saving smelting furnace, and the pulverized coal is sprayed into the furnace for combustion, so that the fuel cost is reduced by more than 66%. This product saves energy and reduces consumption, reduces pollution and increases efficiency. The appearance of this product fills the gap in the country and will provide an ideal replacement product for the smelting industry.

Owner:ANHUI HUAXIN LEAD IND GROUP

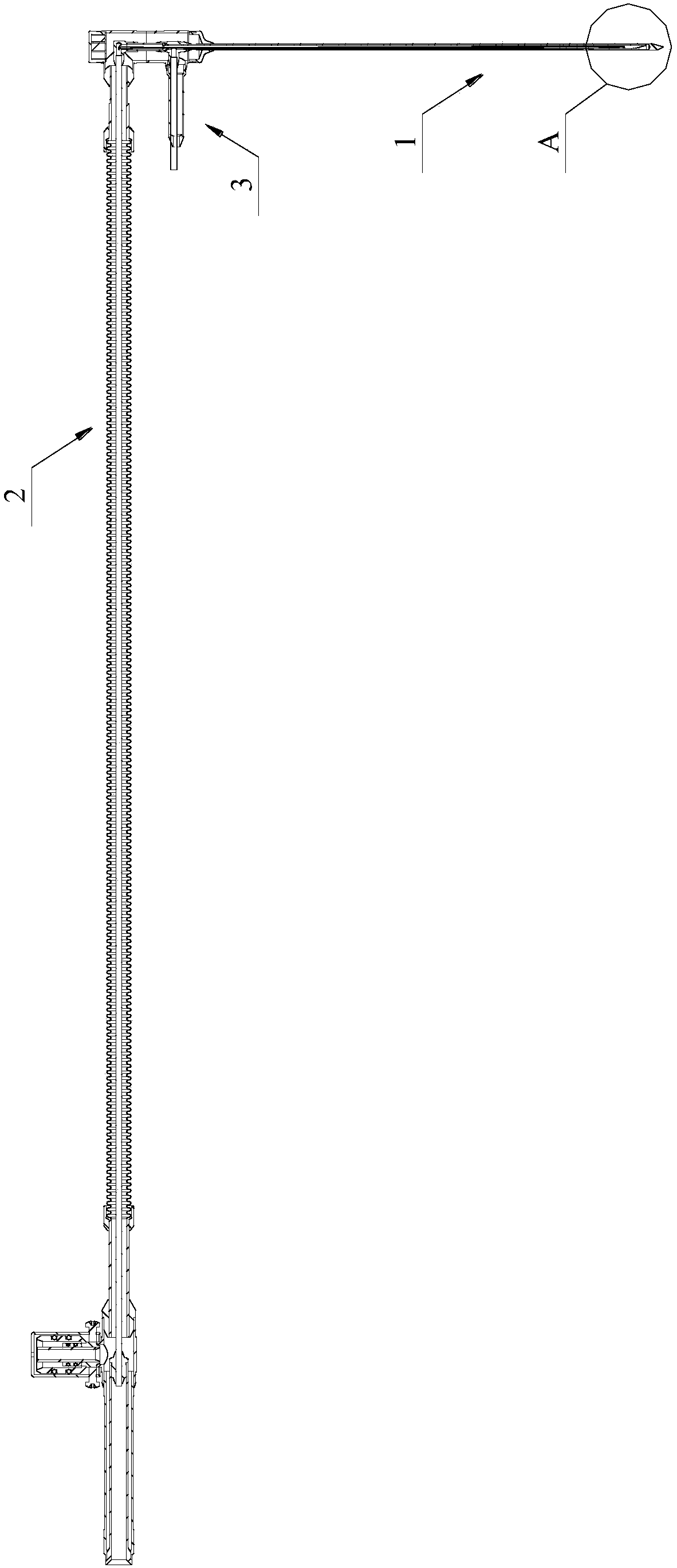

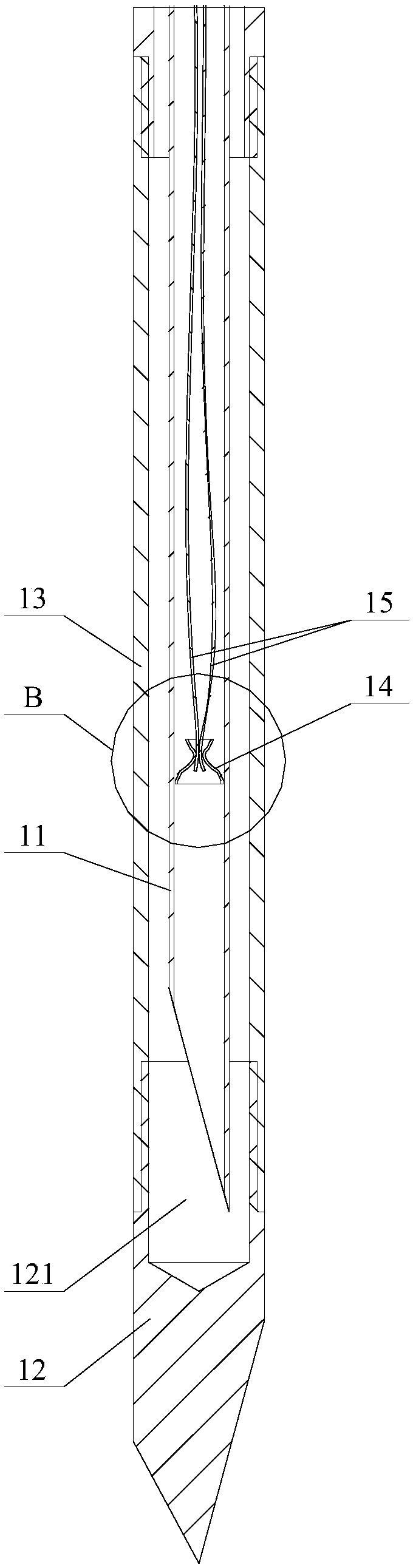

Steam engine for glacier drilling

InactiveCN104100203AHigh strengthReduce weightThermal drillingLiquid/gas jet drillingCombustion chamberGas cylinder

The invention discloses a steam engine for glacier drilling. The steam engine is structurally characterized in that a finned inner container is fixed by a bracket, and is placed in a combustion chamber, wherein a windshield is arranged at the bottom of the combustion chamber; the combustion chamber is wrapped by a heat-preservation jacket, and is connected with a strap; a water filling pipe with a safety valve and a pressure gauge are connected to the upper part of the finned inner container; one end of a steam outlet pipe is connected with the water filling pipe with the safety valve, and the other end of the steam outlet pipe is sequentially connected with a high-pressure heat-preservation rubber pipe, a drill pipe and a steam nozzle through a steam valve; a heating furnace head is arranged on the lower part of the finned inner container, and is connected with a mountain air pipe and regulation valve and an air bottle. According to the steam engine, the accessory equipment of the steam engine is safely, reliably and conveniently connected through quick joints; the steam engine is convenient to carry, easy to operate, safe and reliable, and can be used for drilling a lining pole hole and a temperature hole under a field condition, and necessary technical guarantee is provided for monitoring glacier changes.

Owner:COLD & ARID REGIONS ENVIRONMENTAL & ENG RES INST CHINESE

Pyrolysis garbage technology performed by means of double-cylinder rotary kiln

ActiveCN102706140BHigh calorific value utilizationAvoid build conditionsRotary drum furnacesEnergy inputProduction lineSlag

The invention belongs to the technical field of environmental engineering, and provides a pyrolysis garbage technology performed by means of a double-cylinder rotary kiln. The pyrolysis garbage technology performed by means of the double-cylinder rotary kiln includes the double-cylinder rotary kiln, a cement production line and technology connection pipelines, wherein the double-cylinder rotary kiln includes a pyrolysis passage, an ash heat return passage, a kiln head cover and a kiln tail cover; the cement production line includes a cement rotary kiln, a clinker cooling machine and a predecomposition furnace; and the technology connection pipelines include a tertiary air pipeline for communicating the clinker cooling machine with the kiln tail cover, a composite gas pipeline for communicating the cement rotary kiln with the kiln tail cover, a composite gas shunting pipeline for communicating the ash heat return passage with a composite gas eduction pipe of the kiln tail cover, a waste gas waste heat pipeline for communicating a side hot air inlet of the predecomposition furnace with a waste gas exhaust connector of the kiln head cover, and a garbage slag pipeline for communicating a side feed opening of the predecomposition furnace with a garbage slag outlet of the kiln head cover. The technology is utilized for processing domestic garbage with the cement rotary kiln for cooperation, utilizes the high-temperature pyrolysis garbage cooled by cement clinker to effectively avoid the dioxin generation conditions during the garbage incineration, and effectively utilizes the heat value of garbage, and further completely utilizes the garbage ash in a recycling manner.

Owner:JIANGSU PENGFEI GROUP

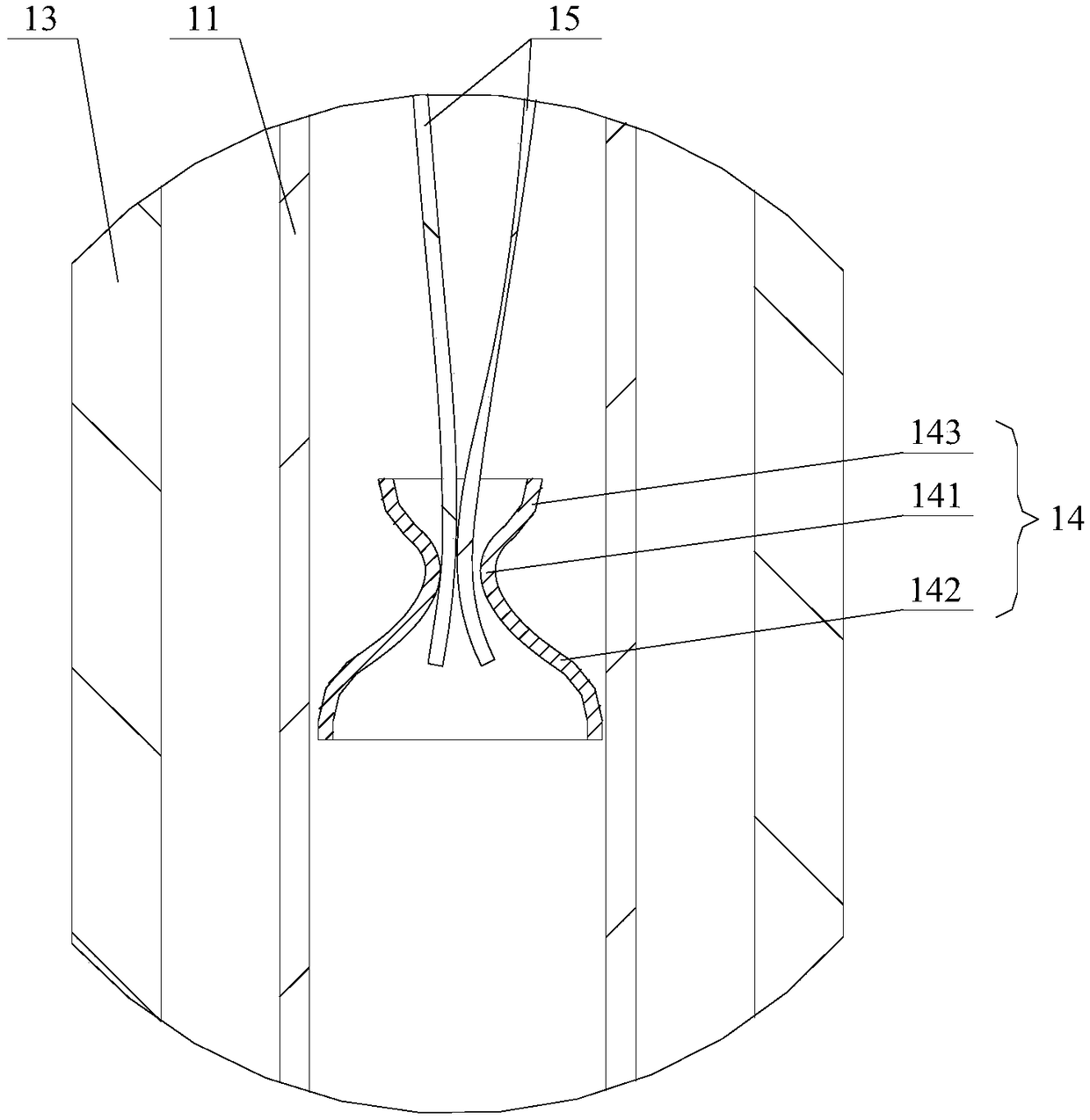

Cryoablation needle and system using same

ActiveCN109171948AHigh calorific value utilizationReduce dosageSurgical instruments for coolingThroatCombustion chamber

The invention discloses a cryoablation needle and a system using the same. The cryoablation needle comprises a needle body, a inlet core tube of the needle body is inserted into an internal cavity ofthe needle tip to form an internal medium circuit. The combustor separator is arranged in the outlet end pipe section of the inlet core pipe so as to form a combustor in the internal cavity between the combustor separator and the needle tip part. The combustor separator is arranged in the outlet end pipe section of the inlet core pipe. The combustor partition has a through-flow throat and a partition extending from the throat to the outlet end, and is configured such that the through-flow cross section from the through-flow throat to the partition is gradually increased. The ignition end of the electronic ignition lead is inserted into the combustor partition and protrudes into the combustor to ignite the ablation combustible mixture gas inputted into the combustor through the internal medium circuit. The scheme makes full use of the combustibility of the ablation medium, can release a lot of energy in a short time by raising the temperature, can effectively improve the calorific valueutilization rate of the gas, reduce the amount of alcohol and greatly reduce the operation time.

Owner:LISHUI CENT HOSPITAL

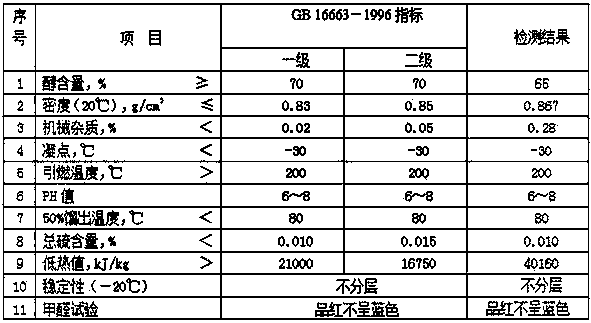

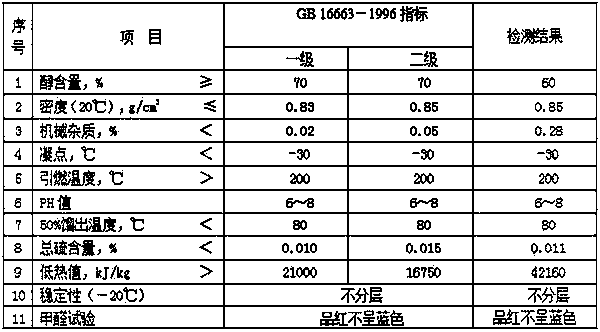

High-clear alcohol-based fuel oil

The invention relates to high-clear alcohol-based fuel oil and belongs to the technical field of fuel processing. The high-clear alcohol-based fuel oil comprises the following components in part by weight: 0.03 to 0.05 part of ferrocene, 25 to 40 parts of absorber oil, 60 to 75 parts of methanol, 1 to 2 parts of toluene, 2 to 3 parts of acetone and 2 parts of isobutanol. In the high-clear alcohol-based fuel oil, the added ferrocene improves the anti-detonating quality of the high-clear alcohol-based fuel oil and has the functions of reducing carbon accumulation in a spray nozzle and assisting combustion; and the added acetone, toluene, isobutanol, methanol and absorber oil, which are organic phases, are mixed, so the intersolubility and swelling performance of the components of the high-clear alcohol-based fuel oil are improved; and the oxygen content is improved to make combustion complete and the emission of carbon oxide compounds is reduced, so the calorific value is improved and an energy-saving and environment-friendly effect is achieved.

Owner:SUIPING CHEM FACTORY OF CHINA PINGMEI SHENMA GRP LANTIAN CHEM

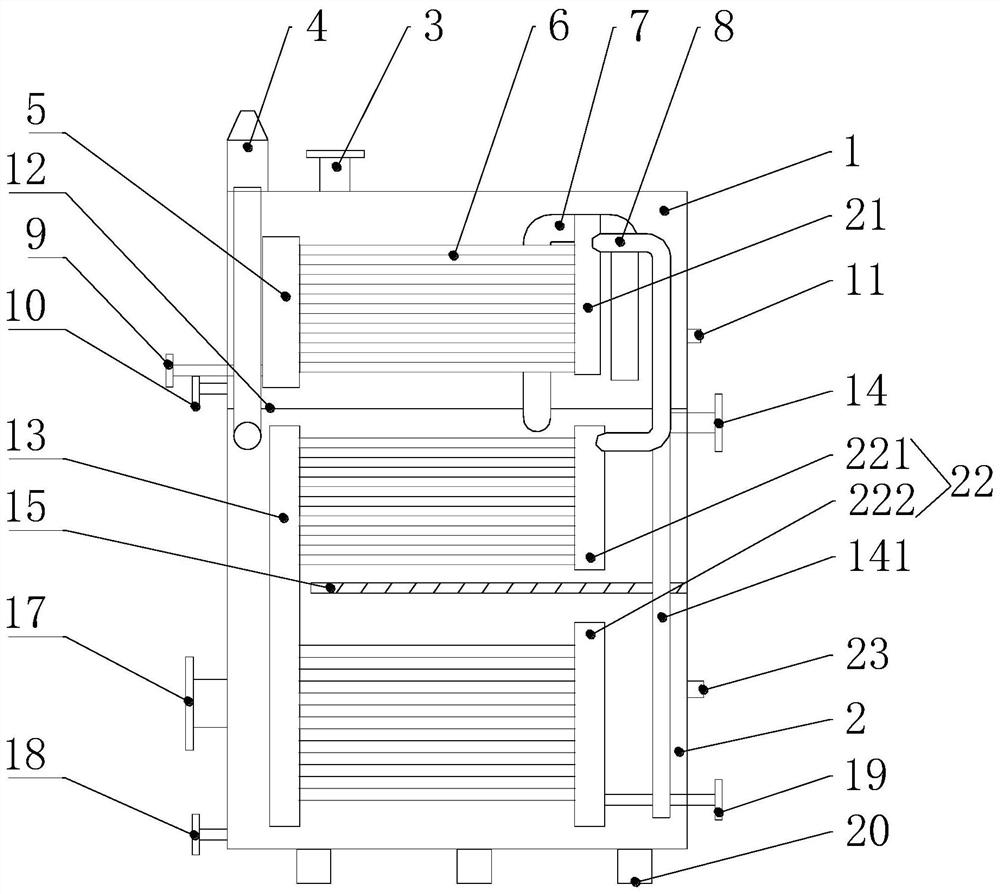

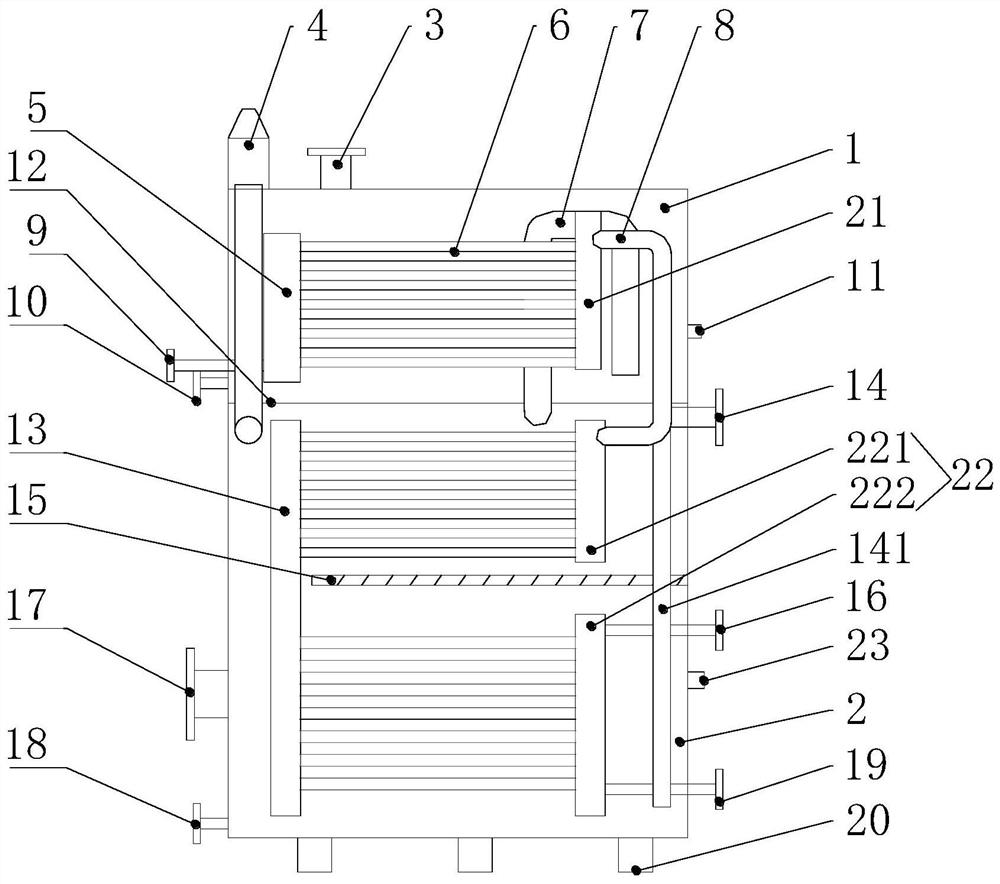

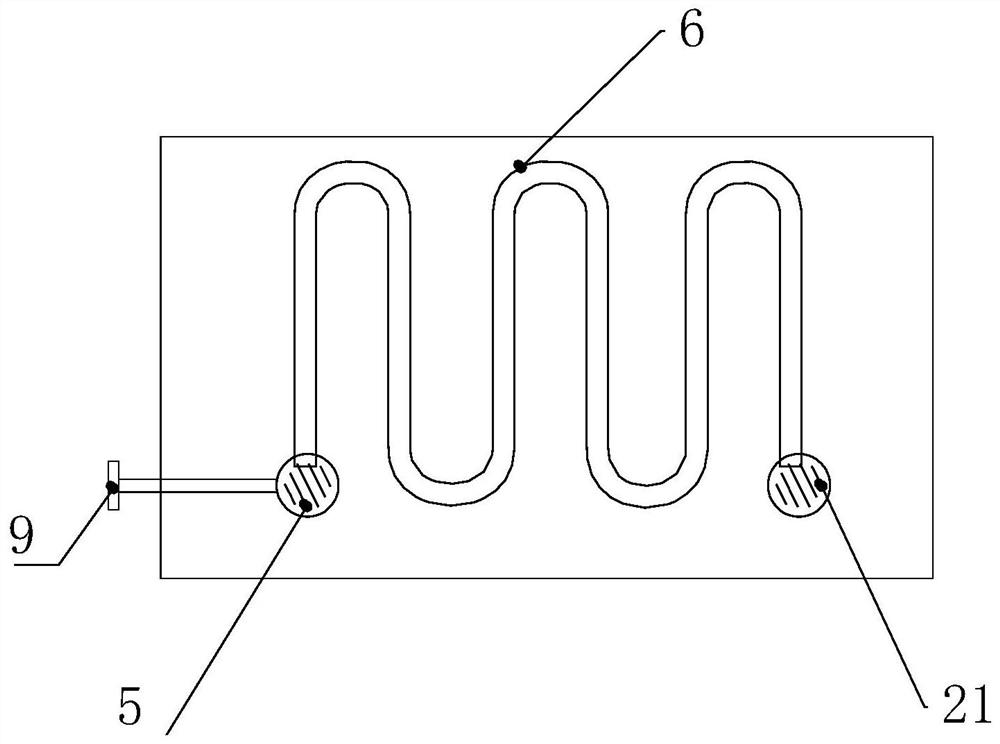

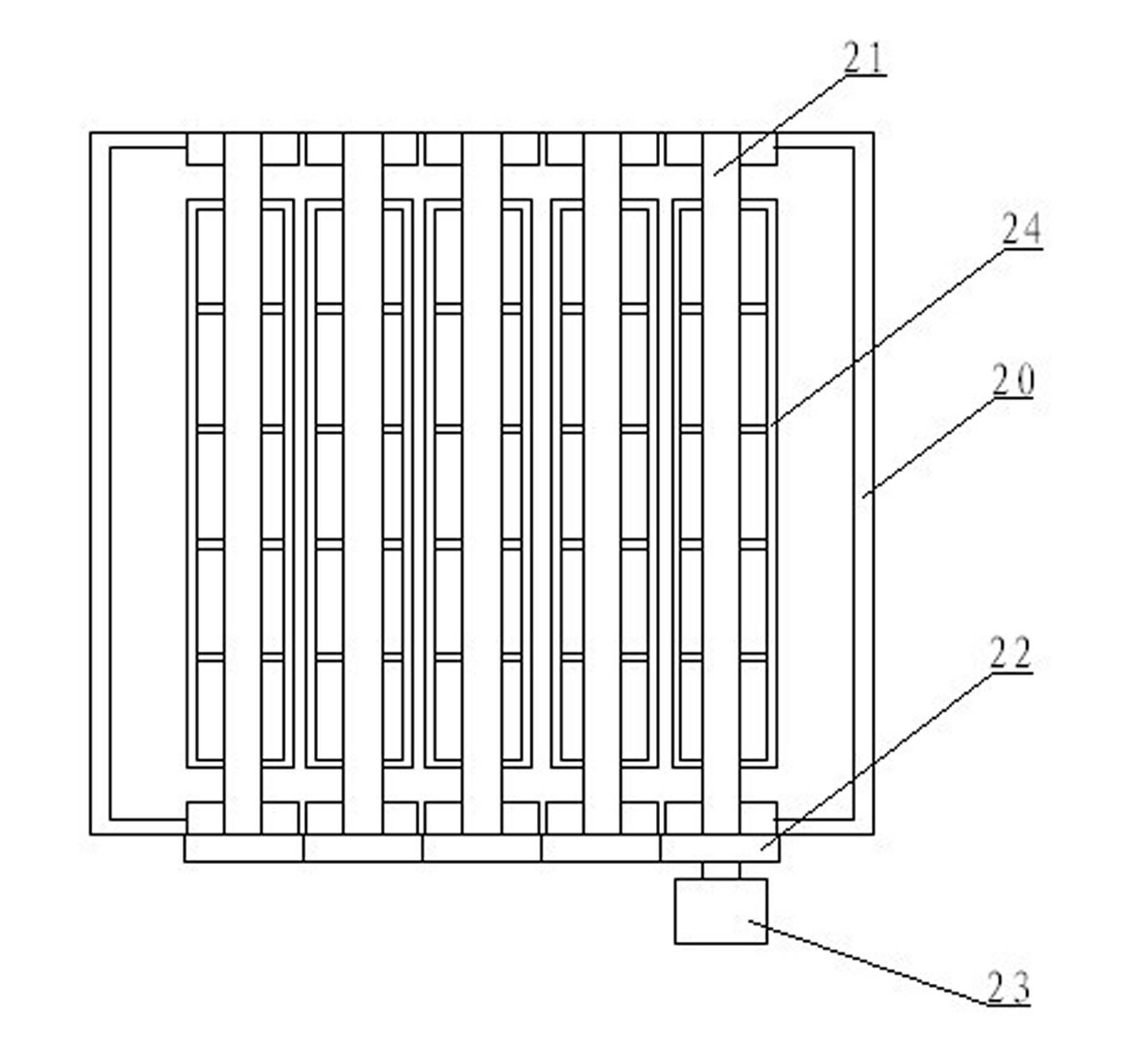

Combined multi-stage energy saver of equipment for recycling residual steam of waste water and waste heat

PendingCN111811310AGuaranteed uptimeCompact structureHeat recovery systemsRecuperative heat exchangersThermodynamicsWastewater

The invention relates to the field of waste water and waste heat recycling, in particular to equipment for recycling residual steam of waste water and waste heat. The equipment is provided with an energy collector and an energy saver, wherein the energy collector and the energy saver are both of a box body structure; the energy collector is installed on the upper part of the energy saver and separated from the energy saver by a bin clamping plate; a first header, a second header, a snakelike pipe, a box body guide pipe and a waste heat guide pipe are arranged in the energy collector; an energystorage inlet device and a condensed water discharge pipe seat are arranged outside the energy collector; a left header, a right header and a snakelike pipe are arranged in the energy saver; and an energy storage discharge device and a residual steam inlet pipe seat are arranged outside the energy saver. The equipment for recycling the residual steam of the waste water and the waste heat has theadvantages of compact structure, convenient operation, smooth running of the residual steam of the waste heat, reverse movement of the energy storage and the residual steam of the waste heat, scientific heat exchange process principle, and high utilization efficiency; and the equipment has a three-stage heat exchange process to ensure the maximum utilization of the residual steam of the waste heat, and a large temperature difference between the energy storage and waste heat is always kept in the three-stage heat exchange process, so that the heat value utilization rate is fully improved, and the heat exchange efficiency is high.

Owner:王国兴 +1

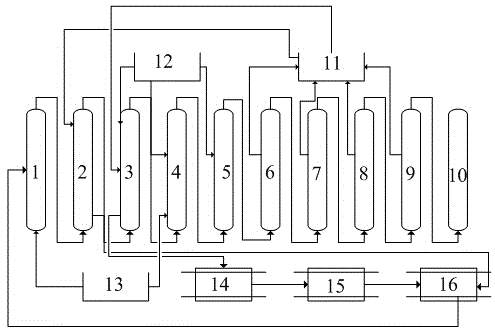

Industrialized preparation method of 2-carboxyl-3-naphthalene formic acid

InactiveCN104892406AIncrease profitProcess conditions Environmental protection and energy savingOrganic compound preparationCarboxylic compound separation/purificationHydration reactionFiltration

The invention discloses an industrialized preparation method of 2-carboxyl-3-naphthalene formic acid. The 2-carboxyl-3-naphthalene formic acid is prepared by feeding raw materials into a first reaction tower, a carboxylation reaction tower, a second reaction tower, a neutralization reaction tower, an acidification reaction tower, a filter pressing reaction tower, a refined filtration reaction tower, a hydration reaction tower, a reaction tower and a finished product storage tower in turn. The 2-carboxyl-3-naphthalene formic acid is high in product purity up to over 98.89%, high in smelting point up to 220 DEG C, low in crystallization rate less than 3% and is yellowish-brown.

Owner:张晨

Alcohol-based fuel combustion improver and alcohol-based fuel

ActiveCN103265981BBurn fullyIncrease the calorific value of combustionLiquid carbonaceous fuelsCombustionAlcohol

The invention discloses an alcohol-based fuel combustion improver and an alcohol-based fuel. The alcohol-based fuel combustion improver consists of 4.9-93 parts by weight of co-solvent, 4.9-93 parts by weight of bio-oil, 0.1-0.3 part by weight of smoke suppression combustion improver and 1.0-3.0 parts by weight of combustion improver; and the alcohol-based fuel is formed by mixing and stirring 80-99 parts by weight of methanol and 1-20 parts by weight of alcohol-based fuel combustion improver. By adopting the combustion improver disclosed by the invention, the prepared alcohol-based fuel is a novel biological environment-friendly alcohol-based fuel, the calorific value is as high as 6,000-10,000 calories / g, and the combustion performance is good; and moreover, the alcohol-based fuel has high flash point and low volatility, and potential safety hazards in the prior art are eliminated. The alcohol-based fuel disclosed by the invention also has the characteristics of being safe and environment-friendly, reproducible, clean and sanitary, convenient to use, cheap and the like.

Owner:QINGYUAN JINGWANG ENVIRONMENTAL PROTECTION EQUIP

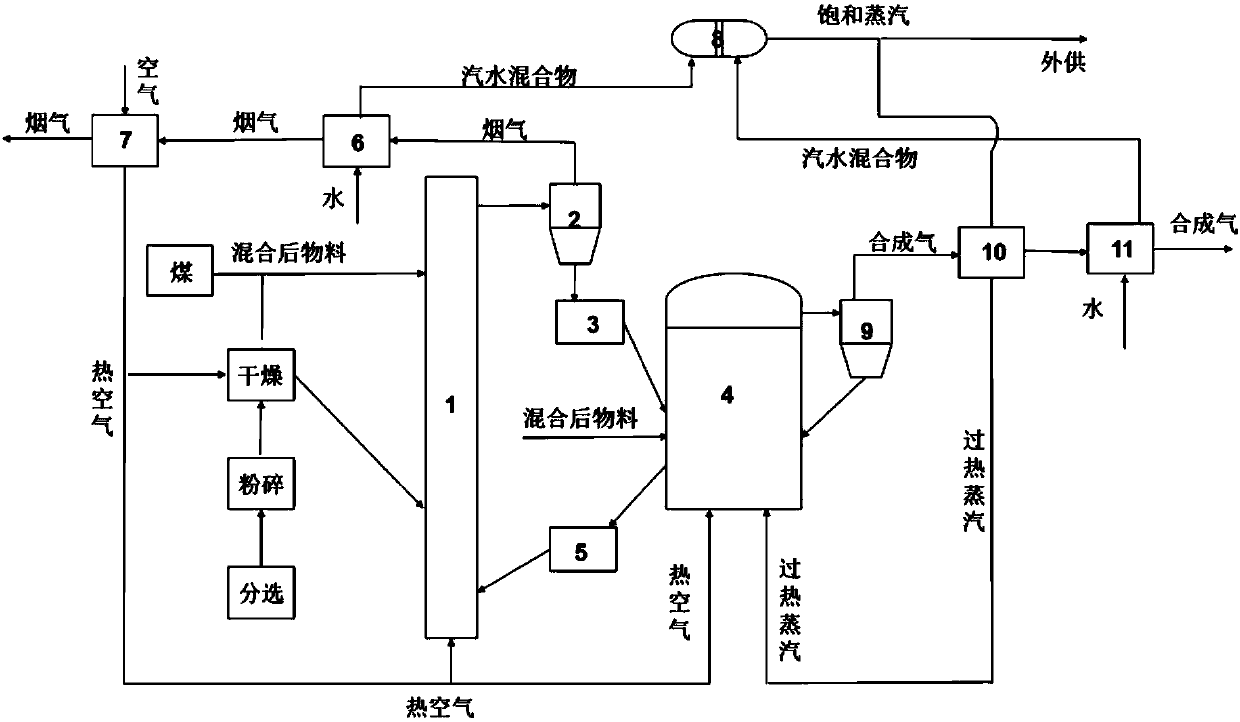

Method and device for high-temperature co-gasification of combustible solid waste, biomass and coal

InactiveCN108034457AReduce processing energy consumptionAchieve recyclingGasification processes detailsGranular/pulverulent flues gasificationGas solidFlue gas

The invention discloses a method and device for high-temperature co-gasification of combustible solid waste, biomass and coal. The method includes the following steps: performing sorting on the combustible solid waste and the biomass, performing crushing, performing drying, and performing mixing with the coal to obtain a mixed material; performing gasification on the mixed material, performing combustion, sending a mixed material which is not completely reacted in the gasification process to the combustion process for combustion, performing gas-solid separation on a flue gas which has high-temperature ash and is generated in the combustion process, and sending the separated high-temperature ash to the gasification process to provide heat for a gasification reaction, so as to make the gasification process coupled with the combustion process. The method provided by the invention not only improves the coal gas calorific value and energy utilization rate of gasified coal, saves the production costs of coal gasification, but also is environmentally friendly, solves the comprehensive treatment and utilization problems of the combustible solid waste and the biomass, and realizes the maximum utilization of energy sources.

Owner:BEIJING LEIHAO ENVIRONMENTAL PROTECTION ENERGY TECH

Combined adjustable bracket for domestic gas cooking appliance

InactiveCN102650441AHigh calorific value utilizationTo achieve the purpose of increasing energy efficiencyStoves/ranges topsProcess engineeringFuel gas

The invention discloses a bracket for a domestic gas cooking appliance. A base of the bracket, a base support and a series combined grade groove on a supporting cylindrical support main body are correspondingly connected, so that the vertical height of a pot and gas flame can be adjusted. Therefore, the bracket is suitable for the domestic gas cooking appliance and achieves the effects of synergism, consumption reduction, emission reduction and energy saving of gas energy sources.

Owner:郝兆阳

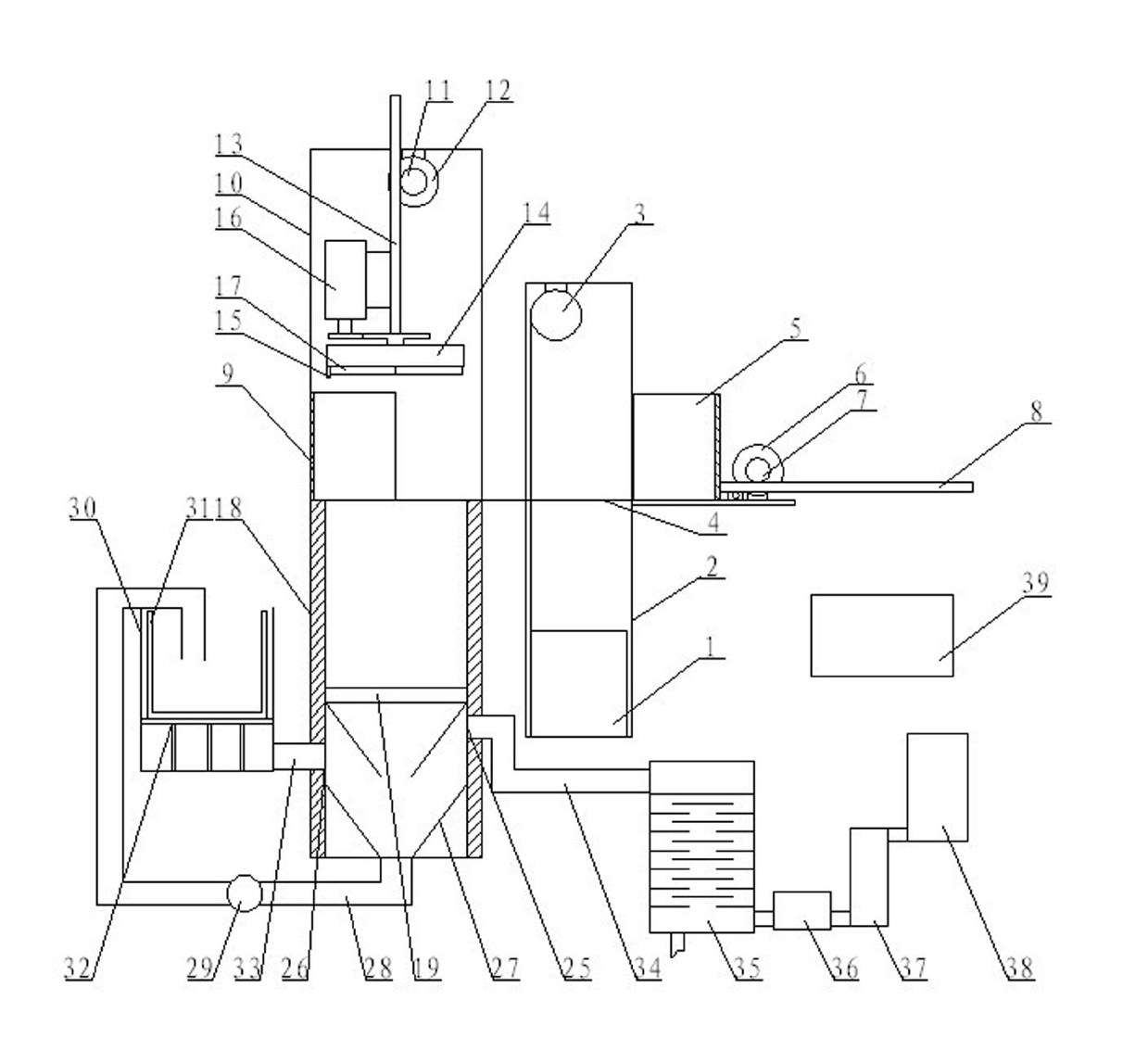

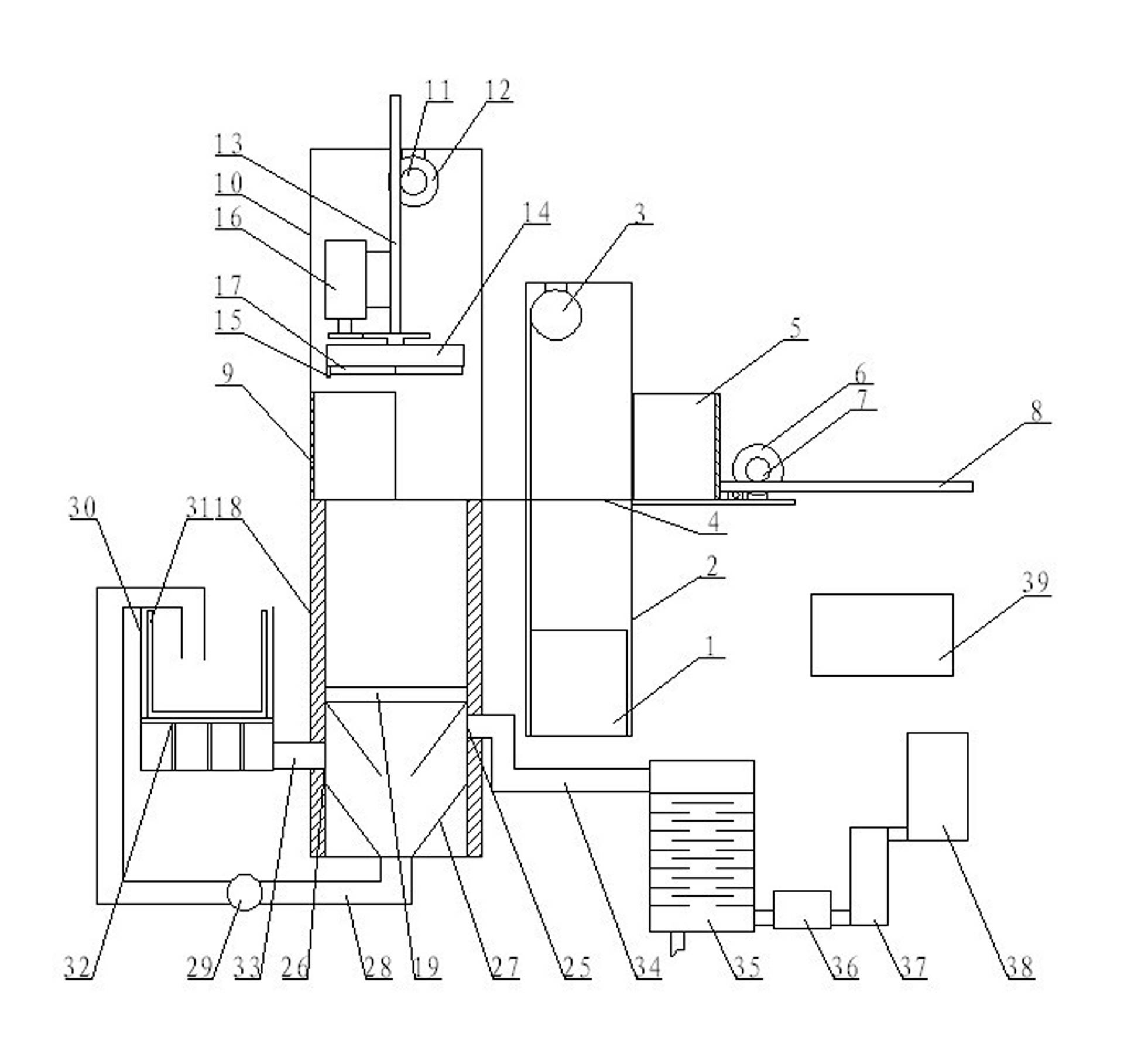

Municipal sludge pyrolysis system and pyrolysis treatment method

ActiveCN107265817AHigh calorific value utilizationImprove thermal decomposition effectSludge treatment by pyrolysisSludgeFlue gas

The invention discloses a municipal sludge pyrolysis system and a pyrolysis treatment method. The municipal sludge pyrolysis system comprises a pedestal and an incinerating furnace body arranged on the pedestal, wherein an incinerating chamber is formed in the incinerating furnace body; a pyrolysis furnace body is arranged inside the incinerating chamber; the end part of the pyrolyzing furnace body is in sealed fit with the incinerating chamber; a pyrolysis furnace motor for driving the pyrolyzing furnace body to rotate in the horizontal axial direction is arranged on the pedestal; a communicated separating chamber is formed in the discharge end of the pyrolysis furnace body; a gas inlet pipe connecting the separating chamber and the incinerating chamber is arranged inside the incinerating furnace body; a discharge opening is formed in the lower end of the separating chamber; a partition board for partitioning the incinerating chamber into an upper incinerating chamber and a lower incinerating chamber is arranged inside the incinerating furnace body; an upper oxygen supplying pipe is arranged inside the upper incinerating chamber; a lower oxygen supplying pipe is arranged inside the lower incinerating chamber; a secondary oxygen supplying chamber is formed in the discharge opening; a hot flue gas pipe flowing into the incinerating chamber in one-way manner is arranged on the upper part of the secondary oxygen supplying chamber; a conveying pipe leading to the lower incinerating chamber is arranged on the lower part of the secondary oxygen supplying chamber. The invention aims to provide the municipal sludge pyrolysis system and the pyrolysis treatment method.

Owner:ZHEJIANG SANLIAN ENVIRONMENT MACHINERY EQUIP

Coal gas anhydrous dust collecting equipment of revolving furnace and technique thereof

ActiveCN101195766BReduce consumptionHigh calorific value utilizationEnergy inputGas dust removalCyclonic spray scrubberHeat energy

Owner:北京中冶设备研究设计总院有限公司

Municipal sludge pyrolyzing device

ActiveCN107448946AHigh calorific value utilizationImprove thermal decomposition effectIncinerator apparatusSludgeLow oxygen

The invention discloses a municipal sludge pyrolyzing device. The municipal sludge pyrolyzing device comprises a table frame and an incinerator body arranged on the table frame, an incineration chamber is arranged in the incinerator body, a pyrolyzing furnace body is arranged in the incineration chamber, the end of the pyrolyzing furnace body is in sealed fit with the incineration chamber, a discharging end of the pyrolyzing furnace body is provided with a separation chamber which communicates with the discharging end, and an air inlet pipeline being connected with the separation chamber and the incineration chamber is arranged in the incinerator body; and a discharging port is formed in the lower end of the separation chamber, a conveying pipeline leading to the bottom of the incineration chamber is arranged in the discharging port, a separation plate dividing the incineration chamber into an upper incineration chamber and a lower incineration chamber is arranged in the incinerator body, an upper oxygen supply pipeline is arranged in the upper incineration chamber, and a lower oxygen supply pipeline is arranged in the lower incineration chamber. The municipal sludge pyrolyzing device can improve the heat value utilization ratio and reduce pollution.

Owner:ZHEJIANG SANLIAN ENVIRONMENT MACHINERY EQUIP

High-clear alcohol-based fuel oil

The invention relates to high-clear alcohol-based fuel oil and belongs to the technical field of fuel processing. The high-clear alcohol-based fuel oil comprises the following components in part by weight: 0.03 to 0.05 part of ferrocene, 25 to 40 parts of absorber oil, 60 to 75 parts of methanol, 1 to 2 parts of toluene, 2 to 3 parts of acetone and 2 parts of isobutanol. In the high-clear alcohol-based fuel oil, the added ferrocene improves the anti-detonating quality of the high-clear alcohol-based fuel oil and has the functions of reducing carbon accumulation in a spray nozzle and assisting combustion; and the added acetone, toluene, isobutanol, methanol and absorber oil, which are organic phases, are mixed, so the intersolubility and swelling performance of the components of the high-clear alcohol-based fuel oil are improved; and the oxygen content is improved to make combustion complete and the emission of carbon oxide compounds is reduced, so the calorific value is improved and an energy-saving and environment-friendly effect is achieved.

Owner:SUIPING CHEM FACTORY OF CHINA PINGMEI SHENMA GRP LANTIAN CHEM

Novel straw direct gasification polygeneration preparation process

InactiveCN102329649AConvenient feeding and conveyingUniform densitySpecial form destructive distillationFixed-bed gasificationAgricultural engineeringGas holder

The invention relates to a novel straw direct gasification polygeneration preparation process, comprising a gasification furnace, a feeding device, a material pushing device, a material pressing device, a material homogenizing device, a carbon discharging device, a washing device, a fan, a water seal filtering device, a gas holder and a control cabinet. By virtue of the feeding device, the material pushing device, a material pressing device and a material homogenizing device, straw requiring no processing is directly fed into a gasification furnace to be gasified, the straw is effectively controlled to polygenerate straw carbon and straw gas, a carbon scraping grate and the carbon discharging device are combined to collect the straw carbon, labyrinth type spraying washing is carried out to separate the straw gas and straw extract, the water seal filtering device filters and collects the straw gas, and the device has high reliability, good safety performance, strong practicability, simple gasification process, good gasification effect, high straw utilization rate and low operation cost.

Owner:顾云江

Coal dry distillation method and device for realizing same

ActiveCN102925175BHigh calorific value utilizationAvoid pollutionCombustible gas coke oven heatingIndirect and direct heating destructive distillationCombustionNitrogen

The invention discloses a coal dry distillation method and a device for realizing the same, which are used for solving the problems of low heat value utilization rate and high equipment manufacturing cost of the existing external-heat dry distillation technology, coal gas mixing in nitrogen in the internal-heat dry distillation technology and difficult semi-coke conveying of the internal / external-heat combined dry distillation technology. In the invention, the coal is subjected to dry distillation sequentially through an external-heat heating area, an internal-heat combustion area and an external-heat heating area with different temperatures and is heated by taking the hot semi-coke generated in the internal-heat dry distillation area as raw material coal, and the smoke generated in the internal-heat heating area is discharged. The device comprises an outer barrel, an inner barrel and a flue between the outer barrel and the inner barrel, wherein a combustion barrel internally communicated with the flue is mounted in the inner barrel, and a horizontal return screw is arranged on the outer wall of the inner barrel and the combustion barrel, thus the coal heating and dry distillation time is prolonged; and meanwhile, the isolation between the direct and indirect heating of the smoke and the coal gas is realized, the quality of the coal gas is guaranteed, and the production efficiency and the dry distillation heat efficiency are improved.

Owner:榆林市榆神工业区能源科技发展有限公司

A method and equipment for mechanically breaking up fluidized drying of coal slime

InactiveCN103604278BLarge dry contact areaIncrease contact areaDrying solid materials with heatDrying gas arrangementsParticulatesThermodynamics

The invention relates to a mechanical dispersion fluidization drying method and equipment for coal slime. The method is used for realizing fluidization drying of coal slime particulates by using hot smoke while dispersing coal slime to be dried into the coal slime particulates. The drying method is high in heat utilization rate and yield as well as wide in application range. The equipment comprises a drying box body and a stirring shaft, wherein the drying box body is provided with a feeding hole, a discharging hole, a gas outlet and a smoke inlet; the stirring shaft is used for dispersing the coal slime to be dried, is arranged at the bottom of the drying box body and is located above the smoke inlet; the coal slime to be dried is dispersed into the coal slime particulates by using the stirring shaft after entering the drying box body through the feeing hole, meanwhile, the hot smoke enters from the smoke inlet at the bottom of the drying box body at a proper flow rate and is discharged from the gas outlet after carrying out fluidization drying on the coal slime particulates, and at the same time, the dried coal slime is output from the discharging hole. The equipment is large in gas and solid drying contact area, long in drying time, high in heat utilization rate and yield and small in floor area.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com