Steam engine for glacier drilling

A technology for steam engines and glaciers, applied in the field of steam engines, can solve problems such as inability to meet temperature holes, limit scientific research work, and environmental pollution of glaciers, and achieve the effects of reducing weight, reducing the weight of monomers, and reducing heat radiation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

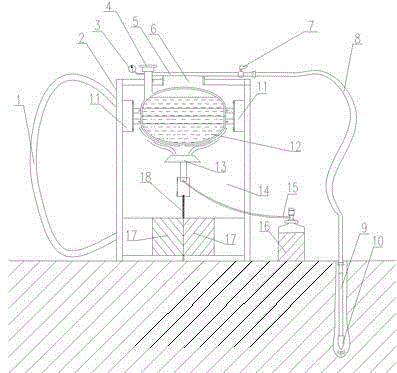

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail by embodiment:

[0018] Such as figure 1 As shown, a steam engine used for glacier drilling, including a strap 1, a thermal insulation jacket 2, a pressure gauge 3, a water injection pipe with a safety valve 4, a steam outlet pipe 5, an air outlet 6, a steam valve 7, and a high-pressure thermal insulation rubber tube 8. Drill pipe 9, steam nozzle 10, bracket 11, finned liner 12, heating furnace head 13, combustion chamber 14, alpine air pipe and regulating valve 15, gas cylinder 16, windshield 17, finned liner 12 (zl201220377469.3) is fixed by the bracket 11 and placed in the combustion chamber 14. The finned inner tank 12 is spliced by two heads; the fins are placed at the bottom of the inner tank, and the water inlet and the steam outlet, or the water outlet, are respectively located on the left and right sides of the inner tank. The bottom of the combustion chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com