Patents

Literature

10330 results about "Gas cylinder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gas cylinder or tank is a pressure vessel for storage and containment of gases at above atmospheric pressure. High-pressure gas cylinders are also called bottles. Inside the cylinder the stored contents may be in a state of compressed gas, vapor over liquid, supercritical fluid, or dissolved in a substrate material, depending on the physical characteristics of the contents. A typical gas cylinder design is elongated, standing upright on a flattened bottom end, with the valve and fitting at the top for connecting to the receiving apparatus.

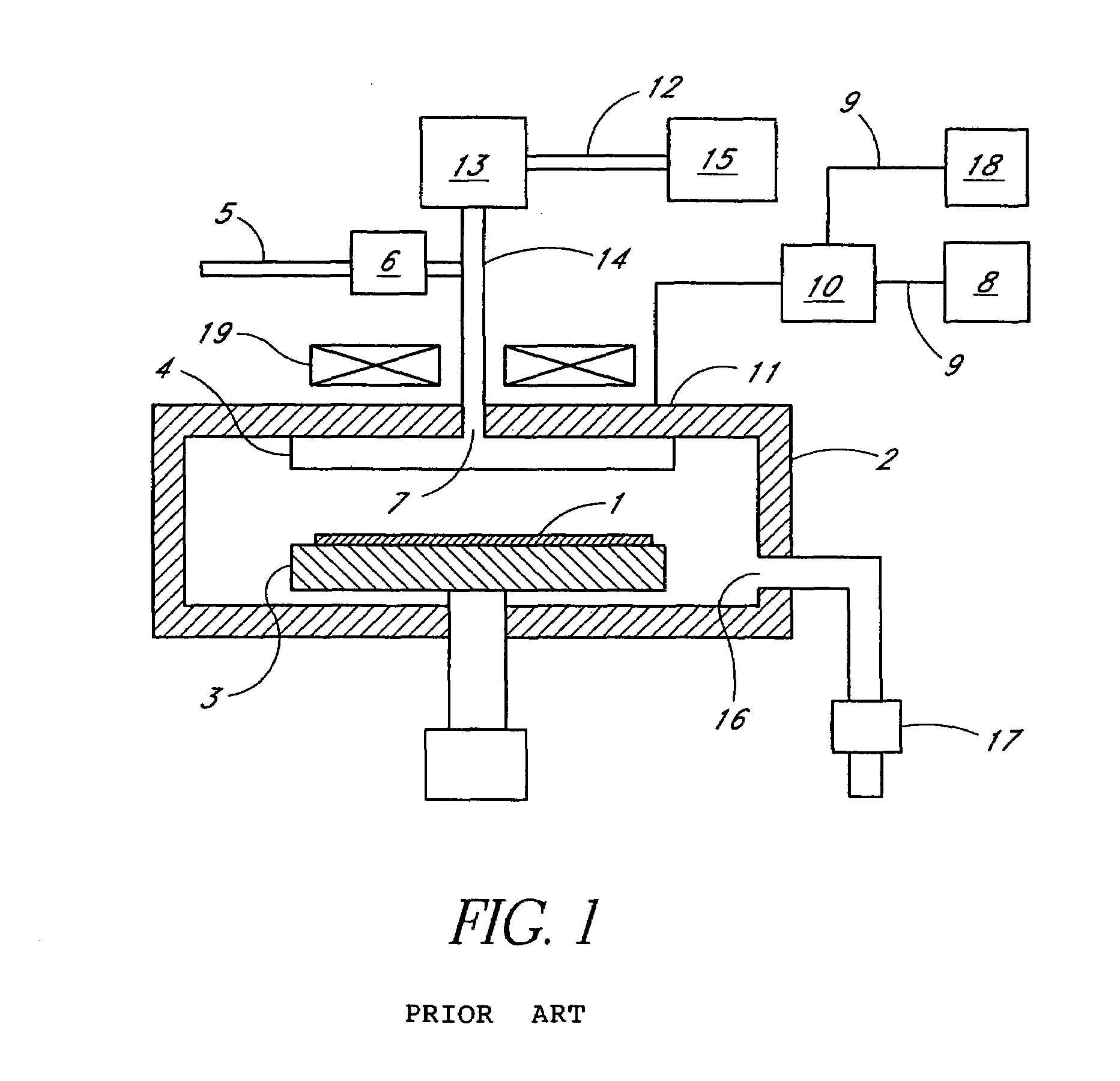

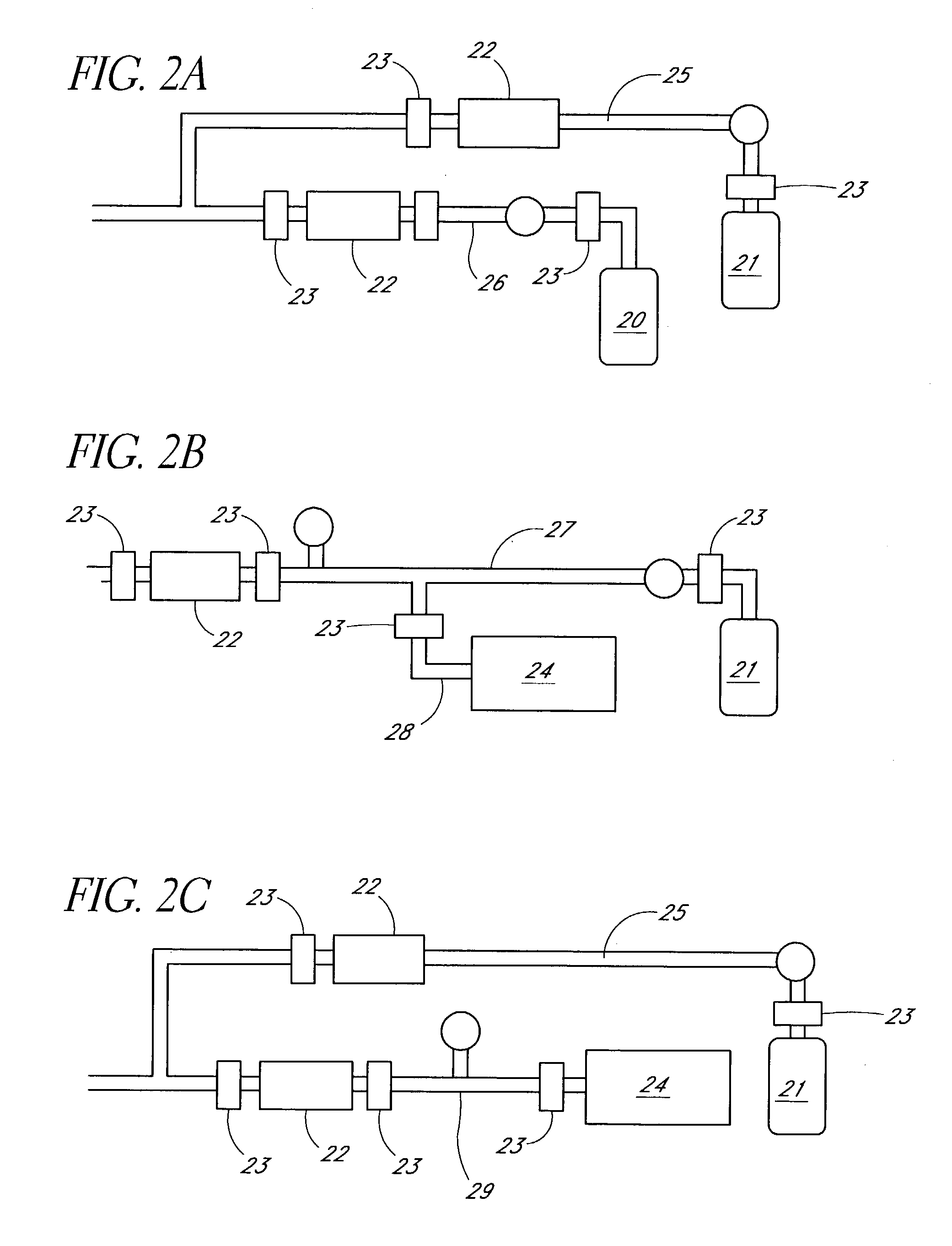

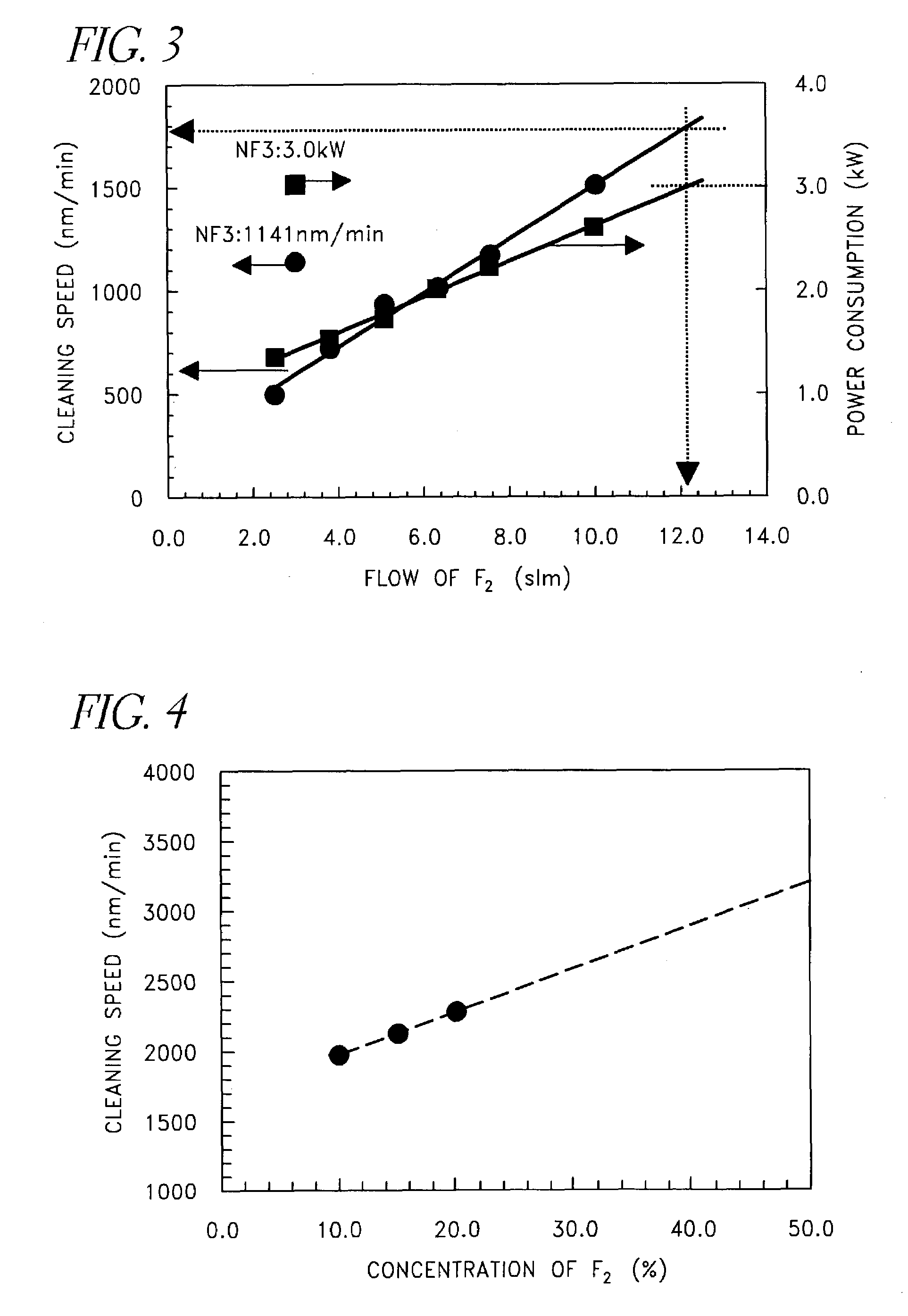

Method of cleaning CVD equipment processing chamber

ActiveUS7234476B2Reduce operating costsImprove efficiencyElectric discharge tubesHollow article cleaningRemote plasmaOperational costs

A method of remote plasma cleaning a processing chamber of CVD equipment, which has high cleaning rates, low cleaning operational cost and high efficiency, is provided. The method comprises supplying cleaning gas to the remote plasma-discharge device; activating the cleaning gas inside the remote plasma-discharge device; and bringing the activated cleaning gas into the processing chamber and which is characterized in that a mixed gas of F2 gas and an inert gas are used as the cleaning gas. A concentration of the F2 gas is 10% or higher. The F2 gas, which is a cleaning gas, is supplied to the remote plasma-discharge device from an F2 gas cylinder by diluting F2 gas at a given concentration by an inert gas.

Owner:ASM JAPAN

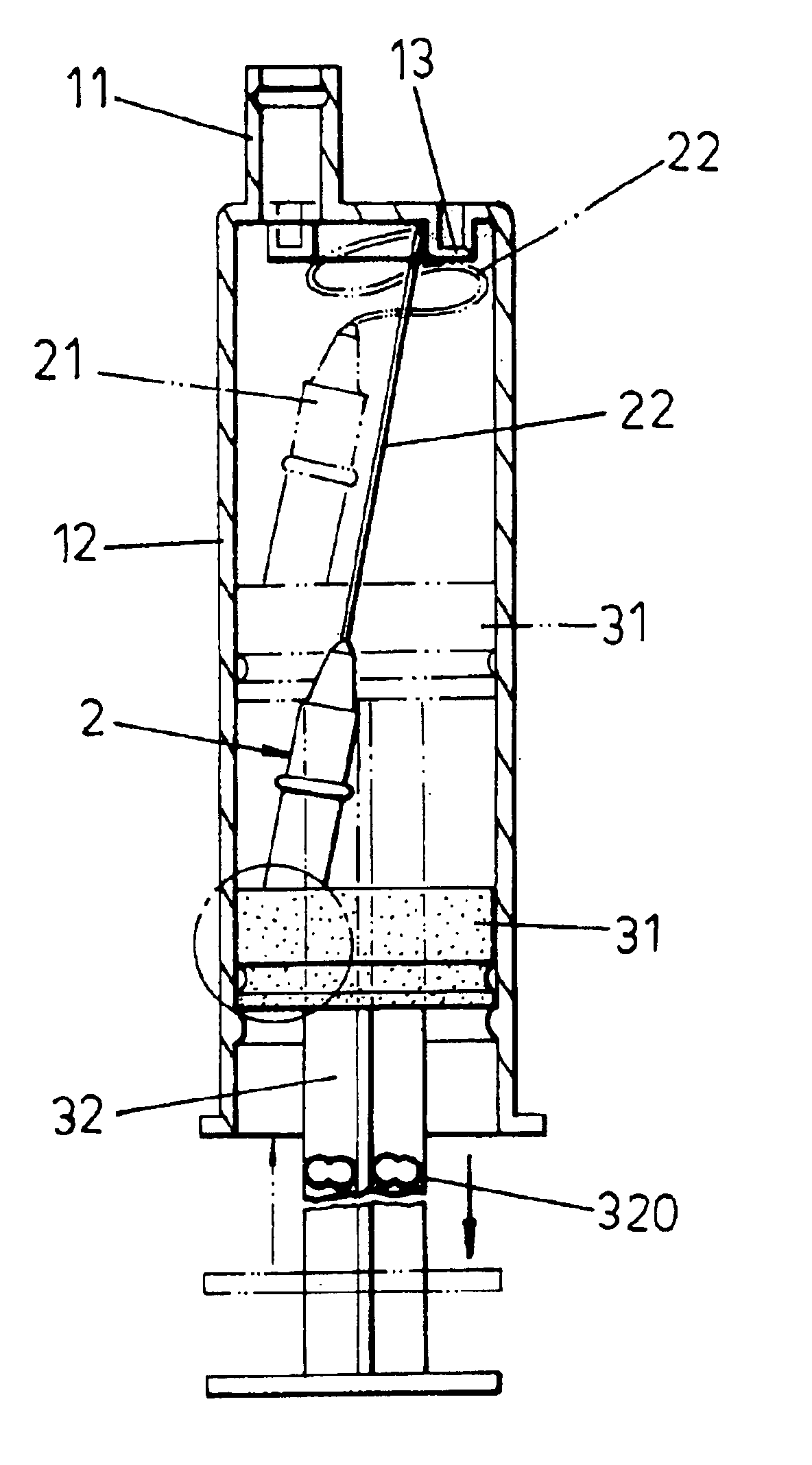

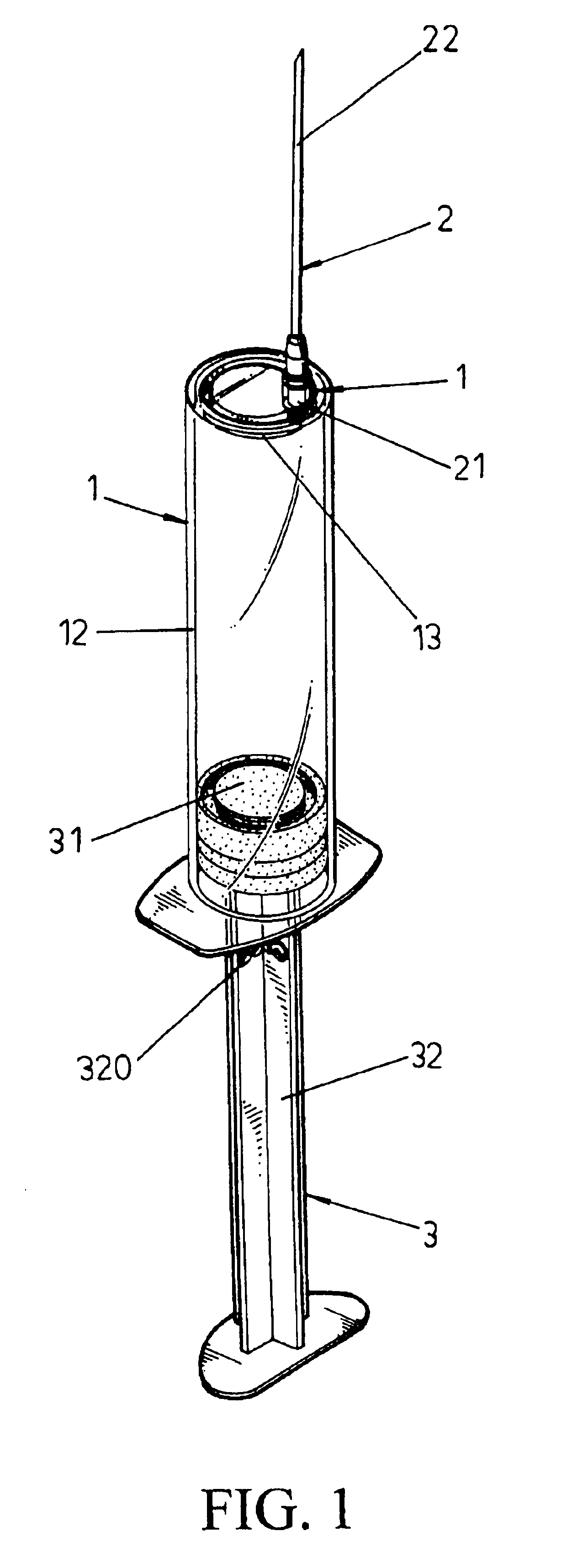

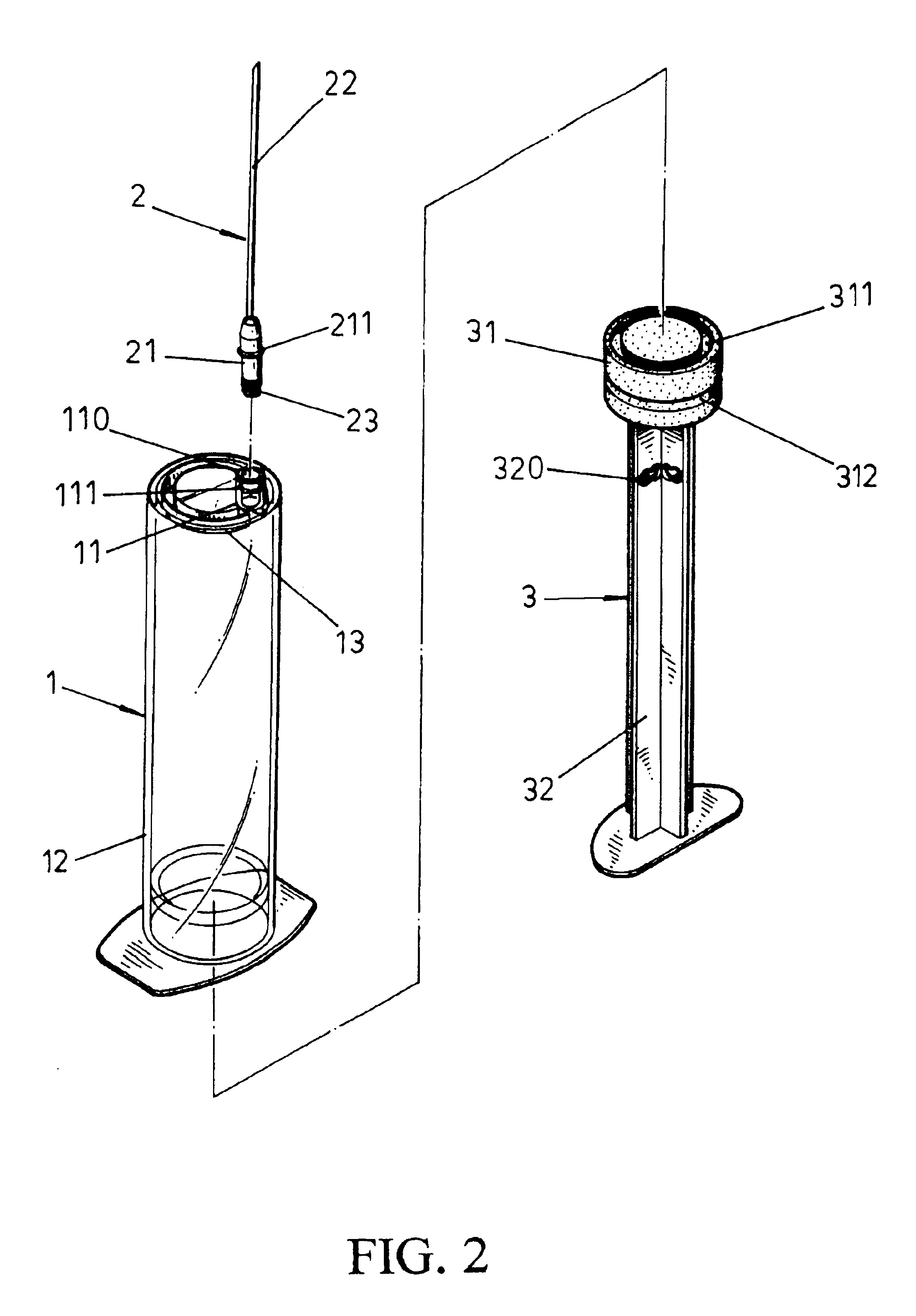

Safety syringe cylinder

A safety syringe cylinder has a structure for attaching a syringe needle precisely. The syringe needle can be retracted into the syringe cylinder for bending. A hook seat is formed at a lower end of the needle. An annular hook groove is formed at a top end of the push rod cap. The hook seat is engaged with the annular hook groove so as to control the displacement and bending process of the syringe needle. Thereby, the processing of undesired syringe needle is safe, reliable and convenient.

Owner:CHIAN LAI WEN

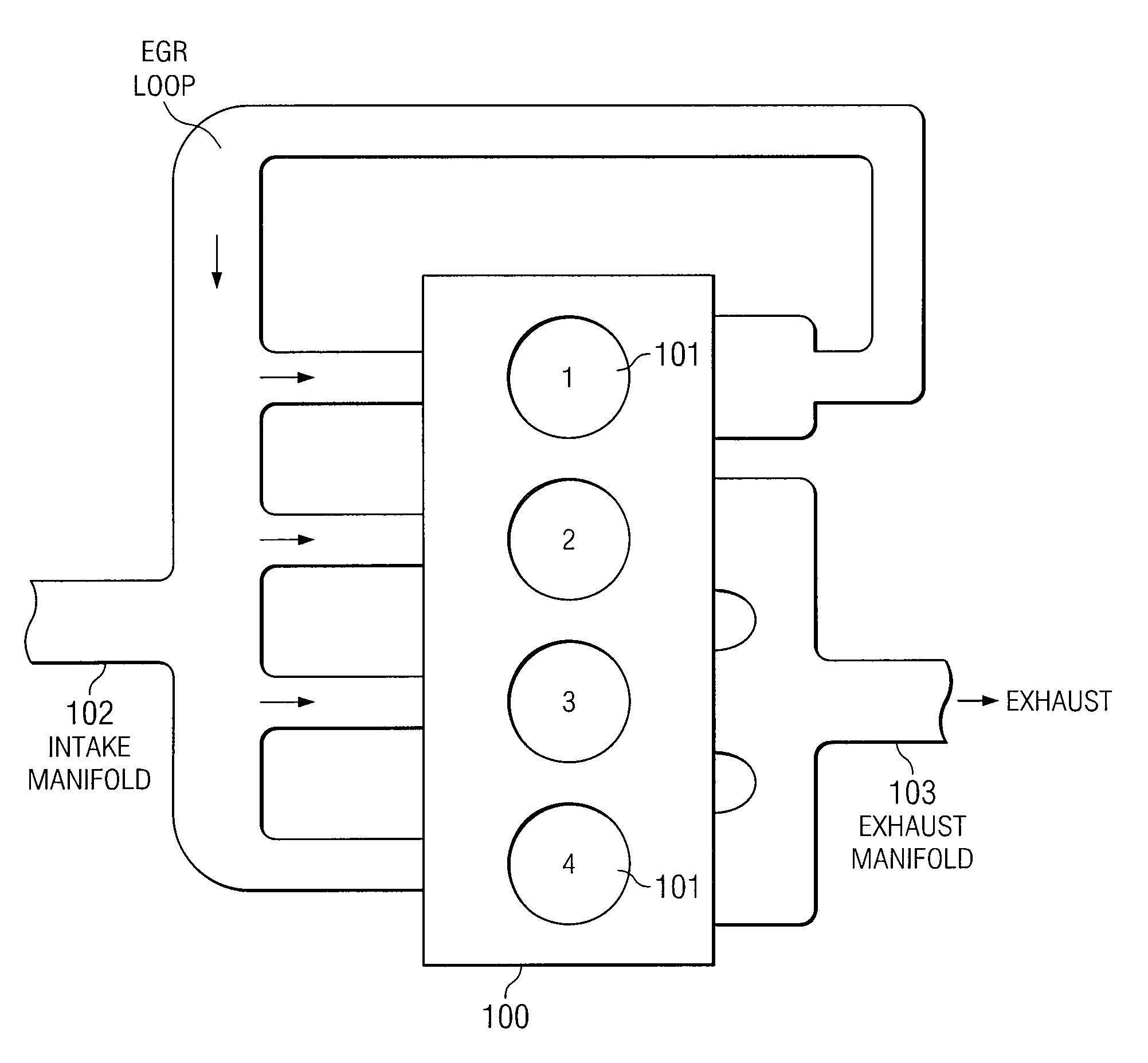

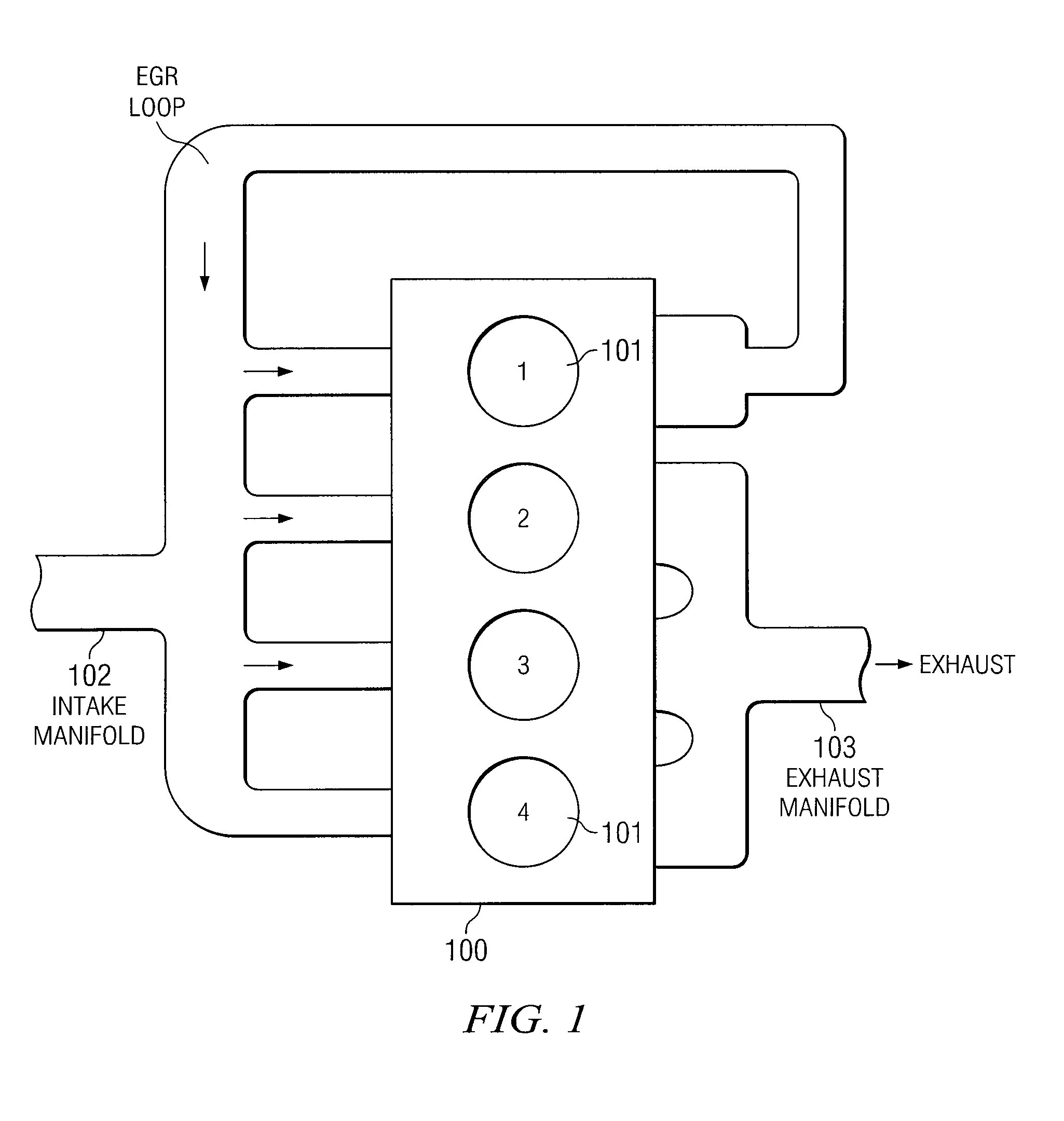

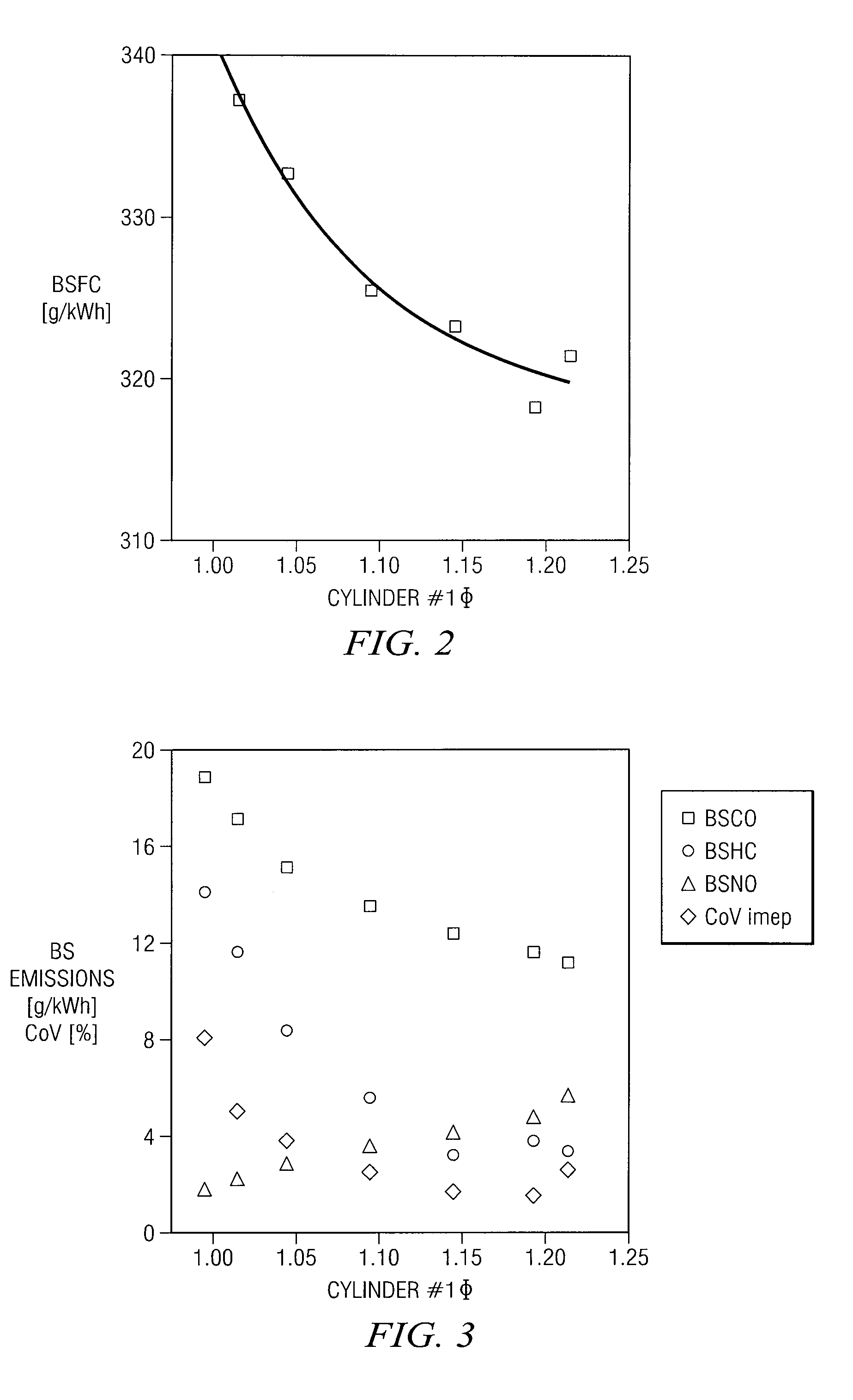

Egr system with dedicated egr cylinders

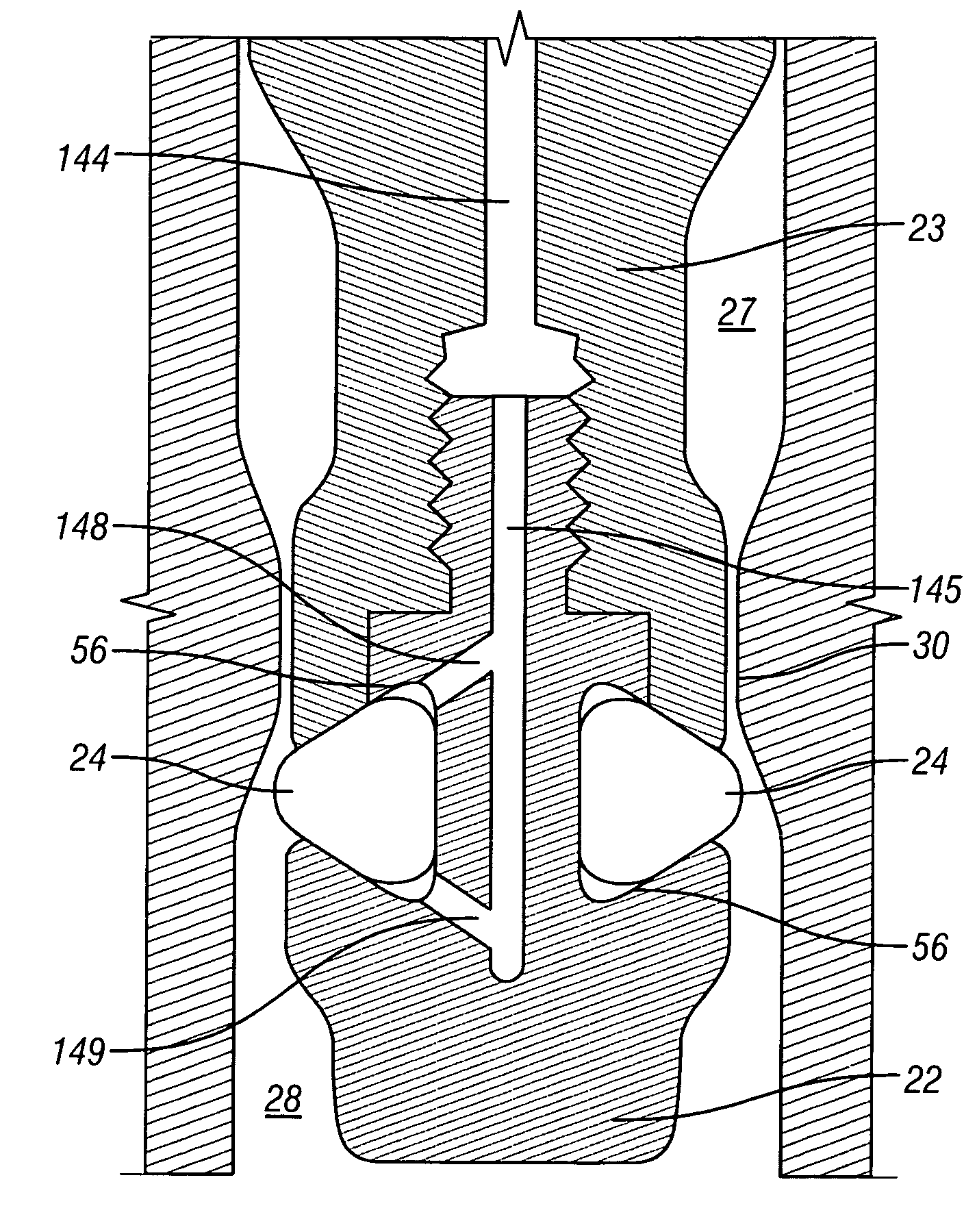

Improved exhaust gas recirculation system and methods that use one or more of the engine's cylinders as dedicated EGR cylinders. All of the exhaust from the dedicated EGR cylinders is recirculated back to the engine intake. Thus, the EGR rate is constant, but the EGR mass flow may be controlled by adjusting the air-fuel ratio of the dedicated EGR cylinders or by using various variable valve timing techniques.

Owner:SOUTHWEST RES INST

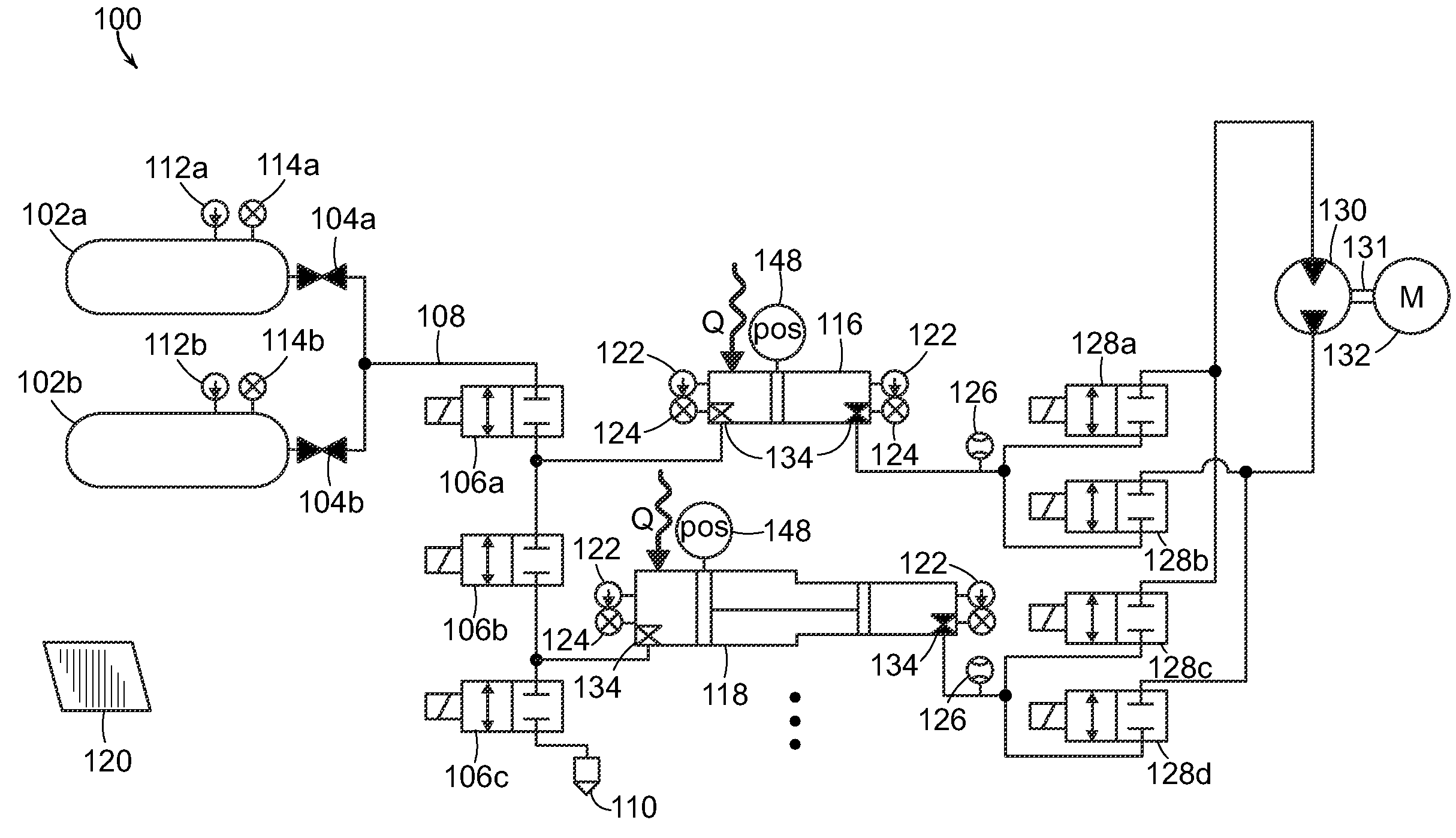

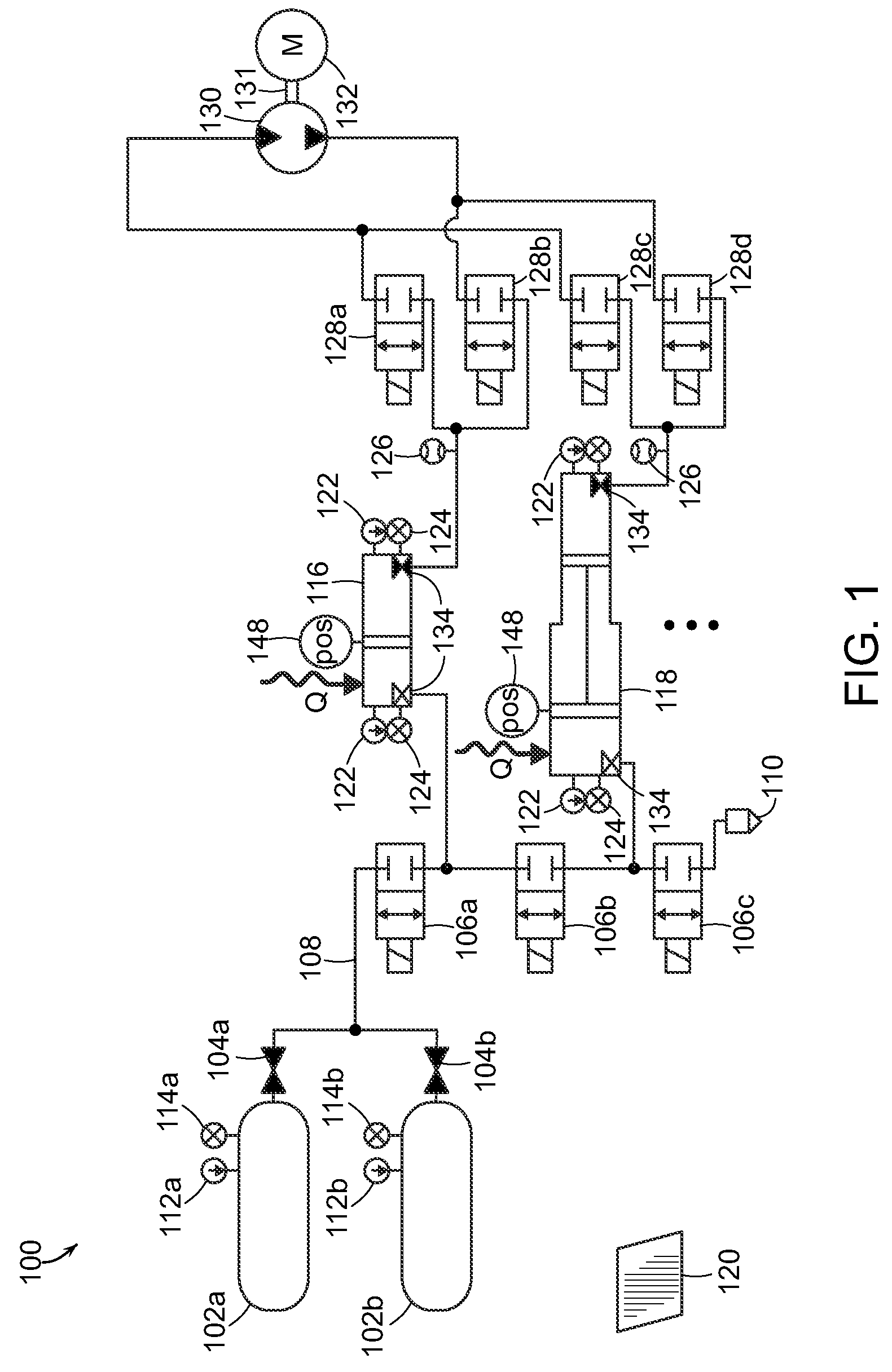

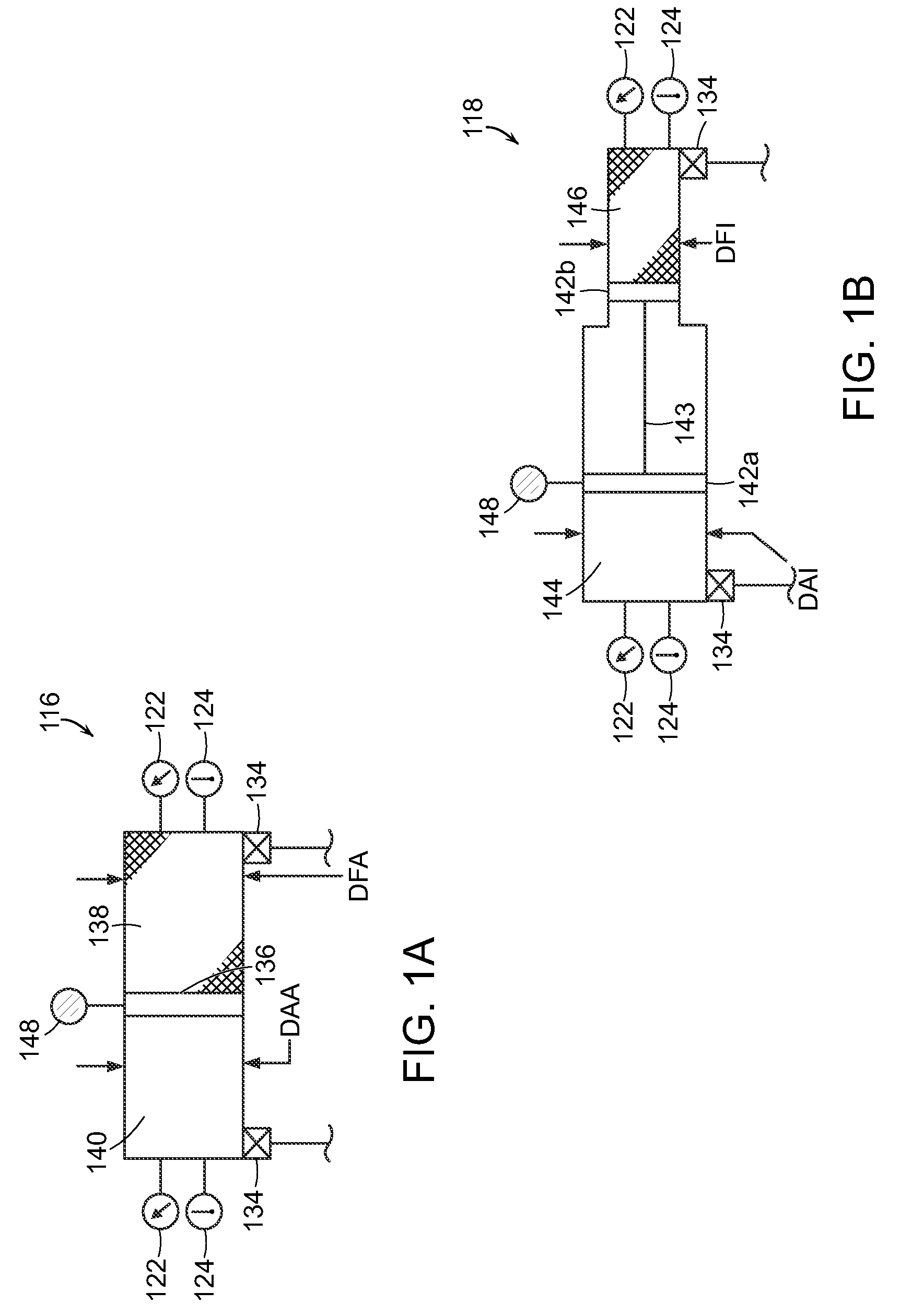

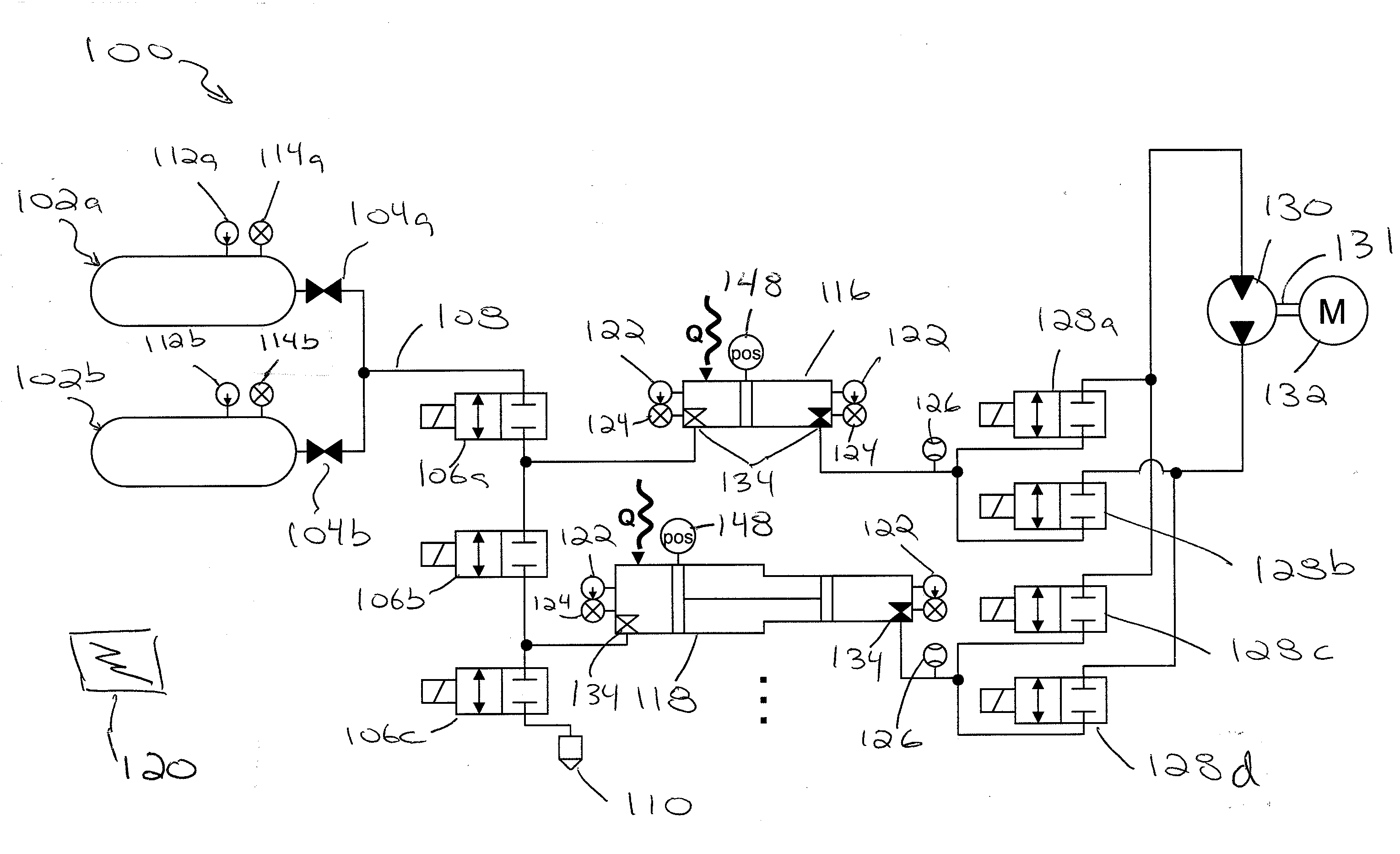

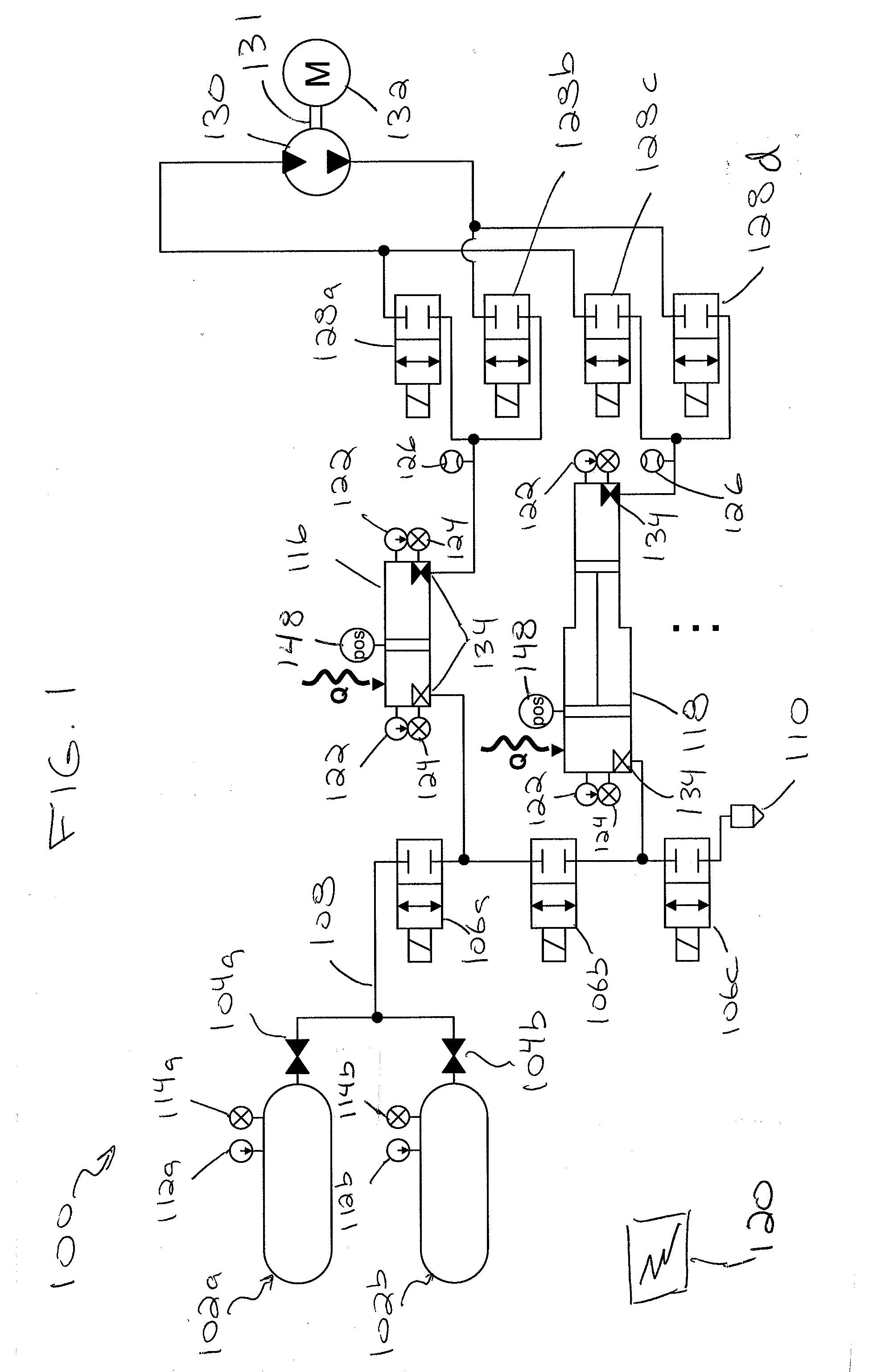

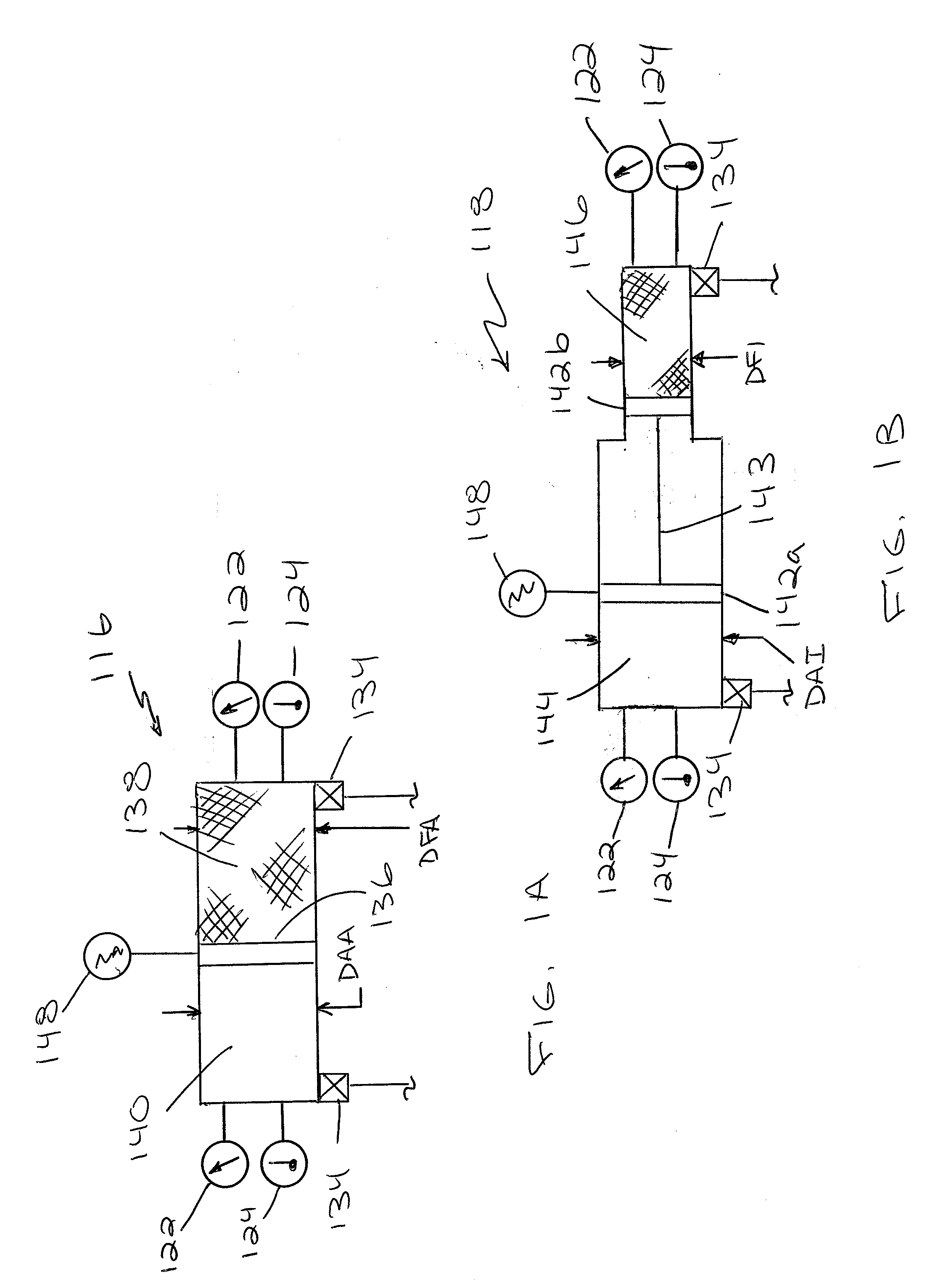

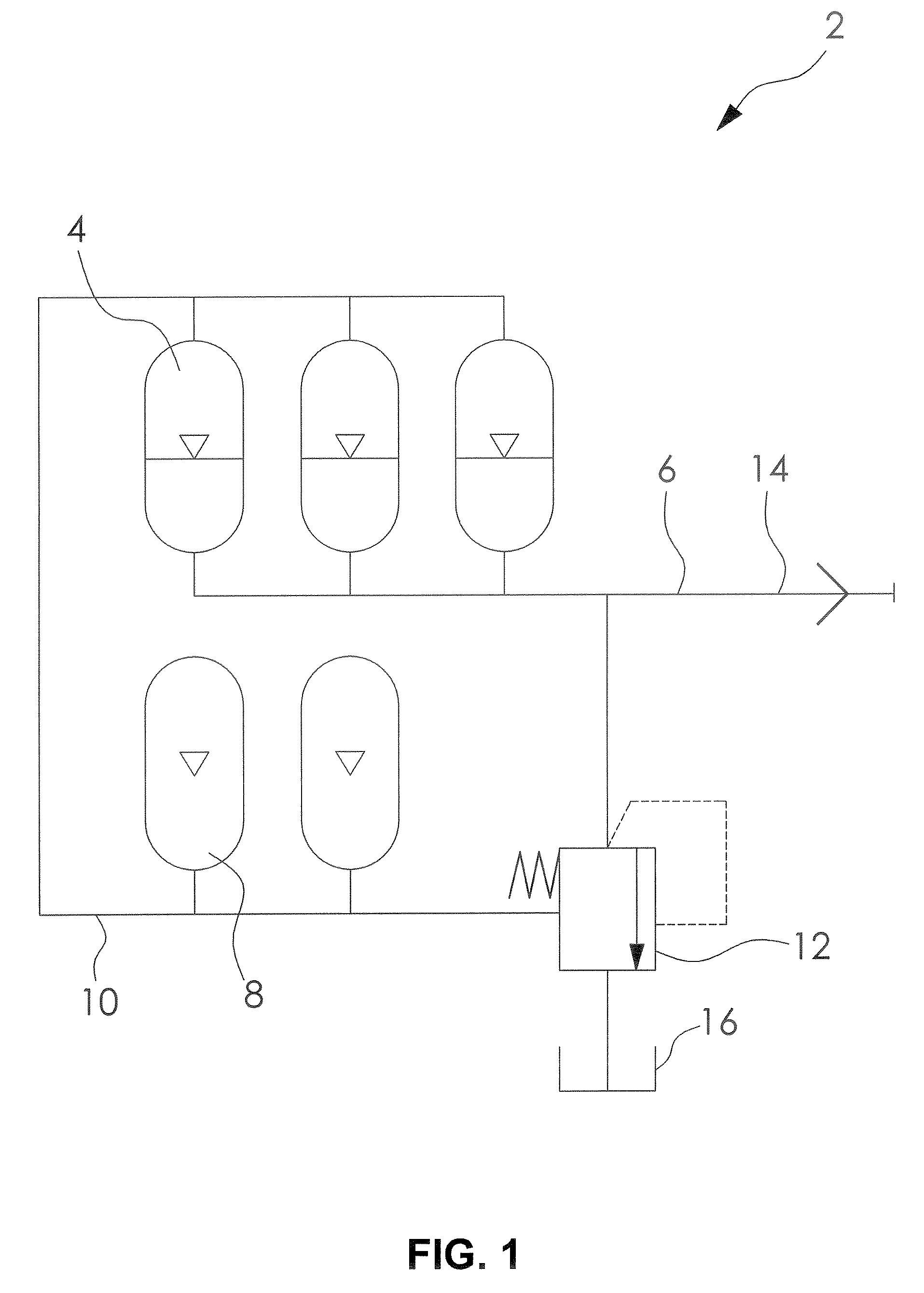

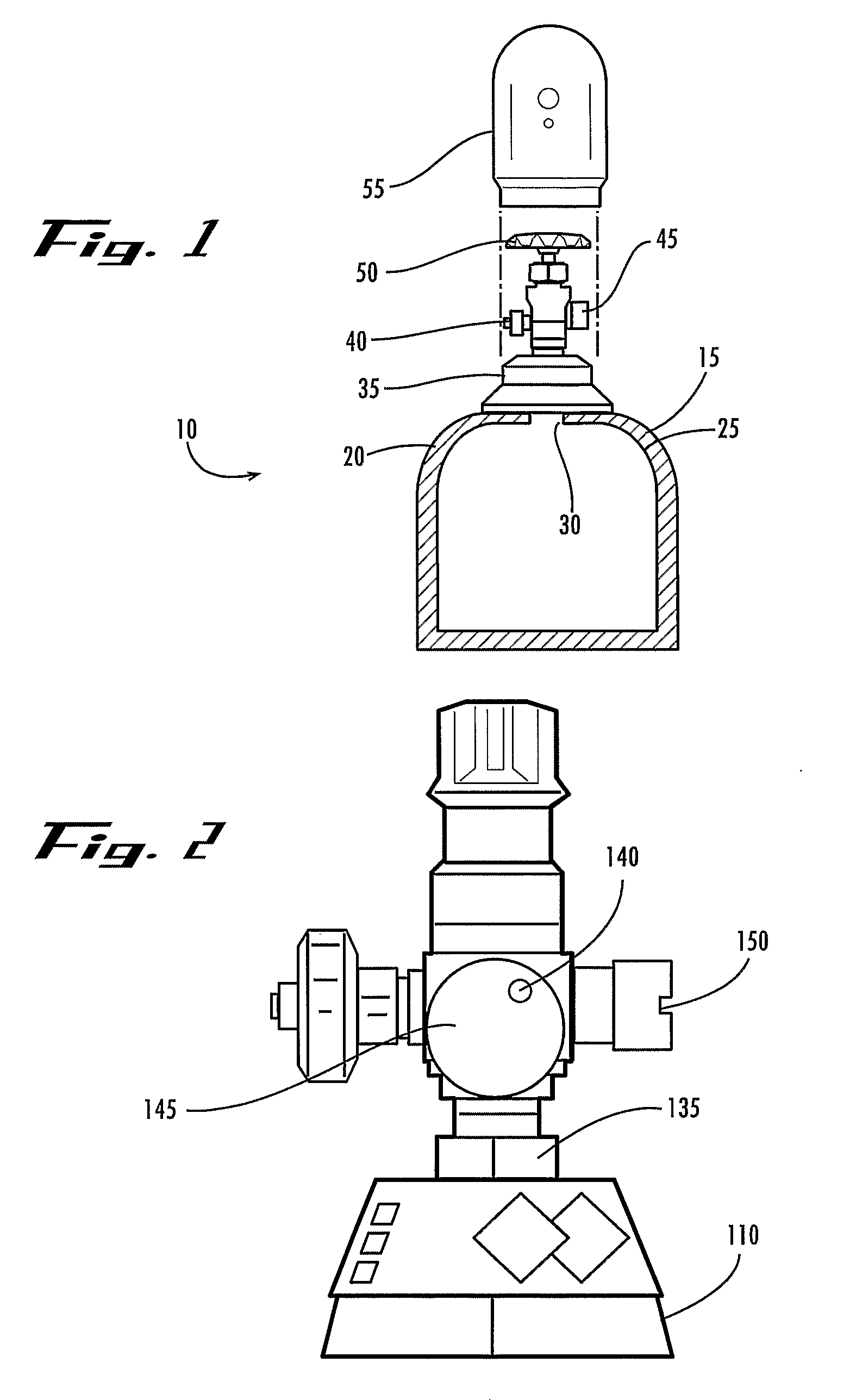

Systems and methods for energy storage and recovery using compressed gas

InactiveUS7832207B2Increase energy densityExpand/compress the gas more evenlyFluid couplingsAccumulator installationsEngineeringHigh pressure

The invention relates to methods and systems for the storage and recovery of energy using open-air hydraulic-pneumatic accumulator and intensifier arrangements that combine at least one accumulator and at least one intensifier in communication with a high-pressure gas storage reservoir on a gas-side of the circuits and a combination fluid motor / pump, coupled to a combination electric generator / motor on the fluid side of the circuits.

Owner:SUSTAINX

Systems and Methods for Energy Storage and Recovery Using Compressed Gas

InactiveUS20090282822A1Increase energy densityExpand/compress the gas more evenlyFluid couplingsAccumulator installationsThermodynamicsGas cylinder

The invention relates to methods and systems for the storage and recovery of energy using open-air hydraulic-pneumatic accumulator and intensifier arrangements that combine at least one accumulator and at least one intensifier in communication with a high-pressure gas storage reservoir on a gas-side of the circuits and a combination fluid motor / pump, coupled to a combination electric generator / motor on the fluid side of the circuits.

Owner:SUSTAINX

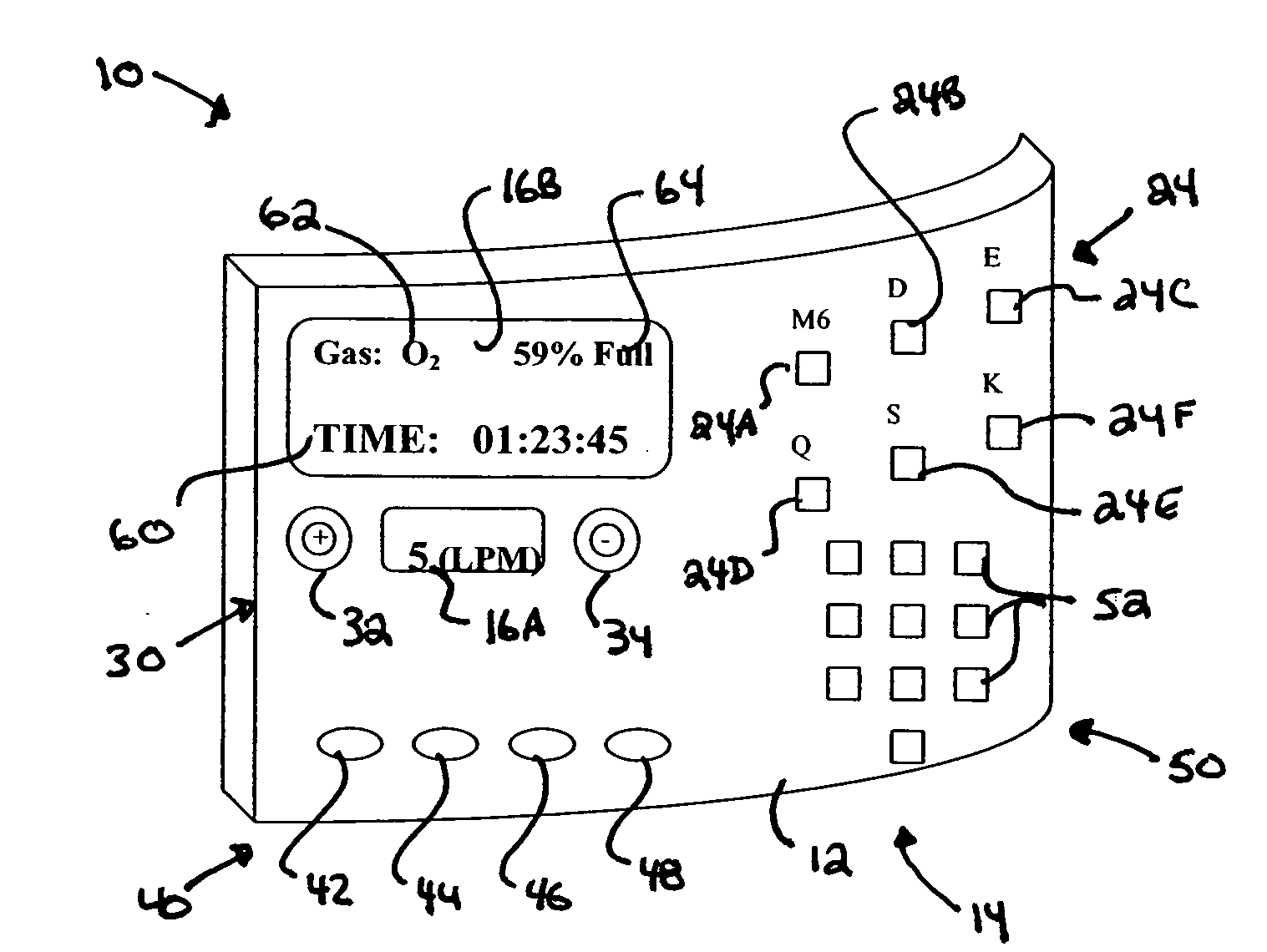

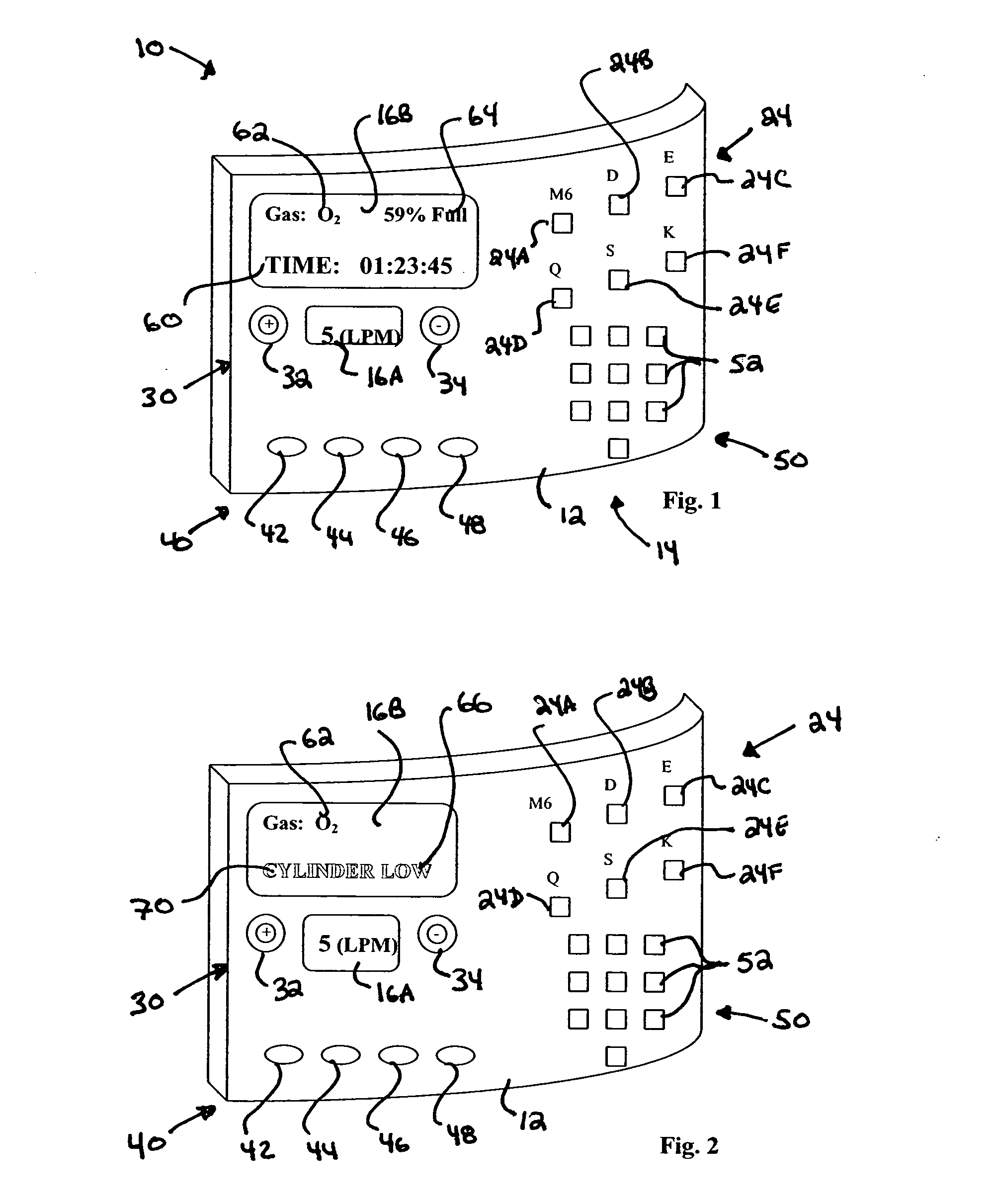

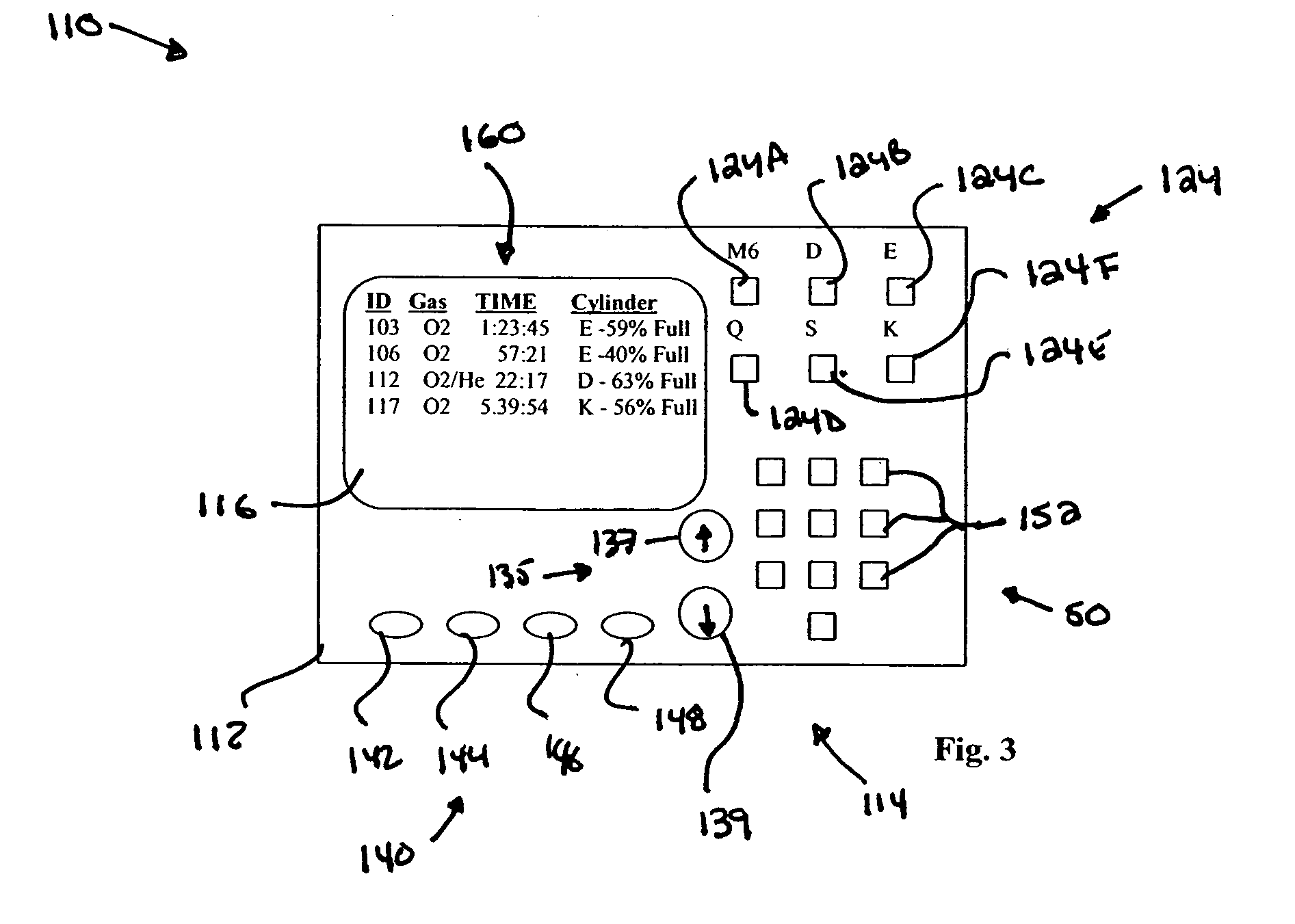

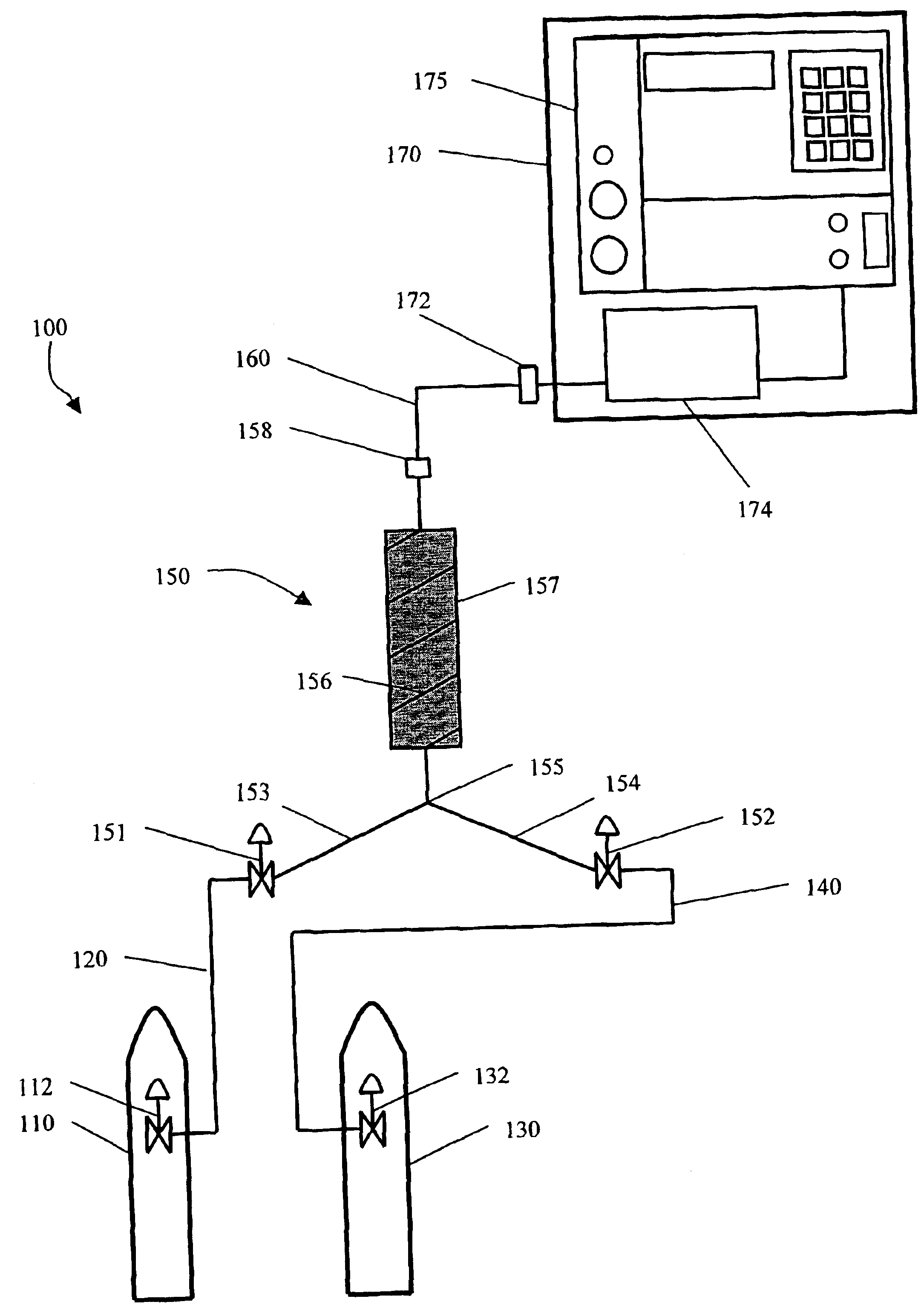

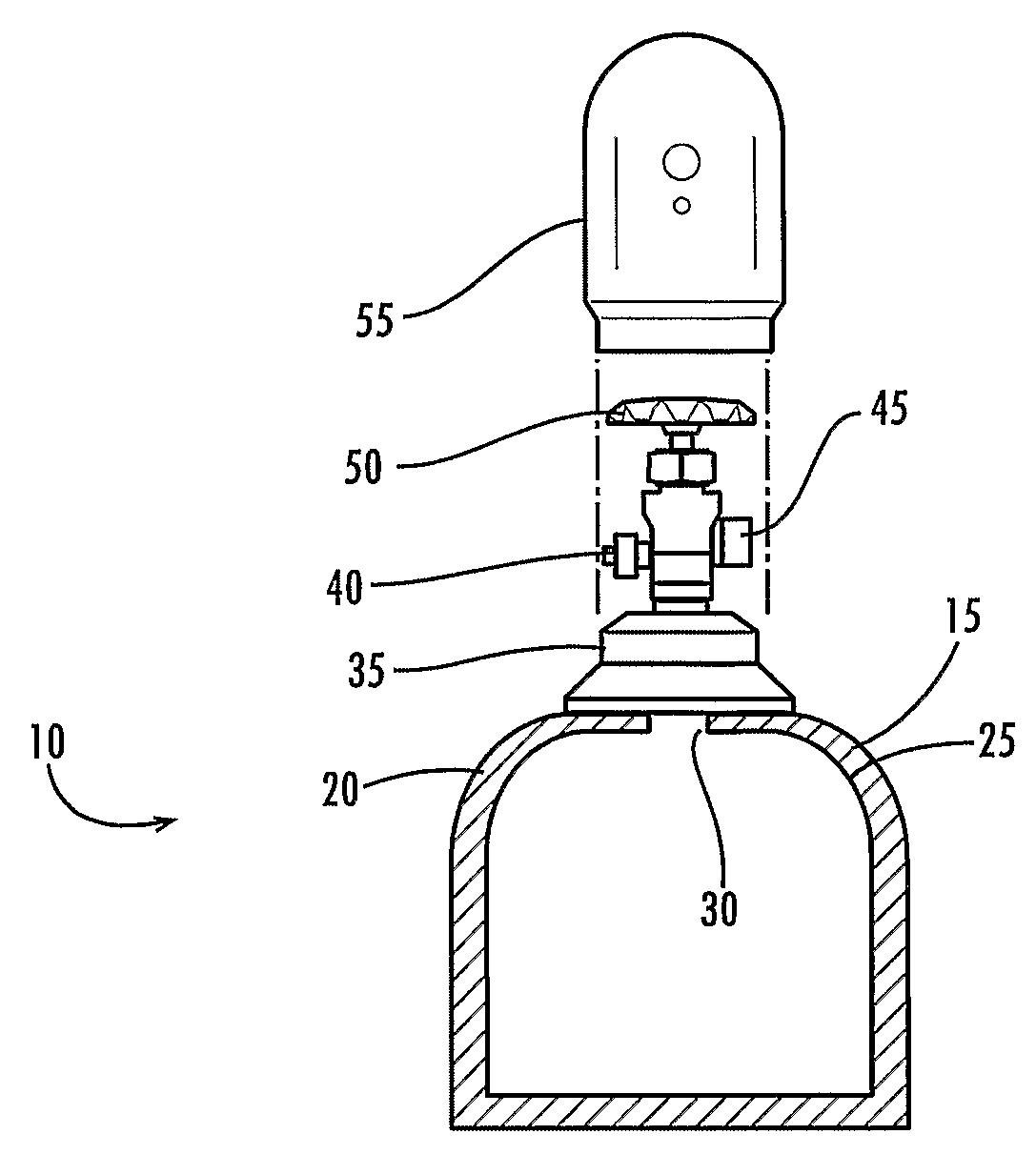

Medical gas cylinder alarm and monitoring system and method

A medical gas cylinder monitoring and alarm device is provided. The medical gas cylinder monitoring and alarm device is a portable device that provides a monitoring function for one or more cylinders and may be carried by a patient or respiratory therapist or may be removably affixed to a medical gas cylinder. The monitoring device is a processor based device adapted to receive selected user inputs for a specific medical gas cylinder application and determine the estimated time remaining before the medical gas cylinder is emptied. The device displays the time remaining for the medical gas cylinder and is also adapted to provide visual and audible alarm notifications when the gas cylinder is near empty.

Owner:PRAXAIR TECH INC

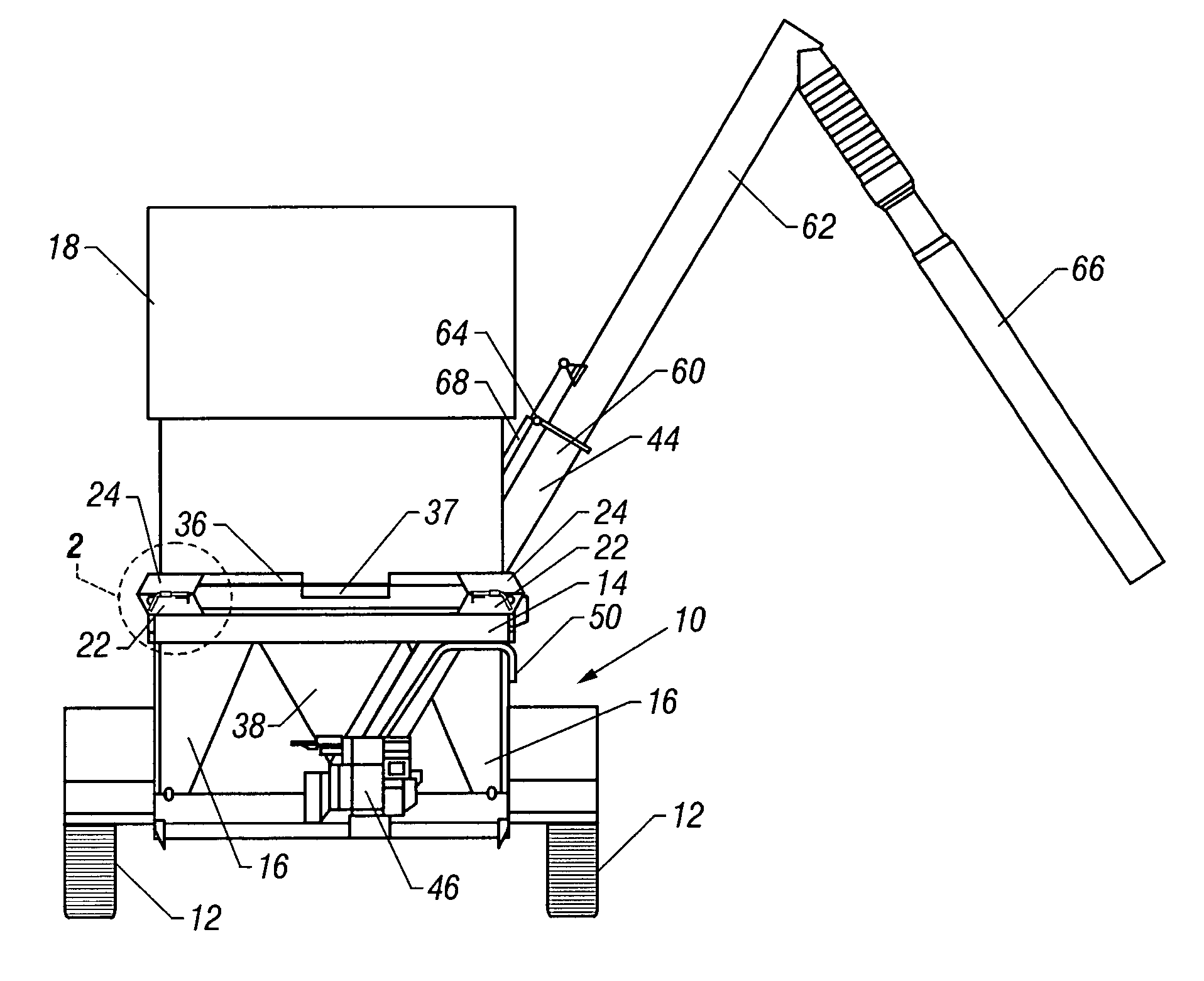

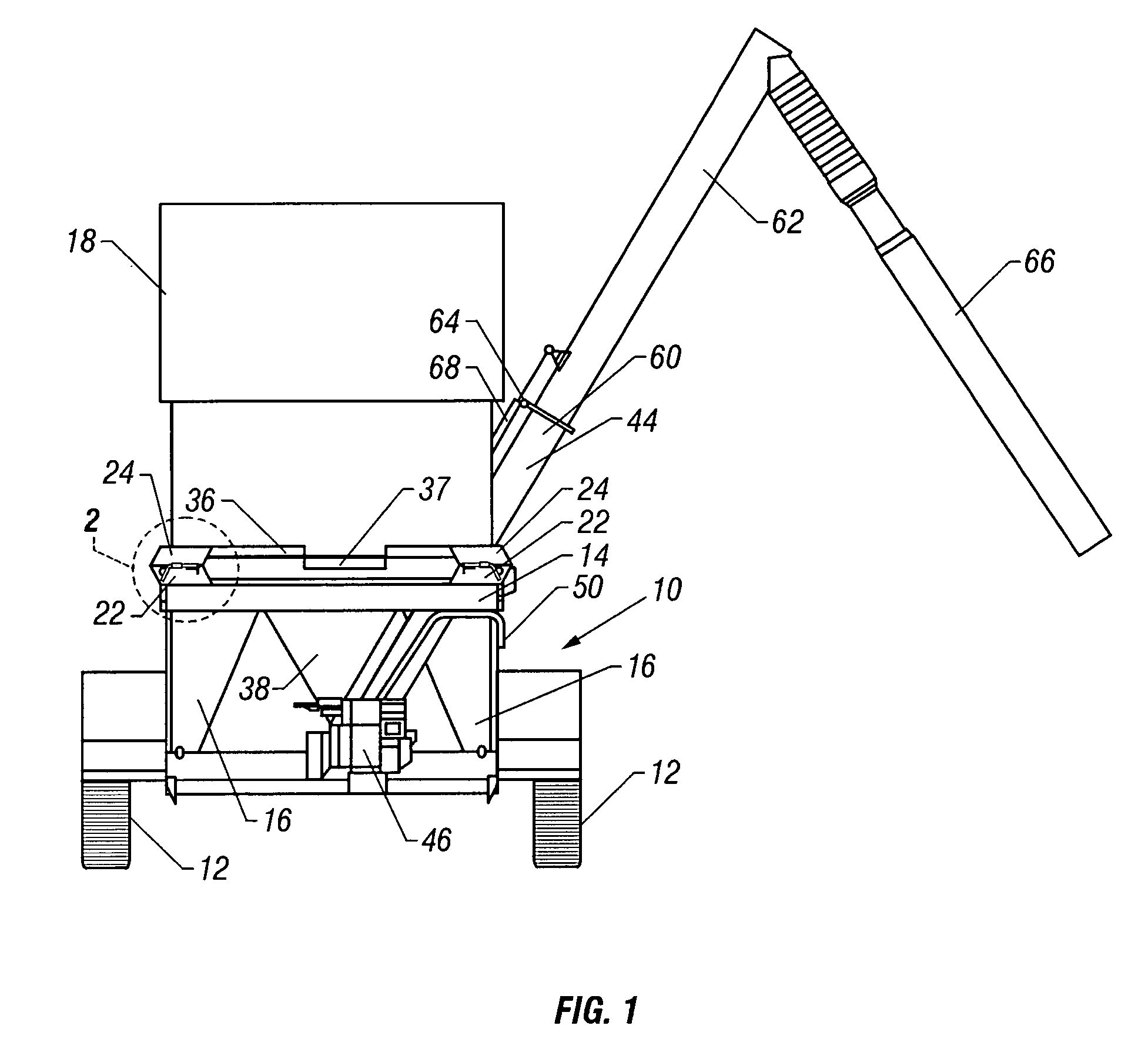

Trailer for transporting bulk seed boxes

InactiveUS6964551B1Promote sportsSecured in quickly and easilyVehicle with removable loadingRefuse receptaclesGas cylinderControl arm

An improved trailer for transporting bulk seed boxes is provided. The trailer includes a bed, a hopper extending below the bed for receiving seed from the bulk seed box, and an auger for unloading seed from the hopper. The bed includes upwardly and outwardly extending guide plates to provide self-centering of the seed box when the box is loaded onto the bed with a forklift truck. The bed includes lock bars moveable between locked and unlocked positions to secure the seed box to the bed. The hopper includes a slide gate with a control arm connected to the gate and extending to the auger side of the trailer for moving the slide gate between open and closed position. The auger includes a foldable upper section which is pivotal between a folded transport position and an extended raised operative position. The folding of the upper auger section is facilitated by a gas cylinder and a lever arm.

Owner:MERIDIAN MFG

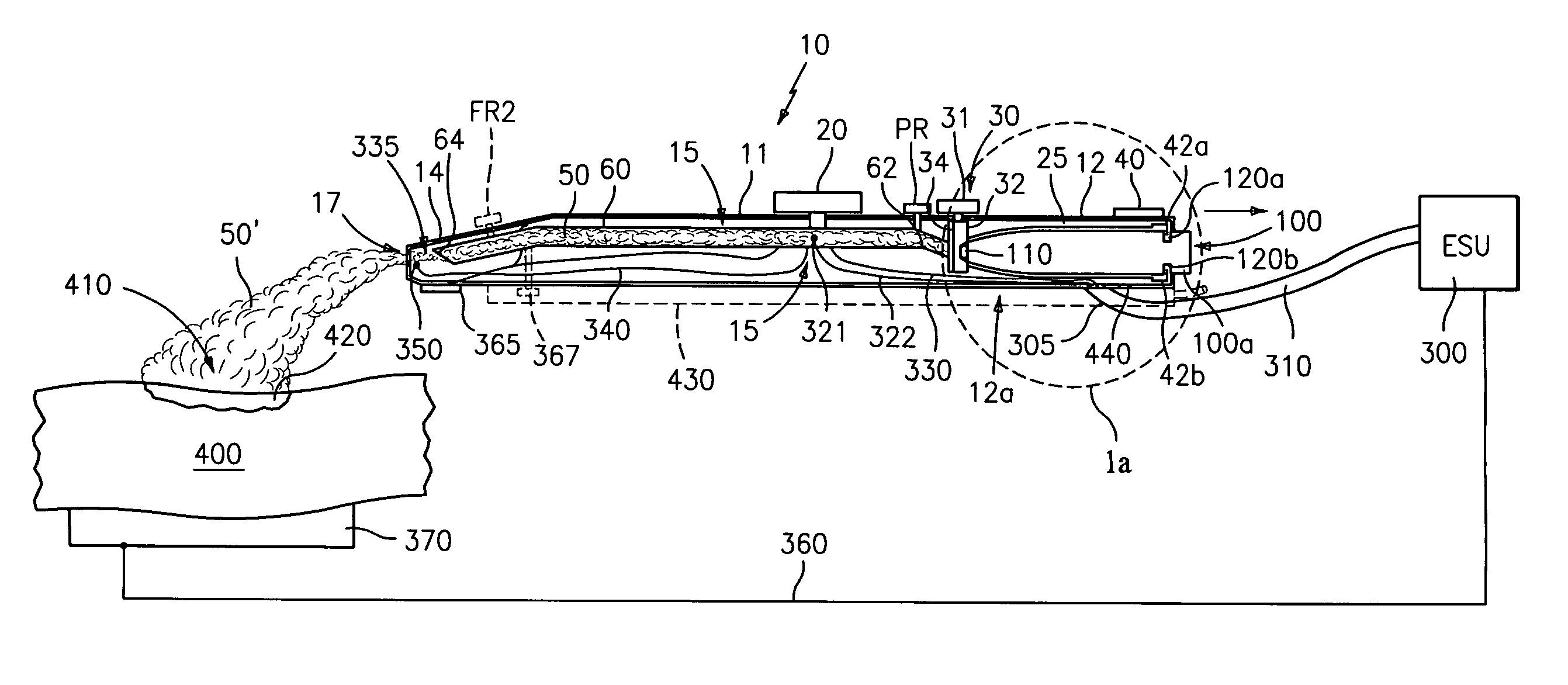

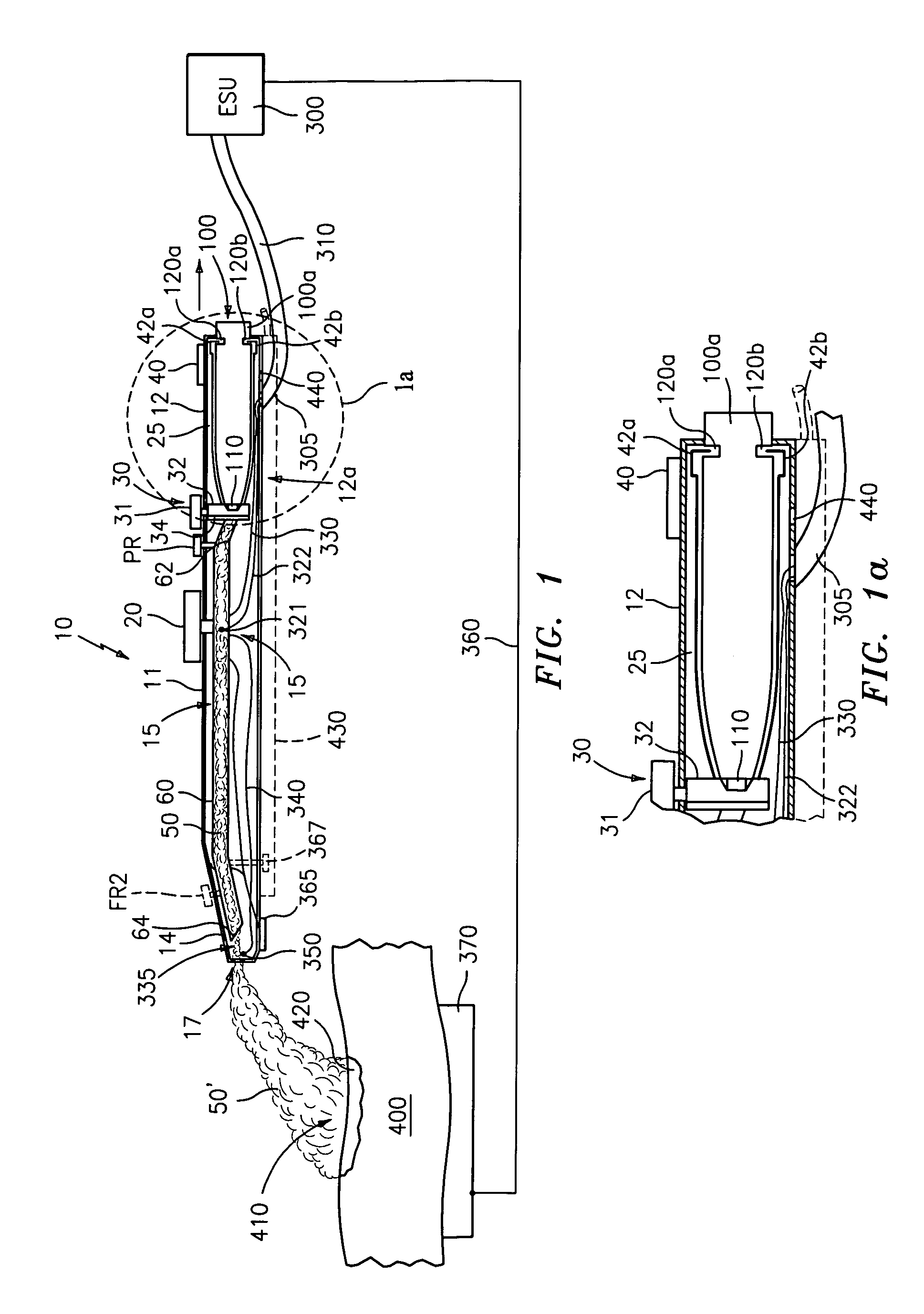

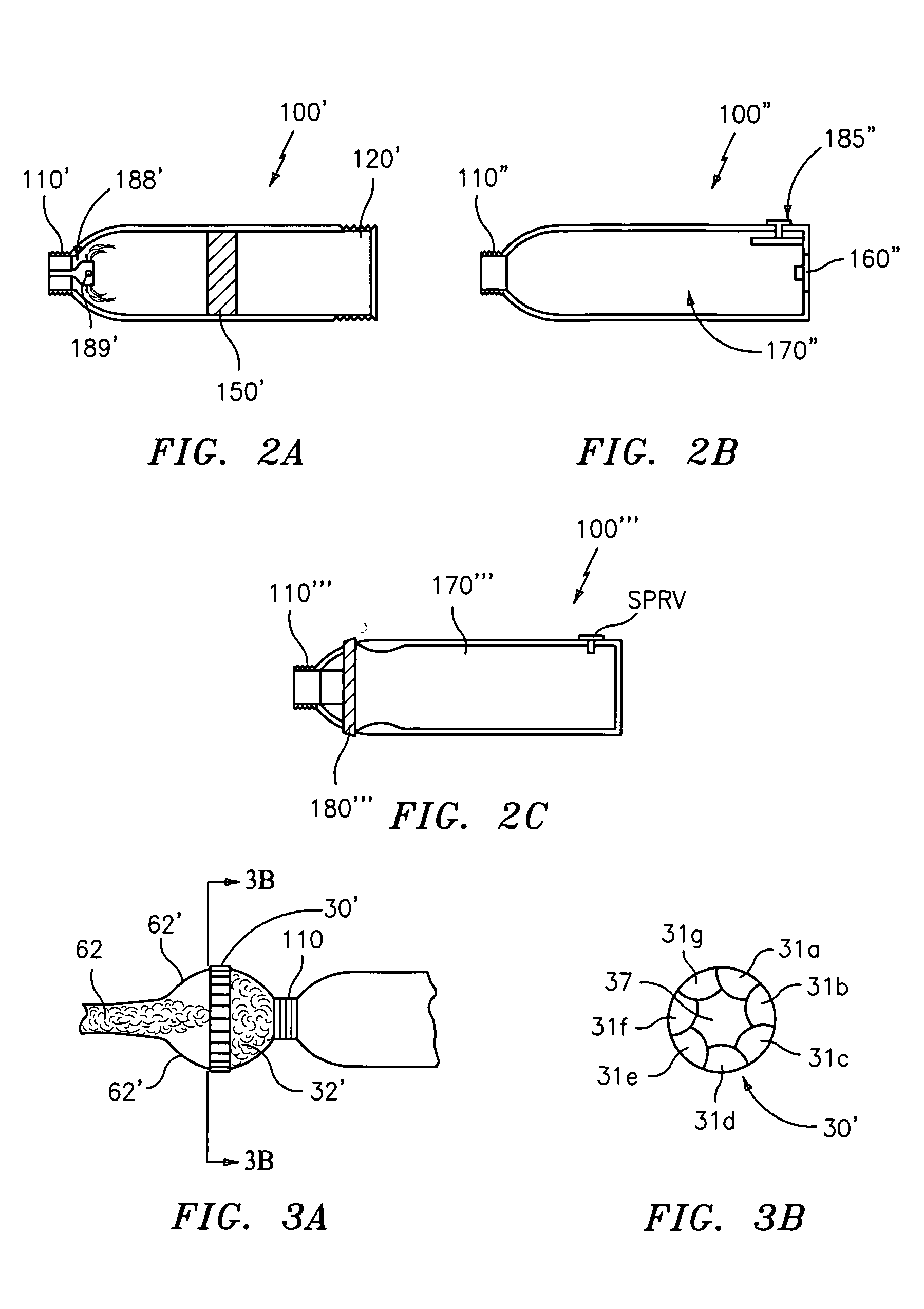

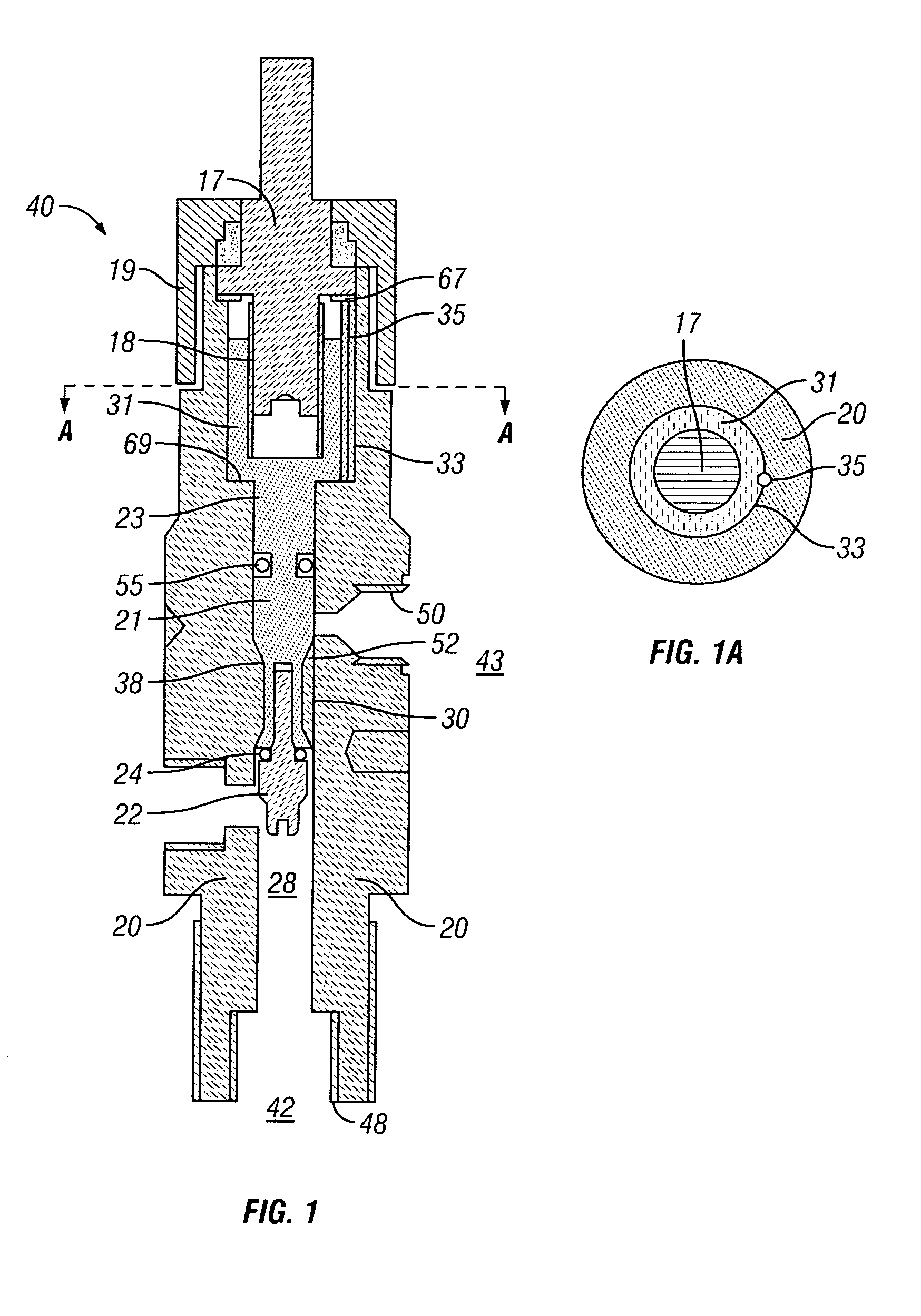

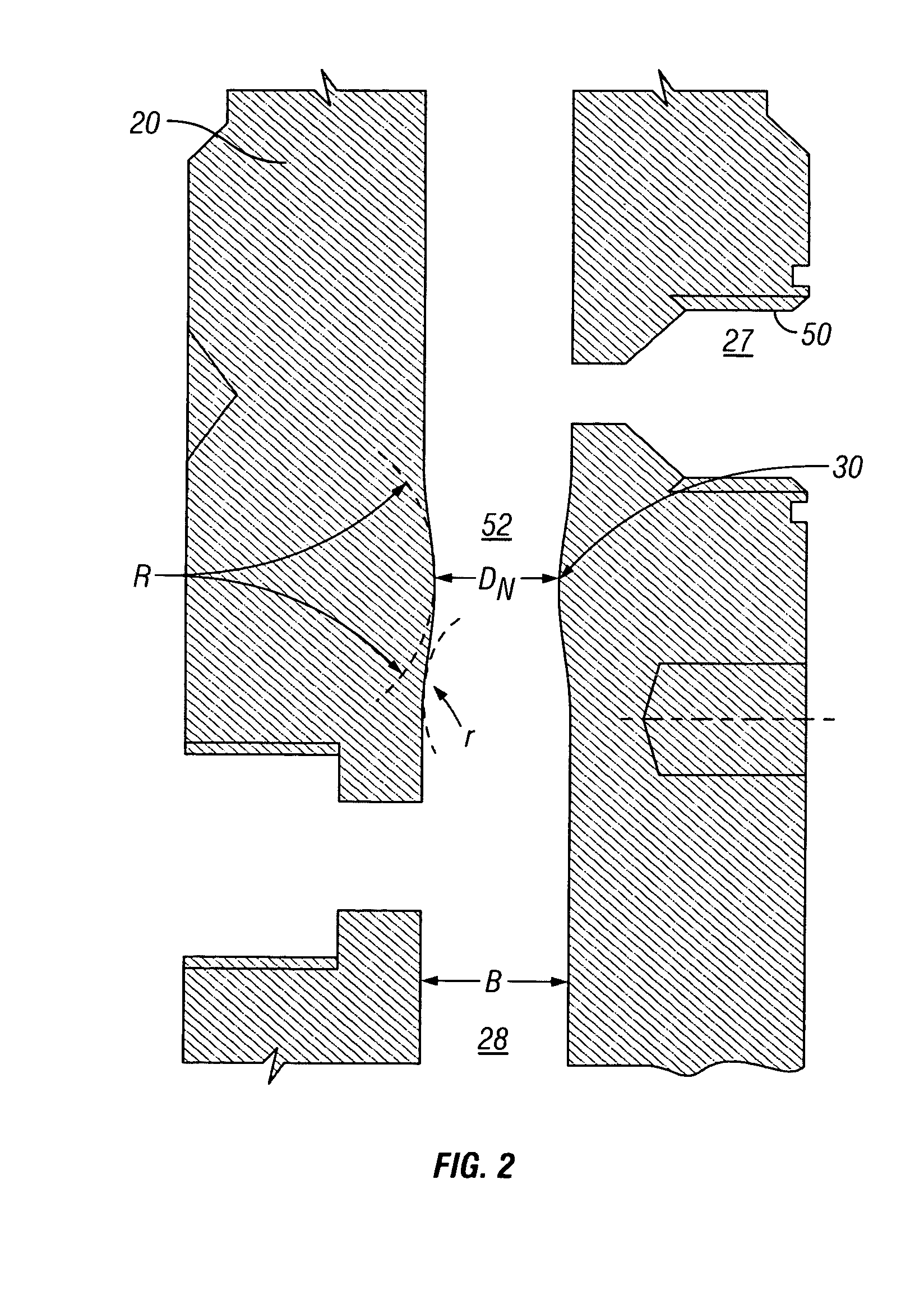

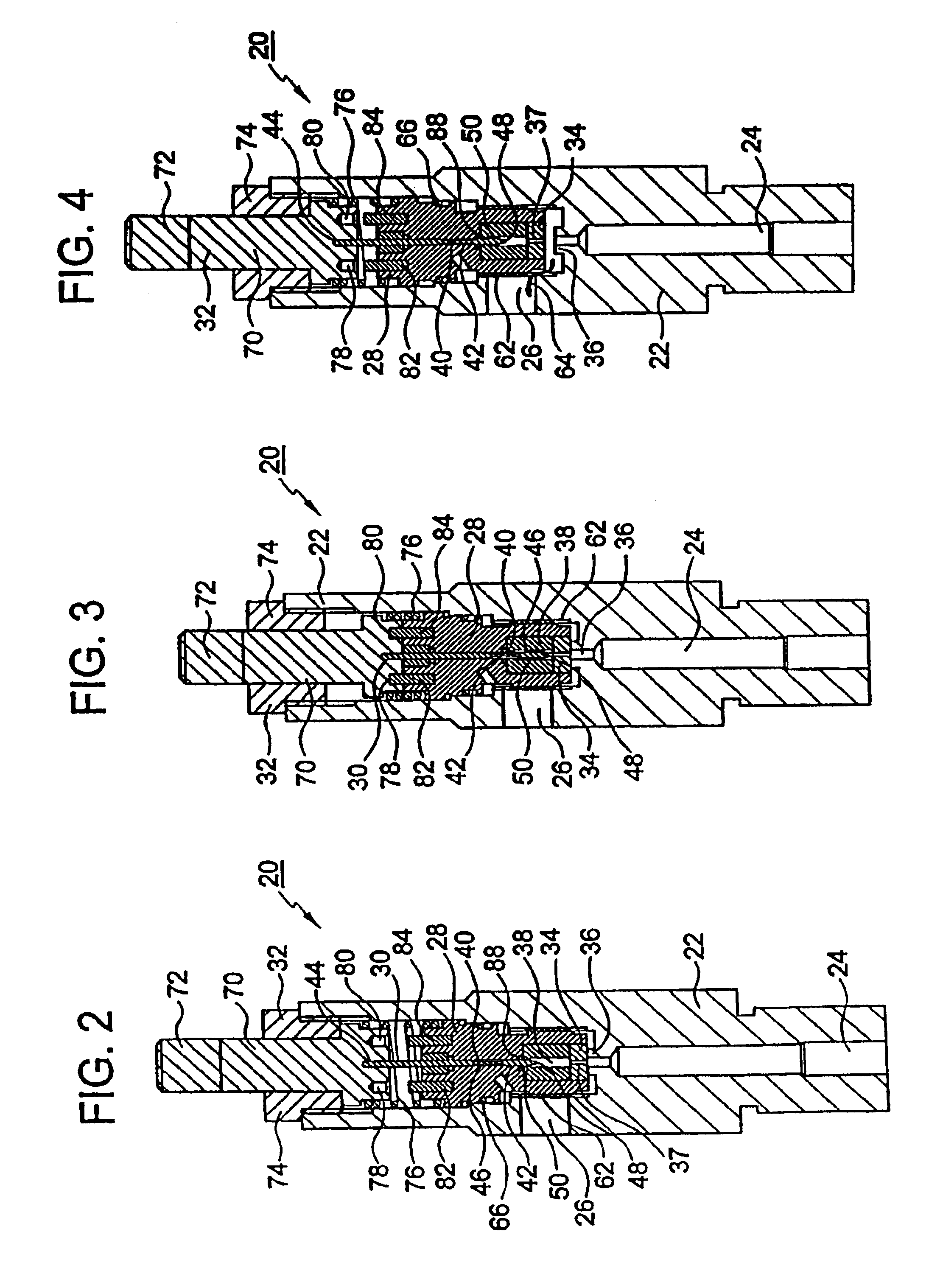

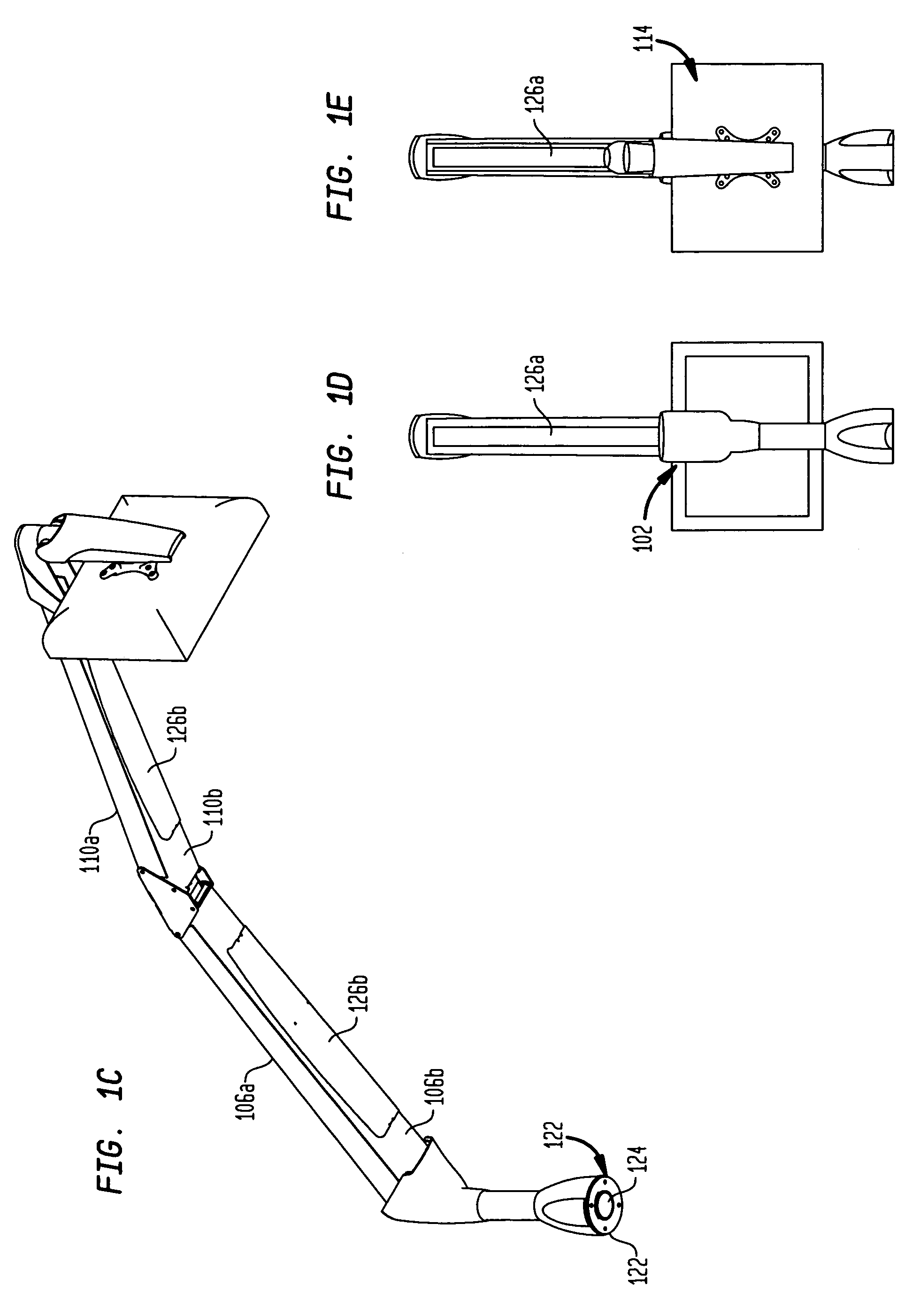

Self contained, gas-enhanced surgical instrument

InactiveUS20050171528A1Safely control releaseSuitable for useSurgical instruments for heatingGas cylinderEngineering

An electrosurgical apparatus for coagulating tissue includes an elongated housing and an electrode located adjacent the distal end of the housing. The electrode can be connected to a source of electrosurgical energy. At least one actuator is included which electrosurgically energizes the electrode. The apparatus also includes a relatively small gas cylinder which contains a pressurized gas consisting of inert gas and which is selectively seated in the housing. Upon actuation of the actuator, gas is dispersed under pressure from the gas cylinder to the electrode and is ionized prior to the distribution of the gas into the operating field.

Owner:COVIDIEN AG

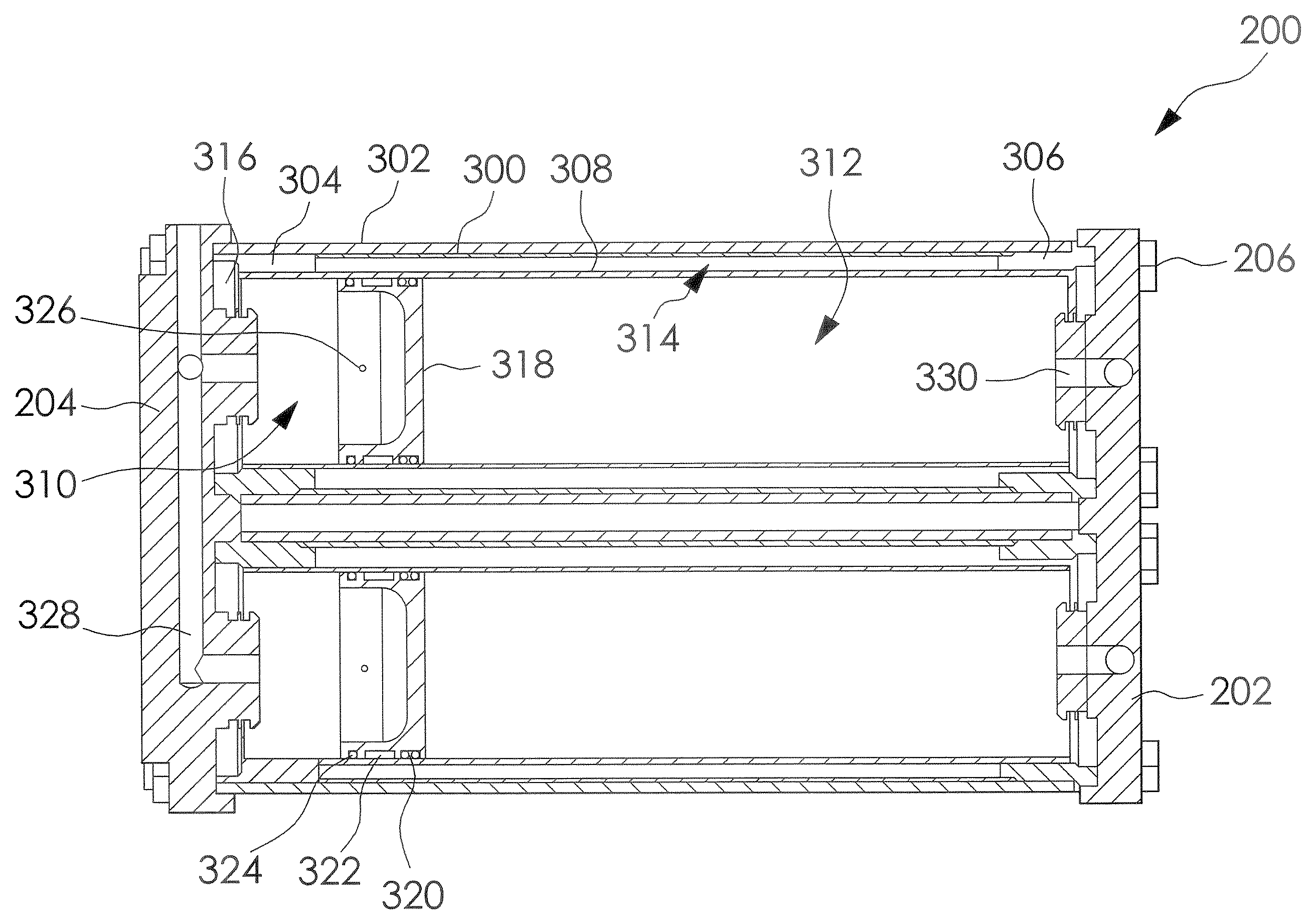

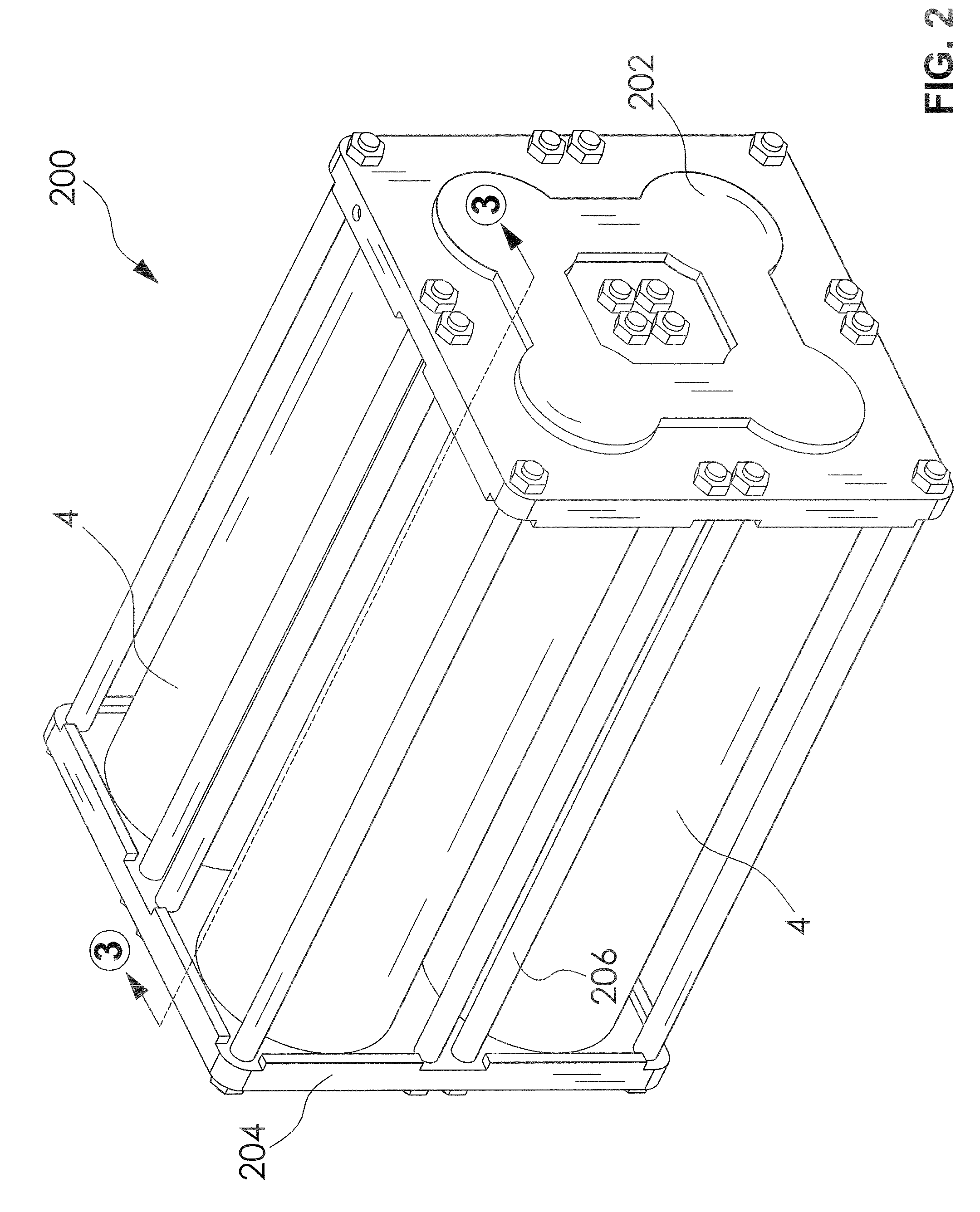

Compact hydraulic accumulator

InactiveUS20080308168A1Light weightEasy maintenanceFluid couplingsCheck valvesWorking fluidGas cylinder

A lightweight, optimally efficient, easily serviced, piston-in-sleeve high pressure accumulator is provided. The accumulator includes one or more cylindrical composite pressure vessel separate end cap manifolds. A piston slidably disposed in a thin impermeable internal sleeve in the accumulator separates two chambers, one adapted for containing a working fluid and the other adapted for containing gas under pressure. Gas is provided in a volume between the impermeable internal sleeve and the composite pressure vessel wall. Additional gas is optionally provided in gas cylinders. Further components are provided for withstanding harmful effects of radial flexing of the composite vessel wall under high pressures, and from stresses present in use in mobile applications such as with a hydraulic power system for a hydraulic hybrid motor vehicle.

Owner:NRG ENTERPRISES

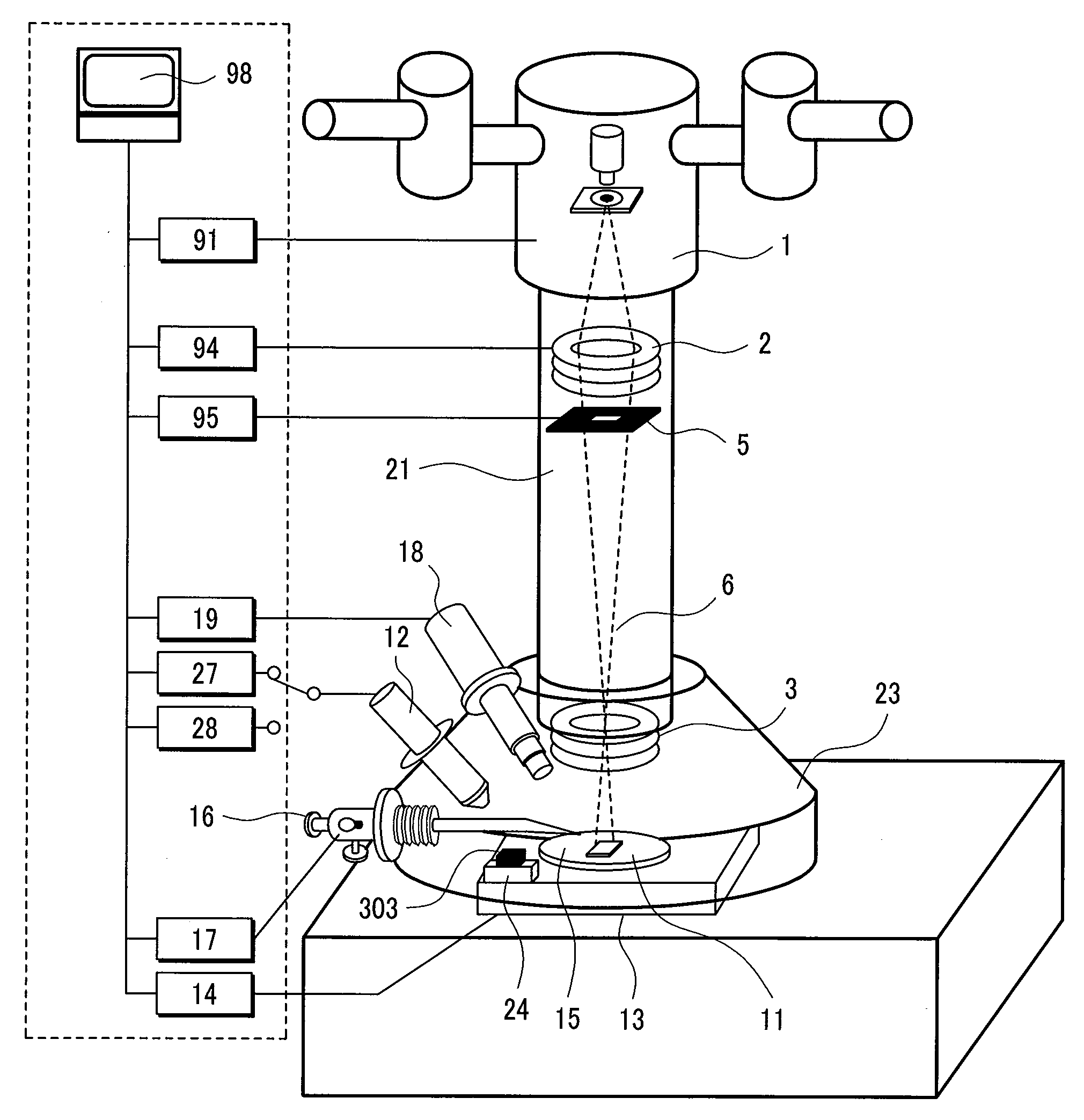

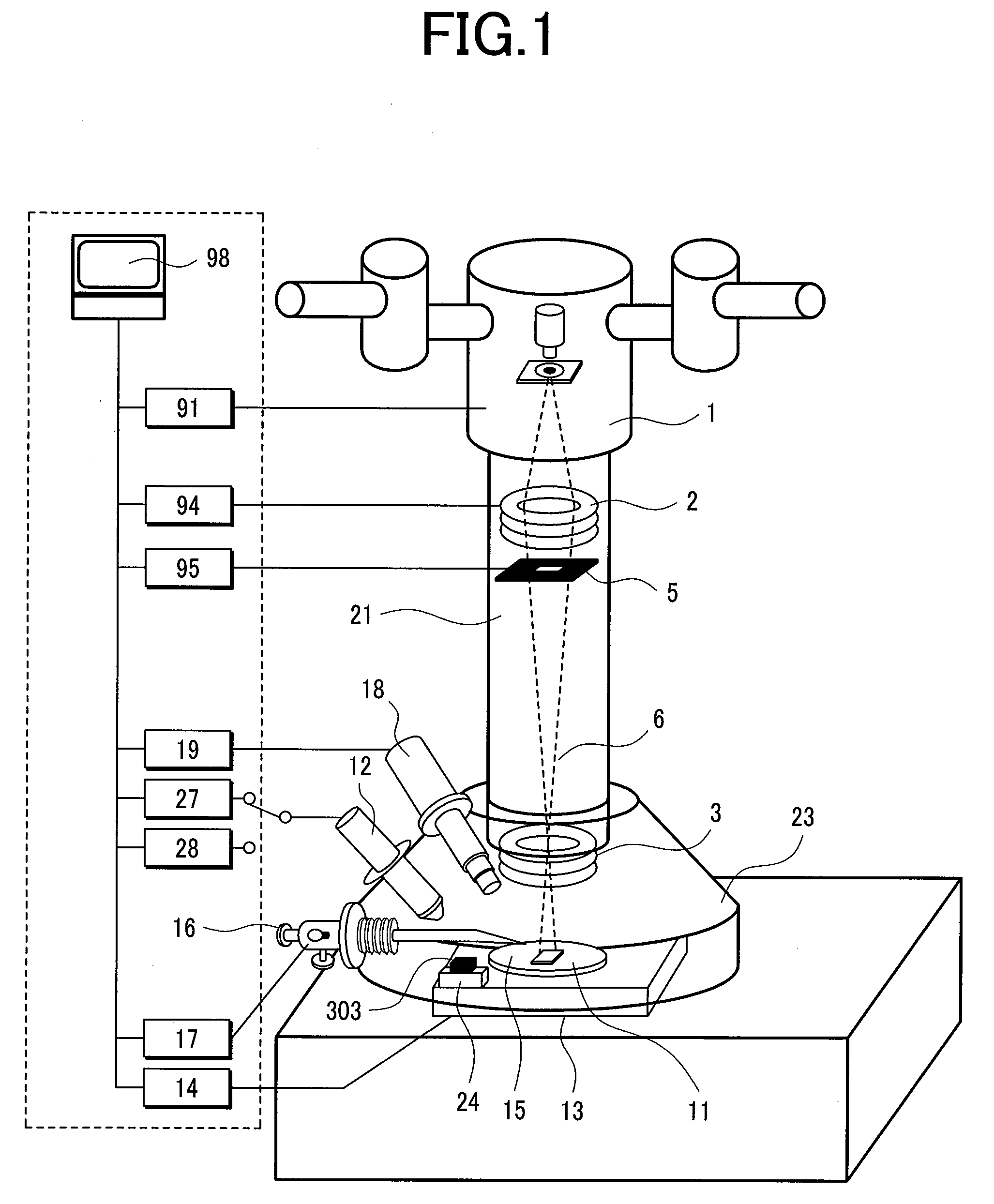

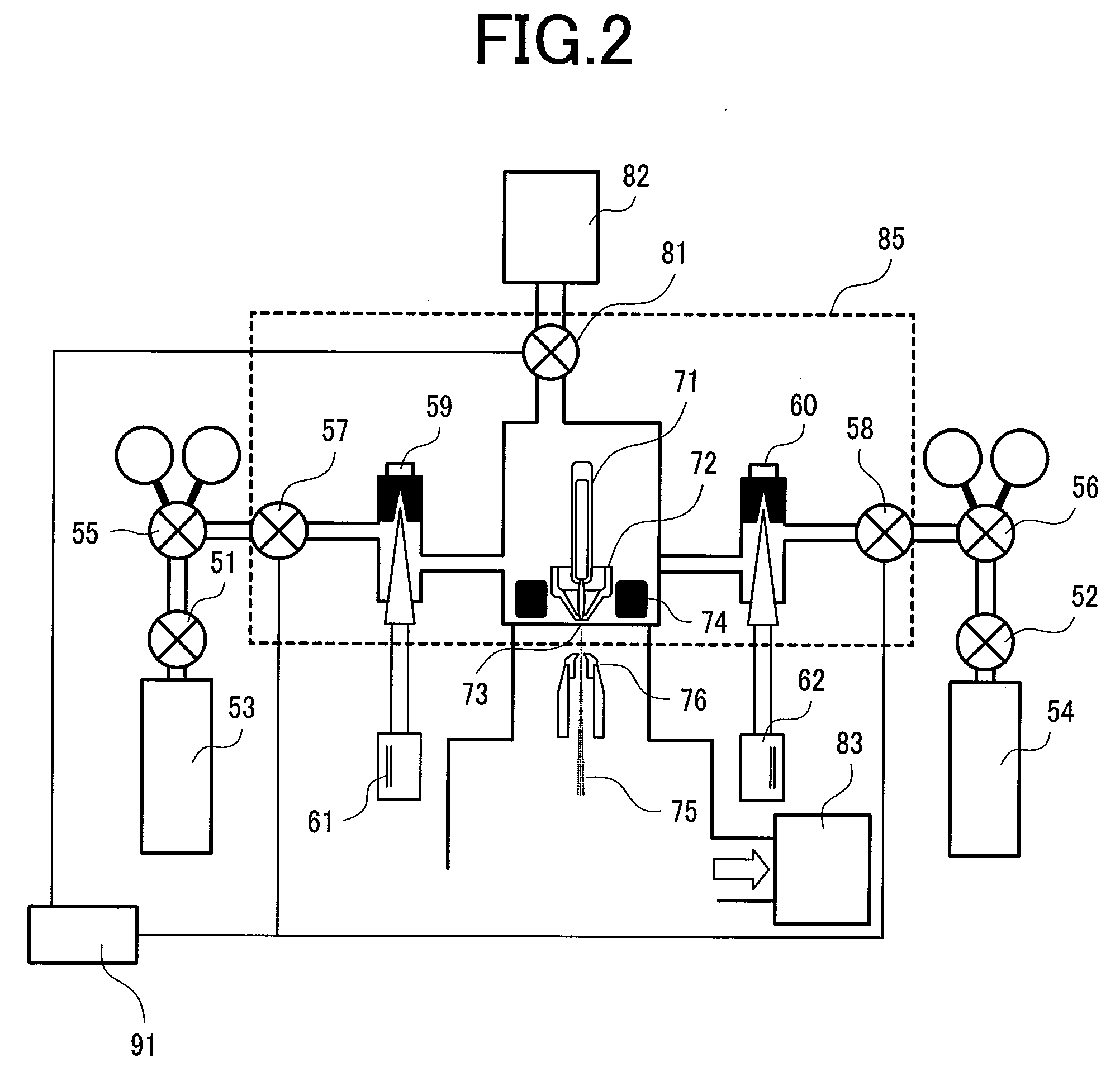

Ion source, ion beam processing/observation apparatus, charged particle beam apparatus, and method for observing cross section of sample

ActiveUS20090230299A1Shorten the timeImprove flatnessVacuum evaporation coatingSputtering coatingIon beam processingGas cylinder

An ion beam machining and observation method relevant to a technique of cross sectional observation of an electronic component, through which a sample is machined by using an ion beam and a charged particle beam processor capable of reducing the time it takes to fill up a processed hole with a high degree of flatness at the filled area. The observation device is capable of switching the kind of gas ion beam used for machining a sample with the kind of a gas ion beam used for observing the sample. To implement the switch between the kind of a gas ion beam used for sample machining and the kind of a gas ion beam used for sample observation, at least two gas introduction systems are used, each system having a gas cylinder a gas tube, a gas volume control valve, and a stop valve.

Owner:HITACHI HIGH-TECH CORP

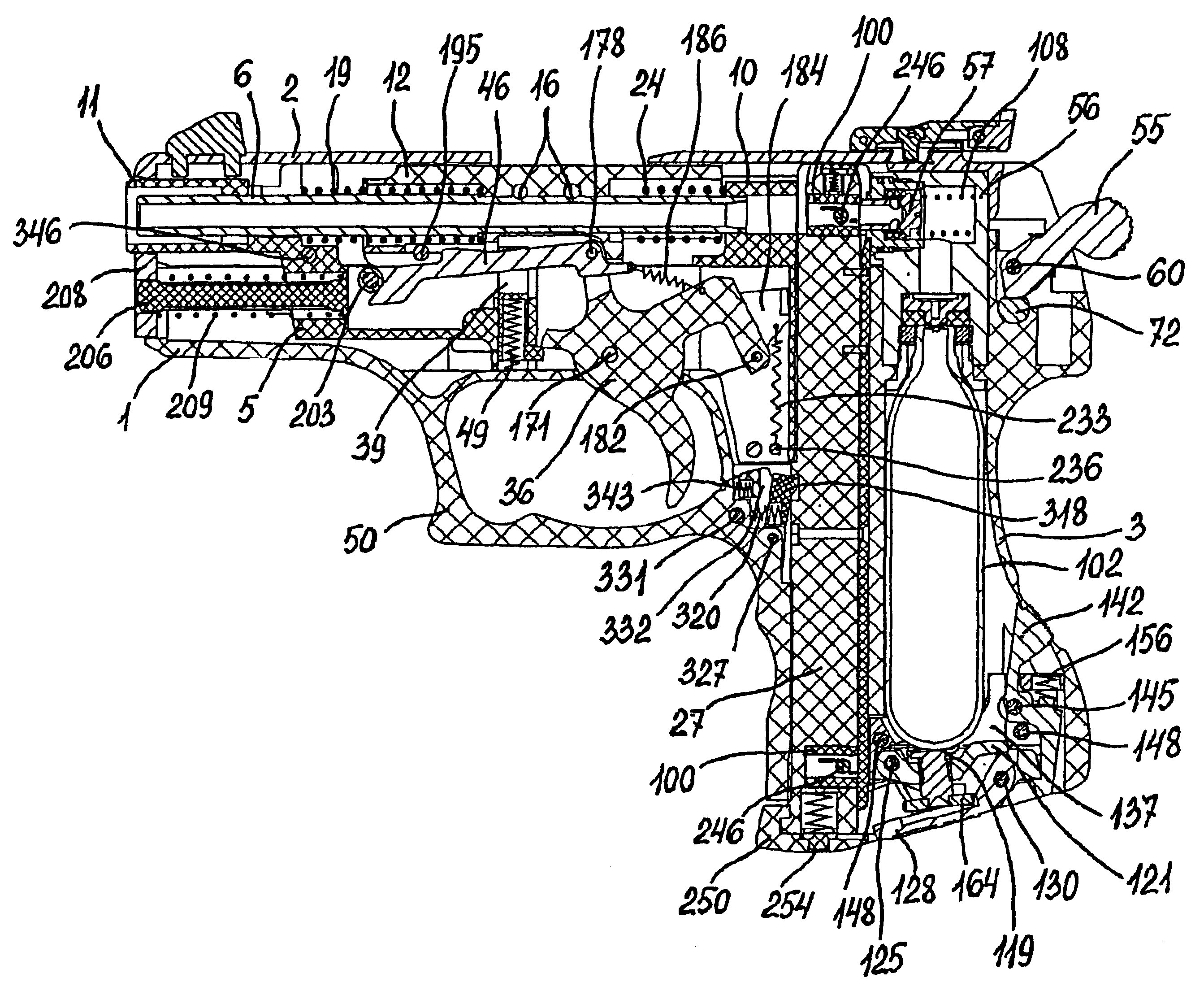

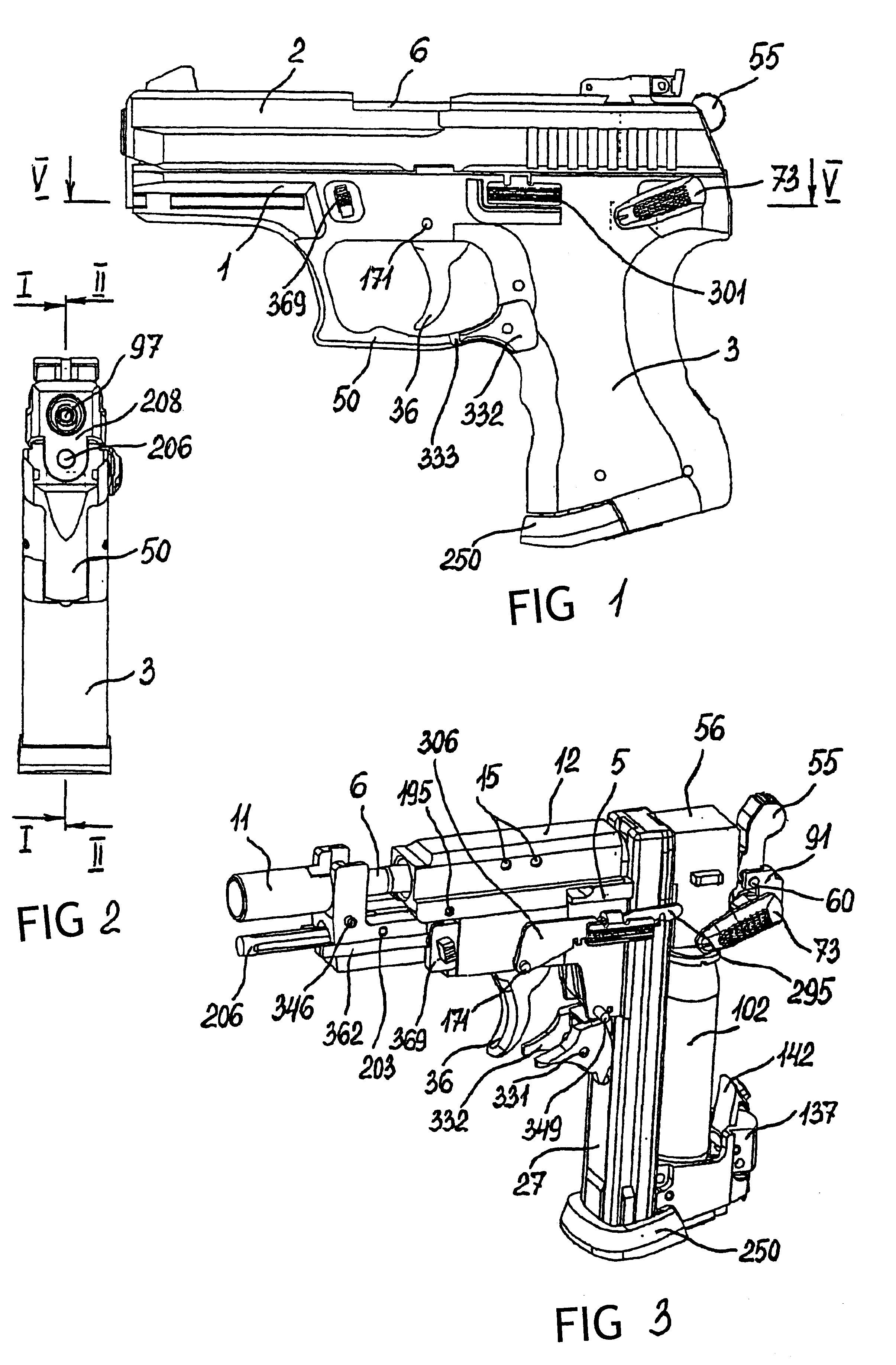

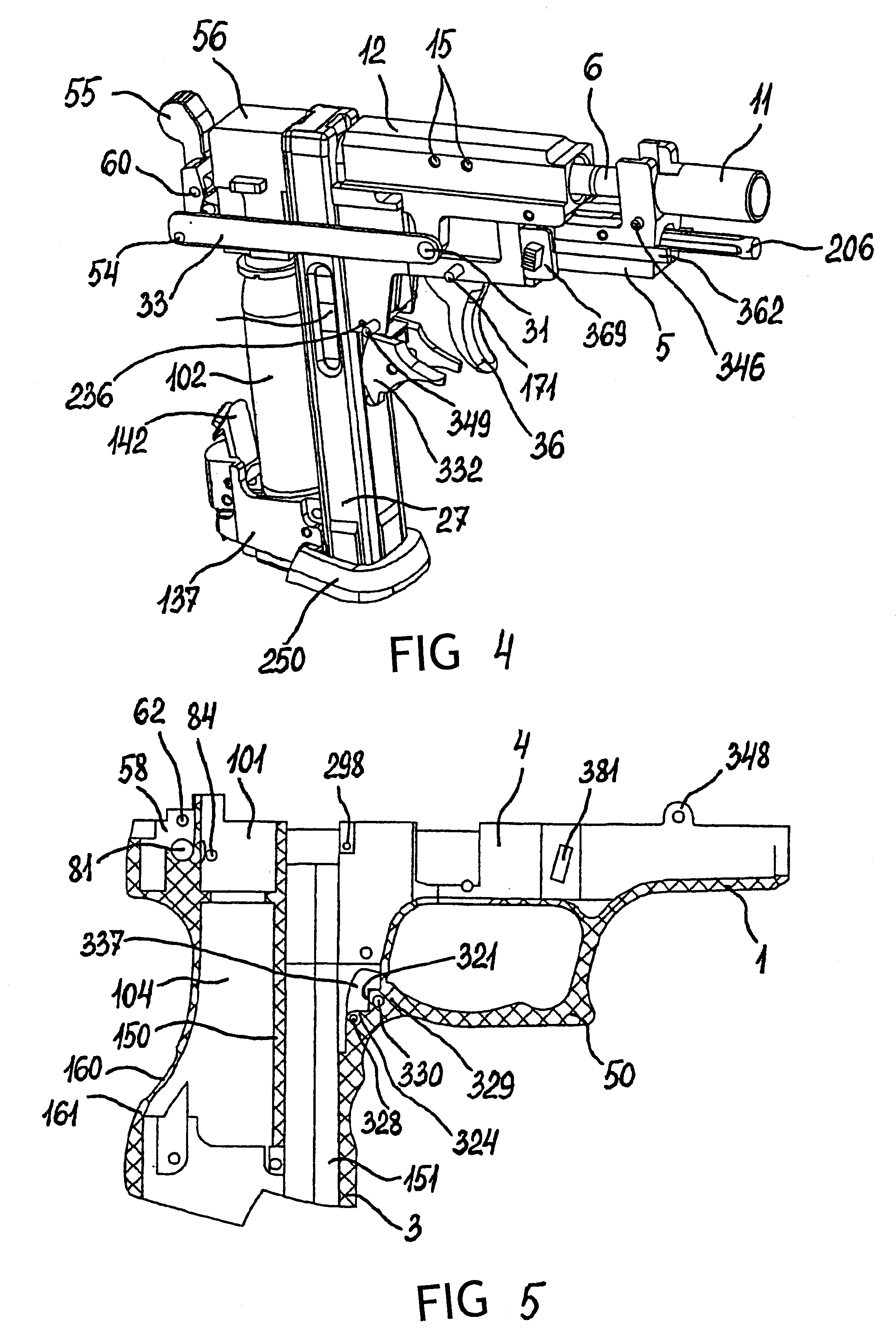

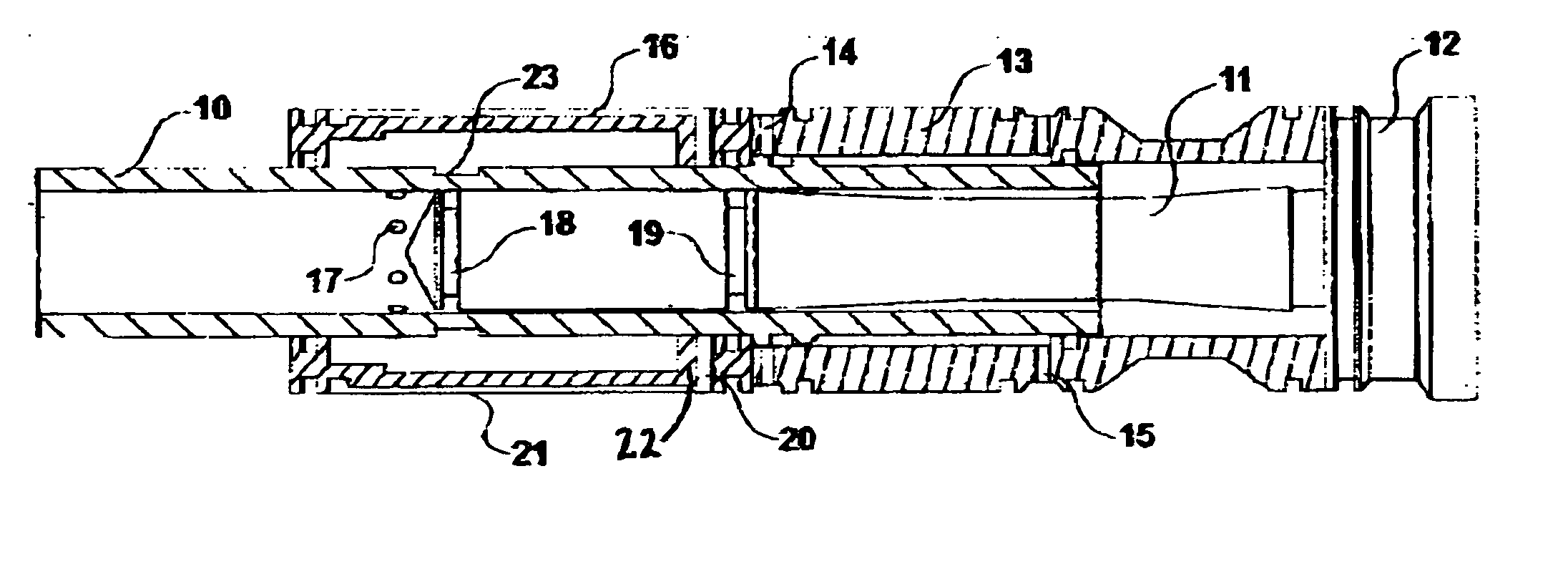

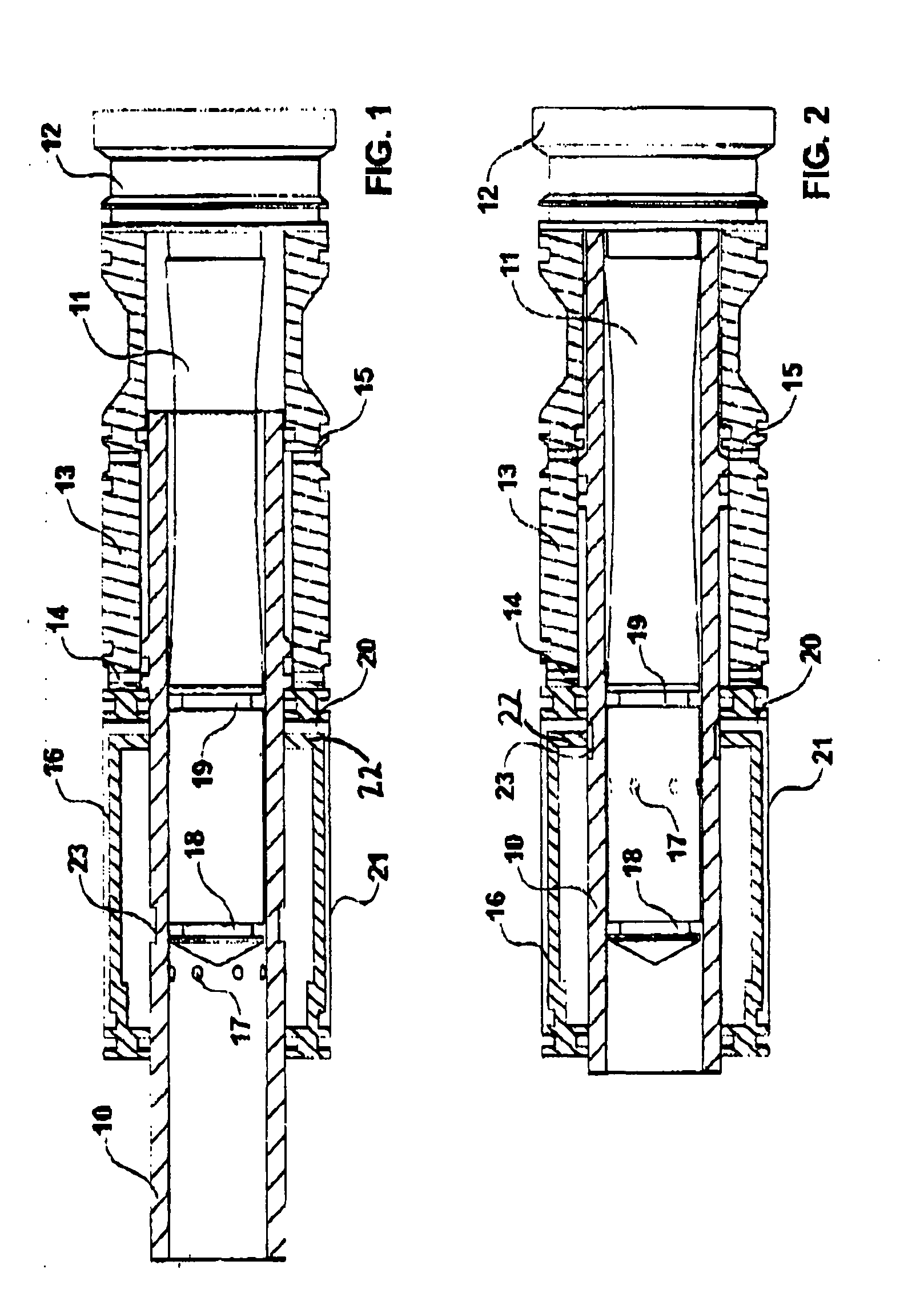

Multi-charge gas-cylinder pistol

InactiveUS6494194B2Improve reliabilityHigh performance featuresFiring/trigger mechanismsAmmunition loadingGas cylinderMainspring

Owner:ZAKRYTOE AKTSIONERNOE OBSHCHESTVO GRP ANICS

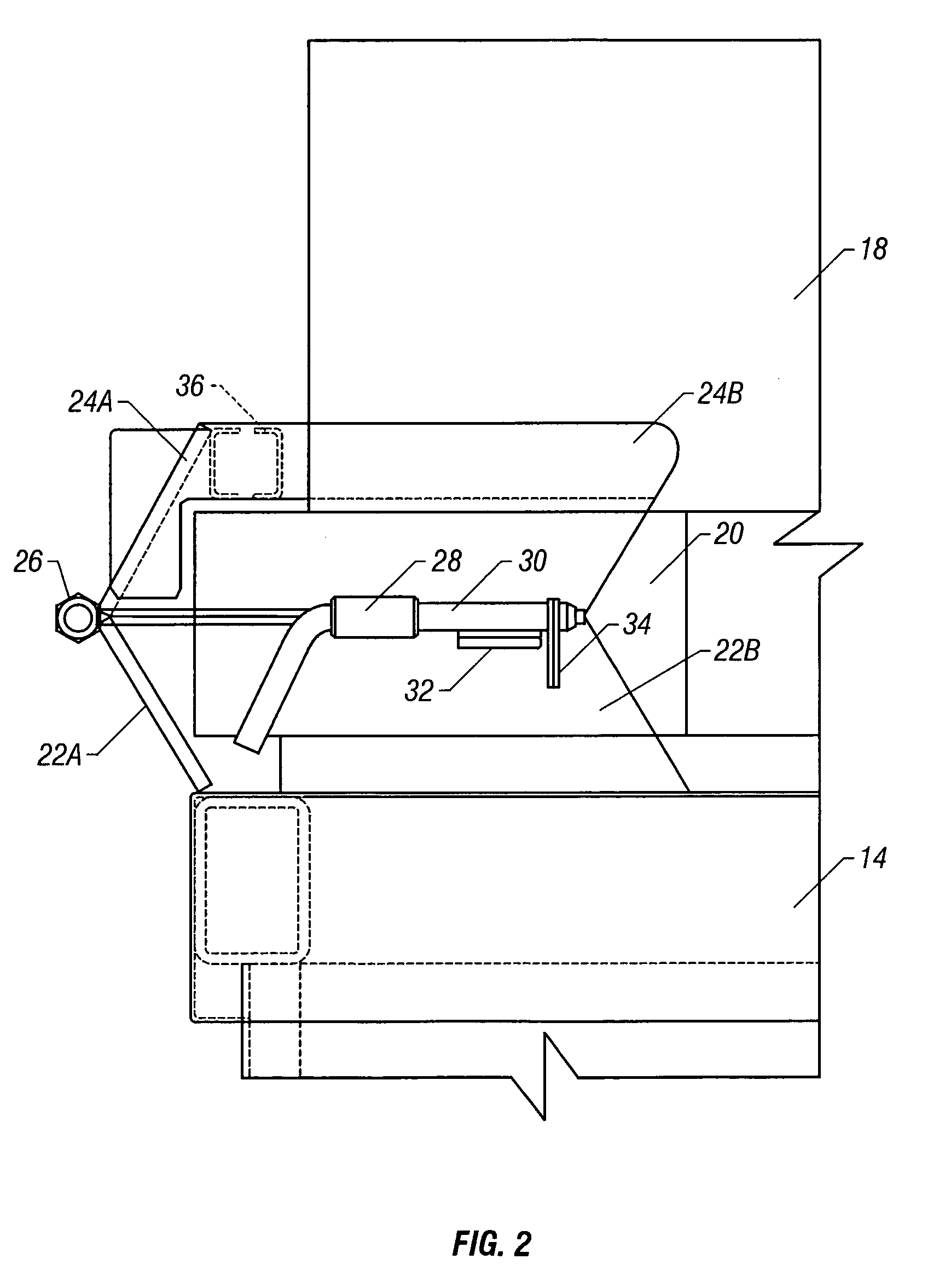

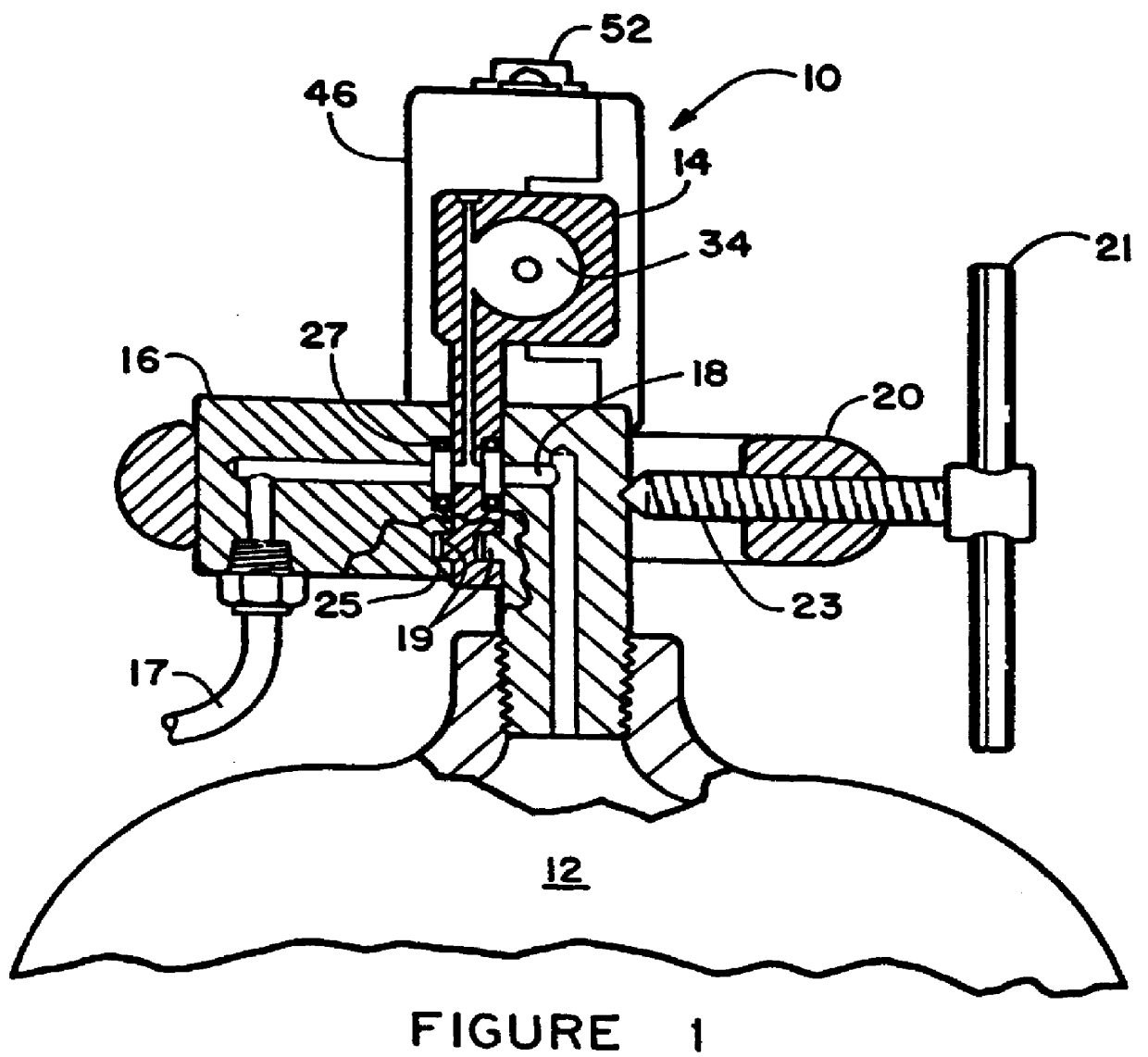

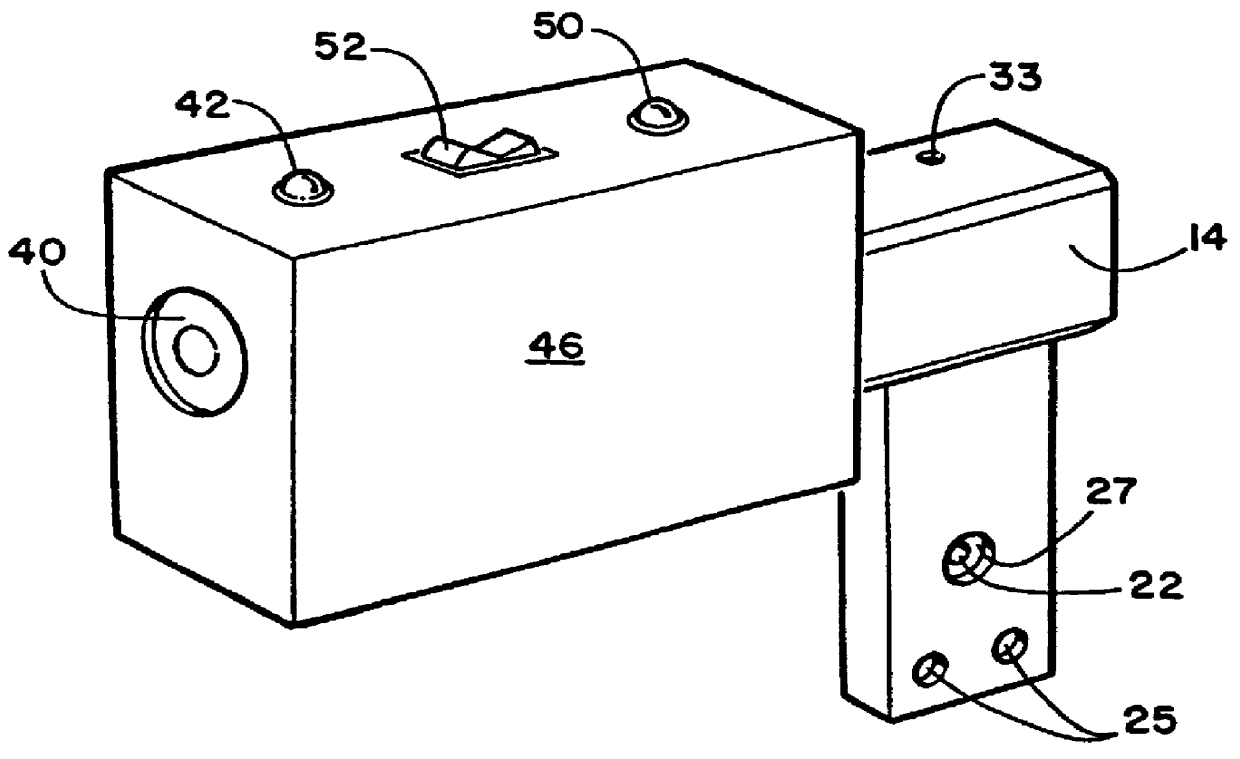

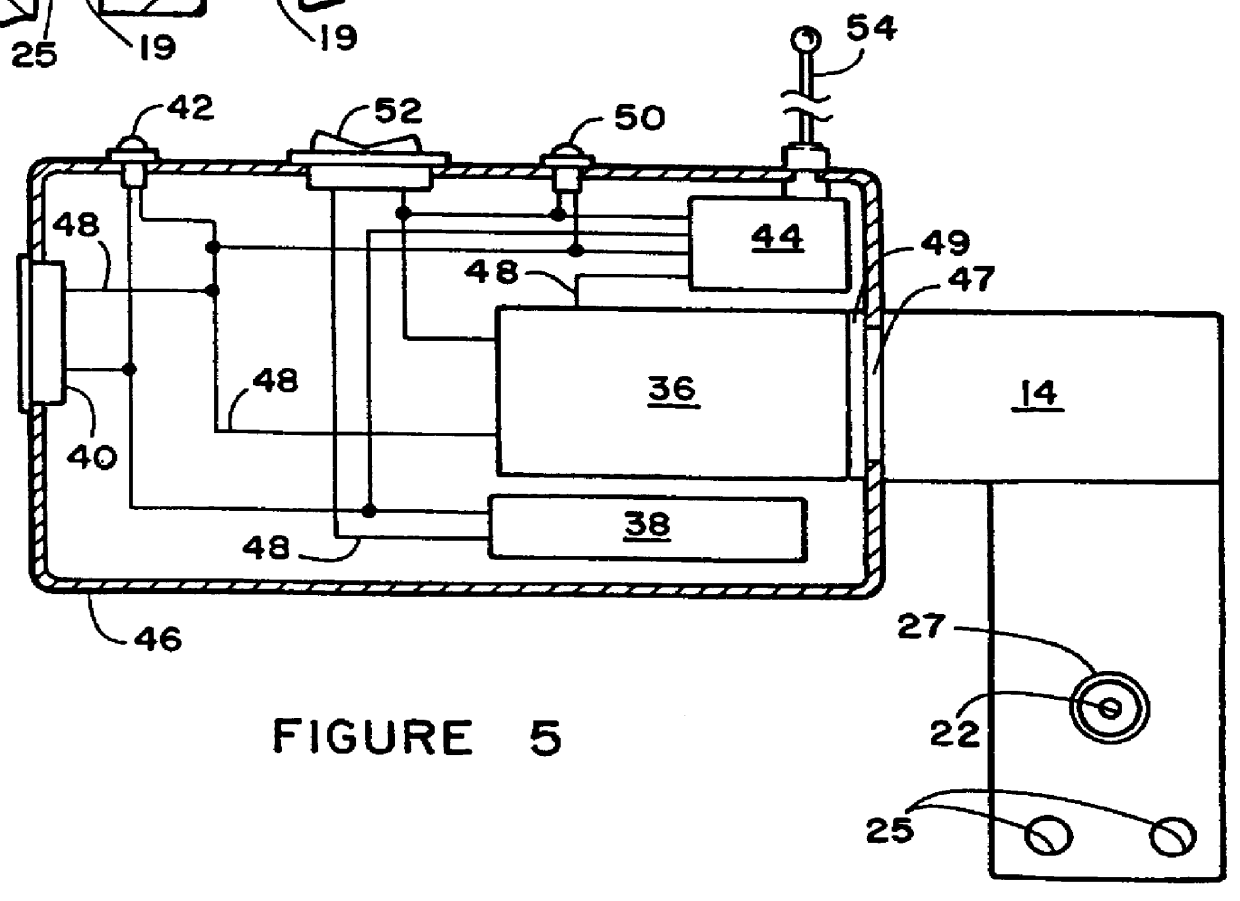

Pressure monitor and alarm for compression mounting with compressed gas storage tank

InactiveUS6137417AImprove securityReduce tank pressureValve arrangementsMeasurement of fluid loss/gain rateGas cylinderEngineering

A warning device configured for removable mounting in combination with a high pressure gas cylinder and a regulator used to regulate the high pressure gas supplied by the cylinder. The device compression mounts between the regulator and tank outlet on conventional portable oxygen and gas supply systems using a specially configured manifold. The device features one or a combination of alarms, from a group including audio, visual, electronic, and remotely transmitted alarms. These alarms are activated by a pressure switch monitoring the remaining supply in the gas cylinder through a conduit the manifold. The alarm signal from the device alerts the user, or a third party monitoring the user, of current tank pressure or will sound an alarm when remaining high pressure gas inside the gas cylinder drops below a predetermined level.

Owner:INGEN TECH

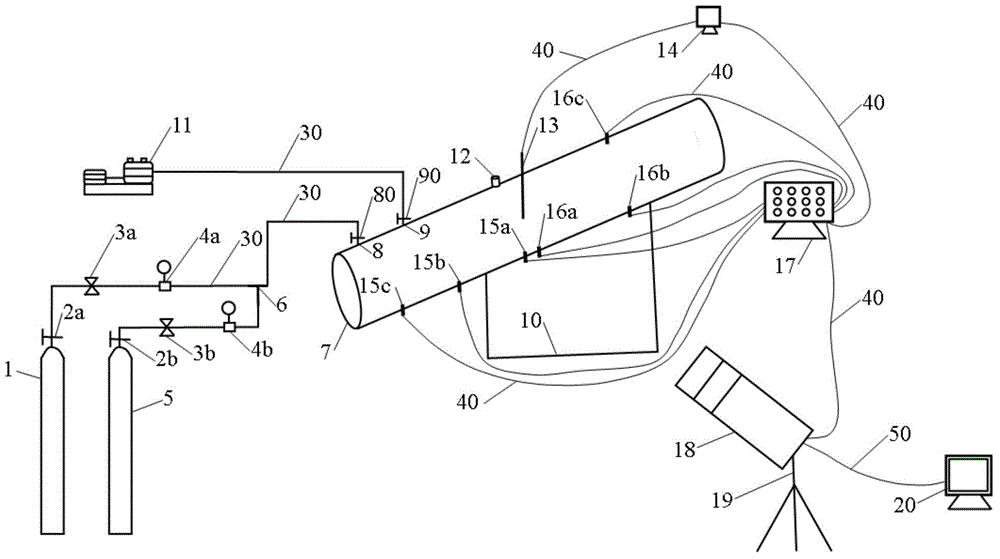

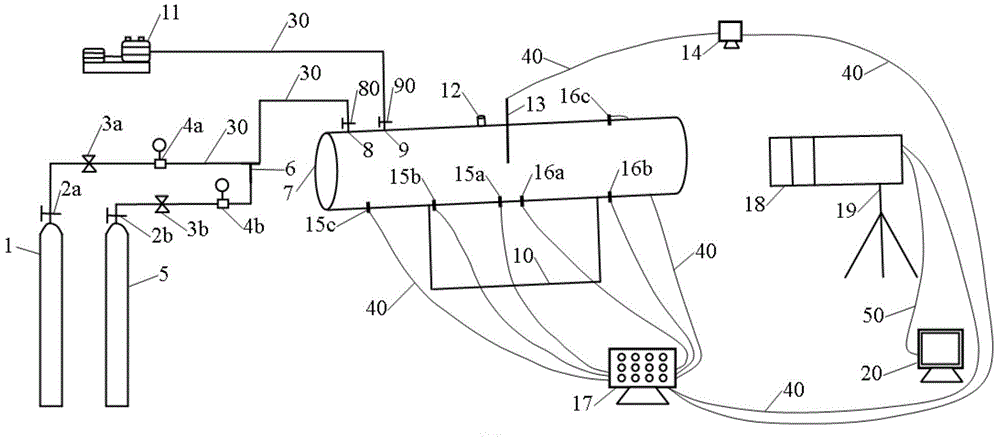

Detonation performance test method for high-energy imploding explosive

InactiveCN102253083AFlexible simulationRealize synchronized measurementsMaterial exposibilityDetonatorExplosive Agents

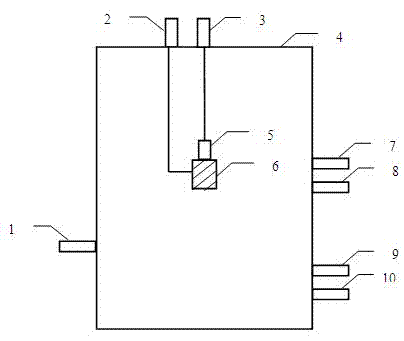

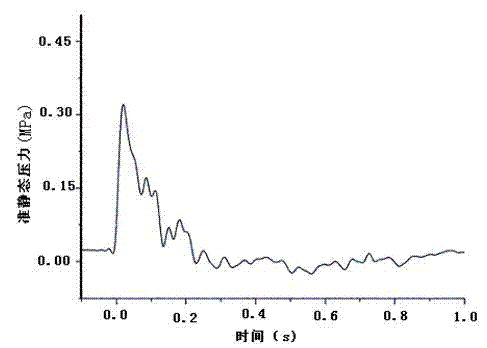

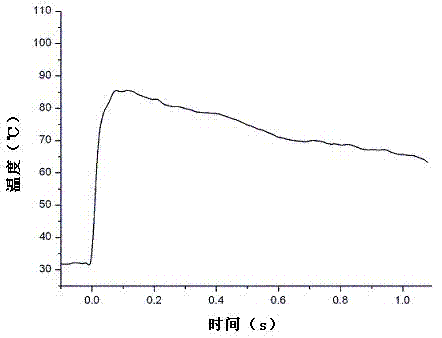

The invention discloses a detonation performance test method for high-energy imploding explosive. The method is characterized in that: a explosive grain with a detonator is placed in a sealed explosion vessel; quasi-static pressure of the explosive, transient temperature of the explosive, detonation velocity of the explosive and gas components of the explosive are detected; a temperature sensor is arranged on the sealed explosion vessel, and is provided for monitoring the temperature changing in the sealed explosion vessel during the test process, a pressure sensor is arranged on the sealed explosion vessel, and is provided for monitoring the pressure changing in the sealed explosion vessel during the test process; the sealed explosion vessel is further connected with a gas collection andtest system, a firing device, a detonation velocity test device, a mechanical vacuum pump and a gas cylinder. The method is applicable for the performance tests of various imploding explosives, and can be provided for performing laboratory quantitative evaluation to the gas expansion working.

Owner:XIAN MODERN CHEM RES INST

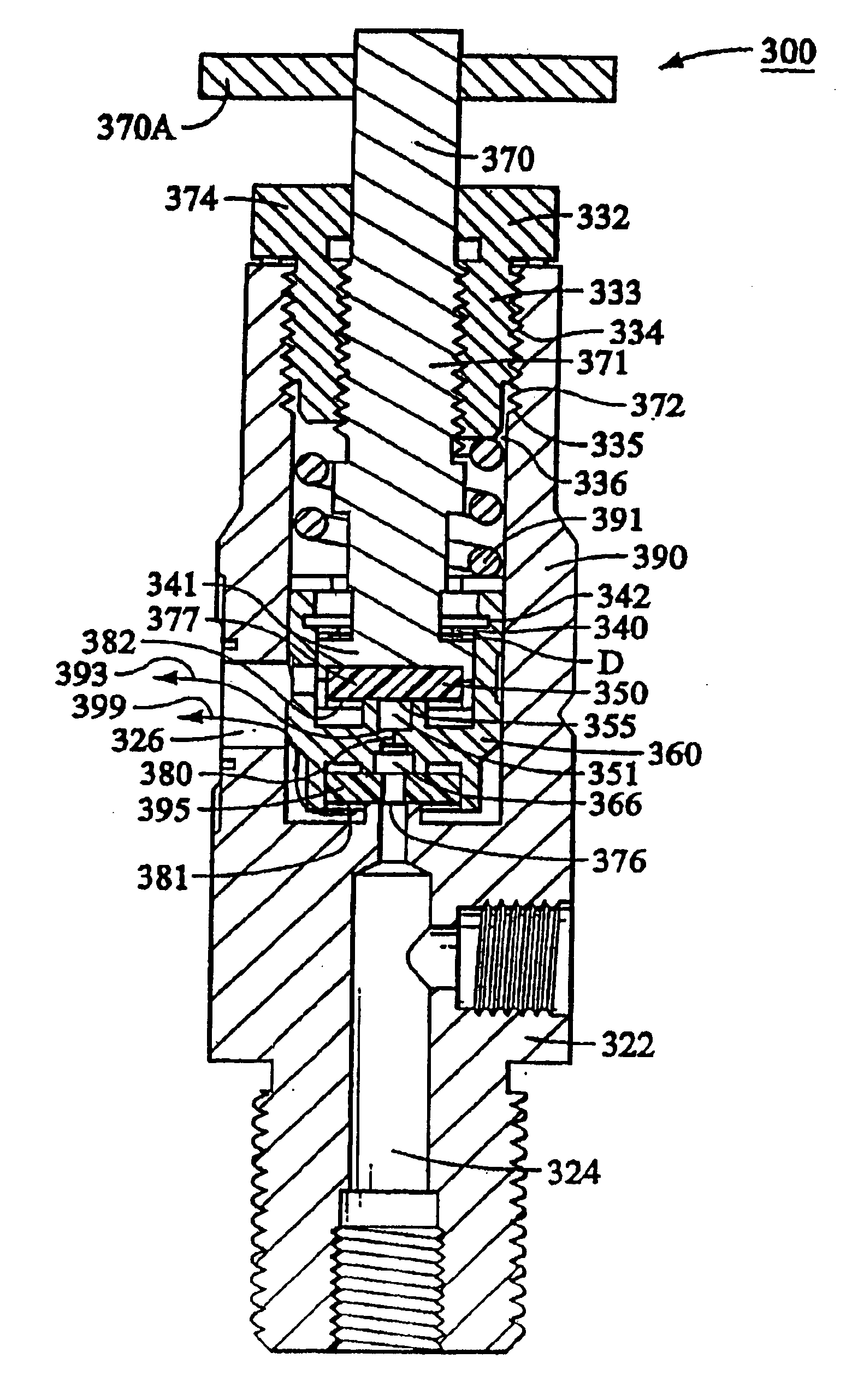

Combination valve and regulator with vented seat for use with pressurized gas cylinders, particularly oxygen cylinders

Owner:LUXFER INC

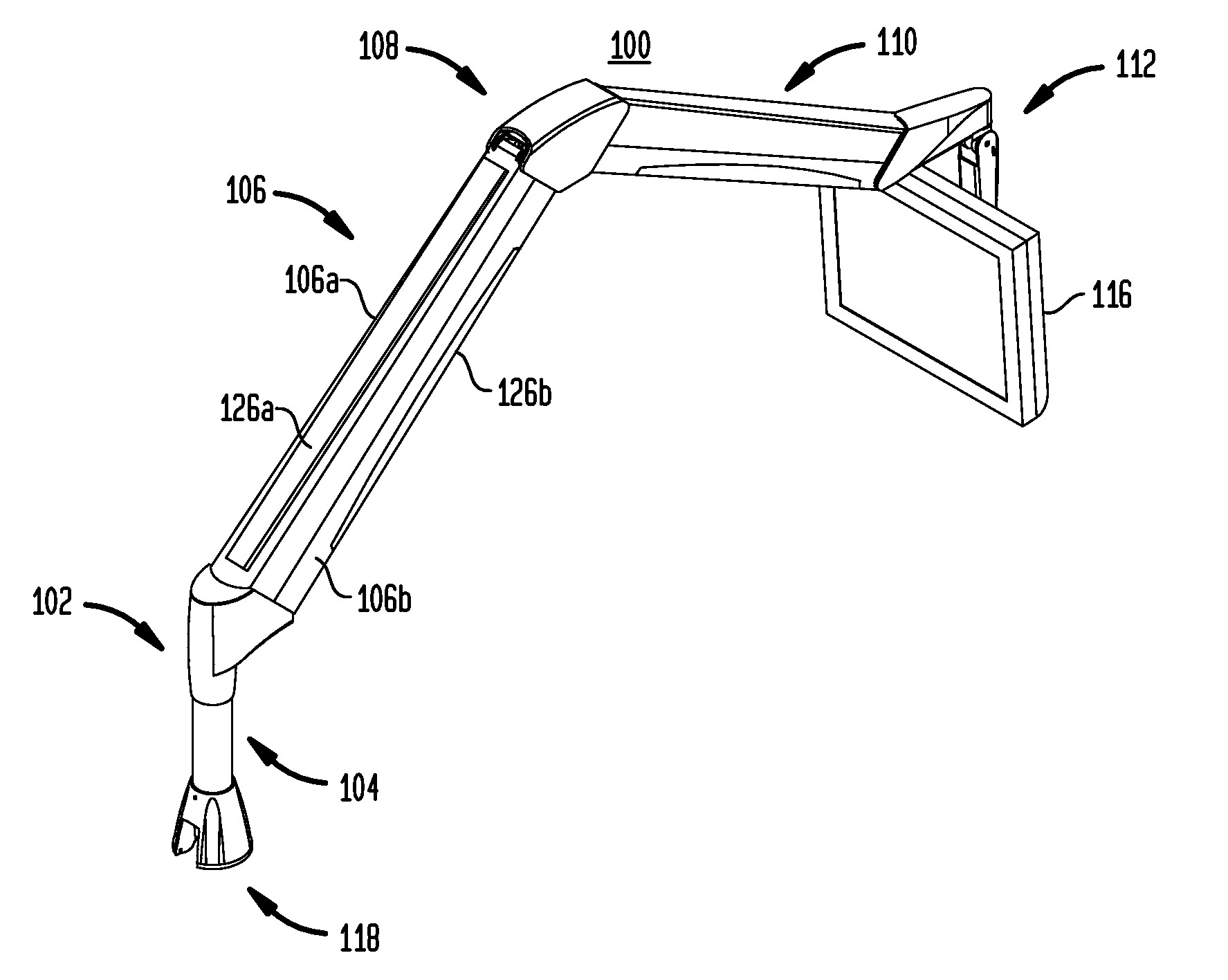

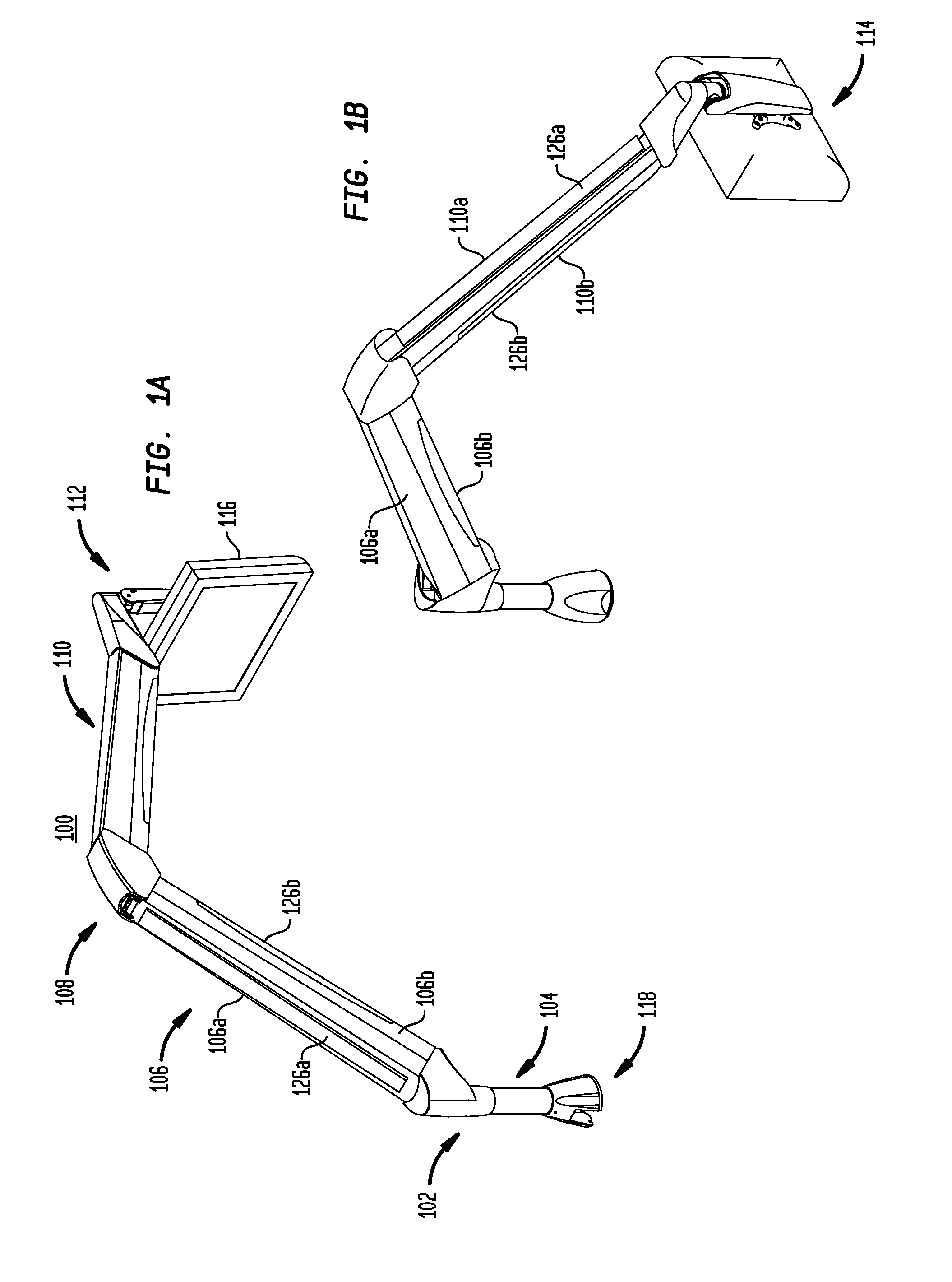

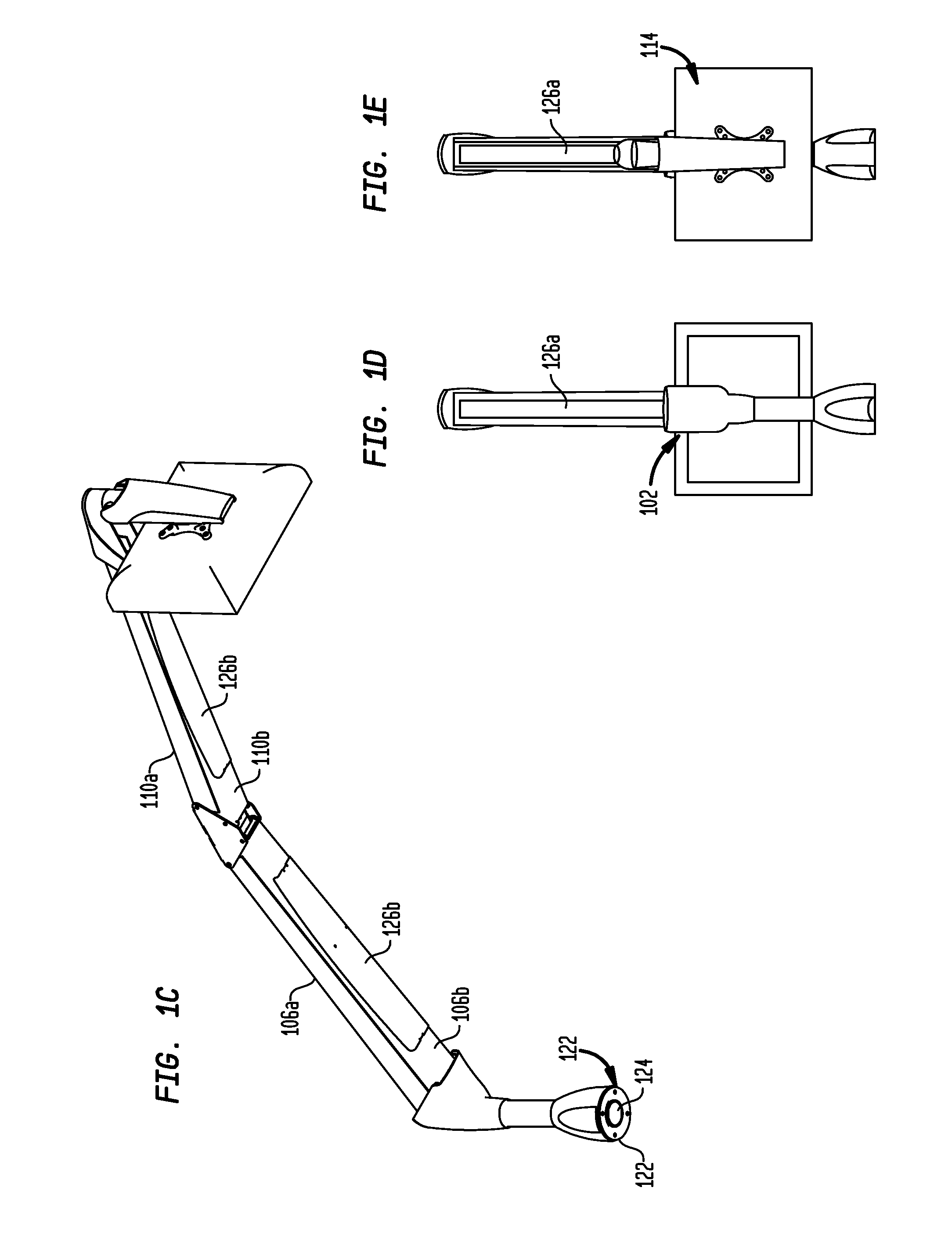

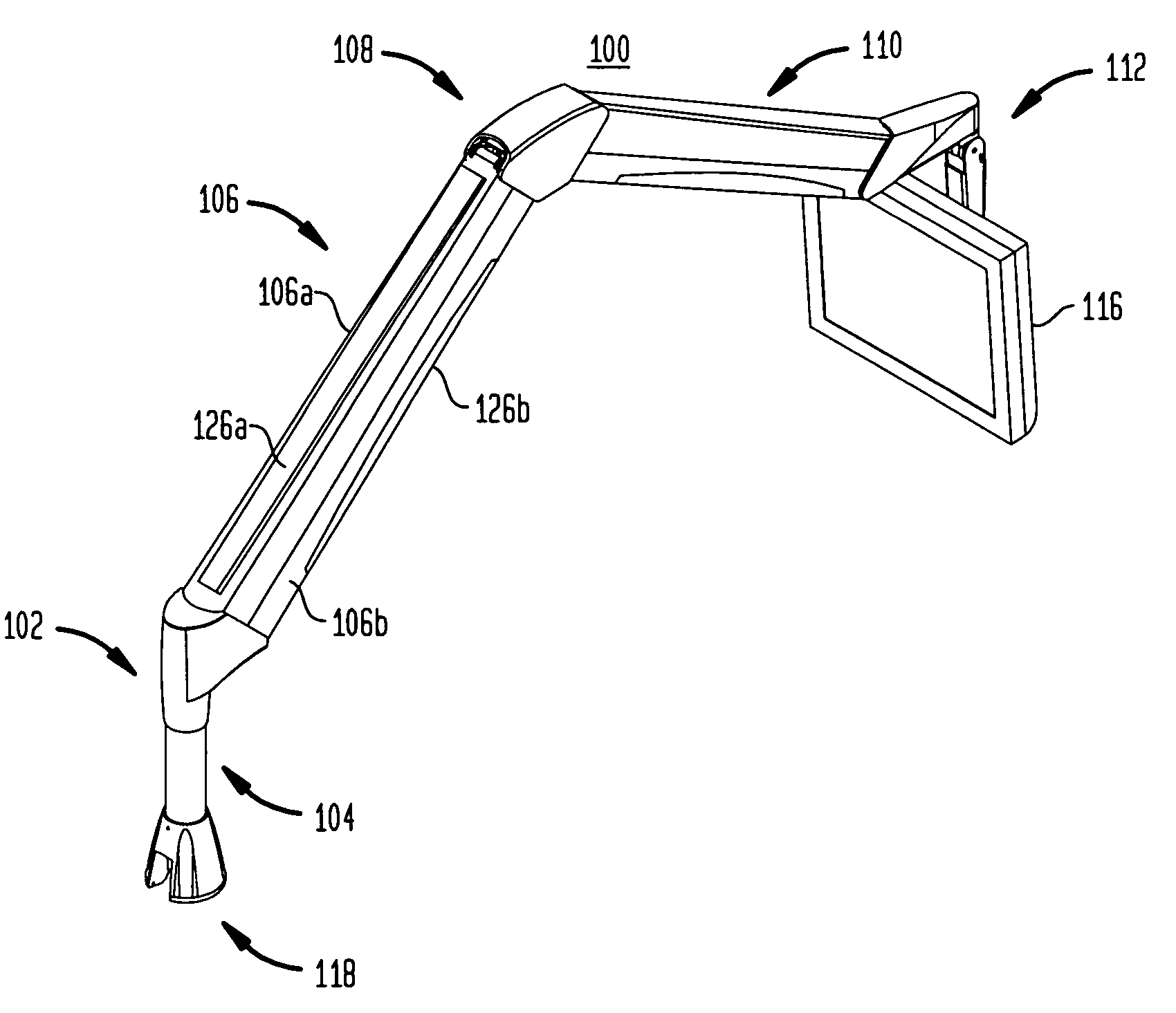

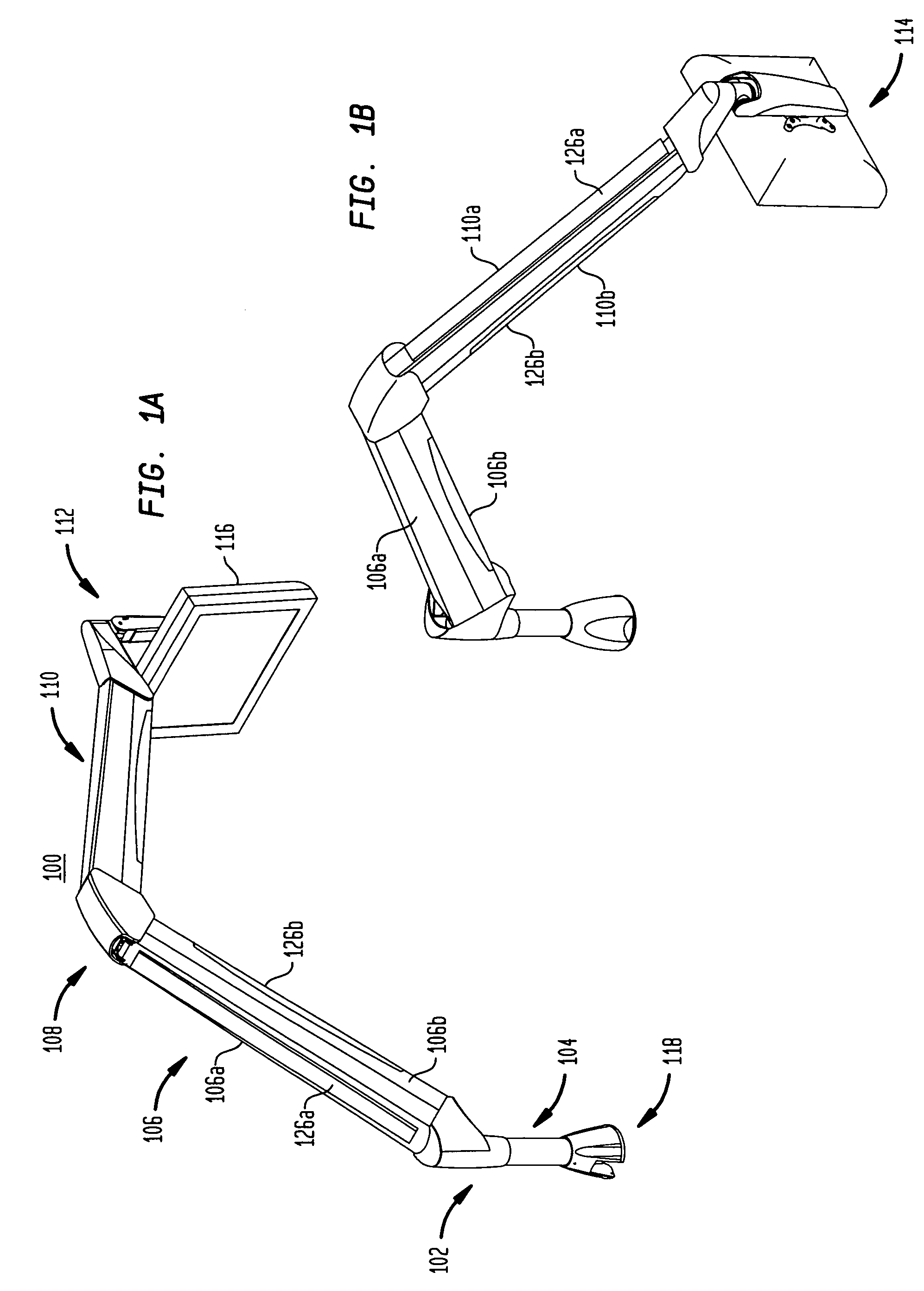

Extension arm with moving clevis and cable management

The present invention pertains to extension arm apparatuses that are adapted to support user devices throughout a range of positions. A given apparatus may include one or more arms that position the user device remotely from a support position. An extension and retraction device such as a gas cylinder is received within each arm, and provides a force to support the user device as the arm is placed into a given position. A variable force clevis is connected to the extension / retraction device within the arm. The variable force clevis is connected to a pair of locations in the arm as well. As the arm moves, for instance up or down, the variable force clevis rotates within the arm and dynamically adjusts the force provided by the extension / retraction device. Removable and / or pivotable covers are provided for managing cables of the user device attached to the extension arm.

Owner:INNOVATIVE OFFICE PROD LLC

Pantograph type current collector of electric automobile and automatic rapid charging station

InactiveCN101531141AEasy to introduceGuaranteed contactCharging stationsElectric vehicle charging technologyElectricityGas cylinder

The invention provides a pantograph type current collector of electric automobile and an automatic rapid charging station. Two pantograph type current collectors are parallel installed on the electric automobile top which has a single main shaft driven by gas cylinder or hydraulic pressure cylinder, and can act local arc movement, a gimbal is installed on the current collector end, a current slide block is fixed on the gimbal; an output end of the electric automobile charging station is two parallel contact plates on the automobile road upper part, two ends of the contact plate has introduce arc and educe arc; the electric automobile runs over the automobile charging station with standard speed along the road under control by relative sensing, detecting and controller which can complete whole process of collecting bow, charging, de-charging and depressing bow automatically.

Owner:田耕

Method and system for delivery of therapeutic gas to a patient and for filling a cylinder

Owner:RESPIRONICS +1

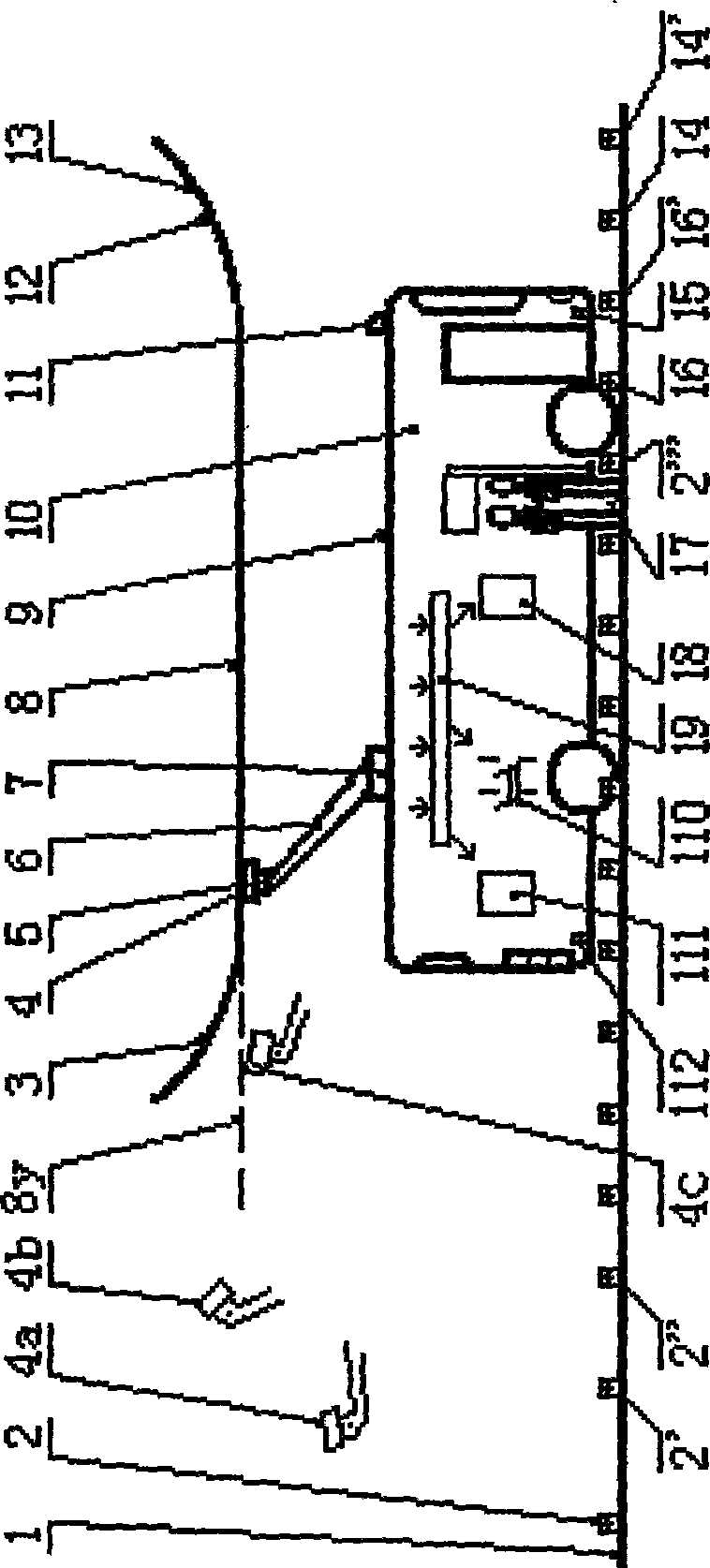

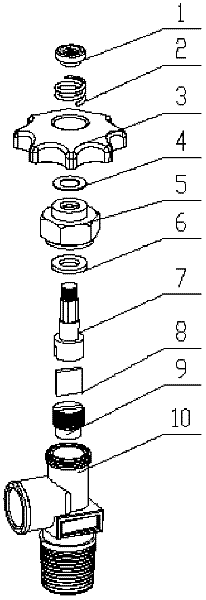

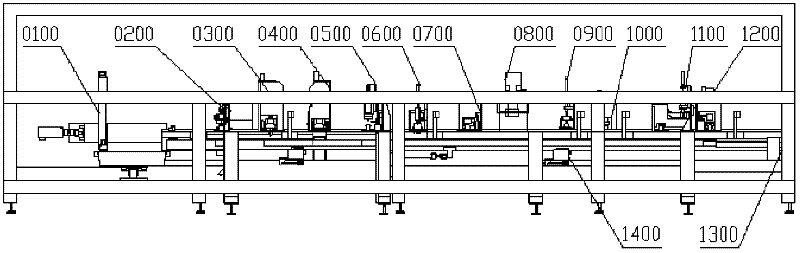

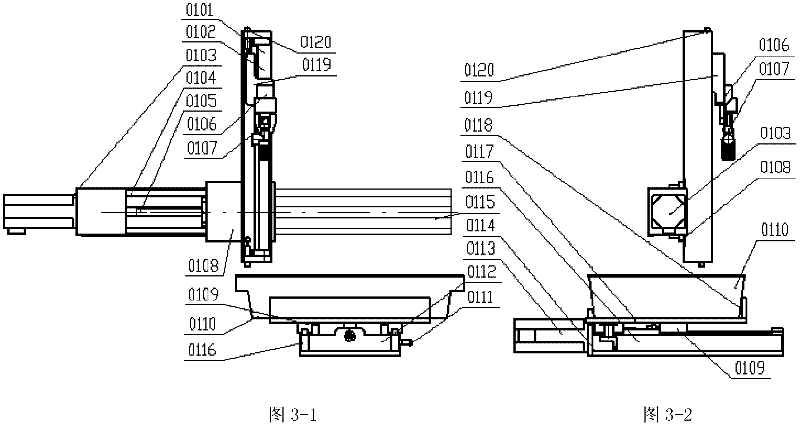

Automatic assembling line of liquefied petroleum gas cylinder valve

InactiveCN102390016AMovement precisionEffective investigationAssembly machinesGas cylinderClosed loop

The invention discloses an automatic assembling line of a liquefied petroleum gas cylinder valve and relates to an improvement on production equipment of a liquefied petroleum gas cylinder valve. The automatic assembling line is characterized by consisting of a loading working platform, a valve core assembling working platform, a connecting piece assembling working platform, a valve rod assembling working platform, a rubber pad assembling working platform, an oil coating working platform, a nut assembling working platform, a nut screwing working platform, a paper pad assembling working platform, a hand wheel assembling working platform, a spring assembling working platform, a round nut assembling working platform, a finished product blanking working platform and a line body. The automatic assembling line has the beneficial effects that a workpiece is clamped and conveyed by adopting a mode of automatic loading of a vibrating disc and stepping transmission so as to be transferred in a reciprocating manner of returning to the original position; and after the assembly of all the working platforms is finished in circulation, the blanking of the workpiece in next circulation is carried out, and the movement of the mechanism is more accurate by utilizing a cylinder and a linear guide rail. A sensor is adopted to sense whether the workpiece exists, a signal is transmitted to a PLC (programmable logic computer) and the PLC sends an instruction to execute the actions of all the working platforms and carry out closed-loop control.

Owner:CHANGCHUN UNIV OF TECH +1

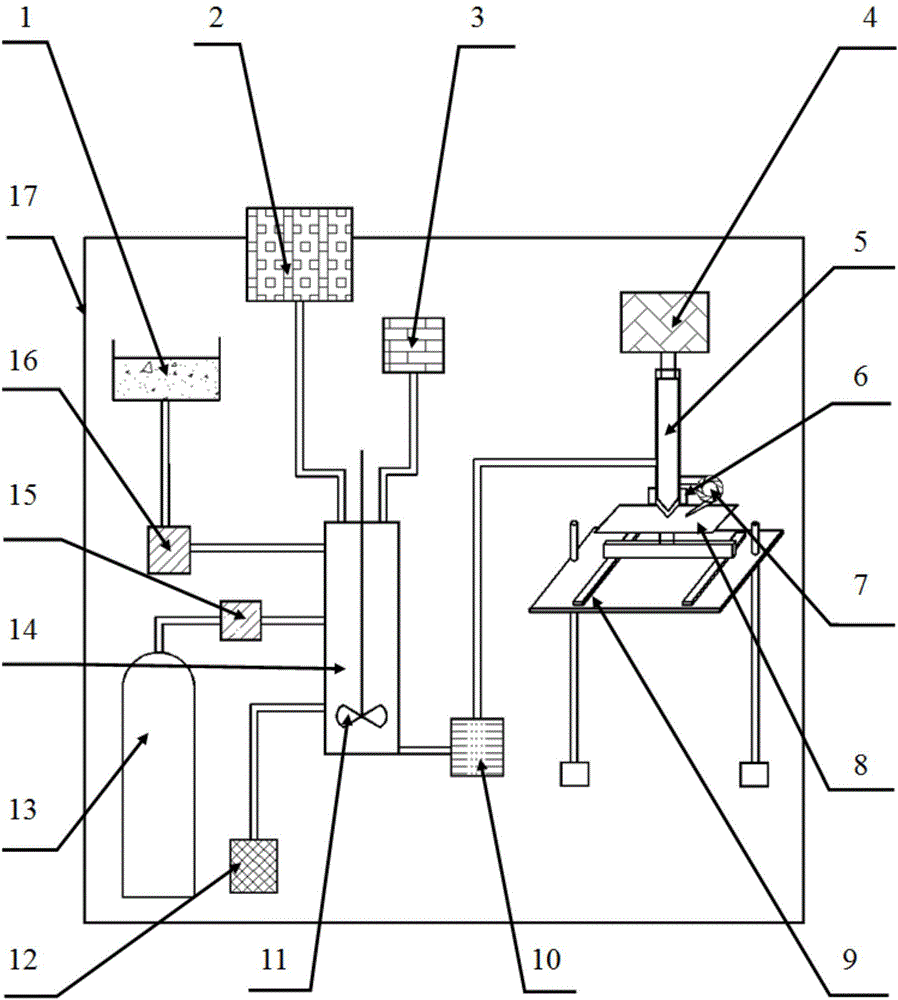

3D printing device and 3D printing method by utilizing supercritical carbon dioxide as solvent

ActiveCN104816478AIncrease profitAvoid emissionsAdditive manufacturing apparatusGas cylinderCarbon dioxide gas cylinder E

The invention discloses a 3D printing device and a 3D printing method by utilizing supercritical carbon dioxide as a solvent. The device mainly comprises a stock unit, an ejection unit, a three-dimensional molding platform unit and a raw material recycling unit, wherein the ejection unit comprises a gas pump, a needle valve, a cooling fan and a resistive heater; the stock unit comprises high polymer material powder, a powder pump, a carbon dioxide gas cylinder, a mixing tank, a liquefied booster pump, a heater, a liquid pump and a gas pump; the three-dimensional molding platform unit comprises an aluminum alloy molding platform and a three-dimensional ball screw sliding table module; and the raw material recycling unit comprises a closed box and a recovered gas pump. According to the method disclosed by the invention, the carbon dioxide gas is turned to be in a supercritical carbon dioxide state, and after the carbon dioxide gas is completely dissolved to produce supercritical carbon dioxide solution containing a high polymer material, the solution is conveyed into the ejection unit by virtue of the liquid pump. The supercritical carbon dioxide serves as a consumable carrier, so that more kinds of high polymer materials are applied to the field of 3D printing, and the overall performances of 3D printing supplies are improved.

Owner:BEIJING UNIV OF CHEM TECH

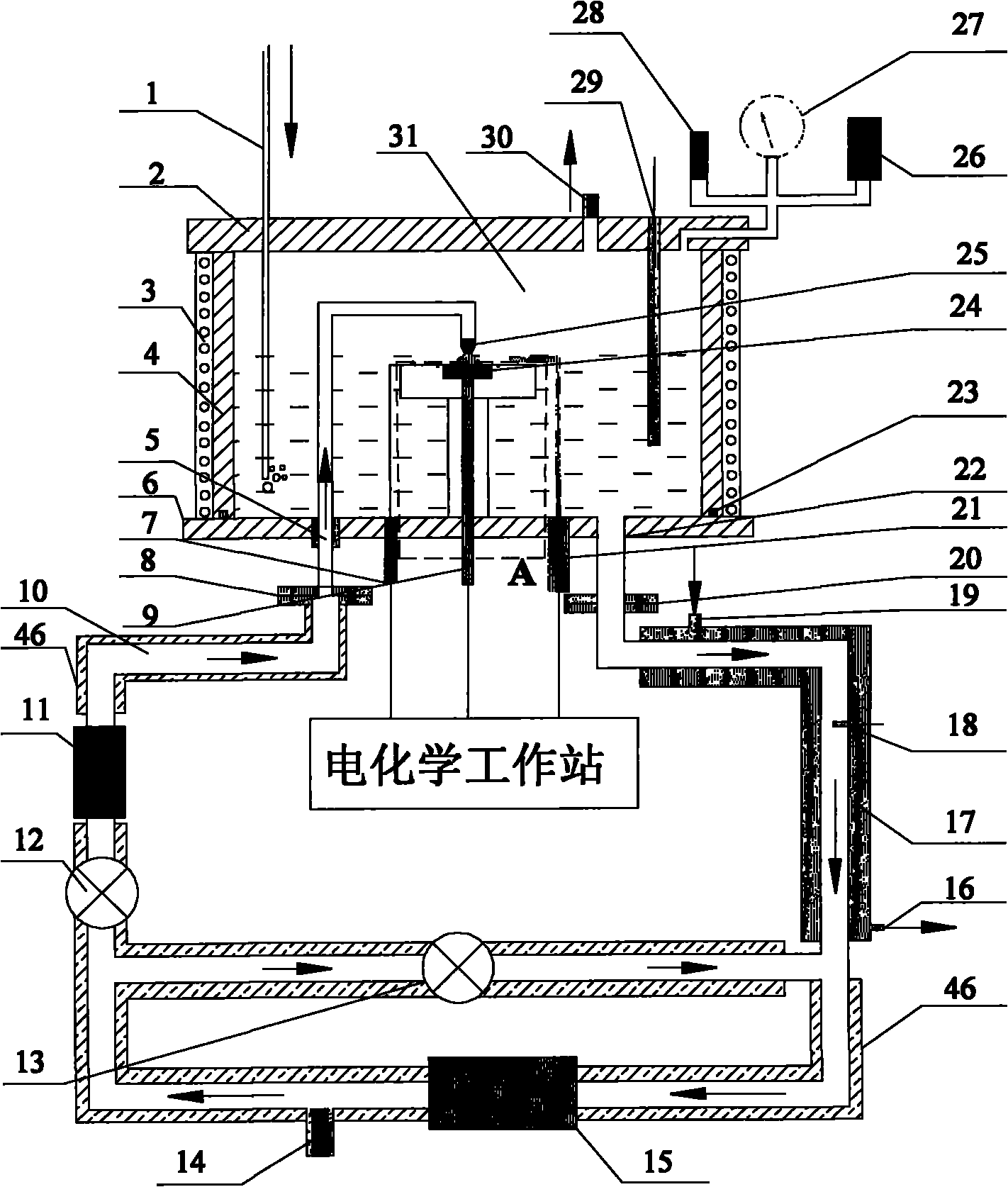

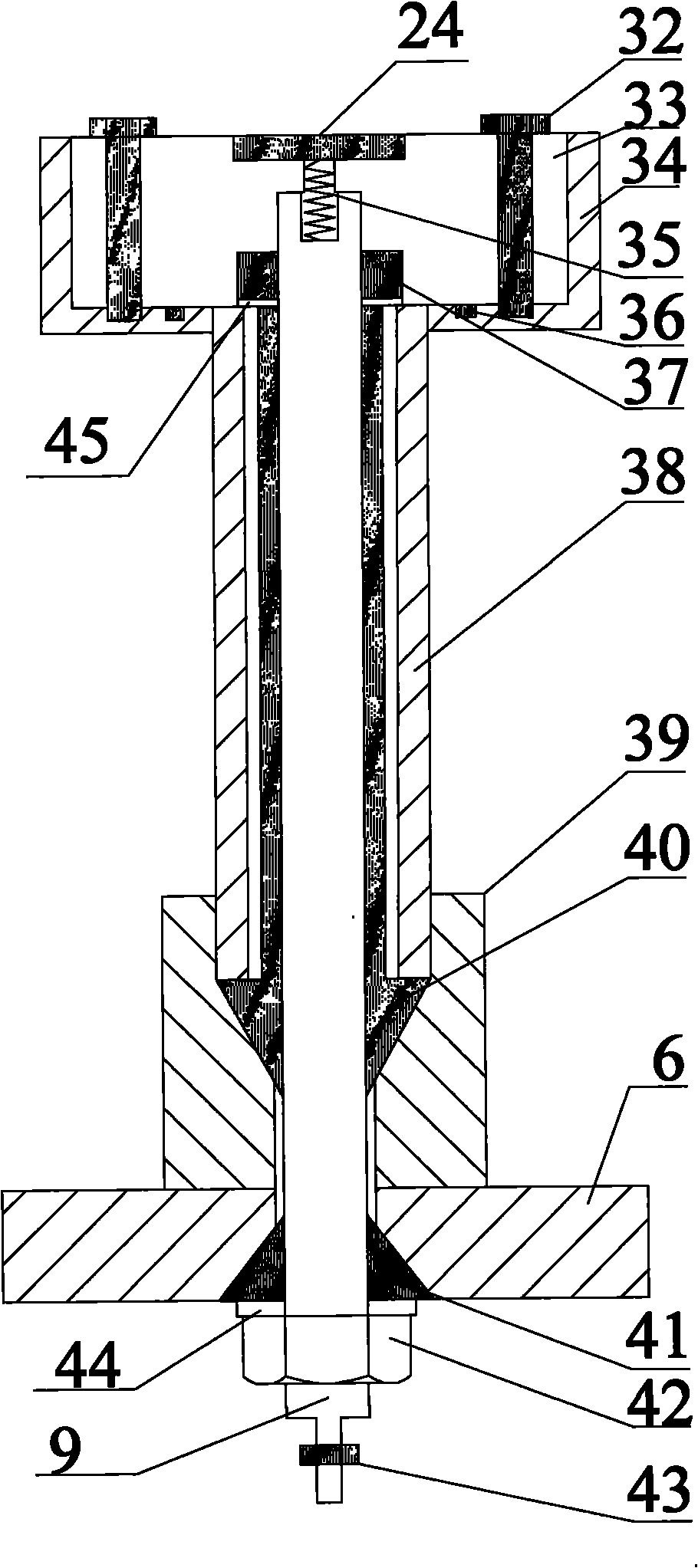

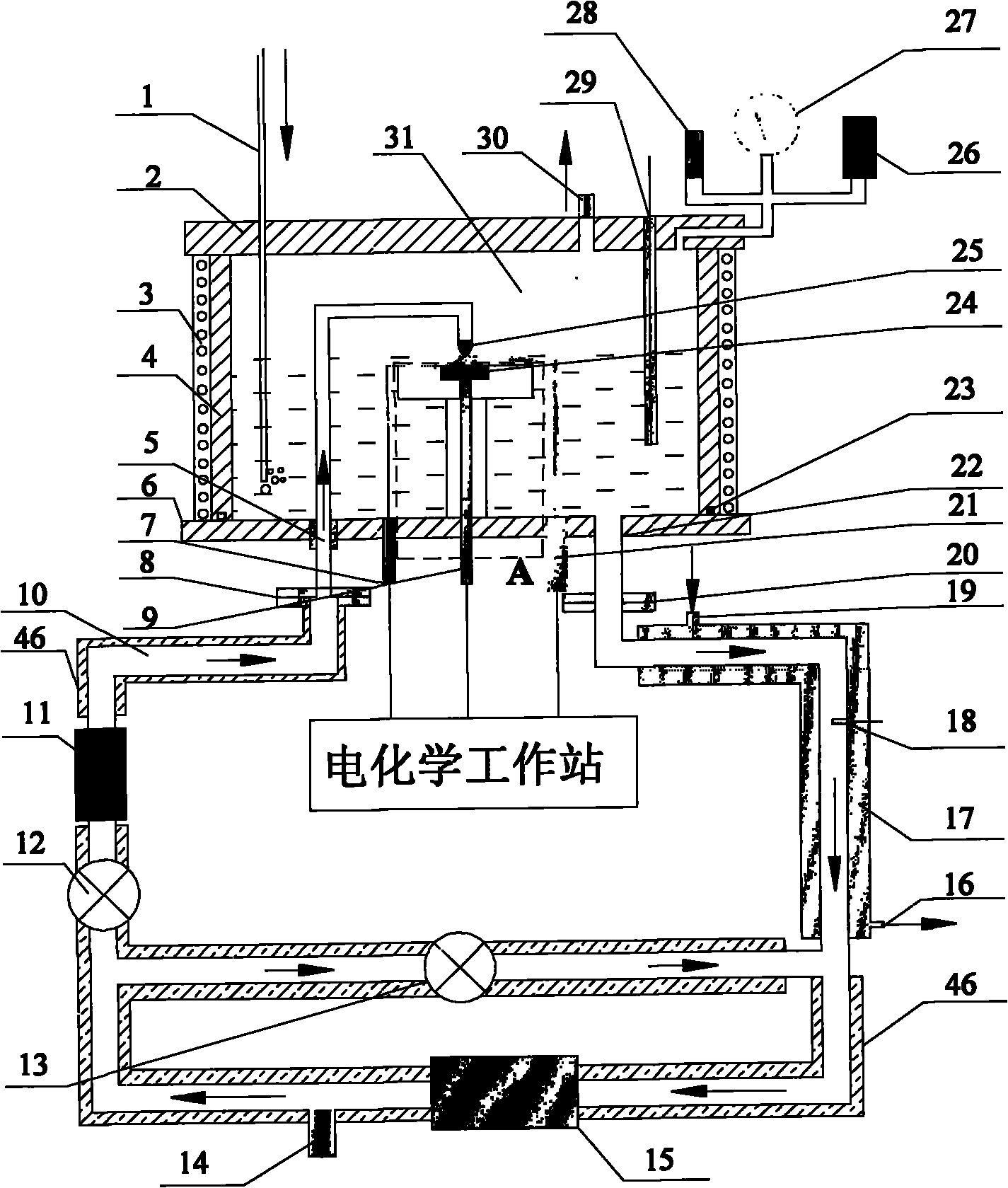

Experimental apparatus for high-temperature high-pressure loop spray corrosion simulation and electrochemical testing

The invention discloses an experimental apparatus for high-temperature high-pressure loop spray corrosion simulation and electrochemical testing, belongs to the electrochemical field, and is particularly suitable for simulation experiment of erosion corrosion caused by simulating the complex components such as elbow, tee and the like in petroleum and gas collection pipes, petroleum and gas conveying pipes and the like so as to convey the high-temperature high-pressure multi-phase fluid pipe components and in-situ electrochemical signal testing of the erosion corrosion of high-temperature high-pressure fluid under erosion conditions. The apparatus comprises a high pressure kettle, a circulating loop, a high-temperature high-pressure flow gauge, a vortex pump, a control box, a circulating condensation system, a three-electrode system, a signal conduction path, an external electrochemical work station and a high pressure gas bottle. The apparatus has the advantages of simulating the erosion corrosion condition of the fluid medium in the oil and gas pipeline well, testing the electrochemical signal of the working electrode under high-speed spray condition such as polar curve, AC impedance and the like and having important significance to the research of the erosion corrosion action, rule and mechanism of the high-temperature high-pressure fluid.

Owner:UNIV OF SCI & TECH BEIJING

Surge prevention device

InactiveUS6901962B2High trafficIncrease flow rateCircuit elementsContainer filling methodsGas cylinderHigh pressure

A surge prevention valve may be used to prevent the formation of an initial surge of high pressure. The valve may be located, for example, between a high pressure gas cylinder and a medical pressure regulator. The valve is provided with first and second valves located within a housing and integrating a pressurization orifice. The initial opening of the valve in an axial direction enables gas to flow through the pressurization orifice at a first flow rate. The full opening of the valve in the axial direction enables the gas to flow through the second valve at a second flow rate, which is much higher than the first flow rate. The controlled pressurization of the gas through the orifice delays the time during which the gas reaches full recompression.

Owner:ALLIED HEALTHCARE PROD INC

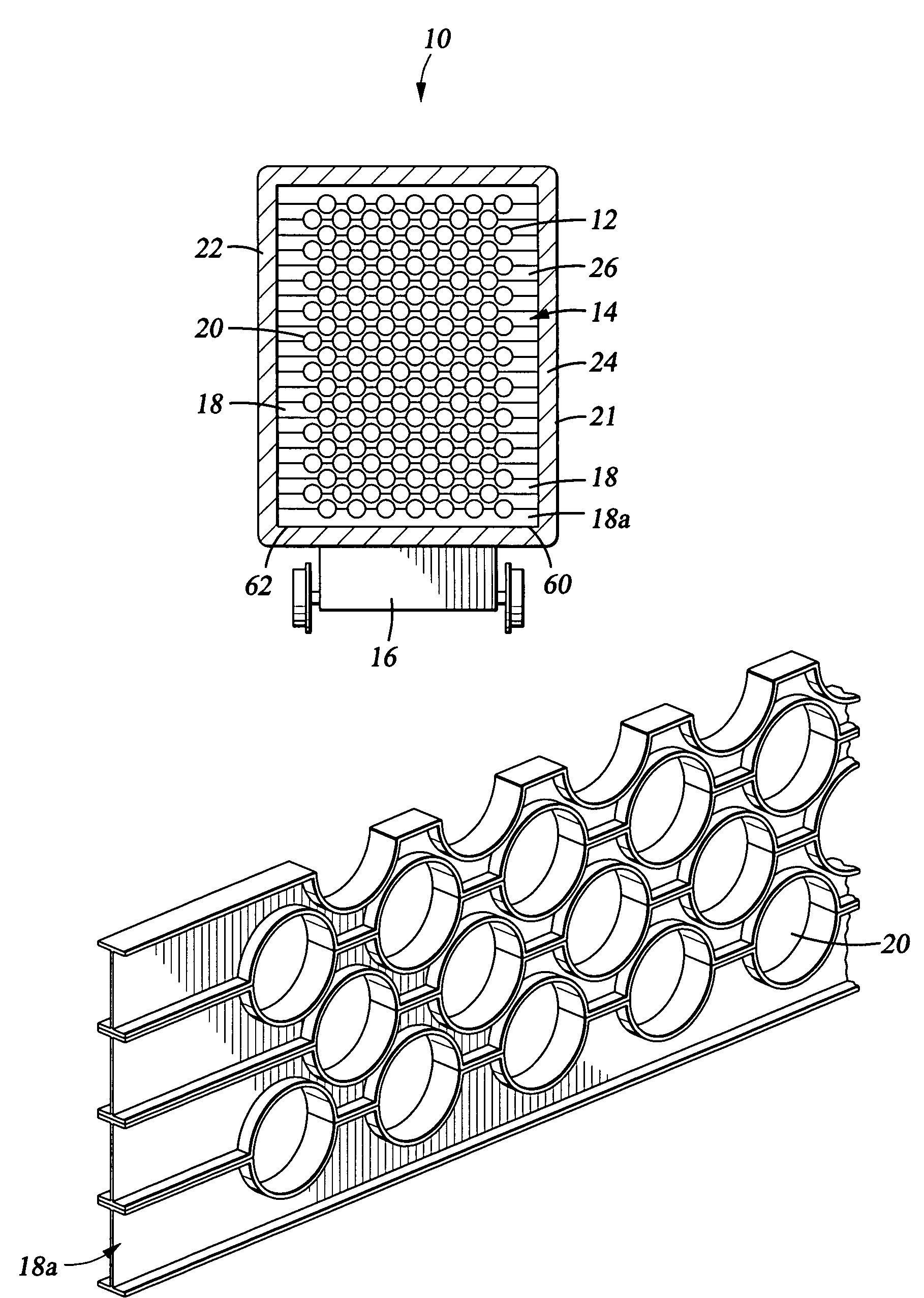

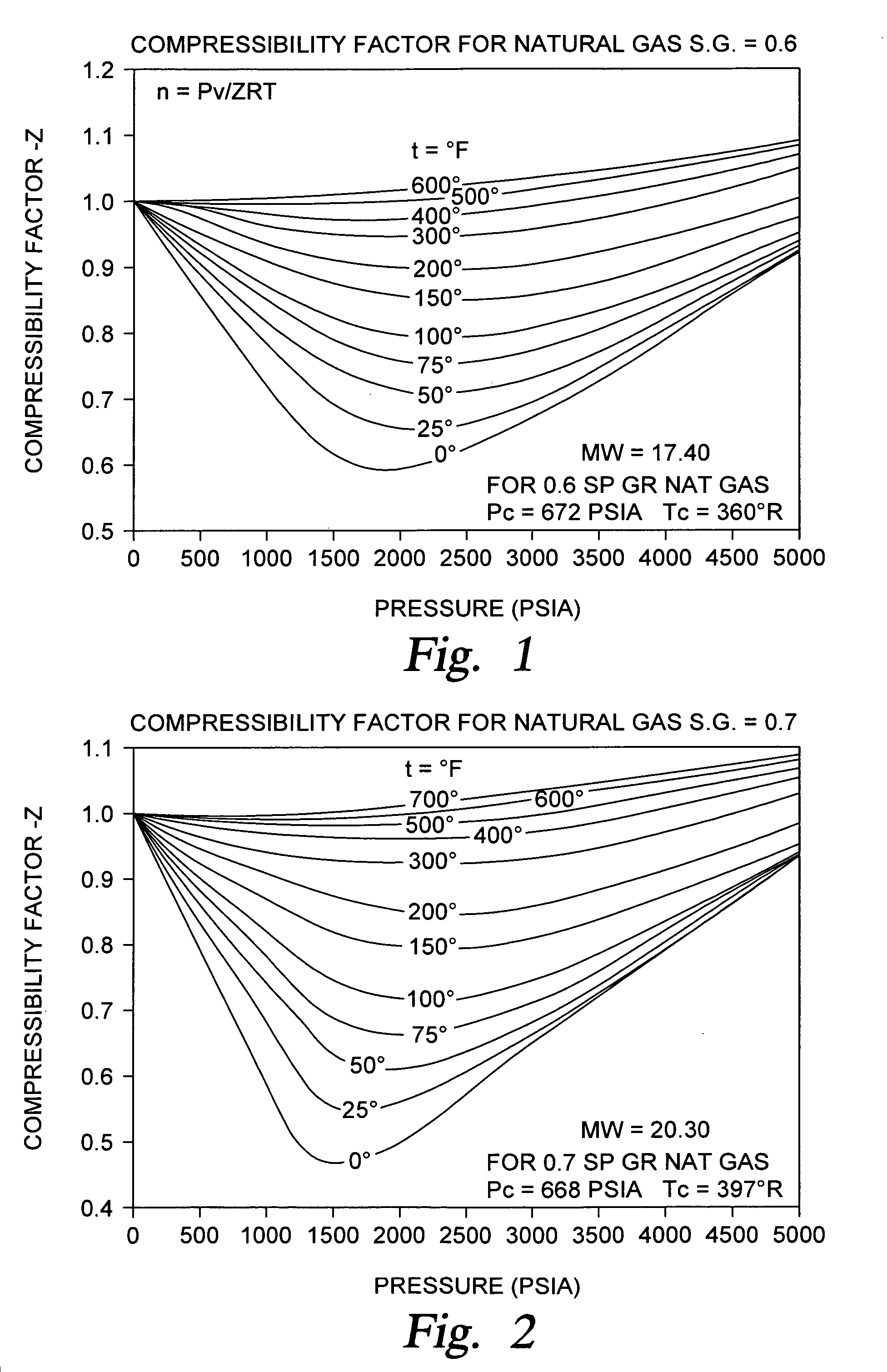

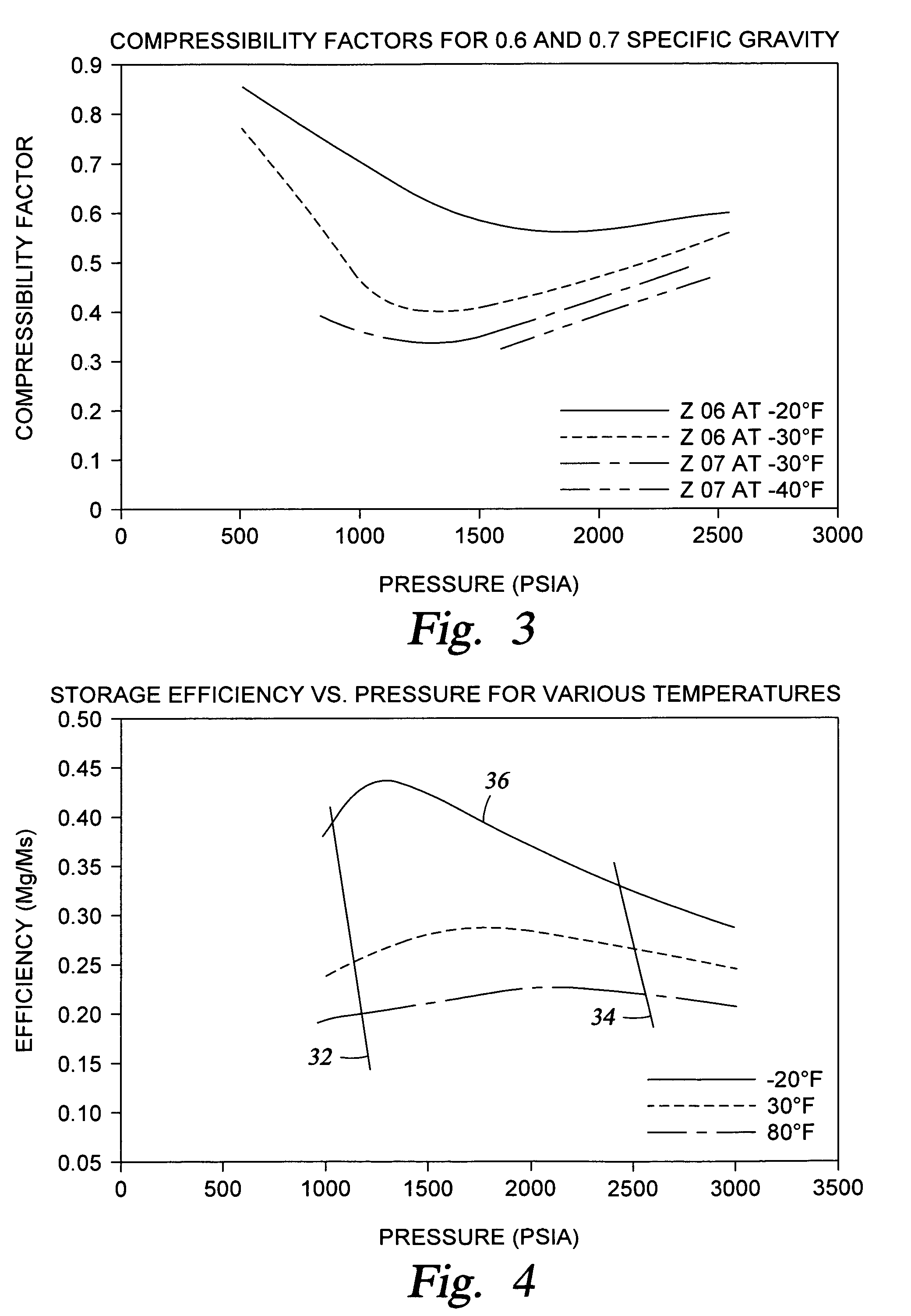

Modular system for storing gas cylinders

InactiveUS6994104B2High procedureIncrease profitabilitySolidificationLiquefactionSystems designGas cylinder

The methods and apparatus for transporting compressed gas includes a gas storage system having a plurality of pipes connected by a manifold whereby the gas storage system is designed to operate in the range of the optimum compressibility factor for a given composition of gas. The pipe for the gas storage system is preferably large diameter pipe made of a high strength material whereby a low temperature is selected which can be withstood by the material of the pipe. Knowing the compressibility factor of the gas, the temperature, and the diameter of the pipe, the wall thickness of the pipe is calculated for the pressure range of the gas at the selected temperature. The gas storage system may either be modular or be part of the structure of a vehicle for transporting the gas. The gas storage system further includes enclosing the pipes in an enclosure having a nitrogen atmosphere. A displacement fluid may be used to offload the gas from the gas storage system. A vehicle with the gas storage system designed for a particular composition gas produced at a given location is used to transport gas from that producing location to a receiving station miles from the producing location.

Owner:ENERSEA TRANSPORT

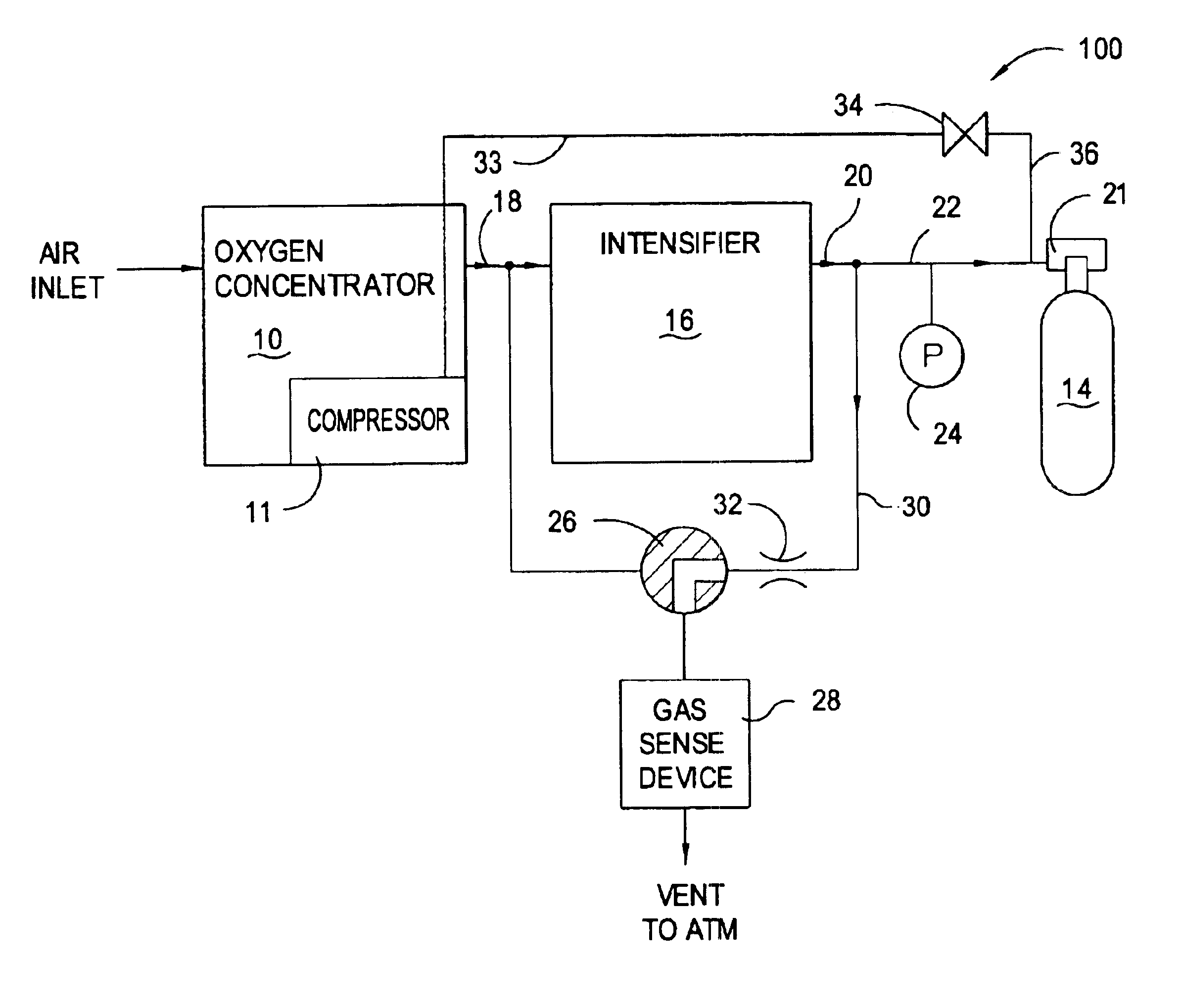

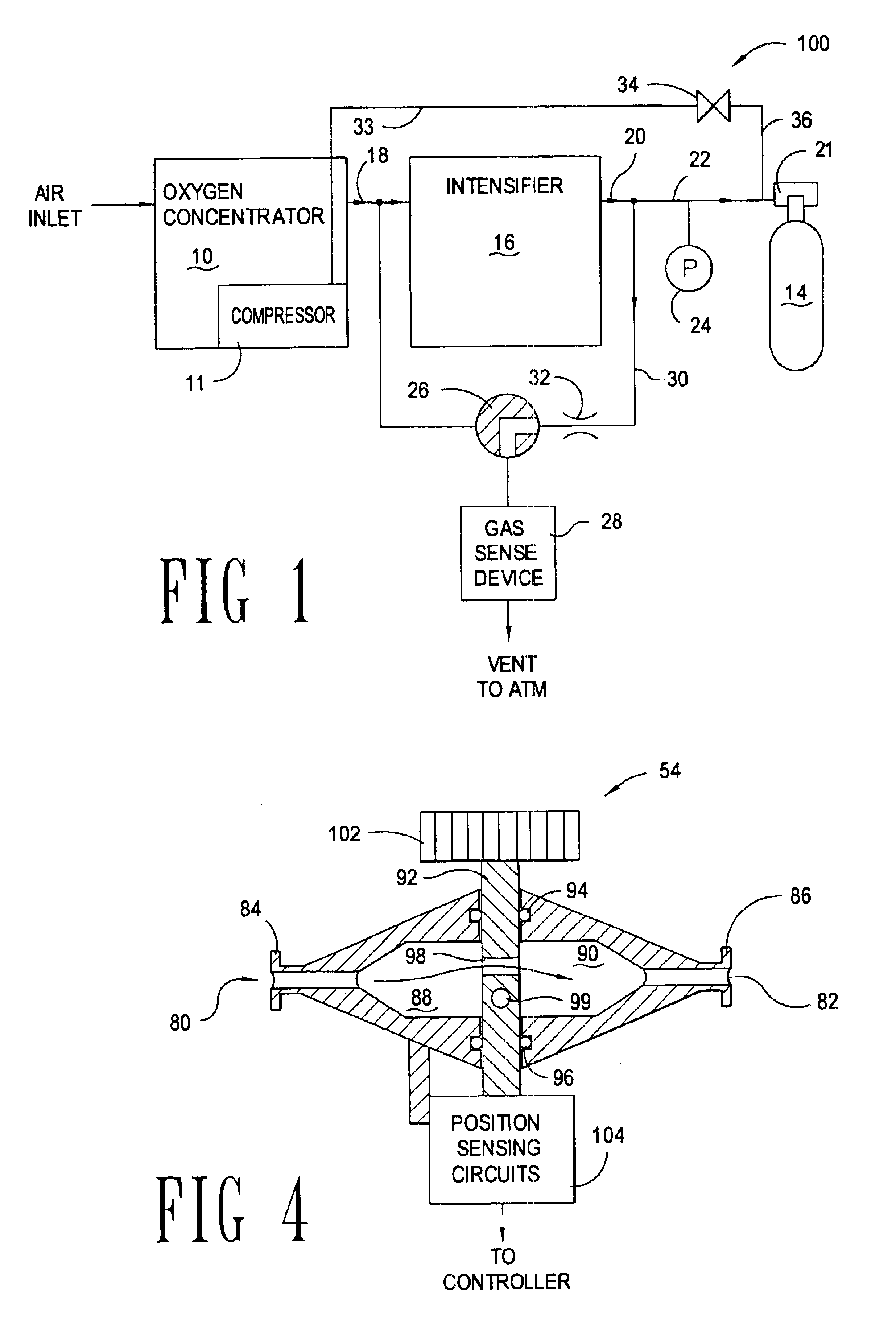

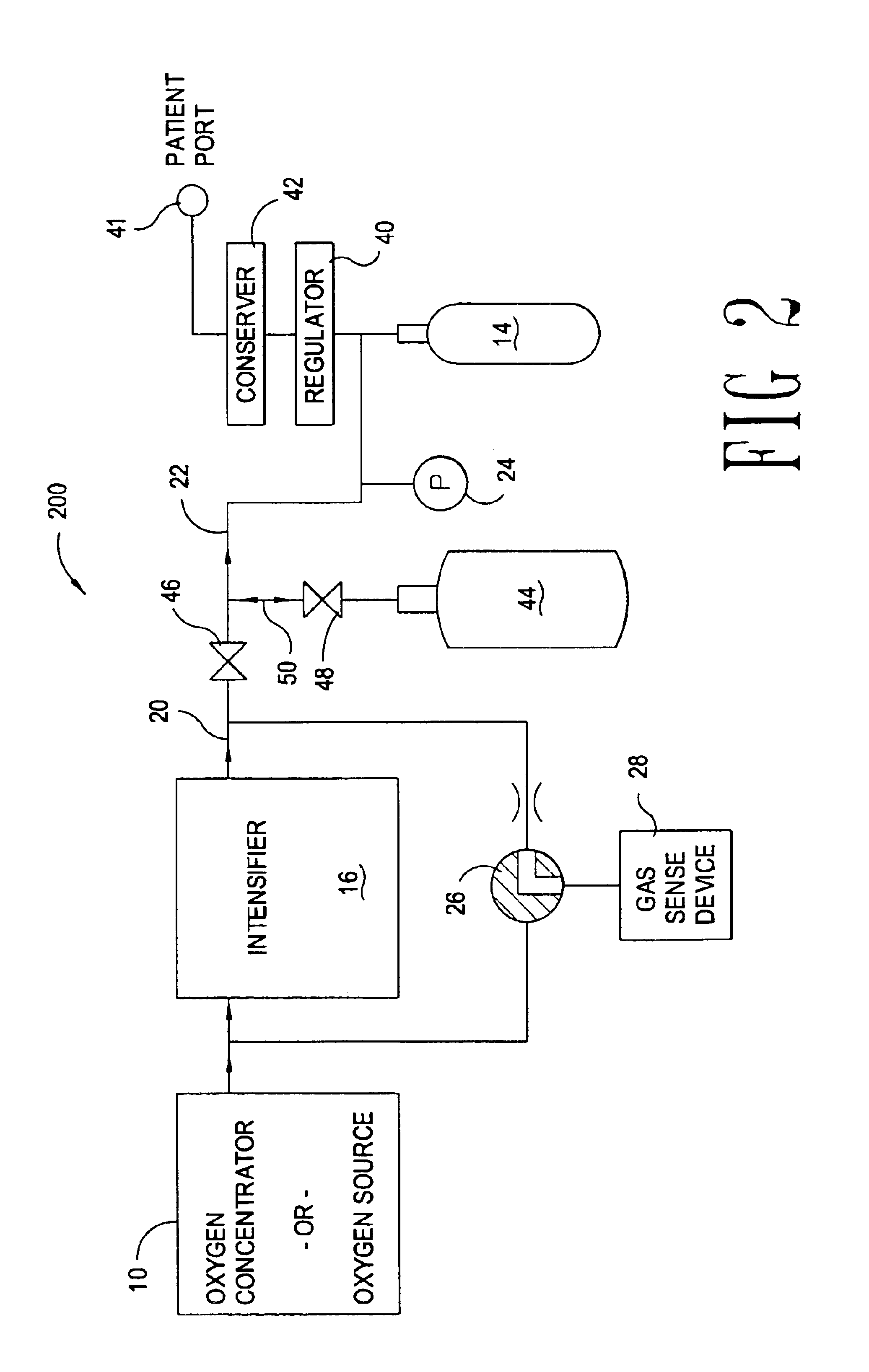

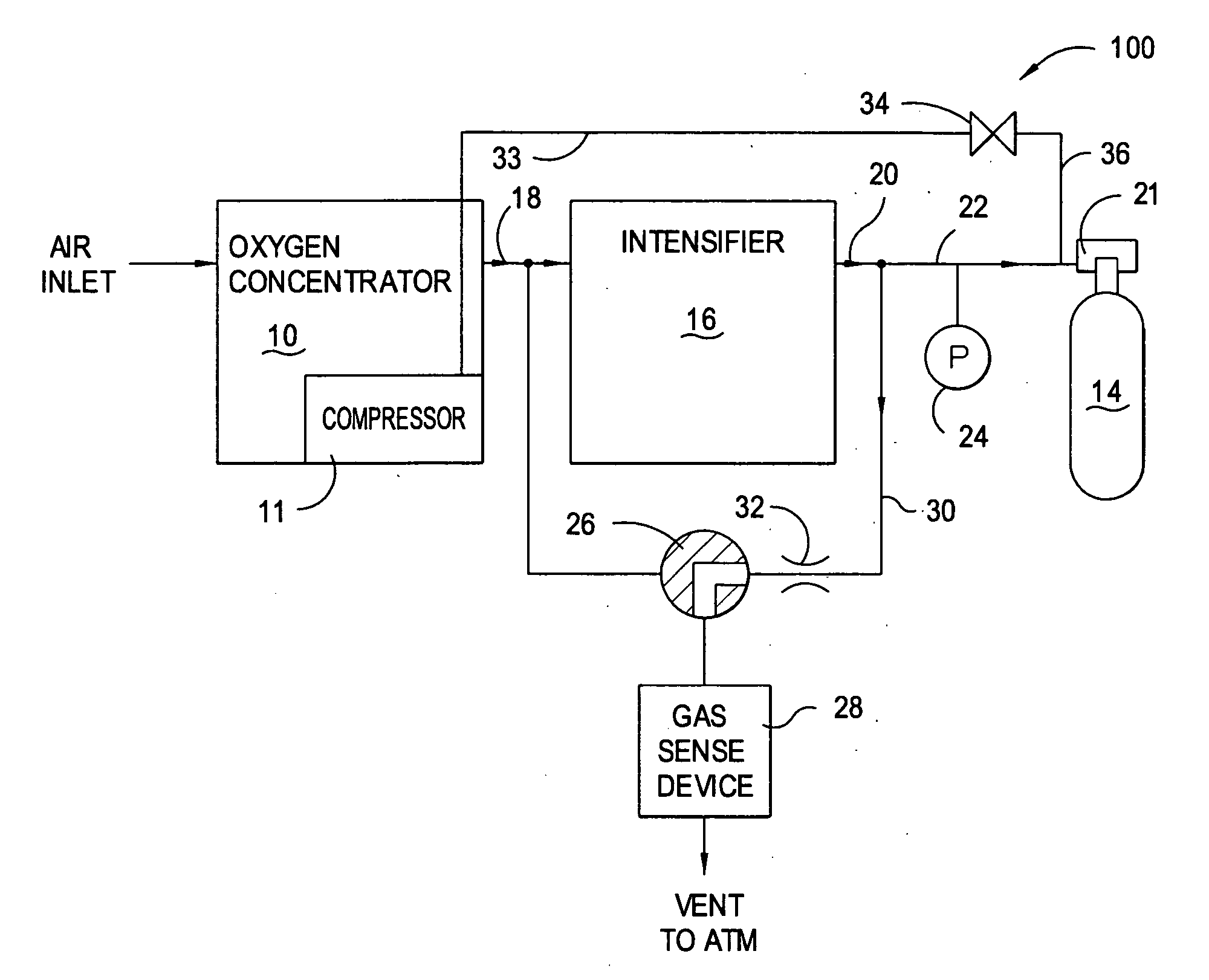

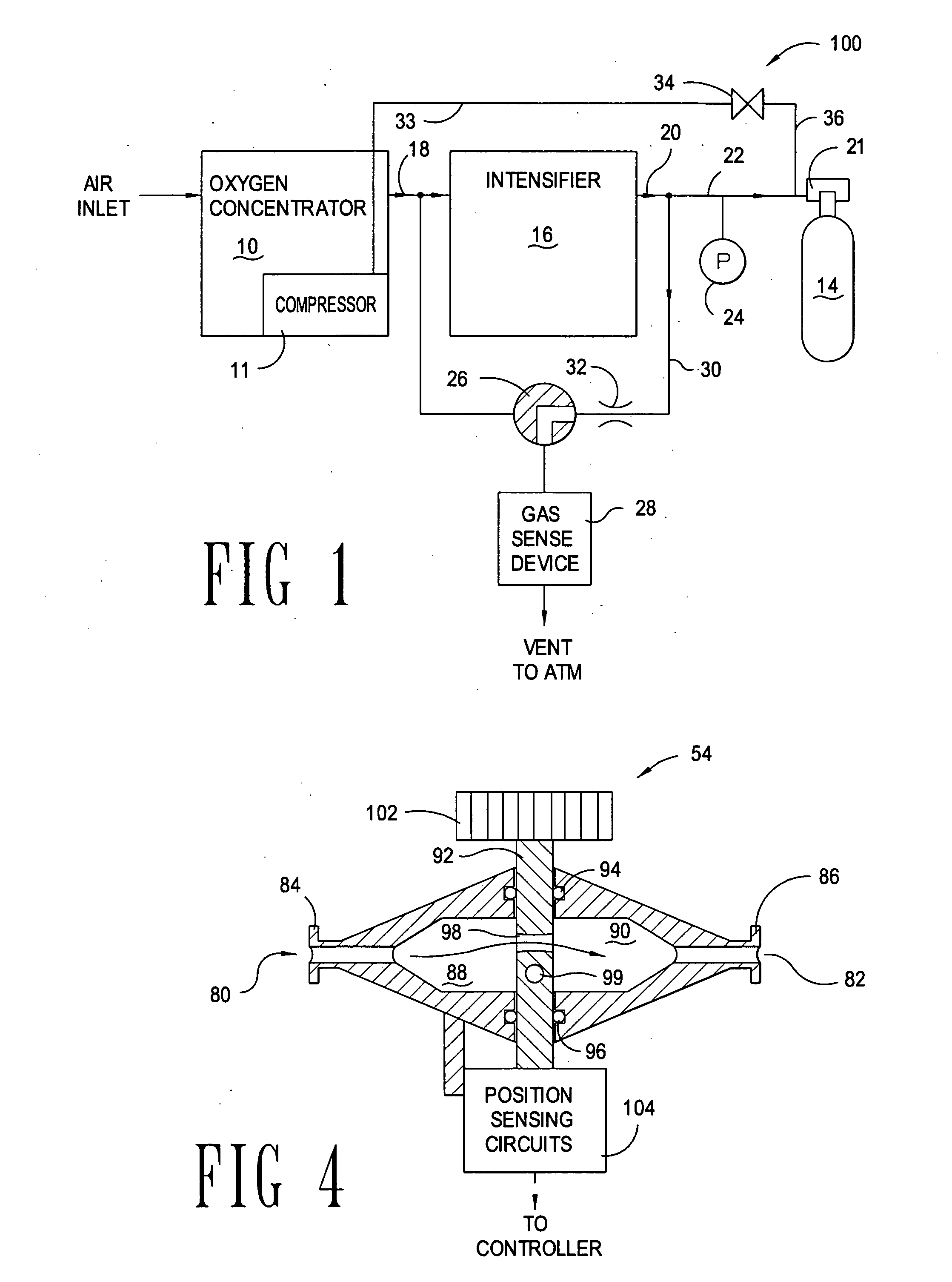

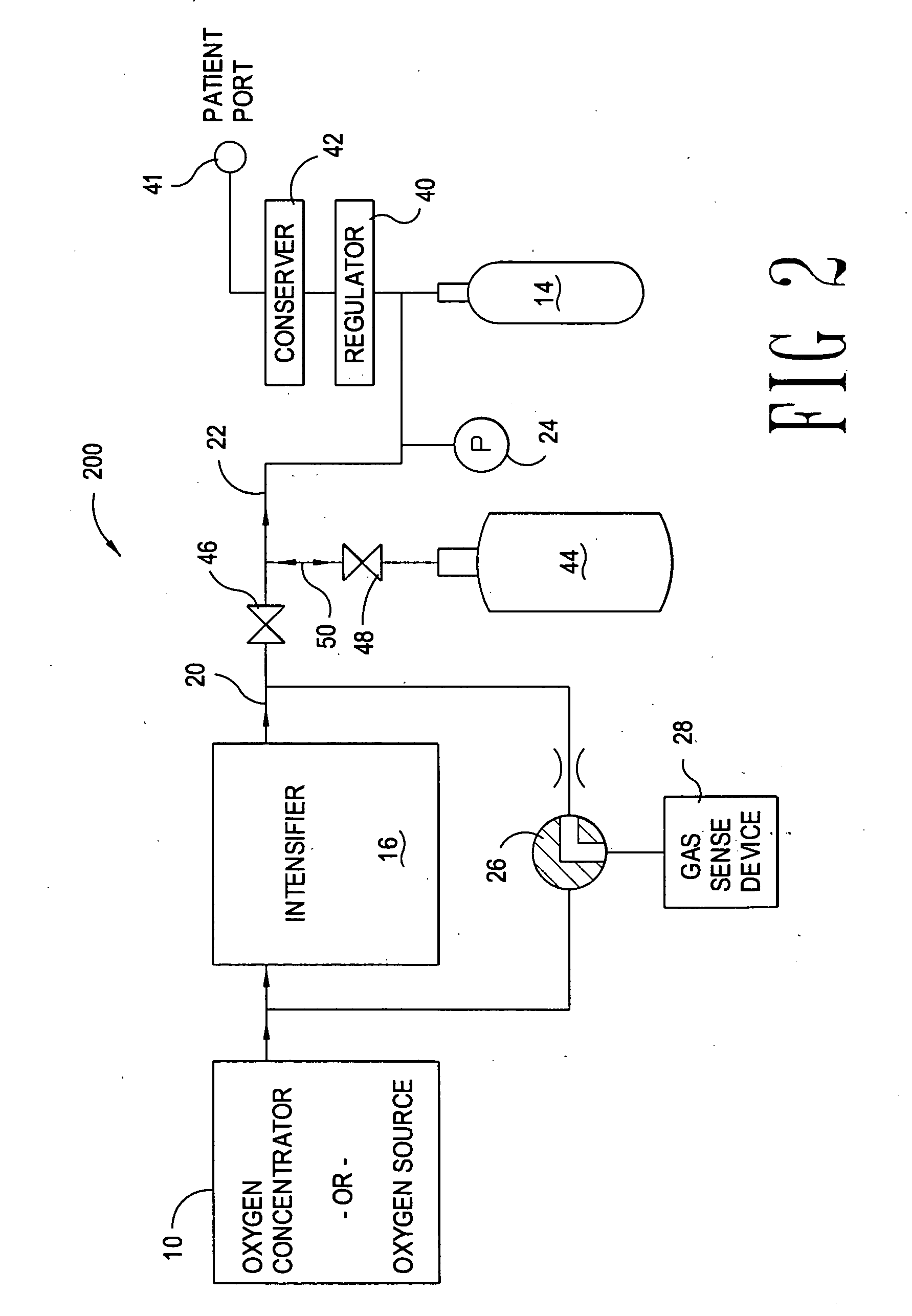

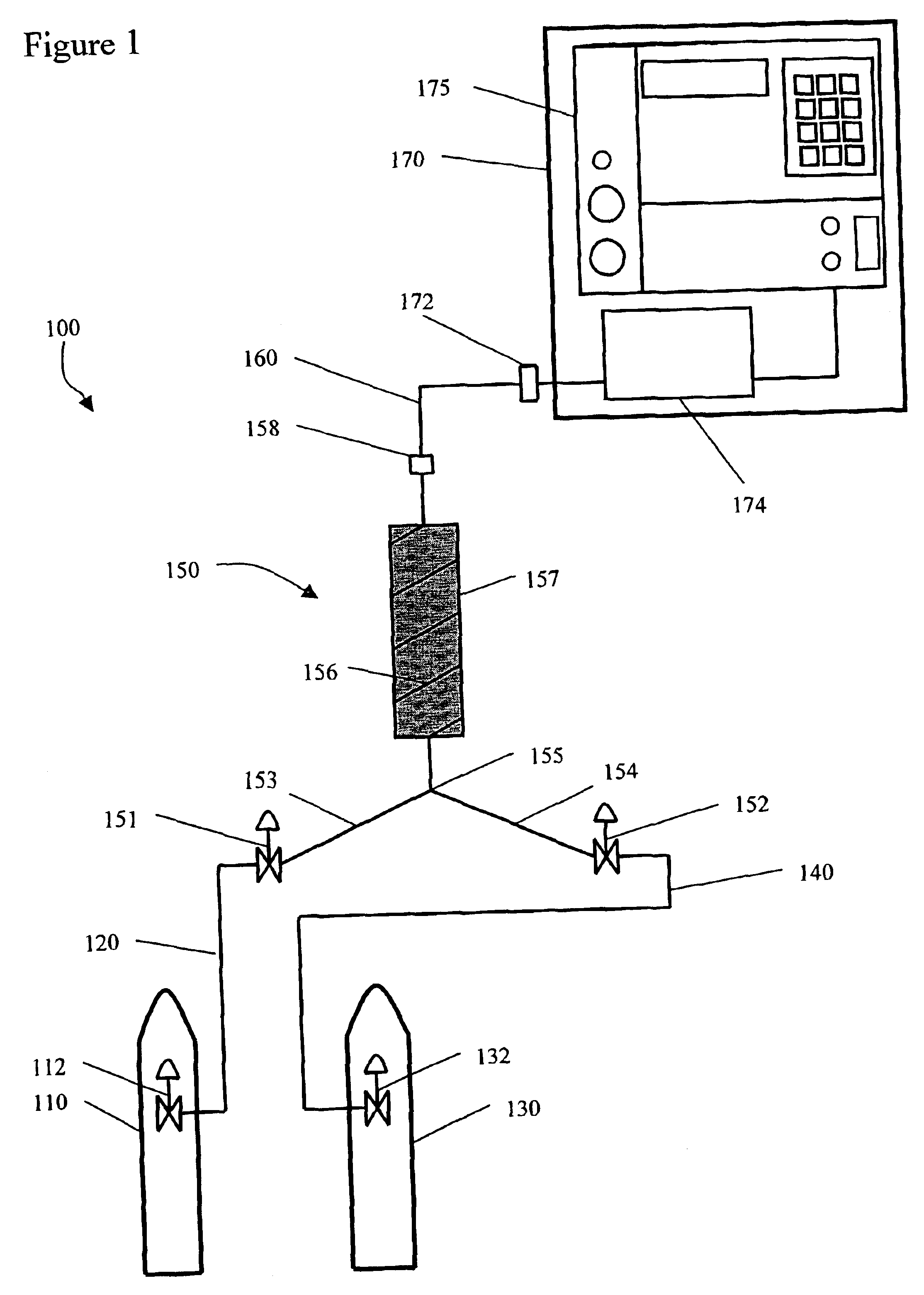

Method and system for delivery of therapeutic gas to a patient and for filling a cylinder

InactiveUS20040079359A1Overcome deficienciesReadily apparentRespiratorsVessel mounting detailsGas cylinderEngineering

A system for filling a portable cylinder with therapeutic gas, and providing therapeutic gas to a patient. Therapeutic gas delivery to a patient may be through a conserver, or may be in a continuous mode. Some embodiments of the invention may test the contents of the portable cylinder prior to filling. The specification also discloses a silent mode of operation where therapeutic gas is provided from the system by means of internal and / or external cylinders.

Owner:RESPIRONICS +1

Method and system for creating a mercury halide standard for use in testing a mercury analyzer system

InactiveUS6852542B2Withdrawing sample devicesMaterial analysis by electric/magnetic meansGas cylinderElemental mercury

A method and system are provided for creating a mercury halide standard, and for using that standard to test a mercury analyzer system. Gaseous elemental mercury of a known concentration from a gas cylinder and a halogen donor are fed to a reaction chamber where they react to form mercury halide. The mercury halide is fed to a mercury analyzer system where it is converted to reform gaseous elemental mercury which is then measured by a mercury analyzer. By comparing either the amount of elemental mercury supplied to the reaction chamber or the amount of mercury halide formed in the reaction chamber with the amount of elemental mercury converted from the mercury halide, the ability of the mercury analyzer system to convert mercury halide to gaseous elemental mercury can be evaluated.

Owner:SPECTRA GASES

Extension arm with moving clevis

Owner:INNOVATIVE OFFICE PROD LLC

Gas explosion simulation test system and method

Owner:ANHUI UNIV OF SCI & TECH

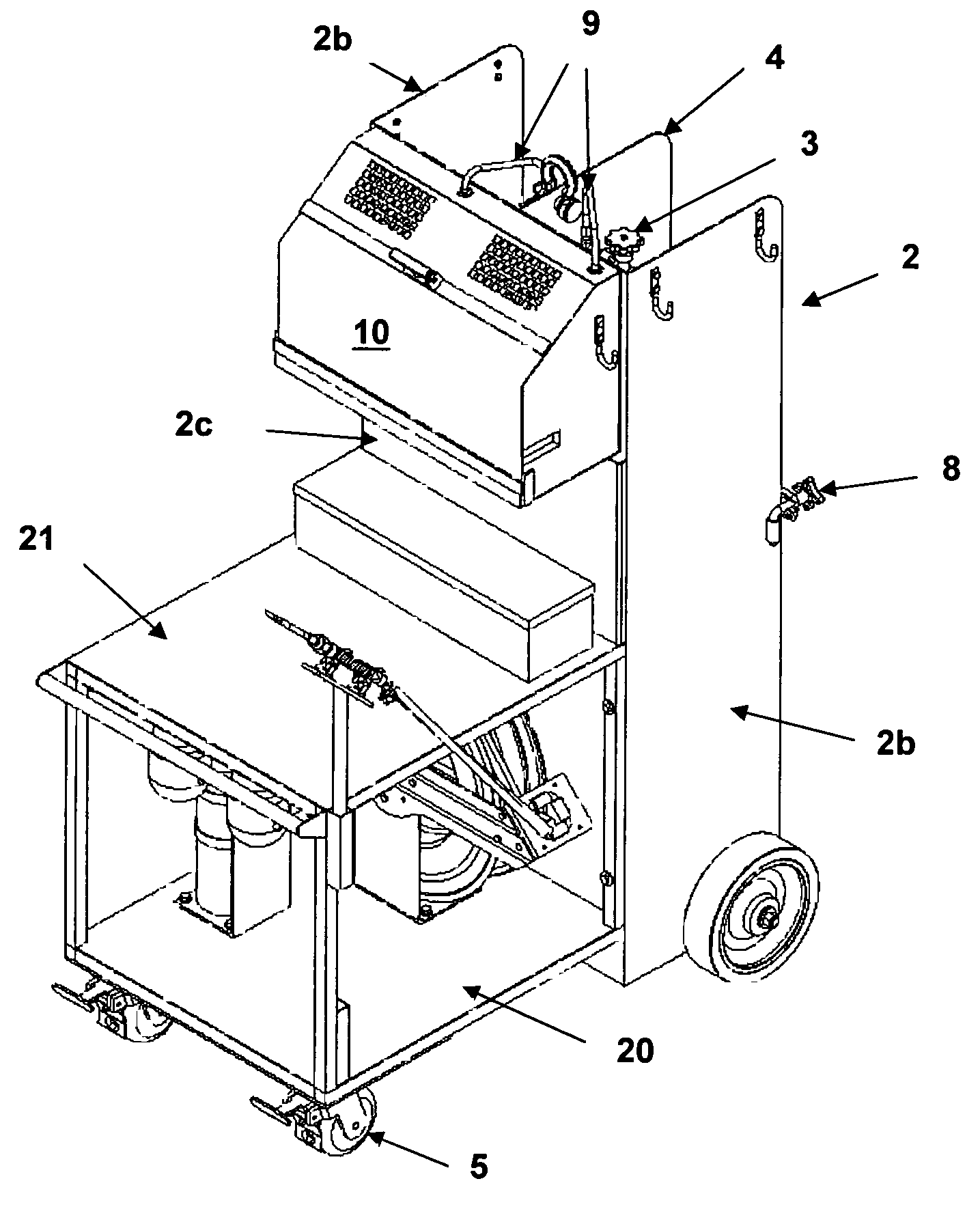

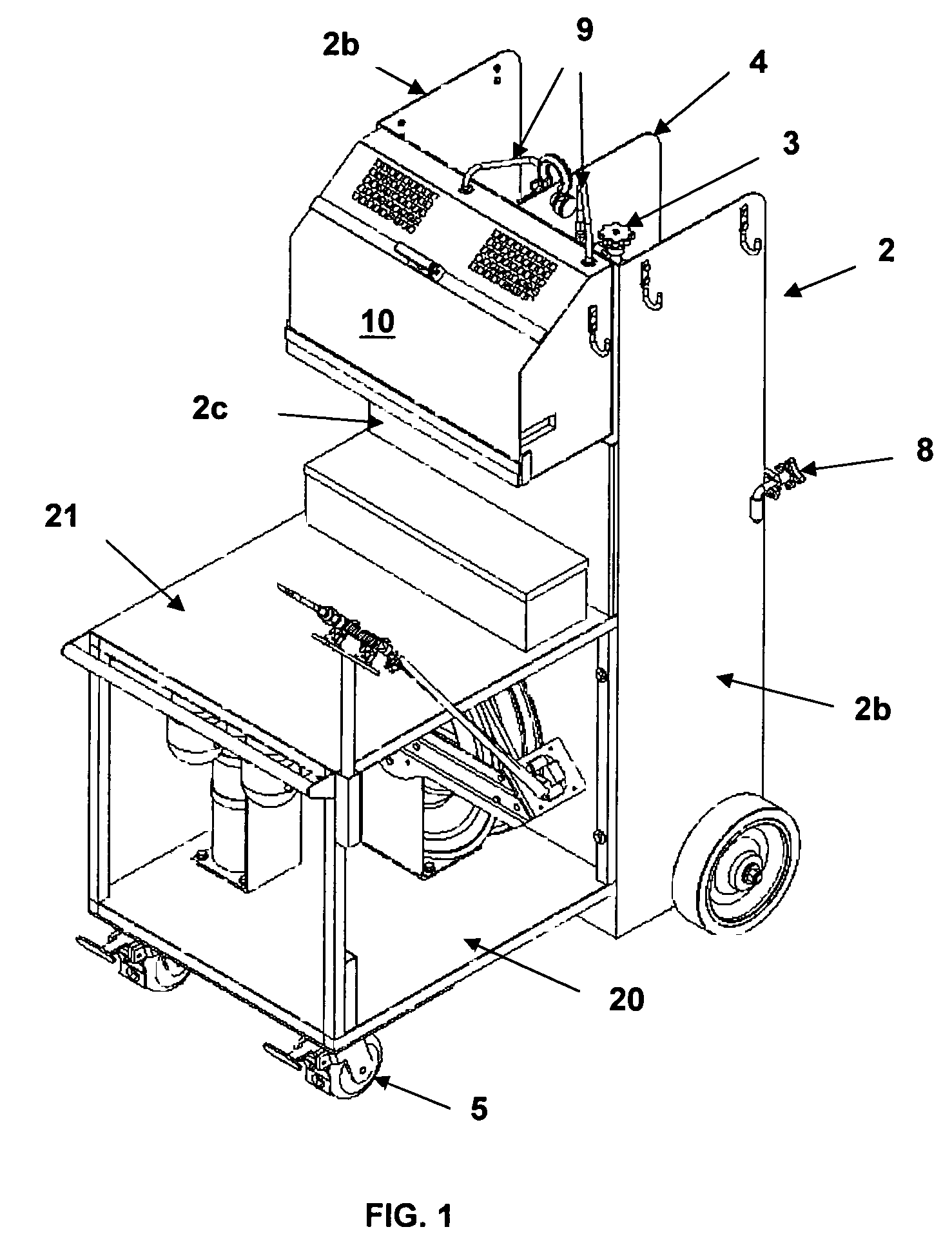

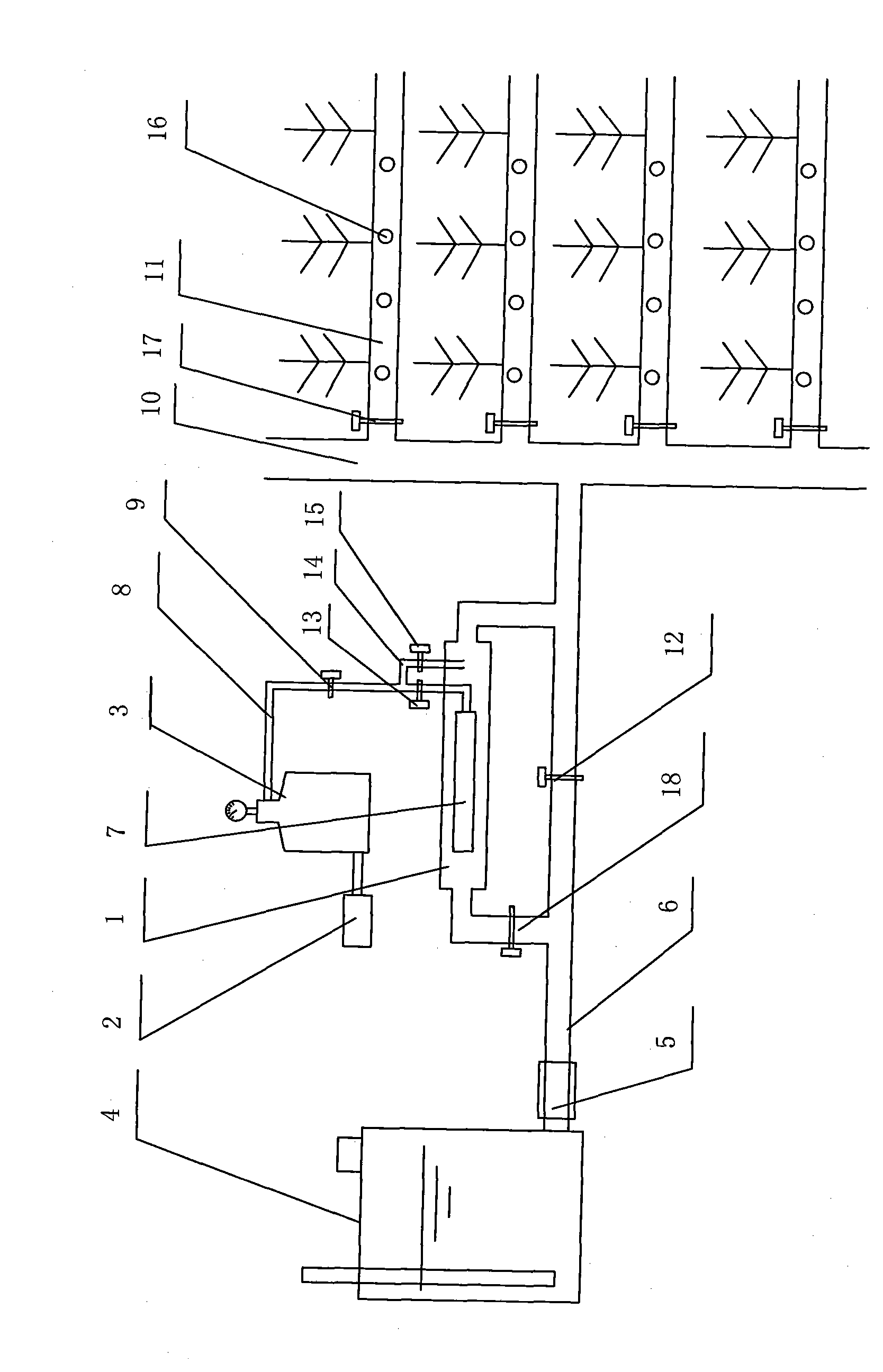

Safety welding cart

ActiveUS7252297B1Improve protectionReduce decreaseCarriage/perambulator with single axisHand carts with one axisGas cylinderFume hood

A safety welding cart structure having a metal box for holding pressurized gas cylinders, a firewall separating the cylinders, individual clamping devices to secure the cylinders, and shelves extending from the back of the box forming a cart set upon a four-wheeled base, which includes two positive-locking swivel casters. The regulators are contained within a ventilated cabinet and the hoses are wound about a reel.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

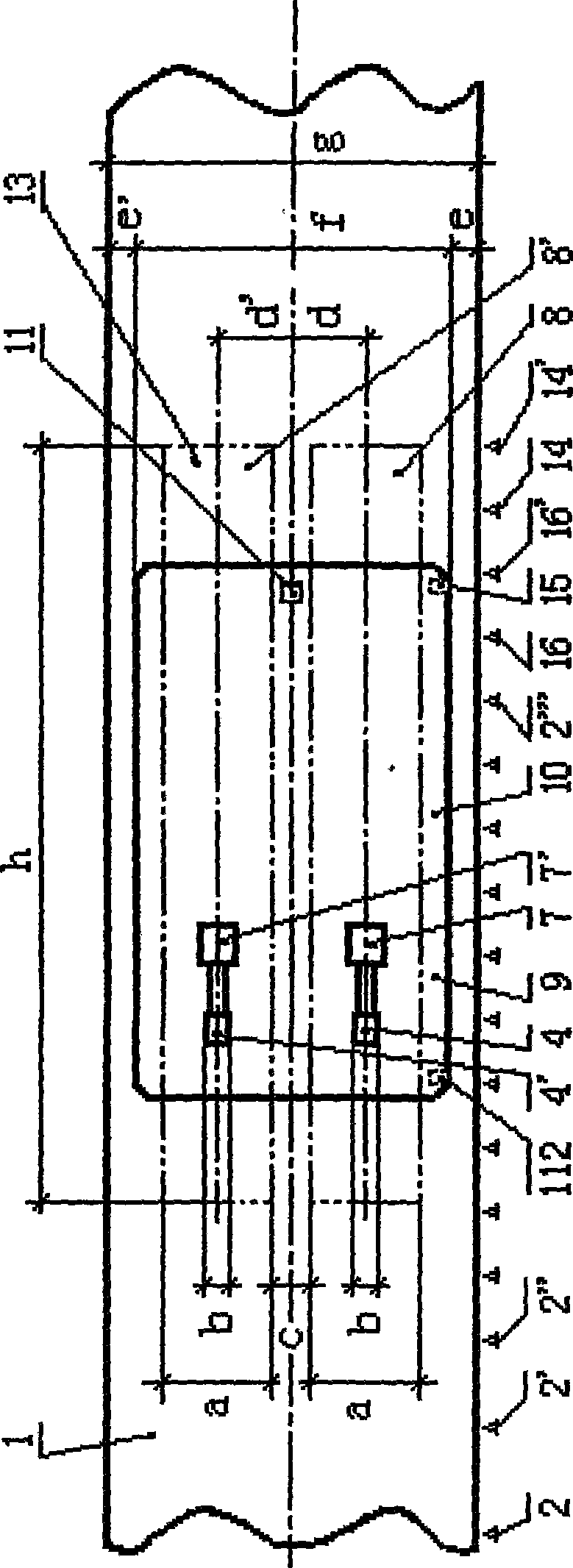

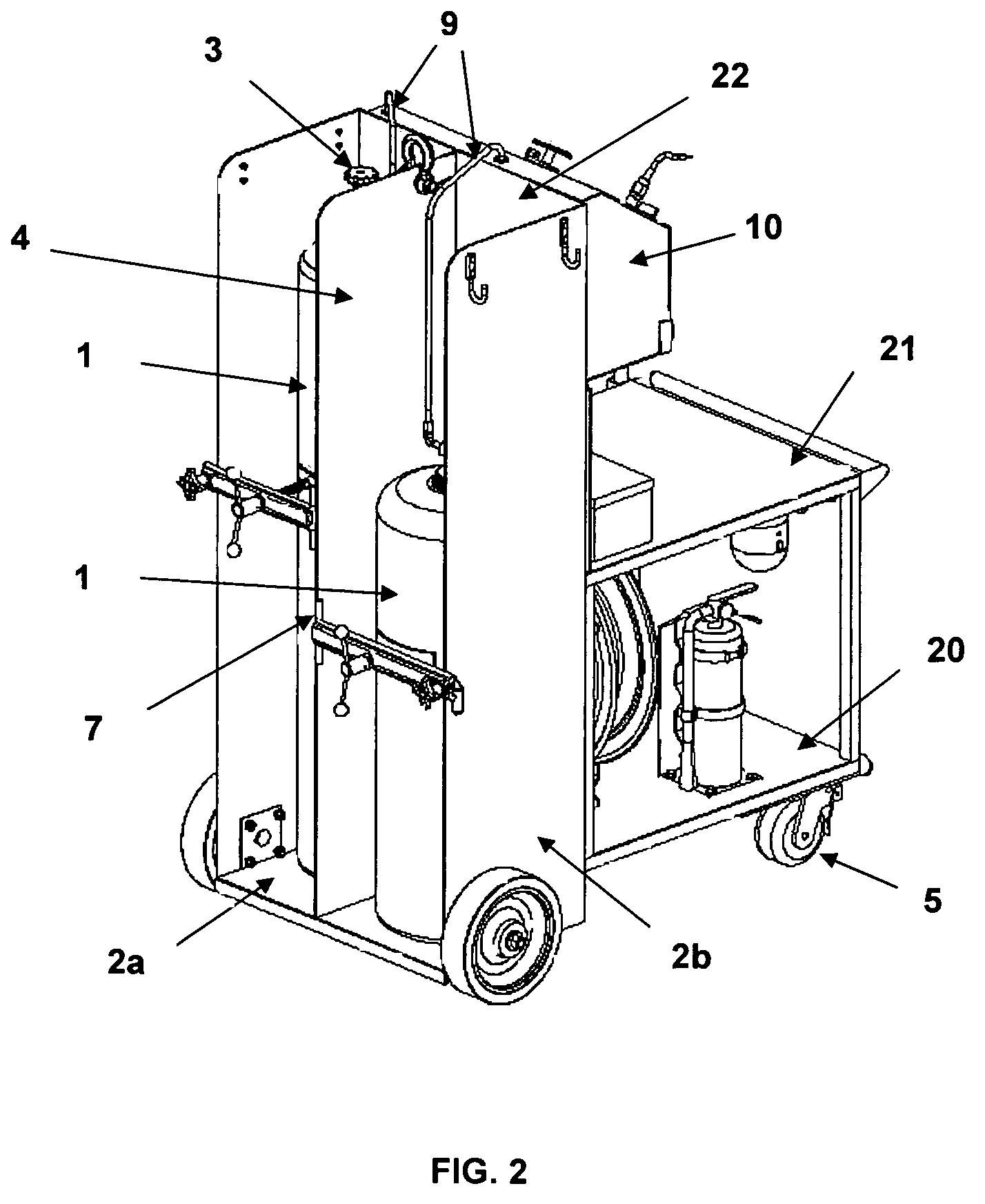

Aeration underground drip irrigation system

InactiveCN101663983APrecise and stable controlRealization of aerated subsurface drip irrigationWatering devicesCultivating equipmentsWater sourceGas cylinder

The invention discloses an aeration underground drip irrigation system which comprises a water source, a delivery main pipe (6), a delivery branch pipe (10) and an irrigation capillary (11), wherein abooster pump (5) is connected in series with the delivery main pipe (6). The aeration underground drip irrigation system is characterized in that an aeration chamber (1) is connected in parallel withthe delivery main pipe (6), a micropore aeration part (7) is arranged in the aeration chamber (1), an air compressor (2) is communicated with the aeration part (7) in the aeration chamber (1) througha gas cylinder (3) and a ventilation hose (8) with a one-way valve (9), and a branch ventilation pipe (14) communicated with the aeration chamber (1) is arranged between the one-way valve (9) and a gas flow control valve (13). The aeration underground drip irrigation system can realize the three functions of ordinary underground drip irrigation, aeration underground drip irrigation and simple underground ventilation through water gas supply and valve control, has simple structure, low cost, less energy loss, controllable aeration ratio, wide aeration range, convenient use, management and maintenance and labor saving, and simultaneously can dissolve fertilizer into water, simultaneously irrigate the fertilizer, the water and gas, improve the utilization efficiency of the fertilizer and reduce the pollution for soil and underground water.

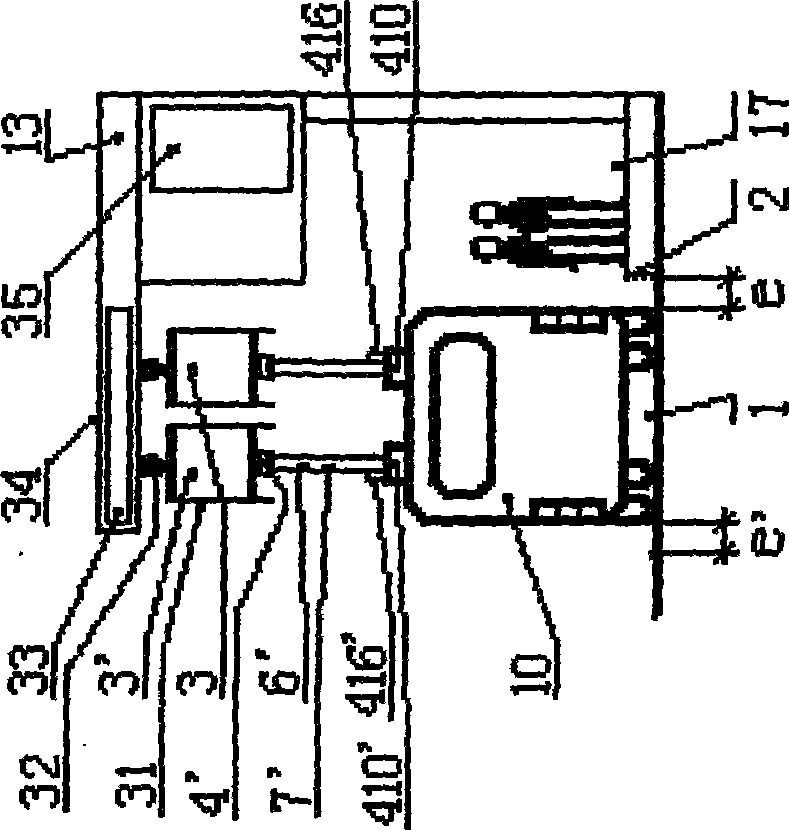

Owner:LUDONG UNIVERSITY

Mechanism for gas operated gun

Owner:EIP MANAGEMENT

Antimicrobial Lining for Gas Cylinders and Coupling Components

This invention relates to the field of gas-containing storage vessels, and more specifically to the provision for antimicrobial surfaces within such vessels and in the connecting hardware associated with various applications of such vessels, so that microbial colonization of the interior of such vessels may be eliminated or retarded. This antimicrobial feature may result in improved safety in the use of such vessels, with reduced risk of the transmission of infection to a user. The invention further includes methods to provide gas-containing storage vessels with antimicrobial surfaces, so that microbial colonization of the interior of such vessels may be eliminated or retarded.

Owner:BOC GRP INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com