Aeration underground drip irrigation system

An underground drip irrigation and aeration technology, applied in the field of agricultural irrigation, can solve the problems of limited aeration ratio, high cost of mixing equipment, large energy loss, etc., and achieve the effect of flexible and convenient adjustment and wide range of air mixing ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

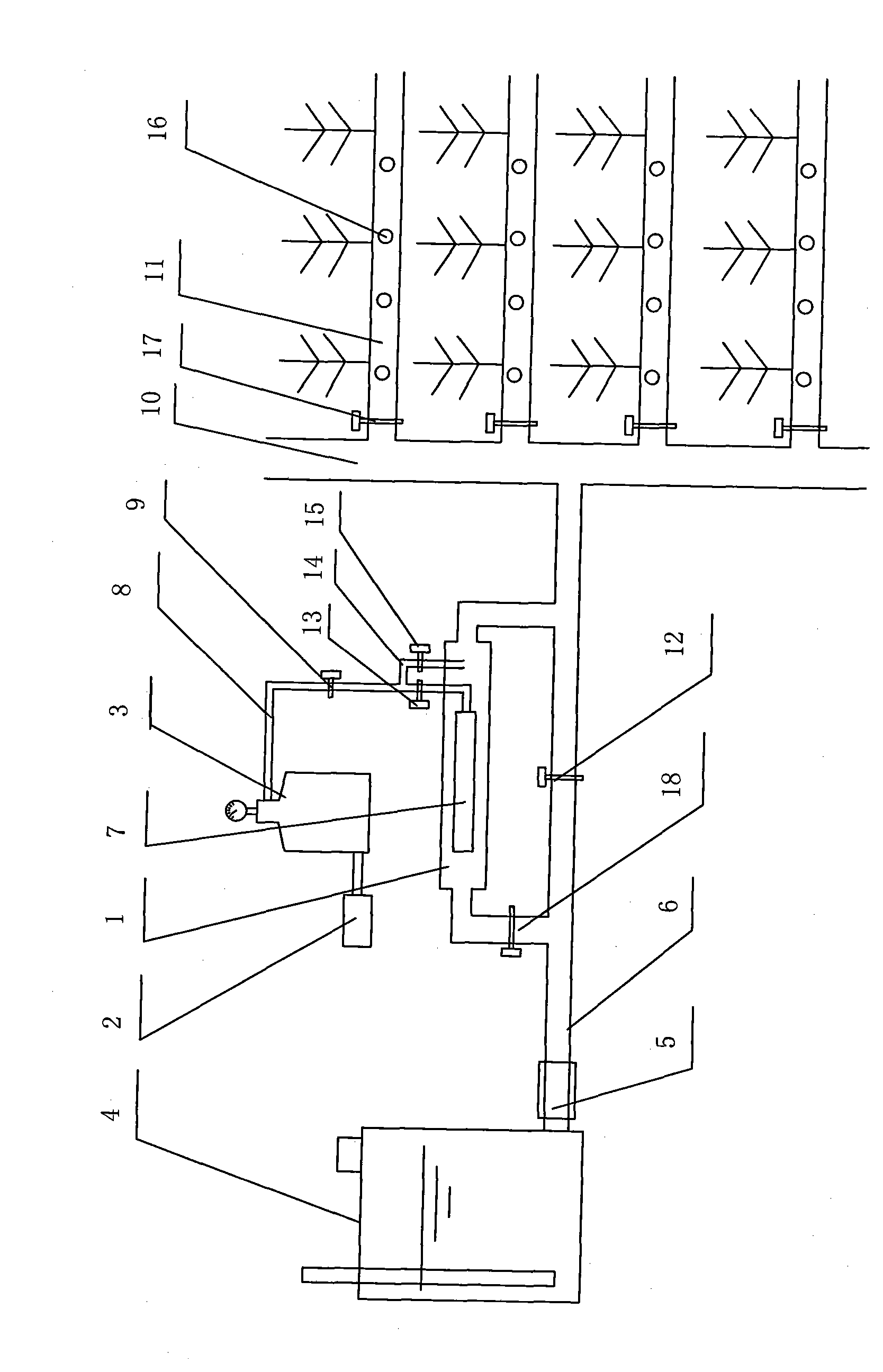

[0018] Example 1, see figure 1 , In the field, each irrigation capillary 11 is buried according to the needs of the crop. The side wall of which is buried in the ground is provided with a water outlet 16, and a flow control valve 17 is installed on the ground part of each irrigation capillary. The irrigation capillary 11 is made of hard polyvinyl chloride. Pipe (UPVC pipe), buried 10-100cm below the ground surface, the specific depth can be determined according to the distribution of crop roots and the planned wetting depth. The distance between the outlet holes 16 on the side wall of the irrigation capillary 11 is between 10-100cm, and the outlet flow rate At 1-10L / h; connect each irrigation capillary 11 with the water branch pipe 10, the water branch pipe 10 is connected to one end of the water main pipe 6, and the other end of the water main pipe 6 is connected to the water source. The water source is a water supply tank 4. It can also be other water sources. The water main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com