Patents

Literature

21678 results about "Polyvinyl chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyvinyl chloride (/ˌpɒlivaɪnəl ˈklɔːraɪd/; colloquial: polyvinyl, vinyl; abbreviated: PVC) is the world's third-most widely produced synthetic plastic polymer, after polyethylene and polypropylene. About 40 million tonnes are produced per year.

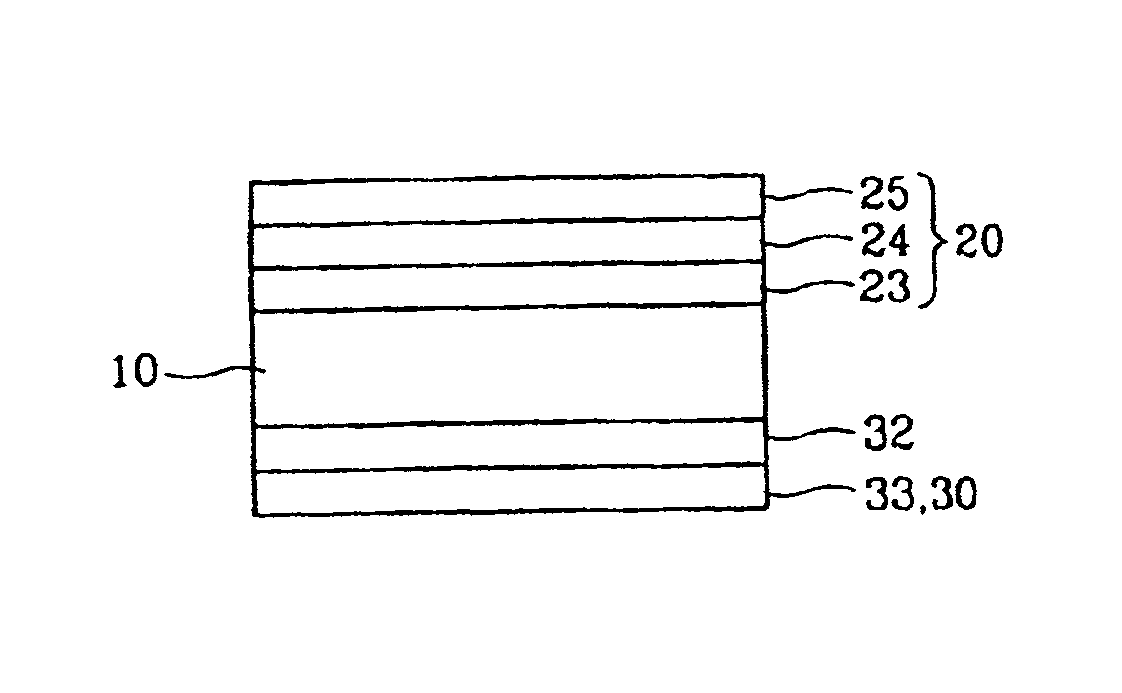

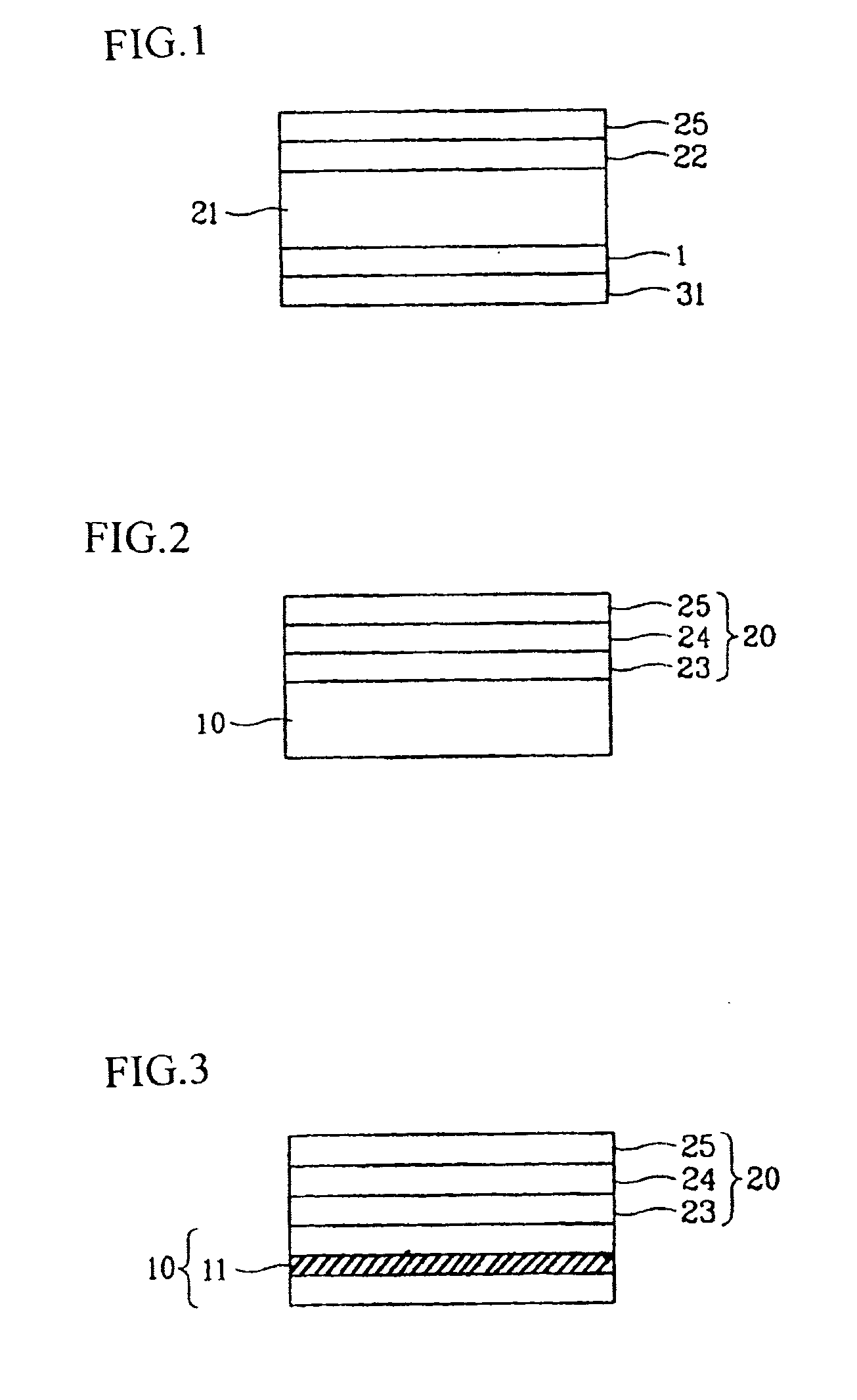

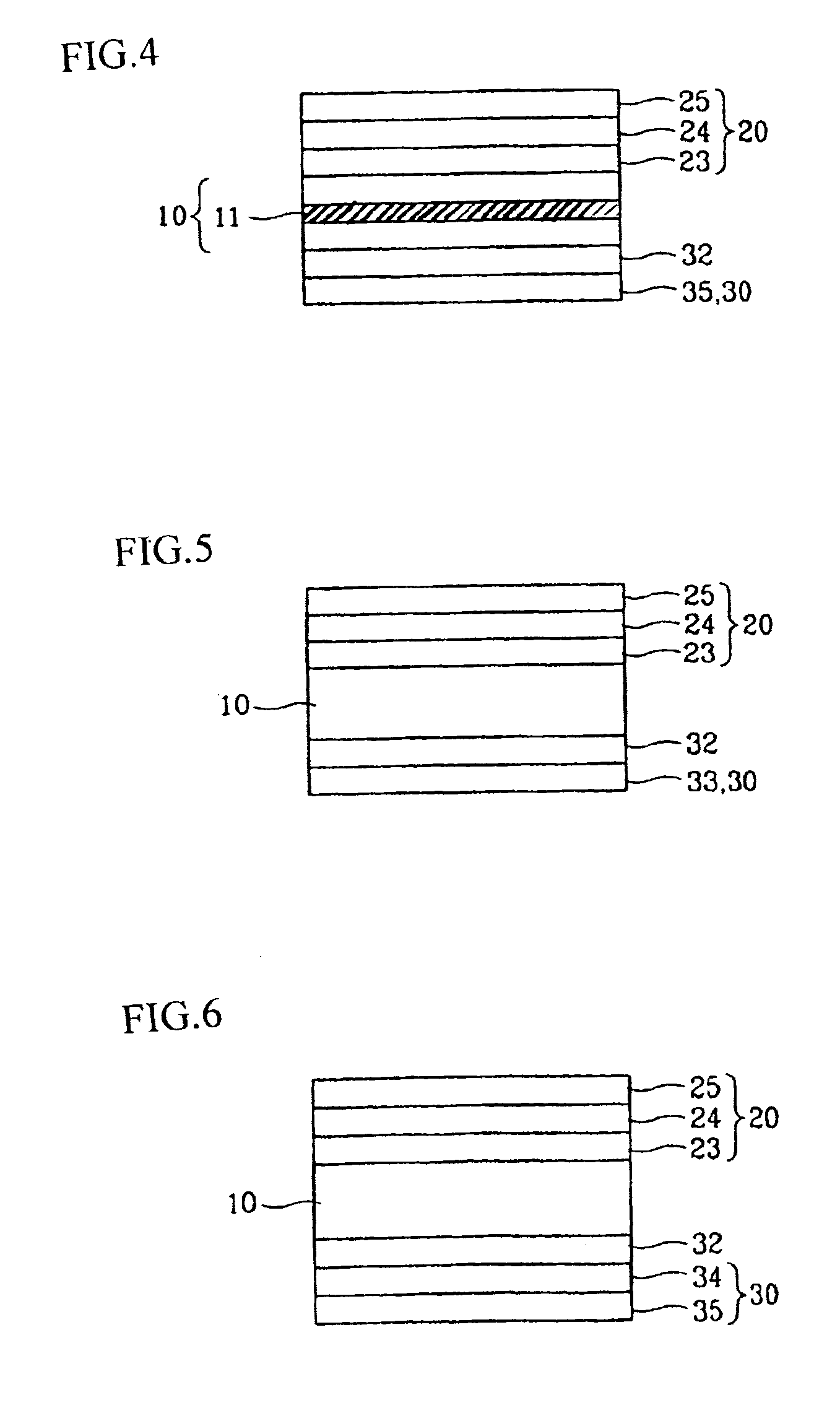

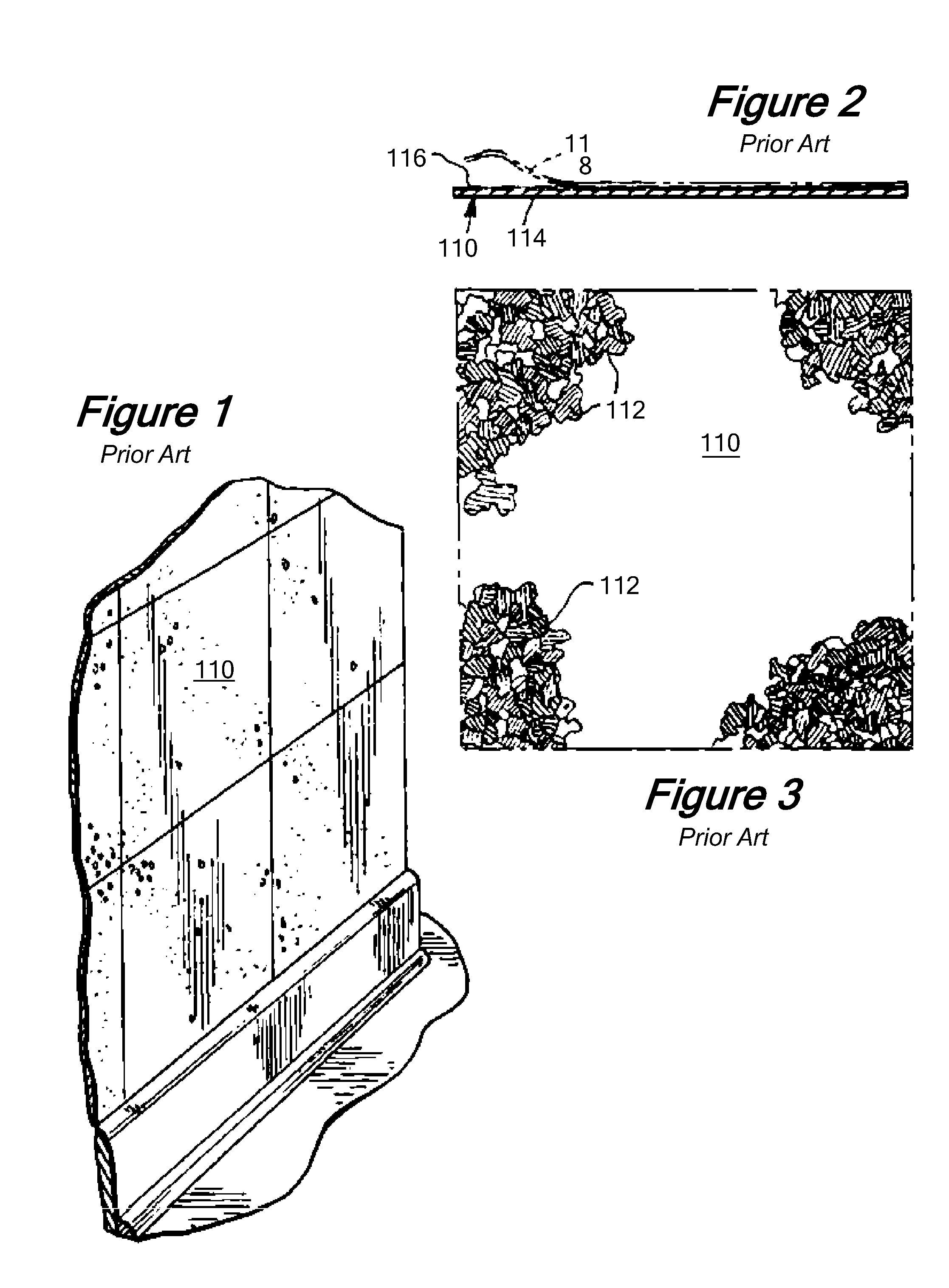

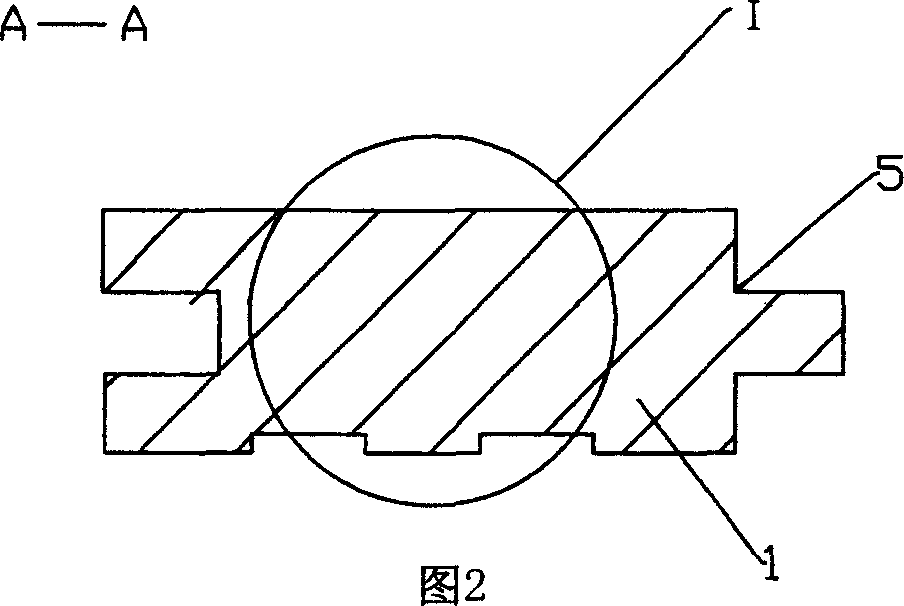

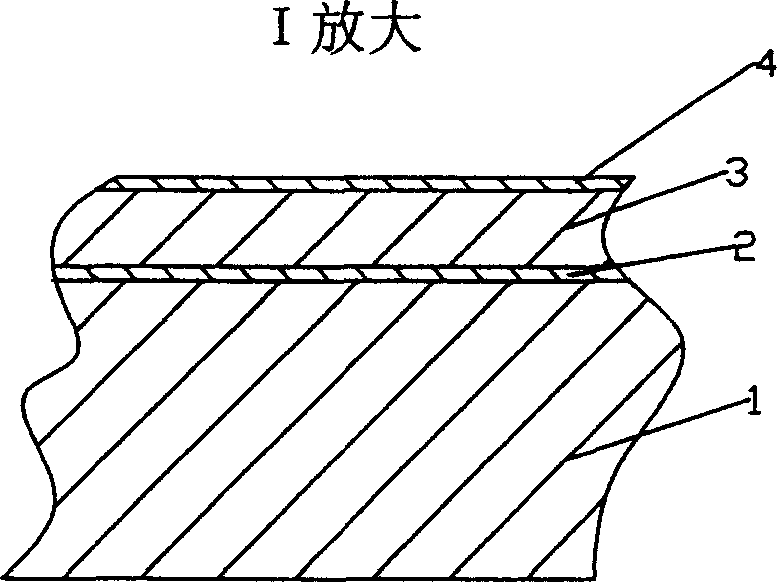

Decorative floor covering comprising polyethylene terephthalate film layer in surface layer and manufacturing method of the same

InactiveUS6933043B1Superior surface printing sharpness and realismEasy to installSynthetic resin layered productsPaper/cardboard layered productsSurface layerPolyethylene terephthalate

The present invention provides a decorative floor covering comprising a surface layer and a substrate layer underneath, wherein the surface layer comprises a polyethylene terephthalate film layer, and a method for preparing the same. Furthermore, the present invention provides a decorative floor covering comprising a surface layer and a substrate layer underneath, wherein a light weight back layer is further comprised under the substrate layer, and a method for preparing the same. A decorative floor covering of the present invention is a decorative floor covering which has superior surface heat resistance, printing sharpness and realism, and it can be installed conveniently since not only can non-foamed polyvinyl chloride resin be used as a substrate layer, but also the weight of a floor covering is light when a light weight back layer is comprised under the substrate layer.

Owner:LG CHEM LTD

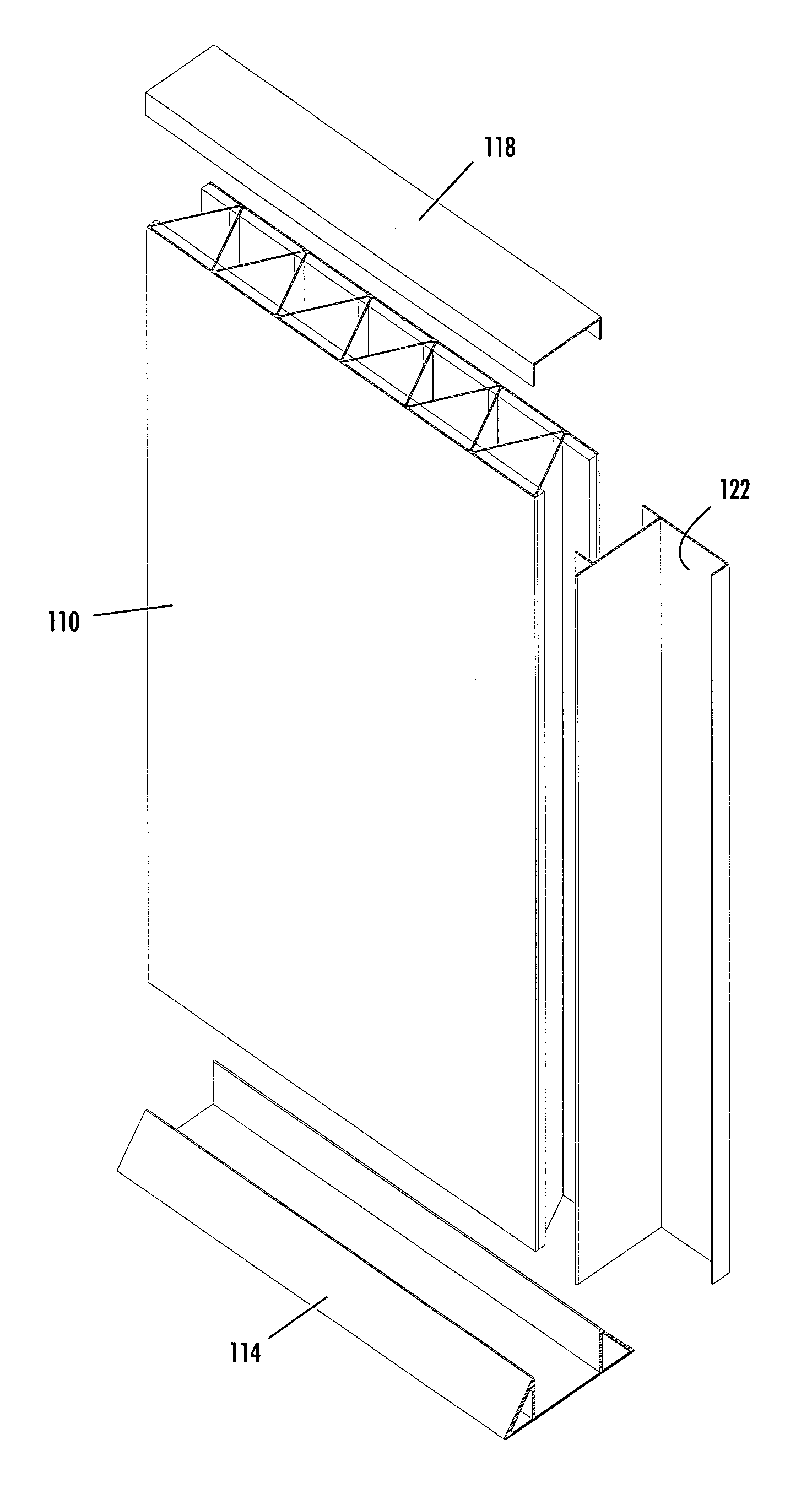

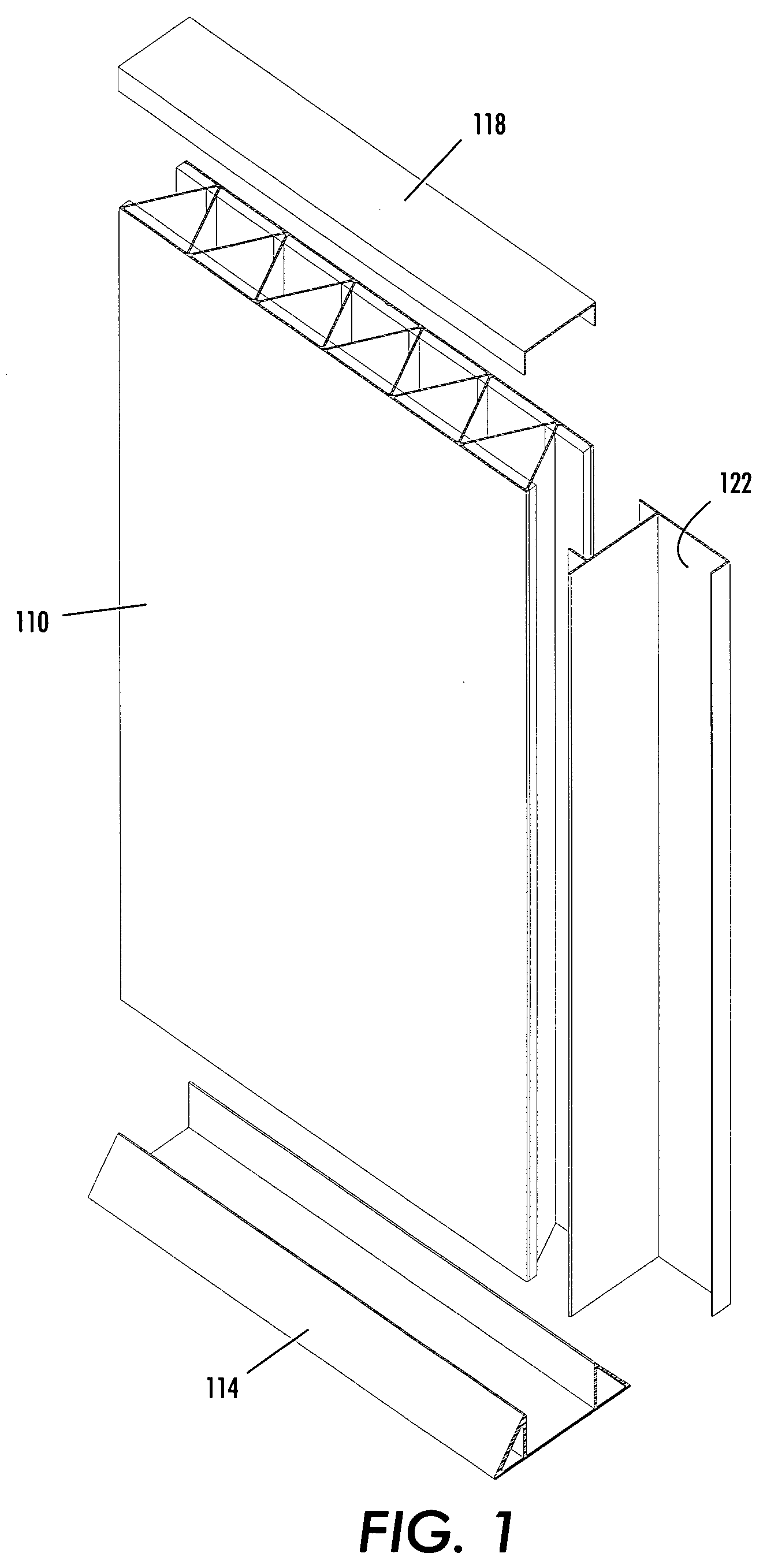

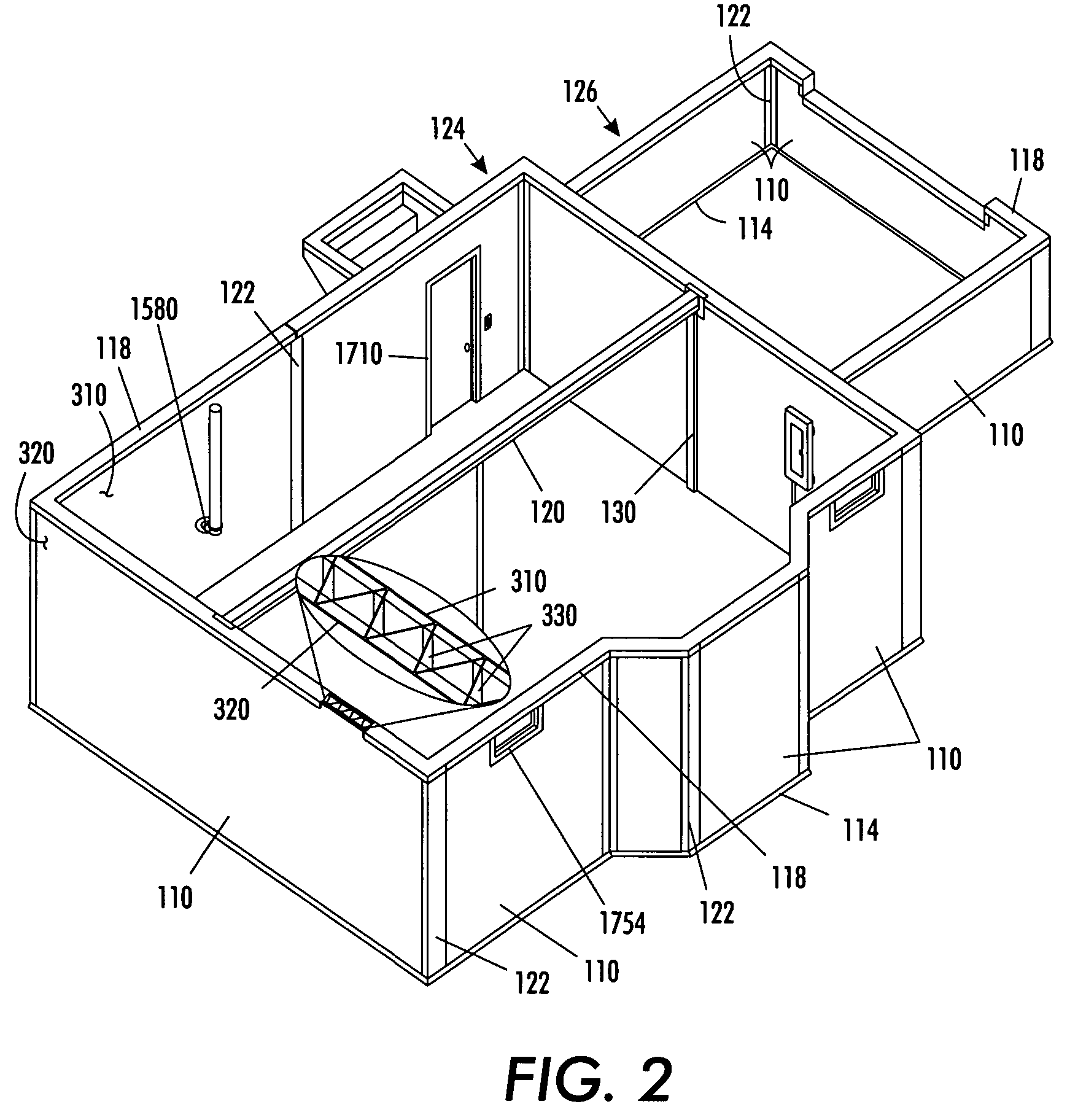

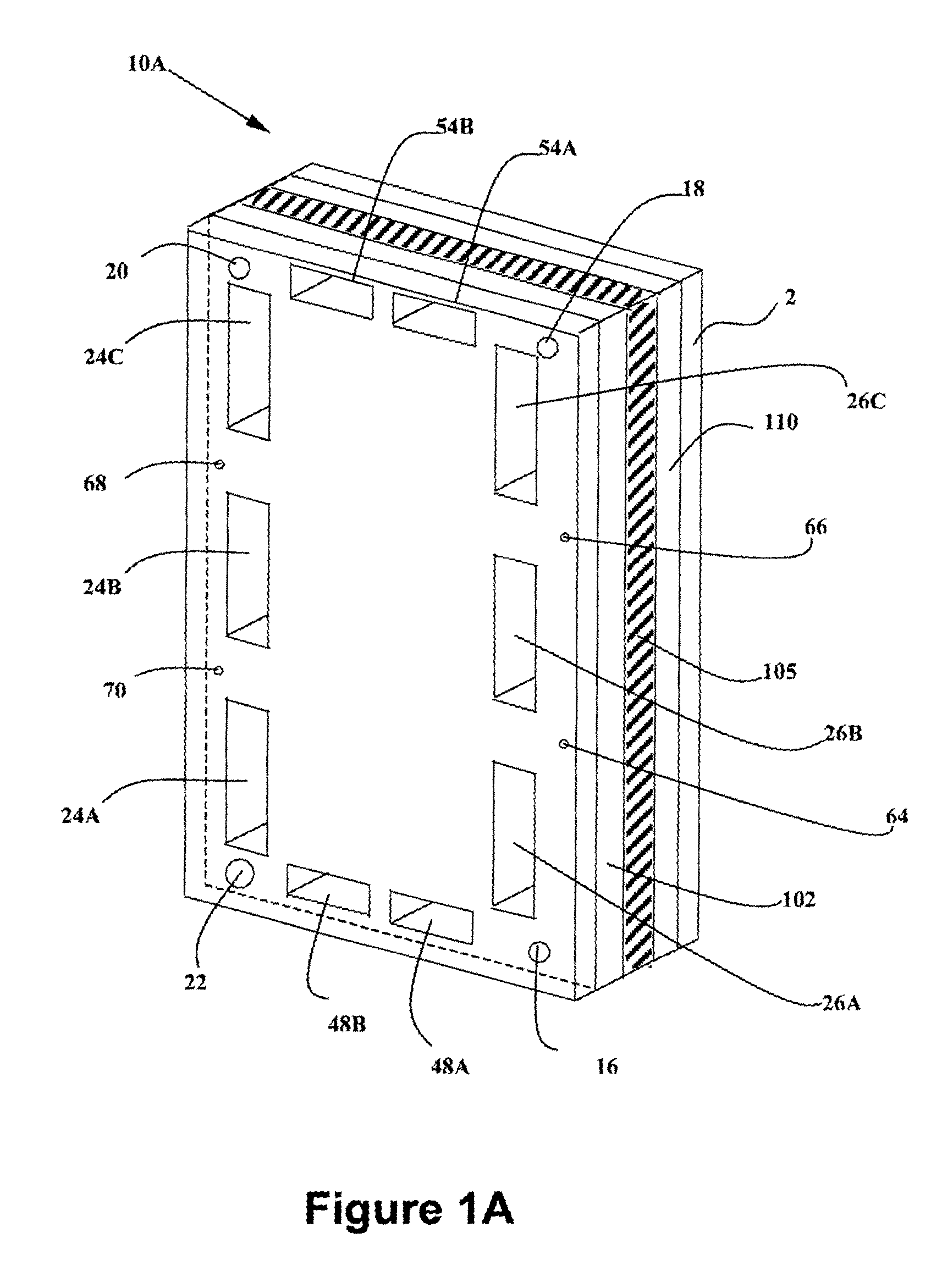

Modular structure for building panels and methods of making and using same

The present invention is a polymeric panel system and method for production and use thereof, enabling the rapid construction of a building foundation wall or other structure and in particular a below-grade foundation. The polymeric foundation system includes polymeric wall panels and other components suitable for withstanding lateral and end compression loads. The walls include two parallel faces separated by a series of webs or ribs, where the webs and faces of the wall panels may be formed of a similar polymer material such as polyvinylchloride (PVC). The wall panels and / or other components may be extruded so as to enable the rapid production of sections of wall panels, where the panels may be cut to length and then affixed to adjacent panels to form a foundation wall. The method of affixing adjacent panels may include welding, gluing or other techniques and may be performed on the job site or in a pre-fabrication facility. Furthermore, the wall panels may be co-extruded with an insulating material inserted in the voids between the parallel faces so as to provide improved thermal performance of the foundation as well.

Owner:DOUGLAS ROBERT B

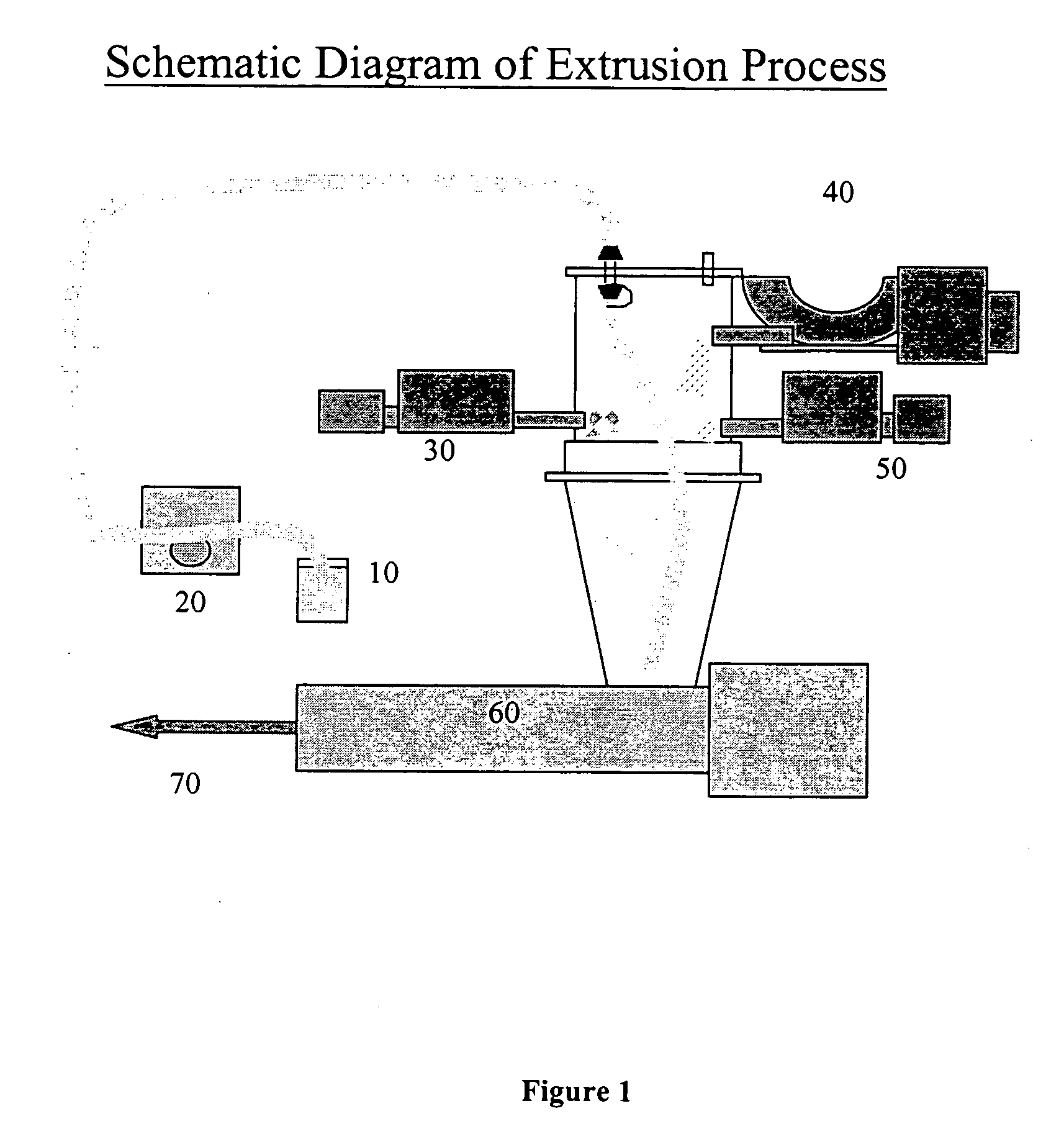

Polymer wood composite

InactiveUS6015612AHigh modulusHigh compressive strengthWood working apparatusRecord information storageFiberThermoplastic

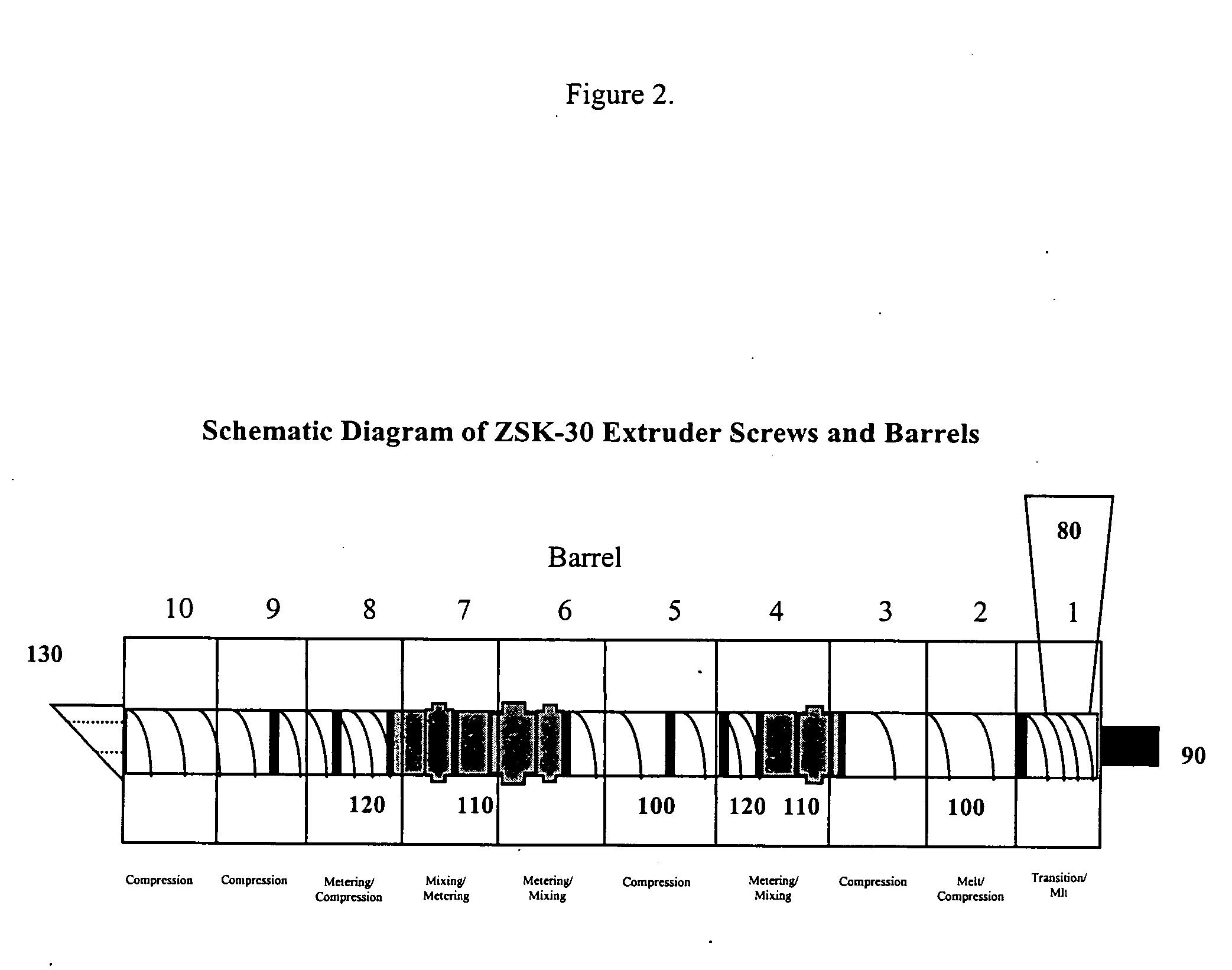

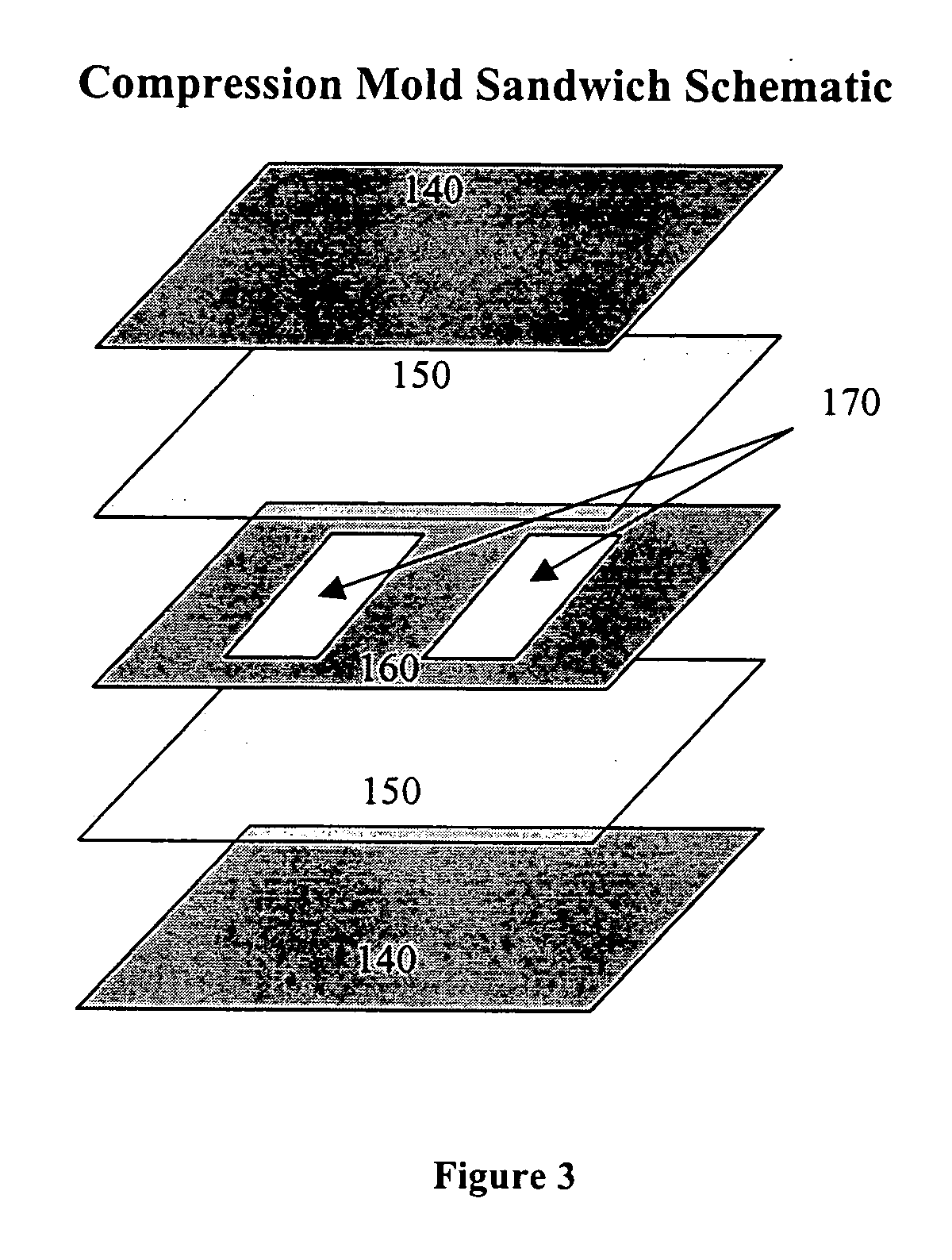

The invention relates to a composition comprising a polymer and wood fiber composite that can be used in the form of a linear extrudate or thermoplastic pellet to manufacture structural members. The polymer and wood fiber composite structural members can be manufactured in an extrusion process or an injection molding process. The linear extrudate or pellet can have a cross-section of any arbitrary shape, or can be a regular geometric. The pellet can have a cross-section shape having a volume of at least about 12 mm3. Preferably the pellet is a right cylindrical pellet having a minimum radius of about 1.5 mm and a minimum length of 1 mm weighing at least 14 mg. The invention also relates to an environmentally sensitive recycle of waste streams. The polymer and wood fiber composite contains an intentional recycle of a waste stream comprising polymer flakes or particles or wood fiber. The waste stream can comprises, in addition to polymer such as polyvinyl chloride or wood fiber, adhesive, paint, preservative, or other chemical stream common in the wood-window or door manufacturing process, or mixtures thereof. The initial mixing step before extrusion of the composite material insures substantial mixing and melt contact between molten polymer and wood fiber. The extruded pellet comprises a consistent proportion of polymer, wood fiber and water. During the extrusion, water is removed intentionally to dry the material to a maximum water content of less than about 10 wt-% based on the pellet weight. To make a structural unit, the pellet is introduced into an extruder or injection molding apparatus wherein, under conditions of temperature and pressure, the composite pellet material is shaped into a useful cross-section. Alternatively, the extruded thermoplastic mass, in the form of a elongated linear extrudate without a pelletizing step, can be immediately directed after formation into an extruder or injection molding apparatus.

Owner:ANDERSEN CORPORATION

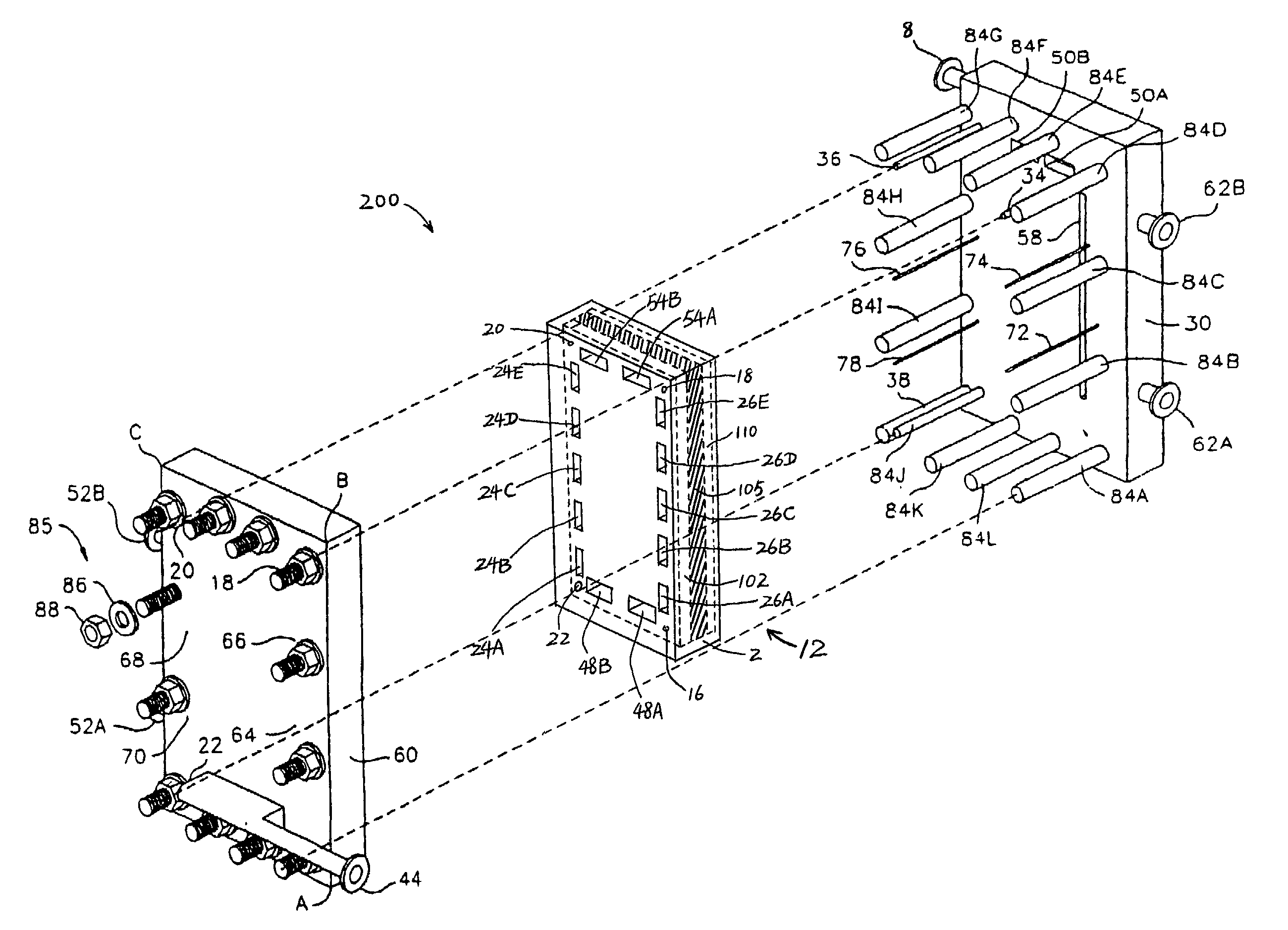

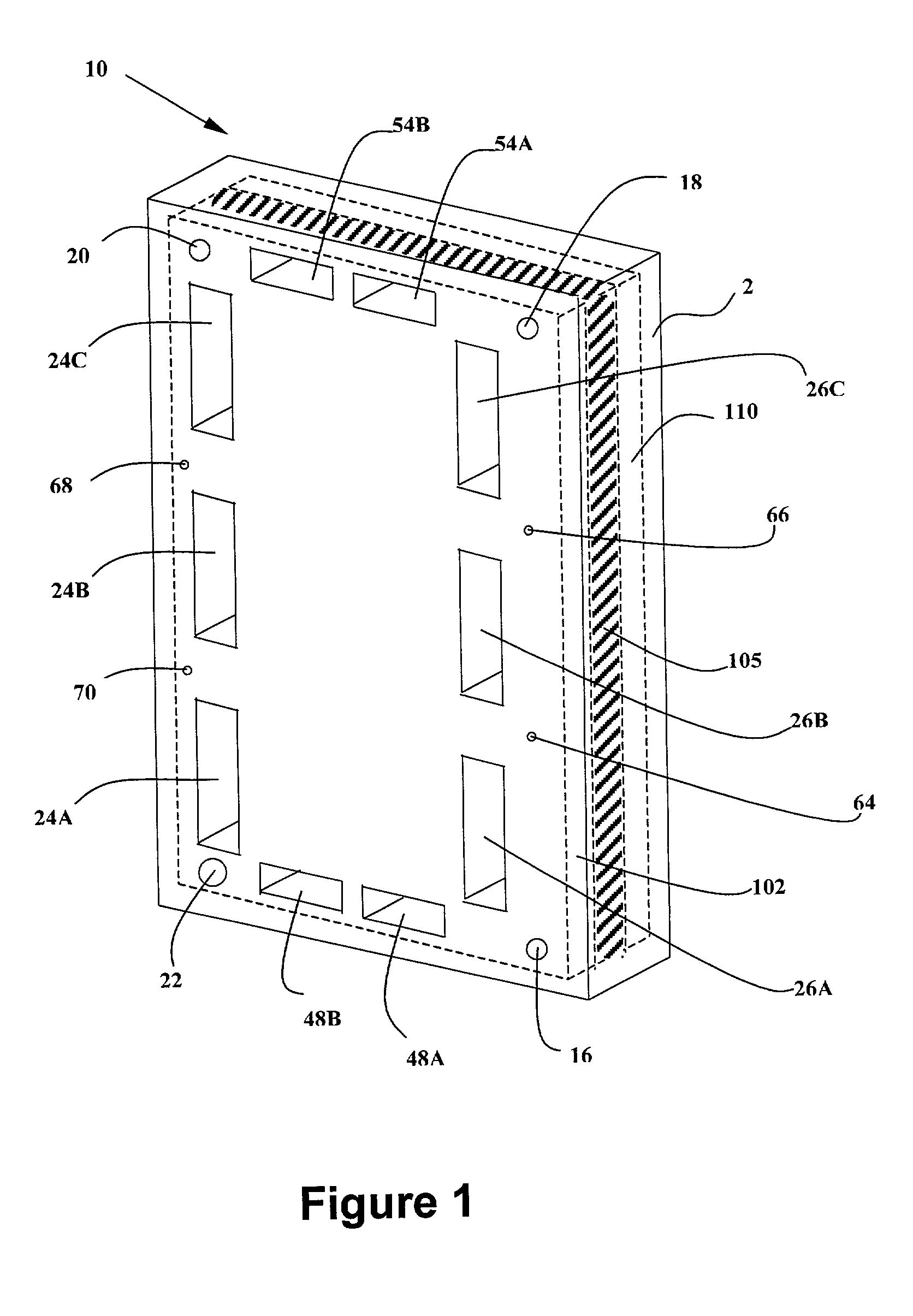

Integral gasketed filtration cassette article and method of making the same

InactiveUS20020139741A1Simple and efficient and economicalLow costSemi-permeable membranesFiltration separationEpoxyPolyester

An integral gasketed filtration cassette structure of a type comprising a filtration cassette fully or partially overcoated by a gasket layer, forming a fluid-tight seal between the filtration cassette and the filtration cassette holder to which the filtration cassette is to be affixed. The filtration cassette comprises filter sheets arranged in a multilaminate, peripherally bonded array, wherein the filter sheets alternate with permeate and retentate sheets. The gasket layer comprises an elastomeric material with suitable hardness and temperature resistance for sealing, such as silicone, ethylenepropylenedienemonomer (EPDM), viton, polyurethane, polypropylene, polyethylene, polyvinylchloride, polyester, epoxy, ethylvinylacetate, bunnas, and styrene butadiene. The filtration cassettes and filter of the invention may be advantageously employed for dewatering of aqueous biomass suspensions, desalting of proteins, removal of secreted metabolites from cellular suspensions, and the like.

Owner:KOPF HENRY III

Advanced compatible polymer wood fiber composite

InactiveUS6210792B1Improve compatibilityGood material compatibilitySynthetic resin layered productsCellulosic plastic layered productsThermoplasticFiber

The invention relates to a composition comprising a thermoplastic polymer and wood fiber composite that can be used in the form of a linear extrudate or thermoplastic pellet to manufacture structural members. The polymer, the fiber or both can be modified to increase compatibility. The wood fiber composite structural members can be manufactured in an extrusion process or an injection molding process. The linear extrudate or pellet can have a cross-section of any arbitrary shape, or can be a regular geometric. The pellet can have a cross-section shape having a volume of at least about 12 mm3. Preferably the pellet is a right cylindrical pellet having a minimum radius of about 1.5 mm and a minimum length of 1 mm weighing at least 14 mg. The invention also relates to an environmentally sensitive recycle of waste streams. The polymer and wood fiber composite contains an intentional recycle of a waste stream comprising polymer flakes or particles or wood fiber. The waste stream can comprises, in addition to polymer such as polyvinyl chloride or wood fiber, adhesive, paint, preservative, or other chemical stream common in the wood-window or door manufacturing process, or mixtures thereof. The initial mixing step before extrusion of the composite material insures substantial mixing and melt contact between molten polymer and wood fiber. The extruded pellet comprises a consistent proportion of polymer, wood fiber and water. During the extrusion, water is removed intentionally to dry the material to a maximum water content of less than about 10 wt-% based on the pellet weight. To make a structural unit, the pellet is introduced into an extruder or injection molding apparatus wherein, under conditions of temperature and pressure, the composite pellet material is shaped into a useful cross-section. Alternatively, the extruded thermoplastic mass, in the form of a elongated linear extrudate without a pelletizing step, can be immediately directed after formation into an extruder or injection molding apparatus.

Owner:ANDERSEN CORPORATION

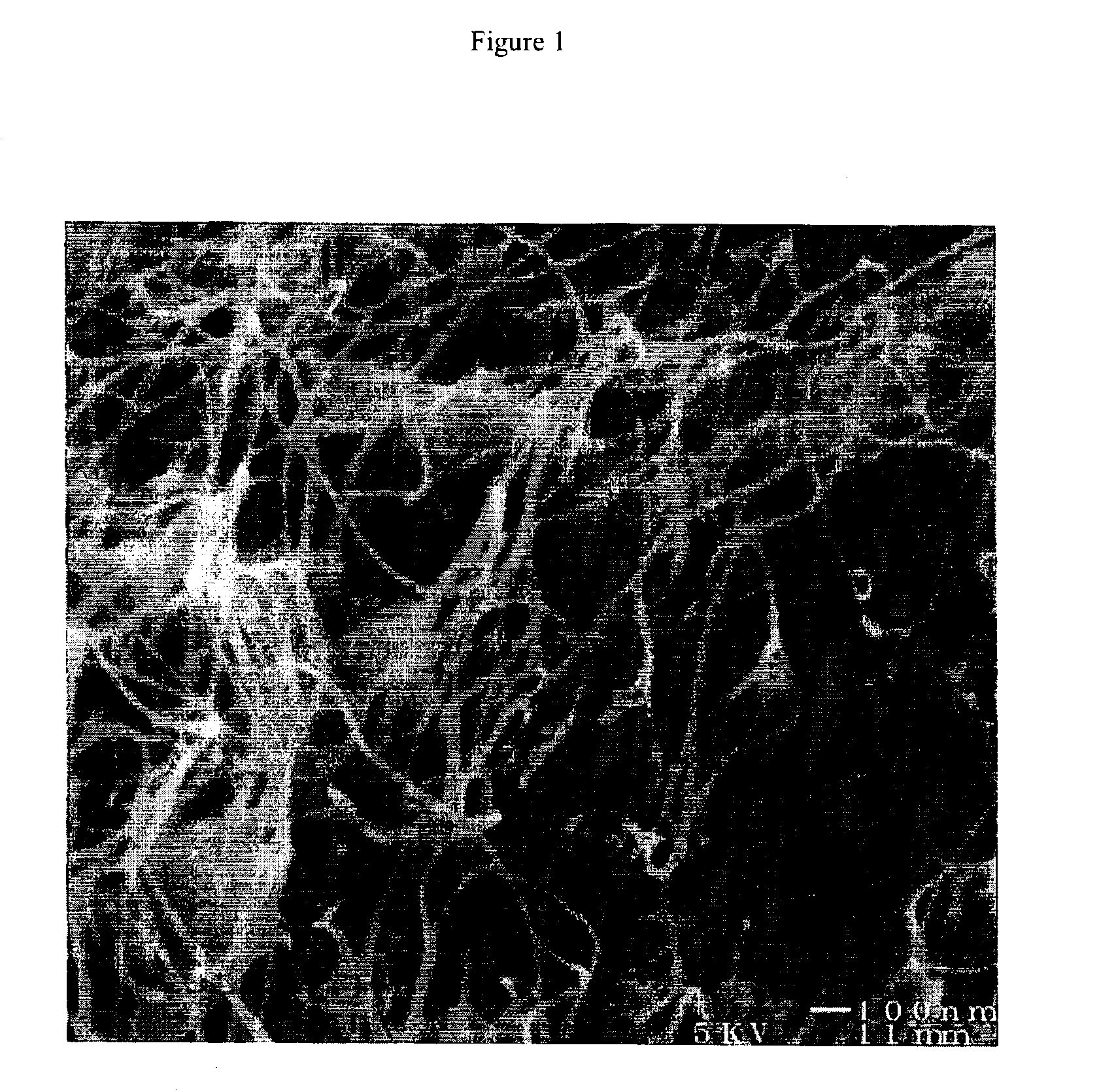

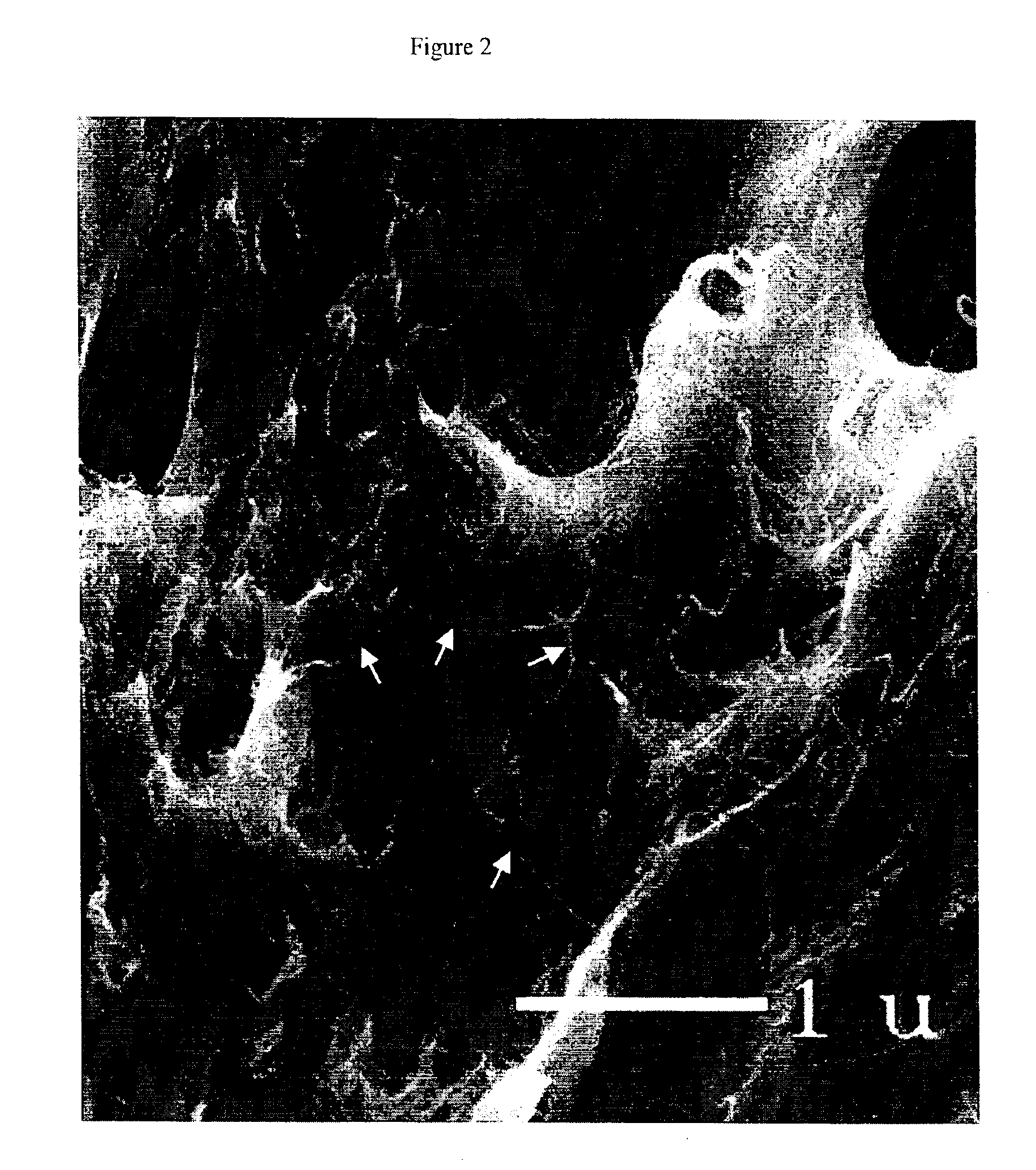

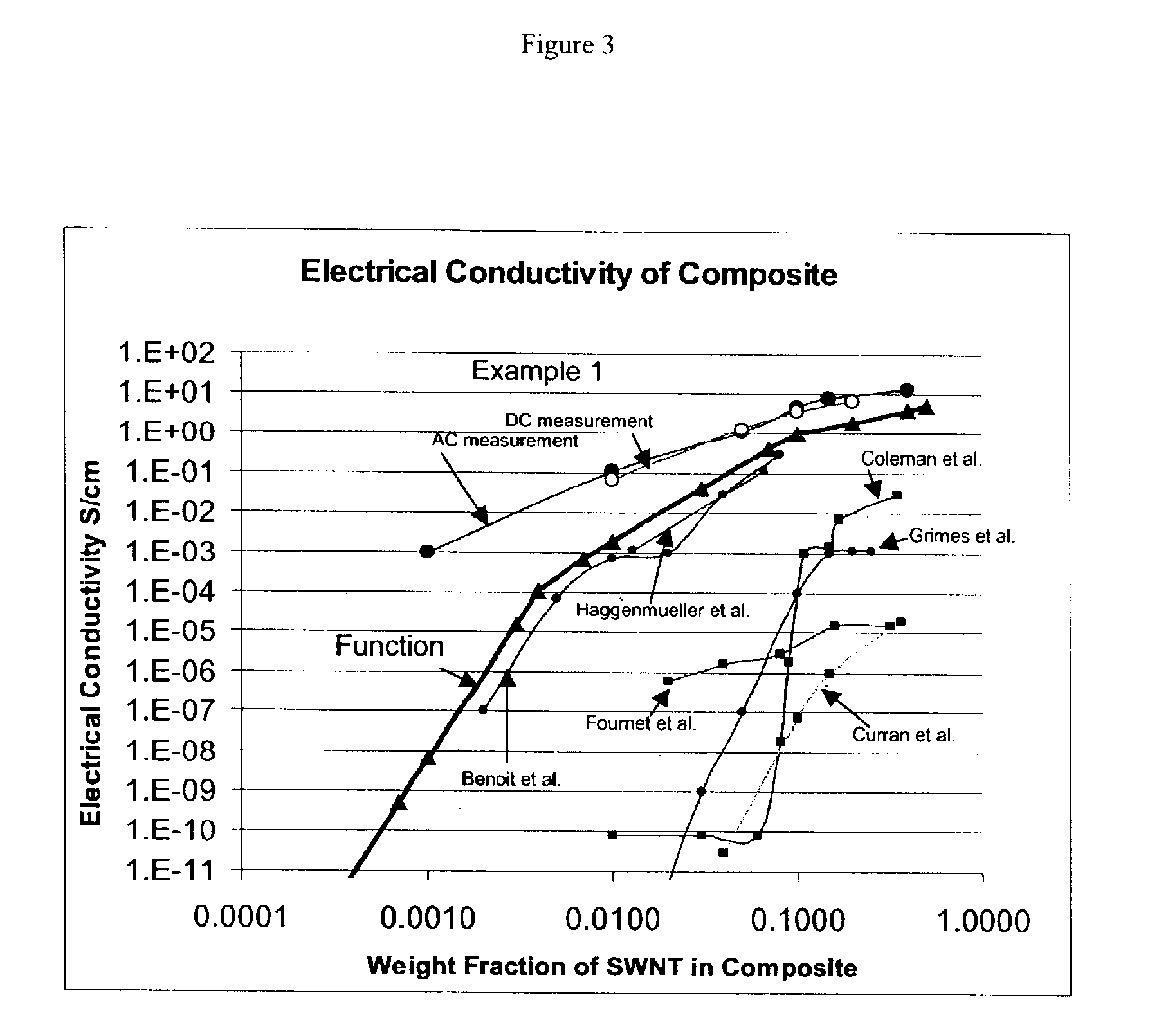

Composite materials comprising polar polymers and single-wall carbon nanotubes

InactiveUS6936653B2Improve conductivityMaterial nanotechnologyIndividual molecule manipulationPolyesterPolymer science

The invention relates to a composite comprising a weight fraction of single-wall carbon nanotubes and at least one polar polymer wherein the composite has an electrical and / or thermal conductivity enhanced over that of the polymer alone. The invention also comprises a method for making this polymer composition. The present application provides composite compositions that, over a wide range of single-wall carbon nanotube loading, have electrical conductivities exceeding those known in the art by more than one order of magnitude. The electrical conductivity enhancement depends on the weight fraction (F) of the single-wall carbon nanotubes in the composite. The electrical conductivity of the composite of this invention is at least 5 Siemens per centimeter (S / cm) at (F) of 0.5 (i.e. where single-wall carbon nanotube loading weight represents half of the total composite weight), at least 1 S / cm at a F of 0.1, at least 1×10−4 S / cm at (F) of 0.004, at least 6×10−9 S / cm at (F) of 0.001 and at least 3×10−16 S / cm (F) plus the intrinsic conductivity of the polymer matrix material at of 0.0001. The thermal conductivity enhancement is in excess of 1 Watt / m-° K. The polar polymer can be polycarbonate, poly(acrylic acid), poly(acrylic acid), poly(methacrylic acid), polyoxide, polysulfide, polysulfone, polyamides, polyester, polyurethane, polyimide, poly(vinyl acetate), poly(vinyl alcohol), poly(vinyl chloride), poly(vinyl pyridine), poly(vinyl pyrrolidone), copolymers thereof and combinations thereof. The composite can further comprise a nonpolar polymer, such as, a polyolefin polymer, polyethylene, polypropylene, polybutene, polyisobutene, polyisoprene, polystyrene, copolymers thereof and combinations thereof.

Owner:SAMSUNG ELECTRONICS CO LTD

Flame-proof smoke-inhibiting wood-plastic composite material

A flame retardant smoke resistant wood plastic composite material relates to a wood plastic composite material, which solves the disadvantages of low flame retardant performance, big smoke mass, large addition of flame retardants, increased cost and decreased mechanical property of existing wood plastic composite materials. The product of the invention is mainly formed by polystyrene and / or polyvinyl chloride fortified with heat stabilizers, lignocellulose, intumescent flame retardant, compatibilizer, lubricant. The flame retardant and smoke-resistant performance of the product of the invention is greatly improved. For wood powder / polystyrene composite material, compared with no addition of flame retardant, the average heat release rate is decreased by 48 percent, the quantity of smoke yield is reduced by 30 percent and the CO yield is decreased by 28 percent during combustion. The product of the invention has high oxygen-index, long ignition time and no droplet, which greatly reduces the fire hazard of the material, and the appearance of the material is similar with wood. The product of the invention also has low cost, wide application range and good creep resistance, forming performance and mechanical property.

Owner:NORTHEAST FORESTRY UNIVERSITY

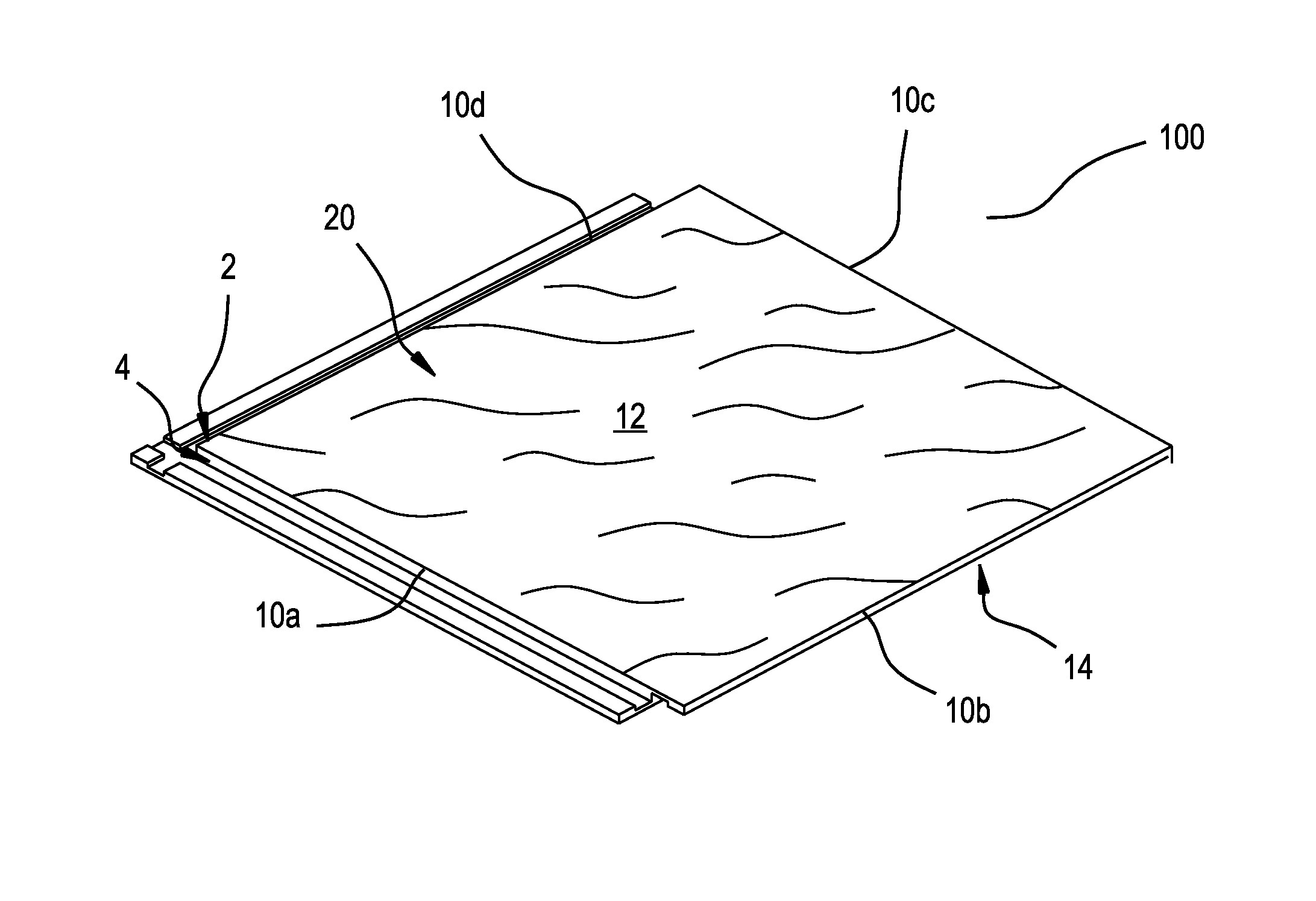

Floor Panel Containing A Polymer And Cork

ActiveUS20100319282A1Improve material performanceSlide fastenersBaby linensPolyvinyl chlorideEngineering

A vinyl floor panel for a flooring system prepared from a blend of a polymer and cork granules. The floor panel includes top and bottom surfaces with a first layer between both surfaces. A printed pattern is located on the top surface. The first layer is prepared from a blend of a polymer polyvinyl chloride and cork granules, where the cork granules are evenly distributed with the polyvinyl chloride throughout the length, width, and thickness of the first layer.

Owner:NOVALIS HLDG

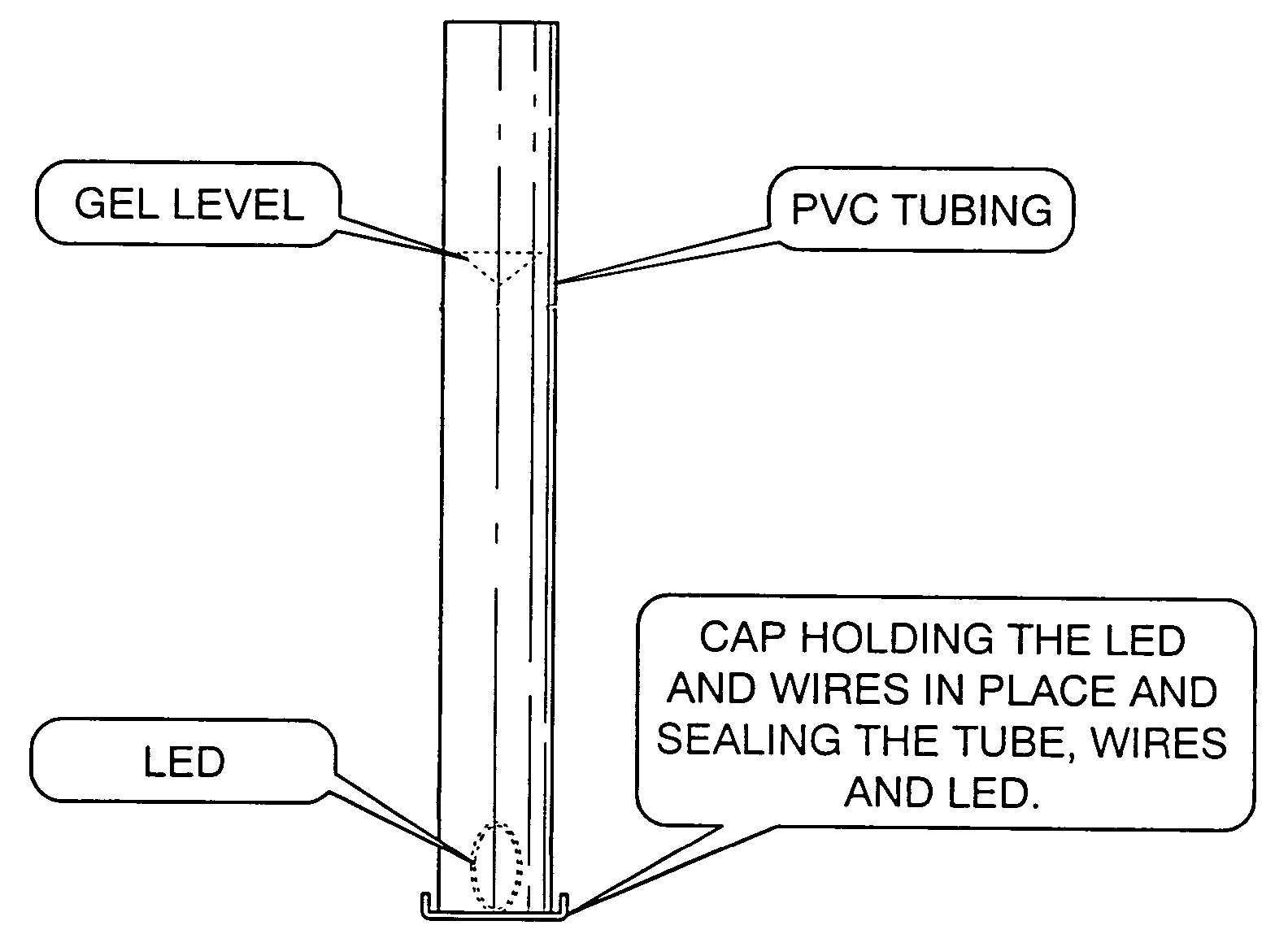

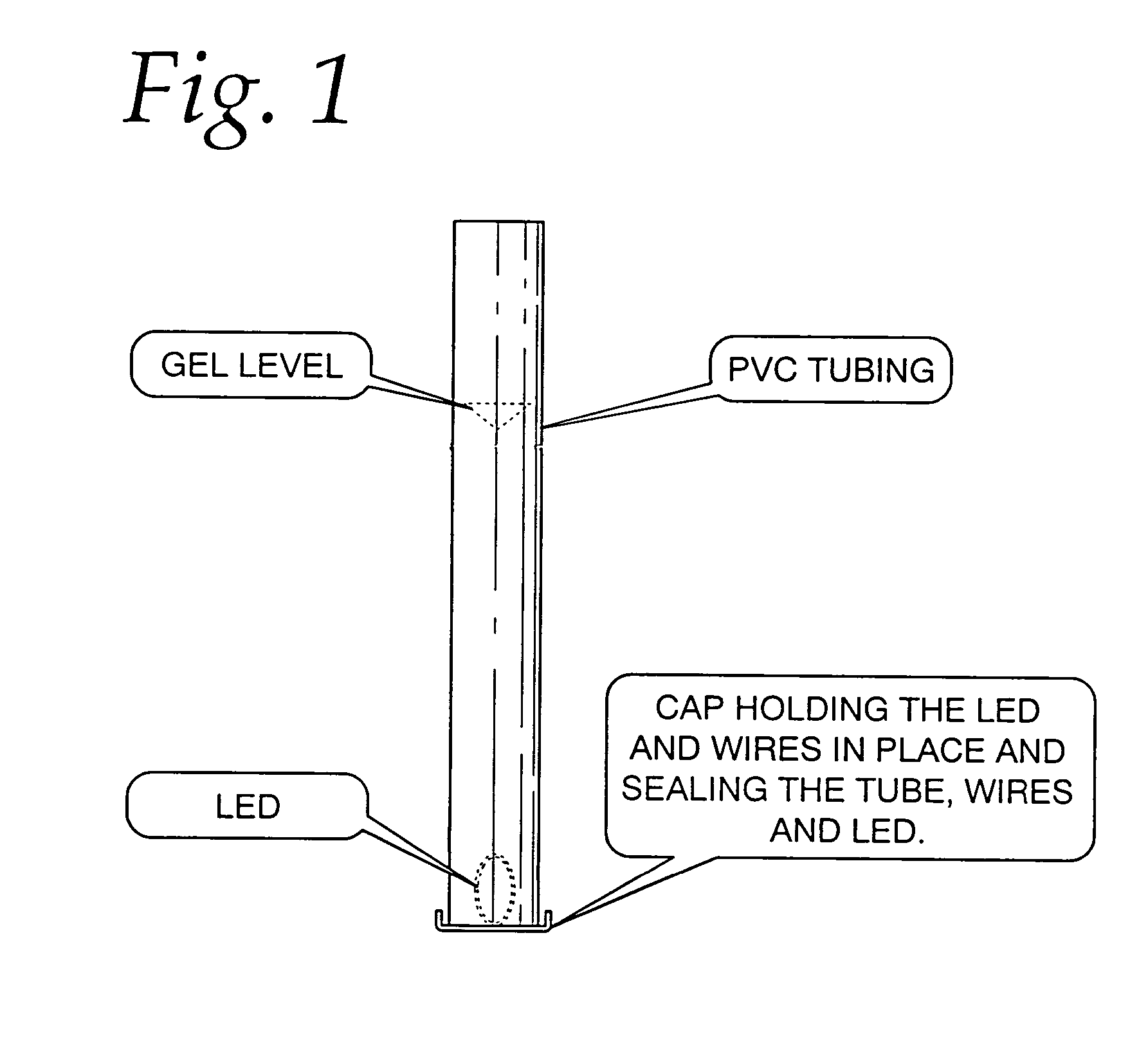

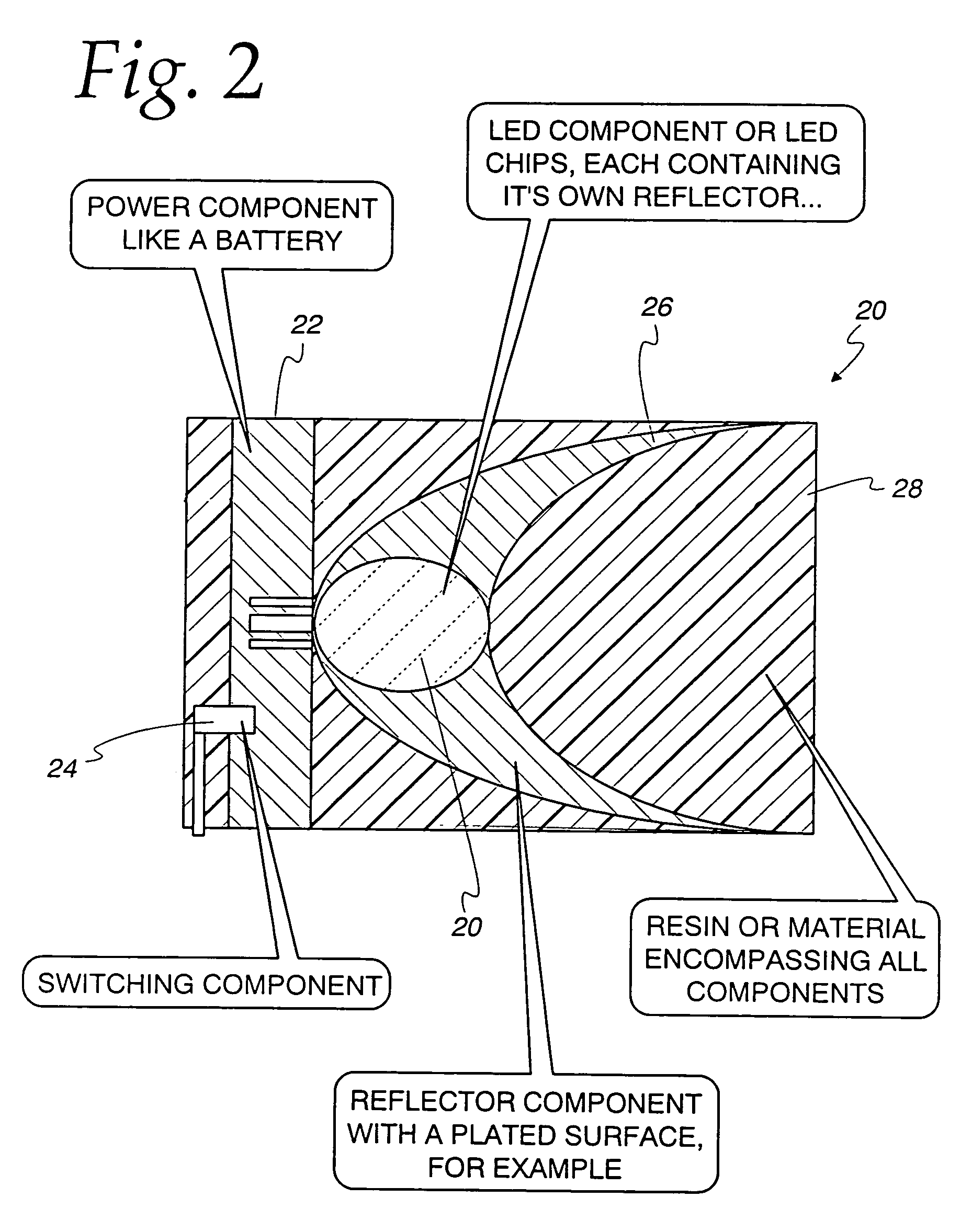

Light emitting medium and illumination system

Owner:ZARIAN JAMES ROUBEN +1

Flame-proof soft vinyl plastics for electric wire and cable

ActiveCN101245166AImprove flame retardant performanceMeet the use requirementsInsulated cablesInsulated conductorsPlasticizerPolyvinyl chloride

The invention relates to a piece of inflaming retarding soft polyvinyl chloride plastic used in electric wires and cables, which belongs to sheath and insulation materials used in electric wires and cables in industrial polymer materials and is composed of the raw materials with the following proportion by weight: 25 to 70 parts by weight of polyvinyl chloride resin 100 plasticizer; 5 to 40 parts by weight of co-polymerization resin, 3 to 12 parts by weight of stabilizing agent; 5 to 20 parts by weight of flame retardant I; 5 to 25 parts by weight of flame retardant II; 30 to 130 parts by weight of flame retardant III; 0 to 40 parts by weight of loading agent and 0.5 to 5 parts by weight of lubricant. The inflaming retarding soft polyvinyl chloride plastic used in electric wires and cables provided by the invention has very good inflaming retarding performance with the oxygen index as high as more than 46 and can meet the requirements of using the electric wires and cables with special inflaming retarding requirements as the sheath and insulation materials; the inflaming retarding soft polyvinyl chloride plastic not only has very good inflaming retarding performance but also has favorable low temperature resistant and embrittlement resistant performances and very good soft performance and processing performance.

Owner:CHANGSHU ZHONGLIAN PHOTOELECTRICITY NEW STUFF +1

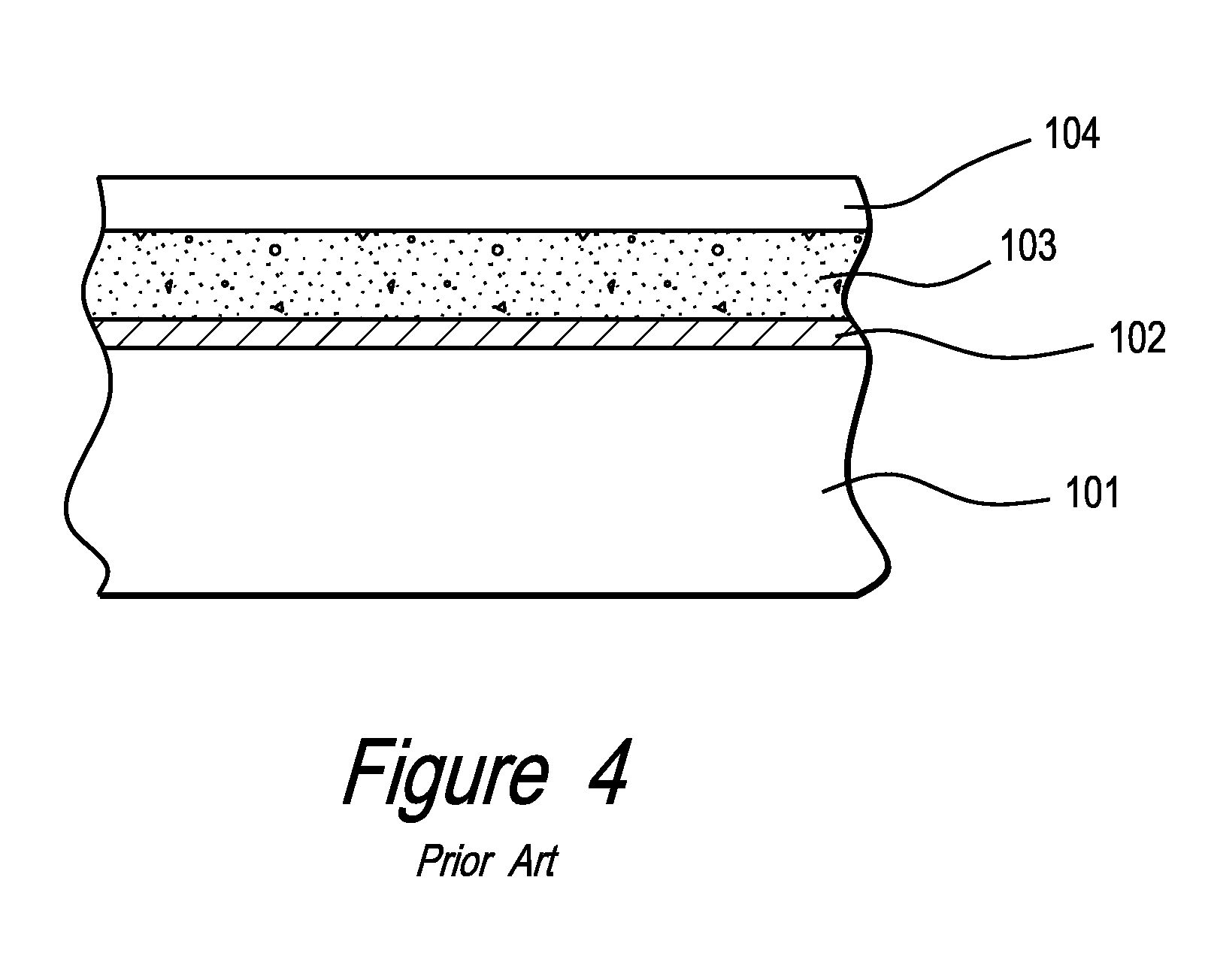

Environmentally friendly polylactide-based composite formulations

Polymeric materials and products, including sheet flooring materials prepared from the polymeric materials, and processes for preparing the polymeric materials, are disclosed. The polymeric materials include a polylactic acid-based polymer in combination with plasticizer and a compatibilizer, and optionally include a filler. The polymeric material can include between about 30 to about 50 percent by weight polyvinyl chloride, polyethylene glycol, polyglycolide, ethylene vinyl acetate, polycarbonate, polycaprolactone, polyhydroxyalkanoates, or polyolefins modified with polar groups, for example, ionomers. The plasticizer is typically an epoxidized vegetable oil or esterified and epoxidized vegetable oil and is typically present in an amount of between about 10 and about 50% by weight. In some embodiments, the compatibilizer is a polyolefin modified with one or more polar functional groups, and is typically present in an amount of between about 5 and about 10% by weight. The material can be used in decorative surface coverings, such as a floor coverings, particularly when it is in the form of a polymeric sheet. The polymeric material can be present in at least one layer of a floor covering, which floor covering can also include one or more additional layers such as wear layers, foamed or foamable layers, top coat layers and design layers. The additional layers can also include the polymeric material.

Owner:AFI LICENSING

Wear-resisting flame-retardant polyvinyl chloride insulation and sheathing materials

ActiveCN102719040AImprove wear resistanceExcellent squeeze performancePlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePlasticizer

The invention relates to insulation materials and sheathing materials, and in particular relates to a wear-resisting flame-retardant polyvinyl chloride insulation and sheathing material. The wear-resisting flame-retardant polyvinyl chloride insulation and sheathing material comprises the following raw materials in parts by weight: 100 parts of polyvinyl chloride resin, 40 to 60 parts of plasticizer, 6 to 30 parts of wearable modifying agent, 4 to 8 parts of stabilizing agent, 4 to 32 parts of fire retardant, 10 to 40 parts of filling agent, and 0.8 to 3 part(s) of lubricating agent. The insulating and sheathing material has good wear-resisting and flame-retardant properties, high squeezing performance, high rolling performance and high flexing performance, as well as high flexibility and processability.

Owner:SUZHOU SILVER AGE TECH CO LTD

Novel wood plastic composite decorative building material and manufacturing method thereof

InactiveCN101955614AImproved performance characteristicsGood environmental characteristicsAntioxidantPolyvinyl chloride

The invention relates to a novel wood plastic composite decorative building material and a manufacturing method thereof. The novel wood plastic composite decorative building material comprises the following components in part by weight: 100 parts of polyvinyl chloride (PVC) resin powder, 30 parts of mixture formed by mixing one or more of wood powder, bamboo powder, rice bran powder and crop straw powder in an arbitrary ratio, 30 parts of calcium powder, 5 to 10 parts of chlorinated polyethylene or MBS resin, 2 to 6 parts of rear earth compound stabilizer, 0.5 to 3 parts of polyethylene wax or oxidized polyethlene wax, 0.5 to 3 parts of stearic acid, 0.5 to 2.0 parts of foaming agent, 5 to 10 parts of blowing promoter, 0.5 to 1 part of antioxidant, 0.5 to 1 part of reinforcing agent, 1 to 3 parts of toner and 0.5 to 1 part of weather resistant agent. PVC plastic is modified by adding the auxiliaries, and the influence of unstable components (such as a vinyl chloride monomer, hydrogen chloride gas and the like) in the PVC on the performance of the building material is eliminated, so that the building material has better performance and environmental protection characteristics on the basis of keeping the original performance.

Owner:CHENGDU AOKINGTH TECH

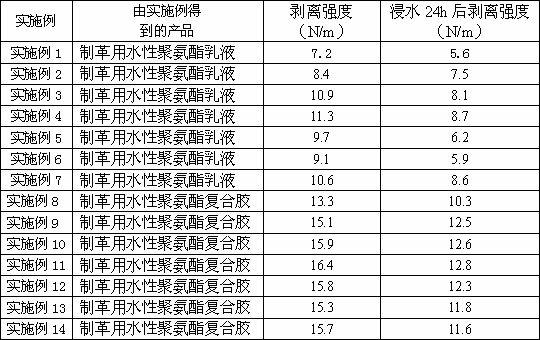

Water-based polyurethane composite adhesive for tanning and preparation method and application of composite adhesive

InactiveCN102618202ATroubleshoot MigrationOvercome the problem that the performance cannot fully meet the requirements of useNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolyol

The invention discloses water-based polyurethane composite adhesive for tanning and a preparation method and application of the composite adhesive, belongs to the technical field of water-based polyurethane composite adhesive preparation methods, and in particular relates to a method for preparing composite adhesive in the fields of artificial leather and synthetic leather. The method for preparing the water-based polyurethane composite adhesive for tanning is characterized by comprising the following steps of: reacting polyol polymer and isocyanate, adding chain extender, hydrophilic chain extender, cross linker, catalyst and solvent, reacting, cooling and emulsifying, to obtain emulsion; and mixing the emulsion, curing agent, wetting agent, tackifier, adsorbent and thickening agent uniformly, and thus obtaining the hot-melt adhesive for artificial leather adhesive layers. The water-based polyurethane composite adhesive for tanning is used for compounding polyvinyl chloride (PVC) / cloth for artificial leather of luggage and clothes. The prepared water-based polyurethane composite adhesive for tanning has high adhesive fastness and good water and solvent resistance, and can be applied to processes of knife coating, roll coating and the like of binding materials of middle layers of artificial leather and synthetic leather in the fields of textiles, leather processing and the like.

Owner:江阴市诺科生物新材料科技有限公司

PVC foaming wood plastic composite material

The invention discloses a PVC foaming wood plastic composite material which is produced by processing the raw materials based on the parts by weight: 100 parts of polyvinyl chloride (PVC), 40-50 parts of lignified plant fiber, 10-20 parts of active light calcium, 3-6 parts of calcium zinc complex stabilizer, 1-3 parts of compound-type foaming agent, 0.5-1.5 parts of lubricating agent OPE wax, 0.5-1 part of compound lubricating agent and 3-8 parts of foaming conditioning agent; the raw materials are evenly mixed by a mixing machine and then are directly put into a screw extruder to be extruded and molded at the temperature of 160-170 DEG C. The PVC foaming wood plastic composite material is added with full dose of heat stabilizer in the process of blending and processing, so that the degradation temperature of plastics can be increased, thermal degradation of the plastics and carbonization of wood powder in the process of mixing and forming can be prevented, and the operation of extruding and molding can be completed in one step, thus greatly simplifying the production technique and reducing the production cost.

Owner:石河子市森力新材料科技有限公司

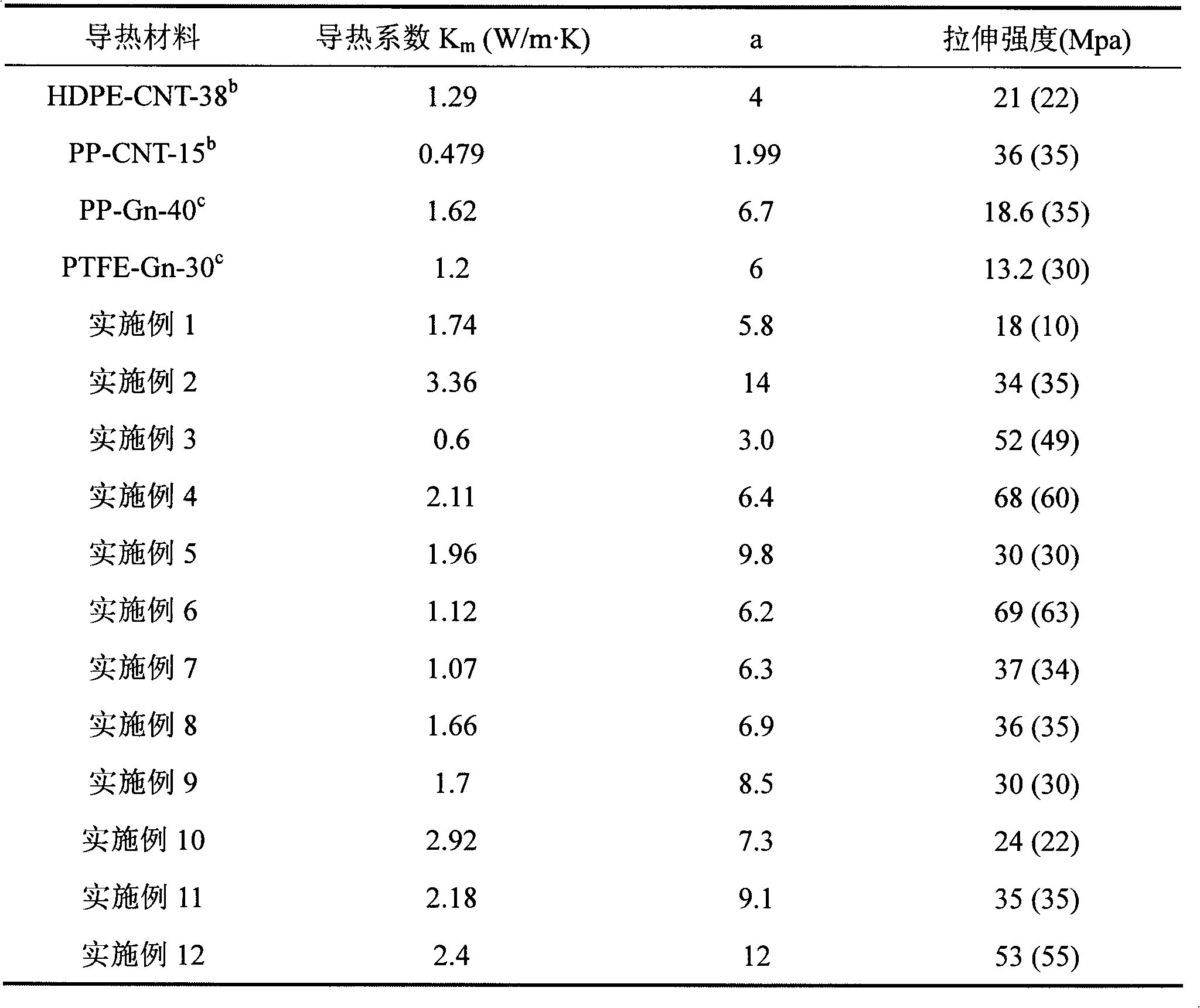

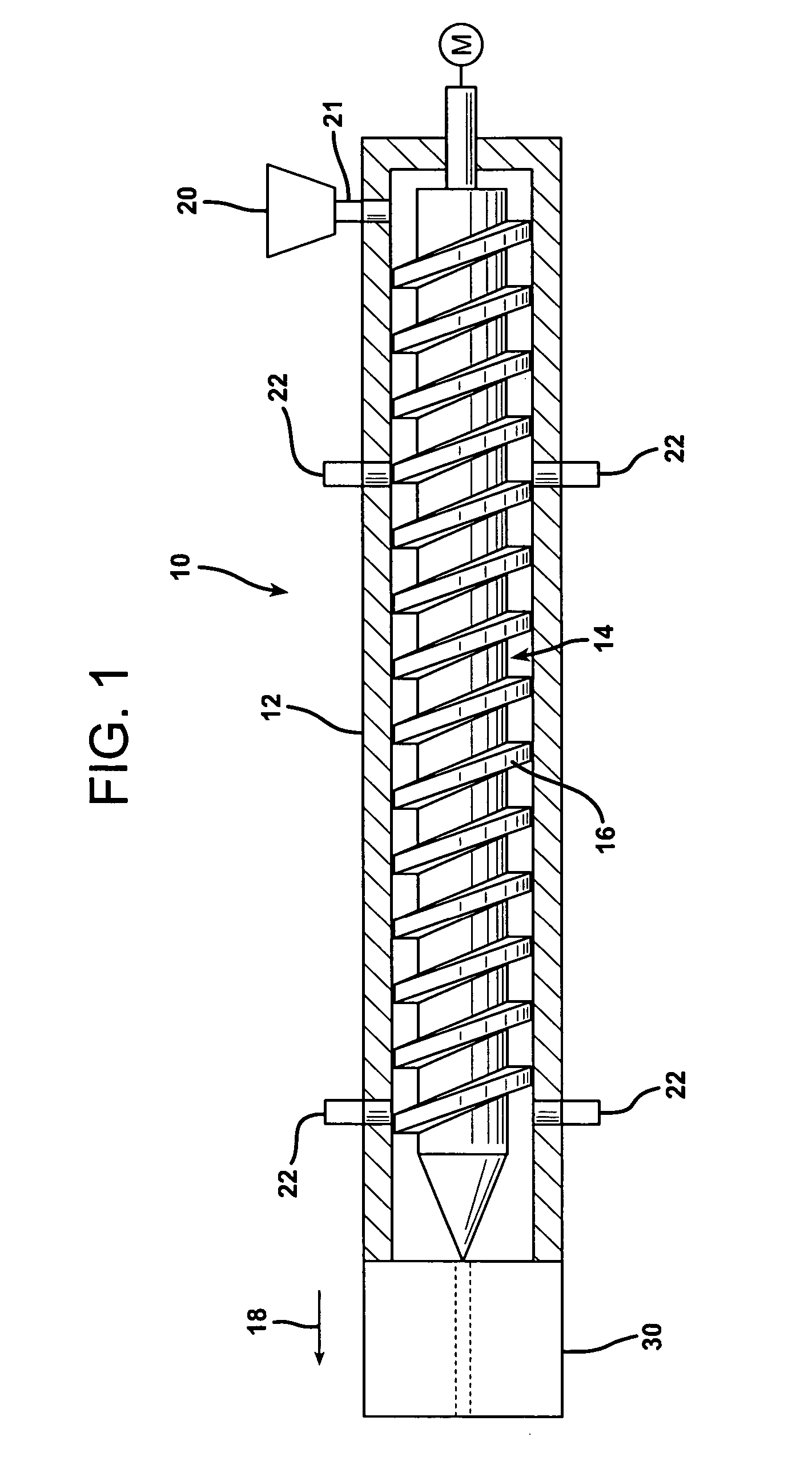

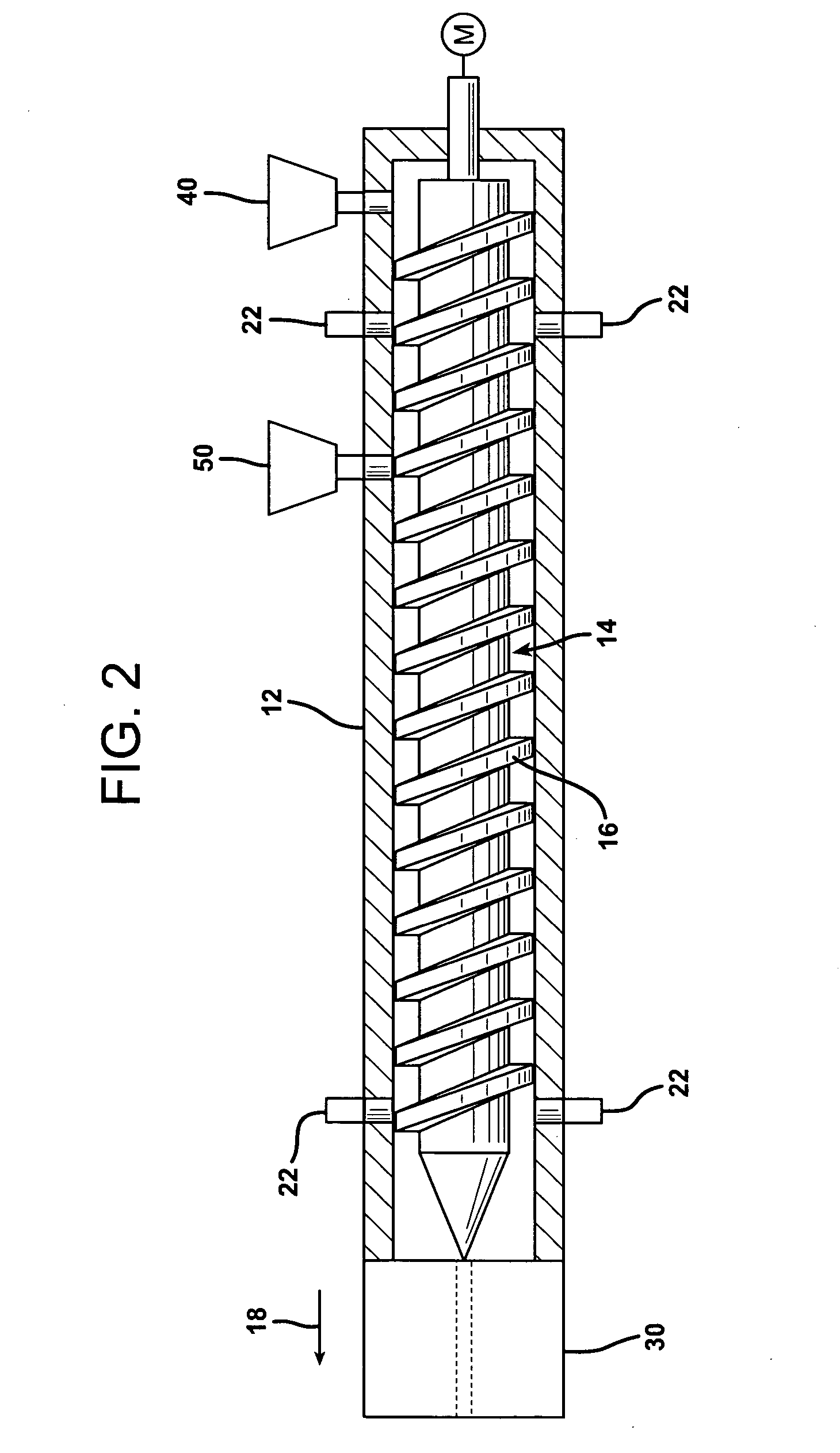

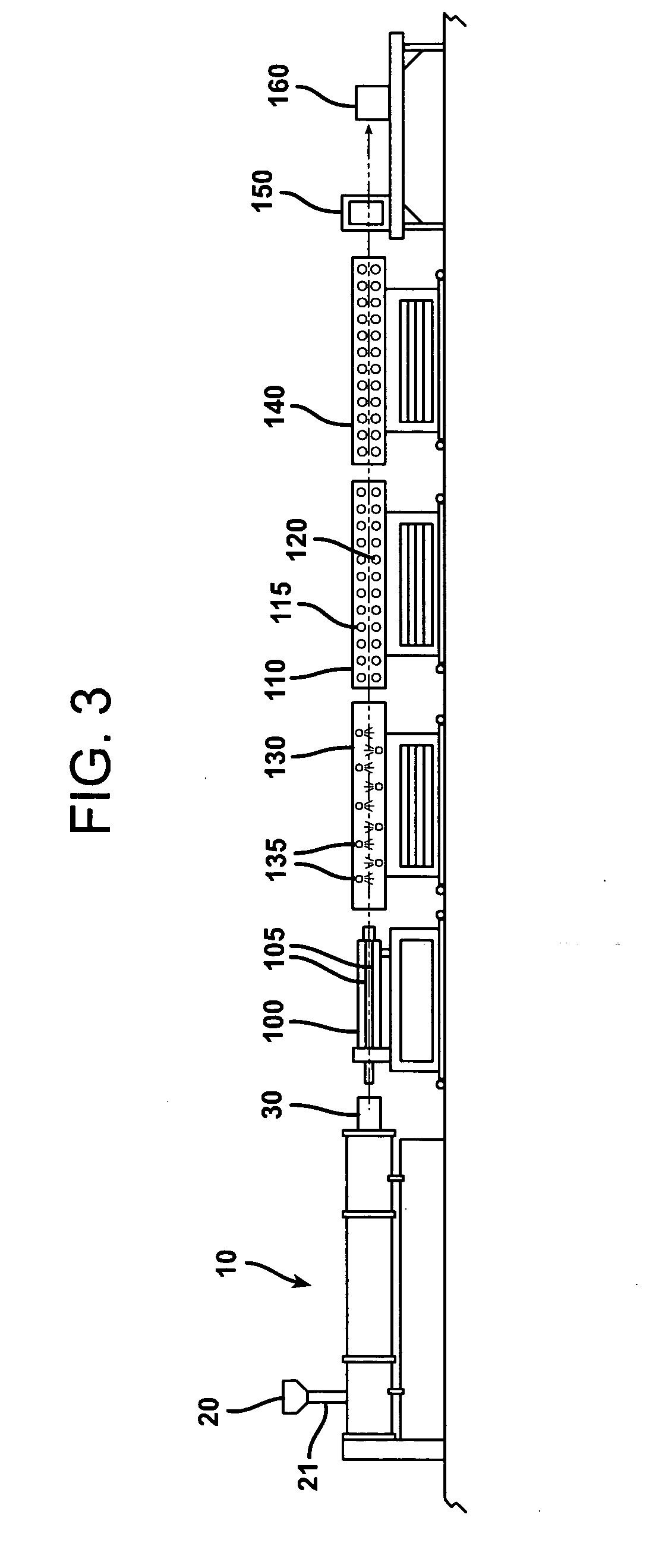

High-heat-conductivity composite material and preparation method thereof

InactiveCN102040761AImprove thermal conductivitySmall amount of thermally conductive fillerFiberCarbon fibers

The invention discloses a high-heat-conductivity composite material and a preparation method thereof. The preparation method comprises the following steps: evenly mixing fibrous heat-conduction filler and high-heat-conductivity filler graphene in a mass ratio of 1:1-1:200 with thermoplastic polymer, dispersing for 0.5-24 hours, granulating to obtain high-heat-conductivity composite grains, and putting the grains in a die to carry out hot molding at 170-280 DEG C under the pressure of 10-18 MPa. The thermoplastic polymer is any one of polyethylene, polypropylene, polyvinylidene fluoride, polytetrafluoroethylene, polyperfluoroalkoxy ester, nylon, polymethyl methacrylate, polycarbonate and polyvinyl chloride. The fibrous heat-conduction filler is carbon fiber or carbon nanotube, and the high-heat-conductivity filler accounts for 5-35 wt% of the high-heat-conductivity composite material. The high-heat-conductivity composite material has the advantages of excellent heat-conduction property, low consumption of heat-conduction filler, favorable mechanical properties, simple preparation technique and low cost.

Owner:SOUTH CHINA UNIV OF TECH

Foamed reinforced composite siding product

A composition for forming a reinforced composite siding product and a composite siding product formed by an extrusion process utilizing the composition is provided. The mixed resin formulation utilized to form the composite siding product includes a polymeric resin, a filler, a processing aid, at least one lubricant, and a thermal stabilizer. In a preferred embodiment, the polymer resin is polyvinyl chloride and the filler is talc. The mixed resin formulation may be extruded with a reinforcement material in a screw extrusion process to form a composite siding product. One or more reinforcing fibers may be utilized in the extrusion process. The reinforcement fibers may be present in the final product in an amount up to 25% by weight of the final product. In at least one preferred embodiment, the reinforcement fibers are glass fibers. A weatherable cap may be co-extruded to form the final reinforced, foamed composite siding product.

Owner:CERTAINTEED CORP

Wear-resistant wood plastic floor and its production technology

The present invention is wear-resistant wood-plastic floor board and its production process, and belongs to the field of decoration material technology. Polyvinyl chloride resin or plastic material is added with waste wood powder or fiber material powder, active calcium carbonate, assistant, stuffer, etc, and the mixture is pelletized, and further treated through extruding, molding, vacuum cooling, settling, drawing and cutting to form the basic wood-plastic board. The basic wood-plastic board is polished, groove milled and covered with surface decoration layer to form the wear resistant wood-plastic floor board product. The wear resistant wood-plastic floor board is beautiful, wear resistant, fireproof, waterproof, non-skid, anticorrosive and environment friendly and has high strength, heat insulation, electrical insulation and other advantages.

Owner:无锡市中德装饰新材料有限公司

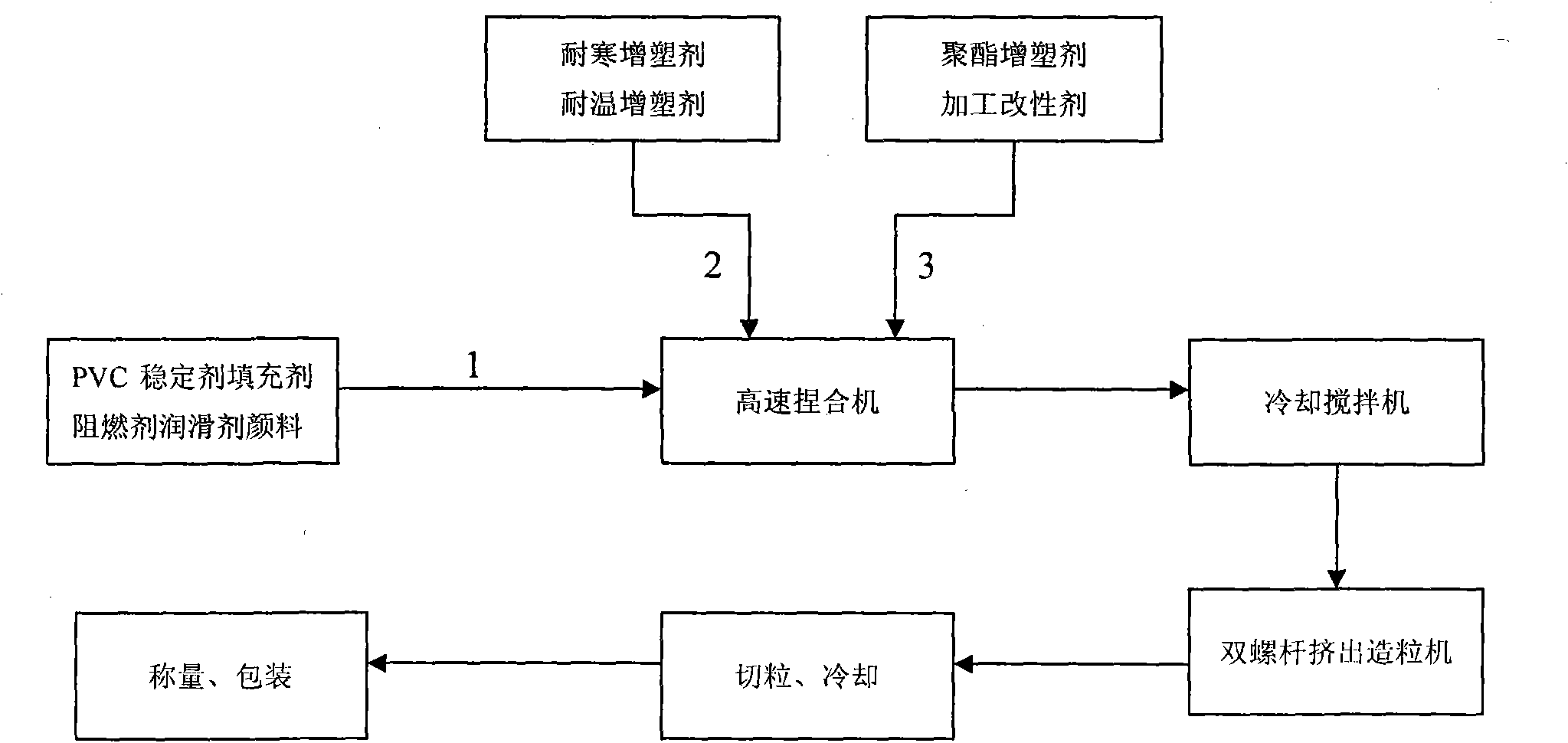

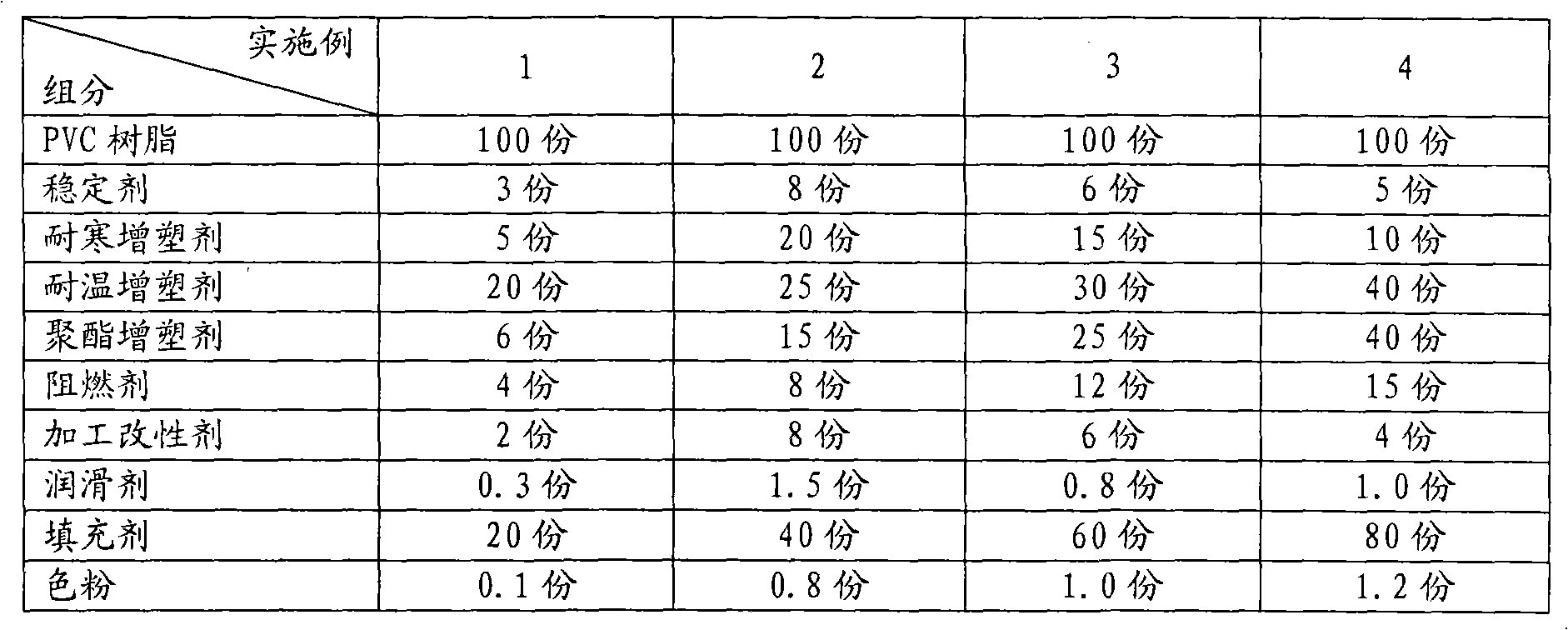

Cold-resistant temperature-resistant flame-retardant surface migration-resistant polrvinyl chloride insulating material

InactiveCN101967250AWon't breakNo migrationPlastic/resin/waxes insulatorsPolyesterEnvironmental resistance

The invention discloses a cold-resistant temperature-resistant flame-retardant surface migration-resistant polrvinyl chloride insulating material. The material comprises the following components in part by weight: 100 parts of polrvinyl chloride (PVC) resin, 5 to 20 parts of cold-resistant plasticizer, 20 to 40 parts of temperature-resistant plasticizer, 6 to 40 parts of polyester polymer plasticizer, 3 to 8 parts of environmentally-friendly heat stabilizer, 20 to 80 parts of filler, 4 to 15 parts of fire retardant, 2 to 8 parts of processing modifier, 0.3 to 1.5 parts of lubricant and 0.1 to 1.2 p[arts of toner. The polrvinyl chloride composite material of the invention has the comprehensive performance, such as low temperature embrittlement resistance, low temperature compact resistance, high temperature aging resistance, fire resistance, surface migration resistance and the like.

Owner:王长明

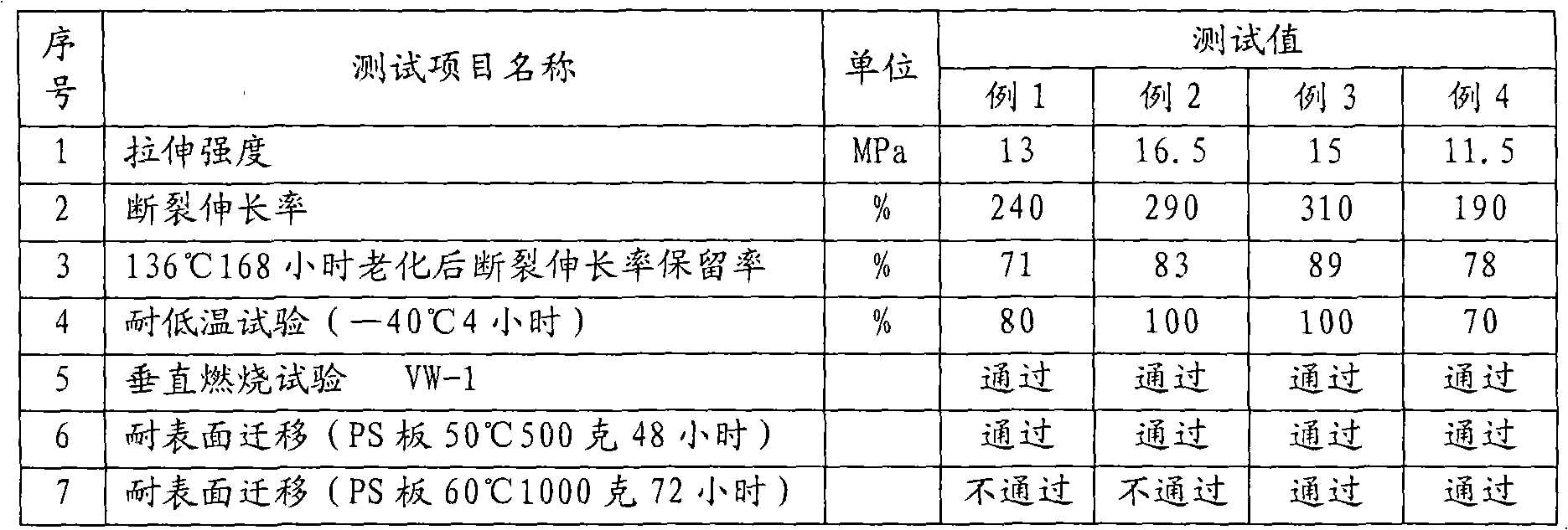

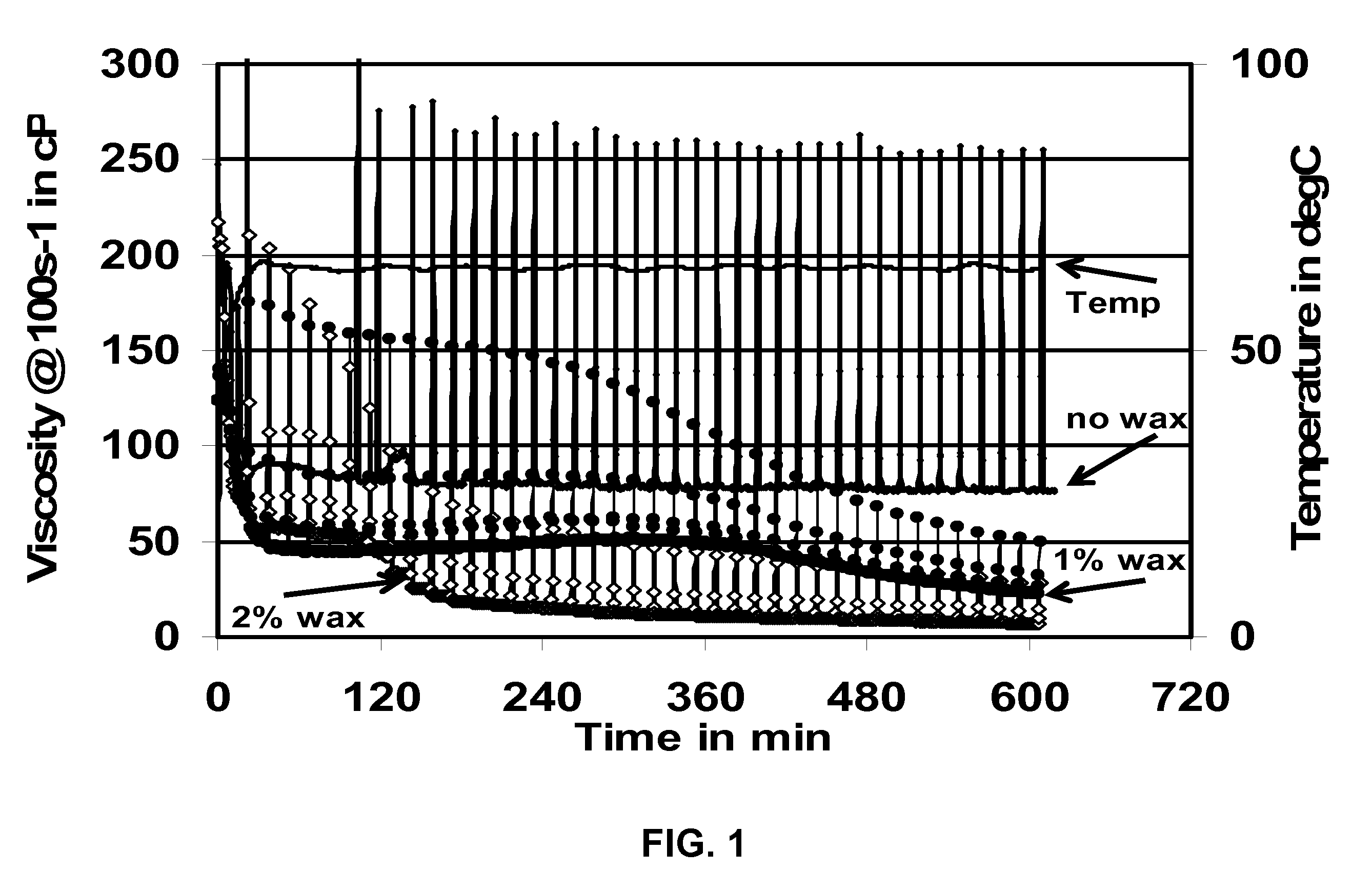

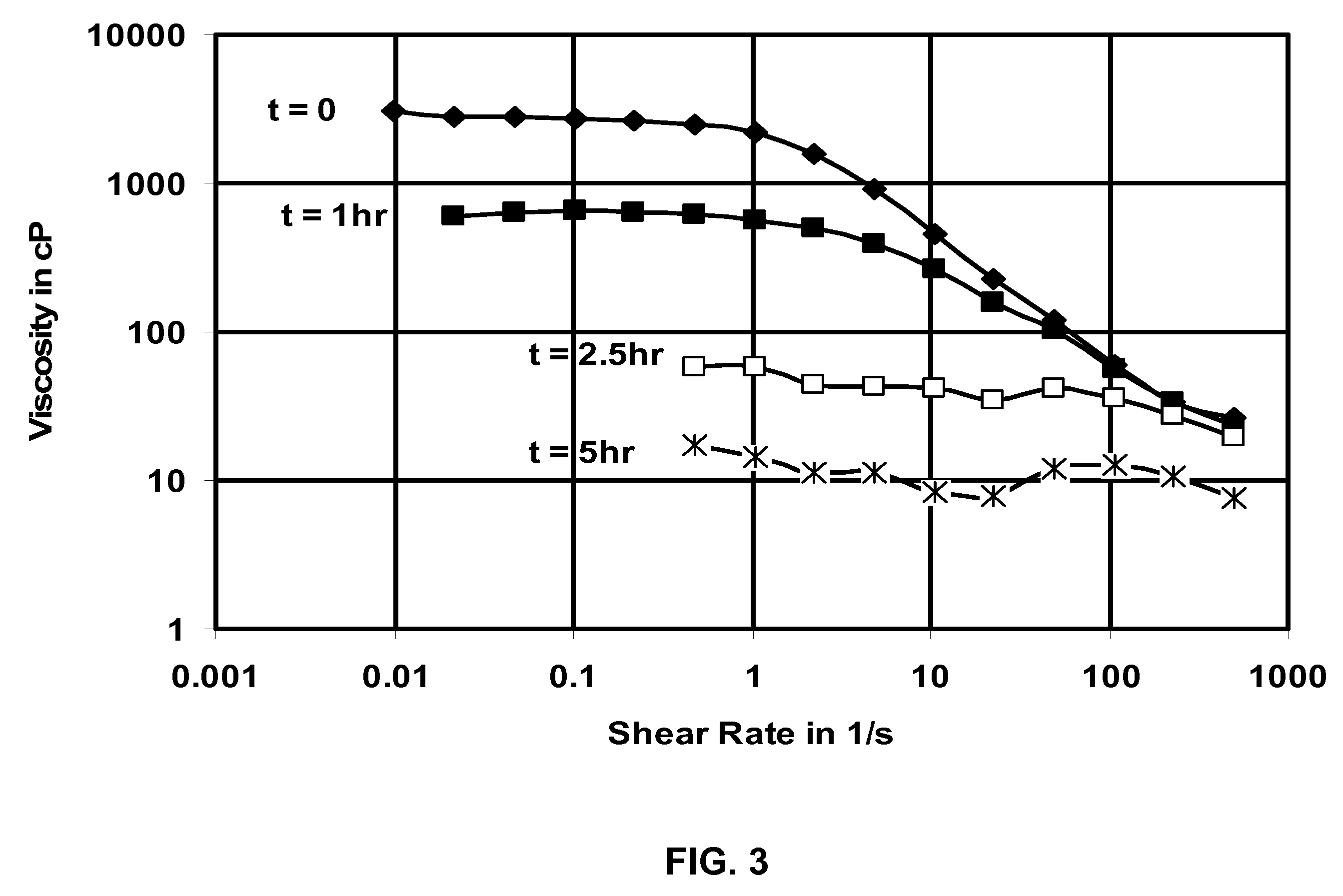

Internal Breaker for Oilfield Treatments

A composition and method for improving the fluid efficiency of many oilfield treatments is given. The composition is a solid additive, in a viscosified fluid, in a size range small enough that it enters formation pores; it optionally bridges there to form an internal filter cake, and then decomposes to provide a breaker for the viscosifying system for the fluid. Examples of suitable additives include waxes, polyesters, polycarbonates, polyacetals, polymelamines, polyvinyl chlorides, and polyvinyl acetates. Degradation of the additive may be accelerated or delayed.

Owner:SCHLUMBERGER TECH CORP

Composite thermotropic phase separation film-making method

The invention relates to a composite thermotropic phase isolated membrane preparation method which is characterized in that used composite diluent is the mixture of water-soluble good solvent and water-soluble additive of polymers. The membrane forming separation is a composite process which mainly takes the thermotropic membrane phase separation as the dominant role and non-solvent induced phaseseparation as the subsidiary role. The membrane prepared through the method has the advantages of high abruption strength, high abruption elongation and high water flux. The method is applicable to the preparation of membranes which are made of a plurality of polymers, including polyvinylidene fluoride, polysulfone, polyether sulfone, polyvinyl chloride and polyacrylonitrile. The performances of the membranes are improved greatly. Thus, the membranes can be widely applied to the fields of drinking water advanced treatment, pretreatment before reverse permeation, membrane bioreactor wastewatertreatment, reclaimed water reuse, etc.

Owner:湖南坎普尔环保技术有限公司

Explosion prevention PVC sheath material for mine cable and preparation method thereof

InactiveCN101159174AImprove antistatic performanceImprove flame retardant performancePlastic/resin/waxes insulatorsOther chemical processesPlasticizerPolyvinyl chloride

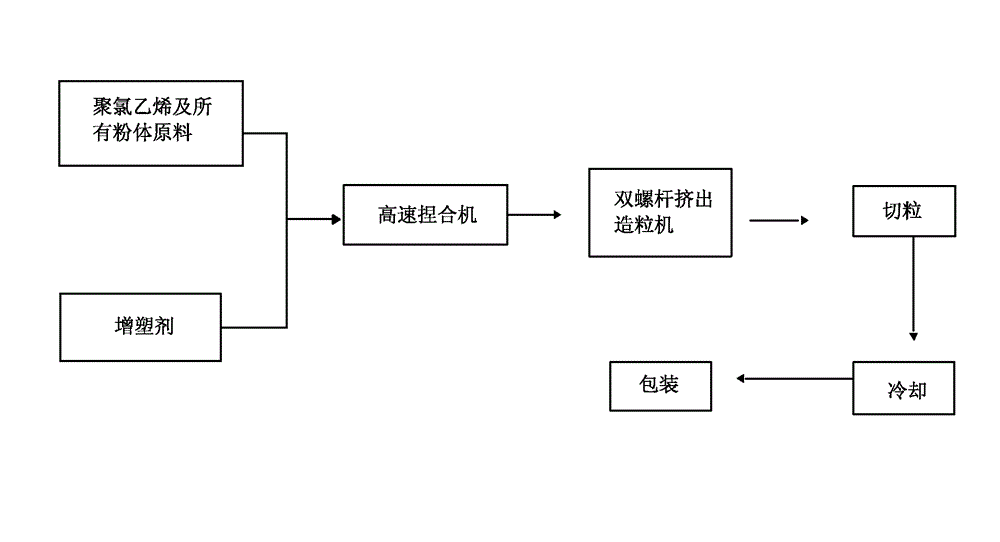

The invention relates to an anti-explosion polyvinyl chloride sheath material for mining cables and a preparation method thereof. The preparation method comprises mixing evenly polyvinyl chloride resin 100 parts by weight, plasticizer 30-80 parts by weight, stuffing 0-60 parts by weight, high-conductivity carbon black 10-40 parts by weight, anti-static agent 0-10 parts by weight, and other auxiliary agent 3-20 parts by weight by a high-speed mixer, extruding at 130-170 DEG C by a single- or double-screw extruder after being melted, water-cooling drawing bar or wind-cooling die-surface hot cutting and granulating, oven-drying, and packaging to obtain the finished product. Compared with the prior art, the invention has the advantages of excellent durable anti-static property and flame retardant property.

Owner:SURREY HI TECH INC

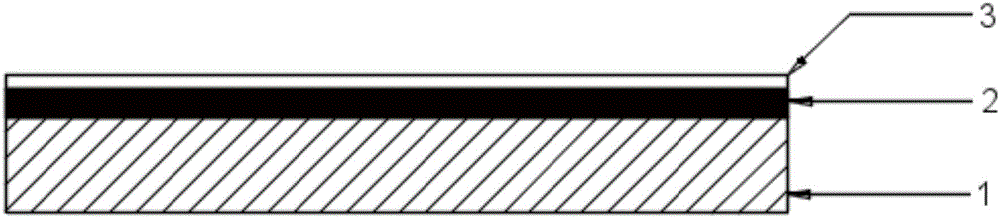

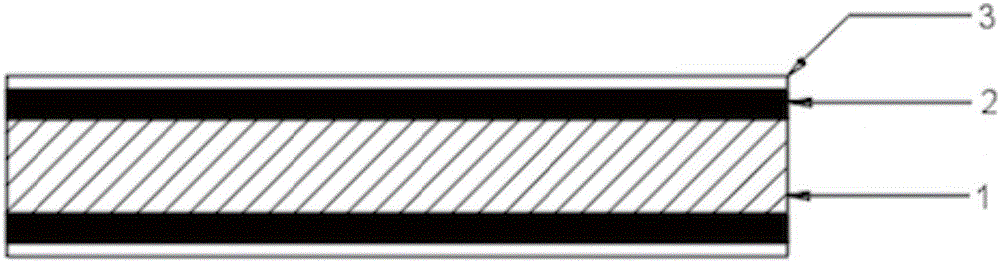

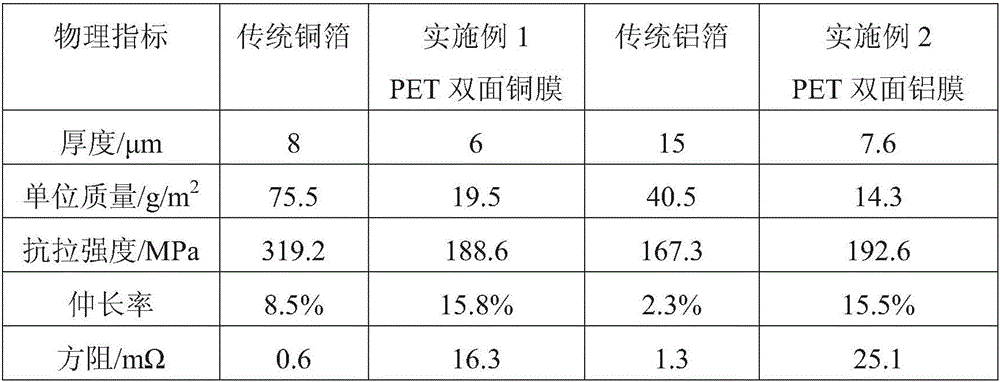

Flexible current collector for lithium battery and preparation method thereof

ActiveCN106654285AEnhanced machinabilityLow mass densityElectrode carriers/collectorsFiberPolyethylene terephthalate glycol

The invention discloses a flexible current collector for a lithium battery and a preparation method thereof. The flexible current collector comprises a flexible substrate layer, a metal conductive plated layer and a conductive anti-oxidization layer which are combined tightly in sequence, wherein the flexible substrate layer is one of polyvinyl chloride, polyethylene, polypropylene, polystyrene, polyethylene terephthalate, polydimethylsiloxane and polyimide; the thickness of the flexible substrate layer is 1-20 microns; the metal conductive plated layer is one of Cu, Al, Ni, Au and Ag and the thickness of the metal conductive plated layer is 0.1-5 microns; and the conductive anti-oxidization layer is at least one of conductive graphite, graphene, carbon nanotubes and carbon nano-fibers, and the thickness of the conductive anti-oxidization layer is more than 0 and smaller than 1 micron. The flexible current collector disclosed by the invention has high machinability and relatively high thermal stability and anti-oxidization energy; and the quality density of a whole body is small.

Owner:ZHEJIANG UNIV

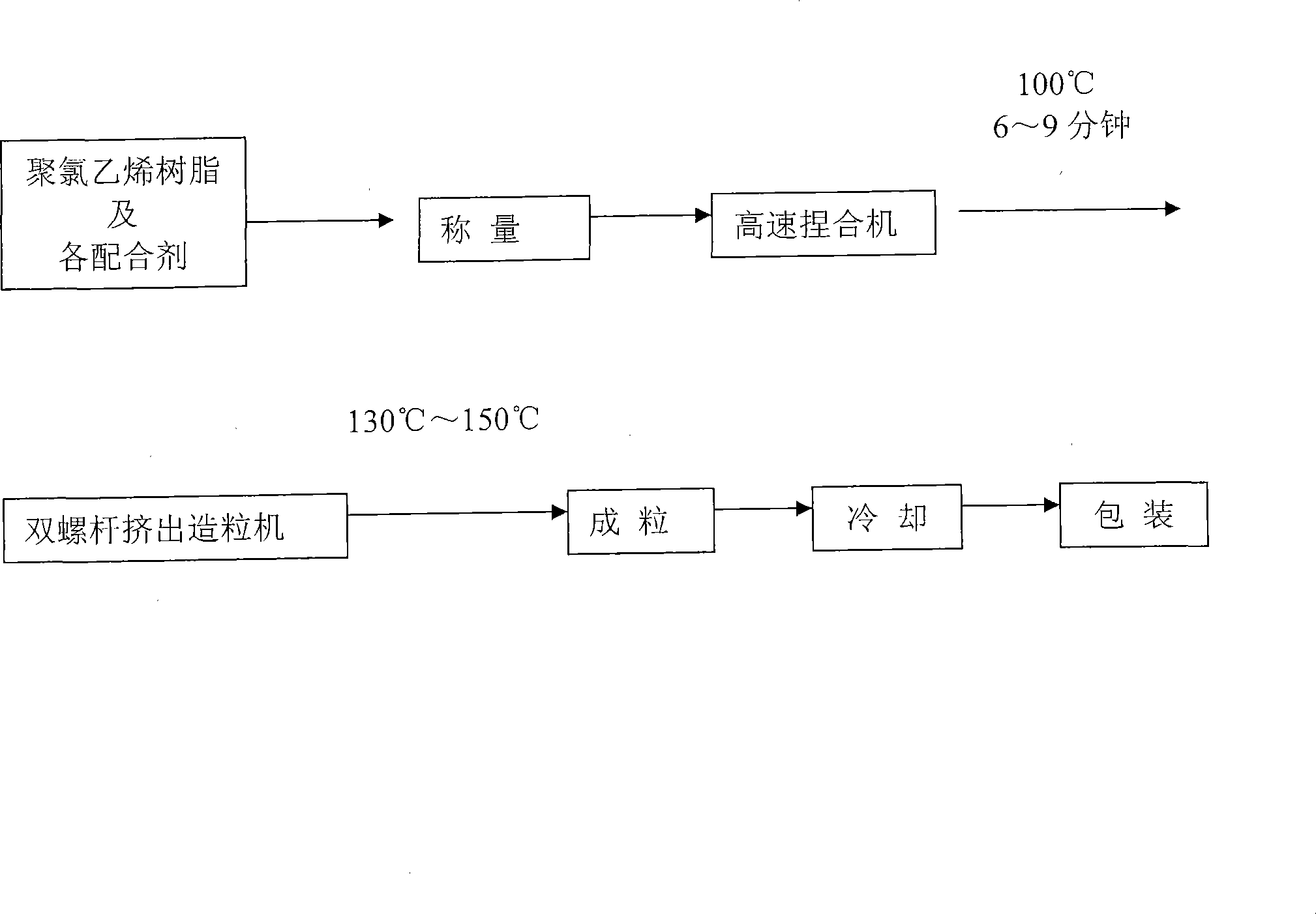

High-temperature resistant thermoplastic polyvinyl chloride cable material and preparation method thereof

ActiveCN103524946AGood physical propertiesHigh strengthInsulated cablesInsulated conductorsProcedure AgentsPolyvinyl chloride

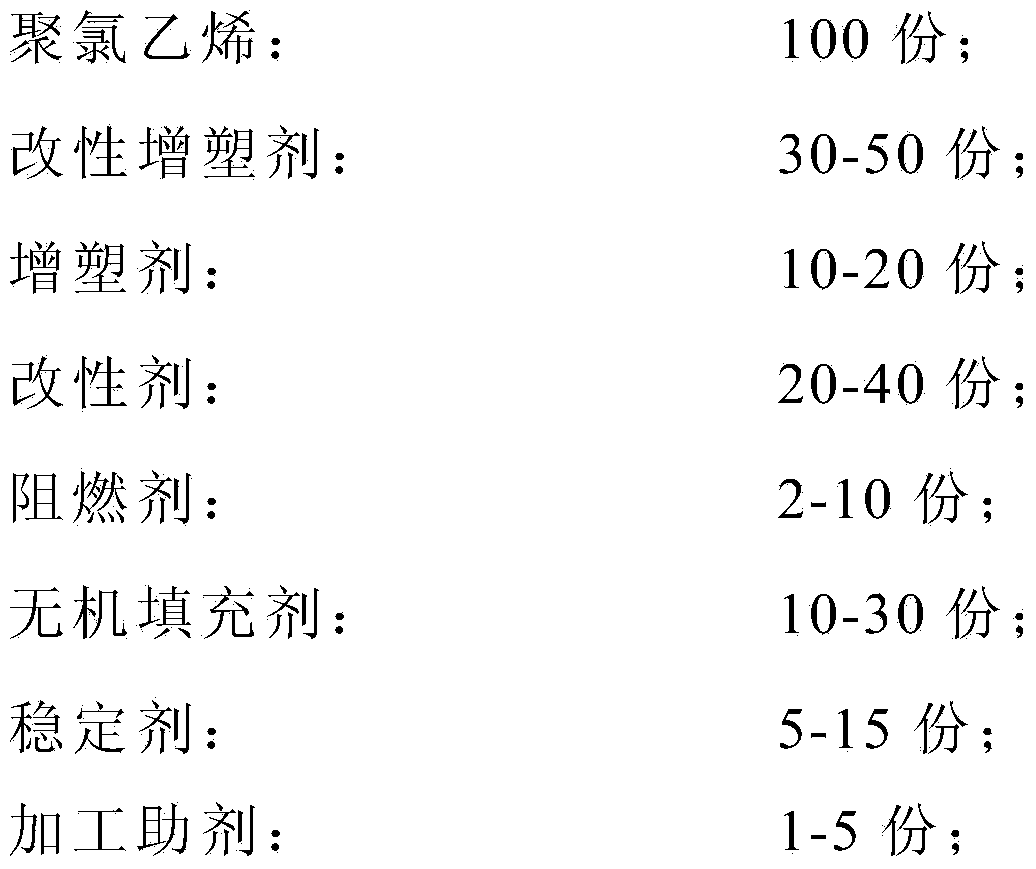

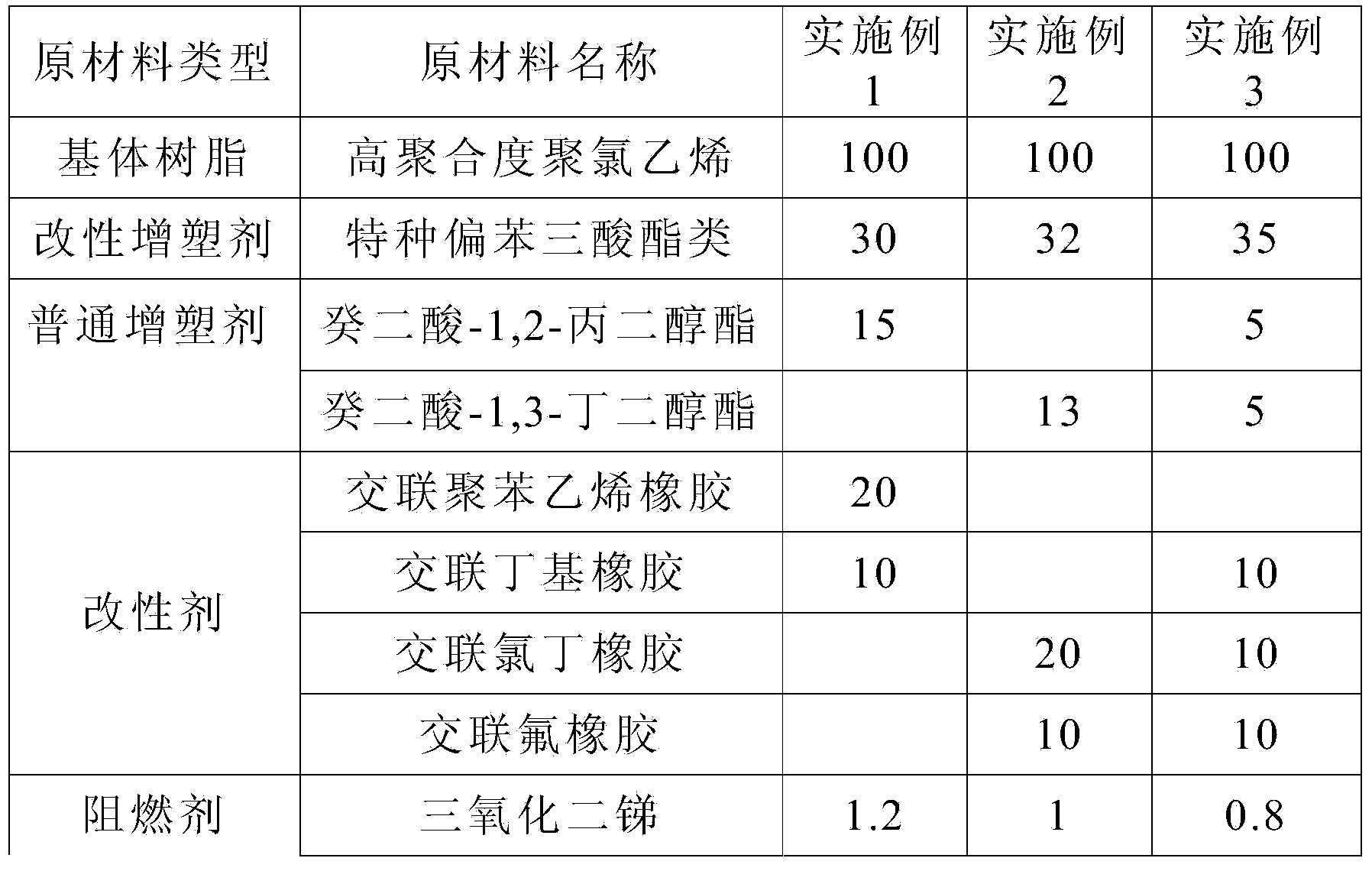

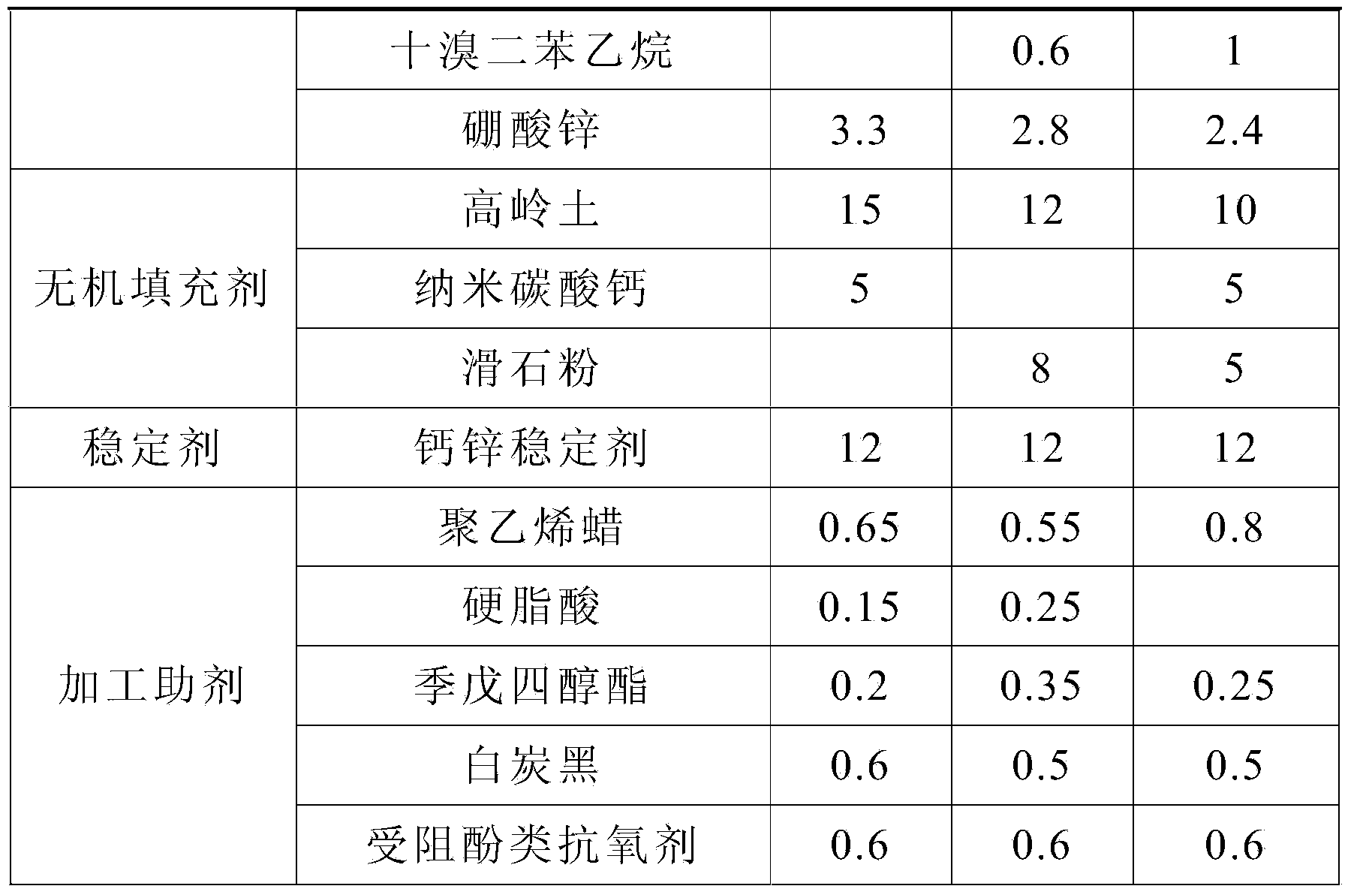

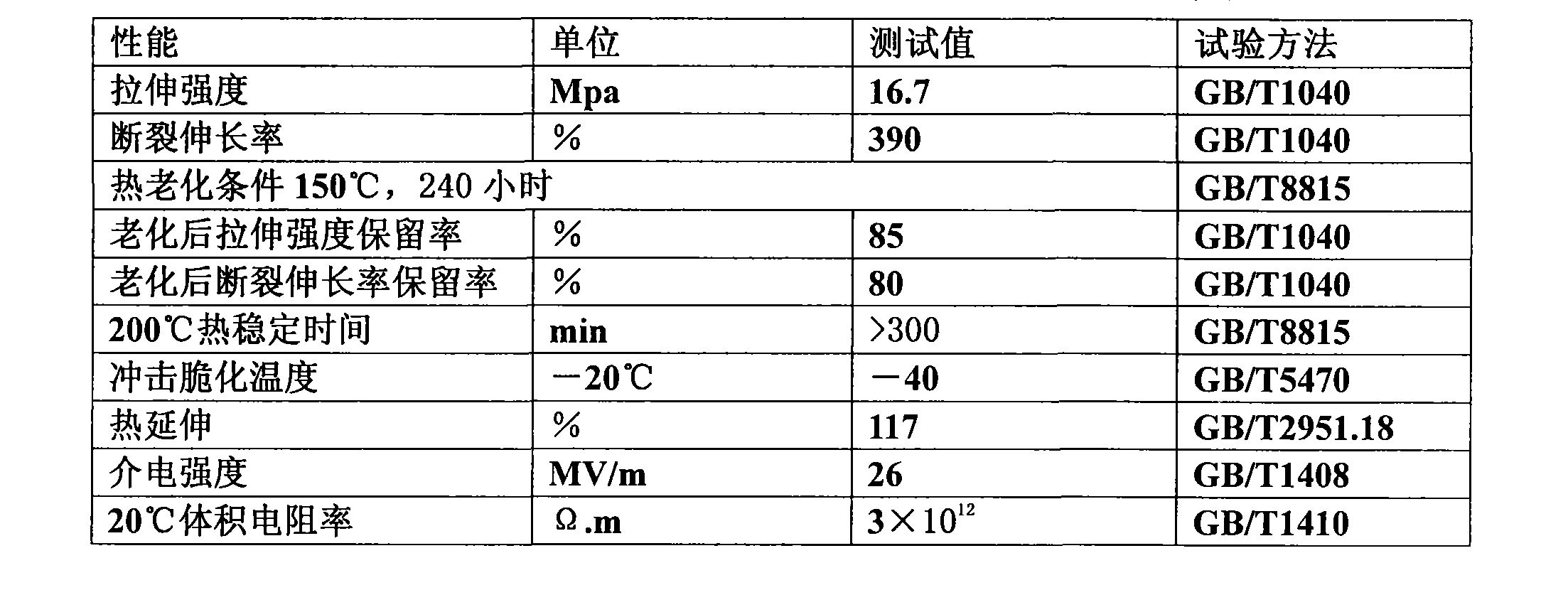

The invention relates to a high-temperature resistant thermoplastic polyvinyl chloride cable material, belonging to the technical field of new materials. The cable material consists of the following components in parts by weight: 100 parts of polyvinyl chloride, 30-50 parts of modified plasticizer, 10-20 parts of plasticizer, 20-40 parts of modifier, 2-10 parts of flame retardant, 10-30 parts of inorganic filler, 5-15 parts of stabilizer and 1-5 parts of processing aid. A preparation method of the cable material comprises the following steps: weighing the raw materials according to the components and weight parts of the cable material; uniformly mixing the polyvinyl chloride and adding the modified plasticizer and the common plasticizer; heating and stirring and adding other raw materials; discharging from a high mixing machine and feeding into a twin-screw extruder for extrusion and granulation; and performing air cooling to obtain the final product. The cable material has the advantages that the physical property is good, the applicable temperature range is wide, little pollution is caused, the flame retardance is good, the smoke output in combustion is low, the preparation method is simple, and the cost is low.

Owner:江西一舟数据技术有限公司

Electric wire and cable soft polychloroethylene plastics for vehicle and preparation method thereof

ActiveCN101386697AHigh tensile strengthImprove wear resistancePlastic/resin/waxes insulatorsPlastic materialsAntioxidant

The invention relates to a cord-cable polyvinyl chloride (PVC) plastic for an automobile, which is formed by chemical crosslinking and mainly comprises PVC, a plasticizing agent, a heat stabilizer, a lubricating agent, an antioxidant, stuffing, a crosslinking agent, an evocating agent, a crosslinking assistant agent and an abrasion resistance modifier. The polymer crosslinking plastic material has the advantages of good abrasion resistance, excellent mechanical property, good high temperature resistance (the heat resistant grade can reach 120 DEG C and the low temperature can reach 40 DEG C below zero), over 70 percent of tensile strength and elongation at break under the ageing condition at 150 DEG C for 168 hours, little weight loss and simple processing technique.

Owner:CHINA PETROLEUM & CHEM CORP

Method for preparing high filling polyvinyl chloride or polyolefin composite material by employing industrial solid wastes

The invention discloses a method for preparing a high filling polyvinyl chloride or polyolefin composite material by employing industrial solid wastes and belongs to the field of chemical materials. According to the method, the industrial solid wastes and polyvinyl chloride or polyolefin serve as main raw materials, the industrial solid wastes are subjected to surface modification, the compatibility between the industrial solid wastes and the polyvinyl chloride or polyolefin is improved, the liquidity and processability of the composite material is improved by utilizing a compound plastifier, and the composite material is subjected to mixing and pelleting under the coaction of a proper amount of aids, so that the high filling polyvinyl chloride or polyolefin composite material is prepared. The method is simple in process, low in cost and high in additional value of products. The composite material has the characteristics of high filling amount of industrial solid wastes, enough strength and toughness, environment friendliness, stable performance and the like and can be widely applied to preparing green building materials and advanced engineering products in various fields of national economy.

Owner:TSINGHUA UNIV

Wood plastic composite material and its preparation method and application

A wood-plastics composition is prepared from used or waste plastics, wooden fibres for modifying plastics, and resin compatibilizer through fusing and proportionally mixing. Said resin compatibilizer is prepared from EVA, acrylic acid or acrylate and polyvinyl chloride through mixing. Its advantages are high strength toughness, and improved machinability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Reaction bonding type node sealant and preparation method thereof

ActiveCN102911638AImprove stabilityImprove bindingNon-macromolecular adhesive additivesOther chemical processesChemical LinkagePolyvinyl chloride

The invention provides a reaction bonding type node sealant and a preparation method thereof. The sealant comprises asphalt, modifiers, an emulsifier, a crosslinking agent, thickeners, a reinforcing agent and water. In the formula system, more appropriate modifiers are adopted compared with the prior art, so that a rubber asphalt mixture can achieve good emulsification effect, elasticity and strength of a sealing layer after drying are greatly improved, and the sealing effect can be good and lasting; the chemical linkage effect with concrete is formed by using the crosslinking agent, and bonding force with the concrete is improved; and a lot of thickeners are used for adjusting the stickness of the sealant system, so that the reaction bonding type node sealant can better adhere to the surface of a pentatricopeptide repeats (PPR) or polyvinyl chloride (PVC) pipe, and good sealing at positions where PPR or PVC water supply and drainage pipes are connected with base surfaces of concrete.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

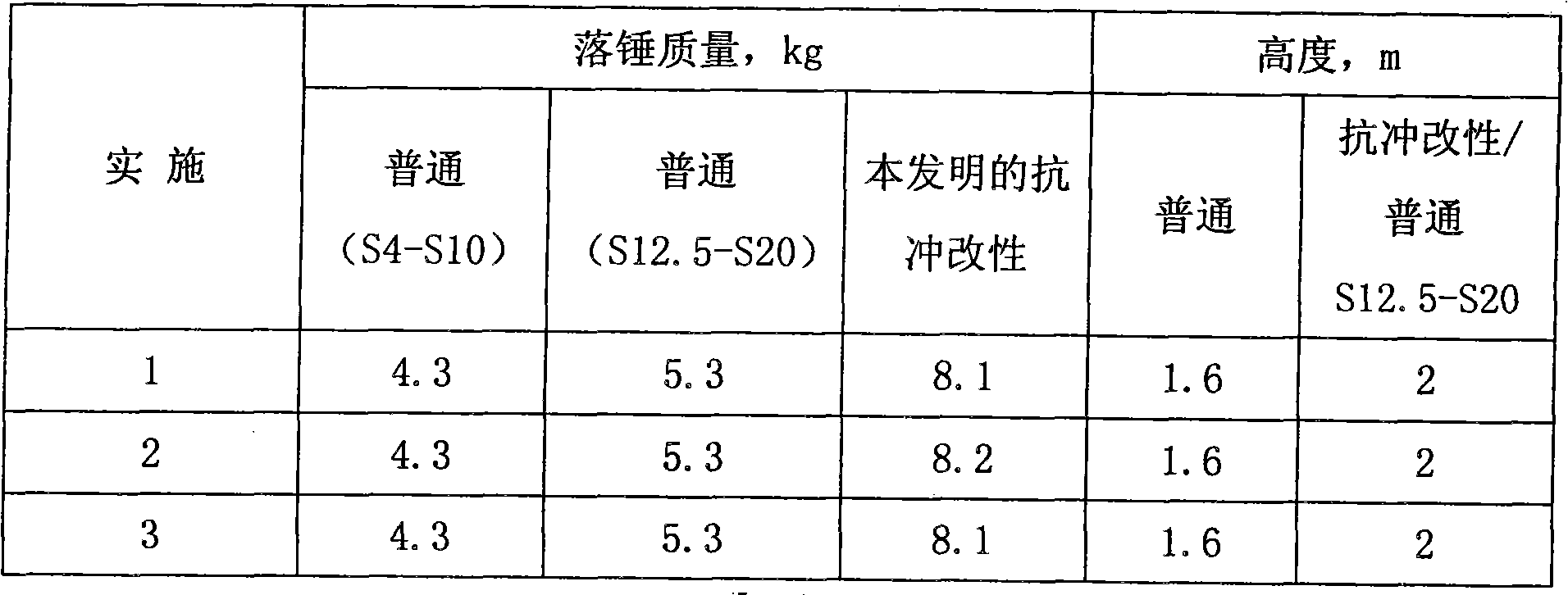

Impact-resistant modified polyvinyl chloride tube material and preparation process thereof

ActiveCN101775180AImprove mechanical propertiesCrack terminationRigid pipesAntioxidantPolyvinyl chloride

The invention discloses an impact-resistant modified polyvinyl chloride tube material, which is prepared from the following components in part by weight: 100 parts of polyvinyl chloride resin, 0.4 to 4.0 parts of stabilizing agent, 2 to 8 parts of toughening agent, 2 to 8 parts of rigid particles, 0.5 to 3.0 parts of processing aid, 1.1 to 2.5 parts of lubricant, 0.05 to 0.5 part of antioxidant, 0.03 to 3 parts of coloring agent and 0 to 5 parts of filling agent. A preparation process for the tube material comprises the following steps: mixing the components uniformly in a high-speed mixer, extruding the mixture to form the tube material by using a double-host single-screw extruder after the components are mixed uniformly in a cooling mixer, and modularizing, vacuuming and cooling-molding the tube material; and cutting and packing the tube material with fixed length. The impact-resistant modified polyvinyl chloride tube material uses a method of cooperative toughening of the toughening agent and the rigid particles, and solves the problem that the impact-resistant PVC tube material difficultly realizes rigidity balance so that the toughness of the tube material is obviously improved while the rigidity of the hard PVC tube material is kept.

Owner:山东华信塑胶股份有限公司

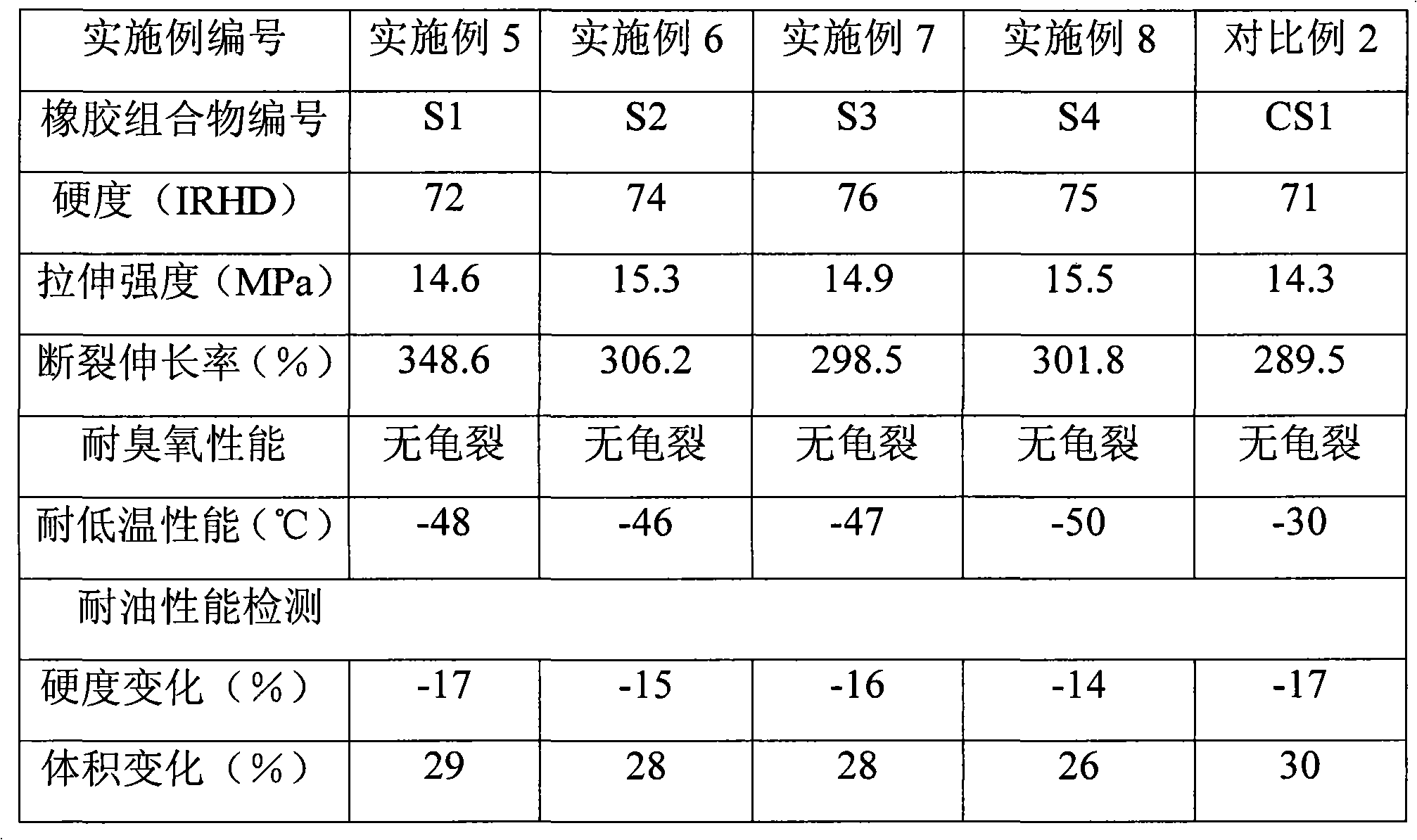

Oil resistant low temperature resistant rubber composition

InactiveCN101353451AGuaranteed oil resistanceGuaranteed ozone resistancePolymer scienceNitrile rubber

The invention relates to a rubber composite, comprising nitrile rubber, polyvinyl chloride, carbon soot, activator, vulcanizator, age inhibitor, antiscorcher, accelerant and plasticizer, wherein, the plasticizer is ethylhexyl sebacate and adipate. The rubber composite of the invention obviously improves the anti-low temperature performance of the rubber composite while ensuring the anti-oil performance, anti-ozone performance, tensile strength and elongation at break.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com