Water-based polyurethane composite adhesive for tanning and preparation method and application of composite adhesive

A water-based technology for water-based polyurethane and leather making, which is used in polyurea/polyurethane adhesives, chemical instruments and methods, adhesives, etc. Improve molecular weight and strength, good solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

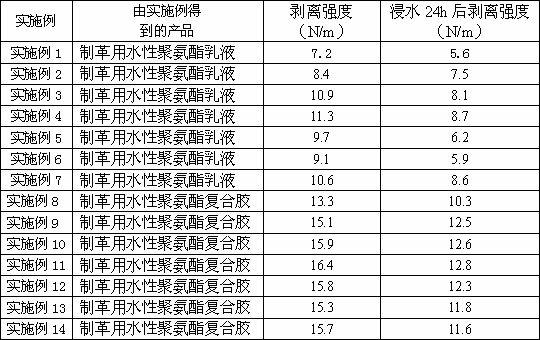

Examples

Embodiment 1

[0073] Example 1: Weigh 26.1 kg of toluene diisocyanate and 100 kg of poly(1,4-butylene adipate) diol with a molecular weight of 2000, add it to the reaction kettle, and react at a constant temperature of 85°C for 1 hour, then add dimethylol propionic acid 4 kg, react at a constant temperature of 90°C for 1 hour, finally add 5.4 kg of diethylene glycol, 0.45 kg of trimethylolpropane, 0.3 kg each of dibutyltin dilaurate and stannous octoate, 60 kg of acetone, and react at a constant temperature of 70°C for 2 Hours later, cool down to 50°C and discharge to obtain a prepolymer, pour the prepolymer into a high-speed shear disperser, pour 3 kg of triethylamine under the condition of 800 rpm, react for 1 minute, and then pour Add 1300 kg of water and stir for 2 minutes to obtain a white emulsion. Distill the obtained emulsion under the conditions of 25°C and -0.08Mpa under reduced pressure to remove the solvent acetone, and obtain a water-based polyurethane emulsion for tanning wi...

Embodiment 2

[0074] Example 2: Weigh 87 kg of toluene diisocyanate, 100 kg of poly(1,4-butylene adipate) diol with a molecular weight of 2000, add it to the reaction kettle, and react at a constant temperature of 60°C for 3 hours, then add dimethylol propionic acid for 15 1 kg, constant temperature reaction at 85°C for 1 hour, finally add 28 kg of diethylene glycol, 2.2 kg of trimethylolpropane, 0.12 kg of dibutyltin dilaurate, 0.12 kg of stannous octoate, 00 kg of acetone, 100 kg of methyl acetate After reacting at a constant temperature of 50°C for 5 hours, the temperature was lowered to 20°C and the material was discharged to obtain a prepolymer. The prepolymer was poured into a high-speed shear disperser, and 11 kg of triethylamine was poured under the condition of 800 rpm. React for 1 minute, then pour 240 kg of water into it, and stir for 2 minutes to obtain a white emulsion. Distill the obtained emulsion under the conditions of 25°C and -0.08Mpa under reduced pressure to remove th...

Embodiment 3

[0075] Example 3: Weigh 43.5 kg of toluene diisocyanate, 100 kg of poly(1,4-butylene adipate) diol with a molecular weight of 2000, add it to the reaction kettle, react at a constant temperature of 85°C for 2 hours, and then add dimethylol butyric acid 8 kg, 85°C constant temperature reaction for 1.5 hours, finally added 11 kg of diethylene glycol, 0.9 kg of trimethylolpropane, 0.25 kg each of dibutyltin dilaurate and stannous octoate, 100 kg of N-methylpyrrolidone, 60 After reacting at a constant temperature of ℃ for 4 hours, the temperature was lowered to 30 ℃ and the material was discharged to obtain a prepolymer. The prepolymer was poured into a high-speed shear disperser, and 6 kg of triethylamine was poured into it under the condition of 1000 rpm, and the reaction was 1 Minutes, then pour 380 kg of water and stir for 2 minutes to obtain a white emulsion, and obtain a water-based polyurethane emulsion for tanning with a solid content of about 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com