Wear-resistant and stain-resistant ultraviolet curing PVC (polyvinyl chloride) floor coating

An ultraviolet light and floor technology, which is used in polyurea/polyurethane coatings, coatings, chemical industries, etc., can solve the problems of easy migration of antifouling additives and reduced antifouling effect, and achieve good antifouling effect of coatings and reduce Curing shrinkage rate and effect of increasing crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of UV curing PVC floor coating, the preparation method is:

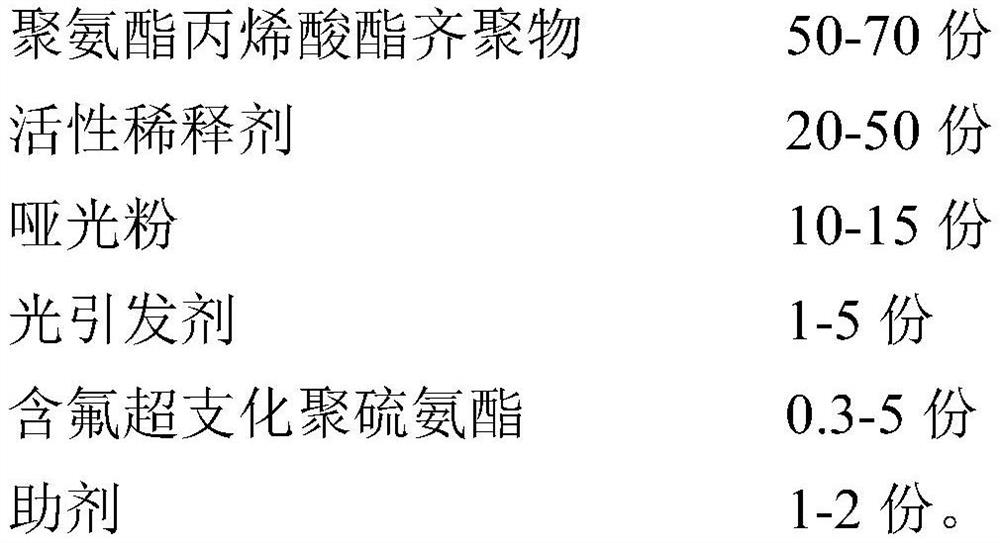

[0035] First, use 5 parts of reactive diluent HDDA, 20 parts of reactive diluent PETA, 0.5 parts of defoamer BYK-066, 0.5 parts of leveling agent BYK-306 and 1 part of wetting and dispersing agent BYK-2009 The high-speed disperser stirs for 10 minutes at the speed of 2000r / min to make the dispersion even.

[0036] Next, add 3 parts of fluorine-containing hyperbranched polythiourethane and 15 parts of matte powder E-1011 in batches, and stir for 30 minutes at a speed of 3500 r / min.

[0037] Finally, add 20 parts of difunctional aliphatic urethane acrylate, 30 parts of hexafunctional aliphatic urethane acrylate, and 5 parts of photoinitiator 1173, and stir evenly at a speed of 2500r / min to obtain a UV-curable PVC floor coating .

[0038] The preparation method of described fluorine-containing hyperbranched polythiourethane is:

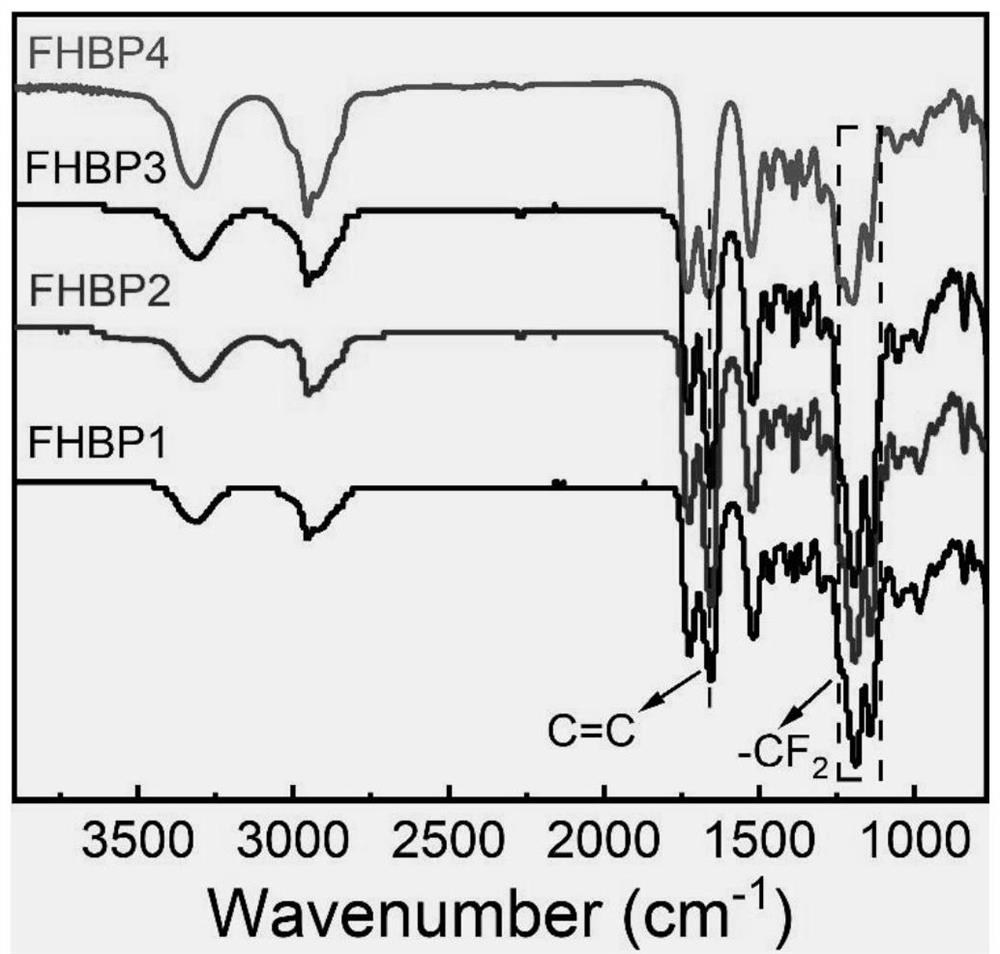

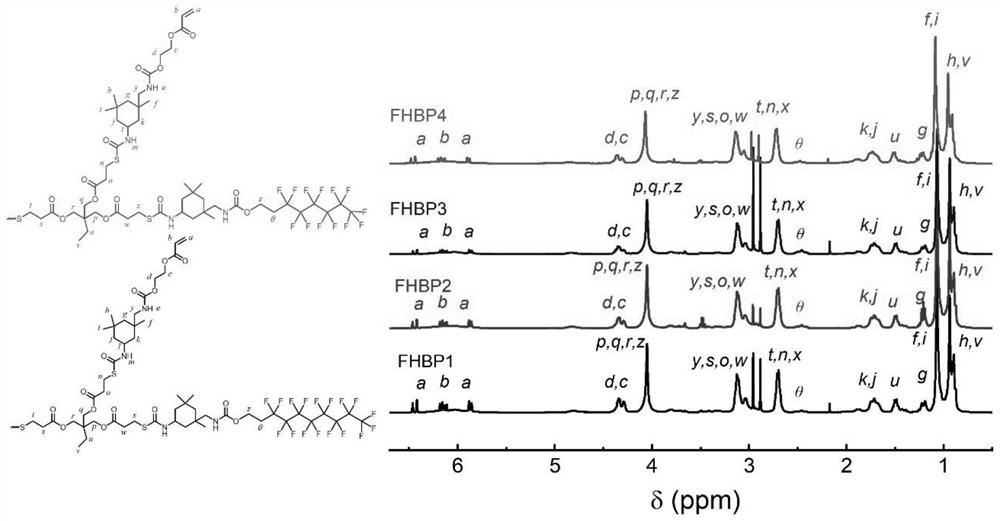

[0039] 3.986 g (10 mmol) of trimethylolpropane tris(3-mercaptopropionate),...

Embodiment 2

[0043] A kind of UV curing PVC floor coating, the preparation method is:

[0044]First, use 5 parts of reactive diluent HDDA, 20 parts of reactive diluent PETA, 0.5 parts of defoamer BYK-066, 0.5 parts of leveling agent BYK-306 and 1 part of wetting and dispersing agent BYK-2009 The high-speed disperser stirs for 10 minutes at the speed of 2000r / min to make the dispersion even.

[0045] Next, add 3 parts of fluorine-containing hyperbranched polythiourethane and 15 parts of matte powder E-1011 in batches, and stir for 30 minutes at a speed of 3500 r / min.

[0046] Finally, add 20 parts of difunctional aliphatic urethane acrylate, 30 parts of hexafunctional aliphatic urethane acrylate, and 5 parts of photoinitiator 1173, and stir evenly at a speed of 2500r / min to obtain a UV-curable PVC floor coating .

[0047] The preparation method of described fluorine-containing hyperbranched polythiourethane is:

[0048] 3.986 g (10 mmol) of trimethylolpropane tris(3-mercaptopropionate), ...

Embodiment 3

[0052] A kind of UV curing PVC floor coating, the preparation method is:

[0053] First, use 5 parts of reactive diluent HDDA, 20 parts of reactive diluent PETA, 0.5 parts of defoamer BYK-066, 0.5 parts of leveling agent BYK-306 and 1 part of wetting and dispersing agent BYK-2009 The high-speed disperser stirs for 10 minutes at the speed of 2000r / min to make the dispersion even.

[0054] Next, add 3 parts of fluorine-containing hyperbranched polythiourethane and 15 parts of matte powder E-1011 in batches, and stir for 30 minutes at a speed of 3500 r / min.

[0055] Finally, add 20 parts of difunctional aliphatic urethane acrylate, 30 parts of hexafunctional aliphatic urethane acrylate, and 5 parts of photoinitiator 1173, and stir evenly at a speed of 2500r / min to obtain a UV-curable PVC floor coating .

[0056] The preparation method of described fluorine-containing hyperbranched polythiourethane is:

[0057] 3.986 g (10 mmol) of trimethylolpropane tris(3-mercaptopropionate),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com