Patents

Literature

3663results about How to "Increase crosslink density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

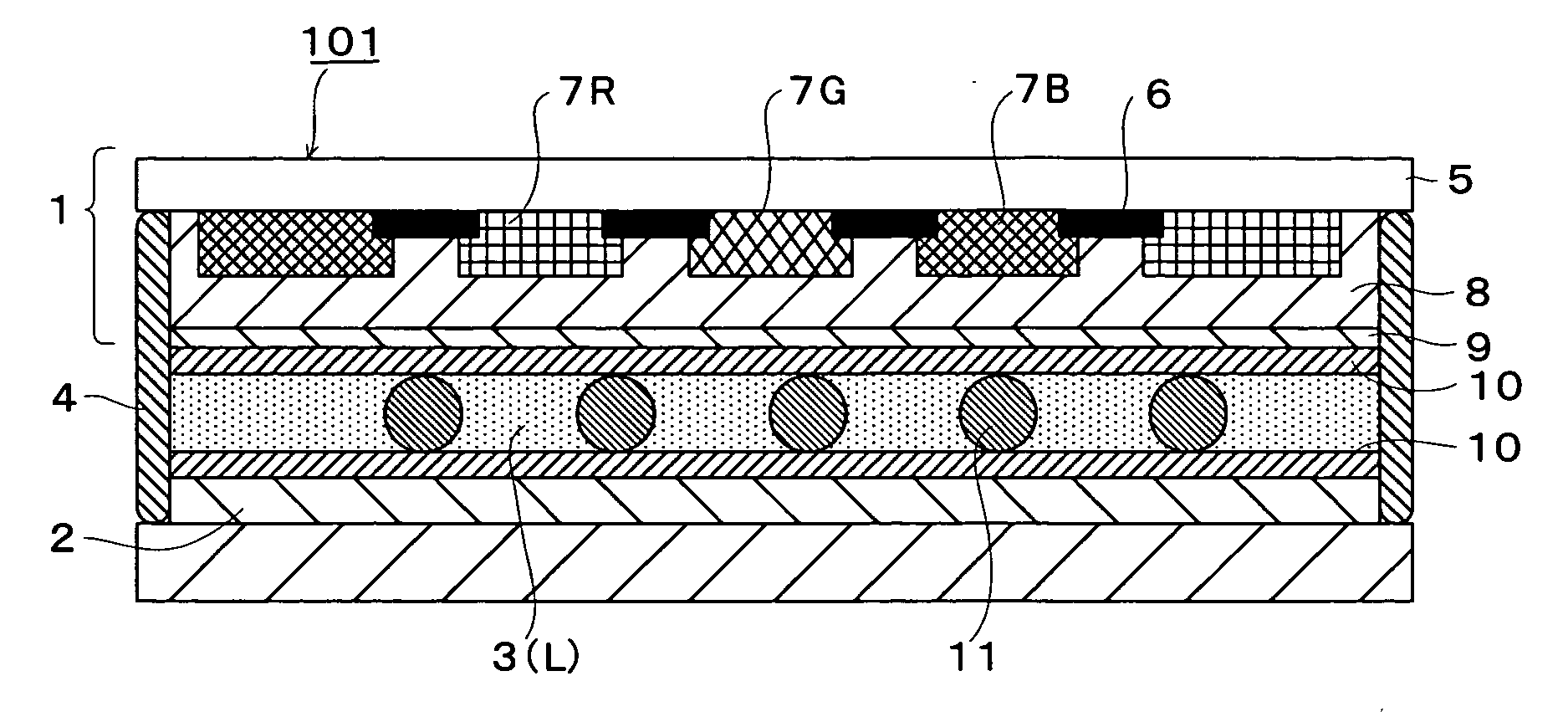

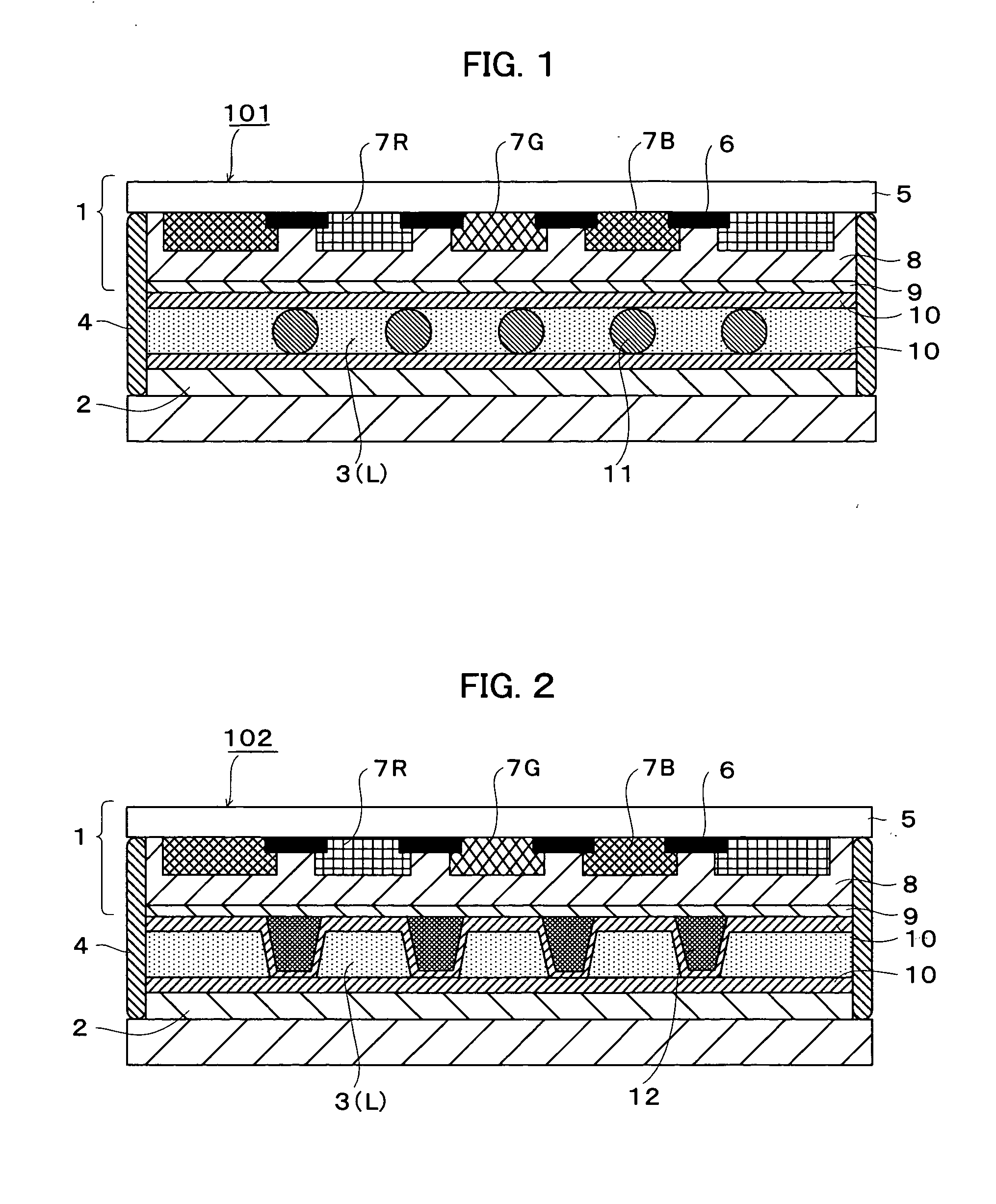

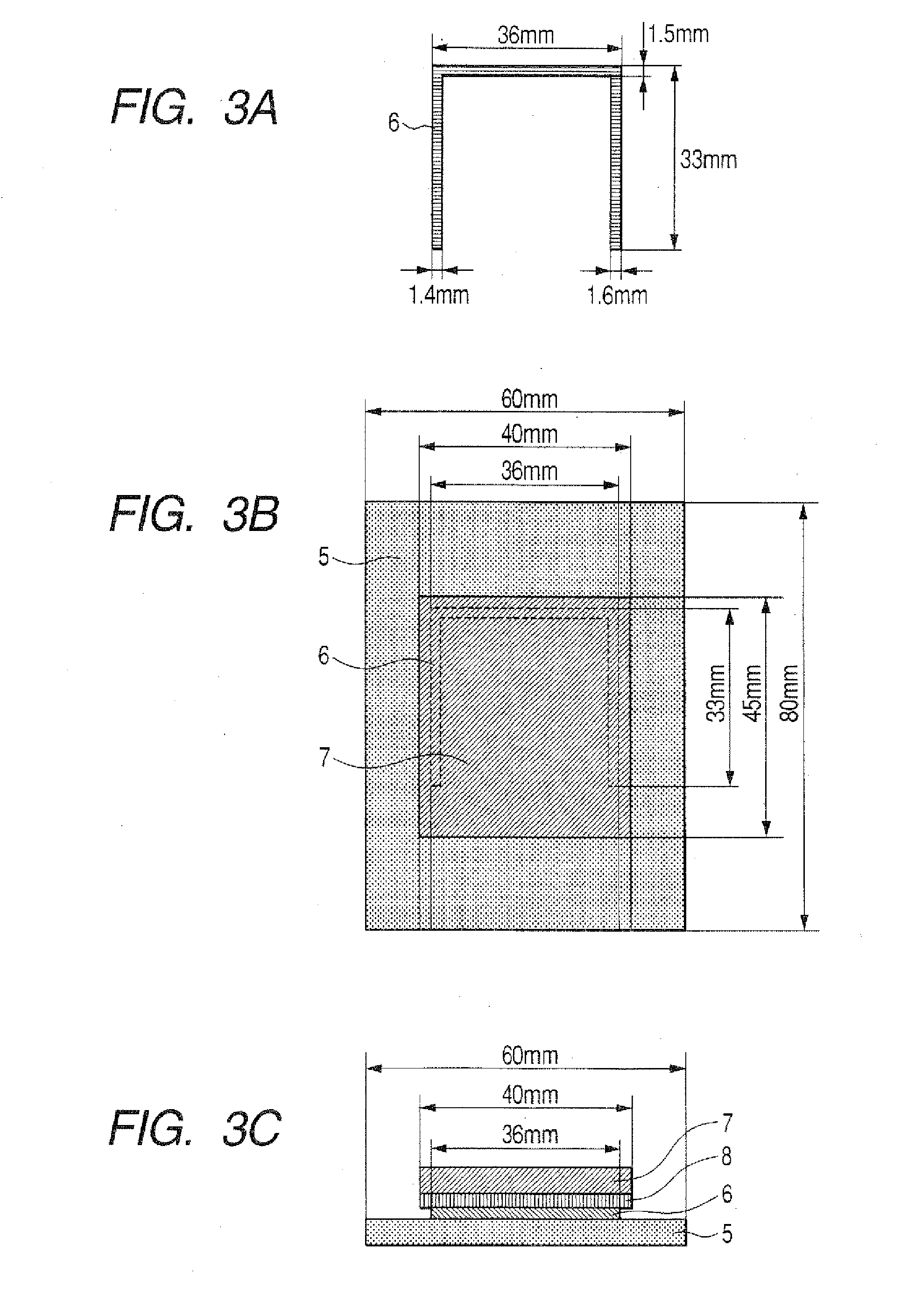

Resin composition for production of optical element, the optical element, and projection screen

InactiveUS6650471B2Increase crosslink densityHigh refractive indexProjectorsOptical articlesTemperature curveProjection screen

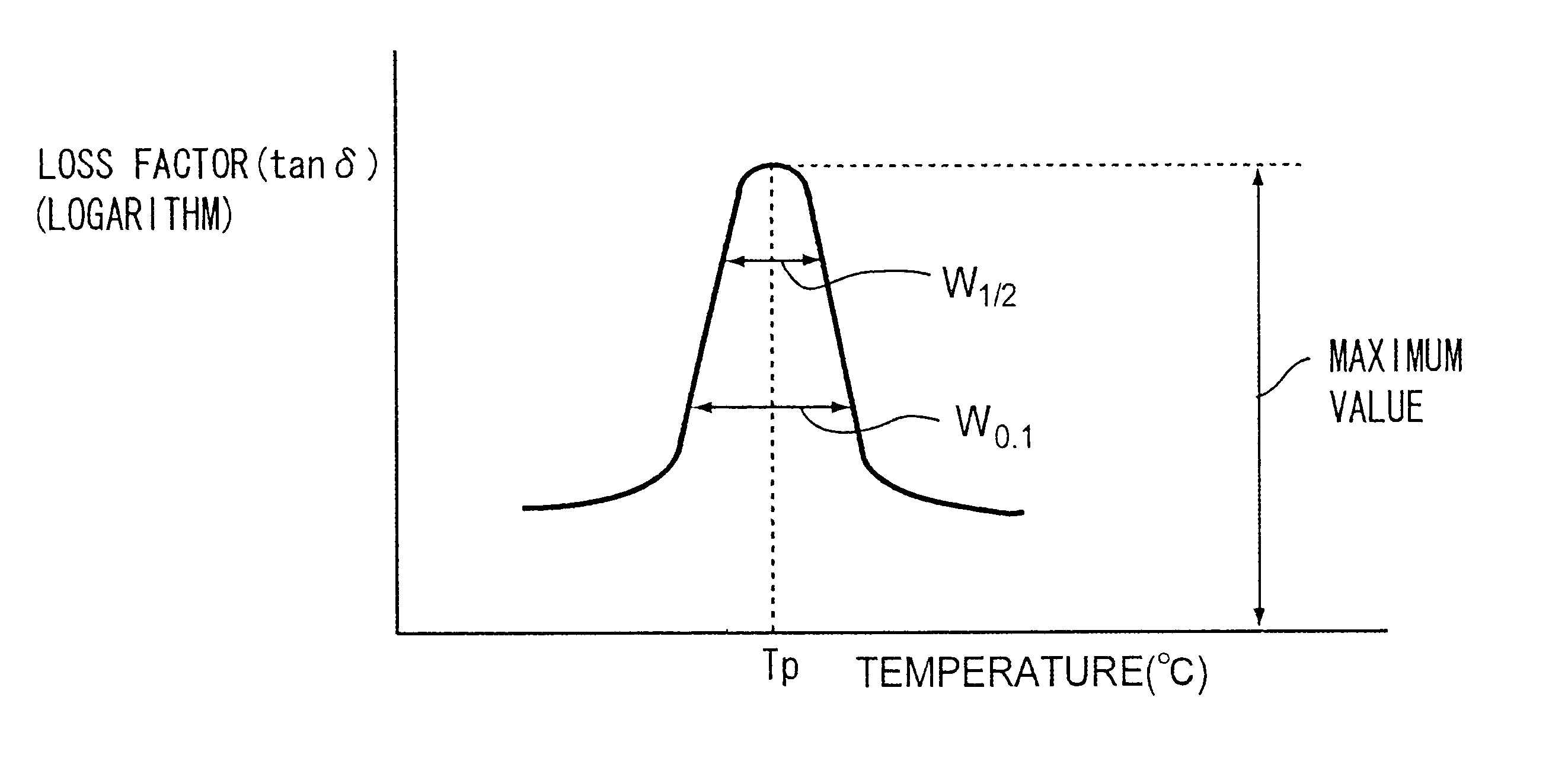

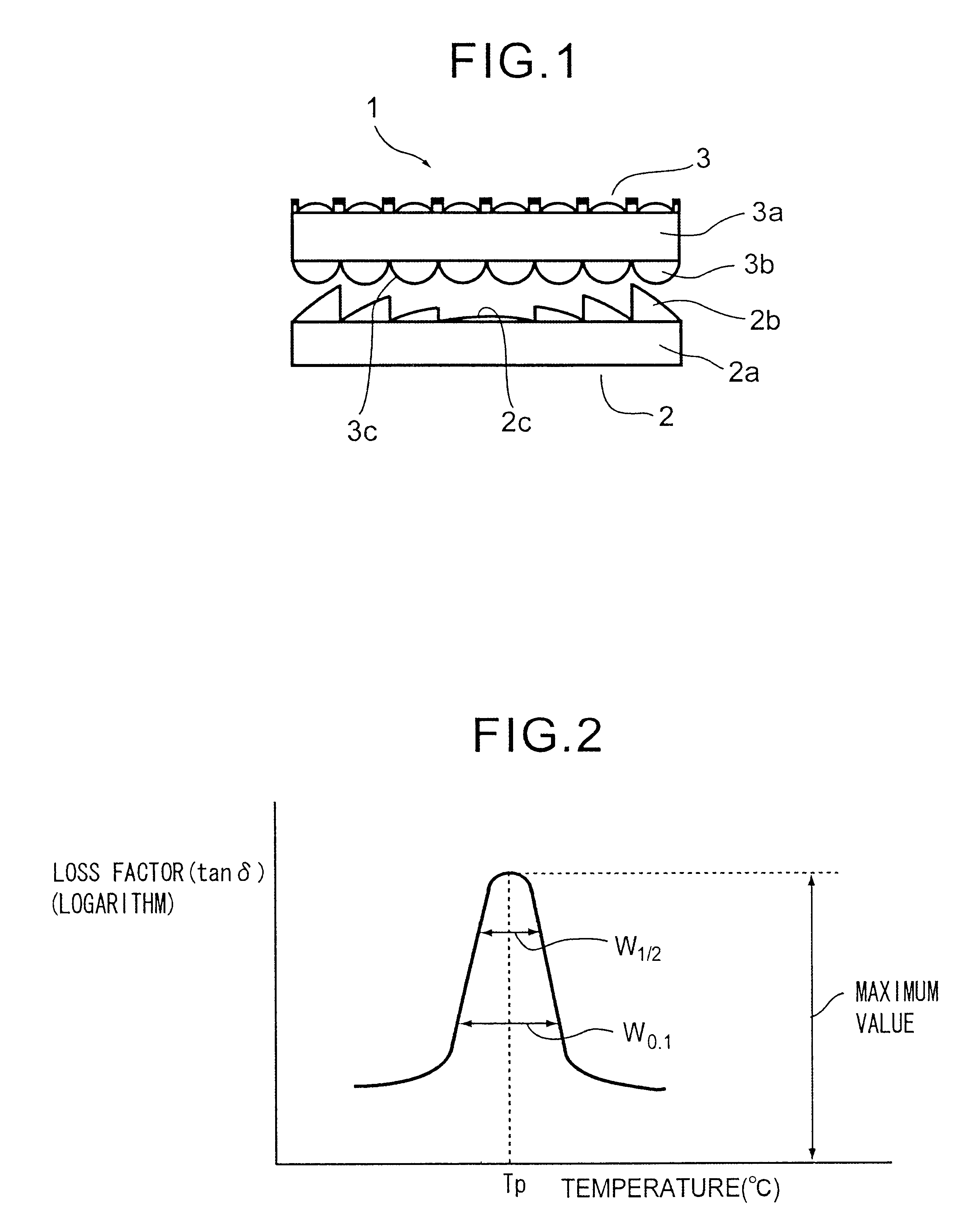

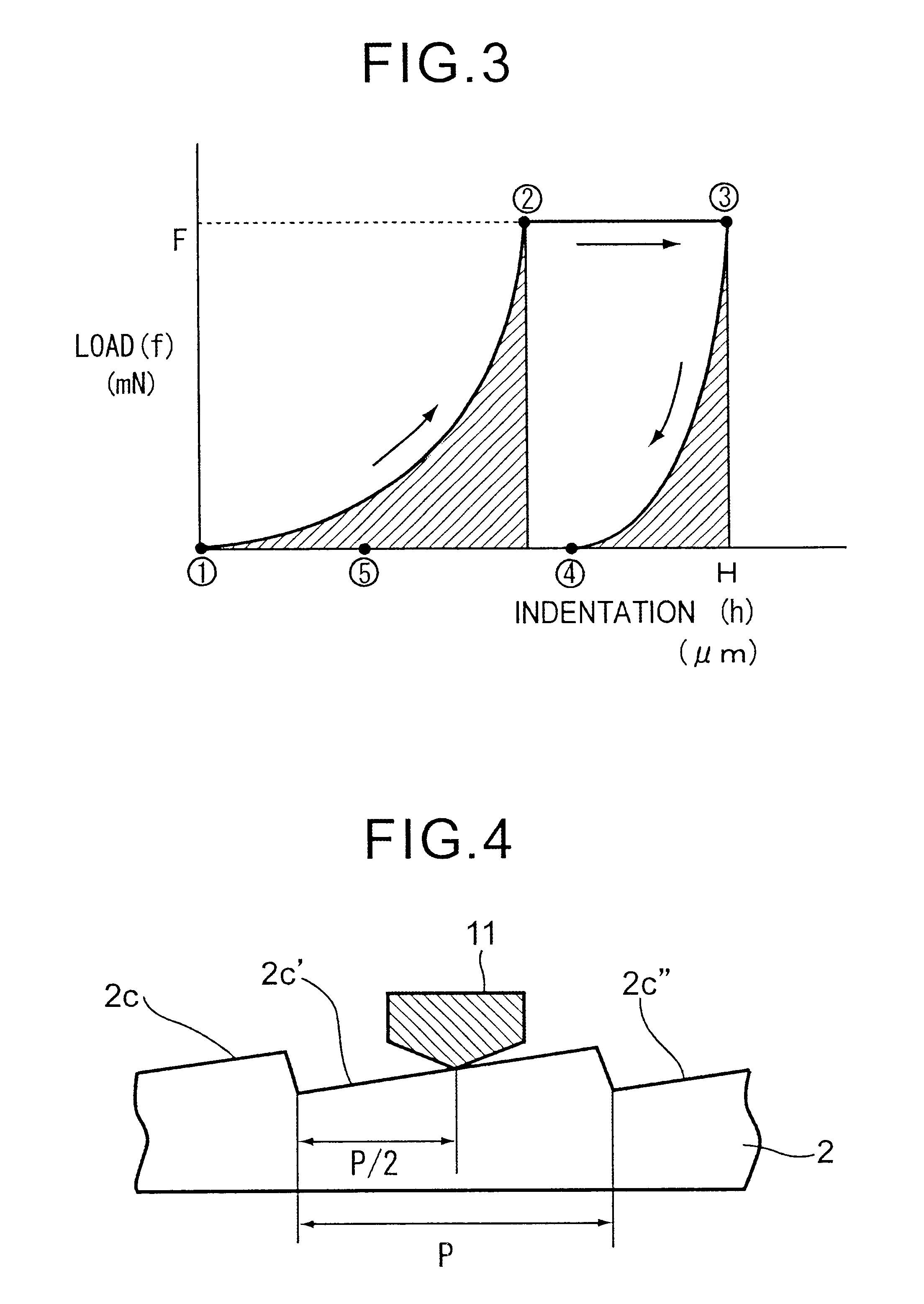

A resin composition for production of an optical element being adapted to form the optical element has a characteristics of which, when W1 / 2 (° C.) represents, regarding a crest portion in a loss factor / temperature curve obtained by measuring the loss factor of the resin composition relative to a change in the temperature, the width of the crest portion at the position of ½ of the maximum value of the loss factor in the crest portion temperature range; W0.1 (° C.) represents, regarding the crest portion, the width of the crest portion at the position of 0.1 of the maximum value of the loss factor; and DeltaW (° C.), the difference between the widths of the two crest portions, is set to be DeltaW=W0.1-W1 / 2, the DeltaW is in the range of from 16° C. to 31° C.

Owner:DAI NIPPON PRINTING CO LTD

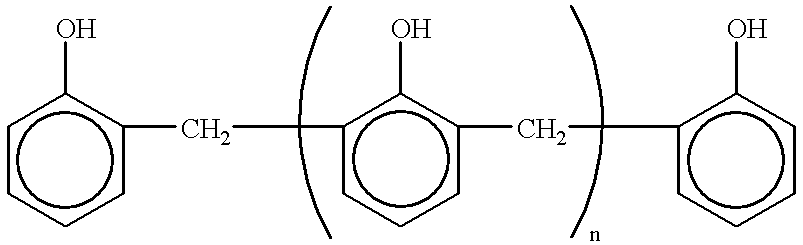

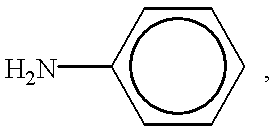

Ternary systems of benzoxazine, epoxy, and phenolic resins

Low viscosity ternary mixtures of benzoxazine, epoxy and phenolic resins have been developed. The blends render homogeneous and void free cured specimen with a wide range of properties. Melt viscosity values as low as 0.3 Pa.s at 100° C. can be achieved. The phenolic resin acts as a cure accelerator to the system, besides its typical function as a hardener of epoxy resin. Glass transition temperatures Tg as high as 170° C. can also be obtained.

Owner:EDISON POLYMER INNOVATION EPIC

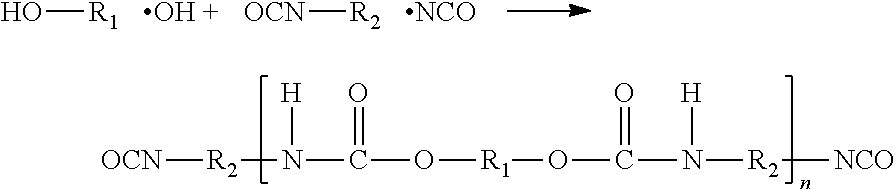

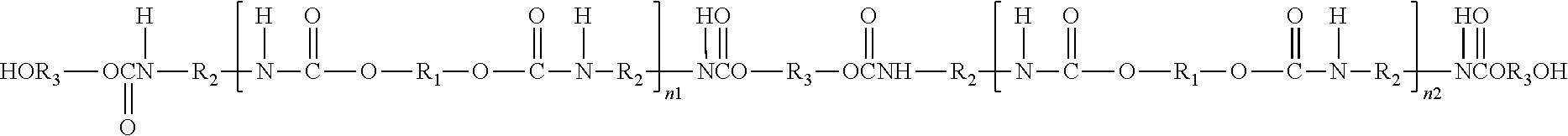

Polyurethanes for osteoimplants

InactiveUS7985414B2Increase crosslink densityBone implantPharmaceutical non-active ingredientsLysine diisocyanatePolymer

Biological-based polyurethanes and methods of making the same. The polyurethanes are formed by reacting a biodegradable polyisocyanate (such as lysine diisocyanate) with an optionally hydroxylated biomolecule to form polyurethane. The polymers formed may be combined with ceramic and / or bone particles to form a composite, which may be used as an osteoimplant.

Owner:WARSAW ORTHOPEDIC INC

Dual-curing coating and preparation method thereof

InactiveCN102181192ACuring shrinkage is smallIncrease crosslink densityCoatingsInformation layerCoating system

The invention discloses a dual-curing coating. The coating contains ultraviolet curing resin monomers, a low polymer, a photo-initiator, polymer resins, an adjuvant and an organic solvent. In the invention, the dual-curing coating is prepared by synergistic copolymerization of an ultraviolet curing coating system and a solvent-based polymer system. The preparation method of the coating comprises the following steps: firstly thermocuring, and then processing information layers and photocuring at the same time; or firstly photocuring, then processing the information layers, and finally heating with an oven or infrared-heating for further cross-linking curing. Therefore, the dual-curing coating has better comprehensive performances such as fast curing speed, small film-coating cure shrinkage and high crosslinking density so as to achieve the characteristics of chemical corrosion resistance, strong wear resistance, strong high temperature resistance, excellent flexibitity, excellent adhesive force and the like; and the coating can be used for laser anti-counterfeit marks of plastics, cosmetic preparations, ceramic materials, glass, paper, leather, wooden products and metal products as well as production of pigment preparations and the like.

Owner:SHANGHAI HONGDUN ANTI COUNTERFEIT MATERIAL

Antimicrobial radiation curable coating

InactiveUS7098256B2The environment is moreOptimal for incorporationBiocideAntifouling/underwater paintsCross-linkCarbamate

Owner:MICROBAN PROD CO INC

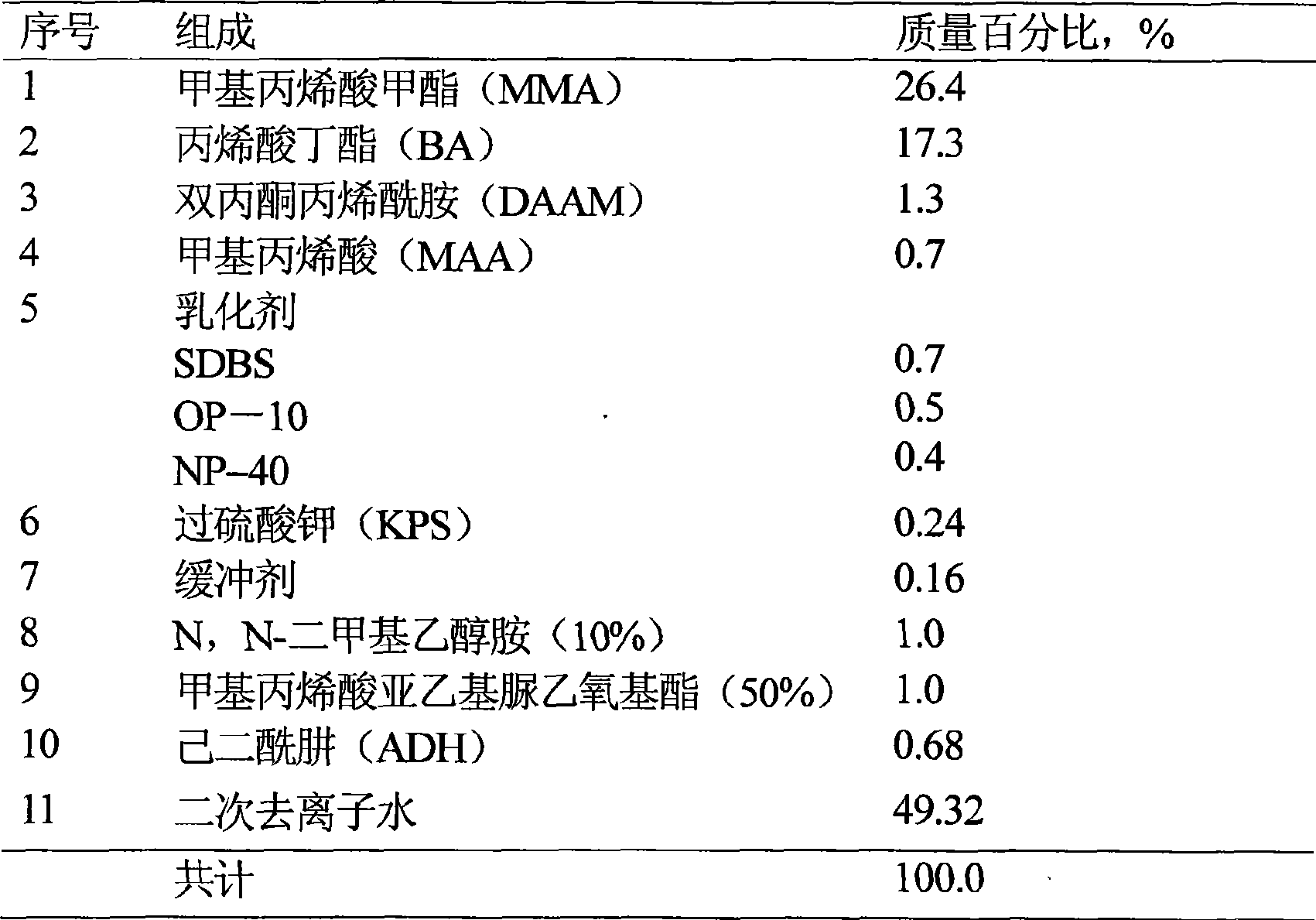

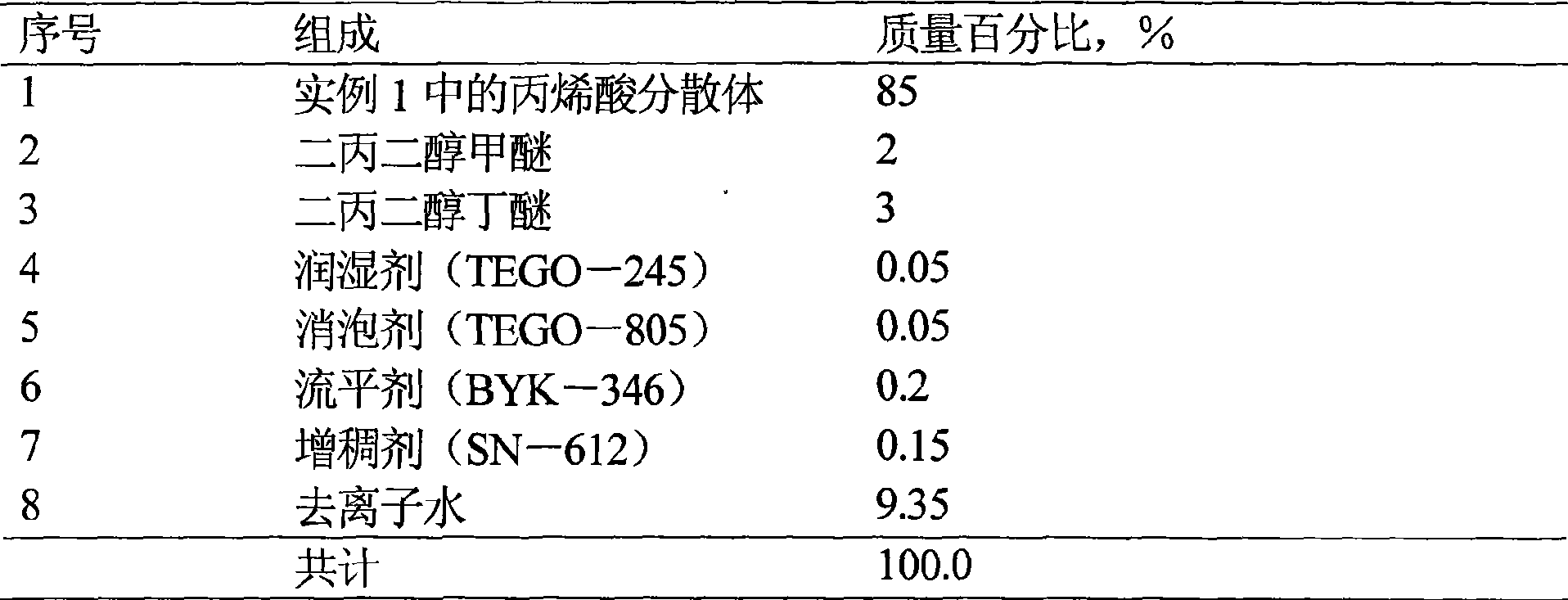

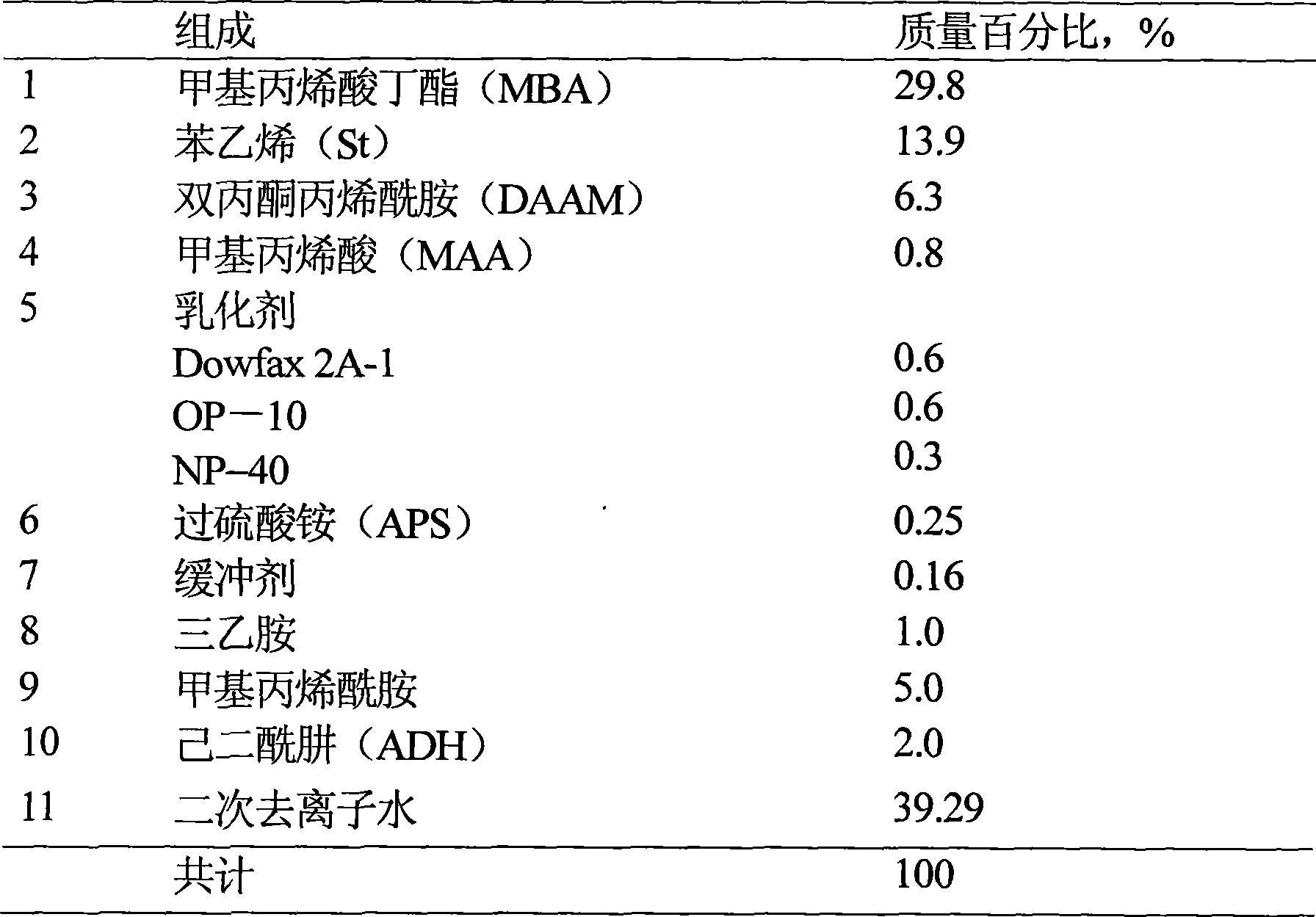

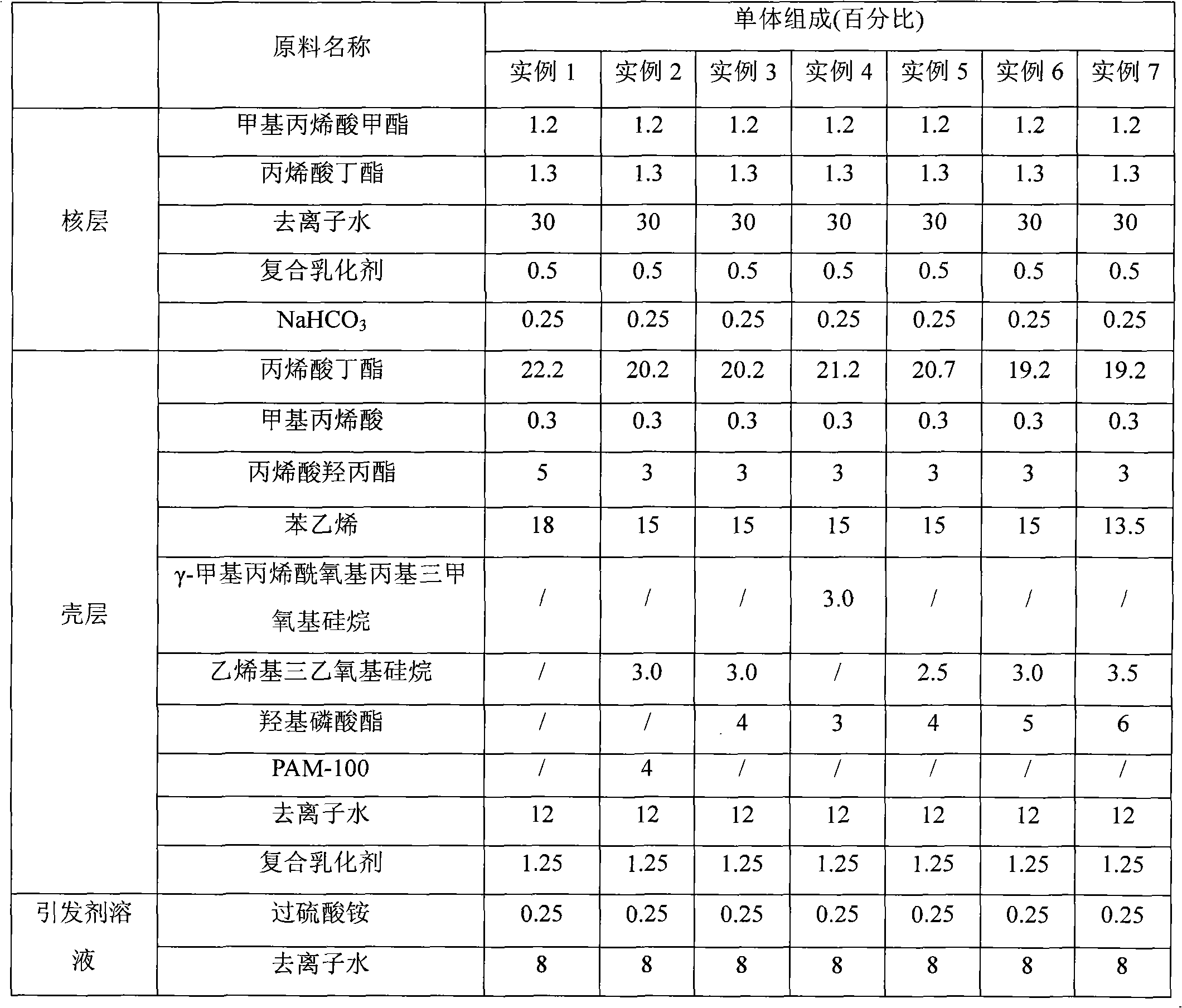

Preparation of high closeness polyacrylacid ester dispersion

The invention relates to a high-sealing polyacrylic ester dispersoid and a preparation method thereof; a multi-element emulsifier system which consists of an anionic emulsifier and a compound non-ionic emulsifier is adopted for controlling the charging process and components of the emulsifier in different polymerization periods, and the room-temperature self-crosslinking high-sealing polyacrylic ester dispersoid is prepared by a semi-continuous seeding emulsion polymerization process. The dispersoid has small particle size, good electrolyte-resistance (calcium ion) stability and high tolerance to various film forming accessory ingredients (various organic solvents with high boiling point). The dispersoid is used as seal coat of water-based wood coating and has good sealing performance to various woods; harmful volatile organic compounds (VOC) such as formaldehyde, and the like sealed against escaping from plates to pollute indoor environment, and the colored compounds such as turpentine, pine oil and tannin and the like are sealed against dissolving out of the plates to pollute pure top coating and white top coating of a water-based wooden ware; and in addition, the dispersoid can be used in water-based leather finishing agents.

Owner:SOUTH CHINA UNIV OF TECH

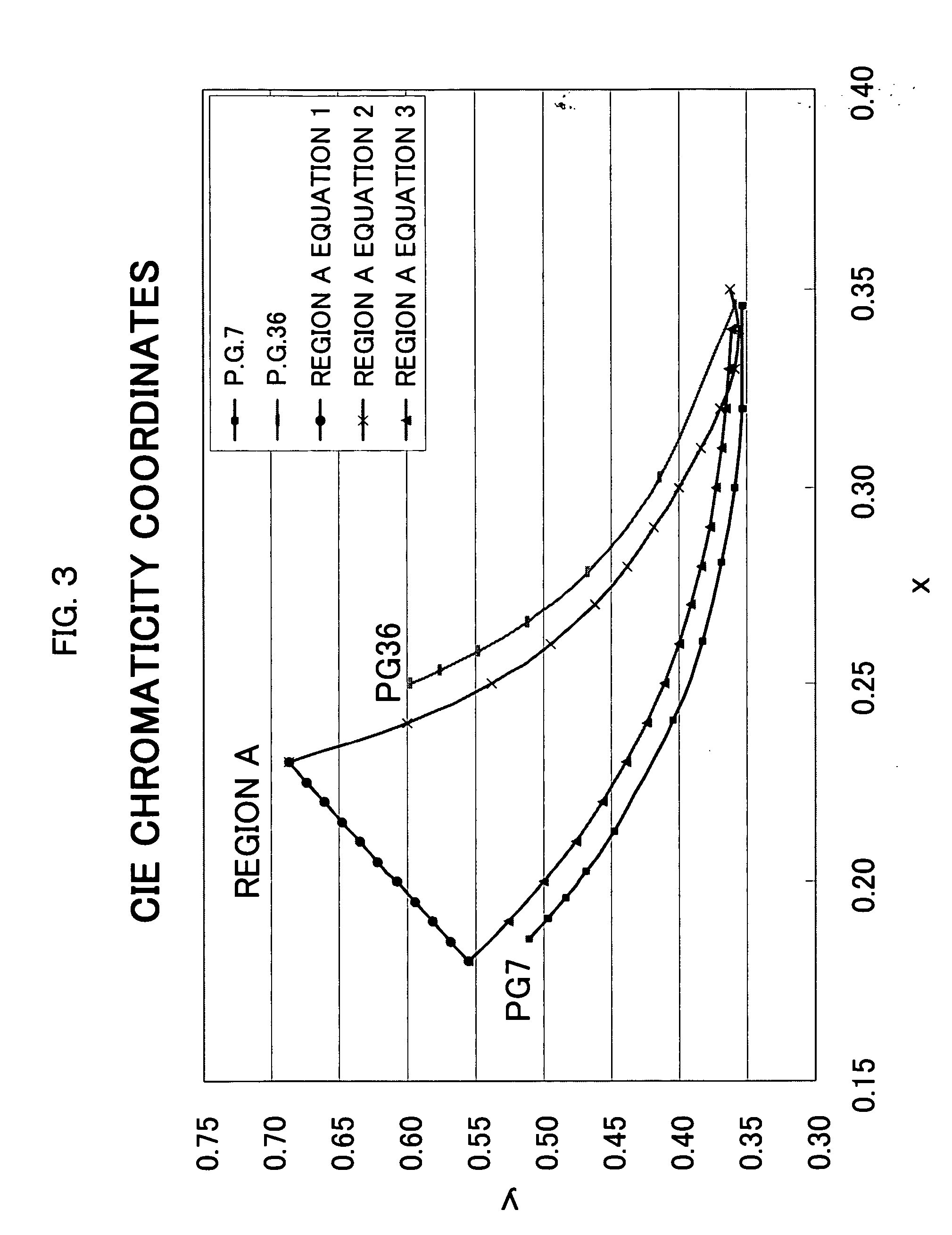

Green pigment for color filter, green pigment dispersion, photosensitive color composition, color filter, and liquid crystal panel

ActiveUS20060098316A1High strengthPromote formationPhotosensitive materialsPhotomechanical apparatusPhotopigmentPigment dispersion

An object of the present invention is to provide a green pigment for a color filter, capable of displaying the chromaticity coordinates not to be displayed by the conventional green pigments, having the excellent color strength as a green color which is not excessively strong in a blue tinge, and a high transmittance, and moreover, to provide a photosensitive color composition, a pigment dispersion, a color filter and a liquid crystal panel, using the above-mentioned green pigment. In order to achieve the above-mentioned object, the present invention provides a green pigment for a color filter comprised of a phthalocyanine green pigment and capable of expressing a region of xy-chromaticity coordinate enclosed by predetermined equations 1, 2 and 3 defined by the XYZ color system of the CIE when the green pigment is solely subjected to colorimetry. Moreover, using the above-mentioned green pigment, it provides a photosensitive color composition capable of forming a color filter having a wide color reproduction range and a high transmittance. Furthermore, it provides a color filter having a wide color reproduction range and a high transmittance with a green pixel formed using the above-mentioned photosensitive color composition, and a liquid crystal panel using the color filter.

Owner:DAI NIPPON PRINTING CO LTD +1

Double-faced pressure-sensitive adhesive tape or sheet, and liquid crystal display apparatus

InactiveUS20070218276A1Improve the immunityIncrease crosslink densityFilm/foil adhesivesEster polymer adhesivesPolymer scienceLiquid-crystal display

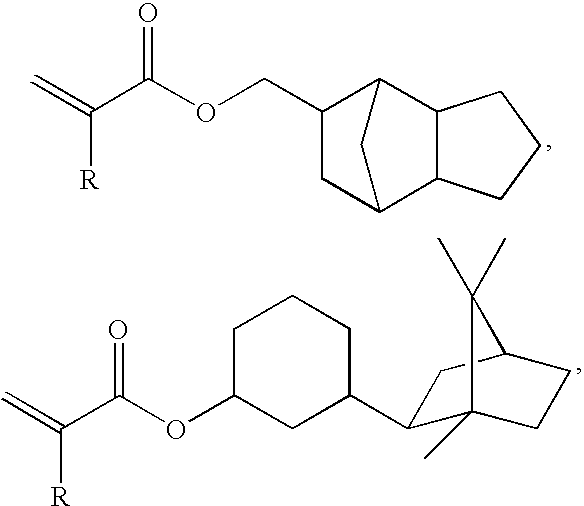

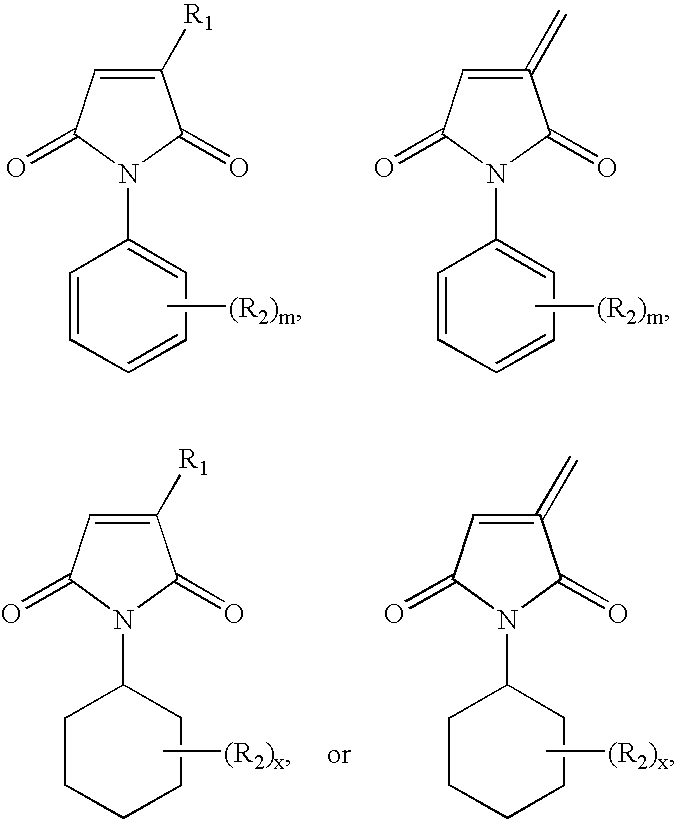

The present invention relates to a double-faced pressure-sensitive adhesive tape or sheet, which comprises: a base material; a pressure-sensitive adhesive layer disposed on one surface of the base material, which is a pressure-sensitive adhesive layer (A) including a pressure-sensitive adhesive composition containing an acrylic polymer (A1), and a silicone rubber fine particle (A2) in a proportion of from 3 to 50 parts by weight with respect to 100 parts by weight of the acrylic polymer (A1), the layer (A) being used so as to adhere to the liquid crystal display module unit; and another pressure-sensitive adhesive layer disposed on the other surface of the base material, which is a pressure-sensitive adhesive layer (B) including a pressure-sensitive adhesive composition containing an acrylic polymer (B1), and a low-molecular weight polymer component (B2), which contains, as a principal monomer component, an ethylenic unsaturated monomer having a glass transition temperature of from 60 to 190° C. when it is formed into a homopolymer and having a cyclic structure within the molecule thereof, and which has a weight-average molecular weight equal to or higher than 3,000 but lower than 20,000, in a proportion of from 5 to 35 parts by weight with respect to 100 parts by weight of the acrylic polymer (B1), the layer (B) being used so as to adhere to the backlight, in which the pressure-sensitive adhesive tape or sheet is for use in fixing a liquid crystal display module unit and a backlight unit.

Owner:NITTO DENKO CORP

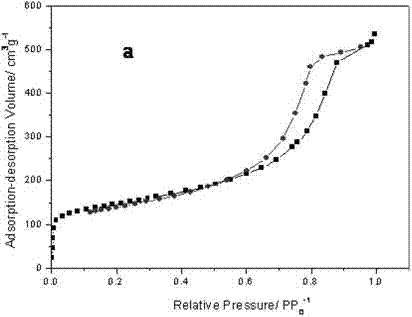

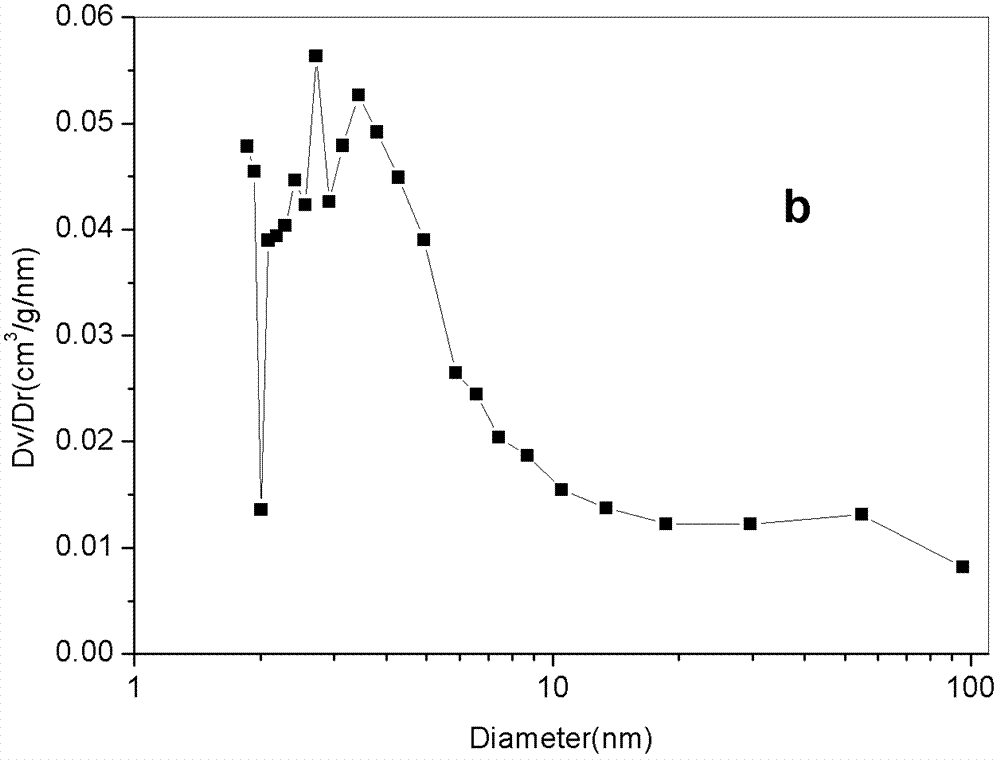

Method for preparing graphene crosslinked type organic aerogel and carbon aerogel by normal-pressure drying

InactiveCN102774824AHigh strengthNot easy to shrinkCarbon preparation/purificationSupercritical dryingCross-link

The invention relates to a method for preparing graphene crosslinked type organic aerogel and carbon aerogel by normal-pressure drying, which takes phenols (P), amines, aldehydes, catalyst and solvent as a reaction system and graphene substances containing active functional groups as a cross-linking agent. The method comprises the steps of: curing to obtain organogel, and then carrying out normal-pressure drying to obtain the organic aerogel; and carrying out pyrolysis on the organic aerogel in the inert atmosphere at the temperature of 500-1600 DEG C to obtain the graphene crosslinked type carbon aerogel. The preparation method of the organic aerogel and the carbon aerogel is simple and rapid in technology; the conventional supercritical drying technology is avoided, and the prepared novel organic aerogel and carbon aerogel materials taking graphene as framework have new performances and wide application prospect; and the industrial production of the carbon aerogel can be expected to be realized.

Owner:BEIJING UNIV OF CHEM TECH

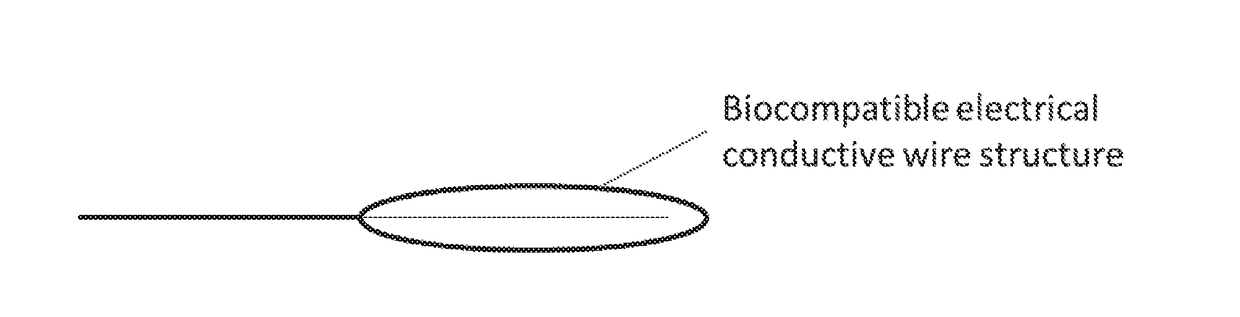

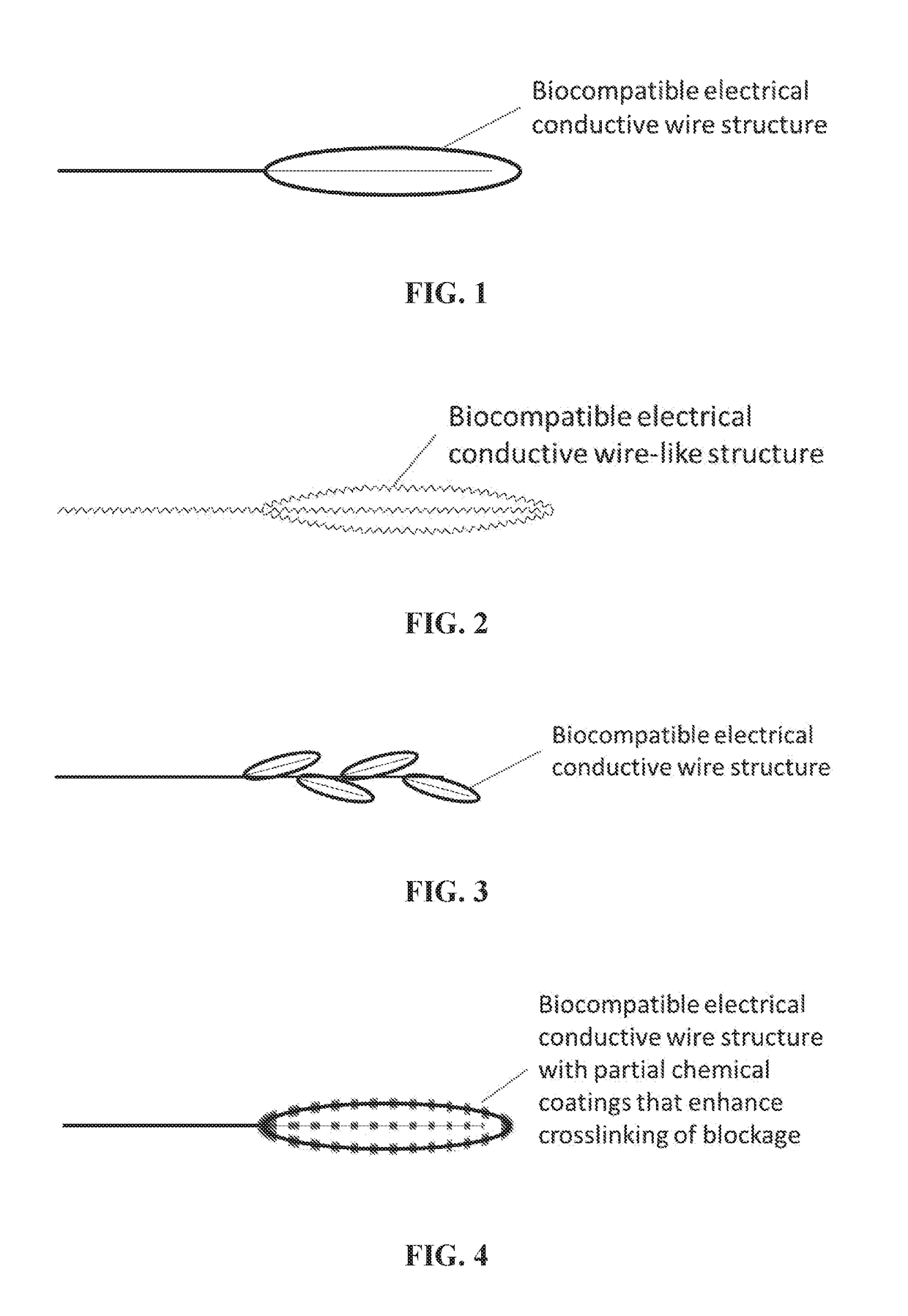

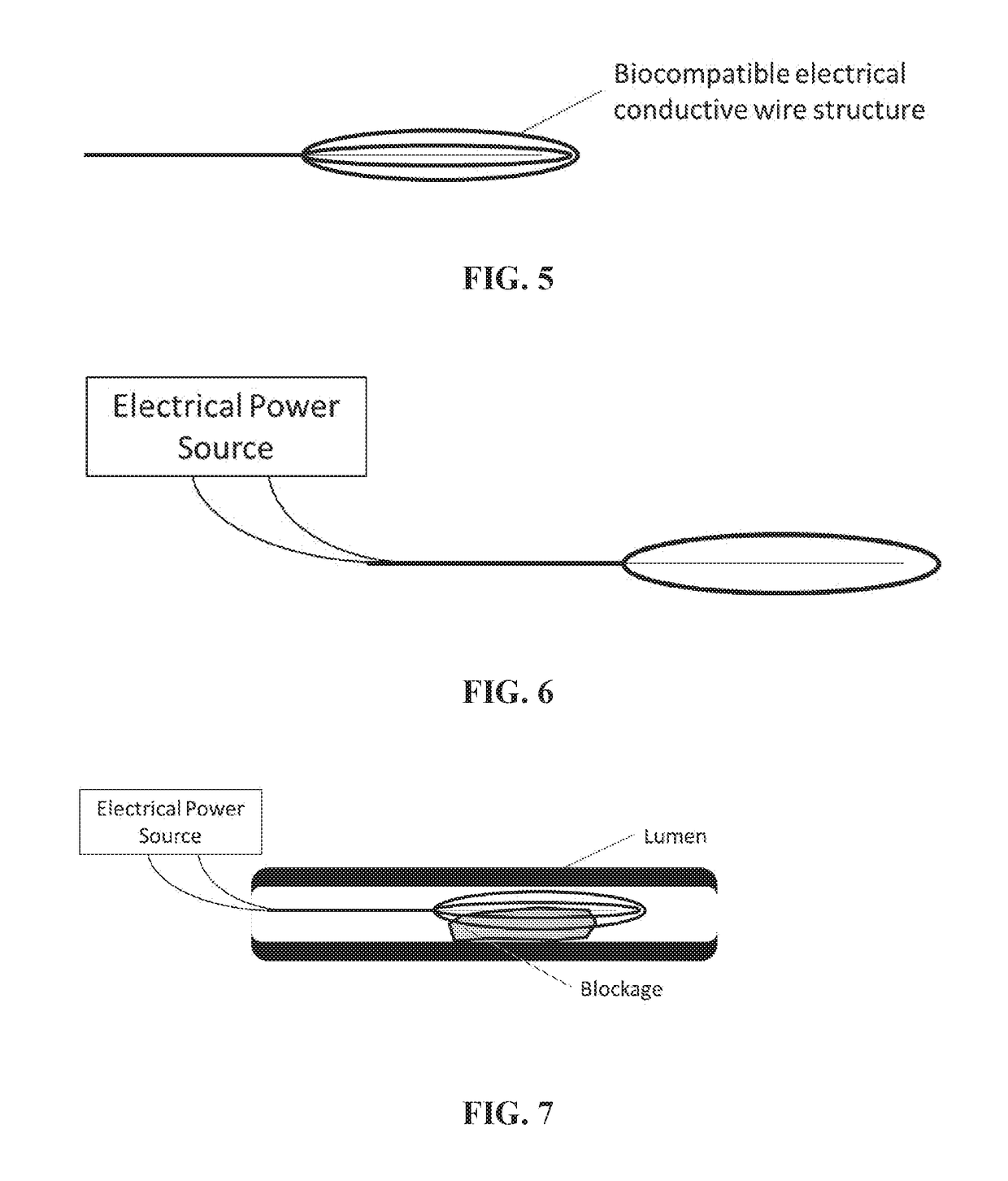

Radio frequency electro-thrombectomy device

ActiveUS20180140354A1Reduce riskImprove adhesionSurgical instruments for heatingCross-linkPower flow

A device is designed to remove blockages in a lumen such as a thrombus, blood clot, or embolus. The device comprises a manipulating wire and a structure that can conduct electrical current to a lumen blockage. The electrical current is preferably in radio frequency (RF). The RF electric current in the blockage can excite the contents such as proteins of the blockage, so that cross-linking density and interfacial adsorption of the entire blockage is enhanced. The enhanced cross-linking density can result in increased fracture resistance of the blockage such that fracture of the blockage during the removal process is unlikely. The enhanced interfacial adsorption results in increased interfacial fracture resistance between the device and blockage so that the blockage can be securely captured during the removal process without using radially applied force.

Owner:THE HONG KONG UNIV OF SCI & TECH

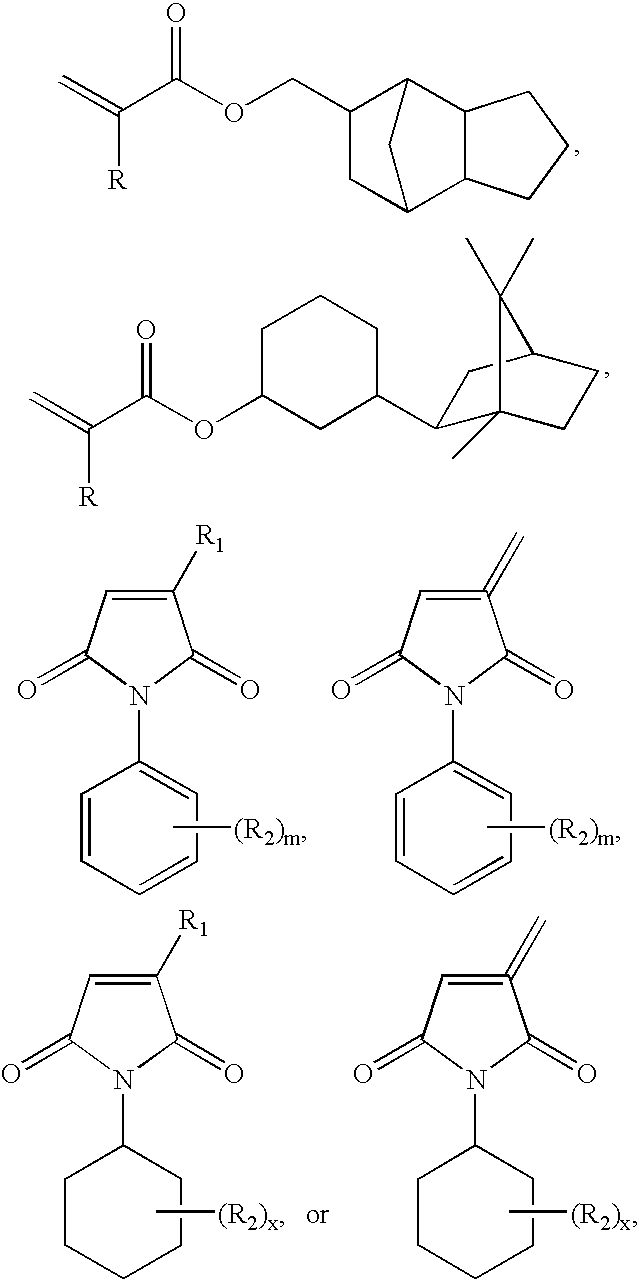

Mono-functional monomers and methods for use thereof

ActiveUS20070155869A1Little weight lossHigh glass transition temperatureCosmetic preparationsToilet preparationsFunctional monomerGlass transition

The invention is based on the discovery that adhesive compositions containing certain low-viscosity, mono-ethylenically unsaturated monomers have surprisingly good cure parameters, resulting in very little weight loss upon cure. Many of these monofunctional monomers used alone or in combination with other monofunctional monomers described herein have high glass transition temperatures when cured. Moreover, since these monomers are monofunctional the crosslink density of the adhesive composition does not increase (relative to multi-functional monomers), which in turns results in lower stress, lower modulus adhesive compositions. As such, these monomers are useful in a variety of thermoset adhesive compositions, such as for example, die attach adhesive compositions.

Owner:DESIGNER MOLECULES

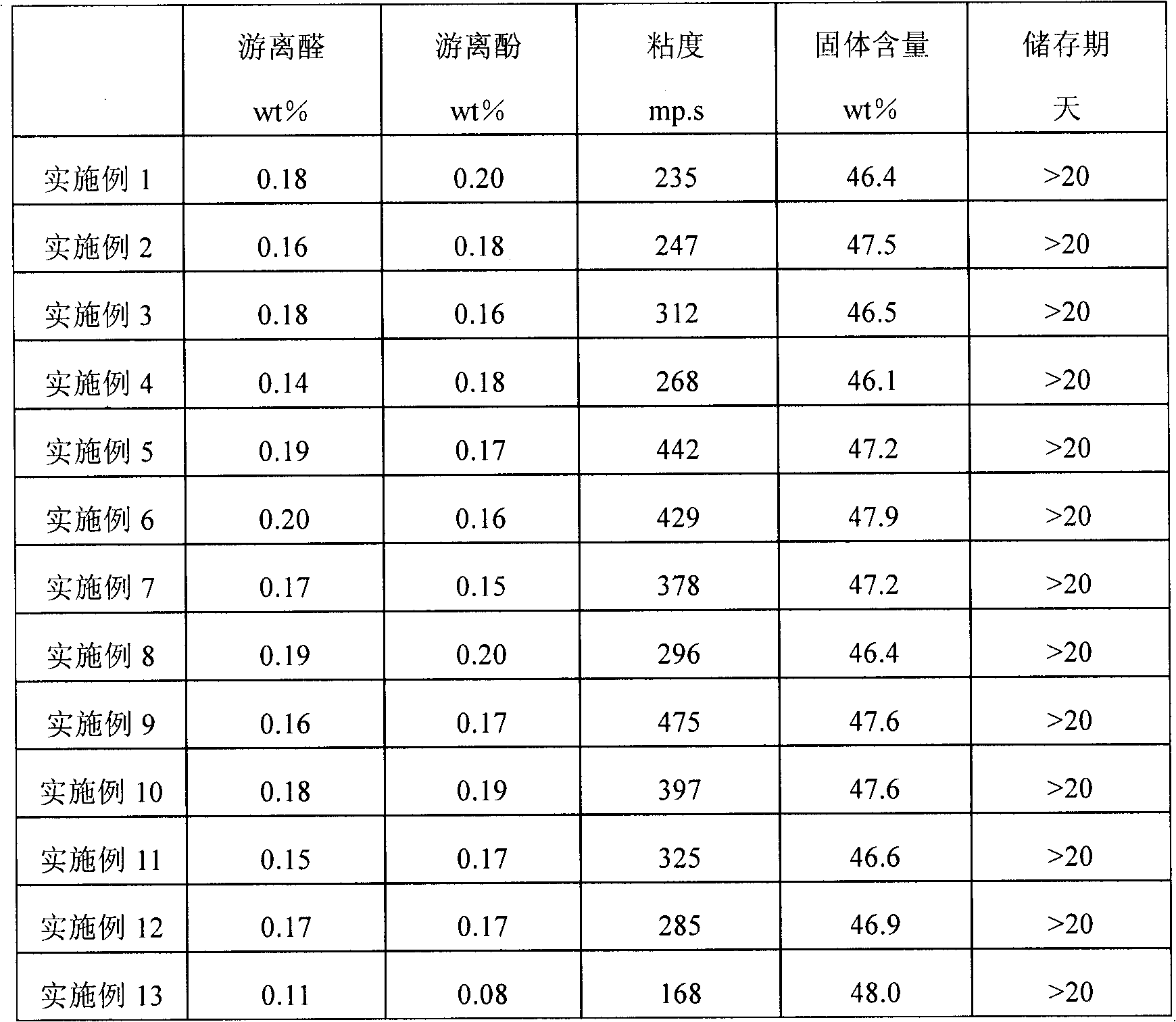

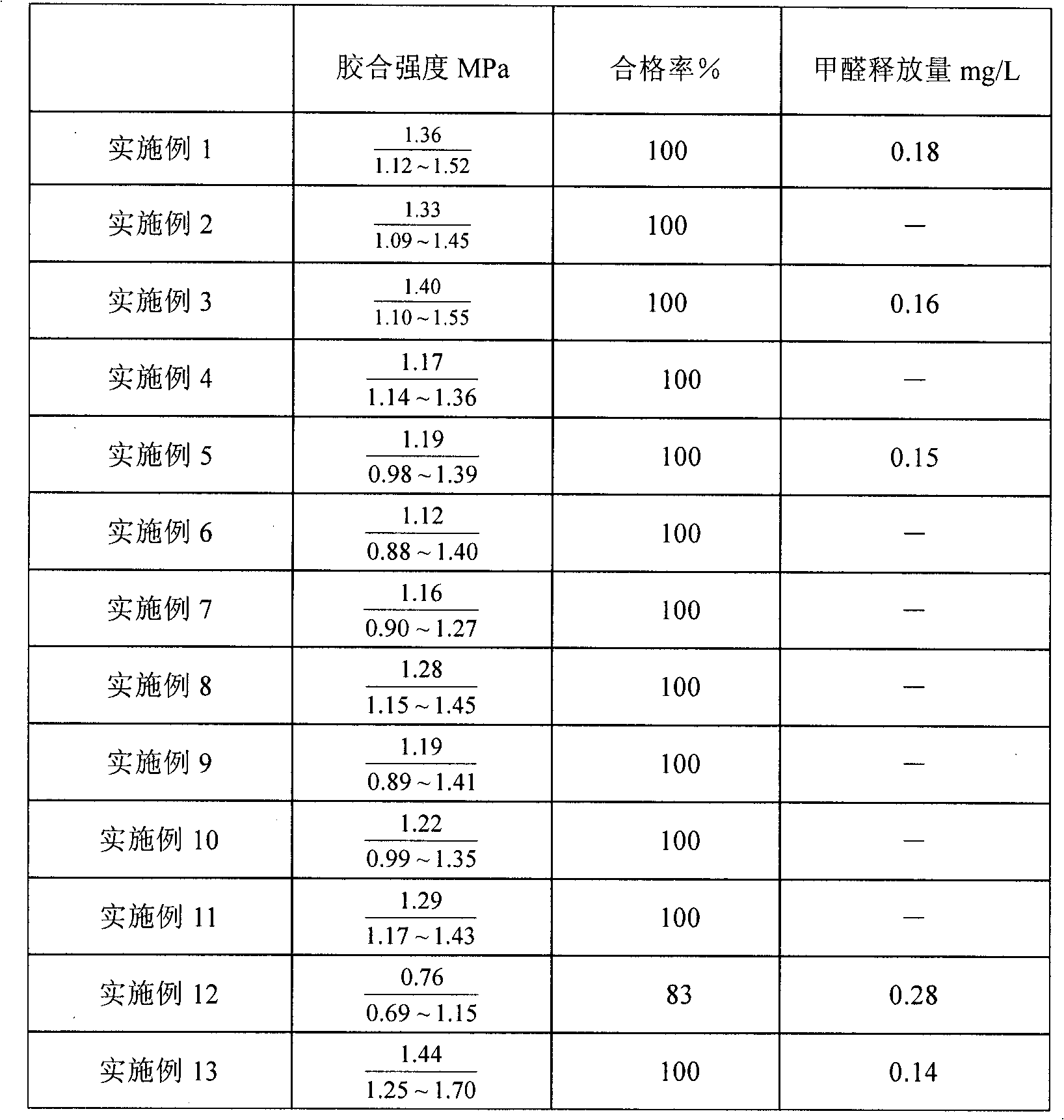

Method for preparing environmentally-friendly adhesive for lignin-based timber

ActiveCN102061141AAdequate responseLow in free phenolsAldehyde/ketone condensation polymer adhesivesAdhesiveTime ratio

The invention discloses a method for preparing an environmentally-friendly adhesive for a lignin-based timber. The method comprises the following steps of: 1) adding phenol, formaldehyde solution, lignin, first alkali liquor and diluting water into a reactor, heating to the temperature of between 75 and 85 DEG C and reacting for 2.5 to 3.5 hours, wherein the molar ratio of formaldehyde to the phenol is 2.20:1-2.40:1; the formaldehyde solution is added for three times in a mass ratio of 1.5 to 1.0 to 1.0; and the reaction time ratio of the added formaldehyde solution is 1.2 to 1.0 to 1.0; 2) cooling to 70 DEG C, adding a formaldehyde collector and second alkali liquor, and reacting at the temperature of between 65 and 70 DEG C for 20 to 50 minutes; and 3) cooling to the temperature of between 30 and 40 DEG C, adding an intensifier, stirring for 10 to 30 minutes, cooling and discharging. In the method, a 50 to 60 percent petroleum-based phenol raw material can be substituted; the methodis stable in reaction, easy to control and easy for industrial production; formaldehyde emission of a plywood reaches E0 level; adhesive strength meets the requirements of national class I plates; and a new approach is provided for the development of an environmentally-friendly biomass-based timber adhesive and recycling of wastes.

Owner:青岛生物能源与过程研究所

Preparation method for formaldehyde-free protein adhesive

InactiveCN101875835ALow costWide variety of sourcesProtein adhesivesMacromolecular adhesive additivesResource utilizationRaw material

The invention discloses a preparation method for a formaldehyde-free protein adhesive, mainly comprising the following steps: 1) adding a protein-containing raw material and water and stirring at room temperature; 2) adding acidity-adjusting agent for reaction at 20-40 DEG C; 3) adding enhancer for reaction at 20-50 DEG C; and 4) adding preservative and stirring at room temperature to obtain the formaldehyde-free protein adhesive. In the invention, the adhesive is prepared based on protein-containing by-products of plants or animals, has the characteristics of low cost, wide source, renewability and the like, does not contain formaldehyde, has no toxicity, is environmental friendly and has superior market prospect. In addition, the existing degreased miscellaneous meal for low value-added product of animal feed, fertilizers and the like can be developed into high value-added products, thus providing a new way for development of environmental-friendly biomass-based wood adhesive and resource utilization of industrial by-products.

Owner:青岛生物能源与过程研究所

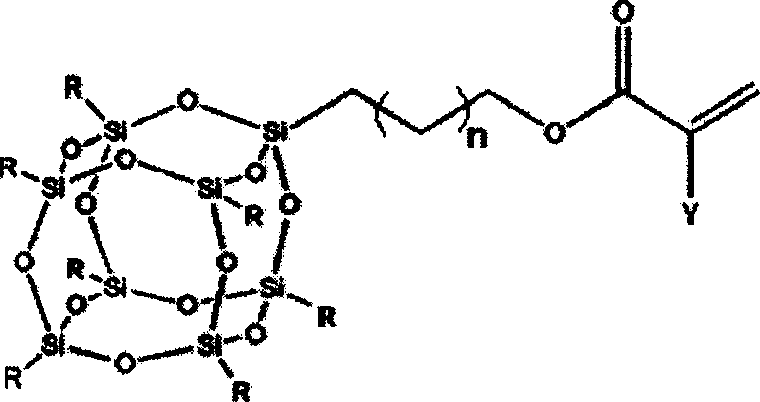

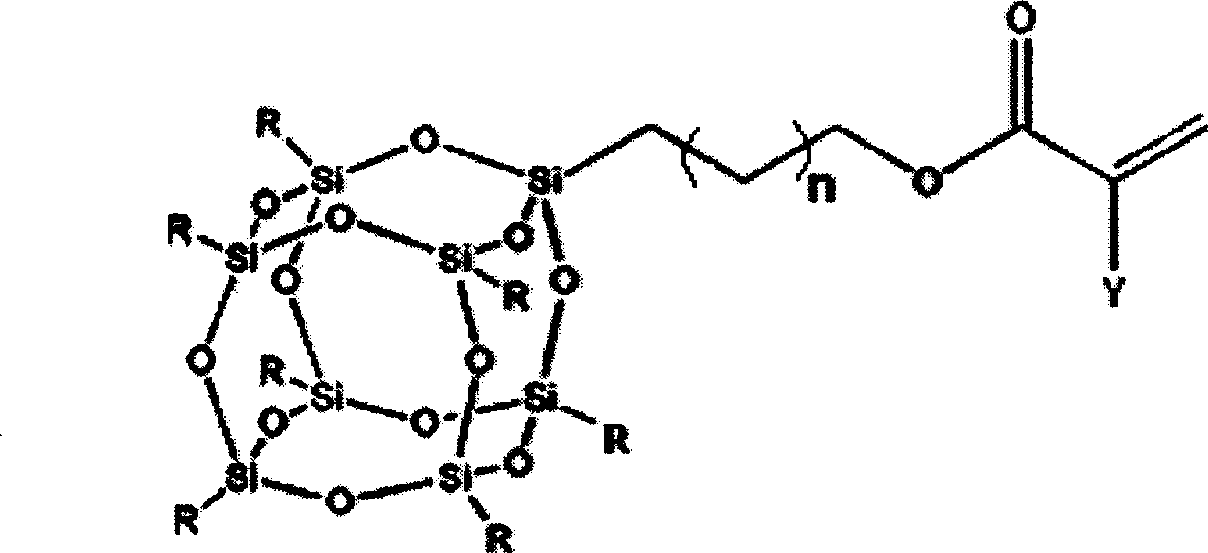

Coating material containing POSS acrylate copolymer and preparing method

The invention relates to a manufacturing method for coat material containing POSS acrylate copolymer. It takes free radical copolymerized to acr monomer and other acr monomer, and uses as modifier adding into the base compounding of UV coat, after taking UV solidification the coat material of high rigidity would be gained. The constituent includes 40-55% light-cured resin, 5-20% active modifier, 20-45% spike, 1-10% photoinitiator, 2-10% anti-foam additive. The rigidity of coat could reach to 6H, and the shrinkage ratio could reach 2%.

Owner:XIAMEN UNIV

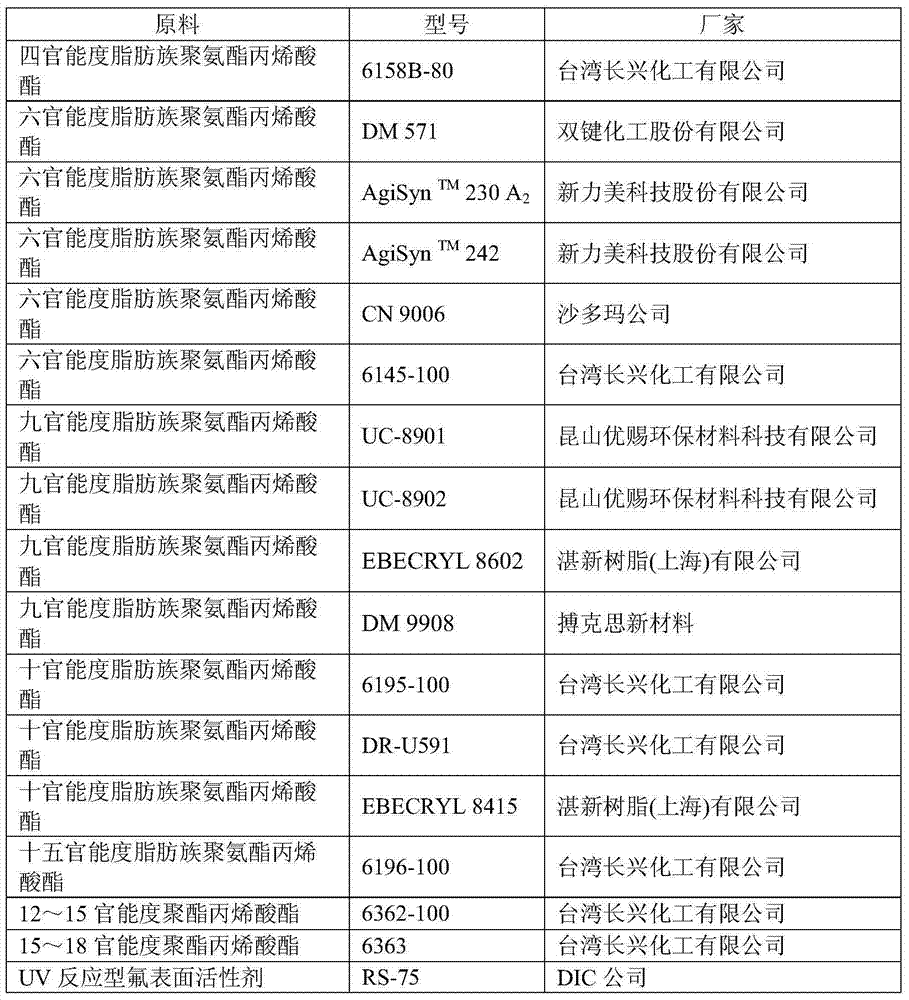

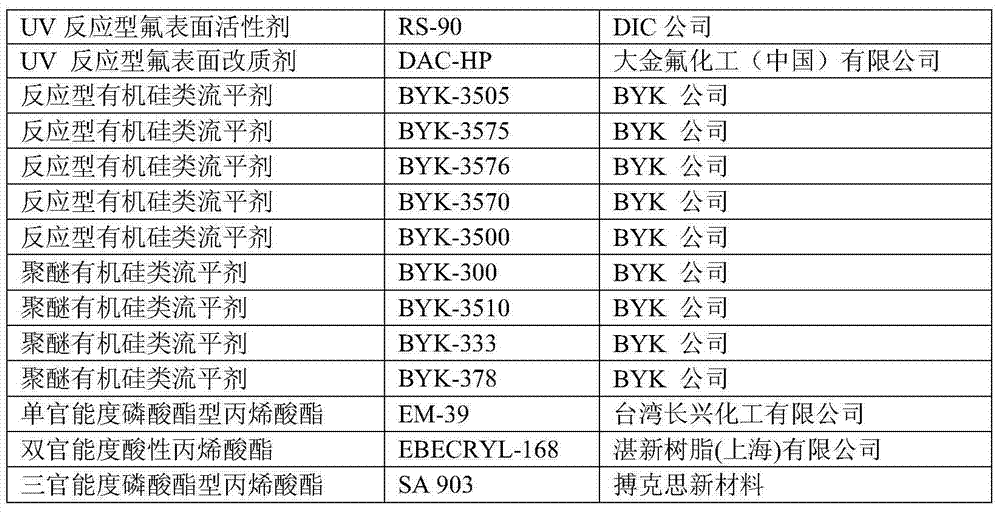

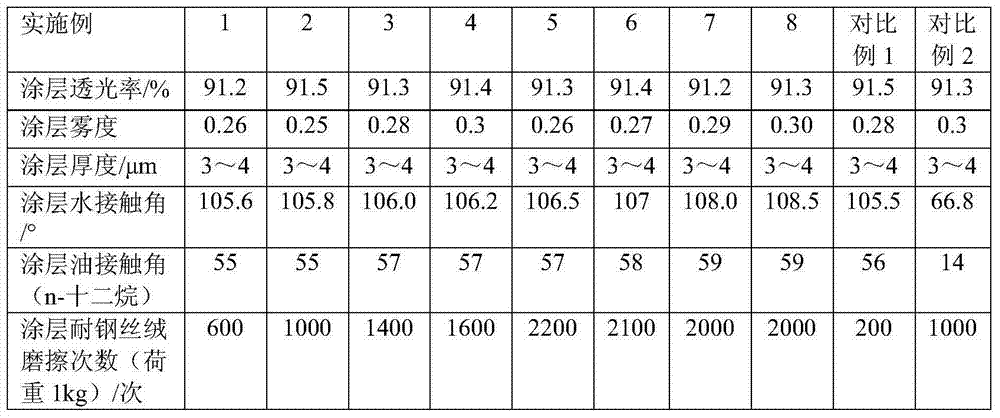

UV curing coating, wear-resistant and antifouling coating layer and mobile phone protection film containing wear-resistant and antifouling coating layer

ActiveCN104845521AHigh reactivityIncrease crosslink densityAntifouling/underwater paintsPaints with biocidesWear resistantPolysilazane

The invention provides an UV curing coating, a wear-resistant and antifouling coating layer and a mobile phone protection film containing the wear-resistant and antifouling coating layer. The coating comprises, in parts by weight, 10-95 parts of a first prepolymer, 5-60 parts of a second prepolymer, 0.05-8 parts of a polysilazane-based polymer, 0.05-8 parts of a fluorine-containing aid, 1-15 parts of a photoinitiator and 100-300 parts of a solvent, wherein the first prepolymer is a urethane acrylate prepolymer with a functionality degree of 4-8; the second prepolymer is an acrylate prepolymer with a functionality degree of 9-18. The wear resistance of the coating layer formed after curing the UV curing coating can be improved by the first prepolymer and the second prepolymer with high functionality degrees, improvement for the wear resistance of the coating layer and prolonging for the service life of the coating layer are benefited due to the adding of the polysilazane-based polymer and a polar compound, and the good antifouling performance of the coating layer can be ensured, and the reduction of the antifouling performance of the coating layer can be suppressed due to the fluorine-containing aid. The coating layer has both good antifouling performance and wear resistance.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

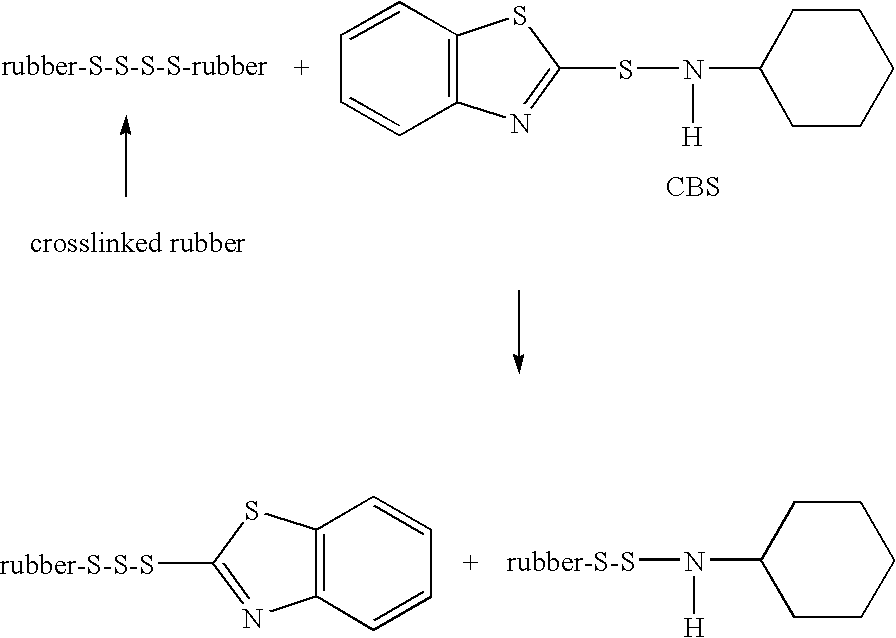

Devulcanization product consisting of scrap rubber, a devulcanization compound, a method for producing same, the reuse thereof in fresh mixtures and the use thereof for producing injection moulded parts

InactiveUS6924319B1High possible phase connectionImprove the level ofPlastic recyclingChemistryScrap

A devulcanization product of comminuted scrap rubber of rubber granules, in which the sulfur bridges of the rubber granule surface are broken and activated for a new vulcanization, is produced by treating the rubber granules to swell the rubber structure of the granule surface and by mixing the treated rubber granules with a devulcanization formulation, acting mechanically and chemically reductively on the rubber granules, in a heating and cooling mixer combination. The rubber granules and the devulcanization formulation are heated to a temperature of 105-150° C. and subsequently immediately cooled. A devulcanization compound is prepared by mixing the devulcanization product with vulcanization and binding agents so as to coat the rubber granules uniformly with them The devulcanization compound can also be prepared by coating the swelled rubber granules in layers by admixing vulcanization agents such as accelerators, activators, auxiliary agents, binding agents, oxygen radical donors and scavengers.

Owner:KRIEG GERHARD +1

Antimicrobial radiation curable coating

InactiveUS20050080158A1Activity depletedInferior antimicrobial efficacyBiocideAntifouling/underwater paintsCross-linkOligomer

The invention is a radiation curable coating containing an antimicrobial agent, where upon irradiation with UV light, the radiation curable coating rapidly cures to a polymeric coating. The polymeric coating has durable antimicrobial properties, being especially effective at preventing the growth of Staphylococcus aureaus and Kleibsella pneunoniae on wood flooring and furniture. The major components in the radiation curable coating are a urethane acrylic oligomer, a radiation cure package, an antimicrobial agent, a cross-linking agent, and optionally, an additive package. The radiation curable urethane oligomer is a relatively short chain backbone urethane polymer that is end capped with a radiation curable moiety, where the moiety is an acrylic. The cross-linking agent is one or more monomers used to lower the viscosity and promote cross-linking, and include acrylate esters of mono-, di-, tri-, or tetrafunctional alcohols. The radiation cure package contains at least one photoinitiator.

Owner:MICROBAN PROD CO INC

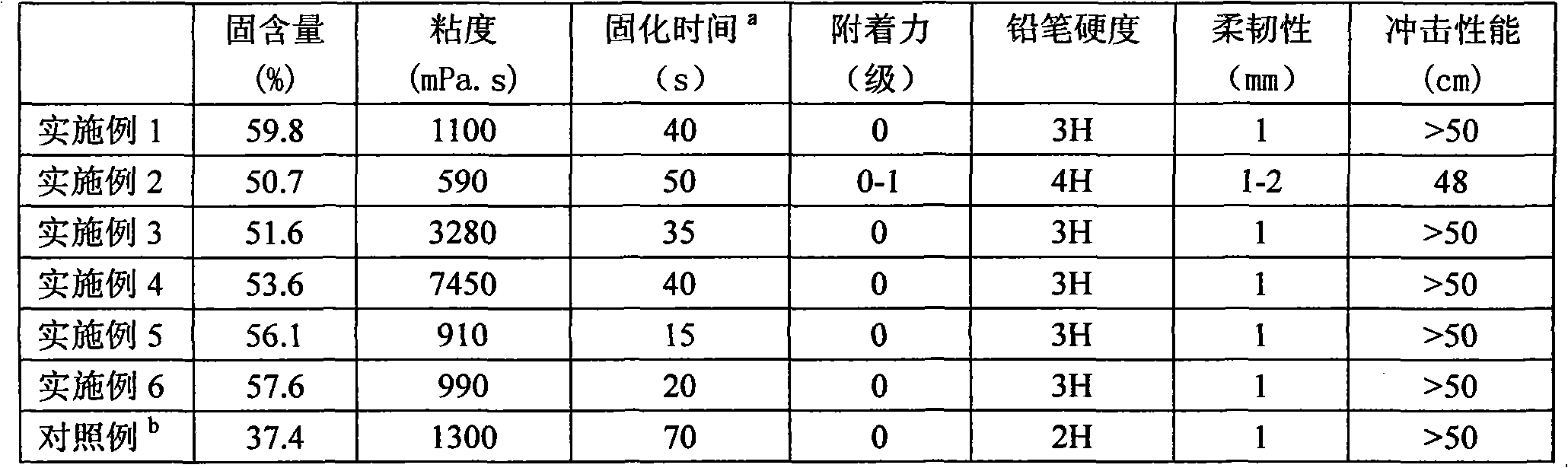

High-solid-content UV (Ultraviolet)-curing aqueous urethane acrylate dispersion liquid and preparation method thereof

InactiveCN102030884AImprove curing efficiencyReduce consumptionPolyurea/polyurethane coatingsDistillationAdhesive

The invention discloses a high-solid-content UV-curing aqueous urethane acrylate dispersion liquid and a preparation method thereof, wherein the method comprises the following steps of: firstly carrying out the monoesterfication reaction on the partial hydroxide group at the tail end of hyperbranched polyester and the anhydride group of dicarboxylic anhydride to obtain an intermediate I; carrying out the end capping reaction on an isocyanate group in diisocyanate and the hydroxide group in a hydroxyalkyl methacrylate monomer to obtain a reaction intermediate II; carrying out the reaction on the residual hydroxide group of the intermediate I and the residual isocyanate group of the reaction intermediate II to obtain a reaction intermediate III; and carrying out alkali neutralization, aqueous dispersion and reduced-pressure distillation on the reaction intermediate III to remove an organic solvent to obtain the UV-curing urethane acrylate aqueous dispersion liquid. The dispersion liquid has the characteristics of high solid content, relatively low viscosity, UV curability, good mechanical performance of a paint film and the like, conforms to the concept of environmental protection, can be applied to the fields of environment-friendly coatings, aqueous ink, aqueous adhesives, fabric coating agents and the like and has broad prospect.

Owner:SOUTH CHINA UNIV OF TECH

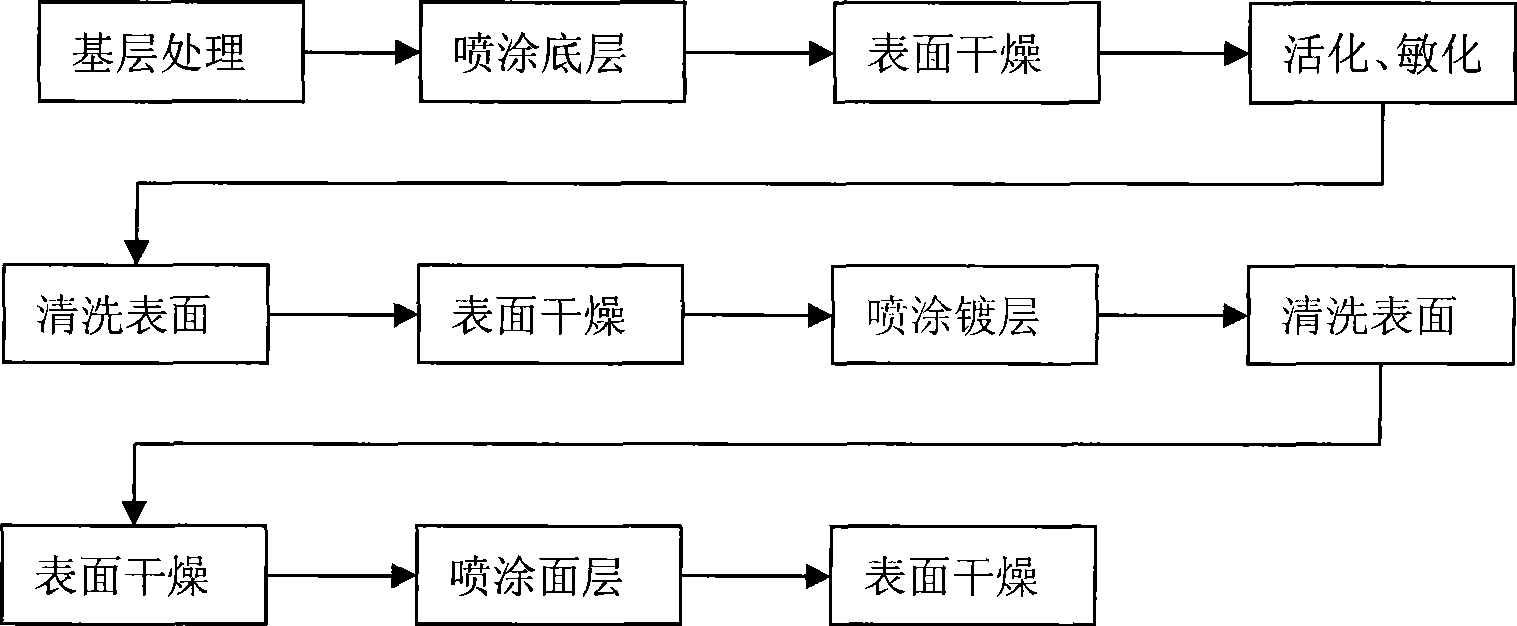

Nano spray plating technique for silver mirror

InactiveCN101469427AAvoid processing powerAvoid environmental problemsLiquid/solution decomposition chemical coatingSuperimposed coating processSurface layerWeather resistance

The invention provides nanometer spray plating for a silver mirror, namely obtain a high glaze metal mirror face by adopting coating technique, which is similar to the brand new decorative effect of plating. The whole technique consists of a paint bottom layer, a metal reflecting layer (spray plating layer) and a paint surface layer. The coating has excellent adhesive attraction, shock resistance, corrosion resistance, weather resistance and marresistance, has rich colors and is bright like a mirror. The nanometer spray plating can be used to various materials such as metal, resin, ABS, PC, PP+PS carbon element resin, plastic, glass, pottery and porcelain, acrylic, wood, plastic wood and calcium plastic.

Owner:汪正红

Exterior coatings for golf balls

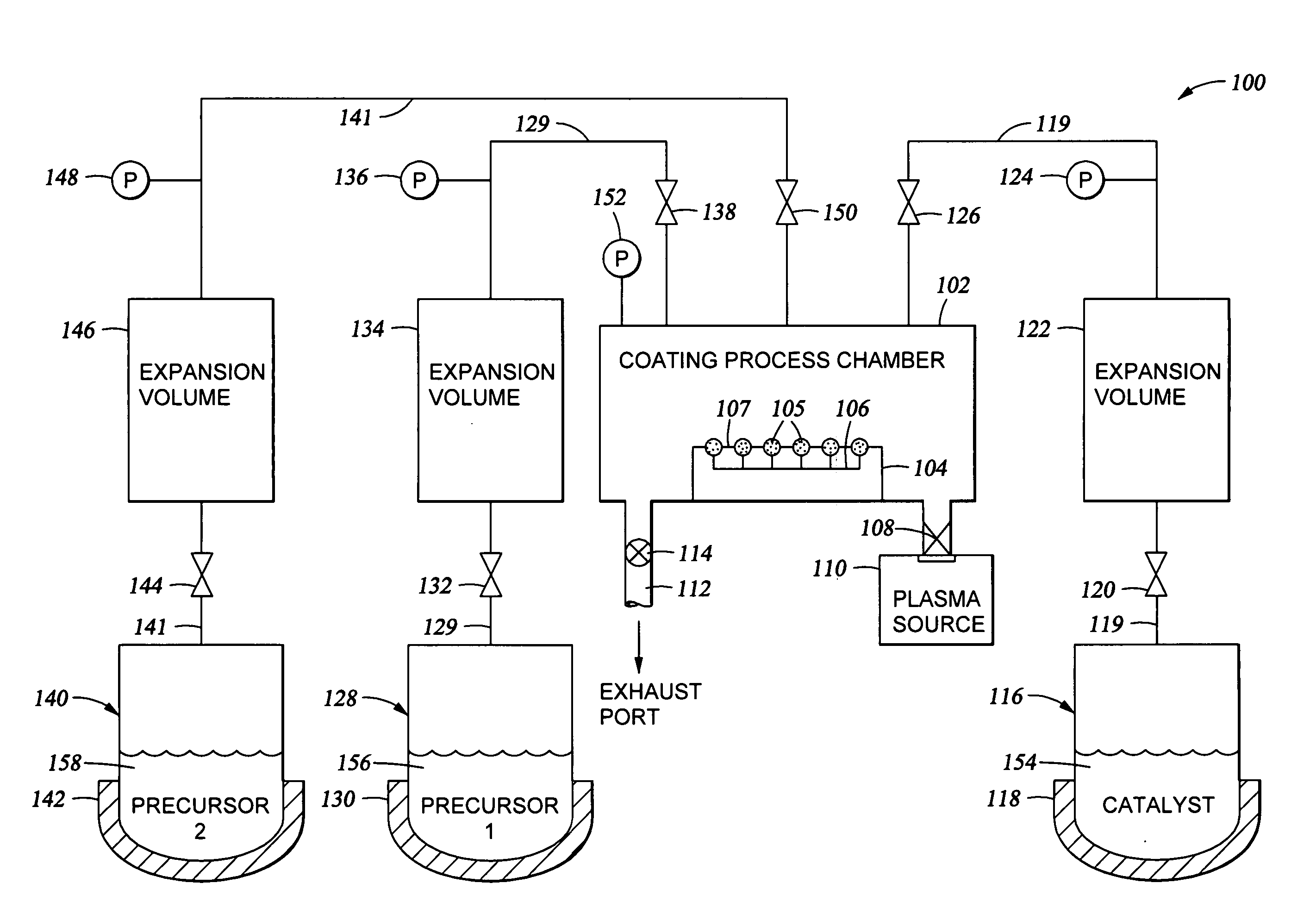

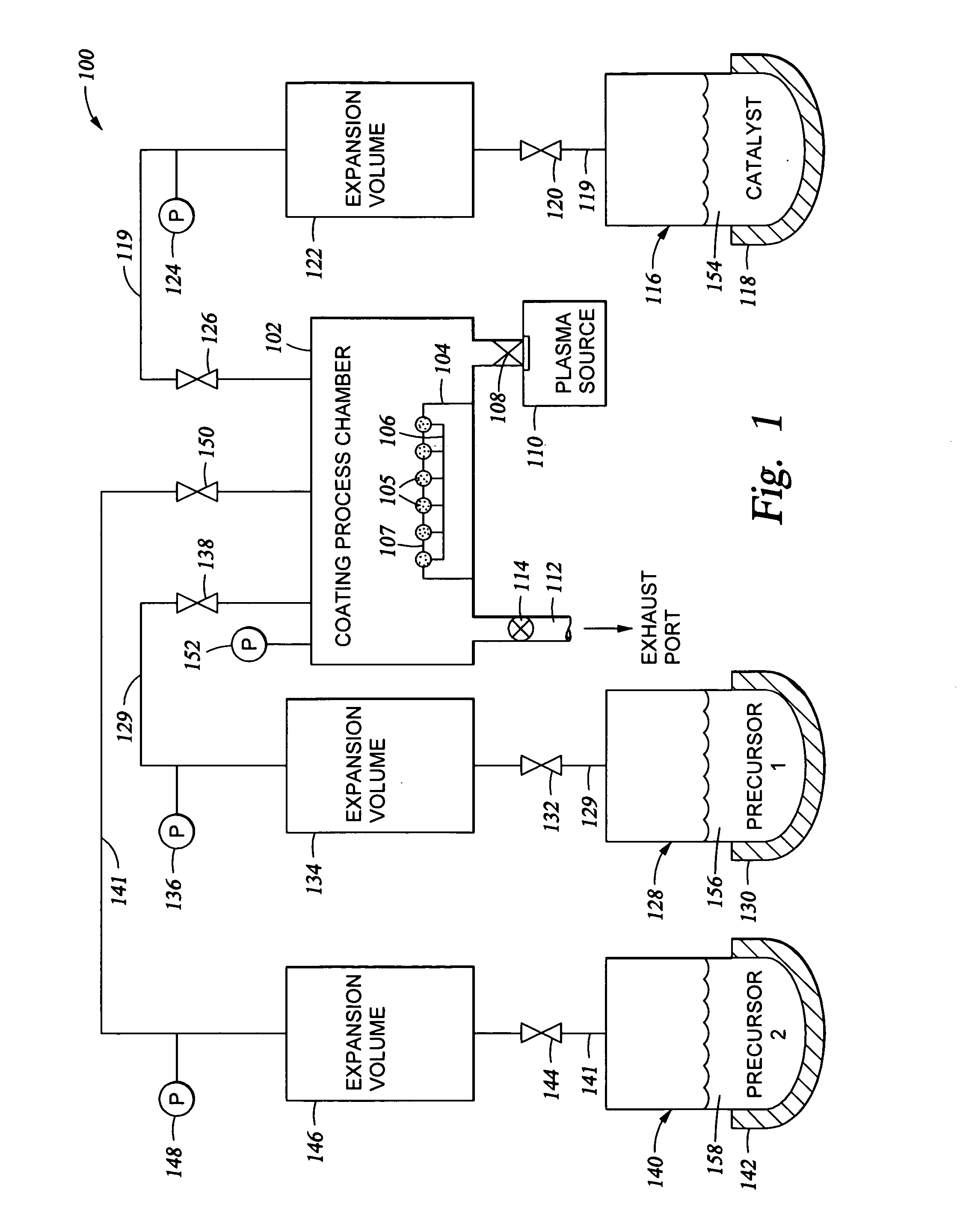

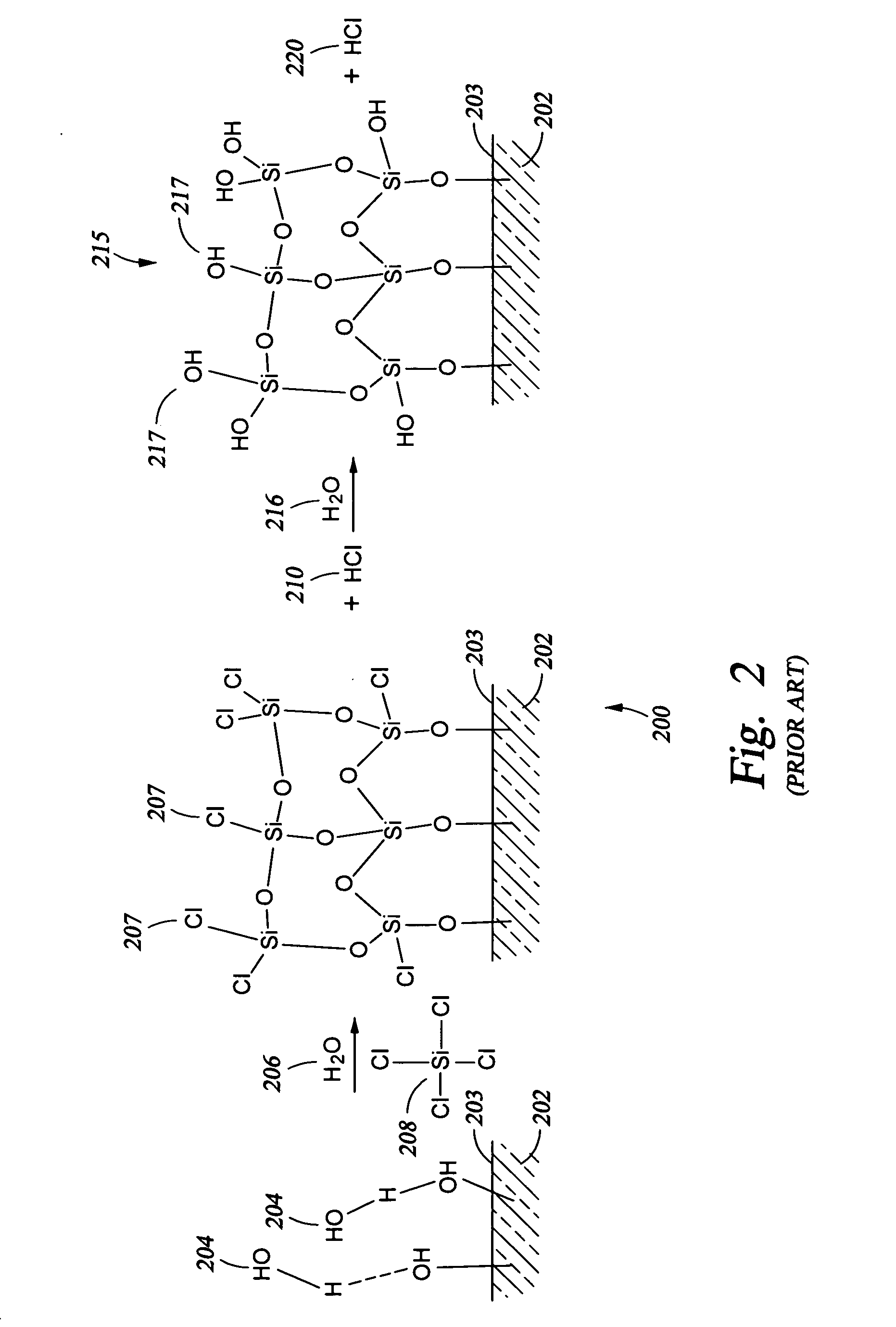

InactiveUS20070213143A1Reduce painting costEasy to controlPretreated surfacesSpecial surfacesGas phaseSurface roughness

Improved golf ball exterior coatings which are used to create an extremely uniform hydrophobic or hydrophilic exterior surface on the golf ball. When the surface of the golf ball is hydrophobic, it tends to repel water, and this reduces drag on the golf ball surface as the golf ball travels through the air. When the surface of the golf ball is hydrophilic, the surface of the golf ball wets uniformly and the ball rolls straighter on a wet green, as the forces acting on the ball are more uniform. The hydrophobic or hydrophilic exterior coating is applied to the golf ball using vapor-phase deposition in instances where strict control over coating thickness uniformity, and / or reduced surface roughness is desired.

Owner:APPLIED MICROSTRUCTURES

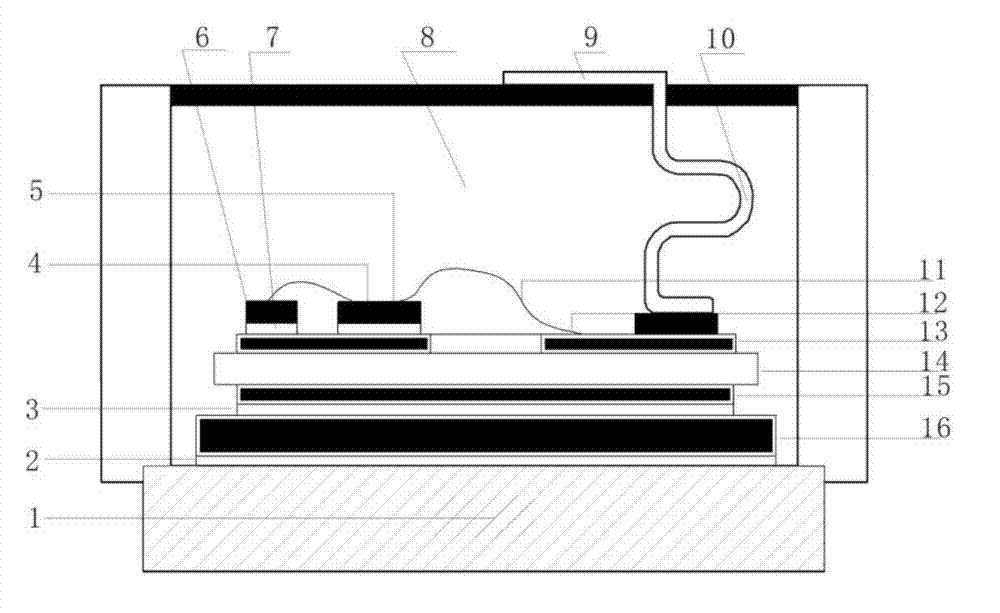

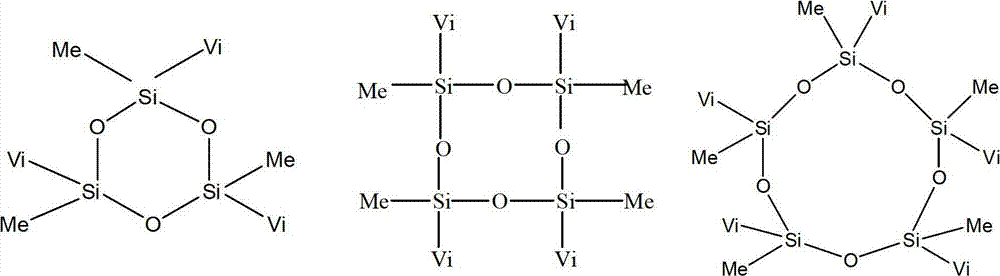

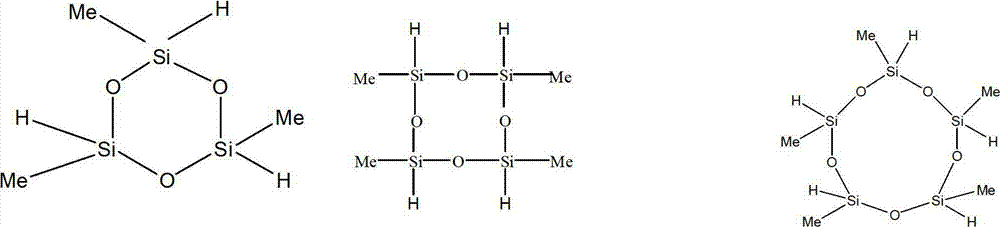

Organic silica gel used for packaging IGBT (insulated gate bipolar translator) module, and preparation method of organic silica gel

InactiveCN102807757AViscosity is convenient and controllableHigh reactivitySemiconductor/solid-state device detailsSolid-state devicesOptical propertyHigh intensity

The invention relates to an organic silica gel used for packaging an IGBT (insulated gate bipolar translator) module and a preparation method of the organic silica gel. The organic silica gel comprises a component A and a component B according to the weight proportion of 1:1, wherein the component A comprises the following raw materials by weight part: 94 to 99.89 parts of base material, 0.01 to 5 parts of silane coupling agent, and 0.1 to 1 part of catalyst; the component B comprises the following raw materials by weight part: 79 to 95 parts of base material, 5 to 15 parts of crosslinking agent, 0.01 to 5 parts of fire retardant and 0.1 to 1 part of inhibitor. The organic silica gel used for packaging the IGBT module has excellent optical property, high strength, low oil leakage, and fire resistance, is transparent, is solidified fast at high temperature, is capable of satisfying the long-term operating requirements under high and / or low temperature environments, and is mainly beneficial to sealing and encapsulation protection of the IGBT modules.

Owner:YANTAI DEBANG ADVANCED SILICON MATERIALS

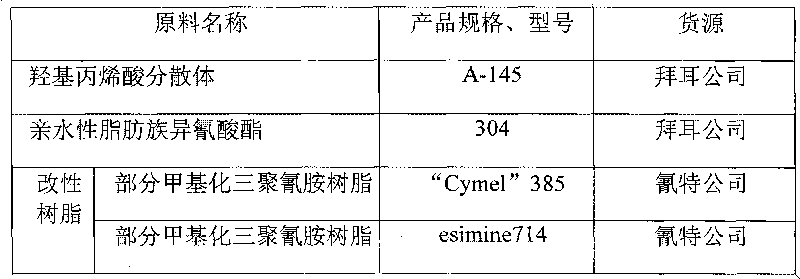

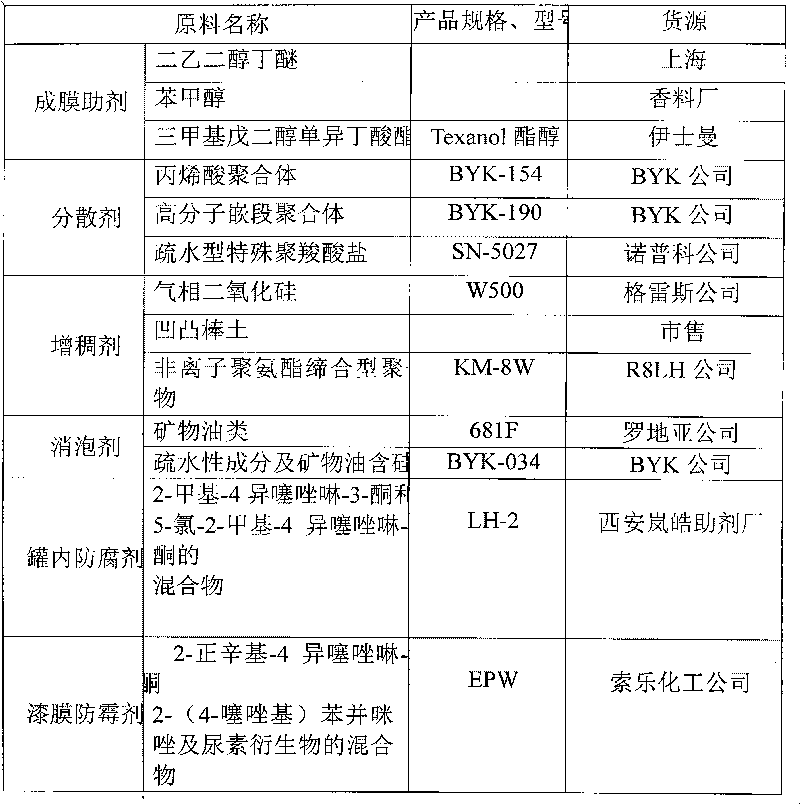

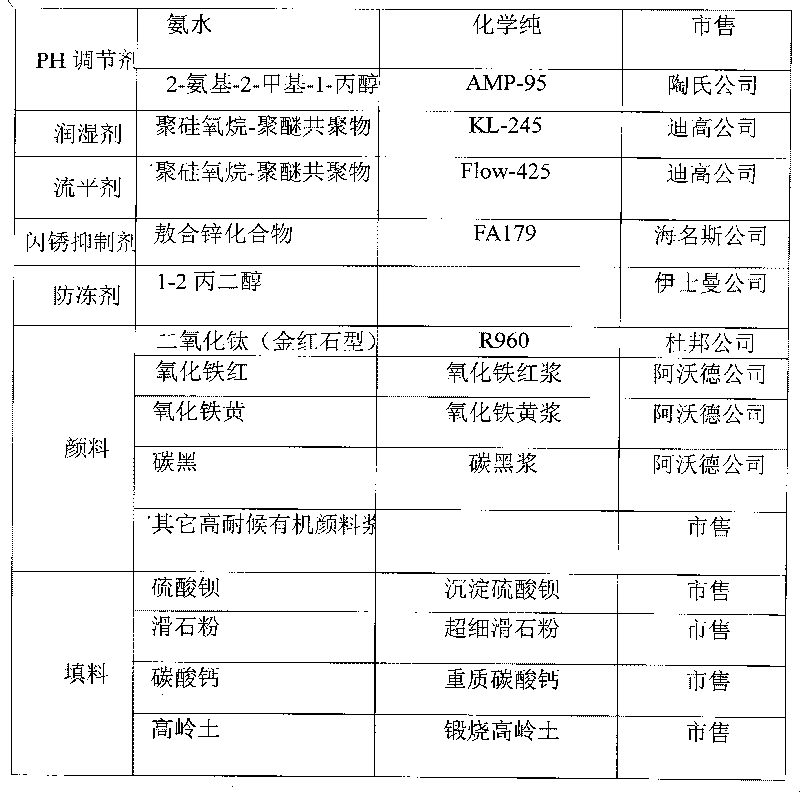

Water-based two-pack polyurethane preservative coating and preparation method thereof

ActiveCN101701128AHigh glossGood chemical resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedDipropylene glycol monomethyl ether acetate

The invention relates to the preservative coating technology, in particular to a water-based two-pack polyurethane preservative coating and a preparation method thereof. The water-based two-pack polyurethane preservative coating comprises two parts, namely paint vehicle and curing agent, wherein the paint vehicle is prepared from water-based hydroxylated acrylic dispersion, modified resin, pigment, filler, additive and water, the curing agent part comprises hydrophilic aliphatic isocyanate, dodecyl ester and propylene glycol methyl ether acetate. When using the coating of the invention, the weight ratio of the paint vehicle to the curing agent is 74-85:15-26 and the coating can solve the defects of the existing preservative coating.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

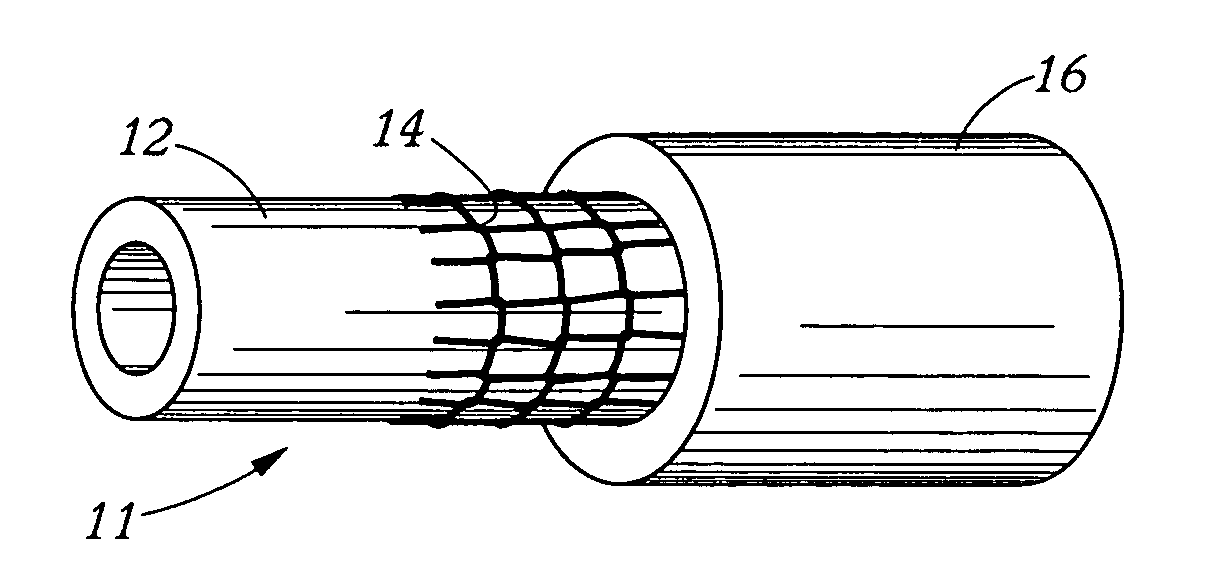

Fluid transfer hose reinforced with hybrid yarn

ActiveUS20080072984A1Improve adhesionDramatic performance improvementEngine sealsInternal combustion piston enginesYarnAramides

A flexible hose comprising a tube, a knit fabric, and a cover. The knit fabric comprises a hybrid yarn which comprises a first yarn of co-para-aramid fibers and a second yarn of meta-aramid fibers. The hose exhibits significantly improved burst pressure and / or improved impulse fatigue resistance.

Owner:THE GATES CORP

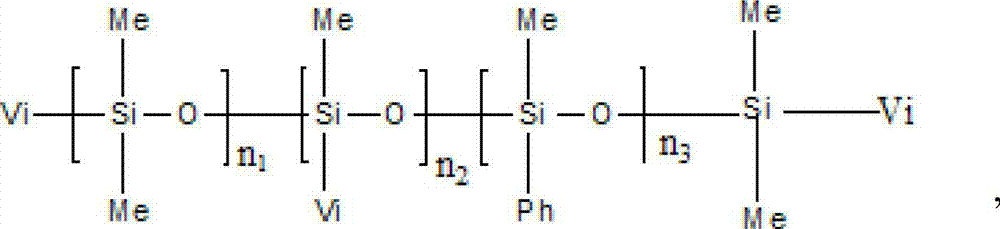

Vulcanization-proof LED (light-emitting diode) packaging silica gel

InactiveCN102965069AStrong adhesionIncrease dosageNon-macromolecular adhesive additivesMacromolecular adhesive additivesVulcanizationAdhesive

The invention relates to an LED (light-emitting diode) packaging silica gel, and in particular relates to a vulcanization-proof LED packaging silica gel, belonging to the technical field of adhesives. The vulcanization-proof LED packaging silica gel comprises a component A and a component B, wherein the weight ratio of the component A to the component B is 1: 1; the component A comprises raw materials based on parts by weight: 50-60 parts of methyl phenyl vinyl silicone oil, 30-60 parts of methyl vinyl MQ resin, 0.1-0.3 part of platinum catalyst and 3-5 parts of bonding agent; and the component B comprises raw materials based on parts by weight: 40-50 parts of methyl phenyl vinyl silicone oil, 30-50 parts of methyl vinyl MQ resin, 5-15 parts of cross-linking agent and 0.1-0.3 part of inhibitor. The vulcanization-proof LED packaging silica gel has excellent adhesive force for silver, phenyl-propanolamine (PPA), glass and the like, and has the light transmittance of more than 98%; and phenyl-containing functional groups and branched chain type vinyl are introduced into the LED packaging silica gel, and the dosage of the vinyl MQ resin is increased, so that the crosslinking density and the curing handness are improved, and therefore, the vulcanization resistance of a packaging adhesive layer can be improved.

Owner:YANTAI DEBANG ADVANCED SILICON MATERIALS

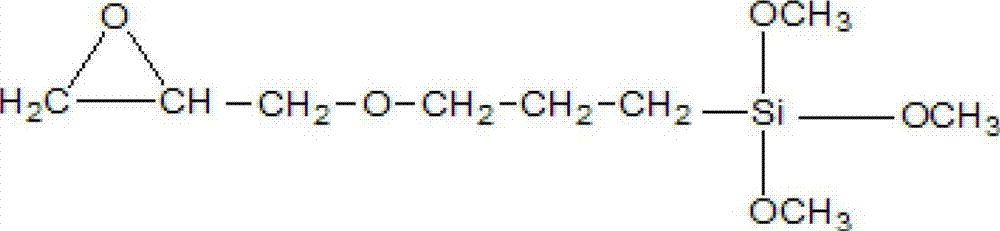

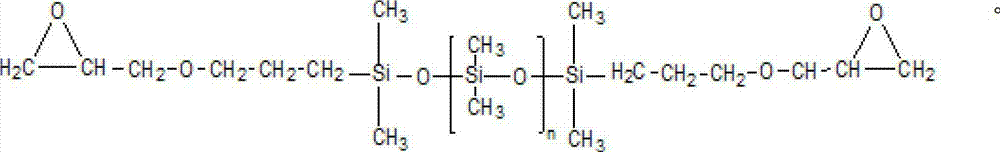

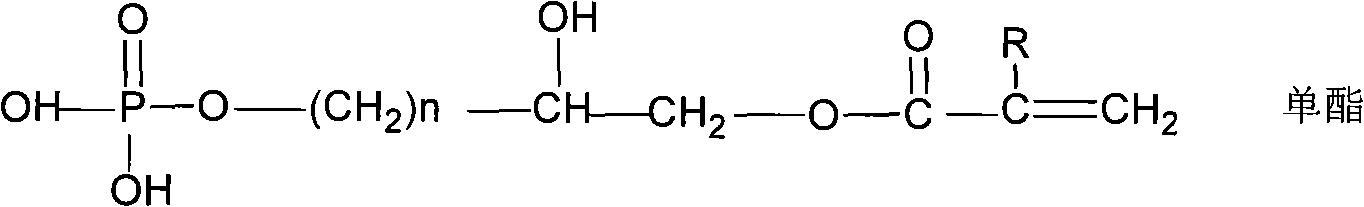

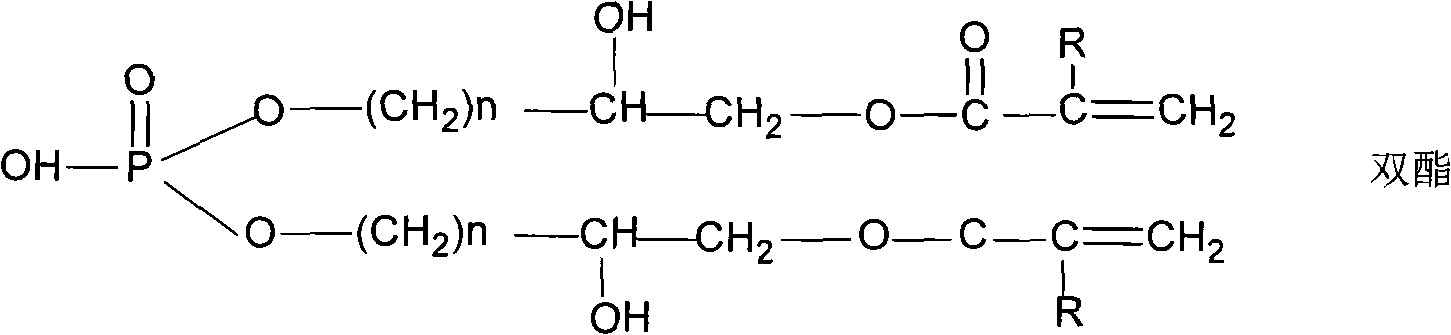

Organic silicon / hydroxyl phosphate composite modified water emulsion acrylic resin and preparation method and application thereof

ActiveCN101775101AIncrease crosslink densityAccelerated corrosionAnti-corrosive paintsWater dispersibleEmulsion

The invention discloses organic silicon / hydroxyl phosphate composite modified water emulsion acrylic resin and a preparation method and application thereof; hydroxy-phosphate and organic siloxane which are synthesized are co-polymerized into modified acrylic resin, wherein the weight percentage of the solid resin is 45 to 55 percent, and the balance is deionized water; the components which form the acrylic resin and the consumption thereof are as follows: 35 to 60 percent of acrylate monomer, 30 to 40 percent of vinyl aromatic monomer, 3 to 10 percent of organic silicon monomer, 5 to 10 percent of hydroxy ester monomer, 1.5 to 4.0 percent of composite emulsifier, 0.5 to 1.0 percent of pH value regulator, and the initiator is 0.5 to 1.5 percent of the consumption of the acrylate monomer; after the resin is prepared into single-component anti-corrosive coating, the anti-corrosive performance of the collating is better than that of the single-component anti-corrosive coating prepared by the traditional water dispersible acrylic resin; and simultaneously, the invention improves the defect that the water dispersible acrylic resin needs to be polymerized through a solution method, facilitates the realization of zero VOC emission, and achieves the purposes of environmental protection and energy saving.

Owner:广东优贝精细化工有限公司

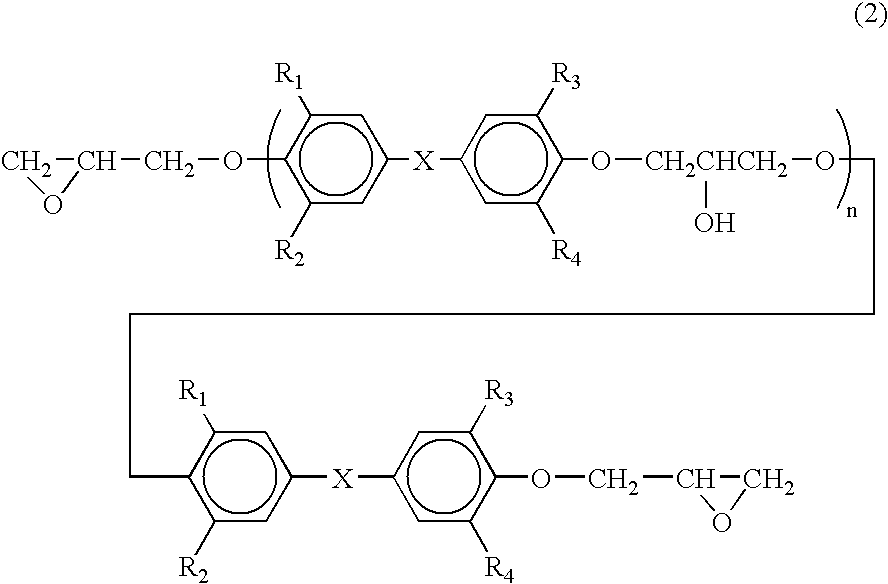

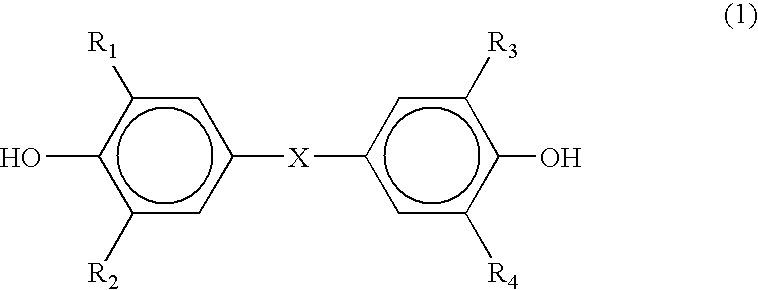

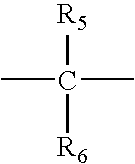

Epoxy resin, epoxy resin composition thereof and cured product thereof

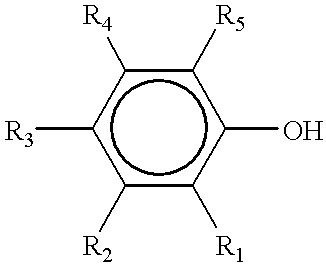

ActiveUS20040176563A1Increase crosslink densityImprove heat resistanceOrganic chemistrySynthetic resin layered productsHydrocarbonEpoxy

An epoxy resin represented by general formula (2), R1-R4 indicate hydrocarbon group of carbon number 1-6, n is 0 or integer of 1 or more and X in aromatic compound (1) is a bond or following general formula wherein R1-R6 indicates hydrogen atom or hydrocarbon group of carbon number 1-6, obtained by reacting aromatic compound represented by general formula (1) and epihalohydrine, having molecular weight distribution comprising, content of n=0 component in the epoxy resin represented by general formula (2) is 60% or less and epoxy equivalent is 250 g / eq or over.

Owner:NIPPON STEEL CHEMICAL CO LTD

High-fullness high-resolution environment protection polyureshane sublight uarnish

InactiveCN1483777AIncreased weight percentageReduce weightPolyurea/polyurethane coatingsKetoneSolvent

The present invention relates to a high-fullness high-distinctness environment-protecting type polyurethane matte varnish. Said varnish consists of the paint component, polyurethane solidifying agent component and diluting agent component according to the ratio of 1:0.5:0.6-0.8. The polyurethane solidifying agent component contains 50-70 wt% of tolylene diisocyanate trimer, and the rest is the affixture of 80% of tolylene diisocyanate and 20% of trimethylol propane, the paint component contains 15-25% of short oil soya alkyd resin whose solid content is 80%, 50-60% of modified saturated polyester resin, 0-5% of castor oil, 10-12% of aldehyde ketone resin whose solid content is 60%, 3-5% of flatting silica, 0.3-1.0% of teflon wax and 4%-10% of conventional adjuvant and solvent, and the diluting agent component contains 70-80% of butyl acetate, 10-20% of mixed diacid dimethyl ester and 10-15% of isophorone.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

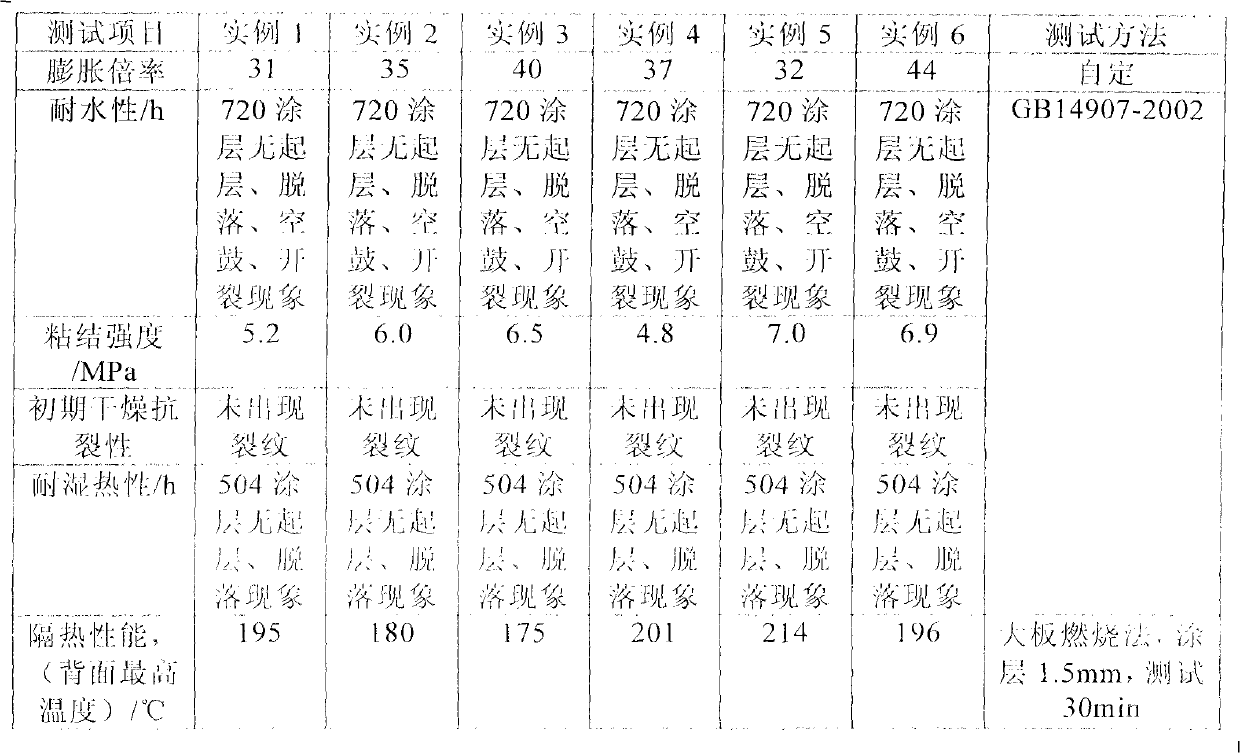

Polyurea expanding type fireproof paint as well as preparation method and application thereof

ActiveCN102559022AImprove insulation performanceImprove fire and heat insulation performanceFireproof paintsPolyurea/polyurethane coatingsFoaming agentPetrochemical

The invention relates to expanding type fireproof paint taking polyurea resin as a film forming substance and application of the expanding type fireproof paint. The expanding type fireproof paint contains a component A and a component B, wherein the component A contains an isocyanate prepolymer, the component B contains an amino-terminated polyether, a polyamine chain expanding agent, a diluting agent, a carbonizing catalyst, a carbonizing agent, a foaming agent, a flame retardant, a smoke suppressing agent, a pigment filler, an adjuvant and a mixed solvent, and the weight ratio of the component A to the component B is 1:5 to 1:7. The fireproof paint is suitable for the fireproof protection of indoor and outdoor steel structures and nonmetal structures and can be used for prohibiting the propagation of flame and the transmission of heat to a substrate. The expanding type fireproof paint is suitable for the fireproof protection in the fields of airport facilities, municipal engineering, vehicles, ships, petrochemical facilities and the like.

Owner:MARINE CHEM RES INST

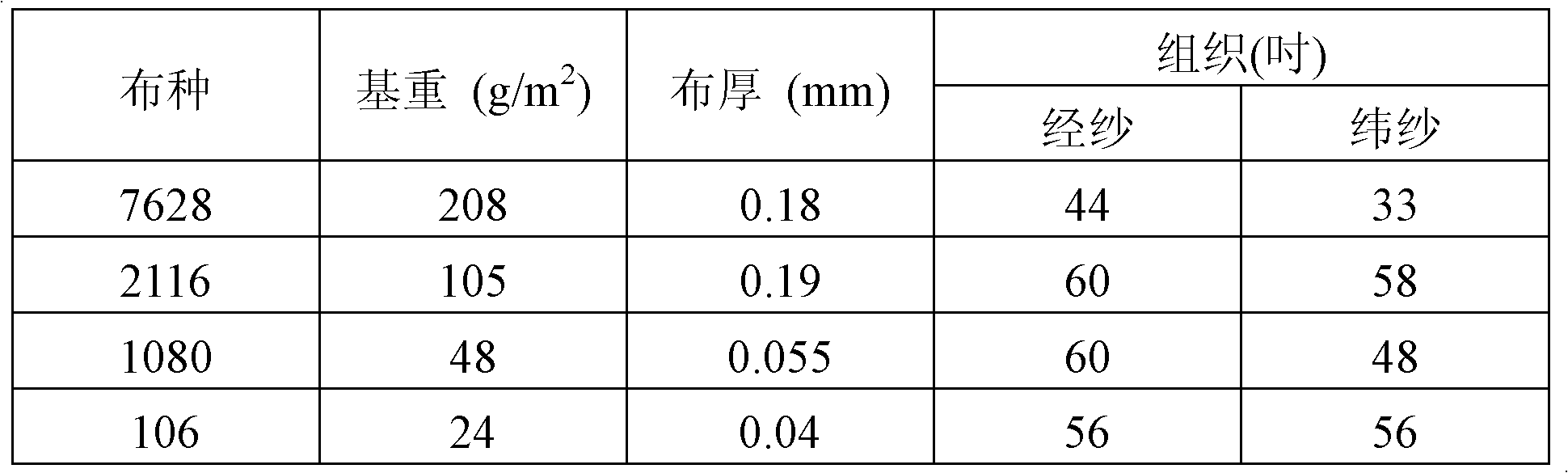

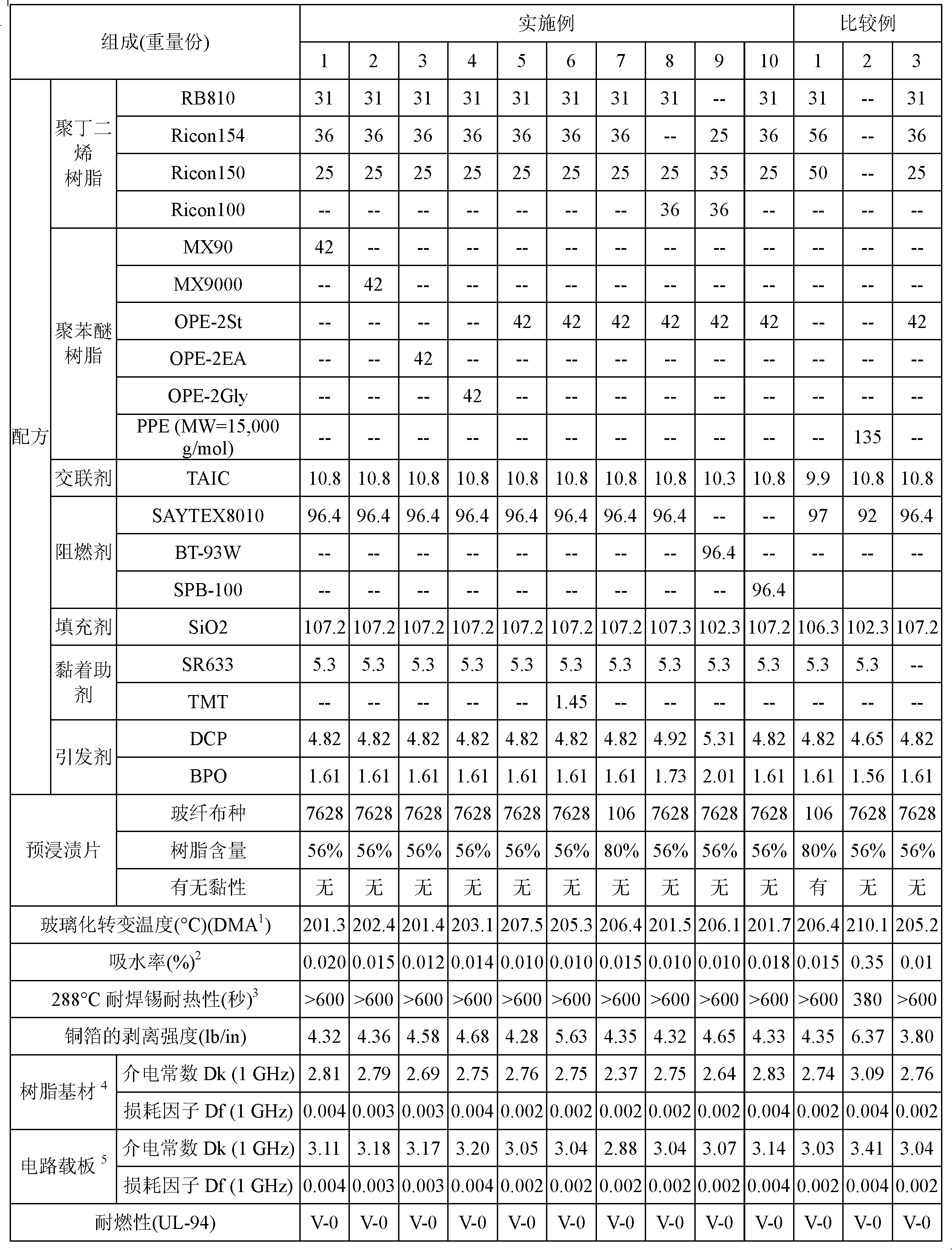

High-frequency copper foil substrate and composite material used thereby

ActiveCN102304264ALow costHigh frequencySynthetic resin layered productsCircuit susbtrate materialsCross-linkSolubility

The invention discloses a high-frequency copper foil substrate with an operating frequency of more than 1GHz, which has a dielectric constant Dk of less than 3.2 and a loss factor Df of less than 0.005 as well as high glass transition temperature, high thermostability and low moisture-absorption characteristic. The high-frequency copper foil substrate contains a special composite material and is prepared by impregnating a reinforcing material with blended resin mixture. The resin mixture of the composite material is prepared by blending the following materials: (a) high molecular weight polybutadiene resin; (b) low molecular weight polybutadiene resin; (c) modified polyphenyl ether thermosetting resin; (d) inorganic powder; (e) flame retardant; (f) cross-linking agent; (g) binding aid; and (h) hardening initiator. In the invention, the drawback of low processability of pure polybutadiene with low viscosity and the drawback of need of adding plasticizer of polyphenyl ether resin (PPE) with low solubility; particularly, the non-viscous pre-impregnated sheets made by the composite material can be processed into copper foil substrates automatically.

Owner:NANYA PLASTICS CORP

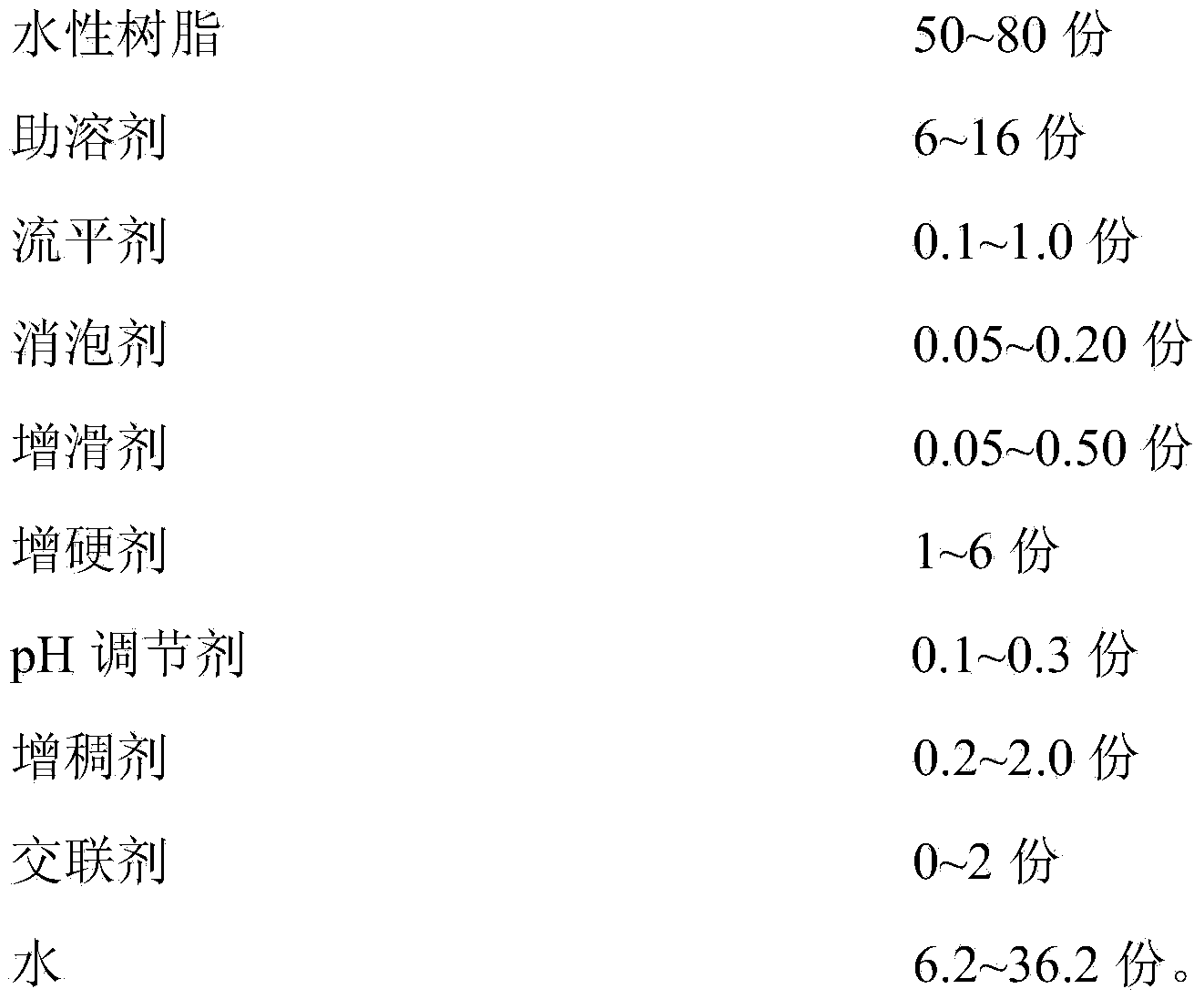

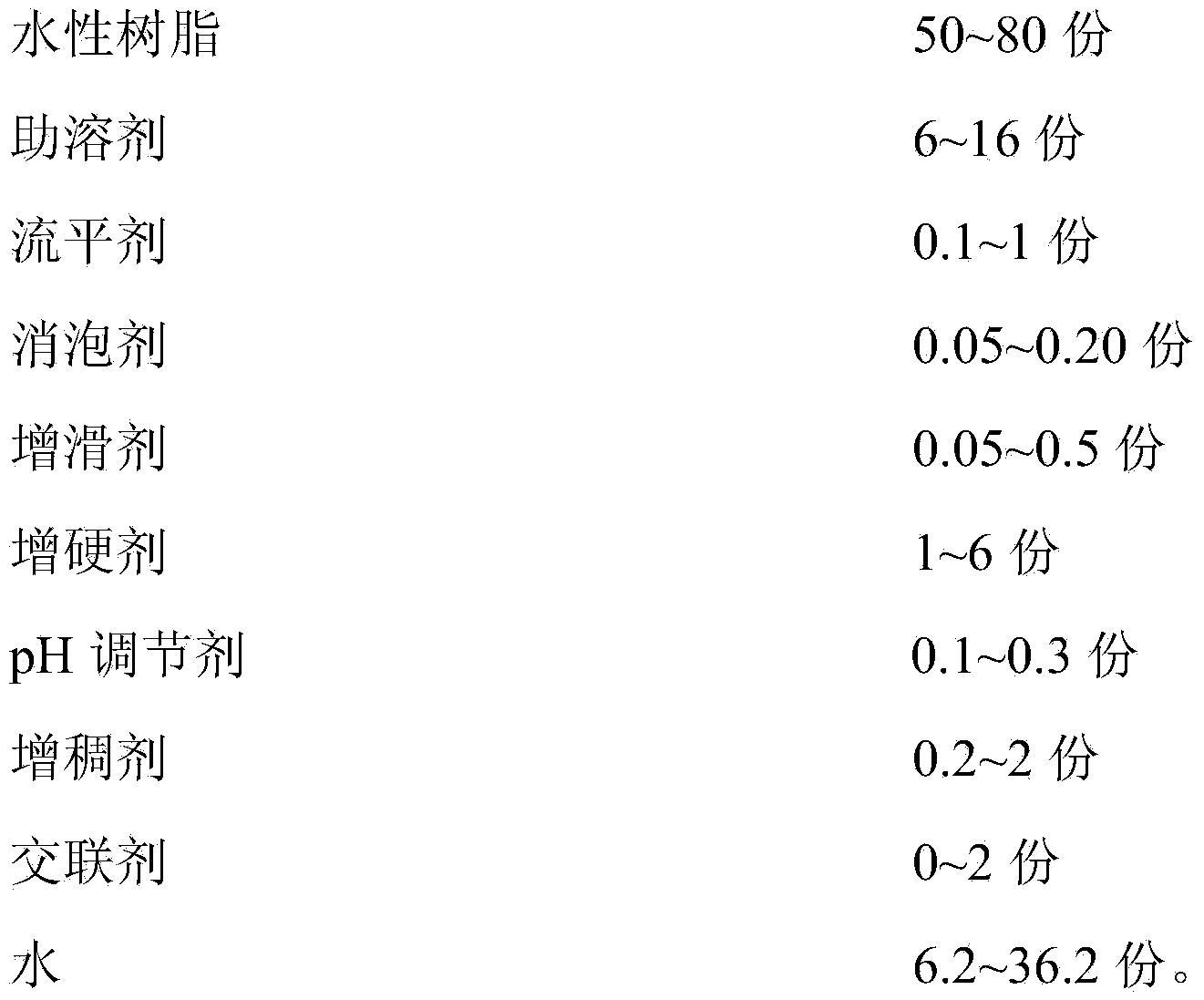

High-strength directly aluminizing water-based base coat and preparation method and application of high-strength directly aluminizing water-based base coat

ActiveCN103866607AGood sealingGood flexibilityNon-fibrous pulp additionPaper/cardboardWater basedWater vapor

The invention discloses high-strength directly aluminizing water-based base coat and a preparation method and application of the high-strength directly aluminizing water-based base coat. The directly aluminizing water-based base coat comprises the following components in parts by mass: 50-80 parts of water-based resin, 6-16 parts of cosolvents, 0.1-1 part of flatting agents, 0.05-0.20 part of antifoaming agents, 0.05-0.5 part of slipping agents, 1-6 parts of hardening agents, 0.1-0.3 part of pH regulator, 0.2-2 parts of thickening agents, 0-2 parts of crosslinking agents and 6.2-36.2 parts of water. With good closure, the direct aluminizing water-based base coat disclosed by the invention guarantees the filling of micropores in the paper surface as well as the separation of water vapor; due to the characteristic of flexibility, the bending resistance of paper is realized; the viscosity resistance ensures that the film rolls are not bonded with each other after base coating on the aluminizing body paper; moreover, by adjusting the leveling property of the selected resin system and the coating, the base coat has high aluminizing metal texture.

Owner:GUANGZHOU HUMAN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com