Patents

Literature

42 results about "Lysine diisocyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethanes for osteoimplants

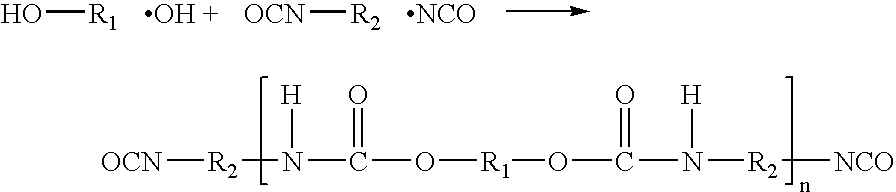

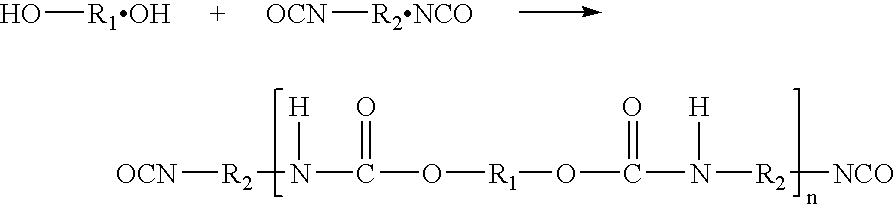

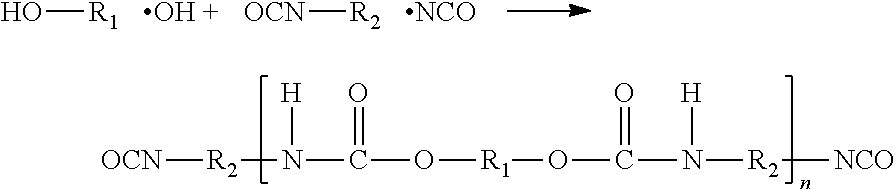

Biological-based polyurethanes and methods of making the same. The polyurethanes are formed by reacting a biodegradable polyisocyanate (such as lysine diisocyanate) with an optionally hydroxylated biomolecule to form polyurethane. The polymers formed may be combined with ceramic and / or bone particles to form a composite, which may be used as an osteoimplant.

Owner:WARSAW ORTHOPEDIC INC

Polyurethanes for osteoimplants

ActiveUS20050027033A1Low and high molecular weightGood flexibilityImpression capsBone implantLysine diisocyanatePolymer

Biological-based polyurethanes and methods of making the same. The polyurethanes are formed by reacting a biodegradable polyisocyanate (such as lysine diisocyanate) with an optionally hydroxylated biomolecule to form polyurethane. The polymers formed may be combined with ceramic and / or bone particles to form a composite, which may be used as an osteoimplant.

Owner:WARSAW ORTHOPEDIC INC

Polyurethanes for osteoimplants

InactiveUS7985414B2Increase crosslink densityBone implantPharmaceutical non-active ingredientsLysine diisocyanatePolymer

Biological-based polyurethanes and methods of making the same. The polyurethanes are formed by reacting a biodegradable polyisocyanate (such as lysine diisocyanate) with an optionally hydroxylated biomolecule to form polyurethane. The polymers formed may be combined with ceramic and / or bone particles to form a composite, which may be used as an osteoimplant.

Owner:WARSAW ORTHOPEDIC INC

Polyurethanes for osteoimplants

ActiveUS8002843B2Good flexibilityLow and high molecular weightImpression capsBone implantLysine diisocyanatePolymer

Owner:WARSAW ORTHOPEDIC INC

Polyureaurethane material and method of producing a polyureaurethane material

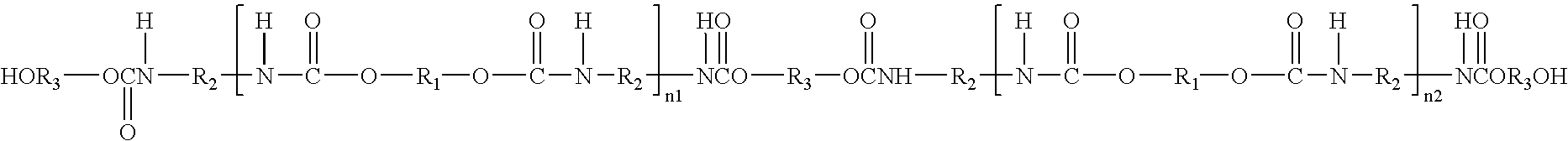

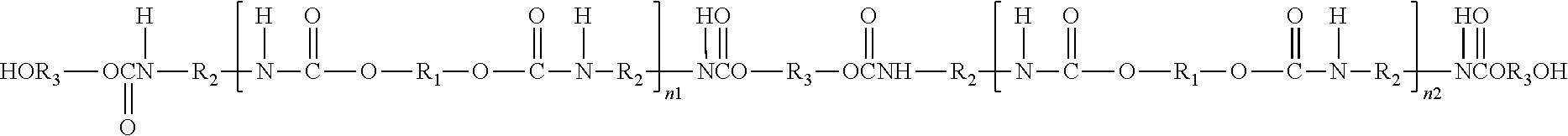

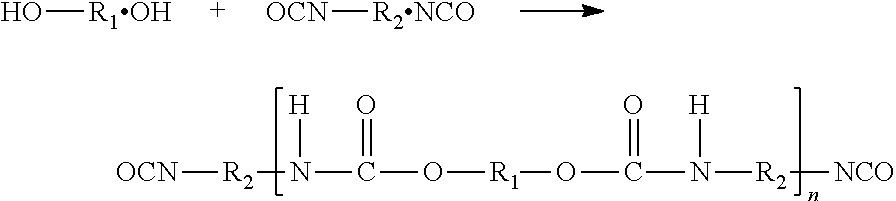

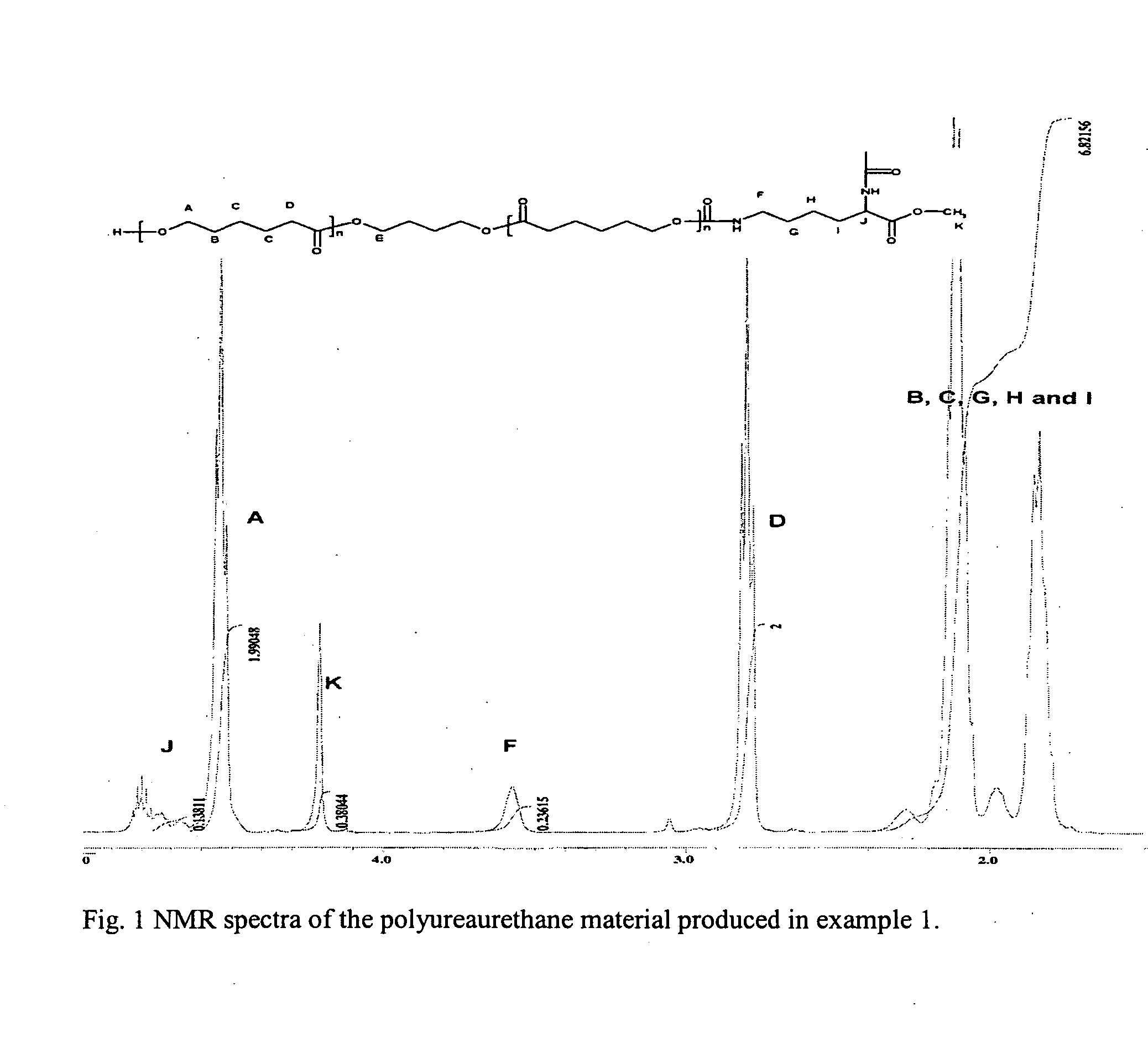

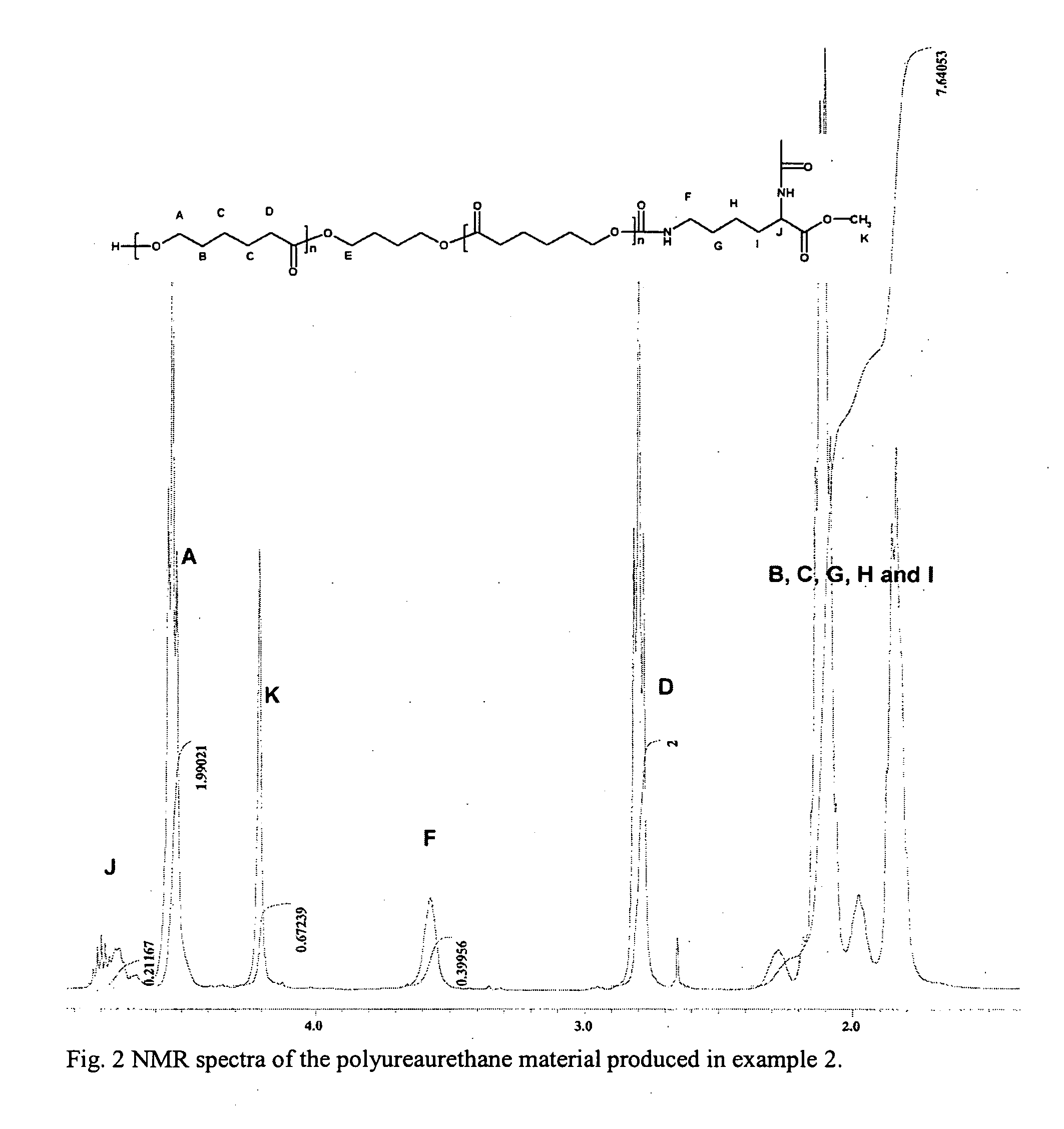

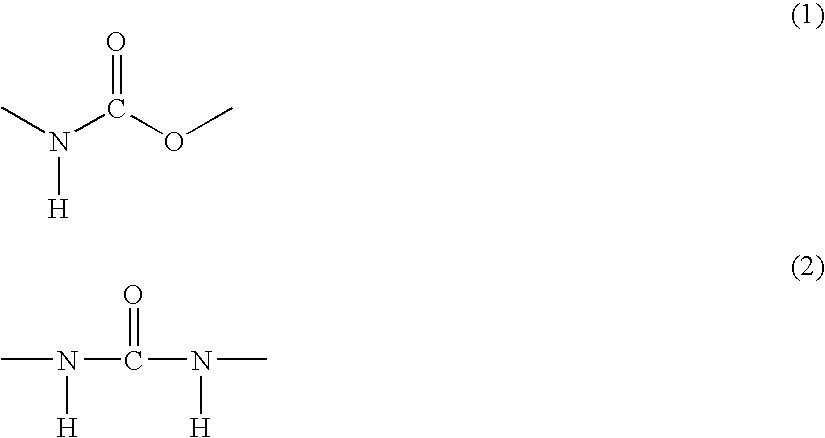

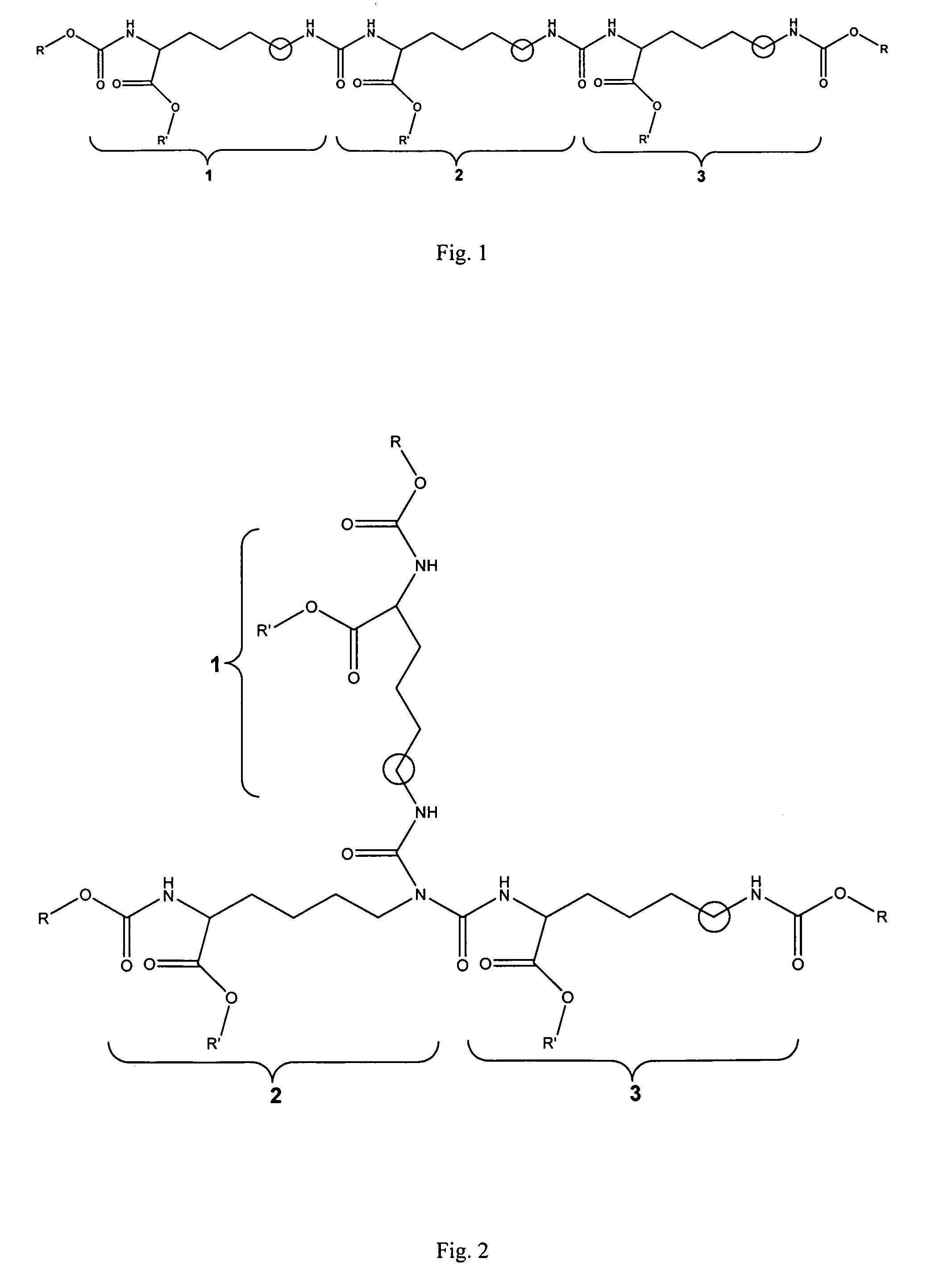

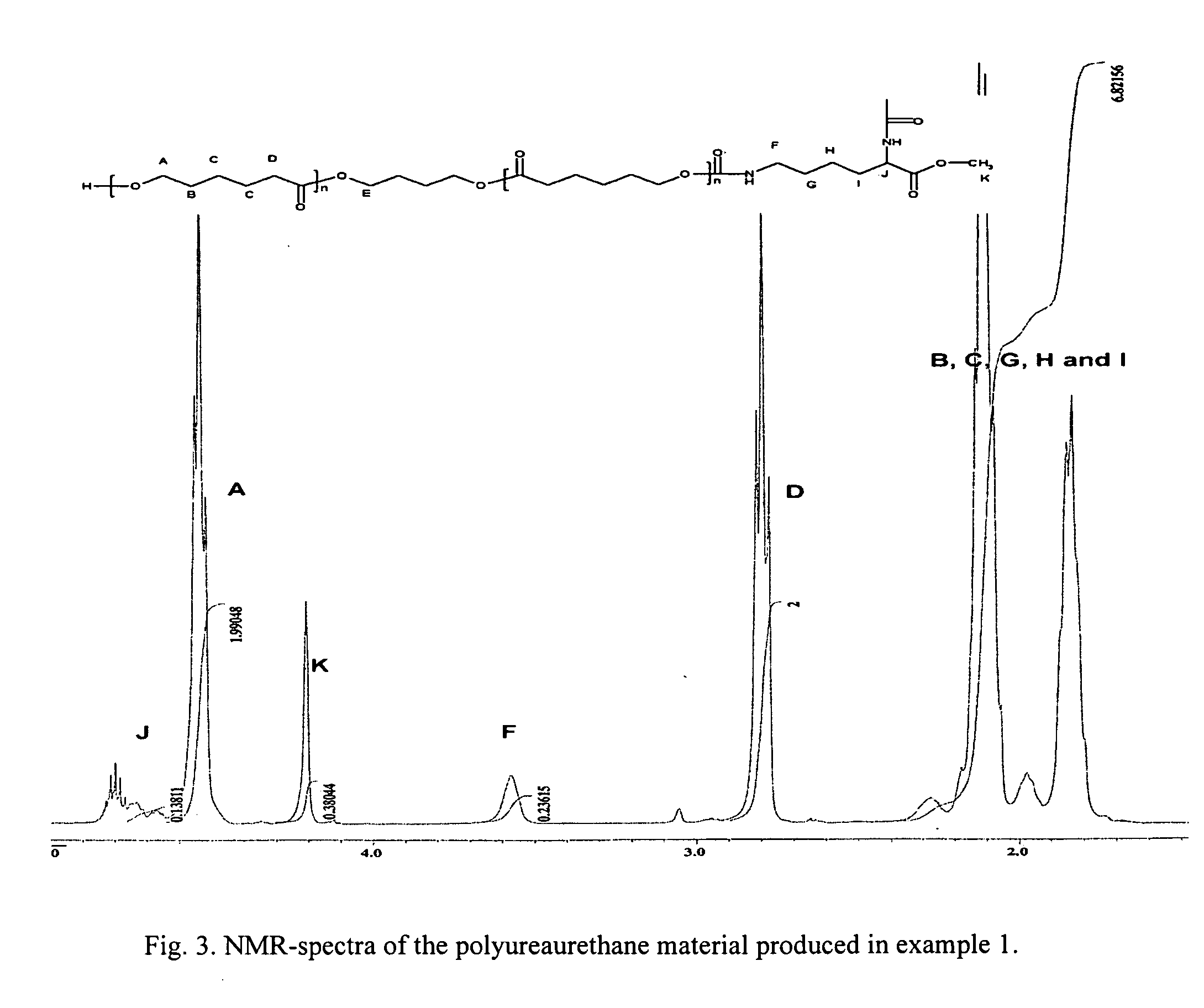

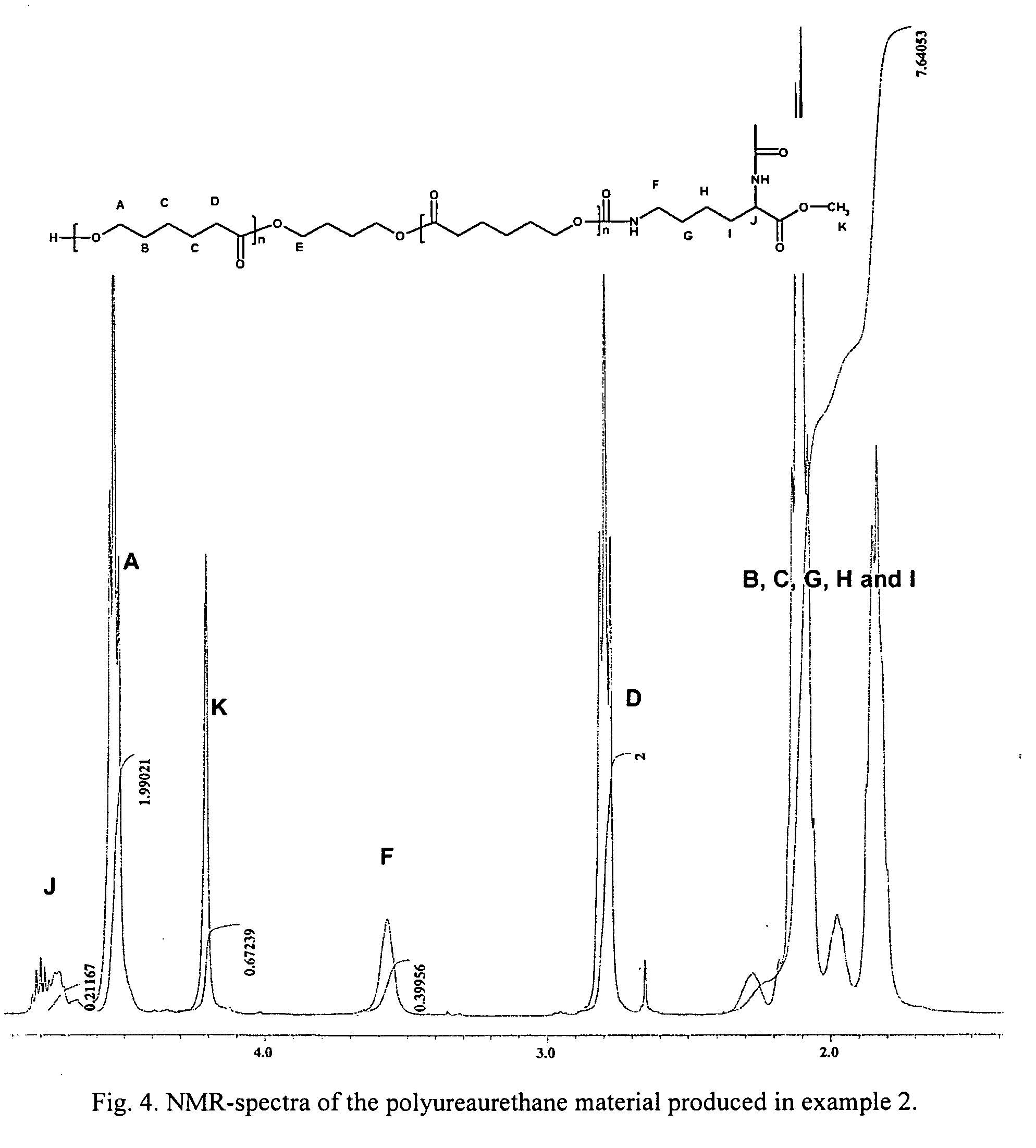

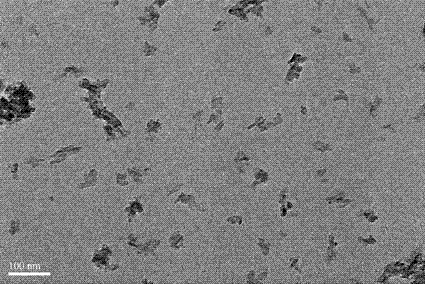

The present invention relates to a linear polyureaurethane polymer, comprising in its hard blocks, at least two urea groups. The hard block of the polyureaurethane material is preferably synthesized by using diisocyante groups in the form of lysine diisocyanate (LDI). The soft block component of the polyureaurethane material is preferably poly(epsilon-caprolactone) (PCL). The invention also relates to a method of producing a polyureaurethane polymer, which in short comprises the steps of reacting a soft block component with a diisocyante group in order to prepare a prepolymer component, combining the prepolymer component with a catalyst in order to define a reaction solution and adding water to the reaction solution, preferably carried to the reaction solution in vapour phase.

Owner:RADI MEDICAL SYST

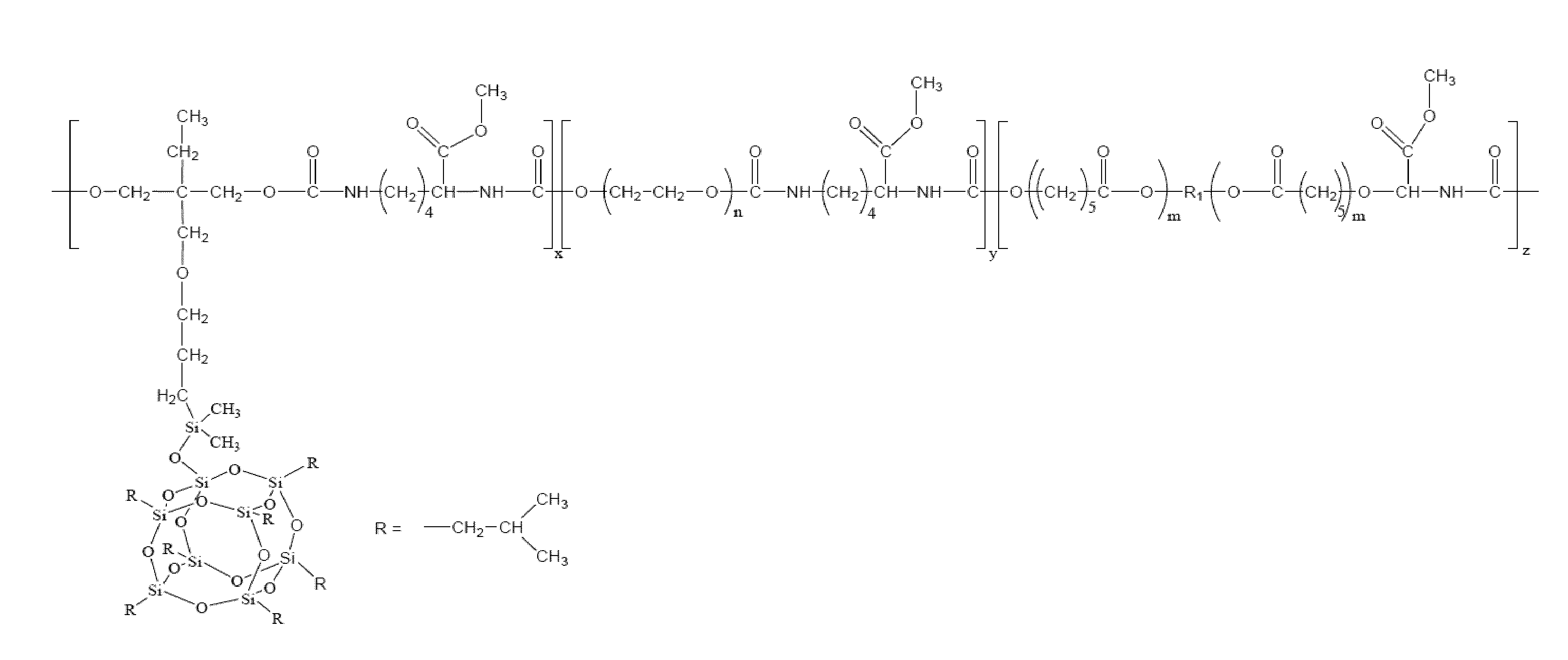

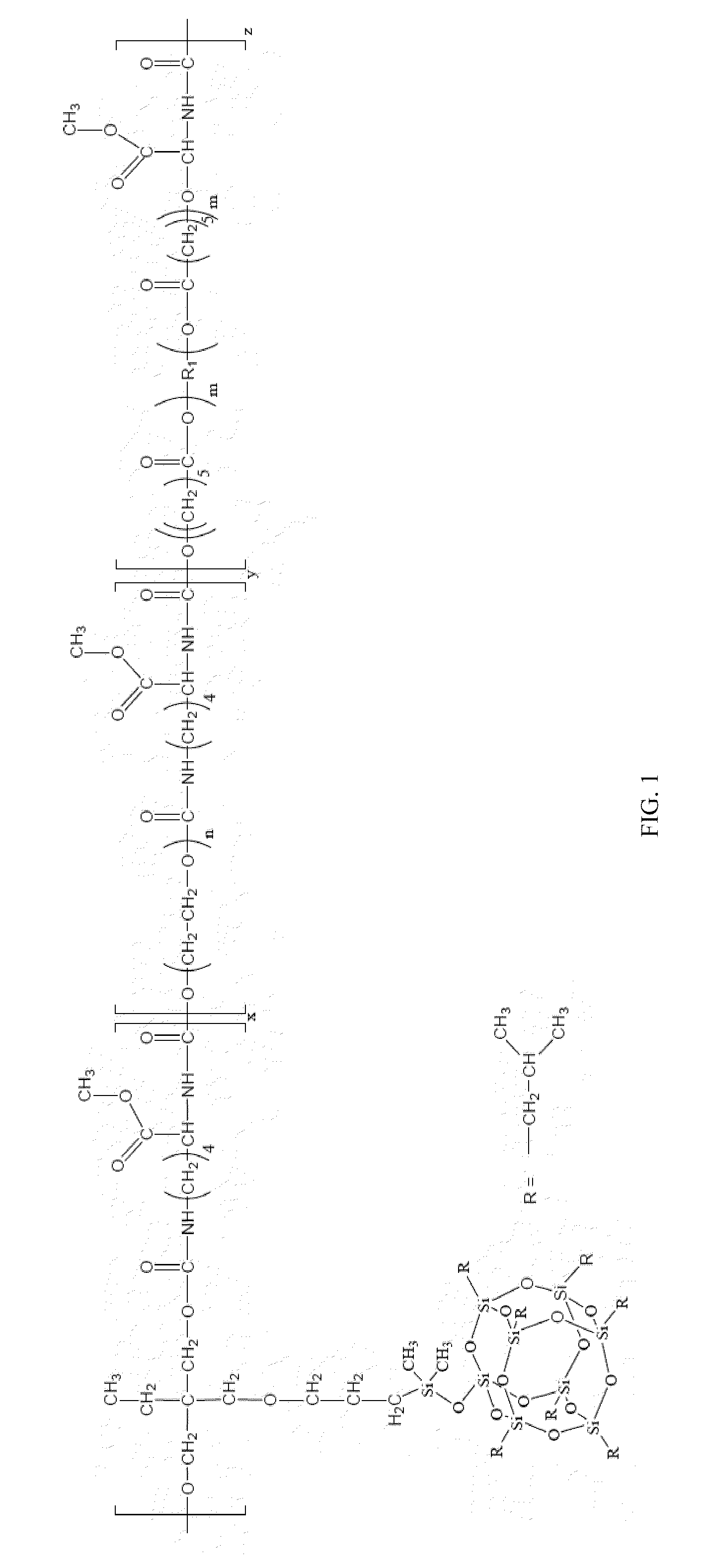

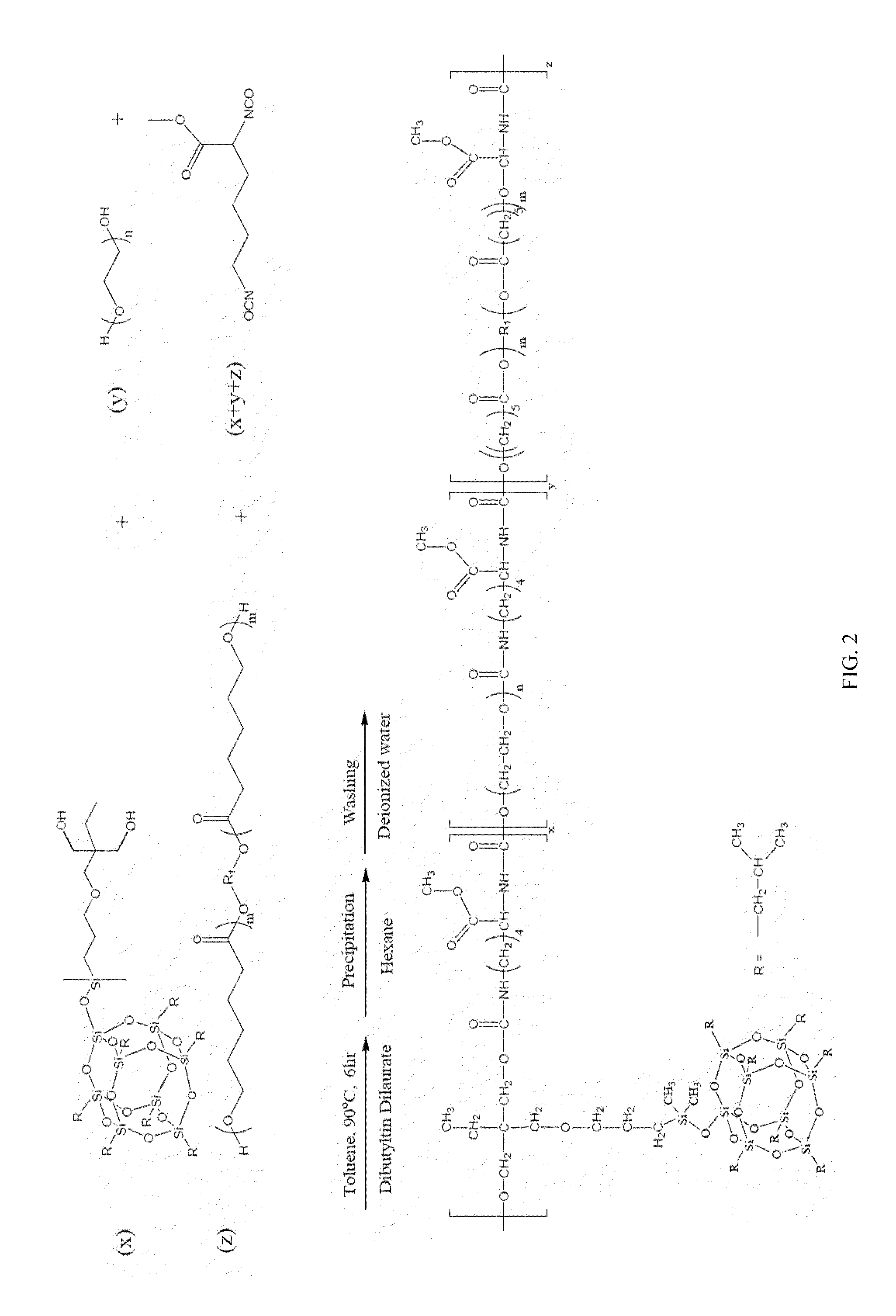

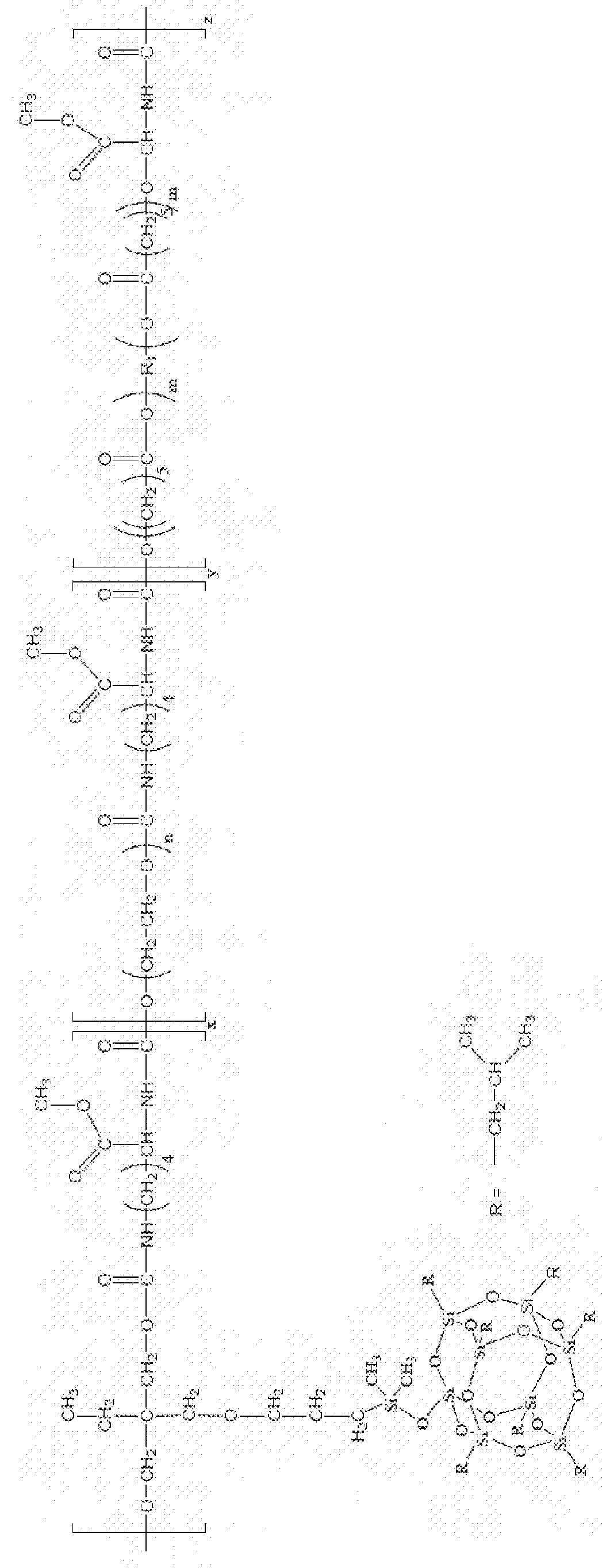

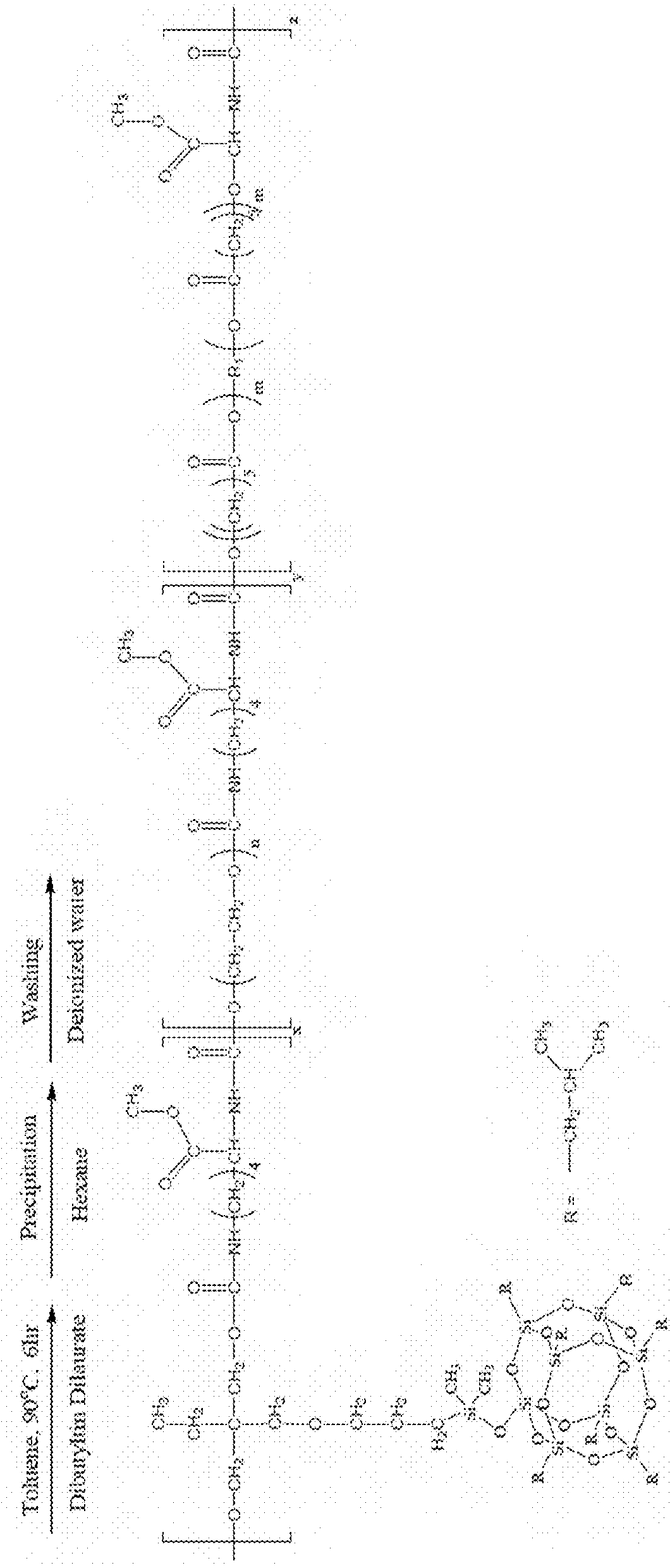

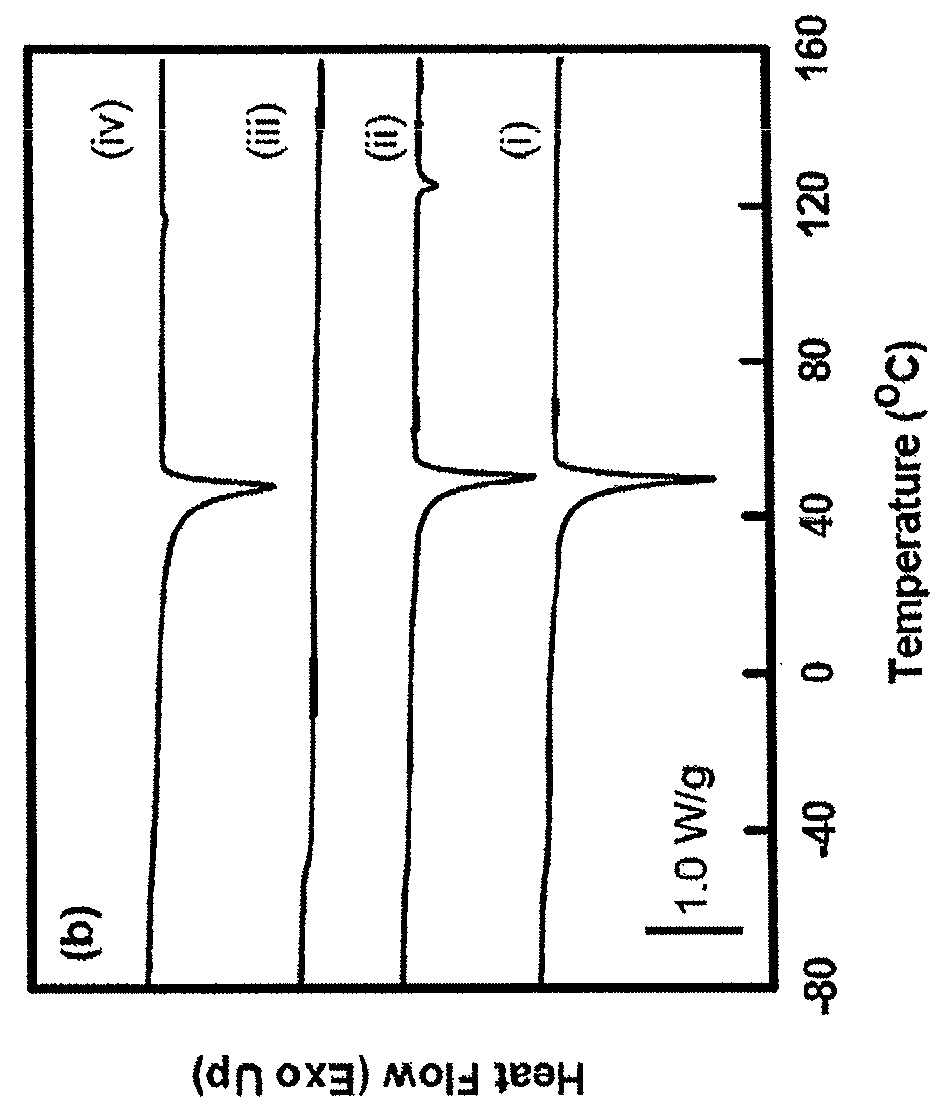

Polyhedral oligomeric silsesquioxane polyurethanes

A multi-block thermoplastic polyurethanes system which incorporates polyhedral oligomeric silsesquioxane into conventional biodegradable thermoplastic polyurethanes built up by poly(ε-caproactone) and polyethylene glycol blocks, resulting in biostability. The multi-block thermoplastic polyurethanes are synthesized from lysine-diisocyanate with poly(ε-caprolactone)-diol, polyhedral oligomeric silsesquioxane-diol, and poly(ethylene glycol) using a one-step synthesis process.

Owner:SYRACUSE UNIVERSITY

Polyureaurethane material and method of producing a polyureaurethane material

The present invention relates to a linear polyureaurethane polymer, produced without the use of any chain extender. The hard block of the resulting polymer thus consists of diisocyante groups linked to each other via without the presence of any chain extender component. The hard block of the polyureaurethane material is preferably synthesized by using diisocyante groups in the form of lysine diisocyanate (LDI). The soft block component of the polyureaurethane material is preferably poly(epsilon-caprolactone) (PCL). The invention also relates to a method of producing a polyureaurethane polymer, which in short comprises the steps of reacting a soft block component with a diisocyante group in order to prepare a prepolymer component, combining the prepolymer component with a catalyst in order to define a reaction solution and adding water to the reaction solution, preferably carried to the reaction solution in vapour phase.

Owner:NOVUS SCI

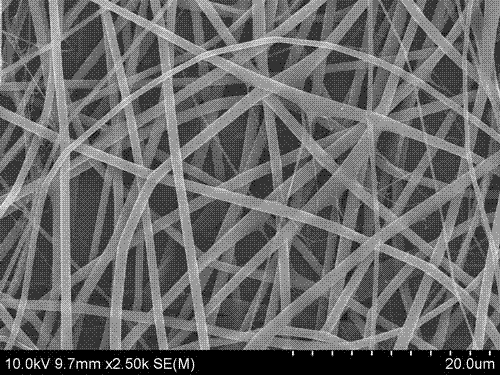

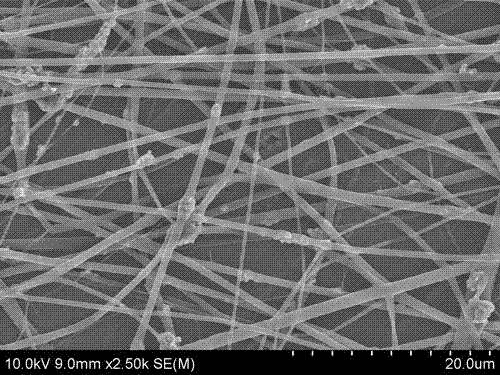

Preparation method of LDI-PCLLA-PEG-PCLLA/hydroxyapatite electrospun fiber membrane as well as product and application thereof

InactiveCN107982575AEasy to prepareGood biocompatibilityTissue regenerationProsthesisLysine diisocyanateCross-link

The invention relates to a method in the technical field of medical materials and in particular relates to a preparation method of an LDI-PCLLA-PEG-PCLLA / hydroxyapatite electrospun fiber membrane as well as a product and application thereof. The preparation method comprises the following steps: taking a main component of a body cross-linked structure biological scaffold which takes polycaprolactone polylactic acid-polyethylene glycol-polylactic acid (PCLLA-PEG-PCLLA) as a soft segment and takes L-lysine diisocyanate (LDI) as a hard segment, taking nano-sized hydroxyapatite particles as an inorganic filling material, and performing electrostatic spinning, thereby obtaining the composite nano fiber membrane. The compounded fiber membrane scaffold achieves effects of promoting bone growth andinducing osteoblast differentiation of cells.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

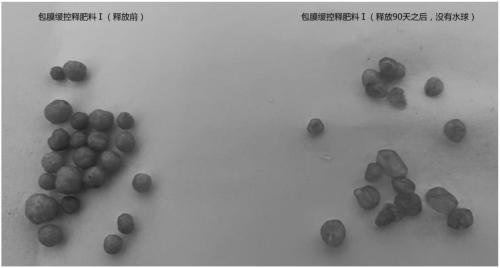

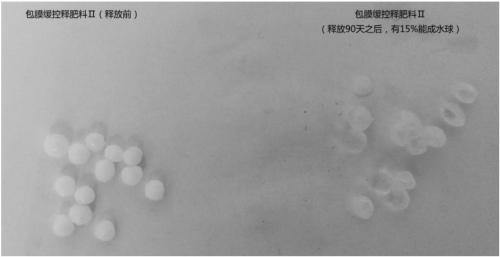

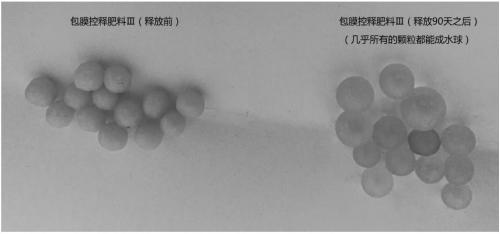

Slow/controlled-release fertilizer having water retention function and preparation method of slow/controlled-release fertilizer

The invention relates to the field of slow / controlled-release fertilizers, and in particular relates to a slow / controlled-release fertilizer having a water retention function and a preparation methodof the slow / controlled-release fertilizer. The slow / release-fertilizer includes a fertilizer inner core and a coating material; and the coating material is formed by mixing an A material and a B material, wherein the A material includes a palm oil polyol, or includes a mixture formed by mixing the palm oil polyol and one or more selected from a polyester polyol and castor oil, the B material includes one of toluene diisocyanate, lysine diisocyanate and polymethylene polyphenyl polyisocyanate or a mixture formed by mixing of two or more selected from the toluene diisocyanate, the lysine diisocyanate and the polymethylene polyphenyl polyisocyanate. The preparation method comprises the steps of polishing the surface of the fertilizer inner core to be smooth, performing heating to 55-80 DEG C,spraying the A material and the B material, performing curing for a period of time, repeating the above step for 2-5 times, finally adding a certain amount of paraffin, and performing uniform rolling. According to the slow / controlled-release fertilizer having the water retention function and preparation method provided by the invention, the slow / controlled-release effects satisfy the growth requirements of plants, and the chemical fertilizer has a high utilization rate, high water retention performance and excellent biodegradability.

Owner:宋继宏

High solid content nanometer polyurethane adhesive and preparation method therefor

InactiveCN104974705AHigh solid contentHigh bonding strengthNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesLysine diisocyanatePolyurethane adhesive

The invention discloses a high solid content nanometer polyurethane adhesive and a preparation method therefor. The high solid content nanometer polyurethane adhesive comprises the following components in parts by weight: 30-40 parts of polyoxypropylene triol , 10-15 parts of polyethylene adipate glycol esterdiol, 5-8 parts of toluene diisocynate, 3-6 parts of dibutyl phthalate, 1.2-1.8 parts of 2,2-dimethylolpropionic acid, 5-8 parts of polyaniline, 3-6 parts of silicon carbide, 1-2.3 parts of ethylene glycol monomethy1 acetate , 2-4 parts of 2,4-sodium diaminophenylsulfonate, 10-20 parts of N-methyl pyrrolidone, 1.3-1.7 parts of lysine-di-isocyanate, 1-4 parts of polyamine, 2-6 parts of sodium alkyl benzene sulfonate, 1-2 parts of sodium dodecyl benzene sulfonate and 20-40 parts of water. The adhesive is high in solid content and high in adhesive strength, and can be quickly cured, the curing time is also greatly shortened, the surface is smooth and free of crack after being dried, and the preparation method is simple and easy in operation.

Owner:SUZHOU POLYMER NEW MATERIALS TECH

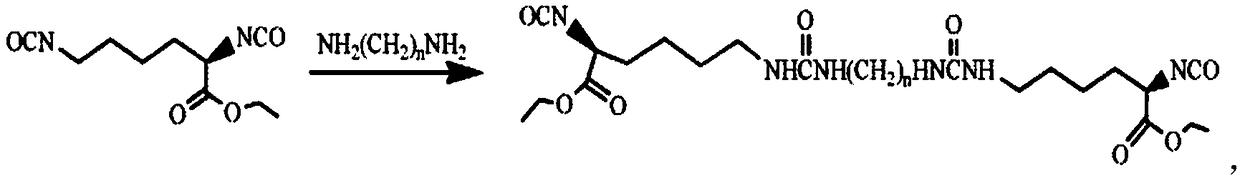

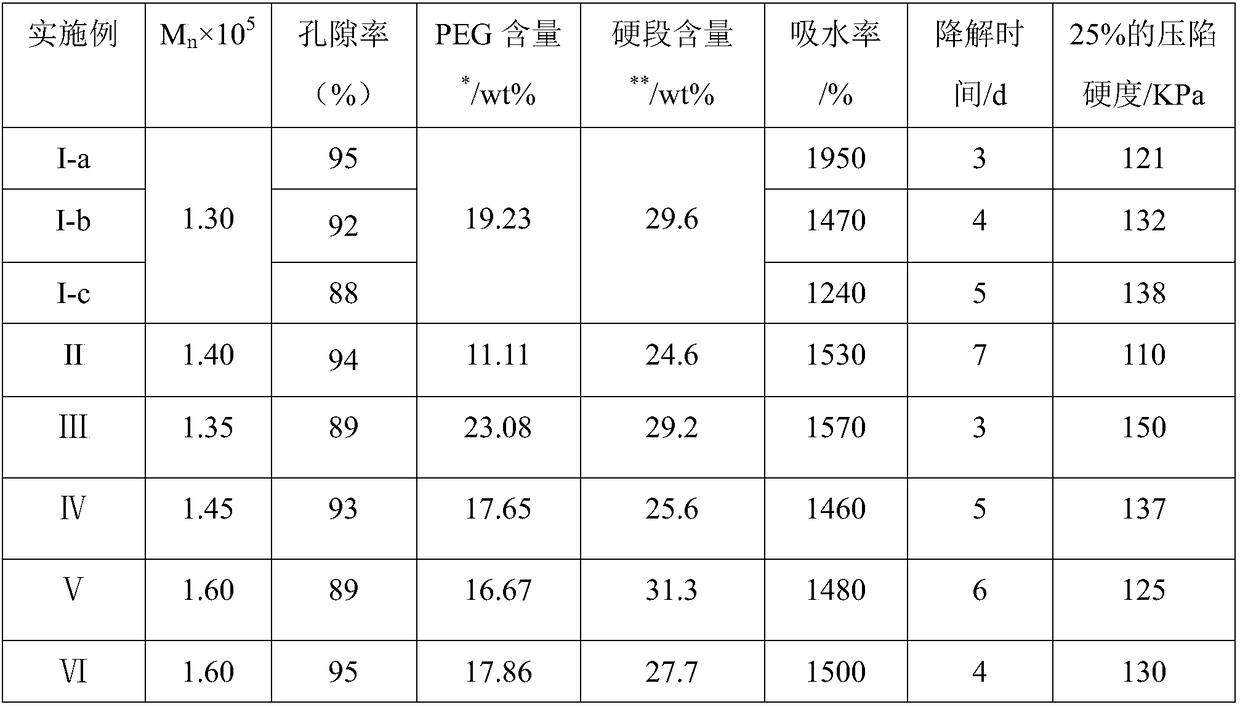

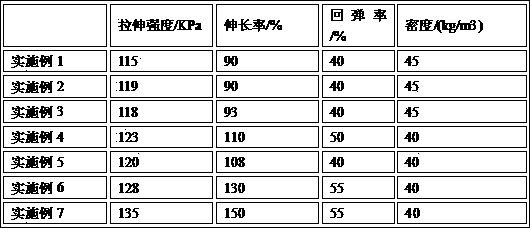

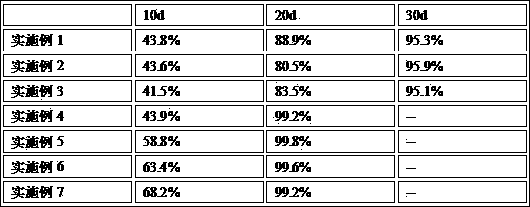

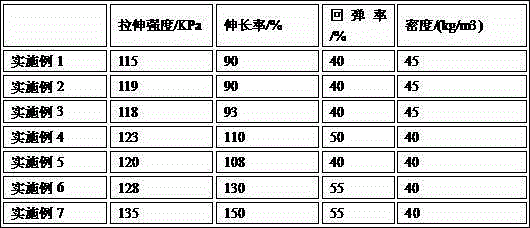

Biodegradable high-strength polyether ester type polyurethane urea foam and preparation method thereof

ActiveCN108586293AEasy to purifyEasy to controlUrea derivatives preparationSurgical adhesivesLysine diisocyanatePolymer science

The invention relates to the technical field of biodegradable materials, specifically to a preparation method for a fully-synthetic biodegradable high-strength hemostatic foam applicable to hemostasisof cavities like ears and noses of human or animals. The biodegradable high-strength polyether ester type polyurethane urea foam is prepared from a polyether ester type polyurethane urea material through freeze-molding, wherein the polyether ester type polyurethane urea is prepared through chain extension of dihydroxy-terminal triblock prepolymer by using diisocyanate with a urea structure as a chain extender; the polyurethane urea material has a number average molecular weight of 1.1 x 105 to 1.8 x 105 and a dispersion coefficient of 1.18 to 1.51; and the diisocyanate chain extender containing the urea structure is selected from the group consisting of L-lysine diisocyanate-1,4-butadiamine-L-lysine diisocyanate and L-lysine diisocyanate-1,6-hexane diamine-L-lysine diisocyanate.

Owner:济南羽时信息科技有限公司

Straw-replaced wood packing material and preparation method thereof

InactiveCN106079014ATake advantage ofReduce manufacturing costDomestic articlesFlat articlesLysine diisocyanateFiber

The invention discloses a straw-replaced wood packing material and a preparation method thereof. The material comprises the following components in parts by mass: 100 parts of straws, 15-30 parts of starch, 2-8 parts of vinyl acetate-ethylene copolymer emulsion, 3-10 parts of paraffin, 1-4 parts of lysine-di-isocyanate, 1-3 parts of dilauryl thiodipropionate, and 2-6 parts of polyphthalimide fibers. The agricultural waste straws are used as main materials; the starch is added as adhesive; the materials are laid on a mold for hot pressing to finally mold a plate; such harmful substances as formaldehyde are not released, so that the manufactured packing material is safe and environment-friendly, and can replace wood packages; the production cost can be reduced; and such wastes as crop straw materials are fully used.

Owner:SUZHOU DINGLI PACKAGING

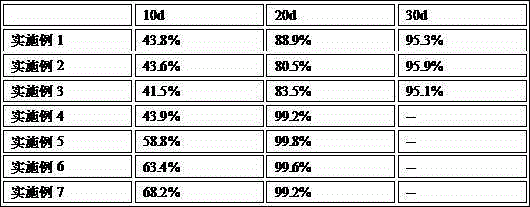

Degradable foamed plastic and preparation method thereof

The invention discloses degradable foamed plastic and a preparation method thereof. The degradable foamed plastic consists of the following components in parts by mass: 60-80 parts of polylactic acid, 20-30 parts of starch, 1.2-3.6 parts of lysine diisocyanate, 5-15 parts of polycaprolactone, 1-6 parts of trimethylolpropane, 1-3 parts of tetrabutyl titanate, 1-5 parts of polyvinyl ester, 1-3 parts of maleic anhydride, 3-8 parts of glycerol, 2-5 parts of a plasticizer, 1-3 parts of an antioxidant and 2-5 parts of a foam stabilizer. The preparation method of the degradable foamed plastic comprises the following steps: uniformly mixing polycaprolactone, polylactic acid and starch, stirring, then, adding maleic anhydride, lysine diisocyanate, trimethylolpropane, tetrabutyl titanate, the polyvinyl ester and glycerol to mix and stir for 20-40 minutes, adding the rest of the components, putting the mixture into an oven to cure, and taking out the mixture after 20 minutes to obtain a finished product degradable foamed plastic. The preparation process is simple and easy to implement, and the prepared foamed plastic is high in degradation rate and short in degradation period.

Owner:SUZHOU POLYMER NEW MATERIALS TECH

Nanometer waterborne polyurethane adhesive and preparation method therefor

InactiveCN104974702AHigh bonding strengthImprove water resistancePolyureas/polyurethane adhesivesCross-linkLysine diisocyanate

The invention discloses a nanometer waterborne polyurethane adhesive and a preparation method therefor. The nanometer waterborne polyurethane adhesive comprises the following components in parts by weight: 20-30 parts of polycaprolactone diol, 10-15 parts of isophorone diisocyanate, 2-6 parts of polyether triol, 3-6 parts of dibutyl phthalate, 0.2-0.8 part of dibutyltin dilaurate, 0.1-0.3 part of ethylene glycol monomethyl acetate, 0.3-0.9 part of trimethylolpropane trimester, 0.2-0.5 part of ethoxy lauryl alcohol, 0.3-0.7 part of lysine-di-isocyanate, 5-10 parts of polyhydric alcohols, 1-4 parts of polyamine, 1-3 parts of sodium alkyl benzene sulfonate, 2-5 parts of sodium dodecyl benzene sulfonate, 1-2 parts of curing agent and 20-40 parts of water. A sulfonate radical hydrophilic chain extender is adopted in the adhesive, the water resistance is improved, the cross-linking agents such as polyhydric alcohols and polyamine are added in a polyurethane system, and the adhesive strength of the adhesive is improved.

Owner:SUZHOU POLYMER NEW MATERIALS TECH

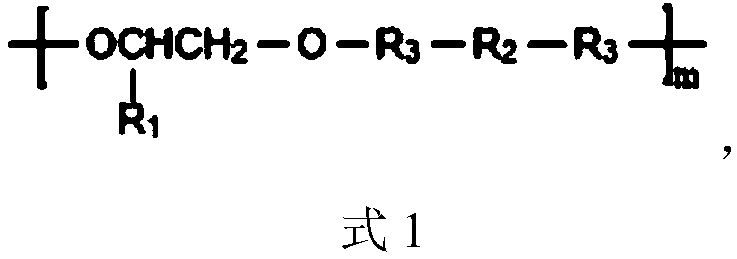

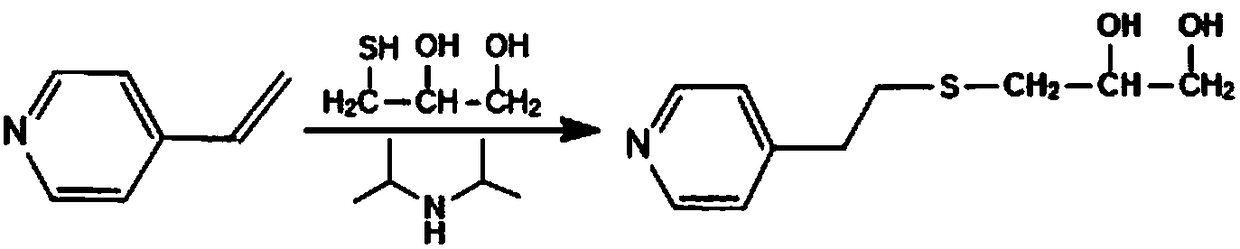

PH sensitive medical polyurethane urea material and preparation method thereof

ActiveCN108530606AGood pH sensitivityFast degradation ratePharmaceutical non-active ingredientsLysine diisocyanateCarbamate

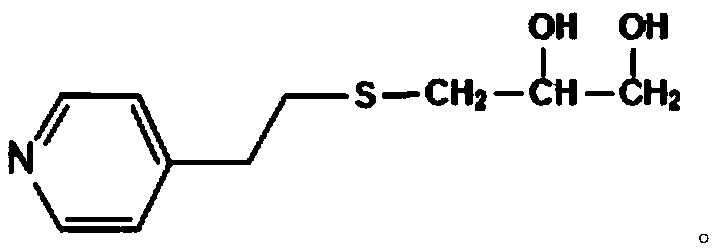

The invention discloses a pH sensitive medical polyurethane urea material and a preparation method thereof. The preparation method comprises the following steps: mixing a terminal dihydroxypyridine compound and a double-end hydroxyl polyethylene glycol to obtain polyurethane urea, and dissolving by adding N,N-dimethylformamide, carrying out chain extension in the presence of urea-containing diisocyanate, and purifying to obtain pH-sensitive polyurethane urea, wherein diisocyanate is L-lysine diisocyanate-1,4-butylenediamine-L-lysine diisocyanate. The pyridine group on a side chain of polyurethane urea is Lewis base, which is able to decompose hydrogen bonds in a polyurethane urea network under acidic conditions, resulting in discontinuous volume expansion of material. According to the invention, H<+> is removed under neutral or alkaline conditions, and N on a pyridine ring and NH on carbamate or ureido form a hydrogen bond, approximating a network structure, so that the polyurethane urea molecular chain shrinks and the swelling degree decreases remarkably. Therefore, by controlling the change of the pH of a medium, the degree of swelling of polyurethane urea can be effectively controlled.

Owner:科莱新材料技术(广州)有限公司

Environment-friendly oil-resistant rubber sealing piece and preparation process thereof

InactiveCN106146923ALow expansion rate after oil immersionGood oil resistancePolymer scienceP-tert-octylphenol

The invention discloses an environment-friendly oil-resistant rubber sealing piece and a preparation process thereof. The sealing piece is prepared from the following raw materials: natural rubber, nitrile rubber, silicon rubber, butylene succinate, p-t-octylphenol formaldehyde resin, calcium stearate, L-lysine diisocyanate, crylic acid-acrylonitrile copolymer, ethylene-octylene-alkadiene terpolymer, spraying carbon black, copper ammonia fibers, ethylene glycol salicylate, tea-seed oil acid, tetrachlorophthalic acid dioctyl phthalate, tri-n-butyl citrate, an aluminate coupling agent, dicumyl peroxide, 2,4-DCBP, zinc dibutyl dithiocarbamate, zinc oxide, N-octyl N-octadecyl sulfo-amino MoDDC and butyl acetate. The rubber sealing piece provided by the invention is high in oil resistance and comprehensive mechanical property, green and environment-friendly, and is very suitable for being used as the rubber sealing piece widely applied to various fields.

Owner:潘明华

Biodegradable plastic material

InactiveUS20130253102A1Highly degradableImprove the level ofPaper coatingCoatingsLysine diisocyanateBiodegradable polyester

A novel high-performance biodegradable plastic material based on biodegradable polyester and starch applying LDI(L-Lysine Diisocyanate) as coupling agent.

Owner:LIU SUNG YUAN

Special adhesive for safe leather

InactiveCN104845557AHigh bonding strengthDoes not contain toxic ingredientsNon-macromolecular adhesive additivesCellulose adhesivesLysine diisocyanatePotassium persulfate

The invention relates to a special adhesive for safe leather, which is prepared from the following raw materials in parts by weight: 25-37 parts of neoprene, 12-24 parts of perchloro-ethylene resin, 6-12 parts of 2,2-dimethylolpropionic acid, 8-14 parts of neopentyl glycol, 7-13 parts of sodium silicate, 5-6 parts of potassium persulfate, 2-4 parts of methyl cellulose, 3-6 parts of borax, 3-7 parts of stabilizer, 5-8 parts of aluminum hydroxide, 12-27 parts of lysine diisocyanate, 2-4 parts of mildew preventive, 12-24 parts of ethyl acetate and 15-28 parts of water. The special adhesive for safe leather has the advantages of high bonding strength, chemical resistance, biological attack resistance, no toxic components, no irritating smell, high safety and no harm to the human body.

Owner:青岛千帆高新技术有限公司

Production method of bio-based solvent-free polyurethane

The invention discloses a production method of bio-based solvent-free polyurethane. The method comprises the following steps: S1, adding a bio-based polymer, polycaprolactone, amino acid diisocyanate,a processing agent, an auxiliary agent and an auxiliary material into a reaction kettle, and uniformly stirring to obtain a mixture; and S2, detecting the obtained mixture, carrying out filtering packaging the qualified product after inspection, and carrying out sub-packaging storage by weight, wherein the viscosity of the bio-based polymer is less than 3000 mPa.S, the bio-based raw material hasthe content of greater than 60%, is prepared by mixing any one or more than two of Sovermol1092, Sovermol810 and Sovermol760 according to any ratio, and does not contain a solvent, the amino acid diisocyanate is lysine diisocyanate or L-lysine diisocyanate and is a degradable non-toxic material, and the processing agent comprises a cross-linking agent and a chain extender. According to the production method of the bio-based solvent-free polyurethane, the reaction effect and the efficiency can be improved, and the overall quality can be improved.

Owner:福建成杰高分子材料有限公司 +1

Medical adhesive for lung trauma repair and use method thereof

PendingCN113952501AGood biocompatibilityImplement comfort and convenienceSurgical adhesivesLysine diisocyanatePolyol

The invention discloses a medical adhesive for lung trauma repair and a use method thereof. The medical adhesive comprises a component A and a component B, the component A is an aliphatic polyurethane prepolymer based on long-chain polyethylene glycol and micromolecular polyol, and the component B is an aliphatic modified secondary amine curing agent; the component A is prepared by the following steps: reacting long-chain polyethylene glycol, namely long-chain PEG, with L-lysine diisocyanate, namely LDI, to obtain an intermediate, and adding a micromolecular polyol chain extender to obtain an aliphatic polyurethane prepolymer; and and the component B is prepared by the following steps: reacting aliphatic diprimary amine with an alpha, beta-unsaturated carbonyl compound according to a functional group molar ratio of-NH2:-C=C at 1.2:1 under a catalysis of a transition metal with a mass percentage of 0.1%, and obtaining an aliphatic modified secondary amine curing agent through a column chromatography separation. The prepared medical adhesive is free of biotoxicity, has good flexibility, equivalence to a lung elasticity modulus and a high adhesive strength and is suitable for blocking and repairing wounds after a clinical local lung operation.

Owner:广州迅合医疗科技有限公司

Polyhedral oligomeric silsesquioxane polyurethanes

A multi-block thermoplastic polyurethanes system which incorporates polyhedral oligomeric silsesquioxane into conventional biodegradable thermoplastic polyurethanes built up by poly(ε-caproactone) and polyethylene glycol blocks, resulting in biostability. The multi-block thermoplastic polyurethanes are synthesized from lysine-diisocyanate with poly(ε-caprolactone)-diol, polyhedral oligomeric silsesquioxane-diol, and poly(ethylene glycol) using a one-step synthesis process.

Owner:SYRACUSE UNIVERSITY

Acrylic carboxyl polyurethane powder coating for ceramics and preparation method thereof

InactiveCN111777939AImprove featuresImprove mechanical propertiesFireproof paintsAnti-corrosive paintsLysine diisocyanateChemical industry

The invention belongs to the technical field of coatings. The invention relates to an acrylic carboxyl polyurethane powder coating for ceramics and a preparation method thereof. In the prior art, a ceramic coating is not hard and has poor flexibility, high temperature resistance, poor durability, pollution and like. The acrylic carboxyl polyurethane powder coating for ceramics solves the above problem. The acrylic carboxyl polyurethane powder coating for the ceramic is prepared from the following raw materials: epoxypropane, glycerinum, yttrium oxide, lysine diisocyanate, an additive, propylene diamine, terpilenol, acrylic acid, polydimethylsiloxane and L-alanine-N-carboxyl-anhydride. According to the acrylic carboxyl polyurethane powder coating for ceramics, the original excellent characteristics of the two-component acrylic acid and the polyurethane are maintained, the mechanical property, the flexibility and the chemical property are substantially improved, and the wear resistance,the corrosion resistance and the high temperature resistance are excellent, the durability is good, and the method can be widely used in the fields of industry, construction, chemical industry and thelike.

Owner:刘希龙

Rapidly solidified adhesive

InactiveCN104388011AGood economic valueNon-macromolecular adhesive additivesEpoxy resin adhesivesLysine diisocyanateEpoxy

The invention provides a rapidly solidified adhesive. The rapidly solidified adhesive is prepared from the following raw materials in parts by weight: 3-10 parts of lysine diisocyanate, 2-8 parts of Kathan, 3-9 parts of nano-zinc oxide, 4-8 parts of ethyl acetate, 3-7 parts of epoxy diluent, 4-10 parts of dimethylaniline, 2-5 parts of polyacrylamide, 3-8 parts of epoxy resin, 4-7 parts of stearic acid, 1-3 parts of insoluble sulfur, 1-5 parts of fortifier, 1-3 parts of accelerant, 5-9 parts of butadiene styrene rubber and 15-22 parts of propylene glycol monomethyl ether acetate. The rapidly solidified adhesive has the beneficial effects of the capability of rapid solidification, and meanwhile, wide application range, applicability to cementing a plurality of materials, and great economic value.

Owner:田琳琳

Leather gloss agent

InactiveCN104356959AStrong adhesionFast curing and dryingPolishing compositionsLysine diisocyanatePolymer science

The invention discloses a leather gloss agent, which is prepared from the following raw materials in parts by weight: 6 to 10 parts of waterborne polyurethane, 5 to 9 parts of silicone oil, 3 to 8 parts of sodium dodecylbenzene sulfonate, 3 to 9 parts of ethoxylated hydrogenated castor oil, 4 to 7 parts of palmitic acid diethanolamide, 3 to 6 parts of dodecyl polyglucoside, 2 to 8 parts of vinyl acetate, 4 to 6 parts of lauryl mercaptan, 4 to 10 parts of lysine diisocyanate, 2 to 5 parts of an anti-aging agent, 1 to 3 parts of ethyl acetate, 4 to 6 parts of methyl methacrylate and 11 to 19 parts of organic silicon powder. The leather gloss agent has the benefits of high adhesive power, high curing and drying speed, nontoxicity, odourlessness and simplicity in preparation.

Owner:QINGDAO KELIKE INFORMATION TECH

Pesticide composition containing dinotefuran and pyrethroid

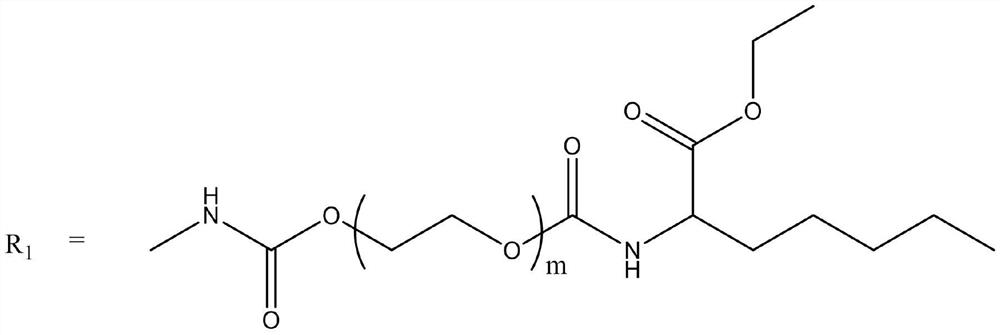

PendingCN113973834AFlow restrictionHigh viscosityBiocidePest attractantsLysine diisocyanateSide chain

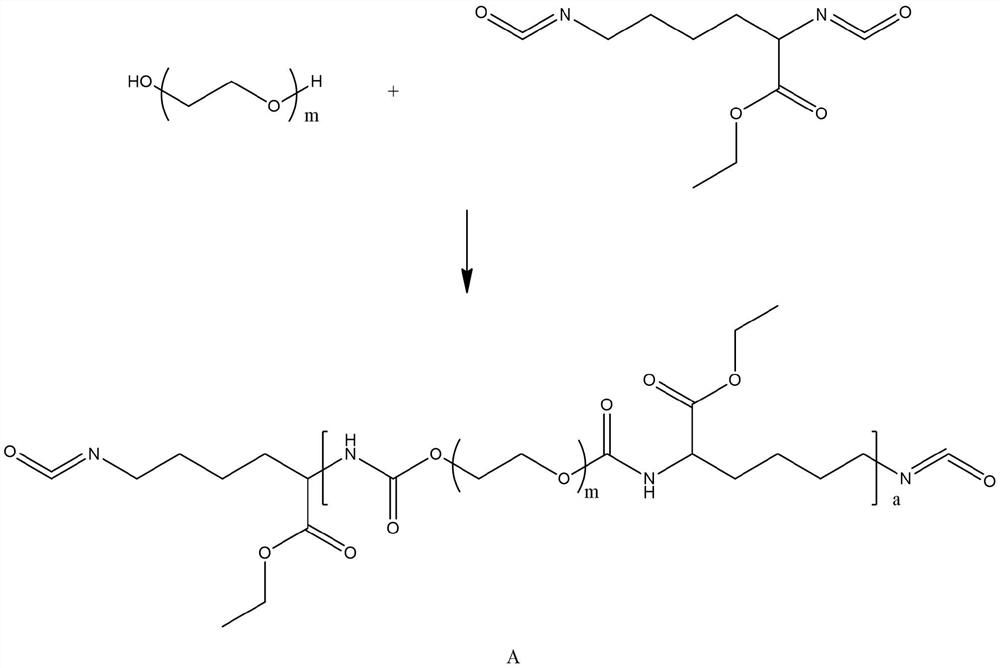

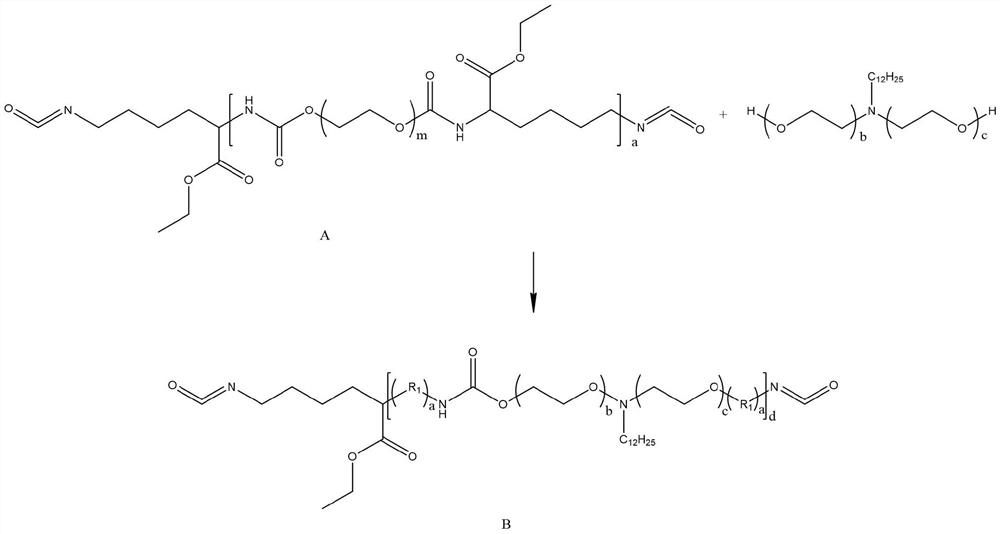

The invention discloses a pesticide composition containing dinotefuran and pyrethroid, and relates to the field of pesticides, dinotefuran and pyrethroid are reasonably compounded, a thickening agent is added, polyethylene glycol is used as a hydrophilic chain segment, L-lysine diisocyanate is taken as a connection point, lauryl amine polyoxyethylene ether containing a long hydrophobic chain segment is taken as a chain extender and n-tetradecanol is taken as an end-capping reagent so that a comb-shaped water-based associative thickener with a hydrophobic chain segment on the side chain is synthesized. The problems that an existing pesticide is prone to flocculation in the storage and use process, and the pesticide cannot be kept in a stable suspension state are solved. Hydrophilic groups of the associated thickening agent and water form hydrogen bonds, flowing of water is limited, hydrophobic groups are associated with each other to form micelles, the hydrophobic groups at the tail ends of the micelles can also adsorb surrounding micelles, the micelles are intertwined, the viscosity of the system is increased, molecules are in multipoint association, the thickening effect is remarkably improved, and thus the purpose of keeping the pesticide in a stable suspension state is achieved.

Owner:合肥巨卓农业科技合伙企业(有限合伙)

A kind of degradable foam plastic and preparation method thereof

Owner:SUZHOU POLYMER NEW MATERIALS TECH

Waterproof cis-1,4-polybutadiene rubber modified epoxy resin anticorrosive paint and preparation method thereof

InactiveCN106349886AGood compatibilityIncrease stiffnessFireproof paintsAnti-corrosive paintsEpoxyLysine diisocyanate

The invention relates to a waterproof cis-1,4-polybutadiene rubber modified epoxy resin anticorrosive paint. The invention is characterized in that the paint is prepared from an epoxy resin E51, cis-1,4-polybutadiene rubber, dichlorobenzene, benzoyl hydroperoxide, molybdenum trioxide, sodium periodate, sodium tartrate, lysine diisocyanate, diethylaminoethanol, aniline, polystyrene hollow microspheres, phosphoric acid, ammonium persulfate, stearin, dimethylbenzene, n-butanol, nano tin oxide, nano magnesium oxide, dodecyl alcohol ether sodium sulfate, bis imidazolidinyl urea, N,N-di(2-hydroxypropyl) aniline, chloroform and a proper amount of deionized water. The anticorrosive paint provided by the invention has the advantages of high saline water resistance, favorable corrosion resistance, no toxicity and environment friendliness and the like.

Owner:马鞍山采石矶涂料有限公司

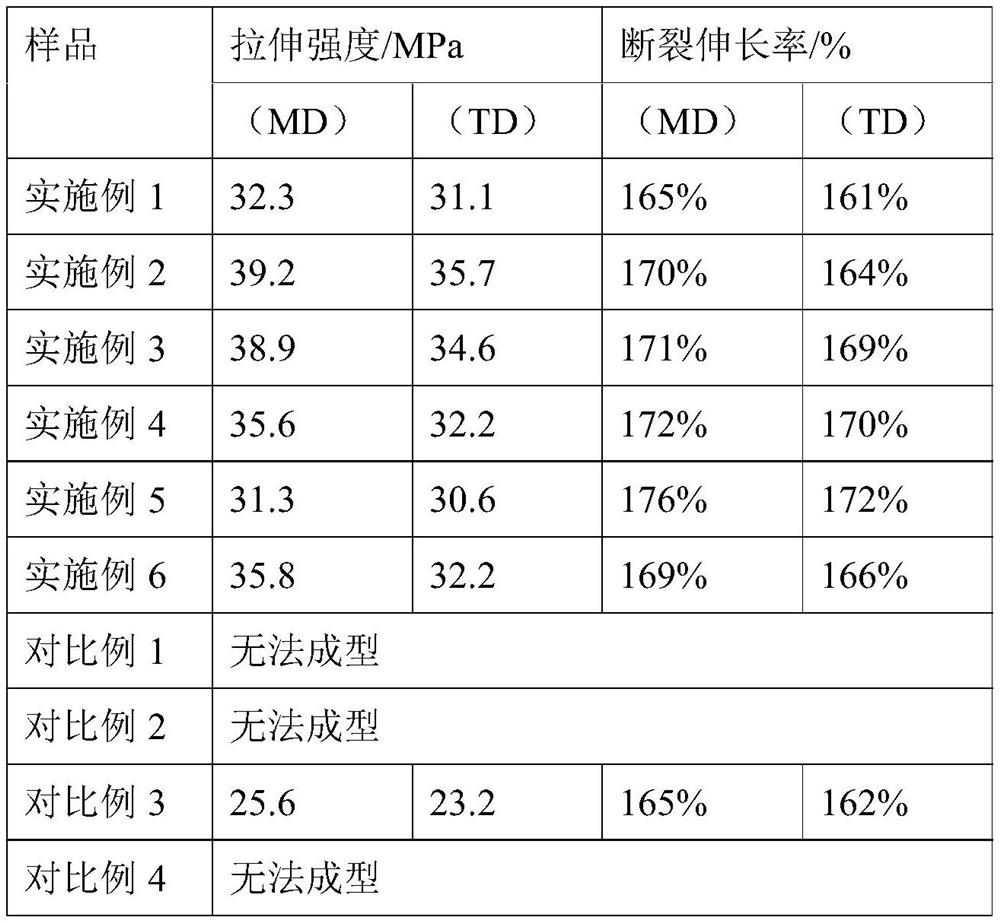

Polyvinyl alcohol film and preparation method thereof

The invention provides a polyvinyl alcohol film and a preparation method thereof, and belongs to the field of biodegradable materials. The polyvinyl alcohol film is prepared from the following raw materials in parts by weight: 100 parts of polyvinyl alcohol, 60-120 parts of starch, 10-30 parts of a reinforcing agent, 0.1-1 part of lysine diisocyanate and 5-10 parts of a plasticizer, the polymerization degree of the polyvinyl alcohol is 1500 to 3500, and the alcoholysis degree of the polyvinyl alcohol is 85 to 99 percent. According to the invention, lysine diisocyanate is adopted to carry out reaction compatibilization on PVA and starch molecules, so that the compatibility of two phases can be improved; by adopting the plasticizer, the melting temperature of the PVA composite material can be reduced by reducing the intermolecular or intramolecular hydrogen-bond interaction of PVA and starch. Through cooperation of the raw materials, the obtained polyvinyl alcohol film shows excellent strength and toughness in the transverse direction and the longitudinal direction, and has high tensile strength and elongation at break.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

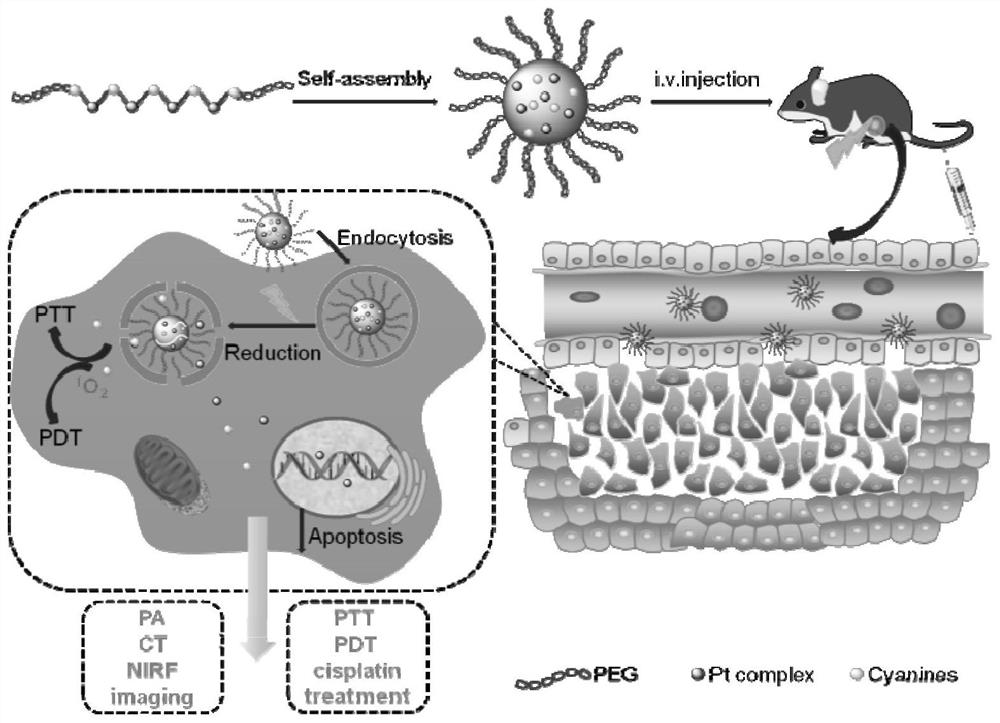

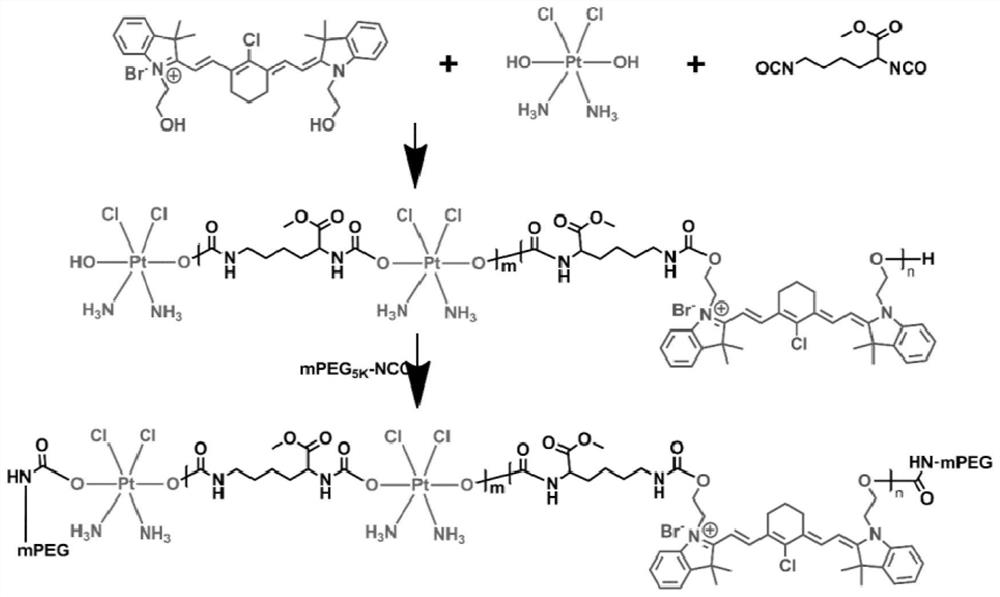

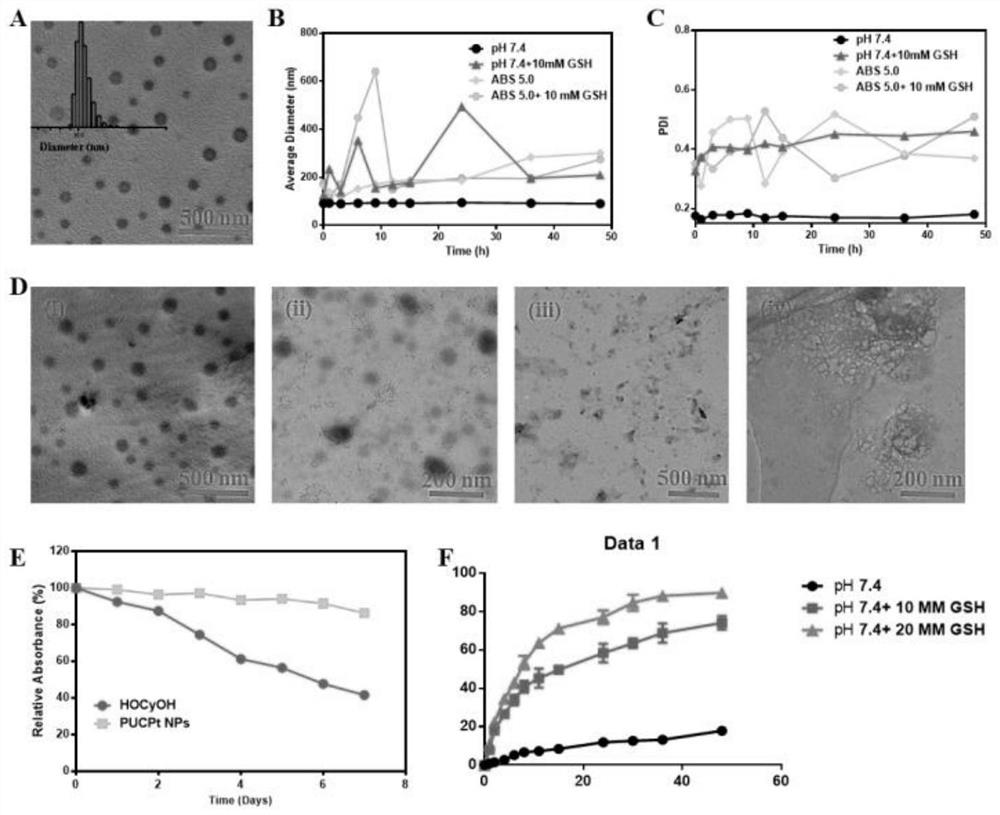

Multifunctional polymeric polyurethane prodrug polymer nano diagnosis and treatment agent

PendingCN114452401AReductively responsiveAvoid controlled releaseOrganic active ingredientsPowder deliveryLysine diisocyanatePolymer science

The invention belongs to the field of medicines, and provides a functional polymerization type polyurethane prodrug polymer nano diagnosis and treatment agent, PUCPt is prepared from cyanine dye, cis, cis, trans-[Pt (NH3) 2Cl2 (OH) 2], lysine diisocyanate and polyethylene glycol monomethyl ether derivatives as raw materials. The main chain type platinum (IV) and cyanine dye (HOCyOH) multifunctional polymeric polyurethane prodrug polymer PUCPt provided by the invention is of an amphiphilic structure, can be self-assembled into nano particles in an aqueous solution, has relatively high drug loading capacity and drug loading efficiency, and shows effective intracellular uptake and enhanced cell proliferation inhibition effects on cancer cells. PUCPt, PUCPt NPs, or drug delivery systems comprising them are promising platforms for platinum and HOCyOH co-based multimode imaging, photothermal therapy in combination with chemotherapy.

Owner:QILU UNIV OF TECH

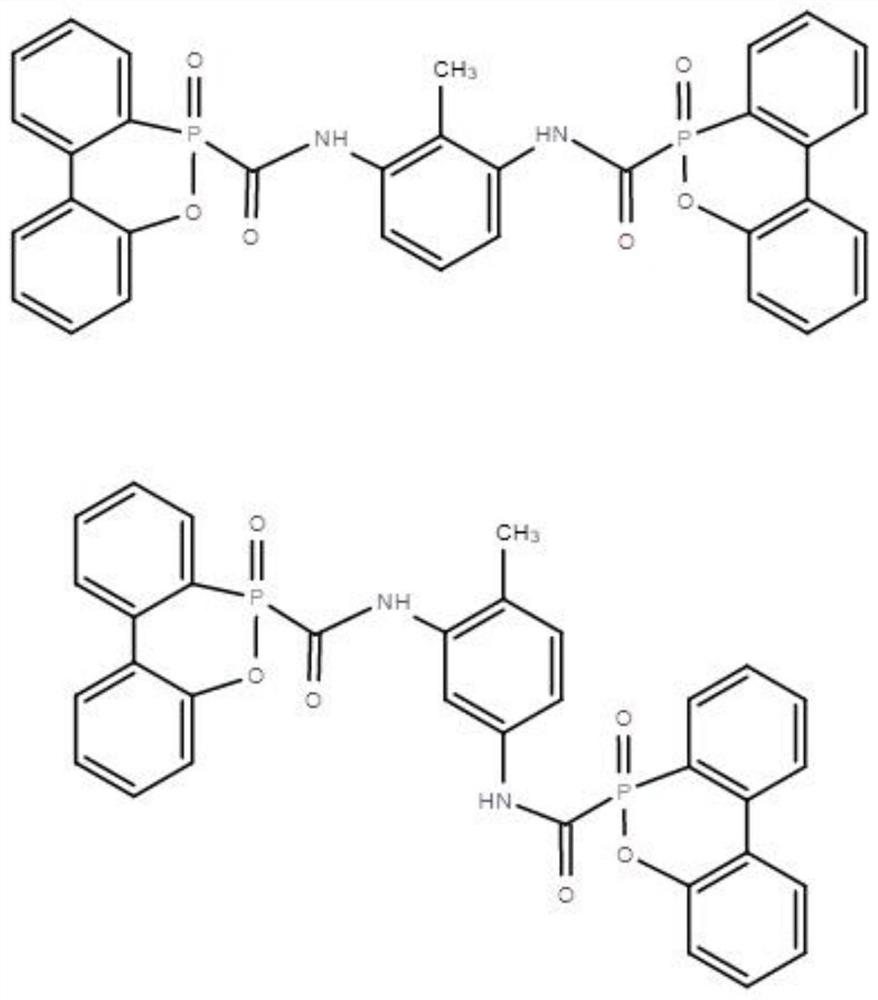

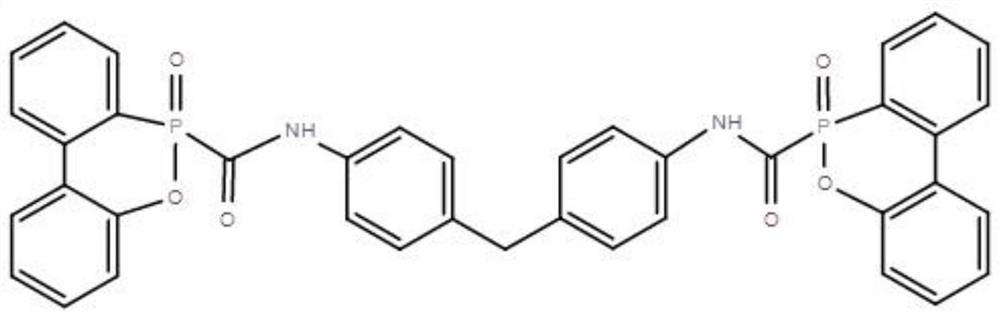

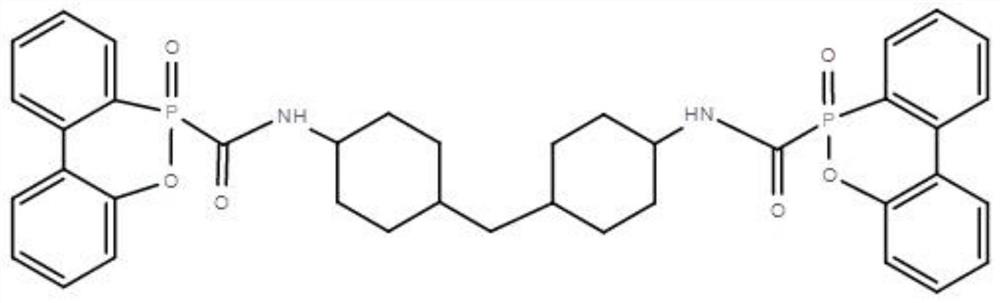

Phosphorus-nitrogen flame retardant and preparation method thereof

InactiveCN114057794AImprove flame retardant performanceLow smoke productionGroup 5/15 element organic compoundsCyclohexanonePolymer science

The invention discloses a phosphorus-nitrogen flame retardant and a preparation method thereof. The phosphorus-nitrogen flame retardant is prepared from the following raw materials: isocyanate, a phosphorus-containing compound DOPO, a solvent and a catalyst, wherein isocyanate includes toluene diisocynate, isophorone diisocyanate, diphenylmethane diisocyanate, dicyclohexylmethane diisocyanate, hexamethylene diisocyanate, lysine diisocyanate and polyisocyanate; and the solvent comprises one or more of benzene, methylbenzene, dimethylbenzene, acetone, butanone, cyclohexanone, dichloromethane, trichloromethane and petroleum ether, a catalyst is added into the solvent, and the catalyst is an imidazole catalyst. The phosphorus-nitrogen flame retardant disclosed by the invention has the advantages of low smoke, low toxicity, high efficiency, good thermal stability, good compatibility with a polymer substrate, migration and volatilization resistance, lasting flame-retardant effect and the like. According to the preparation method provided by the invention, the phosphorus-nitrogen flame retardant can be prepared through a one-step addition reaction, the process steps are simple, the operation is easy, and the preparation method is suitable for large-scale popularization.

Owner:洛阳赛图新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com