Patents

Literature

37 results about "P-tert-octylphenol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phenol-formaldehyde resin by colophony modified with alkyl phenol being mixed and its preparation method

A rosin modified mixed alkylphenol-phenolic resin is prepared from reaction between p-tert-octylphenol, p-nonylphehnol, dodecylphenol and formaldehyde in alkaline condition, modifying by rosin, and esterifying by glycerin and then trihydroxymethyl propane. Its advantages are high soft point, good viscoelasticity, and excellent solubility in fatty hydrocarbon band oil. It can be used for high-speed print color ink.

Owner:山西省应用化学研究所

Method for preparing rubber tackifier p-tert-octylphenol formaldehyde resin

ActiveCN101190961ASolve the problem of high import costsAvoid difficultiesP-tert-octylphenolPolystyrene

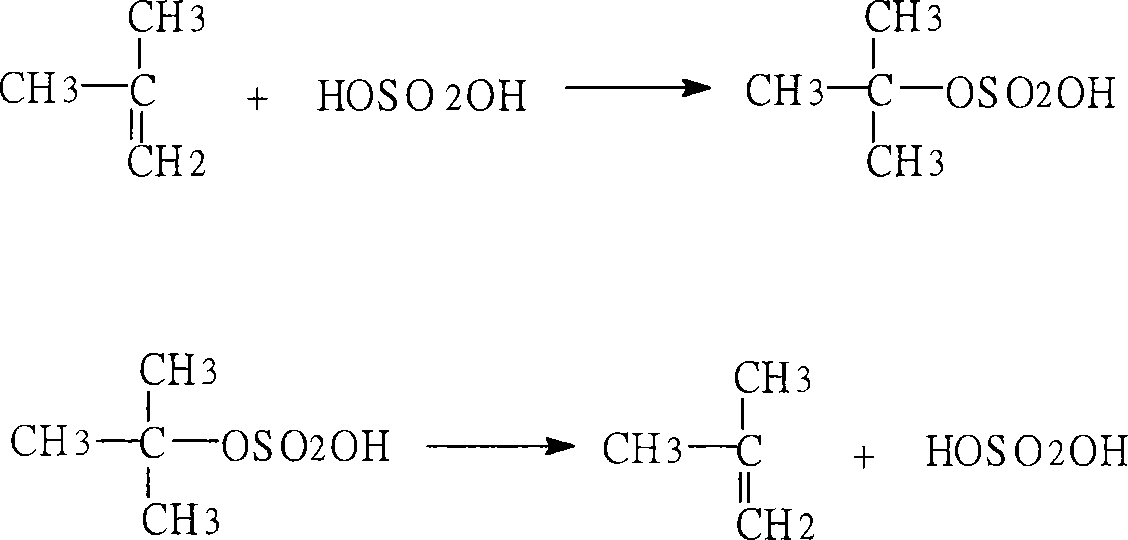

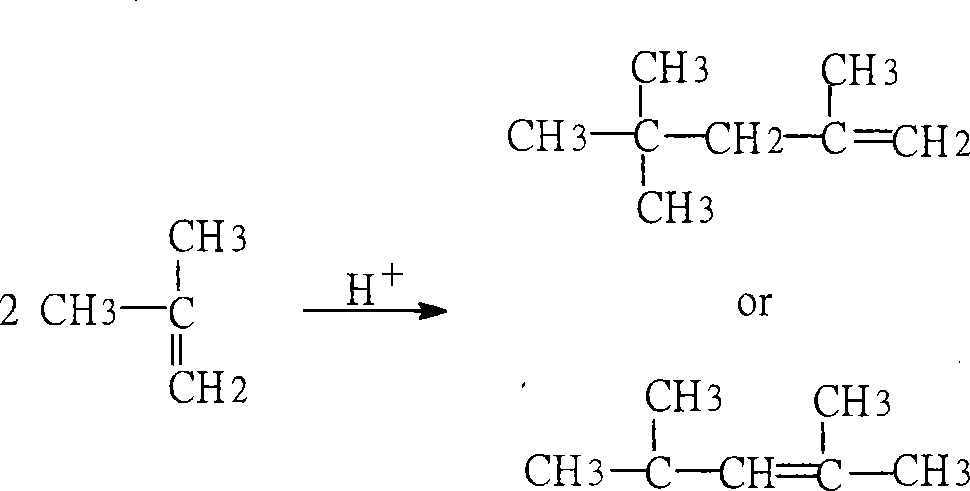

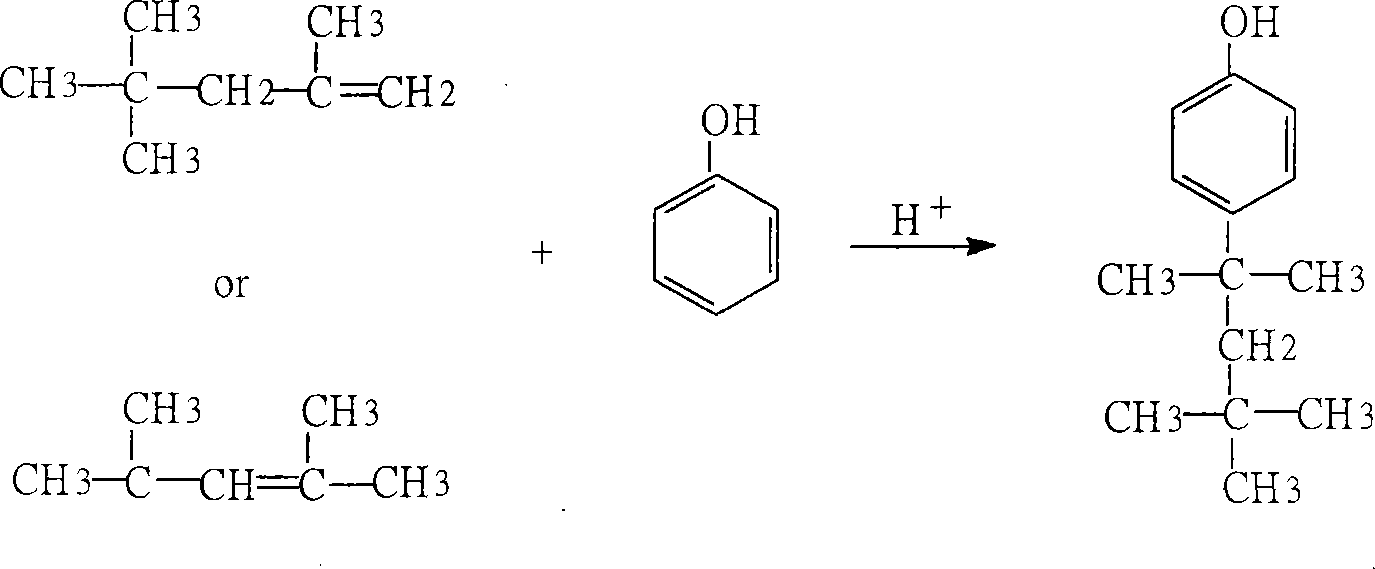

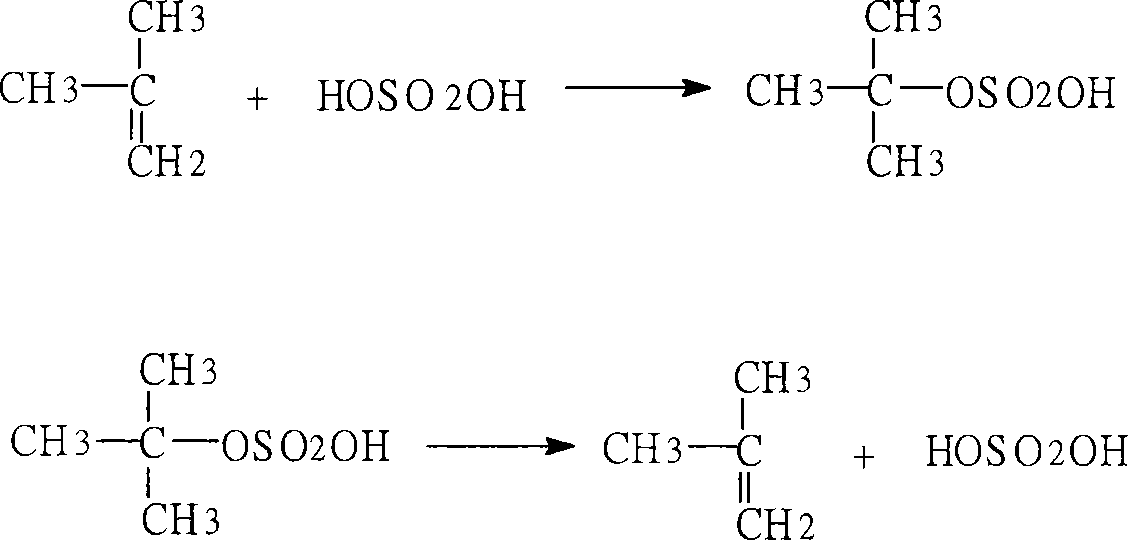

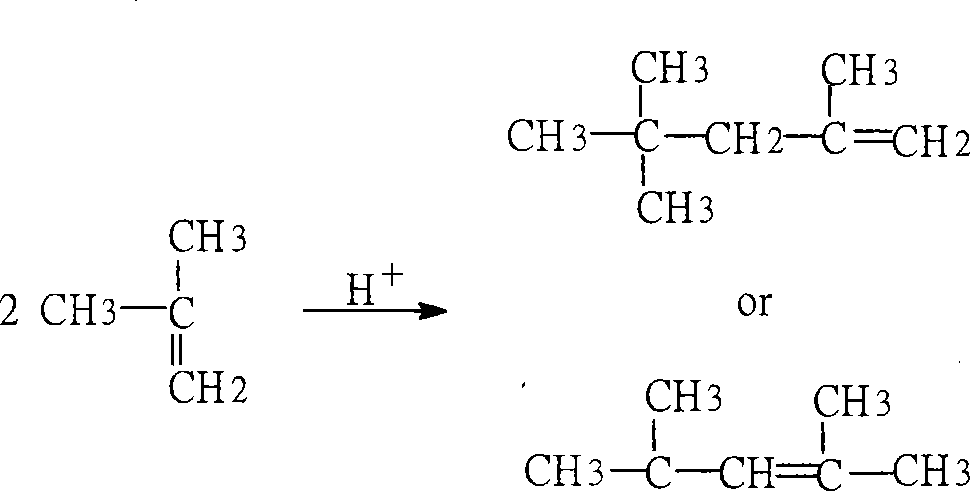

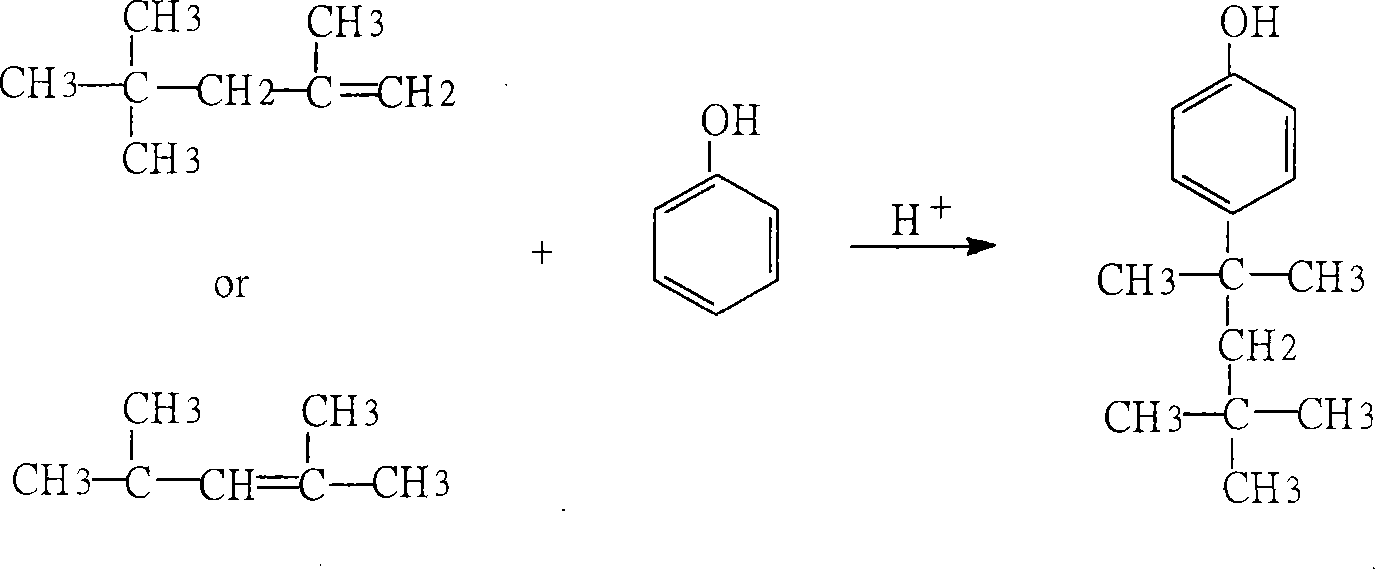

The invention provides a preparation method of p-tert-octyl phenol formaldehyde resins. Mixture of C4 fraction by additive reaction after being treated with a sulfated-degassing process is adopted as raw material; isobutene dimmer with targeted distillate content more than 98 percent after respective evaporation and cutting at the temperature of 75 DEG C-105 DEG C is adopted as alkylating agent; Na-sulfonated polystyrene-polyvinylidene copolymer strong-base anion exchange resin and H-sulfonated polystyrene-polyvinylidene copolymer strong-acid cation exchange resin are adopted as alkylation catalyst so as to obtain the p-tert-octyl phenol alkylate mixture by alkylation reaction under the temperature of 90-100 DEG C; the mixture is then treated with respective evaporation and cutting under the temperature of 220-270 DEG C to prepare the p-tert-octyl phenol with the melting point of 87.5-89.5 DEG C; finally the p-tert-octyl phenol and formaldehyde solution are treated with condensation reaction catalyzed by acid in toluol medium to obtain the p-tert-octyl phenol formaldehyde resins.

Owner:SINO LEGEND CHINA CHEM +1

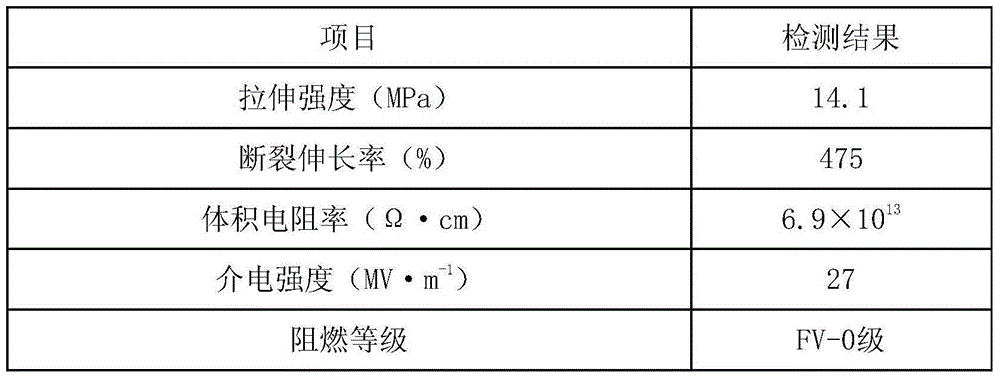

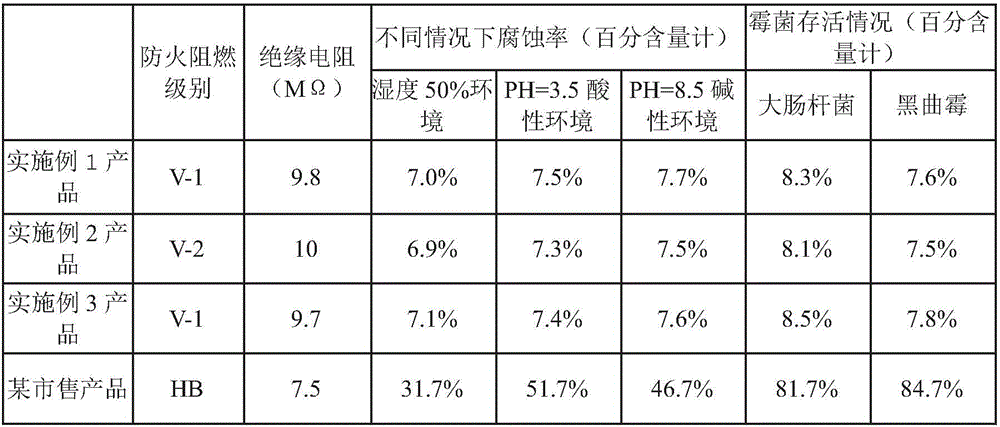

Anti-aging high-flame retardant silicone rubber composite material

InactiveCN108424655AEasy to processImprove low temperature resistancePolymer scienceP-tert-octylphenol

The invention discloses an anti-aging high-flame retardant silicone rubber composite material. The anti-aging high-flame retardant silicone rubber composite material is prepared from the following rawmaterials: silicone rubber, ethylene-propylene-diene monomers, polycarbonate, zinc oxide, stearic acid, sulphur, dicumyl peroxide, iron oxide, titanium dioxide, glass fibres, bromomethyl p-tertiary phenol formaldehyde resin, melamine cyanurate, silicone oil, a silane coupling agent, zinc stearate, an accelerant, an anti-aging agent and a flame retardant; the flame retardant is a mixture of resorcinol (diphenyl phosphate), cucurbituril, magnesium hydroxide and ammonium polyphosphate. The anti-aging high-flame retardant silicone rubber composite material provided by the invention has good heatresistance and aging resistance, and excellent flame retardant property.

Owner:天长市荣盛有机硅科技有限公司

Solar photovoltaic module mounting sealant and preparation method thereof

InactiveCN105733501AGood flow viscosityGood Shore hardnessNon-macromolecular adhesive additivesOil/fat/wax adhesivesPhosphateP-tert-octylphenol

The invention relates to a solar photovoltaic module mounting sealant which consists of methyl cyclohexane, bispolyethylene polydimethylsiloxane, tung oil anhydride, antimony trioxide, polytetrafluoroethylene, konjac glucomannan, vinyl tris(methyl ethyl ketoximine)silane, dibutyltin dilaurate, pearl powder, sodium tungstate powder, rose essential oil, monolauryl phosphate, chitin, acetenyl cyclohexanol, kieselguhr, dioctyl phthalate, tetraethoxysilane, isocyanate modified alkyd resin, hydroxyethyl methylacrylate, sodium dodecyl benzene sulfonate, acetyl benzoyl peroxide, p-tert-octyl phenolformaldehyde resin and castor oil, has good pressure-flow viscosity, shore hardness, shear strength, elongation at break and tensile strength, high pressure resistance sealing ability and excellent performance and is suitable for photovoltaic modules while the sealing property of the product is improved.

Owner:孟根森

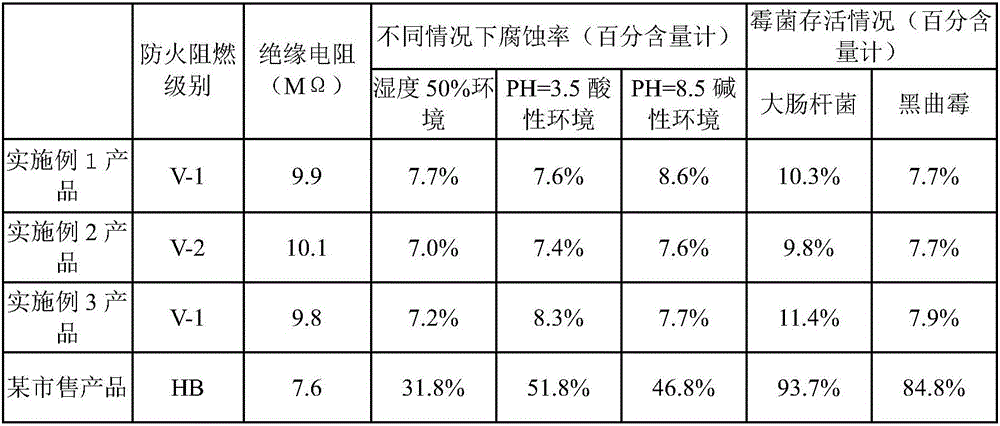

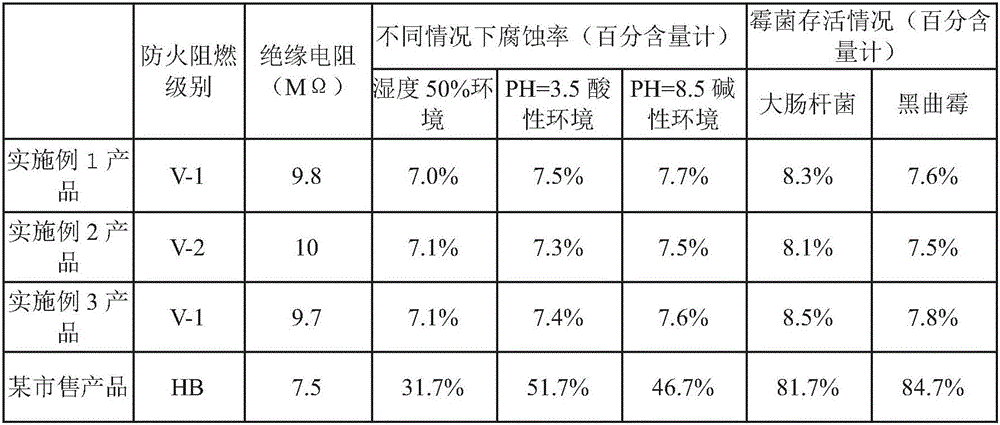

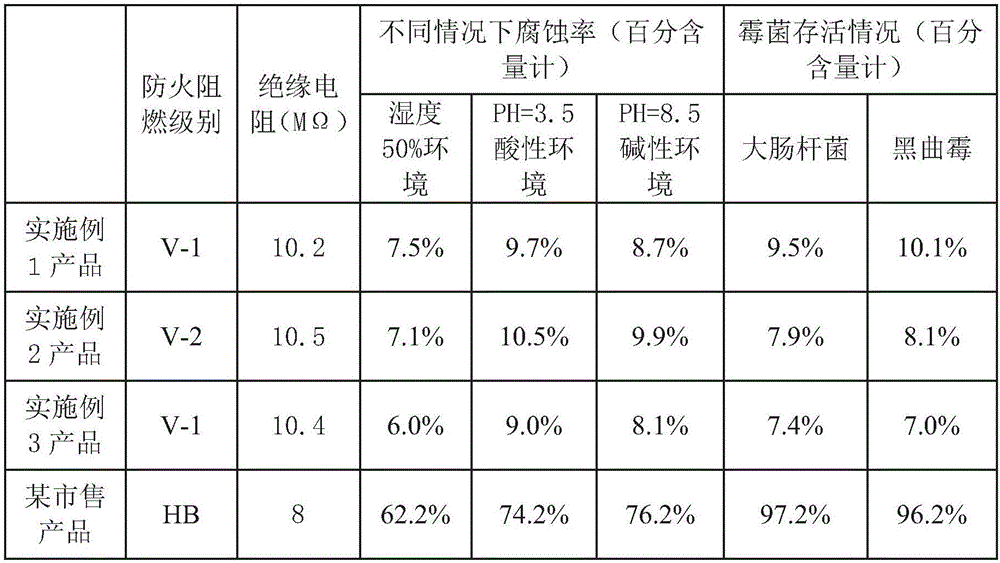

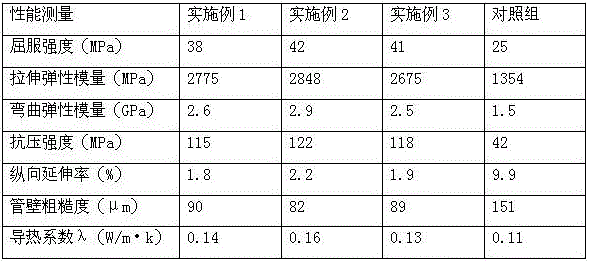

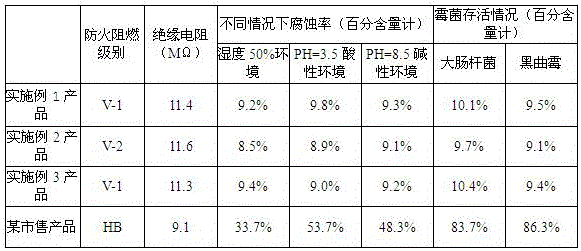

Flame-retarding, acid-alkali-resisting wear-resisting fire hose material

InactiveCN106349721AExcellent flame retardantExcellent flame retardant acid and alkali resistanceDecabromobiphenyl etherDecabromodiphenyl ether

The invention relates to a flame-retarding, acid-alkali-resisting wear-resisting fire hose material. The flame-retarding, acid-alkali-resisting wear-resisting fire hose material is prepared from rosin resin, p-tert-octyl phenolformaldehyde resin, amino resin, polyethylene wax emulsion, tall oil fatty acid, butyl acetate, isoamyl propionate, diethylene glycol dimethyl ether, dimethyl fumarate, sodium perborate, imidazoline, ammonium fluosilicate, guanidine phosphate powder, phenyl triethoxy silane, sodium pyrophosphate, chromium oxide, chromium chloride, menthol, barium chromate powder, ferrous orthophosphate, ethylenedioxydiethyl bis, tricresol phosphate ester, decabromodiphenyl ether, nanometer magnesium hydroxide, lignin, morpholine, polyoxyethylene polyoxy propyl alcohol amine ether, alkyl polyglucoside, propylamine, sodium ricinoleic acid. The product has excellent flame retardance, acid-base resistance, anti-mildew and anti-microbial performances, and the product performance is improved.

Owner:袁华

Method for preparing rubber tackifier p-tert-octylphenol formaldehyde resin

ActiveCN101190961BSolve the problem of high import costsAvoid difficultiesStrong acidsP-tert-octylphenol

The invention provides a preparation method of p-tert-octyl phenol formaldehyde resins. Mixture of C4 fraction by additive reaction after being treated with a sulfated-degassing process is adopted as raw material; isobutene dimmer with targeted distillate content more than 98 percent after respective evaporation and cutting at the temperature of 75 DEG C-105 DEG C is adopted as alkylating agent; Na-sulfonated polystyrene-polyvinylidene copolymer strong-base anion exchange resin and H-sulfonated polystyrene-polyvinylidene copolymer strong-acid cation exchange resin are adopted as alkylation catalyst so as to obtain the p-tert-octyl phenol alkylate mixture by alkylation reaction under the temperature of 90-100 DEG C; the mixture is then treated with respective evaporation and cutting under the temperature of 220-270 DEG C to prepare the p-tert-octyl phenol with the melting point of 87.5-89.5 DEG C; finally the p-tert-octyl phenol and formaldehyde solution are treated with condensationreaction catalyzed by acid in toluol medium to obtain the p-tert-octyl phenol formaldehyde resins.

Owner:SINO LEGEND CHINA CHEM +1

Synthesis method of high-softening-point tackifying resin for rubber

The invention discloses a synthesis method of high-softening-point tackifying resin for rubber. The synthesis method comprises the following steps: adding alkyl substituted phenol and a metal acetate catalyst into a reaction kettle and replacing N2 for air in the kettle, wherein the alkyl substituted phenol is p-nonyl phenol or p-dodecylphenol or p-tert-octylphenol or p-tert-butyl phenol or p-tert-butylphenol, and the metal acetate catalyst is calcium acetate or zinc acetate or cadmium acetate or copper acetate or cobalt acetate; heating the alkyl substituted phenol and the catalyst under the stirring state, introducing acetylene or allylene or 1-butyne or 1-pentyne or 1-hexin, and performing a constant-temperature reaction; and drying the product obtained after the reaction in a vacuum drying box to prepare the high-softening-point tackifying resin for rubber. Compared with the existing preparation method of a tackifier, the synthesis method has the advantages of simple process, low cost and high adhesive property. The softening point of the obtained tackifying resin for rubber is more than 142 DEG C, and the adhesive strength of the tackifying resin for rubber is more than 1.0 kN / m after the tackifying resin for rubber is stored for 100 hours.

Owner:SHANDONG LAIWU RUNDA NEW MATERIAL

Modified-asphalt-modified waterproof material and preparation method thereof

InactiveCN106633956AGood extensibilityImprove waterproof performanceBuilding insulationsExtensibilityBetaine

The invention provides a modified-asphalt-modified waterproof material and a preparation method thereof. The modified-asphalt-modified waterproof material is prepared from asphalt, ABS (acrylonitrile-butadiene-styrene) high rubber powder, a maleic resin, a polybenzofuran resin, vinyl silicone oil, naphthenic oil, n-butyllithium, diallyl phthalate, a p-tert-octyl phenol formaldehyde resin, polyisobutylene, coal gangue, vermiculite, diabase, azobisformamide, octadecylamine, carboxyl betaine, vinyl bis stearamide, allyl polyethyleneglycol and allyl alcohol polyoxy alkyl ether. The asphalt-base waterproof material is not modified by SBS (styrene-butadiene-styrene), so the manufacturing cost is lower. The waterproof material has the advantages of excellent water resistance and high bonding firmness and durability with the substrate. Besides, the asphalt-base waterproof material has favorable extensibility, the elongation percentage at the maximum pull is not less than 48%, and the asphalt-base waterproof material can resist the low temperature of -25 DEG C without cracking and has excellent comprehensive properties and favorable market competitiveness.

Owner:SUZHOU AIBOMAIER NEW MATERIAL CO LTD

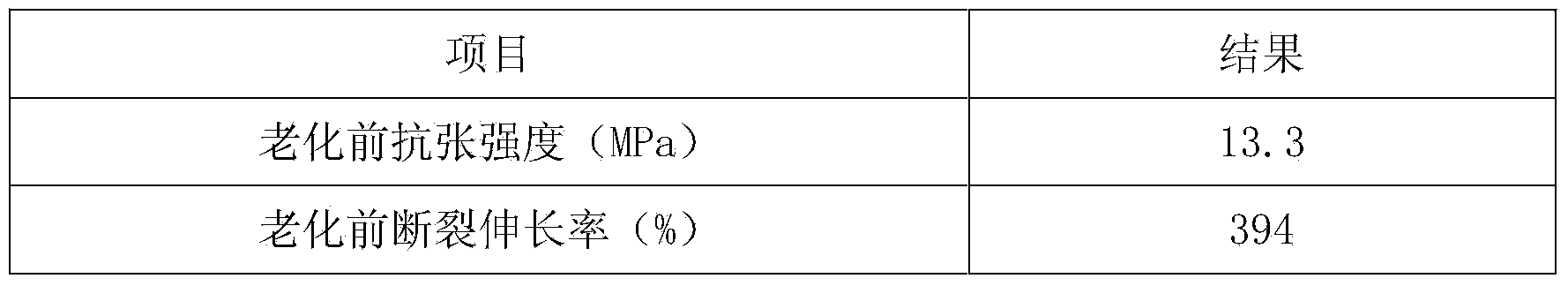

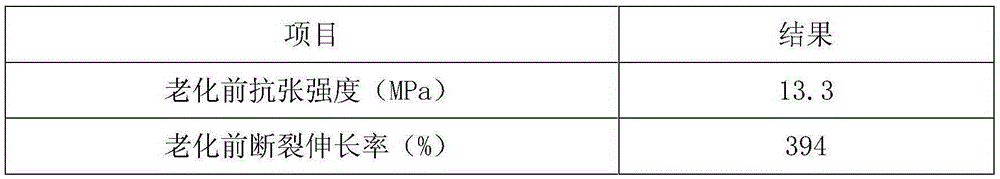

Waterproof and corrosion-resistant rubber material for power line jacket of marine transportation vehicle and preparation method of waterproof and corrosion-resistant rubber material

InactiveCN105111646AImprove water resistanceAccelerated corrosionRubber insulatorsInsulated cablesRubber materialElastomer

The invention discloses a waterproof and corrosion-resistant rubber material for a power line jacket of a marine transportation vehicle and a preparation method of the waterproof and corrosion-resistant rubber material. The waterproof and corrosion-resistant rubber material is prepared from the following raw materials: a tetrapropyl fluoro elastomer, butyl rubber, light calcined powder, vaseline, 10# transformer oil, carboxylated-terminated liquid polybutadine rubber, channel black, an accelerant, an accelerant OTOS, low-molecular-weight polybutylene, zinc stearate, diabase powder, calcium resinate, hydrophobic fumed silica, triethylene tetramine, bromomethyl-p-tert-octyl phenol formaldehyde resin, an accelerant PX, an accelerant DPTT, an anti-aging agent 4010NA, an anti-aging agent BLE, glyceryl tristearate and flame-retardant particles. The waterproof and corrosion-resistant rubber material for the power line jacket of the marine transportation vehicle has excellent waterproofness, corrosion resistance and heat resistance.

Owner:TIANCHANG FUXIN ELECTRONICS

Rubber composition for tire

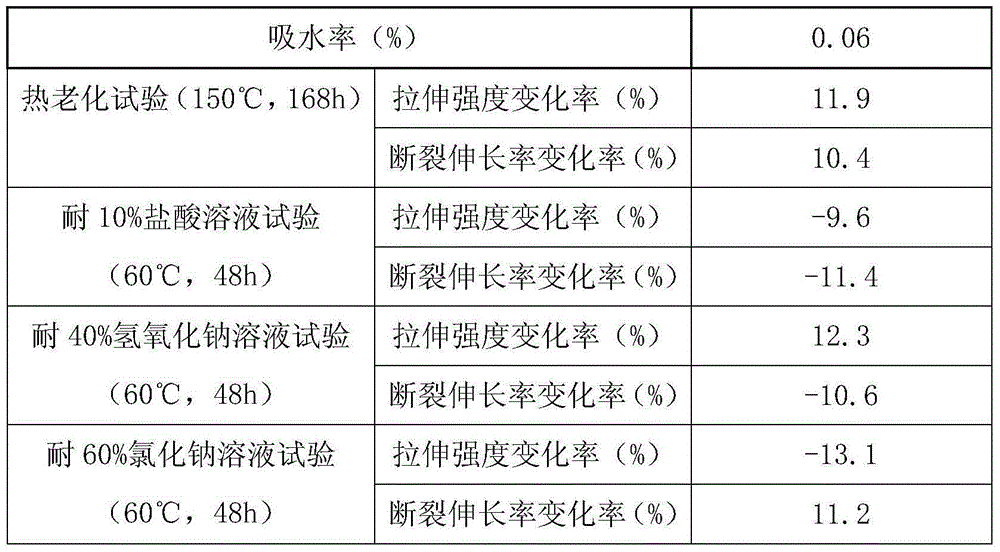

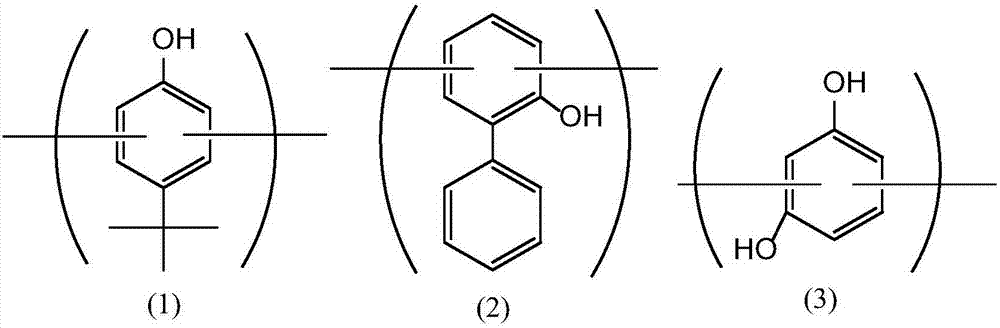

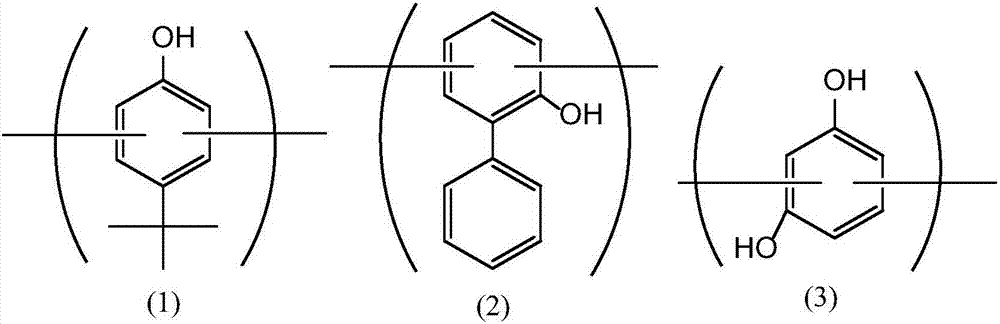

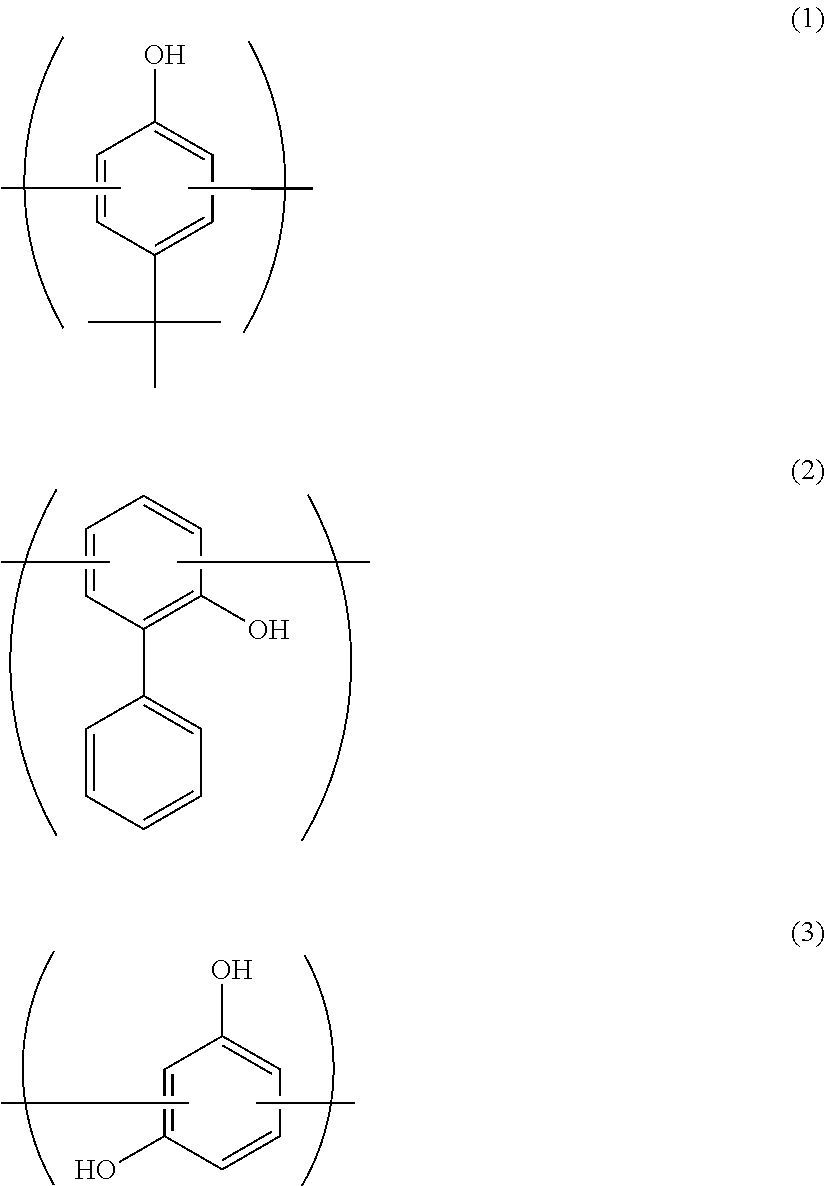

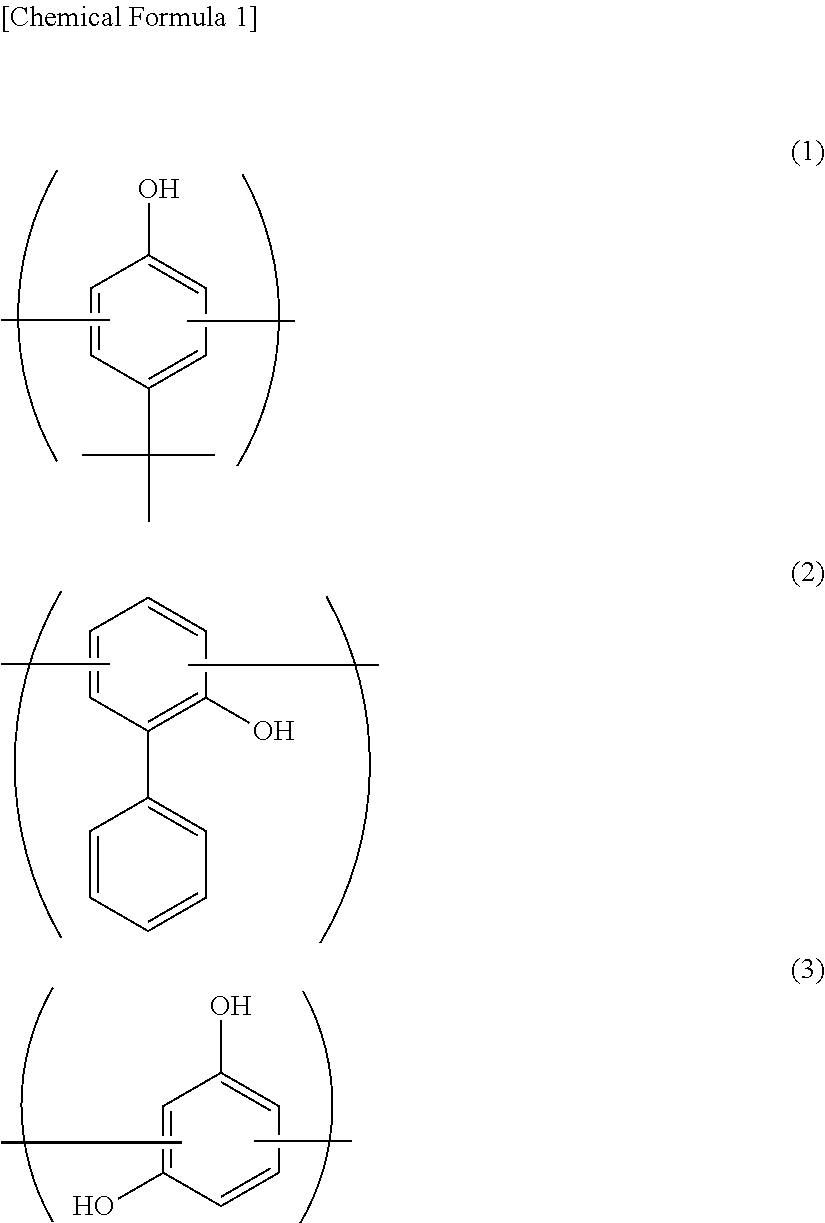

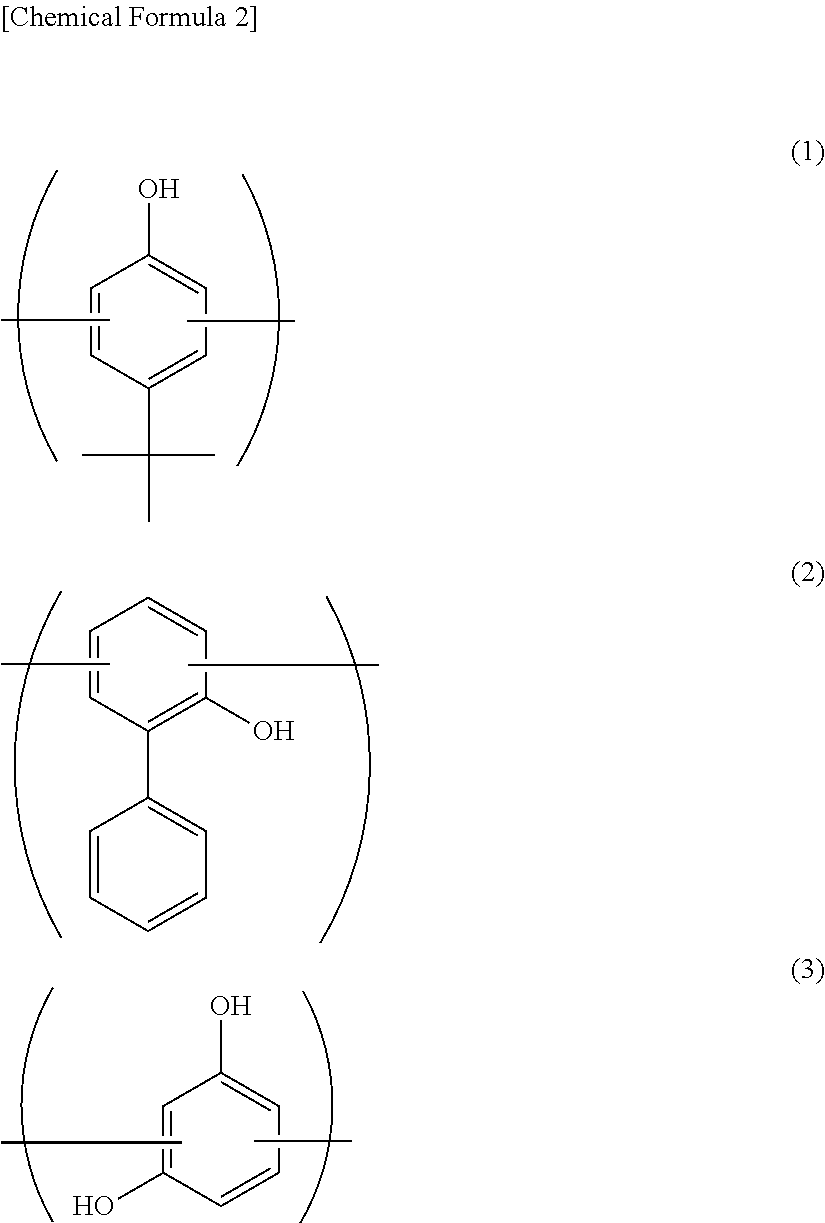

This rubber composition for a tire is obtained by blending a rubber component (A), zinc oxide (B), and a co-condensate (C) that has a softening point of 150 DEG C or less and that contains a p-tert-butylphenol-derived constituent unit represented by formula (1), an o-phenylphenol-derived constituent unit represented by formula (2), and a resorcinol-derived constituent unit represented by formula (3). The nitrogen adsorption specific surface area (N2SA) of the zinc oxide (B) according to the BET method is 6-110 m<2> / g. The blending amount of the zinc oxide (B) is 5-13 parts by mass with respect to 100 parts by mass of the rubber component (A). The blending amount of the co-condensate (C) is 0.1-10 parts by mass with respect to 100 parts by mass of the rubber component (A). The co-condensate (C) can be used as a replacement for p-tert-octylphenol and p-nonylphenol, has a softening point that is lower than the maximum temperature in a rubber processing step, and has excellent dispersibility in rubber.

Owner:BRIDGESTONE CORP

Preparation method of phosphorus-modified phenolic resin

InactiveCN103450263AGood coating performanceImprove heat resistanceGroup 5/15 element organic compoundsEpoxyP-tert-octylphenol

The invention discloses a preparation method of a phosphorus-modified phenolic resin, which comprises the following steps: performing polycondensation on p-tert-octylphenol, paratert-butyl phenol and formaldehyde under the action of a catalyst to obtain a phenolic condensation intermediate; and reacting the intermediate with monobasic alcohols monohydroxy alcohols and organic phosphorus heterocyclic compounds at a preset temperature for preset time under catalytic conditions to prepare the phosphorus-modified phenolic resin. The method solves the problem of complete dependency on the phosphorus-modified phenolic resin imported from abroad in the past, and enhances the heat resistance, binding strength, peel strength, favorable space size, excellent electric properties, mechanical strength and other physicochemical performance indexes of the original phosphorus-modified phenolic resin, so that the phosphorus-modified phenolic resin has relatively good application properties when being applied to the field of electronic chemicals.

Owner:梁劲捷

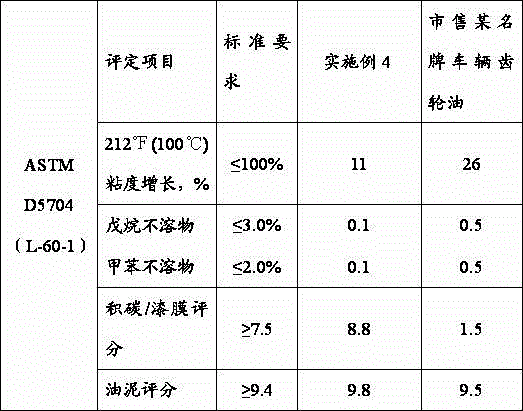

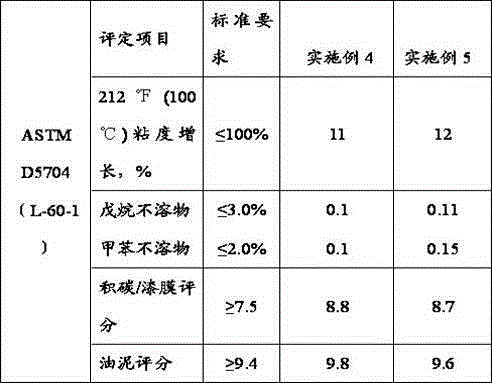

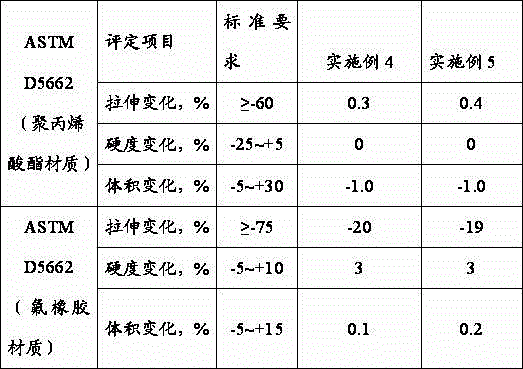

High-temperature antioxidant and preparation method thereof, and applications of high-temperature antioxidant in gear oil

ActiveCN104893788AImprove antioxidant capacityReduce carbon depositionAdditivesAntioxidantP-tert-octylphenol

The present invention belongs to the field of lubricating oils, and relates to antioxidants, particularly to a high-temperature antioxidant and a preparation method thereof, and applications of the high-temperature antioxidant in gear oil. The high-temperature antioxidant comprises p-tert-octylphenol, n-hexane, sulfur dichloride, alkenyl succinic acid phenol, benzene, thio bis-p-tert-octyl phenol benzene, and hydrated copper acetate. Compared with the high-temperature antioxidant, the preparation method and the applications thereof in the prior art, the high-temperature antioxidant, the preparation method and the applications thereof of the present invention have the following advantages and positive effects that the high-temperature antioxidant is provided and is added to the gear oil so as to improve excellent anti-oxidation capacity of the gear oil, effectively reduce the carbon deposition on the vehicle gear surface, reduce the oil seal wear, prolong the oil change period, and improve the economic benefits.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

Multifunctional antibiosis coating layer for children's intelligence development toys

InactiveCN105925038AExcellent flame retardantGood acid and alkali resistanceFireproof paintsAntifouling/underwater paintsNitrocellulosePhosphate

The invention relates to a multifunctional antibiosis coating layer for children's intelligence development toys. The multifunctional antibiosis coating layer comprises an acrylonitrile-butadiene-styrene copolymer, para-tert-octylphenol fomaldehyde resin, nitrocellulose plastic, an ethylene-vinyl acetate copolymer, ammonium polyphosphate, trioctyl phosphate, hexahydrophthalic anhydride, glass fiber powder, molybdenum disulfide powder, silica powder, wollastonite powder, andalusite powder, active zinc oxide, wooden fibers, dipropylene glycol methyl ether, benzotriazole, butanetriol, dipropylene glycol dibenzoate, di-n-octyltin dilaurate, iron naphthenate, xanthan gum, butyl methacrylate, polyamide, aluminum dihydrogen phosphate, tributyl phosphate, trioctyl trimellitate, hydroxymethyl cellulose, hydroabietyl alcohol, nitrocellulose and fatty alcohol polyether amide. The multifunctional antibiosis coating layer has the advantages of superior flame retardation, acid-alkali, mildew and bacterium resistance, and improved performances.

Owner:梁方英

Material for multifunctional power maintenance gloves

InactiveCN105907035AExcellent flame retardantGood acid and alkali resistanceGlovesProtective garmentP-tert-octylphenolStyrene maleic anhydride

The invention relates to a material for multifunctional power maintenance gloves. The material comprises the following components: hexaflumuron, Carbomer, pine tar, boiled tung oil, ethylamine, isothiazolinone, styrene-maleic anhydride copolymers, p-tert-octyl phenol formaldehyde resin, methyl MQ silicone resin, polystyrene resin, arabinogalactan, amino-oligosaccharin, acrylic acid-2-ethyl hexyl ester, clove oil, ethyl p-hydroxybenzoate, dimethyl hydroxyl silicone oil, diisoamyl ether, ammonium chromate, barium peroxide, sulfadiazine silver, poly(butylene succinate), sodium polymethacrylate, trimethyl phosphate, sodium hexametaphosphate, chlorinated polyethylene, morpholine, nano-alumina powder, citric acid, glucose, sorbitol and carboxymethylcellulose. The product prepared from material has excellent flame retardance, acid-base resistance, mildew resistance and mold resistance, and the performance of the product is improved.

Owner:王义金

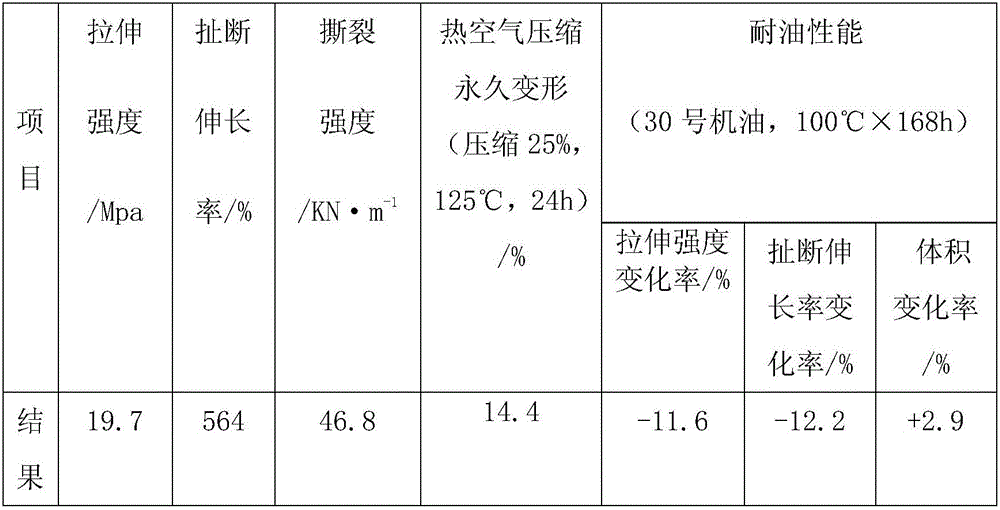

Oil-resistant cable material used for railway locomotive vehicle cable, and preparation method thereof

ActiveCN104017256AImprove flame retardant performanceExtended service lifeRubber insulatorsDi-tert-butyl peroxideP-tert-octylphenol

The invention discloses an oil-resistant cable material used for railway locomotive vehicle cables, and a preparation method thereof. The oil-resistant cable material is prepared from the following raw materials by weight: 60-80 parts of high styrene rubber, 40-60 parts of butadiene-acrylonitrile rubber, 20-40 parts of chloroprene rubber, 15-20 parts of a bromomethyl-p-tert-octyl phenol formaldehyde resin, 10-15 parts of dibutyl maleate, 9-18 parts of polychlorinated biphenyls, 8-16 parts of tridichloropropyl phenyl silicate, 10-15 parts of nano barium titanate, 12-18 parts of heavy calcium carbonate powder, 5-10 parts of fly ash, 24-32 parts of fast extruding furnace carbon blanc N550, 2.5-4.5 parts of di-tert-butyl peroxide, 3-6 parts of dibenzoylquinone dioxime, 2-3 parts of isocyanatopropyl triethoxysilane, 3-5 parts of basic lead carbonate, 2-3 parts of calcium oxide, 6-12 parts of a transformer oil, 4-6 parts of liquid paraffin, 3-5 parts of glyceryl monopalmitate, 1-2 parts of tetraethylthiuram disufide, 2-3 parts of N-tert-butylbenzothiazole-2-sulphenamide, 1.5-2.5 parts of 6-ethoxy-2,2,4-trimethyl-1,2-dihydroquinoline and 10-15 parts of modified stone powder. The cable material provided by the invention has excellent oil resistance, solvent resistance and chemical corrosion resistance, and effectively prolongs the service life of the cable.

Owner:ANHUI KANGLIYA CO LTD

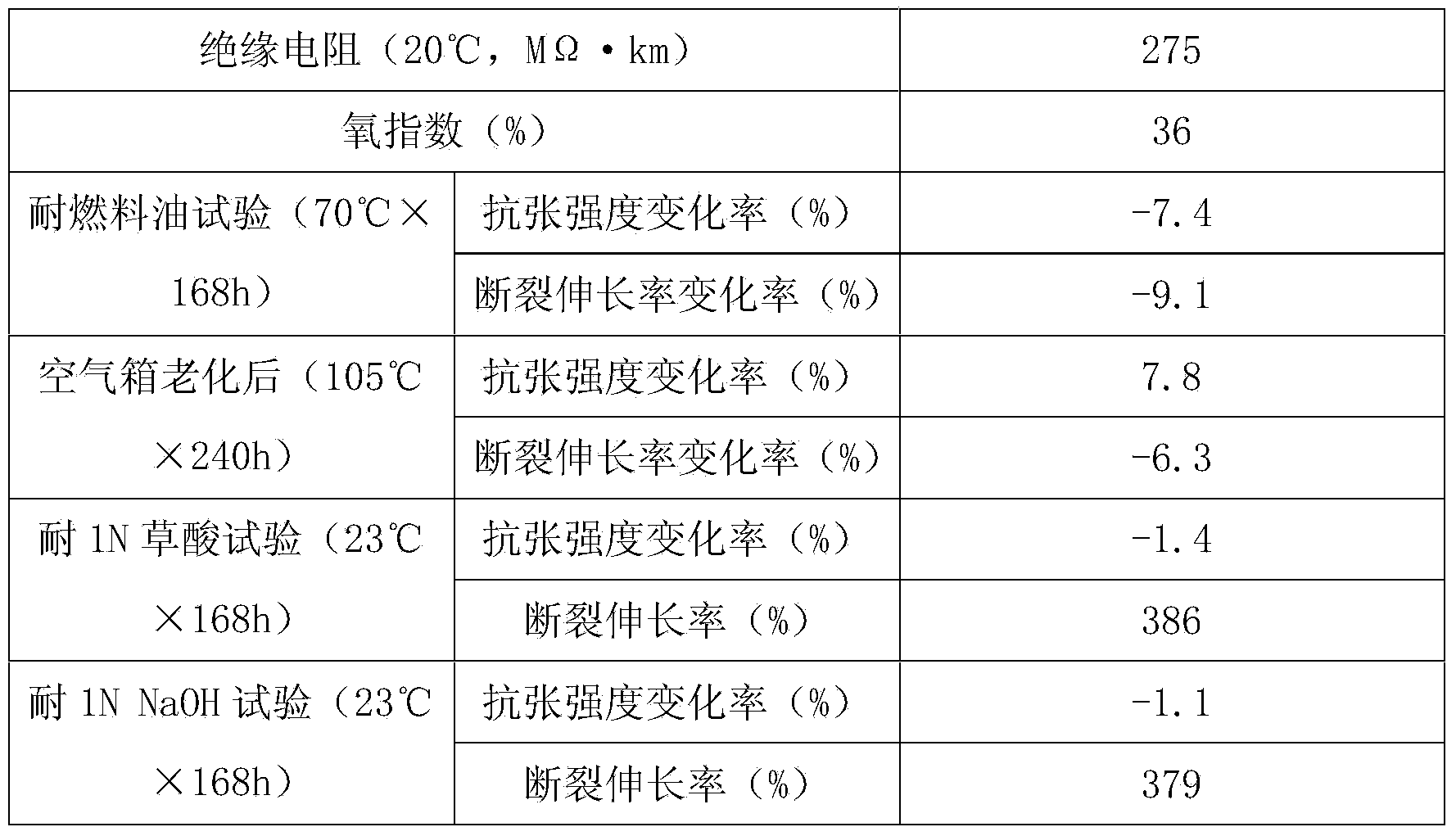

Environment-friendly oil-resistant rubber sealing piece and preparation process thereof

InactiveCN106146923ALow expansion rate after oil immersionGood oil resistancePolymer scienceP-tert-octylphenol

The invention discloses an environment-friendly oil-resistant rubber sealing piece and a preparation process thereof. The sealing piece is prepared from the following raw materials: natural rubber, nitrile rubber, silicon rubber, butylene succinate, p-t-octylphenol formaldehyde resin, calcium stearate, L-lysine diisocyanate, crylic acid-acrylonitrile copolymer, ethylene-octylene-alkadiene terpolymer, spraying carbon black, copper ammonia fibers, ethylene glycol salicylate, tea-seed oil acid, tetrachlorophthalic acid dioctyl phthalate, tri-n-butyl citrate, an aluminate coupling agent, dicumyl peroxide, 2,4-DCBP, zinc dibutyl dithiocarbamate, zinc oxide, N-octyl N-octadecyl sulfo-amino MoDDC and butyl acetate. The rubber sealing piece provided by the invention is high in oil resistance and comprehensive mechanical property, green and environment-friendly, and is very suitable for being used as the rubber sealing piece widely applied to various fields.

Owner:潘明华

Preparation method of phosphorus-modified phenolic resin

The invention discloses a preparation method of a phosphorus-modified phenolic resin, which comprises the following steps: performing polycondensation on p-tert-octylphenol, nonylphenol, bisphenol A and formaldehyde under the action of a catalyst to obtain a phenolic condensation intermediate; and reacting the intermediate with monohydroxy alcohols and organic phosphorus heterocyclic compounds at a preset temperature for preset time under catalytic conditions to prepare the phosphorus-modified phenolic resin. The method solves the problem of complete dependency on the phosphorus-modified phenolic resin imported from abroad in the past, and enhances the heat resistance, binding strength, peel strength, favorable space size, excellent electric properties, mechanical strength and other physicochemical performance indexes of the original phosphorus-modified phenolic resin, so that the phosphorus-modified phenolic resin has relatively good application properties when being applied to the field of electronic chemicals.

Owner:梁劲捷

High-oil-resistant ethylene-propylene-diene monomer rubber sealing gasket and preparing method thereof

The invention discloses a high-oil-resistant ethylene-propylene-diene monomer rubber sealing gasket and a preparing method thereof.The high-oil-resistant ethylene-propylene-diene monomer rubber sealing gasket is prepared from, by weight, 51-63 parts of ethylene-propylene-diene monomer rubber, 38-52 parts of polysulfide rubber, 22-34 parts of chlorosulfonated polyethylene rubber, 5-7 parts of cross-linking agent SQS350, 8-10 parts of sodium alginate, 17-24 parts of basic magnesium sulfate whiskers, 6-12 parts of naphthenic oil, 2-3 parts of tetraethylthiuram disulfide, 1-2 parts of 2-mercaptobenzimidazole, 4-8 parts of brooethyl p-tert-octyl phenolformaldehyde resin, 3-7 parts of N,N'-bis(furfurylidene)acetone, 2-5 parts of zinc carbonate, 10-15 parts of bisadipate, 16-22 parts of steel slag micro powder, 2-3 parts of 2,5-ditert-butylhydroquinone and 17-21 parts of modifying agent.The high-oil-resistant ethylene-propylene-diene monomer rubber sealing gasket has the advantages of being excellent in oil resistance, good in airtight performance, resistant to high temperature, resistant to corrosion and the like, the detect that the requirement for the oil resistance of an existing ethylene-propylene-diene monomer rubber sealing gasket can not be met is overcome, and the requirement of a market can be met.

Owner:ANHUI JINGYI GLASS MACHINERY

Multifunctional power maintenance glove material

InactiveCN105968701AExcellent flame retardantGood acid and alkali resistanceGlovesProtective garmentLow-density polyethylenePhosphate

The invention relates to a multifunctional power maintenance glove material which is composed of a phenol resin, low-density polyethylene, an ethylene-ethyl acrylate copolymer, trioctyl phosphate, pentabromotoluene, bronopol, dimethyl fumarate, boron nitride powder, calcium sulfate dihydrate, lithium chromate powder, volcanic ash, straw powder, ferrous sulfate, aloe powder, polypropylene glycol, lemon oil, N-nitrosodimethylamine, gamma-(2,3-epoxy-propoxy)propyltrimethoxysilane, aminoethyl piperazidine, benzotriazole, sodium benzoate, monopentaerythritol, glycerin monostearate, p-tert-octylphenol, diphenylmethane, dihydroxy polydimethylsiloxane, dibasic lead sulfate, diethylamine, phthalimide peroxide and glycol bismethacrylate. The product has dvantages of excellent flame retardancy, excellent acid / alkali resistance and excellent mildewing resistance, and thus, the product performance is improved.

Owner:梁方英

Preparation method of phosphorus-modified phenolic resin

InactiveCN103450261AGood coating performanceImprove heat resistanceGroup 5/15 element organic compoundsEpoxyAlcohol

The invention discloses a preparation method of a phosphorus-modified phenolic resin, which comprises the following steps: performing polycondensation on p-tert-octylphenol, nonylphenol and formaldehyde under the action of a catalyst to obtain a phenolic condensation intermediate; and reacting the intermediate with monohydroxy alcohols and organic phosphorus heterocyclic compounds at a preset temperature for preset time under catalytic conditions to prepare the phosphorus-modified phenolic resin. The method solves the problem of complete dependency on the phosphorus-modified phenolic resin imported from abroad in the past, and enhances the heat resistance, binding strength, peel strength, favorable space size, excellent electric properties, mechanical strength and other physicochemical performance indexes of the original phosphorus-modified phenolic resin, so that the phosphorus-modified phenolic resin has relatively good application properties when being applied to the field of electronic chemicals.

Owner:梁劲捷

Multifunctional cable for municipal ecological garden construction

InactiveCN106084642ASoft textureExcellent flame retardantInsulated cablesInsulated conductorsPolychlorinated biphenylSodium phosphates

The invention relates to a multifunctional cable for municipal ecological garden construction. The multifunctional cable comprises a plurality of copper alloy wires and protecting covers, the copper alloy wires are arranged in parallel, and the outer layers of all the copper alloy wires are covered with the protecting covers. The protecting covers are prepared from p-tert-octyl phenolformaldehyde resin, fluorosilicon resin, fluororubber, pure acrylic emulsion, butyl acetate, lauryl alcohol phosphate acid ester, spindle oil, dipropylene glycol methyl ether, sodium monofluorophosphate, ethyl p-hydroxybenzoate, didecyl dimethyl ammonium chloride, dibromomethane, corn starch, sodium phosphate, calcium sulphate dehydrate, glass fiber powder, aluminium nitride powder, sodium tetraborate decahydrate, quartz powder, magnesium sulfate, polyethylene wax, trioctyl phosphate, polychlorinated biphenyl, ammonium polyphosphate, sodium ricinoleate, butyraldehyde, polyethylene polyamine, nickel dibutyldithiocarbamate, chlorothalonil and lead sulfate tribasic. By means of the multifunctional cable for municipal ecological garden construction, the using performance of the product is improved.

Owner:王志英

Preparation method of phosphorus-modified phenolic resin

The invention discloses a preparation method of a phosphorus-modified phenolic resin, which comprises the following steps: performing polycondensation on p-tert-octylphenol, nonylphenol, paratert-butyl phenol and formaldehyde under the action of a catalyst to obtain a phenolic condensation intermediate; and reacting the intermediate with monohydroxy alcohols and organic phosphorus heterocyclic compounds at a preset temperature for preset time under catalytic conditions to prepare the phosphorus-modified phenolic resin. The method solves the problem of complete dependency on the phosphorus-modified phenolic resin imported from abroad in the past, and enhances the heat resistance, binding strength, peel strength, favorable space size, excellent electric properties, mechanical strength and other physicochemical performance indexes of the original phosphorus-modified phenolic resin, so that the phosphorus-modified phenolic resin has relatively good application properties when being applied to the field of electronic chemicals.

Owner:梁劲捷

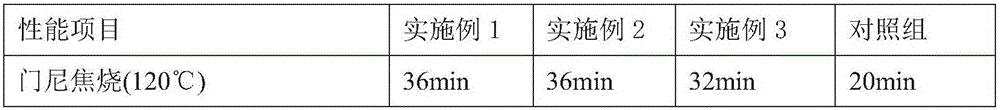

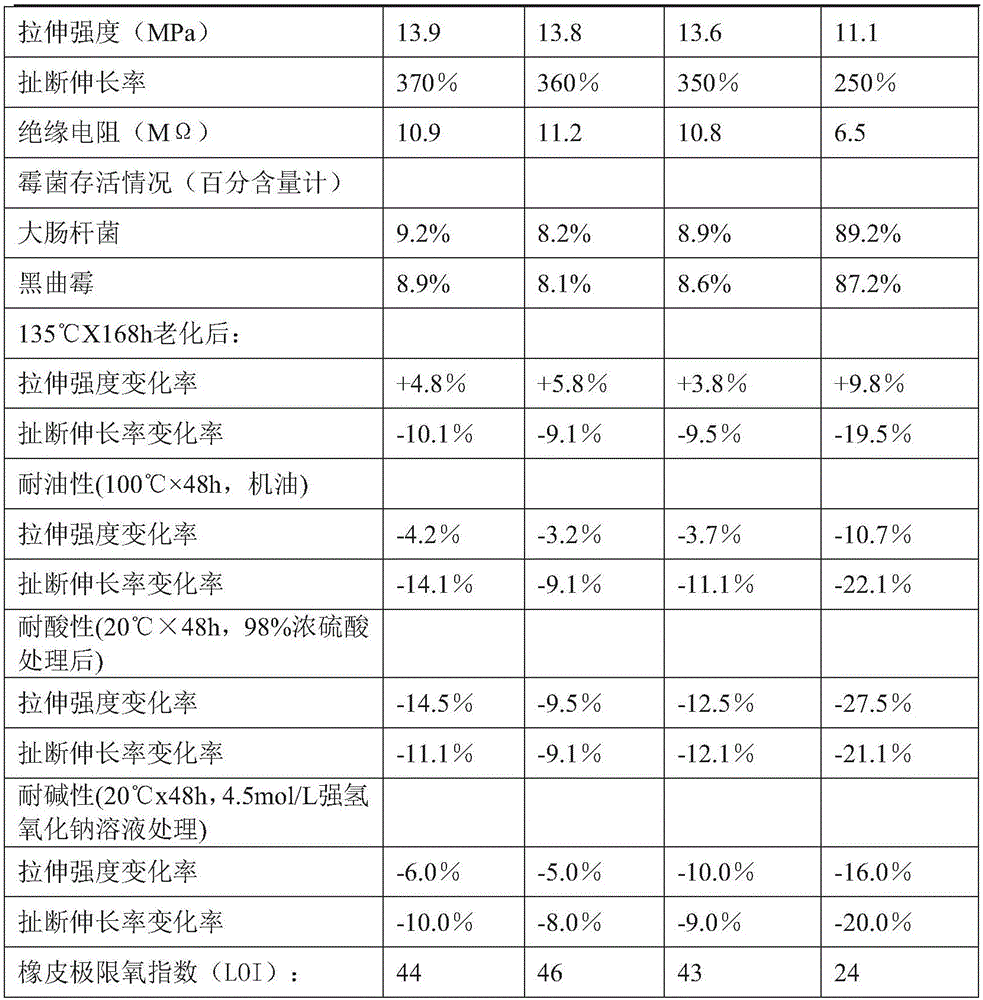

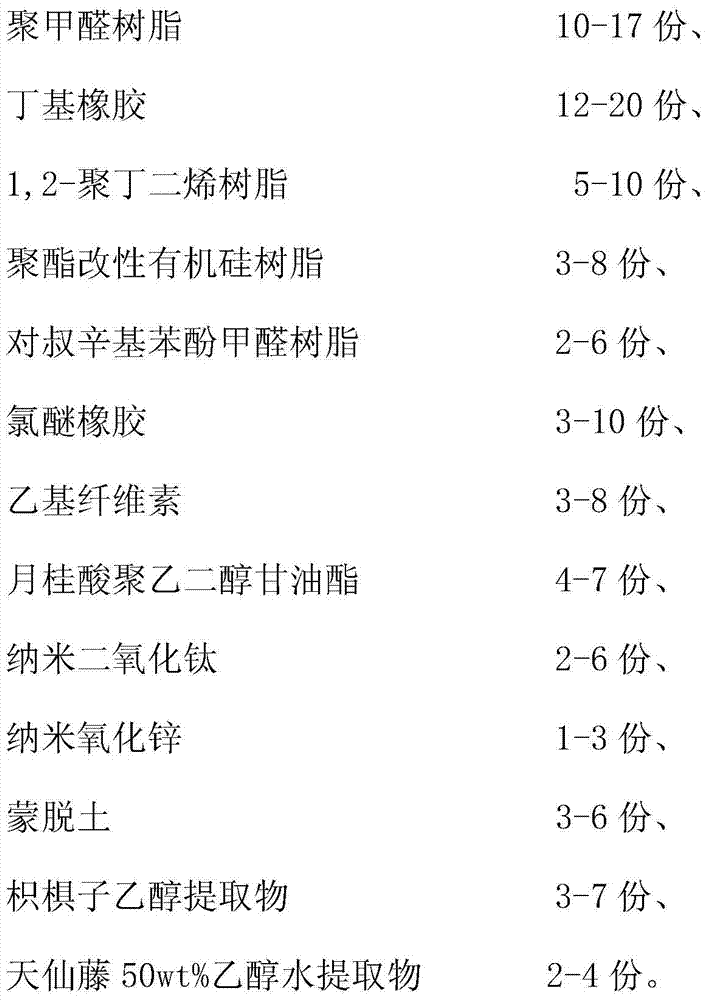

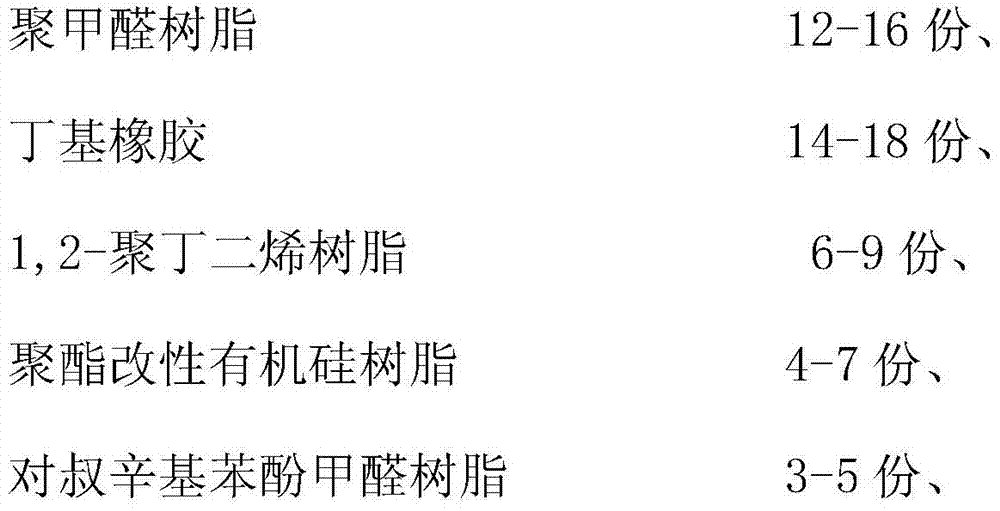

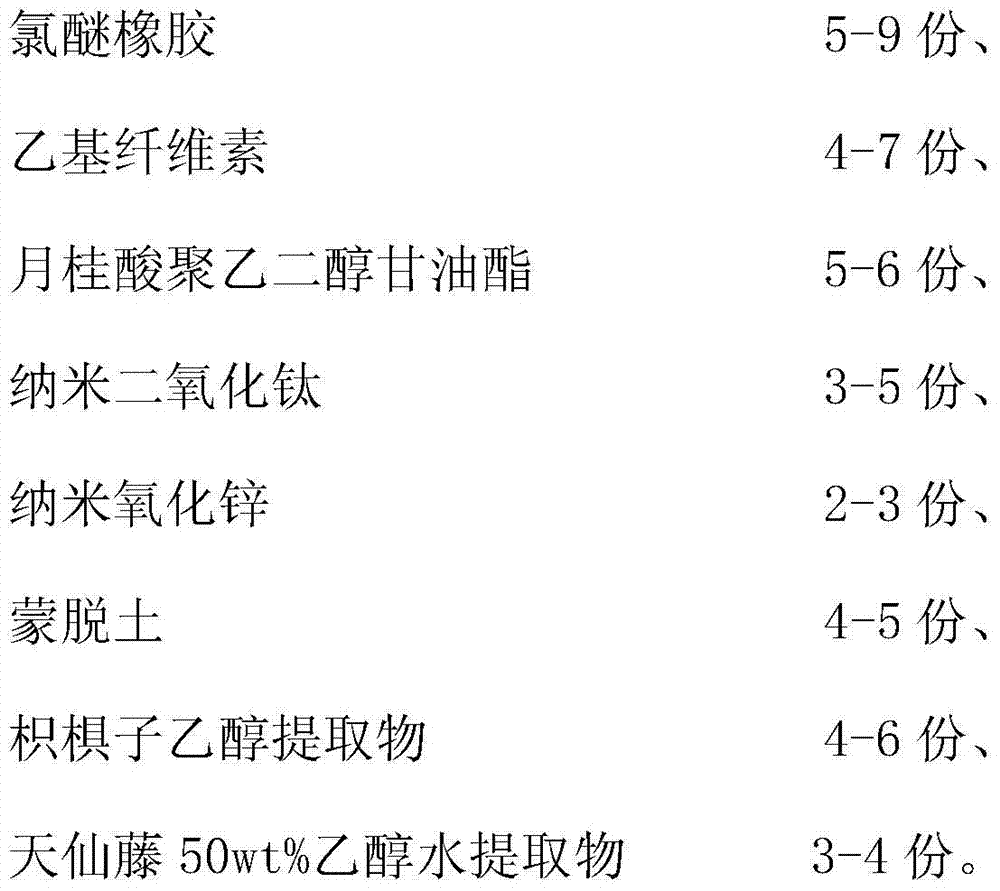

Bacterial inhibition high-hardness shoe material and preparation method thereof

ActiveCN105331040AImprovement without antibacterial propertiesImprove the defect that the strength is not highFootwearPolyesterP-tert-octylphenol

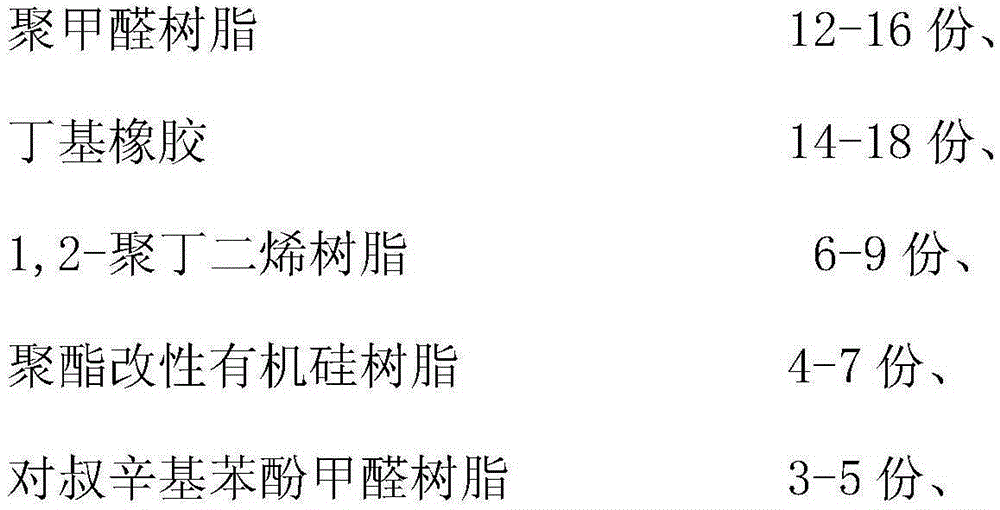

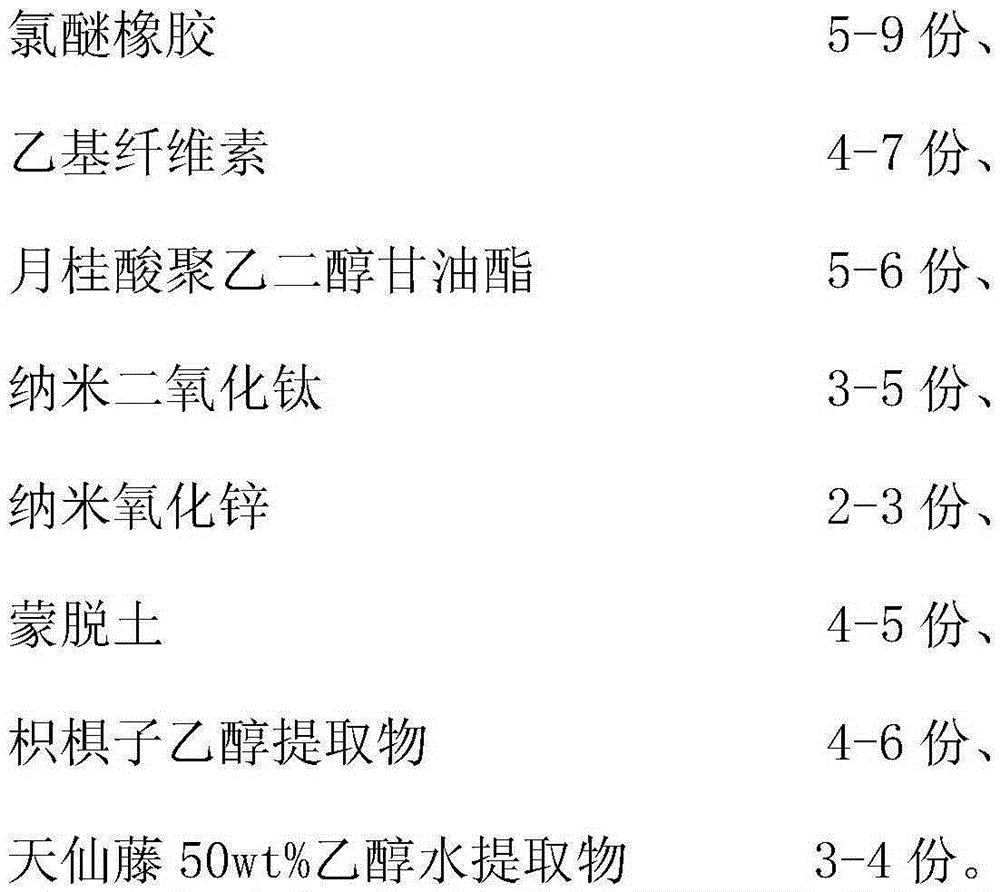

The invention discloses a bacterial inhibition high-hardness shoe material and a preparation method thereof. The preparation method comprises the steps that (1) ethanol extract of hovenia dulcis thunb and 50 wt% ethanol water extract of herba aristolochiae are prepared; (2) the temperature in a reaction kettle is set between 65 DEG C and 85 DEG C, acetal resin, butyl rubber, 1,2-polybutadiene resin, polyester modified organic silicon resin, para-tert-octylphenol formaldehyde resin, epichloro-hydrin rubber, ethyl cellulose and lauric acid polyethylene glycol glyceride are added, and the materials in the reaction kettle are mechanically stirred to be uniform; (3) nanometer titania, nanometer zinc oxide, montmorillonite, the ethanol extract of hovenia dulcis thunb and the 50 wt% ethanol water extract of herba aristolochiae are added, stirring is conducted again, and after being stirred to be uniform, the mixed materials are cooled and pressed into sheets used for preparing the bacterial inhibition high-hardness shoe material. The prepared shoe material has the advantages of being strong in bacterial inhibition effect and high in tensile strength and hardness.

Owner:吴江市旭达鞋业有限公司

Rubber composition for tire

ActiveUS20170233557A1Excellent in initial adhesivenessSpecial tyresPolymer scienceP-tert-Butylphenol

Owner:BRIDGESTONE CORP

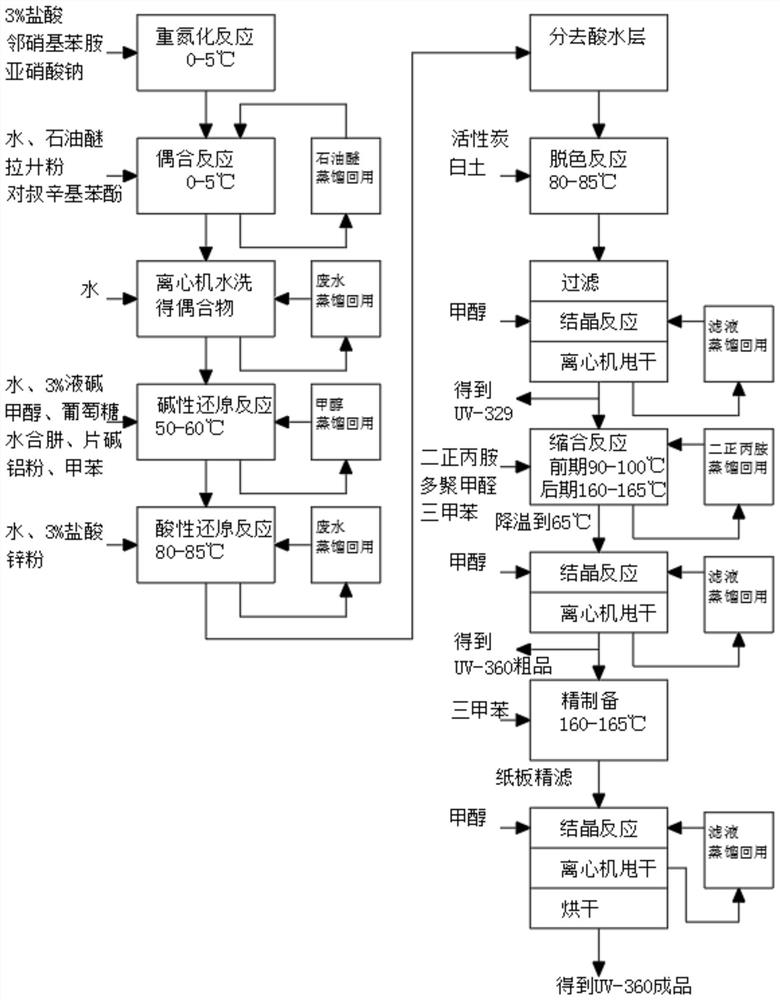

Preparation method of ultraviolet light absorber UV-360

PendingCN113999182AAchieving zero emissionsReduce usageOrganic chemistryIndustrial waste waterUltraviolet lights

The invention discloses a preparation method of an ultraviolet light absorber UV-360. The preparation method comprises the following specific steps: subjecting hydrochloric acid, o-nitroaniline and sodium nitrite to reacting to obtain a diazonium solution; stirring and dissolving water, petroleum ether, nekal and p-tert-octylphenol, adding the diazonium solution, carrying out a coupling reaction, and performing spin-drying to obtain an o-nitroazo compound; carrying out alkalization reaction on water, caustic soda liquid, methanol, glucose, hydrazine hydrate, caustic soda flakes, aluminum powder, toluene and a conjugate, and reserving a toluene layer; subjecting water, hydrochloric acid, zinc powder and the toluene layer to an acidic reaction, and reserving the toluene layer; carrying out decoloration reaction on the toluene layer, activated carbon and carclazyte, conducting filtering, and carrying out a reaction with methanol to obtain UV-329; carrying out condensation reaction on di-n-propylamine, paraformaldehyde, trimethylbenzene and UV-329, and adding methanol for crystallization to obtain a crude UV-360 product; and subjecting the crude UV-360 product to reacting with trimethylbenzene, performing filtering, and carrying out a reaction with methanol to obtain a finished UV-360 product. According to the preparation method, industrial wastewater, washing wastewater and a filtering solvent generated in the preparation process are distilled and reused, so the characteristics of zero discharge of the industrial wastewater and low use amount of the solvent are realized.

Owner:上海雄启化学科技有限公司

Preparation method of phosphorus-modified phenolic resin

InactiveCN103450264AGood coating performanceImprove heat resistanceGroup 5/15 element organic compoundsP-tert-octylphenolPerformance index

The invention discloses a preparation method of a phosphorus-modified phenolic resin, which comprises the following steps: performing polycondensation on p-tert-octylphenol, bisphenol A, paratert-butyl phenol and formaldehyde under the action of a catalyst to obtain a phenolic condensation intermediate; and reacting the intermediate with monohydroxy alcohols and organic phosphorus heterocyclic compounds at a preset temperature for preset time under catalytic conditions to prepare the phosphorus-modified phenolic resin. The method solves the problem of complete dependency on the phosphorus-modified phenolic resin imported from abroad in the past, and enhances the heat resistance, binding strength, peel strength, favorable space size, excellent electric properties, mechanical strength and other physicochemical performance indexes of the original phosphorus-modified phenolic resin, so that the phosphorus-modified phenolic resin has relatively good application properties when being applied to the field of electronic chemicals.

Owner:梁劲捷

A kind of oil-resistant cable material for railway locomotive vehicle cable and preparation method thereof

ActiveCN104017256BImprove flame retardant performanceExtended service lifeRubber insulatorsBarium titanateDi-tert-butyl peroxide

The invention discloses an oil-resistant cable material used for railway locomotive vehicle cables, and a preparation method thereof. The oil-resistant cable material is prepared from the following raw materials by weight: 60-80 parts of high styrene rubber, 40-60 parts of butadiene-acrylonitrile rubber, 20-40 parts of chloroprene rubber, 15-20 parts of a bromomethyl-p-tert-octyl phenol formaldehyde resin, 10-15 parts of dibutyl maleate, 9-18 parts of polychlorinated biphenyls, 8-16 parts of tridichloropropyl phenyl silicate, 10-15 parts of nano barium titanate, 12-18 parts of heavy calcium carbonate powder, 5-10 parts of fly ash, 24-32 parts of fast extruding furnace carbon blanc N550, 2.5-4.5 parts of di-tert-butyl peroxide, 3-6 parts of dibenzoylquinone dioxime, 2-3 parts of isocyanatopropyl triethoxysilane, 3-5 parts of basic lead carbonate, 2-3 parts of calcium oxide, 6-12 parts of a transformer oil, 4-6 parts of liquid paraffin, 3-5 parts of glyceryl monopalmitate, 1-2 parts of tetraethylthiuram disufide, 2-3 parts of N-tert-butylbenzothiazole-2-sulphenamide, 1.5-2.5 parts of 6-ethoxy-2,2,4-trimethyl-1,2-dihydroquinoline and 10-15 parts of modified stone powder. The cable material provided by the invention has excellent oil resistance, solvent resistance and chemical corrosion resistance, and effectively prolongs the service life of the cable.

Owner:ANHUI KANGLIYA CO LTD

A kind of antibacterial type high hardness shoe material and preparation method thereof

ActiveCN105331040BImprovement without antibacterial propertiesImprove the defect that the strength is not highFootwearPolyesterAqueous ethanol

The invention discloses a bacteriostatic high-hardness shoe material and a preparation method thereof. The preparation method comprises the following steps: (1) preparing the ethanol extract of Hovenia dulcis and the 50wt% ethanol water extract of Tianxian vine; (2) preparing The temperature in the reaction kettle is set at 65-85°C, and polyoxymethylene resin, butyl rubber, 1,2-polybutadiene resin, polyester modified silicone resin, p-tert-octylphenol formaldehyde resin, and epichlorohydrin rubber are added , ethyl cellulose, macrogol glycerol laurate, mechanically stir the materials in the reactor evenly; The rattan 50wt% ethanol water extract is stirred again, and after stirring evenly, the mixed material is cooled and pressed into a sheet to prepare a bacteriostatic high-hardness shoe material. The prepared shoe material has the properties of strong antibacterial effect, high tensile strength and high hardness.

Owner:吴江市旭达鞋业有限公司

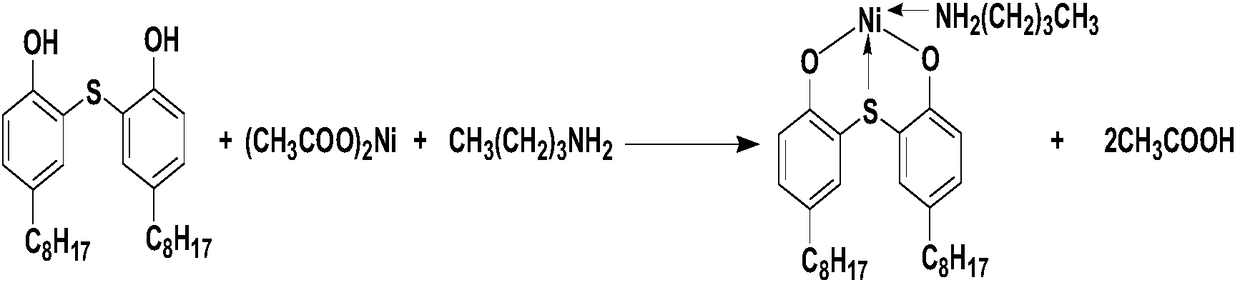

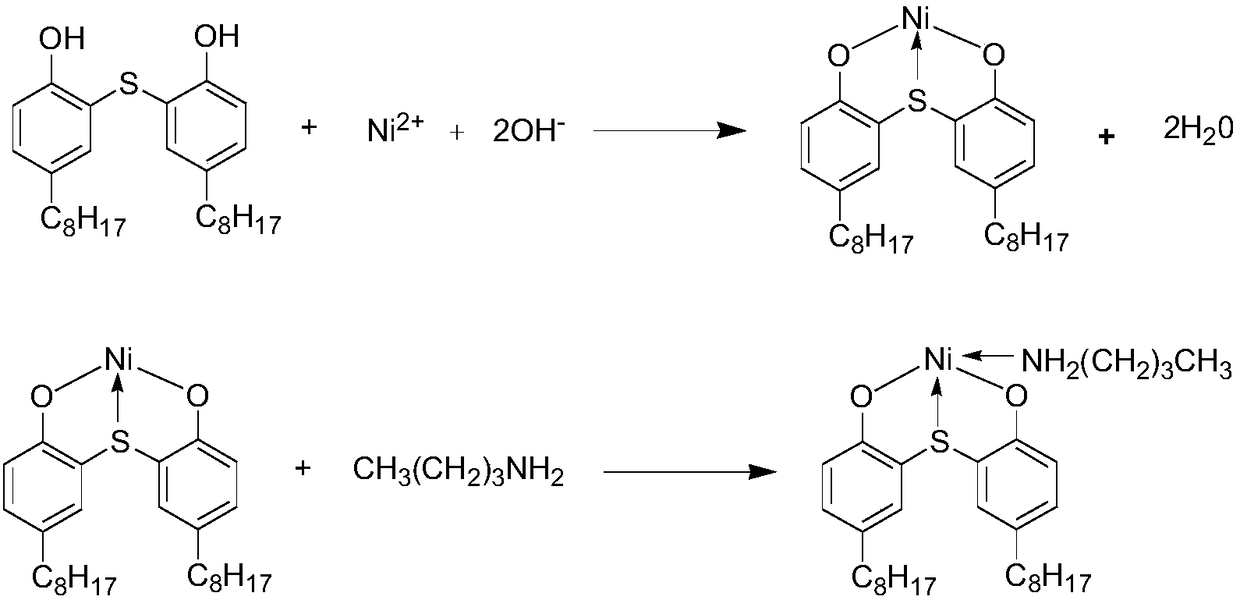

Preparation method for 2,2'-thiobis(4-tert-octylphenolato)-n-butylamine nickel(ii)

ActiveCN108623640AReduce generationImprove reaction stabilityNickel organic compoundsHydrocarbon solventsNickel salt

The invention discloses a preparation method for 2,2'-thiobis(4-tert-octylphenolato)-n-butylamine nickel(ii). The preparation method comprises the following steps: (1) adding hydrocarbon solvent, solvent which mutually dissolves with water, and water into a kettle, adding 2,2'-thio p-(tert-octyl) phenol and nickelous salt under stirring, heating to 40-90 DEG C, evenly dripping inorganic base solution from an elevated tank within 1-3 hours, keeping for 5 hours after the inorganic base solution is added, standing, removing a lower layer of aqueous phase, adding n-butylamine into an organic phase, and stirring at the temperature of 50-80 DEG C for 2 hours; filtering reaction liquid, carrying out distillation to removal solvent, and drying and smashing to obtain a light green powdery product.The solvent which mutually dissolves with water is introduced, and reaction stability is improved so as to improve the content of the product and accelerate product quality to be stable. The inorganicbase serves as acid-binding agent, n-butylamine and nickel salt are separated, and the pollution of excessive n-butylamine and byproducts generated by the n-butylamine for environment can be lightened.

Owner:乐凯化学材料有限公司

High-strength multifunctional polyethylene communication tubular product

The invention relates to a high-strength multifunctional polyethylene communication tubular product. The tubular product is prepared from polyethylene, acrylic resin, aldehyde resin, polyketone resin, p-tert-octyl phenolformaldehyde resin, clove oil, anthracene oil, zanthoxylum oil, polyglycerol, cottonseed oil, hydrogen peroxide, oxymatrine, propargyl chloride, di-octadecyl dimethyl ammonium chloride, aluminium phosphate powder, szaibelyite powder, methyl tertiary butyl ether, n-butyl stearate, allyl methyl sulfide, zinc fluoride, dolomite powder, boron nitride powder, hydrous zinc borate, aluminium stearate, zinc hydroxystannate, hexabromocyclododecane, disodium stannous citrate, starch ether, oxalic acid, dibutyl sebacate, aluminium distearate and diethylenetriamine. Various materials are mixed together to form a novel composite toughening and strengthening system, the toughness, rigidity and elastic modulus performance indexes are good, the anti-ageing performance and use performance of the product are greatly improved, and the tubular product has good corrosion resistance, good antibacterial and flame-retardant effects and good insulating performance.

Owner:龚灿锋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com