Patents

Literature

322 results about "Di-tert-butyl peroxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

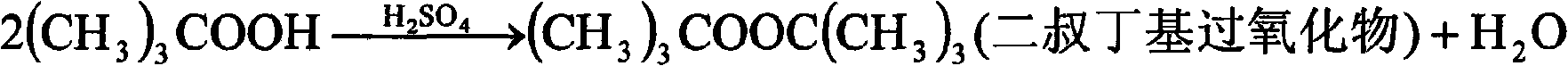

Di-tert-butyl peroxide or DTBP is an organic compound consisting of a peroxide group bonded to two tert-butyl groups. It is one of the most stable organic peroxides, due to the tert-butyl groups being bulky. It is a colorless liquid.

Biodiesel fuel additive

InactiveUS20060201056A1Reduce pollutant emissionsIncreasing lubricity of fuelBiofuelsLiquid carbonaceous fuelsCombustionBiodiesel

The present invention relates generally to a composition and method for decreasing the emissions from combustion of fuel that contains biodiesel, where the composition contains at least one ignition accelerator and at least one plant extract or synthetic component similar to a portion of a plant extract. The ignition accelerator is preferably a peroxide, for example, di-tert-butyl peroxide. The composition may optionally contain meadowfoam oil or jojoba oil. The composition may also enhance the lubricity of the fuel that contains biodiesel.

Owner:AQ

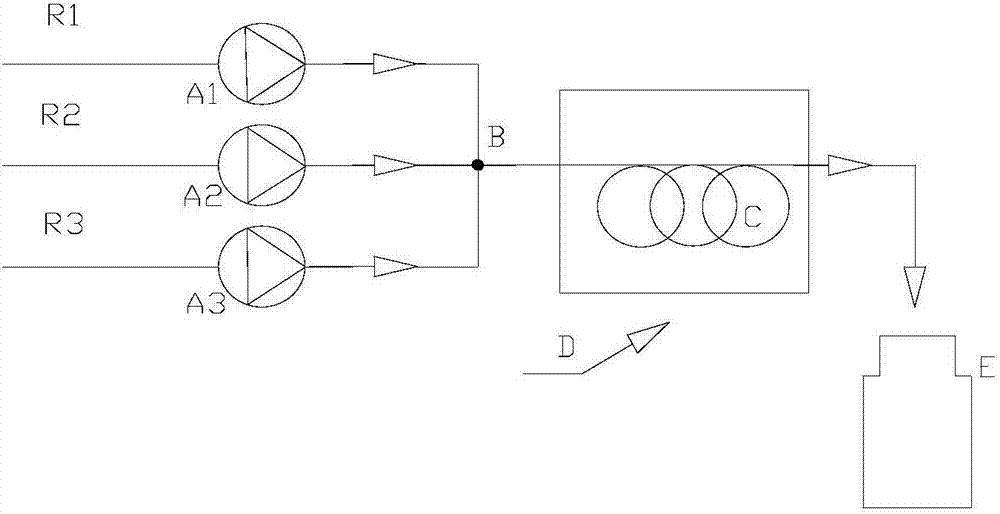

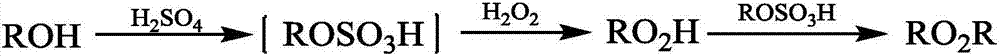

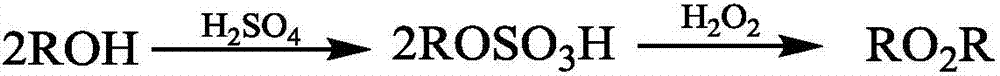

Preparation of tert-butyl hydrogen peroxide and di-tert-butyl peroxide

ActiveCN101298429AMild reaction conditionsHigh yieldOrganic chemistryDi-tert-butyl peroxideOil phase

The invention discloses a preparation method of tert-butyl hydroperoxide and di-t-butyl peroxide which includes the following steps: after mixing vitriol, oxyful and phosphotungstic acid with certain concentration, adding tertiary butyl alcohol into a mixed liquor or adding the mixed liquor into the tertiary butyl alcohol; reacting for 0.5 to 5 hours under 20 to 60 DEG C; obtaining an oil phase after carrying out liquid separation on the crude product of the reaction; obtaining the tert-butyl hydroperoxide and di-t-butyl peroxide products by carrying out decompressing and rectifying on the oil phase; the method has the advantages of simple and convenient operation, low manufacture cost, safety, high efficiency and high yield; in addition, the method of the invention can adjust the relative content of the two reaction products by changing the reaction conditions. The reaction products of tert-butyl hydroperoxide and di-t-butyl peroxide are separated by decompressing and rectifying, thus avoiding the working procedures of acid cleaning and caustic wash in the traditional technique, solving the defect of overlarge waste water amount in the traditional technique, being beneficial to protecting the environment, reducing the manufacture cost and being capable of greatly increasing the enterprise benefits.

Owner:ZHEJIANG JINKE CHEM

Agricultural polyethylene resin composition

An agricultural polyethylene resin composition mainly comprises linear low density polyethylene and di-tert-butyl peroxide, wherein the dosage of di-tert-butyl peroxide is 0.3-0.6 (percentage by weight, based on linear low density polyethylene). The resin composition can be used for blowing agricultural covering films.

Owner:PETROCHINA CO LTD

Preparation method of tert-butyl peroxide

InactiveCN104557652AStrong acidPore structure highOrganic compound preparationPeroxy compound preparationPtru catalystDi-tert-butyl peroxide

The invention provides a method for preparing tert-butyl peroxide by using a heterogeneous catalyst. The method comprises the following steps: by using tert-butyl alcohol and oxydol as raw materials and an acidic ion exchange resin as a catalyst, reacting under reflux, cooling, standing, and separating to obtain an oil phase and a water phase; and washing the oil phase with alkali and water to obtain a di-tert-butyl peroxide solution (DTBP), wherein the oil phase water washing solution and water phase are the tert-butyl hydroperoxide water solution (TBHP). Since the ion exchange resin has the advantages of large pore structure, high acidity and high catalysis efficiency and the large pore structure can not be destroyed in reaction, the catalyst can be easily separated from the reaction product and can be recycled repeatedly, thereby having higher economic value. Besides, no sulfuric acid or any other strong acid is used in the production process, so the method has the advantages of low corrosion to equipment and no environment pollution, and has higher environmental benefit.

Owner:NORTHWEST NORMAL UNIVERSITY

High-performance tracking-resistant silicone rubber and preparation method thereof

ActiveCN104974530AOvercome the disadvantage of high filling volumeImprove tracking resistance performancePolymer scienceVulcanization

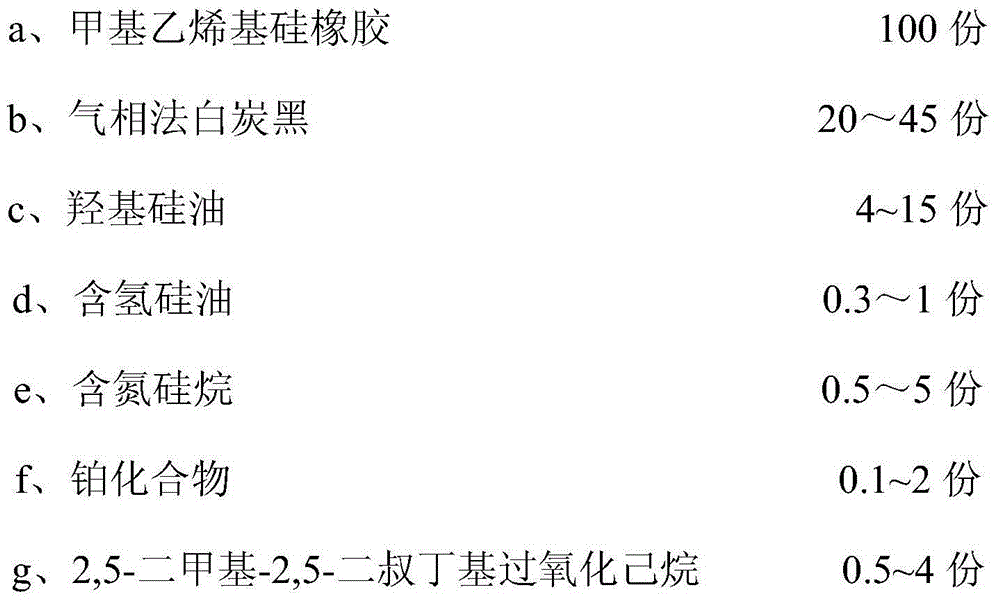

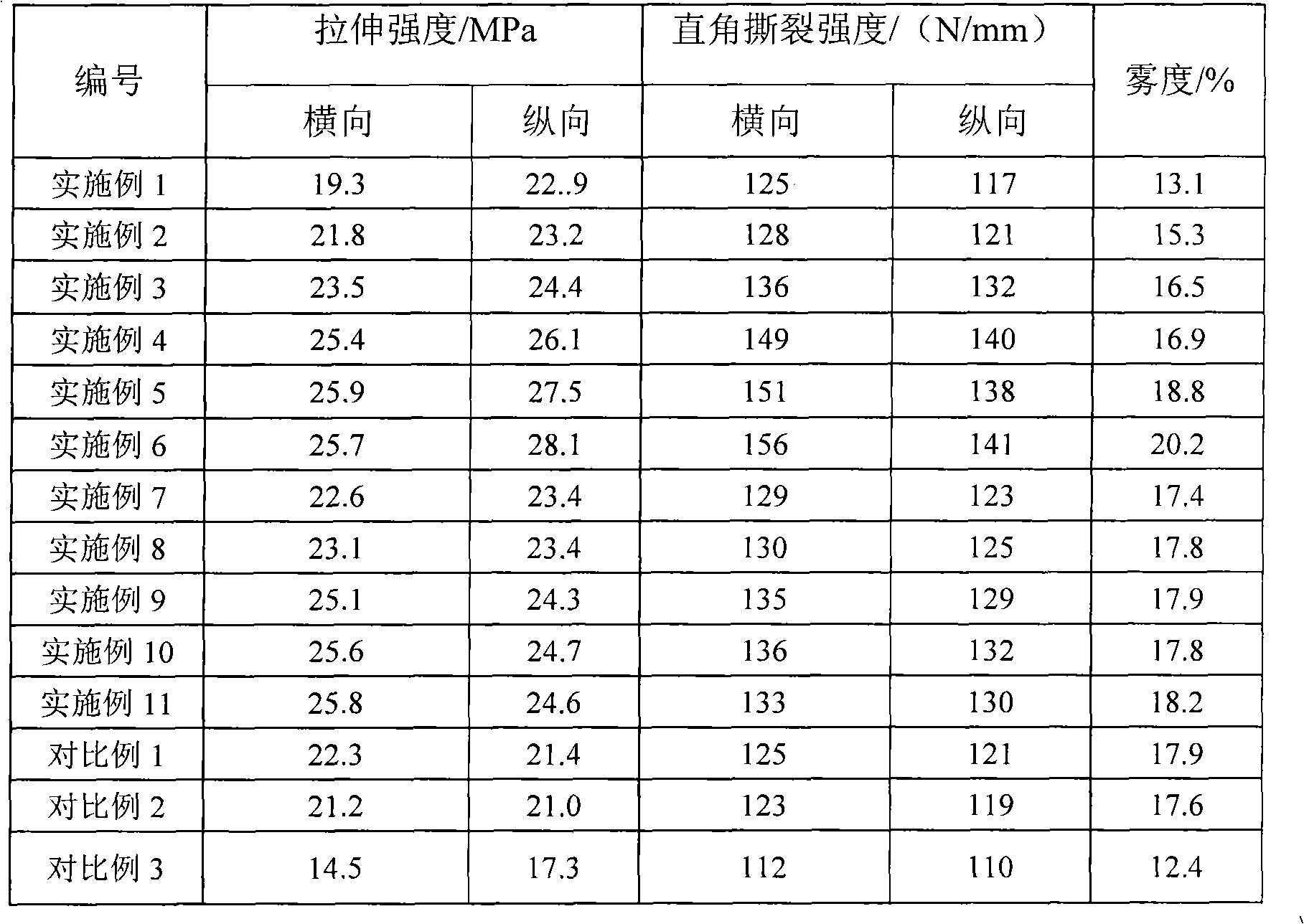

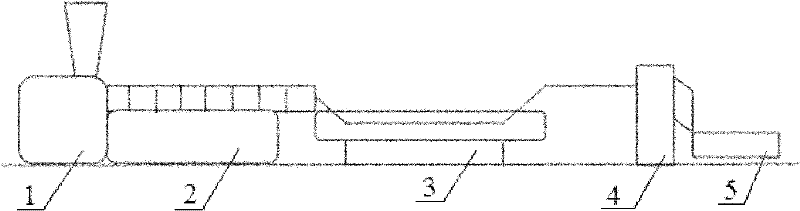

The invention discloses a high-performance tracking-resistant silicone rubber and a preparation method thereof. The tracking-resistant silicone rubber is prepared from the following raw materials in parts by mass: 100 parts of methylvinyl silicone rubber, 20-45 parts of fumed silica, 4-15 parts of hydroxy silicone oil, 0.3-1 part of hydrogen-containing silicone oil, 0.5-5 parts of nitrogenous silane, 0.1-2 parts of platinum compound and 0.5-4 parts of hexane 2,5-dimethyl-2,5-di-tert-butyl peroxide. The preparation method comprises the following steps: uniformly compounding the methylvinyl silicone rubber, fumed silica, hydroxy silicone oil and hydrogen-containing silicone oil in a kneader at room temperature, and carrying out heat treatment to obtain the silicone rubber basic rubber; and uniformly compounding the basic rubber and the other components in an open mill, and carrying out sectional vulcanization. The silicone rubber has excellent tracking resistance and mechanical properties, and can be used in the field of high-voltage insulation. The method has the advantages of accessible raw materials and simple processing technique, and is convenient for large-scale production.

Owner:SOUTH CHINA UNIV OF TECH

Irradiation resistant non-halogen low smoke flame-retardant sheathing material applied to nuclear power stations and preparation method

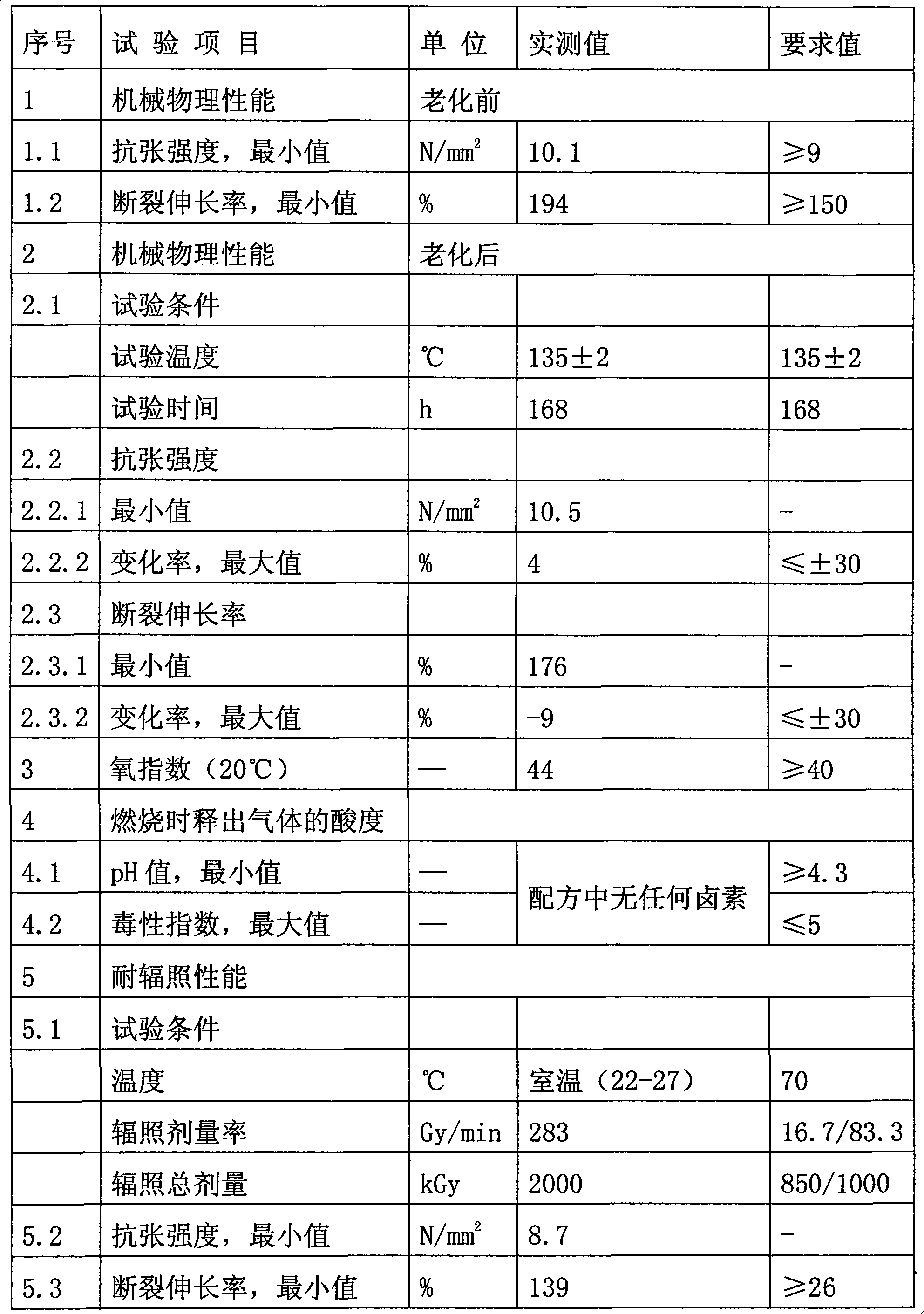

ActiveCN101597397AImprove radiation resistanceThe ratio is scientific and reasonableInsulated cablesInsulated conductorsDi-tert-butyl peroxideNuclear power

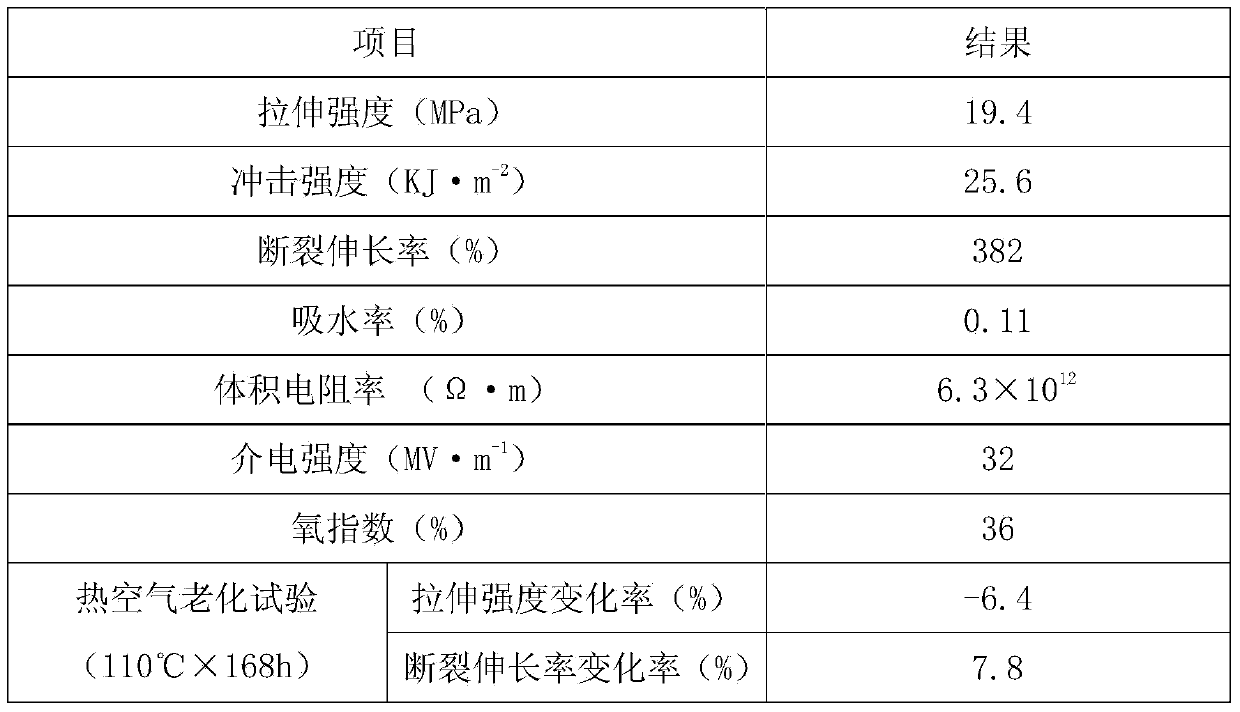

The invention discloses an irradiation resistant non-halogen low smoke flame-retardant sheathing material applied to nuclear power stations and a preparation method. The raw materials comprises ethane-vinyl acetate rubber, maleic anhydride stem grafting ethane-vinyl acetate rubber, magnesium hydroxide fire retardant, organic silicon fire retardant, nano cerium oxide, FEF, zinc stearate, stearic acid, vinyl trisilane, Aflux A-16, Aflux A-25, polycarbonate diimine(PCD-50), 2, 2, 4-trimethyl-1, 2-dihydride quinoline, antiager DDA, di-tert-butyl peroxide cumene, triene propylcyanide uric acid ester and decanedioic acid dioctyl, which are heated and mixed to obtain the materials of the invention. The invention features scientific and reasonable formula and proportion, and the process is advanced. The sheathing material features fine irradiation resistance, excellent mechanical properties and long service life, thus being a good irradiation resistant non-halogen low smoke and flame-retardant sheathing material applied to nuclear power stations.

Owner:BAOSHENG SCI & TECH INNOVATION

Method for operating compression ignition internal combustion engine

InactiveUS20060185644A1Improve flammabilityShorten the overall cycleNon-fuel substance addition to fuelInternal combustion piston enginesHomogeneous charge compression ignitionDi-tert-butyl peroxide

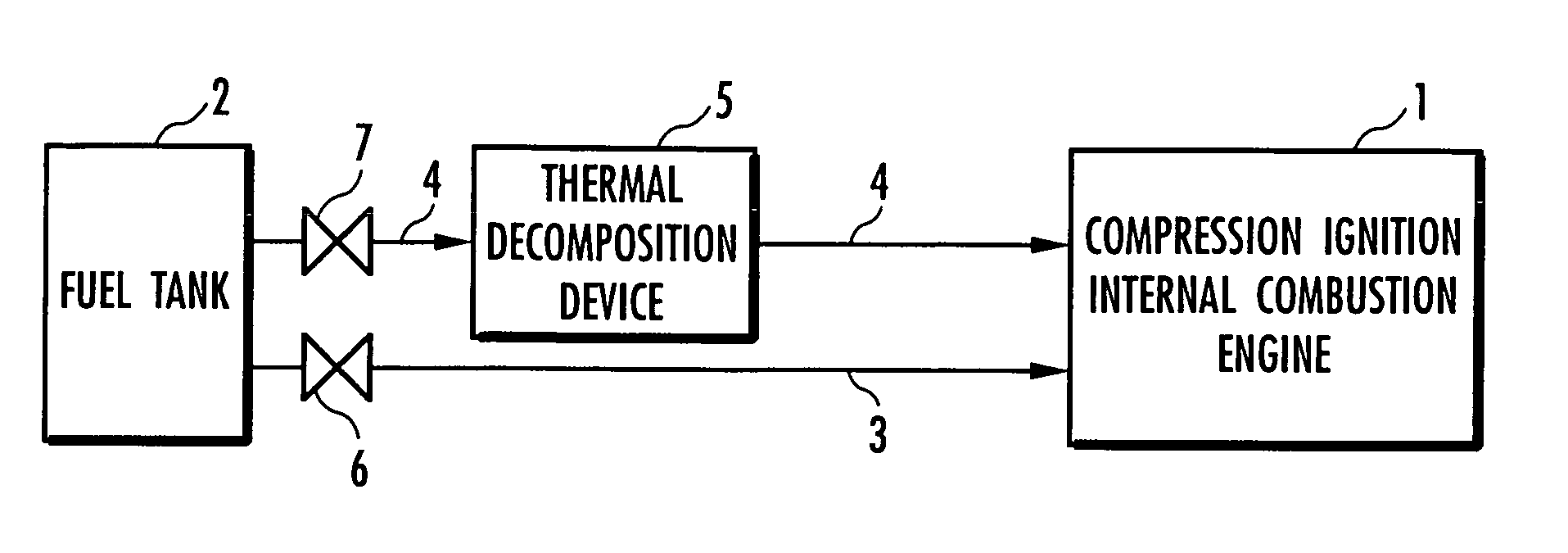

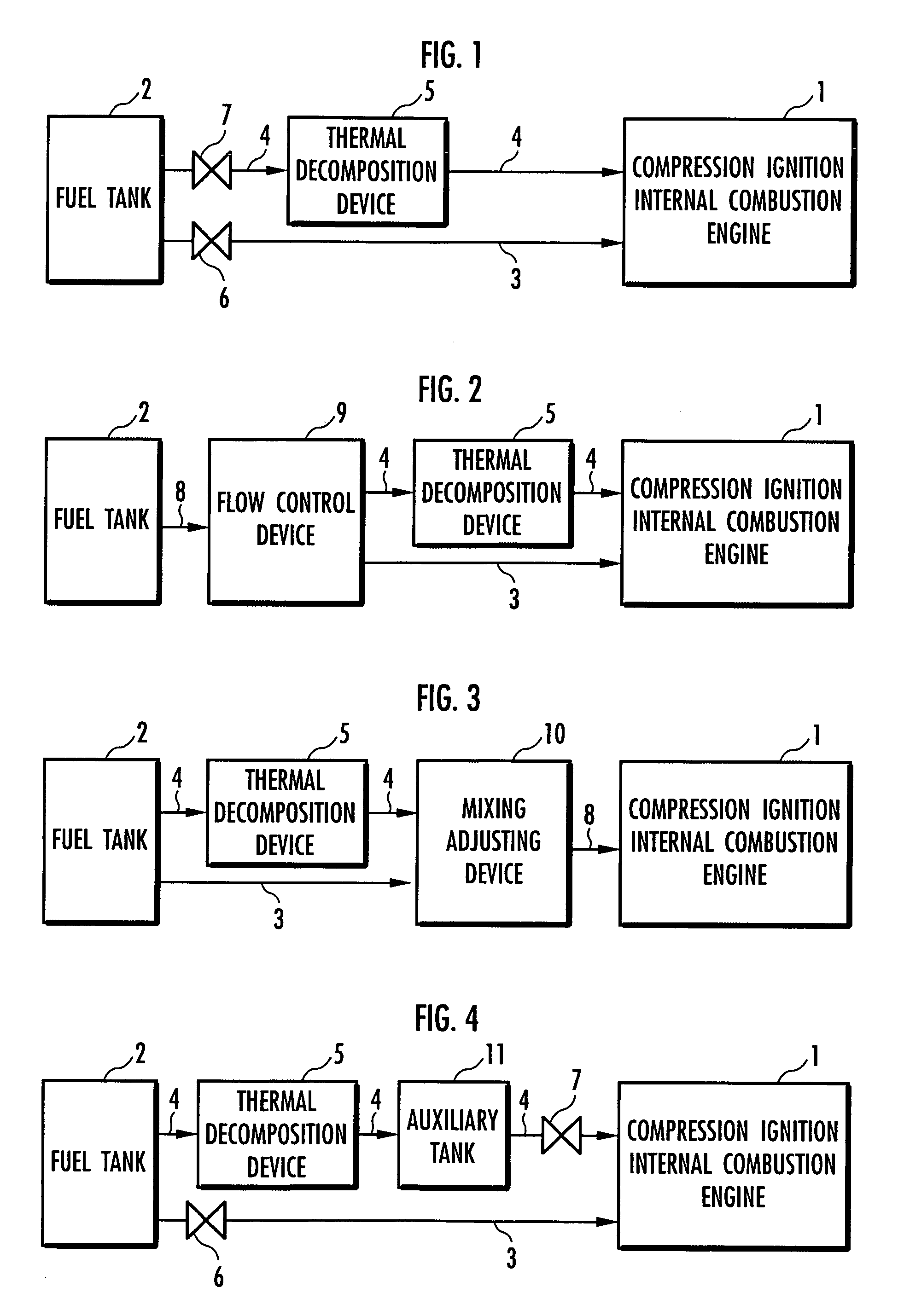

An object is to provide a method for operating a compression ignition internal combustion engine which, using a single fuel, can produce diesel combustion when the load is high, or homogeneous-charged compression ignition combustion when the load is low. The operating method includes: employing a fuel containing 95 to 99.5 wt. % of a base fuel made of one or more compounds selected from the group consisting of a hydrocarbon, an alcohol, an ether and a fatty ester, and 0.1 to 5 wt. % of an additive made of one or more compounds selected from the group consisting of an organic peroxide, a nitric ester, a nitrite ester and an azo compound; and producing diesel combustion when the load is high, or homogeneous-charged compression ignition combustion when the load is low. The organic peroxide is di-tert-butyl peroxide. The nitric ester is n-pentyl nitrate. The nitrite ester is n-pentyl nitrite. The azo compound is 2,2-azobis(2,4-dimethylvaleronitrile).

Owner:HONDA MOTOR CO LTD

Agricultural polyethylene resin composition

ActiveCN101538386AReduce dosageGuaranteed stabilityClimate change adaptationGreenhouse cultivationLow-density polyethyleneCross-link

The invention discloses an agricultural polyethylene resin composition. The composition mainly consists of linear low-density polyethylene LLDPE and organic peroxide, wherein the organic peroxide is combined by di-tert-butyl peroxide DTBP and tert-butyl hydroperoxide TBHP according to the combination ratio of between 1:1 and 6:1, and the consumption of the organic peroxide is between 500 and 2,500ppm (based on each gram of linear low-density polyethylene). In the composition, the linear low-density polyethylene LLDPE is cross-linked by compounding the peroxide, and when the obtained modified high-bath strength LLDPE resin is used for blowing a 80 mum agricultural green house membrane, and under the condition of ensuring the membrane blowing stability and the quality of the membrane, the consumption of the peroxide is lowered, so that the production cost is also lowered.

Owner:PETROCHINA CO LTD

Copper catalyst system for decarboxylation coupling reaction

InactiveCN102614927ANon-toxicLow costOrganic compound preparationOrganic chemistry methodsDi-tert-butyl peroxideIodide

The invention discloses a copper catalyst system for decarboxylation coupling reaction, which comprises a copper-containing compound and an oxidant in a mol ratio of 1:(10-40), wherein the copper-containing compound is one or mixture of cuprous iodide, cupric acetylacetonate, cuprous bromide, cupric sulfate and copper powder; and the oxidant is tert-butyl hydroperoxide, di-tert-butyl peroxide or dicumyl peroxide. The catalyst system can catalyze the decarboxylation coupling reaction of cinnamic acid and methylbenzene compounds to prepare olefin compounds. Compared with the existing noble-metal-containing catalyst system, the catalyst system disclosed by the invention uses the cheap copper-containing compound instead of noble metal, thereby lowering the cost; and the byproduct is only carbon dioxide, thereby being beneficial to environment protection and cost saving, and satisfying the requirement for green chemistry.

Owner:SUZHOU UNIV

Method for preparing tert-butyl hydroperoxide

InactiveCN105523982AShort processReduce corrosionOrganic compound preparationPeroxy compound preparationDi-tert-butyl peroxideDistillation

The invention relates to a method for preparing tert-butyl hydroperoxide. According to the invention, the raw materials are isobutane and di-tert-butyl peroxide, and steps of catalysis, underpressure distillation and crystallization are carried out on the raw materials according to a certain proportion under high temperature and high pressure. According to the invention, the raw materials are isobutane and the di-tert-butyl peroxide with mass ratio being 1:1-3; the high temperature and high pressure condition are 140-160 DEG C and 1.5-2.5 atmospheric pressure; a catalyst is ferric potassium oxalate; the underpressure distillation condition is 0.1-0.3 atmospheric pressure, and temperature is 30-40 DEG C; the crystallization step is characterized in that the collected liquid is dissolved by distilled water at temperature of 20-40 DEG C, then is cooled to the temperature of 1-5 DEG C, is slightly stirred, and is stood for crystallization. The process flow is short, reaction byproduct is less, environment pollution and corrosion degree on production equipment are low, and product purity is high.

Owner:茅海强

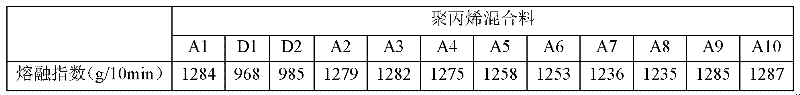

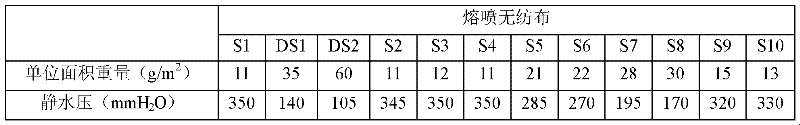

Polypropylene mixture, and preparation method and application thereof

ActiveCN102675732AImprove melt indexIncrease hydrostatic pressureNon-woven fabricsMonocomponent polyolefin artificial filamentPolymer scienceDi-tert-butyl peroxide

The invention discloses a preparation method of a polypropylene mixture. The method comprises the step of subjecting homo polypropylene and di-tert-butyl peroxide to contact reaction. The invention also provides the polypropylene mixture prepared by the method and application of the polypropylene mixture during preparation of melt blown nonwoven fabric. According to the method, the melt index of the homo polypropylene can be increased remarkably, so that the polypropylene mixture prepared by the method is suitable for preparation of the melt blown nonwoven fabric, besides, melt blown nonwoven fabric having low gram weight / unit area and high hydrostatic pressure can be produced rapidly by usage of the polypropylene mixture.

Owner:BEIJING EXPERT IN THE DEV OF NEW MATERIALCO

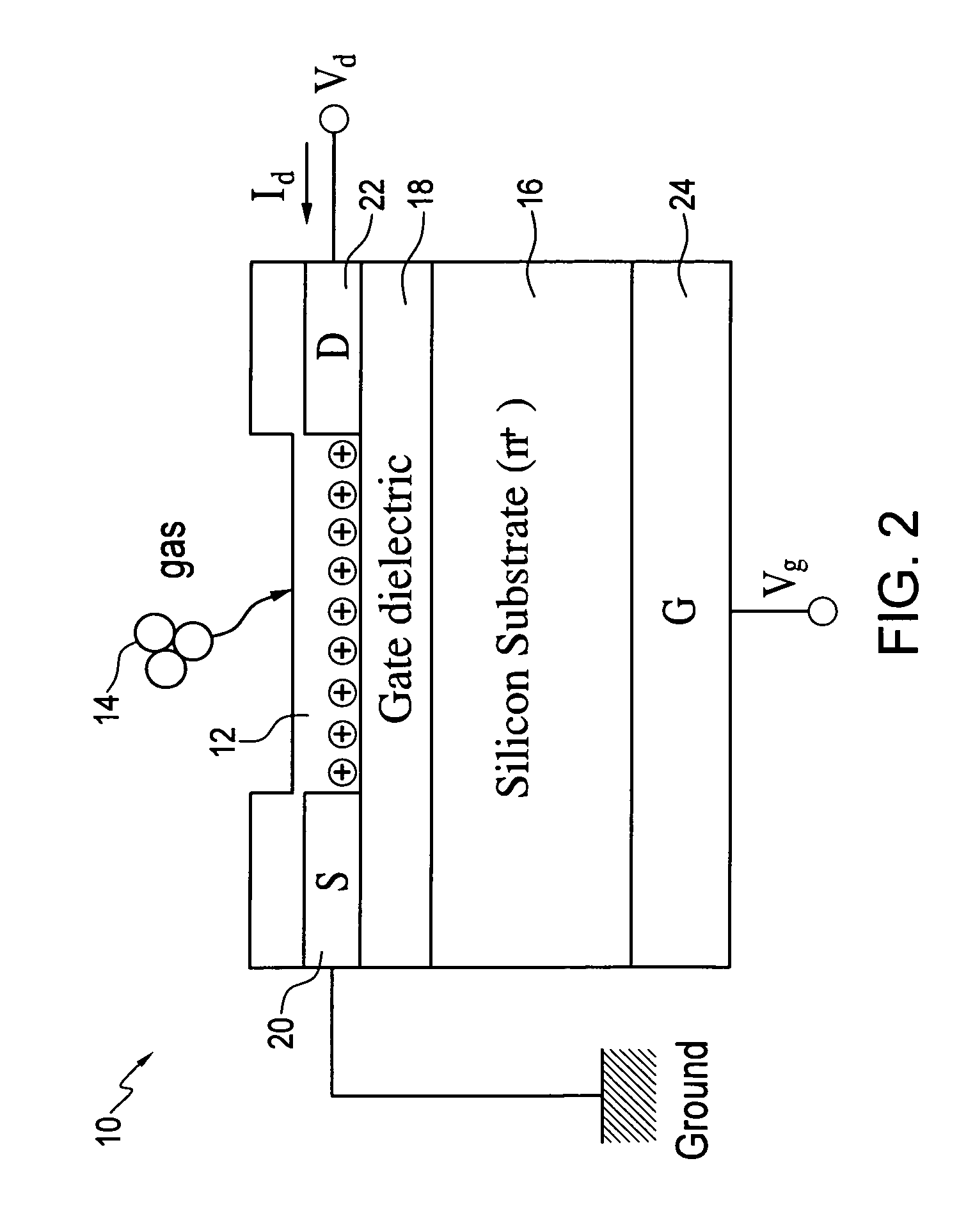

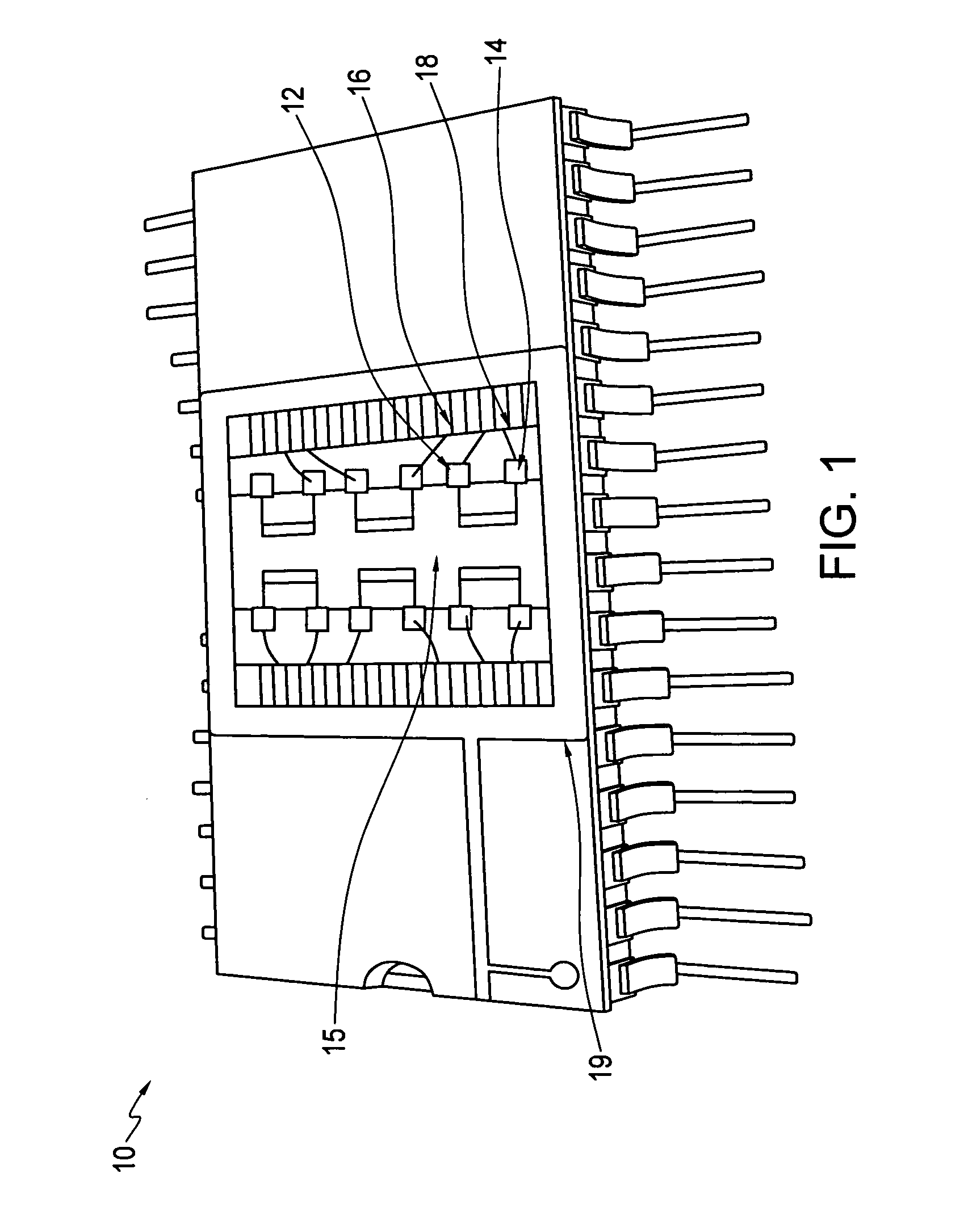

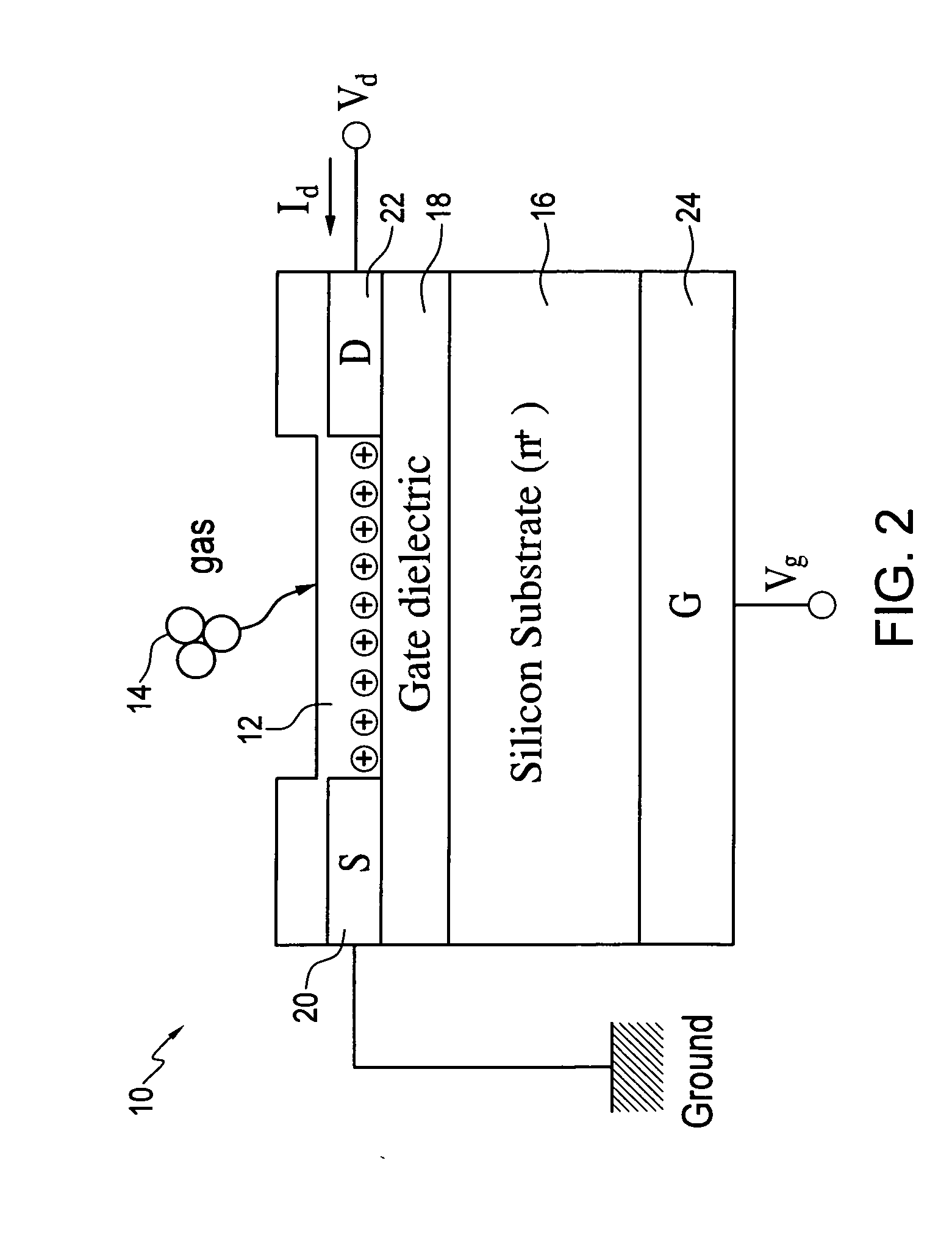

Peroxide chemical sensor and sensing method

InactiveUS8178357B2Material thermal conductivityComponent separationDi-tert-butyl peroxidePhthalocyanine

Sensors, sensing systems and sensing methods of the invention provide for detection of peroxides, including for example, vapor-phase H2O2 and organic peroxides such as di-tert-butyl peroxide. A sensor and sensing method of the invention uses at least two phthalocyanines, one of which exhibits an oxidation reaction with peroxides and the other of which exhibits a reduction reaction with peroxides. A peroxide is readily identified by a sensor of the invention when one of the at least two phthalocyanines exhibits increased resistance to current flow and the other of the at least two phthalocyanines exhibits decreased resistance to current flow.

Owner:RGT UNIV OF CALIFORNIA

Novel high-hardness plastic shell composition for capacitor

The invention discloses a novel high-hardness plastic shell composition for a capacitor. The novel high-hardness plastic shell composition is characterized by consisting of the following components in parts by weight: 35 parts of polypropylene, 15 parts of linear polyethylene, 10 parts of a high barrier film, 5 parts of polypropylene random copolymer, 5 parts of di-tert-butyl peroxide, 2 parts of cassava flour, 5 parts of modified wood plastic powder, 2 parts of tributyl citrate, 2 parts of silicone rubber, 2 parts of glycerol, 5 parts of carbon fiber, 2 parts of a rear-earth light converter, 2 parts of diphenyl silanediol, 2 parts of a plasticizer, 2 parts of silicon carbide micro powder, 2 parts of a lubricant, 2 parts of paraffin, 2 parts of vermiculite, 2 parts of sepiolite fabric, 2 parts of glass fibers, 2 parts of rear earth and 2 parts of talcum powder. The novel high-hardness plastic shell composition disclosed by the invention is simple in component and low in cost; the prepared finished product has good toughness, strong bearing capacity and high compactness, is easy to degrade and nonhazardous under a high temperature environment; meanwhile, the conventional preparation process is changed and a freezing process is increased, so that the safety of the product is improved and the product has relatively good stable performance at a relatively high temperature.

Owner:TONGLING XINTAI ELECTRIC APP & CAPACITOR

Preparation method of di-tert-butyl peroxide

ActiveCN107056670ARapid peroxidationWith operational continuityOrganic compound preparationPeroxy compound preparationDi-tert-butyl peroxideTert-butyl peroxide

The invention discloses a preparation method of di-tert-butyl peroxide. Tert-butyl alcohol, hydrogen peroxide and a catalyst are continuously introduced into a micro-reactor, so that tert-butyl alcohol and hydrogen peroxide are subjected to a peroxidation reaction, and a material flow containing a di-tert-butyl peroxide is prepared; the material flow containing the di-tert-butyl peroxide is led out from the micro-reactor, and the di-tert-butyl peroxide is obtained through separation, washing and drying, wherein the molar ratio of tert-butyl alcohol to hydrogen peroxide is 1:2-1:2.2, and the catalyst accounts for 10-20% of the total mass of tert-butyl alcohol, hydrogen peroxide and the catalyst. The process is simple, the micro-reactor good in safety is used for continuous production, the prepared di-tert-butyl peroxide is high in reaction selectivity and good in yield, the production procedures are reduced, and the production cost is reduced.

Owner:西安万德能源化学股份有限公司

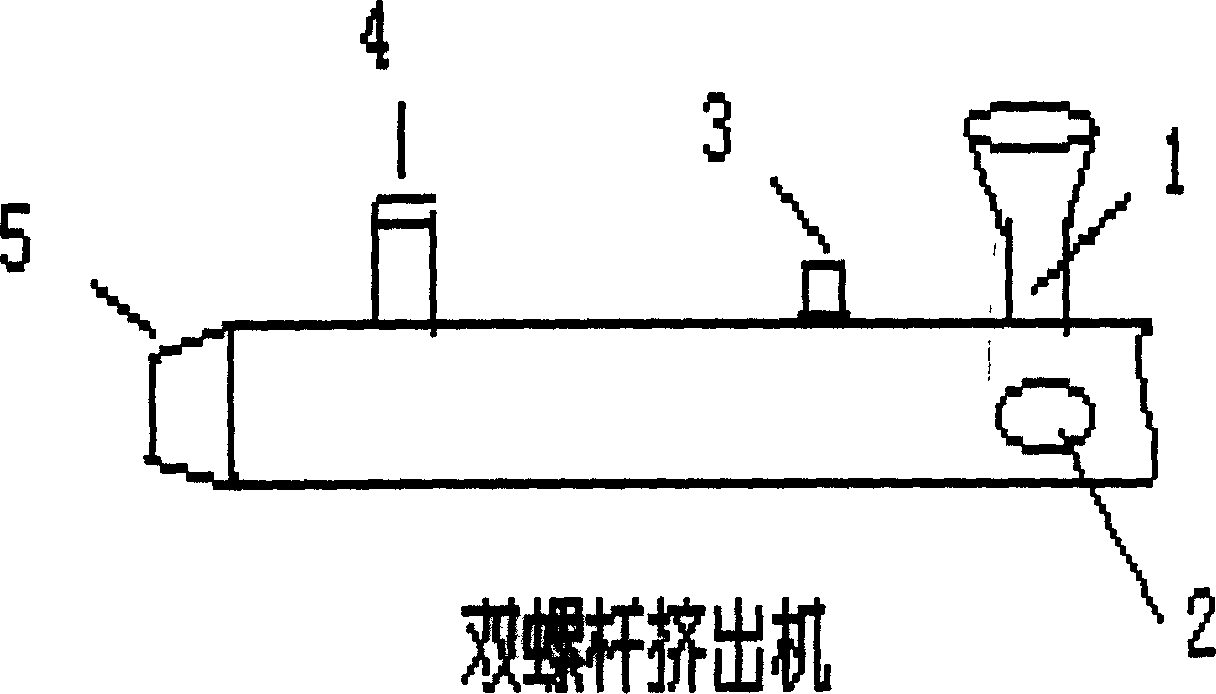

Material special for preparing lithium ion battery diaphragm and preparation method thereof

The invention relates to a material special for preparing a lithium ion battery diaphragm and a preparation method thereof. The material consists of the following components in part by weight: 62.5 to 86 parts of polyethylene, 0.5 to 1.5 parts of di-tert-butyl peroxide, 3 to 5 parts of vinyl triethoxy silane, 10 to 30 parts of titanium dioxide whiskers and 0.5 to 1 part of antioxidant. The preparation method comprises the following steps of: mixing the polyethylene, the di-tert-butyl peroxide, the antioxidant and the vinyl triethoxy silane, performing melt blending by using a double-screw extruder and performing an in-situ grafting reaction to obtain silane-grafted polyethylene; and stirring and blending the silane-grafted polyethylene and the titanium dioxide whiskers to obtain the material special for preparing the lithium ion battery diaphragm. The vinyl triethoxy silane is grafted on a polyethylene molecular chain and an ethyoxyl silane group can further react with the titanium dioxide whiskers so that a cross-linking reaction is realized in an entire membrane system and the intensity of a polyethylene membrane is enhanced.

Owner:SOUTH CHINA UNIV OF TECH

High impact polystyrene sheath material for power cords and preparation method thereof

InactiveCN103992608AImprove insulation performanceHigh mechanical strengthPlastic/resin/waxes insulatorsDi-tert-butyl peroxidePolybutylene

The invention discloses a high impact polystyrene sheath material for power cords and a preparation method thereof. The sheath material is prepared from the following raw materials in part by weight: 45-65 parts of high impact polystyrene, 20-30 parts of polypropylene, 10-15 parts of ethylene propylene diene monomer, 5-10 parts of styrene-isoprene-styrene block copolymer, 4-8 parts of paraffin oil, 3-6 parts of ethylene bis oleamide, 1-2 parts of isopropyl tri(dioctyl pyrophosphate acyloxy) titanate, 10-15 parts of talc powder, 3-5 parts of nano beryllia, 1-2 parts of zinc stearate, 4-6 parts of calcium hydroxide, 2-5 parts of low molecular polybutylene, 15-25 parts of carbon black N550, 2-3 parts of di-tert-butyl peroxide, 1.5-2.5 parts of trihydroxypropane trimethylacrylate, 10-15 parts of acetyl triethyl citrate, 5-10 parts of diphenyl-isooctyl phosphite and 15-20 parts of aid. The sheath material is good in electric insulating property, high in mechanical strength, good in toughness and high in impact resistance, has the characteristics of excellent heat, corrosion, oil and water resistance and the like and is durable, so that the sheath material has a wide application prospect.

Owner:TIANCHANG FUXIN ELECTRONICS

Method for controlling compression ignition internal combustion engine

InactiveUS7165512B2Wide loadGuaranteed uptimeInternal combustion piston enginesNon-fuel substance addition to fuelNitriteDi-tert-butyl peroxide

Owner:HONDA MOTOR CO LTD

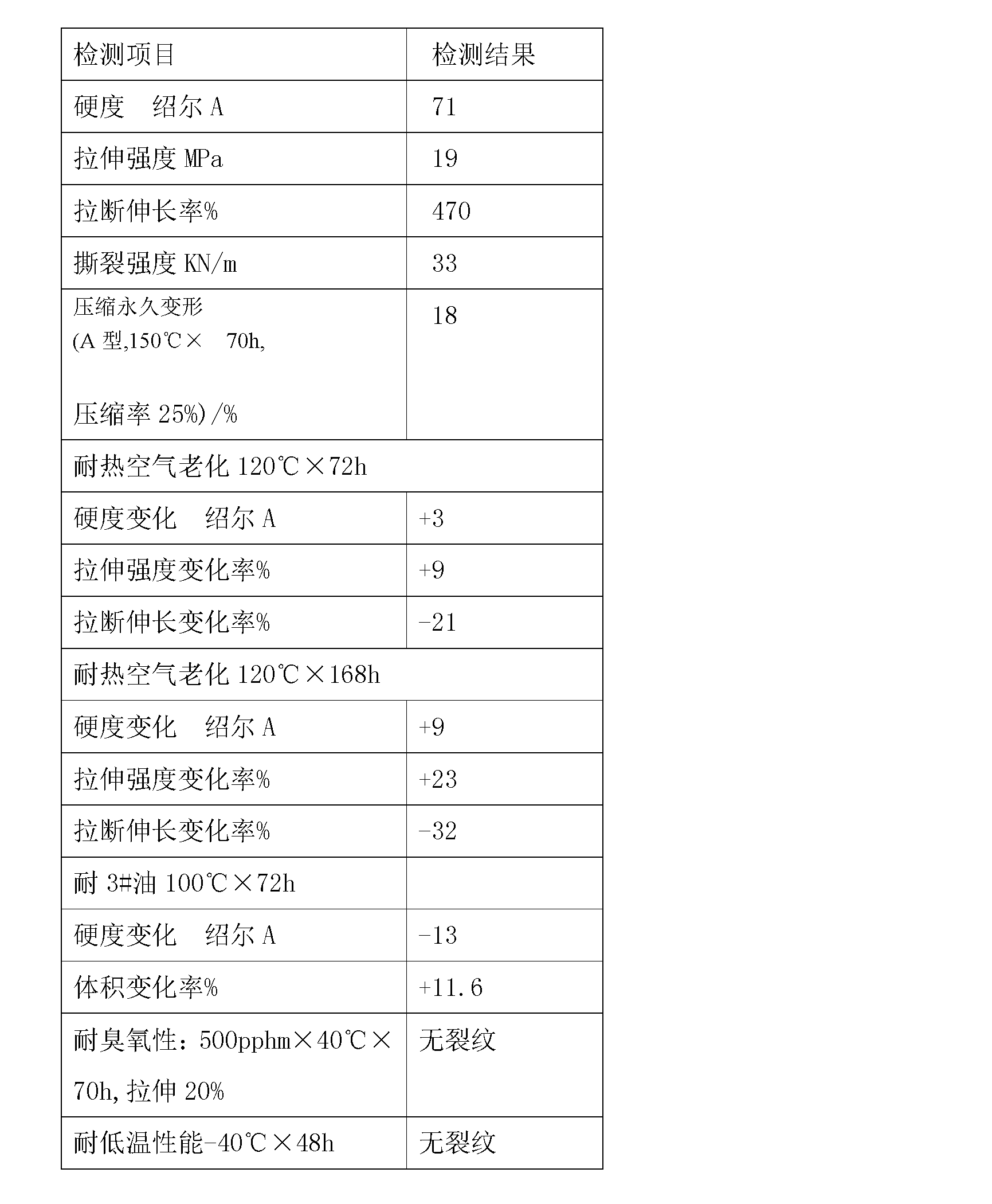

Seal rubber for valve rod of automobile and preparation method of seal rubber

The invention discloses a seal rubber for a valve rod of an automobile. The seal rubber comprises the following raw materials by weight: 64 to 66 parts of acrylic rubber, 14 to 16 parts of butyl rubber BK-1675N (Yanshan Petrochemical), 10 to 12 parts of butadiene-acrylonitrile rubber N240, 8 to 10 parts of chlorosulfonated polyethylene rubber TS-930 (Tosoh), 1 to 2 parts of poly-4-methy-1-amylene, 10 to 20 parts of carbon black N440, 8 to 10 parts of super wear-resisting carbon black N110, 6 to 10 parts of heavy calcium carbonate, 1 to 3 parts of hard vinyl alcohol, 1 to 2 parts of calcium stearate, 0.5 to 0.8 parts of stearic acid, 1 to 2 parts of zinc oxide, 5 to 10 parts of wollastonite in powder, 2 to 4 parts of quartz powder, 9 to 11 parts of modified iron tailings powder, 1 to 2 parts of hexamethyldisilazane, 1 to 2 parts of vulcanizing agent DTBP (Di Tert Butyl Peroxide), 3 to 4 parts of N, N'-metabenzyl bismaleimide, 1 to 2 parts of antioxidant 4010NA, 1 to 2 parts of antioxidant ODA,1 to 3 parts of aminopropyltriethoxysilane, and 14 to 16 parts of epoxidized butyl oleate. The rubber material is excellent in ozone resistance, low-temperature resistance and heat resistance, wide in operating temperature range and environment-friendly in process, and can be used for manufacturing various seal components.

Owner:马鞍山市中澜橡塑制品有限公司

Preparation method of environment-friendly adhesive

ActiveCN104231980AInhibit sheddingImprove adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesDi-tert-butyl peroxideMethyl carbonate

The invention relates to adhesives, particularly to a preparation method of an environment-friendly adhesive. The environment-friendly adhesive is composed of the following raw materials including, by weight parts, 70-95 parts of phthalic anhydride, furfuryl alcohol extracted from natural plant, triethylene glycol, pentanediol, butantriol, zinc oxide, magnesium oxide, chloroprene rubber and elastic rubber, 2-3 parts of softening oil, 20-30 parts of dimethyl carbonate, benzoyl peroxide, ethyl acetate, emulsifier and flour, 5*10-5-9*10-5 parts of nano silver, and fire retardant, wherein the elastic rubber is composed of first elastic rubber and second elastic fiber which are mixed at a weight ratio of 1-3:1. The preparation method of the second elastic rubber comprises heating polyvinyl alcohol solution and waterborne polyurethane water solution, cooling the mixture to 30-50 DEG C and then adding acrylate into the mixture; then adding potassium hydroxide into the mixture and heating the mixture; then adding cementum protein, abietin and plant phenols extracted from natural plant for reaction; then adding sodium benzoate, di-tert-butyl peroxide and the ethyl acetate and mixing the reactants to obtain the environment-friendly adhesive. The environment-friendly adhesive is good in bactericidal activity and high in stability, dispersibility and adhesiveness.

Owner:安吉竹印象家居用品有限公司

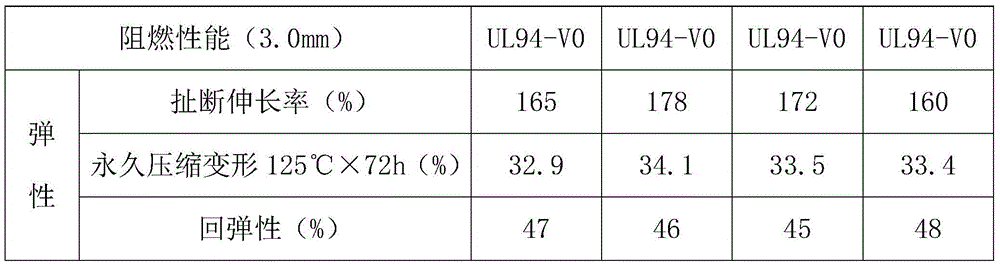

High-elasticity environmentally-friendly flame-retardant rubber material

The present invention discloses a high-elasticity environmentally-friendly flame-retardant rubber material comprising the raw materials of hydrogenated nitrile rubber, EPDM rubber, butadiene styrene rubber, vinyl chloride thermoplastic elastomers, ABS resin, di-tert-butyl peroxide DTBP, sulfur, divinylbenzene, accelerator DM, modified clay, carbon masterbatch, magnesium oxide, stearic acid, a modified flame retardant, polyphenyl ether, diisononyl phthalate DINP, antioxidant D-50, antioxidant SP and epoxy soybean oil. The high-elasticity environmentally-friendly flame-retardant rubber material has excellent flame retardant properties, and is halogen-free, low in toxicity, environmentally-friendly, good in elasticity and other mechanical properties and processing performances, and suitable for a variety of production and living areas.

Owner:宁国市开源橡塑汽车零部件有限公司

Low-temperature-resistant impact-resistant PVC (polyvinyl chloride) pipe material easy to machine

InactiveCN104961995AImprove wear resistanceImprove impact resistanceMethyl linoleateDi-tert-butyl peroxide

The invention discloses a low-temperature-resistant impact-resistant PVC (polyvinyl chloride) pipe material easy to machine. The low-temperature-resistant impact-resistant PVC pipe material easy to machine comprises , by weight, 60 to 80 parts of PVC, 20 to 40 parts of modified thermoplastic polyurethane elastomer, 4 to 6 parts of maleic anhydride grafted ethylene-vinyl acetate copolymer, 15 to 20 parts of silane coupling modified kaolin, 20 to 40 parts of silane coupling modified magnesium hydroxide, 8 to 12 parts of organic phosphine, 10 to 15 parts of epoxidized methyl linoleate, 20 to 25 parts of triethyl citrate, 1 to 3 parts of dicumyl peroxide, 0.5 to 1.5 parts of di-tert-butyl peroxide, 0.5 to 1.5 parts of dibutyltin dilaurate, 3 to 5 parts of organic tin stabilizer, 1 to 2 parts of calcium stearate, 2 to 3 parts of barium stearate, 1 to 2 parts of anti-aging agent AW, 0.5 to 2 parts of anti-aging agent RD, 3 to 5 parts of silicone powder, 2 to 4 parts of paraffin and 2 to 4 parts of titanium dioxide. The low-temperature-resistant impact-resistant PVC pipe material is easy to machine, resistant to low temperature and high in impact resistance.

Owner:ANHUI ZHENGSHI NEW BUILDING MATERIAL

Modified acrylic resin for preparing artificial colored sand and preparation method of artificial colored sand

ActiveCN104072662AImprove adhesionHigh hardnessMulticolor effect coatings(Hydroxyethyl)methacrylateDi-tert-butyl peroxide

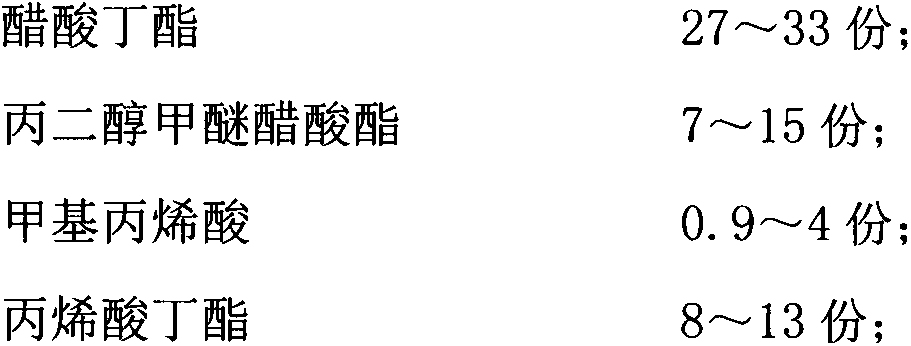

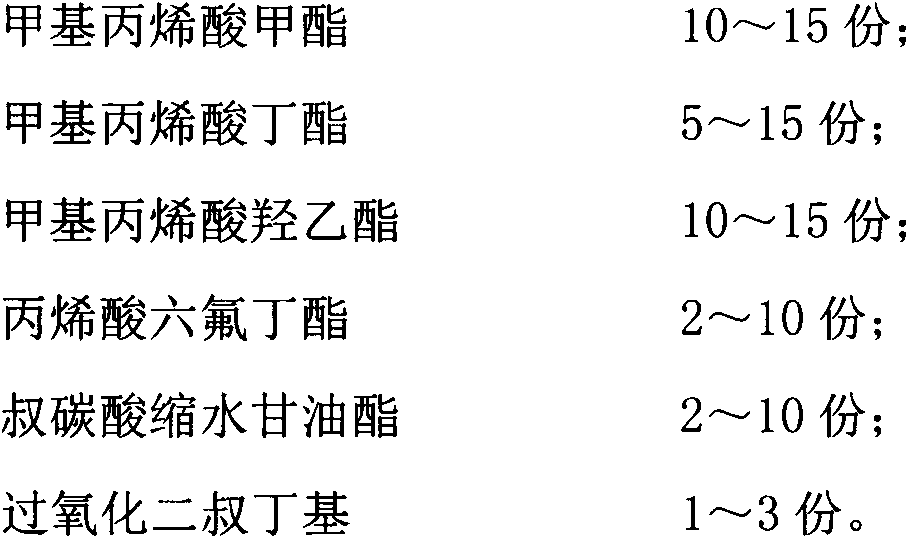

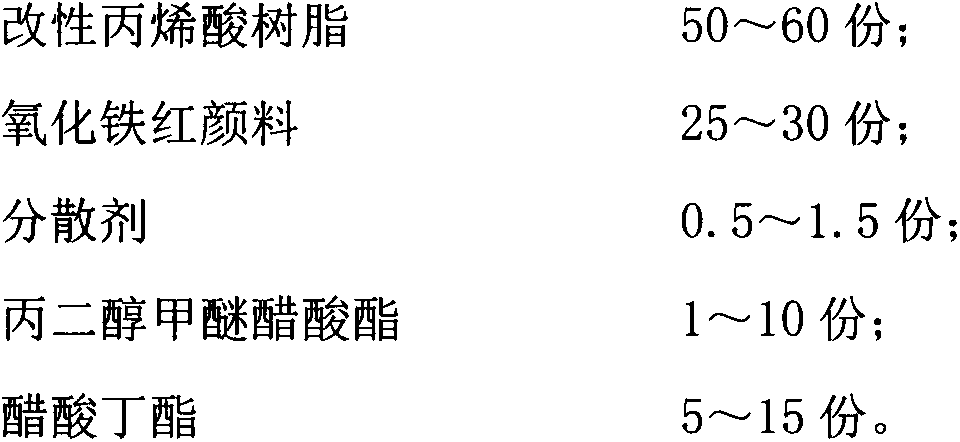

The invention discloses a modified acrylic resin for preparing artificial colored sand and a preparation method of artificial colored sand, and relates to the field of artificial colored sand. The modified acrylic resin for preparing the artificial colored sand consists of 27-33 parts of n-butyl acetate, 7-15 parts of propylene glycol monomethyl ether acetic ester, 0.9-4 parts of methacrylic acid, 8-13 parts of butyl acrylate, 10-15 parts of methyl methacrylate, 5-15 parts of methacrylic acid butyl ester, 10-15 parts of hydroxyethyl methylacrylate, 2-10 parts of hexafluorobutyl acrylate, 2-10 parts of tertiary carbonate glycidyl ester and 1-3 parts of di-tert-butyl peroxide. By introducing fluorine monomer into the acrylic resin and grafting certain tertiary carbonate glycidyl ester, the weather resisting properties such as the adhesion property, the hardness, the acid-alkali resistance of the resin are remarkably improved. The detection shows that the artificial colored sand can meet or even exceed various properties of ordinary colored sand and is good in weather resisting property, and thus really stone paint is diverse in color.

Owner:HUANGSHAN JINZHILI SCI & TECH

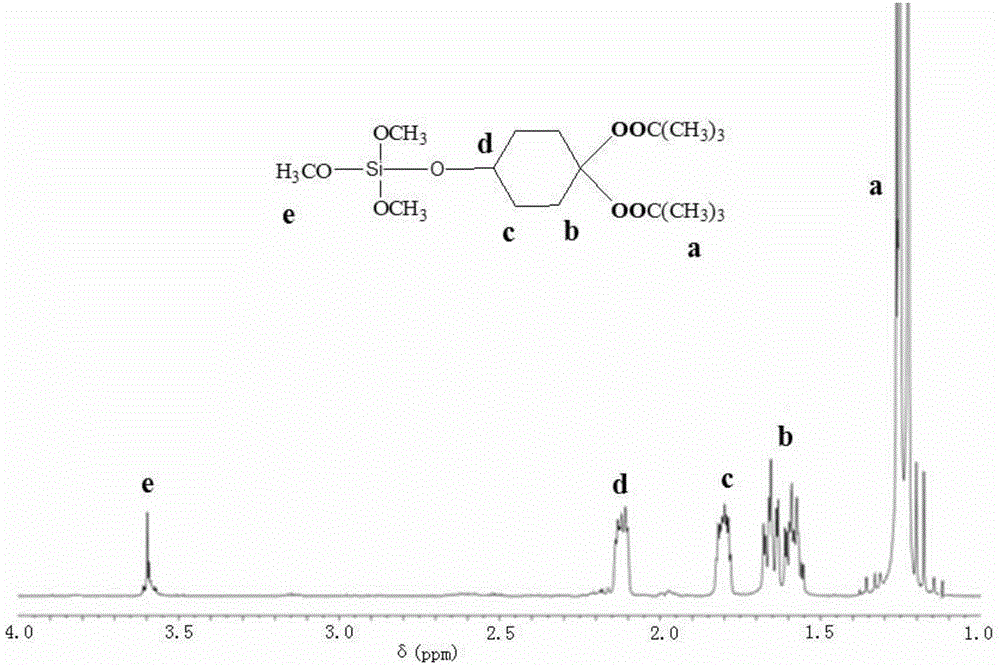

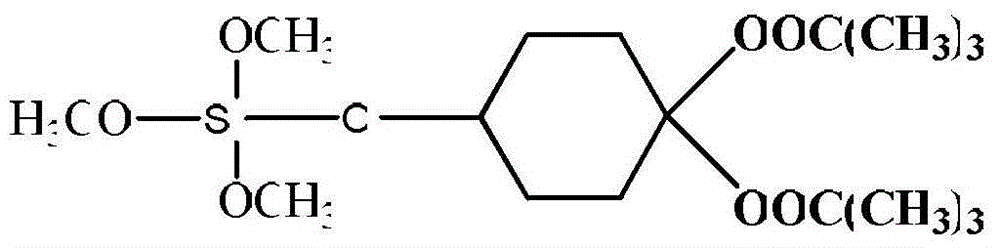

Peroxy-silane coupling agents and preparation method thereof

InactiveCN104478920ASteps to reduce organic processingLess impuritiesGroup 4/14 element organic compoundsCyclohexanoneDi-tert-butyl peroxide

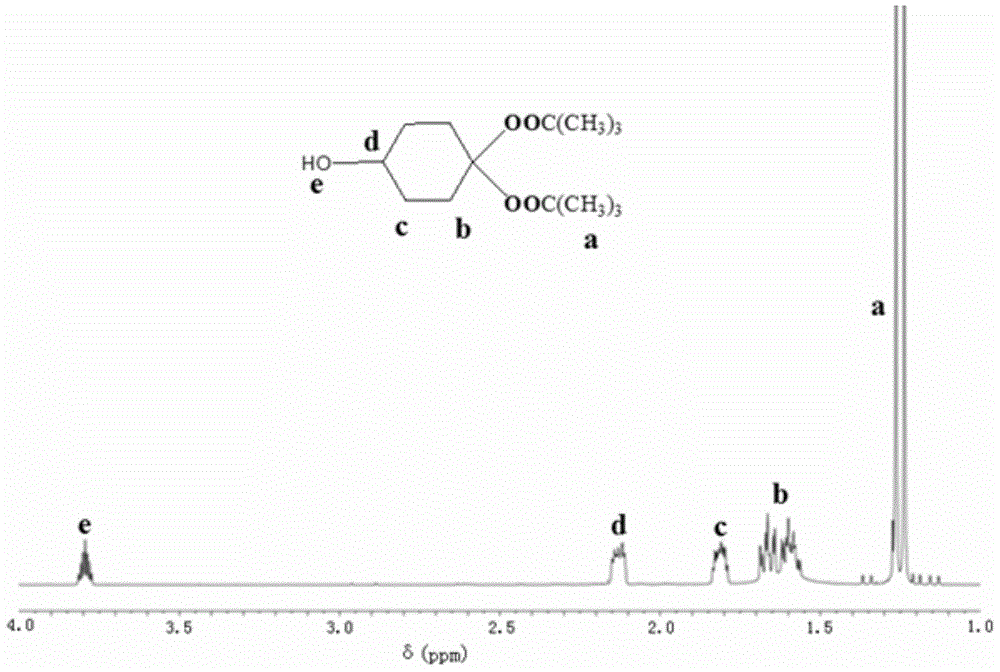

The invention relates to peroxy-silane coupling agents and a preparation method of the peroxy-silane coupling agents in order to resolve the technical problems that an existing process of surface grafting of high polymer on the surface of inorganic materials is complex and high in cost. The peroxy-silane coupling agents are 1,1-di-tert-butyl peroxide,4-hydroxyl cyclohexyl trimethoxy silane, and please see the structural formula in the specifications. The preparation method includes the steps that hydrogen peroxide tertiary butanol and 4- hydroxyl cyclohexanone are put into a reaction still, concentrated sulfuric acid is added at the temperature of minus 10-20 DEG C and stirred for reaction, and 1,1-di-tert-butyl peroxide,4- hydroxyl cyclohexane is obtained; the 1,1-di-tert-butyl peroxide,4- hydroxyl cyclohexane and quadri-methoxy silane are stirred at the temperature of minus 10-50 DEG C for reaction, and the peroxy-silane coupling agents are obtained. The peroxy-silane coupling agents both have the functions of initiator and coupling agents, and can be used for the reaction of surface grafting of high polymer on the surface of inorganic materials.

Owner:QIQIHAR UNIVERSITY

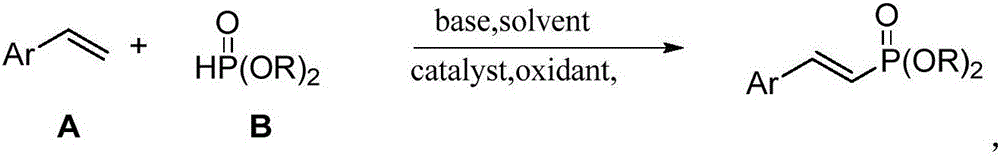

Preparation method of olefin phosphate compound

InactiveCN106674277AReduce usageEfficient synthesisGroup 5/15 element organic compoundsDi-tert-butyl peroxidePhosphate

The invention discloses a preparation method of an olefin phosphate compound. The method comprises the following steps: arylethylene and phosphate according to a mol ratio 1:4-6 are used as raw materials; ferric chloride and copper salt are used as catalysts, and di-tert-butyl peroxide is used as an oxidizing agent; the raw materials and triethylamine are mixed, an organic solvent is added, and under the protection of inert gas, a reaction is carried out at 90-110 DEG C; after the reaction ends, washing is carried out, rotary evaporation is used for removing the solvent, and column chromatography is carried out in order to obtain the olefin phosphate compound. Base metal copper and iron are used as catalysts, reactant arylethylene and phosphate have low price, toxicity is low, the oxidizing agent is green and environmentally friendly, and the yield of the synthetic reaction of the olefin phosphate compound is high.

Owner:NANJING UNIV OF SCI & TECH

Fuel additive of homogeneous premixed compression ignition engine

InactiveCN1900240AImprove physical and chemical propertiesEnables wide range operationLiquid carbonaceous fuelsPentyl etherLow load

The fuel additive for homogeneous premixed compression ignition engine belongs to the field of fuel additive technology. The homogeneous premixed compression ignition engine has the demerits of easy causing fire at low load, easy knocking at high load and narrow running operation condition range, and adopting additive is one simple solution to the demerits. The fuel additive of the present invention includes igniting promoter di-tert-butyl peroxide 5-30 wt%, tert-butyl hydroperoxide 5-35 wt%, superox 736 2-20 wt%, dicumyl peroxide 2-20 wt%, cumene hydroperoxide 2-20 wt%, antidetonator ethanol 5-30 wt%, methanol 1-10 wt%, methyl tertiary pentyl ether 5-20 wt%, and ferrocene 1-10 wt%. The fuel additive of the present invention can expand the running range of HCCI engine effectively, and lower the exhaust of HC and CO.

Owner:BEIJING UNIV OF TECH

Impact and cracking resistant material for combustion gas pipelines

The invention discloses an impact and cracking resistant material for combustion gas pipelines. The material comprises, by weight, 40-60 parts of high density polyethylene, 30-40 parts of ethylene propylene diene monomer, 20-30 parts of acrylonitrile-butadiene-styrene copolymer, 30-40 parts of carbon black, 1.8-2.6 parts of modified montmorillonite, 0.9-0.13 parts of modified carbon nanotubes, 20-30 parts of nonyl cyclohexanedicarboxylate, 20-30 parts of methyl acetylricinoleate, 15-20 parts of ammonium polyphosphate, 10-15 parts of zinc borate, 5-8 parts of red phosphorus, 1-3 parts of di-tert-butyl peroxide, 0.4-0.6 parts of dimethylaminopropylamine, 0.1-0.3 parts of a promoter CZ, 2-4 parts of a Ca / Zn composite stabilizer, 1-2 parts of zinc stearate, 1-2 parts of butylmercaptooxo stannane, 0.5-1 part of an antioxidant D, 0.3-0.5 parts of an antioxidant RD and 1-3 parts of polyethylene wax. The material has the advantages of good impact resistance and high toughness.

Owner:安徽宁国市高新管业有限公司

Dibutyl itaconate modified acrylic resin and preparation method thereof

InactiveCN104987455AImprove wettabilityImprove performanceCoatingsPolymer scienceDi-tert-butyl peroxide

The invention discloses a dibutyl itaconate modified acrylic resin, which is characterized by comprising the following components by mass: 20-40% of xylene, 5%-15% of butyl acetate, 5-8% of acrylic acid, 15%-25% of styrene, 10%-15% of methyl methacrylate, 15%-25% of butyl acrylate, 1%-5% of dibutyl itaconate, 1-3% of acrylamide, and 1-2% of di-tert-butyl peroxide. The dibutyl itaconate modified acrylic resin provided by the invention has good wettability to organic pigments and fillers, has no influence to the paint film, and also greatly improves the comprehensive properties of resin.

Owner:NANTONG PUTHON CHEM

Peroxide chemical sensor and sensing method

InactiveUS20100297776A1Improve the immunityReduce resistanceMaterial thermal conductivityComponent separationDi-tert-butyl peroxidePhthalocyanine

Owner:RGT UNIV OF CALIFORNIA

Hardware electroplating finishing coating

The invention discloses a hardware electroplating finishing coating which is prepared from the following raw materials in percentage by weight: 50-60% of acrylate resin, 10-15% of isobutyl etherified amino resin, 3-7% of high imino methylated amino resin, 5-8% of epoxy resin, 15-20% of diluter, 1-2% of di-tert-butyl peroxide and 0.1-0.2% of diacetone alcohol. The hardware electroplating finishing coating can be cured at high temperature and low temperature; when the finishing coating is cured at low temperature, the coating film has the advantages of superhigh adhesive force, high hardness, high gloss, high resistance, wear resistance and the like; and the technique for producing the hardware electroplating finishing coating is simple and low in cost.

Owner:柳州市五环水暖器材经营部(微型企业)

Treatment and recycling process for initiator CH335 wastewater

InactiveCN102173522AHigh purityQuality improvementMultistage water/sewage treatmentNature of treatment waterChemical synthesisElectrolysis

The invention discloses a treatment and recycling process for production wastewater of 1,1-di-tert-butyl peroxide-3,3,5-trimethyl-cyclohexane (an initiator CH335). In the process, the production wastewater is collected directly from a drain outlet of a production device and is subjected to stabilized treatment, and after the danger of severe decomposition of organic peroxides in the wastewater due to heating is eliminated basically, tertiary butanol, tert-butyl peroxide and sulfuric acid are separated and recovered from the wastewater, wherein the recovered tertiary butanol, tert-butyl peroxide and sulfuric acid can be recycled repeatedly in the production process. Low-concentration wastewater is separated while chemical raw materials are recovered, and after the separated low-concentration wastewater is subjected to hydrolysis-contact oxidization and C-Fe micro-electrolysis decoloration, the major index of the drained wastewater meets the requirement on water pollutant emission limits of newly built enterprises in 'Discharge Standards of Water Pollutants for Chemical Synthesis Pharmaceutical Industry (GB21904-2008)'.

Owner:GANSU AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com