Patents

Literature

56 results about "Trisilane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trisilane /traɪsaɪleɪn/ is a three-silicon silane. It has the chemical formula Si₃H₈ and is a liquid at standard temperature and pressure. It is a silicon analogue of propane.

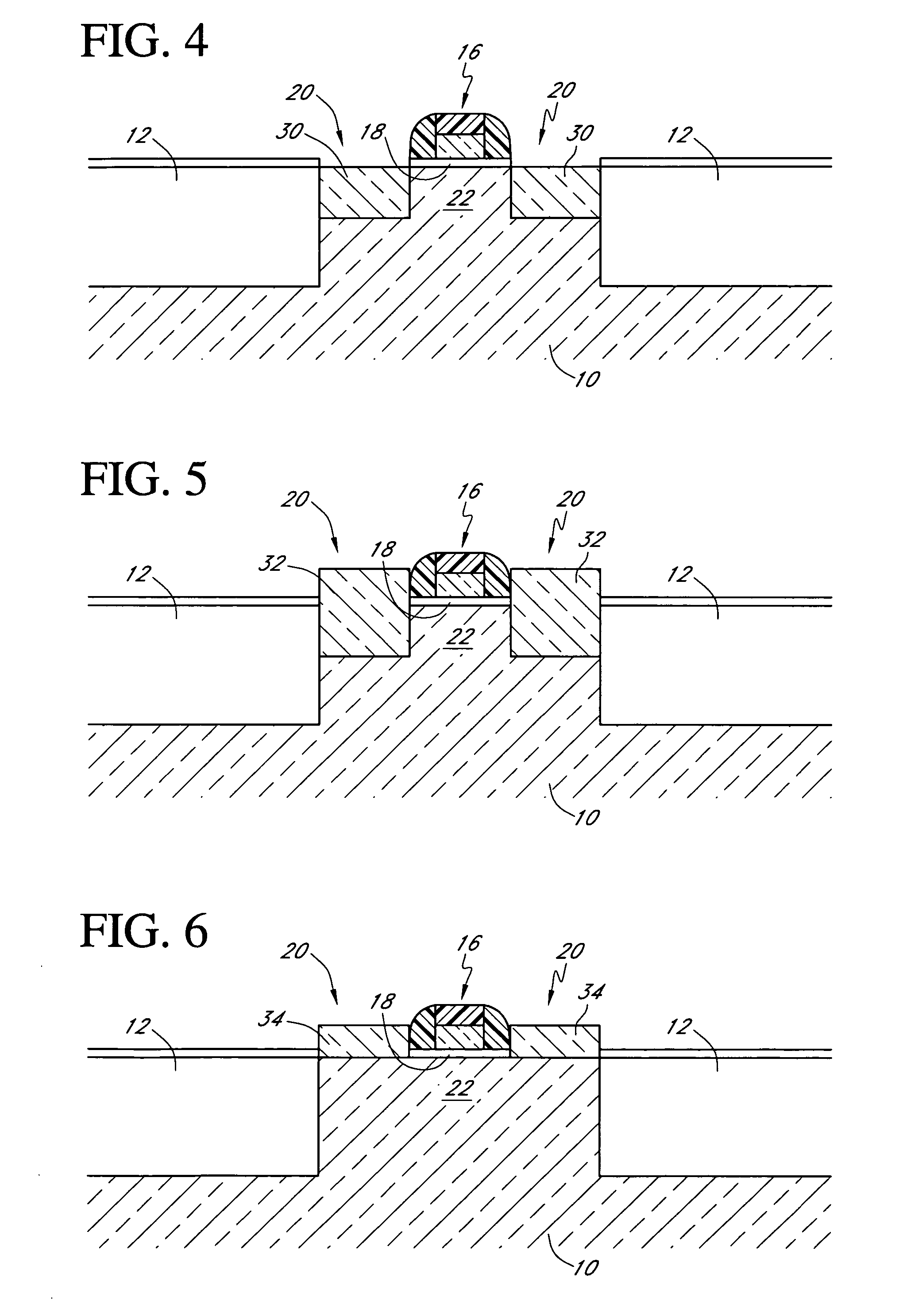

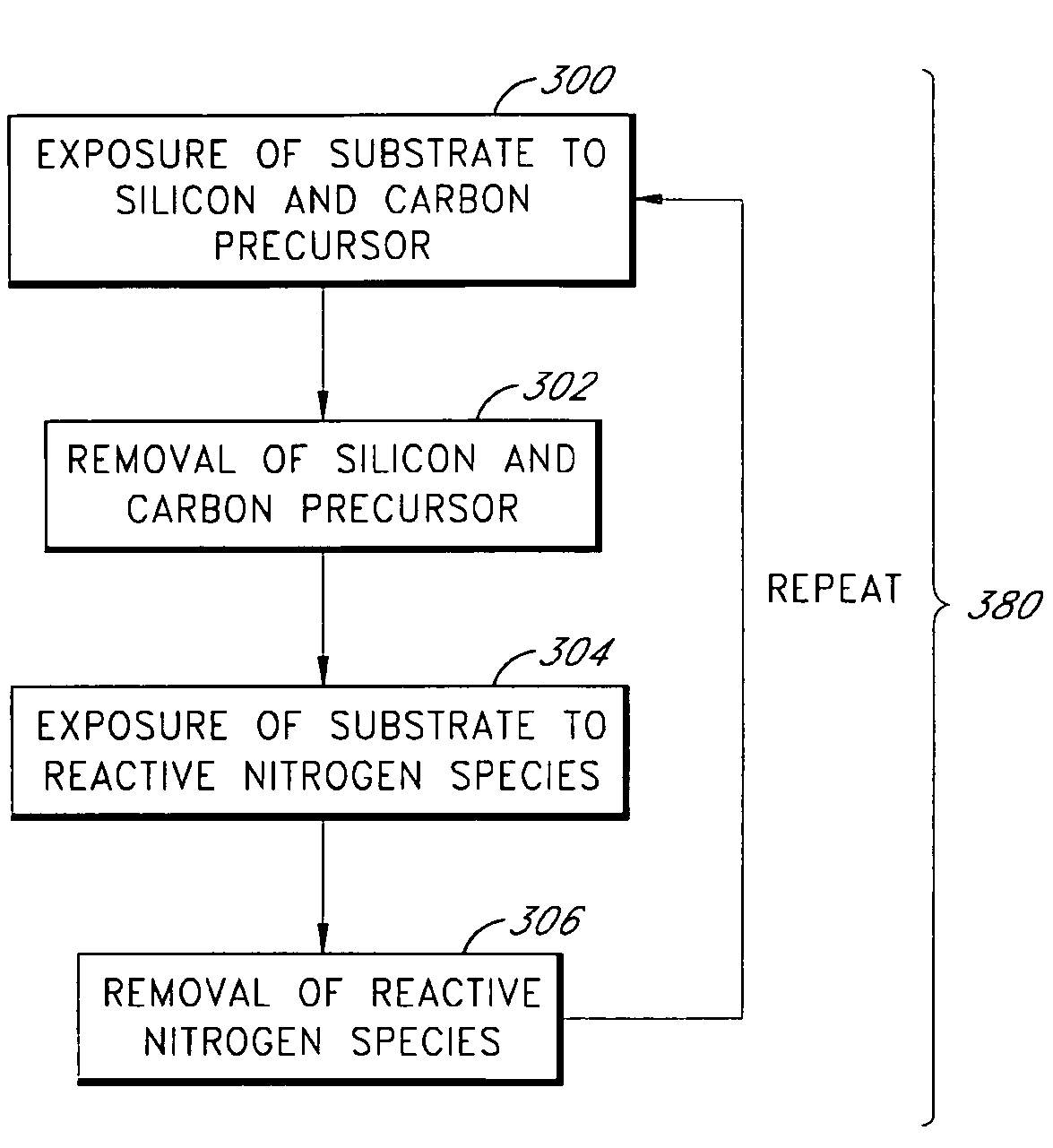

High stress nitride film and method for formation thereof

ActiveUS20060199357A1Increase the tensile stressSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDopantNitrogen

A silicon nitride film is formed on a substrate in a reaction chamber by introducing trisilane and a reactive nitrogen species into the chamber in separate pulses. A carbon precursor gas is also flowed into the chamber during introduction of the trisilane and / or during introduction of the reactive nitrogen species, or in pulses separate from the trisilane and reactive nitrogen species pulses. The carbon is used as a dopant in the silicon nitride film and advantageously allows a high stress silicon nitride film to be formed.

Owner:ASM INTERNATIONAL

Method to form ultra high quality silicon-containing compound layers

InactiveUS7297641B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingTrisilaneReaction chamber

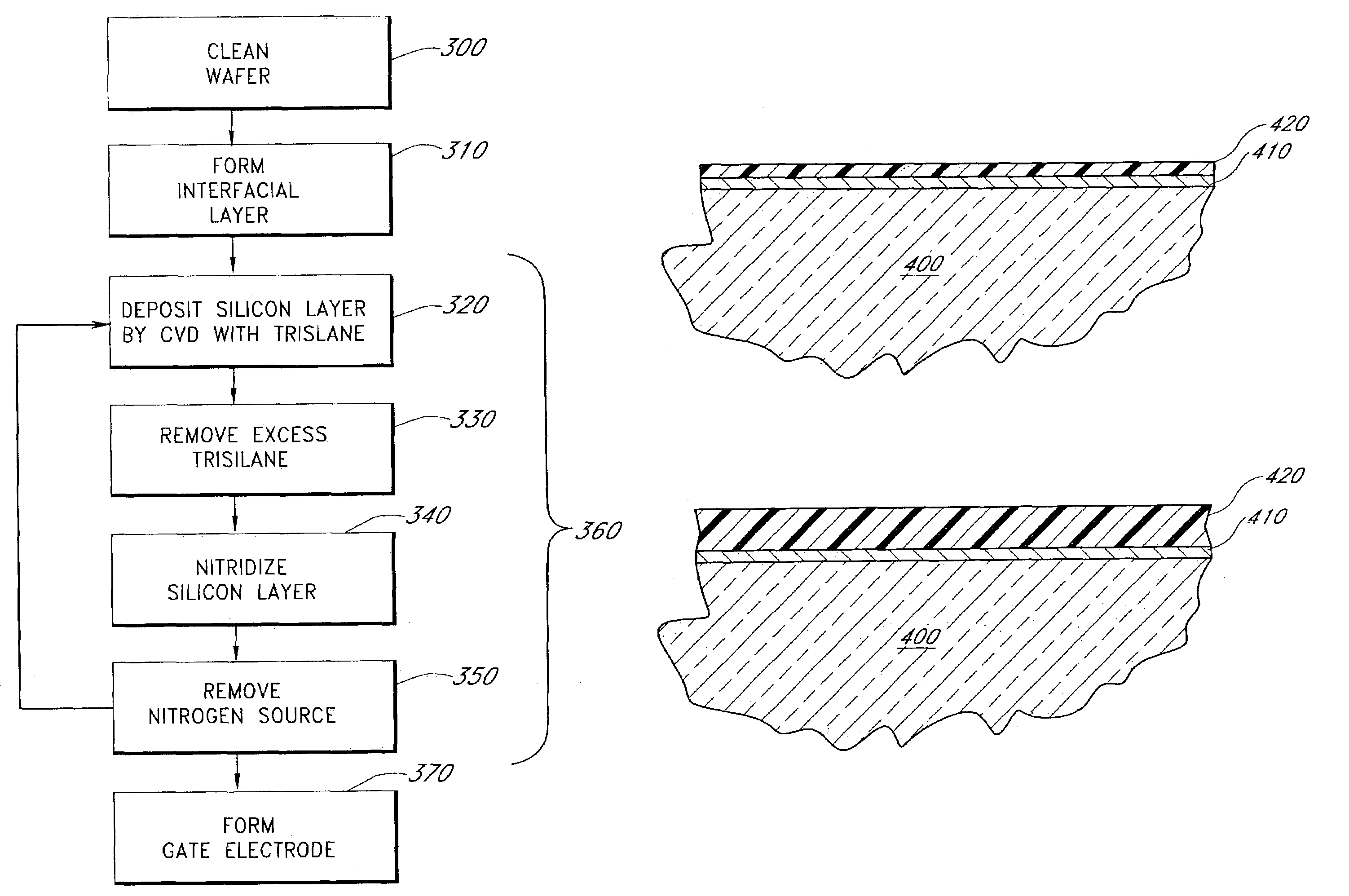

Multiple sequential processes are conducted in a reaction chamber to form ultra high quality silicon-containing compound layers, including silicon nitride layers. In a preferred embodiment, a silicon layer is deposited on a substrate using trisilane as the silicon precursor. A silicon nitride layer is then formed by nitriding the silicon layer. By repeating these steps, a silicon nitride layer of a desired thickness is formed.

Owner:ASM IP HLDG BV

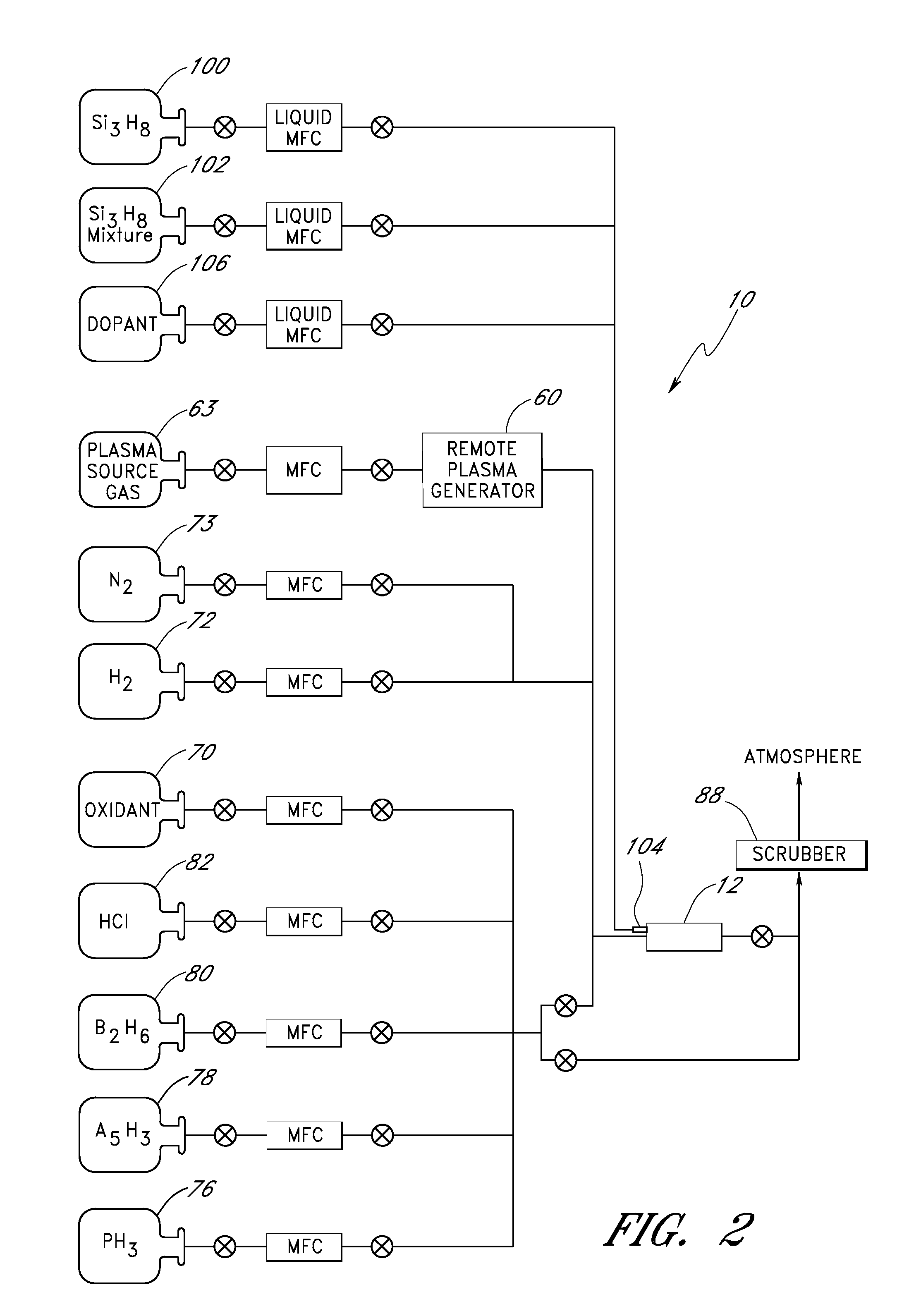

Deposition from liquid sources

ActiveUS20070166966A1Light-sensitive devicesSemiconductor/solid-state device manufacturingDopantSilicon

Owner:ASM IP HLDG BV +1

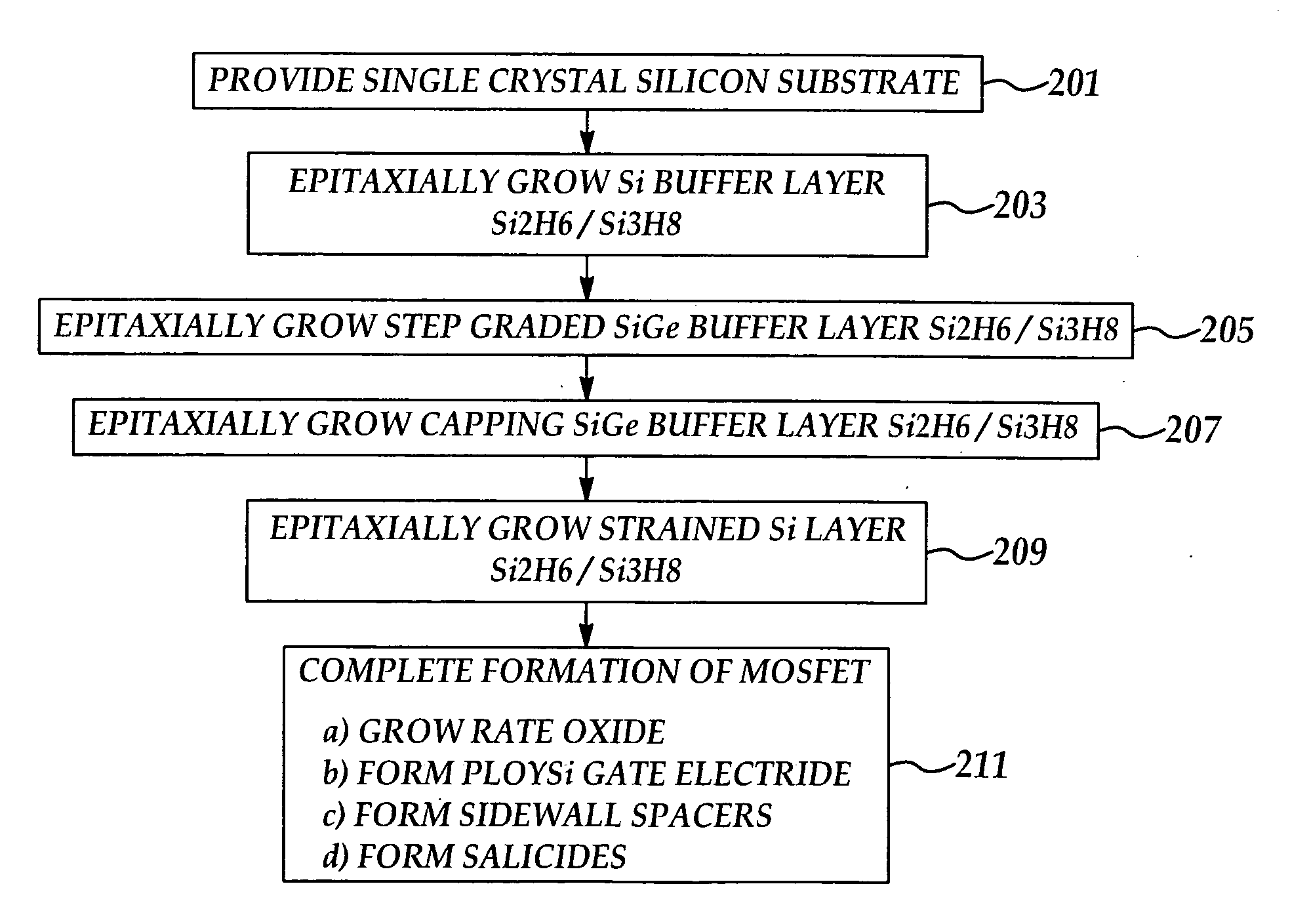

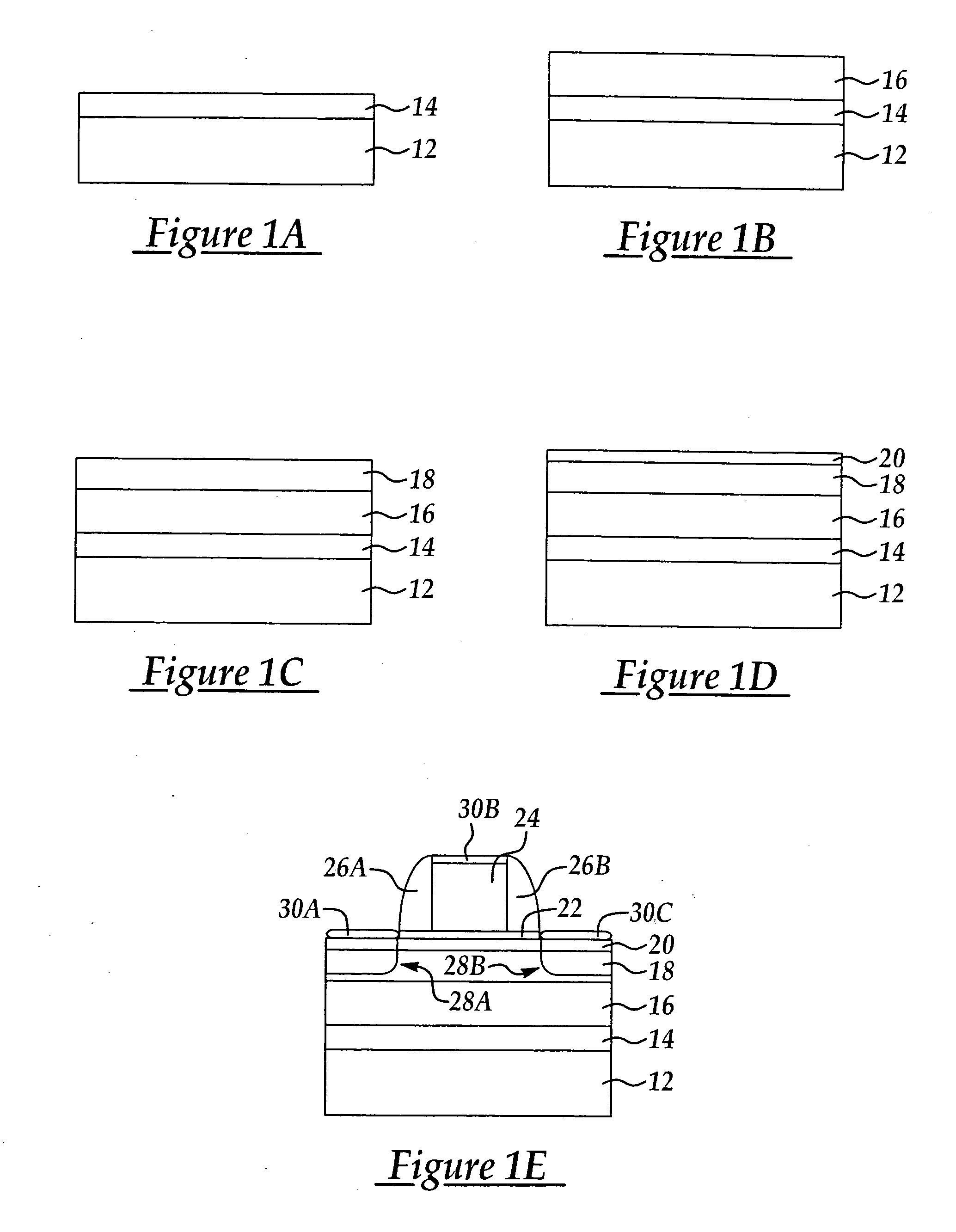

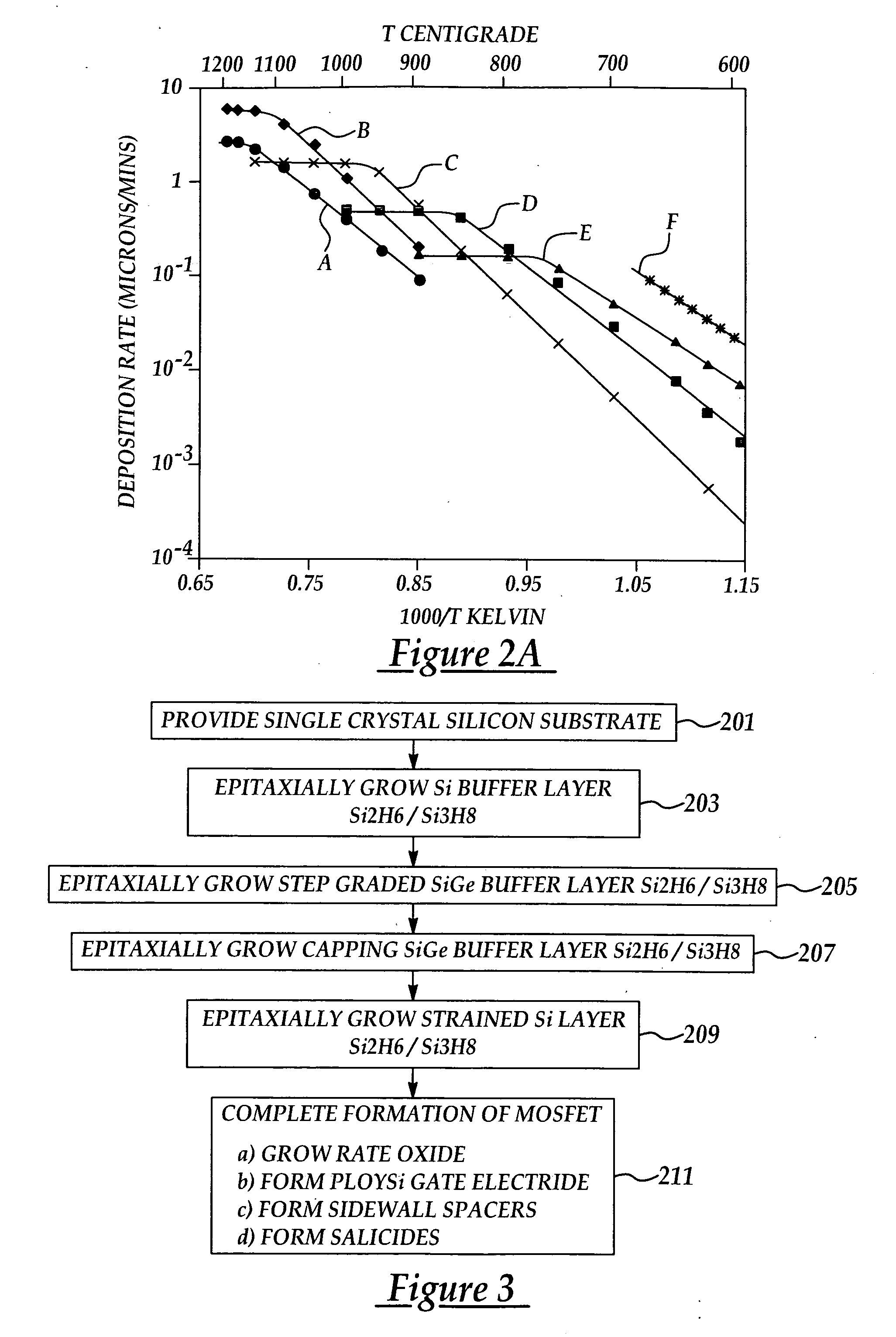

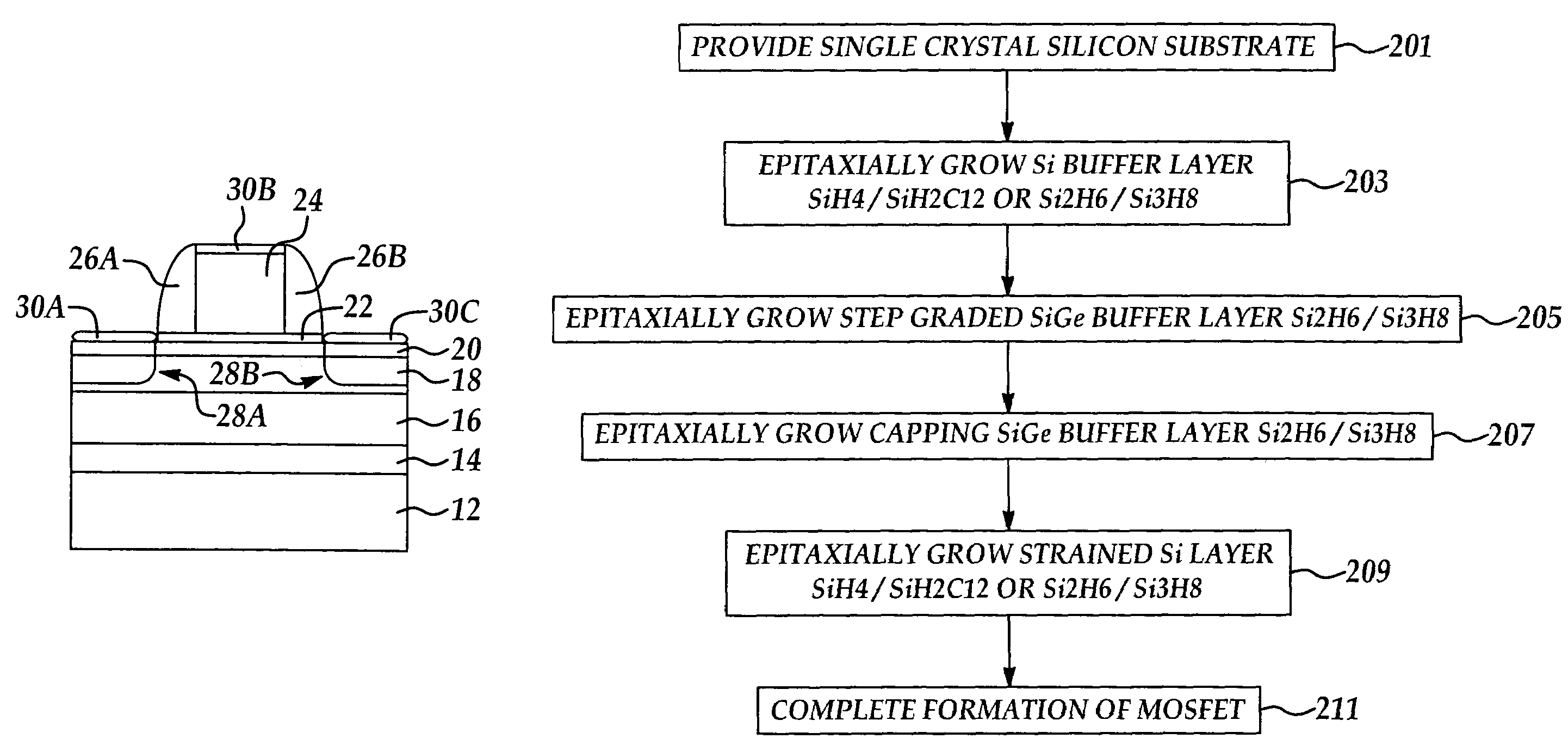

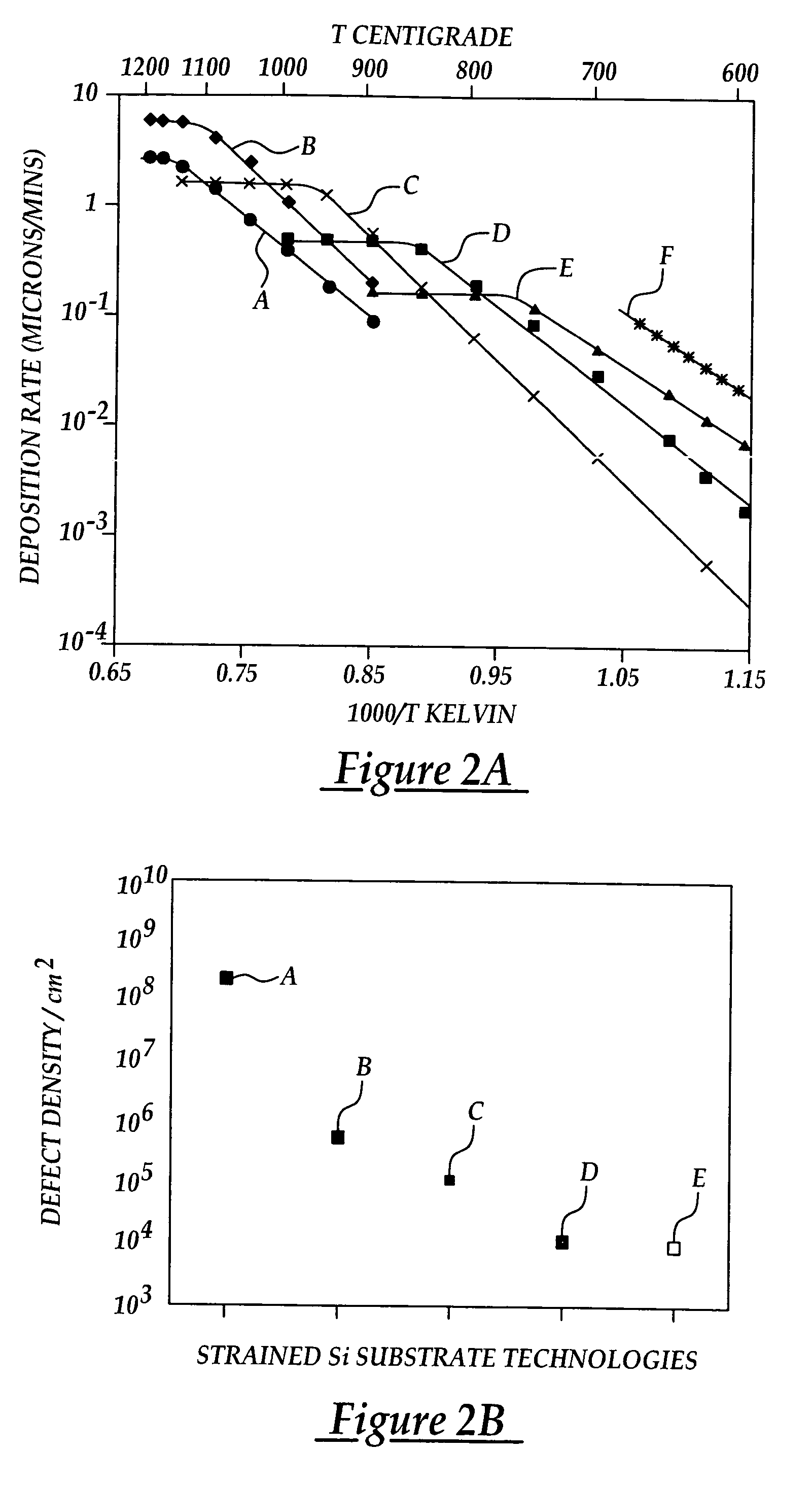

Method for producing high throughput strained-si channel mosfets

InactiveUS20050245058A1Improve throughputReduce defect densityPolycrystalline material growthFrom solid stateSilanesMaterials science

A method for forming a strained silicon layer device with improved wafer throughput and low defect density including providing a silicon substrate; epitaxially growing a first silicon layer using at least one deposition precursor selected from the group consisting of disilane and trisilane; epitaxially growing a step-grade SiGe buffer layer over and contacting the first silicon layer using at least one deposition precursor selected from the group consisting of disilane and trisilane; epitaxially growing a SiGe capping layer over and contacting the step-grade SiGe buffer layer using at least one deposition precursor selected from the group consisting of disilane and trisilane; and, epitaxially growing a second silicon layer using at least one deposition precursor selected from the group consisting of disilane and silane.

Owner:TAIWAN SEMICON MFG CO LTD

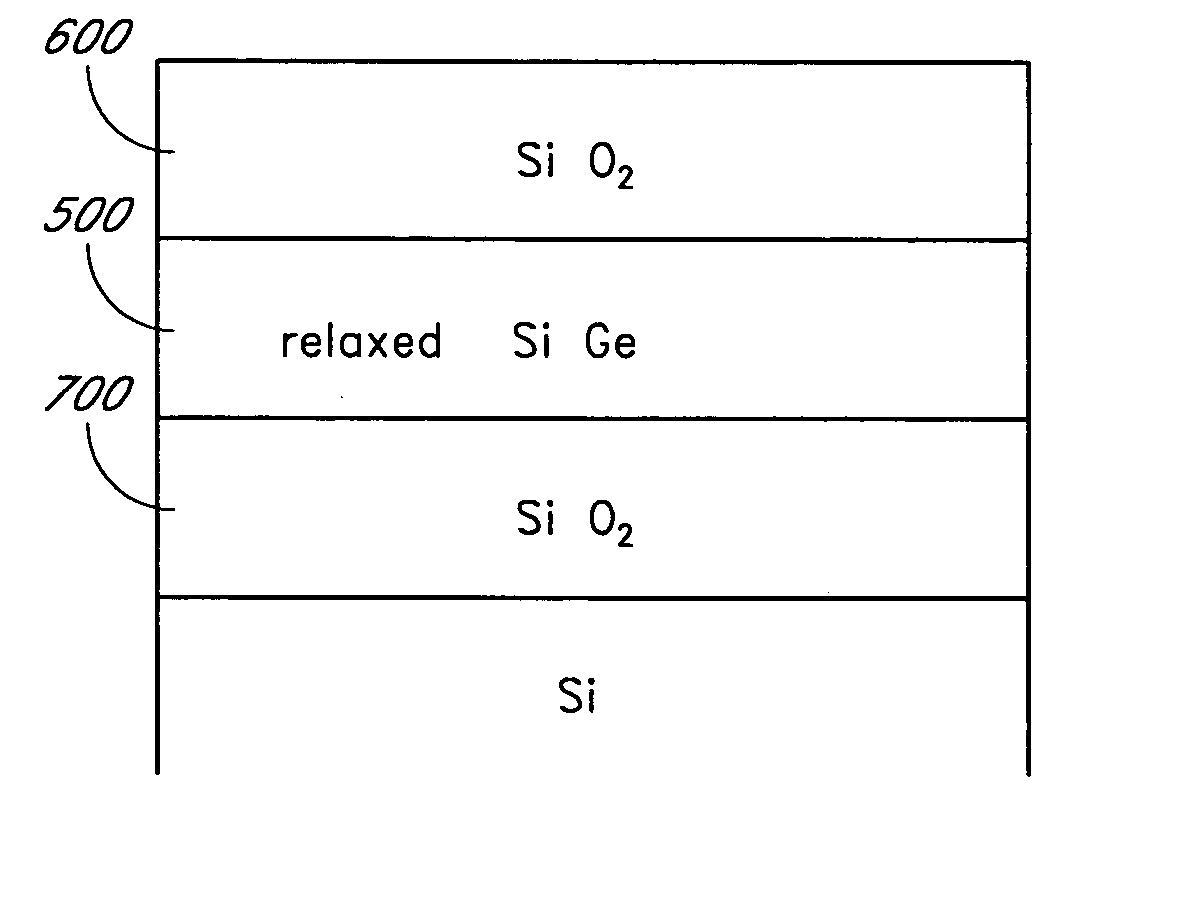

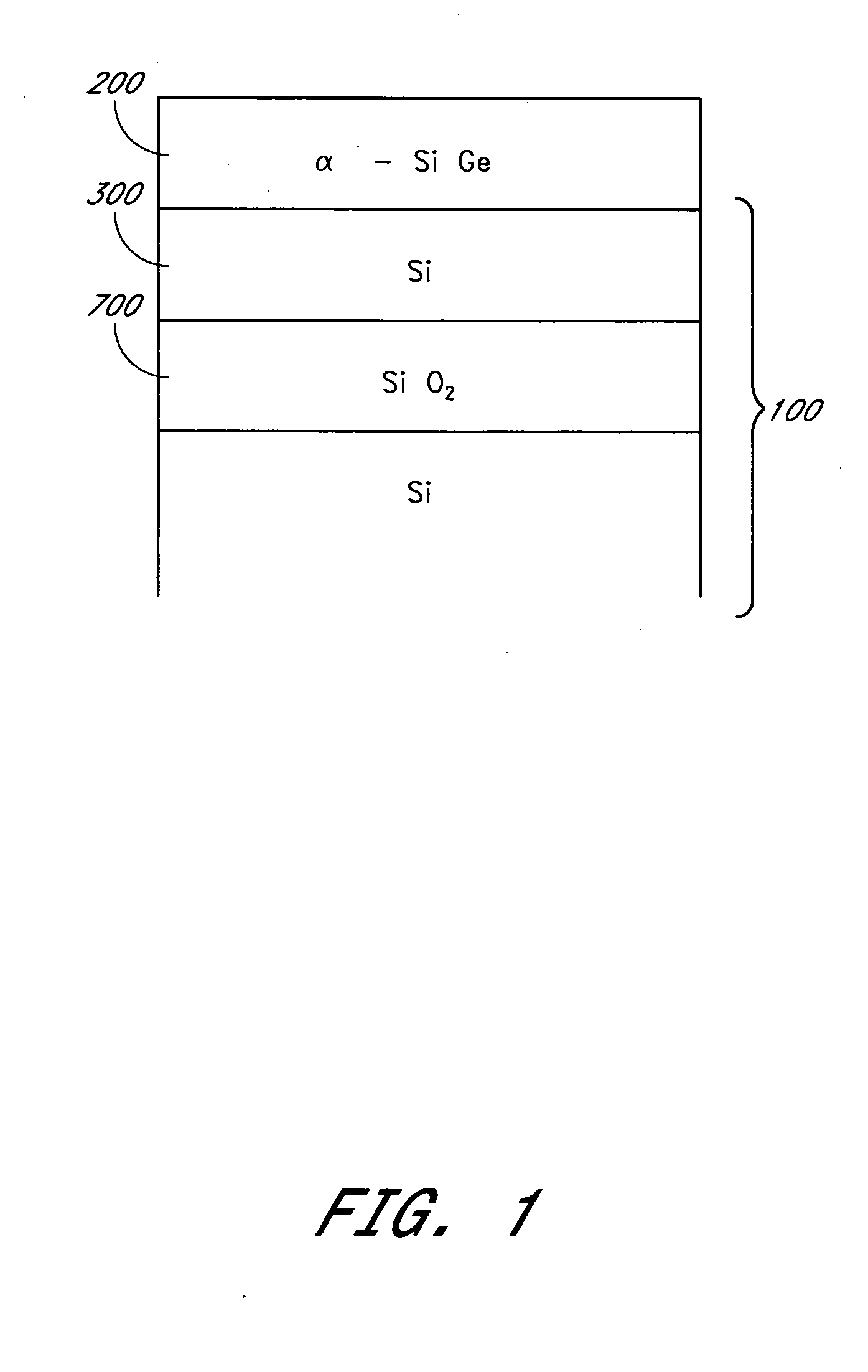

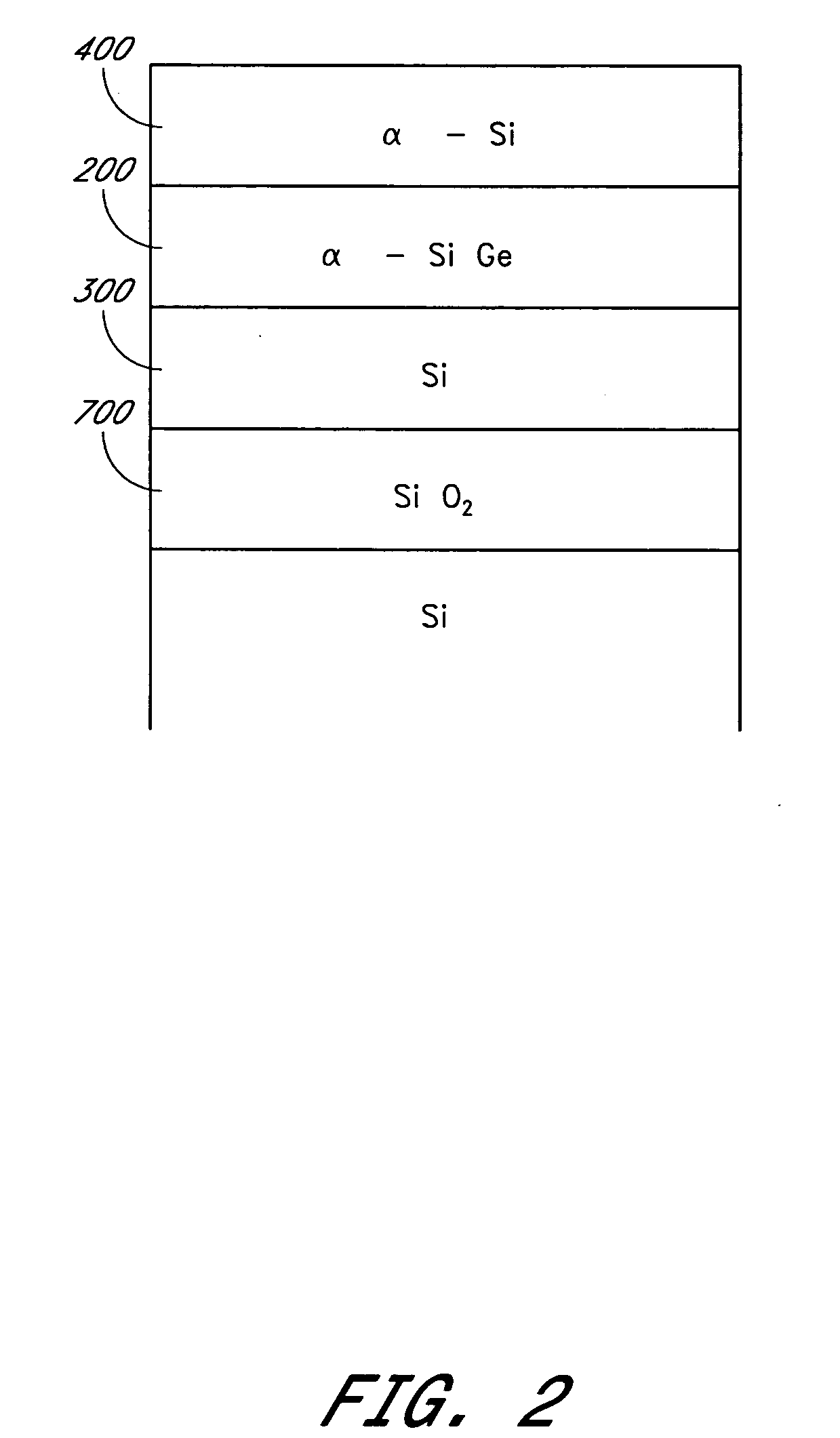

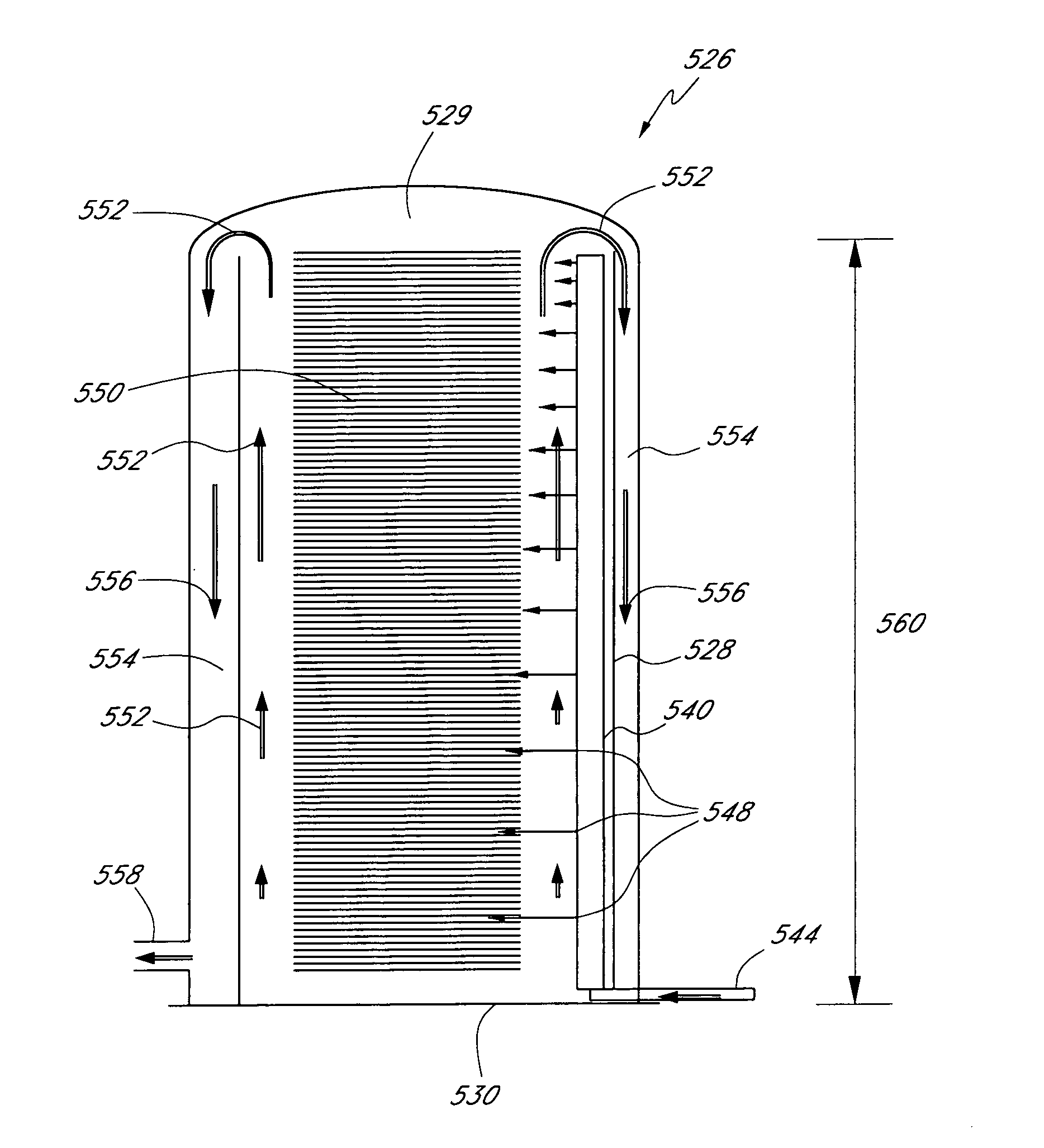

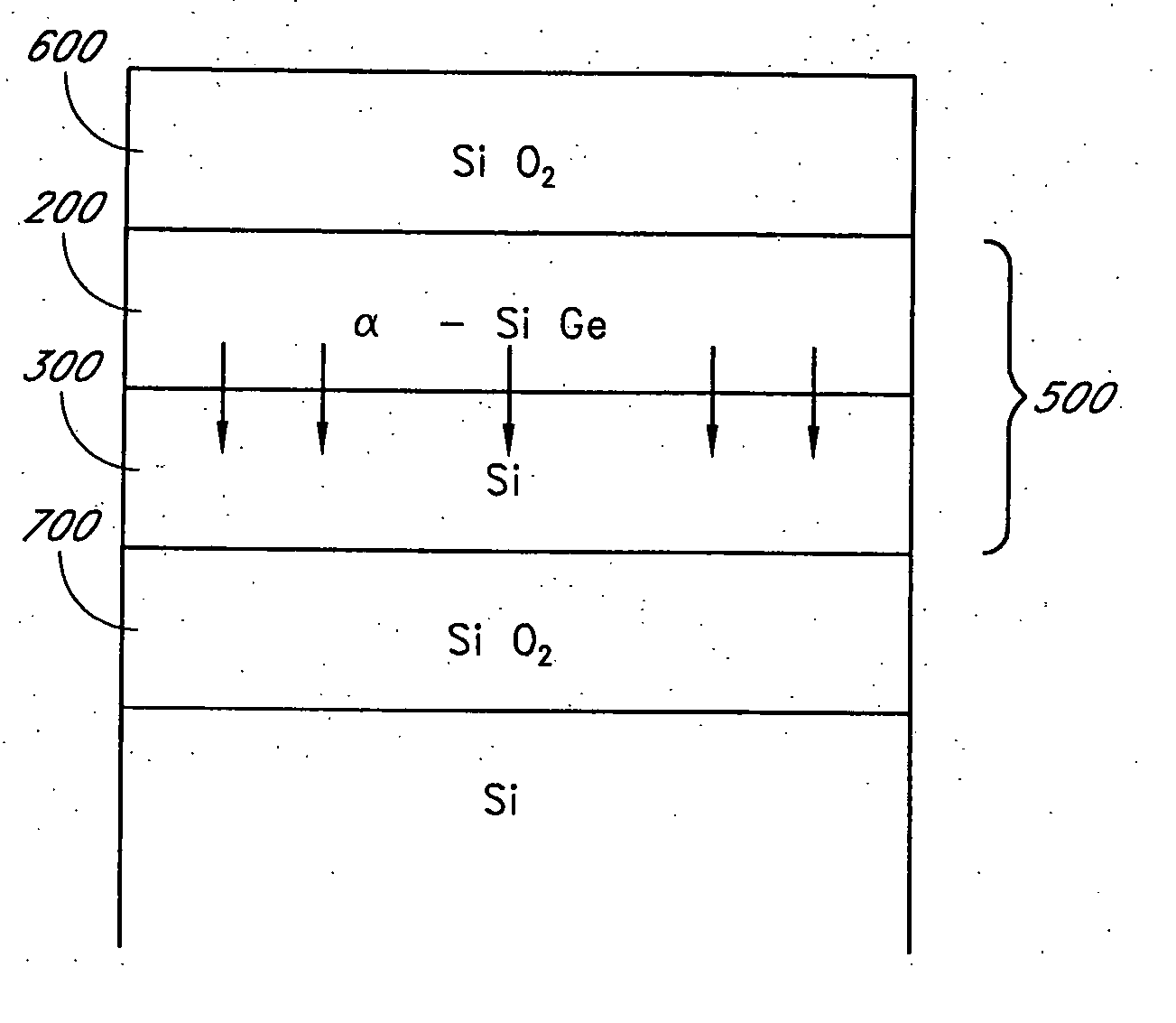

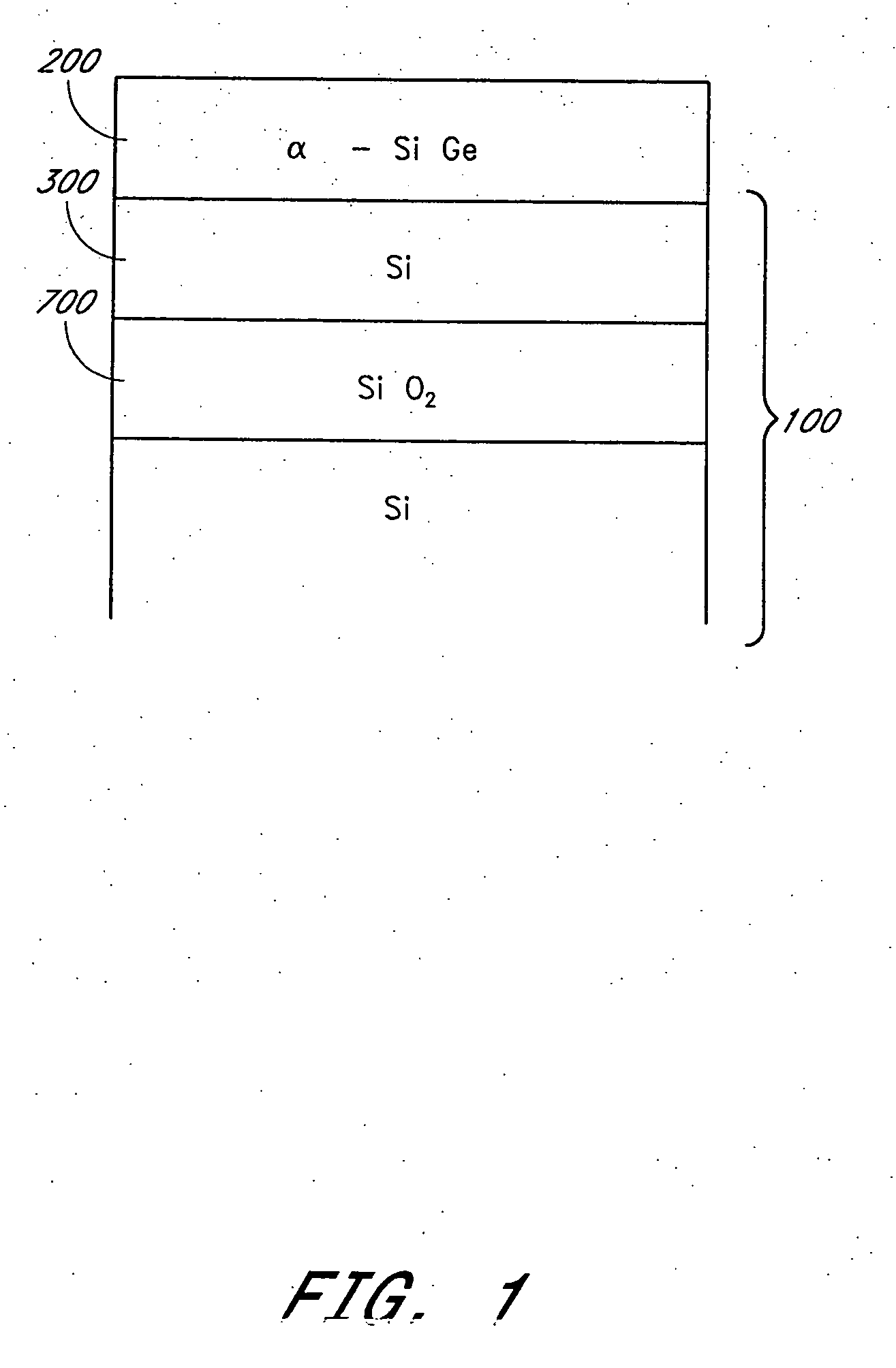

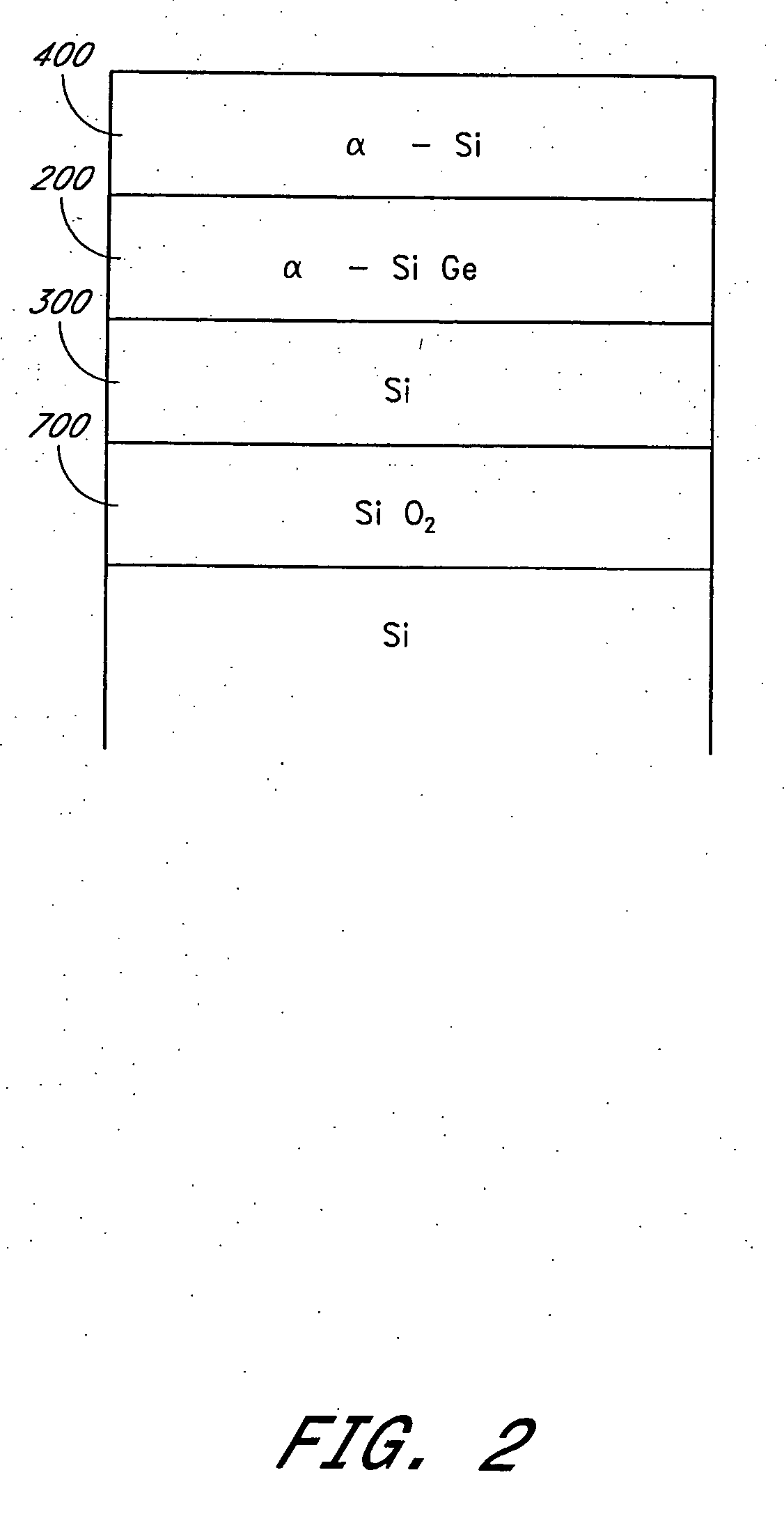

Deposition of silicon germanium on silicon-on-insulator structures and bulk substrates

Methods are provided for producing SiGe-on-insulator structures and for forming strain-relaxed SiGe layers on silicon while minimizing defects. Amorphous SiGe layers are deposited by CVD from trisilane and GeH4. The amorphous SiGe layers are recrystallized over silicon by melt or solid phase epitaxy (SPE) processes. The melt processes preferably also cause diffusion of germanium to dilute the overall germanium content and essentially consume the silicon overlying the insulator. The SPE process can be conducted with or without diffusion of germanium into the underlying silicon, and so is applicable to SOI as well as conventional semiconductor substrates.

Owner:ASM IP HLDG BV

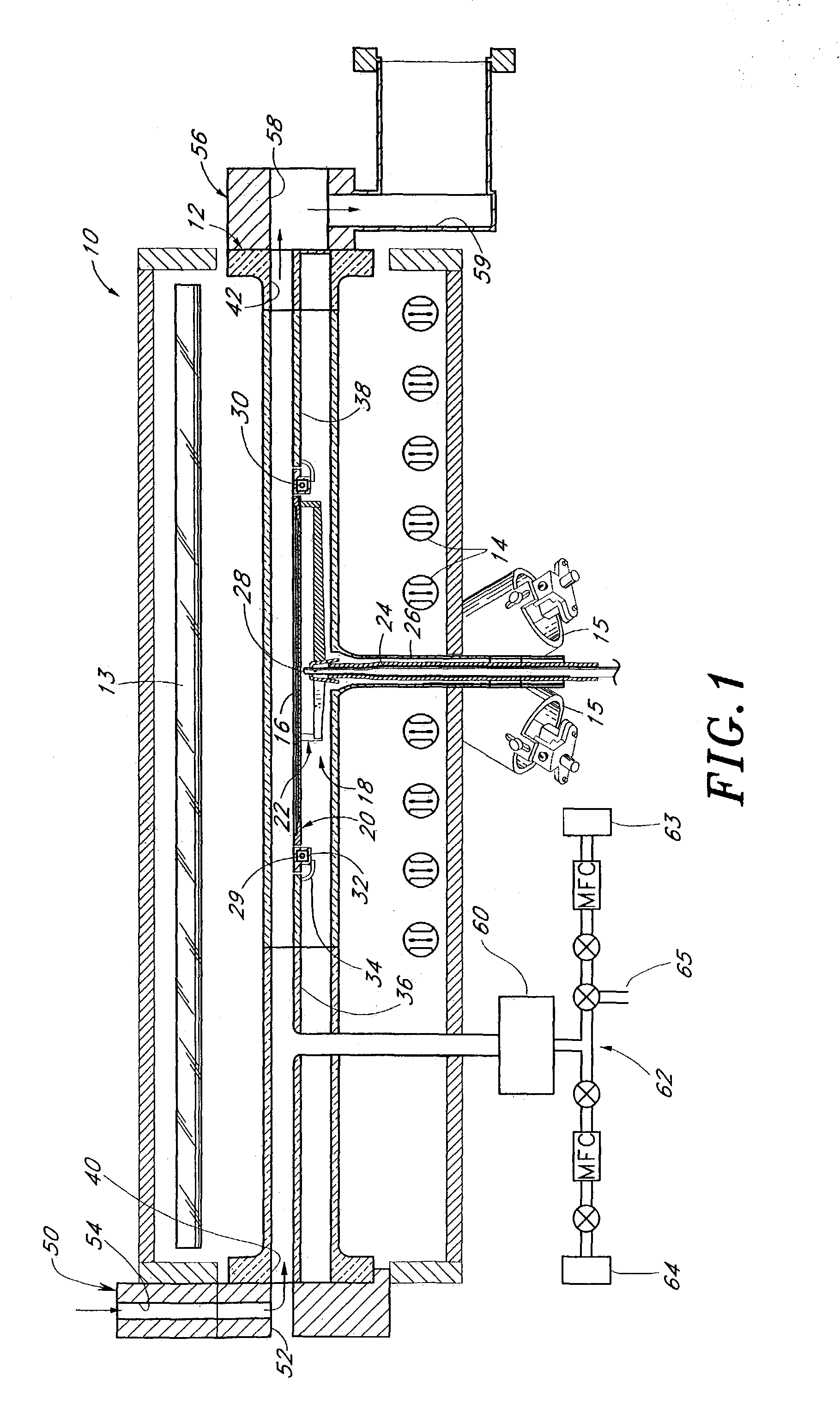

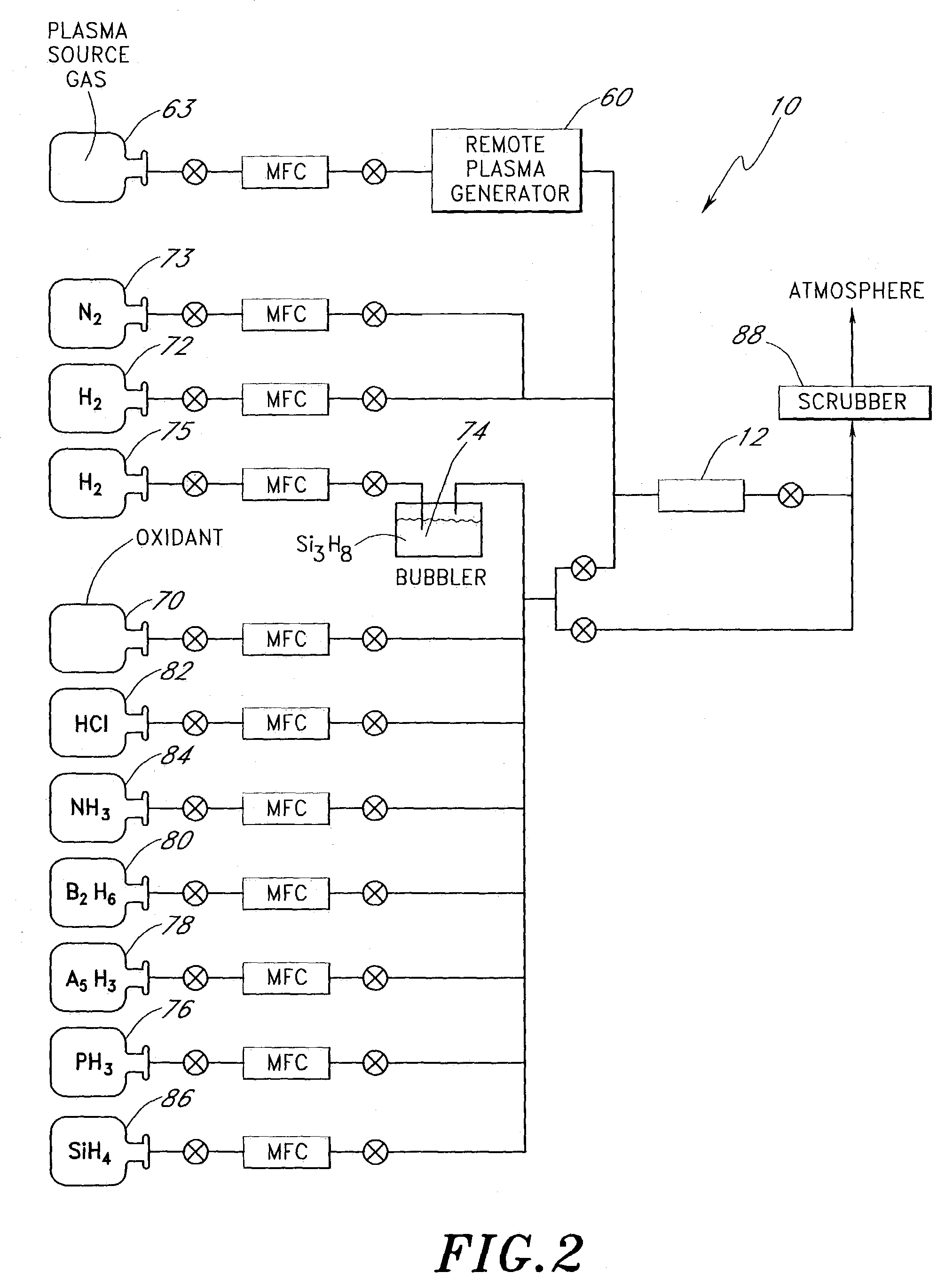

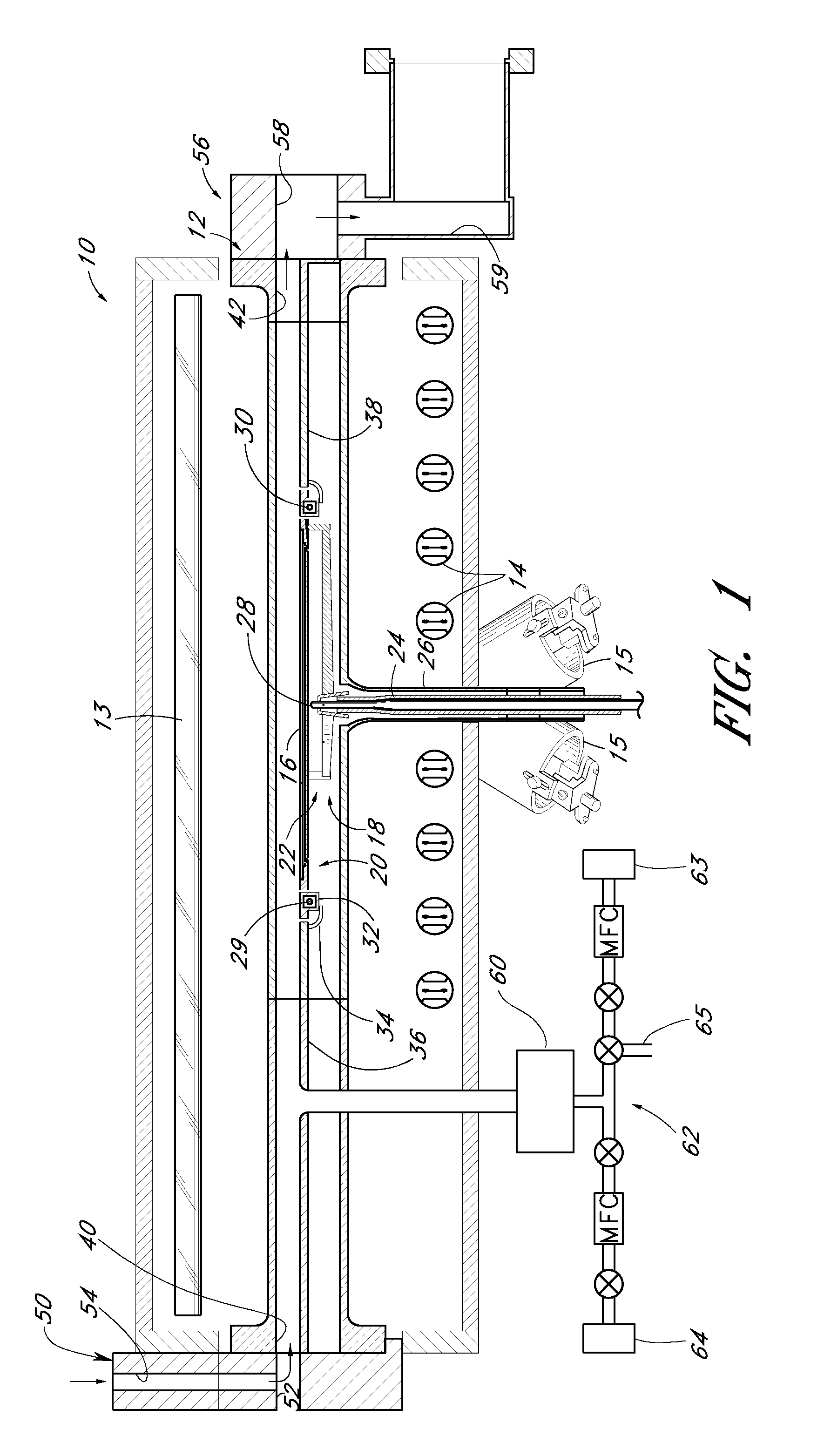

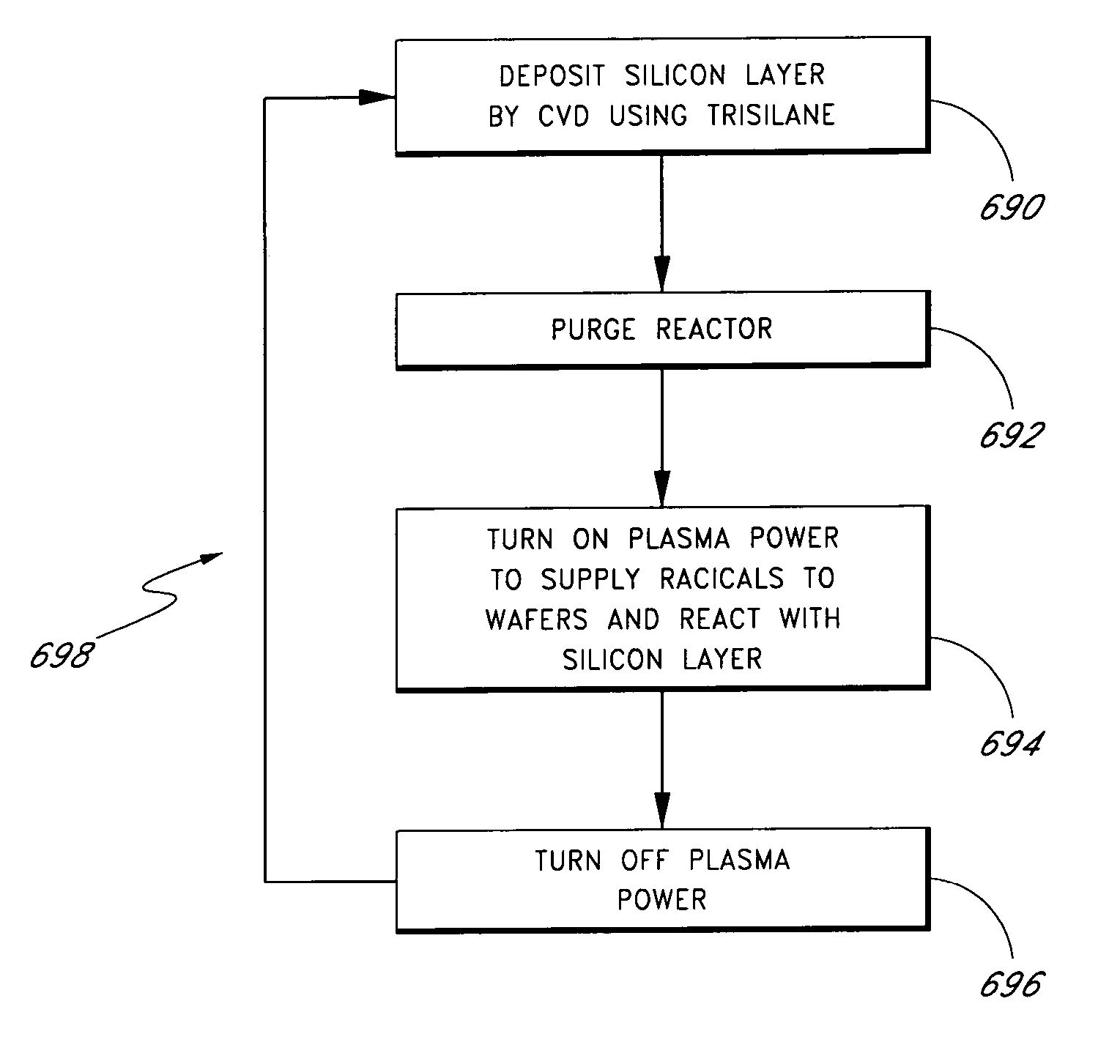

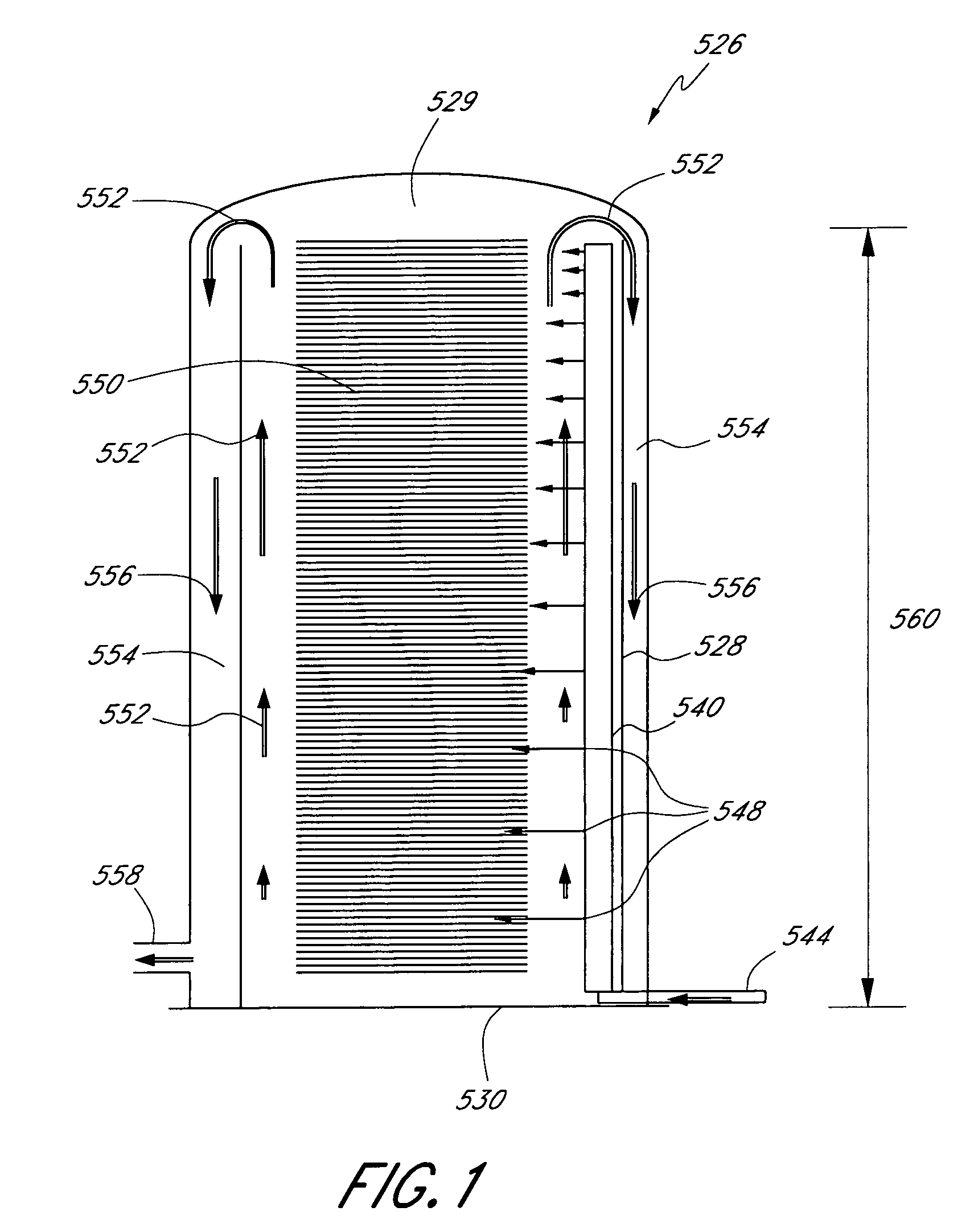

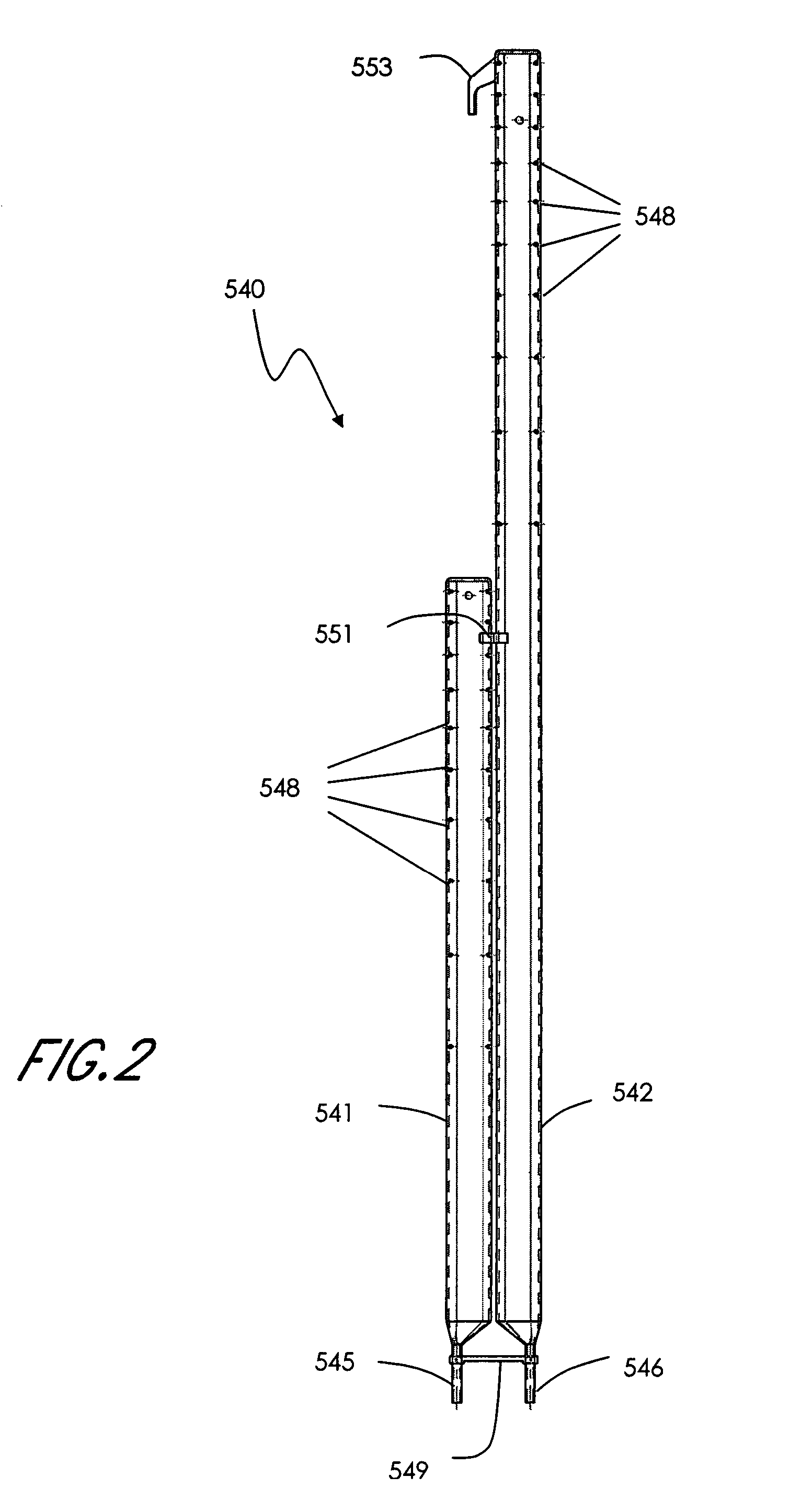

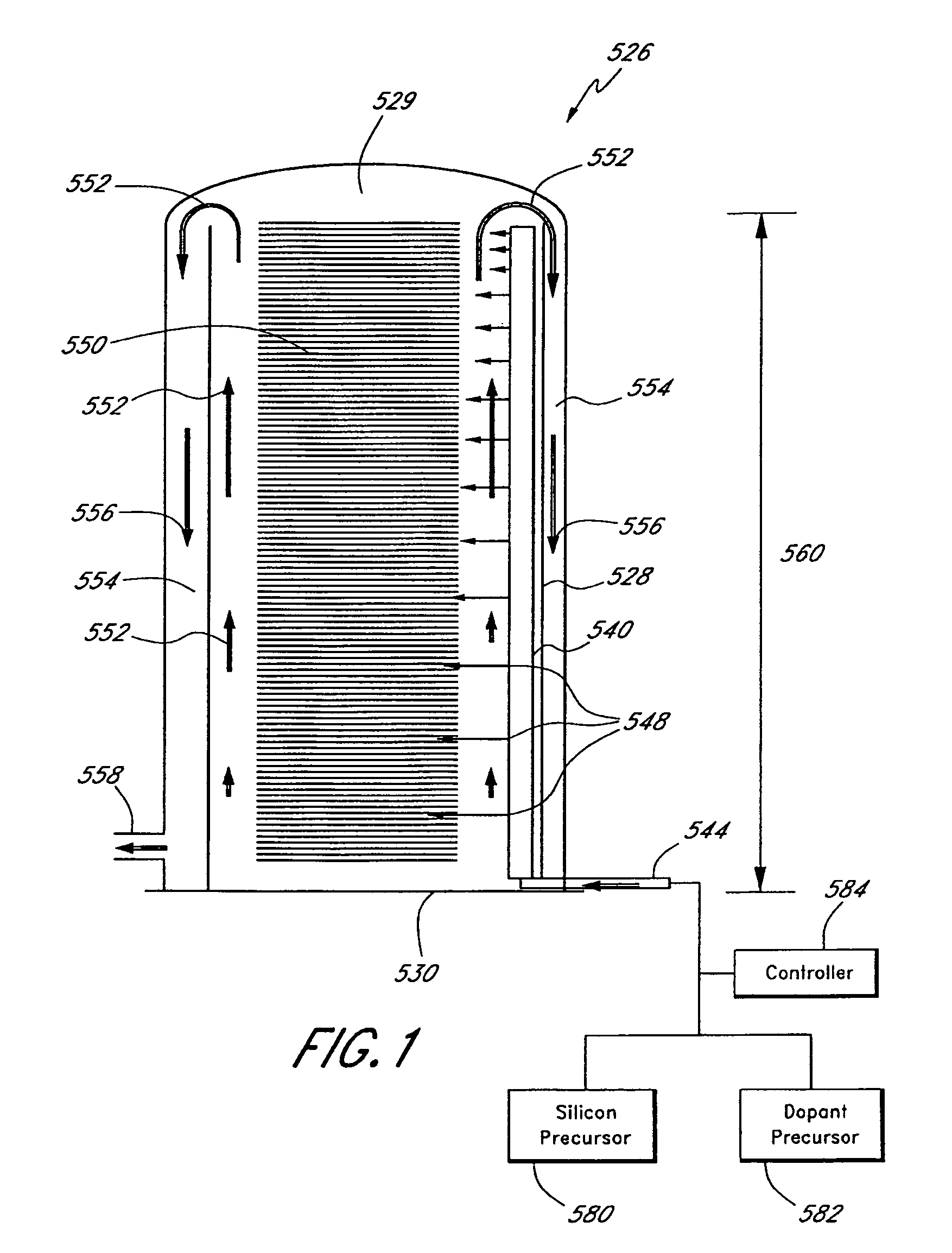

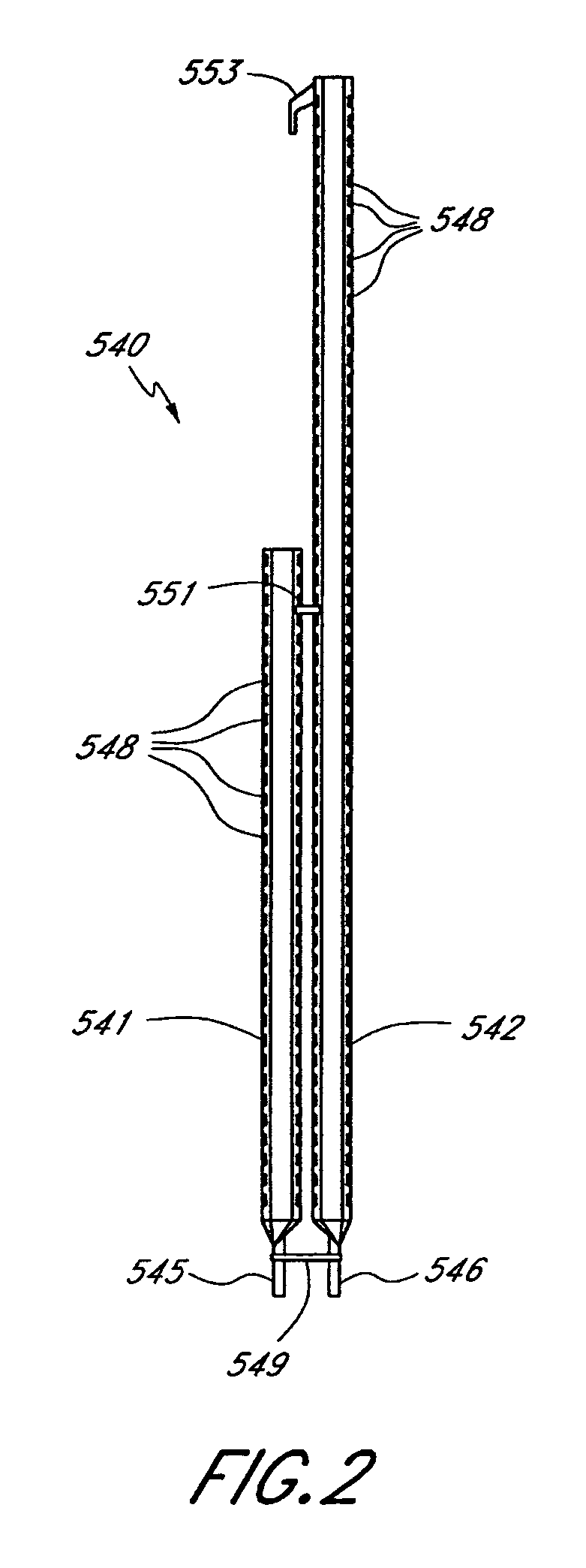

Low temperature silicon compound deposition

ActiveUS20060088985A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingReaction rateGas phase

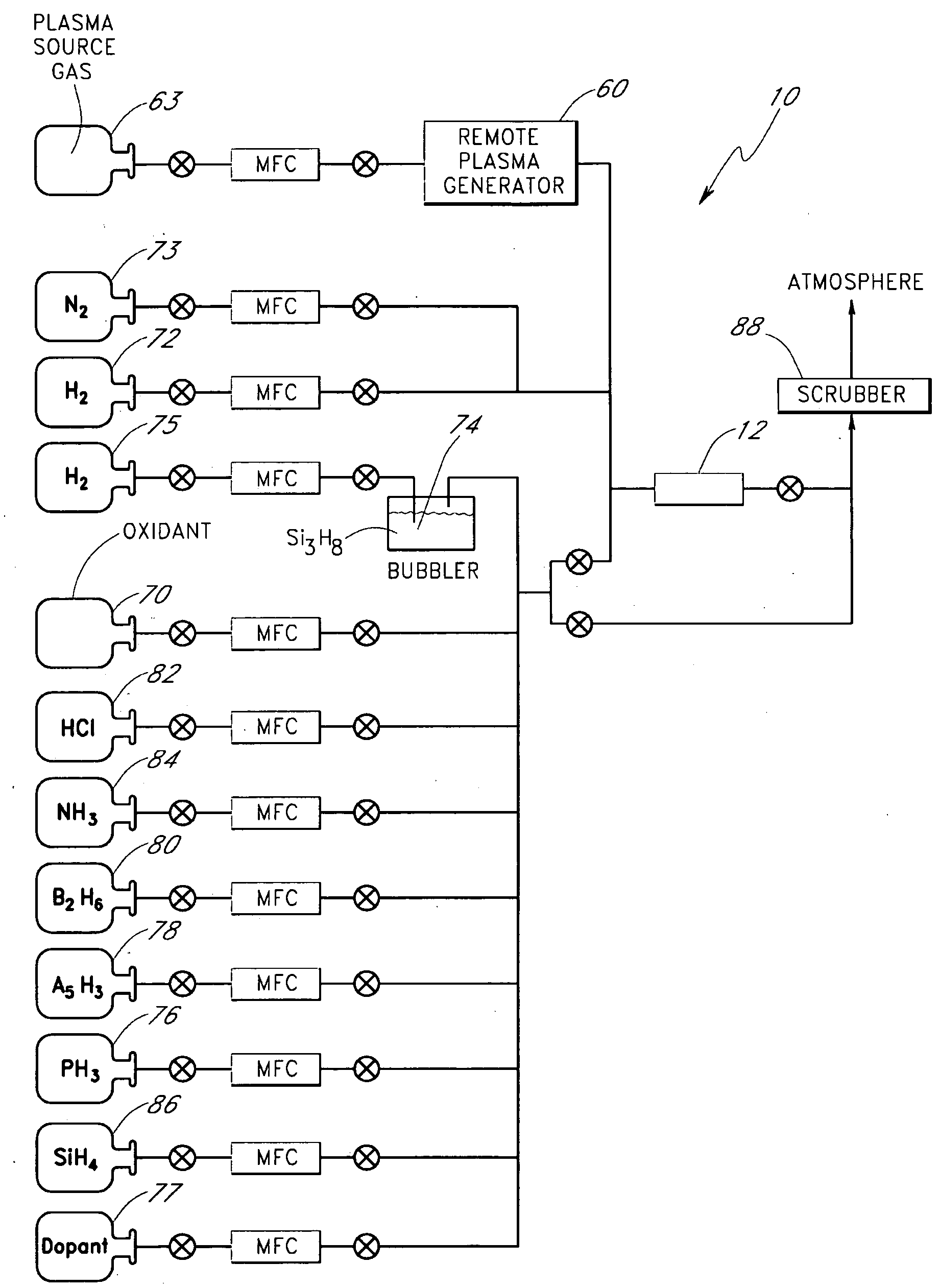

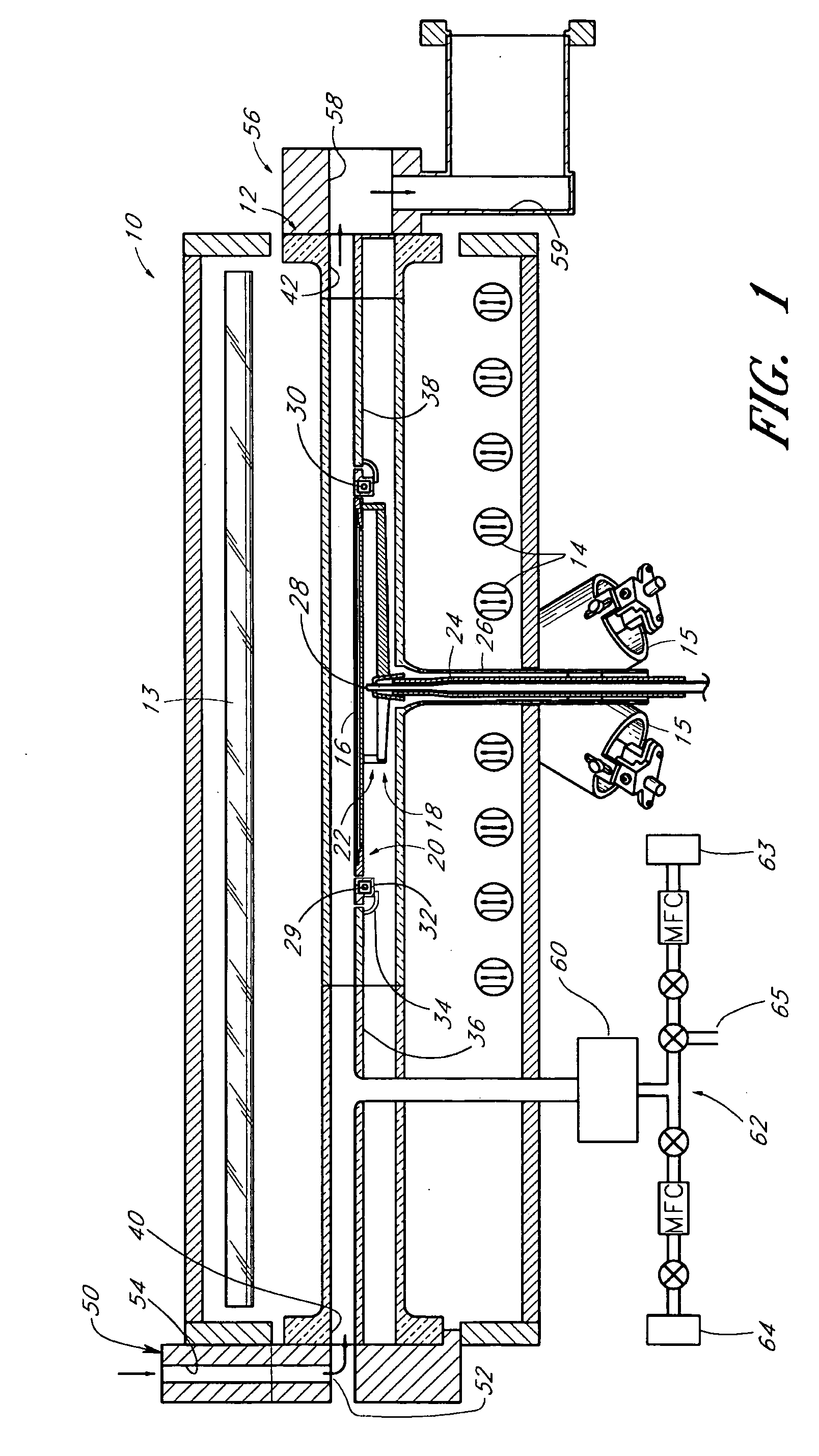

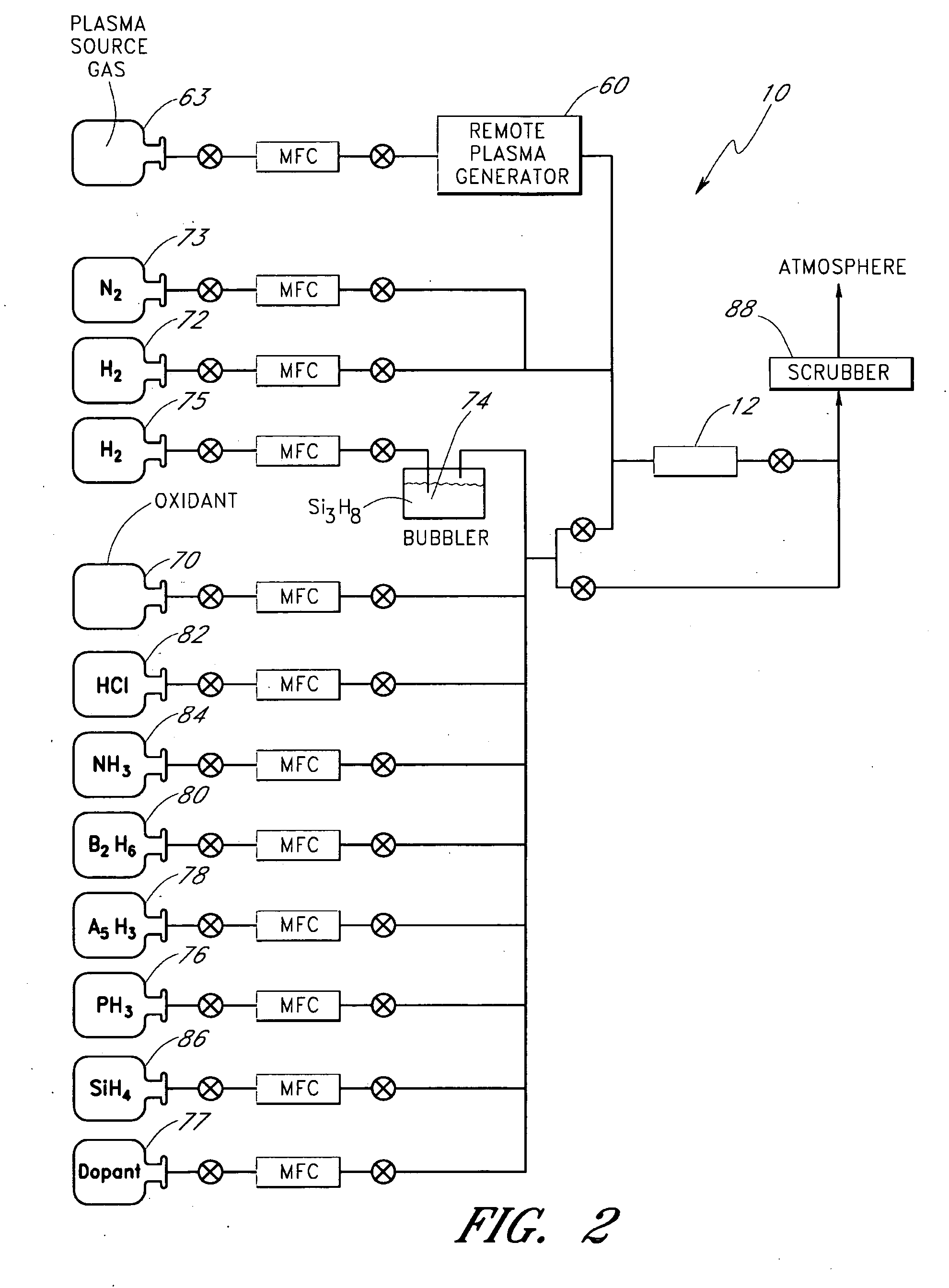

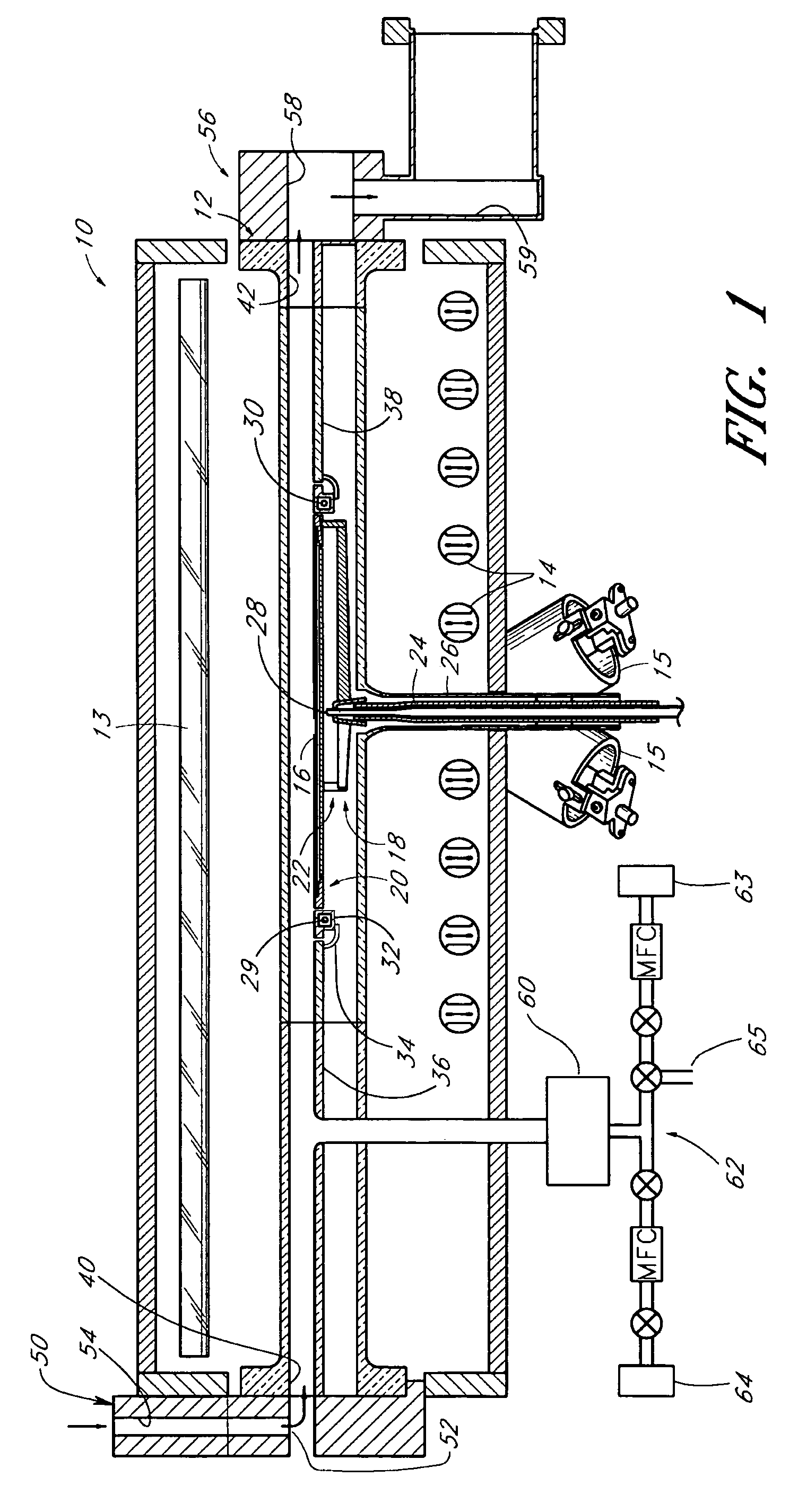

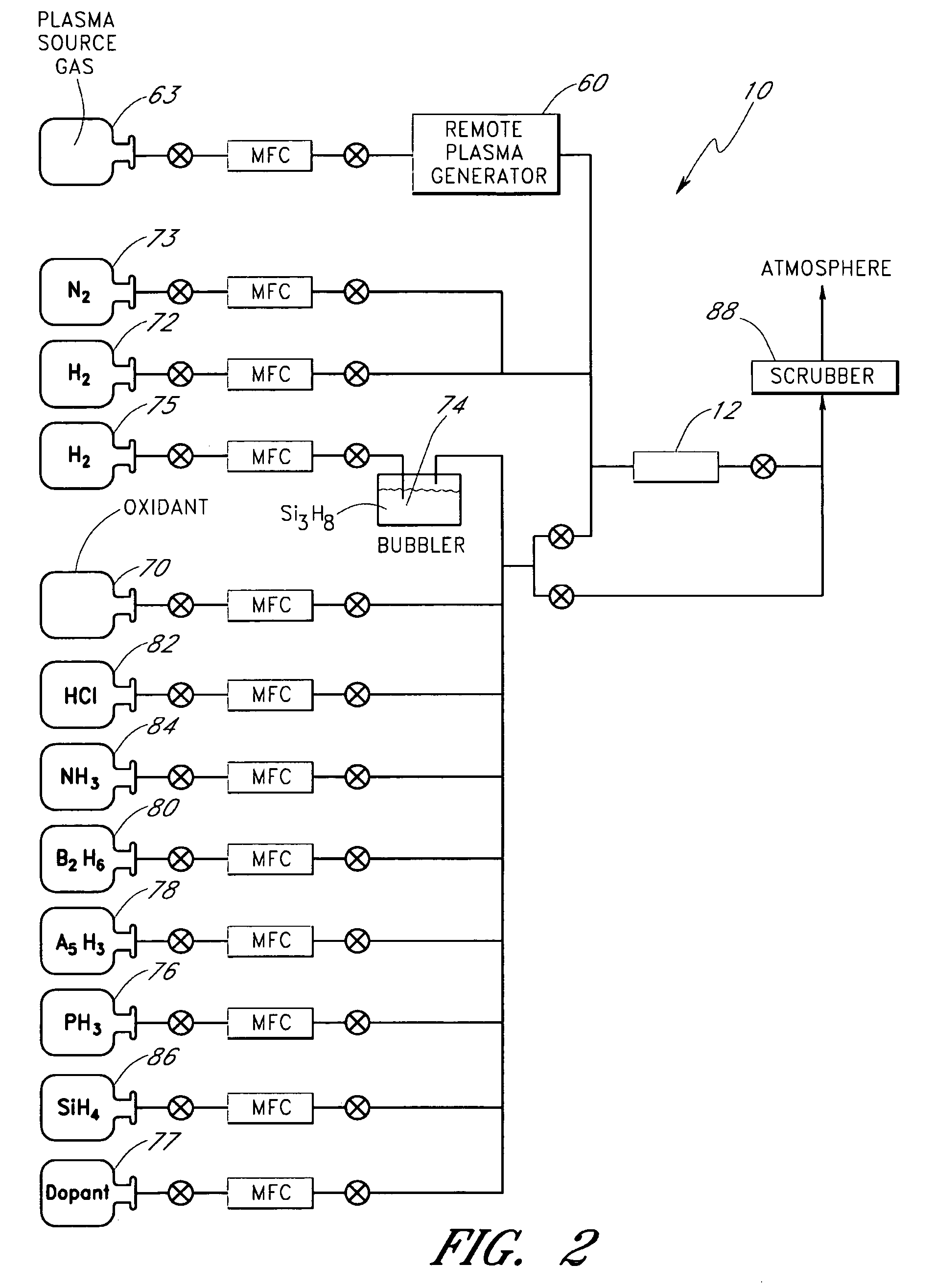

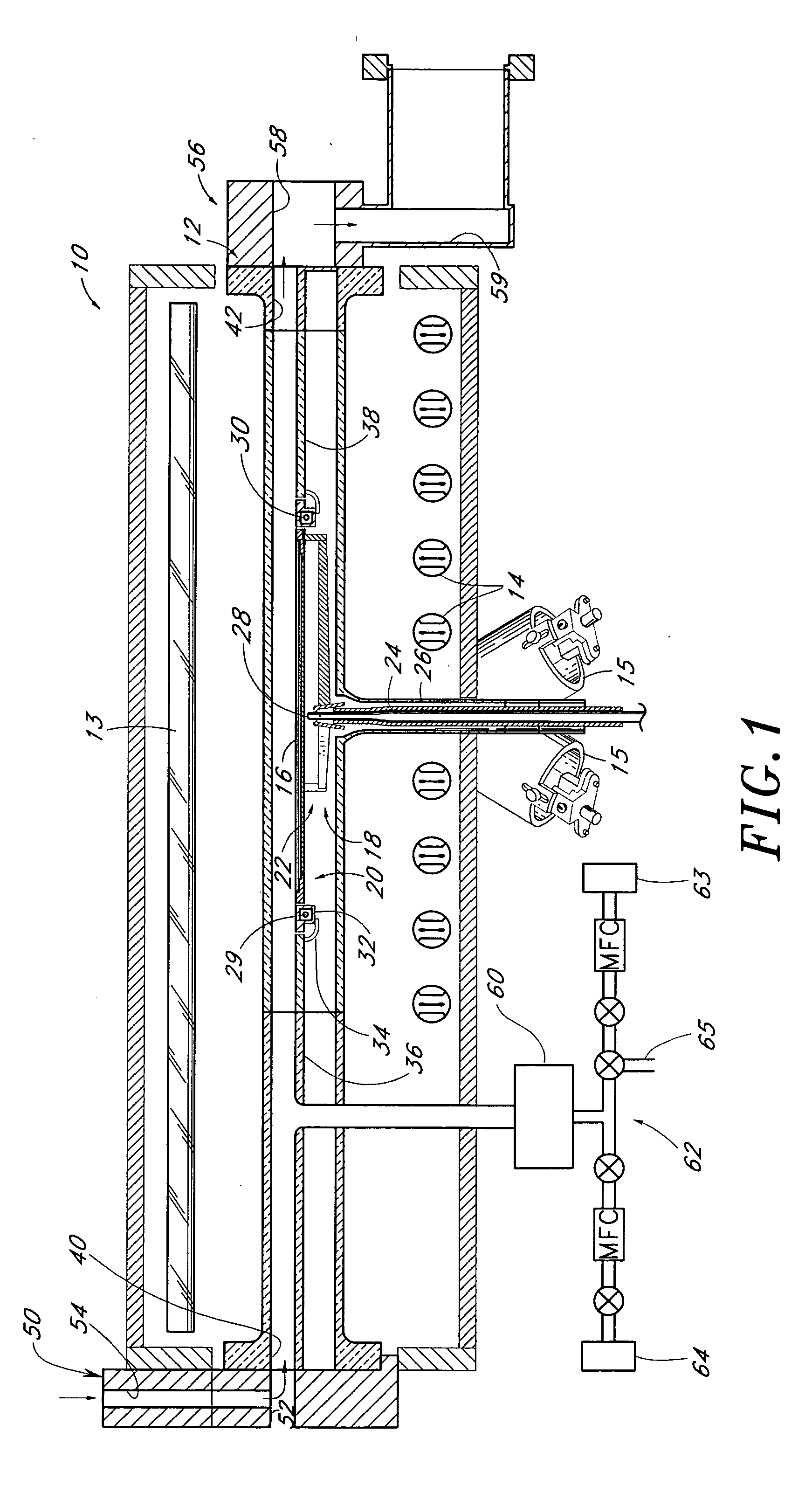

Sequential processes are conducted in a batch reaction chamber to form ultra high quality silicon-containing compound layers, e.g., silicon nitride layers, at low temperatures. Under reaction rate limited conditions, a silicon layer is deposited on a substrate using trisilane as the silicon precursor. Trisilane flow is interrupted. A silicon nitride layer is then formed by nitriding the silicon layer with nitrogen radicals, such as by pulsing the plasma power (remote or in situ) on after a trisilane step. The nitrogen radical supply is stopped. Optionally non-activated ammonia is also supplied, continuously or intermittently. If desired, the process is repeated for greater thickness, purging the reactor after each trisilane and silicon compounding step to avoid gas phase reactions, with each cycle producing about 5-7 angstroms of silicon nitride.

Owner:ASM INTERNATIONAL

Selective deposition of silicon-containing films

ActiveUS20060234504A1Quality improvementImprove surface qualityPolycrystalline material growthSemiconductor/solid-state device manufacturingHalogenGas phase

Chemical vapor deposition methods use trisilane and a halogen-containing etchant source (such as chlorine) to selectively deposit Si-containing films over selected regions of mixed substrates. Dopant sources may be intermixed with the trisilane and the etchant source to selectively deposit doped Si-containing films. The selective deposition methods are useful in a variety of applications, such as semiconductor manufacturing.

Owner:ASM IP HLDG BV

Low temperature silicon compound deposition

InactiveUS7294582B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseSilanes

Sequential processes are conducted in a batch reaction chamber to form ultra high quality silicon-containing compound layers, e.g., silicon nitride layers, at low temperatures. Under reaction rate limited conditions, a silicon layer is deposited on a substrate using trisilane as the silicon precursor. Trisilane flow is interrupted. A silicon nitride layer is then formed by nitriding the silicon layer with nitrogen radicals, such as by pulsing the plasma power (remote or in situ) on after a trisilane step. The nitrogen radical supply is stopped. Optionally non-activated ammonia is also supplied, continuously or intermittently. If desired, the process is repeated for greater thickness, purging the reactor after each trisilane and silicon compounding step to avoid gas phase reactions, with each cycle producing about 5-7 angstroms of silicon nitride.

Owner:ASM INTERNATIONAL

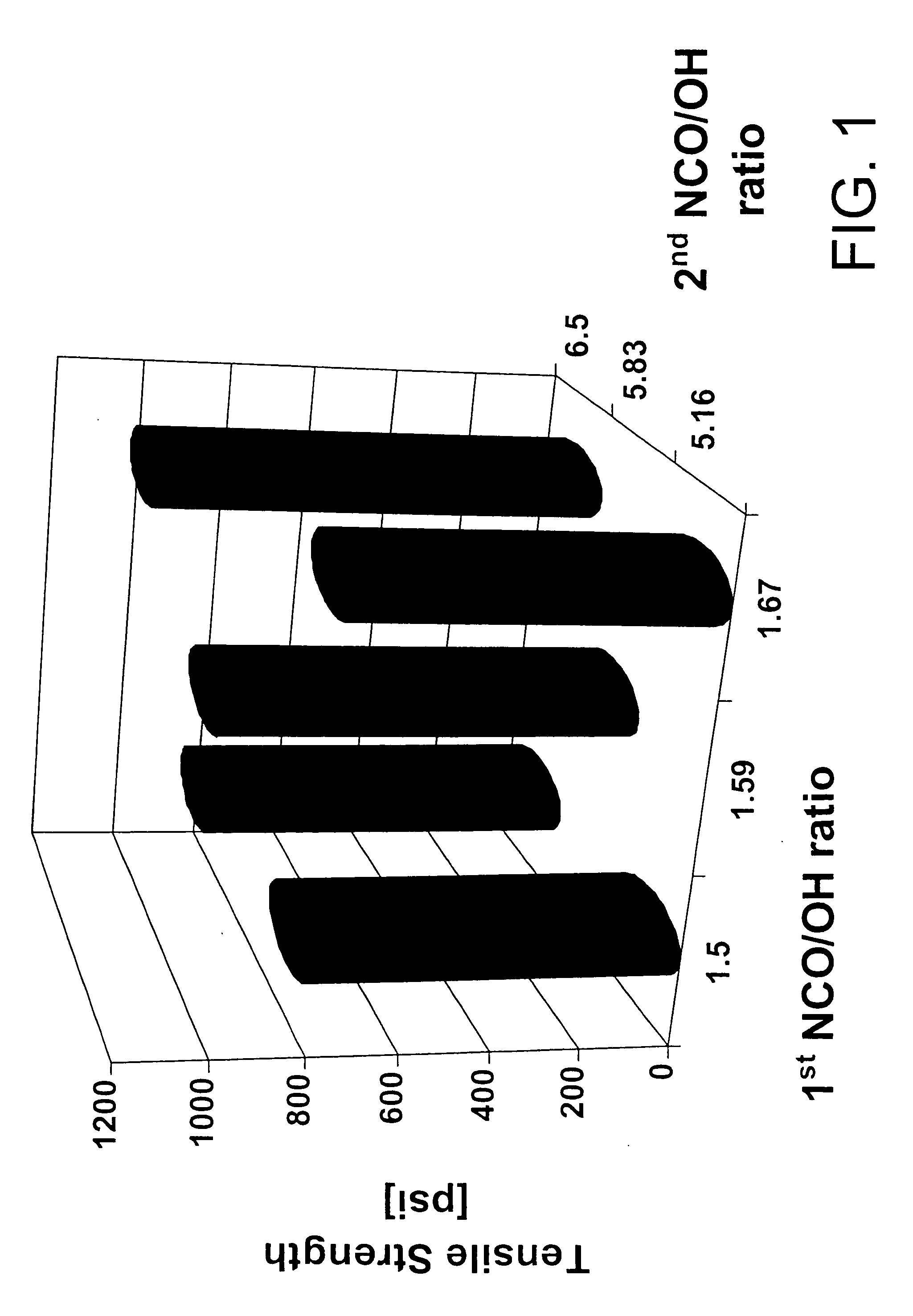

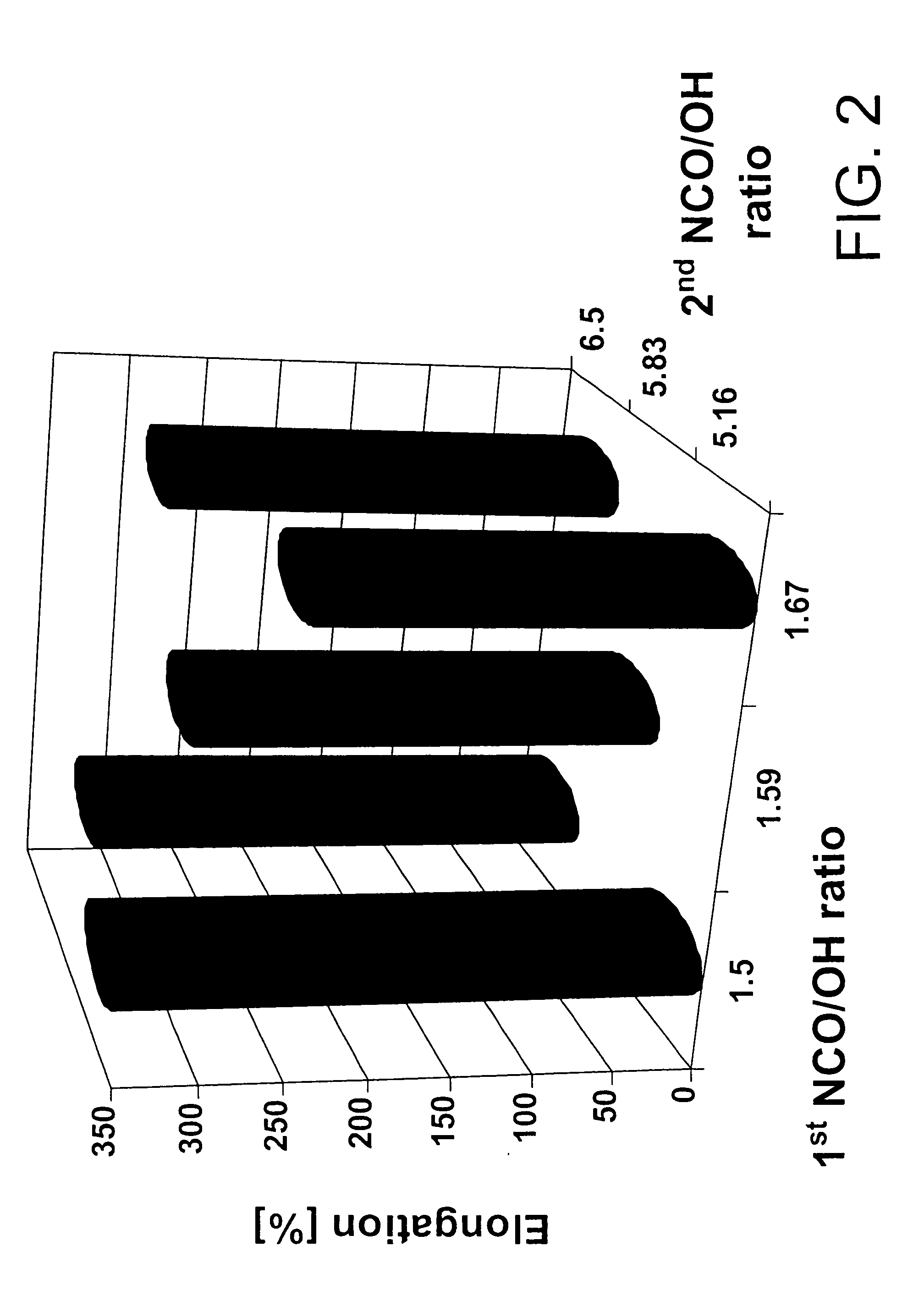

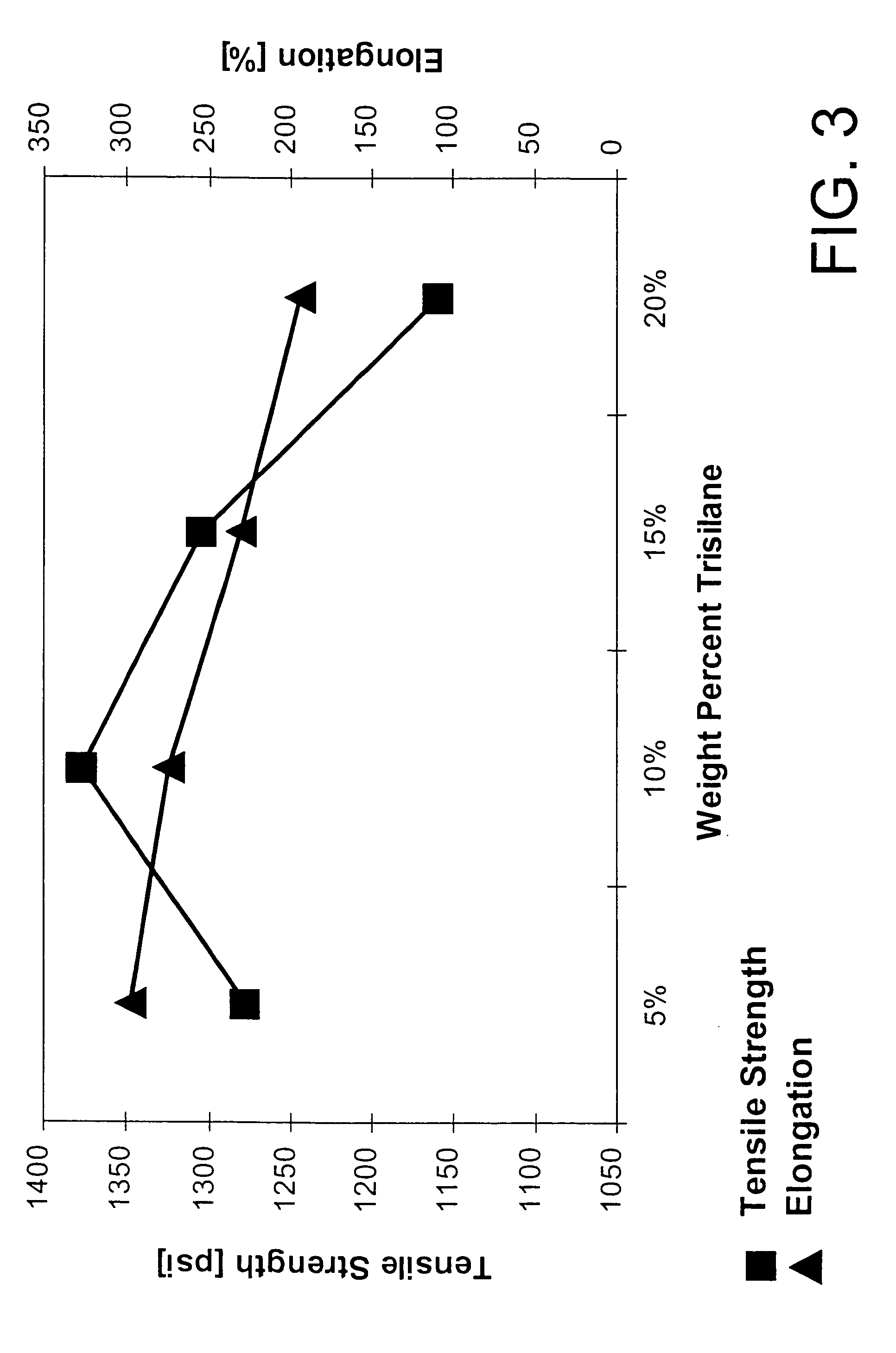

Silane-terminated polyurethanes with high strength and high elongation

A silane-terminated polyurethane composition is the reaction product of a silane-terminated polyurethane prepolymer component, a silane-terminated monomeric diisocyanate, and optionally at least one multifunctional trisilane or tetrasilane component. A method for making a composition includes (a) providing a silane-terminated polyurethane prepolymer component, a silane-terminated monomeric diisocyanate component, and optionally at least one multifunctional trisilane or tetrasilane component, and (b) combining the prepolymer component, monomeric component, and optional multifunctional silane component to form a silane-terminated polyurethane reaction product with a tensile strength of about 4 MPa or greater and an elongation of about 200% or greater.

Owner:CONSTR RES & TECH GMBH

High stress nitride film and method for formation thereof

ActiveUS7629267B2Increase the tensile stressSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDopantNitrogen

A silicon nitride film is formed on a substrate in a reaction chamber by introducing trisilane and a reactive nitrogen species into the chamber in separate pulses. A carbon precursor gas is also flowed into the chamber during introduction of the trisilane and / or during introduction of the reactive nitrogen species, or in pulses separate from the trisilane and reactive nitrogen species pulses. The carbon is used as a dopant in the silicon nitride film and advantageously allows a high stress silicon nitride film to be formed.

Owner:ASM INTERNATIONAL

Environmental-friendly halogen-free low-smoke flame retardant material for coaxial cable and preparation method thereof

InactiveCN101608032AGood effectEnvironmental protection is goodInsulated cablesInsulated conductorsAluminium hydroxideMixed materials

The invention relates to an environmental-friendly halogen-free low-smoke flame retardant material for a coaxial cable and a preparation method thereof. The environmental-friendly halogen-free low-smoke flame retardant material comprises the following materials with the content by weight percent: 15 to 30 percent of ethane-vinyl acetate copolymer, 8 to 15 percent of linear low-density polythene, 25 to 60 percent of fire retardant aluminium hydroxide, 10 to 20 percent of fire retardant magnesium hydroxide, 5 to 10 percent of compatilizer ethane-vinyl acetate copolymer graft maleic anhydride copolymer or ethane graft maleic anhydride copolymer, 0.2 to 0.8 percent of antioxygen triphenyl phosphate, 0.4 to 1 percent of surface active agent ethenyl (beta-methoxyl ethyoxyl) trisilane and 0.5 to 1.2 percent of lubricant zinc stearate. The preparation method of the environmental-friendly halogen-free low-smoke flame retardant material comprises the following steps: firstly, mixing the fire retardant aluminium hydroxide at high speed in a high-speed mixing machine till the temperature of the fire retardant aluminium hydroxide achieves 80 to 90 DEG C; using the surface active agent ethenyl (beta-methoxyl ethyoxyl) trisilane to carry out spraying preprocessing after dehydration; adding the materials by weight percent into the high-speed mixing machine to be stirred at high speed for 3 to 5 minutes so that the materials are uniformly mixed; then delivering the mixed materials into a twin-screw extruder to be processed and prilled, wherein the temperature of each section of a screw is as follows: the temperature of a material feeding section is 90 to 110 DEG C, the temperature of a delivering section is 120 to 130 DEG C, the temperature of a plasticizing section is 130 to 140 DEG C, and the temperature of a machine head is 135-145 DEG C; and drying particles after the mixed materials are prilled so as to obtain finished products.

Owner:SUZHOU HENGLI COMM MATERIAL

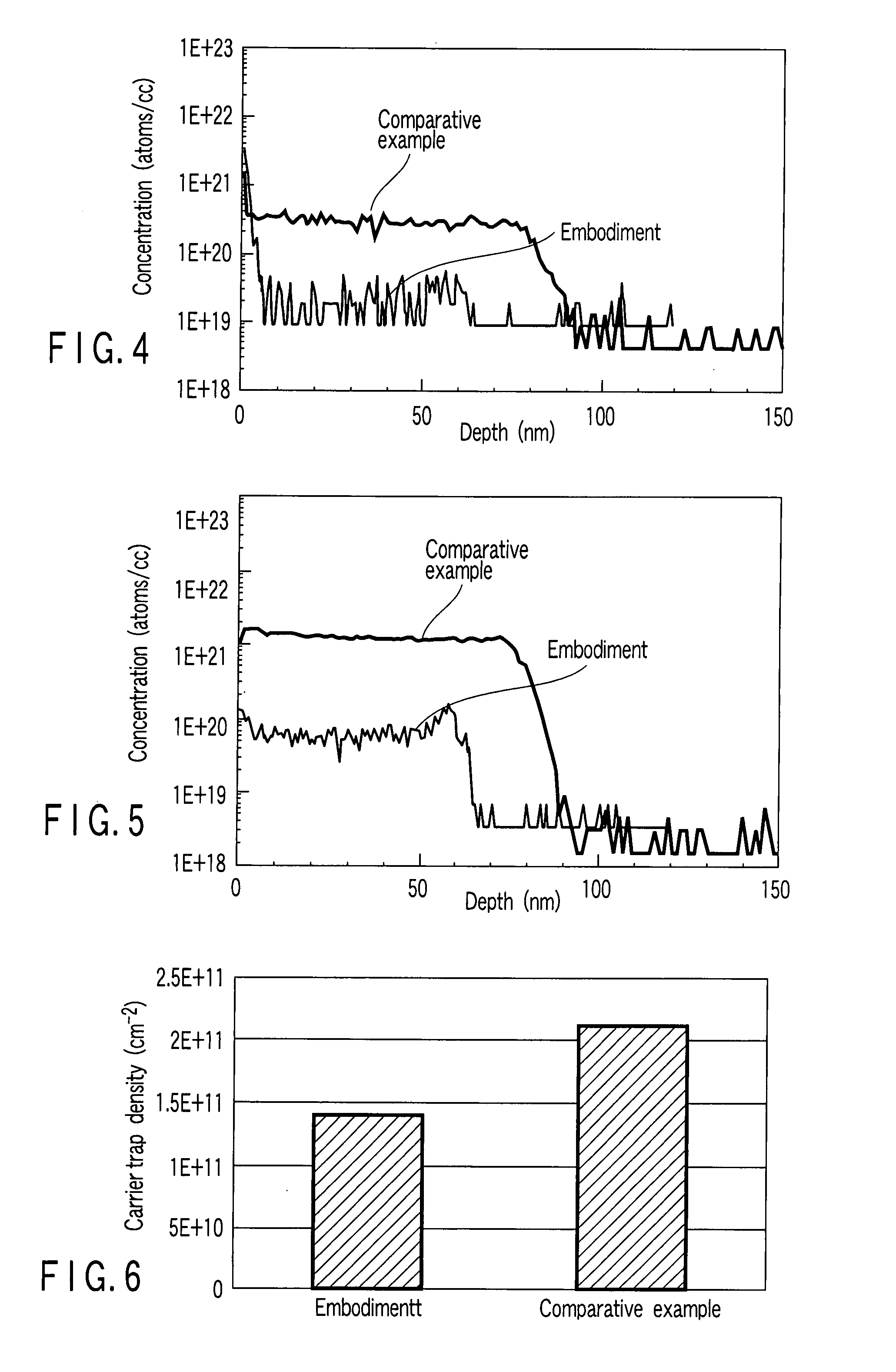

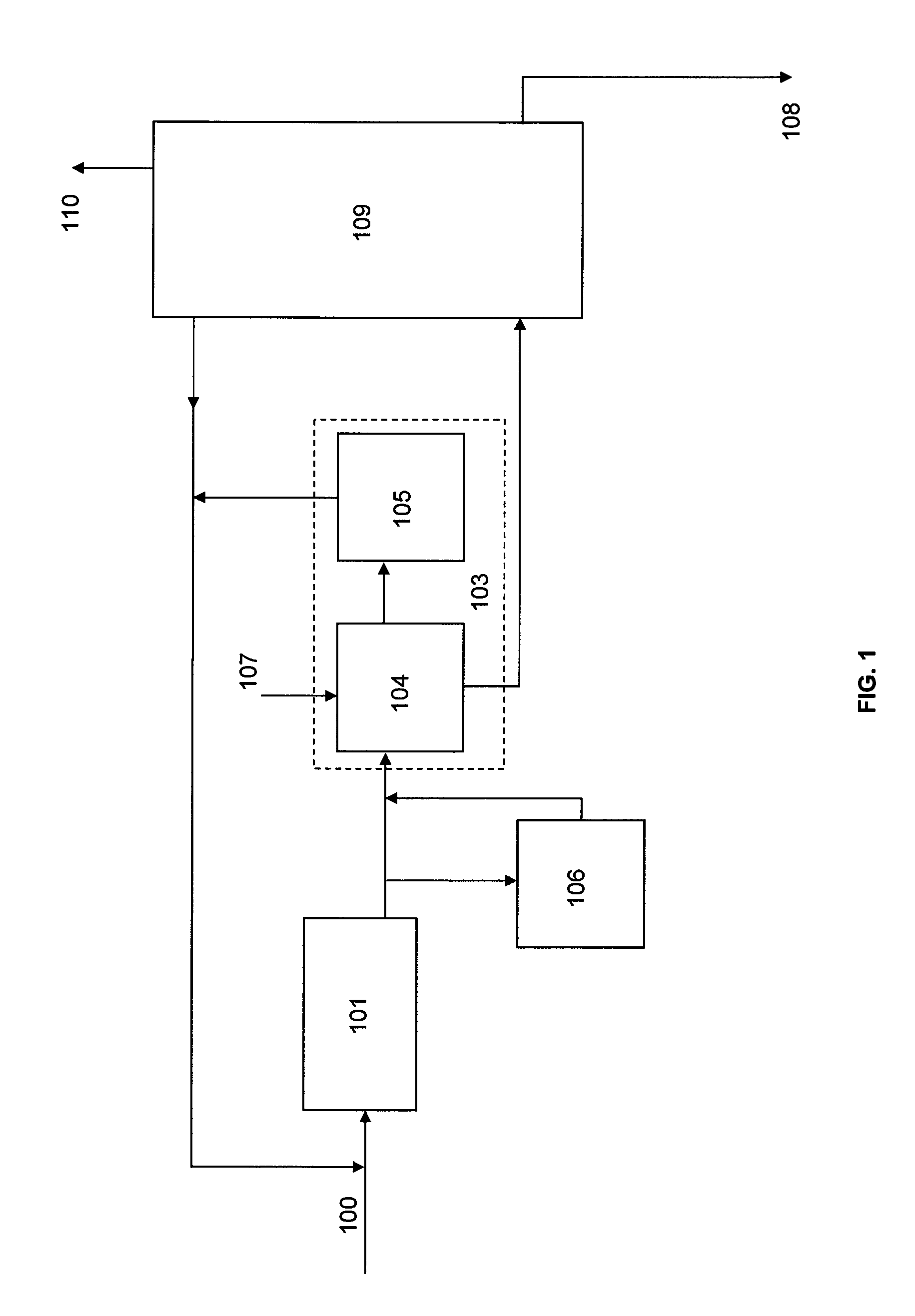

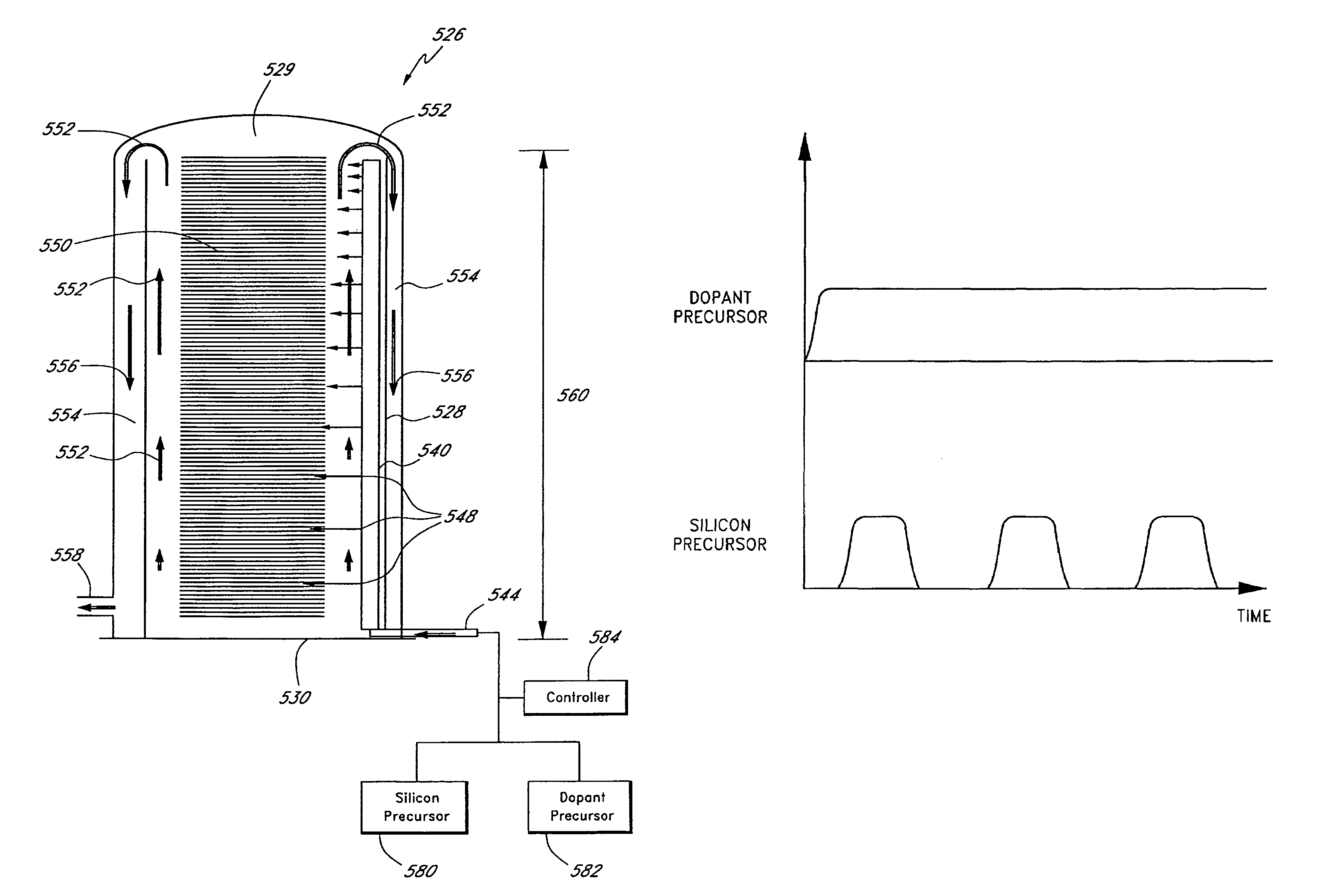

Low temperature doped silicon layer formation

ActiveUS20070141812A1Polycrystalline material growthSemiconductor/solid-state device manufacturingDopantPhosphine

A doped silicon layer is formed in a batch process chamber at low temperatures. The silicon precursor for the silicon layer formation is a polysilane, such as trisilane, and the dopant precursor is an n-type dopant, such as phosphine. The silicon precursor can be flowed into the process chamber with the flow of the dopant precursor or separately from the flow of the dopant precursor. Surprisingly, deposition rate is independent of dopant precursor flow, while dopant incorporation linearly increases with the dopant precursor flow.

Owner:ASM INTERNATIONAL

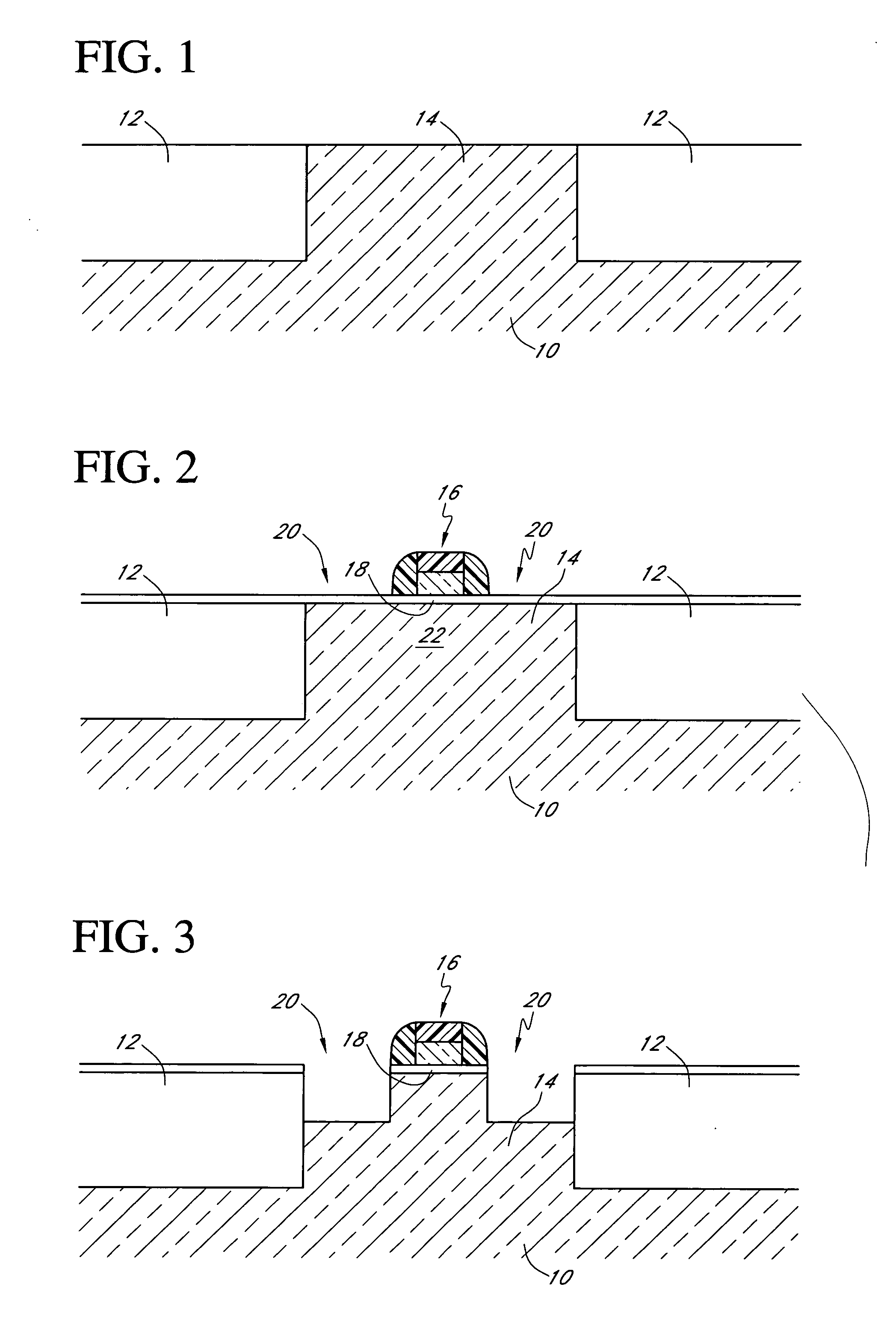

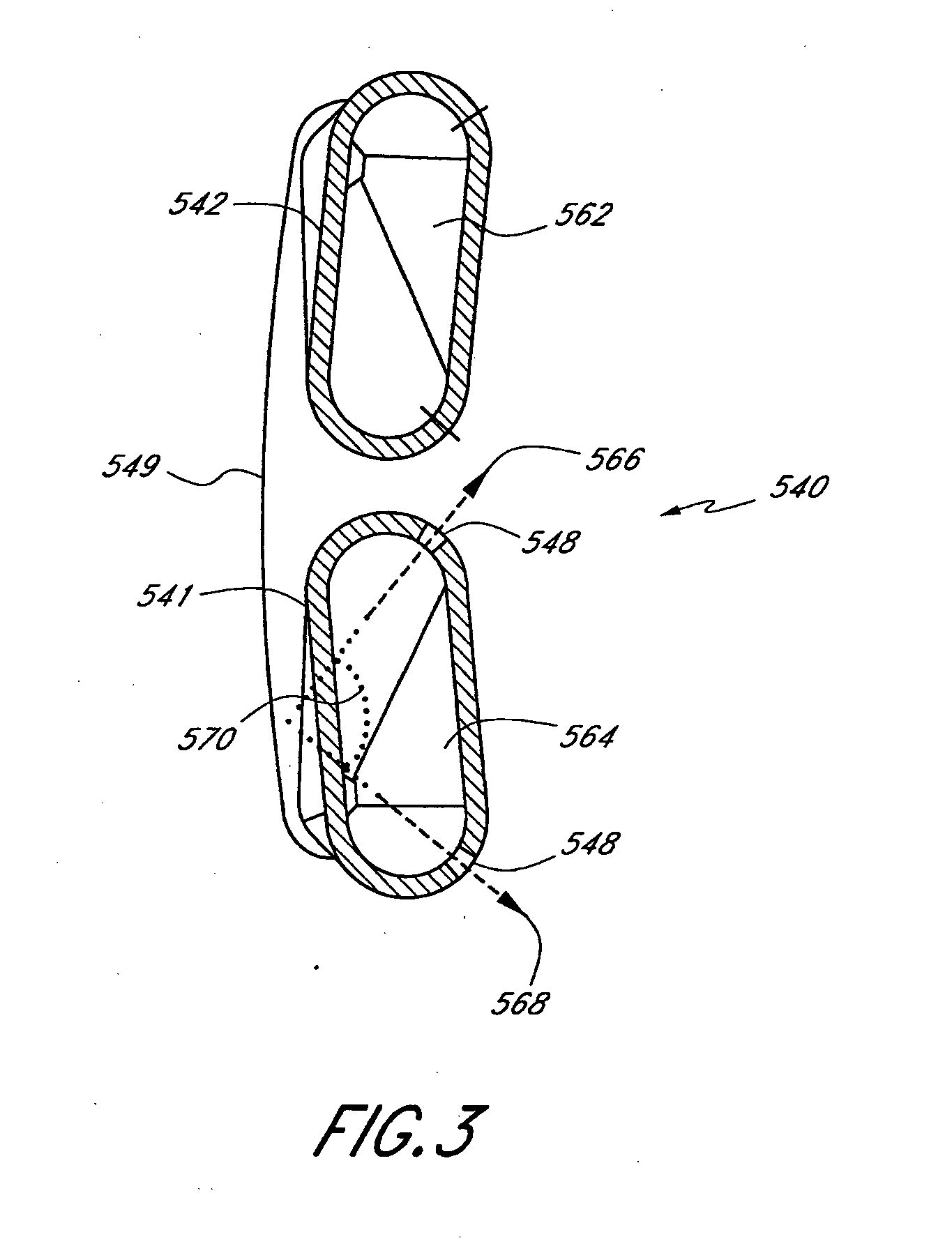

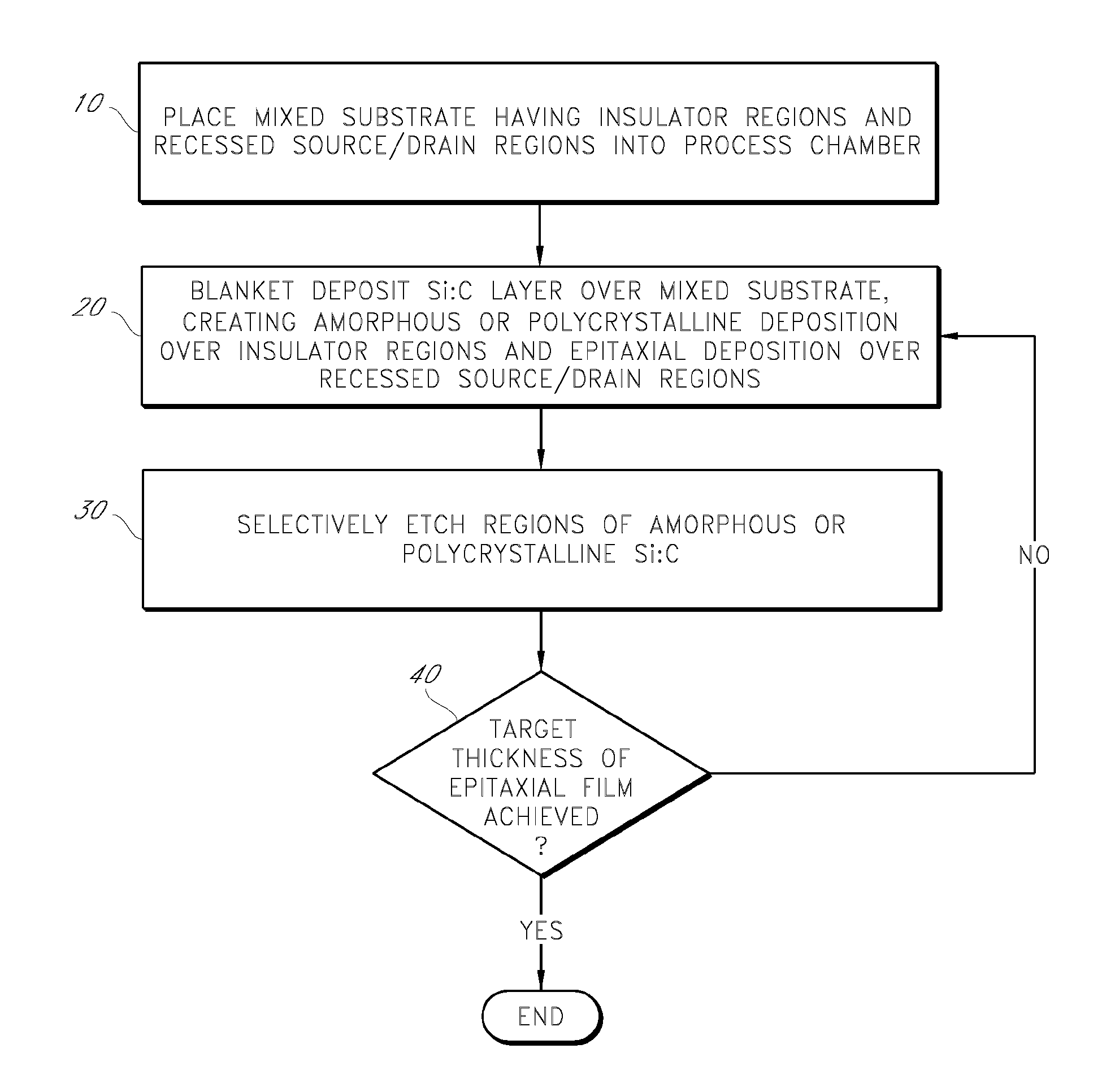

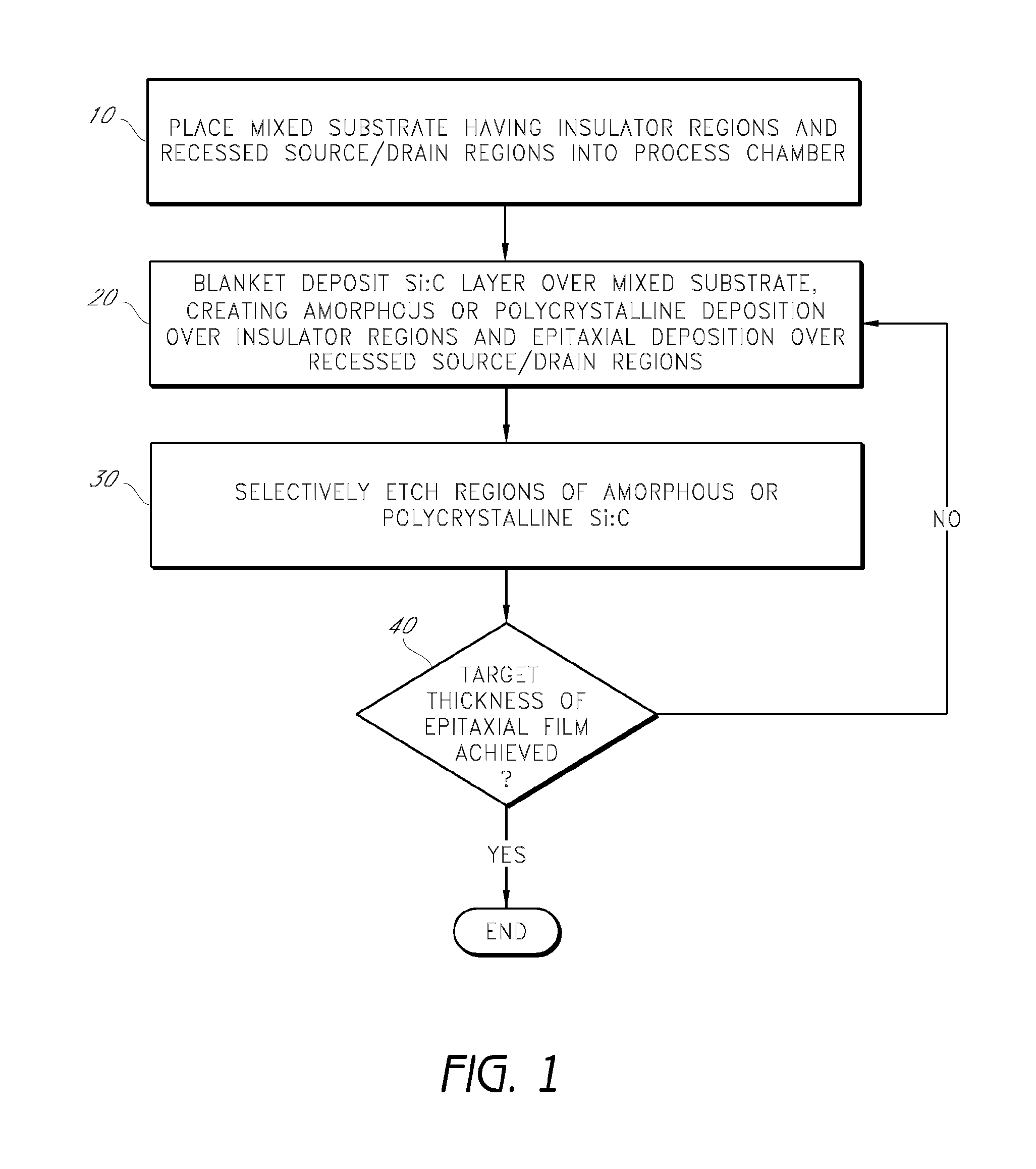

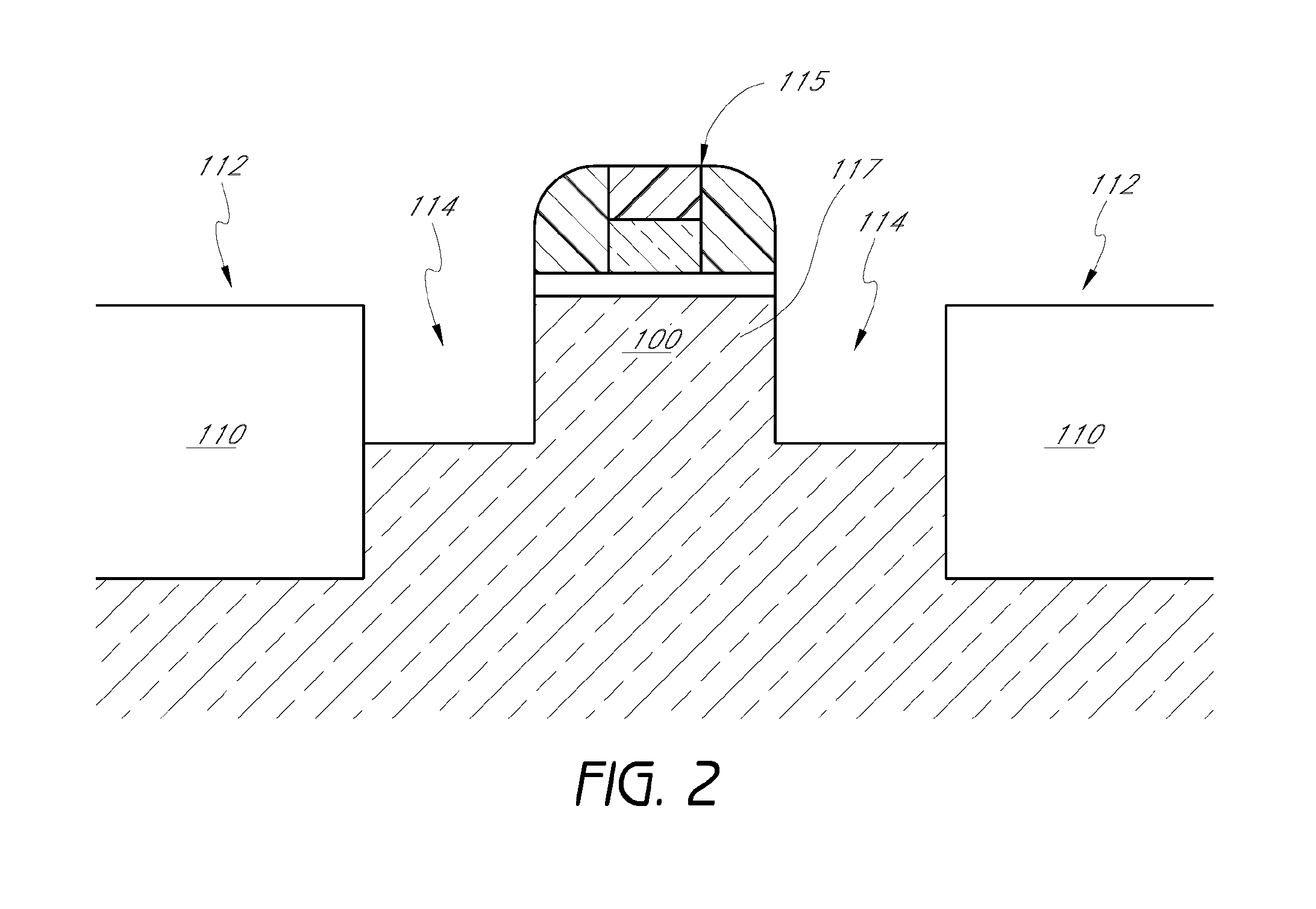

Selective epitaxial formation of semiconductive films

ActiveUS20120244688A1Semiconductor/solid-state device manufacturingSemiconductor devicesMetallurgyEpitaxial material

Epitaxial layers are selectively formed in semiconductor windows by a cyclical process of repeated blanket deposition and selective etching. The blanket deposition phases leave non-epitaxial material over insulating regions, such as field oxide, and the selective etch phases preferentially remove non-epitaxial material while deposited epitaxial material builds up cycle-by-cycle. Quality of the epitaxial material improves relative to selective processes where no deposition occurs on insulators. Use of a germanium catalyst during the etch phases of the process aid etch rates and facilitate economical maintenance of isothermal and / or isobaric conditions throughout the cycles. Throughput and quality are improved by use of trisilane, formation of amorphous material over the insulating regions and minimizing the thickness ratio of amorphous:epitaxial material in each deposition phase.

Owner:ASM IP HLDG BV

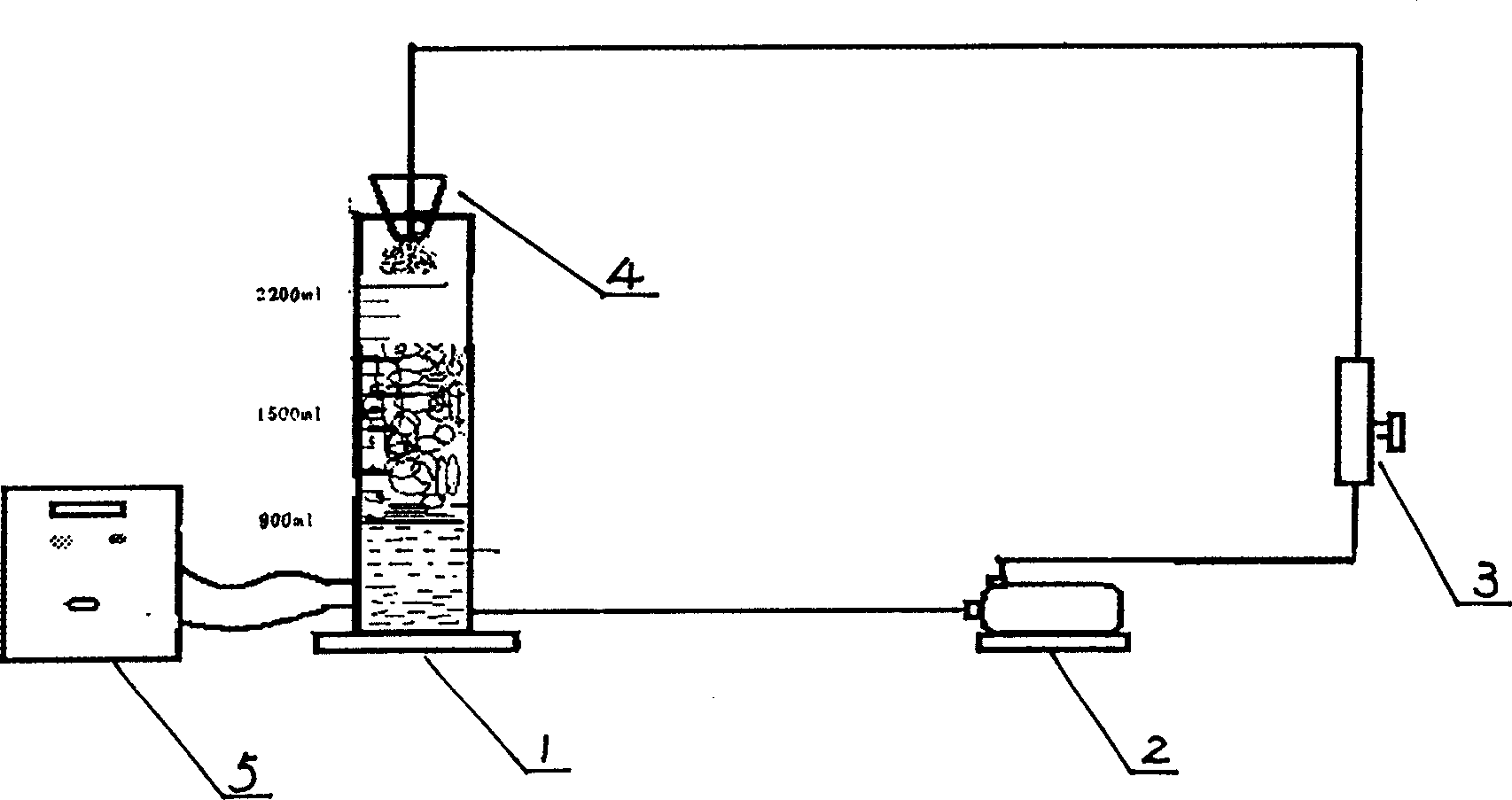

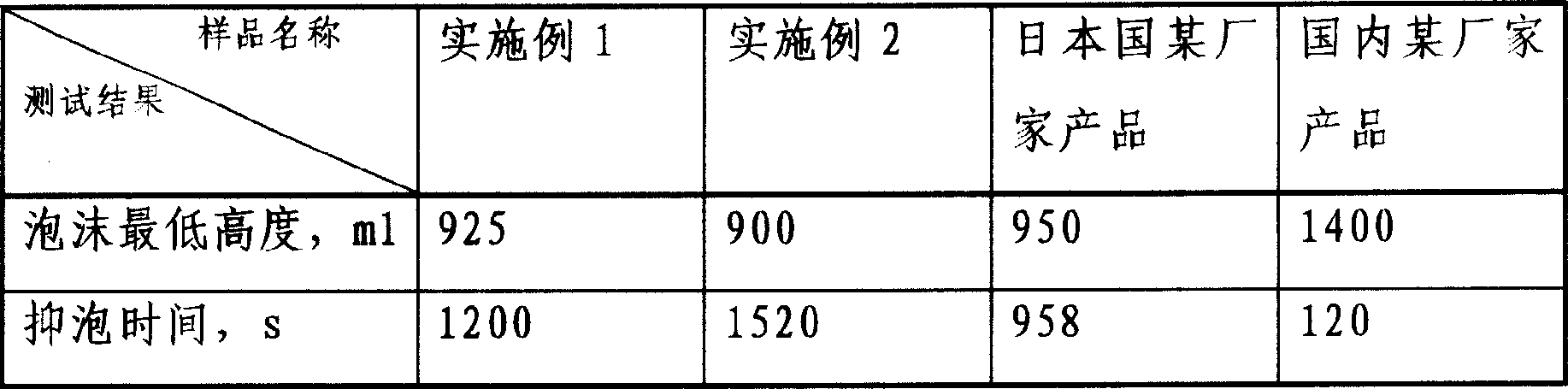

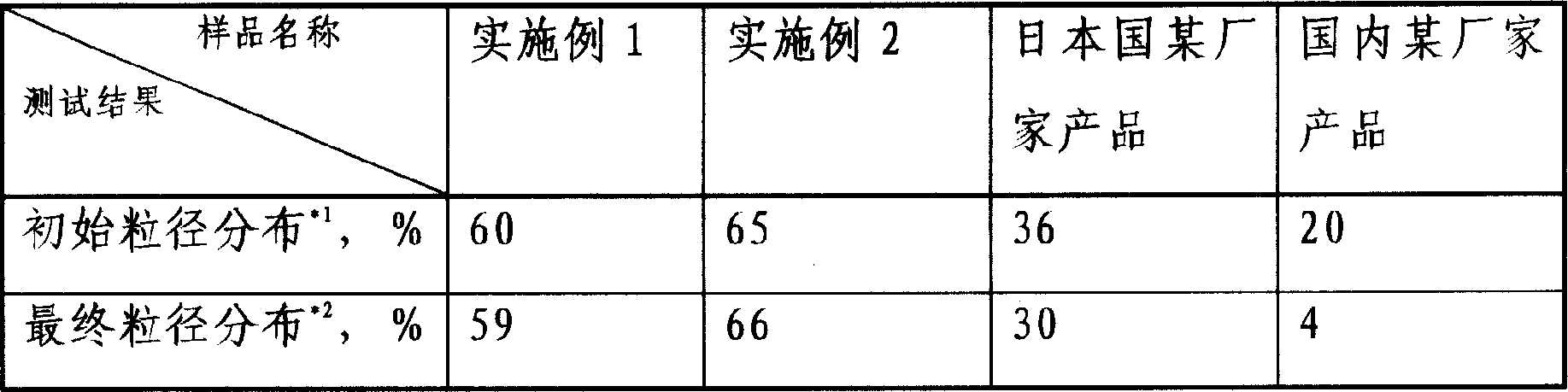

High-temperature and strong alkali organic silicon antifoamer emulsion composition and preparing method thereof

InactiveCN1583212ANarrow particle size distributionImprove stabilityFoam dispersion/preventionEmulsionSolid particle

A composite organosilicon emulsion as defoaming agent with resistance to high temp and strong alkali is prepared from the polydimethyl siloxane terminated by trisilane group, at least one hydrophilic particle of inorganic metal oxide, a modifier for making the surface of said particle hydrophibic, and a catalyst.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

PET (polyethylene glycol terephthalate) fiber/polyacrylonitrile fiber composite sound absorbing cotton and preparation method of PET fiber/polyacrylonitrile fiber composite sound absorbing cotton

InactiveCN102965847AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsSound producing devicesPolymer scienceAntioxidant

The invention discloses PET (polyethylene glycol terephthalate) fiber / polyacrylonitrile fiber composite sound absorbing cotton, which is prepared from the following ingredients in parts by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of polyacrylonitrile fibers, 10 to 15 parts of emulsifying agents OP-20, 5 to 10 parts of peregal O-15, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of SEBS (styrene ethylene butylene styrene), 15 to 20 parts of calcined clay, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of diisooctyl phthalate, 4 to 6 parts of tricresyl phosphate, 2 to 3 parts of polyethylene wax, 1 to 2 parts of vinyl (beta-methoxyethoxy) trisilane, 2 to 3 parts of calcium stearate, 1 to 2 parts of dimethyl dimercapto isooctyl acetate tin, 0.5 to 1.5 parts of anti-aging agents ODA (octyl decyl adipate) and 1 to 2 parts of antioxidants 1035. The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

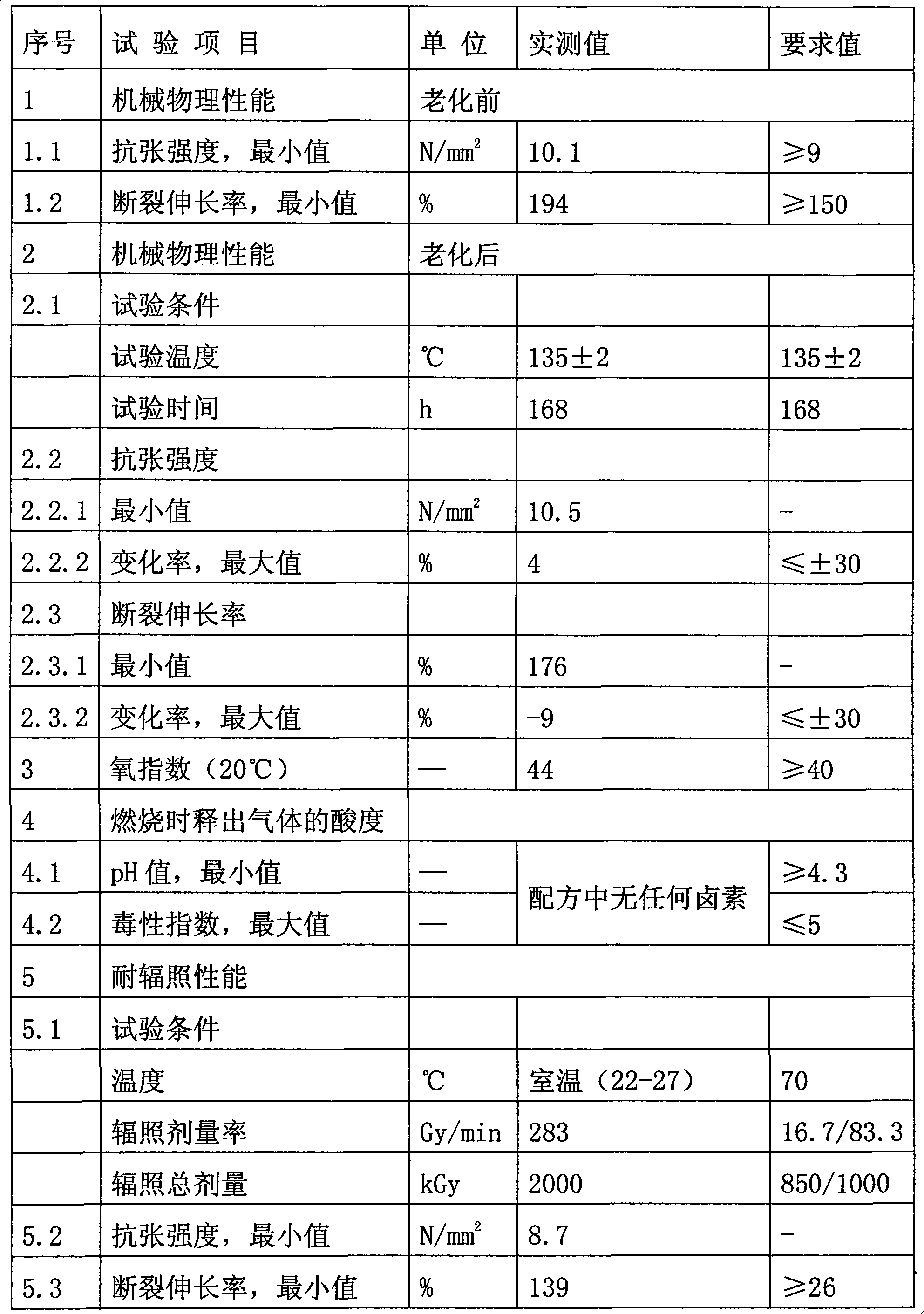

Irradiation resistant non-halogen low smoke flame-retardant sheathing material applied to nuclear power stations and preparation method

ActiveCN101597397AImprove radiation resistanceThe ratio is scientific and reasonableInsulated cablesInsulated conductorsDi-tert-butyl peroxideNuclear power

The invention discloses an irradiation resistant non-halogen low smoke flame-retardant sheathing material applied to nuclear power stations and a preparation method. The raw materials comprises ethane-vinyl acetate rubber, maleic anhydride stem grafting ethane-vinyl acetate rubber, magnesium hydroxide fire retardant, organic silicon fire retardant, nano cerium oxide, FEF, zinc stearate, stearic acid, vinyl trisilane, Aflux A-16, Aflux A-25, polycarbonate diimine(PCD-50), 2, 2, 4-trimethyl-1, 2-dihydride quinoline, antiager DDA, di-tert-butyl peroxide cumene, triene propylcyanide uric acid ester and decanedioic acid dioctyl, which are heated and mixed to obtain the materials of the invention. The invention features scientific and reasonable formula and proportion, and the process is advanced. The sheathing material features fine irradiation resistance, excellent mechanical properties and long service life, thus being a good irradiation resistant non-halogen low smoke and flame-retardant sheathing material applied to nuclear power stations.

Owner:BAOSHENG SCI & TECH INNOVATION

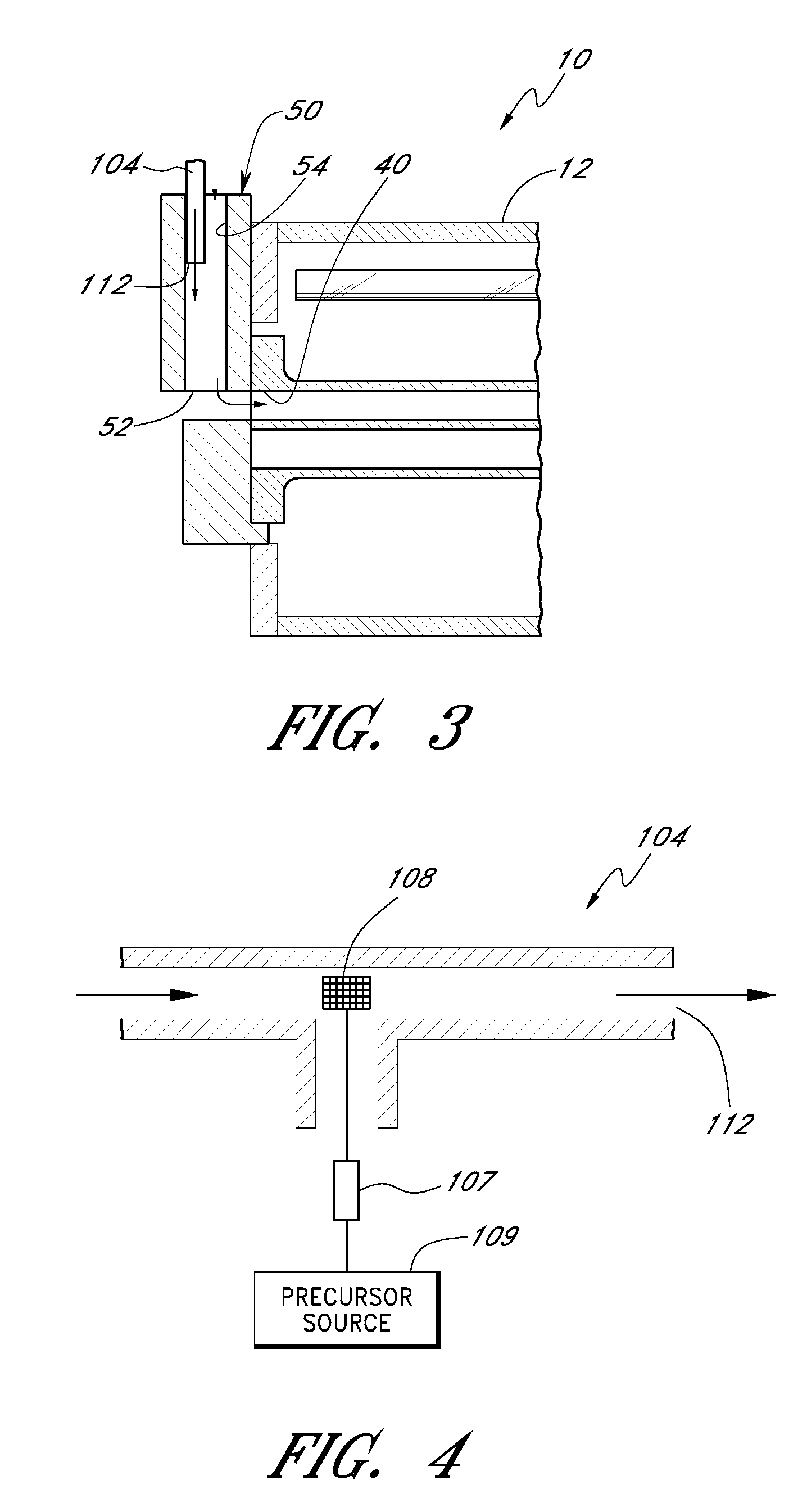

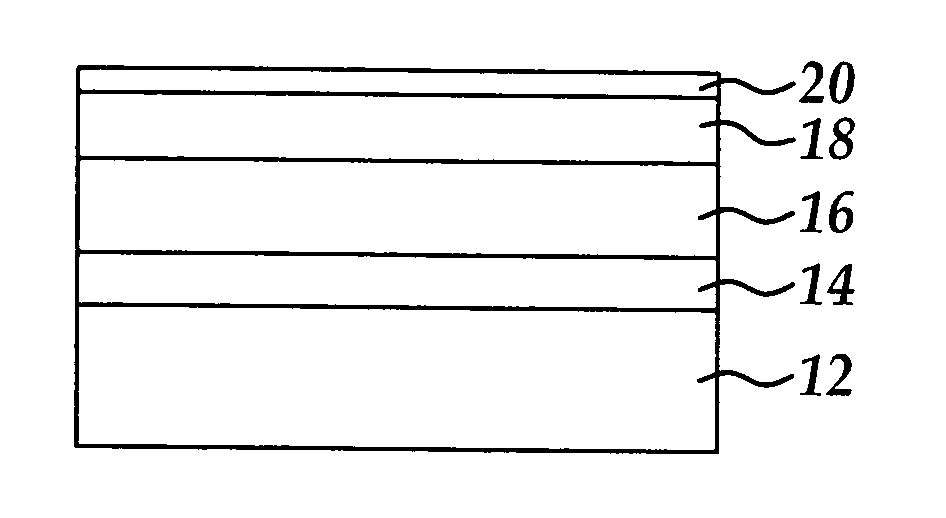

Deposition from liquid sources

ActiveUS20060051940A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDopantSilicon

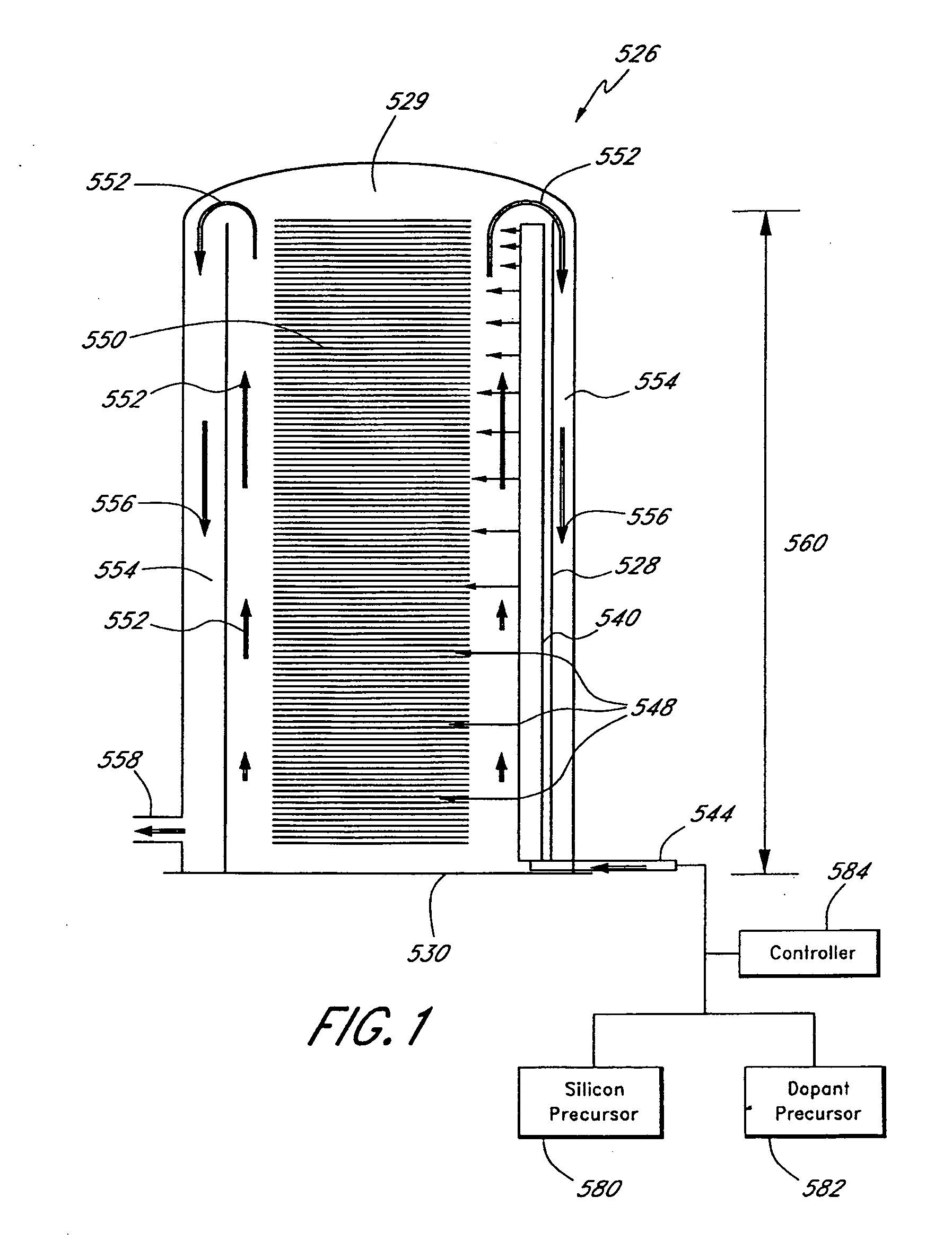

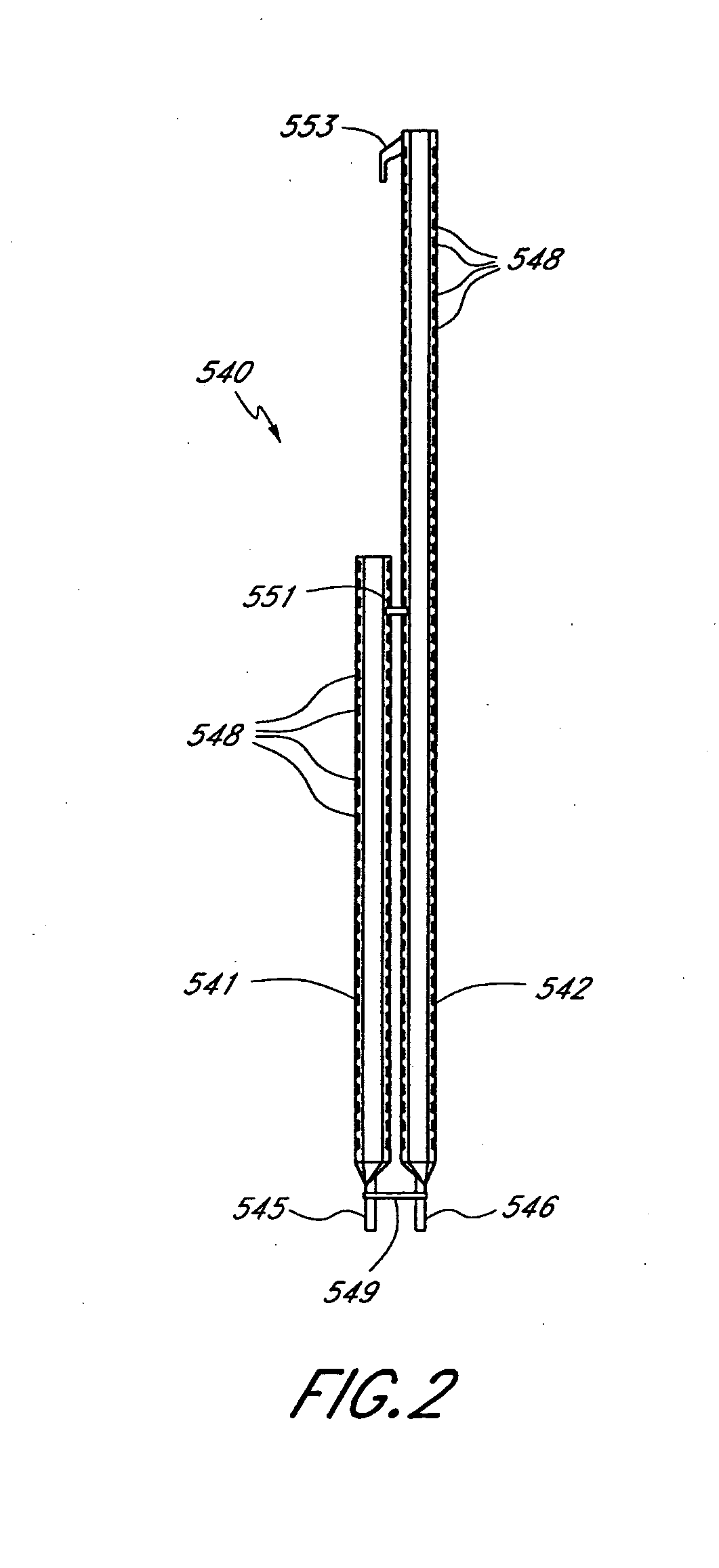

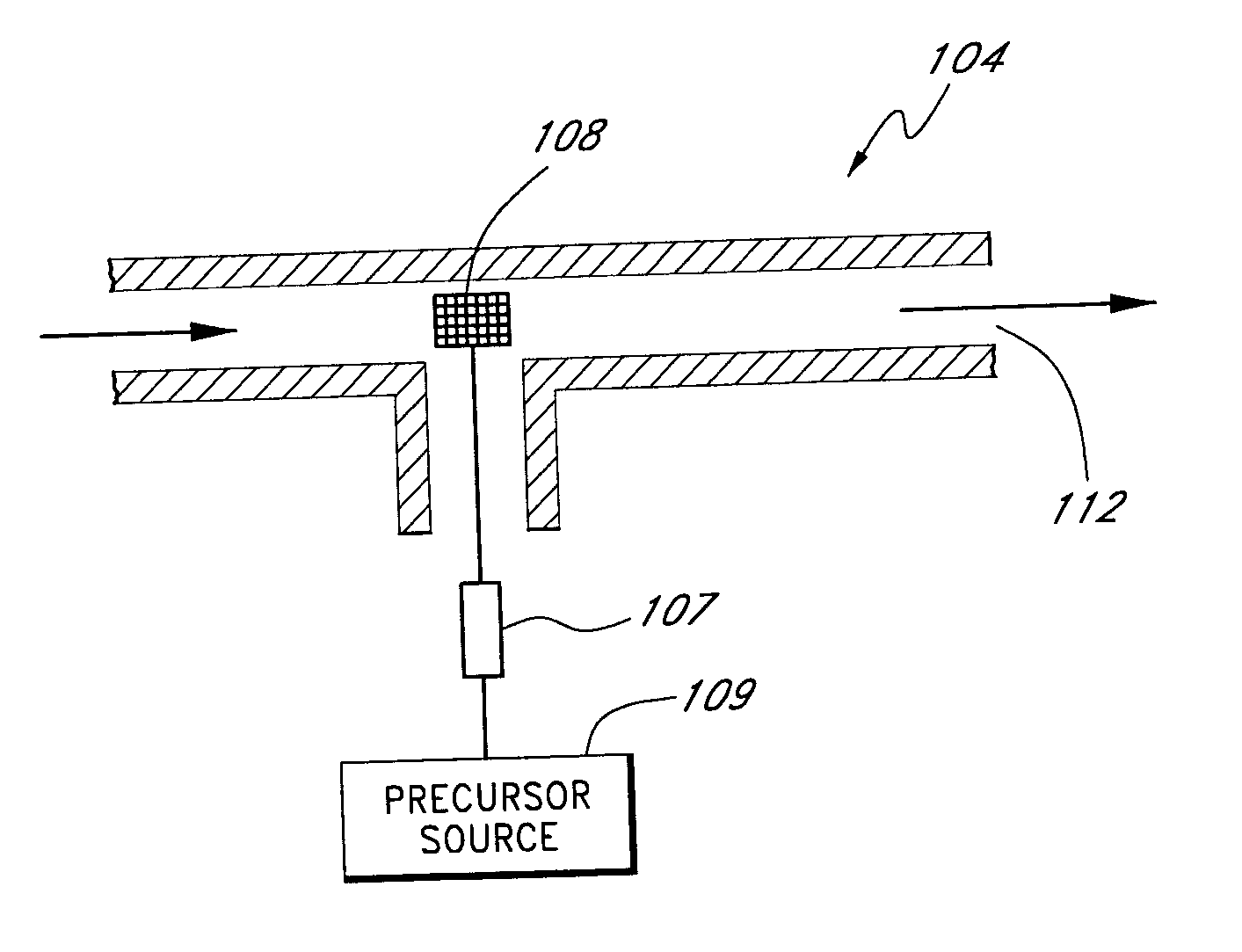

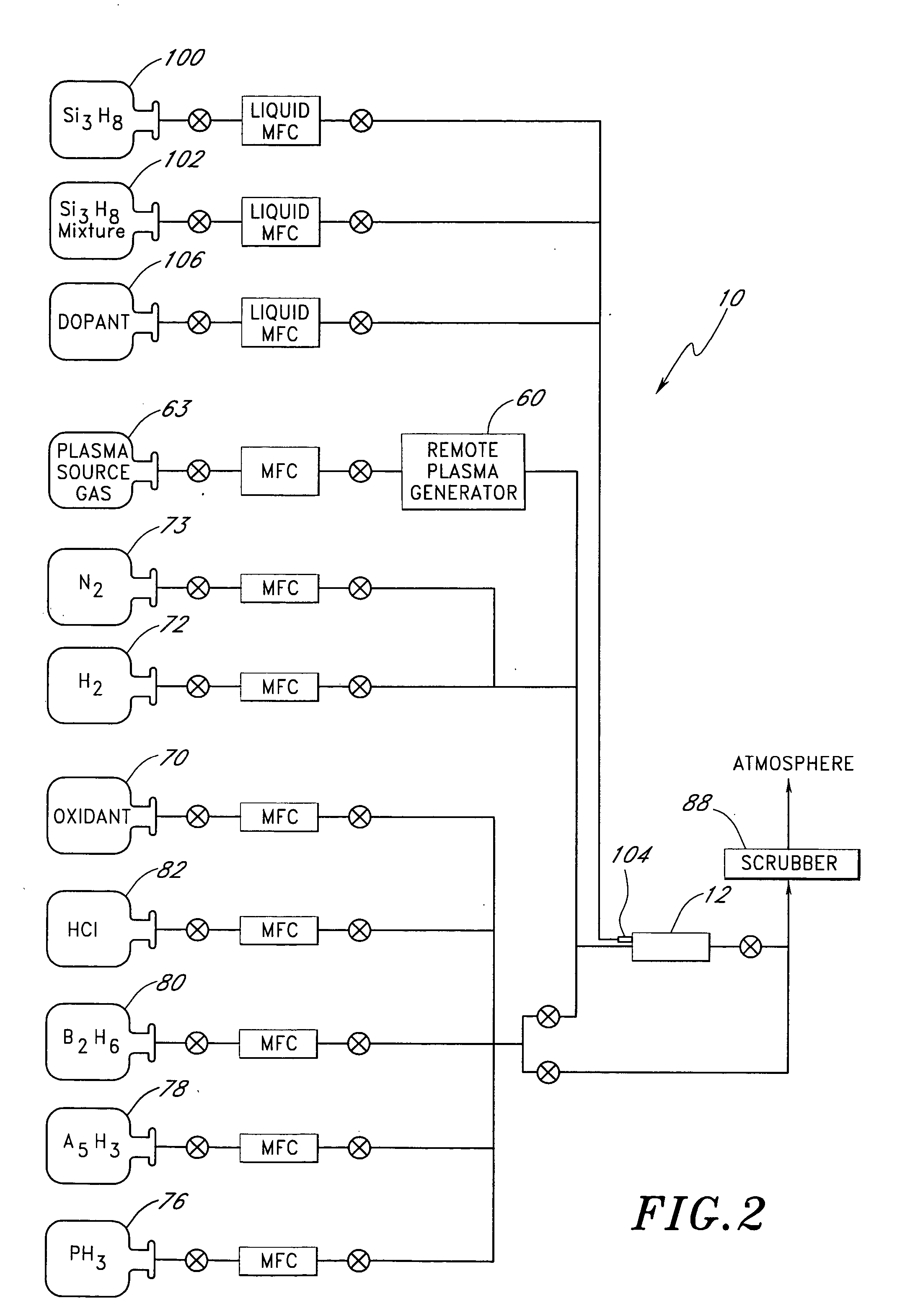

A liquid injector is used to vaporize and inject a silicon precursor into a process chamber to form silicon-containing layers during a semiconductor fabrication process. The injector is connected to a source of silicon precursor, which preferably comprises liquid trisilane in a mixture with one or more dopant precursors. The mixture is metered as a liquid and delivered to the injector, where it is then vaporized and injected into the process chamber.

Owner:ASM IP HLDG BV

PET (polyethylene glycol terephthalate) fiber/ceramic fiber composite sound absorbing cotton and preparation method of PET fiber/ceramic fiber composite sound absorbing cotton

InactiveCN102965840AHigh tensile strengthImprove impact resistanceConjugated synthetic polymer artificial filamentsNon-woven fabricsFiberPolymer science

The invention discloses PET (polyethylene glycol terephthalate) fiber / ceramic fiber composite sound absorbing cotton, which is prepared from the following ingredients in parts by weight: 70 to 80 parts of PET fibers, 40 to 50 parts of ceramic fibers, 10 to 15 parts of emulsifying agents OP-4, 5 to 10 parts of peregal O-15, 80 to 100 parts of PP (propene polymer), 30 to 40 parts of SBR (styrene butadiene rubber), 15 to 20 parts of nanometer bauxite, 10 to 15 parts of modified kieselguhr, 2 to 3 parts of stearic acid, 5 to 8 parts of glycerol triglycerin acid ester, 4 to 6 parts of triphenyl phosphate, 2 to 3 parts of microcrystalline wax, 1 to 2 parts of vinyl (beta-methoxyethoxy) trisilane, 2 to 3 parts of zinc stearate, 1 to 2 parts of lead sulfate tribasic, 0.5 to 1.5 parts of anti-aging agents ODA (octyl decyl adipate) and 1 to 2 parts of antioxidants 168. The sound absorbing cotton prepared by the invention has the advantages that the appearance evenness is good, the thickness is uniform, the hand feeling is soft, the product bonding degree is good, the tensile performance is high, the sound absorbing performance is excellent, the flame retardant effect is good, and the like.

Owner:芜湖跃飞新型吸音材料股份有限公司

Deposition of silicon germanium on silicon-on-insulator structures and bulk substrates

Methods are provided for producing SiGe-on-insulator structures and for forming strain-relaxed SiGe layers on silicon while minimizing defects. Amorphous SiGe layers are deposited by CVD from trisilane and GeH4. The amorphous SiGe layers are recrystallized over silicon by melt or solid phase epitaxy (SPE) processes. The melt processes preferably also cause diffusion of germanium to dilute the overall germanium content and essentially consume the silicon overlying the insulator. The SPE process can be conducted with or without diffusion of germanium into the underlying silicon, and so is applicable to SOI as well as conventional semiconductor substrates.

Owner:ASM AMERICA INC

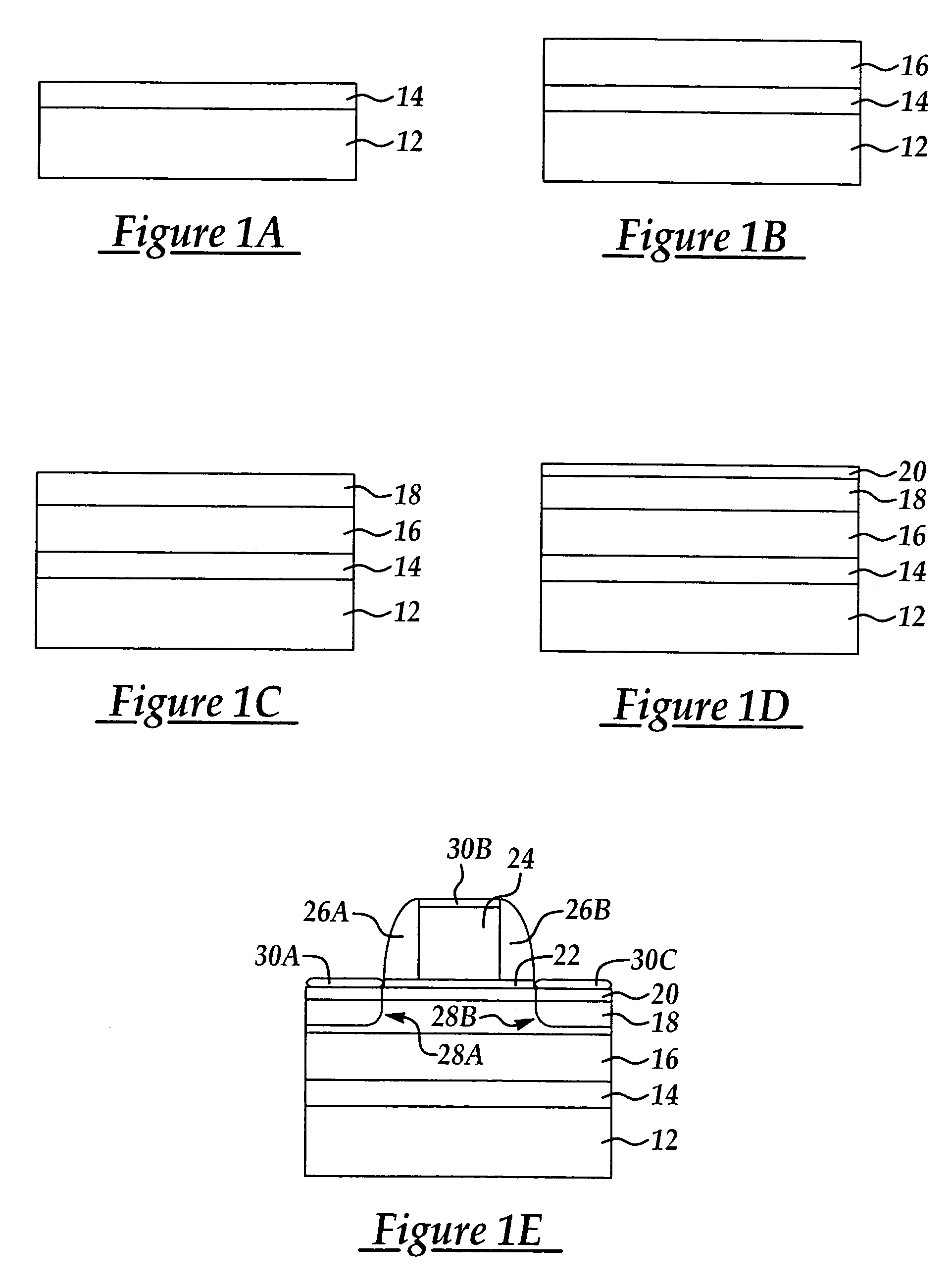

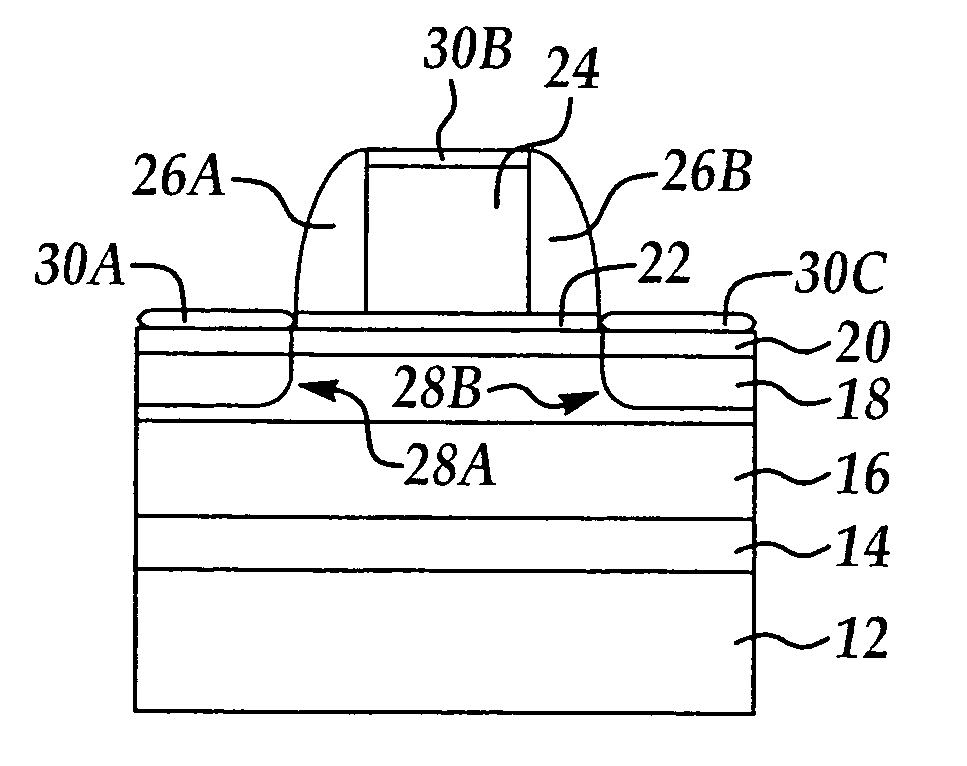

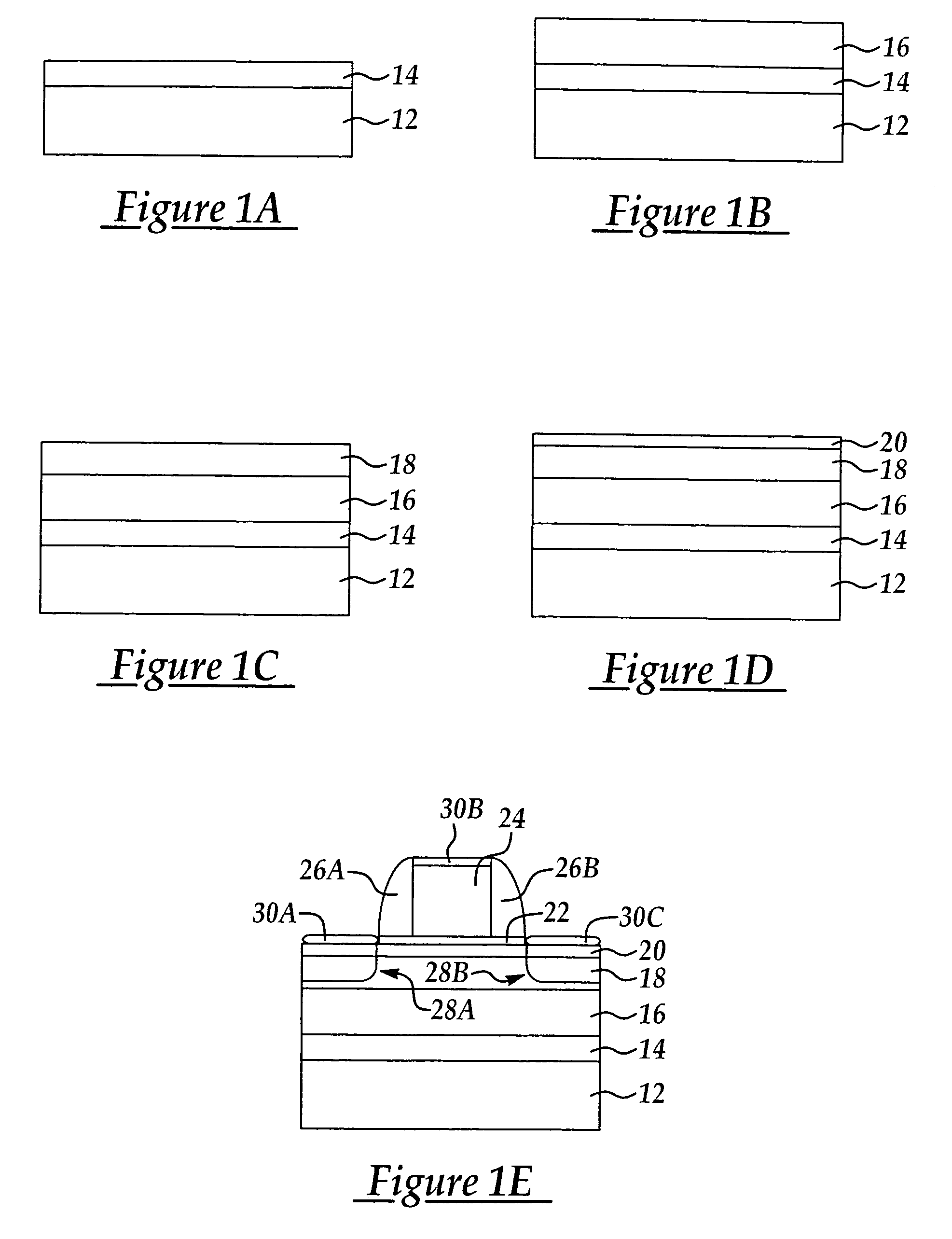

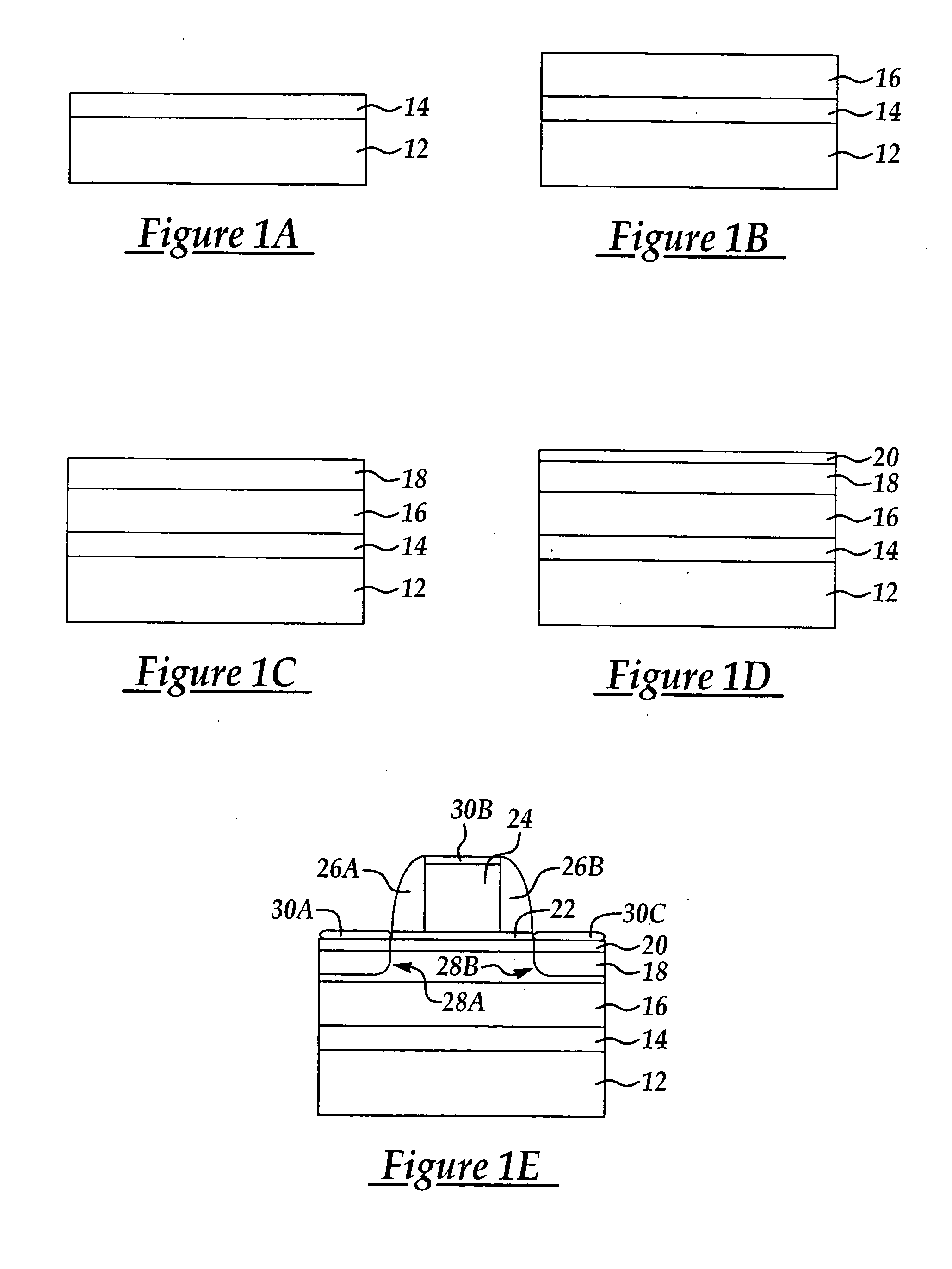

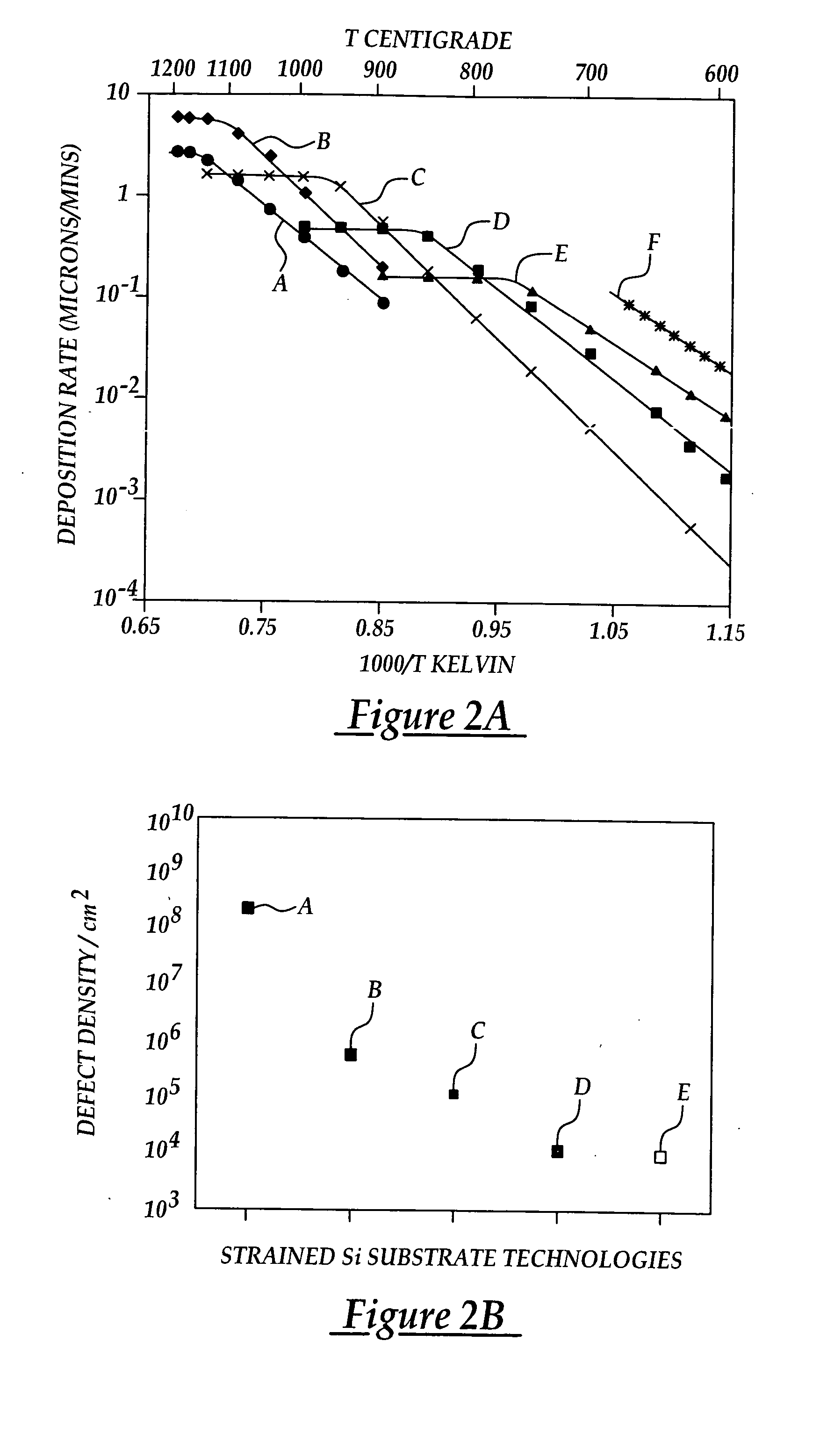

Method for producing low defect density strained -Si channel MOSFETS

InactiveUS7202142B2Improve throughputReduce defect densitySemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETSilanes

A silicon strained channel MOSFET device and method for forming the same the method providing improved wafer throughput and low defect density including the steps of providing a silicon substrate; epitaxially growing a first silicon layer using at least one deposition precursor selected from the group consisting of disilane, trisilane, dichlorosilane, and silane; epitaxially growing a step-grade SiGe buffer layer over and contacting the first silicon layer using at least one deposition precursor selected from the group consisting of disilane and trisilane; epitaxially growing a SiGe capping layer over and contacting the step-grade SiGe buffer layer using at least one deposition precursor selected from the group consisting of disilane and trisilane; and, epitaxially growing a second silicon layer using at least one deposition precursor selected from the group consisting of disilane, trisilane, dichlorosilane, and silane.

Owner:TAIWAN SEMICON MFG CO LTD

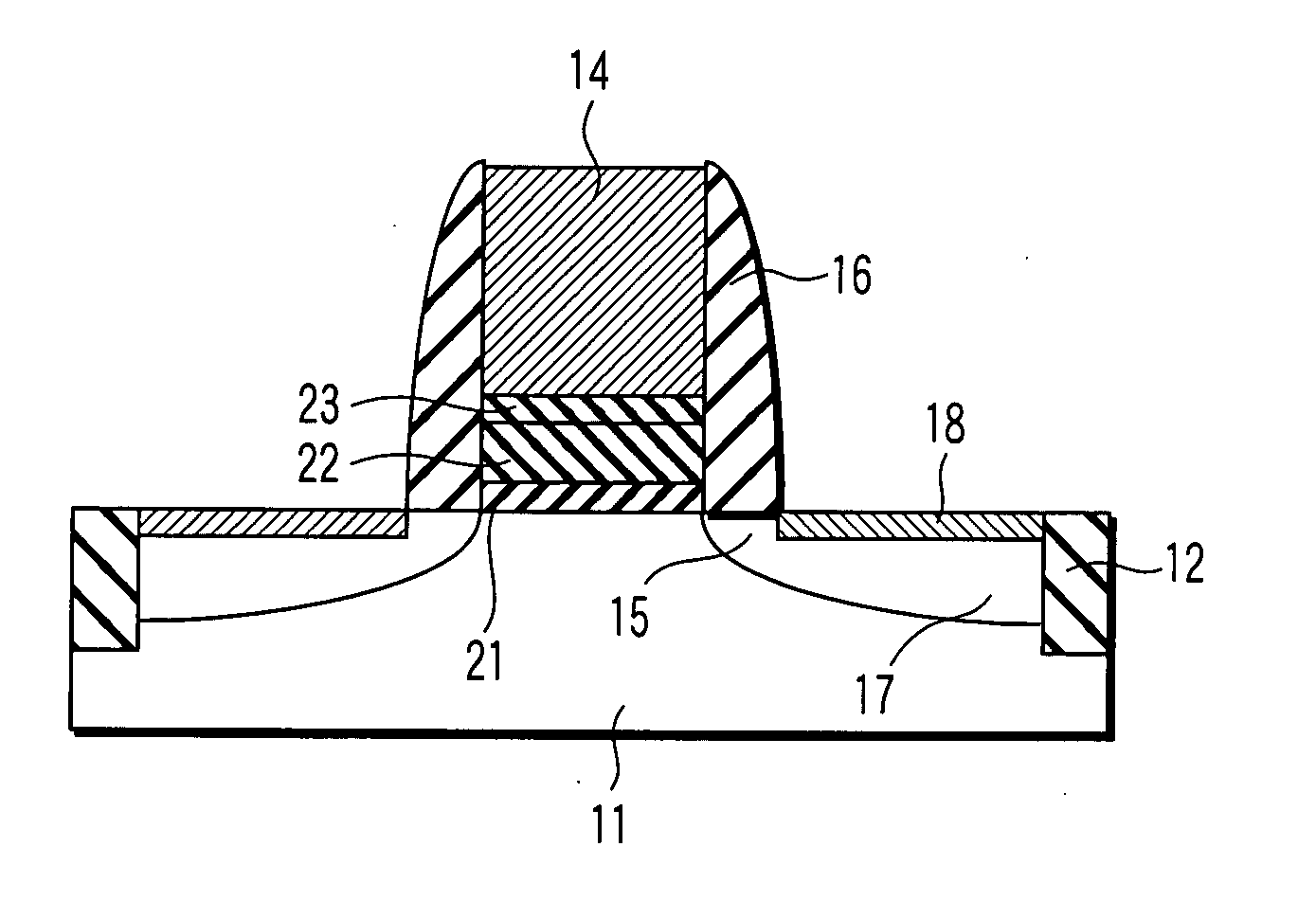

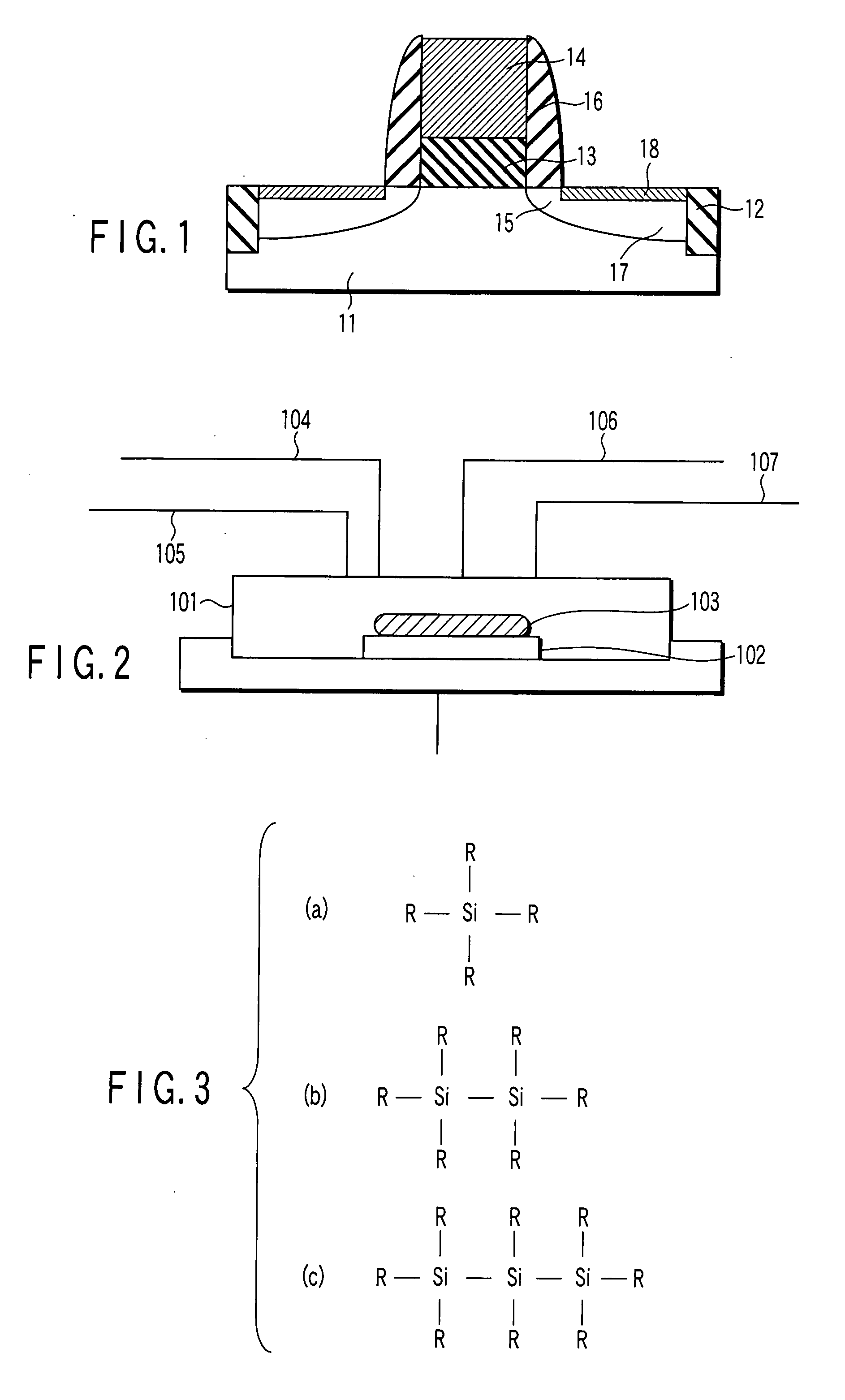

Manufacturing method of semiconductor device

InactiveUS20070190768A1Semiconductor/solid-state device manufacturingSemiconductor devicesHydrogen atomHydrogen

A method of manufacturing a semiconductor device, includes forming a gate insulating film on a semiconductor substrate, and forming a gate electrode on the gate insulting film, wherein forming the gate insulating film includes forming a metal silicate film, and a silicon source used for forming the metal silicate film includes at least one of a first hydrocarbon silicon compound obtained by replacing at least one of hydrogen atoms in monosilane with an alkyl group, a second hydrocarbon silicon compound obtained by replacing at least one of hydrogen atoms in disilane with an alkyl group, and a third hydrocarbon silicon compound obtained by replacing at least one of hydrogen atoms in trisilane with an alkyl group.

Owner:KK TOSHIBA

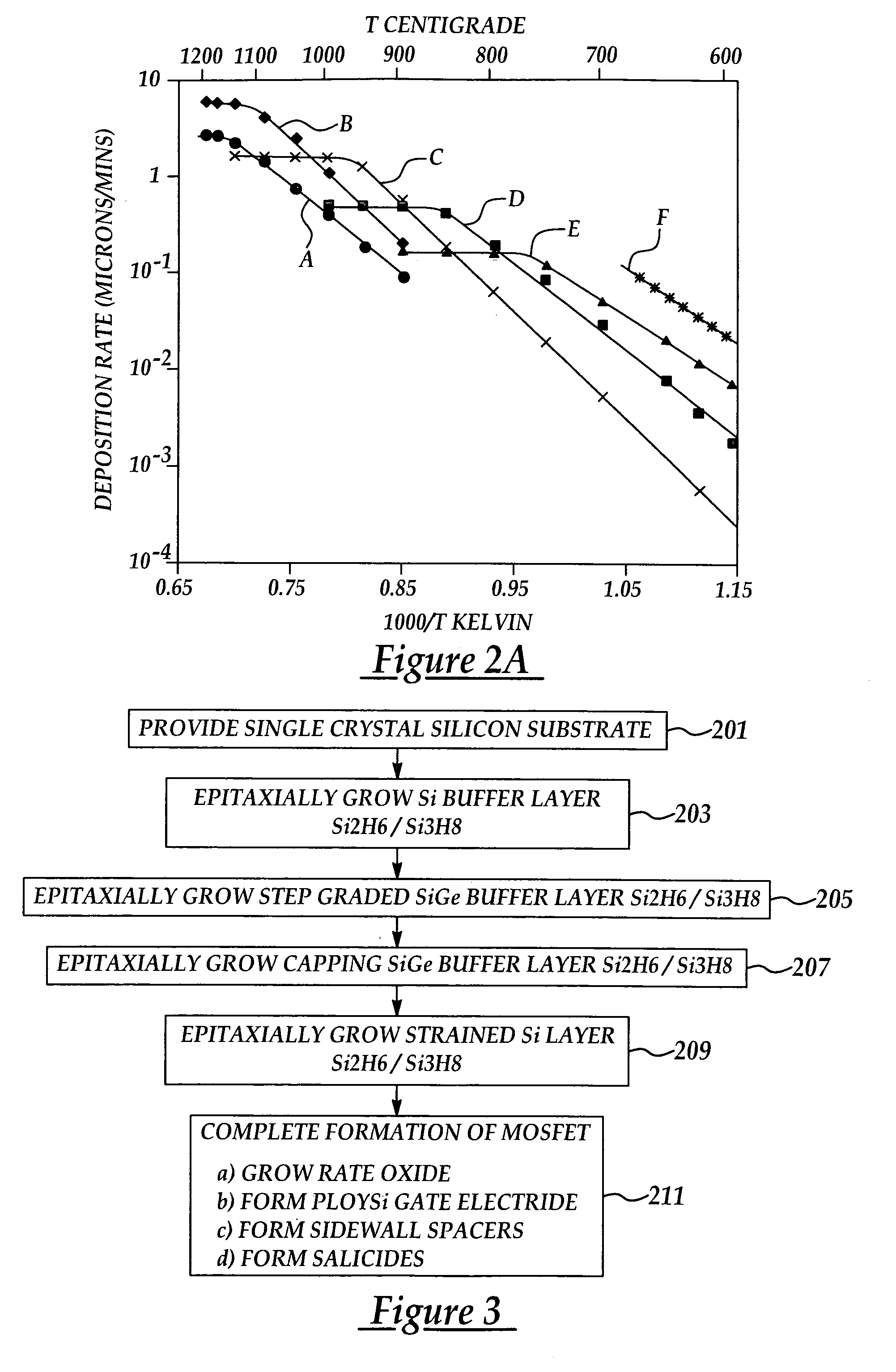

Method for producing high throughput strained-Si channel MOSFETS

InactiveUS6982208B2Improve throughputReduce defect densityPolycrystalline material growthFrom solid stateSilanesTrisilane

A method for forming a strained silicon layer device with improved wafer throughput and low defect density including providing a silicon substrate; epitaxially growing a first silicon layer using at least one deposition precursor selected from the group consisting of disilane and trisilane; epitaxially growing a step-grade SiGe buffer layer over and contacting the first silicon layer using at least one deposition precursor selected from the group consisting of disilane and trisilane; epitaxially growing a SiGe capping layer over and contacting the step-grade SiGe buffer layer using at least one deposition precursor selected from the group consisting of disilane and trisilane; and, epitaxially growing a second silicon layer using at least one deposition precursor selected from the group consisting of disilane and silane.

Owner:TAIWAN SEMICON MFG CO LTD

Method for producing a high purity trisilane product from the pyrolysis of disilane

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

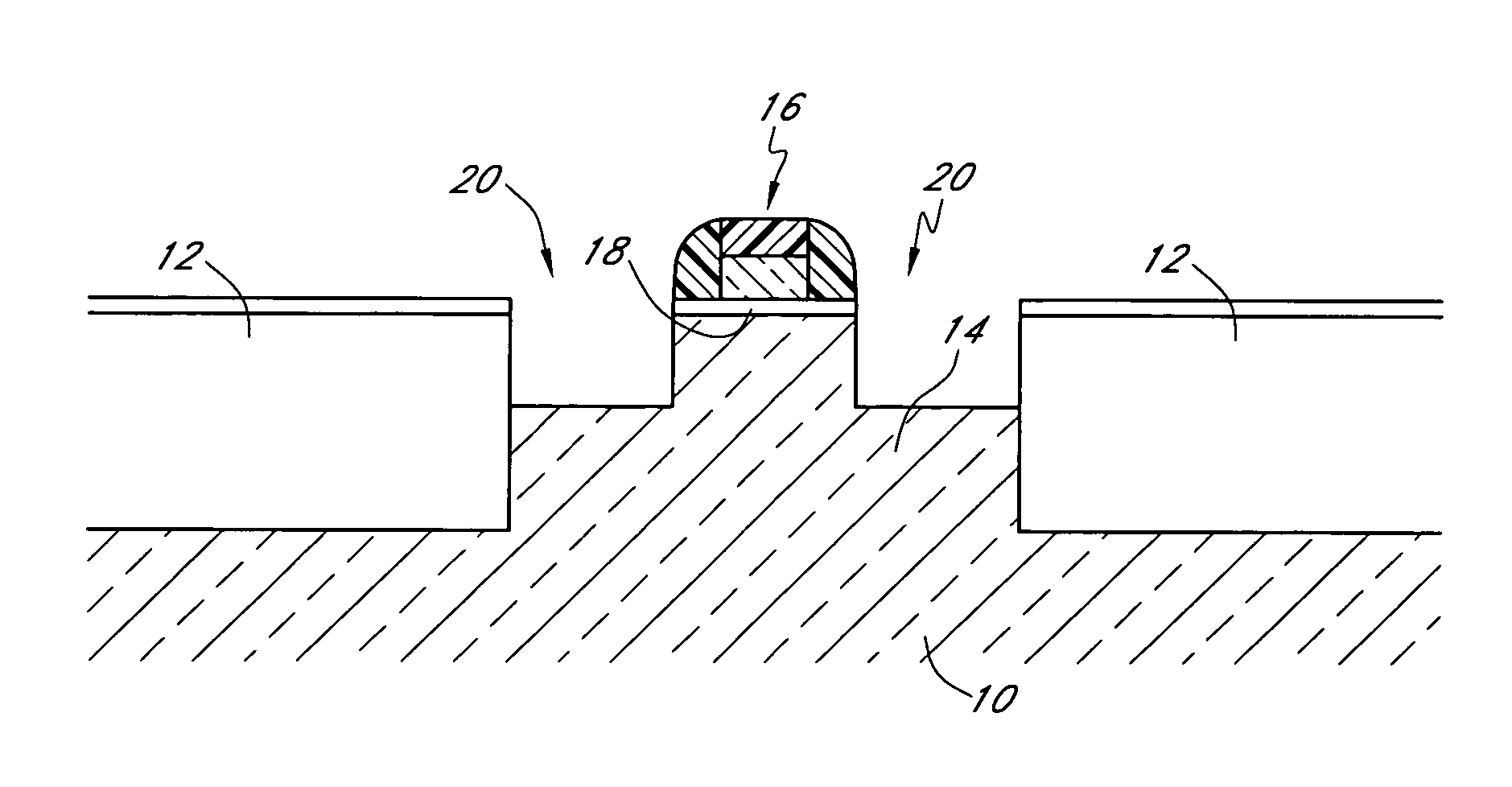

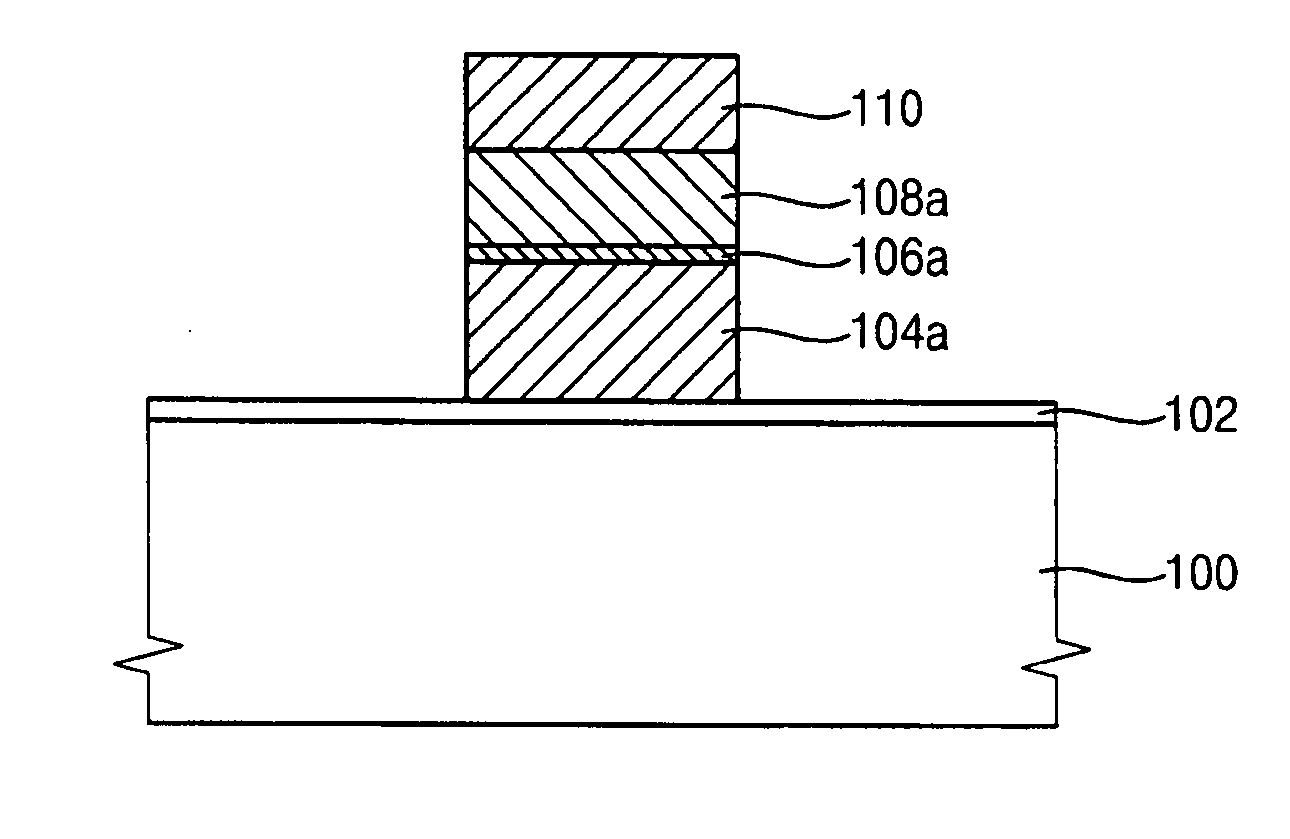

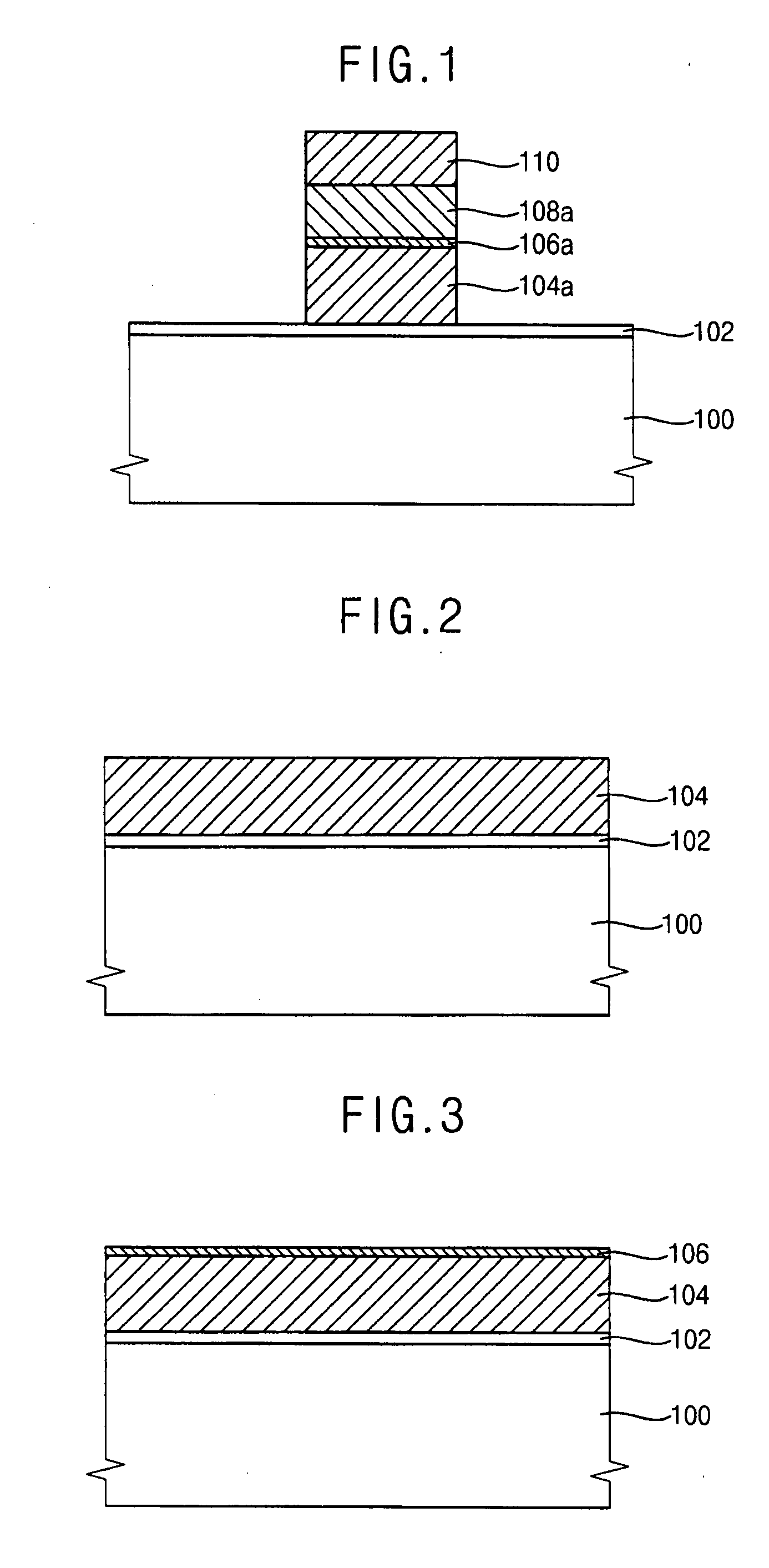

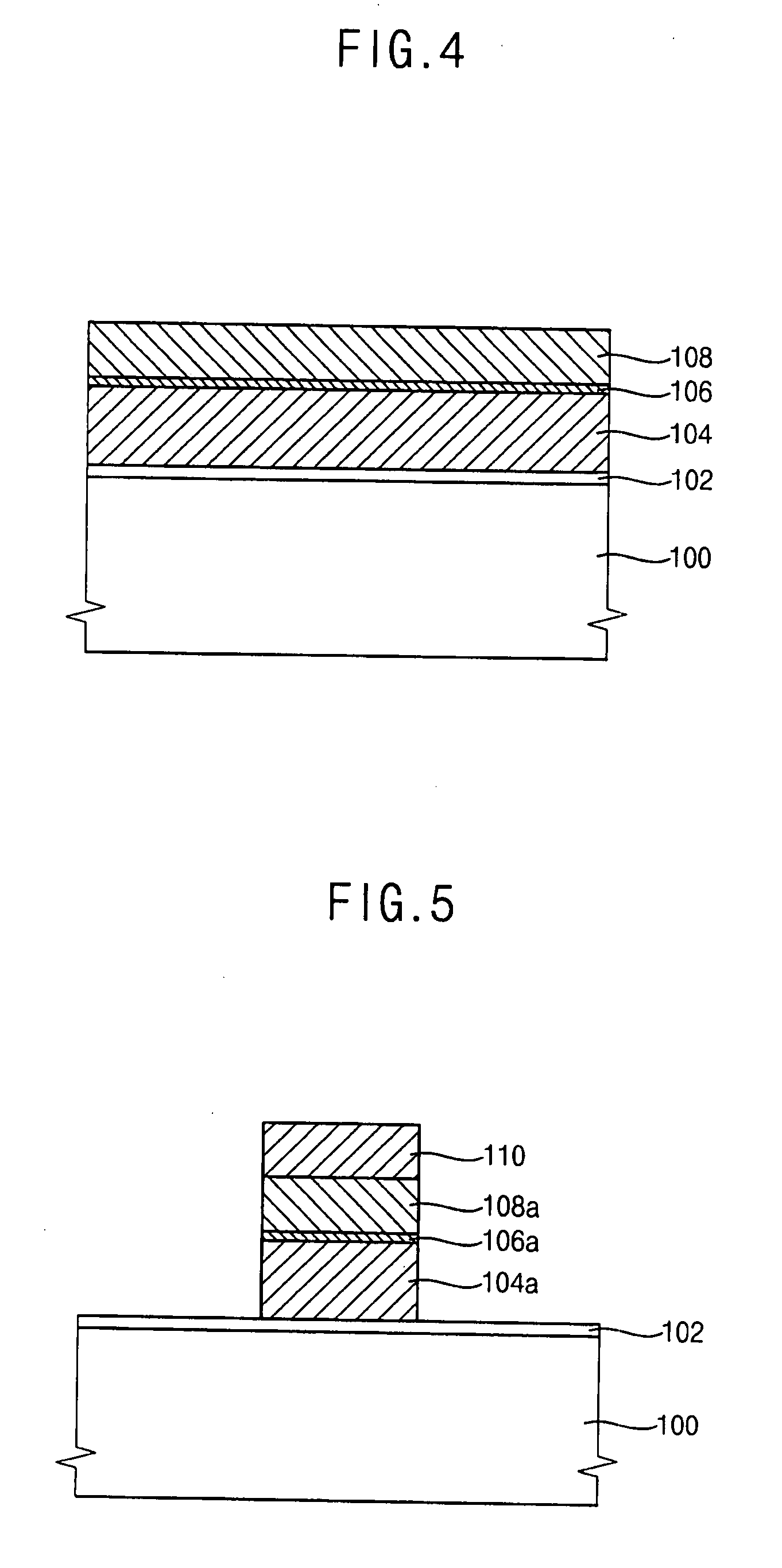

Gate of a transistor and method of forming the same

InactiveUS20080048277A1Improve surface morphologyLower threshold voltageSemiconductor/solid-state device detailsSolid-state devicesGas phaseDevice material

A gate of a transistor includes a gate oxide layer formed on a semiconductor device, a first conductive layer pattern including polysilicon doped with boron and formed on the gate oxide layer, a diffusion preventing layer pattern including amorphous silicon formed by a chemical vapor deposition process using a reaction gas having trisilane (Si3H8) and formed on the first conductive layer pattern, and a second conductive layer pattern including metal silicide and formed on the diffusion preventing layer pattern. Since a gate of PMOS transistor includes a diffusion preventing layer having an excellent surface morphology, diffusion of impurities is sufficiently prevented. Thus, the threshold voltage of PMOS transistor may be reduced and threshold voltage distribution may be improved.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for producing low defect density strained -Si channel MOSFETS

InactiveUS20050245035A1Increase wafer throughputReduce defect densitySemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETSilanes

A silicon strained channel MOSFET device and method for forming the same the method providing improved wafer throughput and low defect density including the steps of providing a silicon substrate; epitaxially growing a first silicon layer using at least one deposition precursor selected from the group consisting of disilane, trisilane, dichlorosilane, and silane; epitaxially growing a step-grade SiGe buffer layer over and contacting the first silicon layer using at least one deposition precursor selected from the group consisting of disilane and trisilane; epitaxially growing a SiGe capping layer over and contacting the step-grade SiGe buffer layer using at least one deposition precursor selected from the group consisting of disilane and trisilane; and, epitaxially growing a second silicon layer using at least one deposition precursor selected from the group consisting of disilane, trisilane, dichlorosilane, and silane.

Owner:TAIWAN SEMICON MFG CO LTD

Method for producing a high purity trisilane product from the pyrolysis of disilane

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Low temperature doped silicon layer formation

ActiveUS7718518B2Polycrystalline material growthSemiconductor/solid-state device manufacturingDopantPhosphine

A doped silicon layer is formed in a batch process chamber at low temperatures. The silicon precursor for the silicon layer formation is a polysilane, such as trisilane, and the dopant precursor is an n-type dopant, such as phosphine. The silicon precursor can be flowed into the process chamber with the flow of the dopant precursor or separately from the flow of the dopant precursor. Surprisingly, deposition rate is independent of dopant precursor flow, while dopant incorporation linearly increases with the dopant precursor flow.

Owner:ASM INTERNATIONAL

High-strength, high-flexibility, water-proof and oil-proof cable

InactiveCN105061841AGood adhesionImprove surface energyInsulated cablesInsulated conductorsPliabilityEngineering

The invention discloses a high-strength, high-flexibility, water-proof and oil-proof cable. The cable comprises a cable core and a sheath layer covering the outer side of the cable core, wherein the sheath layer comprises raw materials in parts by weight as follows: 30-35 parts of butadiene styrene rubber, 26-29 parts of phenolic resin, 22-25 parts of fluorine modified polyacrylate, 1.5-1.8 parts of dicumyl peroxide, 0.7-1 part of stearic acid, 1.8-2.2 parts of sulphur, 0.9-1.2 parts of N-isopropyl-N'-phenylenediamine, 2-3 parts of an anti-aging agent RD, 0.4-0.7 parts of bis(triethoxy trisilane) tetrasulfide, 7-10 parts of chlorinated paraffin and 22-25 parts of carbon black. The cable is excellent in water-proof and oil-proof performance and good in weather resistance and corrosion resistance.

Owner:ANHUI HONGHAI CABLE

Foam concrete insulation board for roofs and preparation method of foam concrete insulation board

InactiveCN106588079AImprove anti-seepage performanceReduce weightSolid waste managementCeramicwareFoam concretePolyvinyl alcohol

A foam concrete insulation board for roofs is characterized by being prepared from raw materials in parts by weight as follows: 500 parts of electric furnace phosphorus slag, 80-100 parts of fly ash, 50-60 parts of kaolin, 30-40 parts of gypsum, 20-30 parts of polyvinyl alcohol, 3-4 parts of sodium fatty alcohol polyoxyethylen ether sulphate, 10-12 parts of glacial acetic acid, 12-15 parts of hydrogen peroxide, 12-15 parts of vinyl acetate, 8-10 parts of diacetone acrylamide, 20-30 parts of cement, 6-8 parts of zinc stearate, 20-30 parts of trisilane, 30-40 parts of ammonium bicarbonate and an appropriate amount of water. The foam concrete insulation board for roofs has the characteristics of being light in weight, low in cost, high in strength and prominent in heat preservation, thermal insulation and sound insulation effect and facilitates construction and installation.

Owner:向往

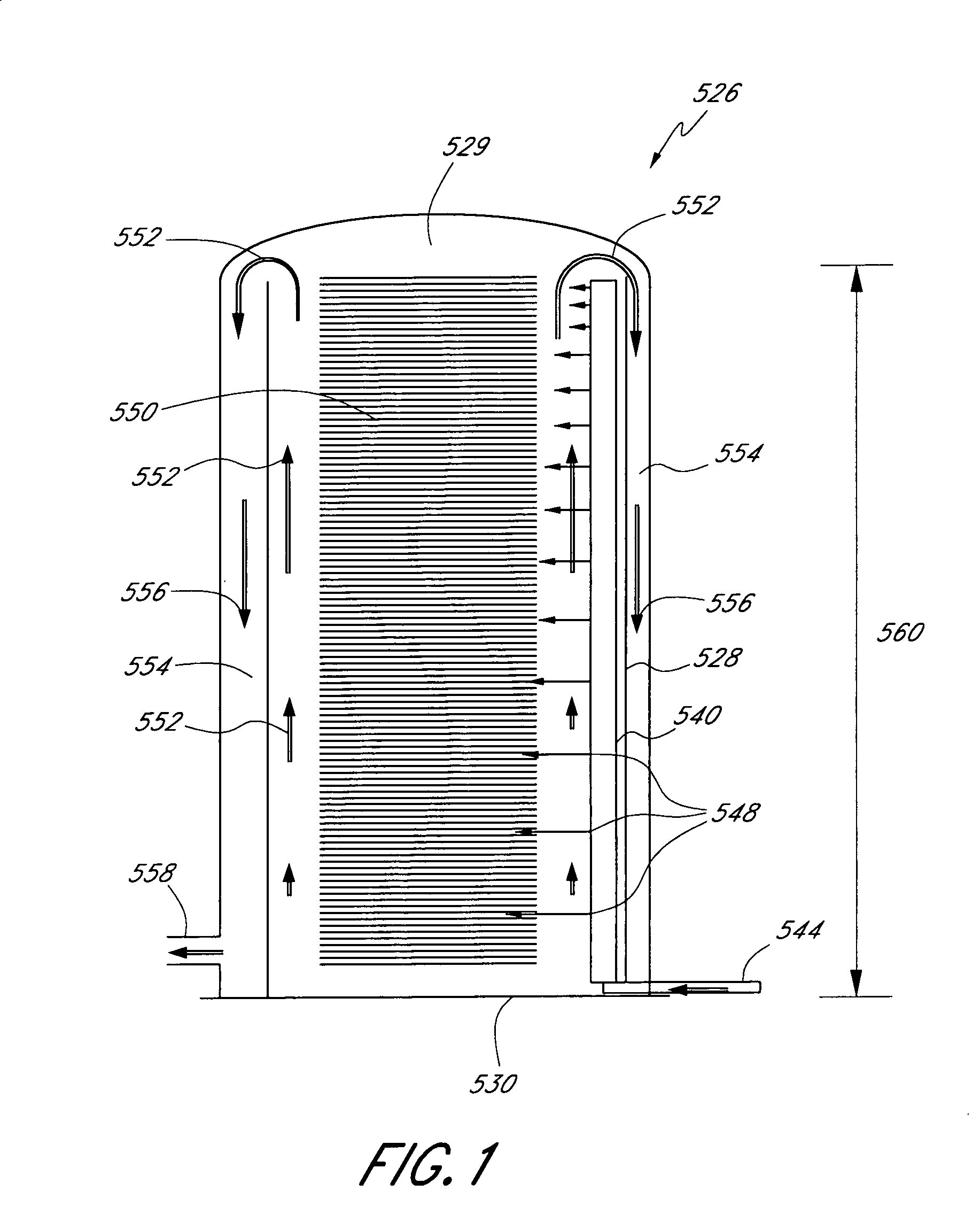

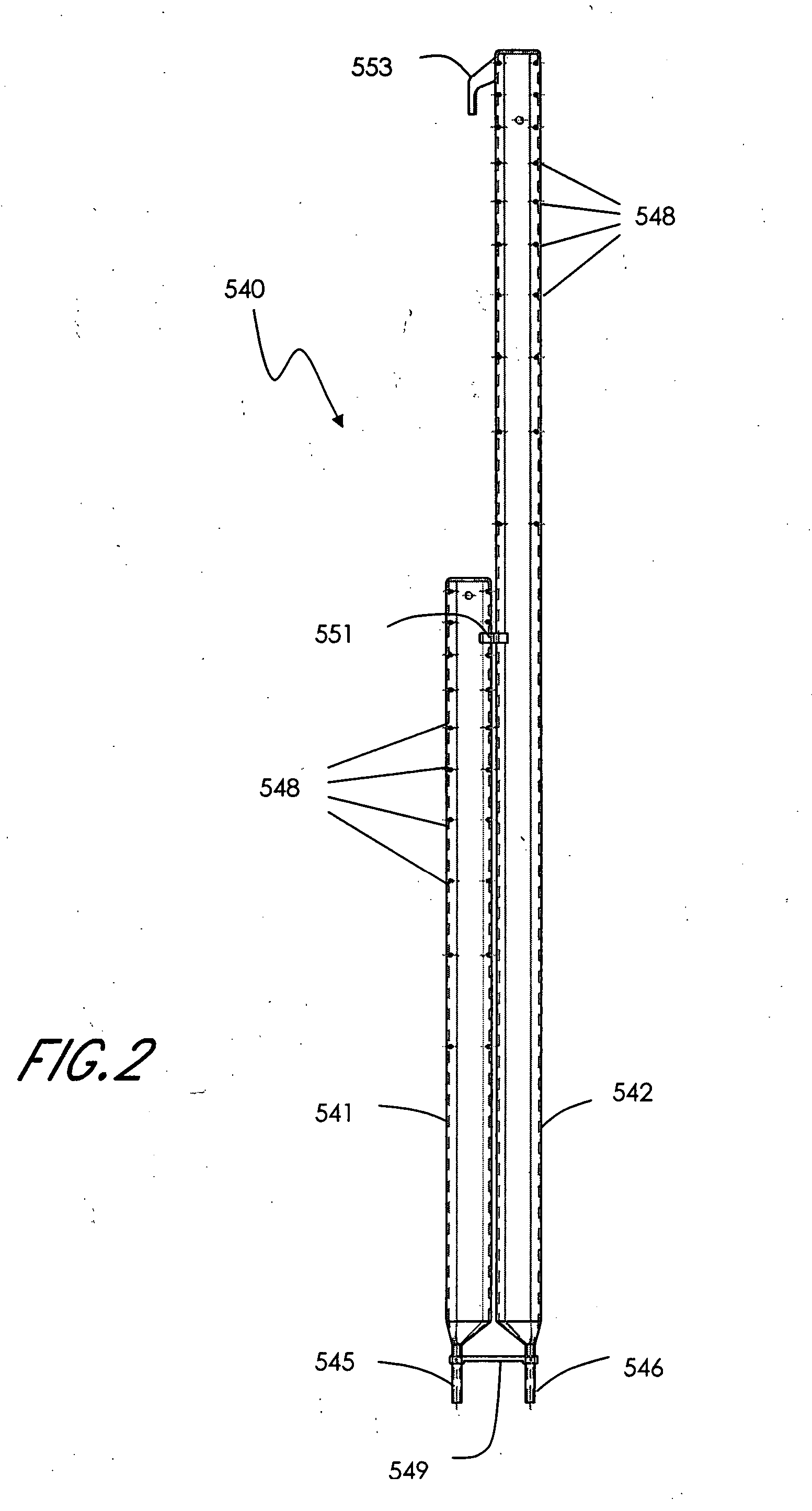

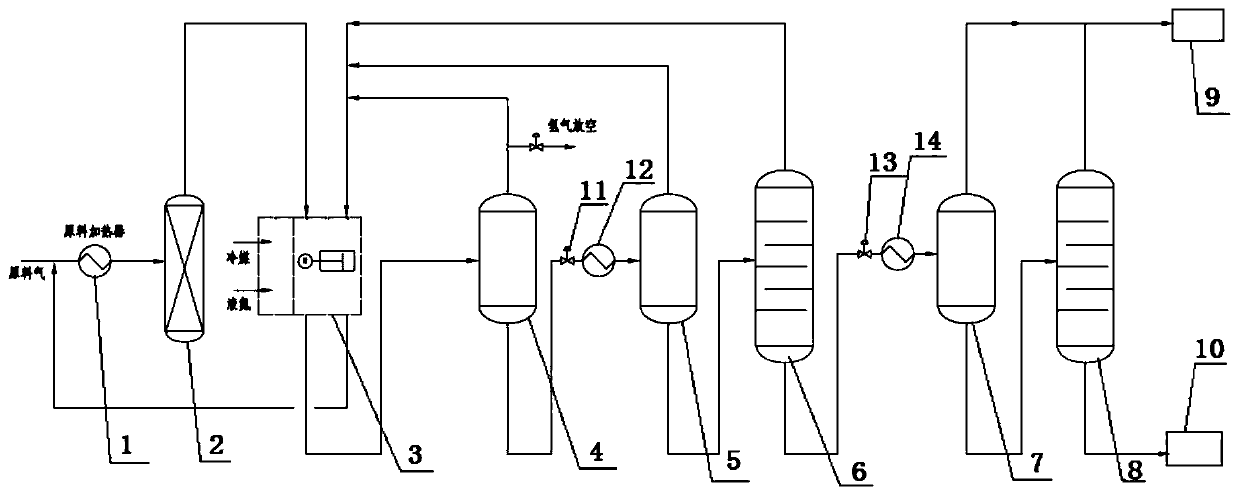

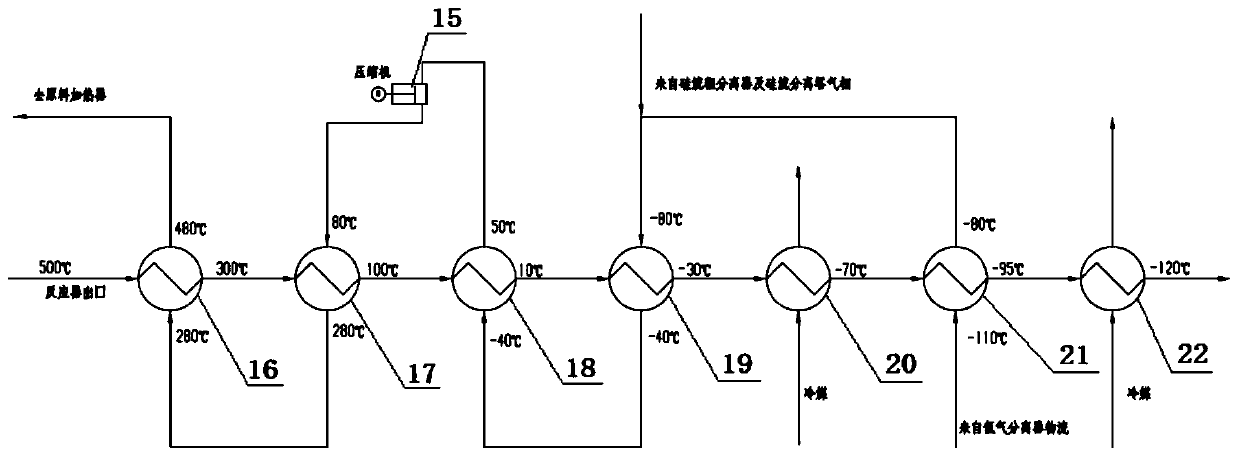

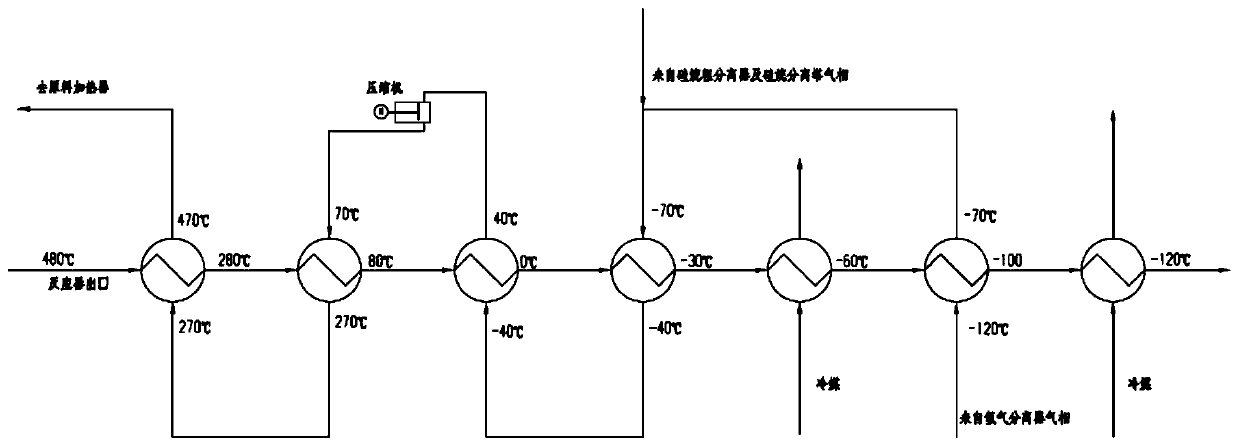

System and method for preparing disilane and propyl silane by silane pyrolysis method

ActiveCN110980738AAchieve separationImprove conversion rateSilicon hydridesFluid phasePhysical chemistry

The invention discloses a system and a method for preparing disilane and propyl silane by a silane pyrolysis method. The system is characterized by comprising a raw material heater, a silane pyrolysisreactor, a heat exchange and compression system, a hydrogen separator, a silane coarse separator, a silane separation tower, a disilane coarse separator and a disilane separation tower which are connected in sequence. The gas phase outlet of the hydrogen separator, the gas phase outlet of the silane coarse separator and the gas phase outlet of the silane separation tower are respectively connected with the shell pass inlet of the heat exchange and compression system; the shell pass outlet of the heat exchange and compression system is connected with the inlet of the raw material heater, the top gas phase outlet of the disilane coarse separator and the top gas phase outlet of the disilane separation tower are connected with an external disilane storage tank, and the bottom liquid phase outlet of the disilane separation tower is connected with an external propyl silane storage tank. The system has the advantages of being good in conversion efficiency and high in product purity.

Owner:SEDIN NINGBO ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com