Patents

Literature

136 results about "Disilane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Disilane is a chemical compound with chemical formula Si₂H₆ that was identified in 1902 by Henri Moissan and Samuel Smiles (1877–1953). Moissan and Smiles reported disilane as being among the products formed by the action of dilute acids on metal silicides. Although these reactions had been previously investigated by Friedrich Woehler and Heinrich Buff between 1857 and 1858, Moissan and Smiles were the first to explicitly identify disilane. They referred to disilane as silicoethane. Higher members of the homologous series SiₙH₂ₙ₊₂ formed in these reactions were subsequently identified by Carl Somiesky (sometimes spelled "Karl Somieski") and Alfred Stock.

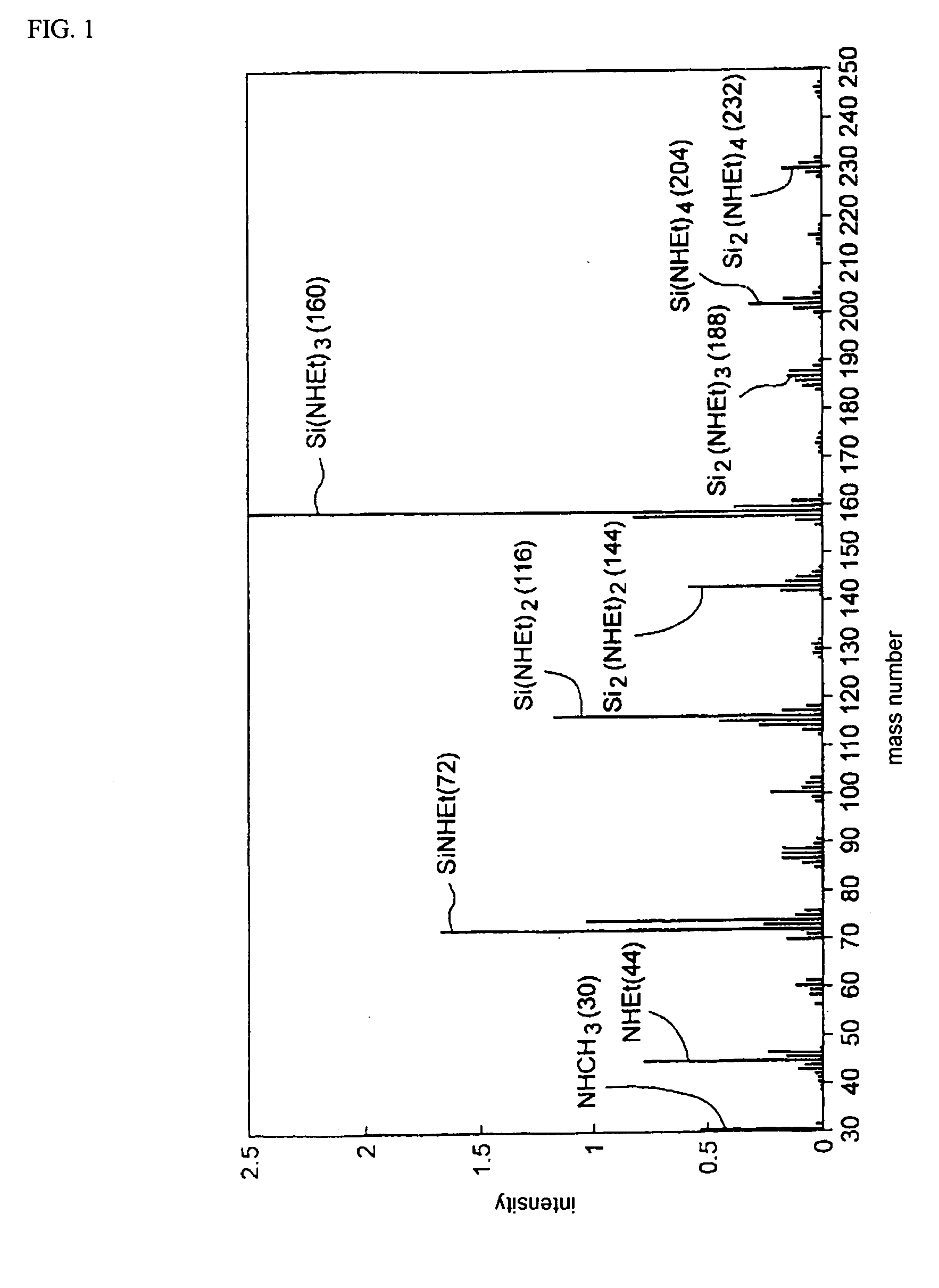

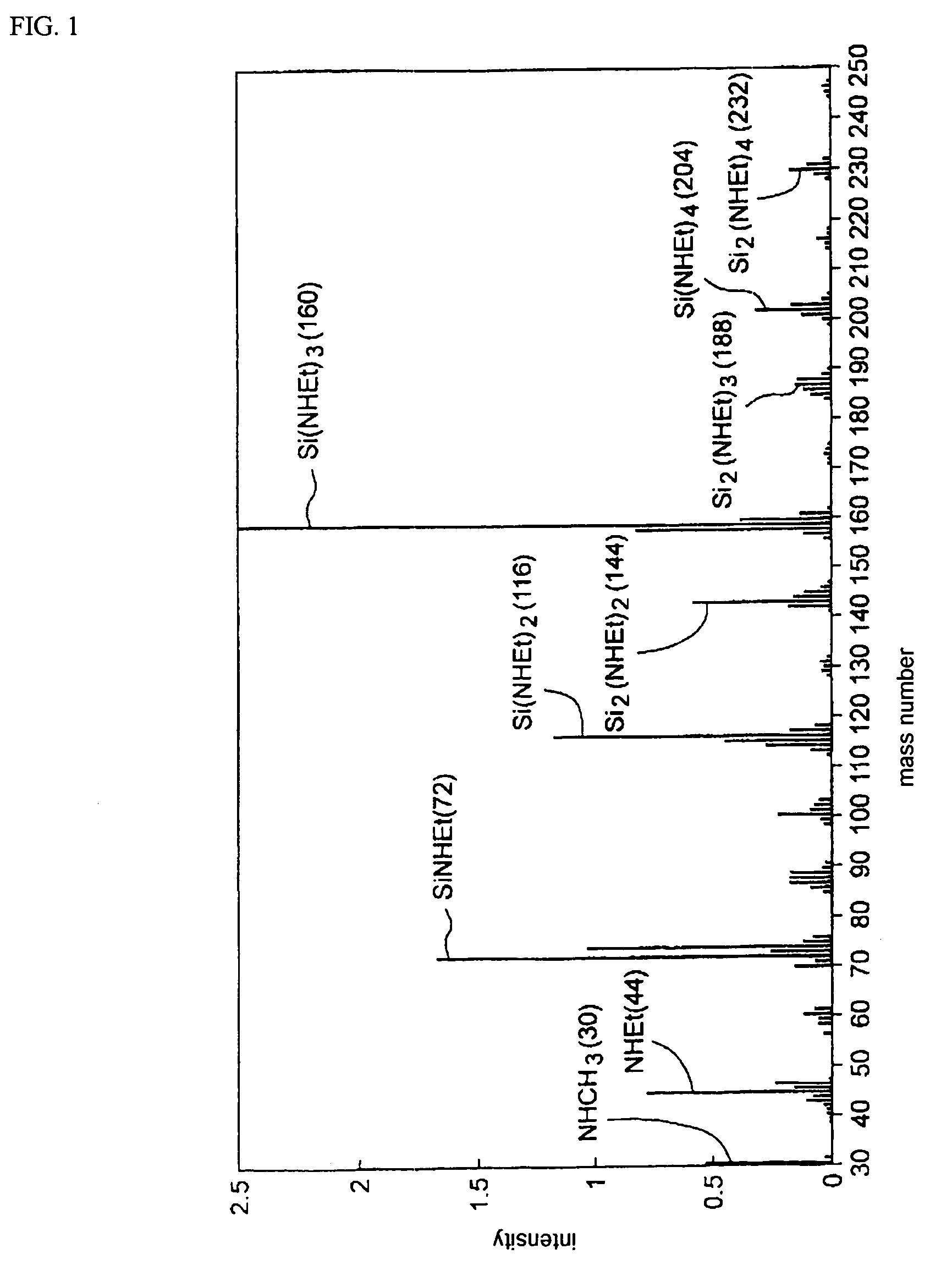

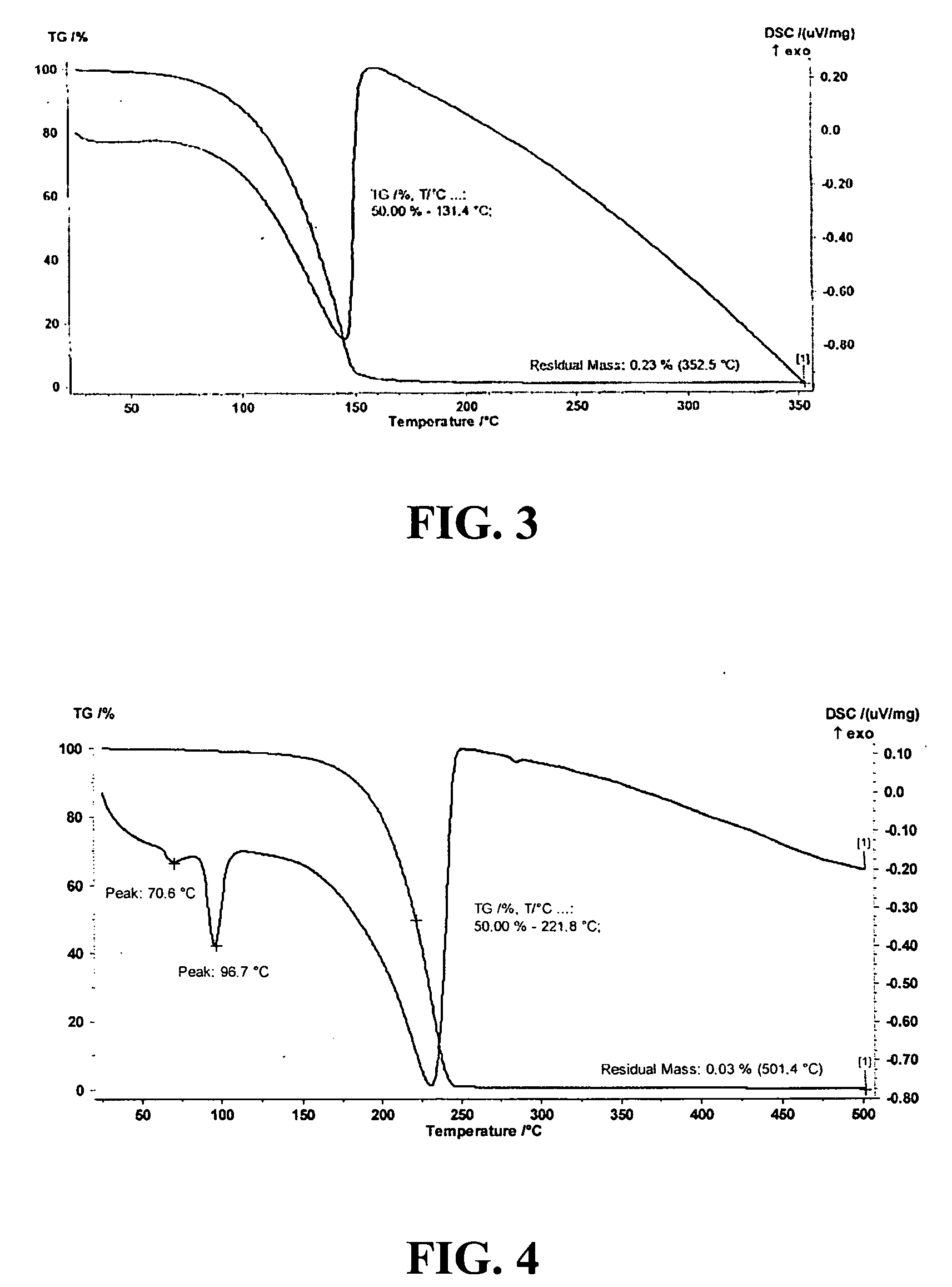

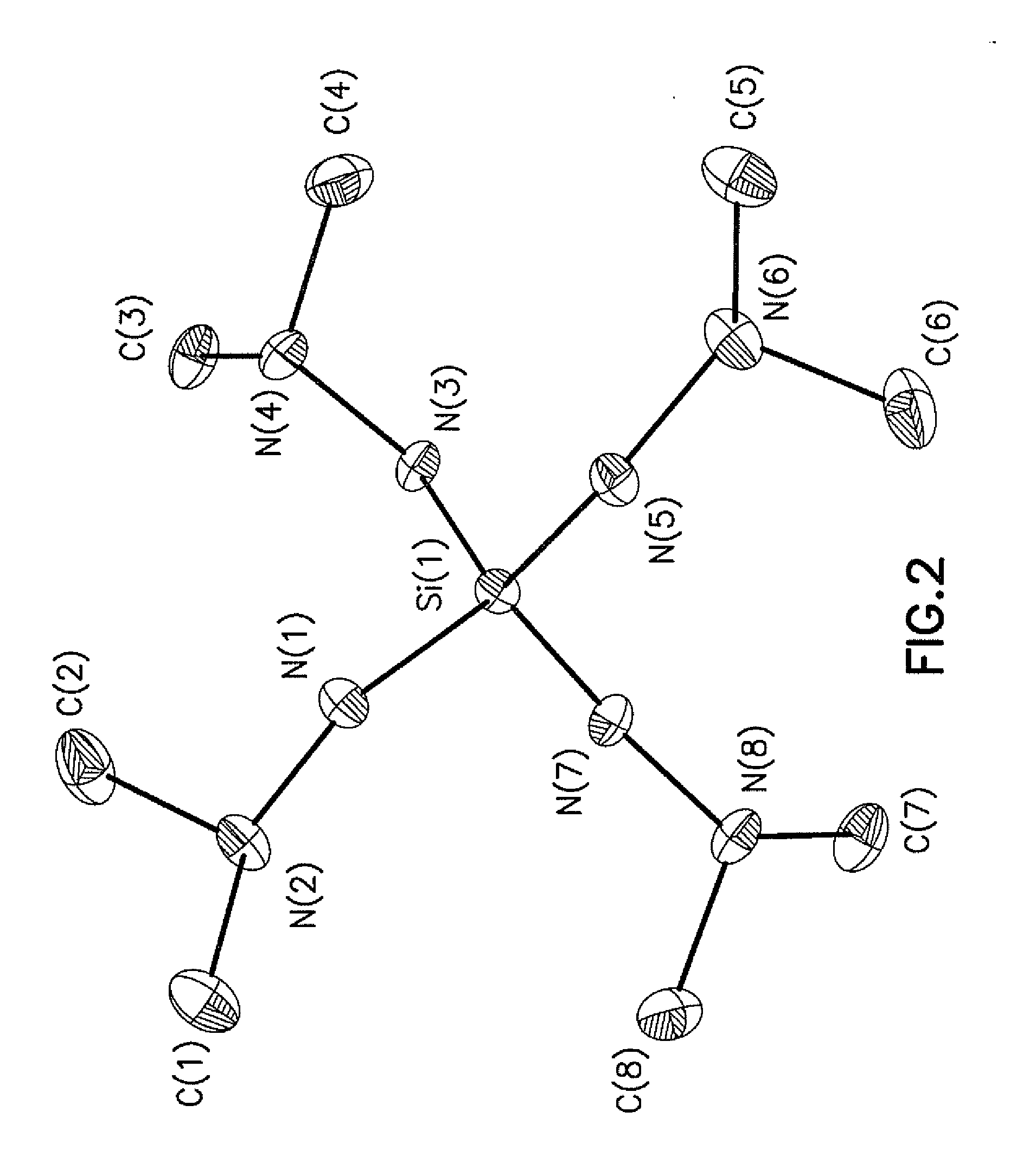

Hexakis(monohydrocarbylamino) disilanes and method for the preparation thereof

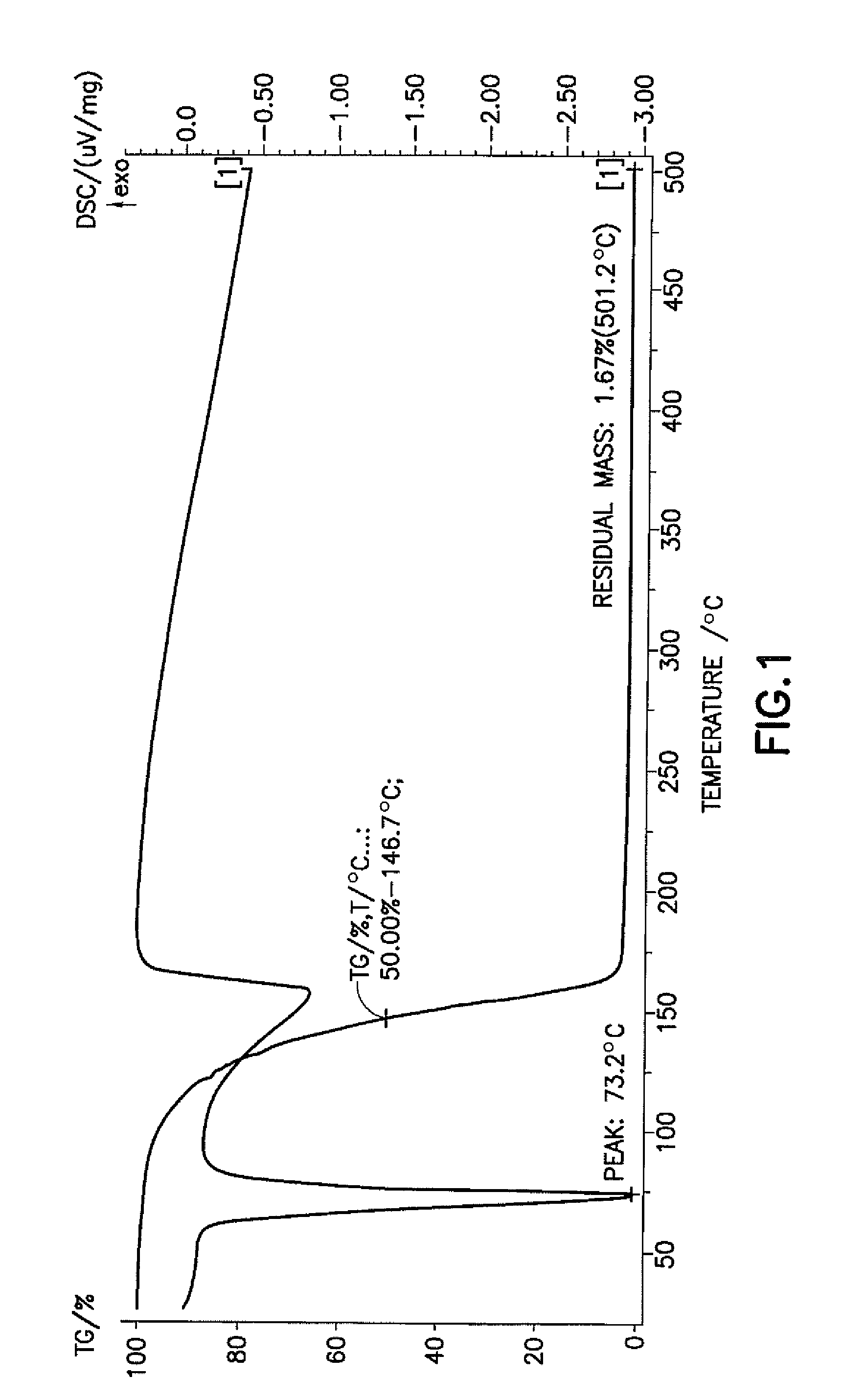

InactiveUS20050107627A1Improve featuresSilicon organic compoundsSemiconductor/solid-state device manufacturingSilane compoundsOrganic solvent

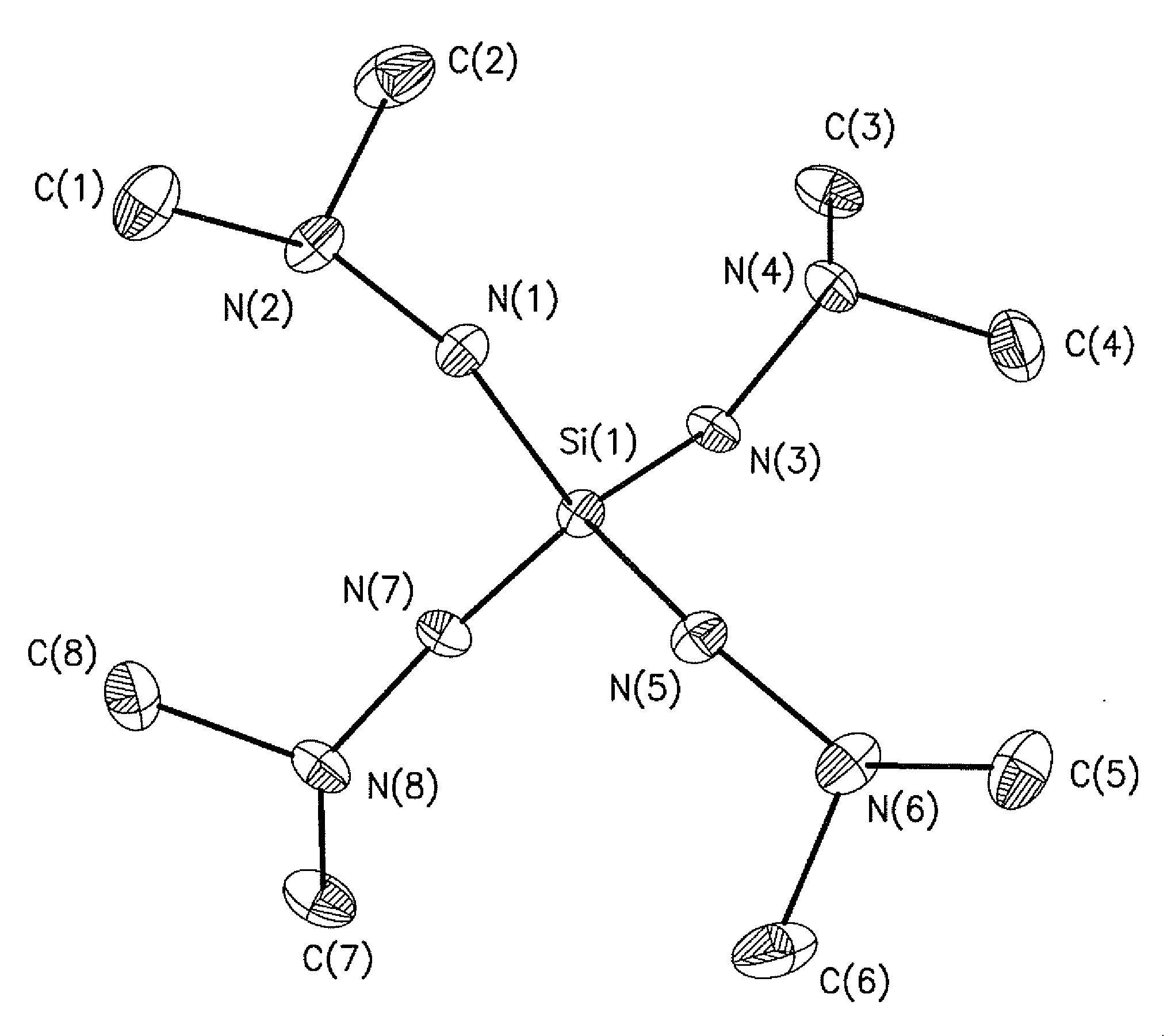

A composition and method of preparation, to provide silane compounds that are free of chlorine. The compounds are hexakis(monohydrocarbylamino)disilanes with general formula (I) ((R)HN)3—Si—Si—(NH(R))3 (I) wherein each R independently represents a C1 to C4 hydrocarbyl. These disilanes may be synthesized by reacting hexachlorodisilane in organic solvent with at least 6-fold moles of the monohydrocarbylamine RNH2 (wherein R is a C1 to C4 hydrocarbyl). Such compounds have excellent film-forming characteristics at low temperatures. These films, particularly in the case of silicon nitride and silicon oxynitride, also have excellent handling characteristics.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

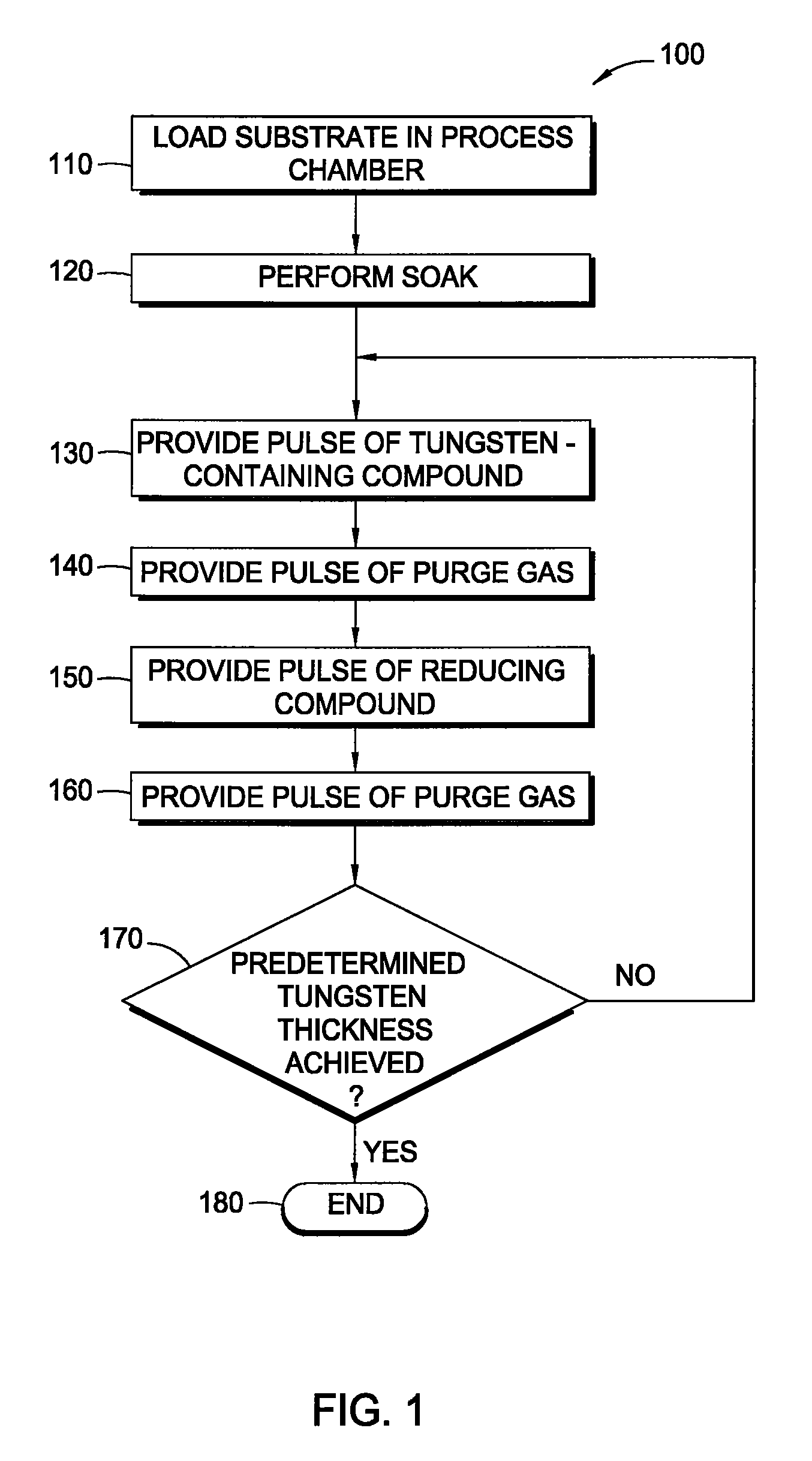

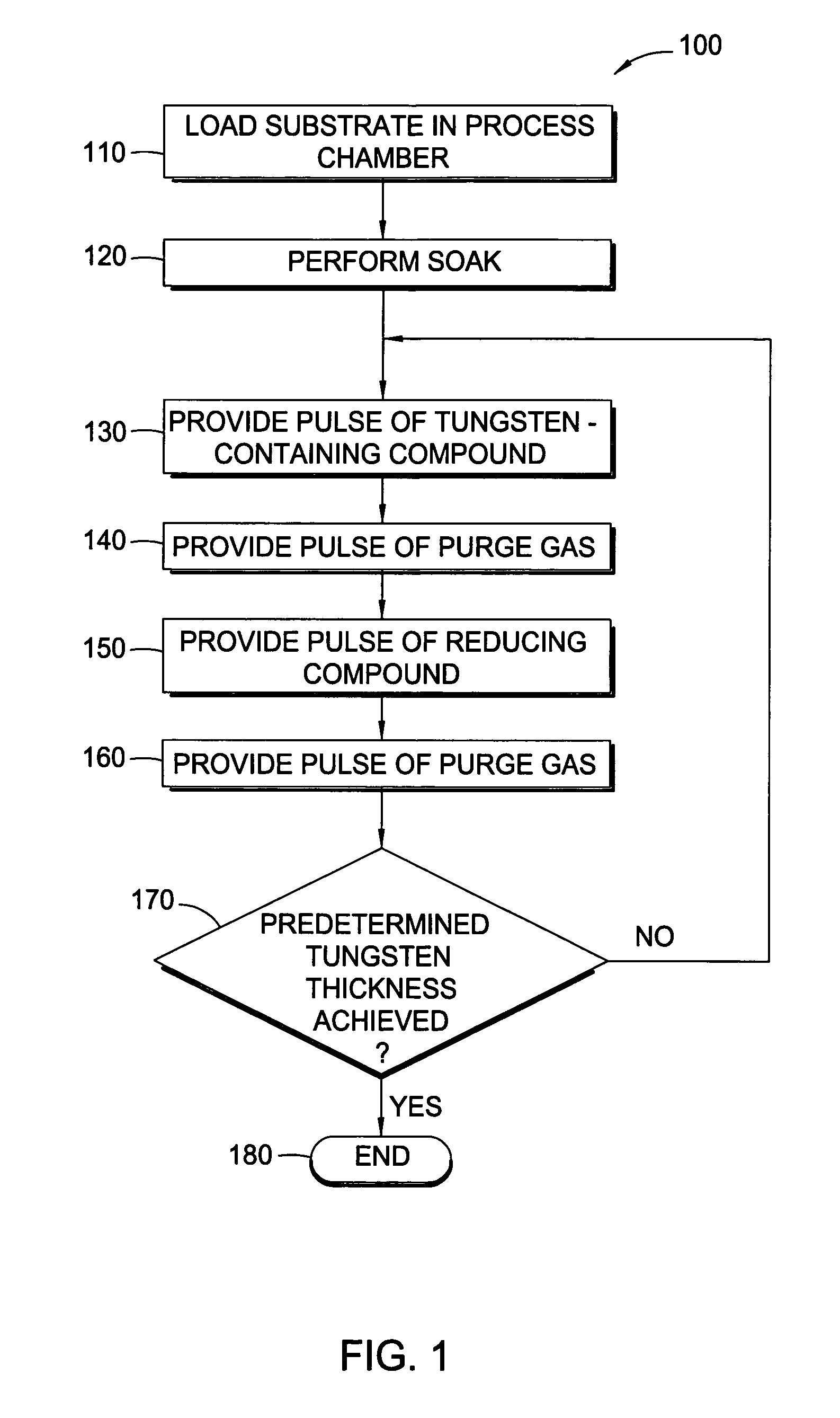

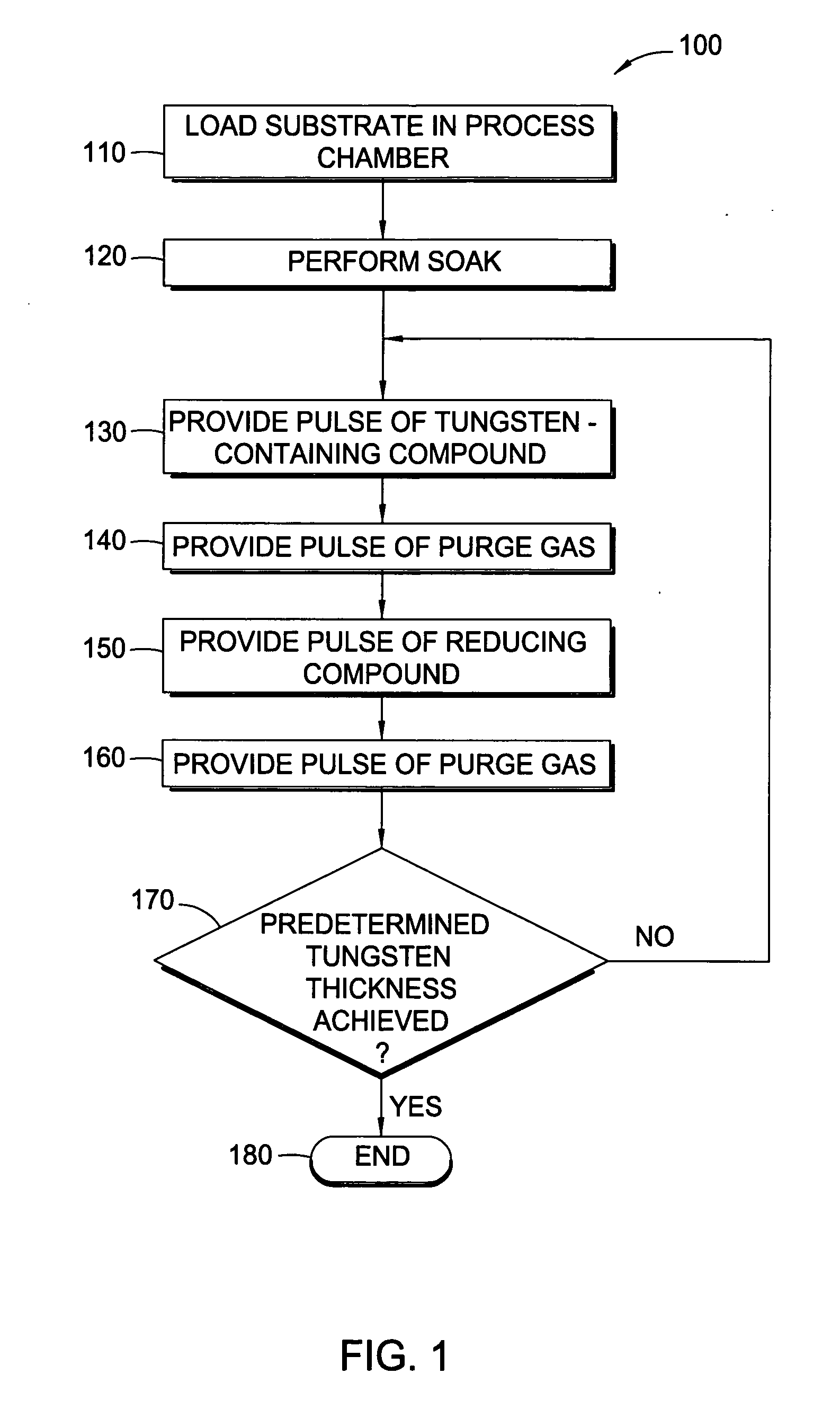

Atomic layer deposition of tungsten materials

ActiveUS7964505B2Improve conductivityImprove throughputSolid-state devicesSemiconductor/solid-state device manufacturingHydrogenSilanes

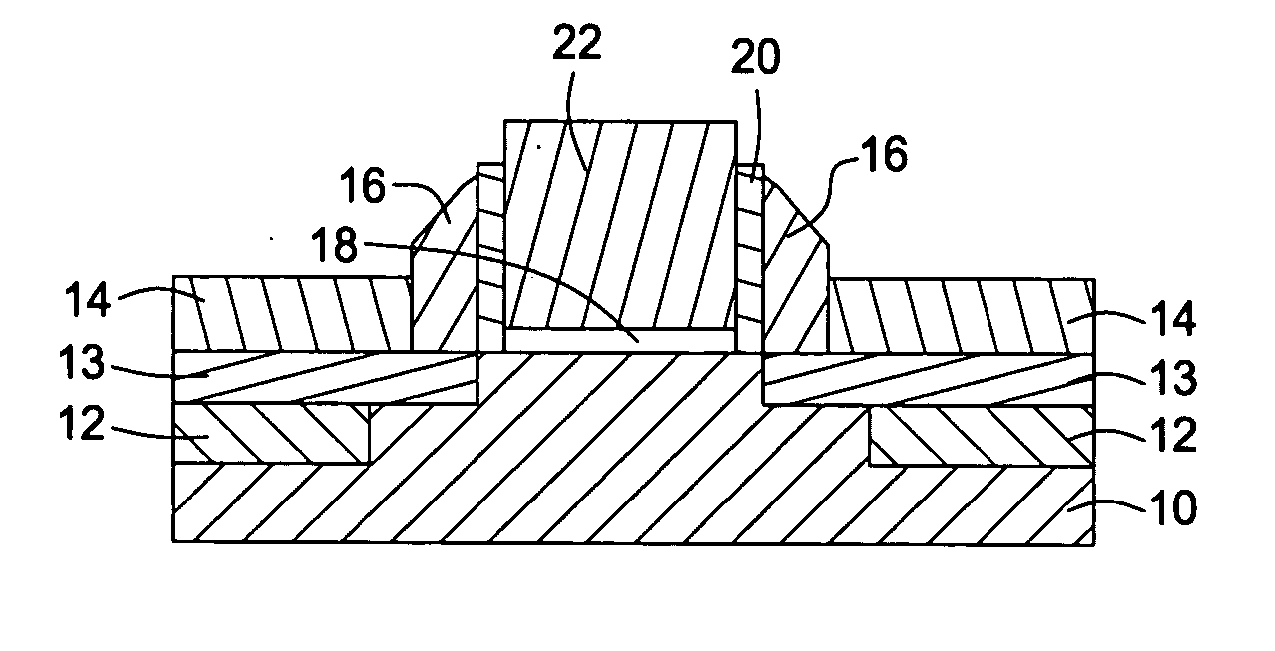

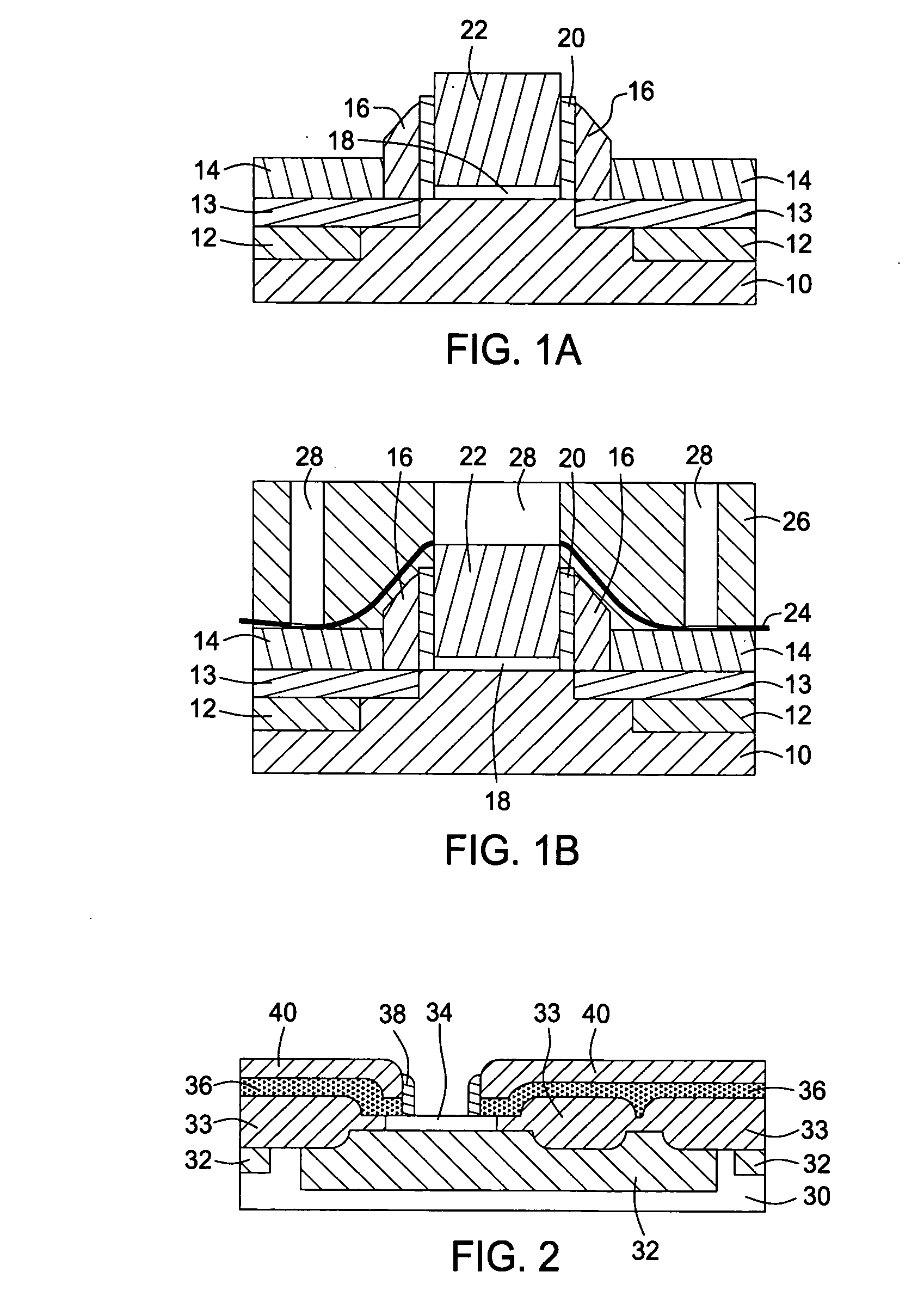

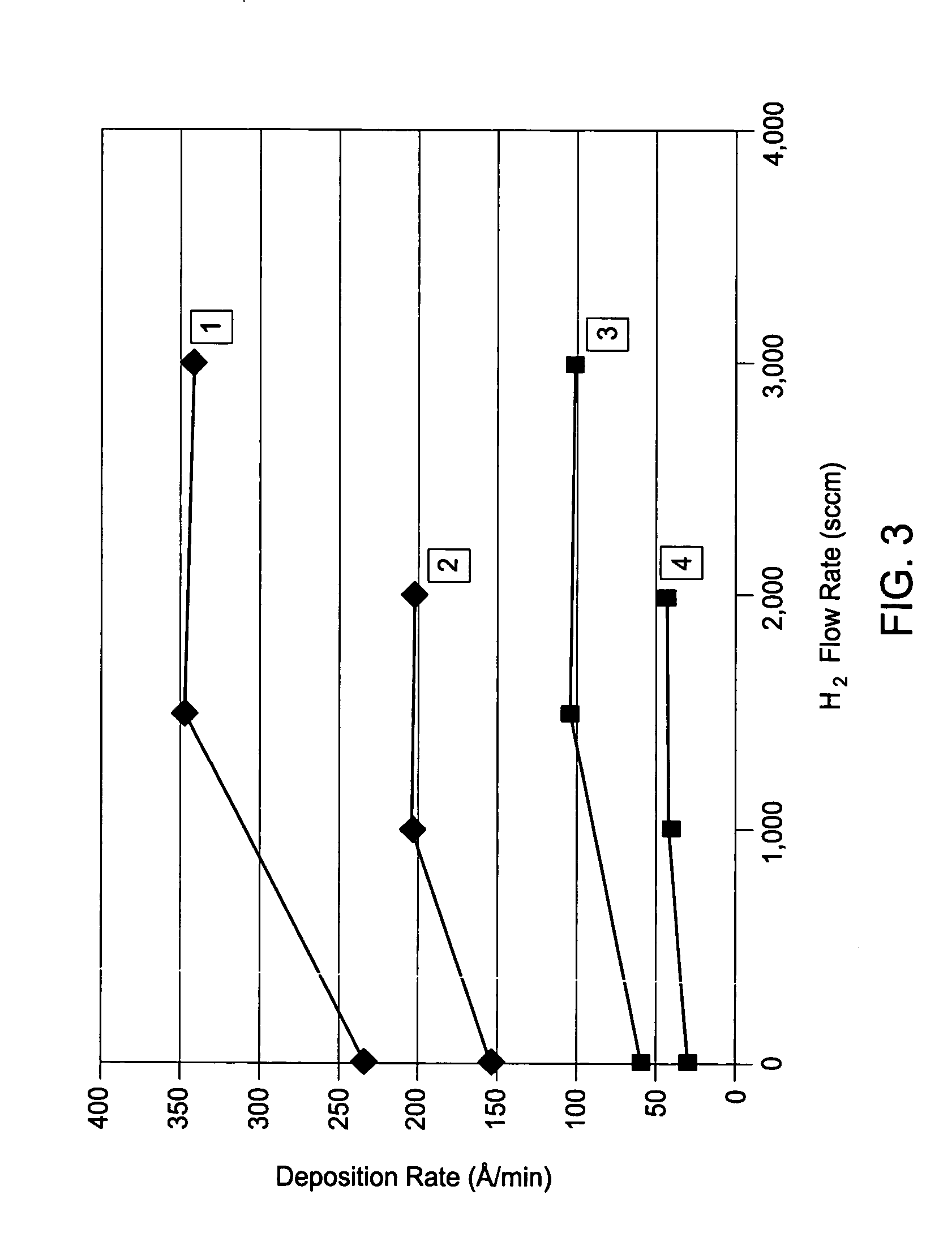

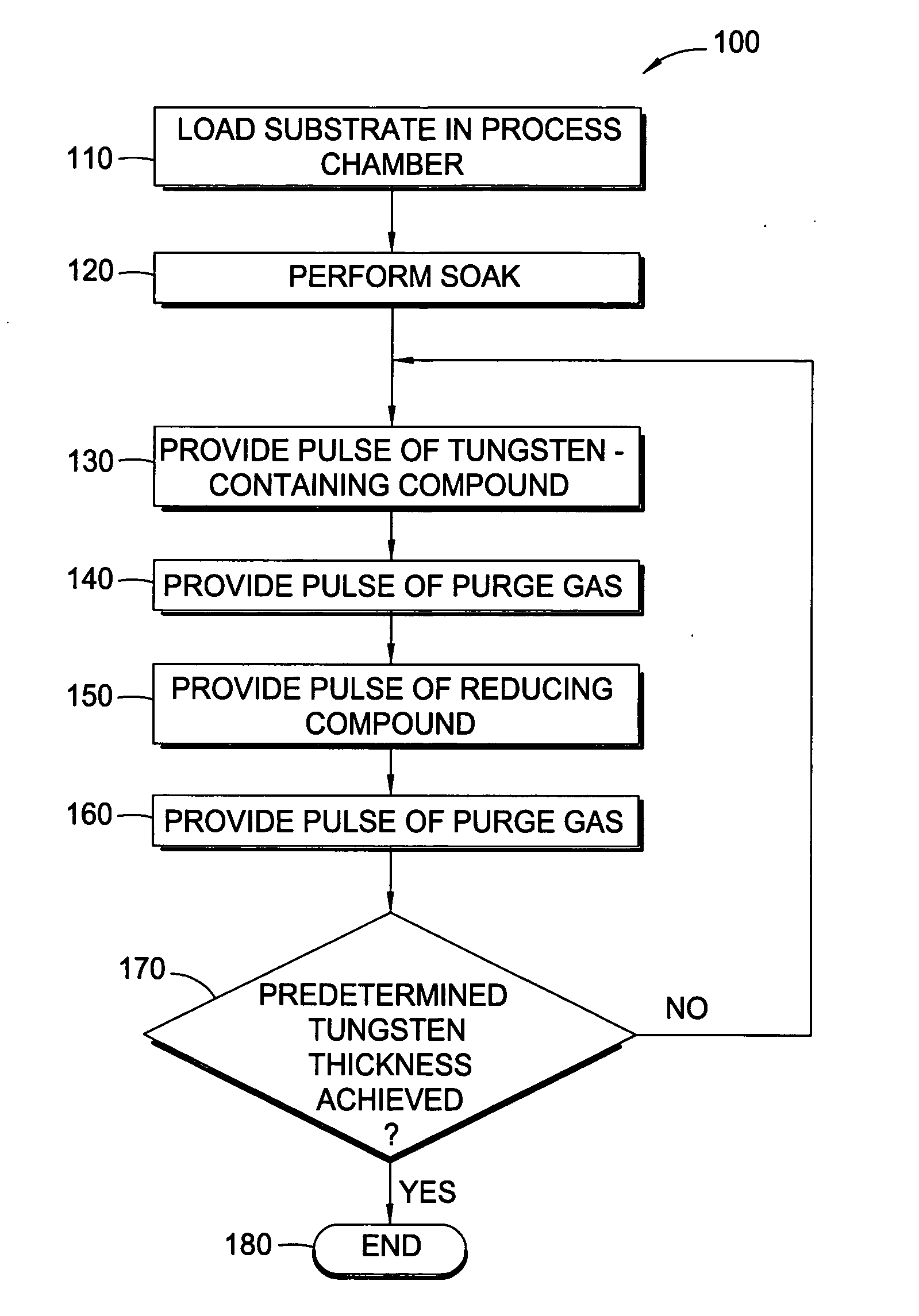

Embodiments of the invention provide an improved process for depositing tungsten-containing materials. The process utilizes soak processes and vapor deposition processes, such as atomic layer deposition (ALD) to provide tungsten films having significantly improved surface uniformity and production level throughput. In one embodiment, a method for forming a tungsten-containing material on a substrate is provided which includes positioning a substrate within a process chamber, wherein the substrate contains an underlayer disposed thereon, exposing the substrate sequentially to a tungsten precursor and a reducing gas to deposit a tungsten nucleation layer on the underlayer during an ALD process, wherein the reducing gas contains a hydrogen / hydride flow rate ratio of about 40:1, 100:1, 500:1, 800:1, 1,000:1, or greater, and depositing a tungsten bulk layer on the tungsten nucleation layer. The reducing gas contains a hydride compound, such as diborane, silane, or disilane.

Owner:APPLIED MATERIALS INC

Hexakis(monohydrocarbylamino) disilanes and method for the preparation thereof

InactiveUS7019159B2Silicon organic compoundsSemiconductor/solid-state device manufacturingSilane compoundsOrganic solvent

A composition and method of preparation, to provide silane compounds that are free of chlorine. The compounds are hexakis(monohydrocarbylamino)disilanes with general formula (I)((R)HN)3—Si—Si—(NH(R))3 (I)wherein each R independently represents a C1 to C4 hydrocarbyl. These disilanes may be synthesized by reacting hexachlorodisilane in organic solvent with at least 6-fold moles of the monohydrocarbylamine RNH2 (wherein R is a C1 to C4 hydrocarbyl). Such compounds have excellent film-forming characteristics at low temperatures. These films, particularly in the case of silicon nitride and silicon oxynitride, also have excellent handling characteristics.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

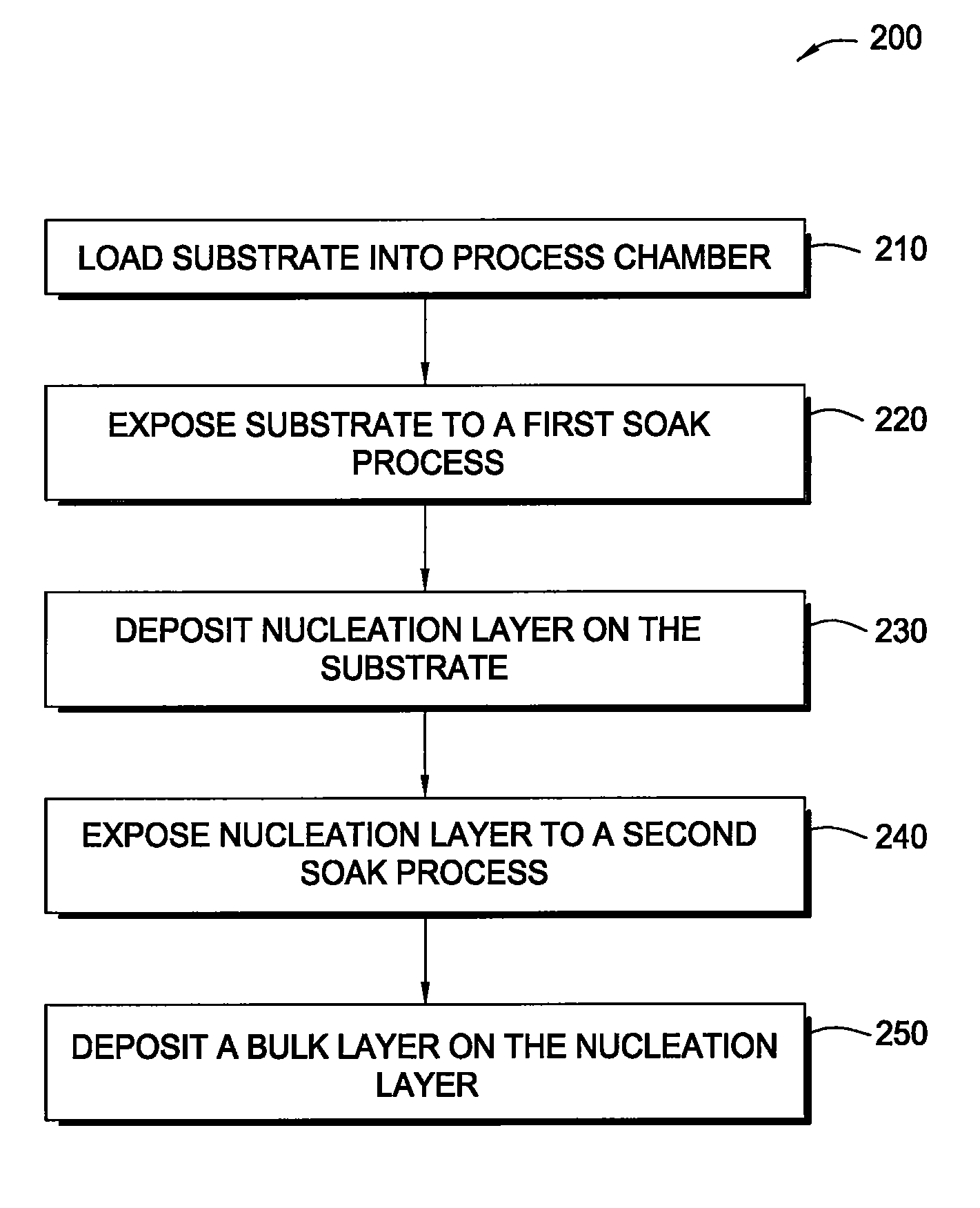

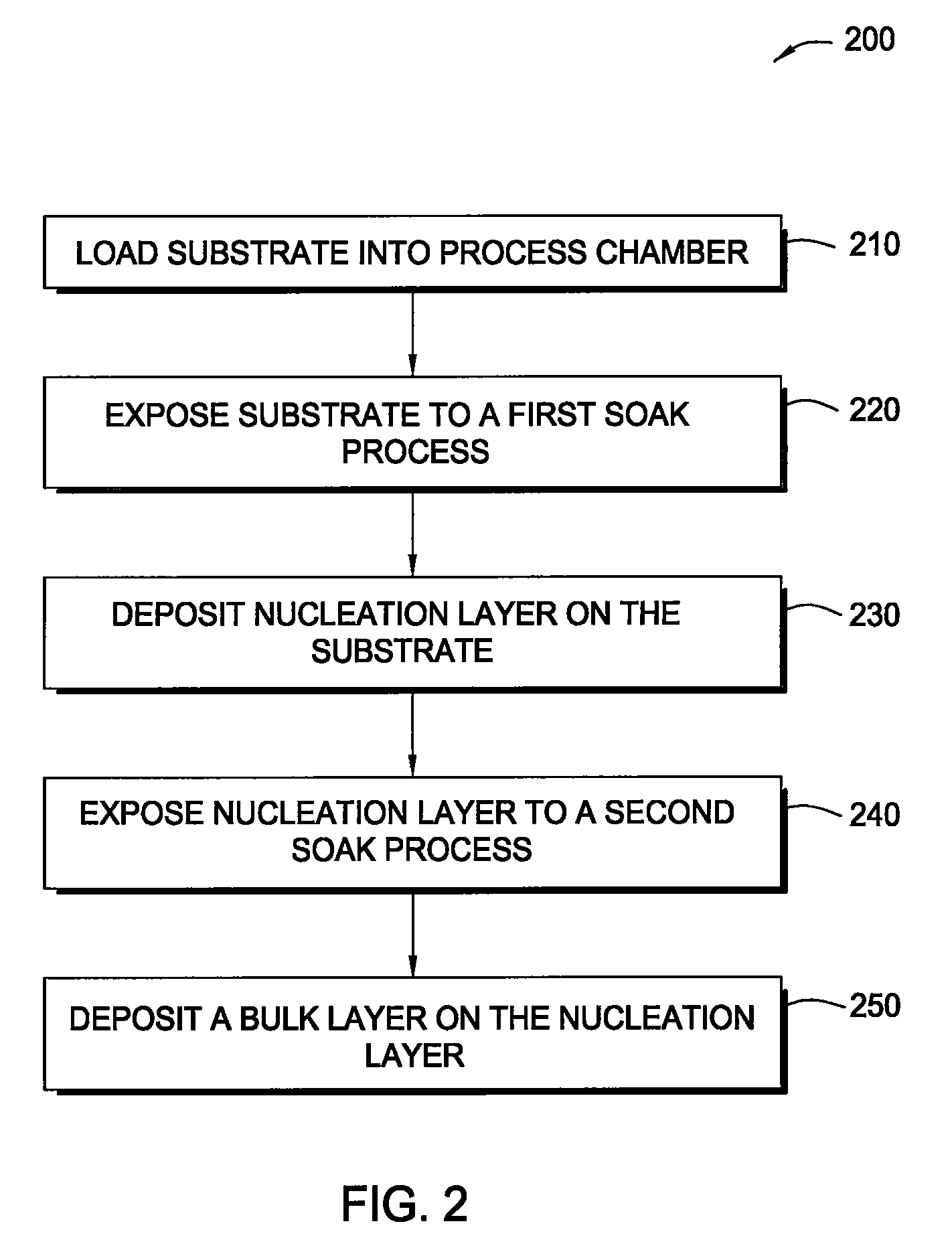

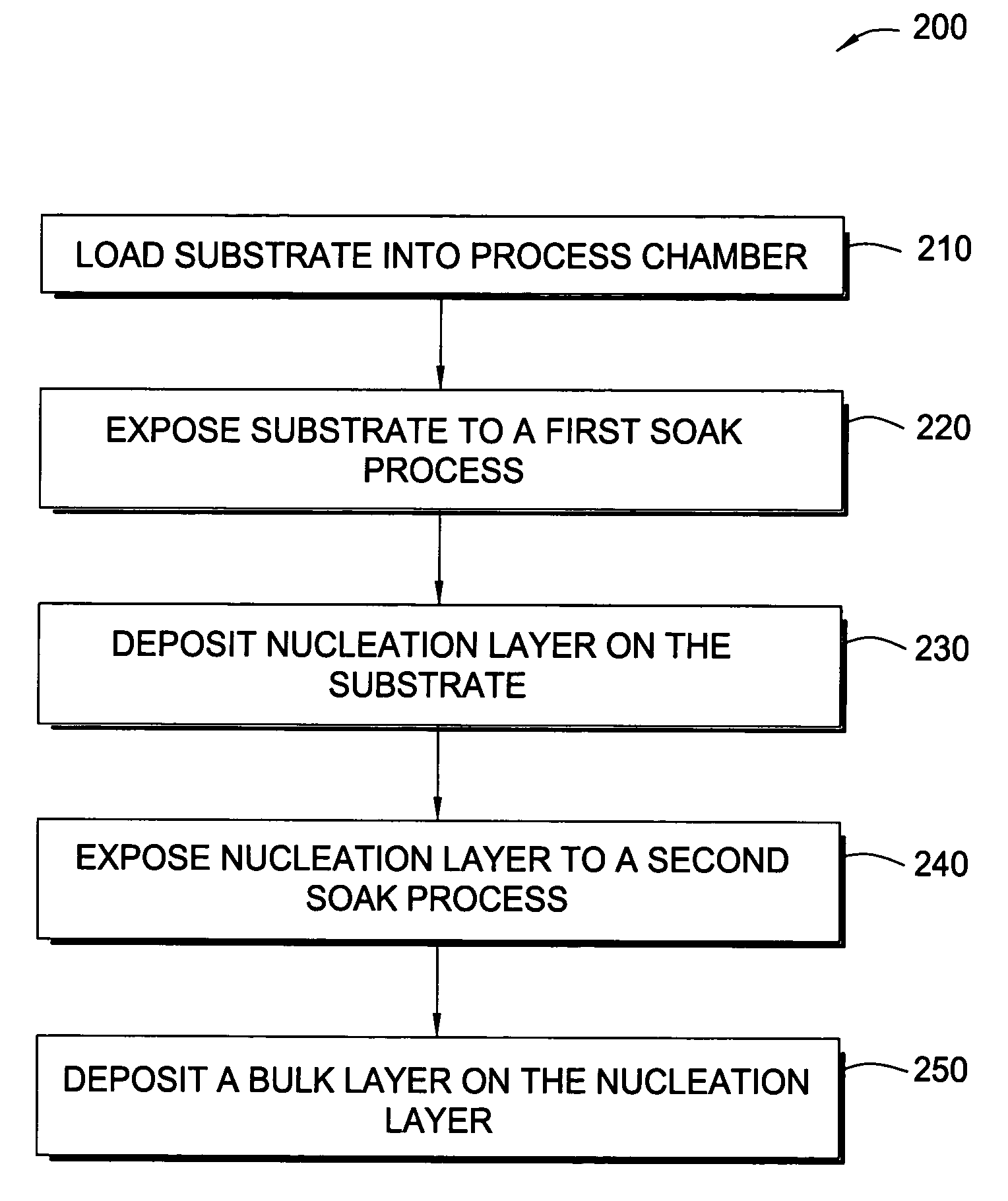

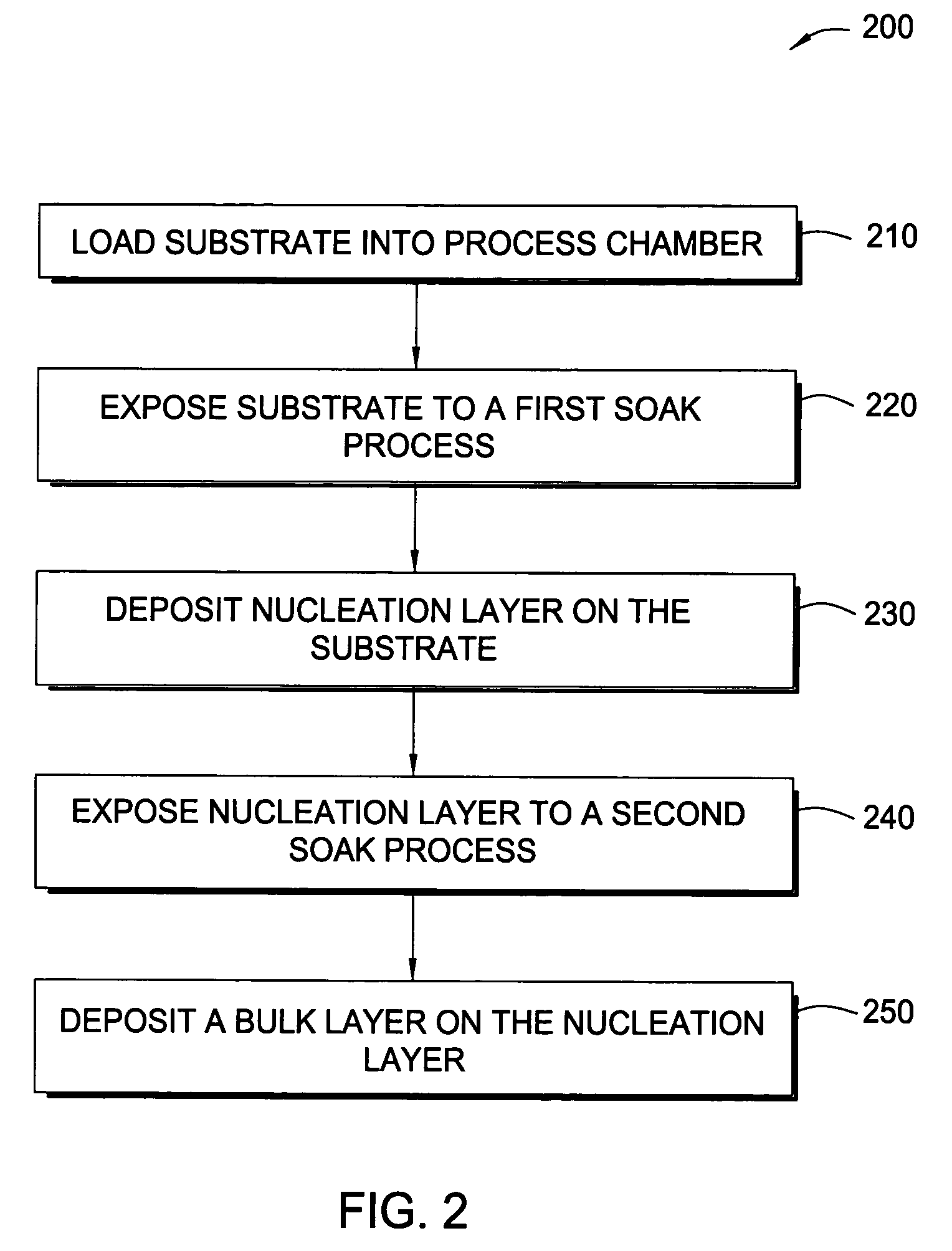

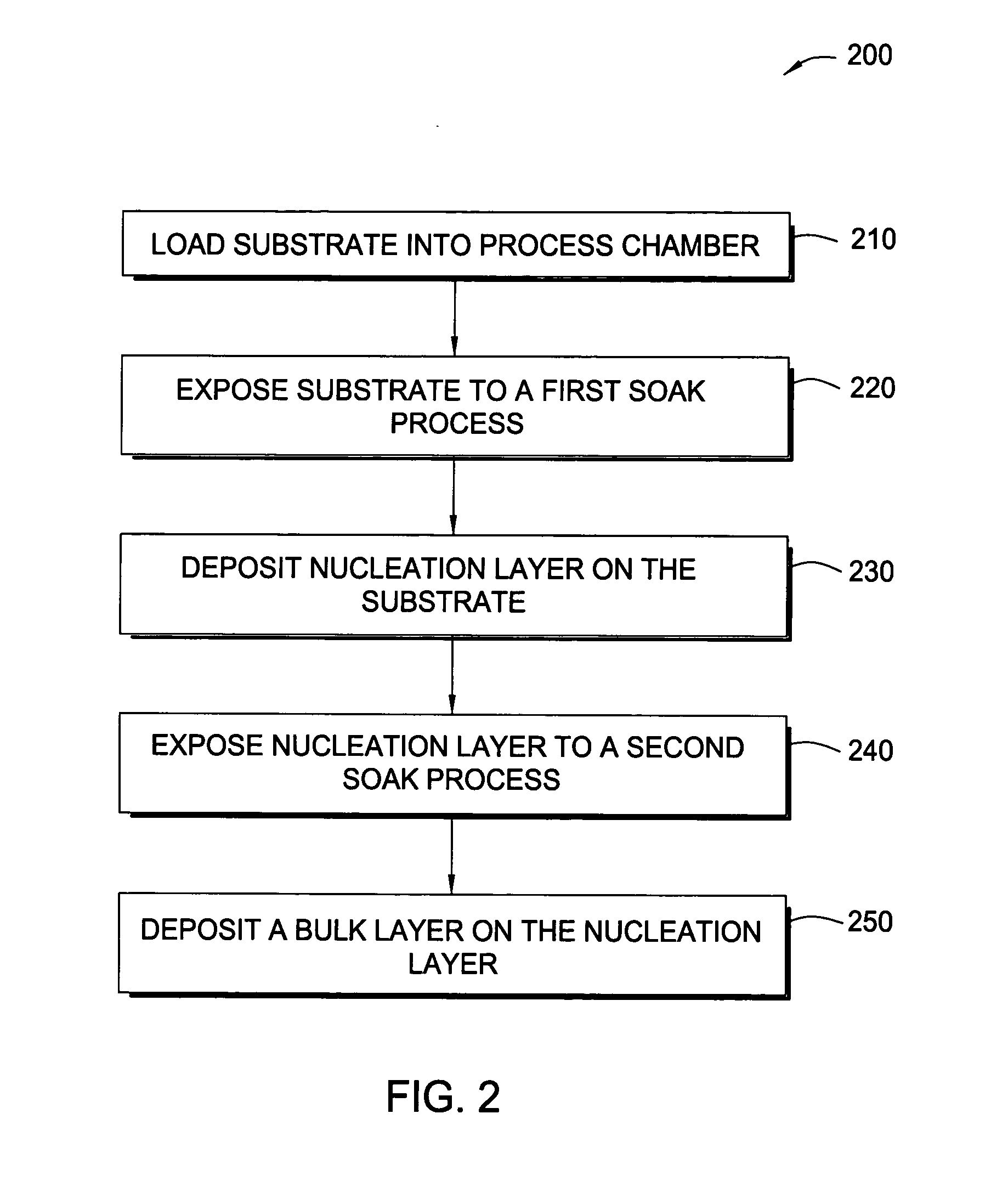

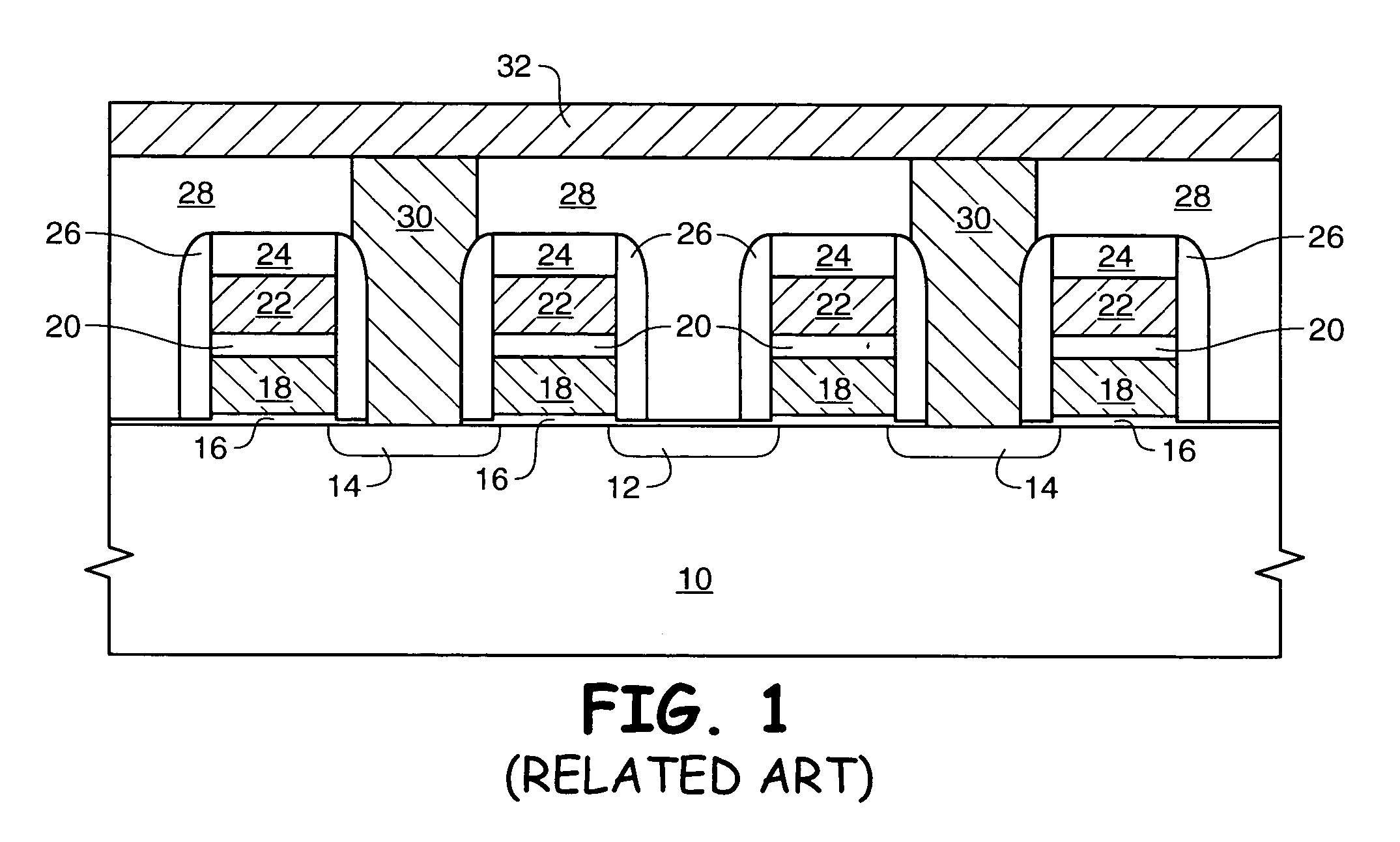

Methods for depositing tungsten layers employing atomic layer deposition techniques

InactiveUS7405158B2Solid-state devicesSemiconductor/solid-state device manufacturingDisilaneGas phase

In one embodiment of the invention, a method for forming a tungsten-containing layer on a substrate is provided which includes positioning a substrate containing a barrier layer disposed thereon in a process chamber, exposing the substrate to a first soak process for a first time period and depositing a nucleation layer on the barrier layer by flowing a tungsten-containing precursor and a reductant into the process chamber. The method further includes exposing the nucleation layer to a second soak process for a second time period and depositing a bulk layer on the nucleation layer. In one example, the barrier layer contains titanium nitride, the first and second soak processes independently comprise at least one reducing gas selected from the group consisting of hydrogen, silane, disilane, dichlorosilane, borane, diborane, derivatives thereof and combinations thereof and the nucleation layer may be deposited by an atomic layer deposition process or a pulsed chemical vapor deposition process while the bulk layer may be deposited by a chemical vapor deposition process or a physical vapor deposition process.

Owner:APPLIED MATERIALS INC

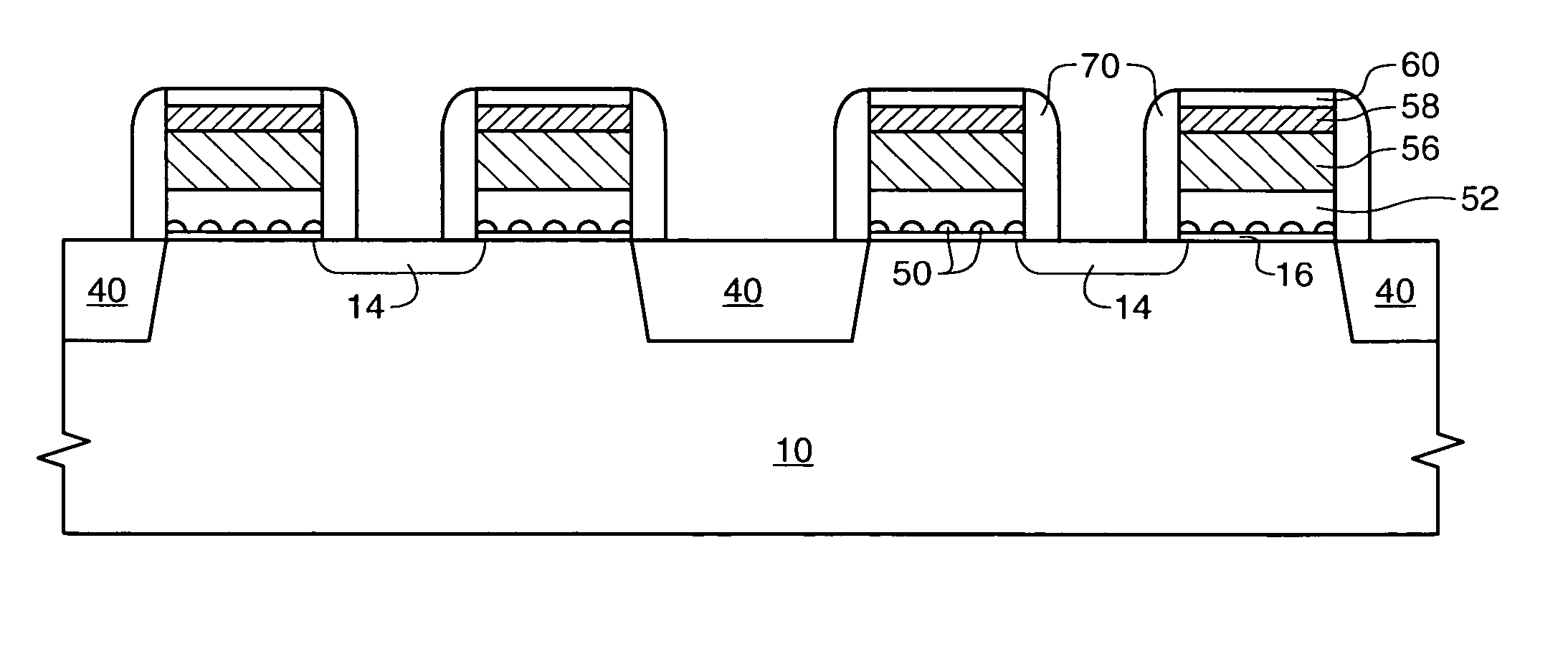

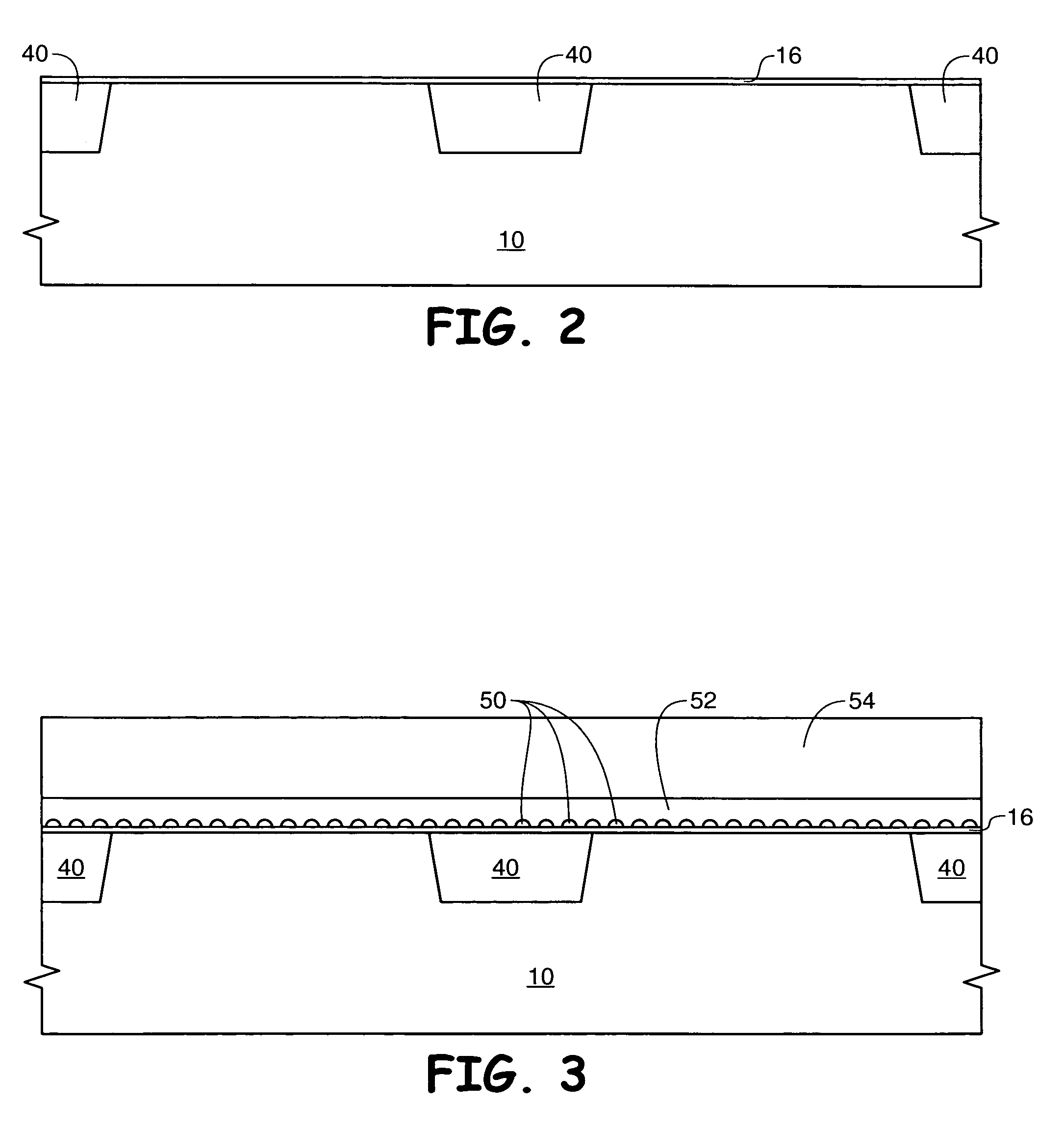

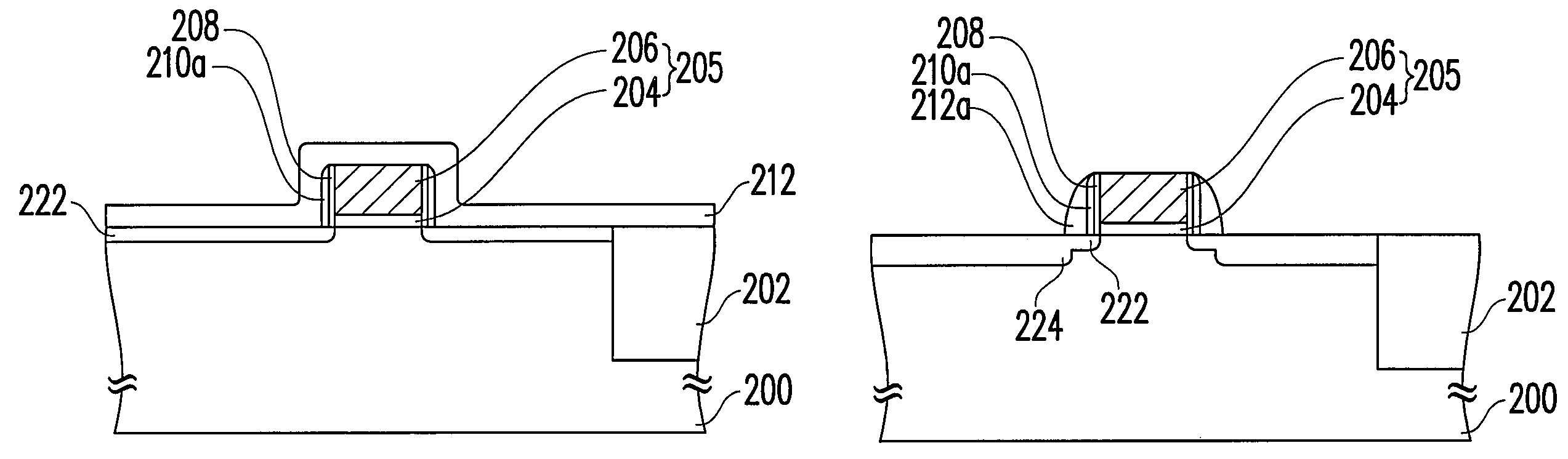

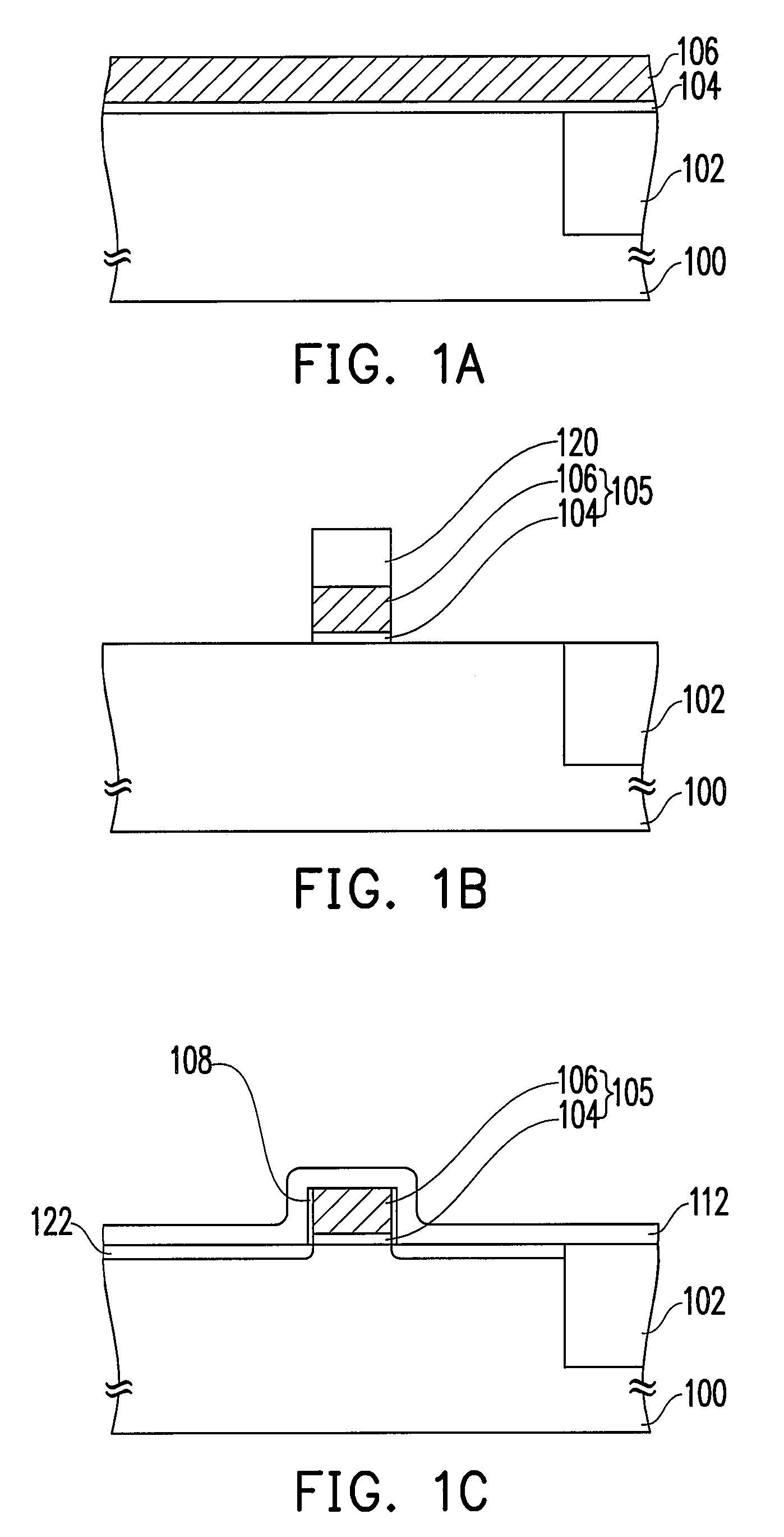

Low thermal budget silicon nitride formation for advance transistor fabrication

InactiveUS20060019032A1Solid-state devicesSemiconductor/solid-state device manufacturingSilane compoundsHydrogen

In one embodiment, a method for depositing a layer containing silicon nitride on a substrate surface is provided which includes positioning a substrate in a process chamber, maintaining the substrate at a predetermined temperature, and exposing the substrate surface to an alkylaminosilane compound and at least one ammonia-free reactant. In another embodiment, a method for depositing a silicon nitride material on a substrate is provided which includes positioning a substrate in a process chamber, maintaining the substrate at a predetermined temperature, and exposing the substrate surface to bis(tertiarybutylamino)silane and a reagent, such as hydrogen, silane and / or disilane.

Owner:APPLIED MATERIALS INC

Methods for depositing tungsten layers employing atomic layer deposition techniques

InactiveUS20060009034A1Solid-state devicesSemiconductor/solid-state device manufacturingDisilaneGas phase

In one embodiment of the invention, a method for forming a tungsten-containing layer on a substrate is provided which includes positioning a substrate containing a barrier layer disposed thereon in a process chamber, exposing the substrate to a first soak process for a first time period and depositing a nucleation layer on the barrier layer by flowing a tungsten-containing precursor and a reductant into the process chamber. The method further includes exposing the nucleation layer to a second soak process for a second time period and depositing a bulk layer on the nucleation layer. In one example, the barrier layer contains titanium nitride, the first and second soak processes independently comprise at least one reducing gas selected from the group consisting of hydrogen, silane, disilane, dichlorosilane, borane, diborane, derivatives thereof and combinations thereof and the nucleation layer may be deposited by an atomic layer deposition process or a pulsed chemical vapor deposition process while the bulk layer may be deposited by a chemical vapor deposition process or a physical vapor deposition process.

Owner:APPLIED MATERIALS INC

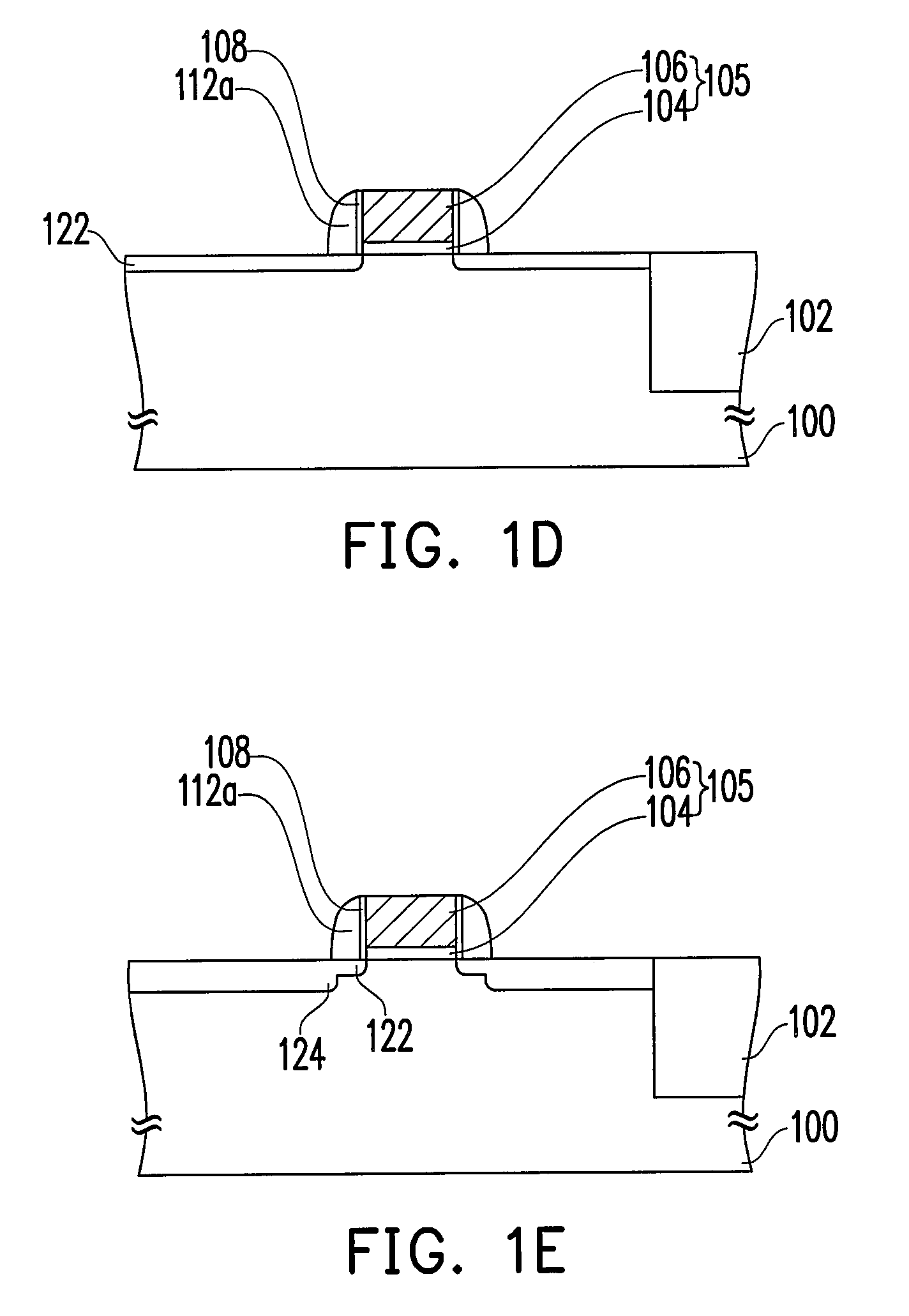

Method for forming a nanocrystal floating gate for a flash memory device

InactiveUS20060046383A1Improve uniformityMore controllabilityNanoinformaticsSolid-state devicesSilanesDisilane

One embodiment of a method used to form a floating gate for a memory device comprises forming a crystallization nucleus seed layer using a process comprising disilane (Si2H6), then converting the seed layer into a plurality of electrically-isolated silicon nanocrystals using a process comprising silane (SiH4). The method described uses lower temperatures than previous silicon nanocrystal formation with improved uniformity of the completed silicon nanocrystals.

Owner:MICRON TECH INC

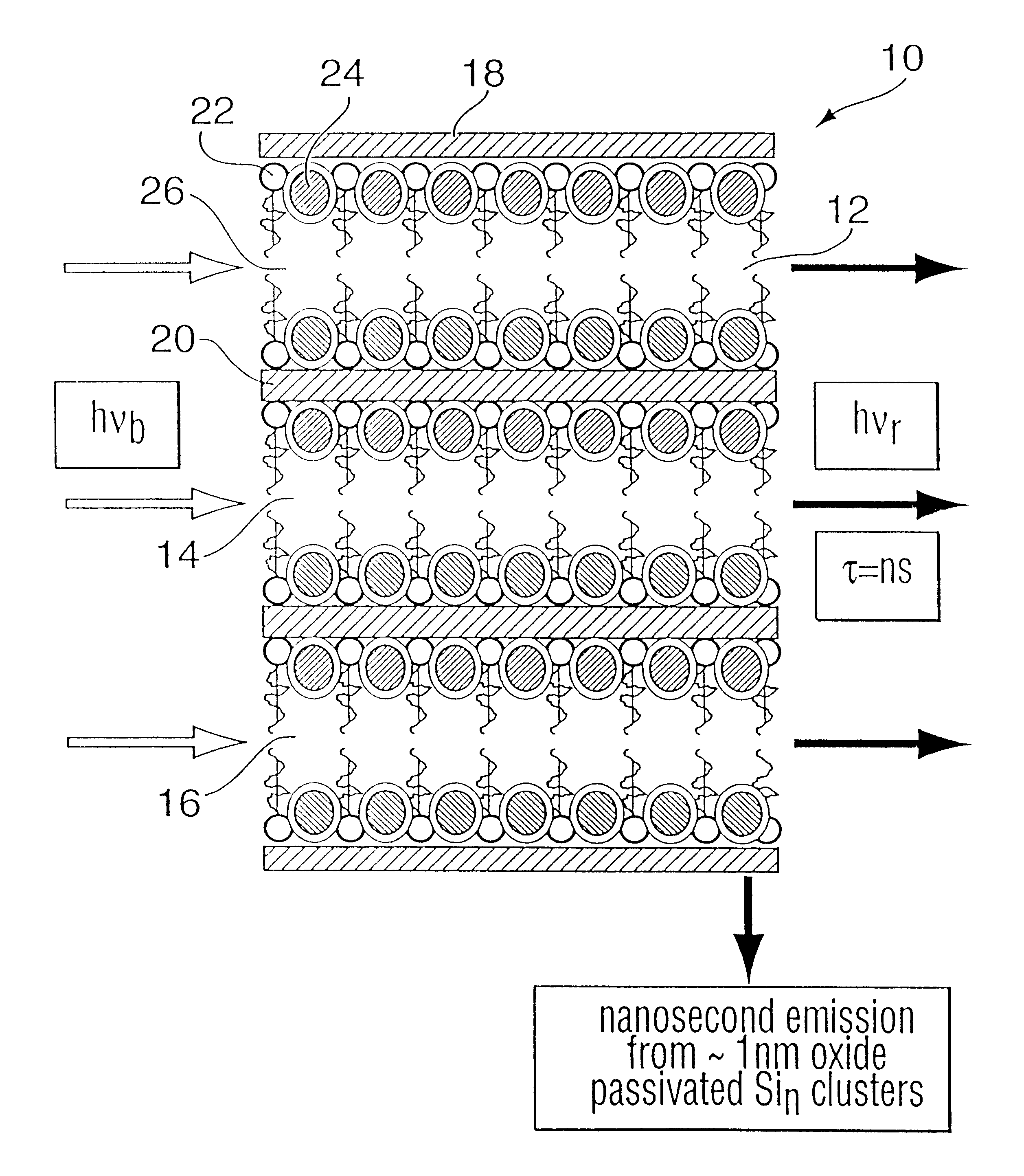

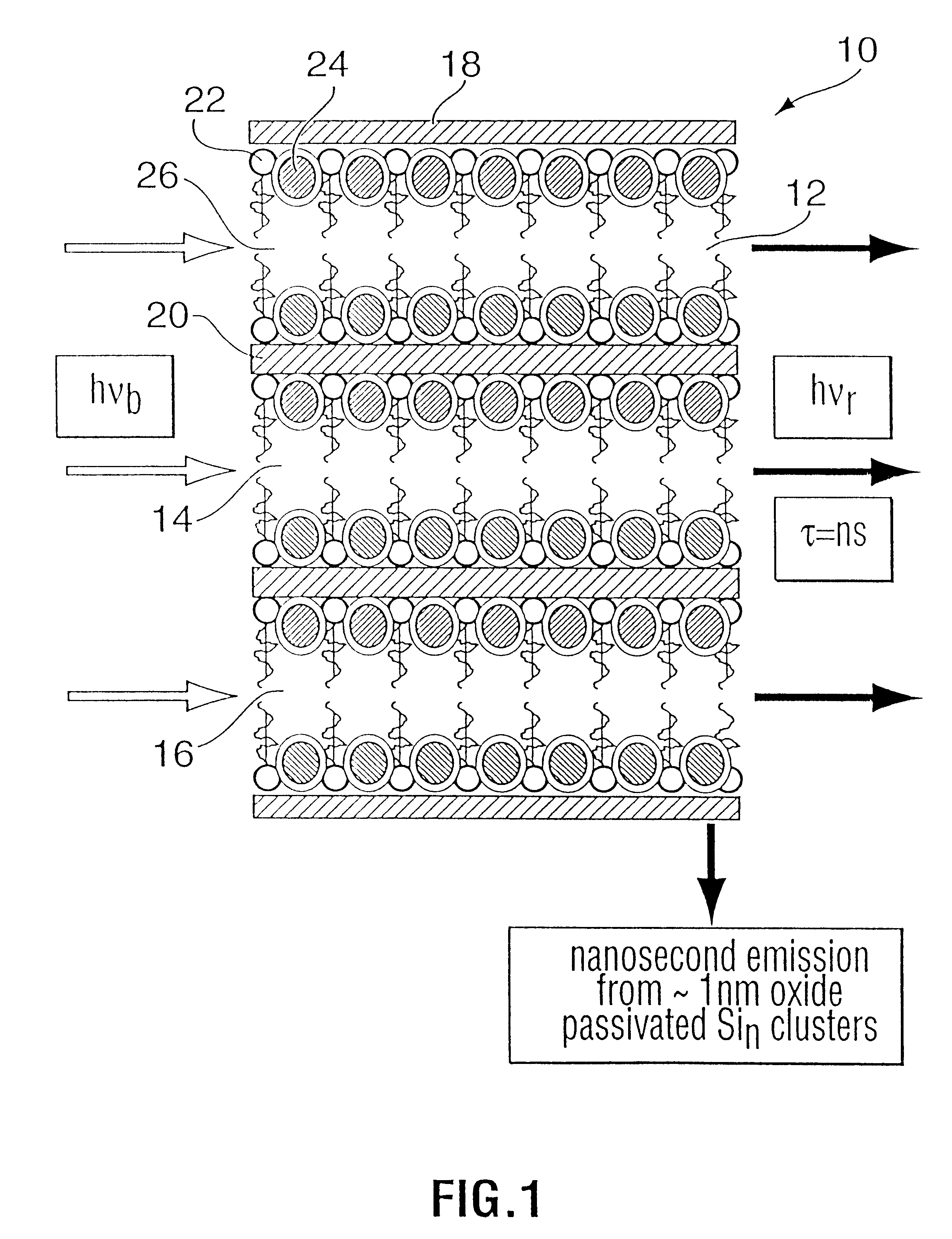

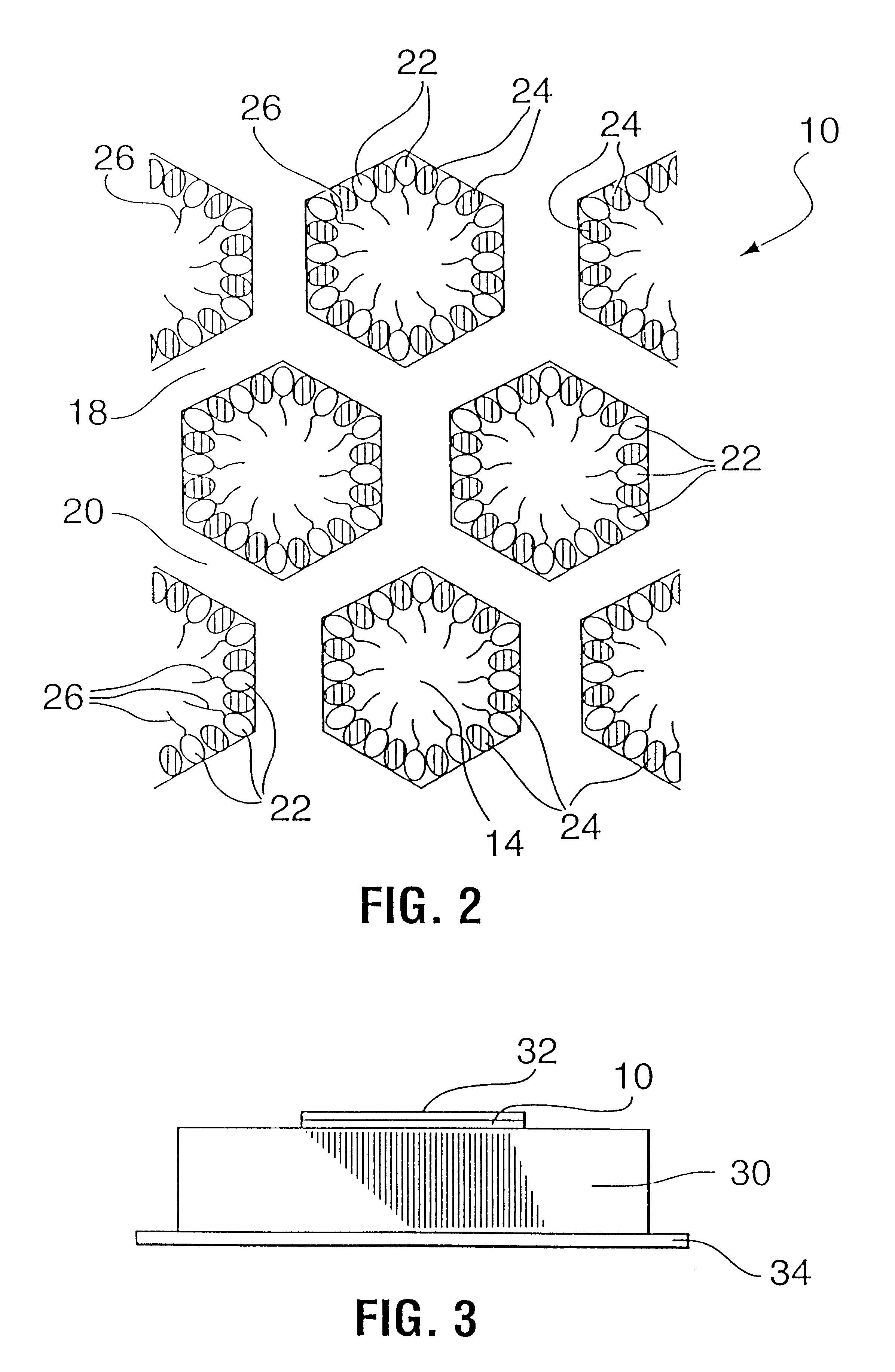

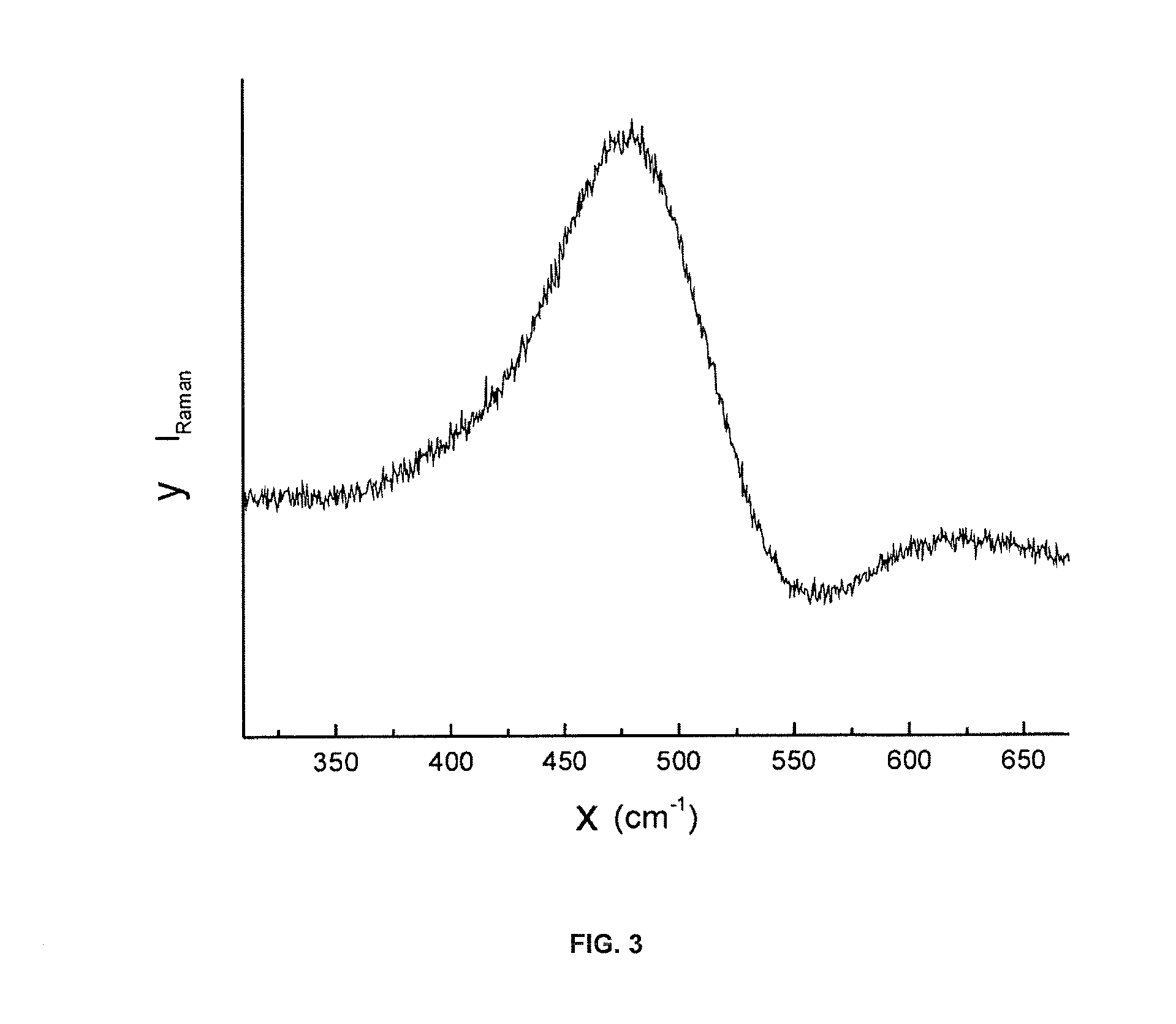

Fast luminescent silicon

There are provided mesoporous silica materials containing in their pores stabilized clusters of silicon atom, of size 2 nanometers or less, and capable of photoluminescence to emit fast photons. They are prepared by chemical vapor deposition of silicon or a silicon precursor such as disilane, under soft conditions such as temperature of 100-150 DEG C., into the mesopores of silicate films which have mesoporous channels prepared by growth of the films using a template to control their sizes, but without removing the template residues from the films prior to the chemical vapor deposition. The template residues serve to limit the size of the silicon clusters which conform. The use of the soft conditions on CVD retains the template residues in an intact, substantially unchanged form. The resultant films have clusters of silicon, of 2 nanometer size or less, anchored to the mesopores, and air stable, so that they can be used in optoelectronic devices in conjunction with standard silicon semiconductors.

Owner:THE GOVERNINIG COUNCIL OF THE UNIV OF TORANTO

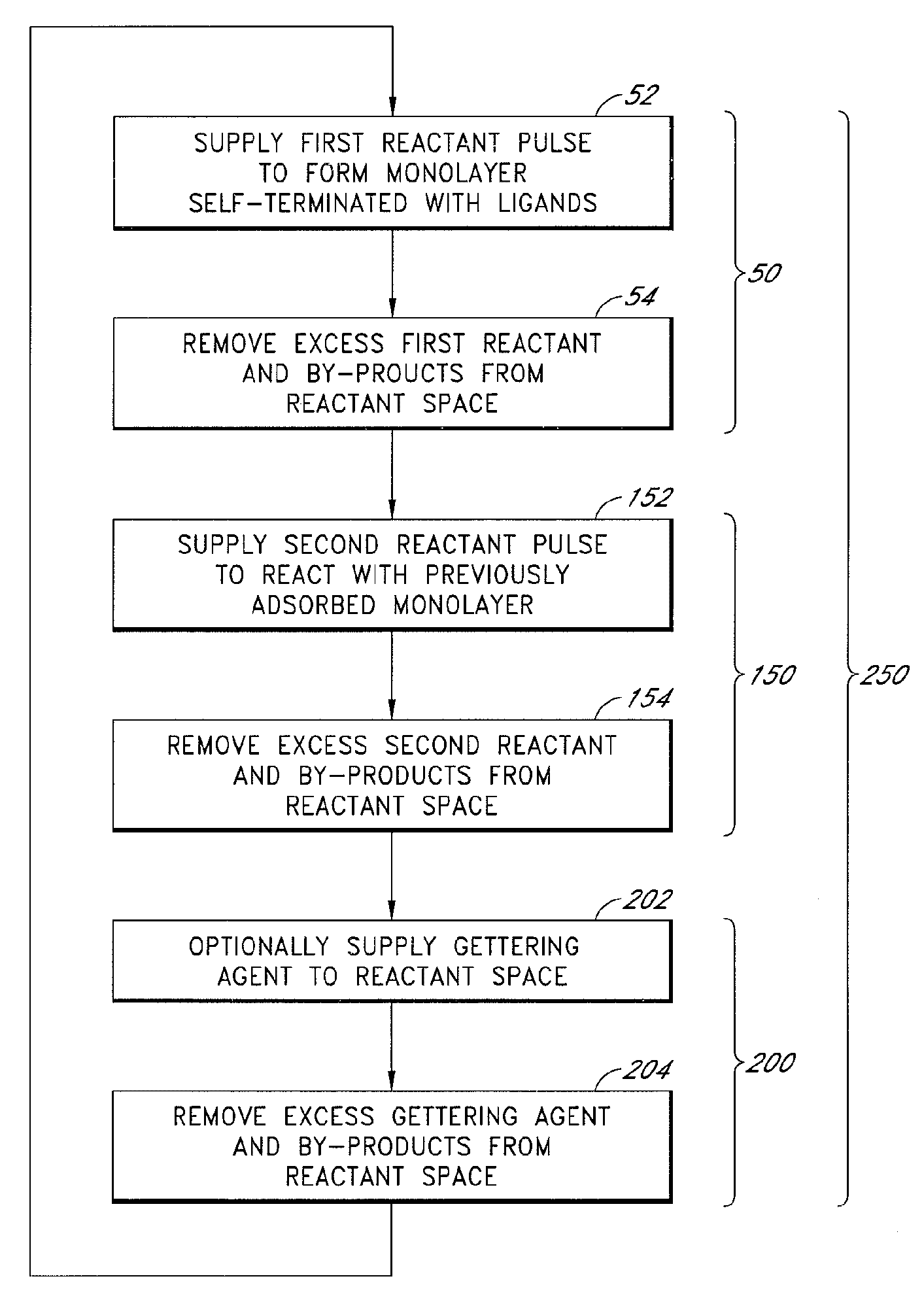

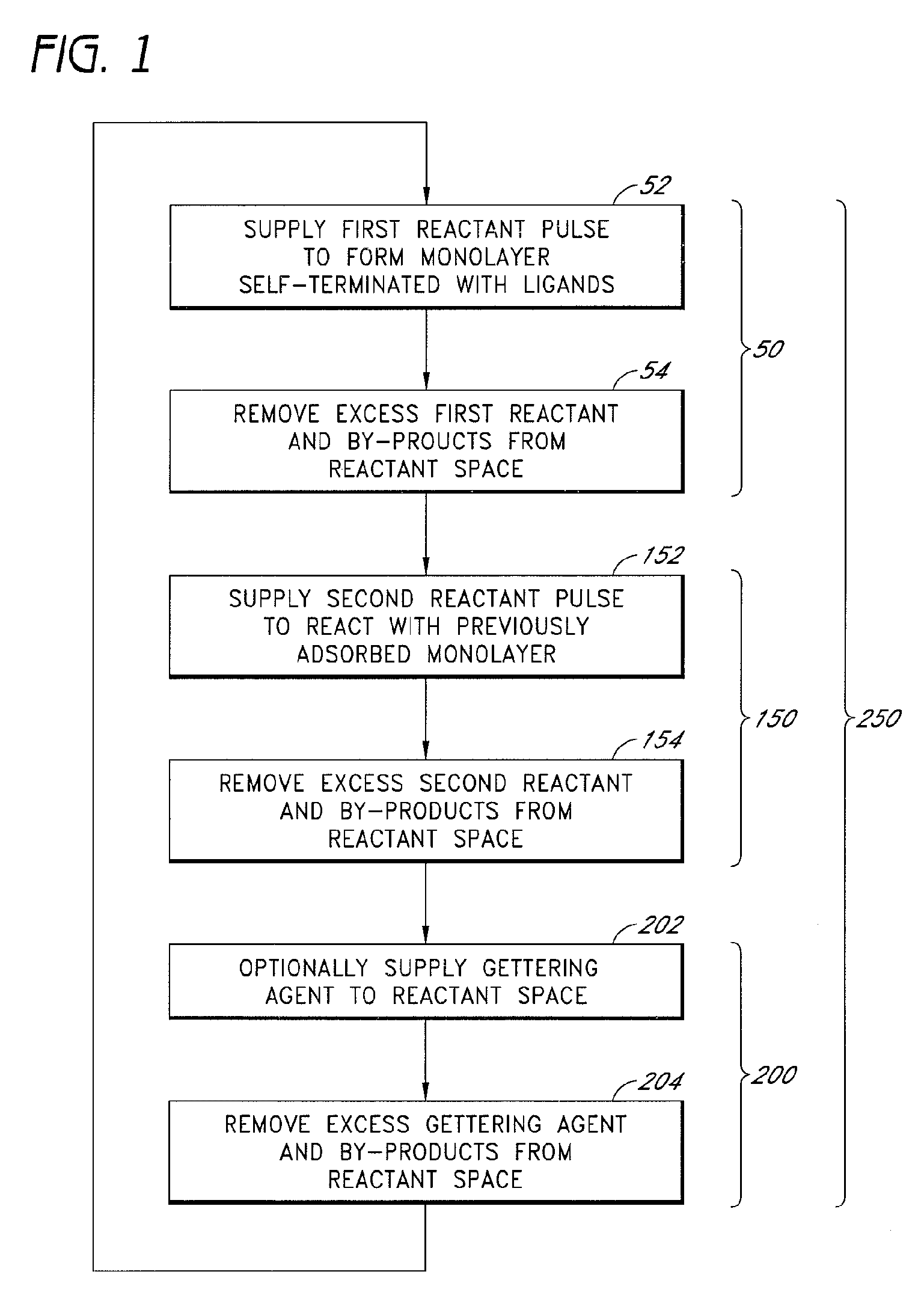

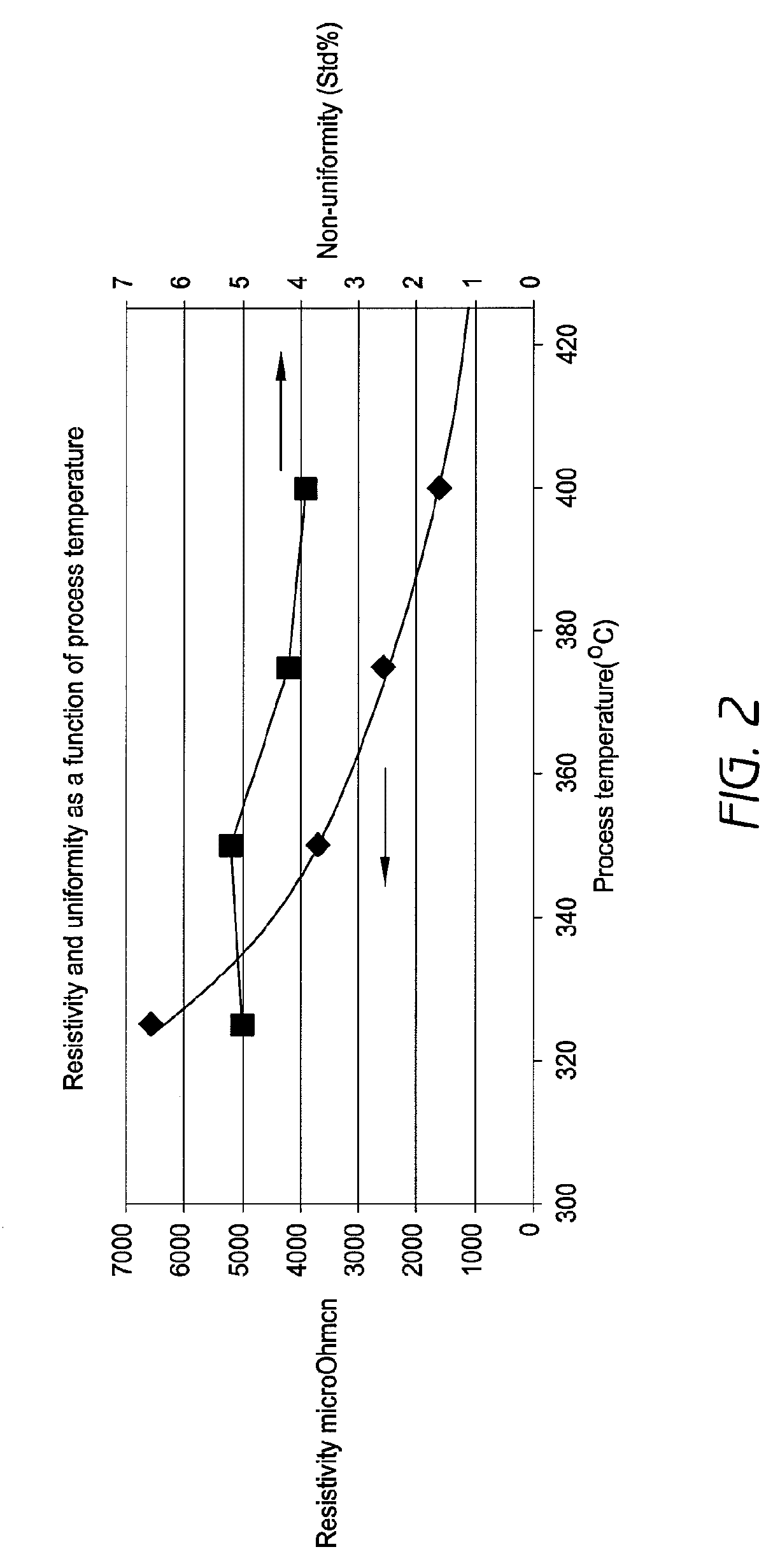

Low resistivity metal carbonitride thin film deposition by atomic layer deposition

ActiveUS7638170B2Polycrystalline material growthFrom chemically reactive gasesBis(trimethylsilyl)amineDisilane

Owner:ASM INTERNATIONAL

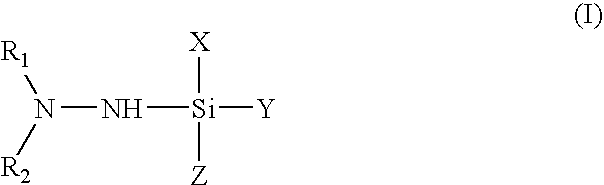

Monosilane or disilane derivatives and method for low temperature deposition of silicon-containing films using the same

This invention relates to silicon precursor compositions for forming silicon-containing films by low temperature (e.g., <550° C.) chemical vapor deposition processes for fabrication of ULSI devices and device structures. Such silicon precursor compositions comprise at least a silane or disilane derivative that is substituted with at least one alkylhydrazine functional groups and is free of halogen substitutes.

Owner:ENTEGRIS INC

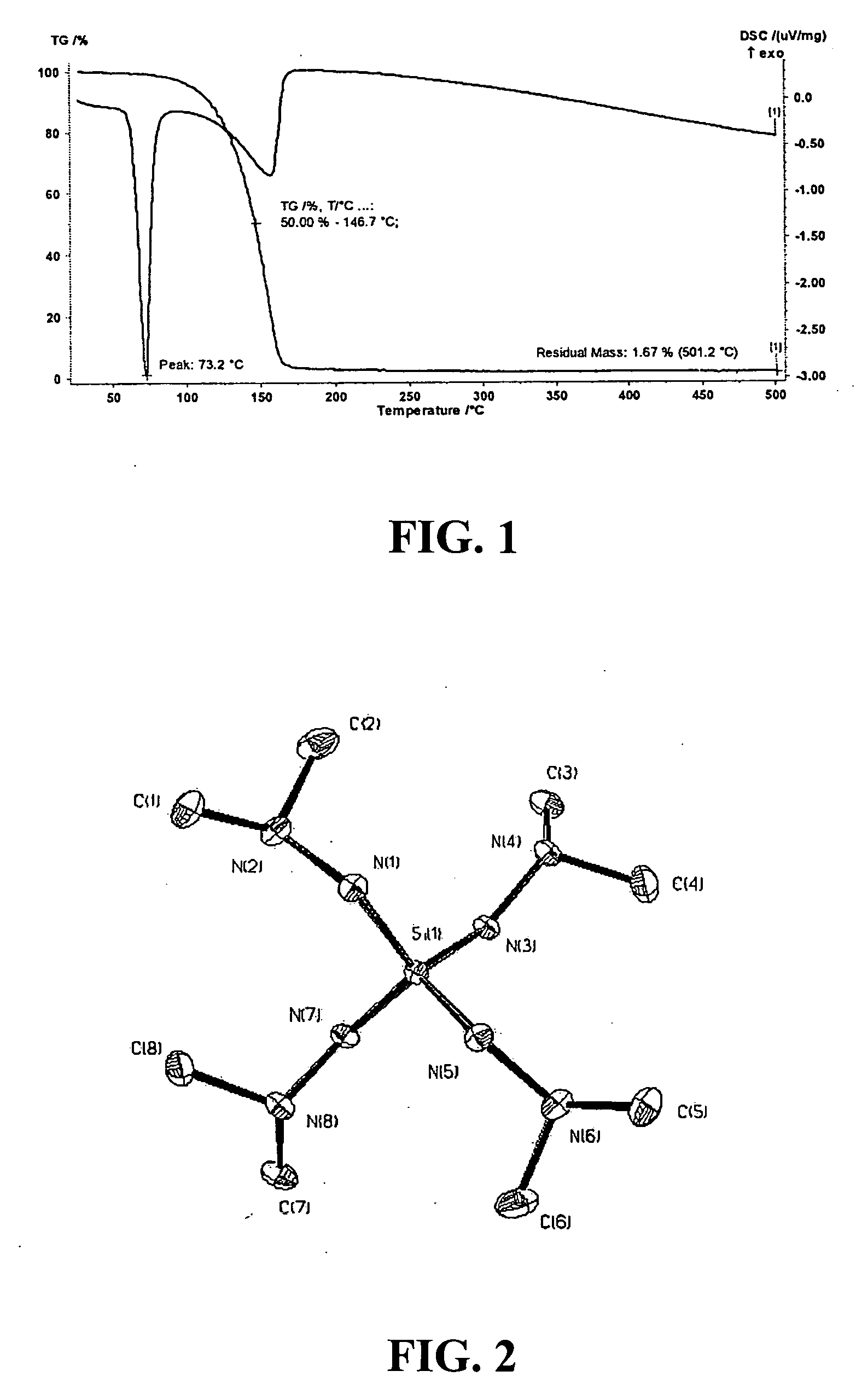

Pentakis(dimethylamino) disilane precursor comprising compound and method for the preparation thereof

ActiveUS8153832B2Improve featuresEasy to disassembleSilicon organic compoundsChemical vapor deposition coatingDielectricGate dielectric

Pentakis(dimethylamino) disilane with general formula (1): Si2(NMe2)5Y, where Y is selected from the group comprising H, Cl or an amino group its preparation method and its use to manufacture gate dielectric films or etch-stop dielectric films of SiN or SiON.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Method for depositing silicon nitride films and/or silicon oxynitride films by chemical vapor deposition

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Fast luminescent silicon

There are provided mesoporous silica materials containing in their pores stabilized clusters of silicon atoms, of size 2 nanometers or less, and capable of photoluminescence to emit fast photons. They are prepared by chemical vapour deposition of silicon or a silicon precursor such as disilane, under soft conditions such as temperature of 100-150° C., into the mesopores of silicate films which have mesoporous channels prepared by growth of the films using a template to control their sizes, but without removing the template residues from the films prior to the chemical vapour deposition. The template residues serve to limit the size of the silicon clusters which conform. The use of the soft conditions on CVD retains the template residues in an intact, substantially unchanged form. The resultant films have clusters of silicon, of 2 nanometer size or less, anchored to the mesopores, and air stable, so that they can be used in optoelectronic devices in conjunction with standard silicon semiconductors.

Owner:THE GOVERNING COUNCIL OF THE UNIV OF TORONTO

Wear-resisting anti-slip mountaineering sole material and preparation method thereof

The invention discloses a wear-resisting anti-slip mountaineering sole material which is characterized by being prepared from the following components in percentage by mass: 25-30% of natural rubber, 10-20% of butadiene rubber, 20-25% of butadiene styrene rubber, 5-10% of an ethylene-vinyl acetate copolymer, 5-10% of a modified starch polymer, 1-3% of short fibers, 5-10% of carbon black, 5-10% of white carbon black (SiO2), 2-3% of stearic acid (SA), 3-5% of zinc oxide, 2-3% of tert-thio disilane (Si-69), 2-5% of sulfur (S), 1-3% of a filling agent, 0.5-0.8% of zinc stearate, 0.5-0.8% of diisopropylbenzene peroxide, 0.3-0.5% of azodicarbonamide, 2-3% of an active agent, 0.5-2.5% of a coupling agent, 0.8-1.0% of an accelerant and 1-2% of an anti-aging agent. The wear-resisting anti-slip mountaineering sole material is outstanding in water absorption property and moisture releasability; the prepared sole is low in hardness, good in flexibility and bending resistance, low in consumption, high in wear resistance and anti-tear property and good in elasticity and puncturing resistance; and the comfort and the security of mountaineering fitness exercise are improved; therefore, the wear-resisting anti-slip mountaineering sole material is wide in market application prospect.

Owner:朱伟萍

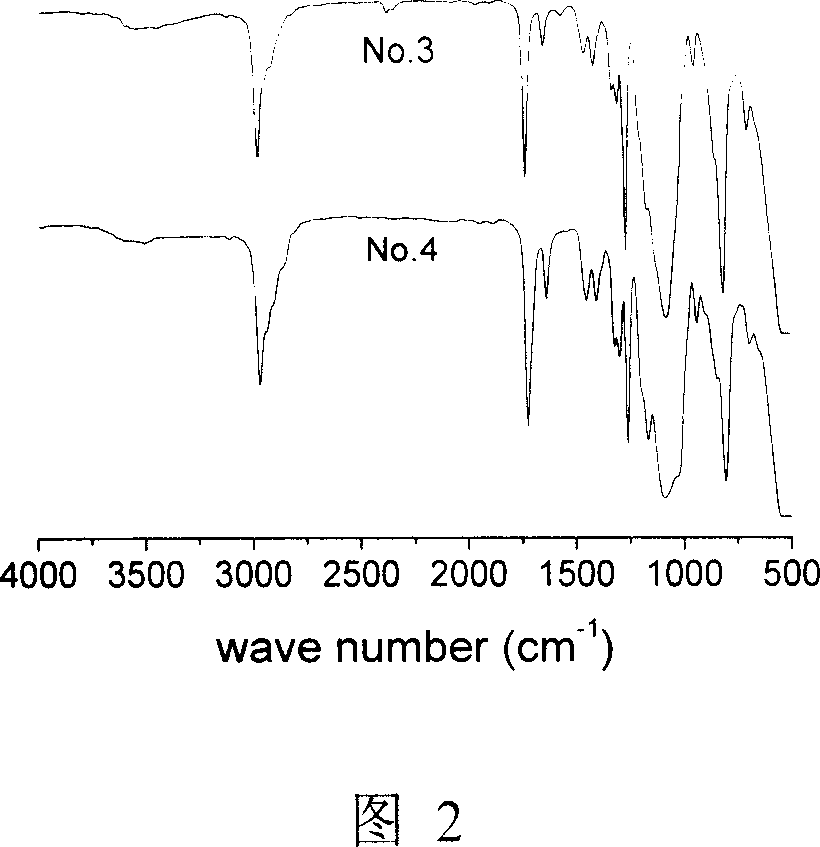

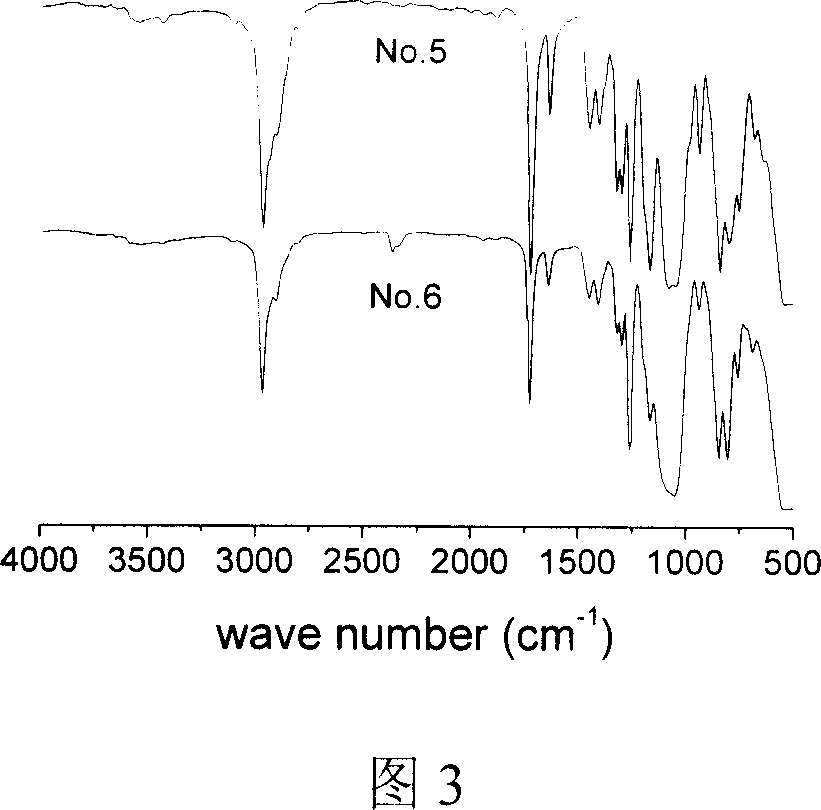

Silicon-containing (methyl) acrylate monomer and its copolymer and their prepn process

InactiveCN1974581AGood adhesionImprove water resistanceGroup 4/14 element organic compoundsSilanesDisilane

The present invention discloses silicon-containing (methyl) acrylate monomer and its copolymer and their preparation process. The silicon-containing (methyl) acrylate monomer as silane or silane oligomer with methyl propenyl acyloxy radical or propenyl acyloxy radical is prepared through the catalytic reaction of silane coupler with (methyl) propenyl acyloxy radical, and hexamethyl disilane or hexamethyl disilane and active organosilicon under the action of catalyst. The present invention also discloses one kind of silicon-containing (methyl) acrylate copolymer and its solution copolymerization, water emulsion copolymerization and ultraviolet curing process. The copolymer has excellent adhering performance, waterproof and antifouling performance and weather resistance.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

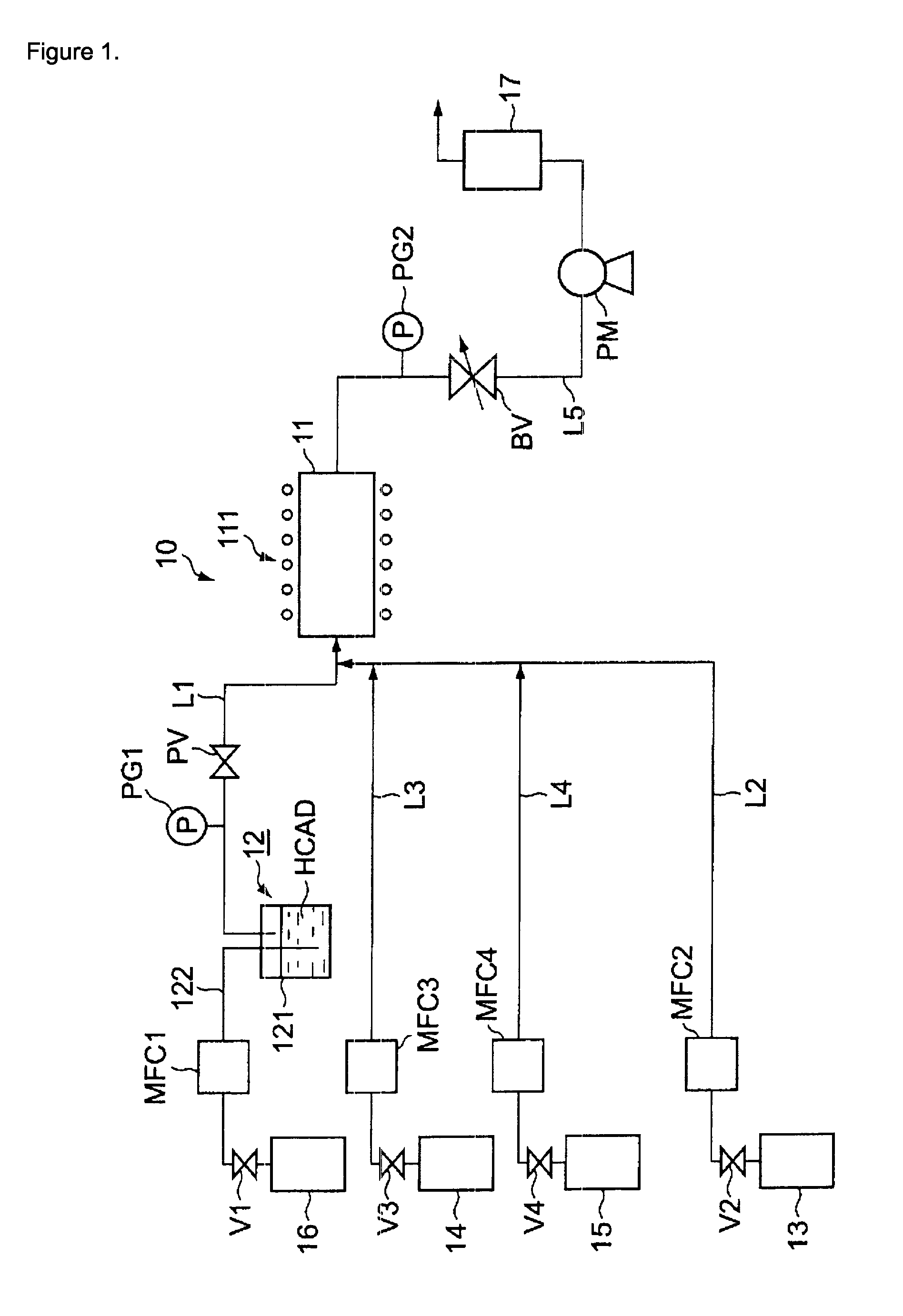

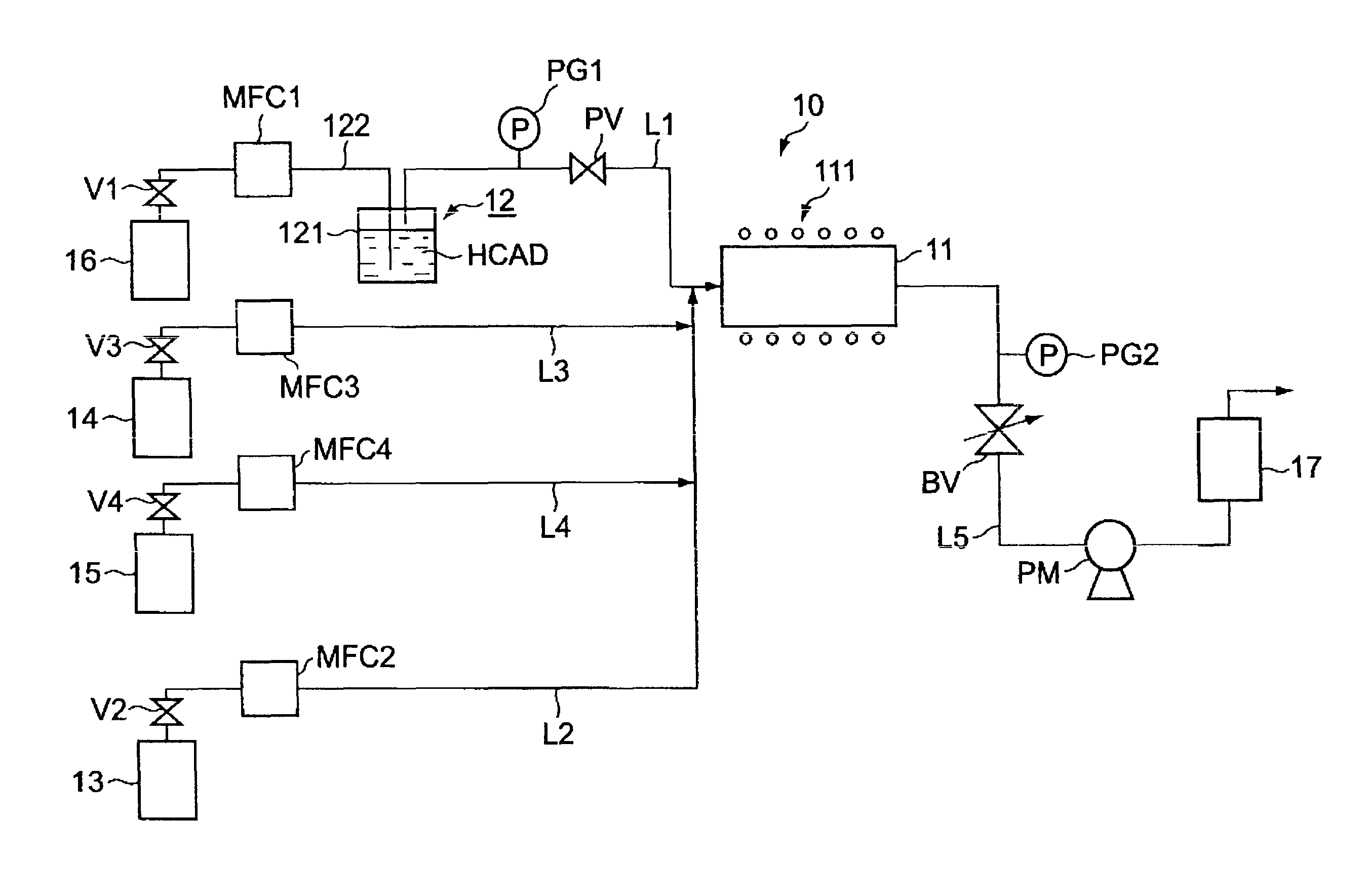

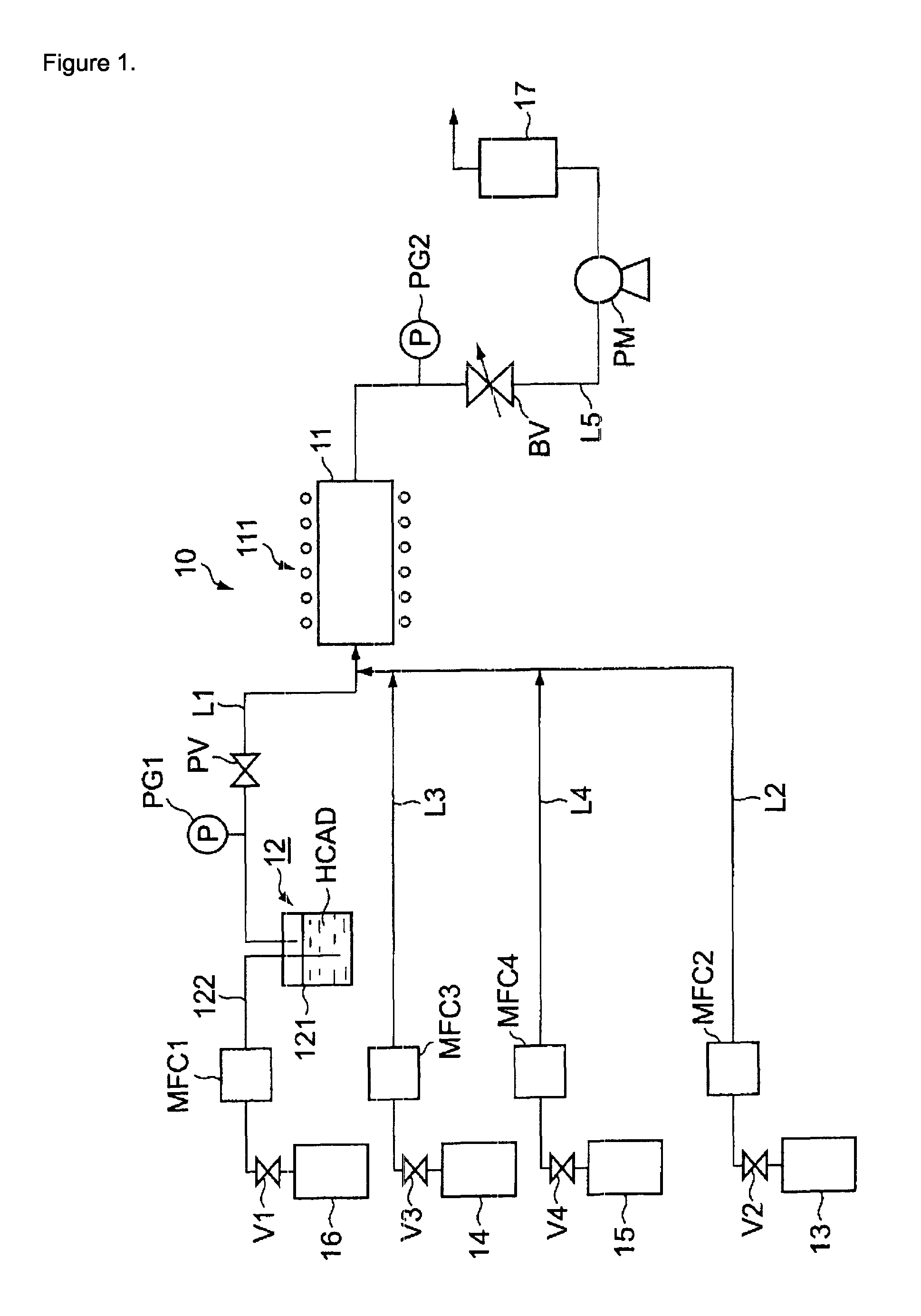

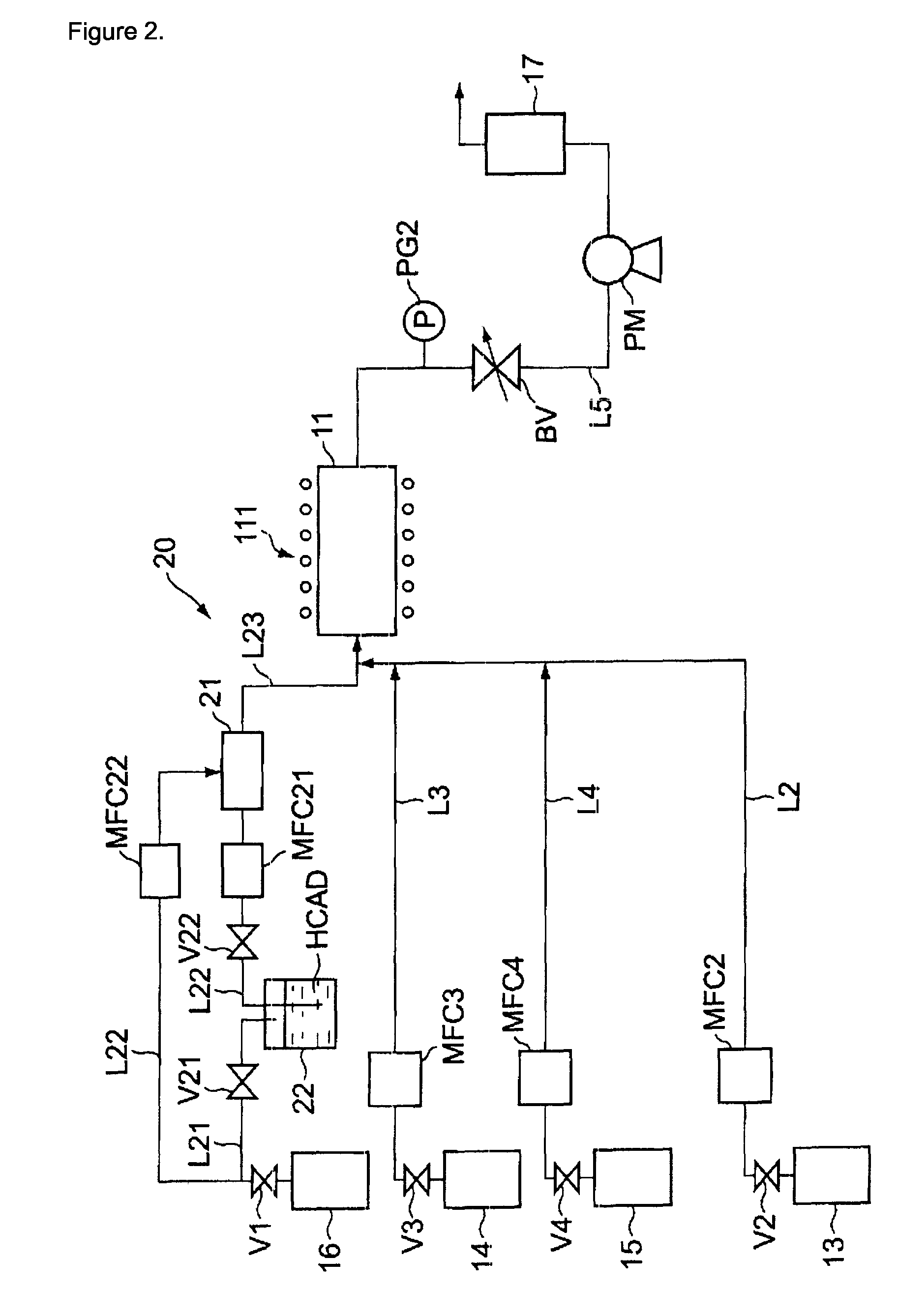

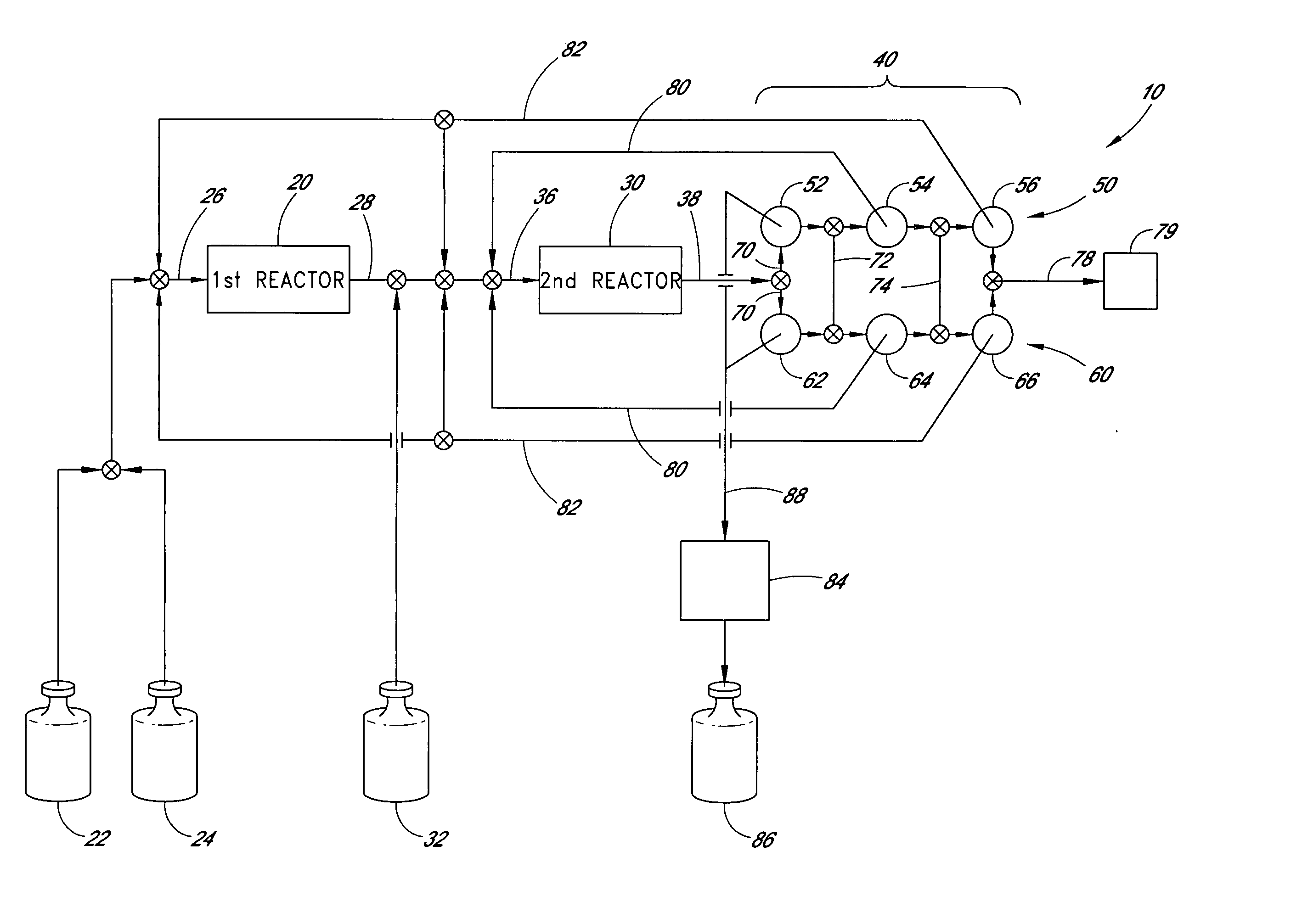

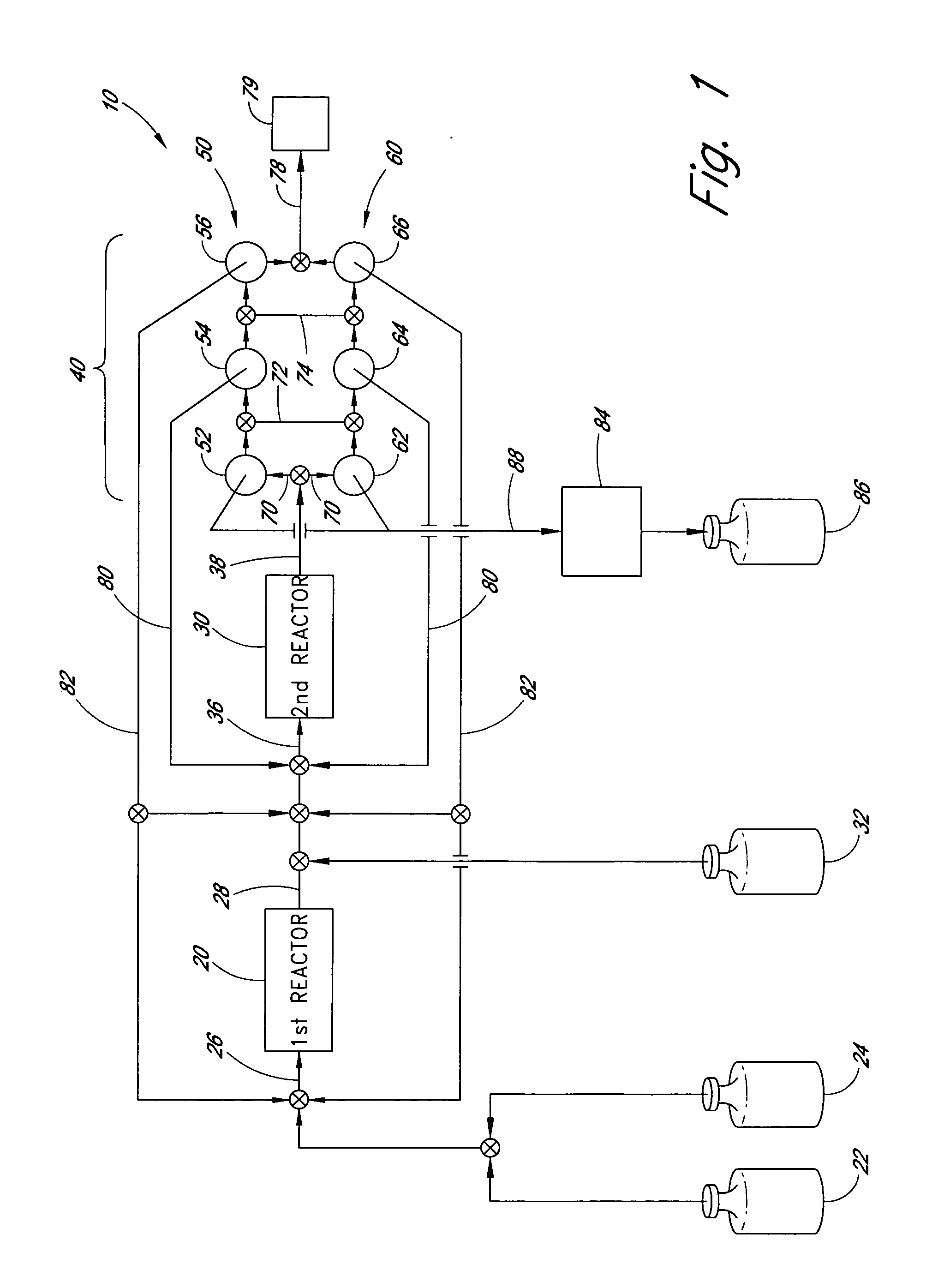

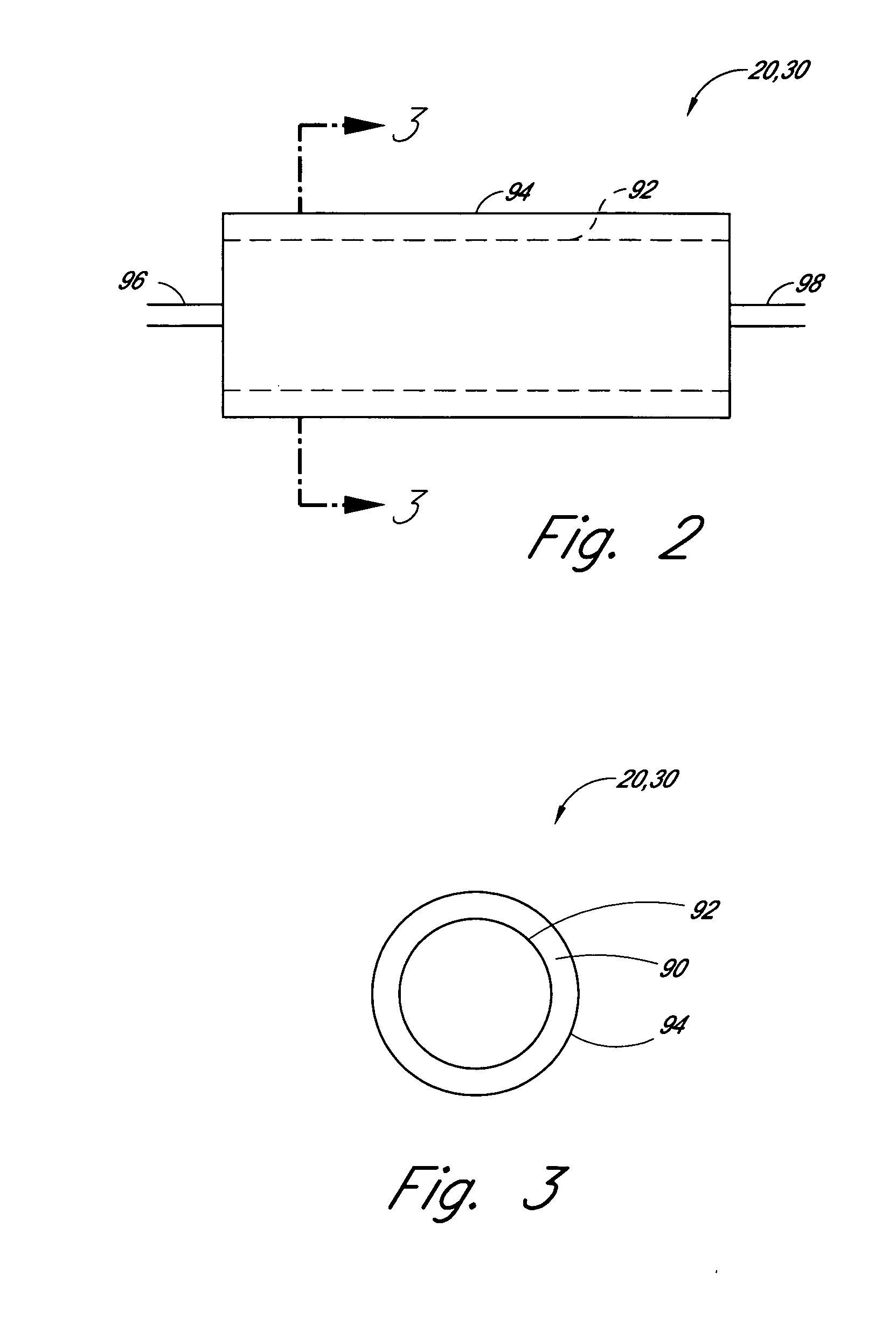

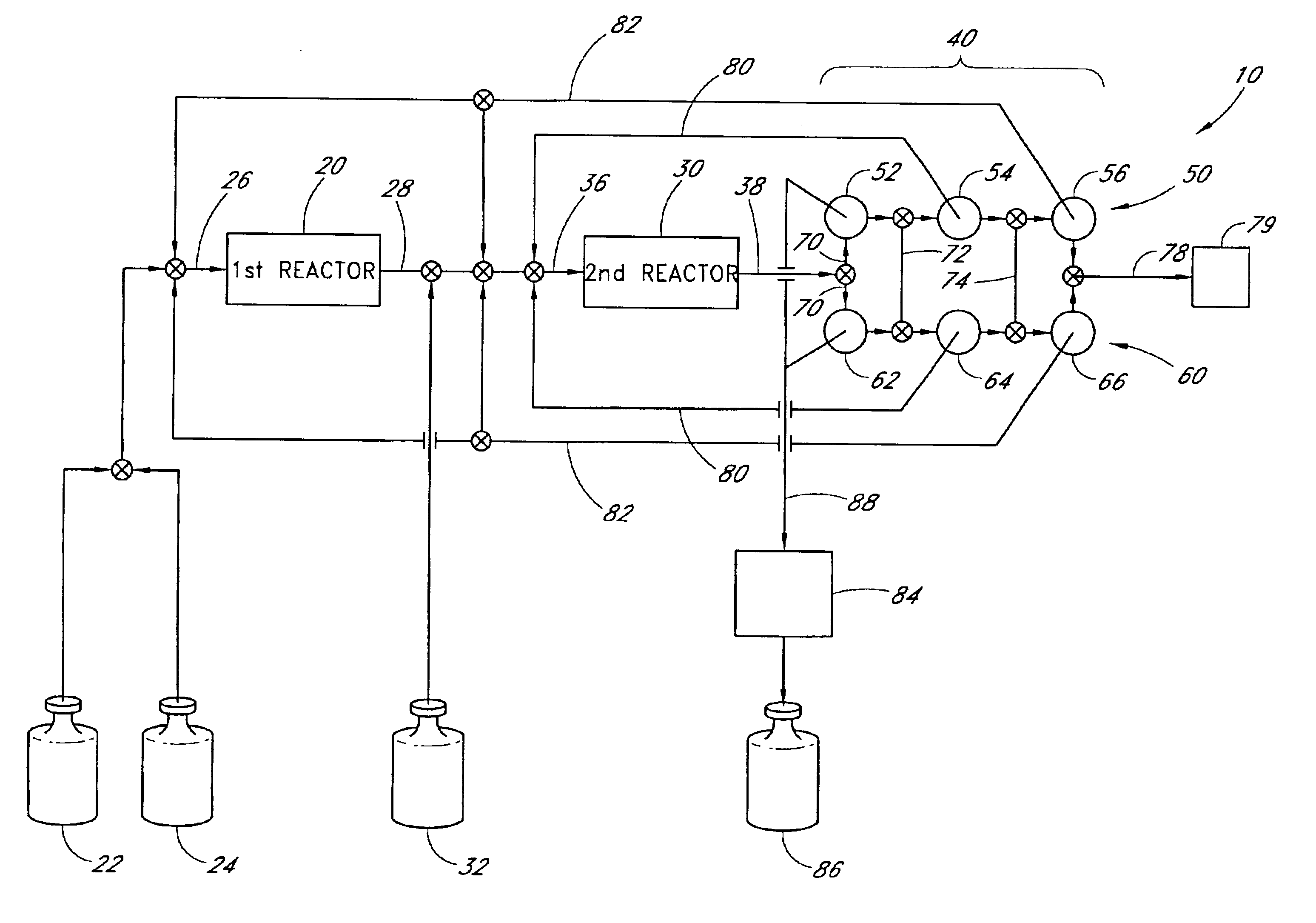

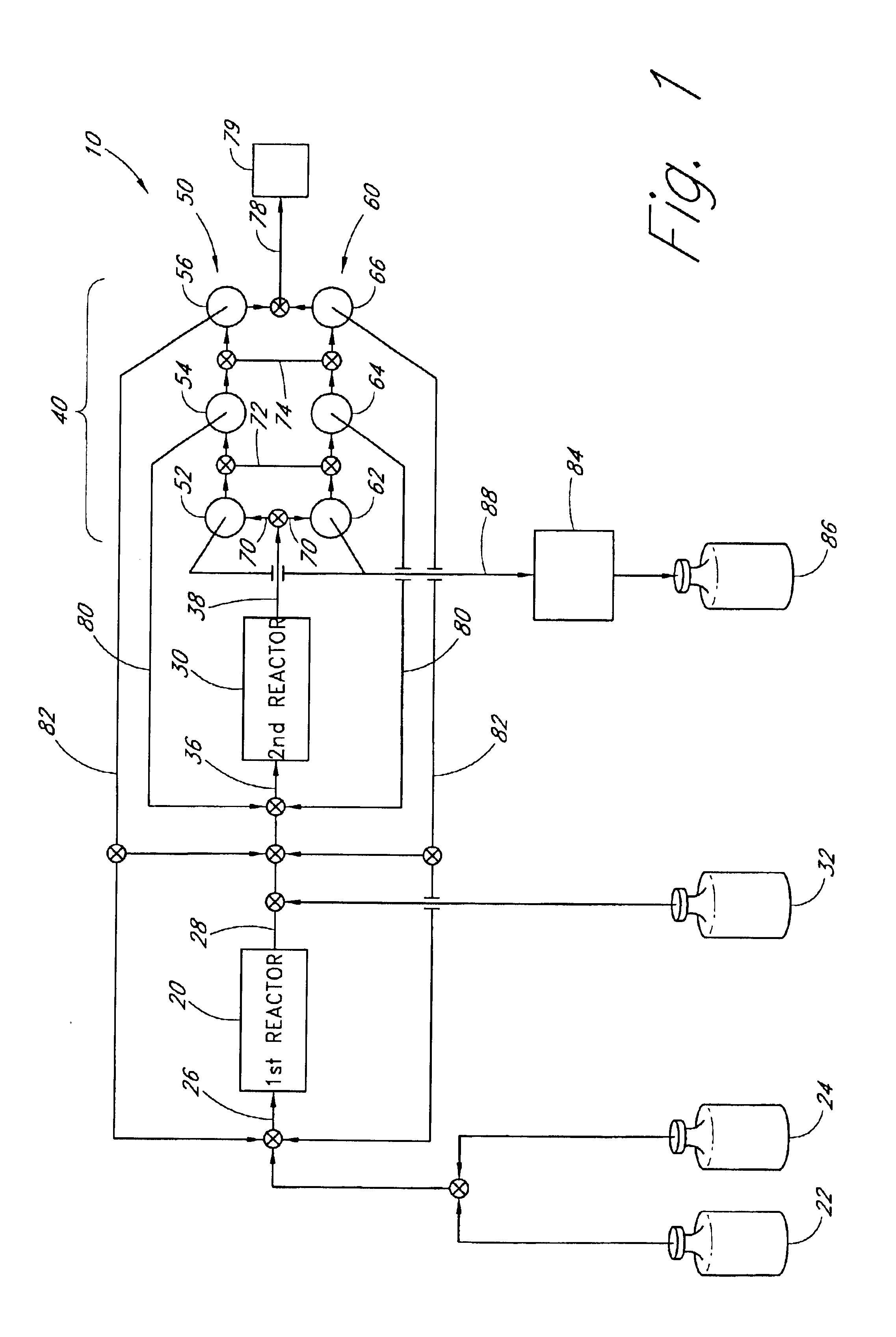

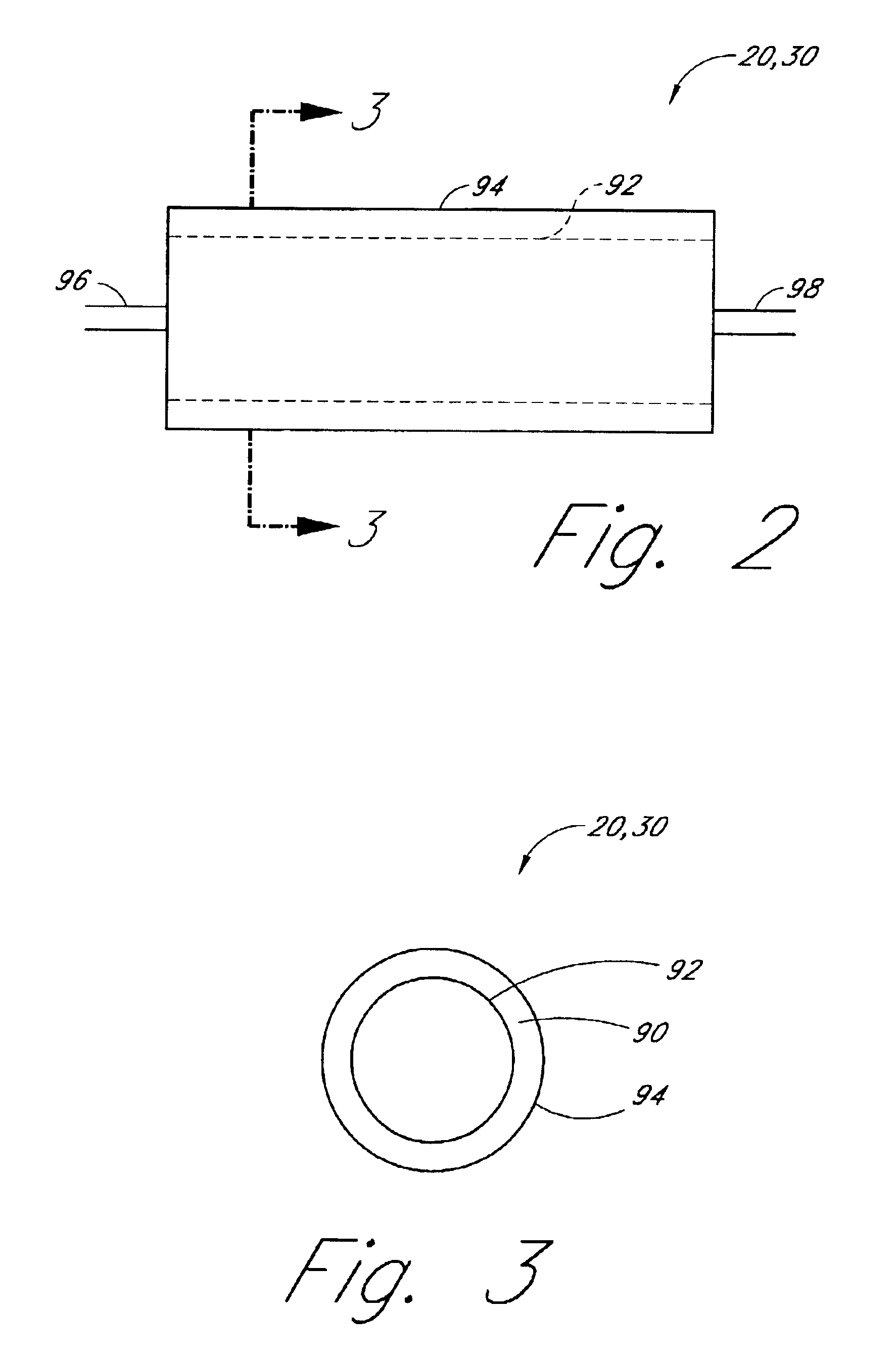

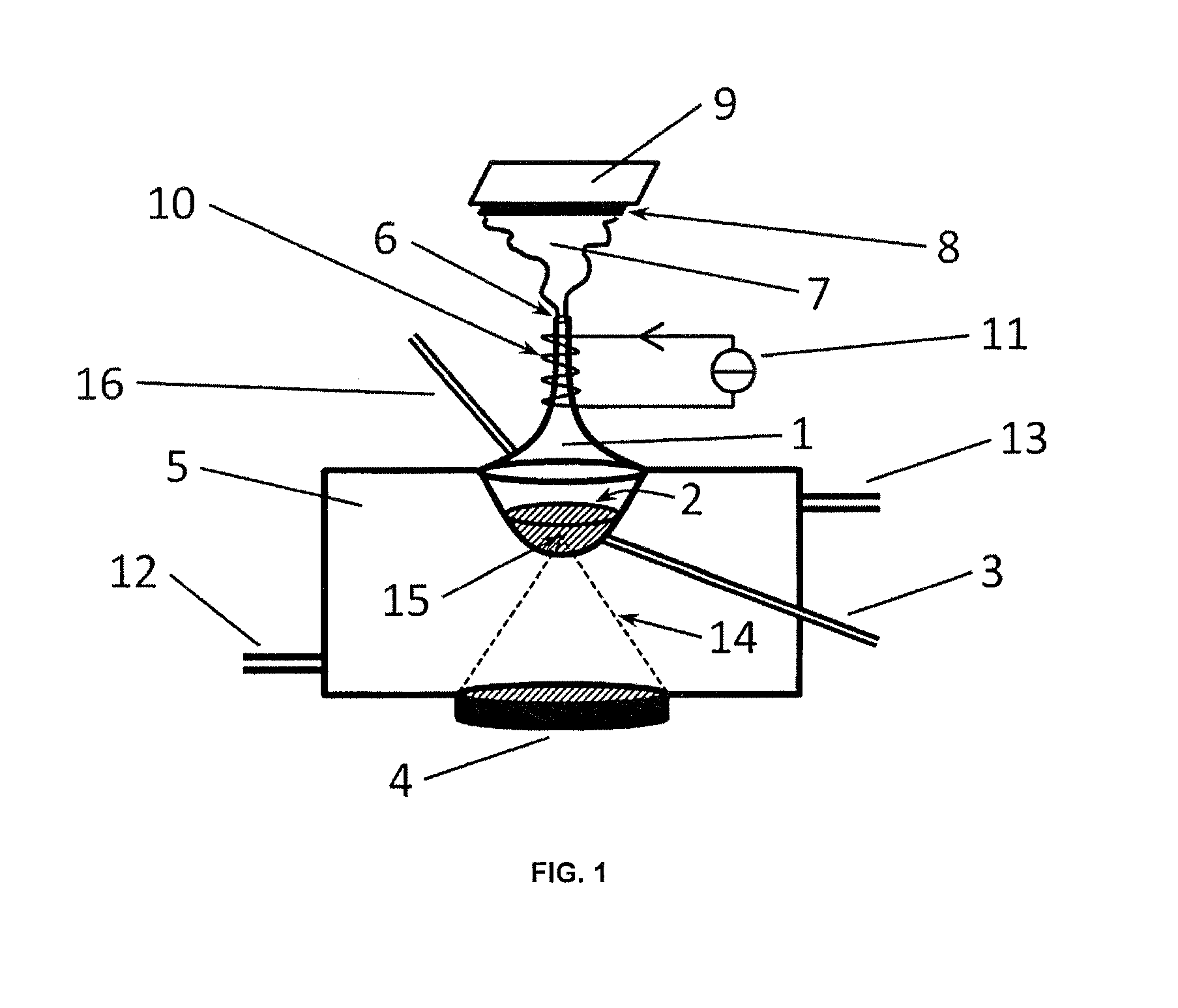

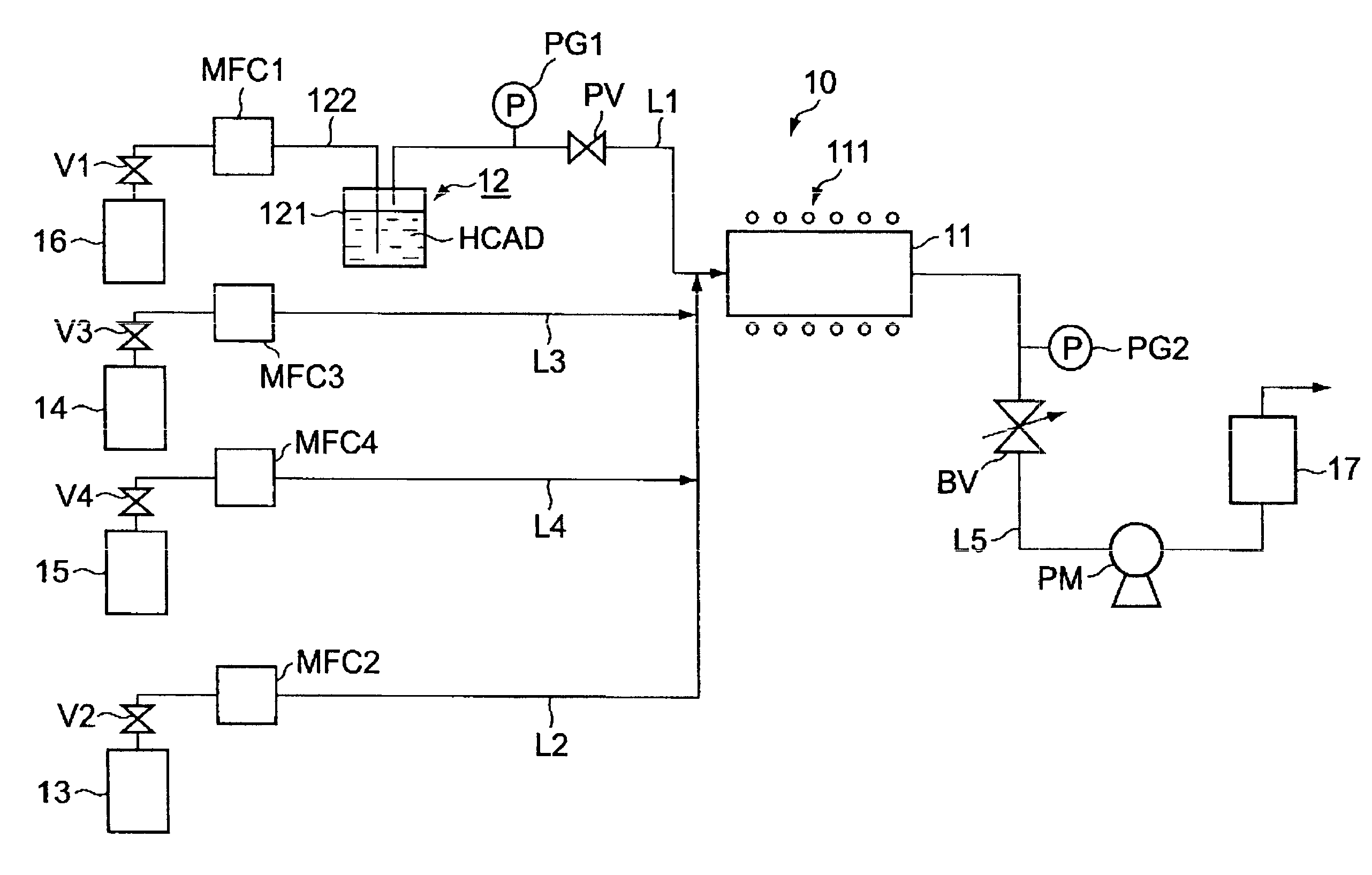

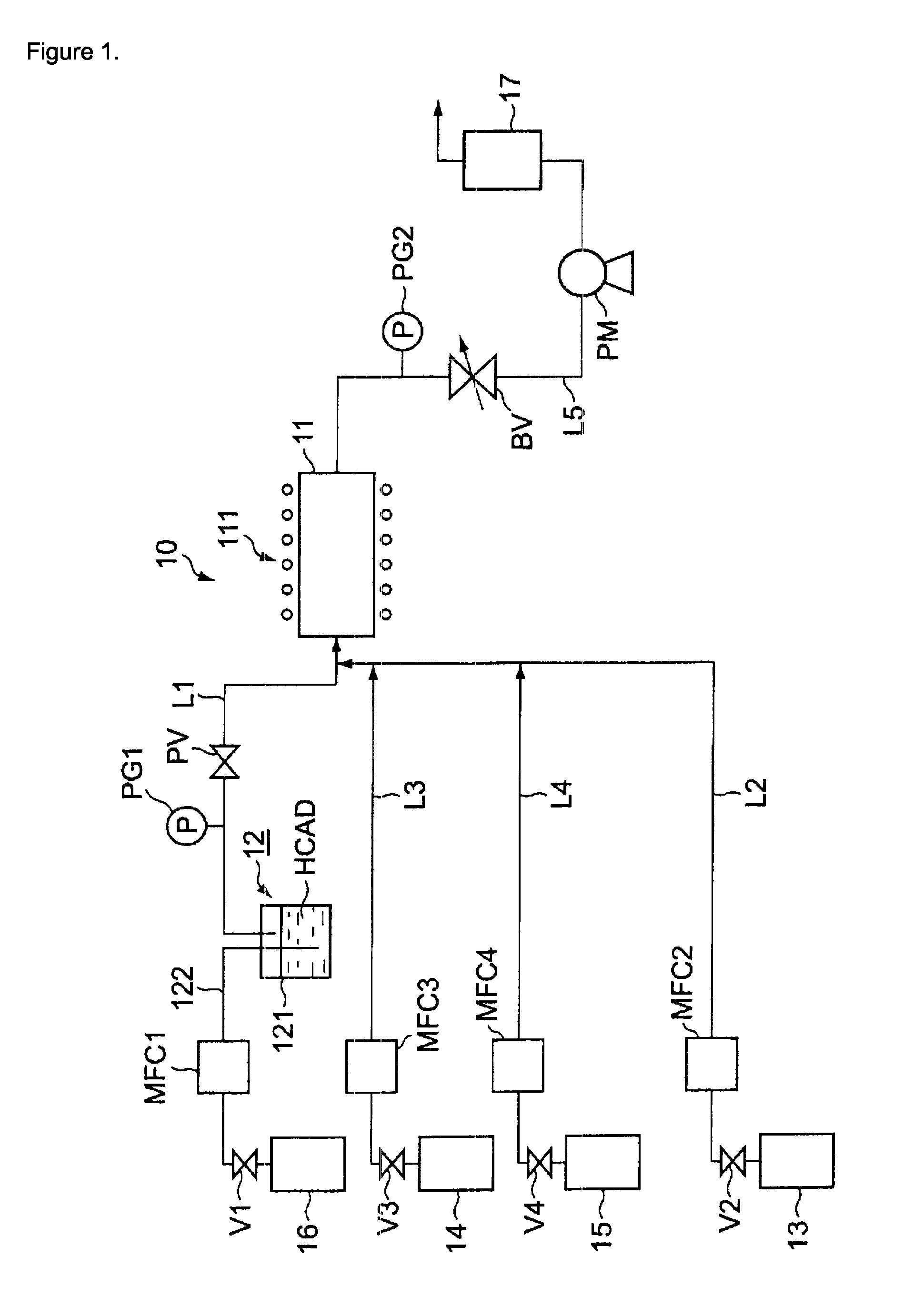

Method and apparatus for chemical synthesis

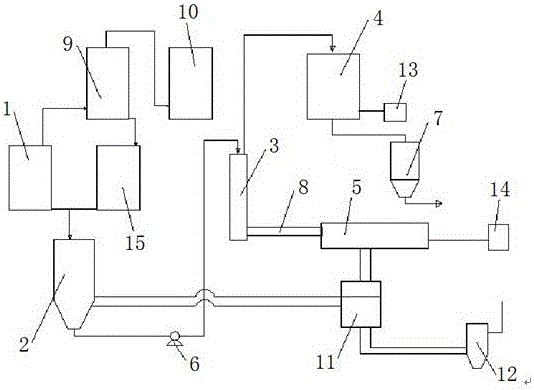

InactiveUS20050142046A1Silicon hydridesEnergy based chemical/physical/physico-chemical processesChemical synthesisCondensation trap

An apparatus is provided for synthesis and collection of higher order chemical compounds from lower order precursors. The apparatus includes a first silent electric discharge reactor configured to synthesize an intermediate product (e.g., disilane) from a precursor chemical (e.g., monosilane). A second silent electric discharge reactor is connected downstream of the first reactor. This second reactor is configured to convert the intermediate product into the higher order chemical compound (e.g., trisilane). Multiple condensation traps are also connected to receive effluent from the second reactor, which will generally include the compound of interest as well as unreacted precursor and intermediate product. In the illustrated embodiment, a parallel second condensation traps is also included to shunt flow and continue collection while the chemical of interest is removed for purification. Moreover, parallel second condensation traps for the intermediate product and unreacted (or recombined) precursor allow continued collection while the contents of the first traps are recycled in the reactor(s).

Owner:ASM AMERICA INC

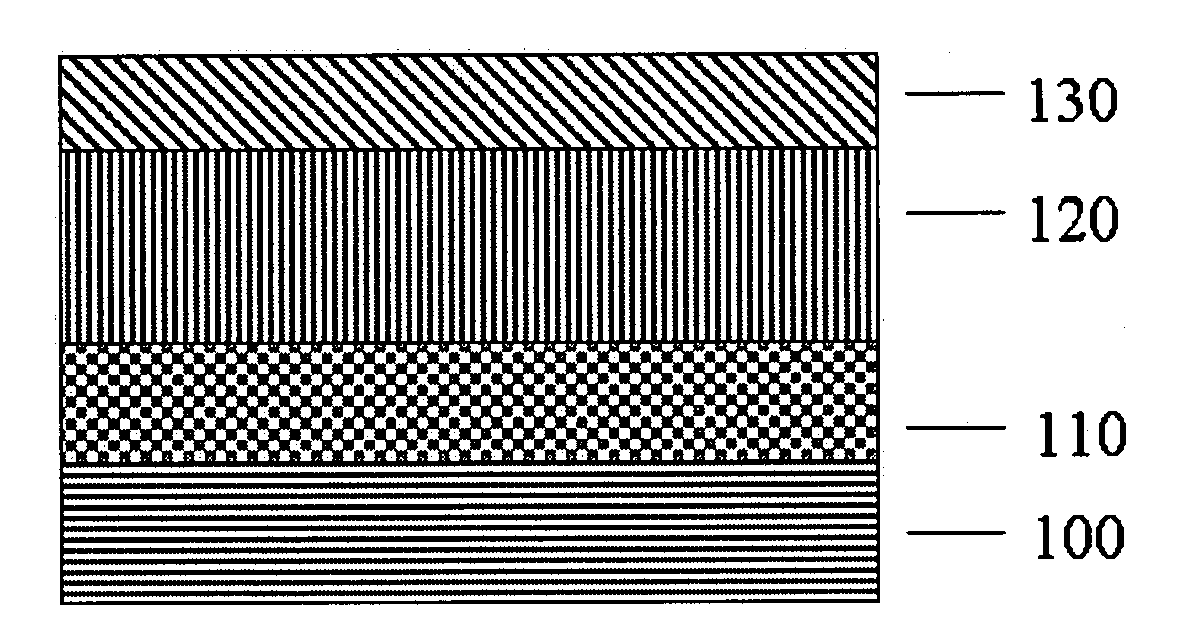

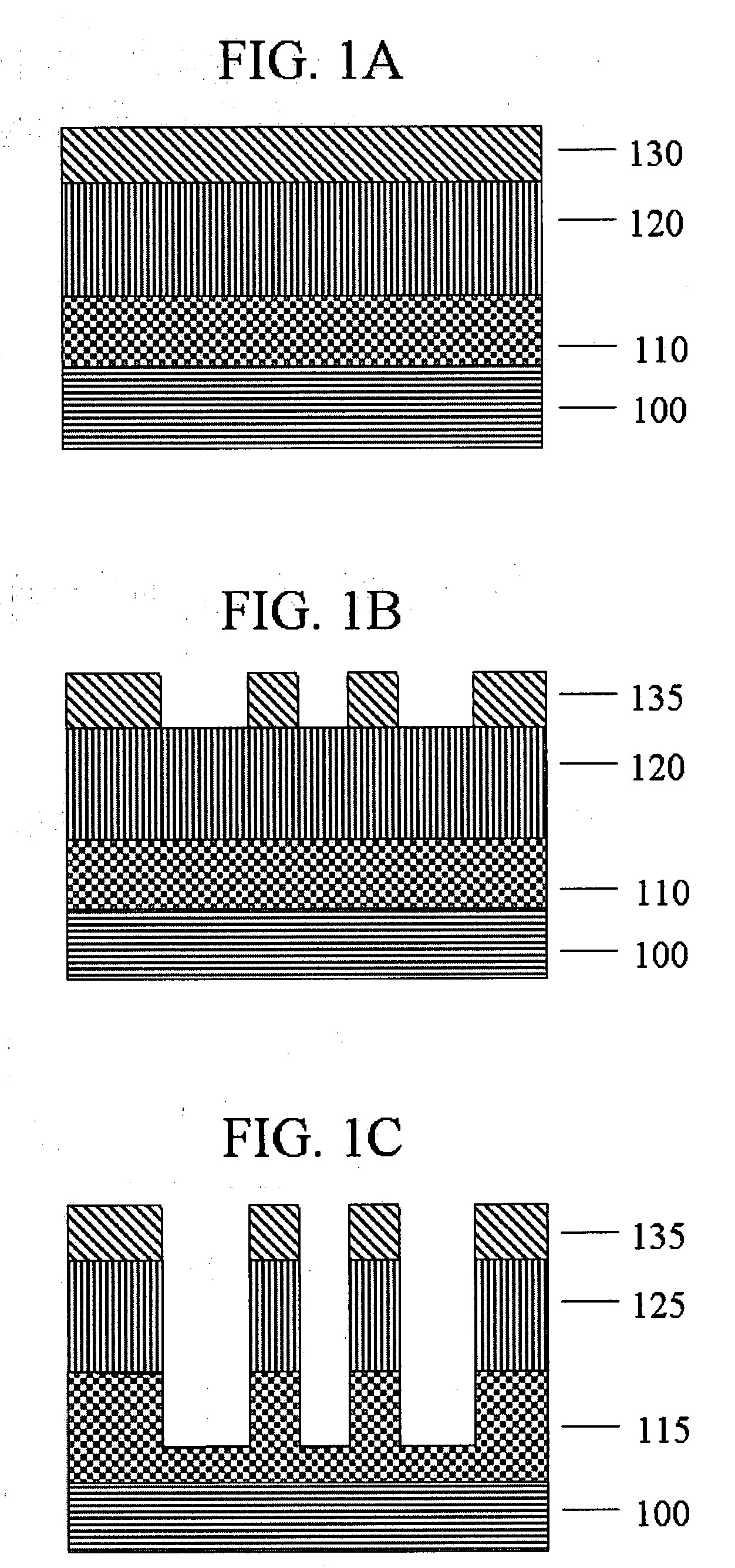

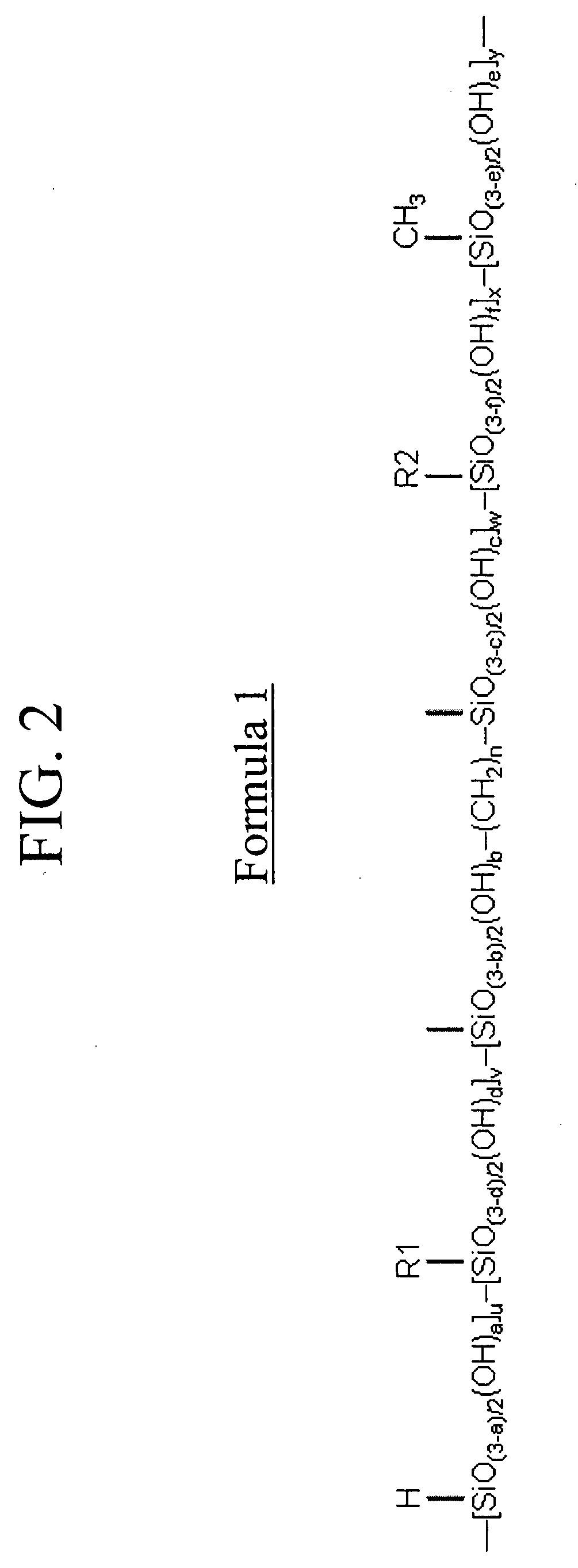

Etch-resistant disilane and saturated hydrocarbon bridged silicon-containing polymers, method of making the same, and method of using the same

ActiveUS20080241748A1Group 4/14 element organic compoundsPhotosensitive materialsDisilaneChromophore

A composition includes a copolymer including a mixture of monomeric units having structures (A), (B), and (C), and one or more of structures (D) or (E):HSiO(3-a) / 2(OH)a (A)Si(3-b) / 2(OH)b—CH2)n—SiO(3-c) / 2(OH)c (B)R1SiO(3-d) / 2(OH)d (C)MeSi(3-e) / 2(OH)e (D)R2SiO(3-f) / 2(OH)f (E)wherein a, b, c, d, e, and f are independently from 0 to 2, n is from 0 to about 10, R1 is a chromophore, and R2 is a hydrophilic group.

Owner:CHEIL IND INC

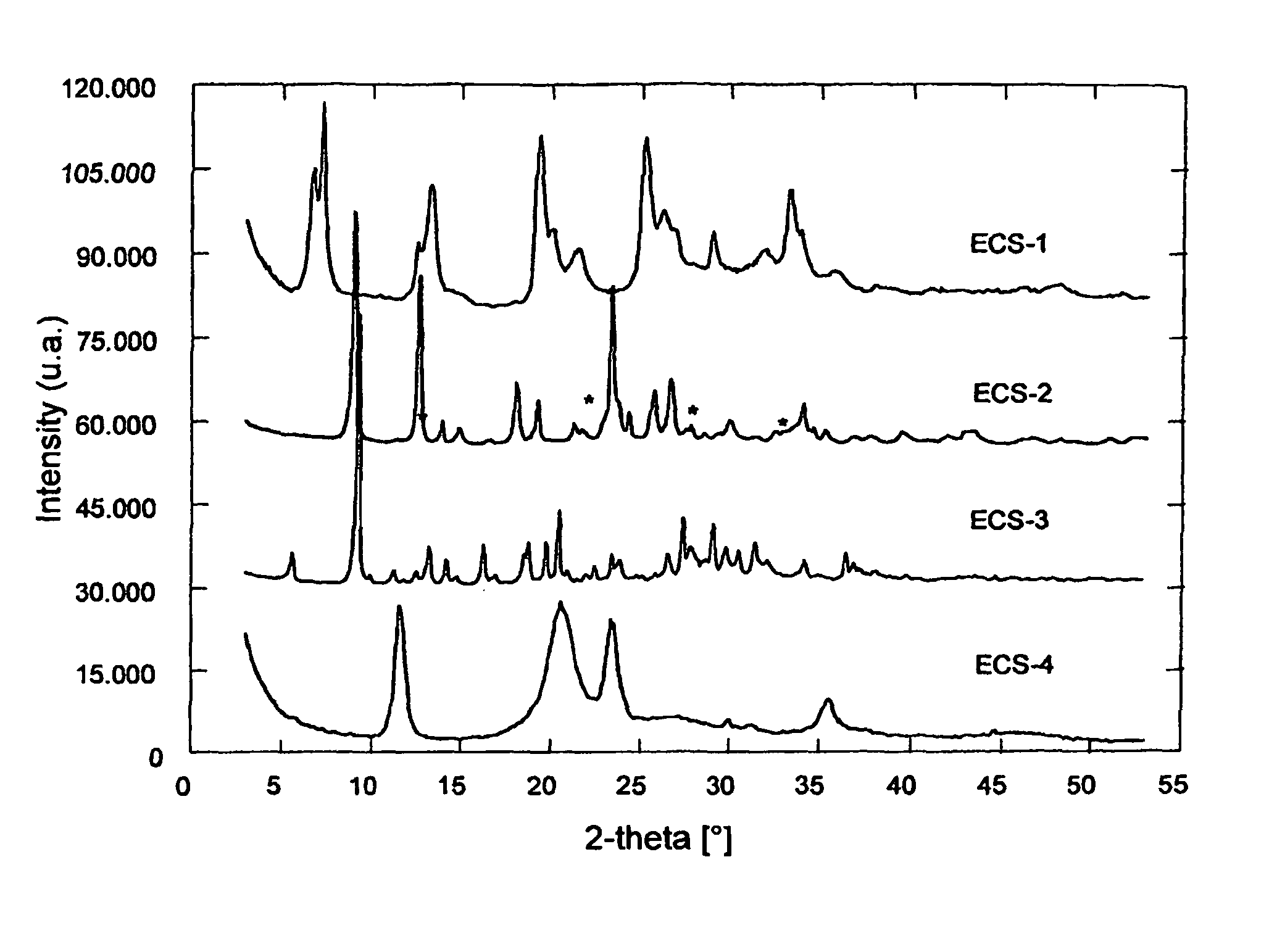

Organic-inorganic hybrid silicates and metal-silicates having an ordered structure

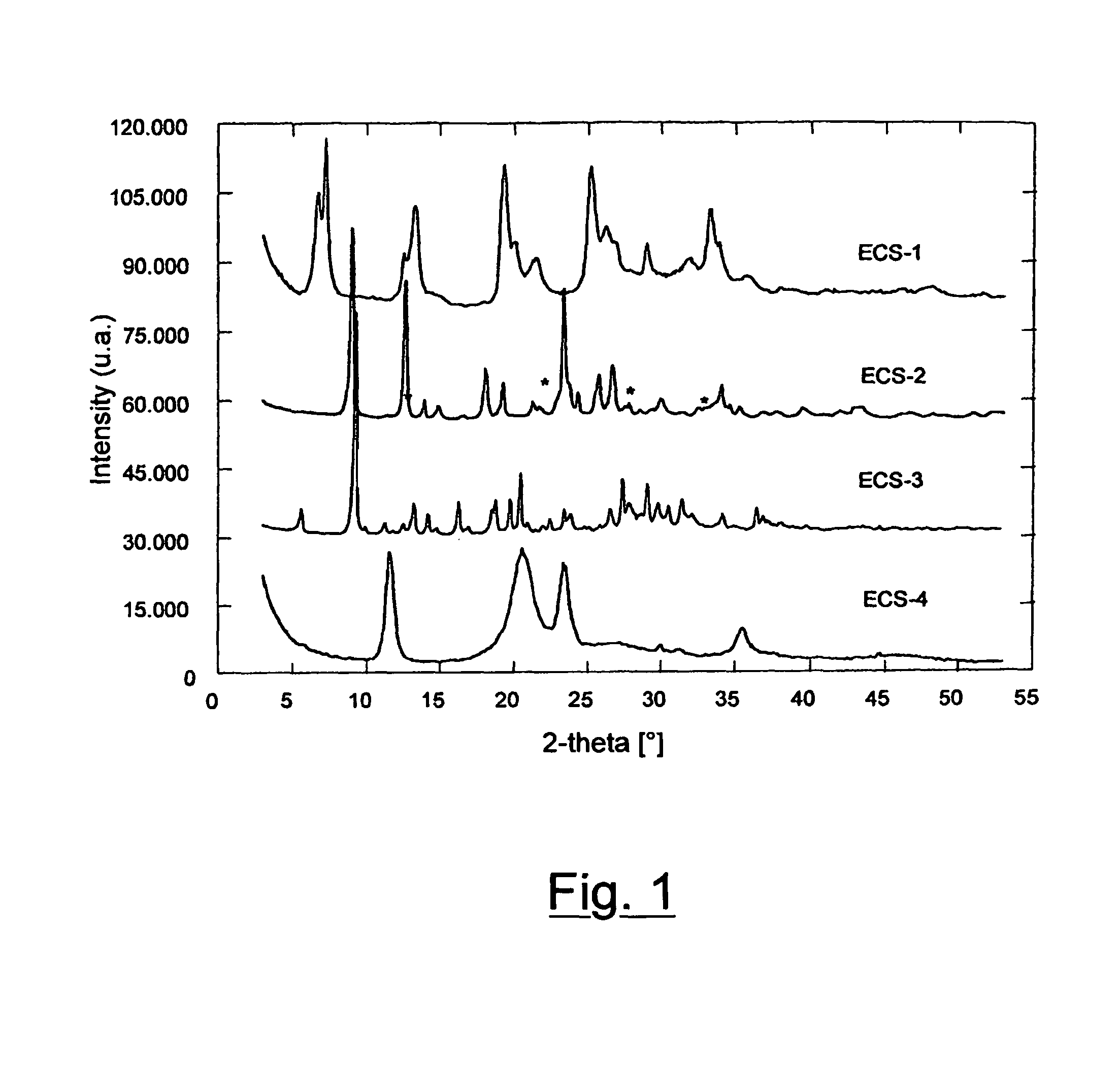

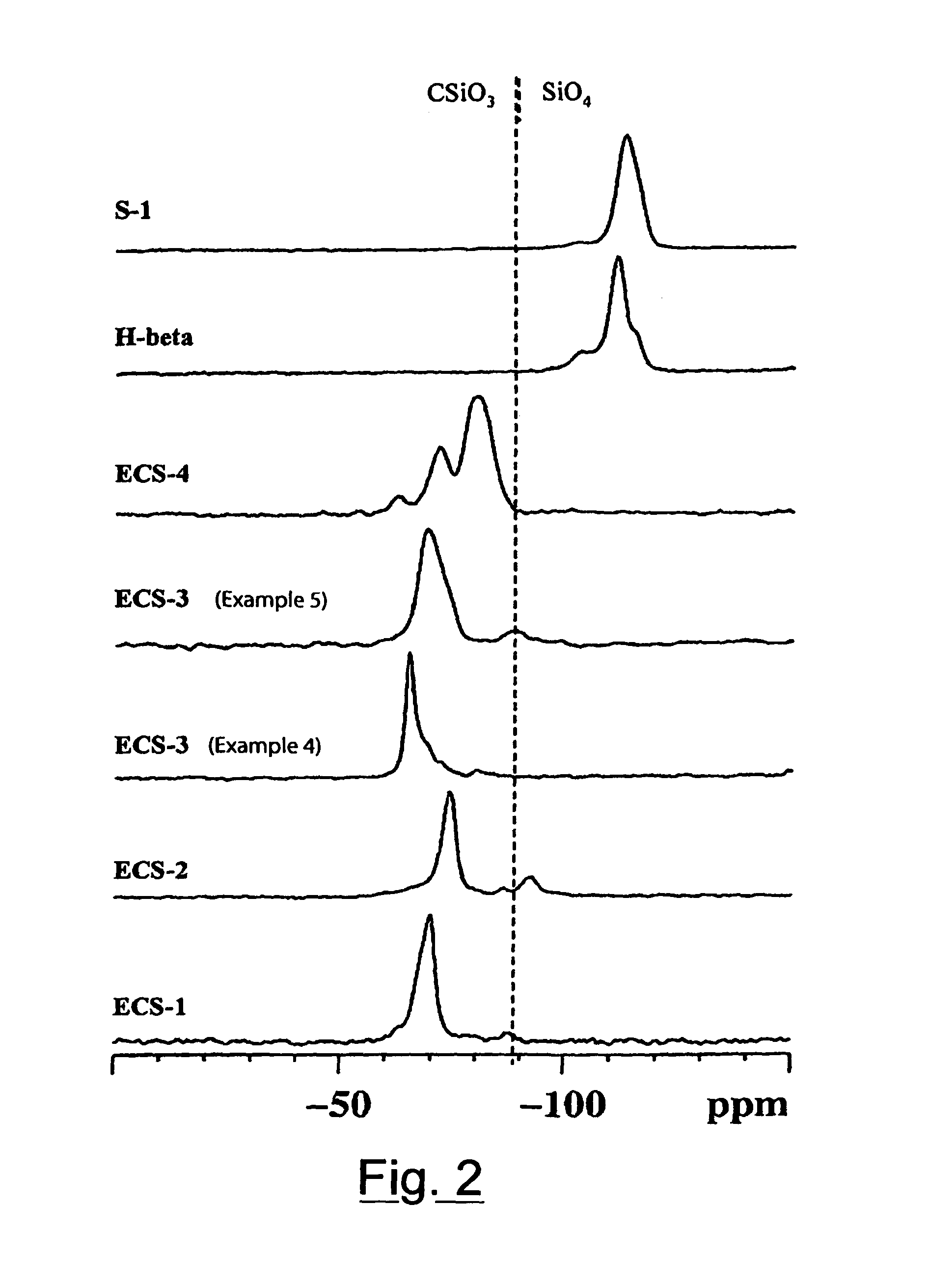

The present invention relates to new organic-inorganic hybrid silicates and metal-silicates called ECS, characterized by an X-ray powder diffraction pattern with reflections exclusively at angular values higher than 4.0° of 2θ, preferably at angular values higher than 4.7°, and an ordered structure containing structural units having formula (a) wherein R is an organic group: Formula (a) and possibly containing one or more elements T selected from groups III B, IV B, V B and transition metals, with a Si / (Si +T) molar ratio in said structure higher than 0.3 and lower than or equal to 1, wherein Si is the silicon contained in the structural unit (a). A process is also described, starting from disilanes, for the preparation of these materials, which does not include the use of templates or surfactants. These materials can be used as molecular sieves, adsorbents, in the field of catalysis, in the field of electronics, in the field of sensors, in the field of nanotechnologies.

Owner:ENI SPA

Treatment process and system for organic silica mud

ActiveCN106623370ATemperature controlImprove leaching rateSolid waste disposalTransportation and packagingSlagDisilane

The invention relates to a treatment process for organic silica mud. The treatment process comprises the following steps of: disilane hydrolysis, copper chloride leaching, pressing and backwashing, copper replacement, silicon slag roasting and tail gas treatment. According to the treatment process, hydrogen chloride gas generated by hydrolysis is effectively utilized, so that hydrogen chloride gas realizes zero discharge; a stirring reaction kettle is adopted for stirring and leaching, so that a leaching rate of copper is as high as 99%, copper content of sponge copper is 70% or higher, and iron chloride content is 30% or higher, and therefore, the economical value is increased; hydrolysis residues are roasted through a rotary kiln, so that silicon oxide content is greater than 98%, and therefore, the whole process route is free of wastewater and waste residue discharge, the waste gas is only carbon dioxide, harms on environment are reduced to be the lowest, the products are metal copper and silicon powder, and the economical value is high. Throughout the process, zero discharge of wastewater and waste residues is realized, so that the environmental benefits are remarkable; hydrolysis and leaching are performed under normal pressure at a temperature lower than 90 DEG C, requirements on the material and strength of equipment are not high, and a roasting temperature of the rotary kiln ranges from 500 DEG C to 850 DEG C; and moreover, silicon powder does not contain corrosive hydrogen chloride, and requirements on the material of the rotary kiln are not high.

Owner:李鹏

Monosilane or disilane derivatives and method for low temperature deposition of silicon-containing films using the same

InactiveUS20080160174A1Silicon organic compoundsMolten spray coatingLow temperature depositionHalogen

Owner:ENTEGRIS INC

Method and apparatus for chemical synthesis

InactiveUS6858196B2Easy to operate continuouslyHighly orderedNitrogen compoundsMetal silicidesCondensation trapChemical synthesis

An apparatus is provided for synthesis and collection of higher order chemical compounds from lower order precursors. The apparatus includes a first silent electric discharge reactor configured to synthesize an intermediate product (e.g., disilane) from a precursor chemical (e.g., monosilane). A second silent electric discharge reactor is connected downstream of the first reactor. This second reactor is configured to convert the intermediate product into the higher order chemical compound (e.g., trisilane). Multiple condensation traps are also connected to receive effluent from the second reactor, which will generally include the compound of interest as well as unreacted precursor and intermediate product. In the illustrated embodiment, a parallel second condensation traps is also included to shunt flow and continue collection while the chemical of interest is removed for purification. Moreover, parallel second condensation traps for the intermediate product and unreacted (or recombined) precursor allow continued collection while the contents of the first traps are recycled in the reactor(s).

Owner:ASM IP HLDG BV

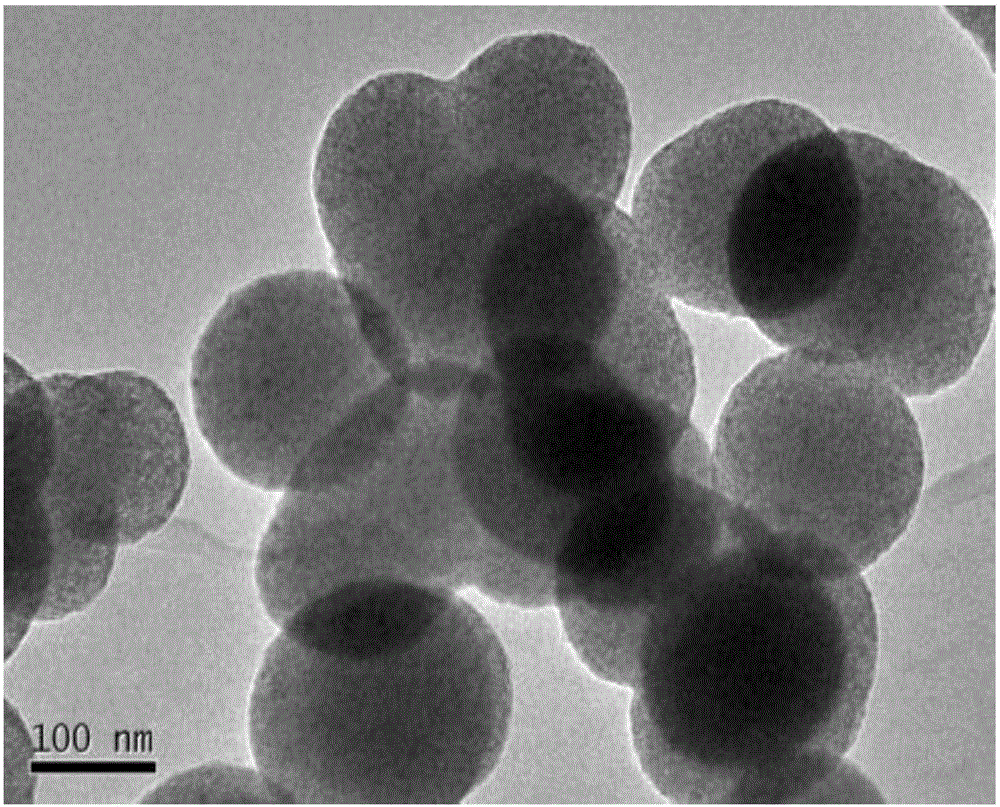

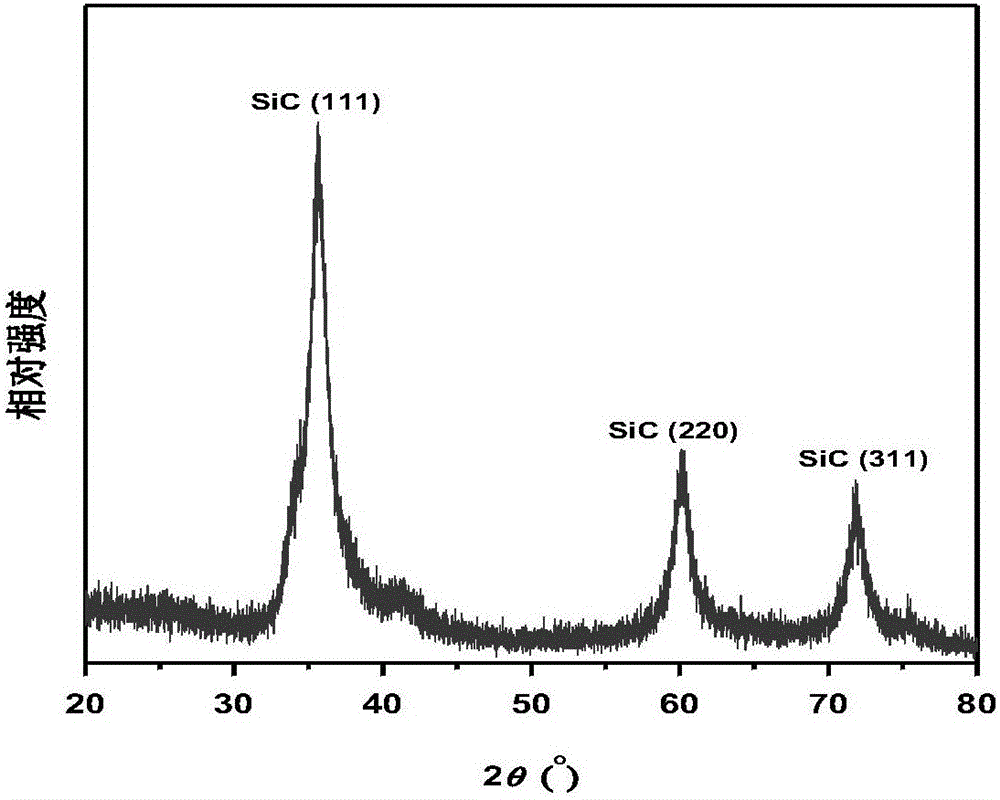

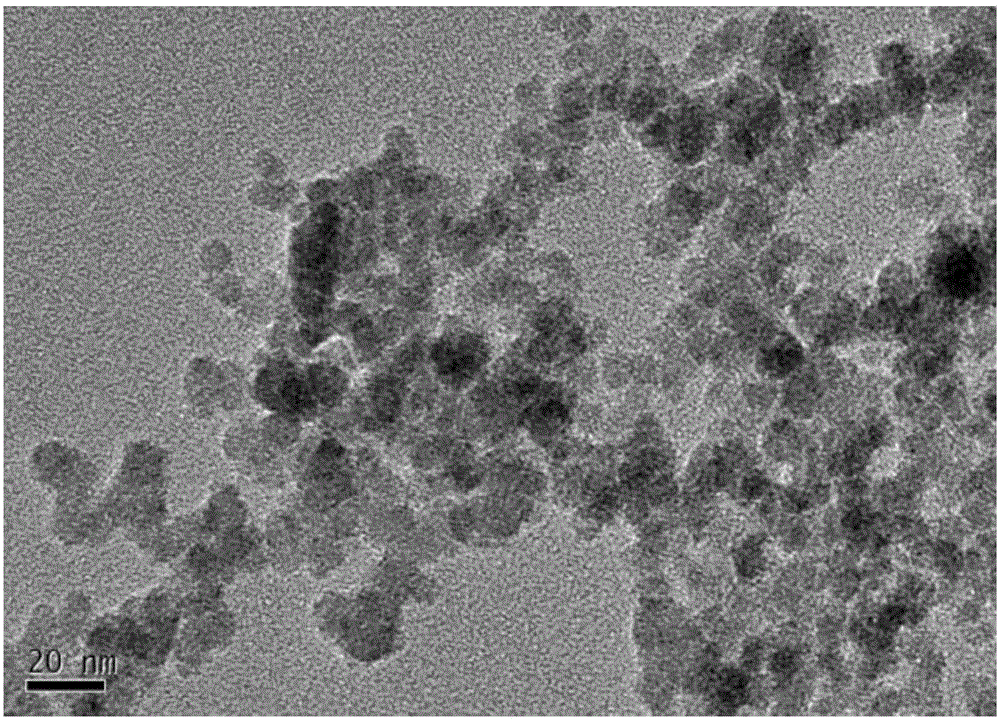

Fluidized bed chemical vapor deposition preparation method of silicon carbide nanoparticle

InactiveCN106082227ANarrow particle size distributionLower sintering temperatureNanotechnologyDisilaneGas phase

The invention relates to a fluidized bed chemical vapor deposition preparation method of silicon carbide nanoparticles. The fluidized bed chemical vapor deposition preparation method comprises the following steps: by using a fluidized bed chemical vapor deposition method, heating a precursor material hexamethyl disilane to generate vapor, and feeding the vapor into a fluidized bed reactor in a gas carrying manner; implementing pyrolytic reaction on the precursor vapor in a high-temperature zone so as to form silicon carbide nanoparticles; conveying the nanoparticles to the upper part of the fluidized bed reactor under the action of a fluidization gas, sucking out by using a negative-pressure device, and collecting so as to obtain silicon carbide nano powder; in the presence of an inert atmosphere, implementing high-temperature thermal treatment, thereby obtaining well-crystallized silicon carbide nanoparticles. The silicon carbide nanoparticles are cubic-phase silicon carbide, are sphere-shaped and are narrow in particle size distribution, and the sizes of the particles are 5-300 nanometers and are adjustable. By adjusting the reaction atmosphere, particles of pure silicon carbide and silicon-enriched or carbon-enriched silicon carbide can be prepared. The fluidized bed chemical vapor deposition preparation method is simple in process procedure, convenient and rapid in process operation, low in cost and beneficial to industrial production.

Owner:TSINGHUA UNIV

Method of forming carbon-containing silicon nitride layer

ActiveUS7371649B2Improve uniformityHigh carbon contentTransistorSemiconductor/solid-state device manufacturingSilanesDisilane

A method for forming a carbon-containing silicon nitride layer with superior uniformity by low pressure chemical vapor deposition (LPCVD) using disilane, ammonia and at least one carbon-source precursor as reactant gases is provided.

Owner:UNITED MICROELECTRONICS CORP

Preparation of alkylhalosilanes

InactiveUS6025513AIncreasing amount of producedQuantity minimizationGroup 4/14 element organic compoundsSilanesDisilane

An alkylhalosilane is prepared by charging a reactor with a contact mass comprising a metallic silicon powder and a copper catalyst, and feeding an alkyl halide into the reactor whereby the silane is formed by direct synthesis. The contact mass contains 1-10,000 ppm of elemental boron. The addition of boron to the contact mass is effective for increasing the throughput of dialkyldihalosilane at desired STY in an inexpensive manner while suppressing formation of unnecessary hydrosilanes and disilanes.

Owner:SHIN ETSU CHEM IND CO LTD

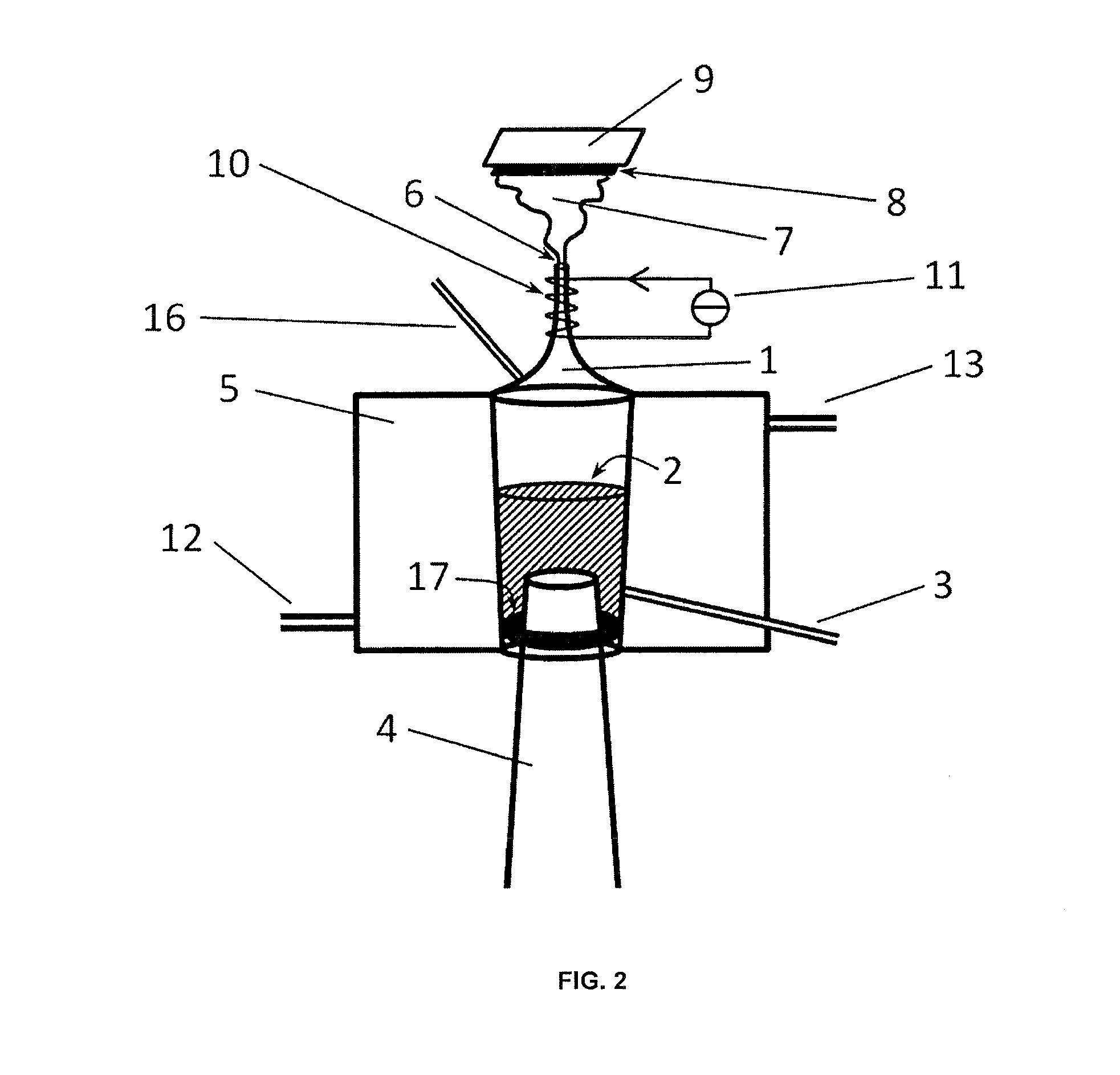

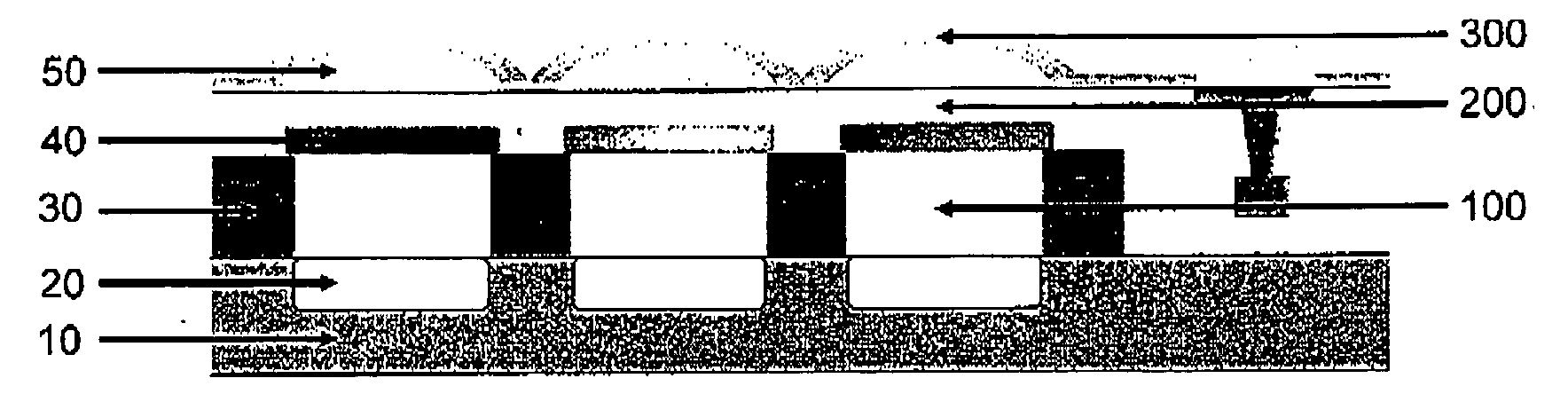

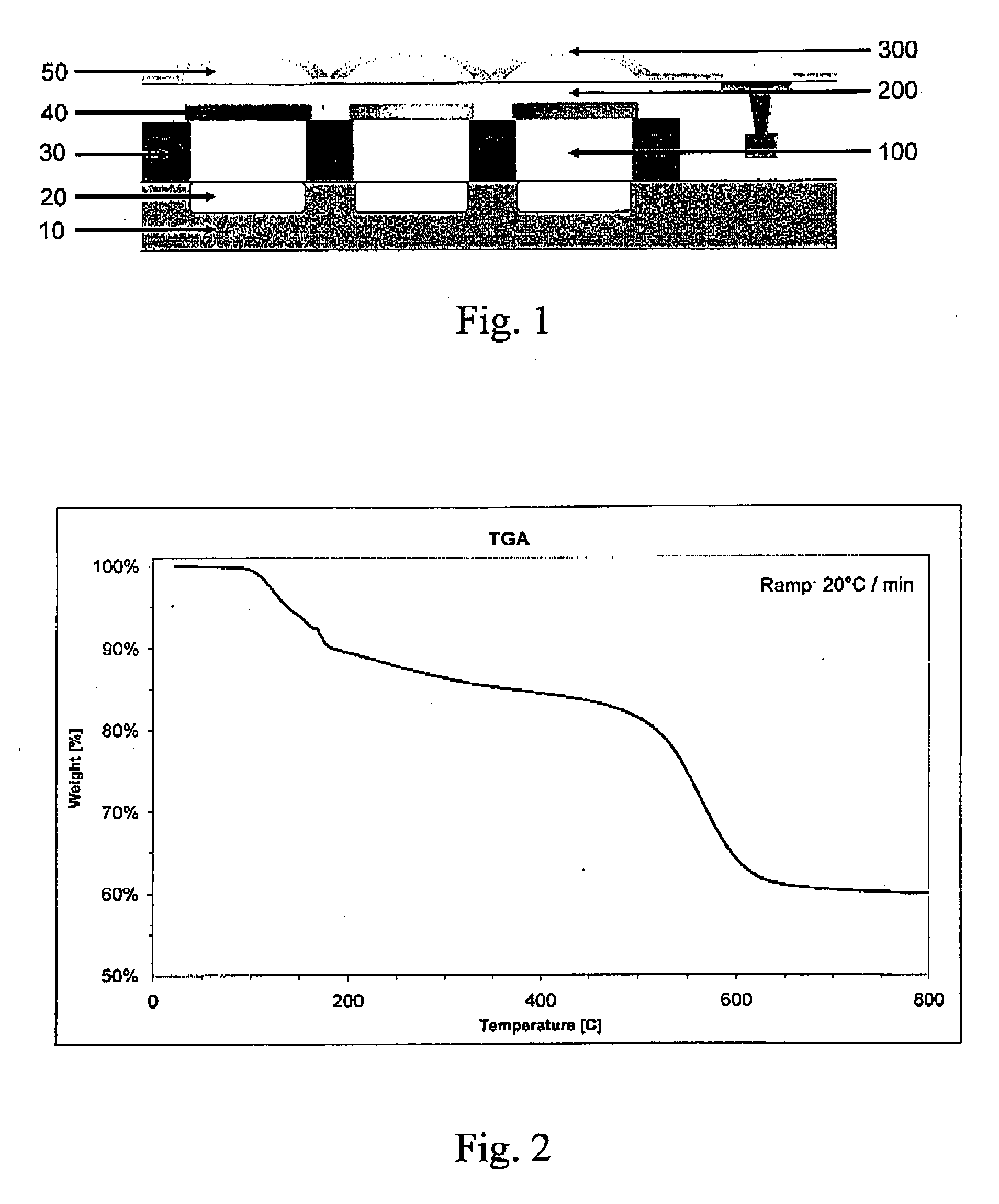

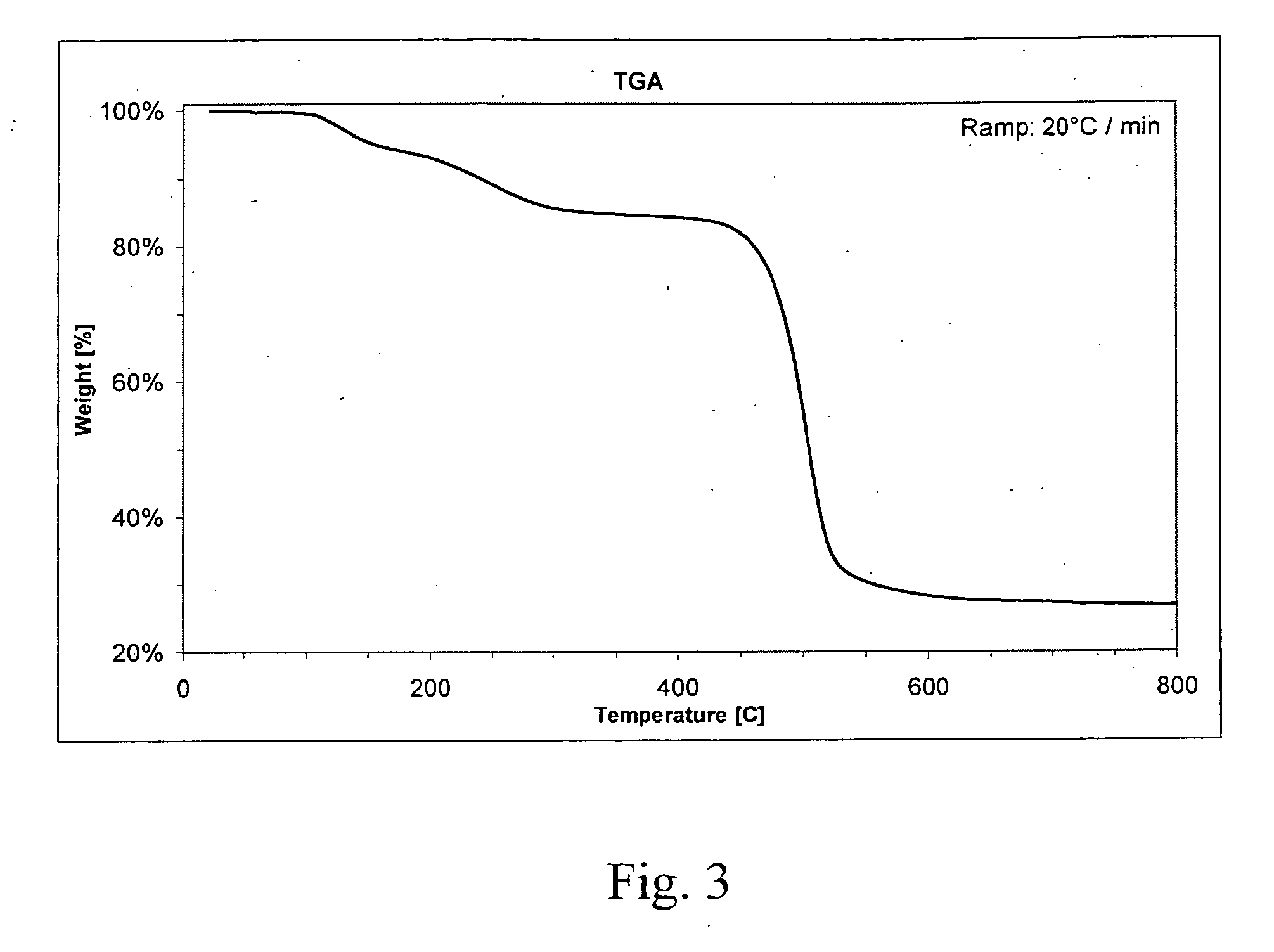

Method and device for polymerizing a composition comprising hydridosilanes and subsequently using the polymers to produce silicon-containing layers

ActiveUS20160297997A1Liquid/solution decomposition chemical coatingSemiconductor devicesNoble gasCavitation

A method for polymerizing a composition including hydridosilanes and subsequently using the polymers to produce silicon containing layers, comprising the following steps: a) providing a substrate; b) providing a composition including at least one hydridosilane that is dissolved in at least one organic and / or inorganic solvent, or including at least one hydridosilane that is already present in liquid form without solvent, wherein the hydridosilanes comprise at least one linear and / or one branched hydridosilane of the general formula SinH2n+2, where n≧3, and / or a cyclic hydridosilane of the general formula SinH2n, where n≧3; c) polymerizing the composition from step b) by way of acoustic cavitation; and d) coating the surface of the substrate with reaction products from step c). A device for polymerizing a composition including hydridosilanes and subsequently using the polymers to produce silicon containing layers, comprising at least one reaction vessel (1) containing a composition that includes at least one hydridosilane that is dissolved in at least one organic and / or inorganic solvent, or at least one hydridosilane that is already present in liquid form without solvent, wherein the hydridosilanes comprise at least one linear and / or branched hydridosilane of the general formula SinH2n+2, where n≧3, and / or a cyclic hydridosilane of the general formula SinH2n, where n≧3, and / or containing the abovementioned hydridosilane solution or the pure liquid hydridosilane, to which at least monosilane and / or disilane and / or boron containing dopant and / or phosphorus containing dopant and / or a noble gas from the group Ar, He and / or nanoparticles and / or a polymerization initiator and / or a catalyst and / or surface tension modifying agents can be added, and an ultrasound source and / or a sound transducer (4) for generating acoustic cavitation and / or capillary waves, wherein the reaction vessel (1) has at least one closable opening (6), the substrate (8) to be coated is disposed opposite the opening (6), and the substrate (8) comprises a heating source (9) on the surface that faces away from the coating surface.

Owner:FORSCHUNGSZENTRUM JILICH GMBH

Composition for providing an abrasion resistant coating on a substrate with a matched refractive index and controlled tintability

InactiveUS7001642B2Improve stabilityIndex matchingGroup 4/14 element organic compoundsFilm/foil adhesivesColloidal silicaOrganic solvent

Owner:SDC TECHNOLOGIES INC

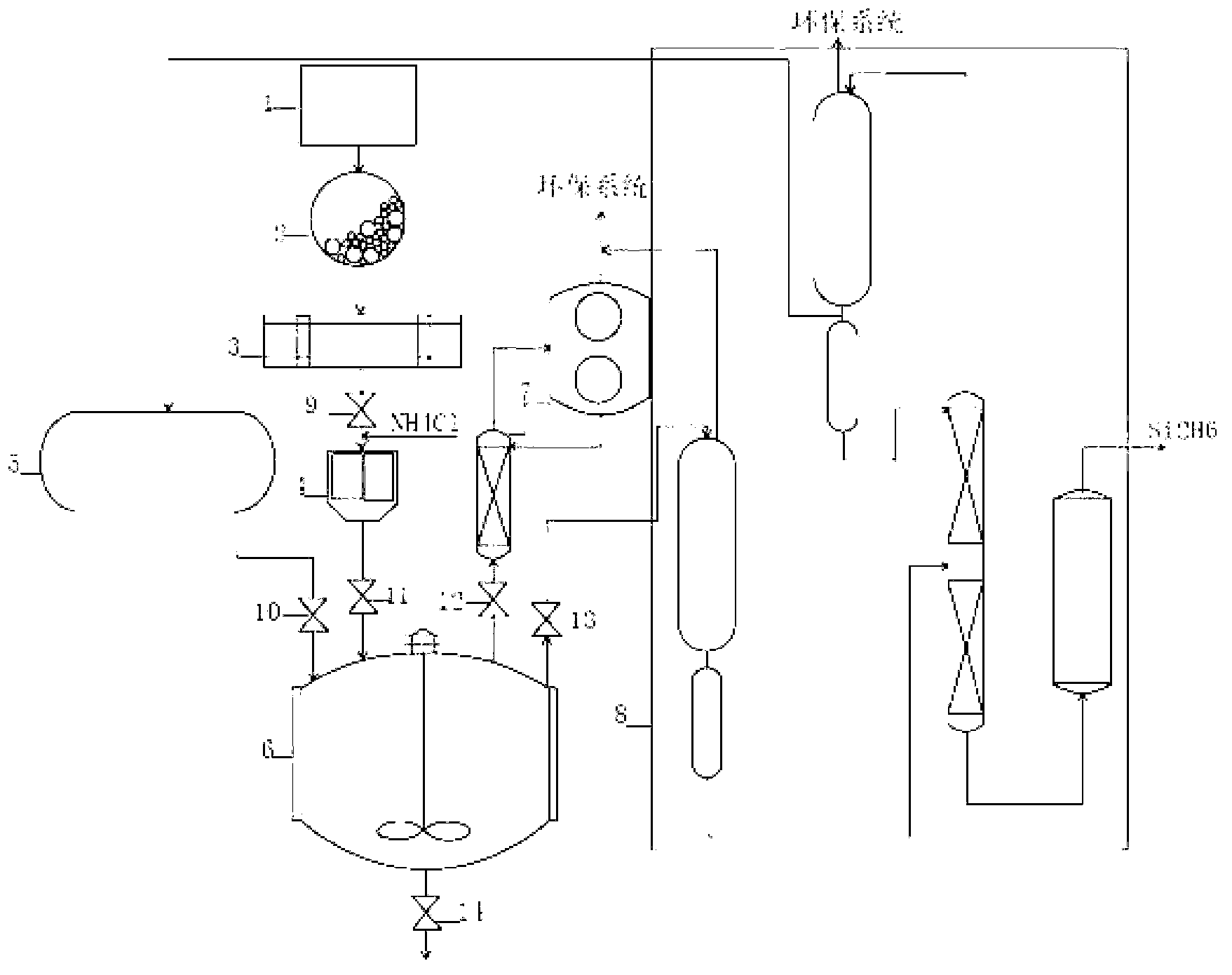

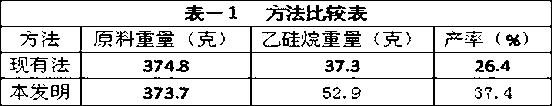

Method and device for producing disilane through reaction of alloyed composition and ammonium chloride in liquid ammonia

The invention provide a method and a device used for producing disilane through a chemical reaction of alloyed hydrogen-metal-silicon composition ammonium chloride in a liquid ammonia medium. According to the invention, hydrogen-metal-silicon composition and a corresponding alloying process are promoted; the composition is subjected to the chemical reaction with ammonium chloride in the liquid ammonia medium, such that monosilane and disilane are produced; monosilane is outputted under the control of a reflux monosilane absorption converter, and crude disilane is subjected to separation purification, such that high-yield disilane is prepared. The hydrogen-metal-silicon composition is composed of Si, H, and at least two components selected from: Mg, Ca, Sr, Ba, Li, Na, K, B, Al, Ti, Fe, and V. The composition is synthesized through a mechanical process, a thermo-mechanical process, or a mechanical chemical bonding process, and is subjected to heat treatment alloying, such that the composition can be utilized.

Owner:烟台万华电子材料有限公司

Novel nanoparticle containing siloxane polymers

ActiveUS20080188032A1Good chemical resistanceLow chemical adsorption behaviorSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceDisilane

A method of producing a polymer composition for semiconductor optoelectronics, comprising the steps of providing at least one type of disilane monomer which is homo- or copolymerized to form a (co)polymer and then combined with nanoparticles to provide a polymer composition. The nanoparticle containing composition has excellent properties with high refractive index or dielectric constant.

Owner:SILECS OY

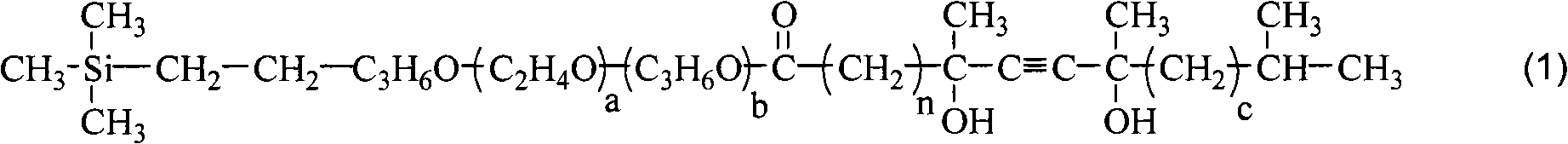

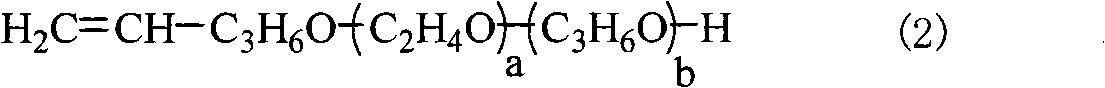

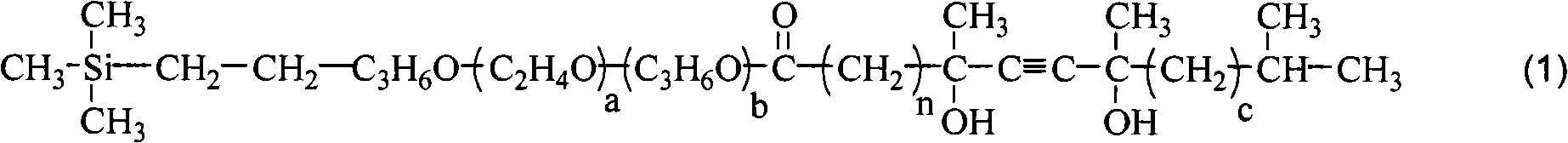

Disilane surfactant, preparation thereof and use thereof

InactiveCN101653708AIncrease moistureStrong adhesionTransportation and packagingMixingPESTICIDE ADJUVANTSDisilane

The invention discloses a disilane surfactant of a structure formula (I), a preparation method thereof and use thereof. By linking alkynol with an organic silicon surfactant through covalent bonds, the prepared disilane surfactant has the excellent defoaming performance, durable foam resisting and prohibiting performance and excellent hydrolysis resistance of an acetylenic glycol surfactant whileretaining the excellent wettability, high adhesive power, high ductility, high air vent permeability and high rain washing resistance of the organic silicon surfactant. The disilane surfactant can beused as a pesticide adjuvant. In the formula, a is an integer between 8 and 600, b is 0 or 1, c is 0 or 1, and n is 1 or 2.

Owner:中国中化股份有限公司 +1

Pentakis(dimethylamino) disilane precursor comprising compound and method for the preparation thereof

ActiveUS20100016620A1Improve featuresEasy to disassembleSilicon organic compoundsChemical vapor deposition coatingDisilaneDielectric

Pentakis(dimethylamino) disilane with general formula (1): Si2(NMe2)5Y, where Y is selected from the group comprising H, Cl or an amino group its preparation method and its use to manufacture gate dielectric films or etch-stop dielectric films of SiN or SiON.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com