Silicon-containing (methyl) acrylate monomer and its copolymer and their prepn process

A technology of acrylates and copolymers, applied in the field of silicon-containing acrylate monomers and their copolymers and their preparation, can solve the problems of single monomer and polymer products, the influence of copolymer strength and use range, and the influence of polymer film Anti-fouling ability, abrasion resistance, scrubbing resistance, interface adhesion performance, etc., to achieve the effect of excellent penetration performance, low viscosity, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The structural formula of silicon-containing (meth)acrylate monomer is as follows:

[0040]

[0041] Add 24.8g of γ-methacryloxypropyltrimethoxysilane (KH570), 16.2g of hexamethyldisiloxane (MM), and 5.8g of water in a 250mL three-necked flask, mix well and add Catalytic amount (0.5% by weight of coupling agent) of trifluoroacetic acid, add 38g of toluene, add a small amount of polymerization inhibitor 2,6-di-tert-butylphenol, stir at room temperature for 6h, then heat up to 50°C for reflux reaction 4h. After the reaction is completed, carry out azeotropic distillation to remove methanol and excess water, and use NaHCO 3 Neutralize, wash with water until neutral, then dry with anhydrous sodium sulfate, add a small amount of 2,6-di-tert-butylphenol to the organic phase, and distill under reduced pressure to remove the solvent toluene and other low-boiling compounds to obtain the silicon-containing ( Meth)acrylate monomer.

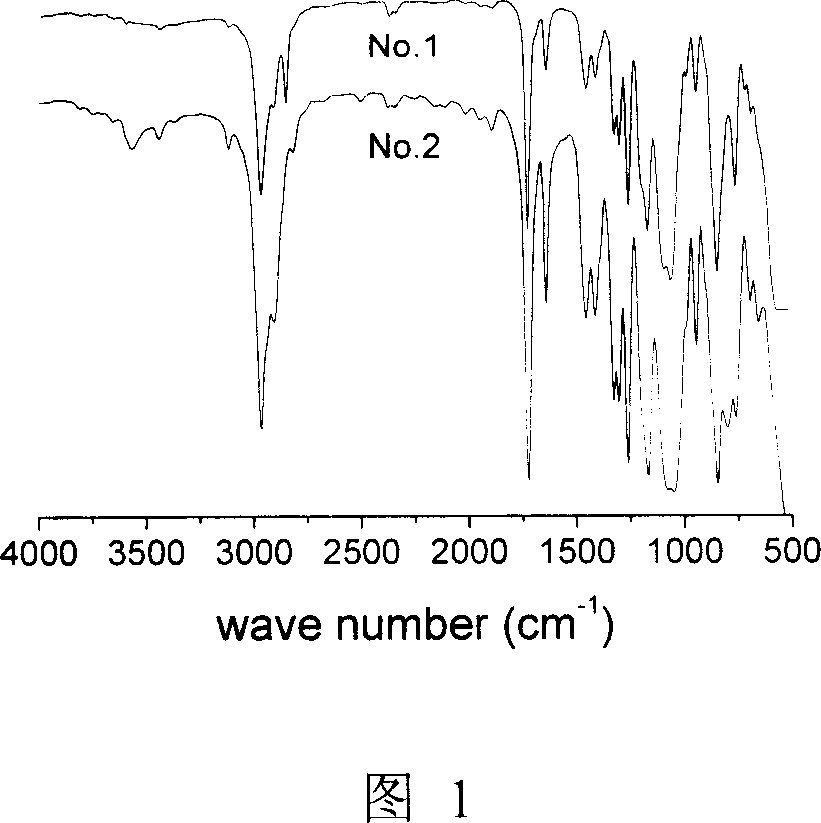

[0042] The IR spectrum of this monomer is...

Embodiment 2

[0044] The structural formula of silicon-containing (meth)acrylate monomer is as follows:

[0045]

[0046] Raw materials and proportioning are: 23.2g of γ-methacryloxypropyldimethoxymethylsilane (KBM), 8.1g of MM; the organic solvent is 59g of toluene; the catalyst is 1.0% p-toluenesulfonic acid .

[0047] Other steps are the same as in Example 1.

[0048] The IR spectrum of this monomer is shown in No.2 in Figure 1.

Embodiment 3

[0050] The main structural formula of silicon-containing (meth)acrylate monomer is as follows:

[0051]

[0052] In a 250mL three-necked flask, add 24.8g of KH570, 8.1g of MM, 29.6g of octamethylcyclotetrasiloxane (D 4 ), after mixing evenly, add a catalytic amount (0.5%) of trifluoromethanesulfonic acid, add 46g xylene and a small amount of 2,6-di-tert-butylphenol, and carry out azeotropic distillation to remove Methanol, CaCO for remainder 3 Neutralize, wash with water until neutral, then dry with anhydrous sodium sulfate, add a small amount of 2,6-di-tert-butylphenol to the organic phase, distill off the solvent xylene and other low-boiling compounds to obtain silicon-containing (meth)acrylic acid ester monomer.

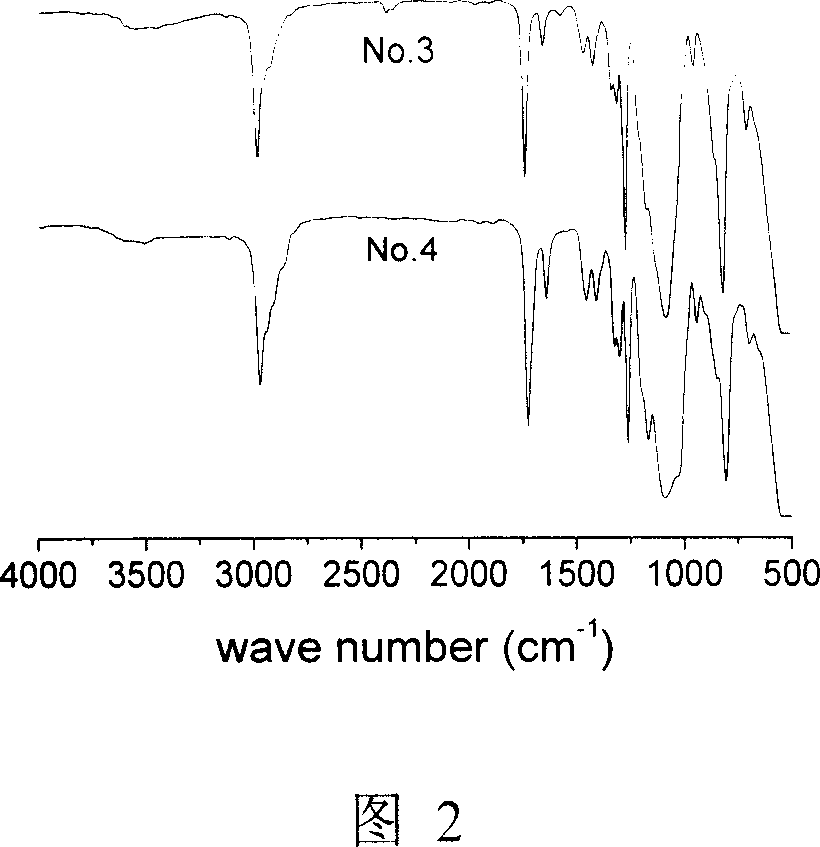

[0053] The IR spectrum of this monomer is shown in No.3 in Figure 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com