Patents

Literature

665 results about "Octamethylcyclotetrasiloxane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Octamethylcyclotetrasiloxane, also called D₄, is an organosilicon compound with the formula [(CH₃)₂SiO]₄. It is a colorless viscous liquid. It is a common cyclomethicone. It is widely used in cosmetics.

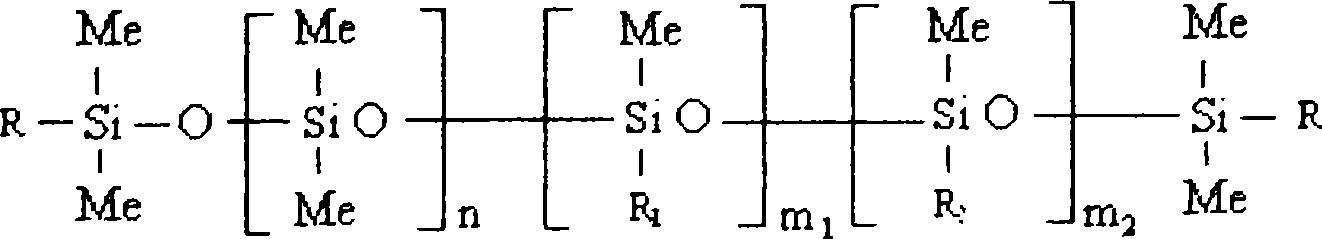

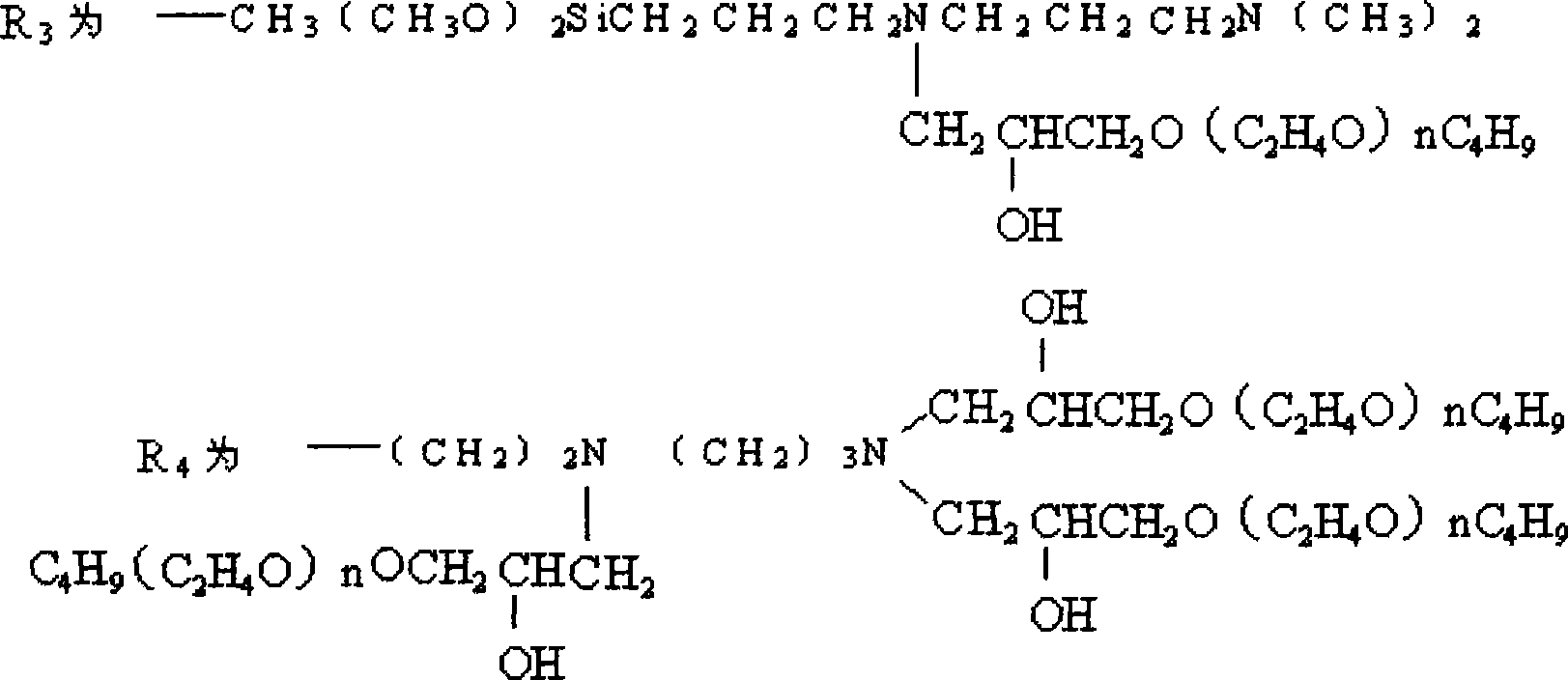

Method for preparing durable hydrophilic polyether modified amino polysiloxane soft agent

The invention discloses a method for preparing a perdurable hydrophilic polyether modified amino-polysiloxane softener. The method is characterized by comprising the following steps: octamethylcy-clotetrasiloxane and amino silane coupling agents with different structures are used as raw materials; with a bulk polymerization method, under the analysis of an alkali catalyst, firstly, an amino organic polysiloxane softener with high ammonia value is generated through ring-opening polymerization; and secondly, on the basis of the amino organic polysiloxane softener, amidogen is subjected to etherifying modification, thereby synthesizing the hydrophilic polyether modified amino-polysiloxane softener with good hand feeling and hydrophilic property. The prepared softener keeps the hydrophilic property and simultaneously improves the softness of hydrophilic silicon oil so that the hand feeling of textile can reach the hand feeling of the prior linearity amino silicon oil after the textile is treated by the softener and the treated textile can keep the hydrophilic property permanently.

Owner:SHAOXING UNIVERSITY

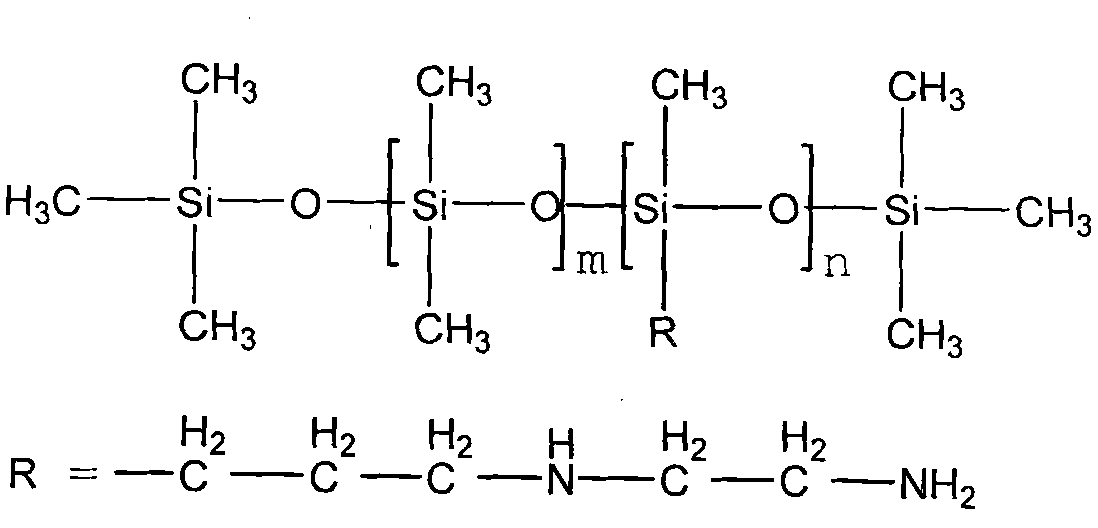

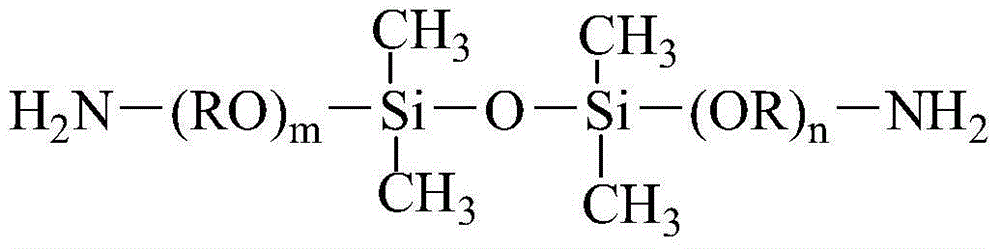

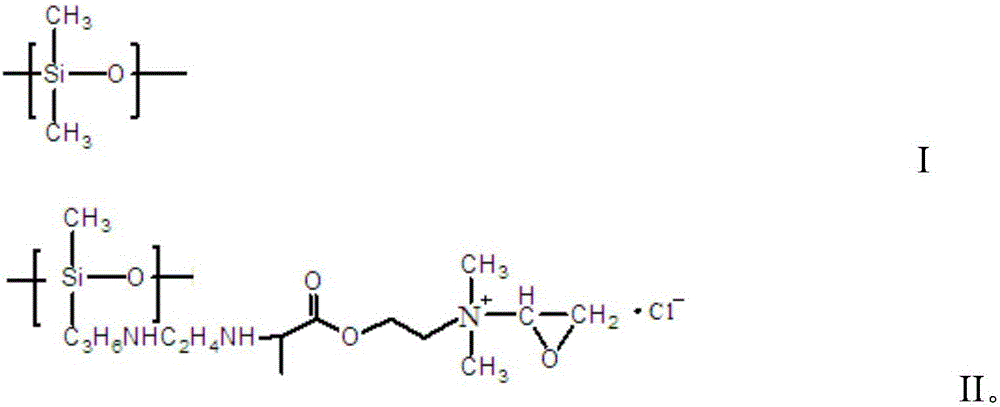

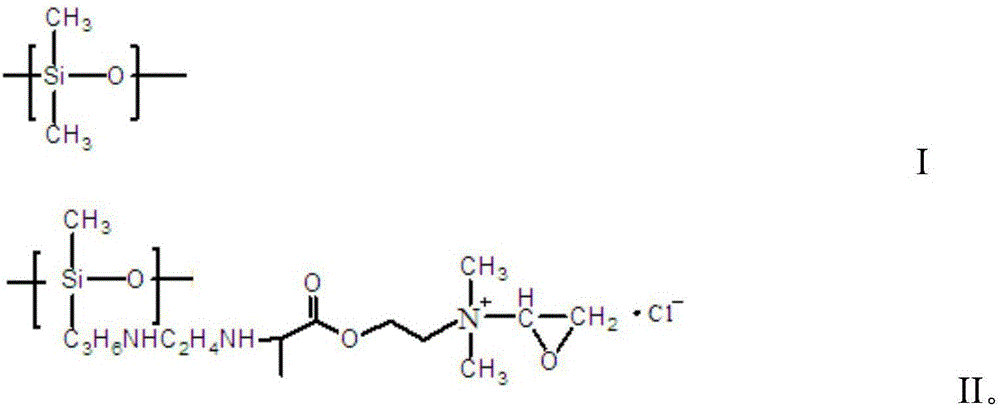

Quaternized modified amino silicone oil softener and preparation and application thereof

InactiveCN101914206AAvoid yellowingImprove hydrophilicityVegetal fibresTetramethylammonium hydroxideDisiloxane

The invention relates to a quaternized modified amino silicone oil softener and preparation and application thereof. The softener comprises the following general formula in the specification. The preparation comprises the following steps of: (1) adding octamethylcy-clotetrasiloxane into a container, adding a coupling agent N-beta-(aminoethyl)-gamma-aminopropyl methyl dimethoxysilane into the container dropwise, adding a tetramethyl ammonium hydroxide catalyst and subsequently a capping agent hexamethyl disiloxane into the container, and then performing reduced pressure distillation to obtain amino silicon oil; (2) dissolving the amino silicon oil into a solvent, adding the mixture into epichlorohydrin, stirring and heating to react under the protection of nitrogen, and removing the solvent by steaming to obtain an intermediate product; and (3) uniformly mixing N,N-dimethyl-decanamide and the solvent to obtain a mixture, stirring with heating, adding the intermediate product dropwise into the mixture under the protection of nitrogen, performing a thermostatic reaction, and removing the solvent by steaming to obtain the product. The softener of the invention has high hydrophilicity and high stability; fabric processed by the softener has excellent soft handfeel, high hydrophilicity, low yellowing, antibacterial property and the like; and the softener is simple to prepare and is suitable for industrial production.

Owner:DONGHUA UNIV

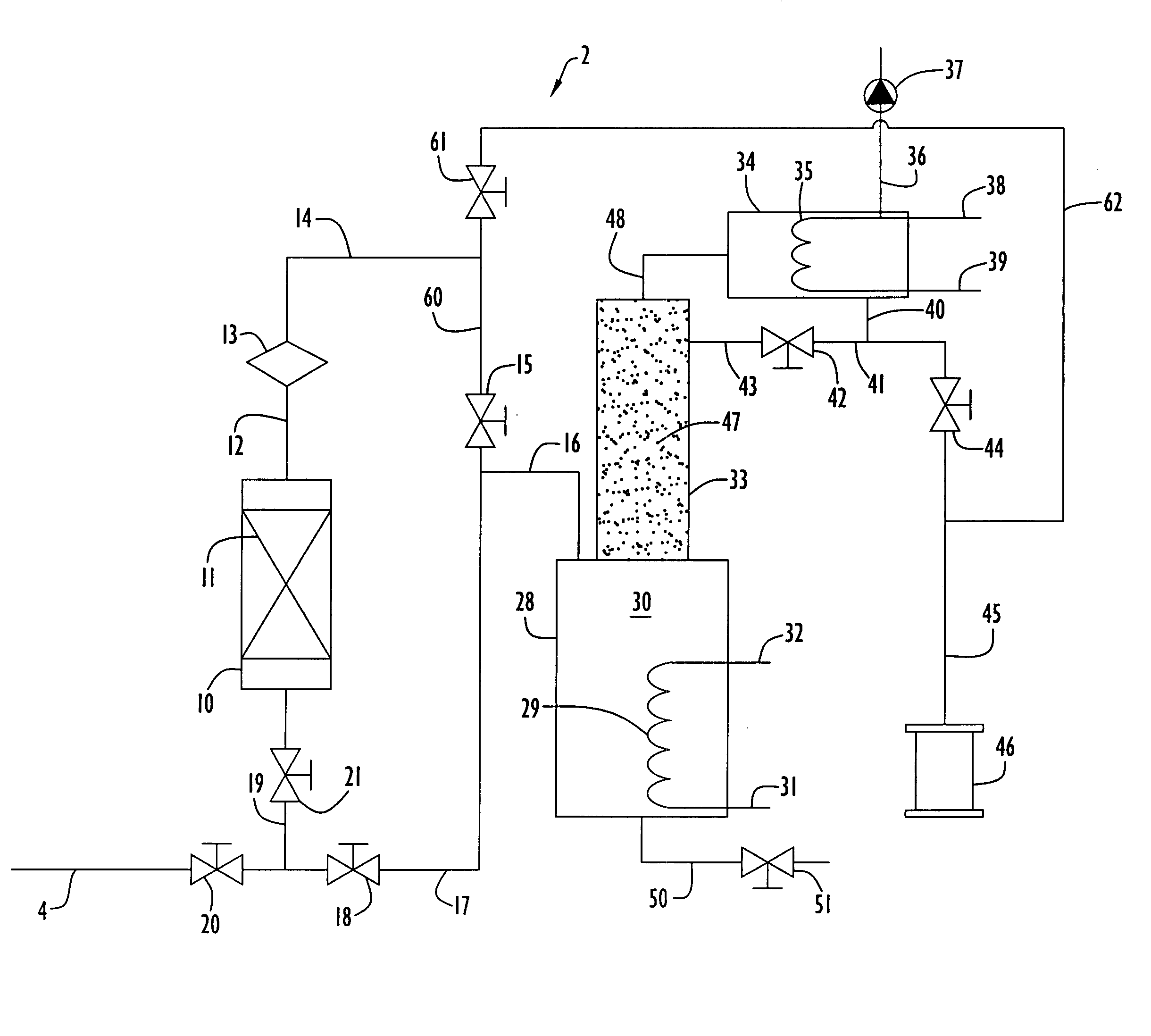

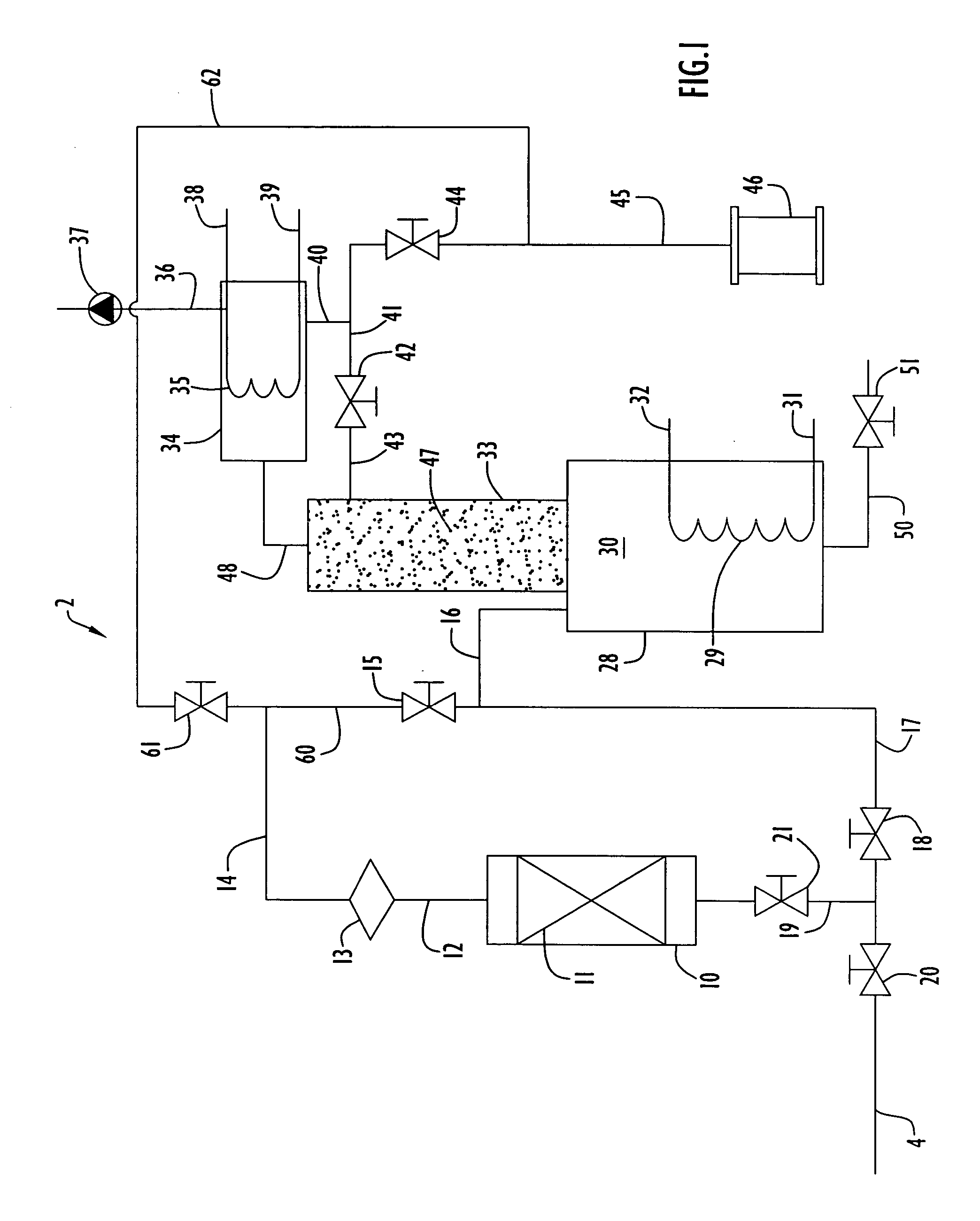

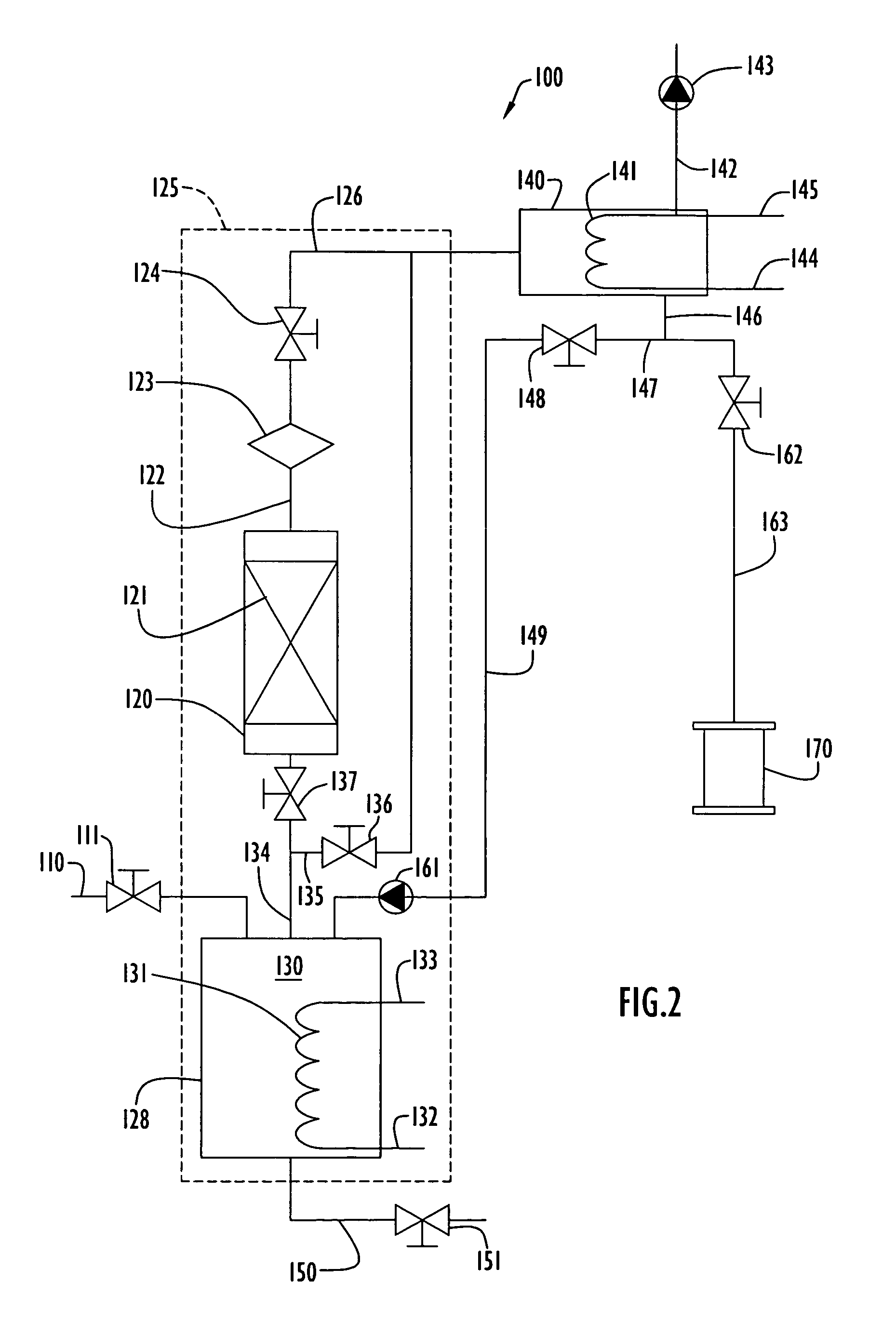

Purification of silicon-containing materials

InactiveUS20050054211A1Impurities increaseSilicon organic compoundsSemiconductor/solid-state device manufacturingSilanesLiquid state

Systems and methods of purifying a silicon-containing material include the step of directing the silicon-containing material in a liquid state through an adsorption unit including an adsorbent material to facilitate adsorption of at least one component from the silicon-containing material. Alternatively, the silicon-containing material is directed, in liquid state and / or gaseous state, through two or more purification units, including an adsorption unit, a vaporization unit, a filter unit and a condenser. The silicon-containing material can be a low-k silicon-containing material such as trimethylsilane, tetramethylsilane, dimethyldimethoxysilane, tetramethylcyclotetrasiloxane, octamethylcyclotetrasiloxane, dimethylphenyl silane, and dimethyldivinyl silane.

Owner:XU MINDI +2

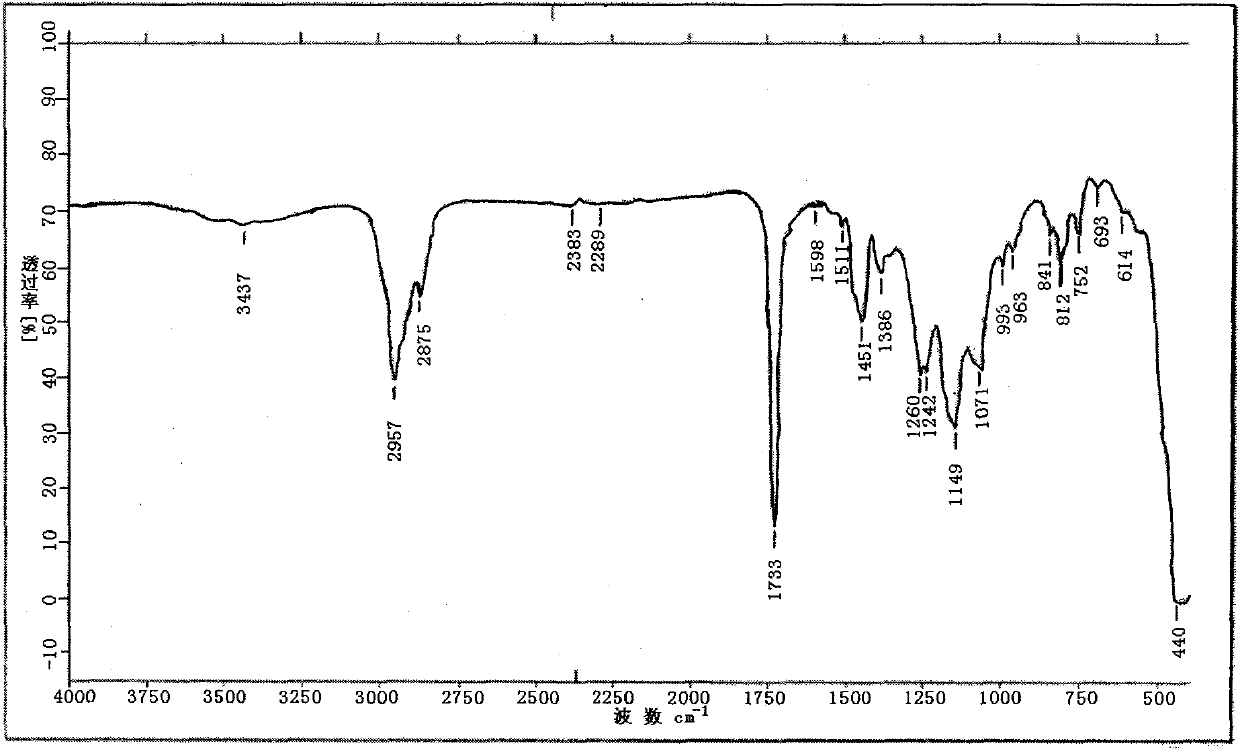

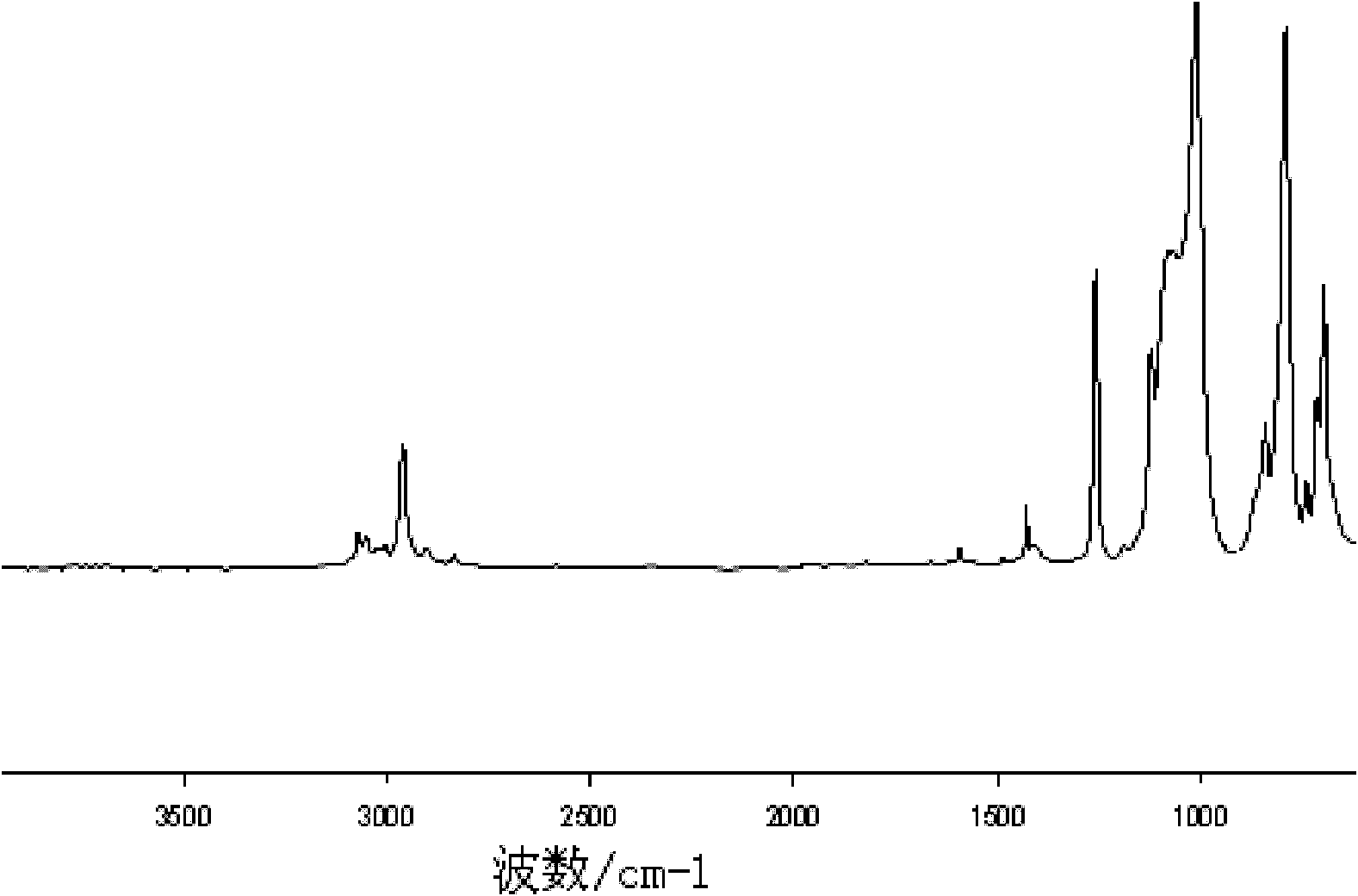

Room-temperature cured phenyl silicon resin conformal coating

The invention discloses a room-temperature cured phenyl silicon resin conformal coating which comprises components A) a segmented copolymer of phenyl silicon resin and linear polyorganosiloxane or methyl phenyl silicon resin and linear polyorganosiloxane, B) alkoxy silane, C) a silane coupling agent containing amino or epoxy group, D) an organic titanium compound, E) organic phosphate flame retardant synergist, and (F) an organic hydrocarbon solvent or low molecular weight siloxane, wherein the organic hydrocarbon solvent is one or multiple of methylbenzene, dimethylbenzene, petroleum ether, cyclohexane and normal heptane; and the low molecular weight siloxane is a mixture of octamethyl-trisiloxan, octamethyl cyclotetrasiloxane or methyl cyclosiloxane. A product produced by the cured resin conformal coating of the invention has the advantages of very high transparency, good elasticity, tough and wearable surfaces as well as excellent high / low temperature performance, waterproofing, heat resistance, cold resistance, weathering resistance, ultraviolet ray resistance, medium resistance, irradiation resistance, flame retarding and the like.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS

Synthesis of epoxy quaternised modified amino-silicone oil

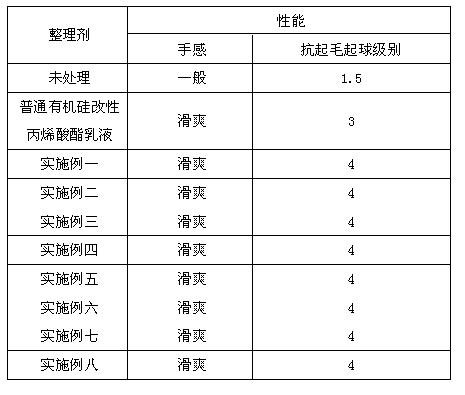

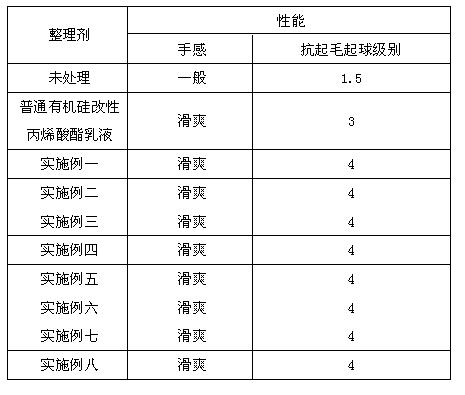

InactiveCN101367941AImprove hydrophilicityImproved anti-pilling propertiesFibre treatmentEpoxyPotassium hydroxide

The invention relates to a method for synthesizing epoxy quaternization modified amino-silicone oil, pertaining to the technical field organic silicide amino-silicone oil preparation. The method includes the following main procedures: (1) synthesis of amino-silicone oil: the raw material of octamethylcy-clotetrasiloxane (D4 linear body), N-Beta-aminoethylGemma- aminopropylmethyldimethyoxysilane (KH-602), hexamethyl dimethyl siloxane (MM), catalyst potassium hydroxide and deionized water are placed in a reactor for reaction for 5-6 hours under 100-110 DEG C, and the desired amino-silicone oil is achieved after being cooled; (2) proper amount of epichlorohydrin is added for reaction under 80 DEG C, the amino-silicone oil is processed by epoxy quaternization to achieve epoxy quaternary ammonium salt amino-silicone oil; (3) the quaternary ammonium salt amino-silicone oil is emulsified by deionized water, water is slowly added under 85 DEG C and stirred, and the water miscible liquid of epoxy quaternization modified amino-silicone oil is finally achieved. The product achieved by the method is applicable to textile fabric neatening and has pilling resistant and fluffing resistant properties.

Owner:SHANGHAI UNIV

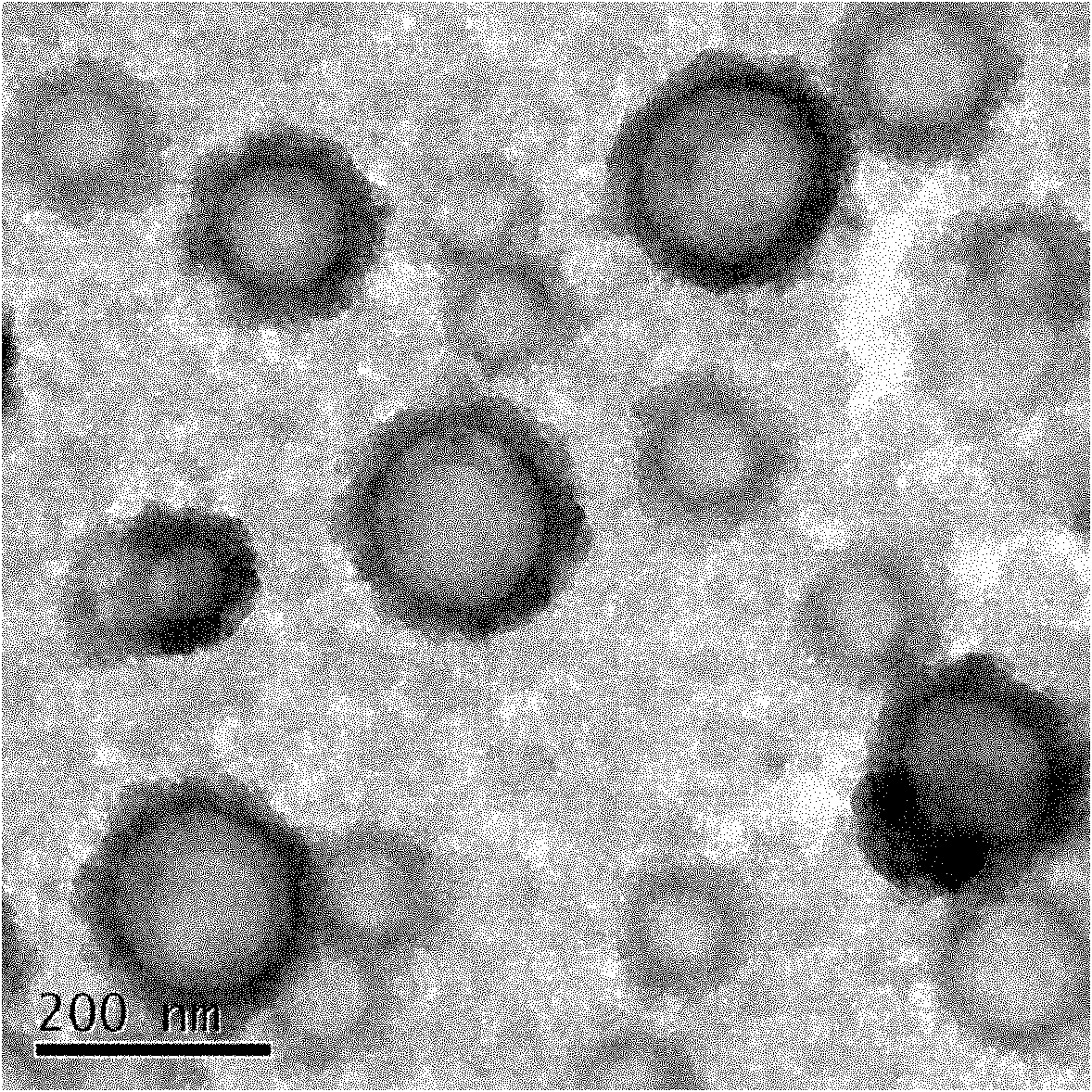

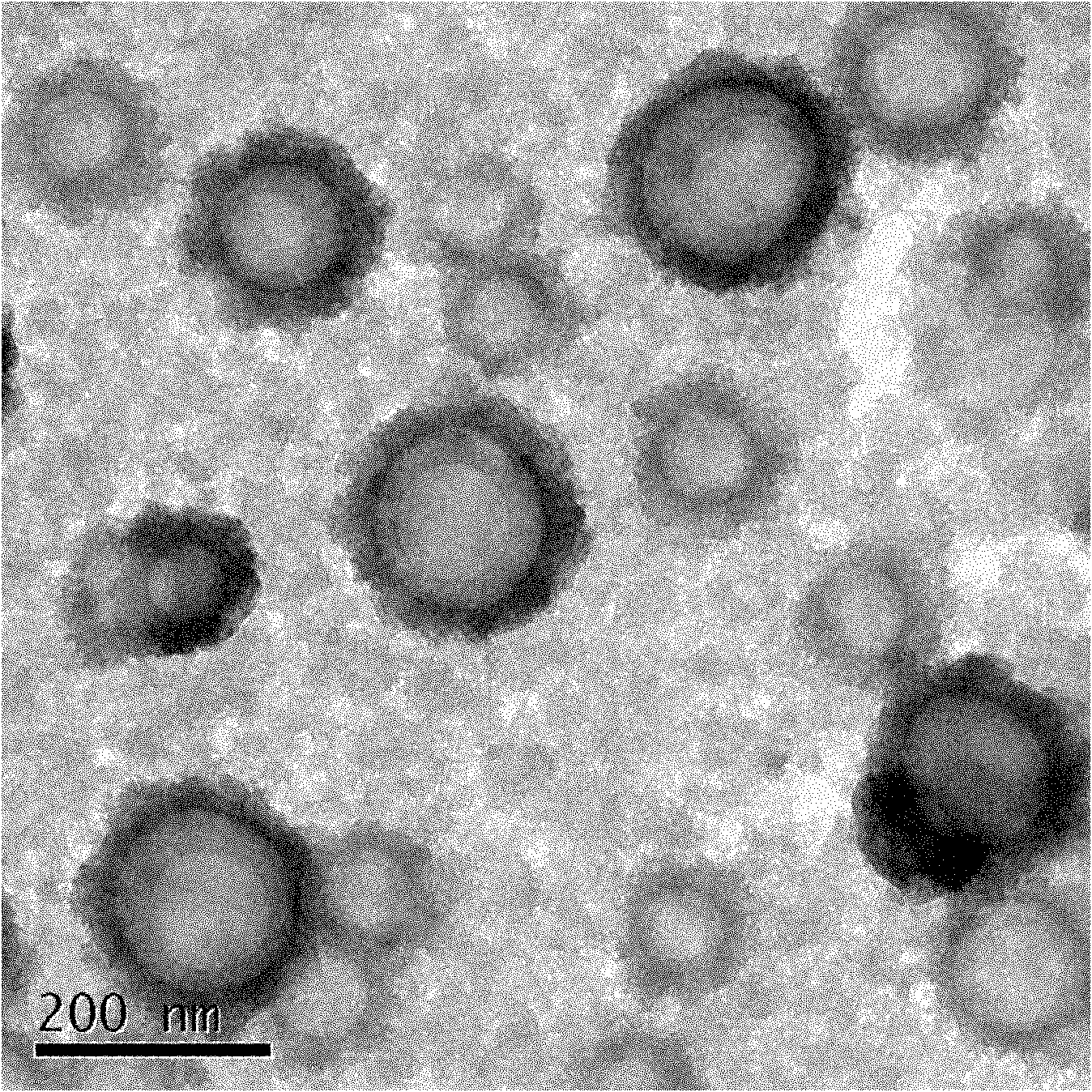

Method for preparing fluorine-containing silicon acrylate emulsion

ActiveCN102127186AStable and excellent water and oil repellencyWide variety of sourcesNon-fibrous pulp additionFibre treatmentEmulsionEmulsion polymerization

The invention belongs to the field of modification of acrylate and in particular relates to a method for preparing fluorine-containing silicon acrylate emulsion by an emulsion polymerization method. The method comprises the following steps of: 1) mixing octamethylcyclotetrasiloxane, trifluoropropylmethyl ring trisiloxane, vinyl siloxane, an acrylate monomer, a composite emulsifier, an initiator, a pH conditioning agent and distilled water to perform pre-emulsification to obtain pre-emulsified liquid; 2) stirring part of the pre-emulsified liquid under the atmosphere of inert gas, heating at the temperature T1, adding the residual pre-emulsified liquid into a reaction system dropwise, and heating at the temperature T2; and 3) cooling to room temperature under stirring, filtering by using a 200-mesh filter screen to obtain the fluorine-containing silicon acrylate emulsion. In the preparation method, the reaction process is mild and easy to control; and the product has excellent waterproof and oilproof properties.

Owner:苏州优诺塑业有限公司

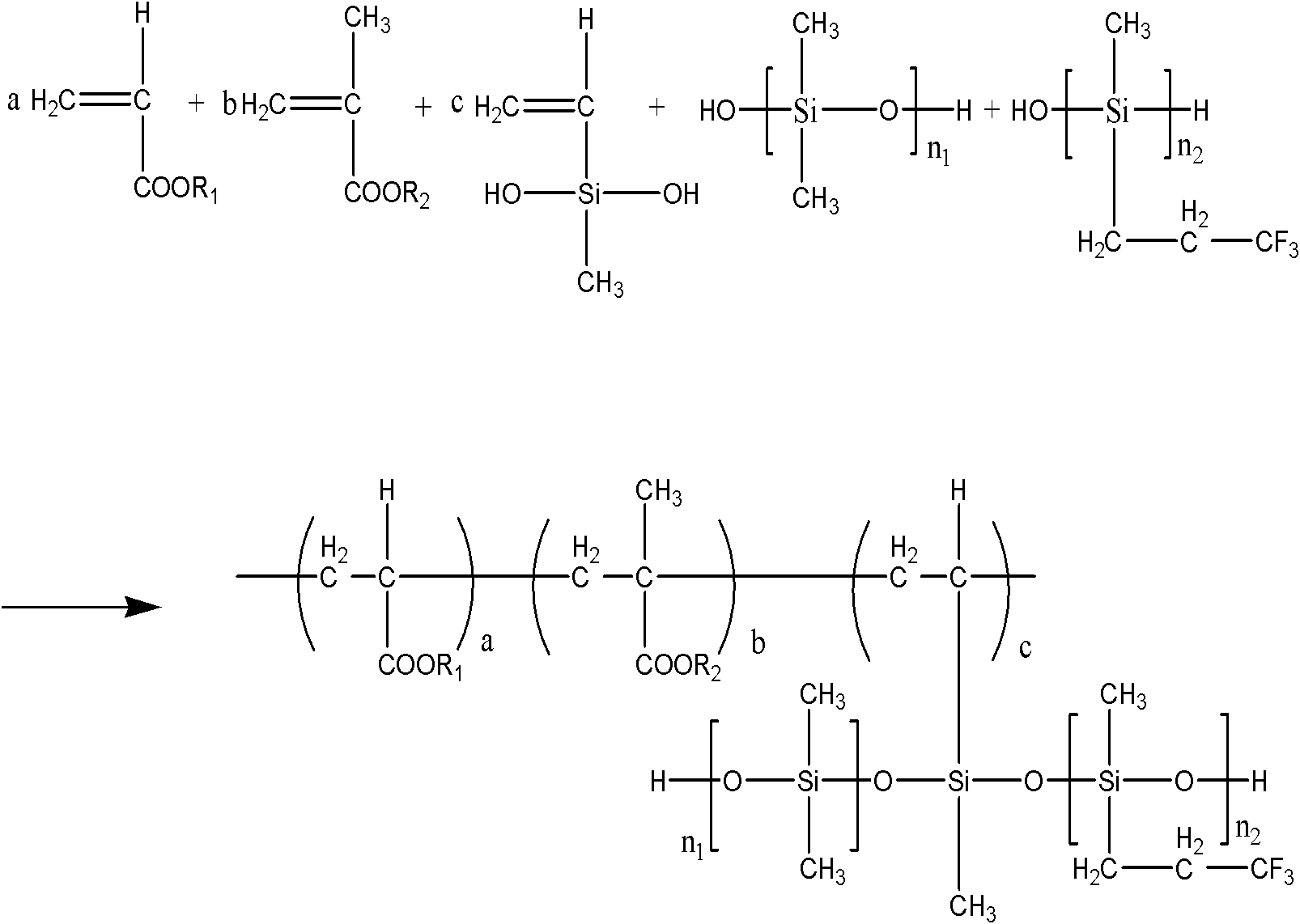

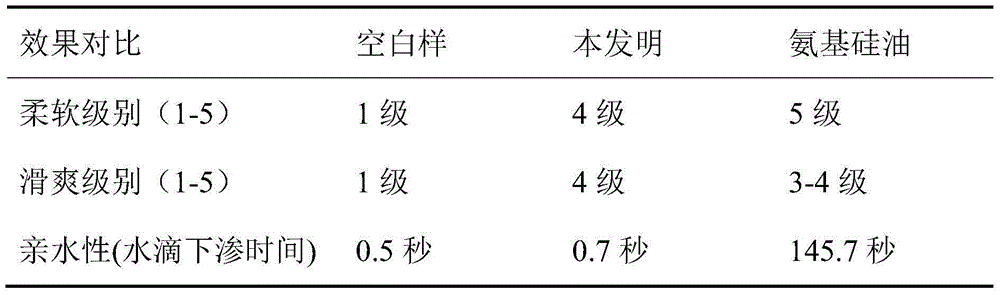

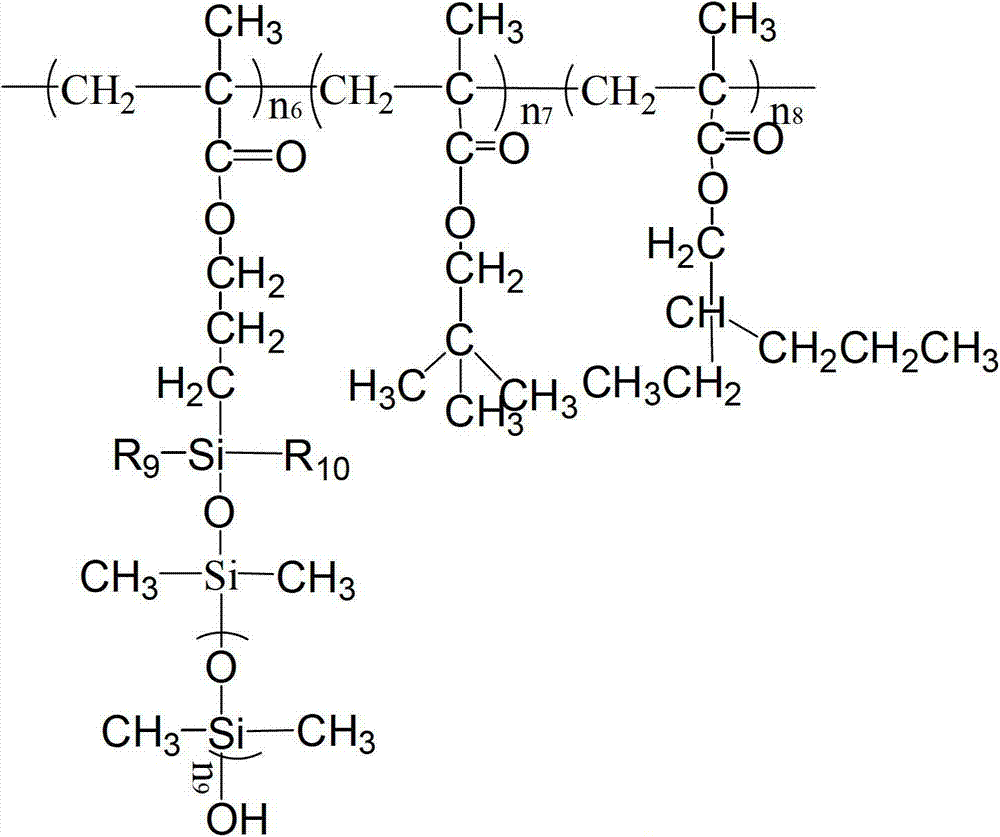

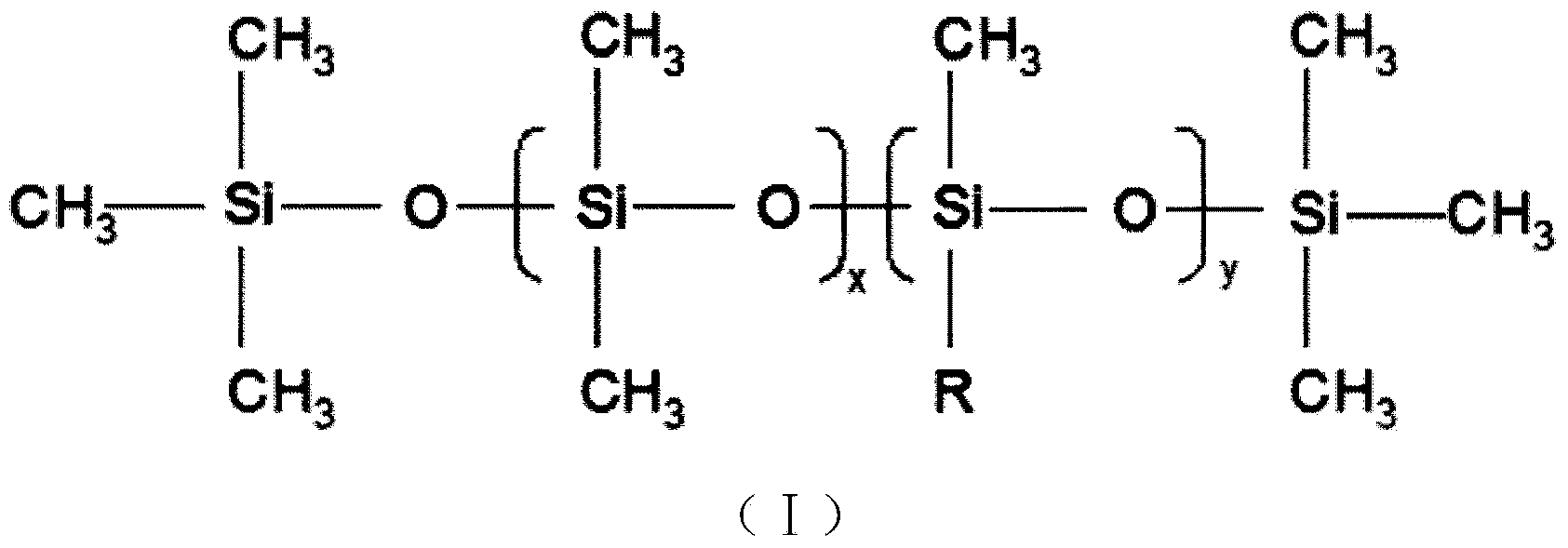

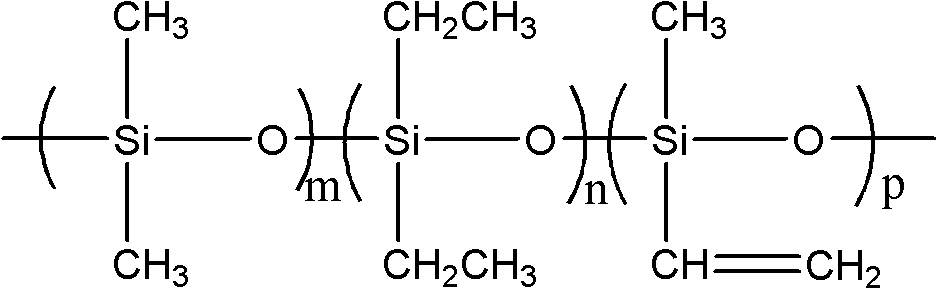

Synthesis method for terpolymer block silicone oil

ActiveCN103214676ANo demulsification and delaminationNo self-emulsifying propertiesSilicon organic compoundsFibre treatmentDisiloxaneEpoxy

Owner:ZHEJIANG JIEFA TECH

Preparation method of polyurethane modified organic silicon multipolymer fabric softening agent

ActiveCN103951809AImprove hydrophilicityImprove wearing moisture absorptionGrip property fibresEpoxyPolyethylene glycol

The invention discloses a preparation method of a polyurethane modified organic silicon multipolymer fabric softening agent. The preparation method comprises the following steps: firstly preparing a polyurethane prepolymer by using polyethylene glycol 2000 and isophorone diisocyanate; then preparing alkylhydroxyl-containing silicone oil by using di-n-butyl amine, epoxy 1,3-bis(3-glycidoxypropyl)-1,1,3,3-tetramethyldisiloxane and octamethyl cyclotetrasiloxane; reacting the polyurethane prepolymer with the alkylhydroxyl-containing silicone oil so as to obtain a polyurethane organic silicon multipolymer; and finally adding deionized water, and emulsifying so as to obtain the polyurethane modified organic silicon multipolymer fabric softening agent. The preparation method of the polyurethane modified organic silicon multipolymer fabric softening agent has the beneficial effects that urethane groups and urethane are introduced into organic silicon and serve as hard chain segments for generation of physical crosslinking, meanwhile, polyether is introduced and serves as a hydrophilic chain segment, the problem that as an amino silicon oil softening agent is easy to yellow and demulsify, oil patches are formed on fabrics, is solved, the hydrophilic performance of the fabrics subjected to soft finish is improved, the wearing hygroscopicity of the fabrics is improved, and the durability of the fabrics is good.

Owner:佛山市澳棉纺织有限公司

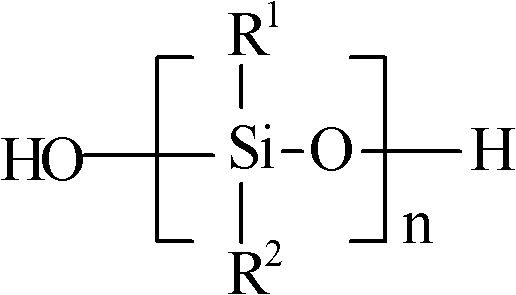

Method for synthesizing dihydroxyl-terminated polysiloxane

InactiveCN102504260AReduce manufacturing costShort overall reaction timeEpoxyTrimethylsilyl chloride

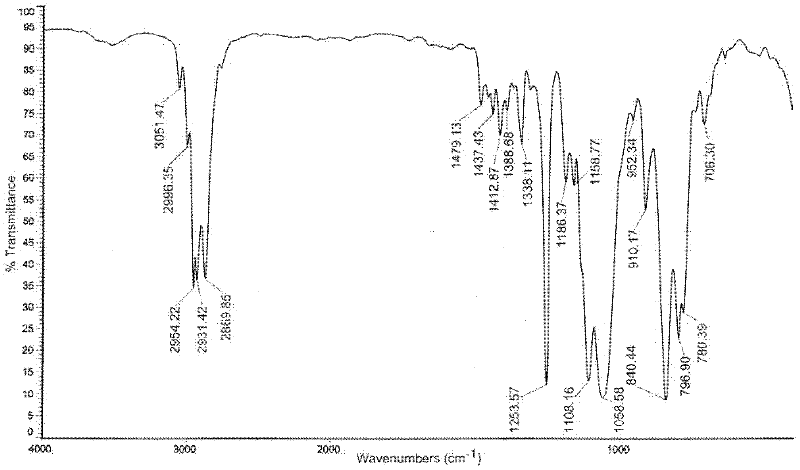

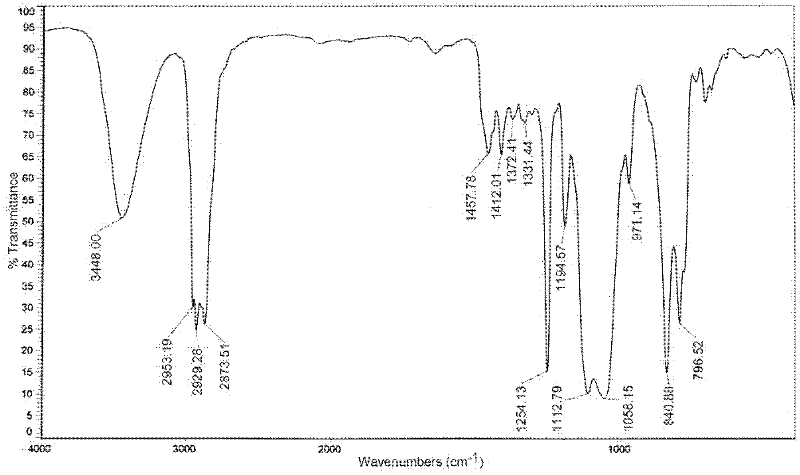

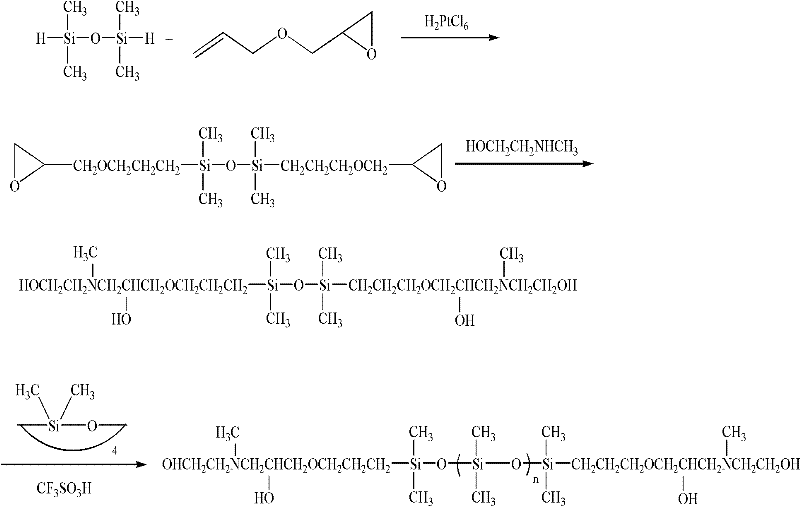

The invention discloses a method for synthesizing dihydroxyl-terminated polysiloxane. The method synthesizes the target dihydroxyl-terminated polysiloxane compound by using unsaturated epoxy compound, tetramethyldisiloxane, methylaminoethanol and octamethylcyclotetrasiloxane as starting materials and by hydrosilylation, epoxy-opening and equilibrium polymerization. The hexamethyldisilazane or trimethylchlorosilane are not needed as a hydroxyl protector, so the production cost is reduced; and hydroxyl protection and deprotection are avoided in a preparation process, so reaction steps are reduced, the total reaction time for synthesizing the final product is short and the production efficiency is increased.

Owner:邬元娟

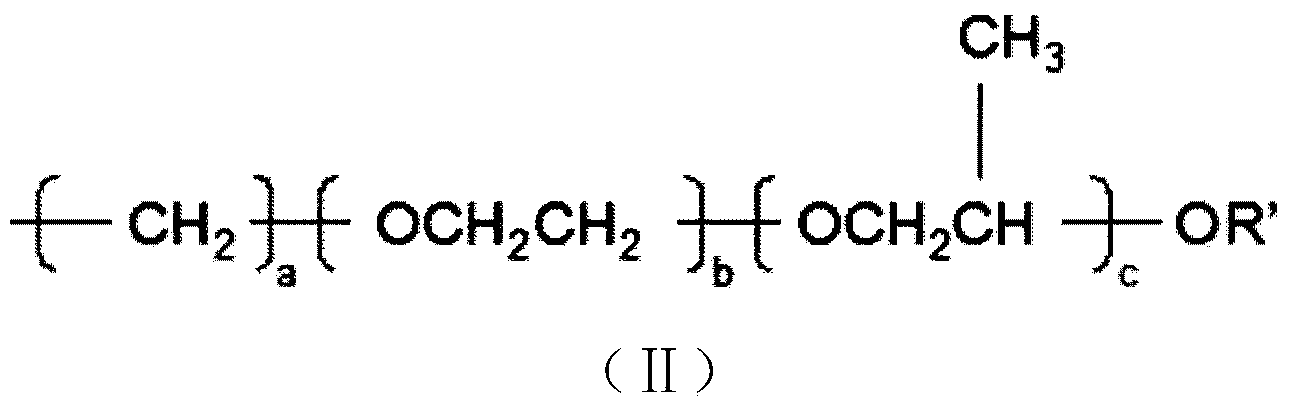

Preparation method of polyurethane foam stabilizer

The invention discloses a preparation method of a polyurethane foam stabilizer. The method comprises the following steps: (1) reacting allyl alcohol with oxirane and epoxypropane with an effect of a basic catalyst under conditions of a temperature of 90 to 130 DEG C and a pressure of not more than 0.5 MPa to obtain allyl-terminated copolyether; (2) reacting octamethylcyclotetrasiloxane with hexamethyldisiloxane and high hydrogenous silicone oil with a hydrogen content of 1.2% to 5% in the presence of an acidic ion exchanger under the condition of the temperature of 30 to 80 DEG C to obtain low hydrogenous silicone oil with the hydrogen content of 0.1% to 1%; and (3) adding the allyl-terminated copolyether obtained in step (1), the low hydrogenous silicone oil obtained in step (2), the catalyst and 1 to 5 wt% of amine ether to a reaction kettle under the conditions of the reaction temperature of 80 to 120 DEG C and the reaction pressure of 0.5 to 2 atm to obtain the polyurethane foam stabilizer. Compared with the prior art, the method of the present invention has the advantages of less pollution and cost reduction.

Owner:苏州思德新材料科技有限公司

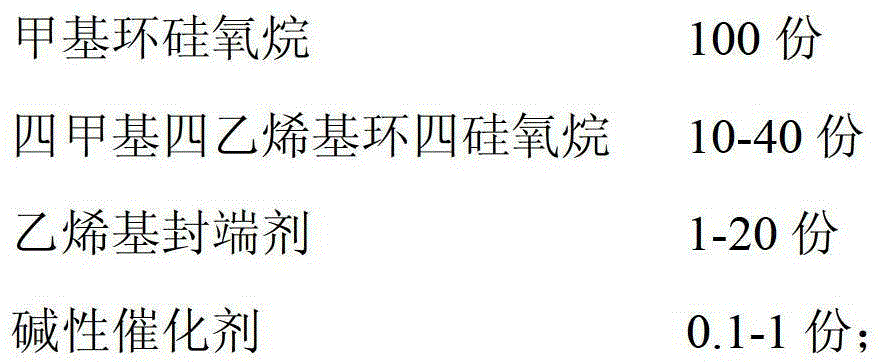

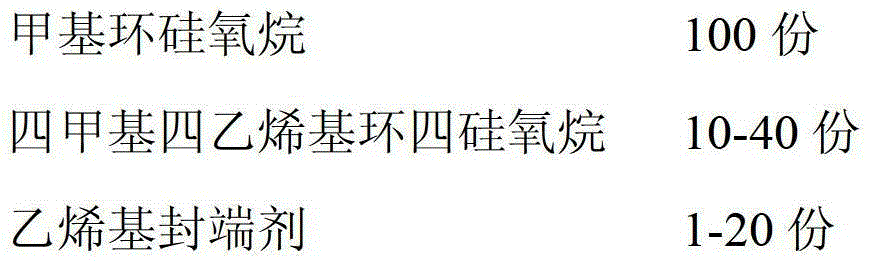

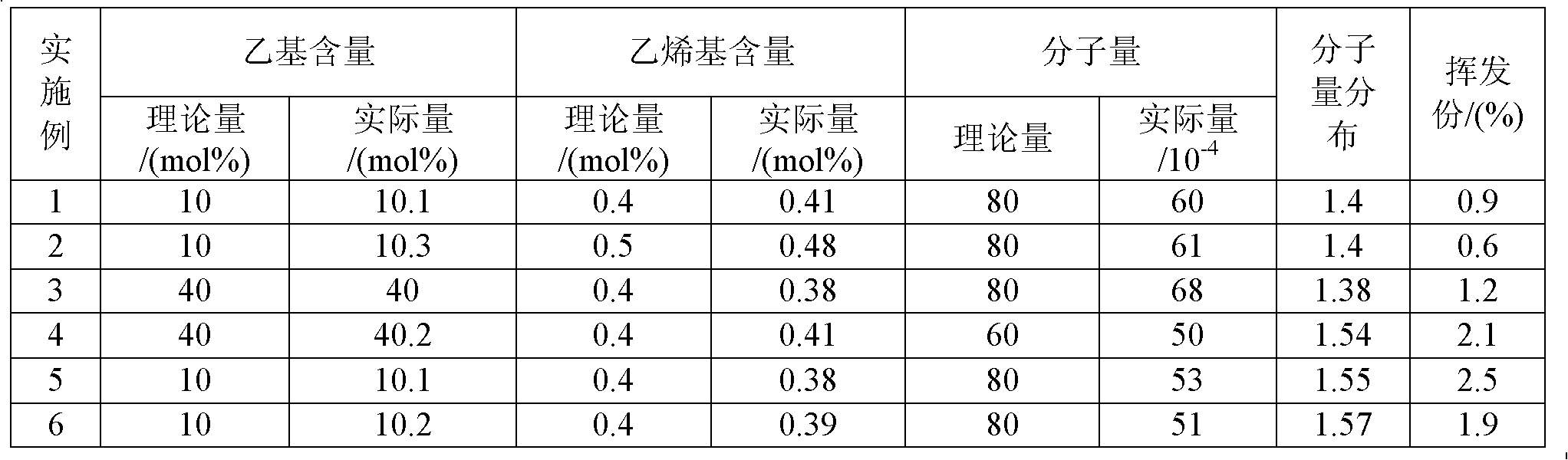

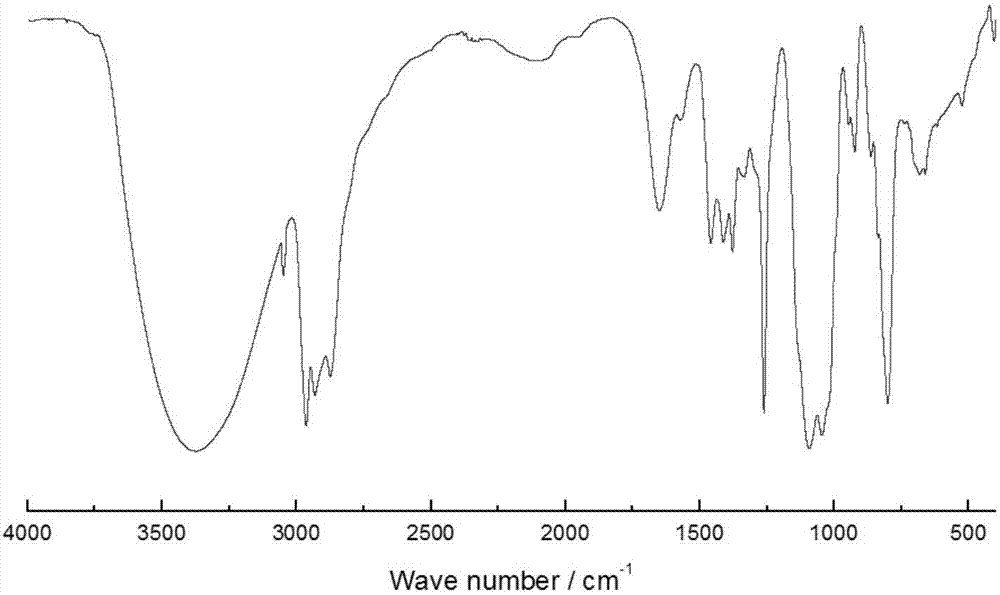

Vinyl silicone oil and synthetic method thereof

The invention discloses vinyl silicone oil and a synthetic method thereof. The vinyl silicone oil comprises the following ingredients in parts by weight: 100 parts of dimethylcydosiloxane, 10-40 parts of tetravinyl tetramethylcyelo tetrasiloxane, 1-20 parts of vinyl end-capping agent, and 0.1-1 part of basic catalyst, wherein the basic catalyst is a basic rubber catalyst which is formed by ring opening polymerization of octamethylcyclotetrasiloxane under the catalysis of basic hydroxide. The synthetic method of the vinyl silicone oil comprises the steps of taking dimethylcydosiloxane and tetravinyl tetramethylcyelo tetrasiloxane as reactive monomers, performing polymerization reaction in the presence of the vinyl end-capping agent and the basic catalyst, after the polymerization reaction, cooling, performing diluted acid neutralization, washing, separating, rectifying polymerization liquid, removing low-boiling-point substances, and obtaining the vinyl silicone oil. The method is simple in technology process, low in cost and high in product yield, the viscosity of the vinyl silicone oil is easy to control, and the vinyl silicone oil is high in reactive activity and good in storage stability, and can be widely applied to synthesis and modifying of new materials such as silicon rubber, polyurethane and polyacrylate.

Owner:JIANGSU TIANCHEN NEW MATERIALS

Preparation method of methylsilicone oil

The invention discloses a preparation method of methylsilicone oil, and specifically relates to methyl silicone oil with different viscosity (molecular weight) prepared by using supported solid superacid SO4<2-> / ZrO2-ZSM-5 as a catalyst and by adopting inexpensive and commercially available methylsilicone oil (Dn), octamethylcyclotetrasiloxane (D4) and hexamethyldisiloxane (MM), so as to fit various needs. Compared with a conventional catalyst for producing methylsilicone oil, the supported solid superacid catalyst provided by the invention has higher catalytic activity, higher stability, lower cost and the like. More importantly, the supported solid superacid catalyst is in a solid state and can be separated via simple filtration and reused, thereby enabling the production to have the advantages of simple process, convenient operation, no pollutions, no corrosion toward equipment, and the like.

Owner:JIANGNAN UNIV

Preparation method of nuclear shell structure high-silicon silicone acrylic emulsion used for building exterior wall

InactiveCN101781390AHigh silicon contentImprove smoothness and beautyCoatingsSODIUM DODECYL BENZENE SULFONATEDodecylbenzenesulfonic acid

The invention discloses a preparation method of nuclear shell structure high-silicon silicone acrylic emulsion used for building exterior walls. Firstly, the invention uses octavinyl cyclotetrasiloxane, octamethylcyclotetra siloxane, dodecylbenzene sulfonic acid, sodium dodecyl benzene sulfonate, emulsifier 0P-10 and deionized water to prepare unsaturated organo-siloxane low polymer emulsion; theorgano-siloxane low polymer emulsion, acrylate monomer mixture, initiator A, emulsifier, pH value regulator, molecular weight regulator and deionized water are adopted to polymerize nuclear emulsion;and finally, silicon acrylic nuclear emulsion, deionized water, anion / non-ion emulsifier, acrylate monomer mixture, VTES coupling agent and initiator B are adopted to polymerize nuclear emulsion to prepare high-silicon silicone acrylic emulsion. The method of the invention effectively inhibits organosilicon self-polymerization, so that the silicone acrylic emulsion of the invention has high silicon content and stable storage, has the properties of favorable weather resistance, smudge resistance, water resistance and the like, has high gloss and beautiful degree and can satisfy the requirements of high-grade buildings on exterior wall paint.

Owner:TIANJIN URBAN CONSTR COLLEGE

(Methyl) acrylic resin with high organic silicon content and preparation method thereof

The invention discloses (methyl) acrylic resin with high organic silicon content and a preparation method thereof. The preparation method of the (methyl) acrylic resin comprises the following steps of: enabling octamethylcyclotetrasiloxane, an anionic emulsifier, a non-ionic emulsifier and water to react for 3 hours to 9 hours at 70 DEG C to 90 DEG C; adding siloxane containing unsaturated double bond to react for 3 hours to 9 hours at 75 DEG C to 90 DEG C; breaking the emulsion by alcohol to obtain long-chain siloxy vinyl siloxane; and enabling the obtained long-chain siloxy vinyl siloxane, (methyl) acrylic resin monomer, non-reactive organic solvent and initiator to react at 60 DEG C to 75 DEG C to obtain the (methyl) acrylic resin with high organic silicon content. The resin is introduced with the long-chain siloxy vinyl siloxane, so the resin has good water resistance; and the appropriate (methyl) acrylic resin monomer is selected, so that the elongation at break and tensile strength of a film which is coated with the (methyl) acrylic resin are increased.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

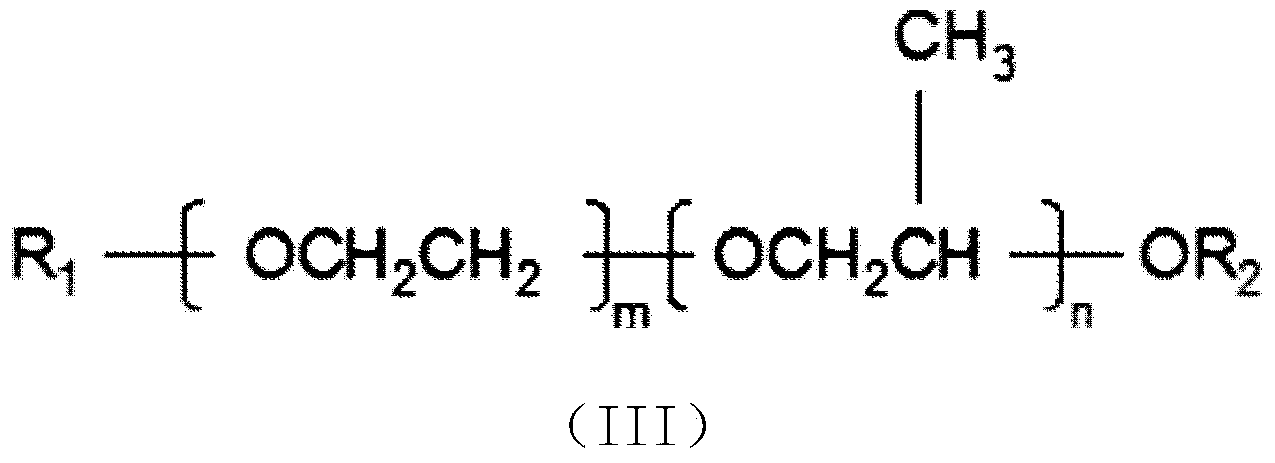

Preparation method of organosilicon foam stabilizer applied to single-component polyurethane foam sealing agent

The invention discloses a preparation method of an organosilicon foam stabilizer applied to a single-component polyurethane foam sealing agent. The preparation method comprises the steps of (1) adding allyl alcohol, ethylene oxide and propylene oxide to a reaction kettle, and reacting under the action of a base catalyst at the temperature of 90-130 DEG C and pressure not more than 0.5MPa for 4-6h to obtain allyl-terminated copolymer ether; (2) reacting the polyether prepared in the step 1 with sodium at 85-120 DEG C, introducing excess haloalkane, and reacting for 4-6h to obtain methyl-terminated copolymer ether; (3) reacting octamethyl cyclotetrasiloxane, hexamethyl disiloxane and high-hydrogen-content silicone oil with hydrogen content of 1-2% in the presence of an acid ion exchanger to obtain low-hydrogen-content silicone oil with hydrogen content of 0.05-1.0%; (4) mixing the products obtained in the steps 1,2, and 3, adding a catalyst, and reacting under the condition of pressure being 0.5-2atm for 3-8h to obtain the organosilicon foam stabilizer. During foaming, the foam stabilizer has excellent dimensional stability and high foaming ratio and fluidity.

Owner:苏州思德新材料科技有限公司

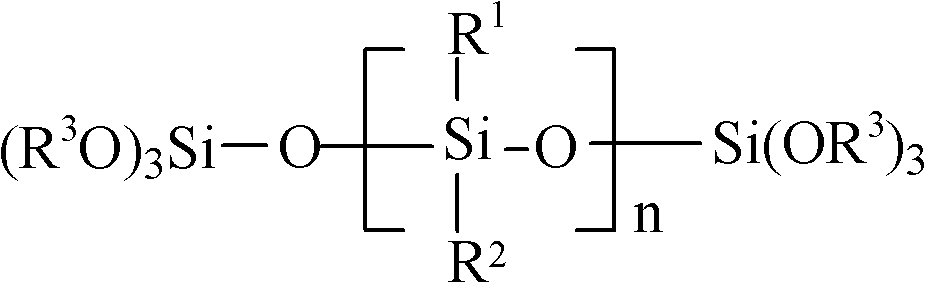

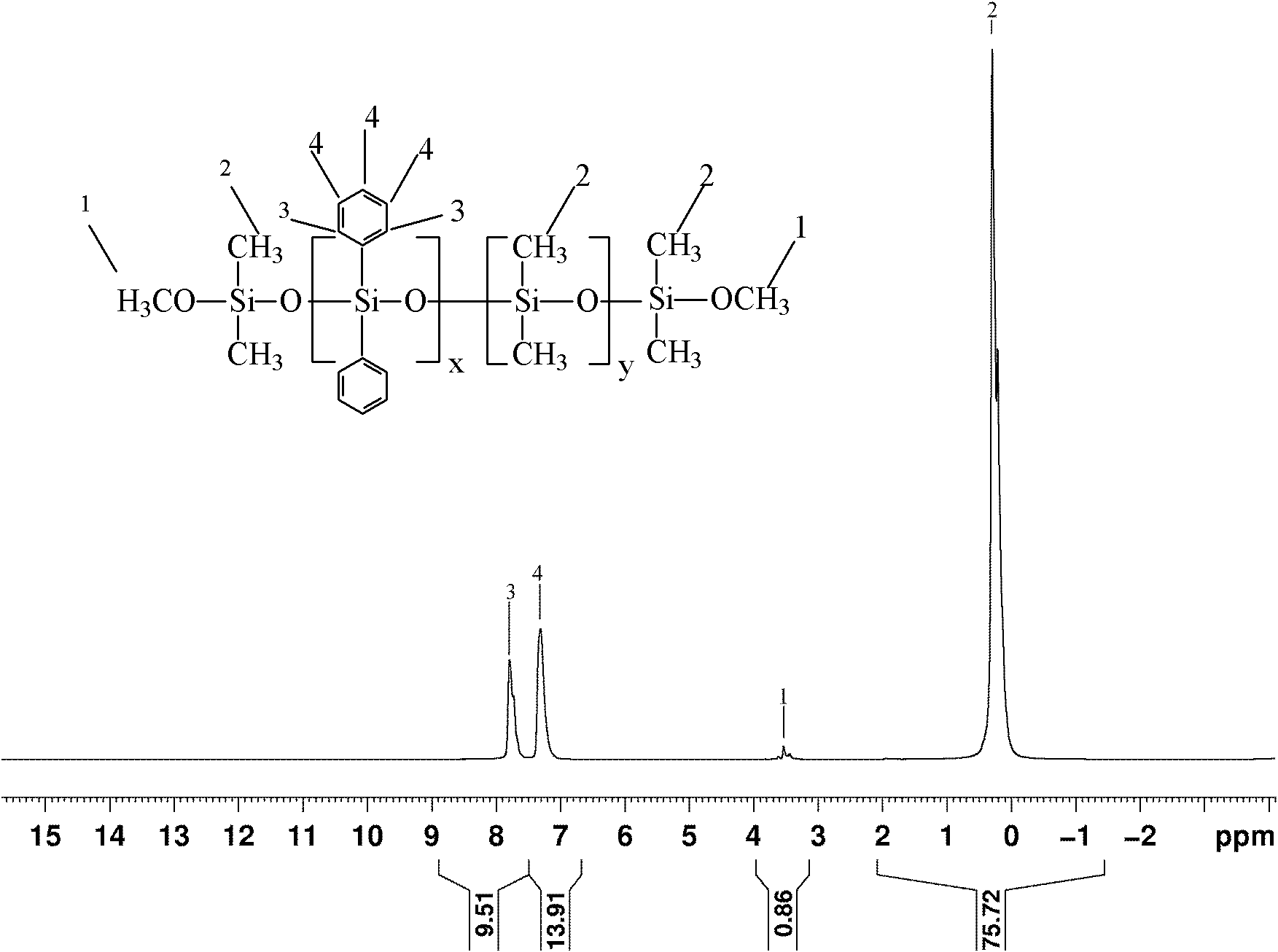

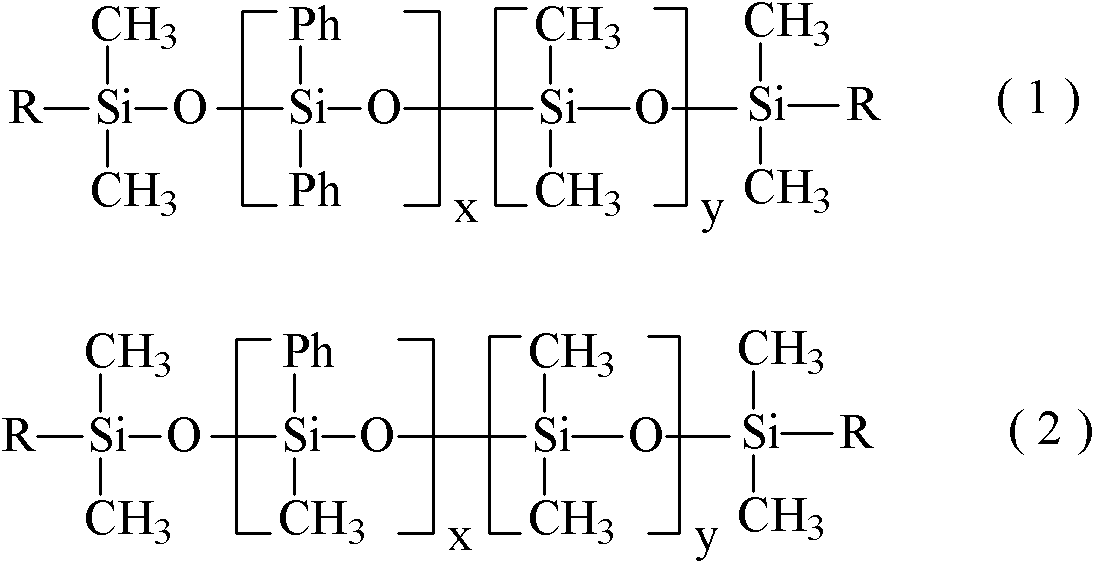

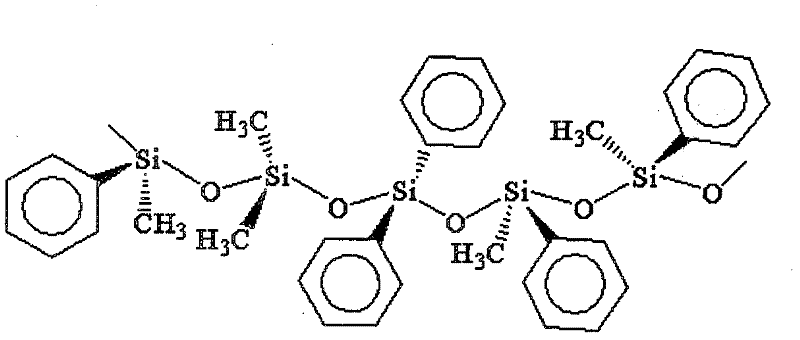

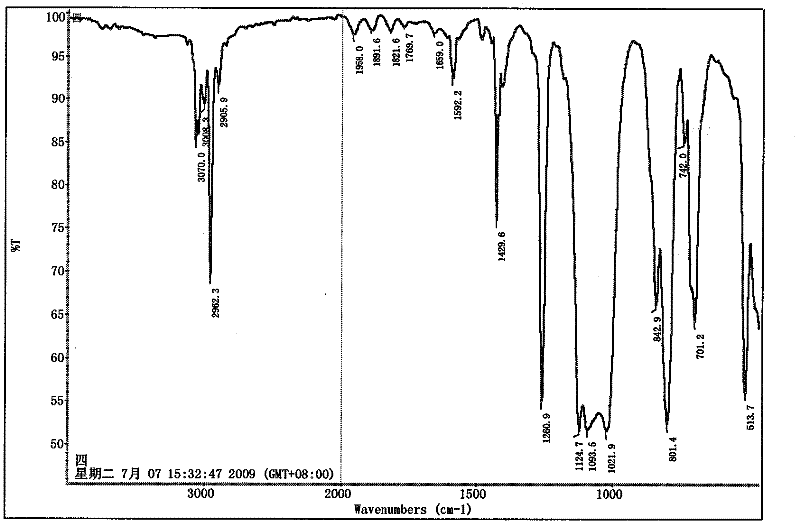

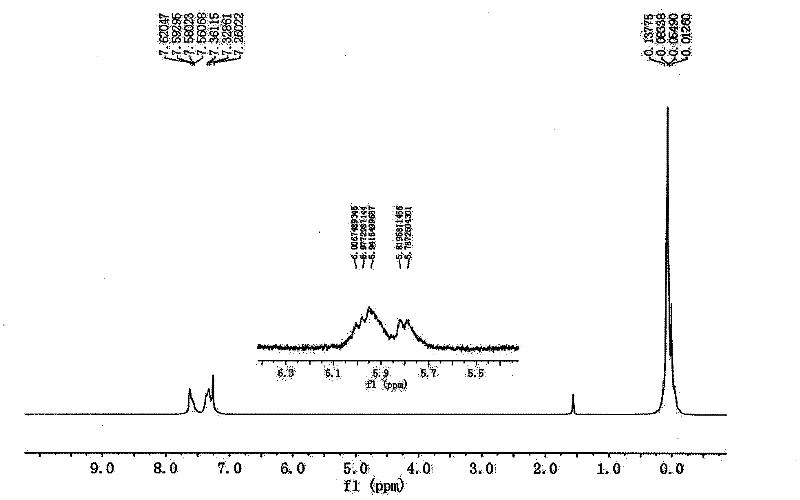

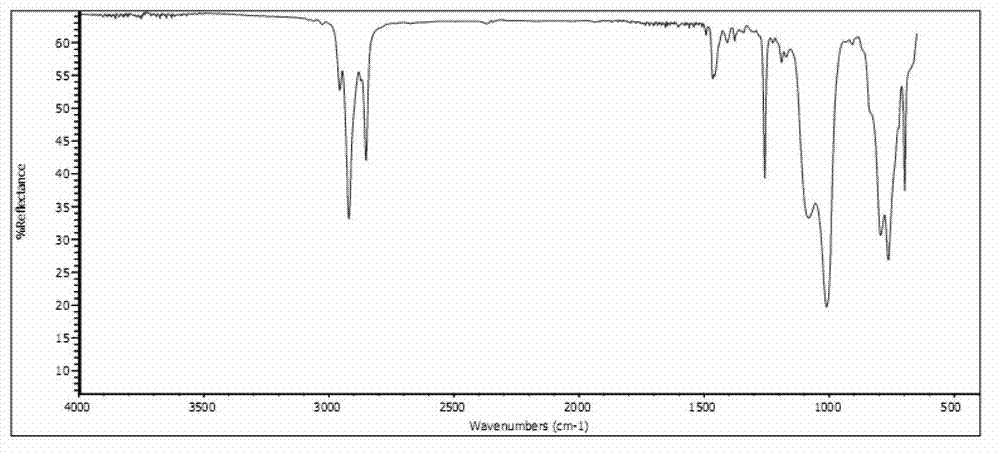

Poly(diphenyl-dimethyl siloxane) with terminals sealed by alkyloxy groups, and preparation method thereof

The invention relates to a poly(diphenyl-dimethyl siloxane) with terminals sealed by alkyloxy groups, and a preparation method thereof. The preparation method comprises that octaphenylcyclotetrasiloxane and octamethylcyclotetrasiloxane as monomers for a polymerization reaction, low viscosity polydimethylsiloxane with terminals sealed by alkyloxy groups as a terminal sealing agent, and potassium silanolate as a catalyst are adopted; the monomers, the terminal sealing agent, the catalyst and accelerating agents are added into a reaction system; the reaction system is sealed up and then the mixture in the reaction system is stirred and heated to a temperature of 120 to 180 DEG C to undergo a polymerization reaction for 1 to 16 hours; and processes of neutralization, filtering and removal of low molecules on the reaction system are carried out. The preparation method has the advantages of high purity of raw materials, simple process, no need of a mass of organic solvents, and environmentally friendly characters. Products prepared by the preparation method has the advantages of high refractive index and good radiation resistance, high-low temperature resistance and climate resistance, and is especially suitable for base polymers of a dealcoholization type room temperature vulcanized silicone rubber, and surface treatment agents of filling materials such as white carbon black and the like utilized in various silicone rubber and other rubber processing.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

Breathable polyurethane synthetic leather preparation method

InactiveCN106087451AImprove breathabilityComfortable to wearTextiles and paperPolymer scienceGluconacetobacter

The invention belongs to the technical field of synthetic leather preparation and relates to a breathable polyurethane synthetic leather preparation method. The method includes: subjecting octamethyl cyclotetrasiloxane and gamma-aminoethyl aminopropyl trimethoxysilane to ring opening and polymerization to obtain amino modified silicon oil; reacting with polytetrahydrofuran glycol to obtain polyether modified amino silicon oil; reacting with isophorone diisocyanate to obtain a prepolymer; reacting with 2,2-dimethylolpropionic acid and the like, and carrying out operations such as neutralizing to obtain polyether amino silicon oil modified polyurethane; fermenting gluconacetobacter and polyether amino silicon oil modified polyurethane to obtain bacterial cellulose; mixing with part of polyether amino silicon oil modified polyurethane, adding additives, stirring, coating, and performing operations of solidifying, washing, drying and the like to obtain breathable polyurethane synthetic leather. The breathable polyurethane synthetic leather prepared according to the method is higher than 720mL / cm<2>.h in air permeability and light and comfortable to wear and is excellent in water permeability which is higher than 952g / m<2>.24h.

Owner:周荣

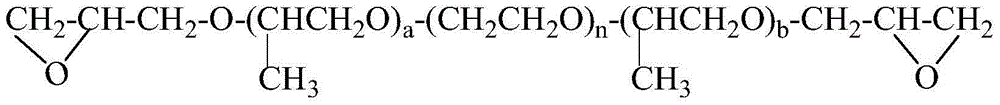

Super-soft/smooth block silicon oil and preparation method thereof

The invention relates to the field of textile finishing agents, particularly a super-soft / smooth block silicon oil and a preparation method thereof. The preparation method comprises the following steps: after mixing octamethylcyclotetrasiloxane and an amino coupling agent, reacting under the action of an alkaline catalyst to obtain a common side chain amino modified silicon oil intermediate A; reacting the prepared A with an amino-terminated polyether coupling agent under the action of an alkaline catalyst to obtain an amino-terminated polyether block and side chain amino modified silicon oil intermediate B; and carrying out polymerization reaction on the prepared B and epoxy-terminated polyether under the action of an organic solvent to finally obtain terpolymer block side chain amino-modified organic silicon oil. By introducing side chain amino group into the straight-chain terpolymer block silicon oil compound, the fabric finished by the compound has excellent soft, fluffy and smooth effects and excellent whiteness, and thus, the compound is suitable for super-soft / smooth finishing of cotton, cotton-chemical fiber blend fabrics and the like.

Owner:GUANGDONG CHUANHUA FULIAN FINE CHEM CO LTD

Long-chain alkyl phenyl modified hydrogen containing silicone oil releasing agent preparation method

InactiveCN104497312AImprove utilization efficiencyImprove conversion rateSilicon organic compoundsNitrogen gasAlpha-olefin

The invention discloses a long-chain alkyl phenyl modified hydrogen containing silicone oil releasing agent preparation method. The method includes the steps of subjecting tetramethyl tetra-hydrogen cyclotetrasiloxane and a catalyst of chloroplatinic acid to reaction, dropping styrene for reaction for some time, dropping long-chain alpha-olefin and a chloroplatinic acid isopropyl propanol solution to obtain an intermediate product of tetramethyl alkyl phenyl cyclotetrasiloxane, subjecting the obtained intermediate product of tetramethyl alkyl phenyl cyclotetrasiloxane, octamethylcyclotetrasiloxane, hexamethyldisiloxane and an acid catalyst to full reaction, fully cooling the obtained liquid, slowly adding calcium hydroxide to adjusting the PH value to 6-7, filtering out solids produced in neutralization with a vacuum pump, adding anhydrous magnesium sulfate to adsorb water produced in neutralization, and filtering to obtain a long-chain alkyl phenyl modified hydrogen containing silicone oil releasing agent. The long-chain alkyl phenyl modified hydrogen containing silicone oil releasing agent prepared through the preparation method has the advantages of being simple in process, high in efficiency, low in cost, short in cycle and the like.

Owner:仪征市新源新材料科技有限公司

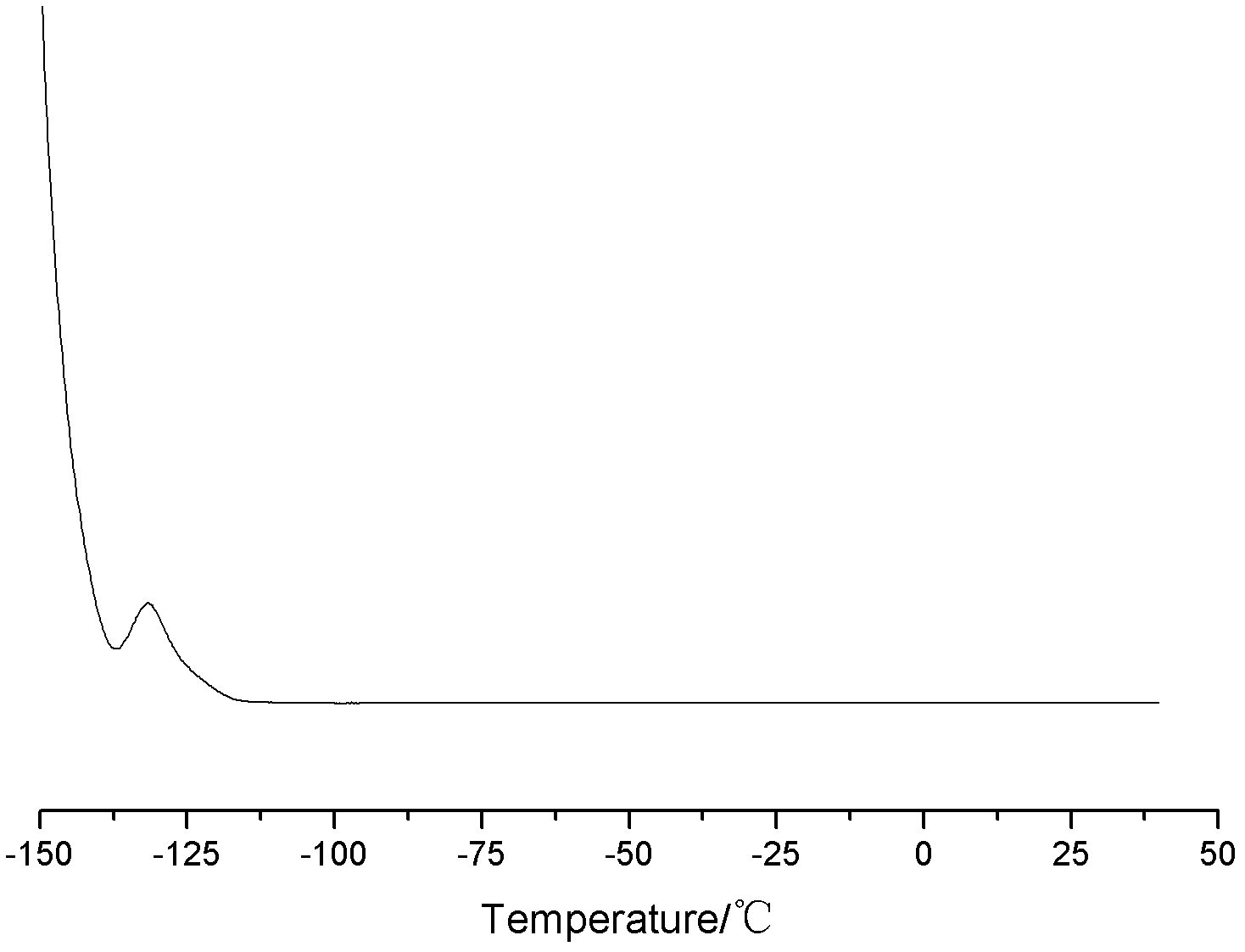

Low-temperature-resisting crude silicon rubber

ActiveCN102532548ALower glass transition temperatureThe polymerization process is simplePolymer scienceBoiling point

The invention discloses a low-temperature-resisting crude silicon rubber which is obtained by polymerizing octamethyl cyclotetrasiloxane (D4), hexaethylcyclotrisiloxane (D3Et), 2,4,6,8-tetravinyl-2,4,6,8-tetramethylcyclotetrasiloxane (D4Vi), a catalyst and an accelerating agent and then heating, removing small molecular low-boiling-point substances in materials in vacuum and cooling to room temperature. According to the invention, the low-temperature-resisting crude silicon rubber product disclosed by the invention is stable, the glass transition temperature (Tg) of the rubber is low and is not crystallized at low temperature; polymerization process is simple and does not need a solvent, and the high-molecular-weight low-temperature-resisting crude silicon rubber can be obtained through severely controlling reaction conditions in short reaction time; and the rubber is high in yield, controllable in molecular weight, simple in posttreatment and easy to produce in a large scale.

Owner:SHANDONG UNIV +1

Glycosyl modified polysiloxane organic silicone softener and preparation method thereof

The invention discloses a glycosyl modified polysiloxane organic silicone softener and a preparation method thereof. The preparation method comprises the steps of enabling gamma-glycidoxy propyl methyl dialkoxy silane and octamethyl cyclotetrasiloxane with the mole rate of 1: (2.5-50) to react in an alkyl polyglucoside surfactant and basic catalyst water solution at the temperature of 60-100 DEG C to obtain a semitransparent alkoxy modified polysiloxane intermediate emulsion; regulating the pH value of the alkoxy modified polysiloxane intermediate emulsion in the step (1) to 0.5-6, adding N, N-dimethyl-N'-glycosylacyl-1, 3-propane diamine, and enabling N, N-dimethyl-N'-glycosylacyl-1, 3-propane diamine and gamma-glycidoxy propyl methyl dialkoxy silane in the step (1) to react at the temperature of 70-95 DEG C to obtain a semitransparent glycosyl modified polysiloxane emulsion, wherein the mole ratio of N, N-dimethyl-N'-glycosylacyl-1, 3-propane diamine to gamma-glycidoxy propyl methyl dialkoxy silane is (0.3-0.8):1. The softener disclosed by the invention has the super softness of amino silicon oil and the solidifying and finishing effects of epoxy modified silicon oil, and can be used for effectively improving the washing fastness and the smoothness.

Owner:SHANGHAI FINE CHEM CO LTD

Synthesis method of quaternized organosilicon modified acrylate emulsion

The invention relates to a preparation method of a quaternized organosilicon modified acrylate emulsion. The method mainly comprises the processes of: (1) synthesizing amino silicone oil by putting otcamethylcyclotetrasiloxane, a double bond-containing silane coupling agent, N-beta-(aminoethyl)-gamma-aminopropylmethyldimethoxysilane, hexamethyldisiloxane, potassium hydroxide and deionized water in a reaction container for reaction at a temperature of 100-110DEG C; (2) adding an alkyl halide or epoxy alkyl halide for quaternization treatment at a temperature of 50-90DEG C, thus obtaining quaternized modified amino silicone oil; (3) adding an emulsifier, acrylate monomers and deionized water into the quaternized modified amino silicone oil obtained on step (2), and employing an oxidation-reduction initiating system for copolymerization reaction, thus obtaining a quaternized organosilicon modified acrylate emulsion. The product of the invention can be used for textile finishing, especially for acrylic fabric, and has good pilling resistance.

Owner:YANCHENG CHANGHUA OUTDOOR PROD CO LTD

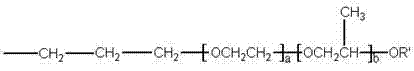

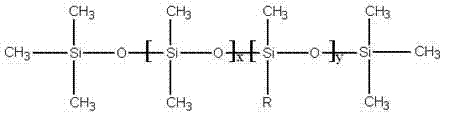

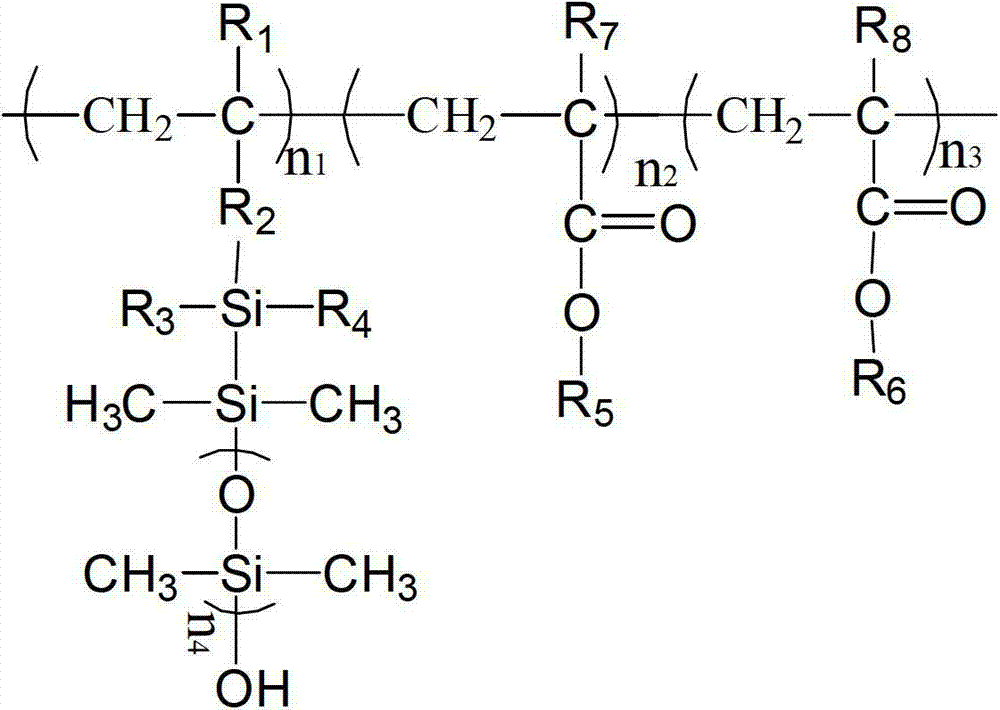

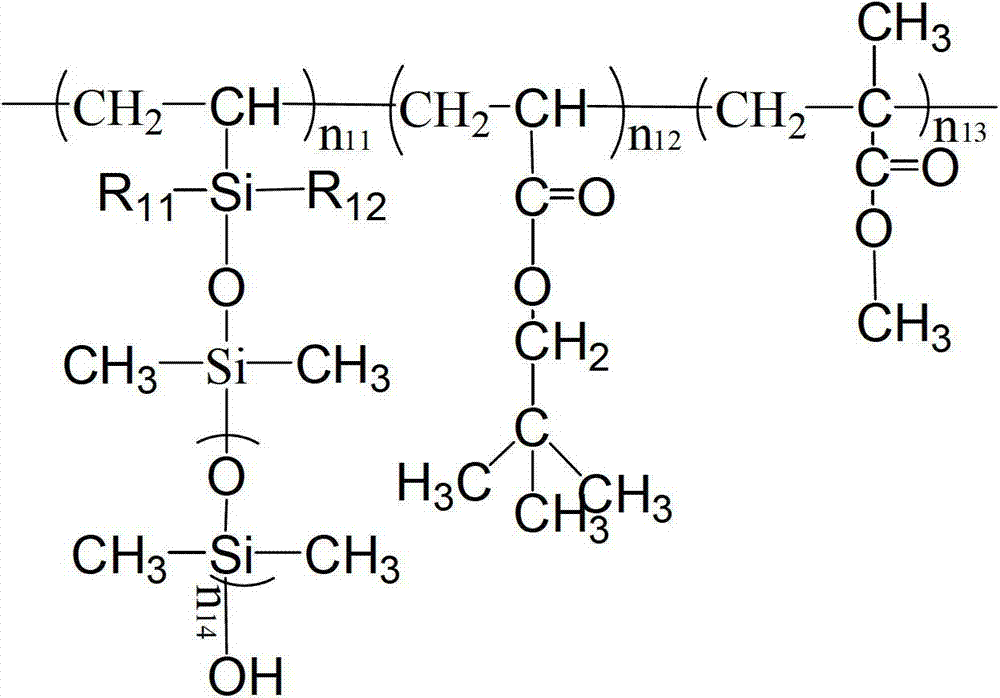

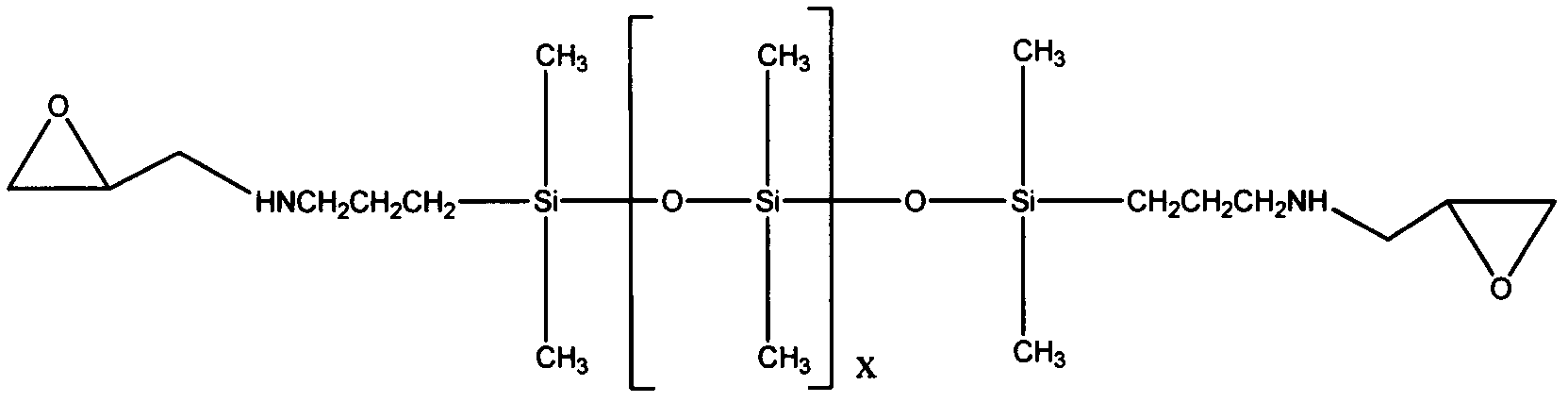

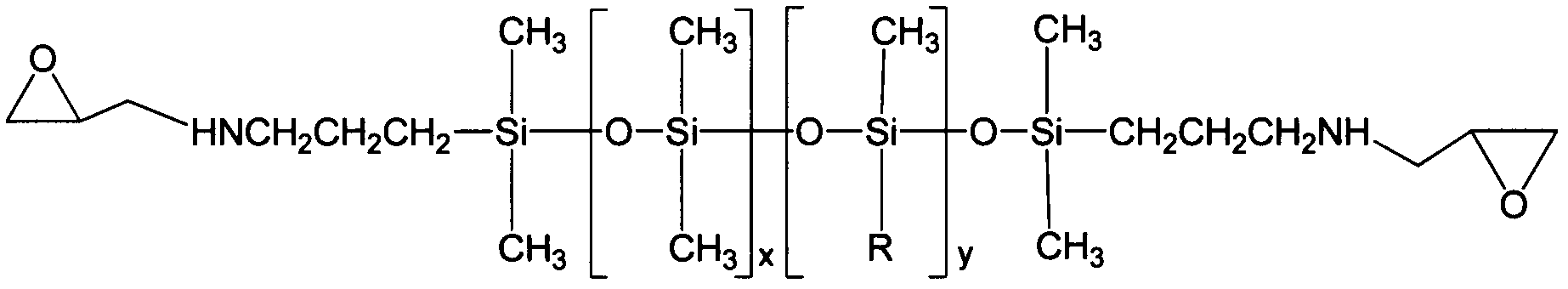

Preparation method of long-chain alkane and epoxy co-modified amino-terminated silicone oil

The invention relates to a preparation method of long-chain alkane and epoxy co-modified amino-terminated silicone oil. The structural formula of the long-chain alkane and epoxy co-modified amino-terminated silicone oil is represented by figure 1 in the specification. The preparation method of the modified silicone oil comprises the following steps: adding octamethylcyclotetrasiloxane, a long-chain alkane coupling agent and an amino-terminated silane end capping agent according to certain proportions, uniformly stirring, heating to 60-80DEG C, adding an alkaline catalyst, reacting under stirring for 0.5-1.5h, controlling the reaction temperature in a range of 90-140DEG C, carrying out a temperature maintenance reaction for a period of time, carrying out reduced pressure distillation to obtain a low-boiling-point substance which is modified silicone oil, dissolving the modified silicone oil in a solvent, reacting with epichlorohydrin at 50-100DEG C for 2-7h, and carrying out reduced pressure evaporation to remove the solvent in order to obtain the long-chain alkane and epoxy co-modified amino-terminated silicone oil. The long-chain alkane and epoxy co-modified amino-terminated silicone oil is mixed with an emulsifier and an acid, are added with deionized water in batch, and undergoes pH adjustment by the acid to about 7 in order to obtain an emulsion of the long-chain alkane and epoxy co-modified amino-terminated silicone oil. The long-chain alkane and epoxy co-modified amino-terminated silicone oil prepared in the invention overcomes the yellow disadvantage of amino silicone oil, and has the advantages of good lubrication property, good hydrophobicity and good fluffy feeling when the long-chain alkane and epoxy co-modified amino-terminated silicone oil is used for texture finishing.

Owner:JIANGNAN UNIV

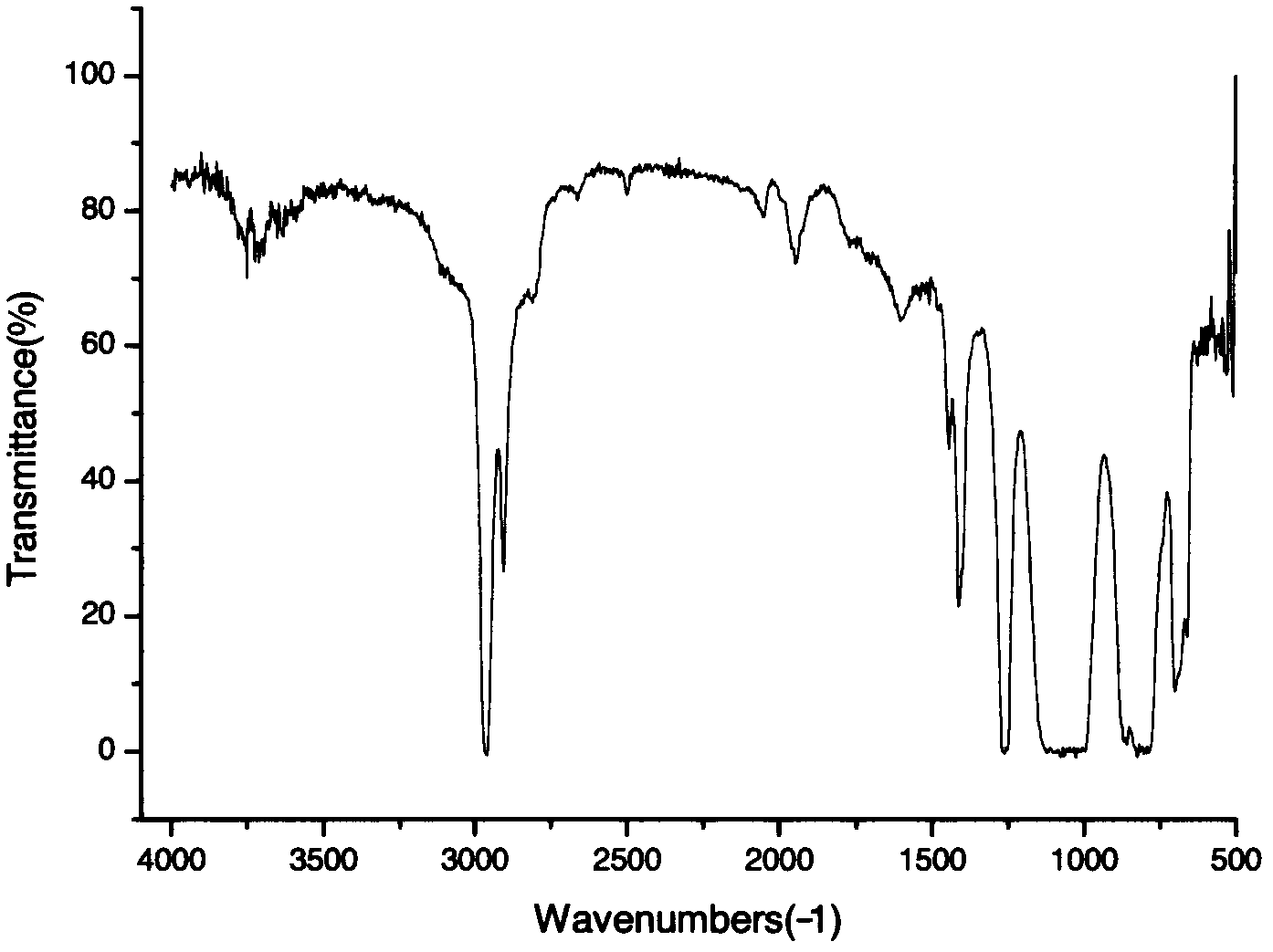

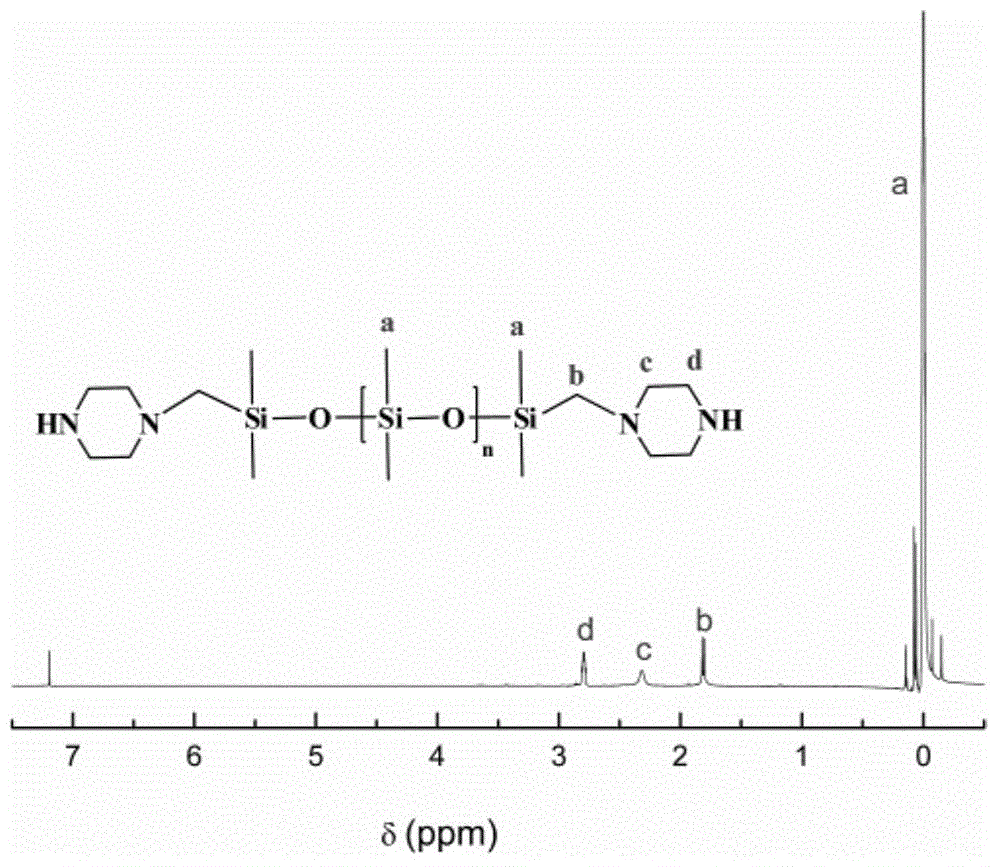

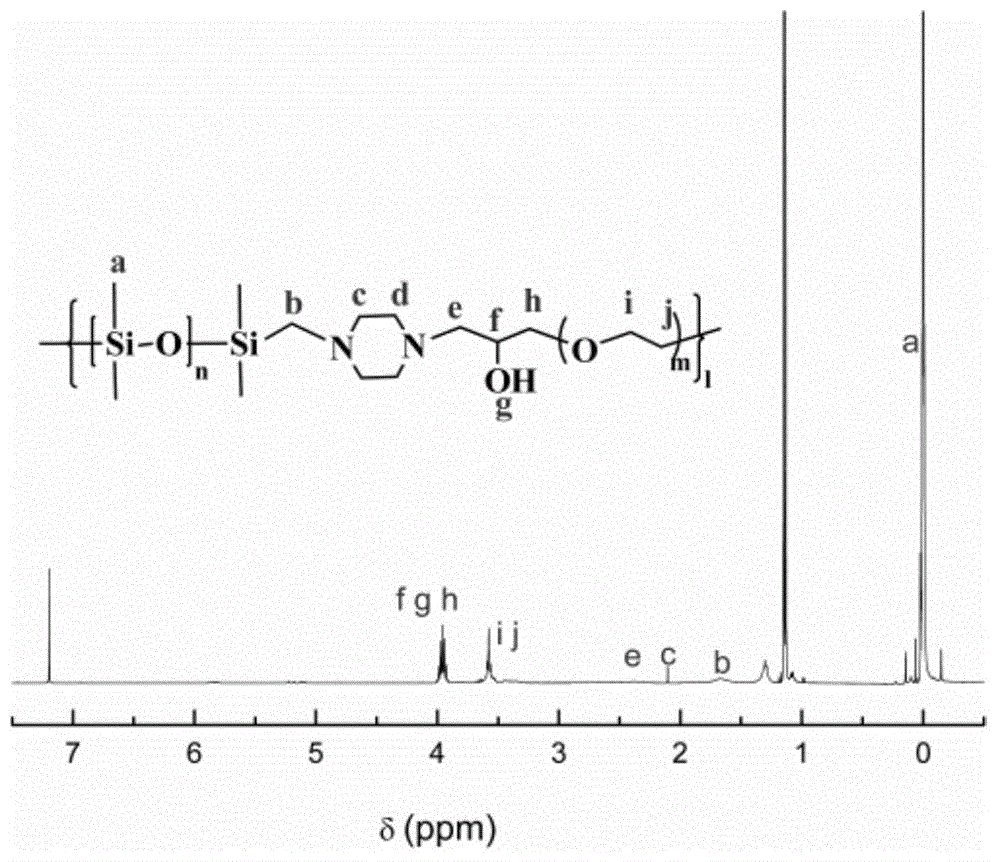

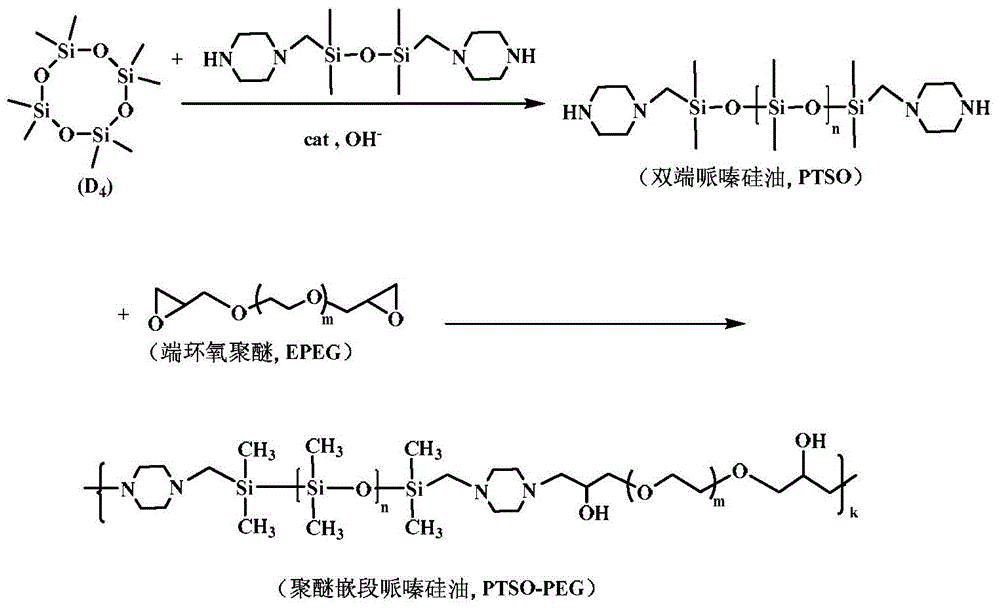

Polyether block piperazine silicone oil as well as preparation method and application thereof in cotton woven finishing

ActiveCN104672460AGood flexibilityOvercome the defect of easy yellowing of fabricVegetal fibresEpoxyBackbone chain

The invention discloses a synthesis of polyether block piperazine silicone oil and an application thereof in cotton woven finishing. The preparation method comprises the following steps: reacting the octamethylcyclotetrasiloxane (D4) and the dipiperazine double end sockets in proportion in the presence of an alkali catalyst to obtain the double-end piperazine silicone oil, reacting the silicon oil with the double-end epoxy terminated polyether to obtain the polyether block piperazine silicone oil. The silicon oil is emulsified for finishing the cotton woven, so that the processed fabric not only has good softness, but also has hydrophilcity, hygroscopicity and yellow resistance. A simple synthetic method is designed by the invention, the piperazine and the polyether groups are introduced into the silicon oil main chain so that the defects of no yellow resistance and bad hydrophilcity of the traditional amino silicon oil processed fabrics can be overcome.

Owner:ZHEJIANG UNIV

Copolymerized high-performance damping silicon rubber and preparation method thereof

The invention discloses copolymerized high-performance damping silicon rubber and a preparation method thereof. The preparation method is characterized by comprising the following steps of: adding 100 parts by mole of octamethylcy-clotetrasiloxane, 0.001-1 part by mole of tetram-ethy1tetravinylcyclotetrasiloxane, 1-50 parts by mole of octaphenyl cyclotetrasiloxane and 1-500 parts by mole of hybrid ring containing methylphenyl siloxane chain links into a reactor; dehydrating by forming nitrogen bubbles at the temperature of between 55 DEG C and 65 DEG C under the protection of nitrogen gas for 1-3 hours; adding 0.01-5 percent by weight of catalyst; continually drying nitrogen bubbles; adding 0.00001-1 part by millimole of end-capping reagent when the viscosity rises; undergoing a balanced reaction at the temperature of between 90 DEG C and 110 DEG C for 7-8 hours; raising the temperature to 145-165 DEG C after the reaction; preserving heat for 1-2 hours; decomposing and breaking the catalyst; raising the temperature to 180-200 DEG C finally; separating low molecular substances out at reduced pressure under the vacuum degree of 6-12 Mpa until distillate is eliminated fully; cooling to room temperature and discharging; and stopping reducing pressure to obtain polymethyl phenyl ethylene siloxane. Phenyl siloxane rubber further prepared from the copolymer has superior damping capacity and mechanical property.

Owner:SICHUAN UNIV

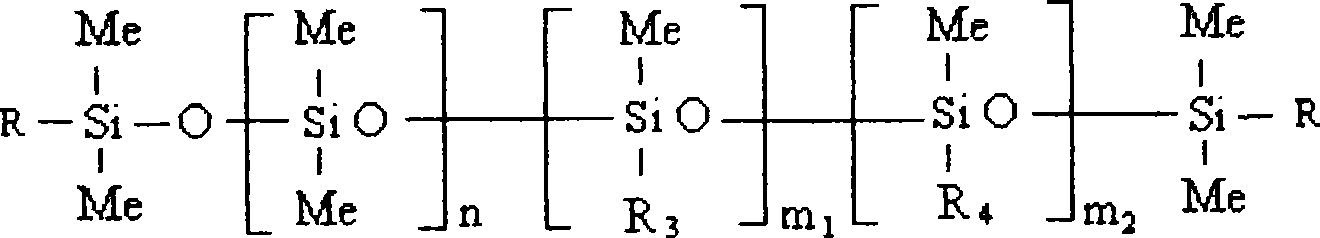

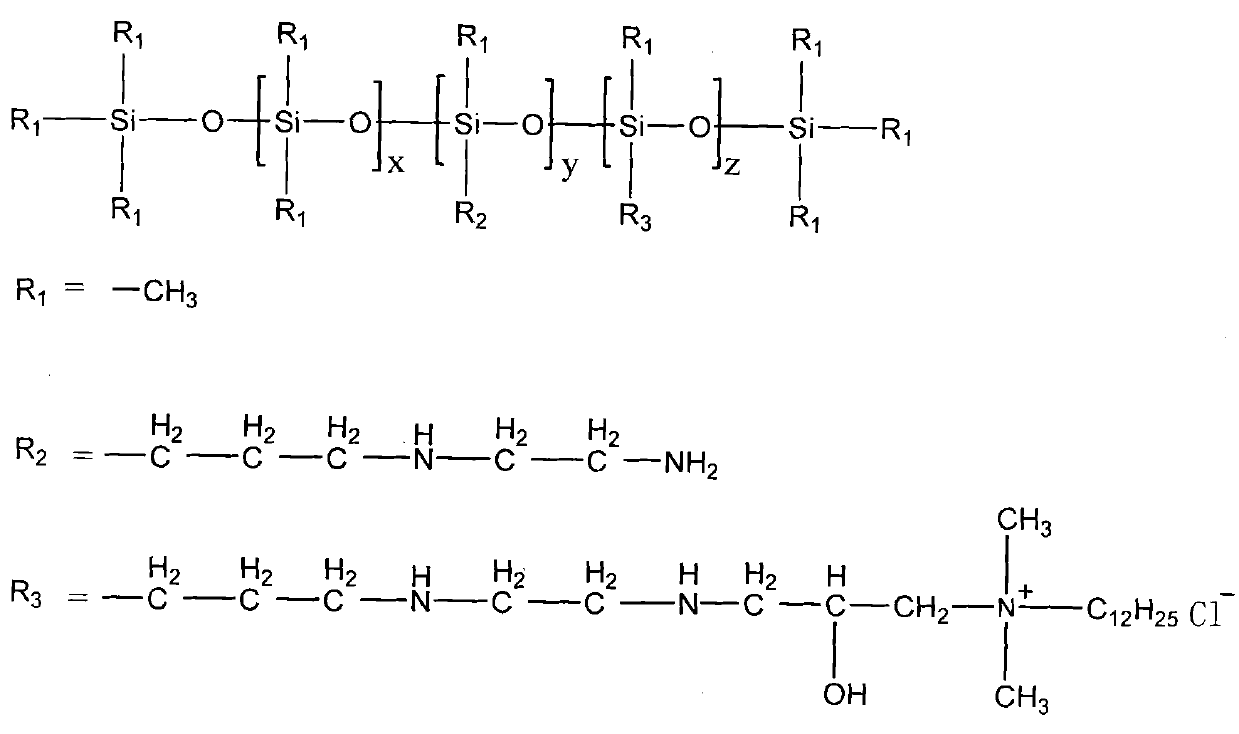

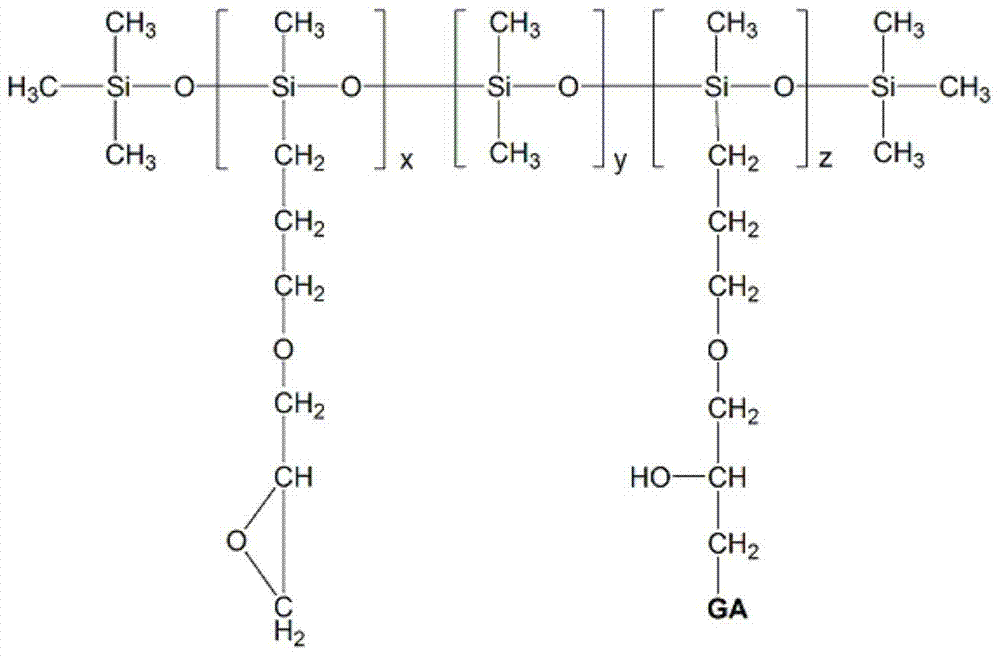

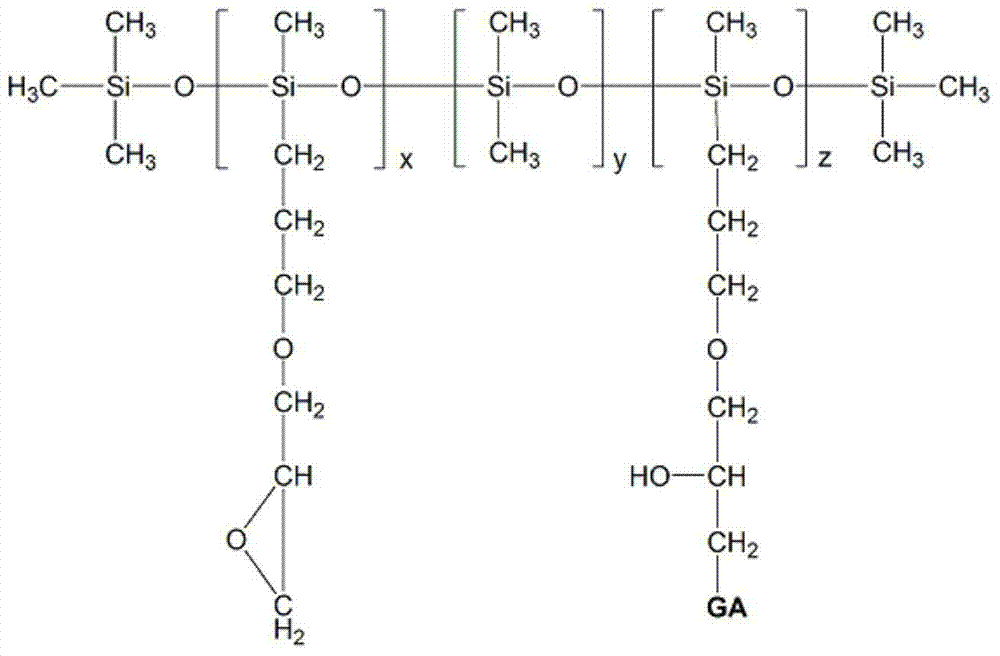

Amphion type amino silicone oil and preparation method thereof

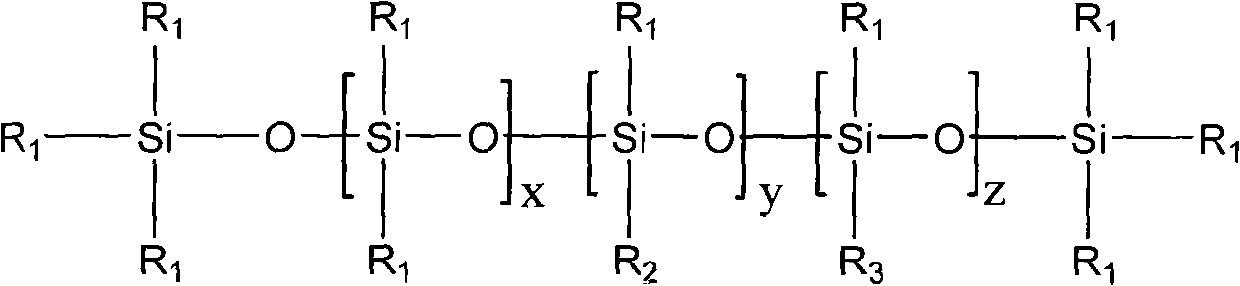

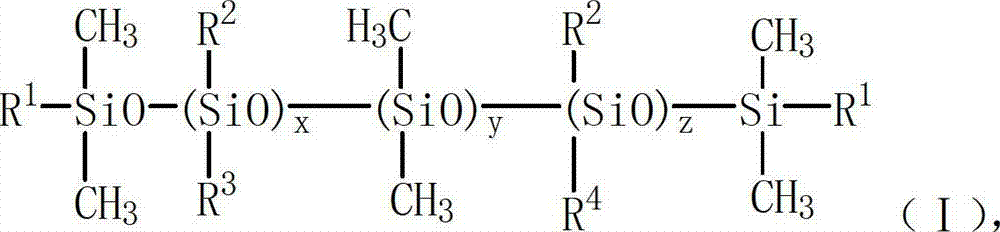

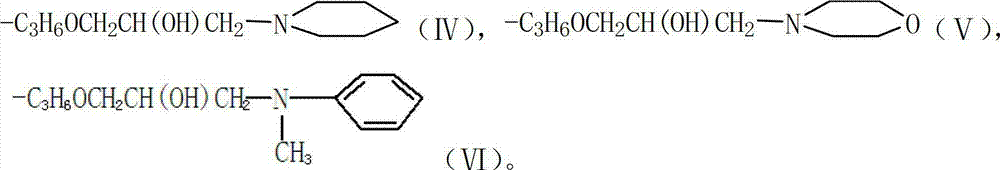

The present invention relates to amphion type amino silicone oil and a preparation method thereof. The amphion type amino silicone oil has a structural formula represented by the following formula, wherein R1 is C1-C12 alkyl, alkoxy or hydroxy, R2 is methyl or hydroxy, R3 is a monoamine group, R4 is an anion modified monoamine group, x, y and z are positive integers, and a sum of x, y and z is more than or equal to 5 and is less than or equal to 1000. The structure characteristics comprise that the main chain contains a silicone-oxygen repeating unit, and the branched chain contains alkyl, amino, hydroxy, a quaternary ammonium cation group and an anion group. The preparation method comprises that: octamethylcyclotetrasiloxane and an epoxy silane cross-linking agent are polymerized to obtain epoxy modified silicone oil; the epoxy modified silicone oil reacts with a monoamine compound to obtain amino modified silicone oil; and finally the amino modified silicone oil reacts with an anion modification agent to obtain the product. With the modified organic silicone oil product, emulsion stability and reactivity during fabric treating are improved, and the treated fabric has good yellowing resistance, washing fastness and fluffy feeling.

Owner:上海氟聚化学产品股份有限公司

High-dielectric constant composite material

The invention relates to a high-dielectric constant composite material. Bismaleimide resin monomer, maleic anhydride, octamethylcyclotetrasiloxane, pentaerythritol tetraacrylate, phenoxy resin, iso-tridecanol polyoxyethylene ether, polycaprolactam resin, filler and ethylene glycol are taken as materials, a resin-based compound system is prepared; the resin-based compound system is then put into a mold and hot-pressed, and thereby the high-dielectric constant composite material is obtained. The high-dielectric constant composite material has excellent mechanical property and heat resistance, and the development and application of high-dielectric constant composite materials can be met.

Owner:苏州凯欧曼新材料科技有限公司

Organosilicon emulsion and preparation method thereof, and fabric finishing agent

ActiveCN105837823AImprove performanceSmall particle sizeGrip property fibresAbrasion resistant fibresSelf emulsifyingAlkaline catalyst

The invention relates to the field of textiles, specifically to a preparation method for an organosilicon emulsion. The preparation method comprises the following steps: subjecting an aqueous solution of a highly basic catalyst, a linear compound of octamethylcyclotetrasiloxane, an ammonia type coupling agent and an end-capping reagent to mixing and reaction so as to obtain amino silicon oil; then reacting the amino silicon oil with dimethylaminoethyl methacrylate so as to obtain modified amino silicon oil; and adding the modified amino silicon oil into chloropropylene oxide and carrying out quaternization. Compared with the prior art, the preparation method for the organosilicon emulsion in the invention has the advantages that Michael addition is employed, and a novel preparation method for the organosilicon emulsion is provided; and the prepared organosilicon emulsion does not need emulsification by an emulsifier and can realize self-emulsifying. The invention also discloses the organosilicon emulsion and a fabric finishing agent.

Owner:科凯精细化工(上海)有限公司

Process for preparing nano grade amino silicon oil emulsion

The invention discloses a preparing method of nanometer grade amino silicon oil emulsion, which comprises the following steps: 1. dissolving cationic emulsifier and non-ionic emulsifier in the right amount water; dripping octamethyl pyrophosphoramide eptetrasiloxane; stirring at high speed; adding amino coupling; producing pre-emulsion through homogeneity; 2. adding the residual cationic emulsion; heating temperature to polymerization temperature; adding catalyst; dripping pre-emulsion; refluxing; cooling; adding glacial acetic acid to neutralize; producing nanometer grade amino silicon oil emulsion. The invention possesses small-grain radius gel particle, whose average grain size is among 10-50 nm.

Owner:ZHEJIANG UNIV

Anti-pollution coating composition and preparation thereof and application to low surface energy antifouling paint

The invention relates to an anti-pollution coating composition and preparation thereof and application to low surface energy antifouling paint. The coating composition comprises an organic polyorganosiloxane polymer. According to a synthetic formula, the anti-pollution coating composition comprises, by weight parts, 100 parts of octamethylcyclotetrasiloxane, 0.05-0.5 part of basic catalyst, 0.5-3 parts of accelerant, 5-100 parts of silane coupling agent, 0.5-3 parts of end capping agent, 0-0.5 part of dehydrating agent and 15-25 parts of butyl acetate, wherein the dosage of organic acid or acid anhydride is 0-200% the molar weight of the silane coupling agent. The anti-pollution coating composition comprises, by weight percentage, 10-70% of organic polyorganosiloxane polymer, 0.5-20% of pigment, 0.5-20% of filler and 5-40% of solvent. The anti-pollution coating composition has the advantages of having low surface energy performance and hydrophilia and can be widely utilized in the ocean anti-pollution coating filed.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com