Patents

Literature

1960 results about "Butyl acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

N-Butyl acetate, also known as butyl ethanoate, is an ester that is a colorless, flammable liquid at room temperature. It is found in many types of fruit, where along with other chemicals, it imparts characteristic flavors and has a sweet smell of banana or apple. It is used as a synthetic fruit flavoring in foods such as candy, ice cream, cheeses, and baked goods. Butyl acetate is often used as a high-boiling solvent of moderate polarity.

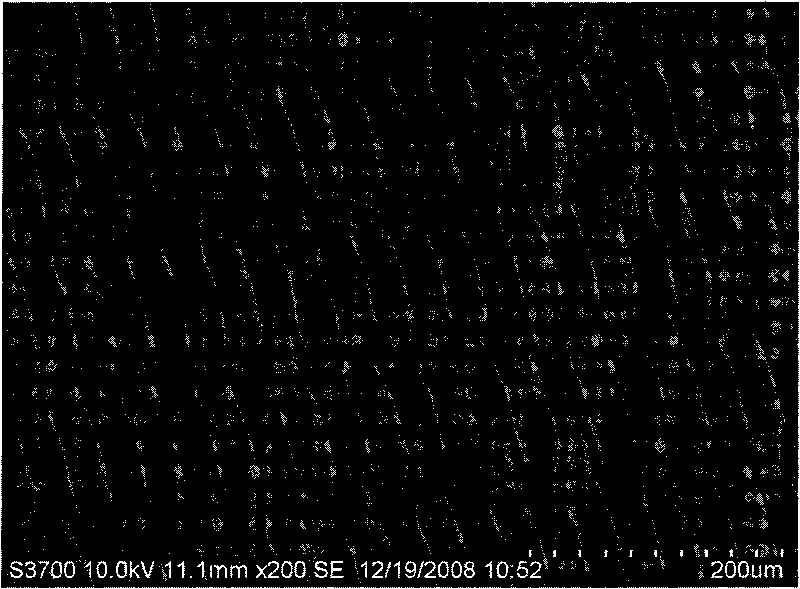

Preparation method of dispersible silane functionalized graphene

The invention provides a preparation method of dispersible silane functionalized graphene. The method comprises the steps of: conducting ultrasonic dispersion to graphene oxide in absolute ethyl alcohol so as to form a uniform graphene oxide dispersion solution, then adjusting the pH value to 3-4, or under the protection of an inert atmosphere, adding silane into the dispersing solution for modification, with silane and graphene oxide in a mass ratio of 0.1:1-5:1, continuing the reaction for 12h-48h at a temperature ranging from normal temperature to 78DEG C, carrying out centrifugation, then adding hydrazine hydrate to the obtained solid, performing heating reduction, and filtering the reaction solution, then washing and drying the filter cake, thus obtaining dispersible silane functionalized grapheme. The method of the invention is simple and practicable, and the obtained silane functionalized grapheme has good dispersibility in solvents like absolute ethyl alcohol, acetone, toluene, ethyl acetate, butyl acetate, and tetrahydrofuran (THF), etc.

Owner:SOUTH CHINA UNIV OF TECH

Carbon nano material/metal nano material composite nano ink

InactiveCN102993820AReduce manufacturing costLow costConductive layers on insulating-supportsInksCyclohexanoneKetone

The invention provides a carbon nano material / metal nano material composite nano ink which comprises solvent, an additive, a carbon nano material and a metal nano material. The carbon nano material / metal nano material composite nano ink is characterized in that the solvent can comprise water, alcohol organic solvent (ethanol(alcohol), isopropanol, n-butanol and the like), ester organic solvent (ethyl acetate, butyl acetate, ethylene-propylene acetate and the like), benzene organic solvent (methylbenzene, dimethylbenzene and the like) and ketone organic solvent (cyclohexanone, acetone, methylethylketone, butanone and the like); the additive comprises surfactant, pH value stabilizer, defoaming agent, diluter, reinforcer and the like; the carbon nano material comprises a single-layer carbon nanotube, a double-layer carbon nanotube, a multi-layer carbon nanotube and graphene; the metal (copper, silver, gold, platinum, nickel and the like, also including an alloy nano material, an ITO metal composite nano material and the like) nano material further comprises a metal nanoparticle, a metal nanowire or a metal nanotube; the components of the nano ink must include one carbon nano component and one metal nano component, such as a single-layer carbon nanotube and copper nanowire composite ink, a double-layer carbon nanotube and silver nanowire composite ink, a single-layer carbon nanotube and silver nanoparticle composite ink or any other possible combination; the components can be regulated according to specific applications; and a composite nano conductive film can be formed on different bases through different electronic printing processes. The ink can be used in the printing of a flexible base material and can be conveniently prepared into a flexible conductive film.

Owner:杨阳

Anti-pollution flashover normal-temperature cured fluorocarbon resin coating and preparation method thereof

ActiveCN102010636AImprove hydrophobicityExcellent hydrophobic migrationAntifouling/underwater paintsSynthetic resin layered productsResin coatingDibutyltin dilaurate

The invention discloses a normal-temperature cured fluorocarbon resin coating, which consists of the following components in percentage by weight: 35 to 70 percent of tetrafluorochloroethylene-vinyl ester polymer, 5.5 to 12 percent of curing agent, 2 to 10 percent of coupling agent, 1 to 10 percent of pigment, 1 to 30 percent of hydrophobic particles, 0.03 to 3 percent of aid, 20 to 40 percent ofsolvent and 0.001 to 1 percent of catalyst, wherein the coupling agent is fluorosilane with a -CF3 group and a -CF2 group; the aid is a flatting agent, an antifoaming agent and a dispersing agent; the solvent is butyl acetate and methyl isobutyl ketone; the catalyst is dibutyltin dilaurate; and the curing agent is aliphatic diisocyanate. By adopting a specific coating formula, due to the combinedaction of the fluorosilane coupling agent and the hydrophobic particles, the anti-pollution flashover fluorocarbon resin coating has a static contact angle theta of 120 degrees, is excellent in hydrophobic performance and hydrophobic migration property, high in anti-pollution flashover performance, high in coating leveling property, smooth in surface, and high in self-cleanliness, chemicals resistance and hot-water resistance, and has an adhesive force reaching a zero level.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Polysiloxane coating composition

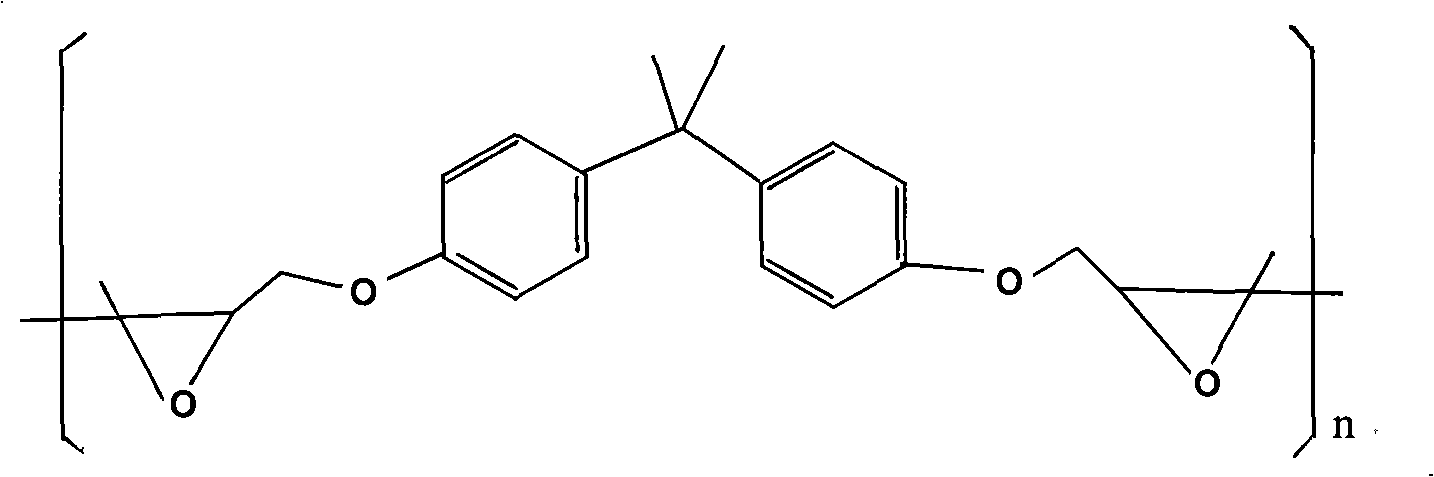

ActiveCN101525519AImprove interlayer adhesionGood weather resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyManufacturing technology

The invention relates to a polysiloxane coating composition belonging to a coating chemical manufacturing technology. The polysiloxane coating composition is obtained by reacting hydrogenated epoxide resin and amino-functionalized siloxane and combining acrylic resin with good coating performance and weatherability and polyetheramine resin with excellent flexibility and adhesion. The invention particularly relates to a polysiloxane coating composition applied to offshore oil platforms. The polysiloxane coating composition has weather-proof, water-proof and corrosion-resistant performances, good flexibility and excellent ply adhesion. The polysiloxane coating composition comprises the following ingredients of 12-50 of epoxide resin, 10-40 of acrylic resin, 0.5-1.5 of dispersant, 20-30 of titanium pigment, 5-25 of French chalk, 5-15 of mica powder, 0.5-1.5 of rheological agent, 0.5-2 of anti-settling agent, 2-10 of dimethyl benzene, 5-10 of butyl acetate, 15-40 of curing agent 1 and 5-25 of curing agent 2 according to the weight percent.

Owner:中山大桥化工集团有限公司

Automobile metal sparkling paint and preparation method thereof

ActiveCN101077954ANo condensationImprove stabilityLiquid surface applicatorsCoatingsFiberWater dispersible

The water-thinned flash paint consists of water dispersible acrylic resin, deionized water, water-thinned curing cross-linking agent, water dispersible aluminum powder, dispersant, carboxymethyl butyl acetate resin fiber and water thinned assistant. The water dispersible acrylic resin is prepared with monomer mixture of methyl methacrylate, styrene, butyl acrylate, methacrylic acid, ethoxy methacrylate and acetyl acetoxy methacrylate, and through free radical polymerization. The water-thinned flash paint has regularly arranged water dispersible aluminum powder, and can form paint film with high flash number, great adhesion of metal grain, high water tolerance, etc.

Owner:GUANGDONG YATU CHEM +1

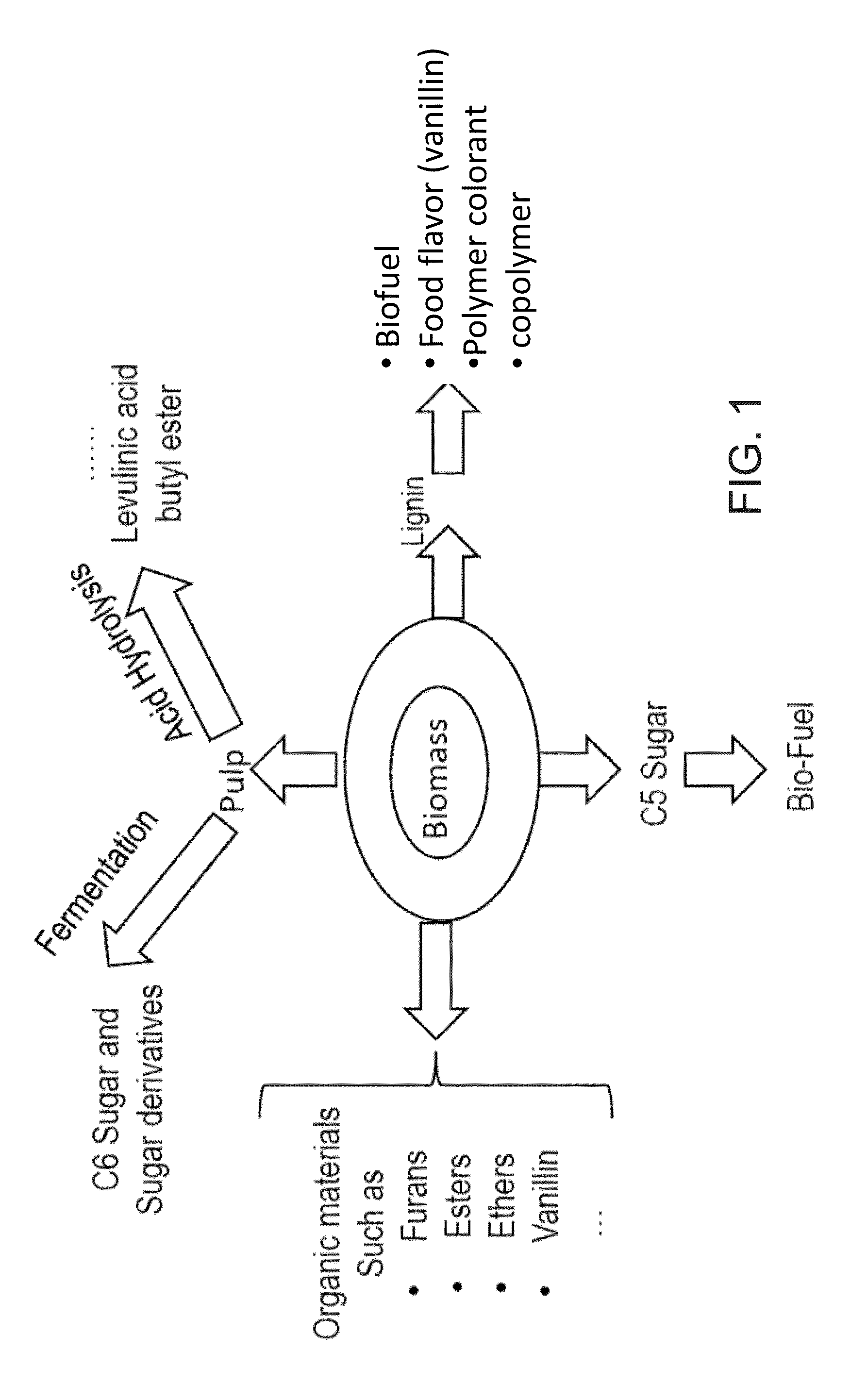

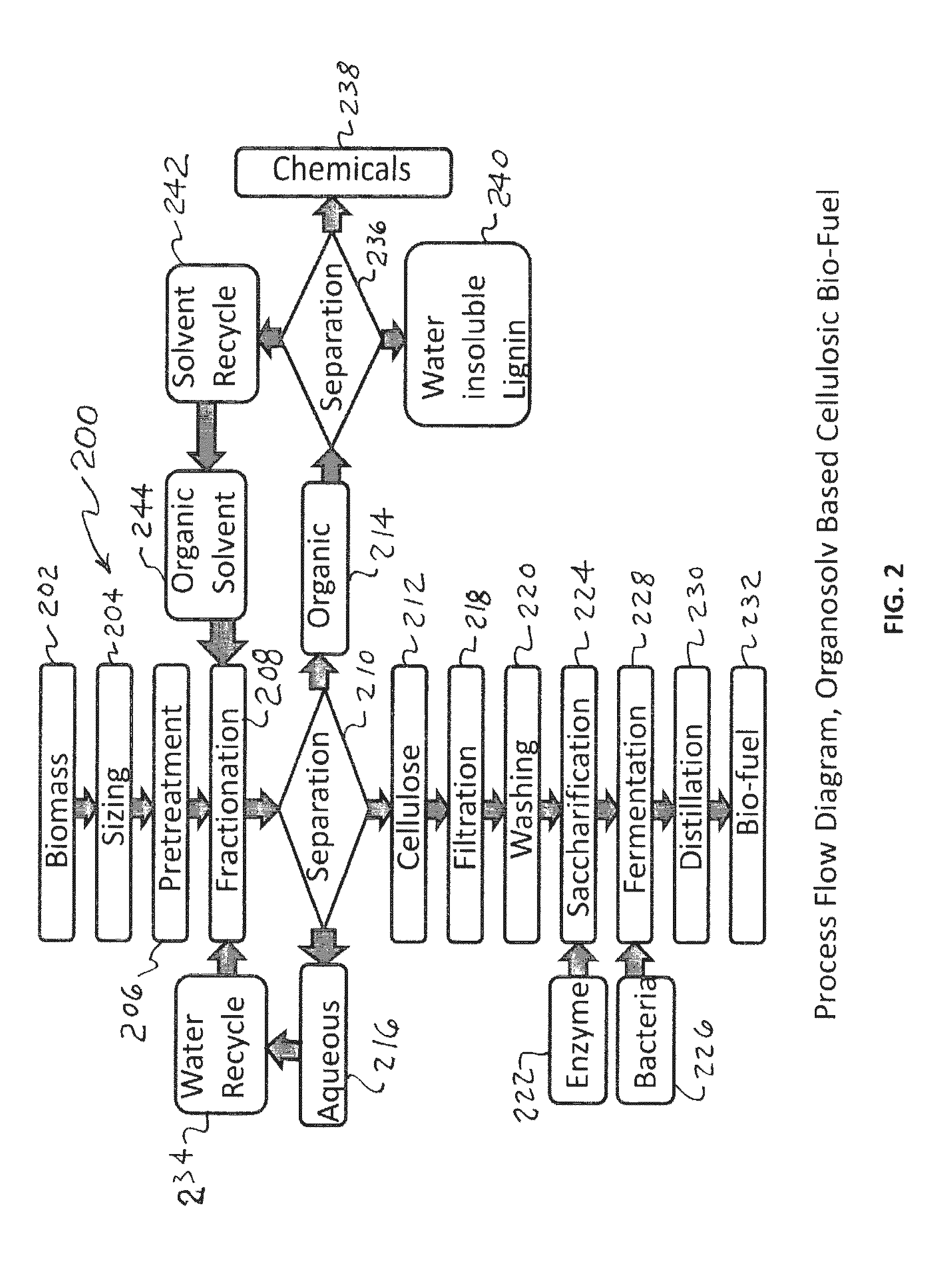

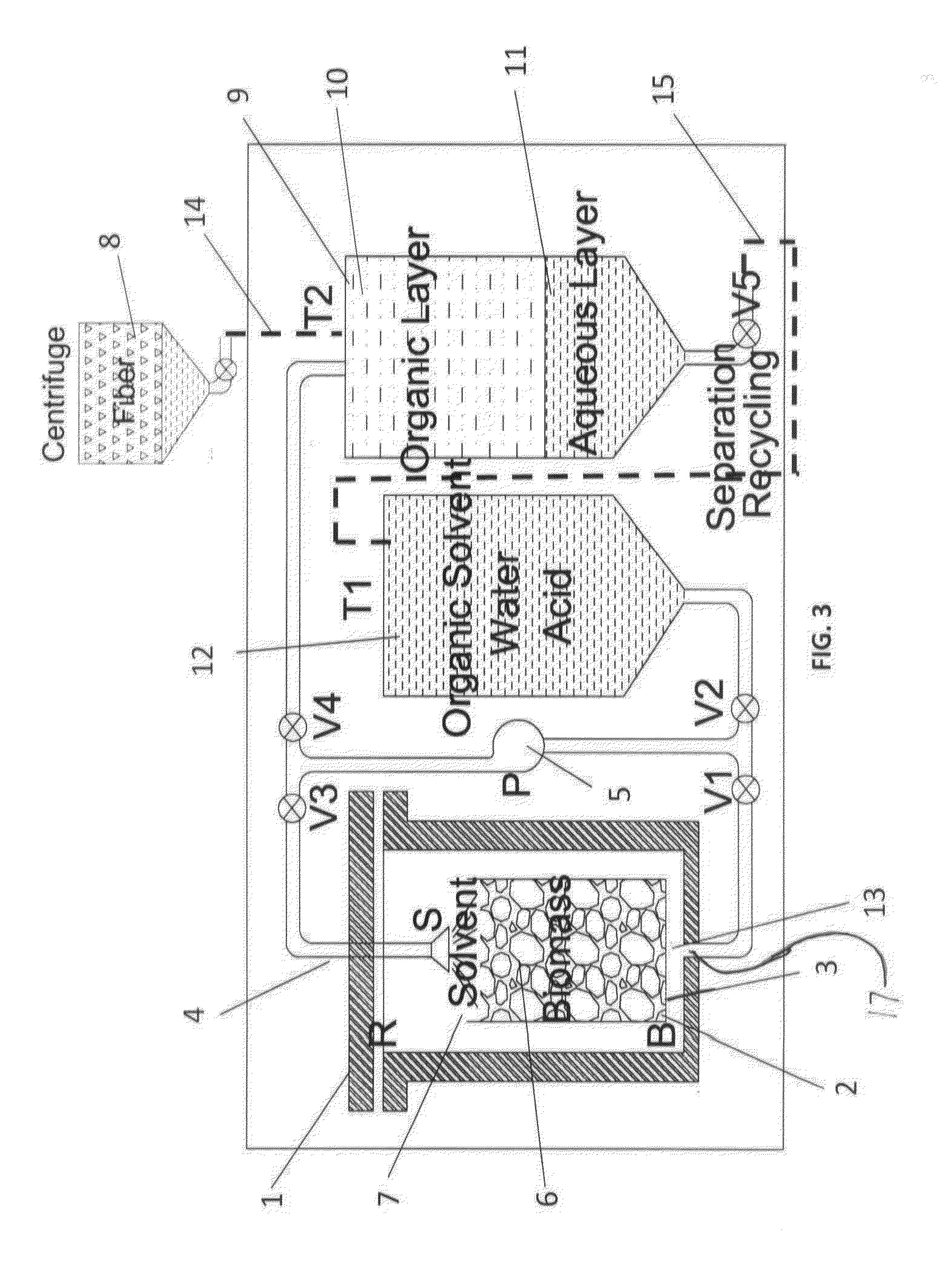

System and method for extraction of chemicals from lignocellulosic materials

ActiveUS20140227161A1Oxygen-containing compound preparationOrganic compound preparationFuranCellulose

An organosolv process for producing bio-products by decomposing lignocellulosic materials comprises providing an initial lignin solvent with water, an acid, and a lignin dissolving chemical comprising at least one of an organic ester, butyl acetate, an organic furan, and furfural. The process also includes placing the lignin solvent in contact with a biomass to form a circulation solvent, and recycling at least a portion of the circulation solvent by circulating the circulation solvent back into contact with the biomass. The circulating of the circulation solvent occurs for a period of time, after which, the process then includes separating material such as chemicals and lignin from the circulation solvent. The chemicals can be recycled as new solvent or sold while lignin can be used as natural and renewable colorant for polymers such as poly lactic acid.

Owner:AMERICAN SCI & TECH

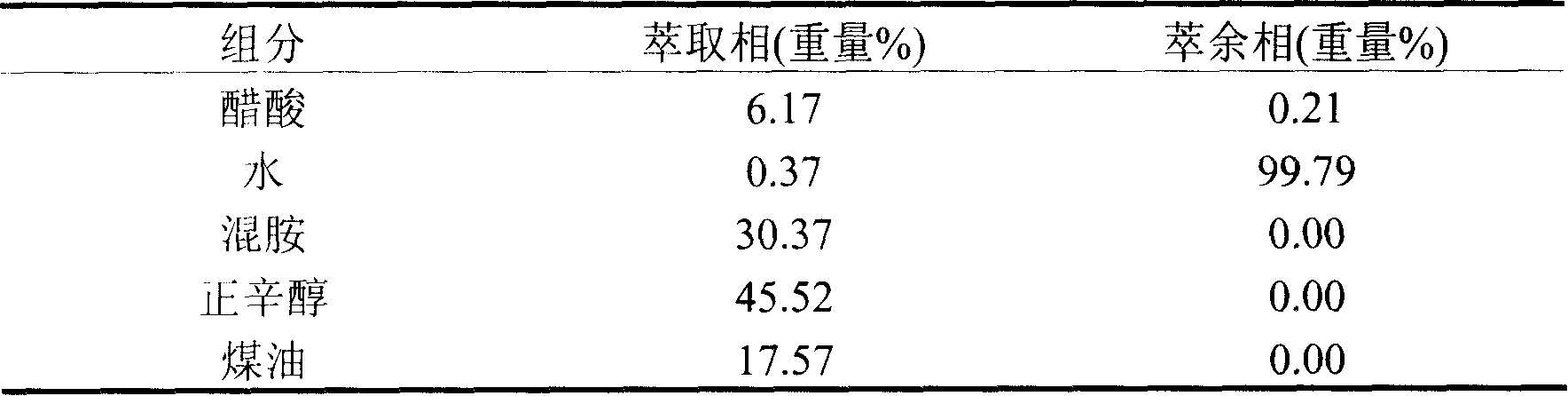

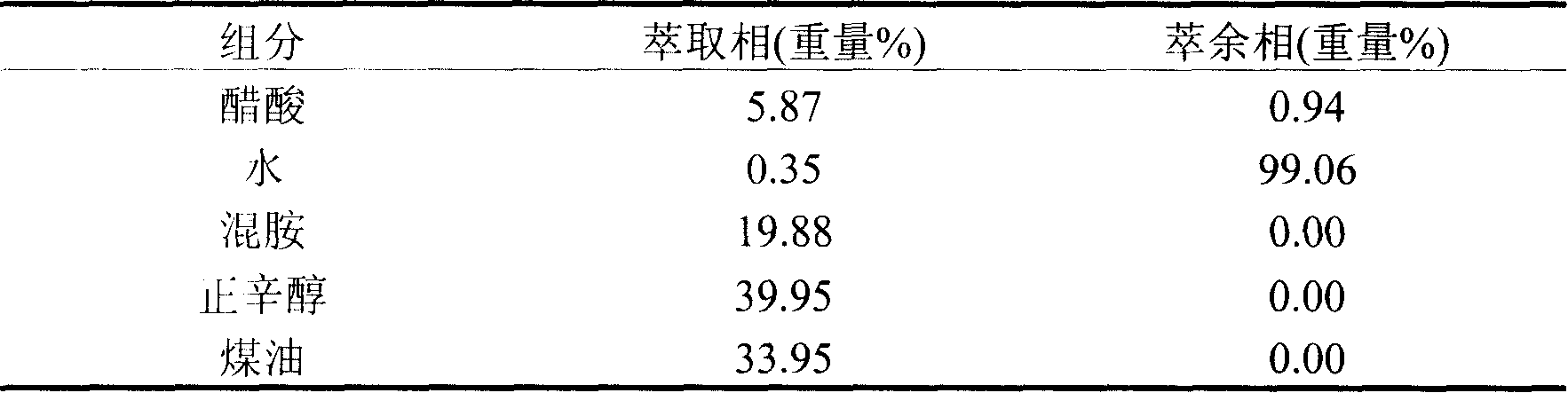

Method for recycling acetic acid in dilute acetic acid

ActiveCN101172941AImprove separation efficiencyIncreased acetic acid contentLiquid solutions solvent extractionCarboxylic compound separation/purificationBenzeneButyl acetate

The invention relates to a method for recycling acetic acid from diluted acetic acid, and aims at solving the problem that the recycling of acetic acid in the hydrolysis of furfural and methyl acetate as well as the Fischer-Tropsch combined production is difficult. The invention comprises the steps as follows: a) diluted acetic acid is extracted by a pulse filling extracting tower, the extractionphase containing extracting agent, the acetic acid and little water for the tower top is acquired, and the residual extraction phase of water containing micro acetic acid from the tower kettle is acquired; b) the extraction phase in an extracting agent recycling tower is conveyed; c) acetic acid 1 is fed into an azeotropic rectifying tower which utilizes one kind of benzene, cyclohexane, ethyl acetate, isopropyl acetate and butyl acetate as the extrainer, two-phase mixture of the extrainer and the water at a phase separator at the top of the tower is acquired, the water is extracted out from the tower top, and the retrainer returns into the tower. The utility model has the technical proposal of producing pure acetic acid at the tower top, solves the problems above, and adapts the industrial productions including recycling of acetic acid from wasted aldehyde water and extracting and refining acetic acid in the methyl acetate hydrolysis technique.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

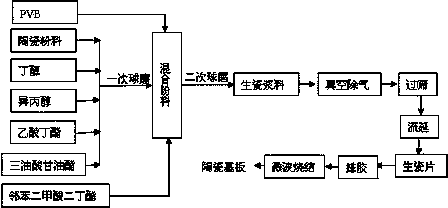

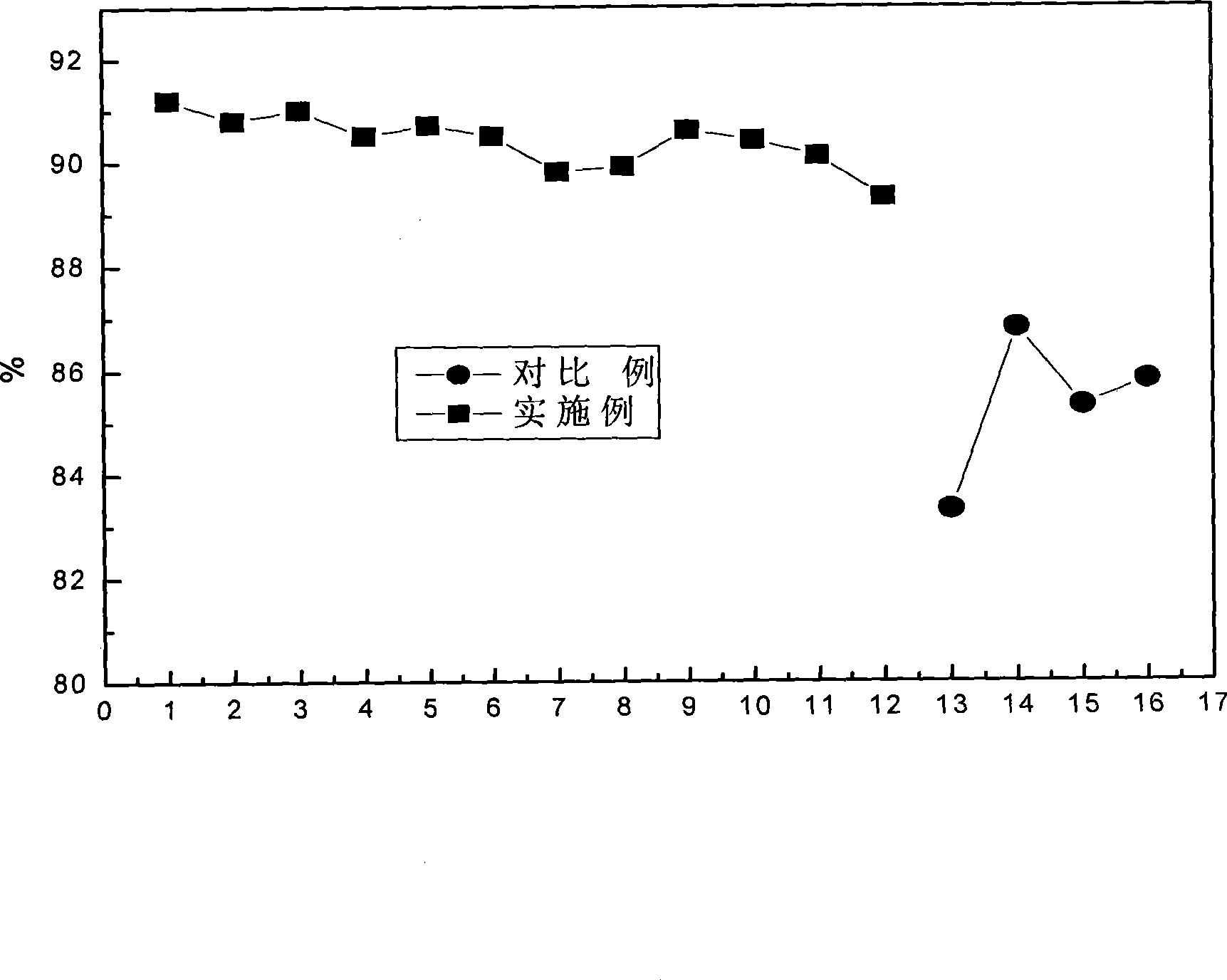

Aluminum oxide ceramic substrate with high heat conductivity and preparation method thereof

The invention discloses an aluminum oxide ceramic substrate with high heat conductivity. The aluminum oxide ceramic substrate is prepared by steps of stirring a ceramic powder material, a binder, a plasticizer, a dispersant and a solvent uniformly, preparing a ceramic raw-ceramic substrate through a tape casting method, glue discharging and sintering. The aluminum oxide ceramic substrate is characterized in that the solvent is a mixture of butanol, isopropanol and butyl acetate, and the ceramic powder material comprises aluminium oxide powder and auxiliary agents. The invention also discloses a preparation method for the aluminum oxide ceramic substrate with the high heat conductivity. According to the aluminum oxide ceramic substrate and the preparation method, the solvent system which comprises the butanol, the isopropanol and the butyl acetate are used as the main solvent in place of traditional toluene, thus enhancing dissolution of PVB by the solvent, thereby guaranteeing uniformity of raw ceramic slurry, making physical properties of sintered ceramic stable, reducing environmental influences of the exhausted gas during production processes compared to traditional modes of production, contributing to energy conservation and emission reduction, and reducing the cost.

Owner:NANJING ZHONGJIANG NEW MATERIAL TECH

Water-solubility printing ink washing agent

InactiveCN101638532ASimple recipeEasy to manufactureChemical paints/ink removersSolubilityAlkylphenol

A water-solubility printing ink washing agent comprises A component, B component and solvent according to weight ratio of 1: (1.5-2.5): (0.04-0.08), wherein raw materials of the A component are as follows according to weight parts: 12-15 parts of fatty alcohol-polyoxyethylene ether, 0.5-1 part of alkylphenol polyoxyethylene, 8-10 parts of aviation kerosene, 2-4 parts of dibutyl phthalate, 1-3 parts of butyl cellosolve, 1-2 parts of benzyl alcohol and 1-3 parts of butyl acetate; raw materials of the B component are as follows according to weight parts: 5-8 parts of sodium dodecyl benzene sulfonate, 1-2 parts of ethanolamine, 1-3 parts of diethanolamide, 0.5-1 part of urea, 0.5-1 part of sodium carbonate, 0.3-0.5 part of sodium silicate, and 45-55 parts of water. The preparation of the invention is simple, has simple and convenient manufacture, stable performance, safe usage, does not easily burn, does not corrode device and does not pollute the environment. The washing agent has good washing effect, is safe and non-toxic, has easily obtained and stored raw materials, has high stability, can be repeatedly used, and has wide market prospect.

Owner:MAOMING COLLEGE

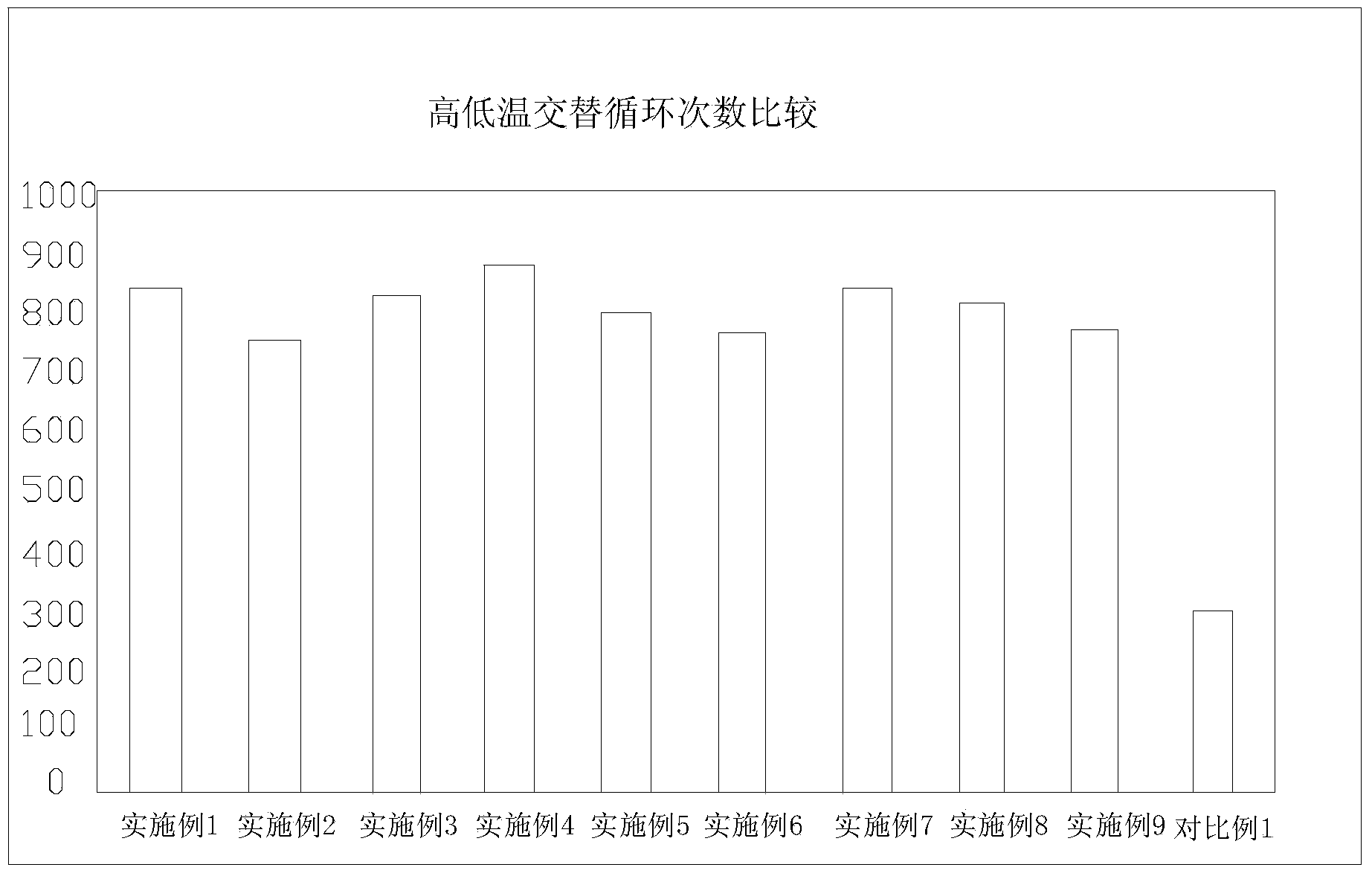

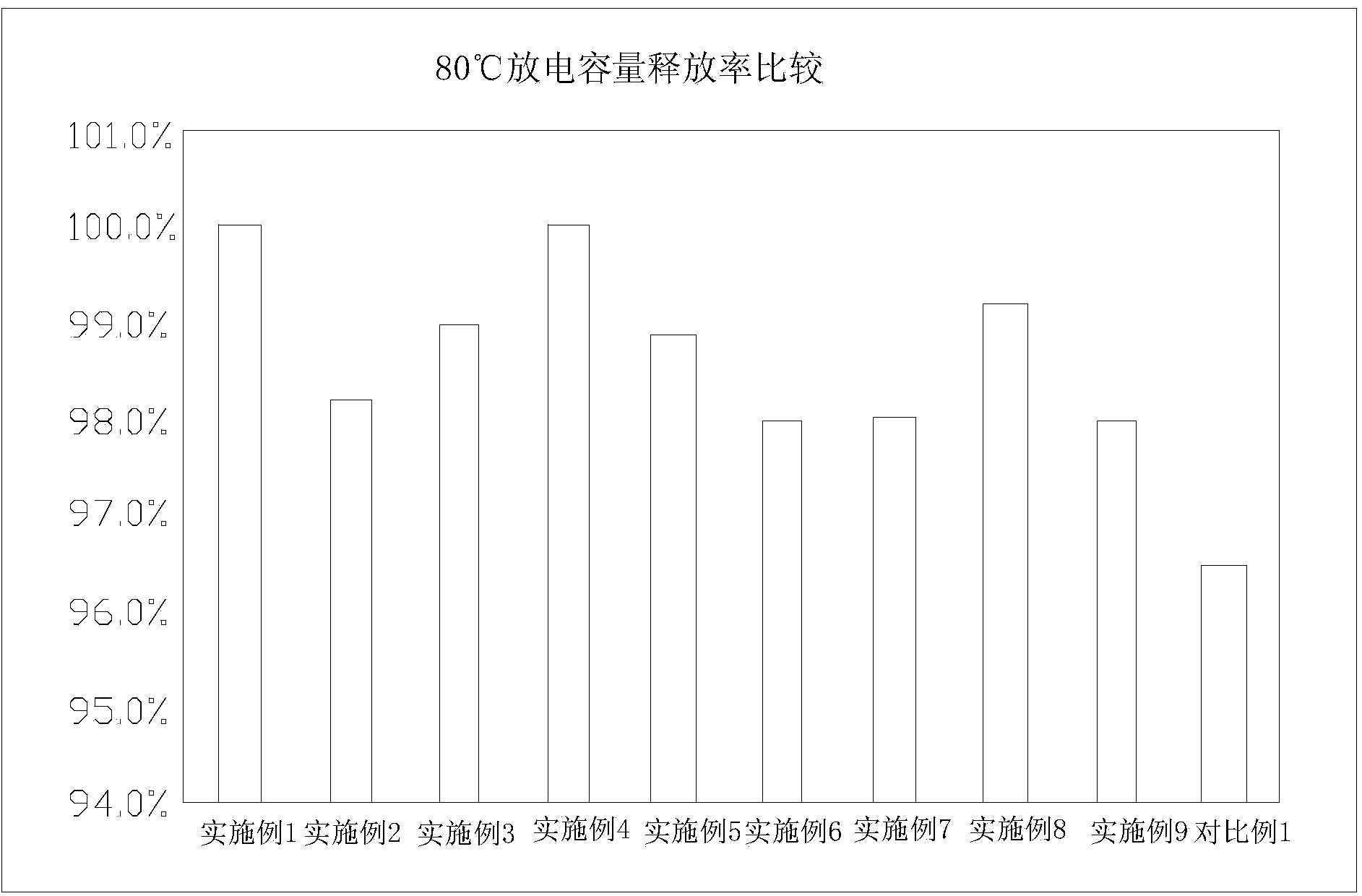

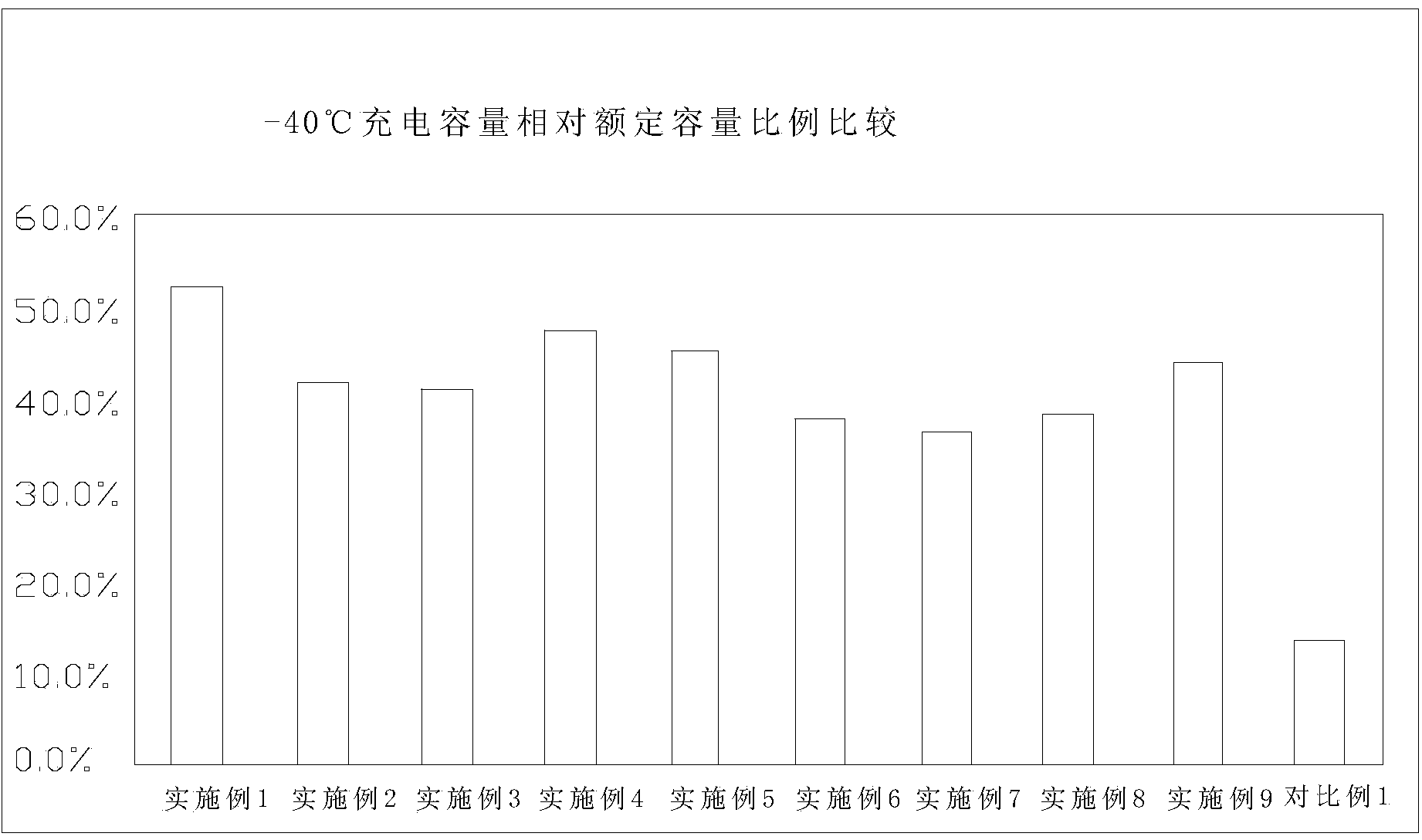

Lithium ion secondary battery using lithium iron phosphate as anode material with overall consideration of high and low temperature performance

InactiveCN101394008AExtended operating temperature rangeWide temperature rangeSecondary cellsPhosphateEthyl butyrate

The invention discloses an aqueous electrolyte solution of a secondary lithium ion battery with ferric phosphate considering as the positive material and with both the high temperature performance and the low temperature performance. The aqueous electrolyte solution comprises LiPF6 lithium salt, an organic solvent and a film-forming additive, and is characterized in that the electrolyte solution further comprises high temperature additive; the organic solvent is composed of one or a plurality of carbonic esters and one or more carboxylic esters with low melting point and high boiling point. The carboxylic esters with low melting point and high boiling point are selected from one or a combination of methyl butyrate, ethyl butyrate, propyl butyrate and butyl acetate. The high temperature additive is 1, 3- propane sultone and 1, 4- butane sultone. The electrolyte solution is used for maintaining both the circulation performance in a high temperature state and the low temperature laying performance of the secondary lithium ion battery with the ferric phosphate lithium as the positive material.

Owner:GUANGZHOU TINCI MATERIALS TECH

Hydrophobic and oleophyllic bi-component acrylic resin and preparation method and application thereof

The invention discloses a hydrophobic and oleophyllic bi-component acrylic resin and a preparation method and application thereof. The hydrophobic and oleophyllic bi-component acrylic resin comprises an A component and a B component, wherein the A component comprises 10 to 15 weight percent of hard monomer, 15 to 25 weight percent of higher alkyl methacrylates, 5 to 10 weight percent of fluorinated acrylic ester, 8 to 15 weight percent of cross linking monomer, 1 to 3 weigh percent of initiator, 10 to 25 weight percent of butyl acetate and 20 to 32 weight percent of dimethylbenzene; and the B component is an isocyanate curing agent of which the NCO content accounts for 10 to 23 percent of the total weight of the curing agent. The preparation method comprises a step of evenly mixing the A component with the B component which accounts for 14 to 32 weight percent of the A component to prepare the hydrophobic and oleophyllic bi-component acrylic resin. The bi-component acrylic resin has hydrophobic and oleophyllic performance and can serve as a coating for porous materials such as stainless steel metal meshes and filter paper to play a role in separating oil from water.

Owner:SOUTH CHINA UNIV OF TECH

Adhesive removing agent as well as preparation and using methods thereof

InactiveCN105199877AEasy to useEfficient removalOrganic non-surface-active detergent compositionsCleaning using liquidsKeroseneHexamethylenetetramine

The invention discloses an adhesive removing agent as well as preparation and using methods thereof. The adhesive removing agent comprises turpentine oil, rosin water, 120# gasoline, kerosene, benzene, methylbenzene, dimethylbenzene, acetone, urotropine, oxalic acid, ethyl acetate, butyl acetate and ethyl alcohol. The turpentine oil, the rosin water, the 120# gasoline and the kerosene are evenly mixed firstly, the benzene, the methylbenzene and the dimethylbenzene are sequentially added, the mixture is evenly mixed, the urotropine is added after complete dissolution, then the oxalic acid, the ethyl acetate and the butyl acetate are added sequentially, the acetone and the ethyl alcohol are added finally, and the mixture is evenly mixed. A plastic layer on the surface of an object is removed by hand, the adhesive removing agent is sprayed on the surface of the adhesive object and soaks the object, the adhesive is wiped with rag, and the object is washed with clear water. The adhesive removing agent can effectively remove the adhesive object and thoroughly remove adhesive objects such as signboards, adhesive tapes and the like, the using method is simple, heating is not required, and the adhesive removing agent can be used through brushing or spraying at the normal temperature and is short in washing time, good in removal effect, environment-friendly and efficient.

Owner:朱建权

Lithium iron phosphate battery with lithium ion battery electrolyte suitable for ultralow-temperature charging and discharging

ActiveCN103367803AFacilitate quick migrationImprove ionic conductivitySecondary cellsMethyl carbonateEthyl butyrate

The invention relates to a lithium iron phosphate battery with lithium ion battery electrolyte suitable for ultralow-temperature charging and discharging. The lithium ion battery electrolyte comprises lithium salt, a multi-element organic solvent and additives, wherein the additives comprise a low-melting-point additive, a film forming additive and a high-temperature additive; the multi-element organic solvent contains at least three of ethylene carbonate, diethyl carbonate, dimethyl carbonate, methyl ethyl carbonate, propylene carbonate and butylene carbonate; the low-melting-point additive contains at least one of 4-methyl-1,3-dioxolane, methyl acetate, methyl propionate, methyl butyrate, ethyl butyrate, propyl butyrate and butyl acetate; the high-temperature additive is at least one of methyl ester, di-n-propyl carbonate and 1,3-propane sultone. The lithium iron phosphate battery with the electrolyte can charge and discharge at an ultralow temperature and in a high-temperature environment, and is stable in performance and long in recycling life.

Owner:HANGZHOU LIAO TECH

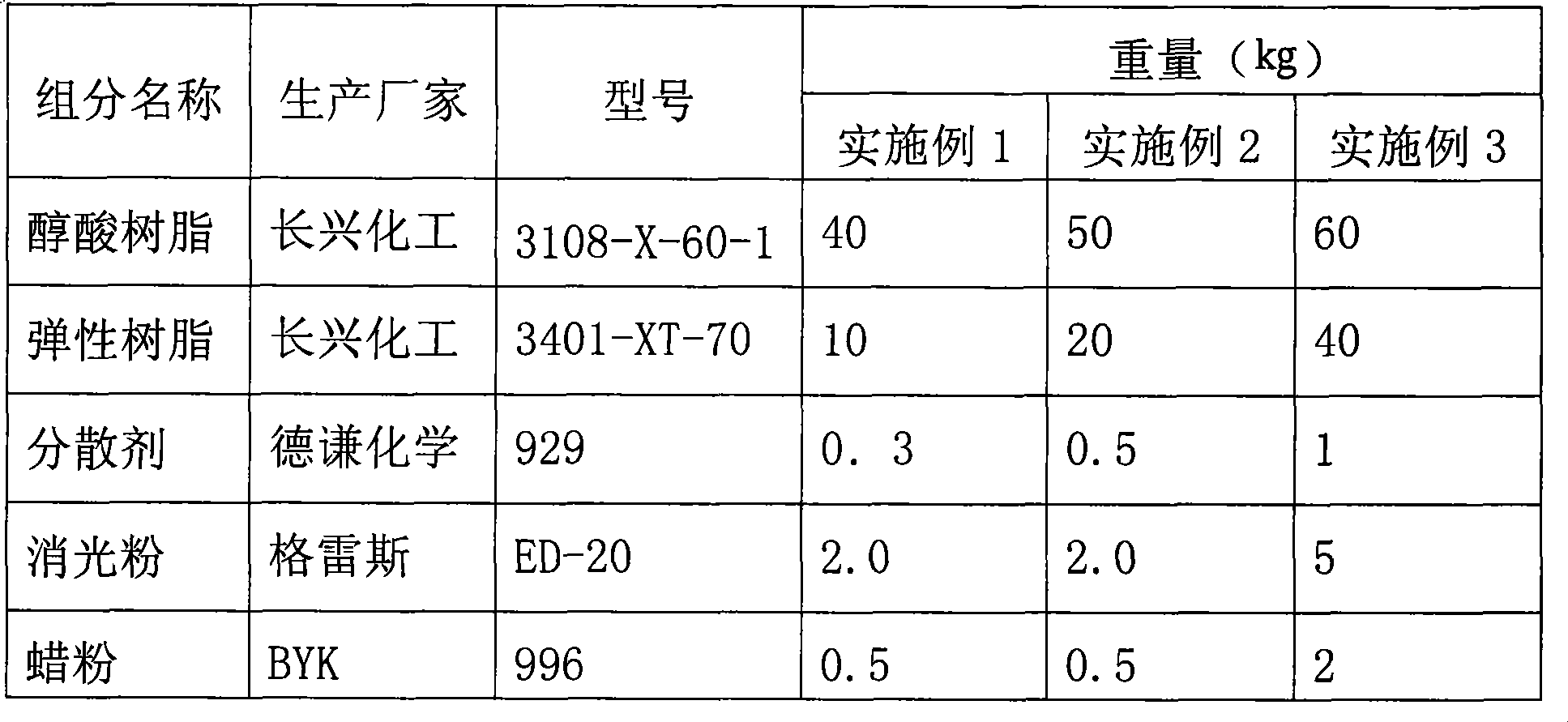

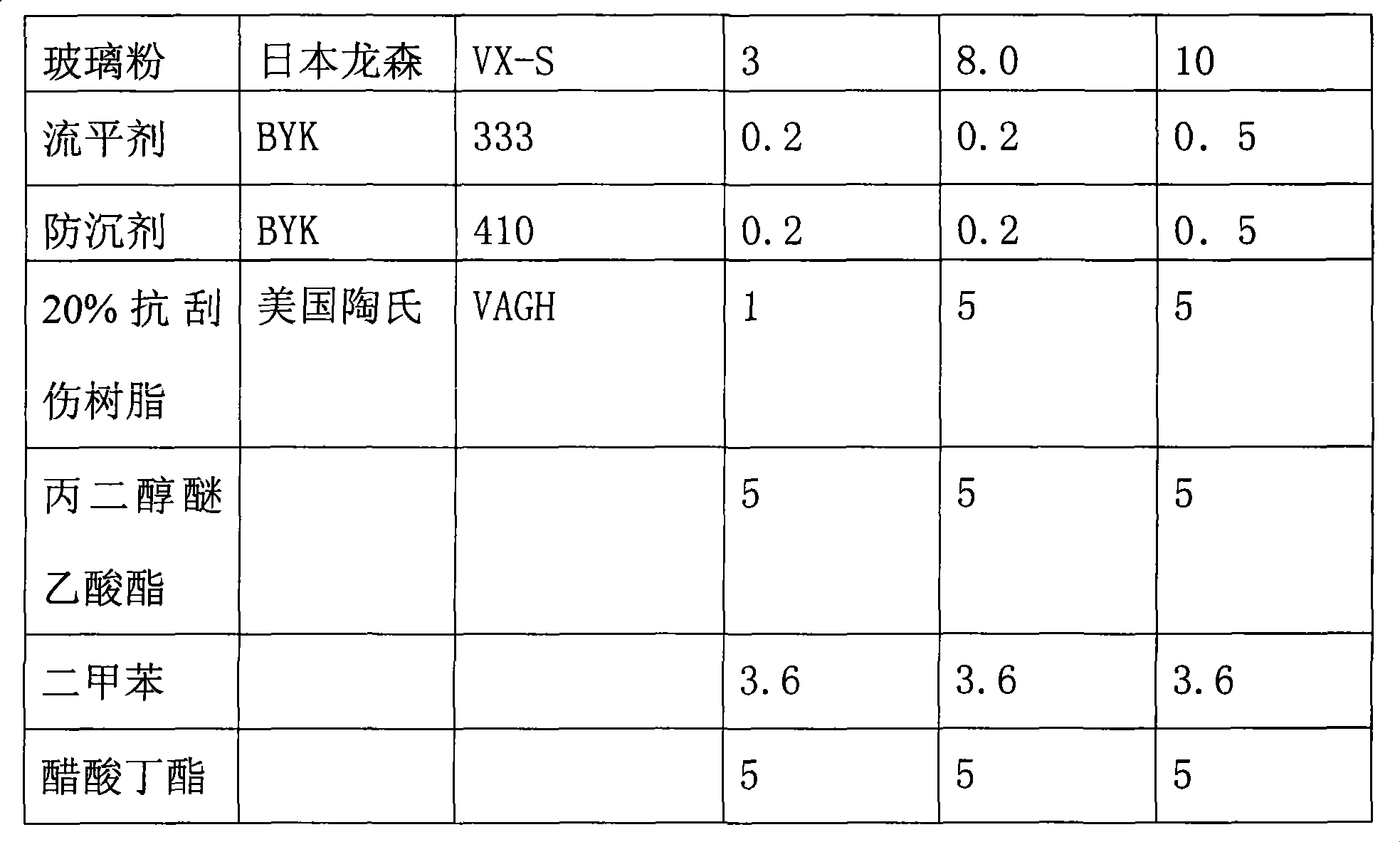

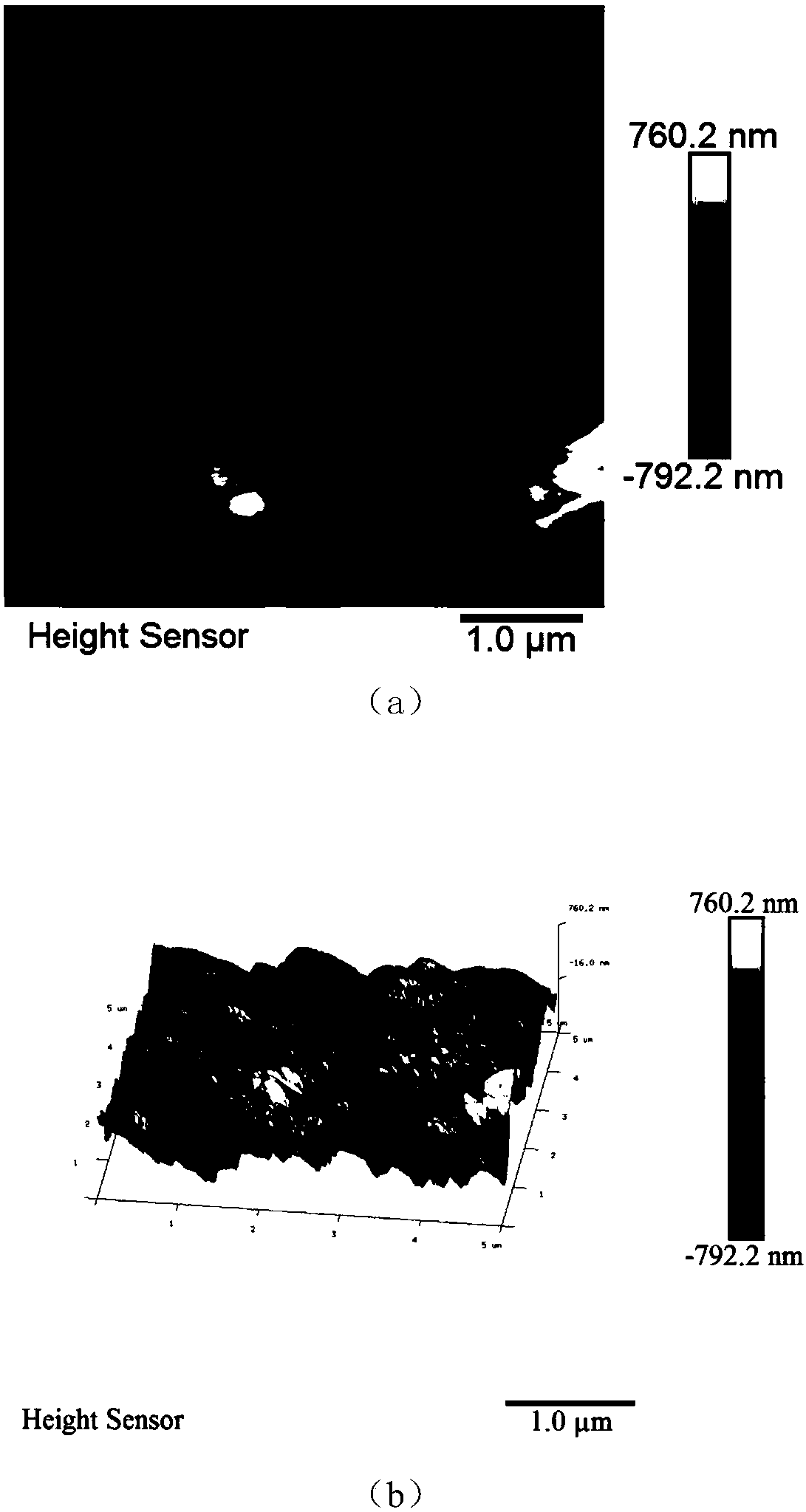

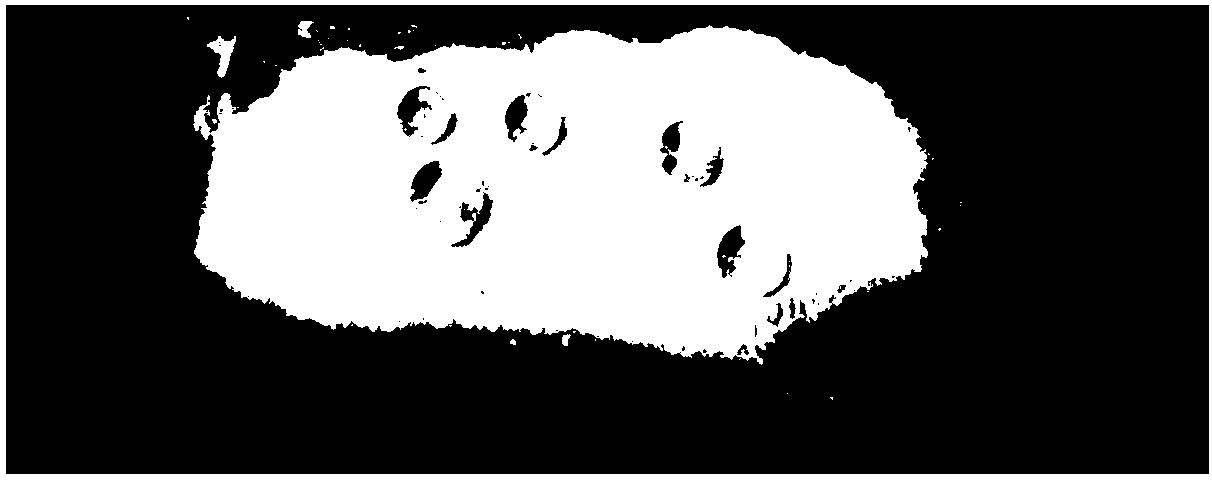

Polyurethane transparent matt topcoat, preparation method and use method thereof

ActiveCN101381581AFeel smoothGood flexibilityLiquid surface applicatorsPolyurea/polyurethane coatingsWaxLow speed

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Self-fixing zinc-rich primer in petroleum storage tank for resisting corrosion and preparation method thereof

InactiveCN101191028AImprove corrosion resistanceGood solvent resistanceAnti-corrosive paintsPolyvinyl butyralDibasic ester

The invention relates to a self-fixed zinc-rich primer using for anticorrosion inside an oil tank and a preparation method thereof. The self-fixed zinc-rich primer comprises A solution which consists of tetraethyl orthosilicate, butanol, ethanol, butyl acetate, dibasic ester, 36-38 percent of hydrochloride and distilled water, and B solution which consists of polyvinyl butyral (PVB), butanol, ethanol, zinc powder, ultrafine ferrophosphorus powder, mica powder, fly ash, alkoxy ammonium salt with acidic group and block copolymers, and polysiloxane-polyether copolymer, when in use, the A solution and the B solution are mixed and solidified to form a paint film which is characterized by self-repairing, corrosion resistance, solvent resistance, static conducting, rapid drying and good construction adaptability, etc. The self-fixed zinc-rich primer can be used for surface anticorrosion treatment of steel structures used in inner walls and outer walls of various storage tanks and offshore drilling platforms, etc.

Owner:CNPC RES INST OF ENG TECH +1

Bottom surface-integrated wear-resistant fluorosilicone-based super-amphiphobic coating, and preparation method and application thereof

The invention discloses a bottom surface-integrated wear-resistant fluorosilicone-based super-amphiphobic coating, and a preparation method and application thereof. The preparation method comprises the following steps: 1) performing synergistic modification treatment on two or more nanoparticles to obtain modified blended particles; 2) adding the blended modified particles into a dispersing solvent, performing ultrasonic dispersion for 1 to 2 hours and then mechanically stirring; 3) adding a certain amount of tert-butyl acetate into fluoro-siloxane resin and performing shearing dispersion to obtain substrate material emulsion; 4) mixing the blended modified particle turbid liquid in the step 2 and the substrate material emulsion in the step 3, adding a coupling agent, heating, stirring anddispersing, and performing dispersion by a high-speed shearing dispersing machine to obtain super-amphiphobic coating; and 5) stirring the super-amphiphobic coating uniformly, spray-coating the surface of an object with the super-amphiphobic coating and drying at room temperature for 10 to 30 minutes to successfully prepare the wear-resistant integrated super-amphiphobic coating. The wear-resistant super-amphiphobic organic-inorganic hybrid coating is obtained by connecting a fluorine-silicon substrate and the blended modified particles through chemical grafting copolymerization reaction.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Leather flatting coating composition and preparation method thereof

The invention relates to a chemical coating used for leather chemical industry and a preparation method thereof, in particular to a leather flatting coating composition and a preparation method thereof. The leather flatting coating composition comprises the following components in percentage by weight: 35 to 50 percent of polyurethane resin, 3 to 10 percent of dimethyl formamide, 10 to 15 percent of butanone, 20 to 30 percent of butyl acetate, 5 to 15 percent of acetic ether, 3 to 6 percent of flatting agent, 0.5 to 2 percent of handfeel agent, 0.5 to 2 percent of dispersant, 0.5 to 2 percent of color developing agent, and 0 to 1.5 percent of thickening agent. In addition, the invention also discloses the method for preparing the flatting coating. Compared with the common market coating, the flatting coating has the characteristics of wide application, high dullness, good transparency and good handfeel. The leather flatting coating composition is suitable for common leather surface treatment and high-grade leather surface treatment, and has lasting effects.

Owner:浙江瑞克涂饰材料有限公司

Preparation method of macrolide antibiotics molecular engram polymer microsphere

InactiveCN101507916AOther chemical processesAlkali metal oxides/hydroxidesWater bathsFunctional monomer

The invention discloses a method for preparing macrolide antibiotics molecular engram polymer microspheres, which is characterized by comprising the following steps: dissolving a dispersant, namely polyvinyl alcohol or hydroxyethyl cellulose into secondary distilled water to prepare a water-phase dispersion liquid; dissolving engram molecules and functional monomers into an organic solvent to prepare an oil-phase mixture; adding the oil-phase mixture into the water-phase dispersion liquid under the action of stirring, adding an initiator, namely azo-bis-iso-butyrynitrile into the mixture, performing thermal initiation polymerization on the mixture in water bath, and obtaining polymer microspheres; and adopting an ultrasonic extraction method to elute the engram molecules in a butyl acetate aqueous solution or a methanol solution of acetic acid, using distilled water to wash the engram molecules, and performing vacuum drying on the engram molecules to obtain the macrolide antibiotics molecular engram polymer microspheres. Through the method, the macrolide antibiotics molecular engram polymer microspheres are prepared in water phases and are recognized in the water phases; the reorganization result is close to that obtained by a natural biological molecular recognition system; and the invention provides a method for recognizing, separating and analyzing hydrophilic medicaments .

Owner:NORTHWESTERN POLYTECHNICAL UNIV

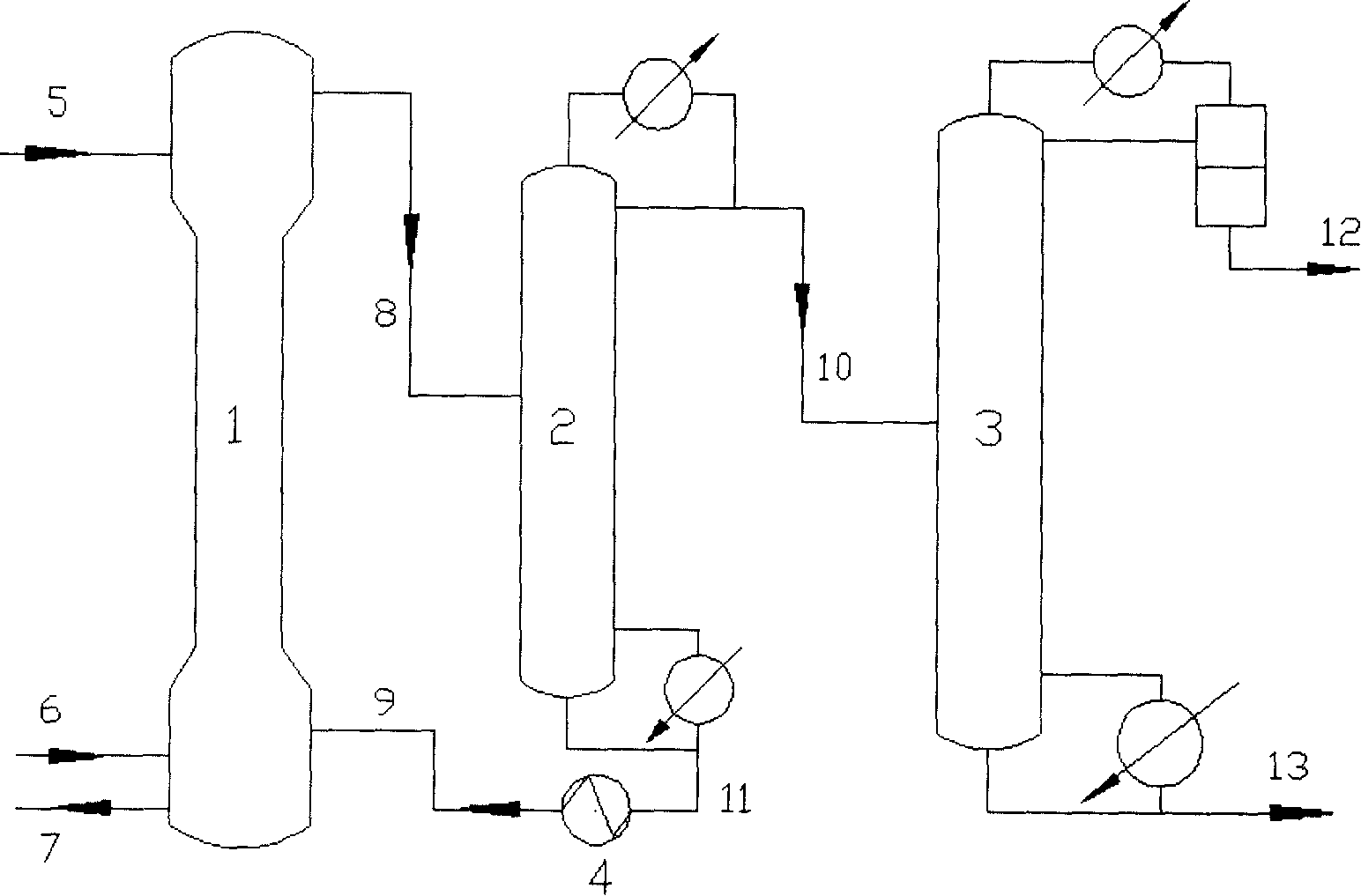

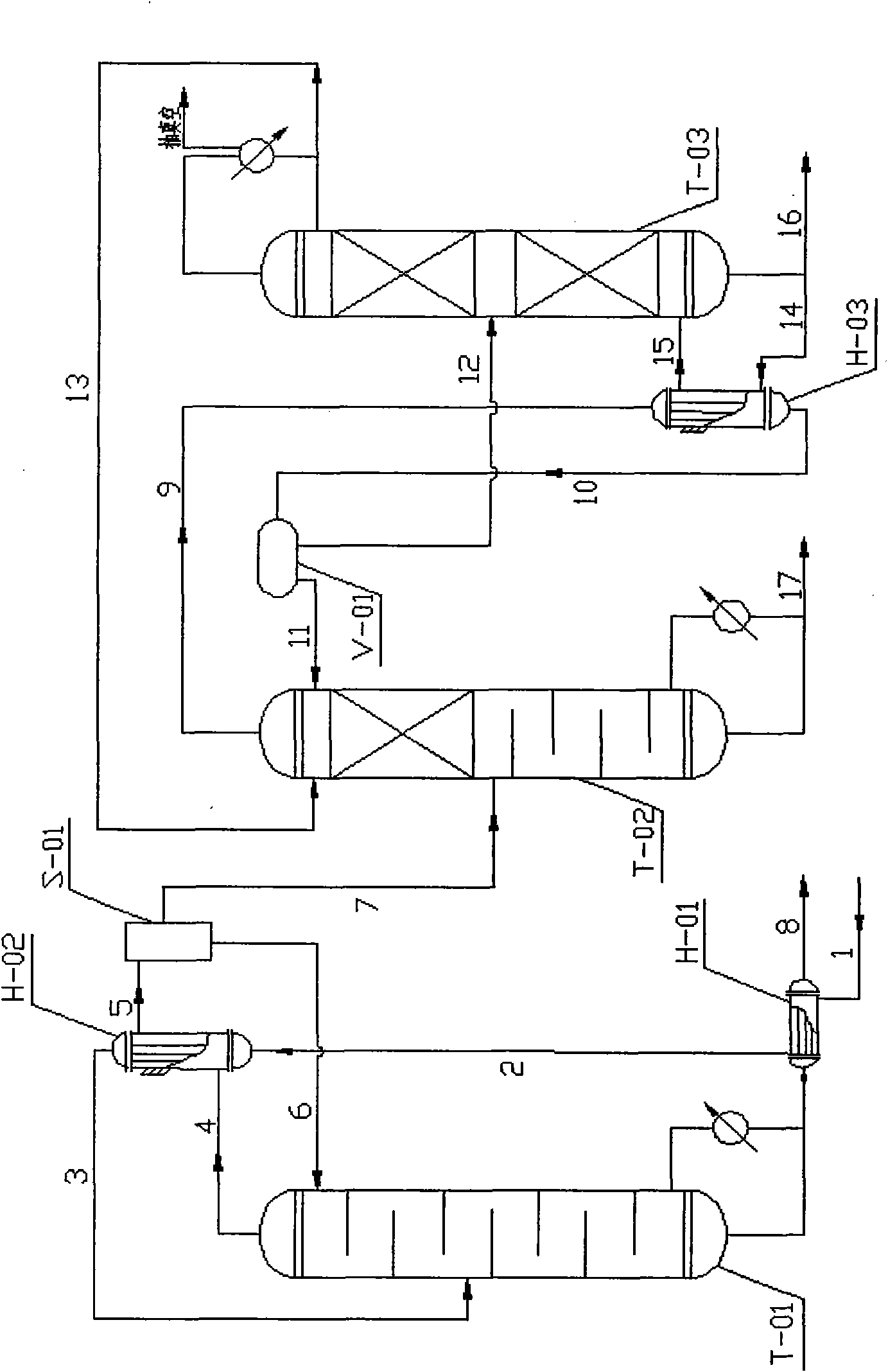

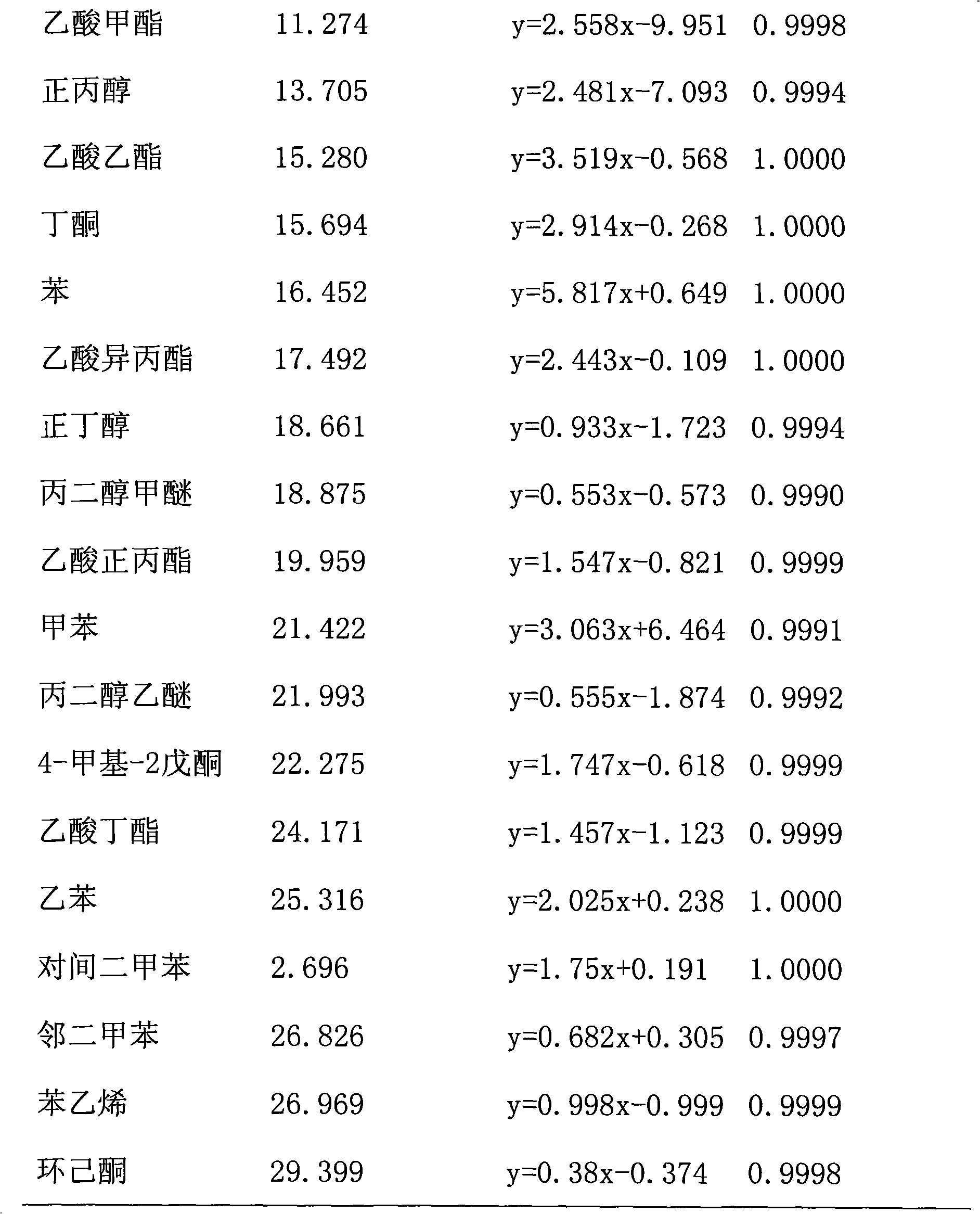

Process for separating and recovering butyl acetate and butyl alcohol in wastewater by using azeotropic rectification

ActiveCN101811965AHigh purityEasy to recycleOrganic compound preparationCarboxylic acid esters preparationAlcoholButyl acetate

The invention relates to a process for separating and recovering butyl acetate and butyl alcohol in wastewater by using azeotropic rectification, comprising the following steps of: carrying out normal-pressure distillation and thickening on the wastewater containing the butyl alcohol, the butyl acetate, water and organic residues in a first rectifying tower T-01 to obtain pure water and the organic residues through a tower kettle; delaminating condensed steam at a tower top, flowing a water layer back, and causing an organic layer to enter a second rectifying tower T-02 for pressurization and rectification under 120-200 Kpa so that the high-purity butyl acetate is extracted by the tower kettle and the steam with the alcohol ester ratio of 3 / 1-9 / 1 is obtained at the tower top; condensing to cause one part of a condensate to back flow and one part of the condensate to enter a third rectifying tower T-03 for pressure reduction and rectification under 3-15 KPa so that the high-purity butyl alcohol is extracted by the tower kettle and the steam with the alcohol ester ratio of 1 / 3-1 / 2 is obtained at the tower top; and after condensing and cooling, causing the steam with the alcohol ester ratio of 1 / 3-1 / 2 to enter the tower from a feed inlet of the second rectifying tower T-02 for continuous thickening and purification. The process has the advantages of environmental protection, low energy consumption, investment saving, no entrainer addition, high recovery rate (above 99%) of solvents and the like.

Owner:NANJING UNIV

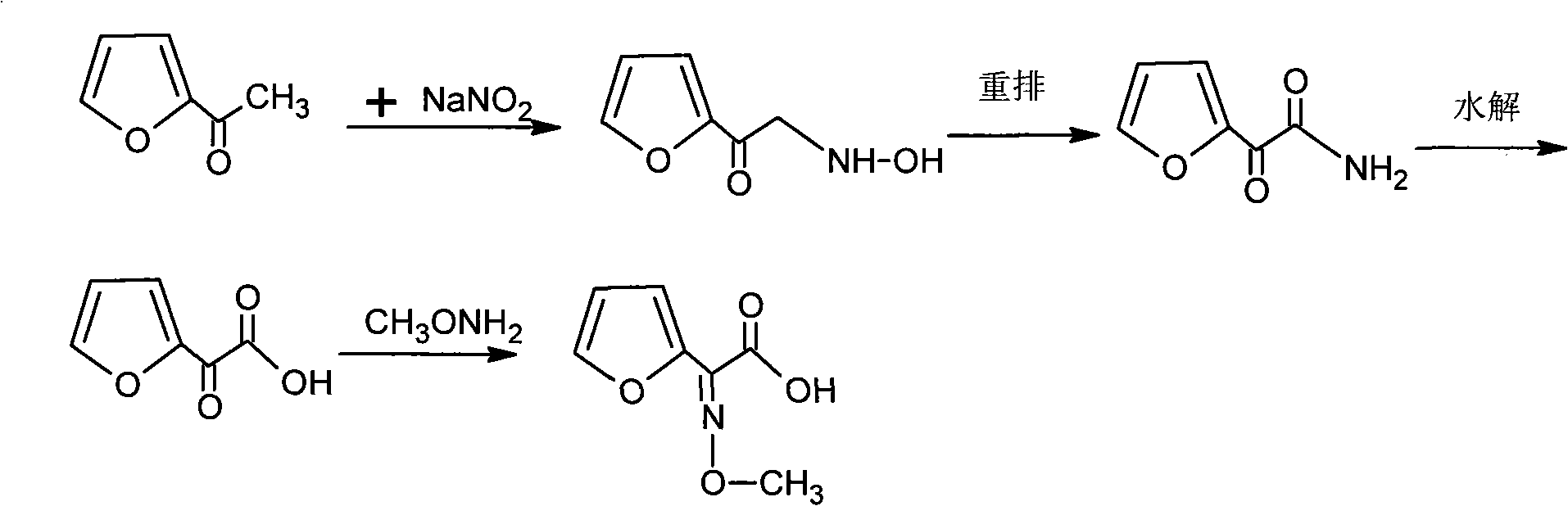

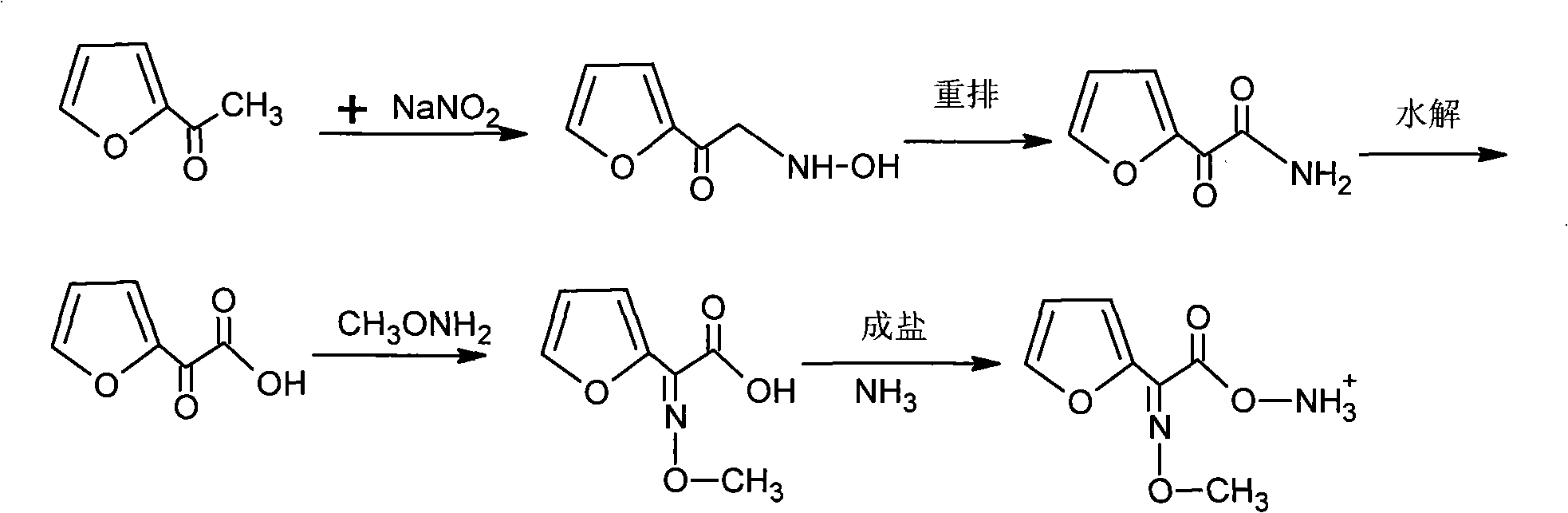

Preparing method of 2-methoxy imino group 2-furan ammonium acetate

InactiveCN101538255AReduce spawn rateReduce unit consumptionOrganic chemistryFuranReaction temperature

The invention relates to a preparing method of 2-methoxy imino group 2-furan ammonium acetate which comprises the following steps: (1) sodium nitrite reacts with acetate furan to generate furan keto acid by oximation, rearrangement and hydrolysis; (2) the furan keto acid is extracted; (3) condensation reaction is carried out on the furan keto and methoxy ammonium hydrochloride to generate 2-imino group 2-furan acetic acid; (4) the 2-imino group 2-furan acetic acid is extracted; (5) ammonia is introduced for salt formation to generate the 2-methoxy imino group 2-furan ammonium acetate; wherein, solvent adopted in the furan keto extraction of step (2) is butyl acetate. Under the same condition, the dissolution loss of the ethyl acetate in water is four times larger than that of the butyl acetate. With the butyl acetate being adopted as the solvent, the unit consumption is lowered by 50 percent, and the production cost is lowered. Furthermore, 58-60 DEG C of the reaction temperature for oximation is adopted by the invention, the production rate of furoic acid is smaller than 1 percent, and the product yield is improved greatly.

Owner:ZHEJIANG TOP MEDICINE

Nano modified anti-rust special primer

InactiveCN1844271AImprove qualityImprove adhesionAnti-corrosive paintsHazardous substanceToxic material

A nanometre-sized modified special rust-inhibiting primer is characterized in that it includes the following components (mass %): 29.0-60.0 % anti-corrosive paint host, 1.0-10.0 % nano oxide addition,5.0-15.0 % curing agent and 30.0-65 % diluent. The said anti-corrosive paint consists of rust-preventive material, coloring pigment, compounded resin and auxiliary agent, the curing agent is compounded by 75 % aromatic isocyanate, dimethylbenzene, butyl acetate, propanol and 2-butanol and the diluent is combination of alcohol and ester solvent. The invention has conducted adequate optimization and association for the components of the rust-inhibiting primer and its proportioning, which has largely reduced the contents of the toxic substance and the harmful substance in the total weight of the products, not only can guarantee the champion cryogenic film-forming property, but also can reduce the degree of pollution to the environment, which can effectively support the health of the maker, the user and the surrounding people, fitting requirement of the environmental protection, simultaneously can further improved the quality of the rust-inhibiting primer.

Owner:彭志伟

Methanol gasoline additive and process for producing methanol gasoline

The invention relates to a preparation method for a methanol oil additive and the methanol oil thereof. The compound additive consists of the components of the following weight percentages; 30 to 50 percent of isopropanol, 10 to 20 percent of tertiary butyl alcohol, 1 to 5 percent of butyl acetate, 1 to 5 percent of methyl ethyl ketone peroxide, 1 to 5 percent of peroxide, 1 to 5 percent of sherwood oil, 5 to 10 percent of dimethylbenzene, 1 to 4 percent of octane enhancing additive, 1 to 5 percent of dimethoxymethane, 0.1 to 0.5 percent of antioxidizing and antigum agent, 0.1 to 0.5 percent of antiseptic, 1 to 8 percent of antiwear agent, 3 to 6 percent of waterproofing agent, 1 to 5 percent of dispersant, 1 to 3 percent of fatty acid amine, 10 to 30 percent of 120# solvent oil as well as 5 to 10 percent of ethanol. The methanol oil consists of the components of the following weight percentages: 10 to 80 percent of methanol, 0 to 85 percent of diesel oil as well as 5 to 20 percent of methanol oil additive. The methanol oil has the advantages of low cost, excellent performance, good environment protection effect, remarkable economic benefit and convenient popularization.

Owner:王宇

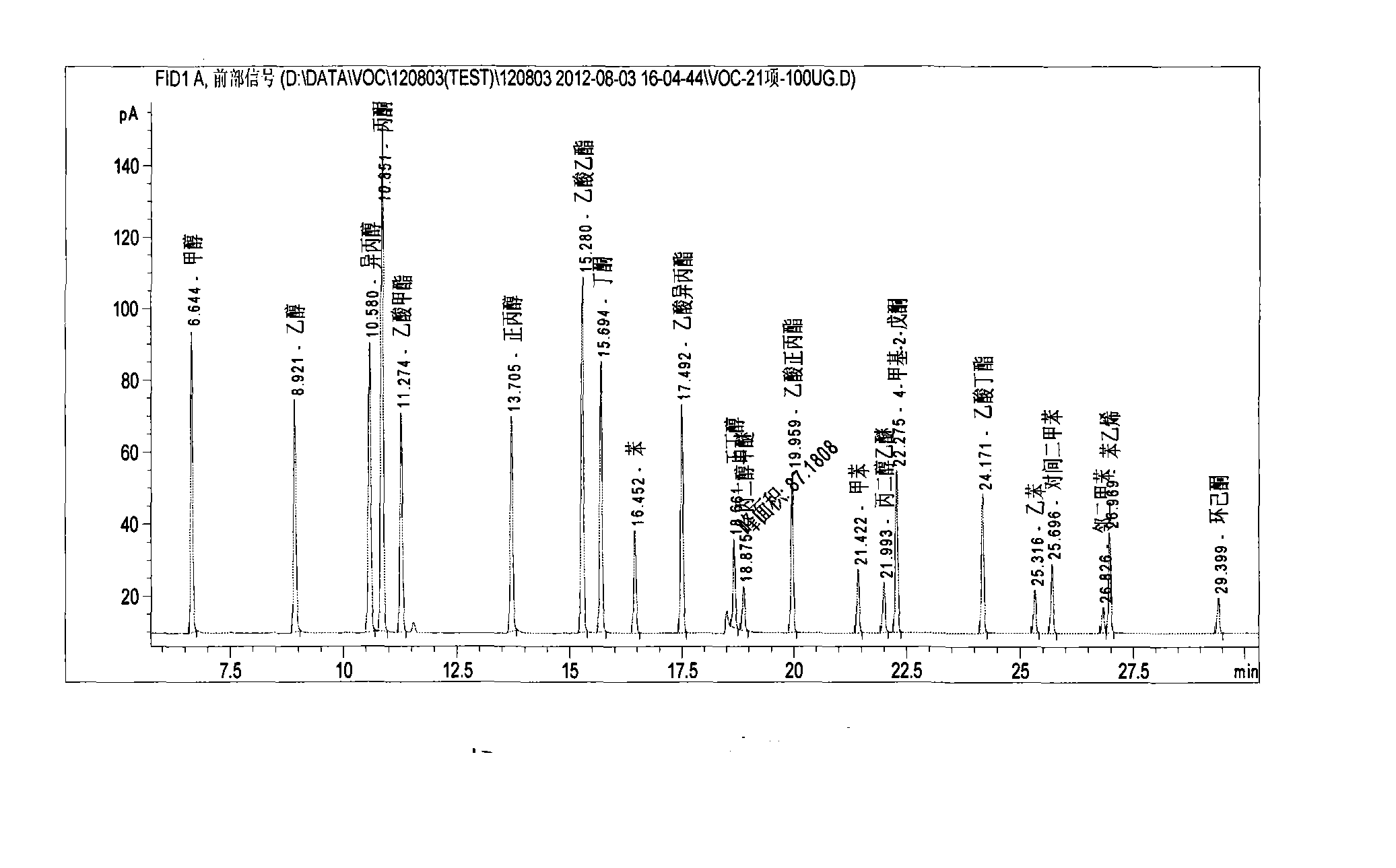

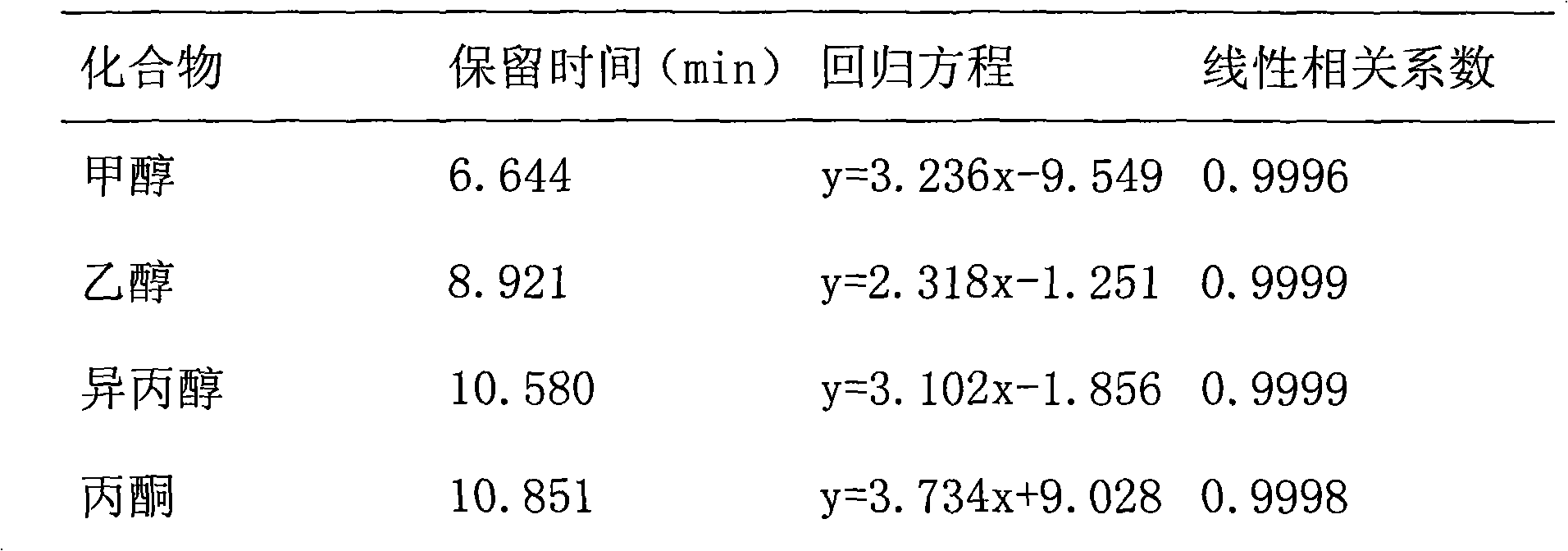

Method for detecting 21 volatile organic compounds (VOC) in tobacco packing box

The invention belongs to the technical field of tobacco packing box, and in particular relates to a method for detecting contents of 21 volatile organic compounds (VOC), including benzene, methyl benzene, p-xylene, m-xylene, o-xylene, styrene, methanol, ethanol, acetone, isopropyl alcohol, methyl acetate, normal propyl alcohol, ethyl acetate, butanone, acetic acid isopropyl ester, n-butyl alcohol, propylene glycol monomethyl ether, n-propyl acetate, propylene glycol monoethyl ether, 4-methyl-2-pentanone, butyl acetate, cyclohexanone in a tobacco packing box. The method for detecting 21 volatile organic compounds in the tobacco packing box disclosed by the invention comprises the following steps of: sample pretreatment: preparing a piece of hard box packing paper; cutting and reserving a main packing surface by an area of 22.0cm*5.5cm; rolling the printing surface of the sample inwards to obtain a barrel-shaped part; putting the barrel-shaped part in a headspace bottle; adding 1000mu l of glycerol triacetate; sealing, and implementing a headspace-gas chromatography detection. The method disclosed by the invention is high in sensitivity, high in recovery rate, and excellent in precision of detecting result.

Owner:GUANGZHOU PONY TESTING TECH

Method for mass producing butyl acetate by reactive distillation method and using sulfuric acid as catalyst

ActiveCN1844076AEasy to separateAvoid corrosionPhysical/chemical process catalystsOrganic compound preparationAcetic acidAlcohol

The refers to a mass production method of isobutyl acetate which uses hydric sulphate as accelerant by reaction fractional distillation, using ethyl acetate and butyl alcohol as raw material, concentrated sulfuric acid as accelerant, continue producing isobutyl acetate by reaction fractional distillation, the whole production system contains three towers, reaction fractionating tower, azeotropy tower and eater fractionating tower, the reaction fractionating tower, azeotropy tower are setted side by side. The ethyl acetate, butyl alcohol and concentrated sulfuric acid are drived into feeder column plate of reaction fractionating tower after esterification prereaction, the gas phase of prereactor going into feeding phase of reaction fractionating tower, the gas phase on top of reaction fractionating tower going into column plate of cellar of azeotropy towder, the liquid phase of towder bottom going into mesomere of eater fractionating tower, the butyl product is continue discharged from side tower. This invention combines the technique which using sulfuric as accelerant by mean improvement of reaction fractional distillation technique, not only ustilizing the advanced technology of reaction fractional distillation, but also making the liquid accelerant's characters of convenience to operate, easy to enlarge production scale getted adequate use.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +1

Polyurethane matte white finish coat for non-benzene and odor-free furniture

ActiveCN102061123AFacilitated releaseReduce harmPolyurea/polyurethane coatingsCyclohexanoneAromatic solvent

The invention relates to polyurethane matte white finish coat for non-benzene and odor-free furniture, which consists of a main agent, a curing agent and a diluent, wherein the main agent comprises hydroxyl acrylic resin, titanium white, solvent, a defoaming agent, a flatting agent, an anti-settling agent, a dispersing agent and a flatting agent; the curing agent comprises a toluene diisocynate tripolymer, toluene diisocynate-trimethylolpropane addition product and butyl acetate; and the diluent comprises the butyl acetate, cyclohexanone and propylene glycol monomethyl acetate. By adopting the technical scheme, the polyurethane matte white finish coat has the advantages that: an obtained paint film has less residual solvent and is tasteless after 12 hours; a formula does not contain chemical substances harmful to body health of human beings, such as benzene, methylbenzene, dimethylbenzene, other aromatic solvents and derivatives, methanol, glycol ether ester solvents, halogenated hydrocarbon and the like, and the excellent decorative and protective effects of the conventional polyurethane (PU) dual-component furniture paint are reserved in the formula; and the polyurethane matte white finish coat is easy to construct and is applicable to various construction modes such as spraying, electrostatic spraying and brush coating.

Owner:上海展辰涂料有限公司

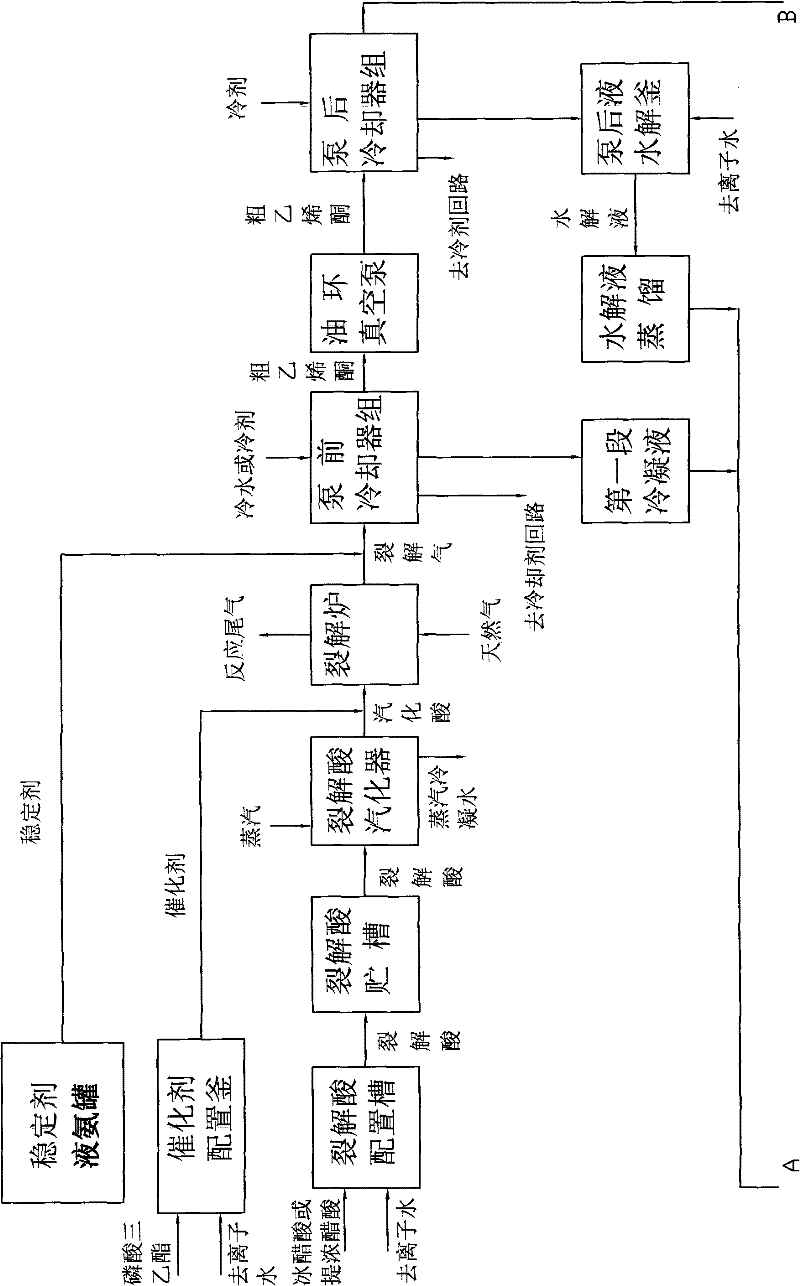

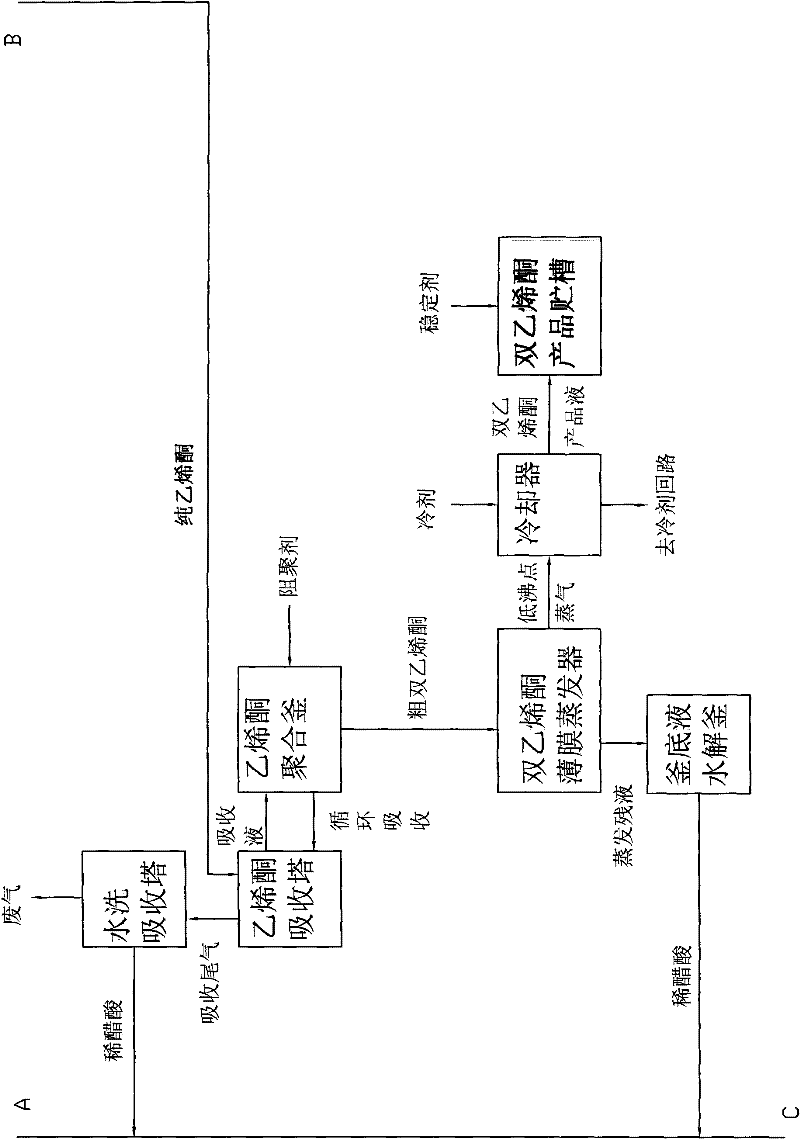

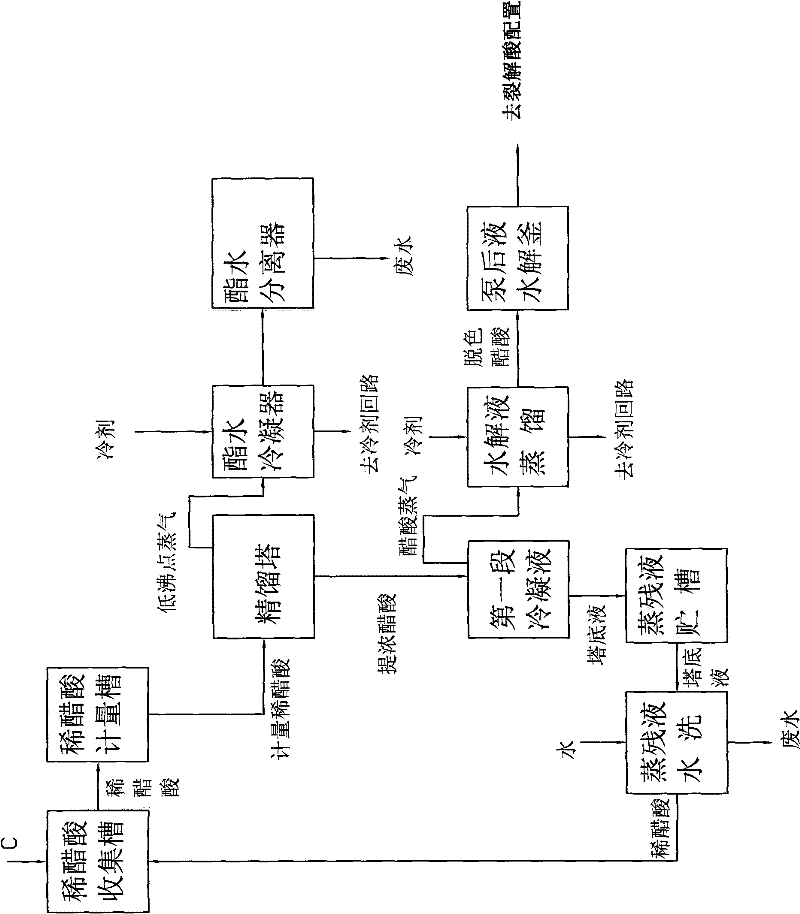

Process for preparing high-purity diketene

The invention relates to a process for preparing high-purity diketene, which overcomes the defects of low purity of ketene, low purity and poor safety of diketene products formed by absorbing and polymerizing ketene, as well as complex process, high cost and high acetic acid content of raffinate in the concentration recovery of dilute acetic acid. The process for preparing high-purity diketene is suitable for absorbing and polymerizing ketene dimer at low temperature on the basis of adopting stable acetic acid cracking conditions and deep refrigeration to remove impurities from cracking gas and generate pure ketene gas, adopting a film evaporator to further purify diketene products at low temperature under low pressure, and adding stabilizers after introducing polymerization inhibitor and diketene for refining during the absorption and polymerization of ketene in order to improve synthesis safety and the stability of products in storage tanks. Meanwhile, the dilute acetic acid produced in the process reasonably matches the temperature of each point of a stripping section through a sensitive plate technique, improves the water-carrying capability of butyl acetate, and greatly reduces the concentration of acetic acid in concentrated raffinate.

Owner:NINGBO WANGLONG TECH

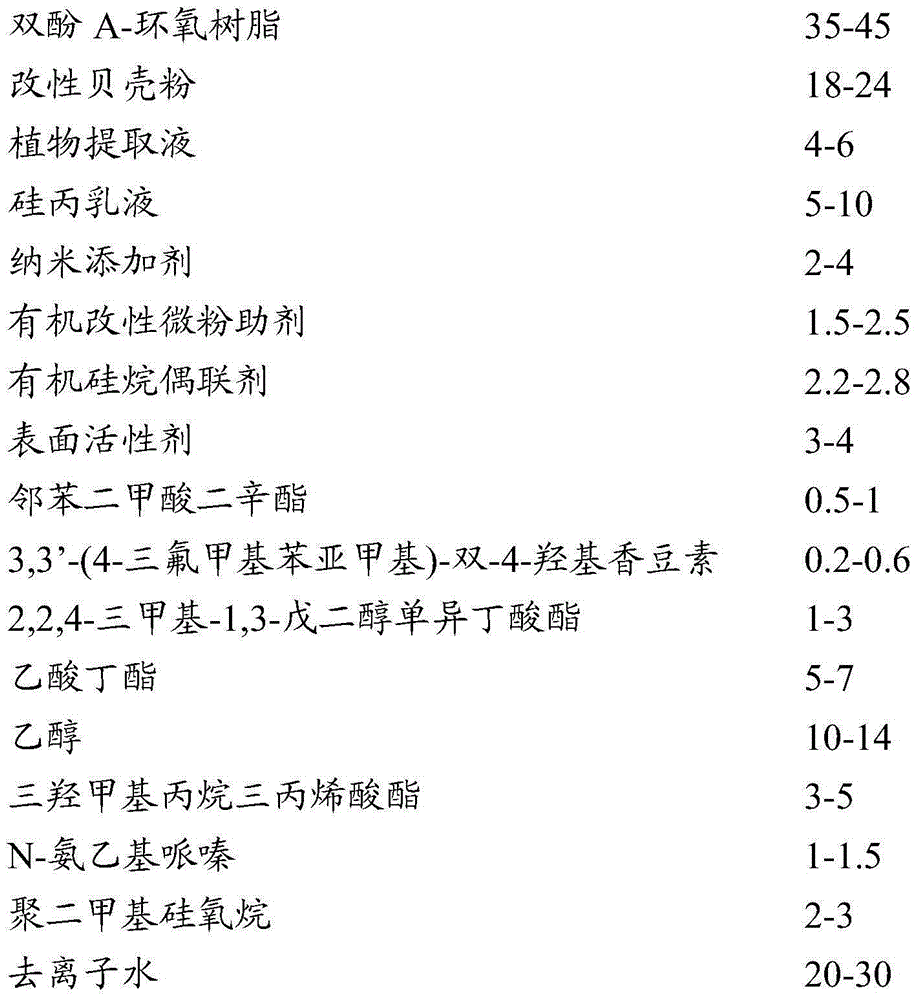

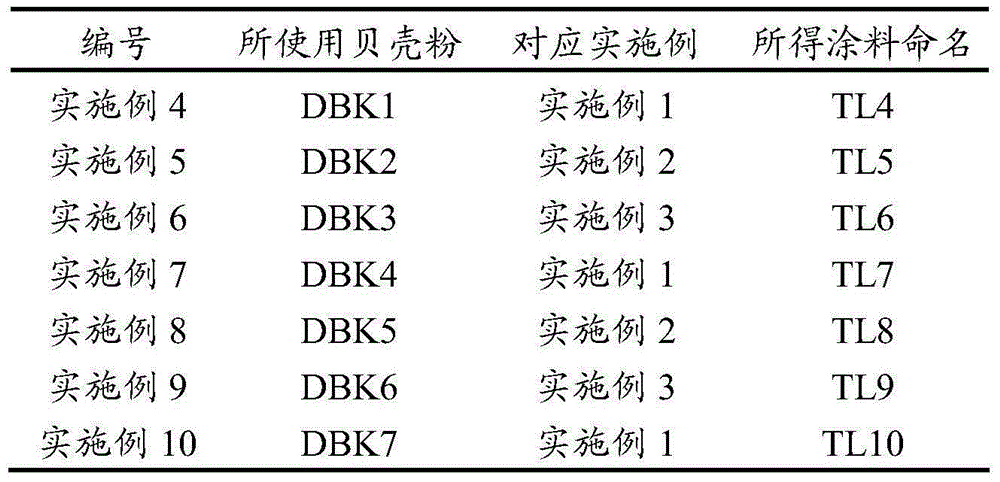

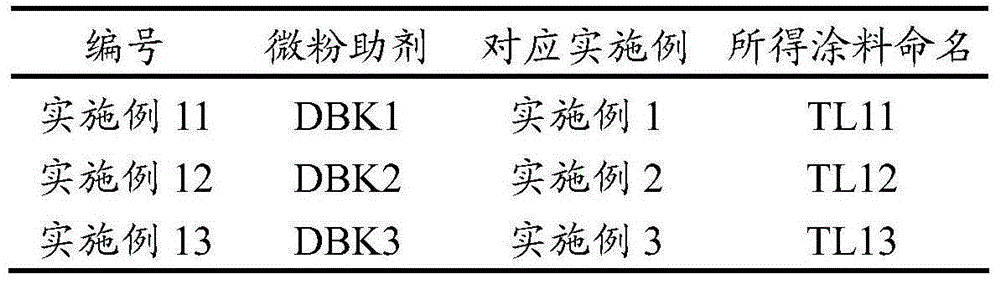

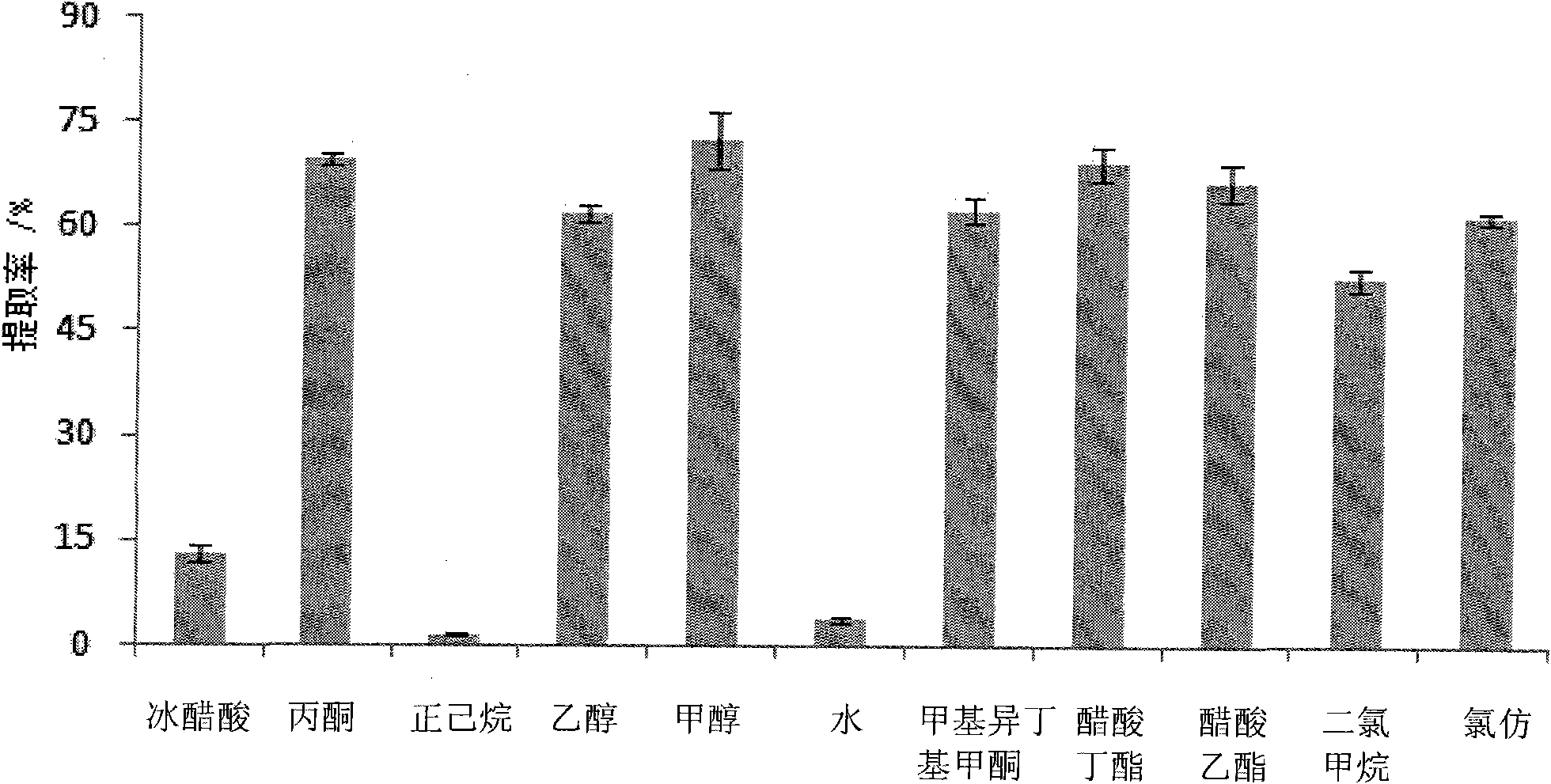

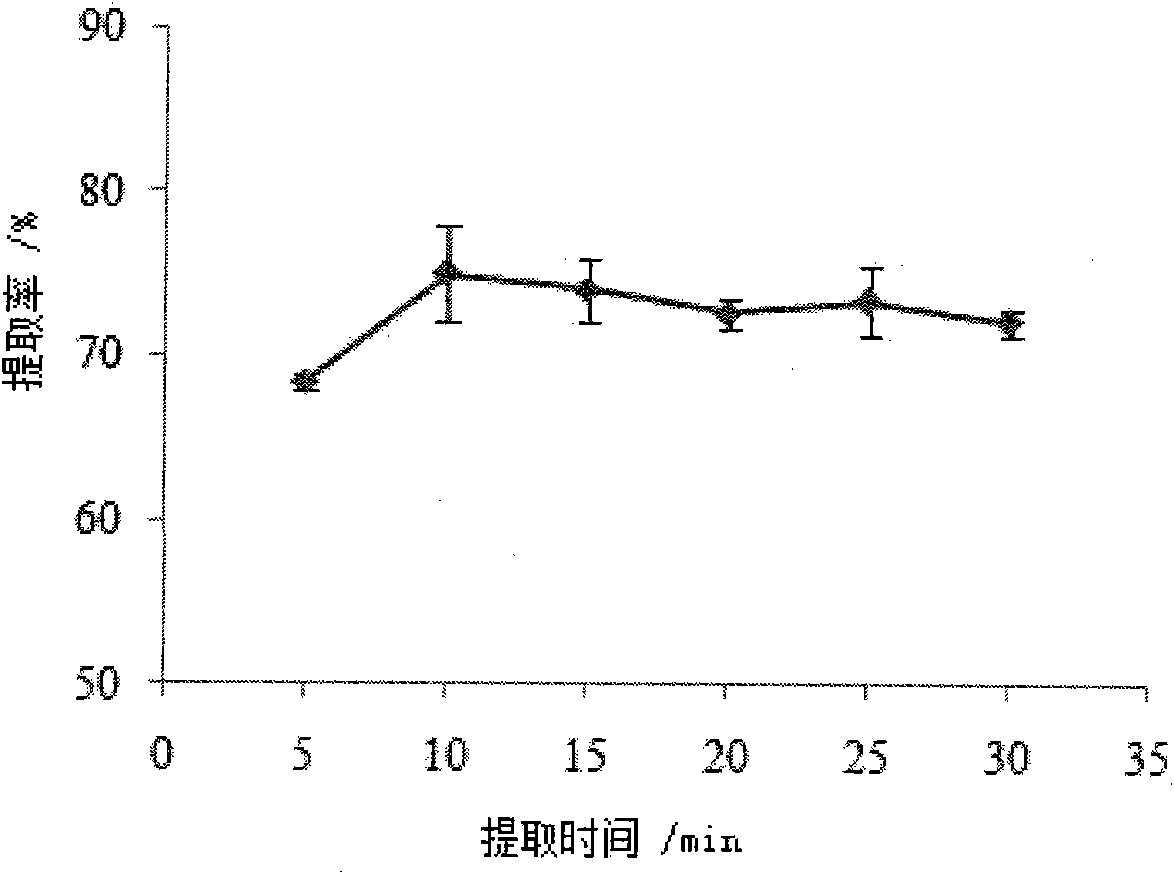

Environmentally friendly shell powder functional coating and preparation method therefor and uses thereof

ActiveCN104987808AImprove performancePractical application value is greatEpoxy resin coatingsDimethyl siloxaneIsoprene

The present invention relates to an environmentally friendly shell powder functional coating, a preparation method therefor and uses thereof. The coating comprises: bisphenol A-epon, modified shell powder, vegetable extract, propyl silicone emulsion, a nano additive, a modified organic micro powder agent, a surfactant, dioctylphthalate, 3, 3'-(4-trifluoromethyl methyl)-bi-4-hydroxy coumarin, 2,2,4-amino trimethyl-1,3-isoprene glycol mono iso-butyl methacrylate, butyl acetate, ethanol, trimethylol propane triacrylate, N-ammonia amino ethyl piperazine, polydimethylsiloxane and deionized water. In the present invention, by modification of a variety of components and materials, selection and collocation of specific components and a specific preparation method, the variety of components exert a synergistic effect, so as to make the prepared coating have significant antimicrobial, environmental-cleaning and wear-resisting properties. The coating has a huge application potential and extensive value in industrial production.

Owner:广西世家丽环保投资有限公司

Colourful environmental-friendly synthesized polymer waterproof paint

InactiveCN102108234AWith comprehensive performanceImprove physical performance indicatorsPolyurea/polyurethane coatingsMulticolor effect coatingsUltravioletSynthetic Polymeric Macromolecules

The invention relates to a colourful environmental-friendly synthesized polymer waterproof paint which comprises the following components in parts by weight: 3-7 parts of petroleum resin, 5-15 parts of styrene-ethylene-butylene-styrene (SEBS), 5-15 parts of styrene-butylene-styrene (SBS), 5-10 parts of thermoplastic polyurethane elastomer, 4-8 parts of terpene resin, 4-8 parts of poly-alpha-methyl styrene, 2-5 parts of tung oil, 10-15 parts of mica powder, 0.2-0.5 part of antiager D, 0.2-0.5 part of antioxidant 264, 0.2-0.5 part of defoaming agent, 0.3-0.5 part of ultraviolet absorber, 35-45 parts of 120 # solvent, 5-15 parts of butyl acetate and 1-3 parts of color paste. The paint has the characteristics of unique waterproof property, acid-base resistance, ultraviolet irradiation resistance, heat insulation, anti-aging property, high adhesion strength, water repellent, good leakage-resisting effect, heat resistance, frost resistance and good elongation; and the paint also has the advantages of wide application range, moderate price, environmental friendliness, durability and the like, and is convenient to use, thereby meeting the demand of people in a real life.

Owner:白铁林

Pleuromutilin solvent extraction process

InactiveCN101838199AHigh crystallinityEasy to purifyOrganic compound preparationCarboxylic acid esters preparationMicroorganismActivated carbon

The invention relates to an extraction process of microorganism source compounds, in particular to a pleuromutilin solvent extraction process; the process comprises the following steps: mycelium is separated out from pleuromutilin producing bacterium total-fermentation broth, is dried, crushed and sifted out, the total water content of the mycelium is baked to be lower than 5 percent, so as to obtain baking mycelium for spare; the obtained baking mycelium is mixed with butyl acetate, the mixture is shaken out and extracted, the extracting solution is filtered, the filtrate is washed, dehydrated and dried, and decolorized by activated carbon, the solvent is recovered until being crystallized, crystallization is carried out by standing, so as to obtain the pleuromutilin; the process has theadvantages of stability, having easy operation, convenient operation, low solvent toxicity, high safety, low solvent consumption level, short extraction time, easy purification of products and low cost.

Owner:SOUTHWEST UNIVERSITY

High-solid low-viscosity acrylic resin and preparation method thereof

InactiveCN104672366AShort synthesis timeLow degree of branchingPolyurea/polyurethane coatingsPolymer scienceButyl acetate

The invention discloses high-solid low-viscosity acrylic resin and a preparation method thereof. The high-solid low-viscosity acrylic resin comprises butyl acetate, methylacrylic acid, glycidyl tertiary carboxylic ester, styrene, styrene dimer, an initiating agent and acrylate. The preparation method of the high-solid low-viscosity acrylic resin comprises the following steps: stirring mixed solution of part of butyl acetate and part of glycidyl tertiary carboxylic ester, heating, carrying out heat preservation, and refluxing for 0.5-1 hour; then dropwise adding part of mixture of initiating agent, acrylate, styrene, styrene dimer and methylacrylic acid, carrying out copolymerization reaction, and then carrying out heat preservation for 0.5-1.5 hours; and finally dropwise adding the rest mixture of butyl acetate, initiating agent and glycidyl tertiary carboxylic ester, then carrying out heat preservation for 1-2 hours, cooling and discharging. The high-solid low-viscosity acrylic resin disclosed by the invention has the advantages that the acrylic resin synthesis time is shortened, the production cost is reduced, the polymer molecular weight is low, and the branching degree is low; meanwhile, the problems that common acrylic resin on the market is high in viscosity and poor in acid and alkali resistance and water resistance are solved.

Owner:SHANGHAI ZHENHUA HEAVY IND CHANGZHOU COATINGS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com